Patents

Literature

567 results about "Ultrasonic beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

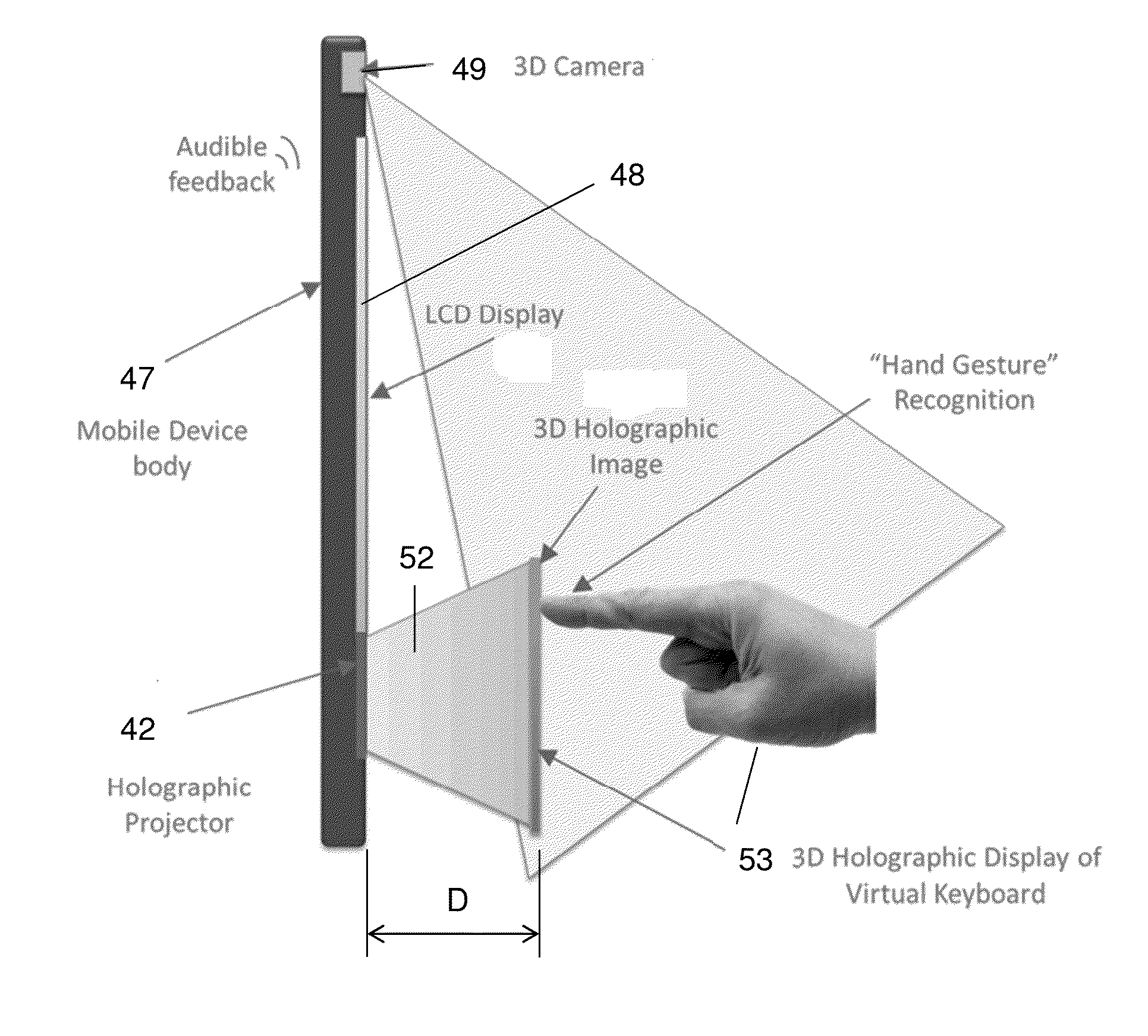

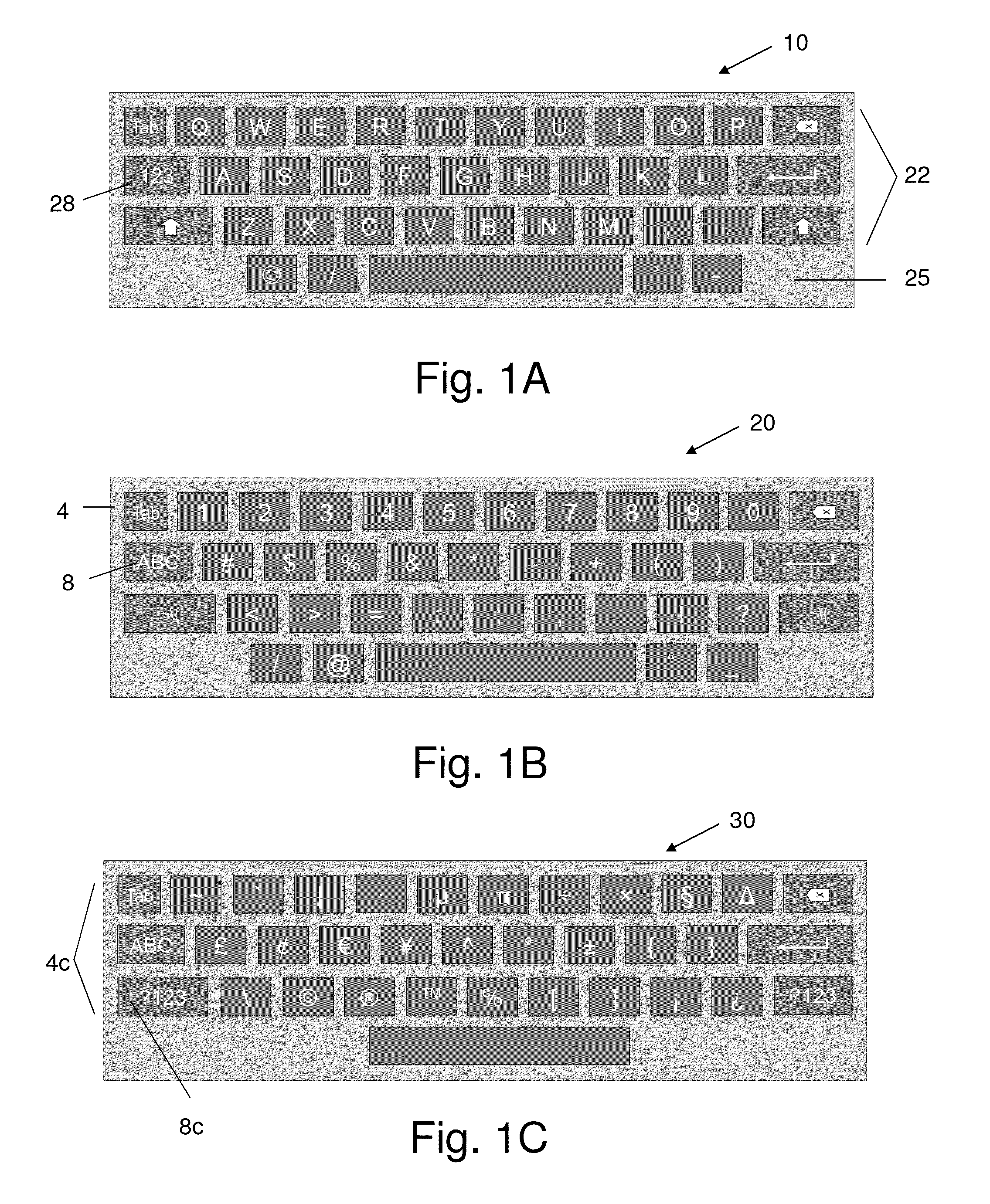

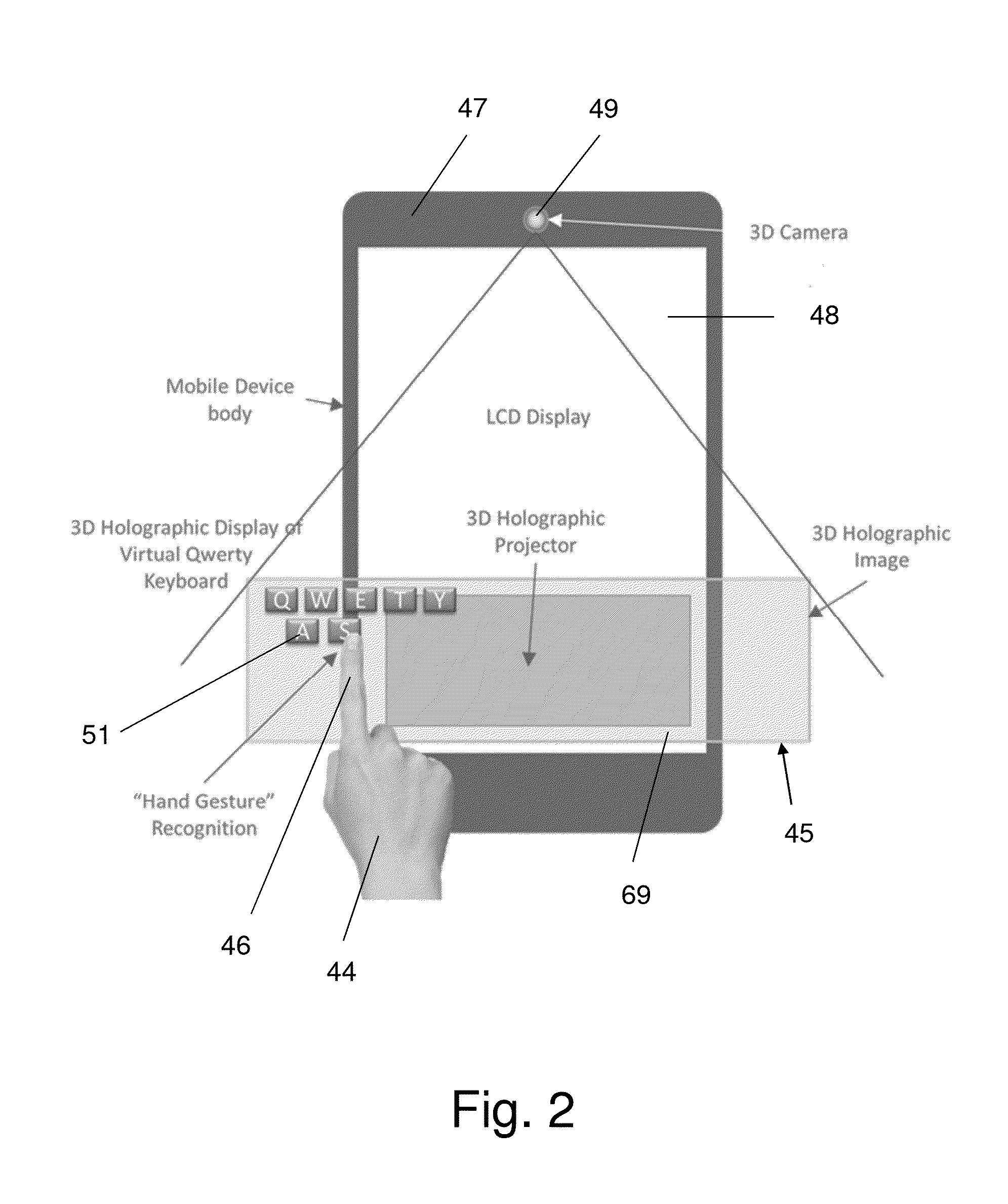

System for generating and controlling a variably displayable mobile device keypad/virtual keyboard

A system for generating and controlling a variably displayable virtual keypad includes a mobile device with a screen on which is displayable selected content, holographic projectors, from image generating data retrievable from a memory, a virtual keypad appearing to be free-floating and suspended in mid-air. An input identification unit identifies a virtual key pressing operation performed in conjunction with the generated virtual keypad, determining which key of the virtual keypad has been virtually pressed, and transmitting an input command in response to the virtual key pressing operation by which the displayed content is modifiable. The input identification unit includes a 3D camera capturing gestures of a user hand and transmitting a signal indicative of gesture related data to a microprocessor for translating the gesture related data into the input command by instructions stored in the memory device. The microprocessor generates feedback in response to the virtual key pressing operation to indicate which key has been virtually pressed and to modify a visualization parameter of the generated virtual keypad. The feedback may be in the form of an ultrasonic beam propagatable to the initiating finger.

Owner:BEN MEIR YORAM

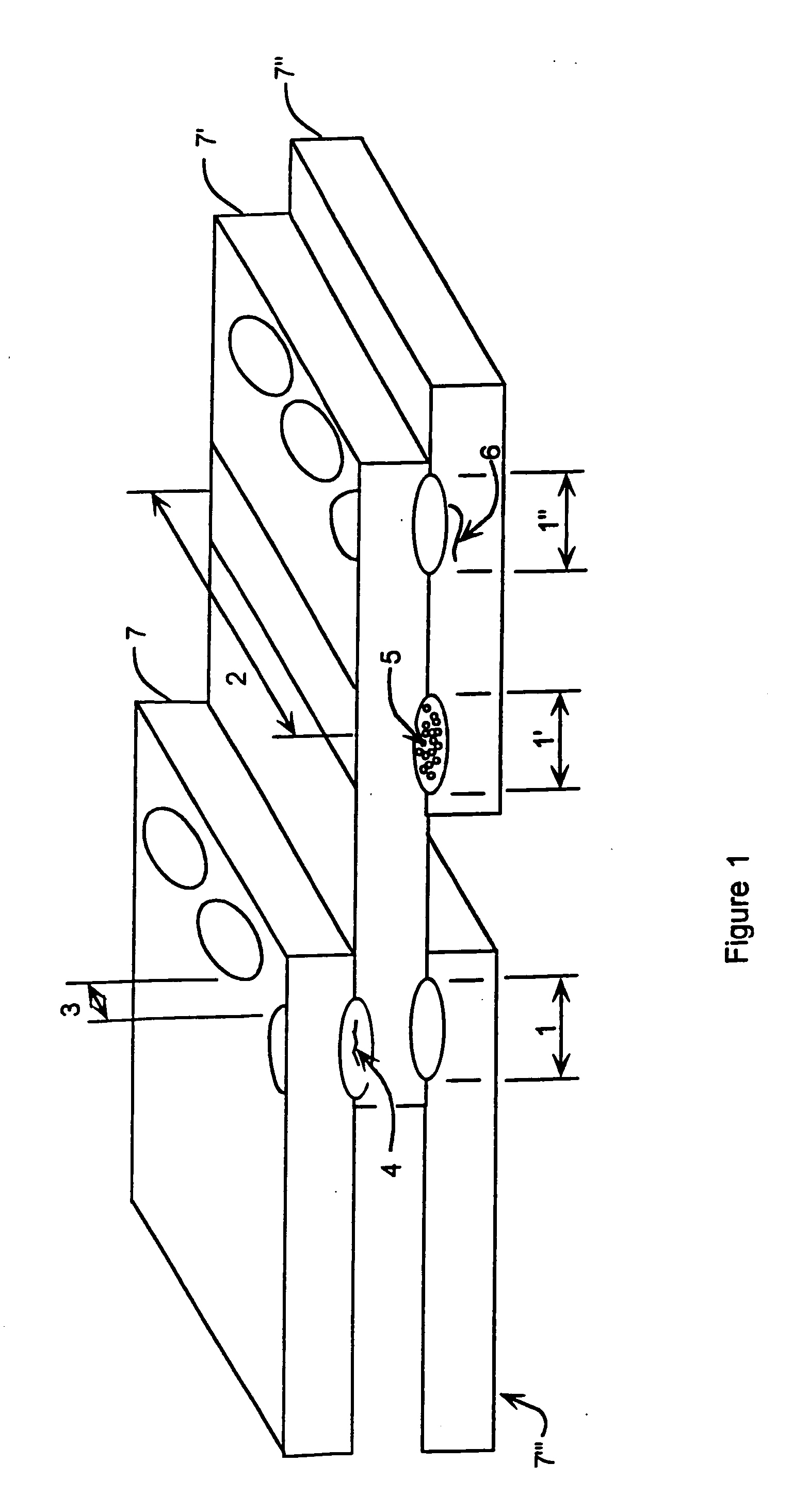

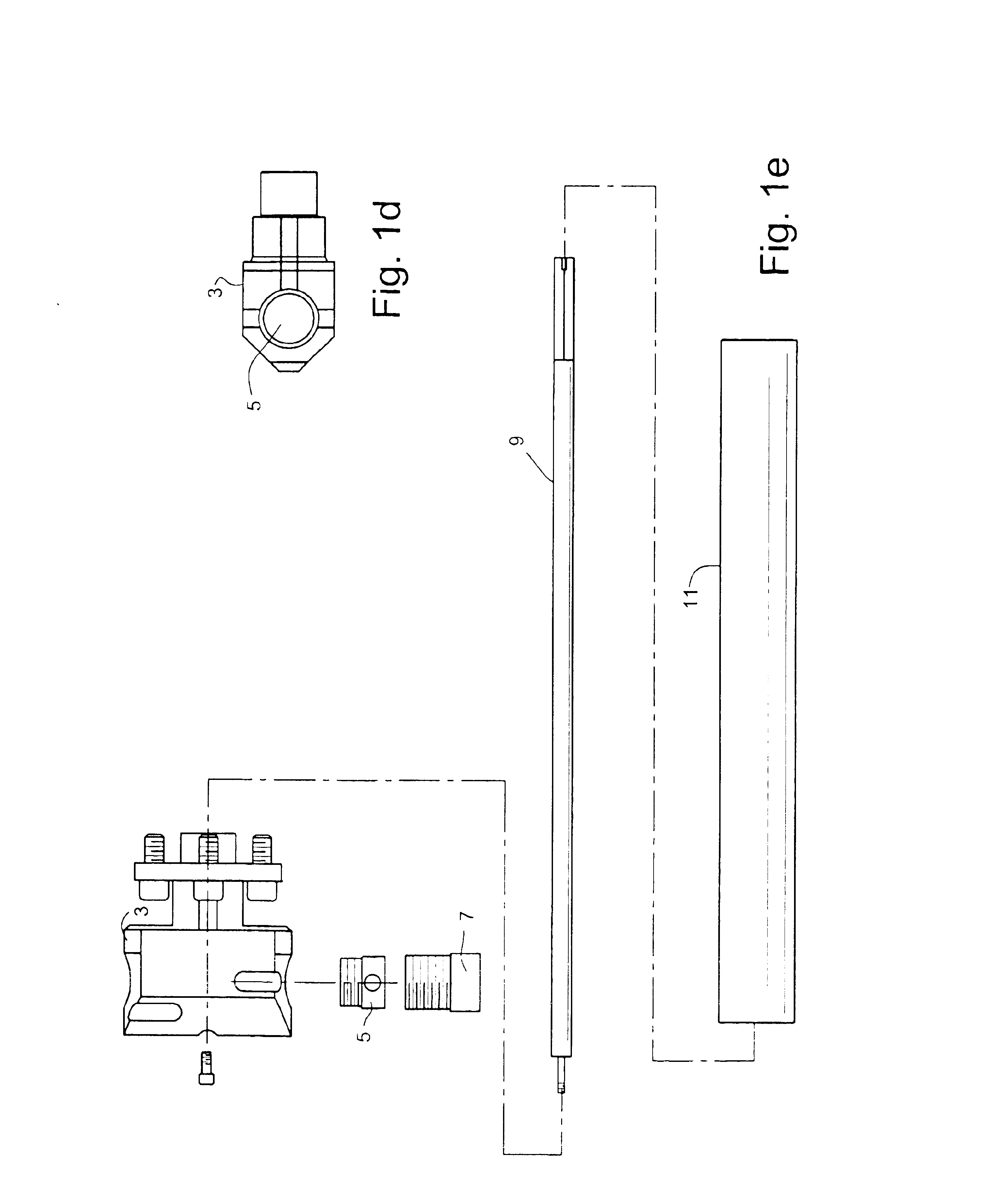

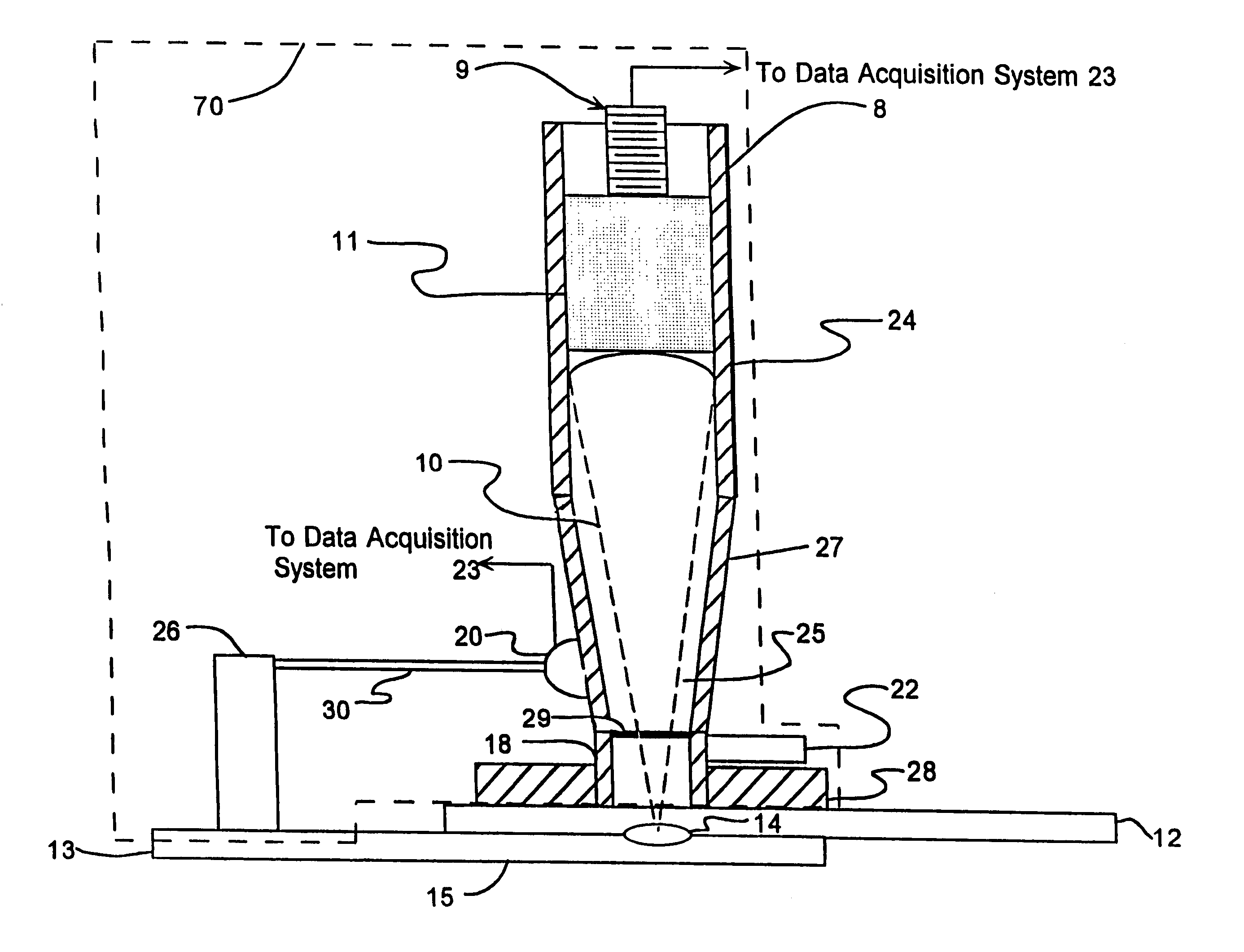

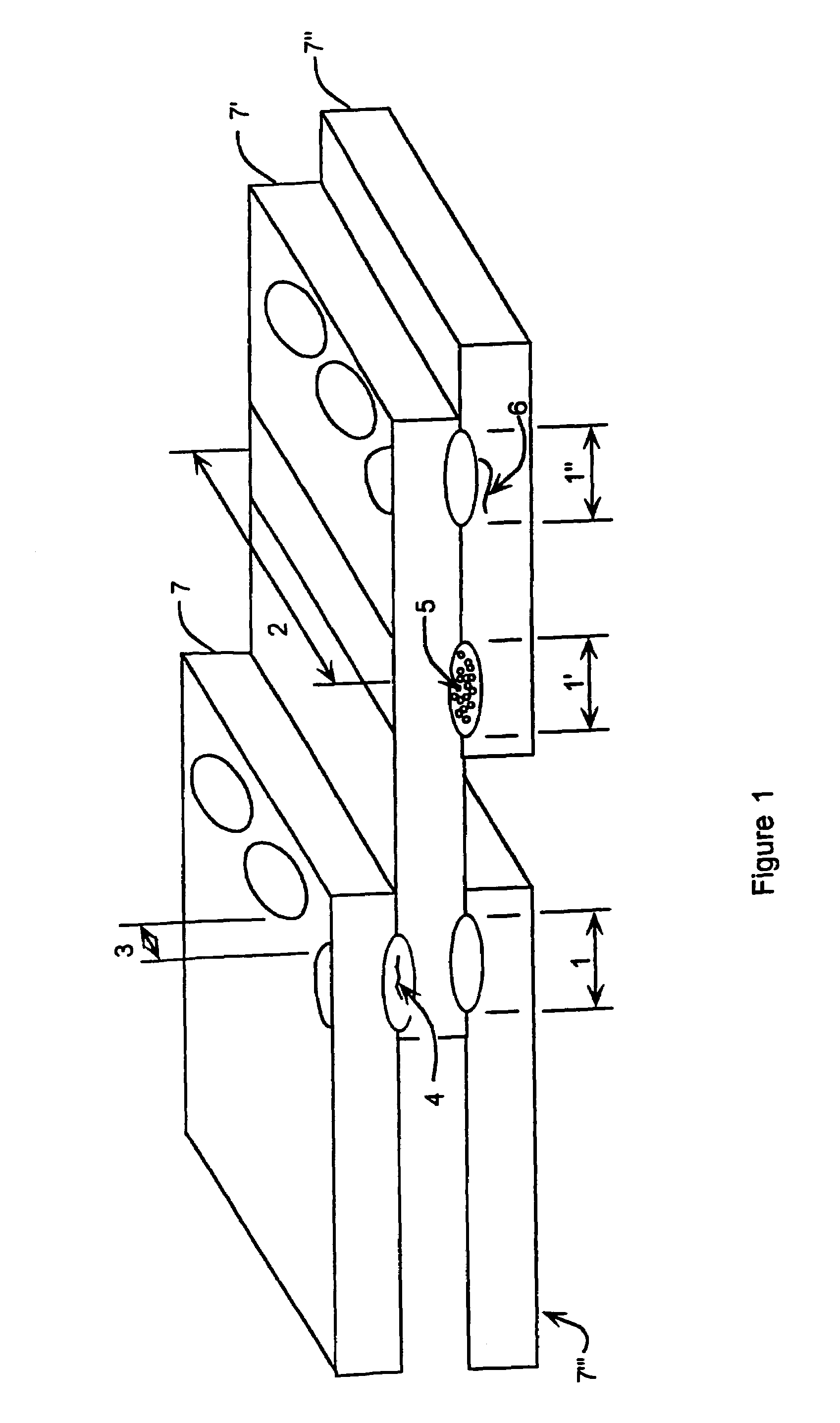

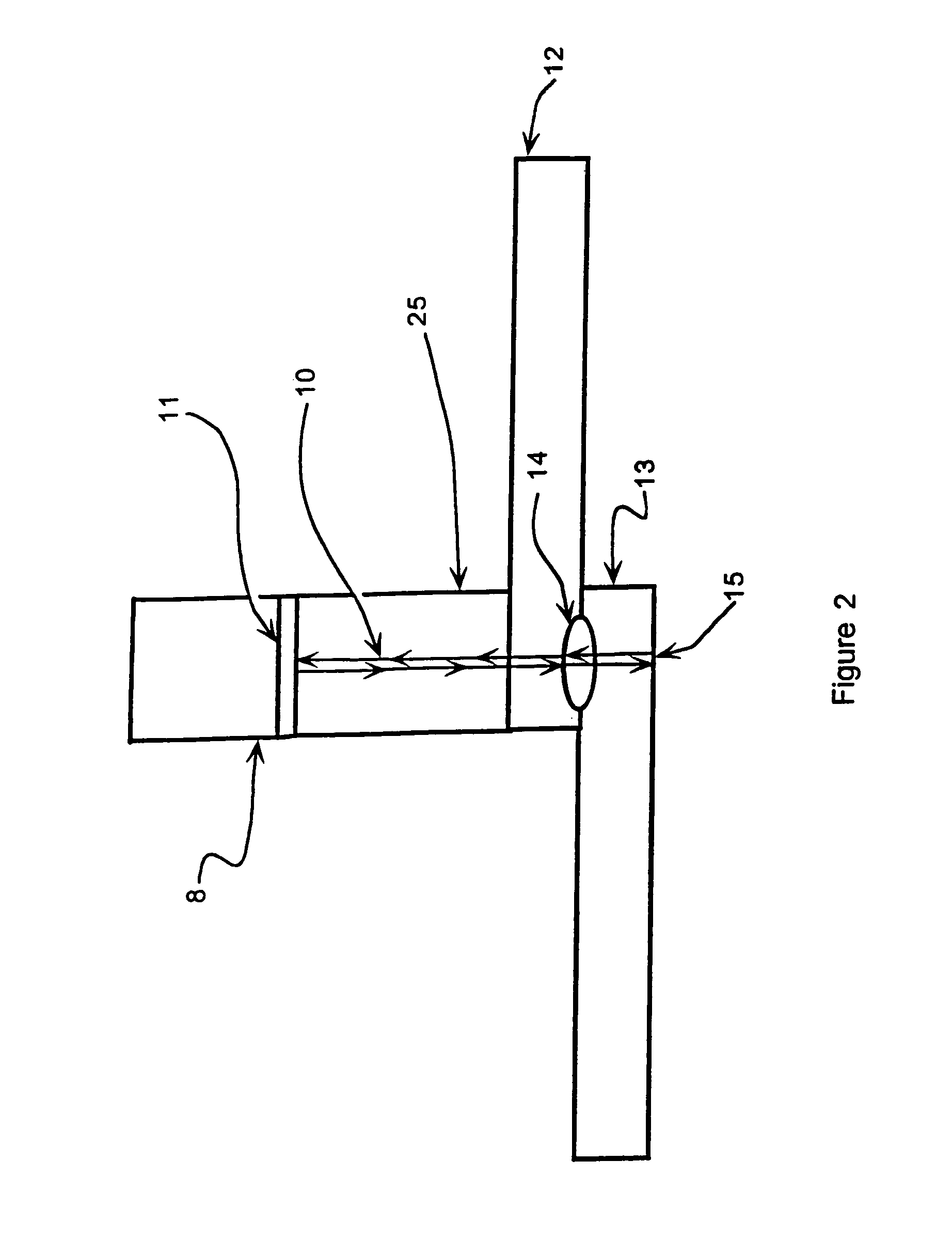

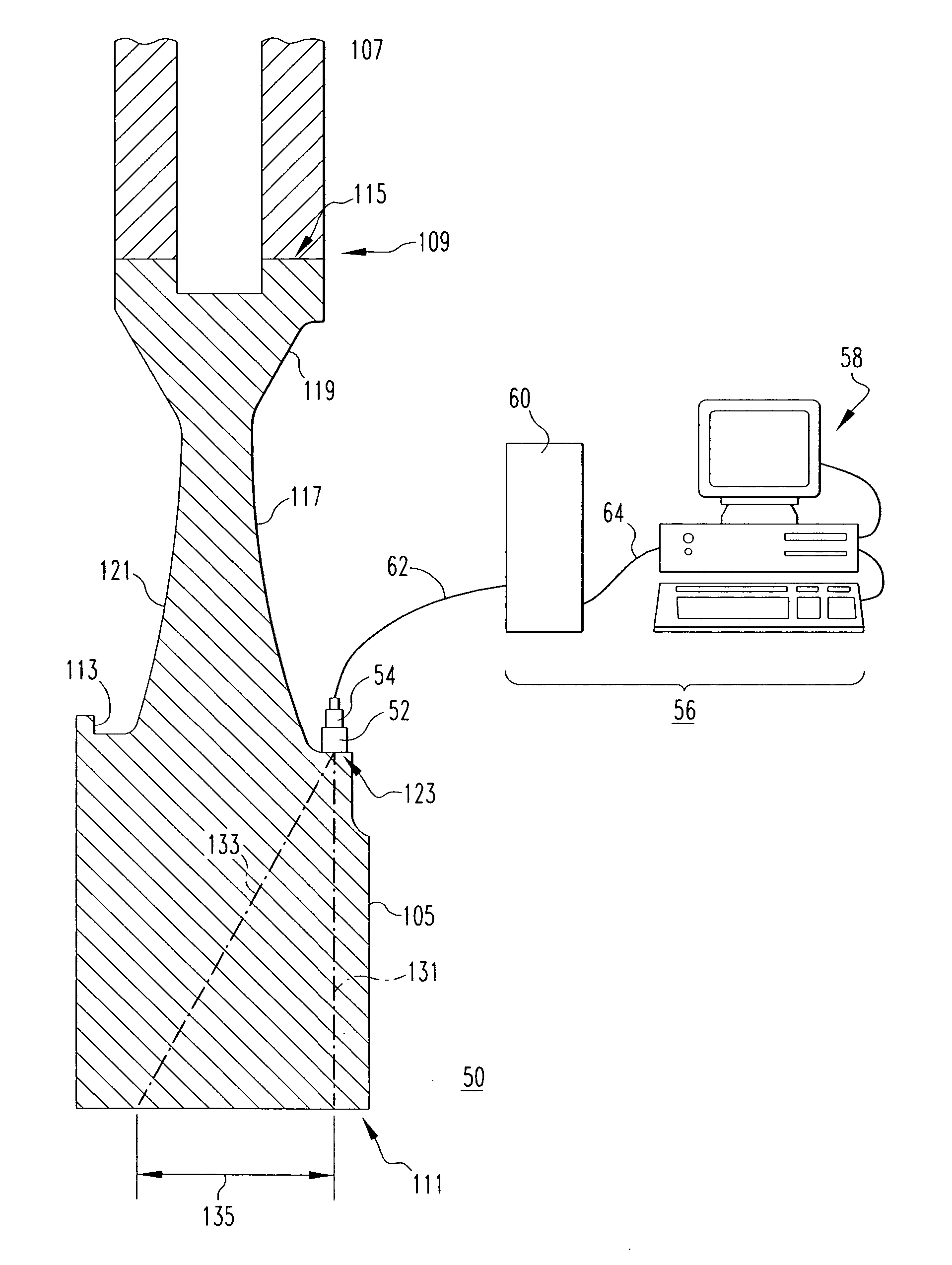

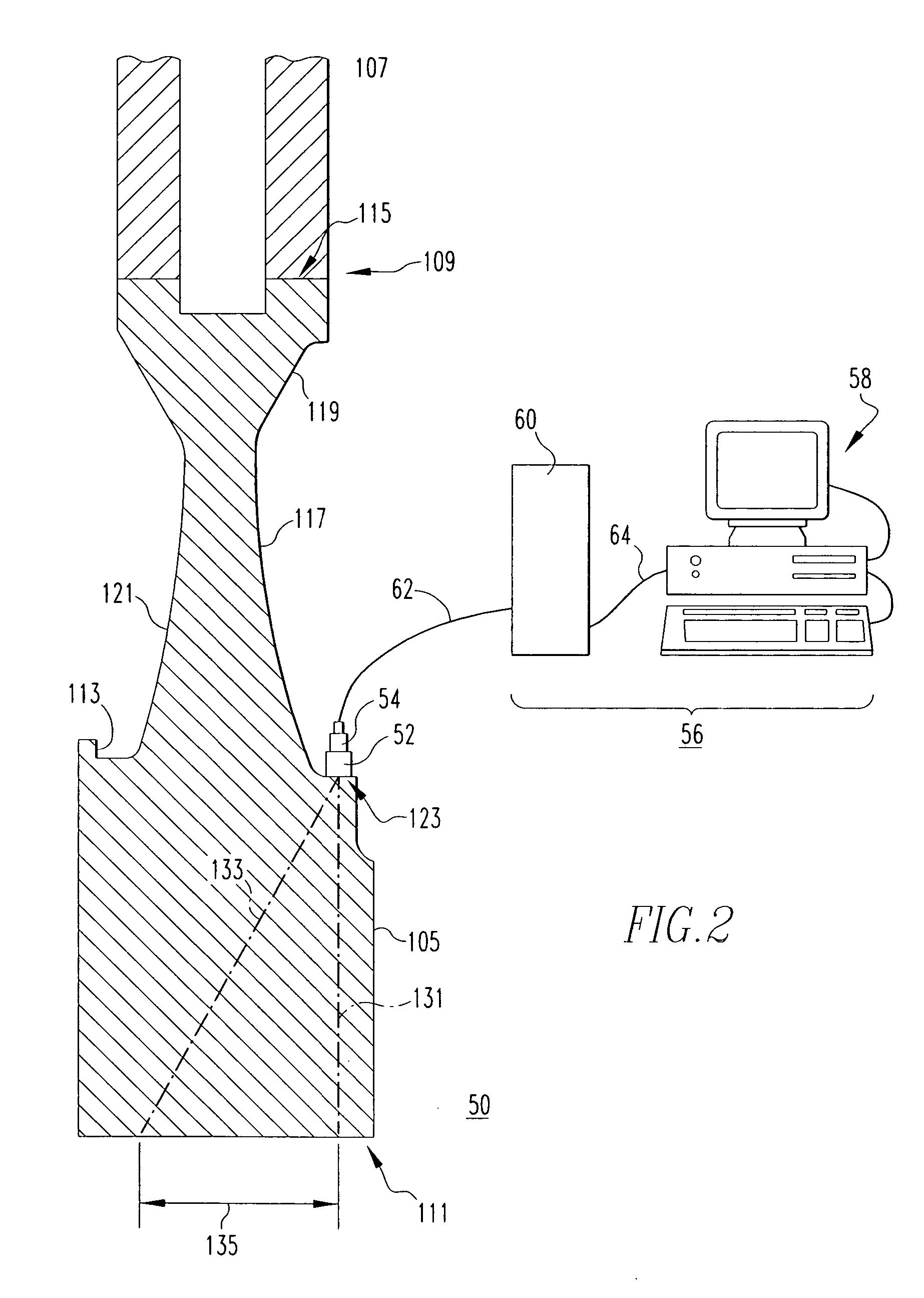

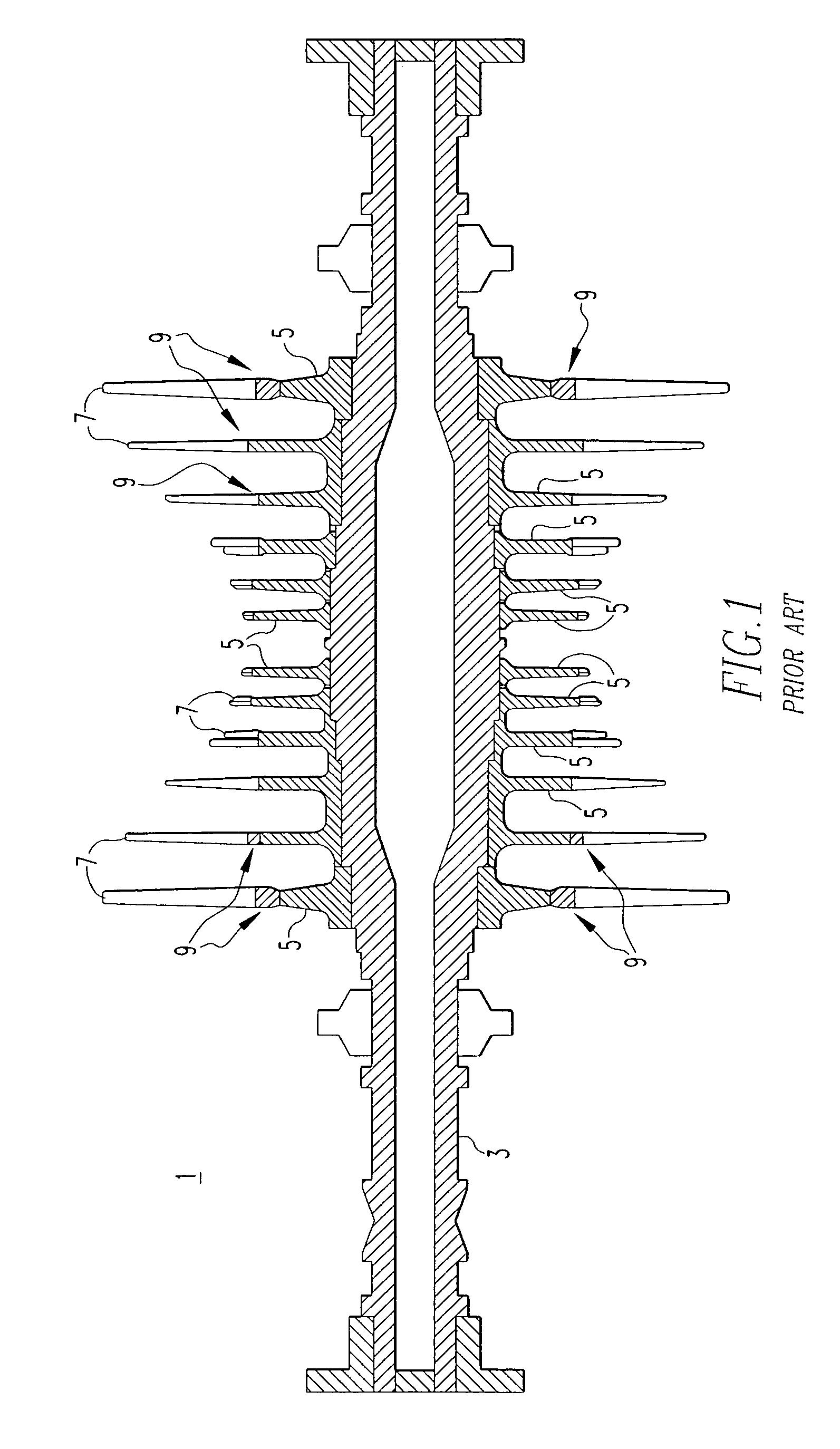

Methods for ultrasonic inspection of spot and seam resistance welds in metallic sheets and a spot weld examination probe system (SWEPS)

InactiveUS20050132809A1Allow flexibilityAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveElectrical resistance and conductance

An external focused ultrasonic beam, non-destructive, open-air, inspection method of sheet metal spot and seam weldments using a probe in combination with motion measurement of the probe over the weldments during inspection without immersion of the material. Reflected ultrasonic waves are received and signals produced and processed or displayed as A-scan, B-scan and C-scan images that are easily recognized. An A-Scan is based on the time-of-flight difference between the outer surface, the weldment and inner and opposite surfaces of the component. B-scan and C-scan indicate the degree of weld fusion and provide data relative to fused thickness and defects sheet metal or welds. A special purpose scanner that enables ultrasonic examination welds. Scanner is pencil like ultrasonic probe with bearing face and position sensing device disposed adjacent a weld position. Scanner collects data for method to determine various characteristics of welded items.

