Patents

Literature

760 results about "Density difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Density is the material per unit volume while specific gravity is the ratio of the density of a substance to the density of a reference substance. The key difference between density and specific gravity is that density is an absolute value, while specific gravity is a relative value for a substance.

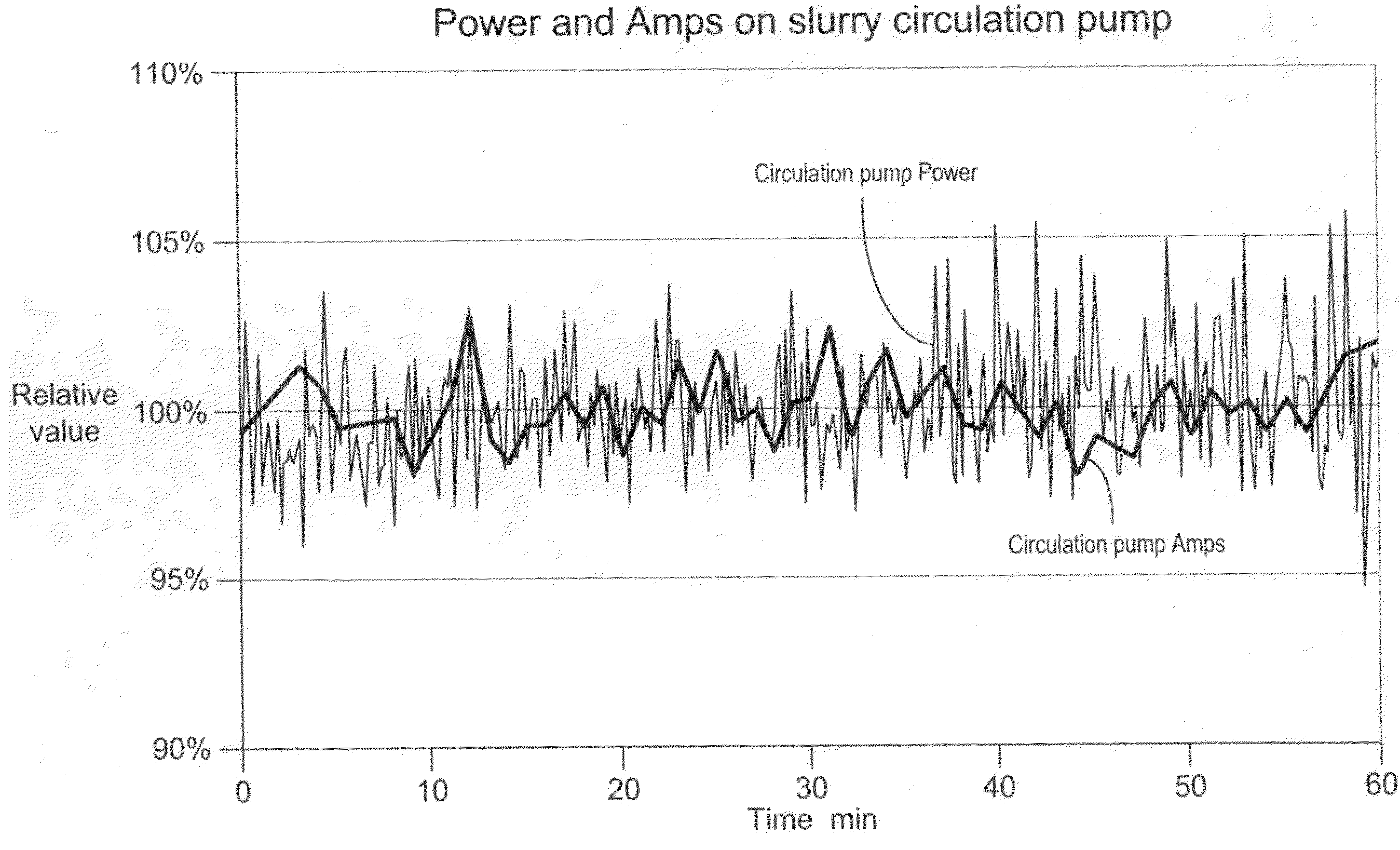

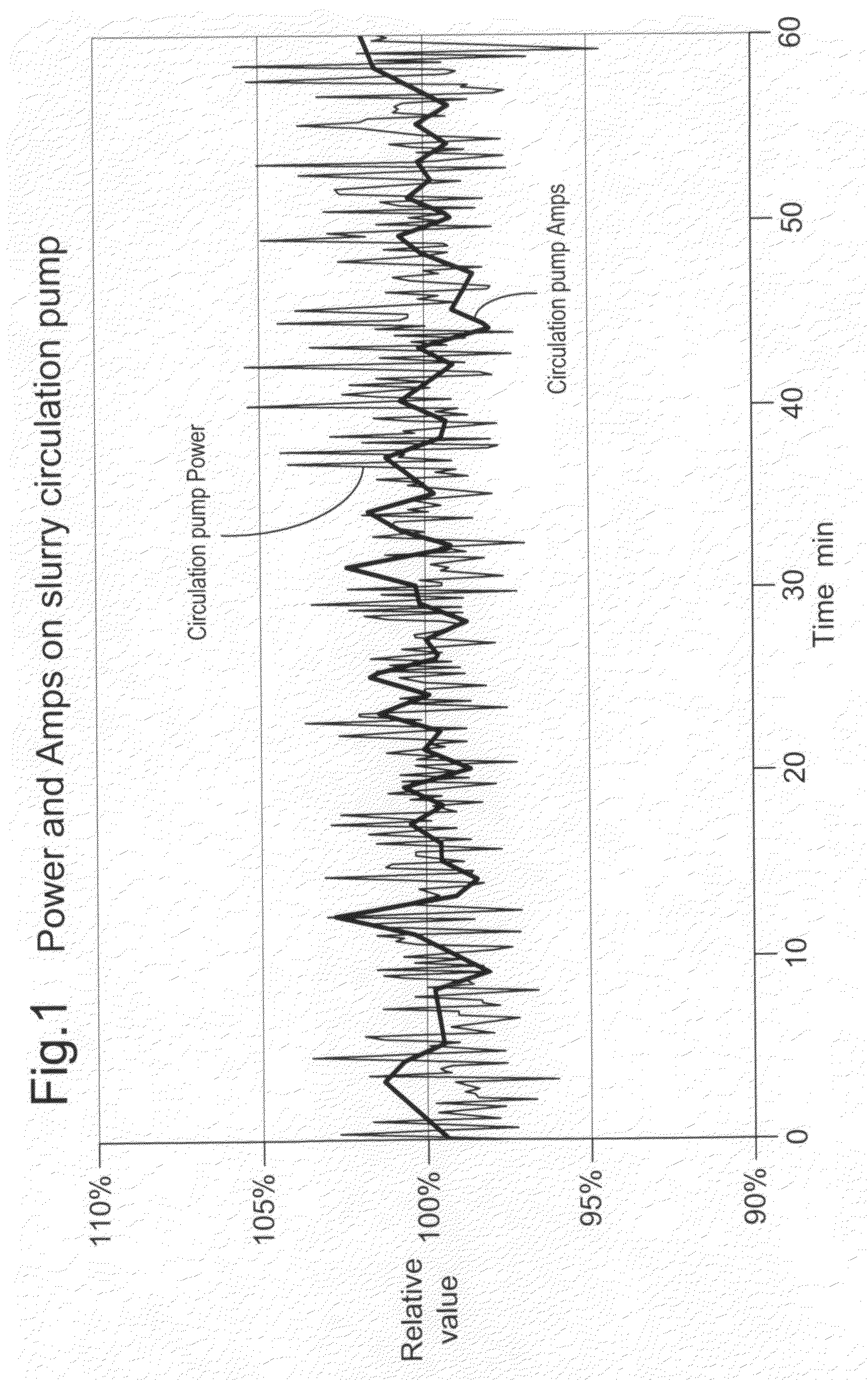

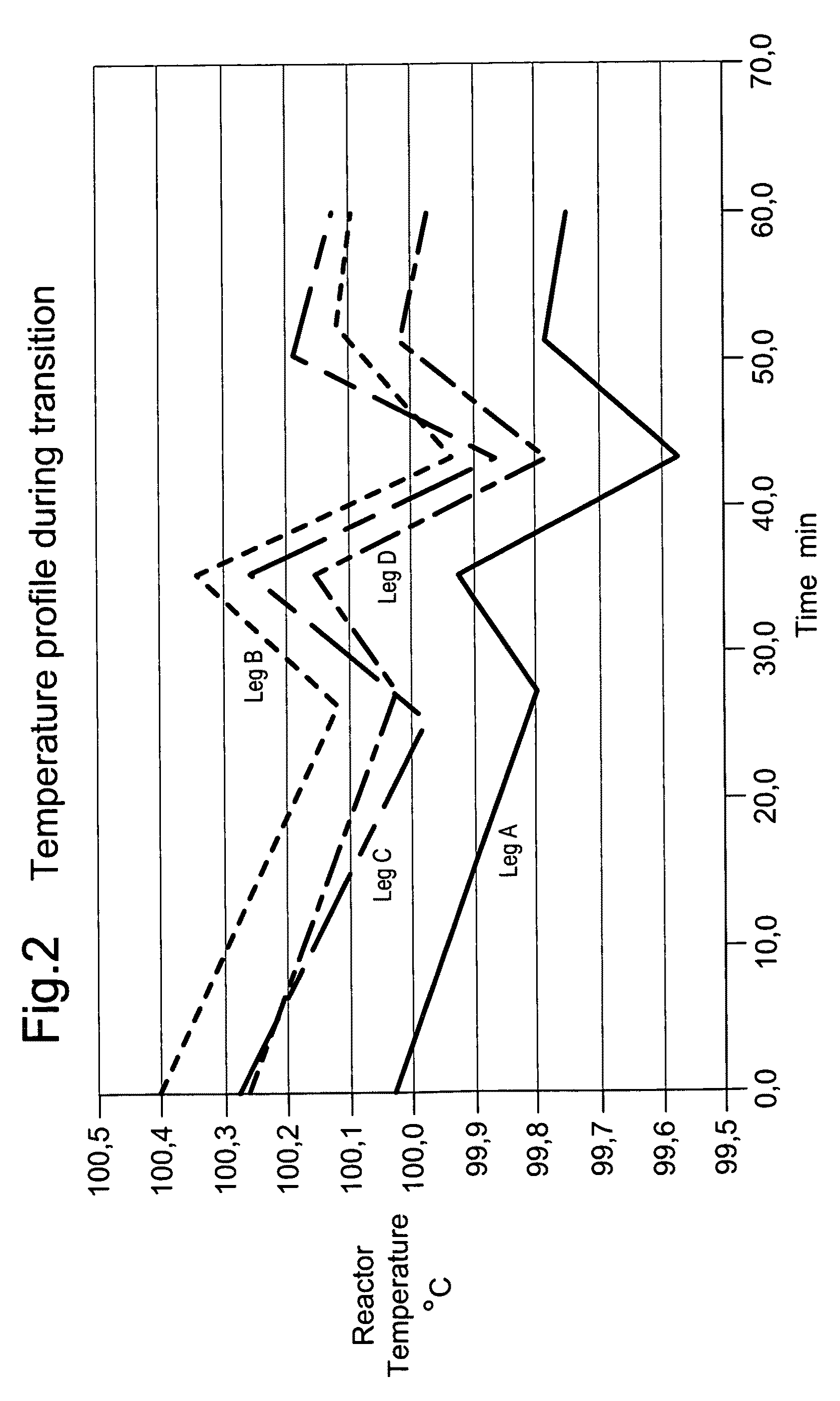

Slurry phase polymerisation process

ActiveUS20100144968A1Avoiding unacceptable reactor foulingReduce energy consumptionChemical/physical/physico-chemical stationary reactorsPolymer scienceSlurry

A process for controlling a slurry phase (co-) polymerisation process in the presence of a polymerisation catalyst, which comprises maintaining the density SPAN of the polymer powder particles (defined as the absolute value of the density difference in g / cm3 between the average density of the polymer particles exiting the reactor with particle size above D90 and the average density of the material with particle size below D10) below 0.005, preferably below 0.003, more preferably below 0.0026, most preferably below 0.0023.

Owner:INEOS EURO LTD

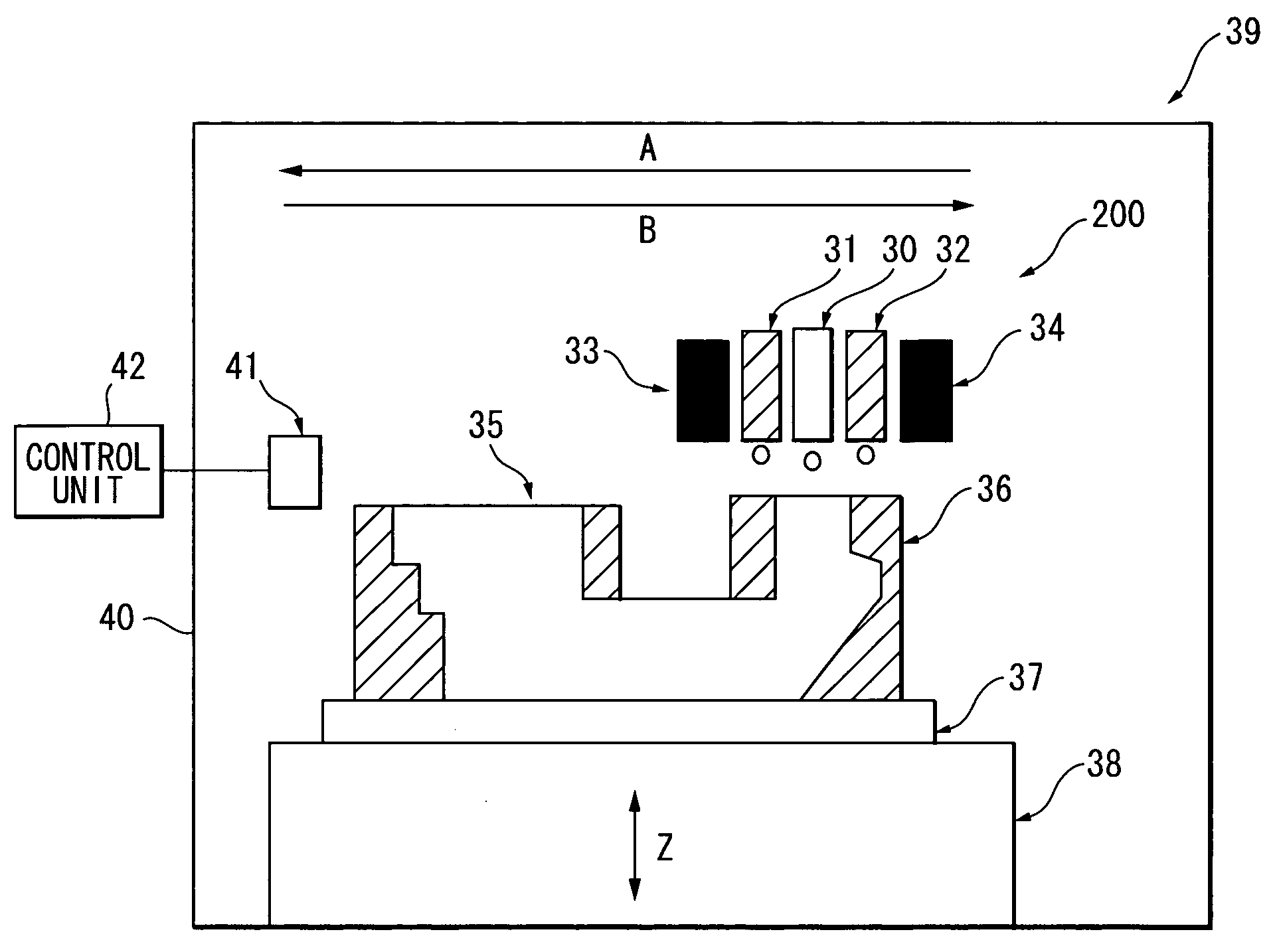

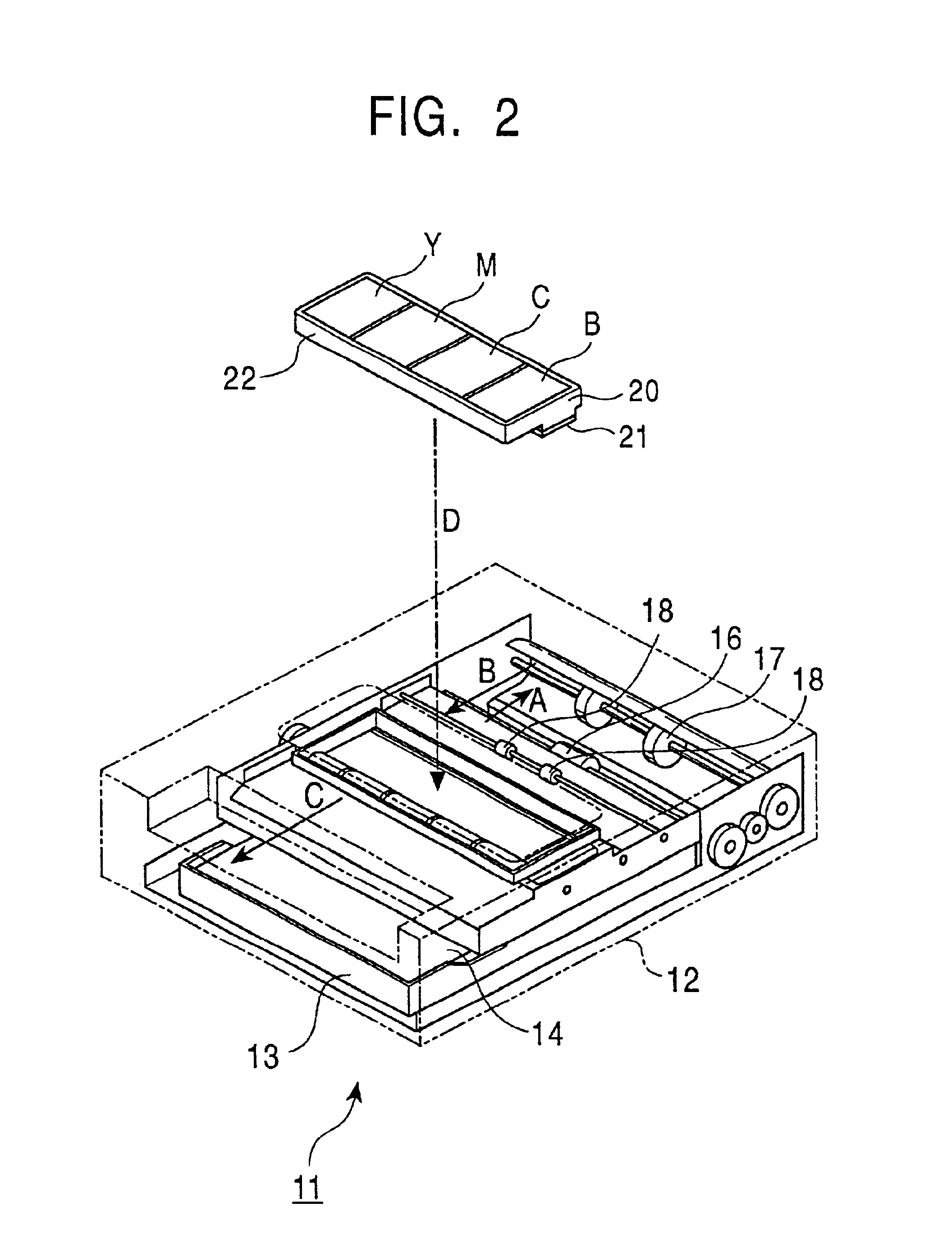

Support material for three-dimensional laminating molding

InactiveUS20050053798A1Increasing of electric power consumptionIncreasing start-up timeAdditive manufacturing apparatusAuxillary shaping apparatusVolumetric Mass DensityDensity difference

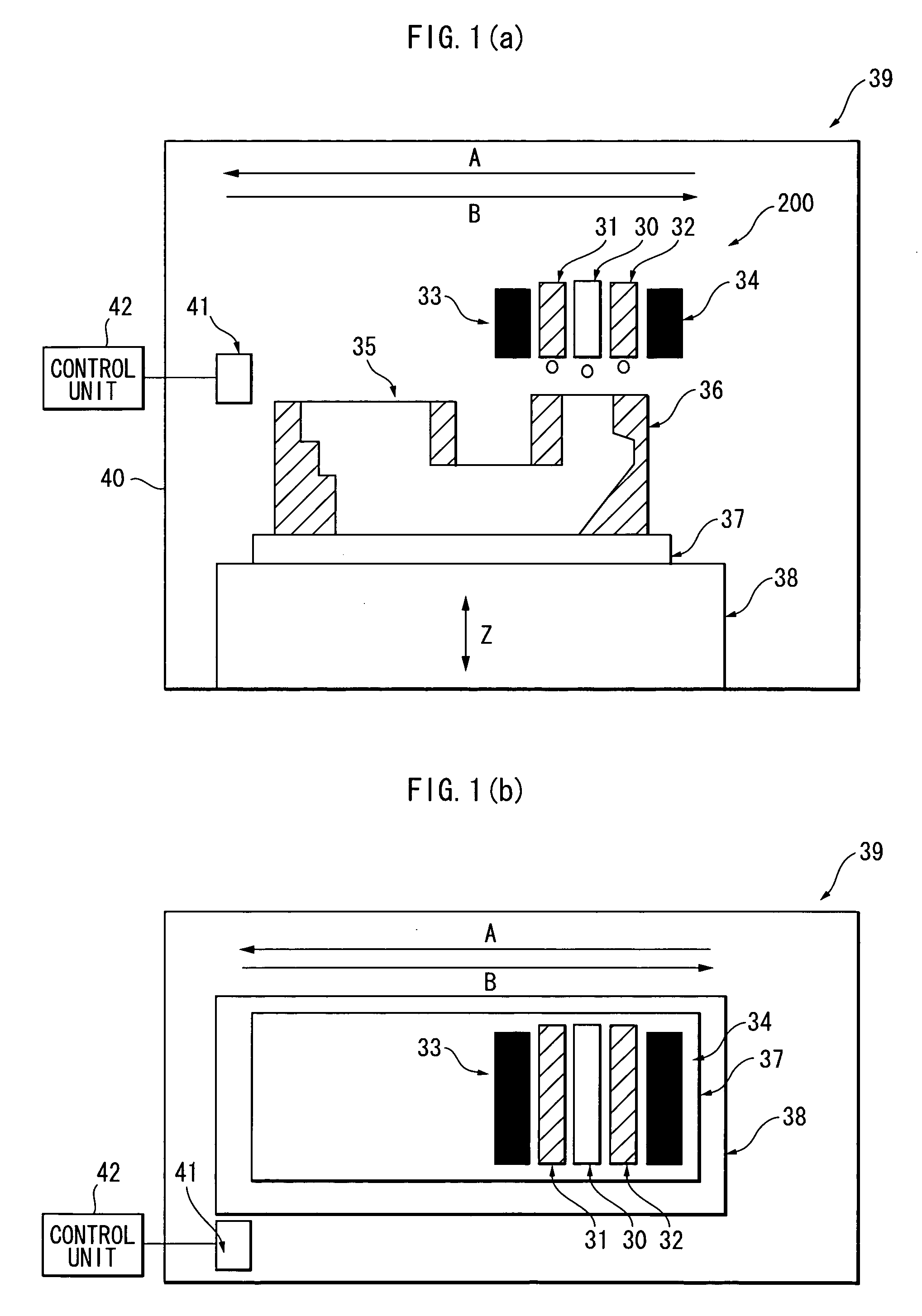

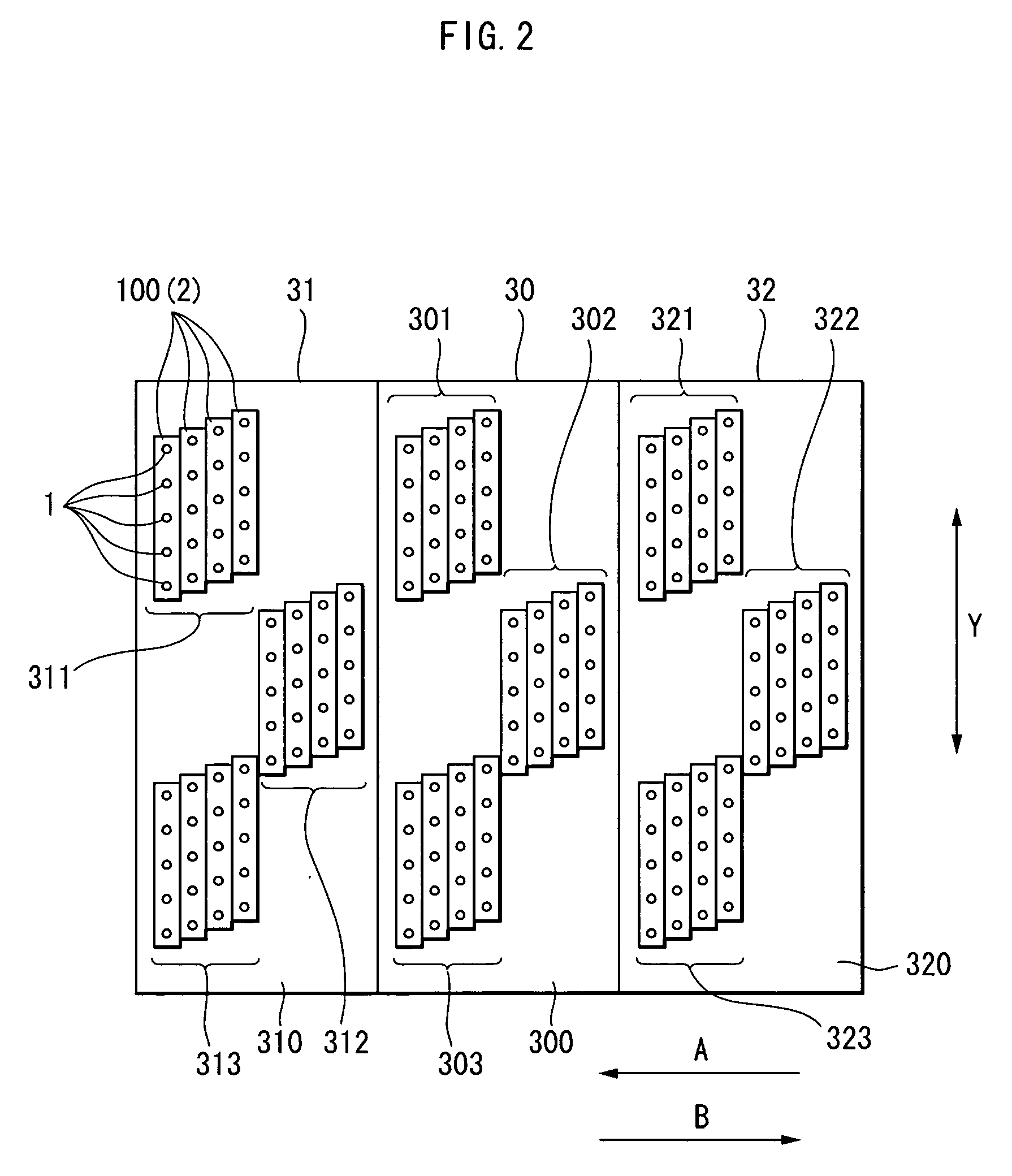

A three-dimensional laminated mold is formed by ejecting a mold material into a groove formed in a support. The support is formed from a support material ejected from an inkjet head. The support material has a ratio of density difference of equal to or less than 13.5%. The ratio of density difference is calculated from an equation: ratio of density difference=((D1-D2) / D1)×100 wherein D1 indicates the density of the support material at 20° C., and D2 indicates the density of the support material at a temperature at which a viscosity of the support material measured using a rotational viscometer falls within the range of 10±1 mPa·s.

Owner:RICOH PRINTING SYST

Printer and printer head

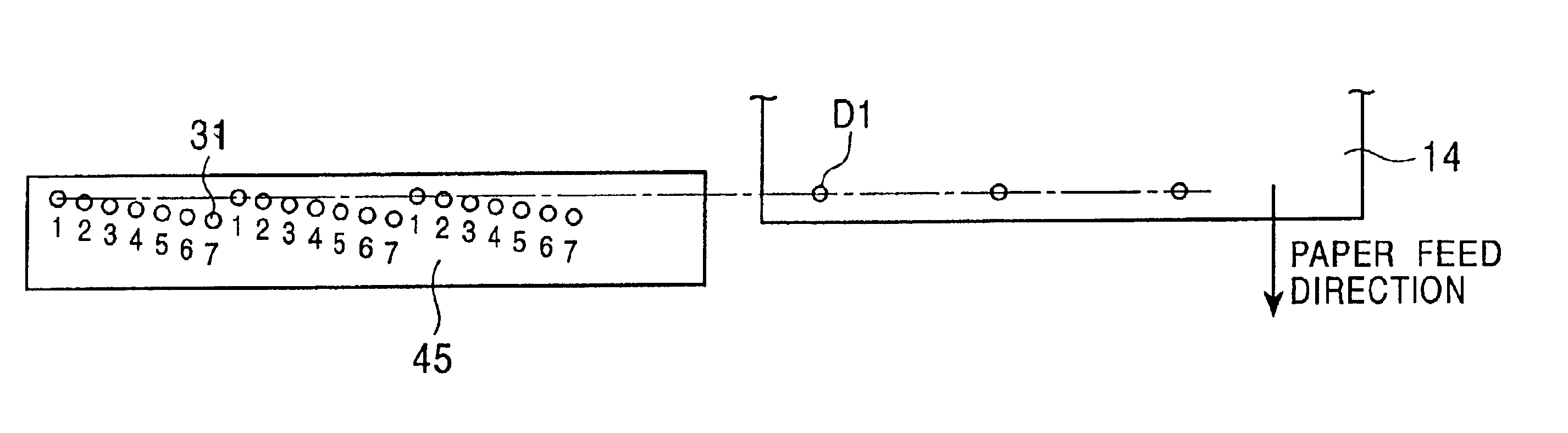

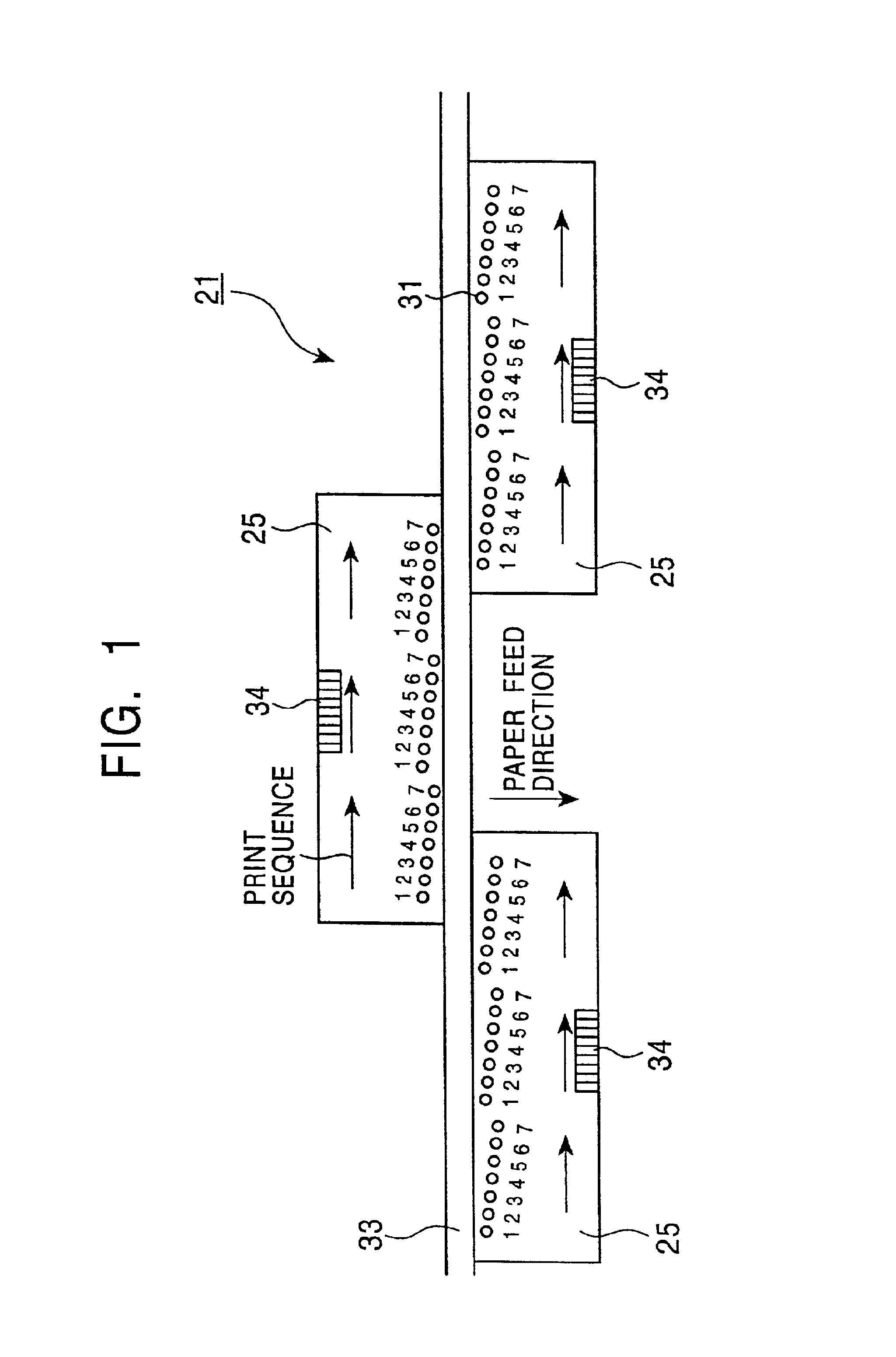

A printer head with overlapping nozzles. A plurality of head chips are formed in an array pattern on the printer head wherein a plurality of nozzles are associated with each head chip. Nozzles associated with one head chip and nozzles associated with an adjacent head chip partly overlap to form an overlapped area. When an ink-ejecting mechanism drives across a print object, the nozzles of the one head chip and the nozzles of the adjacent head chip respectively eject inks which are mixed in the overlapped area to reduce dot density differences on the print object.

