Patents

Literature

6044 results about "Surface shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

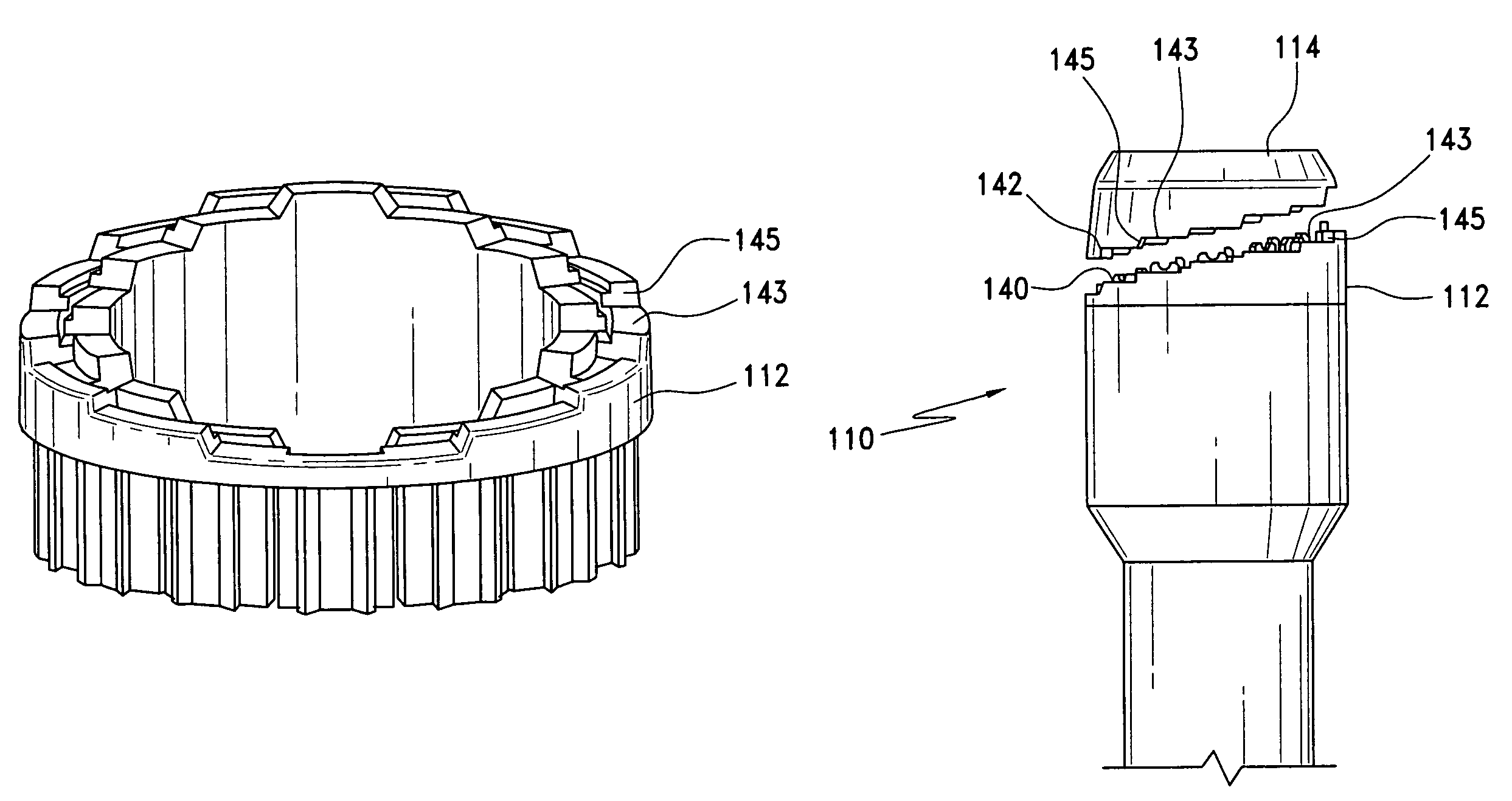

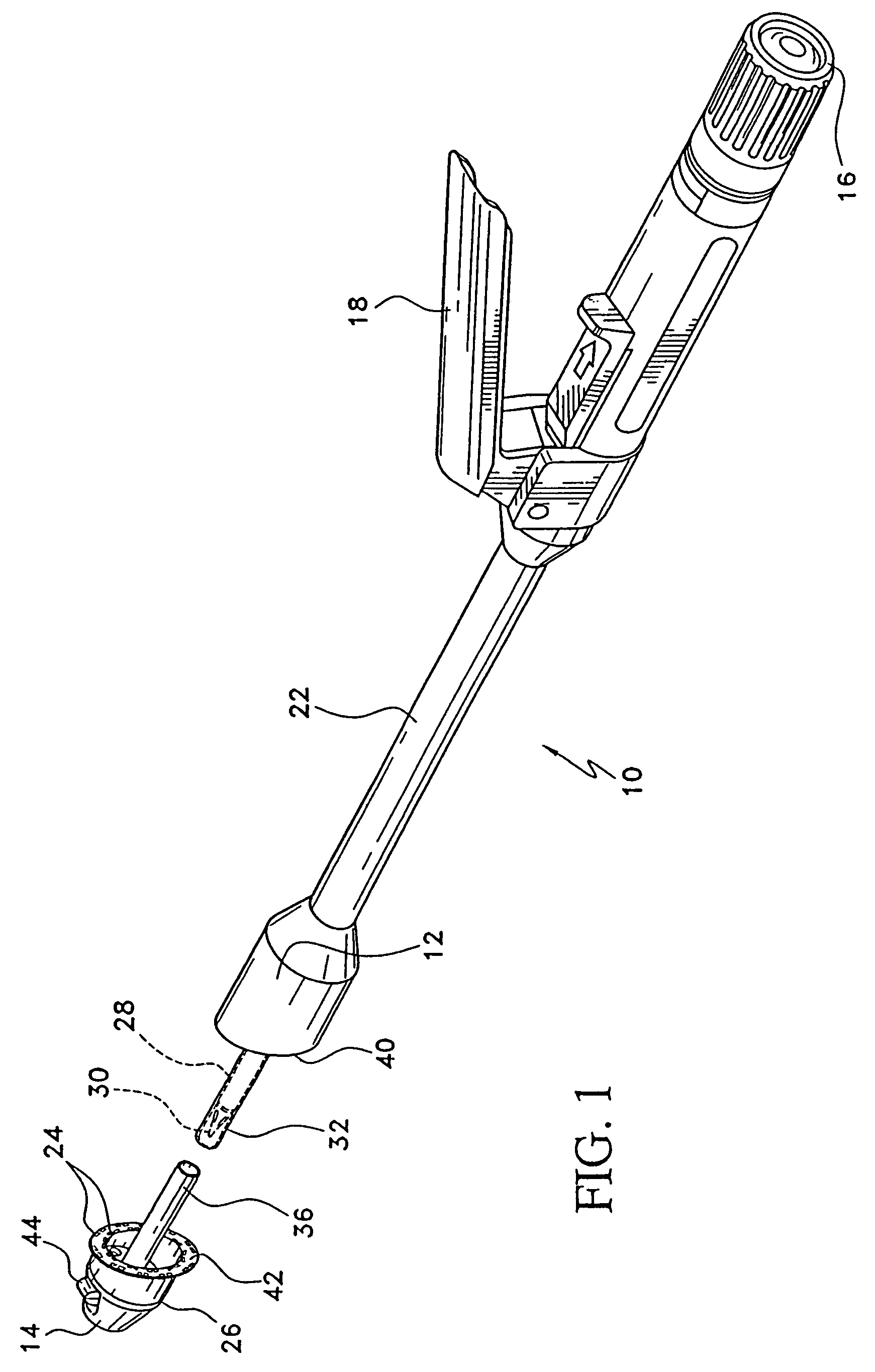

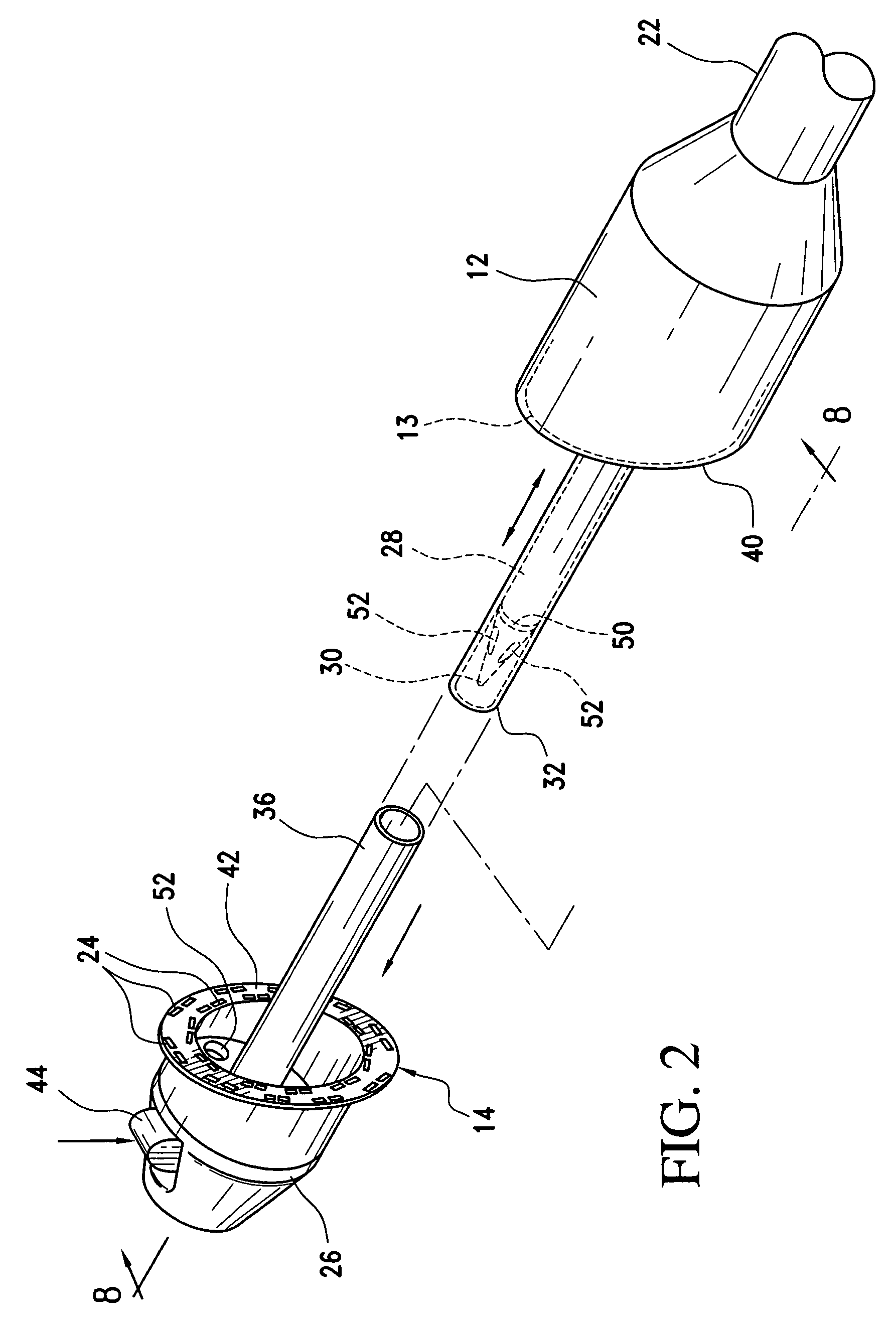

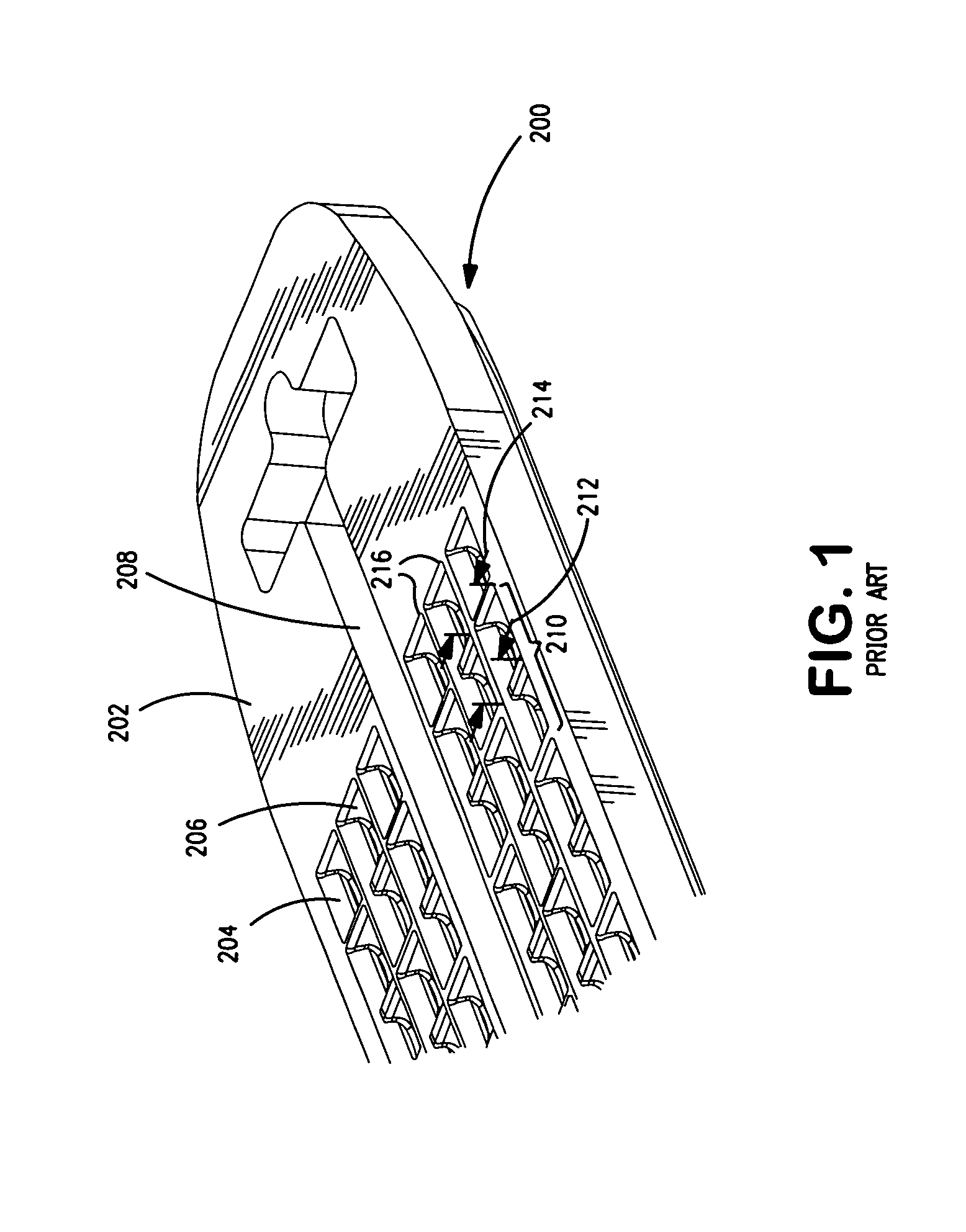

Elliptical intraluminal surgical stapler for anastomosis

Owner:ETHICON ENDO SURGERY INC

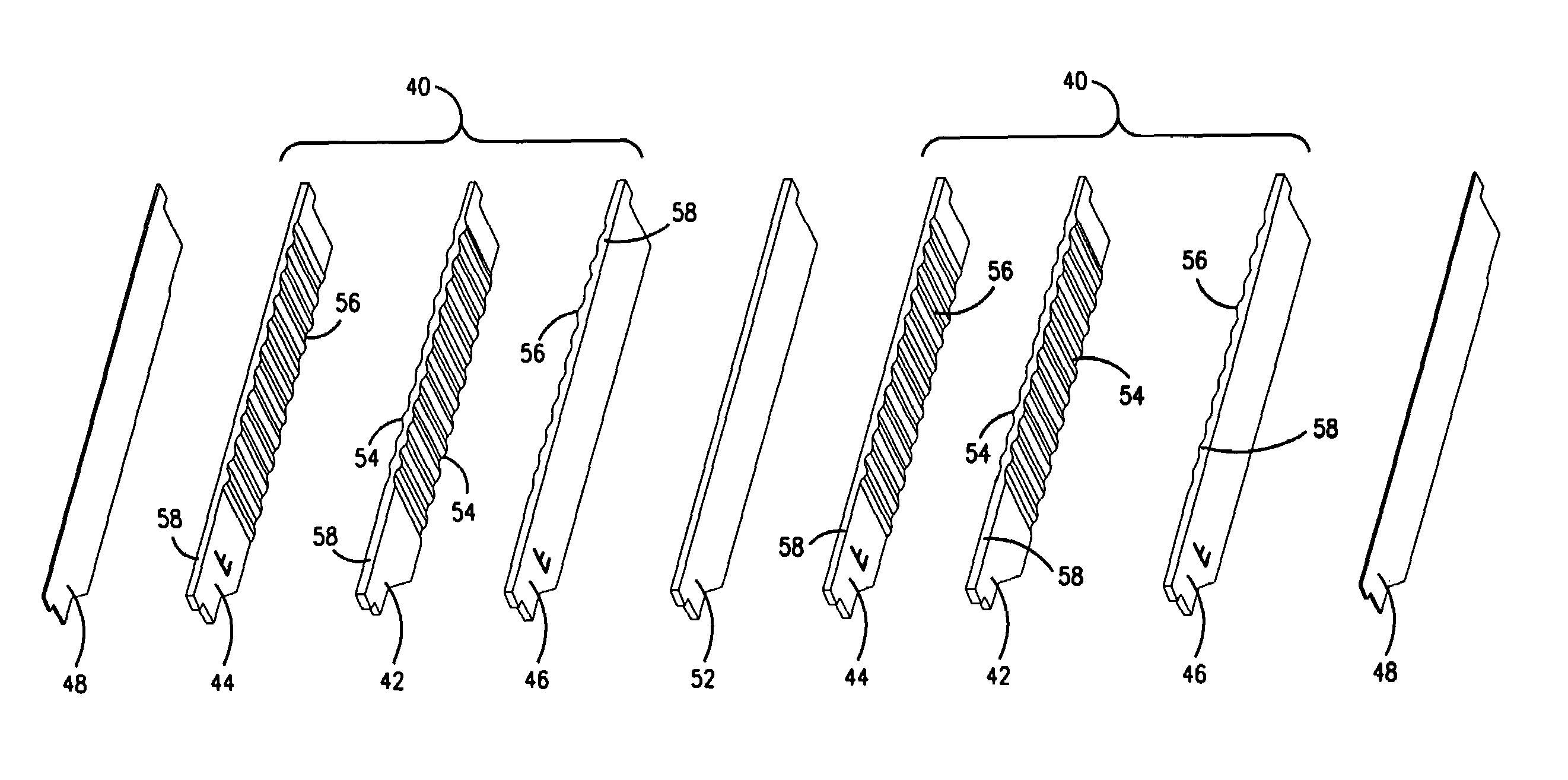

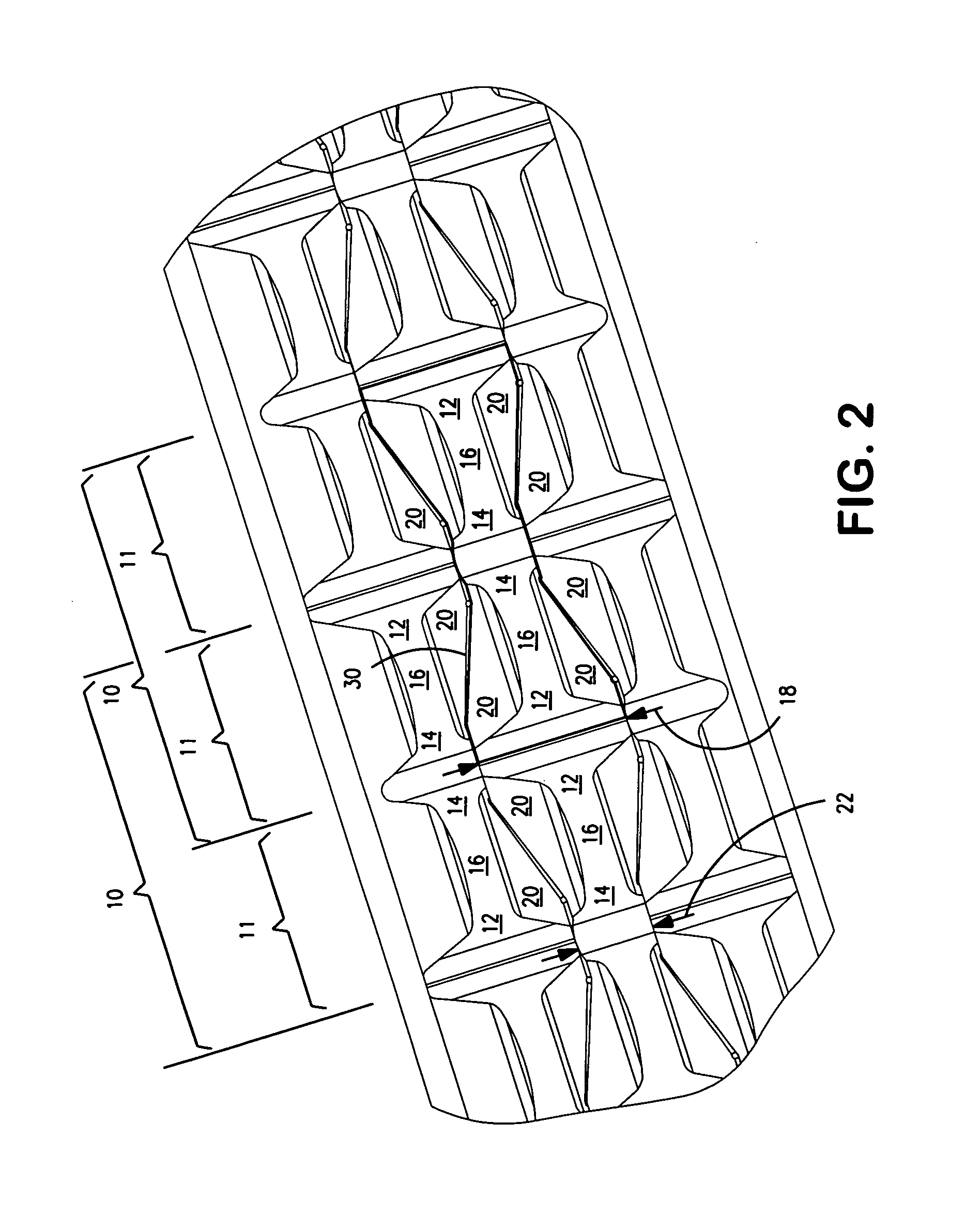

Metal-forming die and method for manufacturing same

InactiveUS7086267B2Good flexibilityIncrease flexibilitySuture equipmentsShaping toolsMetal formingEngineering

A metal-forming die according to the present invention includes die blades with convoluted opposed side surfaces that correspond to variable-width features on the working surface of the die. The convoluted side surfaces and variable-width working surface features permit the impression left by one die blade to fill space taken from an impression made by a laterally adjacent die blade. Such a die permits formation of working surface shapes not possible with flat-sided die components. The die is manufactured in discrete longitudinally extending components, or blades. Dividing the working surface of the die into longitudinally extending portions, each carried by a die blade allows conventional machining processes to be