Owner:APPLIED METRICS

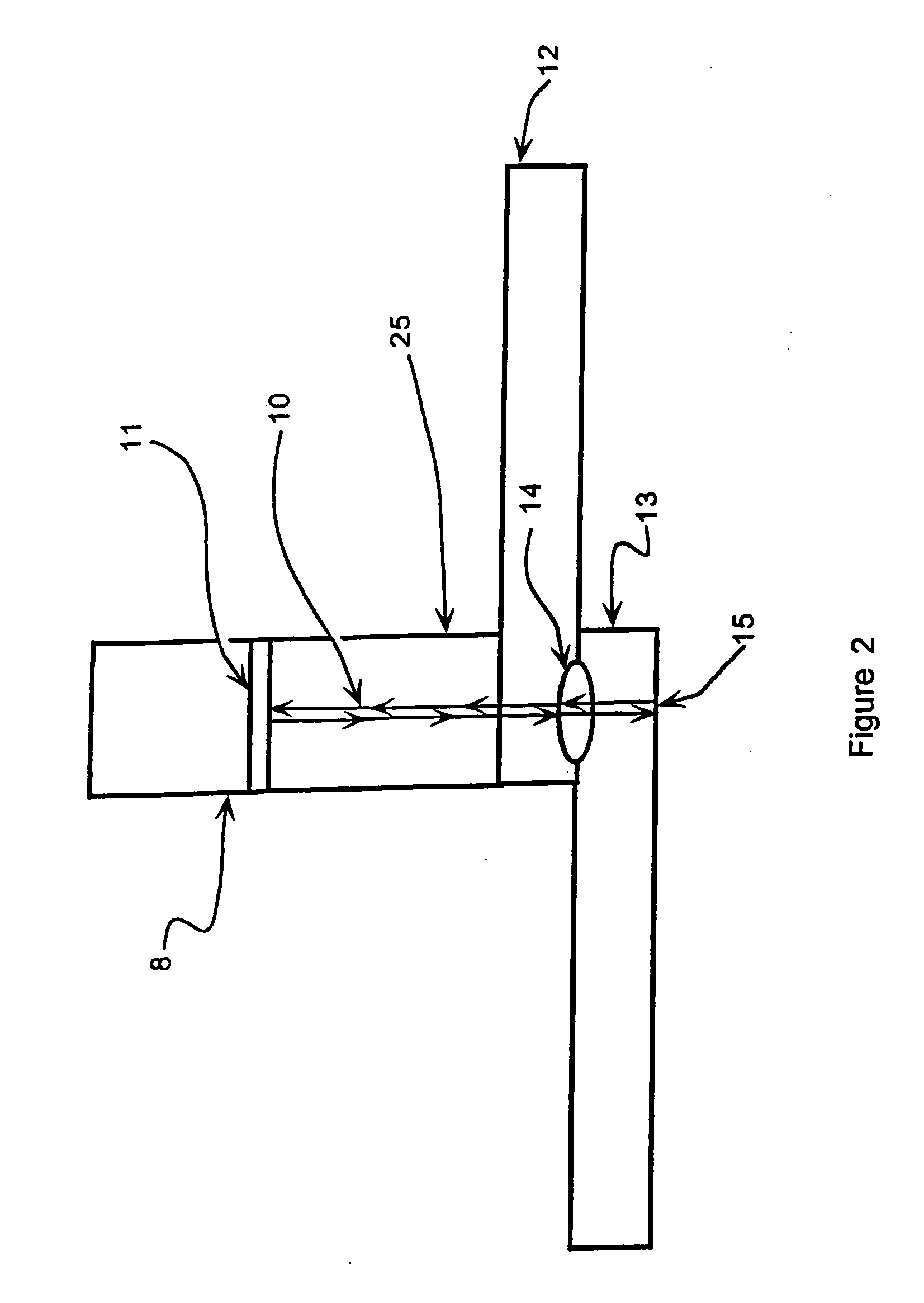

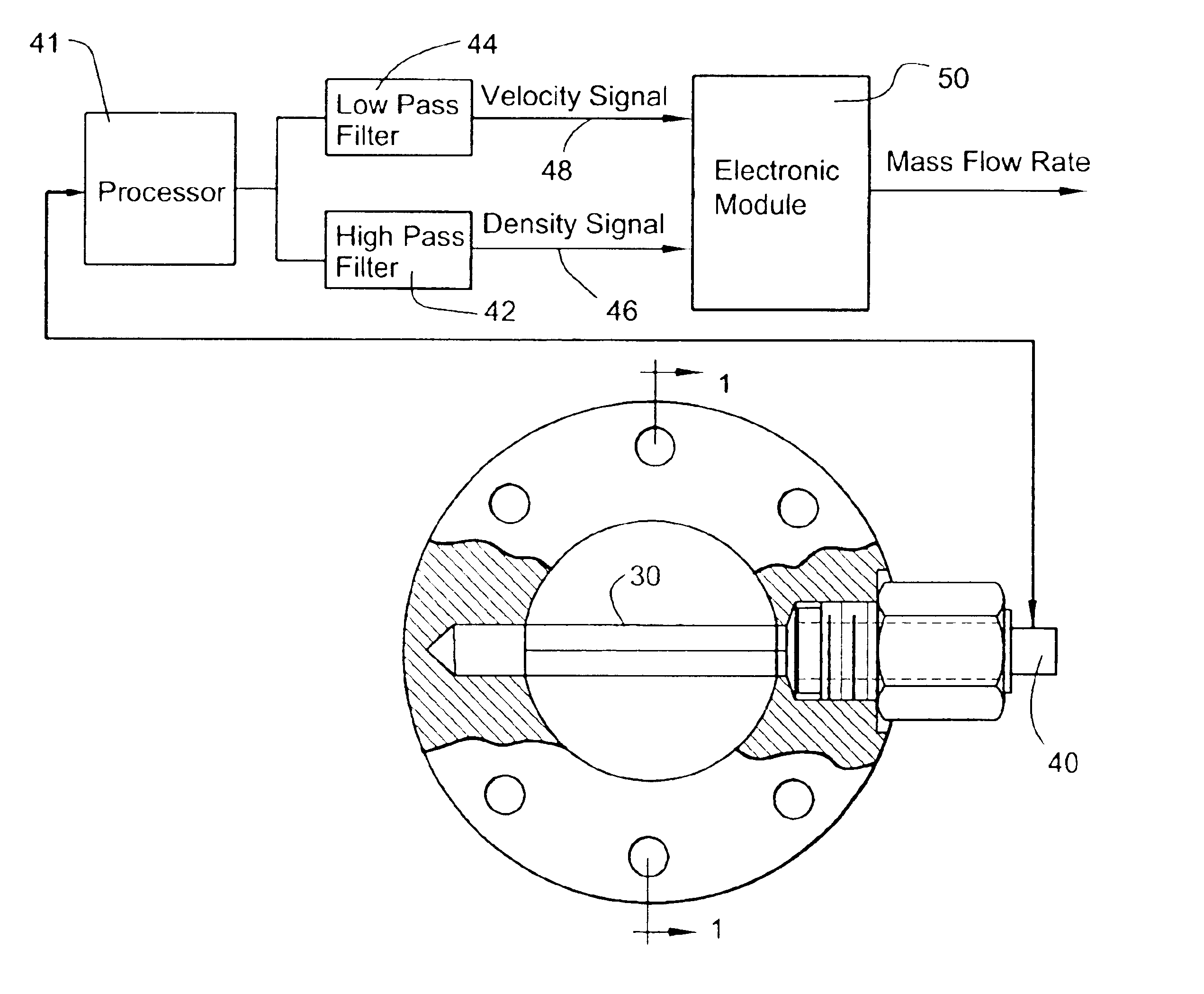

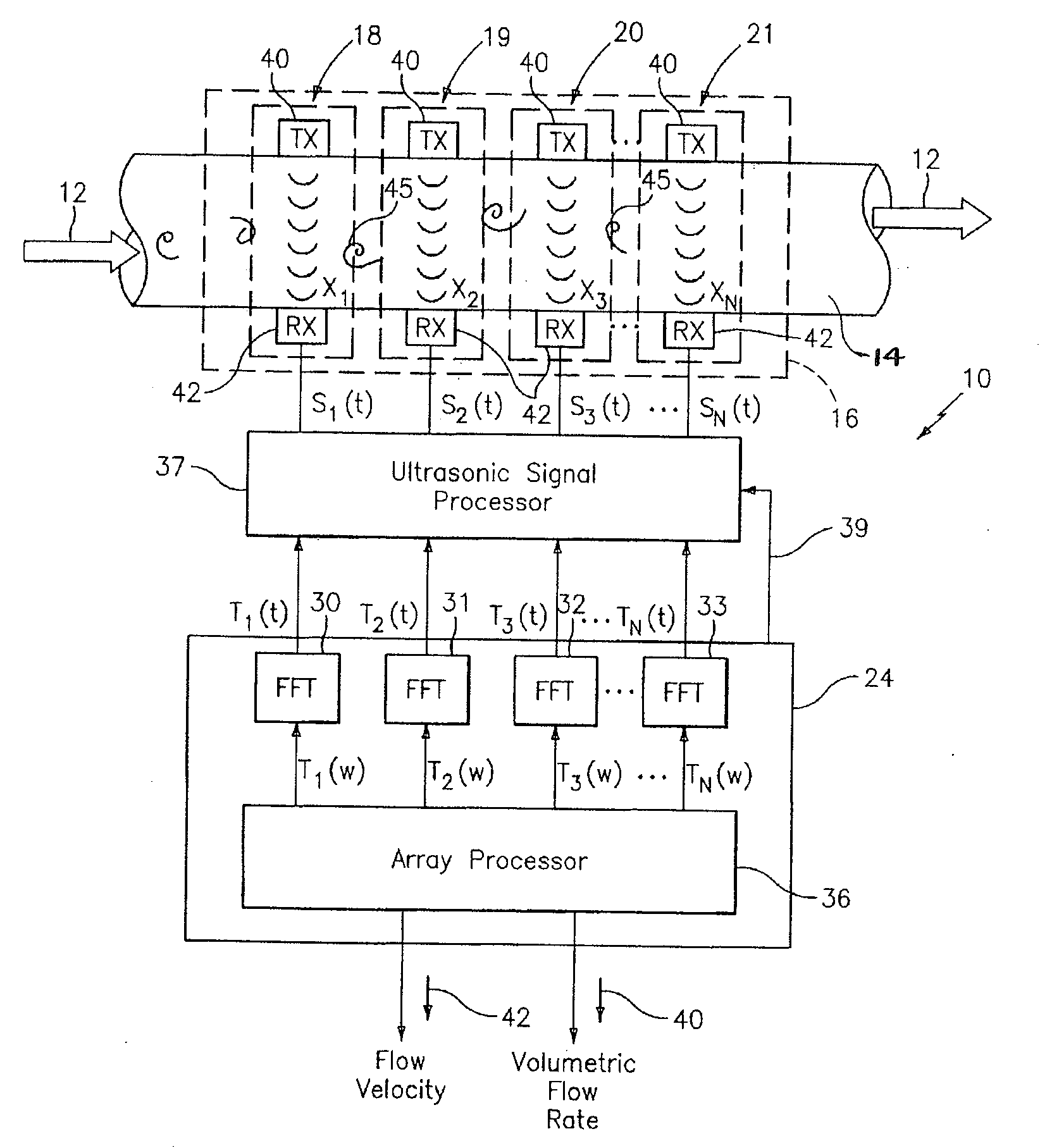

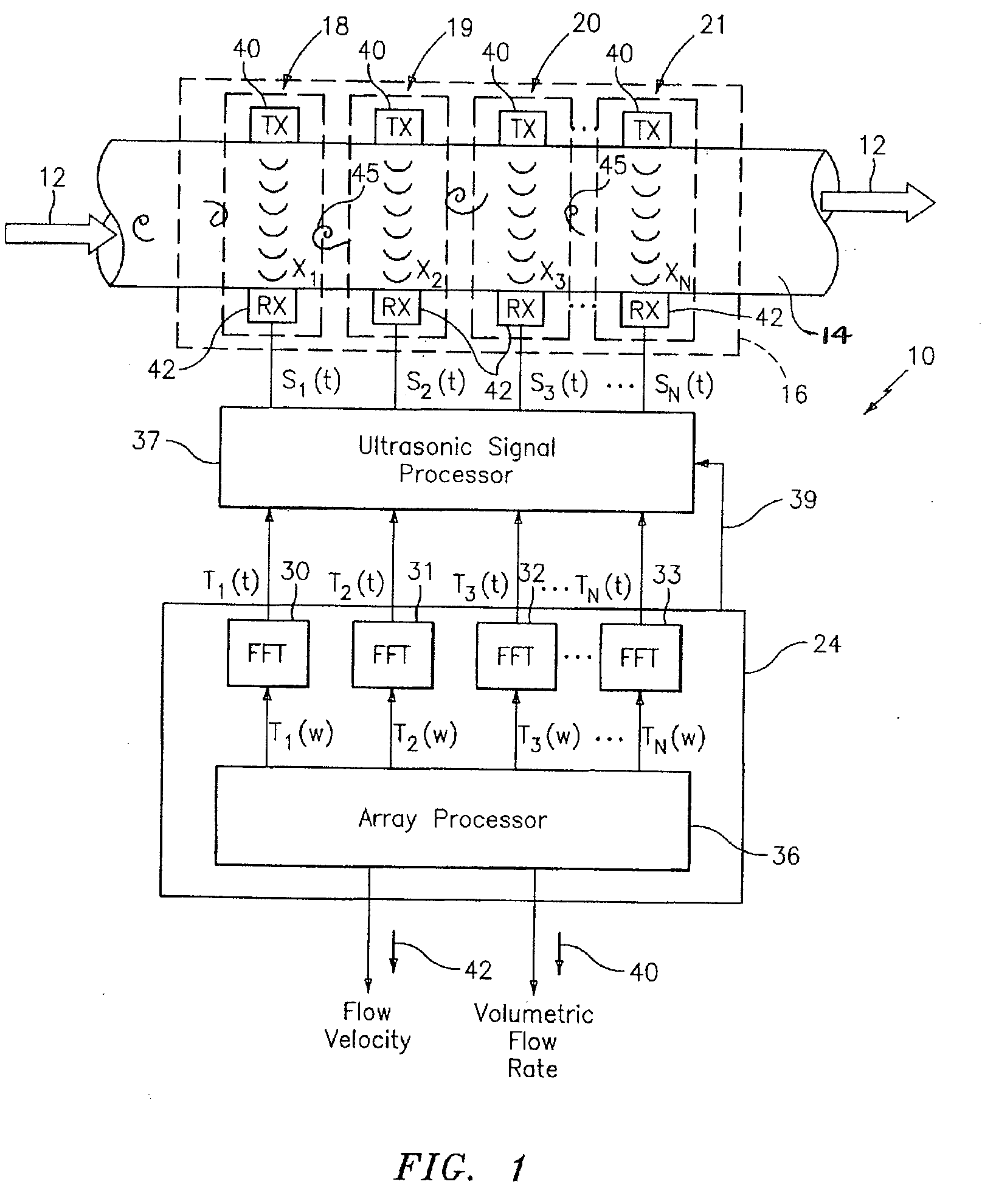

Mass flow sensor and methods of determining mass flow of a fluid

ActiveUS6912918B1Prevent leakageAvoid radiationVolume/mass flow by dynamic fluid flow effectSpecific gravity measurementSonificationUltrasonic beam

The mass flow rate sensor includes a waveguide disposed in a flow passage having a bluff body facing in an upstream direction. Waves are pulsed along the waveguide for interaction with the fluid. A receiver is coupled to the waveguide to detect a propagated wave and provides a first output signal proportional to the transit time of the propagated wave for determining fluid density. The receiver also provides a second output signal proportional to the shedding frequency of vortices from the waveguide to determine velocity. An electronics module calculates mass flow rate from the velocity times density times area of the flow passage and a constant. In other forms, the velocity is ascertained by transmitting an ultrasonic beam through the shedding vortices to determine vortex frequency which is proportional to velocity.

Owner:BAKER HUGHES INC

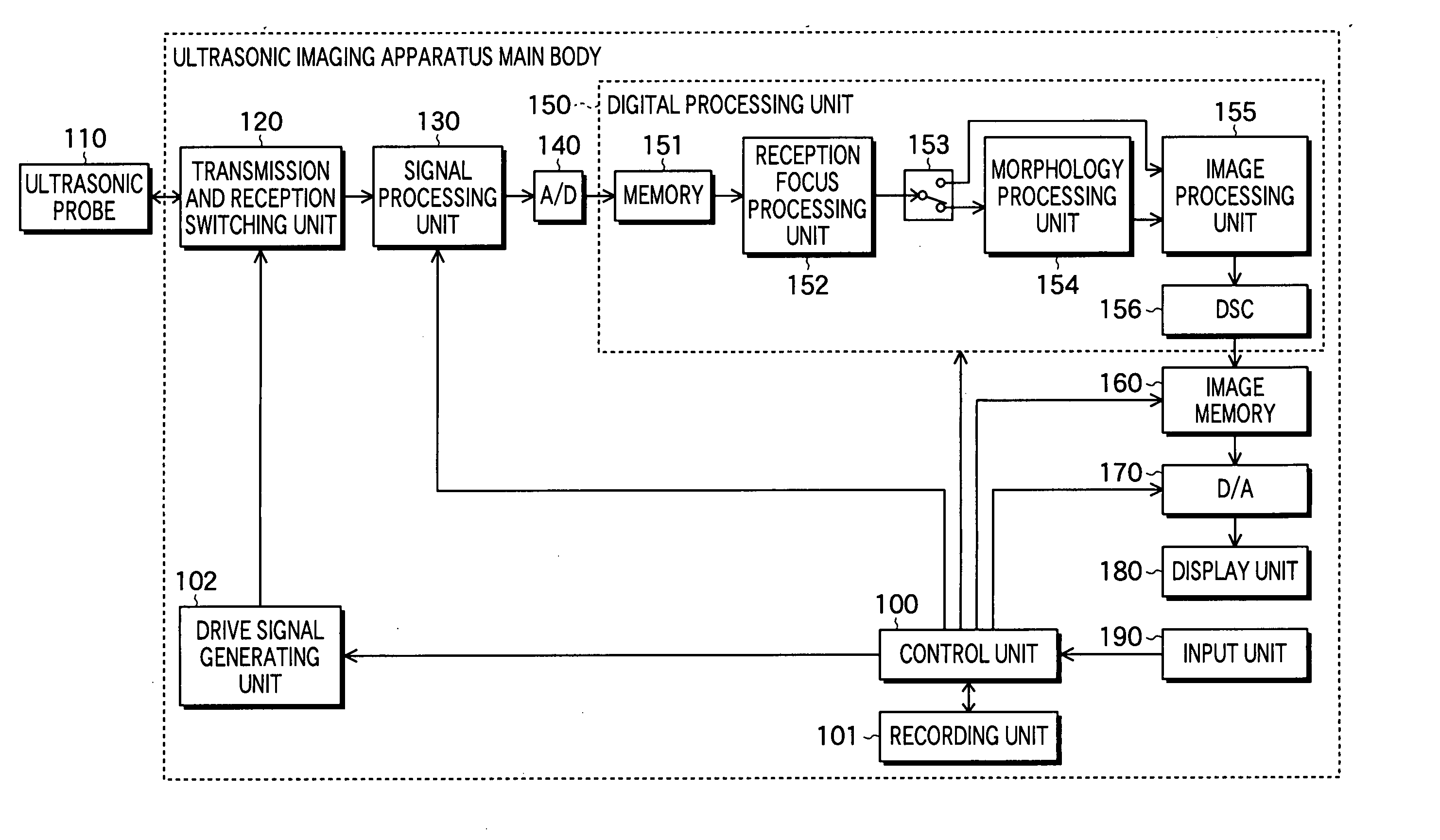

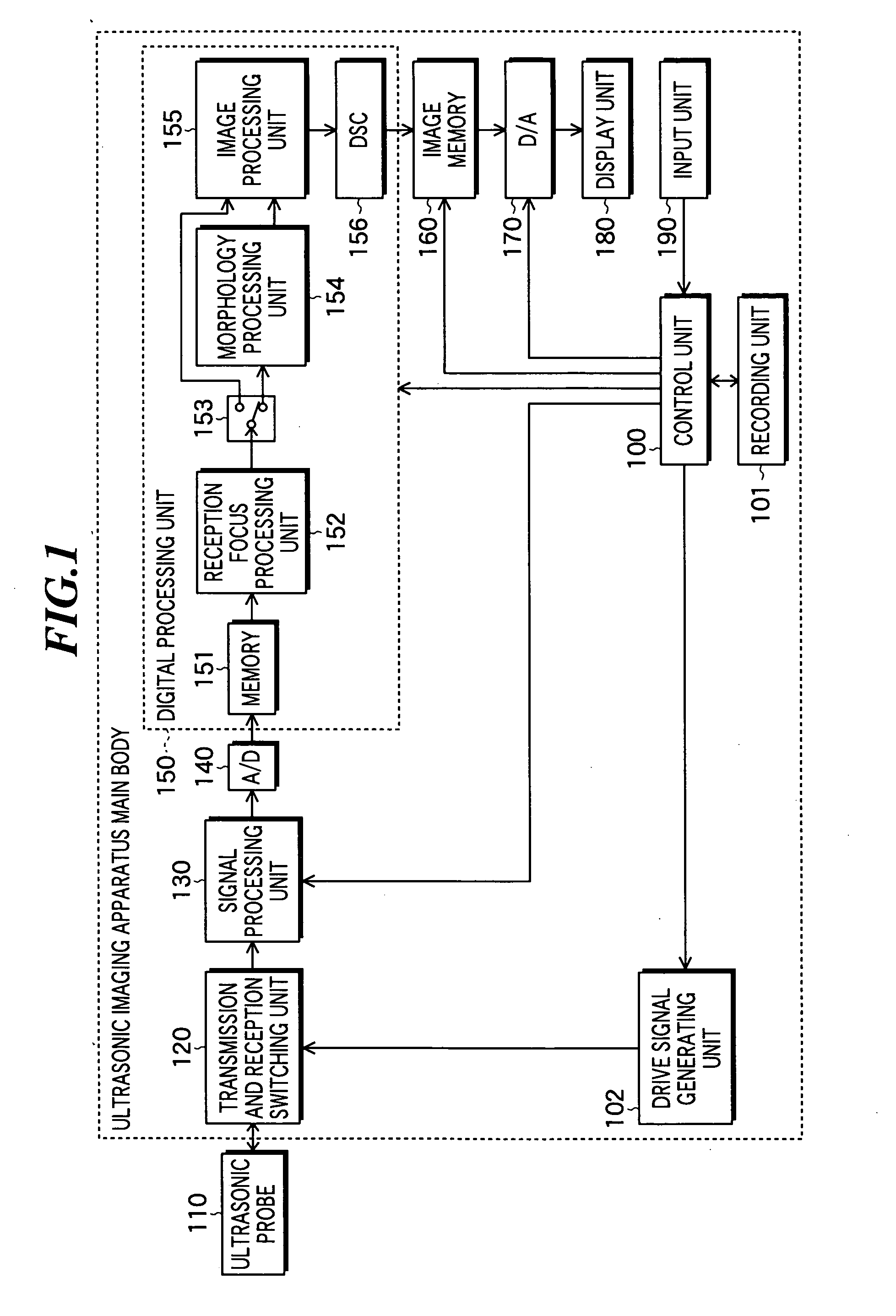

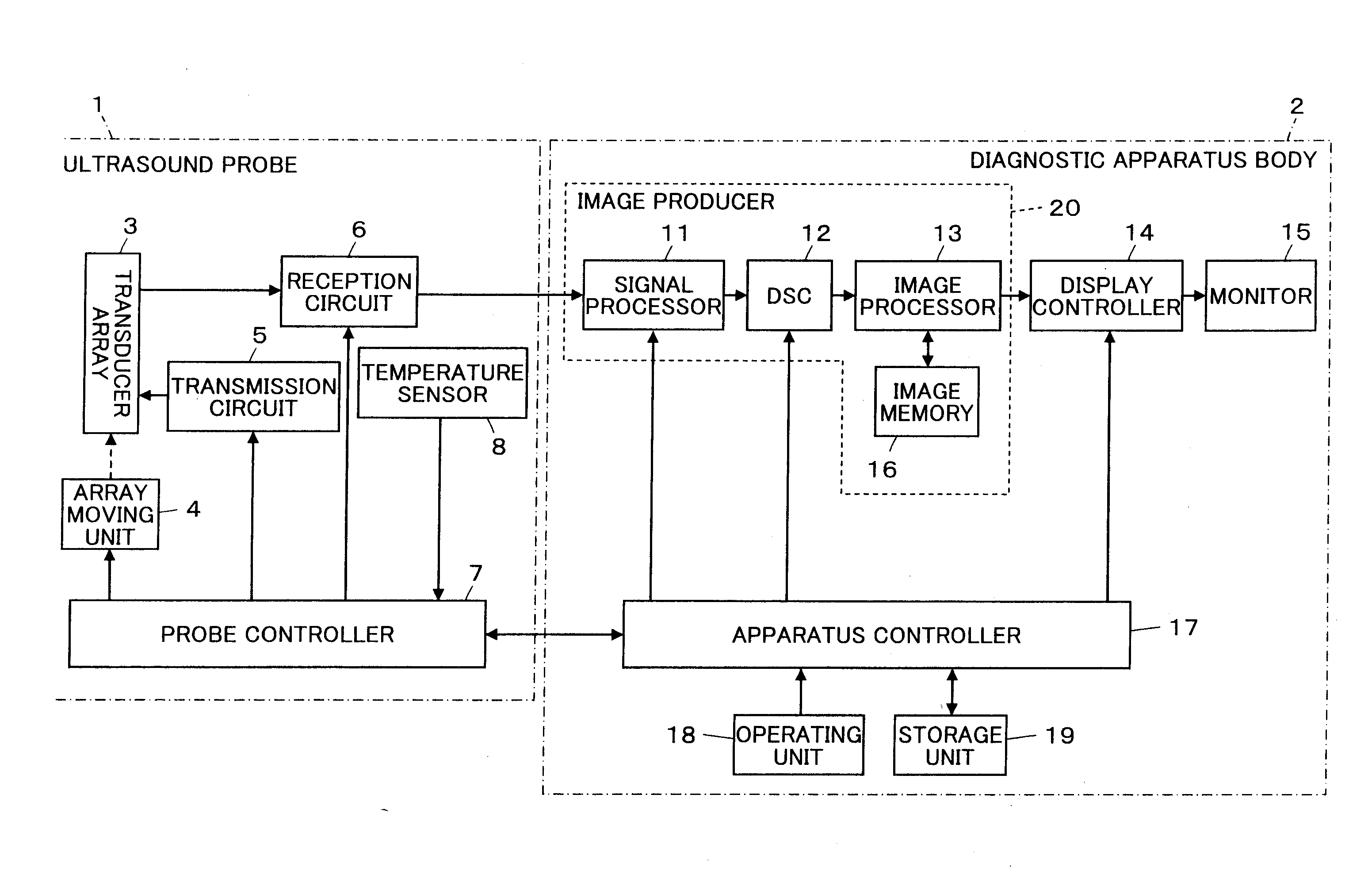

Ultrasonic image processing apparatus, ultrasonic image processing method and ultrasonic image processing program

ActiveUS20050143655A1Improve image qualityUltrasonic/sonic/infrasonic diagnosticsImage enhancementImaging processingUltrasonic beam

An ultrasonic image processing apparatus in which image quality of ultrasonic images can be improved by performing image processing that utilizes image characteristics of the original image. The ultrasonic image processing apparatus processes image data generated based on a signal obtained by scanning an object to be inspected by using an ultrasonic beam and respectively representing pixel values of the plurality of pixels within the ultrasonic image. The ultrasonic image processing apparatus includes a morphology processing unit for processing the image data to reduce speckles appearing in the ultrasonic image, and a DSC for converting a scan format of the image data processed by the morphology processing unit.

Owner:FUJIFILM HLDG CORP +1

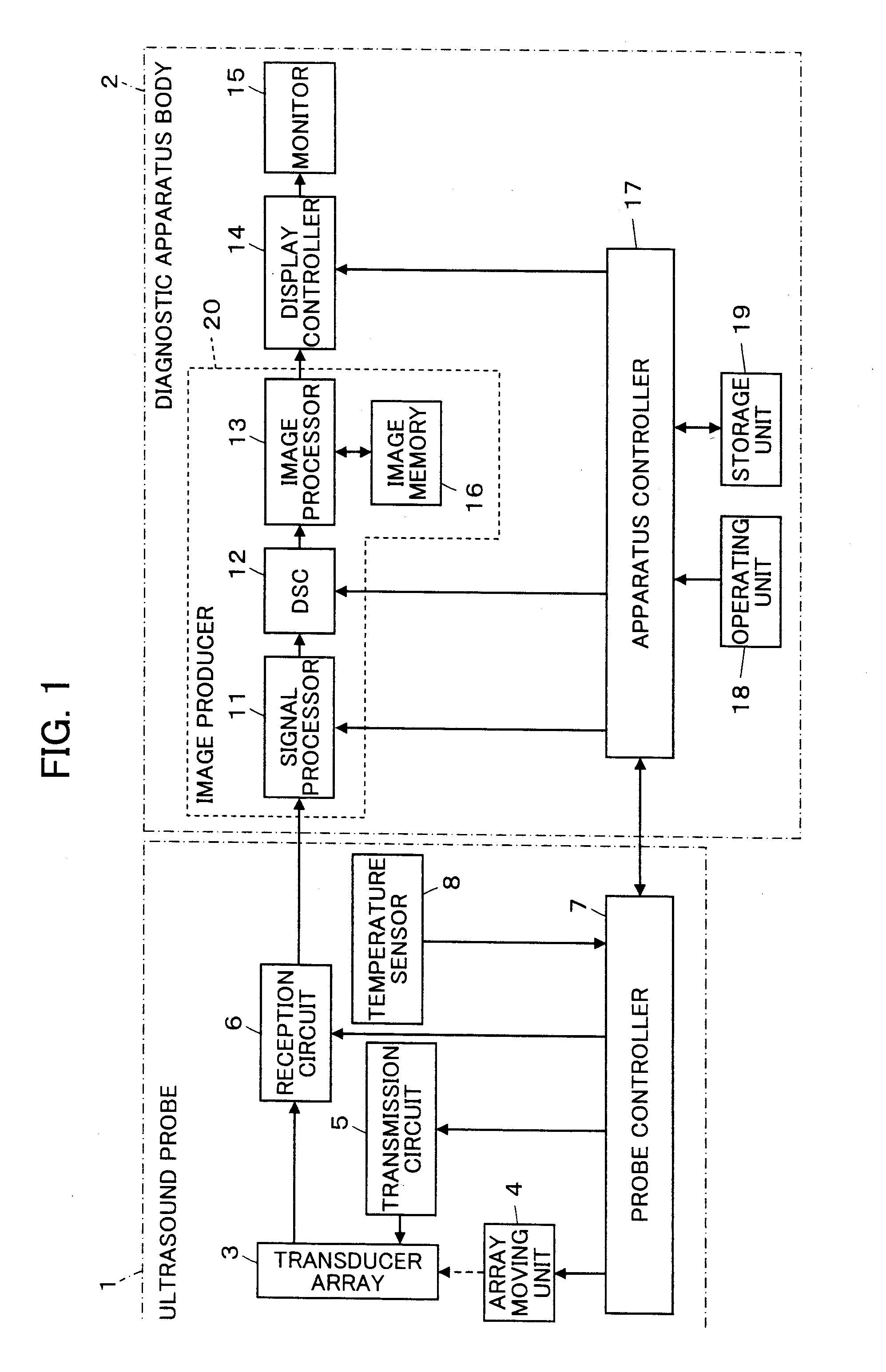

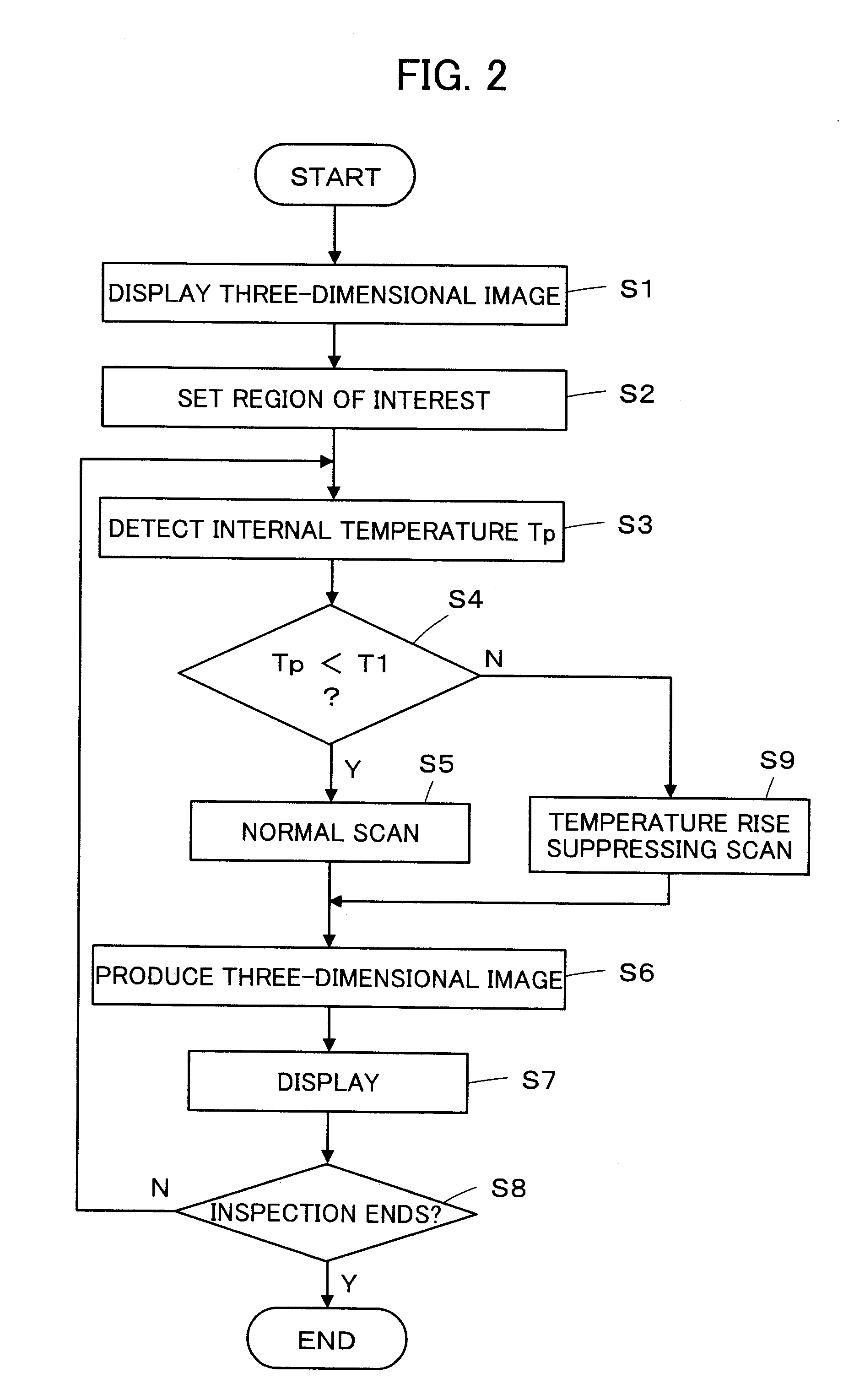

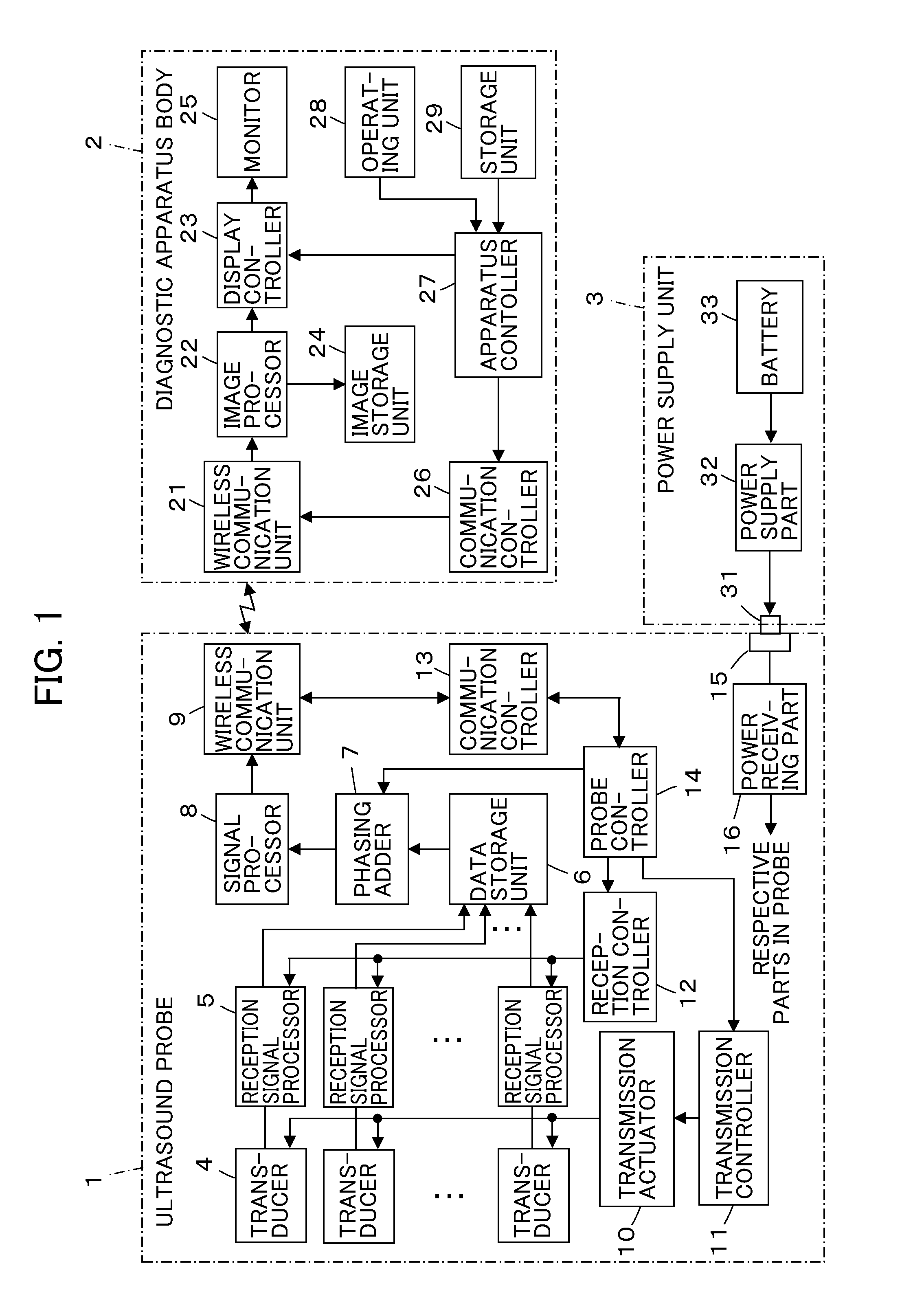

Ultrasound diagnostic apparatus and ultrasound image producing method

InactiveUS20120226160A1Easy to knowImprove image qualityUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsSensor arraySonification

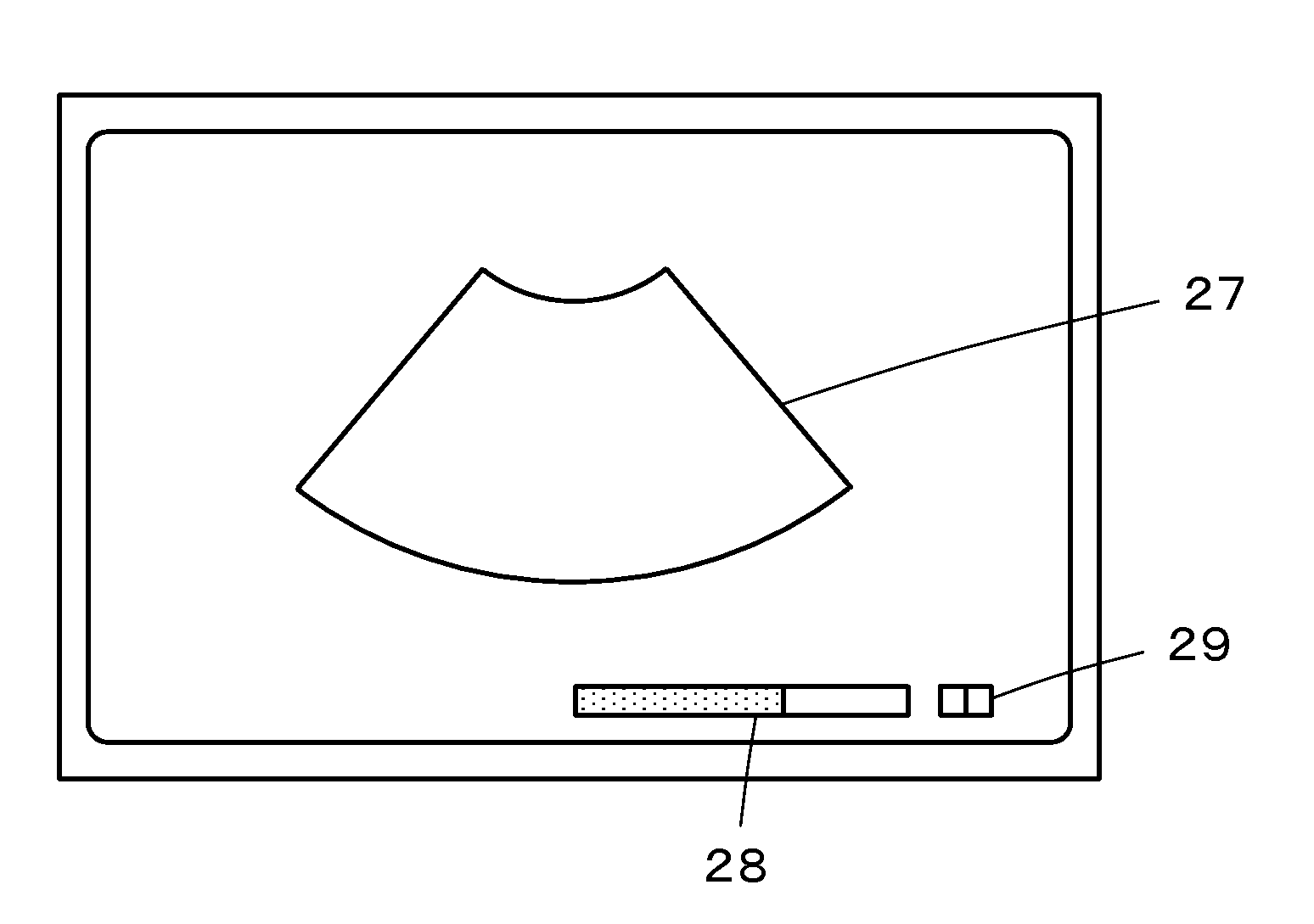

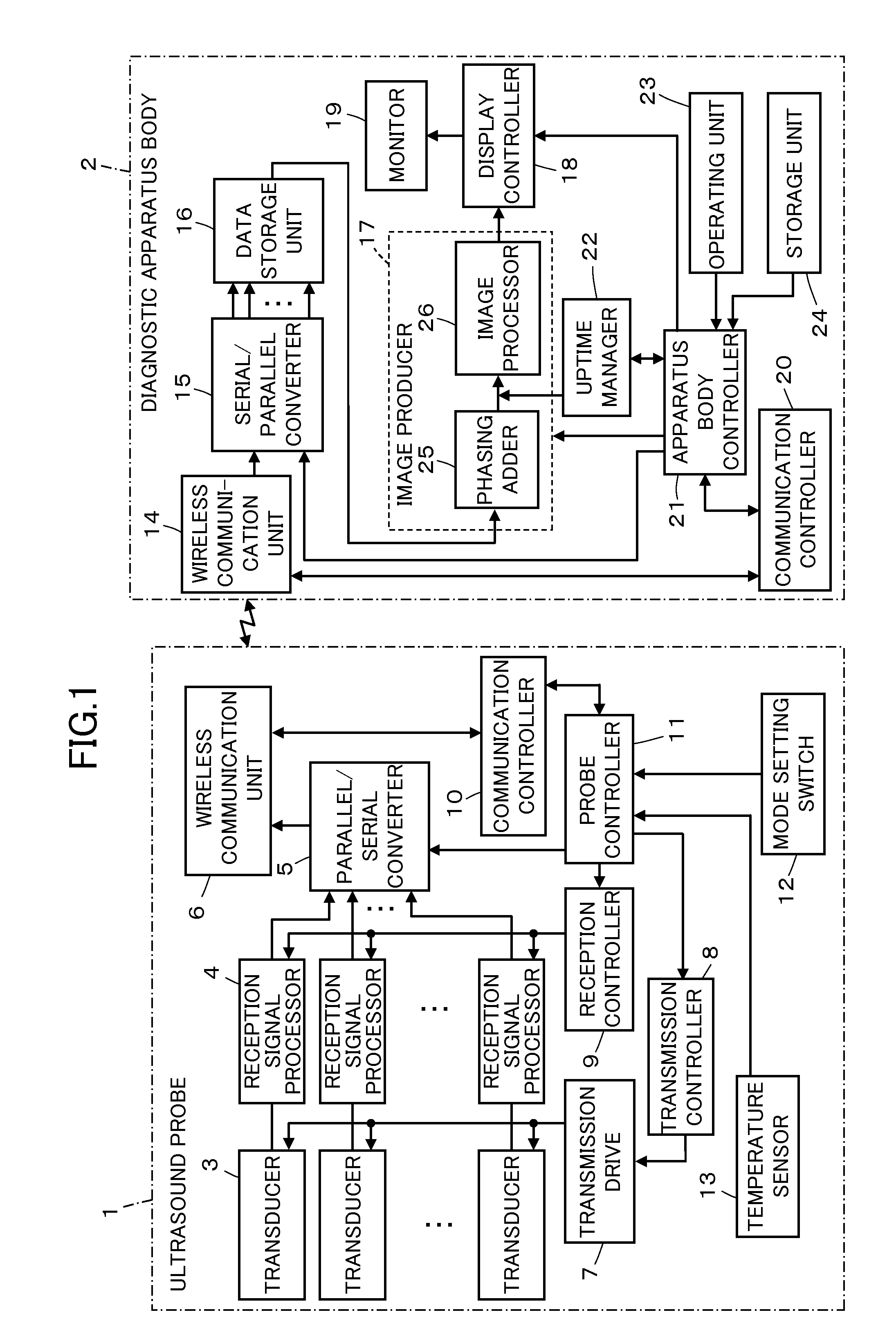

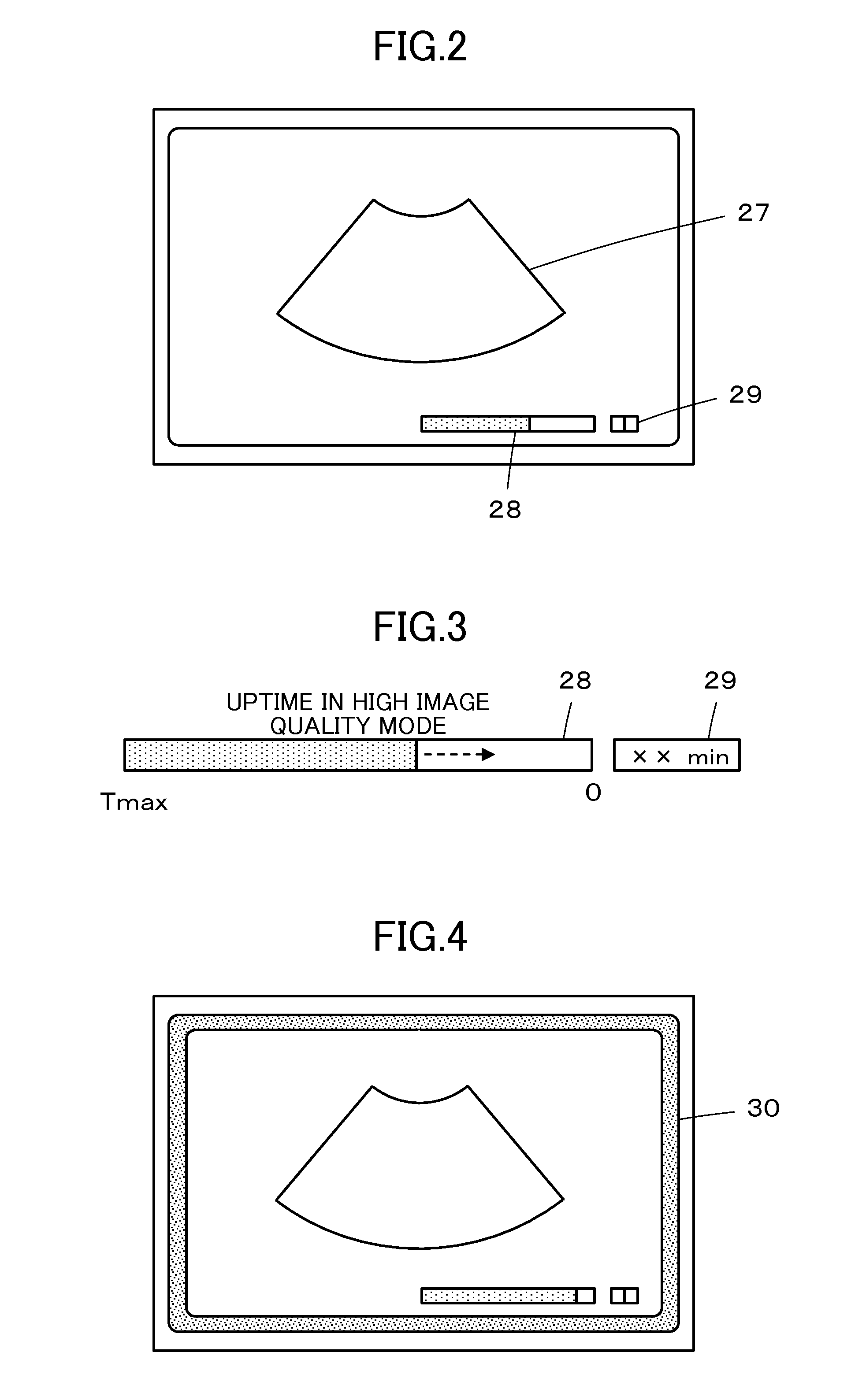

An ultrasound diagnostic apparatus comprises: an ultrasound probe which performs transmission and reception of ultrasonic beams using a transducer array according to a mode selected by an operator from a low image quality mode and a high image quality mode, and which processes reception signals outputted from the transducer array in reception signal processors to generate digital reception data; a diagnostic apparatus body for producing an ultrasound image based on the reception data transmitted from the ultrasound probe and displaying the produced ultrasound image on a monitor; a temperature detecting unit for detecting an internal temperature of the ultrasound probe, and an uptime manager for calculating an uptime in the high image quality mode based on the internal temperature of the ultrasound probe detected by the temperature detecting unit to display the calculated uptime on the monitor.

