Patents

Literature

10207results about "Inking apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electronically addressable microencapsulated ink and display thereof

InactiveUS7148128B2Inexpensive displayInking apparatusMechanical clocksSemiconductor materialsDisplay device

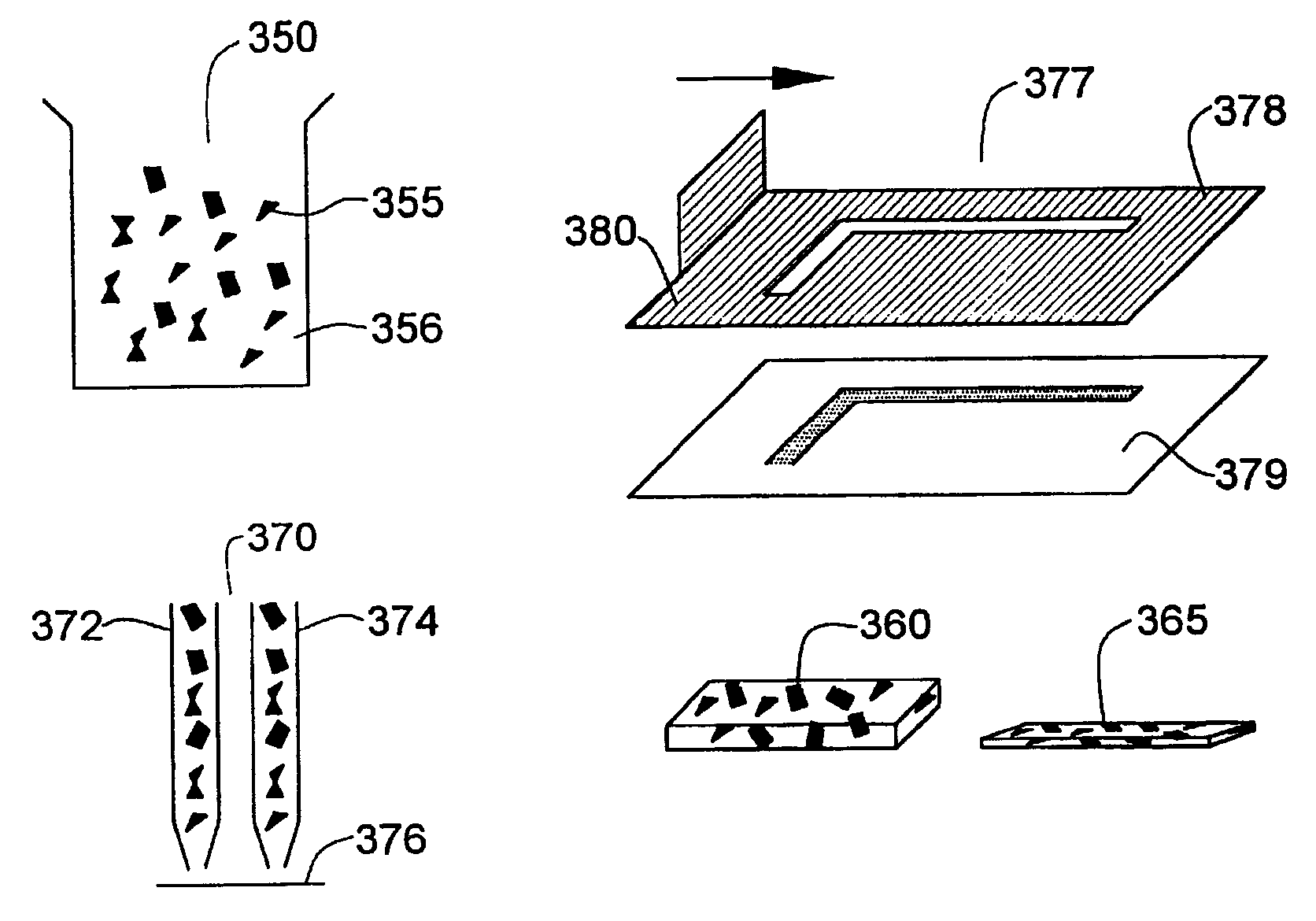

We describe a system of electronically active inks which may include electronically addressable contrast media, conductors, insulators, resistors, semiconductive materials, magnetic materials, spin materials, piezoelectric materials, optoelectronic, thermoelectric or radio frequency materials. We further describe a printing system capable of laying down said materials in a definite pattern. Such a system may be used for instance to: print a flat panel display complete with onboard drive logic; print a working logic circuit onto any of a large class of substrates; print an electrostatic or piezoelectric motor with onboard logic and feedback or print a working radio transmitter or receiver.

Owner:E INK CORPORATION

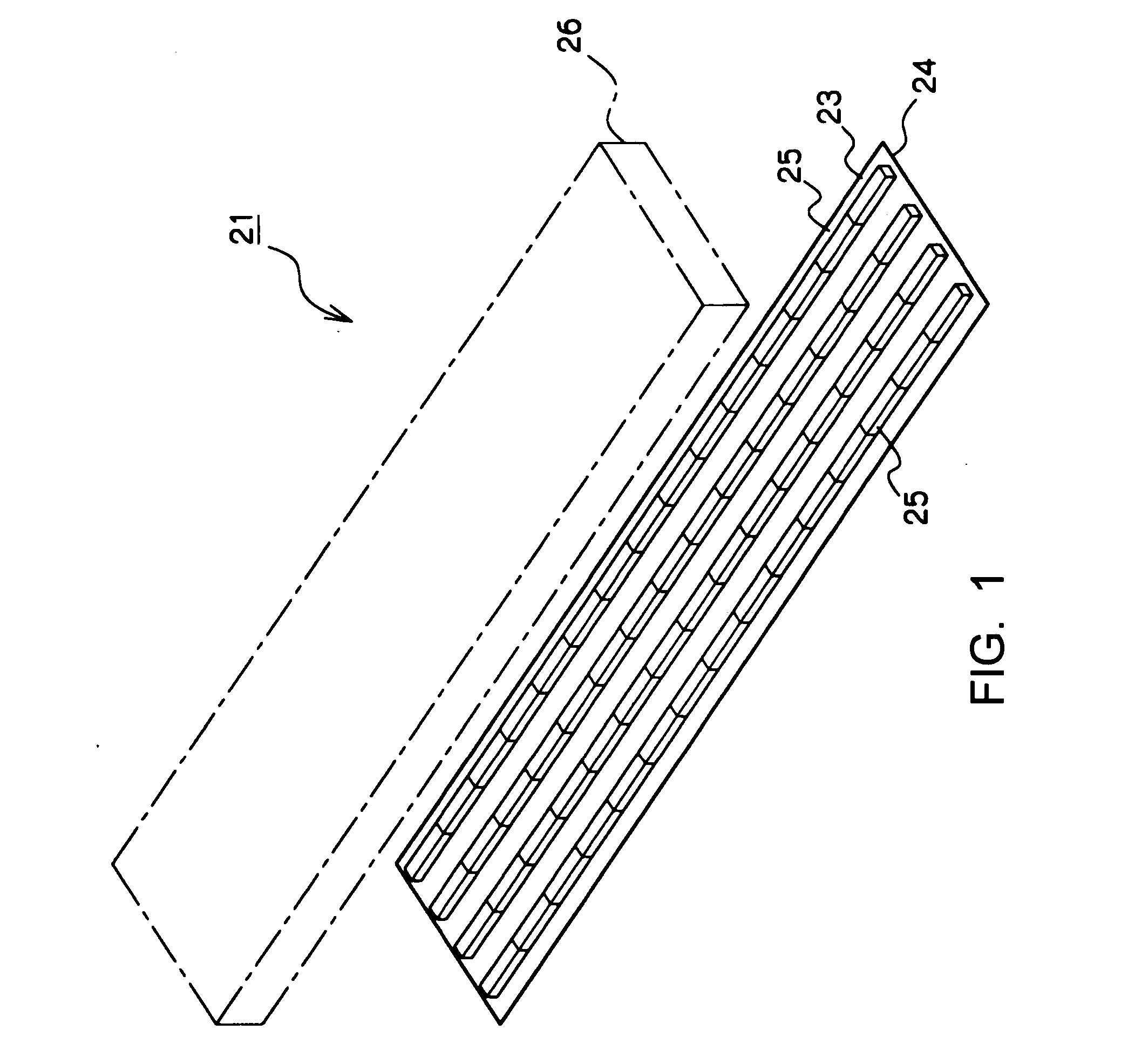

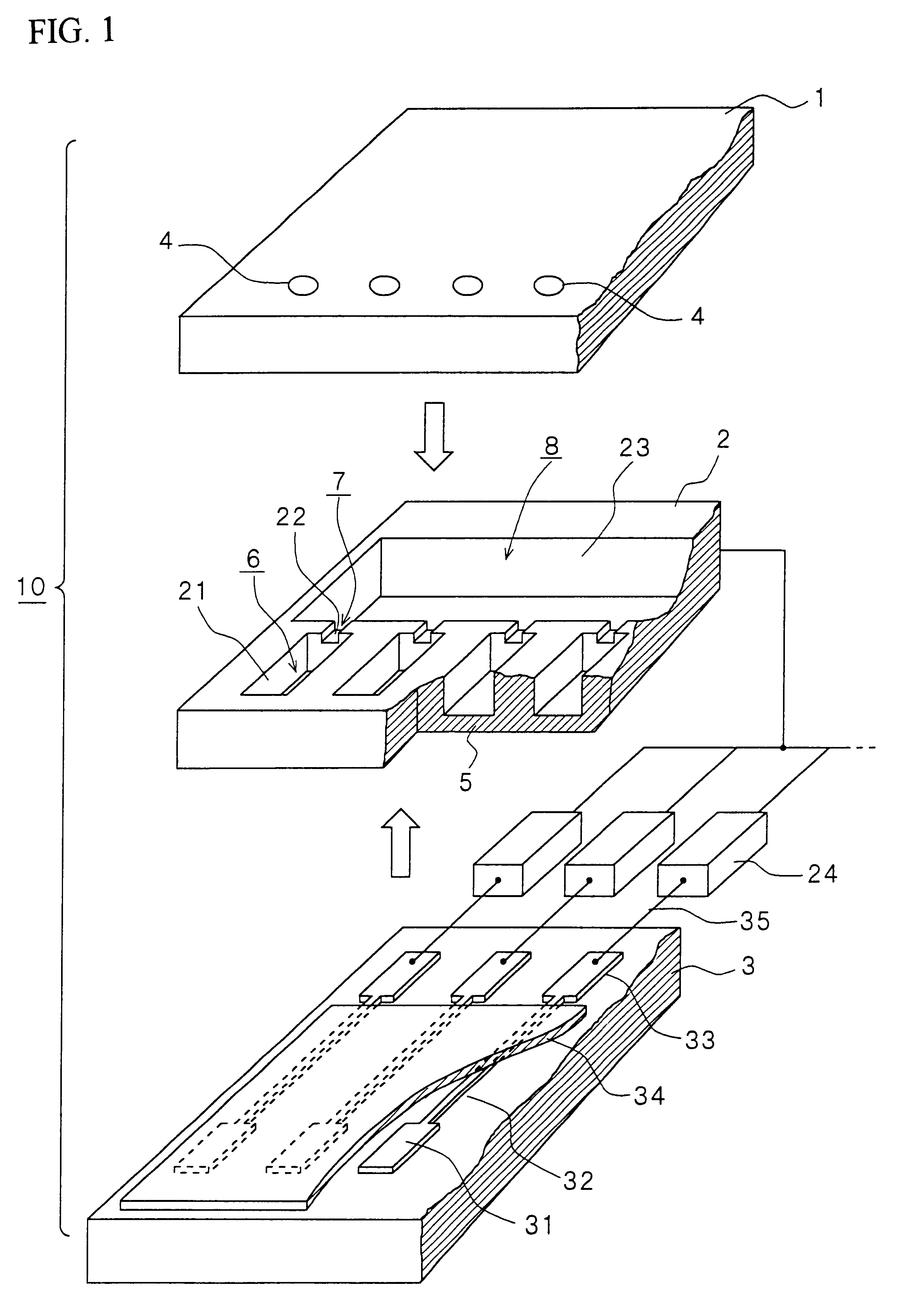

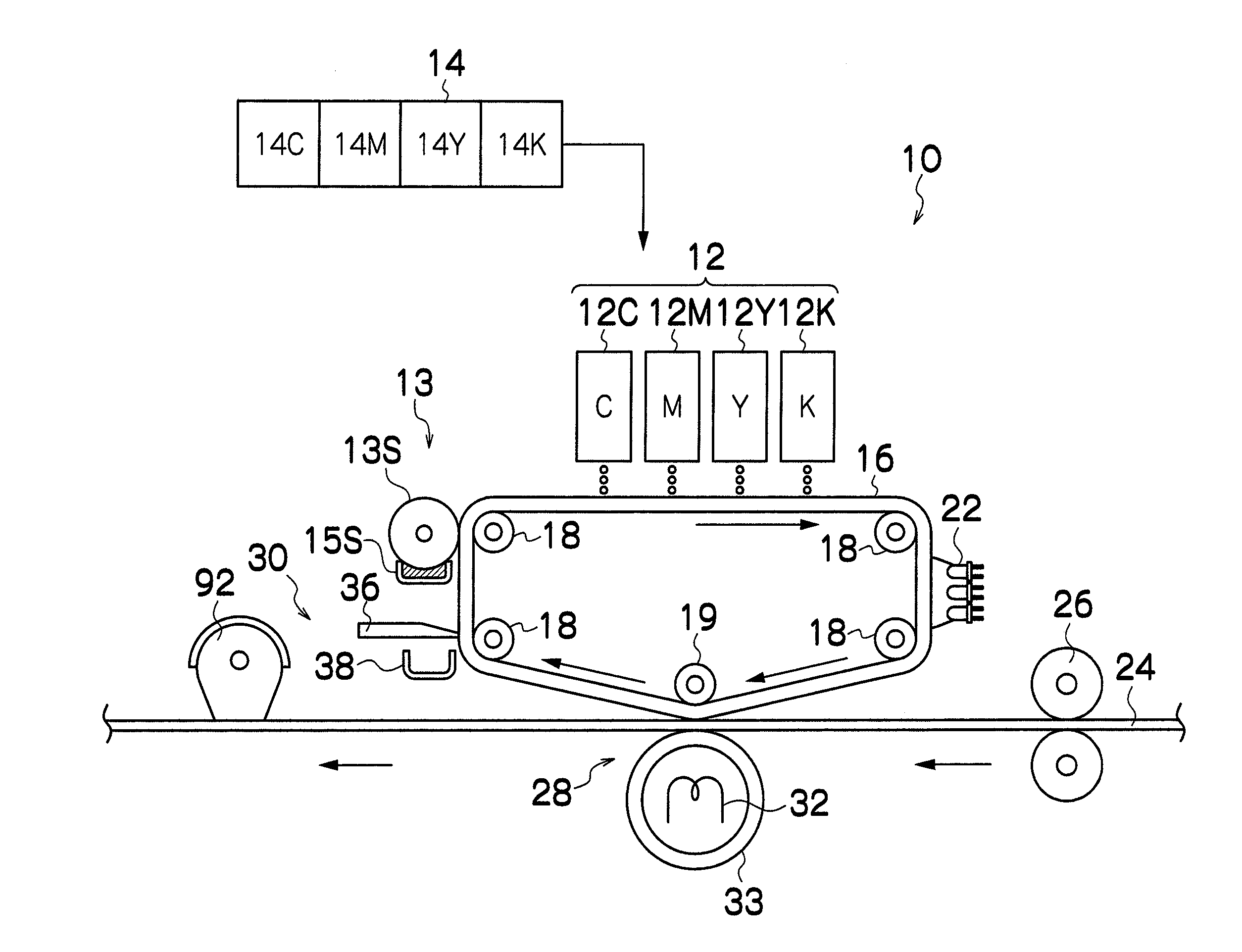

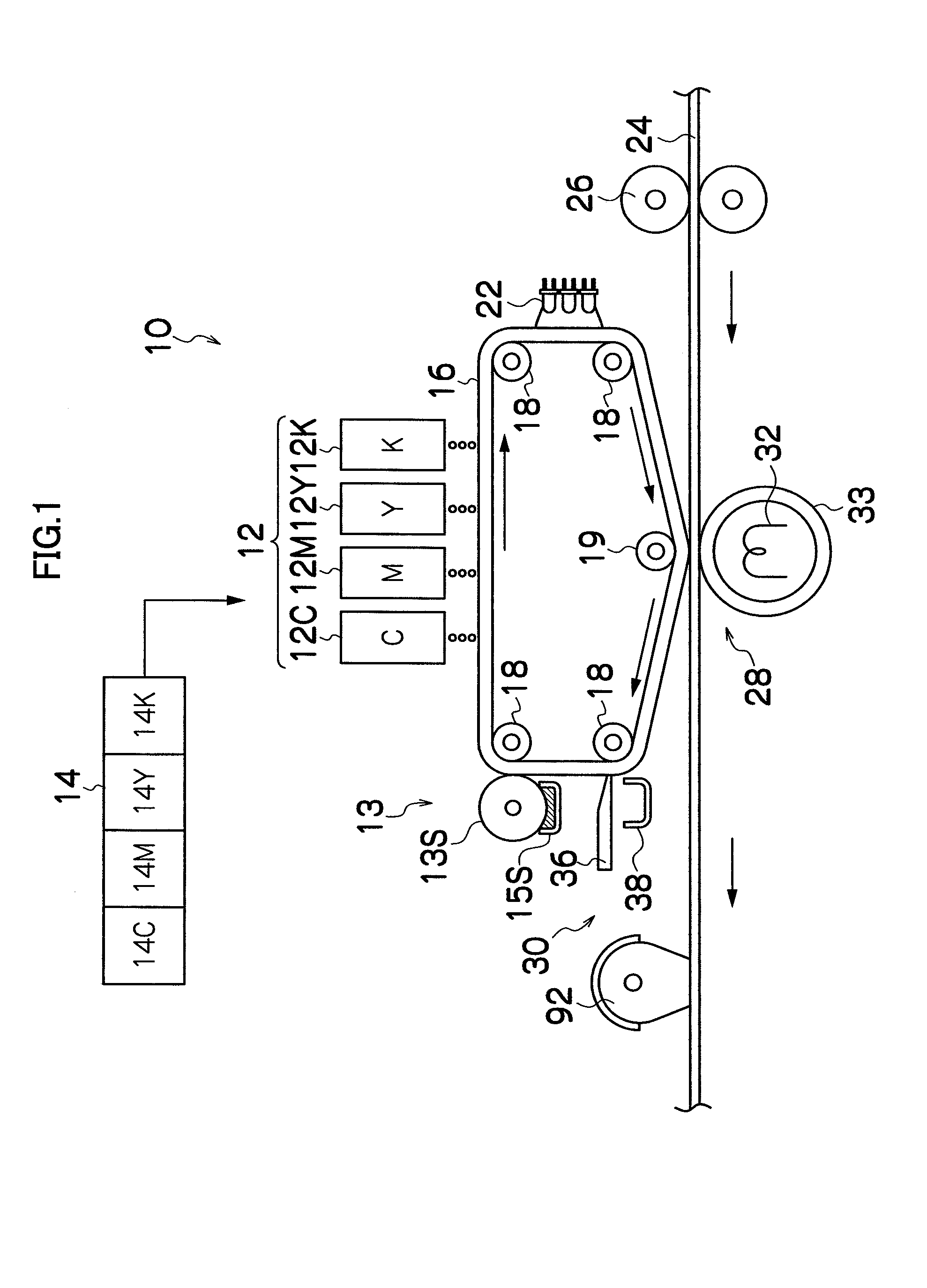

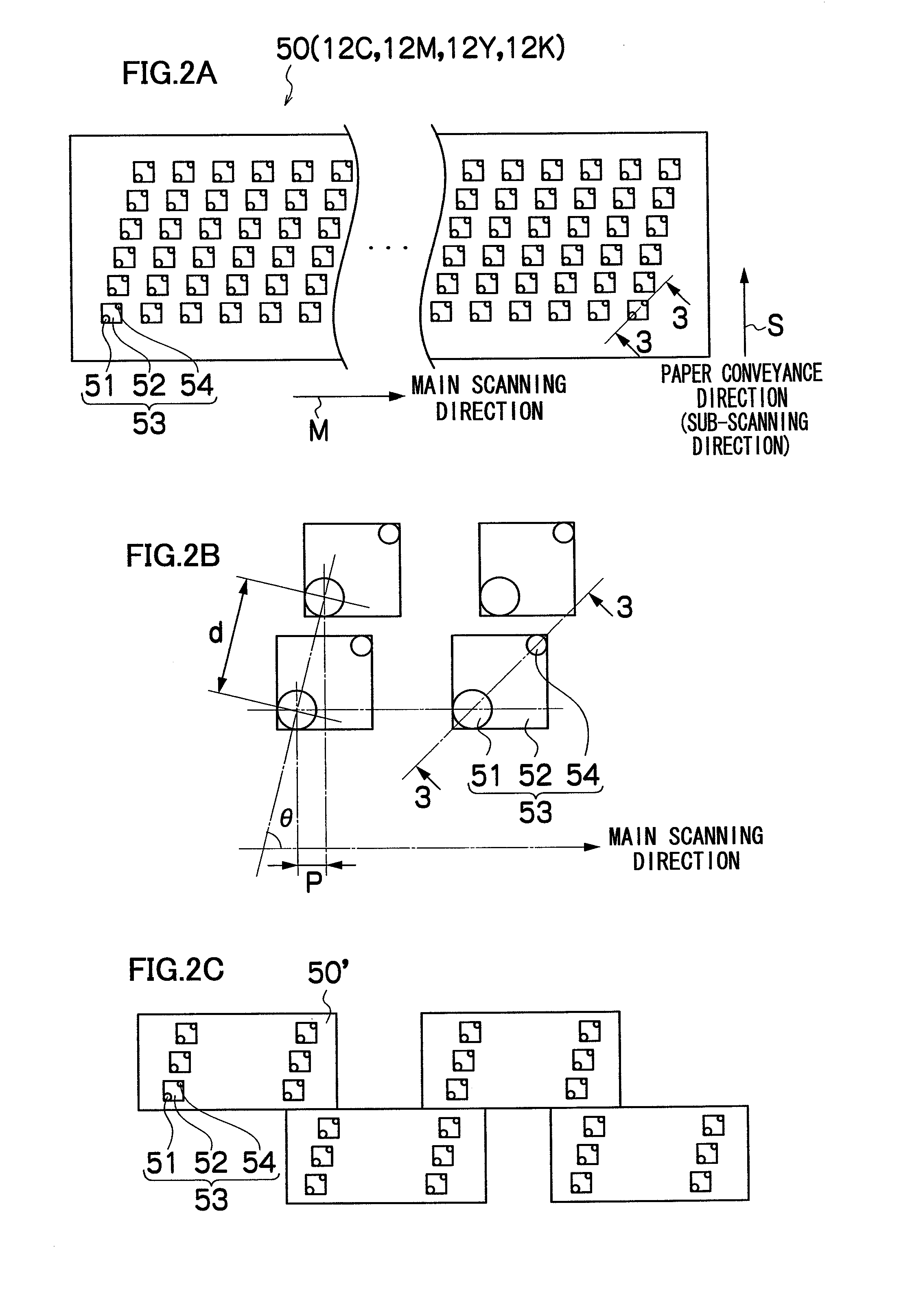

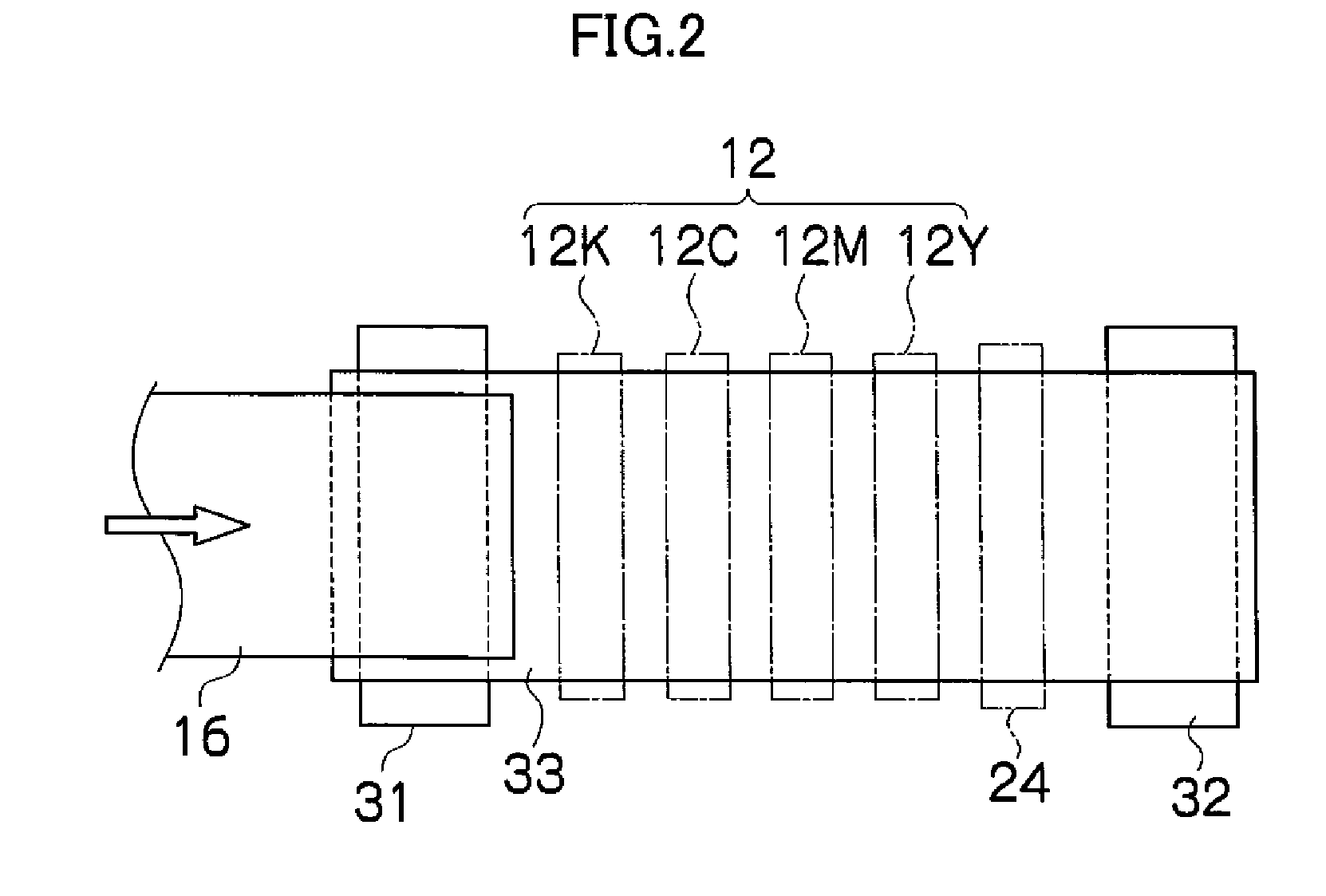

Ink jet print head, inkjet printer including the inkjet print head, and method of manufacturing inkjet print head

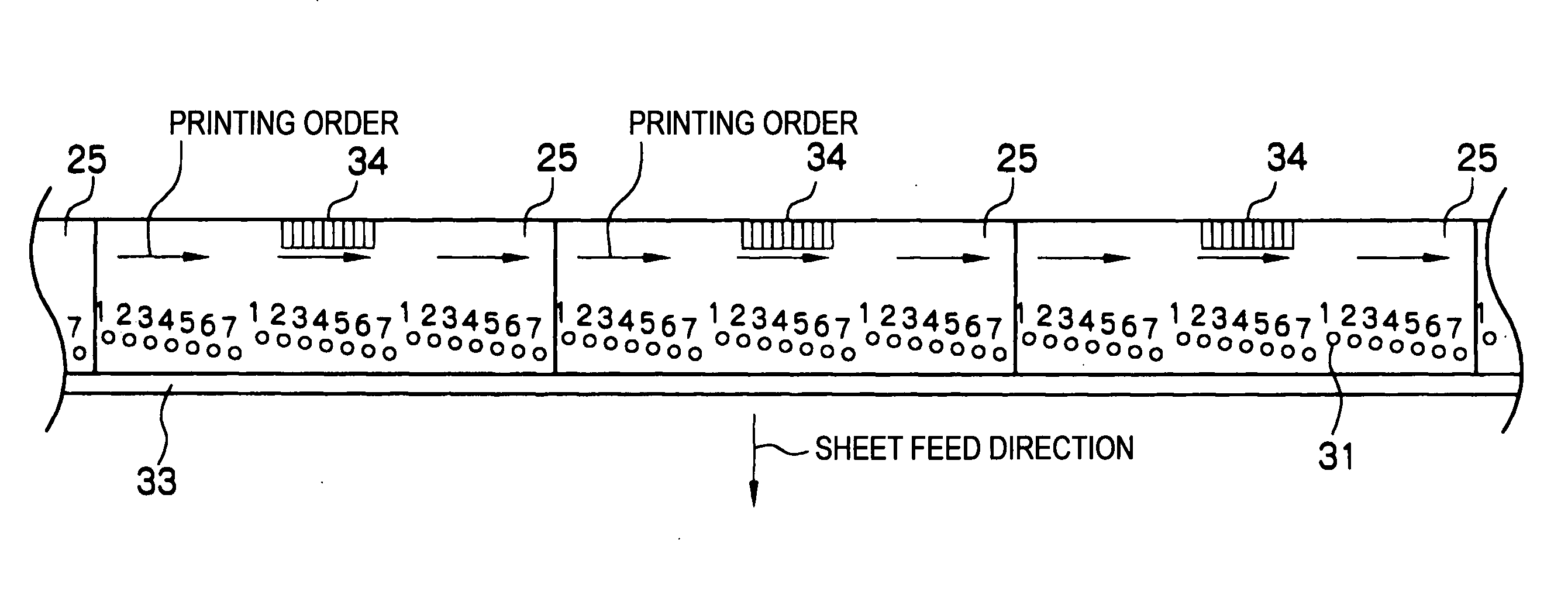

An inkjet print head includes one nozzle sheet (23) and a plurality of head chips (25) including a plurality of heaters. The nozzle sheet (23) is formed of an electroformed metal layer made of nickel or a material comprising nickel, and has discharge nozzle rows for respective colors disposed so that the discharge nozzles are in staggered arrangements and so that each set of discharge nozzles partly overlaps another set of discharge nozzles in a sheet-feed direction. The head chips are positioned at and affixed to a growth surface side of the nozzle sheet (23) in staggered arrangements so that the positions of the discharge nozzles and the positions of the heaters correspond to each other. Accordingly, reduction in printing quality caused by displacement of any of the discharge nozzles is prevented from occurring, and landing positions of discharged ink on a recording sheet are stabilized.

Owner:SONY CORP

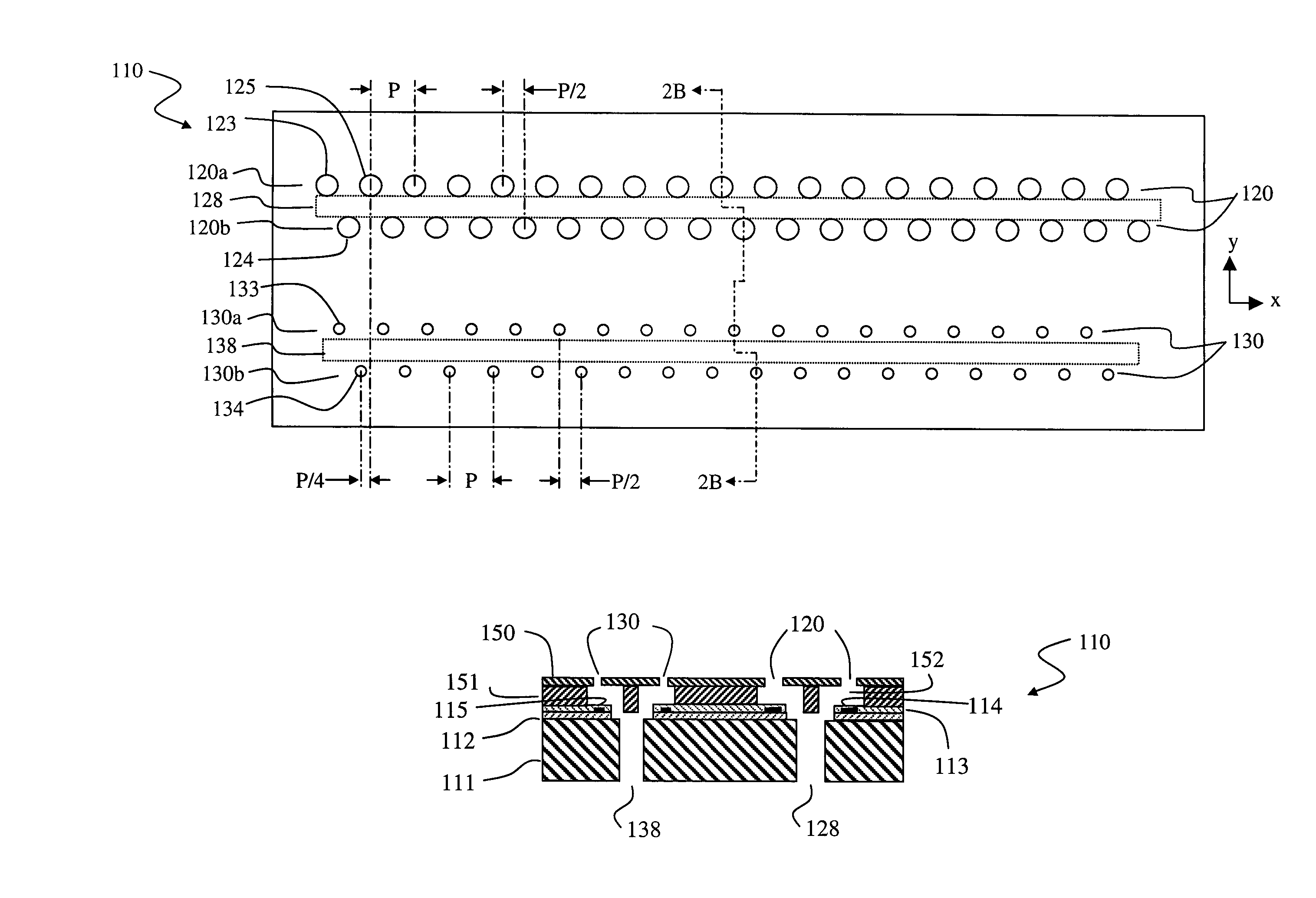

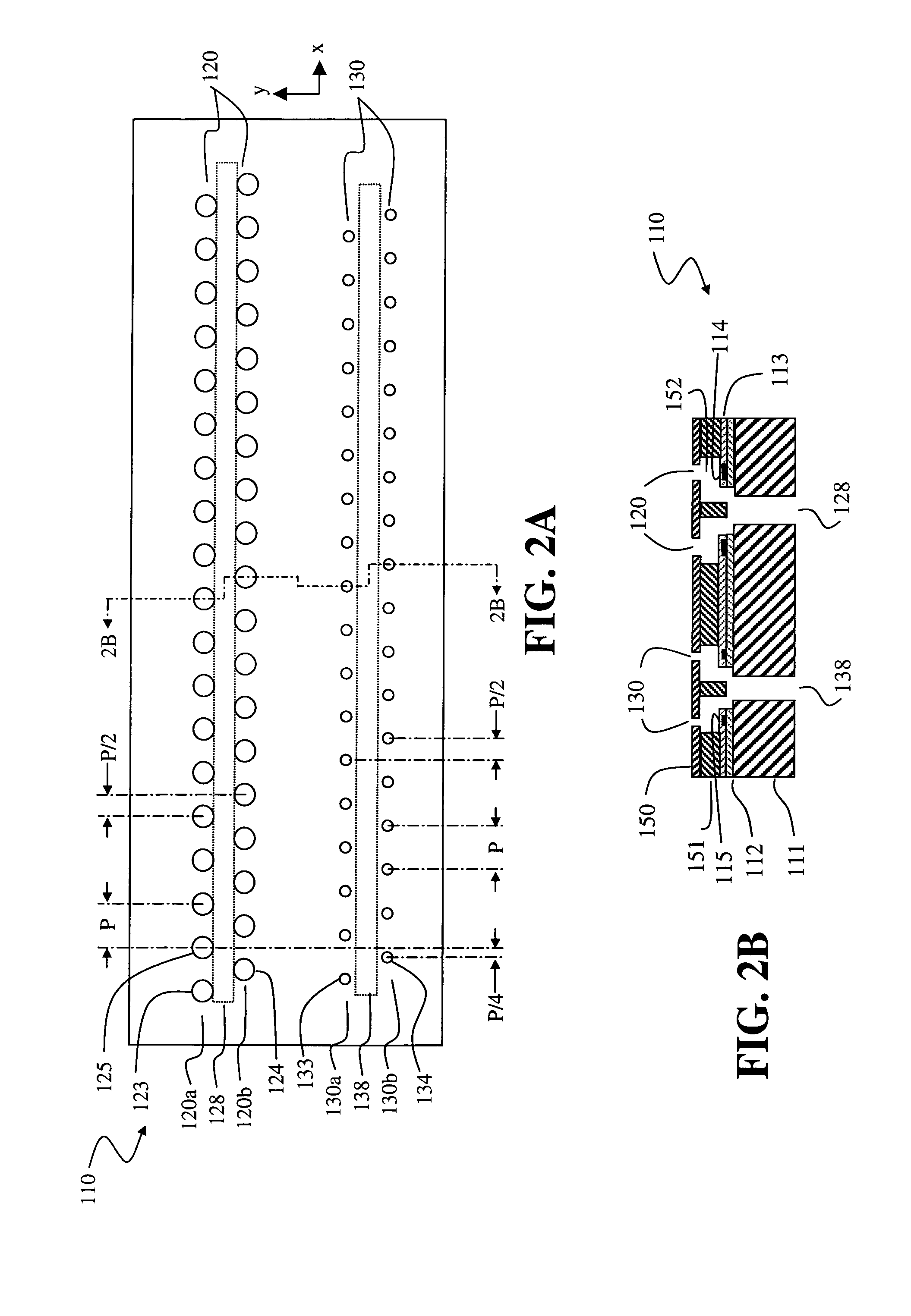

Fluid ejection device nozzle array configuration

A fluid ejection device and a printhead including one or more such fluid ejection devices are provided. The fluid ejection device includes a substrate having a first nozzle array and a second nozzle array, each array having a plurality of nozzles and being arranged along a first direction, the first nozzle array being arranged spaced apart in a second direction from the second nozzle array. A first fluid delivery pathway is in fluid communication with the first nozzle array, and a second fluid delivery pathway is in fluid communication with the second nozzle array. Nozzles of the first nozzle array have a first opening area and are arranged along the first nozzle array at a pitch P. Nozzles of the second nozzle array have a second opening area, the second opening area being less than the first opening area. At least one nozzle of the second array is arranged offset in the first direction from at least one nozzle of the first array by a distance which is less than pitch P. A printhead comprises one or more such fluid ejection devices arranged on a support member.