Owner:SONY CORP

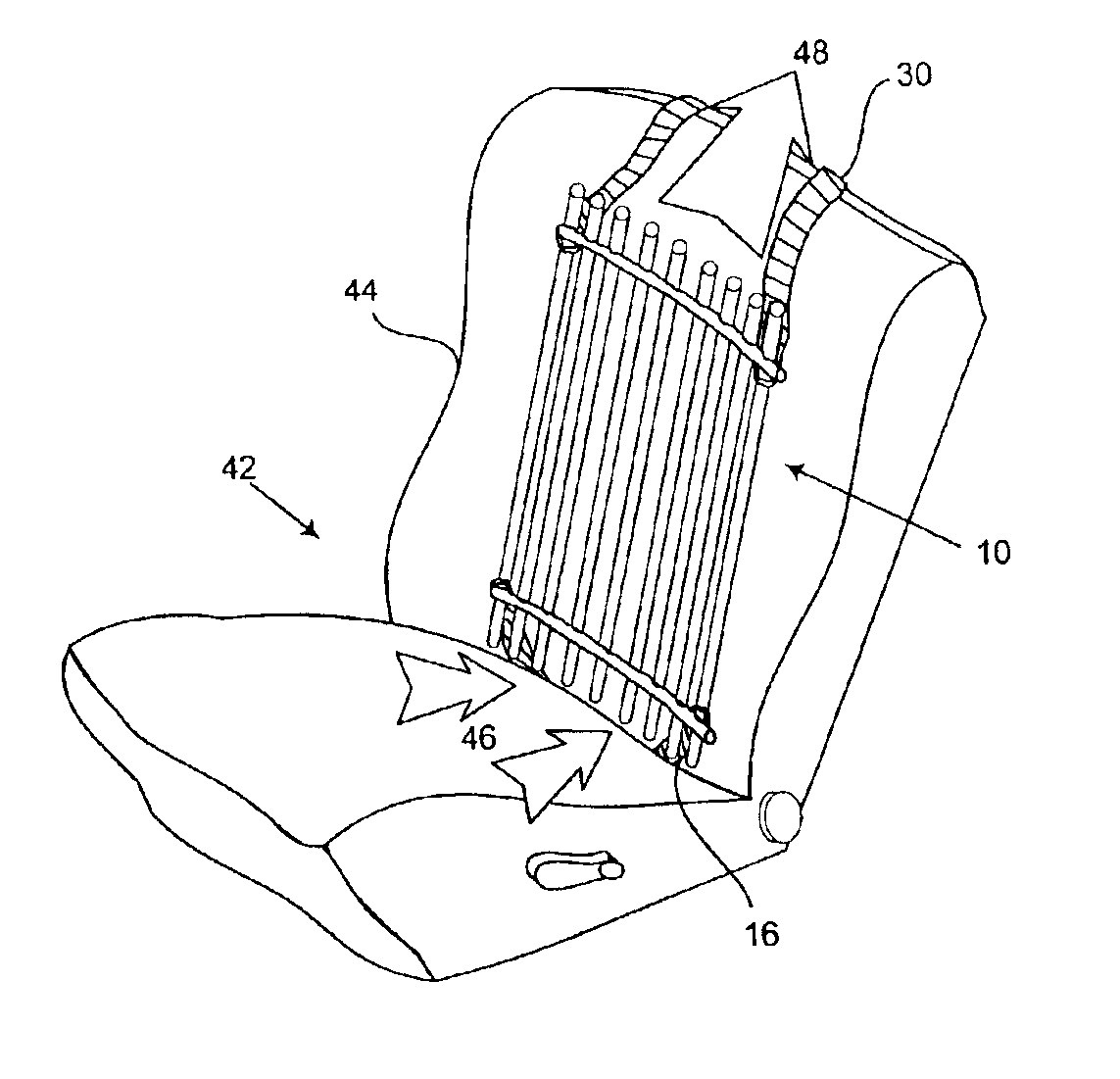

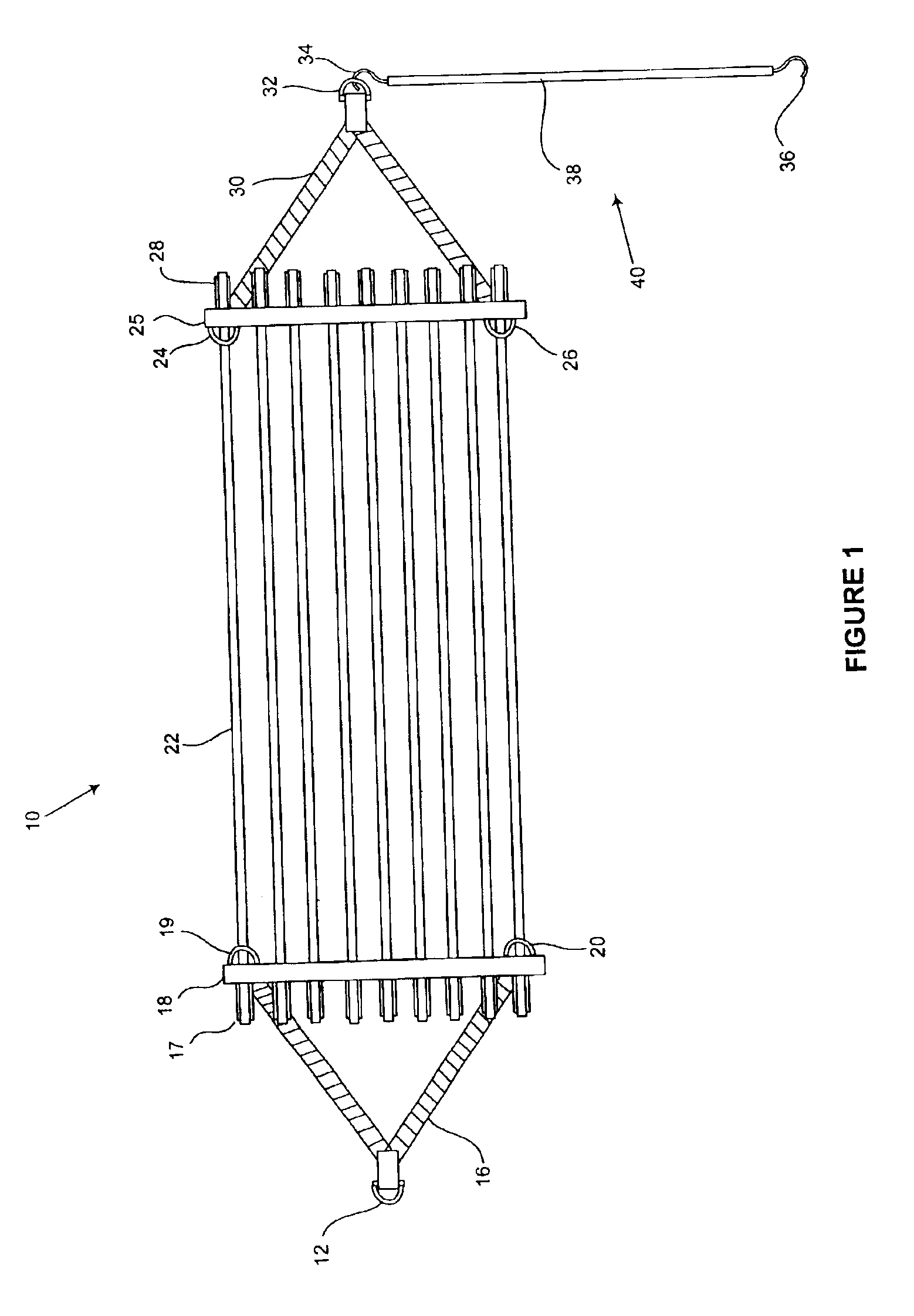

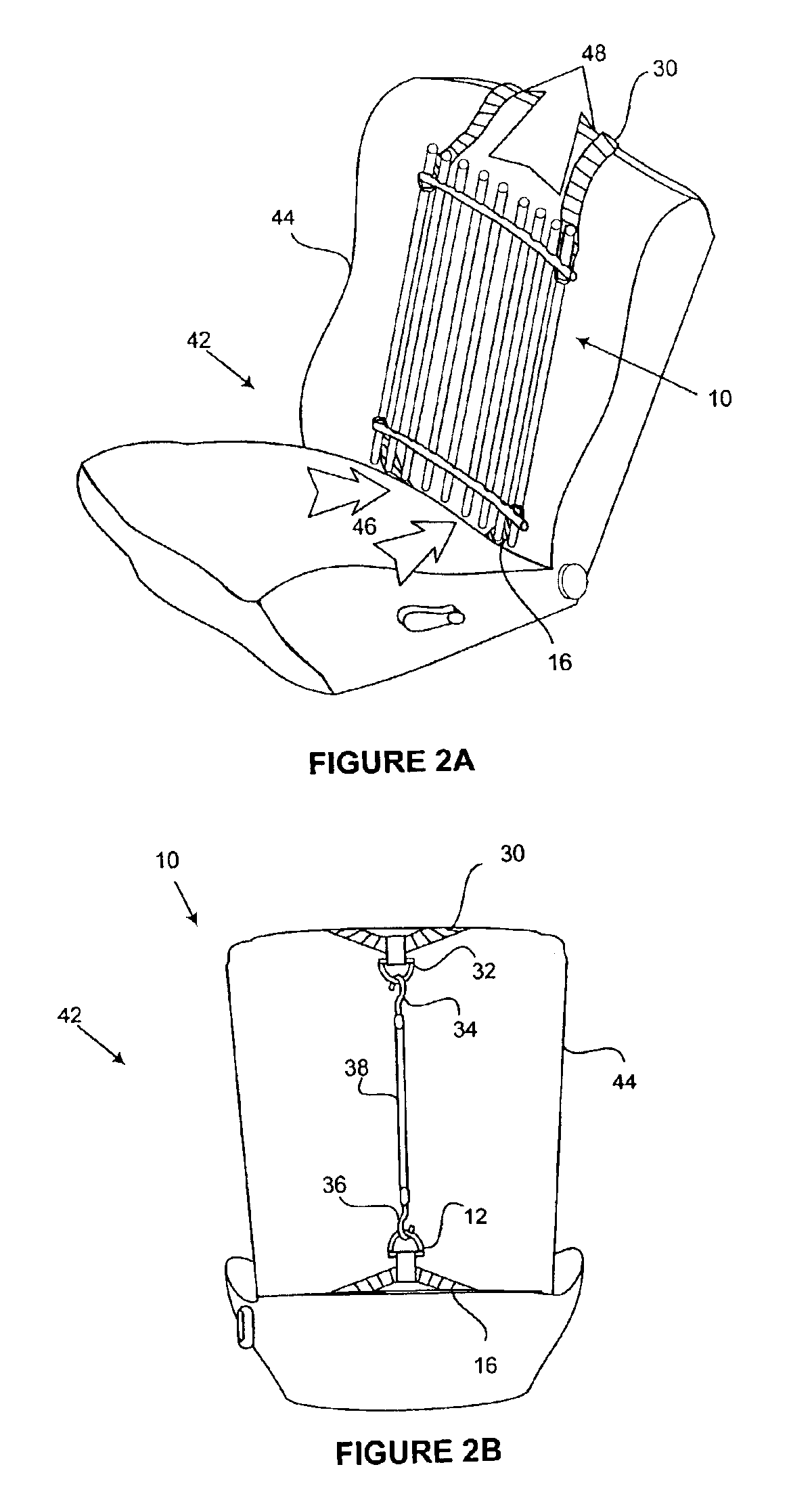

Portable seat cooling apparatus

InactiveUS6857954B2Light weightEasy to disassembleSeat coveringsAir-treating devicesAir movementForced-air

The present invention relates to a seat or chair cooling apparatus. In an embodiment the seat cooling apparatus cools the back of a user without the need of forced air. The seat cooling apparatus includes an array of conduits held in place by a set of supports to form a heat exchanger. Heat from the contact surfaces is removed by free convection, an upward air movement due to density difference. When the seat cooling apparatus is in the preferred substantially vertical arrangement, the warm air exiting the conduits is replaced by cooler air entering the conduits. A seat securing attachment secures the heat exchanger components to a seat. The seat cooling apparatus shapes into the back of the user to provide comfort that is effective in cooling. The seat cooling apparatus can be light weight, portable, and occupies little space, can be quickly installed and removed, easily cleaned and is very low cost to manufacture. In another embodiment, the seat cooling apparatus is easily connected to a forced air cooling source to increase the cooling rate if desired by the user.

Owner:FRONT END SOLUTIONS

Pulp for lithium ionic cell electrode and manufacturing method thereof

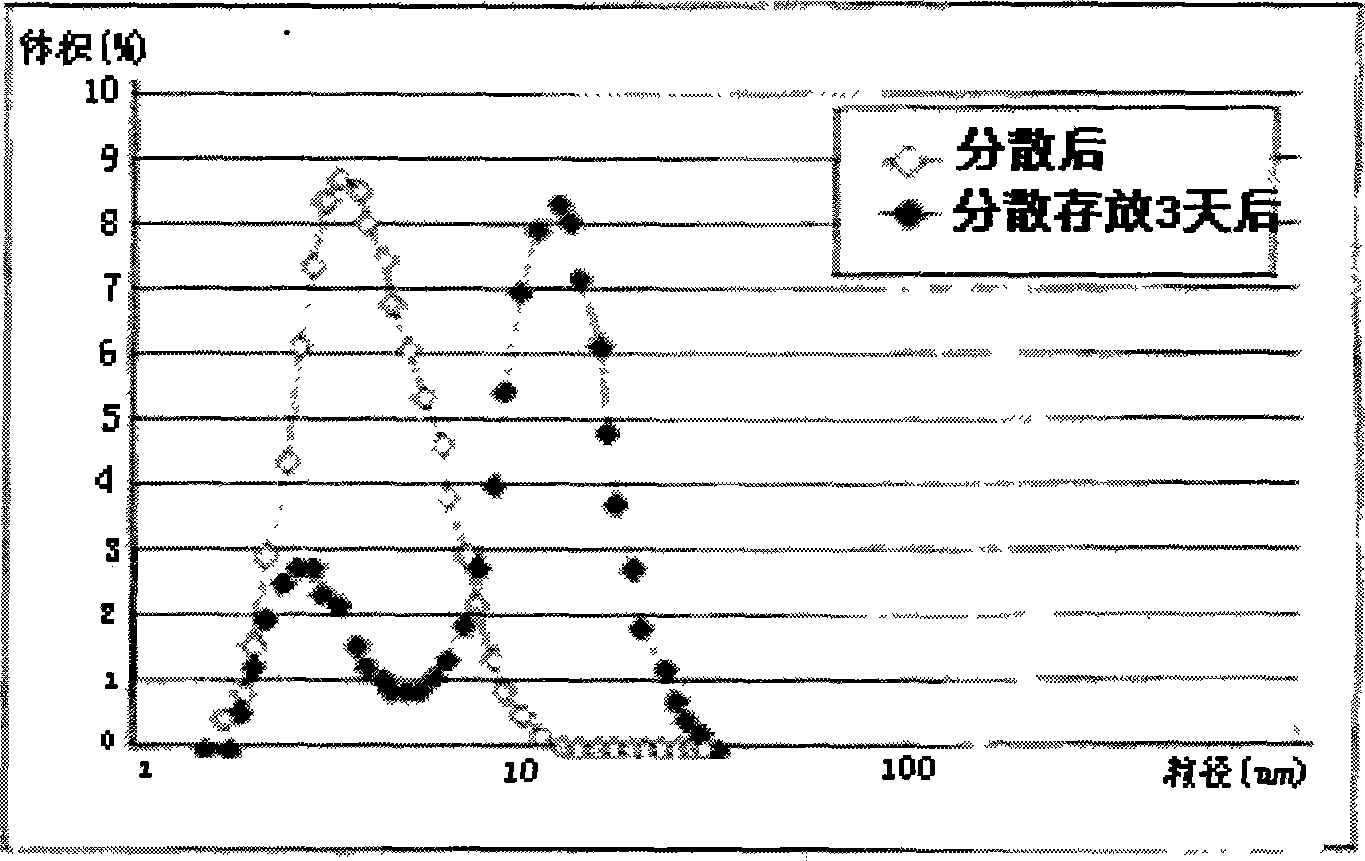

ActiveCN101393978AEasy to useReduce dosageElectrode manufacturing processesActive material electrodesAdhesiveColloid

A sizing material for electrodes of a lithium ion battery mainly comprises an active material, a conductive agent, an adhesive and a solvent, and is characterized in that the distribution ratio of the active material, the conductive agent, the adhesive and the solvent is 100 : 0-4 : 1-7 : 35-100. The preparation process thereof comprises the following steps: 1) mixing the adhesive with partial solvent to prepare a glue body with the viscosity of 1 to 10 percent; 2) mixing the conductive agent weighed according to the distribution ratio with the glue body prepared in the step 1) and stirring to form a conductive glue; 3) mixing the active material and the rest solvent weighed according to the distribution ratio with the conductive glue and stirring to form a premixed sizing material; 4) introducing the premixed sizing material into a dispersion machine rotating at a high speed to conduct dispersion; 5) cooling and vacuumizing the dispersed sizing material to form the sizing material for the electrodes of the lithium ion battery. The sizing material has the better use performance, and the preparation method thereof solves the defect in the traditional mixture that the layering of the conductive agent is easily caused by a larger density difference when the conductive agent is mixed with the active material and the like, thereby ensuring the uniform distribution of each ingredient of the sizing material.

Owner:ZHENGZHOU BAK BATTERY CO LTD

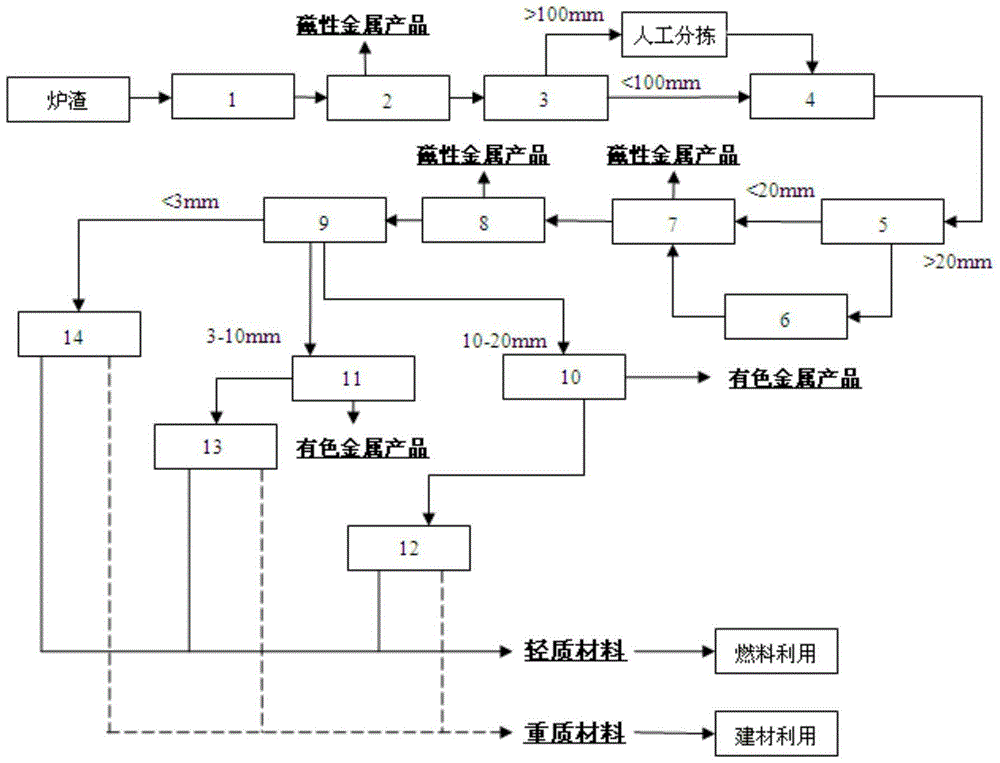

Method for recycling metal and combustibles from domestic waste incineration slag

The invention relates to a method for recycling metal and combustibles from domestic waste incineration slag, and belongs to the field of the solid waste harmless and recycling technology. By means of multi-stage gradient magnetic separation, separation of magnetic metal in the slag is achieved. By means of two-stage eddy current, nonferrous metal in the slag is separated and recycled. According to the grain size distribution and chemical morphological characteristics of the metal in the slag, the metal is crushed and screened in multiple steps so that separated slag particles can be uniform, the recycling rate of magnetic separation and eddy current separation is effectively increased, and finally, according to the density difference of materials, air separation is used for recycling the combustibles in the slag. Finally, the magnetic separation recycling rate of iron in the technological process is 60-80%, the recycling rate of the nonferrous metal aluminum is 60-70%, the recycling rate of the nonferrous metal copper is 40-50%, and separation of the metal in the slag and slag particles can be effectively achieved. The separated metal products can be directly sold or sold after refining, the combustibles can serve as waste incinerator fuel, and the remaining slag can be used as building materials.

Owner:TONGJI UNIV

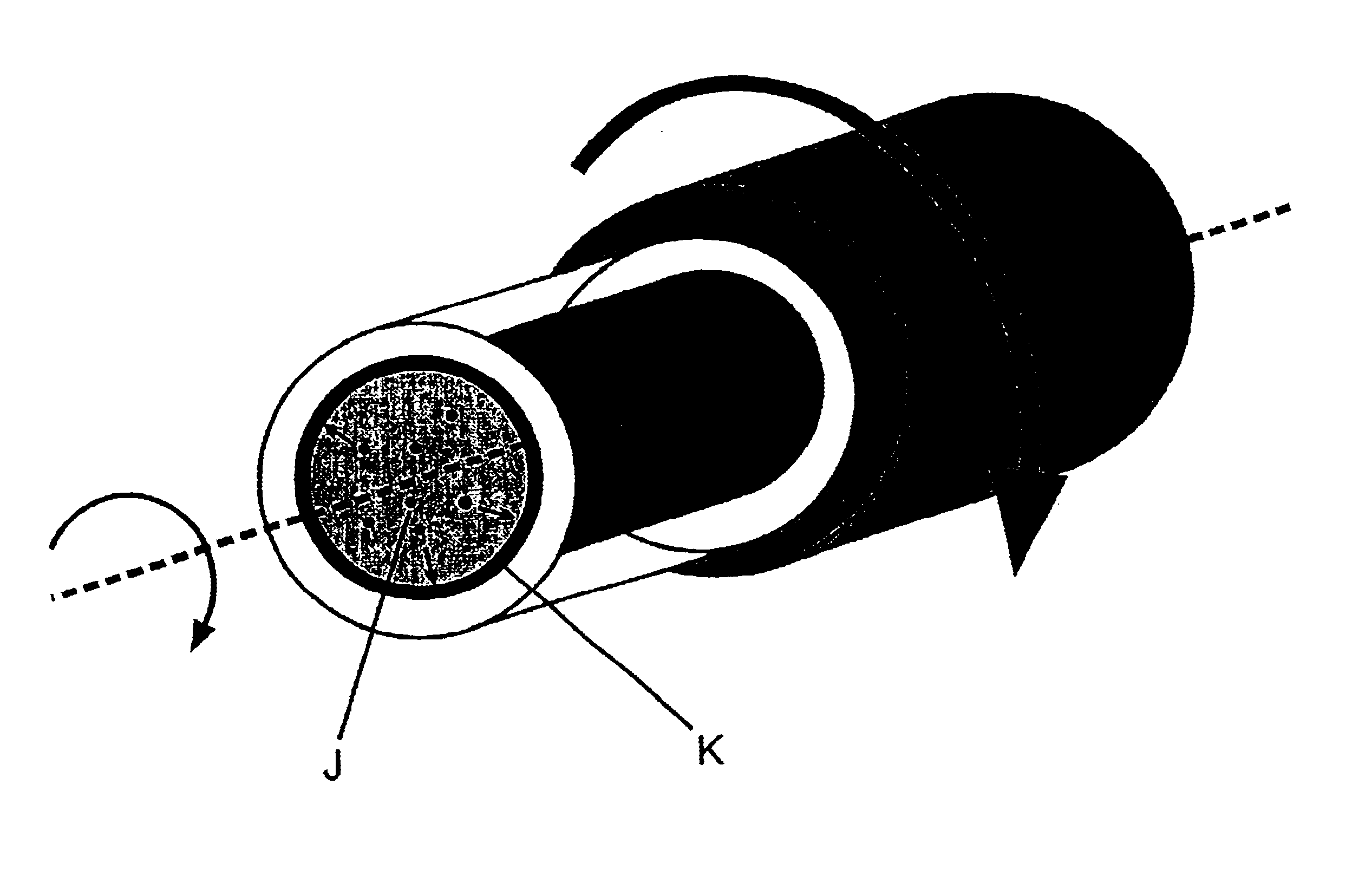

Method of producing structures using centrifugal forces

InactiveUS6969480B2Simple designReduce surface frictionMouldsLayered productsVolumetric Mass DensitySolvent

A variety of hollow structures with unique morphologies were manufactured with a rotational spinning technique. Phase separation of soluble solutions or emulsions was induced within a filled mold as it was being rotated about one of its axis. The density difference between phases results in sediment at the inner lumen of the mold under centrifugal forces. After or during sedimentation, gelation of the phase-separated particles fixes the hollow structure morphology and the solvent remains in the center of the mold. The solvent is removed from the mold resulting in a coating or tube. By controlling the rotational speed and the formulation chemistry, the tube dimensions and wall morphology can be manipulated. This technique offers a new approach to the manufacture of polymeric tubes. It requires small quantities of starting material, permits multi-layering of tubes, is applicable to diverse polymers and can result in highly diffusive hollow structures while maintaining good mechanical strength.

Owner:MATREGEN CORP +3

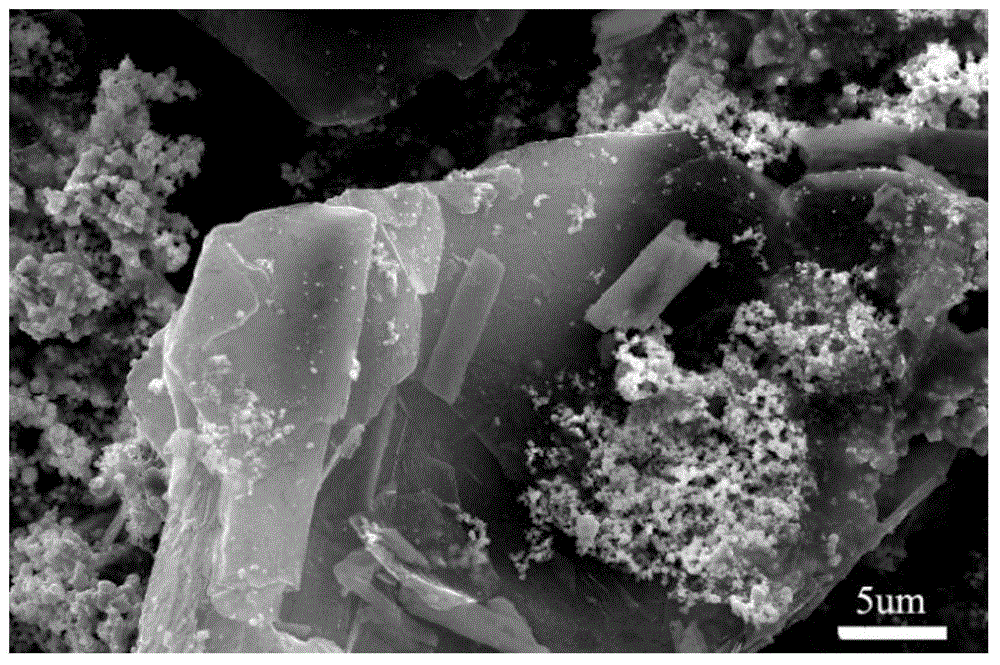

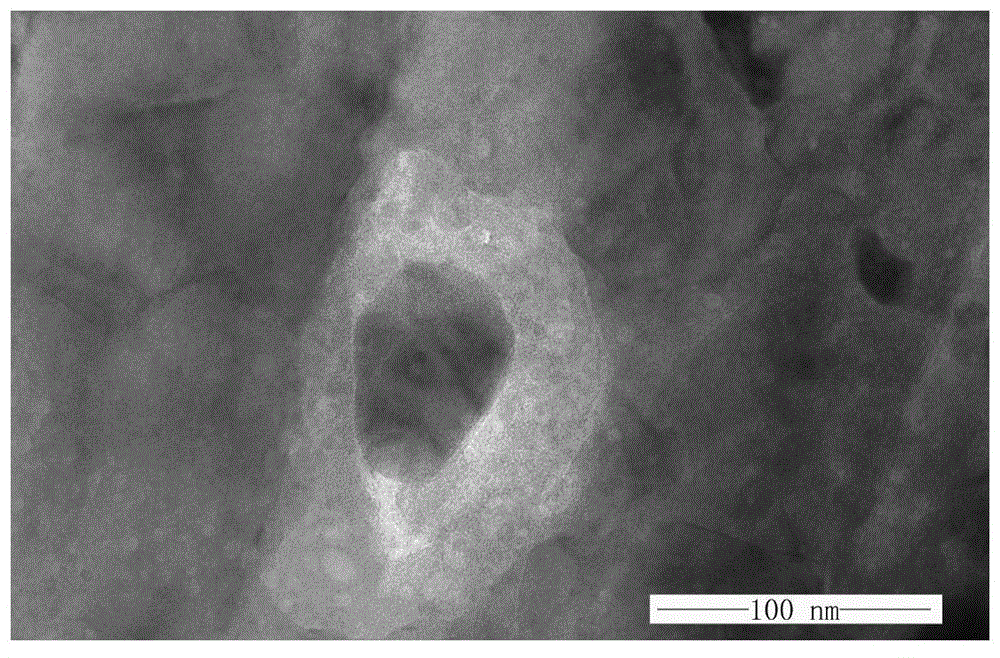

Preparation method of high-thermal conductivity graphene-Sn-Ag composite brazing filler metal

ActiveCN104400247AImprove performanceSolve reunionWelding/cutting media/materialsSoldering mediaDensity differenceCvd graphene

The invention discloses a preparation method of a high-thermal conductivity graphene-Sn-Ag composite brazing filler metal, ad relates to a preparation method of a high-thermal conductivity composite brazing filler metal. The preparation method has the following purposes: the problem of graphene floating and agglomeration in the preparation and application process of the composite brazing filler metal is solved by reducing a greater density difference between graphene and an Sn-Ag brazing filler metal matrix through plating a metal on the graphene; meanwhile, the graphene is dispersed more uniformly in the brazing filler metal matrix; and the reliability of sealing and brazing is improved by improving the heat conductivity of the composite brazing filler metal through adding the graphene. The method comprises the following steps: (1) the metal is plated on the graphene; and (2) the ball milling, the mixing and the medium-temperature smelting are performed for the metal-plated graphene and the Sn-Ag brazing filler metal to obtain the high-thermal conductivity composite brazing filler metal. The prepared composite brazing filler metal is high in thermal conductivity, has a higher wettability compared with a traditional Sn-Ag brazing filler metal, and is a composite brazing filler metal accordant with the present development tendency of an electronic industry as a connecting material of traditional large-scale integrated circuits.