Owner:FUJIFILM CORP

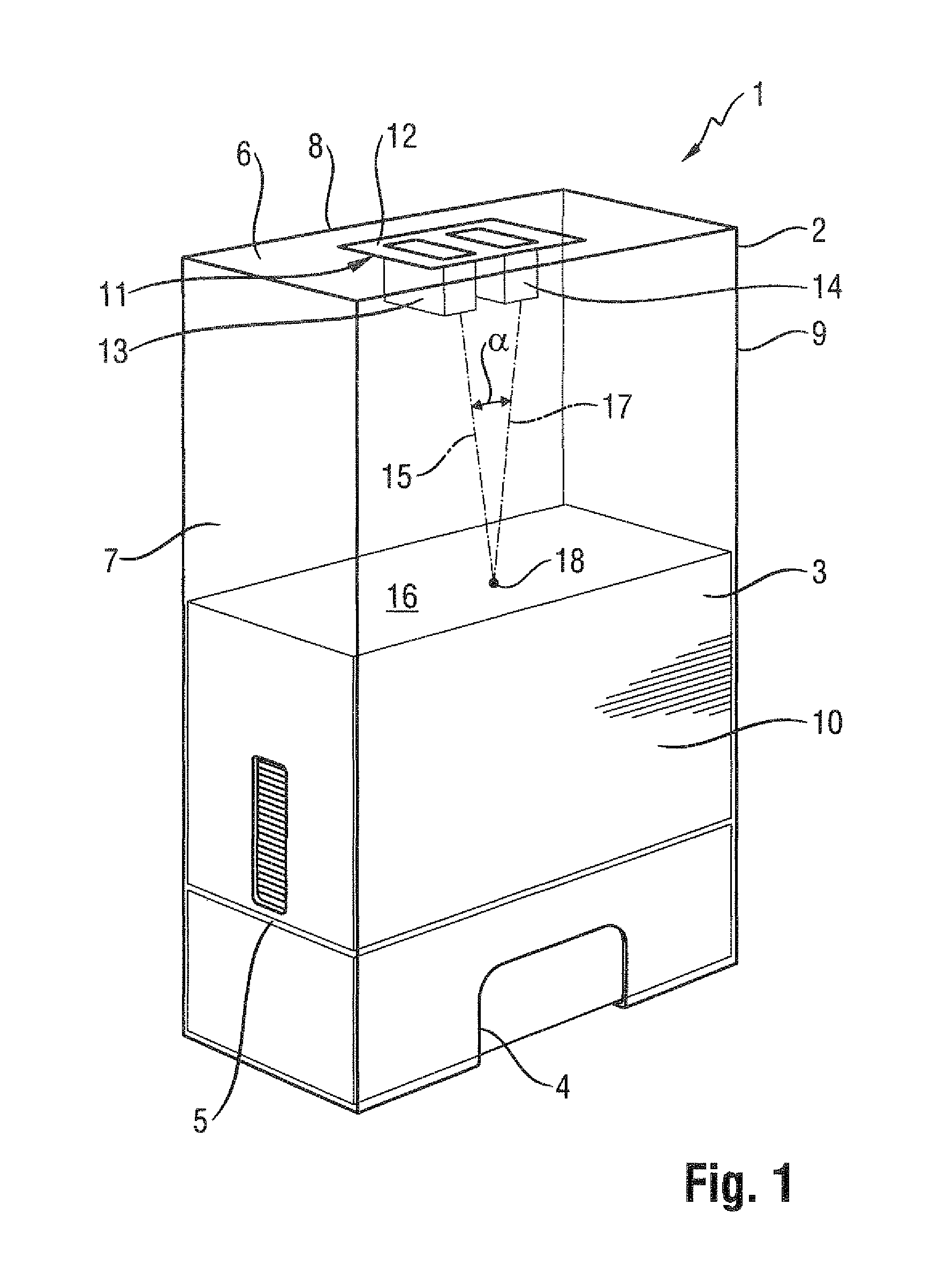

Product Level Sensor for a Product Dispenser

InactiveUS20140367401A1Reduce sheet product levelAvoid exposureFilament handlingCoin-freed apparatus detailsUltrasonic beamLevel sensor

A dispenser for dispensing paper or non-woven sheet product for wiping, wherein the level of sheet product contained in the dispenser decreases as the sheet product is dispensed, the dispenser comprising an ultrasonic level sensor for determining the level of the sheet product contained in the dispenser, wherein the ultrasonic sensor is arranged to direct the ultrasonic beam toward a surface associated with the sheet product, wherein a distance that the beam travels to the surface changes progressively as the level of the sheet product in the dispenser changes from a full condition to an empty condition.

Owner:SCA HYGIENE PROD AB

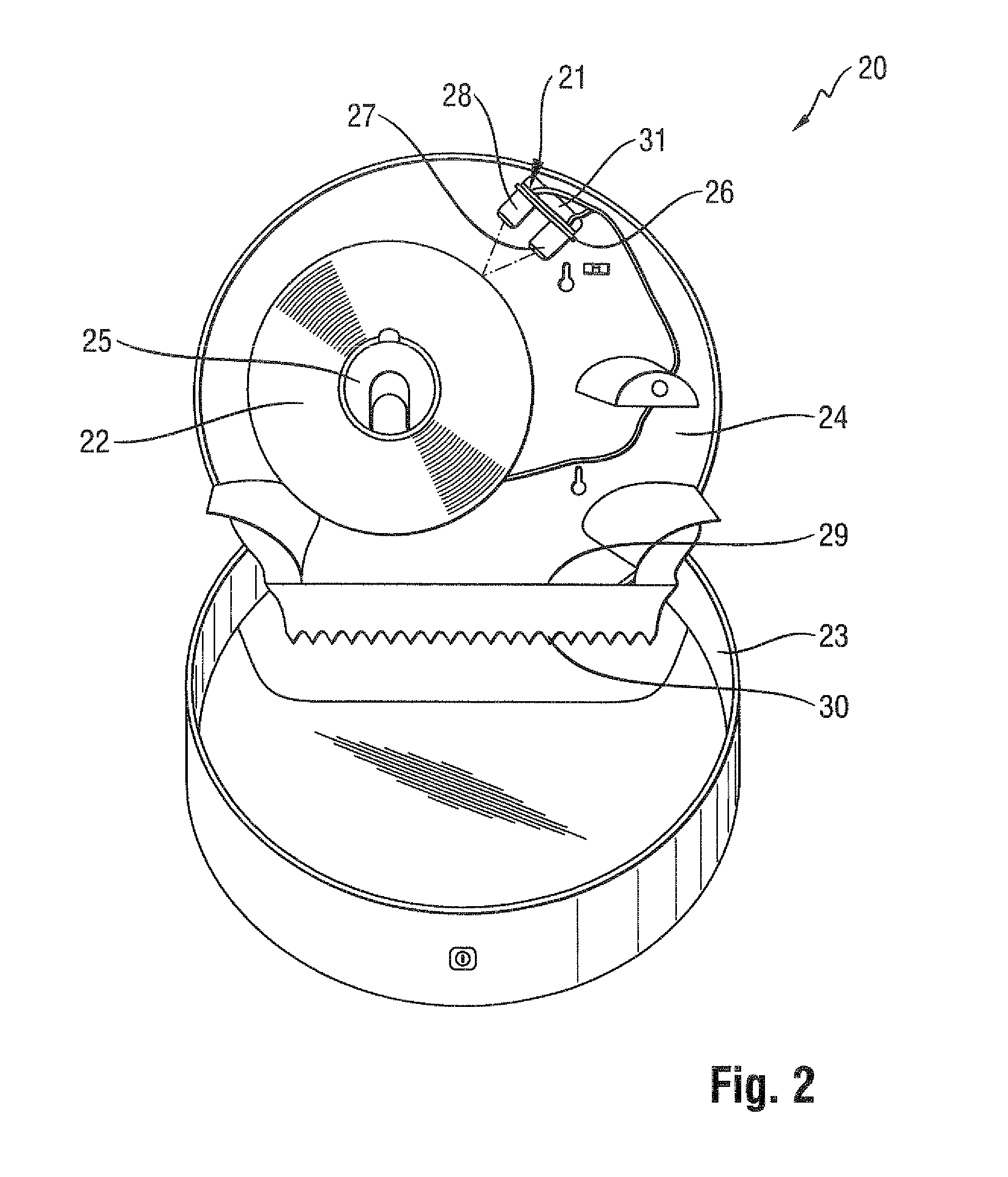

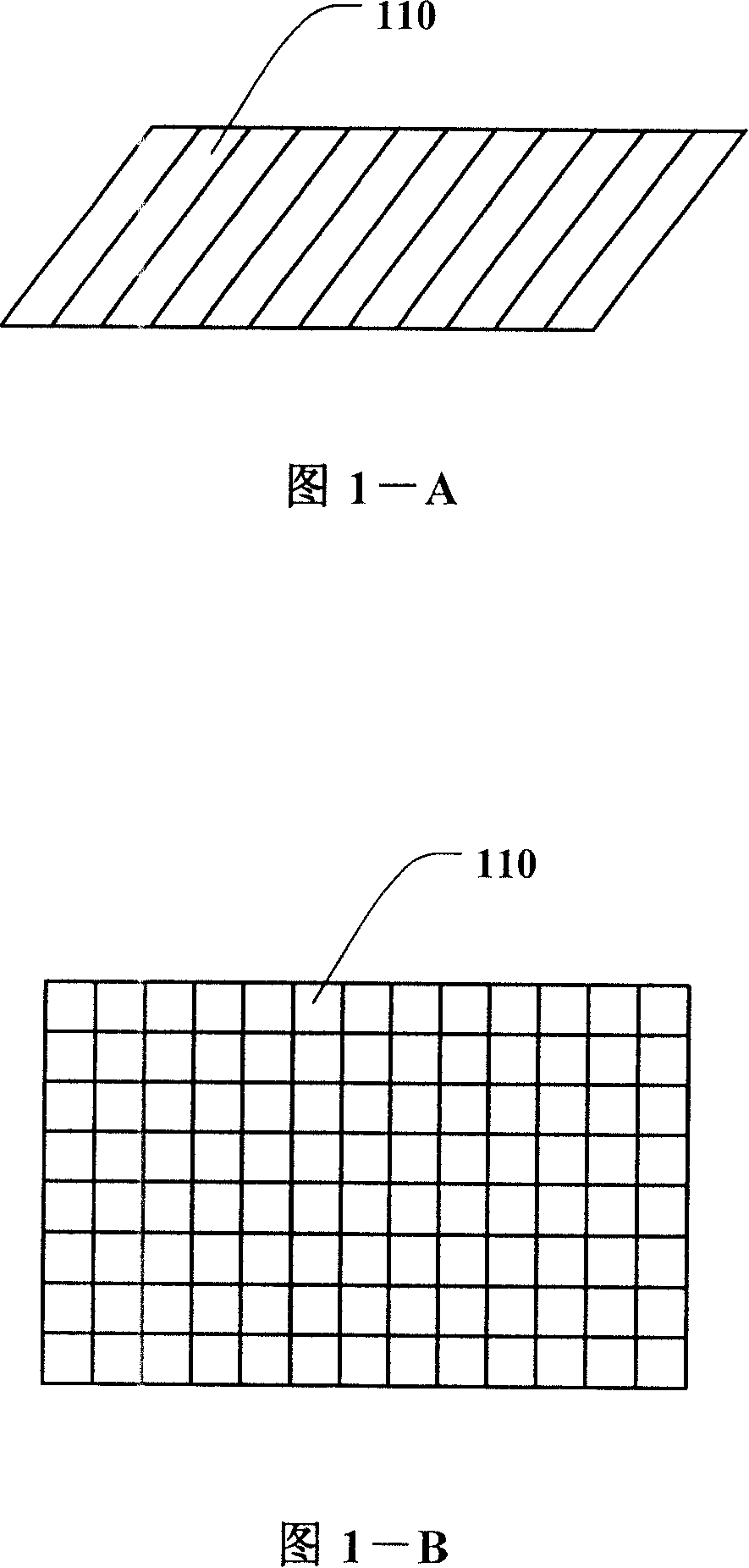

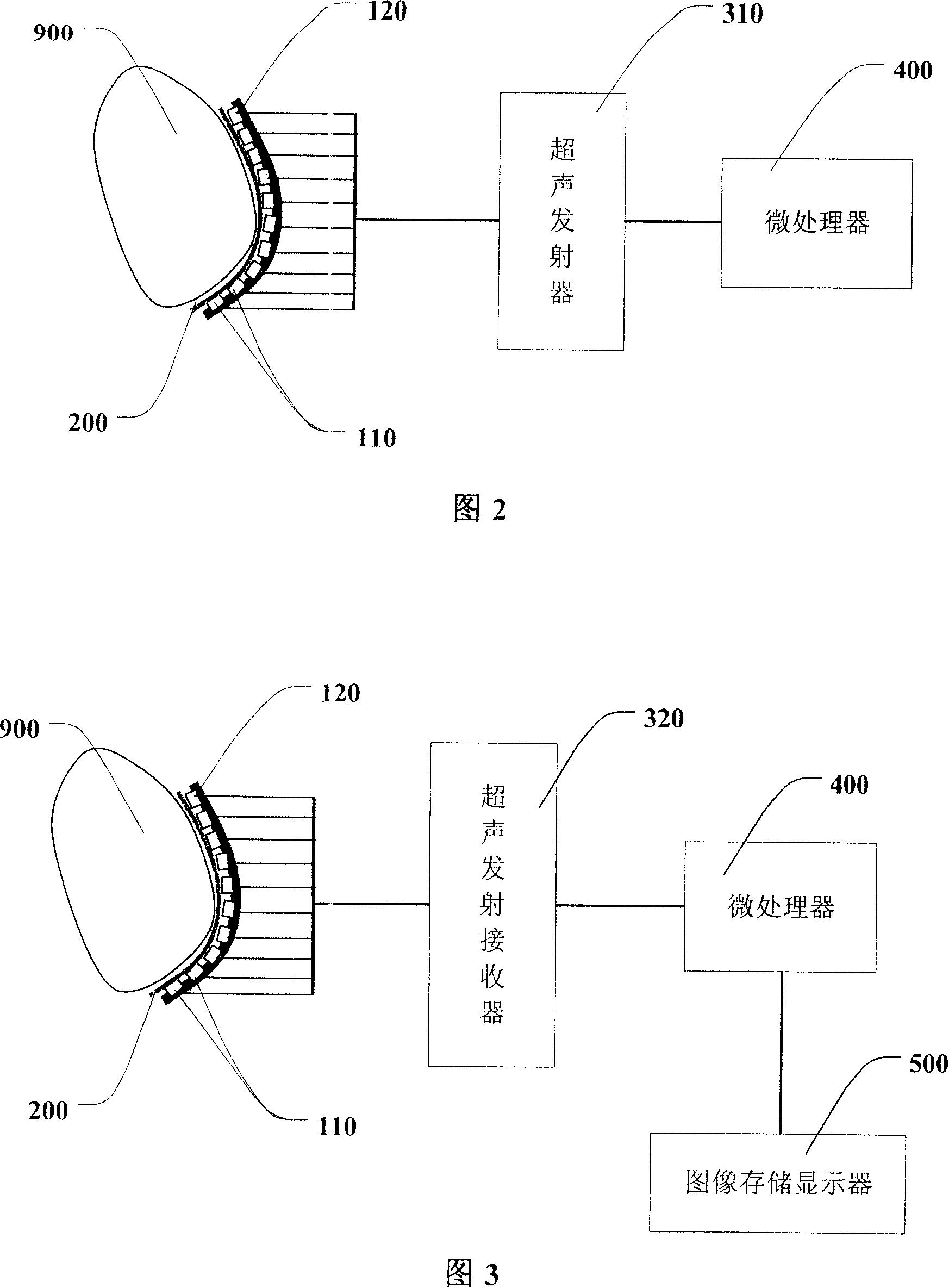

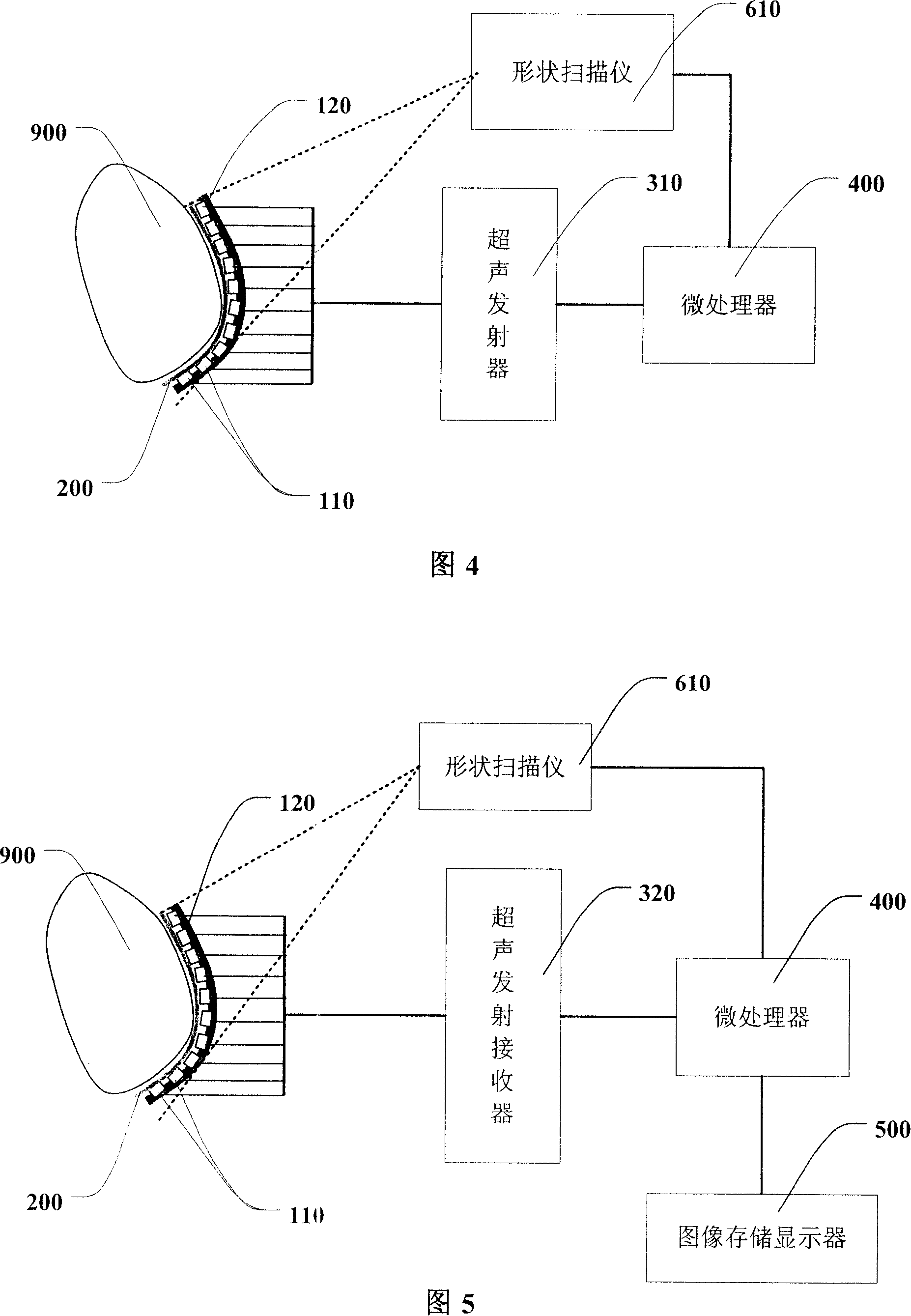

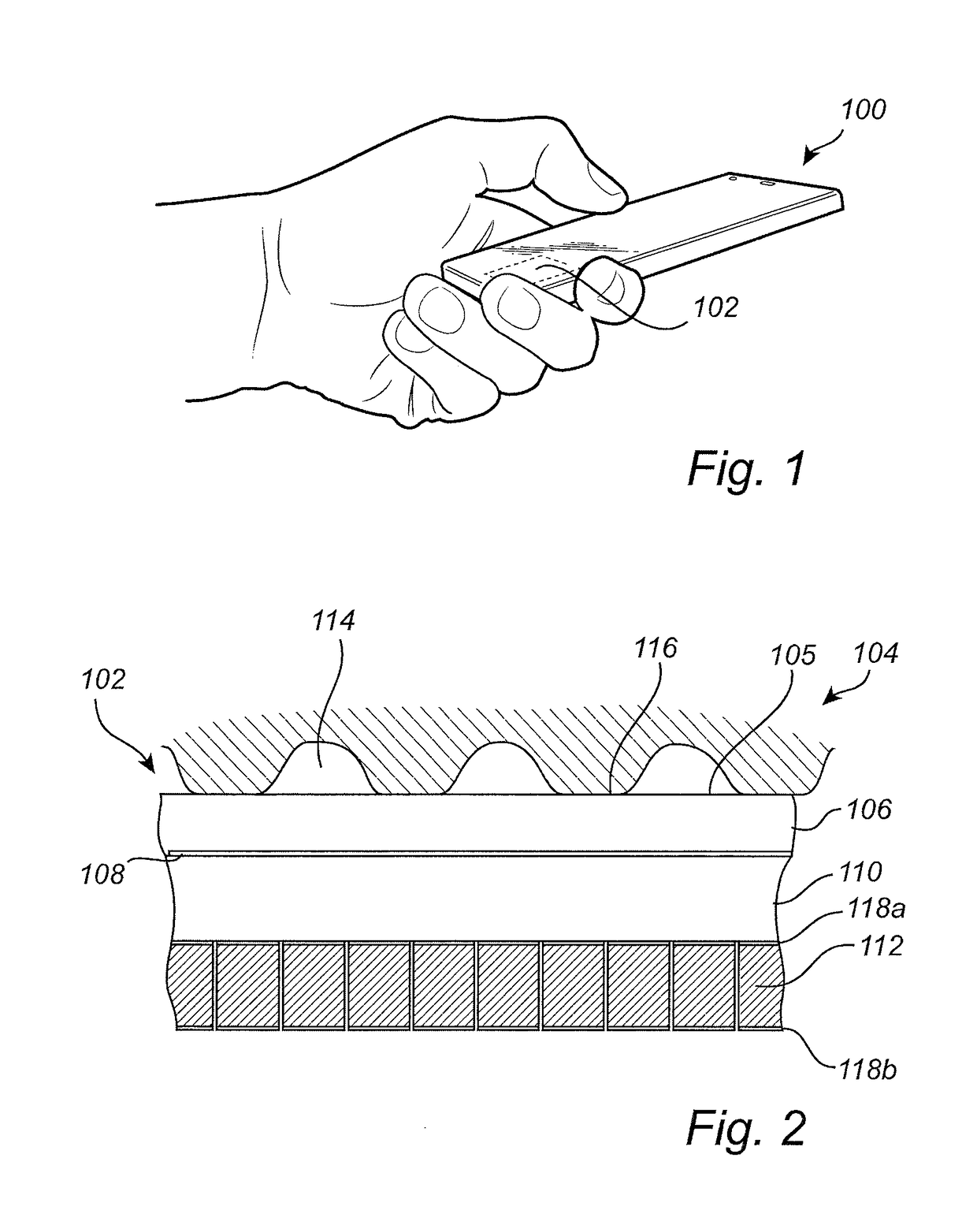

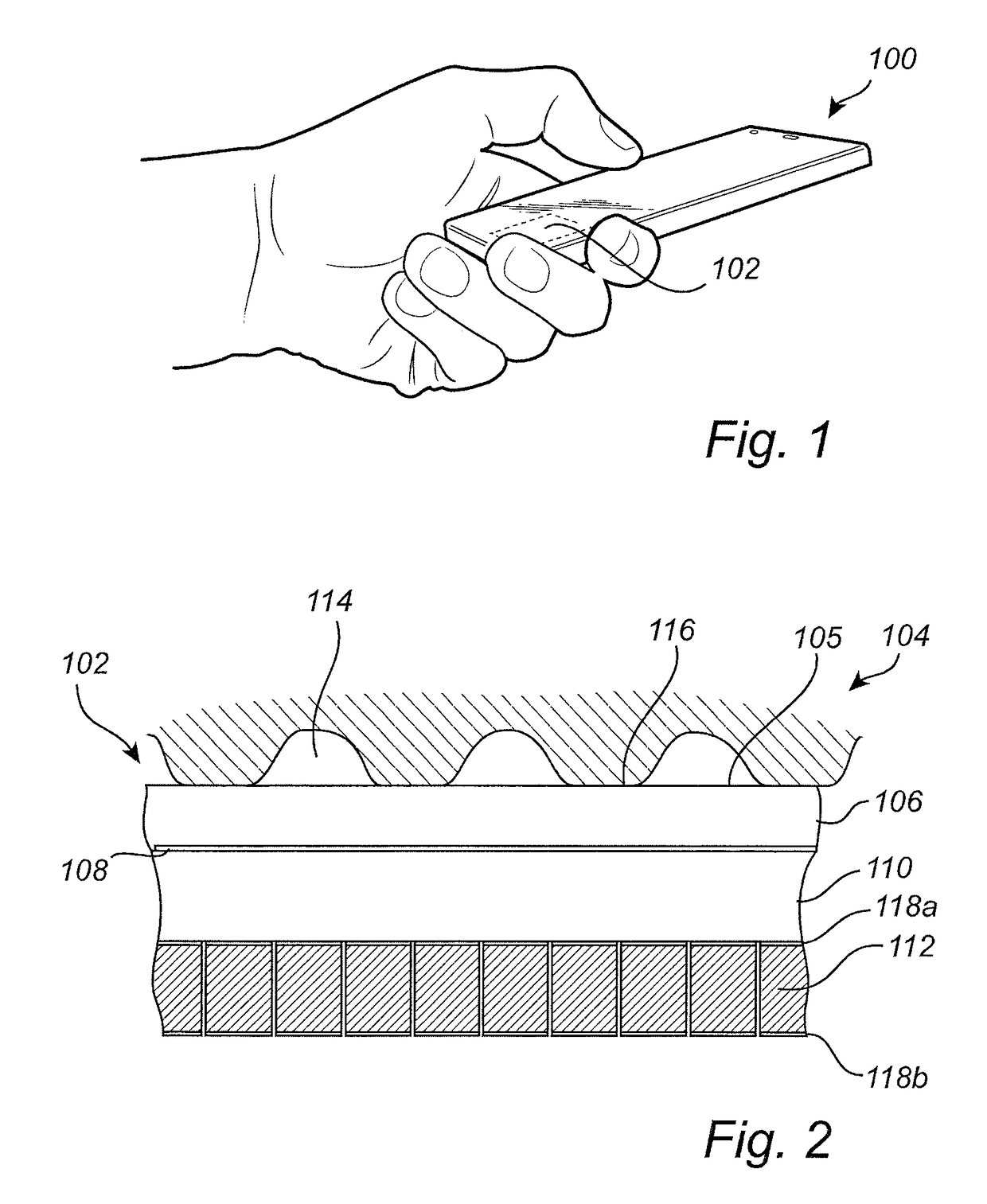

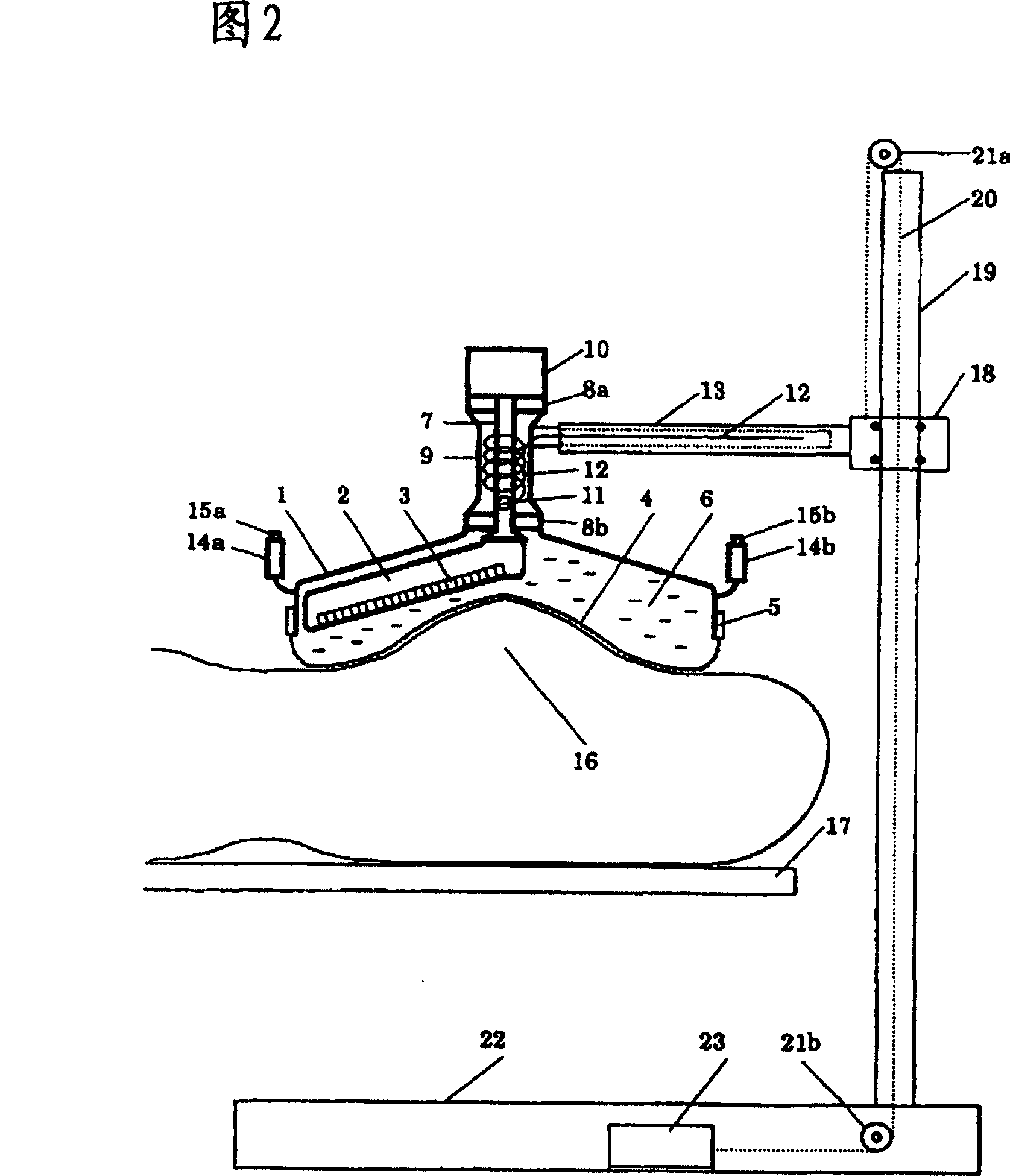

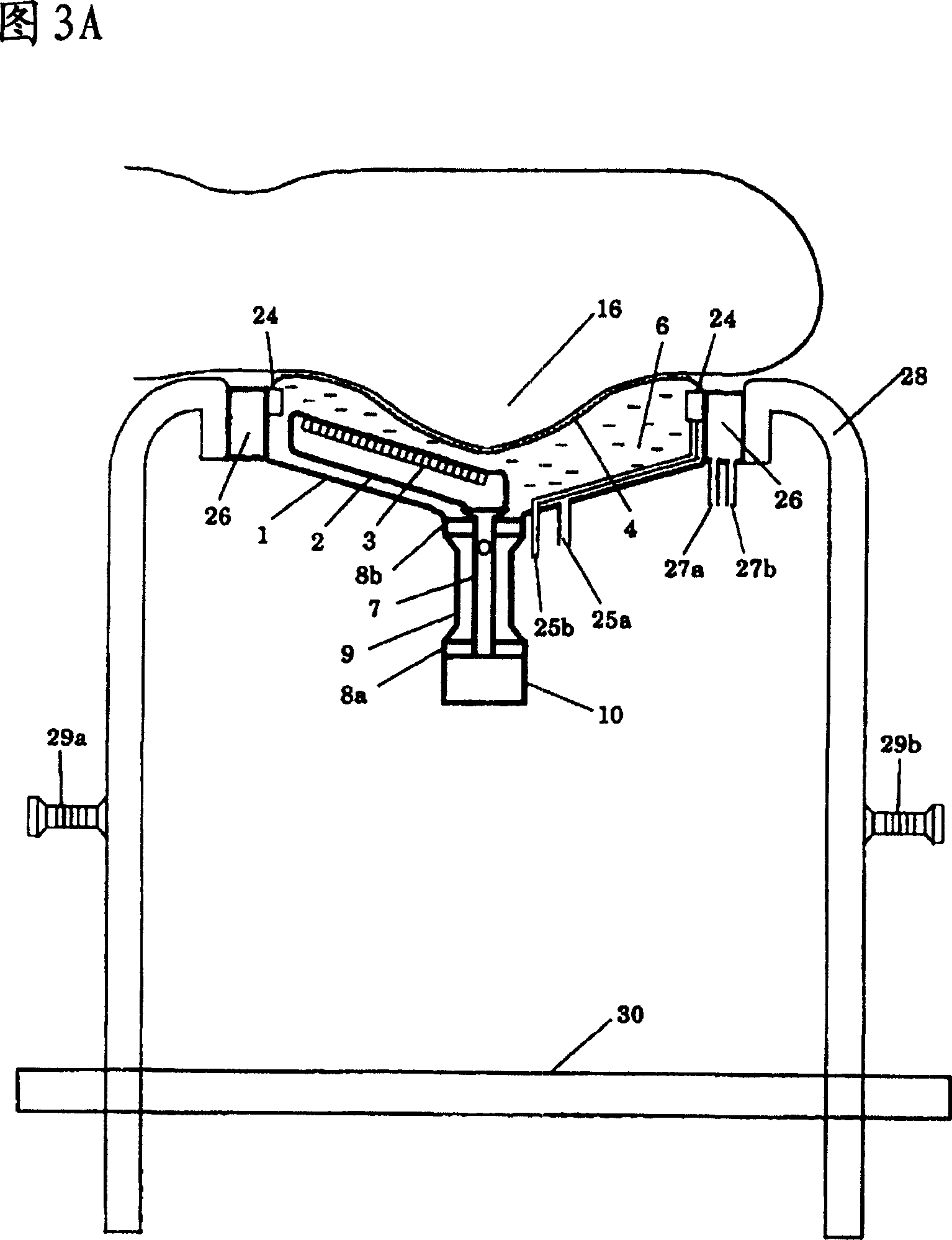

Flexible ultrasonic transducer array and applying device of the same

ActiveCN101152646AImprove Ultrasound Therapy/Imaging ResultsGuaranteed flexibilityUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyUltrasound imagingSonification

The invention provides a flexible ultrasonic transducer array, which comprises at least two ultrasonic transducer units and flexible layer medium. The ultrasonic transducer is arranged in the flexible layer medium or on the surface of the flexible layer medium in the form of array; an ultrasonic device comprises at least two ultrasonic transducer units, an ultrasonic emitter / ultrasonic transceiver, ultrasonic coupling medium, a microprocessor and flexible layer medium, and the ultrasonic transducer unit is arranged in or on the surface of flexible layer medium in the form of array to form flexible ultrasonic transducer array; ultrasonic transducer array and the ultrasonic device also comprises a shape scanner / shape sensor which is used for measuring superficial shape information of flexible ultrasonic transducer array and helping ultrasonic beam focus and orient. As flexible ultrasonic transducer array can attach to body position with different superficial shapes, the technical proposal provided by the invention can realize the effect of ultrasonic treatment / ultrasonic imaging which can be realized by the prior art.