employed in forming the working surface on each die blade. An additional machining process cuts complementary shapes on the sides of the die blades. The die blades and their corresponding working surfaces interfit, or nest together.

Owner:FR W DWORAK

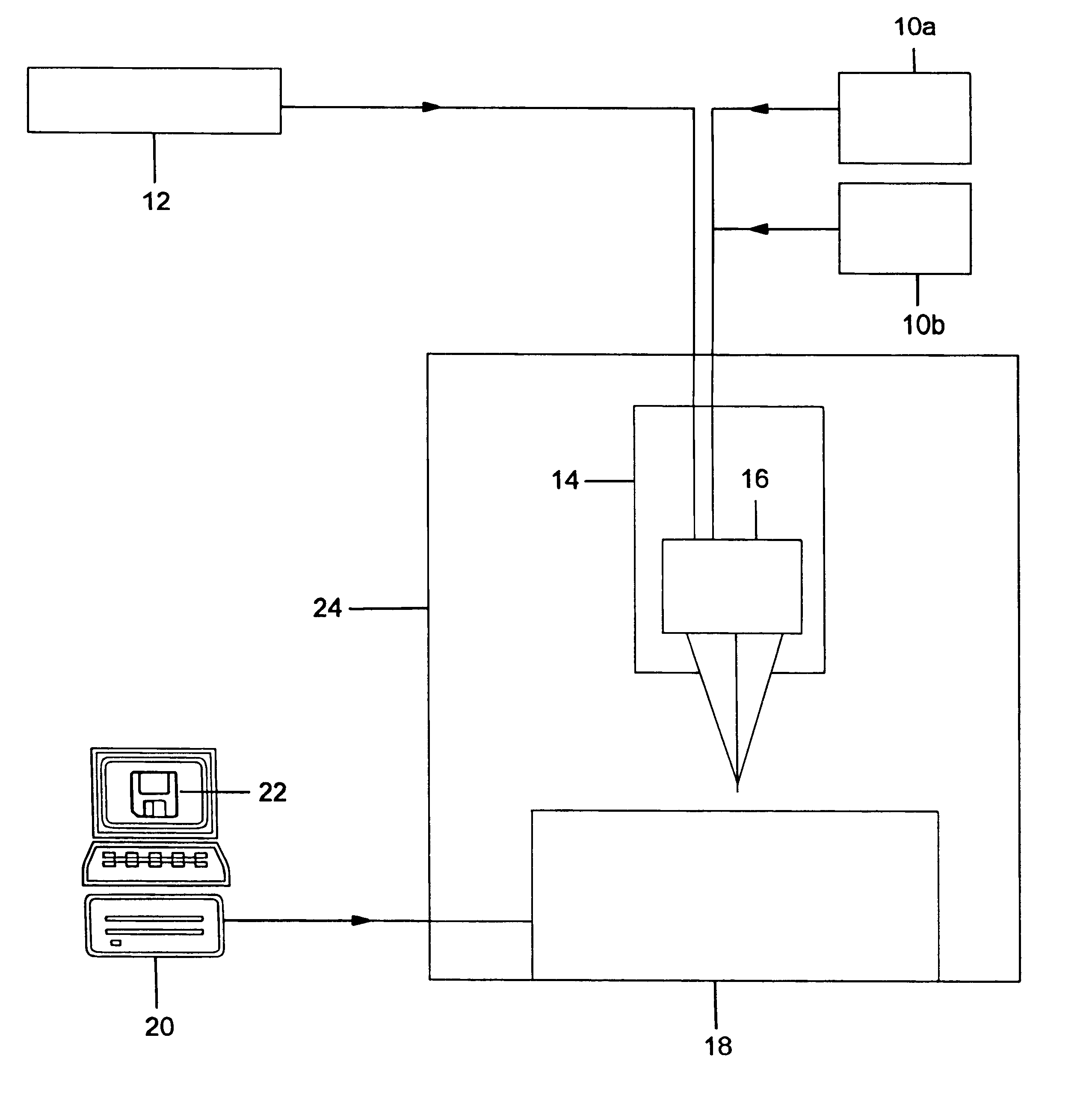

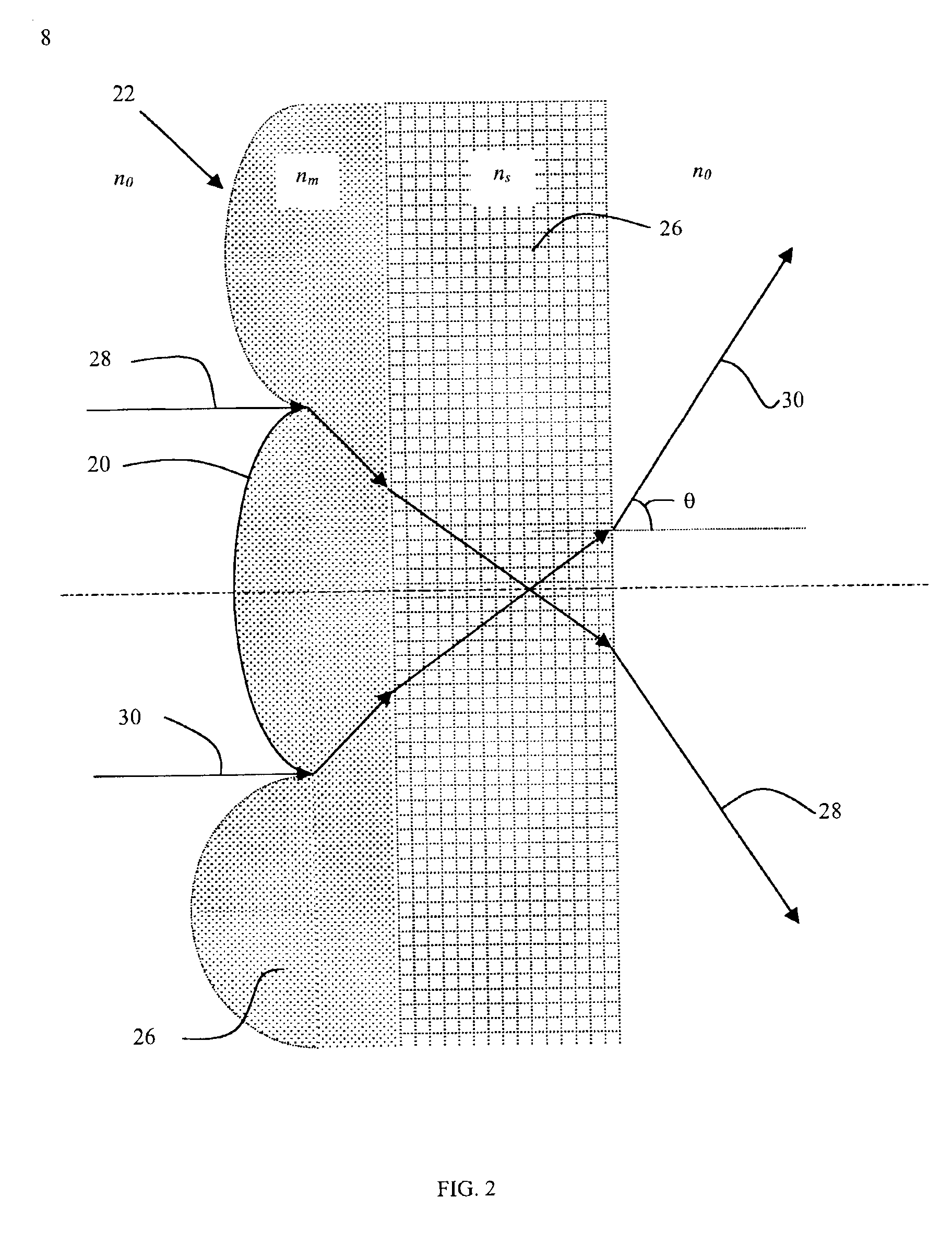

Methods and devices to design and fabricate surfaces on contact lenses and on corneal tissue that correct the eye's optical aberrations

Methods and devices are described that are needed to design and fabricate modified surfaces on contact lenses or on corneal tissue that correct the eye's optical aberrations beyond defocus and astigmatism. The invention provides the means for: 1) measuring the eye's optical aberrations either with or without a contact lens in place on the cornea, 2) performing a mathematical analysis on the eye's optical aberrations in order to design a modified surface shape for the original contact lens or cornea that will correct the optical aberrations, 3) fabricating the aberration-correcting surface on a contact lens by diamond point turning, three dimensional contour cutting, laser ablation, thermal molding, photolithography, thin film deposition, or surface chemistry alteration, and 4) fabricating the aberration-correcting surface on a cornea by laser ablation.