Owner:EASTMAN KODAK CO

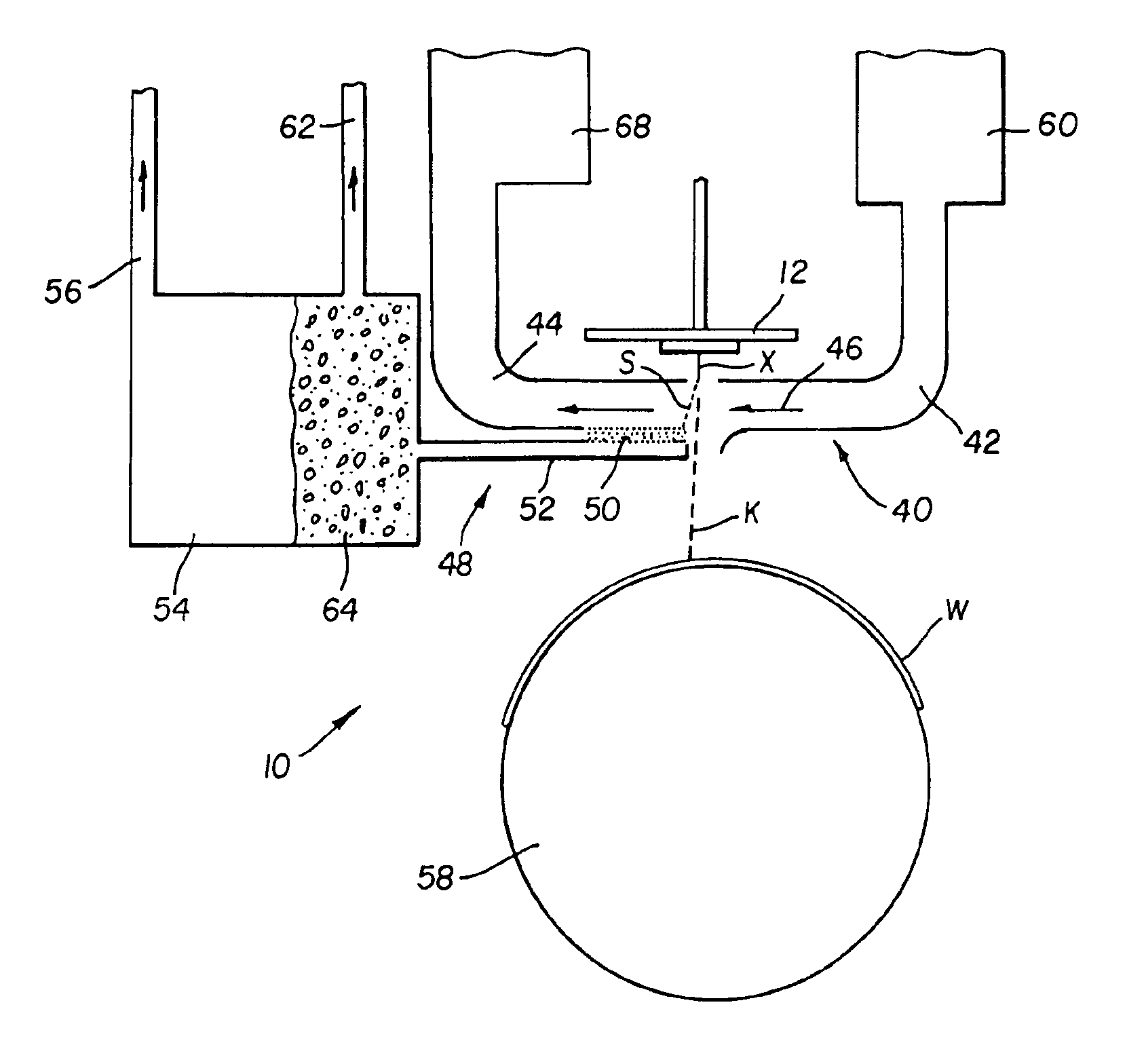

Continuous ink-jet printing apparatus having an improved droplet deflector and catcher

InactiveUS6851796B2Increase deflection angleGood removal effectInking apparatusEngineeringMechanical engineering

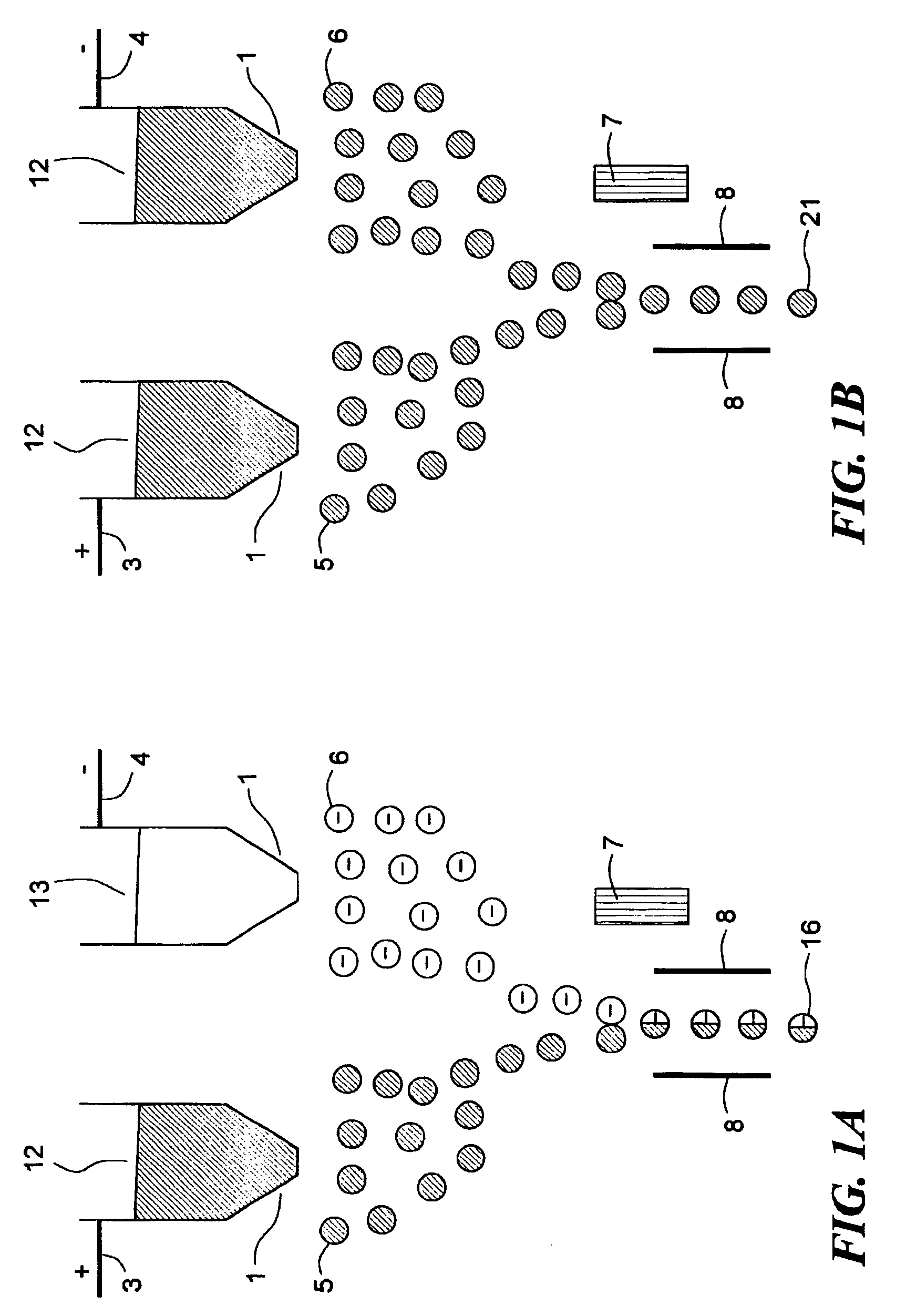

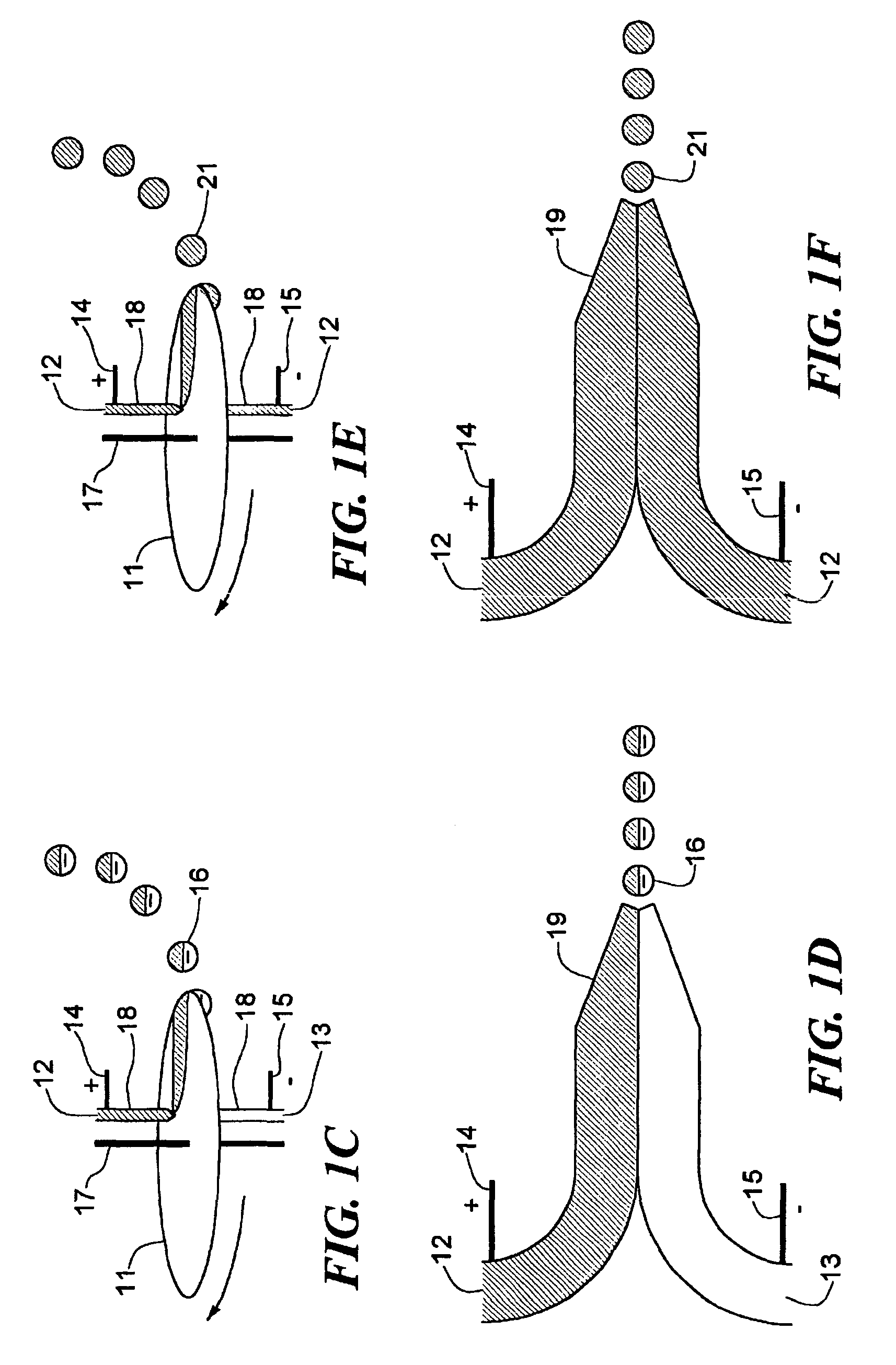

An apparatus for printing an image is provided. The apparatus includes an ink droplet forming mechanism operable to selectively create a stream of ink droplets having a plurality of volumes traveling along a first path. A droplet deflector is positioned at an angle with respect to the stream of ink droplets. The droplet deflector includes a gas flow operable to interact with the stream of ink droplets such that ink droplets having one of the plurality of volumes begin traveling along a second path and ink droplets having another of the plurality of volumes begin traveling along a third path. At least a portion of a catcher including a porous material is at least partially positioned in one of the first, second, and third paths.

Owner:EASTMAN KODAK CO

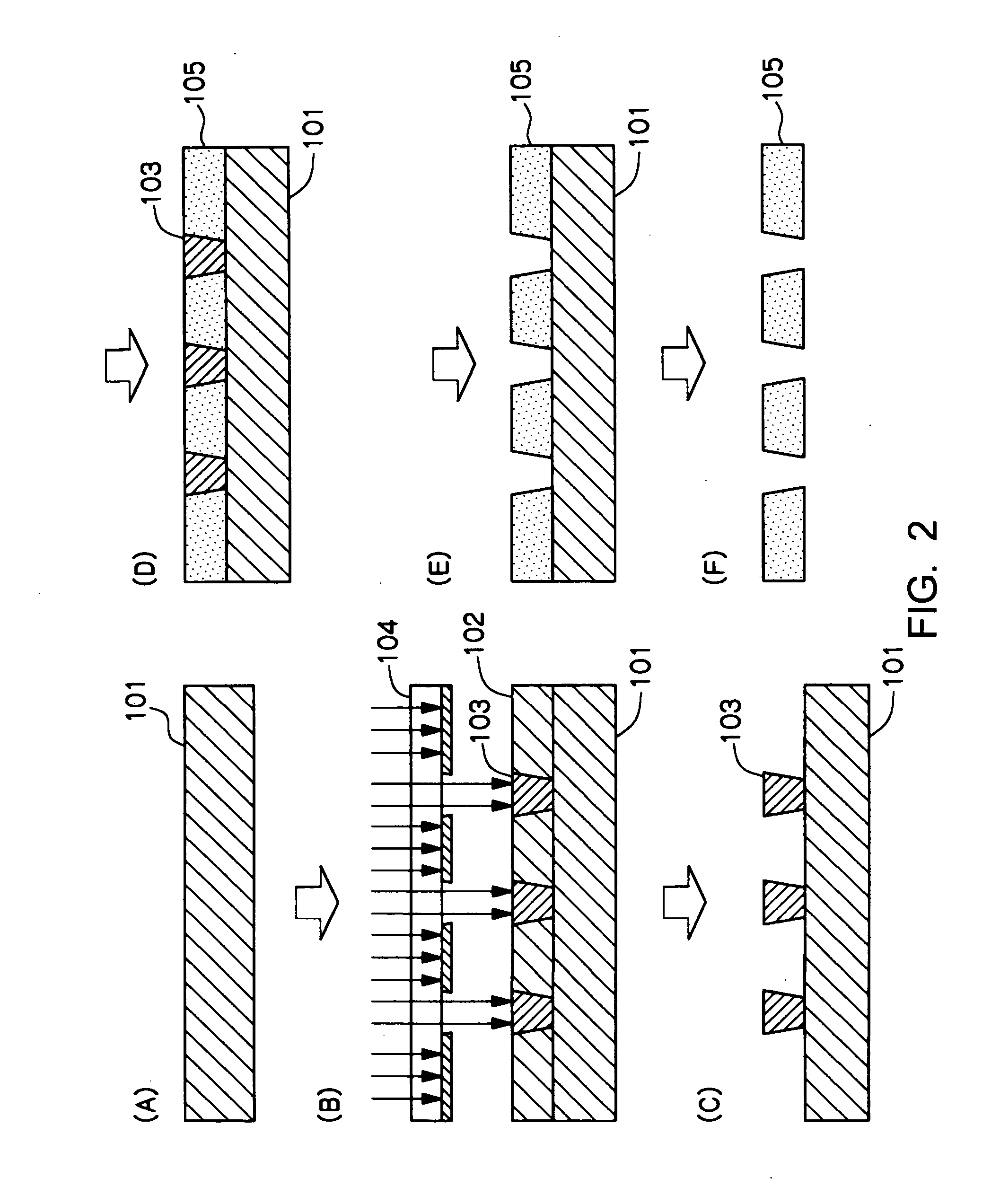

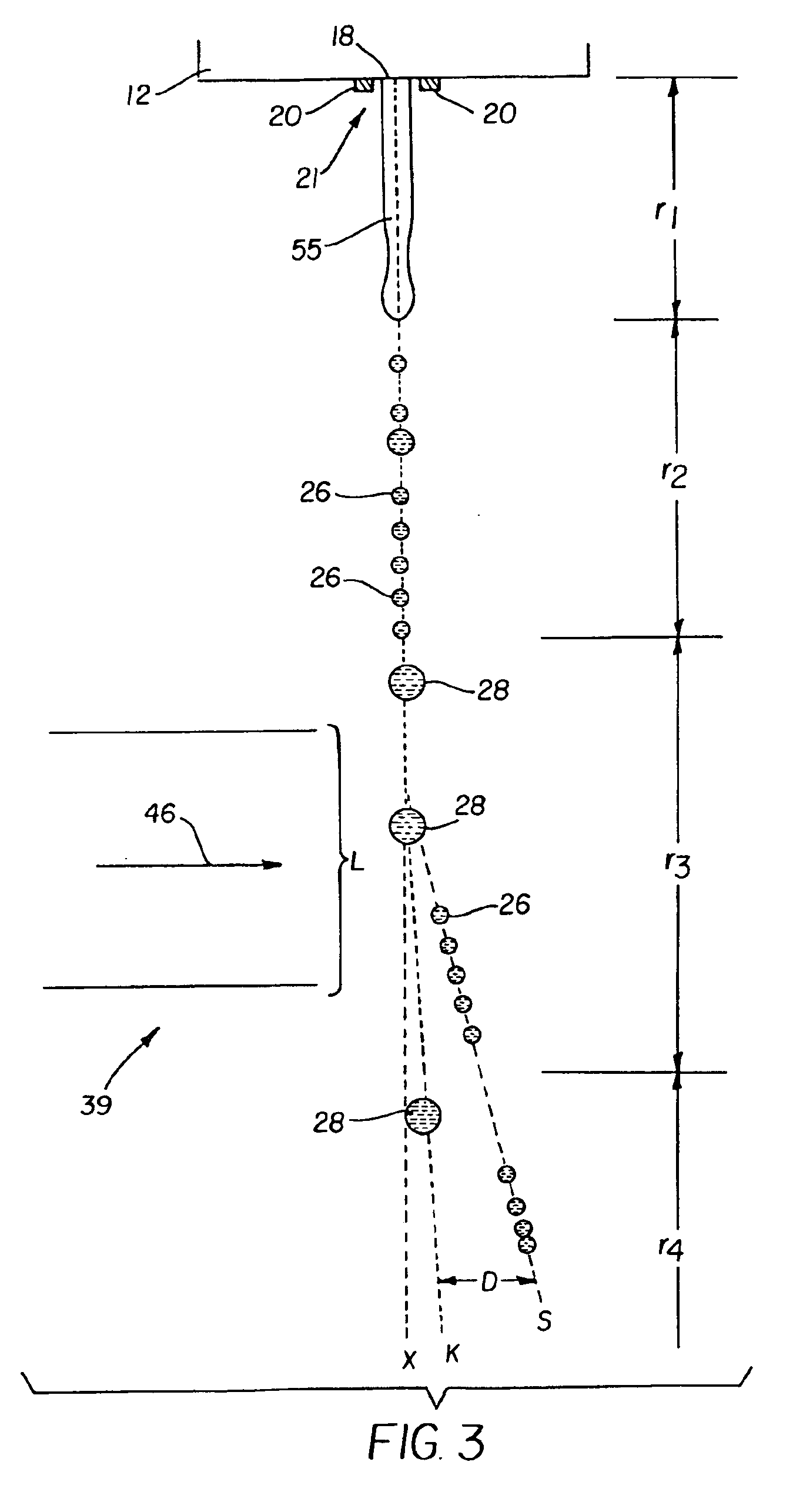

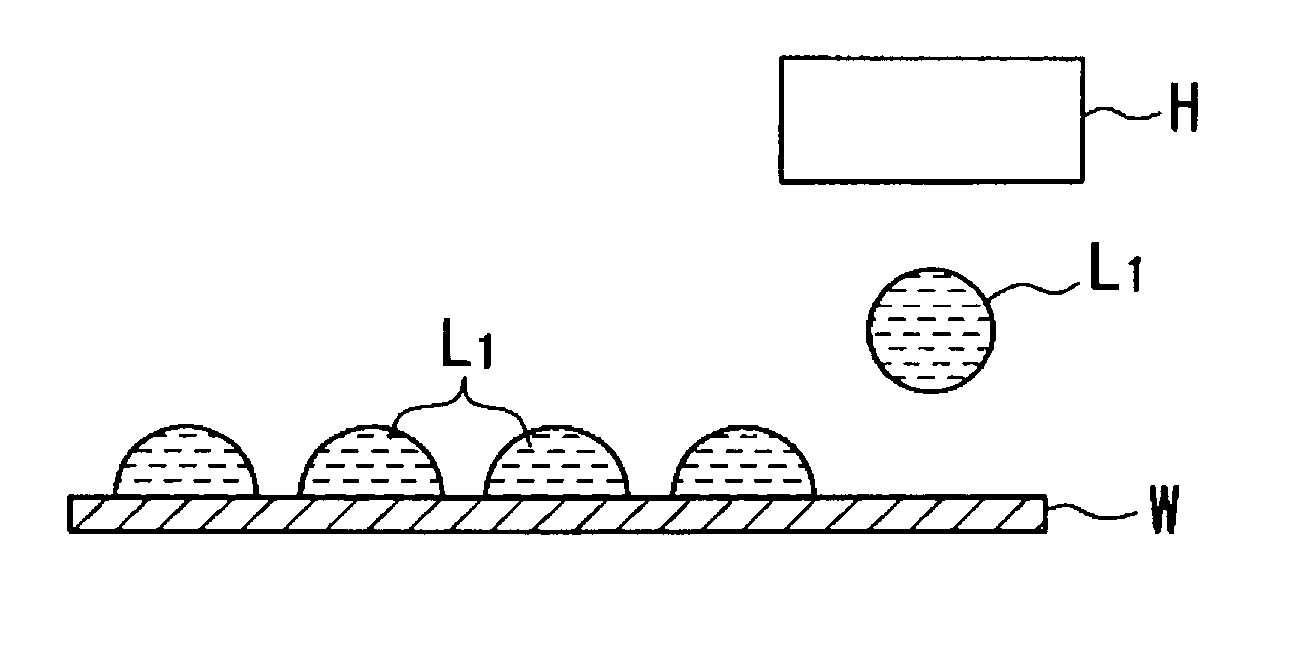

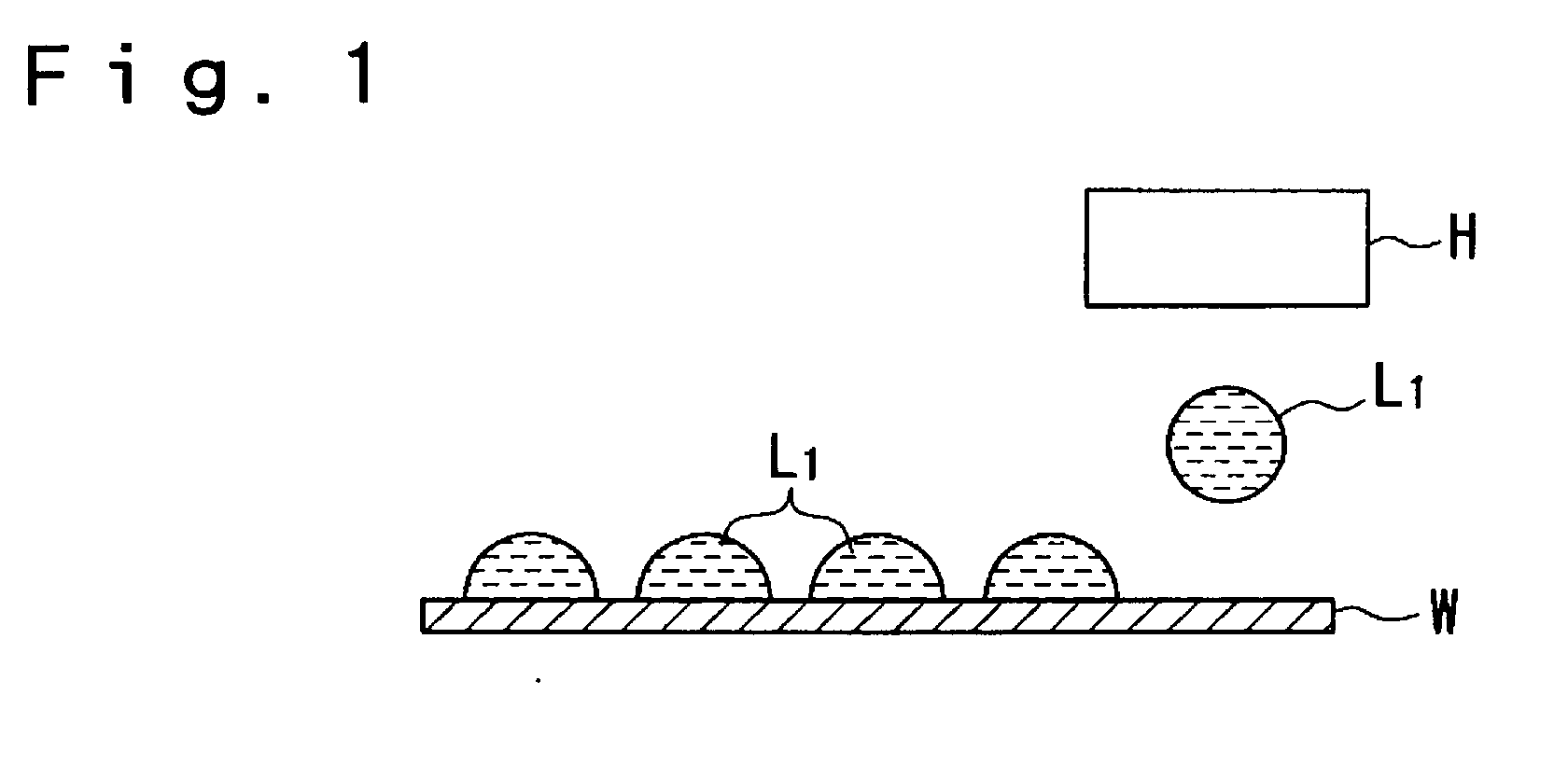

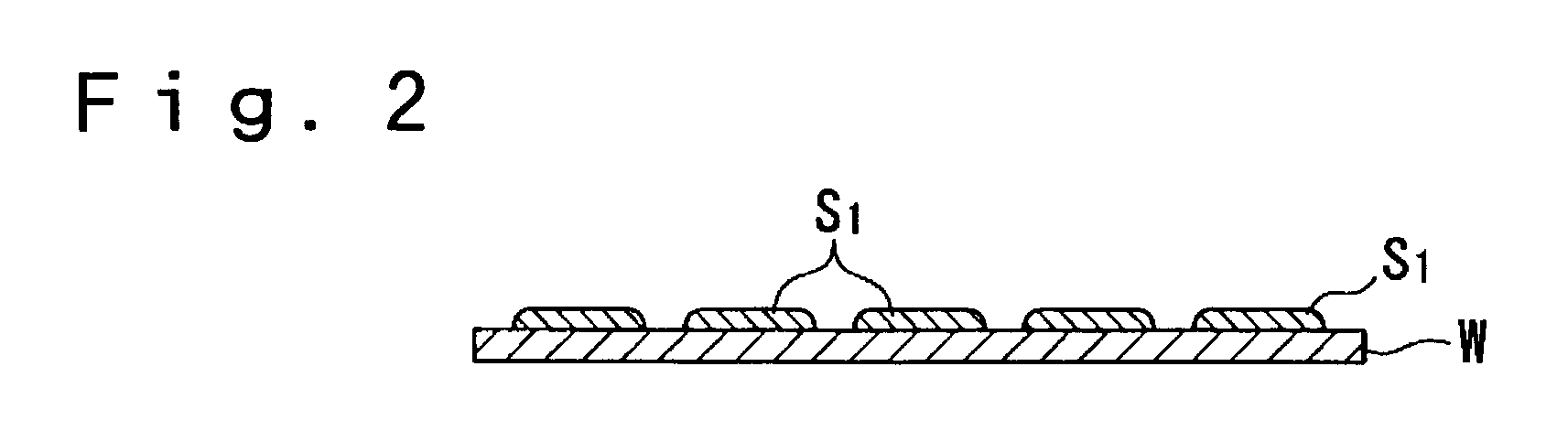

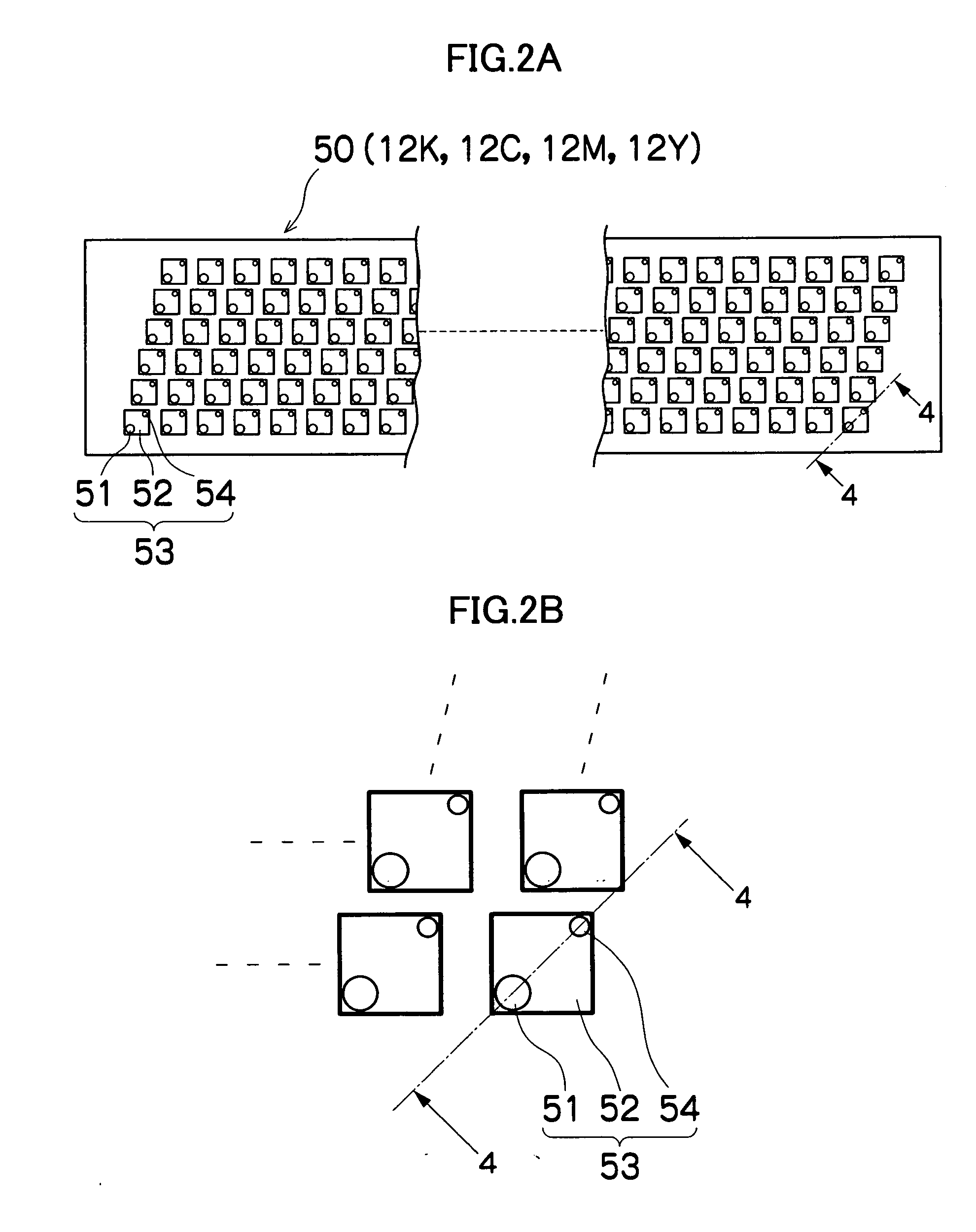

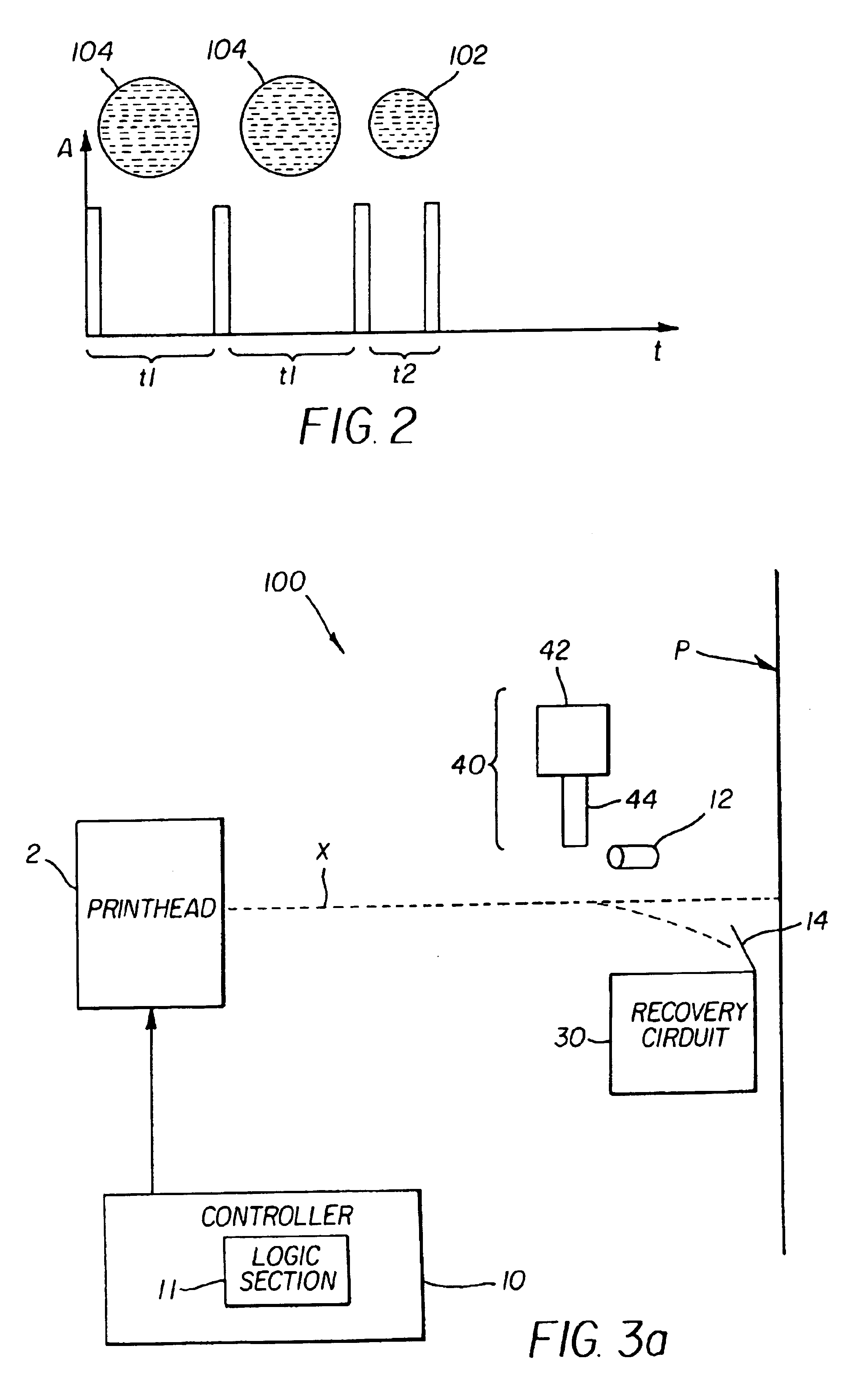

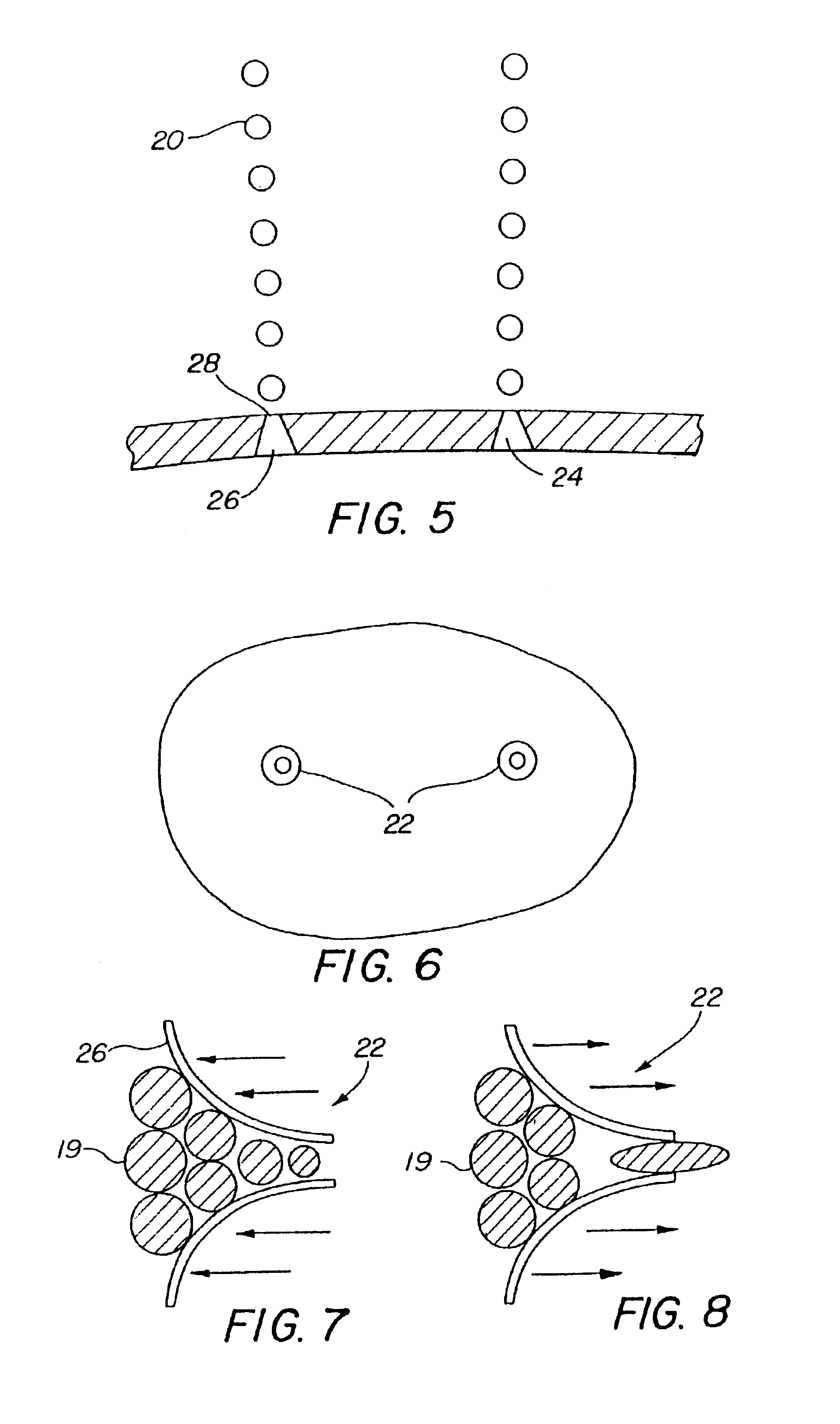

Apparatus and methods for forming film pattern

The invention provides a method for forming a film pattern, in which a method for forming a film pattern by the ink-jet method is improved, an increase in film thickness is achieved efficiently with simple steps, a requirement for a decrease in line width is met and, in addition, problems such as breaks and short circuits are not brought about when a conductive film is made. The method can include a first discharging step, wherein droplets are discharged in the whole film formation region with a pitch larger than the diameter of the droplet after being hit onto the substrate. In the second discharging step, droplets are discharged at positions in the whole film formation region different from the discharge positions in the first discharging step with the same pitch as that in the first discharging step. In the third discharging step, droplets are discharged in the whole film formation region with a pitch smaller than the pitch in the first discharging step. The substrate is treated beforehand in order to have the contact angle of 60 degrees or more with respect to the droplets.

