Patents

Literature

33492results about "Lighting heating/cooling arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

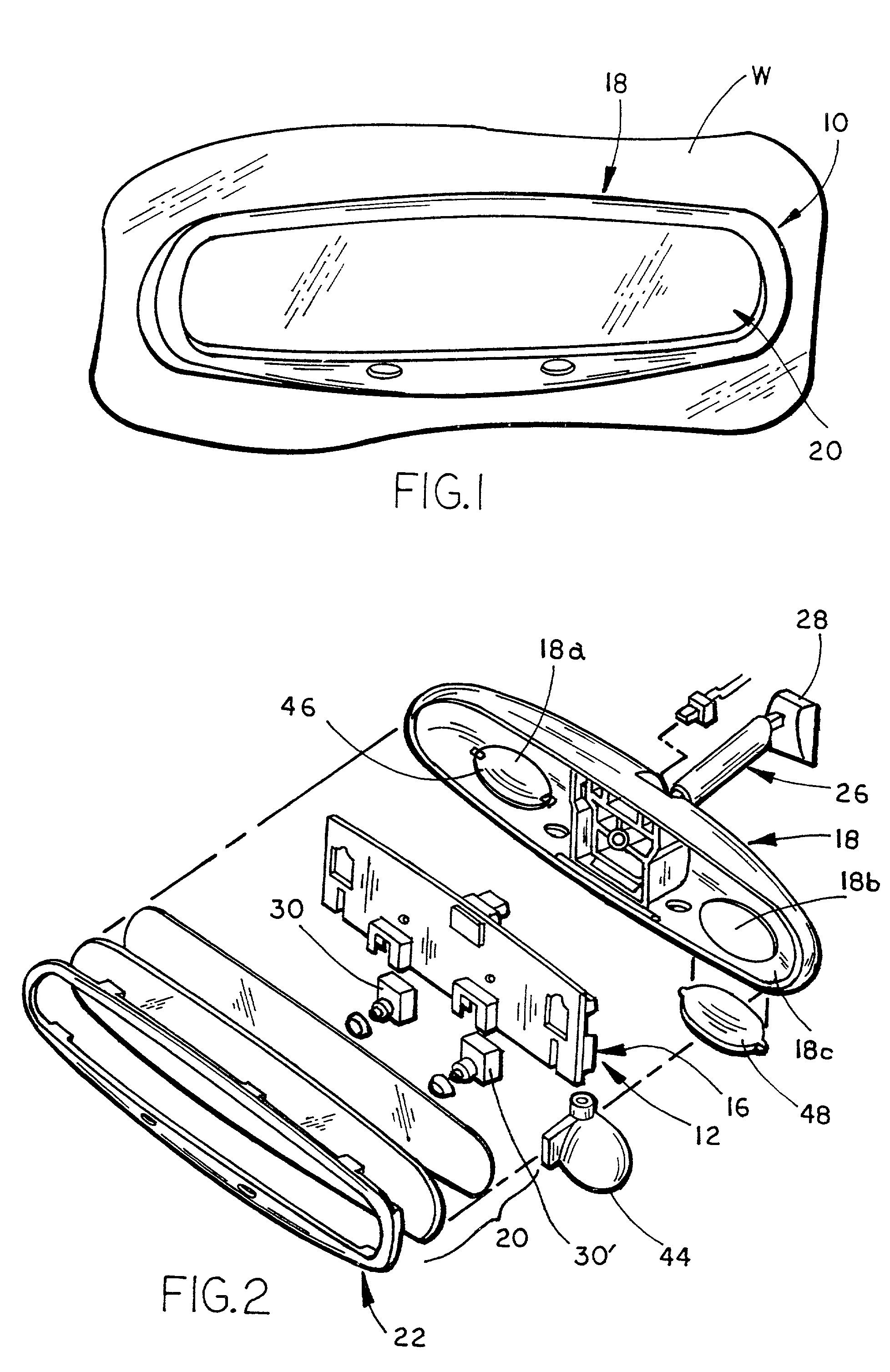

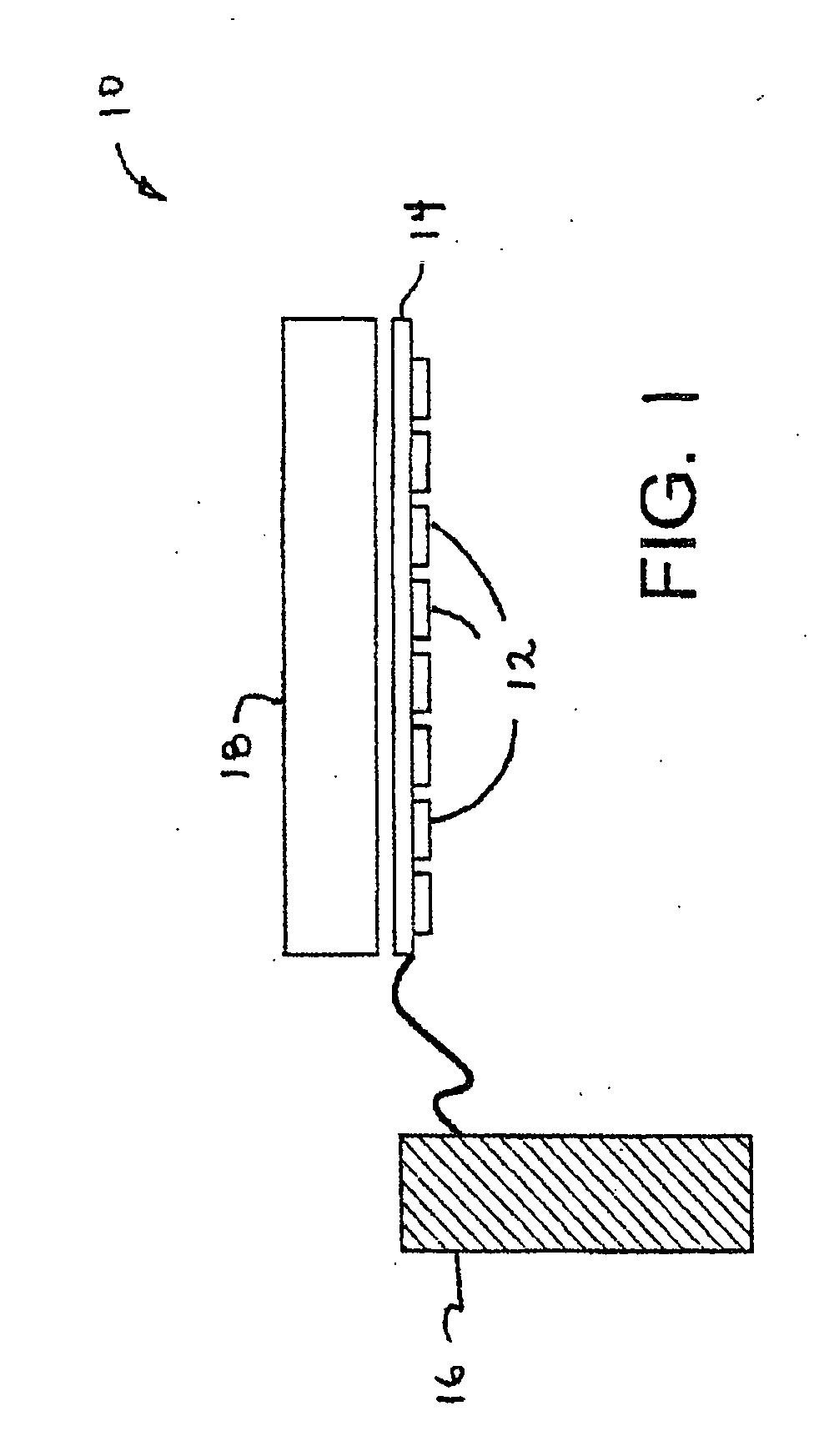

Vehicle interior LED lighting system

InactiveUS7195381B2Efficient powerMaximum power transfer efficiencyLighting circuitsStatic indicating devicesPower flowElectrical battery

A vehicle lighting system for a vehicle includes an accessory module assembly that is adapted for attachment to an interior portion of a vehicle and configured to illuminate, for example, an area inside the vehicle. The module assembly includes a single high-intensity power light emitting diode that has a luminous efficiency of at least about 1 lumen per watt when the light emitting diode is operated and is preferably operated at a forward current of at least 100 milliamps. The system also includes a voltage conversion element for converting the battery / ignition voltage of the vehicle to the forward operating voltage of the light emitting diode.

Owner:DONNELLY CORP

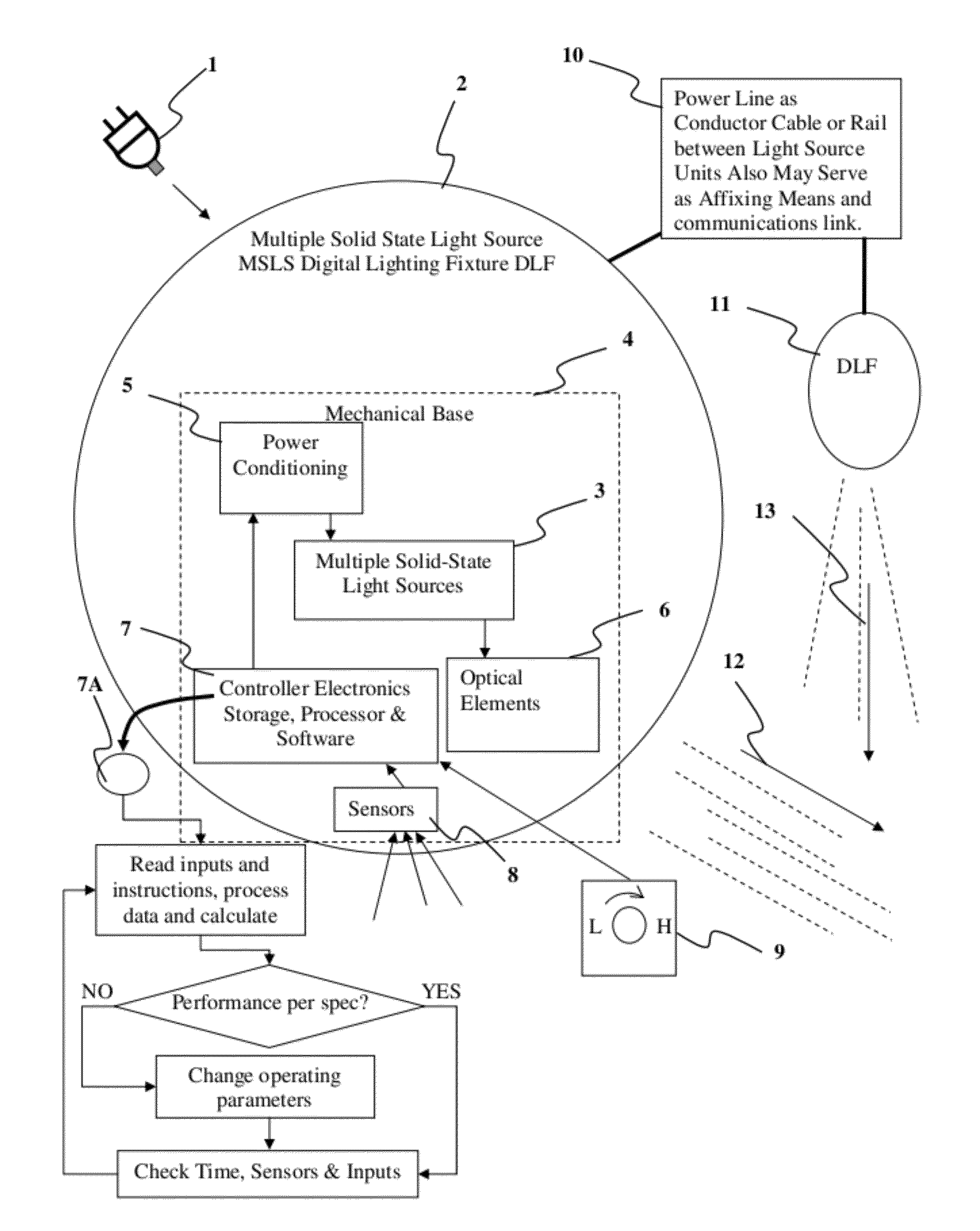

Detector Controlled Illuminating System

ActiveUS20120206050A1Correctly illuminateReduce electricity costsMechanical apparatusLight source combinationsUser needsCost effectiveness

An illuminating device coupled with sensors or an image acquisition device and a logical controller allows illumination intensity and spectrum to be varied according to changing user needs. The system provides illumination to areas according to the principles of correct lighting practice for the optimal performance of visual tasks in the most efficient, cost effective manner. Aspects of the invention include: lighting fixtures which adapt to ambient lighting, movement, visual tasks being performed, and environmental and personal conditions affecting illumination requirements at any given instant. Lighting fixtures having spatial distribution of spectrum and intensity, providing both “background” room lighting, and “task” lighting.

Owner:YECHEZKAL EVAN SPERO

LED light

InactiveUS20050174780A1Increase illuminationLife maximizationPoint-like light sourceElectric circuit arrangementsLeading edgeAir cycle

Disclosed herein is an LED light. The LED light comprises a socket electrically connected to a receptacle, and a cooling fan for forcibly circulating air. The cooling fan is received in a main body, which has a plurality of radial partition walls formed on the outer peripheral surface thereof in such a manner as to be spaced apart from one another with a gap having a slit shape for ventilation. A plurality of LEDs is attached to the outer periphery and / or the inner leading edge of the main body. A circuit board is provided to control the light such that an alternating current supplied from the socket is rectified into a direct current, which is supplied to the cooling fan and the LED.

Owner:DAEJIN DMP

Lighting device

ActiveUS20070139923A1Eliminates thermal interfaceReduce the temperatureCoupling device connectionsPoint-like light sourceElectricityEffect light

A lighting device comprises, or consists essentially of, a housing, a solid state light emitter and conductive tracks. The conductive tracks are positioned on the housing and are coupleable with a power supply. The conductive tracks comprise a positive conductive track and a negative conductive track. Each of the solid state light emitters is in electrical contact with a positive conductive track and a negative conductive track. Another lighting device comprises a fixture and a solid state light emitter in which the fixture comprises conductive elements which are coupleable to at least one power supply and the solid state light emitter is mounted on the fixture. There is also provided a lighting device which provides light of an intensity which is at least 50 percent of its initial intensity after 50,000 hours of illumination.

Owner:IDEAL IND LIGHTING LLC

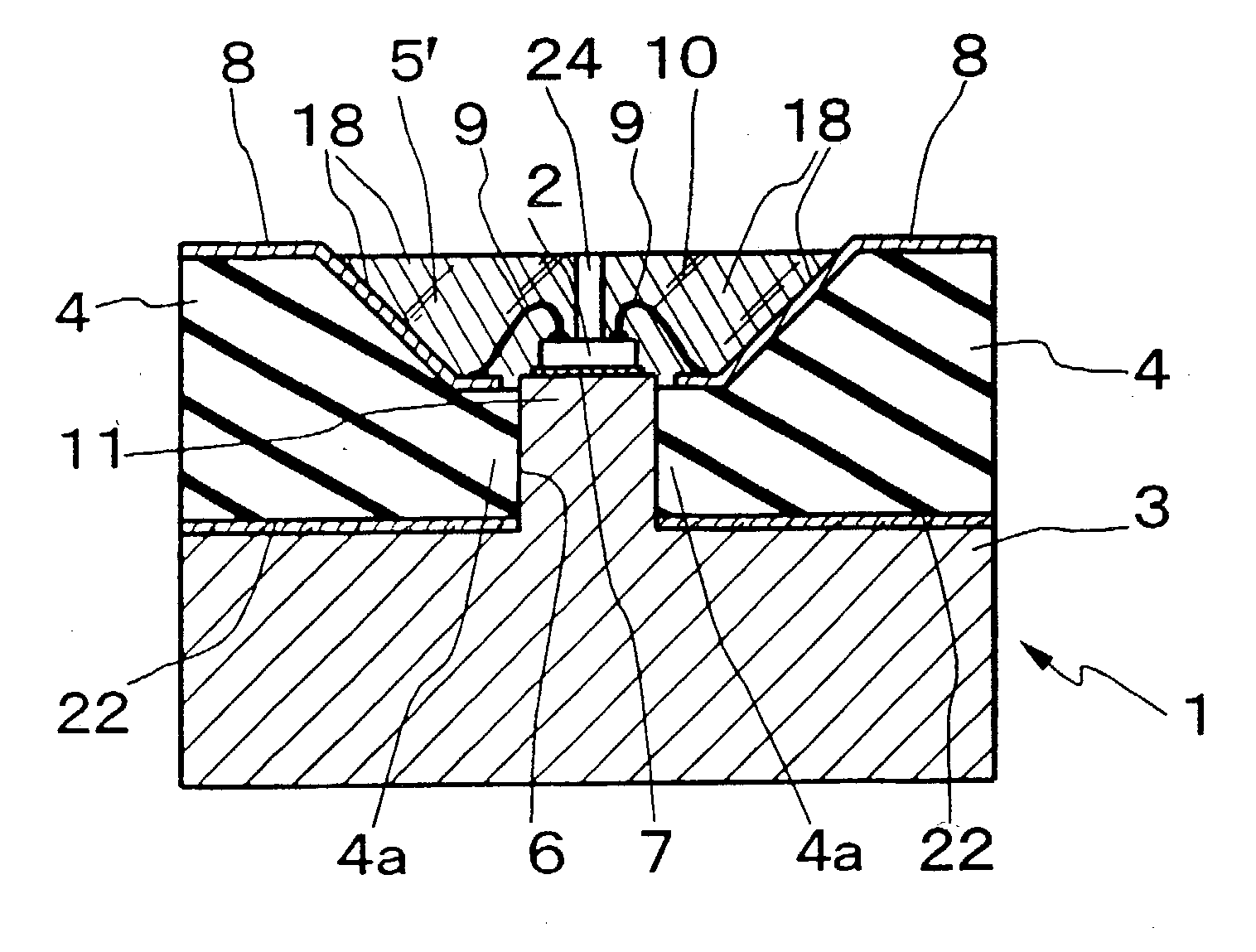

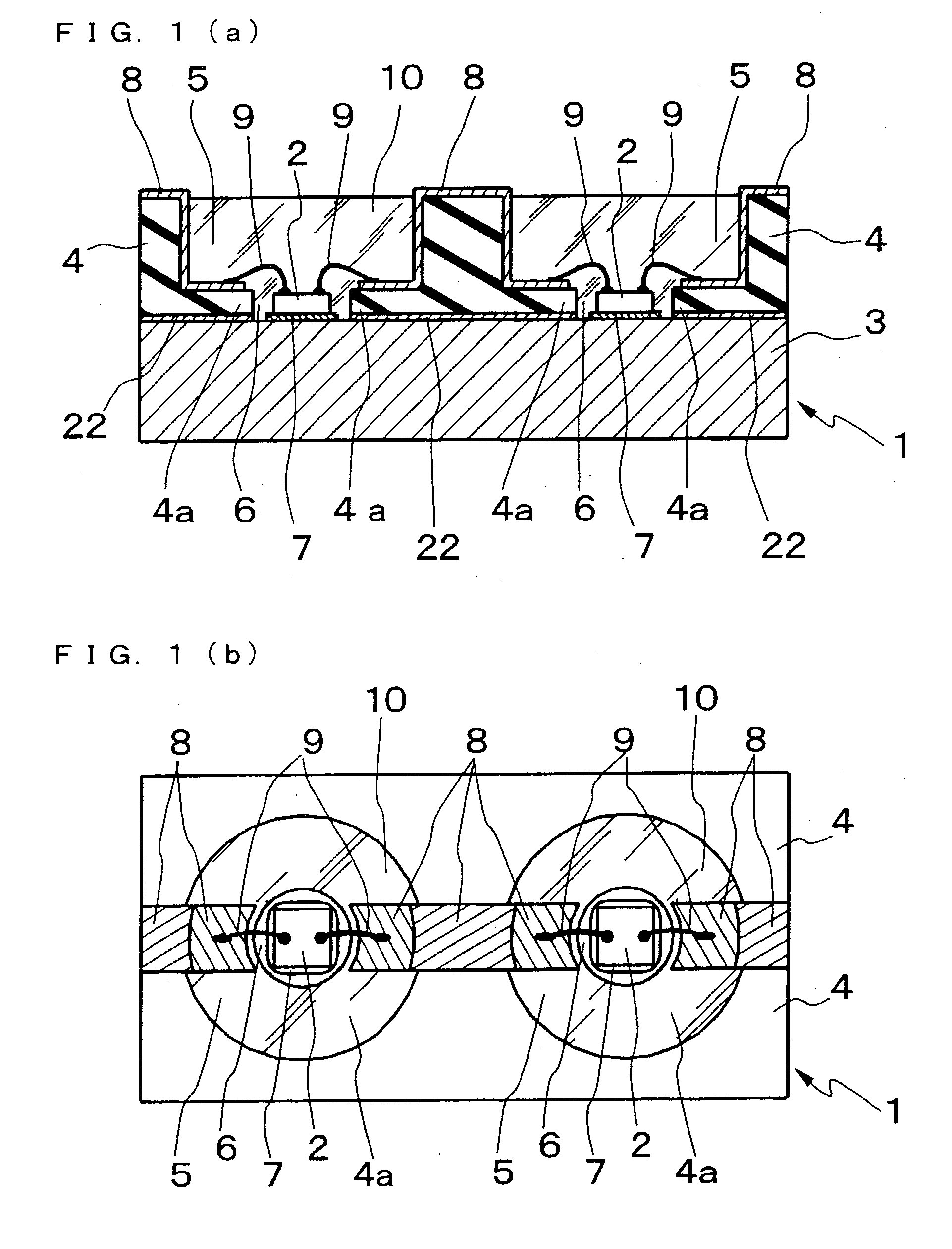

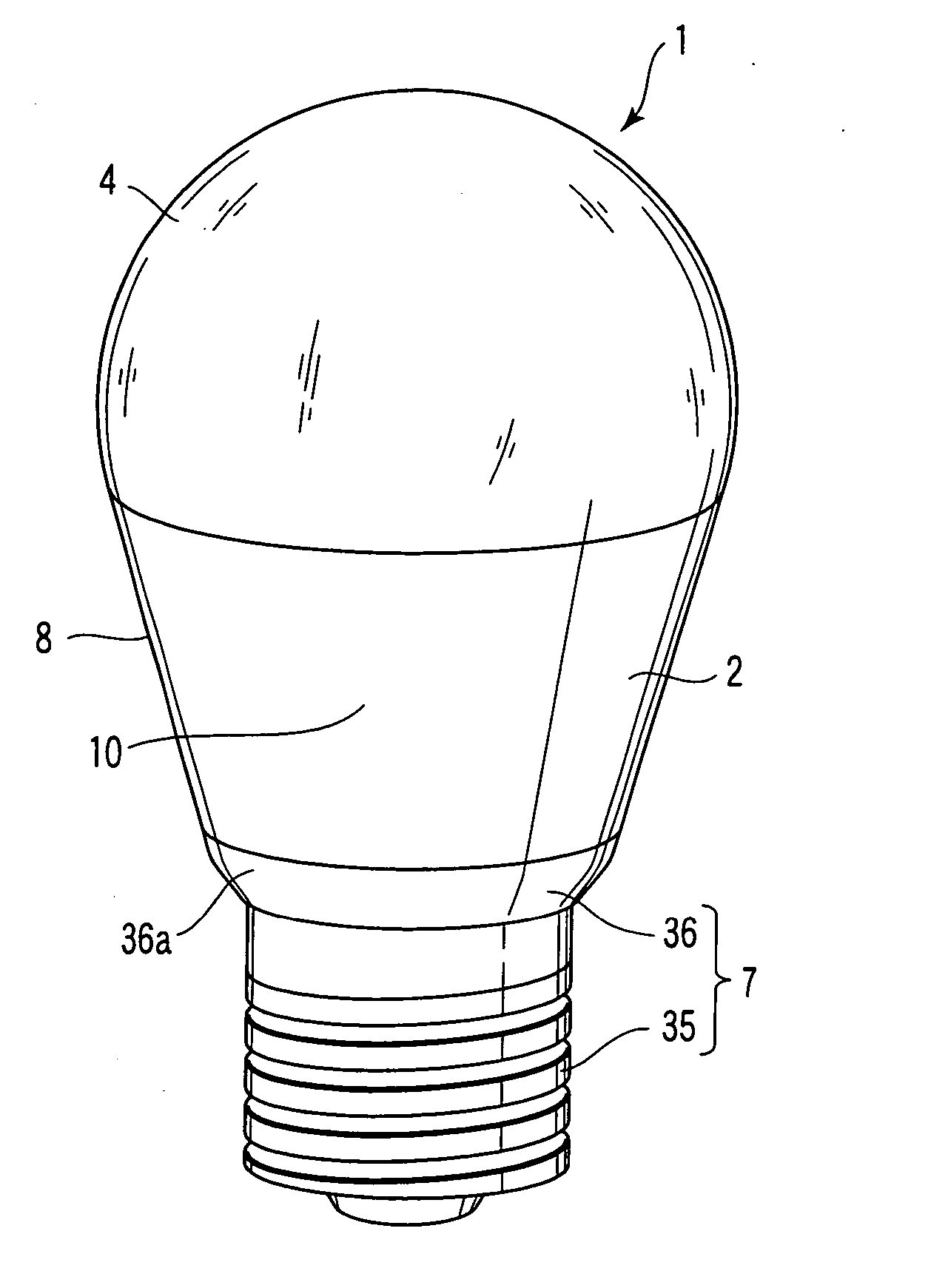

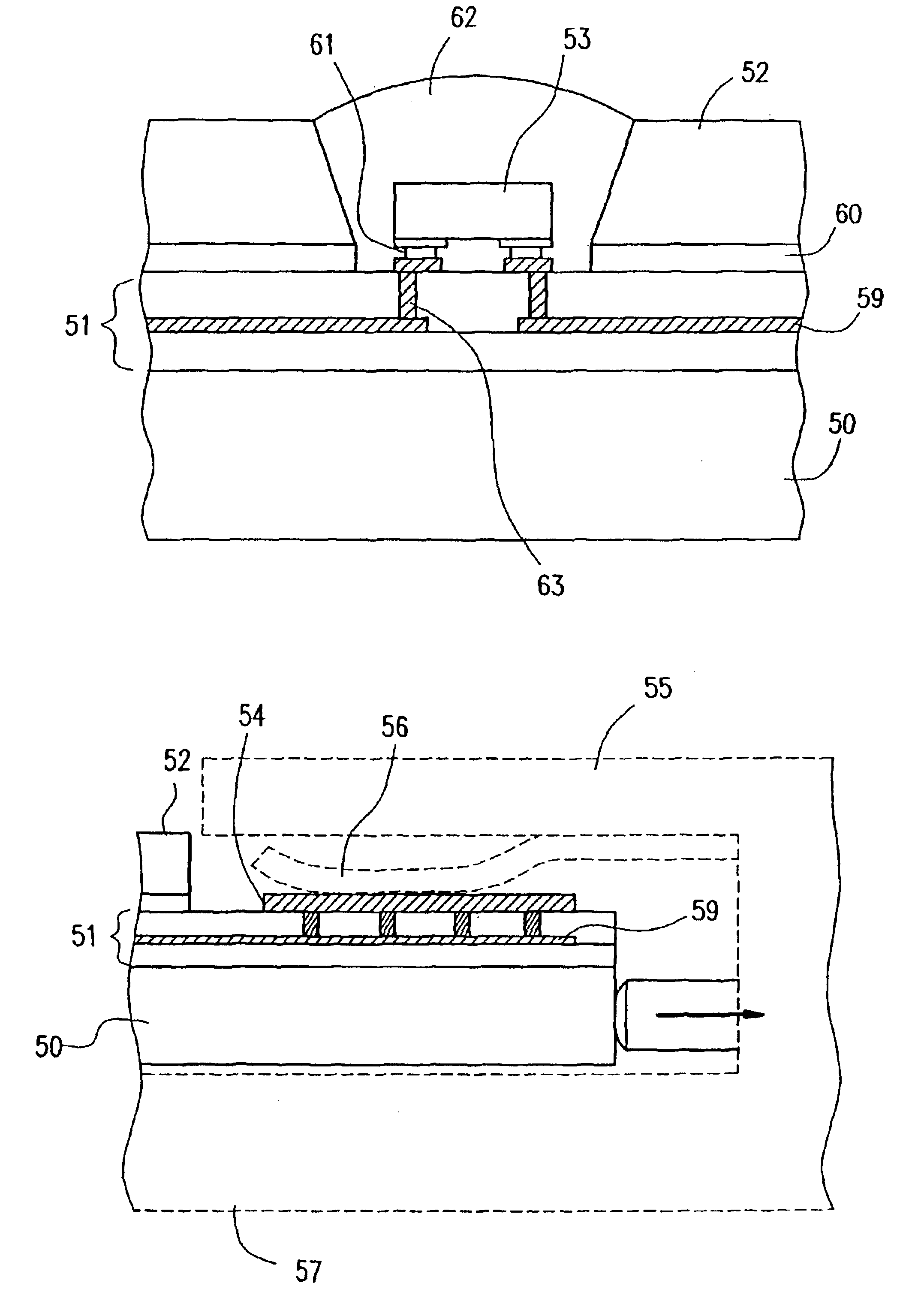

Light source device using led, and method of producing same

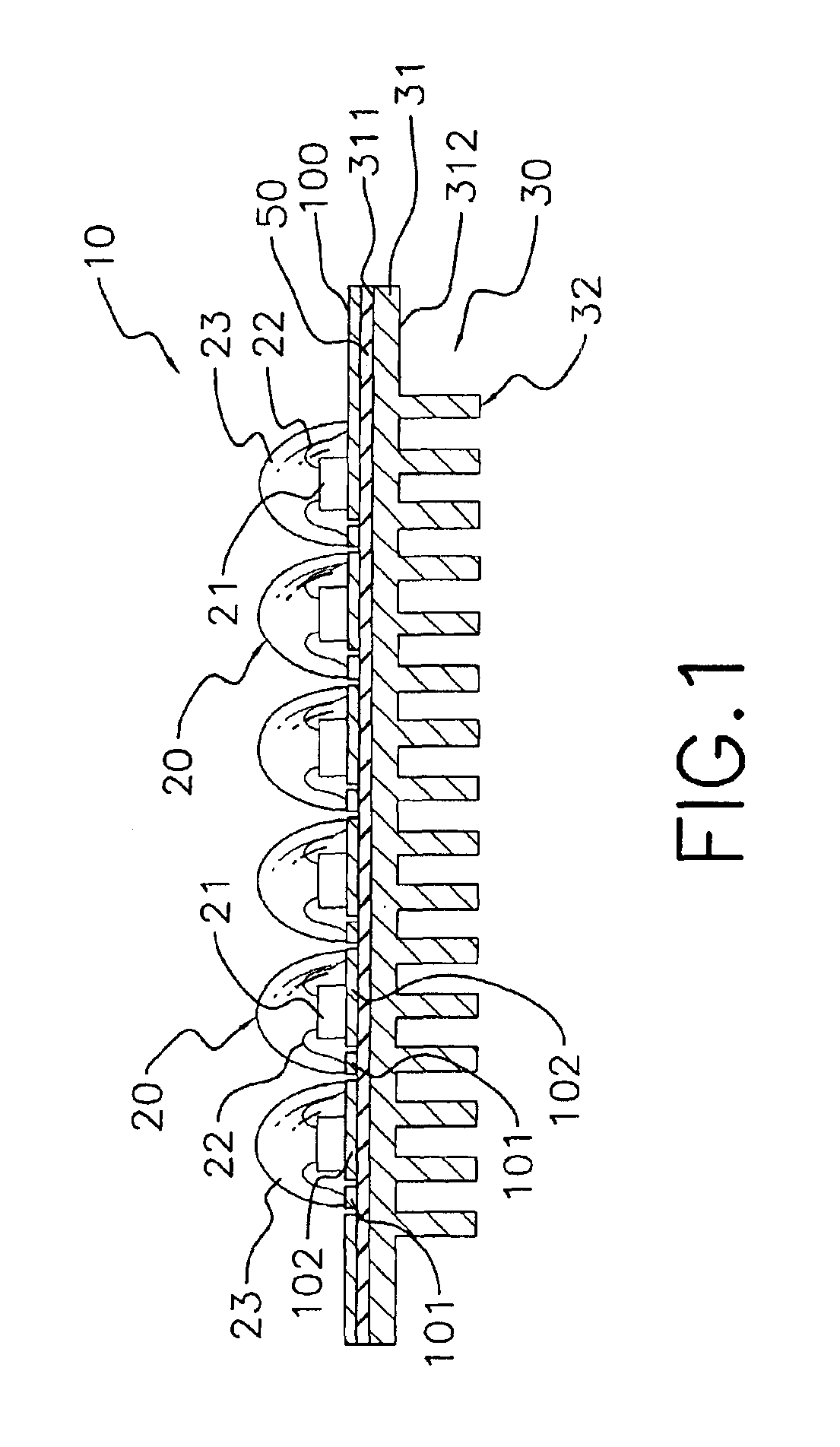

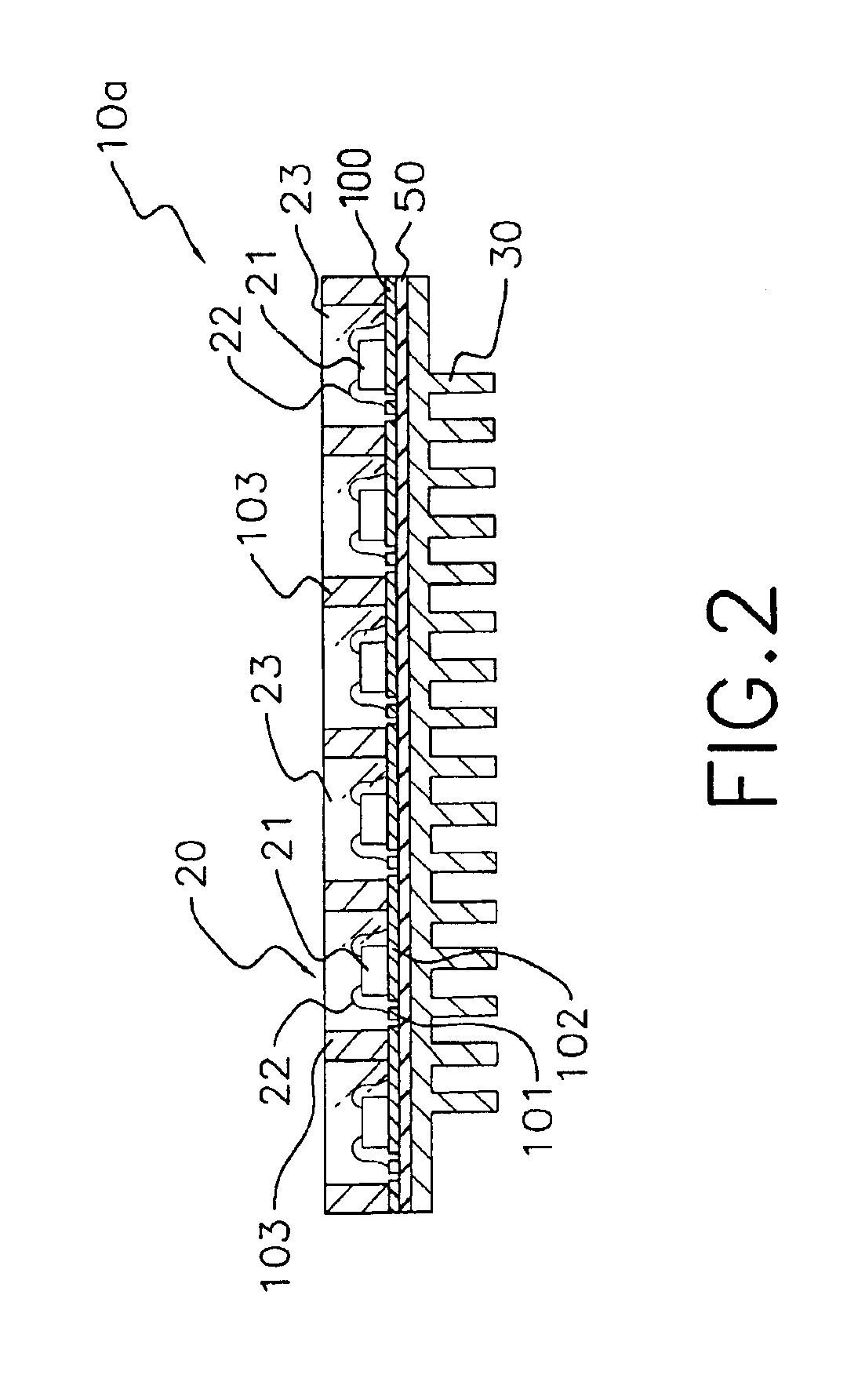

InactiveUS20030189830A1Easy to controlImprove powerLighting heating/cooling arrangementsSolid-state devicesLight emissionOperating life

A light source apparatus which is improved in the efficiency of light emission thus to increase the operating life and the mechanical strength and a method of producing the same are provided. The light source apparatus 1 comprises a radiator plate 3 having thermally conductive properties, an insulating member 4 coupled to at least one side of the radiator plate 3 and having a through hole 6 provided in the side thereof facing the radiator plate 3, an LED chip 2 installed and thermally coupled to an exposed portion of the radiator plate 3 facing the through hole 6, an extension 4a inwardly projecting at the hole 6 from the radiator plate 3 end of the insulating member 4, a wiring pattern 8 provided on the insulating member 4 and electrically isolated by the insulating member 4 from the radiator plate 3, bonding wires 9 electrically connecting between portions of the wiring pattern 8 extended to the extension 4a and the electrodes of the LED chip 2, and a light-transmissive sealing material 10 filled in the through hole 6 for entirely encapsulating the LED chip 2 and the bonding wires 9.

