Patents

Literature

72results about How to "Increase deflection angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

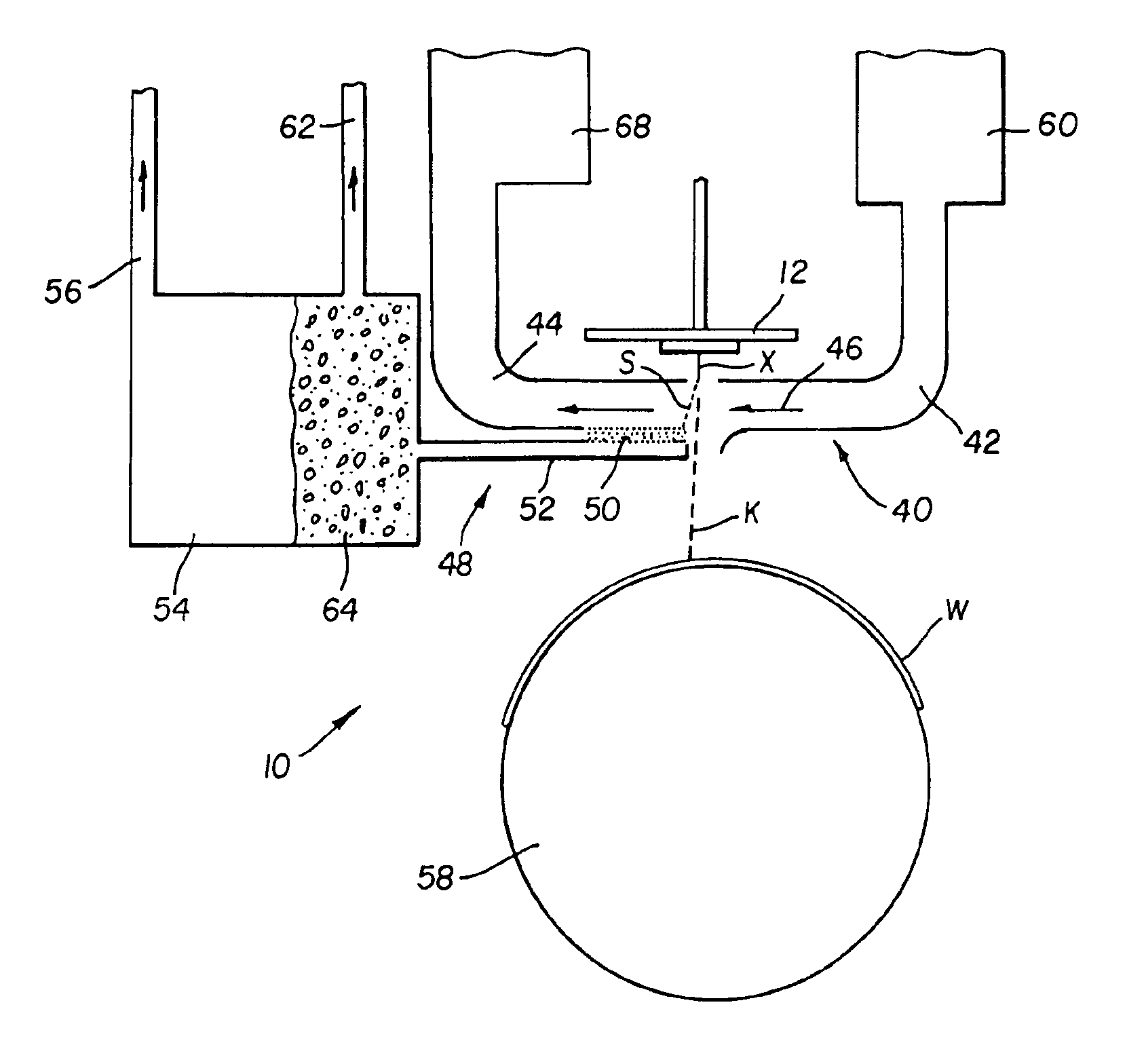

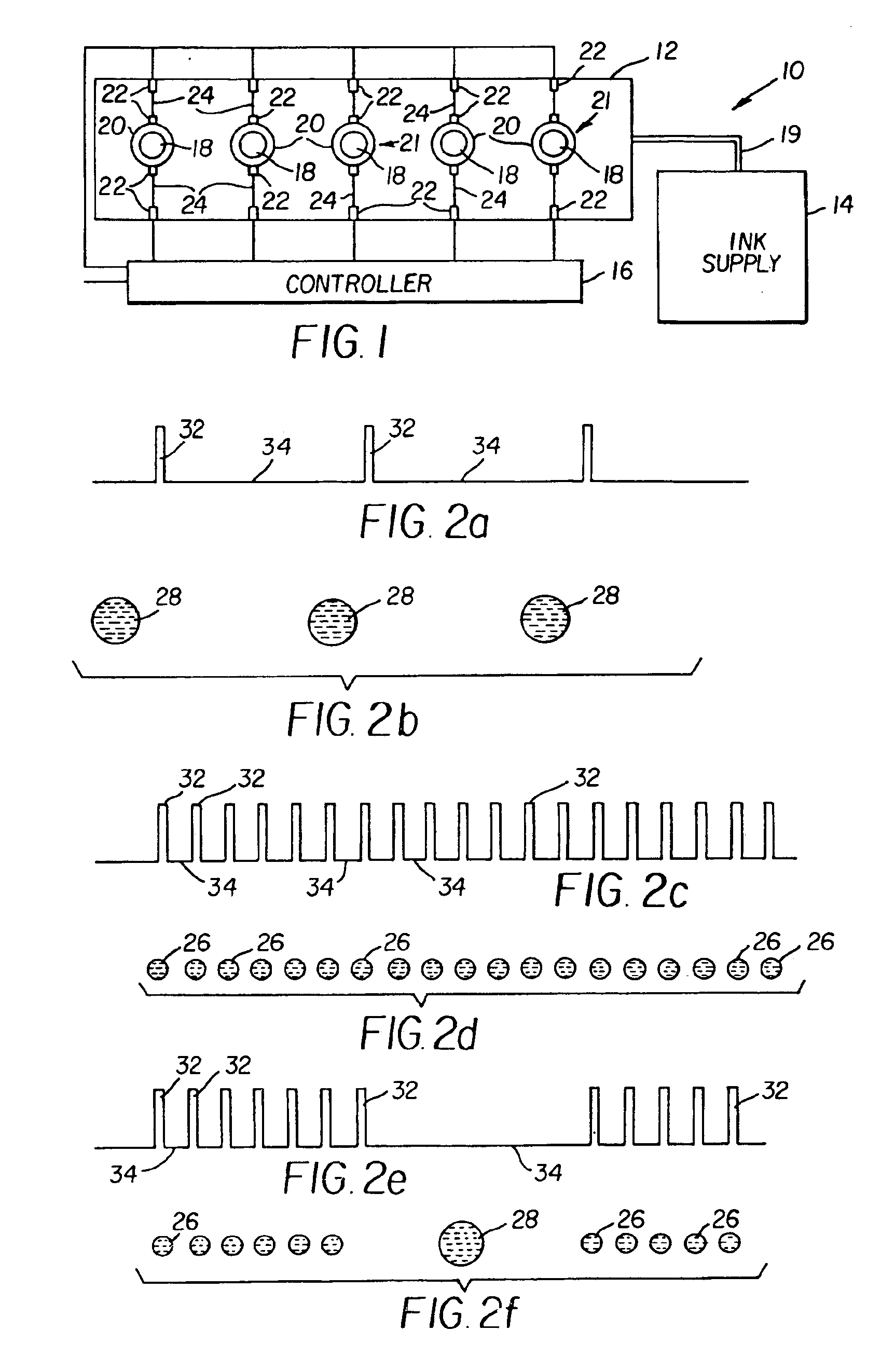

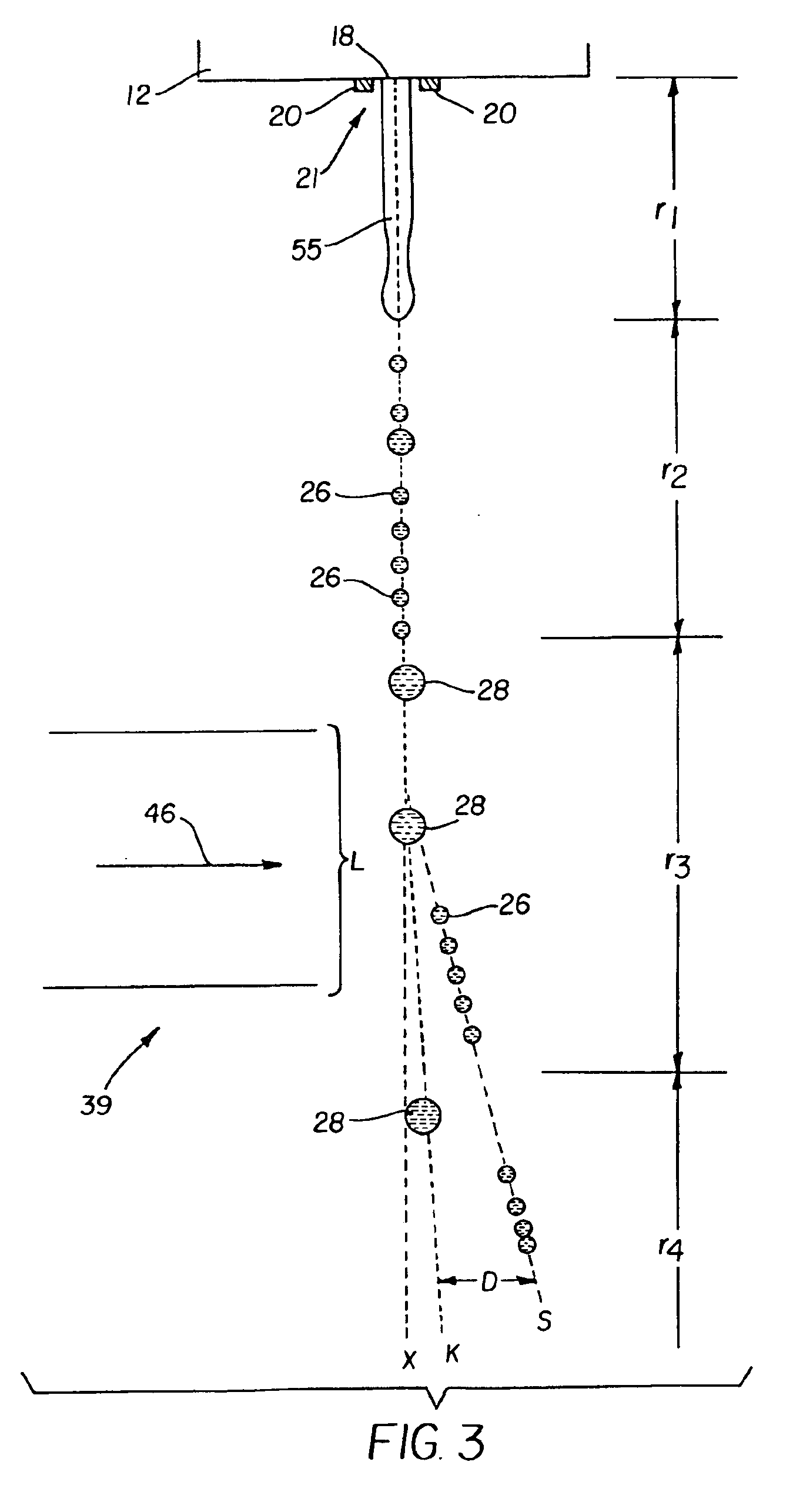

Continuous ink-jet printing apparatus having an improved droplet deflector and catcher

InactiveUS6851796B2Increase deflection angleGood removal effectInking apparatusEngineeringMechanical engineering

An apparatus for printing an image is provided. The apparatus includes an ink droplet forming mechanism operable to selectively create a stream of ink droplets having a plurality of volumes traveling along a first path. A droplet deflector is positioned at an angle with respect to the stream of ink droplets. The droplet deflector includes a gas flow operable to interact with the stream of ink droplets such that ink droplets having one of the plurality of volumes begin traveling along a second path and ink droplets having another of the plurality of volumes begin traveling along a third path. At least a portion of a catcher including a porous material is at least partially positioned in one of the first, second, and third paths.

Owner:EASTMAN KODAK CO

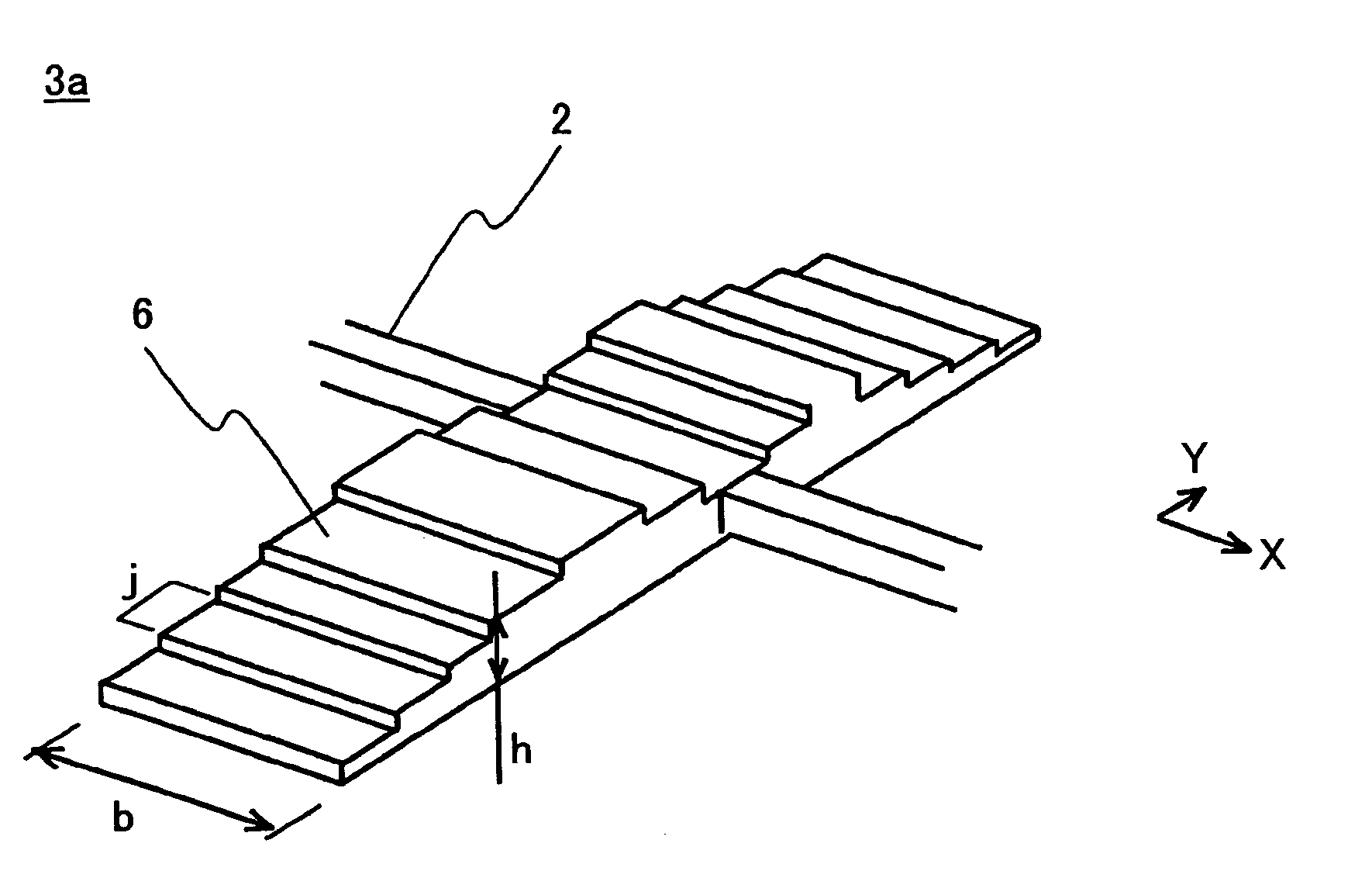

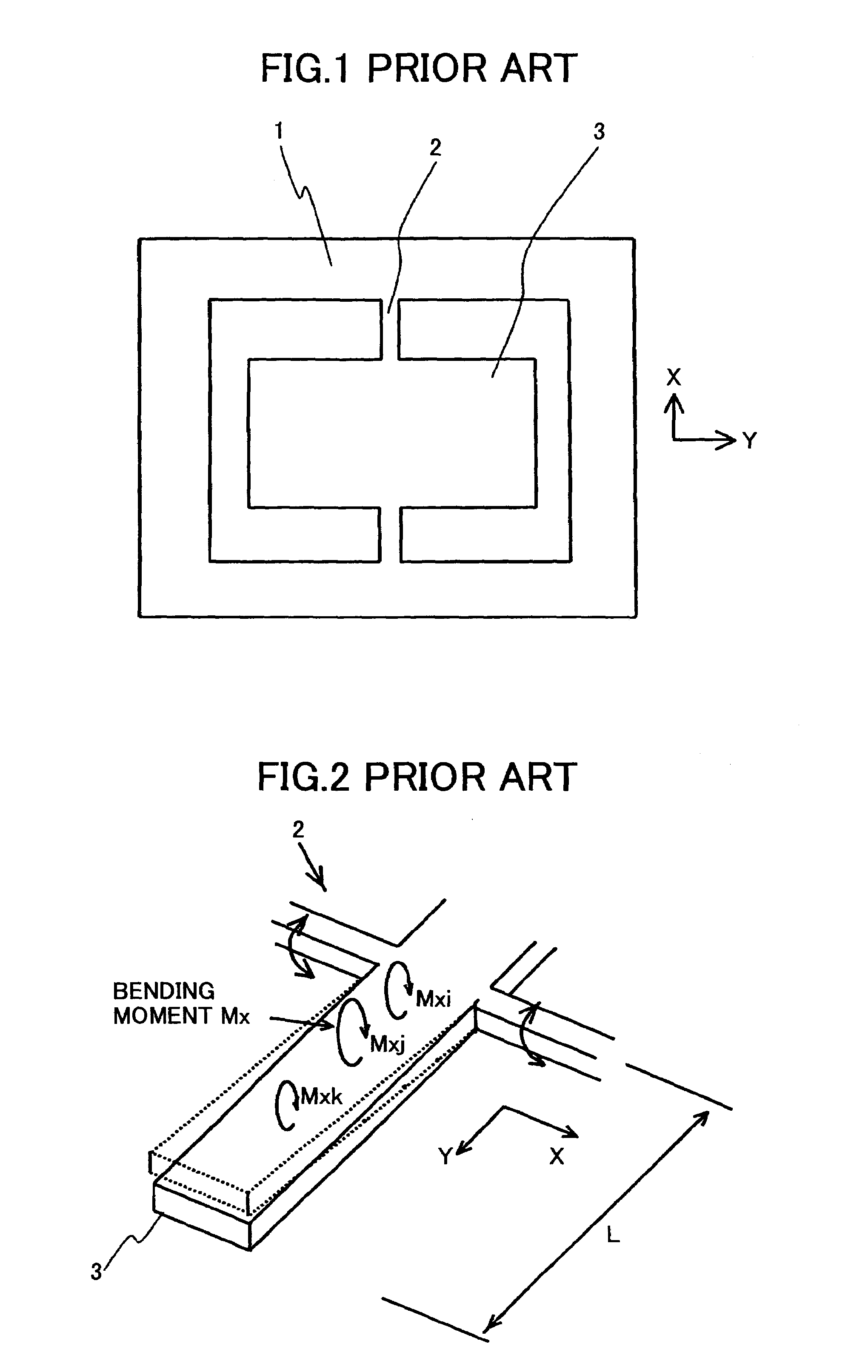

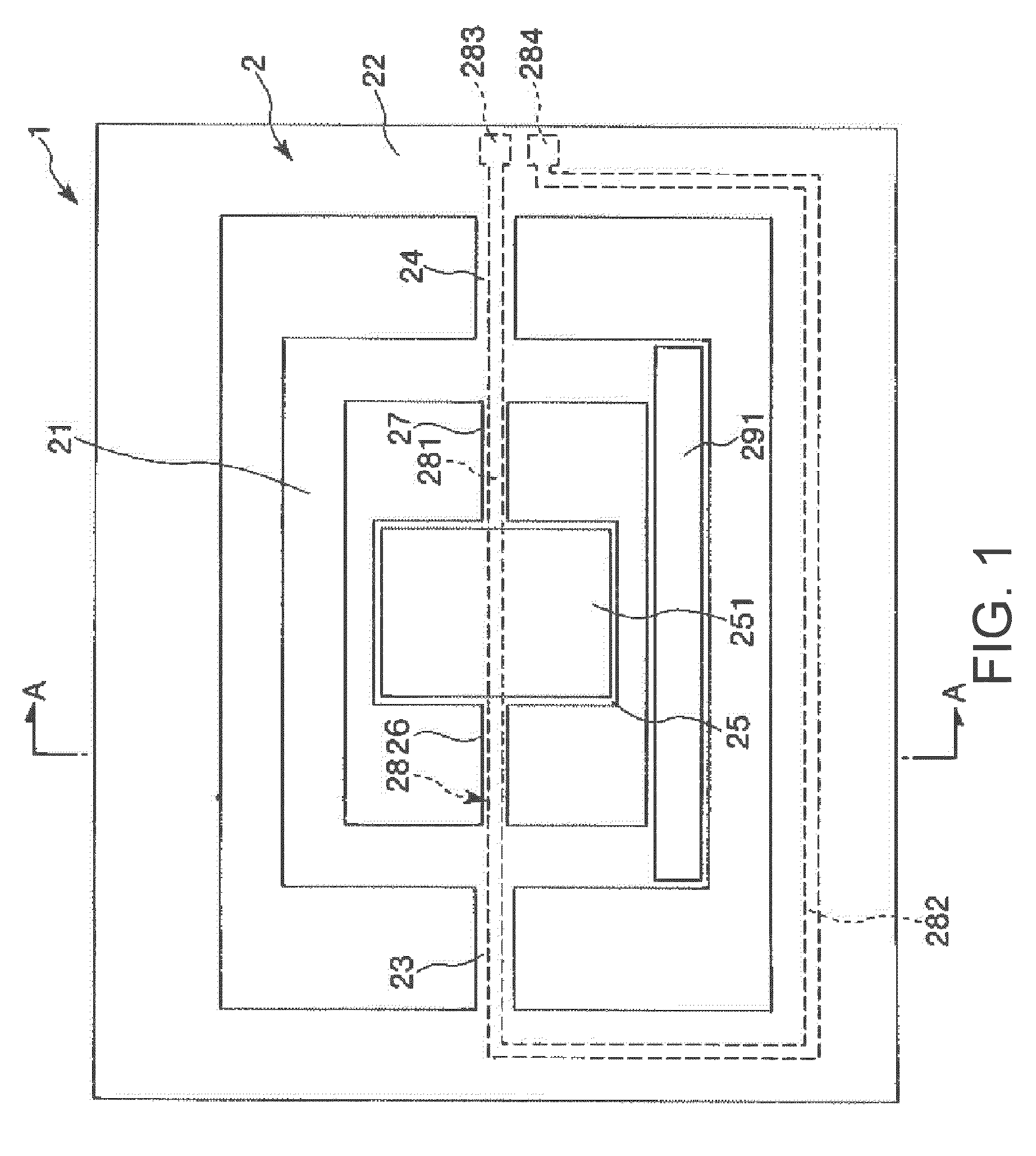

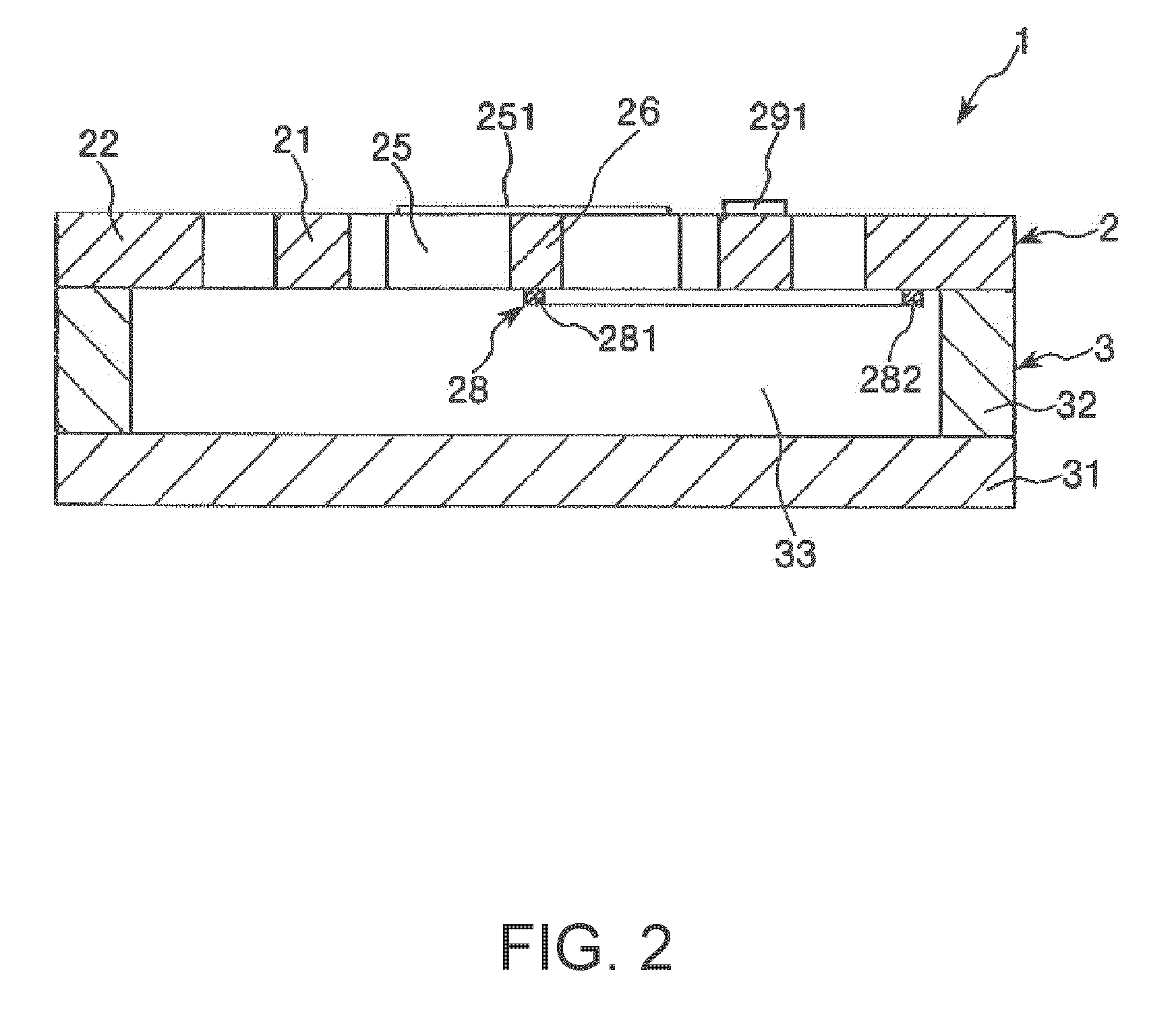

Deflector mirror, optical scanning device, and image forming apparatus

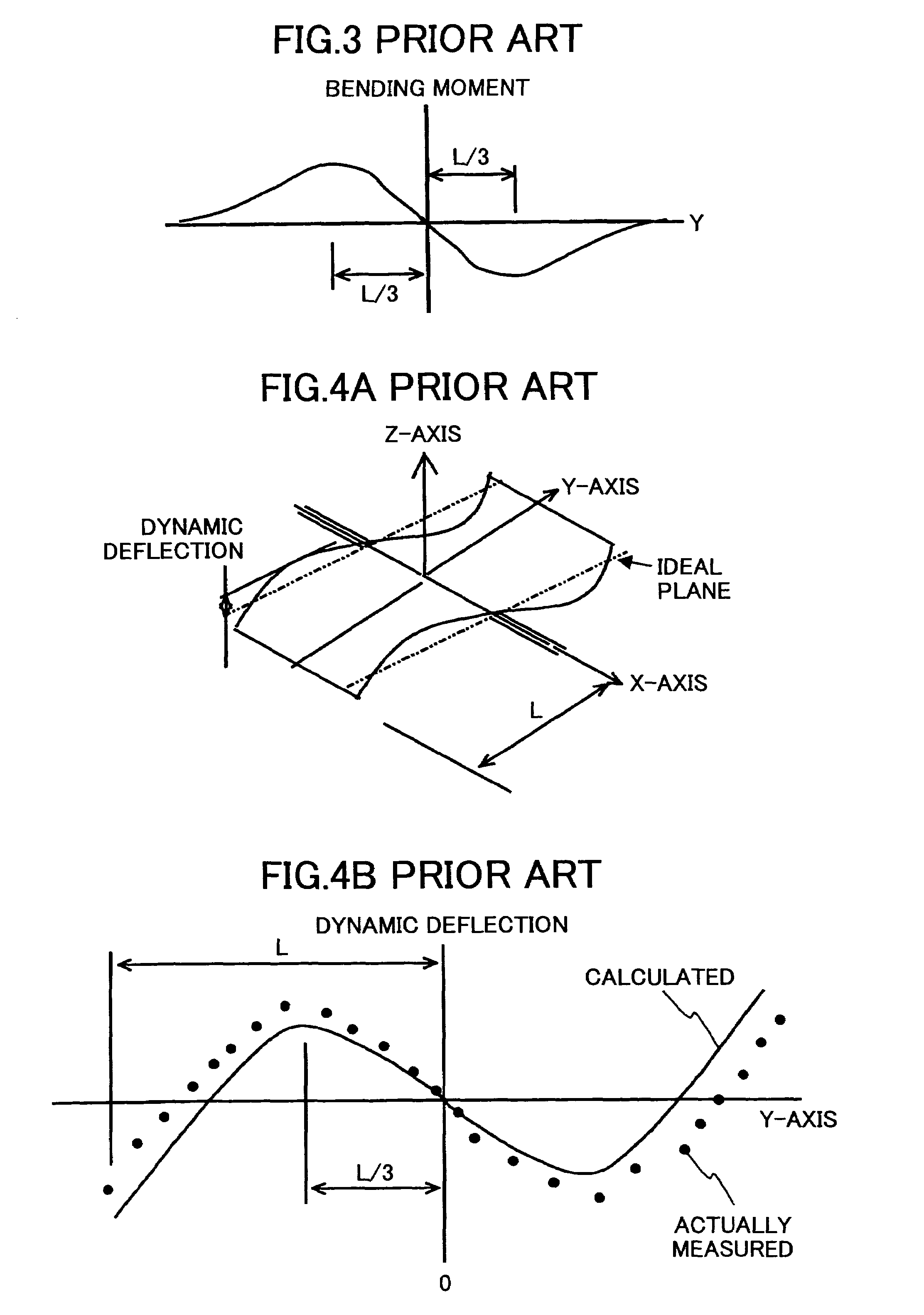

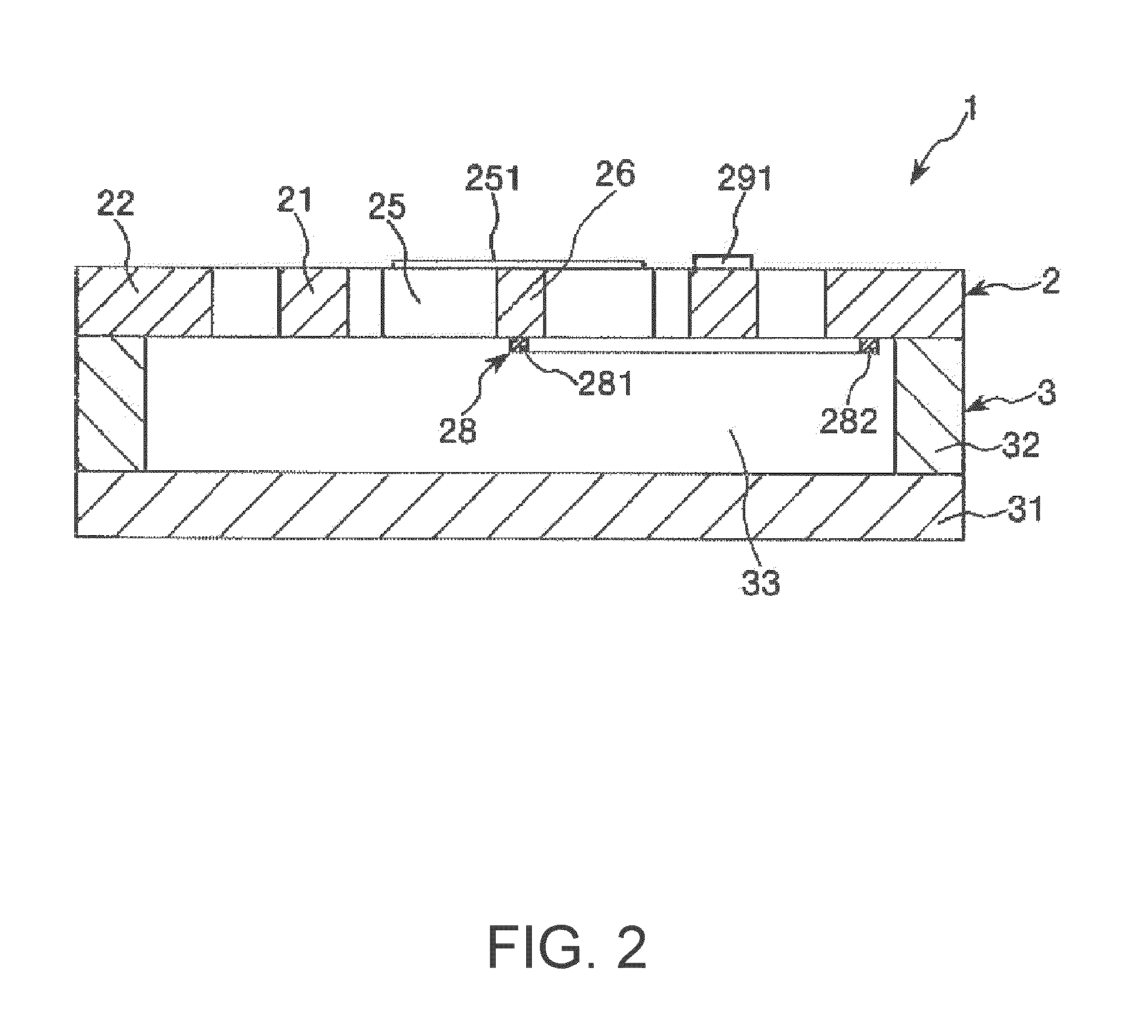

ActiveUS20050243396A1Superior in silence and power savingExcellent characteristicInking apparatusMirrorsFlexural rigidityRotational axis

A deflector mirror is disclosed that includes a mirror substrate configured to vibrate in a reciprocating manner on beams as a torsional rotary shaft so as to deflect a light beam emitted from a light source. The mirror substrate includes multiple regions in each of portions thereof extending from the torsional rotary shaft to respective ends of the mirror substrate, the regions being different in flexural rigidity.