Owner:HARBIN INST OF TECH

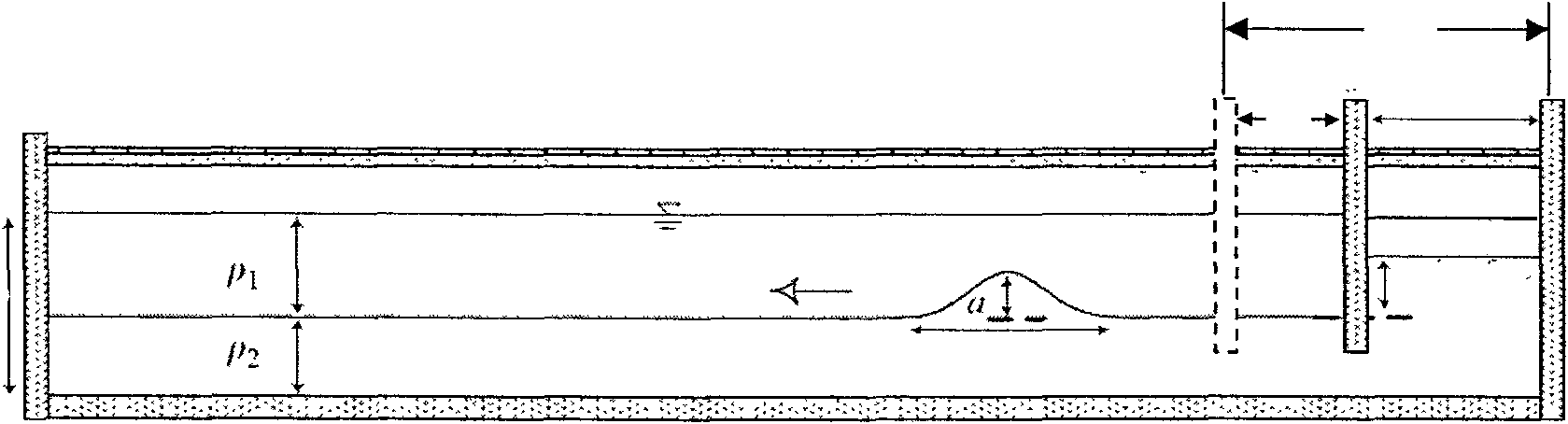

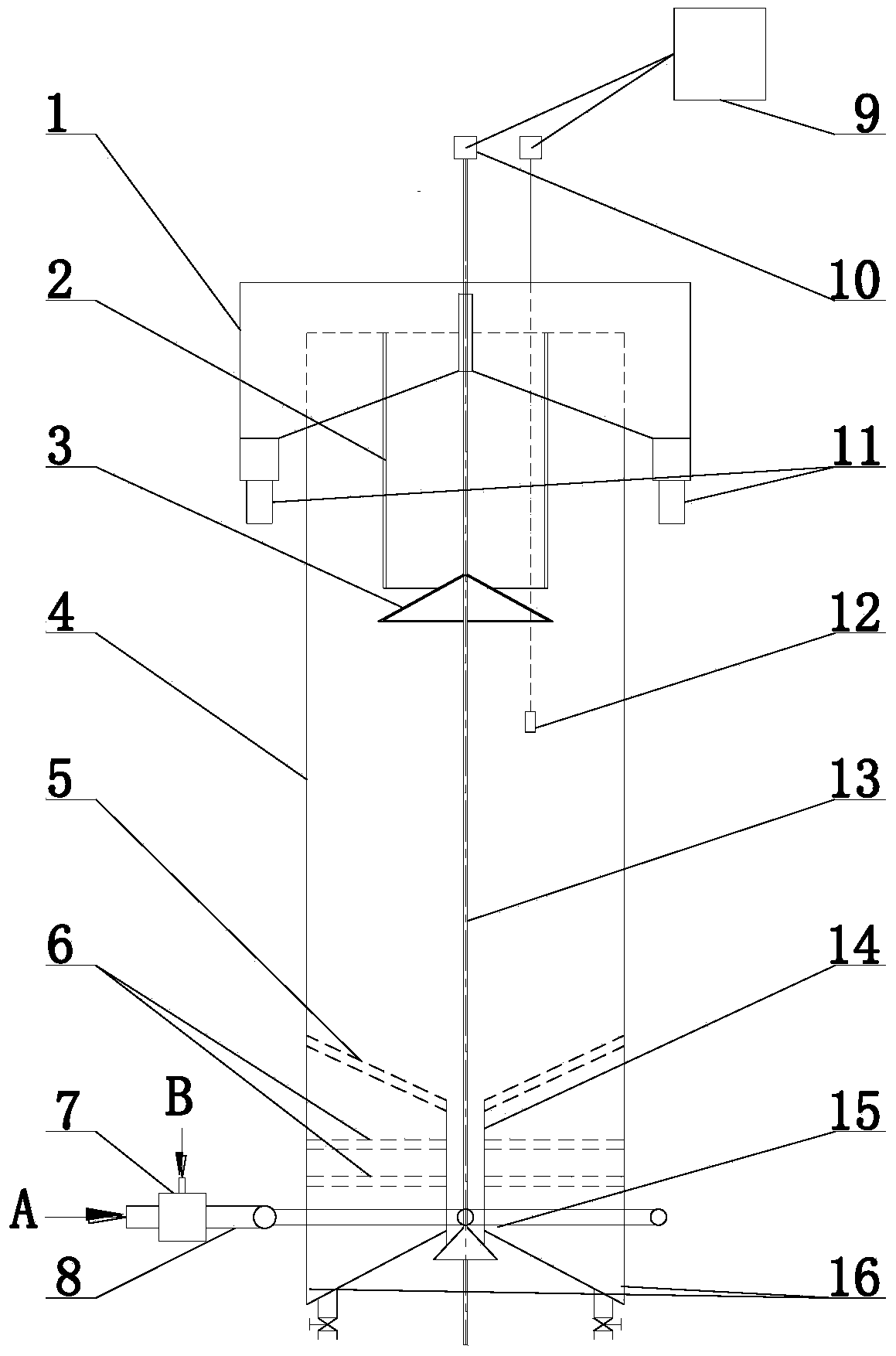

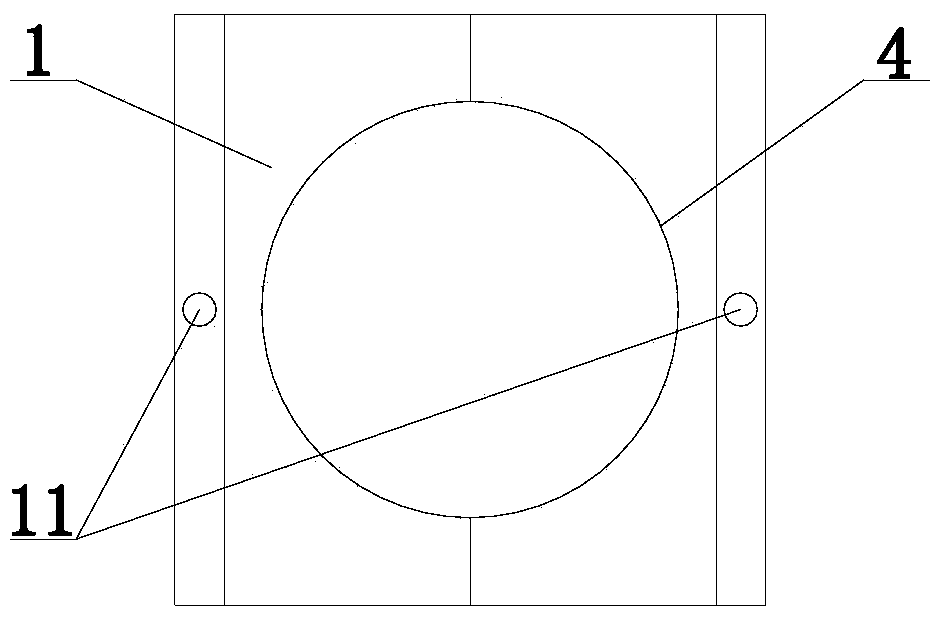

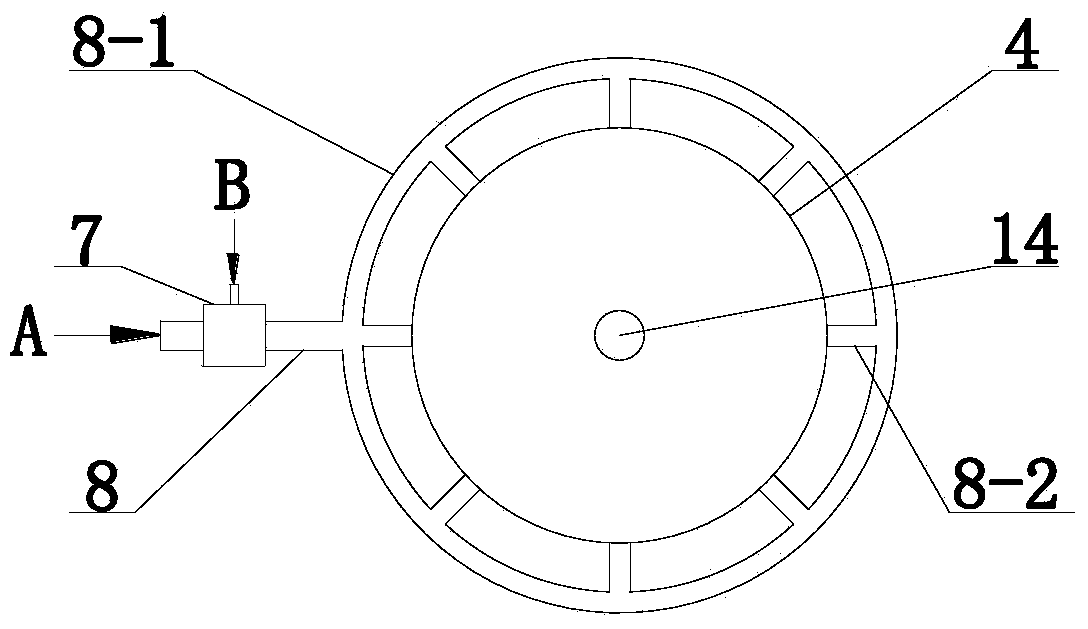

Gravity type internal solitary wave maker with rotary blind door

InactiveCN101788377ASmall range of motionSecurity and Reliability GuaranteeHydrodynamic testingEngineeringDensity difference

A gravity type internal solitary wave maker with a rotary blind door comprises a blind door and a linkage control mechanism, wherein the blind door comprises a plurality of long and thin stainless steel vanes; partition doors formed by all the vanes are arranged in an overlap mode; the overlap parts have good tightness when the partition doors are closed; the linkage control mechanism comprises link rod sliders, a slide guide, a cylinder and a steam pump; each stainless steel vane is riveted with upper and lower axes; all the upper axes are connected one ends of the link rod sliders corresponding to the upper axes; all the link rod sliders rotate around the corresponding upper axes on the vanes; the other ends of all the link rod sliders are connected with a cylinder piston rod; the link rod sliders reciprocate on the slide guide; a cylinder piston drives the link rod sliders to move to drive the upper axes on the vanes to simultaneously rotate 90 degrees while driving the piston rod to reciprocate, thus realizing synchronous opening and closing of the blind door. The movement amplitude of the mechanism generating the internal solitary waves through the interface density difference is greatly reduced, the quality of the made waves is effectively improved and the mechanical device has concise overall structure and is convenient to operate.

Owner:中国人民解放军理工大学理学院

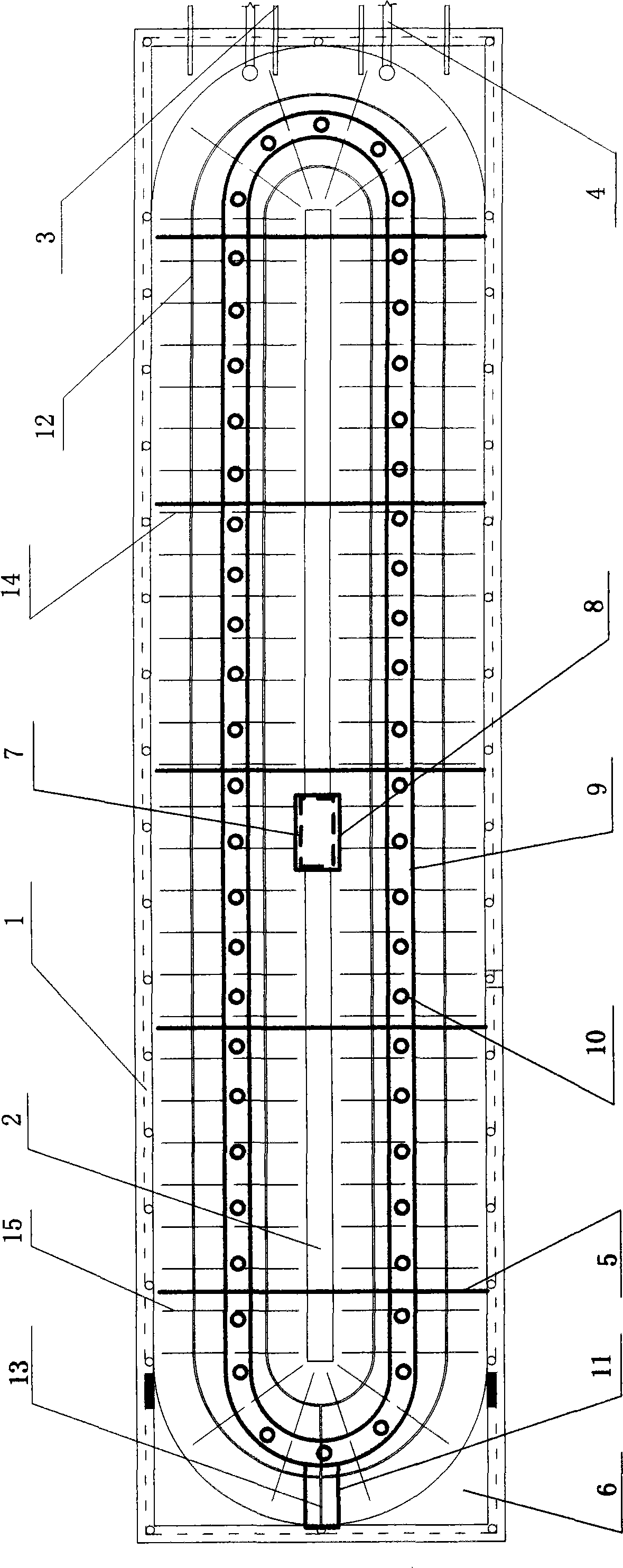

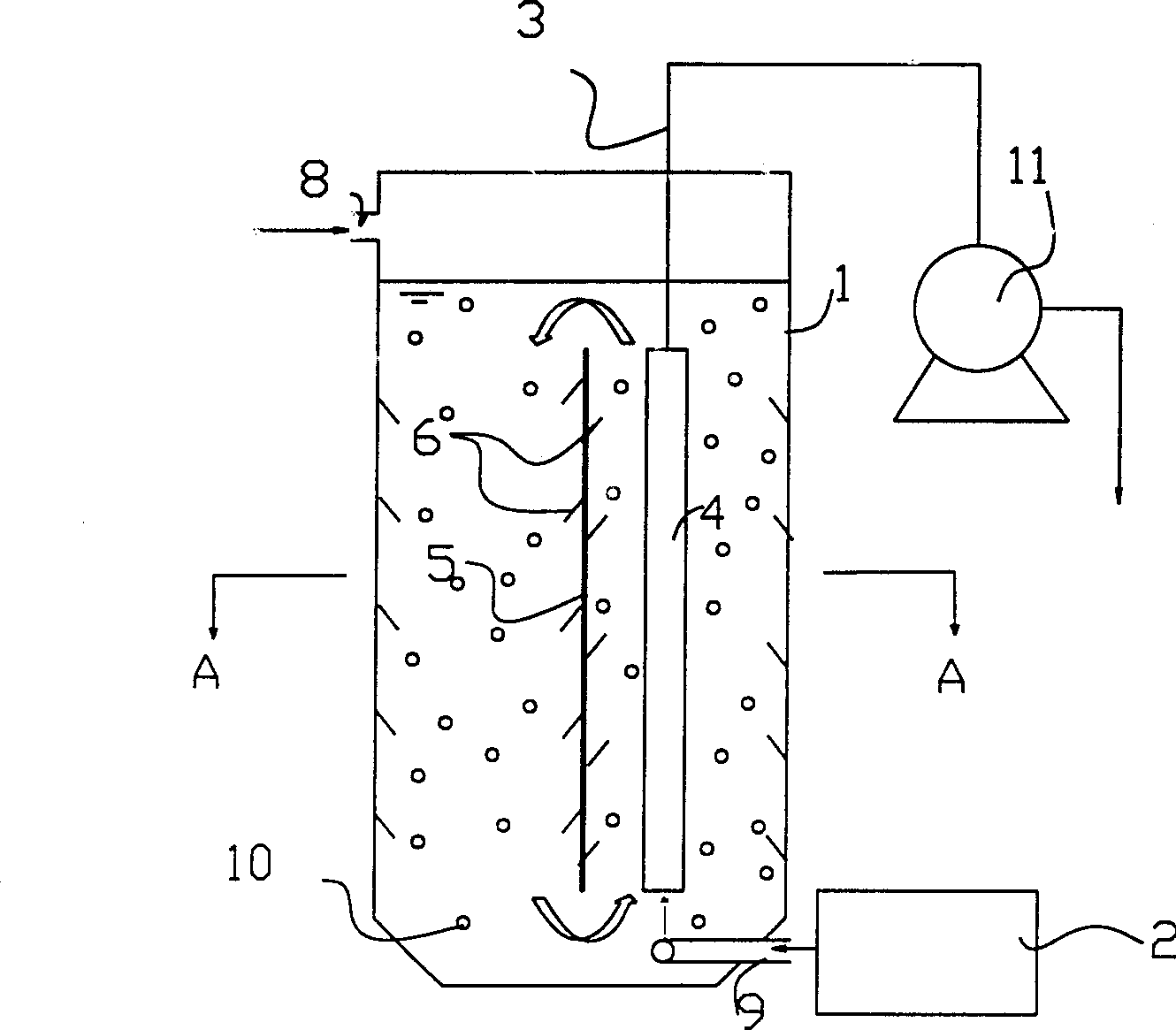

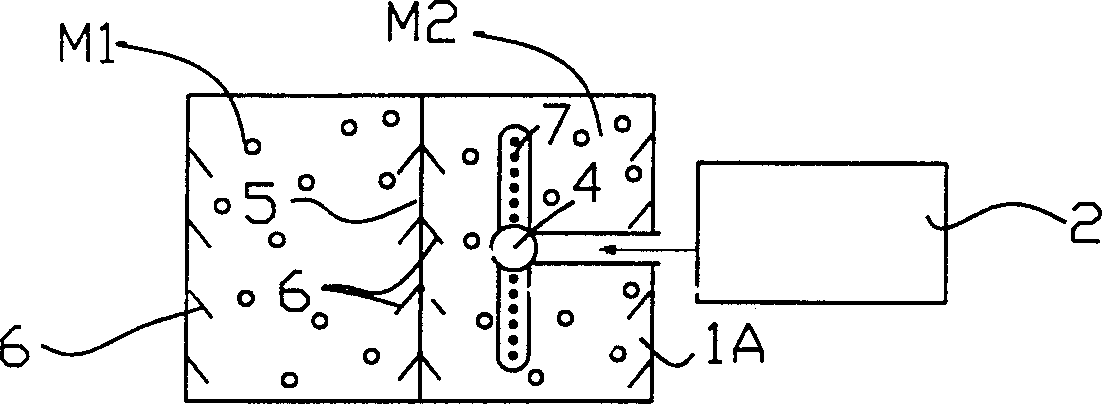

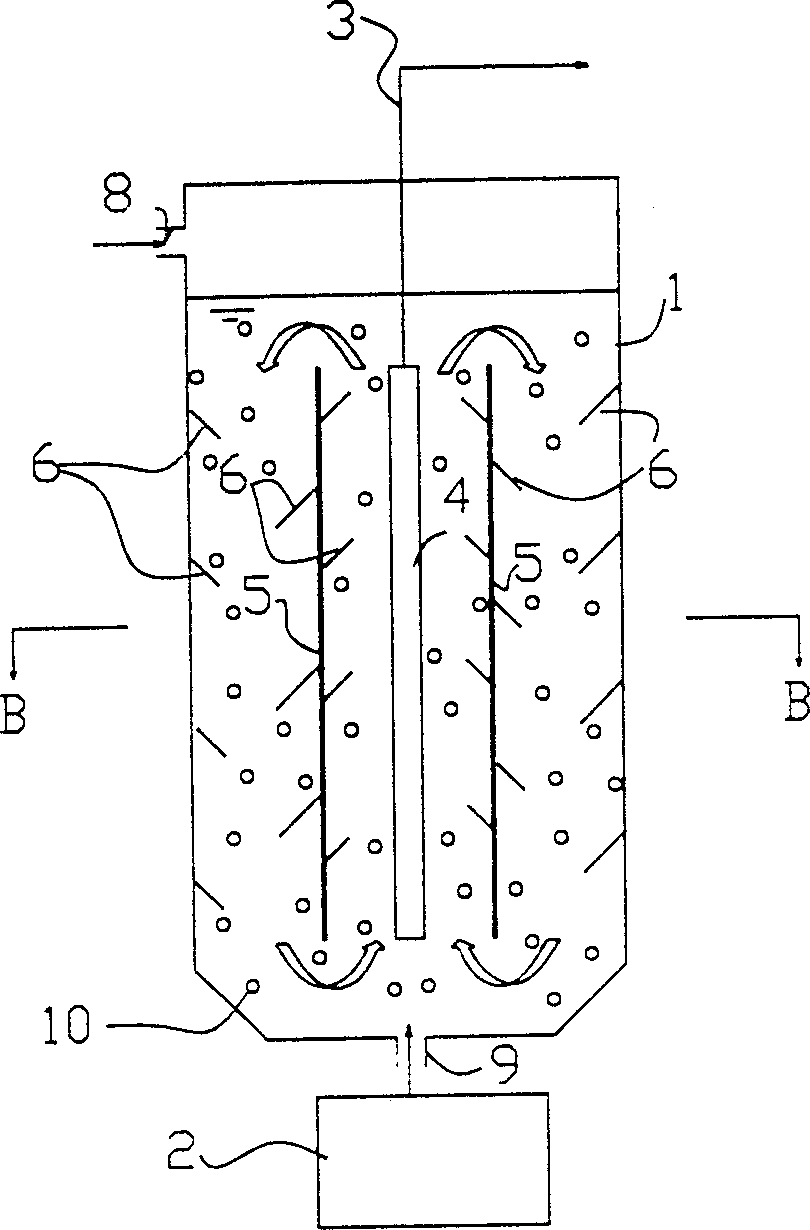

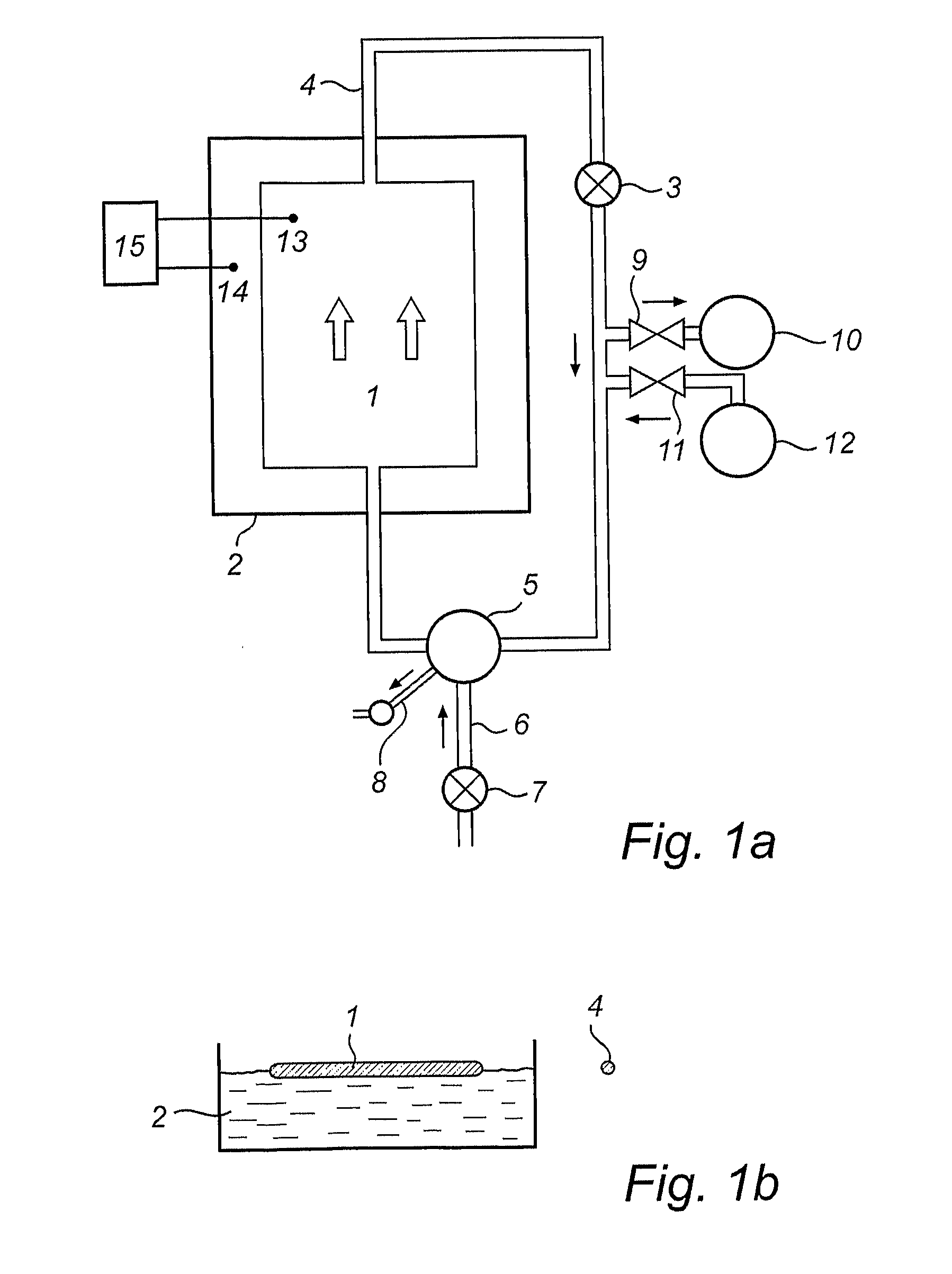

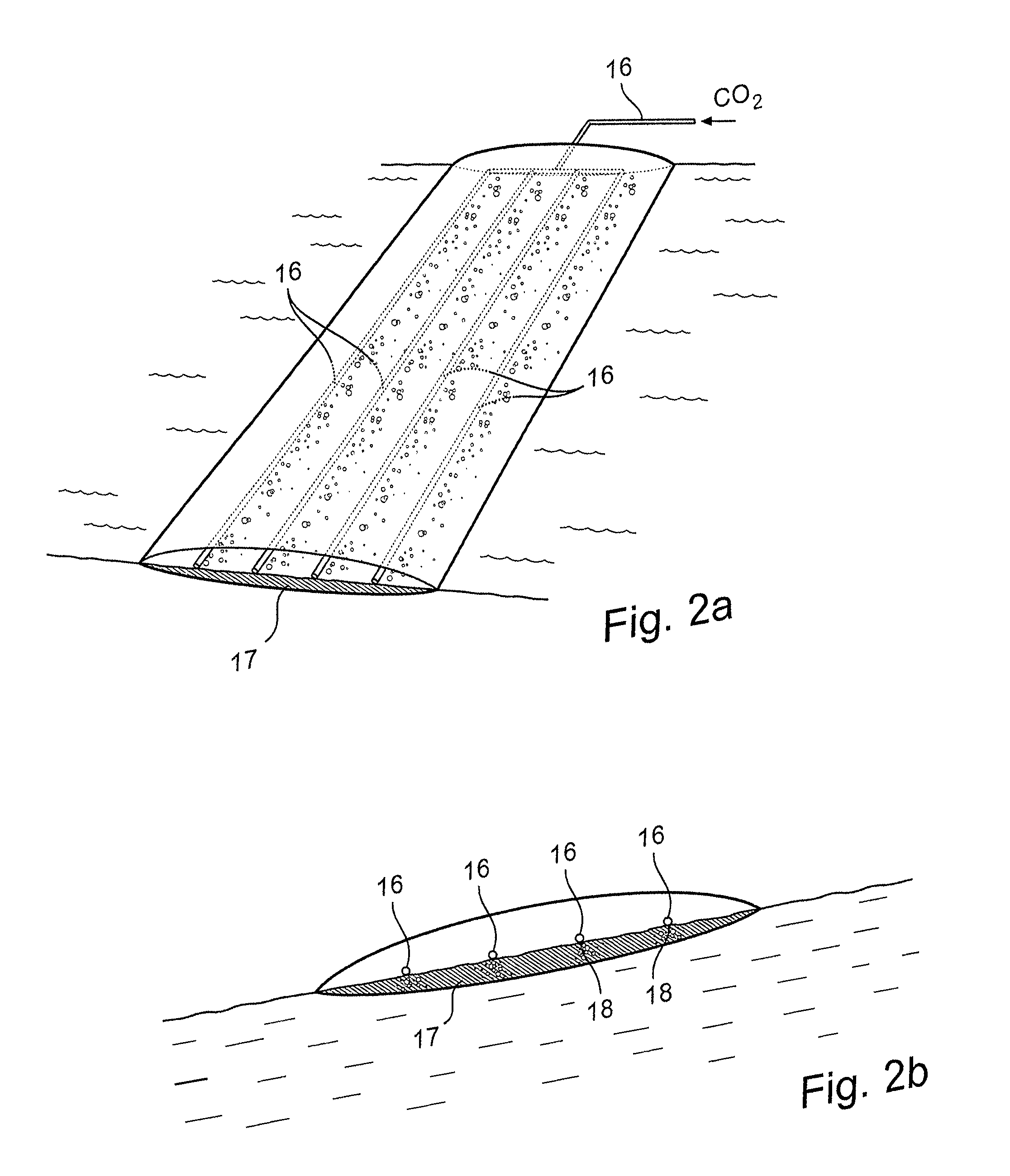

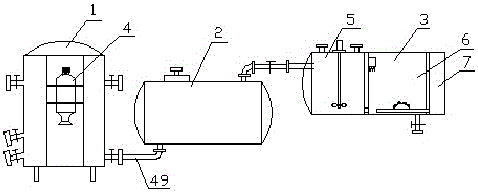

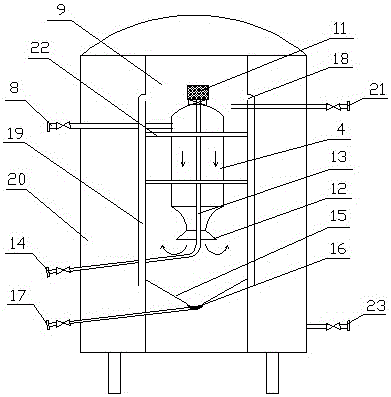

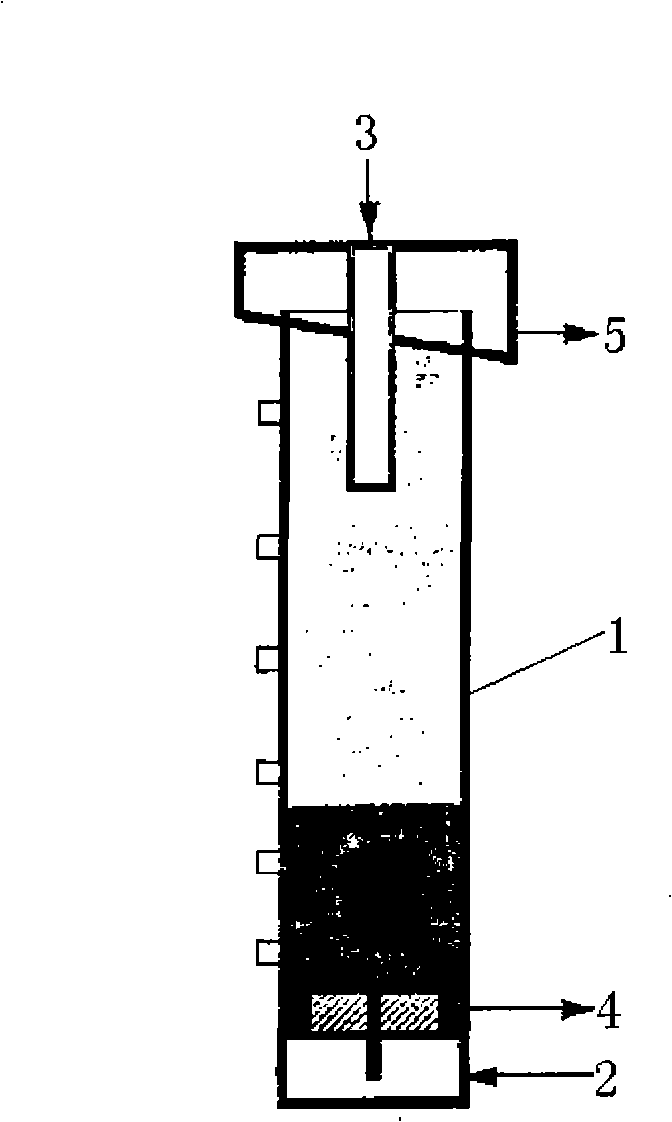

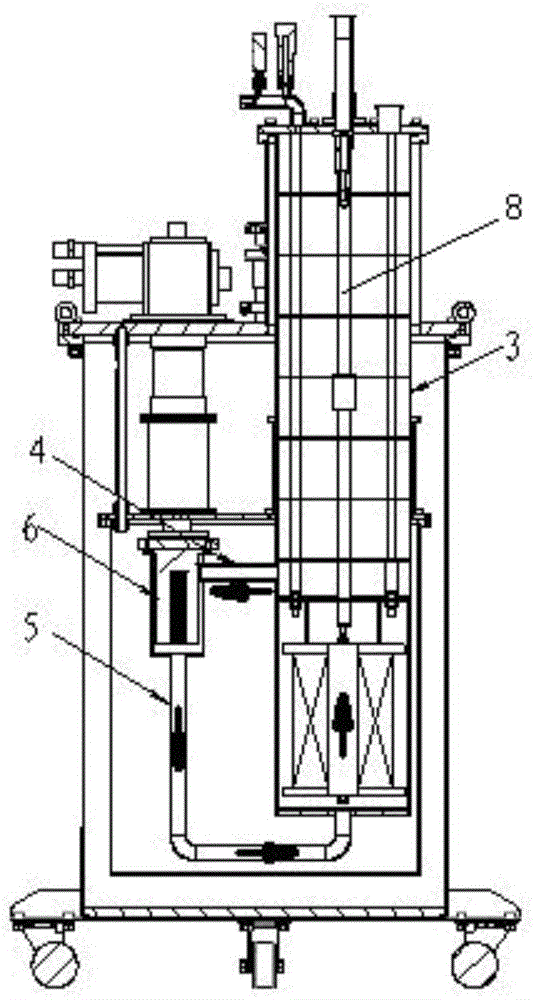

Aeration type photobioreactor and method of use thereof

InactiveCN101497473ALow costTreatment using aerobic processesSustainable biological treatmentDesorptionOxygen