Owner:THE HONG KONG POLYTECHNIC UNIV

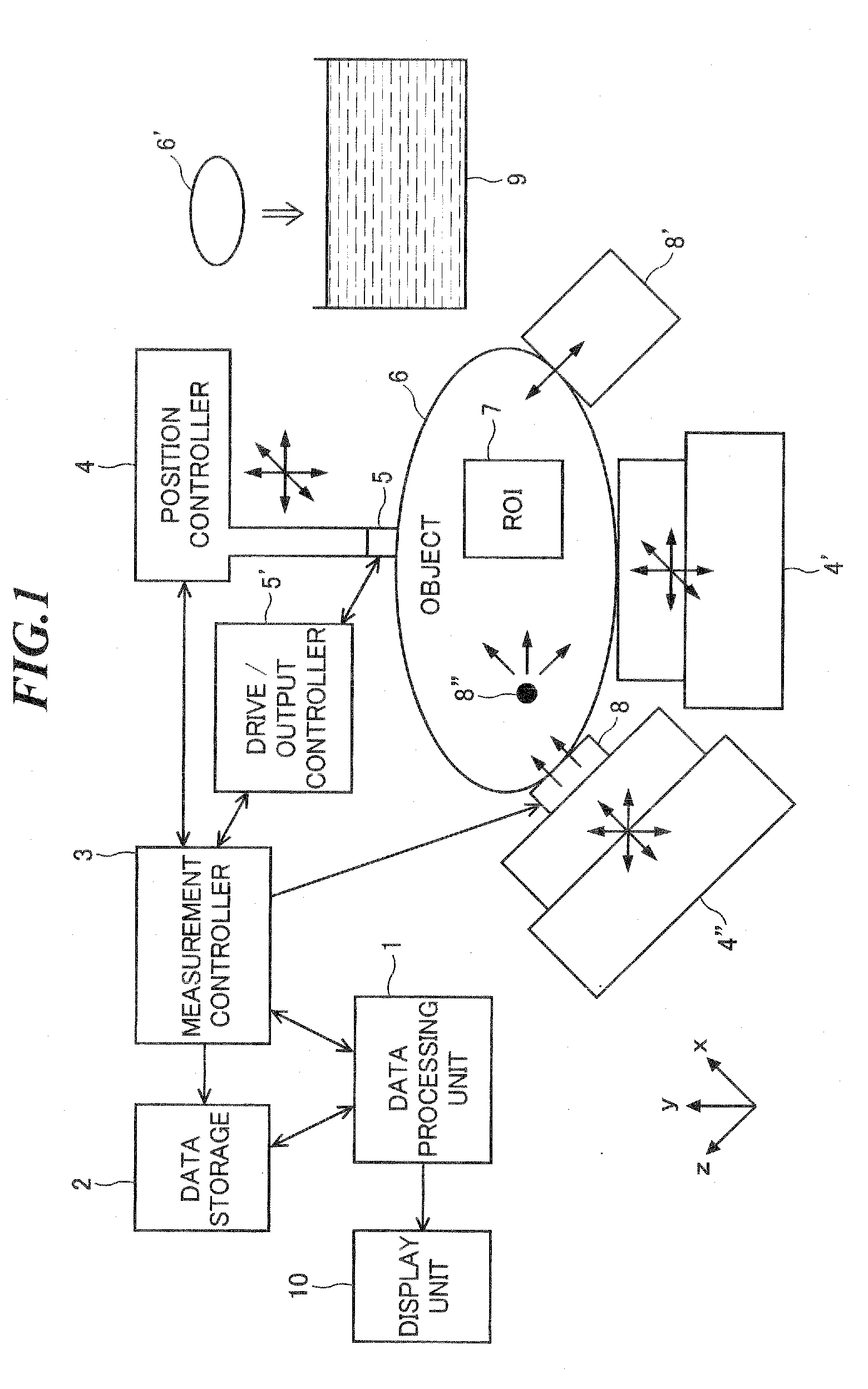

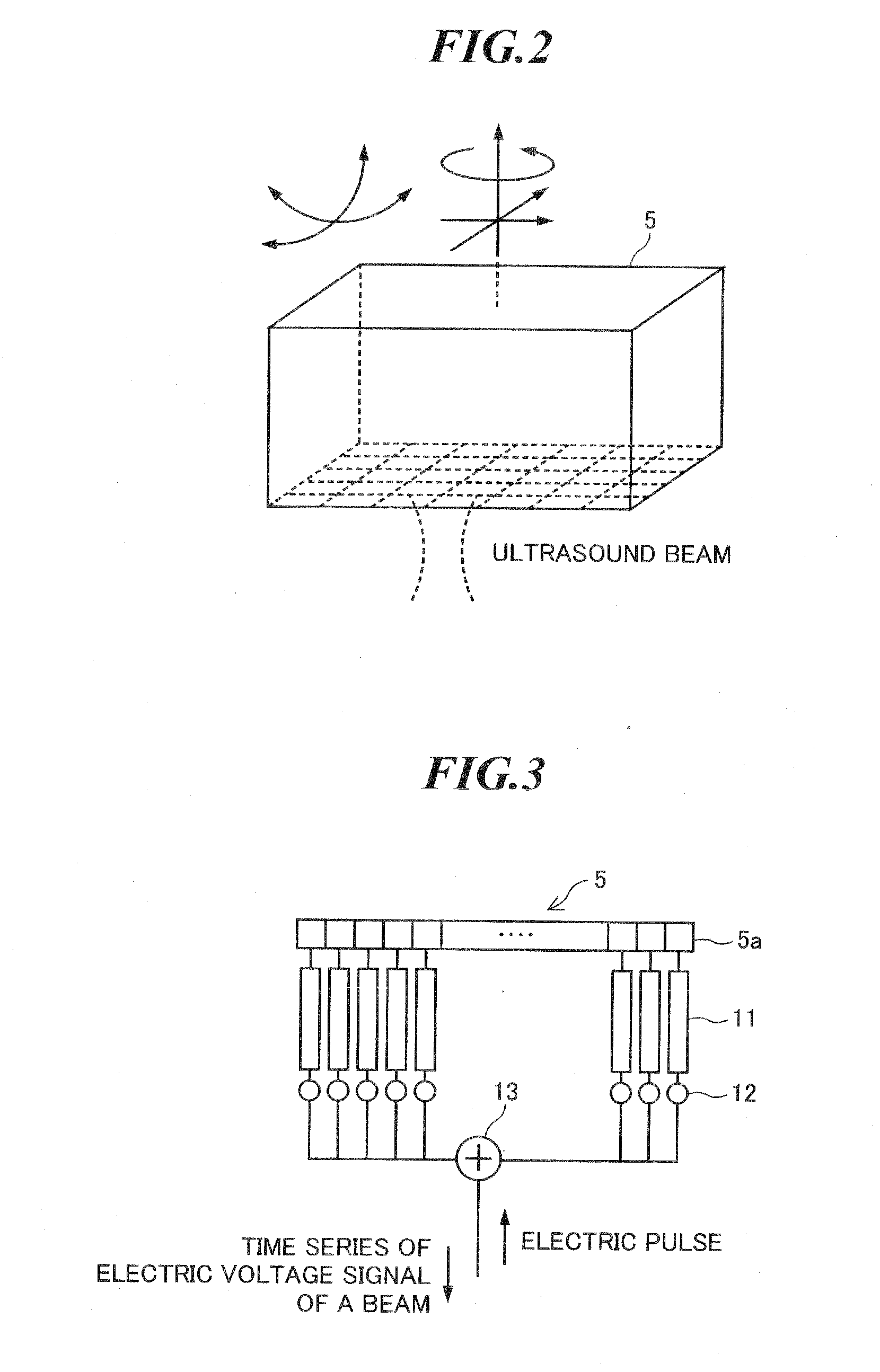

Displacement measurement method and apparatus, and ultrasonic diagnostic apparatus

ActiveUS20110172538A1Accurate measurementReduce errorsImage analysisMagnetic measurementsOrthogonal coordinatesElectricity

An accurate real-time measurement of a displacement vector is achieved on the basis of the proper beamforming that require a short time for obtaining one echo data frame without suffering affections by a tissue motion. The displacement measurement method includes the steps of: (a) yielding ultrasound echo data frames by scanning an object laterally or elevationally using an ultrasound beam steered electrically and / or mechanically with a single steering angle over an arbitrary three-dimensional orthogonal coordinate system involving existence of three axes of a depth direction, a lateral direction, and an elevational direction; and (b) calculating a displacement vector distribution by implementing a block matching on the predetermined ultrasound echo data frames yielded at more than two phases.

Owner:SUMI CHIKAYOSHI

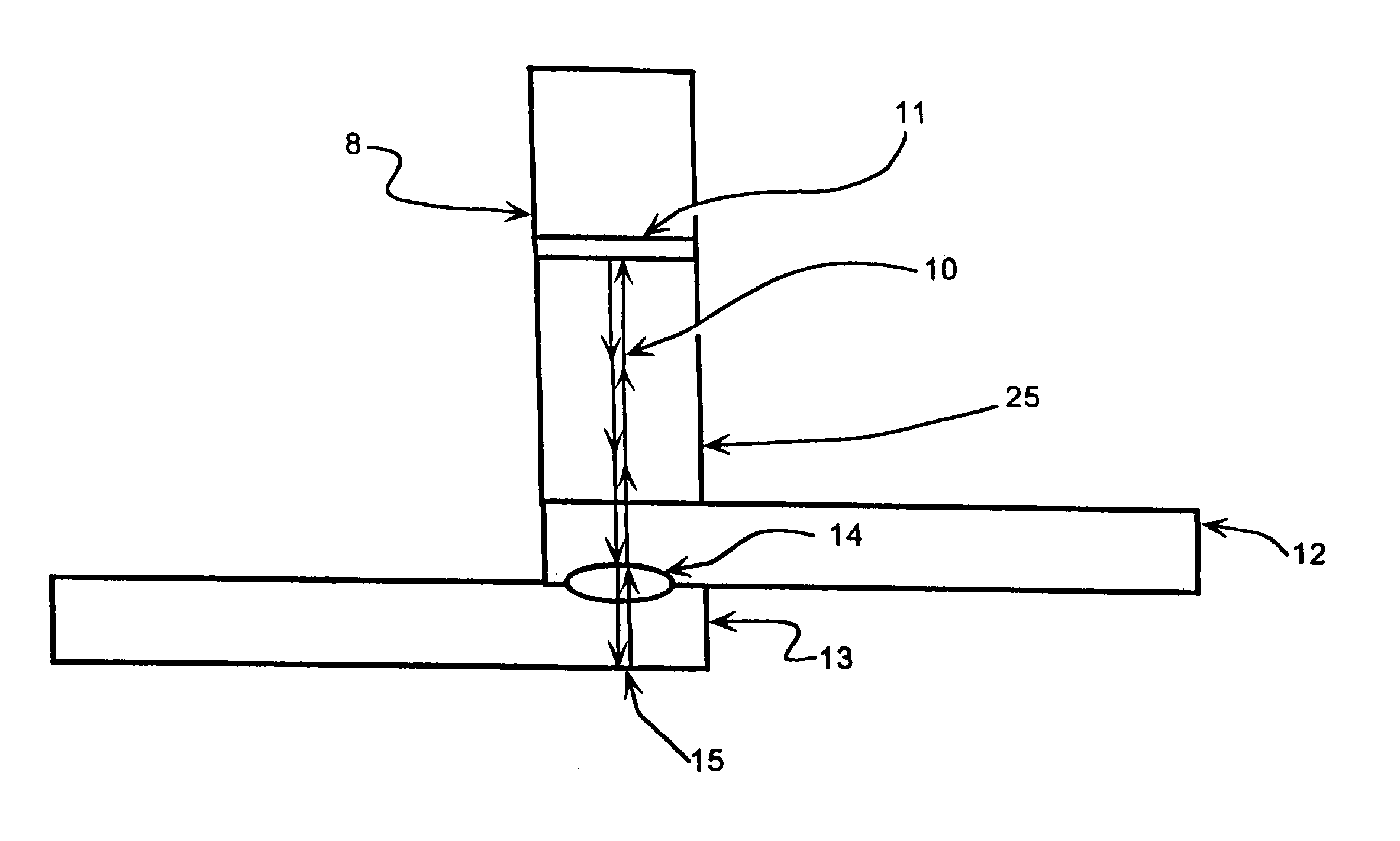

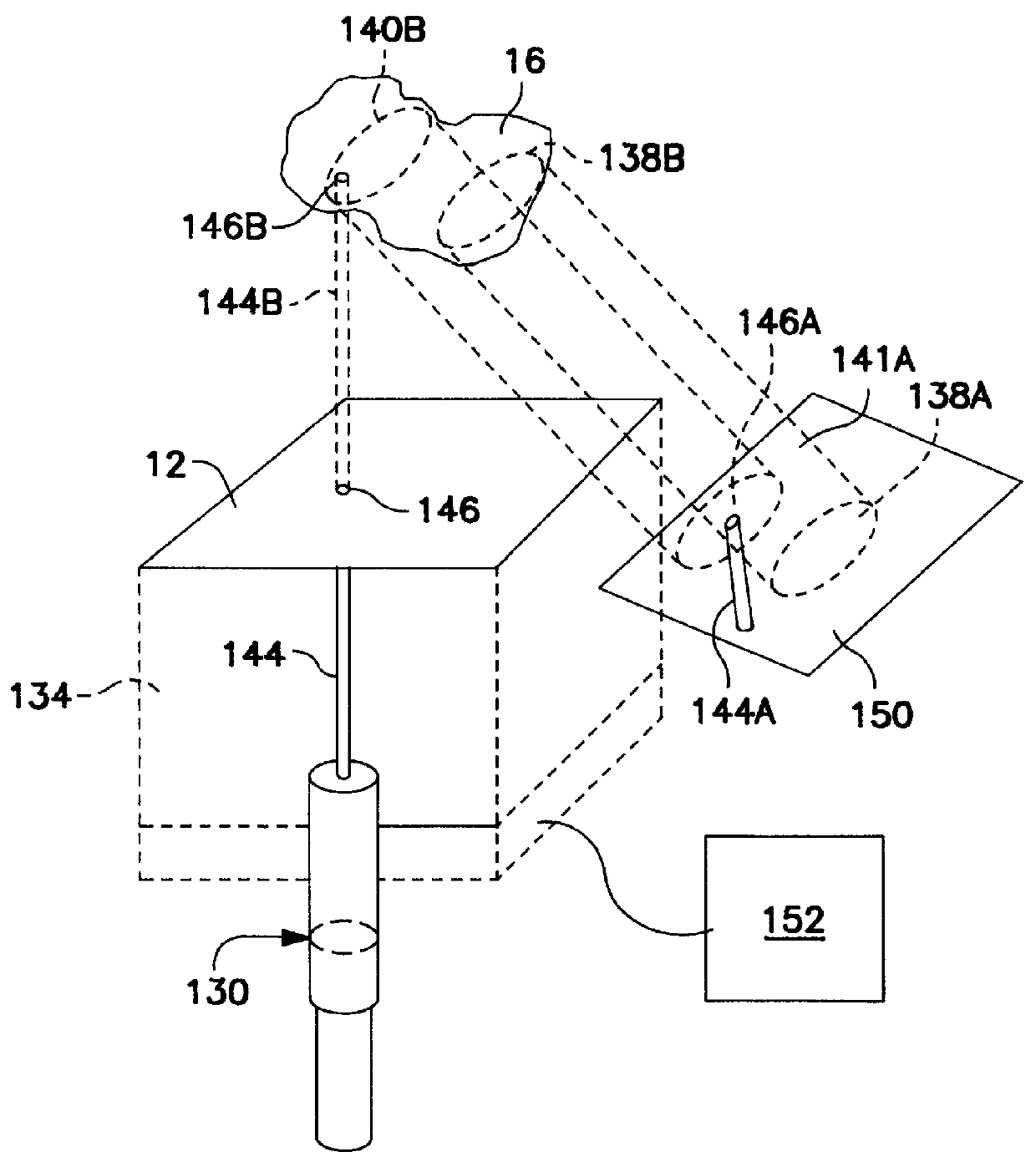

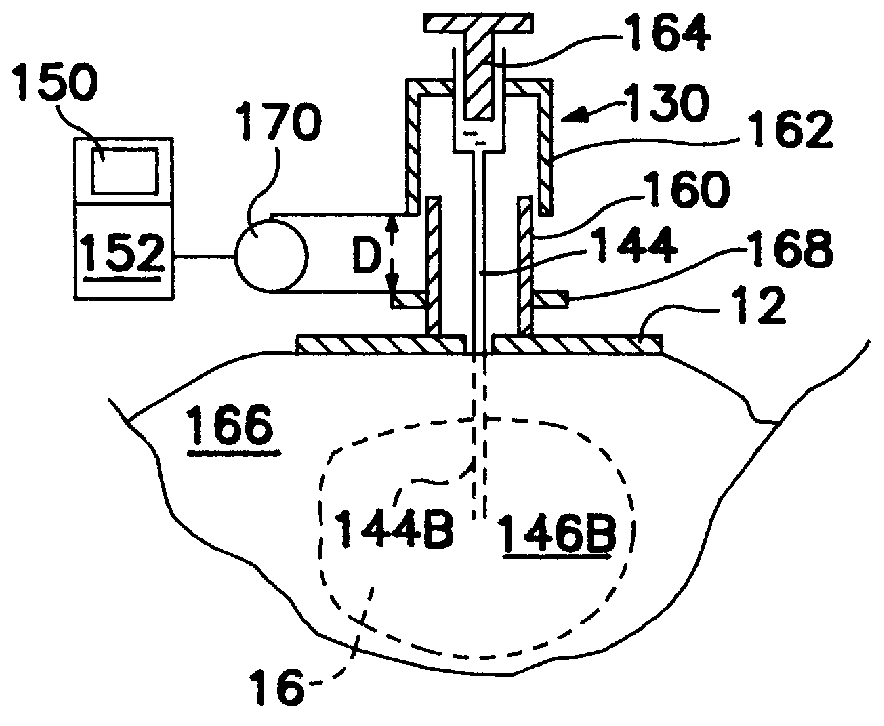

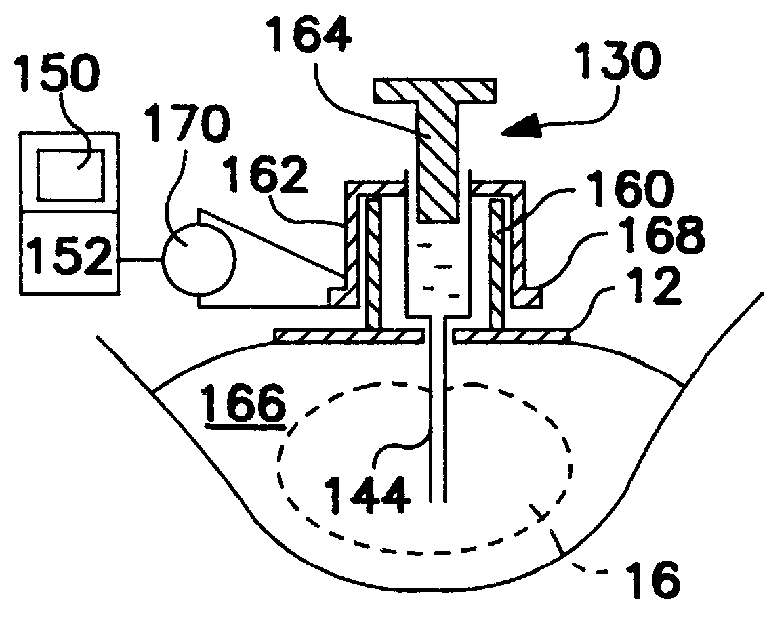

Methods for ultrasonic inspection of spot and seam resistance welds in metallic sheets and a spot weld examination probe system (SWEPS)

InactiveUS6948369B2Allow flexibilityAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveElectrical resistance and conductance

An external focused ultrasonic beam, non-destructive, open-air, inspection method of sheet metal spot and seam weldments using a probe in combination with motion measurement of the probe over the weldments during inspection without immersion of the material. Reflected ultrasonic waves are received and signals produced and processed or displayed as A-scan, B-scan and C-scan images that are easily recognized. An A-Scan is based on the time-of-flight difference between the outer surface, the weldment and inner and opposite surfaces of the component. B-scan and C-scan indicate the degree of weld fusion and provide data relative to fused thickness and defects sheet metal or welds. A special purpose scanner that enables ultrasonic examination welds. Scanner is pencil like ultrasonic probe with bearing face and position sensing device disposed adjacent a weld position. Scanner collects data for method to determine various characteristics of welded items.

Owner:APPLIED METRICS

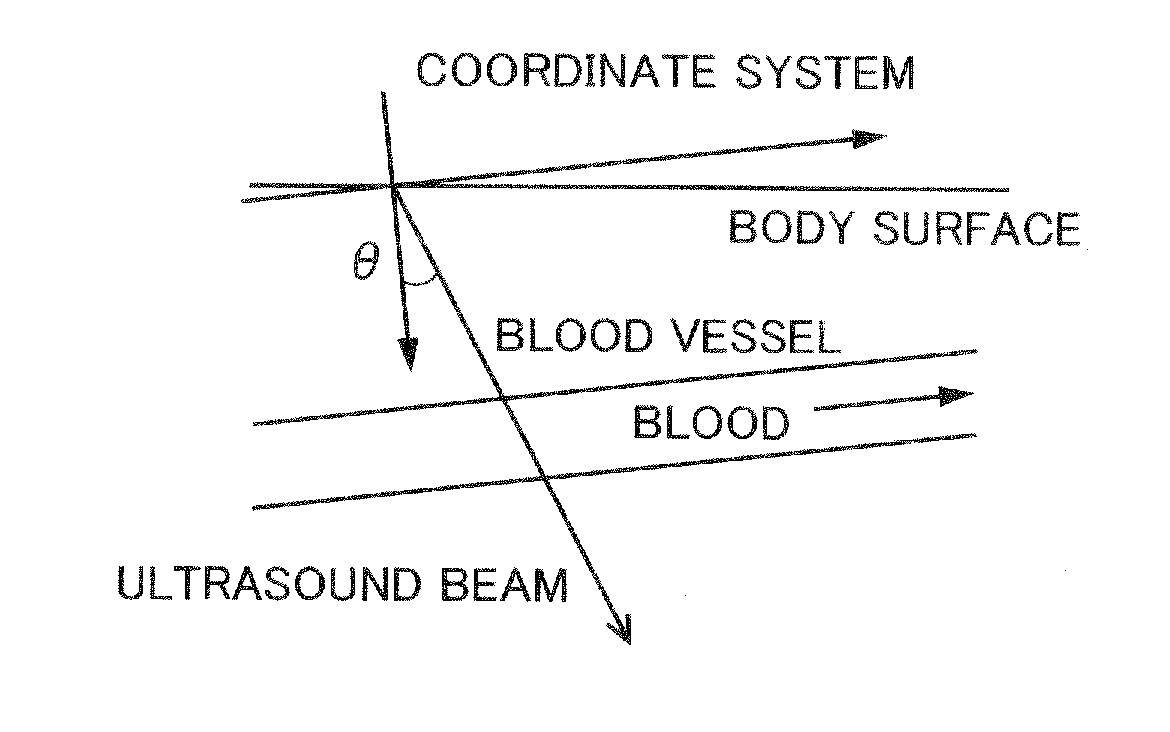

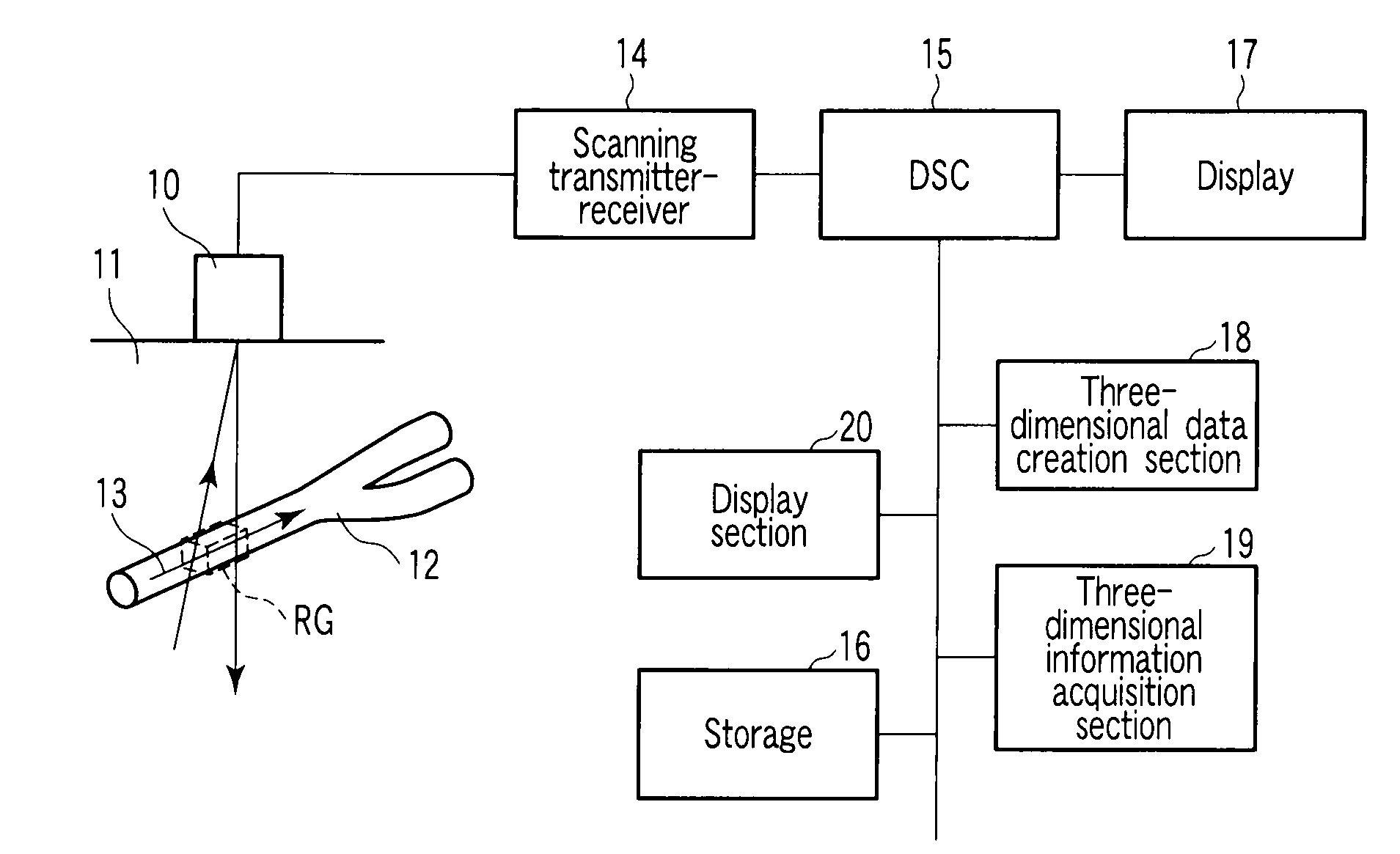

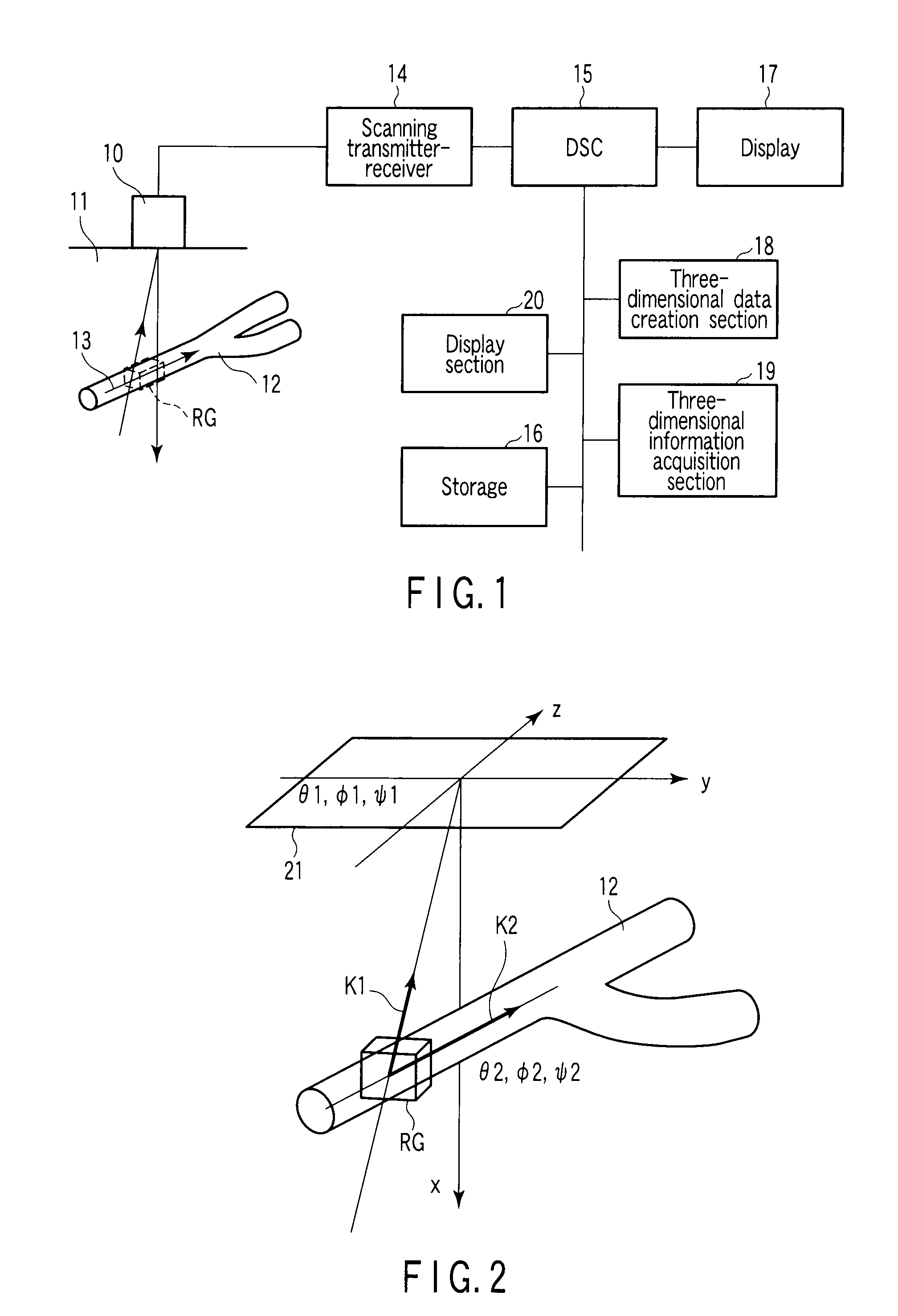

Ultrasonic diagnostic apparatus and method of measuring velocity with ultrasonic waves

InactiveUS20080306386A1Blood flow measurement devicesInfrasonic diagnosticsElevation angleSonification

A multiple ultrasonic beam is transmitted from an ultrasonic probe, and a velocity of blood flow, azimuth and elevation angle of a sample such as a blood flow are acquired by a three-dimensional information acquisition section, as three-dimensional fluid information in a range gate, based on a Doppler signal output from the ultrasonic probe.

Owner:KK TOSHIBA +1

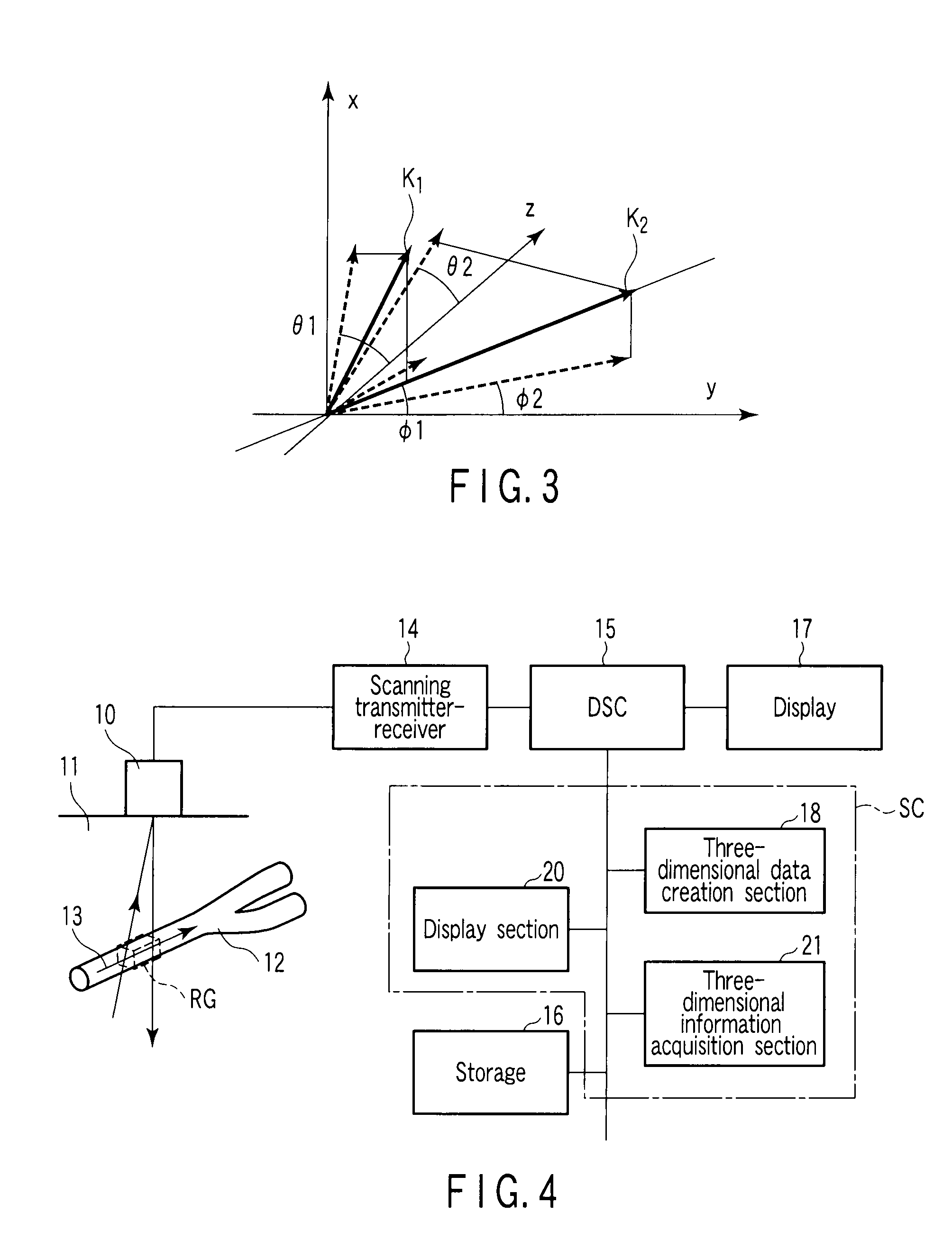

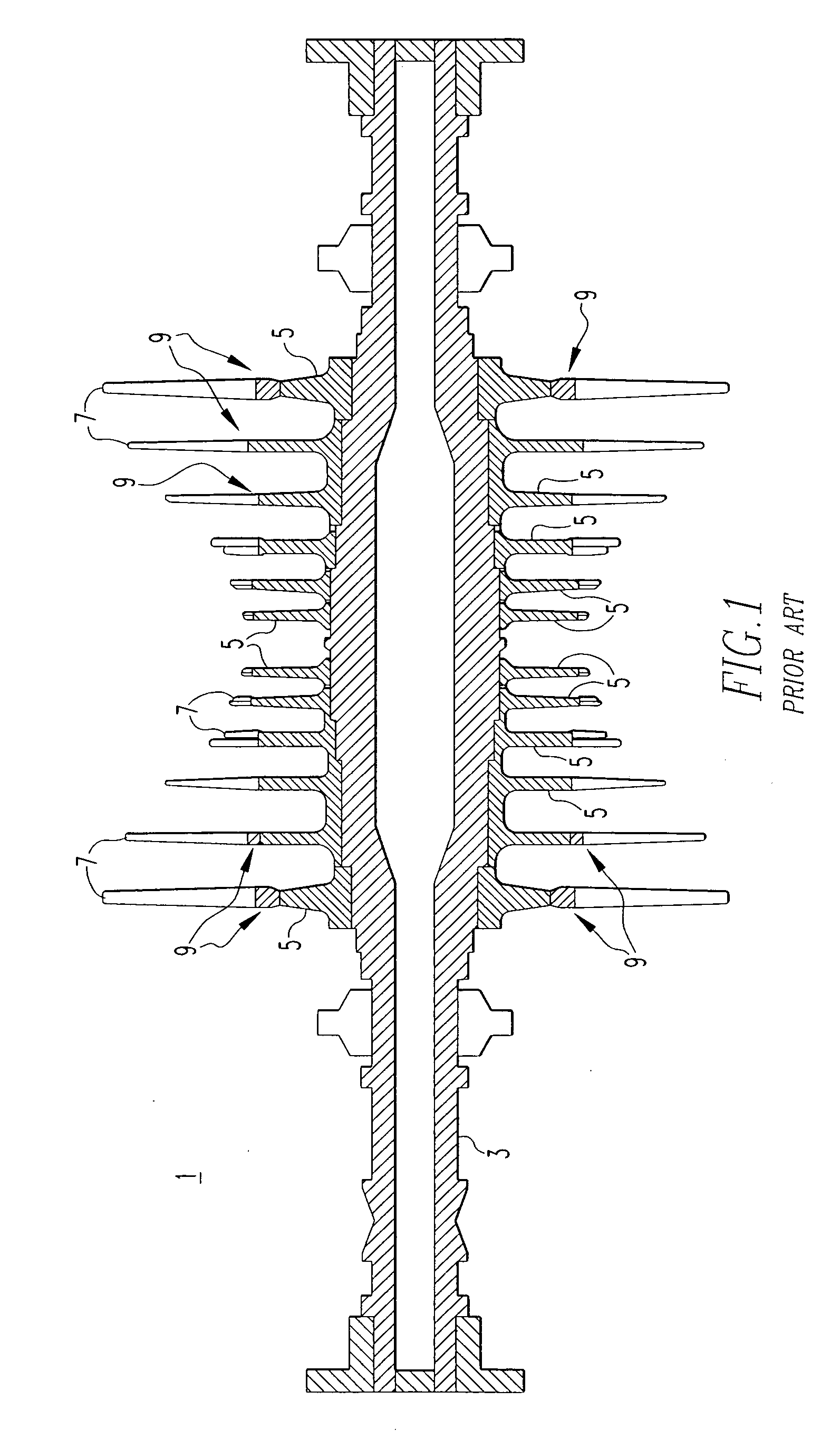

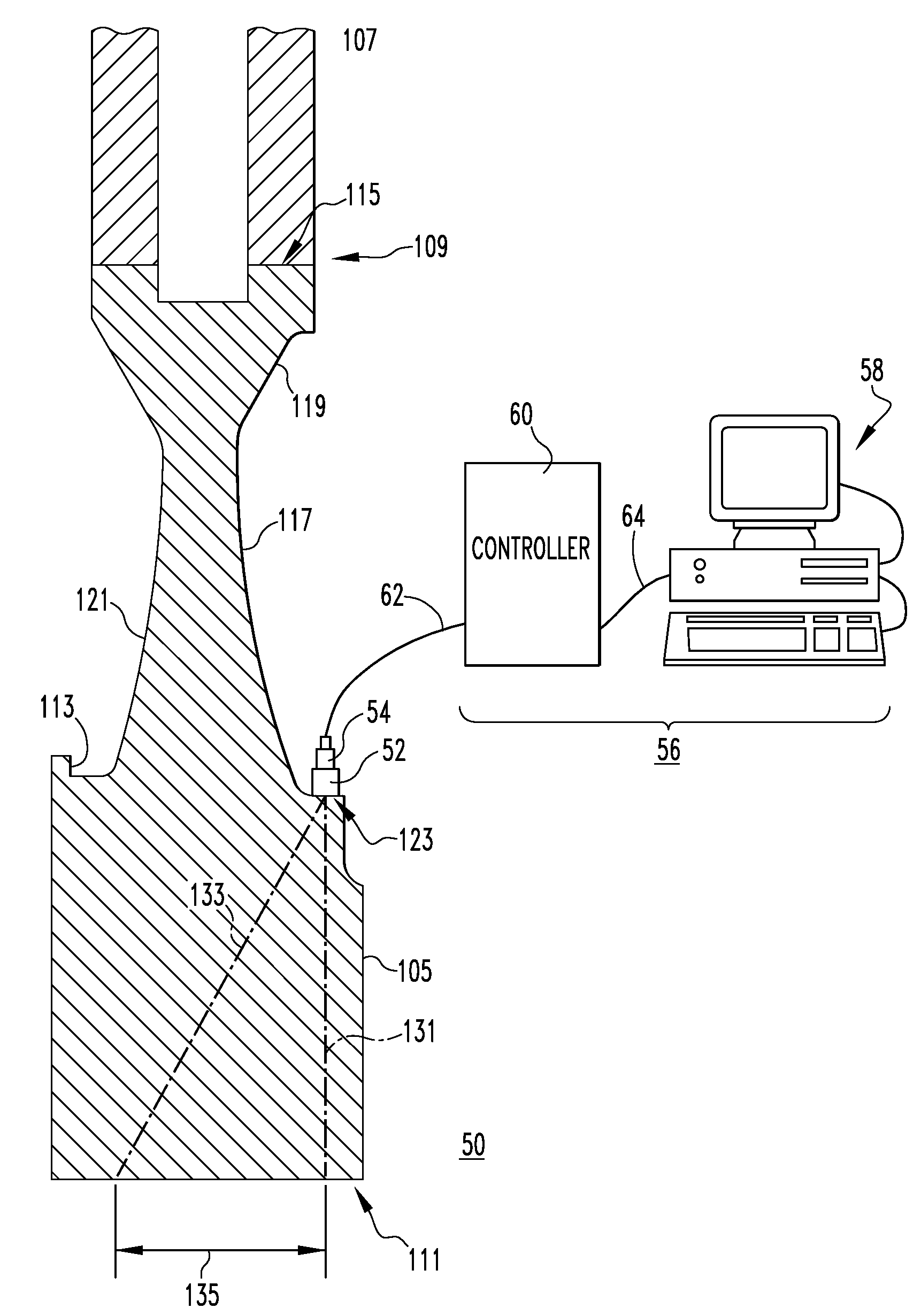

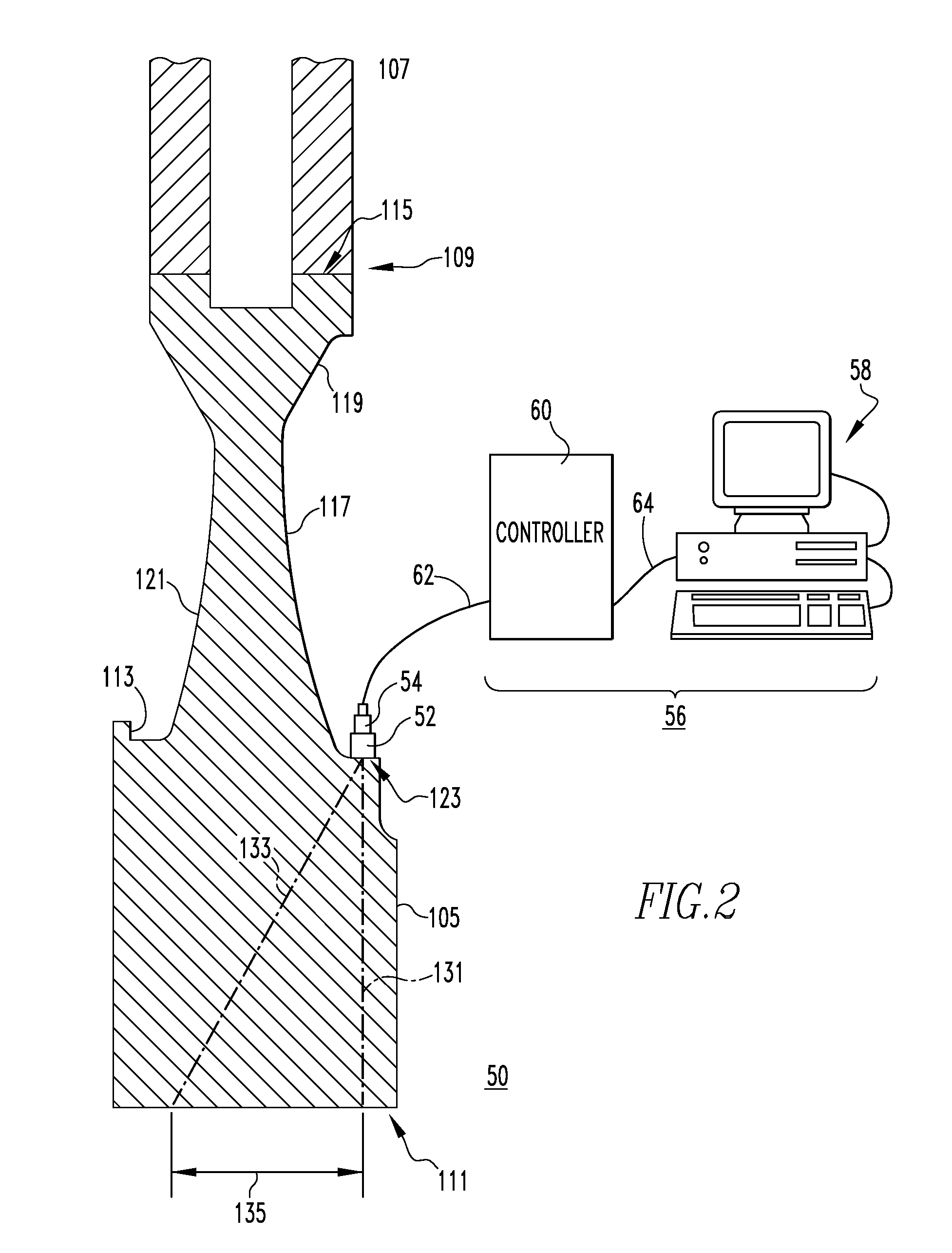

Phased array ultrasonic testing system and methods of examination and modeling employing the same

ActiveUS20060283250A1Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesCircular discSonification

A phased array ultrasonic testing system is for examining turbine disc bores and blade attachments for discontinuities, such as stress corrosion cracking. The system is particularly suited to perform an accurate and efficient inspection of components despite their having a relatively complex geometry, such as axial entry blade attachments and bores of associated discs. The system includes a control system with a computer and a controller for programming, emitting, and steering an ultrasonic beam via at least one two-dimensional phased array probe, thereby precisely inspecting the area of interest while simultaneously accommodating the aforementioned complex geometry of the disc or blade attachment. Computer control of the beam permits the number of inspection locations and the number of different probe wedges to be reduced providing for an efficient, timely inspection. Methods of profiling and examining turbine components of known and unknown geometries, are also disclosed.