Owner:SEIKO EPSON CORP

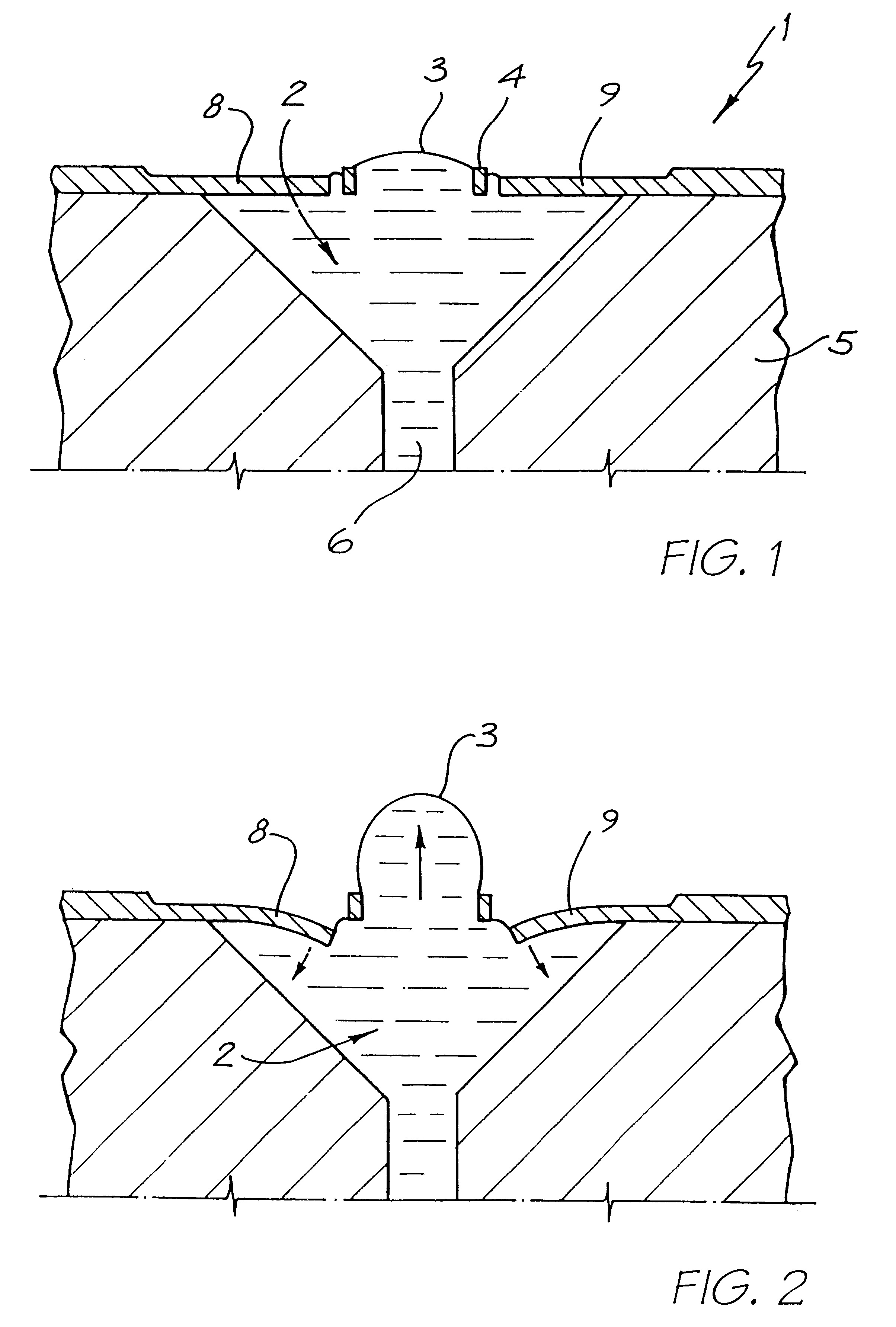

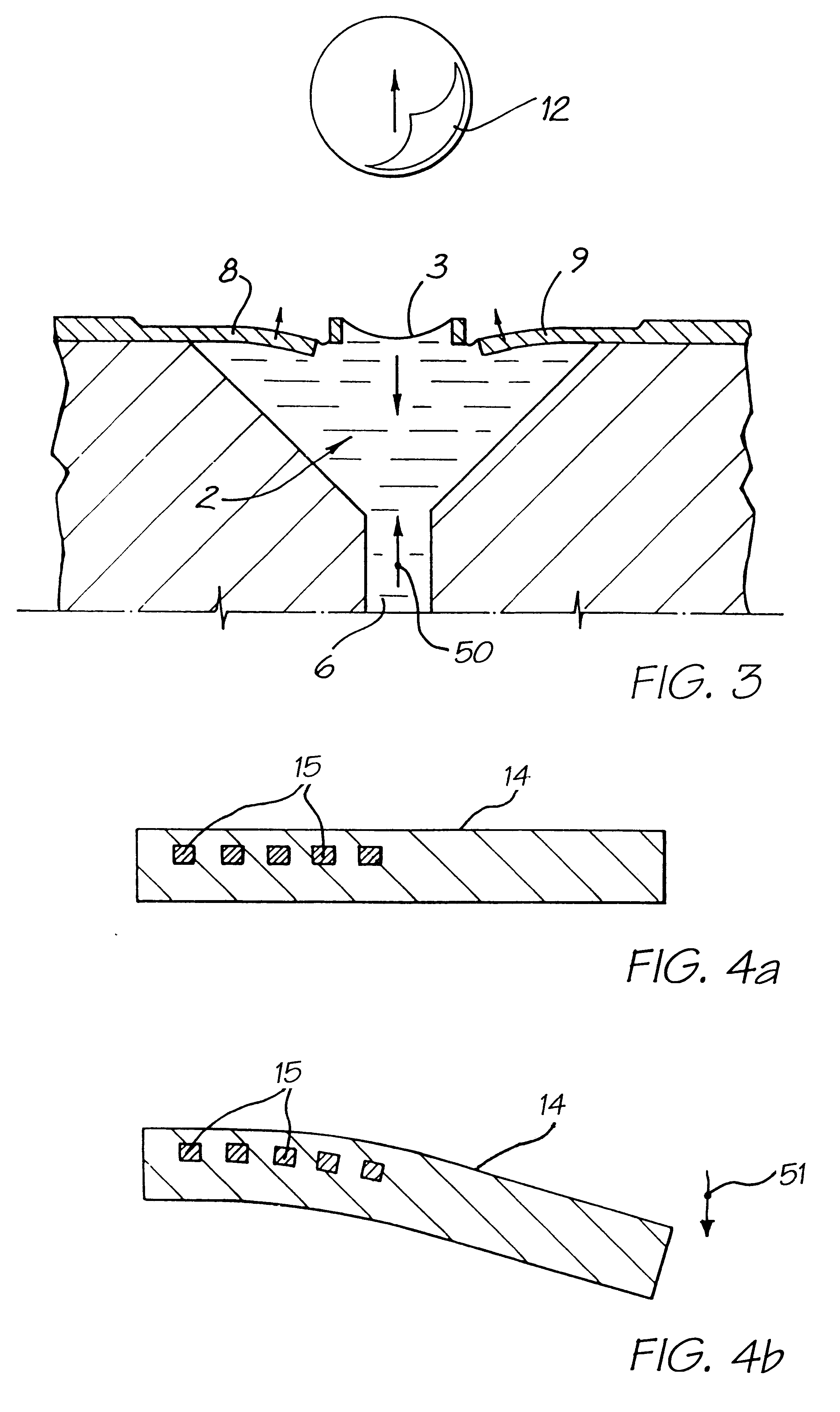

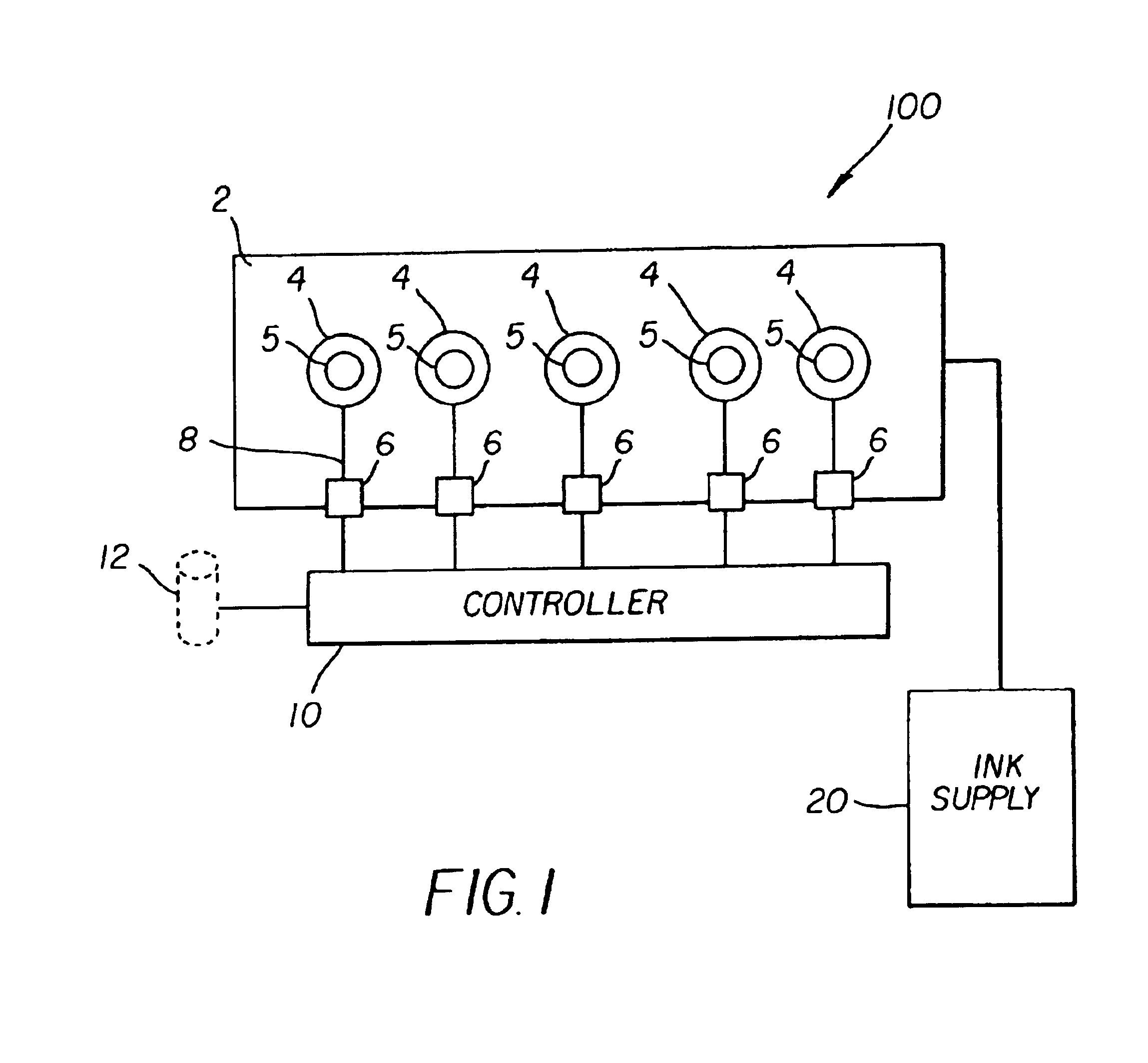

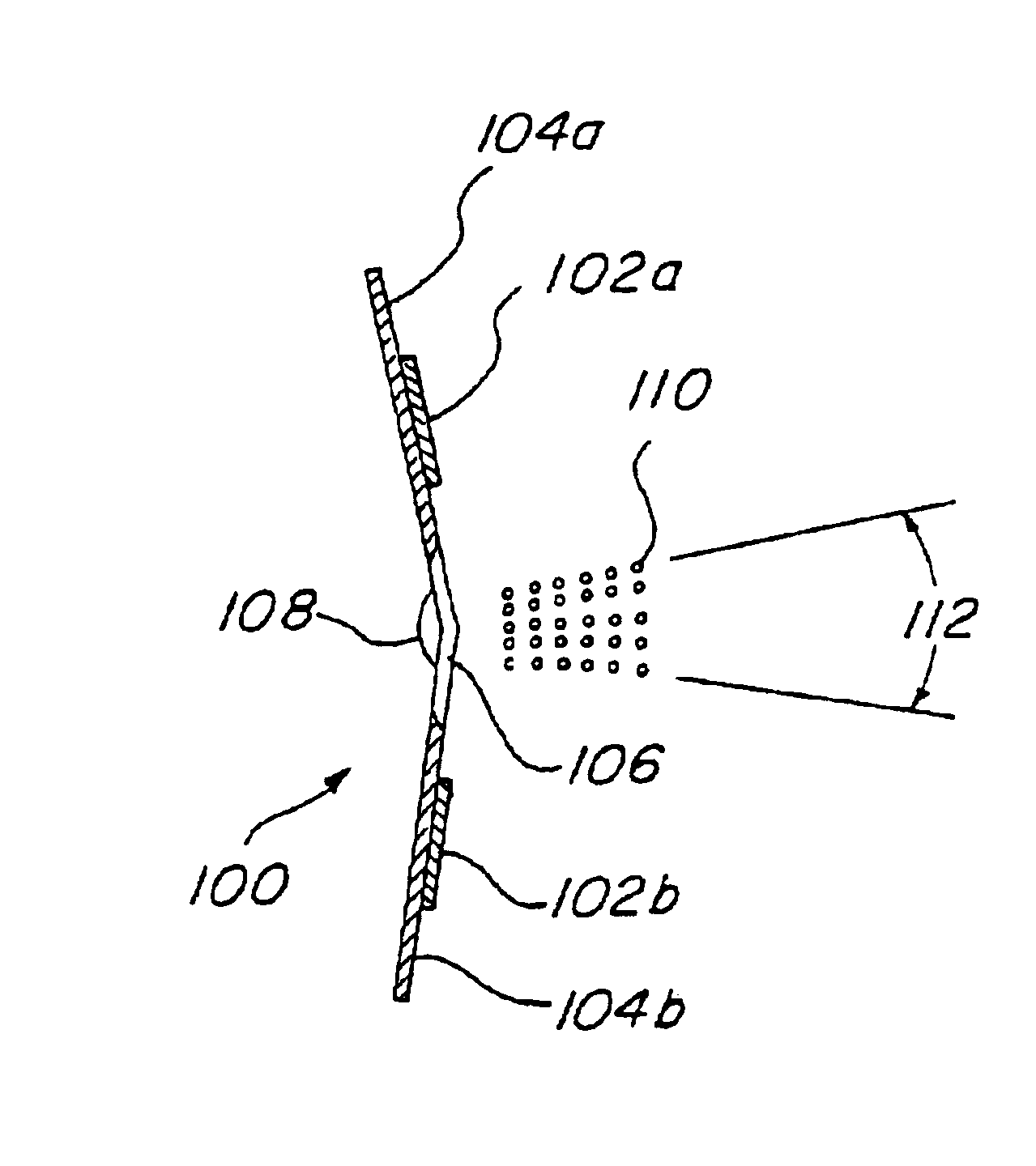

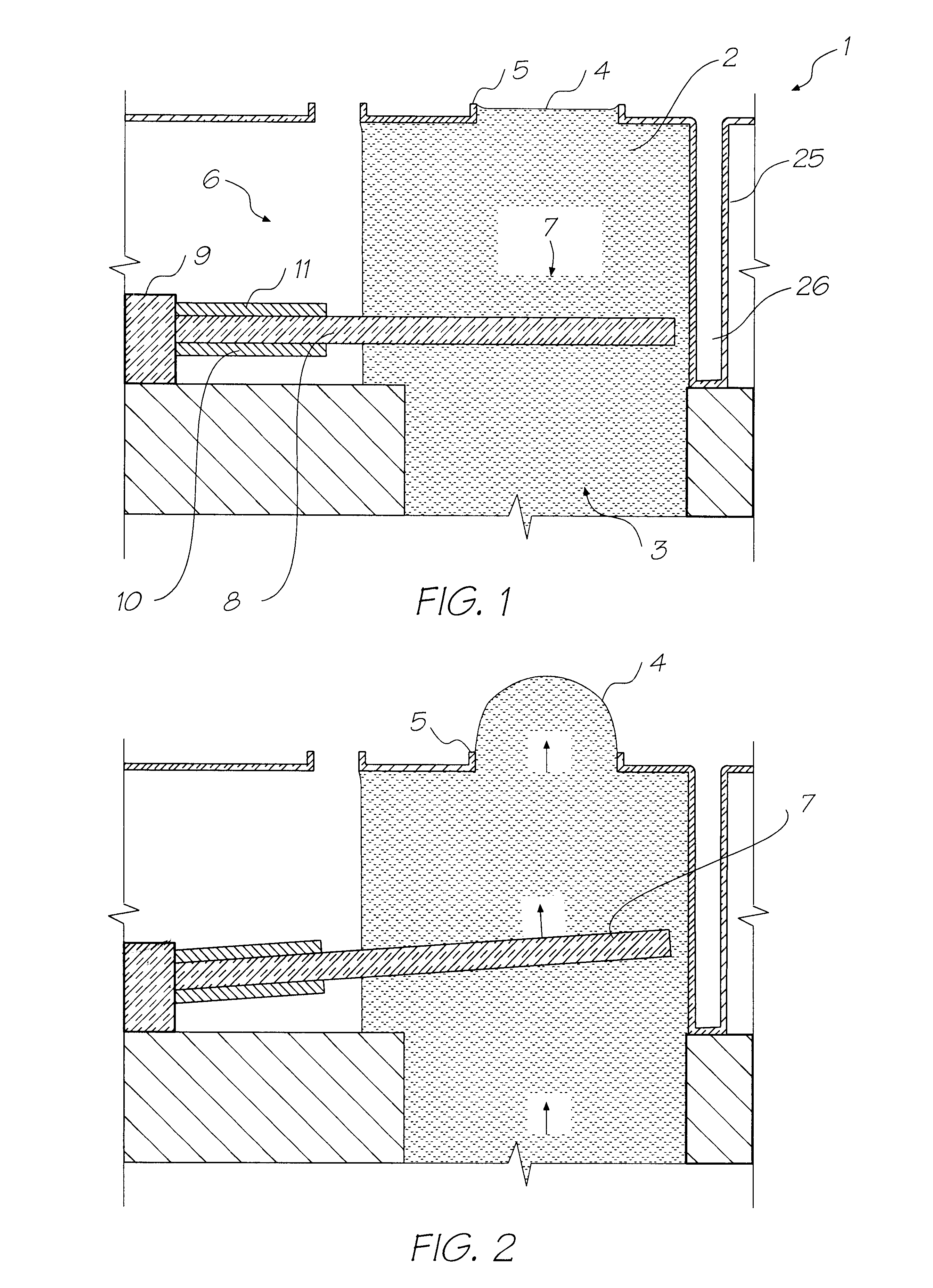

Inverted radial back-curling thermoelastic ink jet printing mechanism

A nozzle arrangement for an ink jet printhead includes a wafer substrate having a nozzle chamber defined therein. The nozzle arrangement has a nozzle chamber wall that defines an ink ejection port and a rim about the ink ejection port. A series of radially positioned actuators are connected to the wafer substrate and extend radially inwardly towards the rim. Each actuator is configured so that a radially inner edge of each actuator is displaceable, with respect to the nozzle rim, into the chamber, upon actuation of the actuator and so that, upon such displacement, a pressure within the nozzle chamber is increased, resulting in the ejection of ink from the ejection port.

Owner:SILVERBROOK RES PTY LTD +1

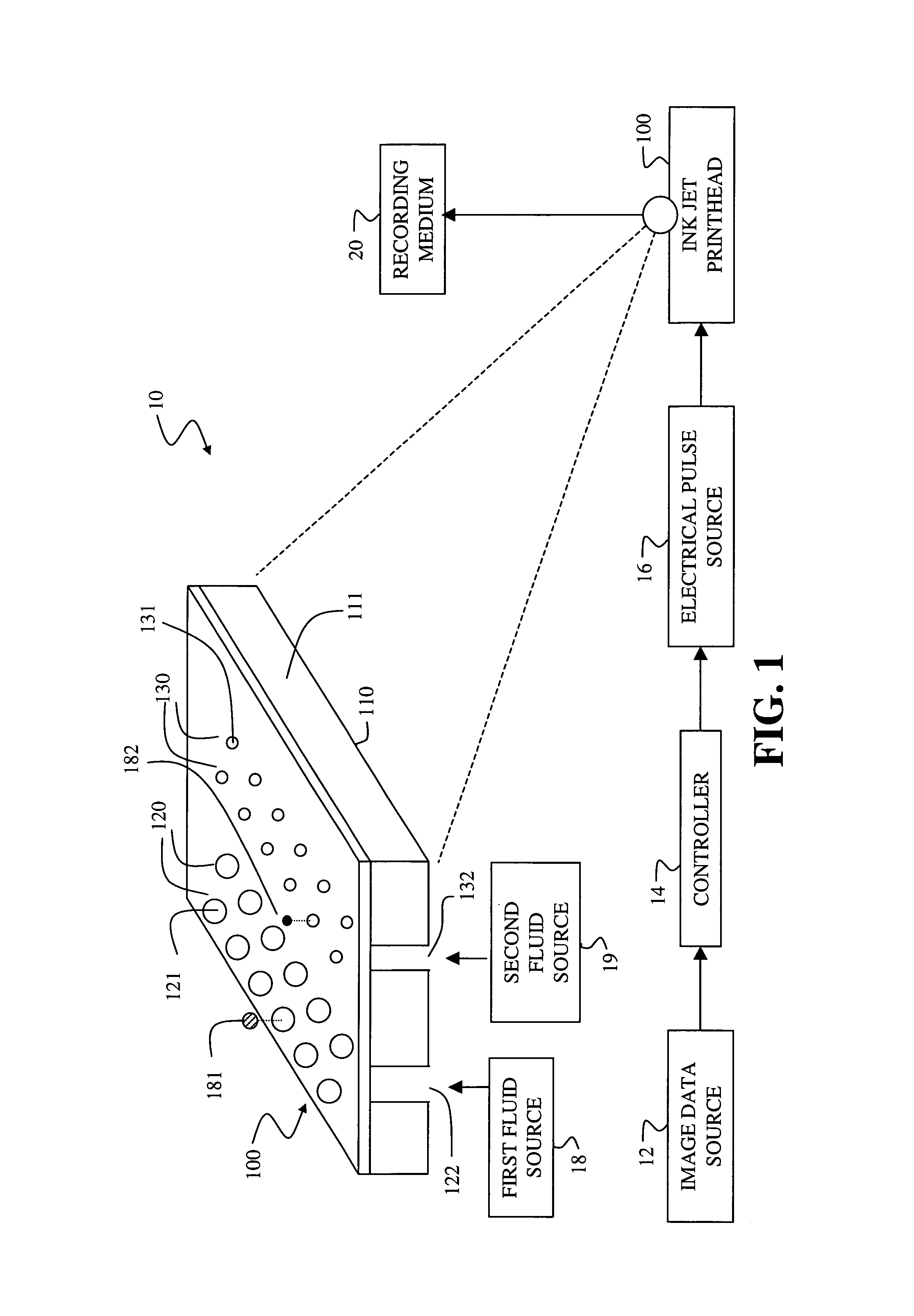

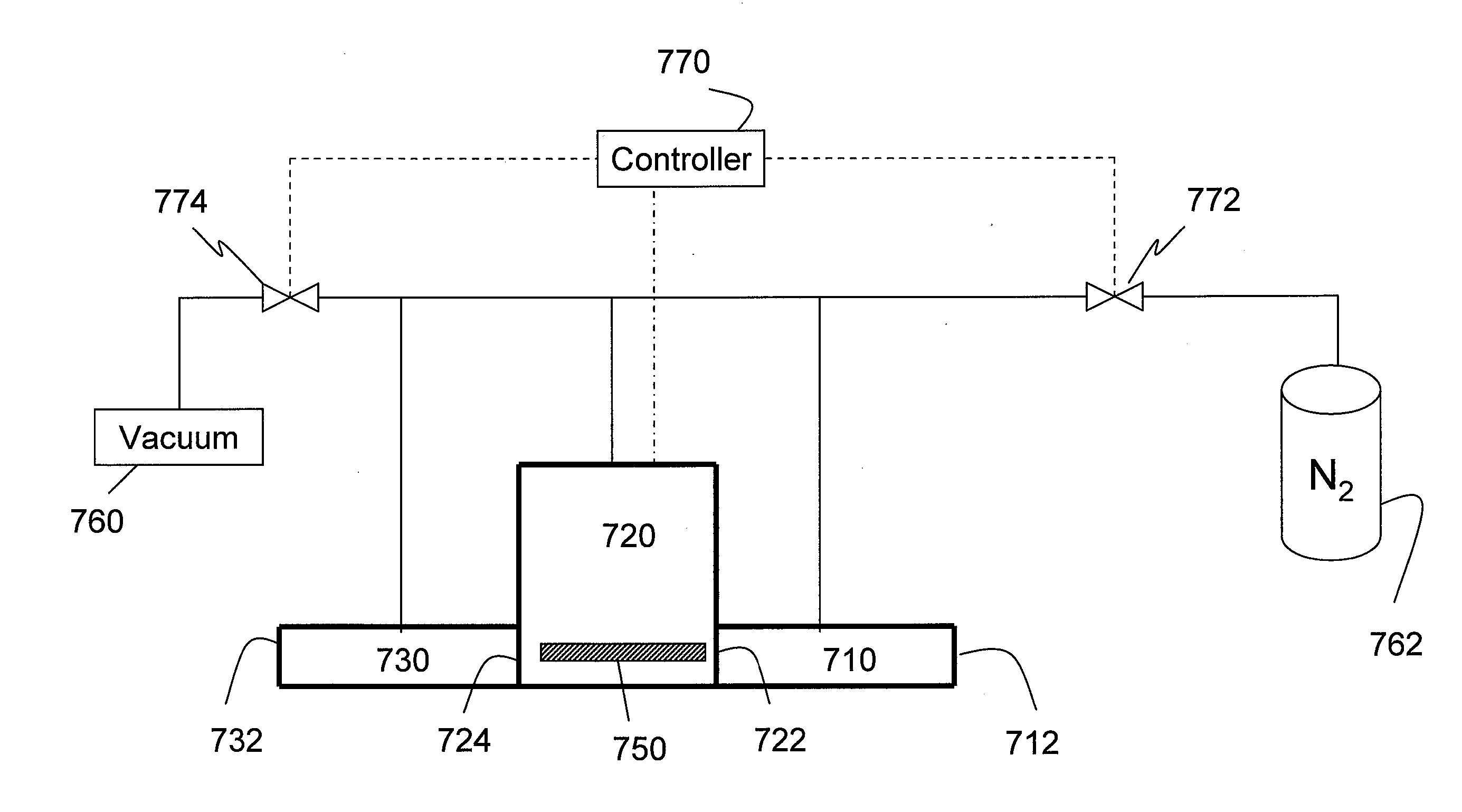

Method And Apparatus for Load-Locked Printing

ActiveUS20100201749A1Prevent oxidationAvoid contaminationInking apparatusMolten spray coatingElectrical and Electronics engineering3D printing

The disclosure relates to a method and apparatus for preventing oxidation or contamination during a circuit printing operation. The circuit printing operation can be directed to OLED-type printing. In an exemplary embodiment, the printing process is conducted at a load-locked printer housing having one or more of chambers. Each chamber is partitioned from the other chambers by physical gates or fluidic curtains. A controller coordinates transportation of a substrate through the system and purges the system by timely opening appropriate gates. The controller may also control the printing operation by energizing the print-head at a time when the substrate is positioned substantially thereunder.

Owner:KATEEVA

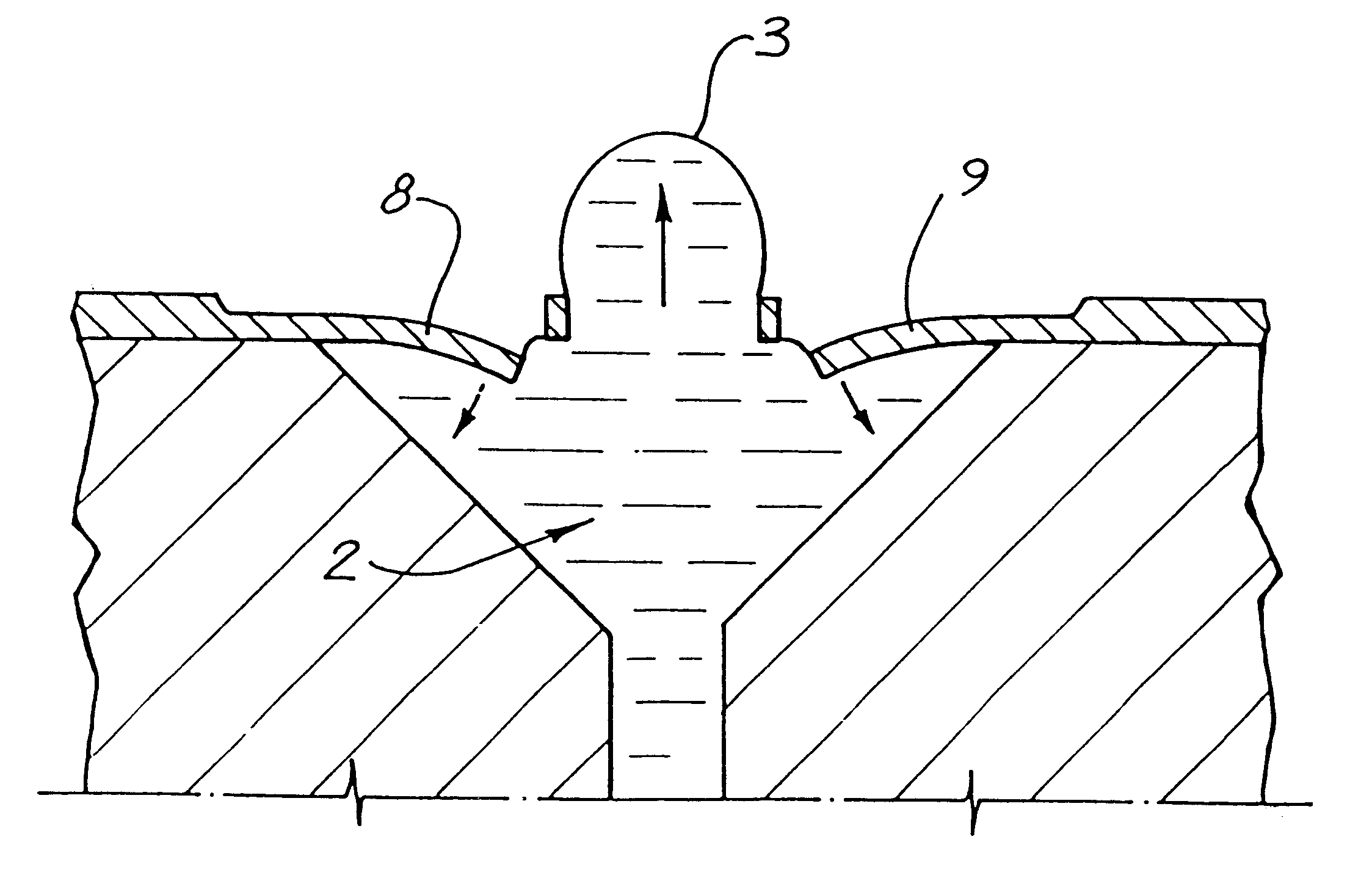

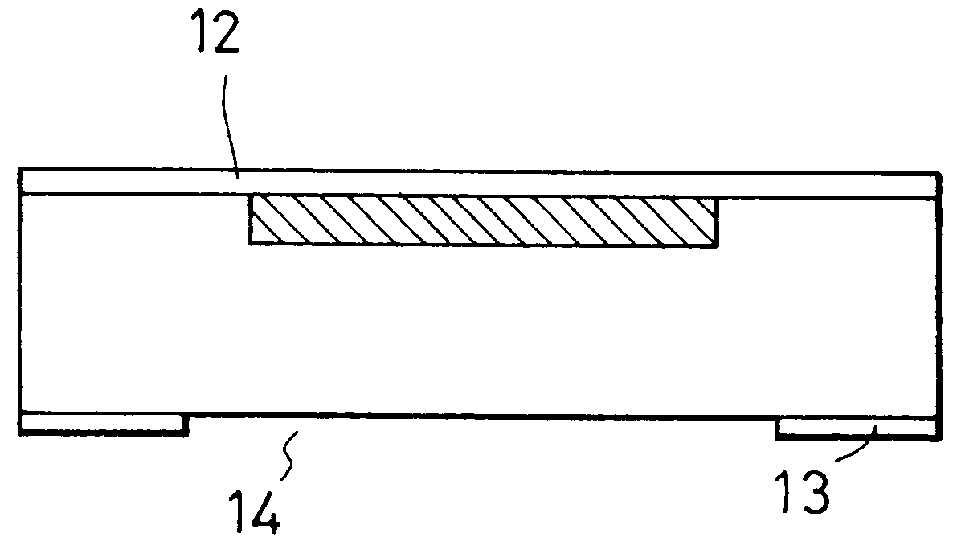

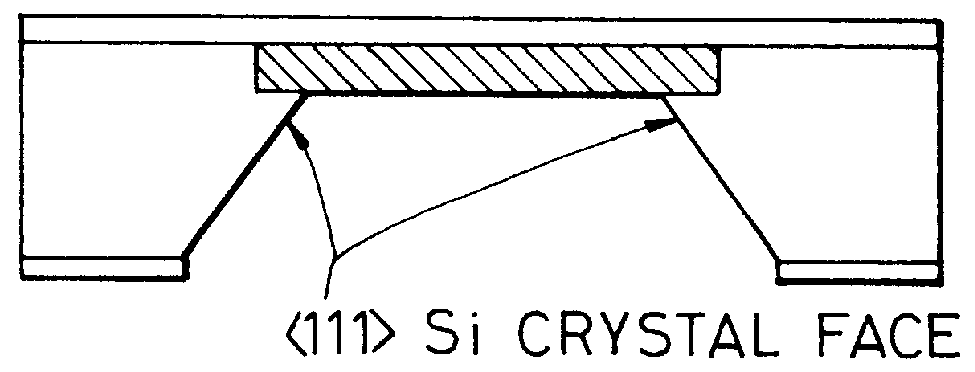

Method of producing a through-hole, silicon substrate having a through-hole, device using such a substrate, method of producing an ink-jet print head, and ink-jet print head

The invention provides a method of producing a through-hole, a substrate used to produce a through-hole, a substrate having a through-hole, and a device using such a through-hole or a substrate having such a through-hole, which are characterized in that: a through-hole can be produced only by etching a silicon substrate from its back side; the opening length d can be precisely controlled to a desired value regardless of the variations in the silicon wafer thickness, and the orientation flat angle, and also regardless of the type of a silicon crystal orientation-dependent anisotropic etchant employed; high productivity, high production reproducibility, and ease of production can be achieved; a high-liberality can be achieved in the shape of the opening end even if temperature treatment is performed at a high temperature for a long time; and a high-precision through-hole can be produced regardless of the shape of a device formed on the surface of a substrate.