The invention relates to the field of microalgae cultivation engineering, in particular to an aeration type optical bioreactor for cultivating microalgae and a method for applying the same. The bioreactor comprises an annular wading pool, a liquid inlet main pipe, an annular liquid replenishing pipe, an atomization nozzle, a hot water pipe coil, an air inlet main pipe, an annular air inlet trunk pipe, an air distribution branch pipe and an aeration device. The bioreactor is characterized in that density difference between microbubbles generated by the aeration device through aeration and peripheral algae liquid promotes the floating of the microbubbles and the declining of the algae liquid; countless gas liquid generated by the annular wading pool circulates and flows up and down so that the upper layer and the lower layer of the algae liquid are mixed; the floating of the bubbles strengthens desorption of dissolved oxygen in the algae liquid; oxygen is taken to the liquid level by the bubbles and is released; and carbon dioxide gas is aerated and simultaneously dissolved in the algae liquid to provide a carbon source for the growth of the microalgae. The invention combines the advantages of an open type optical bioreactor and a closed type optical bioreactor to form a novel closed type optical bioreactor which can use the carbon dioxide gas as the carbon source and cultivate the microalgae in low cost and large scale.

Owner:上海大祺环保工程有限公司

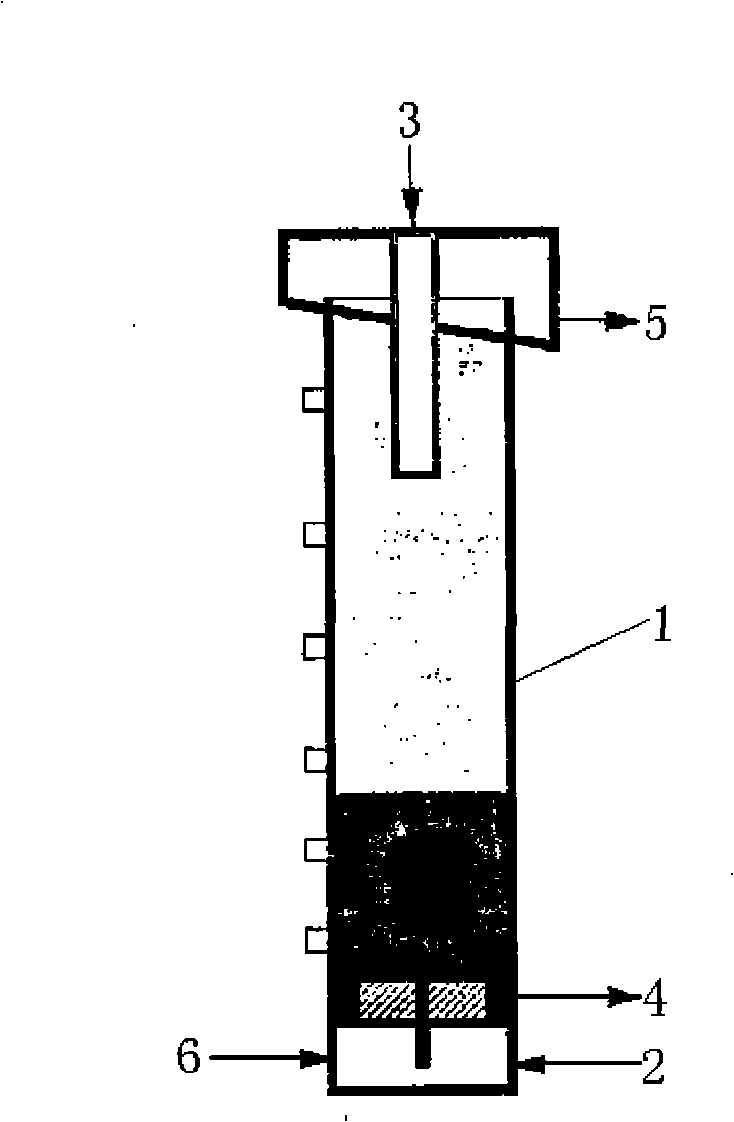

Stuffing-throwing fluidized bed membrane bioreactor and water treating method

InactiveCN1374258ACompact structureImprove degradation efficiencyTreatment using aerobic processesWater/sewage treatment bu osmosis/dialysisCycloneSolubility

The present invention relates to water, including waste water, treating technology. Stuffing with certain specific surface area is thrown into reactor and under sufficient aeration condition and the action of gas density difference, inflecting board and cyclone, the triphase of solid, liquid and gas inside the reactor reaches fluidized state and forms cyclonic circulation. the adsorption and growth of microbes on the stuffing results in even high organic matter eliminating efficiency and the stuffing has certain adsorption to soluble organic matter in water. The suspended microbes in the bioreactor and those in the surface of membrane are reduced. The present invention is especially suitable for use in relatively lower organic matter density. Compared with traditional membrane bioreactor,the present invention can avoid the pollution to membrane and make system operate more stably and at lower power consumption.

Owner:TSINGHUA UNIV

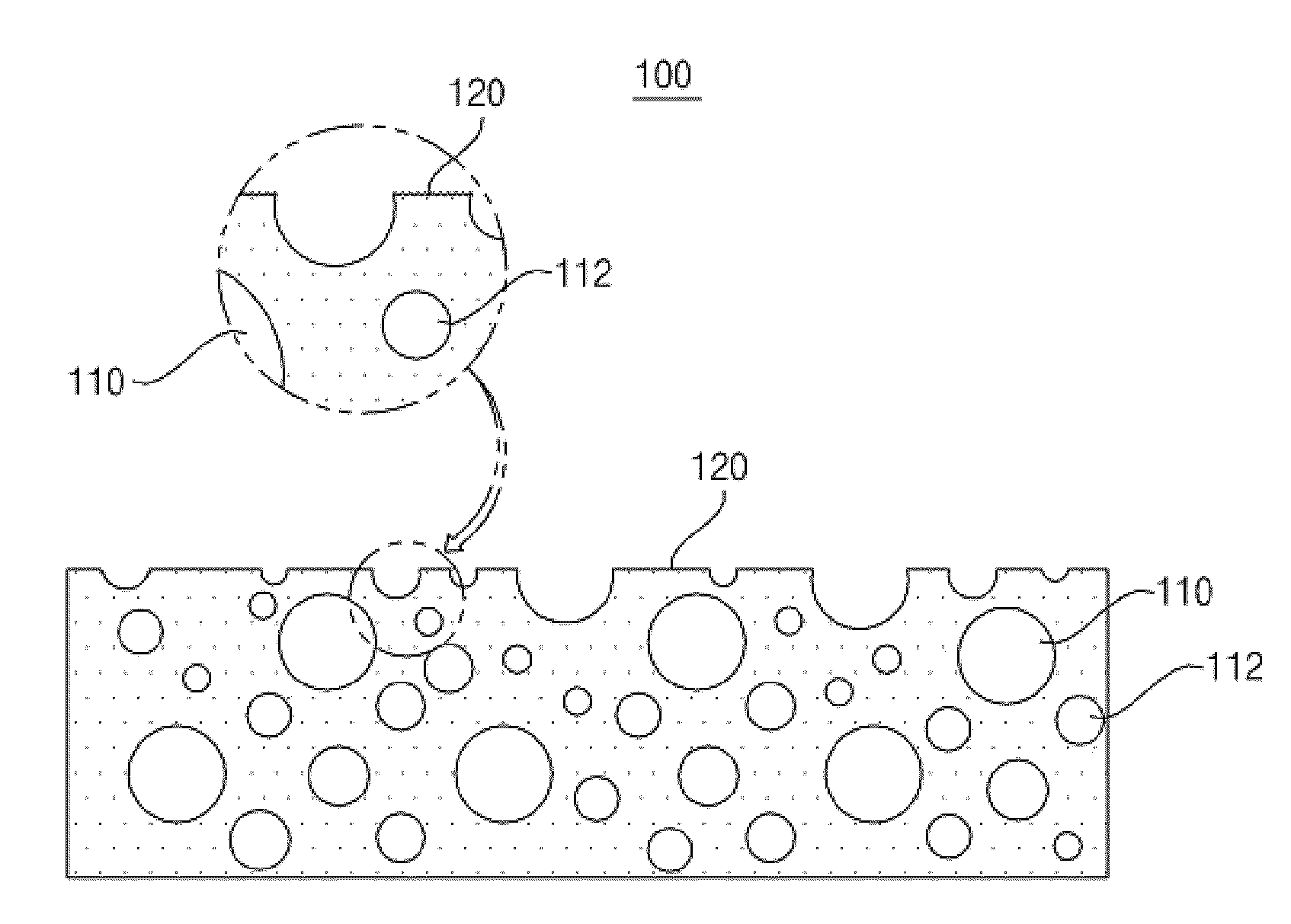

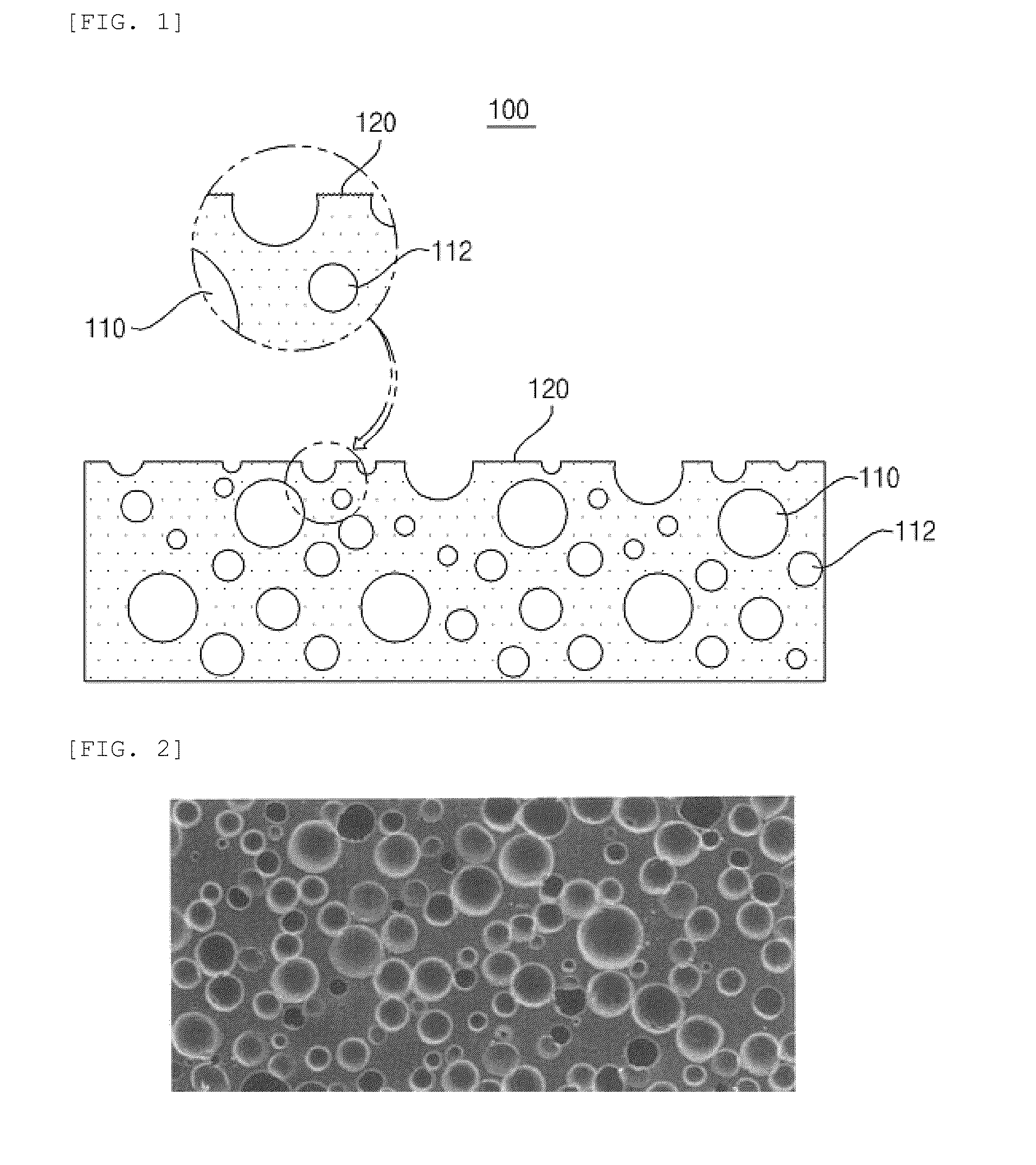

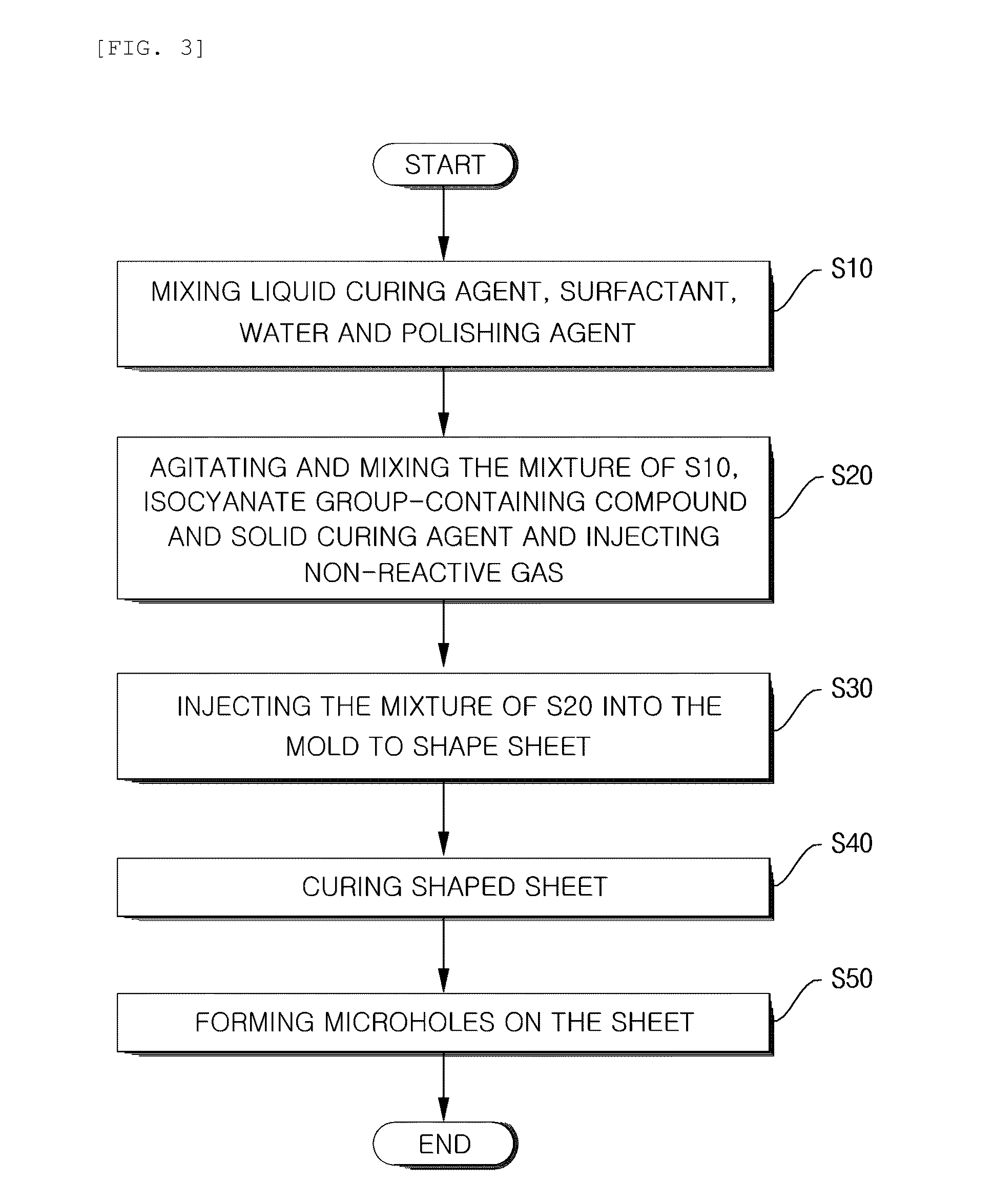

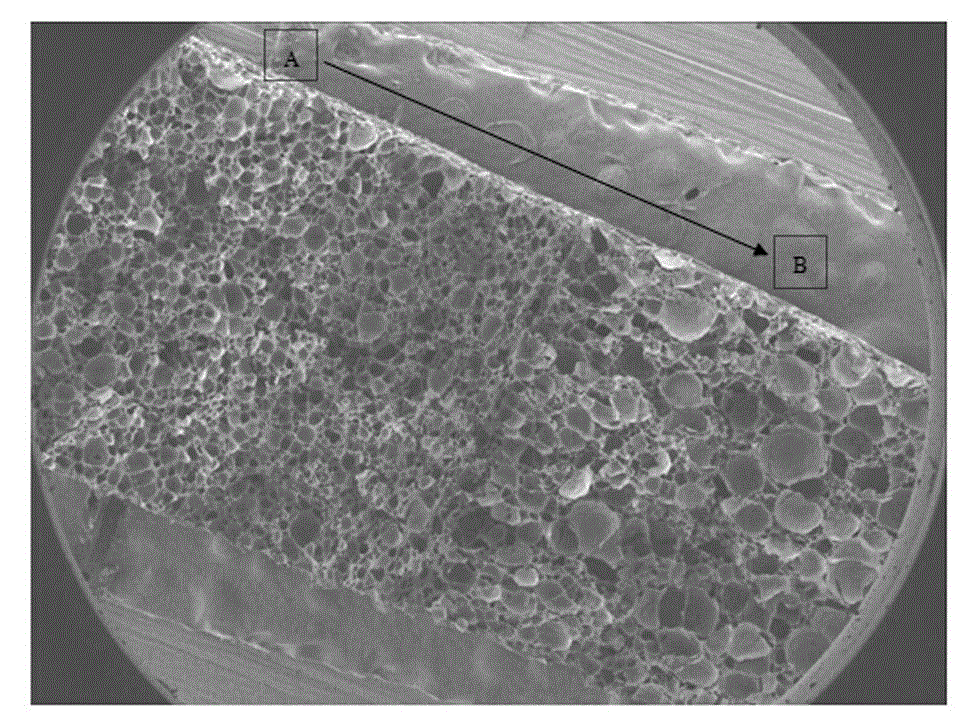

Polyurethane porous product and manufacturing method thereof and polishing pad having polyurethane porous product

InactiveUS20100247868A1Improve stabilityImprove uniformitySynthetic resin layered productsAbrasion apparatusIn planeHardness

The present invention relates to a method for manufacturing a polyurethane porous product, a polyurethane porous product according to the manufacturing method, and a polishing pad having the polyurethane porous product. According to the present invention, it is possible to manufacture a polishing pad that has excellent polishing efficiency and has a minimal difference in the polishing characteristic during a polishing process and improves uniformity in plane of material that will be polished because the polyurethane porous product of the present invention has small density difference, small hardness difference, and the stabilized quality of material.

Owner:CHA YOON JONG +1

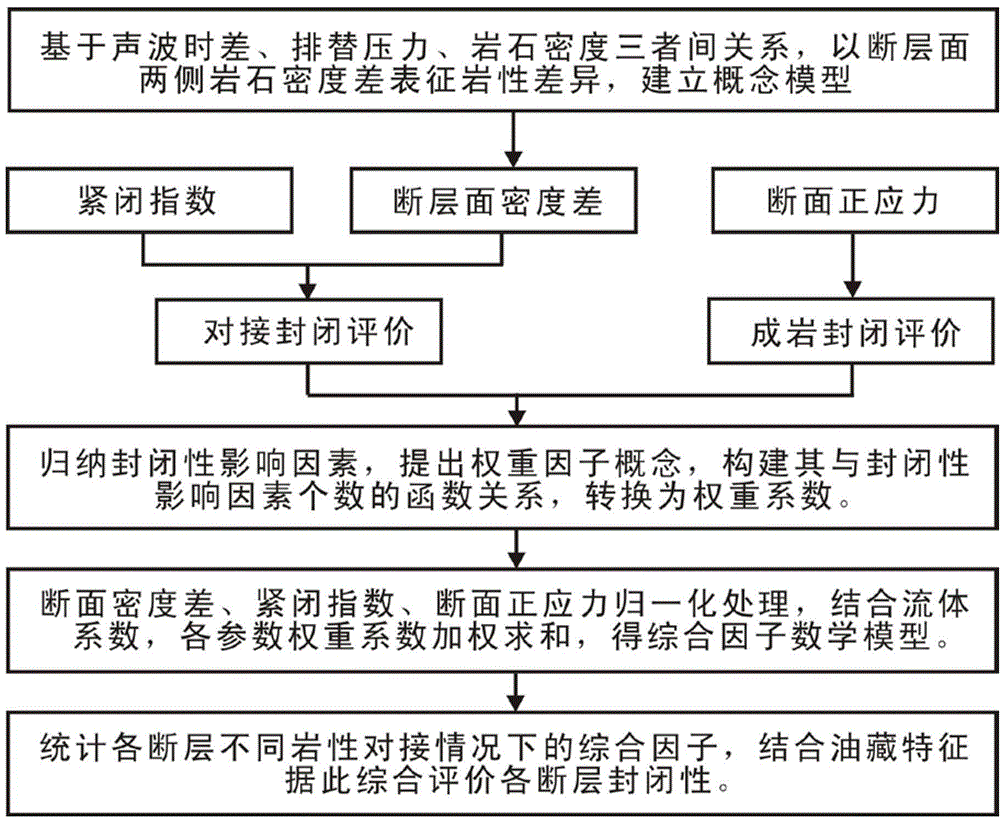

Volcanic zone fault sealing comprehensive evaluation method

InactiveCN104914481ASure objectiveReduce uncertaintyGeological measurementsFracture zoneWeight coefficient

The invention discloses a volcanic zone fault sealing comprehensive evaluation method specifically based on Karamay oilfield volcanic rock development area. A volcanic zone fault sealing forming mechanism is mainly lithologic opposition and diagenesis. A lithologic opposition characteristic can be reflected in the aspect of the difference between the density of rock stratums on both sides. The diagenesis of a fault zone is affected by cross section pressure, closeness and the like. Through the filling of argillaceous debris and the injection of late fluid, the fault zone is strongly closed. According to the invention, a concept model of fault plane density difference is established; a variety of parameters (cross section normal stress, closeness index and the like) are combined to evaluate diagenesis closeness and docking closeness; closeness influence factors are induced; a weight factor is proposed; through a weight coefficient, a mathematical model is built to acquire a comprehensive factor; and the fault sealing is comprehensively evaluated. According to the invention, a variety of geological factors are considered; accurate requirements of fault sealing quantitative evaluation can be met; and the method can be widely applied to the field of oil and gas resource geological exploration and development evaluation.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

