Patents

Literature

98593results about How to "Improve cooling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

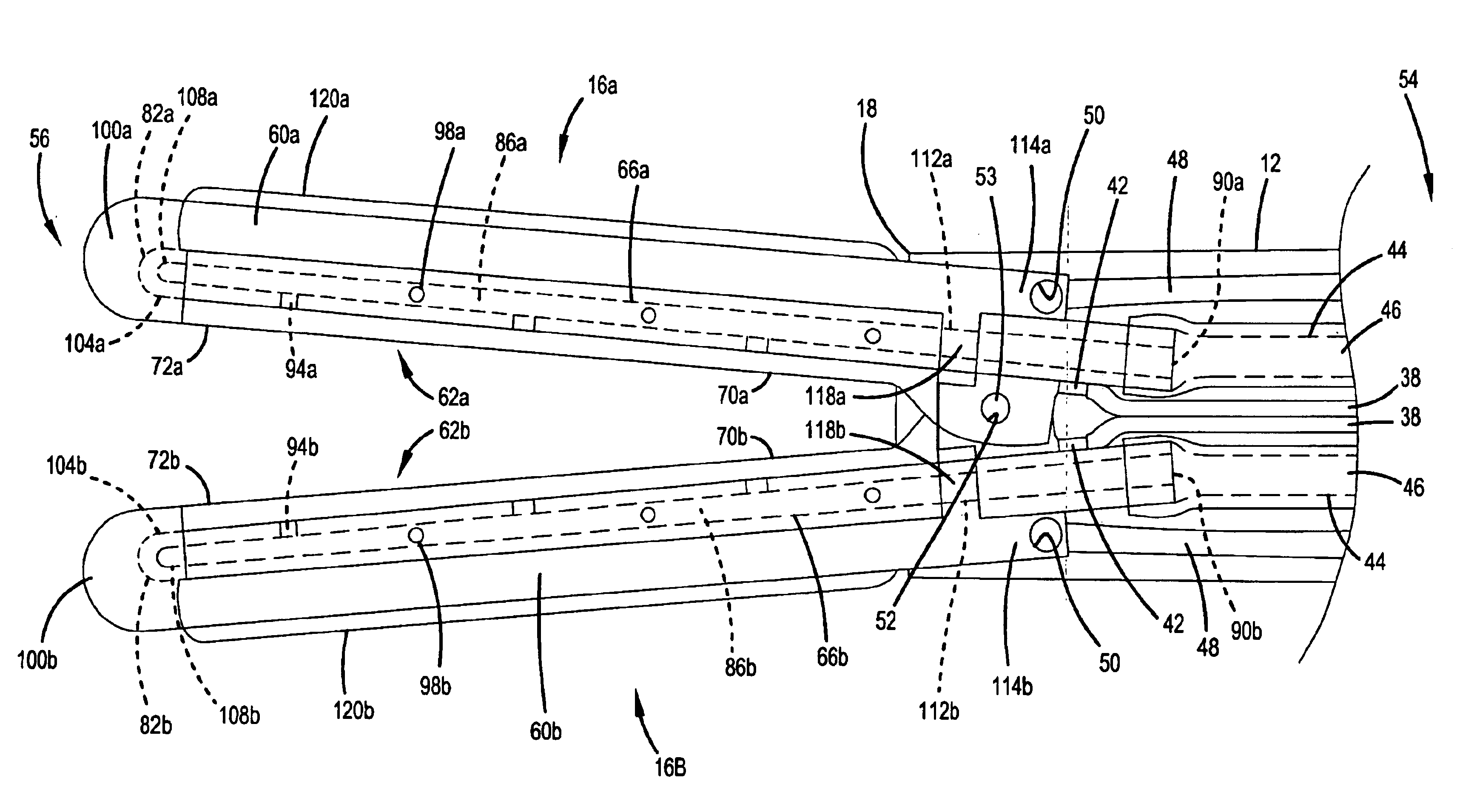

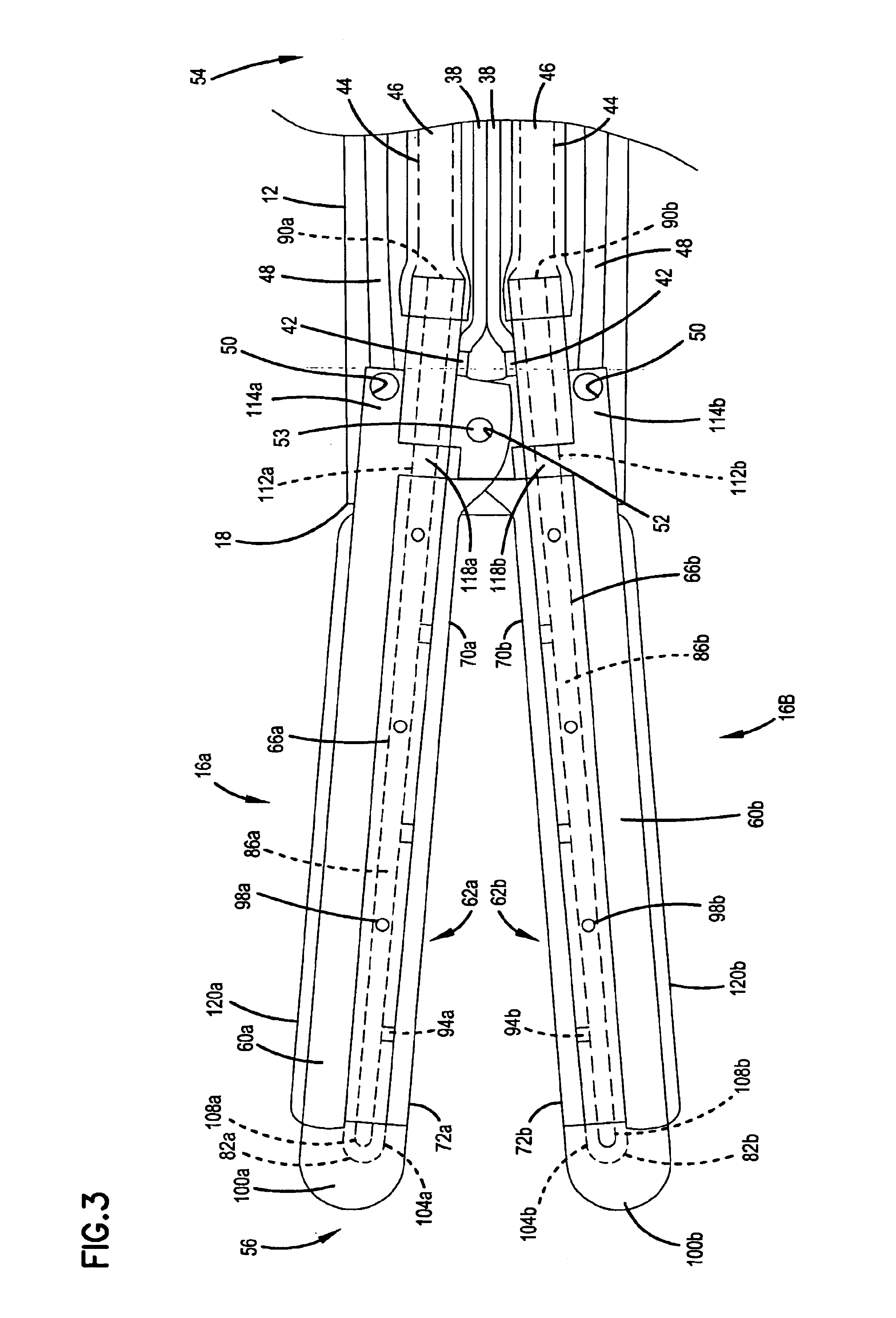

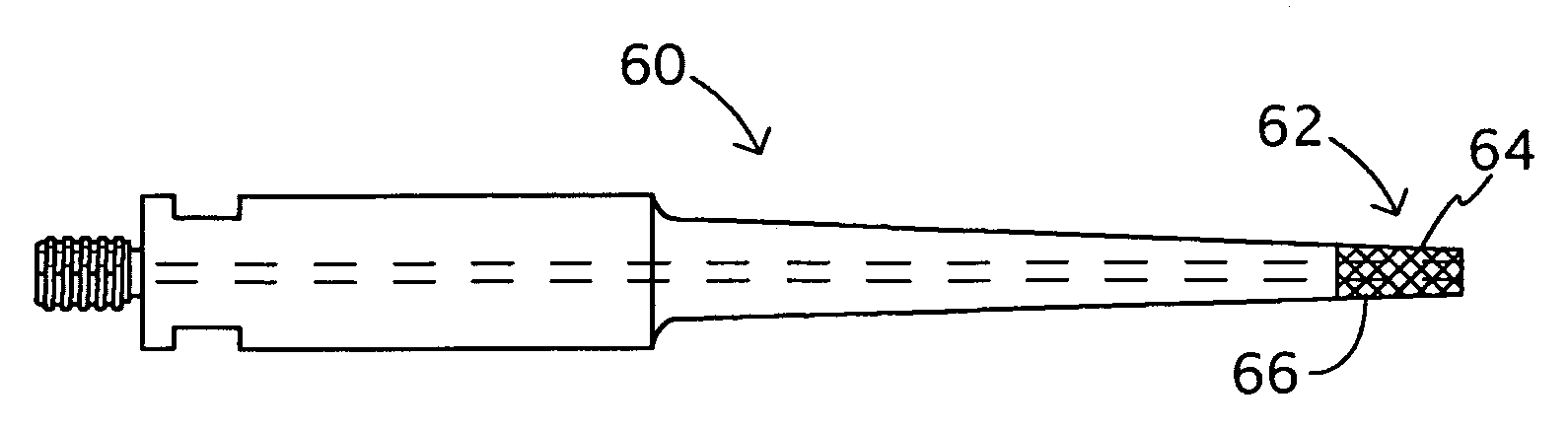

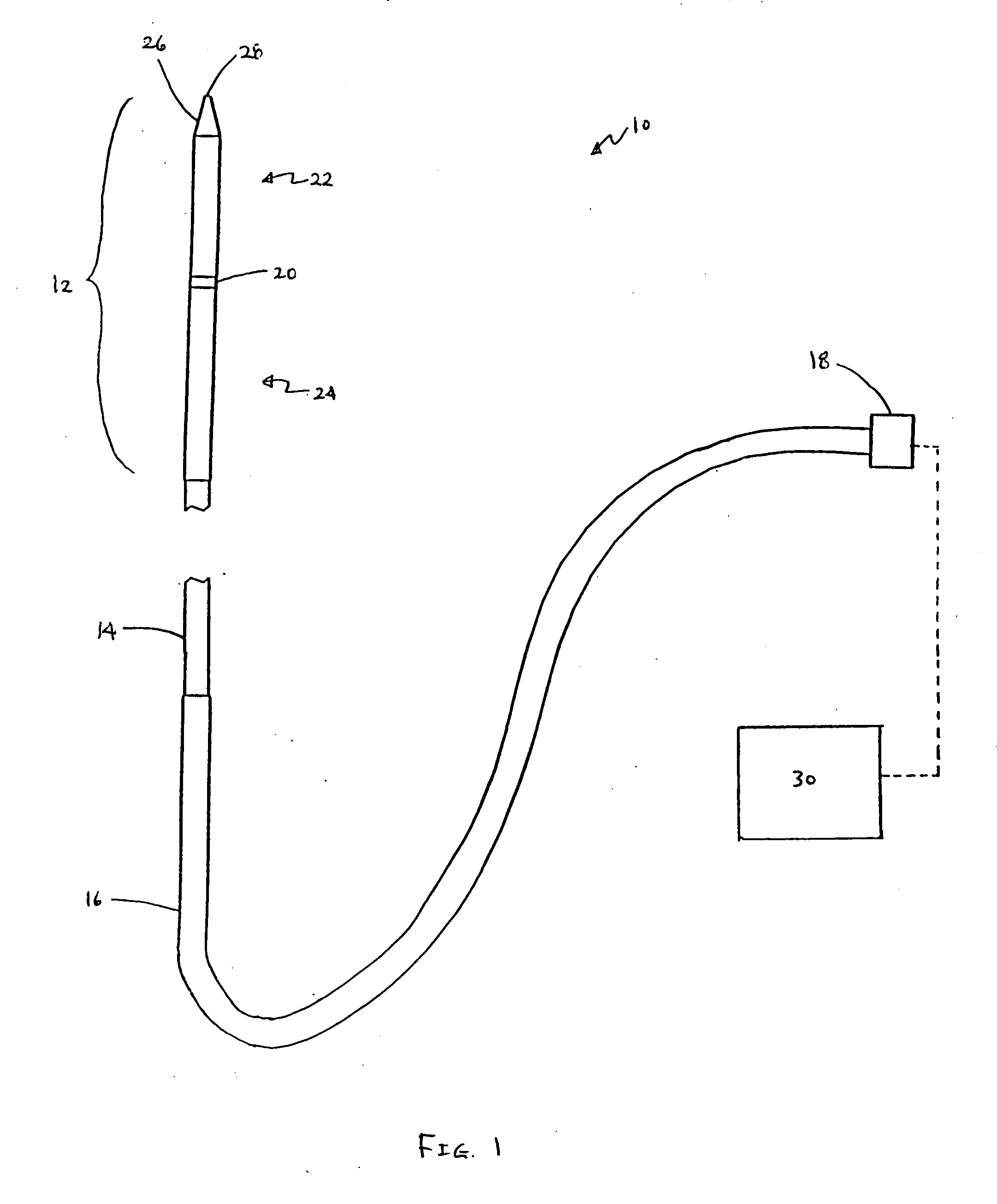

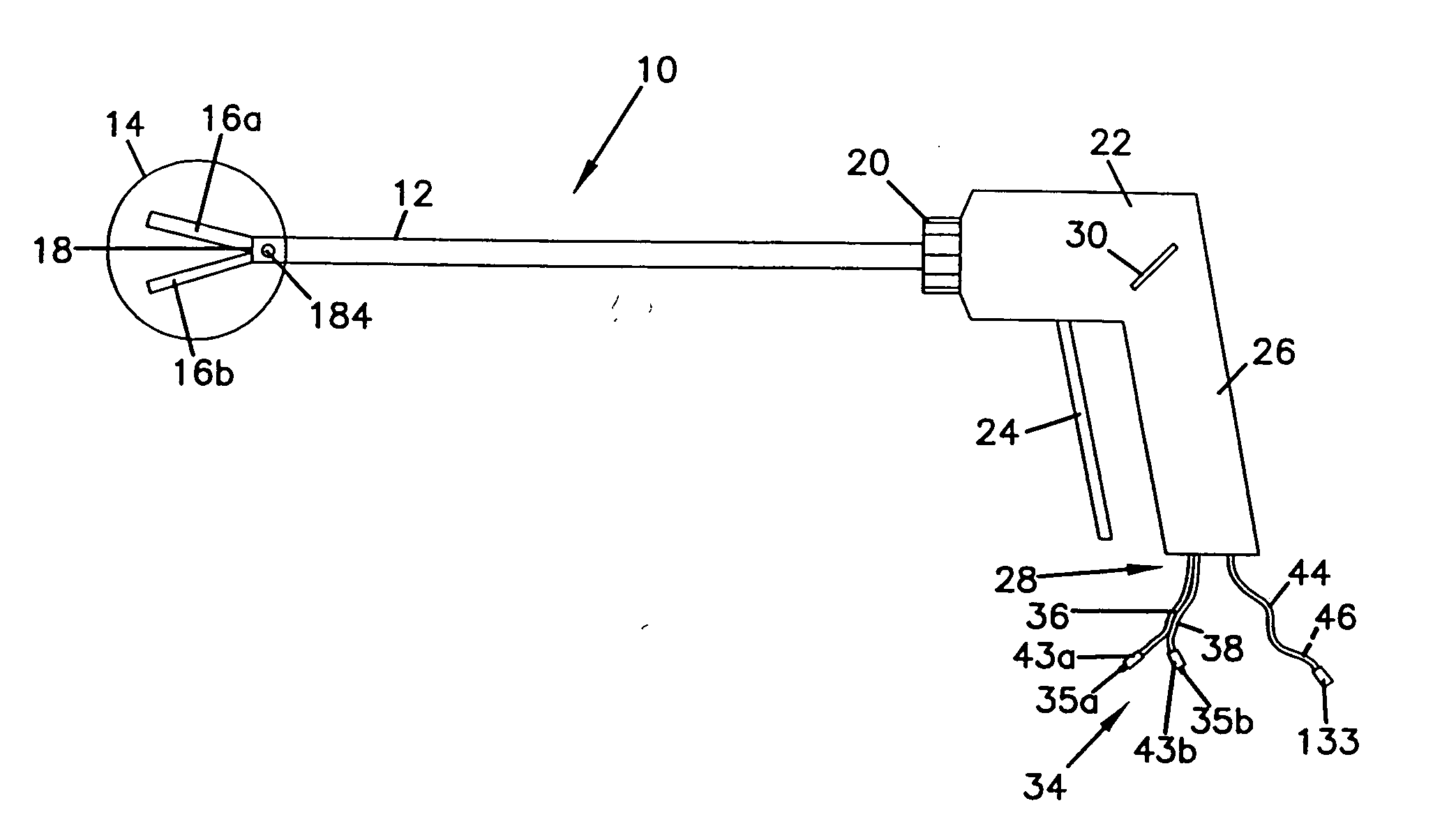

Fluid-assisted medical devices, systems and methods

Surgical devices, systems and methods for treating tissue are provided. An exemplary surgical device comprises a tip portion including first and second jaws each having a tissue grasping surface, at least one of the jaws being movable toward the other jaw. The tissue grasping surface of each jaw has includes an electrically insulative surface. The device also includes first and second electrodes connectable to different terminals of an RF generator to generate electrical current flow therebetween, with each of the electrodes having an electrode surface. One of the electrode surfaces is located on one of the jaws separated from one edge of the tissue grasping surface, and the other of the electrode surfaces is located on one or the other of the jaws separated from the other edge of the tissue grasping surface. The device also includes at least one fluid passage being connectable to a fluid source.

Owner:MEDTRONIC ADVANCED ENERGY

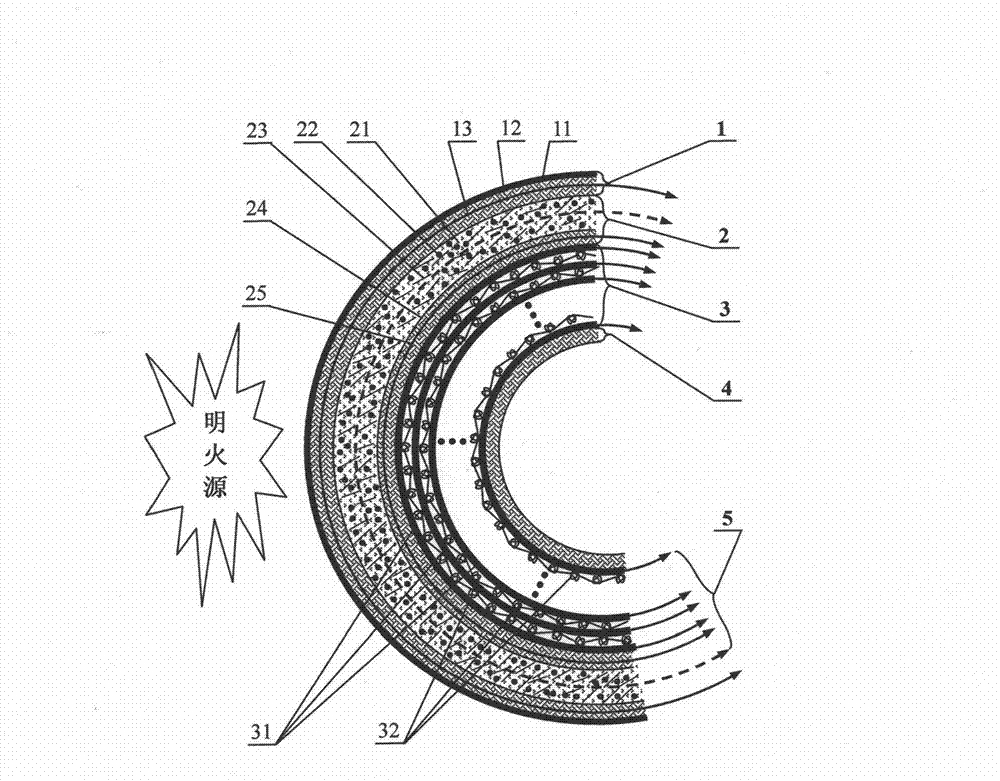

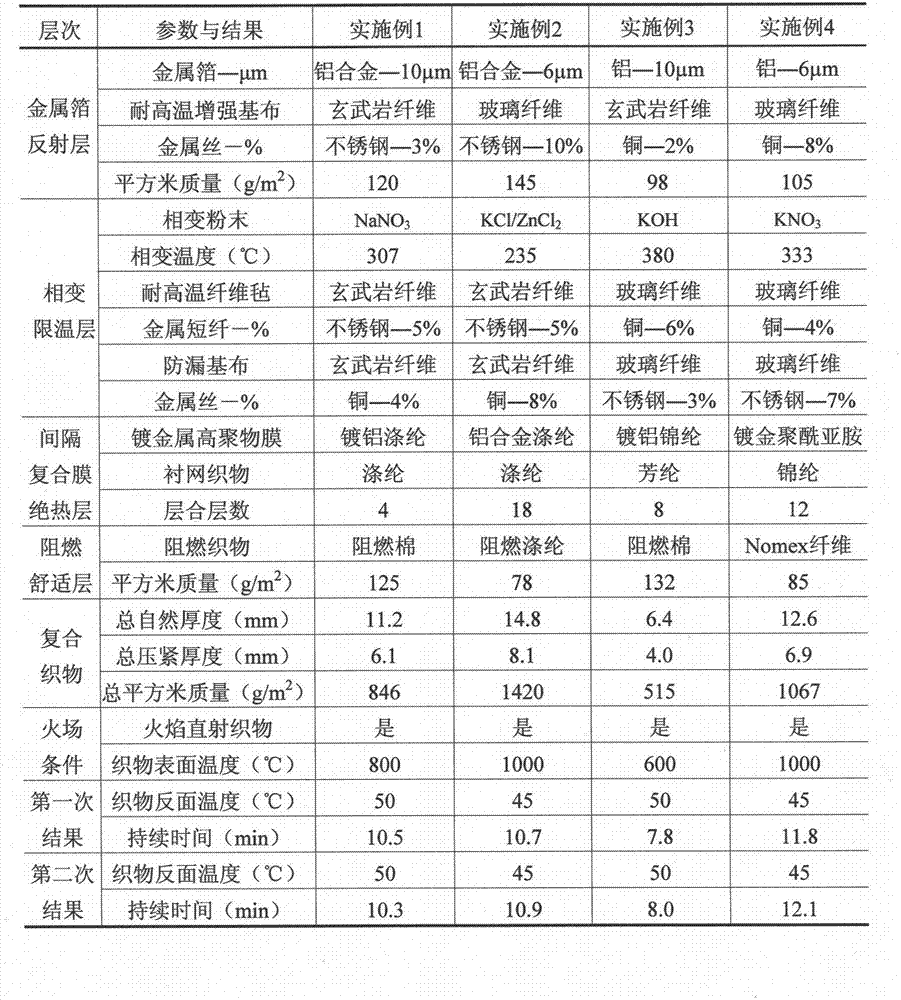

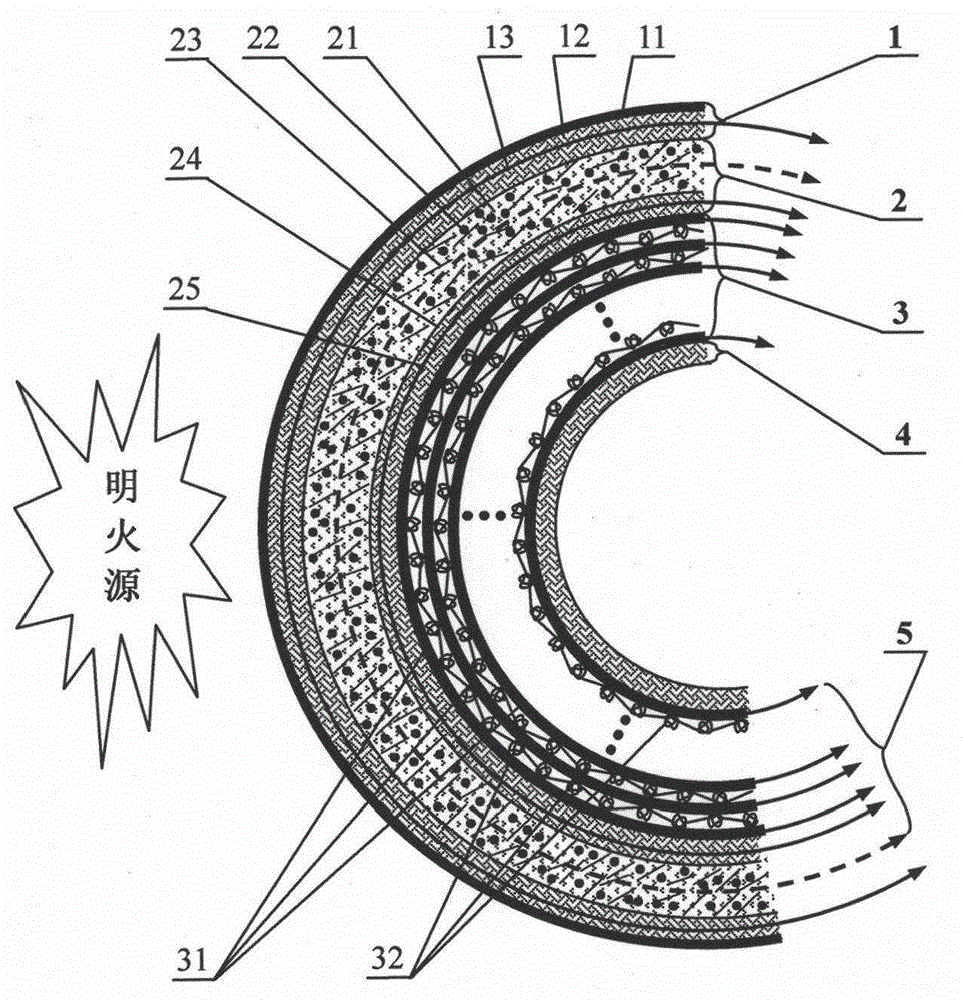

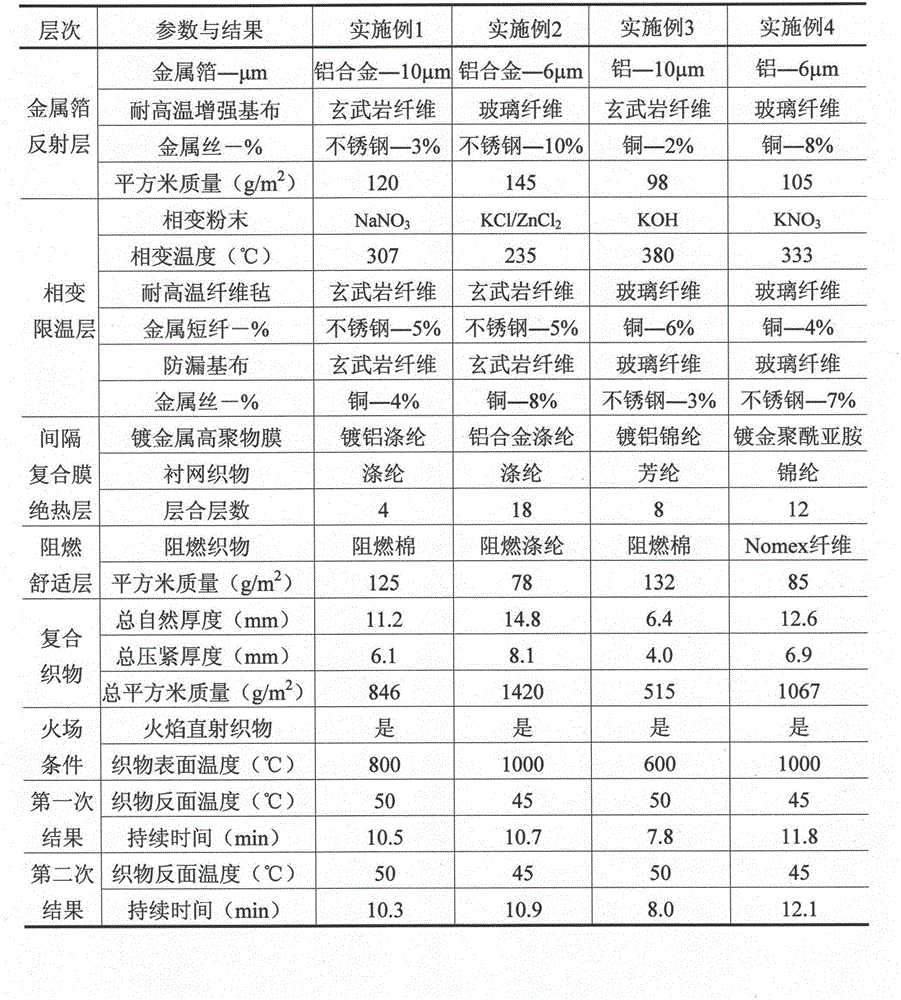

Multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric, preparation method and application

ActiveCN102783741AImprove permeabilityPromote absorptionLaminationLamination apparatusInsulation layerMetal foil

The invention relates to a preparation method and an application of multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric. The multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is formed by successively arranging and laminating a metal foil reflection layer, a phase change temperature limitation layer, an interval composite membrane heat-insulation layer and a flame-retardant comfortable layer, wherein the metal foil reflection layer has high reflectivity and an enhanced heat-dissipation function; the phase change temperature limitation layer has functions of high energy consumption absorption and evenly-distributed heat conduction; the interval composite membrane heat-insulation layer has the functions of reflection insulation and even distribution of heat; and the flame-retardant comfortable layer has the functions of low-contact heat conduction, heat insulation and comfort. When the front side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is under the action of open fire and strong heat flow environment, the back side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric can be kept below 50DEG C which is near the safe temperature state of the human skin, and the integral structural form and the mechanical property are stable. The natural thickness of the composite fabric is 5-15mm, the compression thickness of the composite fabric is 3-8mm, and the square meter quality of the composite fabric is 400-1500g / m<2>. The composite fabric is fire-proof heat-insulation material which is totally sealed, stuck and sewn and can be used for individual protection and environment heat insulation in special high-temperature occasions, such as fire control, military, exploration, safe escape and industry and the like.