Owner:BROOKFIELD OPTICAL SYST

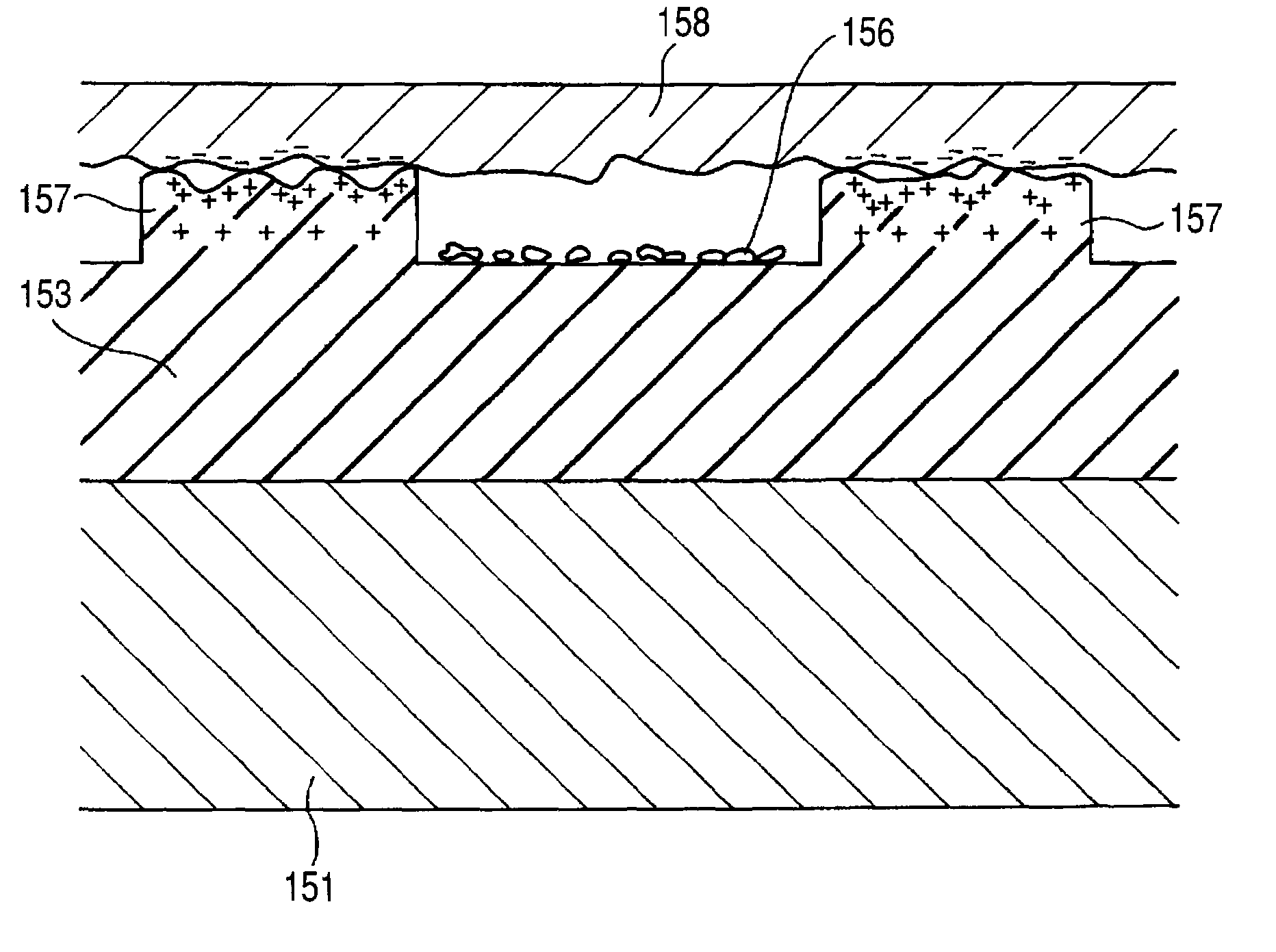

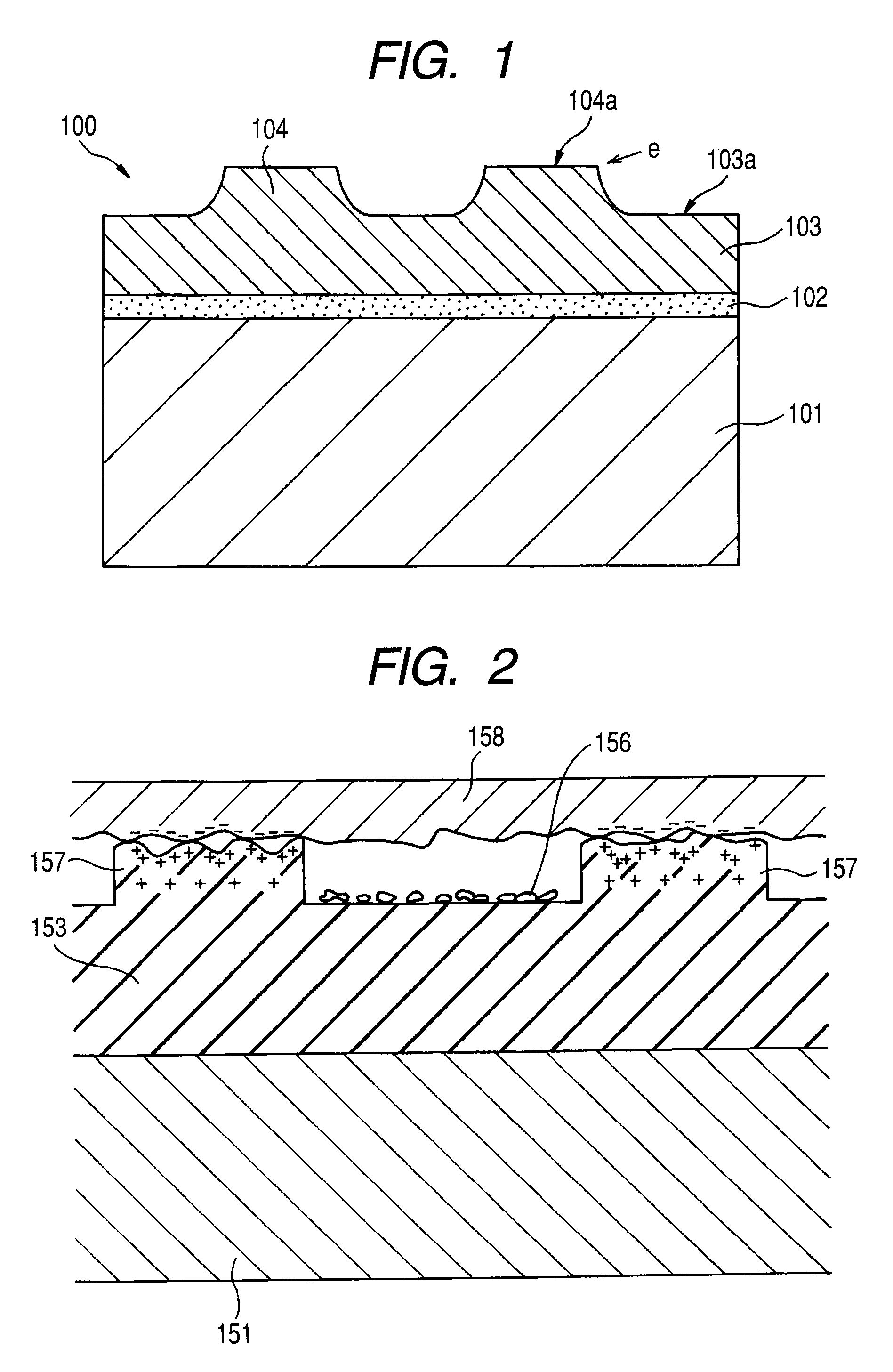

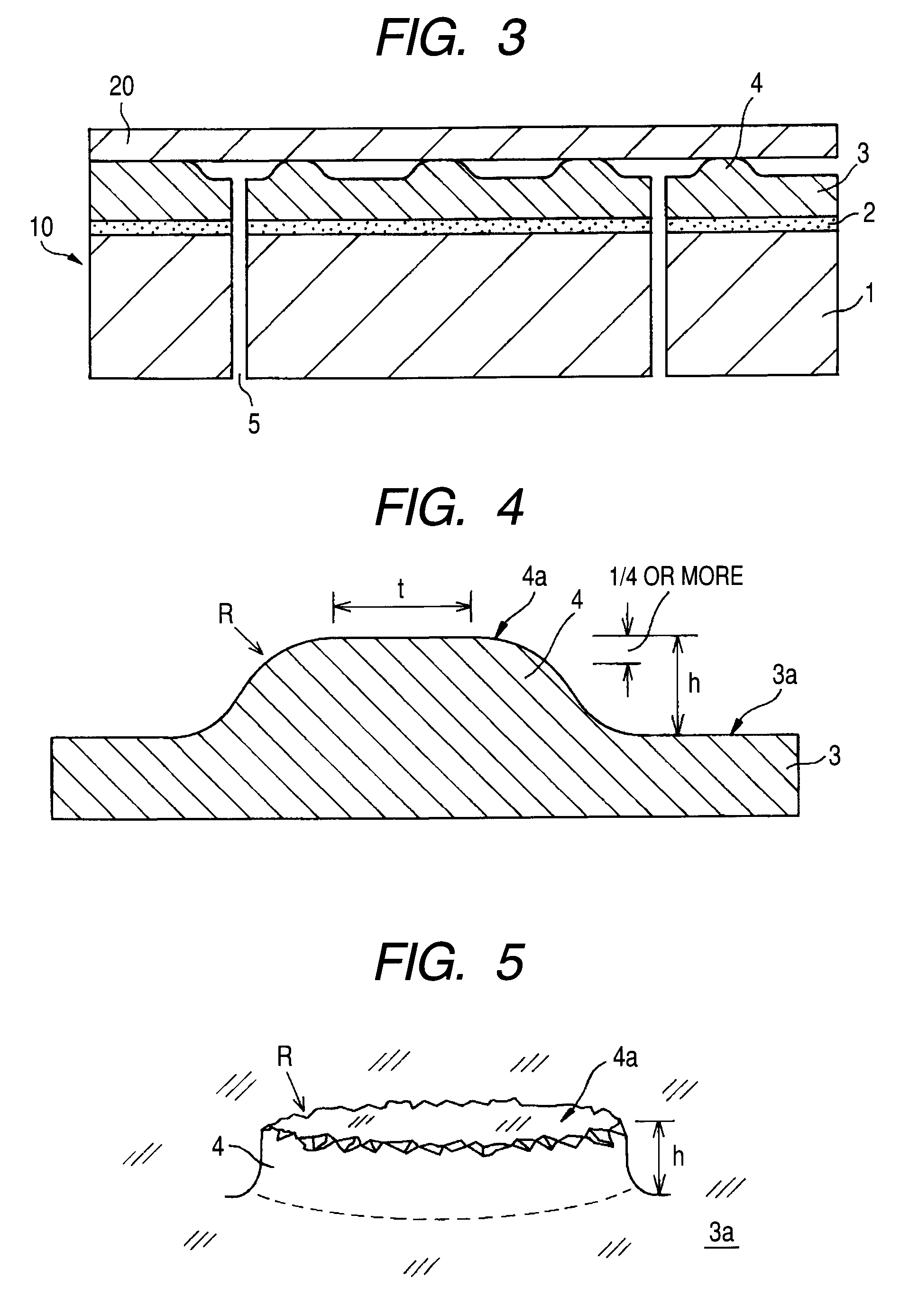

Electrostatic chuck member, method of manufacturing the same, and electrostatic chuck device

InactiveUS20090056112A1Good effectComplicated processingSleeve/socket jointsWave amplification devicesEngineeringMechanical engineering

A plurality of protruded portions is formed through embossing and is distributed and arranged regularly or irregularly on an electrostatic chuck surface, and has a circular or almost circular top surface shape and a roundness (R) of 0.01 mm or more is applied to an edge part defined by an intersection of the top surface and a side surface and a portion to which the roundness is applied occupies a quarter of a height h of the protruded portion or more.