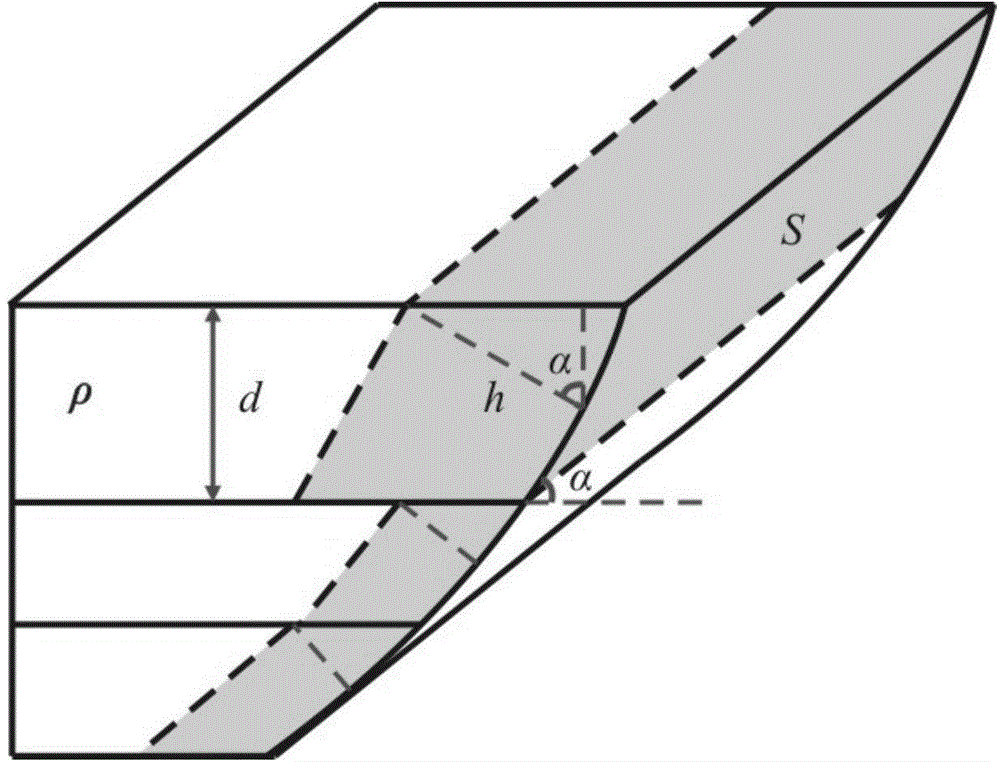

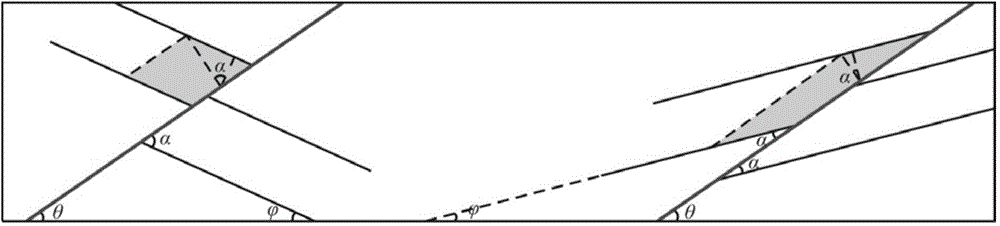

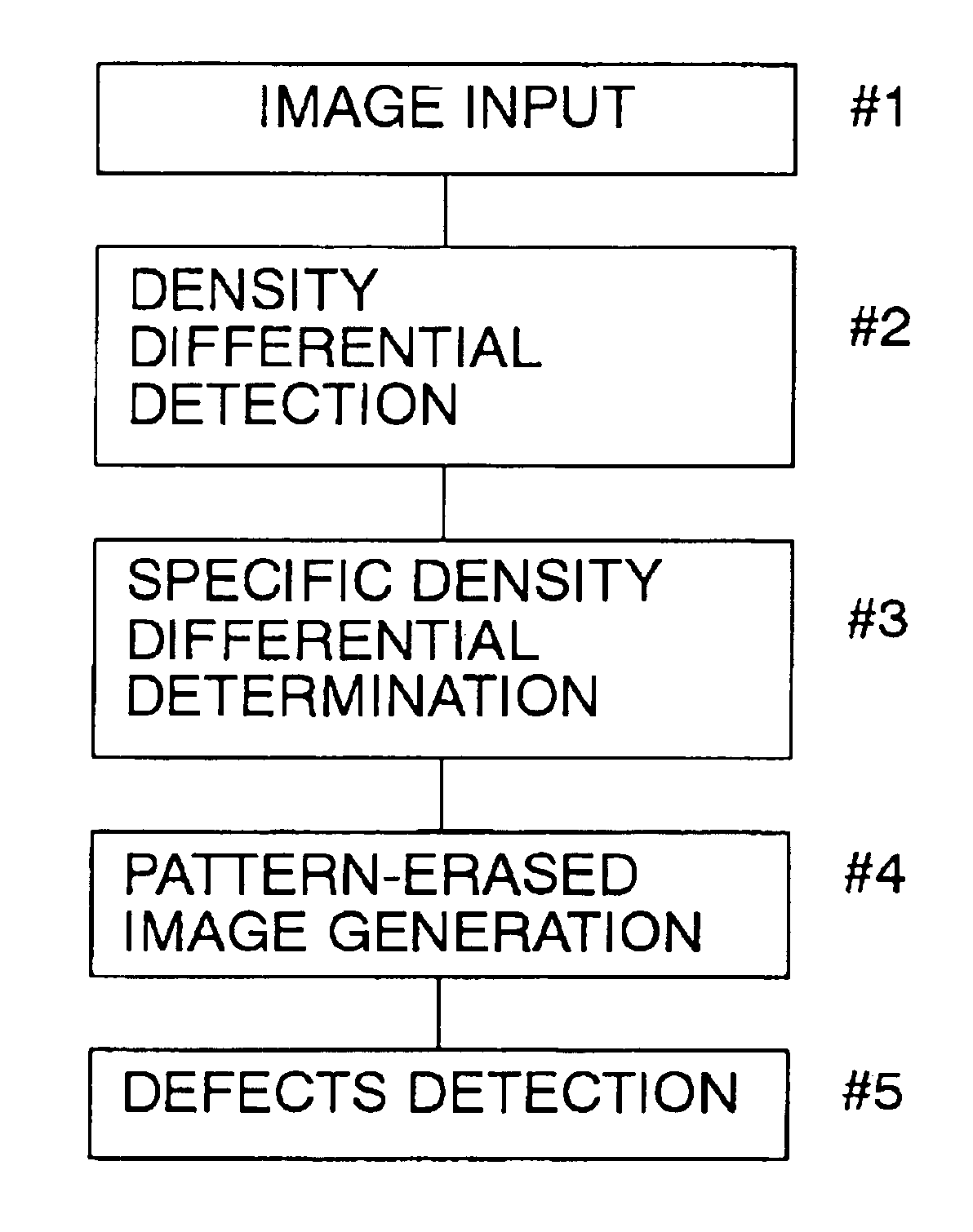

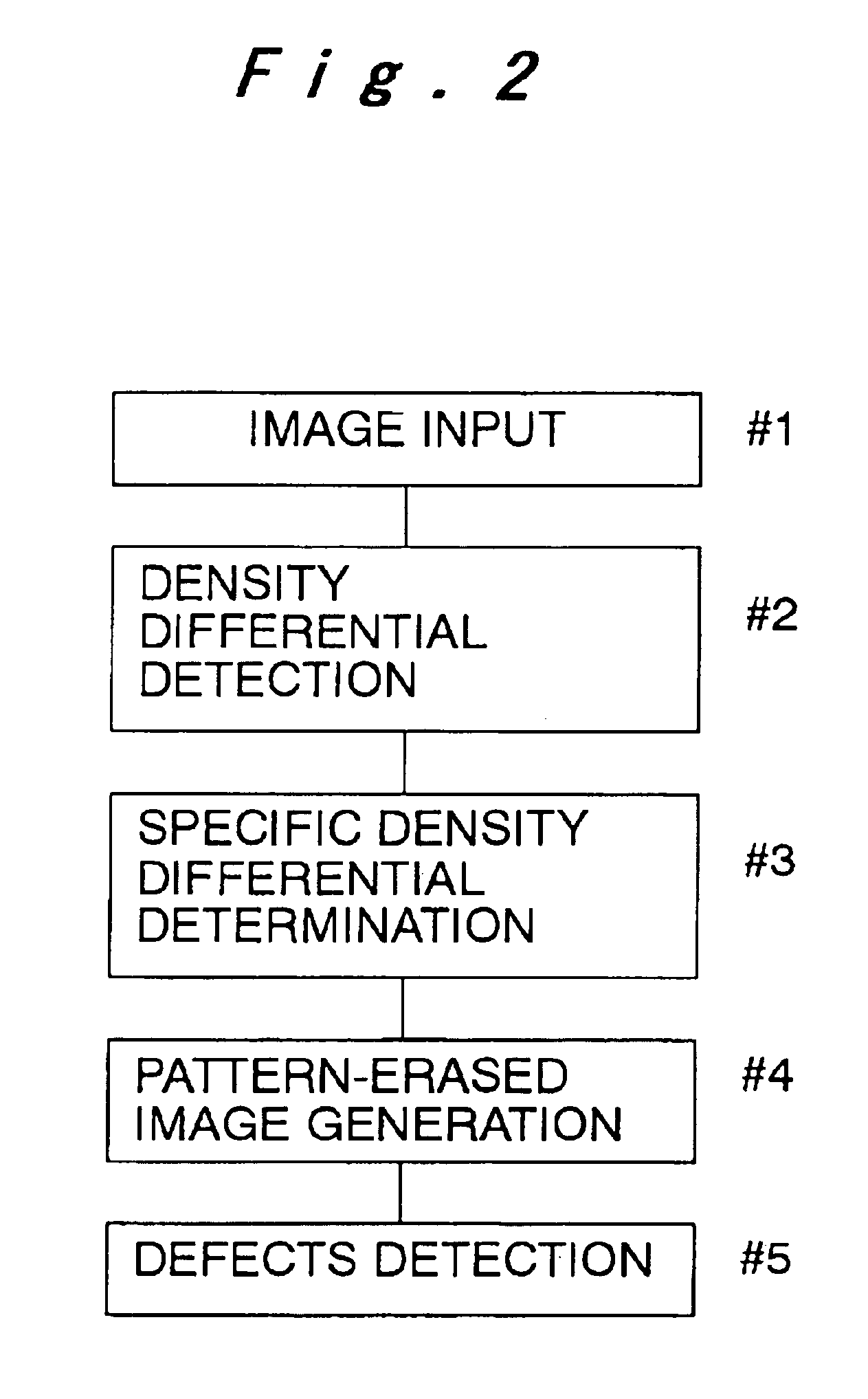

Method of erasing repeated patterns and pattern defect inspection device

An image of a subject of inspection is picked up, and this image is demarcated into a plurality of areas. Density differences are found between reference pixels and a plurality of comparison pixels in the demarcated areas, and a density difference that is closest to 0 is determined as a specific density difference. The specific density difference is then applied to the reference density in the image of the subject, whereby repeated patterns in the image are erased.

Owner:PANASONIC CORP

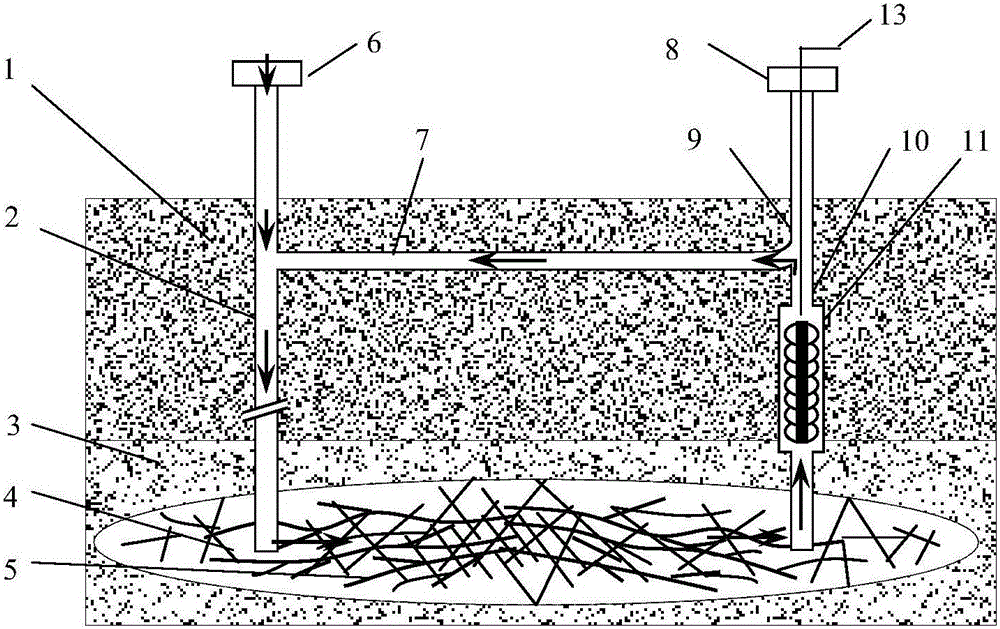

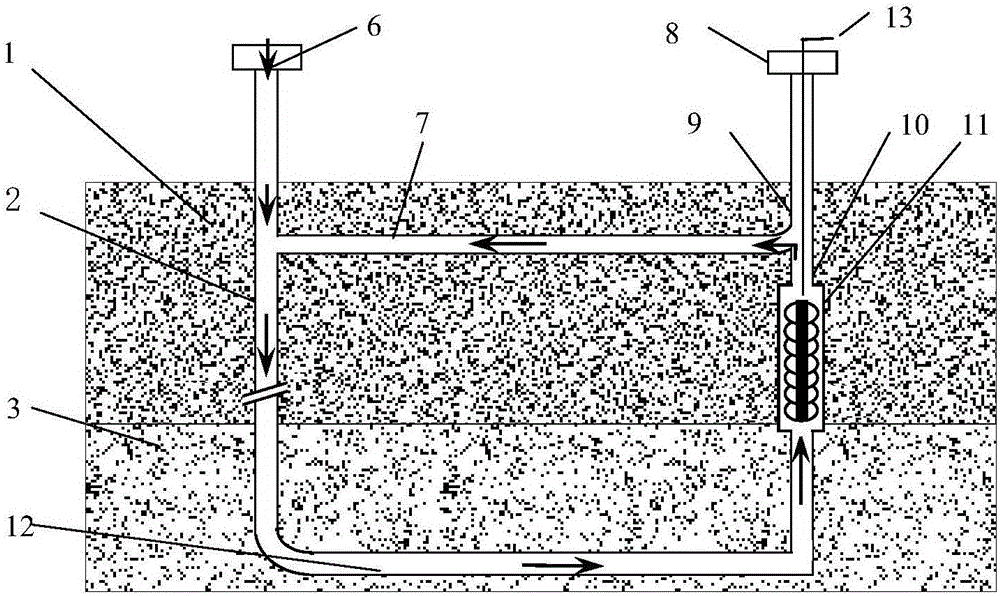

Method for exploring dry-hot-rock geotherm through underground heat siphon self-circulation

InactiveCN105863568ALow densityGo undergroundOther heat production devicesGeothermal energy generationSiphonGeothermal exploration

The invention relates to the field of geothermal exploitation and provides a method for exploring dry-hot-rock geotherm through underground heat siphon self-circulation. The method includes the steps that a heat-carrying medium circular flowing channel is built underground, and self-circulation flowing of the heat-carrying medium in the underground channel is achieved by fully utilizing the phenomenon of heat siphon caused by the density difference of the heat-carrying medium at various temperature differences. The circular flowing channel can be achieved by drilling two horizontal well holes in different depth positions of an injection and production well, and can also be achieved by fracturing fractures and an upper horizontal well hole of the well bottom injection and production well. The heat-carrying medium flowing in a circulating mode drives a turbine generator to rotate for power generation in the flowing process, and accordingly the dry-hot-rock geothermal energy is explored as electric energy. According to the method, the heat siphon phenomenon of the heat-carrying fluid is fully utilized, underground self-circulation flowing is achieved, extra power from the outside is not needed, and the method is suitable for geothermal exploration of dry-hot-rock reservoirs with high reservoir temperature and severe ground environment.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

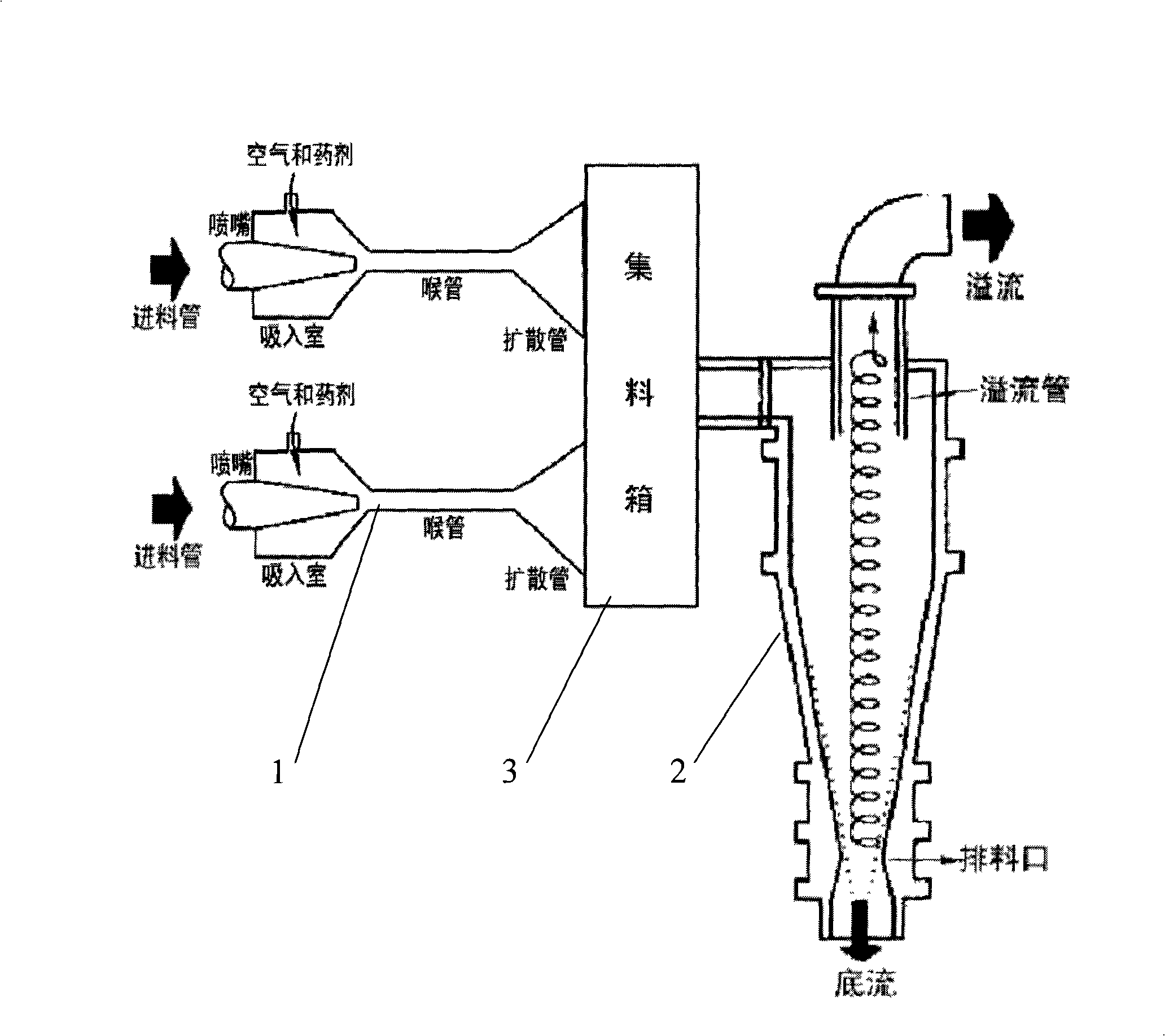

Microbubble swirl separation method and divice

InactiveCN101306398AMeet the requirements for separationSimplify the sorting processFlotationWet separationMicro bubbleVolumetric Mass Density

The invention discloses a micro-bubble rotational flow separation method and the separation equipment, and belongs to the flotation and the separation fields. The invention applies the principles of the air floating separation method and the swirl nozzle separation method, ore pulp preprocessed by a flotation agent passes through a bubble generator before entering a swirl nozzle, micro-bubble is added into the ore pulp, the bubble and the ore pulp collide and are mineralized, and a three-dimensional elliptic type strong rotating shear turbulent motion is generated after the mixed liquor tangentially enters the swirl nozzle from the periphery of the swirl nozzle with a certain pressure,. Because of the granularity difference (density difference) between the coarse grains (heavy phase) and the fine grains (light phase), the centrifugal force, the centripetal buoyancy force, and the fluid drag force are different, most of the coarse grains (heavy phase) are separated from the bubble and discharged from the bottom opening of the swirl nozzle under the action of centrifugal settling, and most of the fine grains (light phase) are carried by the bubble and discharged from an overflow pipe, thereby realizing the purposes of separation and grading. The micro-bubble rotational flow separation method has the advantages of simplified separation process and device and enhanced processing capacity.

Owner:SHANGHAI DATUN ENERGY

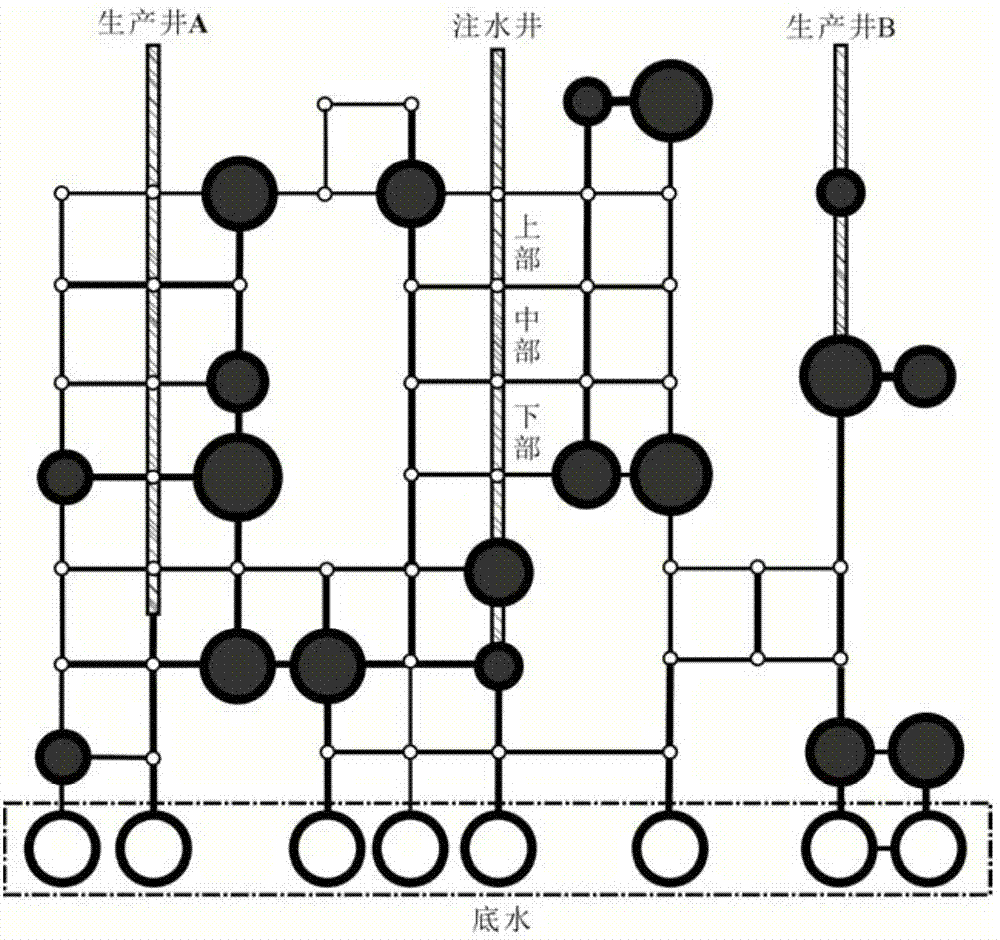

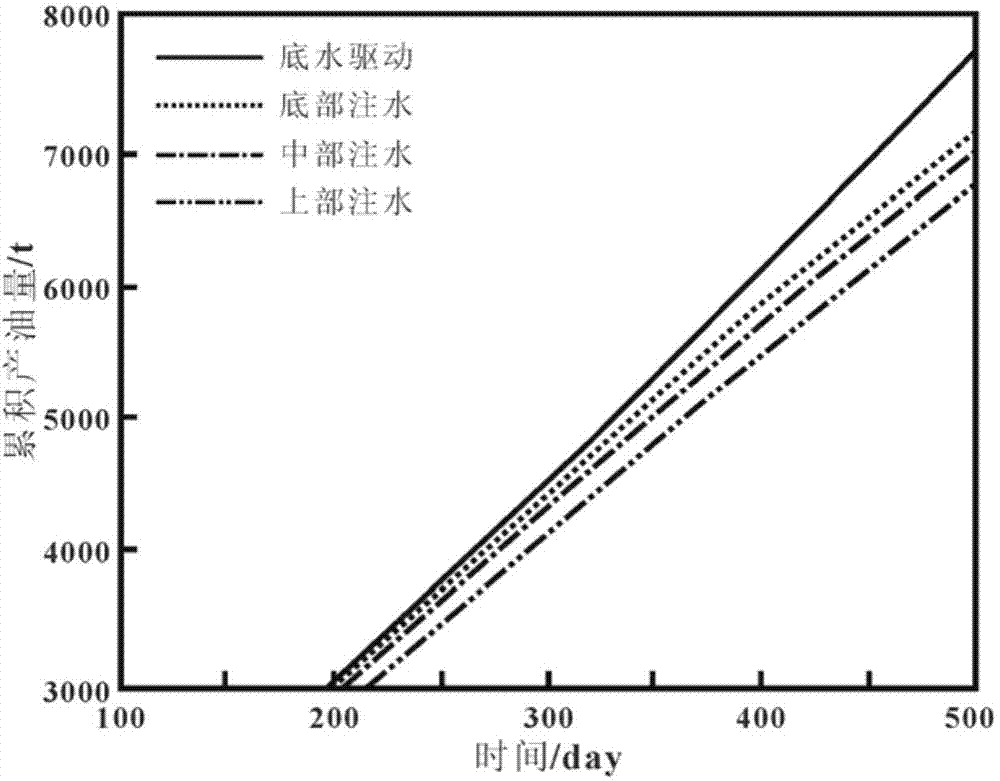

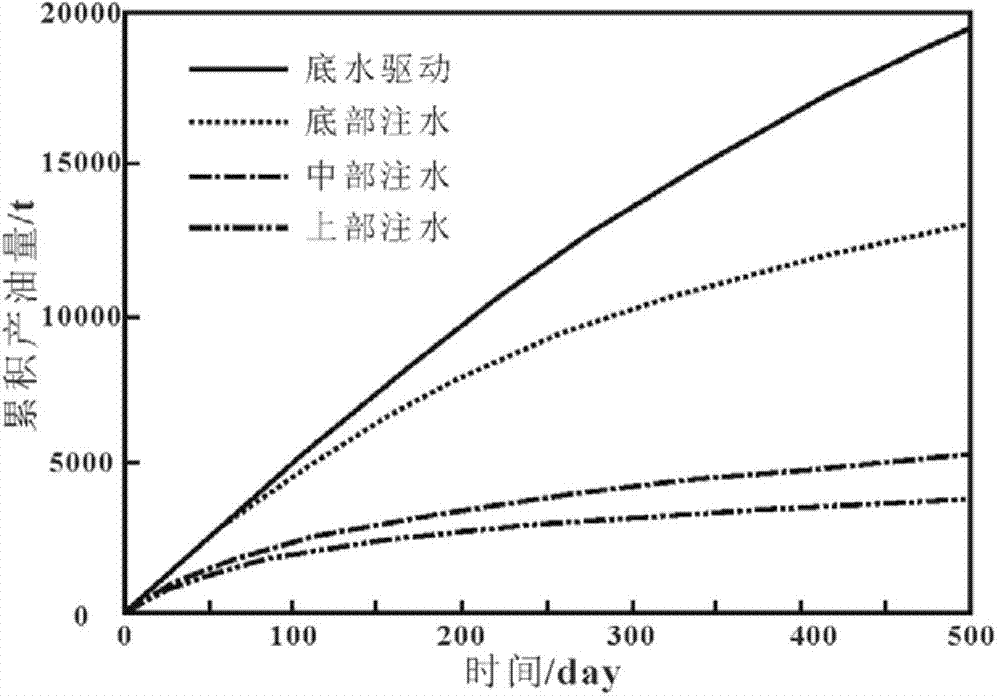

Fracture-cavity type oil deposit analyzing method for water-flooding development and application thereof

ActiveCN104747180AImprove accuracyFully reflect the impact of development lawsFluid removalDecision takingEngineering

The invention relates to a fracture-cavity type oil deposit analyzing method for water-flooding development and application thereof. According to the method, history matching is conducted on a first geologic feature parameter of multiscale reservoir bodies constructing a multiscale reservoir body distribution conceptual model to obtain a second geologic feature parameter of the multiscale reservoir bodies constructing the finely drawn multiscale reservoir body distribution geologic model. In history matching, the independent representation multi-sided conductivity is adopted for dealing with the influence caused by connection position differences of different side fractures and caves on the oil water flowing rule; the virtual time step is adopted for reflecting the oil water replacement momentary balancing effect caused by oil water density difference; for anisotropy characters of the fractures, the tensor permeability of an arbitrarily fracture of the space is obtained by the adoption of conversion of a geodetic coordinate system and a space coordinates system. The fracture-cavity type oil deposit analyzing method for the water-flooding development is used for conducting fracture-cavity type oil deposit water-flooding development and decisions, the geologic model is more accurate, the flowing rule and the oil-displacement mechanism are more complete, and optimized decision through technologies and development effect predication are more accurate and reliable.

Owner:CHINA PETROLEUM & CHEM CORP +1

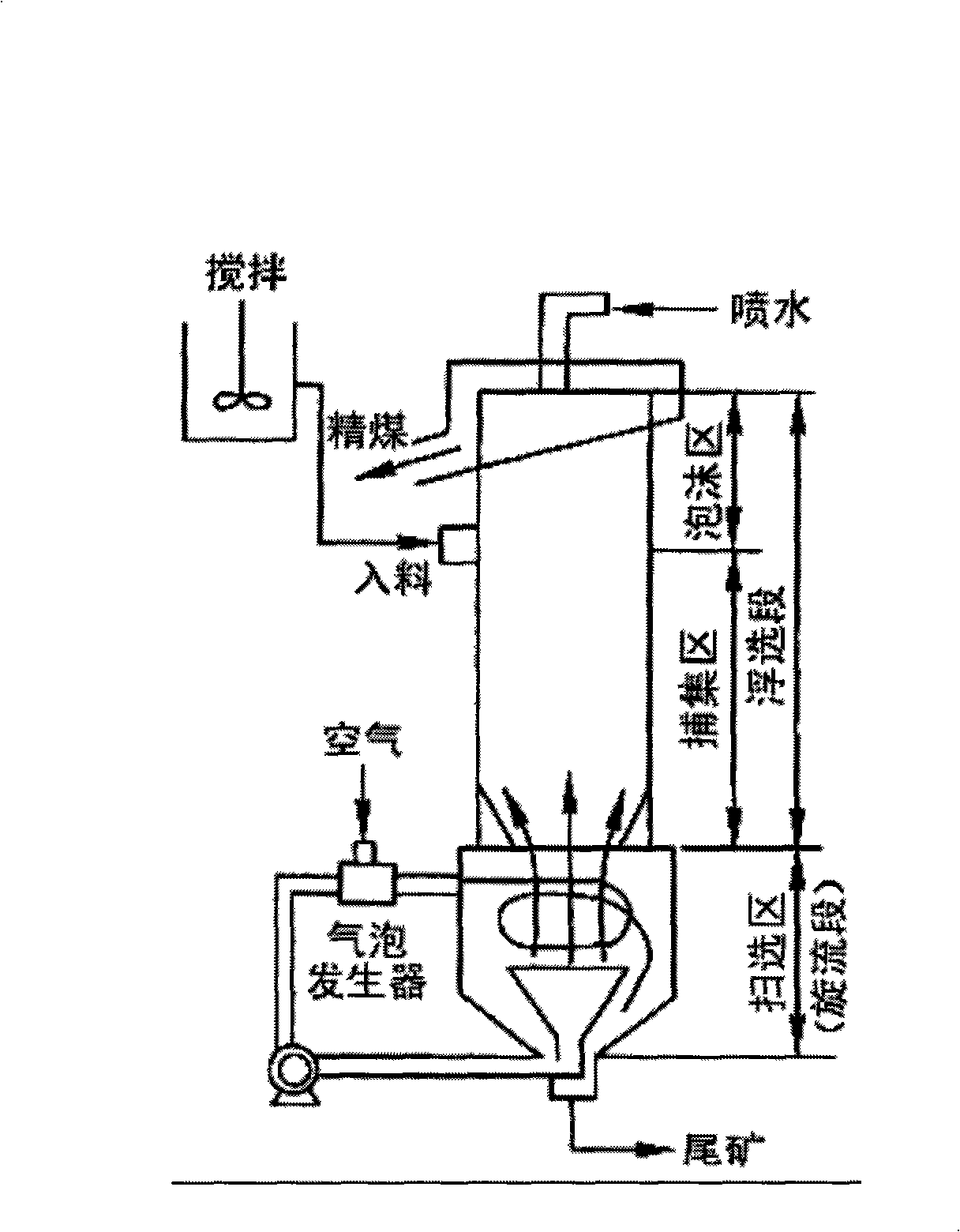

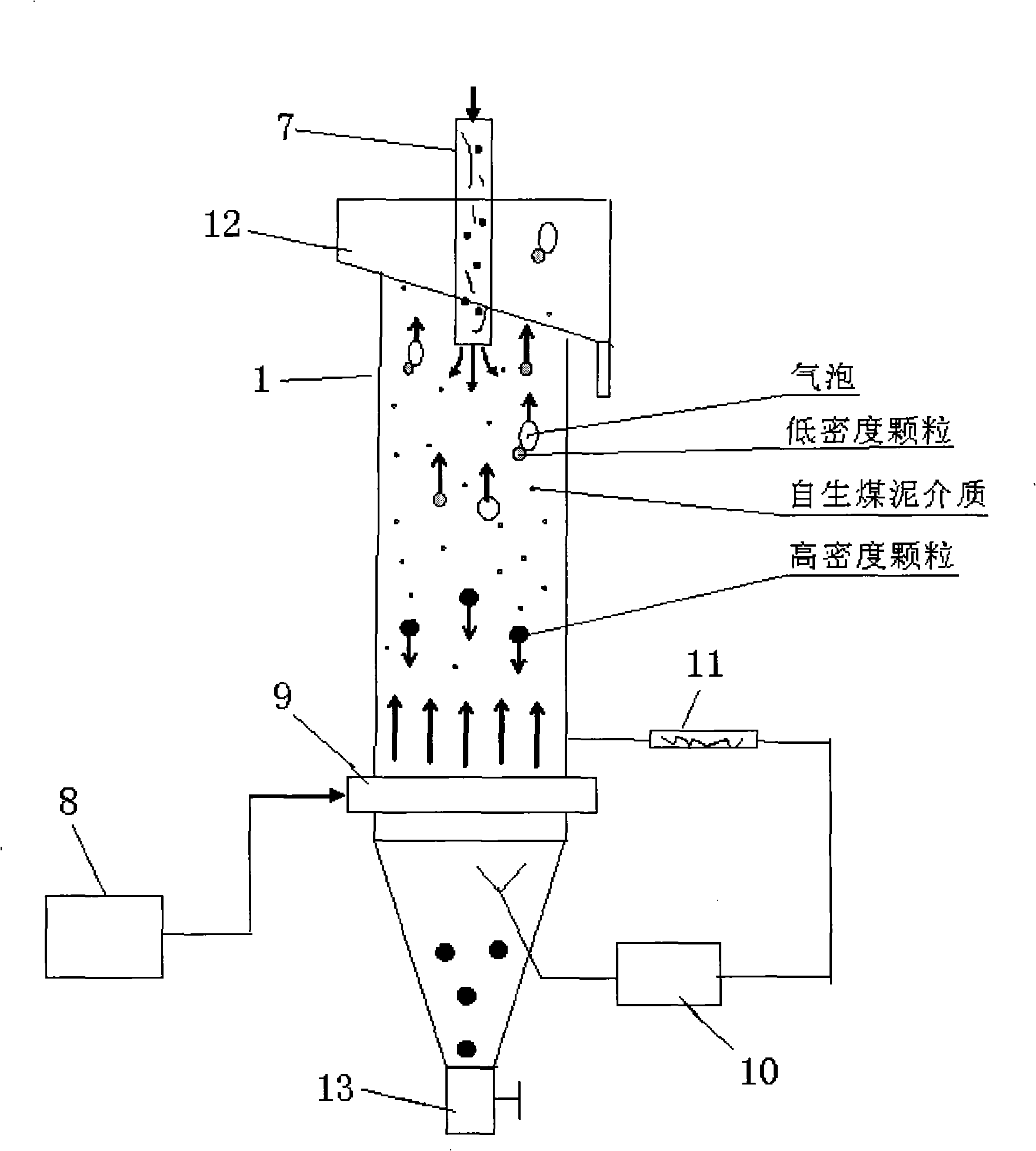

Gas-liquid-solid three-phase fluidized bed sorting machine and sorting method thereof

ActiveCN103657839AHigh sorting accuracyImprove loosenessFlotationWet separationAutomatic controlEngineering

The invention provides a gas-liquid-solid three-phase fluidized bed sorting machine and a sorting method thereof. The sorting machine comprises a sorting barrel, a center feeding barrel, a conical distribution plate, a fine coal overflow collecting tank, a bubble generator, a fluid distribution master and branch pipe, a buffering and discharging fluid distribution plate, a bed online densimeter, a programmable density controller, an underflow discharging automatic control actuator and an underflow discharging valve. The sorting method includes the steps that water flow passes through the bubble generator and the fluid distribution master and branch pipe and enters the sorting barrel and a uniform and stable ascending gas-liquid two-phase fluid is formed in the sorting barrel under the action of the buffering and discharging fluid distribution plate, and materials entering the sorting barrel are separated according to differences of density and surface properties, so that sorting precision of the materials according to density differences is improved, and the loss that low-density rough particles enter underflow and the defect that high-density fine silt pollutes fine coal are effectively avoided. The gas-liquid-solid three-phase fluidized bed sorting machine is simple in structure and method, low in sorting lower limit, wide in processing particle range, high in sorting precision, high in reliability and wide in applicability.