Owner:DONGHUA UNIV

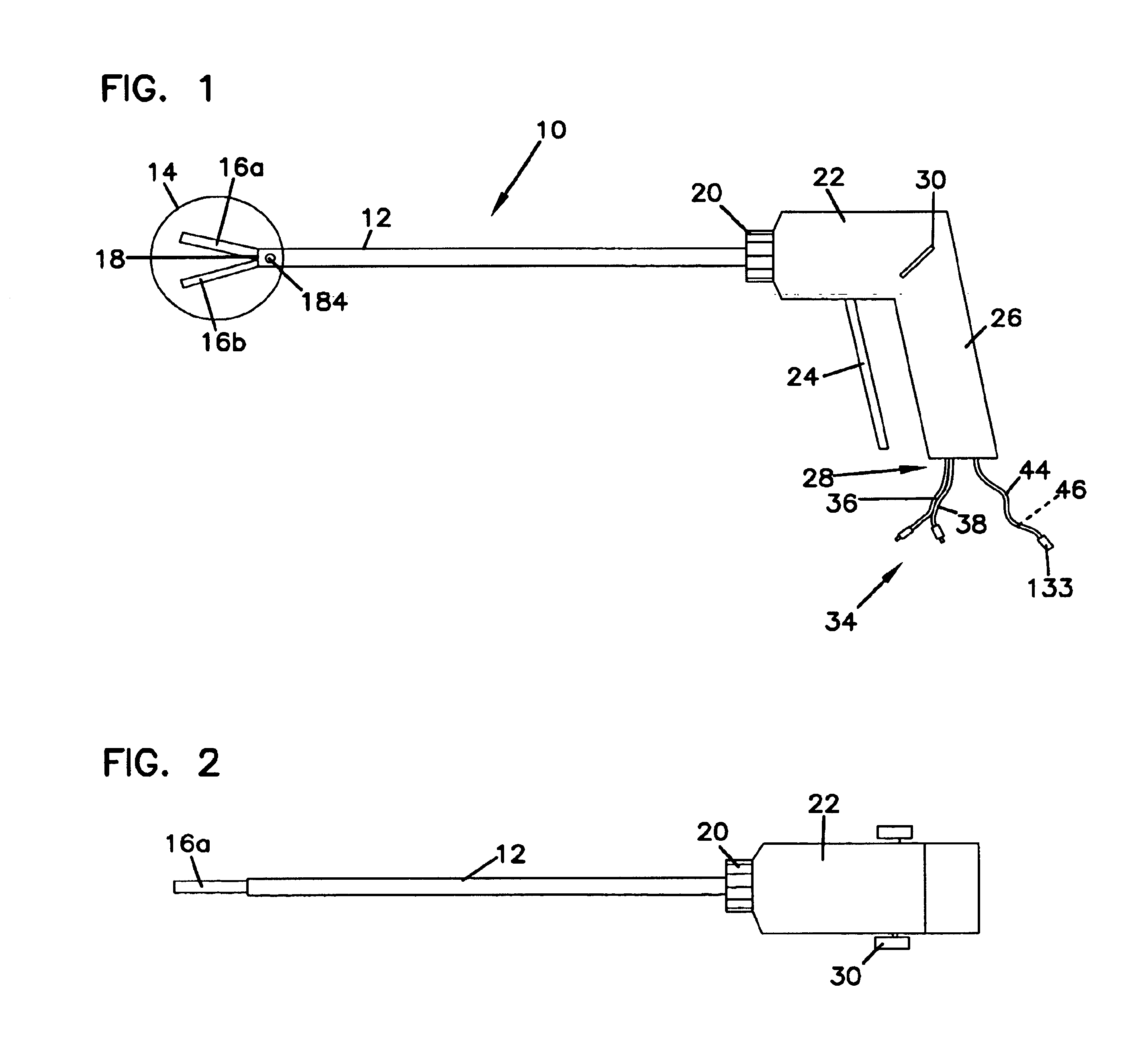

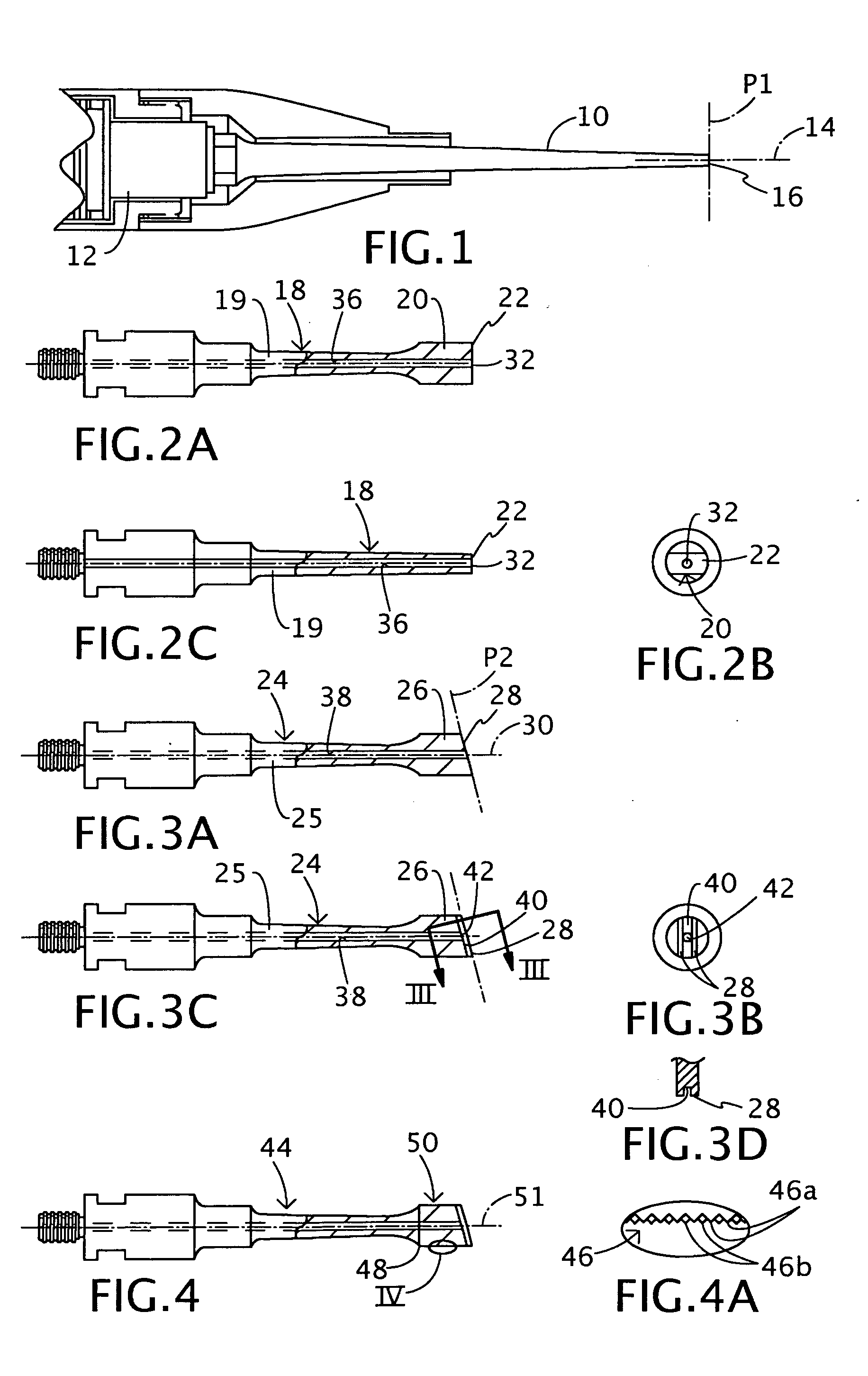

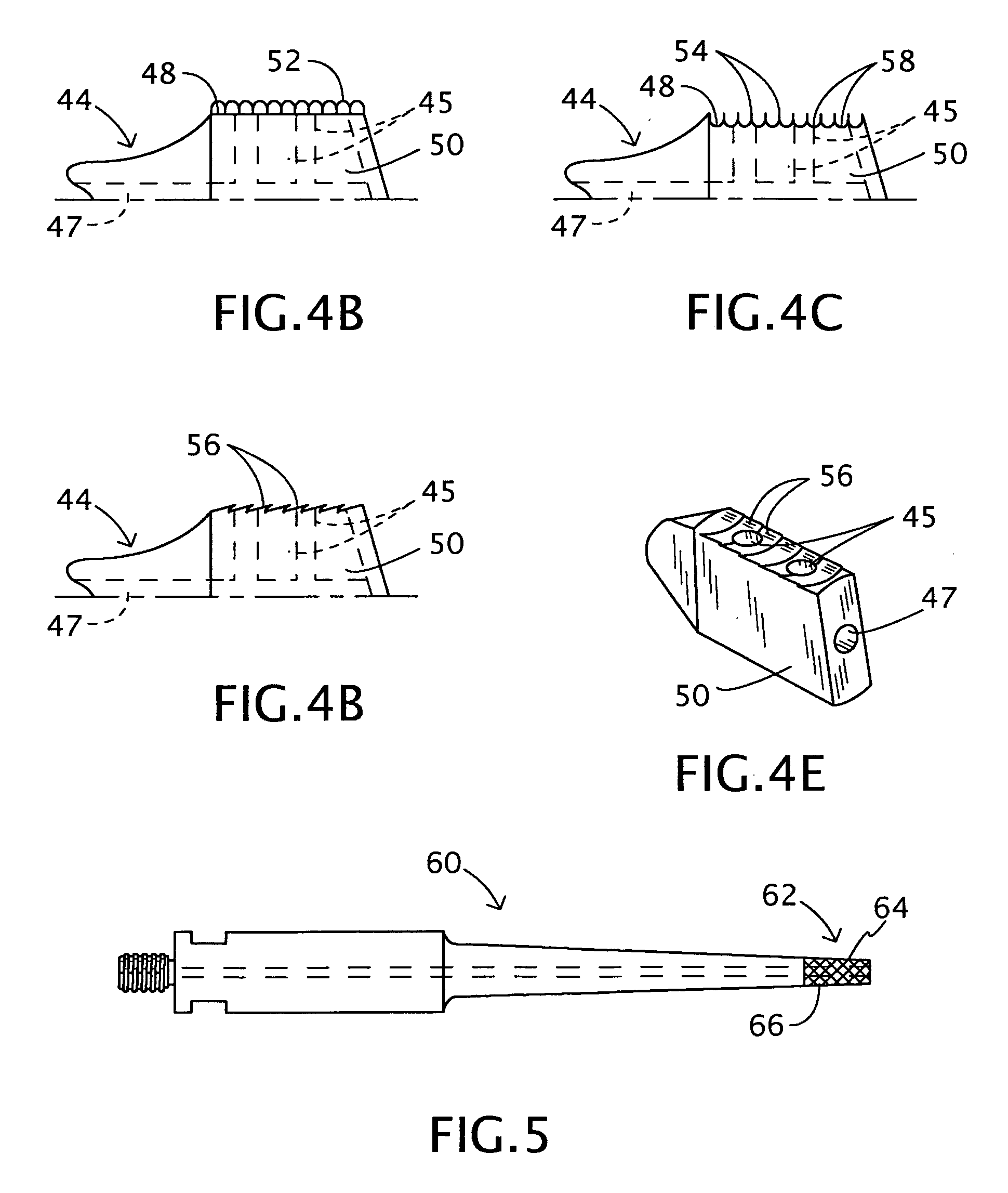

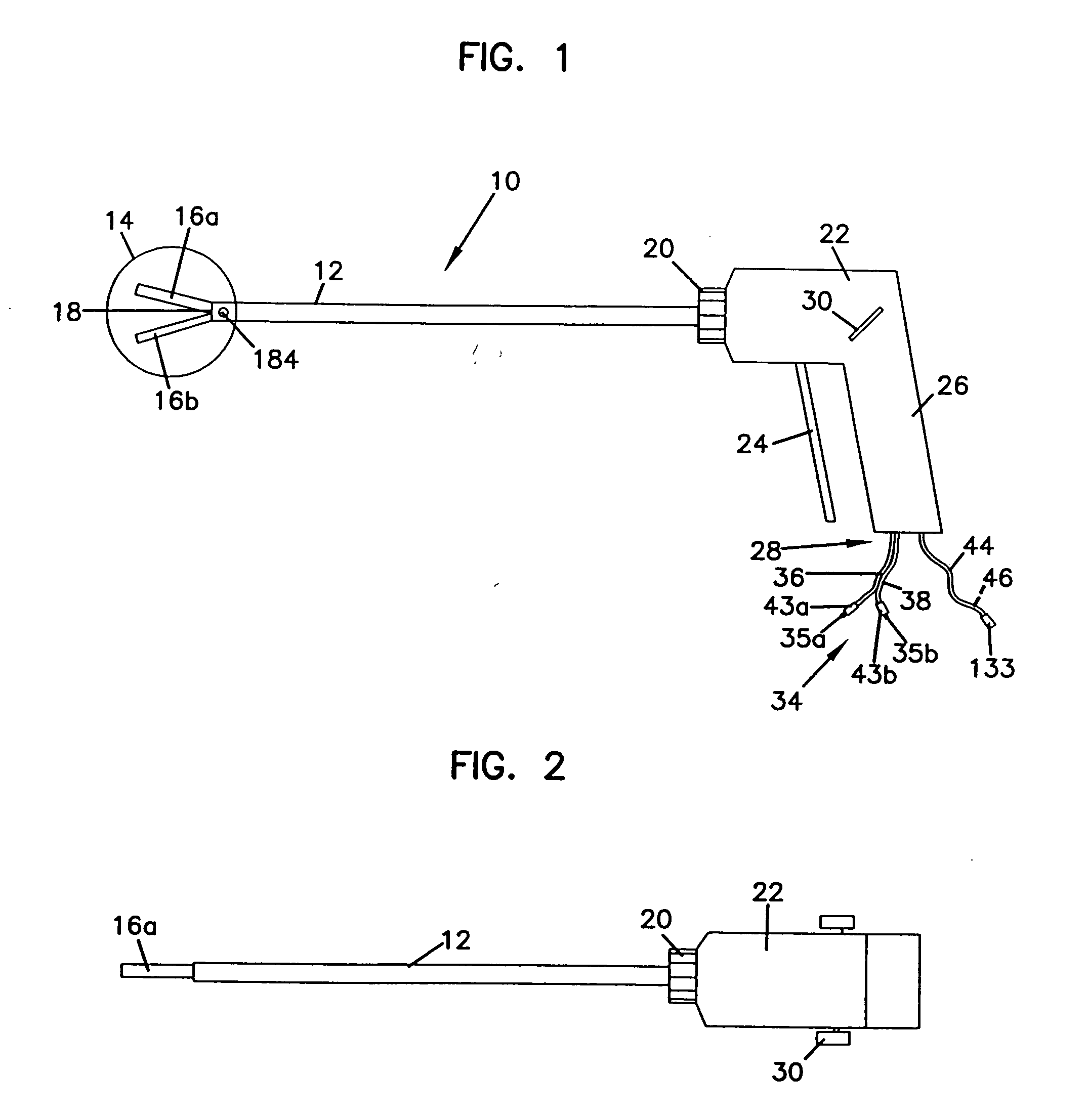

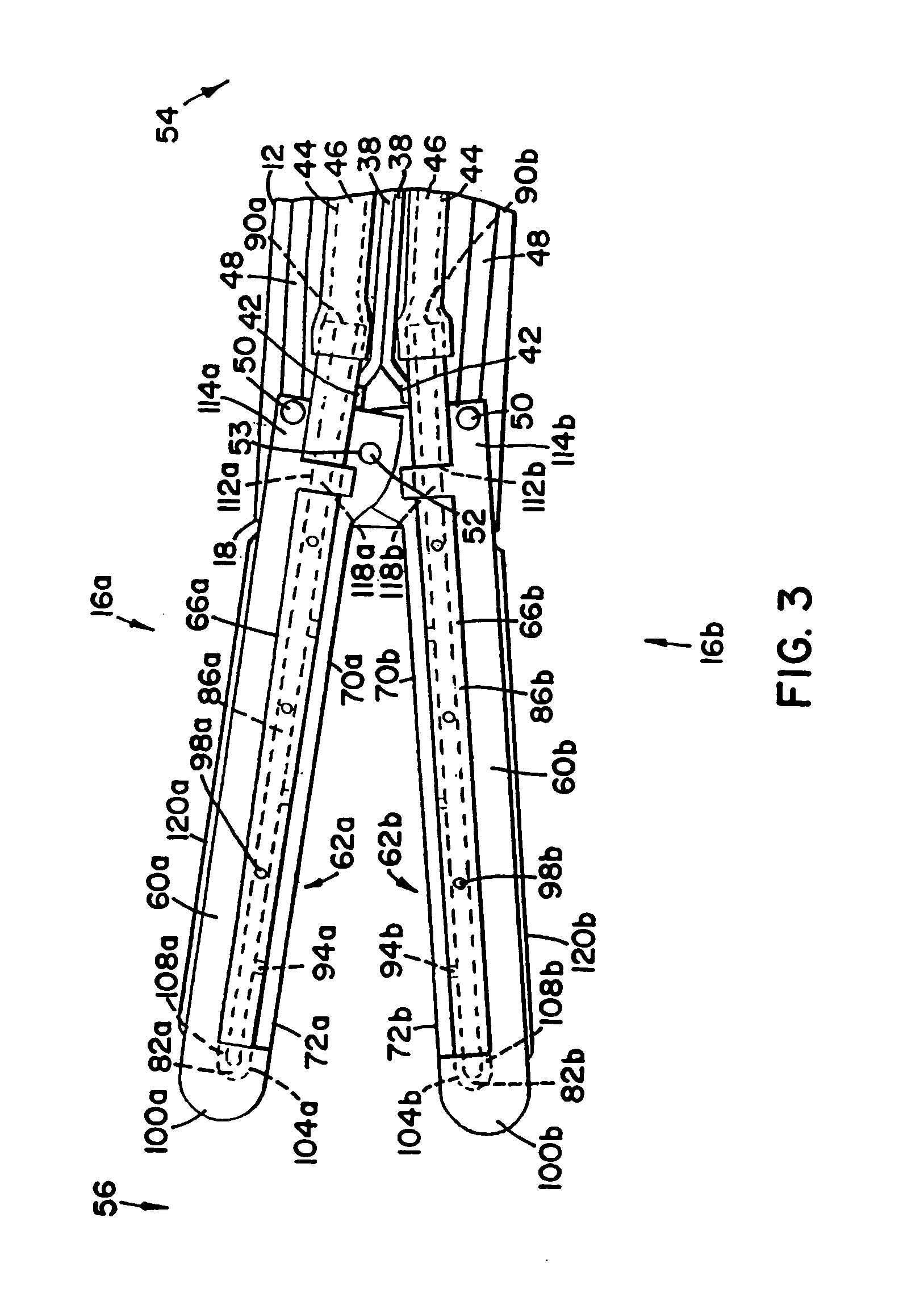

Ultrasonic surgical instruments

ActiveUS9375230B2Reduce heat damageImprove cooling effectDiagnosticsSurgical instrument detailsSurgical deviceUltrasonic Surgery

An ultrasonic surgical instrument is provided. The ultrasonic surgical instrument includes a housing having an elongated shaft extending therefrom. The shaft defines a longitudinal axis therethrough and has at least one jaw member disposed at a distal end thereof. The jaw member(s) is movable between open and clamping configurations. A probe extends through the shaft and operably couples to the housing. The probe includes a cutting blade at a distal end thereof adjacent the jaw member(s) to treat tissue of interest. The jaw member(s) and cutting blade are configured such that heat damage to tissue adjacent tissue of interest that has been treated by the cutting blade is reduced and / or eliminated.

Owner:TYCO HEALTHCARE GRP LP

Fire-proof and heat-insulating composite fabric with multi-stage expansion and heat dissipation, preparation method and application

ActiveCN102783741BImprove permeabilityPromote absorptionLaminationLamination apparatusInsulation layerMetal foil

The invention relates to a preparation method and an application of multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric. The multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is formed by successively arranging and laminating a metal foil reflection layer, a phase change temperature limitation layer, an interval composite membrane heat-insulation layer and a flame-retardant comfortable layer, wherein the metal foil reflection layer has high reflectivity and an enhanced heat-dissipation function; the phase change temperature limitation layer has functions of high energy consumption absorption and evenly-distributed heat conduction; the interval composite membrane heat-insulation layer has the functions of reflection insulation and even distribution of heat; and the flame-retardant comfortable layer has the functions of low-contact heat conduction, heat insulation and comfort. When the front side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is under the action of open fire and strong heat flow environment, the back side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric can be kept below 50DEG C which is near the safe temperature state of the human skin, and the integral structural form and the mechanical property are stable. The natural thickness of the composite fabric is 5-15mm, the compression thickness of the composite fabric is 3-8mm, and the square meter quality of the composite fabric is 400-1500g / m<2>. The composite fabric is fire-proof heat-insulation material which is totally sealed, stuck and sewn and can be used for individual protection and environment heat insulation in special high-temperature occasions, such as fire control, military, exploration, safe escape and industry and the like.

Owner:DONGHUA UNIV

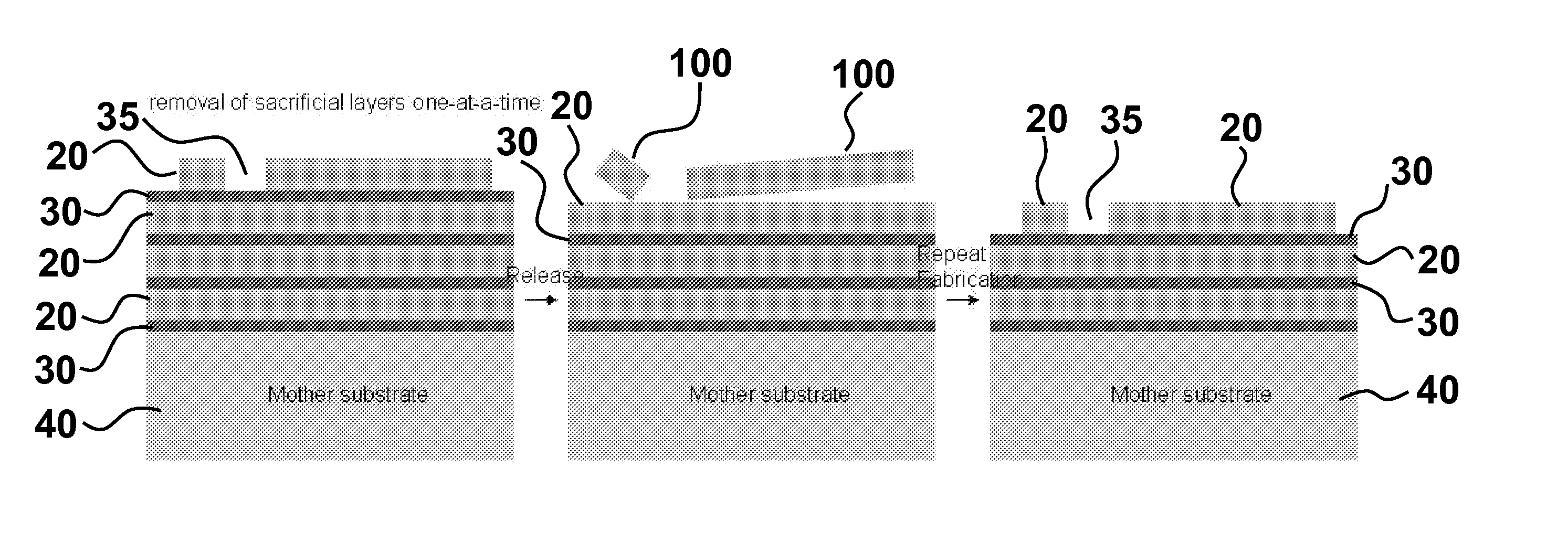

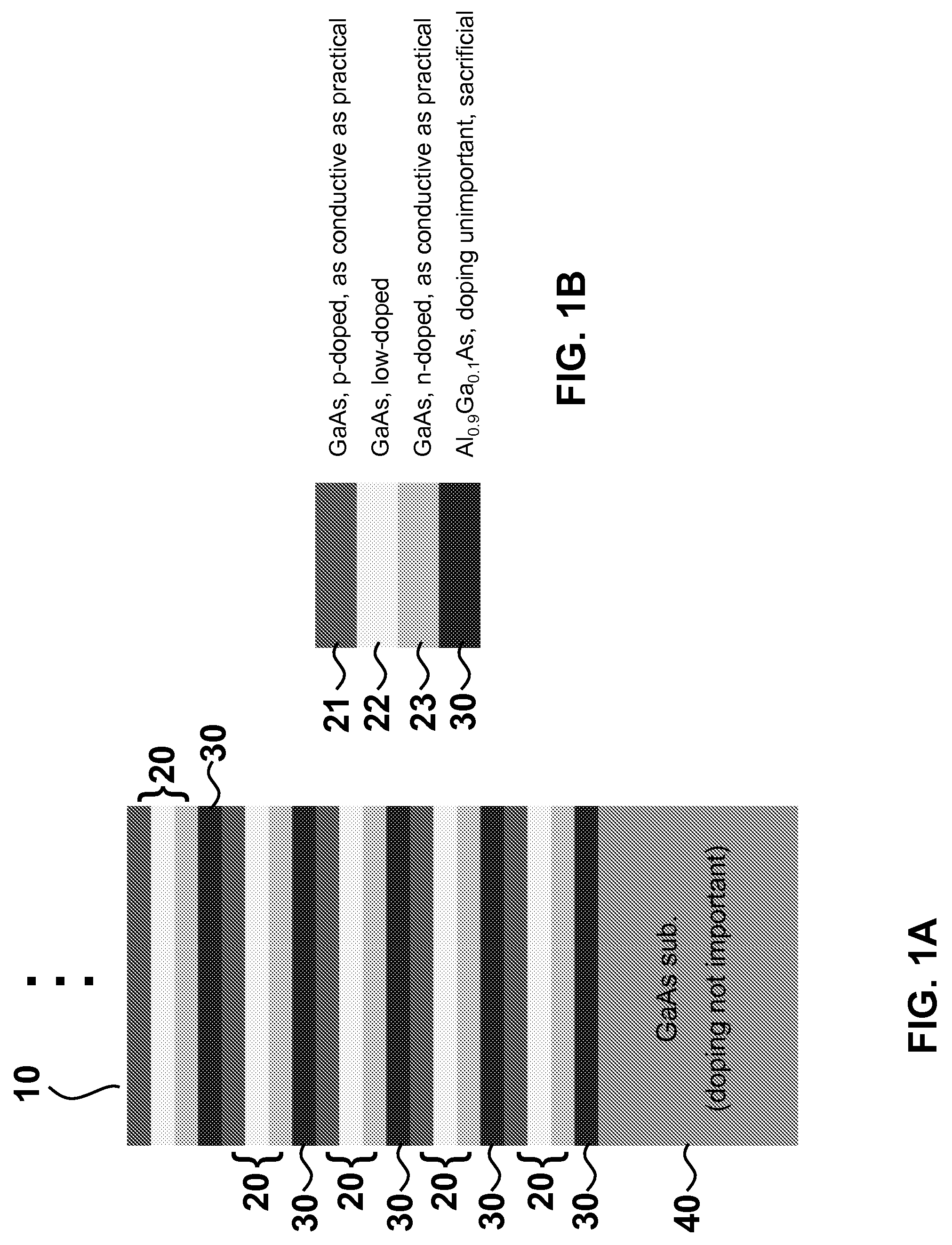

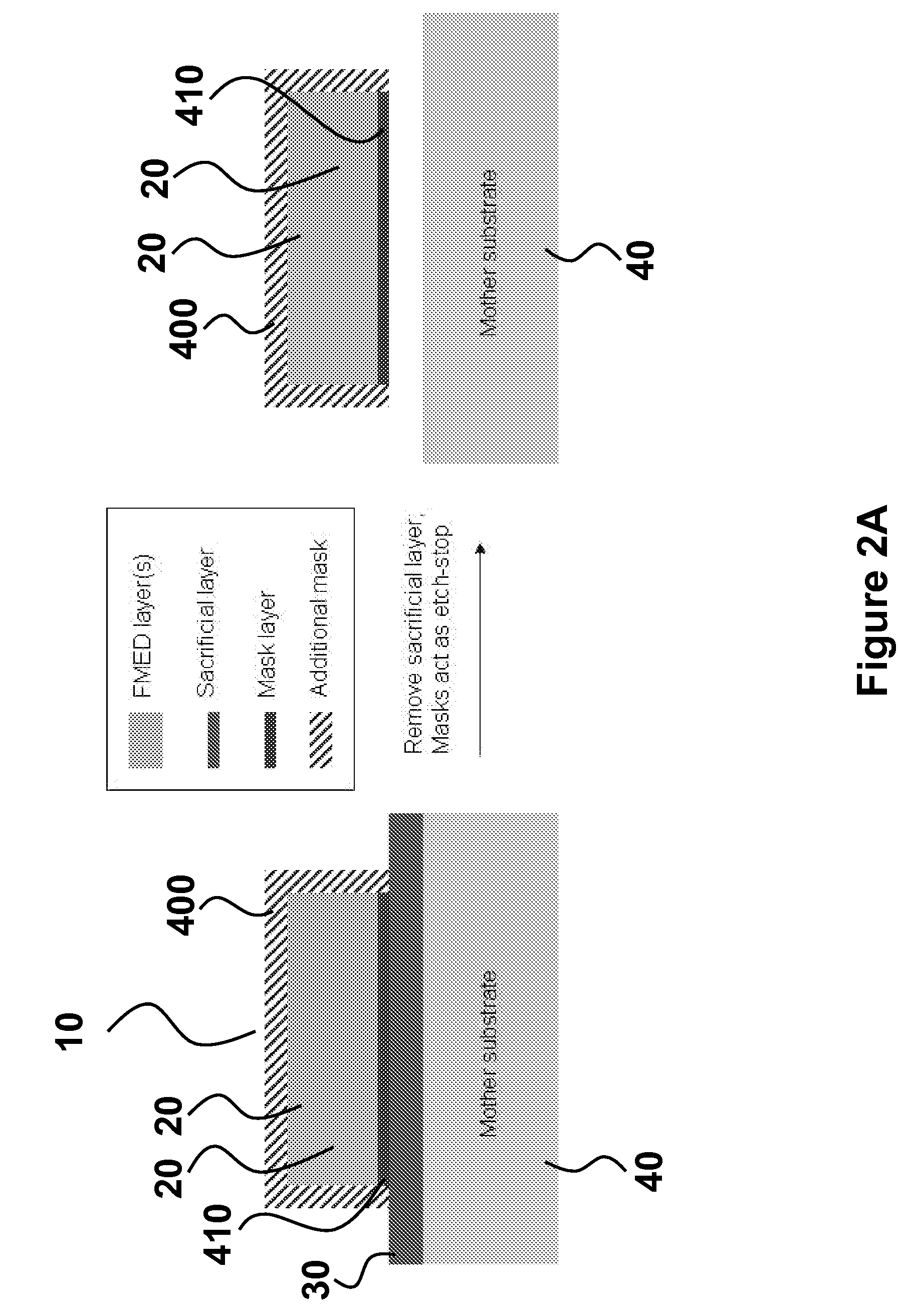

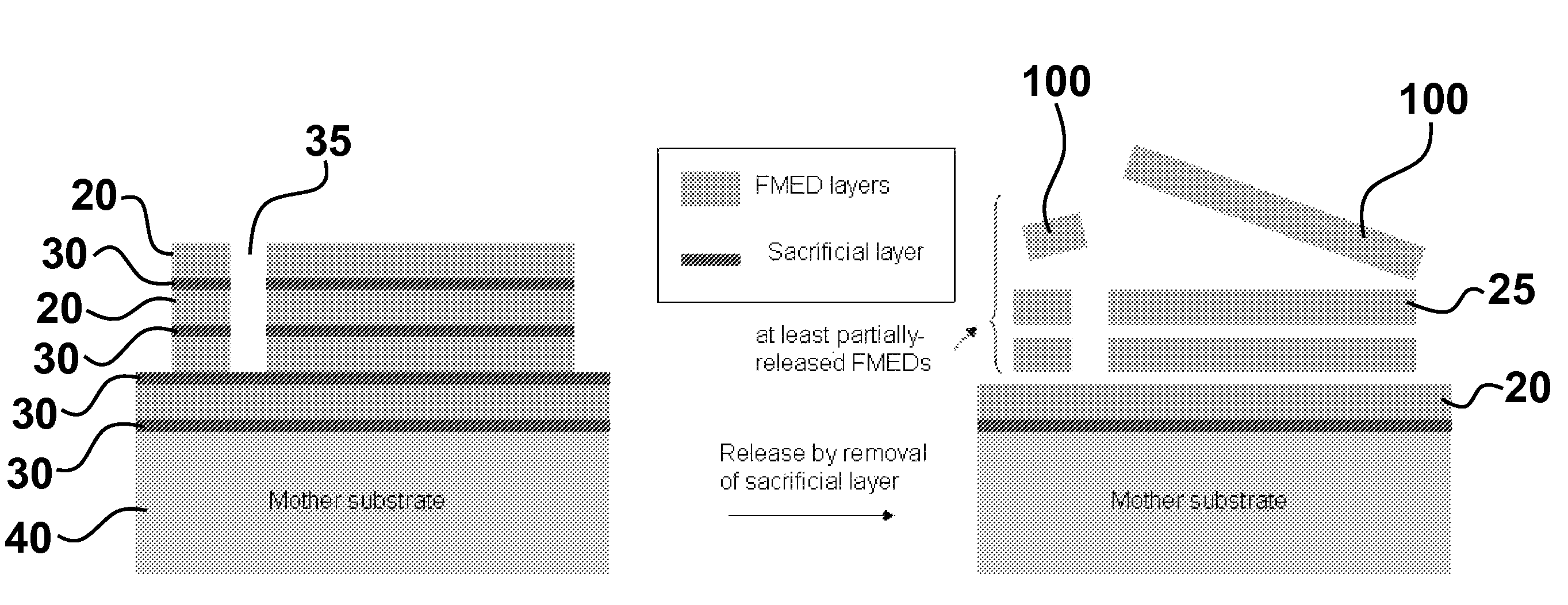

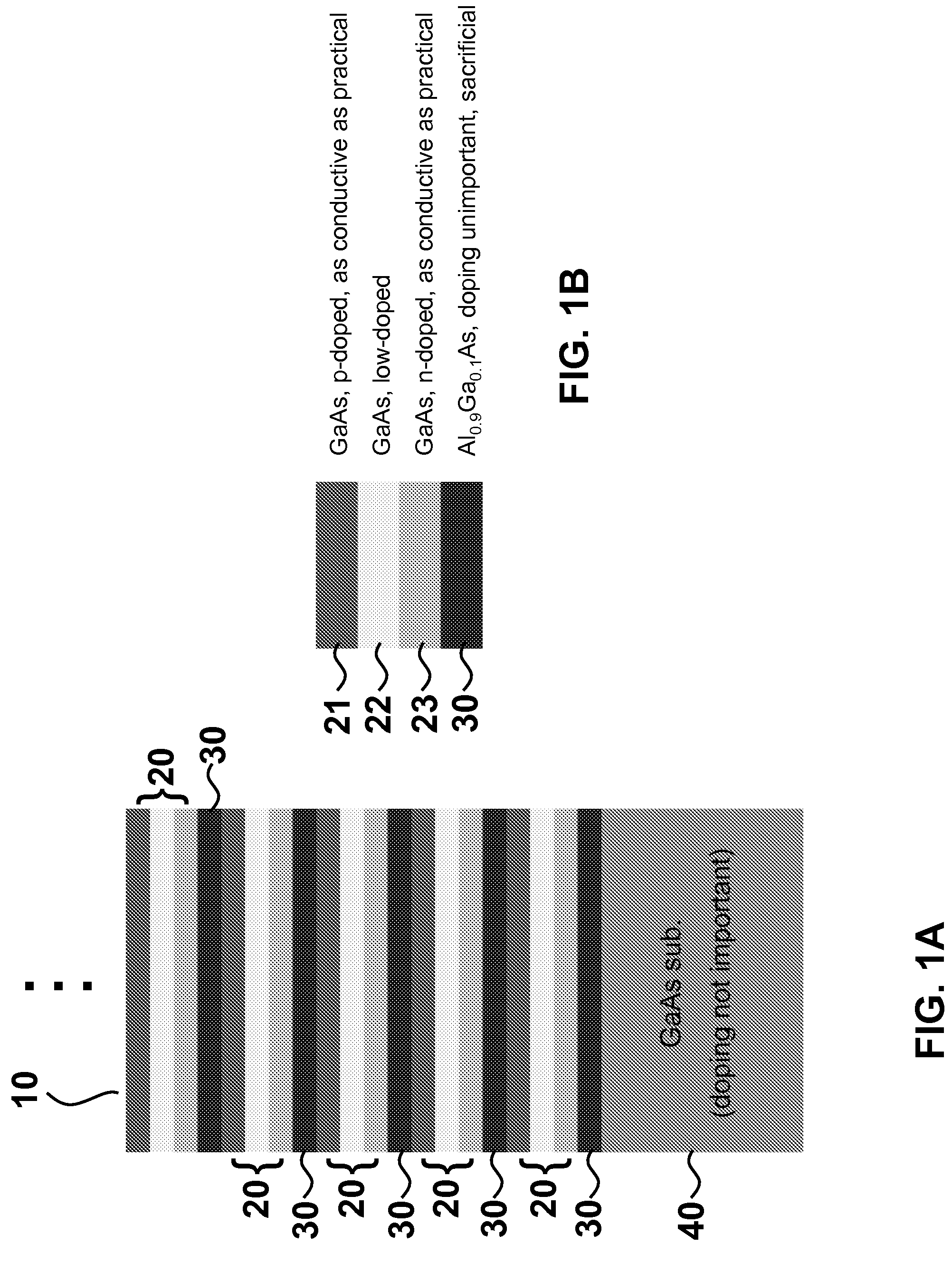

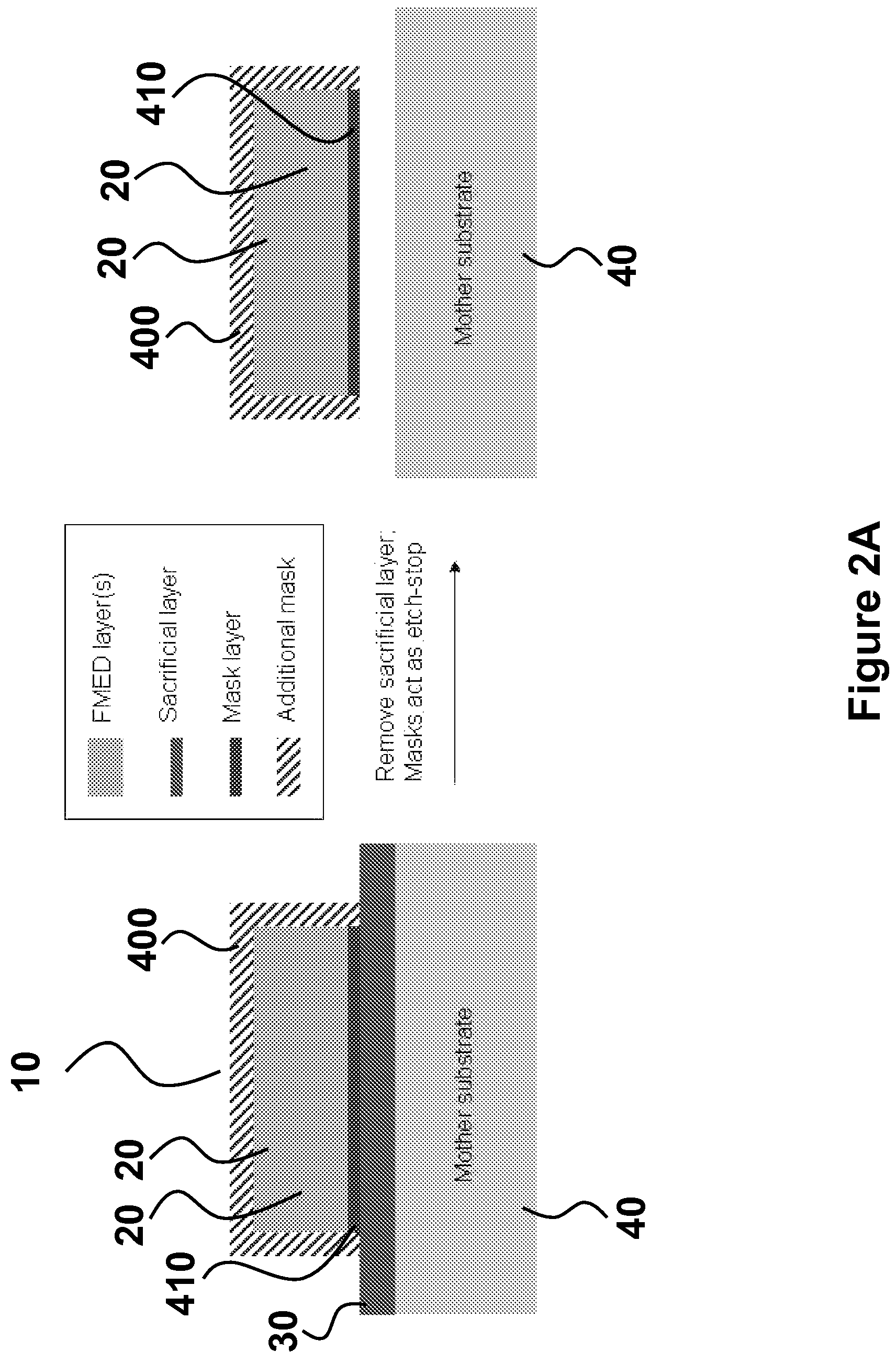

Release strategies for making transferable semiconductor structures, devices and device components

ActiveUS20080108171A1Low cost structureLow costFinal product manufactureNanoinformaticsSemiconductor structureDevice Subassembly

Provided are methods for making a device or device component by providing a multilayer structure having a plurality of functional layers and a plurality of release layers and releasing the functional layers from the multilayer structure by separating one or more of the release layers to generate a plurality of transferable structures. The transferable structures are printed onto a device substrate or device component supported by a device substrate. The methods and systems provide means for making high-quality and low-cost photovoltaic devices, transferable semiconductor structures, (opto-)electronic devices and device components.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