Owner:SHINKO ELECTRIC IND CO LTD

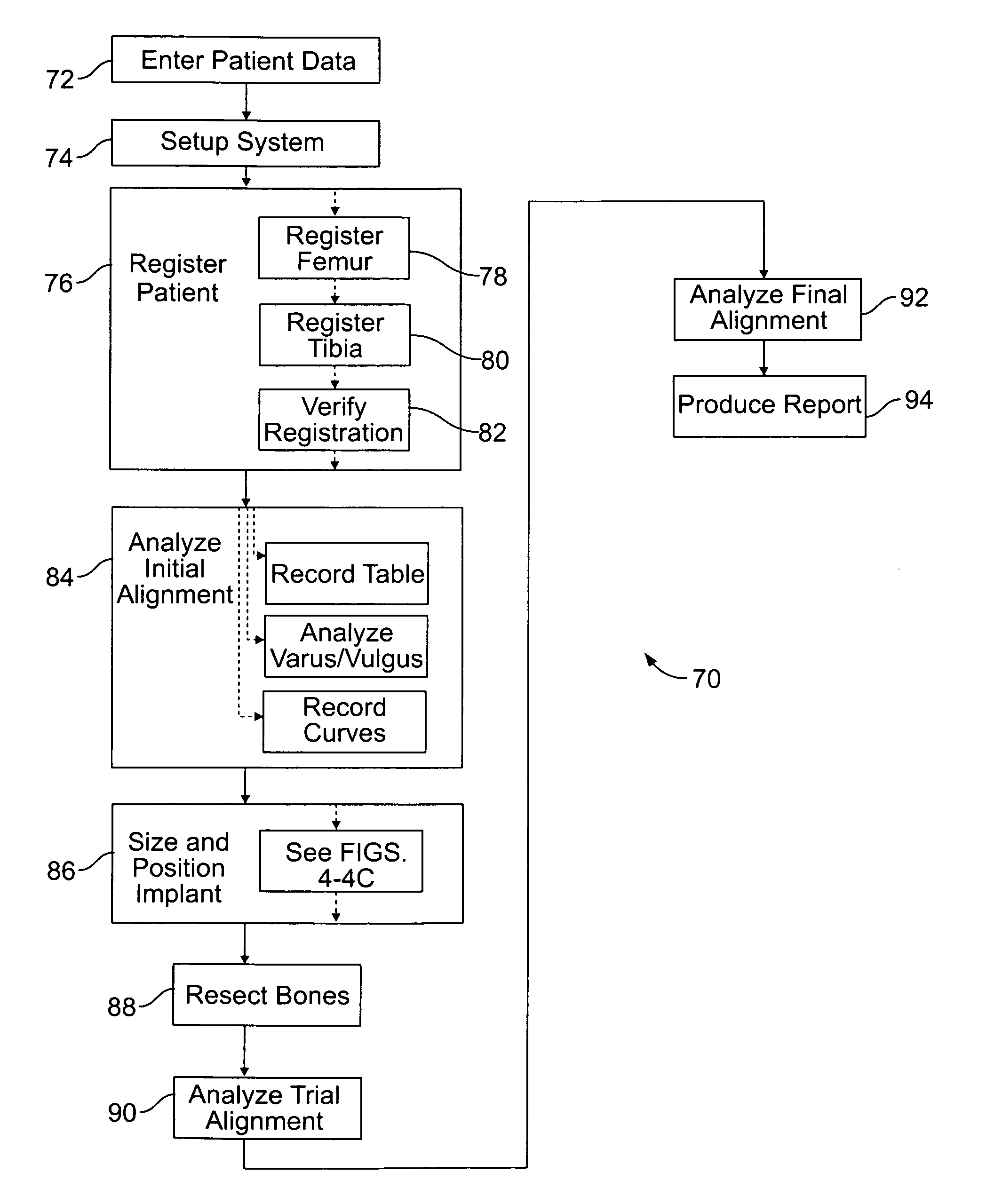

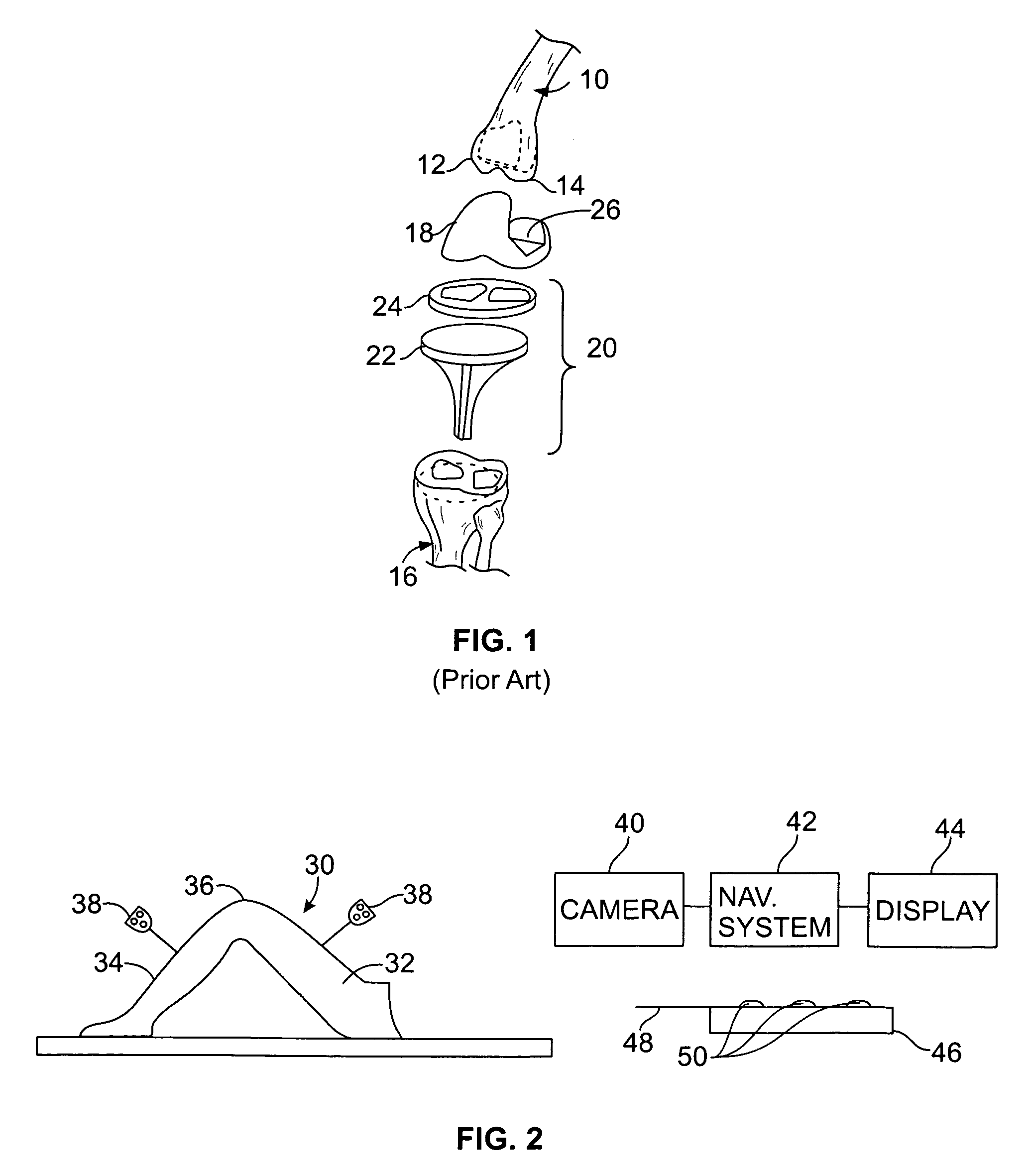

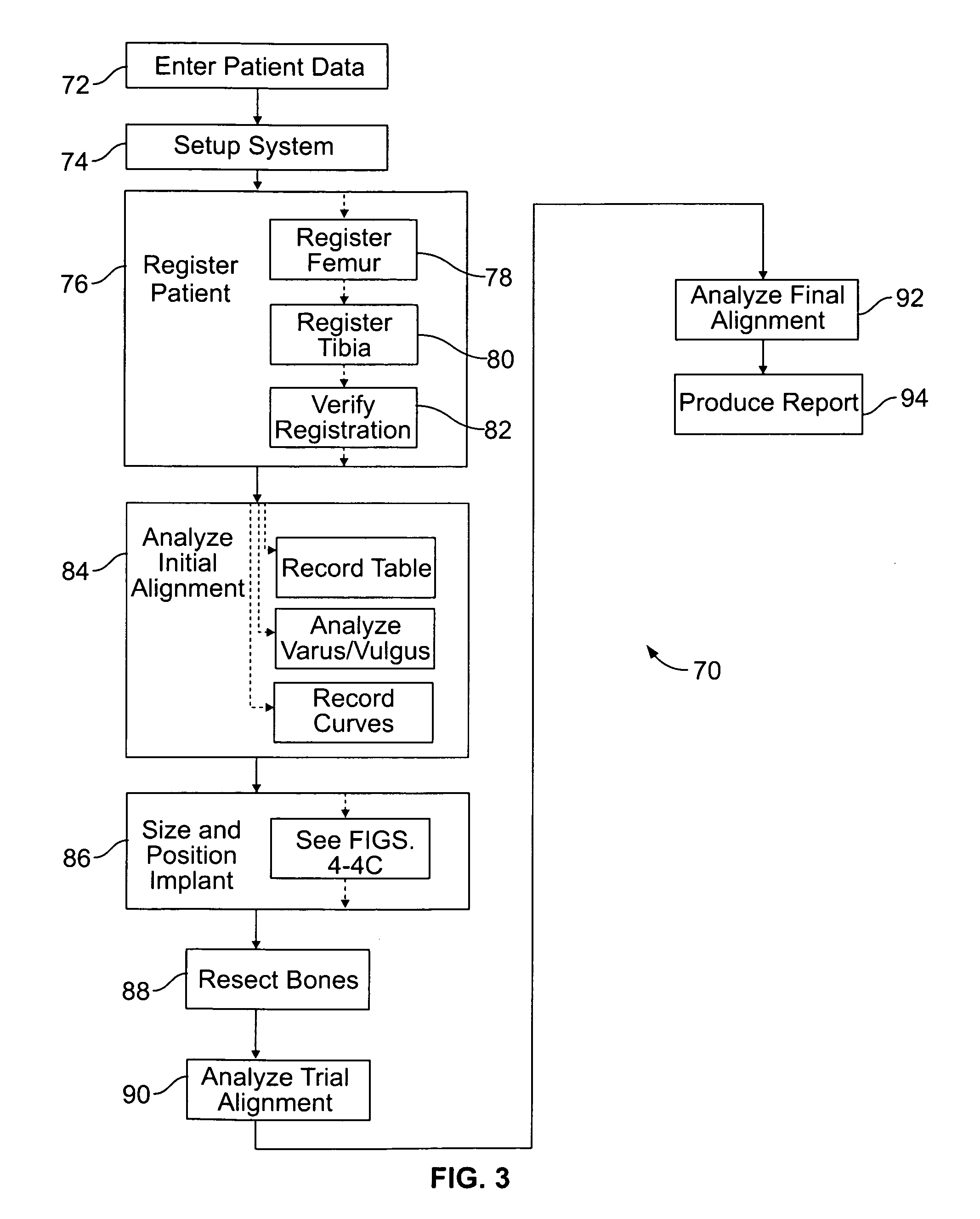

Method of and system for planning a surgery

ActiveUS20090043556A1Analogue computers for chemical processesDiagnostic recording/measuringSurgery procedureBiomedical engineering

A system for virtually planning a size and position of a prosthetic implant for a bone on a patient includes a database containing pre-defined form factor information for a plurality of different implants and a circuit for obtaining surface shape information of the bone. The system further includes a circuit for defining baseline location parameters for an implant location in relation to a virtual representation of the bone based on the surface shape information and a circuit for assessing a fit calculation of each implant in relation to the virtual representation of the bone based on the form factor in formation and a plurality of fit factors at each of a plurality of incremental positions in relation to the bone. Still further, the system includes a circuit for selecting a best fit implant size and position from all of the fit calculations.