Owner:SIEMENS ENERGY INC

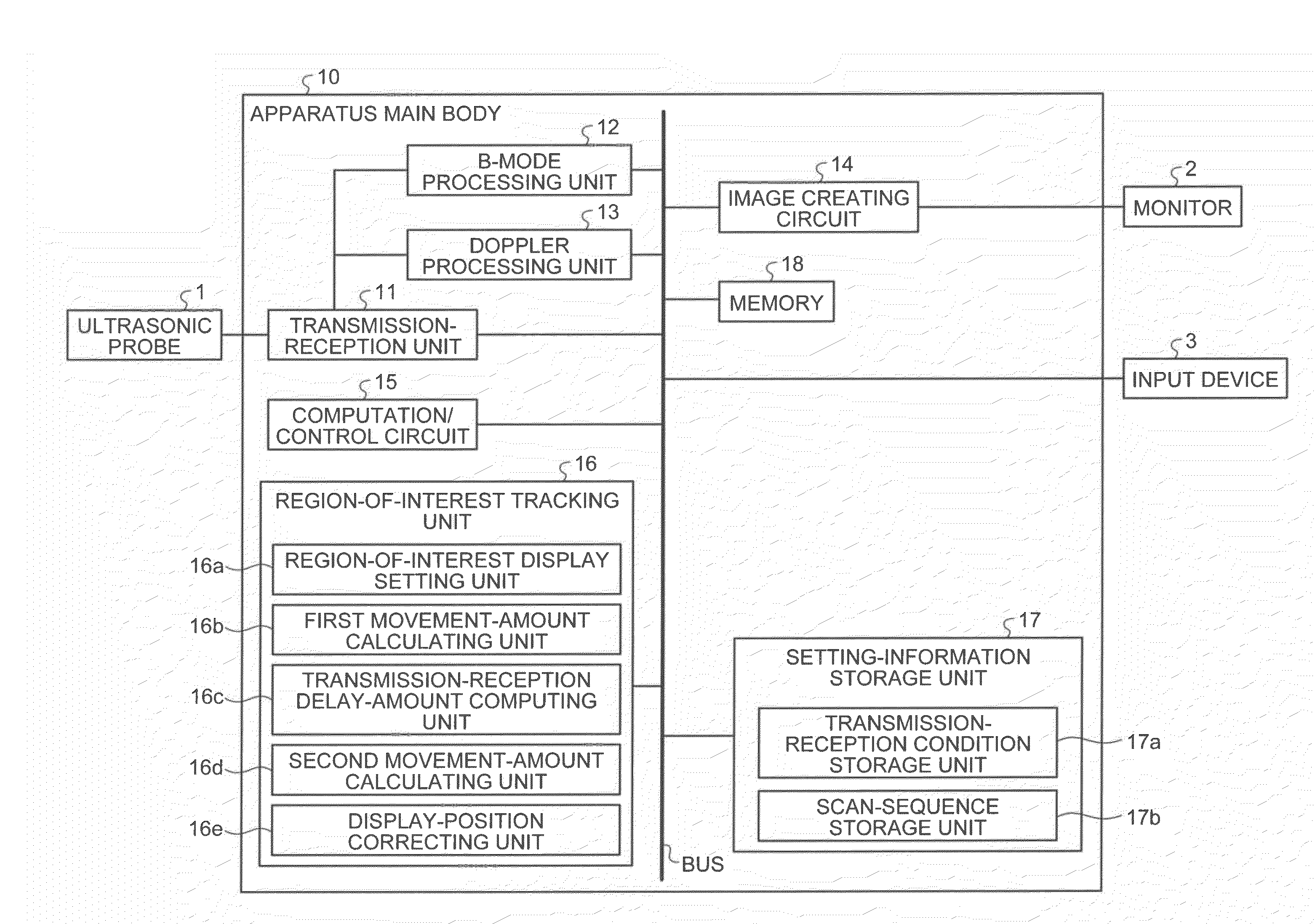

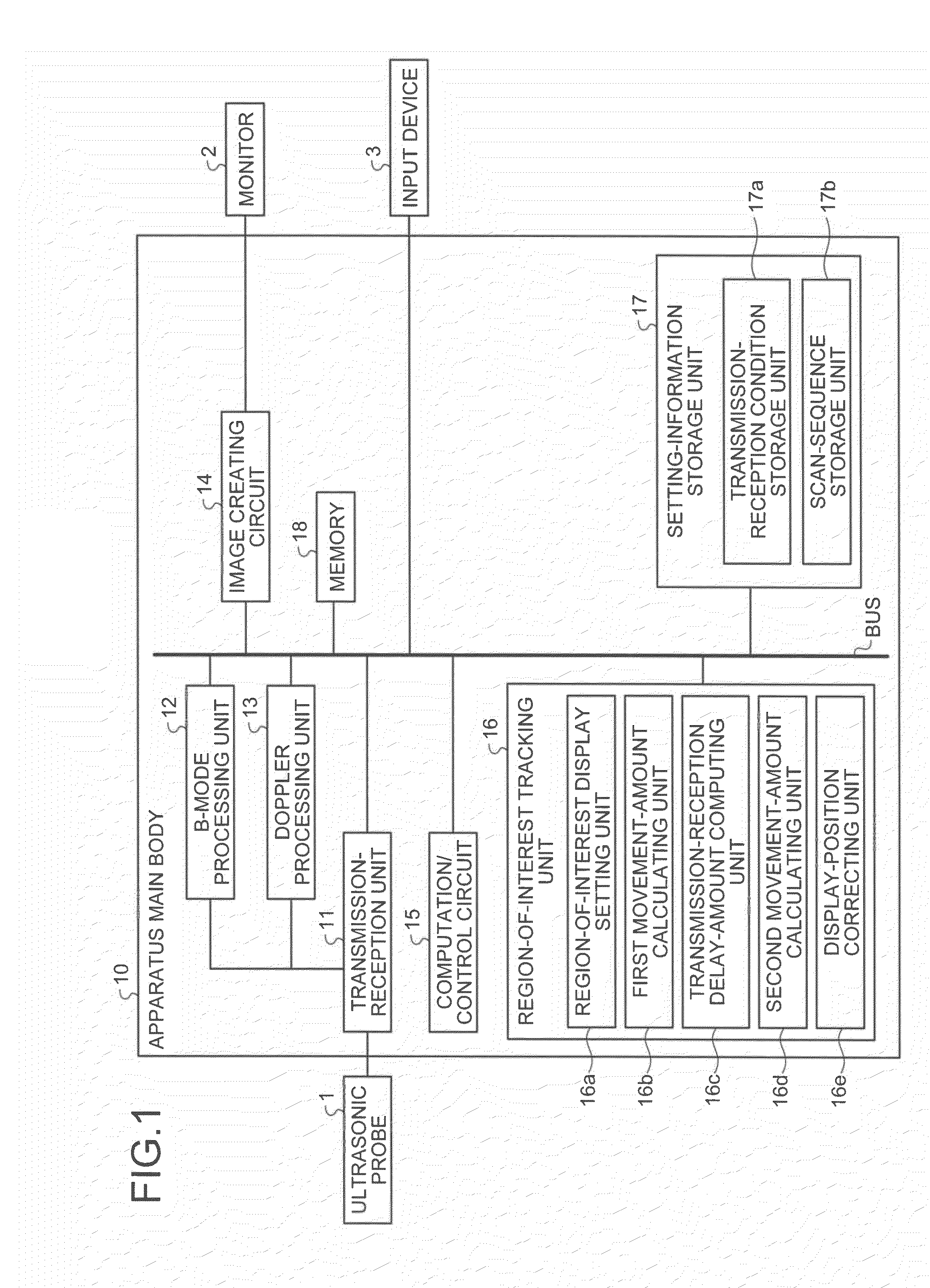

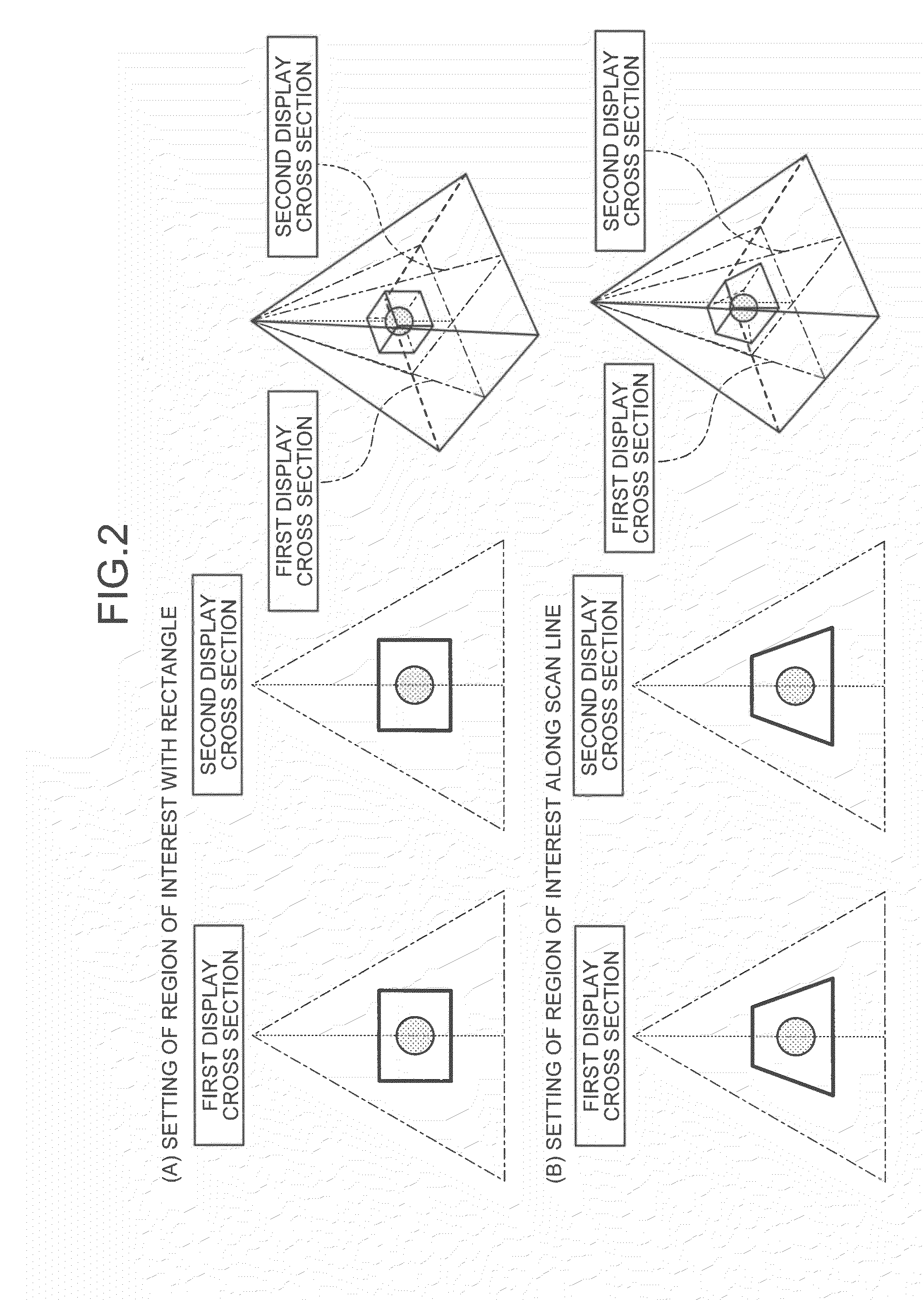

Ultrasonic diagnostic apparatus and computer program product

ActiveUS20100069756A1Reduce scan timeImage quality of a created ultrasound image is lowerOrgan movement/changes detectionCharacter and pattern recognitionSonificationUltrasonic beam

A region-of-interest setting unit sets a region of interest to be included in an ultrasound image. A first movement-amount calculating unit sequentially calculates a movement amount of the set region of interest between reception data along the time sequence as a first movement amount. A transmitting-receiving delay-amount computing unit computes a delay amount for sequentially shifting a scan region of an ultrasonic beam based on the sequentially calculated first movement amount. A computation / control circuit performs control so as to generate a high voltage pulse based on the computed delay amount. A second movement-amount calculating unit sequentially calculates a movement amount of the region of interest between image data along the time sequence as a second movement amount. A display-position correcting unit performs a correction such that the region of interest included in the image data is to be displayed at the same display position, based on the second movement amount.

Owner:TOSHIBA MEDICAL SYST CORP

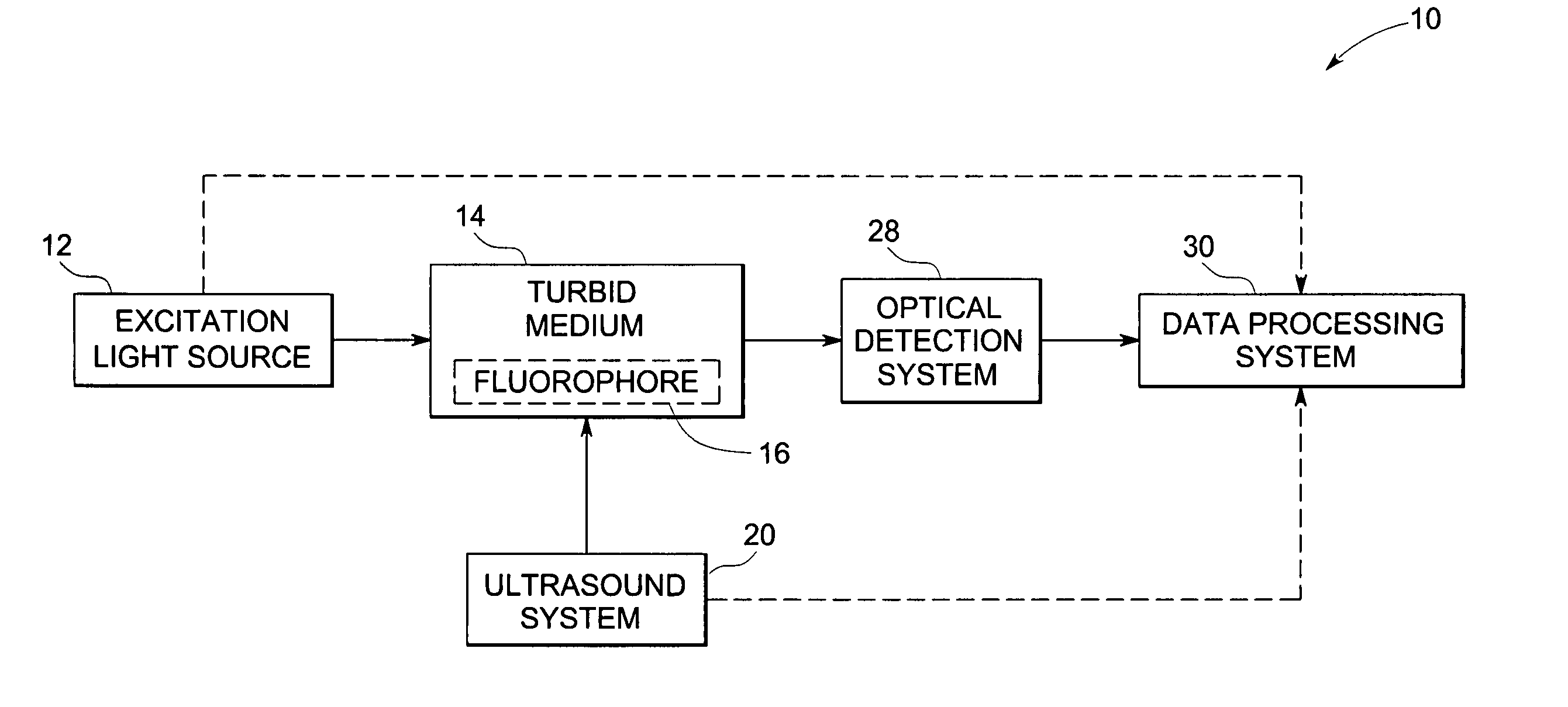

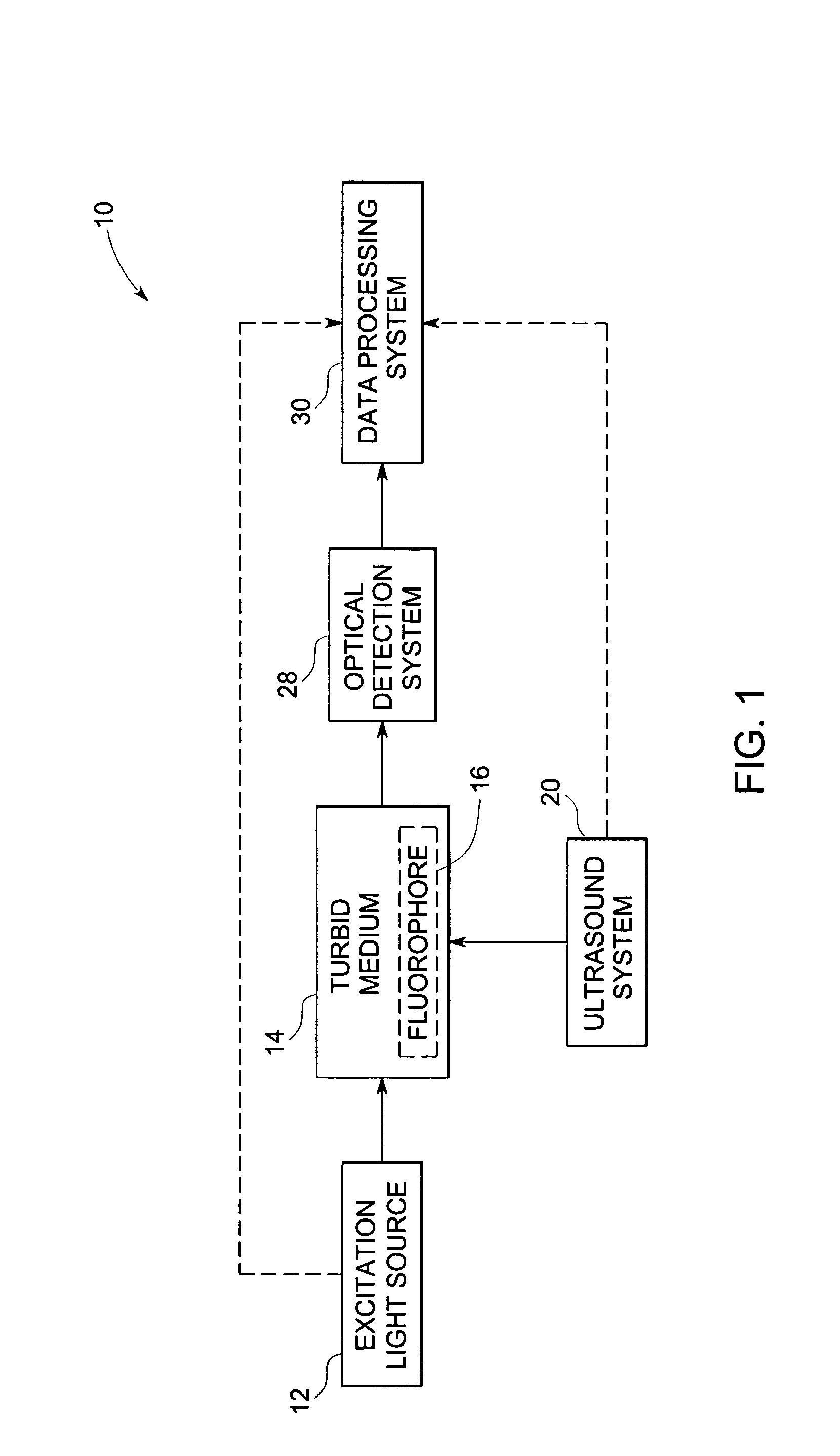

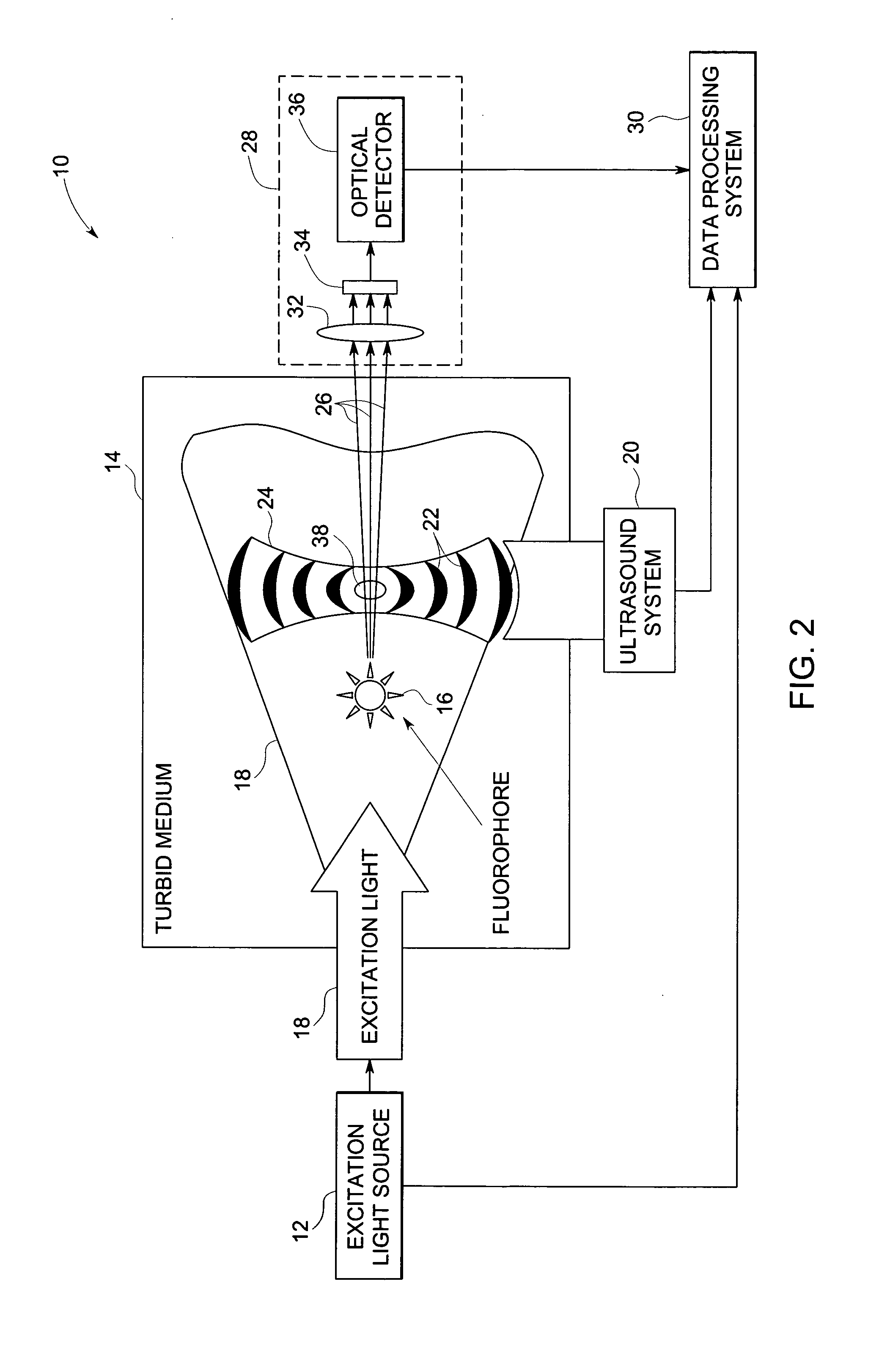

System and method for imaging based on ultrasonic tagging of light

ActiveUS20060058685A1Ultrasonic/sonic/infrasonic diagnosticsDiagnostics using vibrationsUltrasonic beamLight irradiation

A technique is provided for imaging based on localization of fluorescence in a medium. The technique includes illuminating the medium with an excitation light to excite fluorescence, scanning the medium at a plurality of locations via an ultrasonic beam, modulating a portion of the emitted light from the fluorescence via the ultrasonic beam at each of the plurality of locations, differentially detecting the modulated light at a boundary of the medium, and reconstructing an image from the detected signal.

Owner:GENERAL ELECTRIC CO

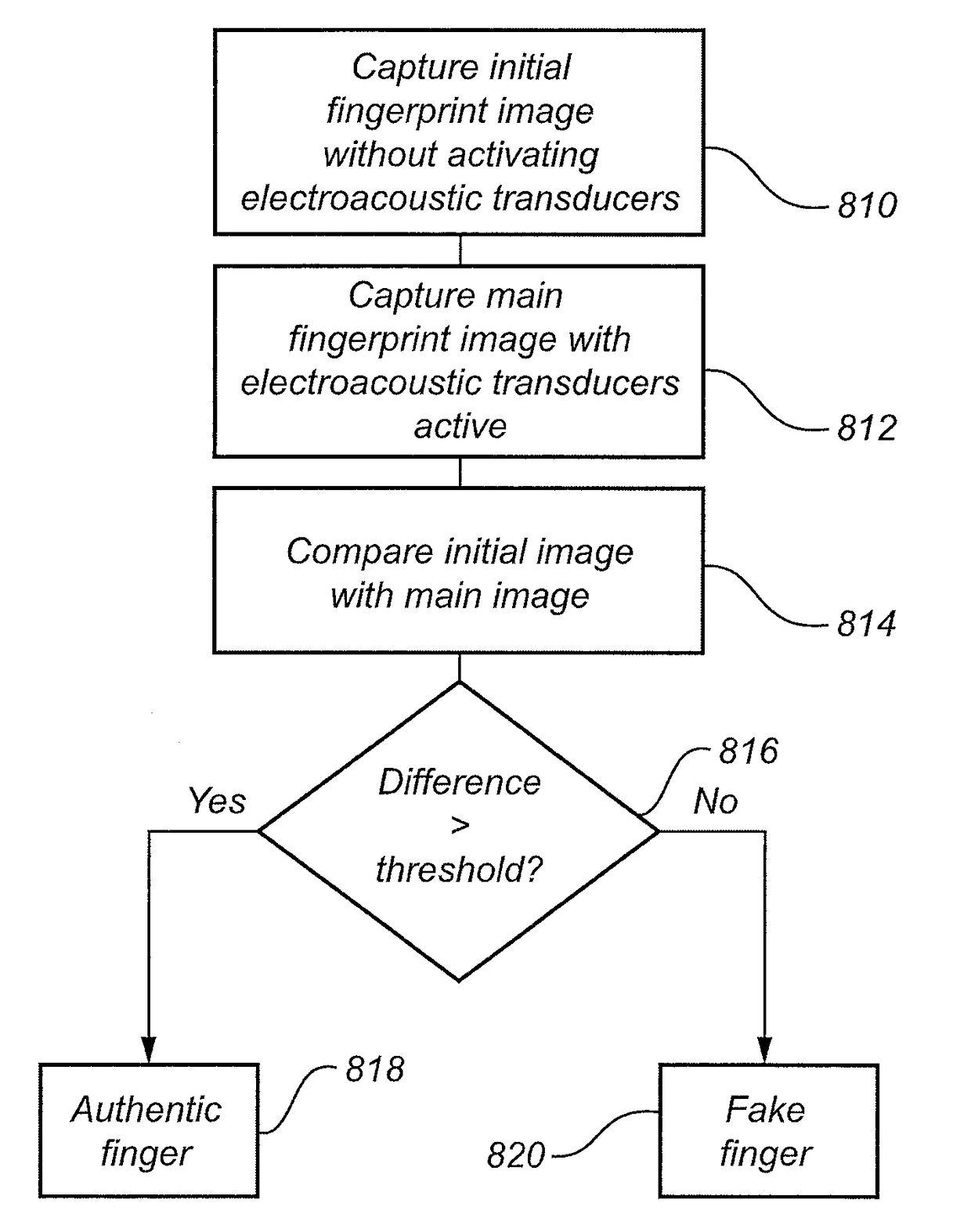

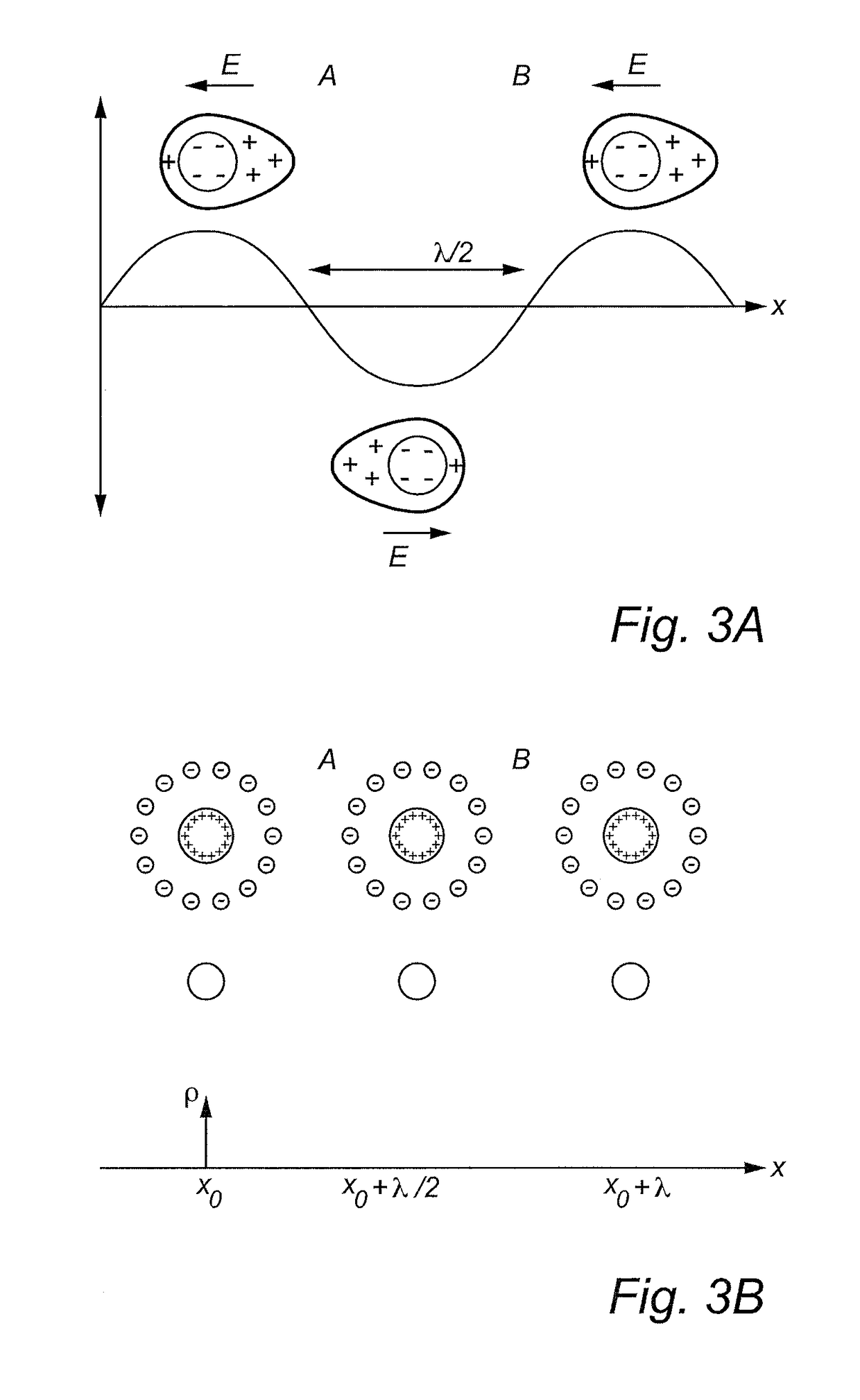

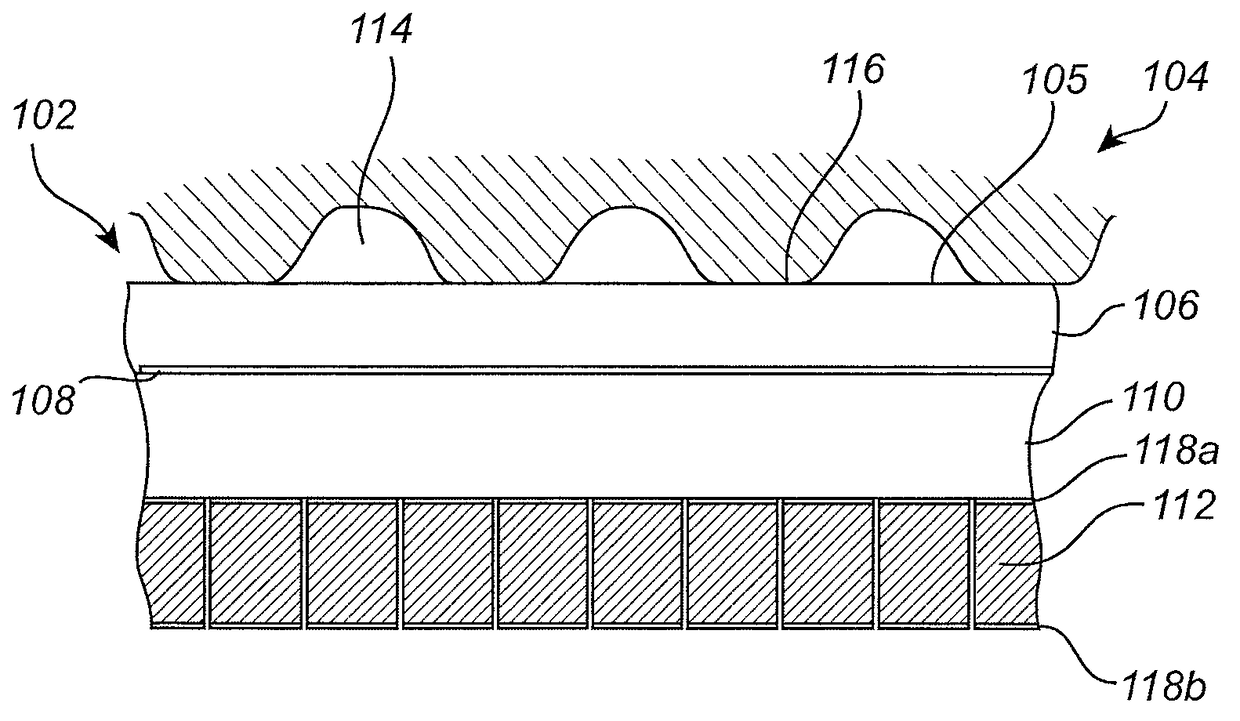

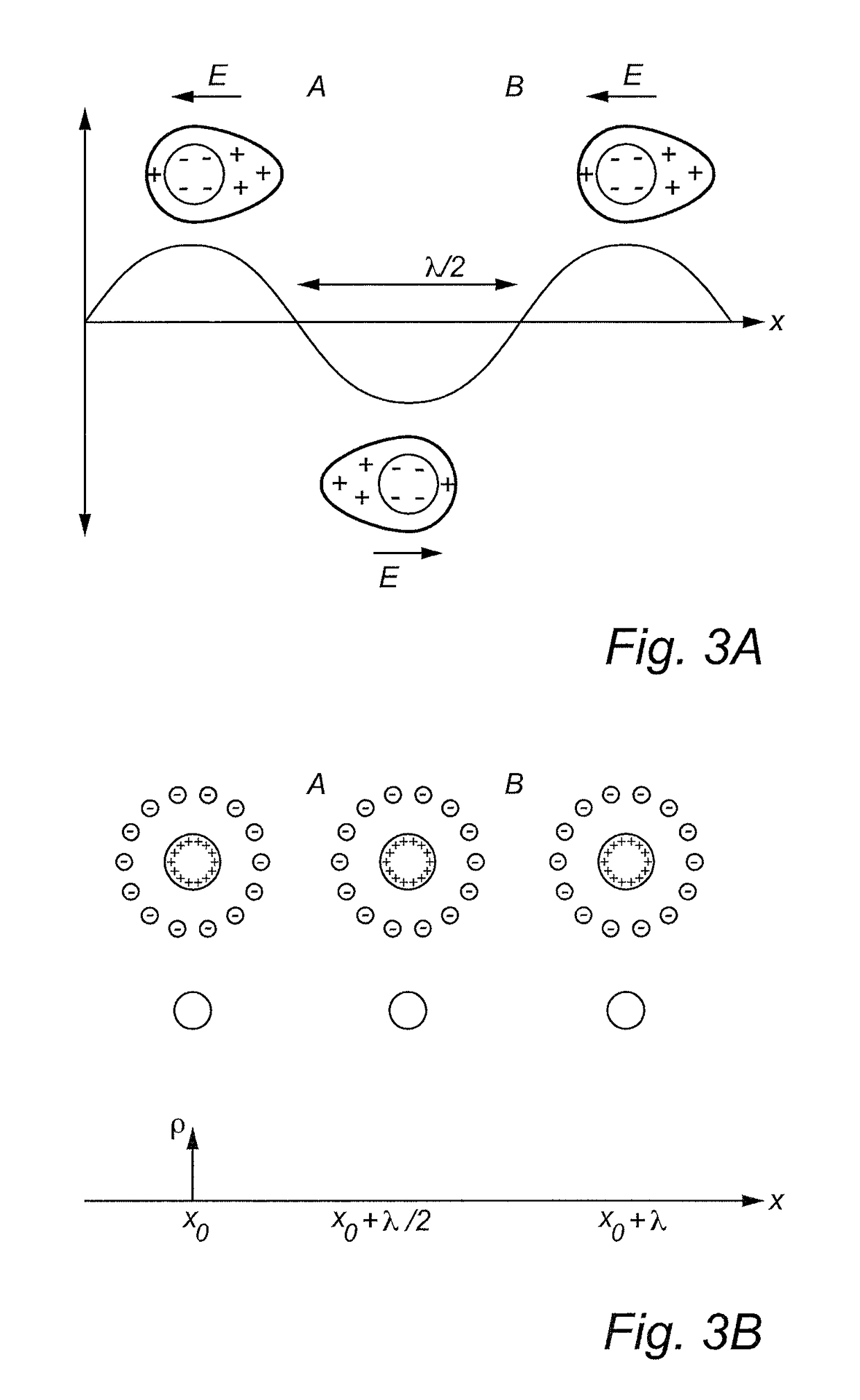

Capacitive fingerprint sensing device and method for capturing a fingerprint using the sensing device

ActiveUS20170316243A1Reduce energy consumptionShorten the timePrint image acquisitionMatching and classificationCapacitanceUltrasonic beam

There is provided a capacitive fingerprint sensing device for sensing a fingerprint pattern of a finger, the capacitive fingerprint sensing device comprising: a protective dielectric top layer having an outer surface forming a sensing surface to be touched by the finger; at least one electrically conductive sensing structure arranged underneath the top layer; readout circuitry coupled to the at least one electrically conductive sensing structure to receive a sensing signal indicative of a distance between the finger and the sensing structure; and a plurality of individually controllable electroacoustic transducers arranged underneath the top layer and configured to generate a focused ultrasonic beam, and to transmit the ultrasonic beam through the protective dielectric top layer towards the sensing surface to induce an ultrasonic vibration potential in a ridge of finger placed in contact with the sensing surface at the location of the ultrasonic beam.