Owner:SIGNIFY HLDG BV

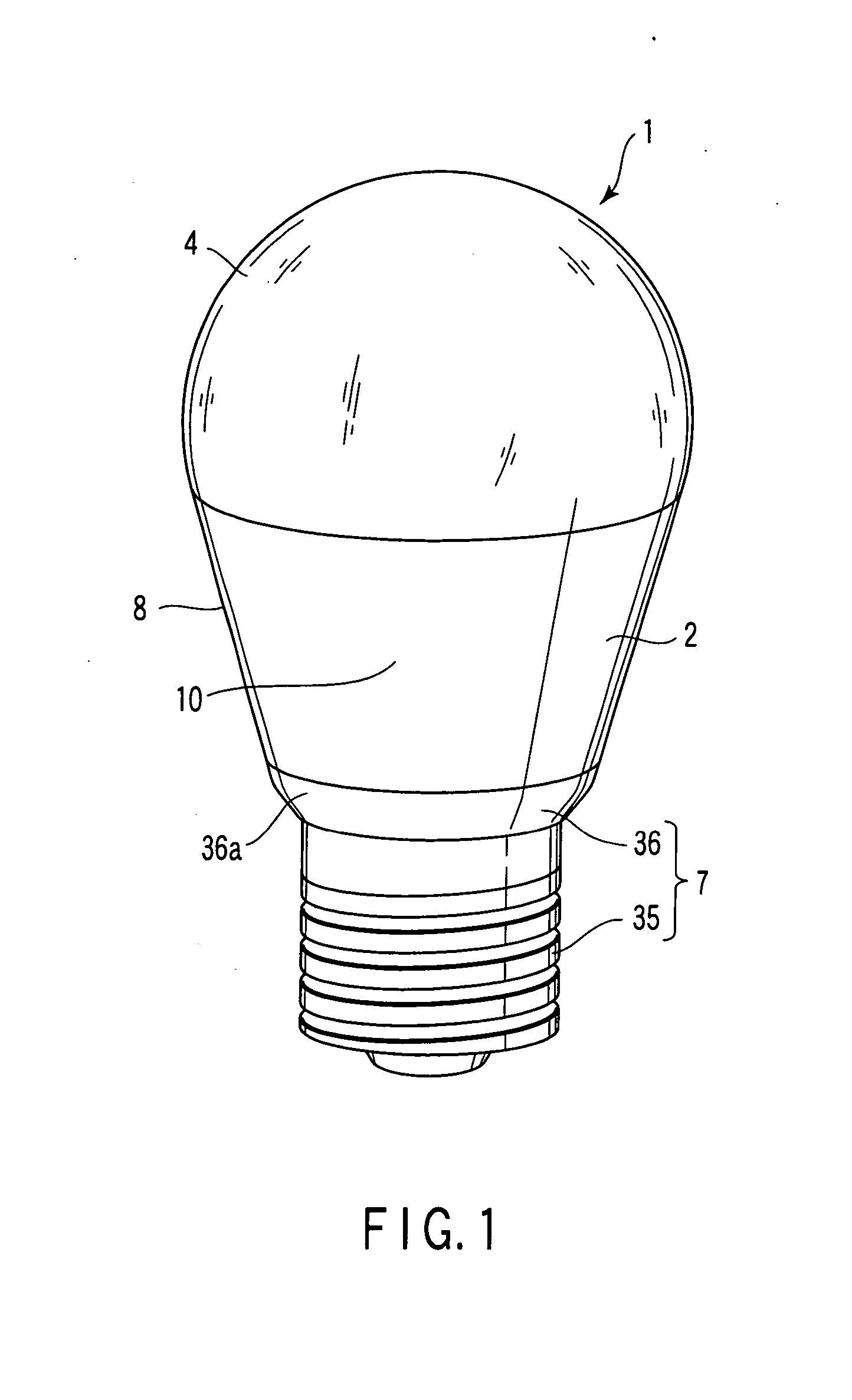

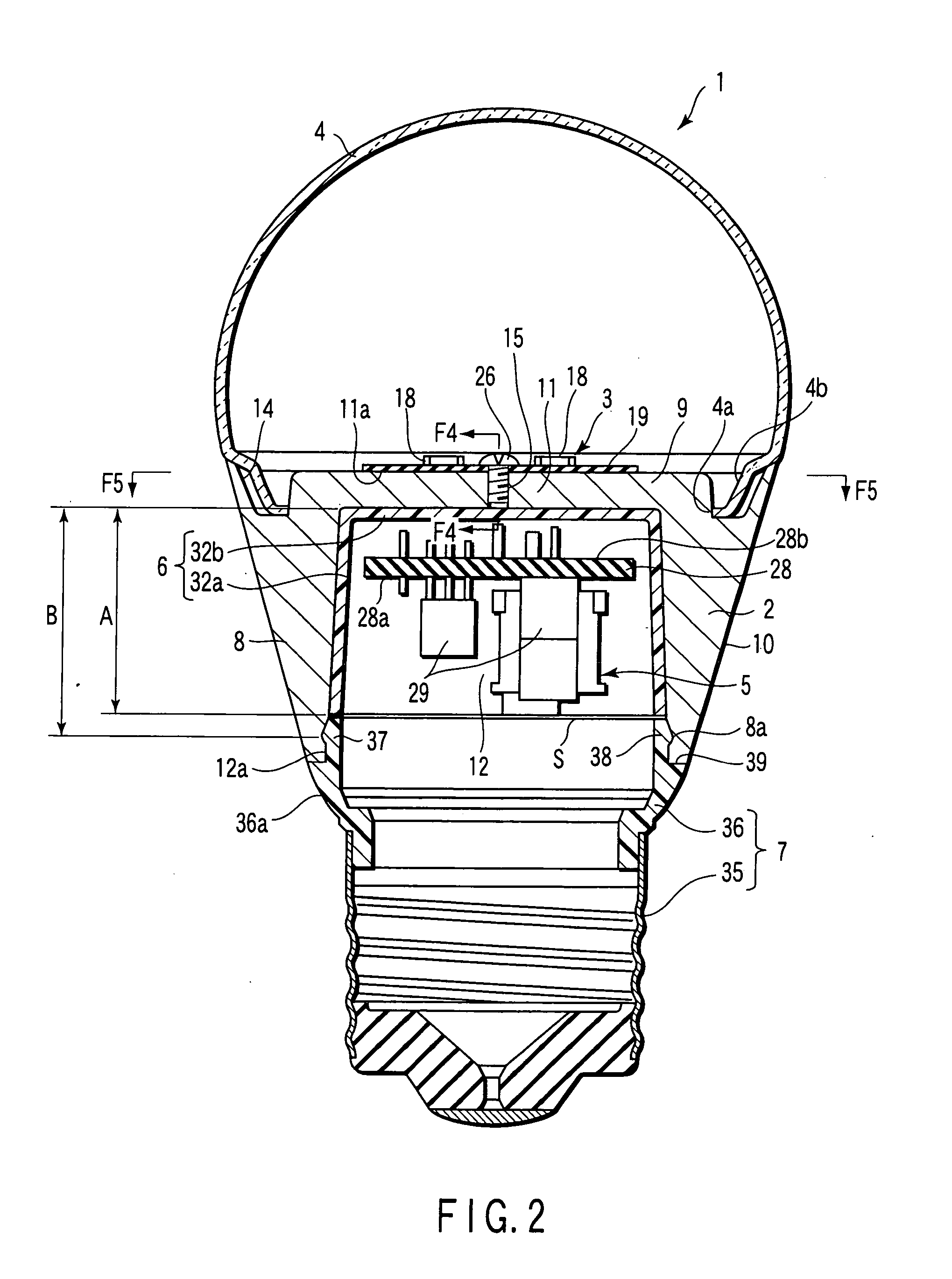

Lamp having outer shell to radiate heat of light source

InactiveUS20060227558A1Efficient transferImprove thermal conductivityCoupling device connectionsPoint-like light sourceEffect lightThermal radiation

Owner:TOSHIBA LIGHTING & TECH CORP

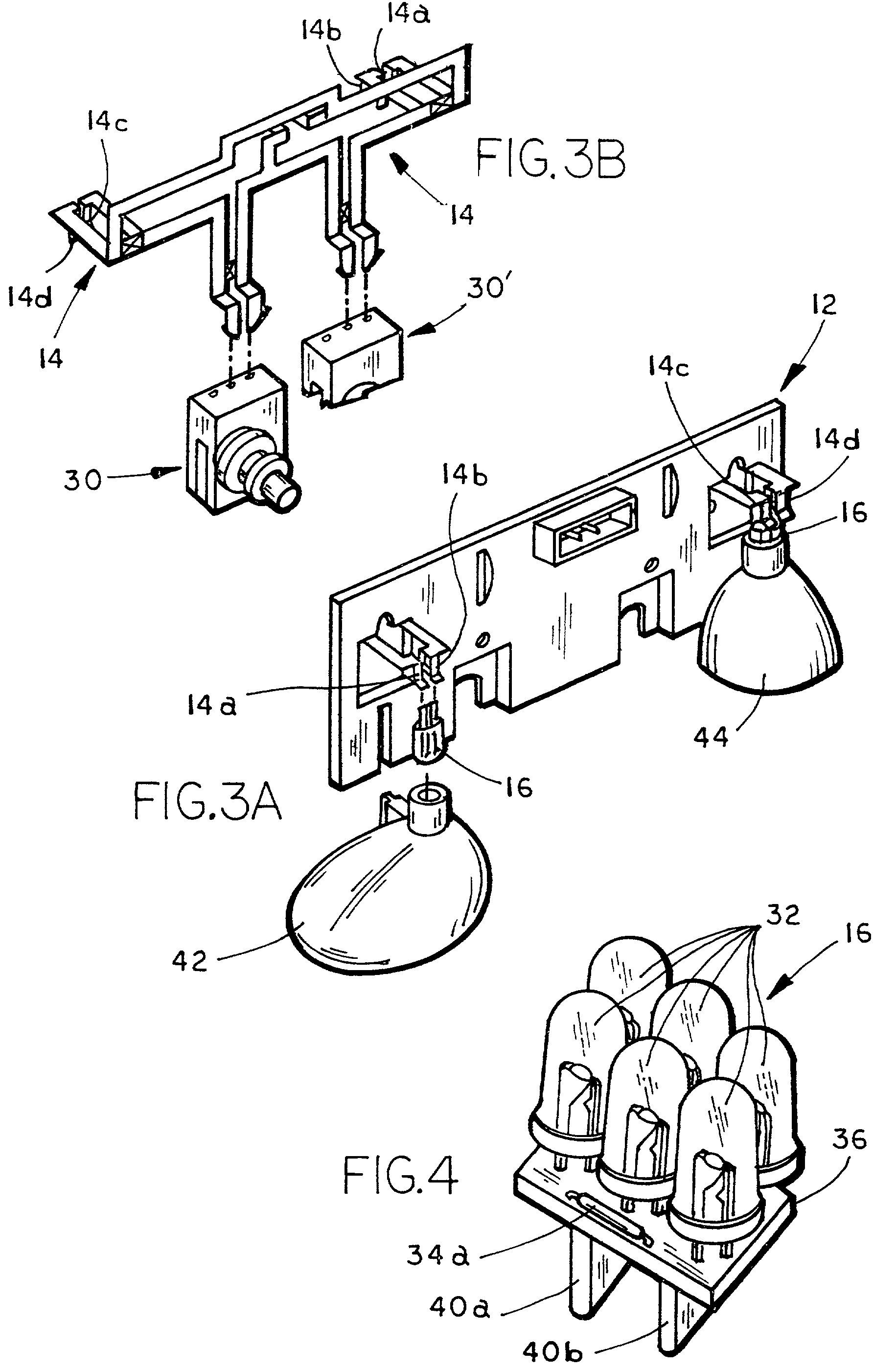

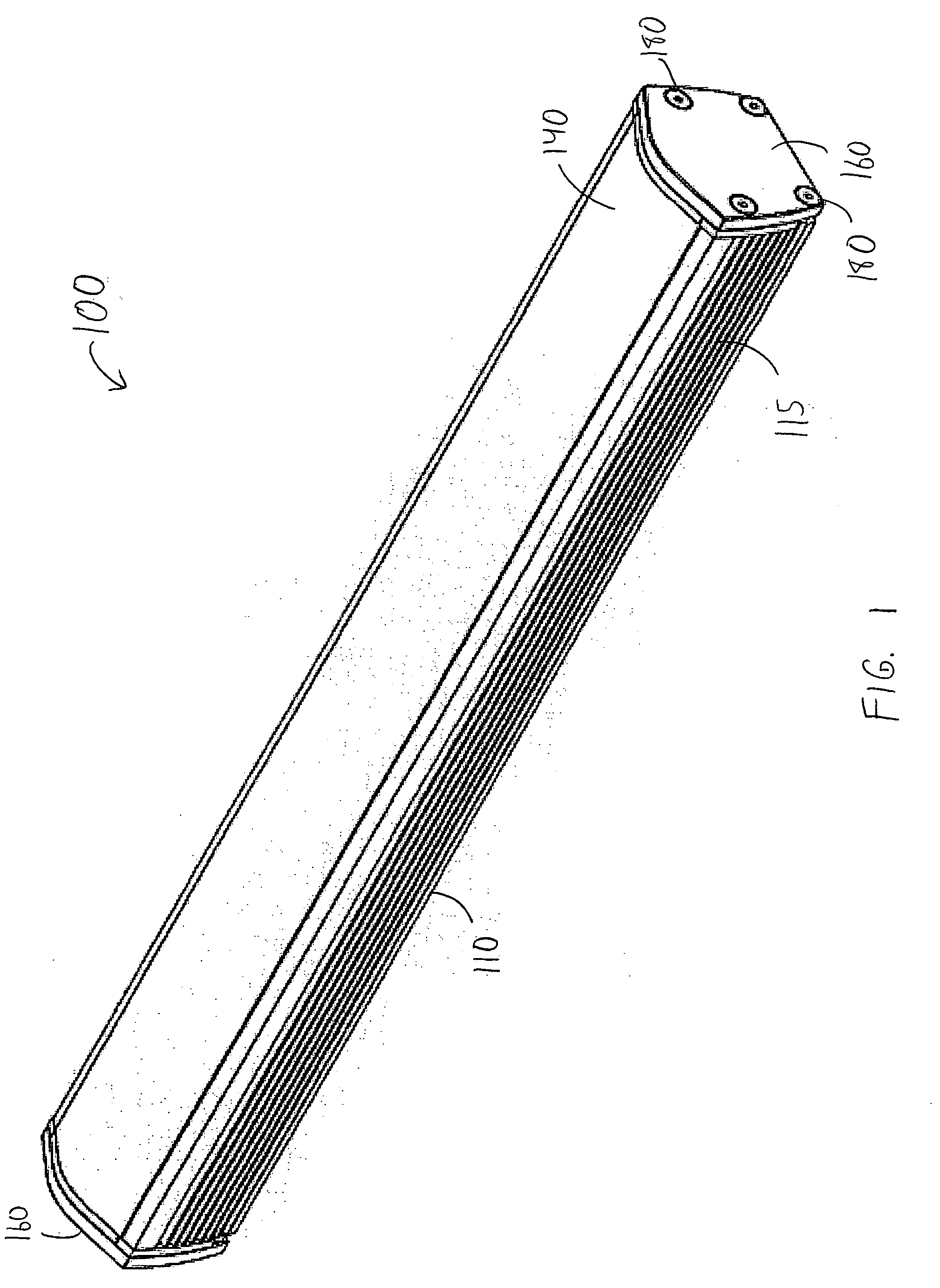

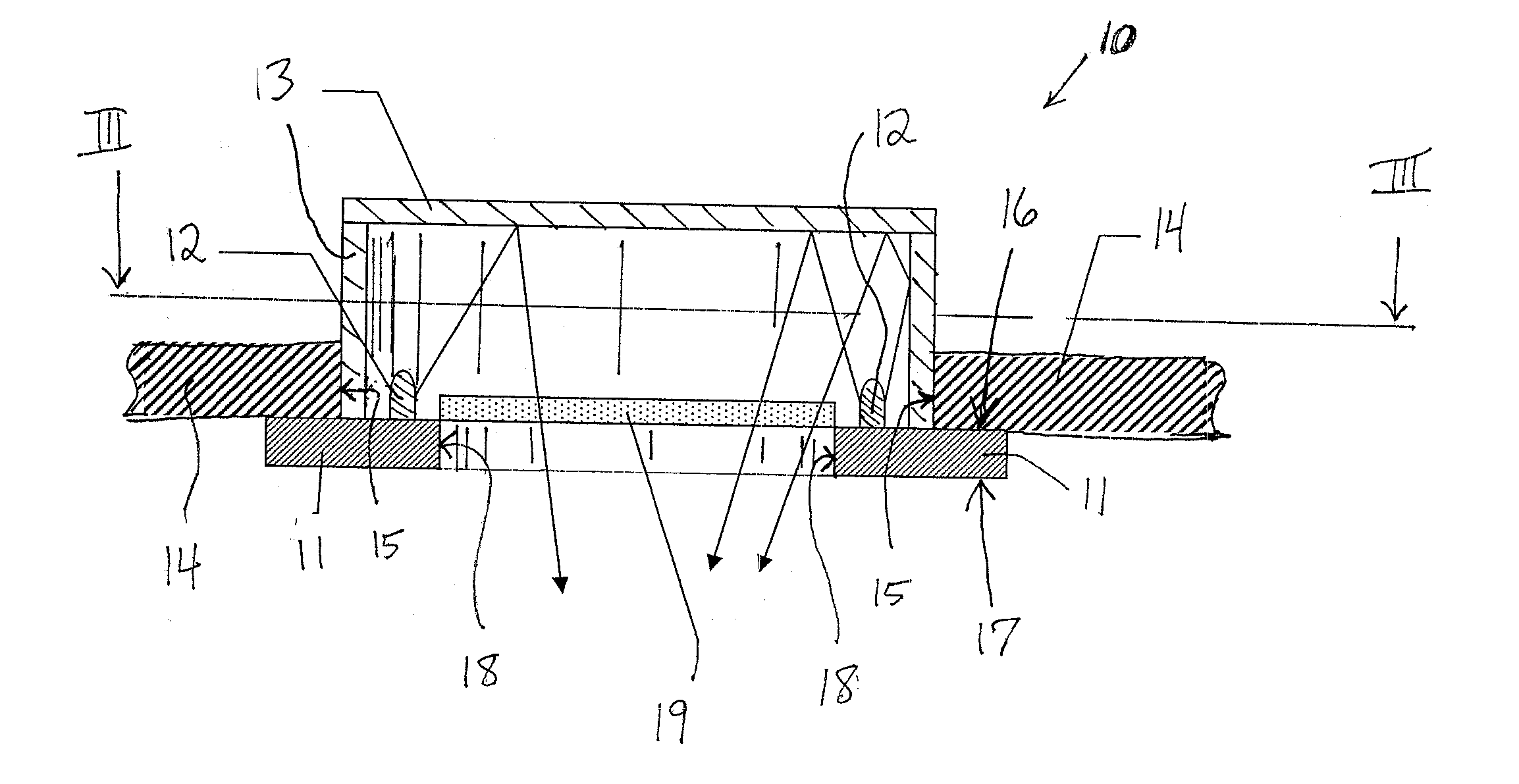

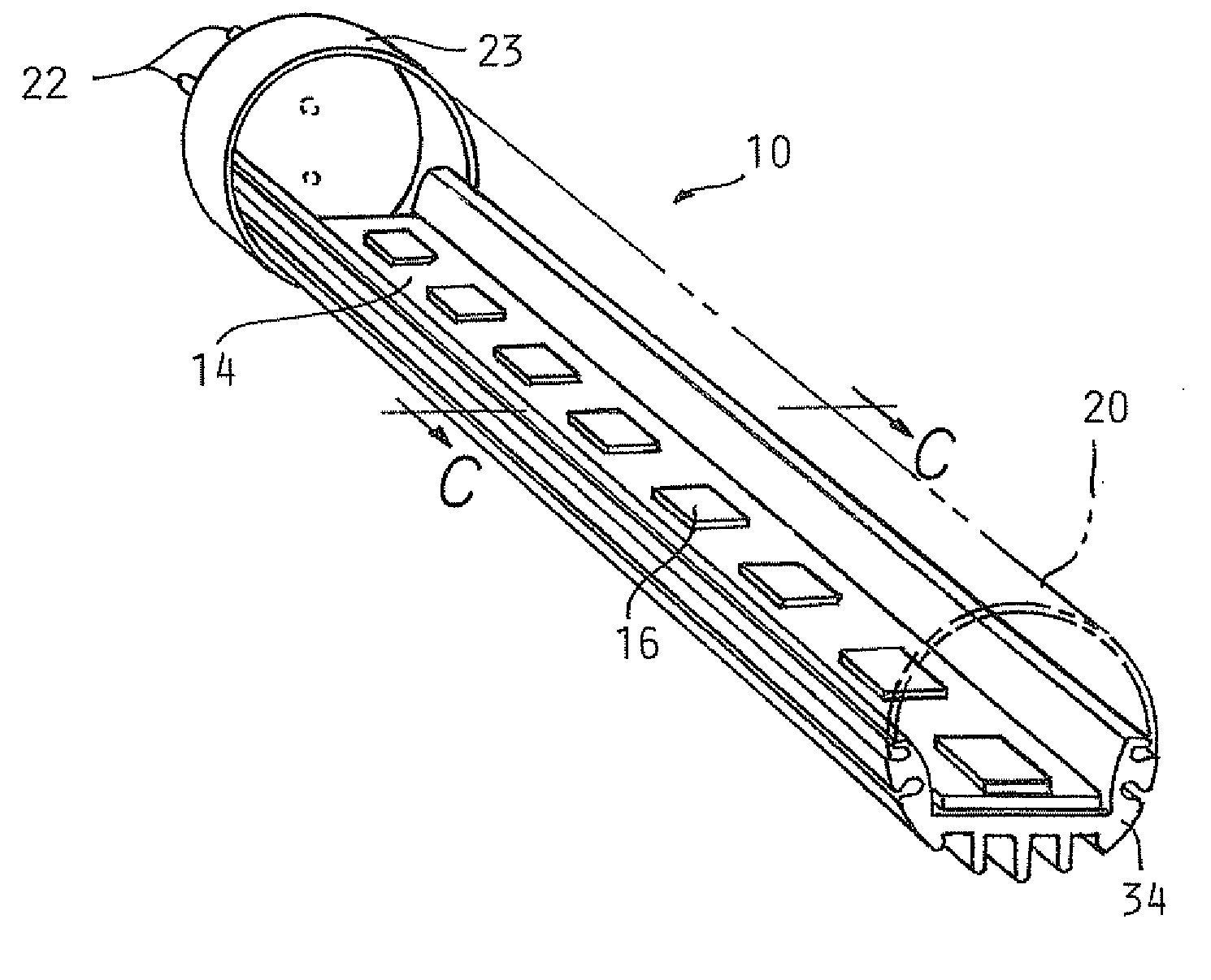

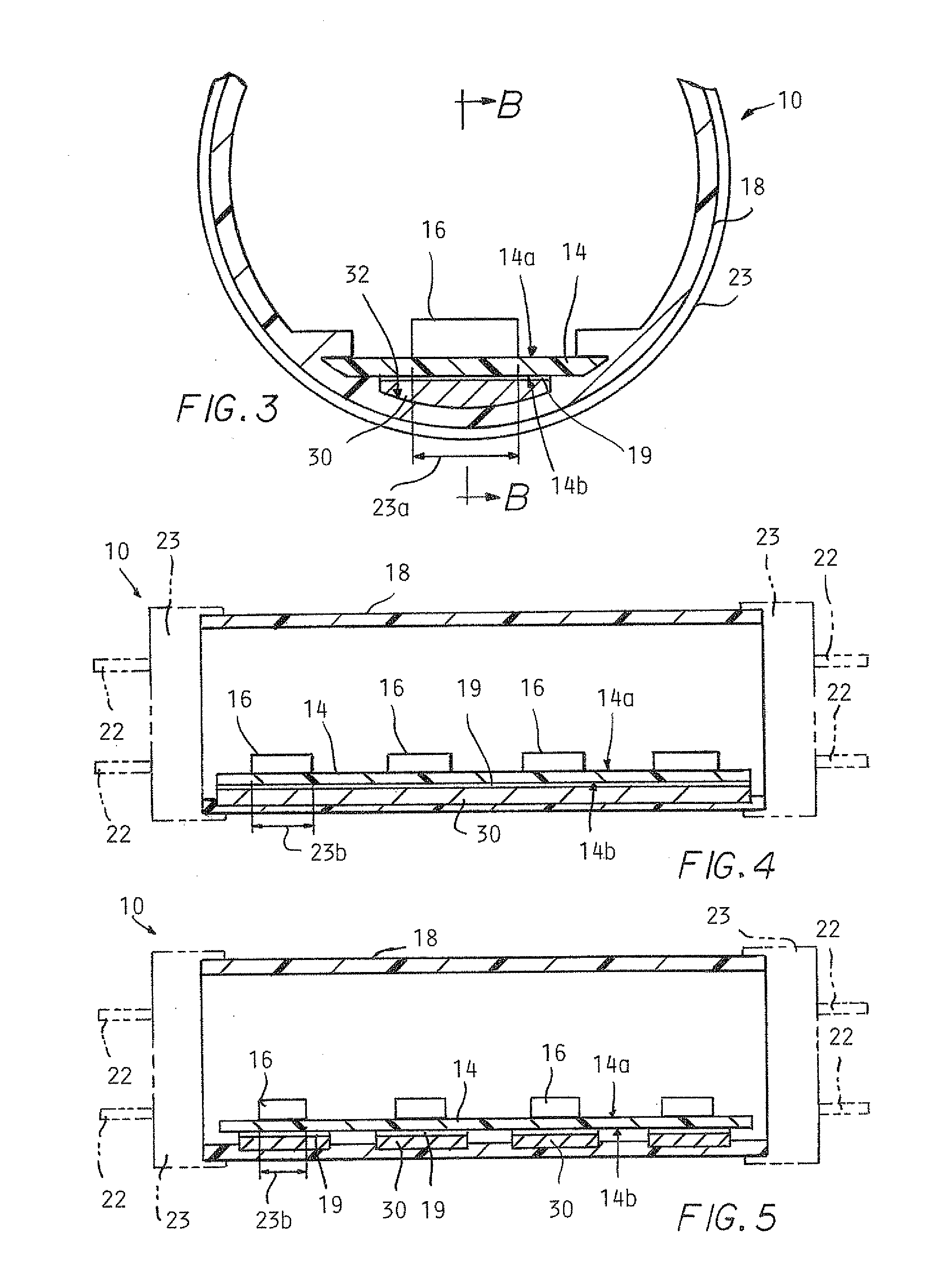

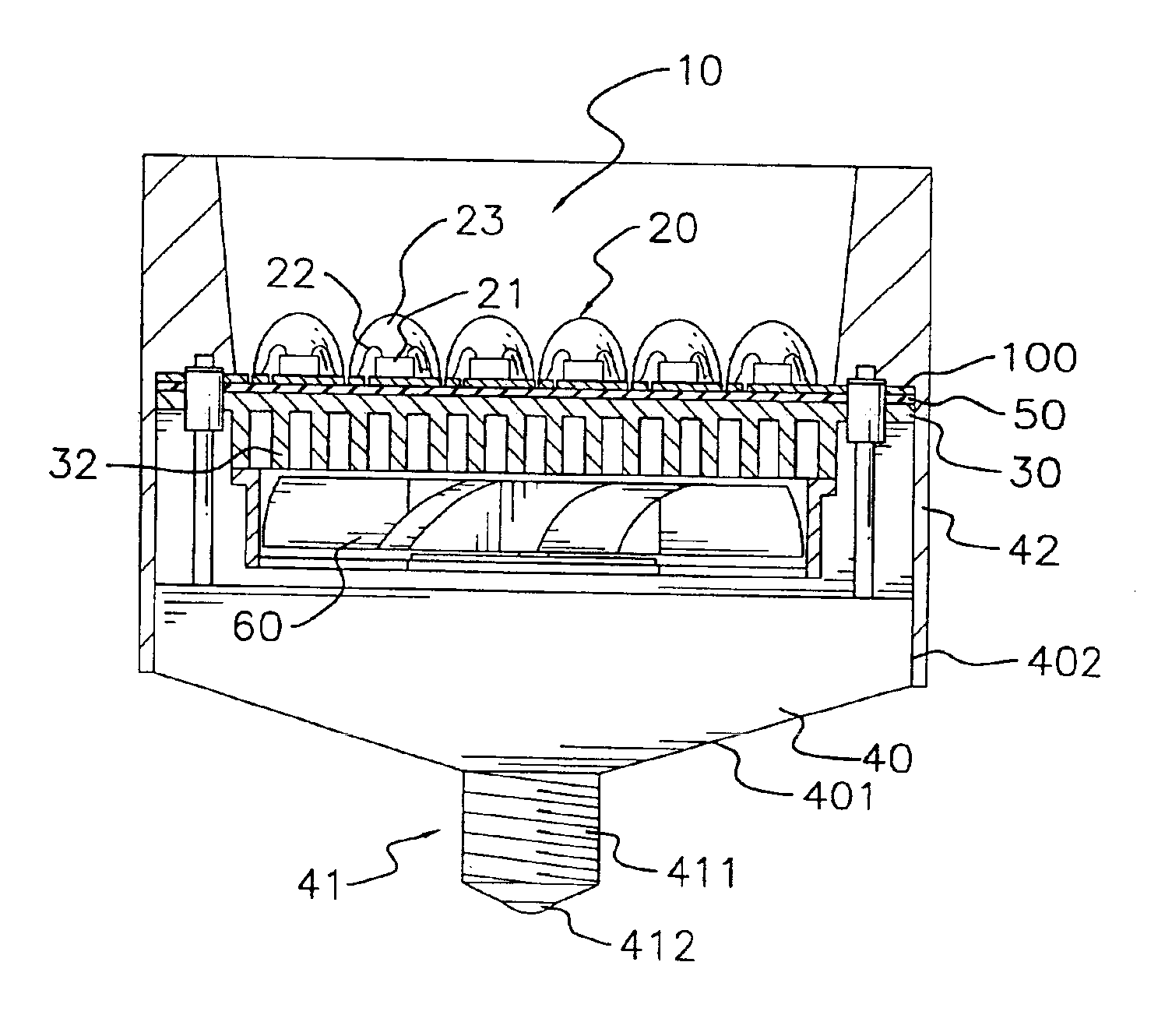

Linear lighting apparatus with improved heat dissipation

InactiveUS20060146531A1Improve cooling effectDissipate energyMechanical apparatusPoint-like light sourceThermal energyEffect light

The present invention provides a linear lighting apparatus with improved heat dissipation and a method for improving the heat dissipation in a linear lighting apparatus. The apparatus includes a plurality of light emitting diodes, a plurality of primary optical assemblies and an apparatus housing. The primary optical assemblies are each in contact with one of the plurality of light emitting diodes. The primary optical assemblies and a second optical assembly are configured to refract the light so as to create a linear light source emanating from the apparatus. The apparatus housing is configured to dissipate thermal energy from the light emitting diodes.