Owner:STRYKER EURO OPERATIONS HLDG LLC

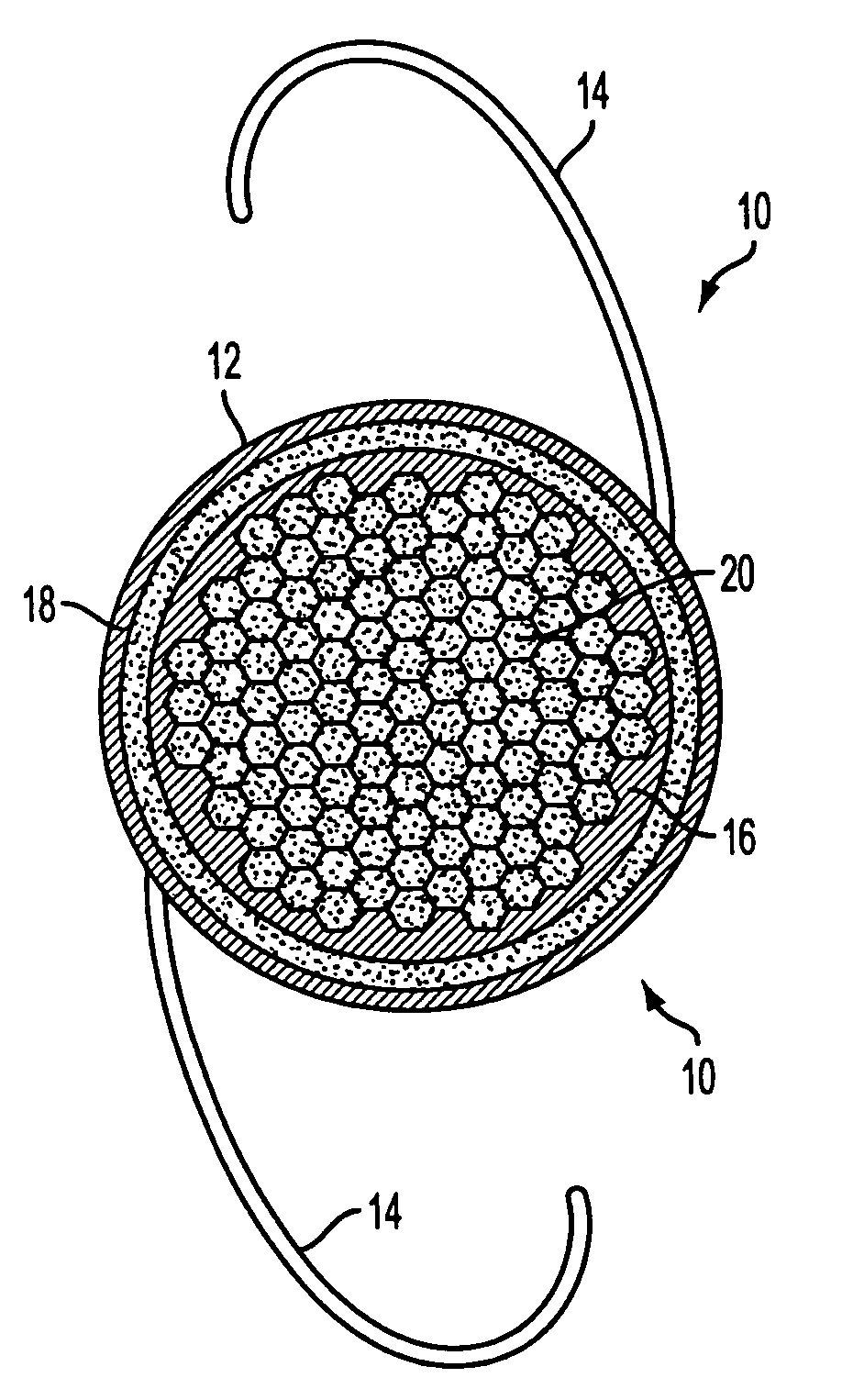

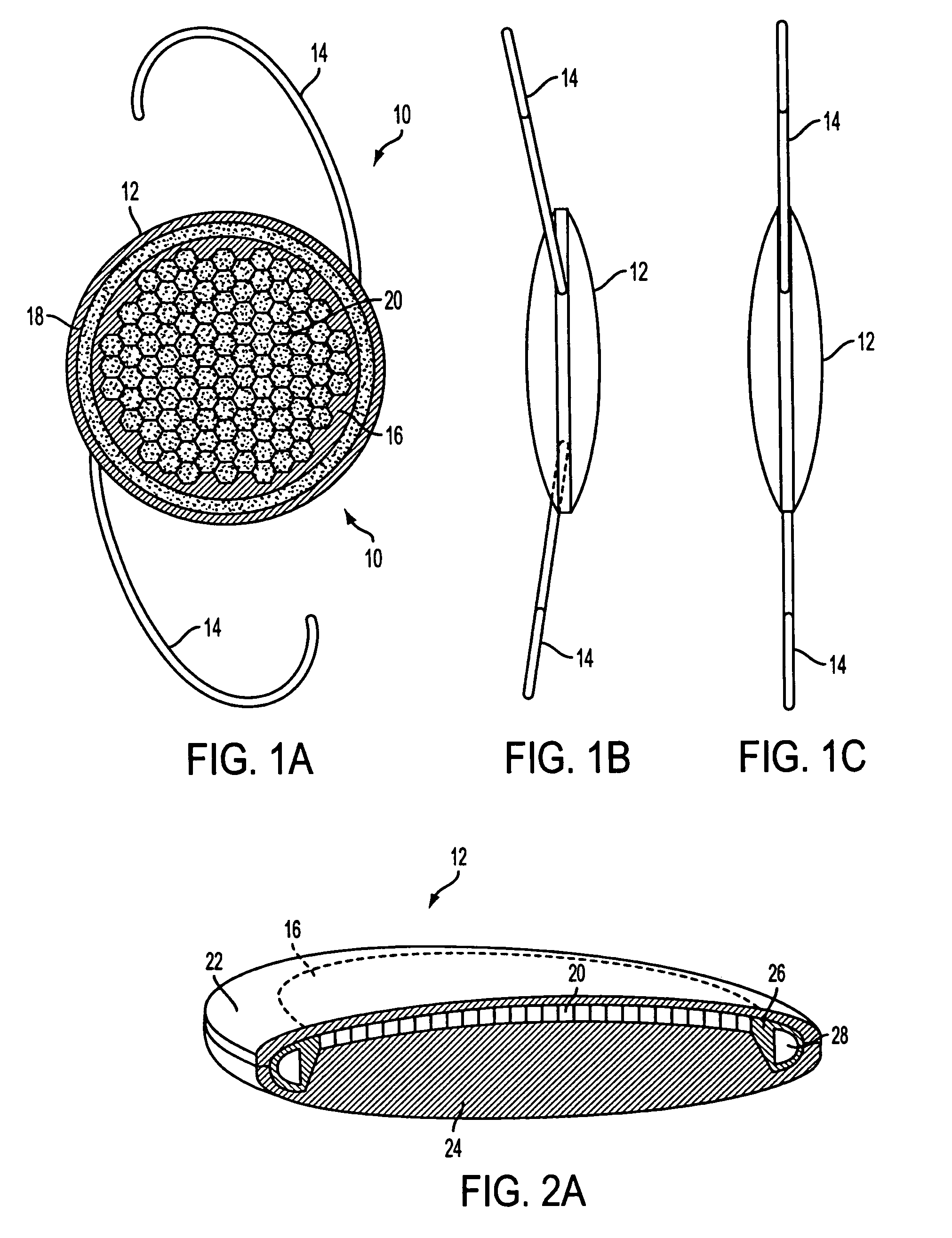

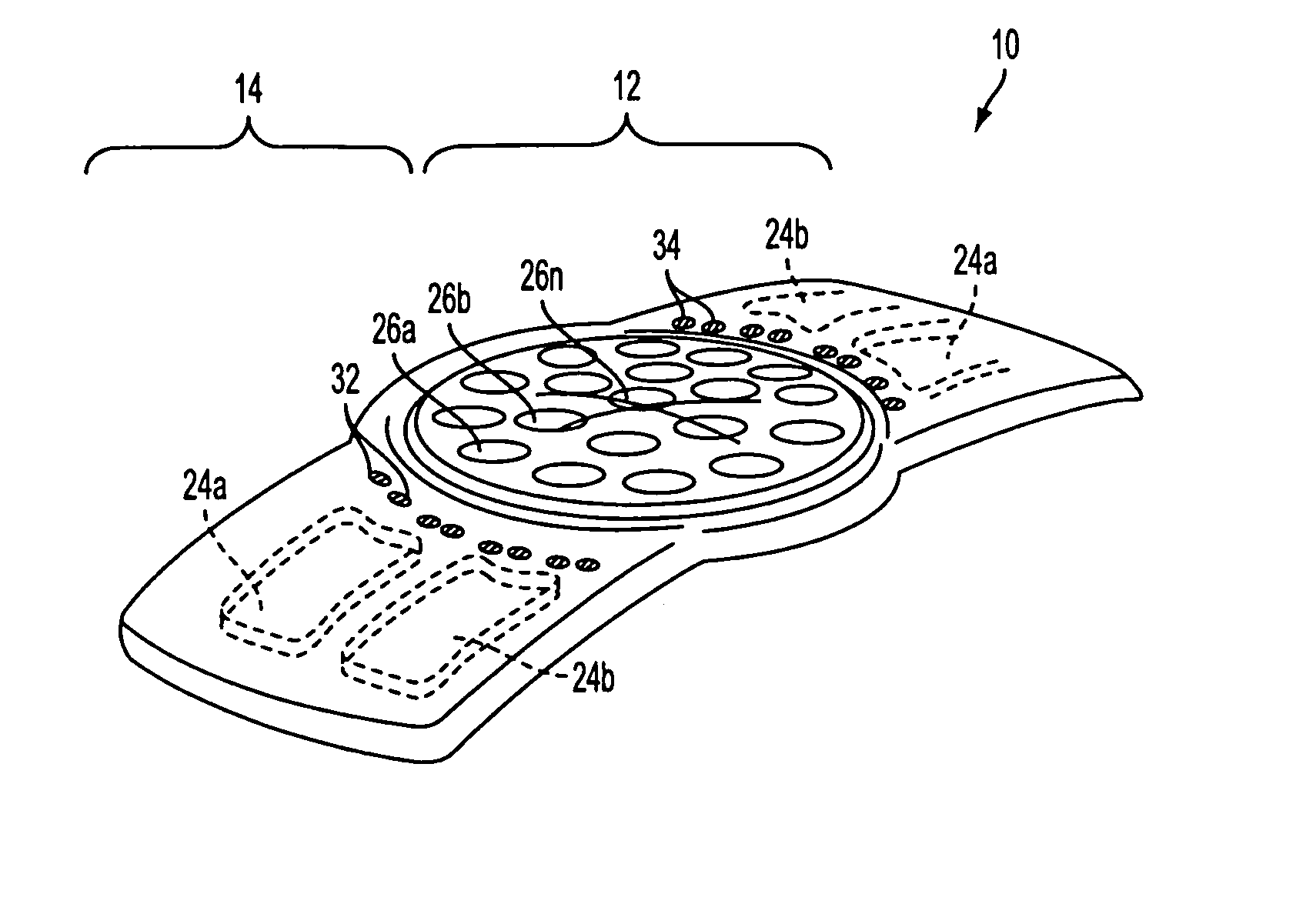

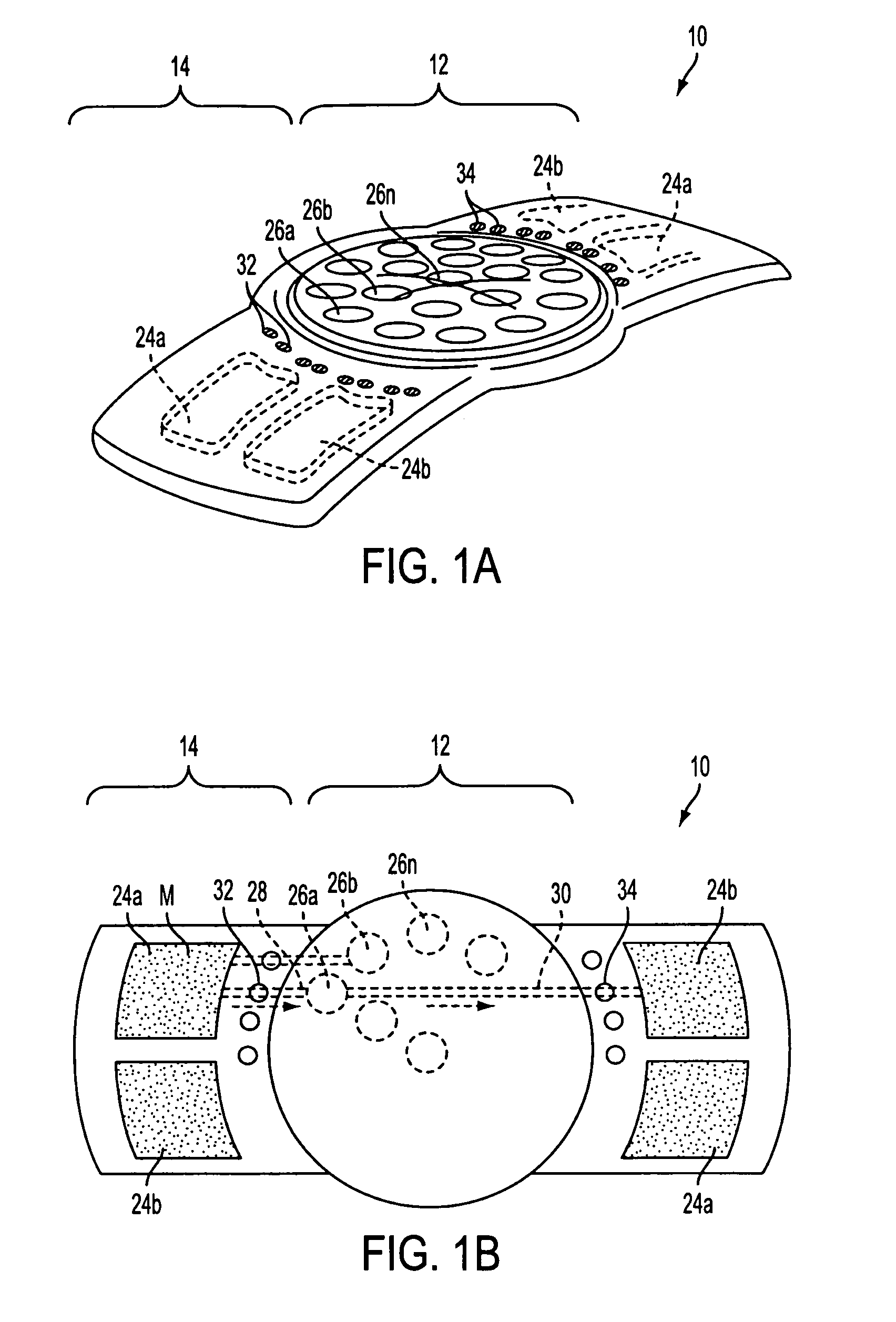

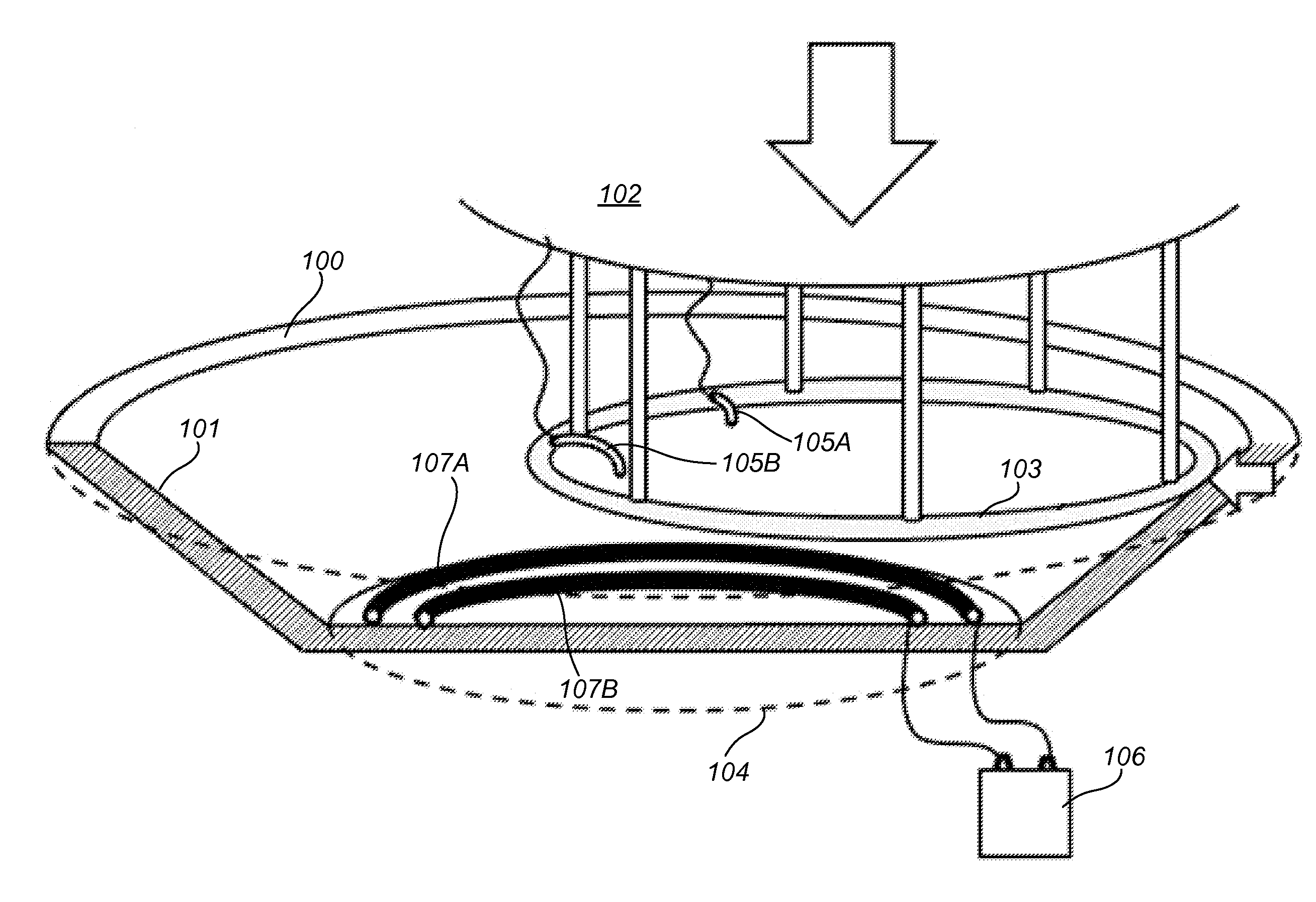

Lens system and method for power adjustment

A lens is provided that having optical parameters that may be adjusted in-situ, and is particularly useful as an IOL for use in cataract patients that require an adjustment in the optical power of the lens post-implantation. In one embodiment, the lens body carries an array of interior fluid-filled cells in which fluid is controllably moved upon application of energy from an external source to move a fluid media into or out of the cells to thereby alter the lens surface shape.