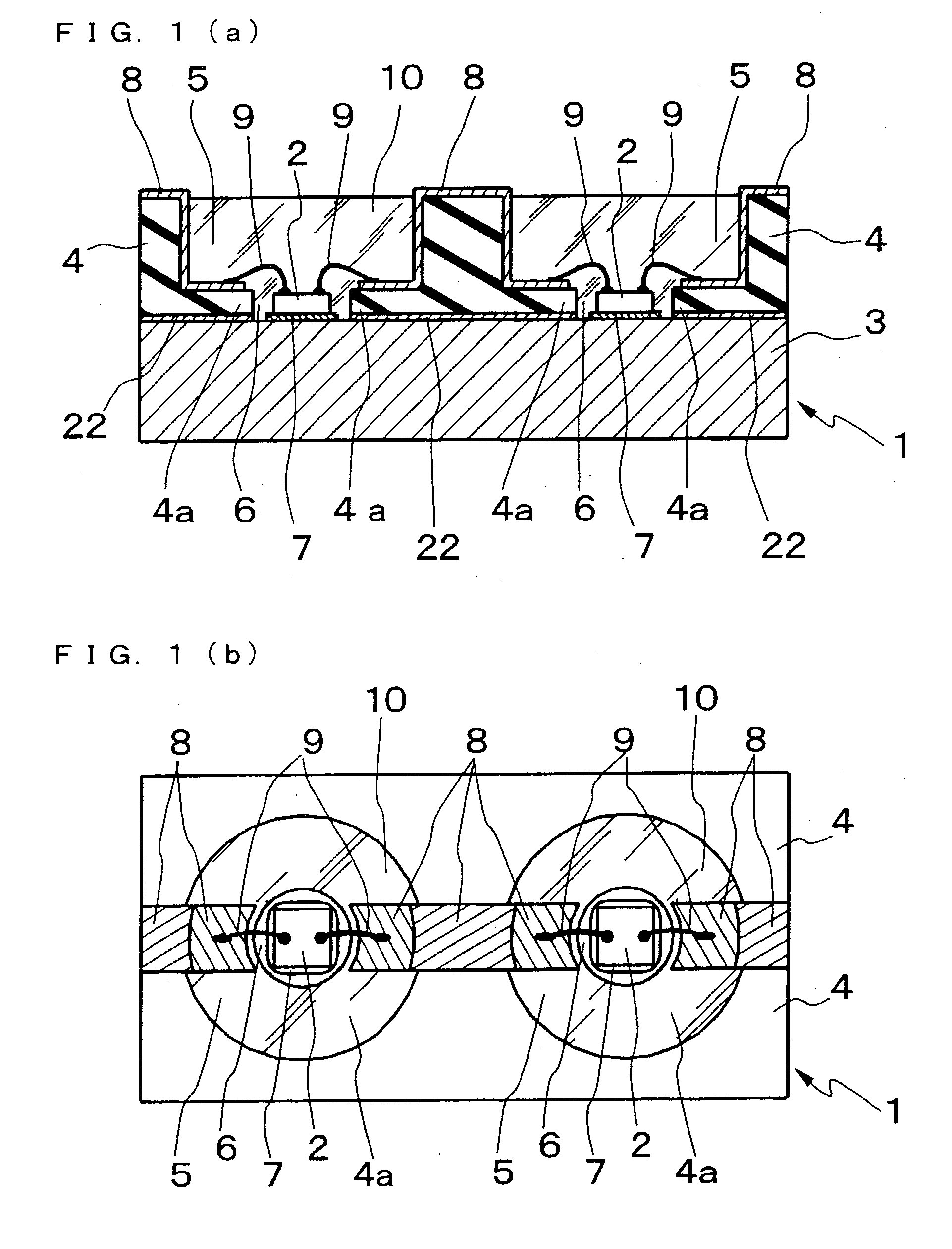

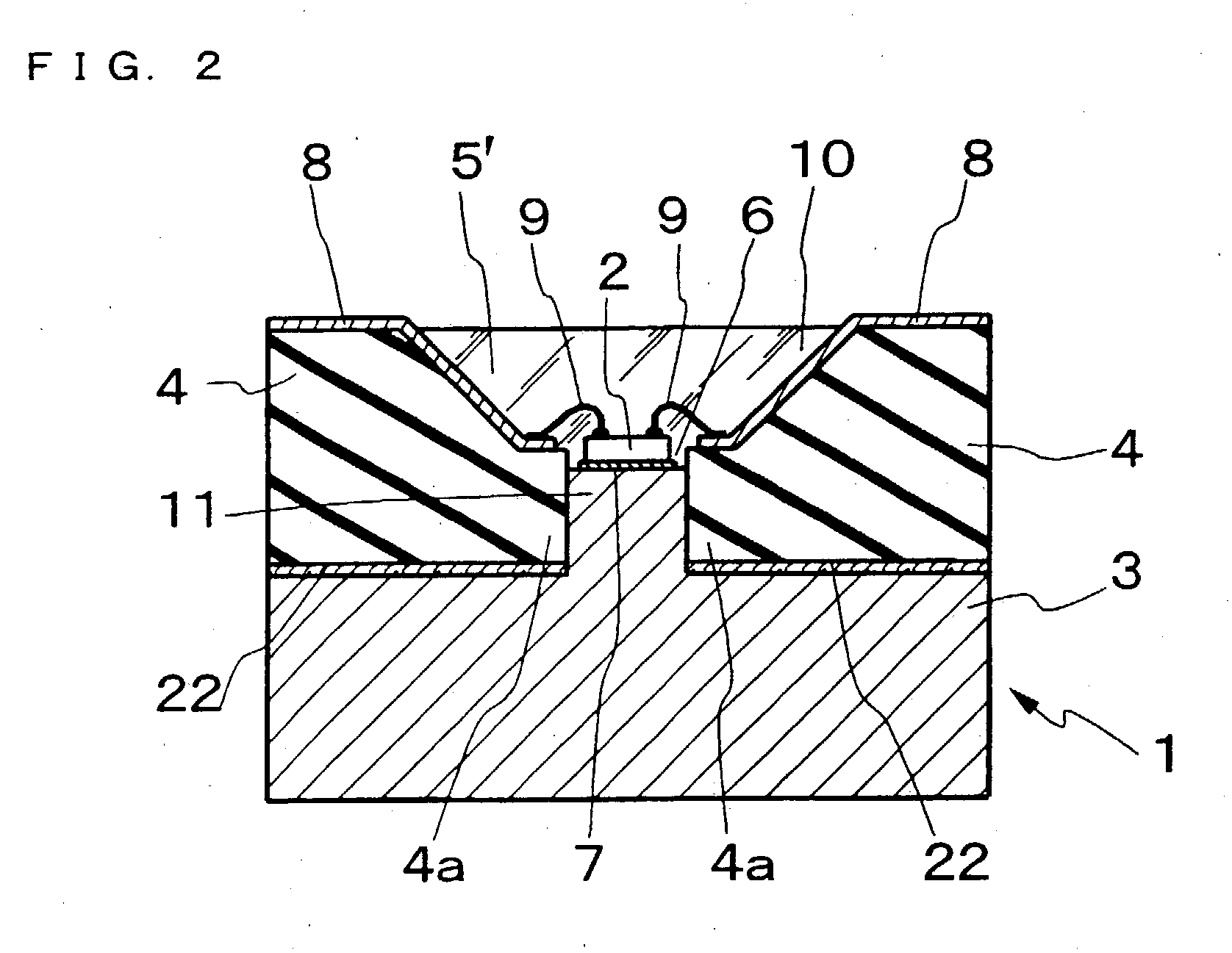

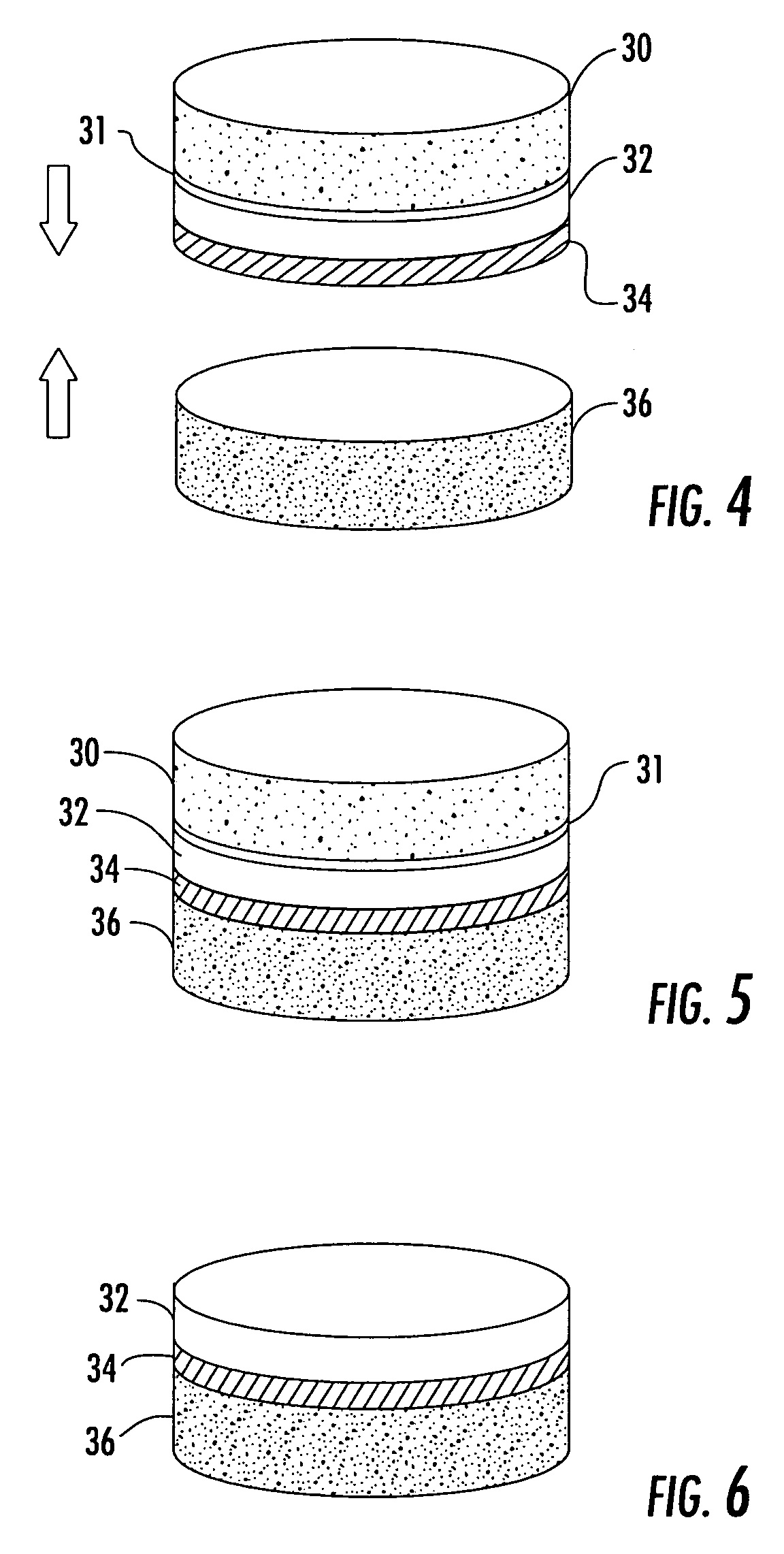

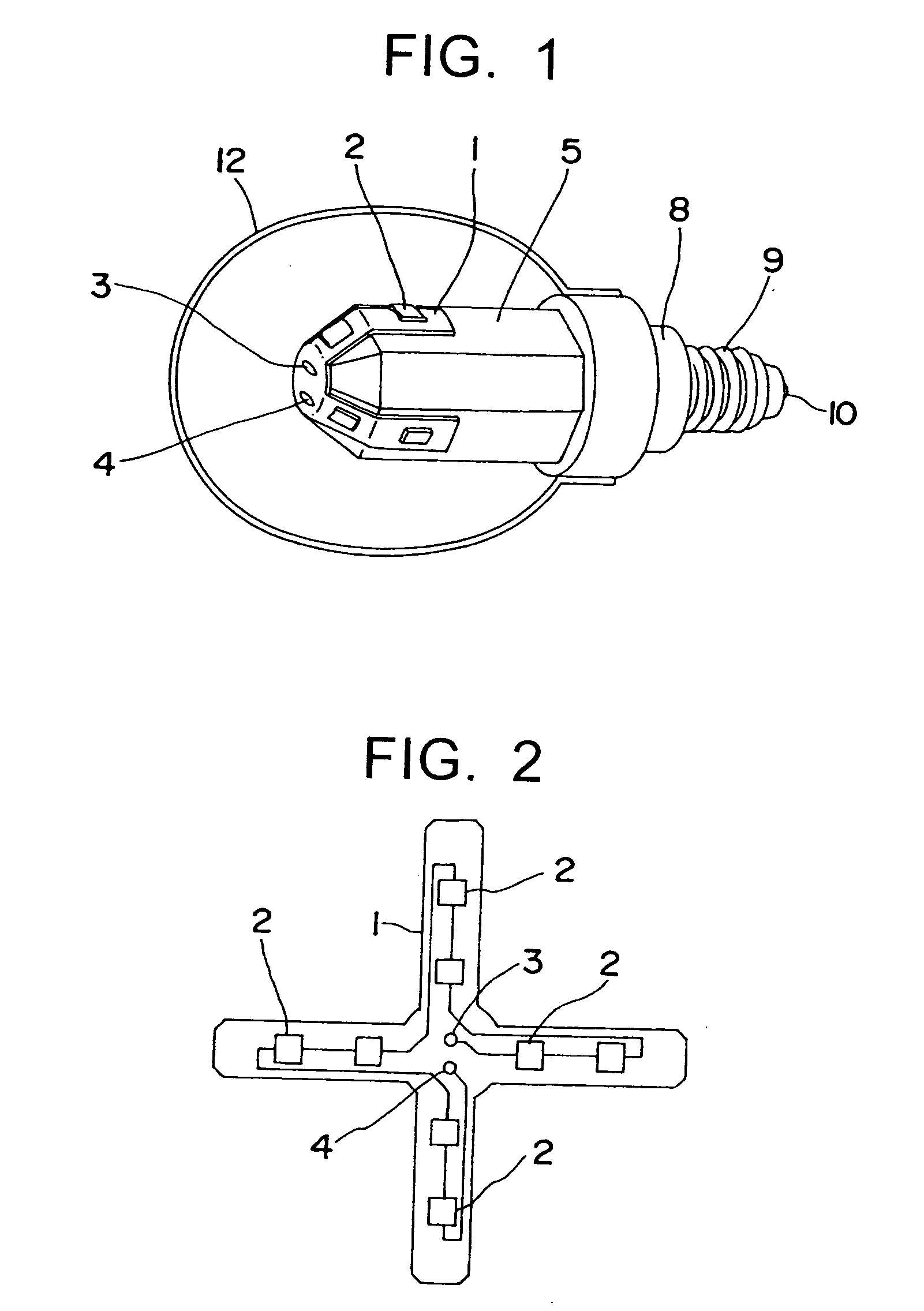

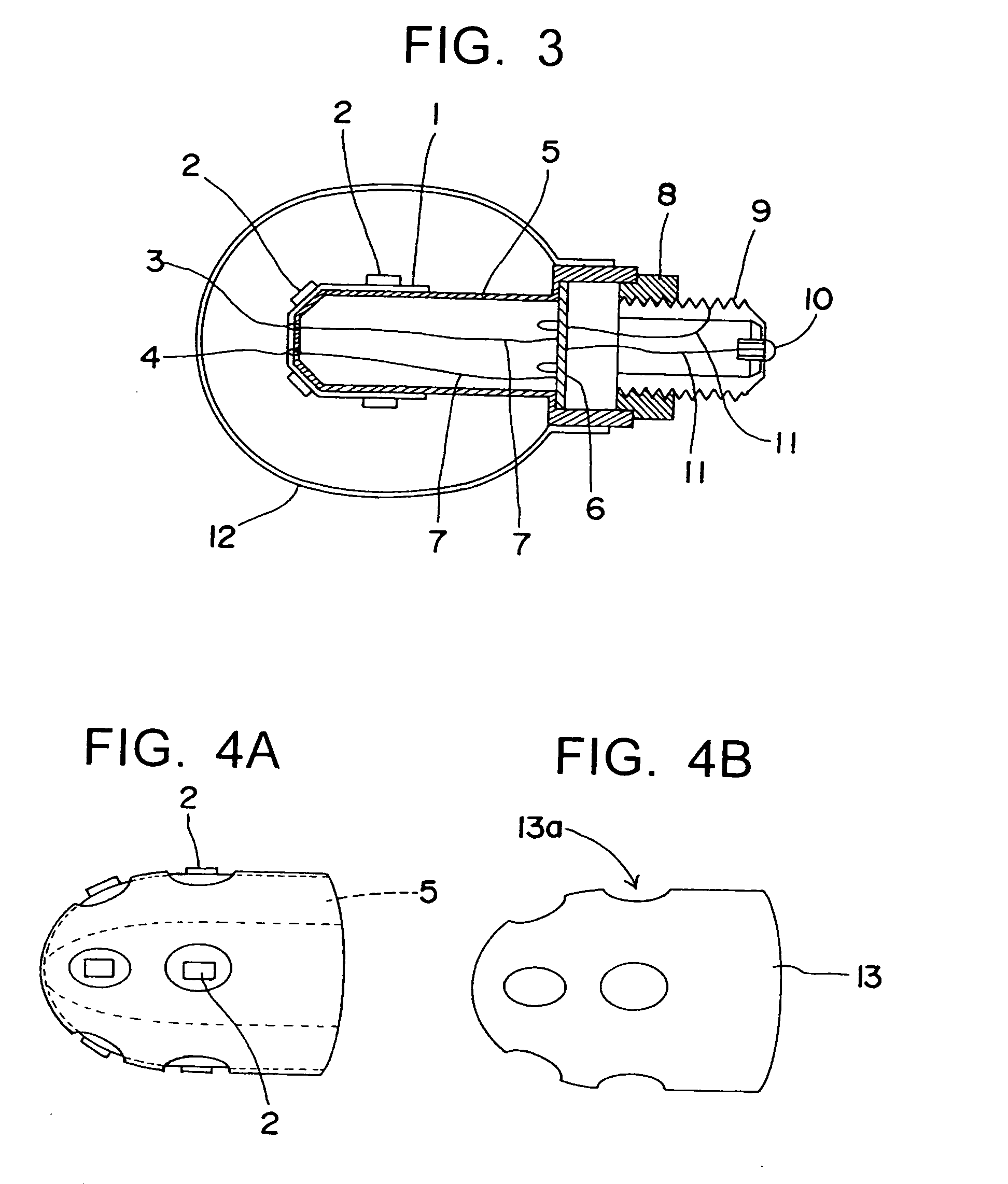

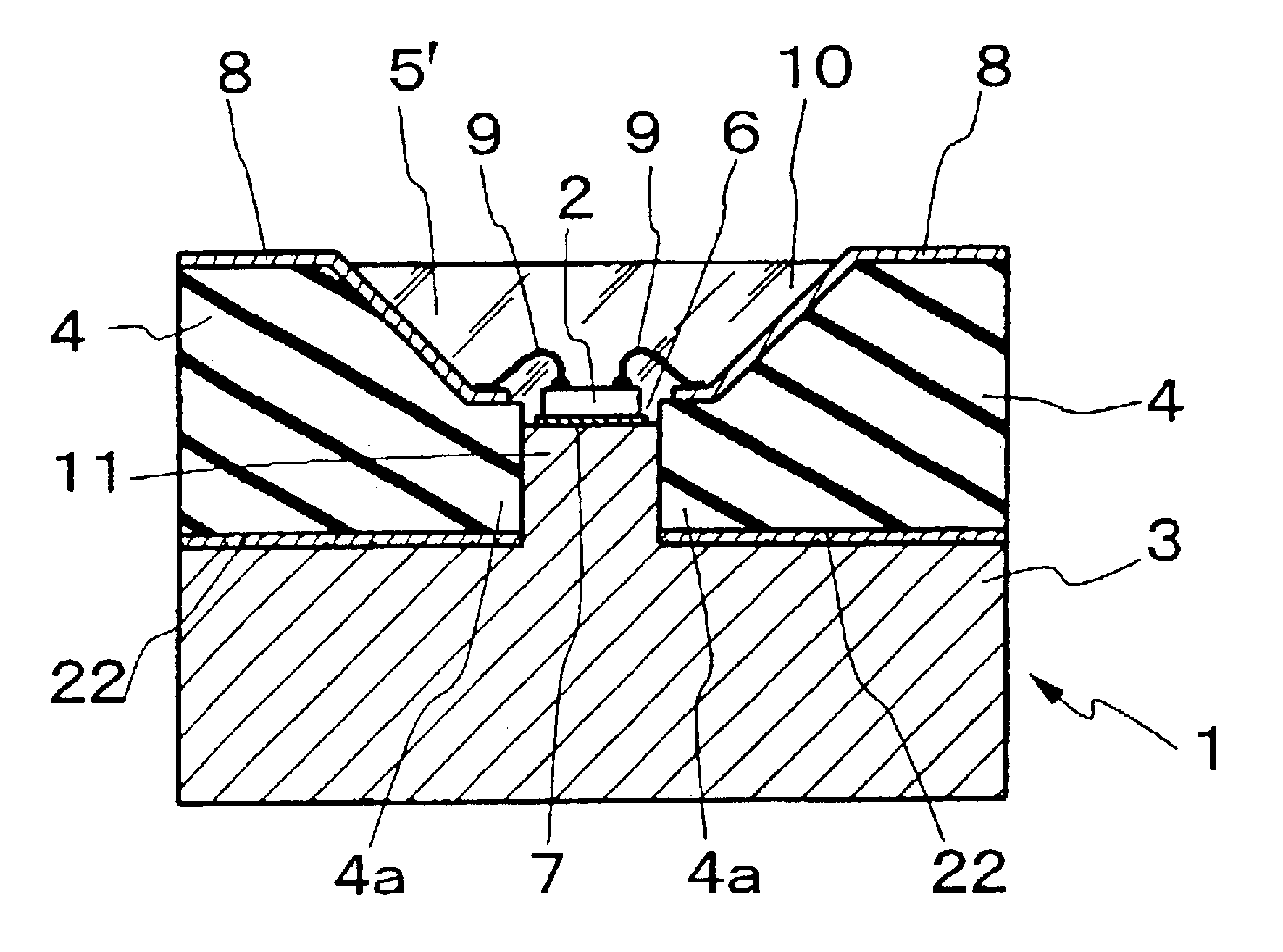

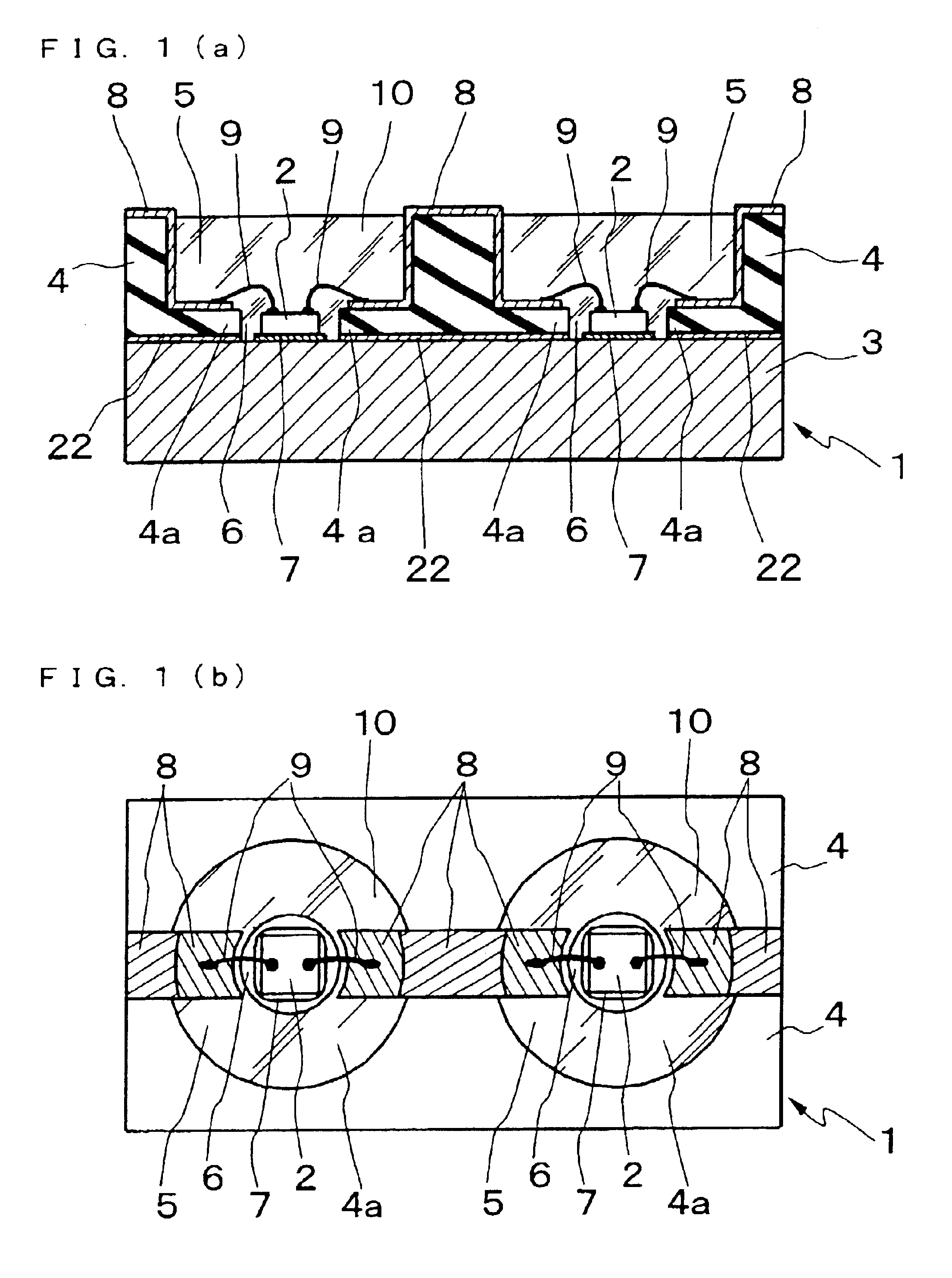

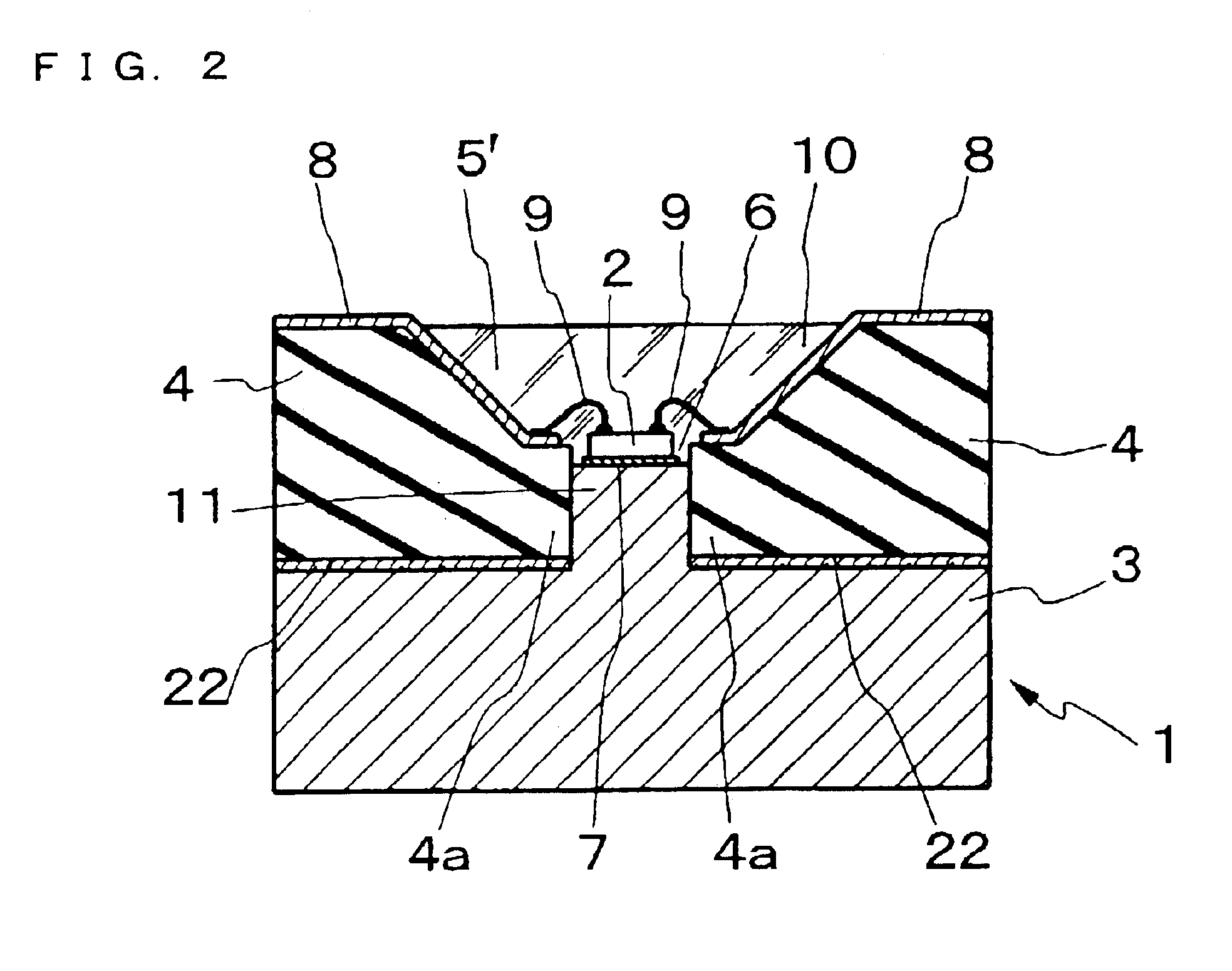

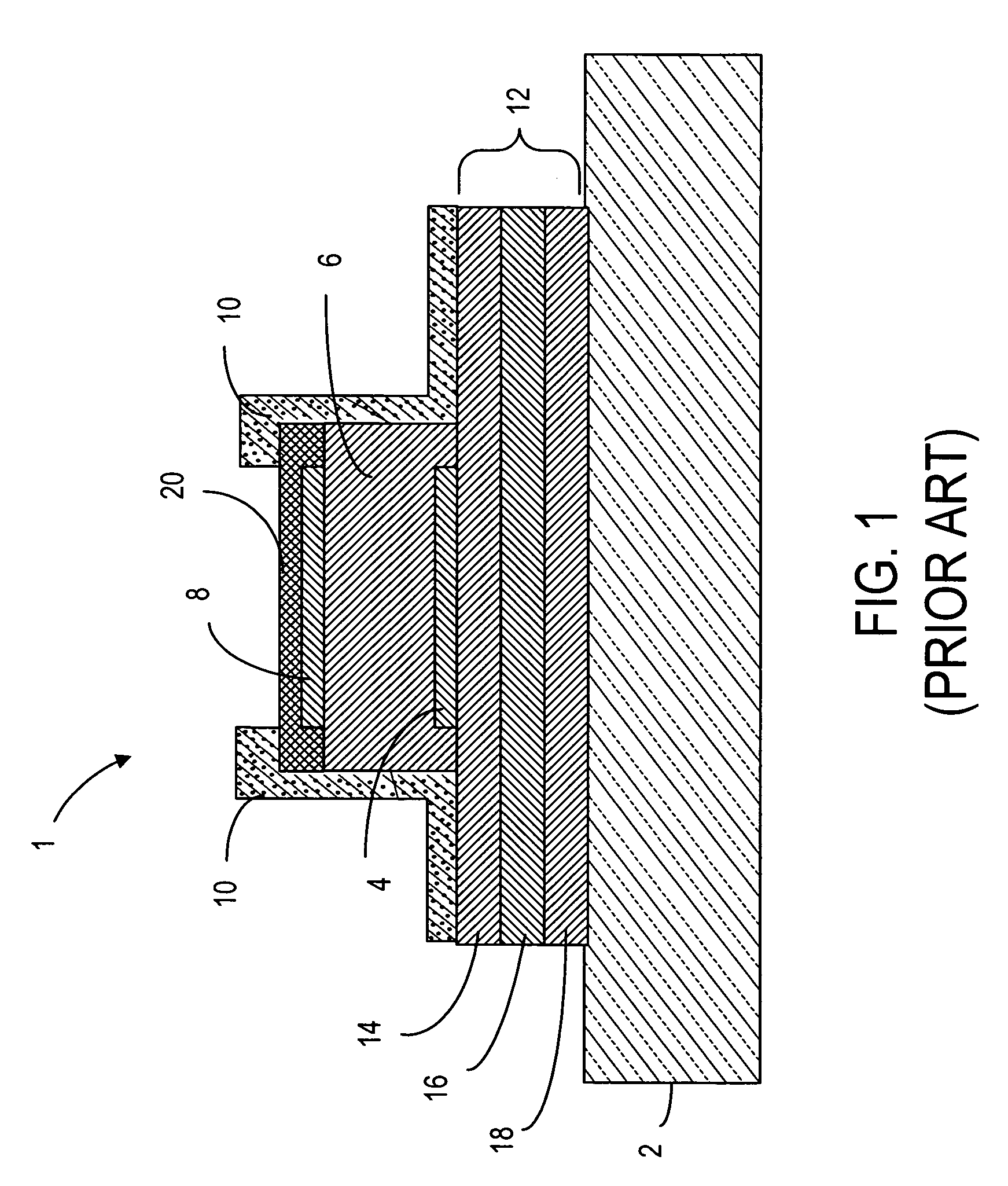

Light source device using led, and method of producing same

InactiveUS20030189830A1Easy to controlImprove powerLighting heating/cooling arrangementsSolid-state devicesLight emissionOperating life

A light source apparatus which is improved in the efficiency of light emission thus to increase the operating life and the mechanical strength and a method of producing the same are provided. The light source apparatus 1 comprises a radiator plate 3 having thermally conductive properties, an insulating member 4 coupled to at least one side of the radiator plate 3 and having a through hole 6 provided in the side thereof facing the radiator plate 3, an LED chip 2 installed and thermally coupled to an exposed portion of the radiator plate 3 facing the through hole 6, an extension 4a inwardly projecting at the hole 6 from the radiator plate 3 end of the insulating member 4, a wiring pattern 8 provided on the insulating member 4 and electrically isolated by the insulating member 4 from the radiator plate 3, bonding wires 9 electrically connecting between portions of the wiring pattern 8 extended to the extension 4a and the electrodes of the LED chip 2, and a light-transmissive sealing material 10 filled in the through hole 6 for entirely encapsulating the LED chip 2 and the bonding wires 9.

Owner:SIGNIFY HLDG BV

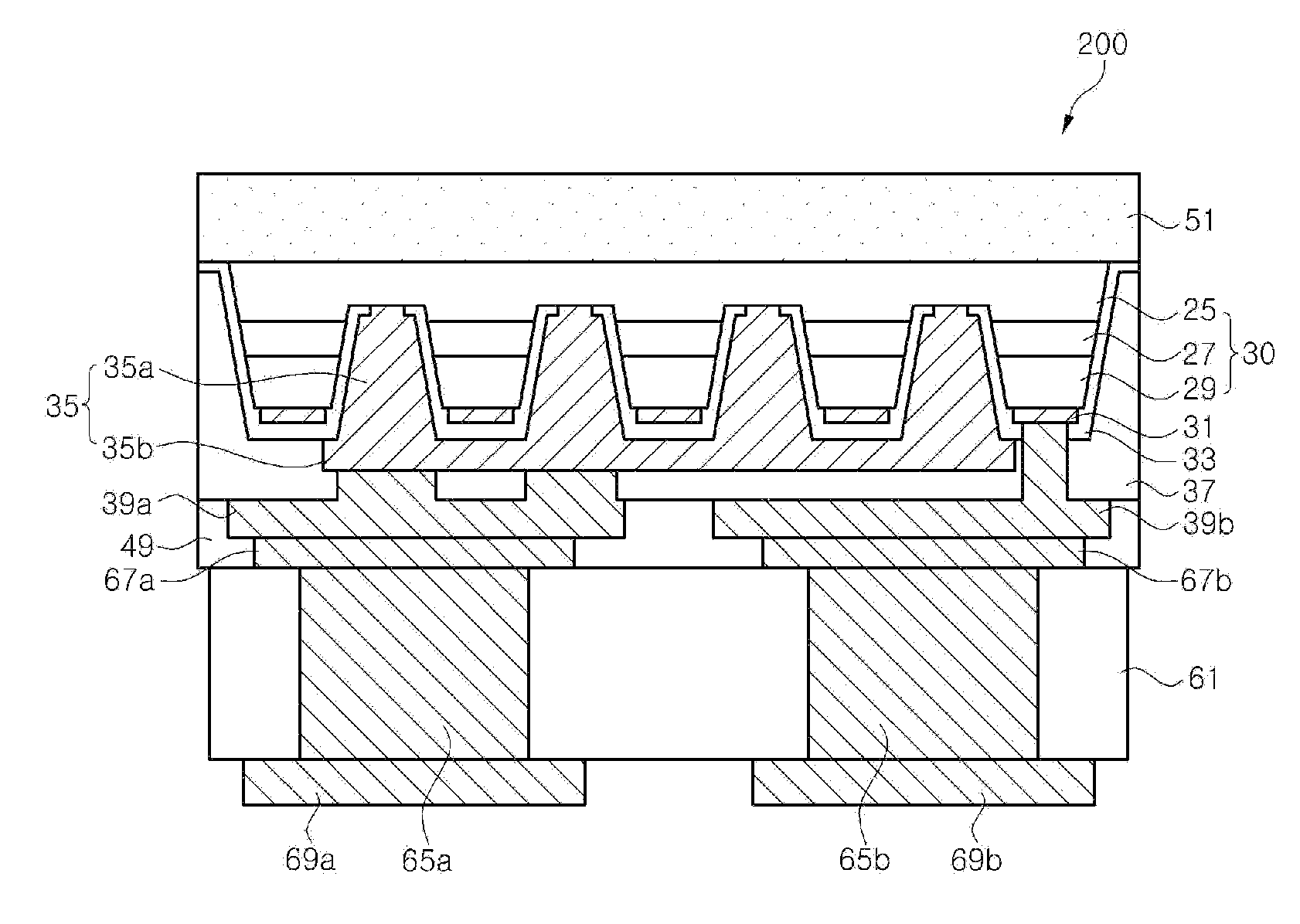

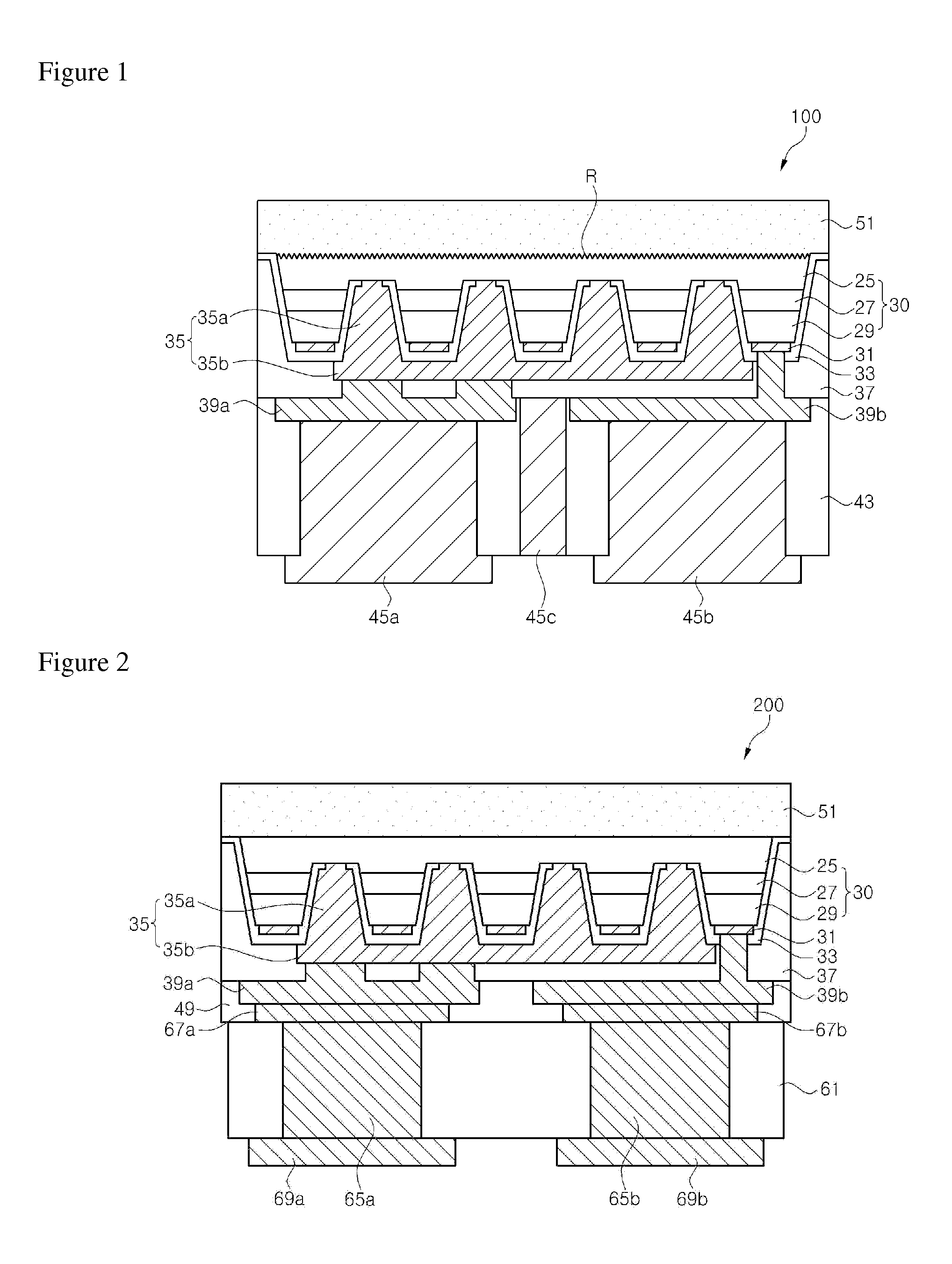

Wafer-level light emitting diode package and method of fabricating the same

ActiveUS20120074441A1Improve efficiencyImprove cooling effectSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerEngineering

Exemplary embodiments of the present invention provide a wafer-level light emitting diode (LED) package and a method of fabricating the same. The LED package includes a semiconductor stack including a first conductive type semiconductor layer, an active layer, and a second conductive type semiconductor layer; a plurality of contact holes arranged in the second conductive type semiconductor layer and the active layer, the contact holes exposing the first conductive type semiconductor layer; a first bump arranged on a first side of the semiconductor stack, the first bump being electrically connected to the first conductive type semiconductor layer via the plurality of contact holes; a second bump arranged on the first side of the semiconductor stack, the second bump being electrically connected to the second conductive type semiconductor layer; and a protective insulation layer covering a sidewall of the semiconductor stack.