Owner:IO LIGHTING

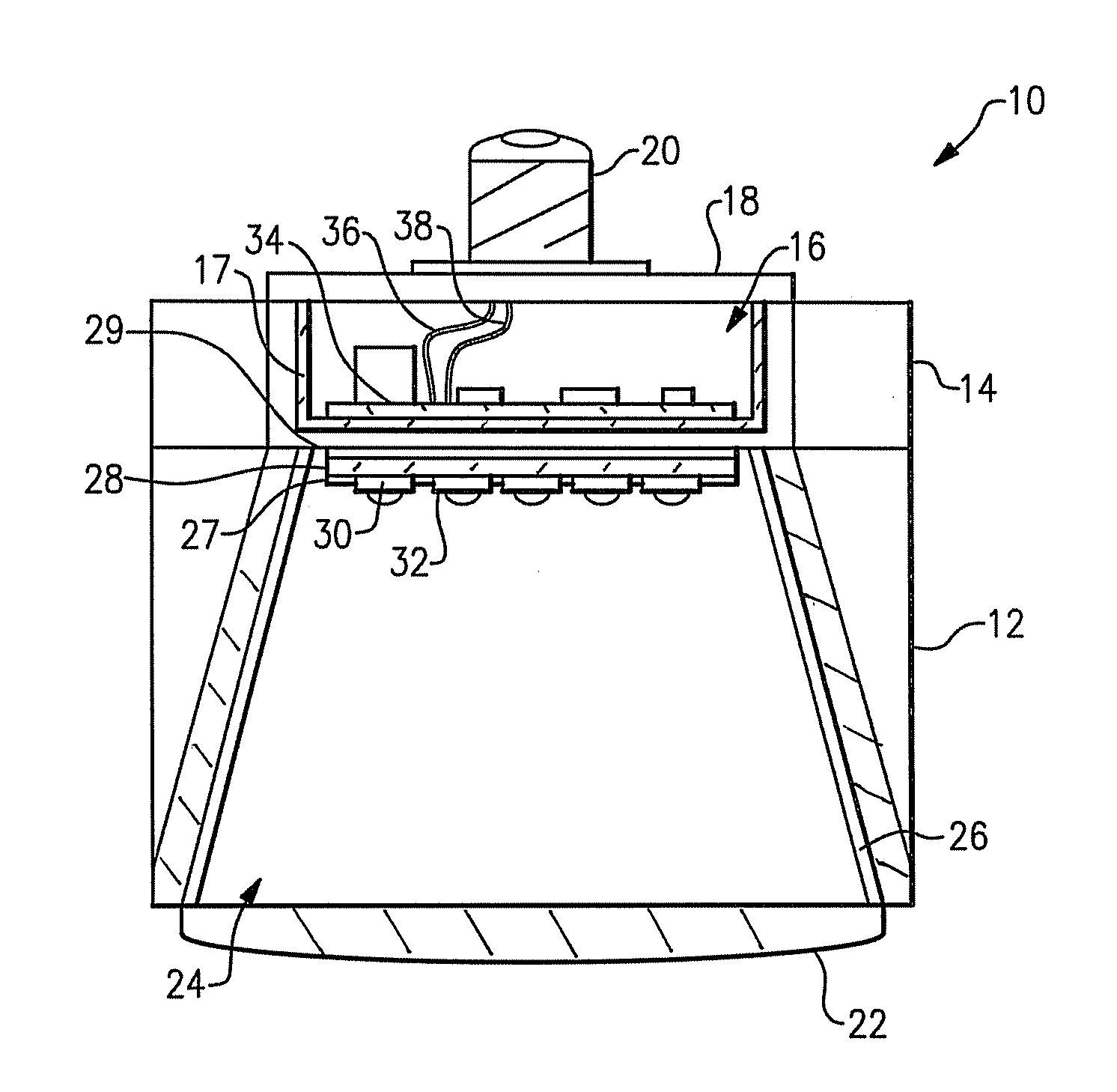

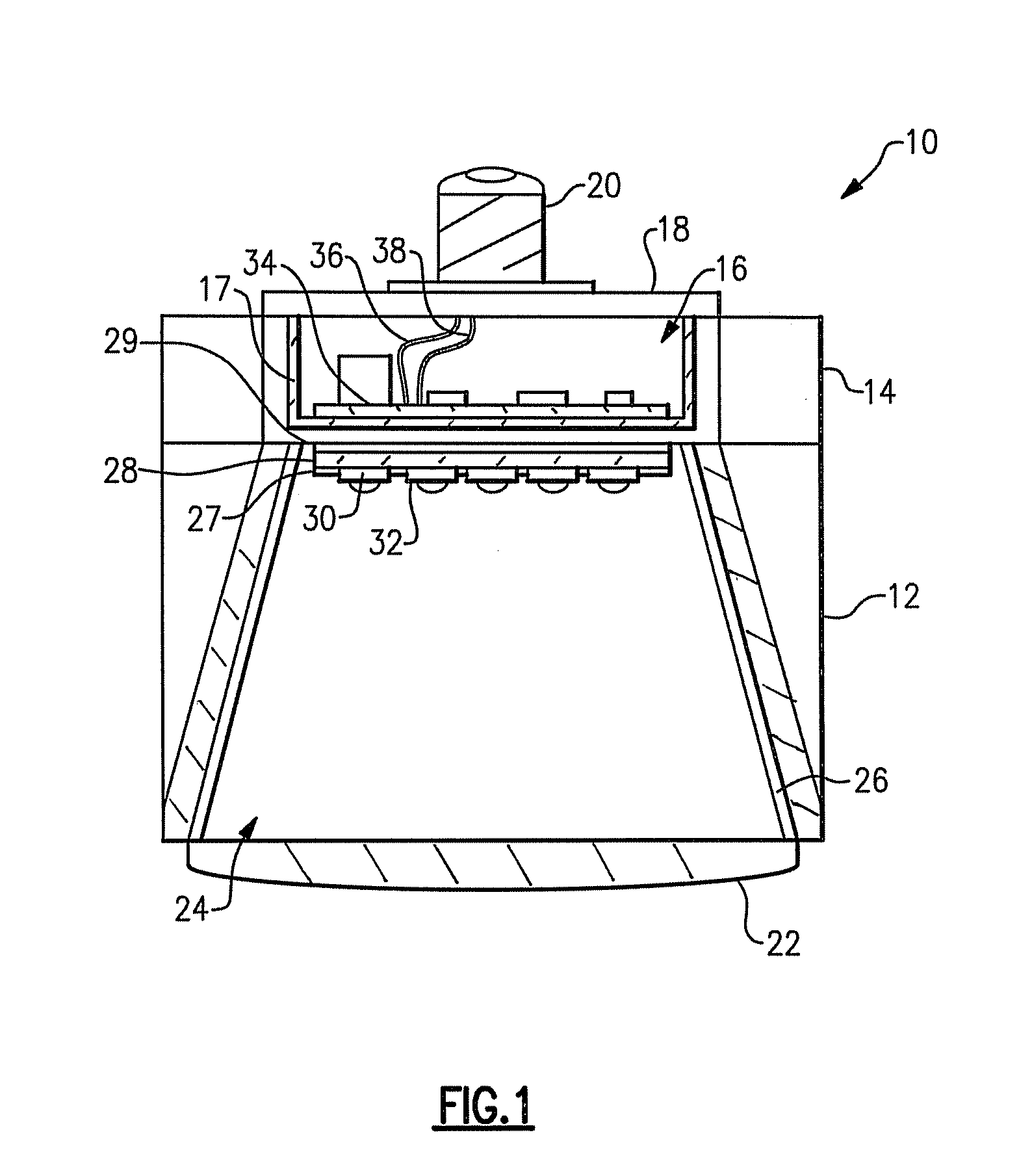

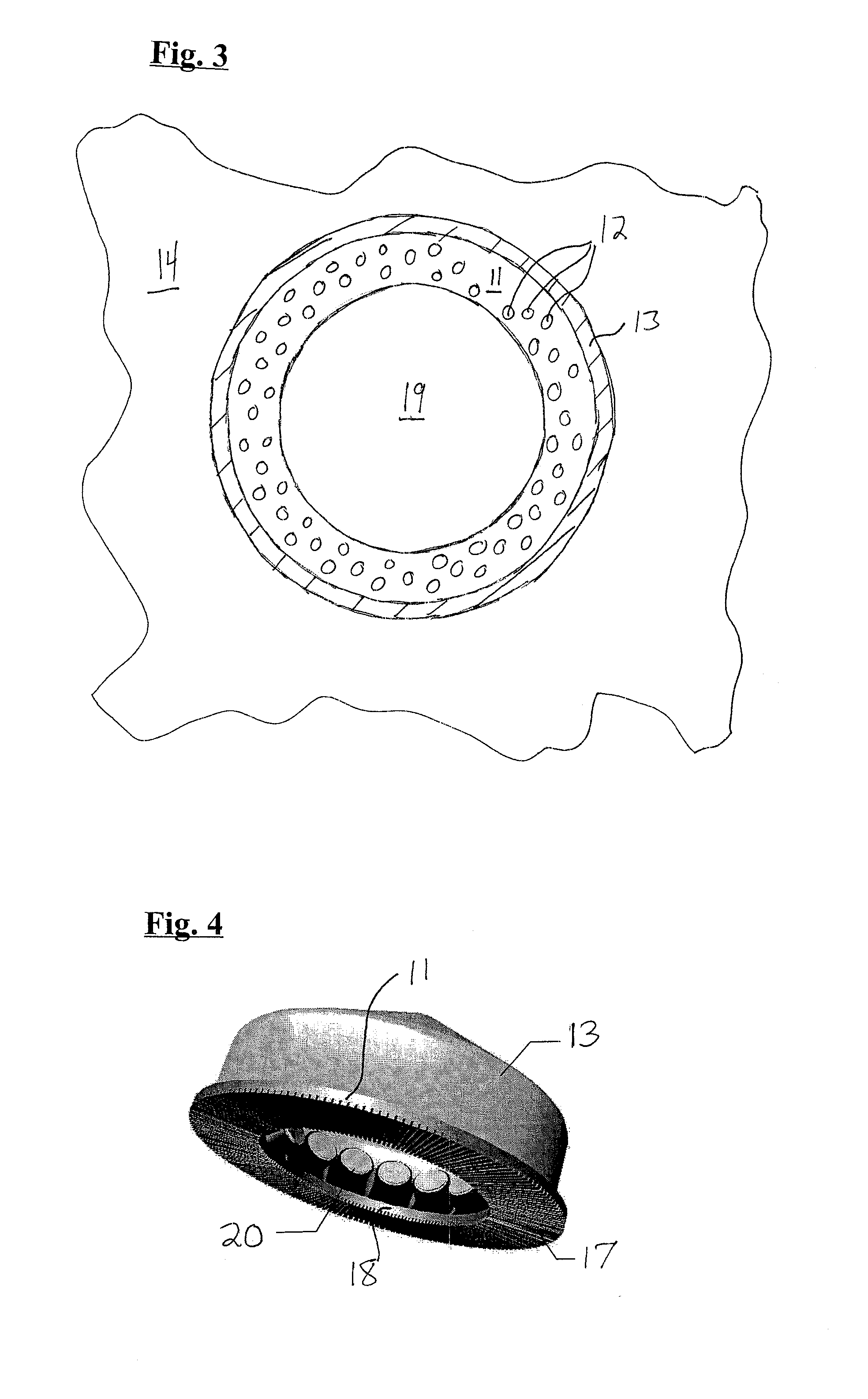

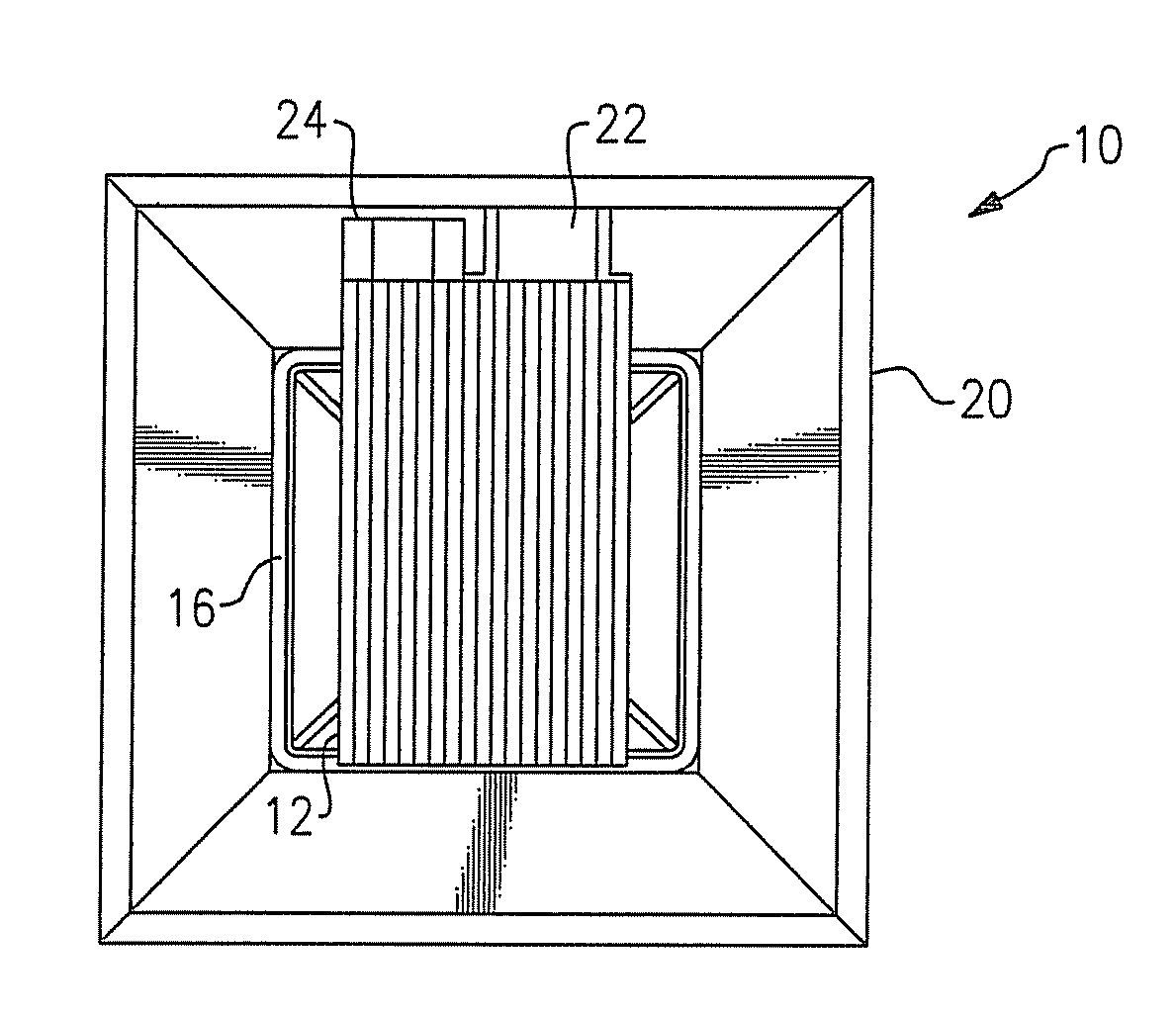

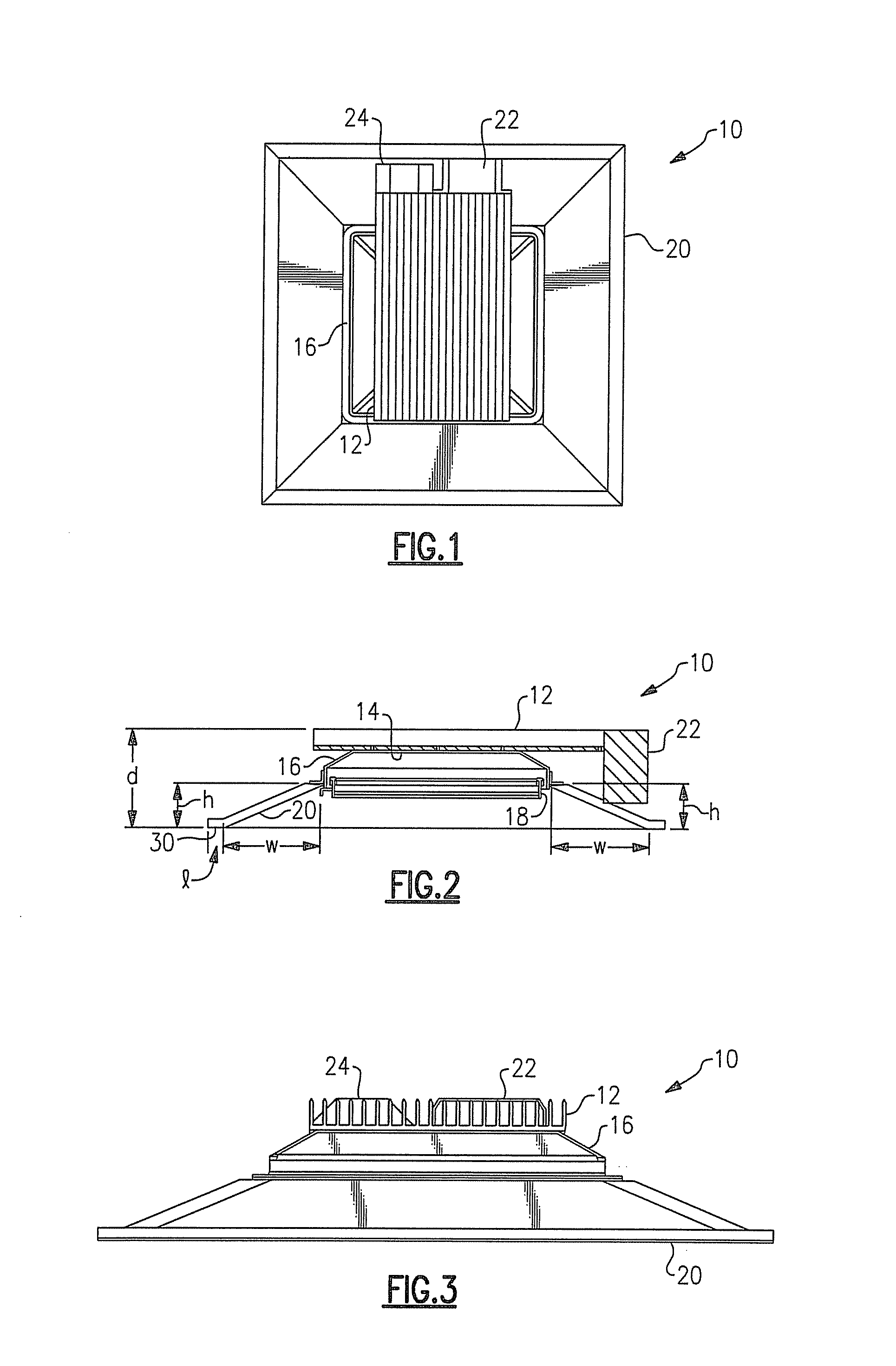

Lighting assemblies and components for lighting assemblies

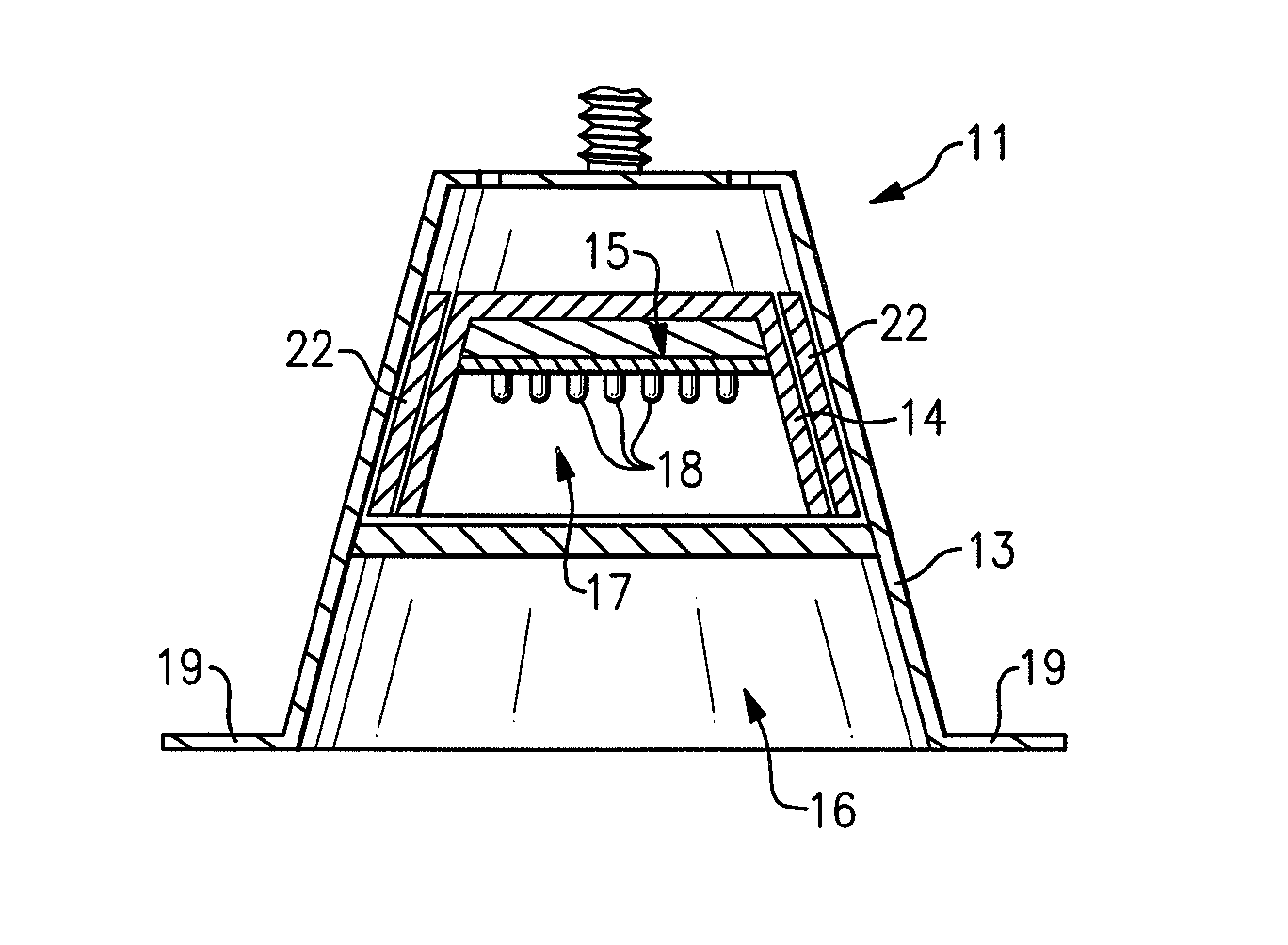

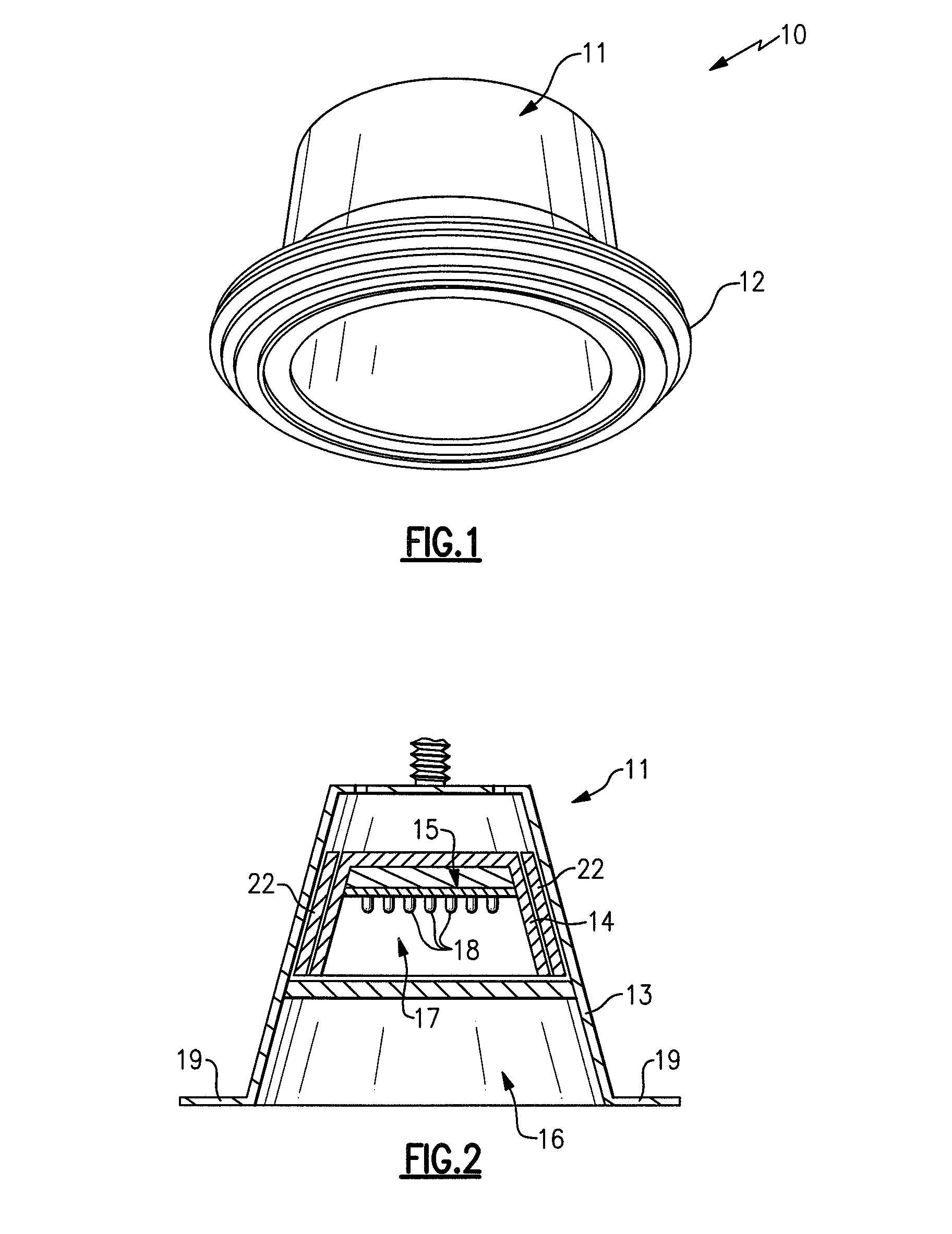

ActiveUS20080112170A1Add additional massIncrease surface areaPlanar light sourcesMechanical apparatusInterior spaceEffect light

A lighting assembly, comprising a light engine assembly and a room-side element. The room-side element is in contact with the light engine assembly. The light engine assembly comprises at least one trim element and a light engine. The trim element defines a trim element internal space. The light engine comprises at least one solid state light emitter, and is positioned within the trim element internal space. Also, a lighting assembly, comprising a light engine assembly and means for dissipating heat from the light engine assembly.

Owner:IDEAL IND LIGHTING LLC

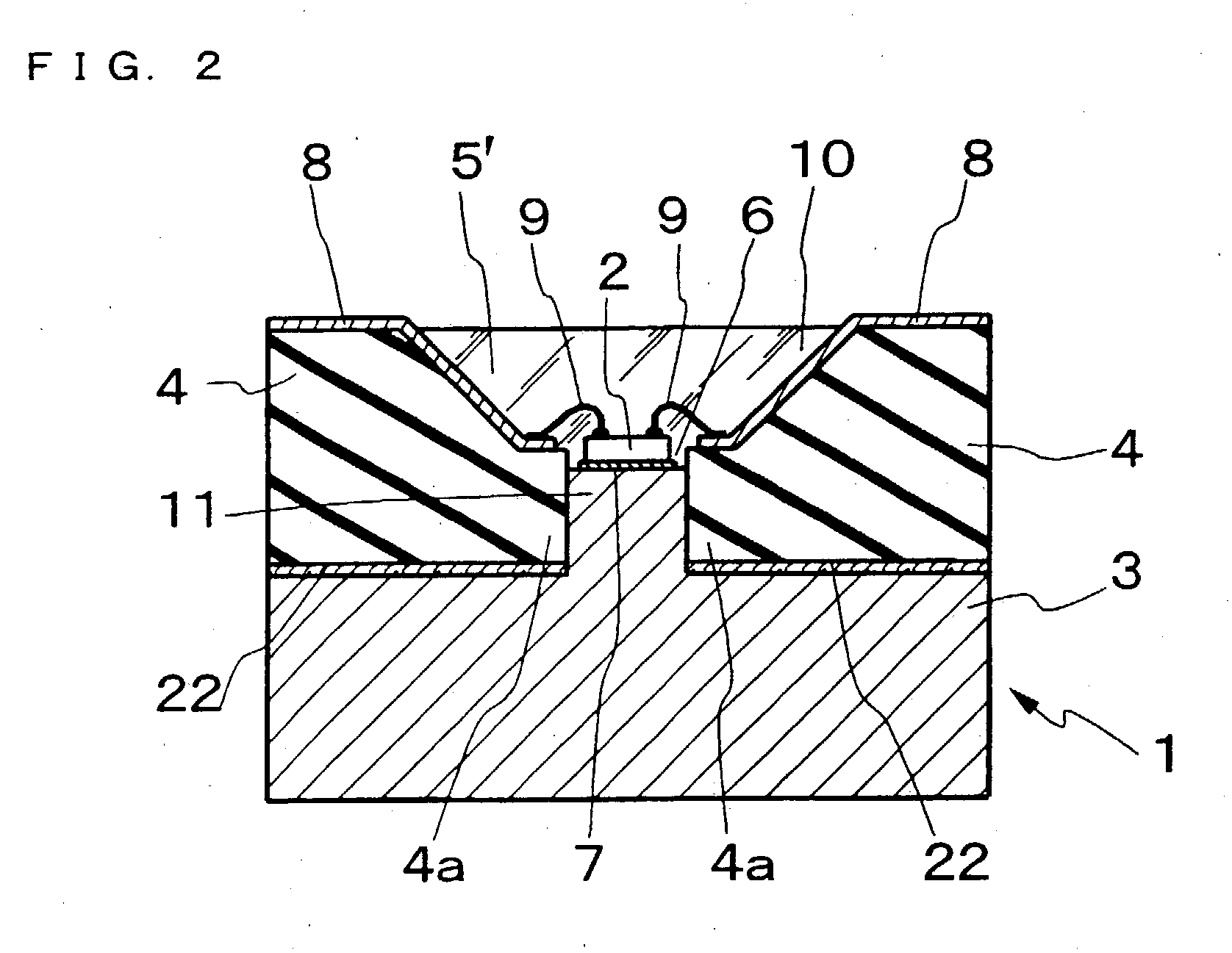

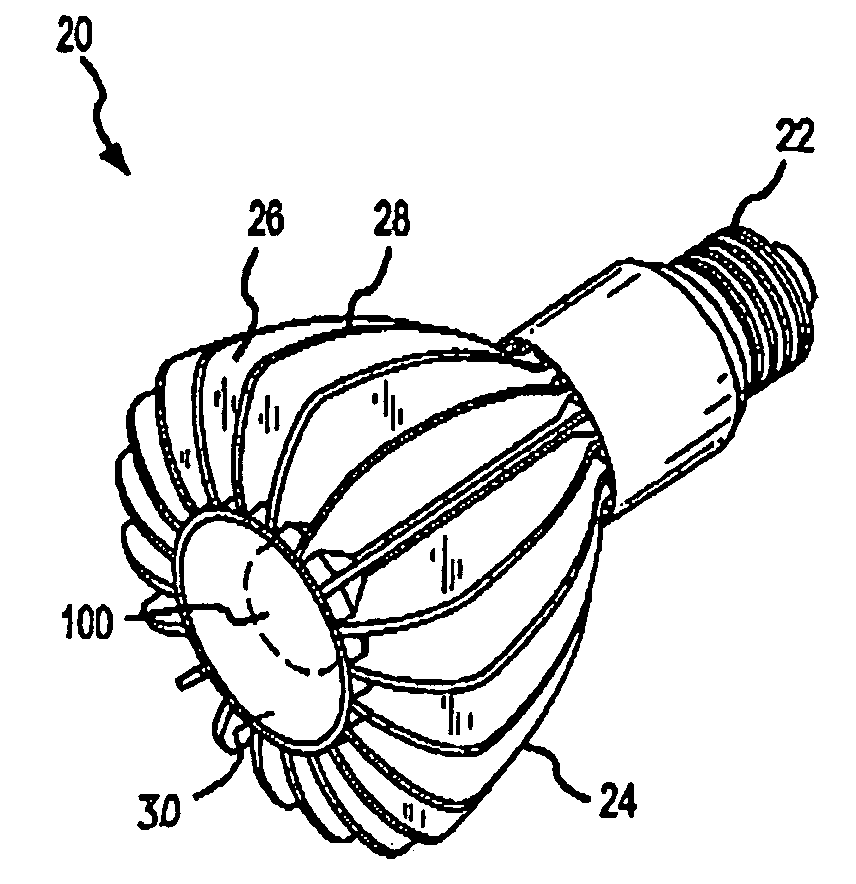

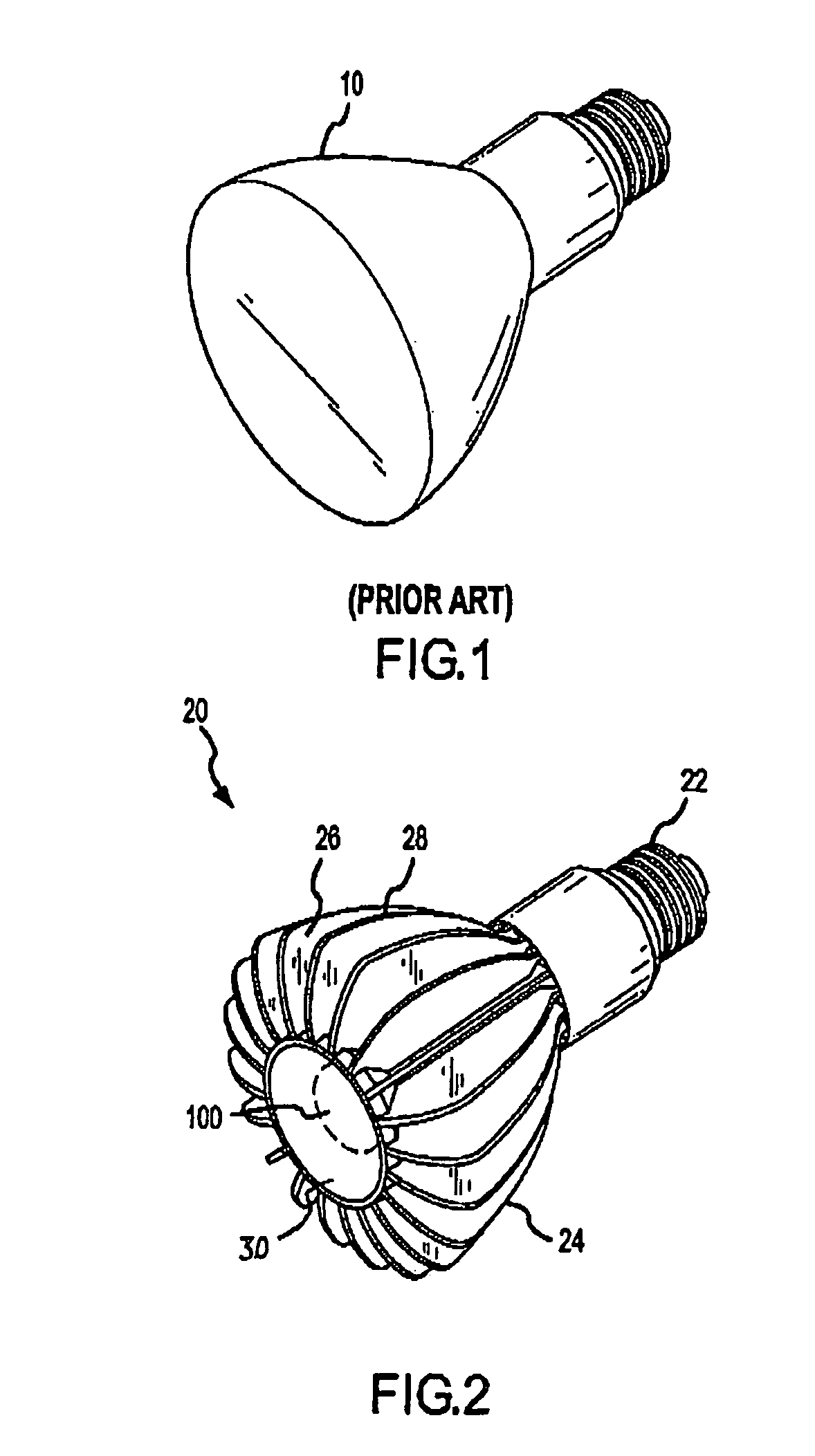

Methods and apparatus for an LED light

An LED lighting device for use in place of a commercial-standard light bulb. For example, a commercial-standard light bulb typically has an outer surface profile, generally defining its shape and the LED lighting device has its own surface profile which substantially mimics the surface profile of the commercial-standard light bulb. Additionally, LED lighting device may further comprise a heat sink for dissipating energy generated by the LED lighting device. In accordance with various embodiments, the heat sink creates the LED lighting device's outer surface profile and is configured to substantially mimic the outer surface profile of the commercial-standard light bulb.

Owner:ENERTRON INC

Lighting device and method of lighting

There is provided a lighting device which emits light with an wall plug efficiency of at least 85 lumens per watt. The lighting device comprises at least one solid state light emitter, e.g., one or more light emitting diodes, and optionally further includes one or more luminescent material. In some embodiments, the output light is of a brightness of at least 300 lumens. In some embodiments, the output light has a CRI Ra of at least 90. Also, a method of lighting, comprising supplying electricity to a lighting device which emits light with a wall plug efficiency of at least 85 lumens per watt.

Owner:IDEAL IND LIGHTING LLC

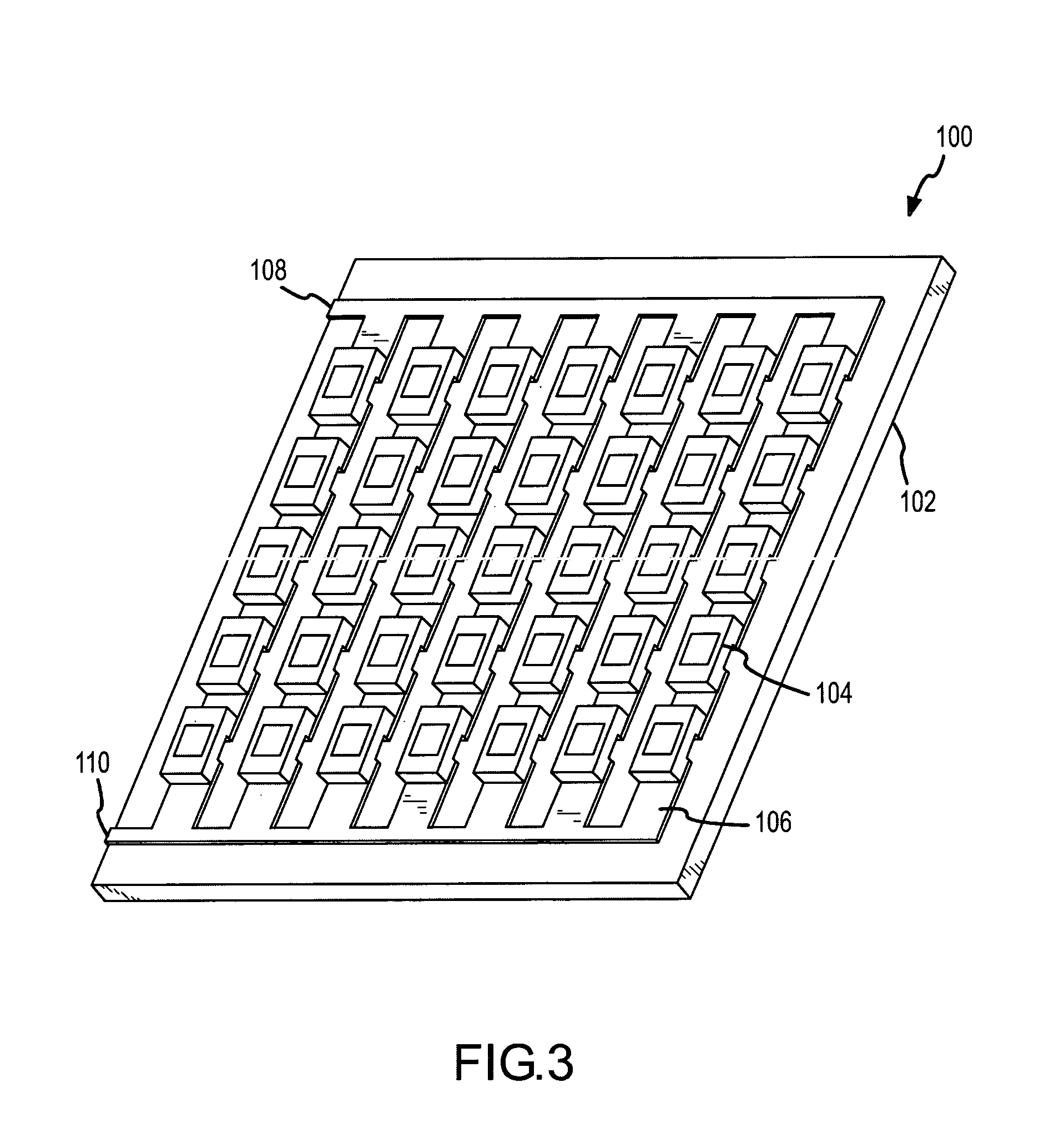

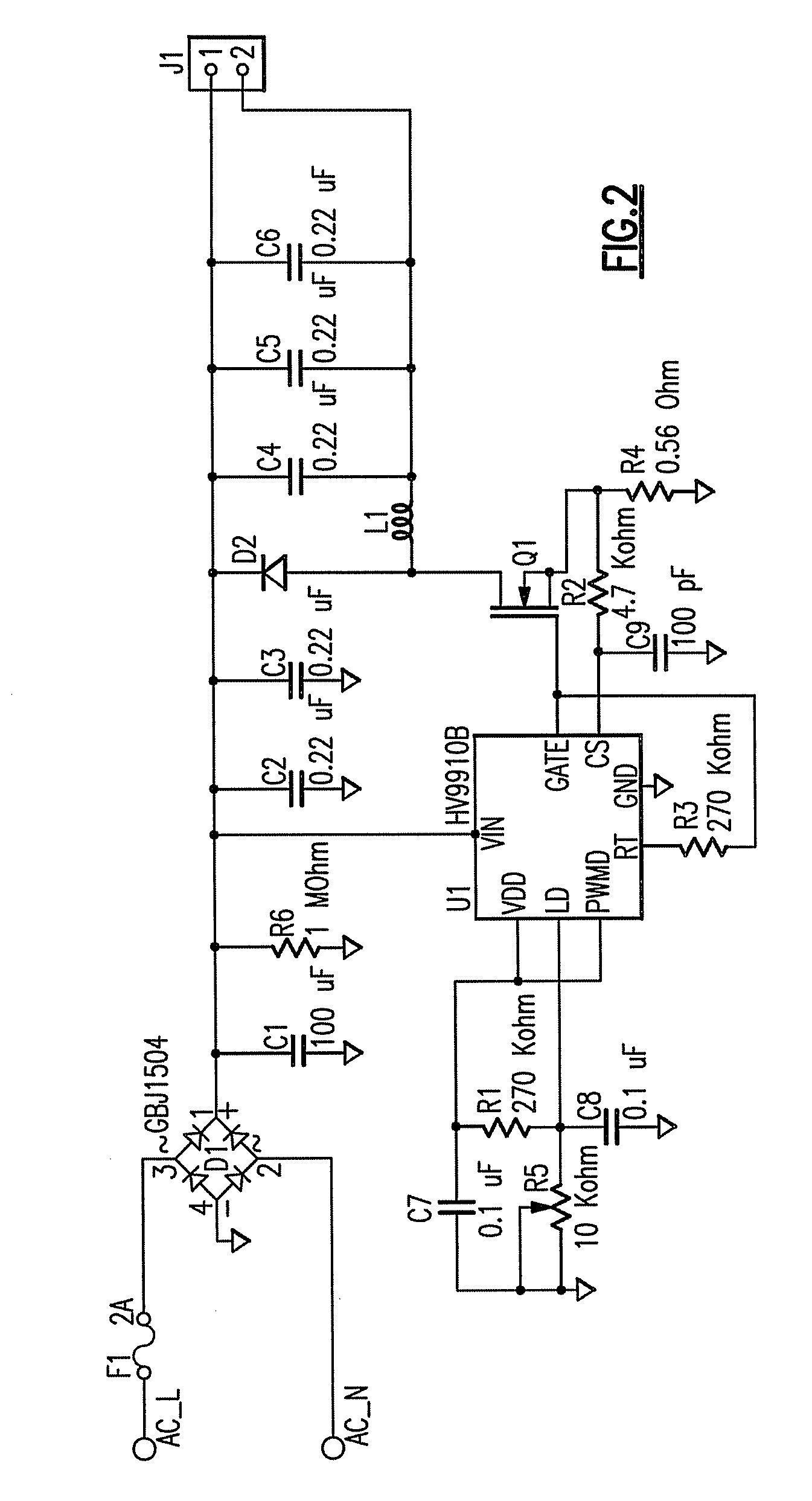

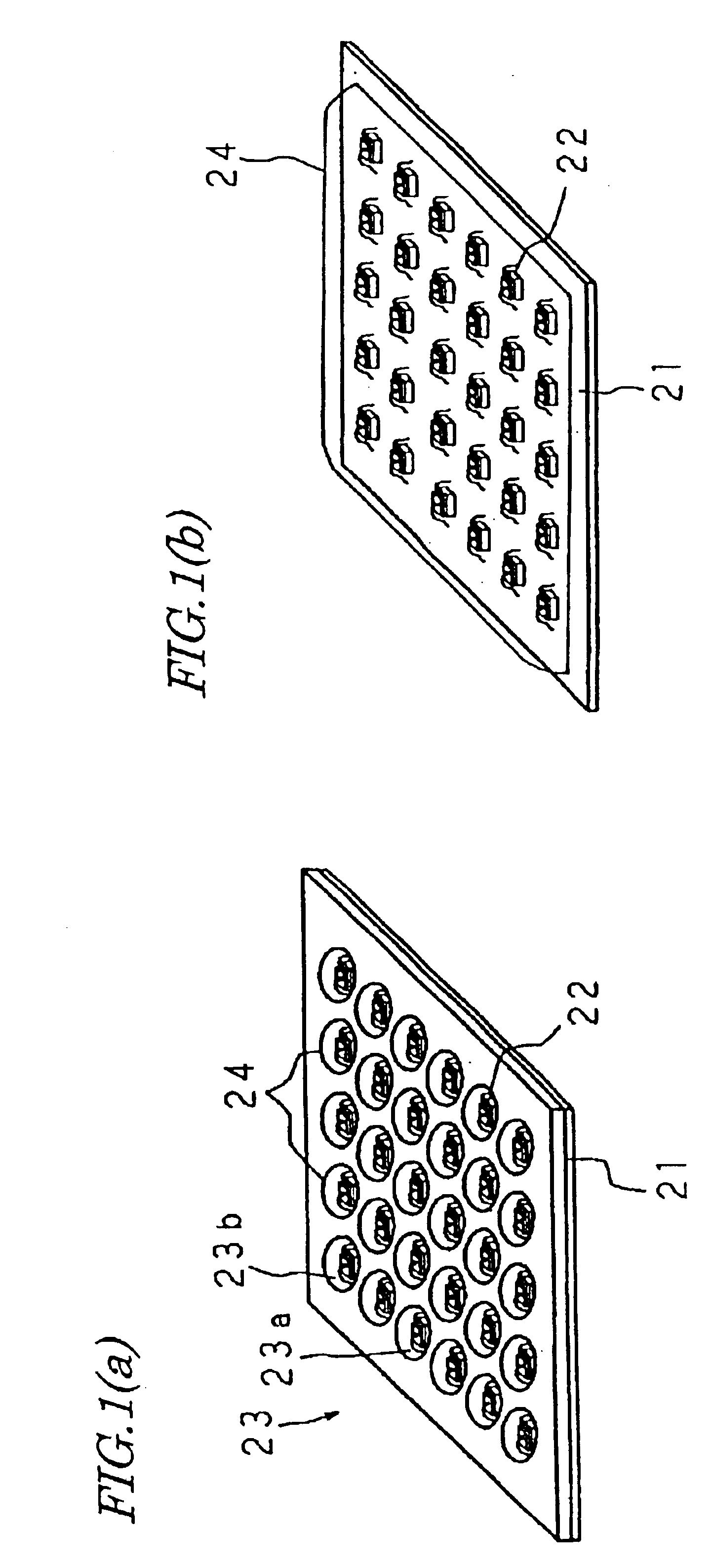

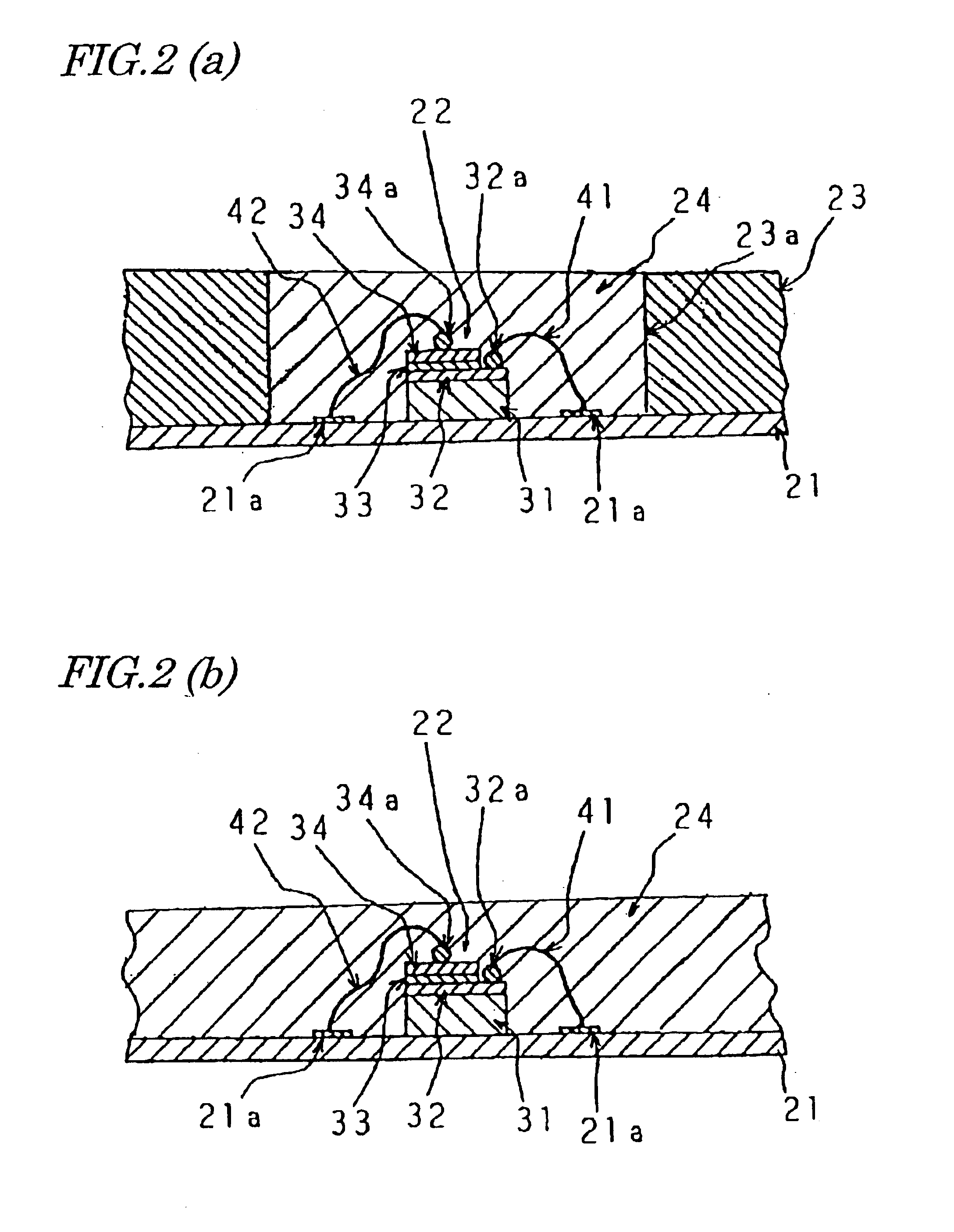

LED illumination apparatus and card-type LED illumination source

An LED illumination apparatus according to the present invention includes at least one connector and a lighting drive circuit. The connector is connected to an insertable and removable card-type LED illumination source, which includes multiple LEDs that have been mounted on one surface of a substrate. The lighting drive circuit is electrically connected to the card-type LED illumination source by way of the connector. The card-type LED illumination source preferably includes a metal base substrate and the multiple LEDs that have been mounted on one surface of the metal base substrate. The back surface of the metal base substrate, including no LEDs thereon, thermally contacts with a portion of the illumination apparatus. A feeder terminal to be electrically connected to the connector is provided on the surface of the metal base substrate on which the LEDs are provided.