Owner:FINGERPRINT CARDS ANACATUM IP AB

Ultrasound diagnostic apparatus and method of producing ultrasound image

InactiveUS20120238876A1Reduce spatial resolutionUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsSonificationUltrasonic beam

Owner:FUJIFILM CORP

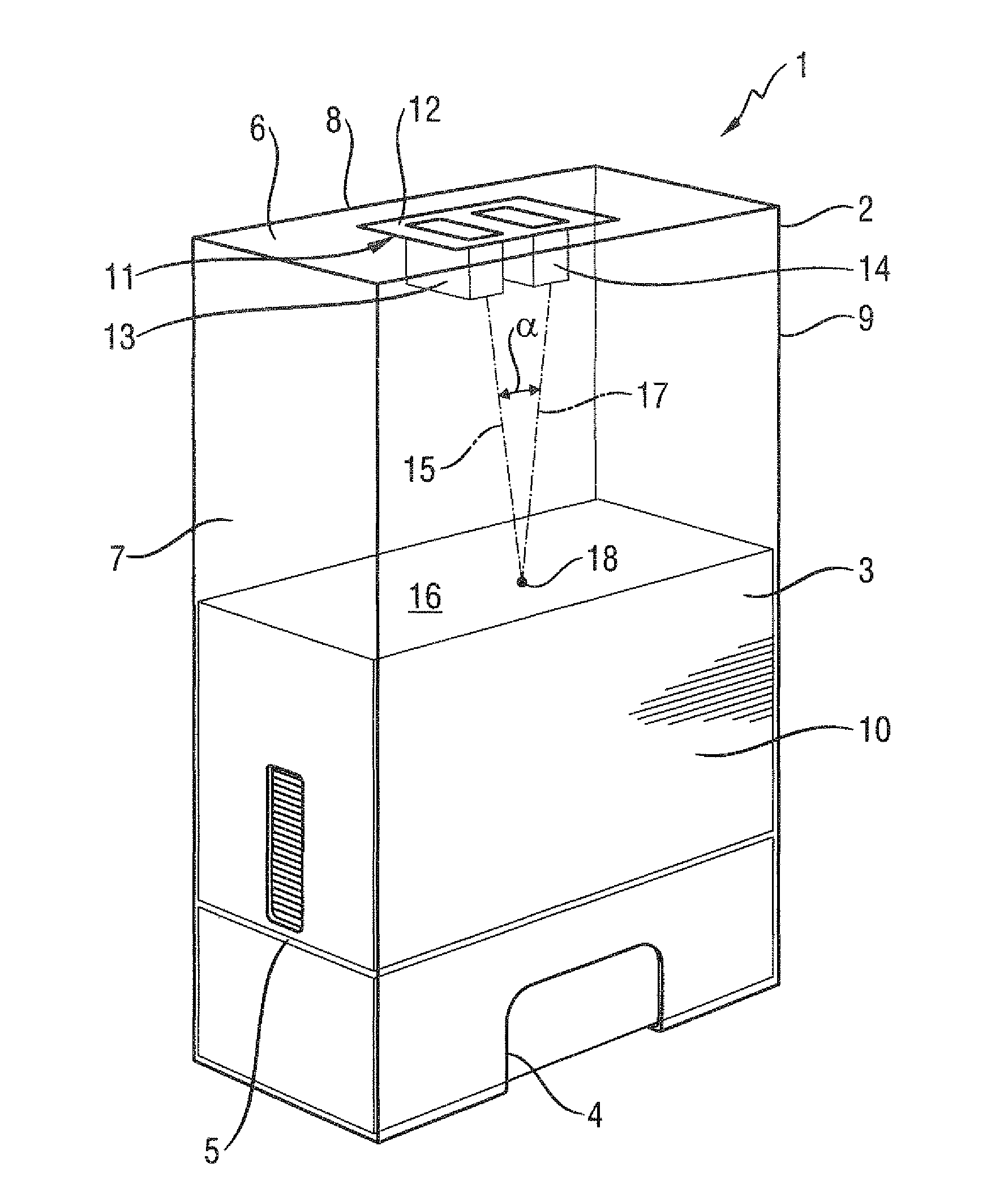

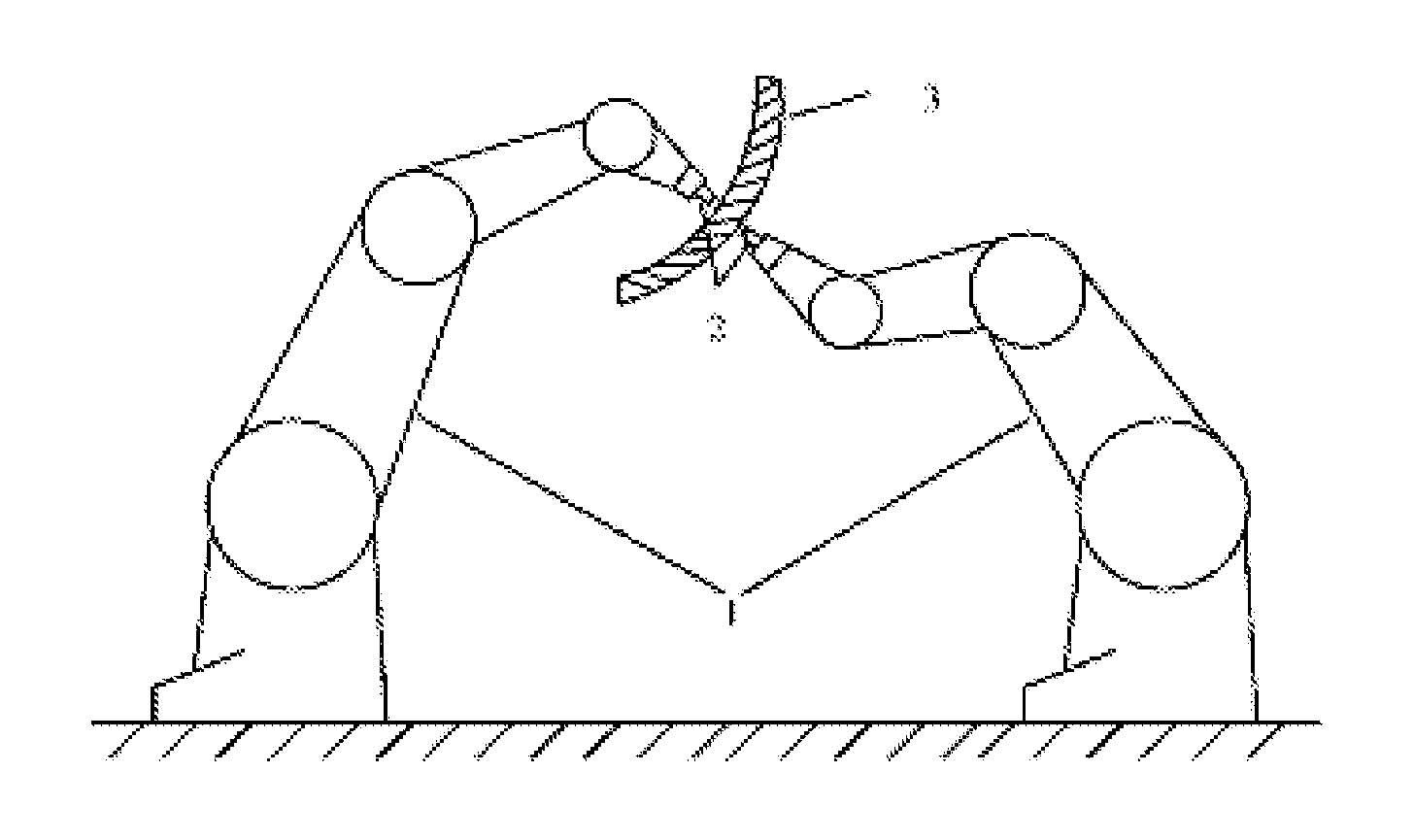

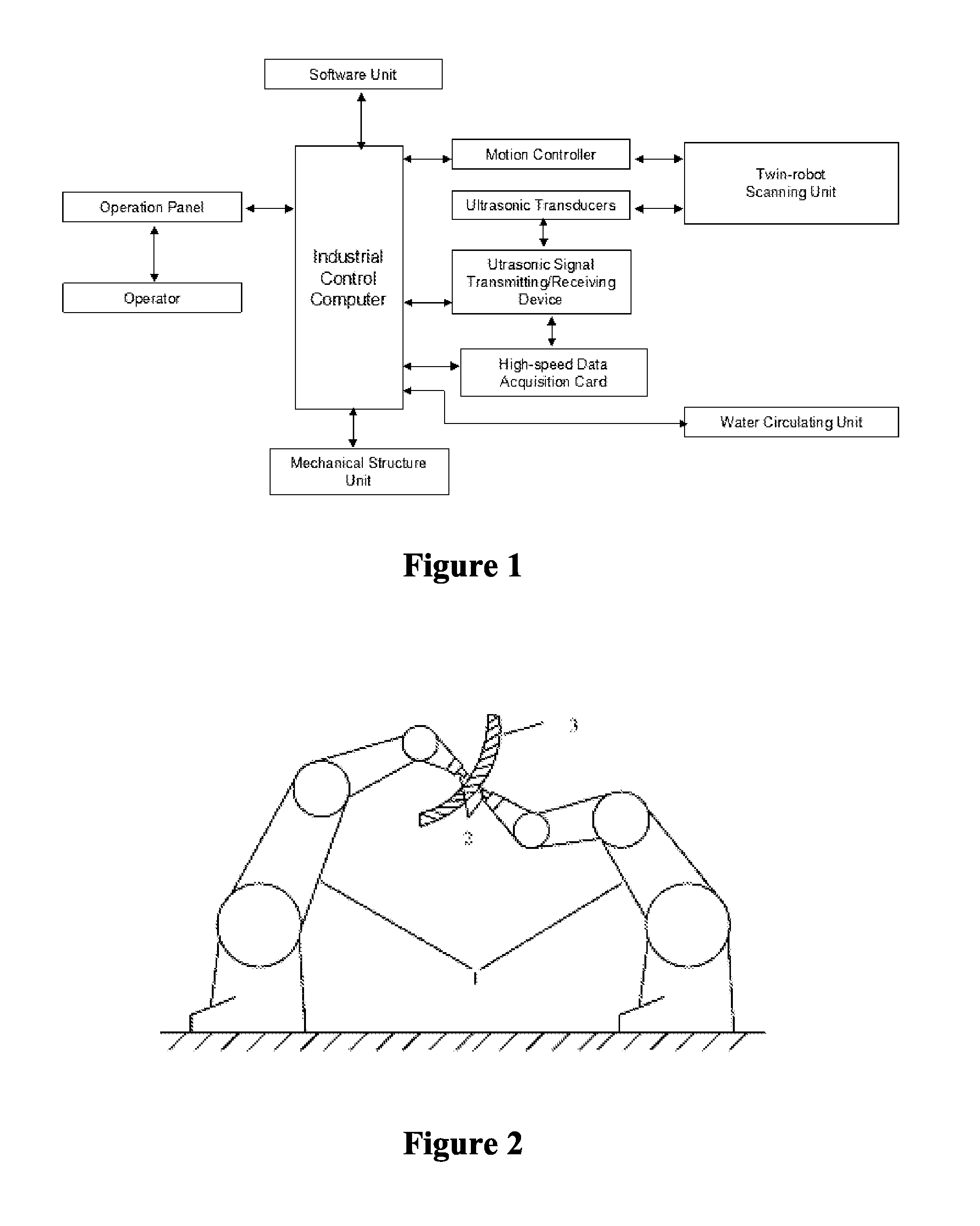

Dual Robot Detection Apparatus For Non-Damage Detection

InactiveUS20150177194A1Improve accuracyIncrease speedProgramme controlProgramme-controlled manipulatorNon destructiveUltrasonic beam

Disclosed is a twin-robot testing apparatus for non-destructive testing. The apparatus comprises two robots (1) for detecting a workpiece (3) from front and back sides thereof; a water circulating unit, comprising a pressure pump, two water ejection coupling probes (2) and water pipes, for providing a coupled water column; an ultrasonic transmitting / receiving device, comprising two ultrasonic transducers, a pulse transmitting / receiving card, and a high-speed data acquisition card, wherein the two ultrasonic transducers are respectively attached at the end-effector of the two robots (1), for transmitting ultrasound and receiving ultrasound respectively, the ultrasonic pulse transmitting / receiving card and the high-speed data acquisition card are mounted on the robot controller mechanism for transmitting and receiving, and acquiring pulse signals, the two robots perform a synchronous transmission testing, with ultrasound transmitted by one robot being received by the other robot, and the ultrasonic transducers are adjusted in position and gesture with the change in the surface shape of the workpiece (3) such that the incidence direction of ultrasonic beam is always in coincidence with the normal direction of the curved surface. The apparatus is used for automatic non-destructive testing of a curved-surface workpiece made of a composite material, and can improve the accuracy, sensitivity and efficiency of the testing.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

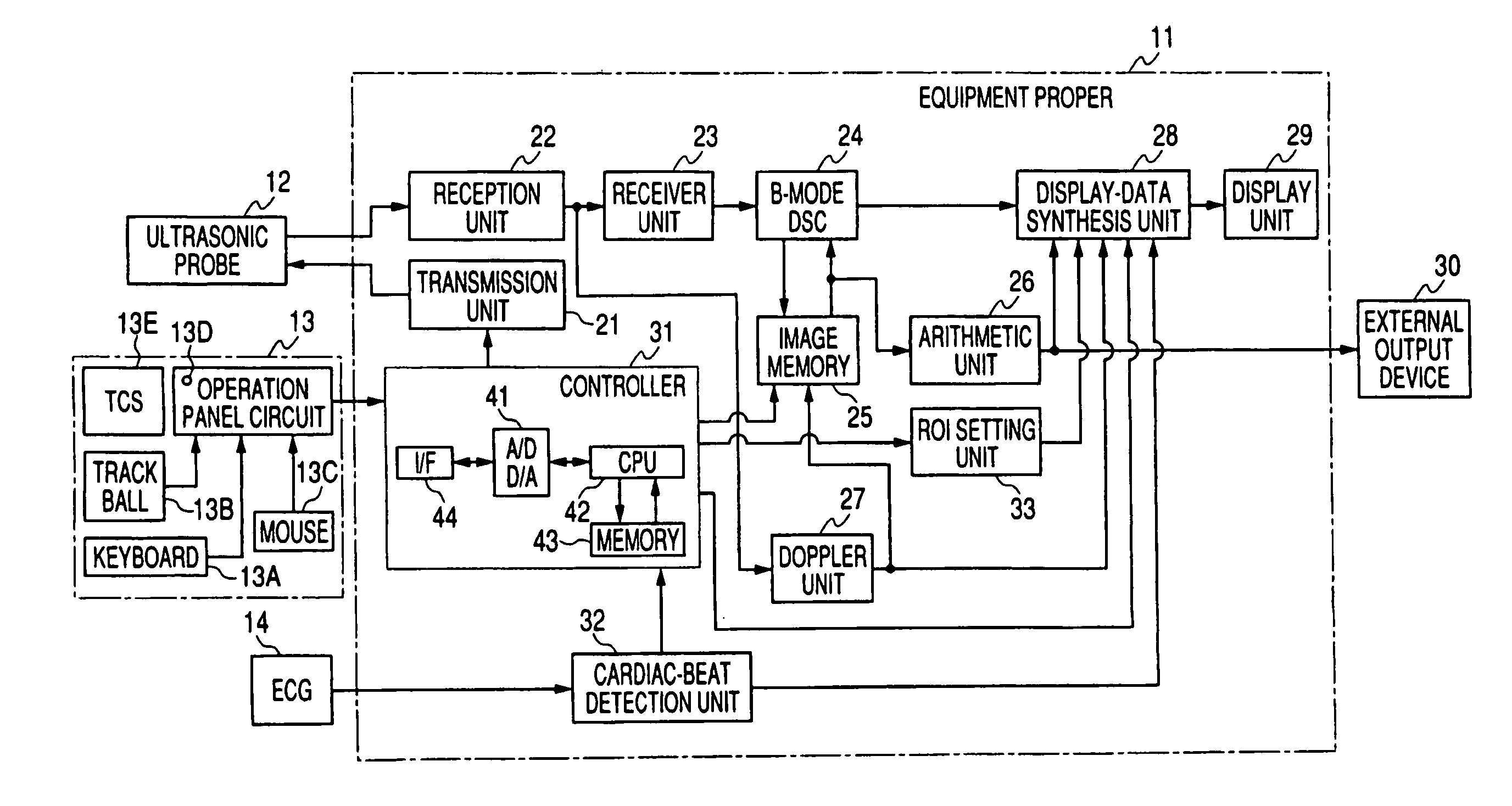

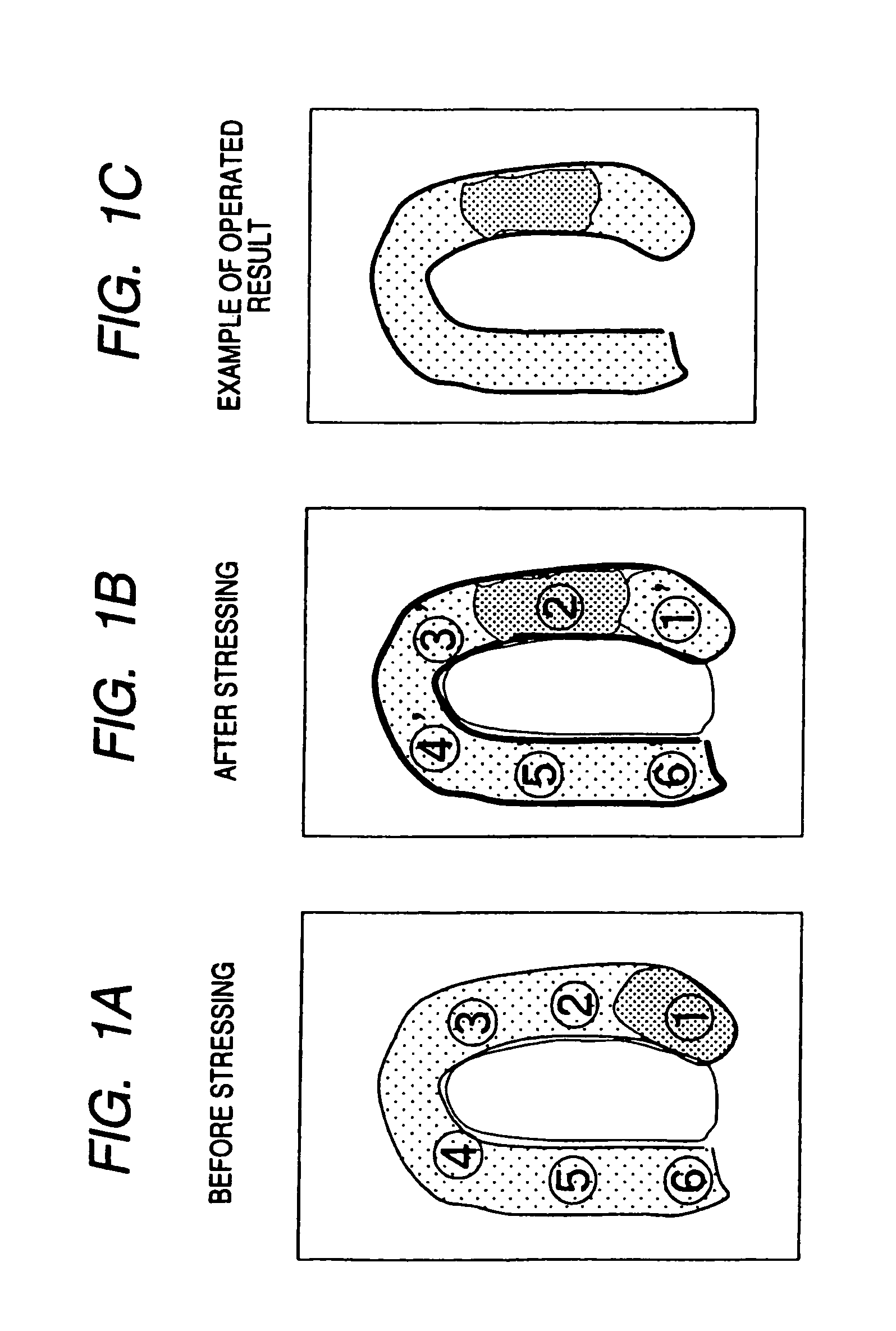

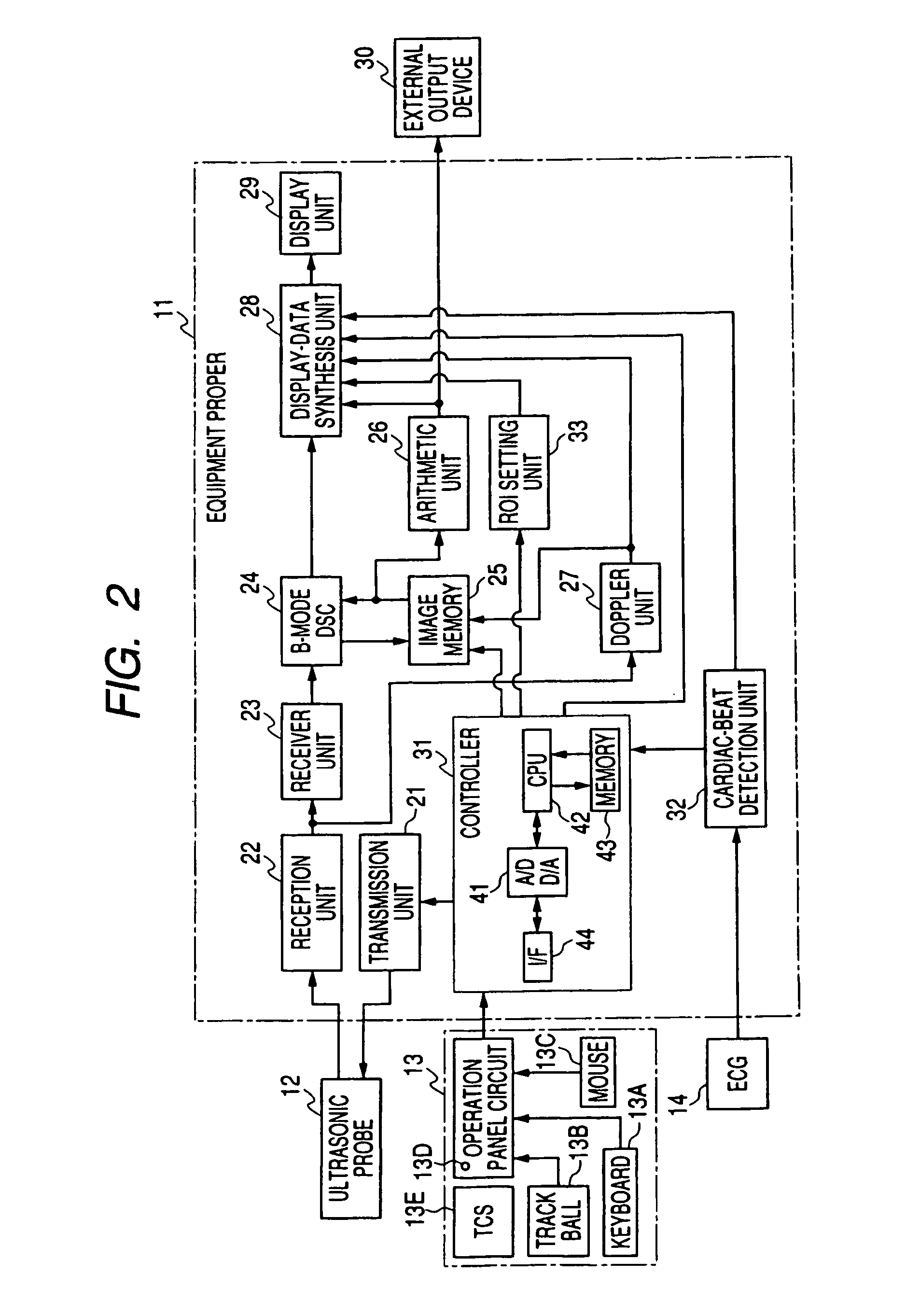

Ultrasonic diagnostic equipment and imaging processing apparatus

ActiveUS20050101863A1Accurate comparisonEasy and accurate settingBlood flow measurement devicesOrgan movement/changes detectionSonificationImaging processing

Each of an ultrasonic diagnostic apparatus and an image processing apparatus according to the present invention is characterized by comprising image acquisition means for acquiring image data by scanning a patient into whom an ultrasonic contrast medium has been injected, with ultrasonic beams, same-part correspondence means for bringing same parts into correspondence with each other, between a plurality of images concerning the same parts of the identical patient and acquired by the image acquisition means, arithmetic operation means for arithmetically operating image information items on changes of intensities between the plurality of images by using the intensities of those corresponding pixels of the plurality of images which have been brought into correspondence by the pixel correspondence means, and display means for displaying results operated by the arithmetic operation means. According to the construction, it is possible to provide the ultrasonic diagnostic equipment and the image processing apparatus which can compare the images before and after injection of a vasodilator drug, more accurately in contrast echo imaging.

Owner:TOSHIBA MEDICAL SYST CORP

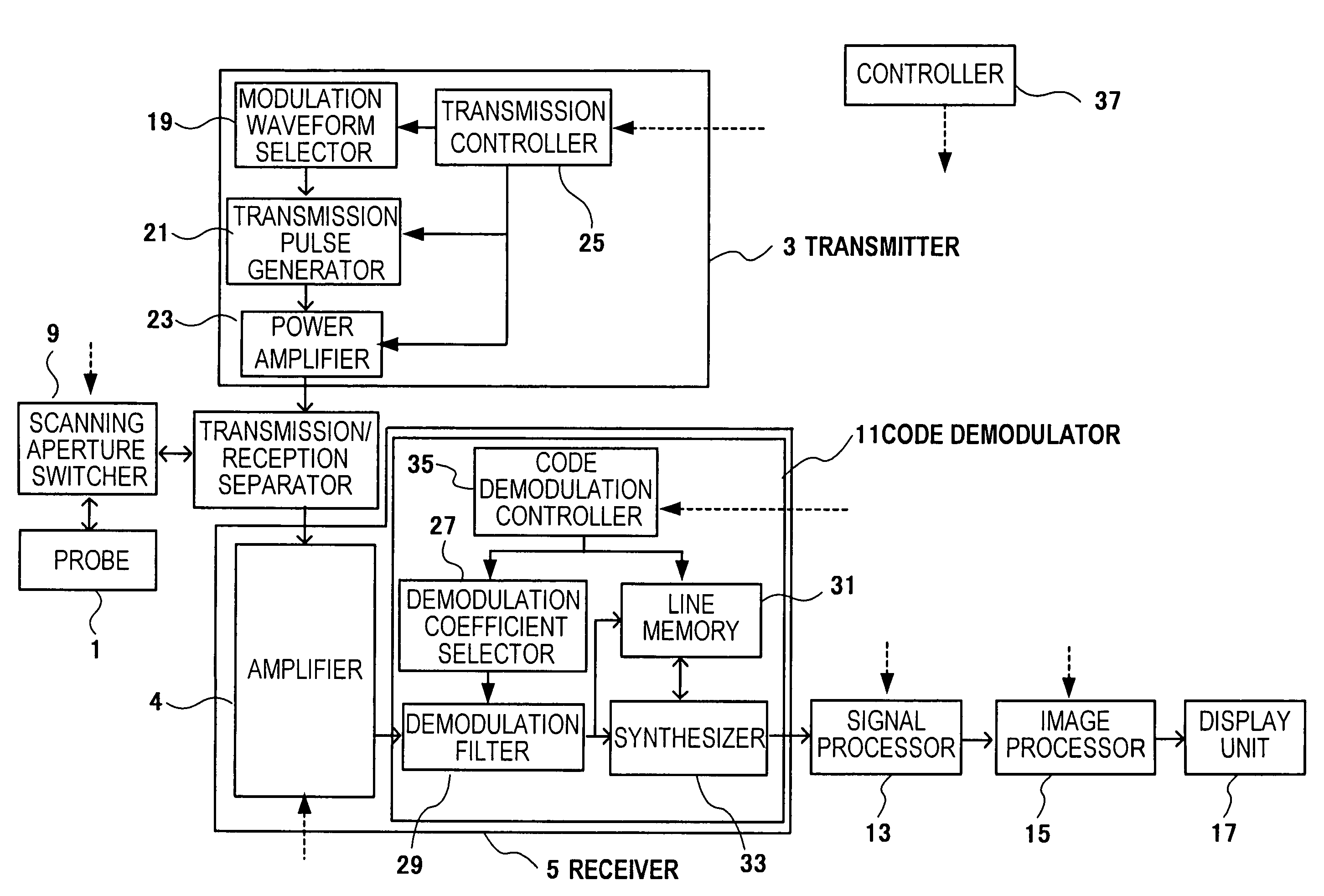

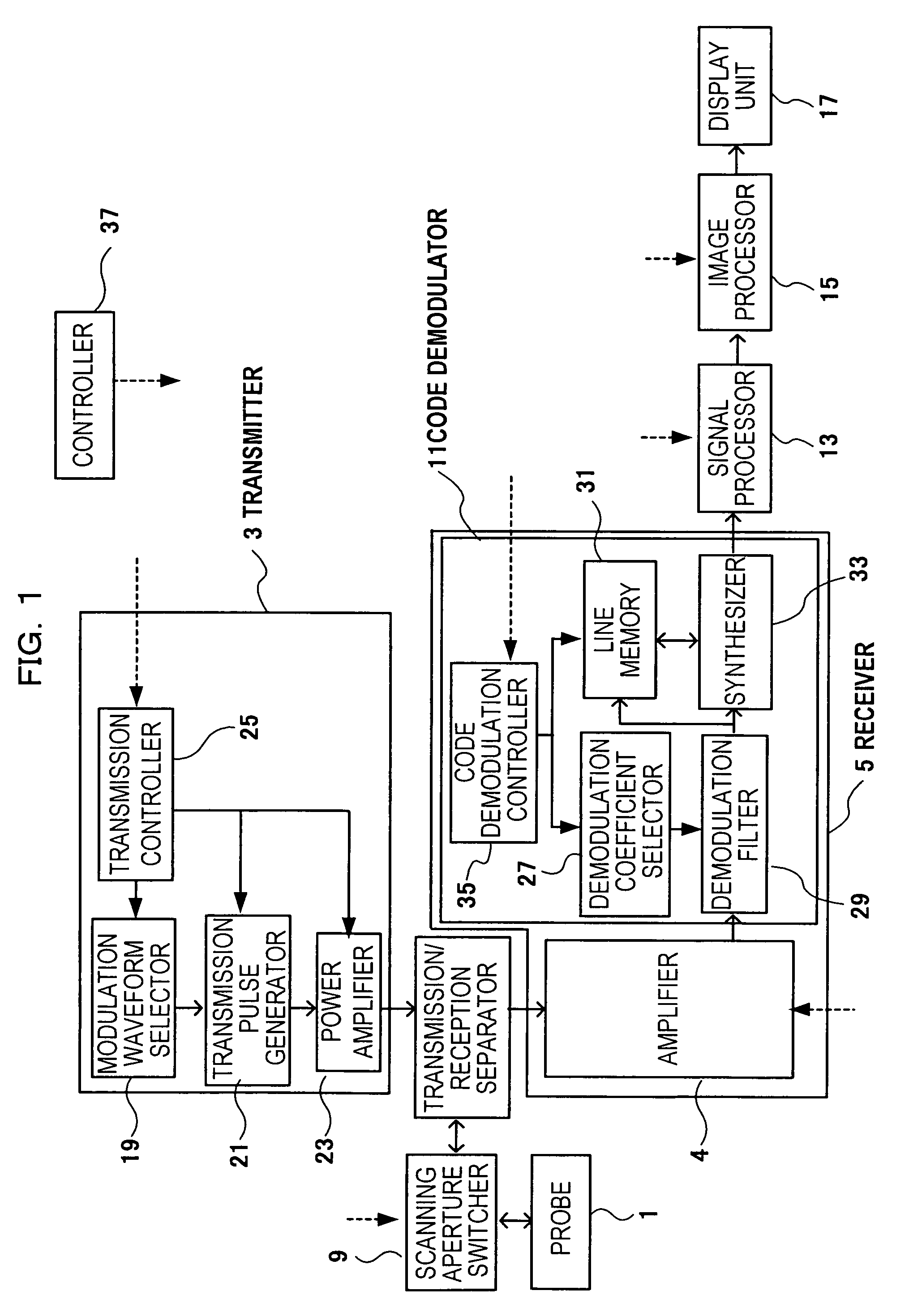

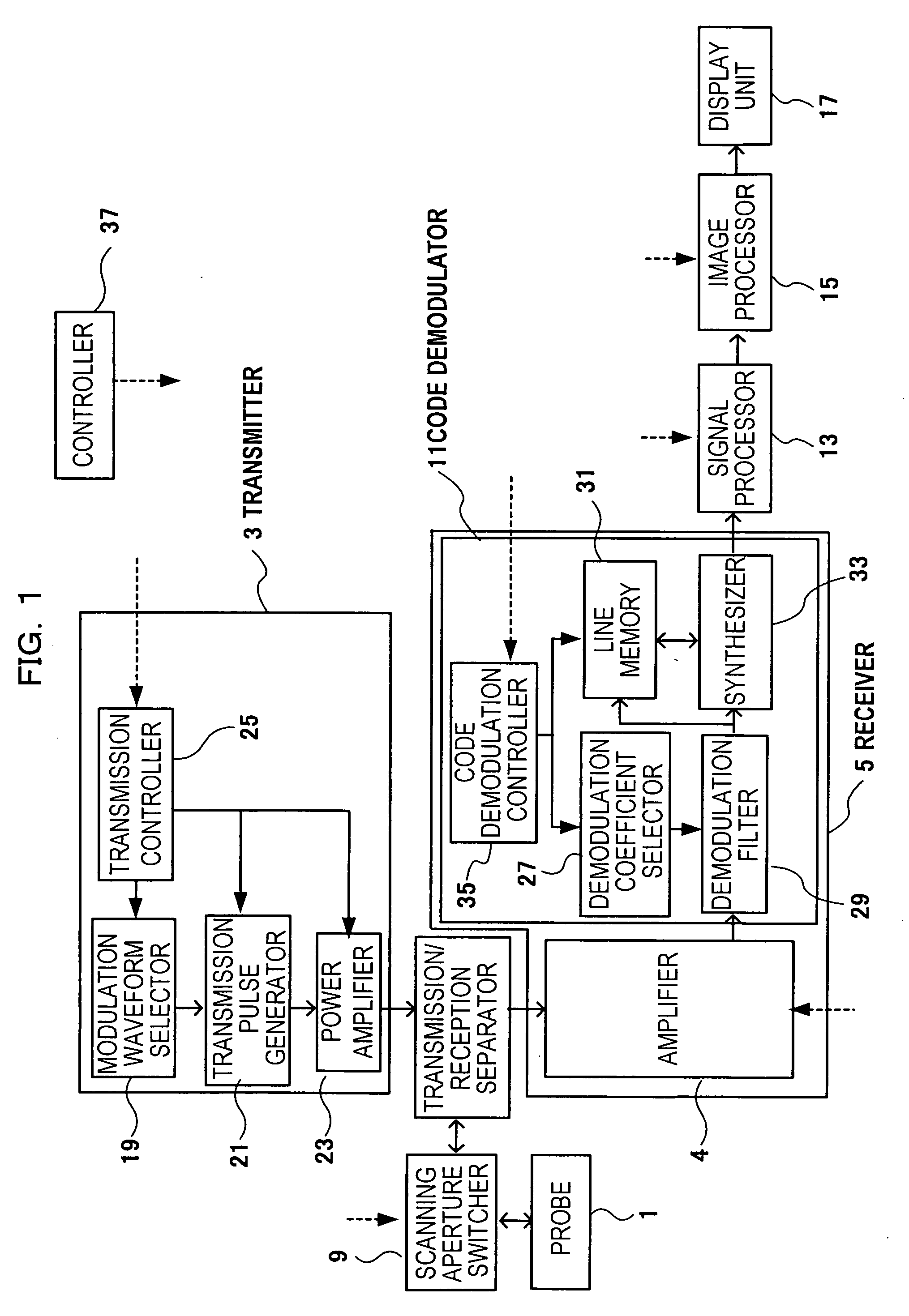

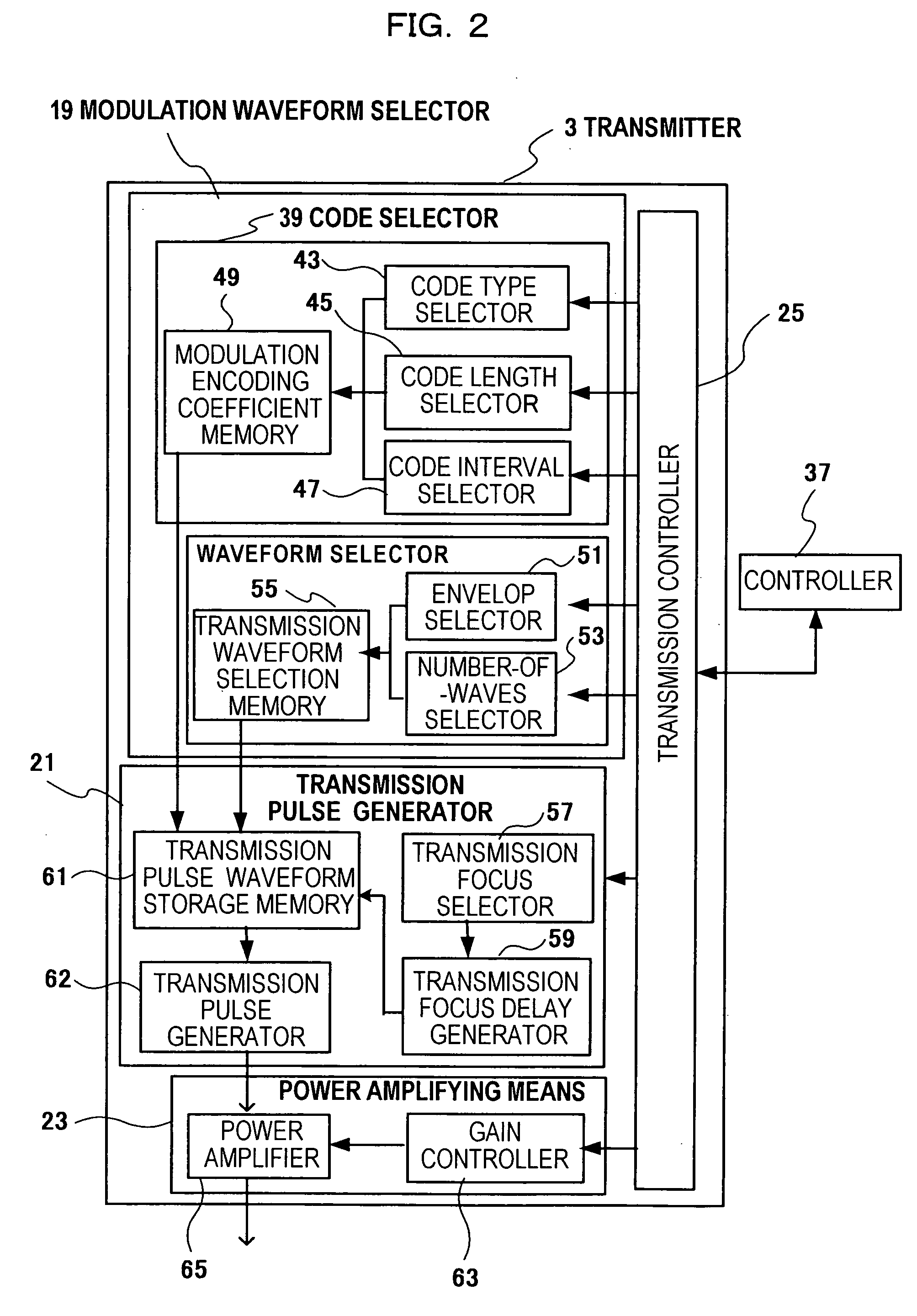

Ultrasonographic method and ultrasonographic device

InactiveUS7354400B2Ultrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsUltrasonic beamSonification

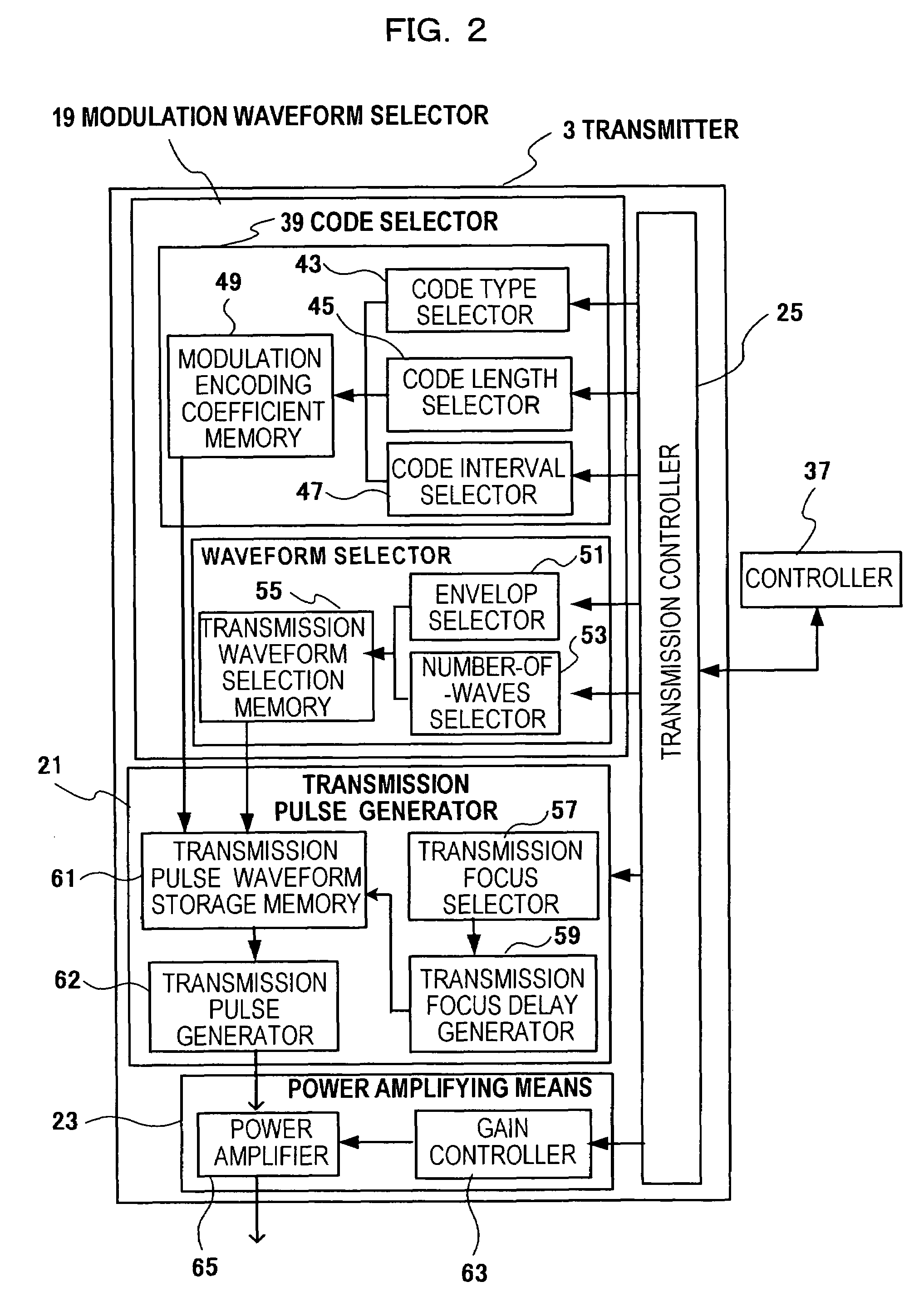

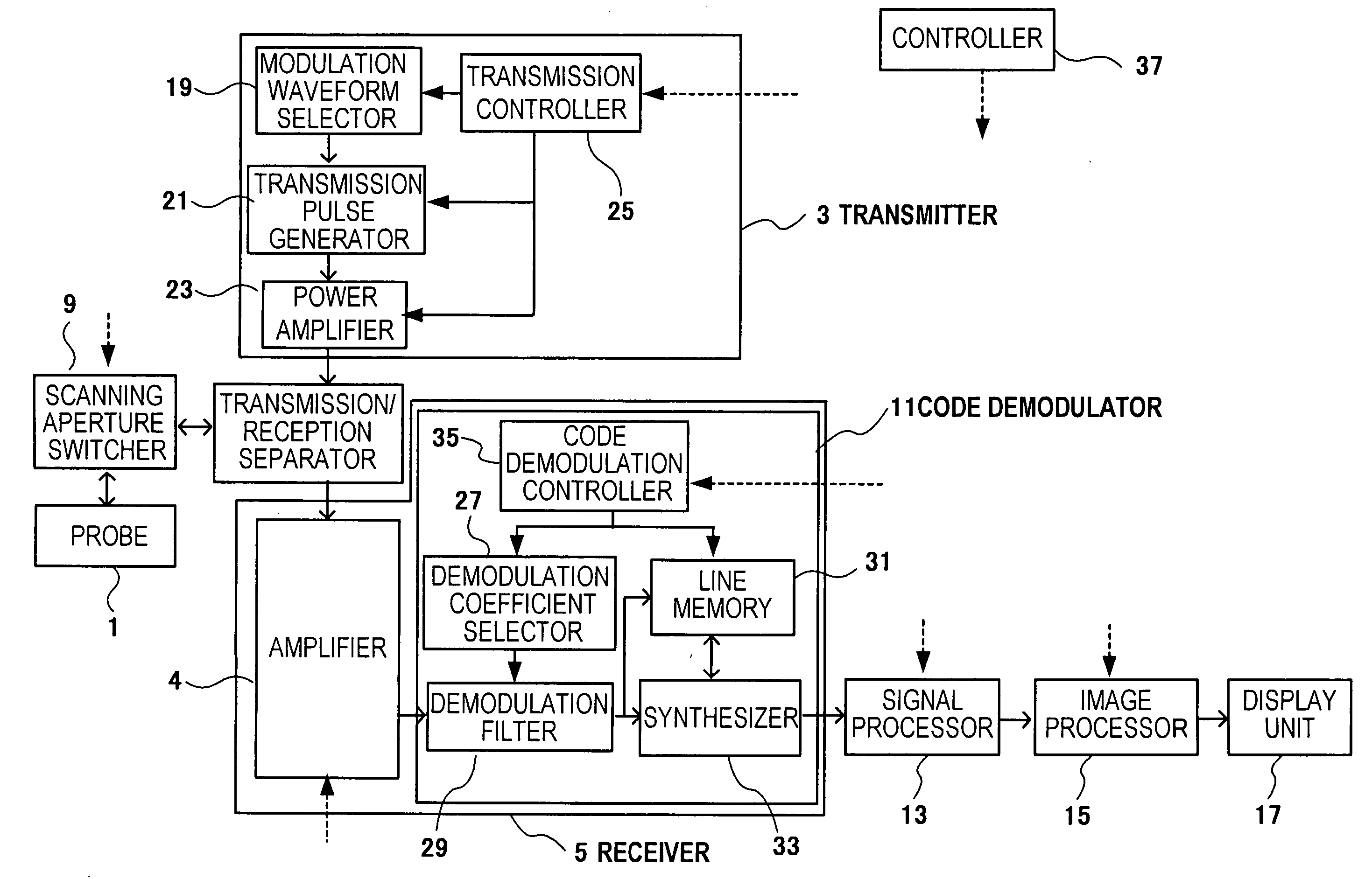

An ultrasonographic method includes: a first encoding transmission / reception step for transmitting an ultrasonic beam encoded by an encoding set consisting of a plurality of modulation codes in which at least two are in complementary relationship and demodulating reception signals corresponding to the ultrasonic beam; a step for obtaining a first synthesis signal by synthesizing the demodulation signals demodulated by the first encoding transmission / reception step; a second encoding transmission / reception step for transmitting an ultrasonic beam encoded by a reverse encoding set consisting of a plurality of modulation codes in which the arrangement order of modulation codes of the encoding set is reversed and demodulating the reception signals corresponding to the ultrasonic beam; a step for obtaining a second synthesis signal by synthesizing the demodulated signals demodulated by the second encoding transmission / reception step; a step for obtaining a third synthesis signal by synthesizing the first synthesis signal and the second synthesis signal; and a step for reconstructing the ultrasonograph according to the third synthesis signal.