Owner:RICOH KK

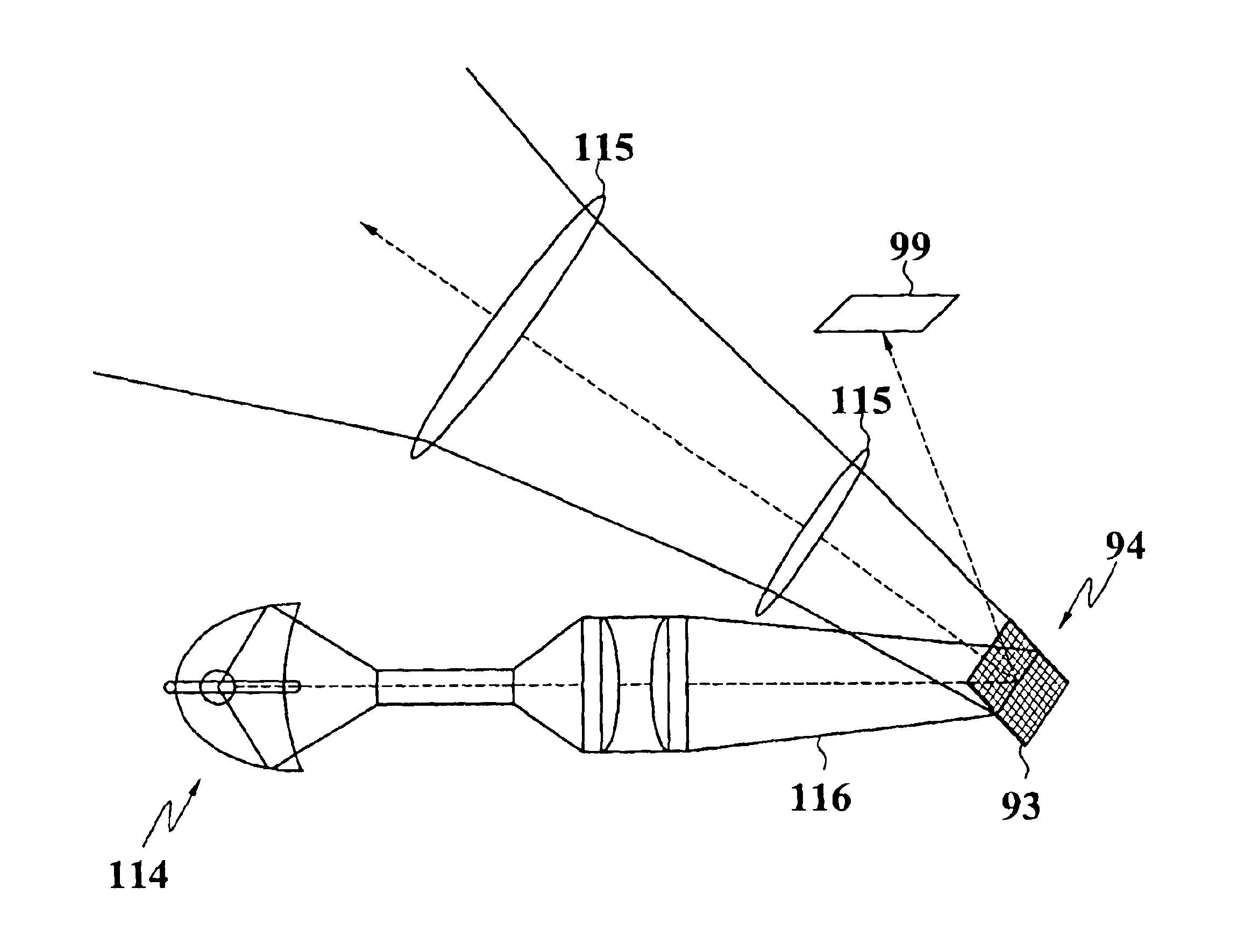

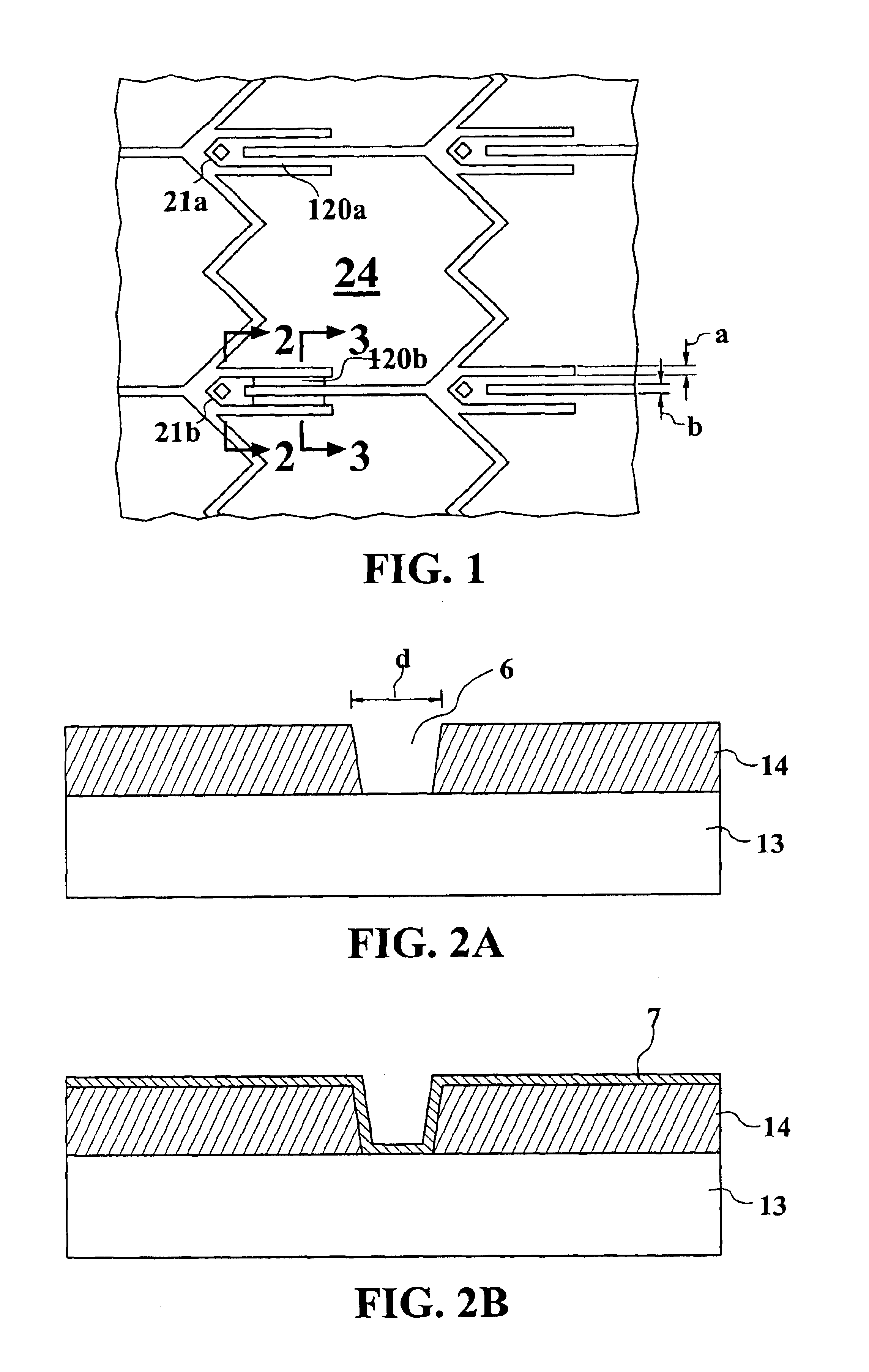

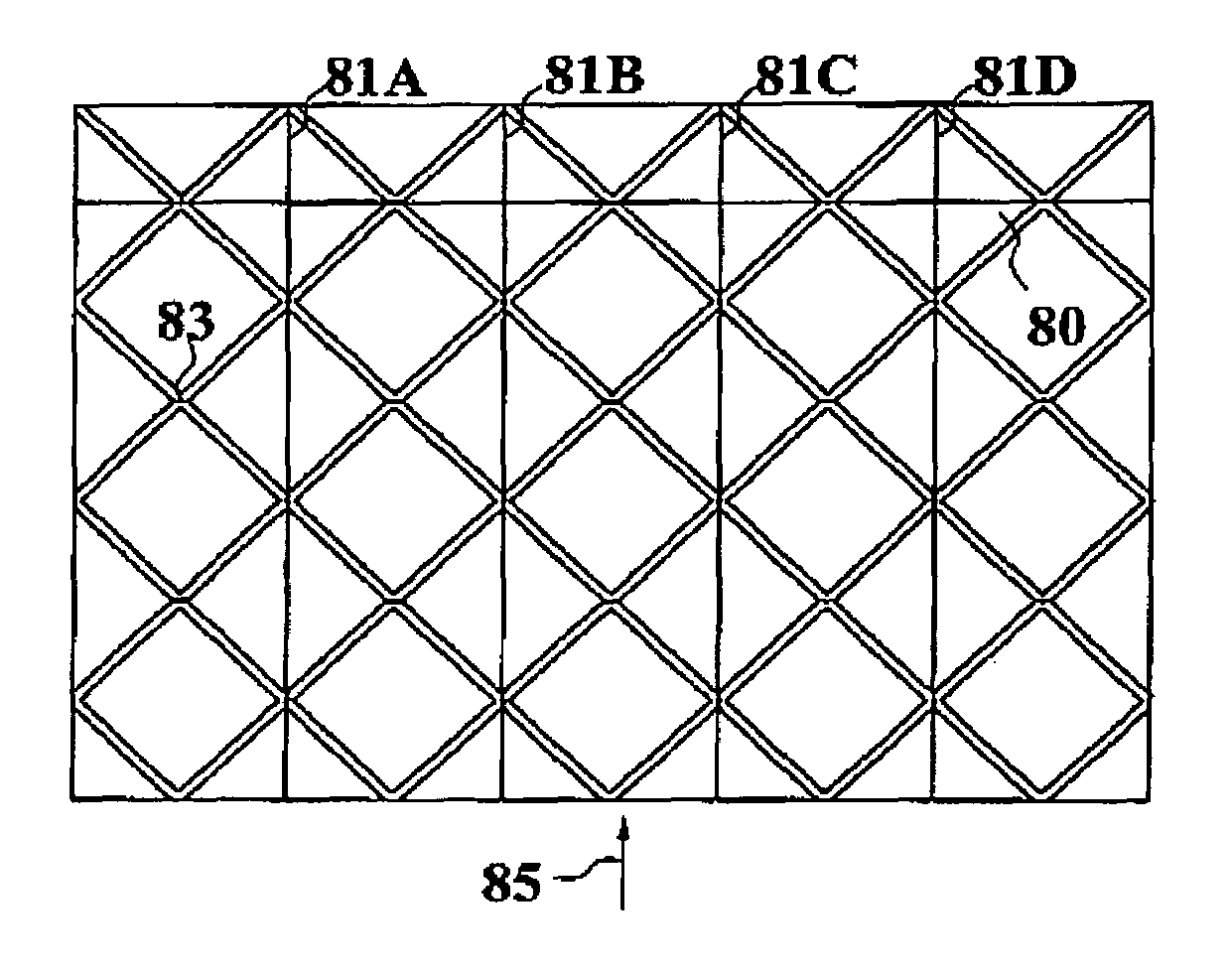

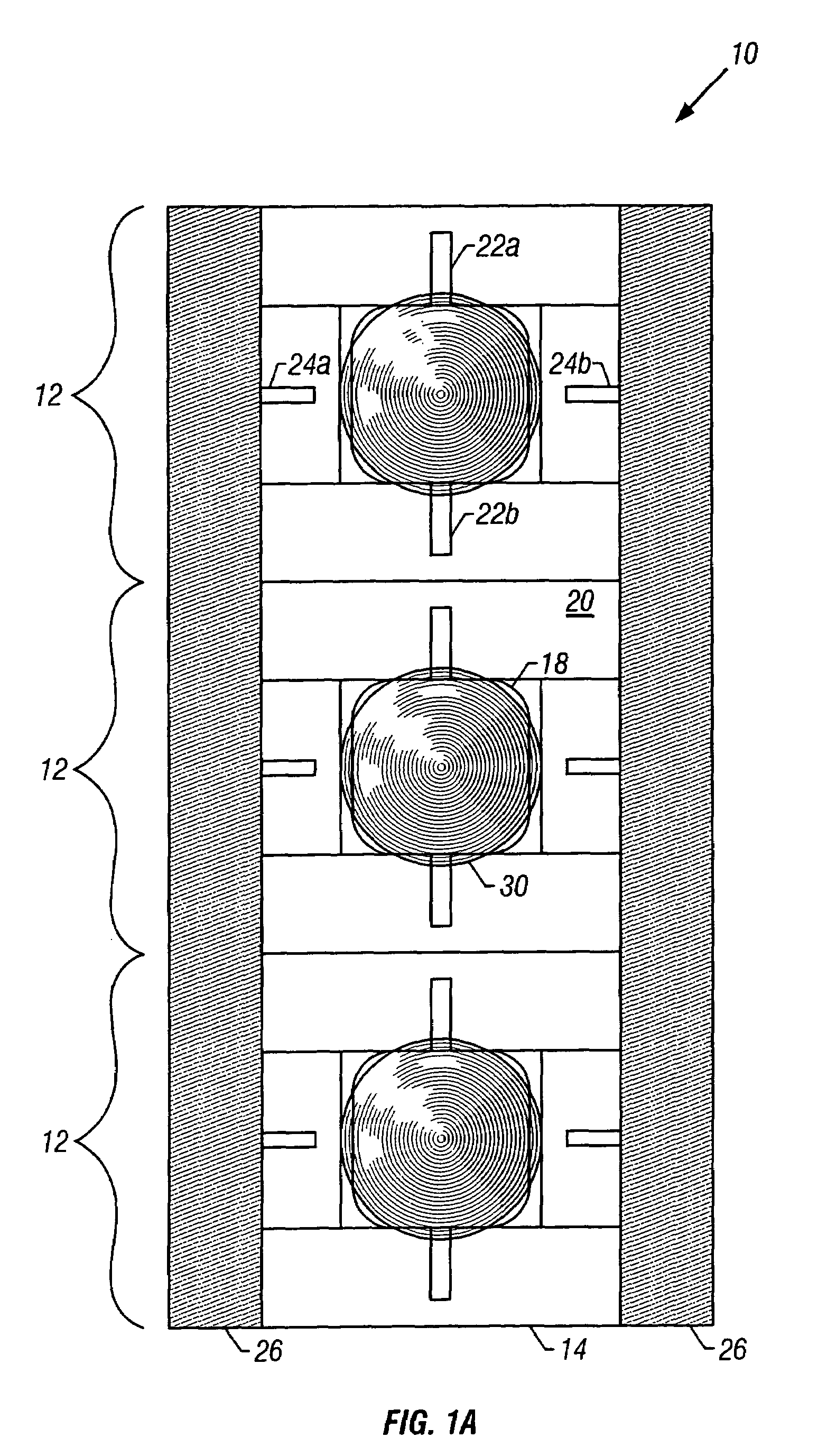

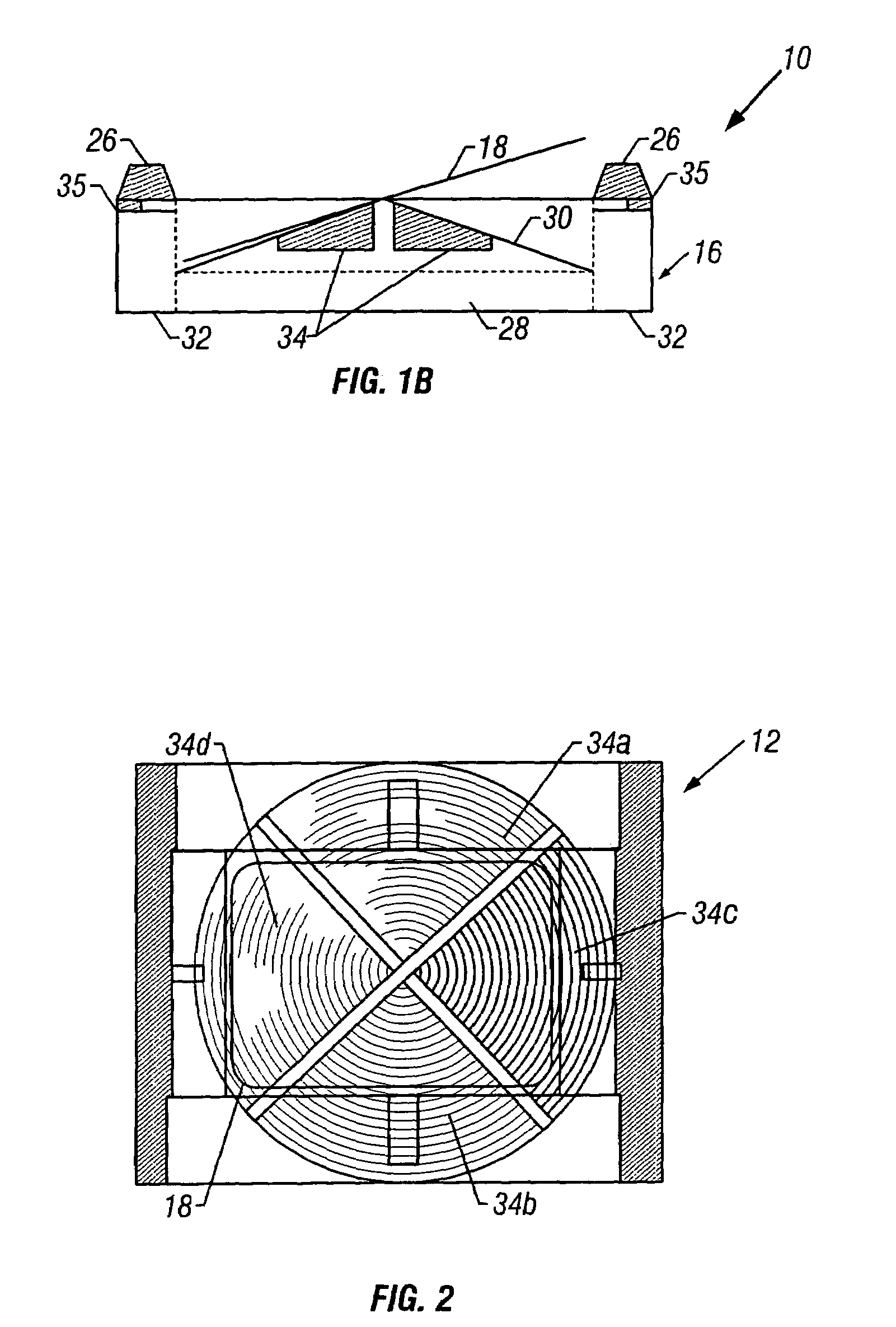

Micromirror elements, package for the micromirror elements, and projection system therefor

InactiveUS6962419B2Minimize light diffractionContrast ratio is reducedTelevision system detailsProjectorsLight beamLight diffraction

In order to minimize light diffraction along the direction of switching and more particularly light diffraction into the acceptance cone of the collection optics, in the present invention, micromirrors are provided which are not rectangular. Also, in order to minimize the cost of the illumination optics and the size of the display unit of the present invention, the light source is placed orthogonal to the rows (or columns) of the array, and / or the light source is placed orthogonal to a side of the frame defining the active area of the array. The incident light beam, though orthogonal to the sides of the active area, is not however, orthogonal to any substantial portion of sides of the individual micromirrors in the array. Orthogonal sides cause incident light to diffract along the direction of micromirror switching, and result in light ‘leakage’ into the ‘on’ state even if the micromirror is in the ‘off’ state. This light diffraction decreases the contrast ratio of the micromirror. The micromirrors of the present invention result in an improved contrast ratio, and the arrangement of the light source to micromirror array in the present invention results in a more compact system. Another feature of the invention is the ability of the micromirrors to pivot in opposite direction to on and off positions (the on position directing light to collection optics), where the movement to the on position is greater than movement to the off position. A further feature of the invention is a package for the micromirror array, the package having a window that is not parallel to the substrate upon which the micromirrors are formed. One example of the invention includes all the above features.

Owner:VENTURE LENDING & LEASING IV +1

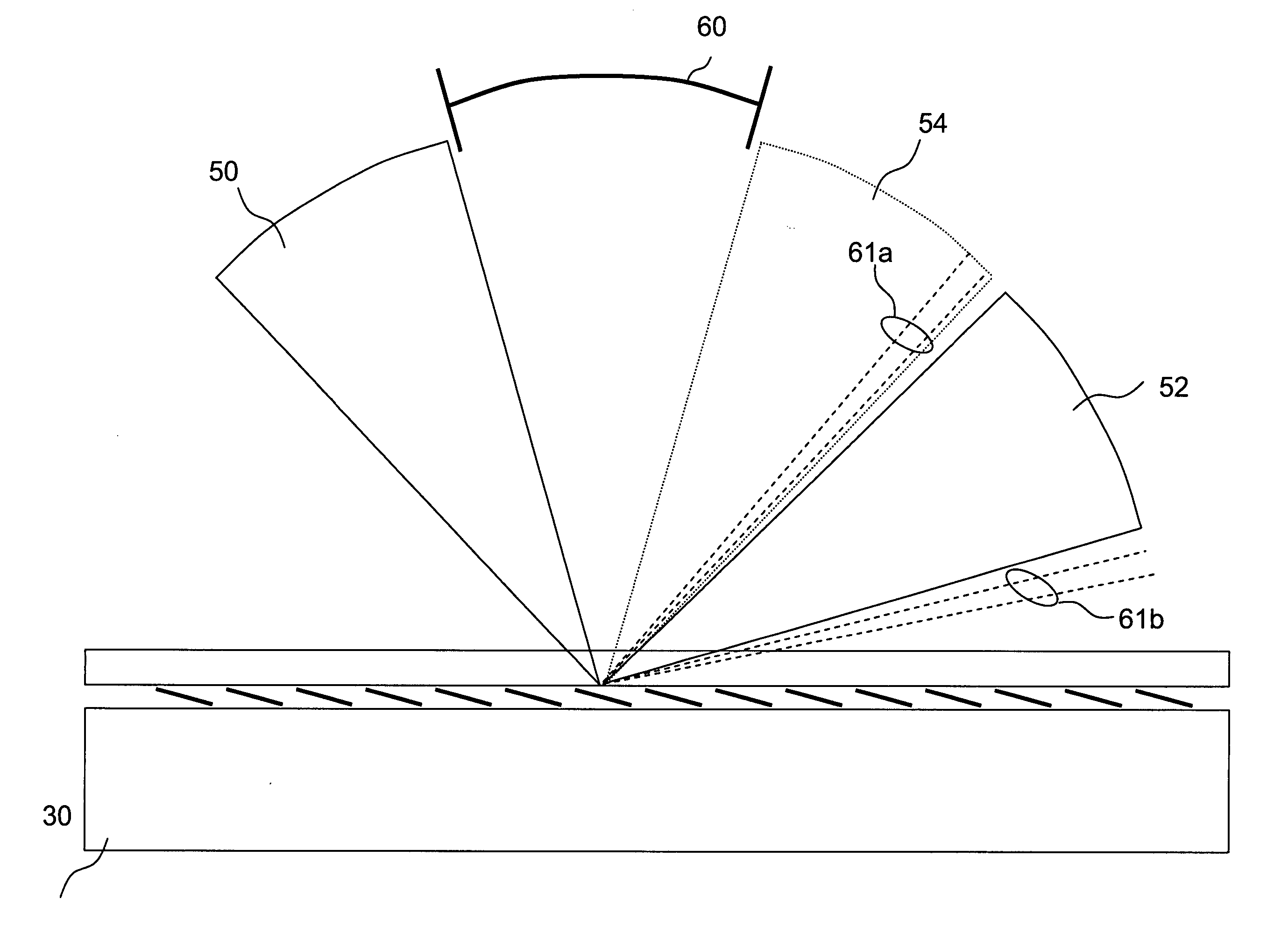

Projection display

InactiveUS20050030490A1Low costReduce the ratioTelevision system detailsProjectorsLight beamLight diffraction

In order to minimize light diffraction along the direction of switching and more particularly light diffraction into the acceptance cone of the collection optics, in the present invention, micromirrors are provided which are not rectangular. Also, in order to minimize the cost of the illumination optics and the size of the display unit of the present invention, the light source is placed orthogonal to the rows (or columns) of the array, and / or the light source is placed orthogonal to a side of the frame defining the active area of the array. The incident light beam, though orthogonal to the sides of the active area, is not however, orthogonal to any substantial portion of sides of the individual micromirrors in the array. Orthogonal sides cause incident light to diffract along the direction of micromirror switching, and result in light ‘leakage’ into the ‘on’ state even if the micromirror is in the ‘off’ state. This light diffraction decreases the contrast ratio of the micromirror. The micromirrors of the present invention result in an improved contrast ratio, and the arrangement of the light source to micromirror array in the present invention results in a more compact system. Another feature of the invention is the ability of the micromirrors to pivot in opposite direction to on and off positions (the on position directing light to collection optics), where the movement to the on position is greater than movement to the off position. A further feature of the invention is a package for the micromirror array, the package having a window that is not parallel to the substrate upon which the micromirrors are formed. One example of the invention includes all the above features.

Owner:TEXAS INSTR INC +1

Rear projection TV with improved micromirror array

InactiveUS20050007557A1Minimize light diffractionContrast ratio is reducedTelevision system detailsProjectorsLight beamLight diffraction

In order to minimize light diffraction along the direction of switching and more particularly light diffraction into the acceptance cone of the collection optics, in the present invention, micromirrors are provided which are not rectangular. Also, in order to minimize the cost of the illumination optics and the size of the display unit of the present invention, the light source is placed orthogonal to the rows (or columns) of the array, and / or the light source is placed orthogonal to a side of the frame defining the active area of the array. The incident light beam, though orthogonal to the sides of the active area, is not however, orthogonal to any substantial portion of sides of the individual micromirrors in the array. Orthogonal sides cause incident light to diffract along the direction of micromirror switching, and result in light ‘leakage’ into the ‘on’ state even if the micromirror is in the ‘off’ state. This light diffraction decreases the contrast ratio of the micromirror. The micromirrors of the present invention result in an improved contrast ratio, and the arrangement of the light source to micromirror array in the present invention results in a more compact system. Another feature of the invention is the ability of the micromirrors to pivot in opposite direction to on and off positions (the on position directing light to collection optics), where the movement to the on position is greater than movement to the off position. A further feature of the invention is a package for the micromirror array, the package having a window that is not parallel to the substrate upon which the micromirrors are formed. One example of the invention includes all the above features.

Owner:VENTURE LENDING & LEASING IV +1

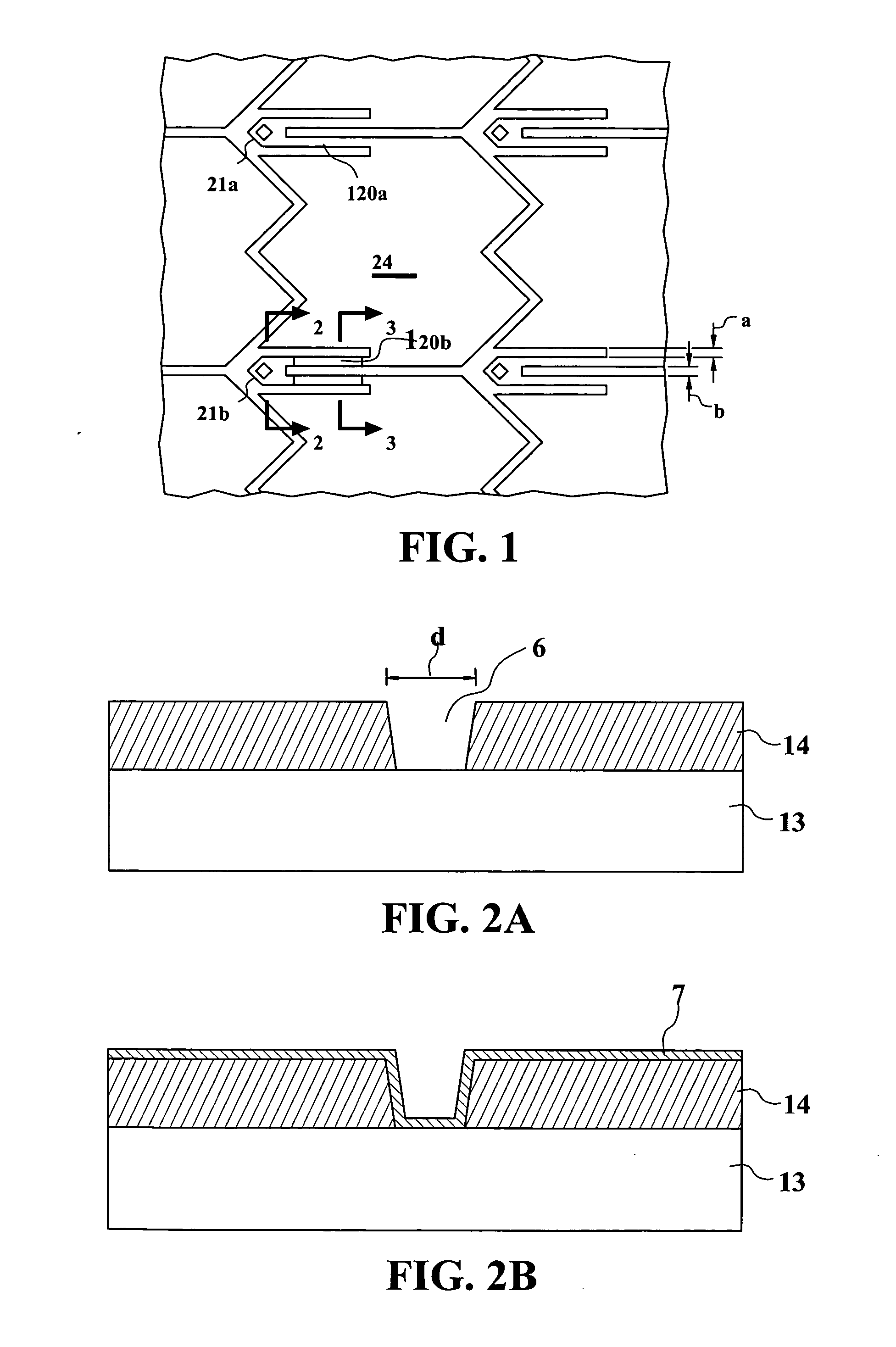

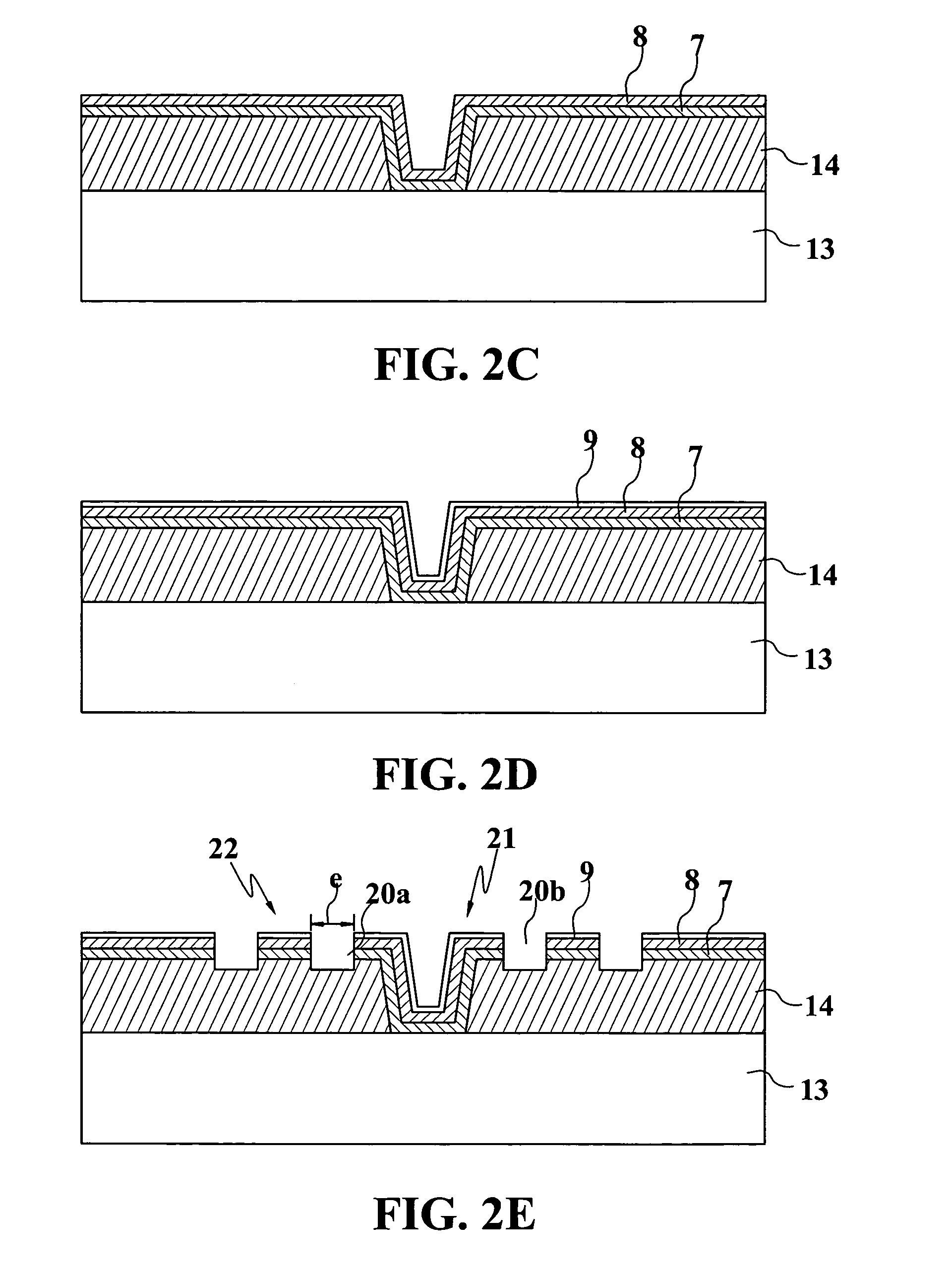

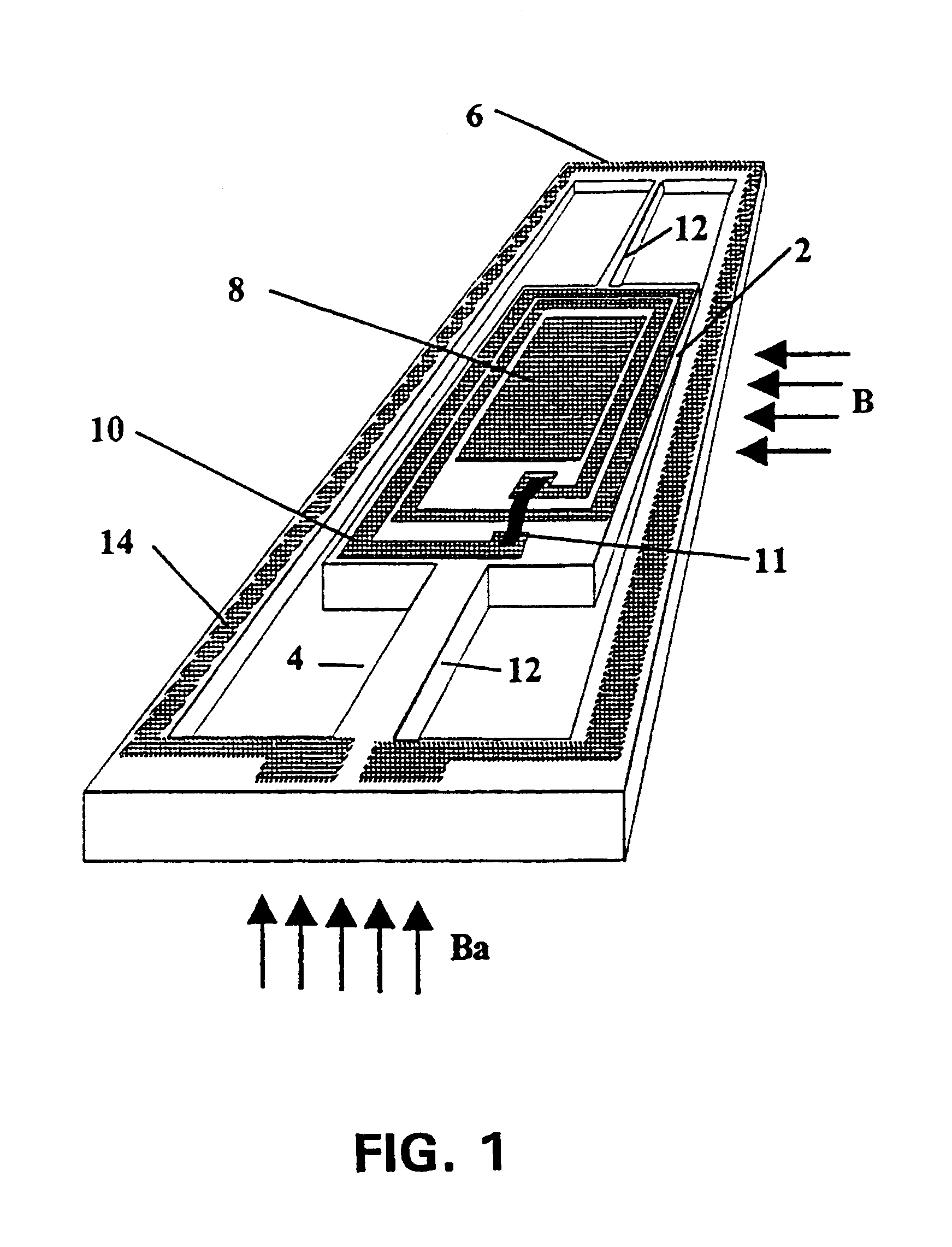

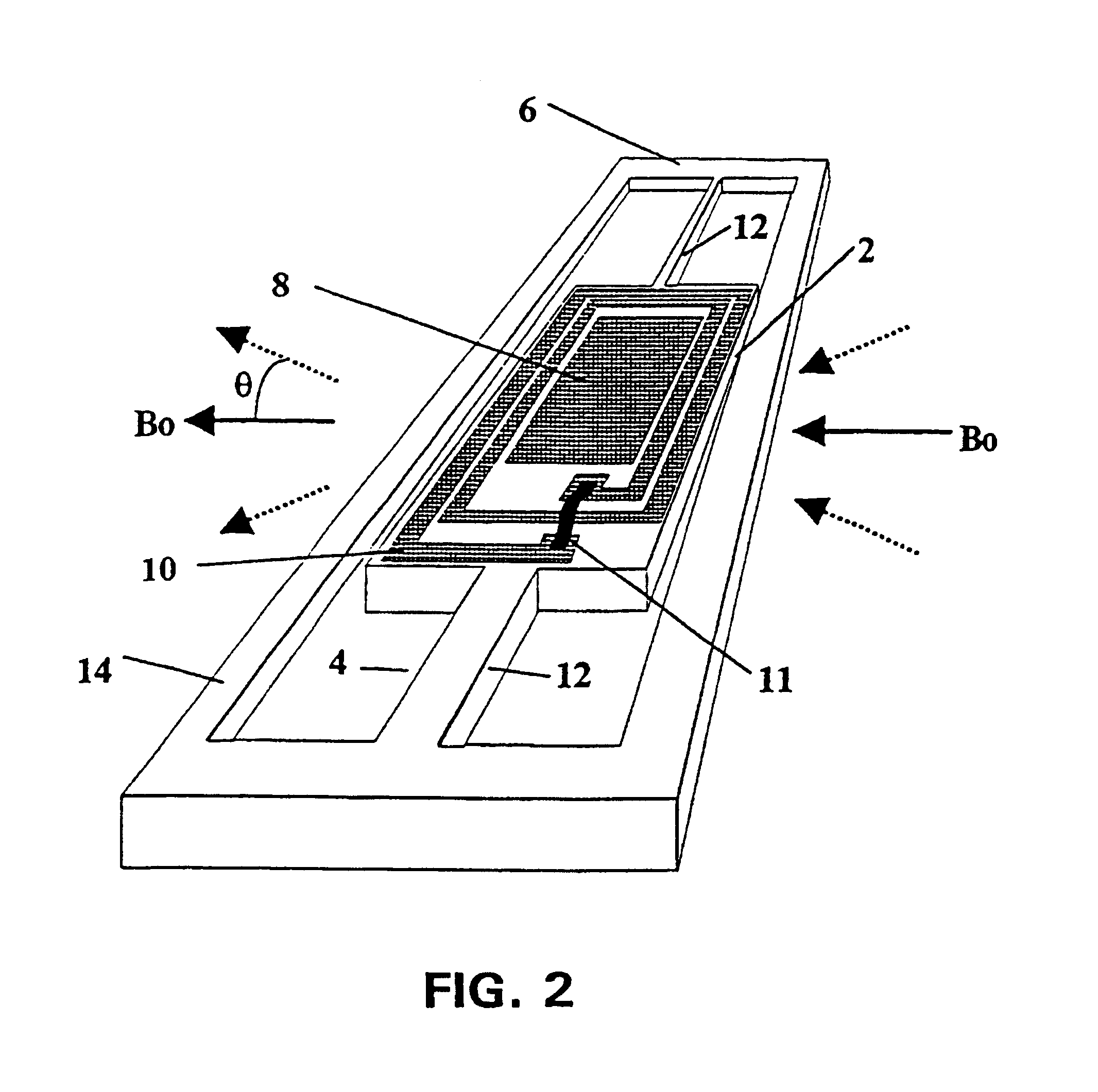

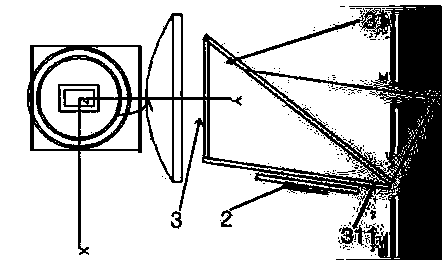

Induction microscanner

InactiveUS6285485B1Consumes less powerIncrease deflection angleDynamo-electric machinesOptical elementsControl electronicsPhysics

A micro-electromechanical scanner is disclosed for the efficient, controlled deflection of light beams. The device comprises a moving rotor, a suspension system, and a stator. The rotor comprises a closed-circuit coil and a mirror. The suspension system may be, for example, a set of torsion bars on which the rotor is mounted. The stator may be, for example, a rectangular frame holding the suspension system. When placed in a constant magnetic field and excited by an alternating magnet field, the rotor oscillates at the frequency of the alternating magnetic field, All else being equal, the highest deflection angles occur at the natural mechanical resonance frequency of the rotor-suspension combination. Compared to conventional devices, the novel device can be smaller, can be less expensive, can consume less power, and may exhibit higher deflection angles over a given time scale than other micromechanical devices operating on different actuation principles. The novel device may be used, for example, to replace the scanning devices currently used in laser printers, laser bar-code readers, and laser image projectors (e.g., large screen televisions). The control electronics may optionally be manufactured on the same device, eliminating the need for a separate controller and reducing costs.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

Deflector mirror with regions of different flexural rigidity

ActiveUS7529011B2Eliminate disadvantagesReduce deflectionInking apparatusMirrorsLight beamEngineering

A deflector mirror is disclosed that includes a mirror substrate configured to vibrate in a reciprocating manner on beams as a torsional rotary shaft so as to deflect a light beam emitted from a light source. The mirror substrate includes multiple regions in each of portions thereof extending from the torsional rotary shaft to respective ends of the mirror substrate, the regions being different in flexural rigidity.