Owner:SEOUL SEMICONDUCTOR

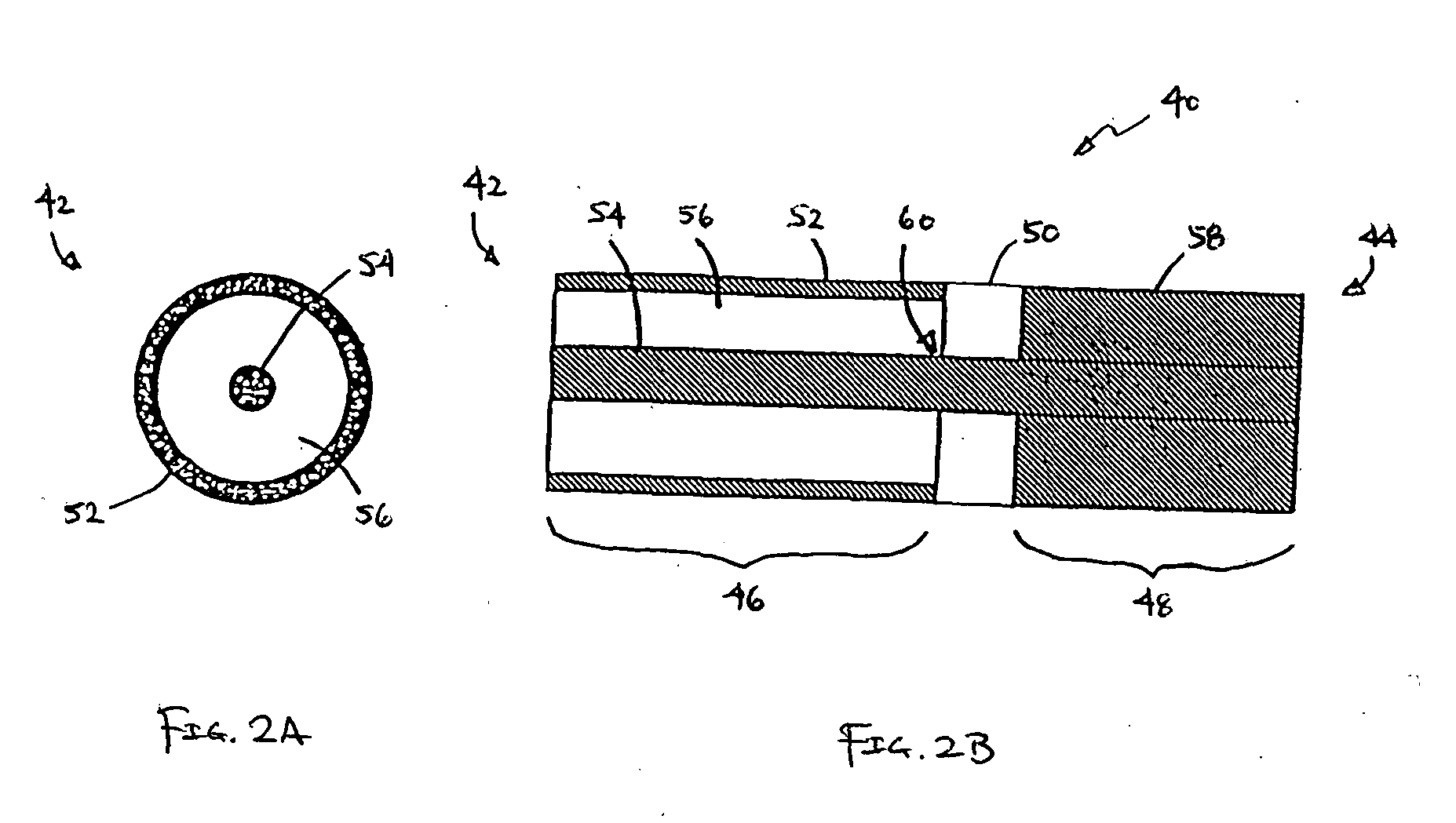

Ultrasonic debrider probe and method of use

InactiveUS20080058775A1Reduce temperature riseAvoid cloggingSurgical instrument detailsBiomedical engineeringMedical treatment

An ultrasonic medical probe has an elongate shaft with a head portion having a distal end face oriented at least partially transversely to a longitudinal axis of the shaft. The head portion has a lateral surface extending substantially parallel to the longitudinal axis, the lateral surface being provided with outwardly or radially extending projections. The shaft of the probe is provided with an internal longitudinal channel or bore and at least one ancillary or tributary channel communicating at an inner end with the longitudinal channel or bore and extending to the lateral surface. The ancillary or tributary channel has an outer end disposed in a region about the projections. The projections may be finely configured and distributed so as to form a knurled surface on the head portion.

Owner:MISONIX INC

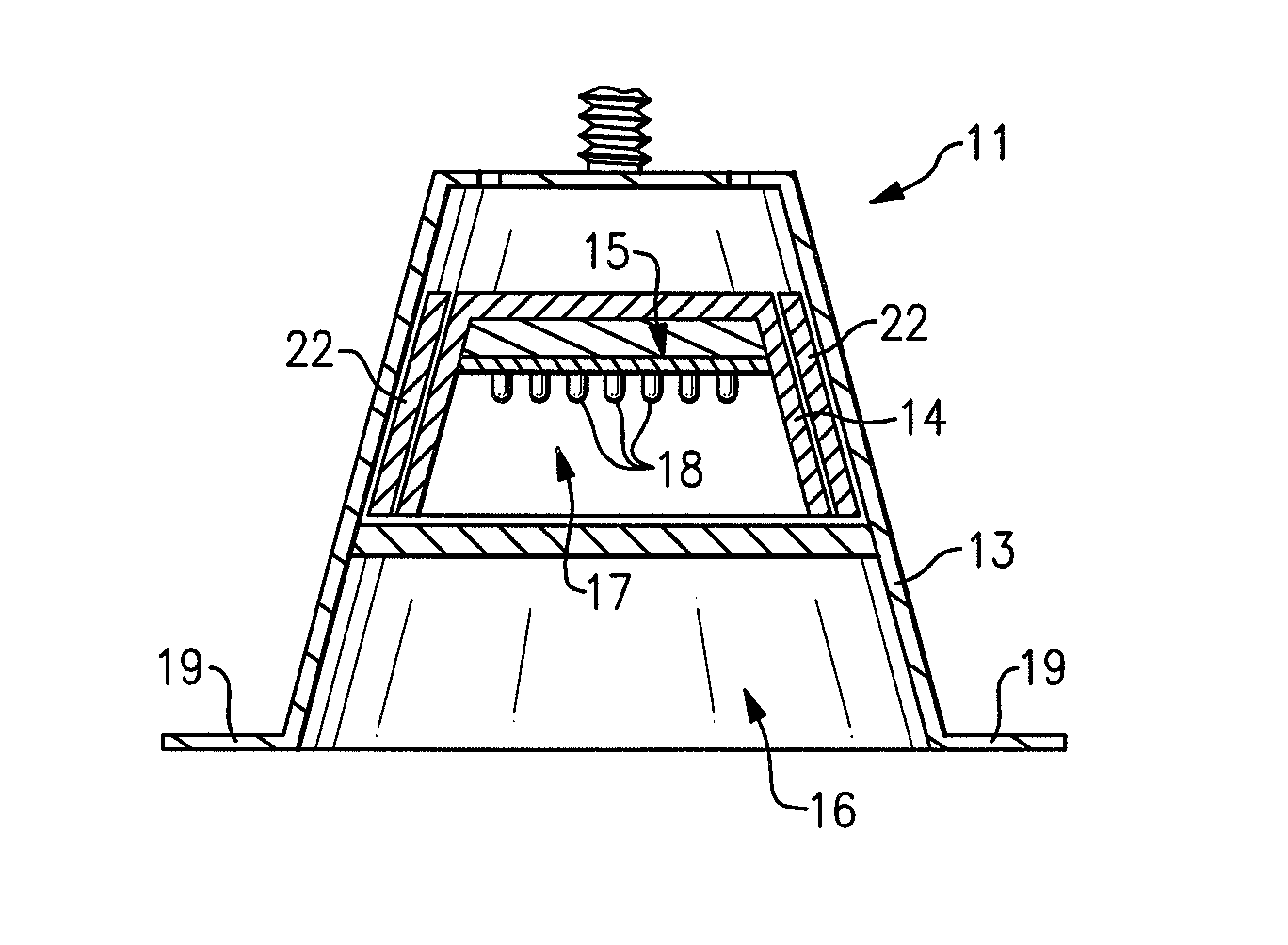

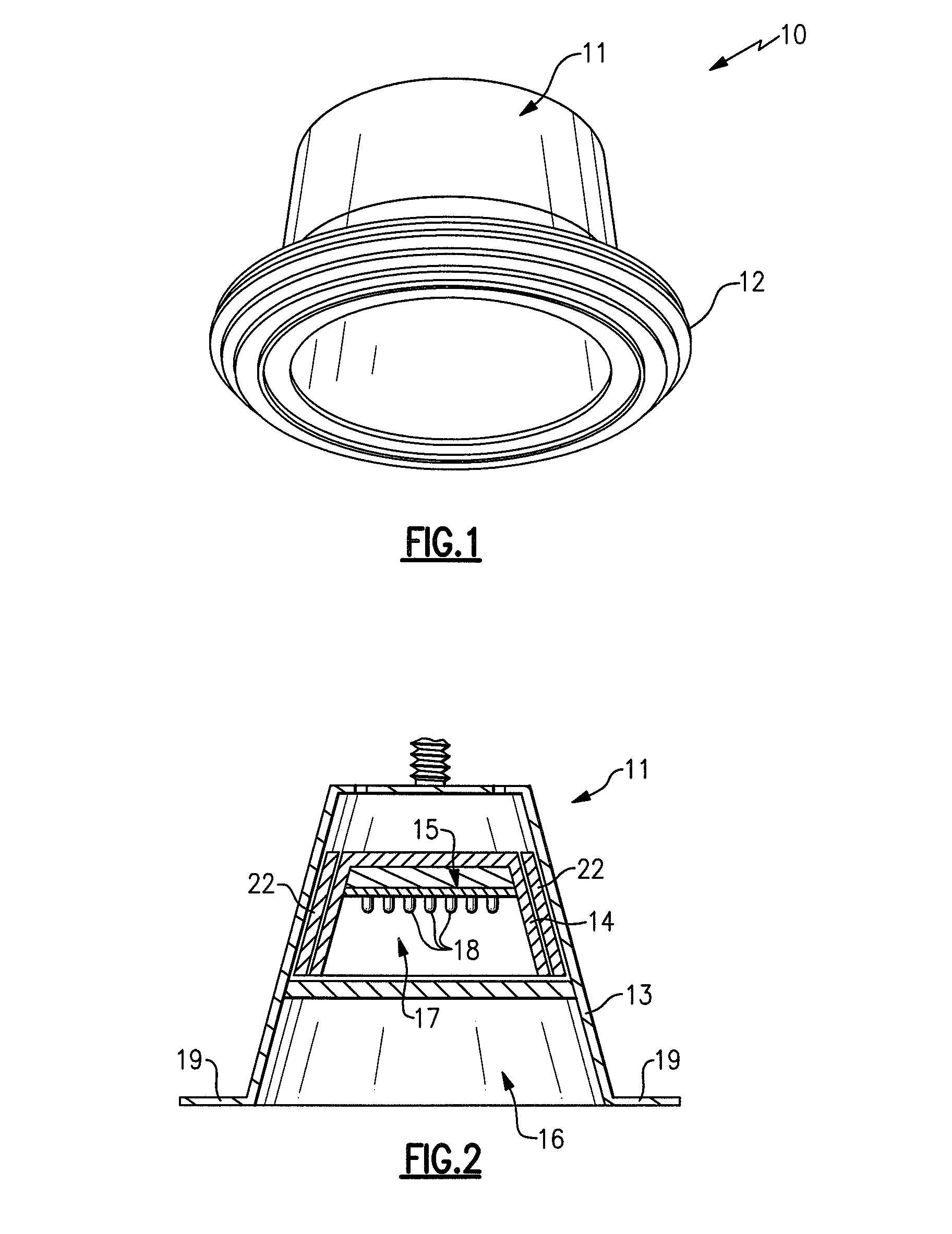

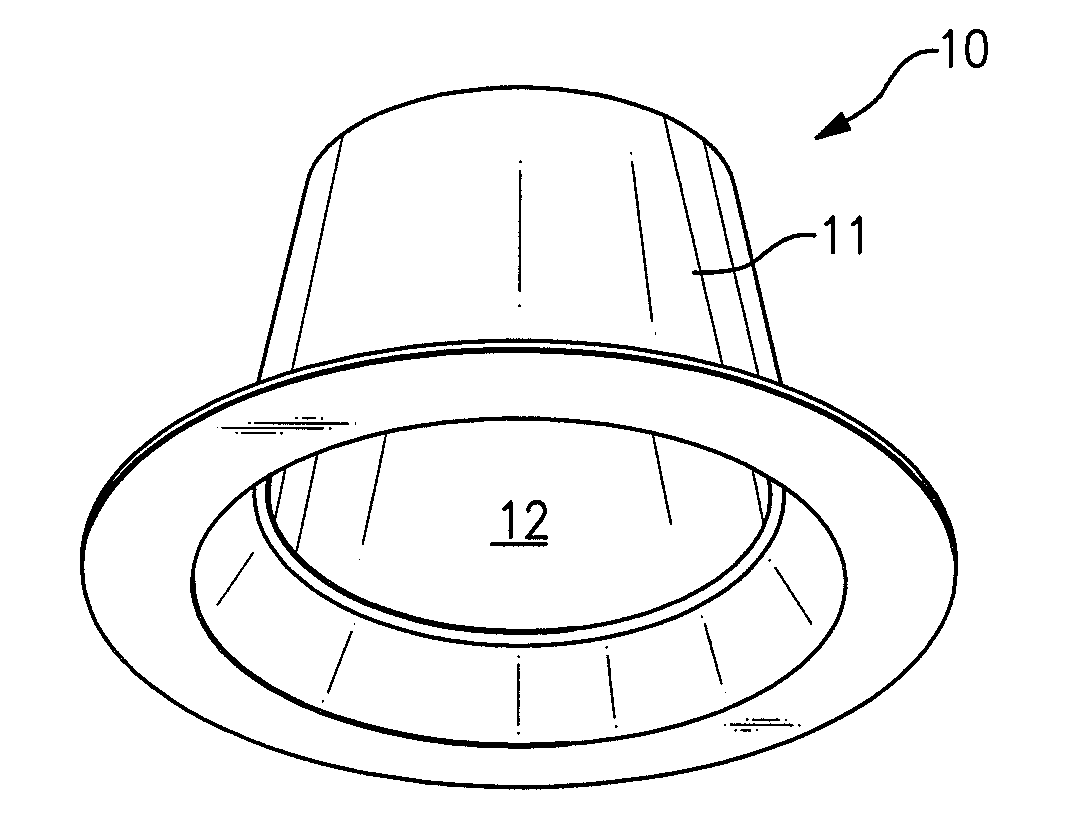

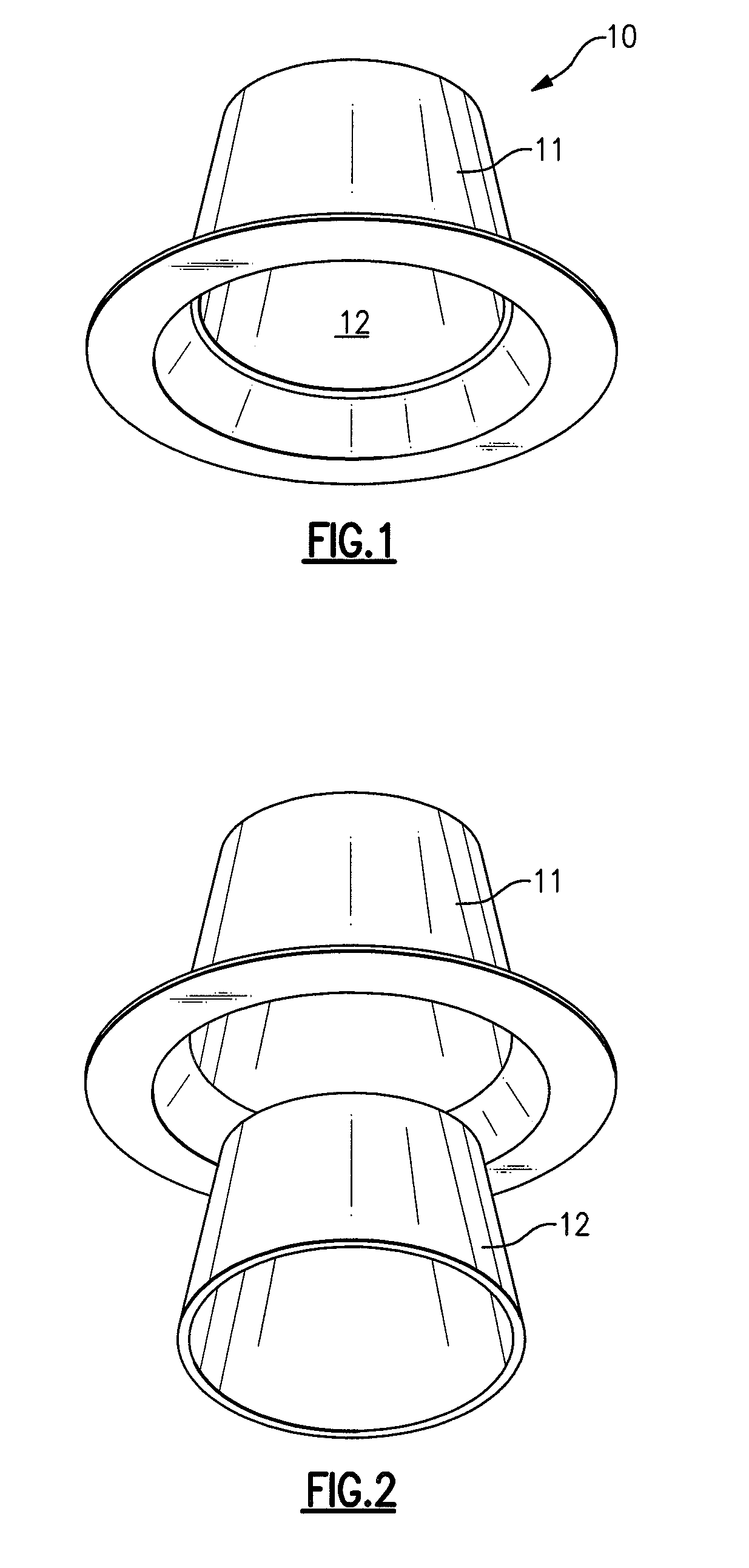

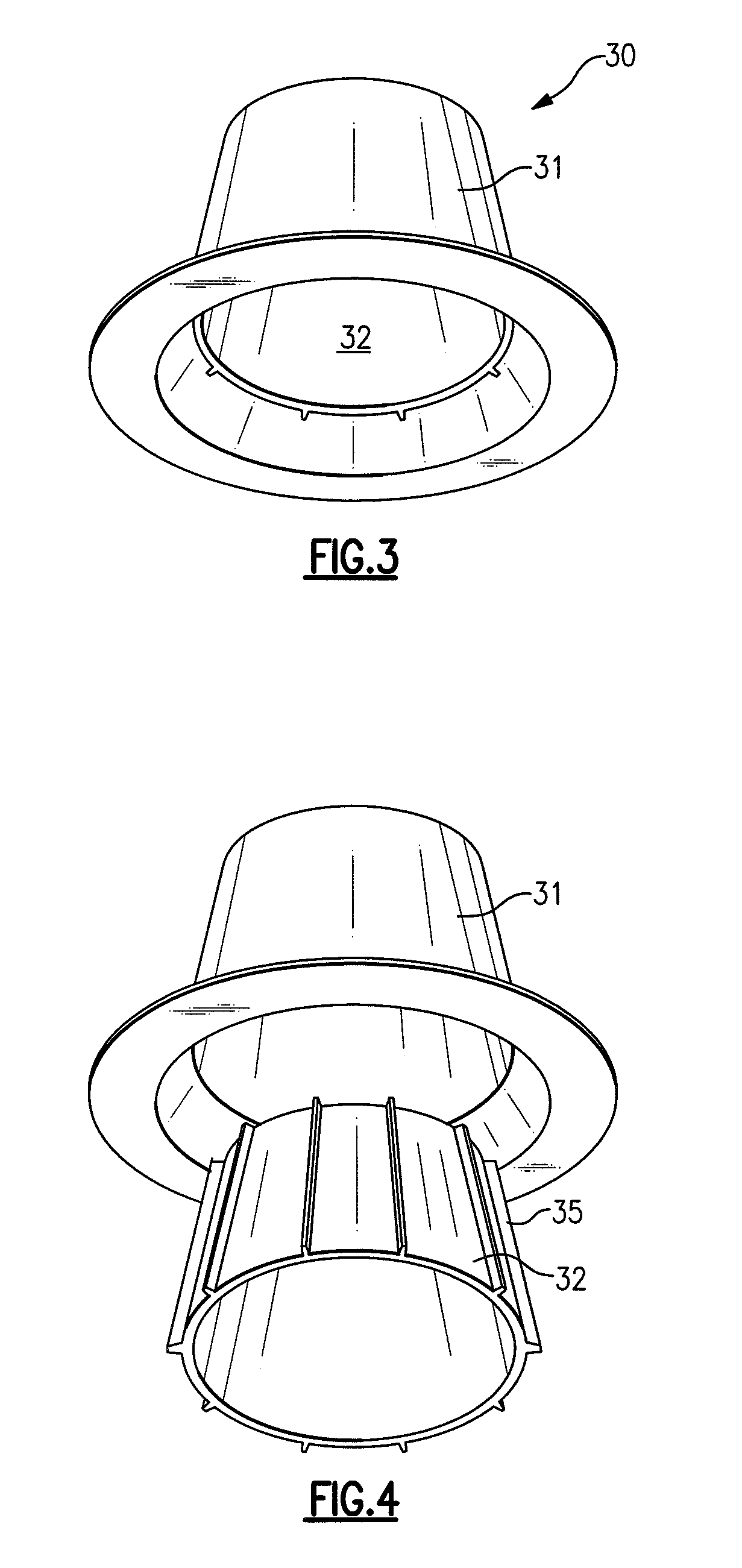

Lighting assemblies and components for lighting assemblies

ActiveUS20080112170A1Add additional massIncrease surface areaPlanar light sourcesMechanical apparatusInterior spaceEffect light

A lighting assembly, comprising a light engine assembly and a room-side element. The room-side element is in contact with the light engine assembly. The light engine assembly comprises at least one trim element and a light engine. The trim element defines a trim element internal space. The light engine comprises at least one solid state light emitter, and is positioned within the trim element internal space. Also, a lighting assembly, comprising a light engine assembly and means for dissipating heat from the light engine assembly.

Owner:IDEAL IND LIGHTING LLC

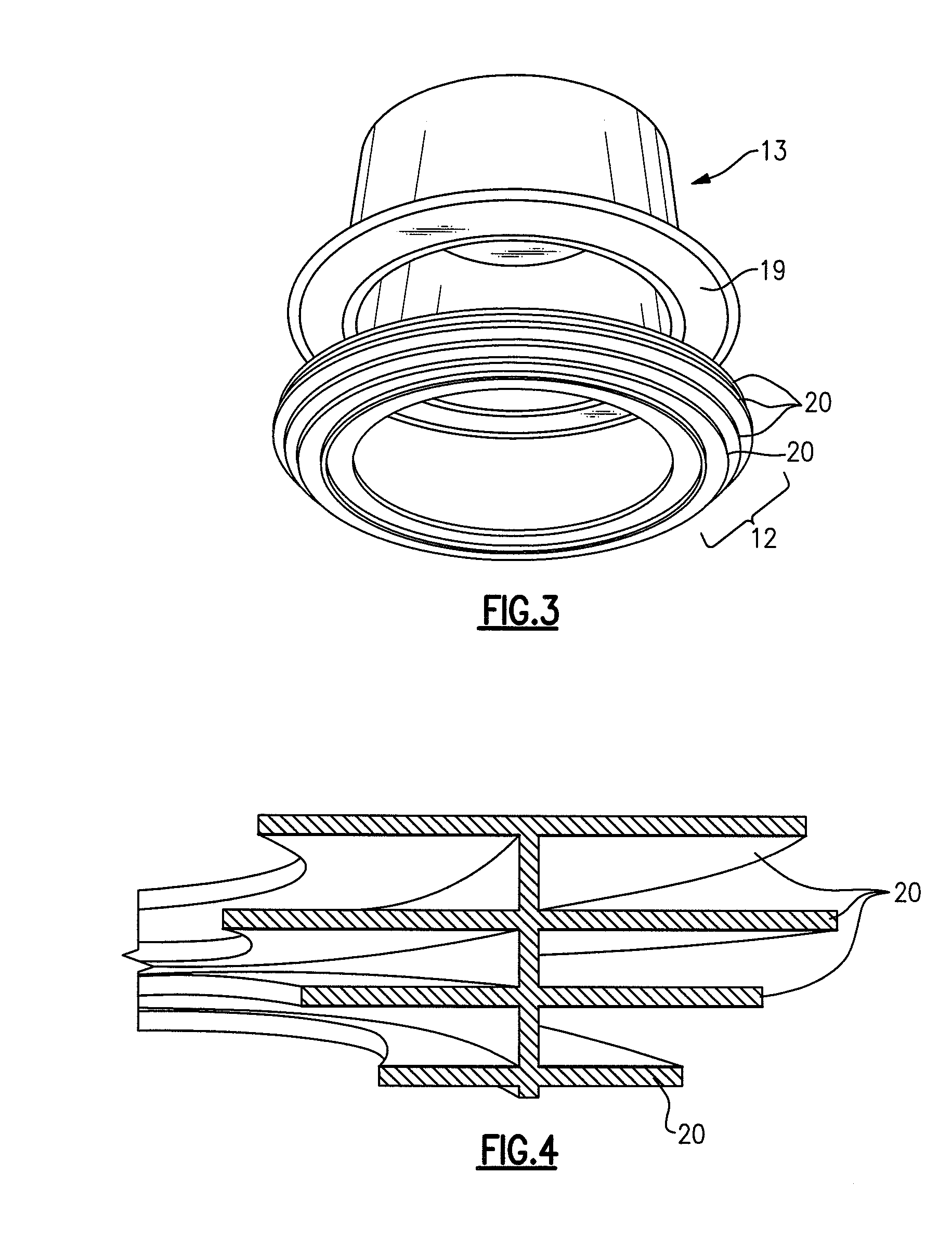

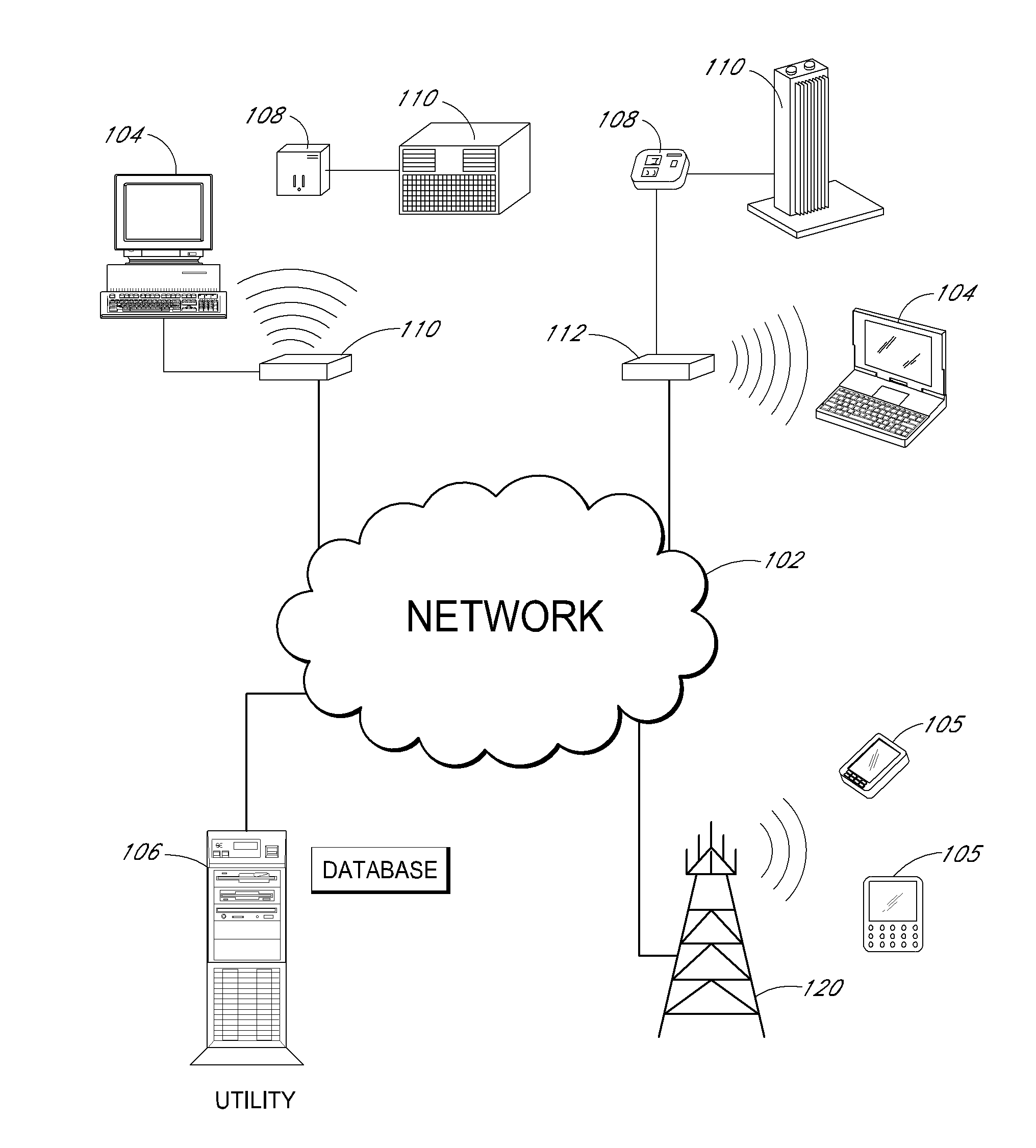

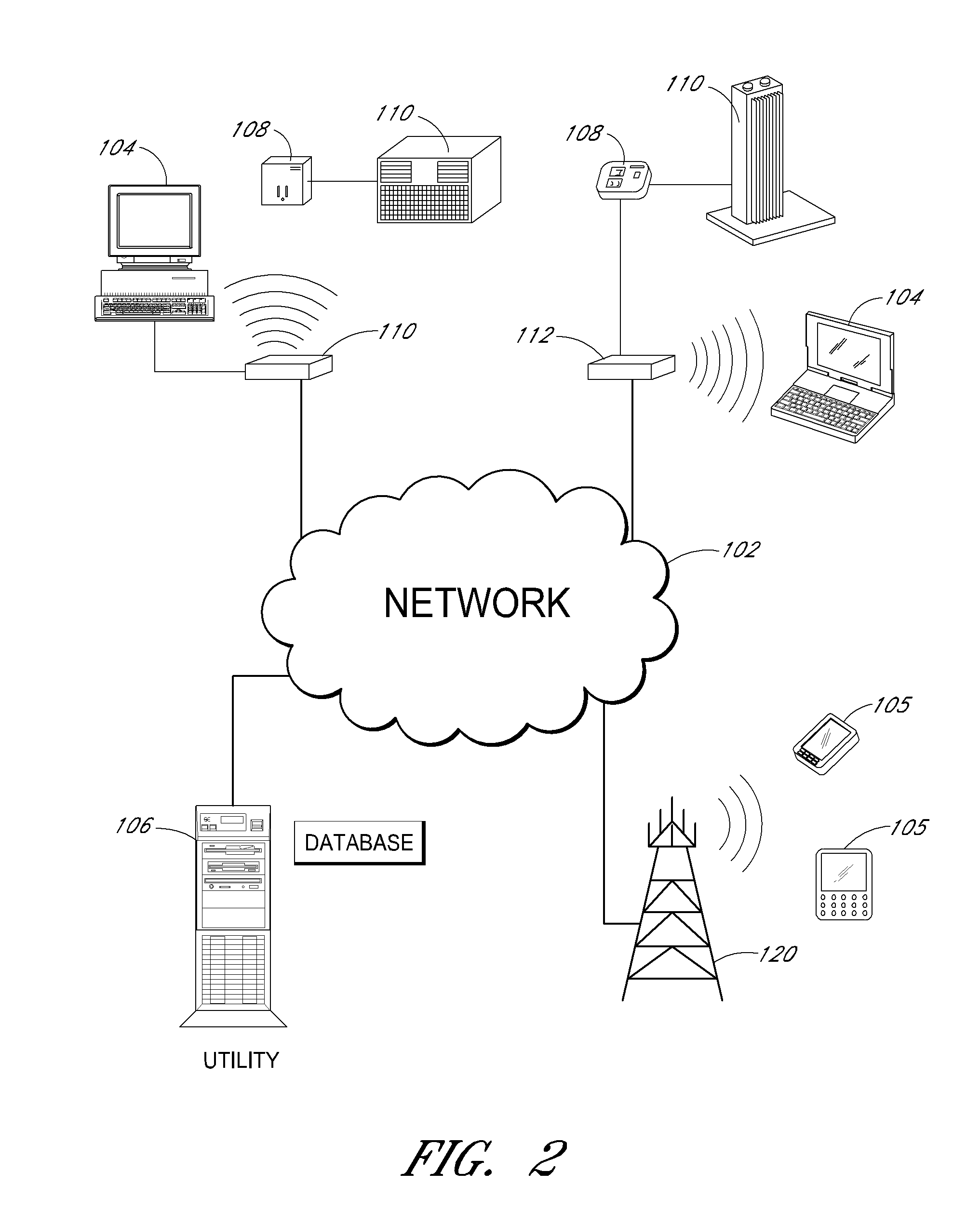

System and method for optimizing use of plug-in air conditioners and portable heaters

InactiveUS8090477B1Improve cooling effectImprove the heating effectMechanical apparatusLevel controlEngineeringEnergy management system

Thermostatic HVAC and other energy management controls that are connected to a computer network. For instance, remotely managed load switches incorporating thermostatic controllers inform an energy management system, to provide enhanced efficiency, and to verify demand response with plug-in air conditioners and heaters. At least one load control device at a first location comprises a temperature sensor and a microprocessor. The load control device is configured to connect or disconnect electrical power to the an attached air conditioner or heater, and the microprocessor is configured to communicate over a network. In addition, the load control device is physically separate from an air conditioner or heater but located inside the space conditioned by the air conditioner or heater.