Owner:HITACHI MEDICAL CORP

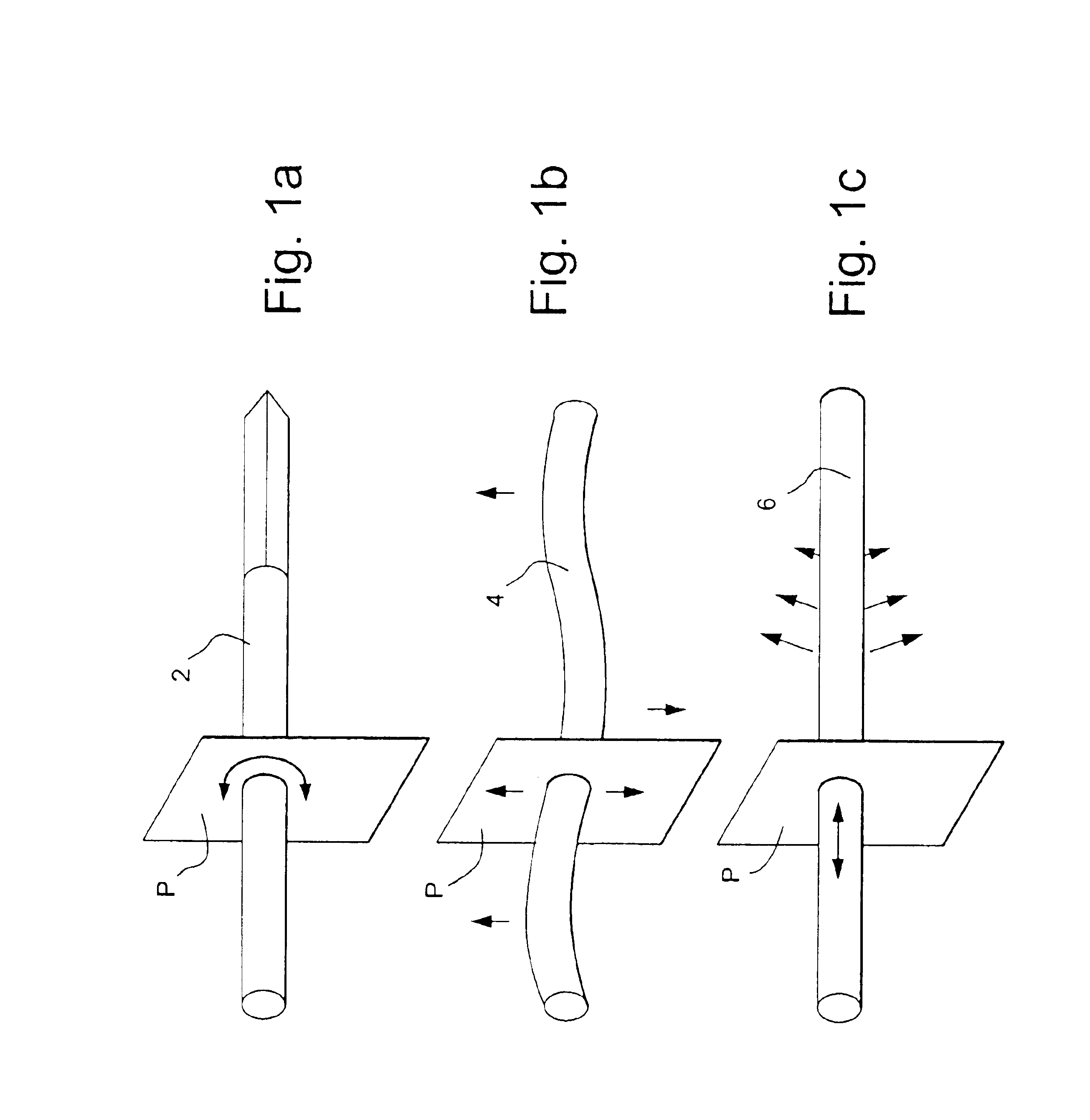

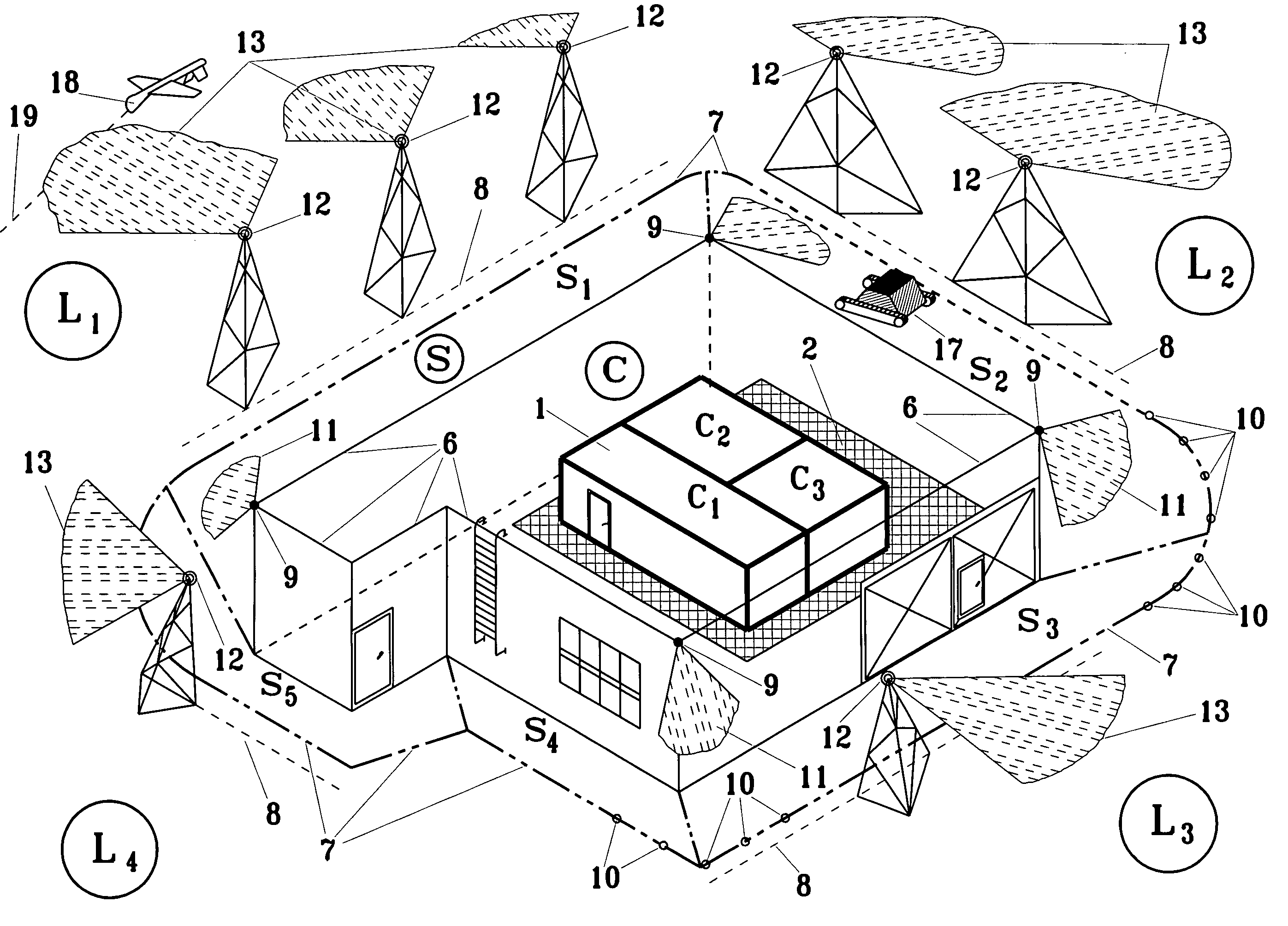

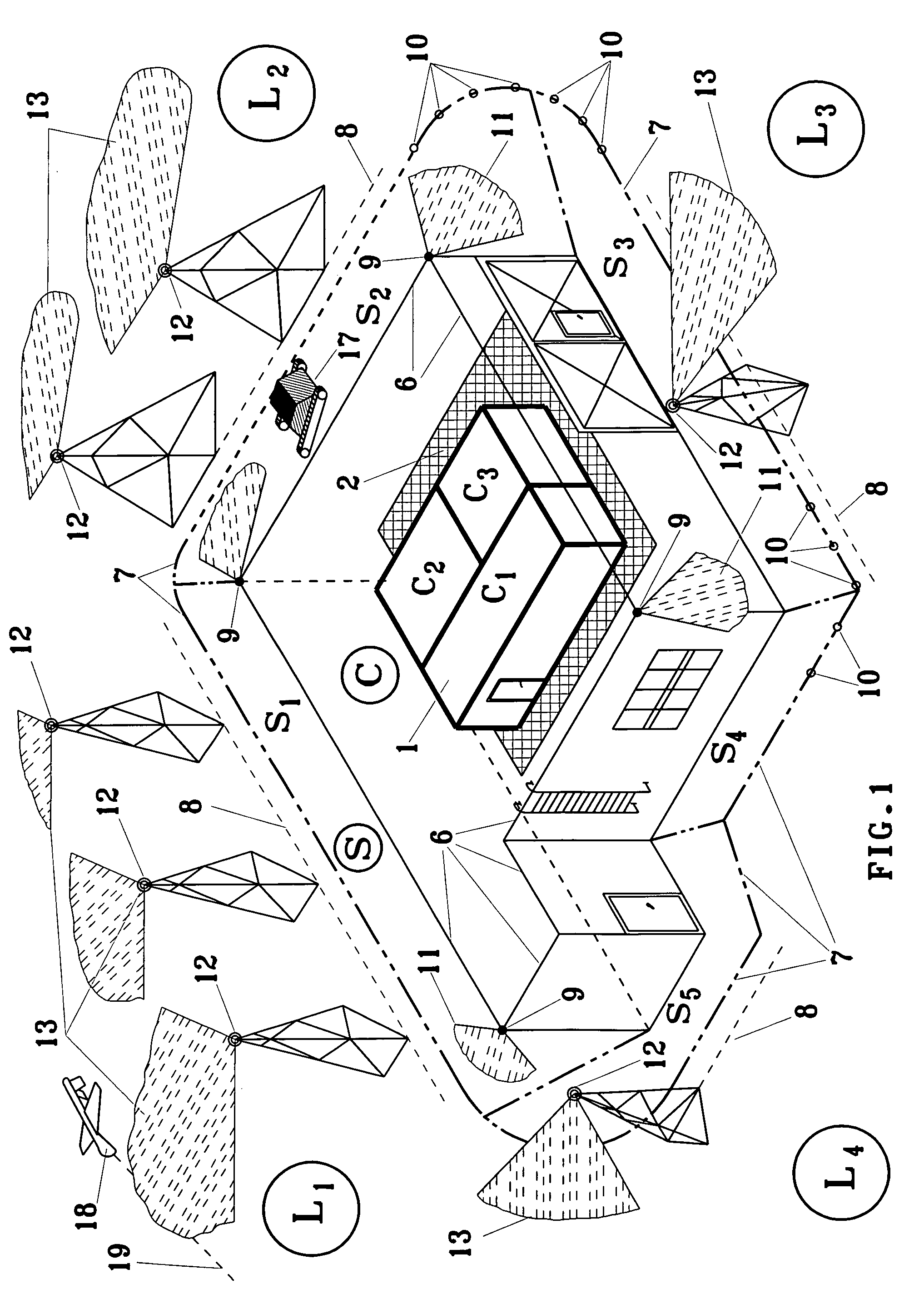

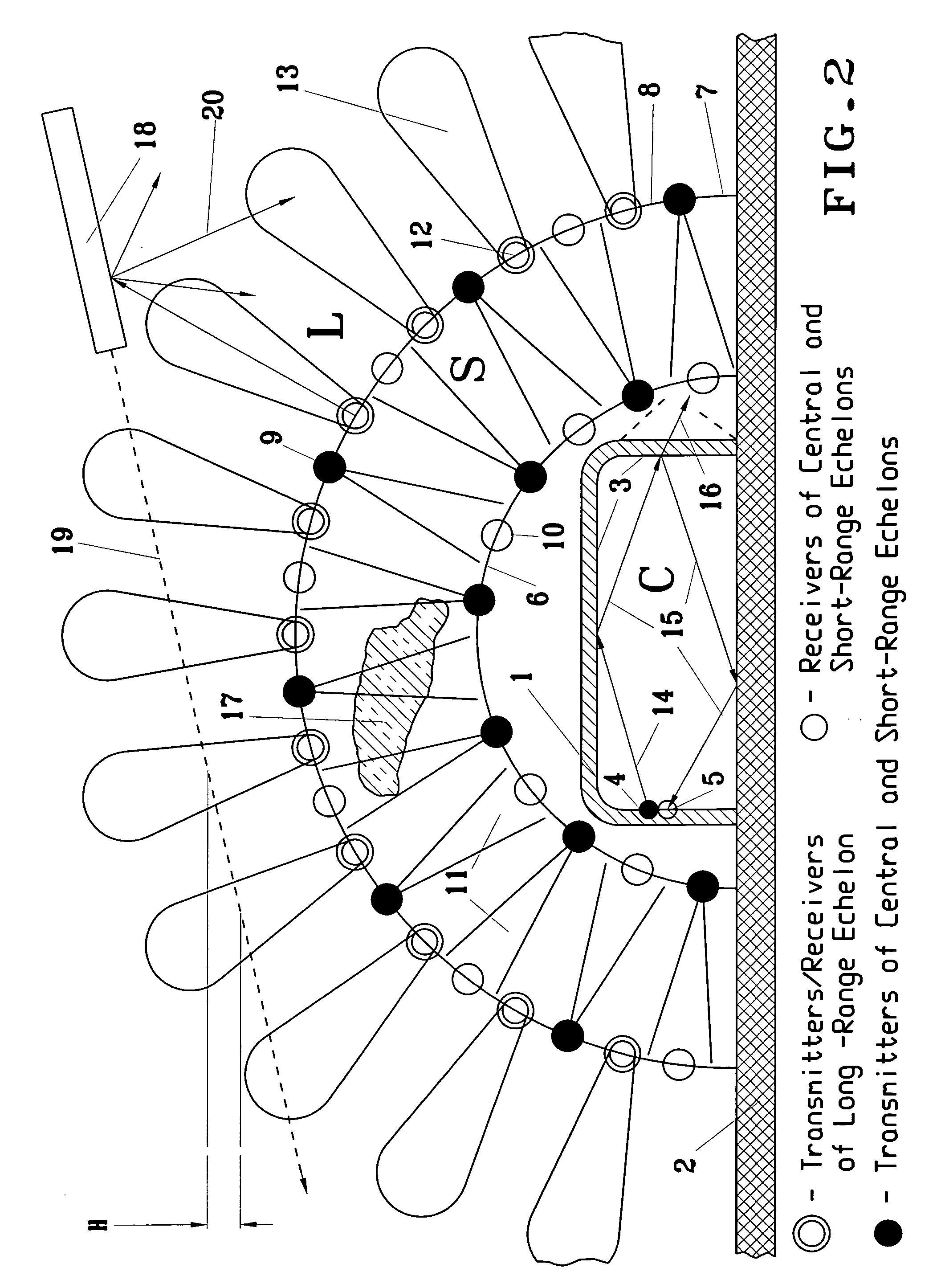

Method of defense-in-depth ultrasound intrusion detection

InactiveUS7233243B2Burglar alarm mechanical vibrations actuationBurglar alarm short radiation actuationSonificationUltrasonic beam

Method of ingress or egress intrusion detection by ultrasound surveillance throughout volumetric multi-area room around a protected object, where the surveyed room is arranged in juxtaposed volumetric closed or open areas that represent central, short-range and long-range echelons of defense-in-depth intrusion protection infrastructure. The used techniques of ultrasound intrusion detection are based on the phenomena of reflection, refraction by edge diffraction, and interference by shadowing of ultrasonic beams. The ultrasonic beam patterns are closely disposed in 2-D curvilinear or polygonal array, or in 3-D curved surface lattice over multilevel substantial openwork frames of different echelons. The informational and processing inter-echelon interrelation is being treated by control software algorithm that features situational logic transition driven by IF-THEN operator. The disclosed method shall enhance the distance of location, trustworthiness and cost-effectiveness of ultrasonic intrusion detection arrangements.

Owner:CTRL SYST

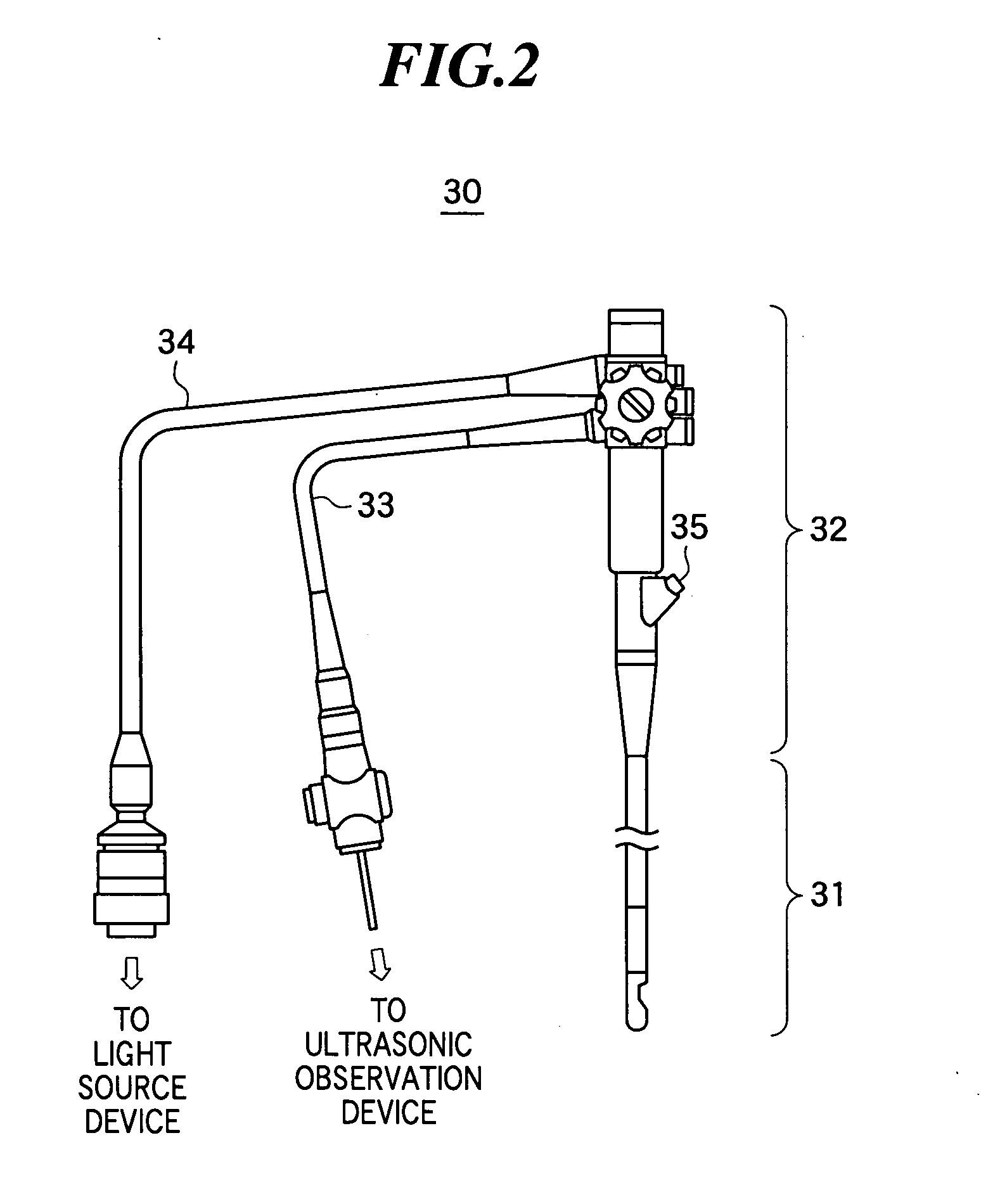

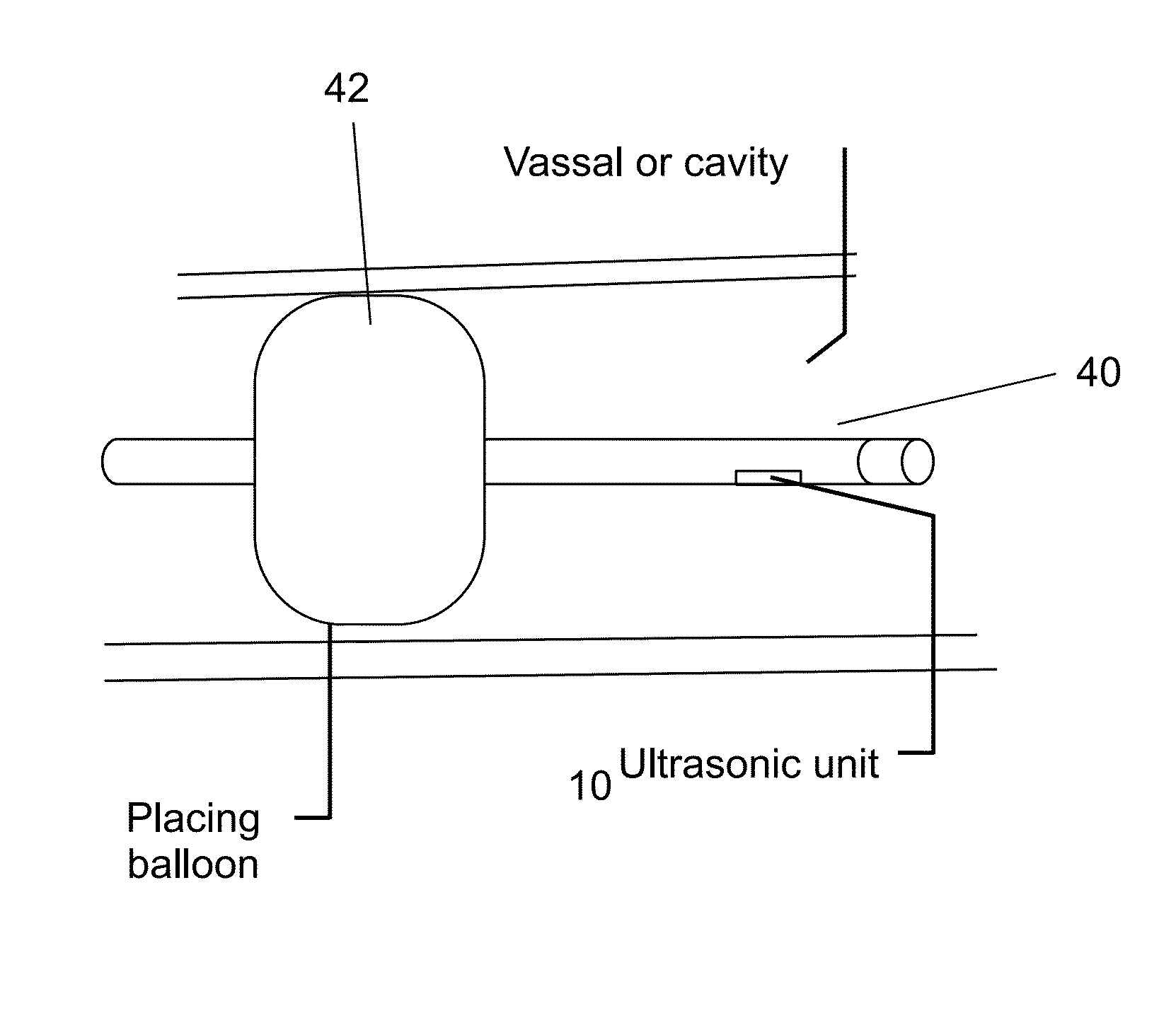

Ultrasound image assisted administering of medication

InactiveUS6126600AAvoid damageUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsSonificationUltrasonic beam

An apparatus and method for injecting a drug into a precisely selected location in a patient's body which is a combination scanner and drug injector. The scanner is a planar array of ultrasonic transducers which transmits a focused ultrasonic beam over the entire region of interest. The injector is preferably a hypodermic syringe mounted with the array on a base. The syringe is mounted to slide between one position where the injector conduit is retracted from the patient and another position where the adjustably positioned exit end of the conduit is in the desired location for injection of the drug. As the operator holds the scanner-injector against the patient's body with injector conduit retracted, he views on a monitor screen a virtual image of the conduit which is the image of the conduit after the conduit is injected into the body. The operator electronically adjusts the length of the virtual image and adjusts the position of the scanner-injector so that the exit tip of the virtual image is located at the desired location of the image of the region on the screen. Then the conduit is inserted into the body up to a length where the exit tip of the injector is at the desired location. Then the drug is injected into the patient. In another application of the apparatus and methods of the invention, a vacuum source is attached to the injector conduit and the device is used to aspirate fluids. instead of a drug In another embodiment, a portion of the ukltrasonic beam is focused on the region of interest before and during insertion of the conduit and drug to facilitate entry of the drug into the region of interest.

Owner:KONINKLJIJKE PHILIPS NV +1

Capacitive fingerprint sensing device and method for capturing a fingerprint using the sensing device

ActiveUS9898640B2Increase capacityEnhanced signalPrint image acquisitionMatching and classificationUltrasonic beamEngineering

There is provided a capacitive fingerprint sensing device for sensing a fingerprint pattern of a finger, the capacitive fingerprint sensing device comprising: a protective dielectric top layer having an outer surface forming a sensing surface to be touched by the finger; at least one electrically conductive sensing structure arranged underneath the top layer; readout circuitry coupled to the at least one electrically conductive sensing structure to receive a sensing signal indicative of a distance between the finger and the sensing structure; and a plurality of individually controllable electroacoustic transducers arranged underneath the top layer and configured to generate a focused ultrasonic beam, and to transmit the ultrasonic beam through the protective dielectric top layer towards the sensing surface to induce an ultrasonic vibration potential in a ridge of finger placed in contact with the sensing surface at the location of the ultrasonic beam.

Owner:FINGERPRINT CARDS ANACATUM IP AB

Phased array ultrasonic testing system and methods of examination and modeling employing the same

ActiveUS7428842B2Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationEngineering

A phased array ultrasonic testing system is for examining turbine disc bores and blade attachments for discontinuities, such as stress corrosion cracking. The system is particularly suited to perform an accurate and efficient inspection of components despite their having a relatively complex geometry, such as axial entry blade attachments and bores of associated discs. The system includes a control system with a computer and a controller for programming, emitting, and steering an ultrasonic beam via at least one two-dimensional phased array probe, thereby precisely inspecting the area of interest while simultaneously accommodating the aforementioned complex geometry of the disc or blade attachment. Computer control of the beam permits the number of inspection locations and the number of different probe wedges to be reduced providing for an efficient, timely inspection. Methods of profiling and examining turbine components of known and unknown geometries, are also disclosed.

Owner:SIEMENS ENERGY INC

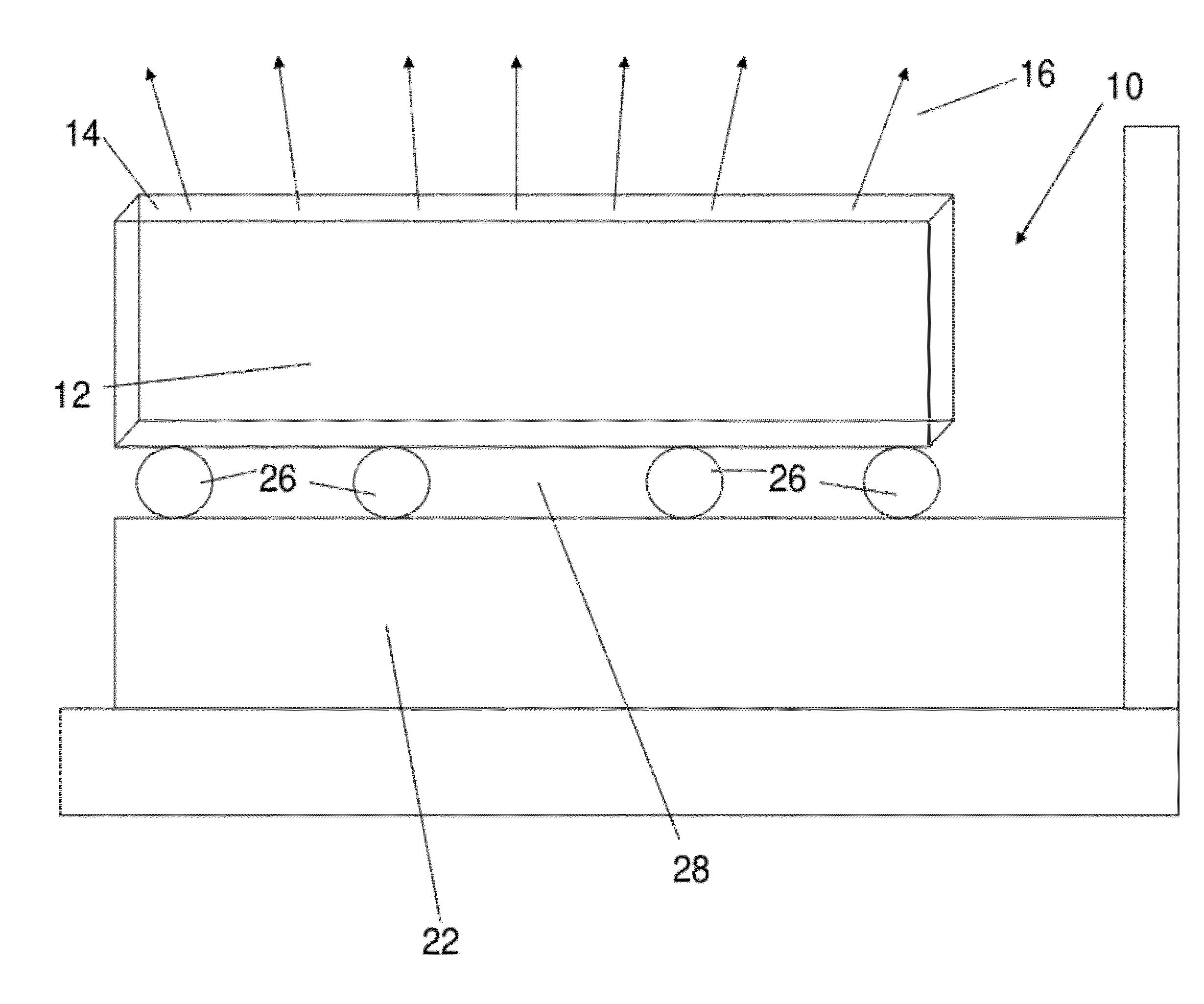

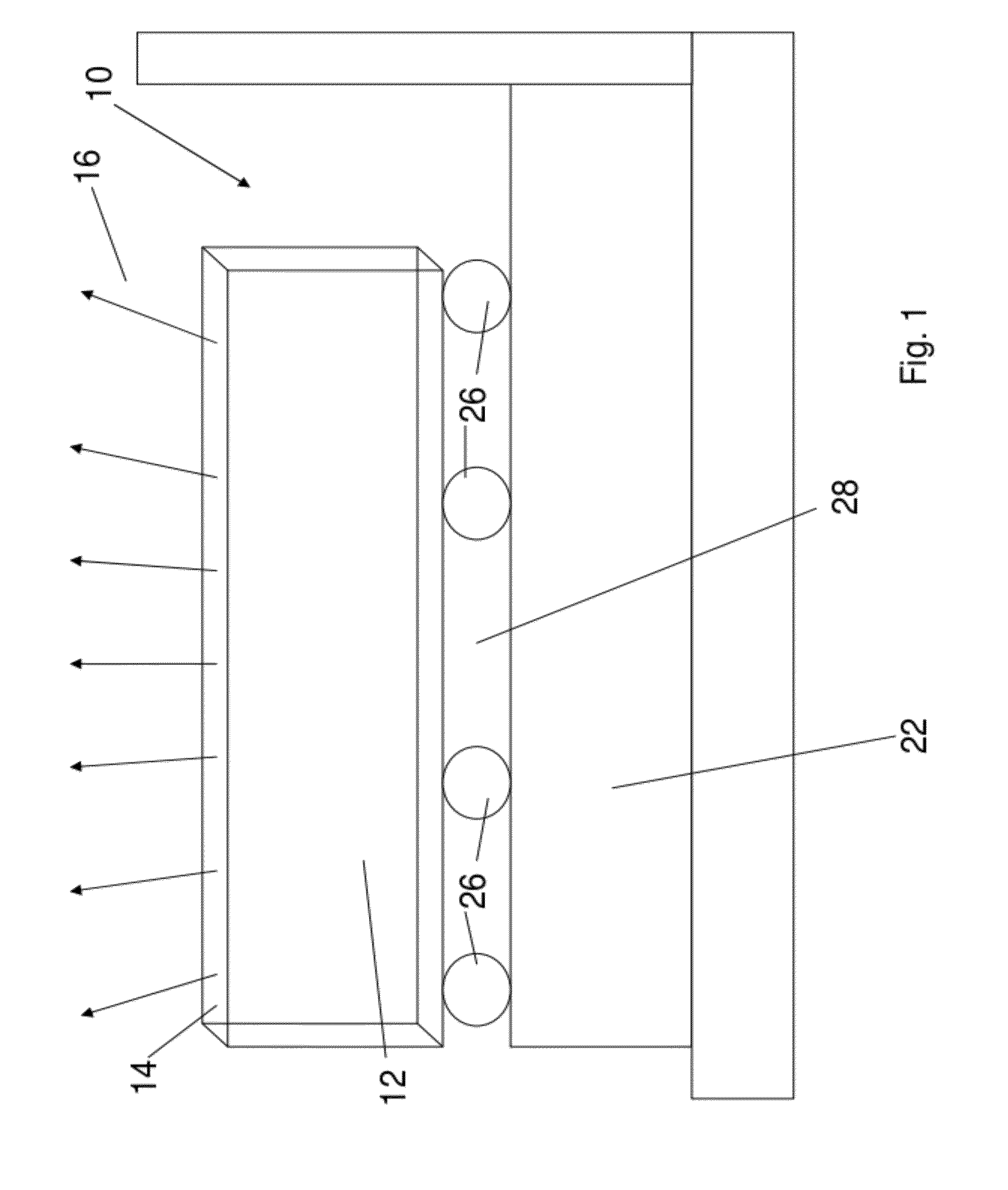

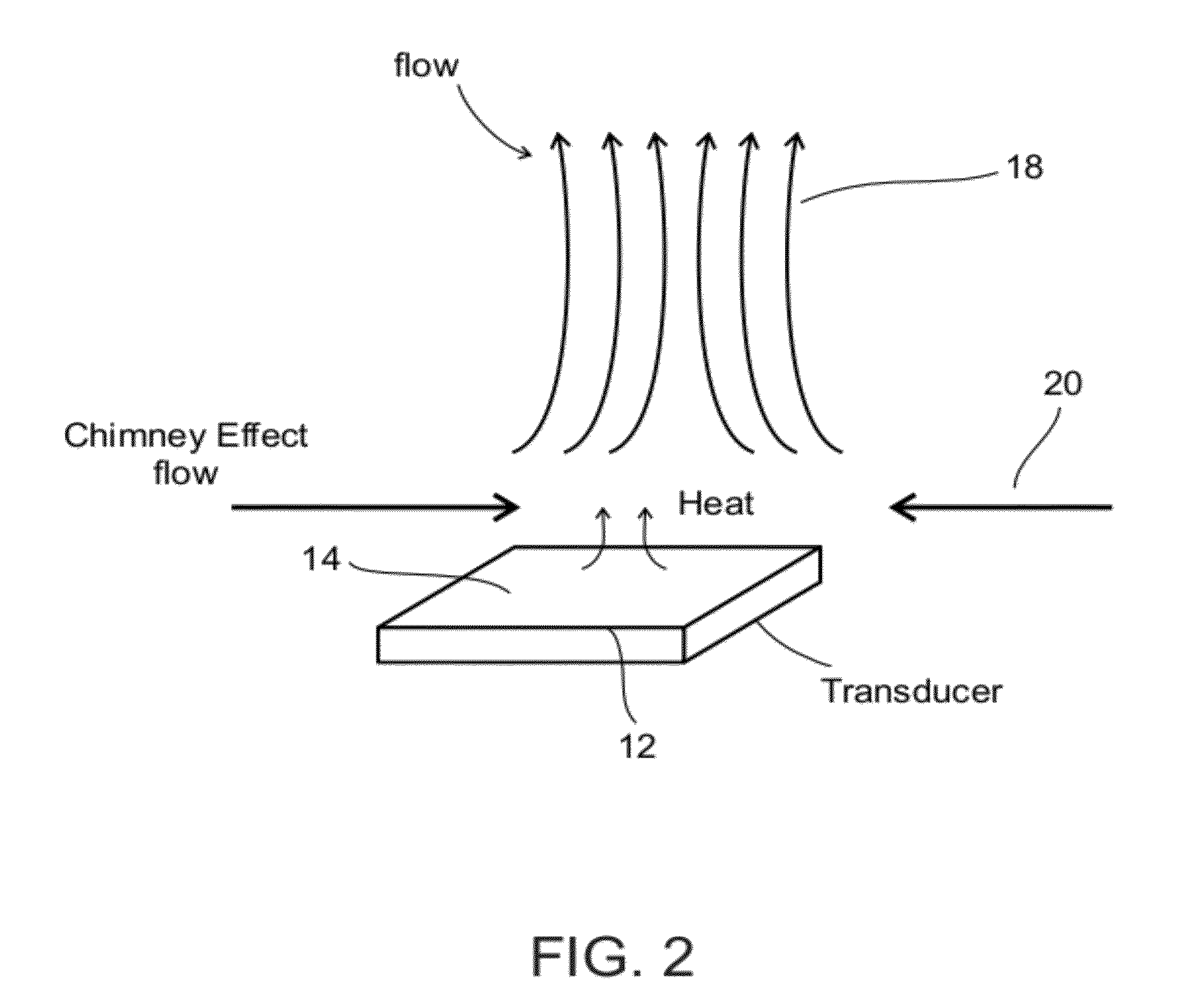

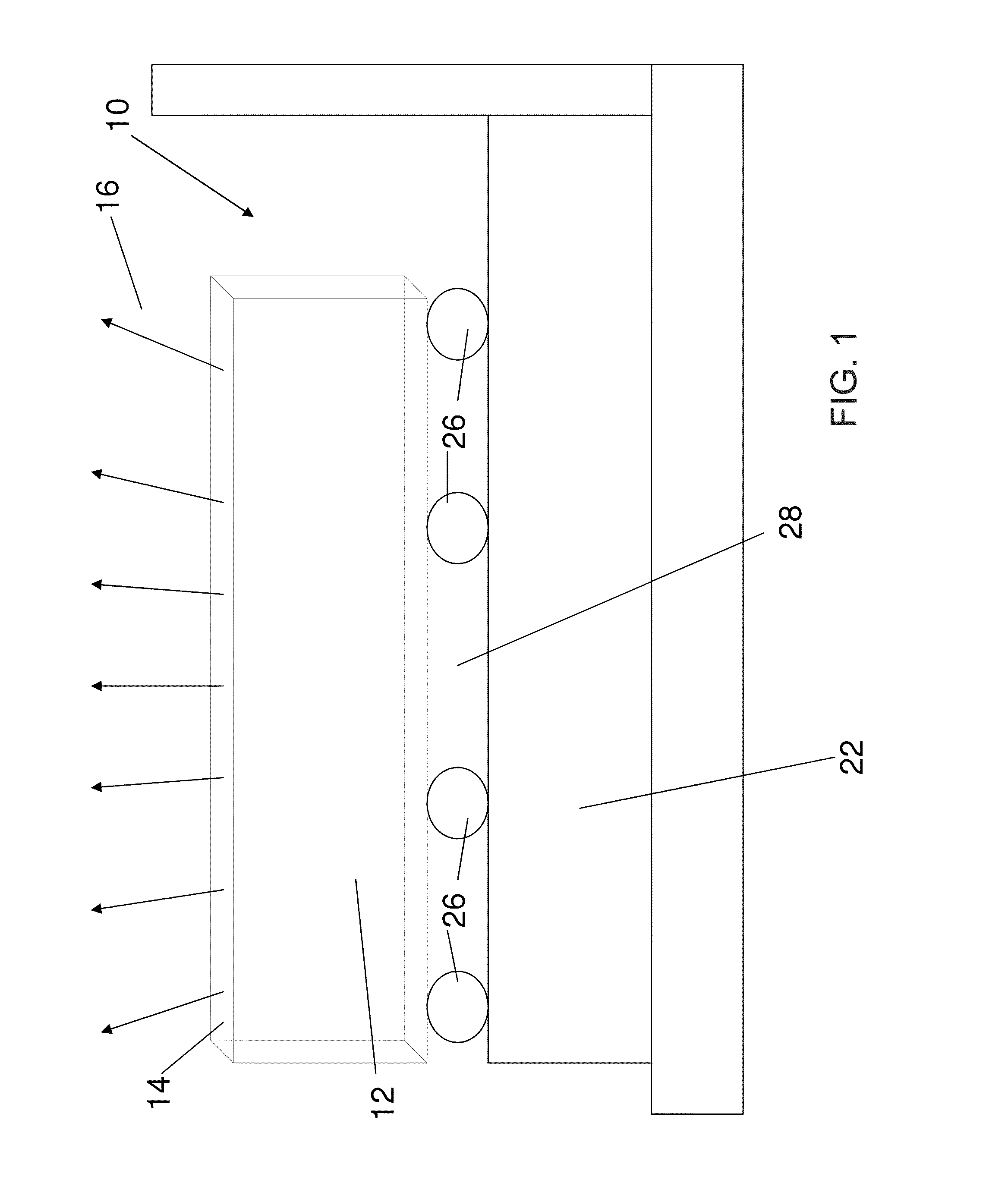

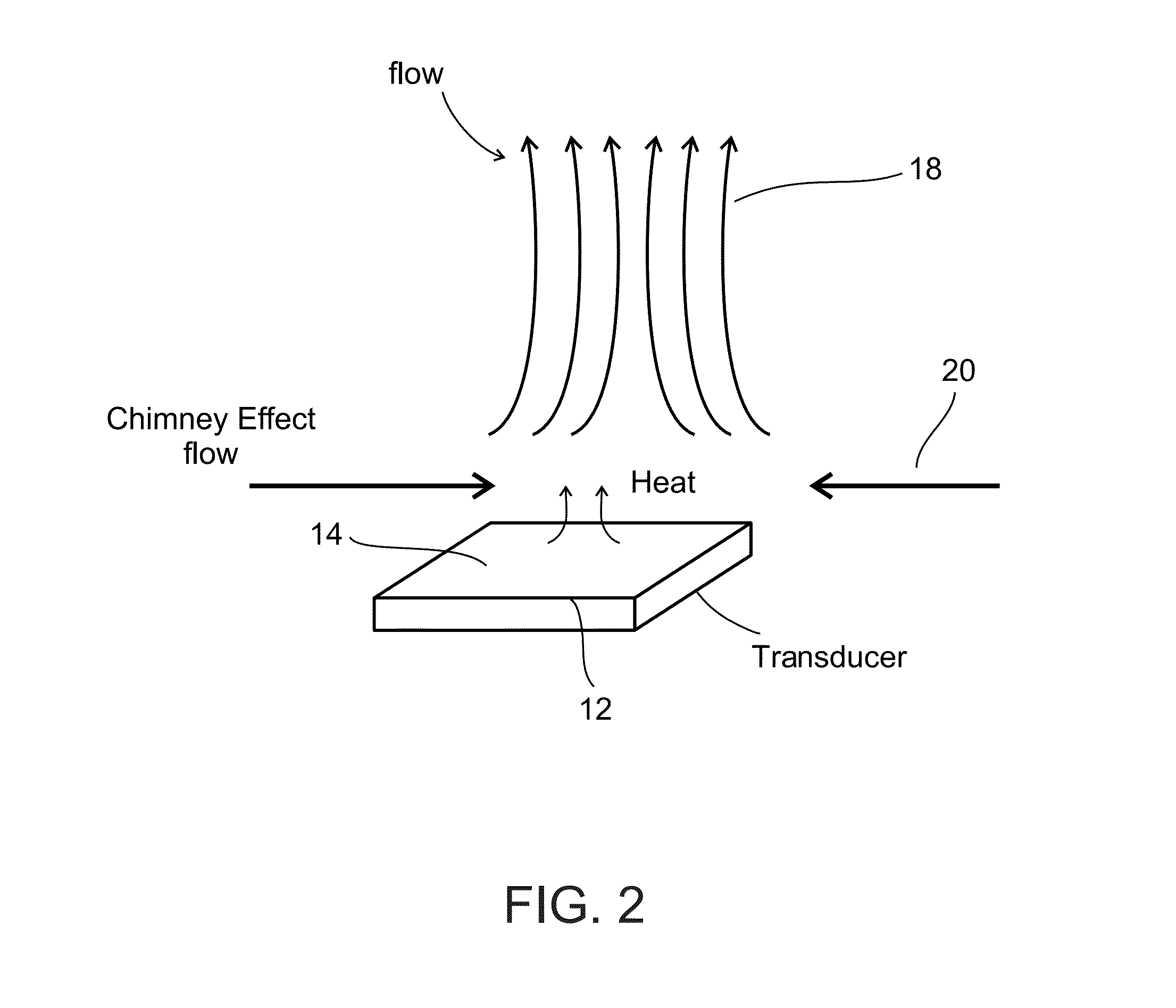

Ultrasound transducer and cooling thereof

InactiveUS20120095371A1Reduce the possibilityImprove heat transfer performanceUltrasound therapyDiagnosticsUltrasonic beamLight beam

An ultrasonic transducer device for producing ultrasonic beams comprises a body vibratable at ultrasonic frequencies and an extensive surface for beam emanation, the device configured to produce an unfocused, or alternatively a focused, power beam for tissue ablation, the power beam being produced by vibration over the body of the transducer and emanating from the extent of the surface, whereby the extensive surface becomes subject to convective cooling when immersed in a fluid by a chimney effect set up by said unfocused beam.