Owner:CANON KK

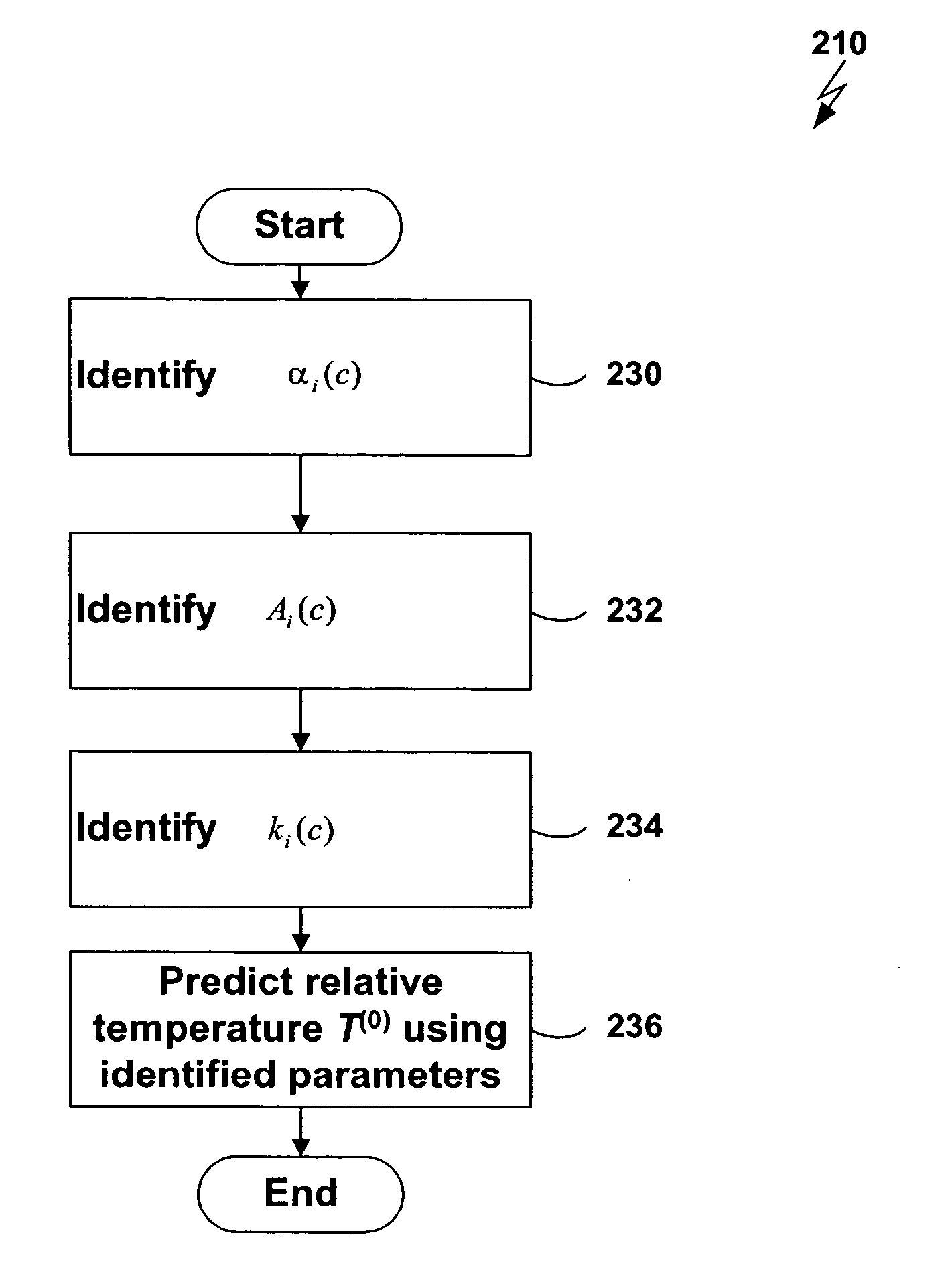

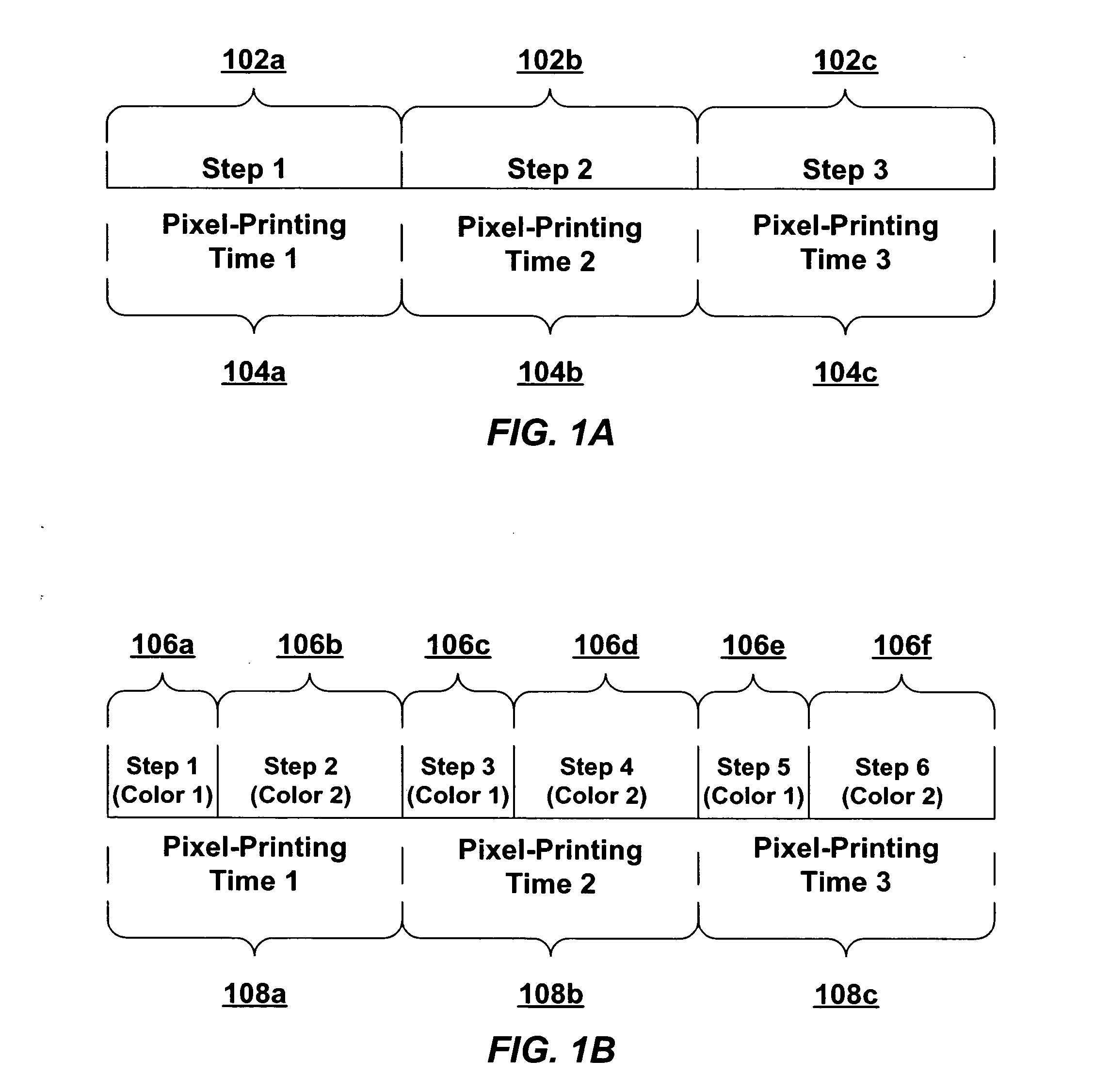

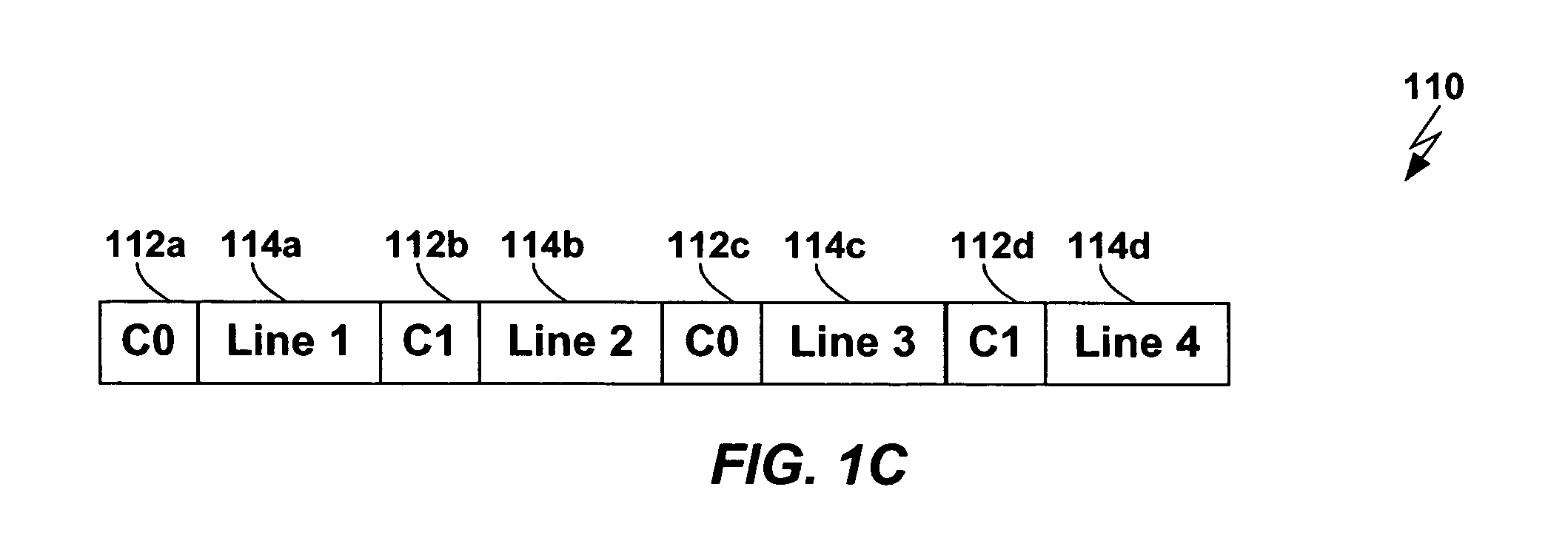

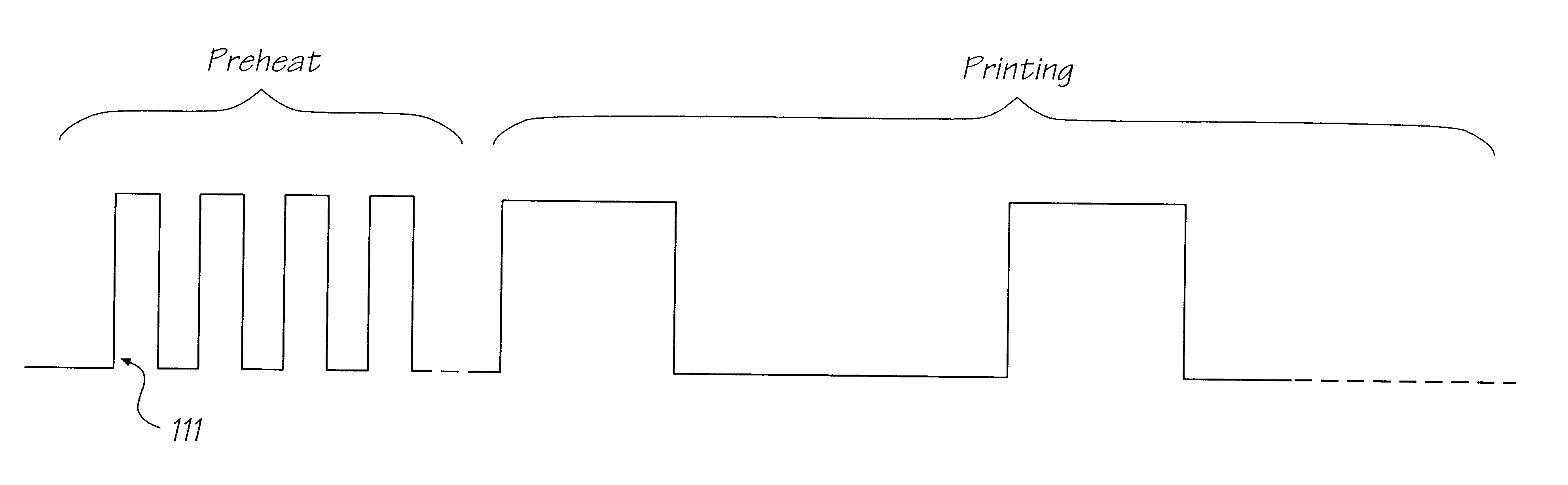

Thermal response correction system

Techniques are disclosed for performing thermal history control in a thermal printer in which a single thermal print head prints sequentially on multiple color-forming layers in a single pass. Each pixel-printing interval may be divided into subintervals, which may be of unequal duration. Each sub-interval may be used to print a different color. The manner in which the input energy to be provided to each print head element is selected may be varied for each of the subintervals. For example, although a single thermal model may be used to predict the temperature of the print head elements in each of the subintervals, different parameters may be used in the different subintervals. Similarly, different energy computation functions may be used to compute the energy to be provided to the print head in each of the subintervals based on the predicted print head temperature.

Owner:TPP TECH LLC

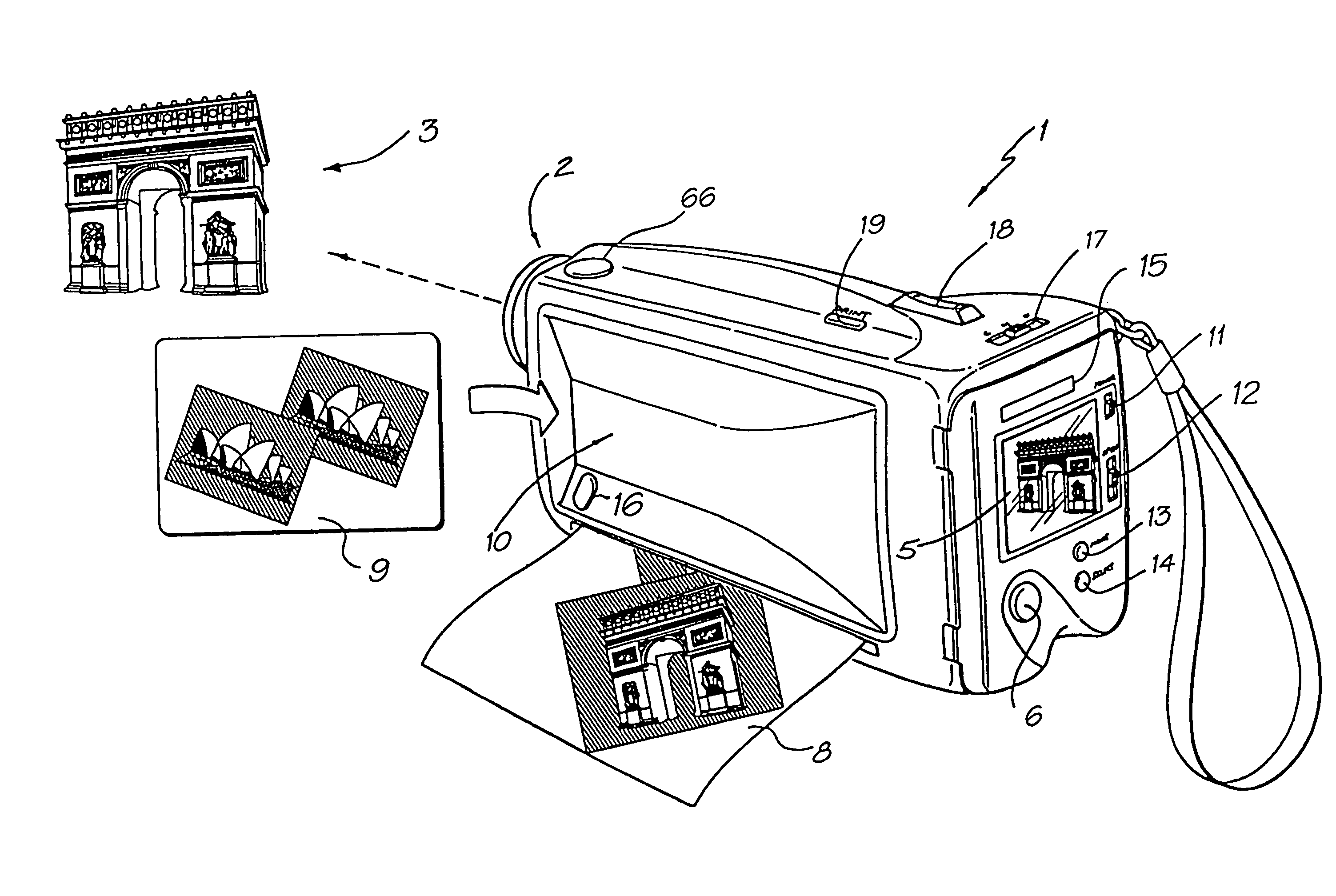

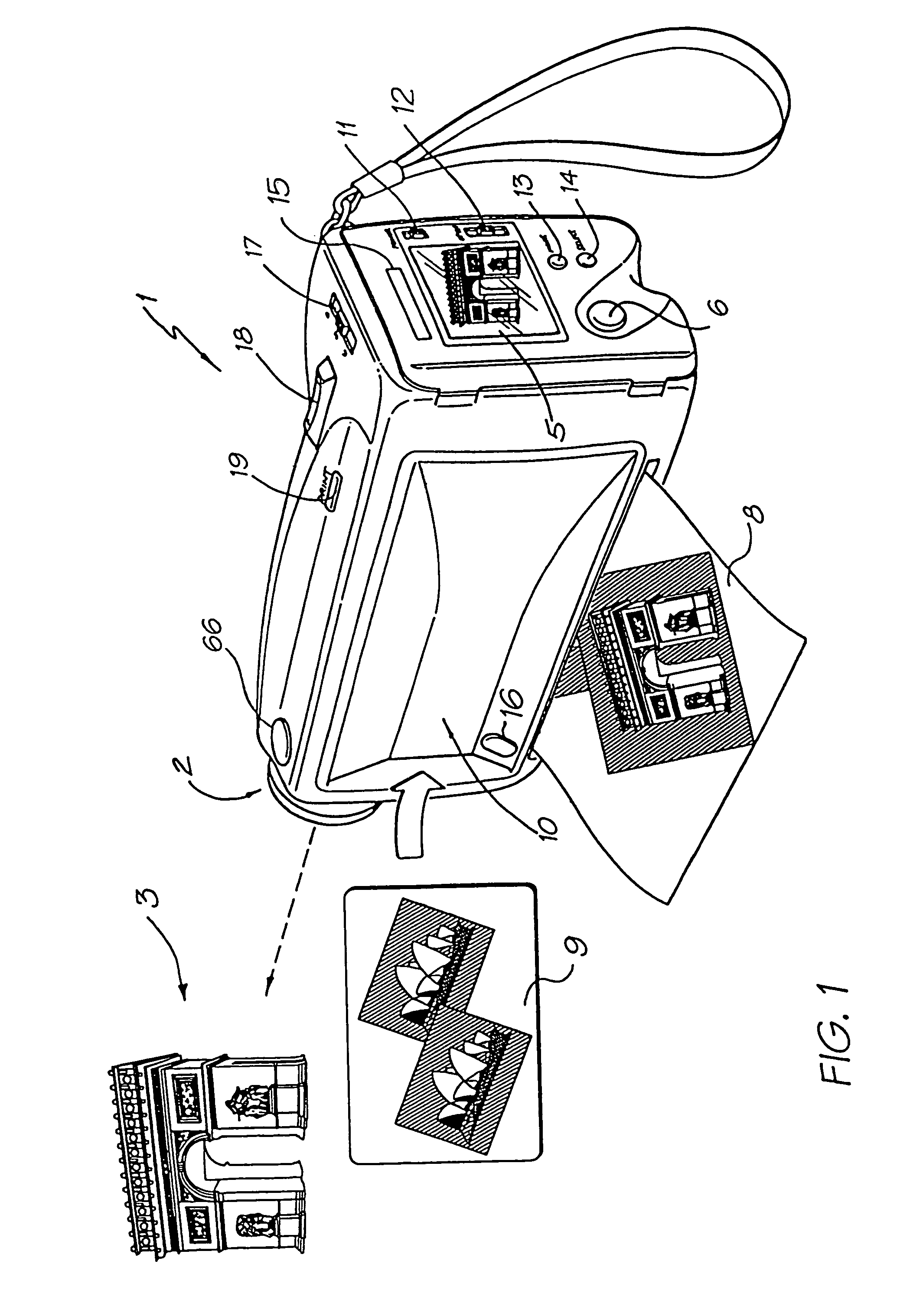

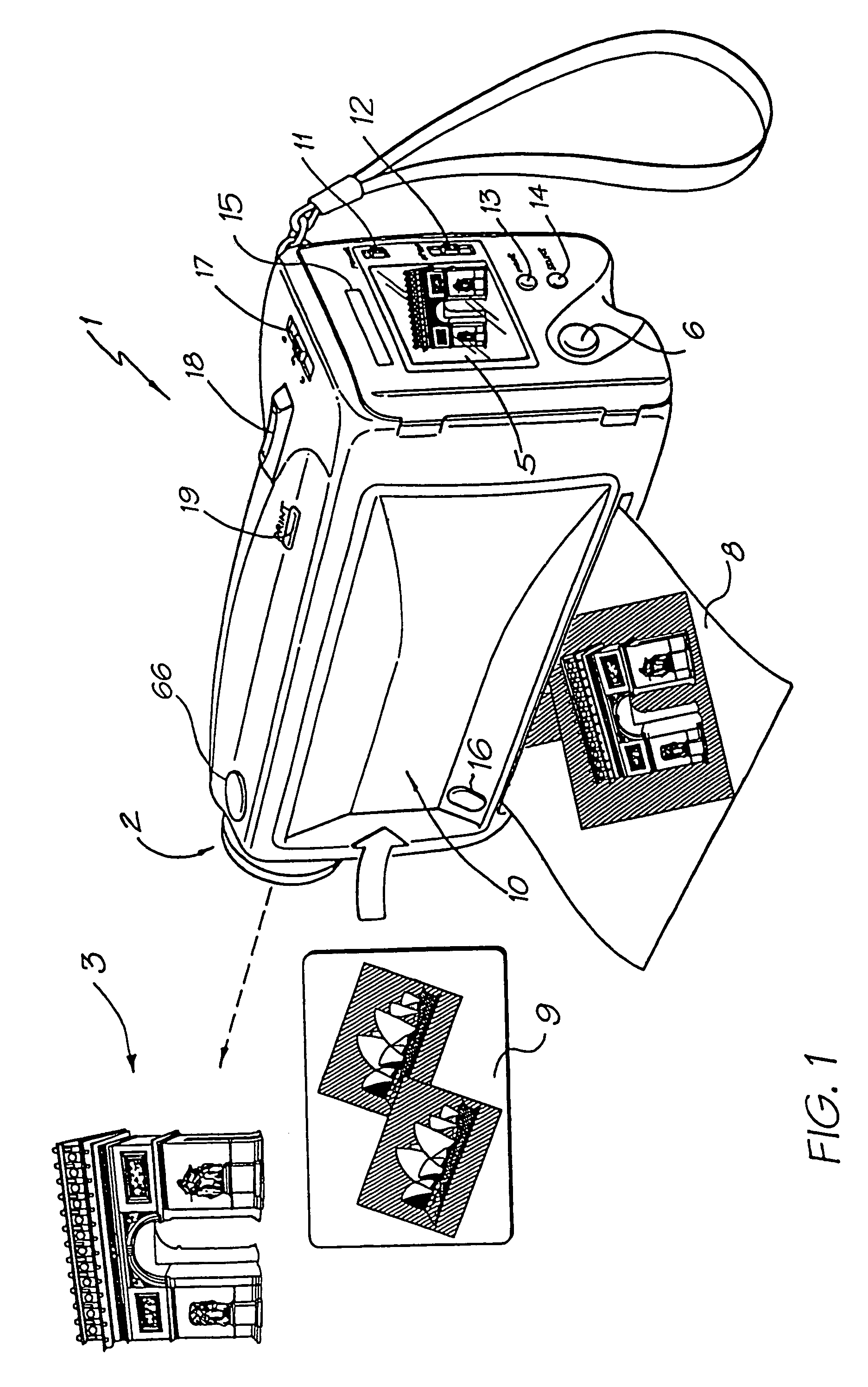

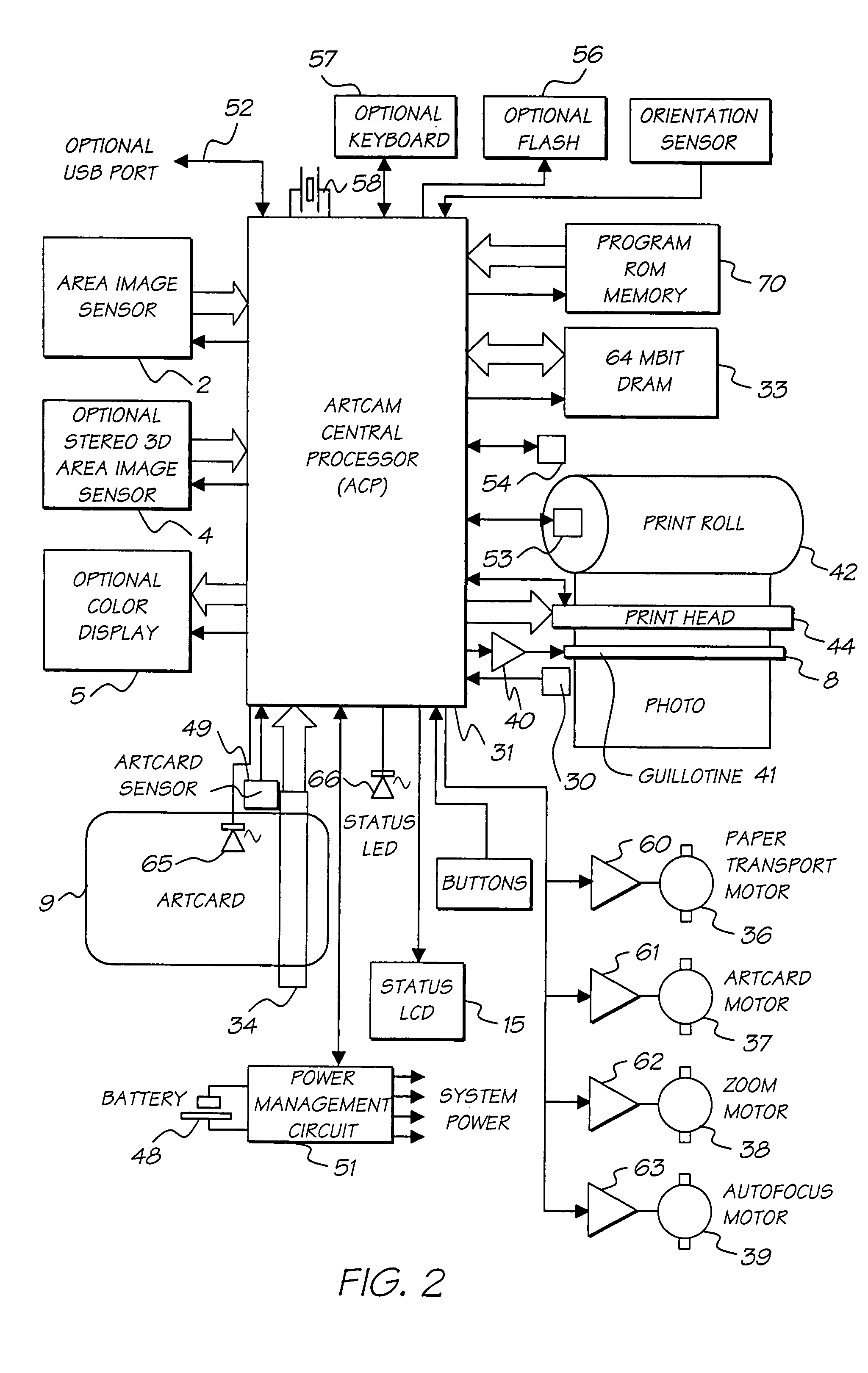

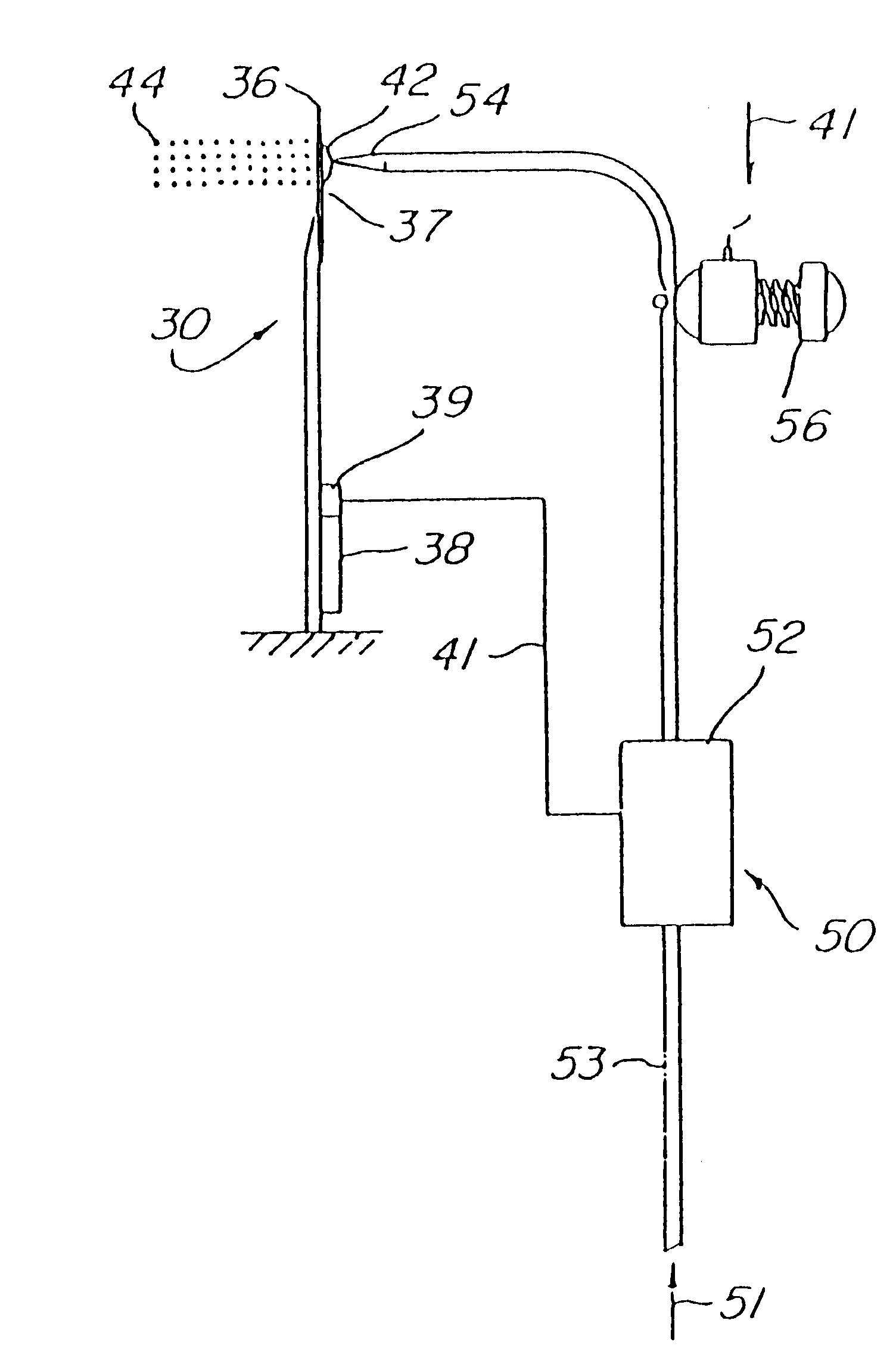

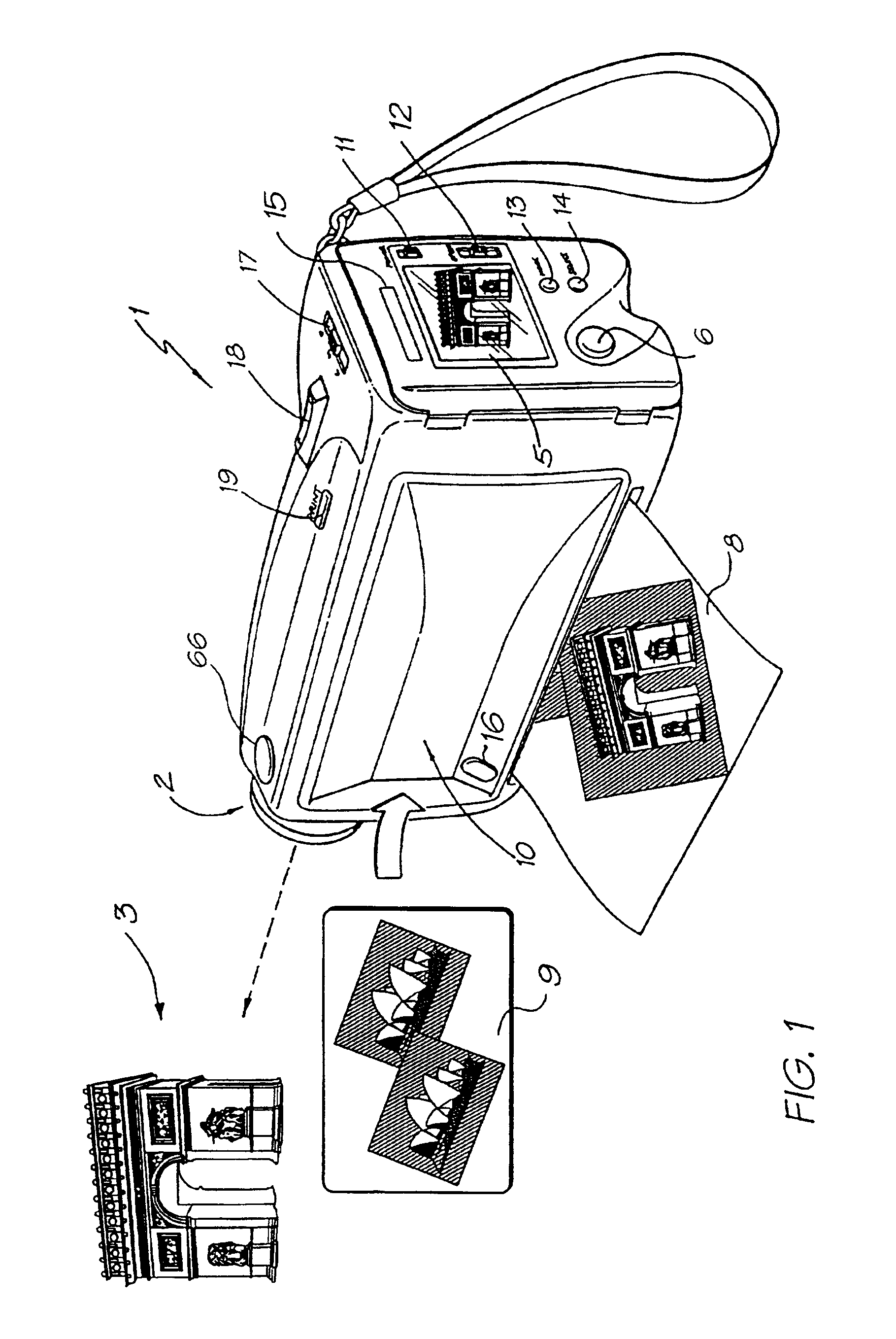

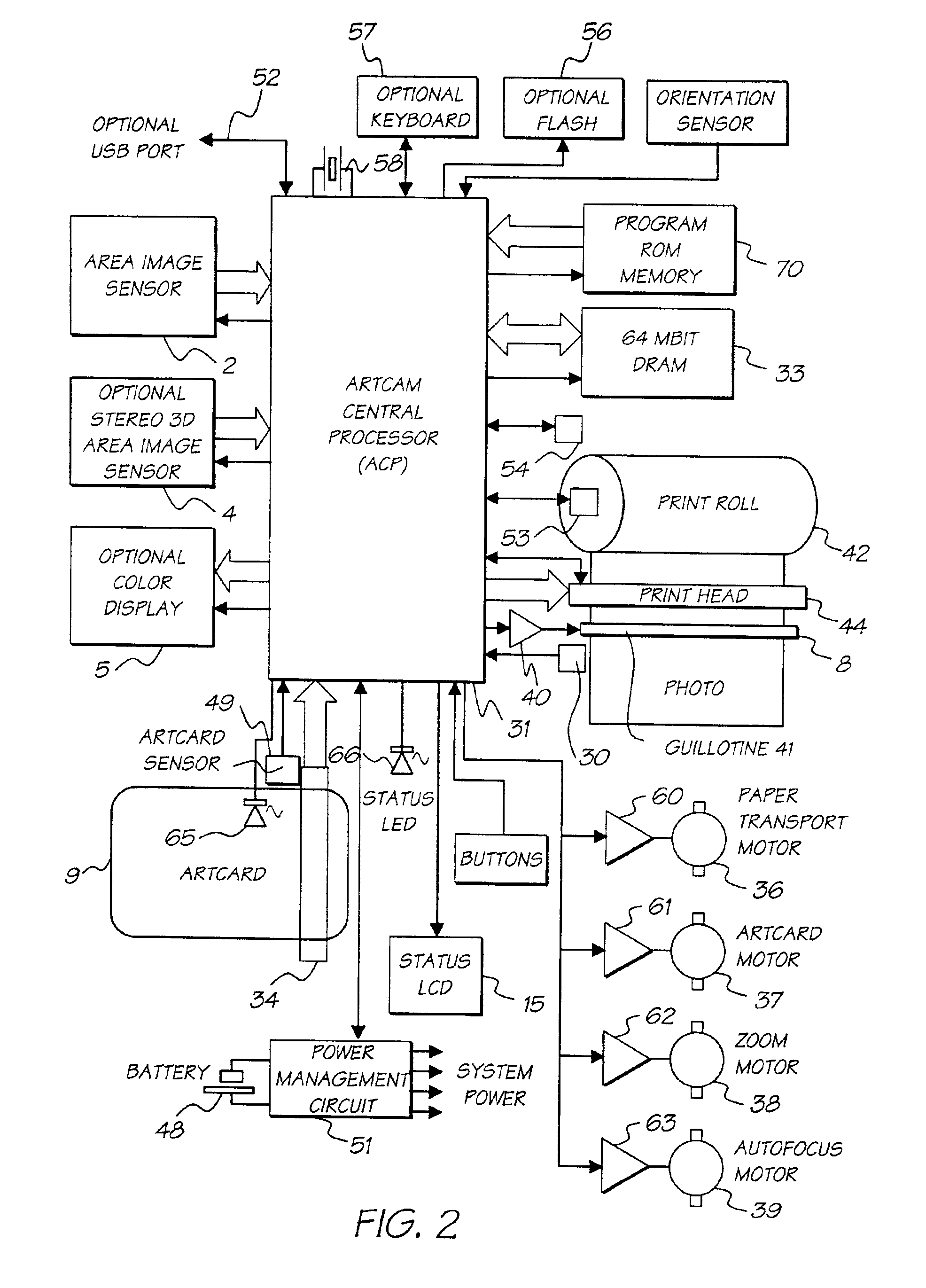

Portable hand held camera

InactiveUS7453492B2Increasing of apparent resolutionImprove graphicsTelevision system detailsInking apparatusPrint mediaHand held

A camera system comprising:at least one area image sensor for imaging a scene;a camera processor means for processing said image scene in accordance with a predetermined scene transformation requirement; anda printer for printing out said processed image scene on print media, utilizing printing ink stored in a single detachable module inside said camera system;said camera system comprising a portable hand held unit for the imaging of scenes by said area image sensor and printing said scenes directly out of said camera system via said printer.