Owner:ECOFACTOR

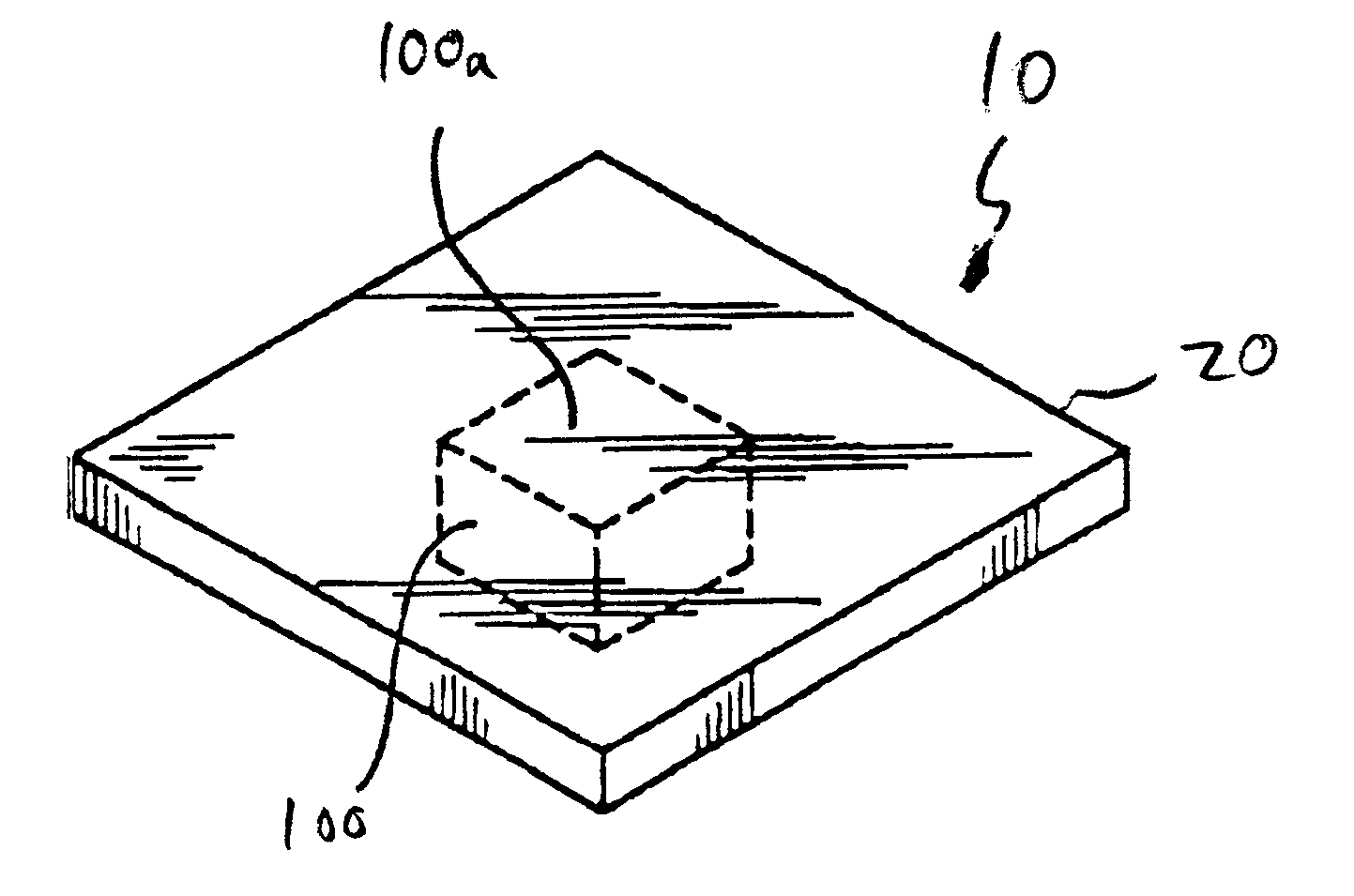

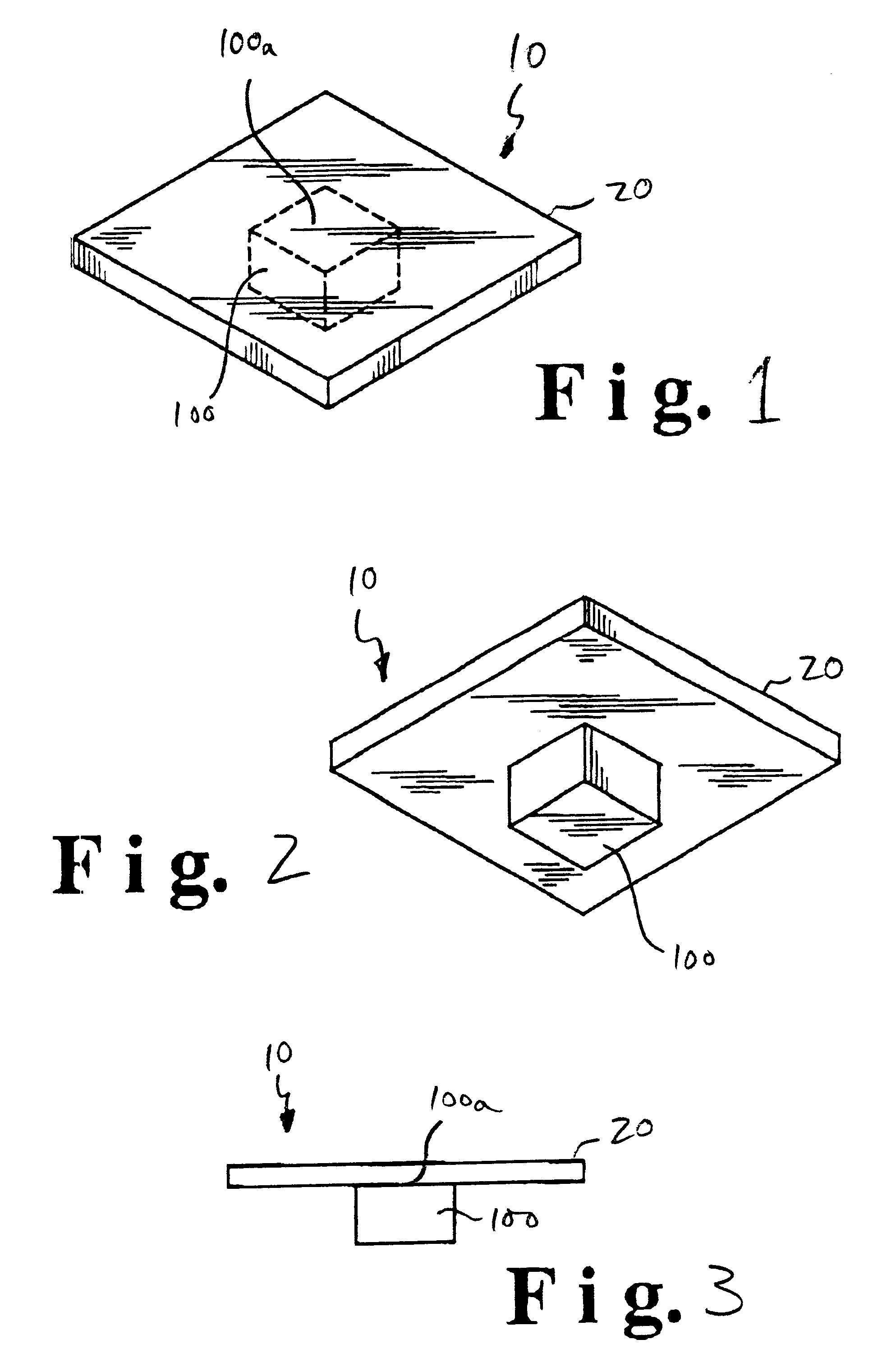

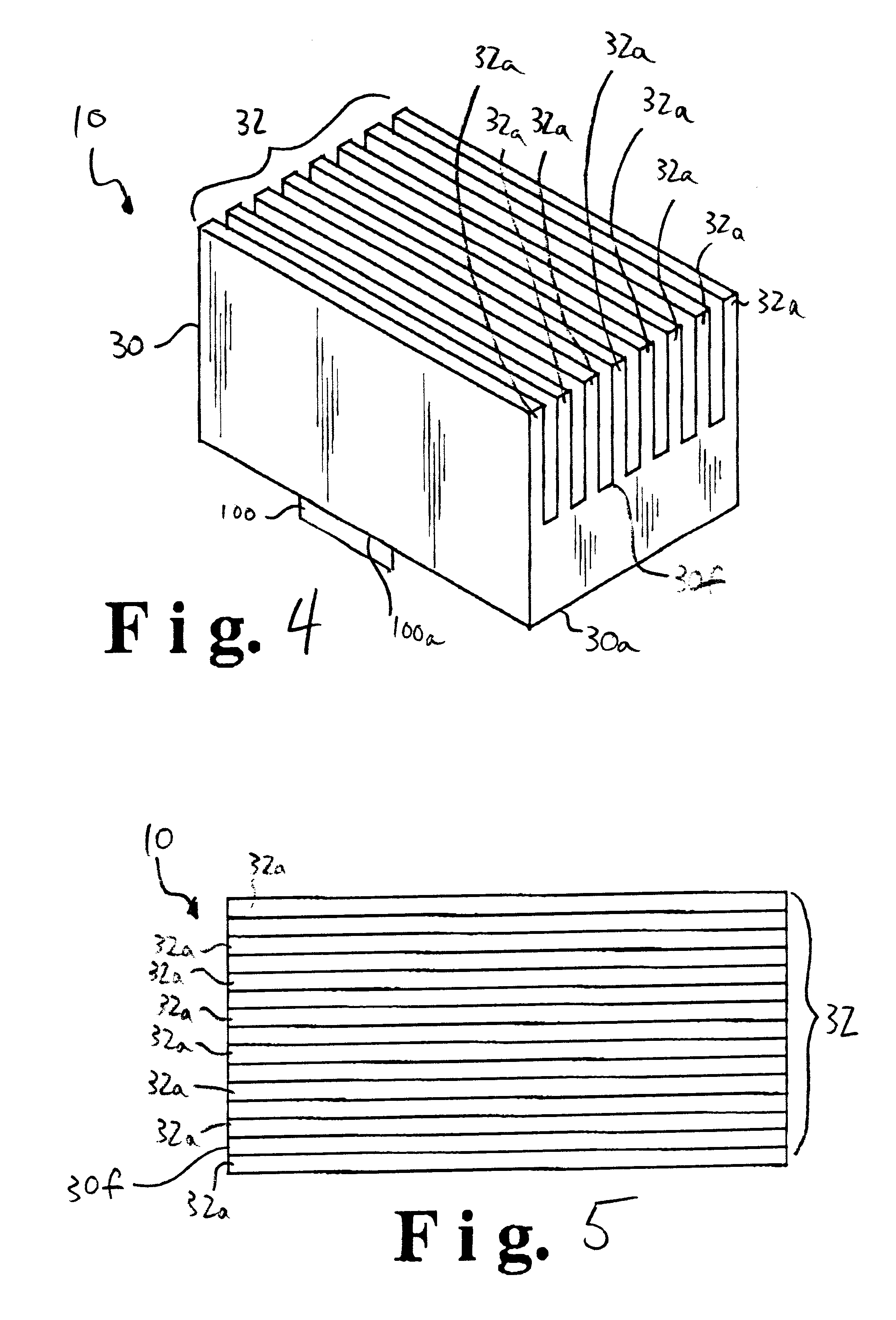

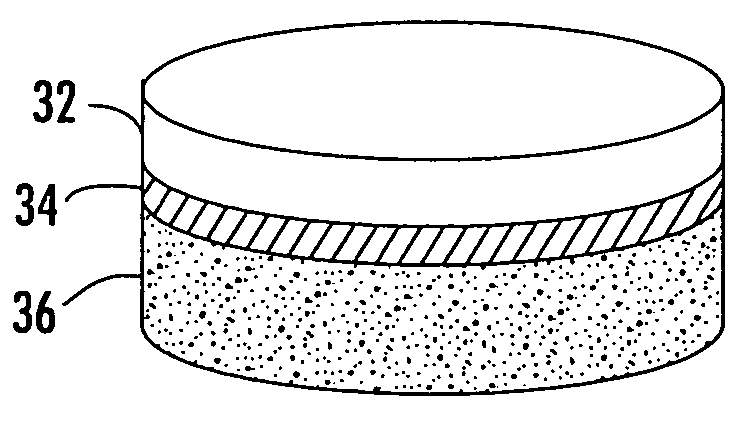

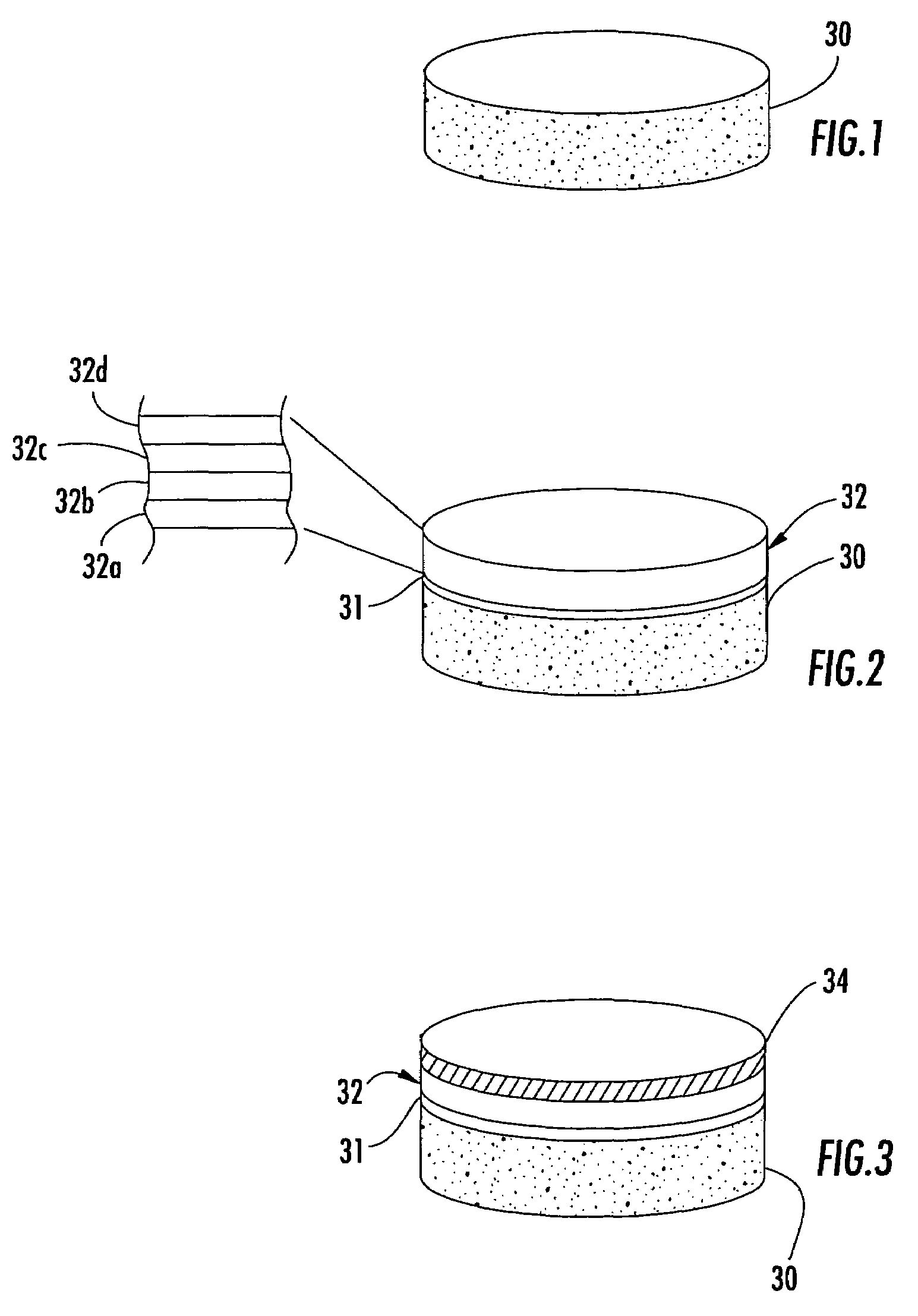

Thermal management system

InactiveUS6482520B1Improve cooling effectIncreased anisotropyLayered productsSemiconductor/solid-state device detailsEngineeringThermal management system

The present invention relates to a system for managing the heat from a heat source like an electronic component. More particularly, the present invention relates to a system effective for dissipating the heat generated by an electronic component using a thermal management system that includes a thermal interface formed from a flexible graphite sheet and / or a heat sink formed from a graphite article.

Owner:NEOGRAF SOLUTIONS LLC

Light engine assemblies

ActiveUS20080112168A1Improve cooling effectLighting applicationsPlanar light sourcesEngineeringLight emitter

Owner:IDEAL IND LIGHTING LLC

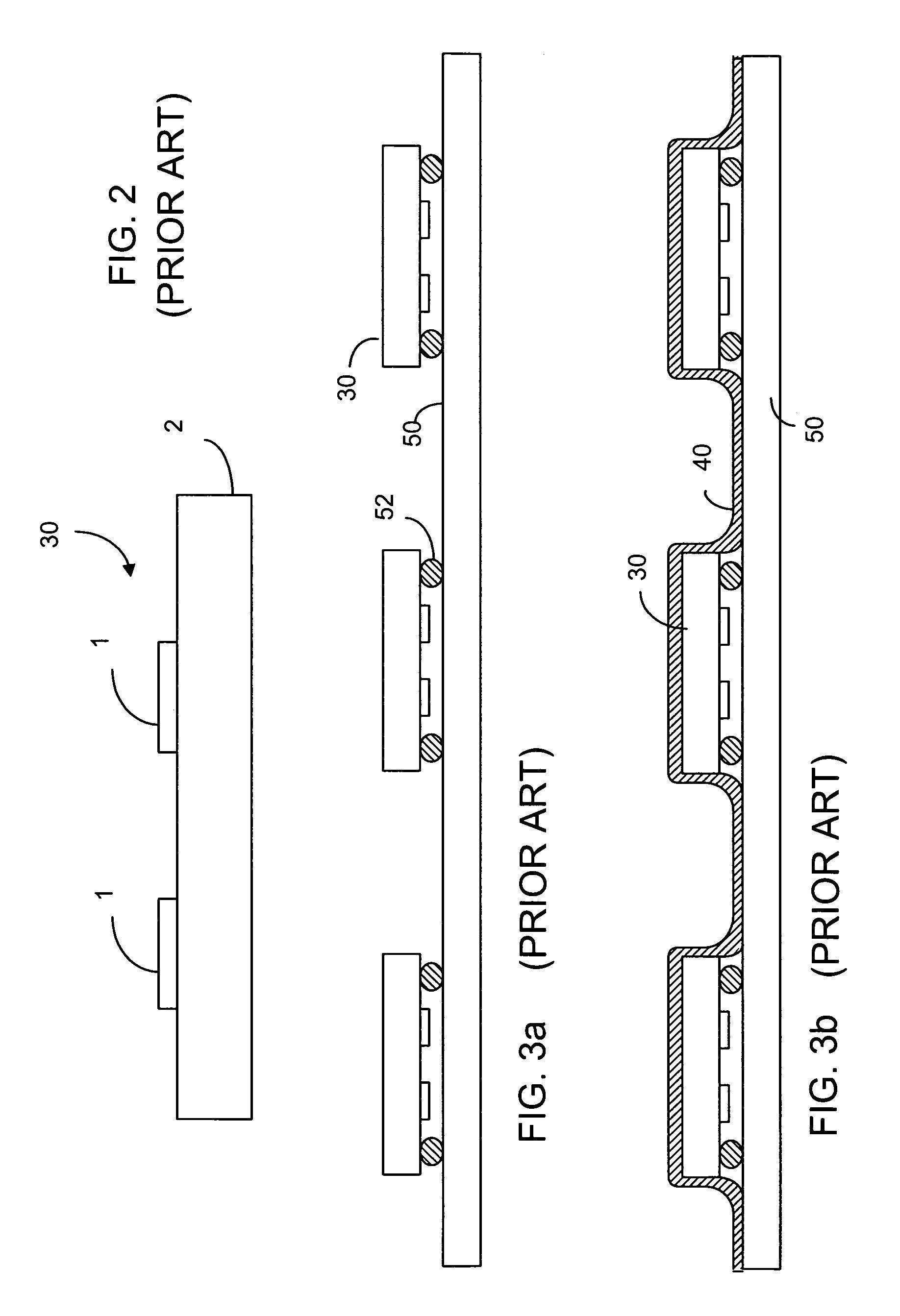

Semiconductor package and method for fabricating the same

InactiveUS6395578B1Improve cooling effectUniform encapsulationSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor chip

Semiconductor packages having a thin structure capable of easily discharging heat from a semiconductor chip included therein, and methods for fabricating such semiconductor packages, are disclosed. An embodiment of a semiconductor package includes a semiconductor chip having a first major surface and a second major surface, the semiconductor chip being provided at the second major surface with a plurality of input / output pads; a circuit board including a resin substrate having a first major surface and a second major surface, a first circuit pattern formed at the first major surface and provided with a plurality of ball lands, a second circuit pattern formed at the second major surface and provided with a plurality of bond fingers connected with he ball lands by conductive via holes through the resin substrate, cover coats respectively coating the first and second circuit patterns while allowing the bond fingers and the ball lands to be exposed therethrough, and a central through hole adapted to receive the semiconductor chip therein; electrical conductors that electrically connect the input / output pads of the semiconductor chip with the bond fingers of the circuit board, respectively; a resin encapsulate that covers the semiconductor chip, the electrical conductors, and at least part of the circuit board; and, a plurality of conductive balls fused on the ball lands of the circuit board, respectively.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

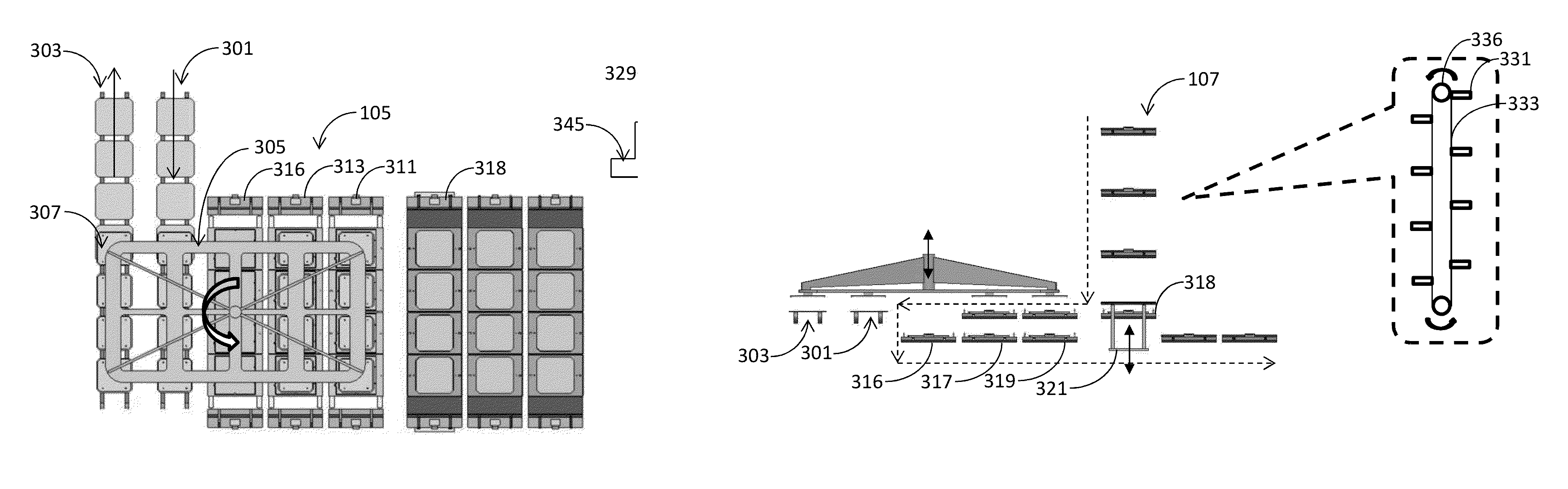

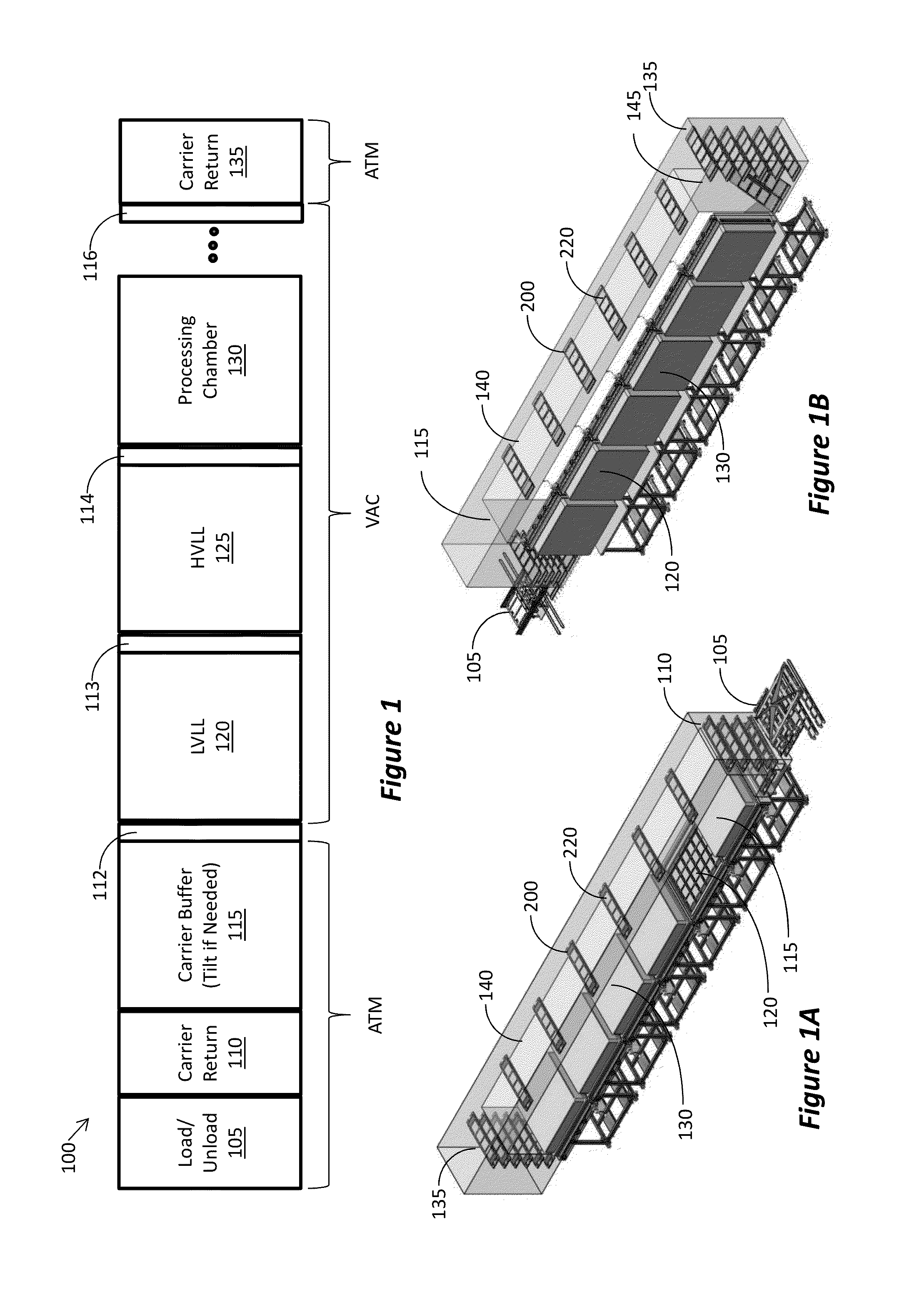

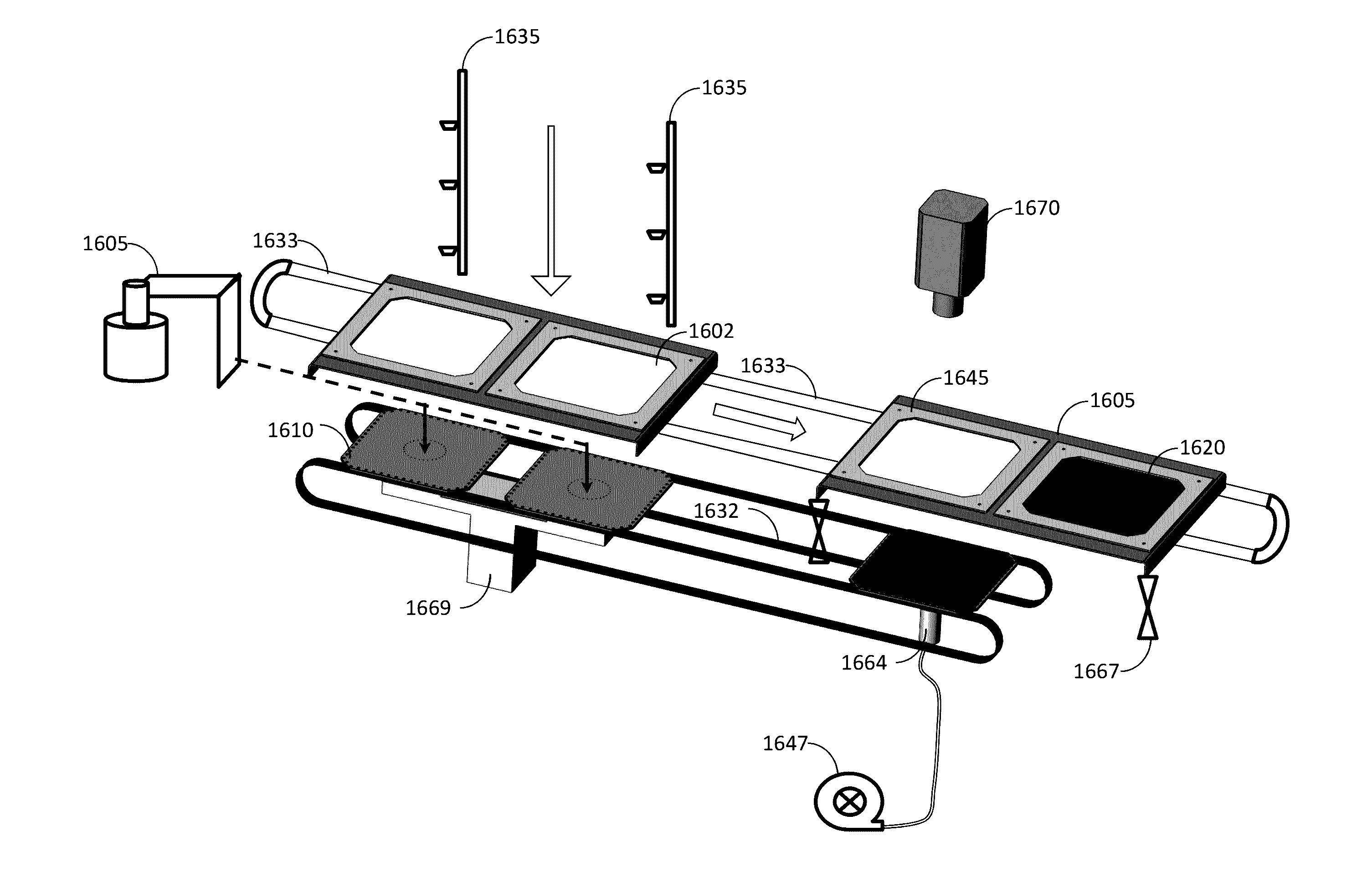

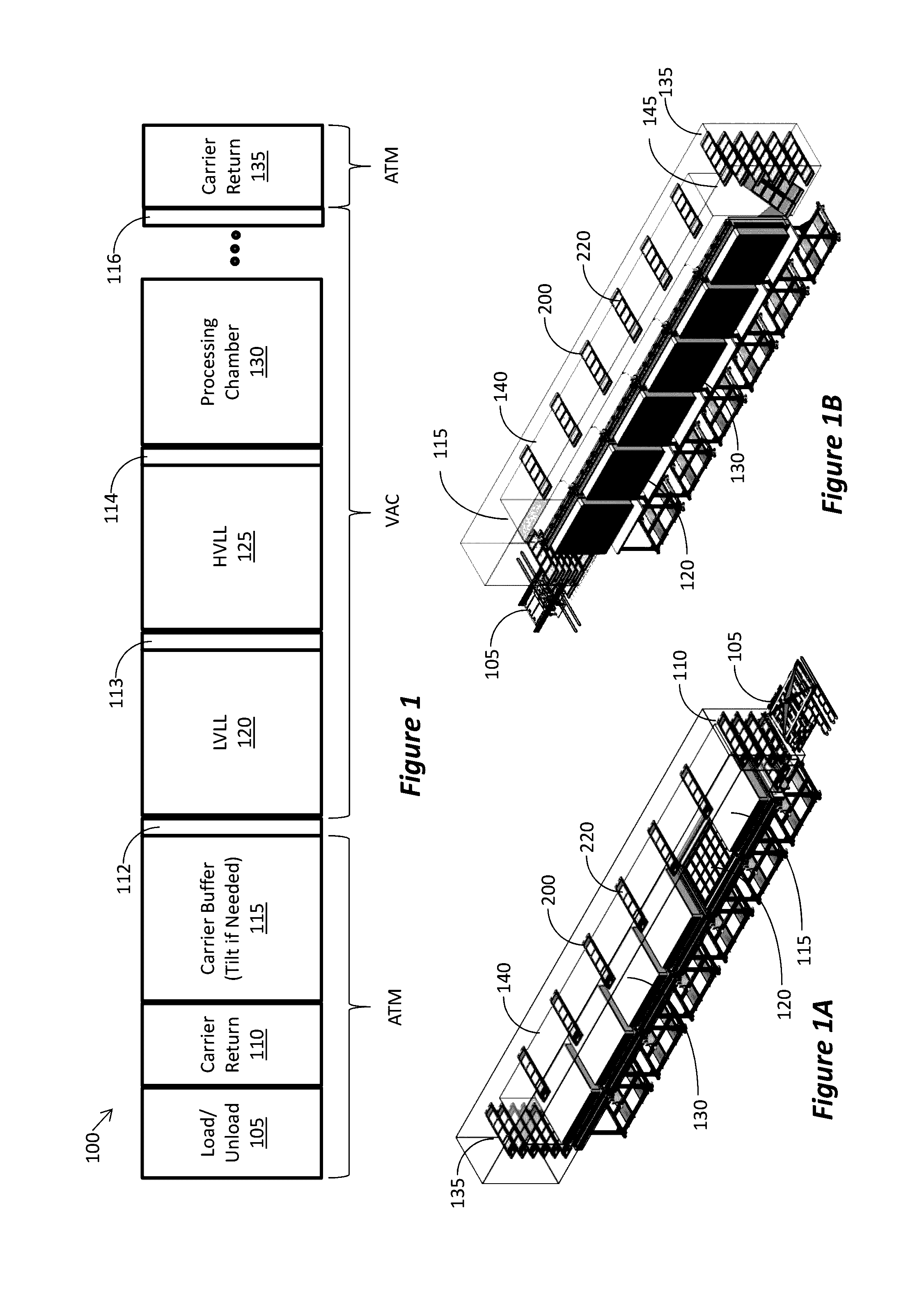

System architecture for vacuum processing

ActiveUS20130287526A1Improve cooling effectAvoid accidental movementSemiconductor/solid-state device manufacturingConveyor partsMechanical engineeringPlasma chamber

A system for processing substrates in plasma chambers, such that all substrates transport and loading / unloading operations are performed in atmospheric environment, but processing is performed in vacuum environment. The substrates are transported throughout the system on carriers. The system's chambers are arranged linearly, such that carriers move from one chamber directly to the next. A conveyor, placed above or below the system's chambers, returns the carriers to the system's entry area after processing is completed. Loading and unloading of substrates may be performed at one side of the system, or loading can be done at the entry side and unloading at the exit side.

Owner:INTEVAC

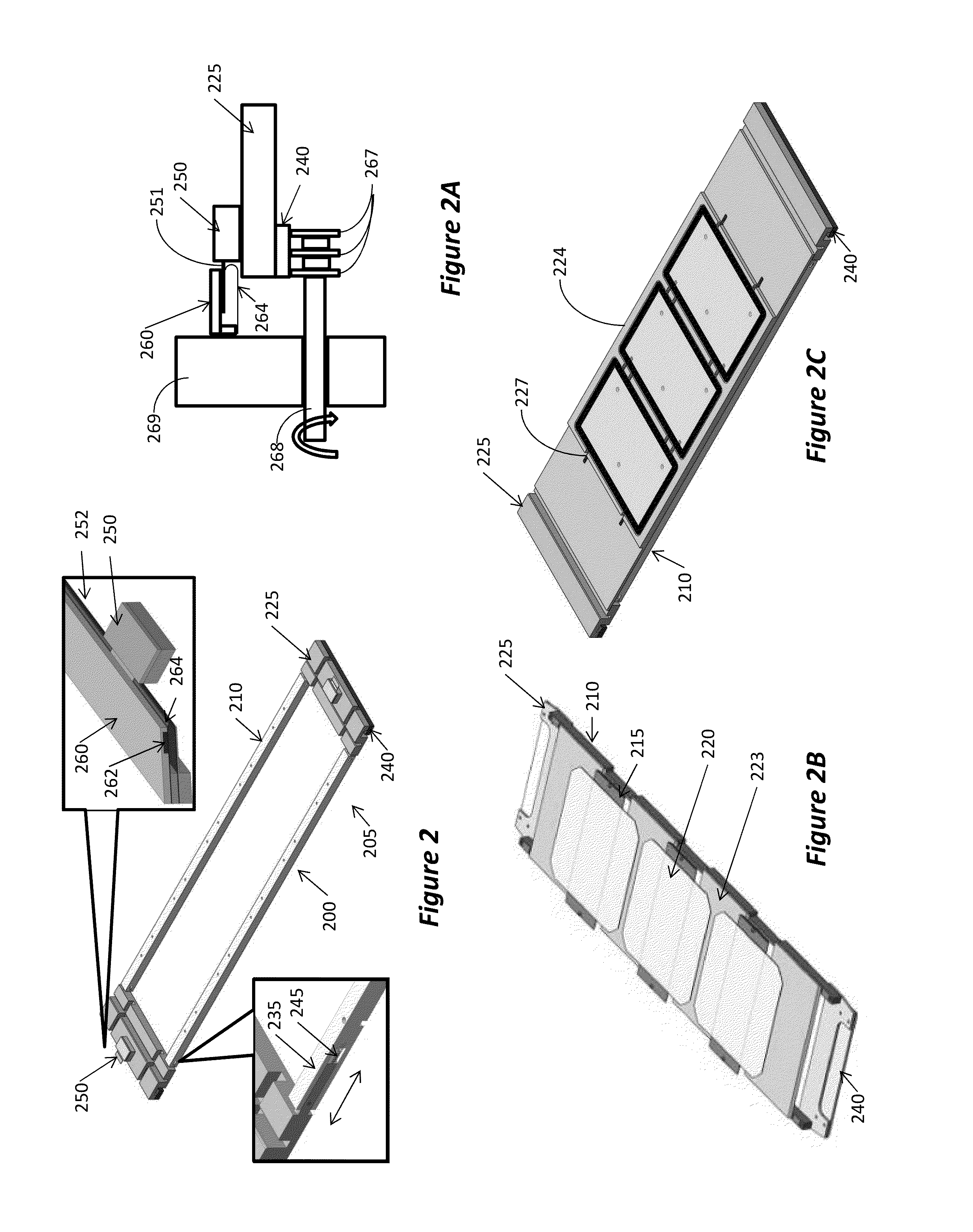

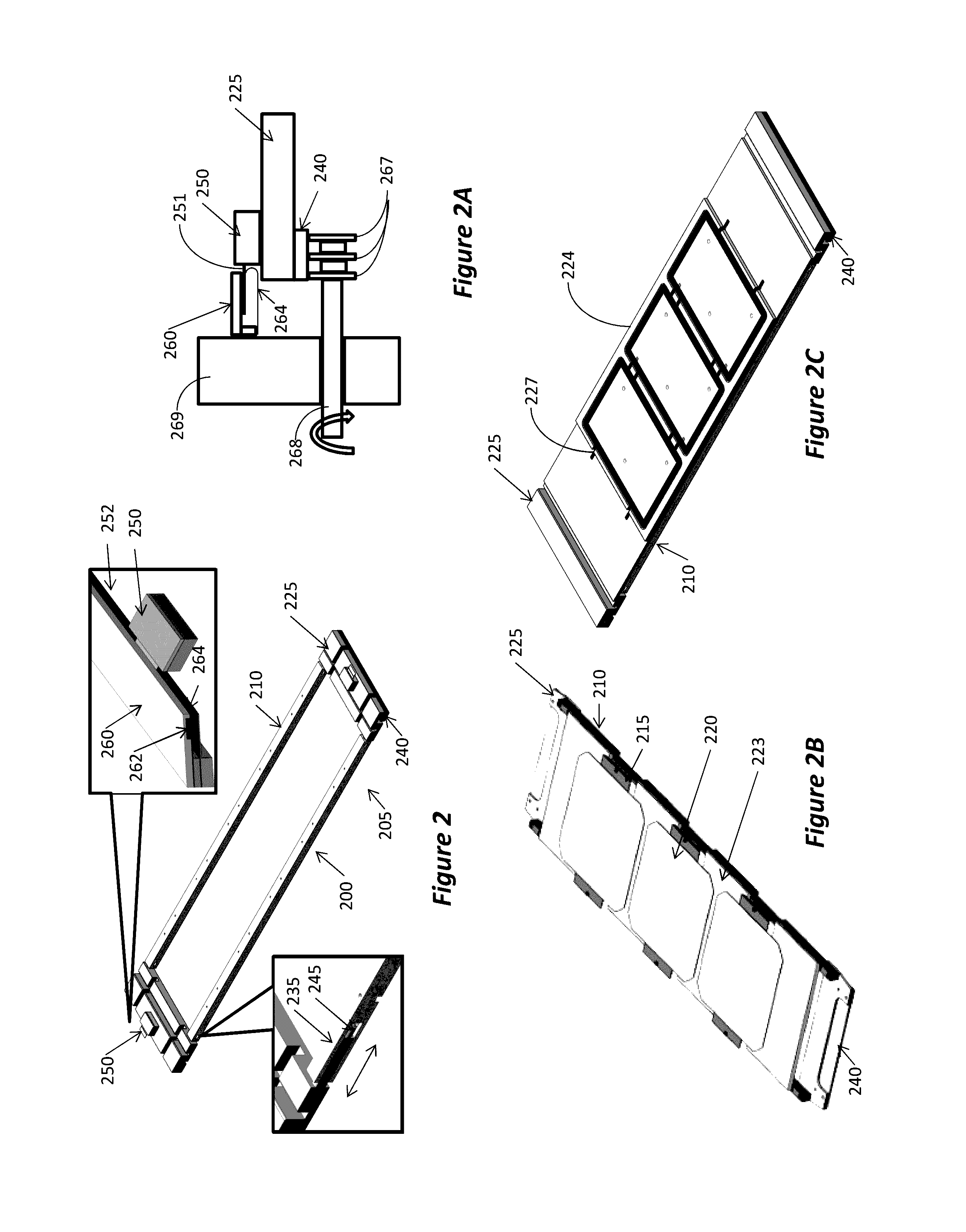

Wafer plate and mask arrangement for substrate fabrication

ActiveUS20170062258A1Improve cooling effectAvoid accidental movementVacuum evaporation coatingSemiconductor/solid-state device manufacturingCarrier signalMechanical engineering

A system for processing wafers in a vacuum processing chamber. Carrier comprising a frame having a plurality of openings, each opening configured to accommodate one wafer. A transport mechanism configured to transport the plurality of carriers throughout the system. A plurality of wafer plates configured for supporting wafers. An attachment mechanism for attaching a plurality of wafer plates to each of the carriers, wherein each of the wafer plates is attached to a corresponding position at an underside of a corresponding carrier, such that each of the wafers positioned on one of the wafer carriers is positioned within one of the plurality of opening in the carrier. Mask attached over front side of one of the plurality of opening in the carrier. Alignment stage supports wafer plate under the opening in the carrier. A camera positioned to simultaneously image the mask and the wafer.