Owner:ALCON INC

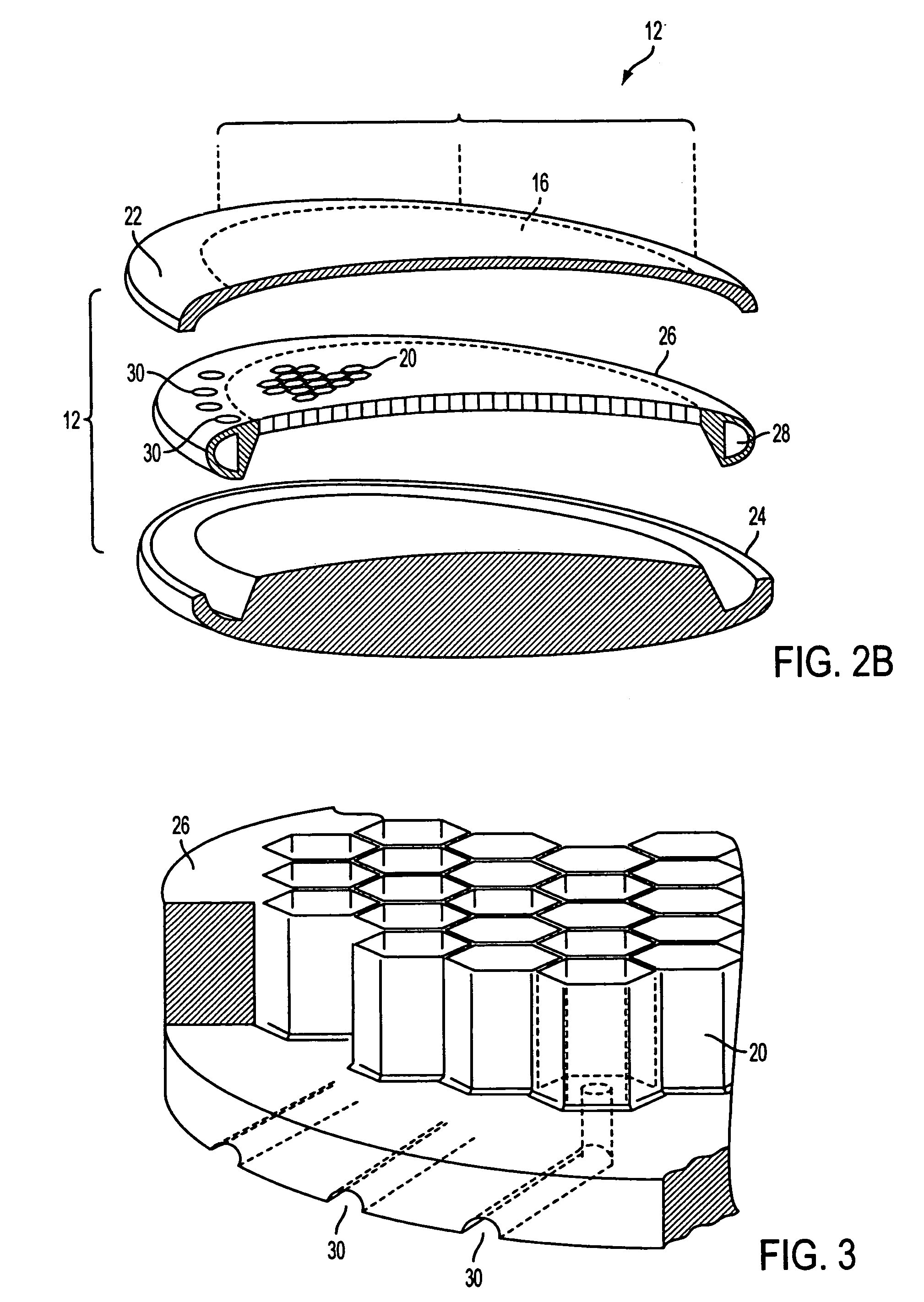

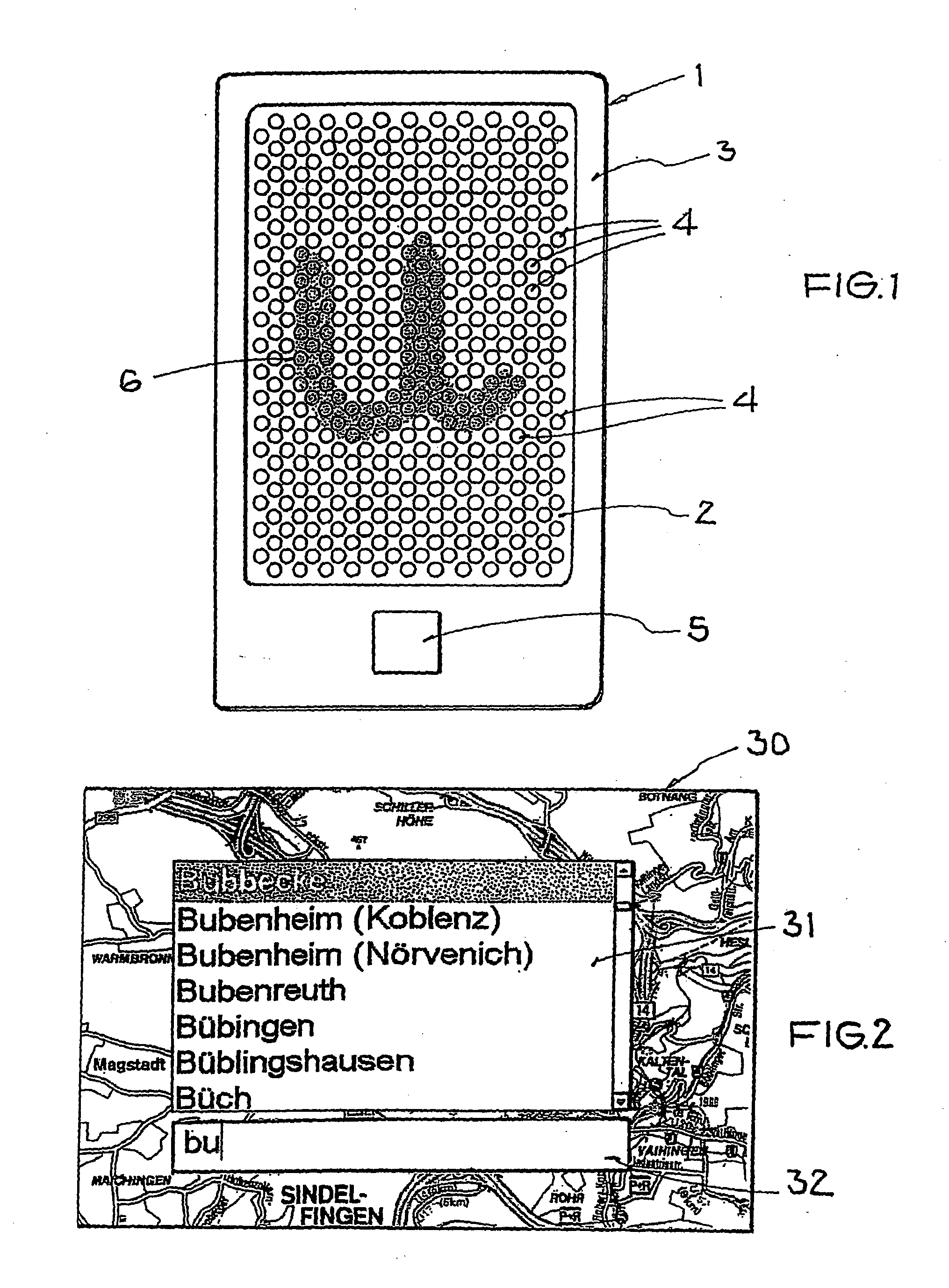

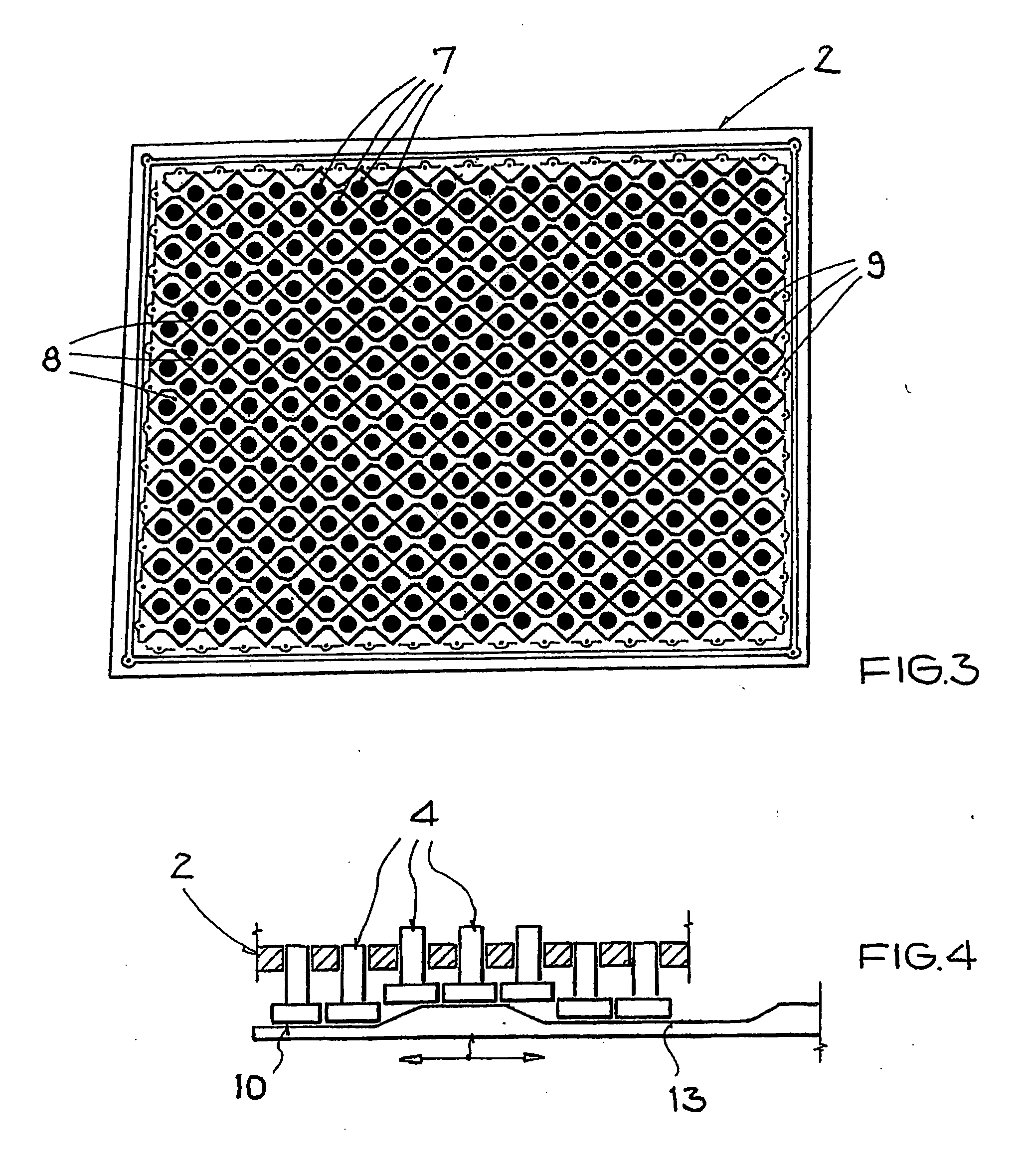

Operator control device

InactiveUS20070182718A1Guaranteed uptimeDashboard fitting arrangementsInstrument arrangements/adaptationsGraphicsControl system

An operator control device for controlling systems in a motor vehicle by inputs by a user includes a touch-sensitive operator control panel on which it is possible to represent two surface shapes which may be changed into one another alternately, with the first surface shape being structured so as to be capable of being sensed in a tactile fashion so that it may be used to select zones on the operator control panel in order to select menu items. The individual selectable zones may be configured differently in shape, extent and their position on the operator control panel, and the second surface shape is smoothed in comparison with the first shape so that hand-written and graphic inputs are possible with it.