Owner:EVERLIGHT ELECTRONICS

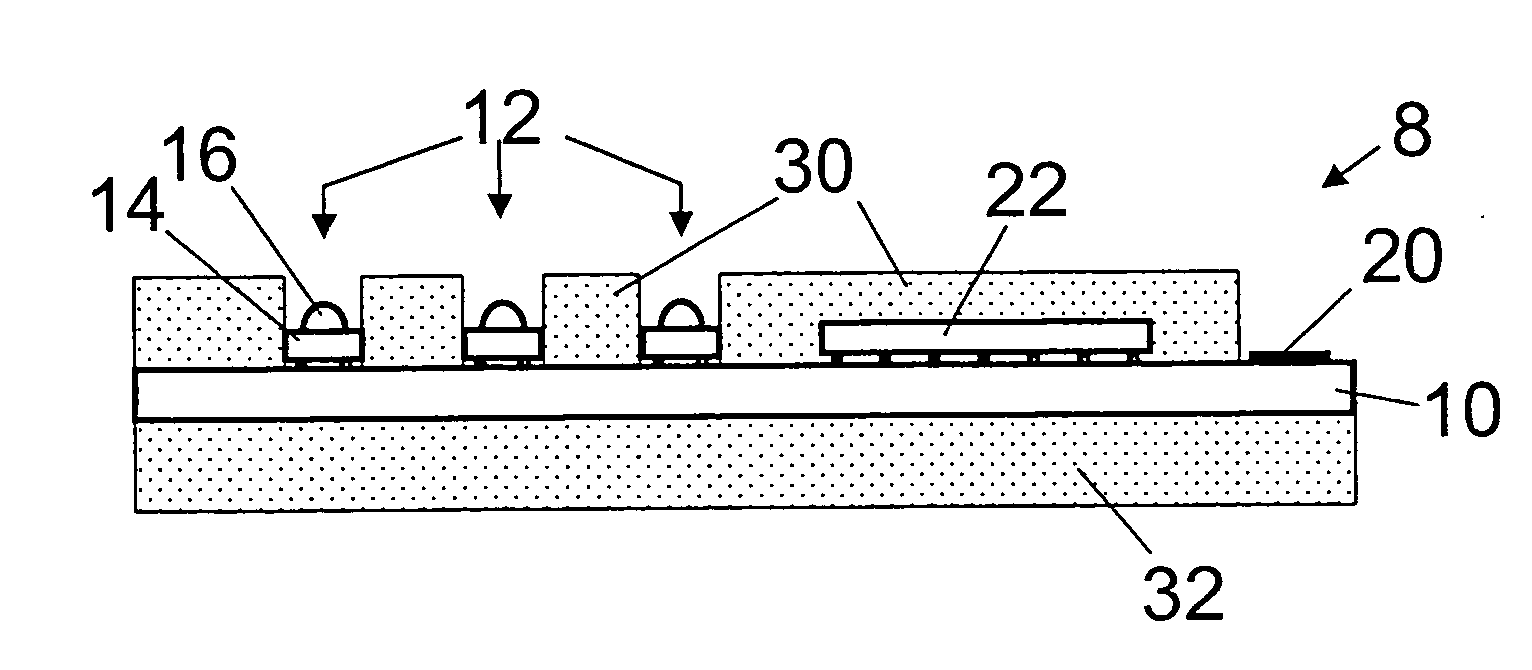

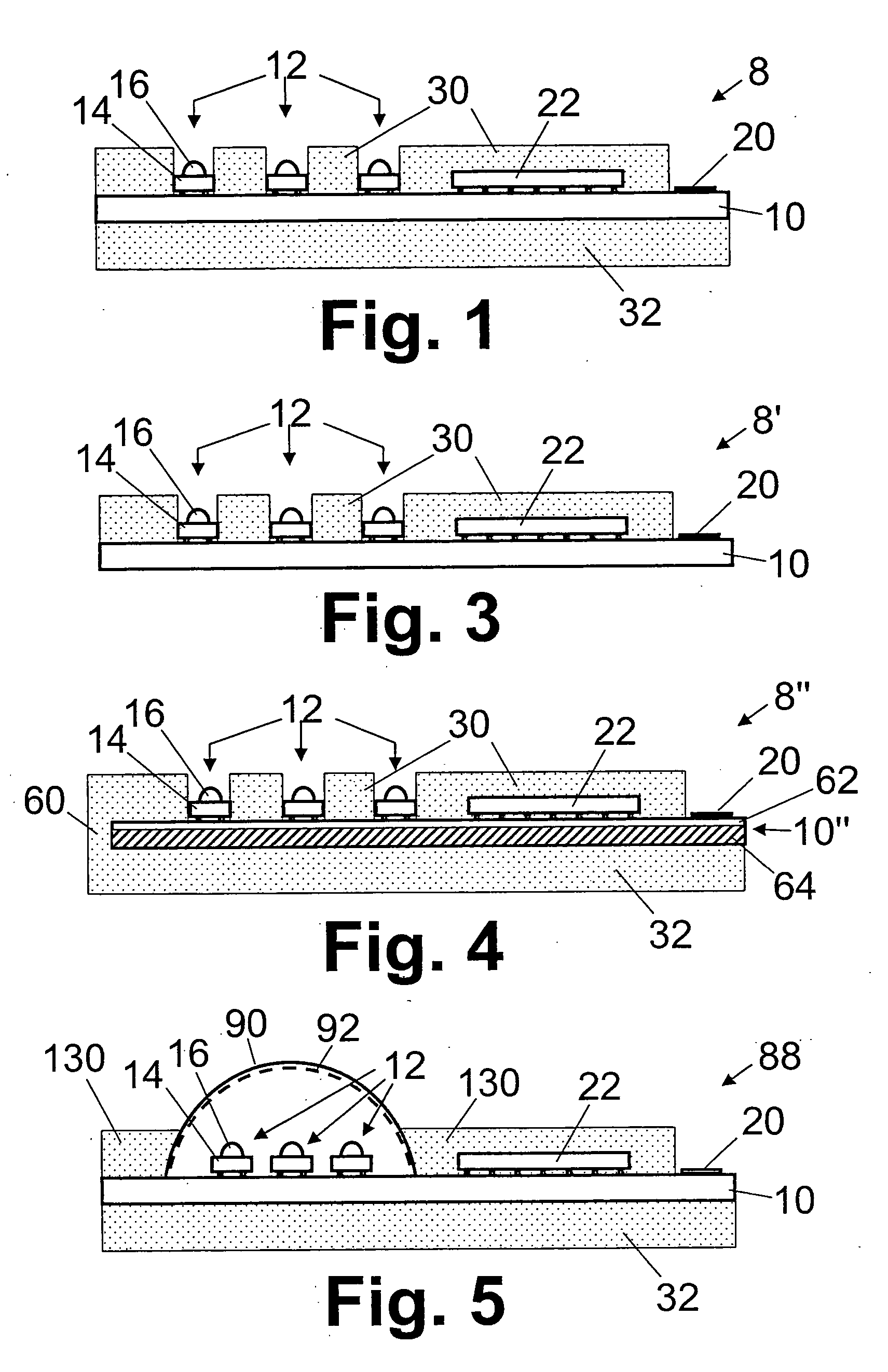

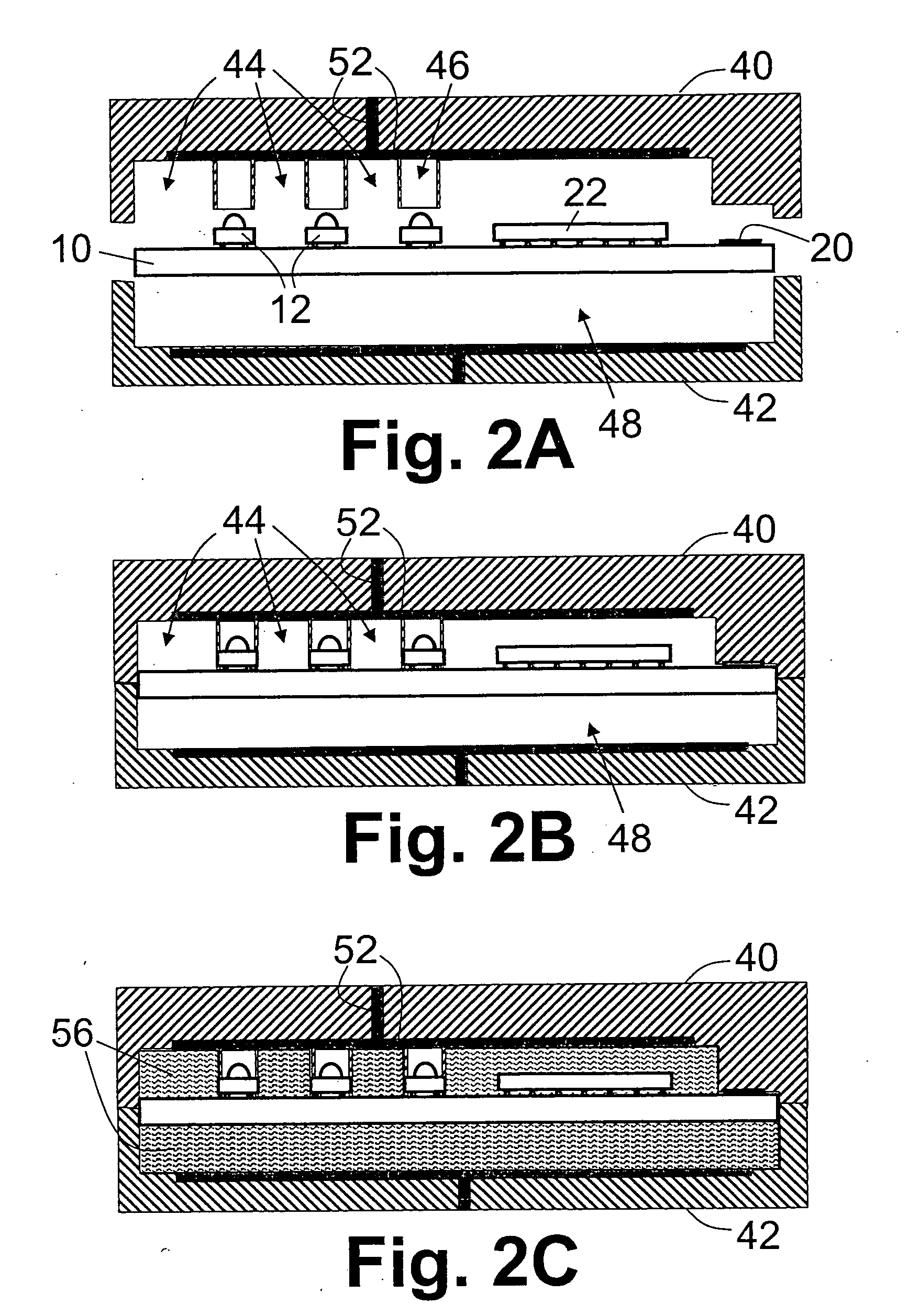

LED lighting assemblies with thermal overmolding

ActiveUS20070121326A1Thermal conductivityPoint-like light sourceElectric circuit arrangementsEffect lightEngineering

One or more light emitting diode diodes (LEDs) are attached to a printed circuit board. The attached LEDs are connectable with a power source via circuitry of the printed circuit board. An overmolding material is insert molded an over at least portions of the printed circuit board proximate to the LEDs to form a free standing high thermal conductivity material overmolding that covers at least portions of the printed circuit board proximate to the LEDs. The free standing high thermal conductivity material has a melting temperature greater than about 100° C. and has a thermal conductivity greater than or about 1 W / m·K. In some embodiments, the free standing high thermal conductivity material is a thermoplastic material.

Owner:GE LIGHTING SOLUTIONS LLC

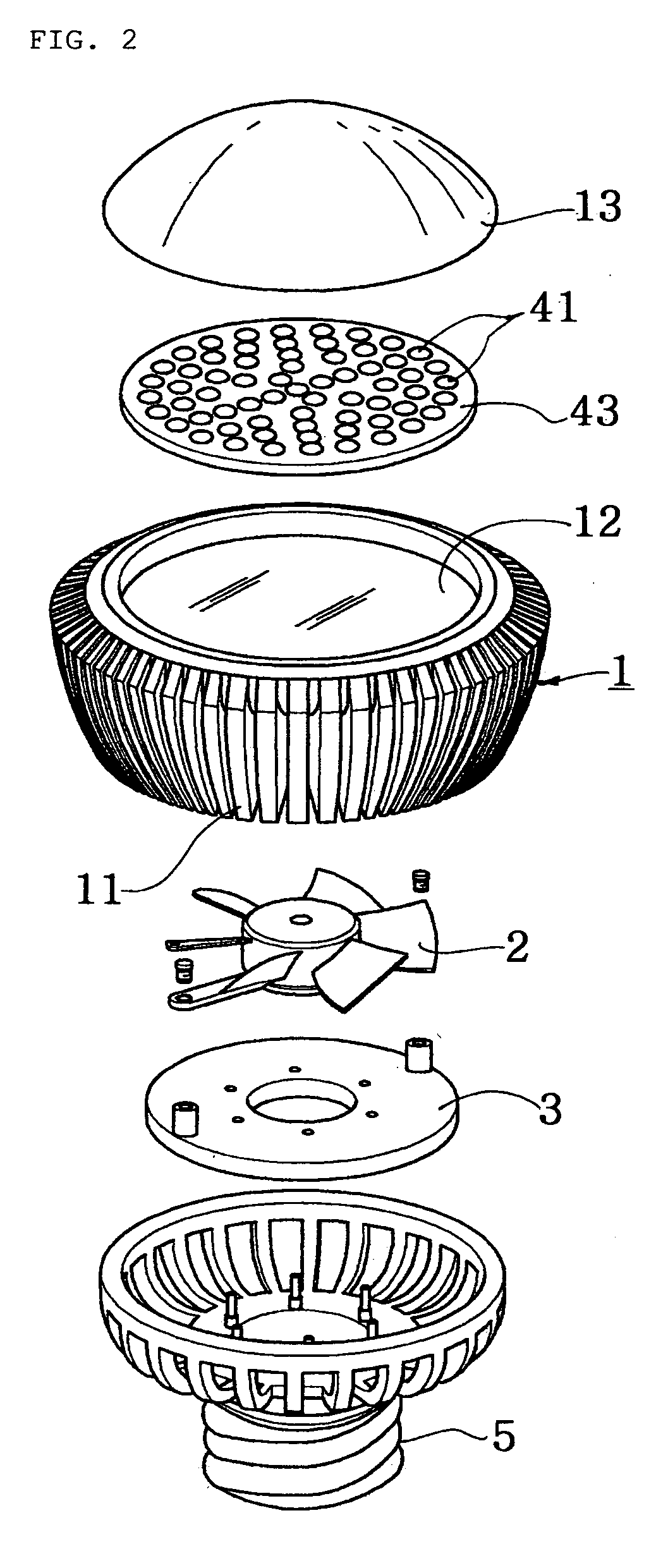

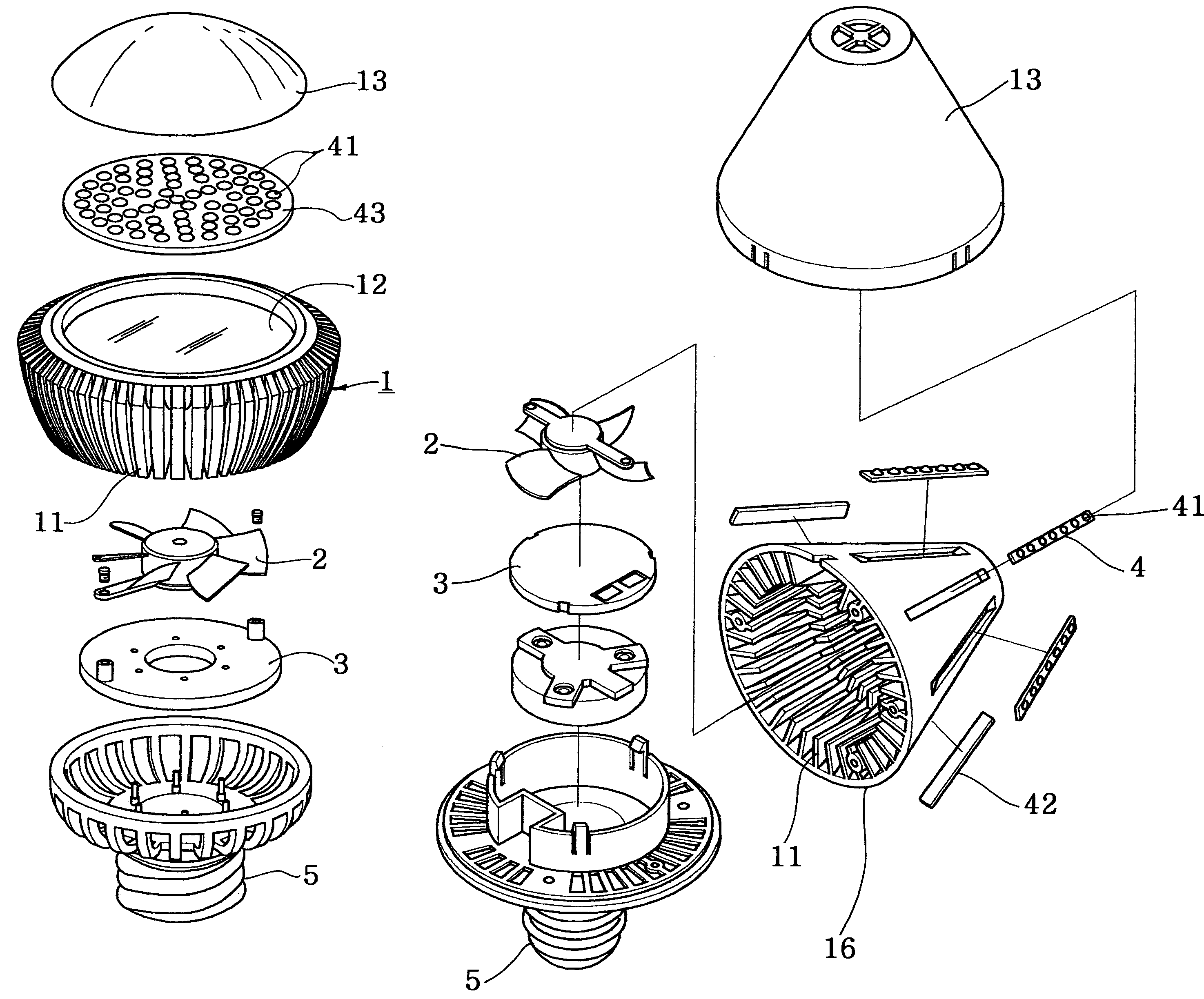

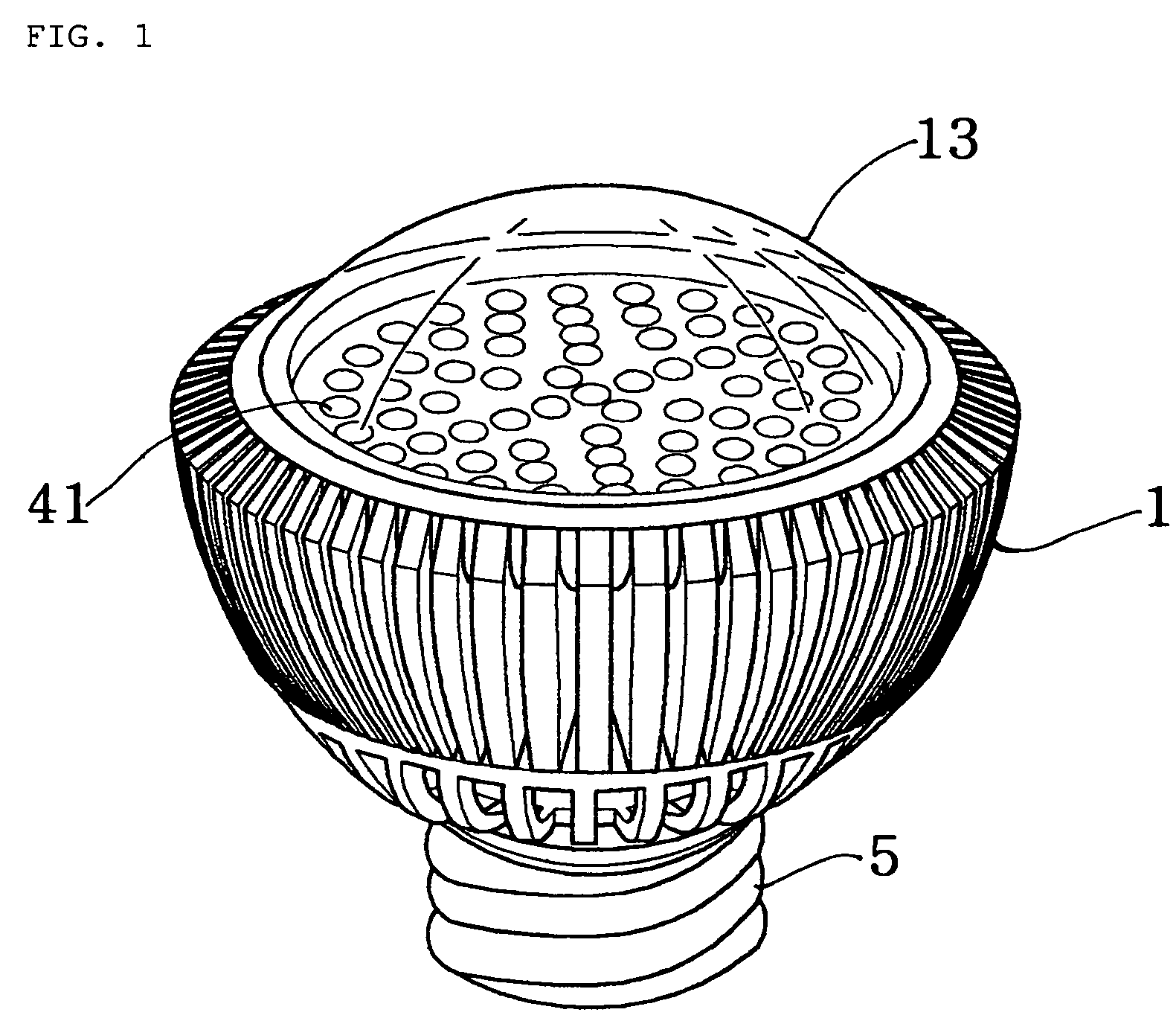

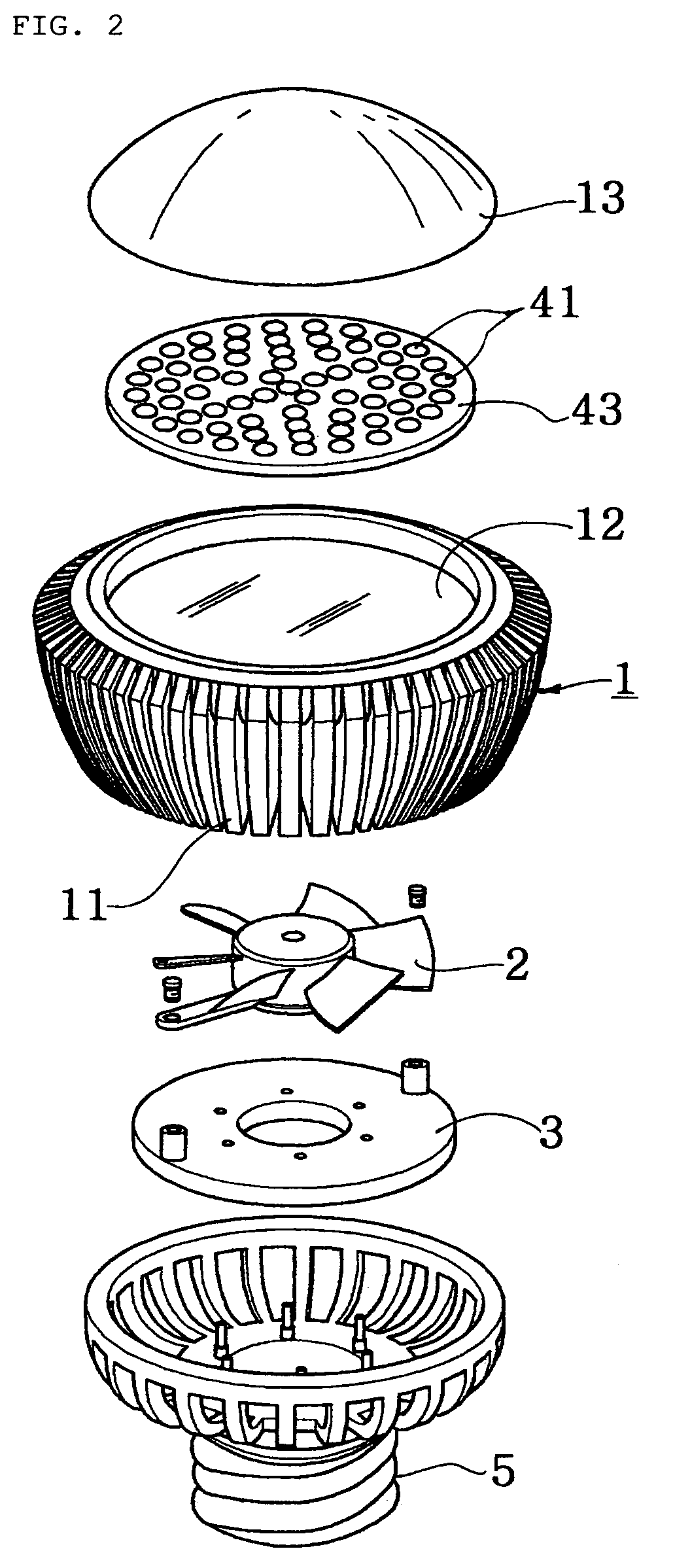

LED light

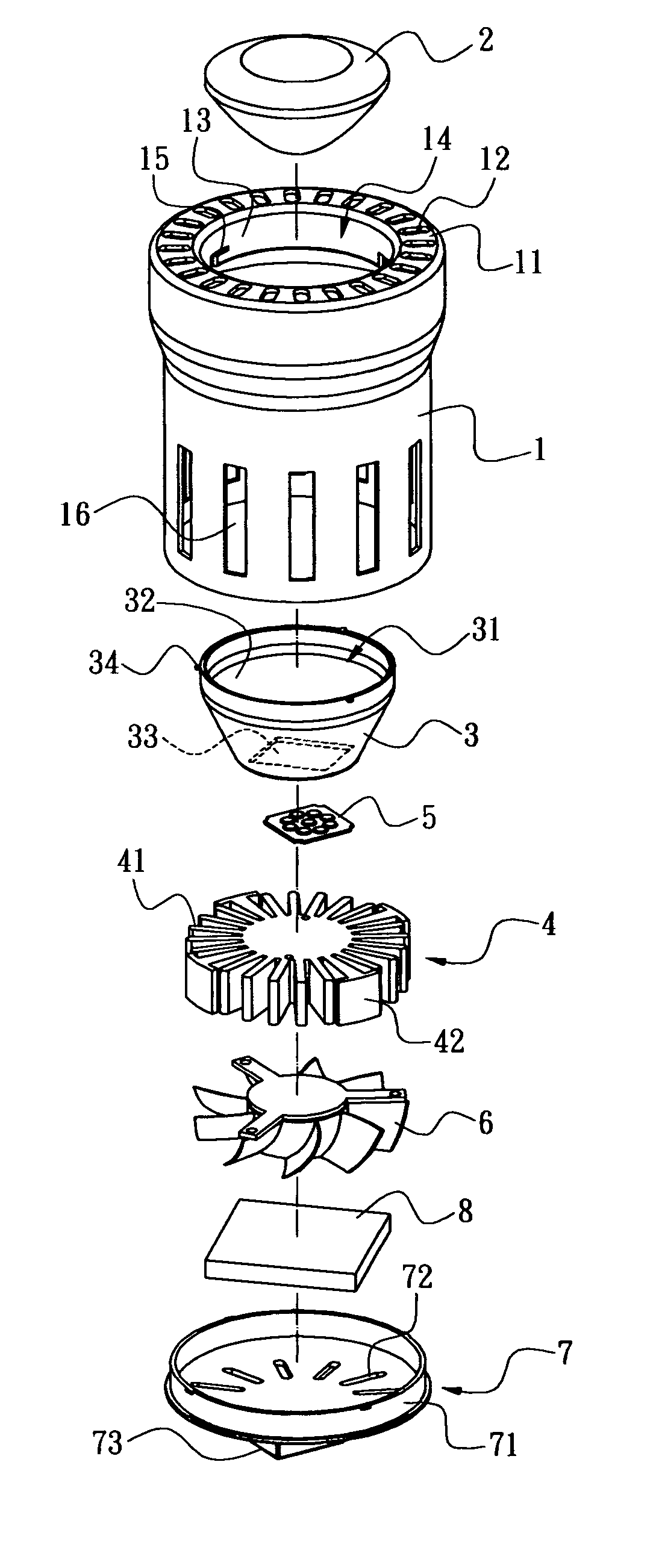

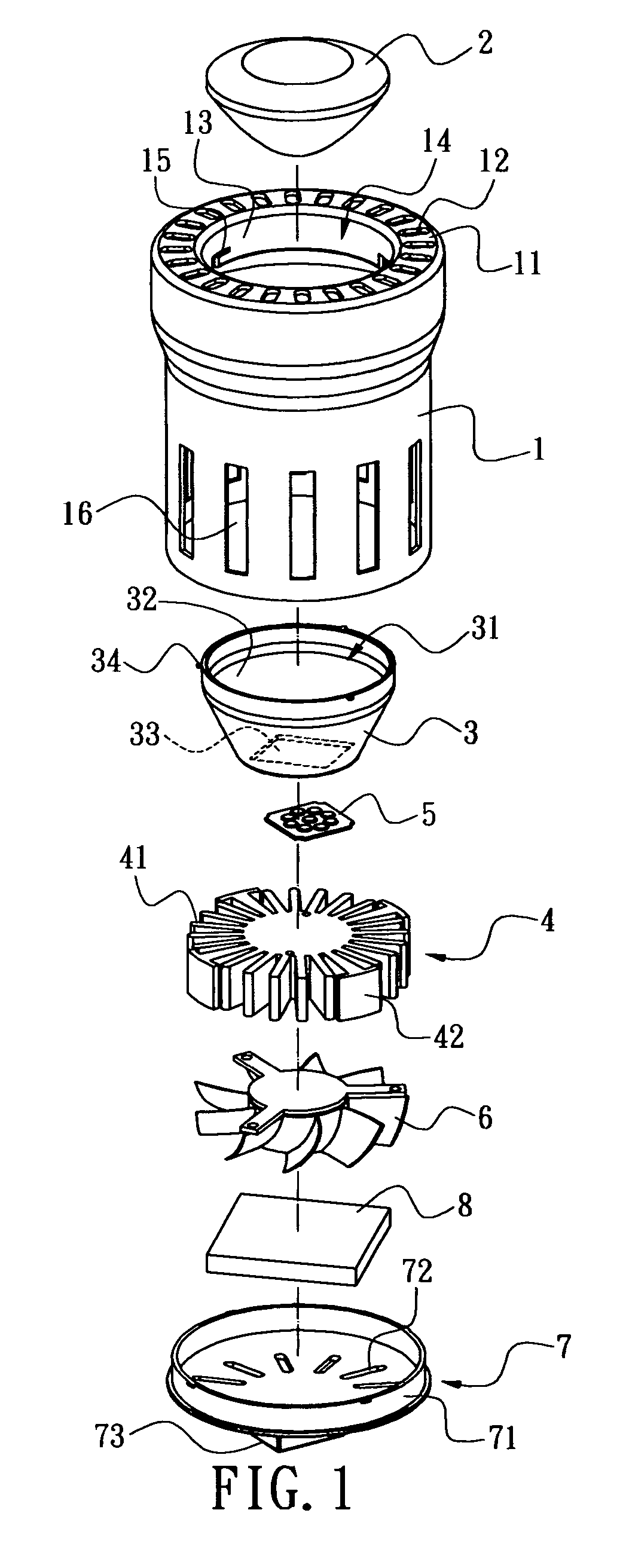

InactiveUS7524089B2Increase illuminationElectric circuit arrangementsLighting heating/cooling arrangementsElectricityLeading edge

Disclosed herein is an LED light. The LED light comprises a socket electrically connected to a receptacle, and a cooling fan for forcibly circulating air. The cooling fan is received in a main body, which has a plurality of radial partition walls formed on the outer peripheral surface thereof in such a manner as to be spaced apart from one another with a gap having a slit shape for ventilation. A plurality of LEDs is attached to the outer periphery and / or the inner leading edge of the main body. A circuit board is provided to control the light such that an alternating current supplied from the socket is rectified into a direct current, which is supplied to the cooling fan and the LED.

Owner:DAEJIN DMP

Lighting device

ActiveUS20070263393A1Reduce glareEfficient transferMechanical apparatusPoint-like light sourceEffect lightEngineering

Owner:IDEAL IND LIGHTING LLC

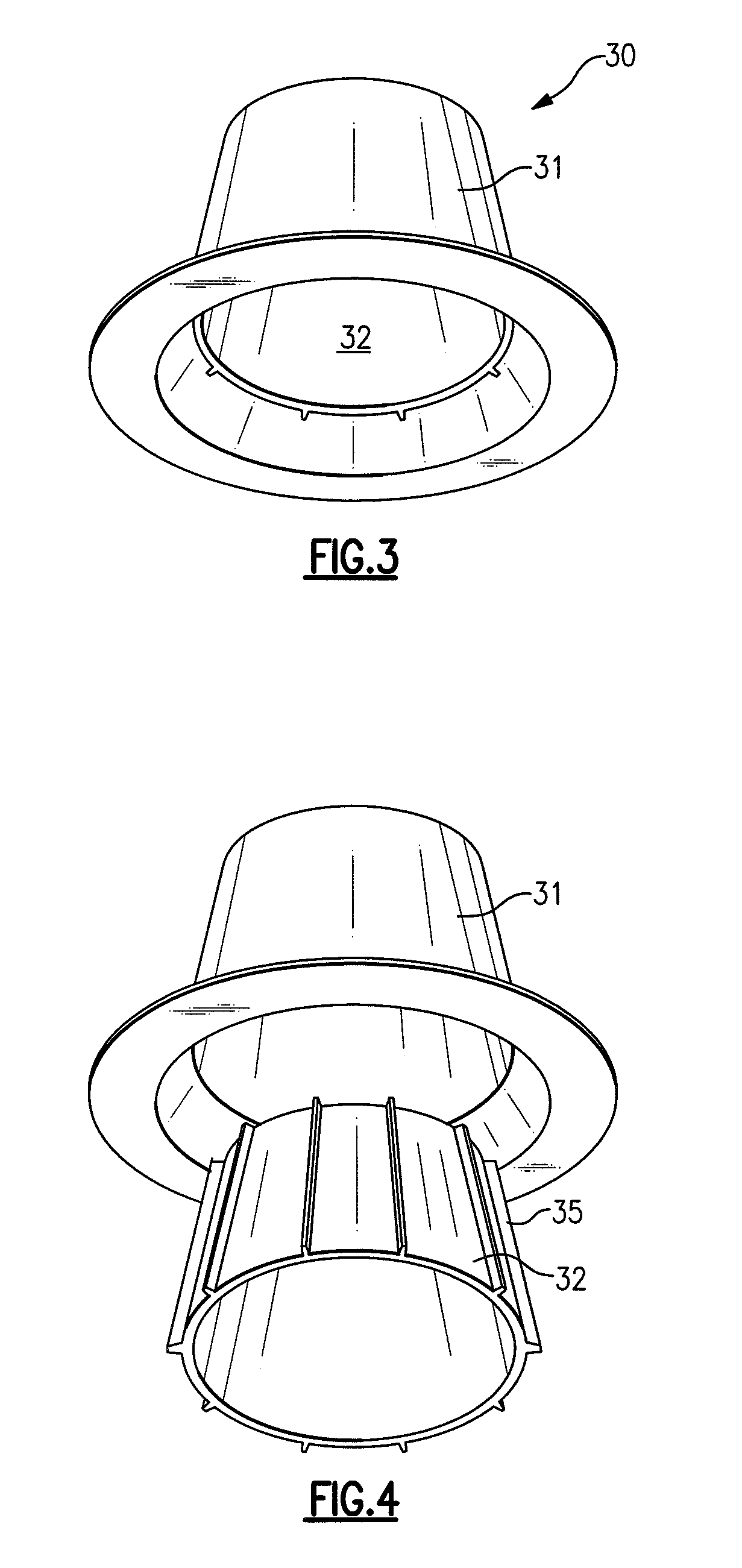

Light engine assemblies

ActiveUS20080112168A1Improve cooling effectLighting applicationsPlanar light sourcesEngineeringLight emitter

Owner:IDEAL IND LIGHTING LLC

Heat dissipating apparatus for lighting utility

InactiveUS20060193139A1Versatile operation modeEffective coolingPoint-like light sourceLighting heating/cooling arrangementsEffect lightEngineering