Owner:INTEVAC

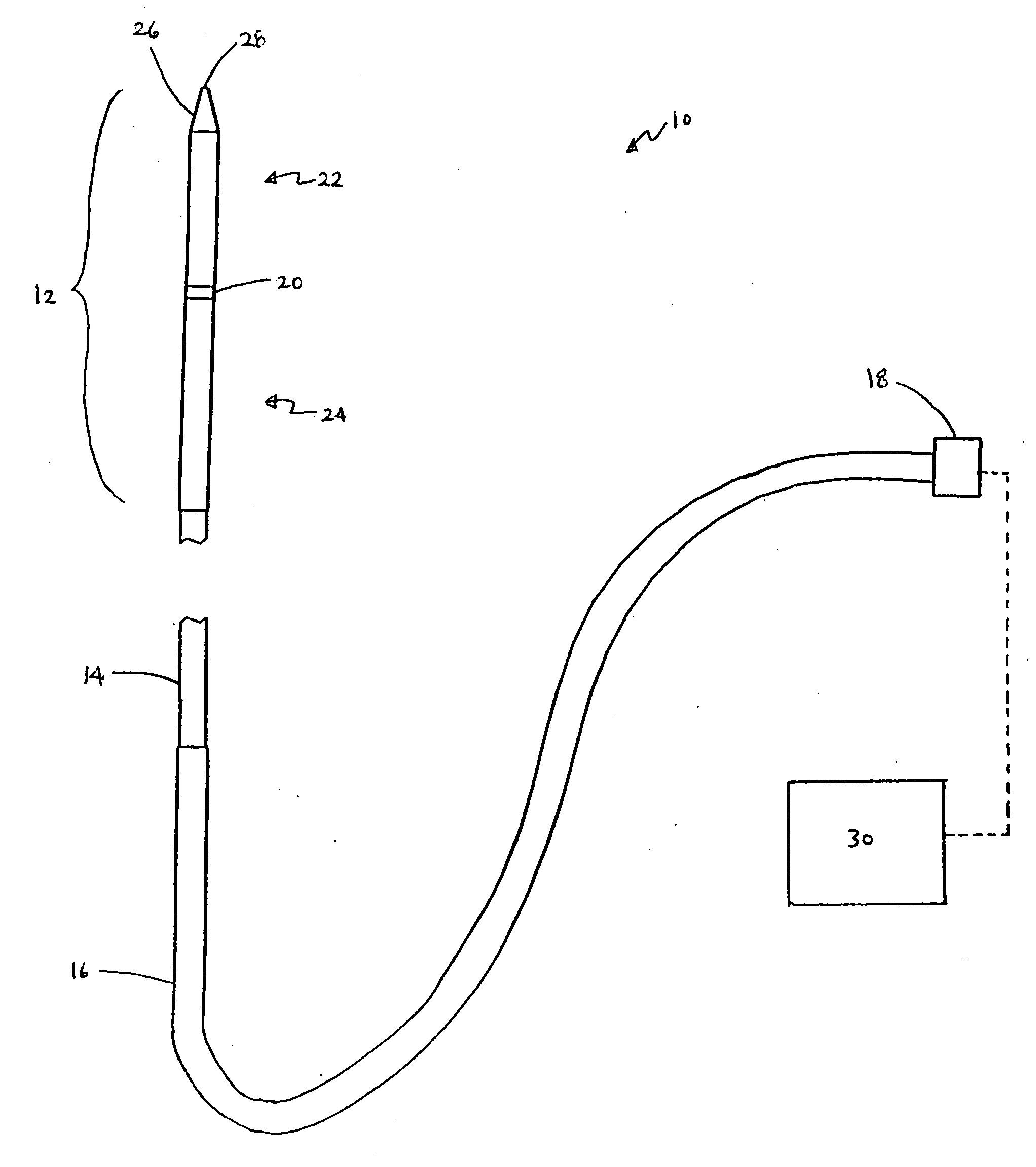

Devices and methods for cooling microwave antennas

InactiveUS20050015081A1Improve cooling effectElectrotherapySurgical instruments for heatingChemical reactionCompound (substance)

Devices and methods for cooling microwave antennas are disclosed herein. The cooling systems can be used with various types of microwave antennas. One variation generally comprises a handle portion with an elongate outer jacket extending from the handle portion. A microwave antenna is positioned within the handle and outer jacket such that cooling fluid pumped into the handle comes into contact directly along a portion of the length, or a majority of the length, or the entire length of the antenna to allow for direct convective cooling. Other variations include cooling sheaths which form defined cooling channels around a portion of the antenna. Yet another variation includes passively-cooled systems which utilize expandable balloons to urge tissue away from the surface of the microwave antenna as well as cooling sheaths which are cooled through endothermic chemical reactions. Furthermore, the microwave antennas themselves can have cooling lumens integrated directly therethrough.

Owner:TYCO HEALTHCARE GRP LP

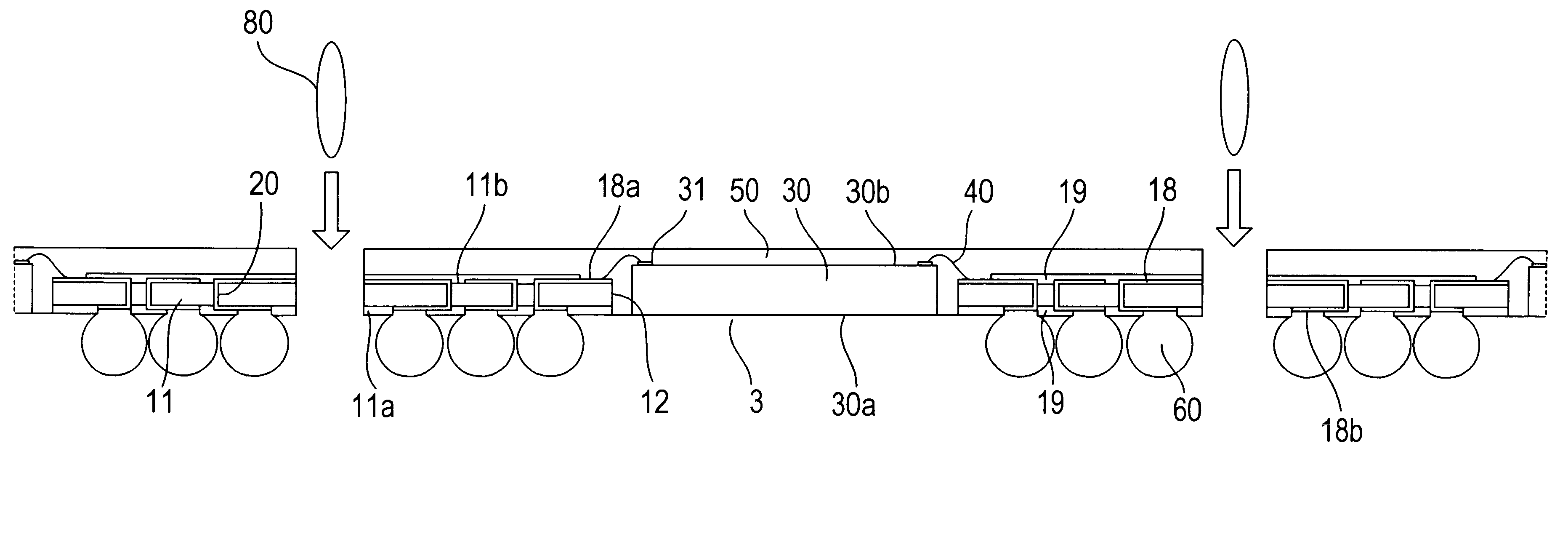

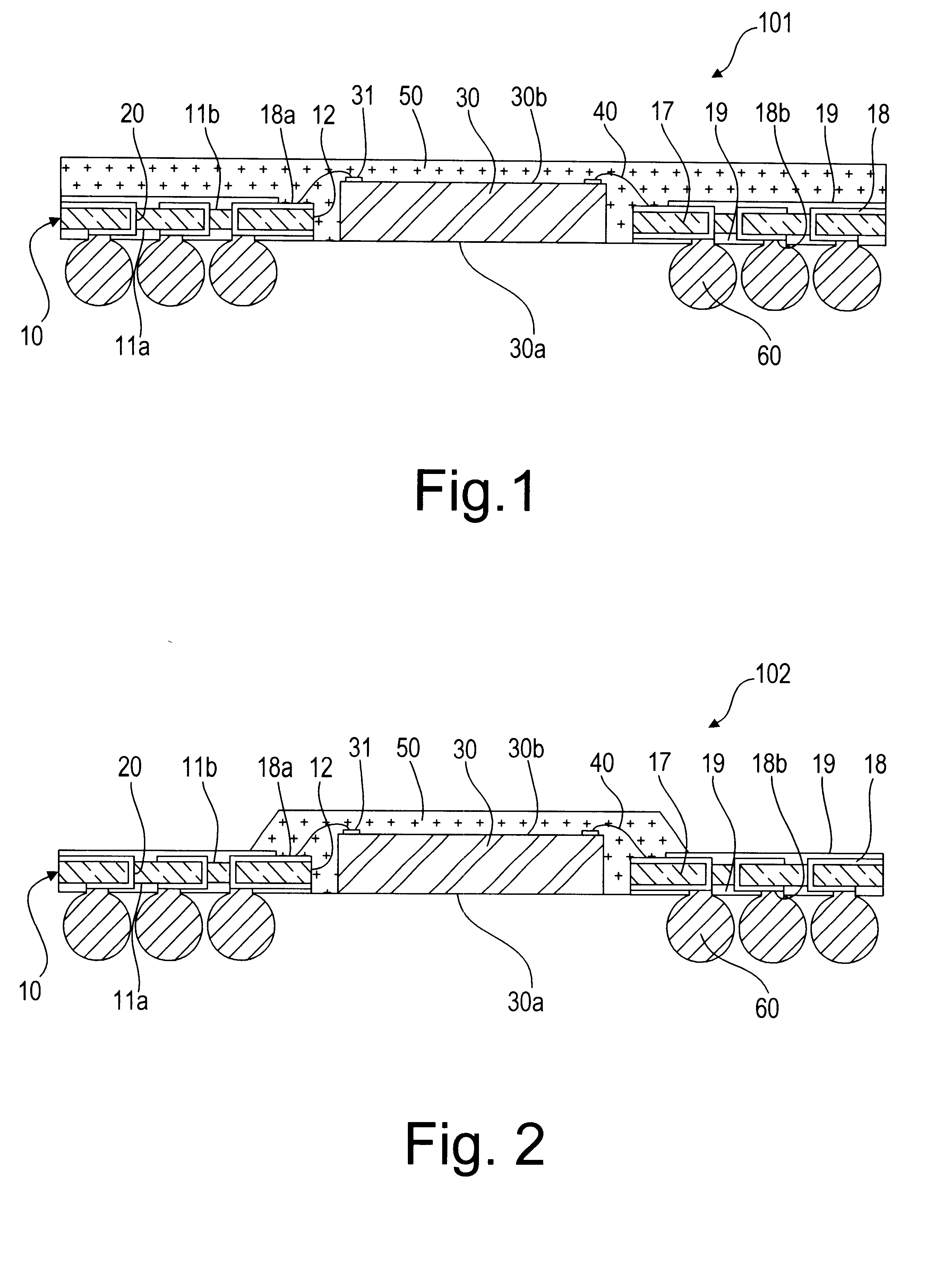

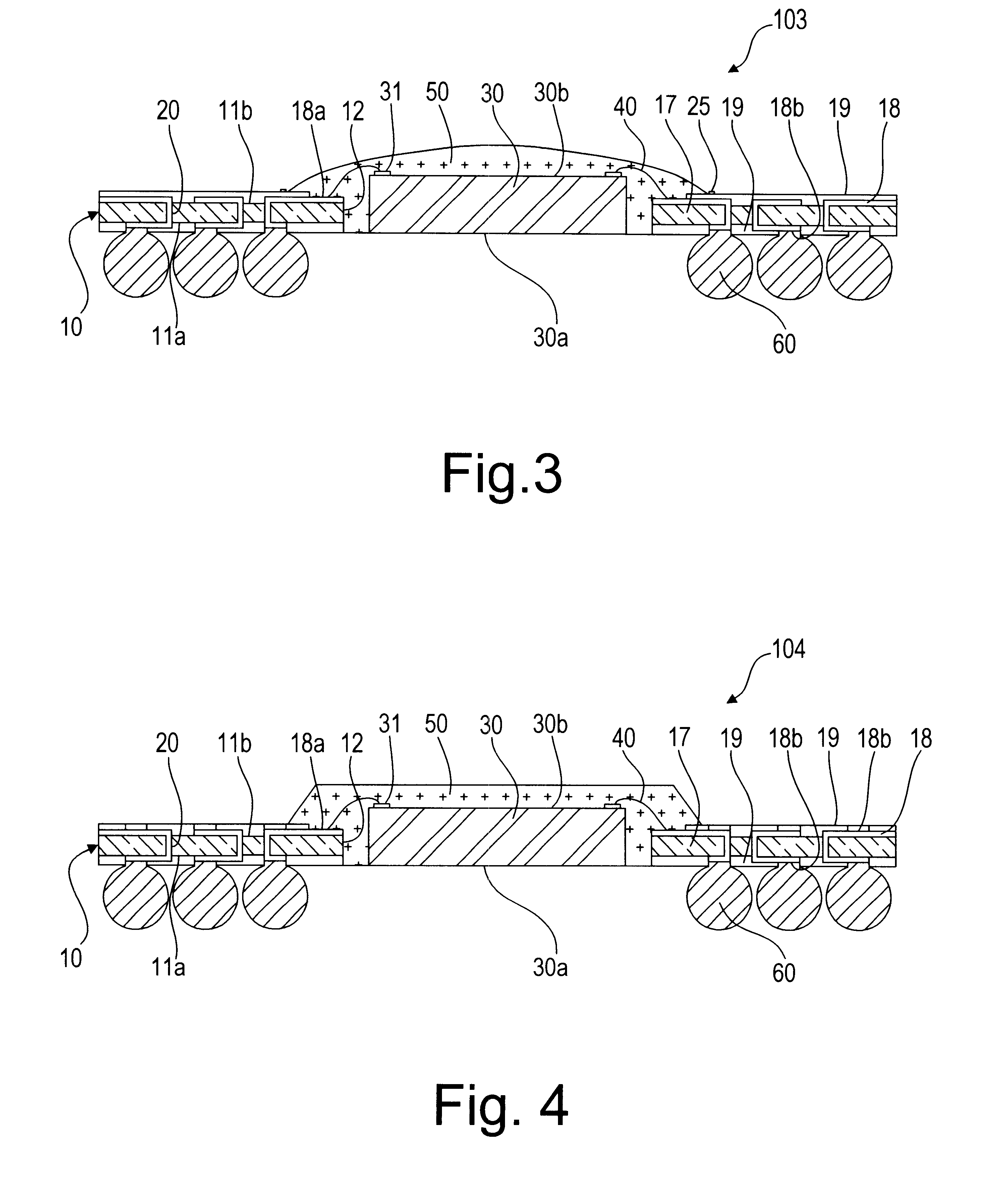

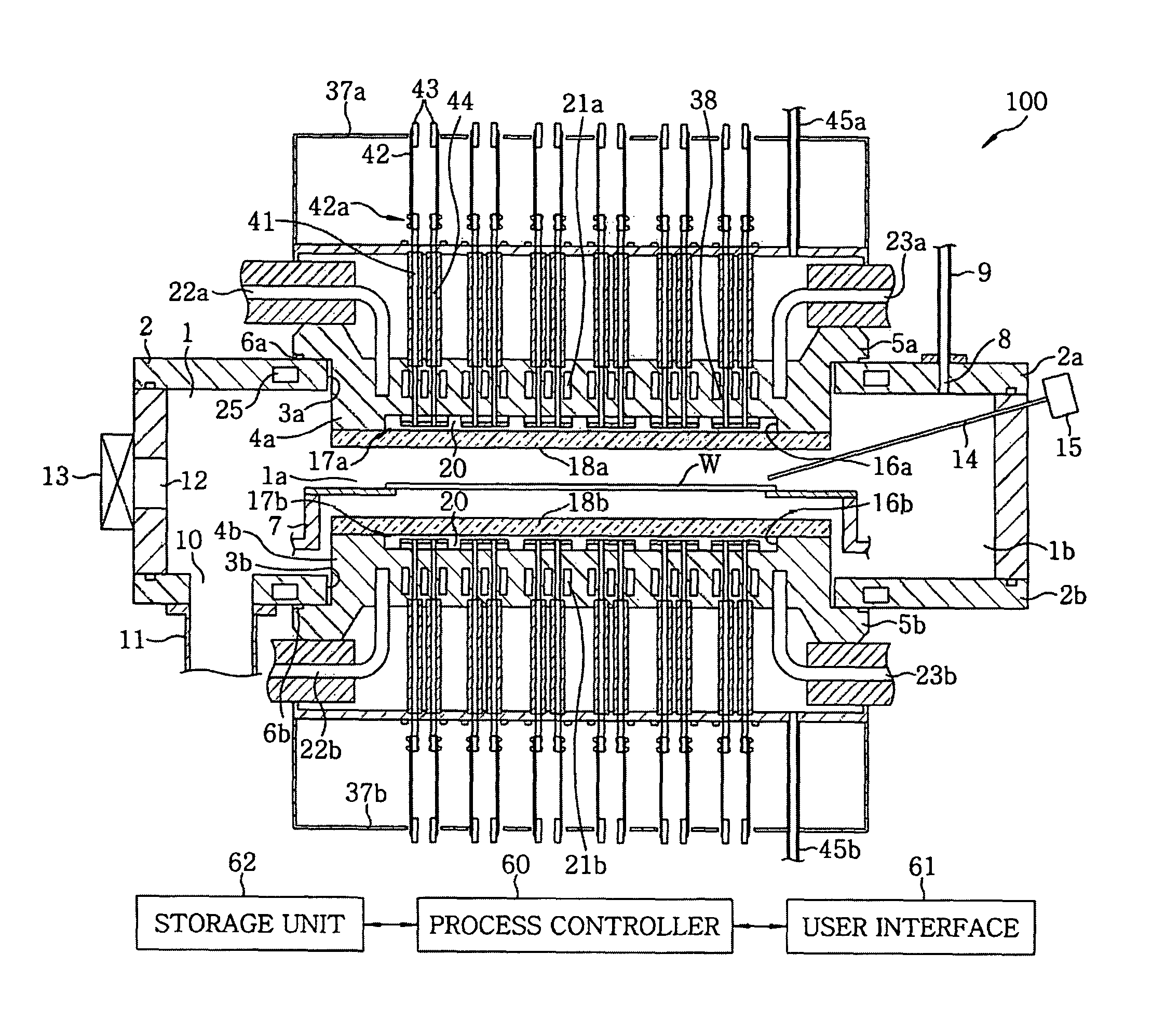

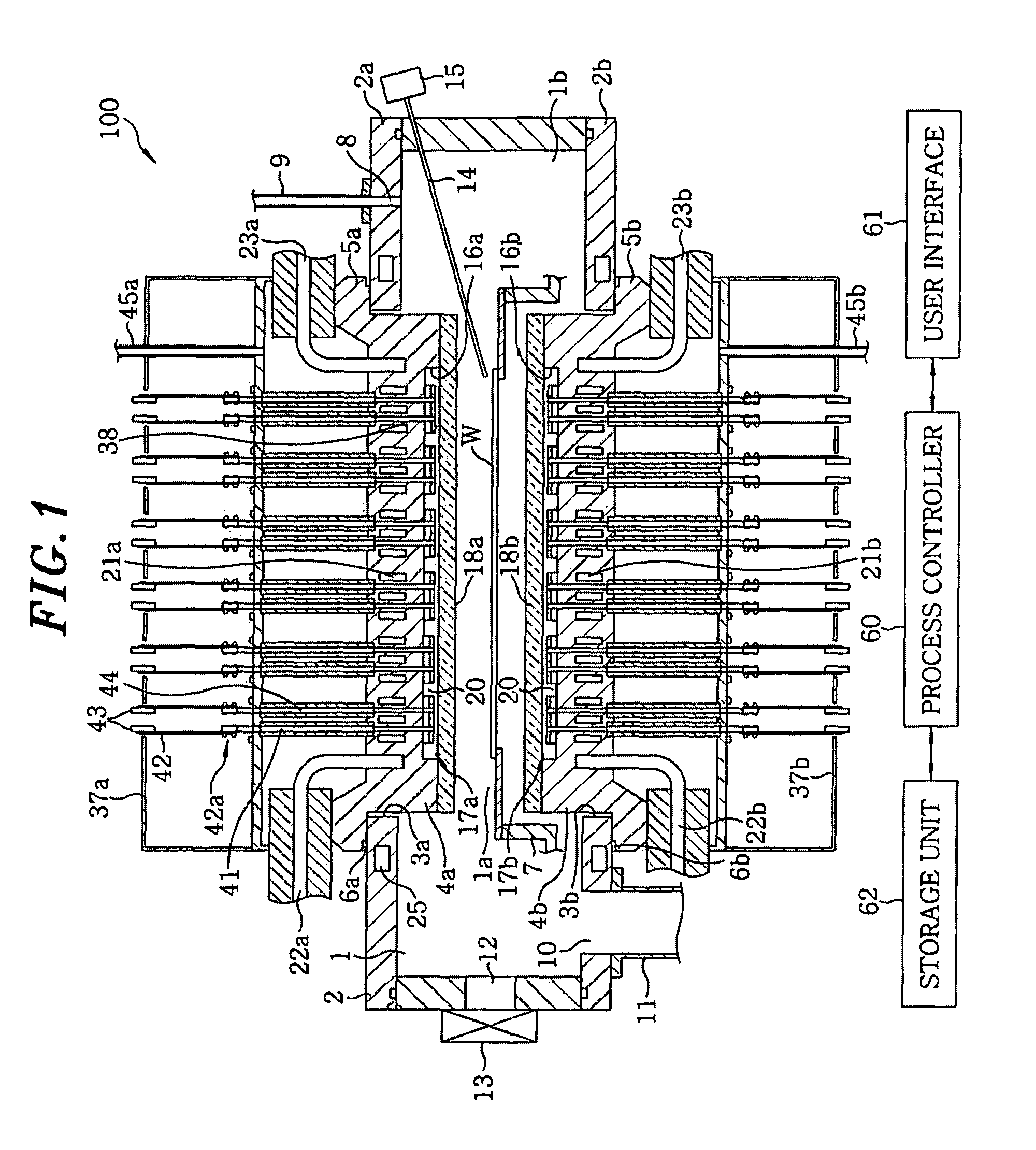

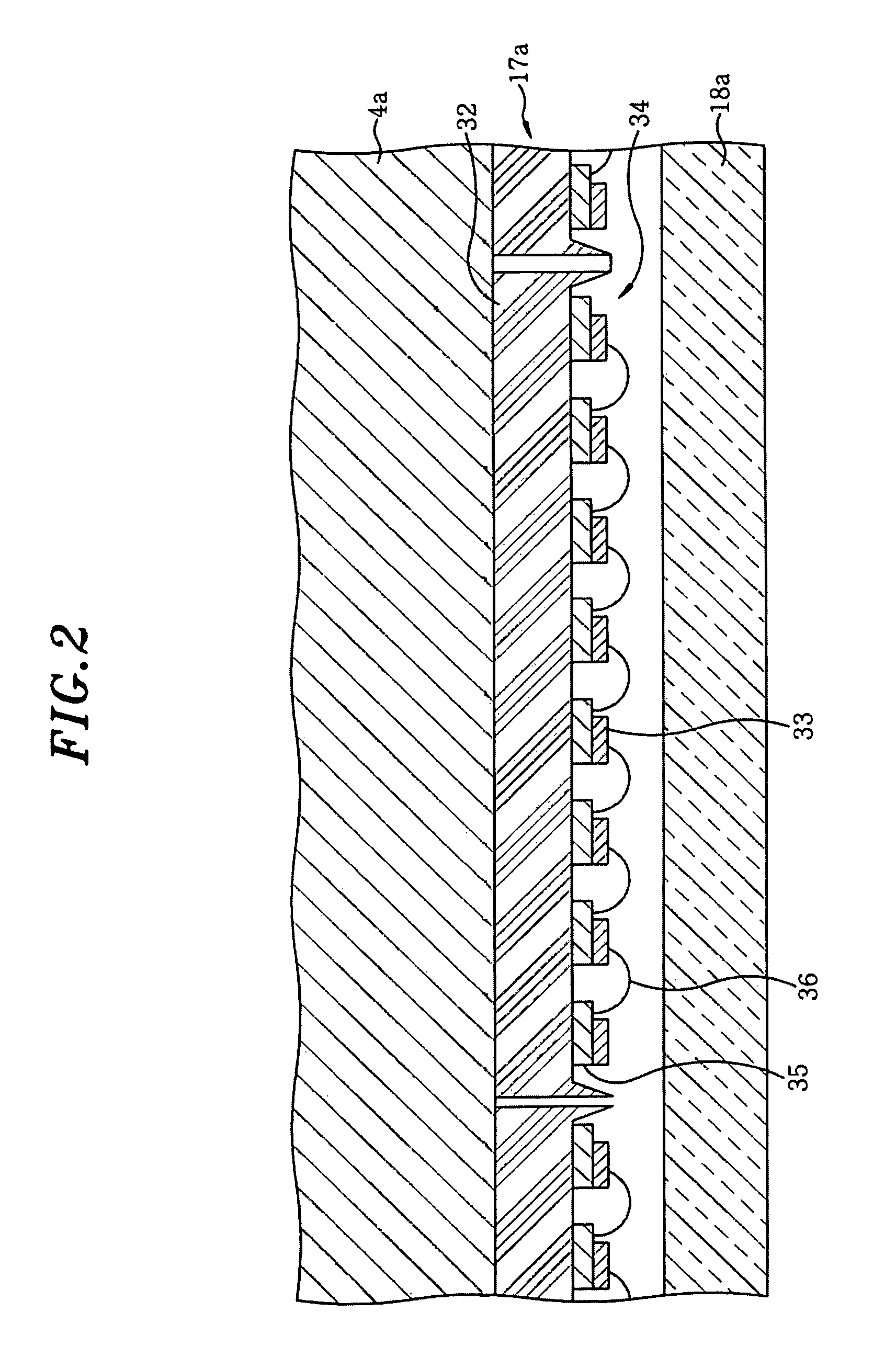

Annealing apparatus

ActiveUS8246900B2Improve performanceLow efficiencyDomestic stoves or rangesDrying solid materials with heatLight energyLight emission

Provided is an annealing apparatus, which is free from a problem of reduced light energy efficiency resulted by the reduction of light emission amount due to a heat generation and capable of maintaining stable performance. The apparatus includes: a processing chamber 1 for accommodating a wafer W; heating sources 17a and 17b including LEDs 33 and facing the surface of the wafer W to irradiate light on the wafer W; light-transmitting members 18a and 18b arranged in alignment with the heating sources 17a and 17b to transmit the light emitted from the LEDs 33; cooling members 4a and 4b supporting the light-transmitting members 18a and 18b at opposite side to the processing chamber 1 to make direct contact with the heating sources 17a and 17b and made of a material of high thermal conductivity; and a cooling mechanism for cooling the cooling members 4a and 4b with a coolant.

Owner:TOKYO ELECTRON LTD

Release strategies for making transferable semiconductor structures, devices and device components

ActiveUS7932123B2Low costReduce layeringFinal product manufactureNanoinformaticsSemiconductor structureElectron

Provided are methods for making a device or device component by providing a multilayer structure having a plurality of functional layers and a plurality of release layers and releasing the functional layers from the multilayer structure by separating one or more of the release layers to generate a plurality of transferable structures. The transferable structures are printed onto a device substrate or device component supported by a device substrate. The methods and systems provide means for making high-quality and low-cost photovoltaic devices, transferable semiconductor structures, (opto-)electronic devices and device components.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