Owner:DAIMLER AG

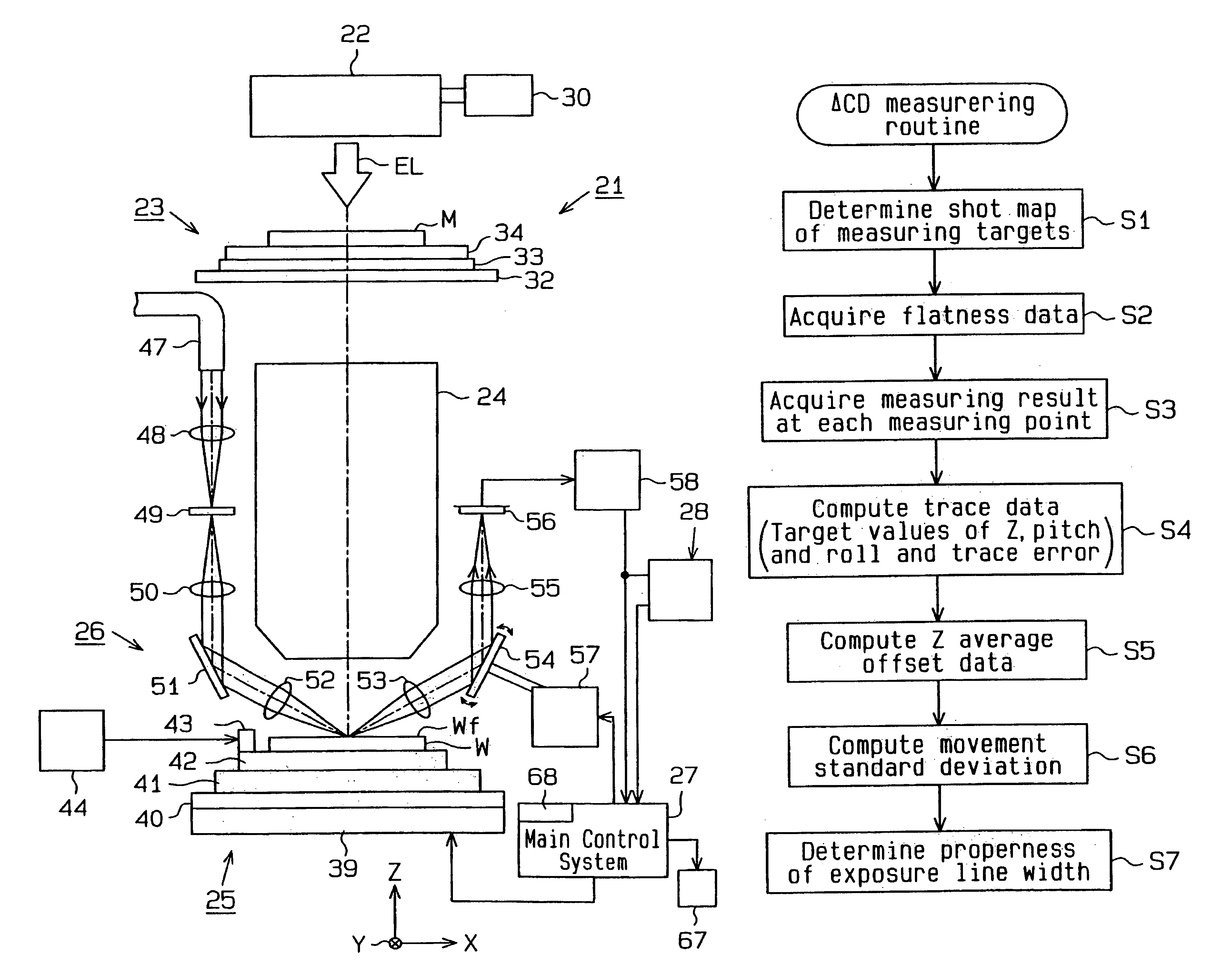

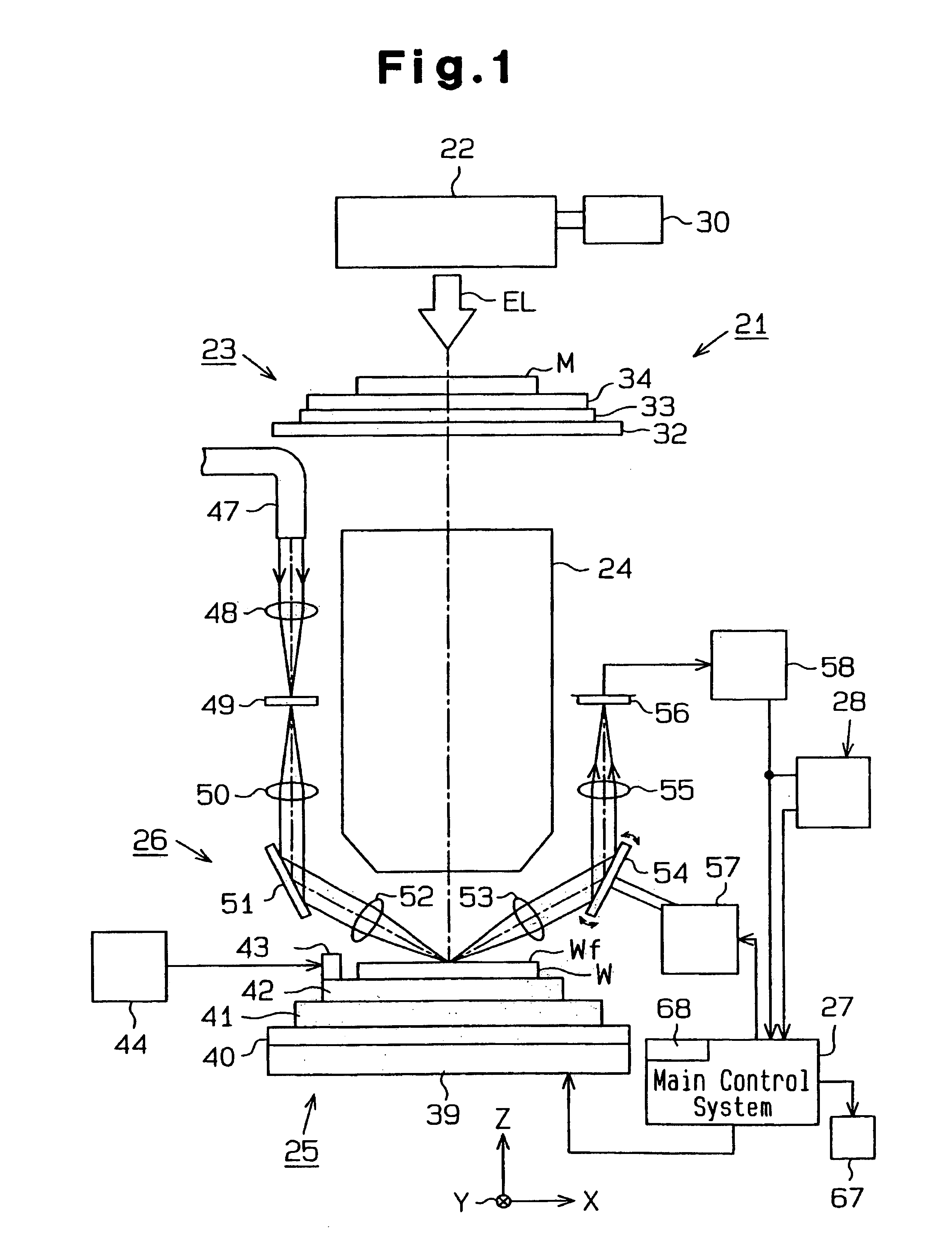

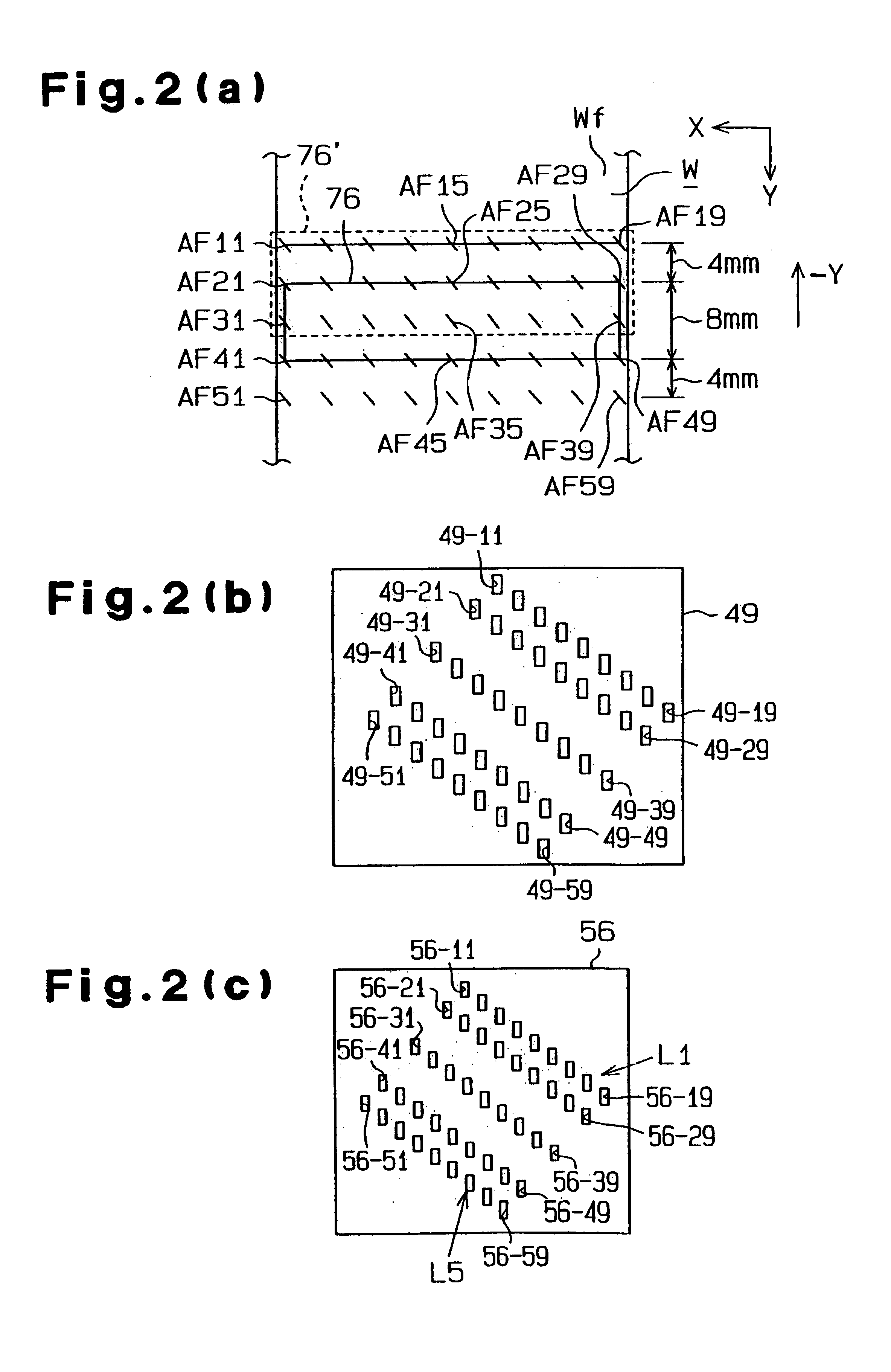

Scanning exposure apparatus

InactiveUS6992751B2Quick analysisUsing optical meansPhotomechanical exposure apparatusLine widthBiomedical engineering

A scanning exposure apparatus which promptly analyzes a cause for a variation in exposure line width. The scanning exposure apparatus includes a mask stage on which a mask is placed, a wafer stage on which a wafer is placed, a focusing mechanism which detects surface position information of the wafer and adjustment means which adjusts the surface position of the wafer. Control means acquires pose information of the wafer adjusted by the adjustment means at the time of exposure and stores the pose information in a memory in association with preacquired surface shape information of an exposure area. A state in which the exposed surface of the wafer has been exposed with respect to exposure light is known from the pose information and the surface shape information.