Owner:RICOH KK

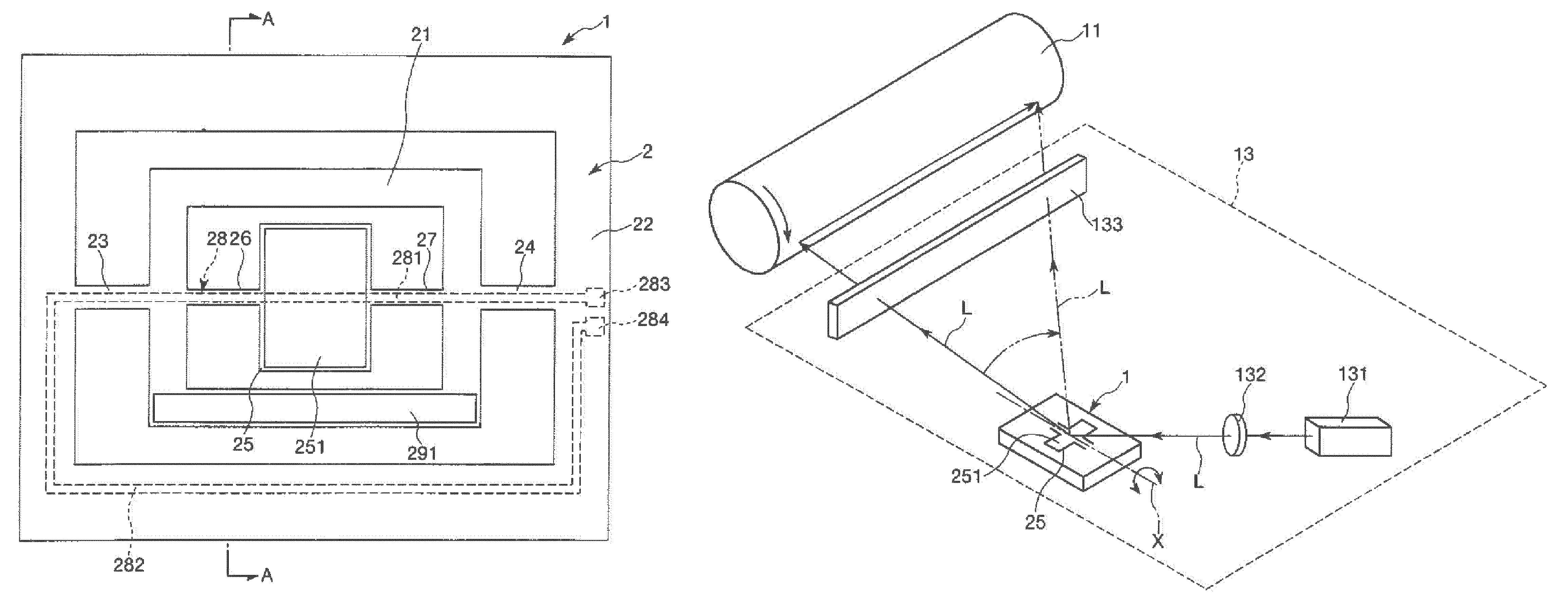

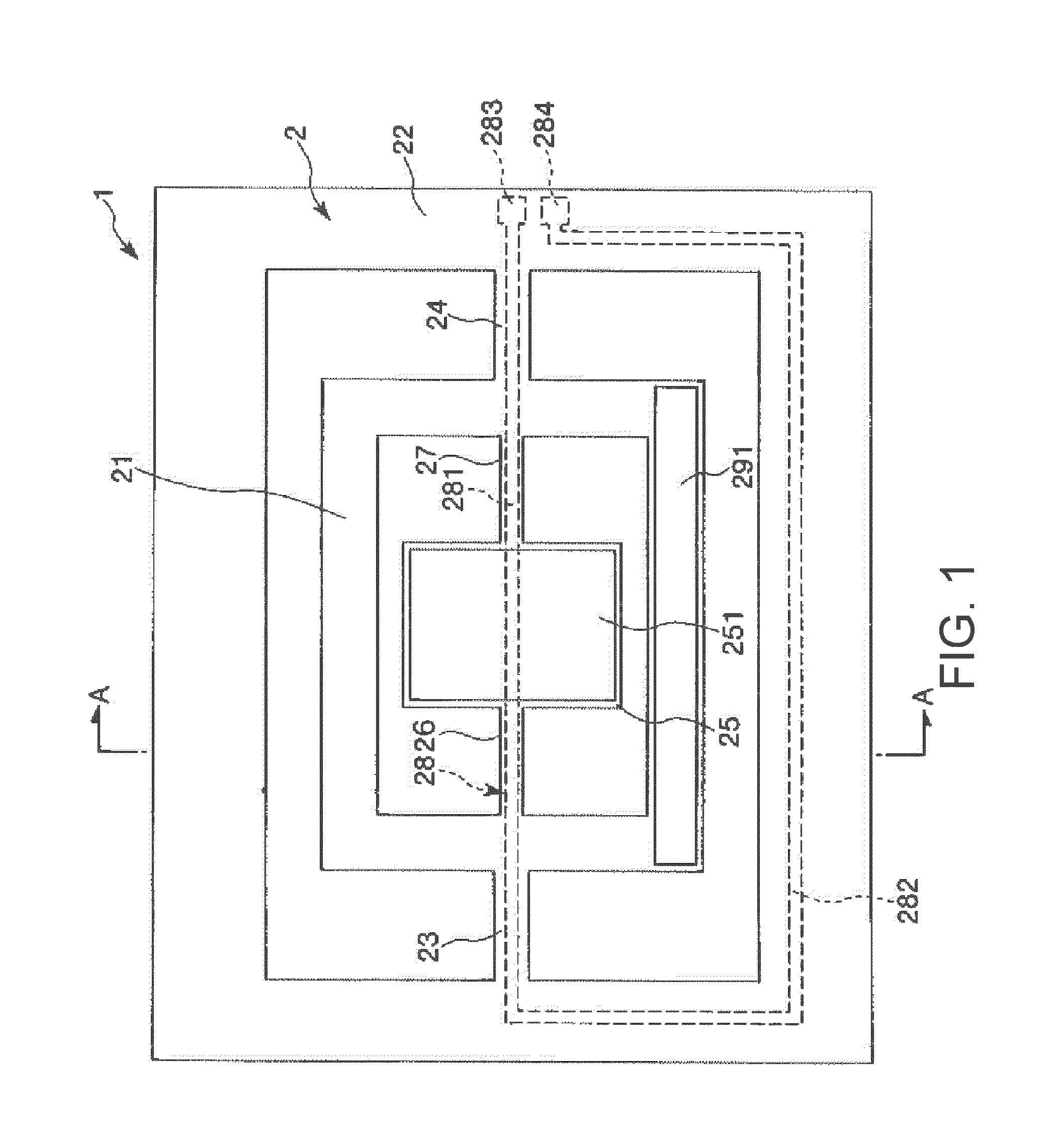

Optical deflector including piezoelectric sensor incorporated into outermost piezoelectric cantilever

ActiveUS20130301103A1Increase deflection angleEasy to controlOptical elementsMeanderPiezoelectric actuators

In an optical deflector including a mirror, a movable frame supporting the mirror, a first piezoelectric actuator for rocking the mirror with respect to a first axis of the mirror, a support body supporting the movable frame, and a second piezoelectric actuator for rocking the mirror through the movable frame with respect to a second axis of the mirror, at least one piezoelectric sensor is provided for sensing rocking vibrations of the mirror caused by the first and second piezoelectric actuators. The second piezoelectric actuator includes a pair of meander-type pieoelectric actuators opposite to each other with respect to the first axis. Each of the second meander-type piezoelectric actuators includes a plurality of piezoelectric cantilevers folded at every cantilever and connected from the support body to the movable frame in parallel with the first axis. The piezoelectric sensor is incorporated into an outermost one of the piezoelectric cantilevers.

Owner:STANLEY ELECTRIC CO LTD

Piezoelectric/electrostrictive device and method of fabricating the same

InactiveUS20020121843A1Improve reliabilityHighly dense arrangementPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersEngineeringElectrostriction

Owner:NGK INSULATORS LTD

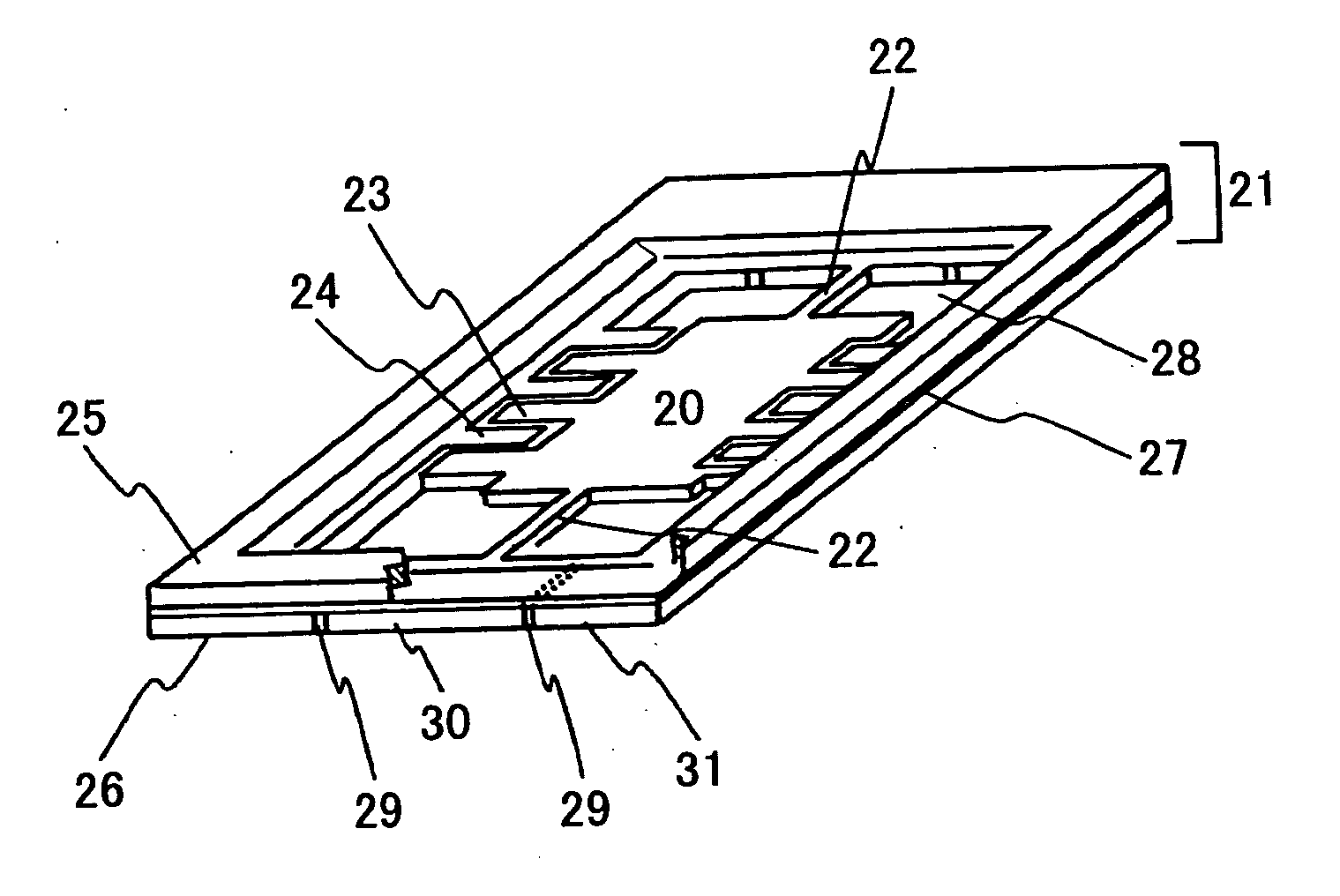

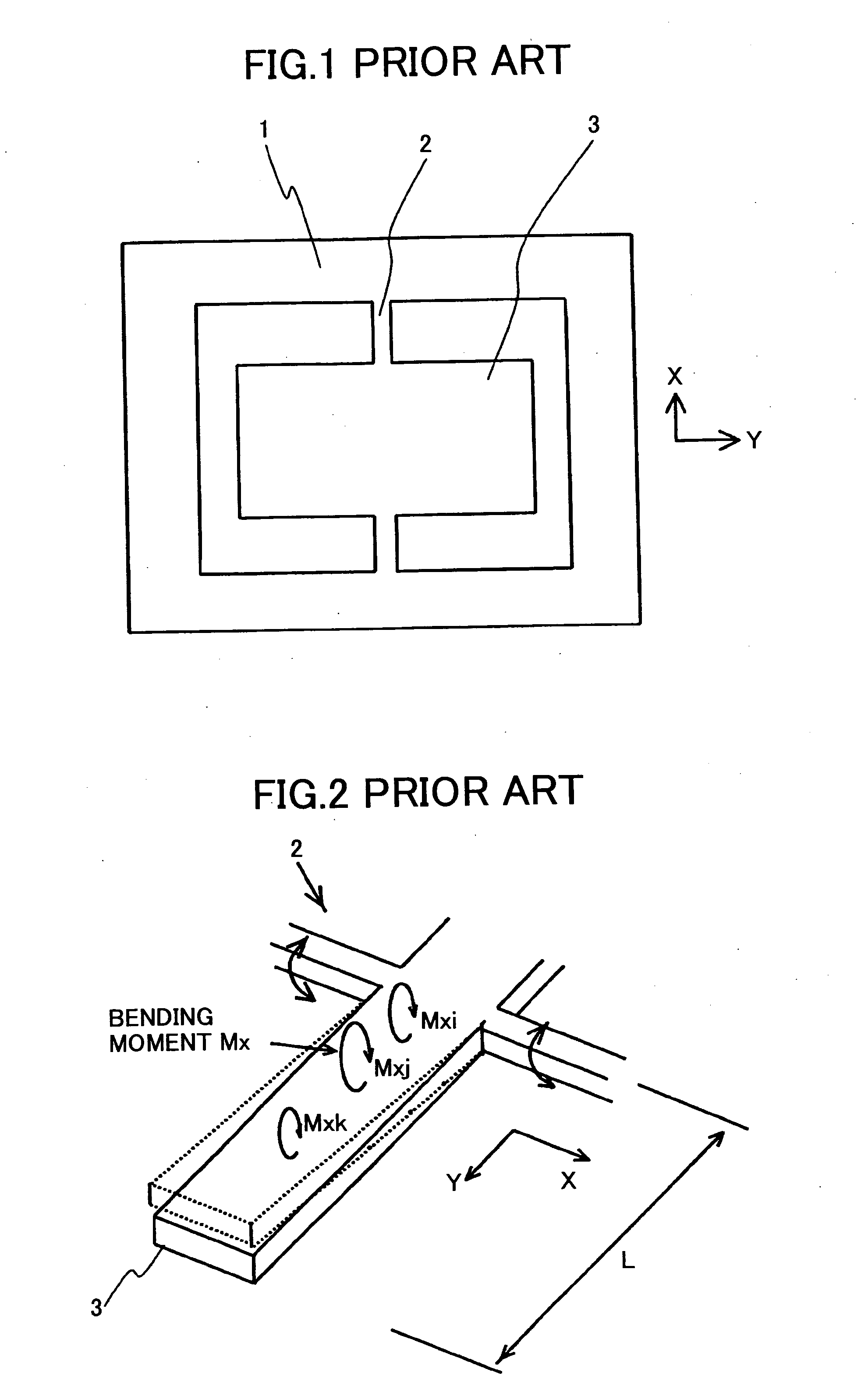

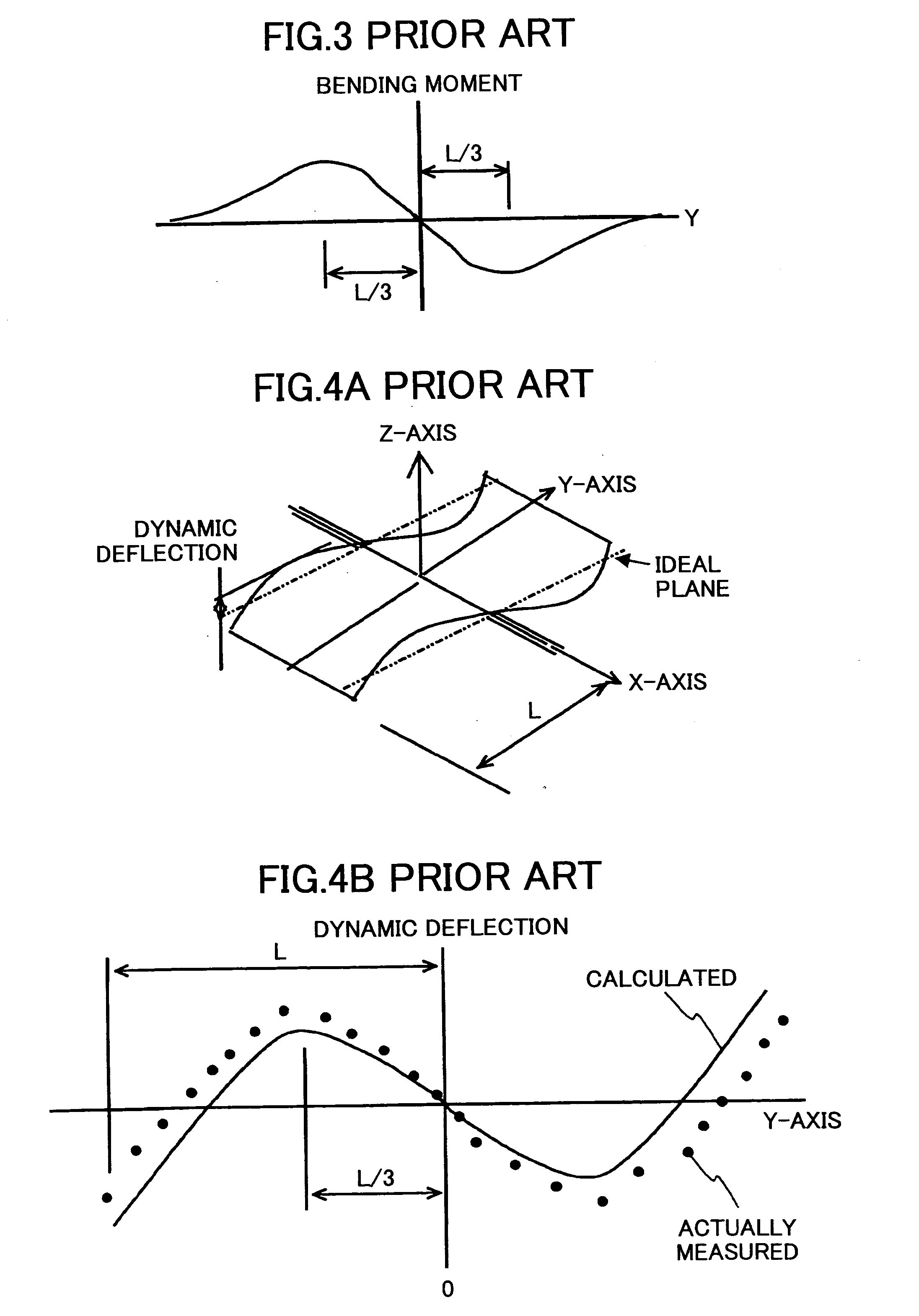

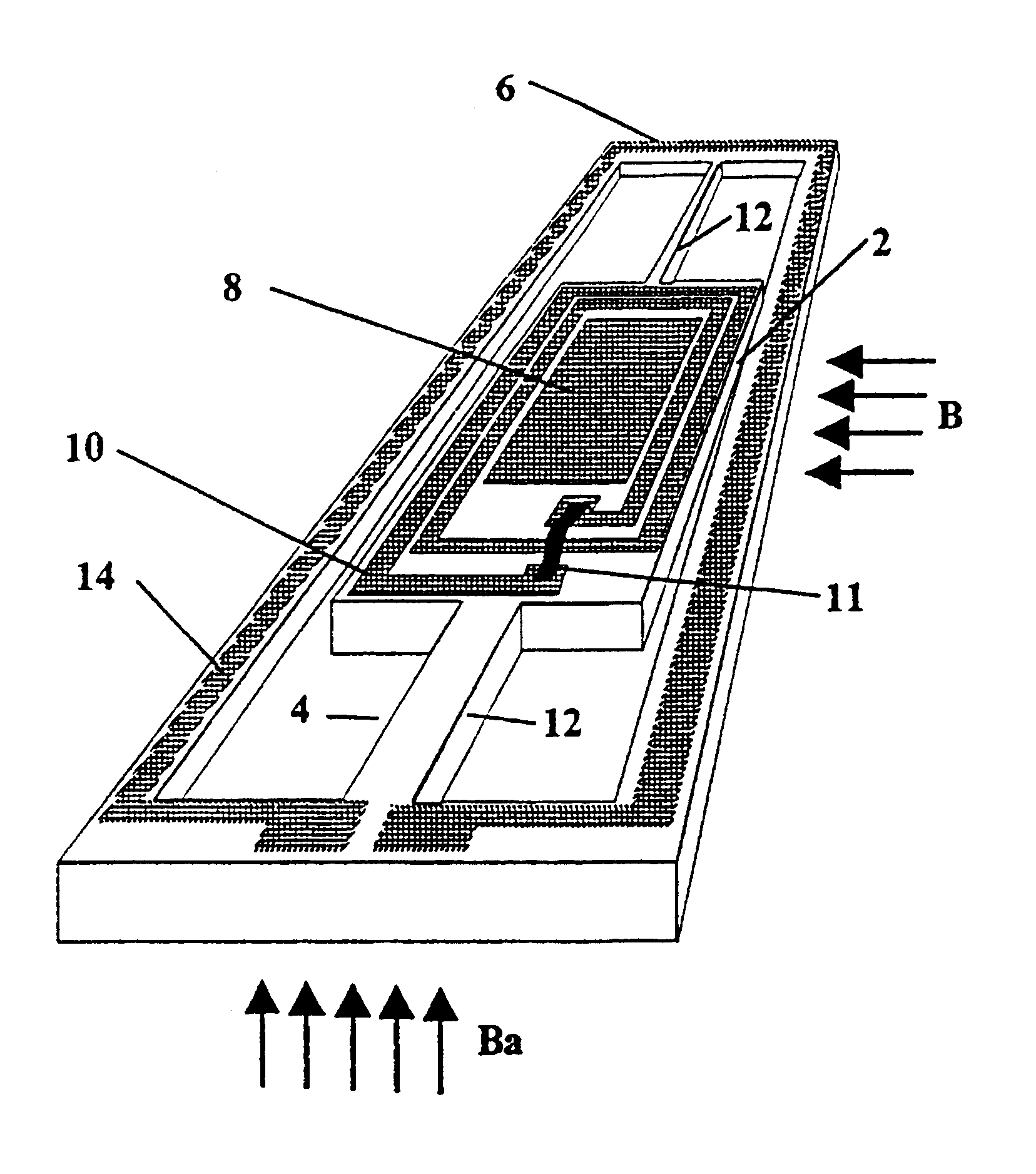

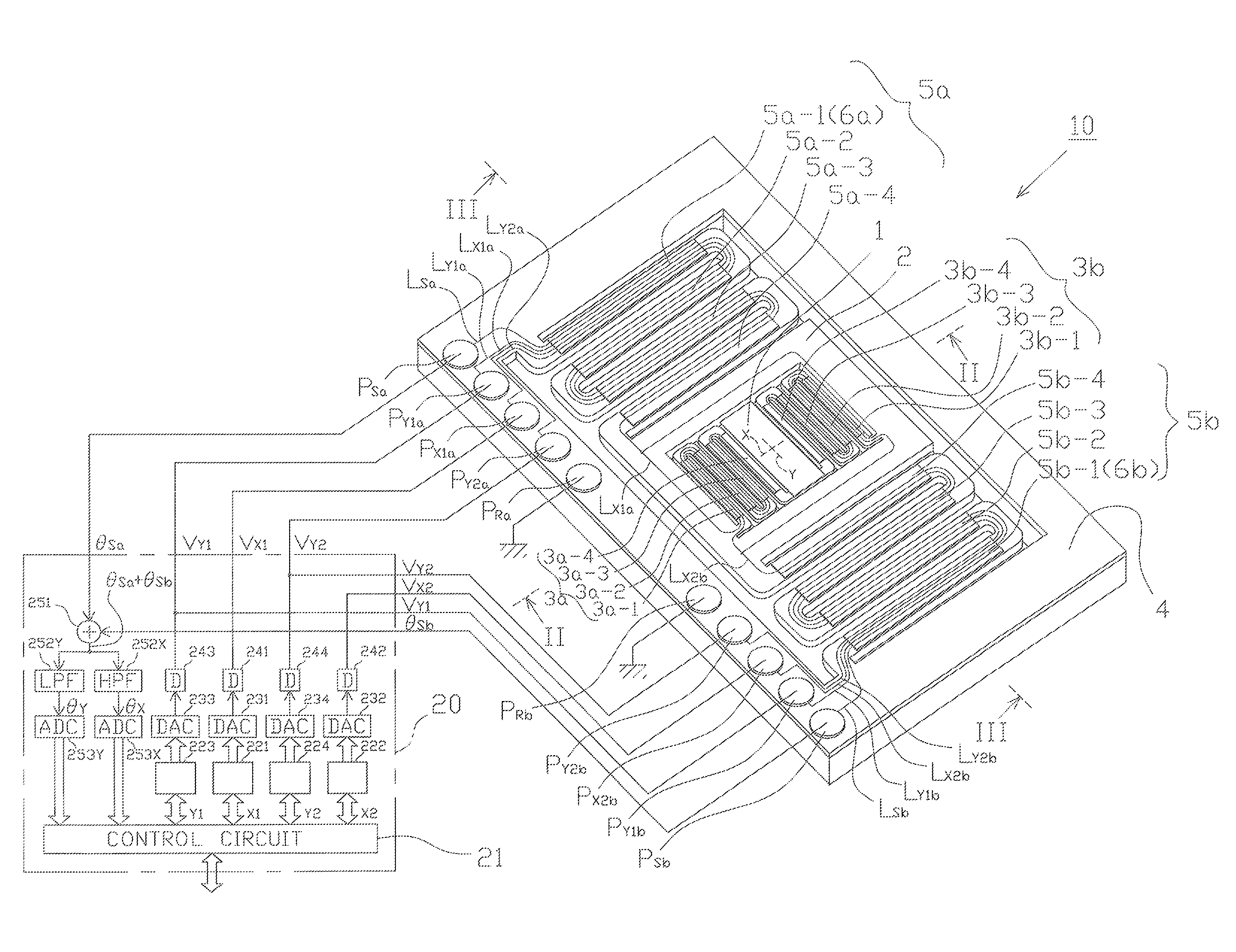

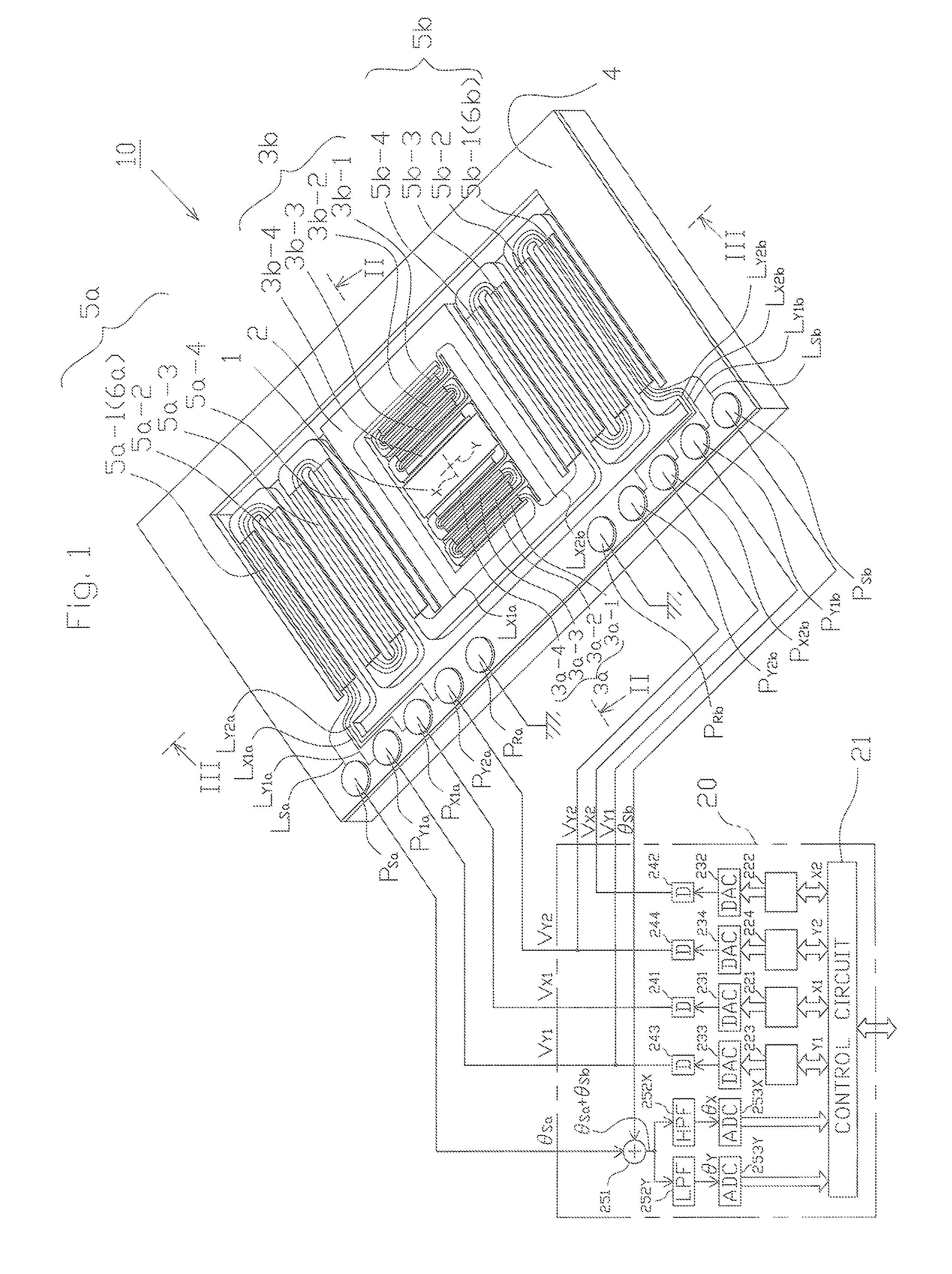

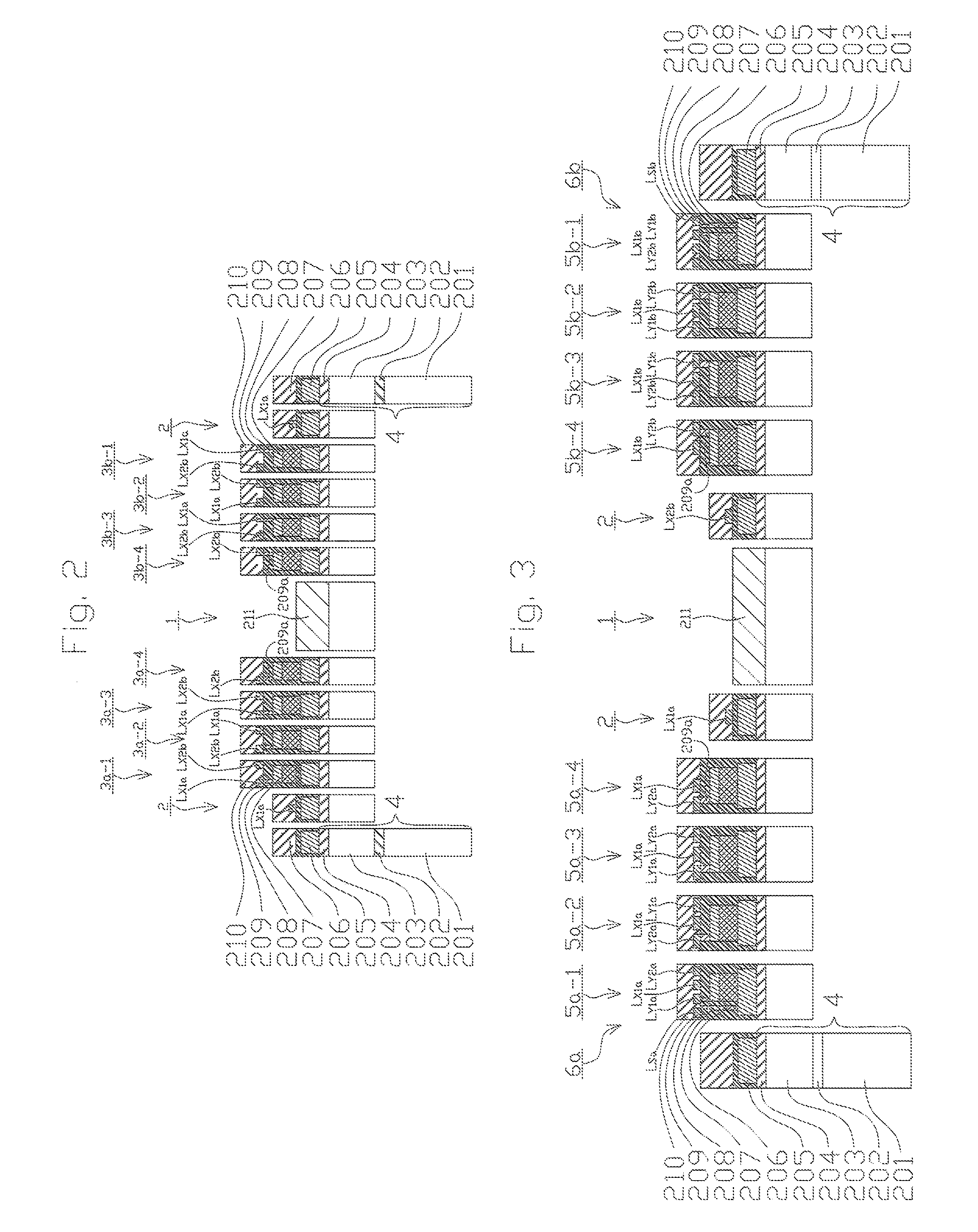

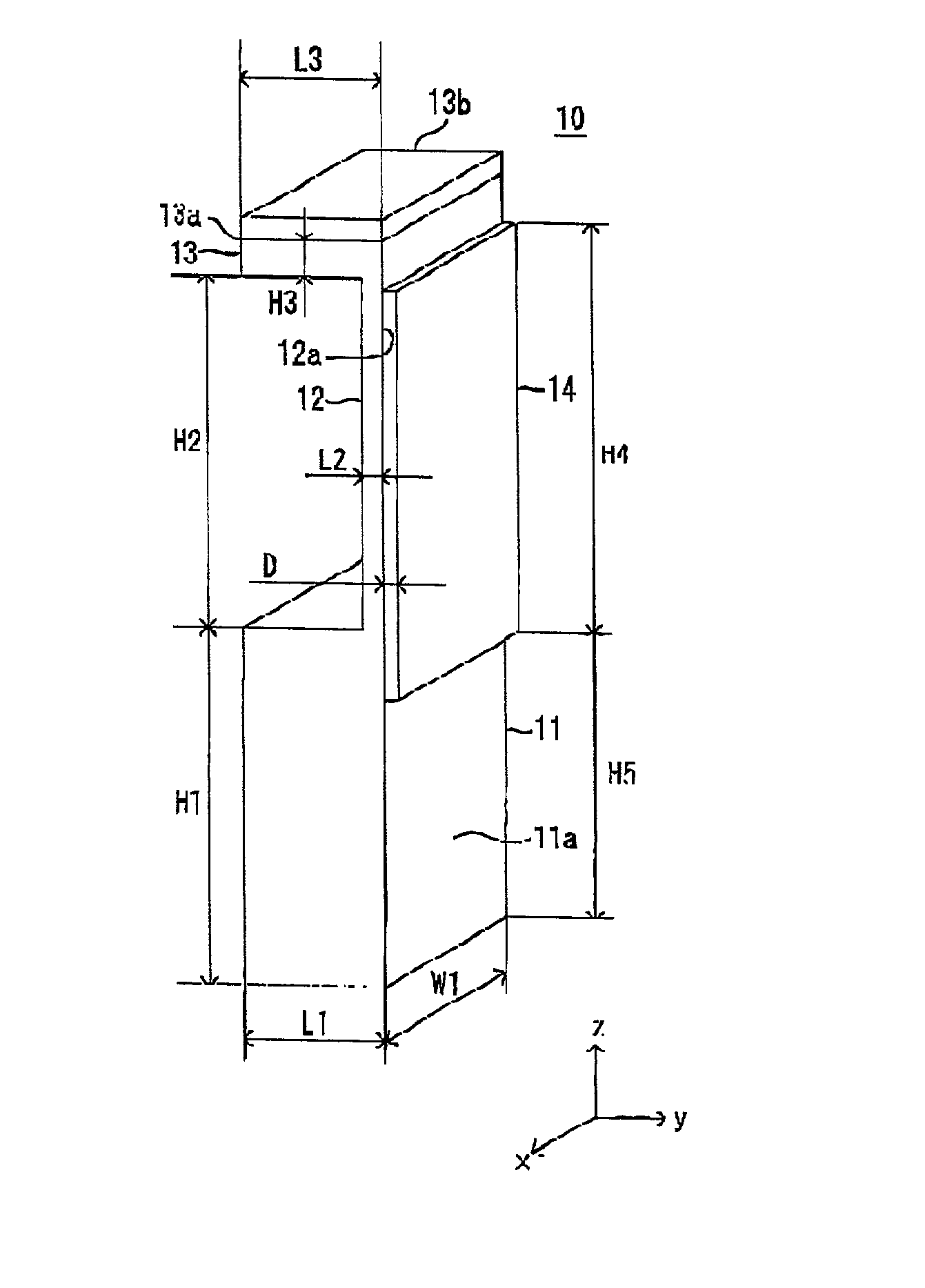

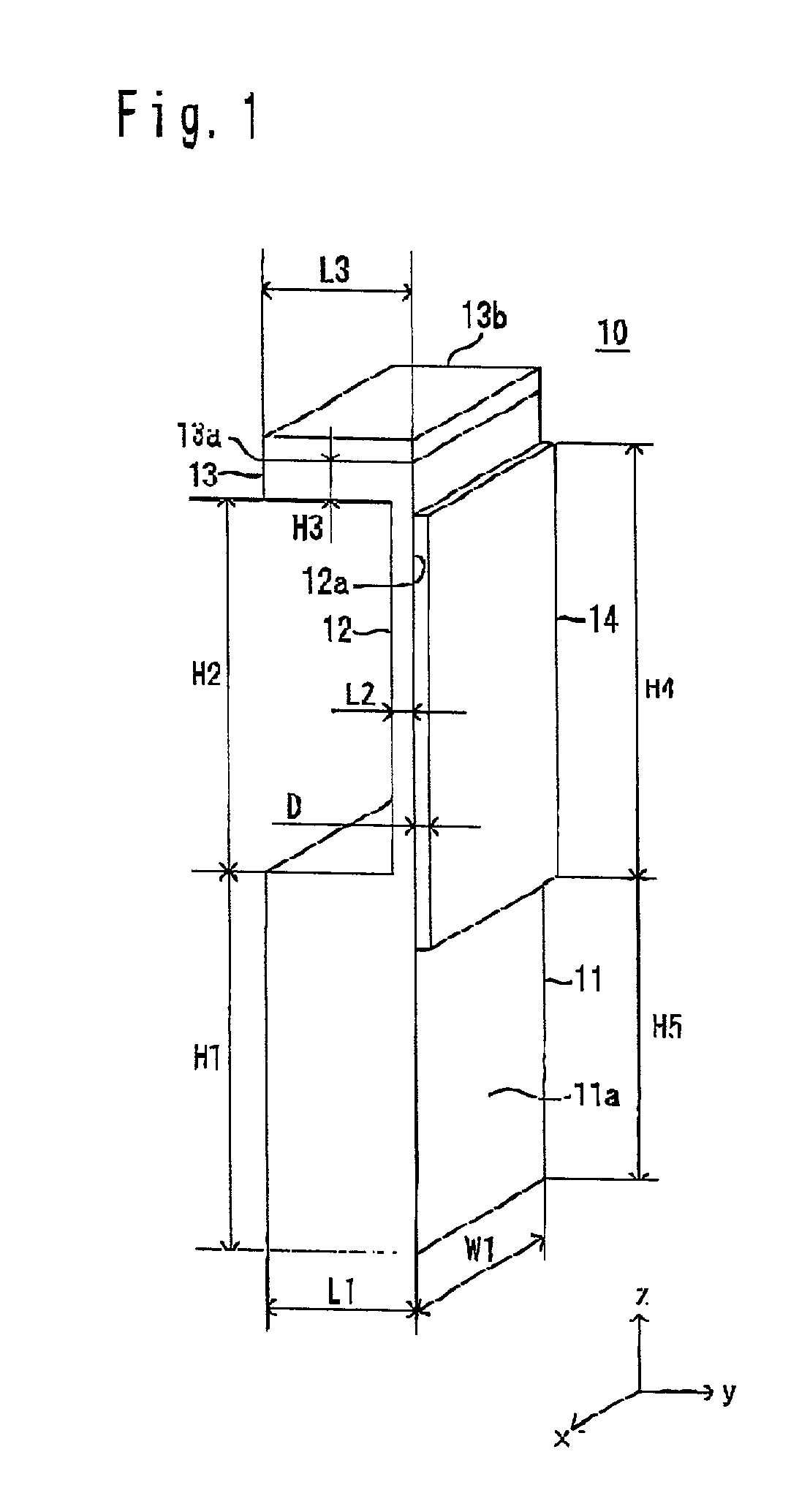

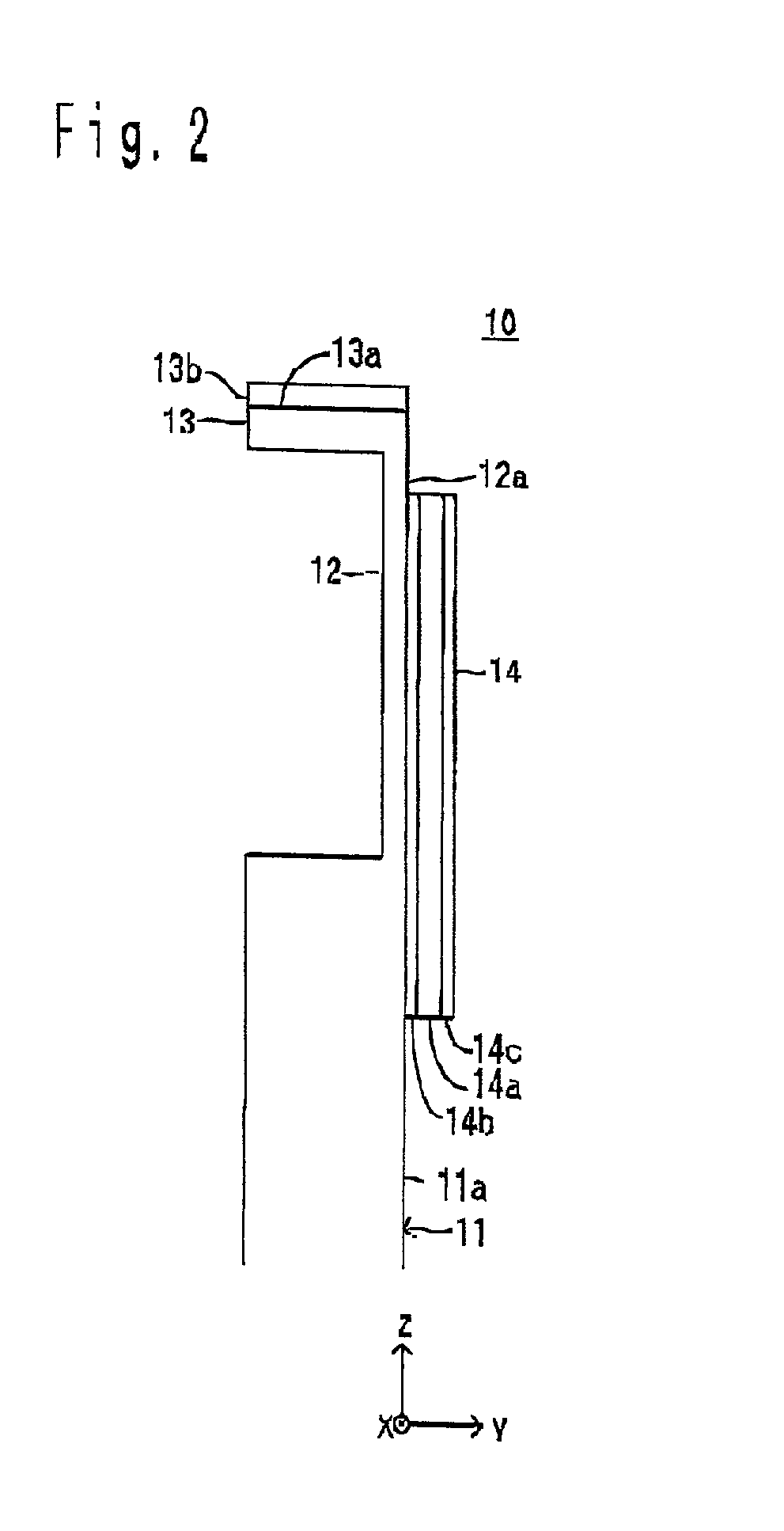

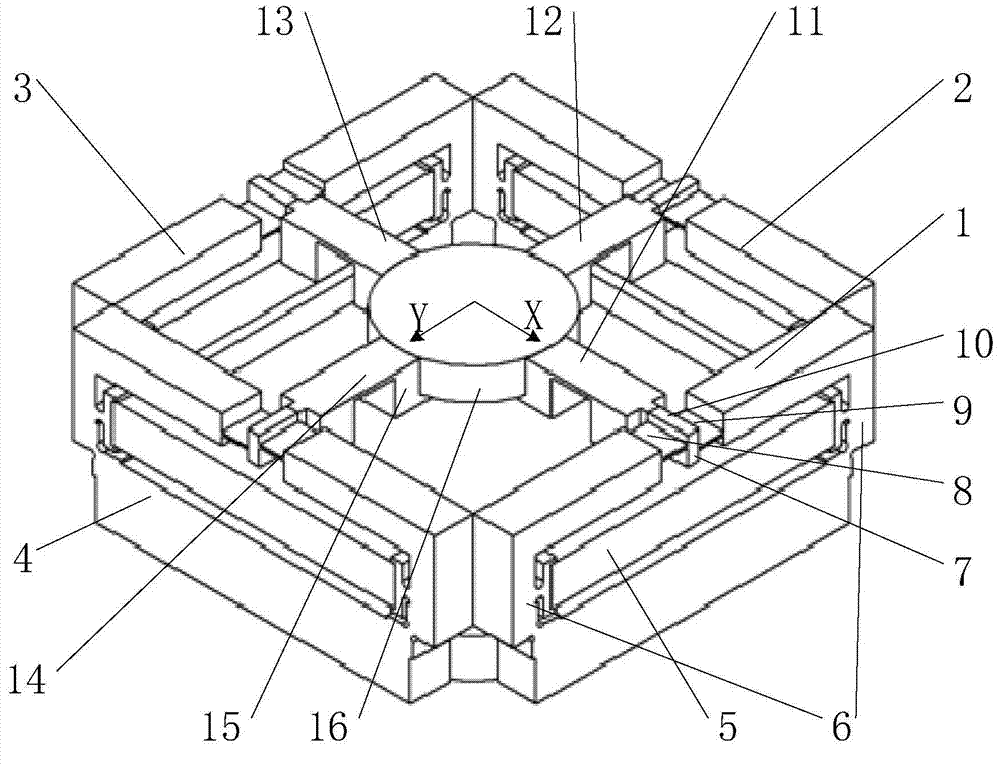

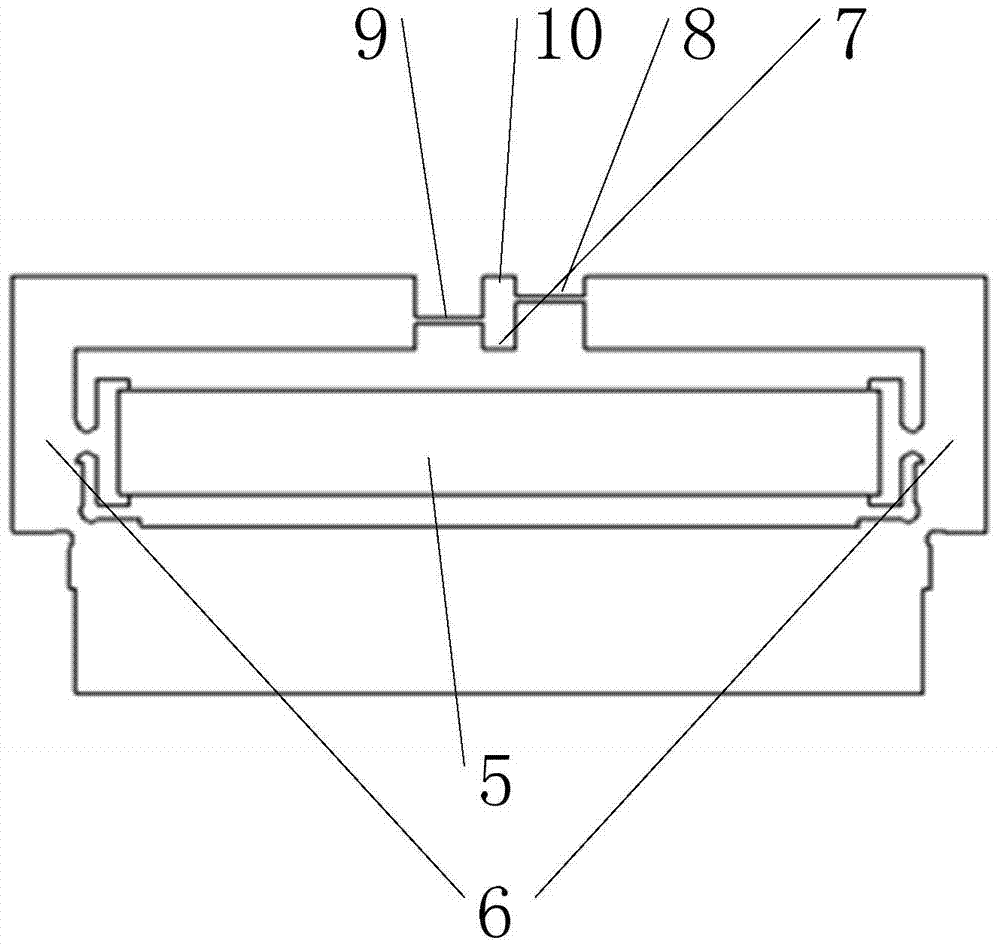

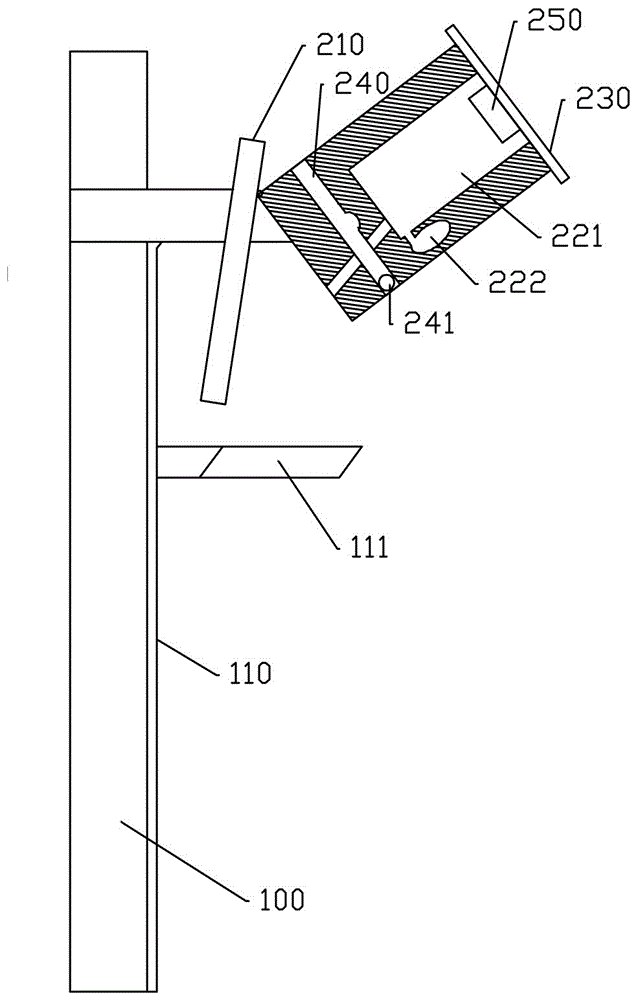

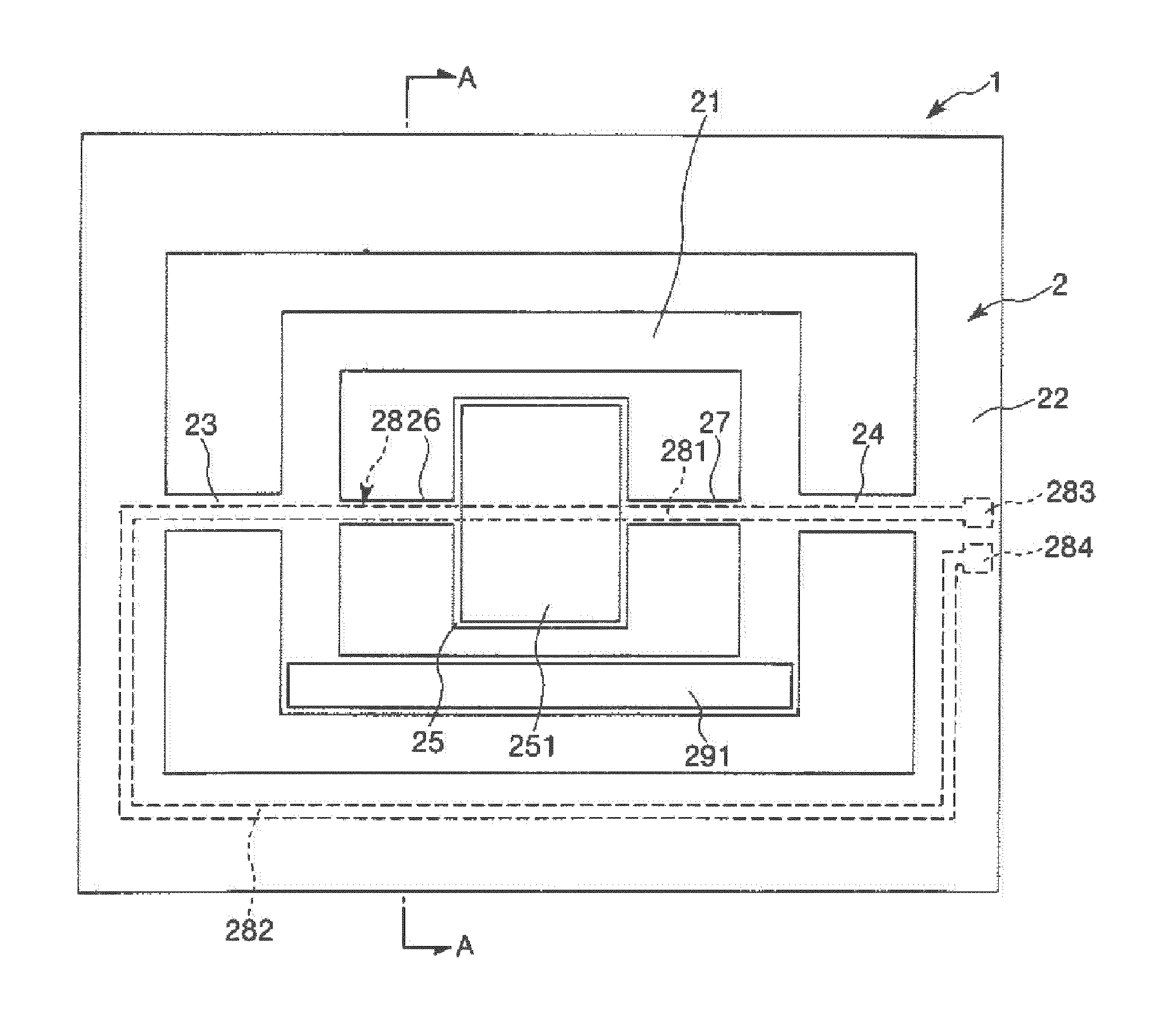

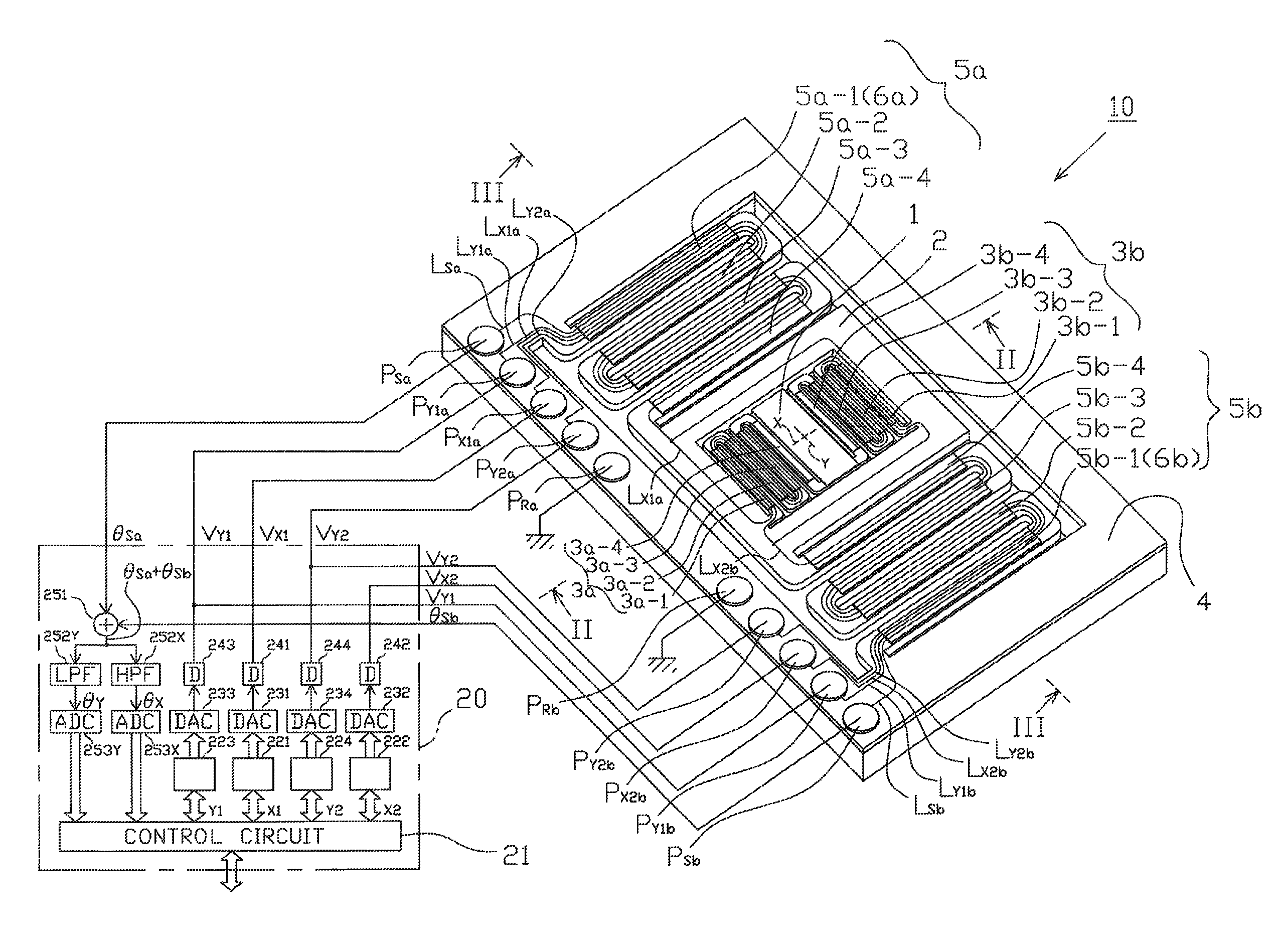

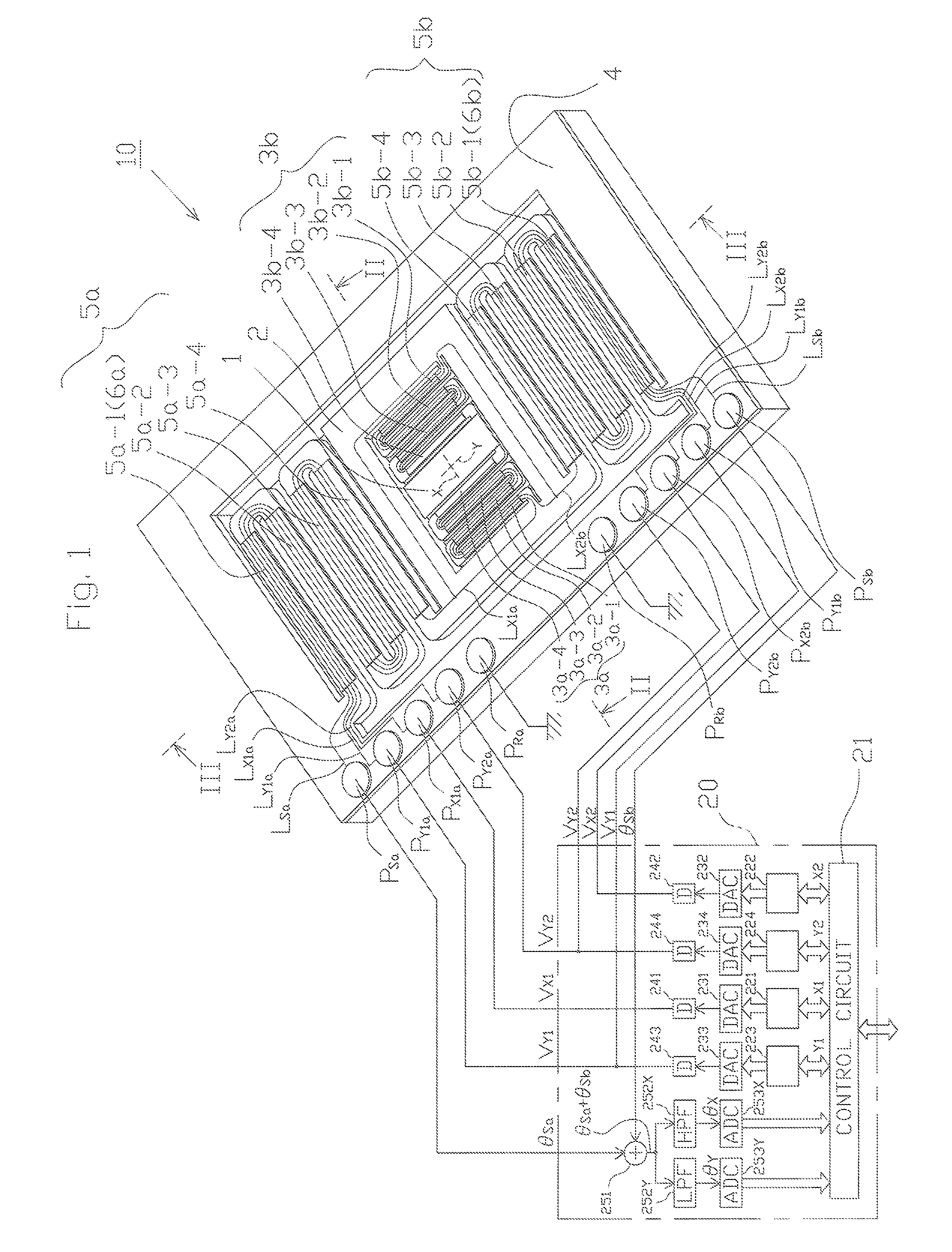

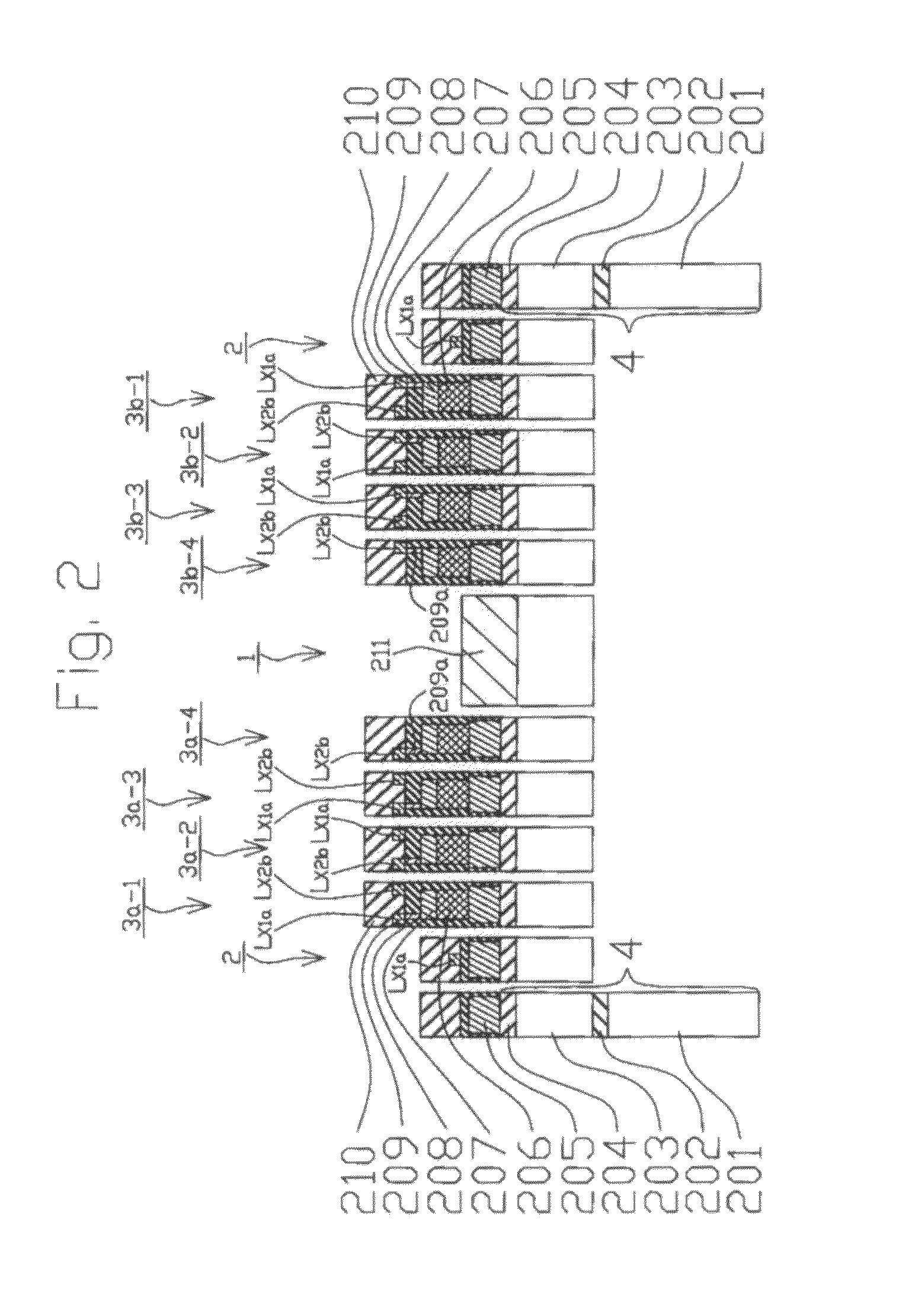

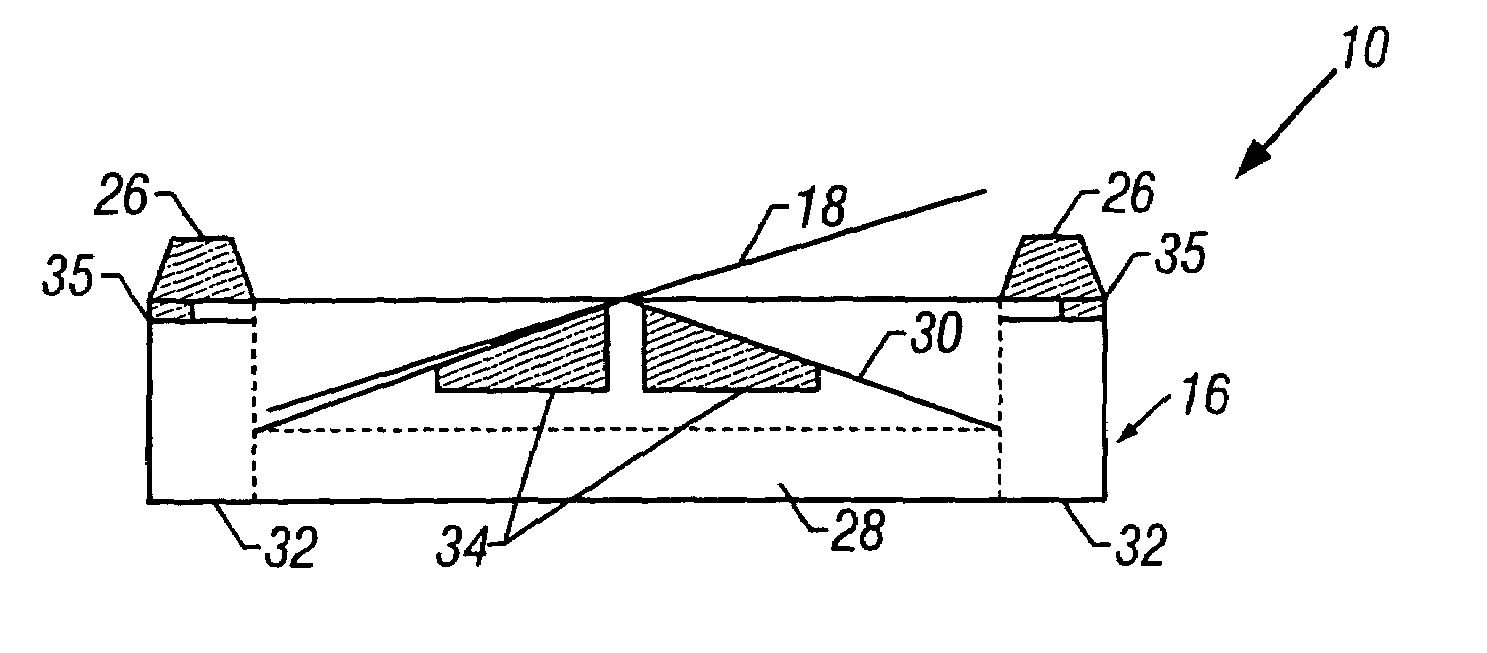

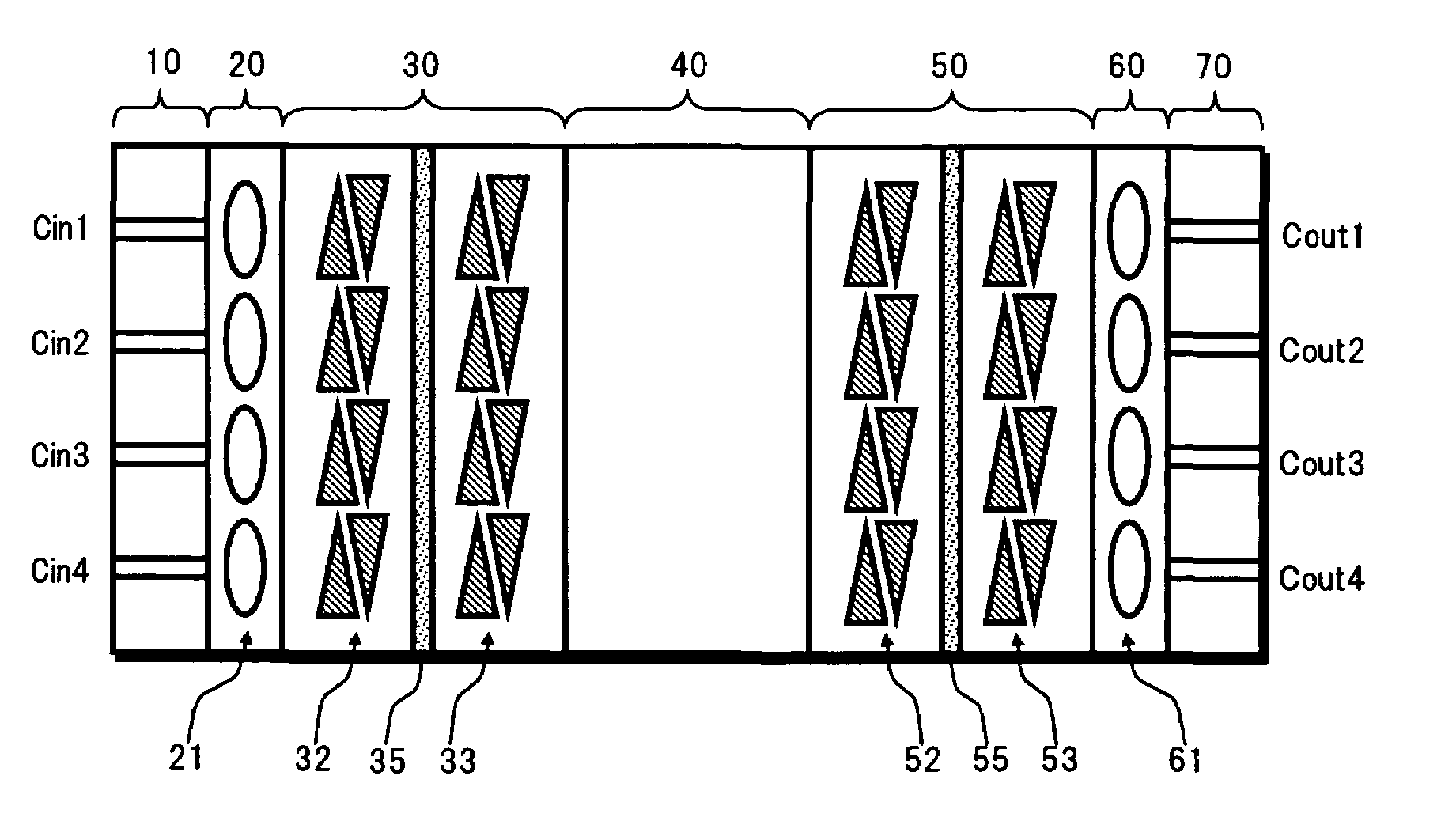

Actuator, optical scanner, and image forming apparatus

ActiveUS7408690B2Increase deflection angleSmall sizeDynamo-electric machinesElectromagnets with armaturesOptical scannersImage formation

An actuator includes a frame-shaped first mass portion; a supporting portion that supports the first mass portion and takes the shape of a frame so as to surround a perimeter of the first mass portion; a pair of first elastic portions coupling between the first mass portion and the supporting portion so that the first mass portion is supported by the supporting portion; a second mass portion provided inside the frame-shaped first mass portion; a pair of second elastic portions coupling between the second mass portion and the first mass portion so that the second mass portion is supported by the first mass portion; and a driver for rotating the first mass portion. The driver includes a ferromagnet provided on the first mass portion in a position separate from a rotation central axis of the first mass portion; a coil formed along the rotation central axis of the first mass portion and the supporting portion so as to surround and orbit a perimeter of the ferromagnet if the first mass portion is seen from above; and a voltage application unit for applying a voltage to the coil. An operation of the voltage application unit included in the driver causes the coil to generate a magnetic field. The generation of the magnetic field causes displacement of the ferromagnet relative to the coil. The displacement of the ferromagnet causes the first mass portion to rotate while torsionally deforming the pair of first elastic portions. The rotation of the first mass portion causes the second mass portion to rotate while torsionally deforming the pair of second elastic portions.