Owner:EDISON-OPTO

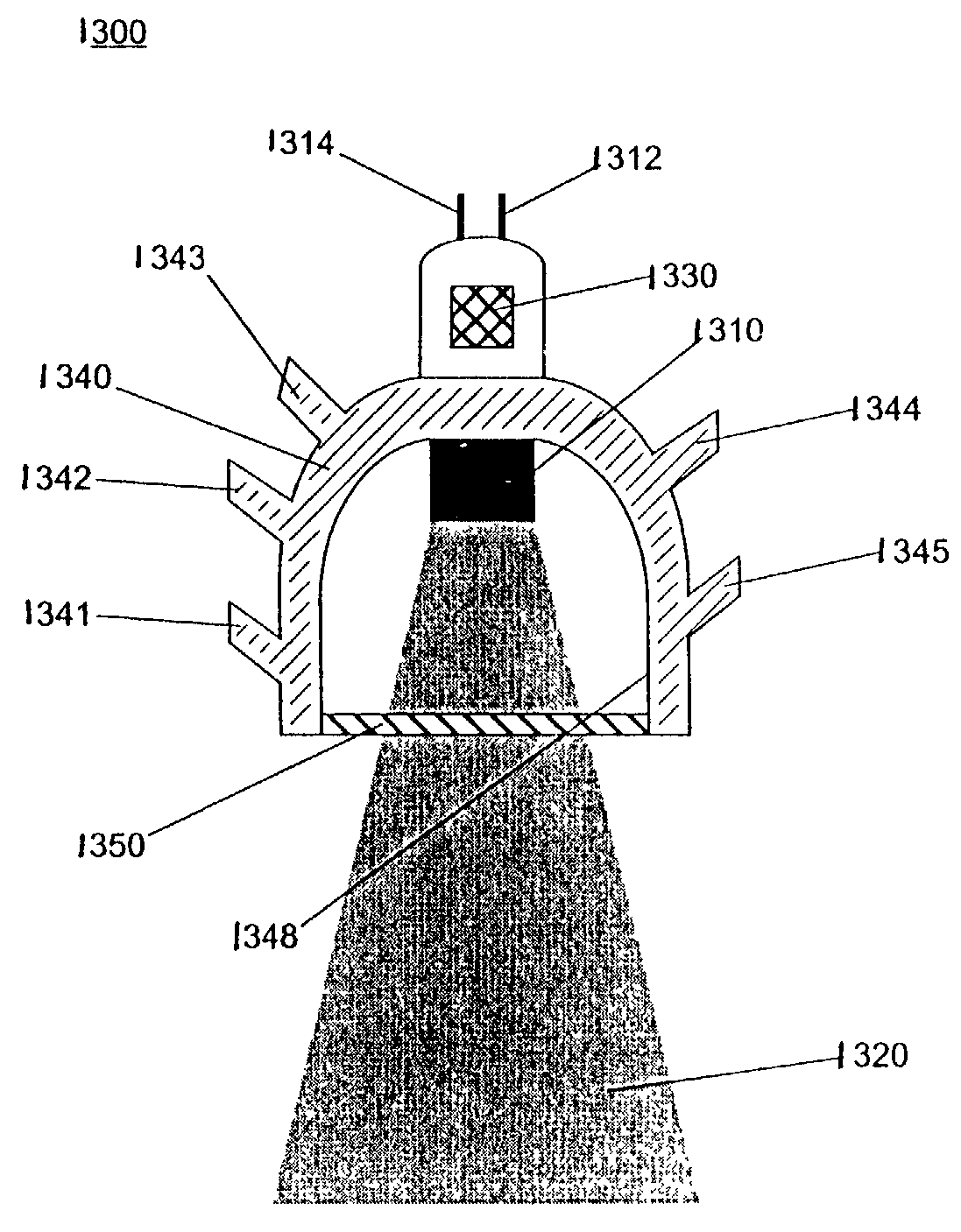

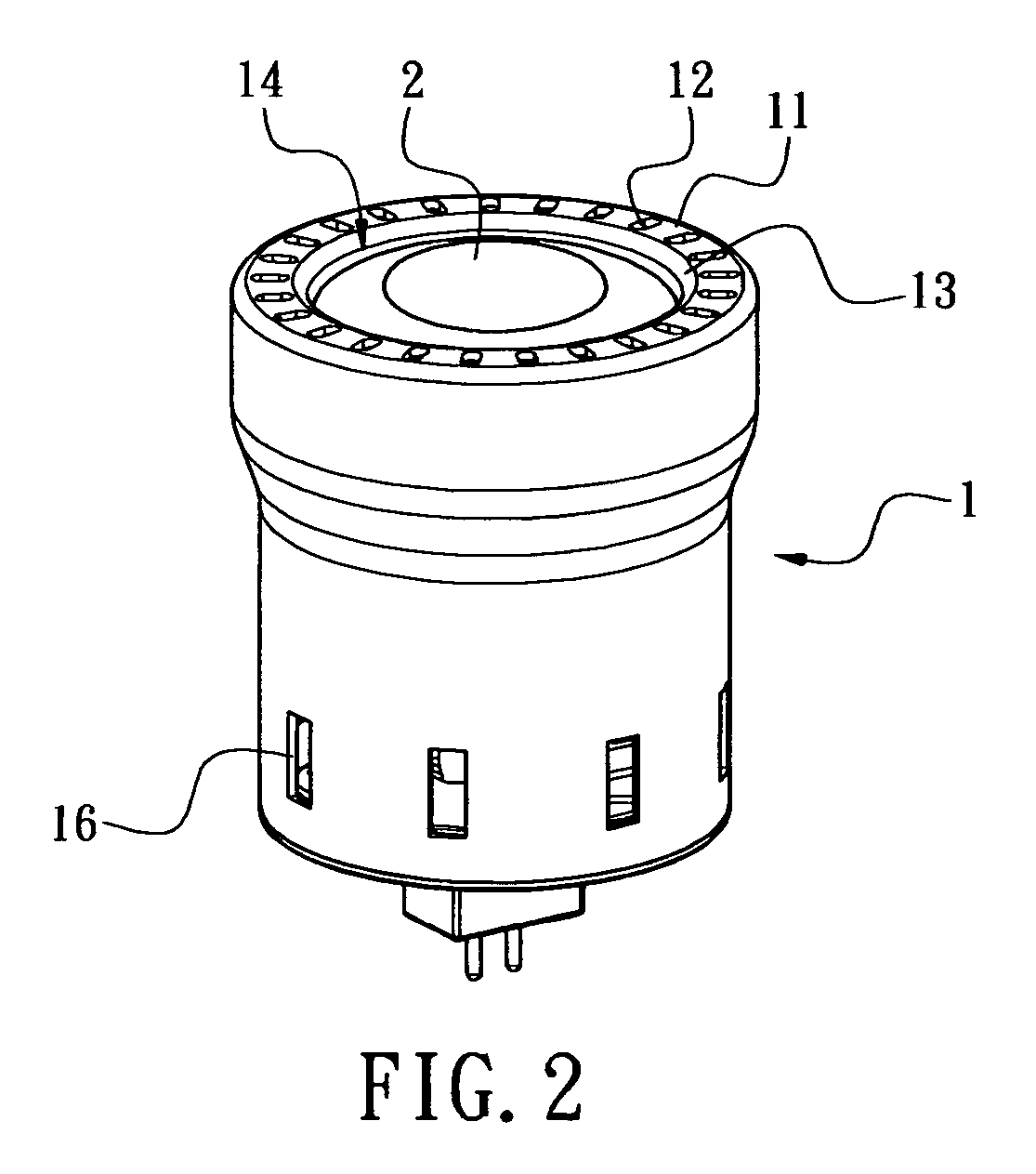

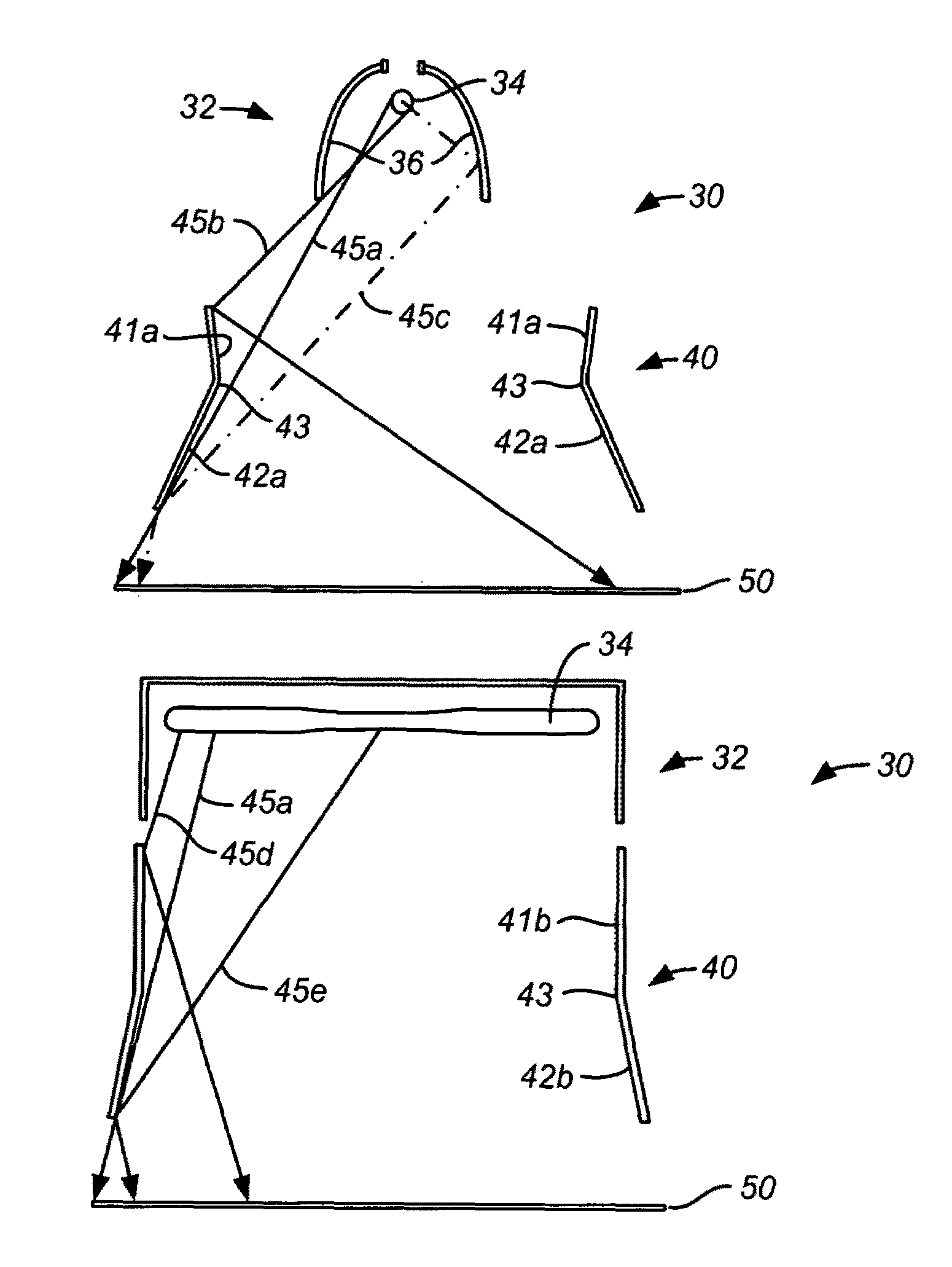

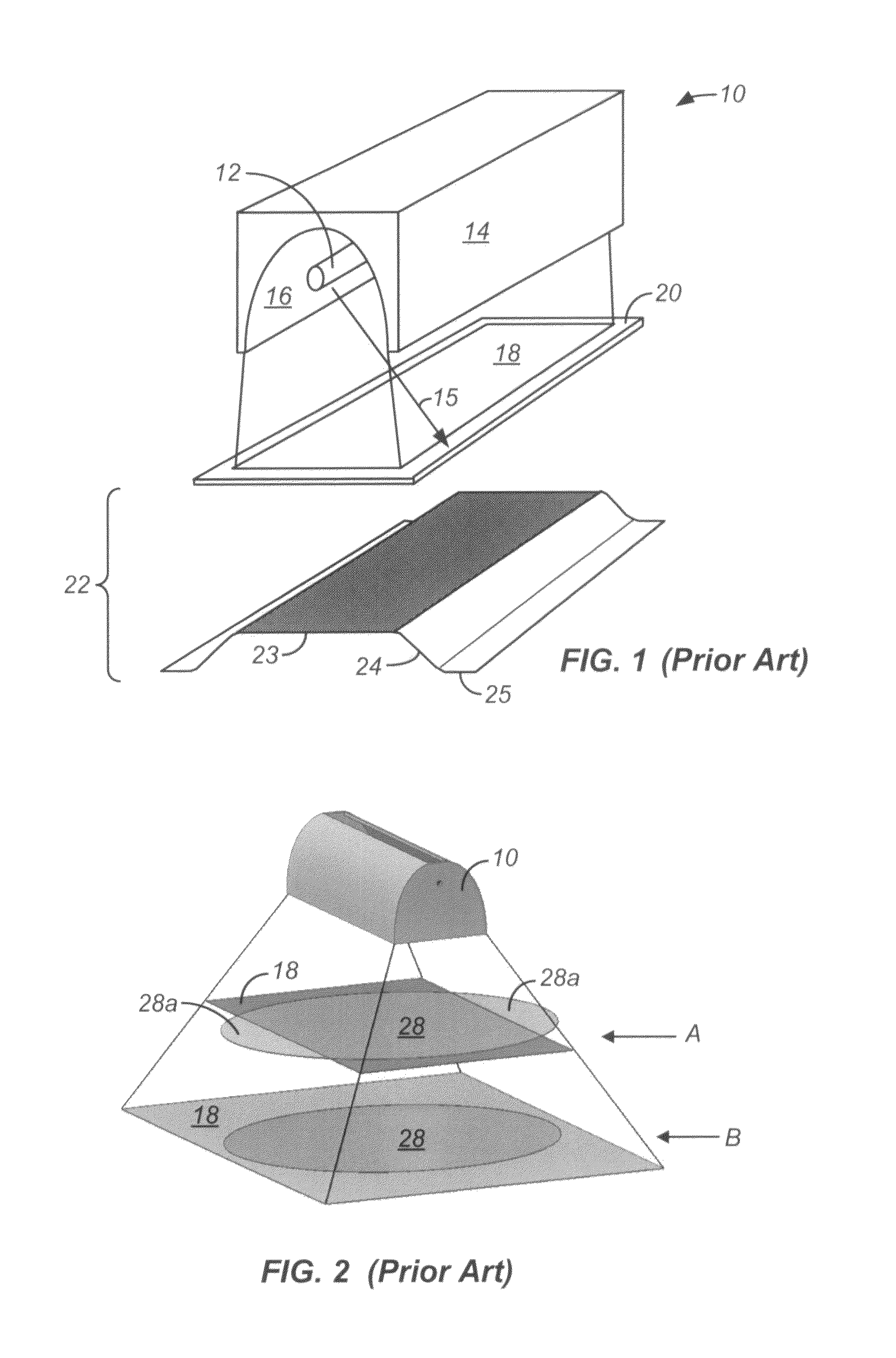

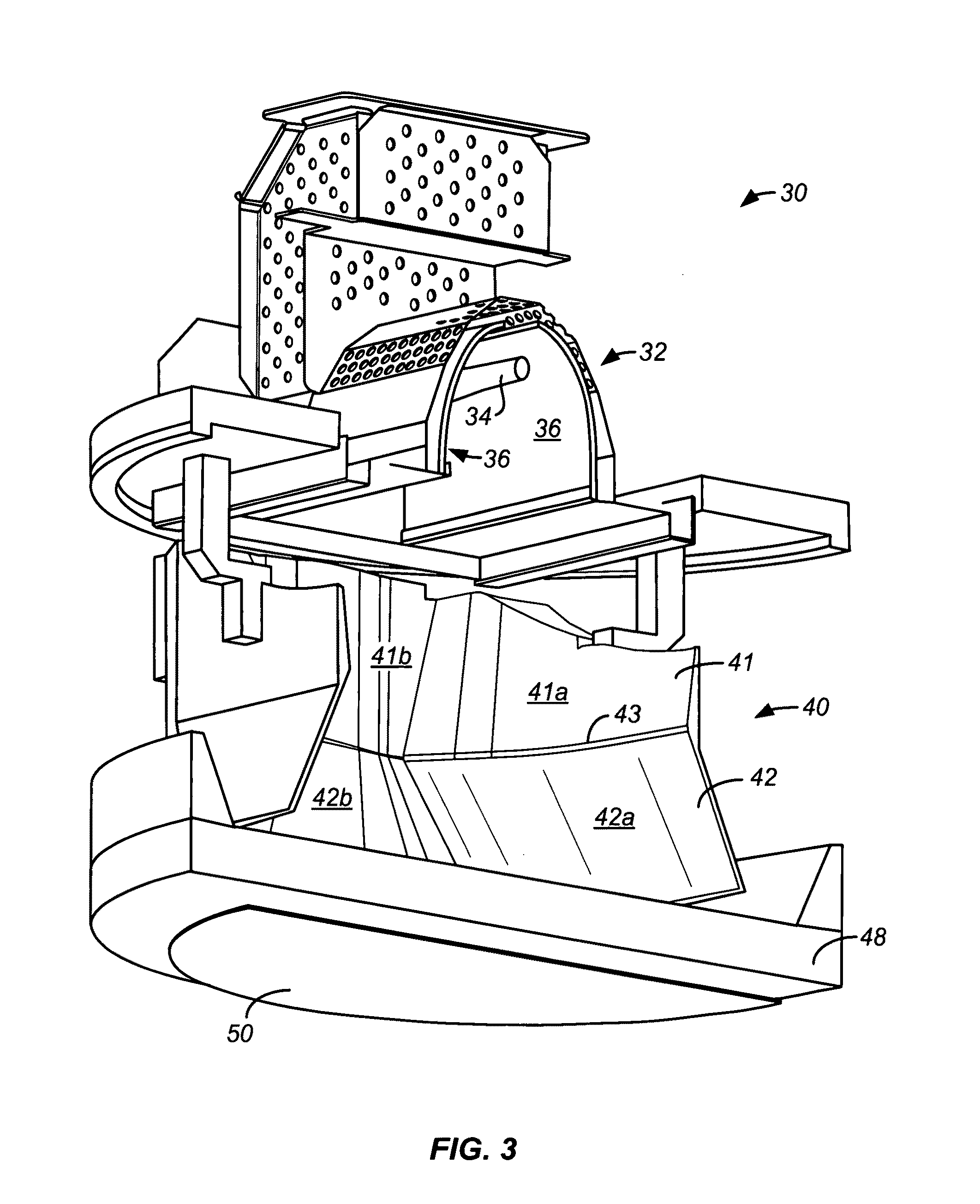

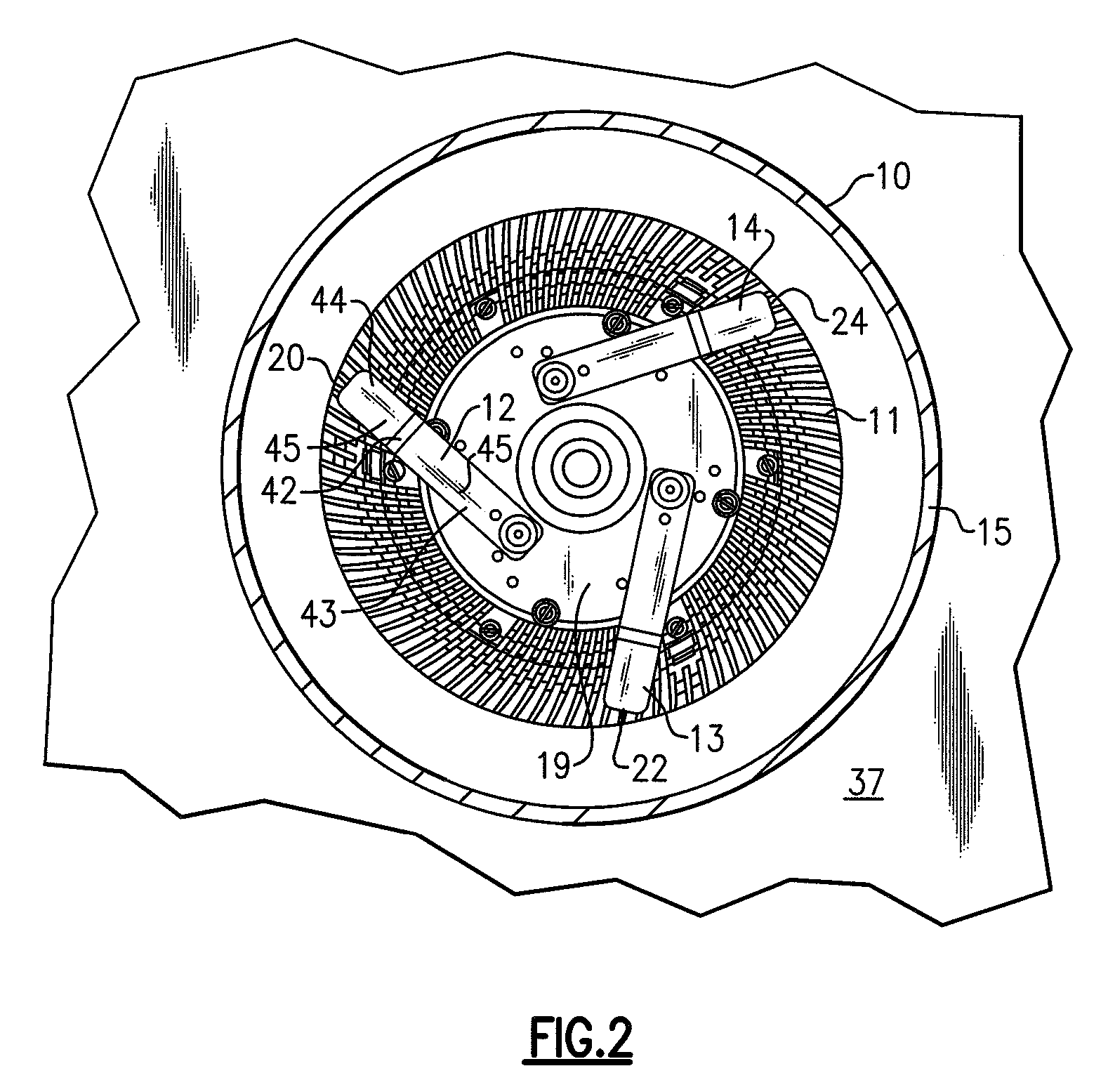

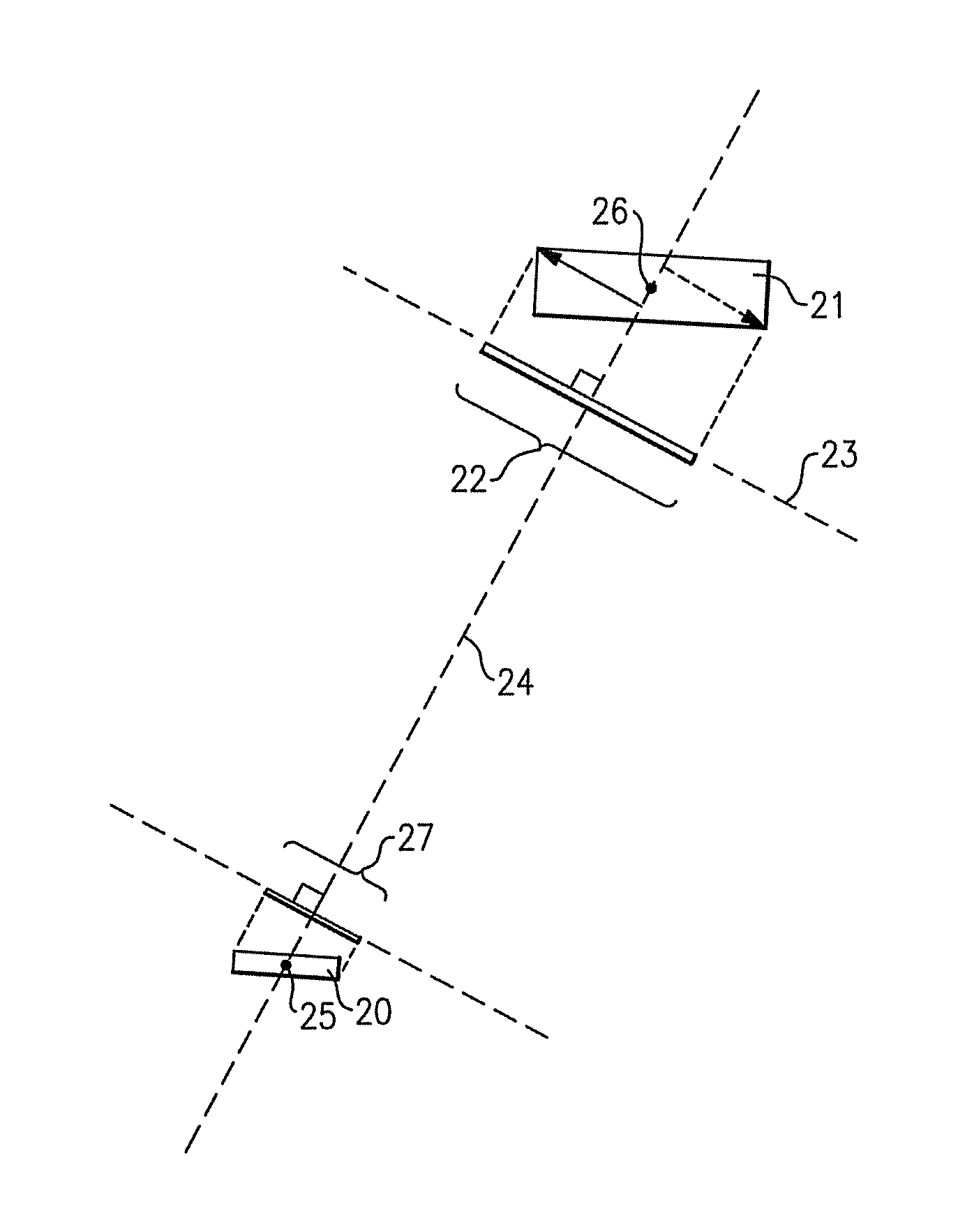

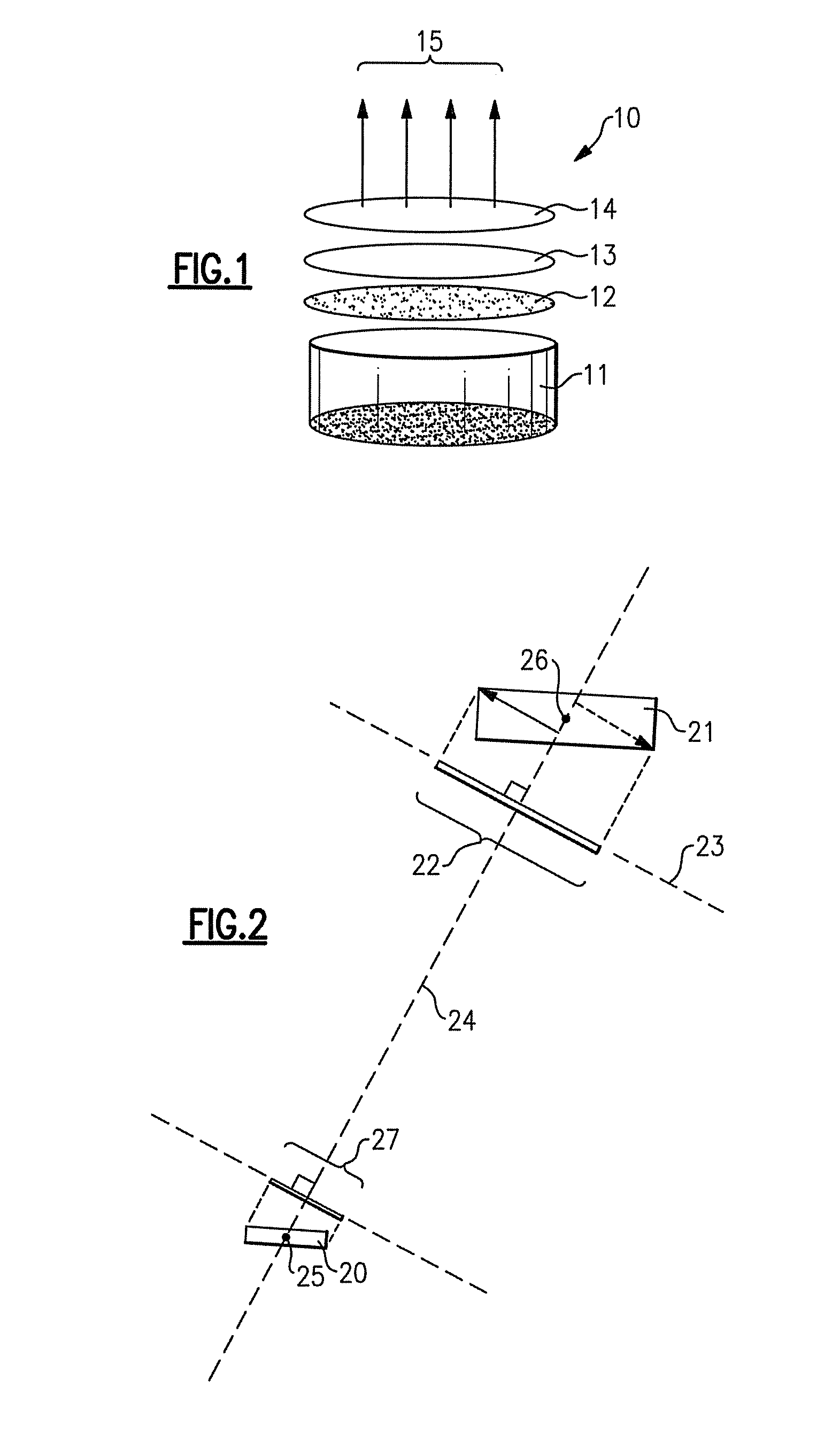

Apparatus and method for exposing a substrate to UV radiation using asymmetric reflectors

ActiveUS7692171B2Reduce light lossNanoinformaticsSemiconductor/solid-state device manufacturingProcess regionUltraviolet radiation

Embodiments of the invention relate generally to an ultraviolet (UV) cure chamber for curing a dielectric material disposed on a substrate and to methods of curing dielectric materials using UV radiation. A substrate processing tool according to one embodiment comprises a body defining a substrate processing region; a substrate support adapted to support a substrate within the substrate processing region; an ultraviolet radiation lamp spaced apart from the substrate support, the lamp configured to transmit ultraviolet radiation to a substrate positioned on the substrate support; and a motor operatively coupled to rotate at least one of the ultraviolet radiation lamp or substrate support at least 180 degrees relative to each other. The substrate processing tool may further comprise one or more reflectors adapted to generate a flood pattern of ultraviolet radiation over the substrate that has complementary high and low intensity areas which combine to generate a substantially uniform irradiance pattern if rotated. Other embodiments are also disclosed.

Owner:APPLIED MATERIALS INC

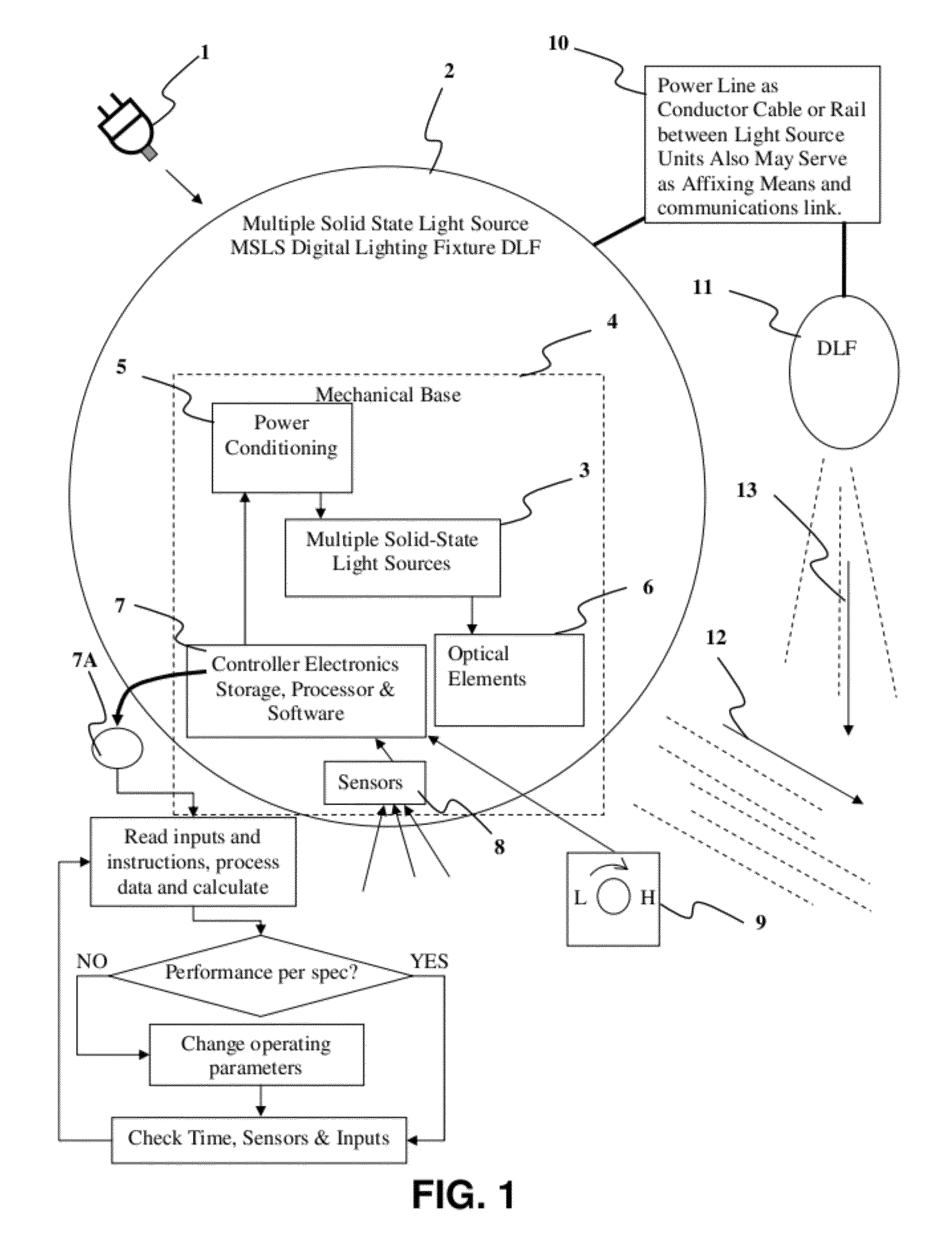

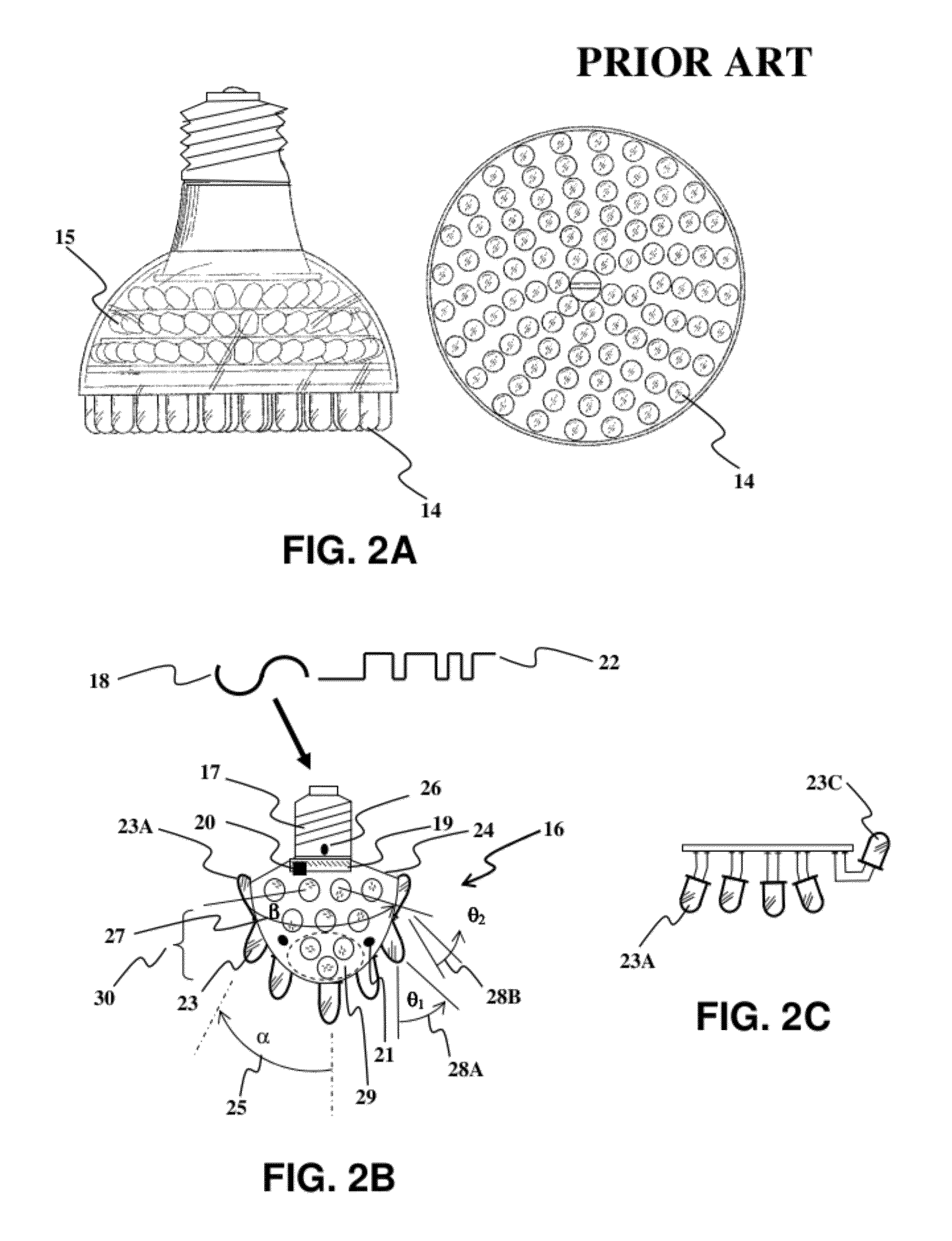

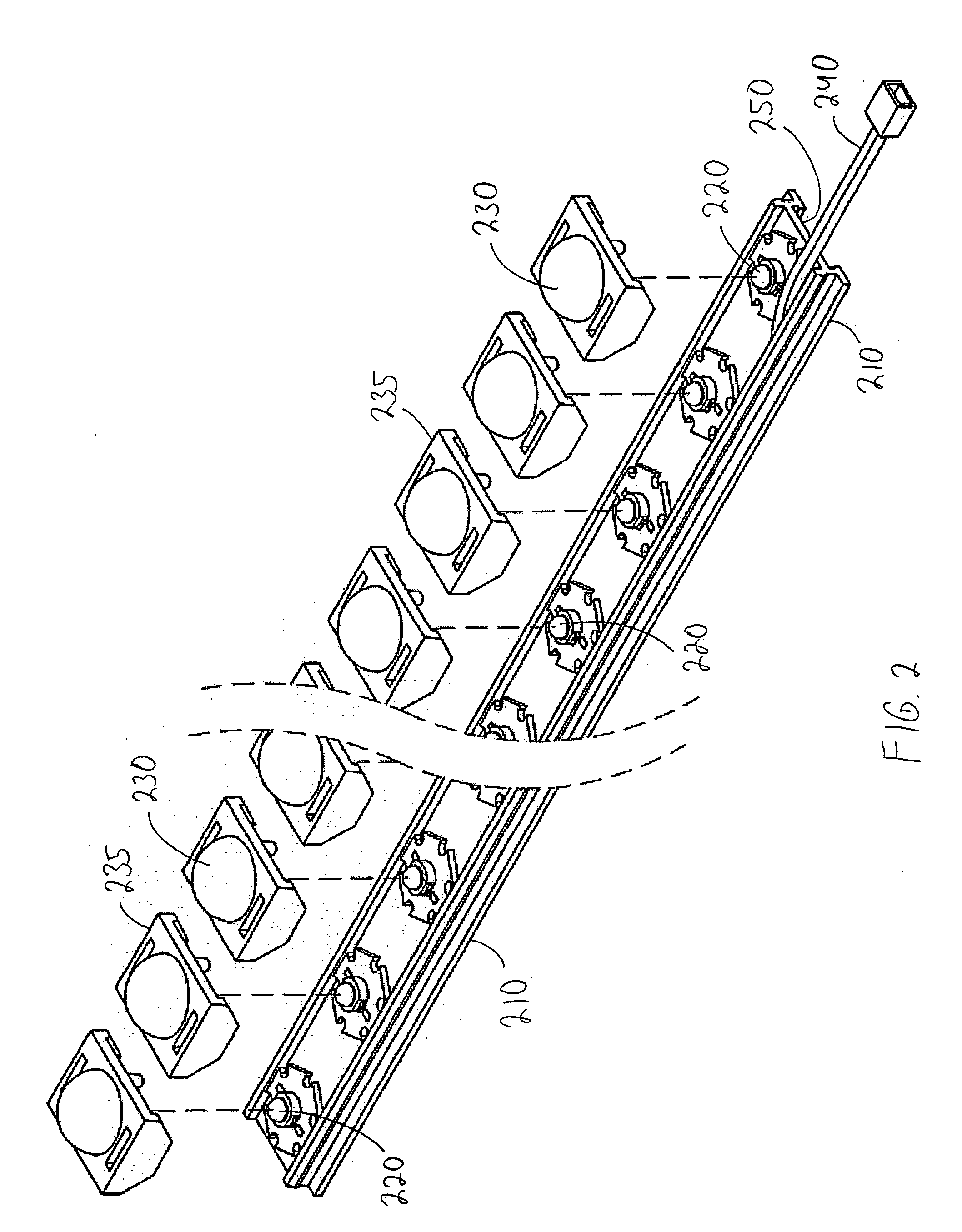

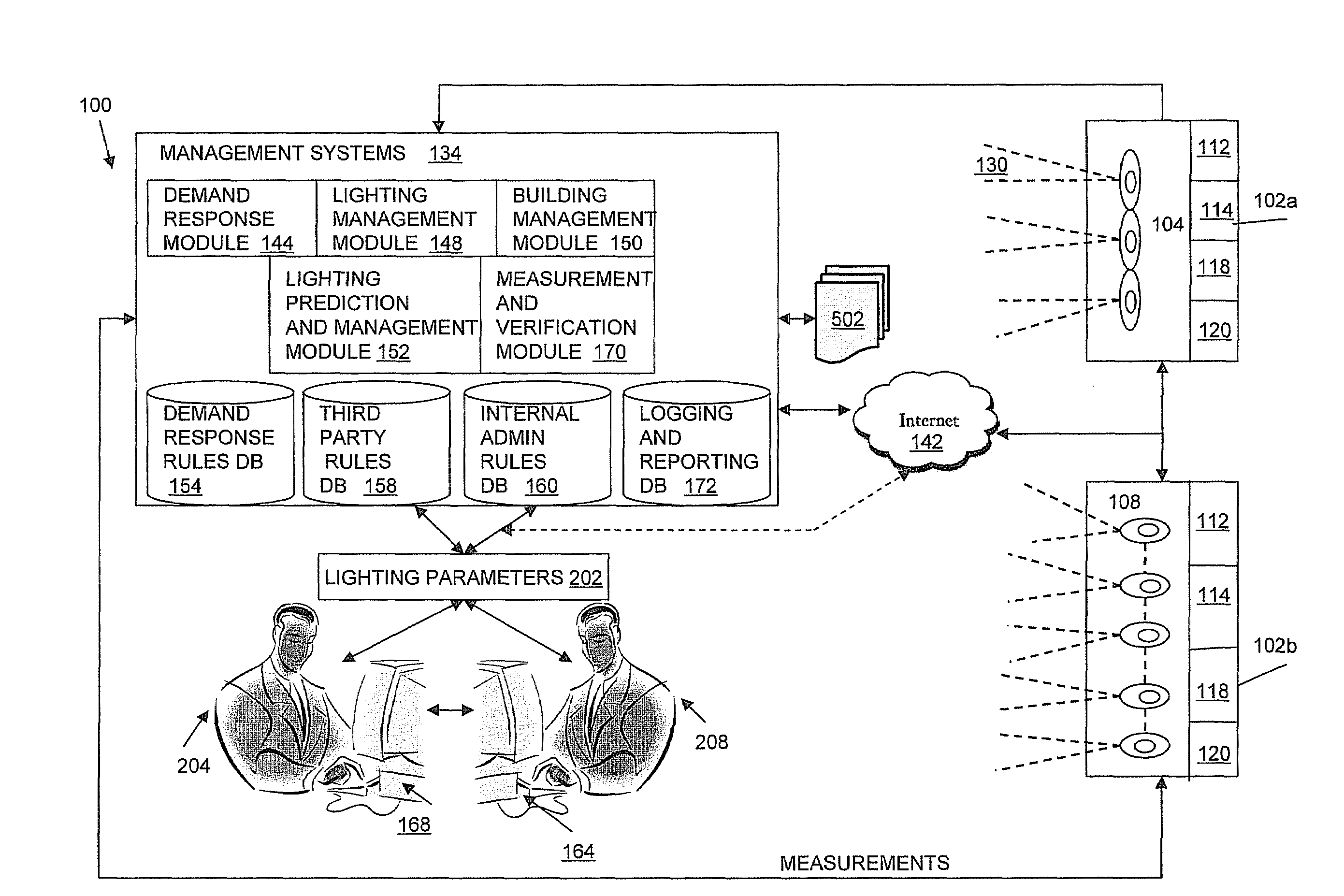

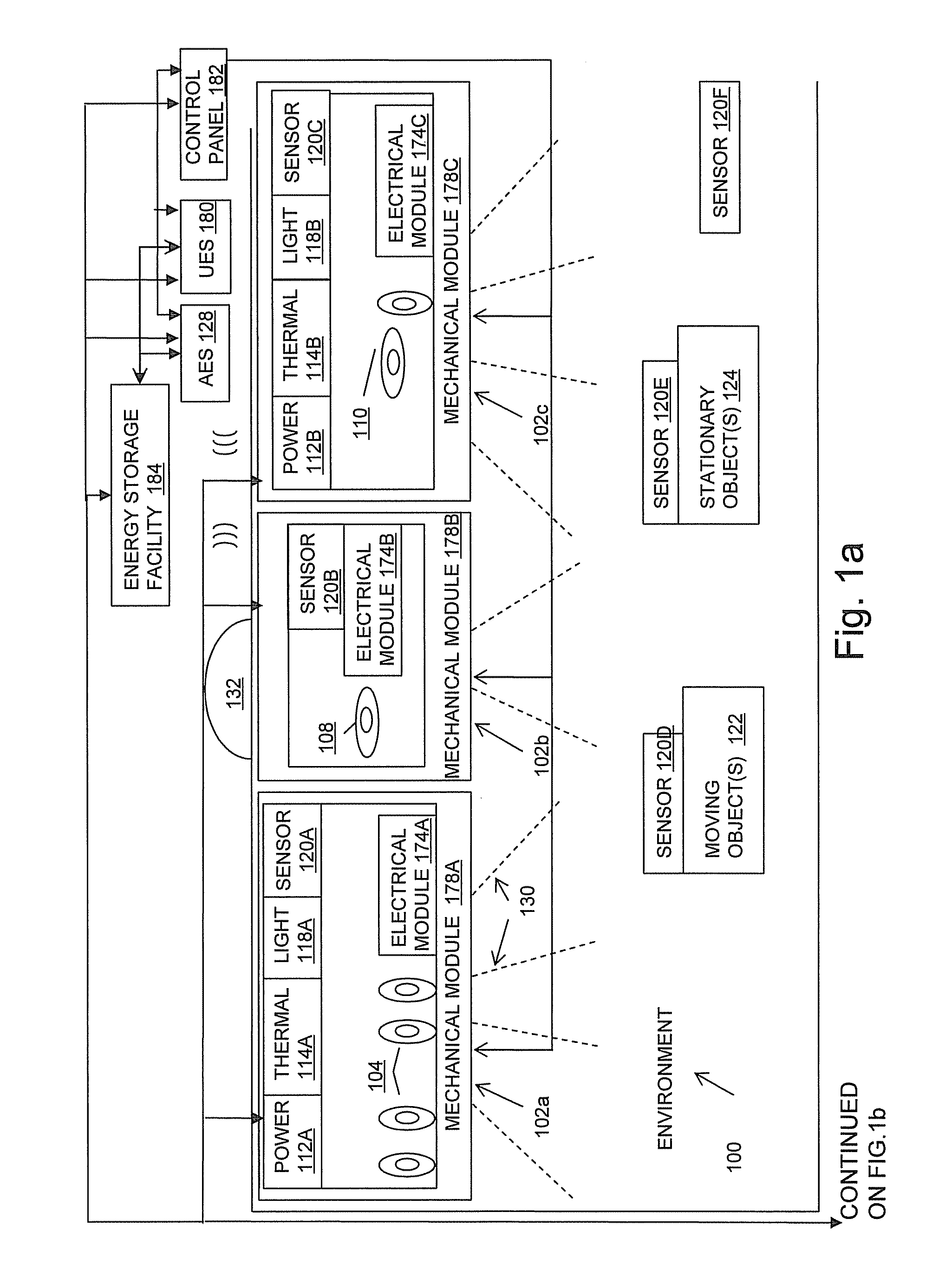

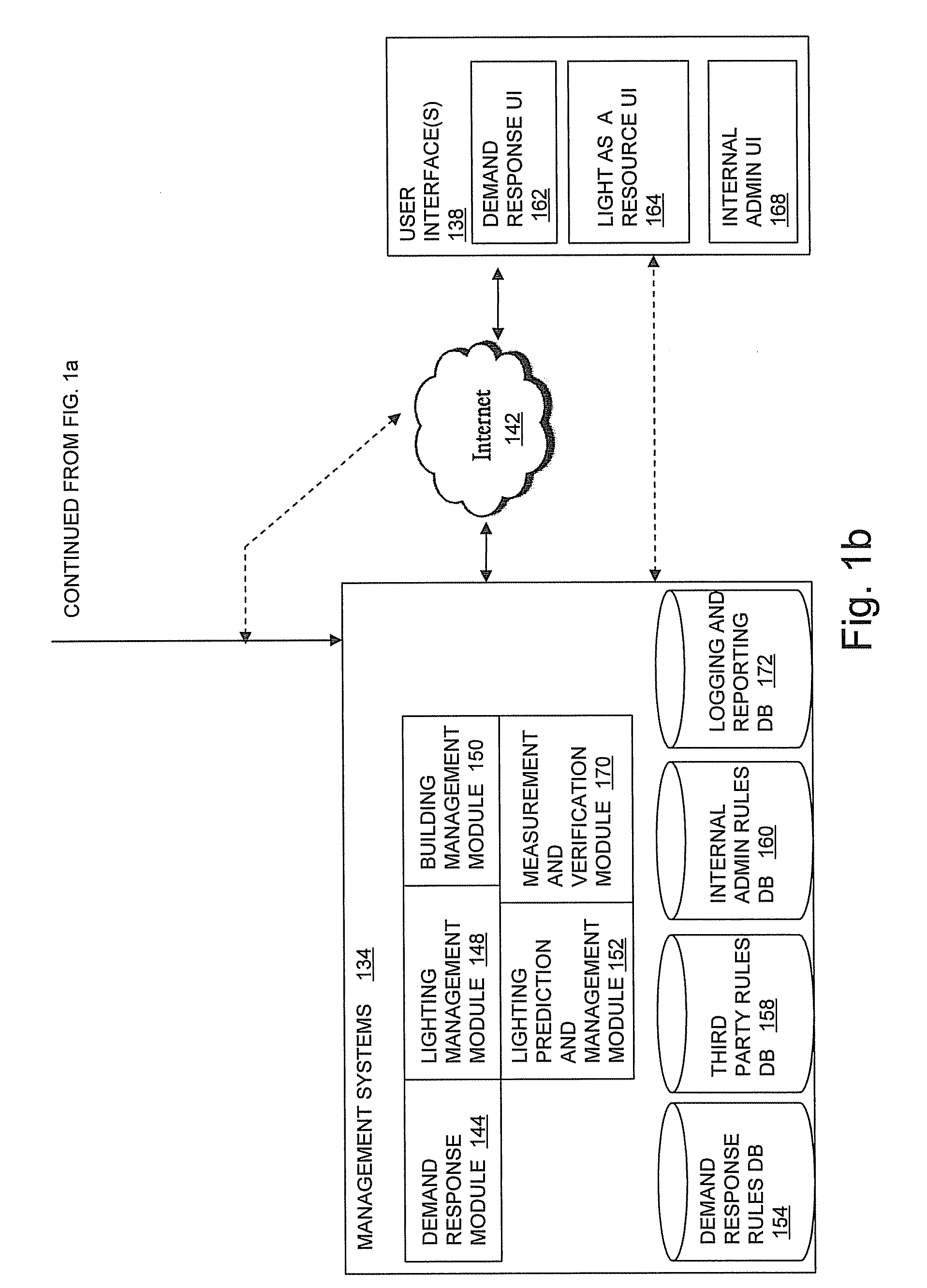

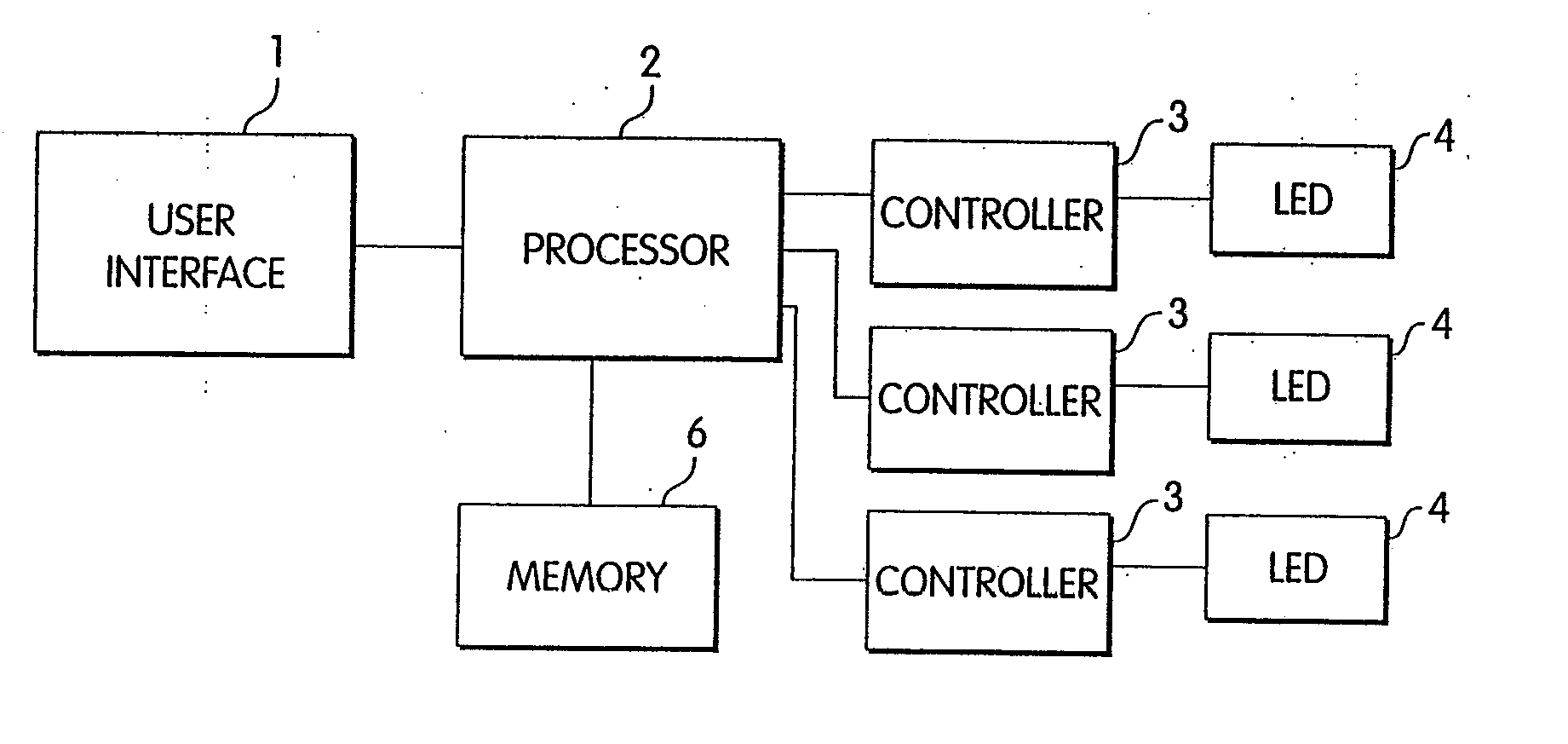

Modular Lighting Systems

ActiveUS20090267540A1Maintain lightMechanical apparatusLighting support devicesIntelligent lightingEffect light

In embodiments of the present invention, a method and system is provided for designing improved intelligent, LED-based lighting systems. The LED based lighting systems may include fixtures with one or more of rotatable LED light bars, integrated sensors, onboard intelligence to receive signals from the LED light bars and control the LED light bars, and a mesh network connectivity to other fixtures.