Owner:GOOGLE LLC

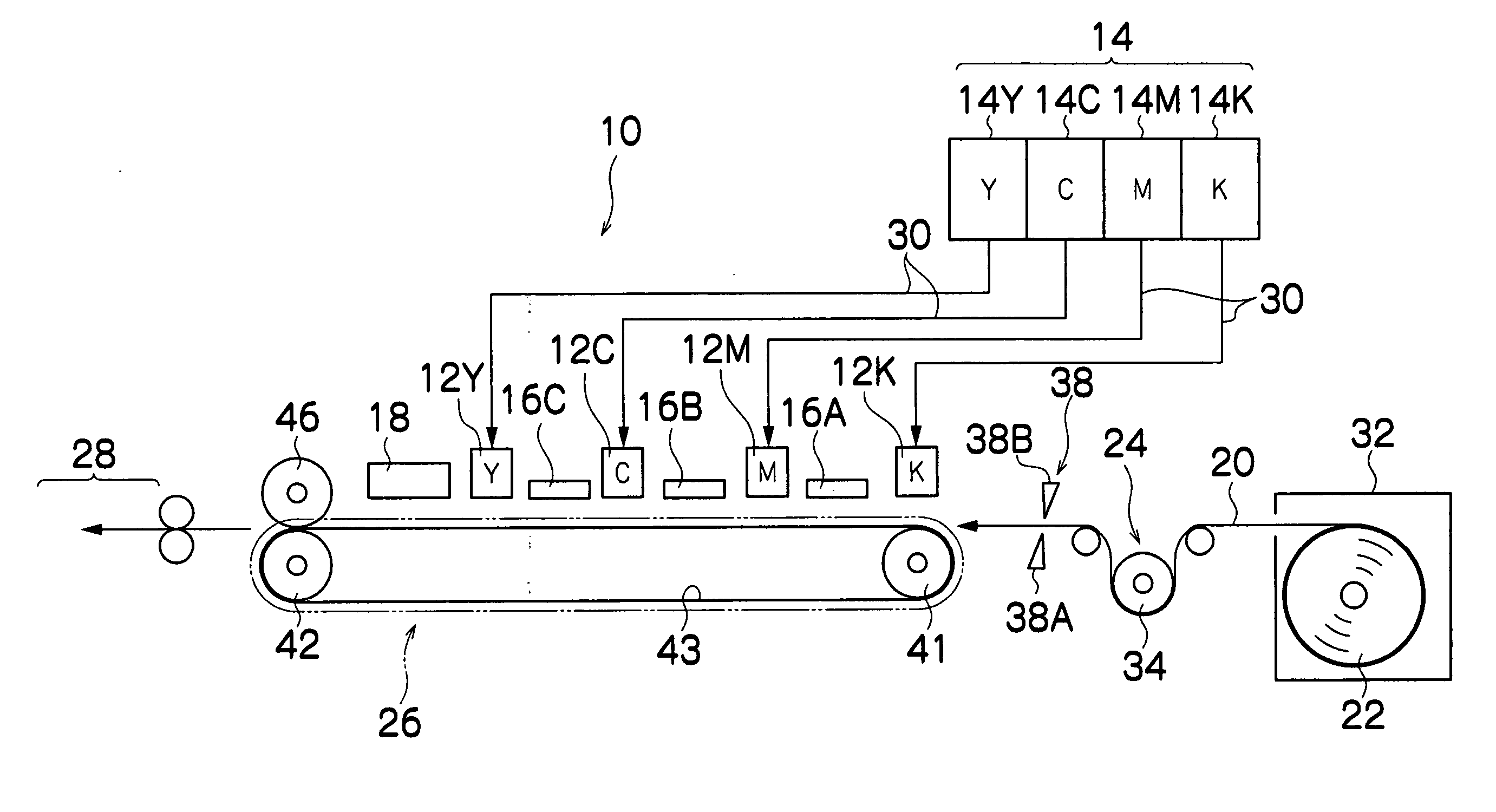

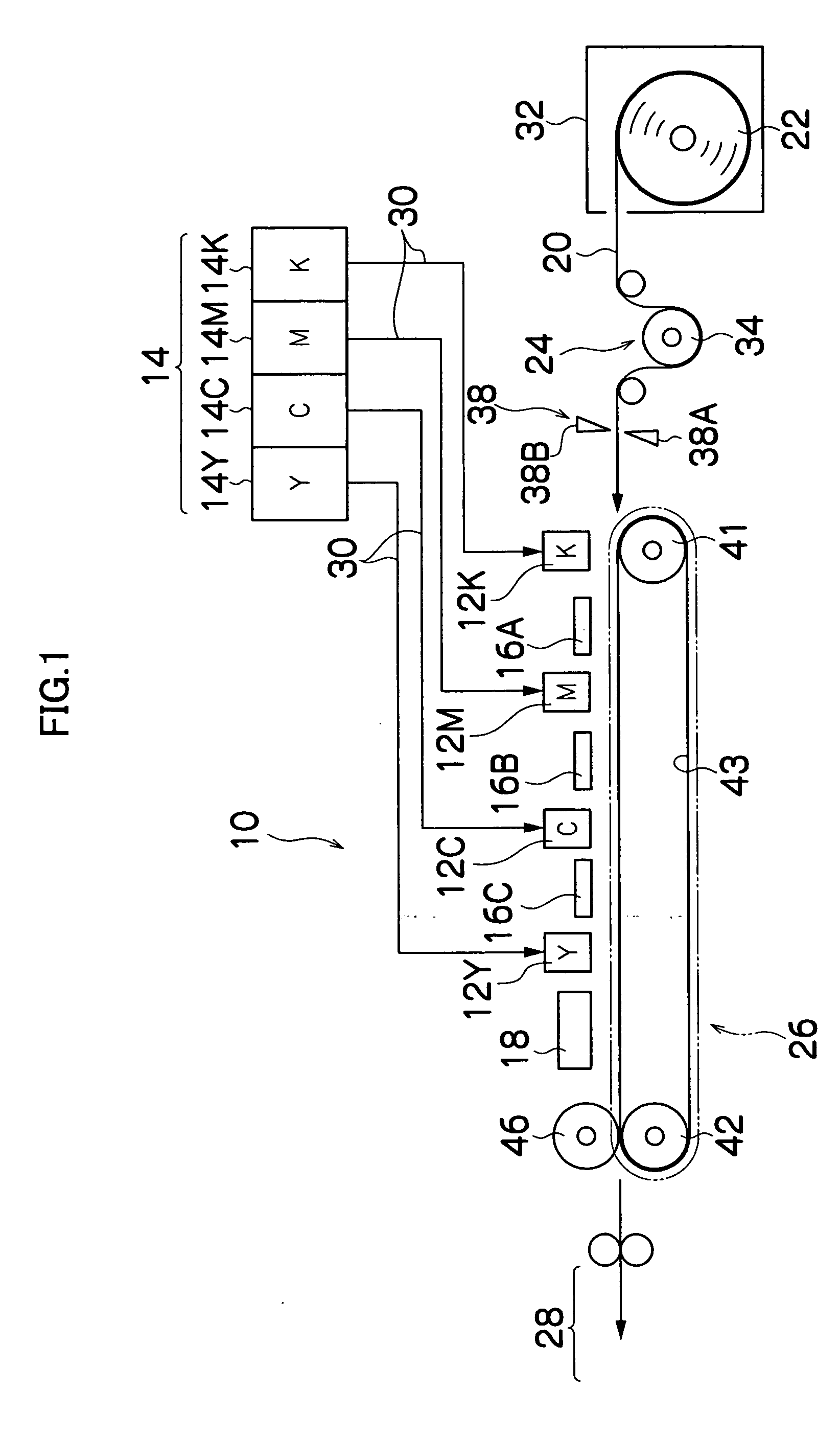

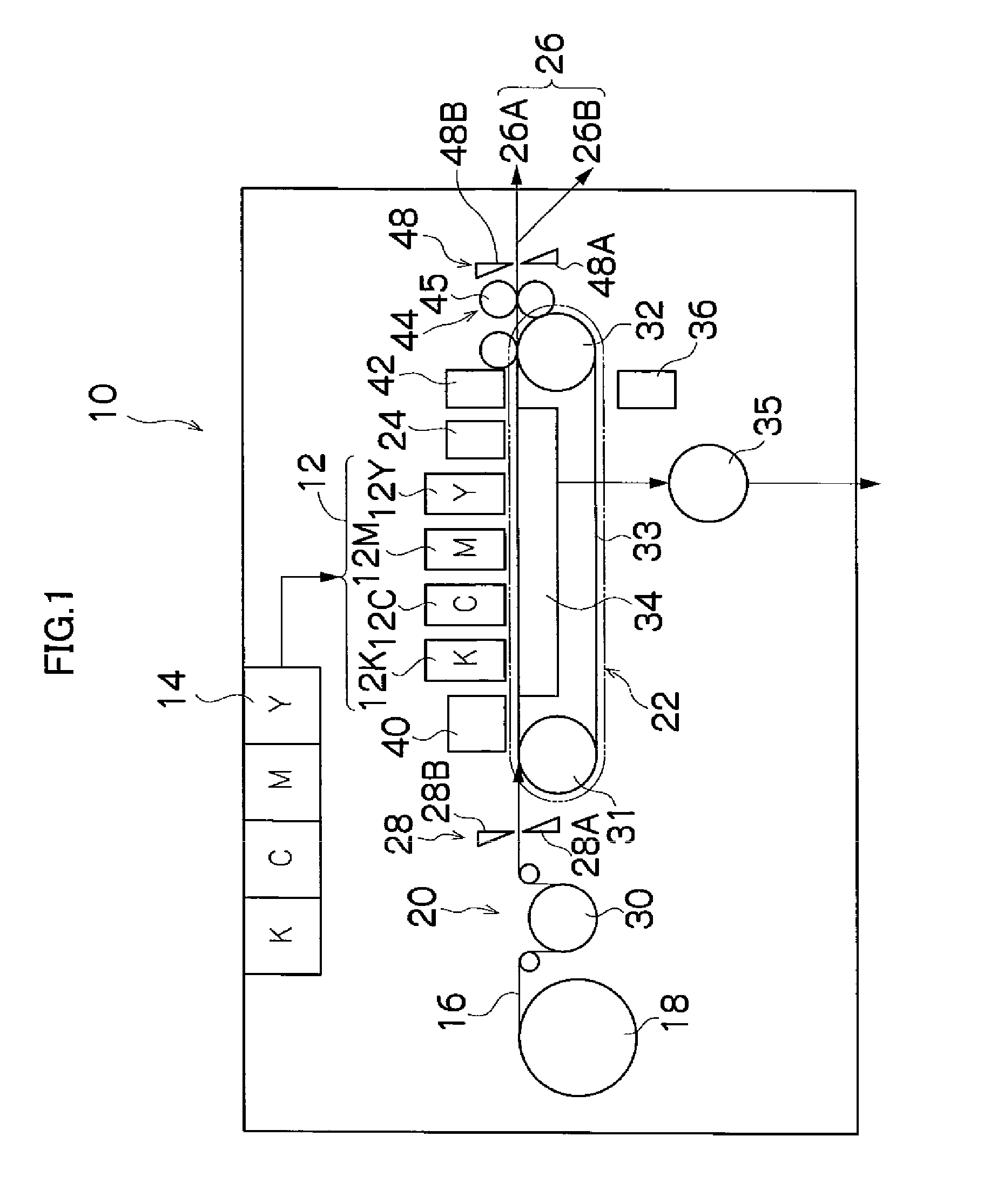

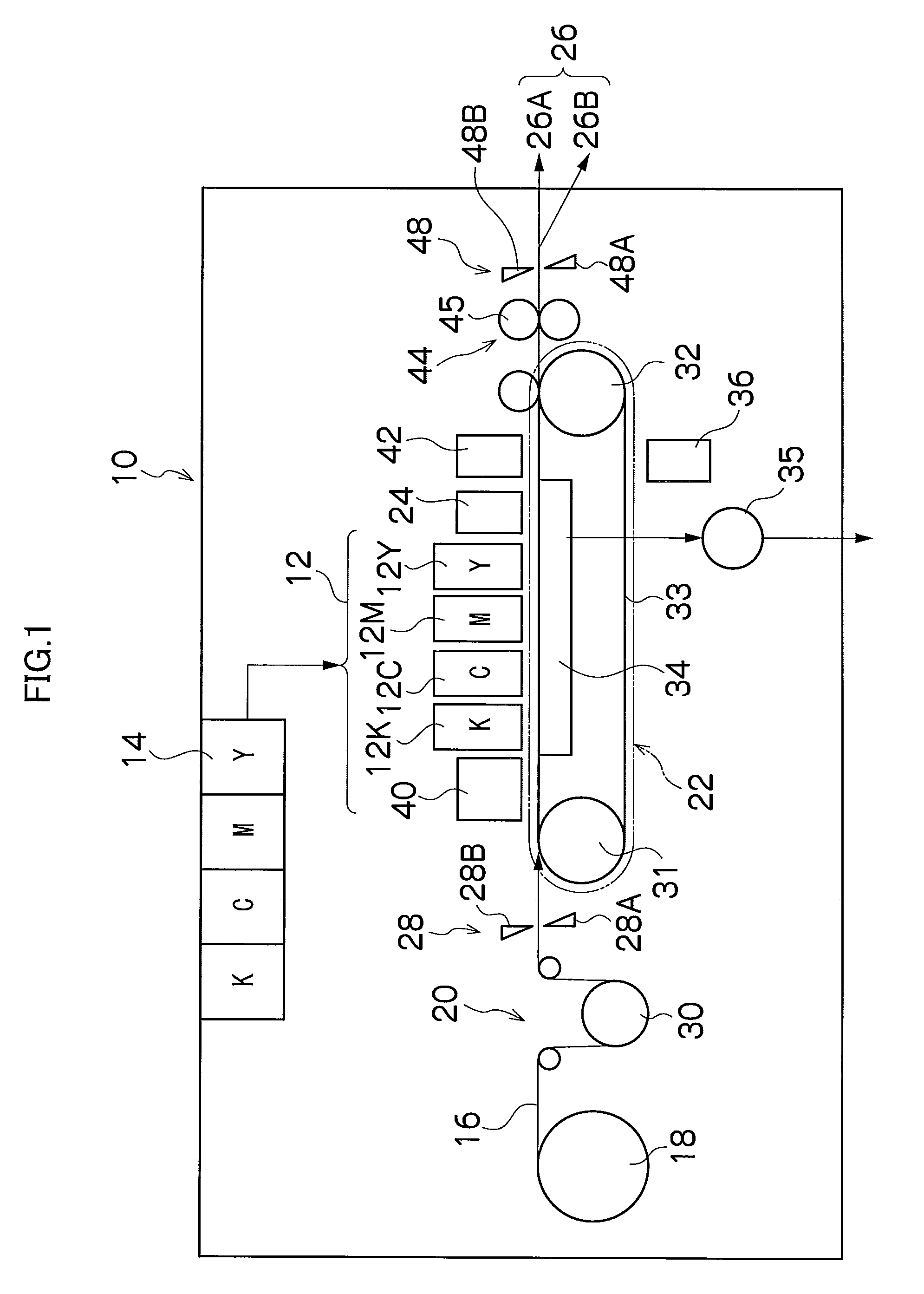

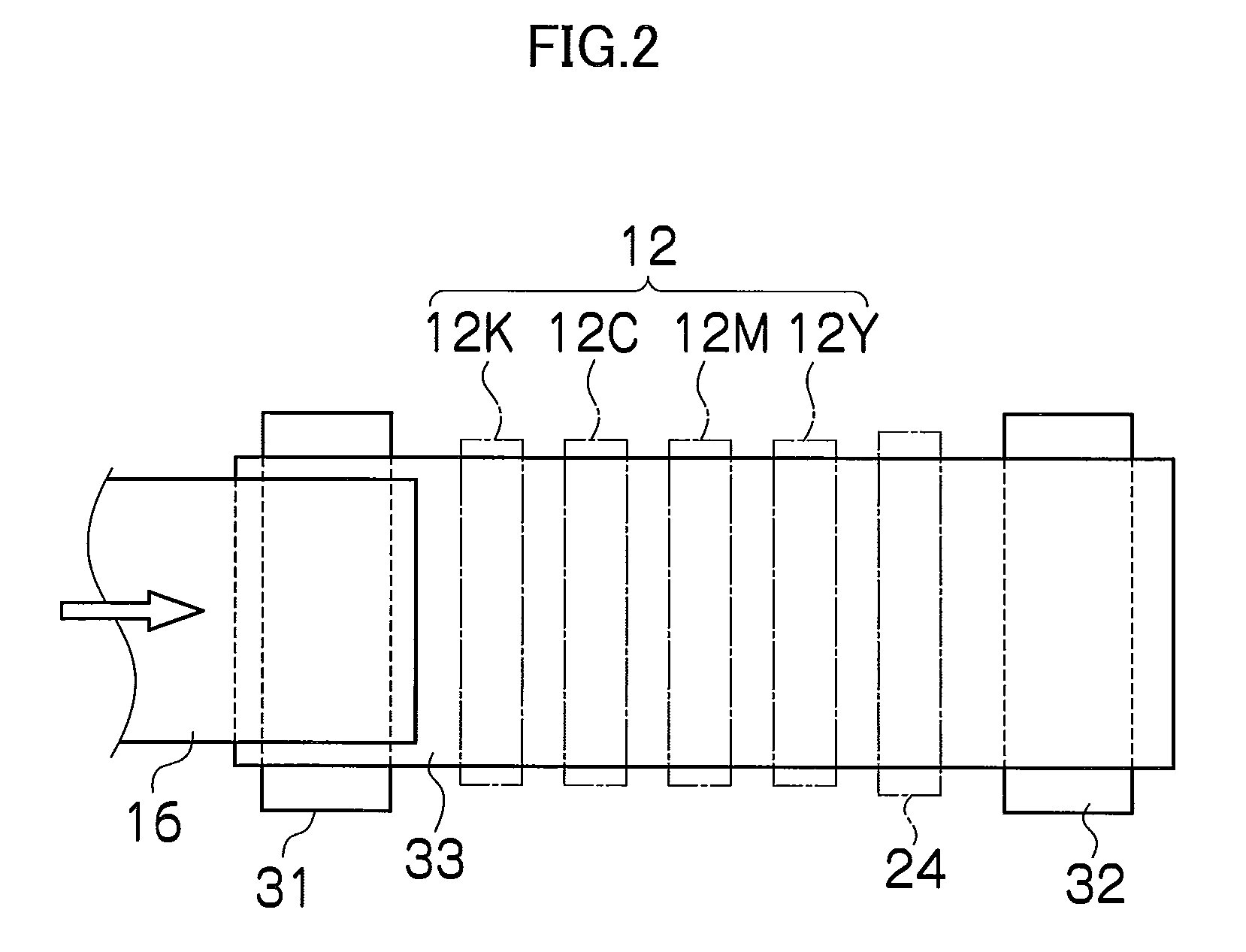

Image forming apparatus and method

InactiveUS20050190248A1Avoid cracking and peelingImage deterioration is causedInking apparatusOther printing apparatusUltraviolet lightsImaging equipment

The image forming apparatus comprises: an ink discharge device comprising a plurality of full line type inkjet heads arranged separately for a plurality of inks of different colors, each of the inkjet heads having a nozzle row in which a plurality of nozzles for discharging droplets of the ink toward a surface of a recording medium are arranged through a length corresponding to a full width of the recording medium; an ink supply device which supplies ultraviolet curable inks of corresponding colors to the inkjet heads; a conveyance device which causes the inkjet heads and the recording medium to move relatively to each other by conveying at least one of the recording medium and the inkjet heads in a direction substantially perpendicular to a breadthways direction of the recording medium; a first curing device which irradiates ultraviolet light for causing the droplets of the ink, deposited on the surface of the recording medium by one of the inkjet heads on an upstream side in a direction of relative conveyance of the recording medium with respect to the inkjet heads, to semi-cure to a degree whereby the droplets of the ink discharged from the inkjet head on the upstream side do not mix on the surface of the recording medium with the droplets of the ink discharged by a next one of the inkjet heads situated on a downstream side in the direction of relative conveyance, the first curing device comprising an ultraviolet light source including a group of light emitting elements arranged in a linear form and disposed between the inkjet heads of the respective colors; and a second curing device which irradiates ultraviolet light for performing main curing of the droplets of the ink on the recording medium to a degree whereby image degradation does not occur upon subsequent handling of the cured droplets of the ink, the second curing device being disposed after one of the inkjet heads situated in a furthest downstream position of the inkjet heads.

Owner:FUJIFILM CORP

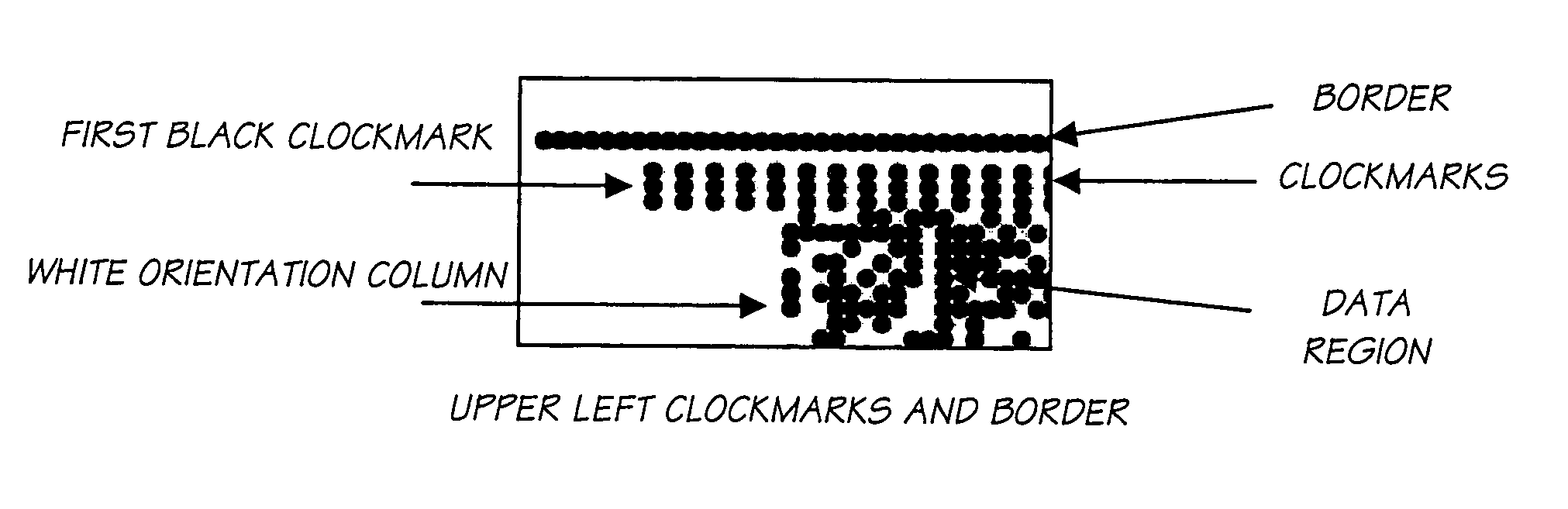

Redundantly encoded data structure for encoding a surface

A data structure encoded on a surface of an objectincludes a plurality of block data regions. Each of the block regions includes a spatially distributed redundantly encoded data region containing data in encoded form, a clock mark structure located adjacent a first peripheral portion of the encoded data region, and a target structure located adjacent the clock mark structure. Each of the block data regions further includes an orientation data structure indicative of an orientation of the data structure.

Owner:GOOGLE LLC

Methods and apparatus for dispensing liquids as an atomized spray

InactiveUS6540153B1Sufficient volumeHigh trafficRespiratorsRecording apparatusEngineeringMechanical engineering

Owner:NOVARTIS FARMA

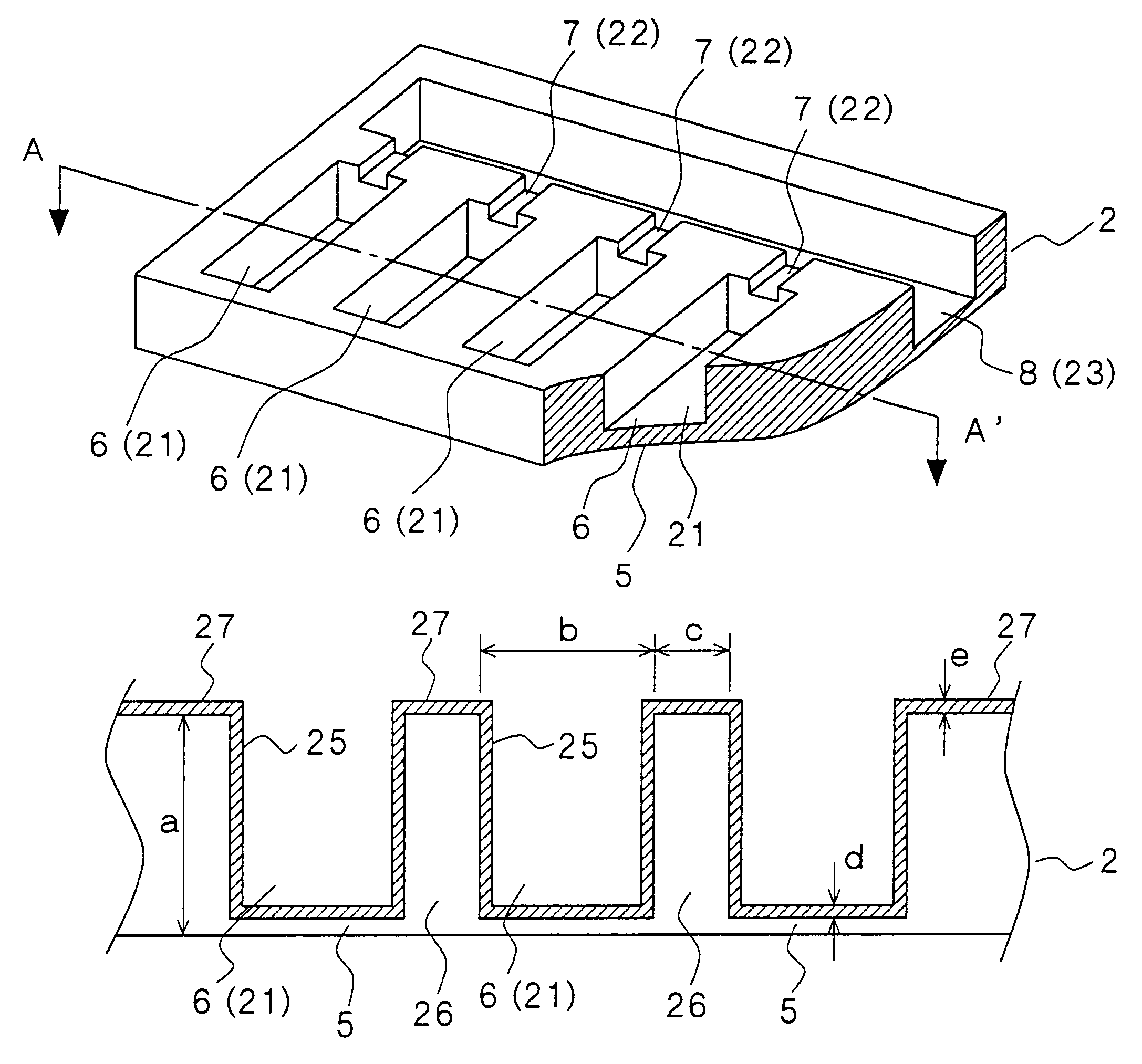

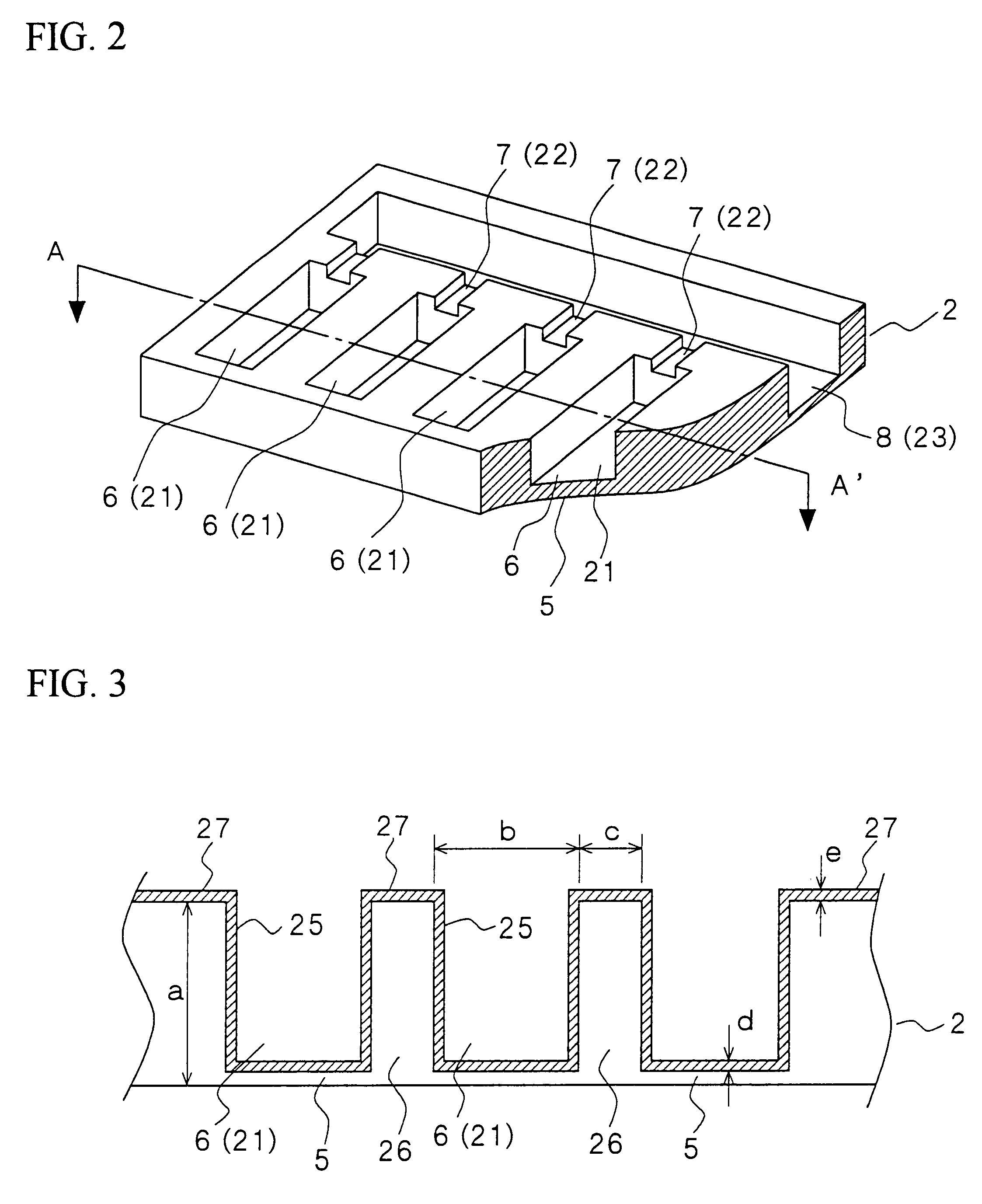

Printing head and ink jet recording apparatus using the same

InactiveUS6447107B1Easily affected by corrosionCorrosion by ink can be preventedInking apparatusBrushing washing machinesEngineeringCorrosion

An ink jet head which is -prevented from corrosion by ink, and an ink jet recording apparatus using the same. An ink-resistant thin film (25) made of Ti, a Ti compound, or Al2O3 is formed on the surface of recess portions (21 to 23) of a substrate in which a reservoir (8) for reserving ink, orifices (7) and pressure chambers (6) are formed. Since this ink-resistant thin film (25) is formed, corrosion can be restrained without reducing printing quality, without necessity to change the component / composition of the ink and the material of the head, and with little change of its manufacturing process, even if there is a fear that the head material may be corroded by the ink.

Owner:SEIKO EPSON CORP

Image forming method and apparatus

InactiveUS20080166495A1Improve ink adhesionHigh strengthInking apparatusDuplicating/marking methodsImage formationPhotochemistry

The image forming method includes the steps of: ejecting and depositing an ink containing a coloring material and a radiation polymerizable compound on an intermediate transfer body, the radiation polymerizable compound having a molecular structure including a radical polymerizable group and a cationically polymerizable group; then irradiating the ink on the intermediate transfer body with a first radiation so that one of the radical polymerizable group and the cationically polymerizable group is selectively polymerized and cured; then heating the selectively polymerized and cured ink to a temperature not lower than a softening point of the selectively polymerized and cured ink and not higher than a temperature above the softening point by 10° C., while transferring the selectively polymerized and cured ink from the intermediate transfer body to a recording medium; and then irradiating the ink on the recording medium with a second radiation so that the other of the radical polymerizable group and the cationically polymerizable group is polymerized and cured.

Owner:FUJIFILM CORP

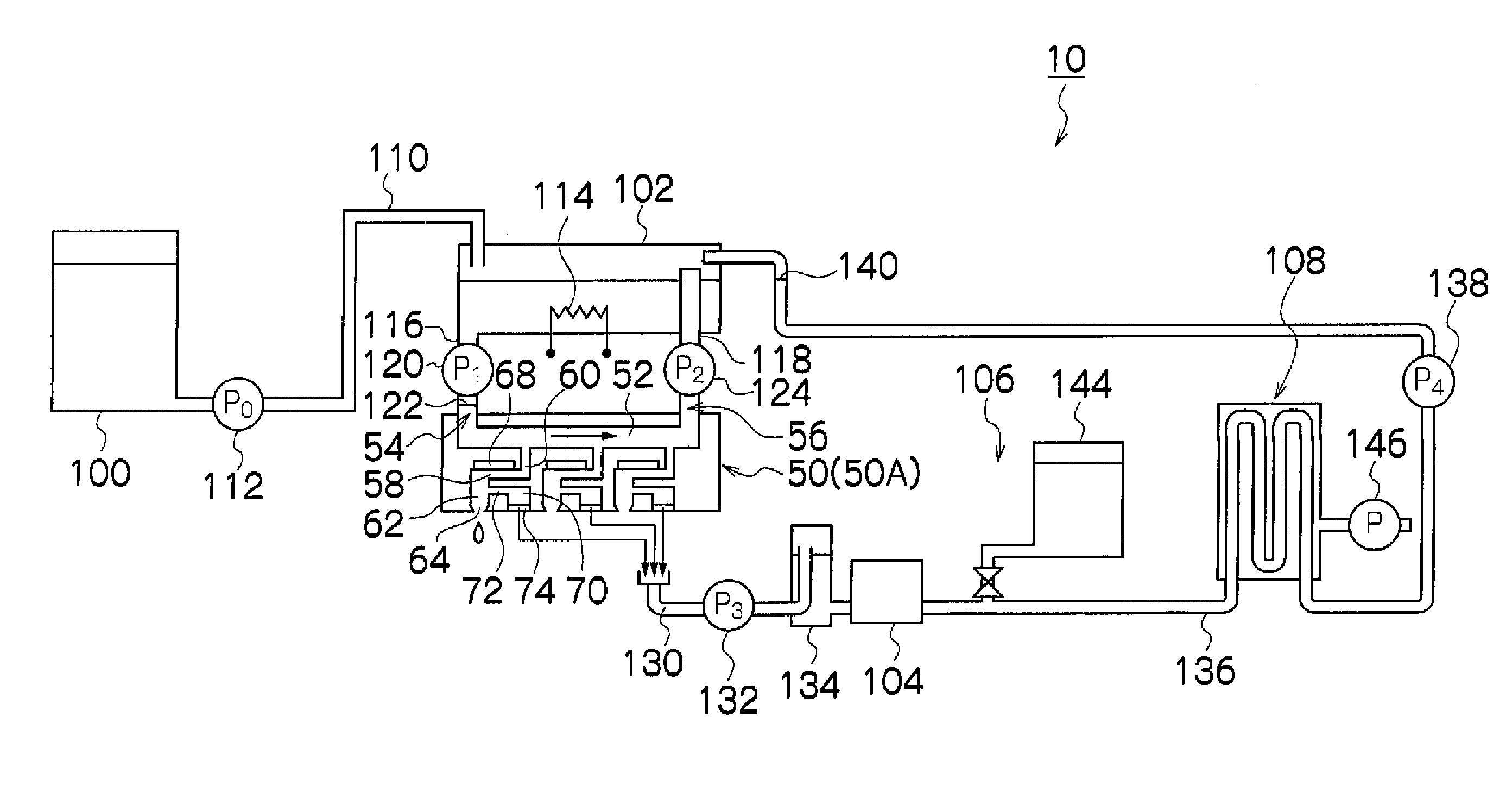

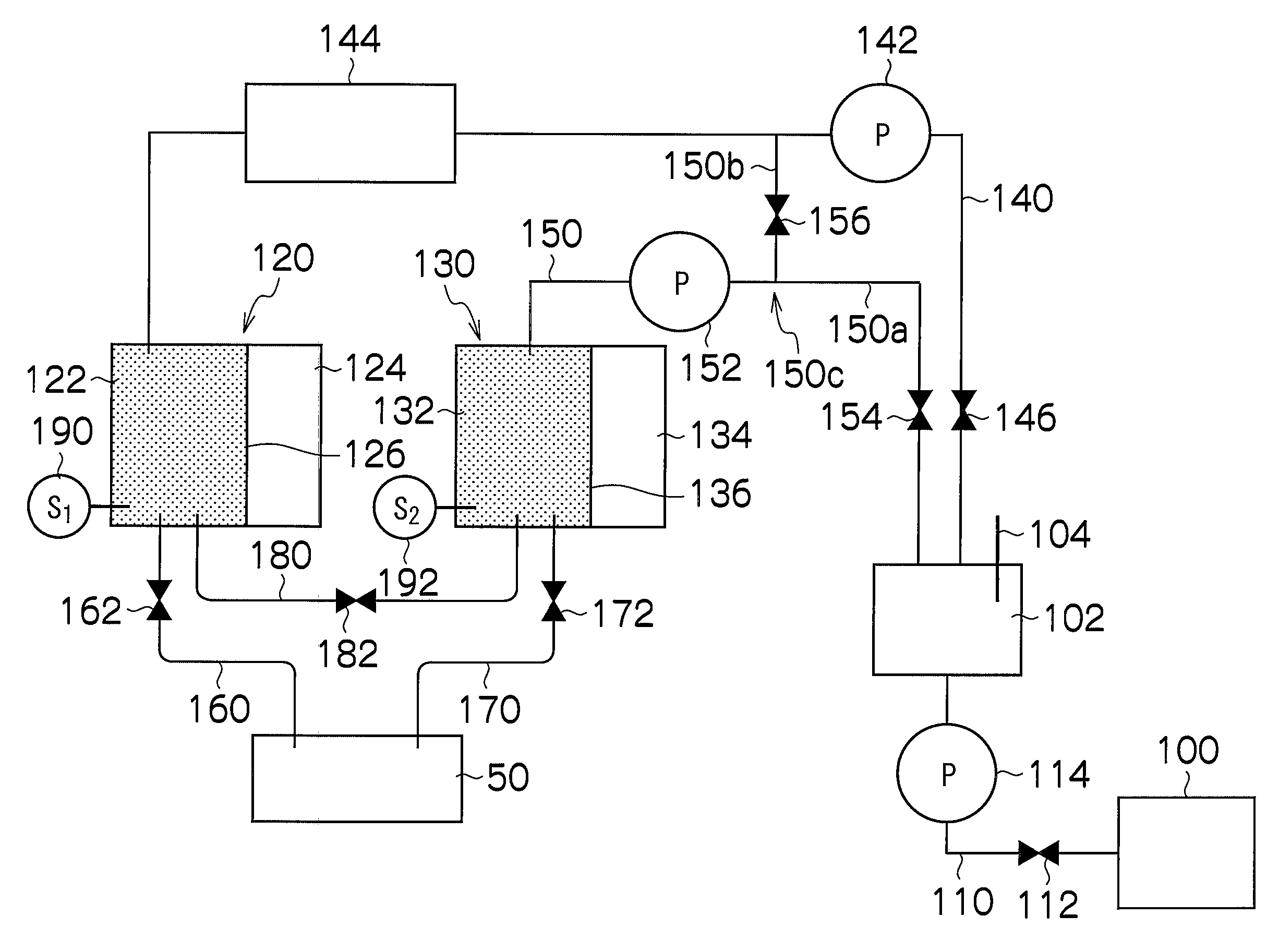

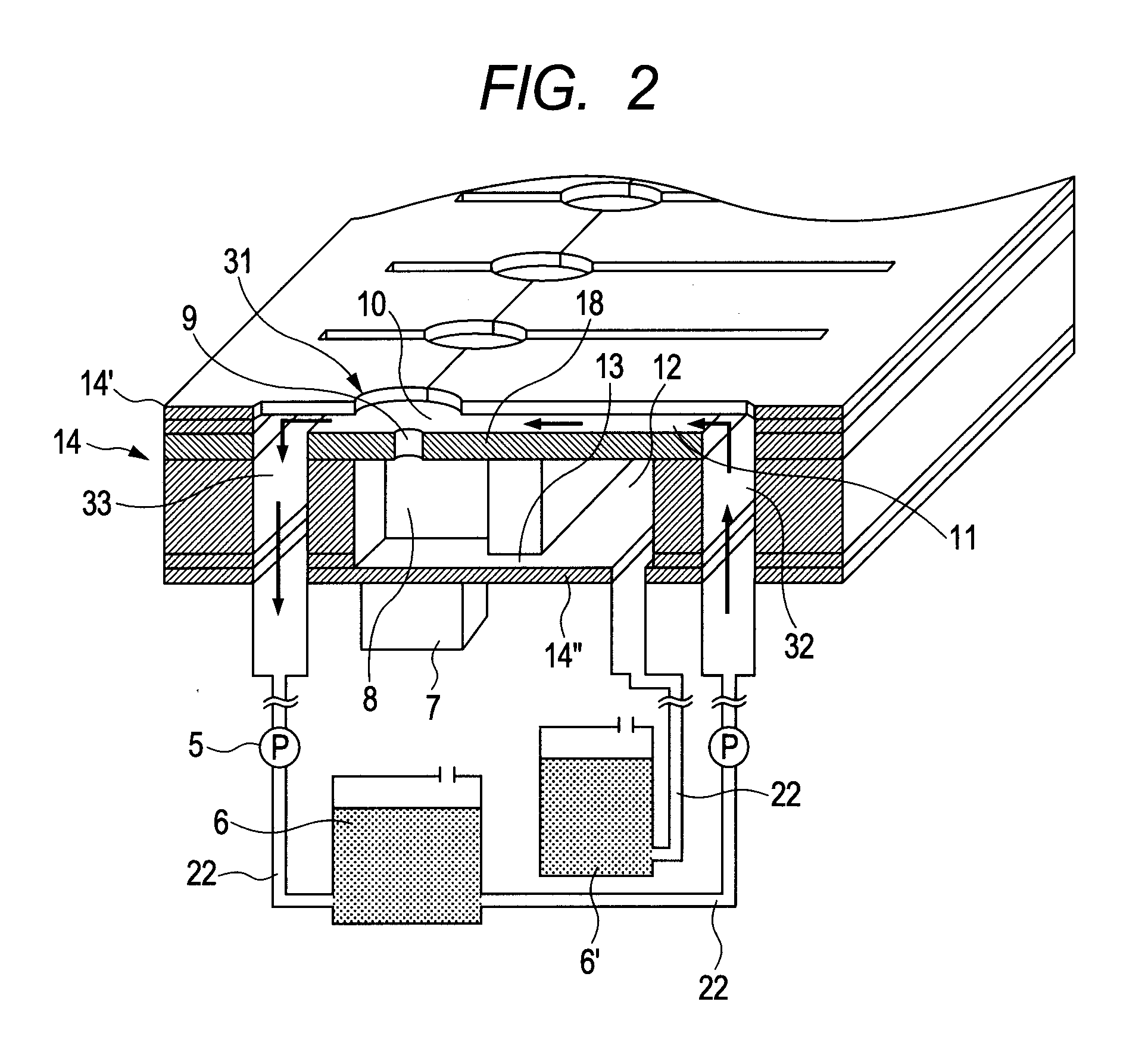

Liquid circulation apparatus, image forming apparatus and liquid circulation method

InactiveUS20080238980A1Promote circulationPrevent ejection defectInking apparatusOther printing apparatusElectricityLiquid jet

A liquid circulation apparatus includes: a plurality of liquid ejection elements each of which includes a nozzle, a pressure chamber which is connected to the nozzle and accommodates liquid, and a piezoelectric element which displaces a wall of the pressure chamber to eject the liquid in the pressure chamber through the nozzle; a plurality of individual supply channels which are respectively connected to the liquid ejection elements; a common supply channel which is connected to the individual supply channels, the liquid being supplied from the common supply channel to the liquid ejection elements through the individual supply channels; a plurality of individual circulation channels which are respectively connected to the liquid ejection elements; a common circulation channel which is connected to the individual circulation channels, the liquid being circulated from the liquid ejection elements to the common circulation channel through the individual circulation channels; and a control device which controls a circulation volume of the liquid circulated from the liquid ejection elements to the common circulation channel, by adjusting a supply volume of the liquid supplied from the common supply channel to the liquid ejection elements in accordance with an ejection volume of the liquid ejected from the liquid ejection elements.