Owner:SEIKO EPSON CORP

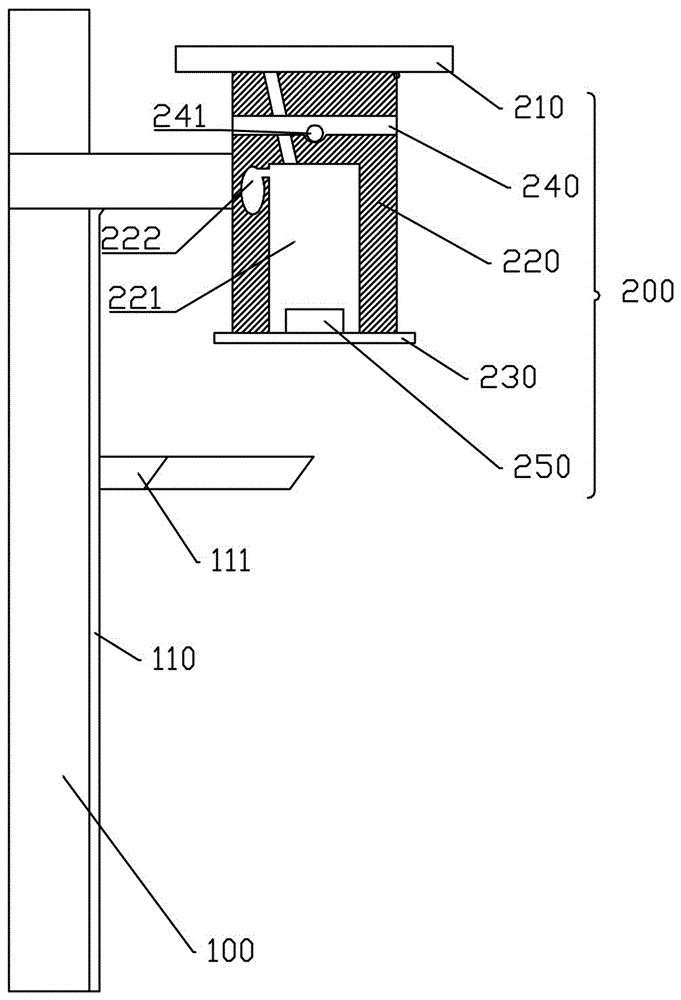

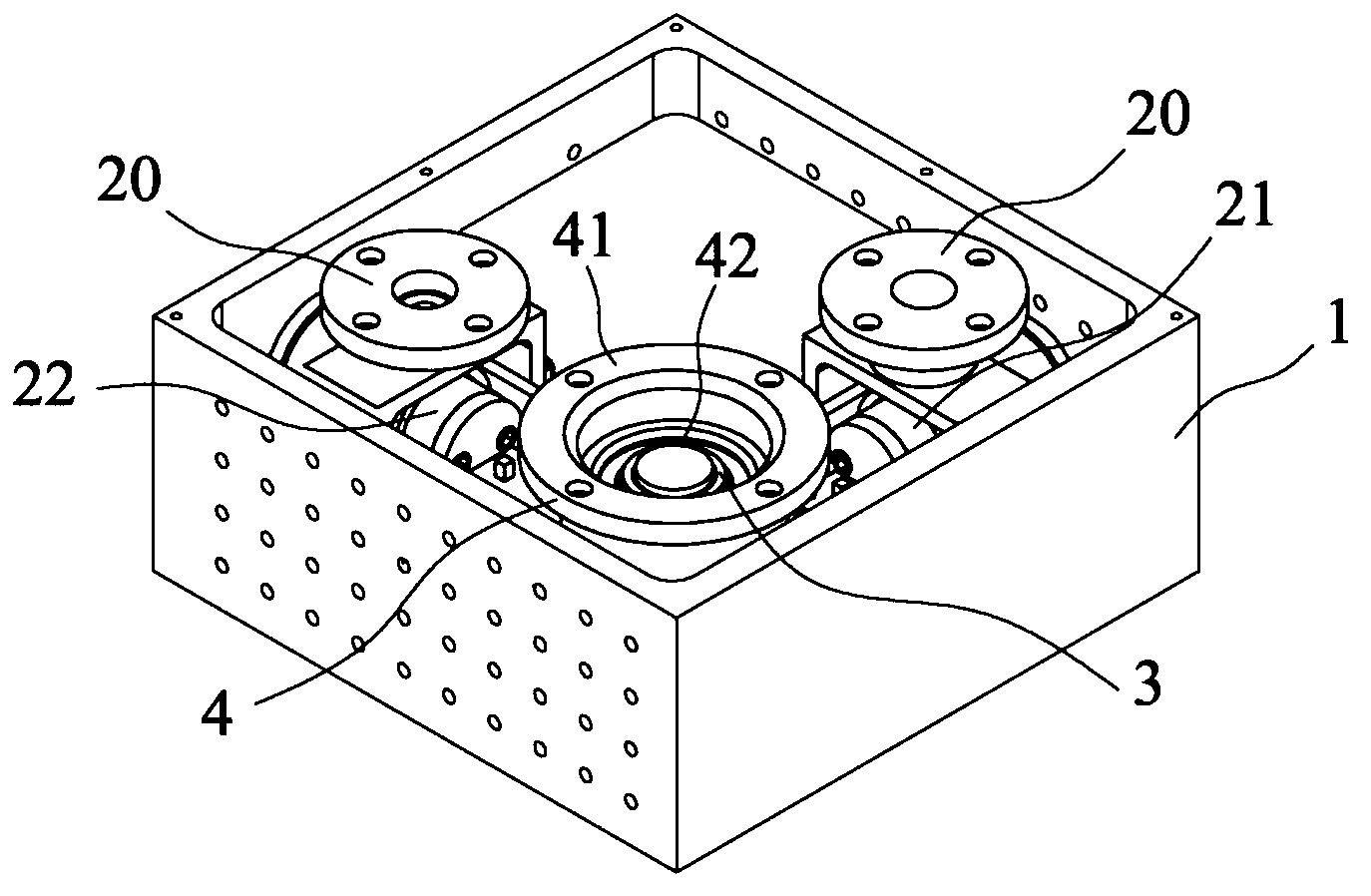

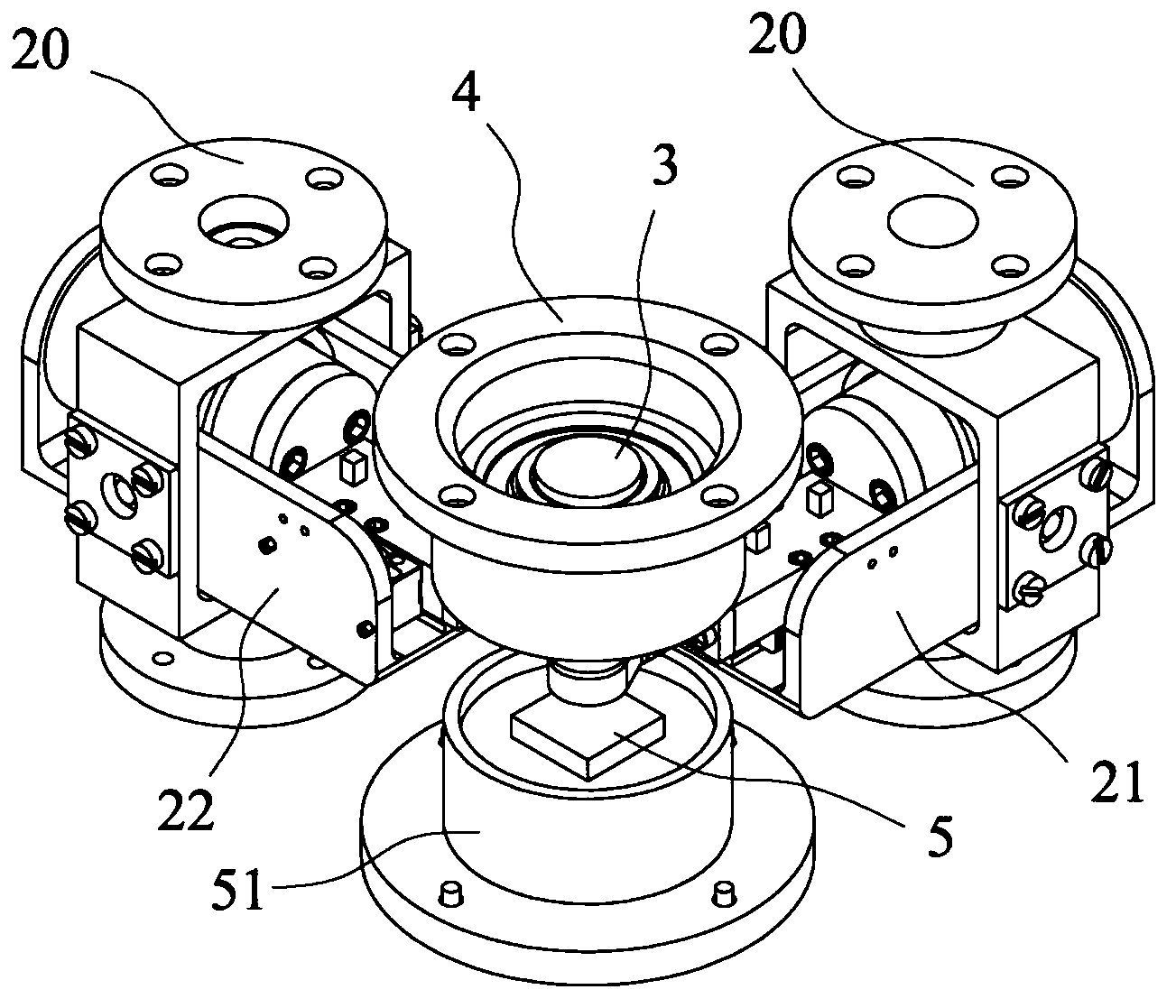

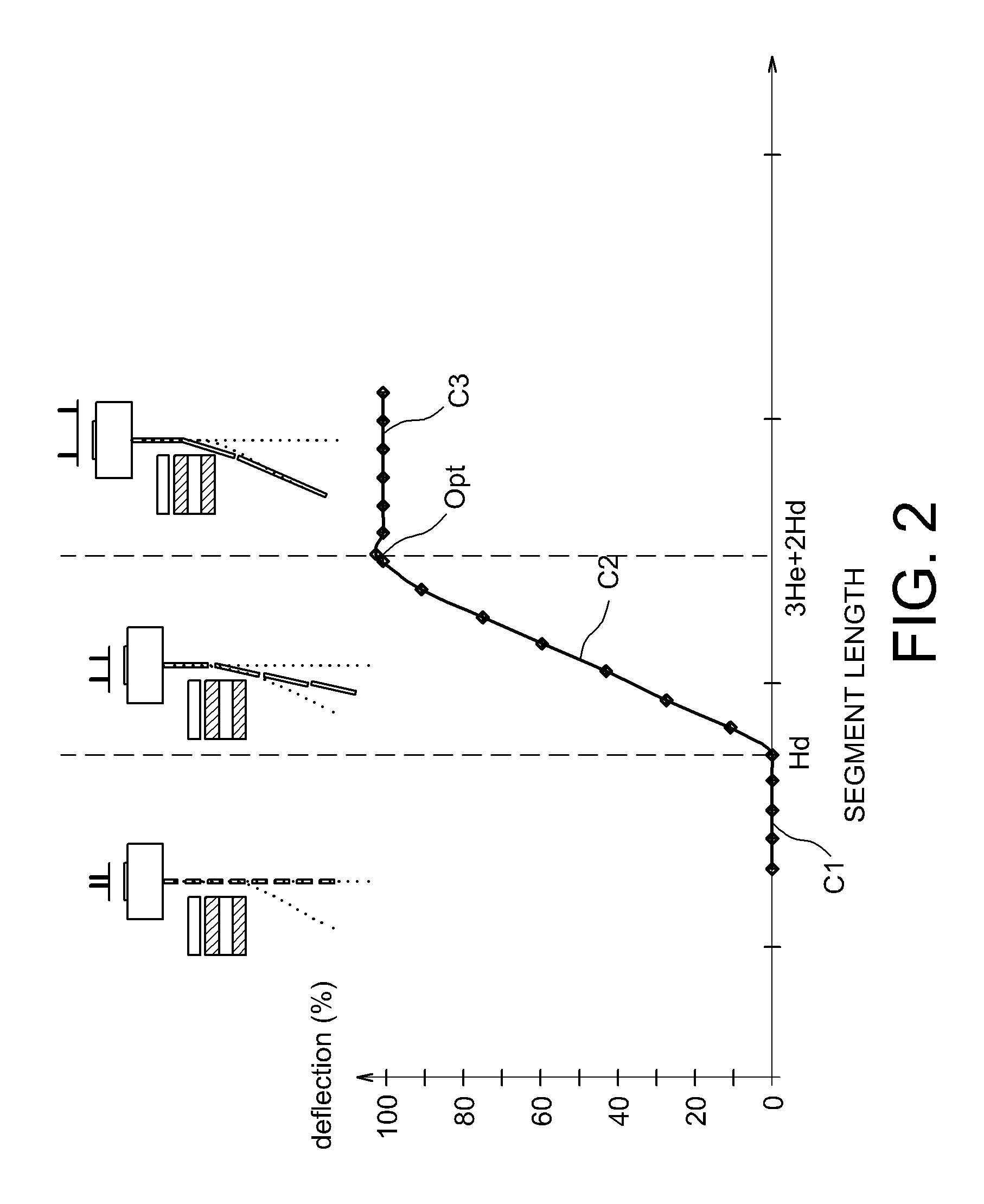

Control mechanism for rapid deflection reflection mirror with rotation center arranged at reflection surface and method thereof

ActiveCN104849858AHigh control precisionReduce mistakesOptical elementsMechanical engineeringLarge deflection

The invention provides a control mechanism for a rapid deflection reflection mirror with the rotation center arranged at the reflection surface and a method thereof. The control mechanism comprises a first driving mechanism and a third driving mechanism which are arranged at the two ends of an X-axis of deflection and symmetrical about a Y-axis of deflection, and a second driving mechanism and a fourth driving mechanism which are arranged at the two ends of the Y-axis of deflection and symmetrical about the X-axis of deflection. The first driving mechanism is connected with a mirror supporting structure via a first flexible hinge perpendicular to the first driving mechanism. The structure and the size of the second driving mechanism, the third driving mechanism and the fourth driving mechanism are identical to those of the first driving mechanism, and the second driving mechanism, the third driving mechanism and the fourth driving mechanism are connected with the mirror supporting structure via a second flexible hinge, a third flexible hinge and a fourth flexible hinge respectively. The side surface of the reflection mirror is fixed on the mirror supporting structure. The mirror surface of the reflection mirror and the X-axis of deflection and the Y-axis of deflection are arranged in the same plane. The invention also provides a control method of the control mechanism. The control mechanism has relatively large deflection range and also has the characteristics of high response speed, small size and low weight.

Owner:XI AN JIAOTONG UNIV

Micromirror array for projection TV

In order to minimize light diffraction along the direction of switching and more particularly light diffraction into the acceptance cone of the collection optics, in the present invention, micromirrors are provided which are not rectangular. Also, in order to minimize the cost of the illumination optics and the size of the display unit of the present invention, the light source is placed orthogonal to the rows (or columns) of the array, and / or the light source is placed orthogonal to a side of the frame defining the active area of the array. The incident light beam, though orthogonal to the sides of the active area, is not however, orthogonal to any substantial portion of sides of the individual micromirrors in the array. Orthogonal sides cause incident light to diffract along the direction of micromirror switching, and result in light ‘leakage’ into the ‘on’ state even if the micromirror is in the ‘off’ state. This light diffraction decreases the contrast ratio of the micromirror. The micromirrors of the present invention result in an improved contrast ratio, and the arrangement of the light source to micromirror array in the present invention results in a more compact system. Another feature of the invention is the ability of the micromirrors to pivot in opposite direction to on and off positions (the on position directing light to collection optics), where the movement to the on position is greater than movement to the off position. A further feature of the invention is a package for the micromirror array, the package having a window that is not parallel to the substrate upon which the micromirrors are formed. One example of the invention includes all the above features.

Owner:TEXAS INSTR INC +1

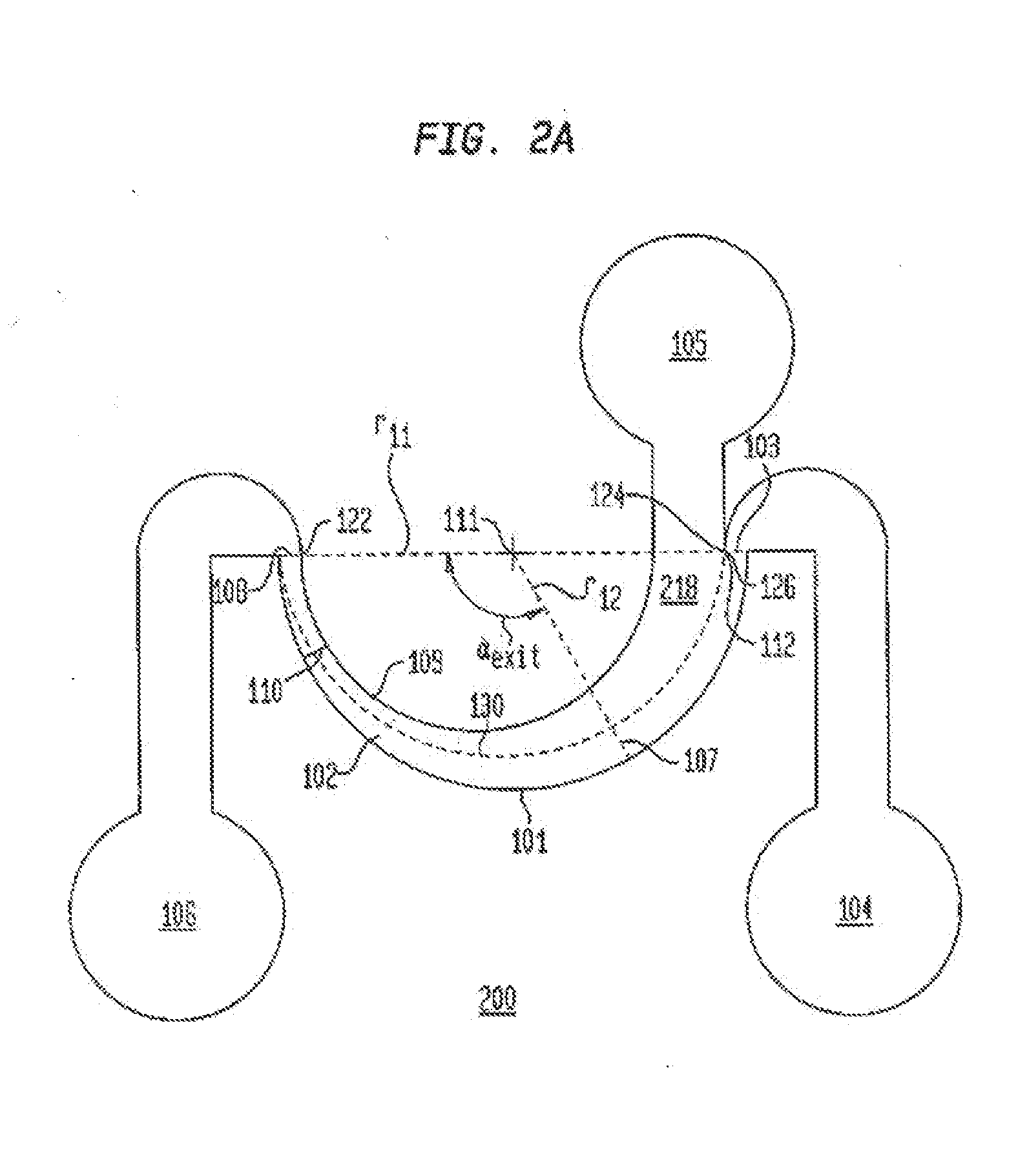

Configurable microwave deflection system

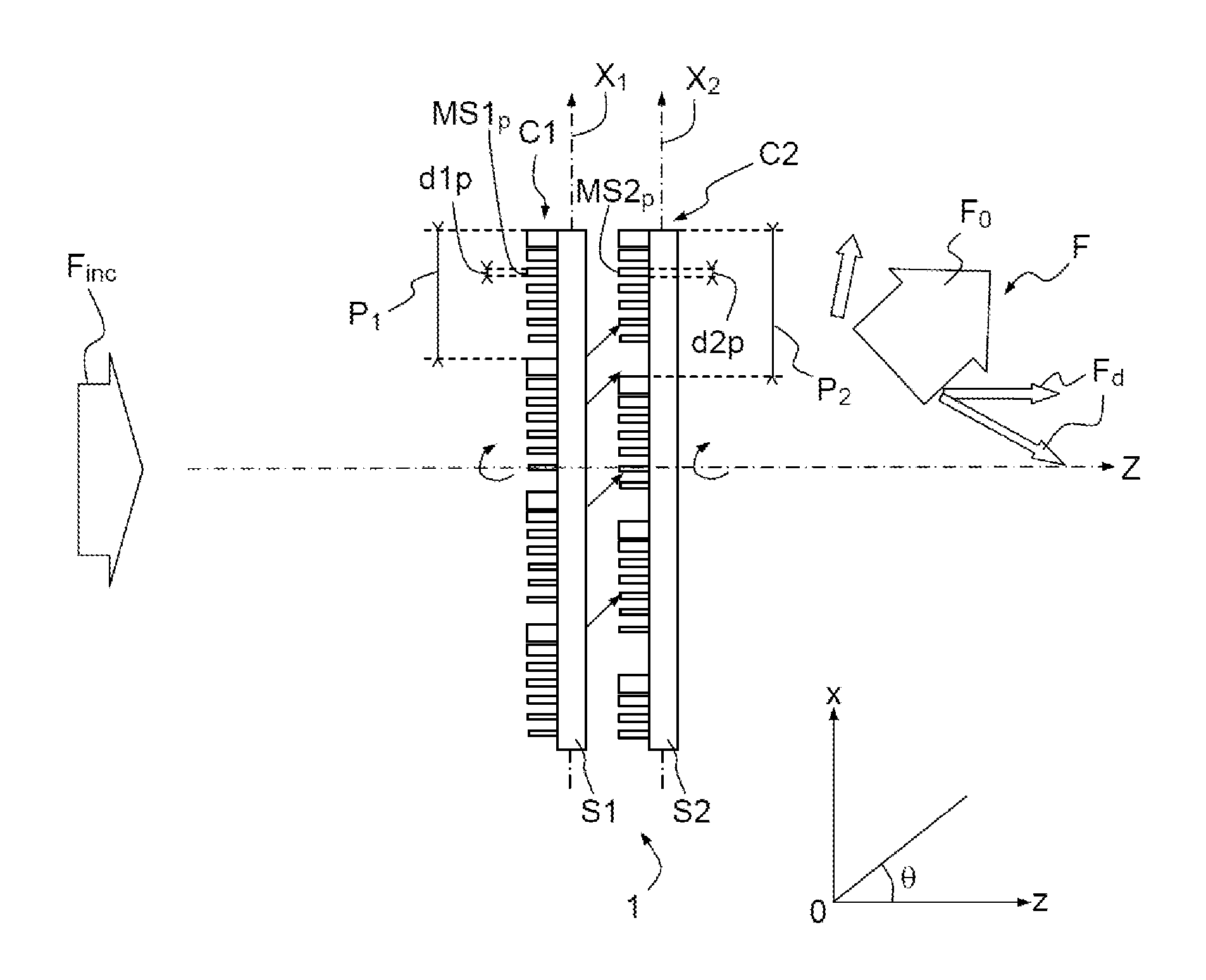

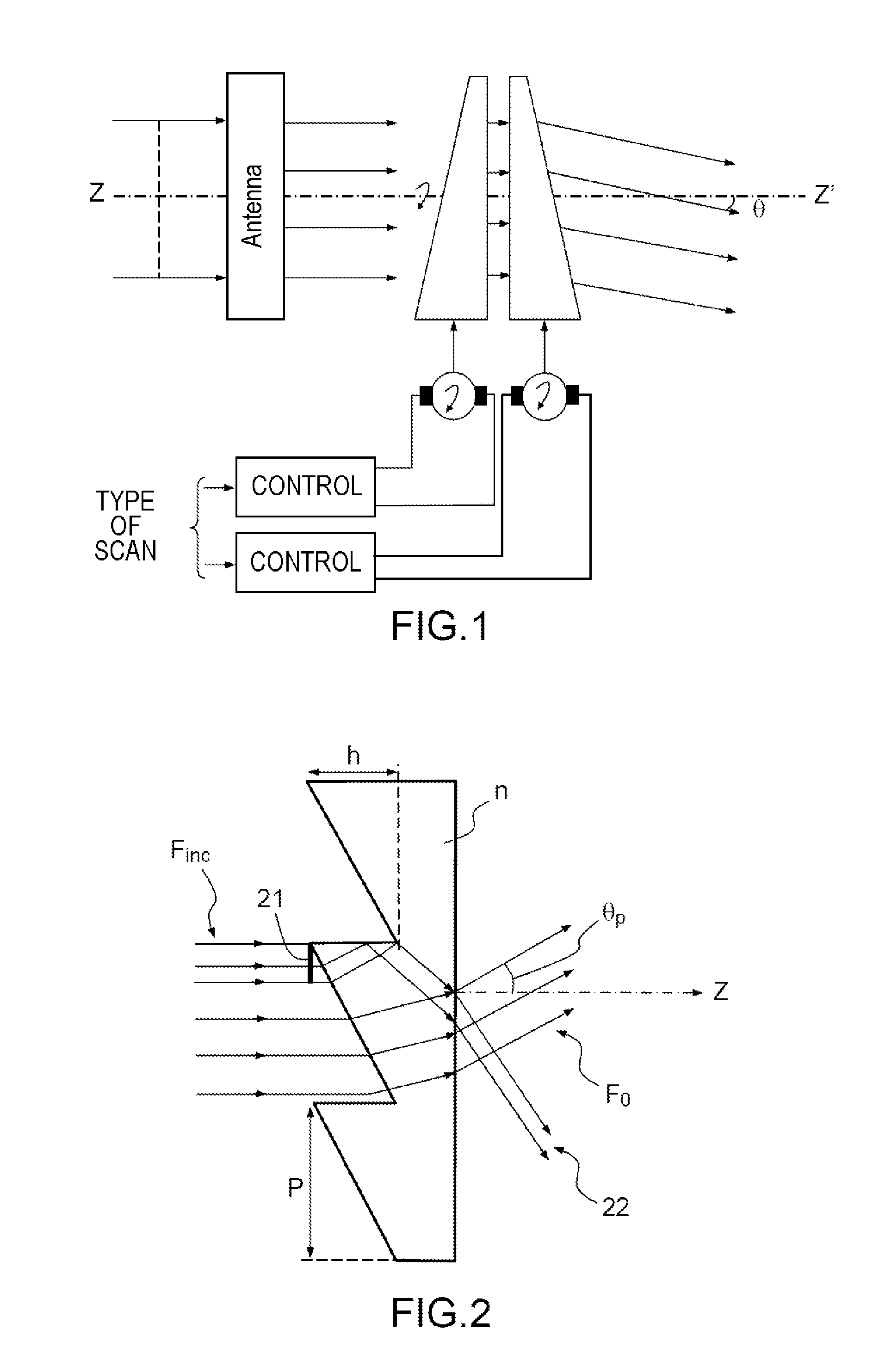

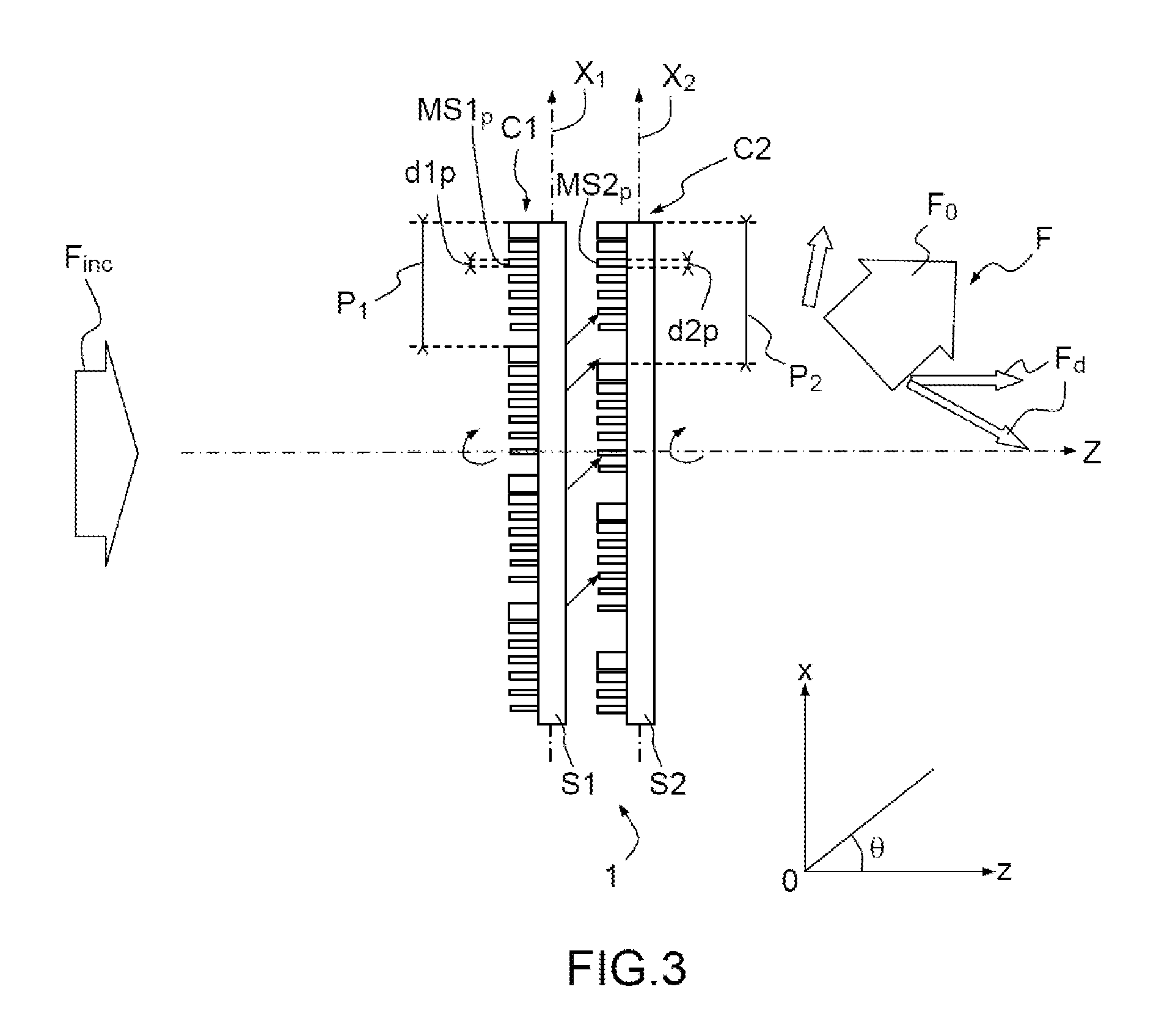

ActiveUS20150380829A1Increase deflection angleImprove the attenuation effectAntennasRefractive indexLength wave

A configurable deflection system for an incident microwave frequency beam exhibiting a wavelength contained in a band of wavelengths corresponding to the microwave frequencies, comprising: a first and a second diffractive dielectric component suitable for each performing a rotation about a rotation axis Z, the deflection system being suitable for generating a microwave frequency beam by diffraction of the incident microwave frequency beam on the first and second components, the microwave frequency beam being oriented according to an angle that is a function of the angular positioning between the first and said second diffractive components, the first and second components respectively exhibiting a first and second periodic structure of first and second periods according to a first and second axis, the first and second structures respectively comprising a plurality of first and second primary microstructures formed respectively on a first and second substrate of first and second substrate refractive indices.