Owner:CHINA UNIV OF MINING & TECH

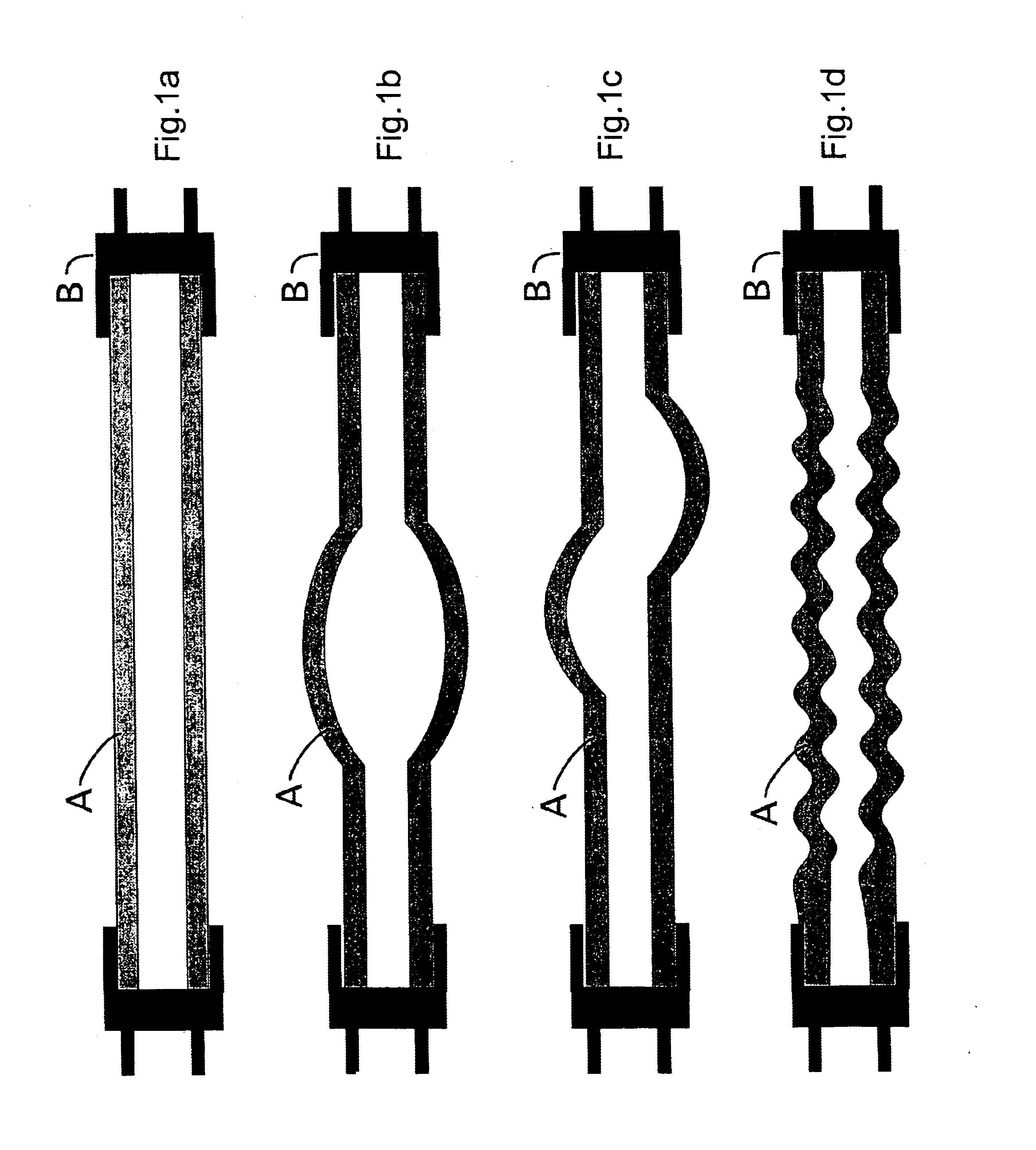

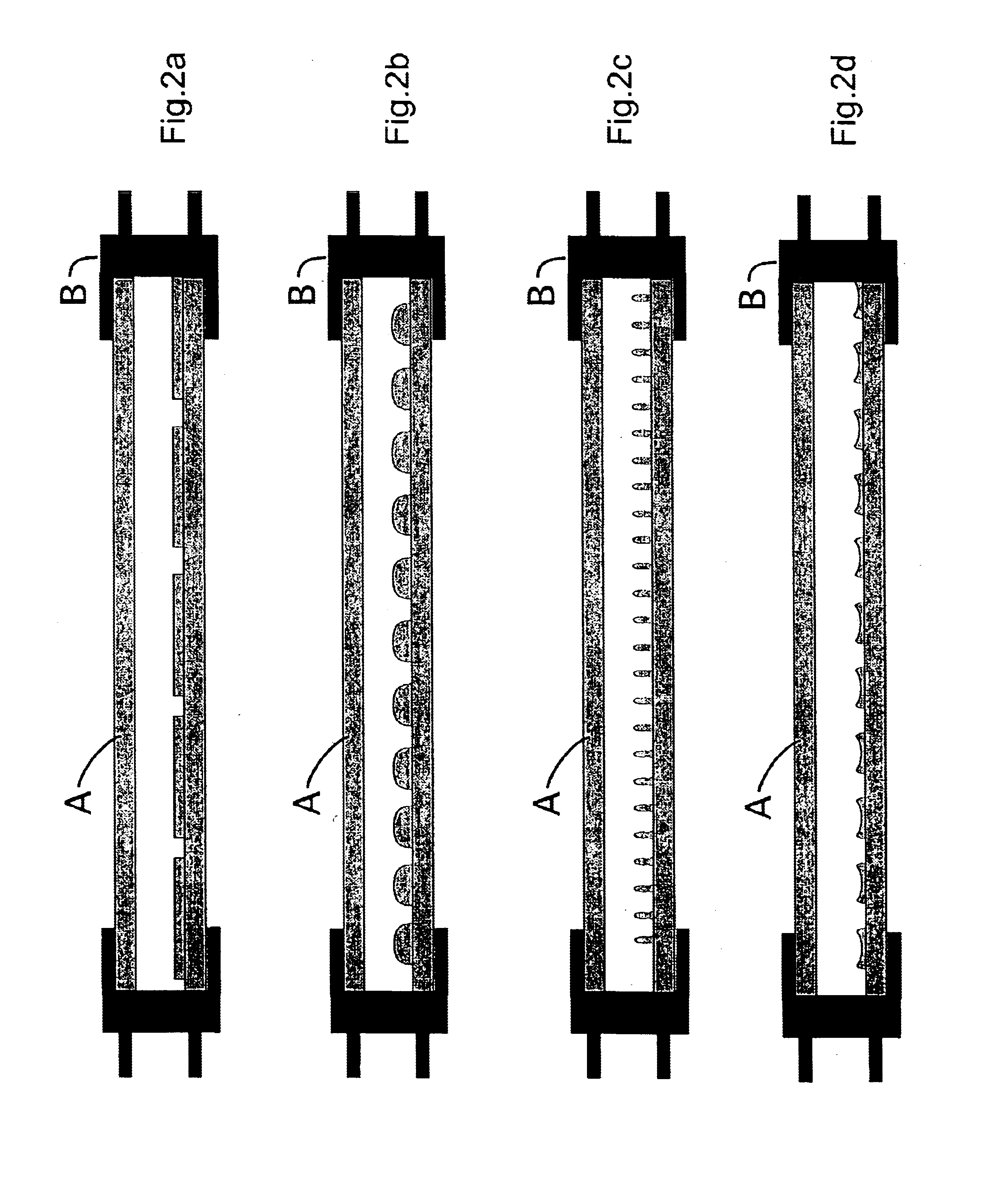

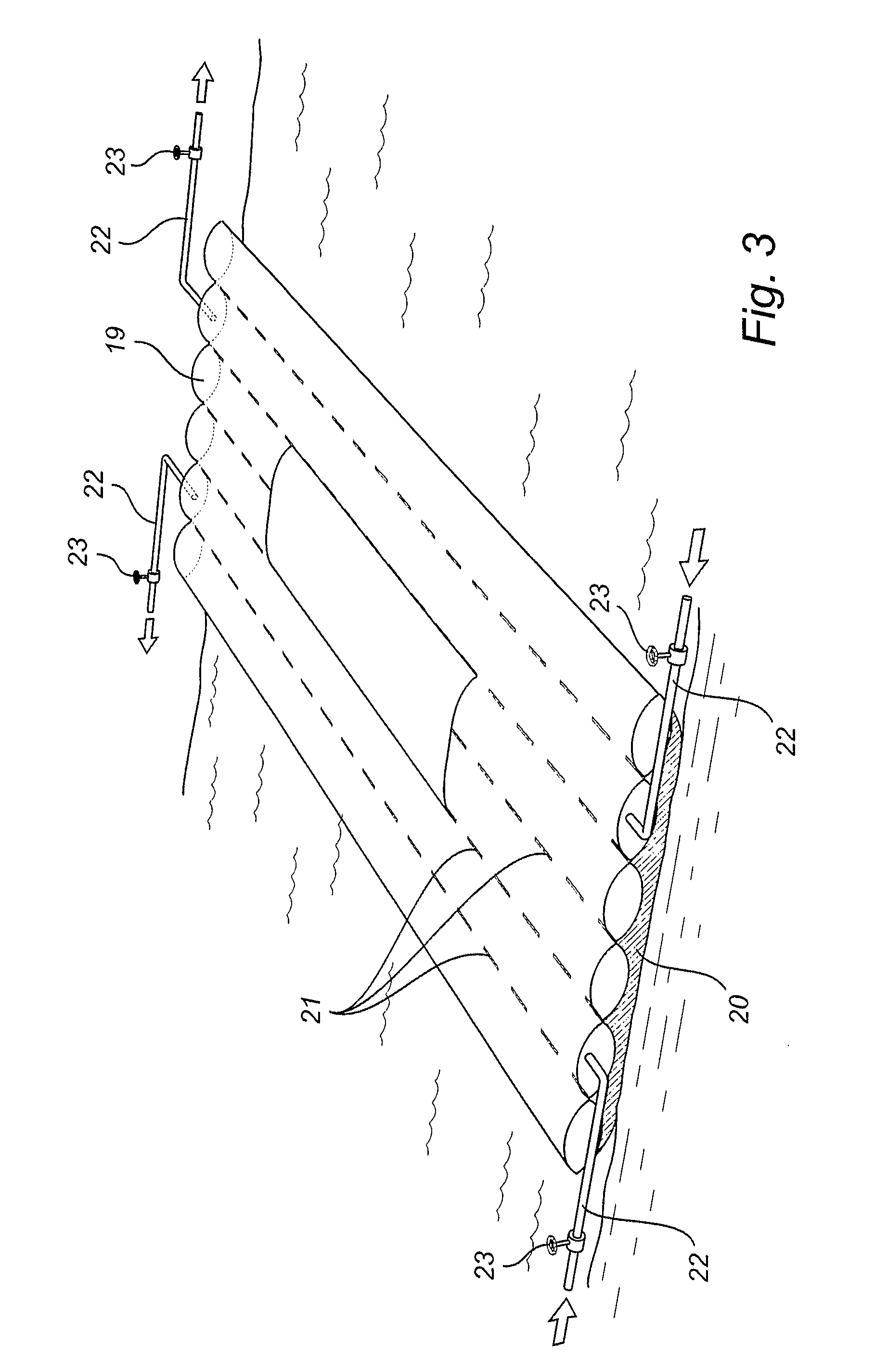

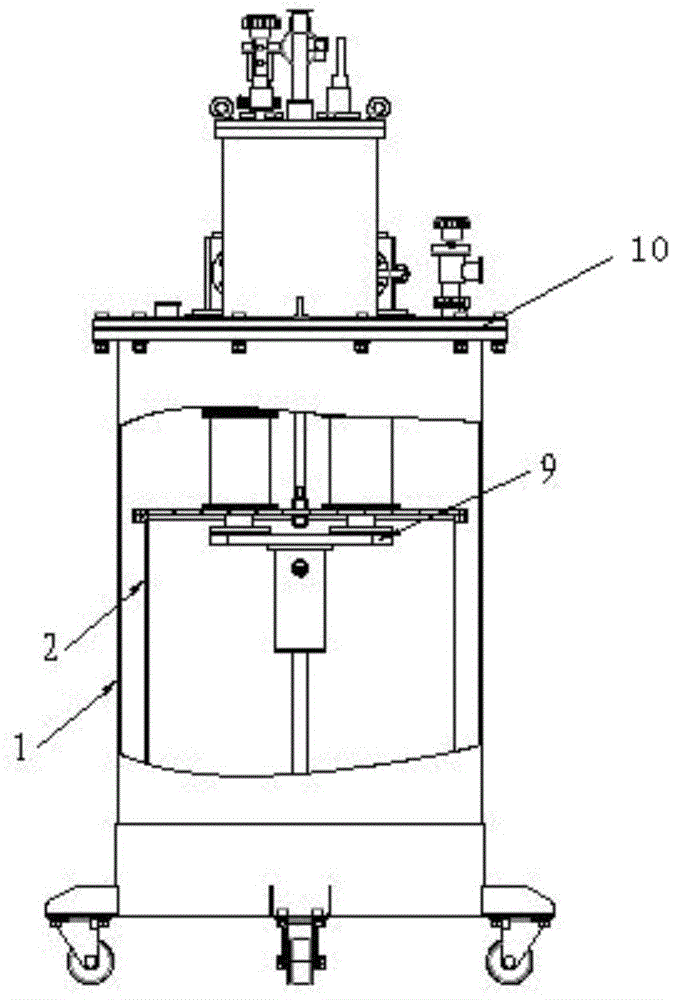

Photobioreactor

ActiveUS20110124087A1Low costLow production costBioreactor/fermenter combinationsBiological substance pretreatmentsPhotobioreactorMicrobiology

Owner:AVESTON GRIFFORD

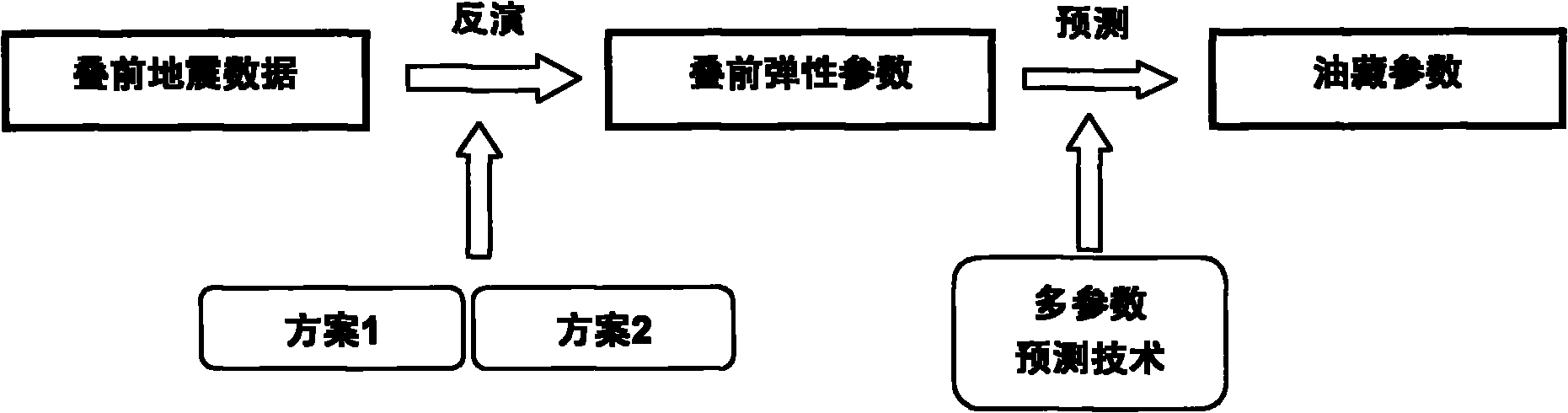

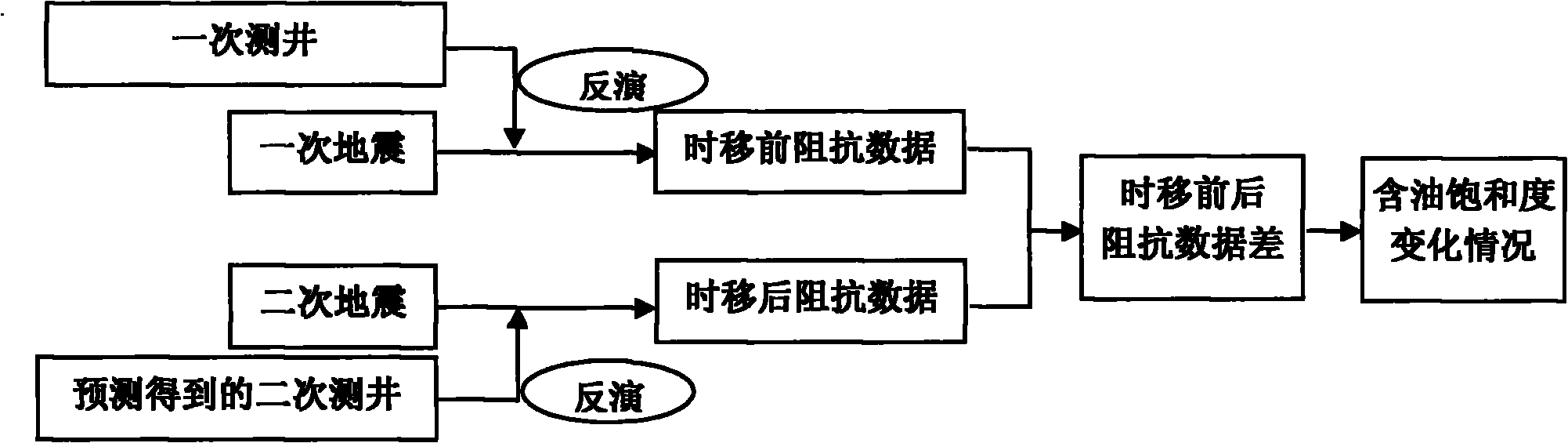

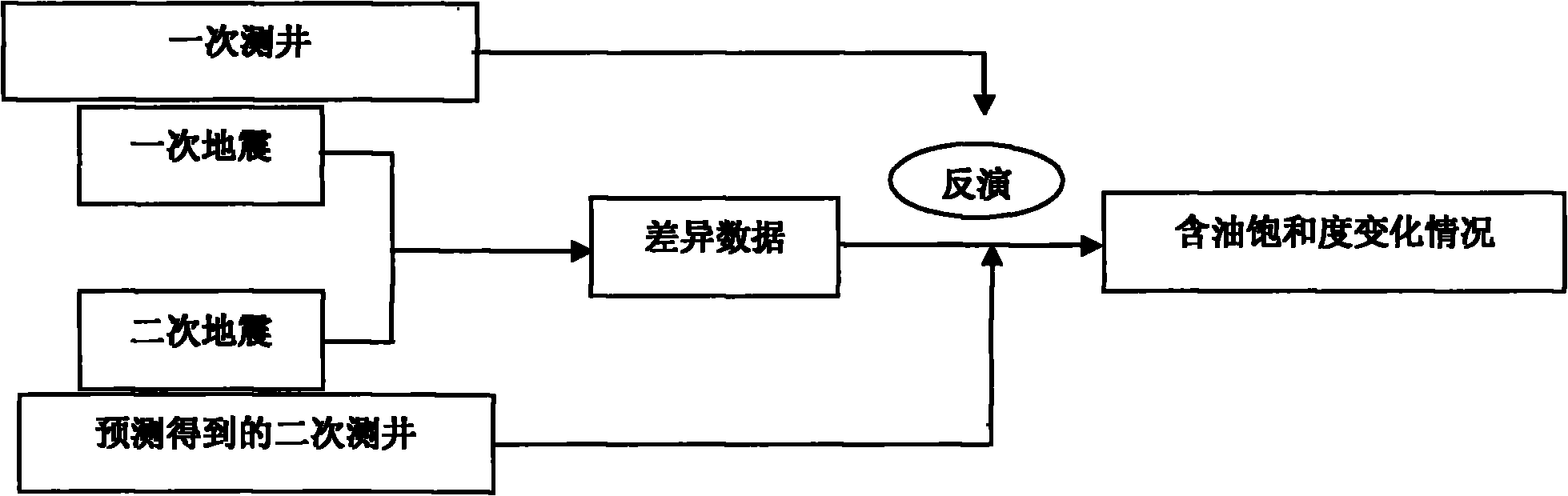

Method for carrying out well design by using time-lapse seismic

ActiveCN101872024ASmall amount of calculationHigh precisionSeismic signal processingSeismology for water-loggingLongitudinal waveChange prediction

The invention discloses a method for carrying out well design by using time-lapse seismic, which comprises the following steps: 1) respectively obtaining seismic data of two different time points according to methods of the step a and the step b: a. detecting the stratum basic parameters of a region to be detected, manufacturing an oil deposit profile of the region to be detected, establishing a stratum profile module according to the oil deposit profile, and obtaining three data bodies: the longitudinal wave speed, the transverse wave speed and the density according to the stratum basic parameters and the stratum profile module; and b. carrying out AVO forward modeling to obtain the overlapped seismic data of each incidence angle; 2) processing the seismic data in the two times to obtain seismic data difference; 3) carrying out reversion on the seismic data difference to obtain longitudinal wave difference, transverse wave difference, density difference and longitudinal and transverse wave speed ratio difference; 4) predicting the oil deposit parameter change; and 5) carrying out well design. The invention forms the difference reversion based on the time-lapse seismic for realizing the oil deposit parameter change prediction process and determining the well design, and the goal can not be realized by using conventional methods.

Owner:CHINA NAT OFFSHORE OIL CORP +1

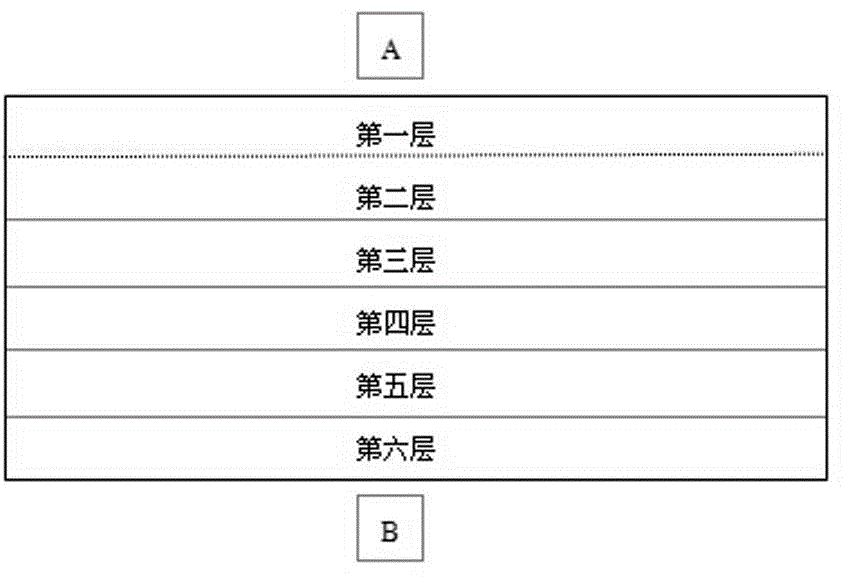

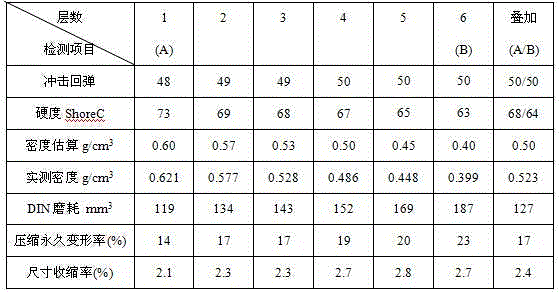

Lightweight wear-resistant density-gradient foamed sole material and preparation method thereof

The invention relates to a lightweight wear-resistant density-gradient foamed sole material and a preparation method thereof. The lightweight wear-resistant density-gradient foamed sole material is mainly composed of EPDM, ethylene-octene copolymer, low density polyethylene, a cross-linking agent, a filling material, a foaming agent and a foaming promoter. On the basis of foaming of EPDM, POE and LDPE and through control of a foaming ratio and density difference values of each layer of materials, a heterogeneous expandable rubber compound composed of a plurality of layers and having quasi-continuously changing performances in the thickness direction of the materials are subjected to one-shot mould pressing, foaming and moulding so as to prepare the foamed sole material, and function gradient differences of density, hardness and wear resistance are realized. Due to gradual change of density, stress concentration is mitigated, and the prepared foamed sole material does not warp. The foamed material has low density at one side close to the vola while the foamed material has high density at one side close to the outer sole, so the foamed sole material has good wear resistance, reduces the weight of the sole and has improved wearing comfortableness.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST +1