Owner:CARDIOSONIC

Ultrasound transceiver and cooling thereof

ActiveUS20130204167A1Reduce the possibilityImprove heat transfer performanceUltrasound therapyDiagnosticsUltrasonic beamTransceiver

An ultrasonic transceiver device for producing ultrasonic beams comprises a body vibratable at ultrasonic frequencies and an extensive surface for beam emanation, the device configured to produce an unfocused, or alternatively a focused, power beam for thermal tissue damage, the power beam being produced by vibration over the body of the transceiver and emanating from the extent of the surface, whereby the extensive surface becomes subject to convective cooling when immersed in a fluid by a chimney effect set up by said unfocused beam.

Owner:SONIEVIE

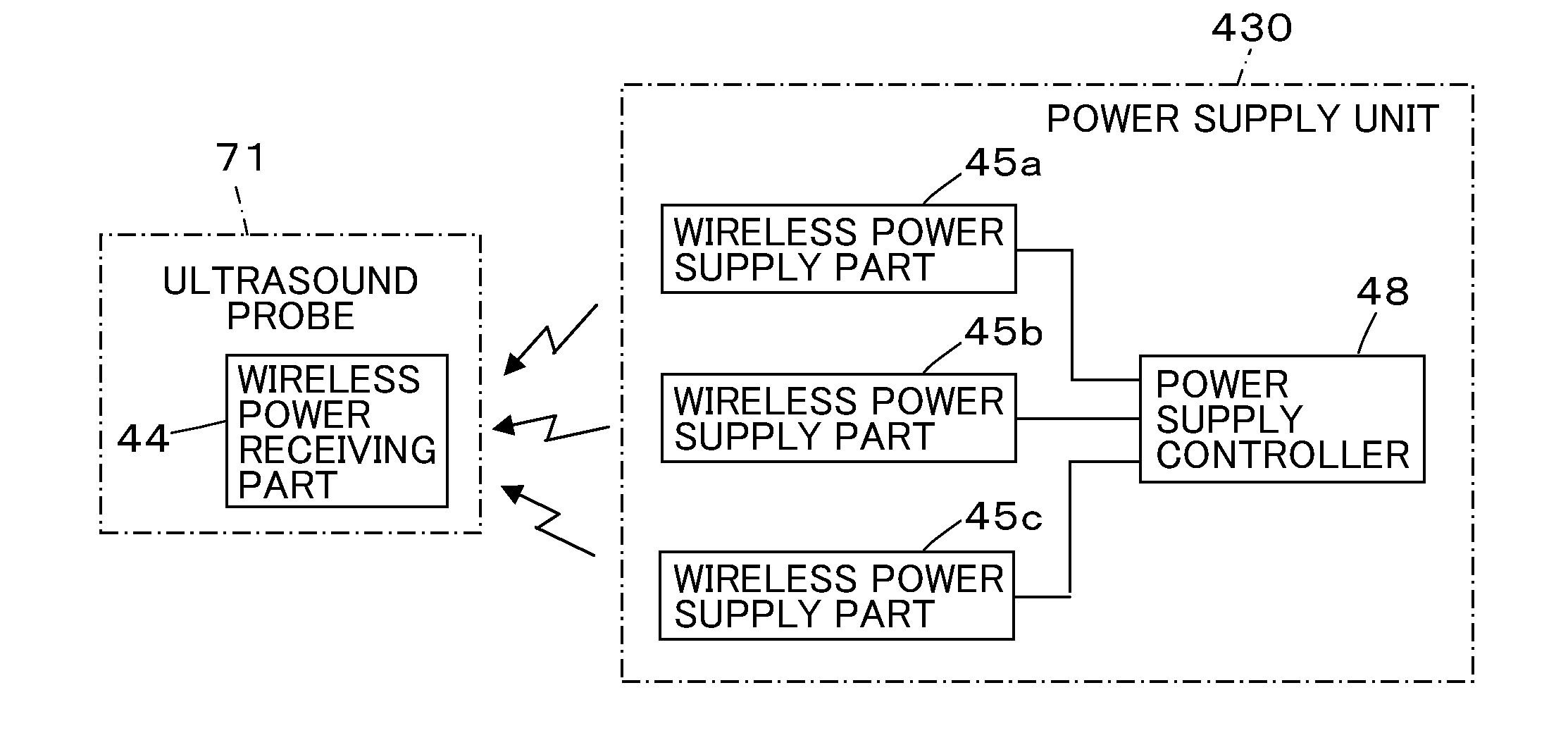

Ultrasound diagnostic apparatus

InactiveUS20120197124A1High image-quality ultrasound imageSimple structureDiagnostic probe attachmentInfrasonic diagnosticsElectricityUltrasonic beam

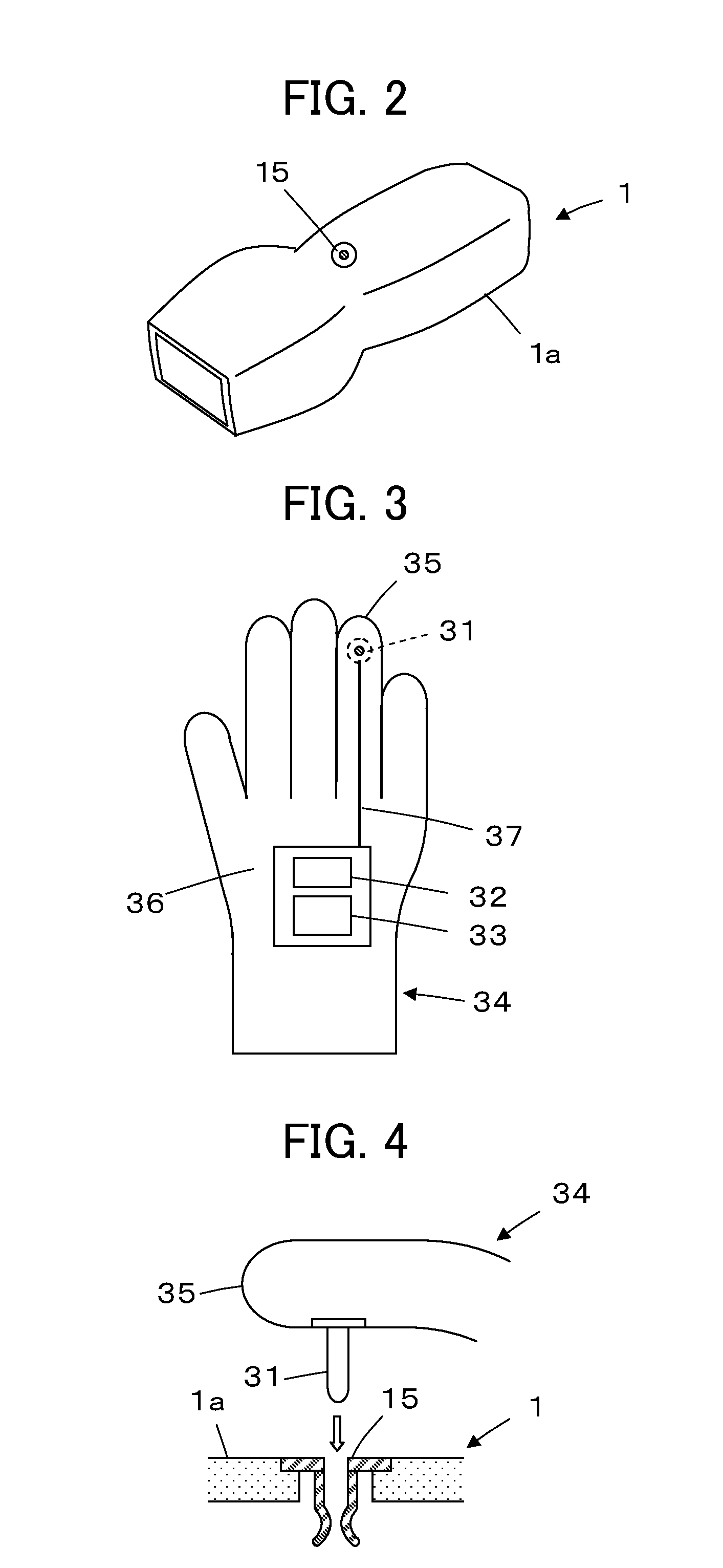

An ultrasound diagnostic apparatus comprises: an ultrasound probe that has a transducer array transmitting an ultrasonic beam toward a subject and receiving an ultrasonic echo by the subject to output reception signals; a diagnostic apparatus body that is connected to the ultrasound probe by wireless communication and generates an ultrasound image on the basis of the reception signal output from the transducer array; at least one power receiving terminal that is arranged at the ultrasound probe and electrically connected to respective parts in the ultrasound probe; and a power supply unit that is capable of being attached to an operator's body and is detachably connected to the power receiving terminal so as to perform power supply to the respective parts in the ultrasound probe.

Owner:FUJIFILM CORP

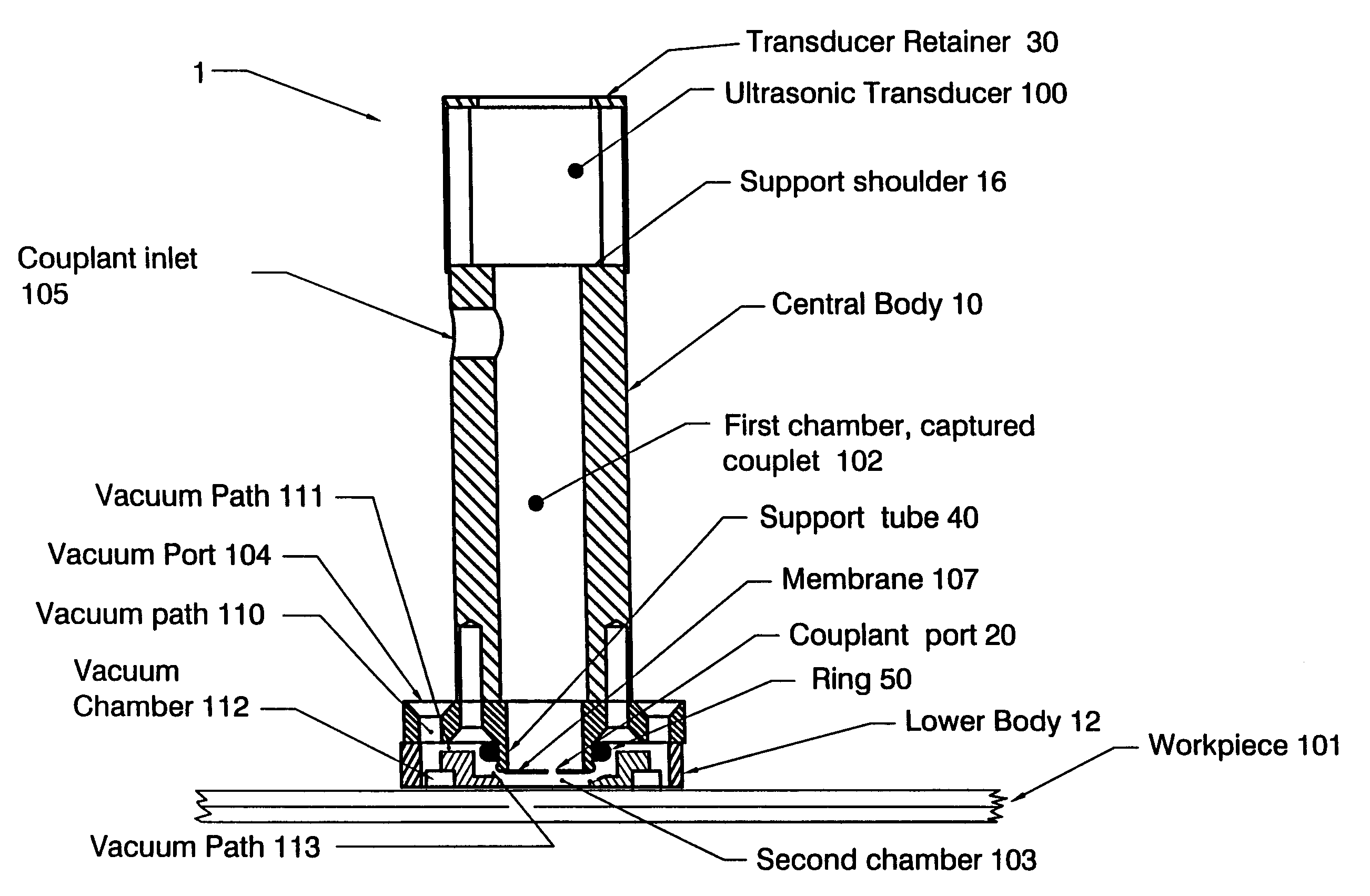

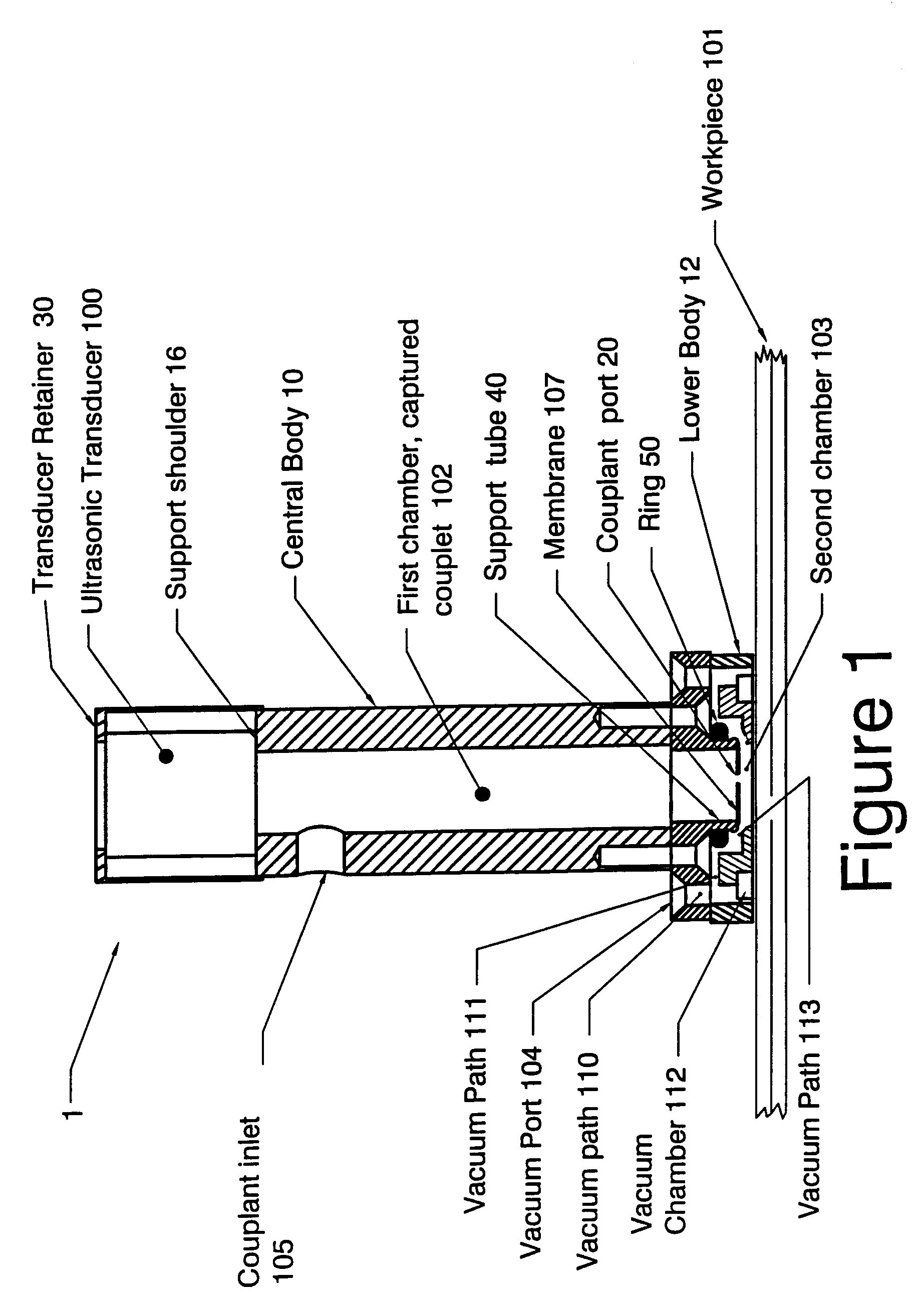

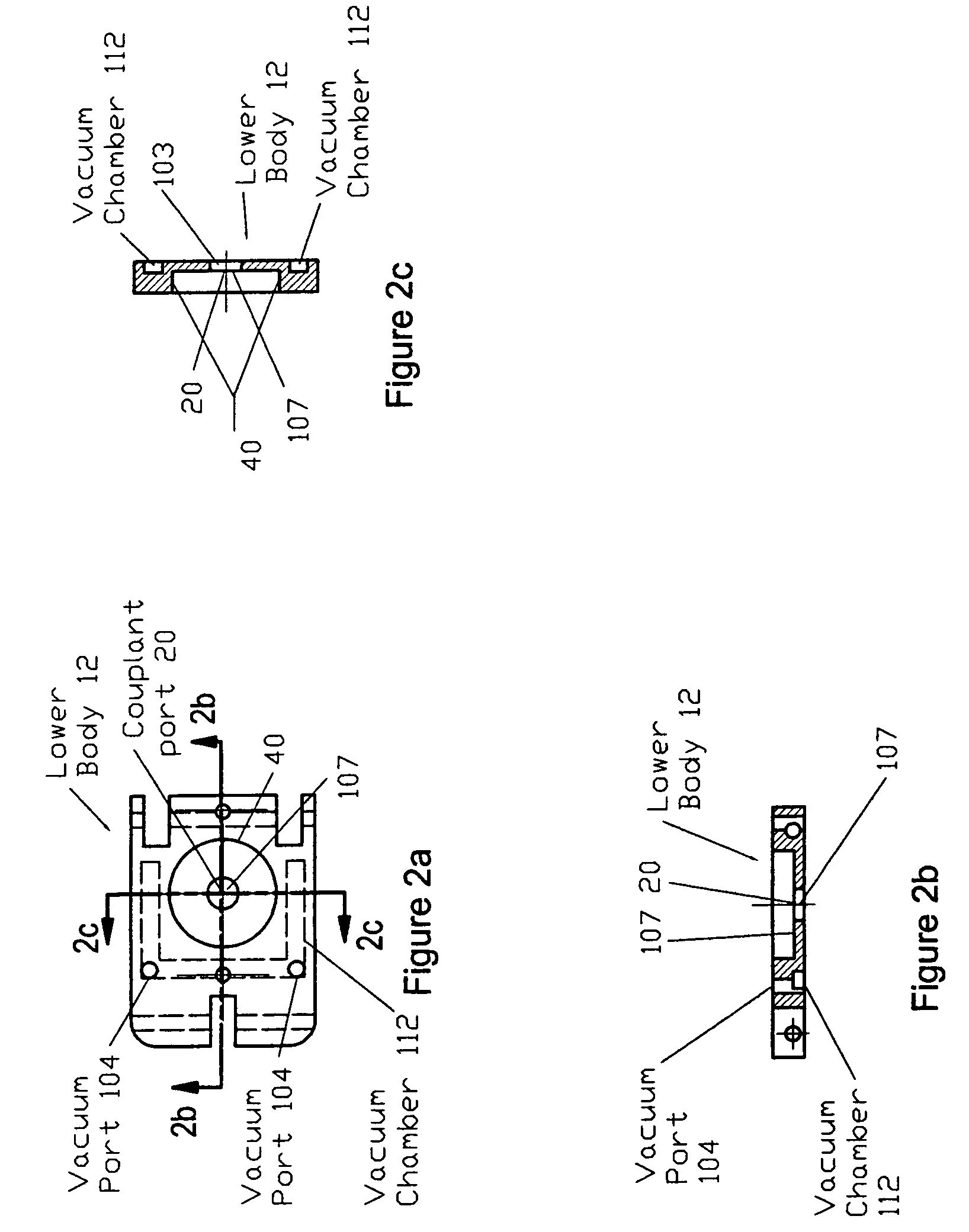

Rigid-contact dripless bubbler (RCDB) apparatus for acoustic inspection of a workpiece in arbitrary scanning orientations

InactiveUS7284434B1Reliable couplingReduced footprintAnalysing solids using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsUltrasonic beamCoupling

A lightweight apparatus for performing ultrasonic immersion inspection of a workpiece in an arbitrary orientation that uses significantly less couplant and has a reduced footprint size while providing ultrasonic performance levels comparable to those typically reached using immersion tanks, bubblers, or Dripless Bubblers™ while accommodating large and small ultrasonic beamwidths. The apparatus can be used with manual, automated, or electronic scanning techniques. The apparatus provides a quickly enabled ultrasonic coupling means that minimizes the area of the part wetted, and also can recover spent couplant. As a result, this reduces the number and type of contaminates to which the workpiece is exposed when used when compared to prior art immersion tanks and bubblers.

Owner:FLEMING MARVIN F

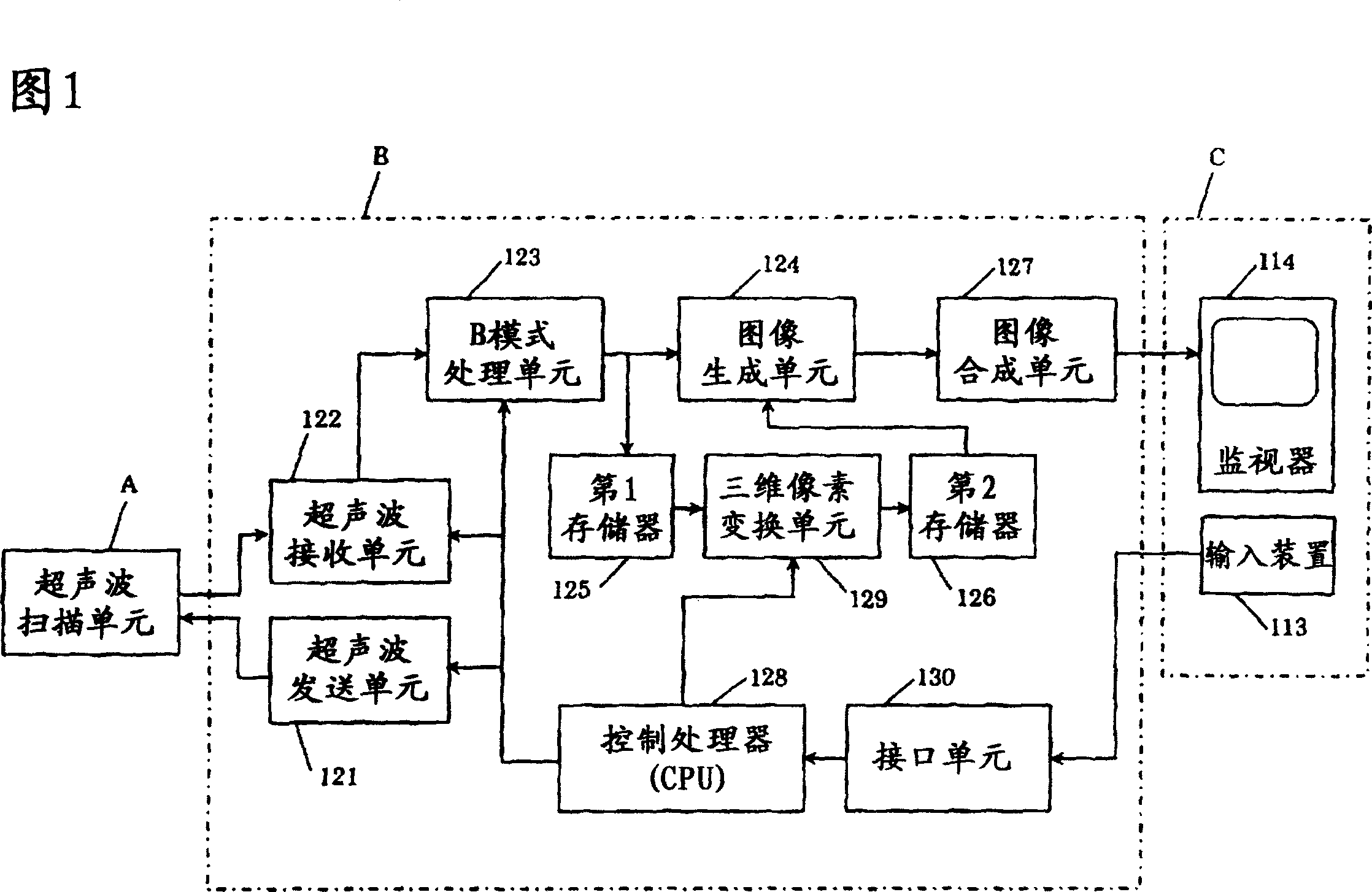

Supersonic wave checking device

InactiveCN101002690AReduce the burden onEffective diagnosisUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsElectricityUltrasonic beam

Owner:KK TOSHIBA +1

Non-invasive and optimized system for the rejuvenation and removal of wrinkles of the skin

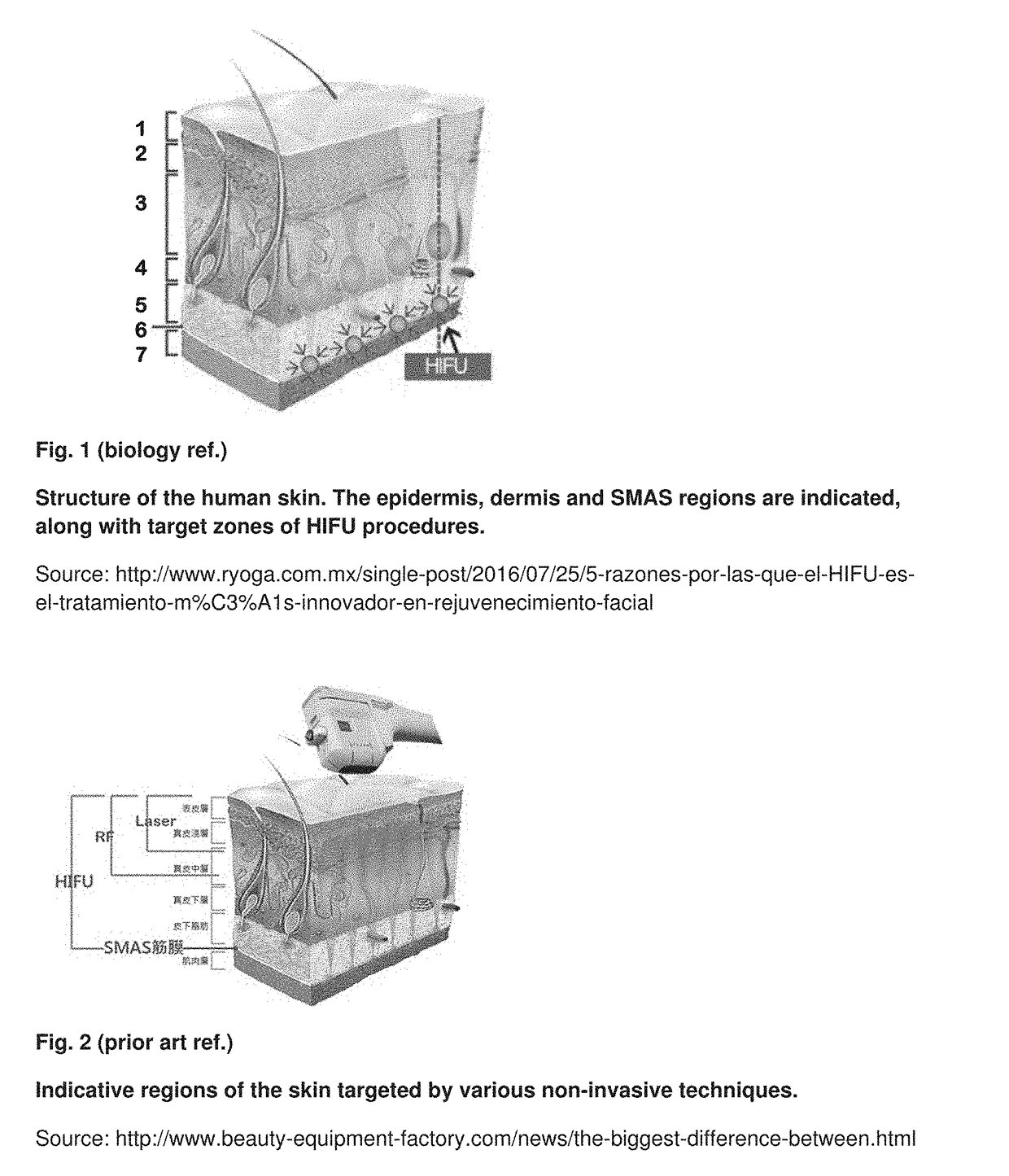

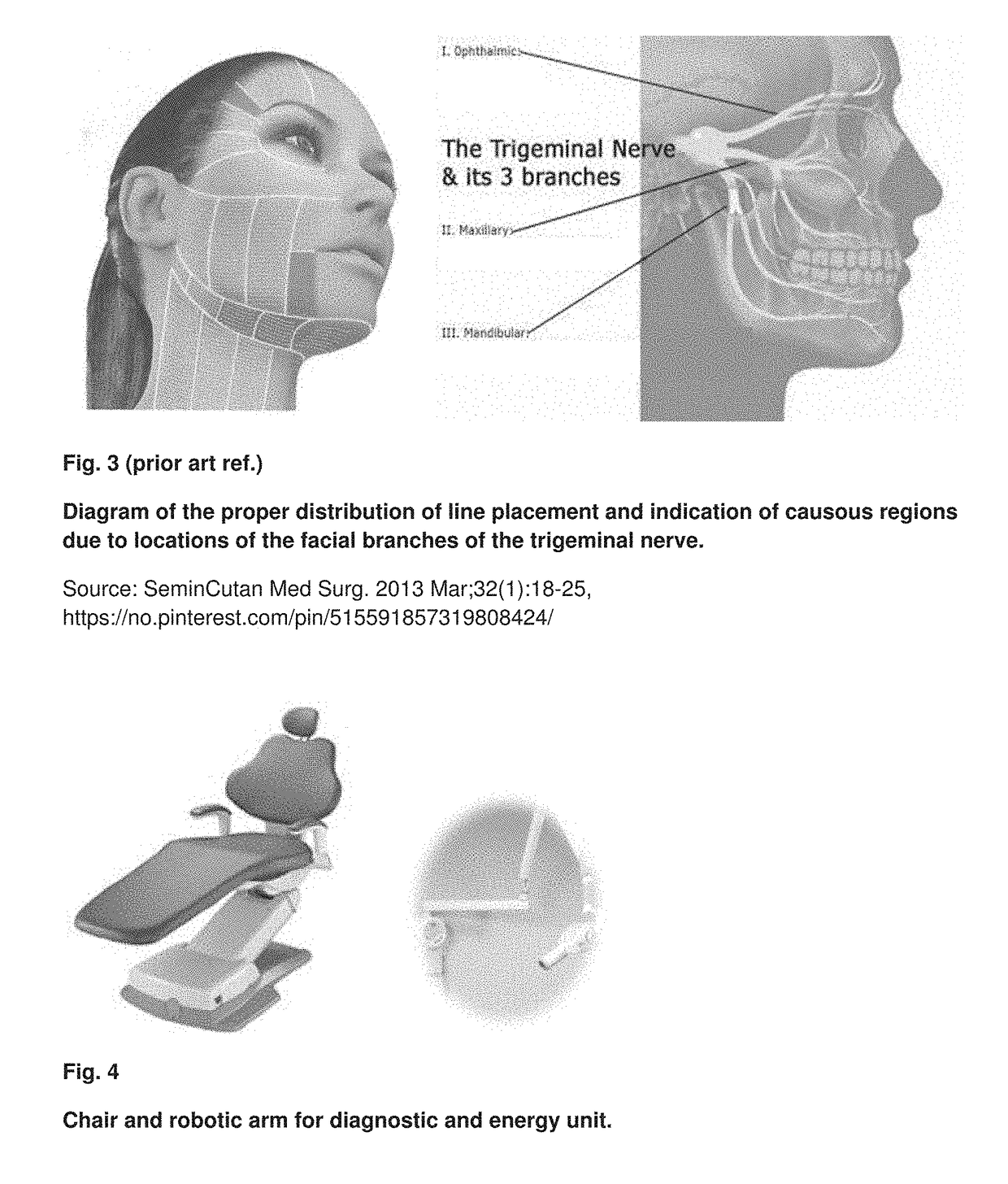

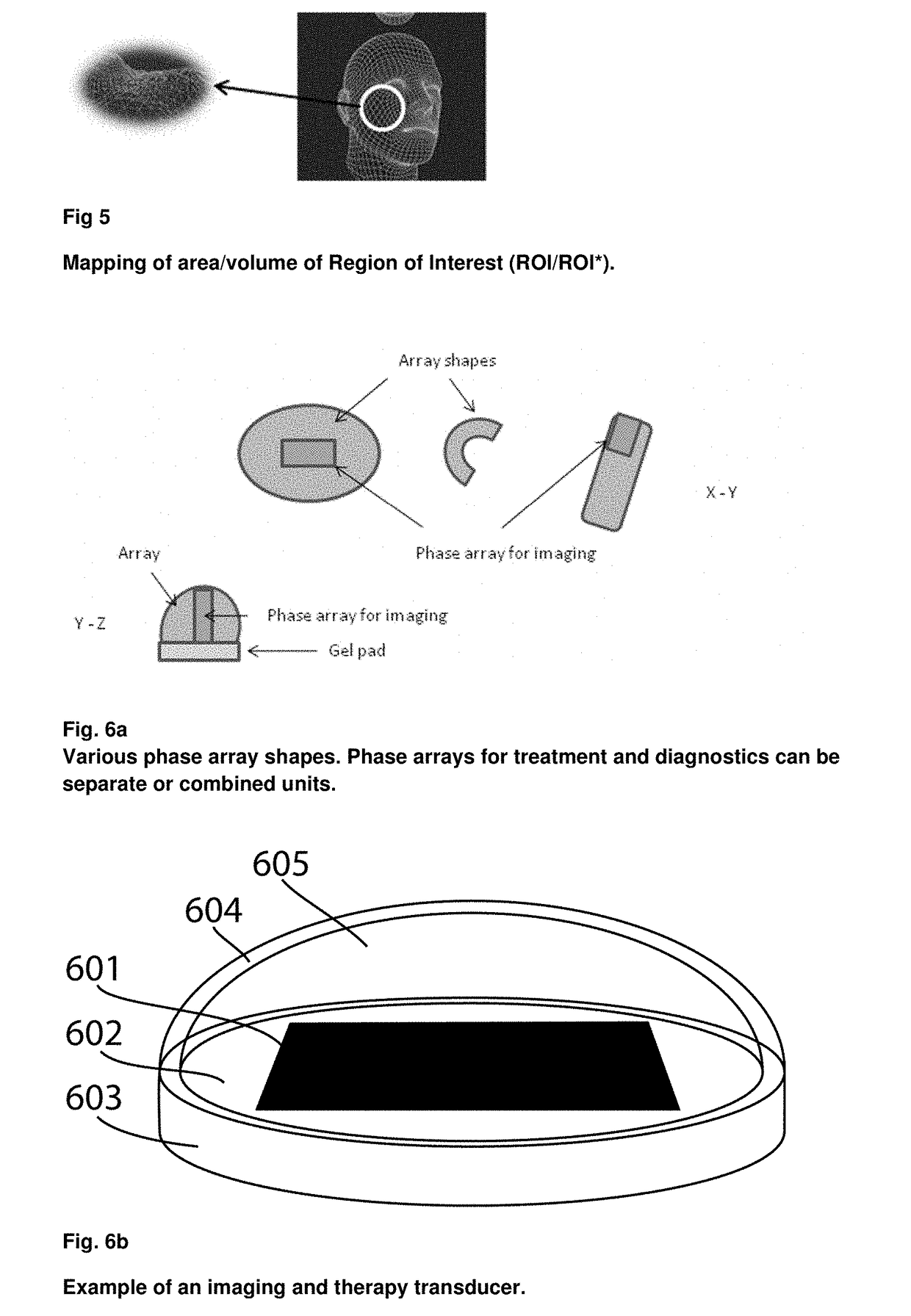

InactiveUS20190009111A1Increase effective transmitted pulse lengthReduce multiple reflectionsUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyWrinkle skinUltrasonic beam

The invention relates to a system and method for the removal of wrinkles and / or provide the rejuvenation of the human skin by use of ultrasound. The method comprises determining a 3D image of a region of the skin using ultrasound, determining a focal depth of the ultrasonic beam for different locations of the skin based on the 3D image, performing the treatment by heating the skin at different locations using an ultrasonic beam, and adjusting the focal depth of the ultrasonic beam according to the determined focal depths during the process of heating the skin at different locations.

Owner:MYHR GUNNAR +1

Ultrasonographic method and ultrasonographic device

InactiveUS20060173305A1Ultrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsUltrasonic beamSonification

An ultrasonographic method includes: a first encoding transmission / reception step for transmitting an ultrasonic beam encoded by an encoding set consisting of a plurality of modulation codes in which at least two are in complementary relationship and demodulating reception signals corresponding to the ultrasonic beam; a step for obtaining a first synthesis signal by synthesizing the demodulation signals demodulated by the first encoding transmission / reception step; a second encoding transmission / reception step for transmitting an ultrasonic beam encoded by a reverse encoding set consisting of a plurality of modulation codes in which the arrangement order of modulation codes of the encoding set is reversed and demodulating the reception signals corresponding to the ultrasonic beam; a step for obtaining a second synthesis signal by synthesizing the demodulated signals demodulated by the second encoding transmission / reception step; a step for obtaining a third synthesis signal by synthesizing the first synthesis signal and the second synthesis signal; and a step for reconstructing the ultrasonograph according to the third synthesis signal.

Owner:HITACHI MEDICAL CORP

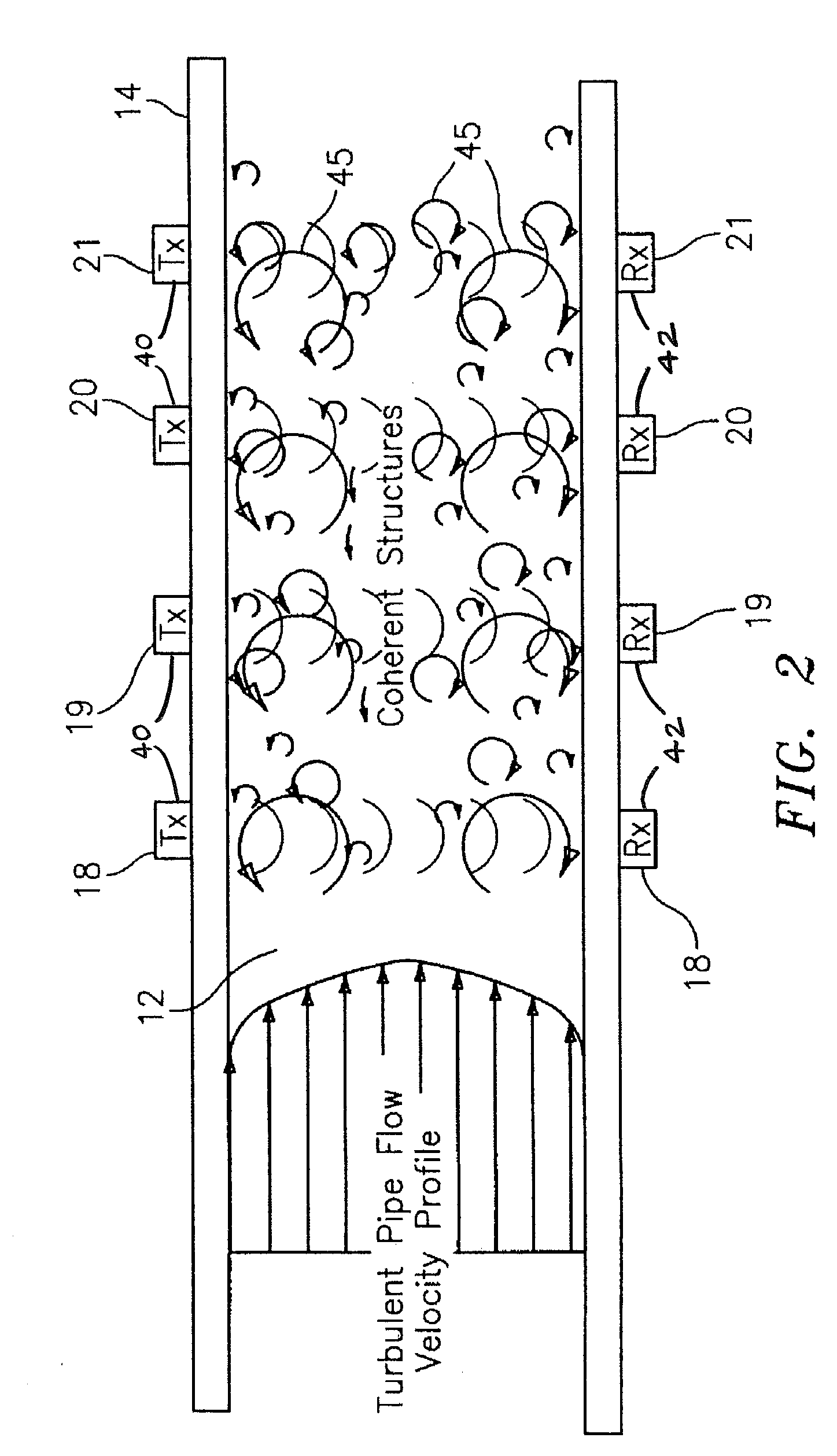

Apparatus And Method of Lensing An Ultrasonic Beam For An Ultrasonic Flow Meter

ActiveUS20080098824A1Accurate inductionOptimize signal characteristic of signalVolume/mass flow measurementSonificationUltrasonic beam

A method for sensing flow within a pipe having an internal passage disposed between a first wall portion and a second wall portion is provided, comprising the steps of: 1) providing a flow meter having at least one ultrasonic sensor unit that includes an ultrasonic transmitter attached to the first wall portion and an ultrasonic receiver attached to the second wall portion and aligned to receive ultrasonic signals transmitted from the transmitter; 2) selectively operating the ultrasonic transmitter to transmit a beam of ultrasonic signal, which beam has a focal point such that within the pipe, the beam is either colliminated, divergent or convergent; and 3) receiving the ultrasonic signals within the beam using the ultrasonic receiver. An apparatus operable to perform the aforesaid method is also provided.

Owner:EXPRO METERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com