Owner:THALES SA

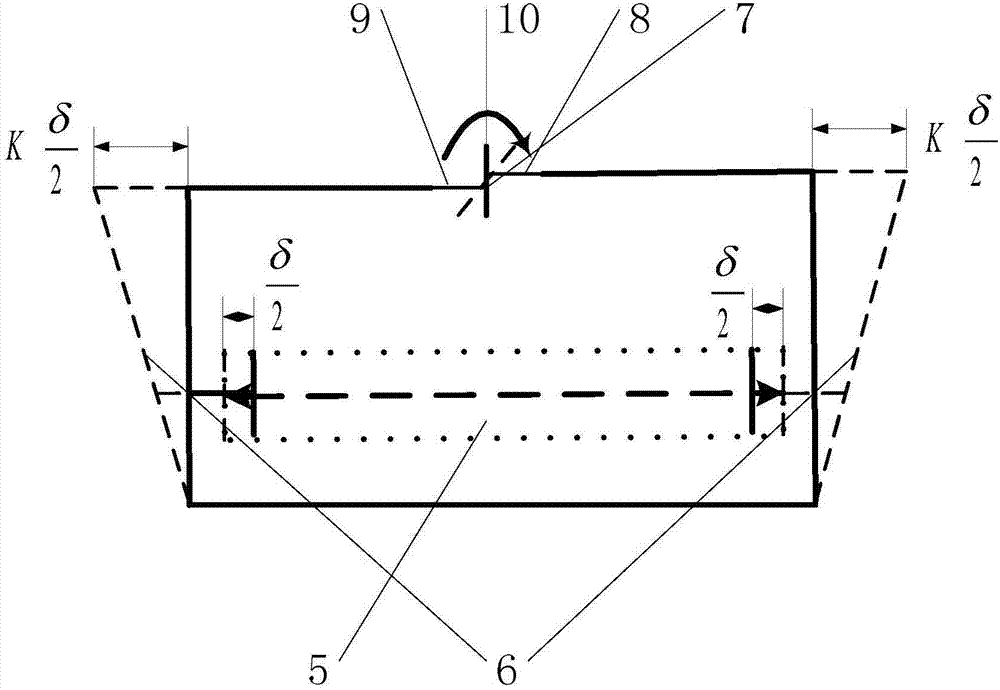

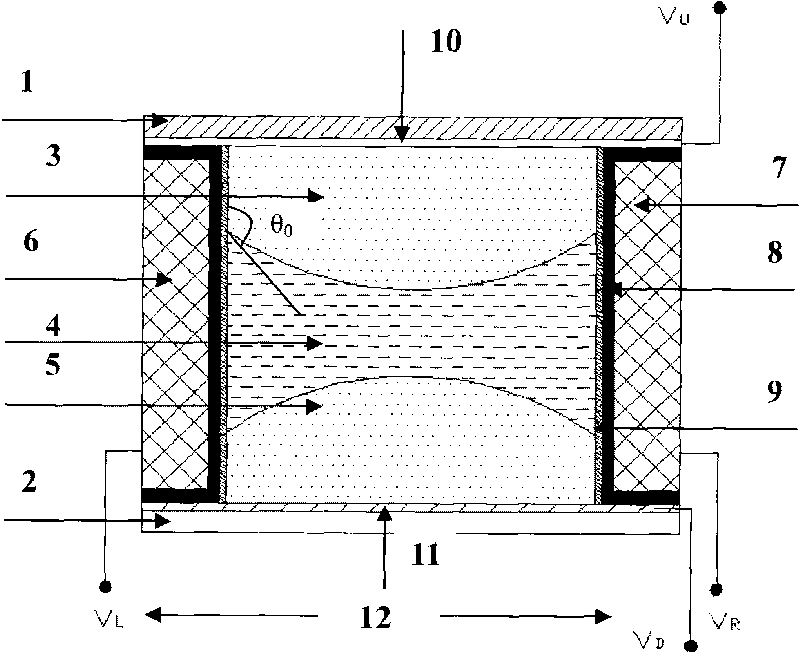

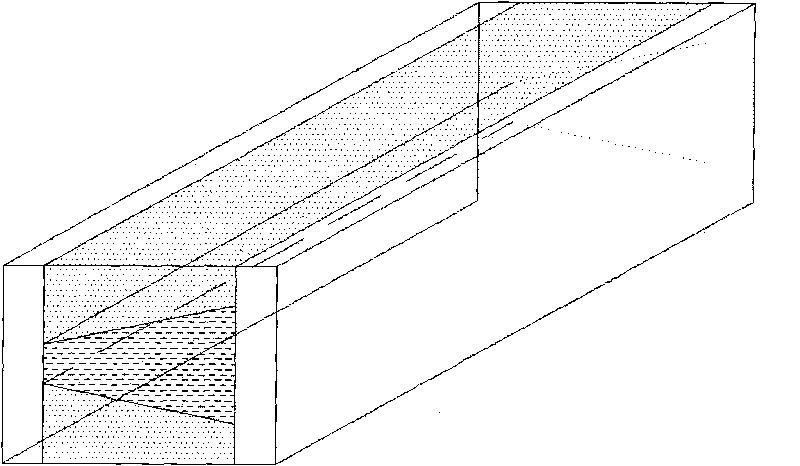

Electric-control wide-angle light scanning device and array thereof

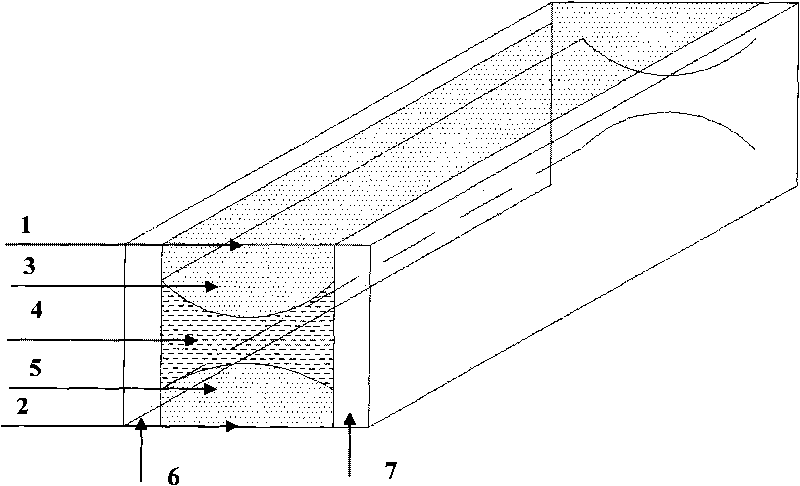

InactiveCN101694543ARealize electronically controlled tuningIncrease deflection angleOptical elementsDevice formControl system

The invention relates to an electric-control wide-angle light scanning device and an array thereof. The device is a container for a fluid prism which can contain a conductive fluid, an insulation fluid and another conductive fluid, such as a fluid bath. The upper end and the lower end of the fluid bath are respectively provided with a transparent upper cover plate (1) and a transparent lower cover plate (2), and a fluid prism cavity used for storing fluid prism materials is formed by the space between the transparent upper cover plate (1) and the transparent lower cover plate (2). Three indissoluble fluids, namely a first conductive fluid (3), an insulation fluid (4) and a second conductive fluid (5) are respectively arranged in the fluid bath from top to bottom. The three fluids form fluid prism media and respectively have different refractive indexes. A left wall (6) and a right wall (7) of the fluid bath are made of conductive materials and are respectively used as a left electrode and a right electrode, and an upper electrode and a lower electrode are respectively arranged in an upper transparent conductive layer (10) on the upper cover plate and a lower transparent conductive layer (11) on the lower cover plate. Under the control of a voltage-controlled system (11), the device forms an edge-adjustable fluid prism system.

Owner:NANJING UNIV OF POSTS & TELECOMM

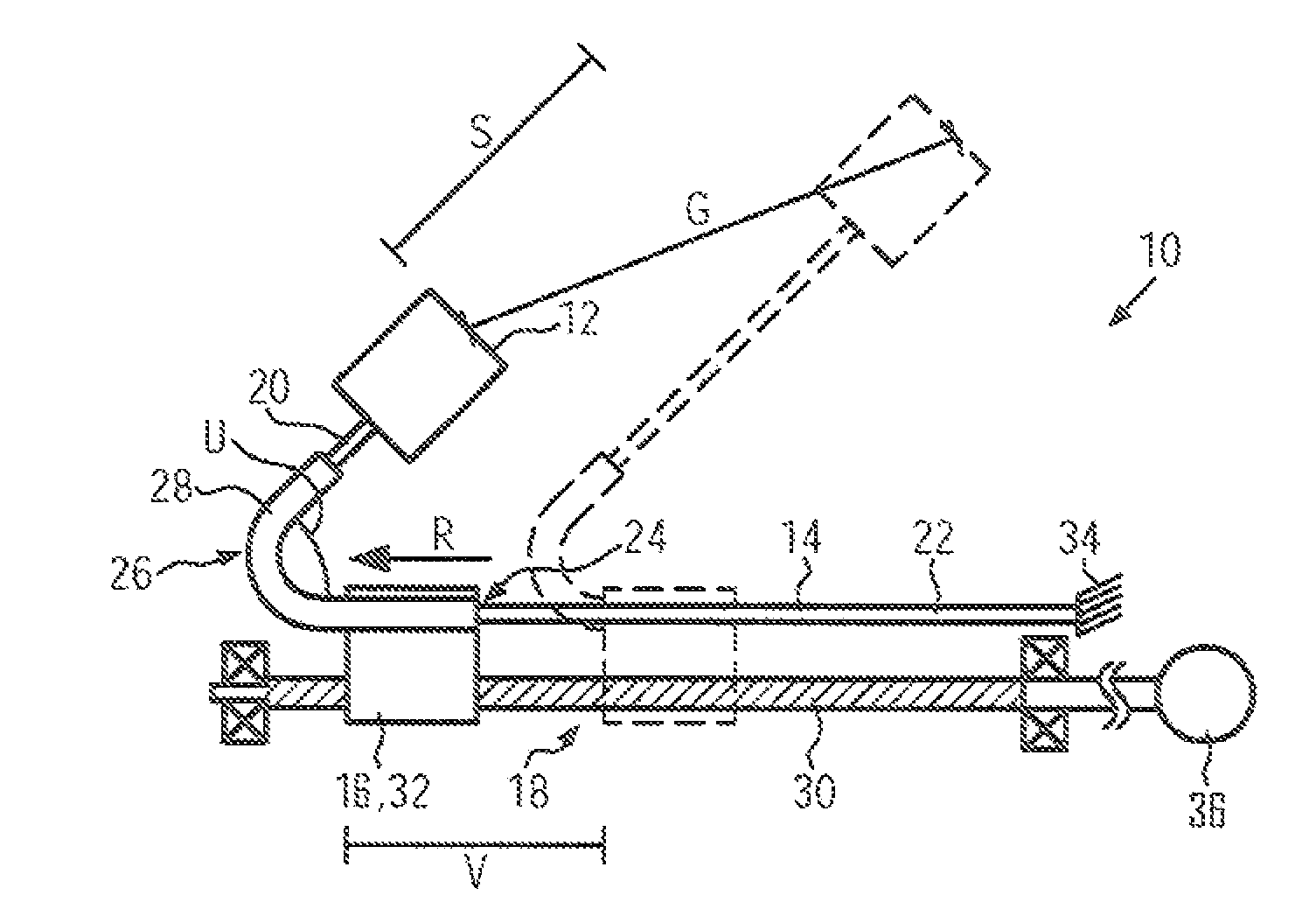

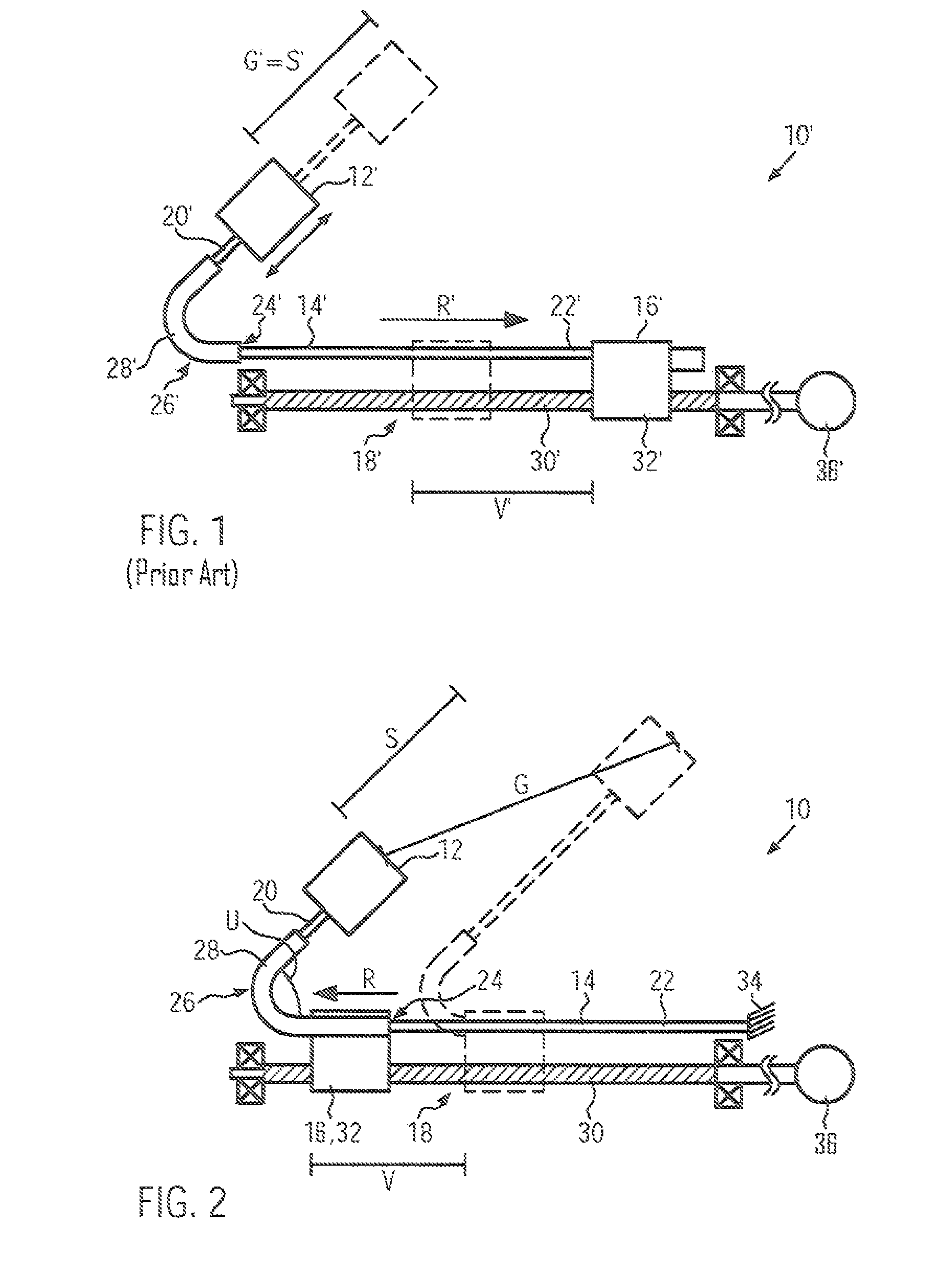

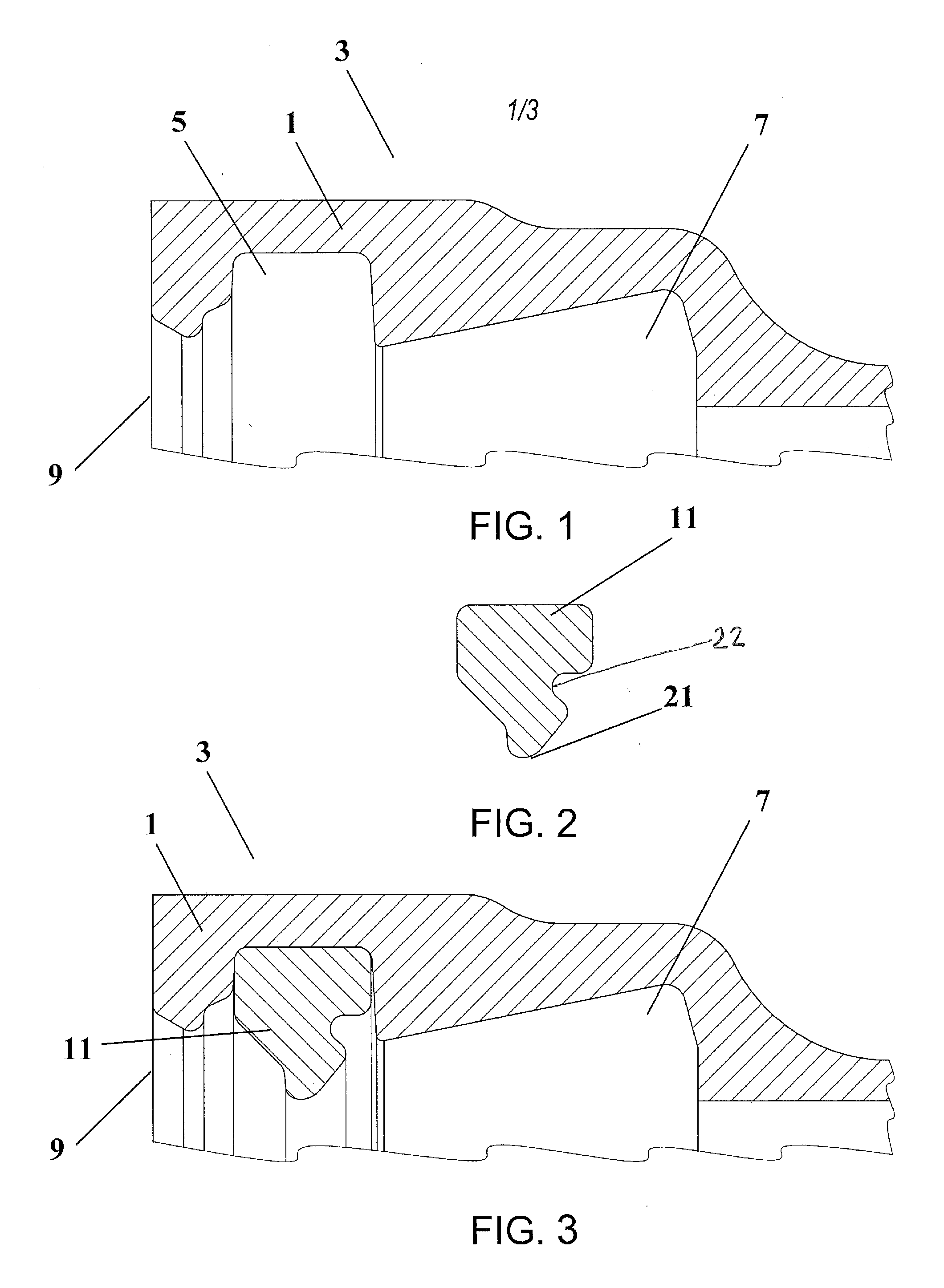

Belt tensioner

ActiveUS8317228B2Increase gear ratioIncrease deflection angleSafety beltsBelt retractorsSeat beltEngineering

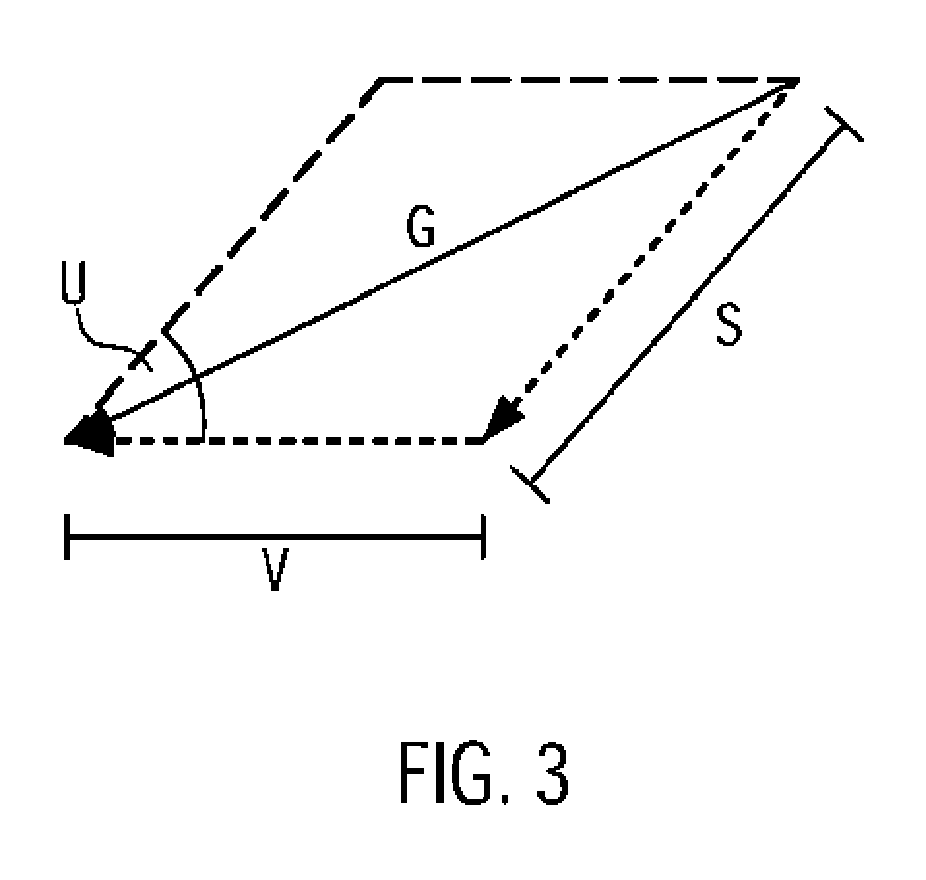

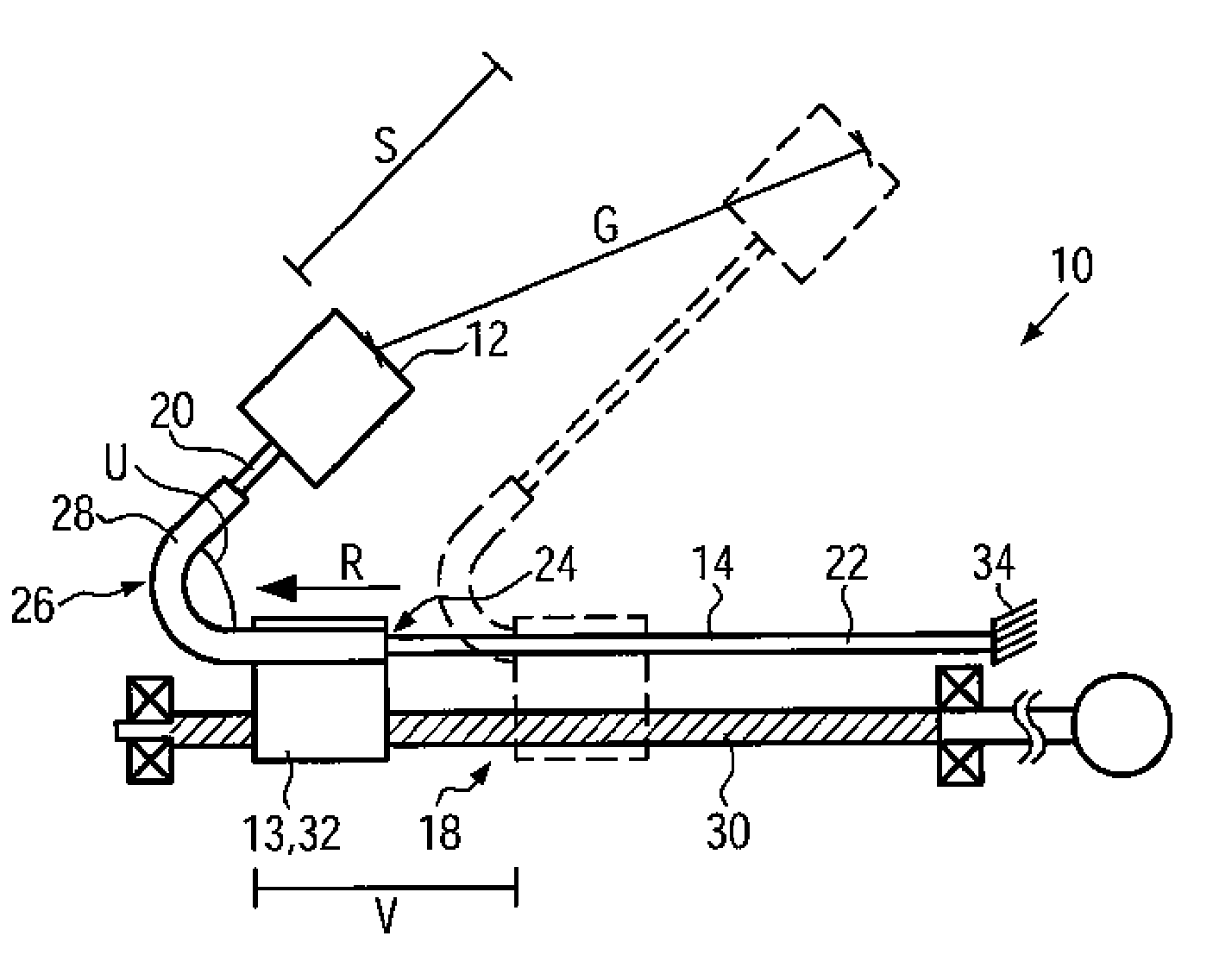

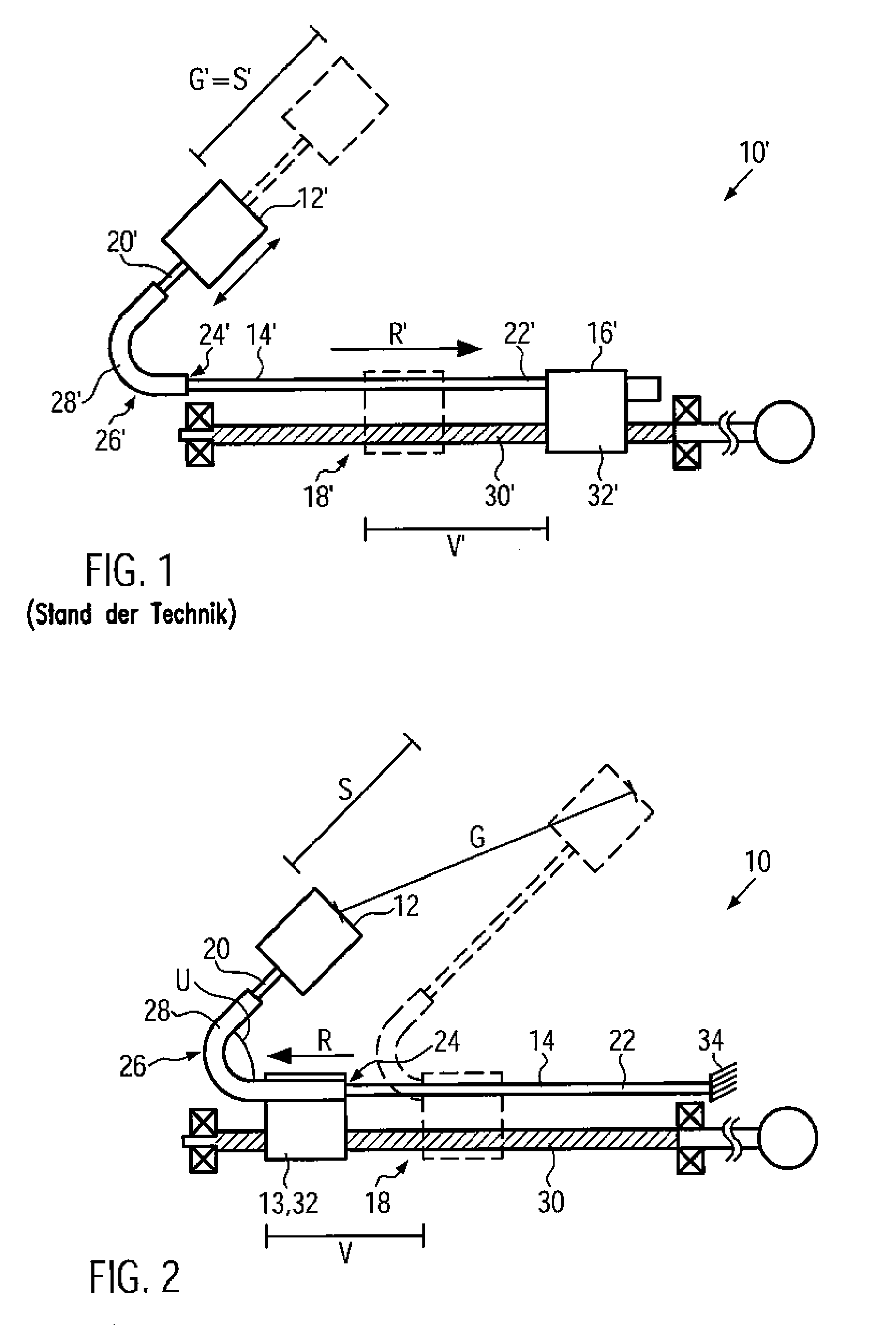

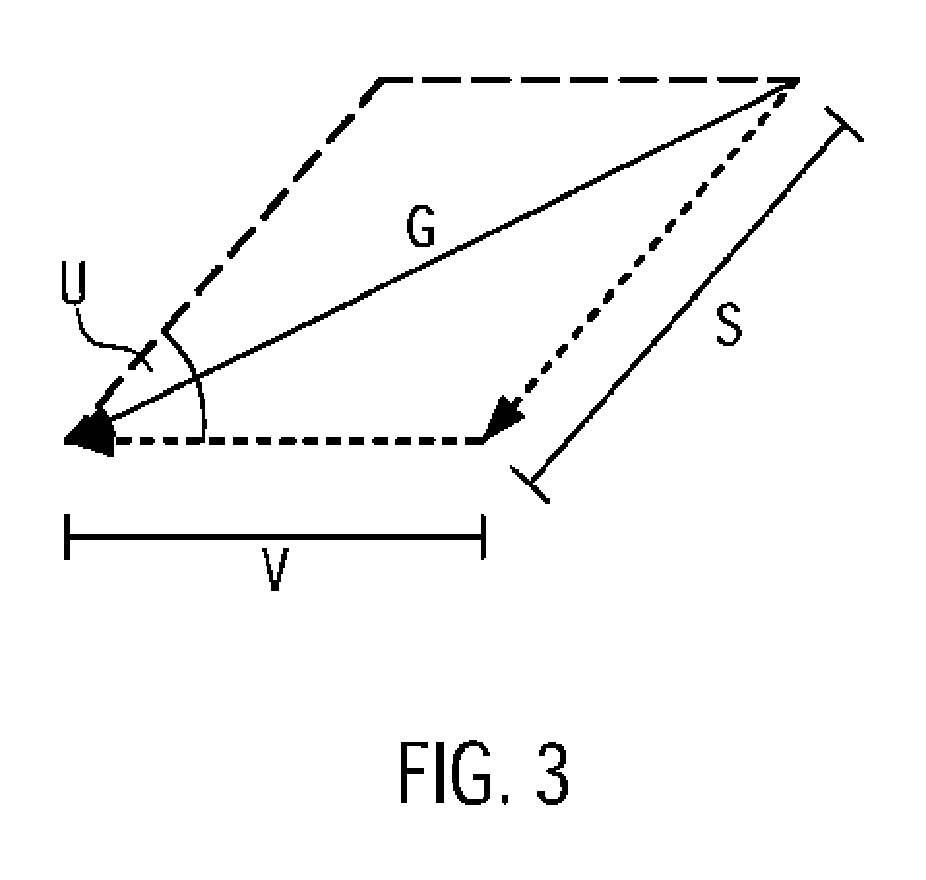

A belt tensioner of a vehicle occupant restraint system, especially a belt buckle tensioner, comprises a coupling member (12) to the vehicle seat belt, a drive unit (18), a flexible tension transmitting means (14) and a deflector (26). The flexible tension transmitting means (14) is connected at least indirectly to the coupling member (12) and is moved via the drive unit (18) in the event of tensioning. The deflector (26) deflects the tension transmitting means (14) in the direction of the coupling member (12). The tension transmitting means (14) is moved along the deflector (26) in the event of tensioning. According to the invention, the drive unit (18) is coupled in terms of drive to the deflector (26) such that the drive unit (18) moves the deflector (26) upon activation and thus displaces the coupling member (12) in the tensioning direction (R).

Owner:TRW AUTOMOTIVE GMBH

Belt tensioner

ActiveUS20110012418A1Save building spaceIncrease gear ratioBelt retractorsSafety beltsSeat beltBelt safety

A belt tensioner of a vehicle occupant restraint system, especially a belt buckle tensioner, comprises a coupling member (12) to the vehicle seat belt, a drive unit (18), a flexible tension transmitting means (14) and a deflector (26). The flexible tension transmitting means (14) is connected at least indirectly to the coupling member (12) and is moved via the drive unit (18) in the event of tensioning. The deflector (26) deflects the tension transmitting means (14) in the direction of the coupling member (12). The tension transmitting means (14) is moved along the deflector (26) in the event of tensioning. According to the invention, the drive unit (18) is coupled in terms of drive to the deflector (26) such that the drive unit (18) moves the deflector (26) upon activation and thus displaces the coupling member (12) in the tensioning direction (R).

Owner:TRW AUTOMOTIVE GMBH

Solar lamp capable of being cleaned easily

ActiveCN106764885AAchieve cleanupImprove cooling effectLighting heating/cooling arrangementsWith built-in powerEngineeringSolar lamp

The invention relates to solar lamps, in particular to a solar lamp capable of being cleaned easily. The solar lamp capable of being cleaned easily comprises a lamp pole and a lamp body arranged on the lamp pole. The lamp body comprises a light-emitting mechanism and a cooling mechanism. The cooling mechanism comprises a solar cell cooling plate, an LED lamp cooling plate and a vertical water storage pipe. The solar cell cooling plate is fixed to the top of the vertical water storage pipe. The LED lamp cooling plate is located at the bottom of the vertical water storage pipe. The LED lamp cooling plate is provided with a water collecting notch. The water collecting notch is connected with a flow guide pipe and further communicates with the vertical water storage pipe through the flow guide pipe. A torsional spring is connected between the lamp body and the lamp pole. The lamp body is further connected with a balancing weight. The vertical water storage pipe is provided with a water storage part and a deflection part. The deflection part is located above the water storage part and communicates with the water storage part. When the water storage part is used for storing water, the center of gravity of the lamp body can be kept stable. When the deflection part is used for storing water, the center of gravity of the lamp body can deflect. The solar lamp capable of being cleaned automatically is provided.

Owner:重庆博钻太阳能灯具有限公司

Actuator, optical scanner, and image forming apparatus

ActiveUS20080068688A1Increase deflection anglePromoting power-savingDynamo-electric machinesElectromagnets with armaturesOptical scannersImage formation

An actuator includes a frame-shaped first mass portion; a supporting portion that supports the first mass portion and takes the shape of a frame so as to surround a perimeter of the first mass portion; a pair of first elastic portions coupling between the first mass portion and the supporting portion so that the first mass portion is supported by the supporting portion; a second mass portion provided inside the frame-shaped first mass portion; a pair of second elastic portions coupling between the second mass portion and the first mass portion so that the second mass portion is supported by the first mass portion; and a driver for rotating the first mass portion. The driver includes a ferromagnet provided on the first mass portion in a position separate from a rotation central axis of the first mass portion; a coil formed along the rotation central axis of the first mass portion and the supporting portion so as to surround and orbit a perimeter of the ferromagnet if the first mass portion is seen from above; and a voltage application unit for applying a voltage to the coil. An operation of the voltage application unit included in the driver causes the coil to generate a magnetic field. The generation of the magnetic field causes displacement of the ferromagnet relative to the coil. The displacement of the ferromagnet causes the first mass portion to rotate while torsionally deforming the pair of first elastic portions. The rotation of the first mass portion causes the second mass portion to rotate while torsionally deforming the pair of second elastic portions.

Owner:SEIKO EPSON CORP

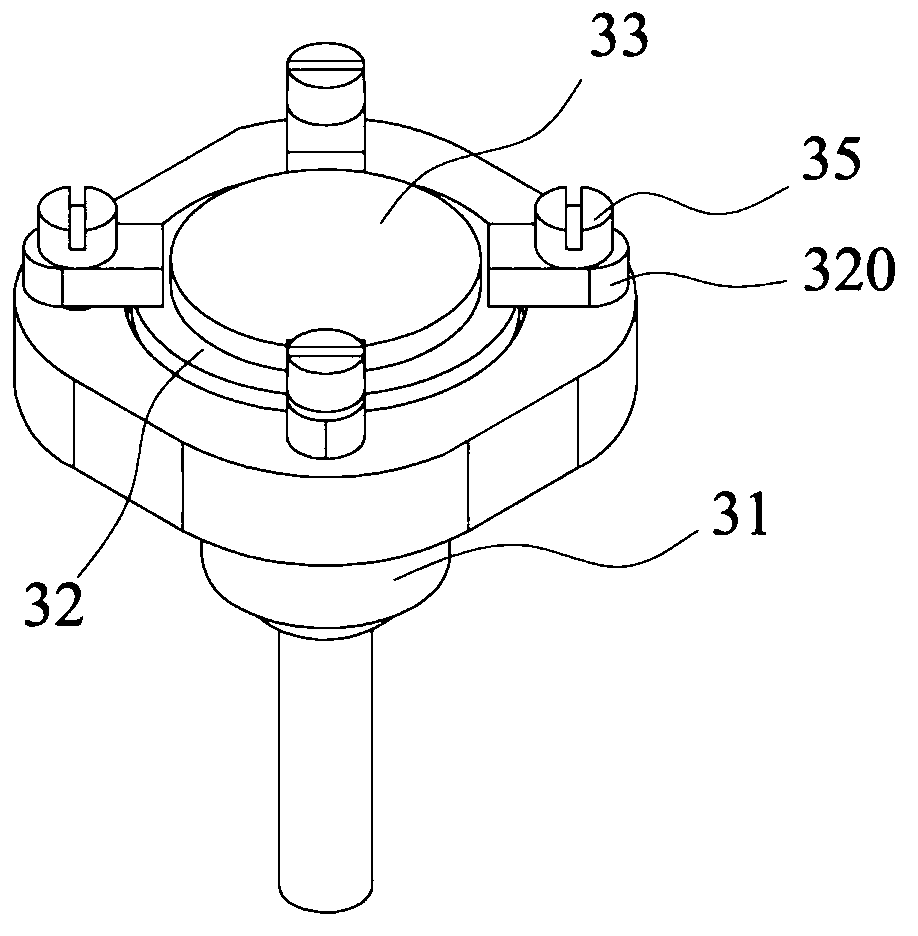

Two-degree-of-freedom high-speed parallel scanning platform and perpendicularity error calibration method thereof

InactiveCN103176270AIncrease stiffnessIncrease deflection angleControl using feedbackMountingsMirror reflectionClosed loop

The invention relates to a two-degree-of-freedom high-speed parallel scanning platform and a perpendicularity error calibration method thereof. The two-degree-of-freedom high-speed parallel scanning platform comprises a shell, and a linear driving mechanism, a reflector shaft mechanism, a joint bearing and a phase-sensitive detector (PSD) position sensor which are arranged in the shell. The two-degree-of-freedom high-speed parallel scanning platform provided by the embodiment has a single reflector structure, the scanning operation can be finished through one-step reflection only, and the error amplification effect brought by the double-mirror reflection is avoided; meanwhile, by adoption of a two-input two-output structure, the two-degree-of-freedom high-speed parallel scanning platform is easily controlled compared with the prior art; by adoption of a joint bearing structure, the scanning platform can have high rigidity and a large deflection angle; and because the two-dimensional PSD position sensor serves as a feedback device of the normal position of a reflector, a full closed loop is realized, and the high precision can be achieved. The two-degree-of-freedom high-speed parallel scanning platform has the characteristics of high precision, high rigidity and high bearing capacity.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Optical deflector including piezoelectric sensor incorporated into outermost piezoelectric cantilever

ActiveUS9151947B2Increase deflection angleEasy to controlOptical elementsMeanderPiezoelectric actuators

In an optical deflector including a mirror, a movable frame supporting the mirror, a first piezoelectric actuator for rocking the mirror with respect to a first axis of the mirror, a support body supporting the movable frame, and a second piezoelectric actuator for rocking the mirror through the movable frame with respect to a second axis of the mirror, at least one piezoelectric sensor is provided for sensing rocking vibrations of the mirror caused by the first and second piezoelectric actuators. The second piezoelectric actuator includes a pair of meander-type piezoelectric actuators opposite to each other with respect to the first axis. Each of the second meander-type piezoelectric actuators includes a plurality of piezoelectric cantilevers folded at every cantilever and connected from the support body to the movable frame in parallel with the first axis. The piezoelectric sensor is incorporated into an outermost one of the piezoelectric cantilevers.