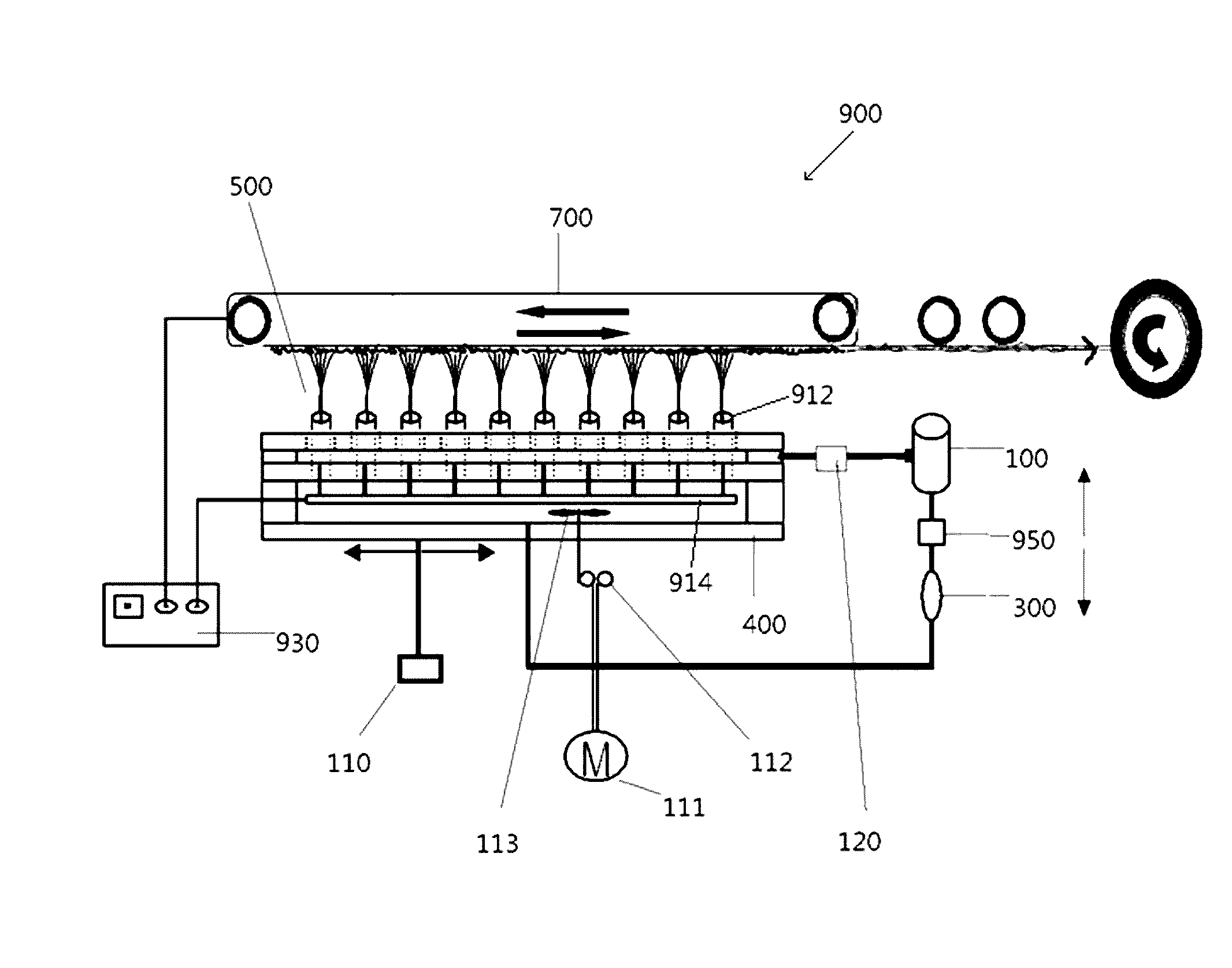

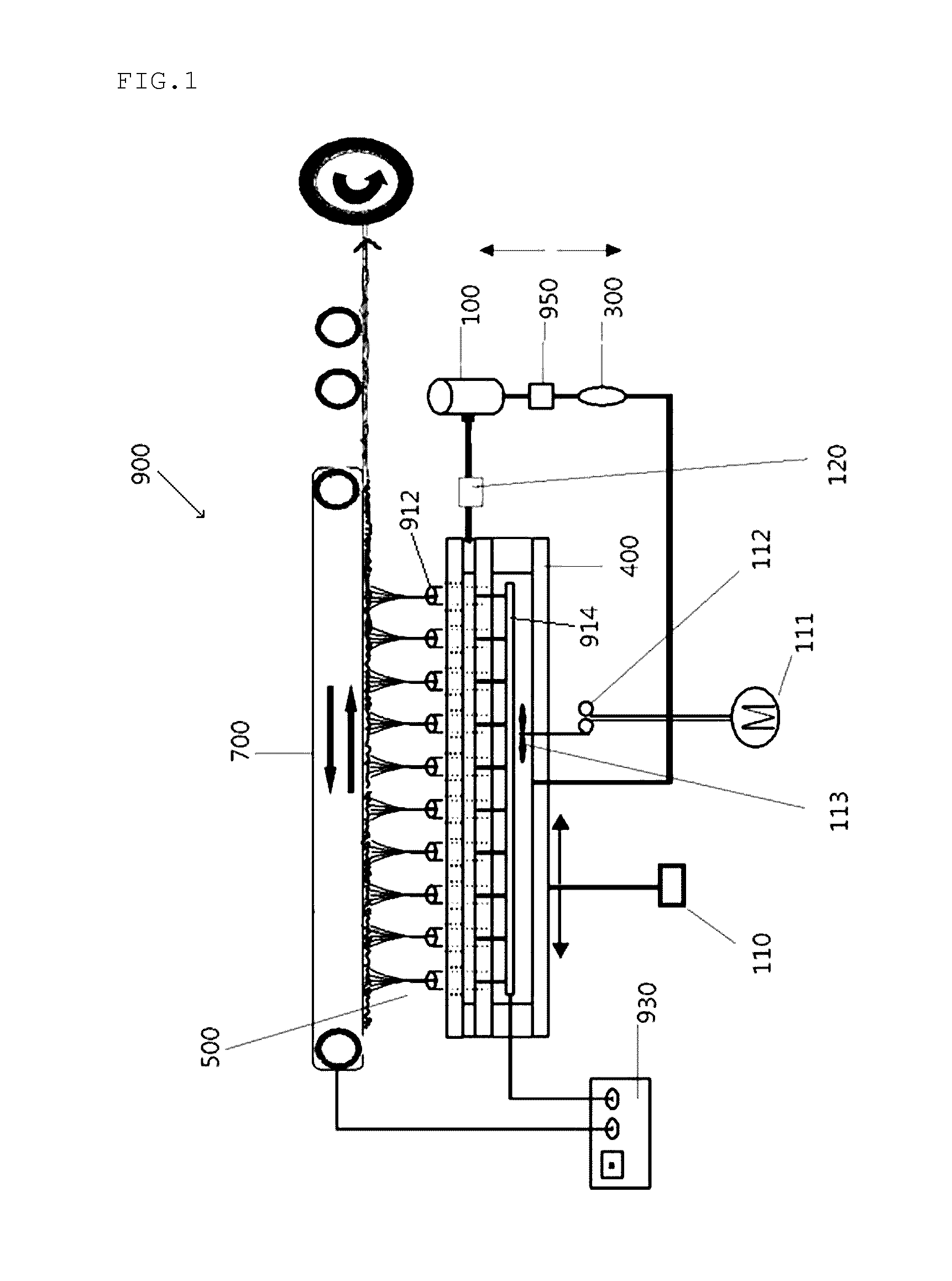

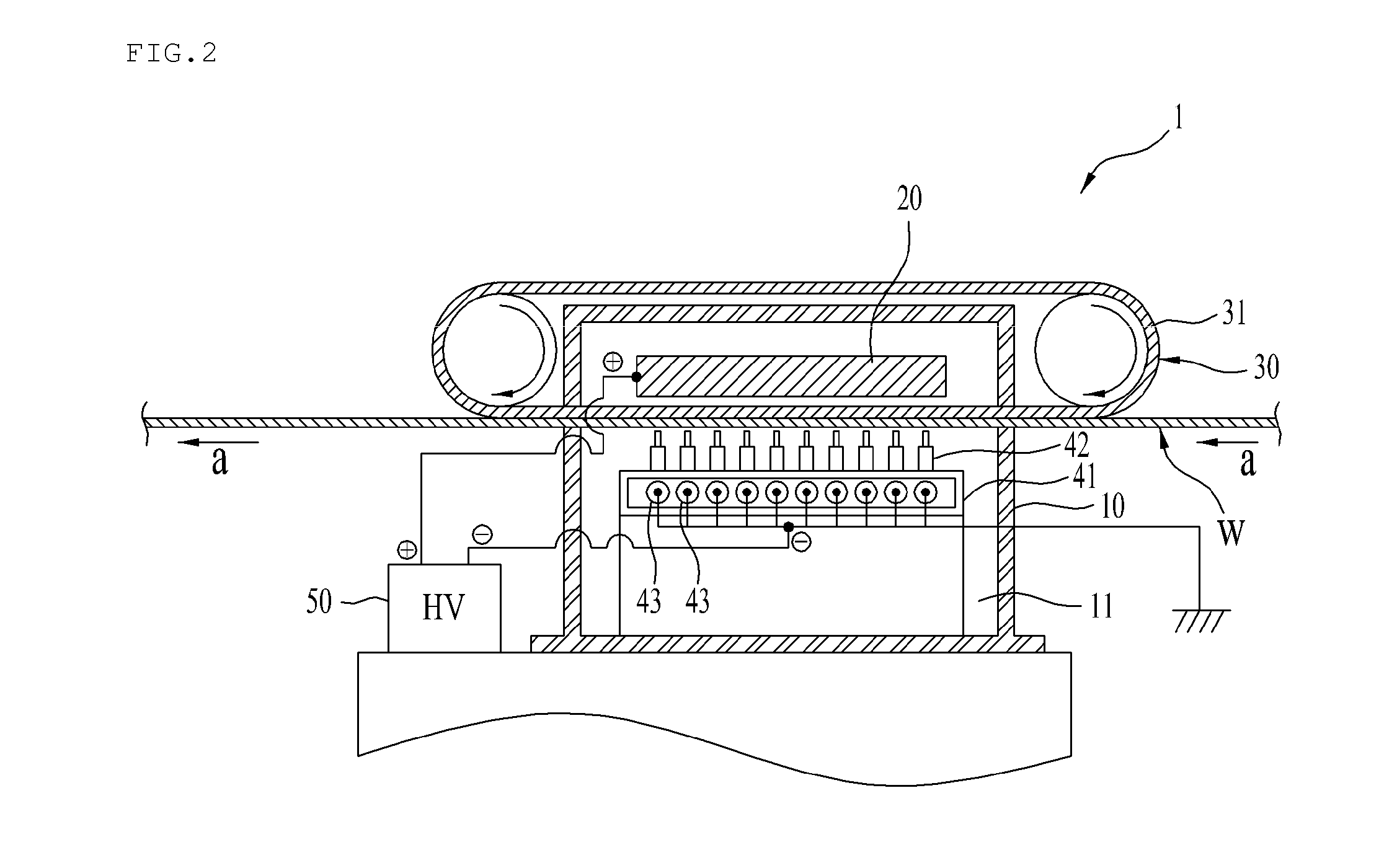

Electrospinning apparatus

InactiveUS20160083868A1Uniform qualitySimple manufacturing processSpinning solution filteringArtificial filament recoveryHigh volume manufacturingElectrospinning

The present invention relates to an electrospinning apparatus, and the purpose of the present invention is to provide an electrospinning apparatus capable of producing nanofiber having various ingredients and thicknesses by controlling the temperature of at least one solution discharged from nozzles mounted on the tubular bodies of a nozzle block and thus controlling the viscosity of the solution which is electrospun; producing nanofiber having uniform quality without applying a density difference and a voltage difference by disposing the front end portions of the nozzles in a flare shape; and mass-producing nanofiber at a low cost as well as reducing the amount of the solution used by removing an overflow prevention system and using a metering pump alone or by using the metering pump and the overflow prevention system alternatively or in a hybrid manner.

Owner:FINETEX ENE

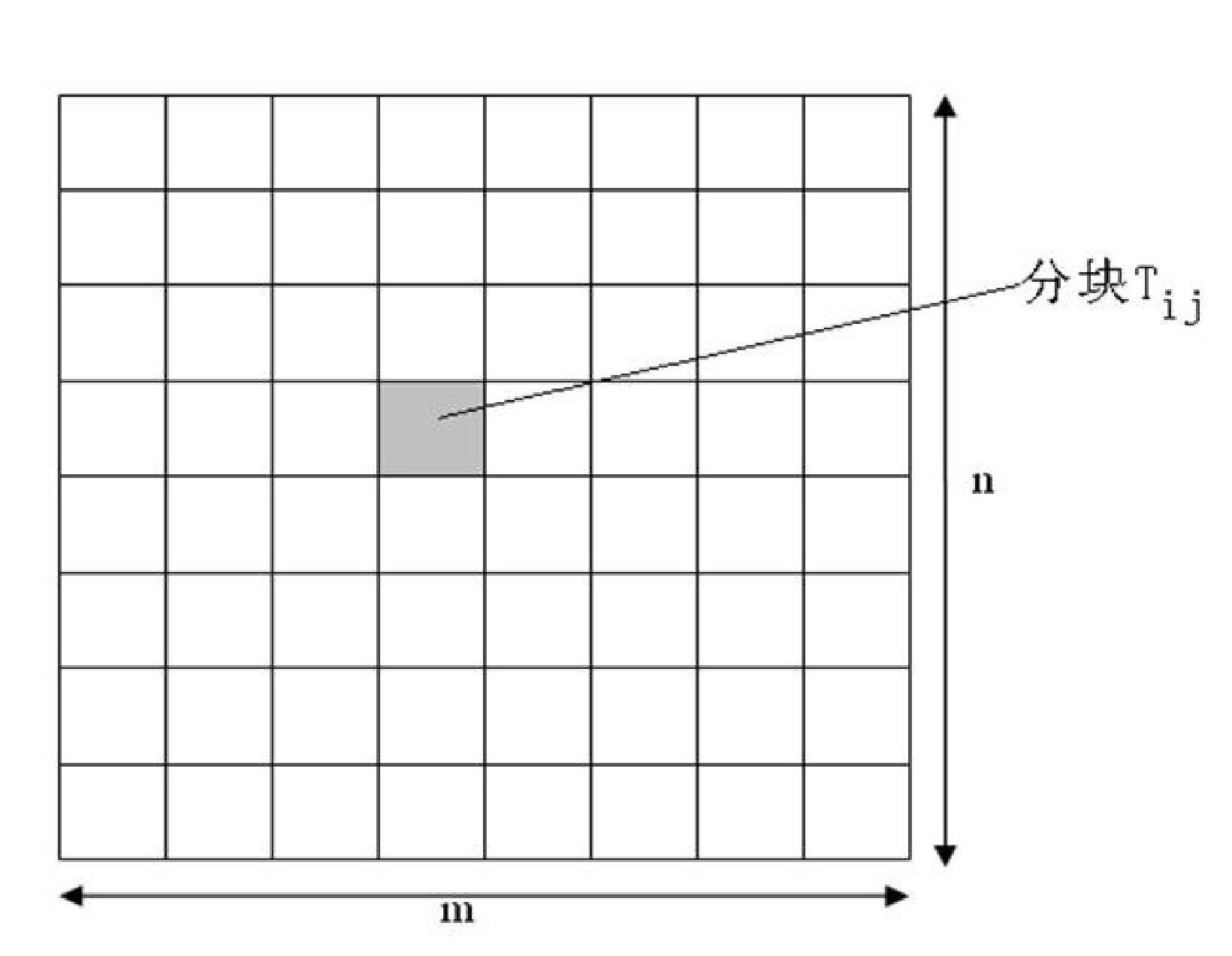

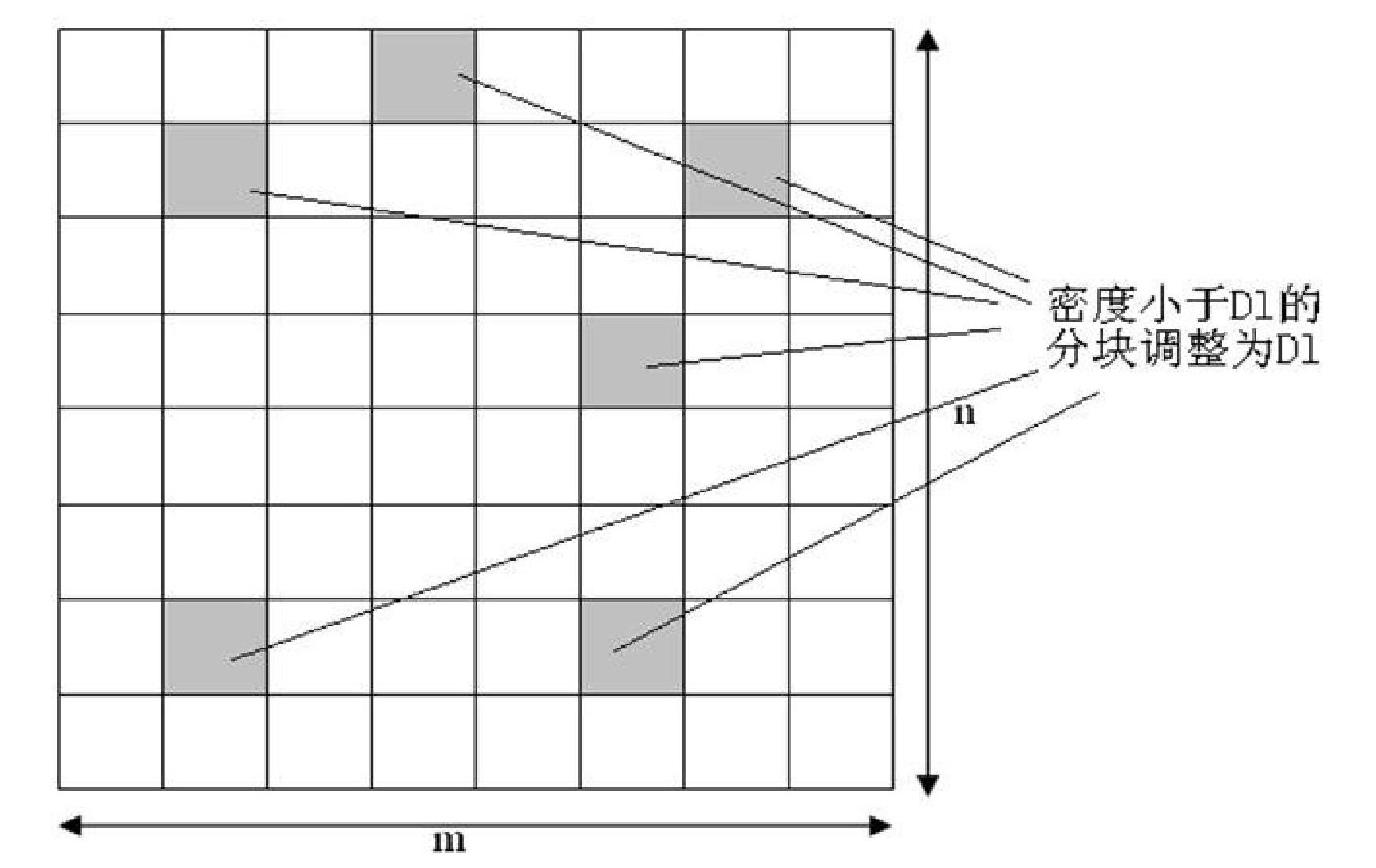

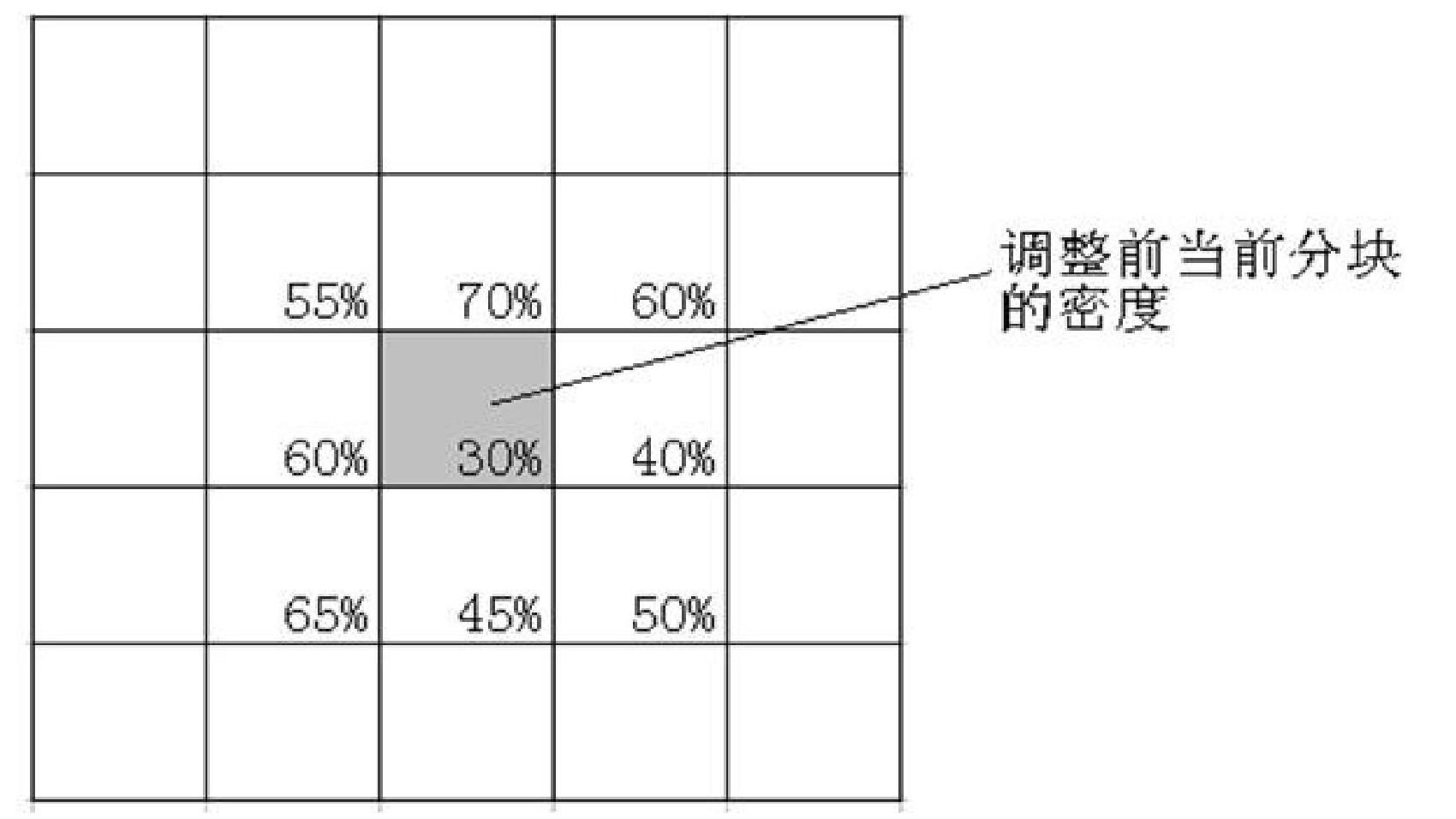

Preprocessing method using redundancy metal filling for realizing layout density uniformity

ActiveCN102117348AHomogenize Global DensitySemiconductor/solid-state device manufacturingSpecial data processing applicationsLower limitPretreatment method

The invention relates to a preprocessing method using redundancy metal filling for realizing layout density uniformity, belonging to the technical field of integrated circuit manufacturing process and layout design. The method can determine the density of each block by a design rule check rule through a pre-setting the block density lower limit and pre-setting the allowable density undulating quantity and then dividing the layout into blocks having the same size. For the method, the density of each block is adjusted to be above the density lower limit, and then the density difference between each block and the adjacent blocks is limited within the preset allowable undulating quantity range, so that the density difference among different blocks is reduced, the uniformity of the metal wire density on the layout is improved, better smoothness is realized and chip quality is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Oil removing pretreatment technology for petroleum oil refining wastewater

ActiveCN106007209AStructural scienceSimple processFatty/oily/floating substances removal devicesTreatment involving filtrationCycloneWater based

The invention discloses an oil removing pretreatment technology for petroleum oil refining wastewater. According to the oil removing pretreatment technology, a water collecting tank with gratings is used for separating sand and sludge; a three-phase cyclone liquid separation floating oil collecting and discharging adjusting tank is used for achieving separation of water, oil and residues; a cyclone oil coarse graining polymerization oil-water separator is used for removing fine oil grains; a dissolved air flotation device is used for demulsification and flocculation reaction, wherein air bubbles and suspended solids in wastewater make contact for adhesion and float upwards, and the standard is met through residue scraping. The technology is simple, the structure is scientific, the three-phase cyclone liquid separation floating oil collecting and discharging adjusting tank, the cyclone liquid coarse graining polymerization oil-water separator and the dissolved air flotation device jointly serve as the core treatment scheme, oily wastewater is pretreated through the density difference of oil and water based on the fluid dynamics principle, a physical method and a chemical method act jointly, and the oil content in the pretreated oily wastewater is smaller than or equal to 20 mg / L and reaches the standard. The oil removing pretreatment technology is large in daily treatment amount, high in oil removing efficiency, remarkable in oil collecting effect and considerable in economic benefit, and the water content of the recycled waste oil is 5% or lower.

Owner:江苏中嘉华新环保科技有限公司

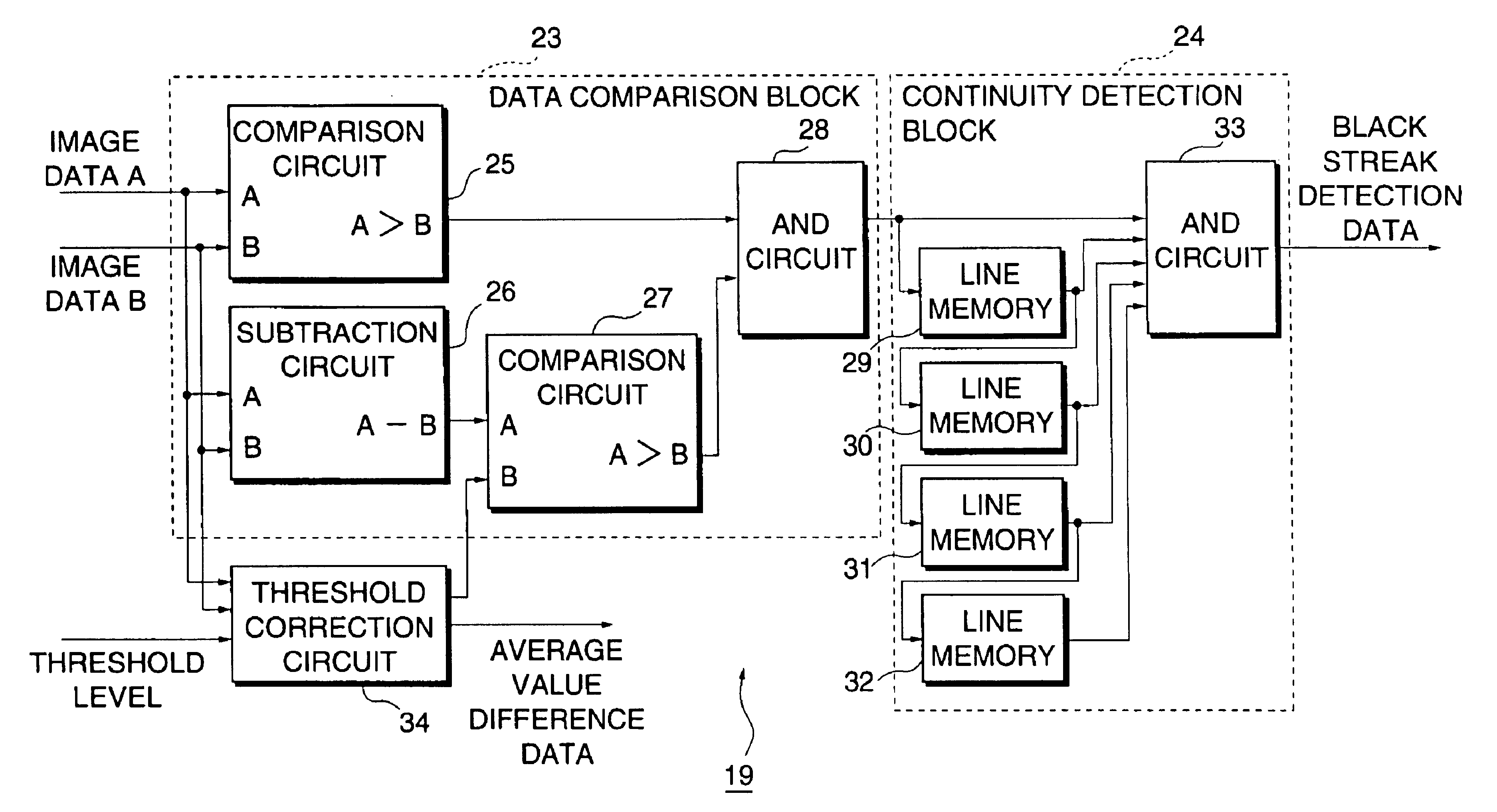

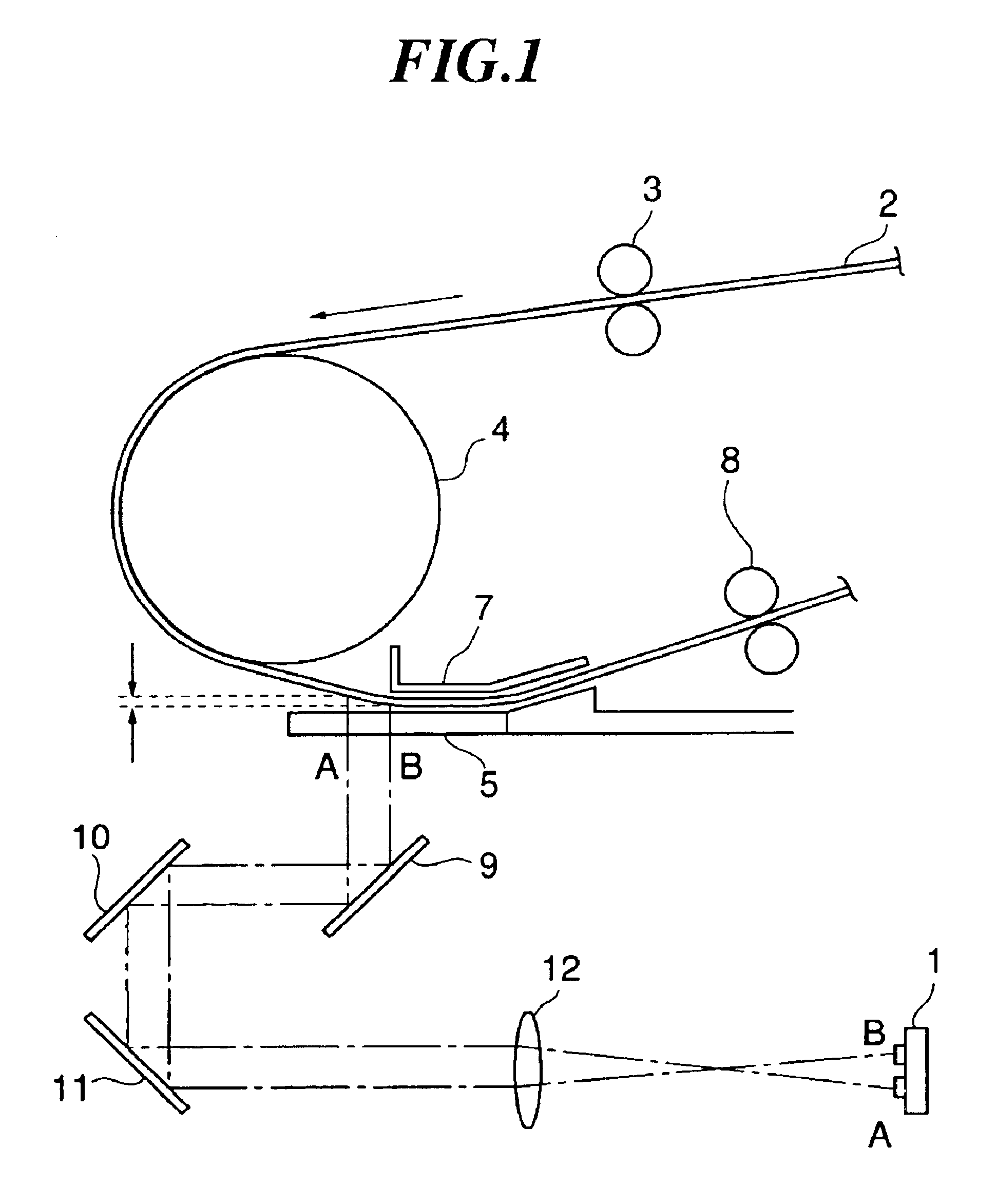

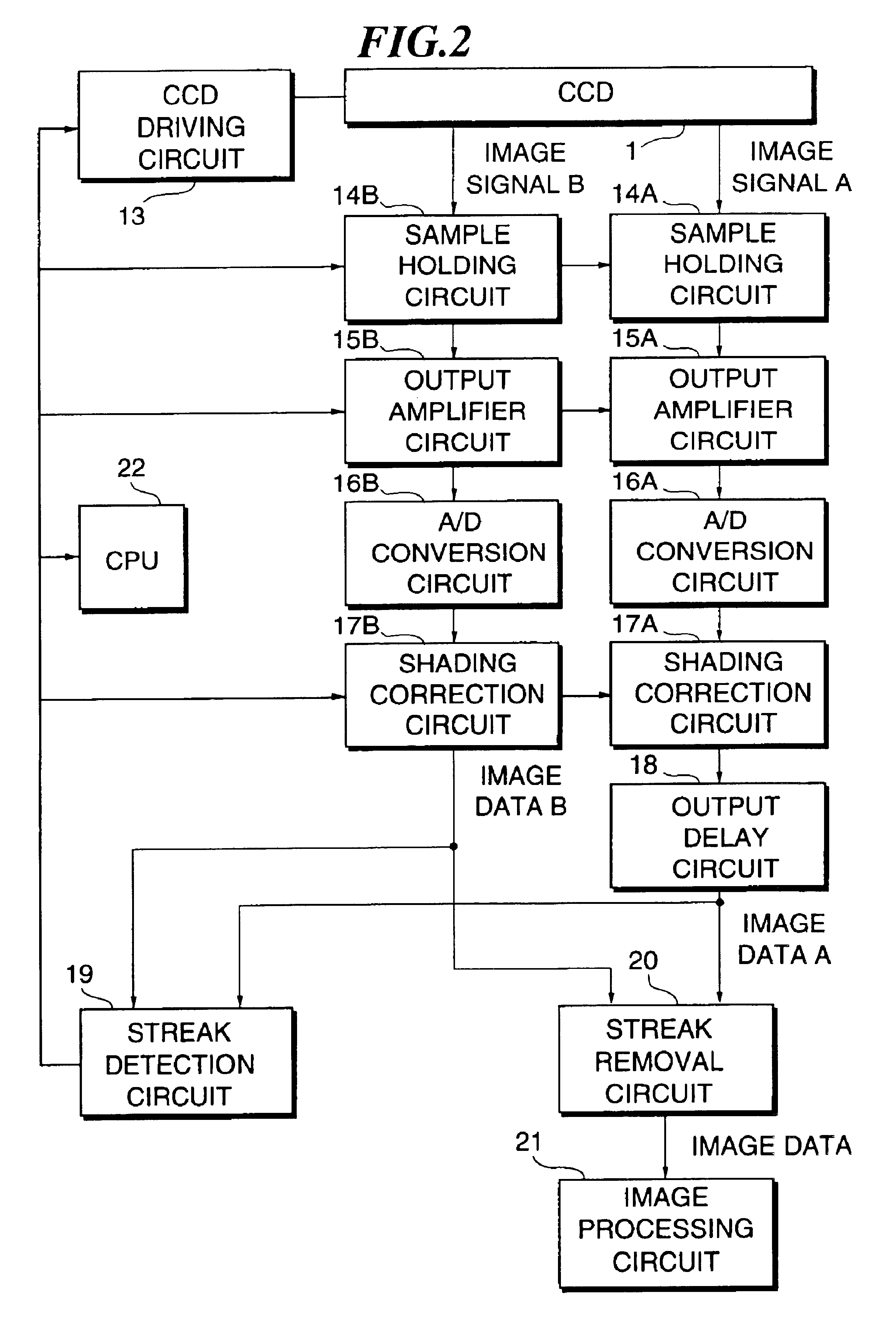

Image reader and image reading method

InactiveUS6839153B1Accurate detectionNoise can be reliablyVisual presentationPictoral communicationPattern recognitionDensity difference

Even if there may exist a difference in reading density between reading positions, there will be provided an image reader capable of accurately detecting and removing streaks-shaped noise caused by the adhesion of dust particles to the reading unit. A CCD reads an original at each reading position, and image data A and B in each reading position are obtained from an output delay circuit and a shading correction circuit. A streak detection circuit judges a difference A−B between each image data through the use of a threshold corrected on the basis of an average density difference between each image data A and B, and outputs black streak detection data in accordance with the judgment result. A streak removal circuit always outputs the image data A, but if black streak detection data is outputted, image data B corrected on the basis of the average density difference is outputted in place of the image data A.