Owner:FUJIFILM CORP

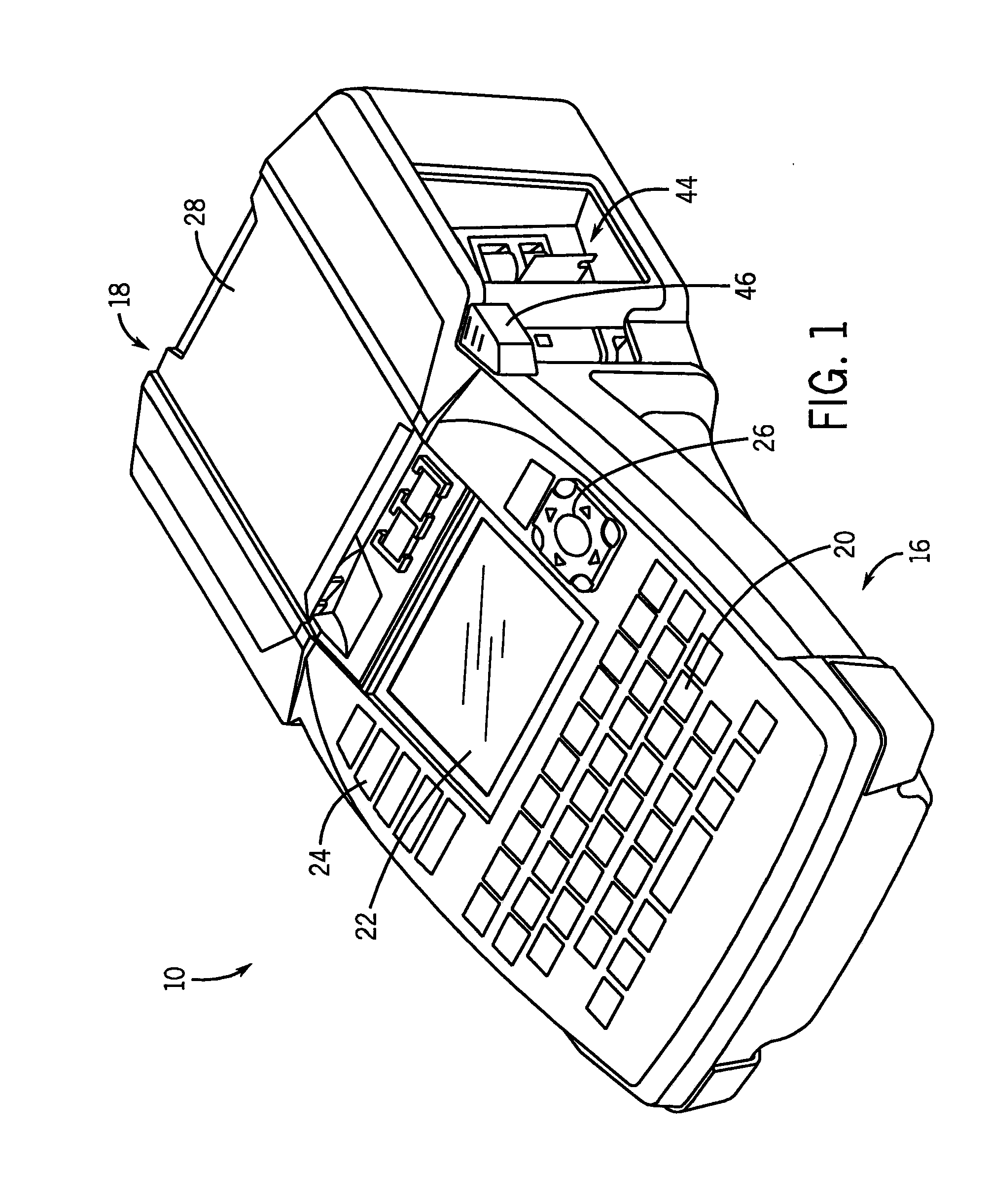

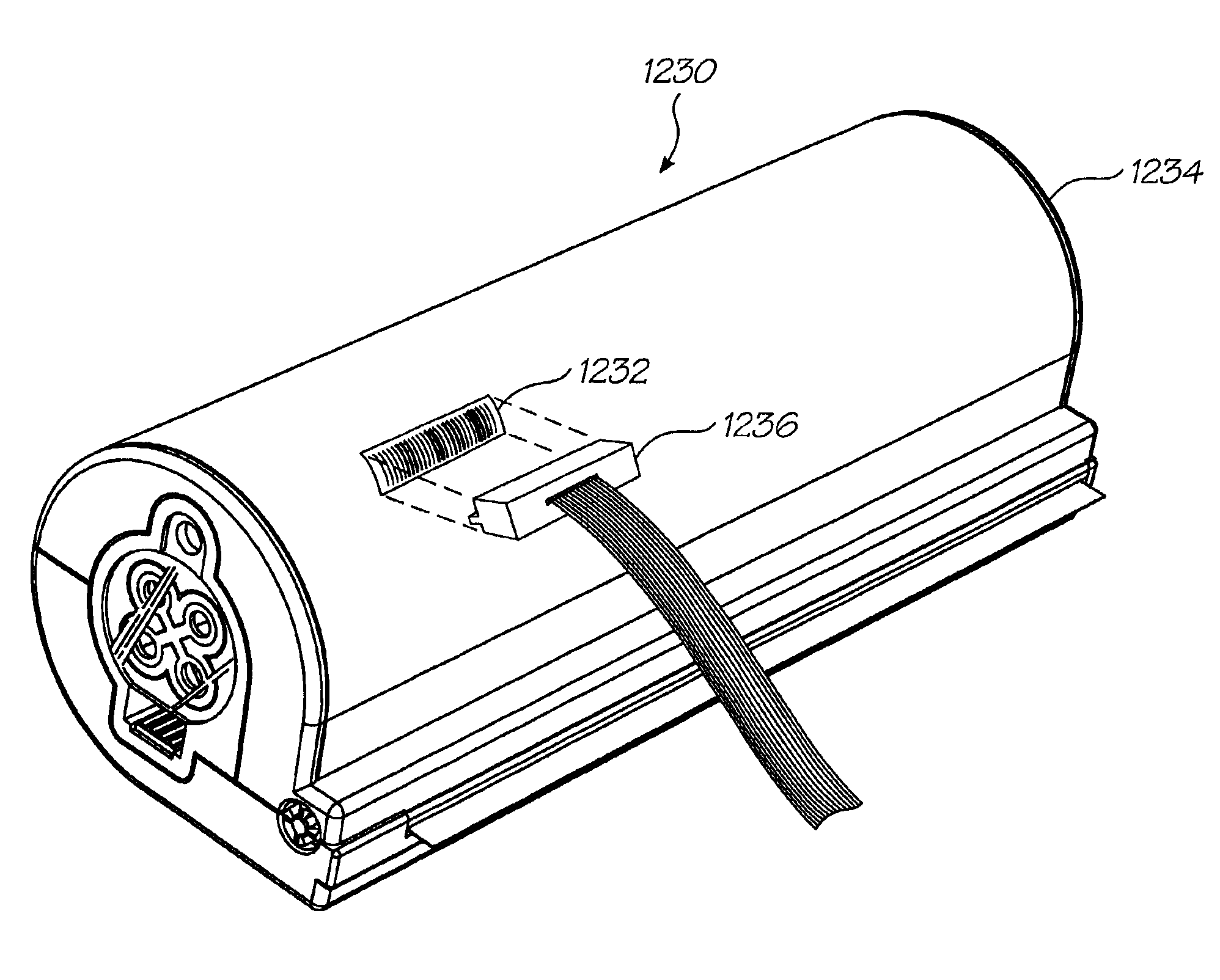

Media cartridge with shifting ribs

ActiveUS20120027485A1Reduce the possibilityAvoid contactPrinting mechanismsInking apparatusEngineering

A media cartridge is disclosed for insertion into a cartridge receptacle of a printer. The media cartridge includes a cartridge housing having one or more shifting ribs on the cartridge housing. At a position of initial insertion of the media cartridge into the cartridge receptacle, the shifting ribs are configured to center a length of media and an ink ribbon of the media cartridge between a print head and a platen roller in the cartridge receptacle. As the insertion of the media cartridge into the cartridge receptacle continues, the shifting ribs shift the length of media and the ink ribbon toward one of the print head and the platen roller.

Owner:BRADY WORLDWIDE INC

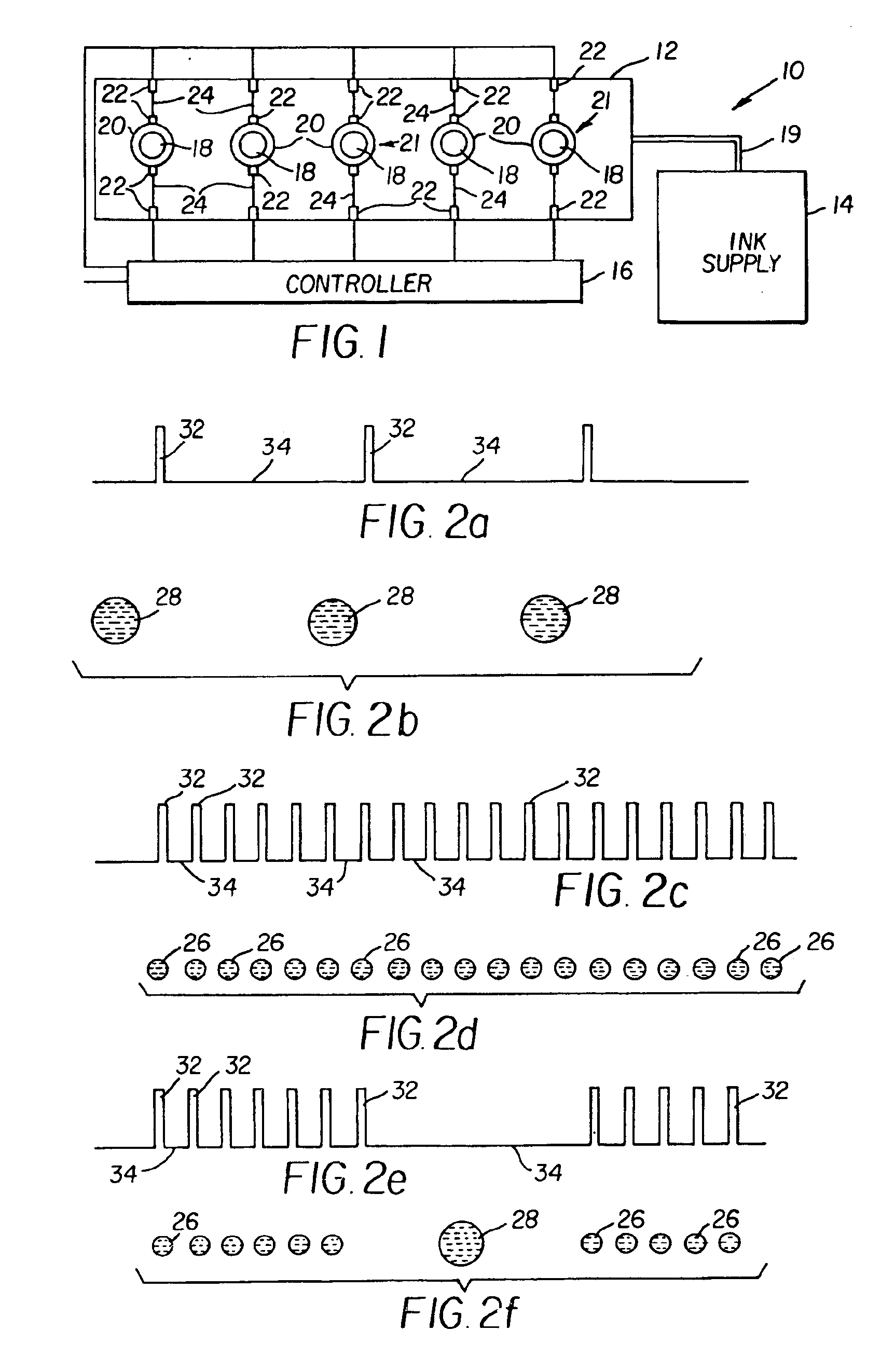

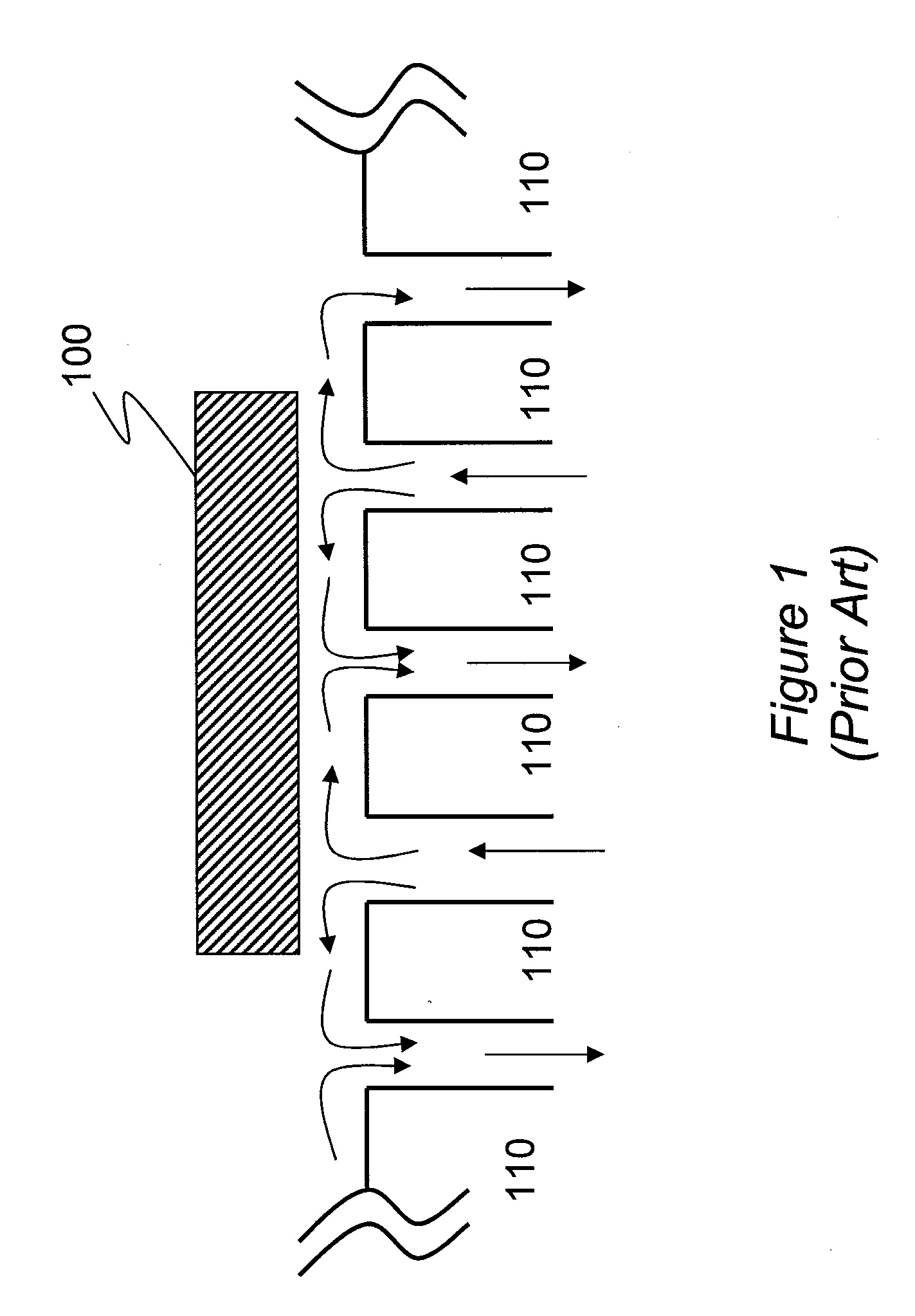

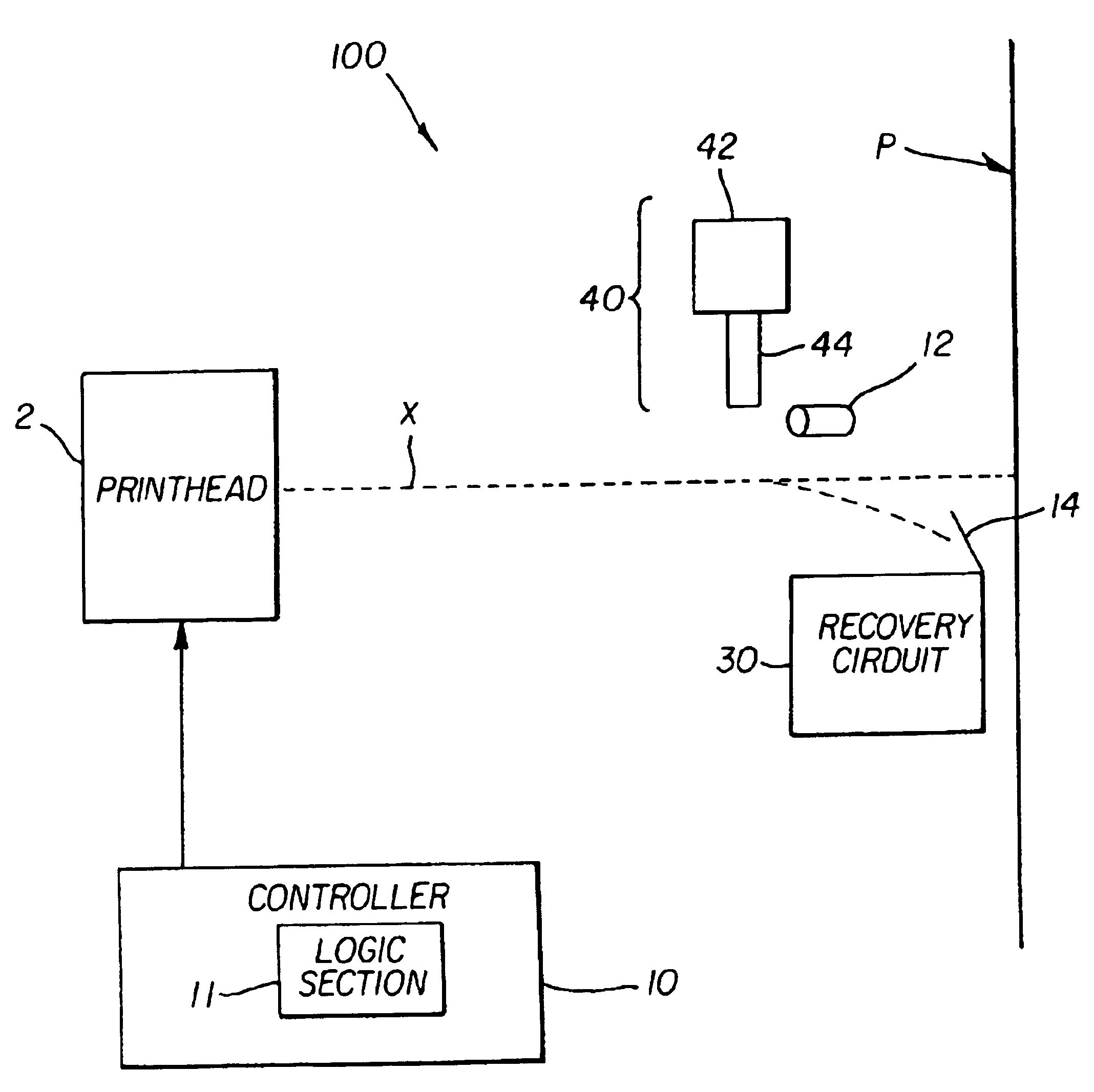

Apparatus and method for improving gas flow uniformity in a continuous stream ink jet printer

InactiveUS6866370B2Improve printing qualityImproves airflow uniformityInking apparatusProcess engineeringPrinting ink

A method of enhancing print quality of a continuous ink jet printing device and such a printing device in which selected droplets in a stream of droplets are selectively deflected to impinge on a print medium, the method including the steps of providing a plurality of ink droplets, each printing ink-droplet being substantially same size, providing a gas flow that deflects the plurality of ink droplets, monitoring uniformity of the gas flow, and adjusting a flow characteristic of the gas flow based on the monitored uniformity. The step of adjusting flow characteristic of the gas flow is attained by changing flow rate of the gas flow or flow area of the outlet. In one embodiment, the step of monitoring uniformity of gas flow includes monitoring trajectory paths of the deflected plurality of ink droplets.

Owner:EASTMAN KODAK CO

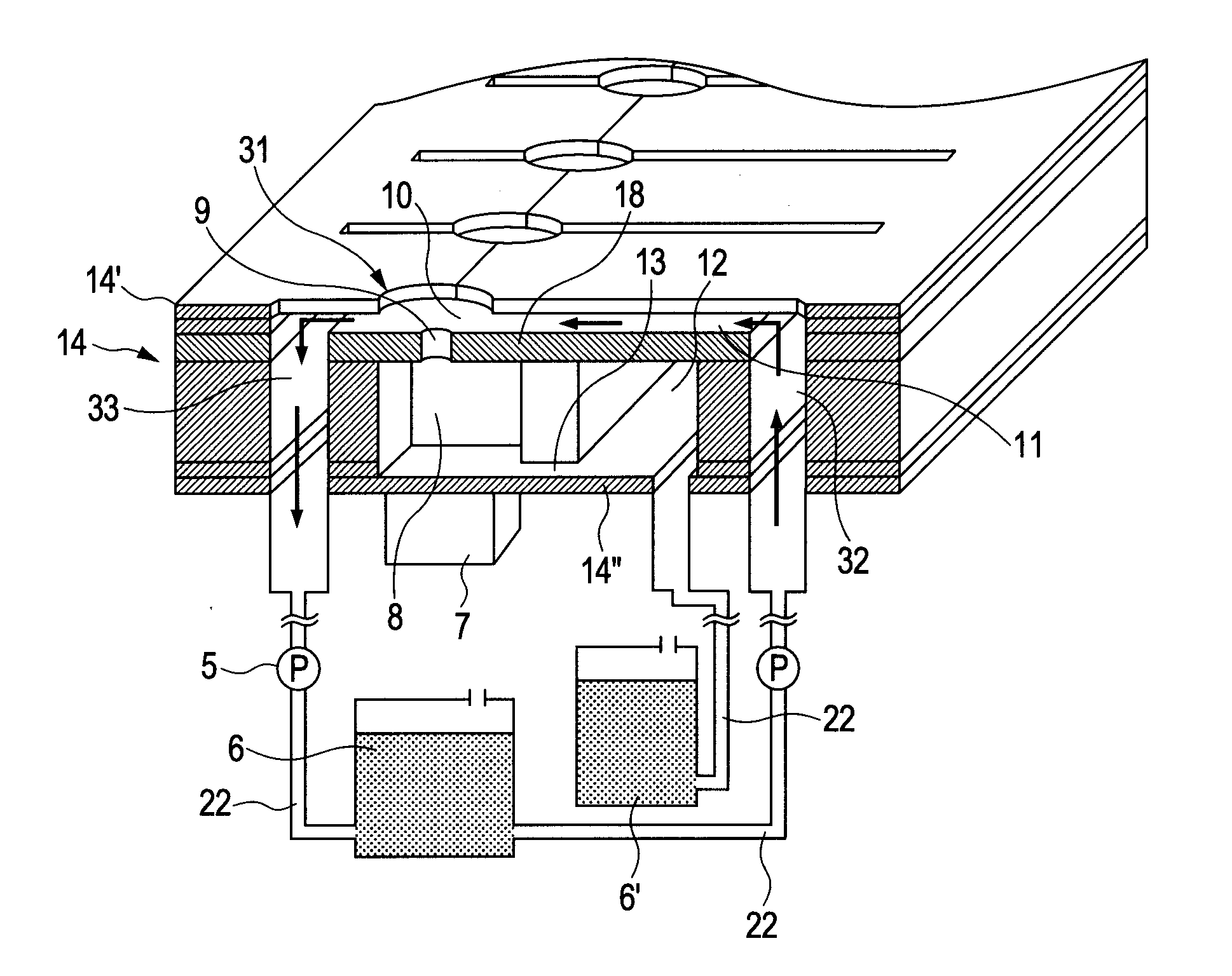

Inkjet recording apparatus

ActiveUS20100085396A1Improve printing qualityHighly accurate pressure adjustmentInking apparatusOther printing apparatusInternal pressureEngineering

Inkjet apparatus includes: a tank; a first flow channel; a first liquid chamber; a second flow channel; a second liquid chamber; a first liquid movement; a second liquid movement device; a first pressure determination device; a second pressure determination device; a pressure control device which controls pressures in the first and second liquid chambers by respectively controlling the first and second liquid movement devices, in accordance with determination results of the first and second pressure determination devices, in such a manner that the internal pressures of the first and second liquid chambers respectively remain at the target pressures; a circulation path through which the liquid inside the first liquid chamber is circulated without passing through the inkjet head; and a deaeration device which is provided at an intermediate point of the circulation path and which removes dissolved gas.

Owner:FUJIFILM CORP

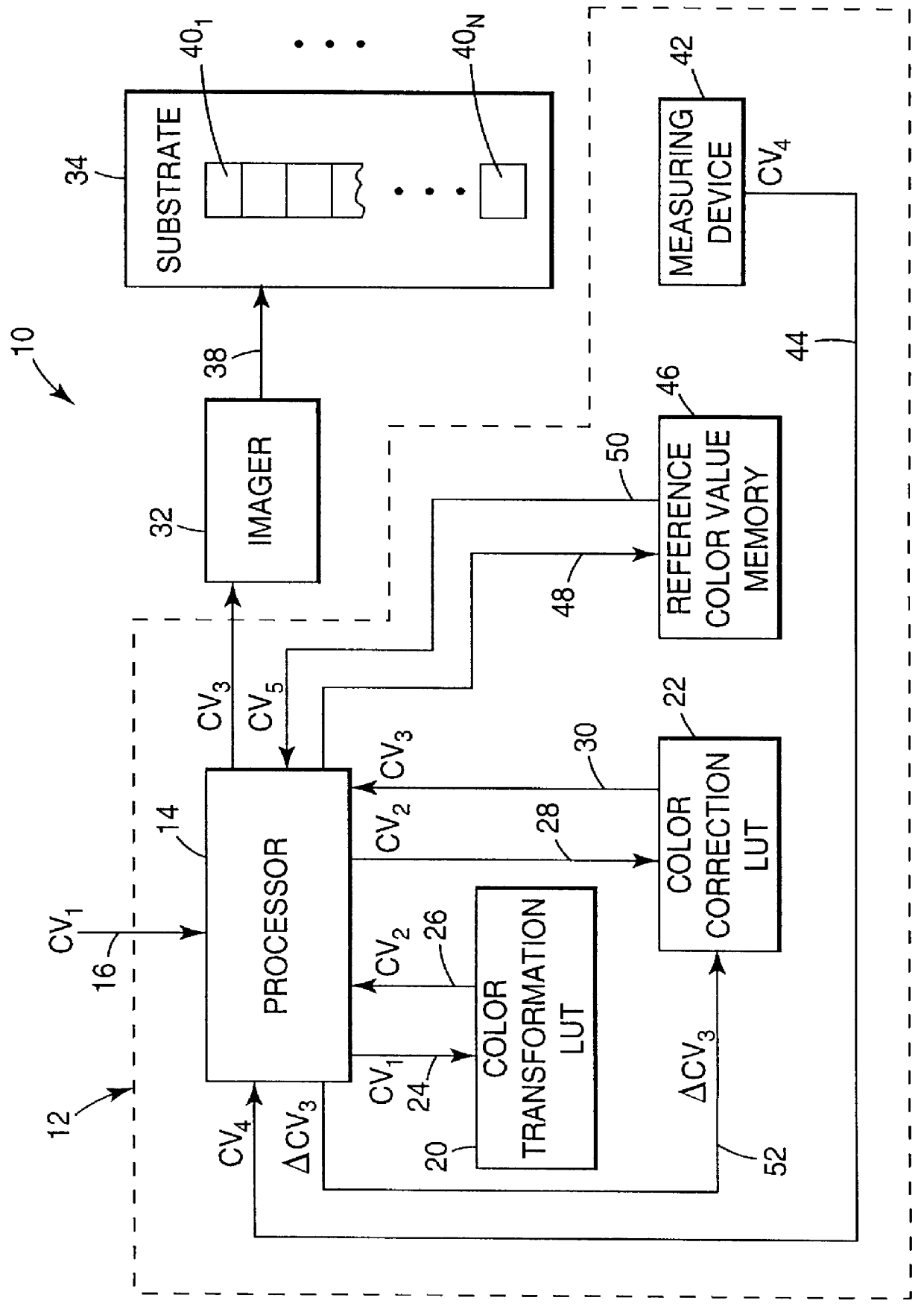

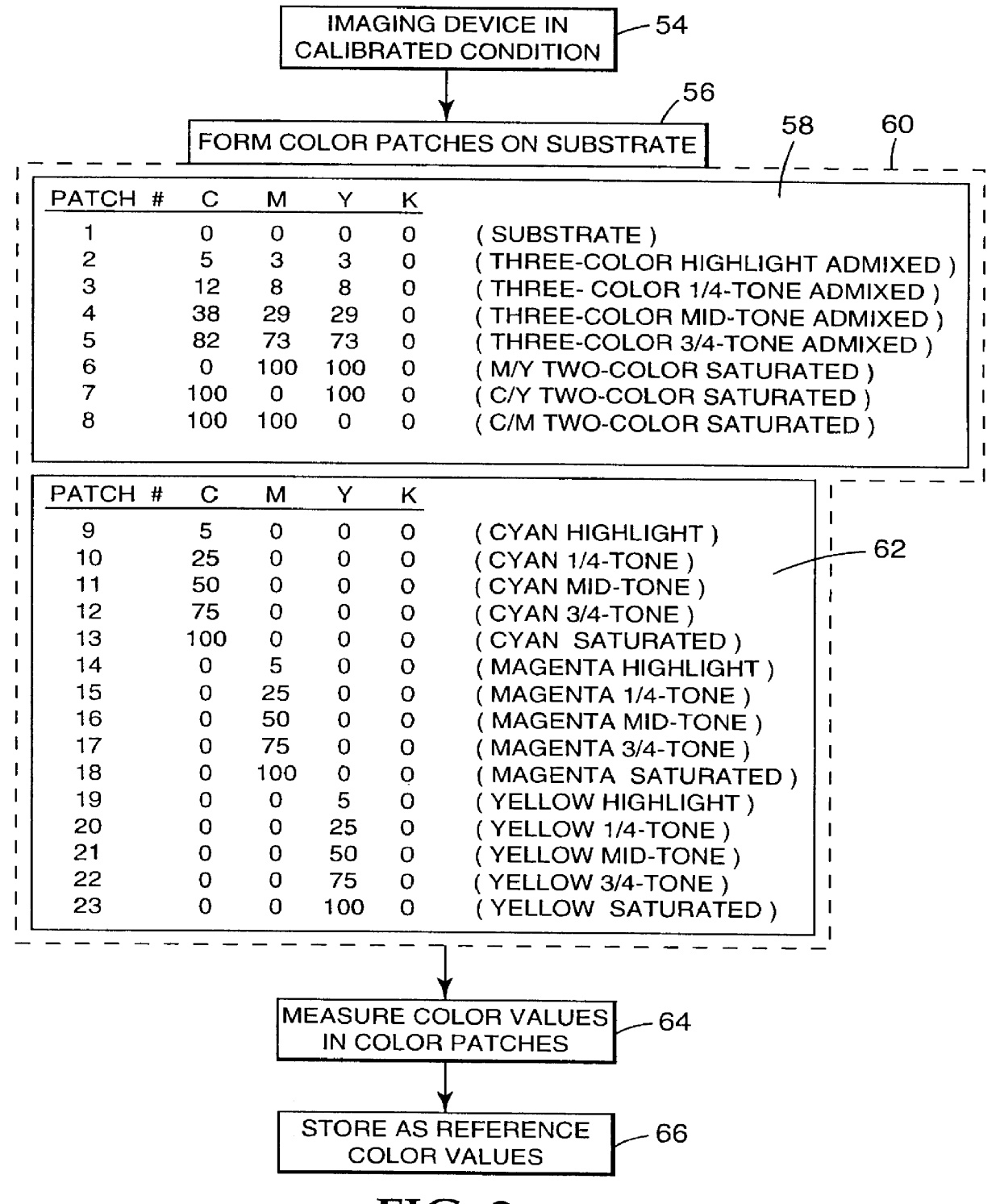

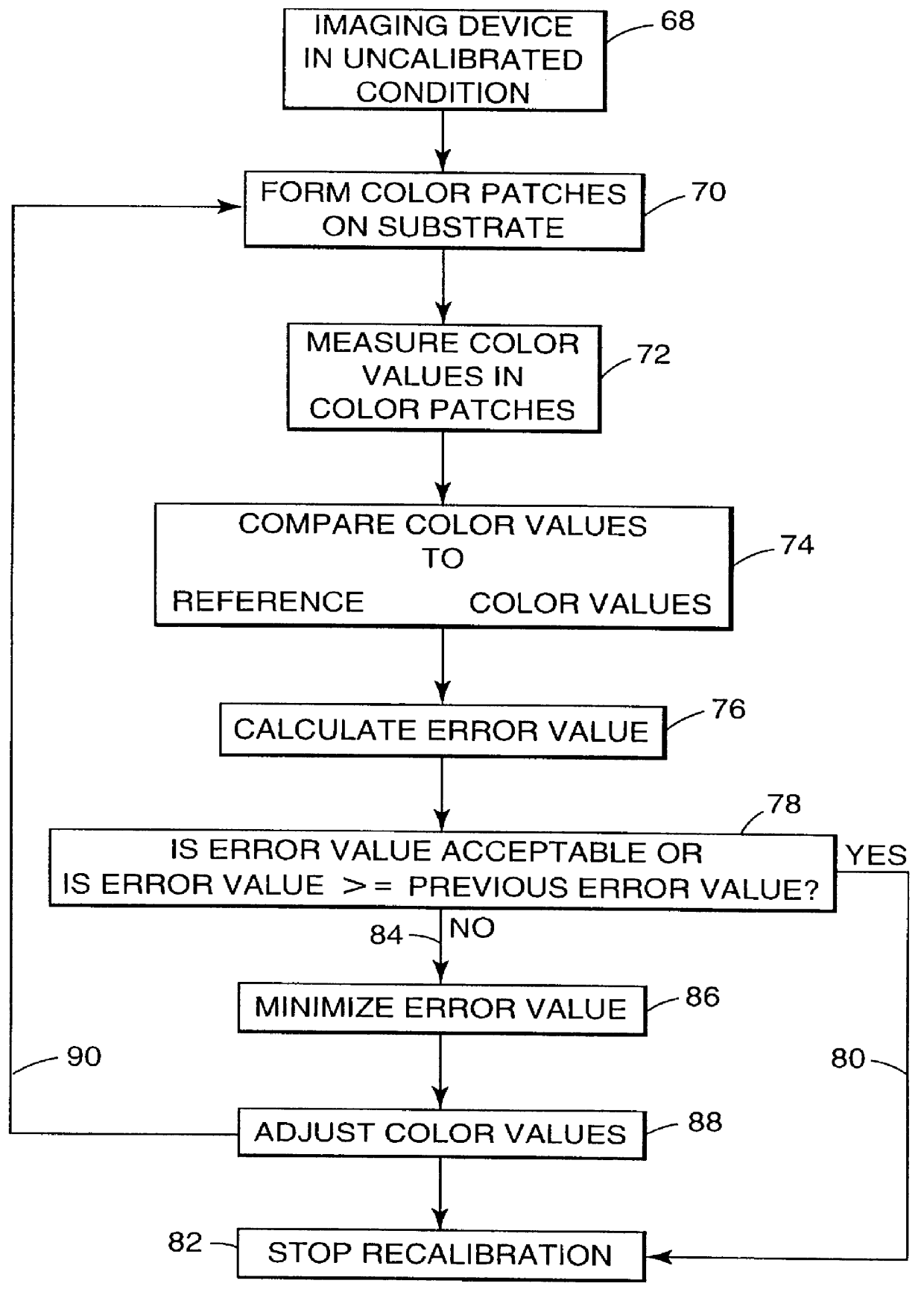

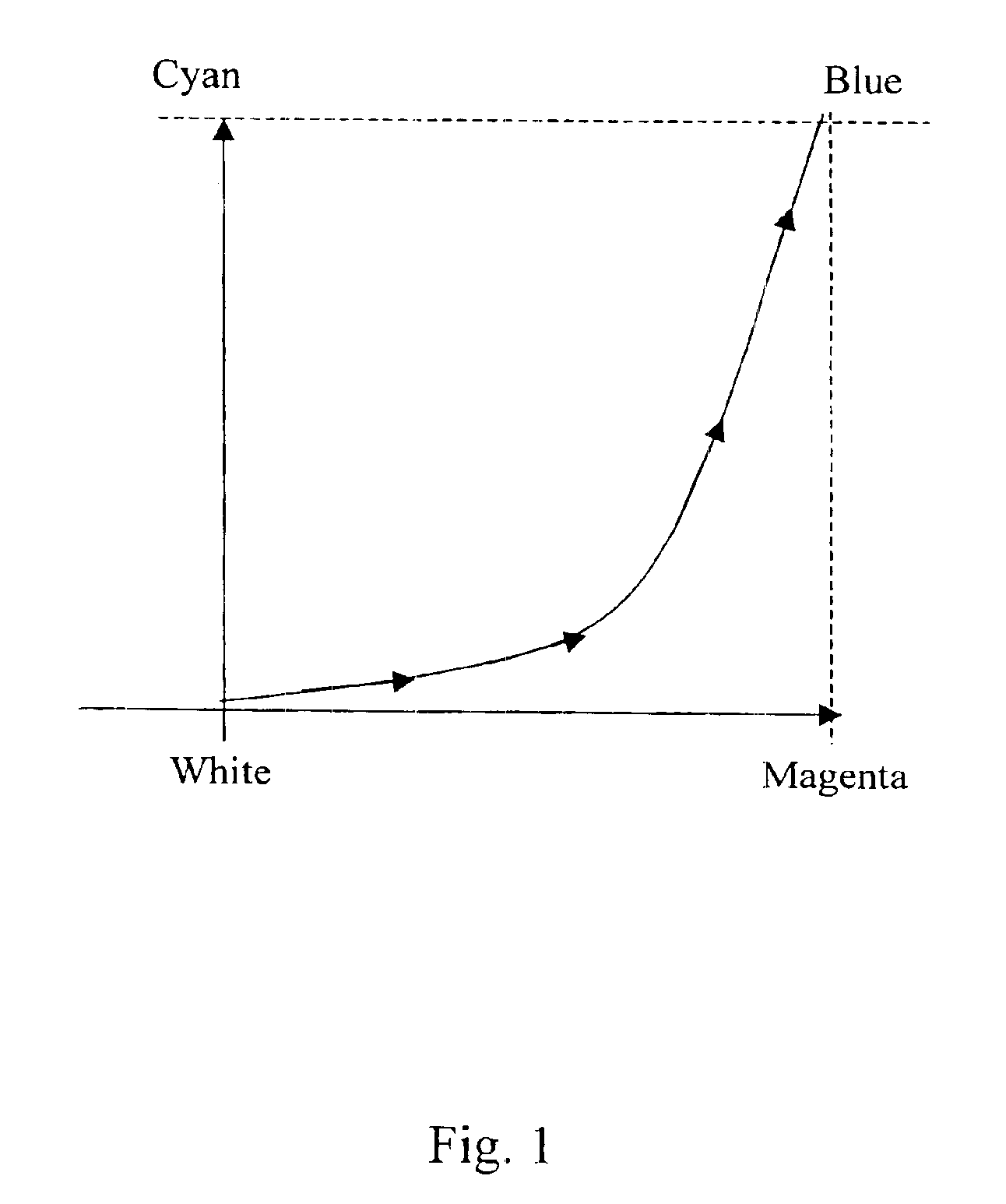

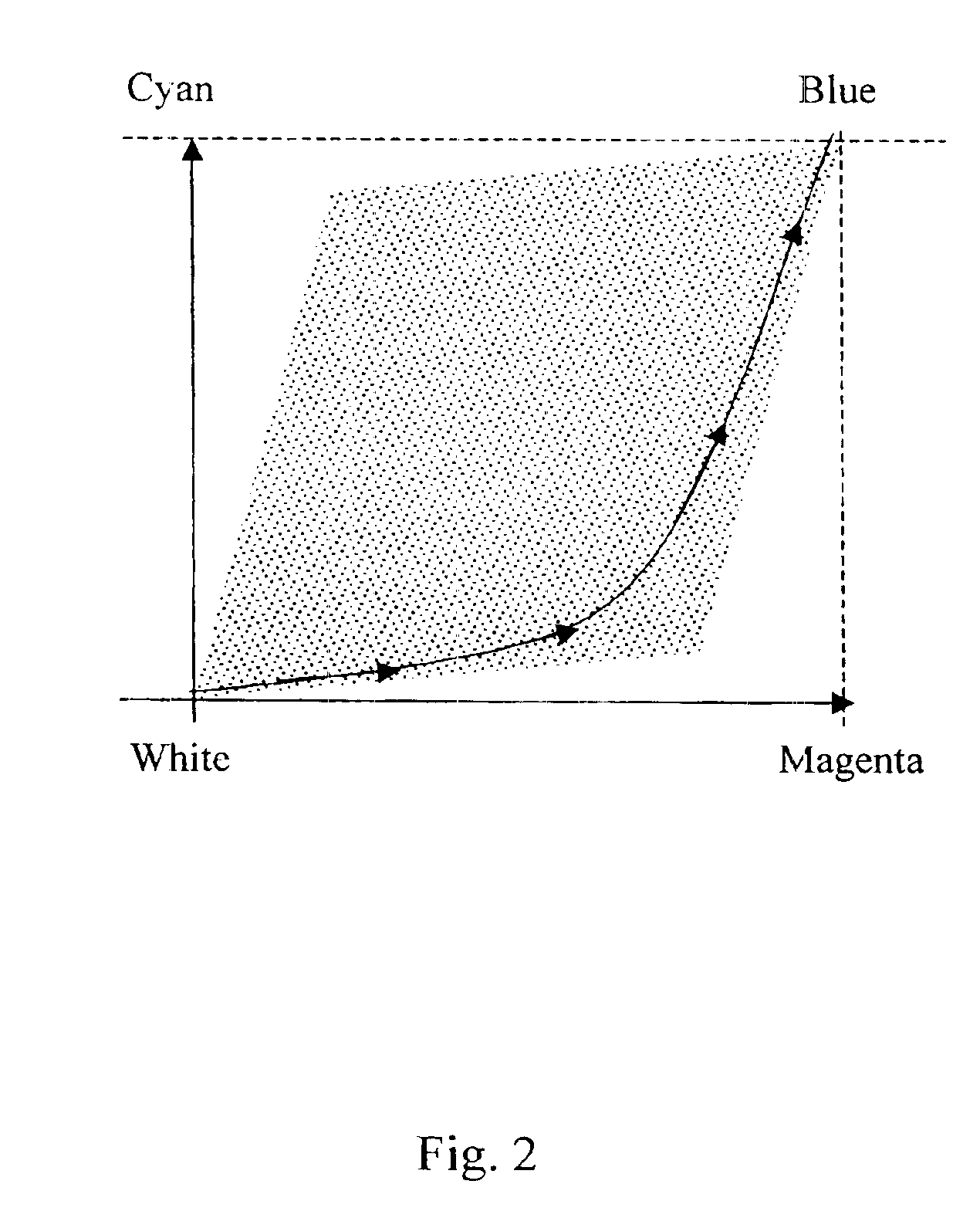

Recalibrating a multi-color imaging system

An apparatus and method for recalibrating a multi-color imaging system are provided. The multi-color imaging system is capable of applying different colorants to a substrate based on a plurality of input color values. The input color values control amounts of the colorants to be applied to the substrate by the imaging system. A subset of the input color values is selected and used to control the imaging system to apply one or more of the different colorants to the substrate, thereby forming a plurality of different color patches on the substrate. The subset of input color values is selected such that one or more of the different color patches is formed by application of a combination of at least two of the different colorants to the substrate. Color values are measured for each of the different color patches, and compared to reference color values, representing a calibrated condition of the imaging system. An error value is calculated. The error value represents a deviation of the measured color values from the reference color values. The input color values for each colorant then are independently adjusted to reduce the error value to a predetermined degree.