Owner:STANLEY ELECTRIC CO LTD

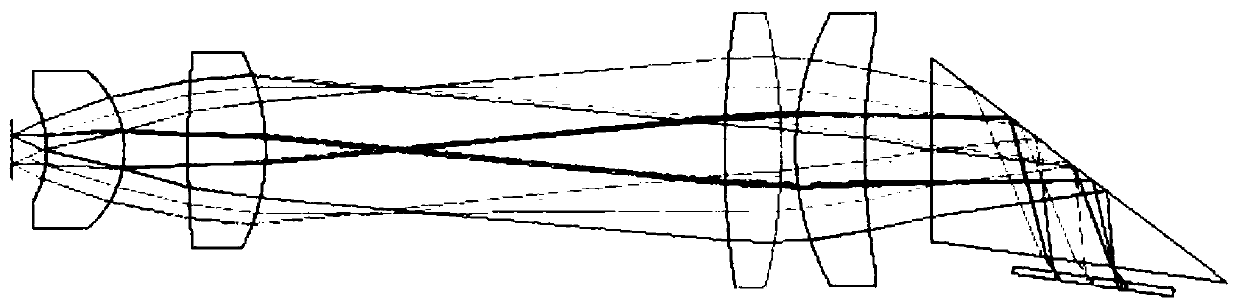

Lighting assembly applied in laser projection device

InactiveCN108803219APerformance is not affectedReduce horizontal sizeProjectorsTotal internal reflectionEffect light

The invention provides a lighting assembly applied in a laser projection device. The lighting assembly includes a first spherical lens, a second spherical lens, and an aspherical lens, wherein the first spherical lens is located on a path of a first outgoing light beam emitted from a photoconductive tube for increasing the deflection angle of the first outgoing light beam and performing field curvature correction and distortion correction on the first outgoing light beam; the second spherical lens is located on a path of a second outgoing light beam emitted from the first spherical lens for performing field curvature correction and distortion correction on the second outgoing light beam; and the aspheric lens is located on a path of a third outgoing light beam emitted from the second spherical lens for performing aberration correction on the third outgoing light beam and projecting the third outgoing light beam to a TIR (Total Internal Reflection) prism, so as to enable the TIR prism to totally reflect the third outgoing light beam to a DMD module. The scheme of the lighting assembly applied in a laser projection device reduces the lateral dimension and the longitudinal height of the lighting assembly by reducing the number of lenses and using special lenses, and also reduces the overall cost at the same time, so as to solve the problem that the lighting assembly is large in the volume and high in the cost on the premise of guaranteeing that the performance of the laser projection device is not affected.

Owner:QINGDAO HISENSE LASER DISPLAY CO LTD

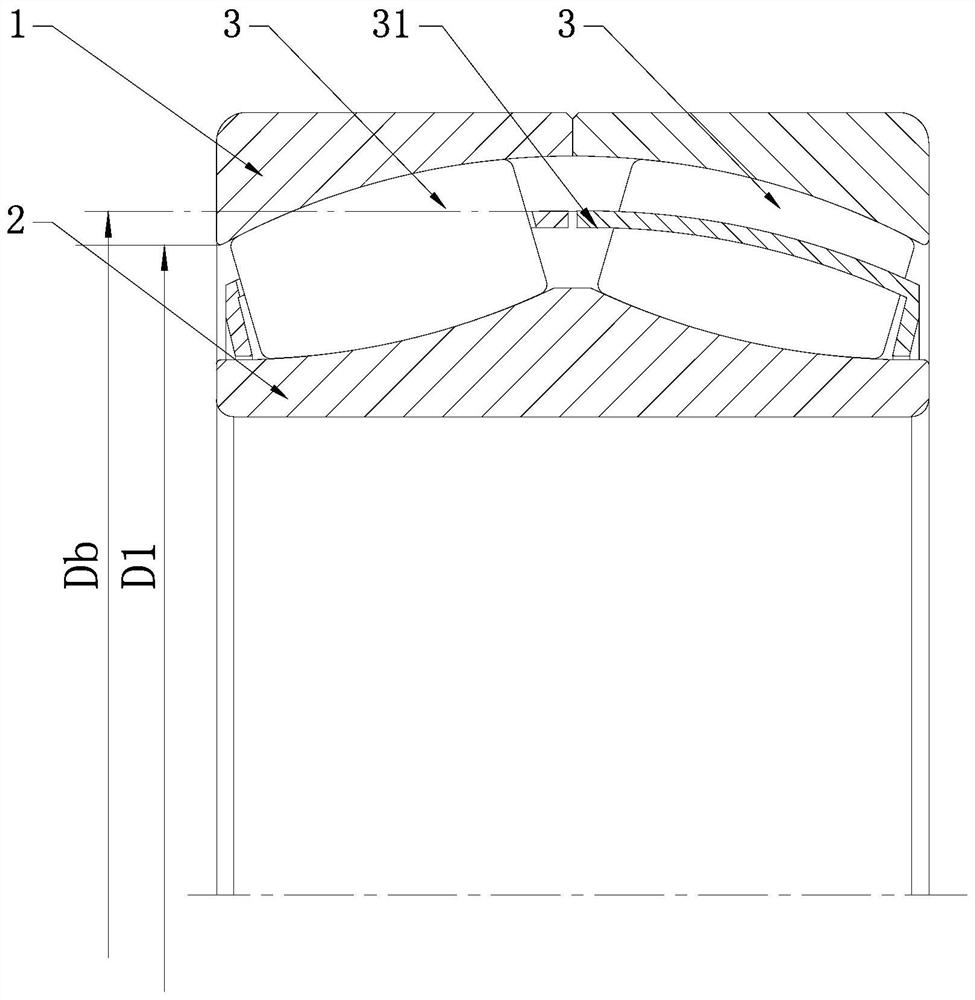

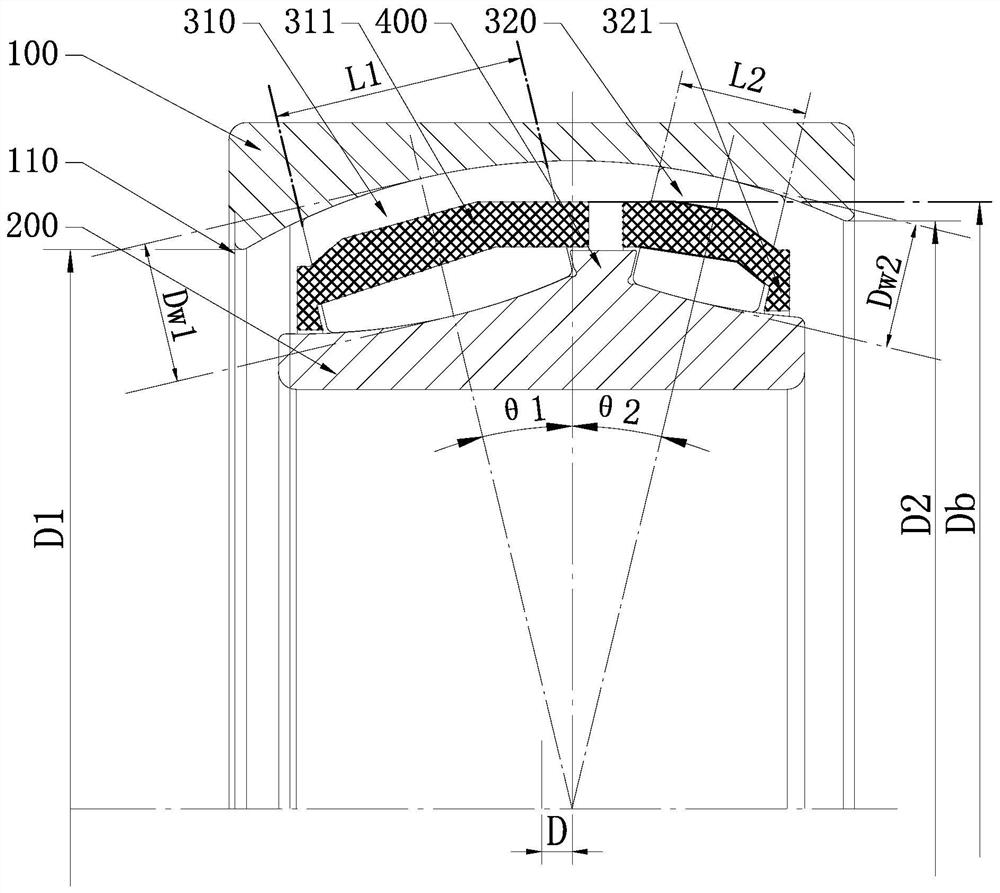

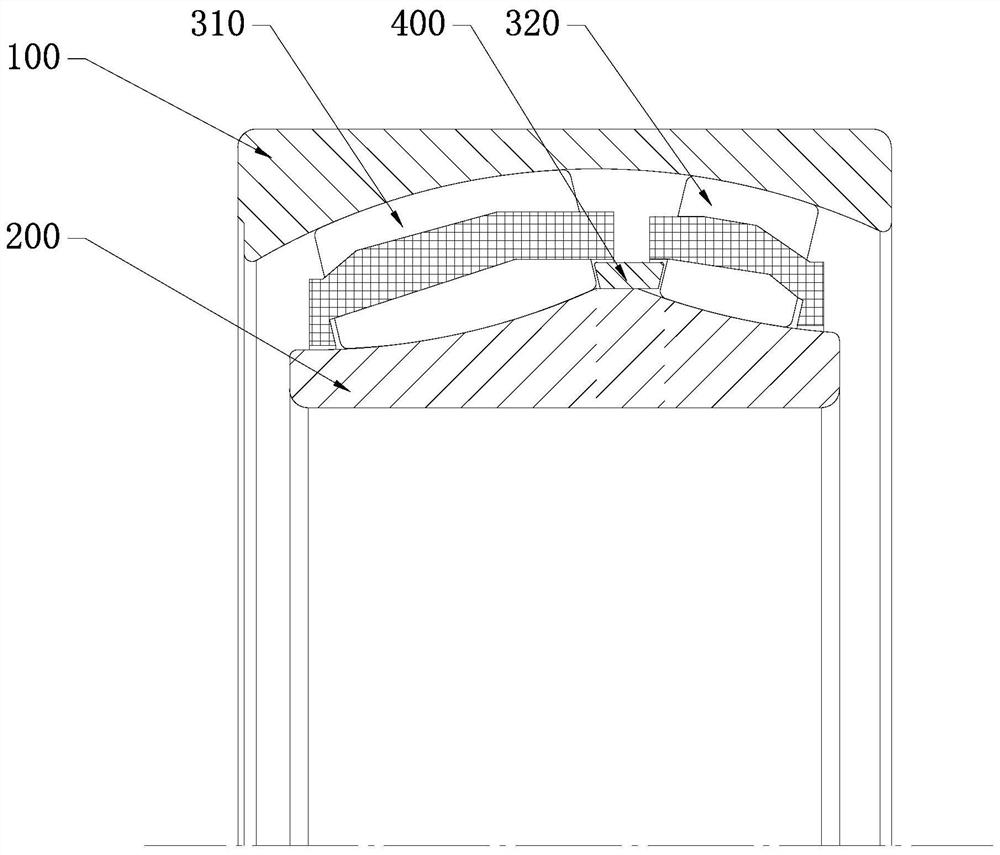

Self-aligning roller bearing suitable for axial and radial unbalance loading working conditions and heat treatment process

PendingCN111720434AIncrease deflection angleDimensionally stableRolling contact bearingsShaftsElectric power equipmentEngineering

The invention discloses a self-aligning roller bearing suitable for axial and radial unbalance loading working conditions and a heat treatment process, and belongs to the technical field of bearings.The bearing comprises an outer ring, an inner ring and two rows of symmetrical spherical rollers kept between the two inner roller paths and a shared outer roller path through a retainer correspondingly, wherein the the two rows of rollers are different in length so as to enable the two rows of rollers to form long rollers and short rollers correspondingly, the maximum diameters of the short rollers are smaller than the maximum diameters of the long rollers, and the sphere center of the spherical surface where the outer roller path is located deviates from the axial center of the bearing towards one end of the short rollers in the axial direction of the bearing. According to the self-aligning roller bearing suitable for the axial and radial unbalance loading working conditions and the heattreatment process, a deflection angle of the bearing is increased, the contact stress of the rollers on the two sides and the roller paths is uniform, the overall service life of the bearing is prolonged, the bearing still has high hardness, stable size and high wear resistance at high temperature, and the bearing is suitable for output end shafts of main transmission cases of ocean engineering equipment, metallurgical machines, electric power equipment, special vehicles, axial flow fans and the like.

Owner:SHANDONG YUJIE BEARING MFG CO LTD

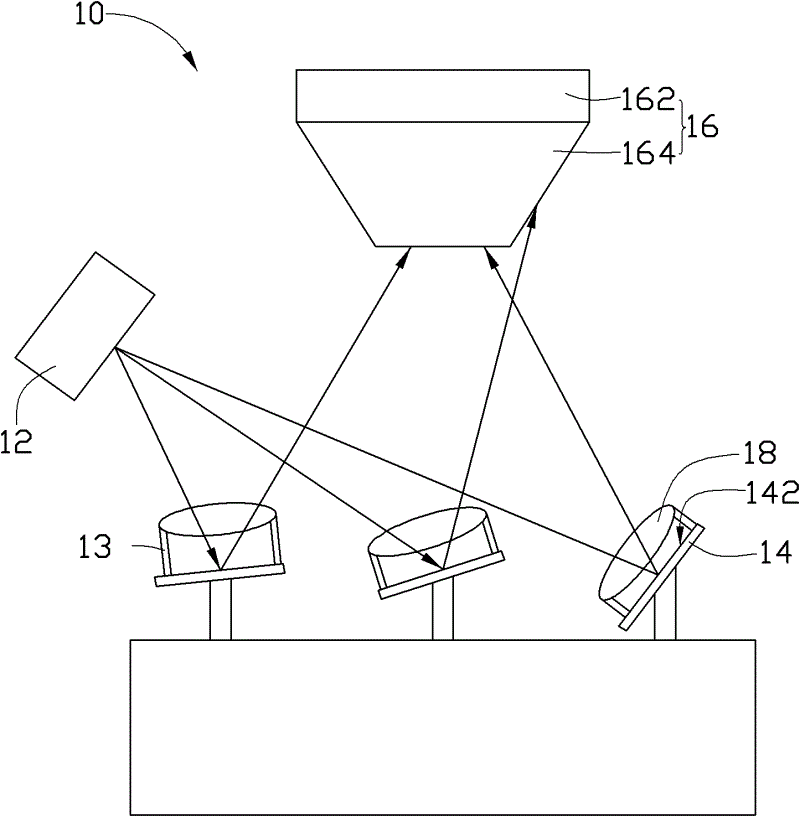

Projection device

The invention provides a projection device, wherein the projection device comprises a light source, three digital micromirror devices and a projection lens. The light source is used to emit light to the three digital micromirror devices. Each of the digital micromirror devices comprises a plurality of micromirrors. The projection lens is used to project light to a projection screen. Each of the micromirrors is used to selectively reflect light to the projection lens. Each of the digital micromirror devices is provided with a condenser lens, wherein each of the condenser lenses is located between the corresponding digital micromirror device and the projection lens. In the projection device provided in the invention, light beams reflected by the micromirrors are narrowed after focused by the condenser lenses, such that the volume of the projection lens can be reduced and projection accuracy of the reflected light can be enhanced, thereby projection picture quality is improved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

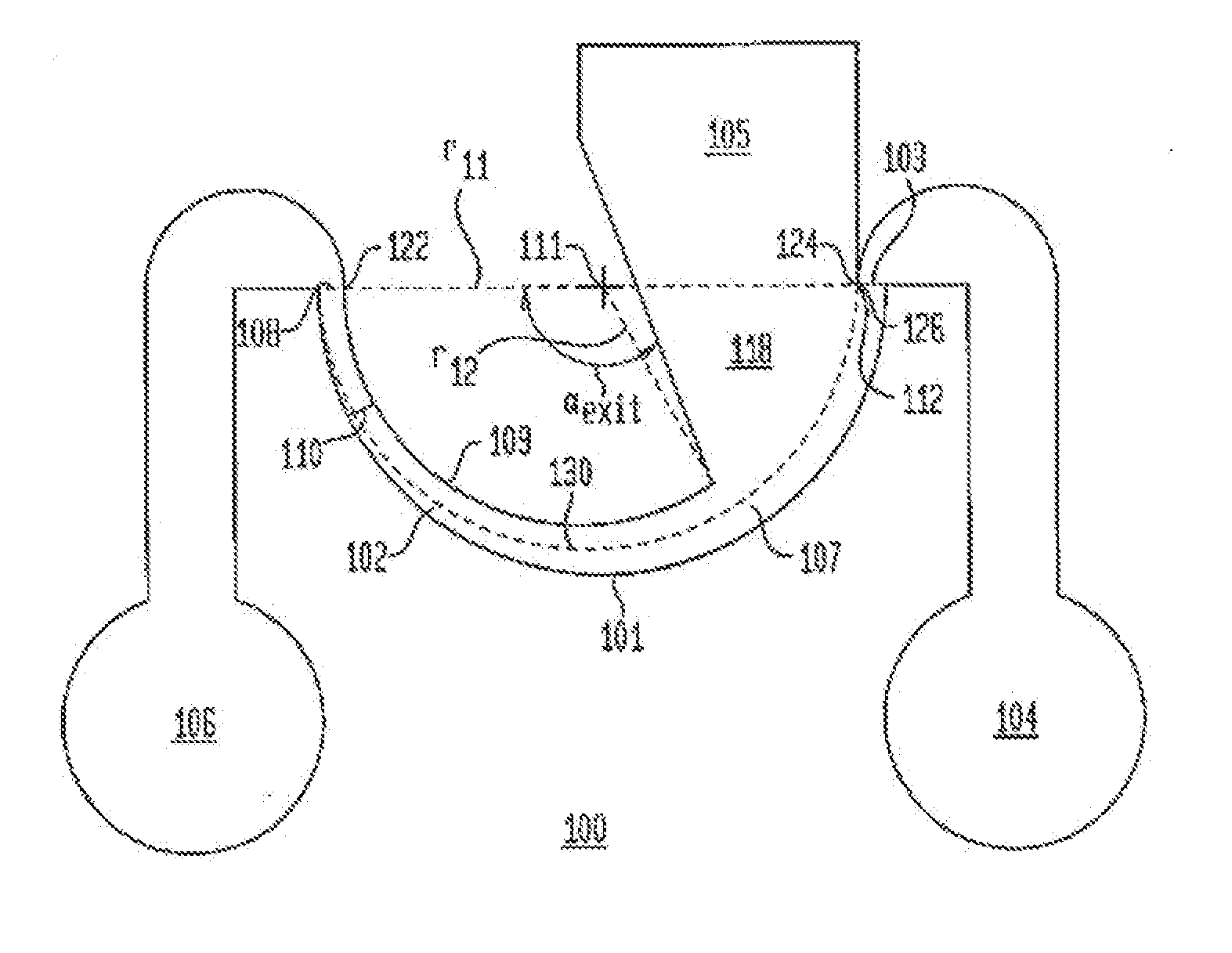

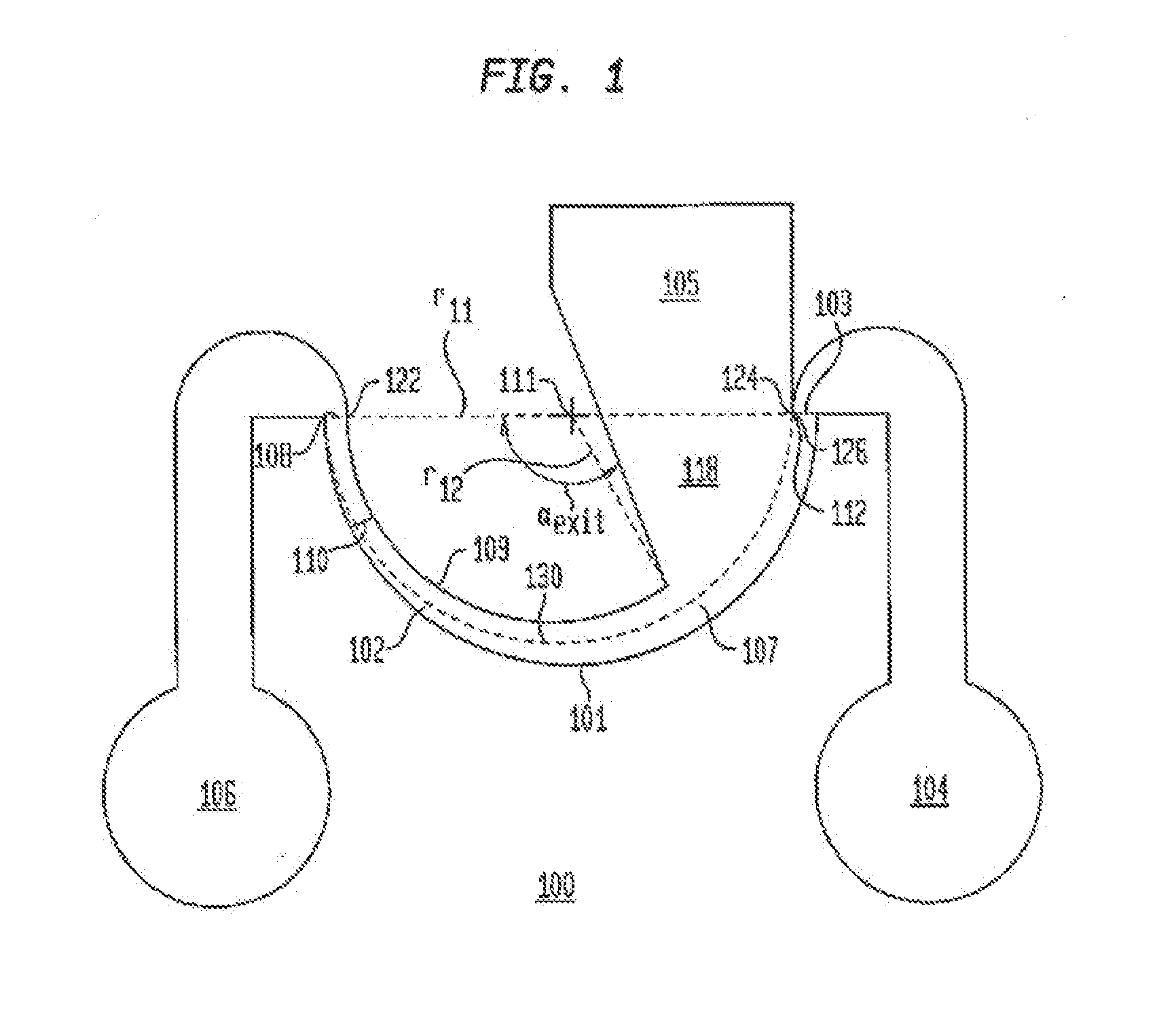

Aerodynamic separation nozzle

InactiveUS20130174602A1Increase pressureHigh speedRefrigeration componentsSteam engine plantsTemperature controlGas phase

Multiple designs and methods for aerodynamic separation nozzles and systems for integrating multiple aerodynamic separation nozzles into a single system are disclosed herein. These aerodynamic separation nozzles utilize a combination of aerodynamic forces and separation nozzle structure to induce large centrifugal forces on the fluids that in combination with the structure of the nozzle are used to separate heavier constituents of the fluid from lighter constituents, and more particularly to separate a first or liquid phase from gaseous phases. In some embodiments a number of separation nozzles are combined into a single system suitable for dynamic processing of a process gas. In other embodiments the separation nozzles are temperature controlled to condition the incoming gas to a temperature in order to encourage a phase change in certain constituents of the gas to occur within the nozzle to further enhance separation.