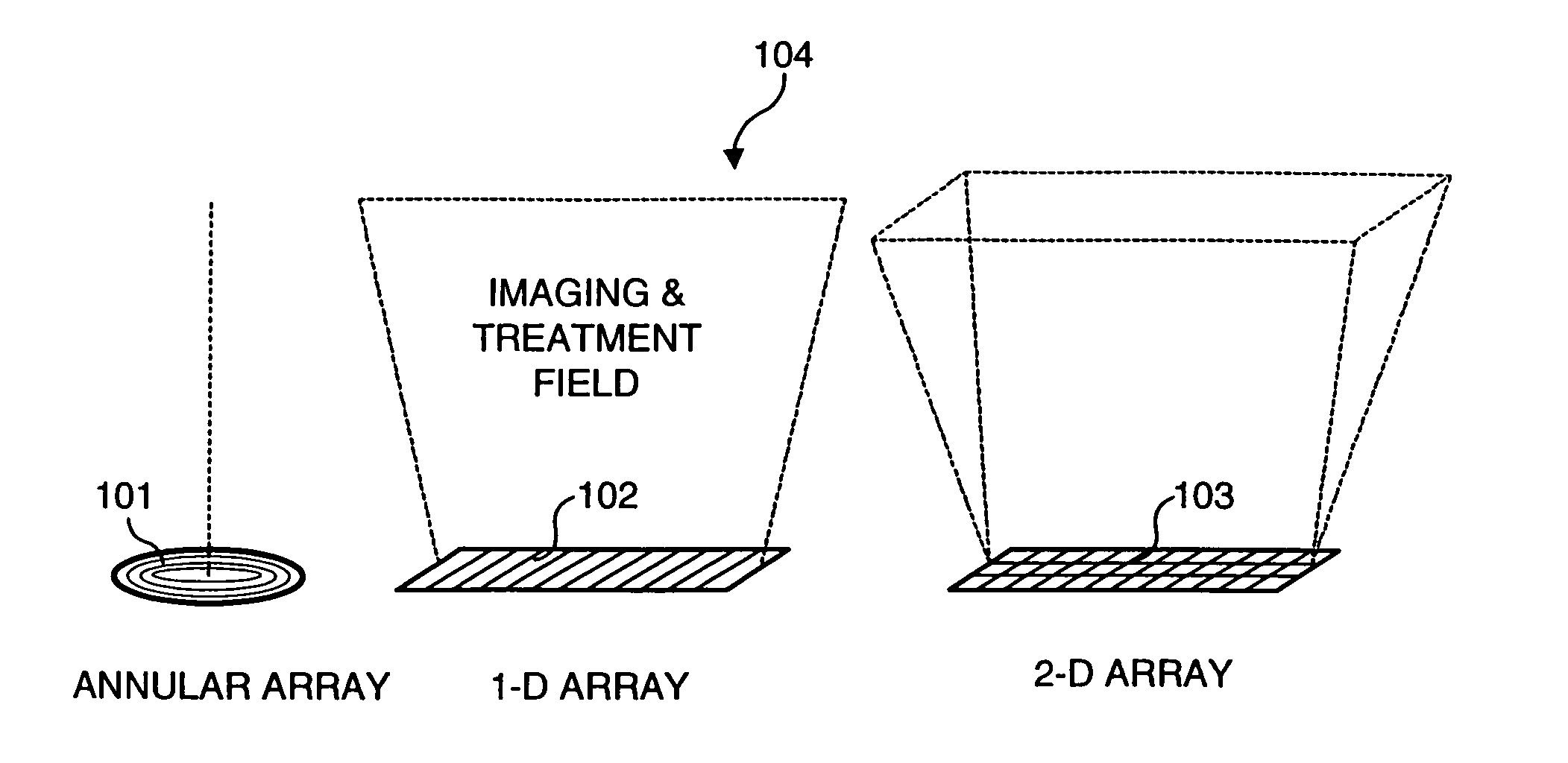

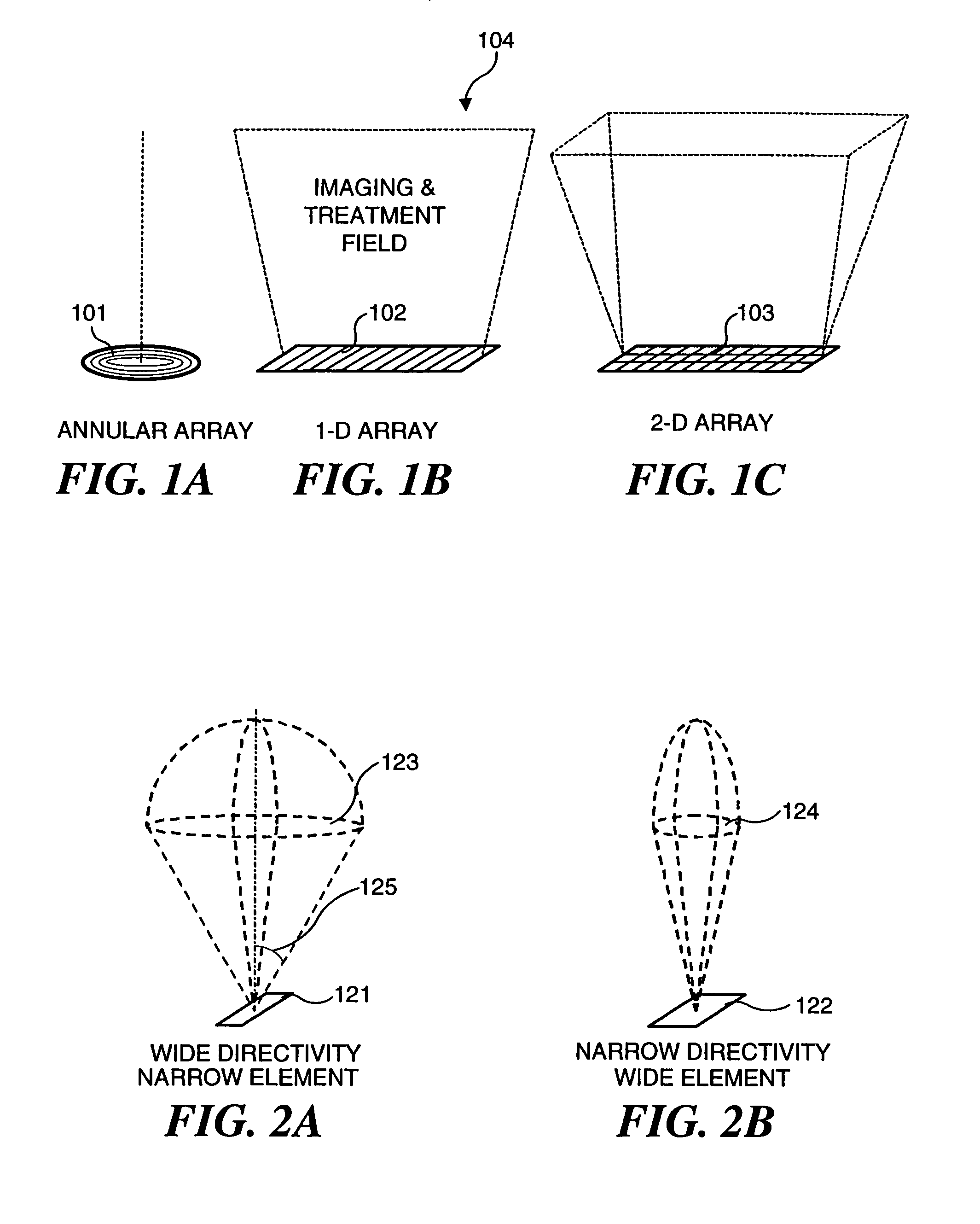

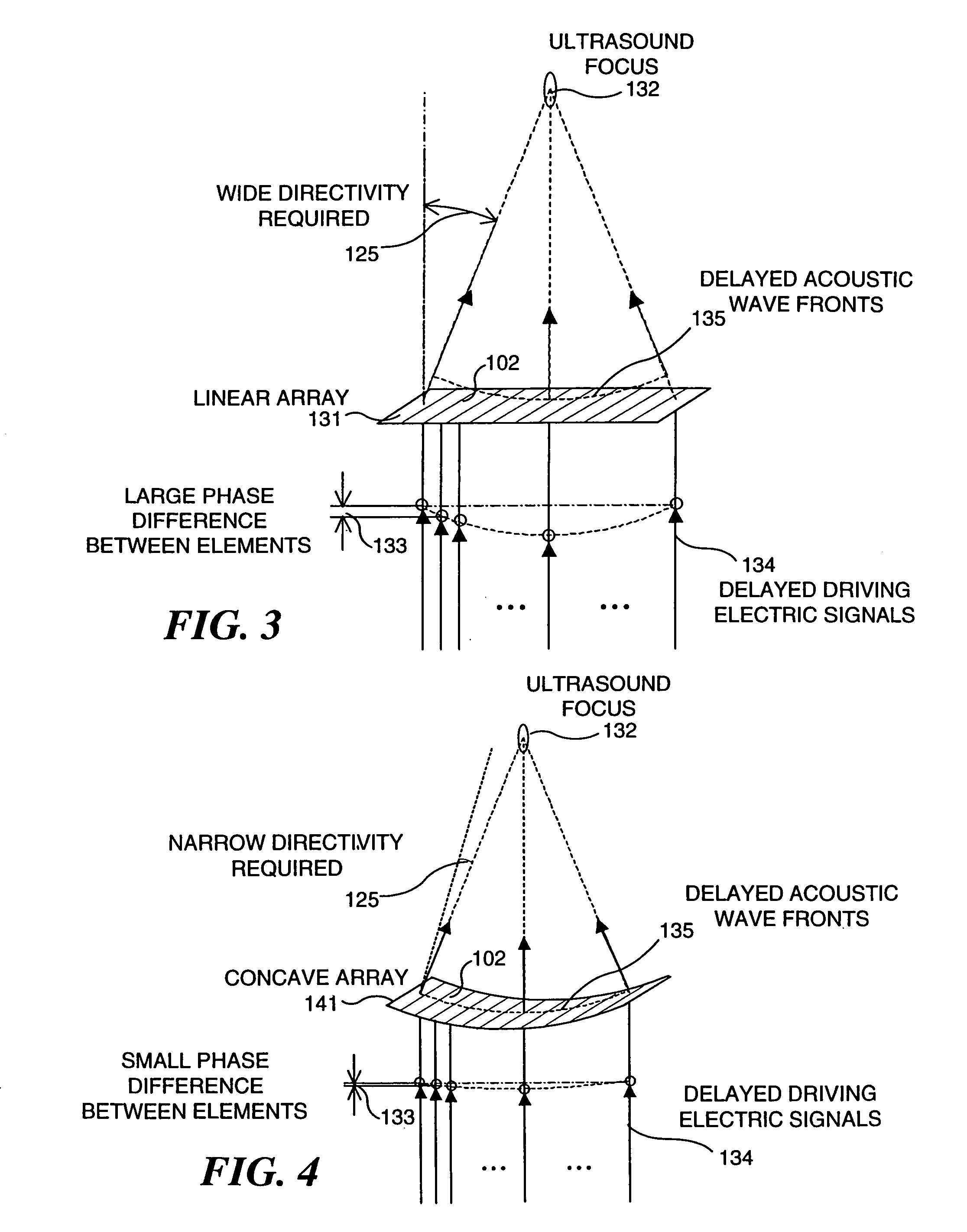

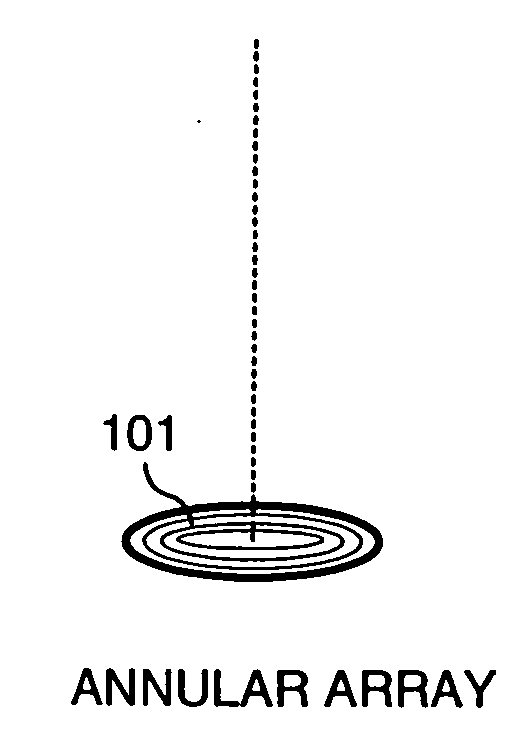

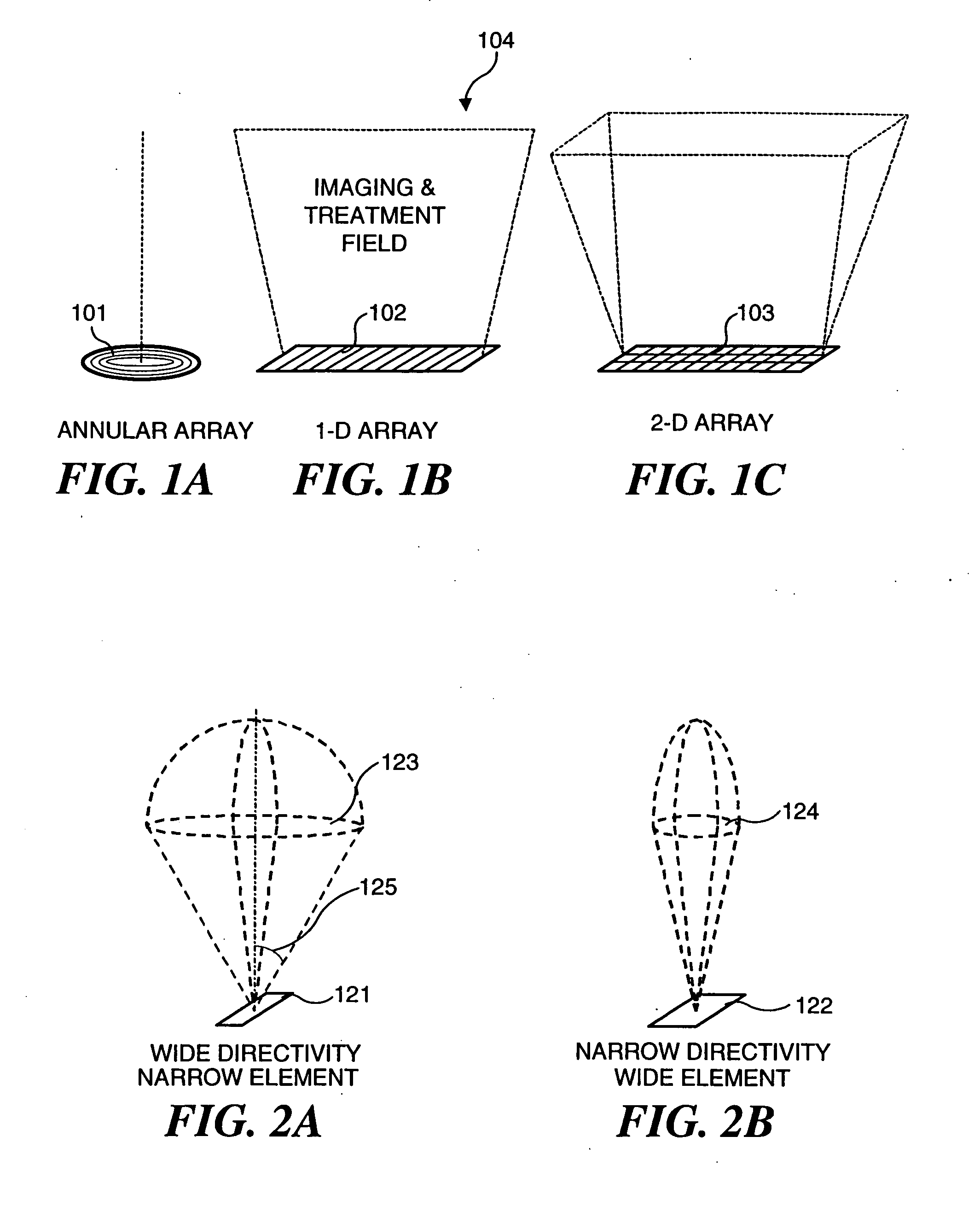

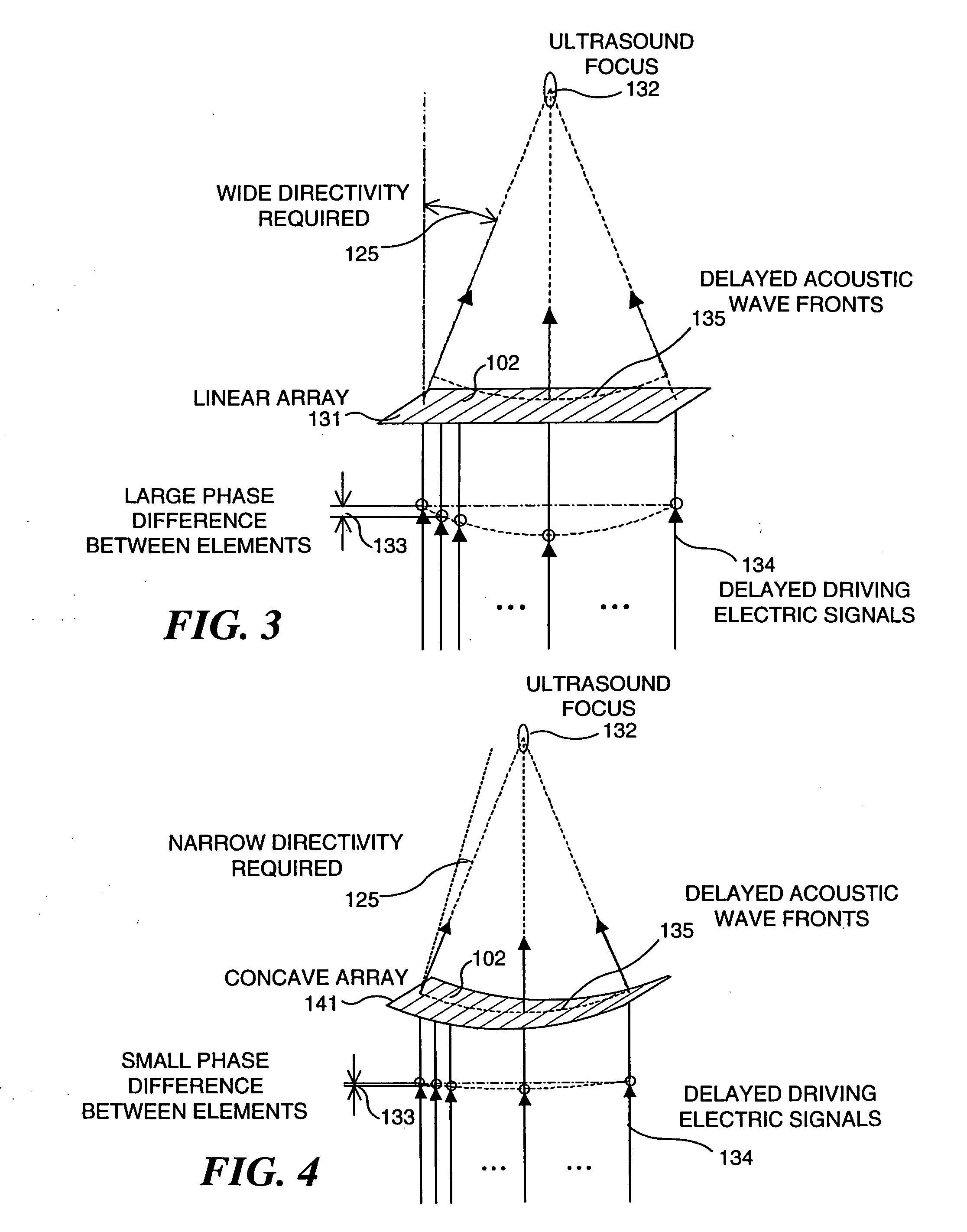

Ultrasound transducers for imaging and therapy

InactiveUS7063666B2Reduce in quantityReducing cross-talk and heatingUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyElectrical resistance and conductanceSonification

Owner:OTSUKA MEDICAL DEVICES

Method for making Group III nitride devices and devices produced thereby

InactiveUS7033858B2Improve cooling effectThin active areaPolycrystalline material growthSolid-state devicesLithium aluminateNitride

A method is for making at least one semiconductor device including providing a sacrificial growth substrate of Lithium Aluminate (LiAlO2); forming at least one semiconductor layer including a Group III nitride adjacent the sacrificial growth substrate; attaching a mounting substrate adjacent the at least one semiconductor layer opposite the sacrificial growth substrate; and removing the sacrificial growth substrate. The method may further include adding at least one contact onto a surface of the at least one semiconductor layer opposite the mounting substrate, and dividing the mounting substrate and at least one semiconductor layer into a plurality of individual semiconductor devices. To make the final devices, the method may further include bonding the mounting substrate of each individual semiconductor device to a heat sink. The step of removing the sacrificial substrate may include wet etching the sacrificial growth substrate.

Owner:CRYSTAL PHOTONICS

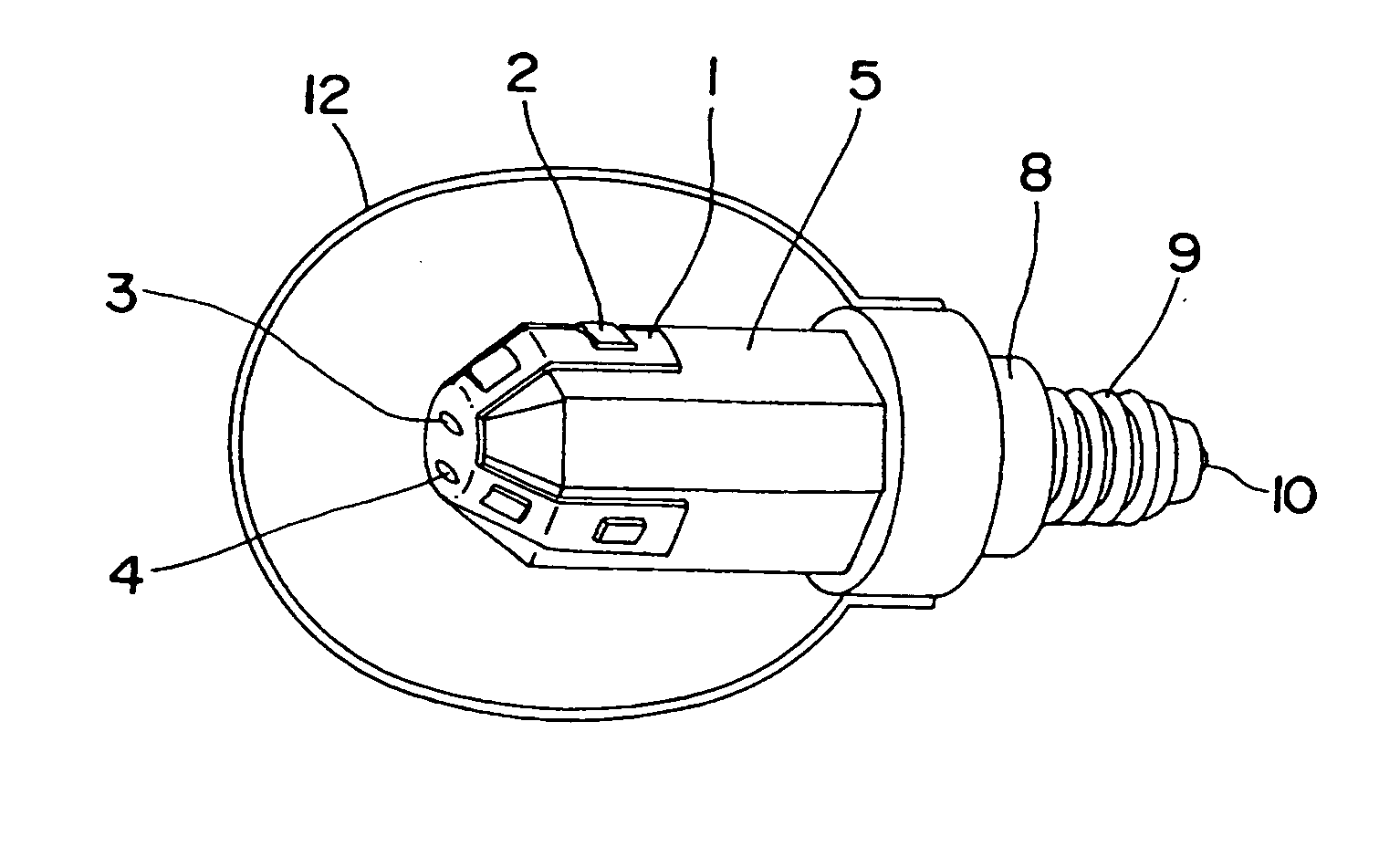

LED lighting system

InactiveUS20060193130A1Reduce heat resistance requirementsImprove cooling effectPoint-like light sourceLighting heating/cooling arrangementsHeat resistanceAdhesive

Provided is an LED lighting system with a smaller heat resistance of the LED, which can be produced by simpler mounting steps and is capable of three-dimensionally arranging the LEDs depending on required directivity of each system. A plurality of LEDs 2 are mounted on an FPC 1 which has a radial shape and can be flat when developed. The LEDs 2 connected by printed wiring to each other and linked to terminals 3 and 4 are attached on a surface of a core 5 made of a material having a high thermal conductivity. Heat generated at a p-n junction of the LEDs 2 is transmitted to the core 5 via the FPC 1 and a thermal-conductive adhesive.

Owner:ATEX CO LTD

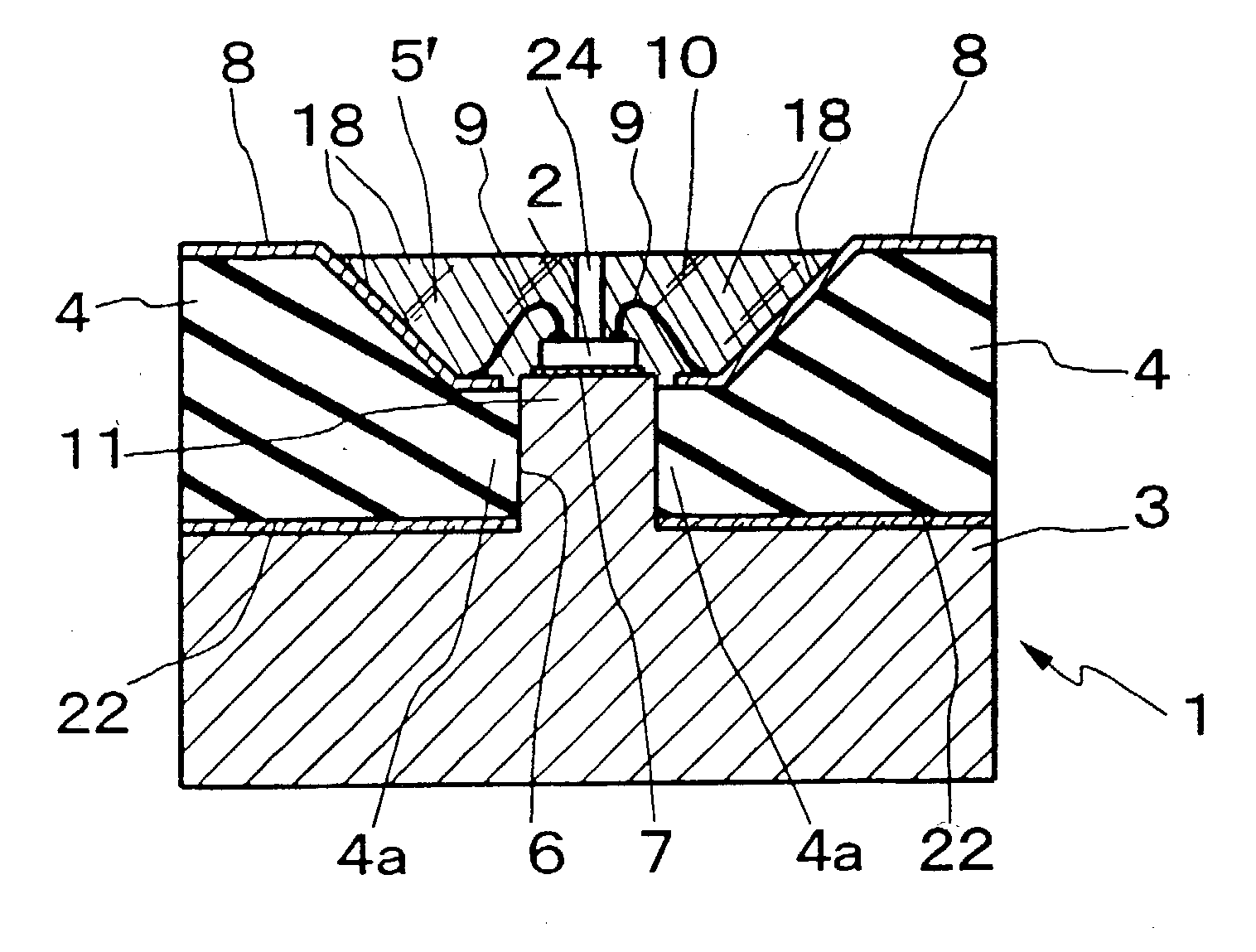

Light source device using LED, and method of producing same

InactiveUS6874910B2Improve cooling effectMinimize temperature increaseLighting heating/cooling arrangementsSolid-state devicesEngineeringElectrical and Electronics engineering

A light source apparatus having a radiator plate having thermally conductive properties and an insulating member coupled to at least one side of the radiator plate having a through hole provided in a side thereof facing the radiator plate. The light source apparatus further including a LED chip installed and thermally coupled to an exposed portion of the radiator plate facing the through hole, an extension inwardly projecting at the through hole from the radiator plate end of the insulating member, and a wiring pattern provided on the insulating member electrically isolated by the insulating member from the radiator plate. The light source apparatus also including bonding wires electrically connecting portions of the wiring pattern on the extension and the electrodes of the LED chip, and a light-transmissive sealing material filling the through hole for entirely encapsulating the LED chip and the bonding wires.

Owner:SIGNIFY HLDG BV

Ultrasound transducers for imaging and therapy

InactiveUS20050096542A1Improve likelihoodImprove bonding strengthUltrasonic/sonic/infrasonic diagnosticsUltrasound therapySonificationUltrasonic beam

Ultrasound applicators able to both image a treatment site and administer ultrasound therapy include an array of transducer elements that can be focused. In several embodiments, an electronically phased array is used for controlling the focal point of an ultrasound beam. The ultrasound beam produced thereby can also be electronically steered. To reduce the quality factor or Q of the array when the array is used for imaging, an electronic switch is selectively closed, placing a resistance in parallel with each of the array elements. A flexible array is employed in several embodiments and is selectively bent or flexed to vary its radius of curvature and thus control the focal point and / or a direction of focus of the array. In another embodiment, each of the transducer elements comprising the array are individually mechanically pivotable to steer the ultrasonic beam produced by the transducer elements.

Owner:OTSUKA MEDICAL DEVICES

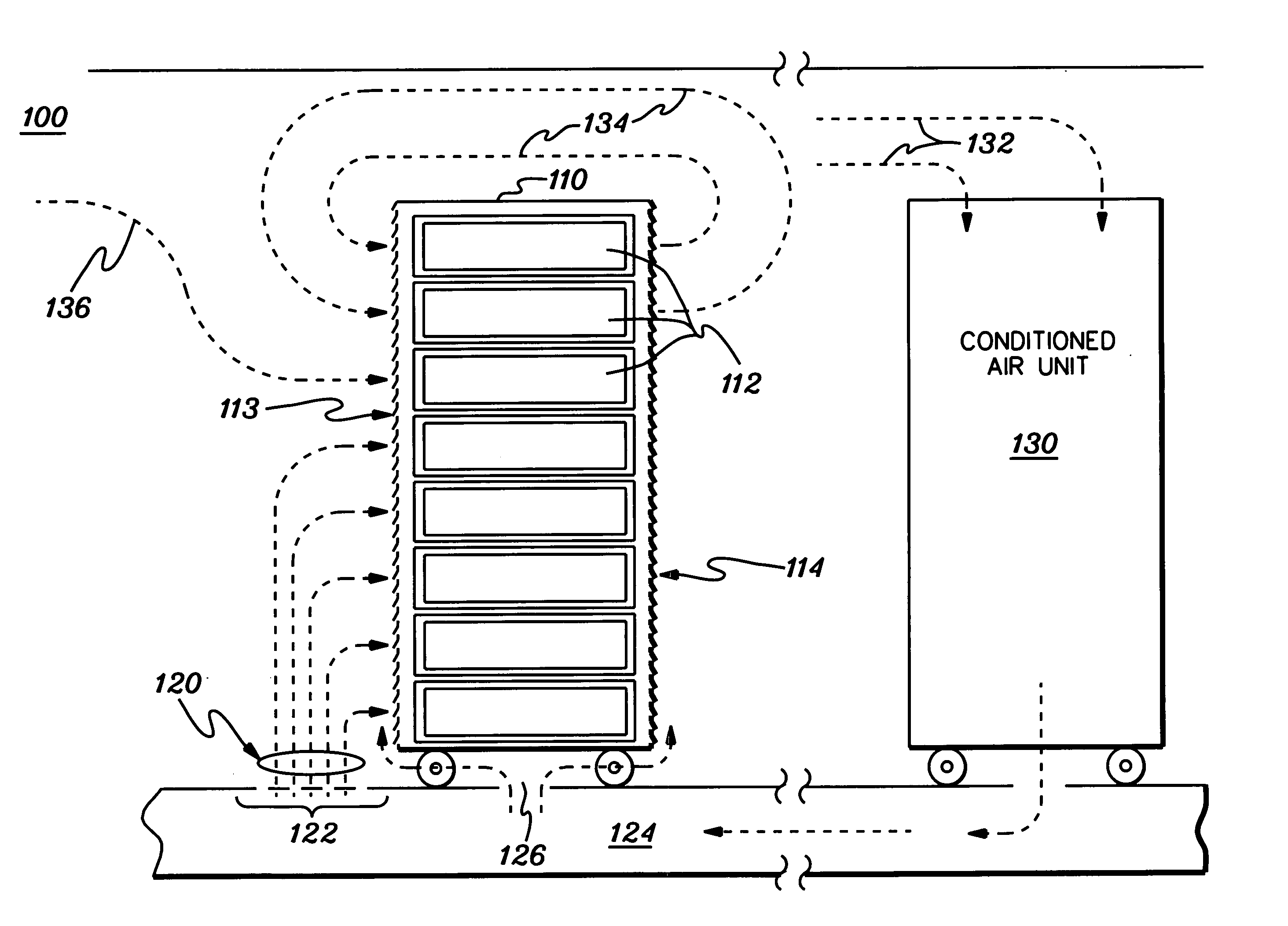

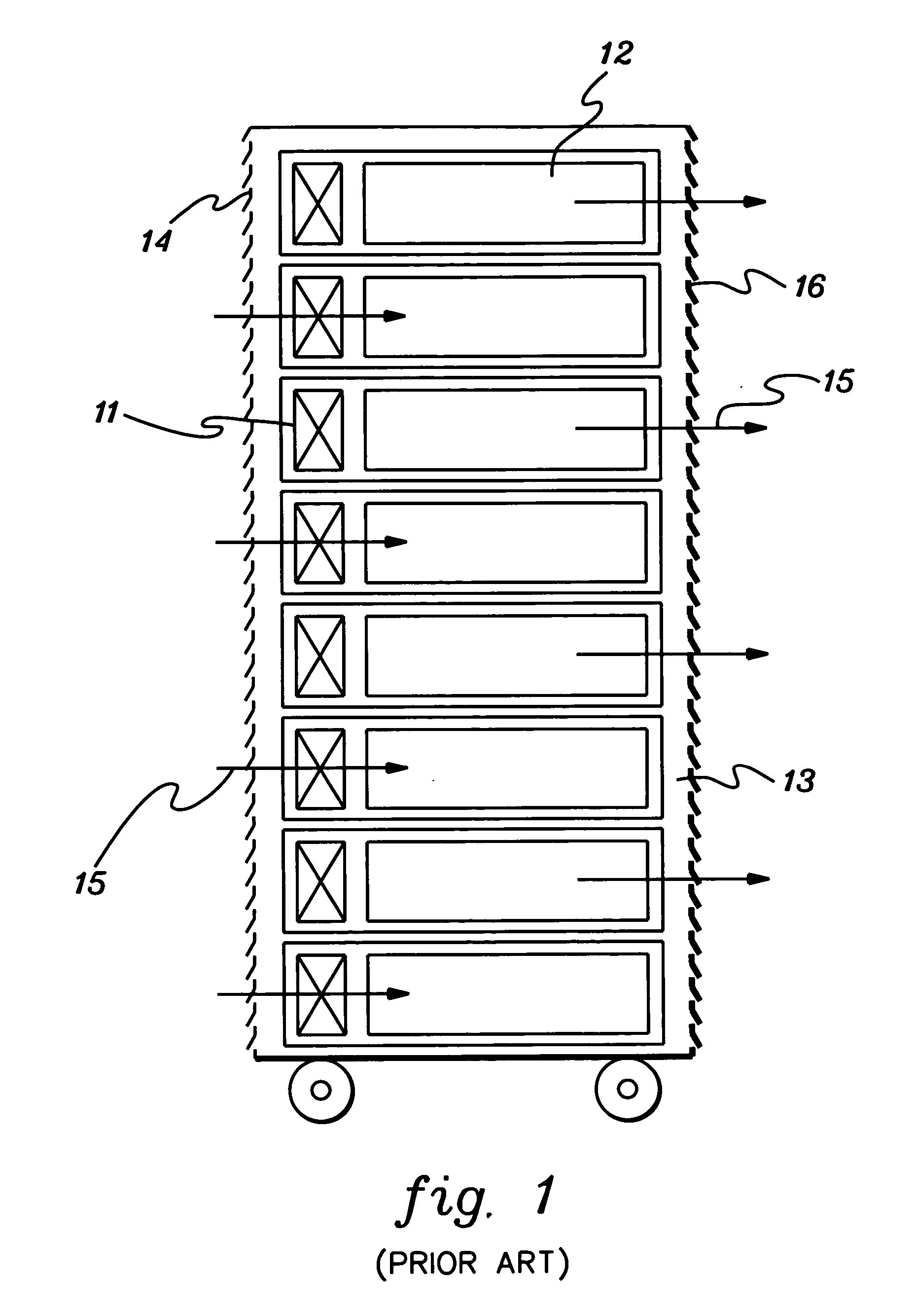

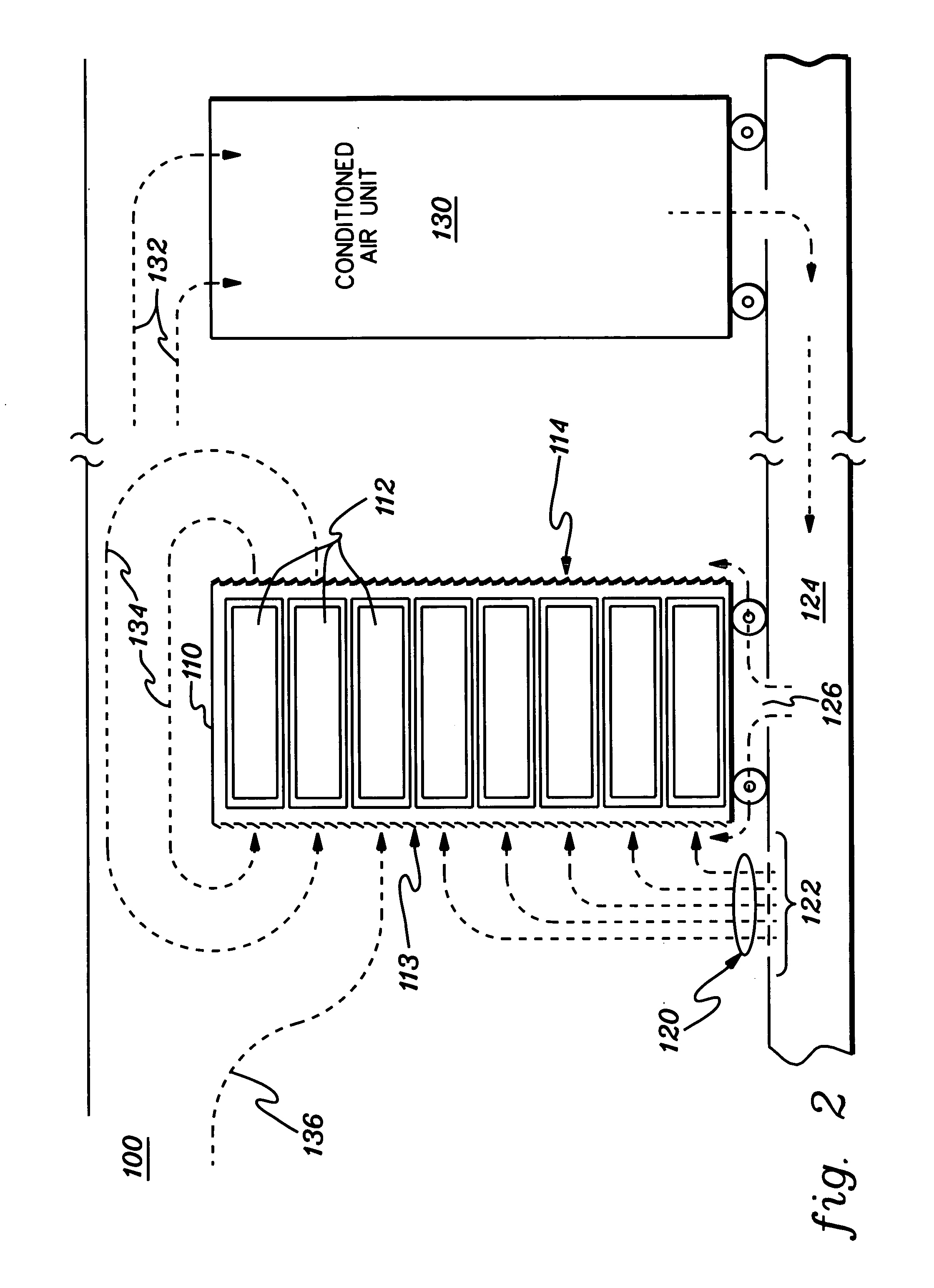

Air flow system and method for facilitating cooling of stacked electronics components

InactiveUS20050237716A1Improve cooling effectWell mixedCooling/ventilation/heating modificationsElectronic componentElectronics

An air flow system and method are provided which include a duct configured to mount either as an inlet or outlet duct to an electronics rack. When mounted to cover an air-intake side of the electronics rack, a supply air flow plenum is defined for directing conditioned air to the air-intake side. The duct includes a first air inlet at a first end for receiving the conditioned air, and is tapered from the first end to a second end thereof, with the supply plenum having a varying air flow cross-section. The duct further includes a second air inlet for providing supplemental room air to the plenum. The second inlet is disposed adjacent to the first inlet, thereby facilitating mixing of conditioned air with room air within the supply air flow plenum prior to delivery thereof to the air-intake side of the electronics rack.

Owner:IBM CORP

Fluid-assisted medical devices, systems and methods

InactiveUS20060116675A1Improve uniformityEnhanced couplingDiagnosticsCatheterElectricityMedical device

Surgical devices, systems and methods for treating tissue are provided. An exemplary surgical device comprises a tip portion including first and second jaws each having a tissue grasping surface, at least one of the jaws being movable toward the other jaw. The tissue grasping surface of each jaw has includes an electrically insulative surface. The device also includes first and second electrodes connectable to different terminals of an RF generator to generate electrical current flow therebetween, with each of the electrodes having an electrode surface. One of the electrode surfaces is located on one of the jaws separated from one edge of the tissue grasping surface, and the other of the electrode surfaces is located on one or the other of the jaws separated from the other edge of the tissue grasping surface. The device also includes at least one fluid passage being connectable to a fluid source.

Owner:MEDTRONIC ADVANCED ENERGY

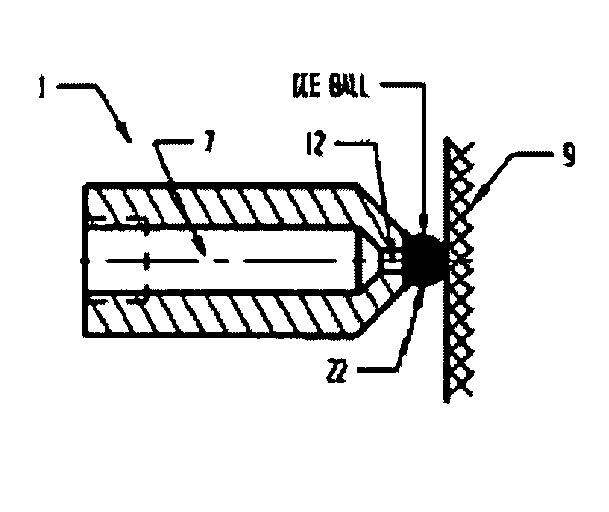

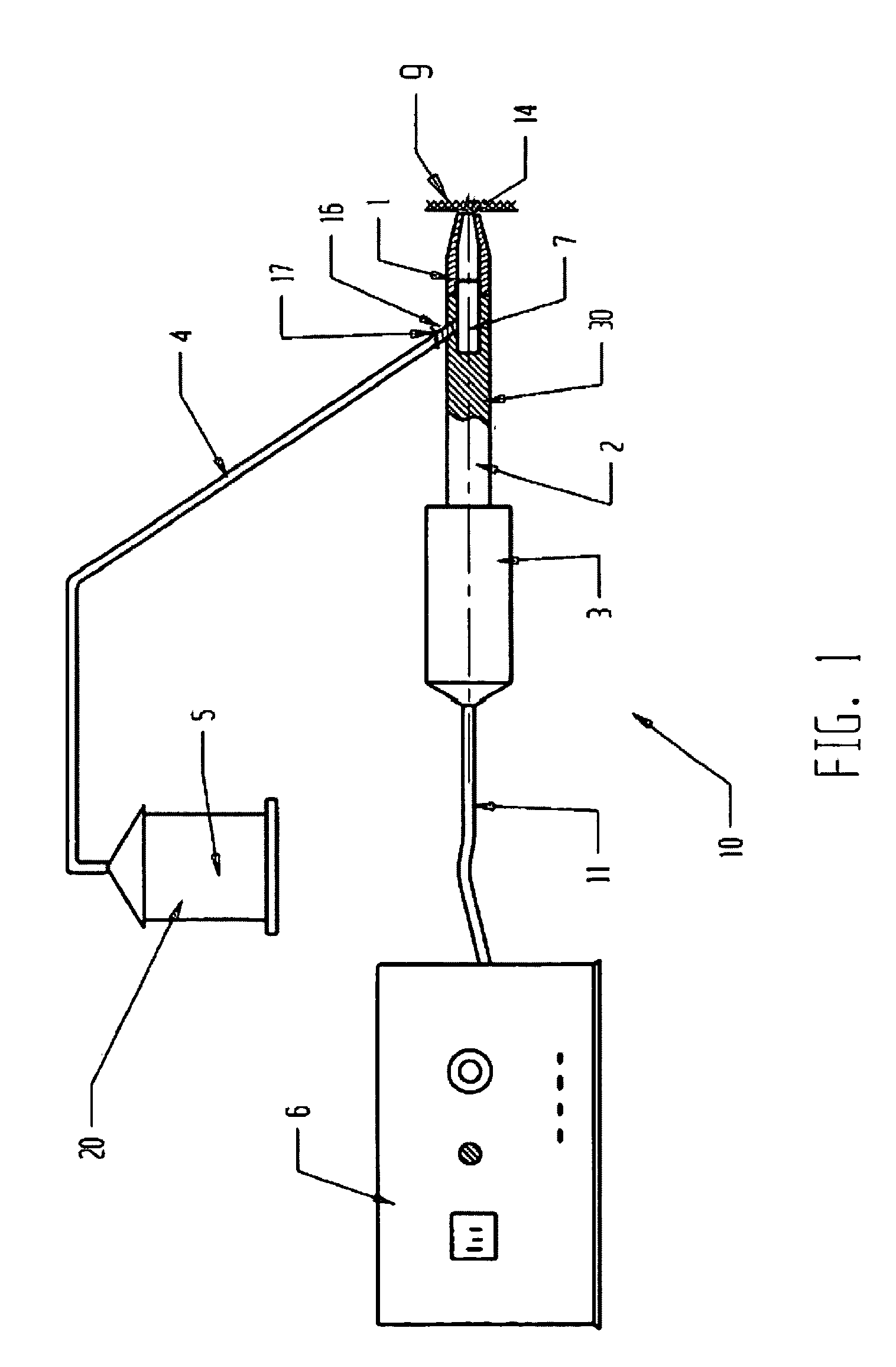

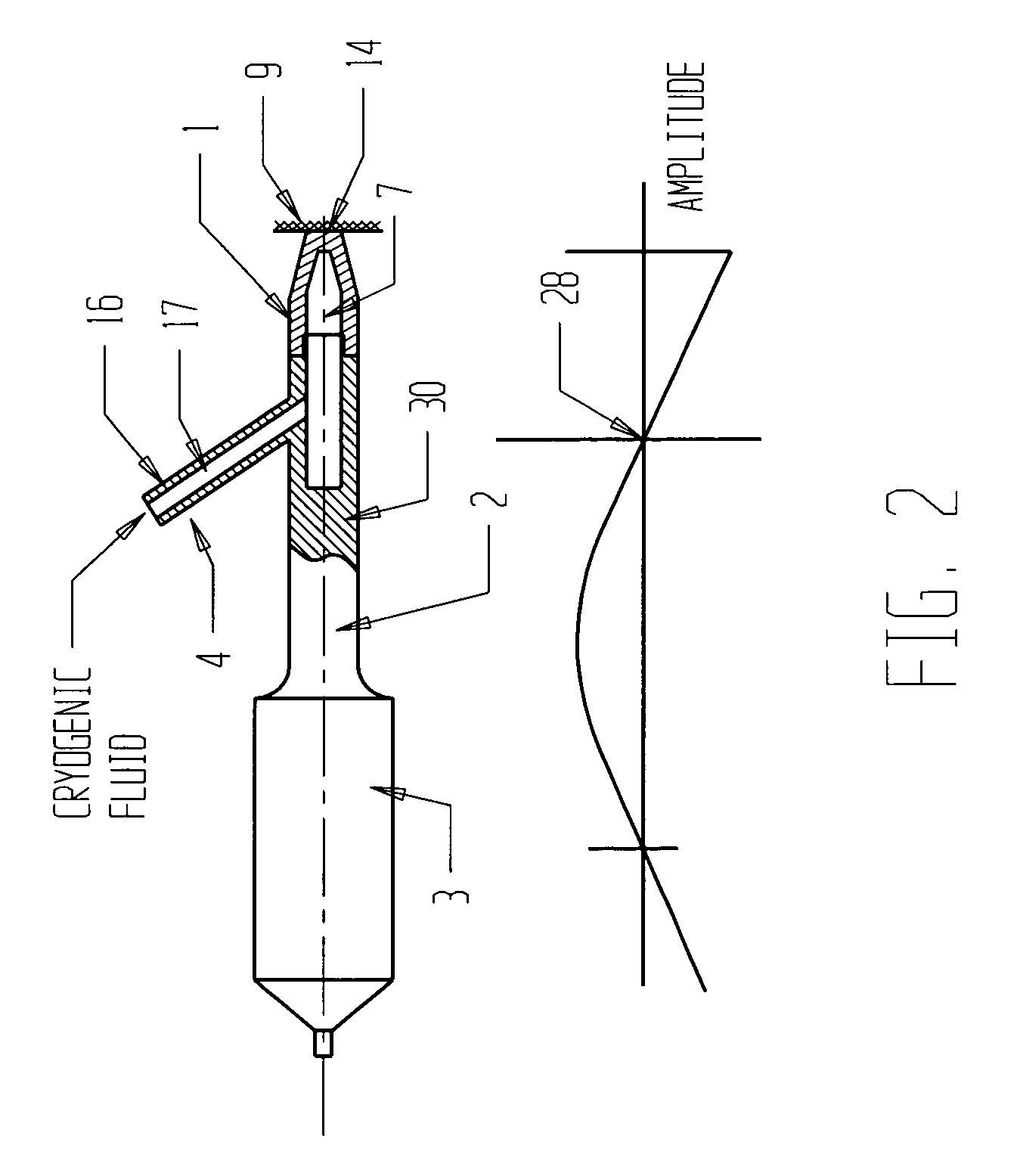

Apparatus and methods for the selective removal of tissue using combinations of ultrasonic energy and cryogenic energy

InactiveUS7572268B2Improve cooling effectAvoid stickingUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyUltrasound deviceUltrasound energy

An ultrasonic apparatus and method is provided for the selective and targeted removal of unwanted tissues. The apparatus and methods may utilize combinations of ultrasonic and cryogenic energy for the selective removal tissue. The apparatus generates and delivers to the tissue cryogenic and ultrasonic energy either in combination or in sequence, provides resize ablation of unwanted tissue parts, and may be used on various body tissues including internal organs.