Owner:FUJIFILM BUSINESS INNOVATION CORP

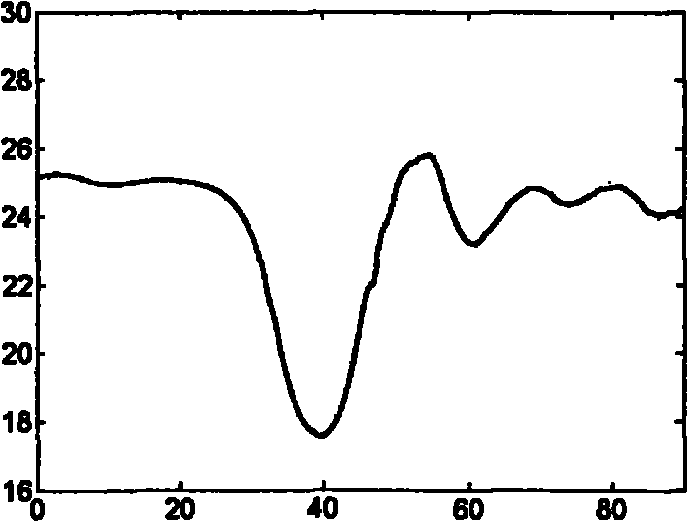

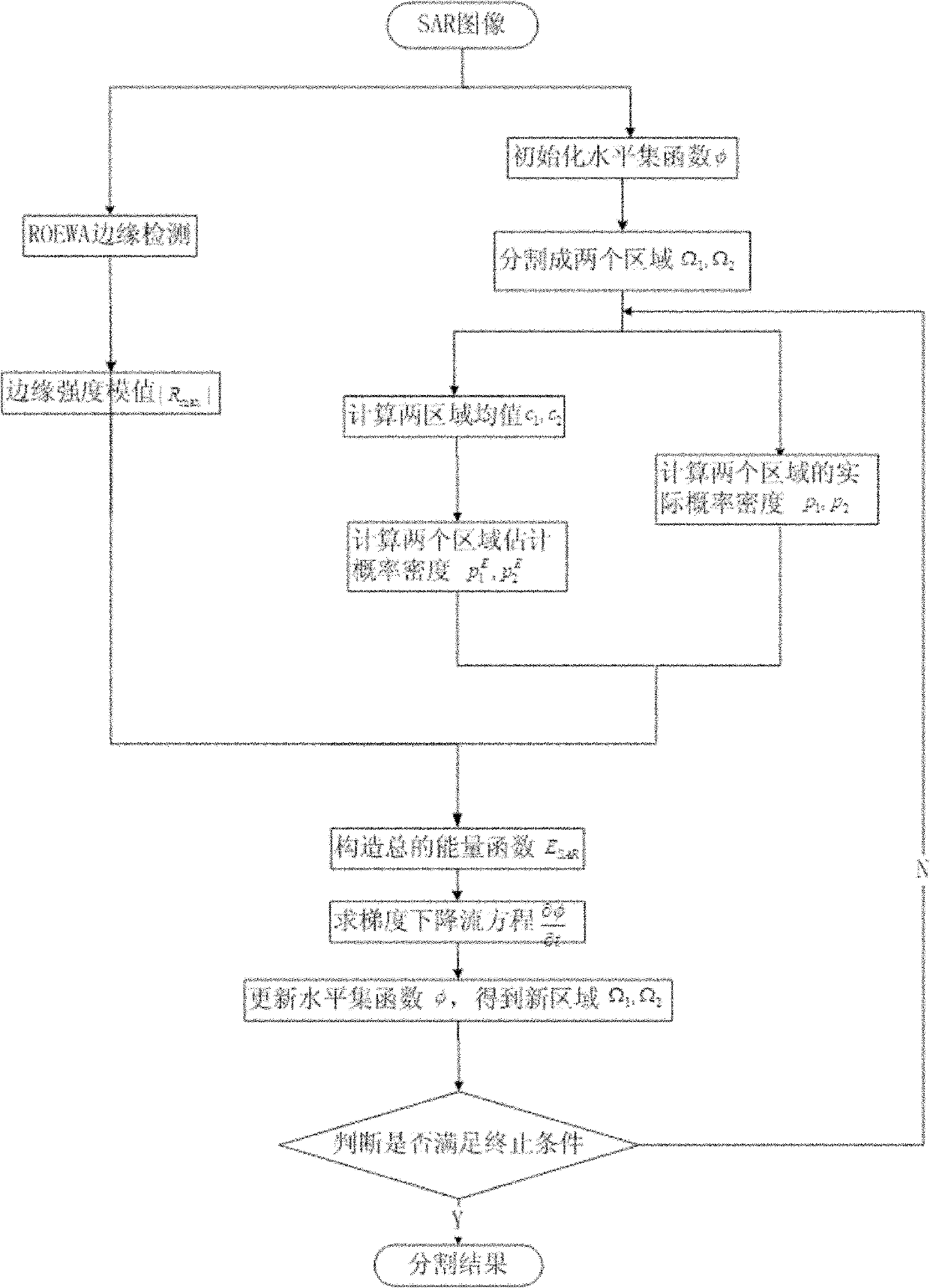

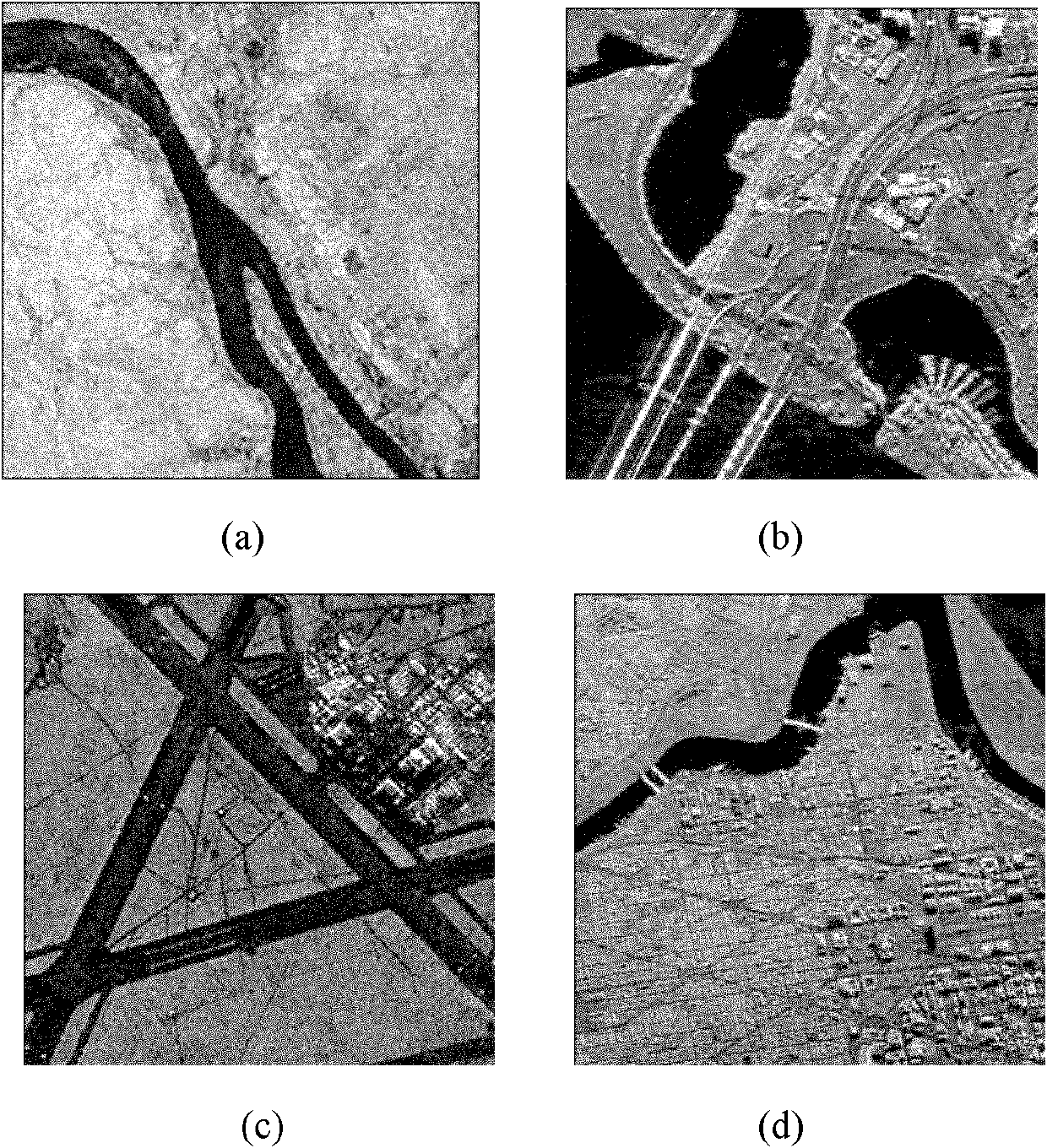

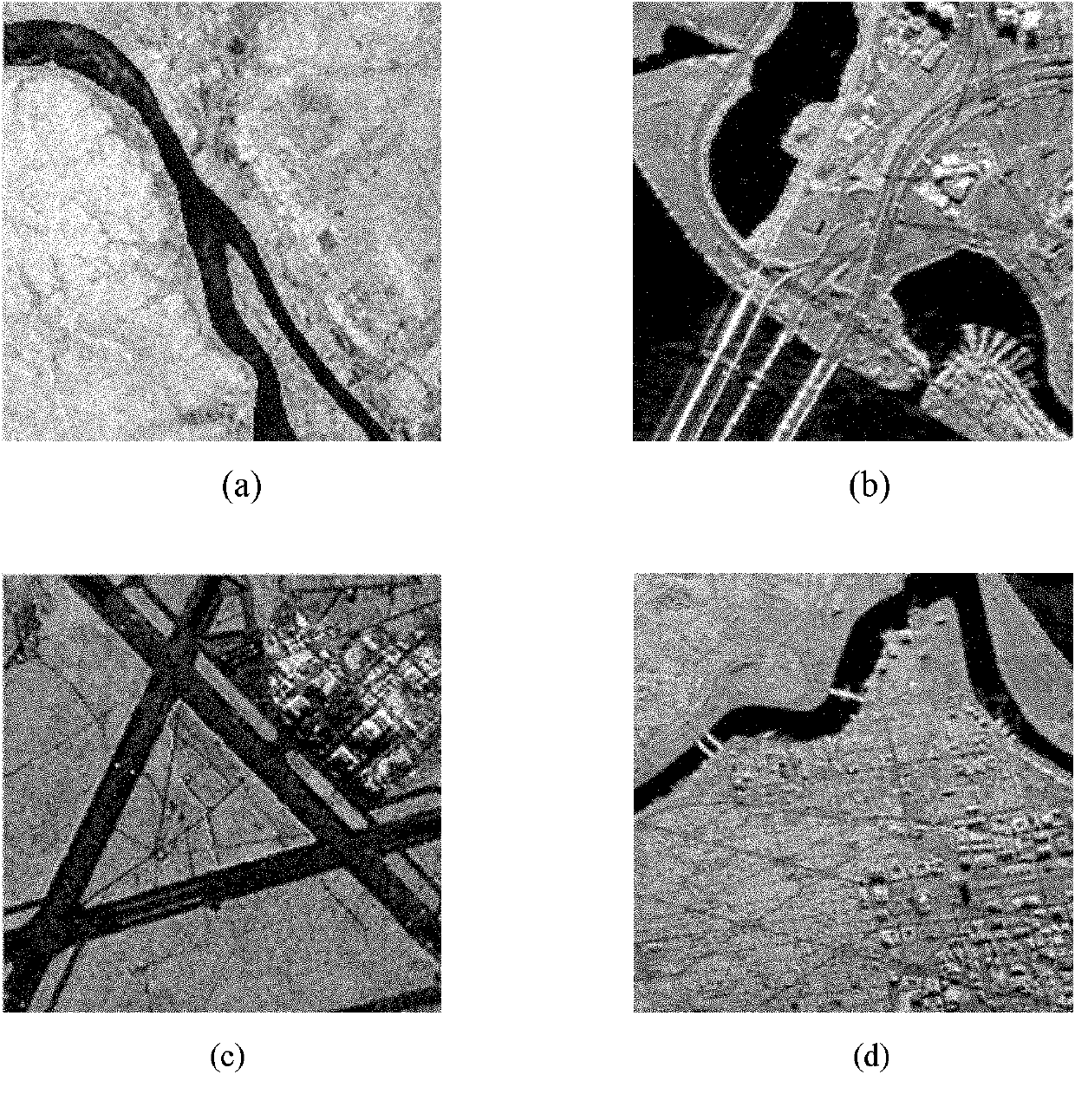

Level set SAR (Synthetic Aperture Radar) image segmentation method by combining edges and regional probability density difference

ActiveCN101976445AImprove segmentationImprove robustnessImage analysisCharacter and pattern recognitionPattern recognitionImaging processing

The invention discloses a level set SAR (Synthetic Aperture Radar) image segmentation method by combining edges and a regional probability density difference, belonging to the technical field of image processing and mainly solving the problems of difficult segmentation of SAR images with fuzzy edges and inaccurate positioning to real edges of the SAR images, of the traditional level set method. The method comprises the following implementation steps of: firstly, detecting an edge intensity modulus absolute value of Rmax of an SAR image by applying an ROEW operator; secondly, initializing a level set function phi, segmenting the SAR image into an inner region omega1 and an outer region omega2, and solving for the intensity mean values c1 and c2 of the two regions; thirdly, solving for the estimated probability densities of the two regions omega1 and omega2 according to c1 and c2 and calculating the actual probability densities p1 and p2 of the two regions; and fourthly, constructing a total energy function ESAR, solving for a gradient downstream equation by applying a variational method, and updating the level set phi to obtain new segmentation regions omega1 and omega2. Indicated by experimental results, the segmentation method can be used for obtaining more ideal segmentation effect and be used for the edge detection and the target identification of the SAR images.

Owner:XIDIAN UNIV

Coarse slime interference bed separation equipment based on gravity force and interfacial force, method and uses thereof

InactiveCN101402063AEfficient sortingHigh sorting accuracyWet separationVolumetric Mass DensityEngineering

The invention discloses a sorting device for a coarse coal slime interference bed based on gravity and interfacial force, a method and application thereof, wherein air bubbles are introduced into the sorting device of the interference bed. Under the action of ascending water flow, an environment similar to heavy medium sorting is formed by using fluidization of fine coal slime carried in fed materials; and the introduced air bubbles are attached to hydrophobic low density particles so that the real density of an air bubble-hydrophobic particle polymer is reduced and the density difference between head coals and minerals is increased. The sorting device realizes the sorting based on the combined action of gravity and interfacial force in a solid-liquid-gas three-phase interference bed, has large adaptation range to the particle size of the fed materials and high sorting precision, can effectively sort coarse coal slime which has wide level and is difficult to sort, and is in particular applicable to the sorting of the coarse slime of which the particle diameter is between 2 and 0.3 millimeter.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

High-temperature superconducting low-temperature helium self-circulation cooling system

ActiveCN103606430ARealize self-circulationSimplify operating proceduresCompression machinesSuperconducting magnets/coilsHigh-temperature superconductivitySuperconducting Coils

The invention discloses a high-temperature superconducting low-temperature helium self-circulation cooling system. Vertical temperature and density differences of low-temperature helium in the system allow natural convective circulation to form, and the problems that the superconducting magnet used in the direct cooling manner of a small refrigerator is poor in cooling effect and the necessary application of expensive low-temperature helium pumps in forced convective circulation cooling causes high cost are solved. After the system stabilizes, operating pressure is low; the safety problem is solved. A superconducting magnet and a current lead form a whole which can be lifted in or out of magnet mounting space and which is convenient to demount, mount and change; cooling medium helium has controllable temperature, and conditions for the study on performances of high-temperature superconducting magnets at specific temperature are provided.

Owner:VACREE TECH +1

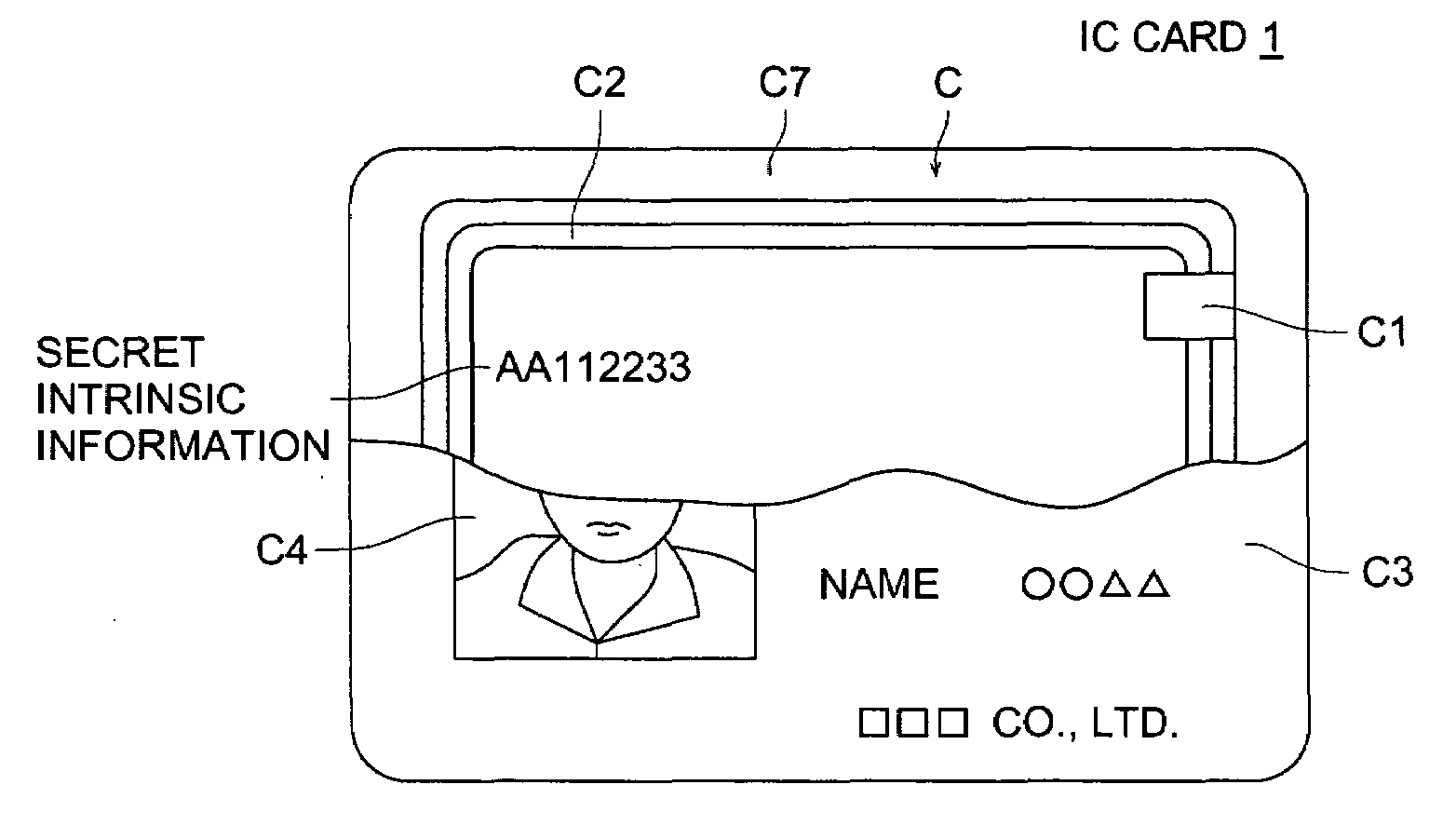

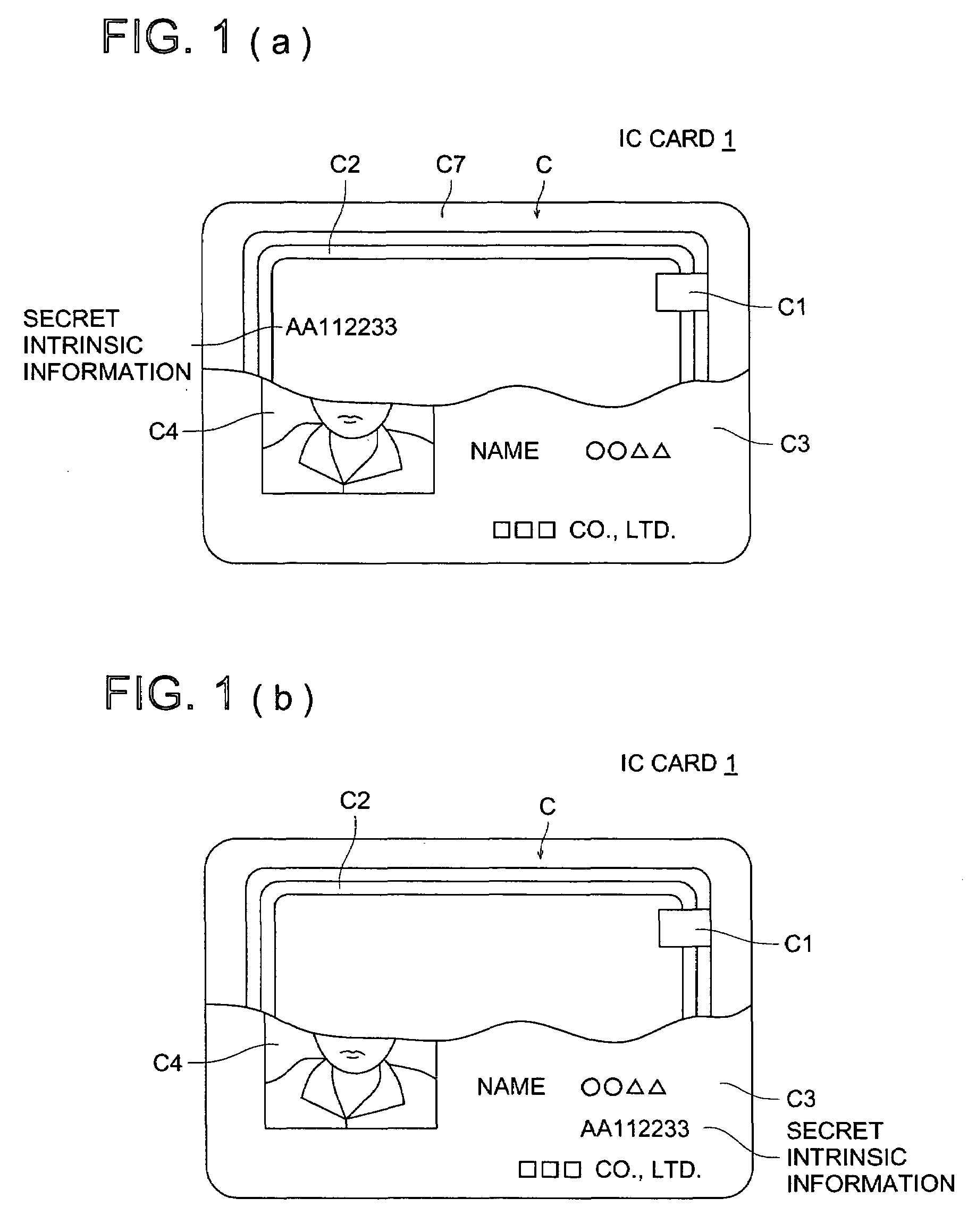

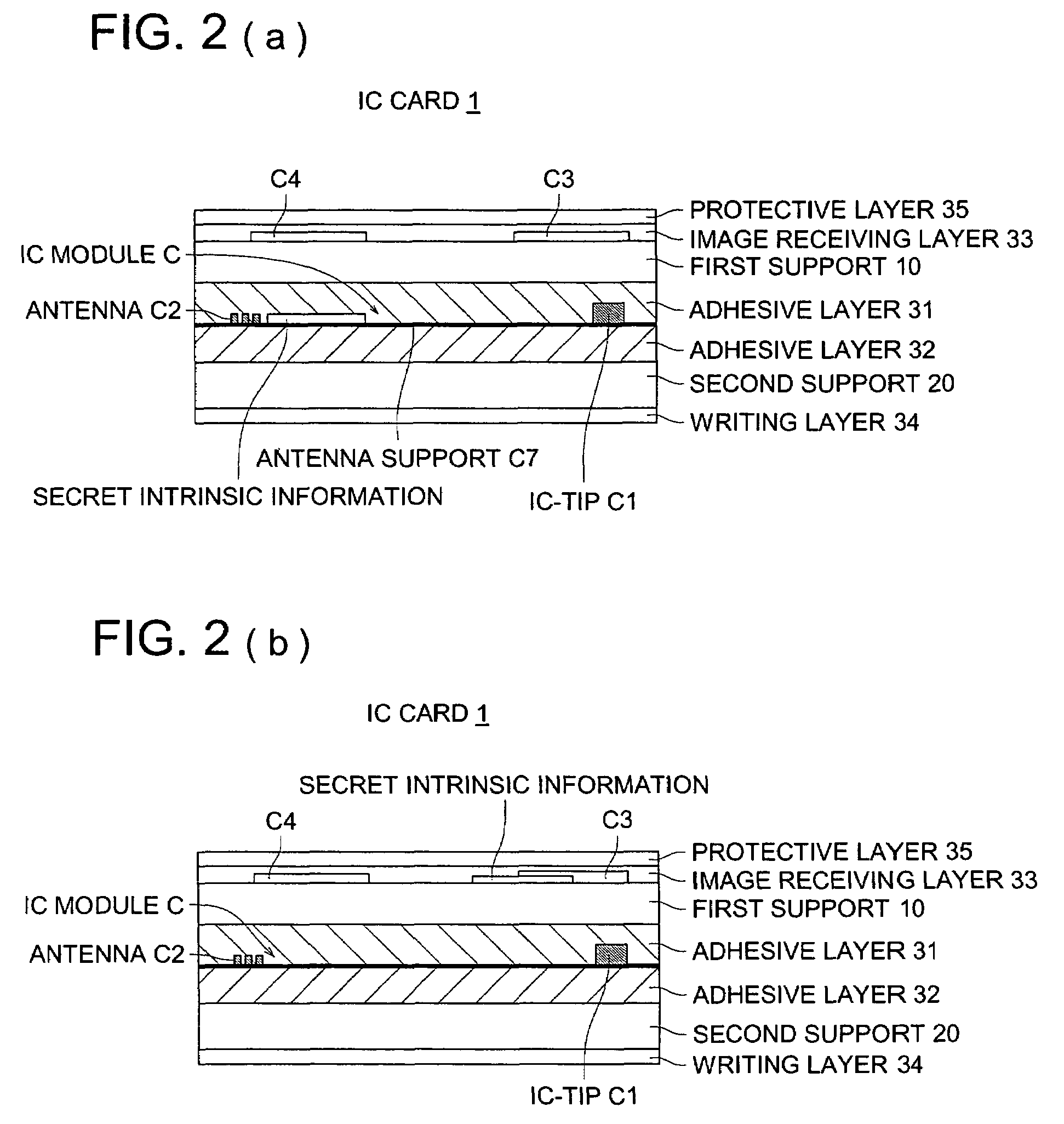

IC card, IC card manufacturing method, IC card manufacturing apparatus and IC card judgement system

InactiveUS7143953B2Improve securityImprove efficiencyRecord carriers used with machinesSensing by electromagnetic radiationManufactured apparatusEngineering

An IC card comprising: an IC module including an IC-chip in which intrinsic information is stored at the stage of card manufacturing or card issuing and an antenna supported by an antenna supporting member; and two base plates between which the IC module incorporated with an adhesive layer; wherein hidden intrinsic information corresponding to the stored intrinsic information is recorded on a part of the antenna supporting member in such a way that the hidden intrinsic information is invisible by reflection light from the surface of the IC card and is read out from transmission light due to a transmission density difference between the recorded part of the hidden intrinsic information and a non-recorded part.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

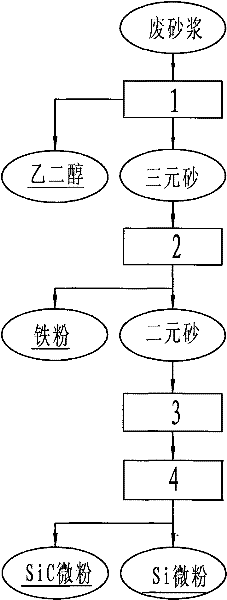

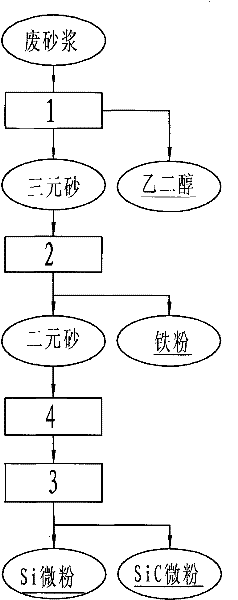

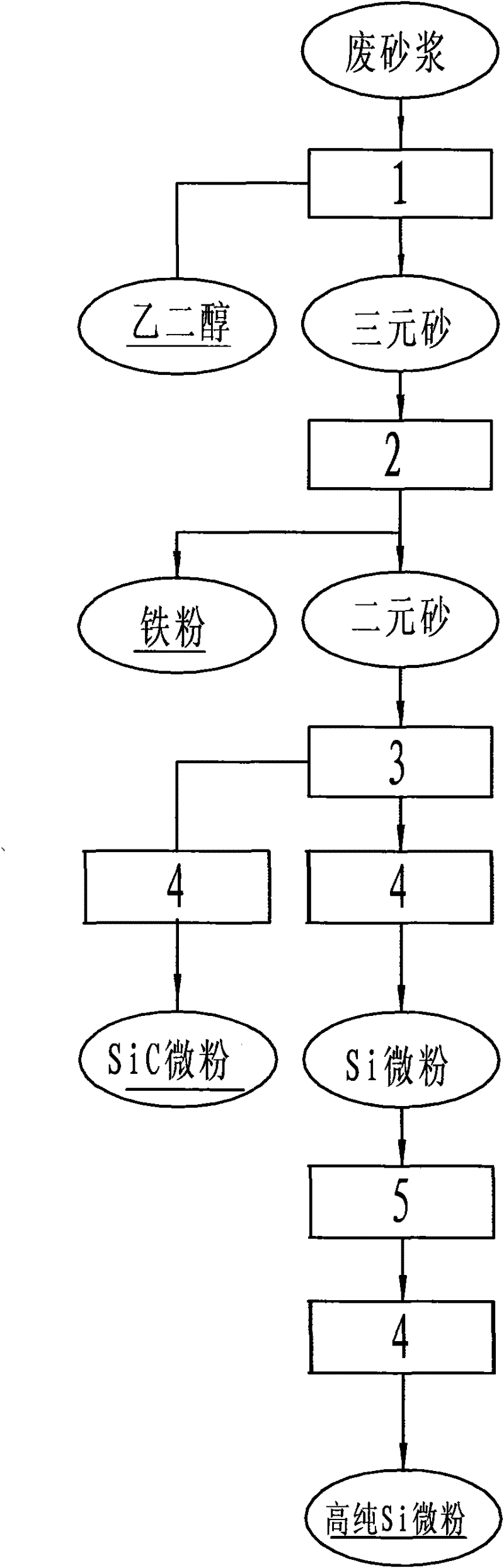

Novel method for comprehensively treating waste mortar formed by processing photovoltaic cell crystalline silicon

InactiveCN102211769AReduce consumptionImprove efficiencySiliconWaste processingChemical reactionGranularity

The invention discloses a novel method for comprehensively treating waste mortar formed by processing photovoltaic cell crystalline silicon. Aiming to different physicochemical properties of four components of the waste mortar formed by processing photovoltaic cell crystalline silicon and under the condition of ensuring that Si micropowder is not subjected to a chemical reaction, PEG (Polyethylene Glycol) and iron are separated and recovered; SiC and Si binary sand is treated by adopting various treatment methods to obtain corresponding SiC and Si series products; the SiC and Si micropowder is hydraulically sorted or sorted by air current by utilizing the granularity difference and the density difference of the SiC micropowder and the Si micropowder in the binary sand to obtain SiC micropowder and Si miropowder; the Si miropowder is washed and purified with purified water and reagent-grade inorganic acid to obtain high-purity Si miropowder; the sorted Si miropowder is fed into an electrical furnace for melting and recasting to obtain a silicon cast ingot material; the binary sand is fed into the furnace for melting and recasting to obtain a metallurgical silicon cast ingot material and a Si and SiC mixed cast ingot material; a proper amount of carbon is fed into the binary sand to react and generate SiC; and SiC, Si and Fe ternary sand is fed into the electrical furnace for melting and recasting to obtain a silicoferrite material for metallurgy.

Owner:尹克胜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com