Owner:EASTMAN KODAK CO

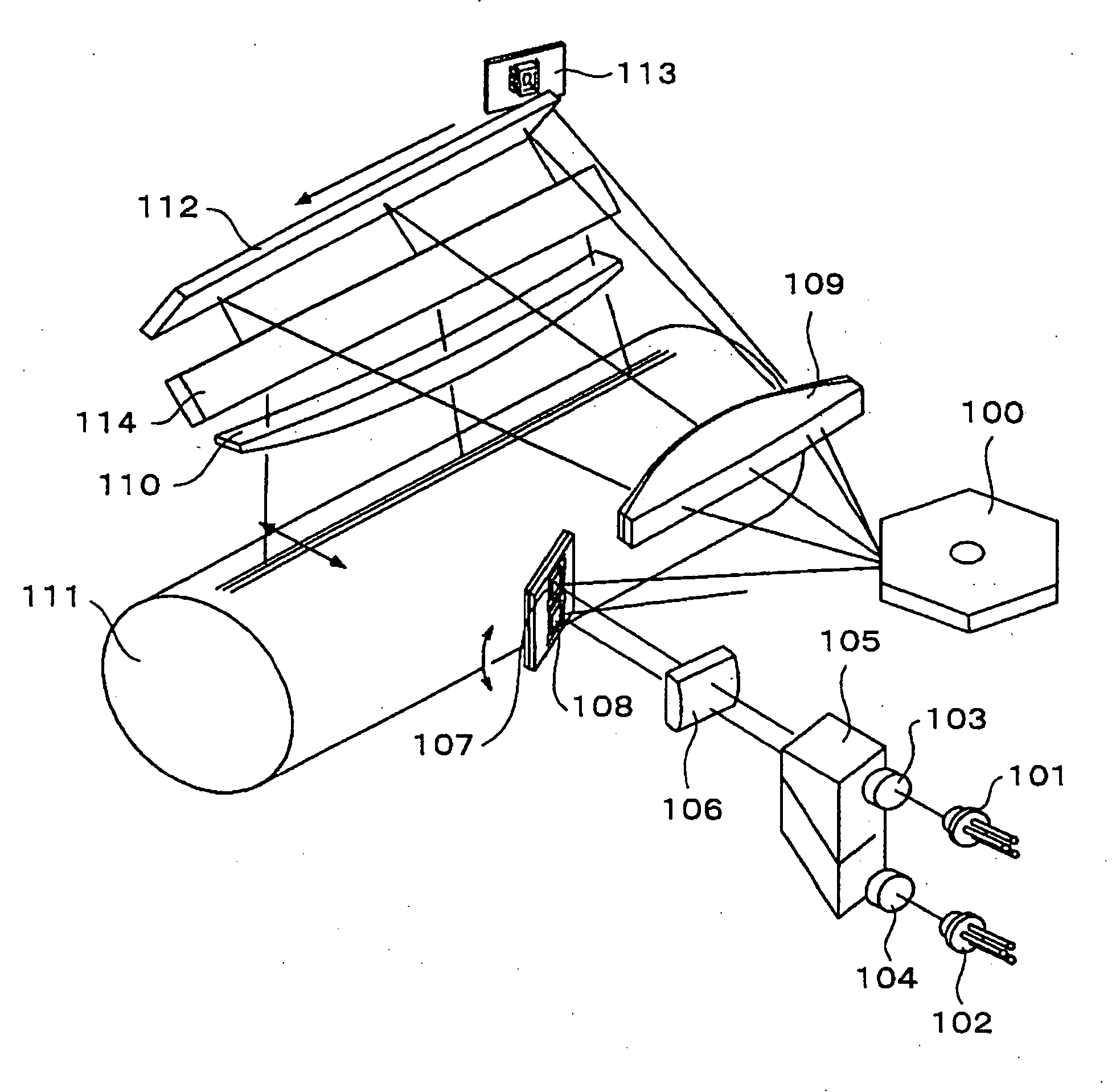

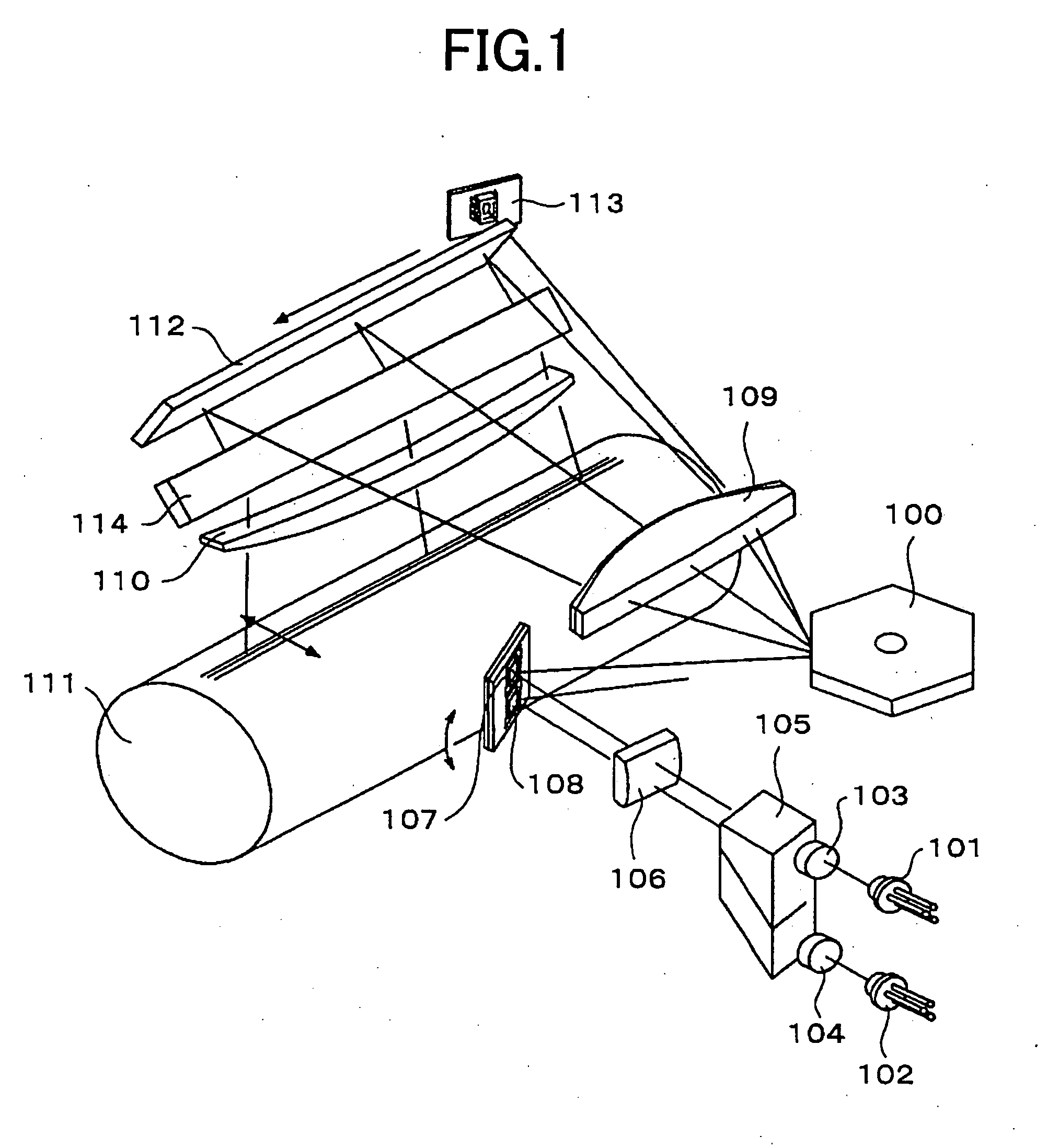

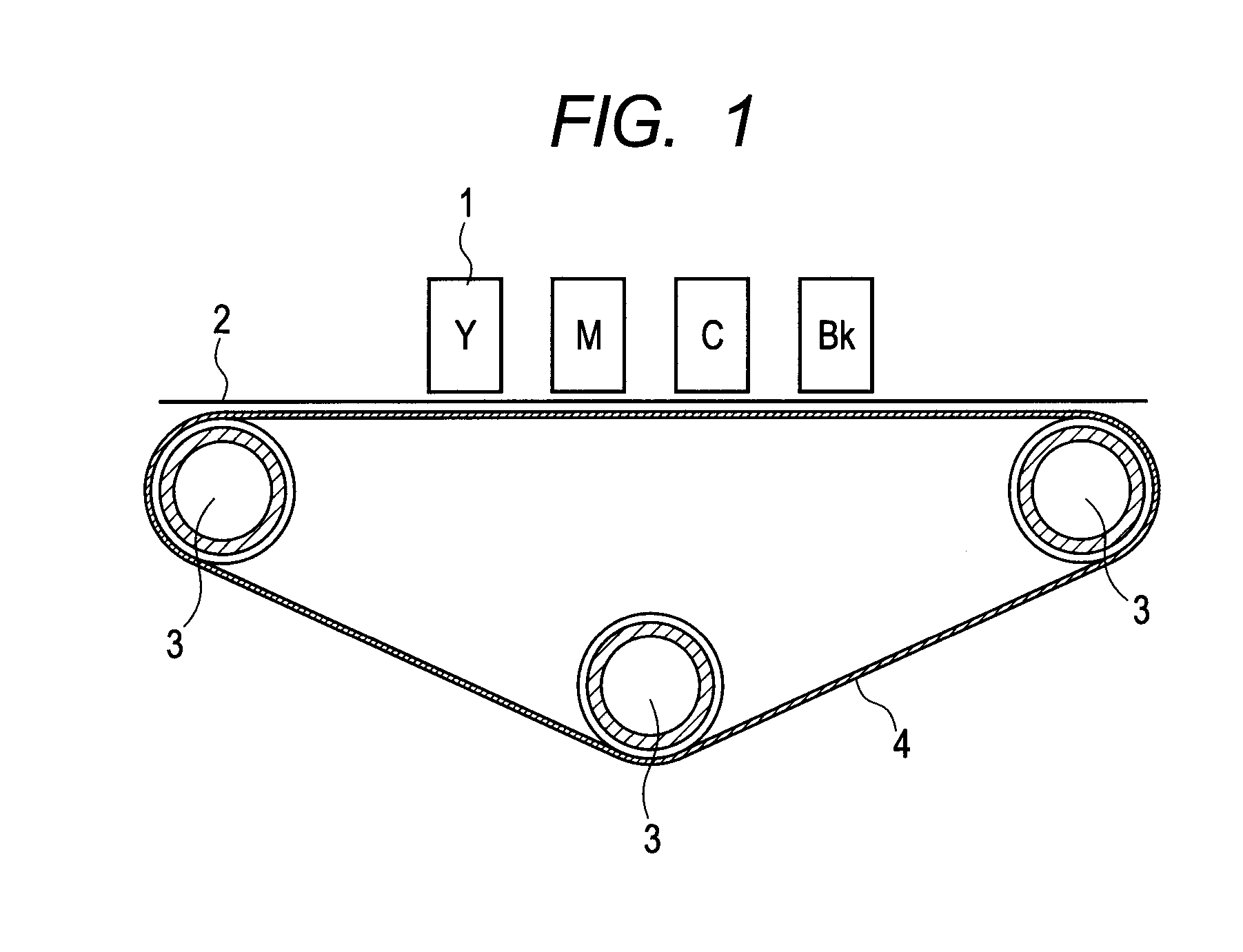

Optical scanner and image forming apparatus

InactiveUS20060232660A1Correct difference of colorEasy to correctInking apparatusVisual representatino by photographic printingColor imageResist

An optical scanner is capable of effectively correcting a difference with respect to the sub-scanning direction between the positions of optical spots for scanning photoconductor drums of a tandem type color image forming apparatus. The optical scanner includes an optical axis adjusting part. The optical axis adjusting part uses a deflecting mirror or a wedge-shaped prism to deflect the optical axis of an optical beam with respect to the sub-scanning direction. As a result, it is possible to accurately correct a resist difference among individual image forming stations and form a high-quality color image without any color displacement.

Owner:RICOH KK

Printing cartridge with barcode identification

A printing cartridge is releasably engageable with a printing device having a linear reader for reading a barcode and a central processor capable of interpreting data carried on a barcode. The printing cartridge includes a housing. Media and media colorant supply arrangements are positioned within the housing and contain a supply of media and a supply of media colorant, respectively. Feed mechanisms are positioned in the housing for feeding the media and the media colorant to a printing mechanism. A barcode is depicted on the housing, the barcode being readable by the linear reader and defining a code representing data relating to the media and the media colorant.

Owner:ZAMTEC +1

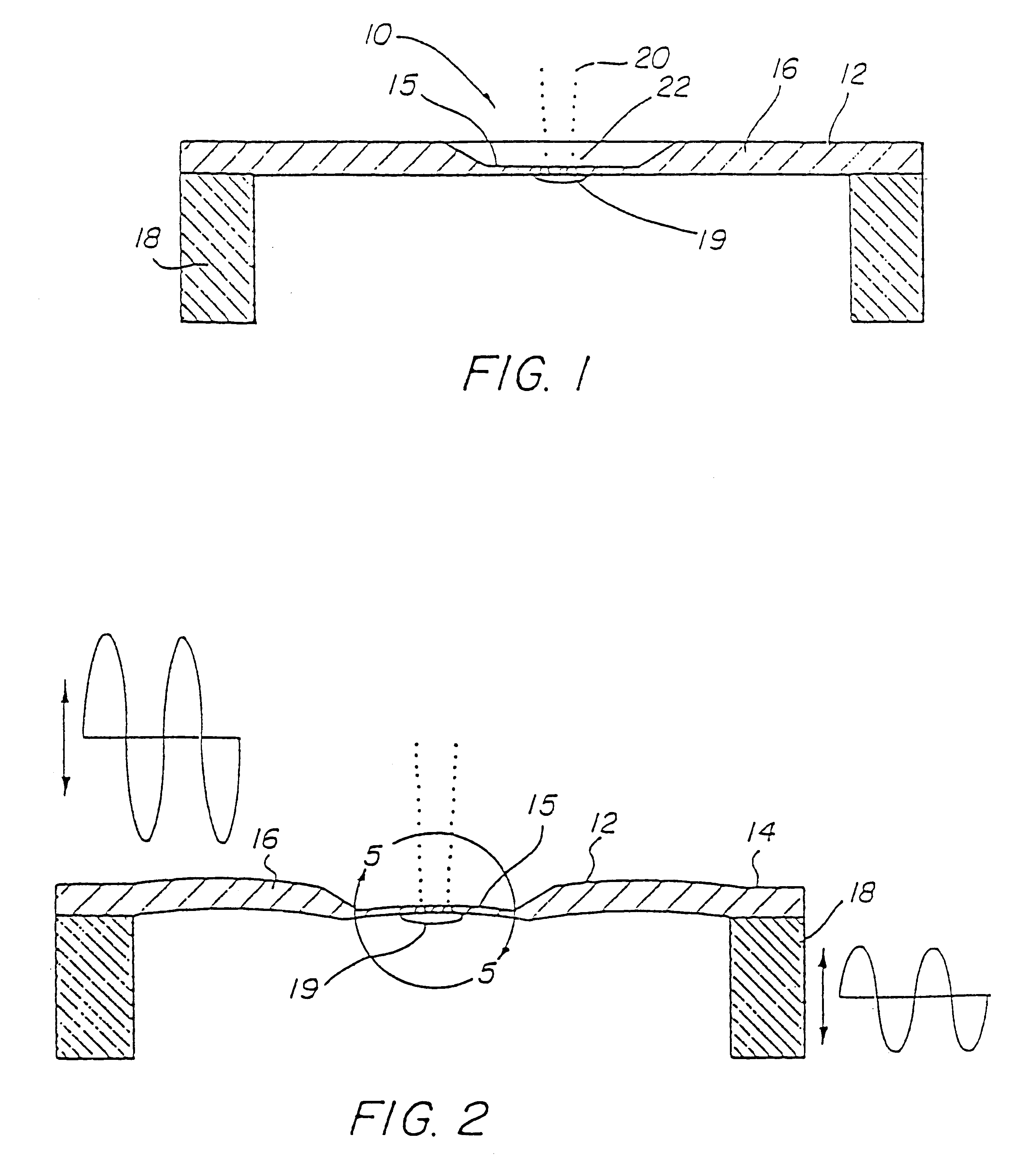

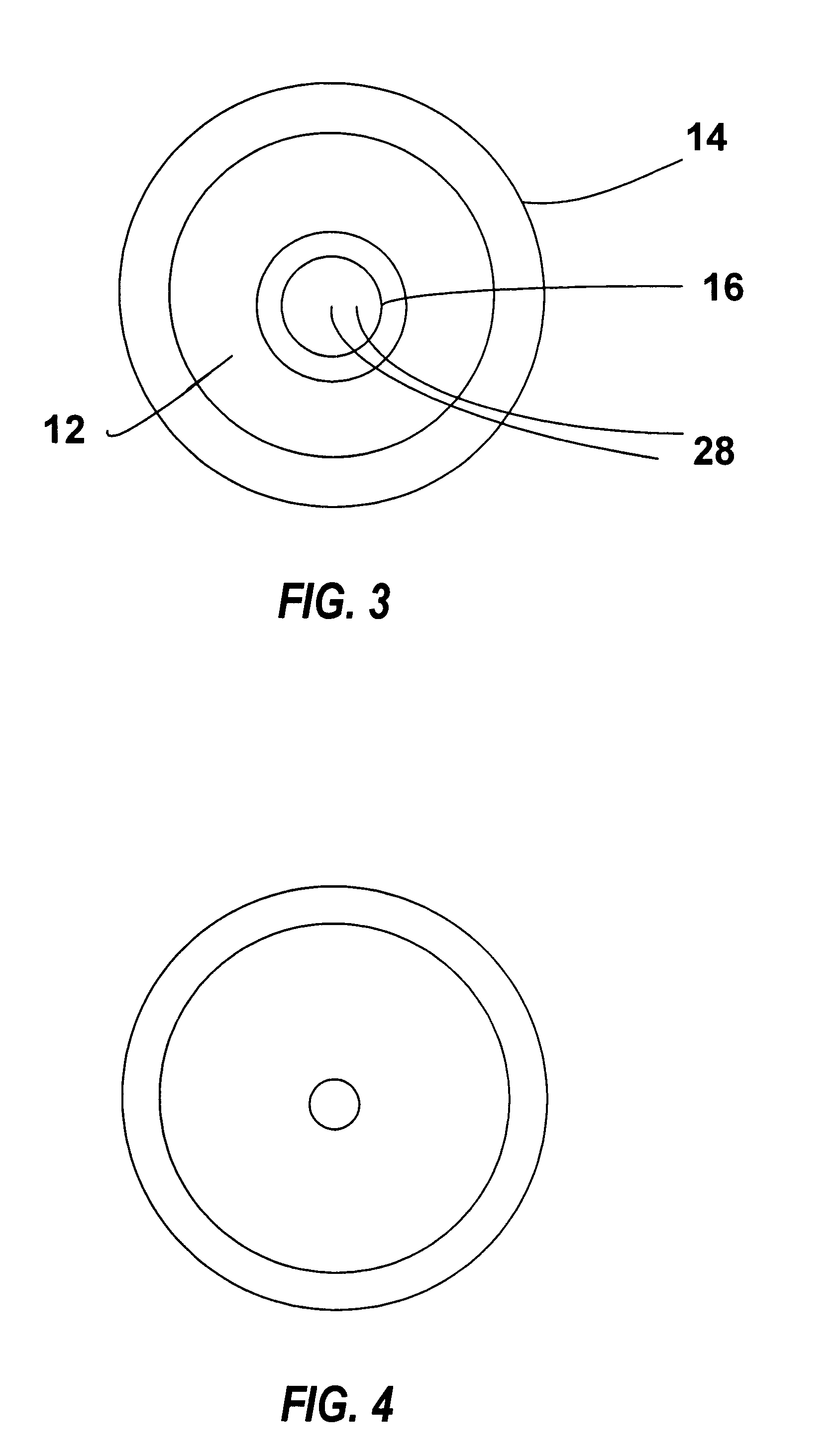

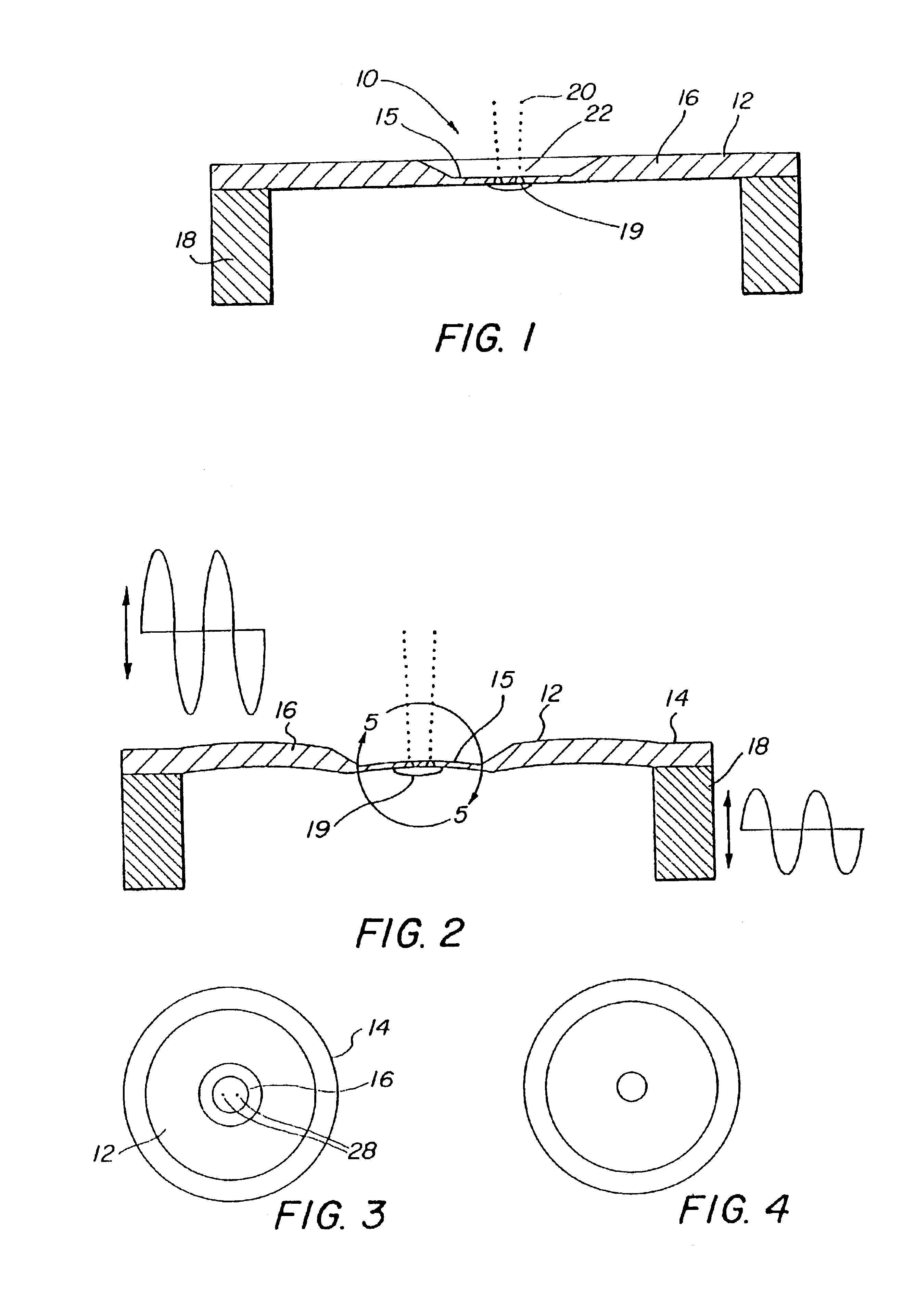

Droplet ejector with oscillating tapered aperture

InactiveUS6926208B2Easy to operateLittle has been producedInking apparatusMovable spraying apparatusFluid injectionFluid supply

A fluid injection device for ejecting fluid droplets in response to electrical signals comprises an oscillating surface that has one or more tapered apertures, each aperture having a first and second opening. The first opening of each aperture is larger than the second opening. The first opening is in surface tension contact with the fluid to be ejected. The fluid interaction with the tapered aperture wall creates cycles of fluid compression and decompression inside the aperture, causing fluid to be drawn from the large opening and ejected out the small opening of the aperture. The device includes a fluid supply nozzle that transports fluid to the oscillating surface at the large opening of the apertures. A discharge valve controls the fluid supply. An electronic wave generator induces oscillation in the tapered aperture containing surface. The device is used to great advantage for fluid atomization and fluid spray.

Owner:NOVARTIS FARMA

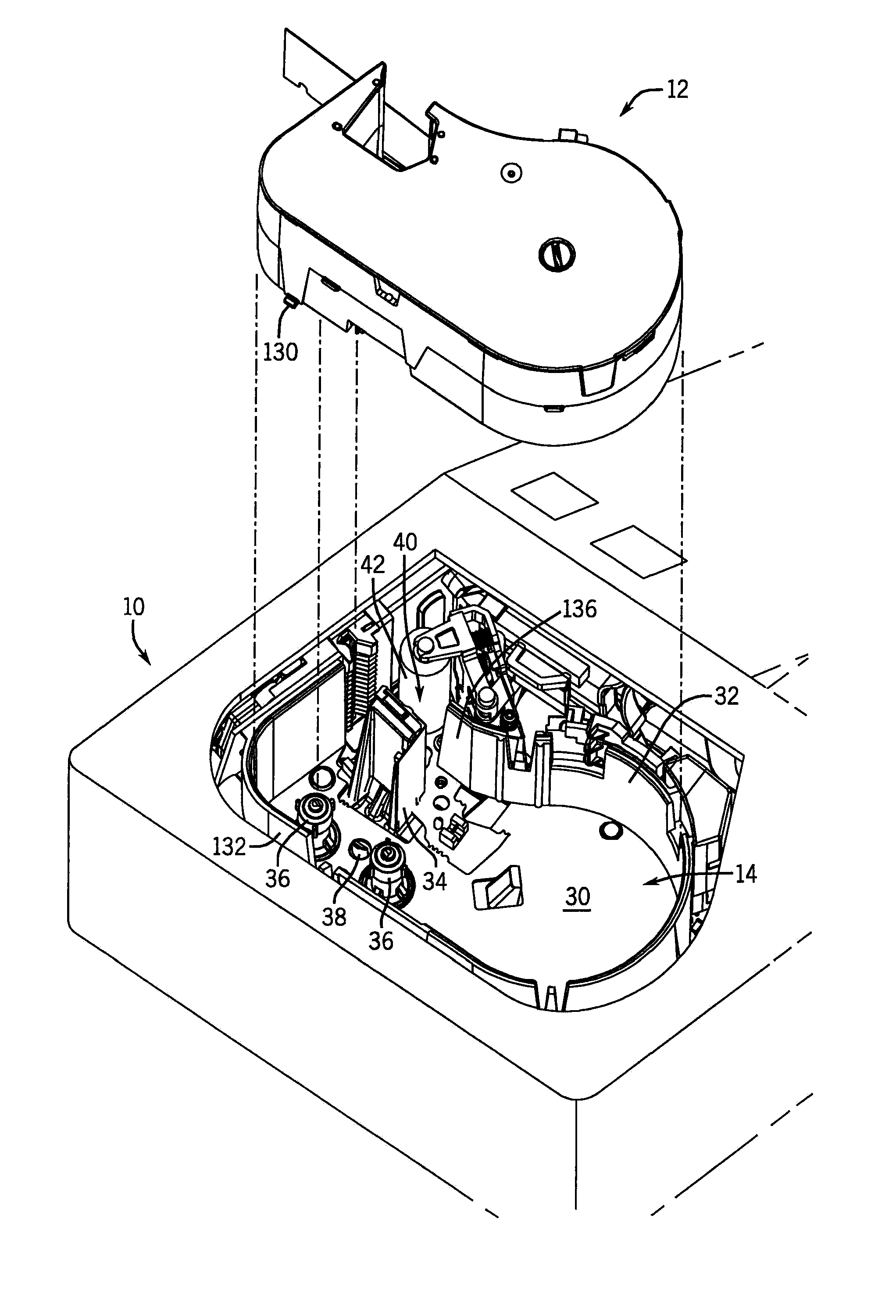

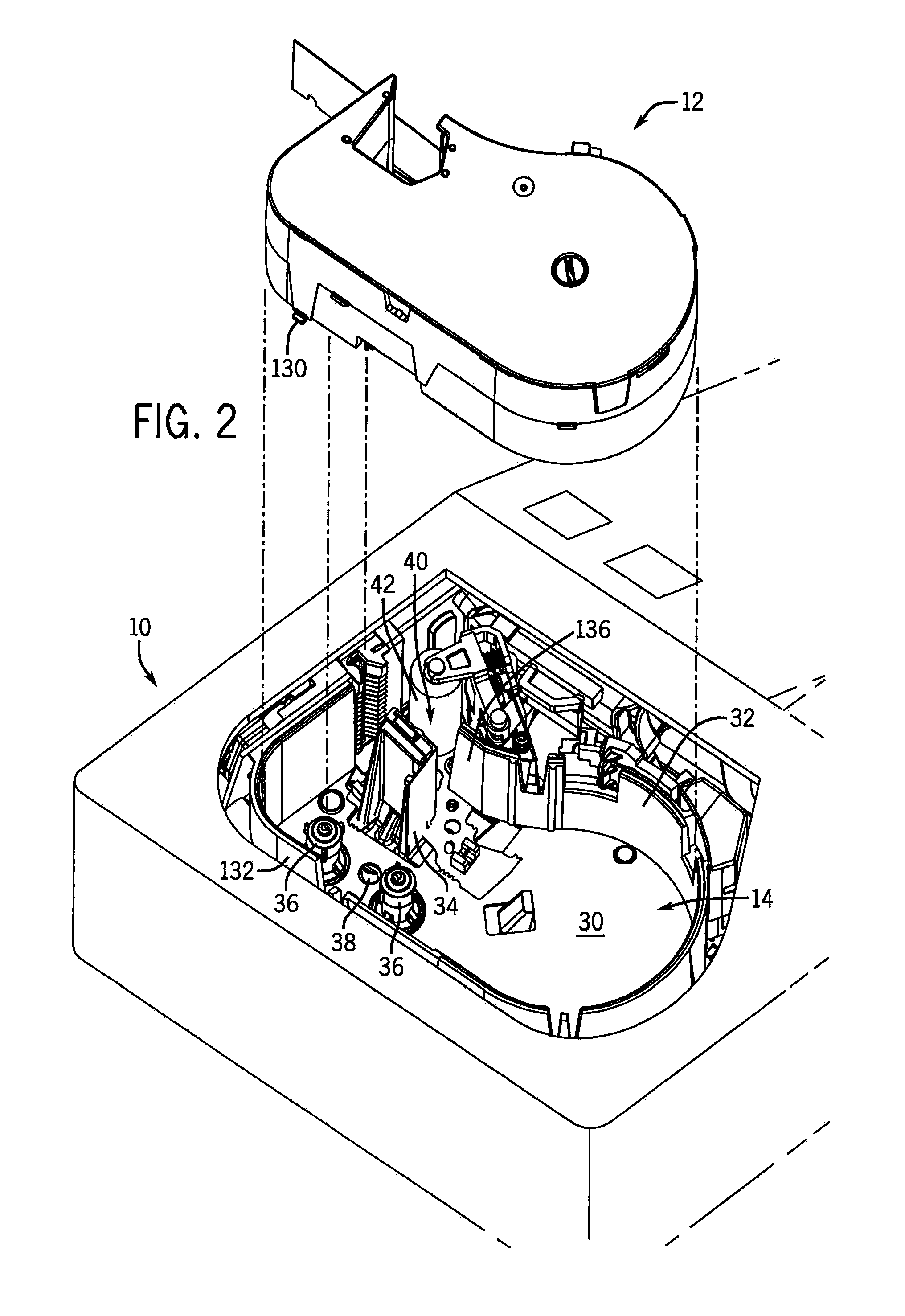

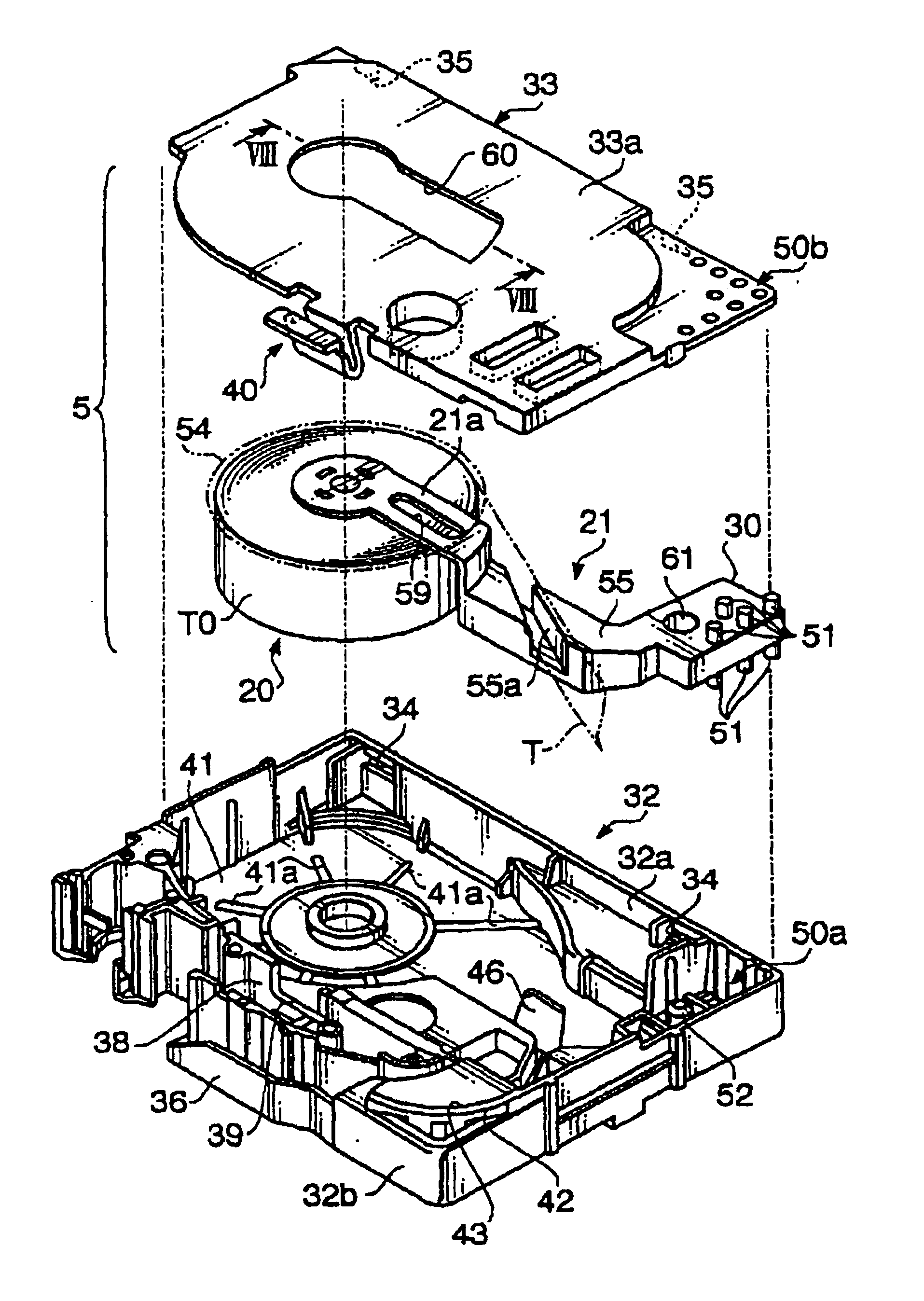

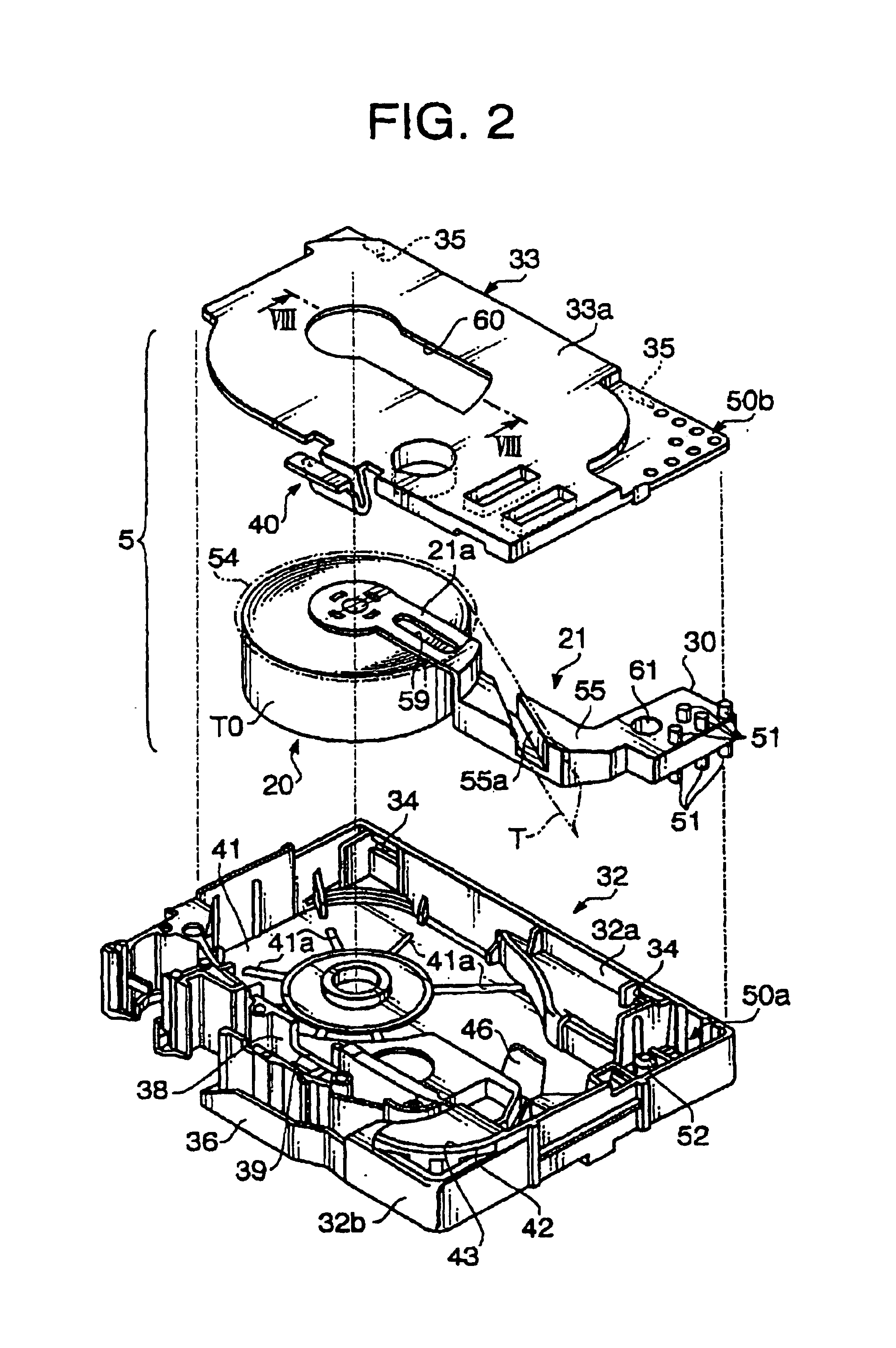

Tape cassette and tape unit

InactiveUS6955318B2Erroneous loadingPicture changing apparatusInking apparatusMagnetic tapeCassette tape