Owner:OSRAM SYLVANIA INC

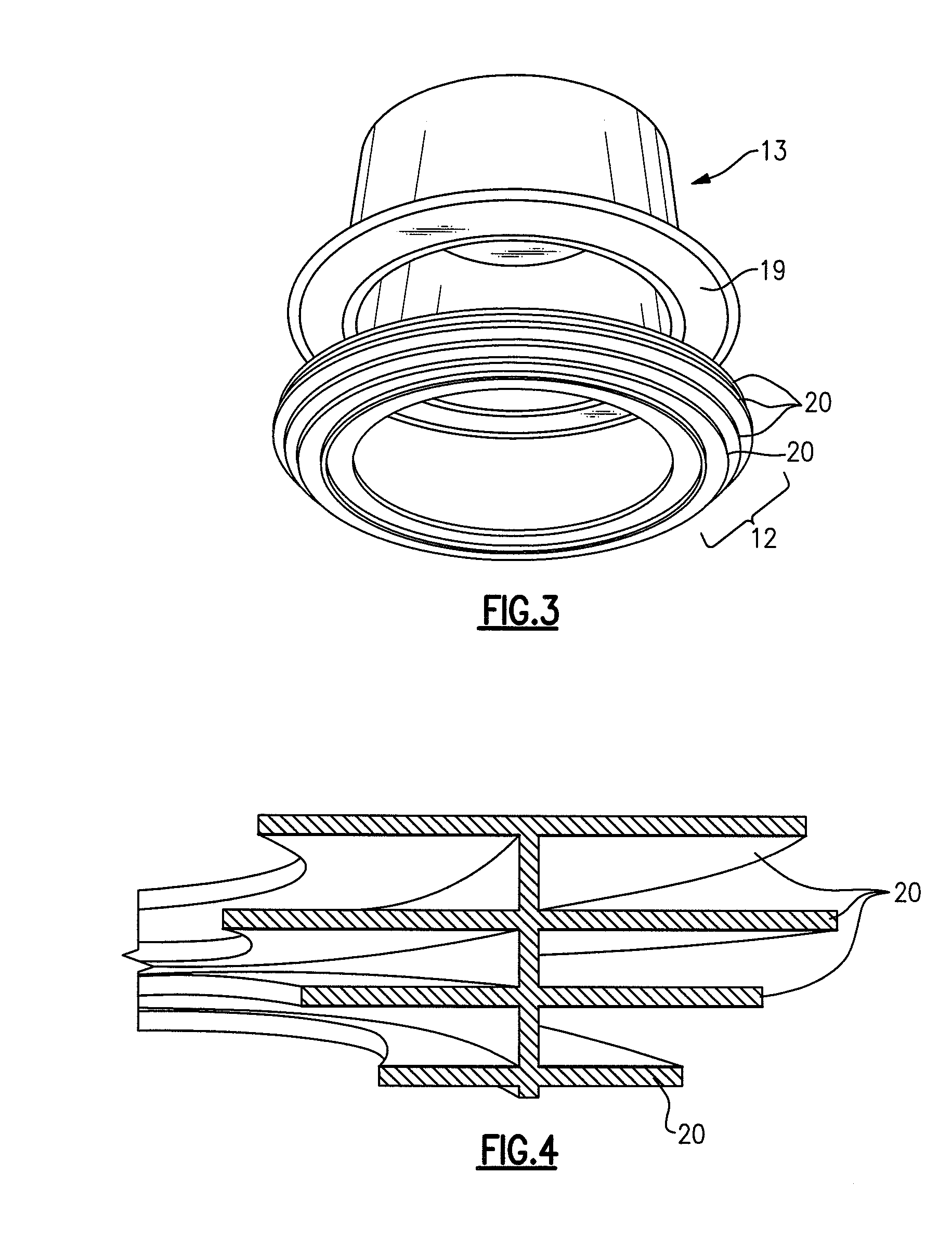

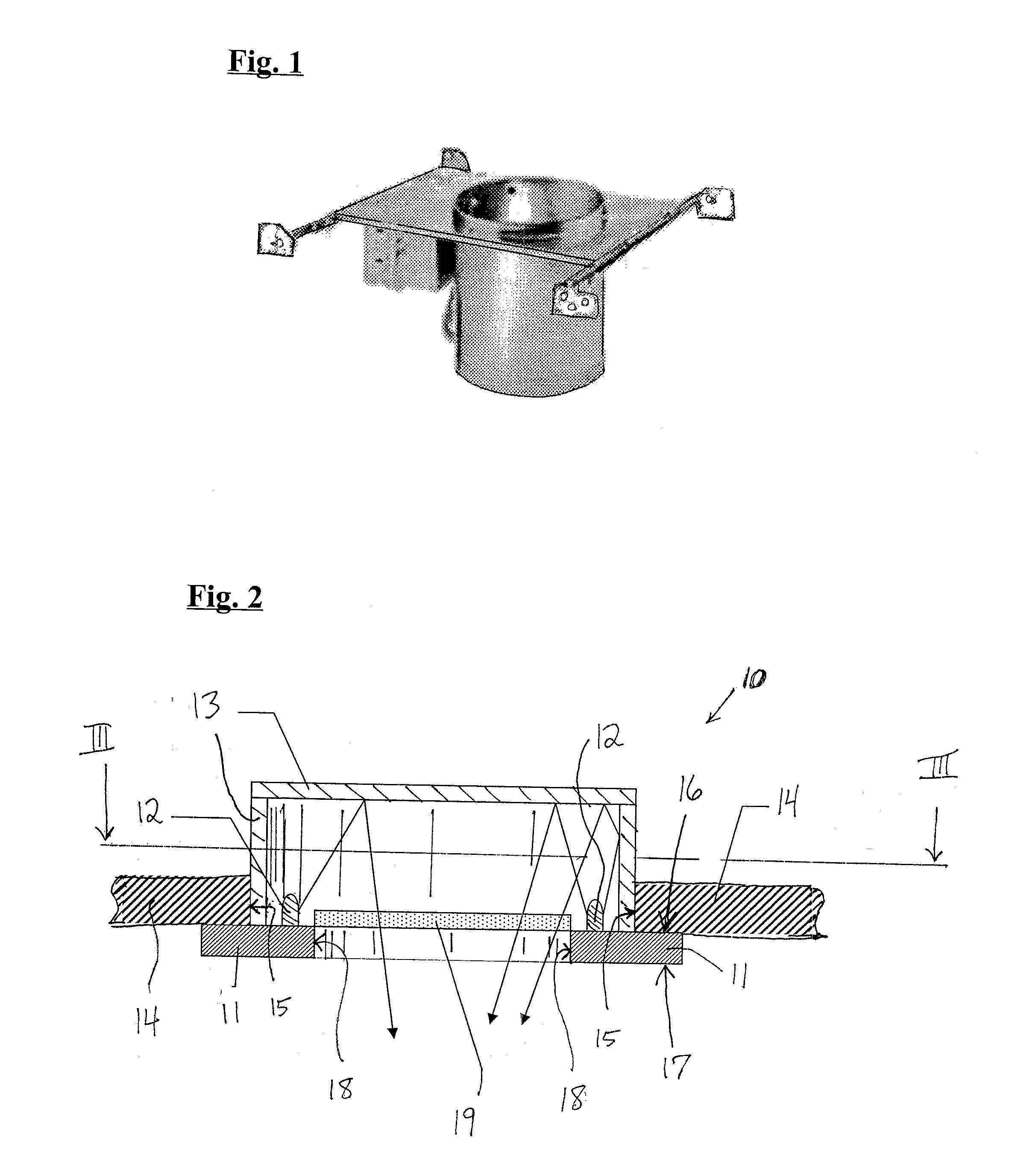

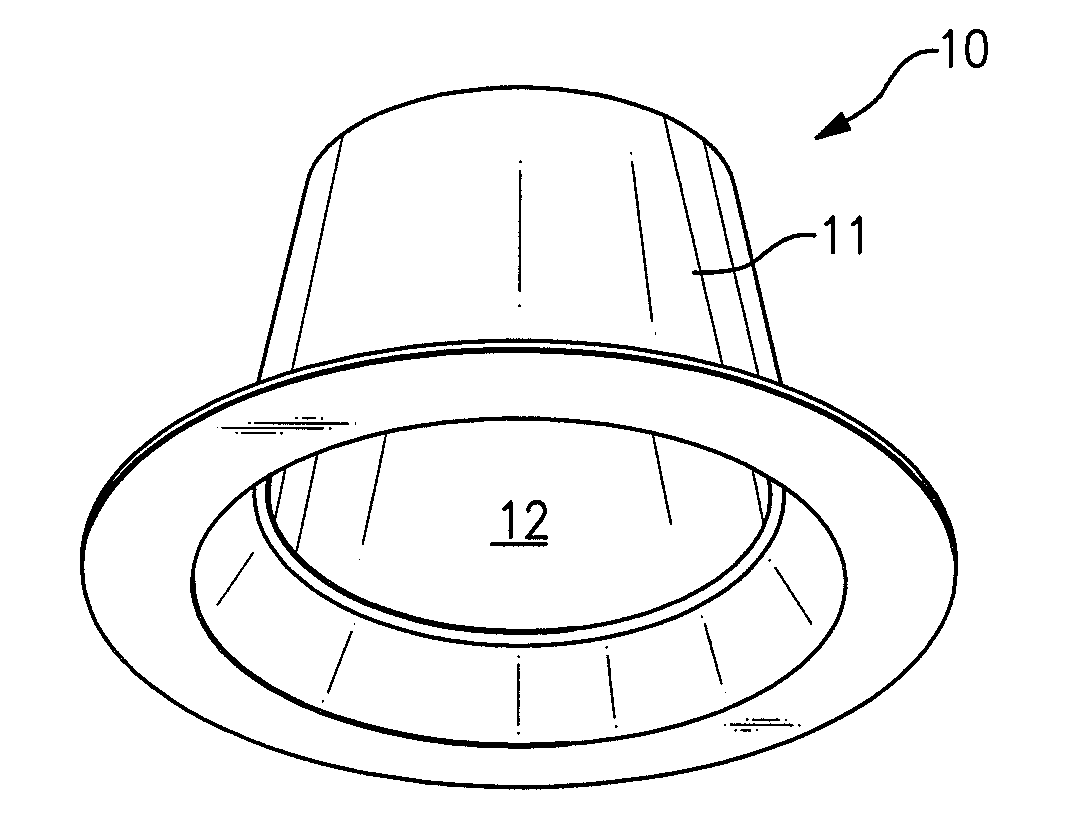

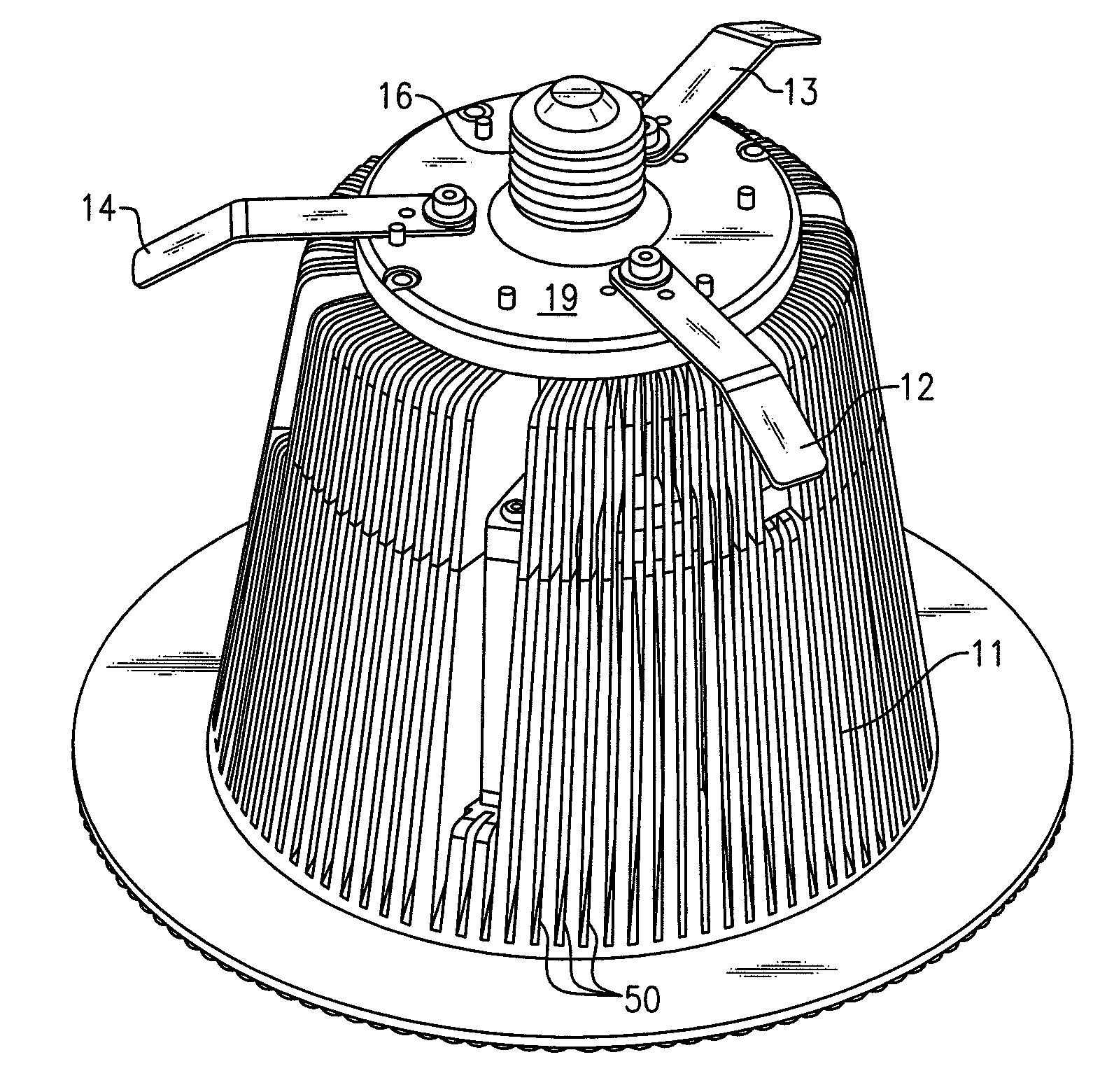

Lighting devices and methods of installing light engine housings and/or trim elements in lighting device housings

ActiveUS20080106907A1Easy to useReduce and eliminate tendency for sagging-thatPicture framesPoint-like light sourceElectricityElectrical connection

A lighting device, comprising a housing and at least one mounting clip. The housing comprises an electrical connection region engageable in an electrical receptacle. The mounting clip is pivotable from a first position, where an end region of the mounting clip does not extend beyond a periphery of the housing, to a second position, where the end region extends beyond the housing periphery. Also, a lighting device, comprising a housing, a trim element and at least one mounting clip. The mounting clip is pivotable, such that if the mounting clip is in a second position and then the trim element is rotated, the mounting clip will pivot to a third position, where the mounting clip engages the housing such that the trim element is biased toward a ceiling or other structure in which the lighting device is mounted. Also, methods of installing housings and / or trim elements.

Owner:IDEAL IND LIGHTING LLC

Lighting device

ActiveUS7614759B2Maximizing light extractionReduce probabilityPoint-like light sourceLighting elementsElement spaceEffect light

A lighting device comprising at least one solid state light emitter and at least one luminescent element spaced from the light emitter, a surface of the luminescent element being at least twice as large as the illumination surface of the light emitter. Also, a lighting device comprising at least one solid state light emitter and at least one luminescent element spaced from the light emitter, a surface of the luminescent element surface being at least twice as large as and substantially parallel to the illumination surface of the light emitter. Also, a lighting device comprising at least one solid state light emitter and at least one luminescent element spaced from the light emitter, a surface area of a projection of the luminescent element being at least twice as large as a surface area of a projection of the light emitter.

Owner:CREELED INC

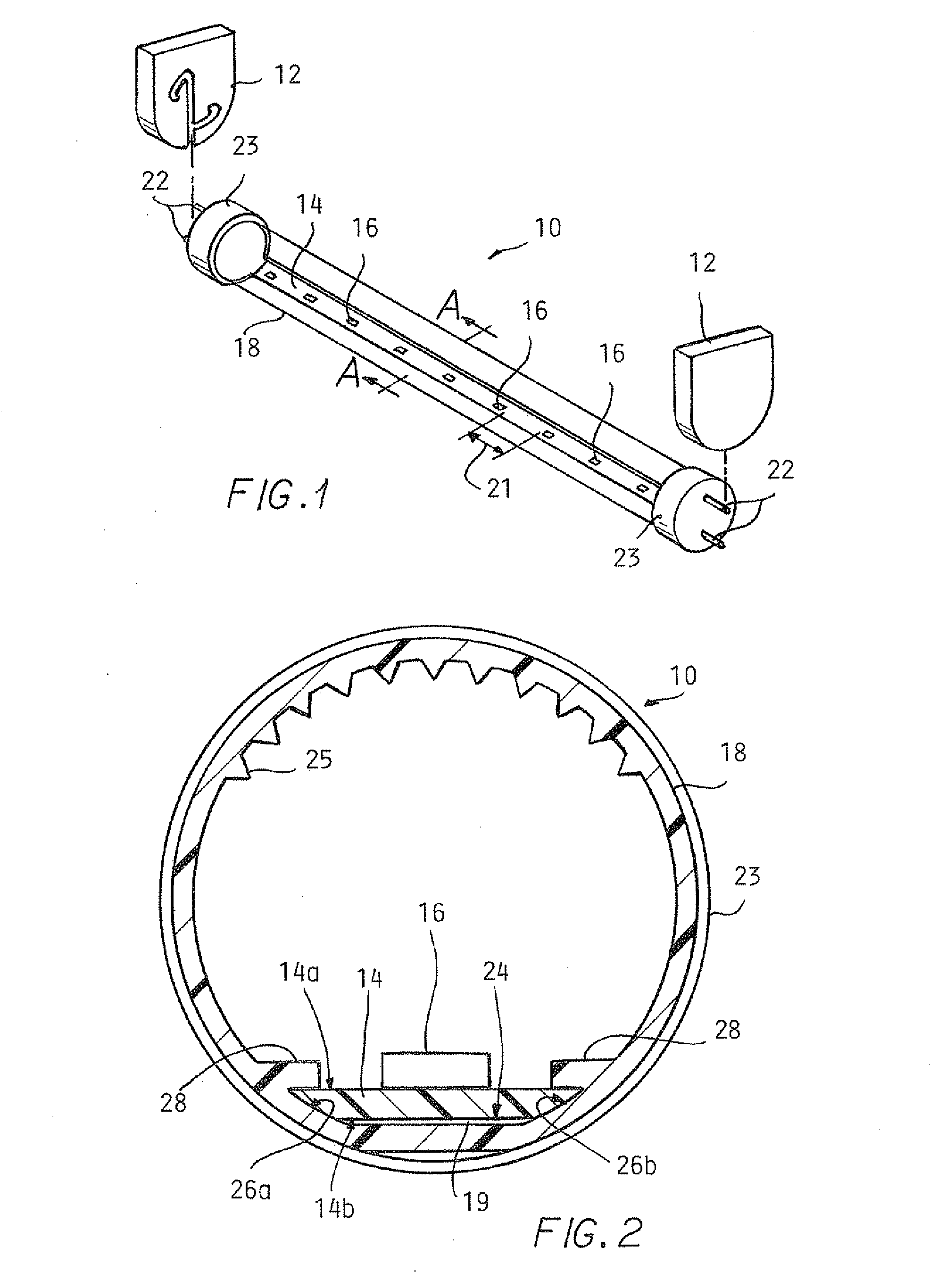

D-shaped cross section l.e.d. based light

InactiveUS20100220469A1Launch evenlyNon-electric lightingLighting support devicesElectrical connectorBoard structure

A LED-based replacement light for a fluorescent socket is constructed such that a tubular housing has a D-shaped cross section with a flat base with opposing longitudinal edges, opposing sides extending generally perpendicular to the flat base from the opposing longitudinal edges, and a curved surface spanning the opposing sides opposite the flat base. A circuit board structure defines a LED-mounting side with multiple LEDs mounted on the LED-mounting side at predetermined intervals along a length of the circuit board, with at least areas of a primary heat transferring side directly underlying the respective LEDs in thermally conductive relation with the tubular housing for highly electrically insulated thermal transmission of heat generated by the multiple LEDs from the circuit board to an ambient environment surrounding an exterior of the tubular housing. At least one electrical connector is at a longitudinal end of the housing in electrical communication with the circuit board.

Owner:ILUMISYS

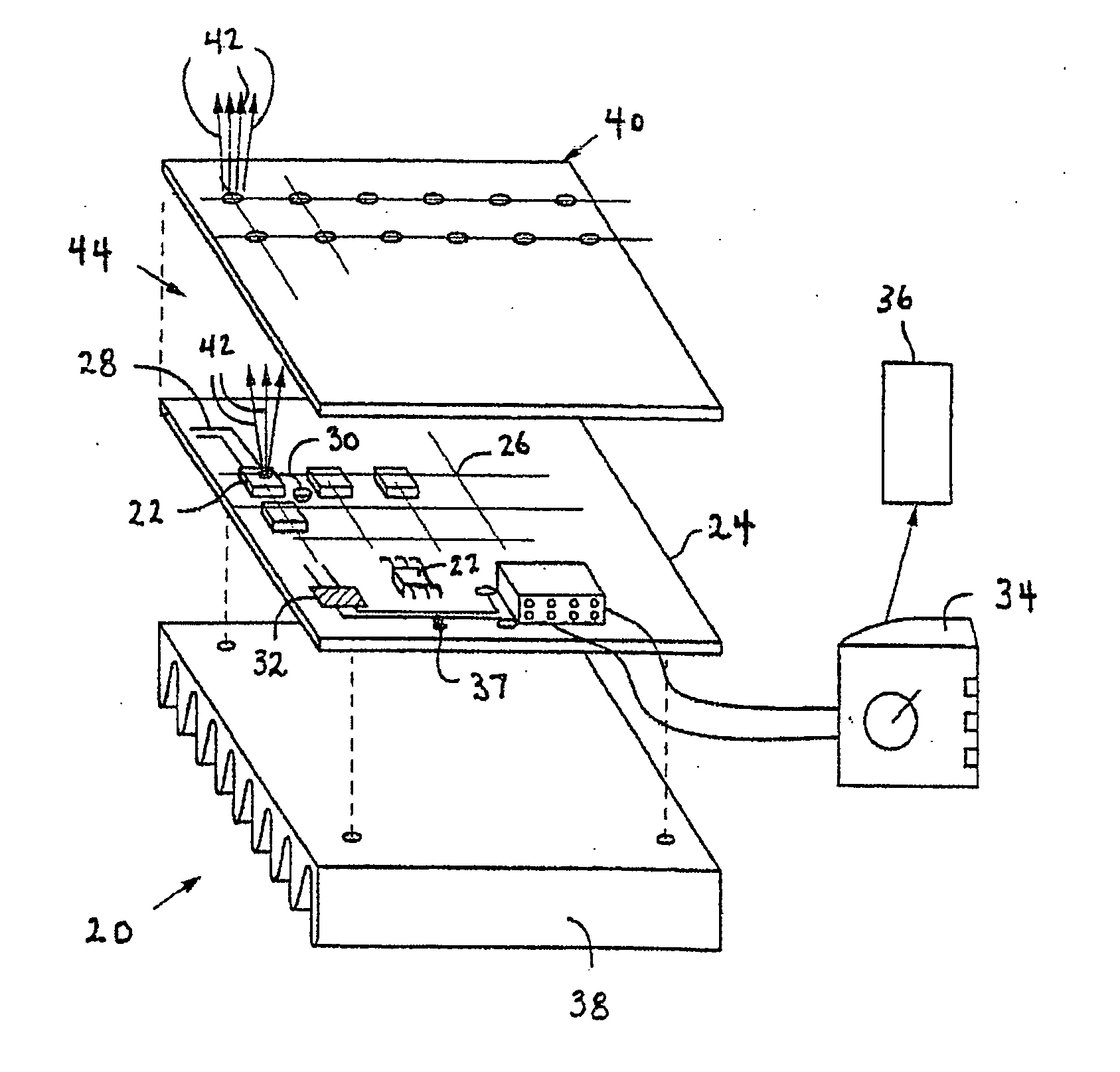

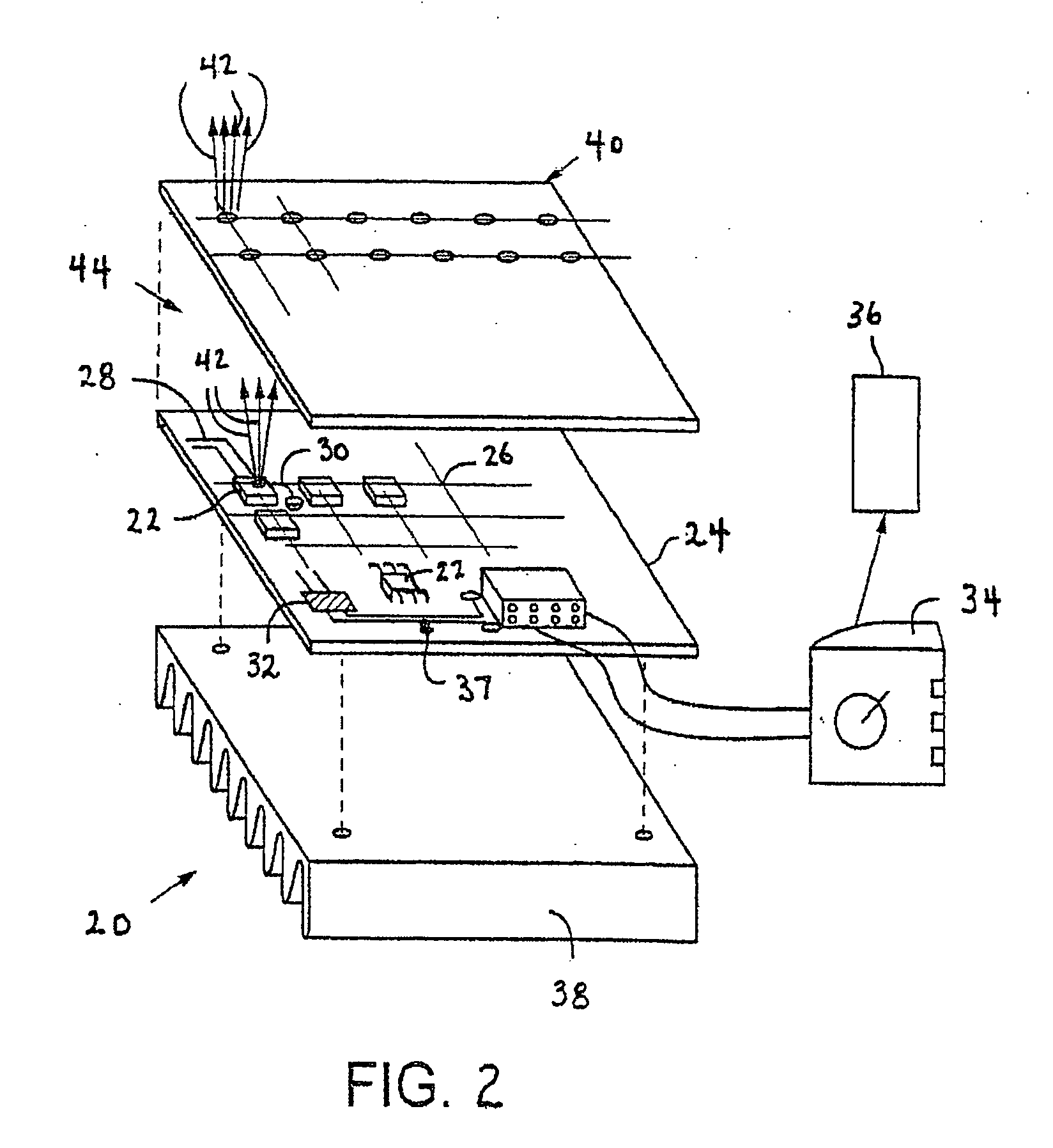

High efficiency solid-state light source and methods of use and manufacture

ActiveUS20050152146A1Eliminate needImprove light outputOptical radiation measurementPoint-like light sourceDevice materialFluorescence

A high-intensity light source is formed by a micro array of a semiconductor light source such as a LEDs, laser diodes, or VCSEL placed densely on a liquid or gas cooled thermally conductive substrate. The semiconductor devices are typically attached by a joining process to electrically conductive patterns on the substrate, and driven by a microprocessor controlled power supply. An optic element is placed over the micro array to achieve improved directionality, intensity, and / or spectral purity of the output beam. The light module may be used for such processes as, for example, fluorescence, inspection and measurement, photopolymerzation, ionization, sterilization, debris removal, and other photochemical processes.