Owner:BACOUSTICS LLC

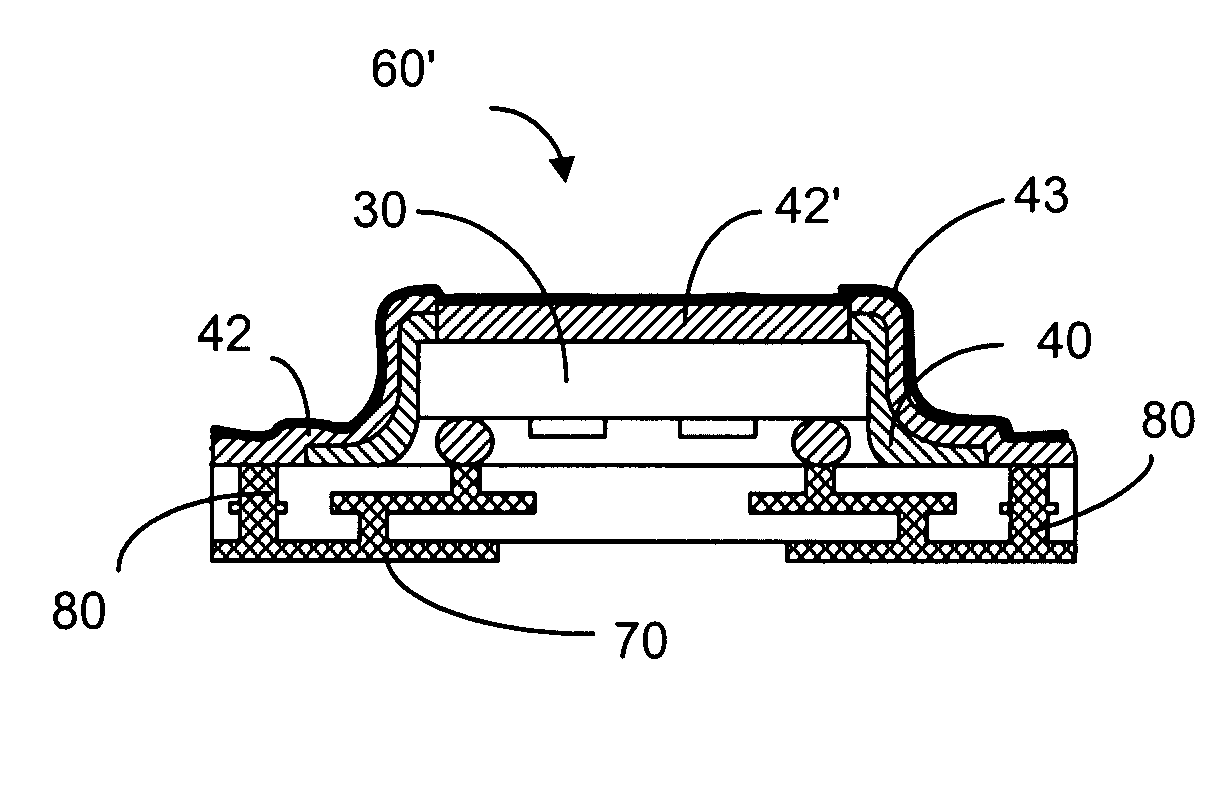

Encapsulated electronics device with improved heat dissipation

ActiveUS6992400B2Improve cooling effectImpedence networksSemiconductor/solid-state device detailsHermetic sealHeat conducting

A method for improving heat dissipation in an encapsulated electronic package usually referred to as a chip-size SAW package. The package comprises one or more acoustic-wave components fabricated on a die, which is disposed on an electrically non-conductive carrier separated by electrically conducting bumps. The top of the package is covered by a laminate and a hermetic seal layer. Heat dissipation can be improved by removing a part of the laminate and then depositing a layer of thermal conducting material on the package, and by providing one or more heat conducting paths through the carrier.

Owner:NOKIA CORP

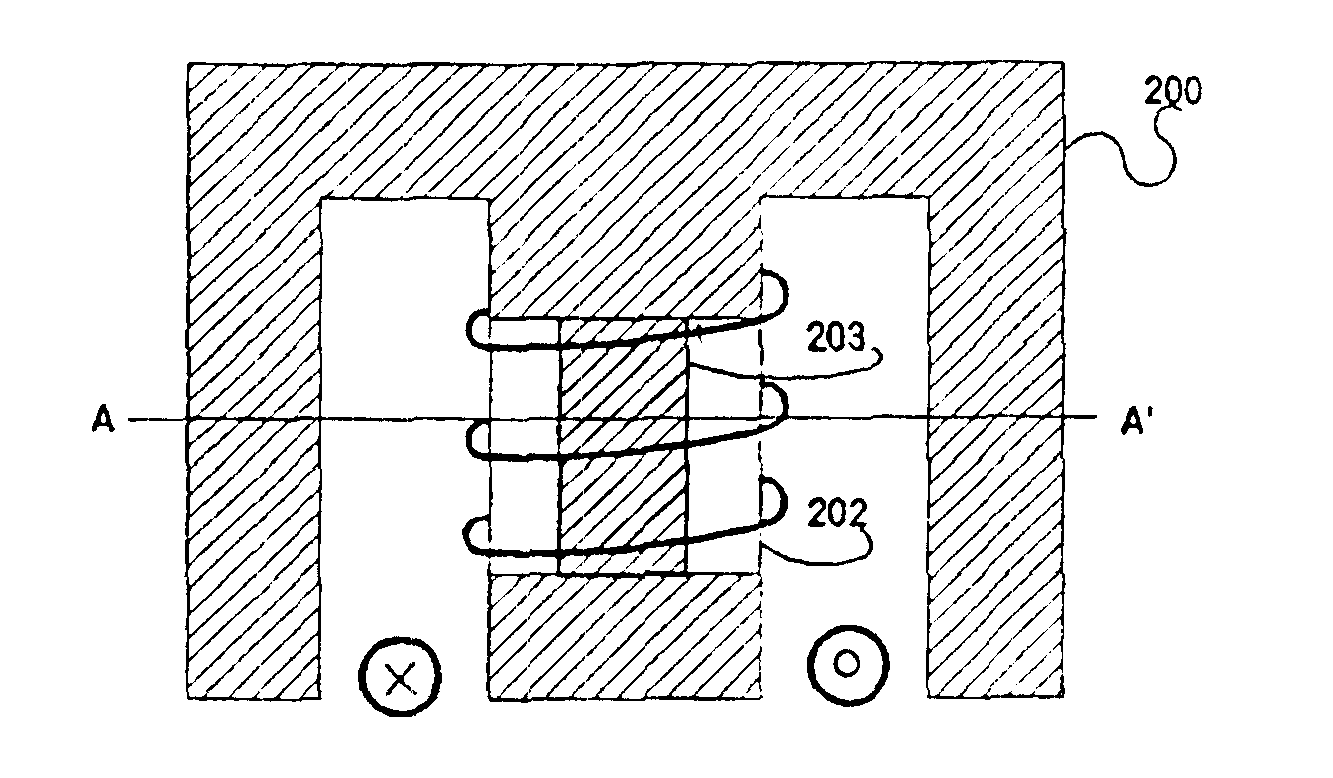

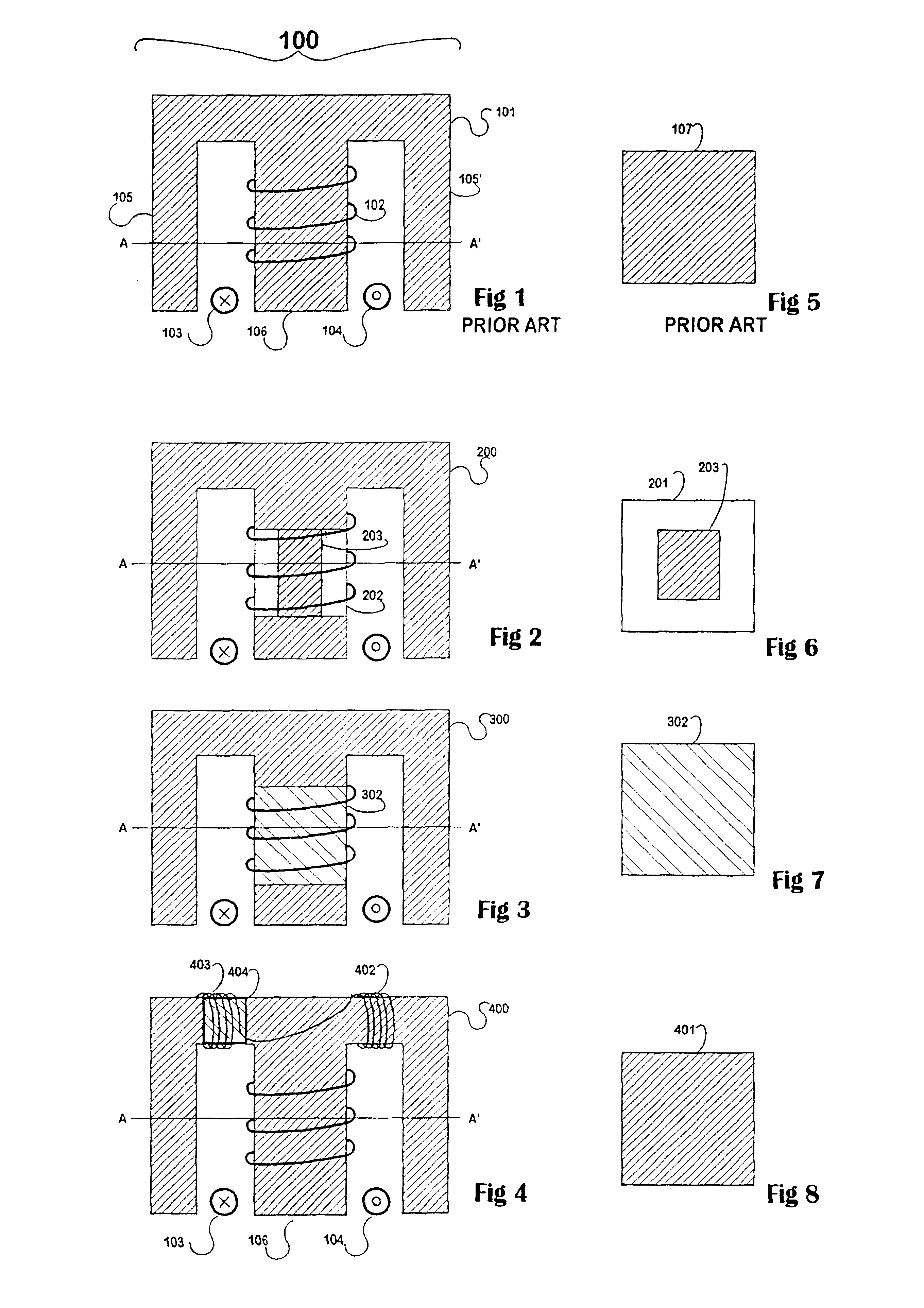

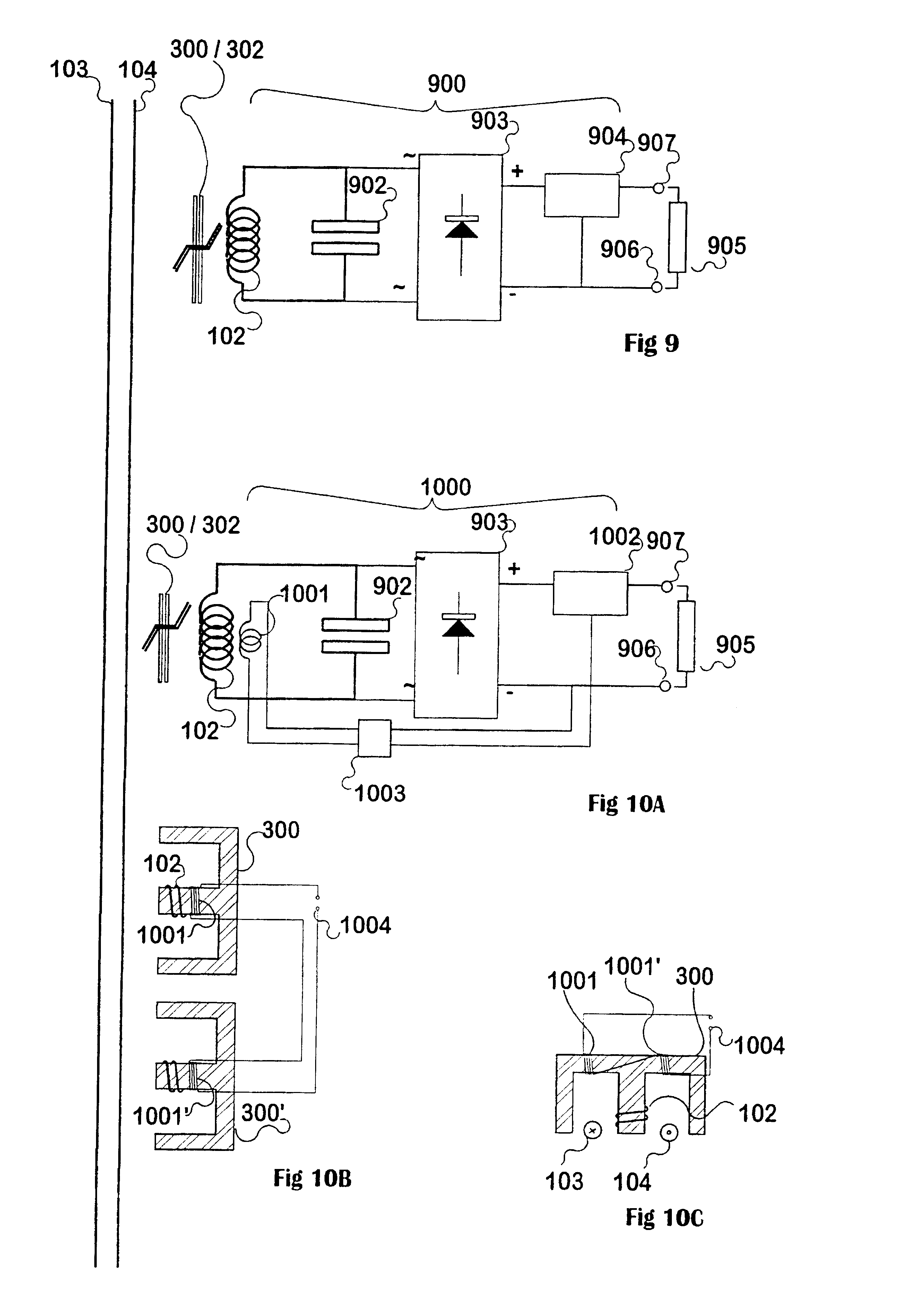

Control of inductive power transfer pickups

InactiveUS6483202B1Reliable fail-safe control featureDecrease in saturation capacityRail devicesElectromagnetic wave systemDc currentEngineering

Secondary resonant pickup coils (102) used in loosely coupled inductive power transfer systems, with resonating capacitors (902) have high Q and could support large circulating currents which may destroy components. A current limit or "safety valve" uses an inductor designed to enter saturation at predetermined resonating currents somewhat above normal working levels. Saturation is immediate and passive. The constant-current characteristic of a loosely coupled, controlled pickup means that if the saturable section is shared by coupling flux and by leakage flux, then on saturation the current source is terminated in the saturated inductor, and little detuning from resonance occurs. Alternatively an external saturable inductor (1101, 1102) may be introduced within the resonant circuit (102 and 902), to detune the circuit away from the system frequency. Alternatively DC current may be passed through a winding to increase saturation of a saturable part of a core. As a result, a fail-safe pickup offering a voltage-limited constant-current output is provided.

Owner:AUCKLAND UNISERVICES LTD

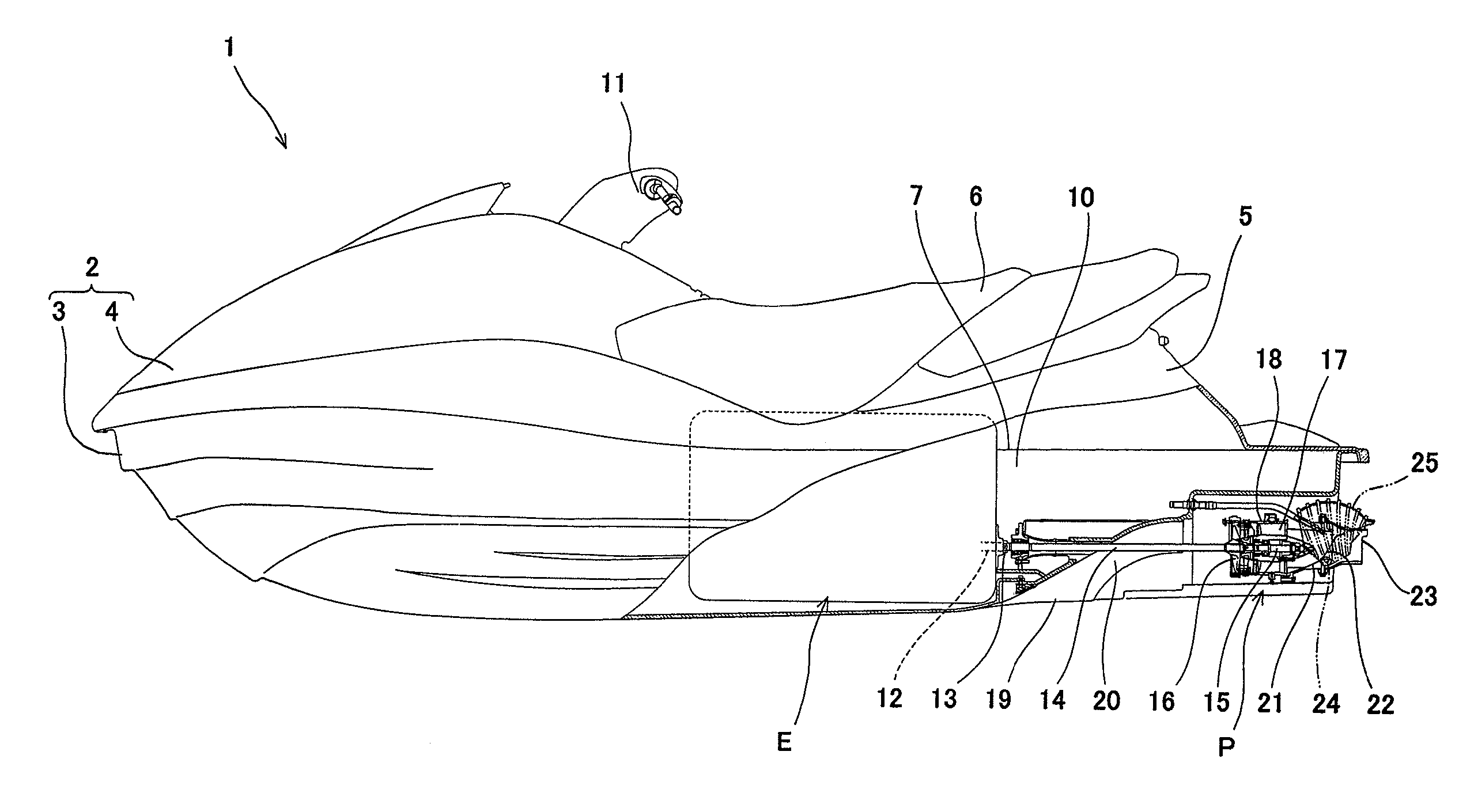

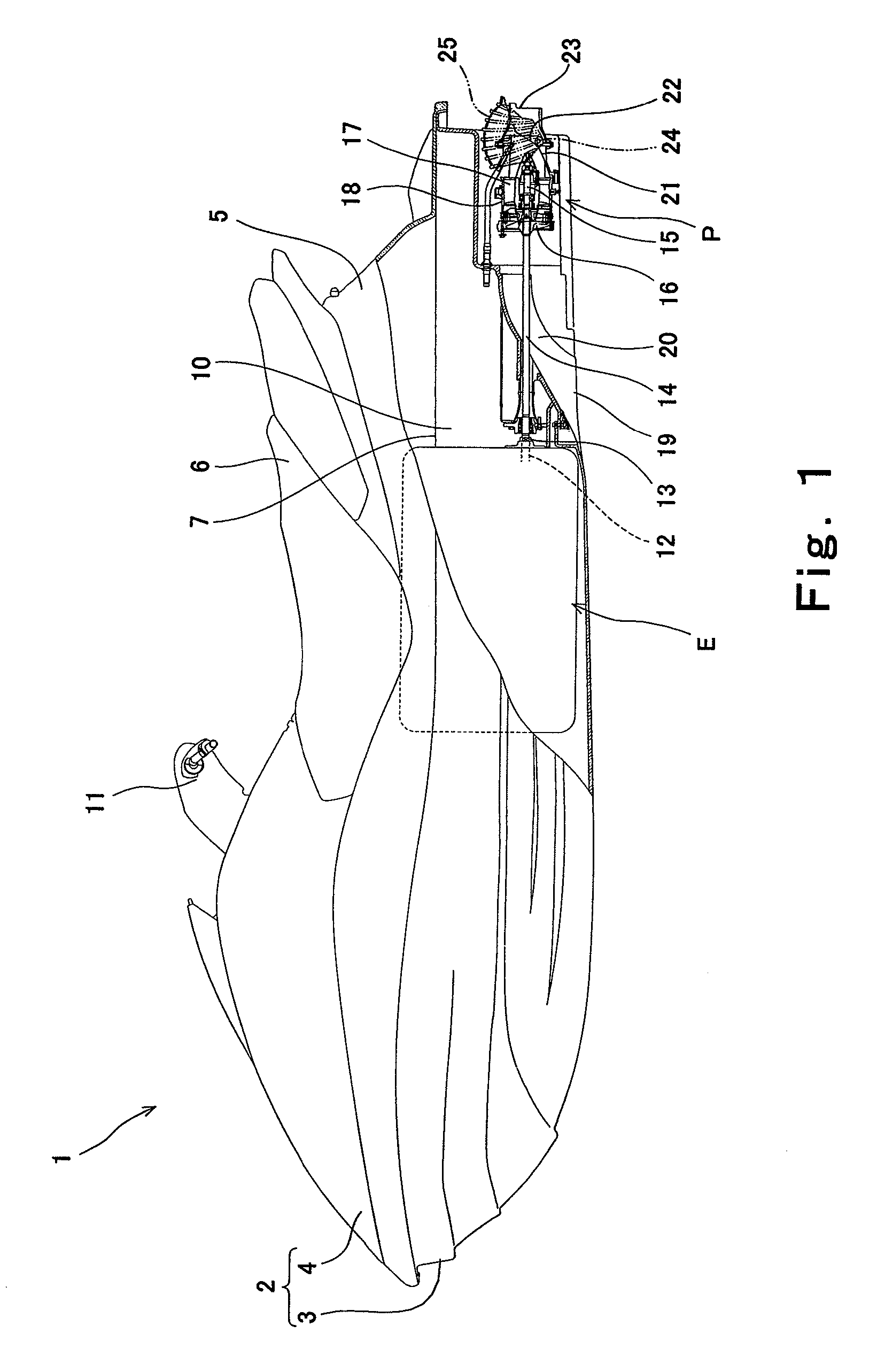

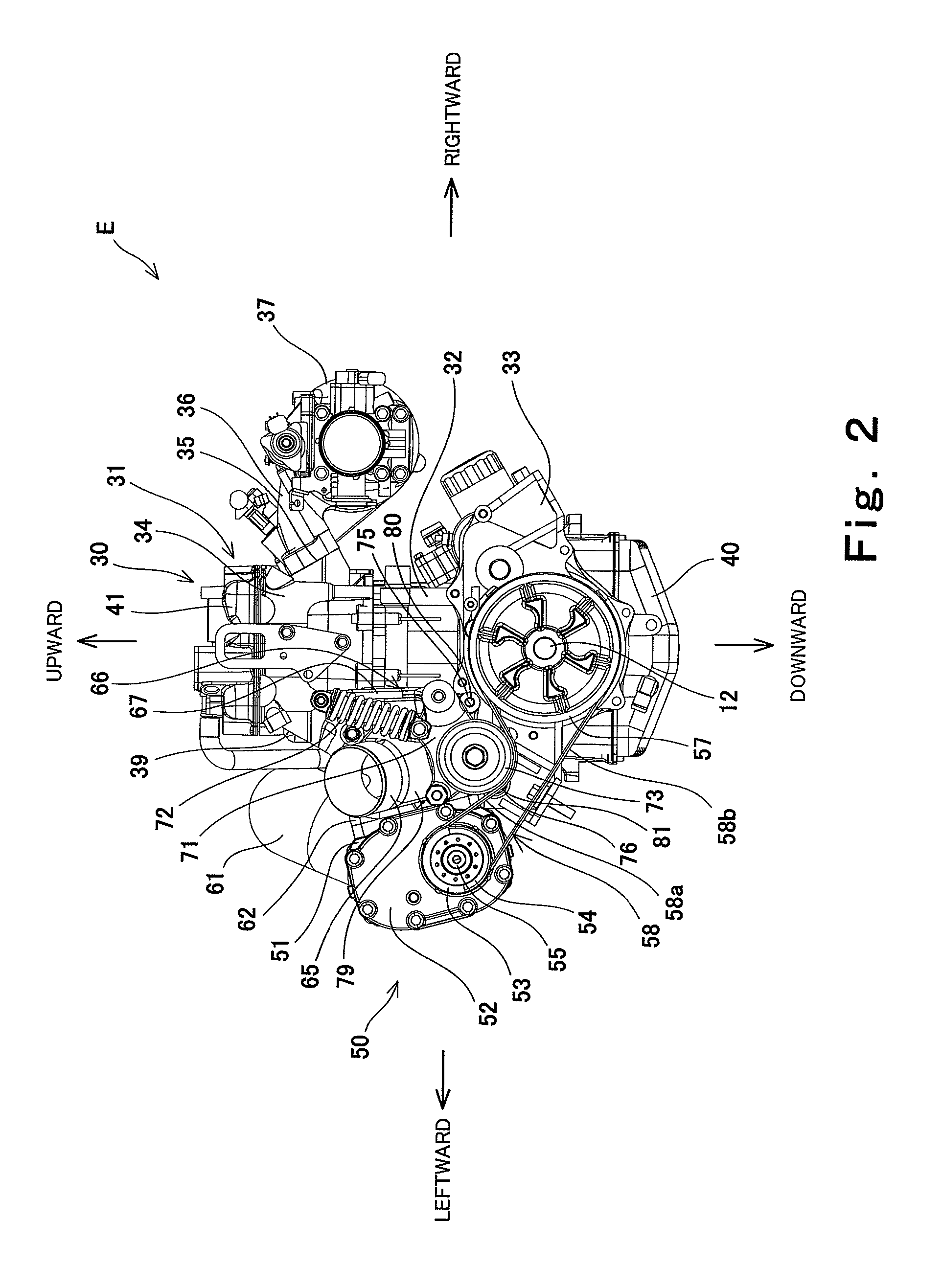

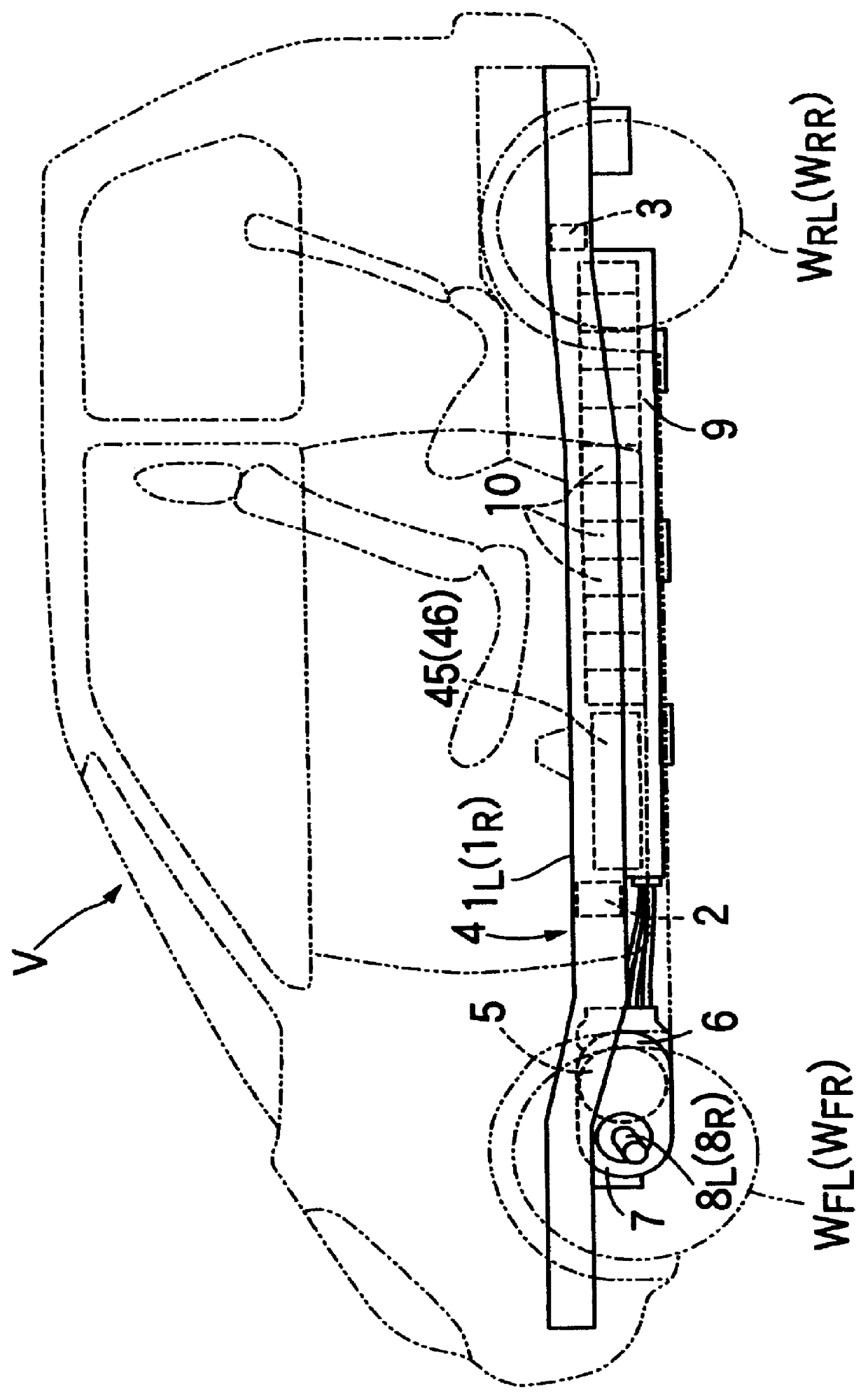

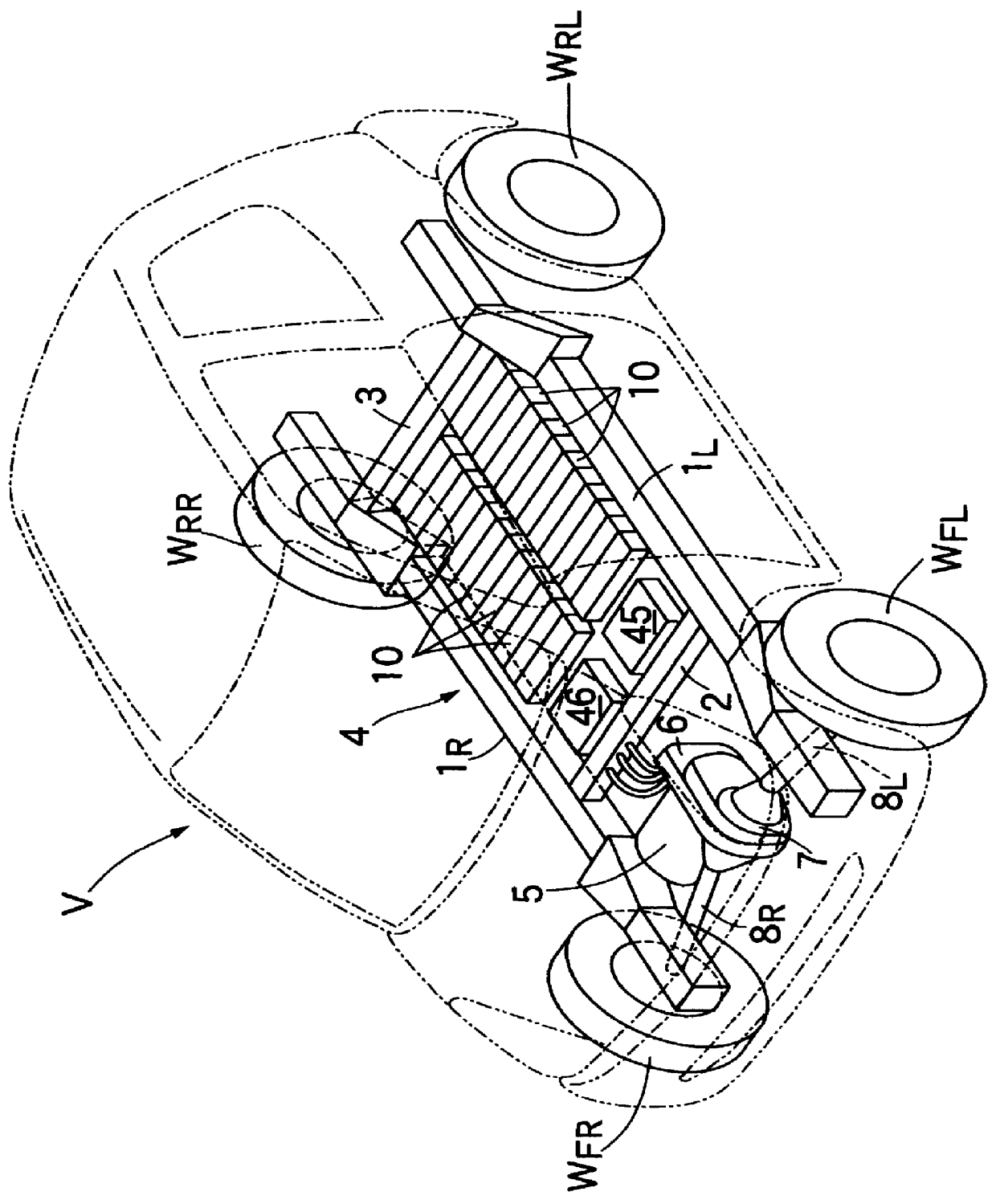

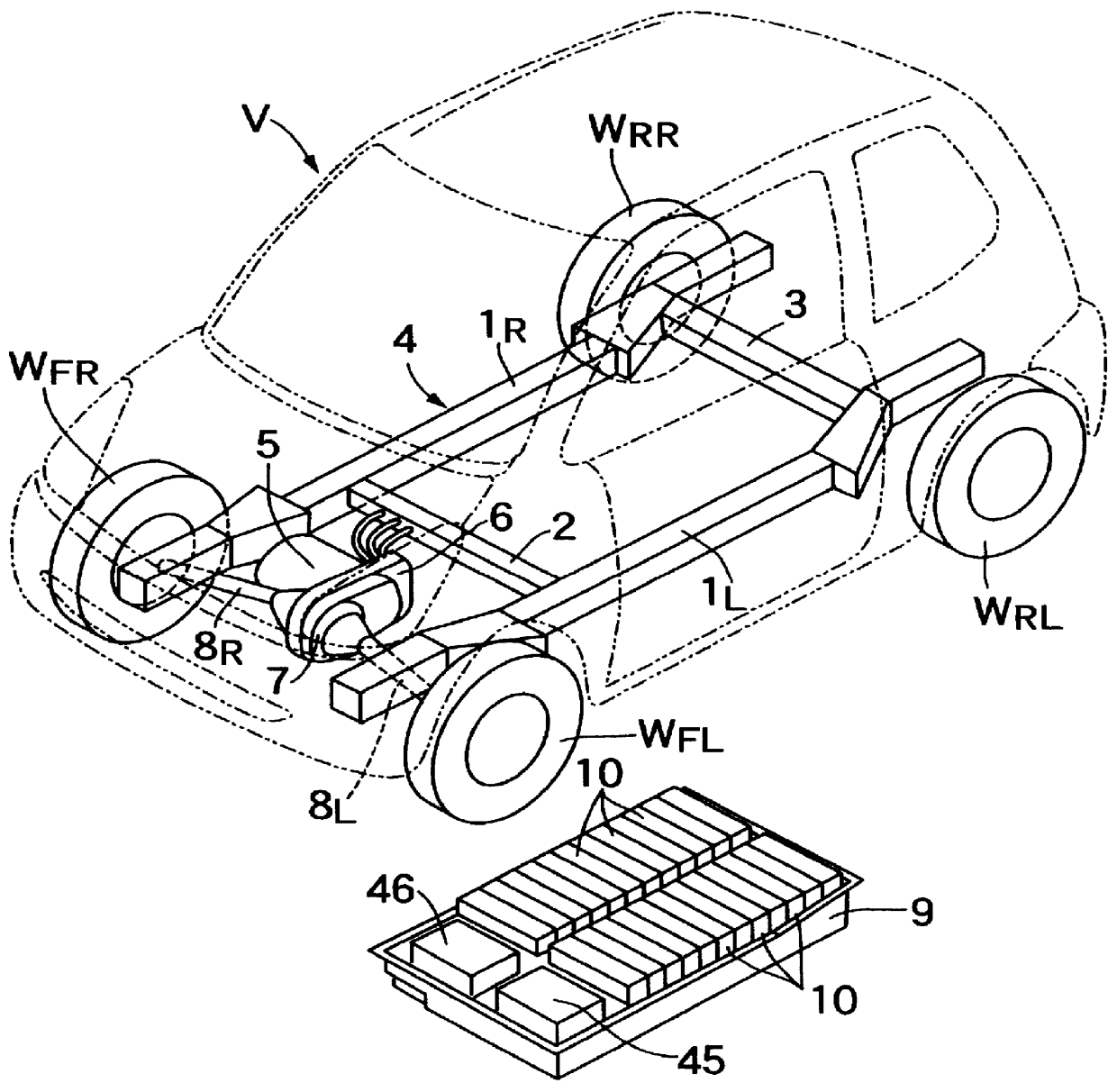

Cooling structure an electric vehicle

InactiveUS6094927AReliable coolingImprove cooling effectDomestic cooling apparatusLighting and heating apparatusAirflowThermal resistance

An electric vehicle includes plurality of batteries accommodated in a rear portion of a battery box, and an electric part is accommodated in an electric part accommodating chamber provided in a front portion of the battery box. Cooling air supplied from a cooling fan to the rear portion of the battery box cools the batteries having a large thermal resistance, while being passed through a first cooling air passage around outer peripheries of the batteries at a low flow rate. A second cooling air passage having a smaller sectional area than that of the first cooling air passage is provided below the electric part accommodating chamber, and cooling fins protruding downwards from the electric part are exposed within the second cooling air passage. The second cooling air passage extends continuously the first cooling air passage in a downstream direction of airflow, so that cooling air which has first cooled the batteries then cools the electric part having a smaller thermal resistance, while being passed through the second cooling air passage at a higher flow rate than that in the first cooling air passage.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com