Owner:TENOROC

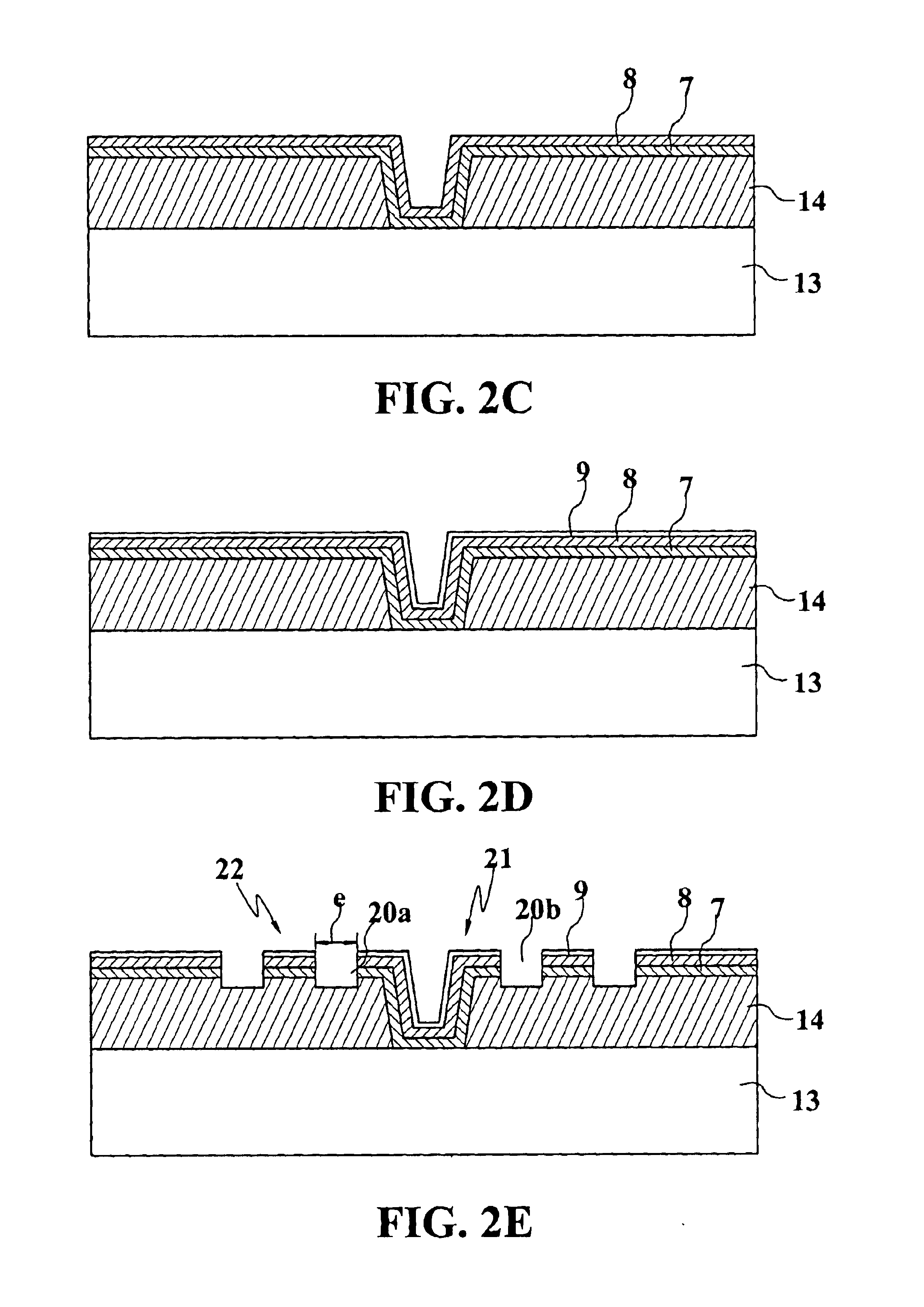

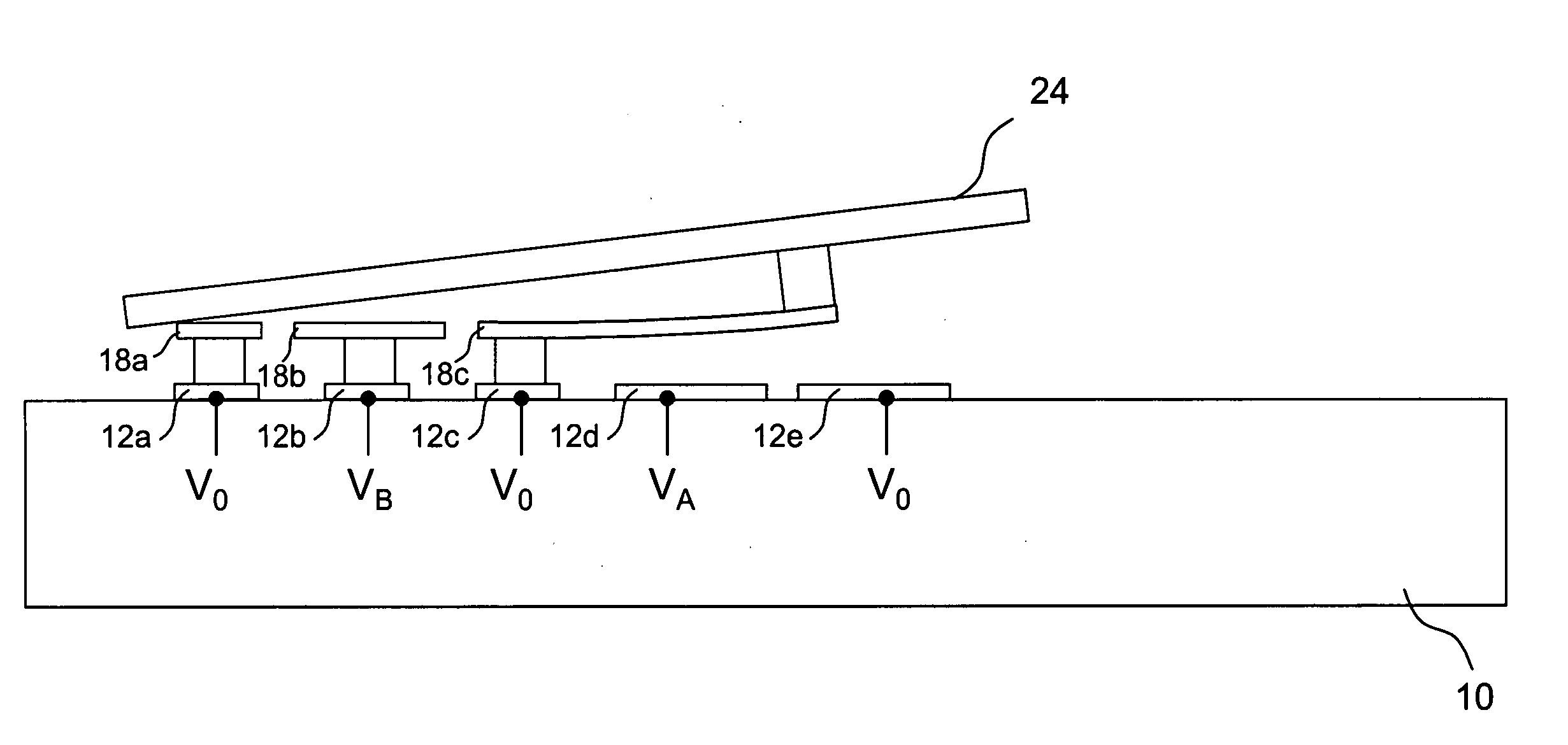

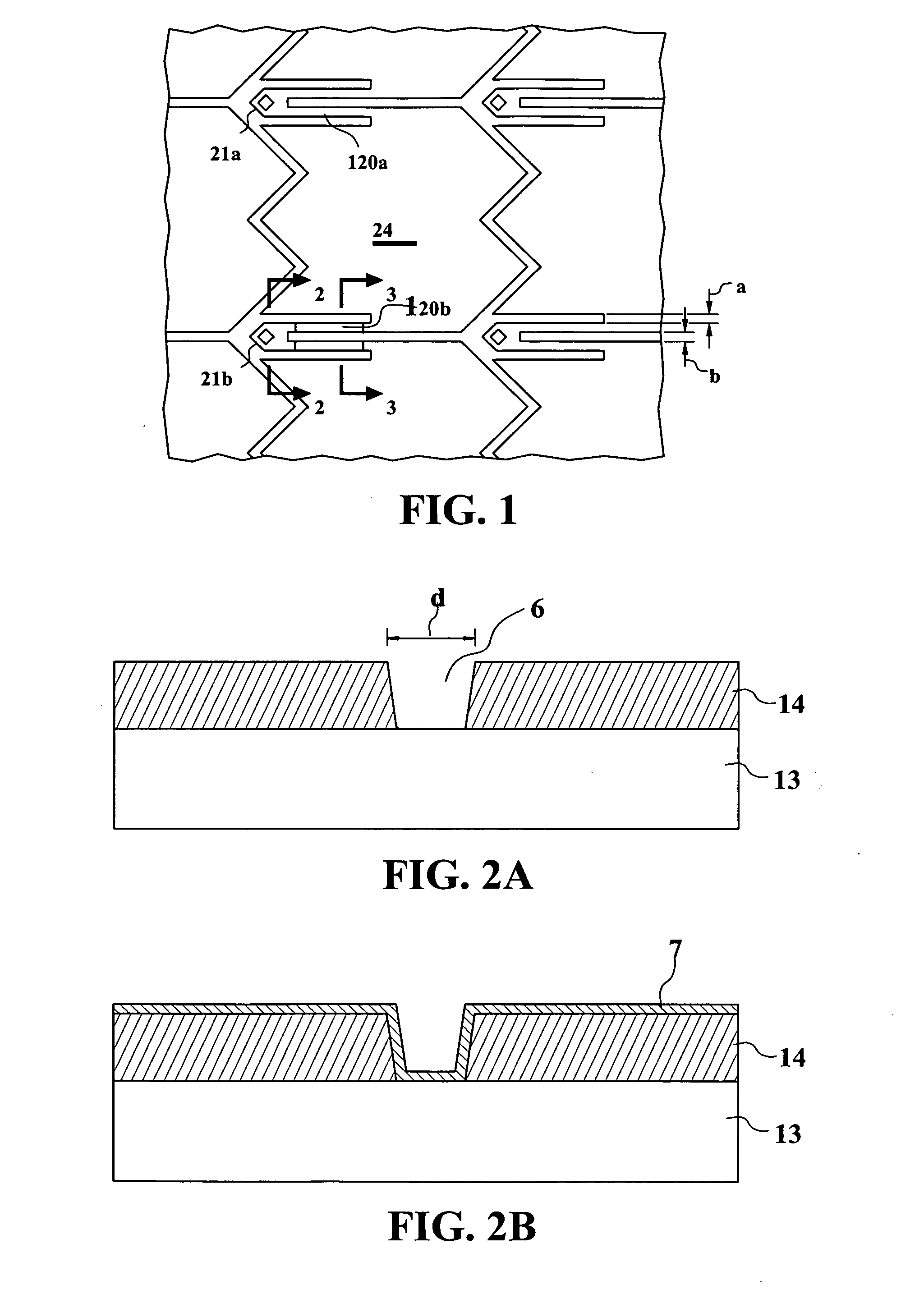

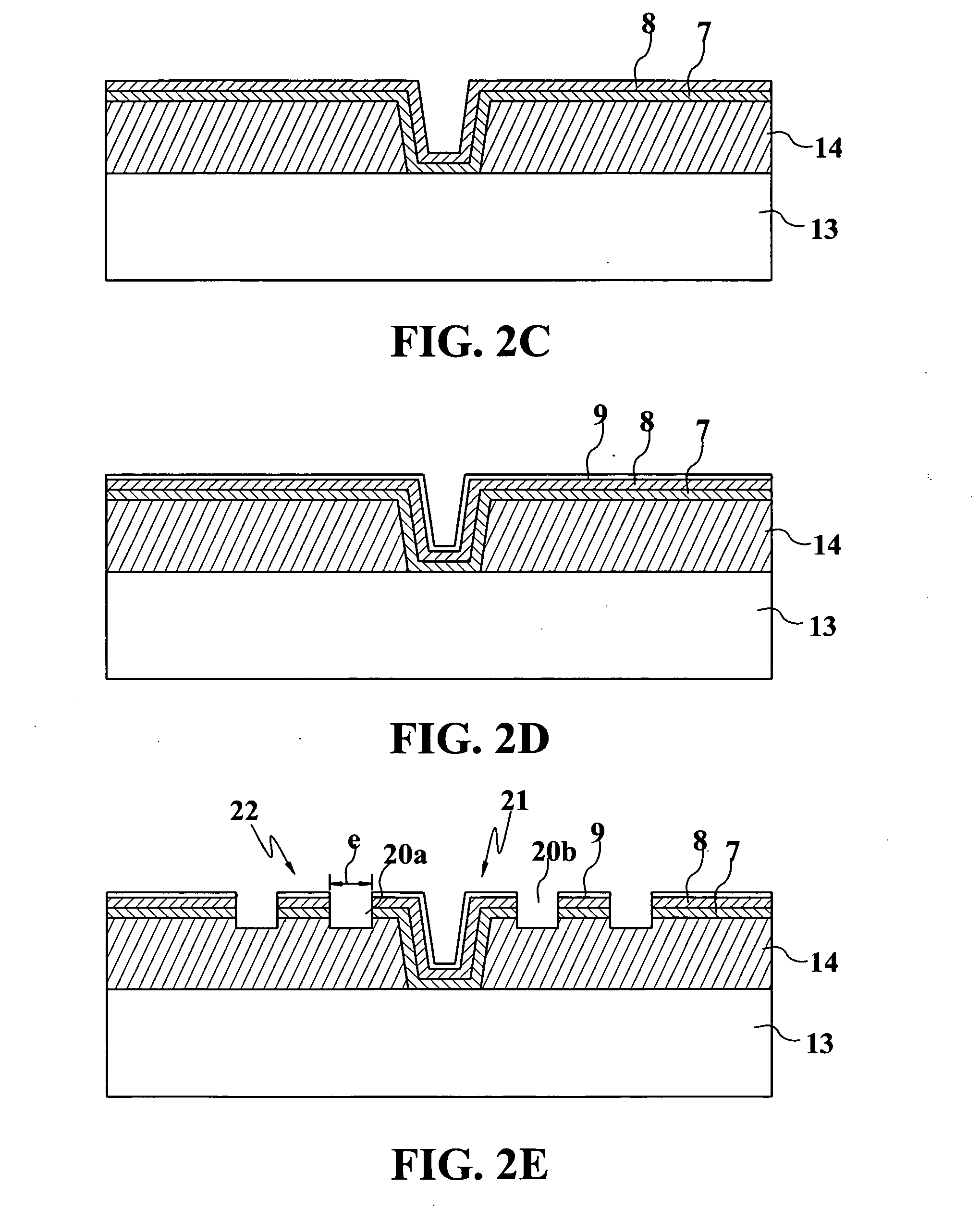

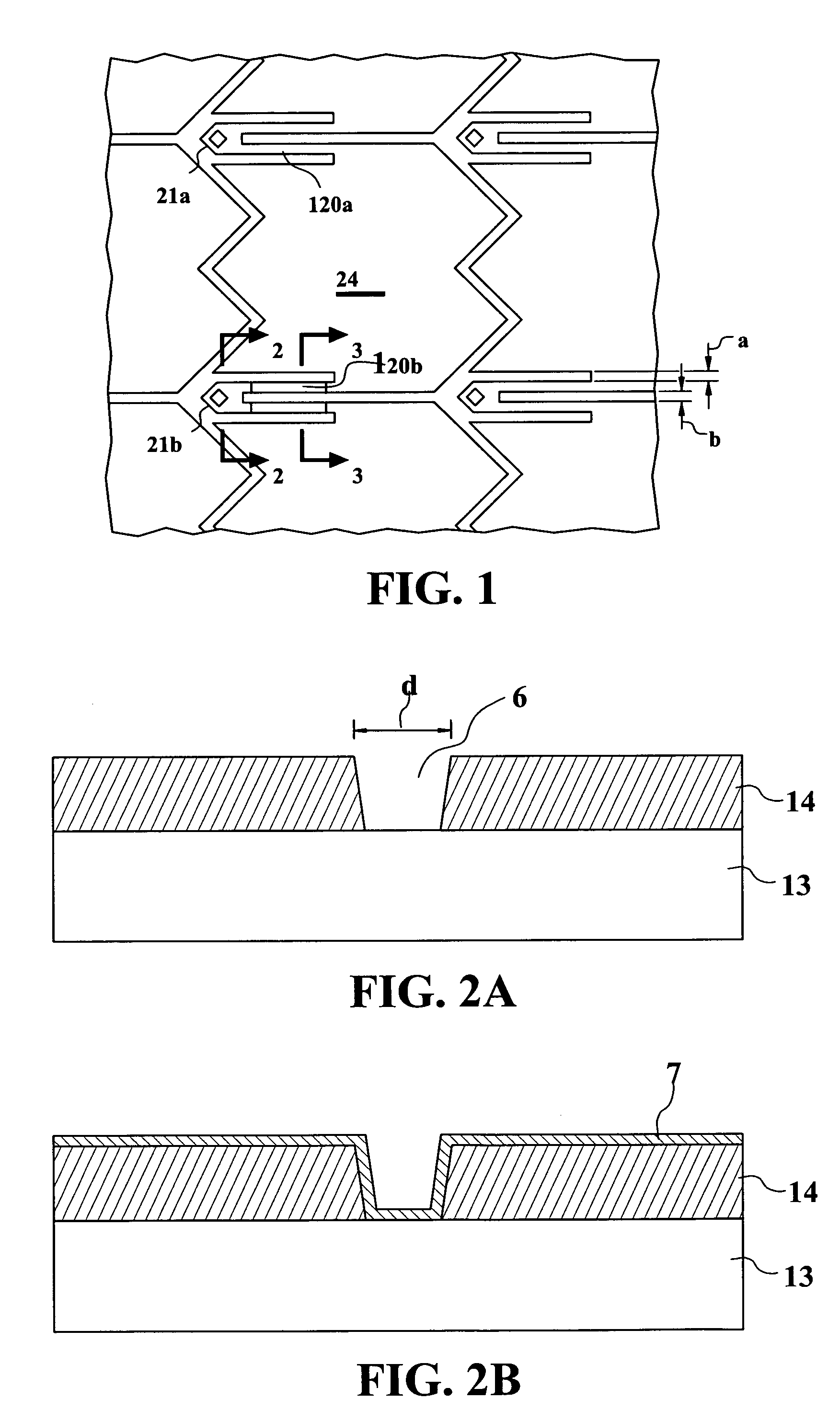

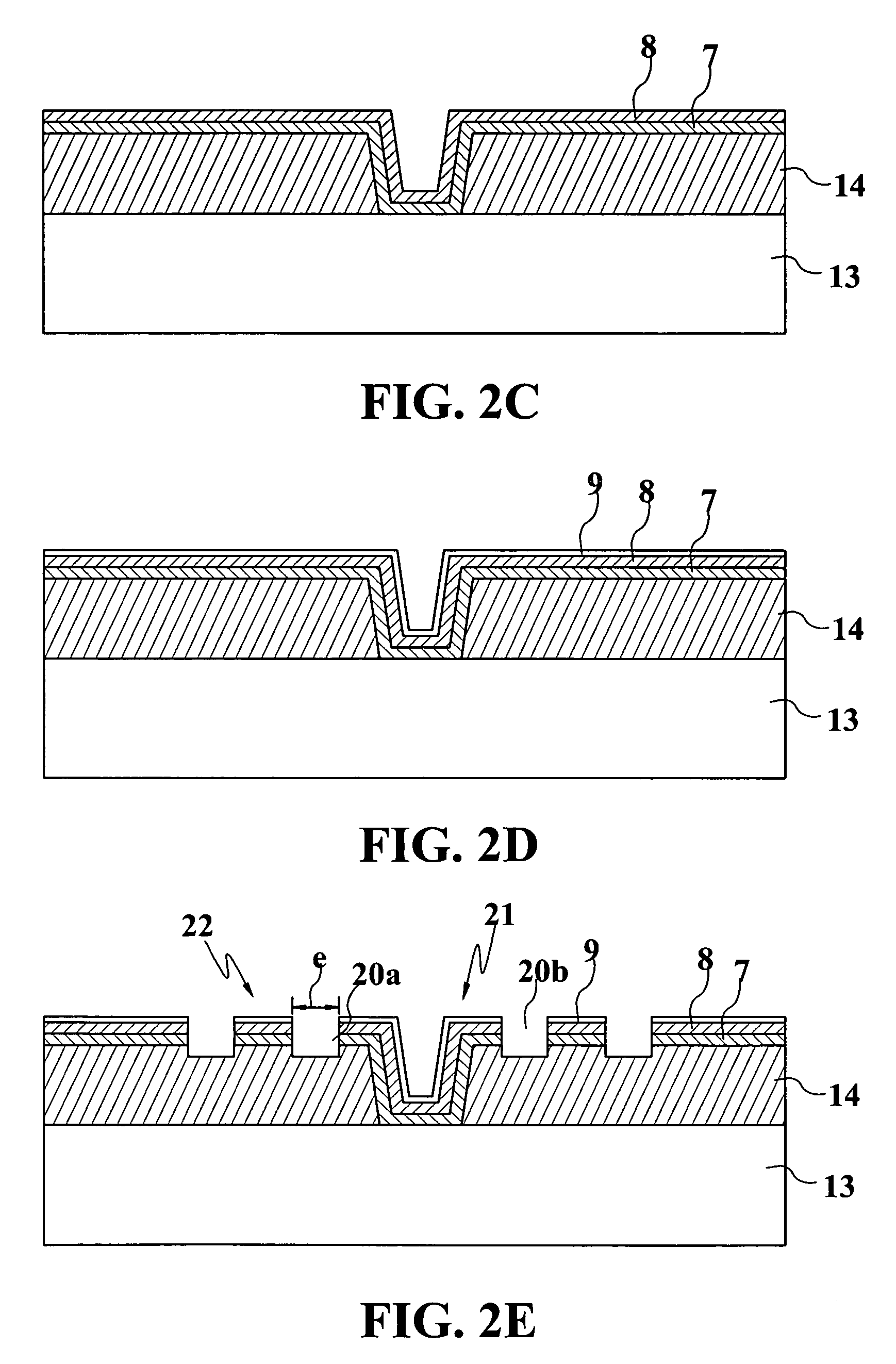

Two-dimensional micro-mirror array enhancements

InactiveUS7031045B2Improve instabilityIncrease deflection angleCoupling light guidesRotational axisMicro mirror

A micro-mirror strip assembly having a plurality of two-dimensional micro-mirror structures with improved deflection and other characteristics is presented. In the micro-mirror structures, electrodes for electrostatic deflection are disposed on conical or quasi-conical entities that are machined, attached or molded into a substrate. The electrodes are quartered approximately parallel to or offset by 45 degrees from rotational axes to form quadrants. Torsion sensors are provided along the axes of rotation to control deflection of the quadrant deflection electrodes.

Owner:RPX CLEARINGHOUSE

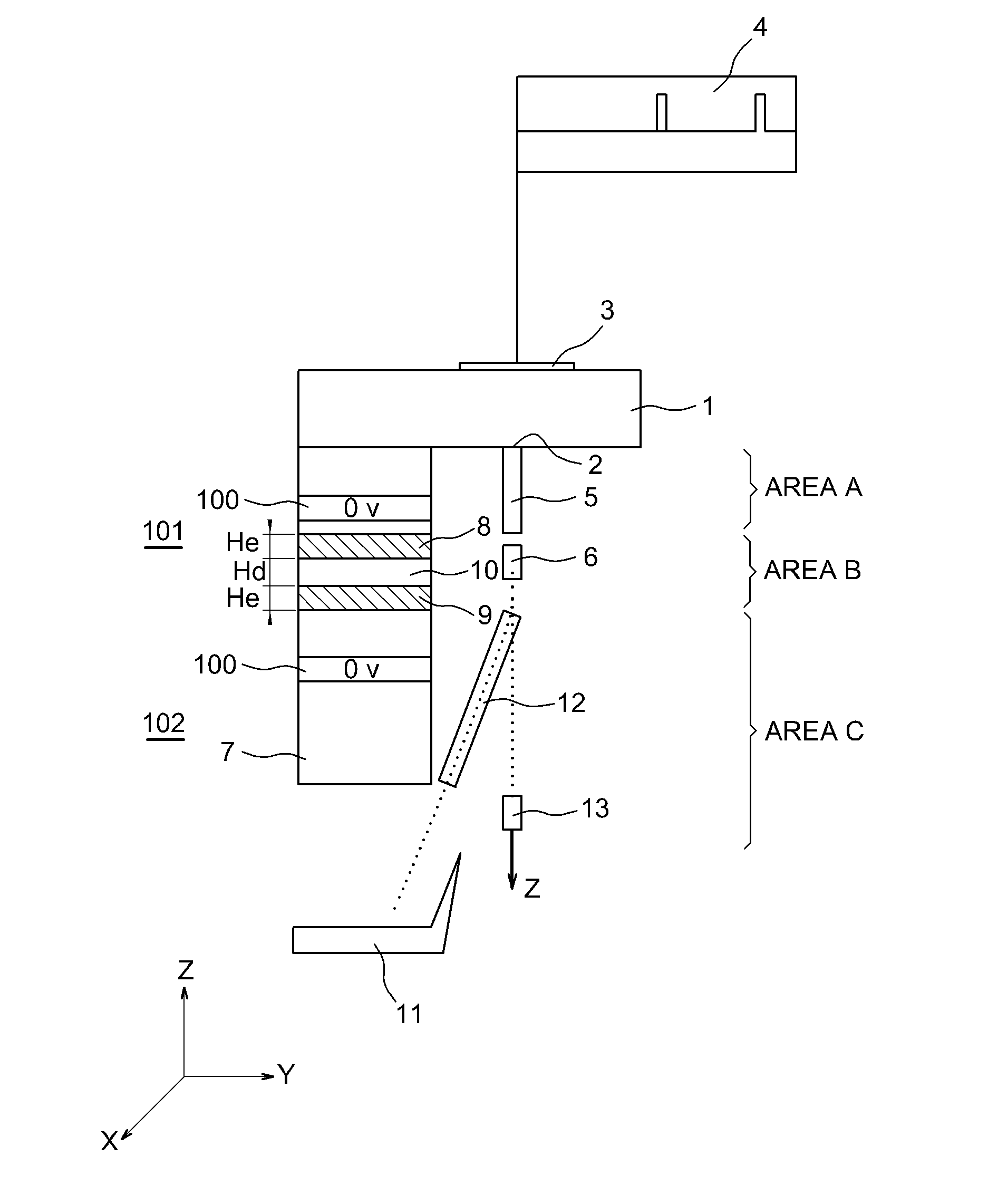

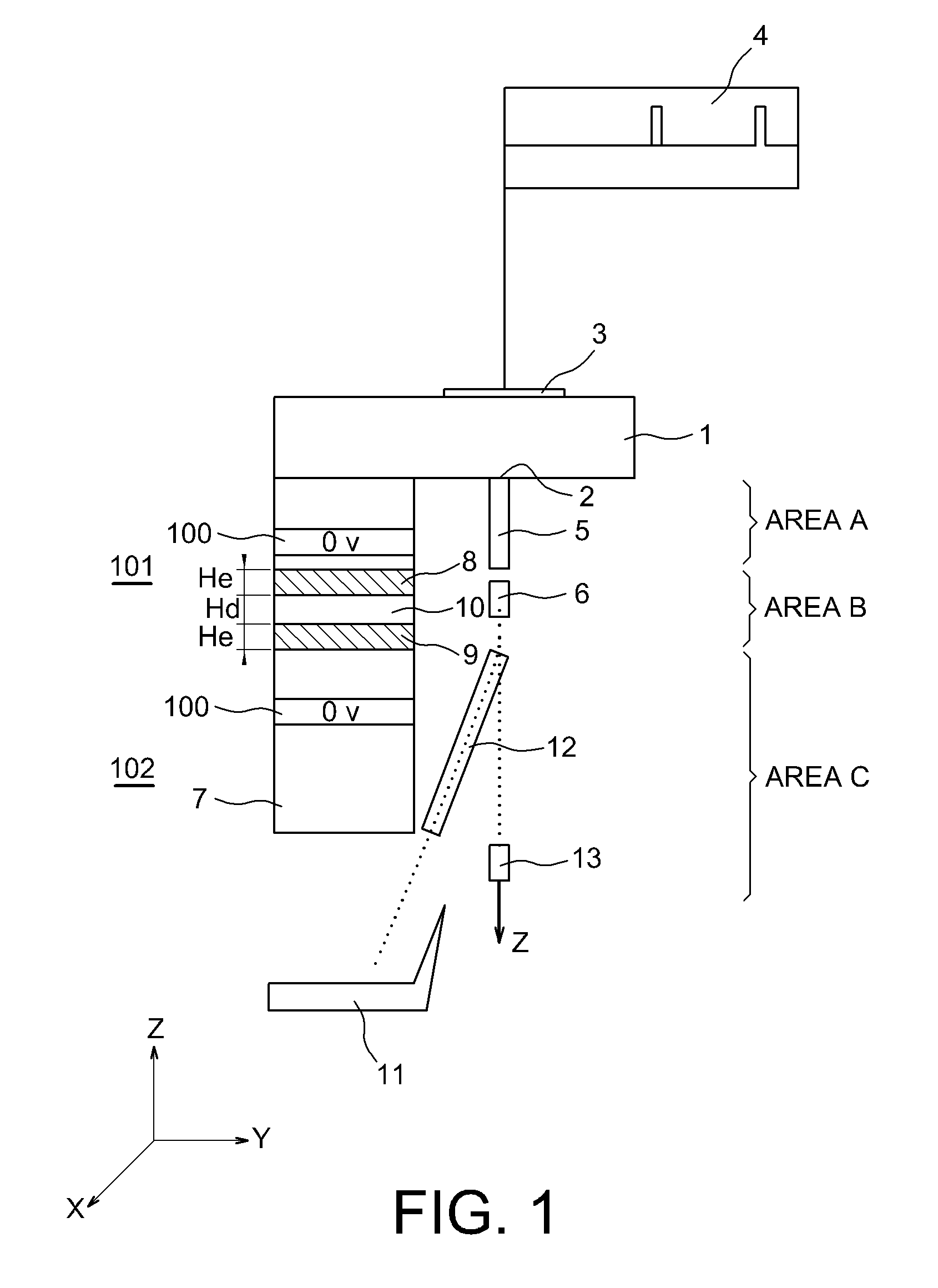

Inkjet printer operating a binary continuous-jet with optimum deflection and maximised print speed

InactiveUS20110216136A1Improve printing qualityFacilitates design and dimensioningPrintingEngineeringPulse period

Owner:MARKEM IMAJE LTD

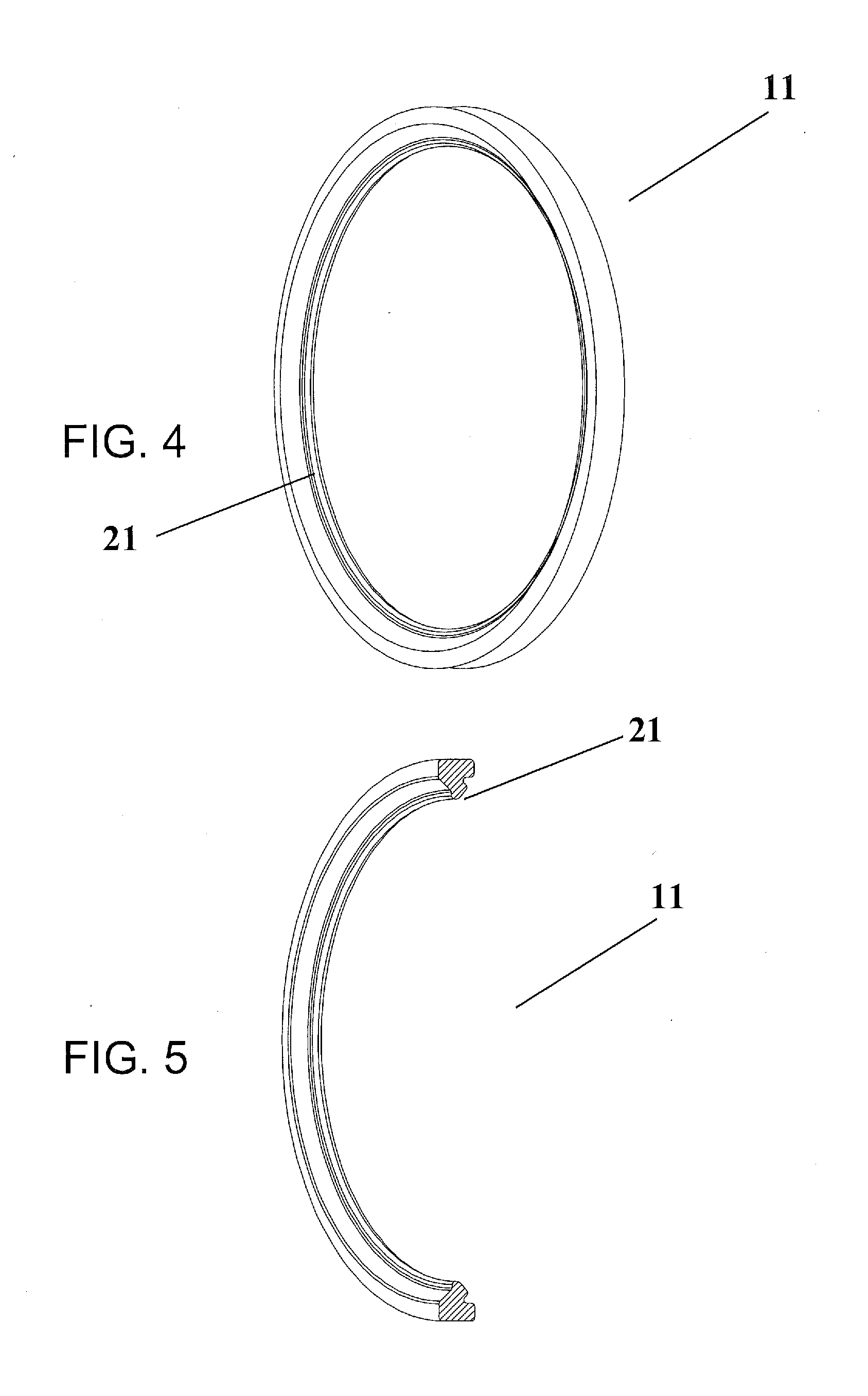

High deflection unrestrained pipe joint

InactiveUS20160341344A1Increase deflection angleSleeve/socket jointsAdjustable jointsMechanical engineeringDeflection angle

The present disclosure generally pertains to systems and methods for an improved pipe joint. The system includes a first pipe having a bell socket end and a second pipe having a male or spigot end. The bell socket end of the first pipe is configured to include an inner groove within which a sealing member may be inserted. The bell socket end of the first pipe further includes a pivot cavity. The spigot end of the second pipe may be inserted into socket end of the first pipe to form an unrestrained, push-fit, ring-seal assembly when operatively joined, such that a sealing member is located within the inner groove, the sealing member having a sealing surface that is longitudinally related with the pivot point of the two pipes thereby allowing a high joint deflection angle while maintaining a relatively small pipe bell and sealing member mass.

Owner:MCWANE

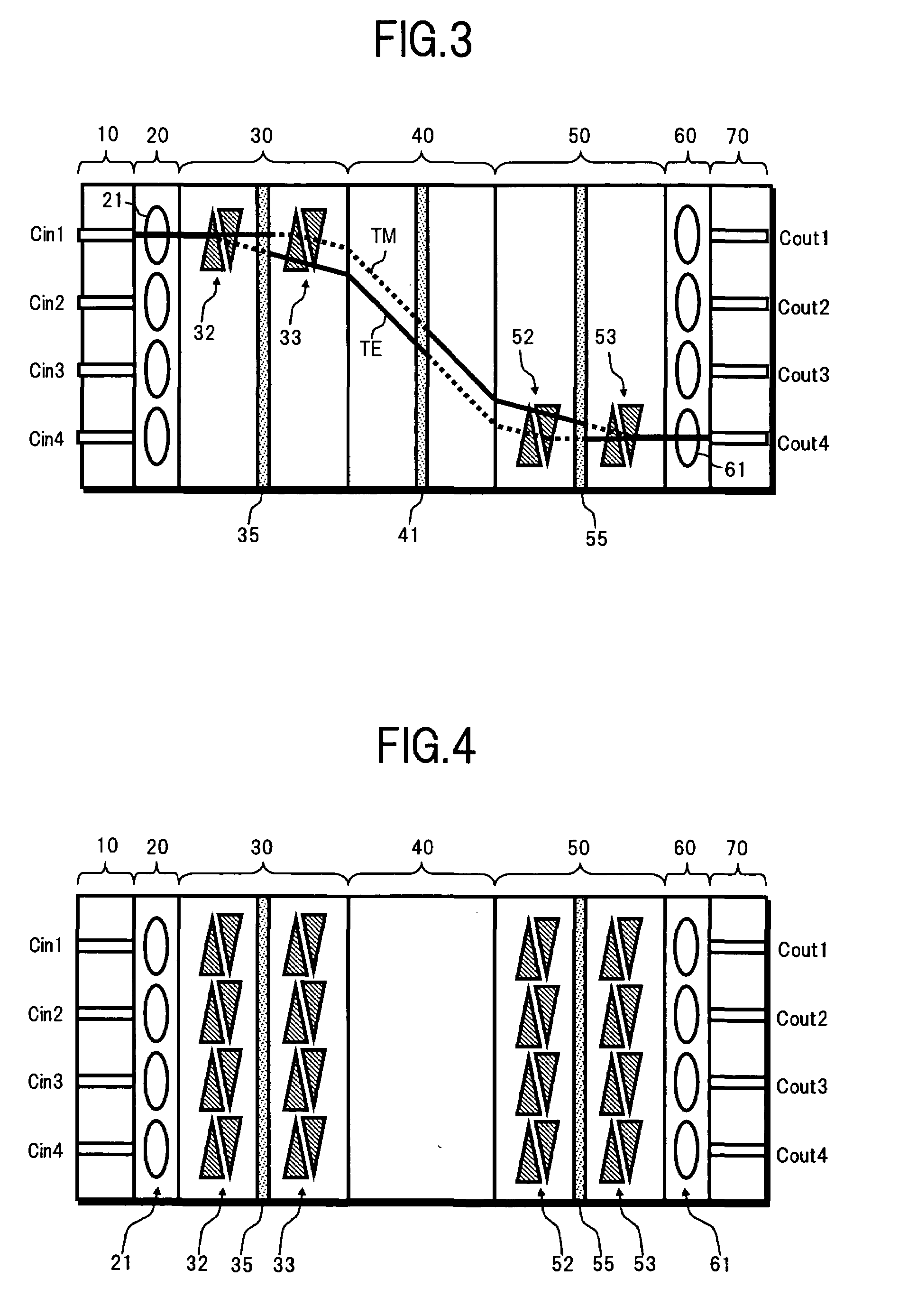

Optical switch

An optical switch of the present invention is for deflecting a light given to an input channel waveguide by first and second optical deflecting sections arranged respectively on the former and latter stages of a slab type optical waveguide section, so that a deflection angle by the first optical deflecting section is symmetrical to that by the second optical deflecting section, to guide the light to a desired output channel waveguide. The first and second optical deflecting sections each includes a half-wave plate between input side upper electrode portions and output side upper electrode portions each of which is formed with prism type electrodes, and the slab type optical waveguide also includes a half-wave plate on the center thereof. As a result, by forming an optical deflection element using a material having the polarization dependence and a high electro-optic effect, it becomes possible to achieve the reduction of drive voltage and an increase of deflection angle, and also, to reduce a loss occurred due to the polarization dependence of the deflection angle.

Owner:FUJITSU LTD

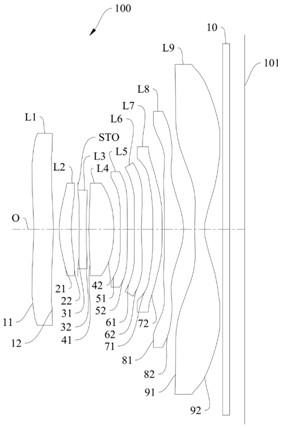

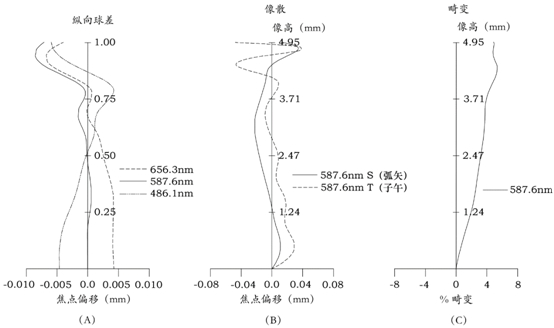

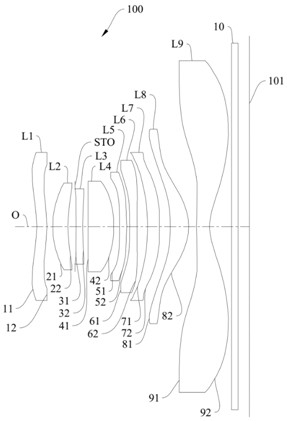

Optical lens, camera module and electronic equipment

ActiveCN114660783ALarge field of viewReduce sensitivity to resolution changesOptical elementsOphthalmologyImaging quality

The invention discloses an optical lens, a camera module and electronic equipment, and the optical lens comprises a first lens with refractive power, a second lens with refractive power, a third lens with refractive power, a fourth lens with refractive power, a fifth lens and a sixth lens which are sequentially arranged from an object side to an image side along an optical axis, the object side surface and the image side surface of the second lens are respectively a convex surface and a concave surface; a third lens element with negative refractive power having a concave image-side surface; the object side surface and the image side surface of the fourth lens are convex surfaces; the object side surface and the image side surface of the fifth lens are respectively a concave surface and a convex surface; the object side surface and the image side surface of the sixth lens are concave surfaces; a seventh lens element with refractive power having a concave object-side surface; the image side surface of the eighth lens is a convex surface; the object side surface and the image side surface of the ninth lens are respectively a convex surface and a concave surface; the optical lens satisfies 0.3 lt; sD < 12 > / IMGHlt; and 0.5. With the adoption of the scheme, while the imaging quality is ensured, the optical system has the characteristics of miniaturization and large field angle.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

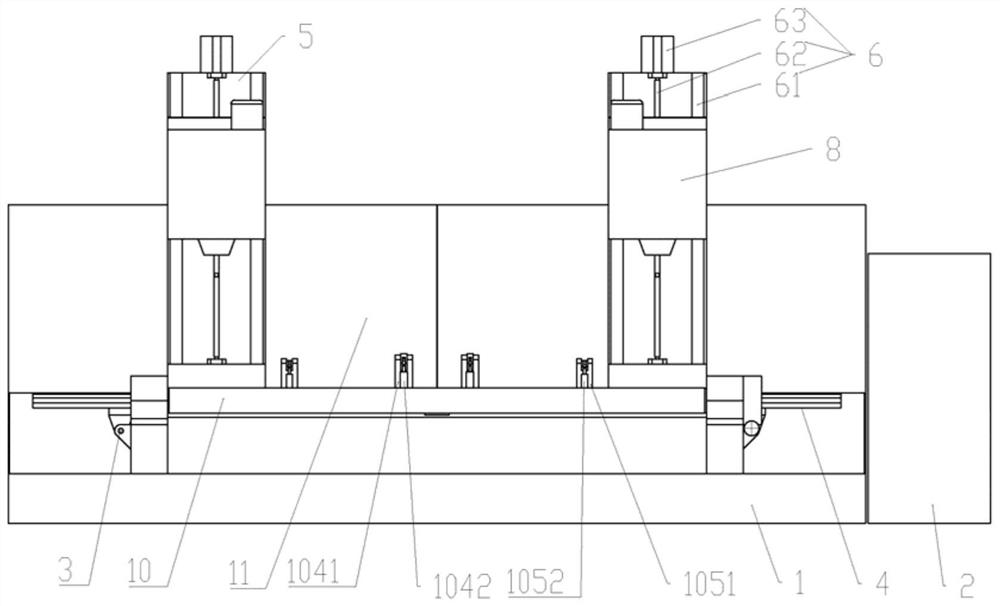

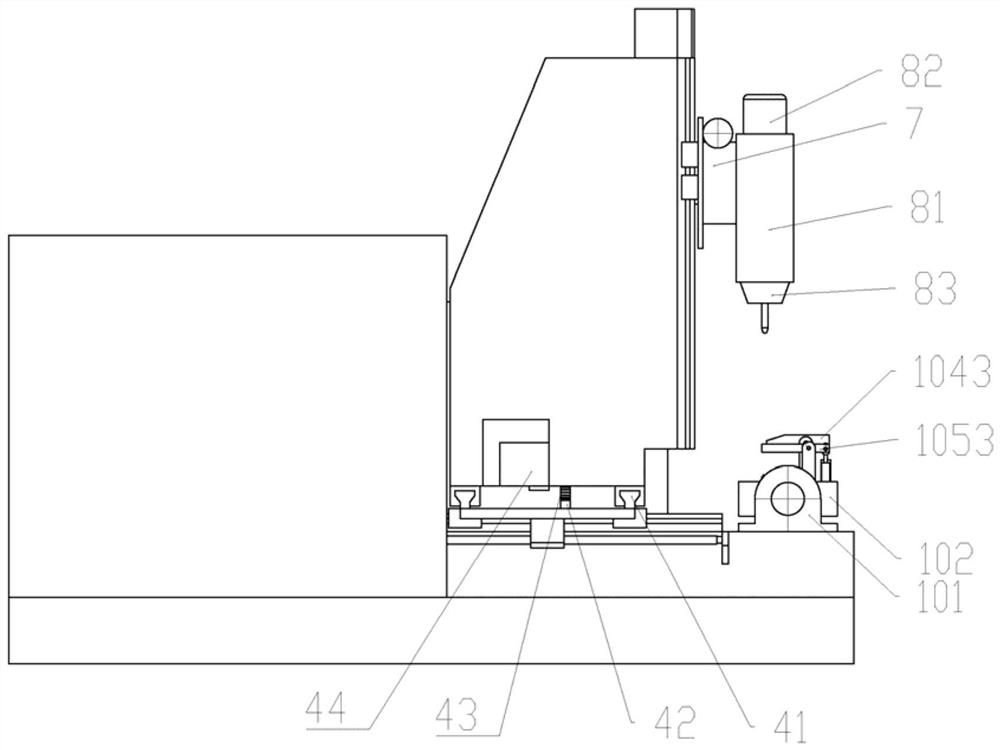

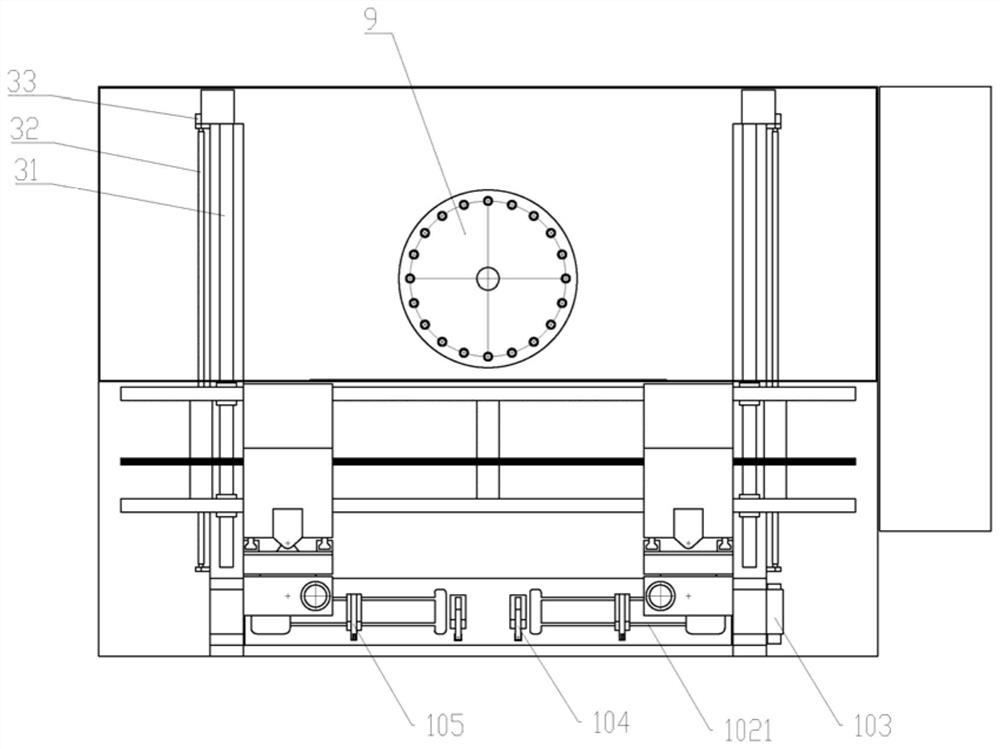

Full-process automatic machining system for front shaft

PendingCN111975424AIncrease deflection angleIncrease cutting forceFeeding apparatusLarge fixed membersEngineeringMachining system

Owner:HUBEI TRI RING AXLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com