Owner:SILICON VALLEY BANK

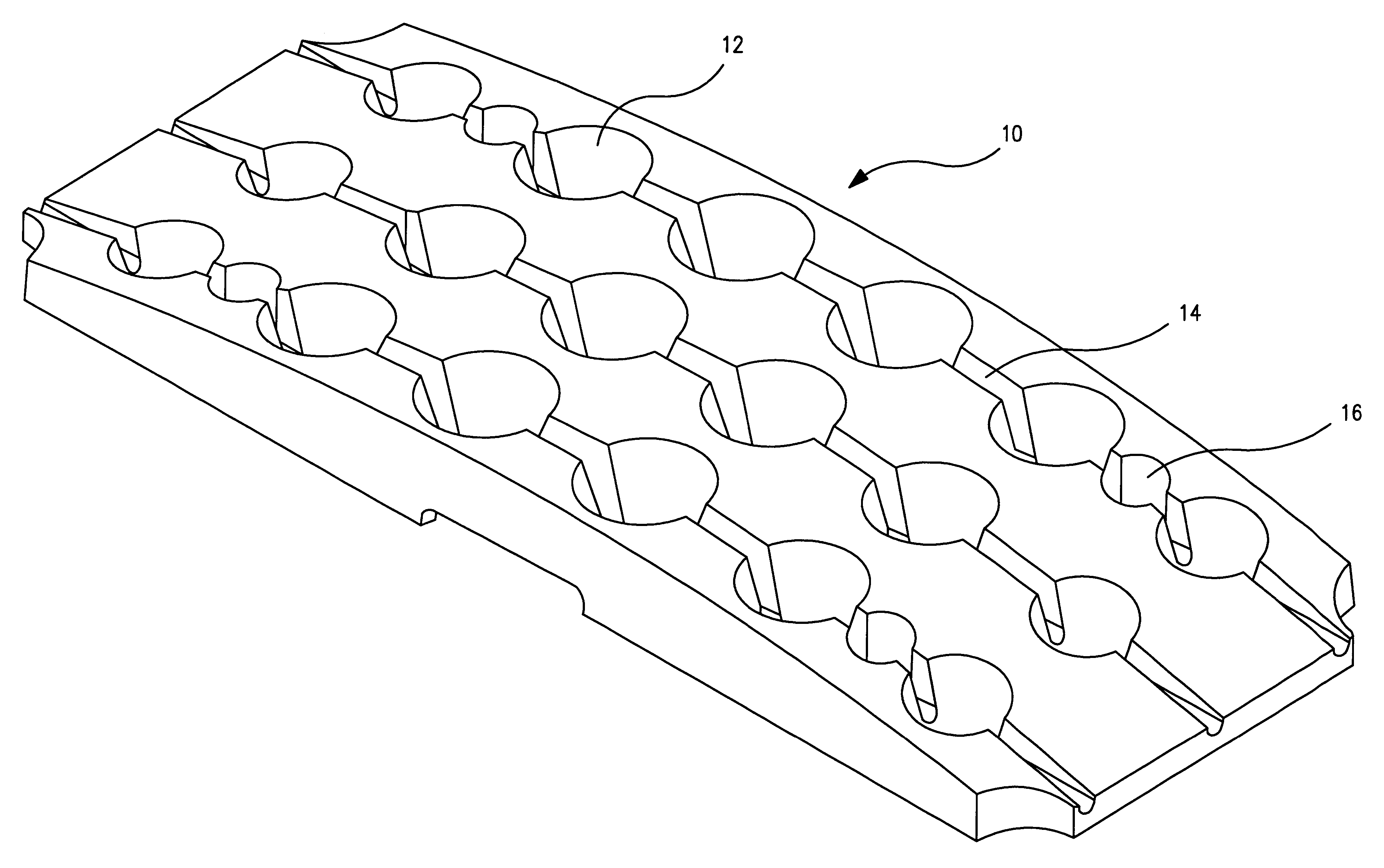

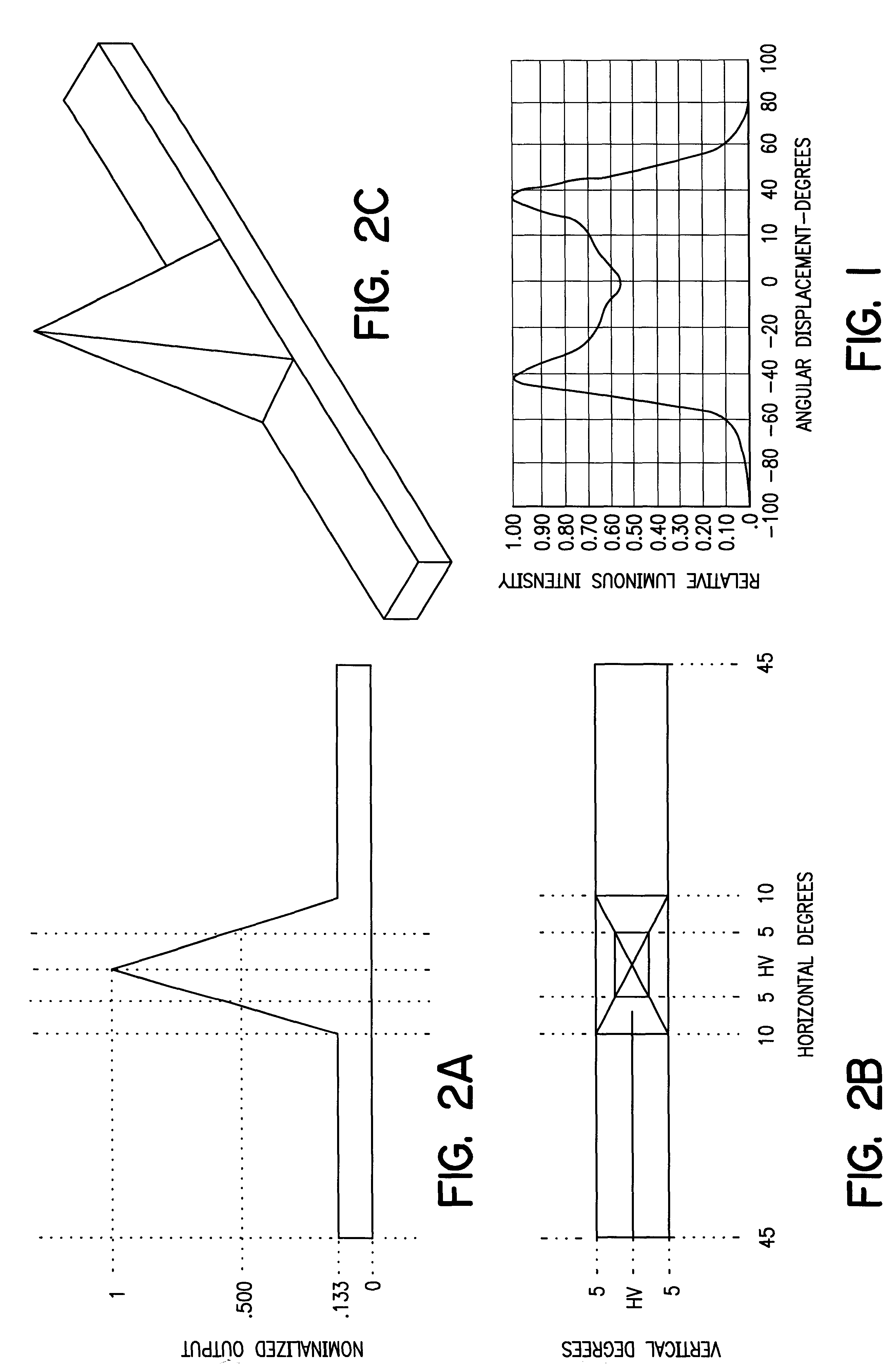

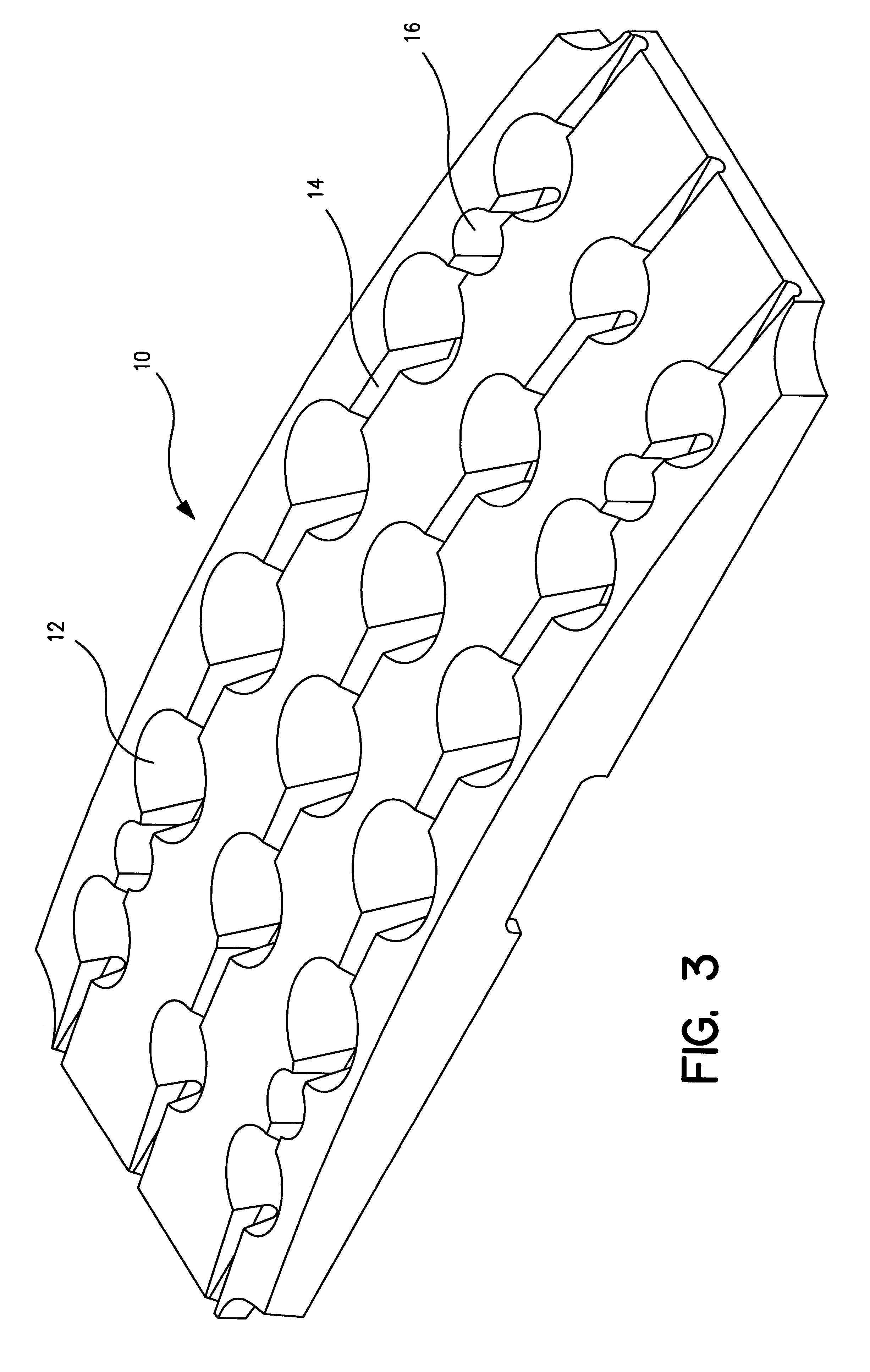

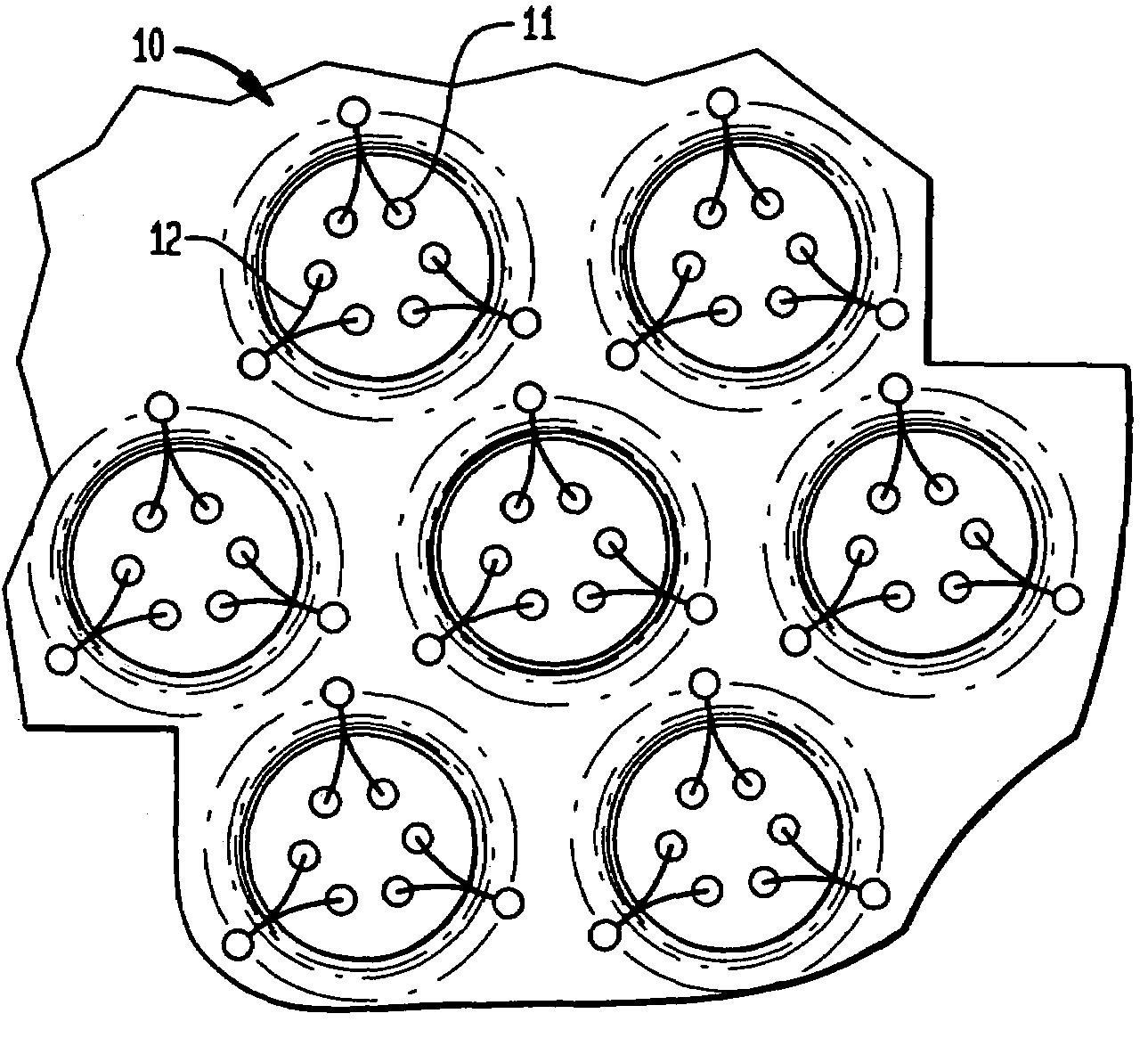

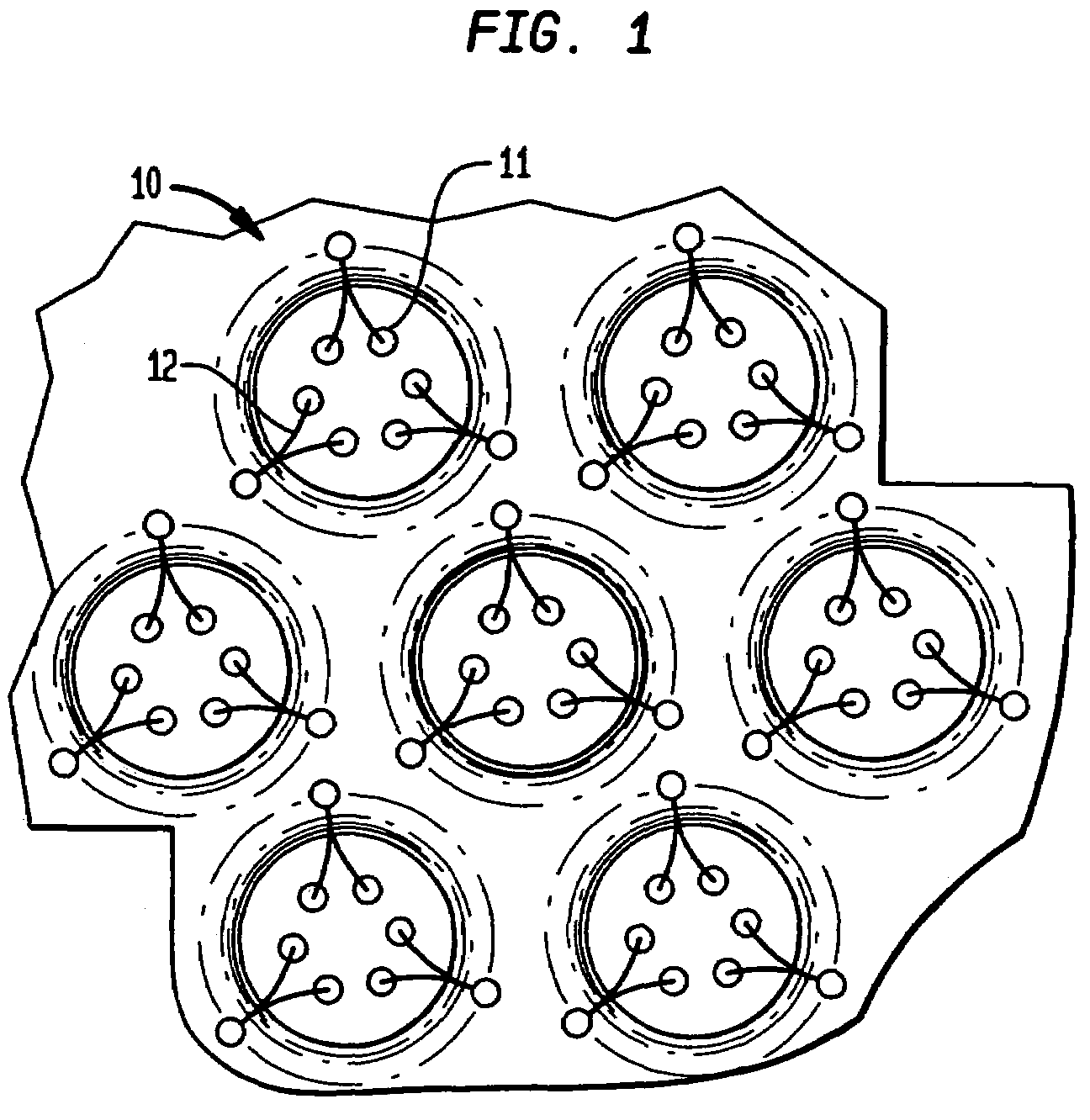

High flux led assembly

InactiveUS6318886B1Point-like light sourceLighting heating/cooling arrangementsHigh fluxHigh intensity

A high intensity light source employs a plurality of light emitting diodes associated with a unitary reflector subassembly. The reflector subassembly defines an array of frustoconical reflectors arranged in rows and columns with the adjacent reflectors of each row being connected by a diverging slot with reflective wall surfaces. The light emitting diodes are mounted on a printed circuit board which forms a component of heat sink subassembly.

Owner:WHELEN ENGINEERING COMPANY

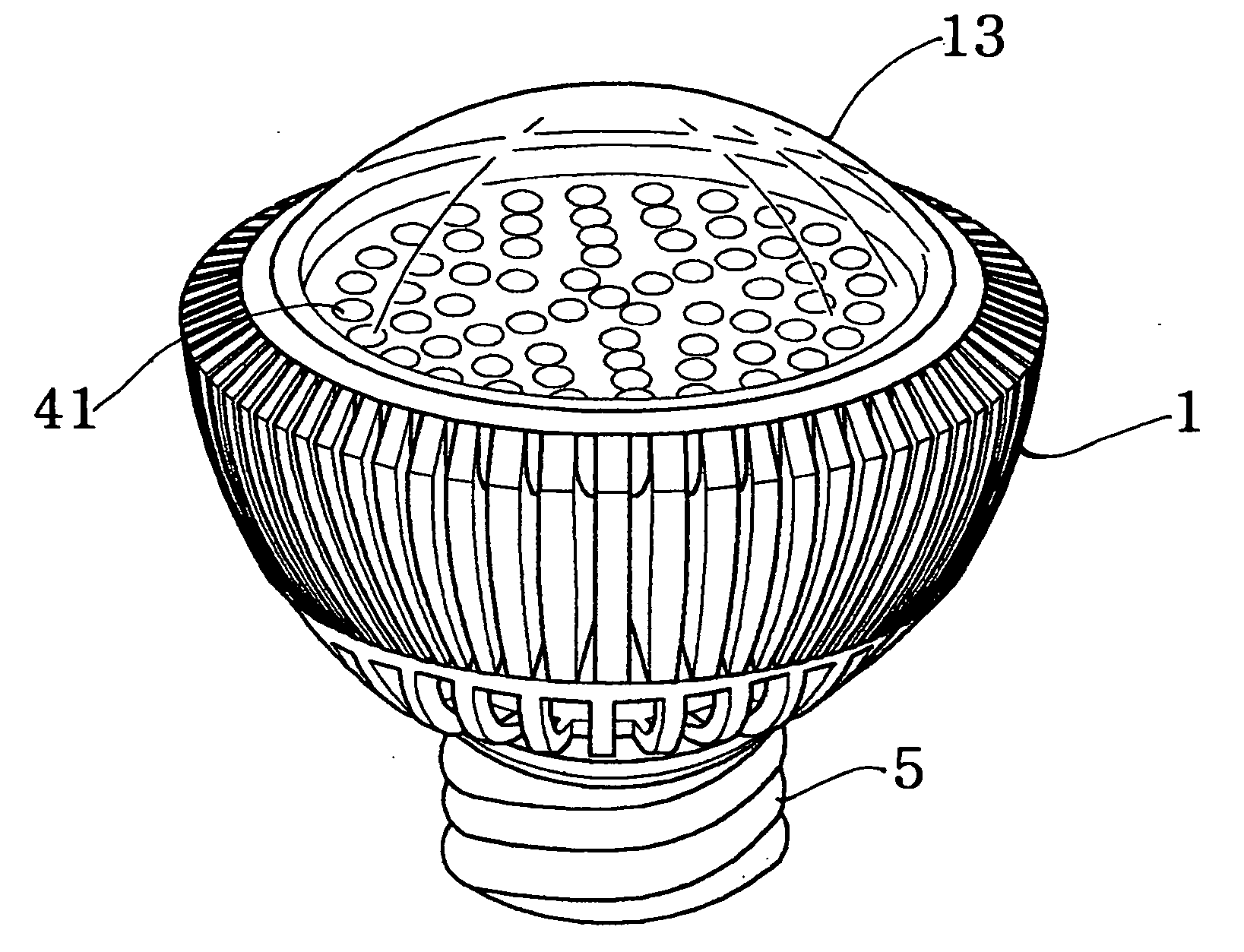

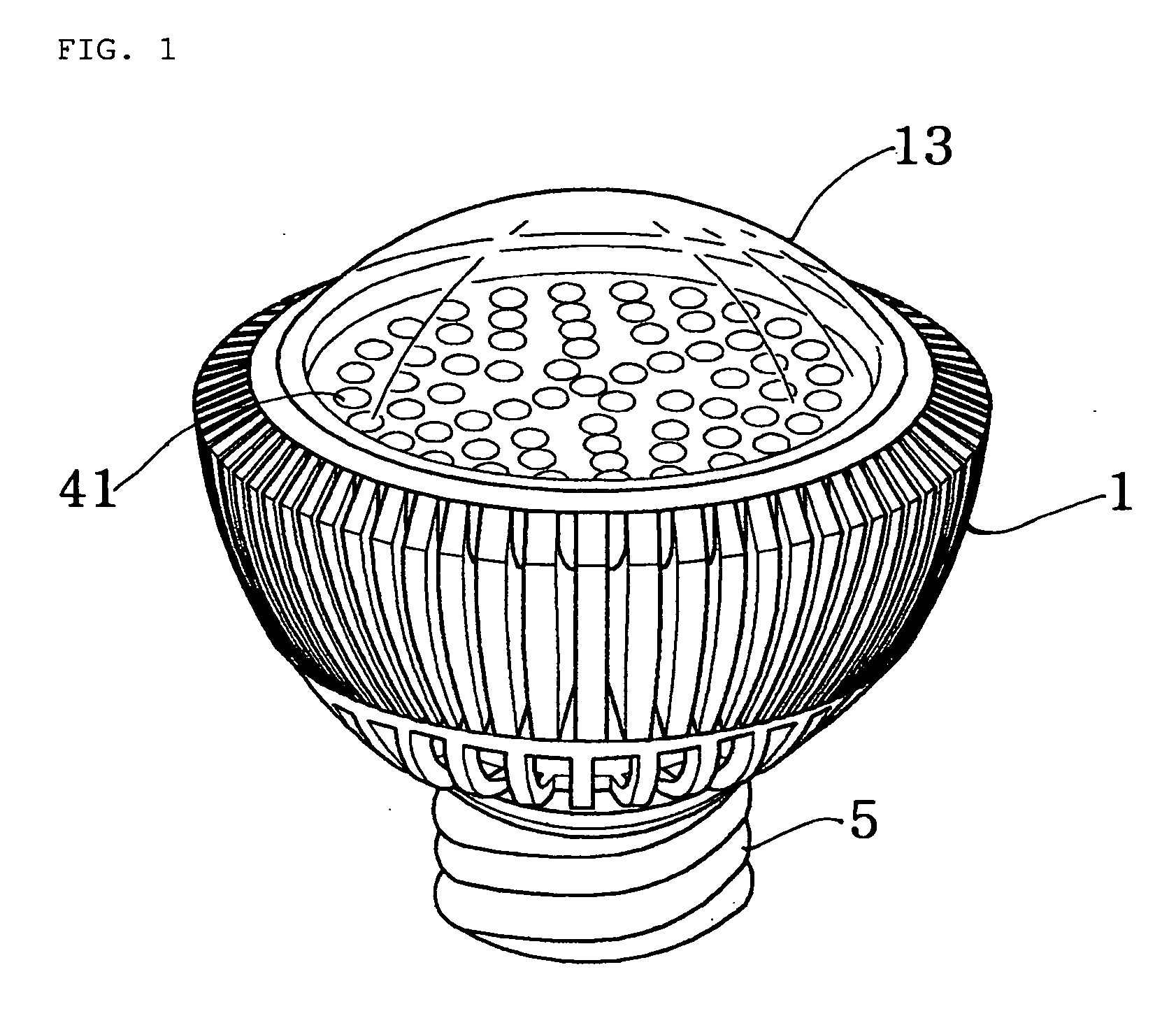

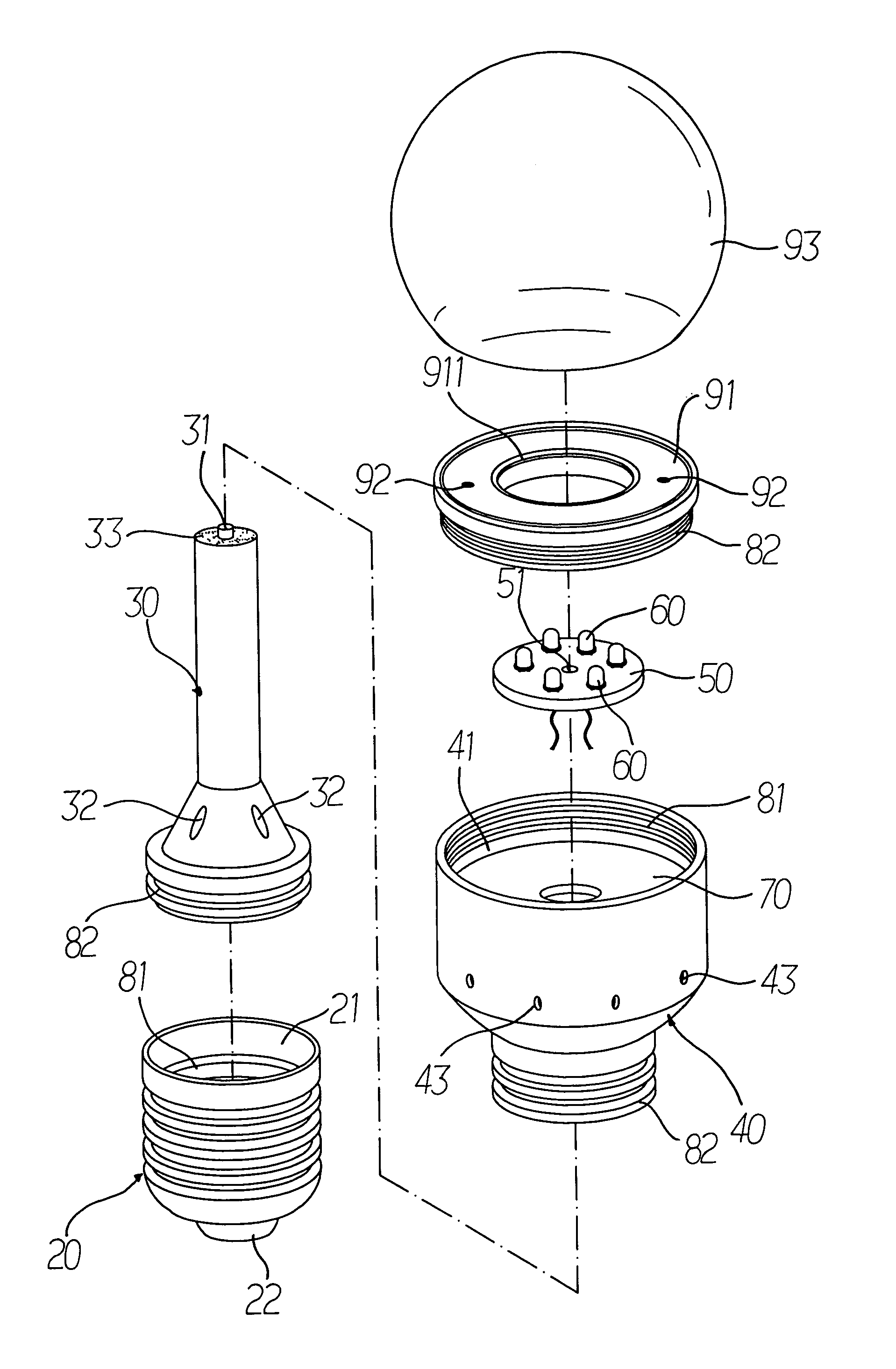

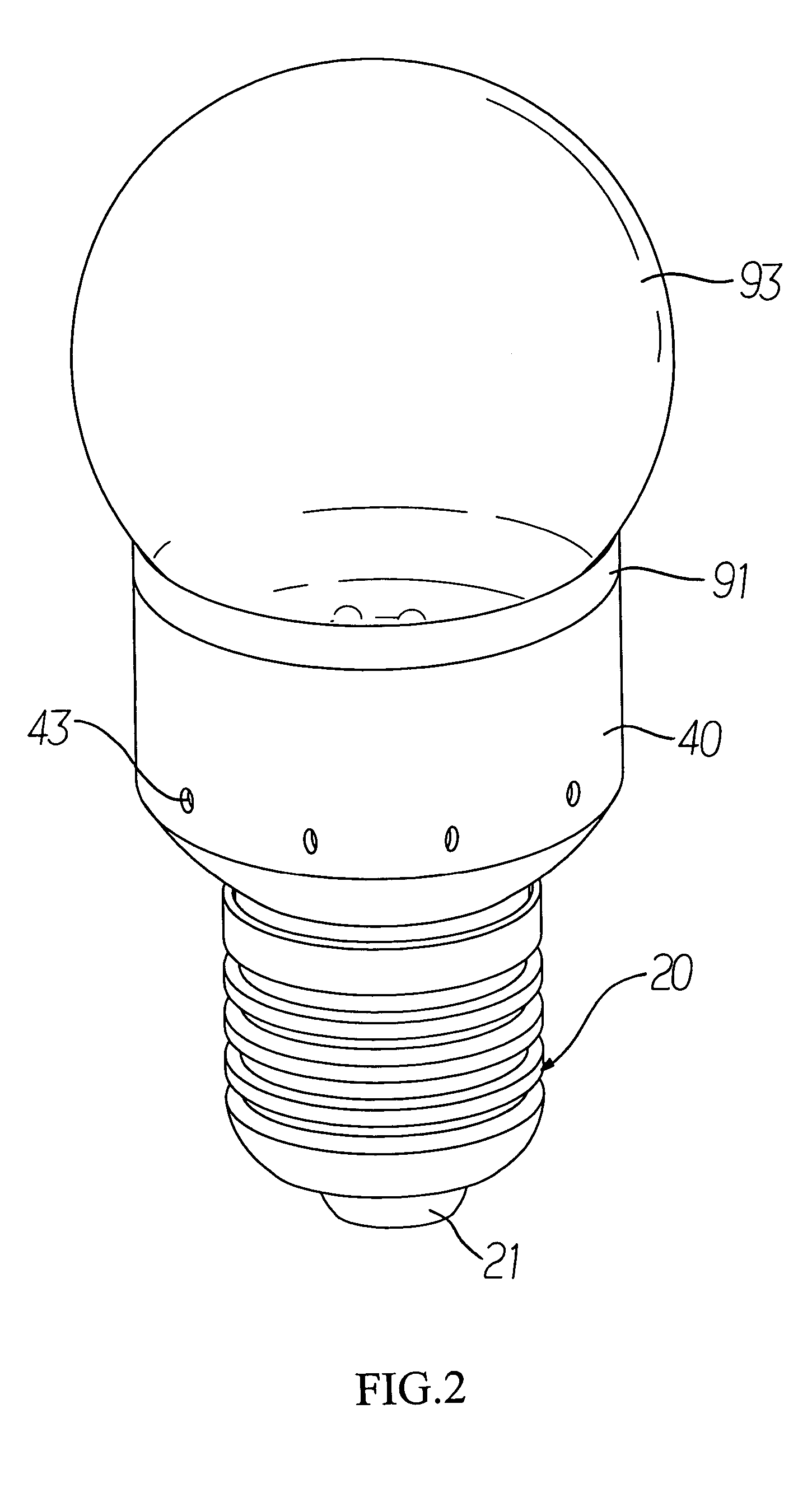

Light emitting diode bulb having high heat dissipating efficiency

InactiveUS6864513B2Easily and quickly dissipate heatOperation be often erratic and unstableLighting applicationsLight source combinationsElectricityEngineering

A light emitting diode (LED) bulb includes a heat sink, a circuit layer having two opposite sides, multiple LEDs mounted on one side and an electrical insulating layer connected between the opposite side and the heat sink. Heat generated by the LEDs is conducted to the heat sink through the circuit layer and the electrical insulting layer and is dissipated quickly. Further, a fan can be mounted on the fins to dissipate heat from the heat sink more quickly. Therefore, the LED bulb has good heat dissipating efficiency.