Owner:BROTHER KOGYO KK

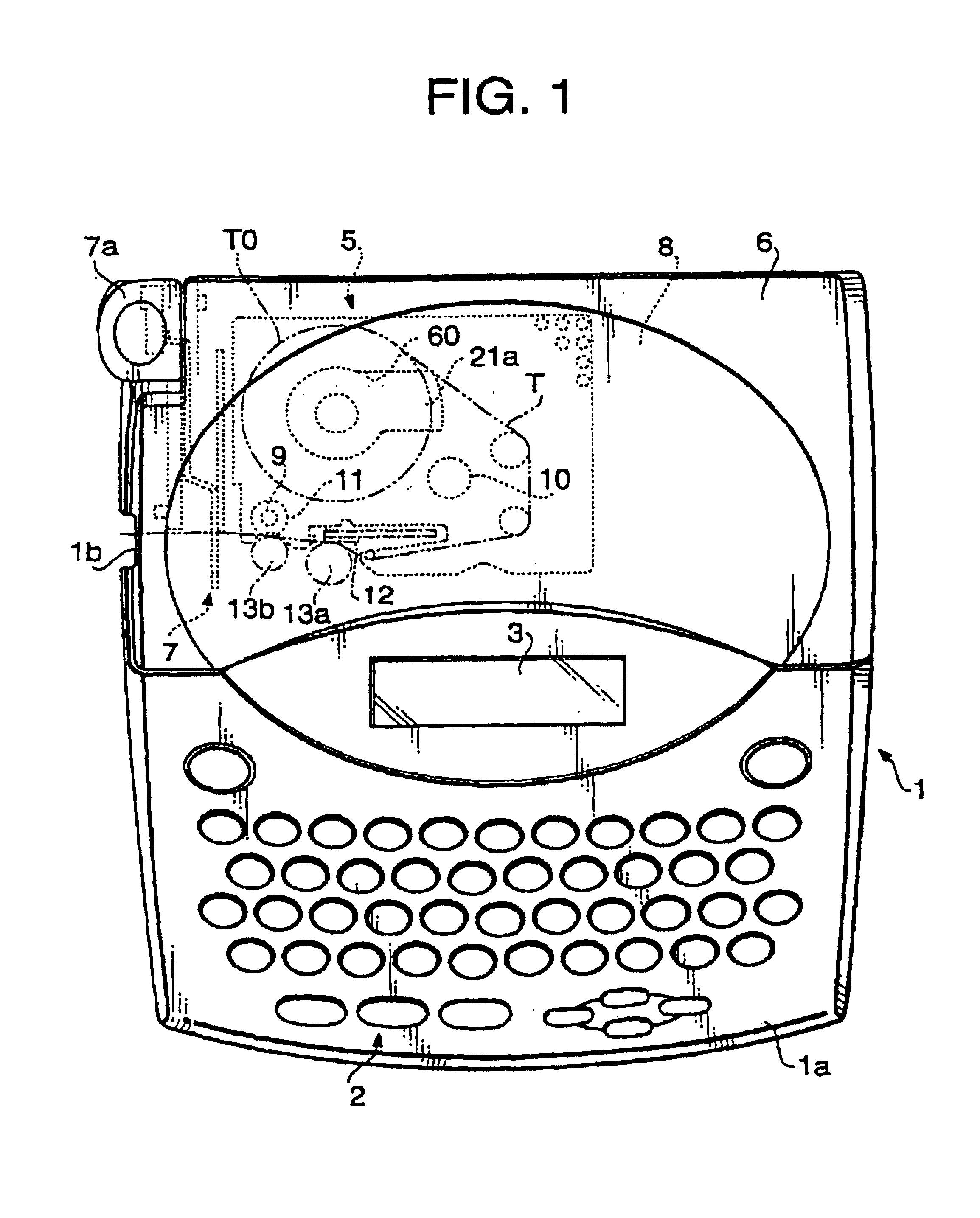

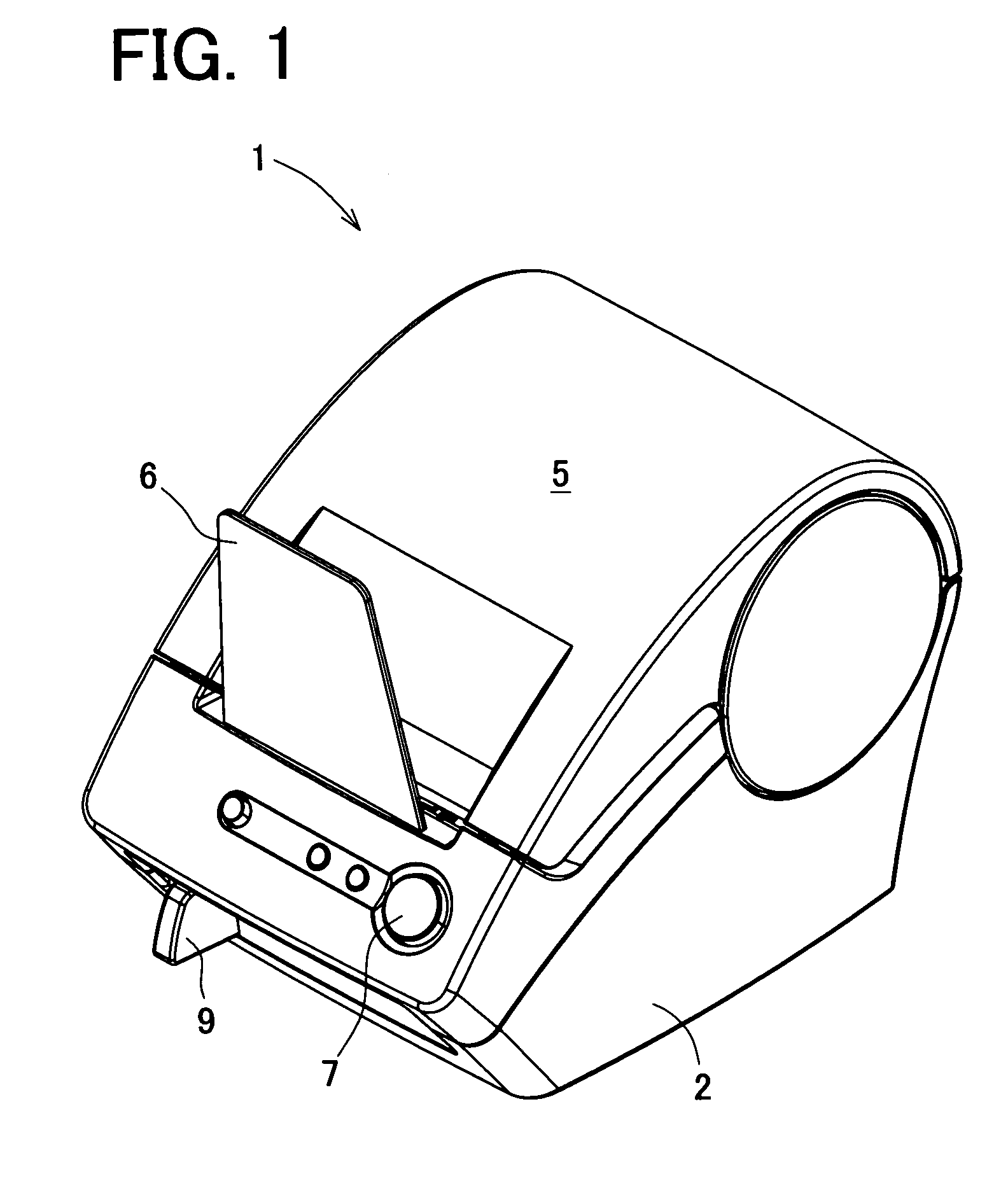

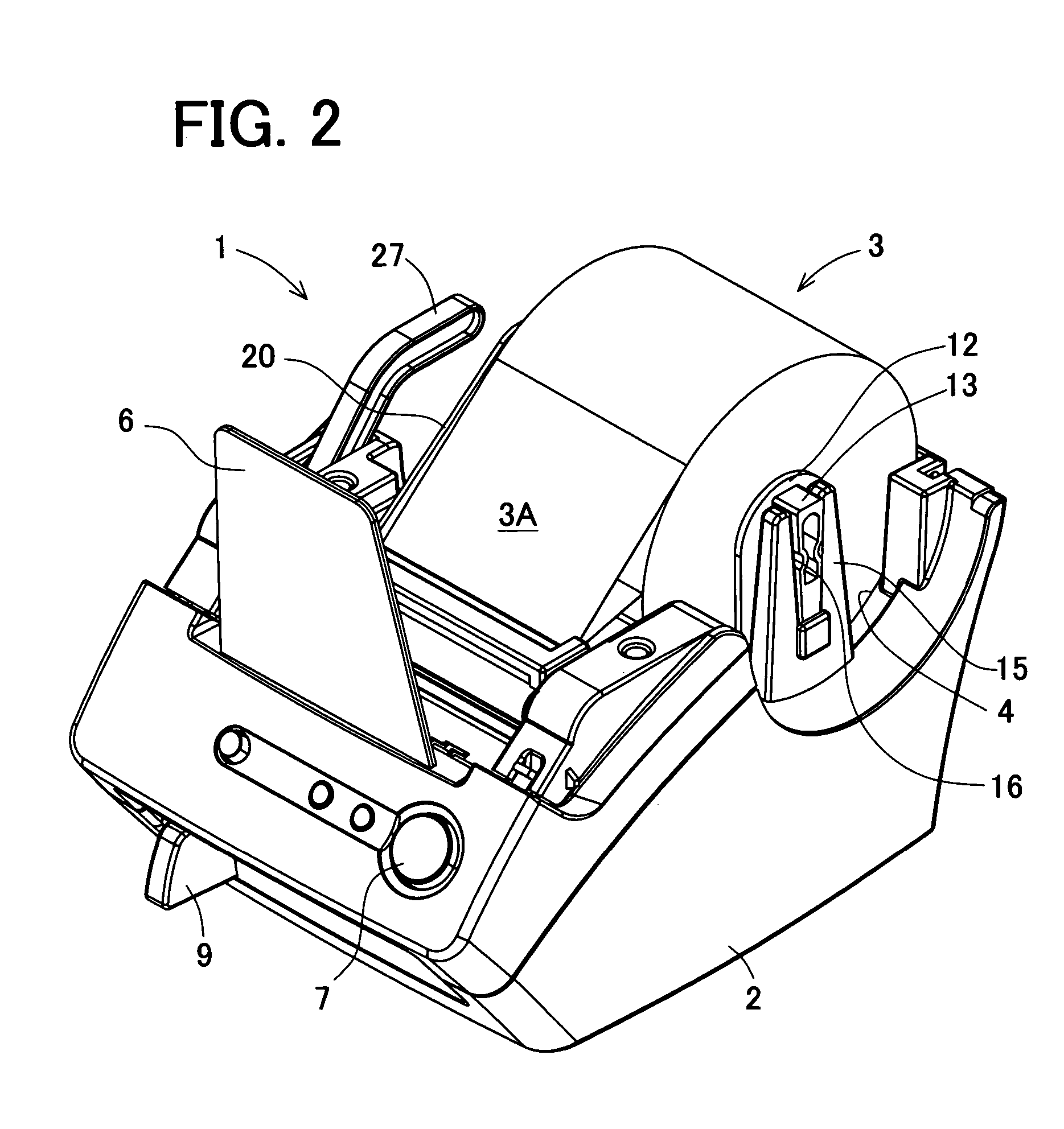

Roll sheet holder and tape printer

ActiveUS7070348B2Avoid partialImprove detection accuracyInking apparatusProjector film strip handlingRolling paperEngineering

Owner:BROTHER KOGYO KK

Recording apparatus and liquid ejection head

A recording apparatus including an ink tank and a recording head having a flow path forming portion that has an ejection orifice plate having plural ink ejection orifices and a liquid chamber provided for each orifice to supply ink to the orifices, and an energy generating element for ejecting ink in the chamber. A surface layer of the flow path forming portion opposes to the outside of the plate. An opening is provided opposing to the orifices in the surface layer. An ink reservoir is provided between the plate and the opening. A circulation flow path communicating with the ink reservoir is provided. The area of the opening is larger than that of the orifice. Both ends of the circulation flow path are respectively connected to inlet and outlet portions connected to the circulation flow path. The inlet and outlet portions and liquid chamber are connected to the ink tank.

Owner:CANON KK

Temperature regulation of fluid ejection printheads

Owner:SILVERBROOK RES PTY LTD +1

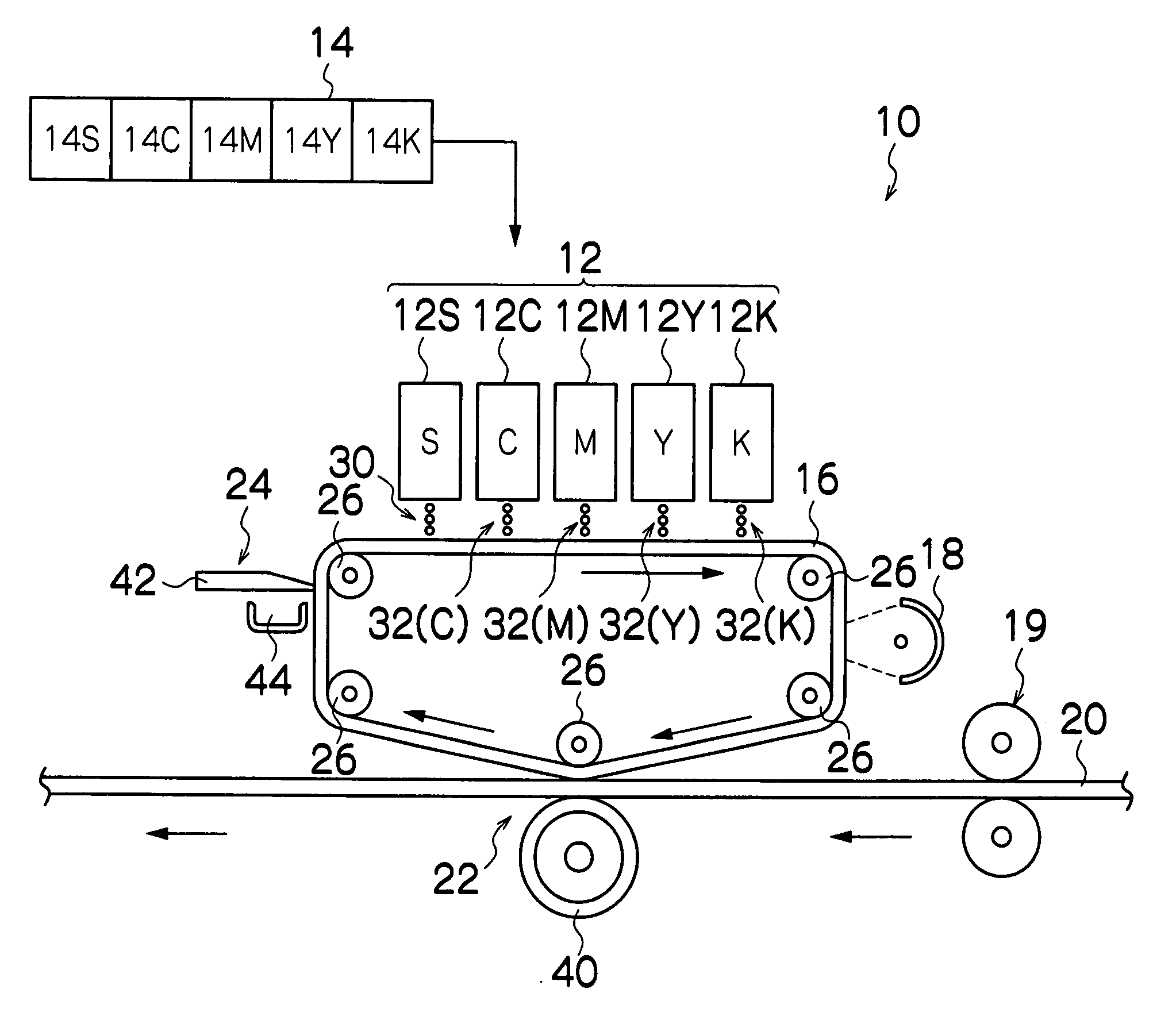

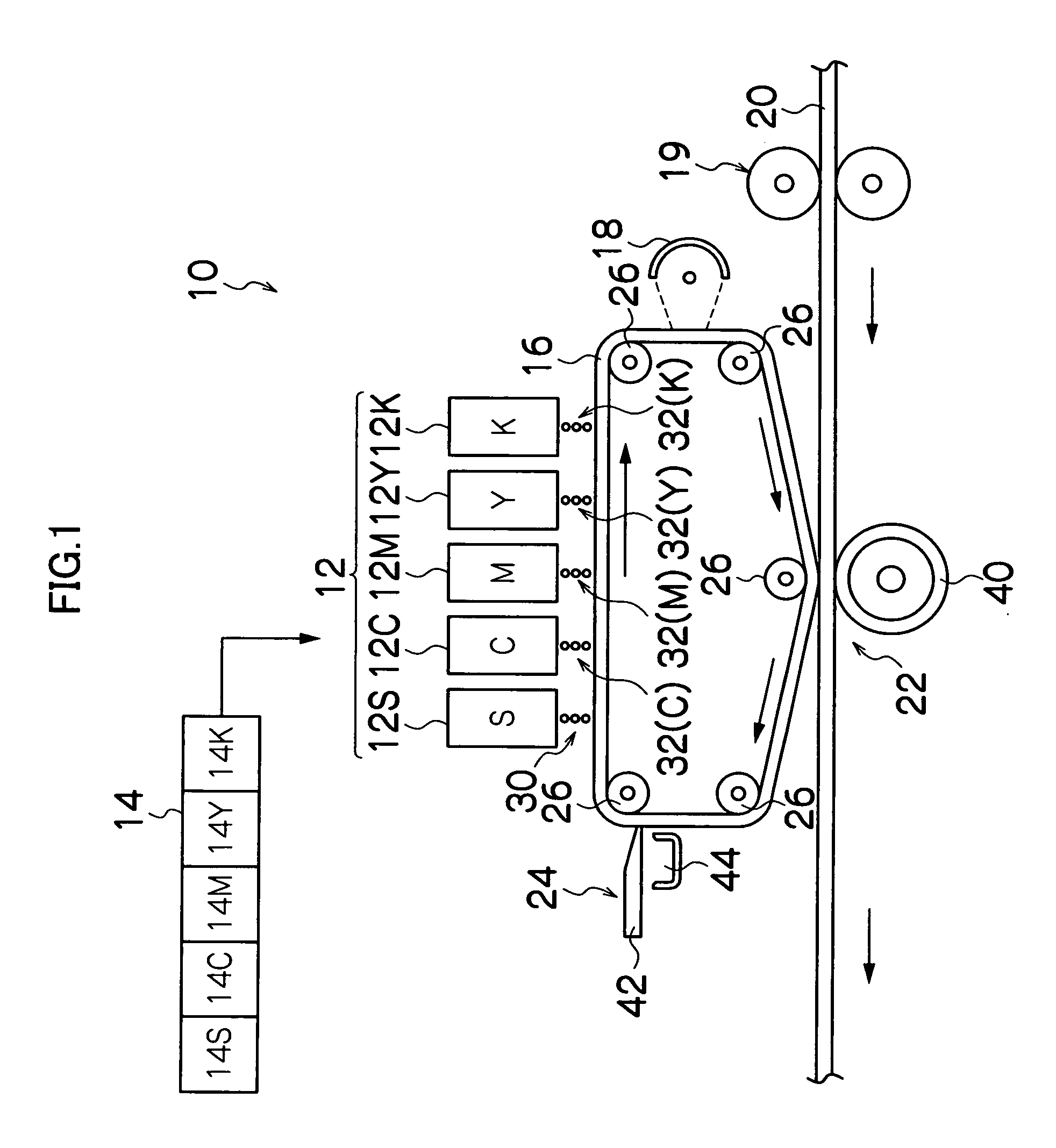

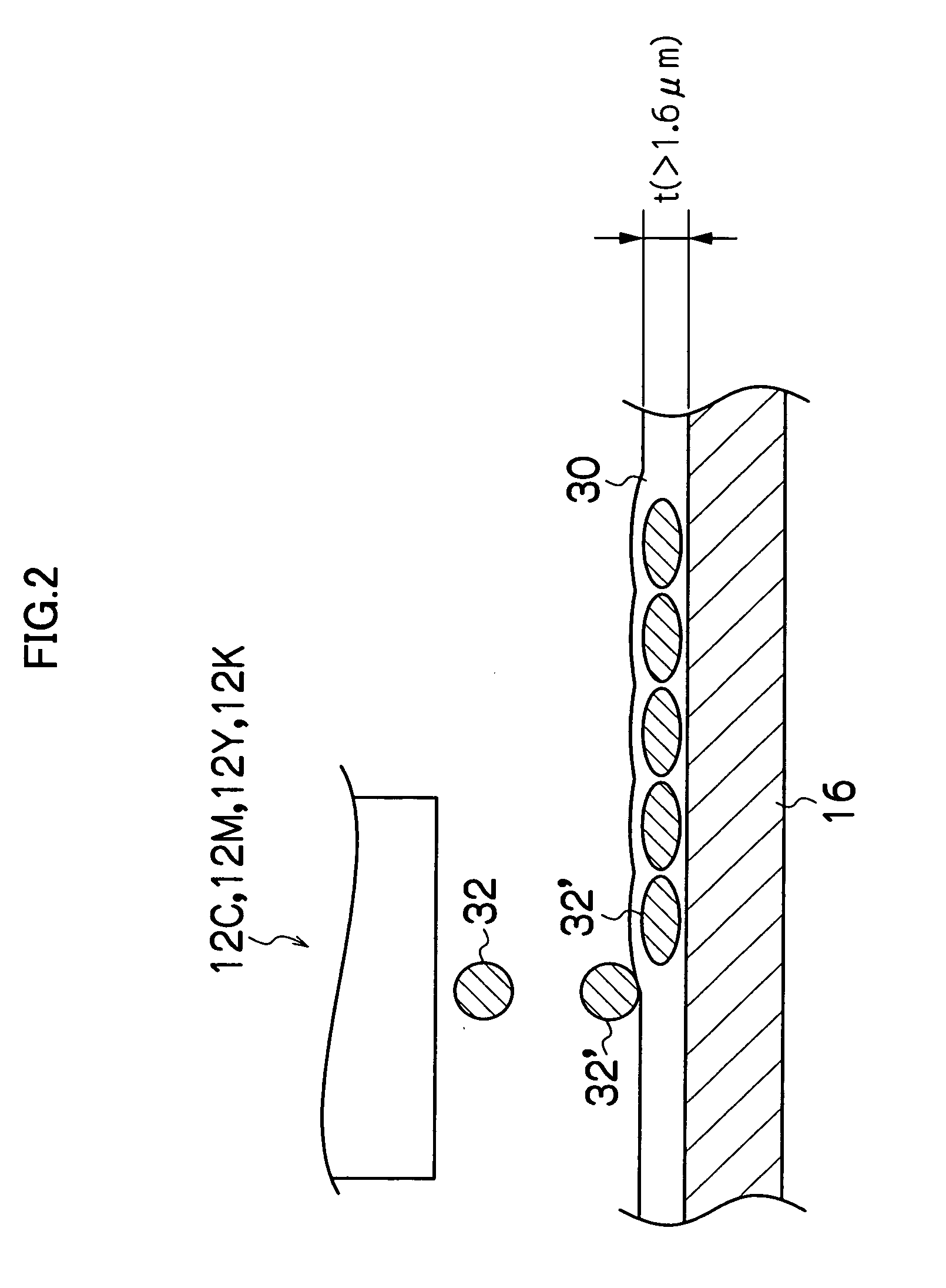

Image forming apparatus and image forming method

InactiveUS20070176995A1Increase speedRaising viscosity of secondInking apparatusImage formationEngineering

The image forming apparatus includes: an intermediate transfer body; a liquid adhesion device which provides a first liquid having a viscosity not less than 15 mPa·s and not greater than 300 mPa·s at 25° C, on the intermediate transfer body; a droplet ejection device which ejects a second liquid containing a coloring material onto a region of the intermediate transfer body where the first liquid is provided by the liquid adhesion device, in a state where the first liquid on the intermediate transfer body has a thickness not less than 1.6 μm; a viscosity raising device which raises a viscosity of the second liquid on the intermediate transfer body; and a transfer device which transfers an image including dots of the second liquid formed on the intermediate transfer body, onto a recording medium.

Owner:FUJIFILM CORP

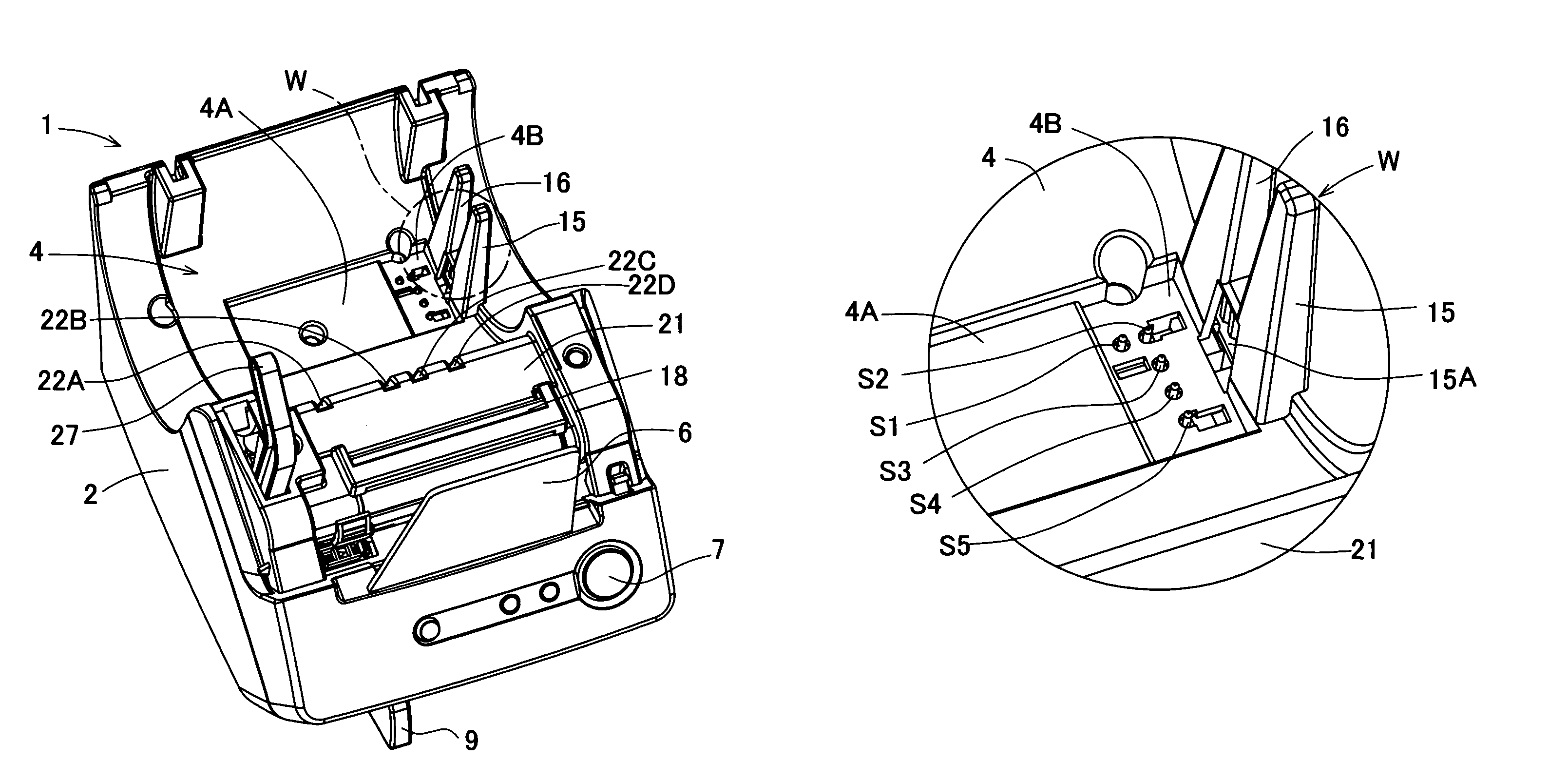

Ribbon feeder and printer

InactiveCN1914045AEliminate wrinklesUniform tensionPrinting mechanismsInking apparatusConductor CoilMechanical engineering

The invention relates to a ribbon feeder of printer. Ribbon tension detecting means (20, 21) each consisting of a plate-like lever body (35) are disposed upstream and downstream, respectively, of a ribbon path from a platen (7). The plate-like lever body (35) has first and second rollers (47, 48) disposed upstream and downstream of the ribbon path and swings around the axis of the rotary shaft of the second roller (48) according to the tension on the ribbon traveling as guided by these rollers (47, 48). When the amount of swing is above or below a fixed vale, a ribbon feed motor (18) or a ribbon winding motor (19) is driven. Further, the ribbon tension detecting means (20, 21) are each provided with a wrinkle eliminating member adapted to contact an ink ribbon (13) so as to eliminate wrinkles formed in the ink ribbon (13).

Owner:CITIZEN WATCH CO LTD

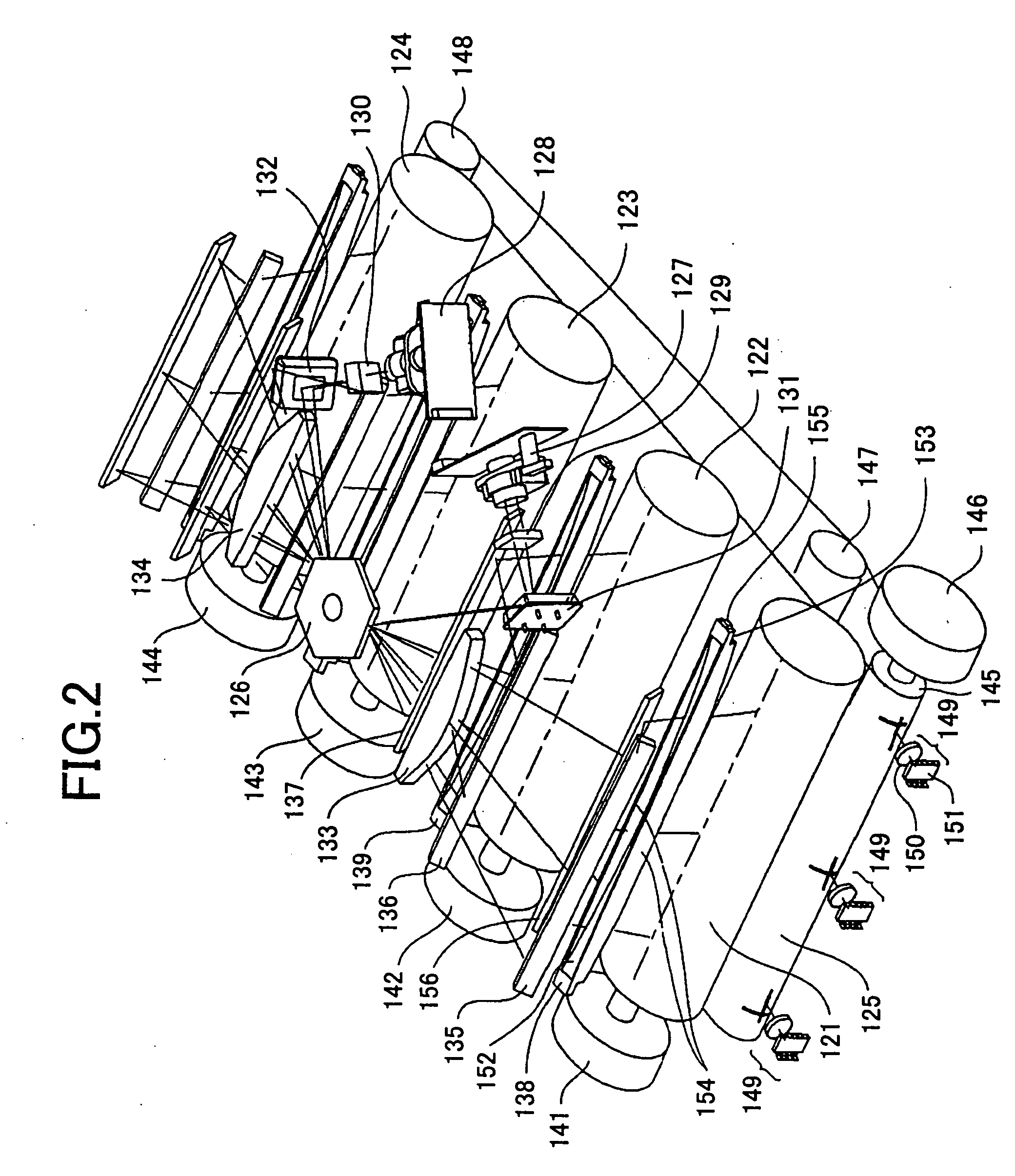

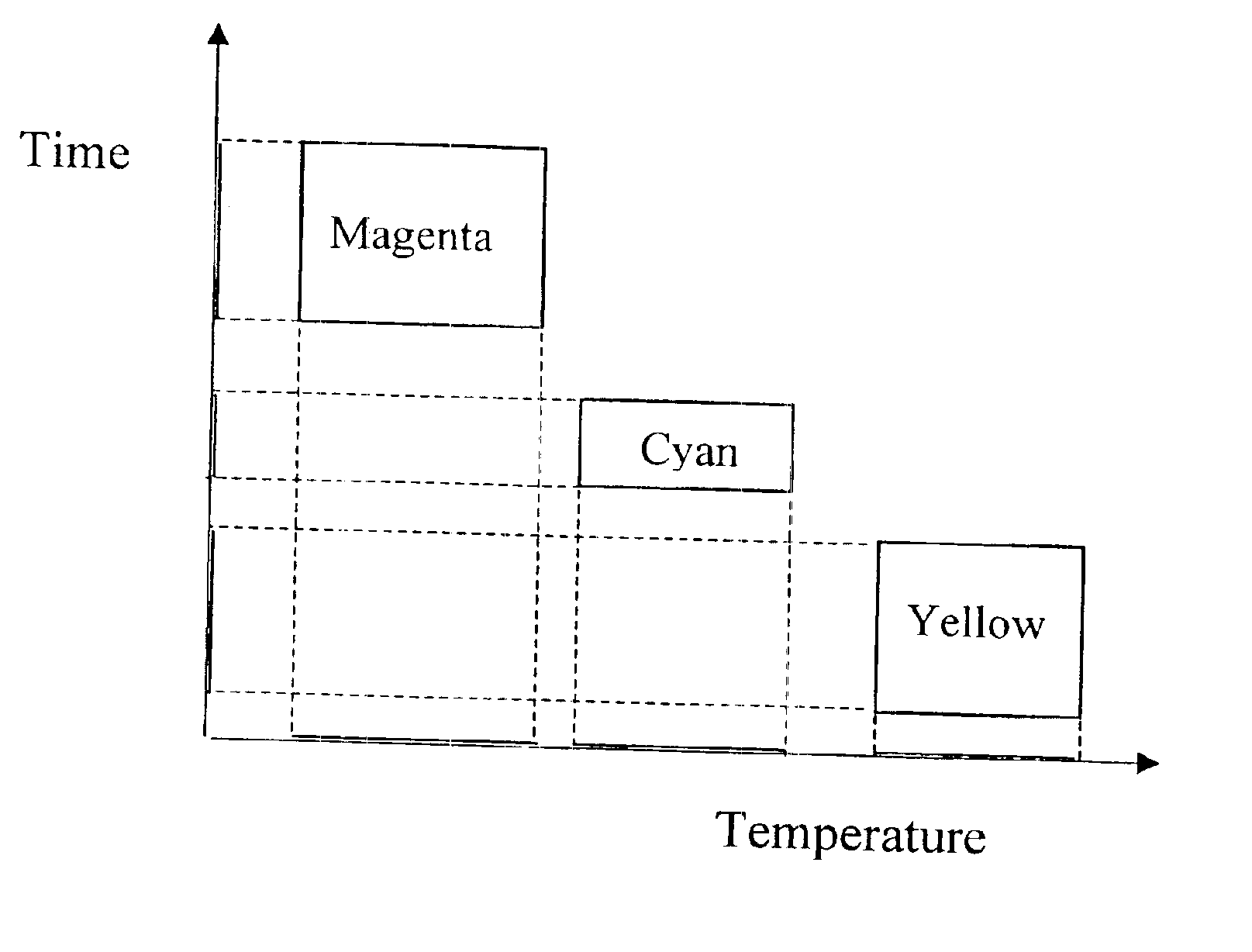

Thermal imaging system

A multicolor imaging system is described wherein at least two, and preferably three, different image-fonning layers of a thermal imaging member are addressed at least partially independently by a thermal printhead or printheads from the same surface of the imaging member by controlling the temperature of the thermal printhead(s) and the time thermal energy is applied to the image-forming layers. Each color of the thermal imaging member can be printed alone or in selectable proportion to the other color(s). Novel thermal imaging members are also described.

Owner:ZINK IMAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com