Owner:KAYLU IND CORP

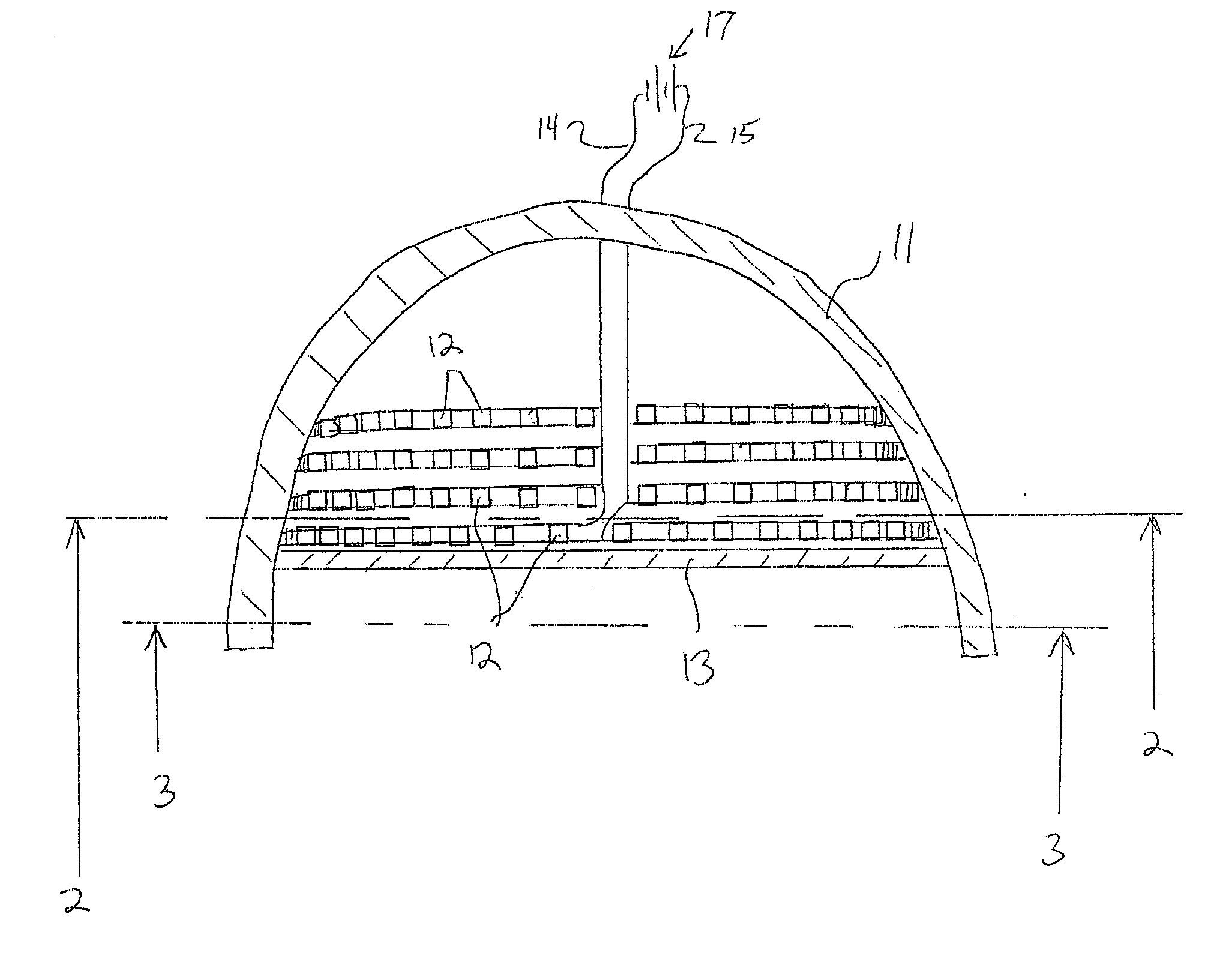

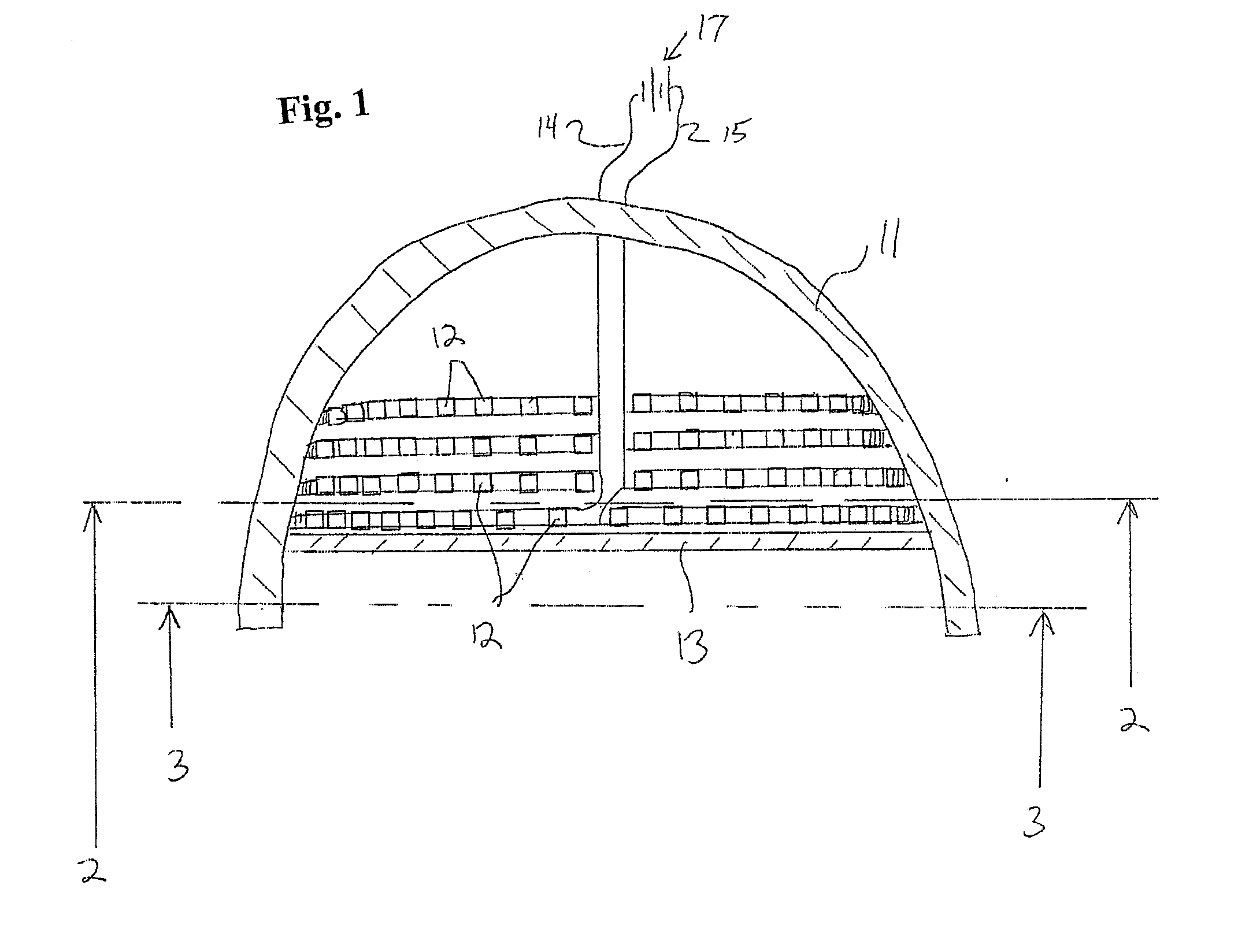

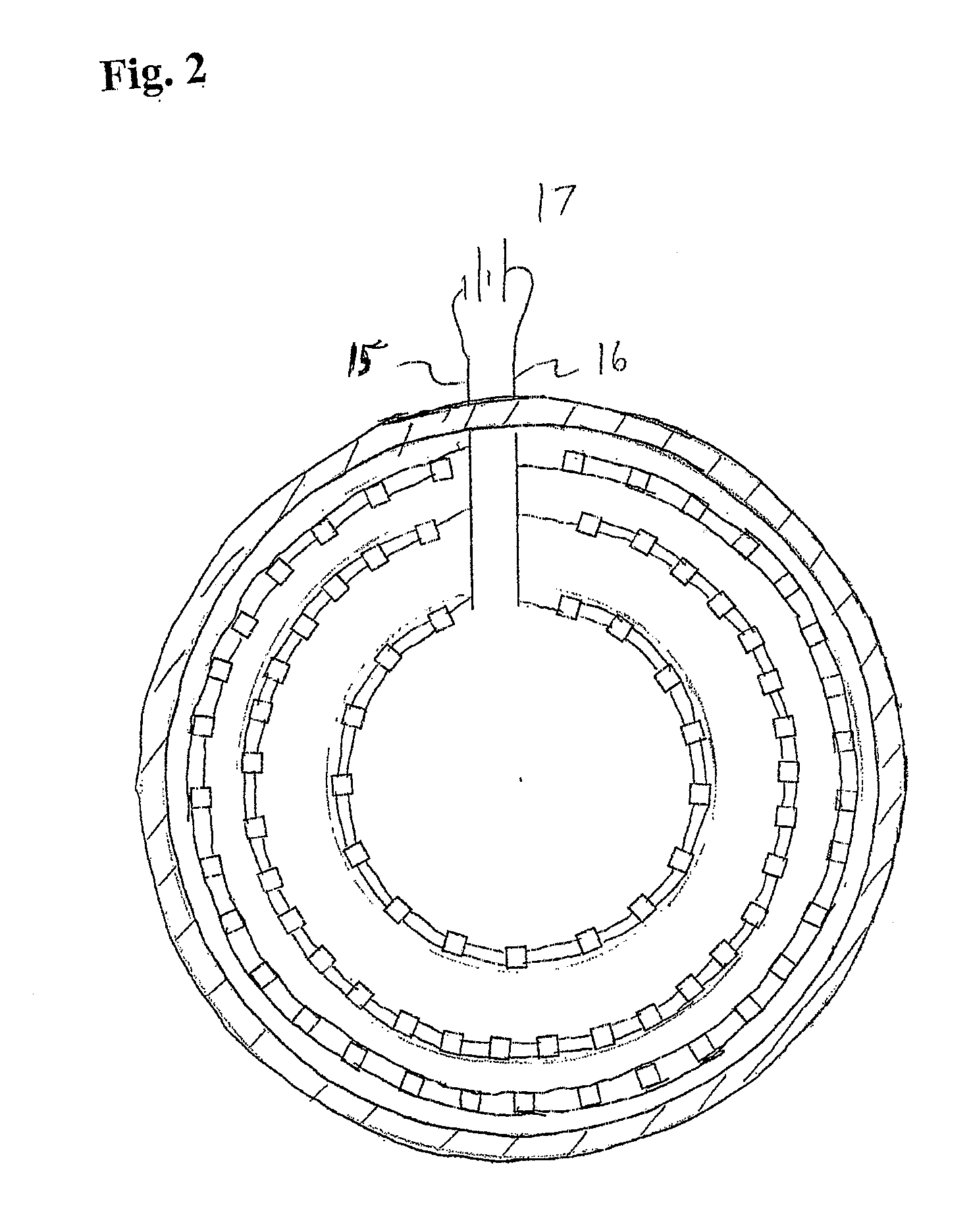

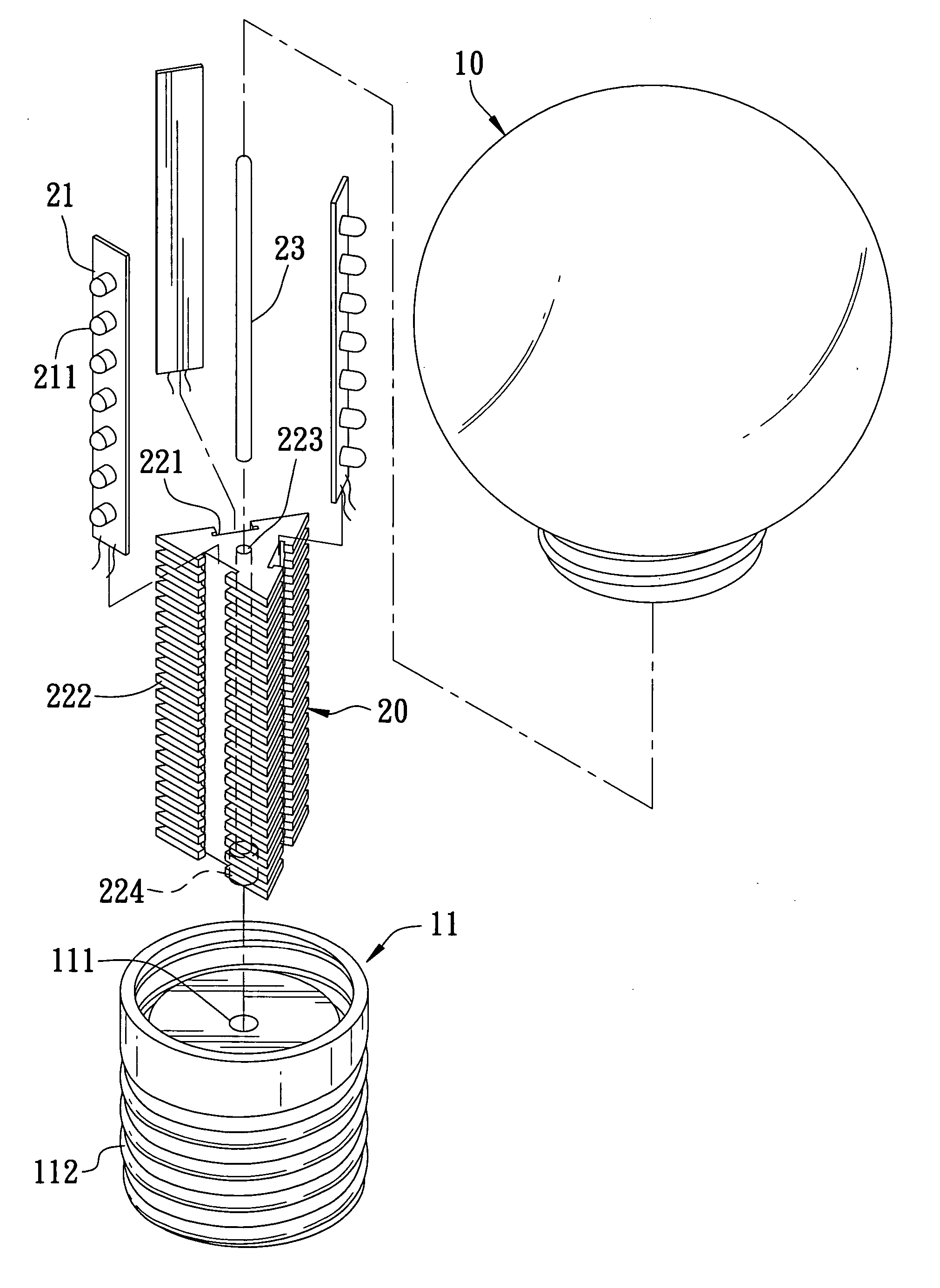

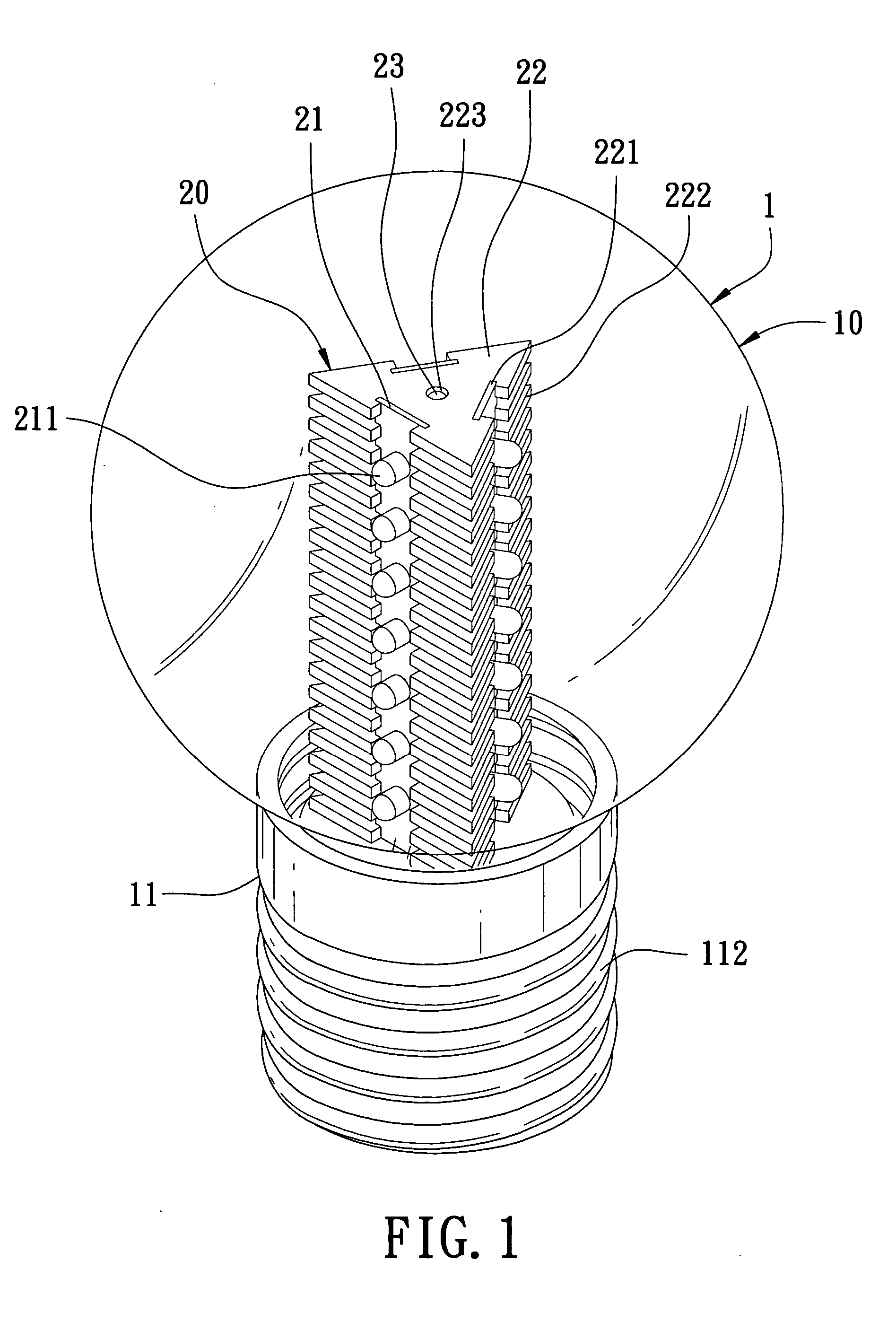

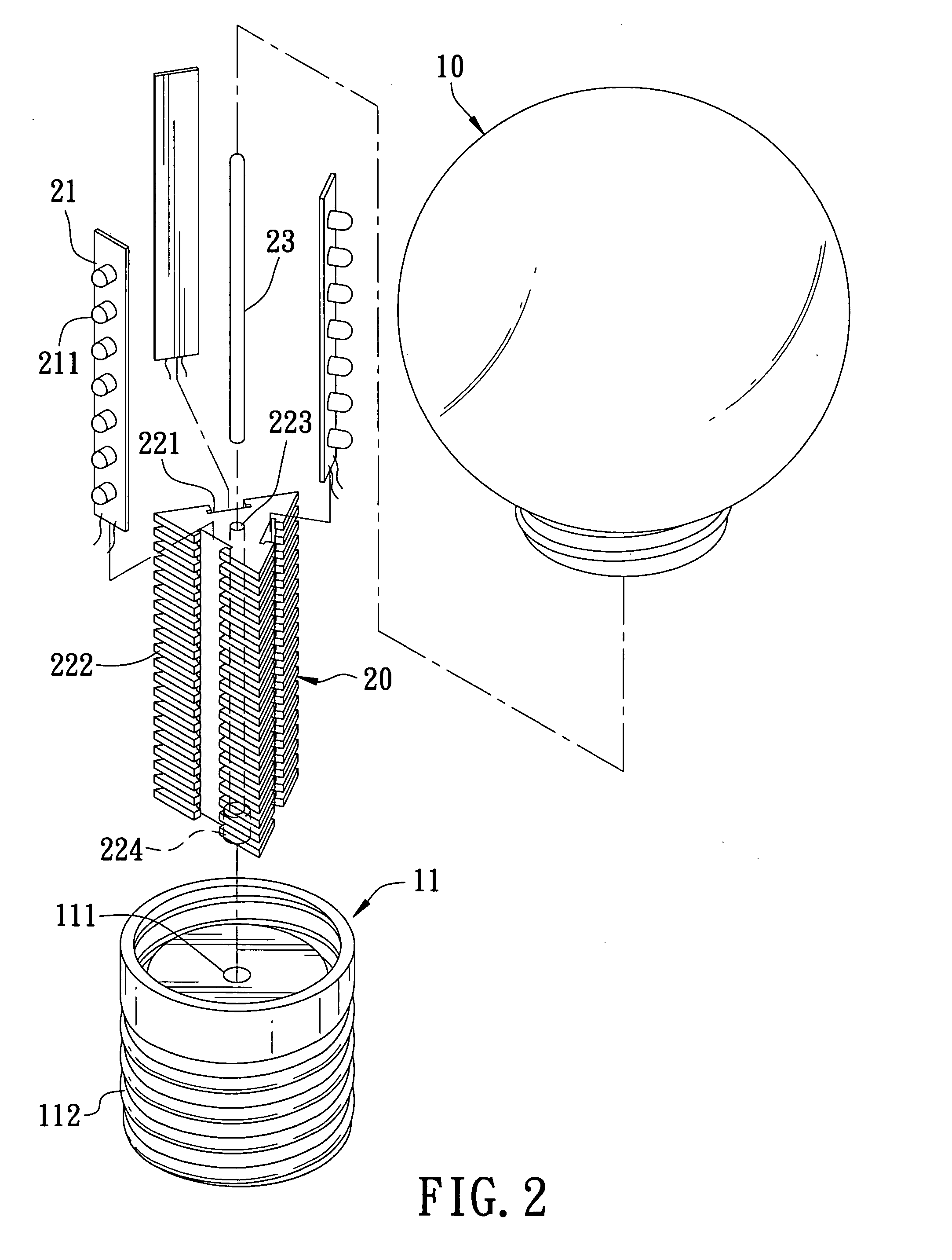

Vertical LED lamp with a 360-degree radiation and a high cooling efficiency

InactiveUS20070159828A1Improve cooling efficiencyIncrease the areaPoint-like light sourceLighting heating/cooling arrangementsEngineeringConductive materials

A vertical LED lamp with a 360-degree radiation and a high cooling efficiency includes a lampshade, a lamp base and a LED module. The LED module is contained in a chamber surrounded by the lampshade and the lamp base. The lamp base is able to provide DC for the LED module to work. The LED module is composed of a cooling column and a preset number of LED boards. The cooling column, shaped as a triangle or a tetragon or polygon and made of a thermal conductive material, is provided with a plugging slot on each surface for fitting with the LED bulb board, and plural fins formed on each surface for increasing areas to contact air Therefore, the LED lamp has 360-defree radiation and can perform with a better brightness and obtain a longer life.

Owner:CERAMATE TECH CO LTD

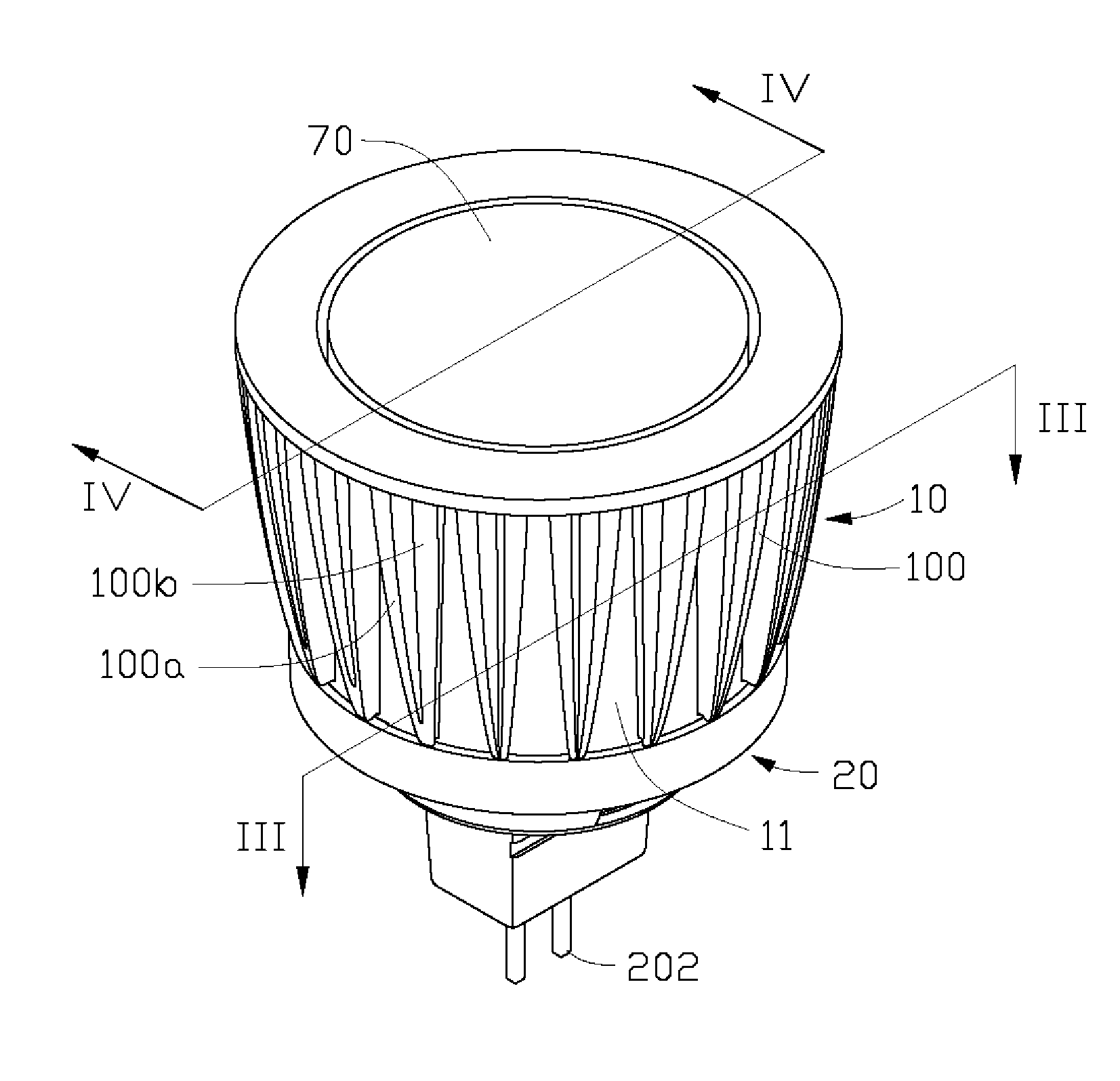

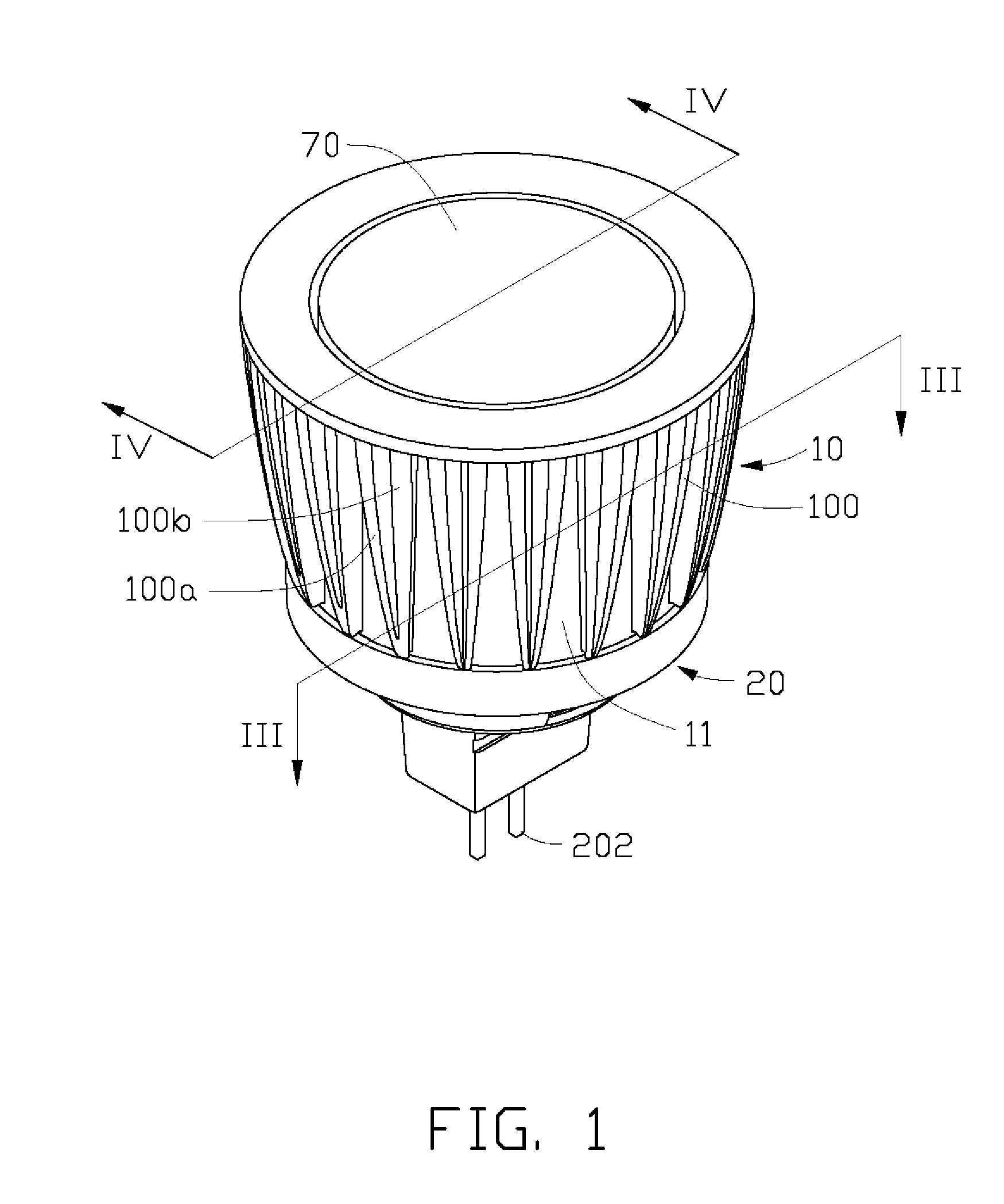

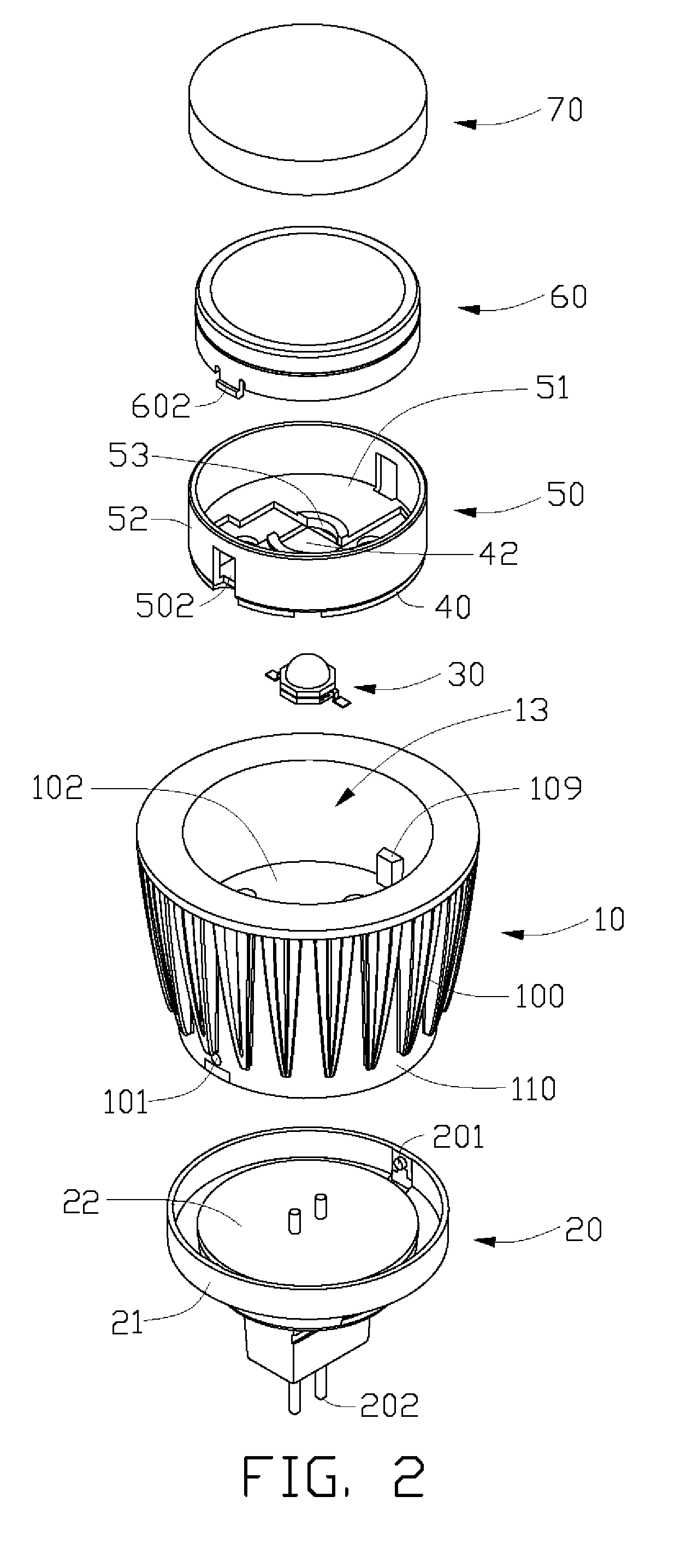

Light-emitting diode lamp

InactiveUS20080158887A1Point-like light sourceLighting heating/cooling arrangementsEngineeringLight-emitting diode

A light-emitting diode (LED) includes a heat sink (10) having a cross section along an axial direction thereof being U-shaped. The heat sink includes a substrate (102) and a sidewall (11) extending from an outer periphery of the substrate. A circuit board (40) is received in the heat sink and arranged on the substrate. At least one LED (30) is arranged on and electrically connected to the circuit board and thermally connected with the substrate of the heat sink. A plurality of fins (100) extend outwardly from an outer surface (110) of the sidewall of the heat sink. Each fin has a plurality of branches (100a, 100b) being connected together at the outer surface of the sidewall and being spaced from each other at outer-peripheries thereof.

Owner:HON HAI PRECISION IND CO LTD

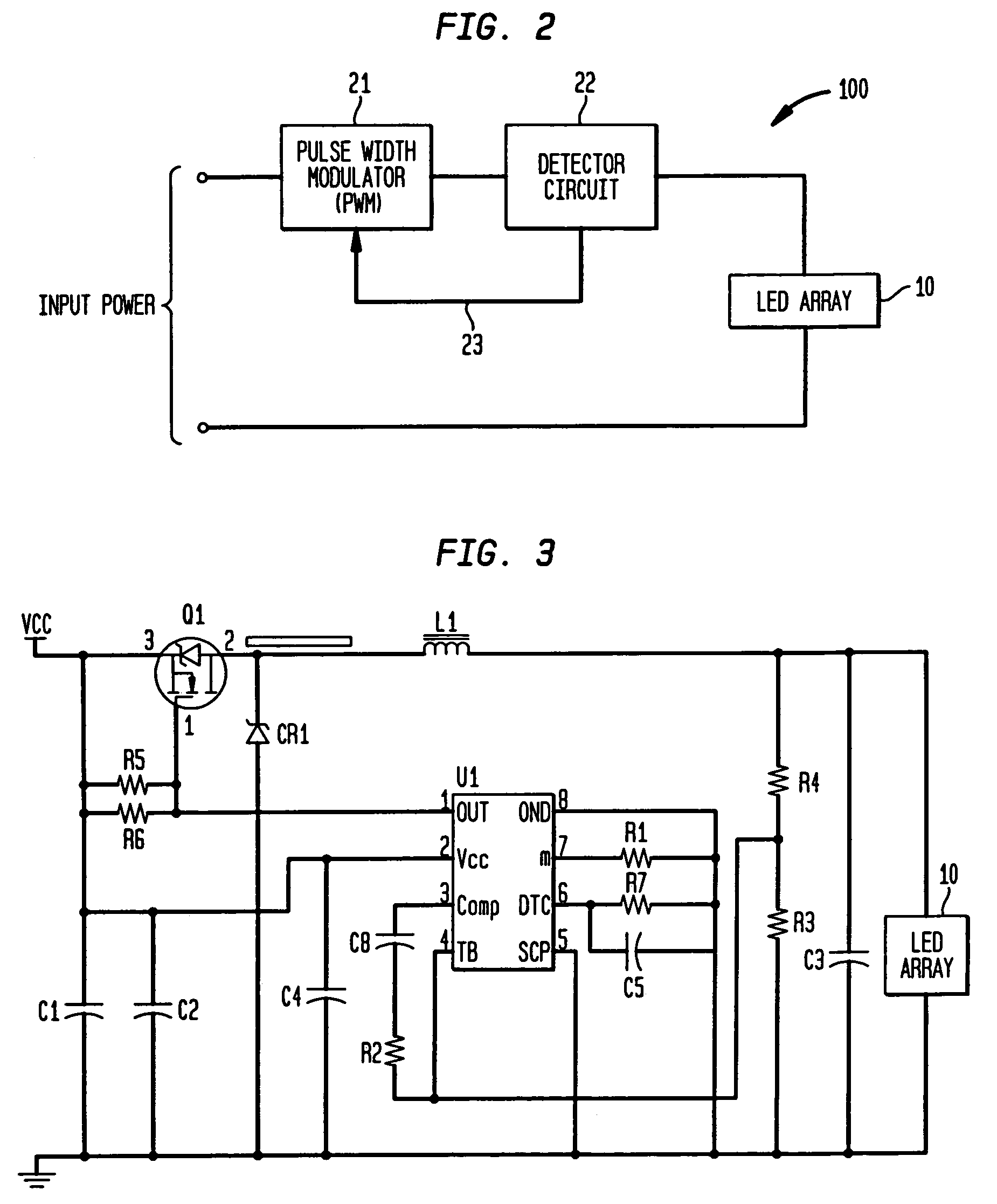

LED array package with internal feedback and control

ActiveUS7252408B2Electric circuit arrangementsLighting heating/cooling arrangementsDriver circuitElectricity

A packaged LED array for high temperature operation comprises a metal base, the metal base including an underlying thermal connection pad. One or more layers of ceramic overly the metal base. The array includes a plurality of LED dice, each LED die having electrodes. And, the LED thermally coupled to the metal base. A driver circuit is electrically connected to the LED die electrodes and controls the LED array current. An LED driver is mounted within the LED array package, and thermally coupled to the metal base. In a second embodiment, one or more of the LED dice can be switched from the driver to a measurement circuit and used as a photodetector to measure the light output of the LED array. The measured photodetector signal can further be used as a feedback signal to control the LED array light output.

Owner:LIGHTING SCI GROUP

Light emitting diode based products

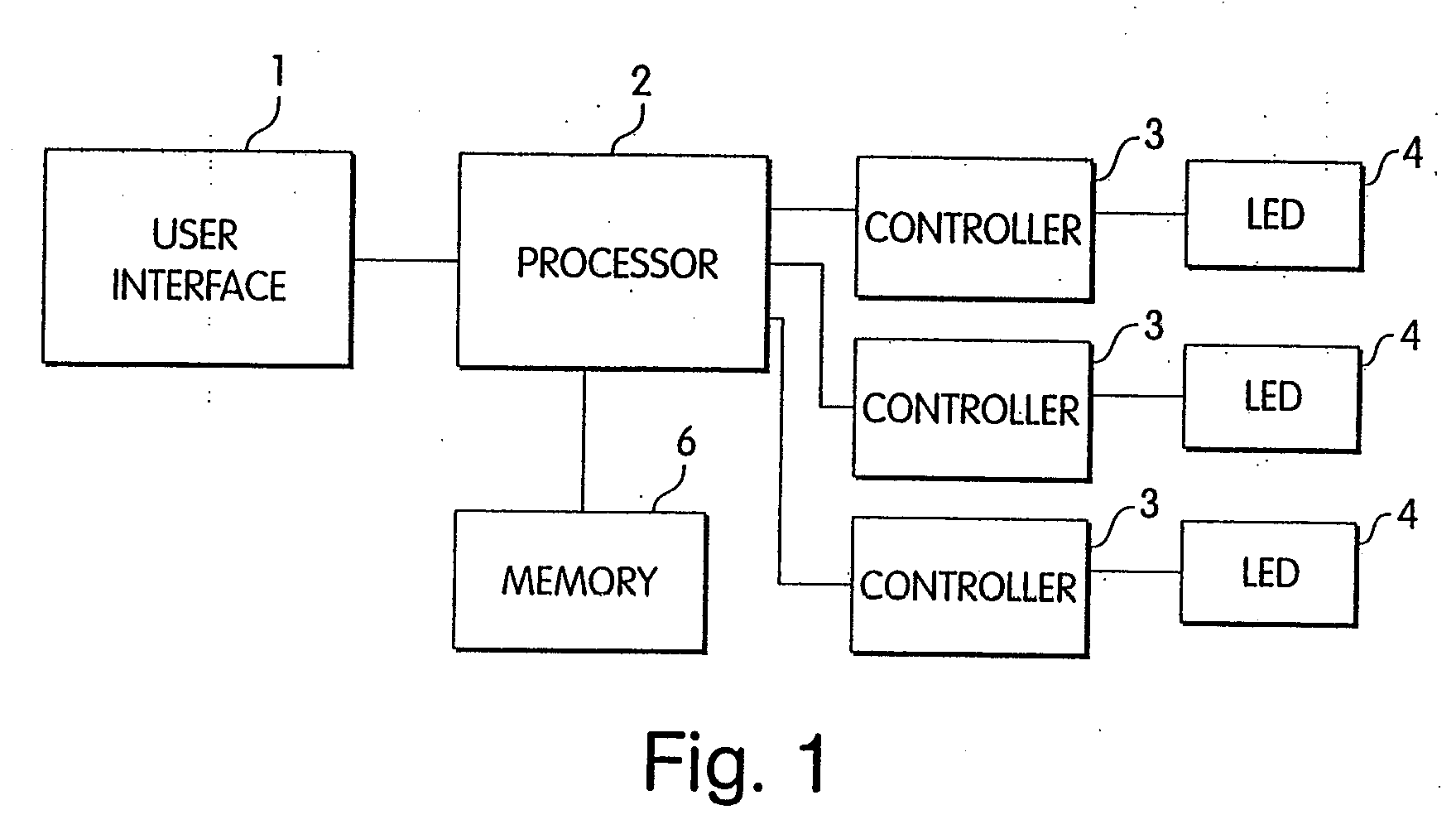

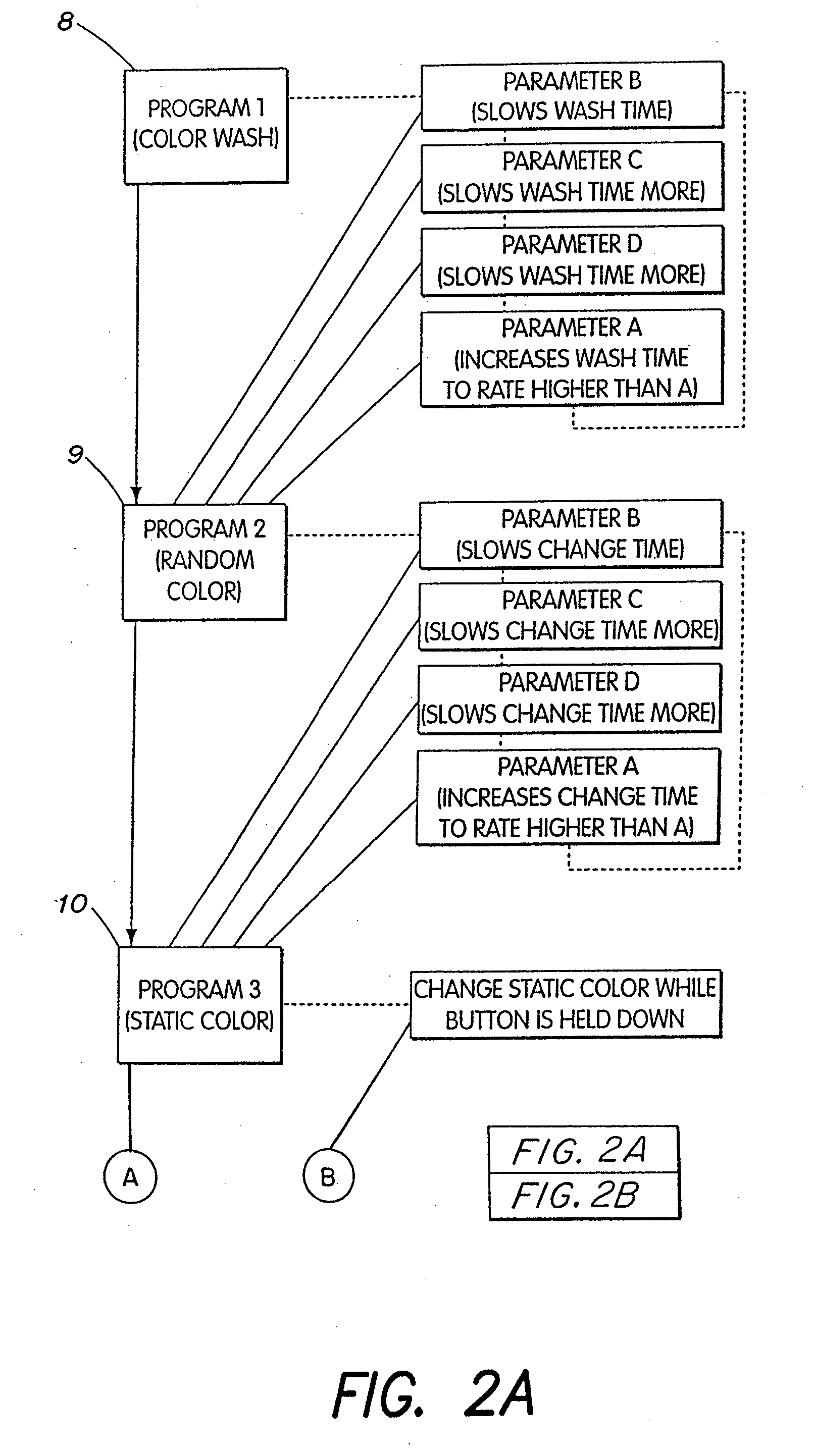

Methods and apparatus for downloading one or more lighting programs including one or more lighting effects. The lighting program(s) may be downloaded from a web site to one or more LED-based lighting devices that are configured to execute the downloaded lighting program(s) so as to reproduce the lighting effect(s). In various examples, a variety of programming devices may be employed to facilitate wired or wireless downloading, including one or more computers, personal digital assistants (PDAs), cell phones, media players (e.g., MP3 players), and the like. Information may be uploaded to the web site to facilitate selection and / or creation of lighting effect(s) that are included in the downloaded lighting program(s).

Owner:SIGNIFY NORTH AMERICA CORP

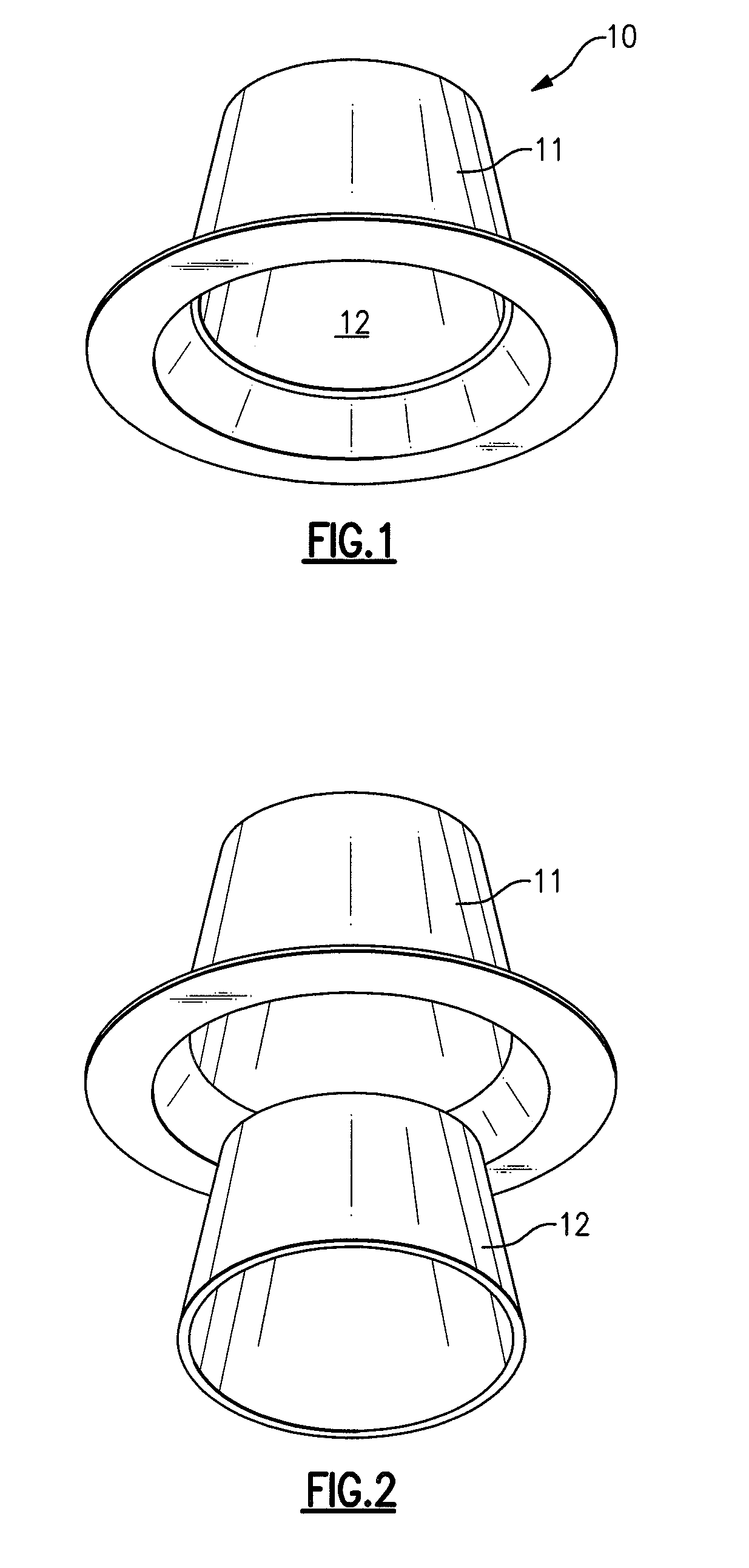

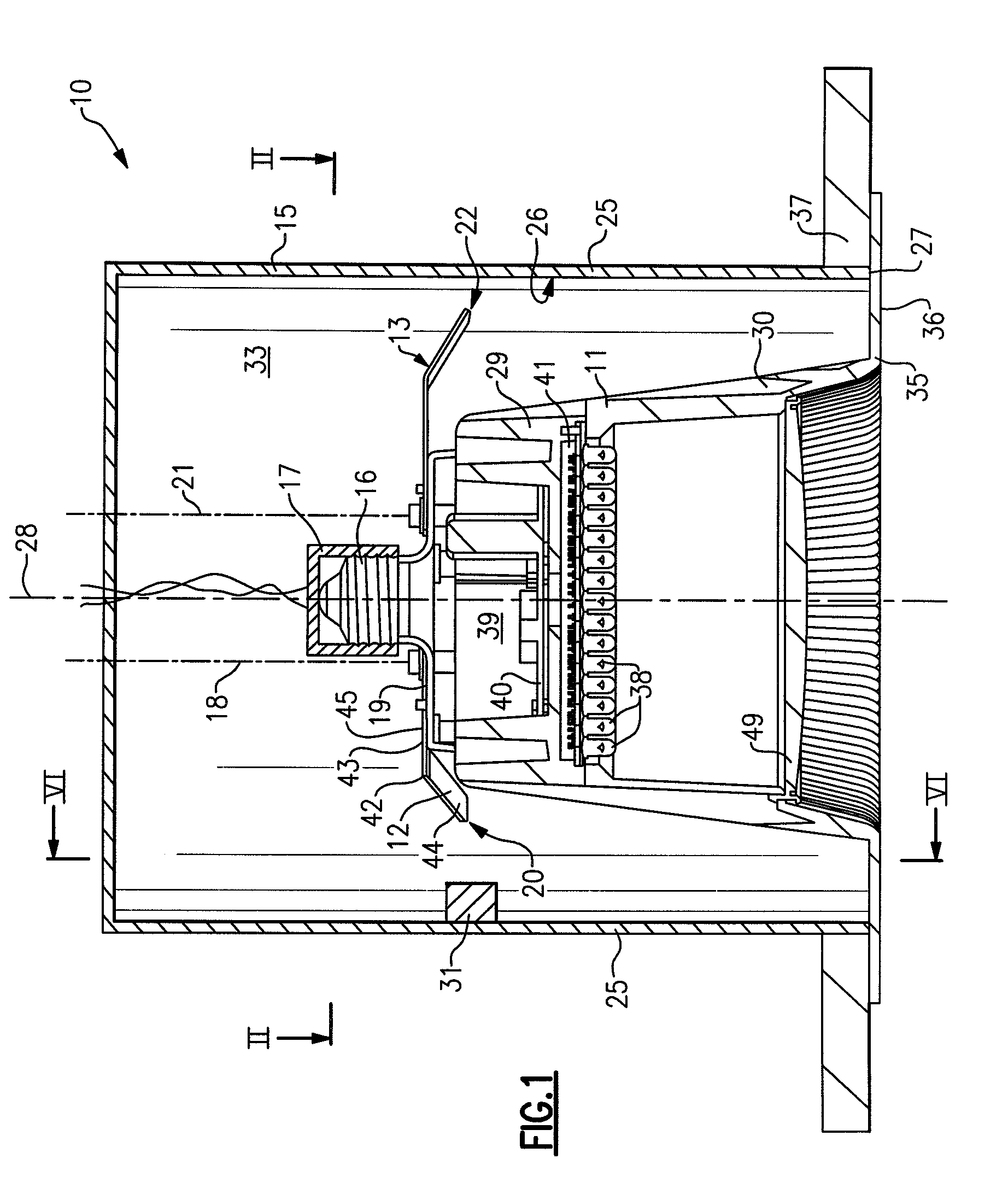

Light fixtures and lighting devices

ActiveUS20080278950A1Minimize striationMinimize hot spot projected wallLighting support devicesPoint-like light sourceLight equipmentEffect light

A lighting device comprises a heat sink, a housing mounted to and / or thermally coupled to the heat sink, a basket assembly attached to the housing, a solid state light emitter thermally coupled to the heat sink, and a baffle assembly attached to the housing. Also, a lighting device comprising a basket assembly and a baffle assembly. In some embodiments, the basket assembly comprises a first member defining a first opening, a second member, a space between the first and second members, and lenses in the opening and in the space. In some embodiments, the heat sink extends farther in a first direction in a first plane than a largest dimension of the housing in any plane which is parallel to the first plane. In some embodiments, at least one additional component (e.g., a power supply module or a junction box) is in contact with the heat sink element.

Owner:IDEAL IND LIGHTING LLC

Light emitting diode illumination apparatus

ActiveUS7226189B2Effective lightingEfficient heatingCoupling device connectionsPoint-like light sourceLight-emitting diodeMetal substrate

The present invention describes a light emitting diode illumination apparatus made of a light bulb base, a heat dissipating device, a plastic lid, a drive substrate, a metal substrate, a circular insulated base and a casing, and the heat dissipating device is in contact with the metal substrate in normal conditions, such that the heat source produced by each light emitting diode is conducted to the heat dissipating device through the metal substrate and then conducted from the heat dissipating device to the light bulb base for effectively dispersing the heat source and maintaining the light emitting efficiency of each light emitting diode.

Owner:TAIWAN OASIS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com