Owner:NIKON CORP

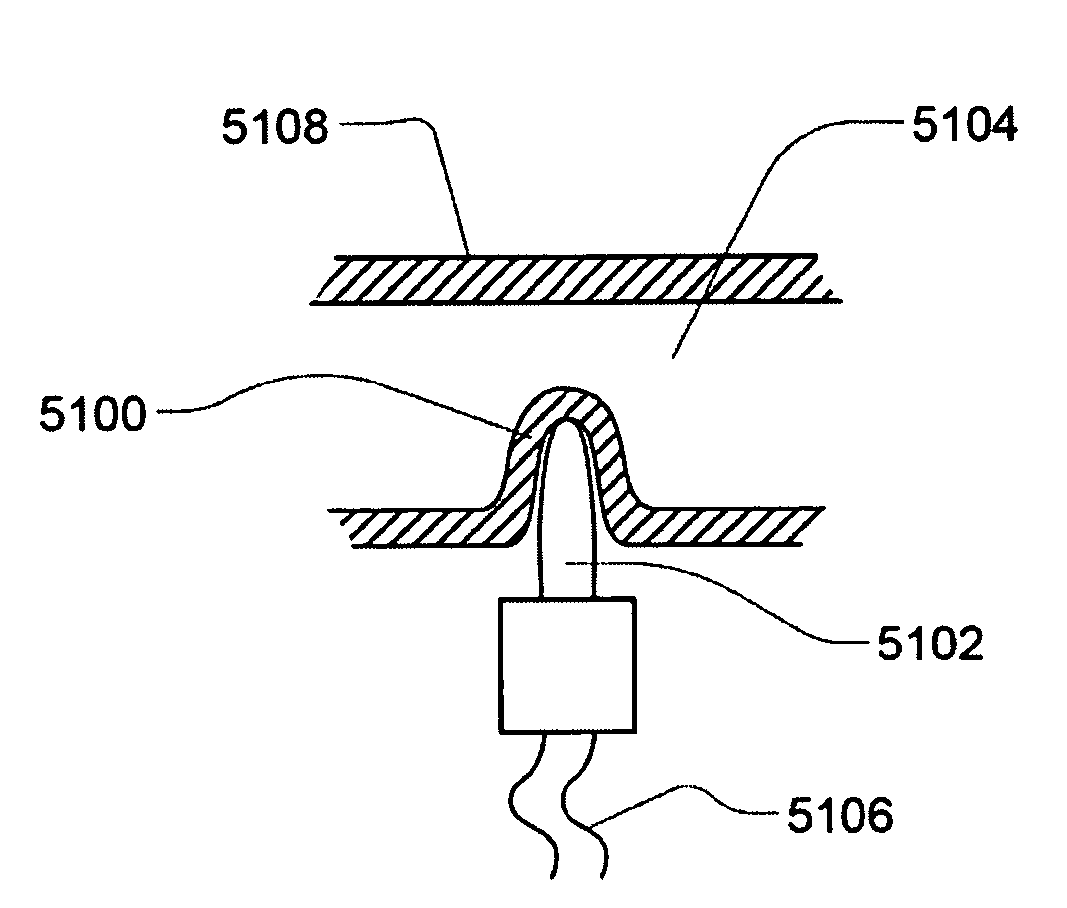

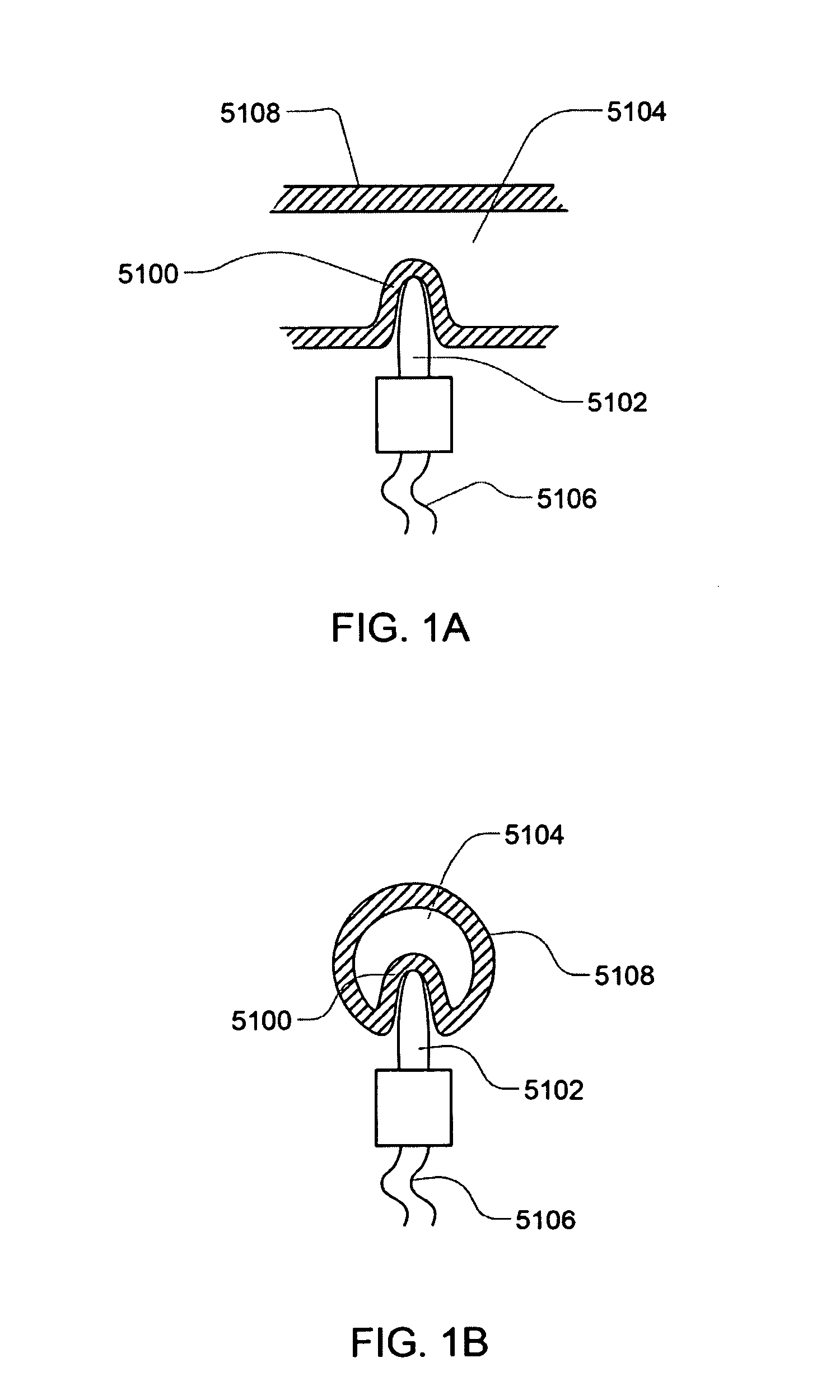

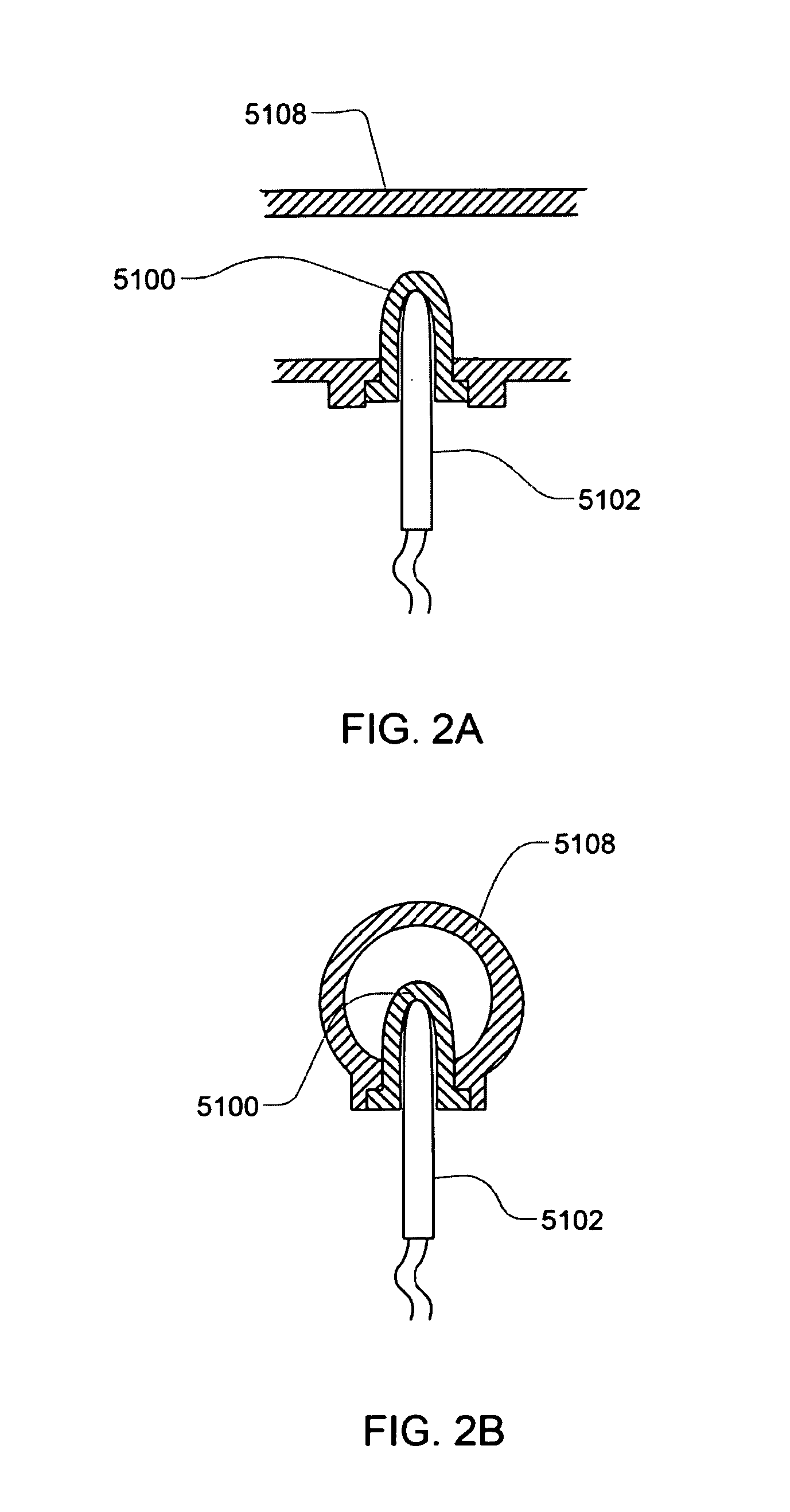

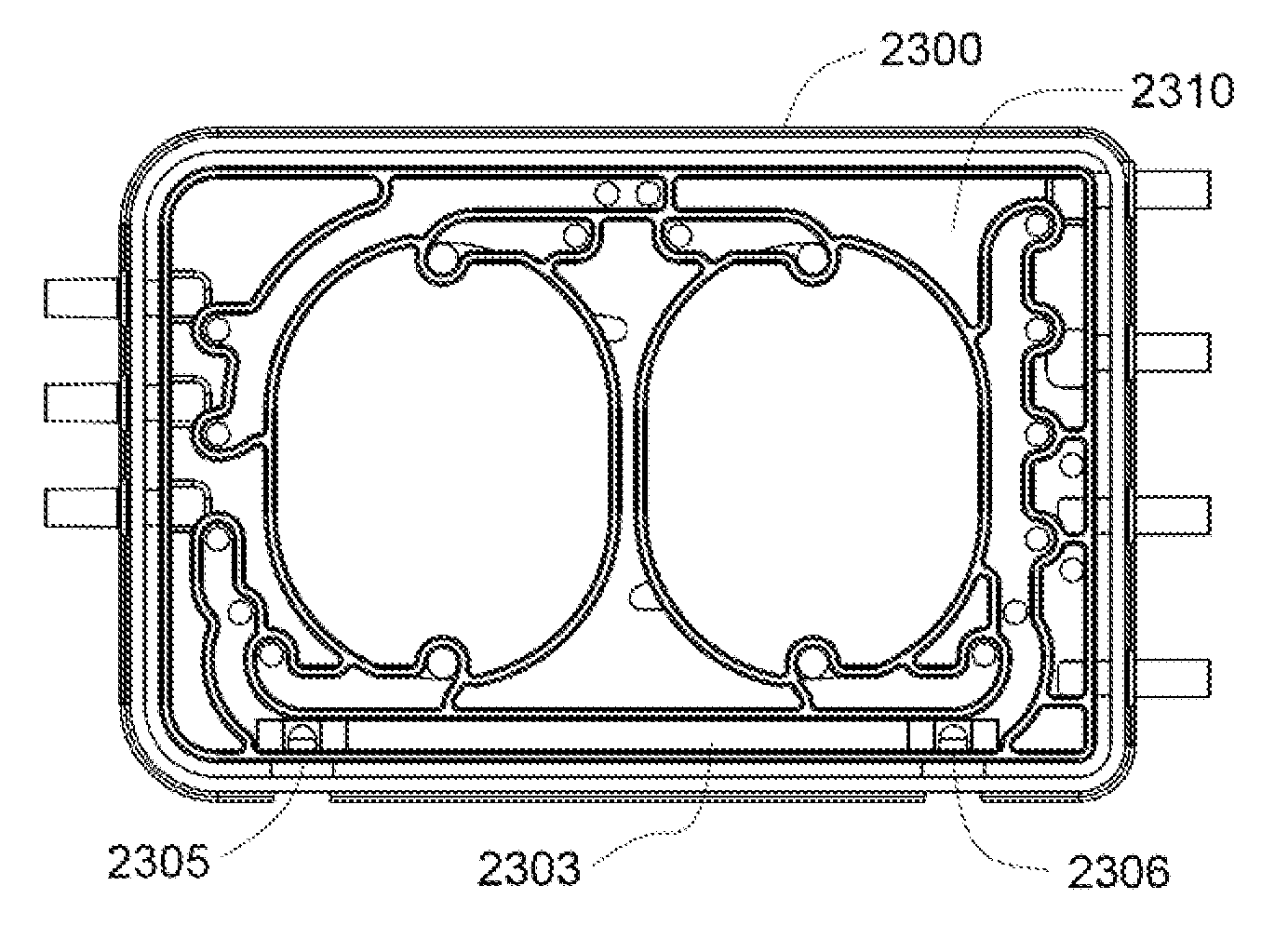

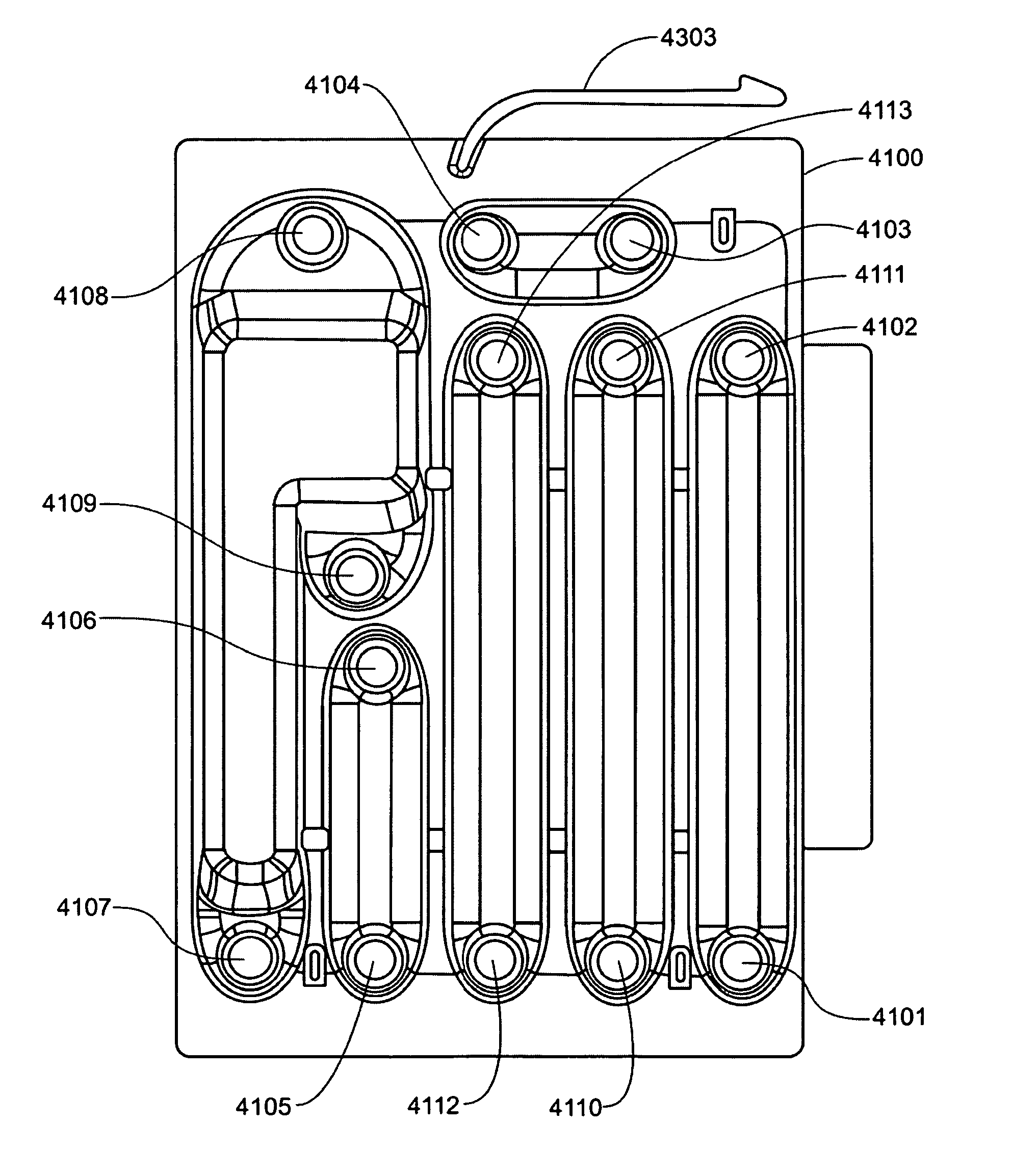

Sensor Apparatus Systems, Devices and Methods

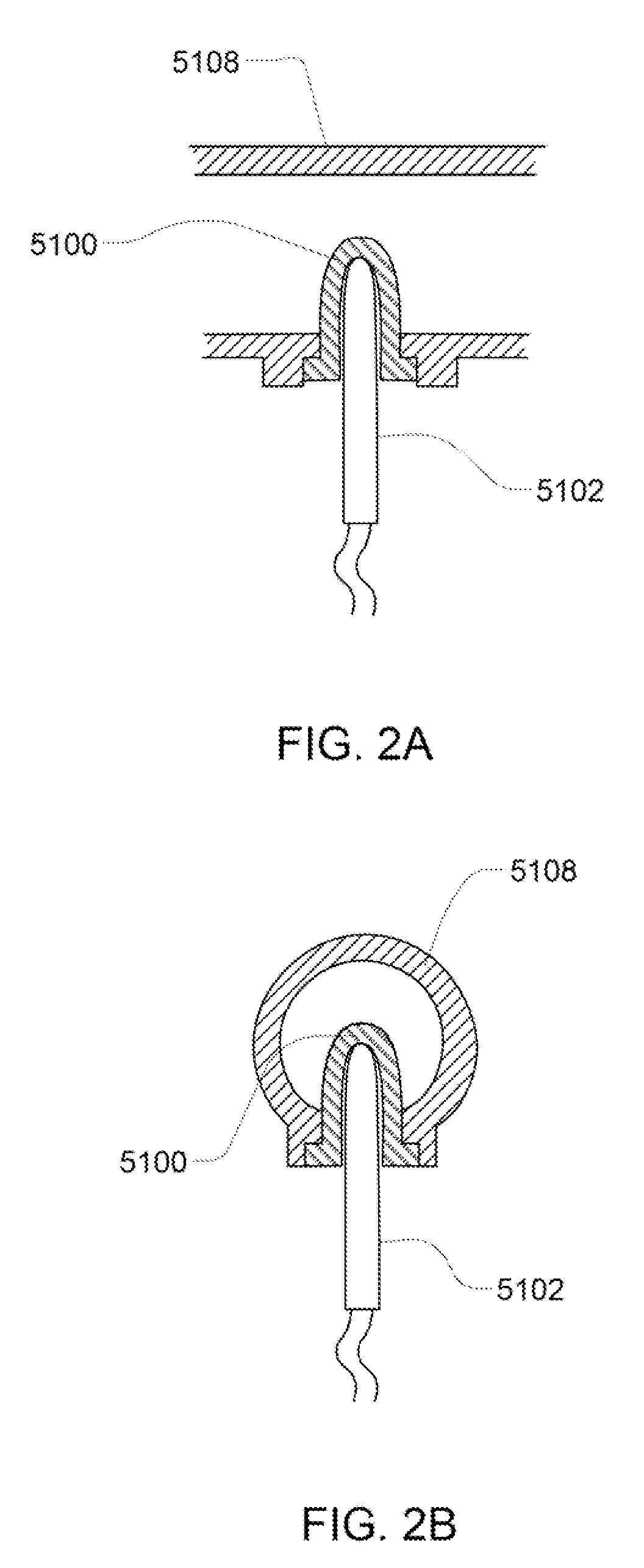

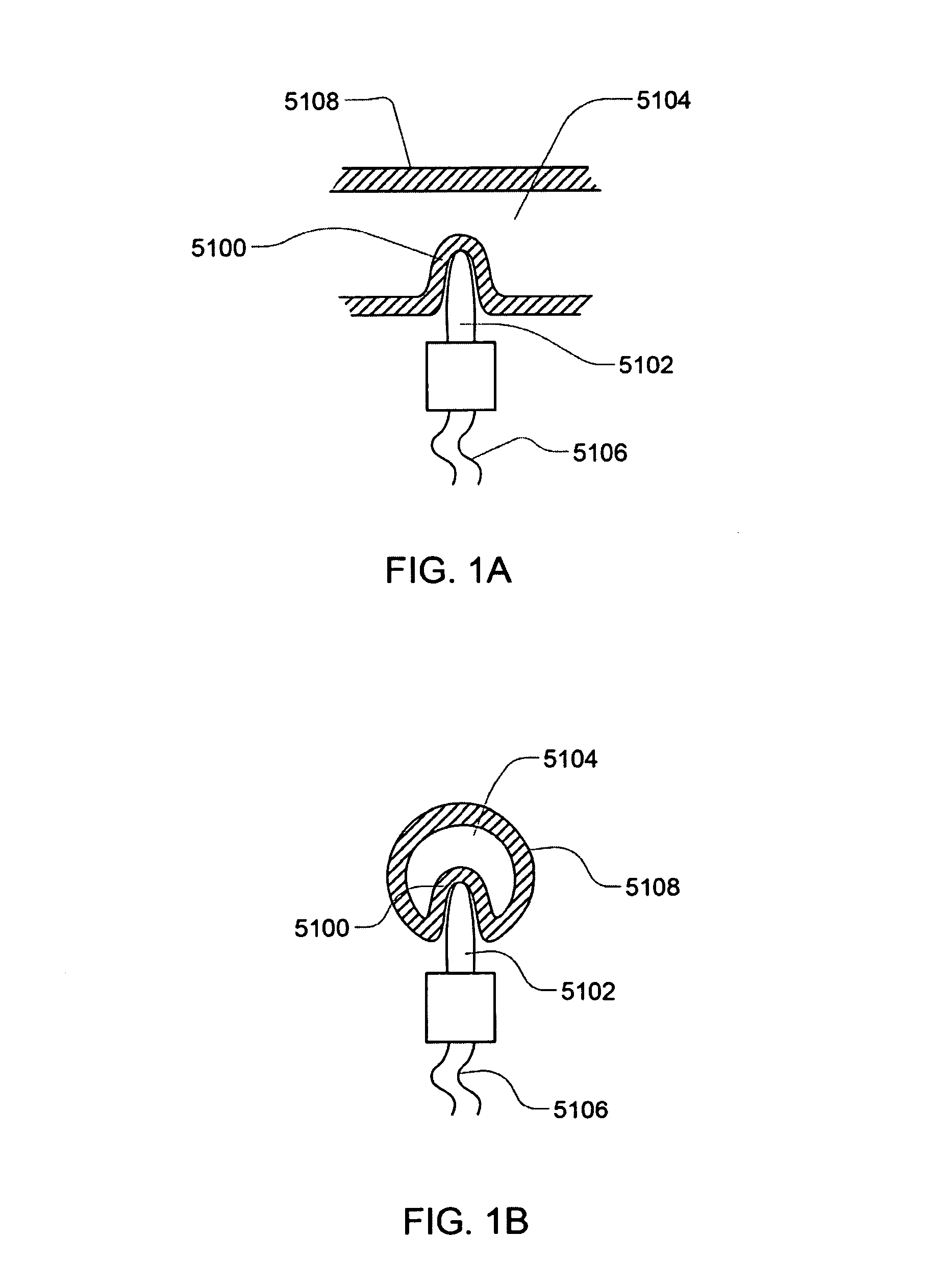

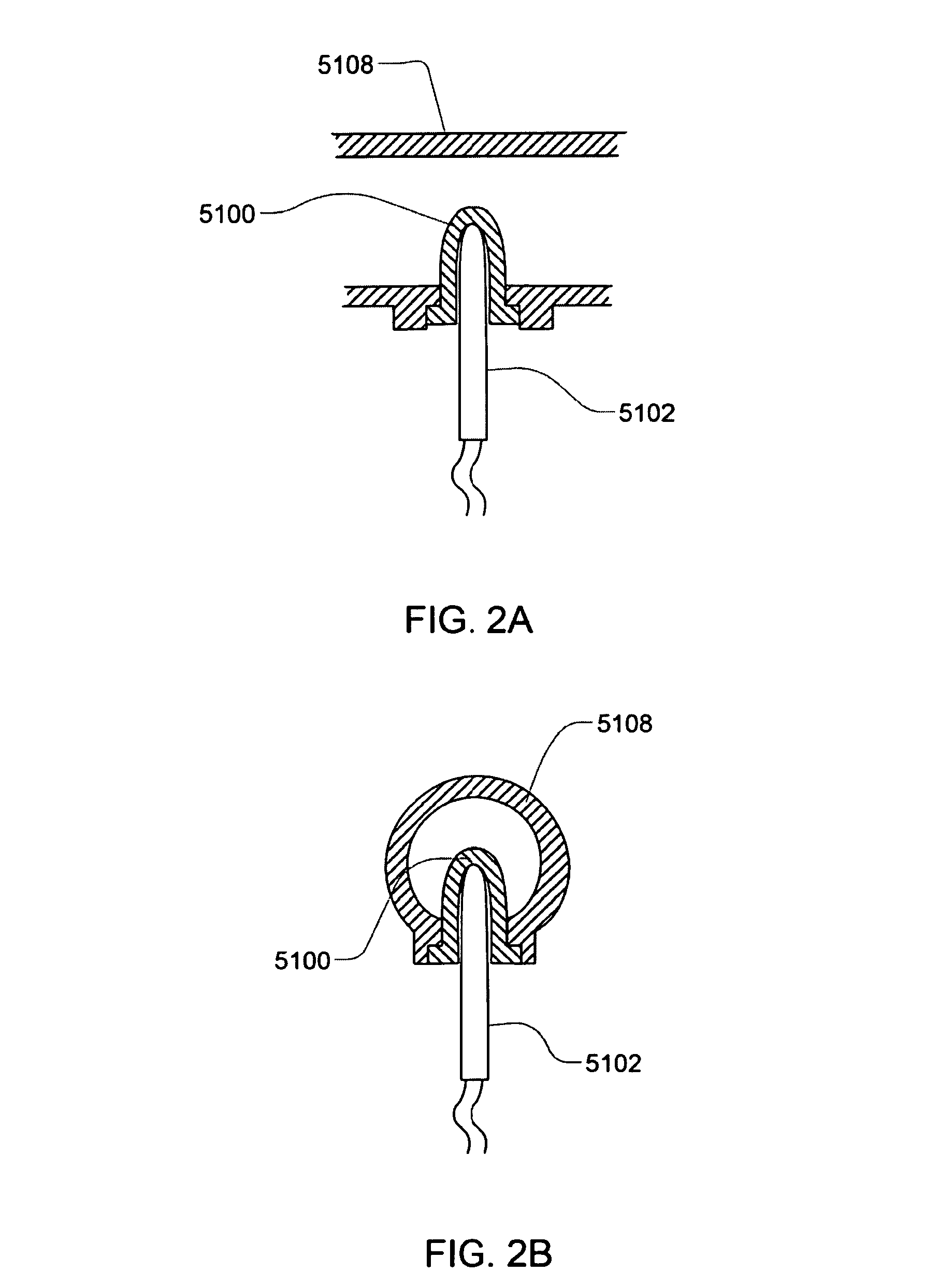

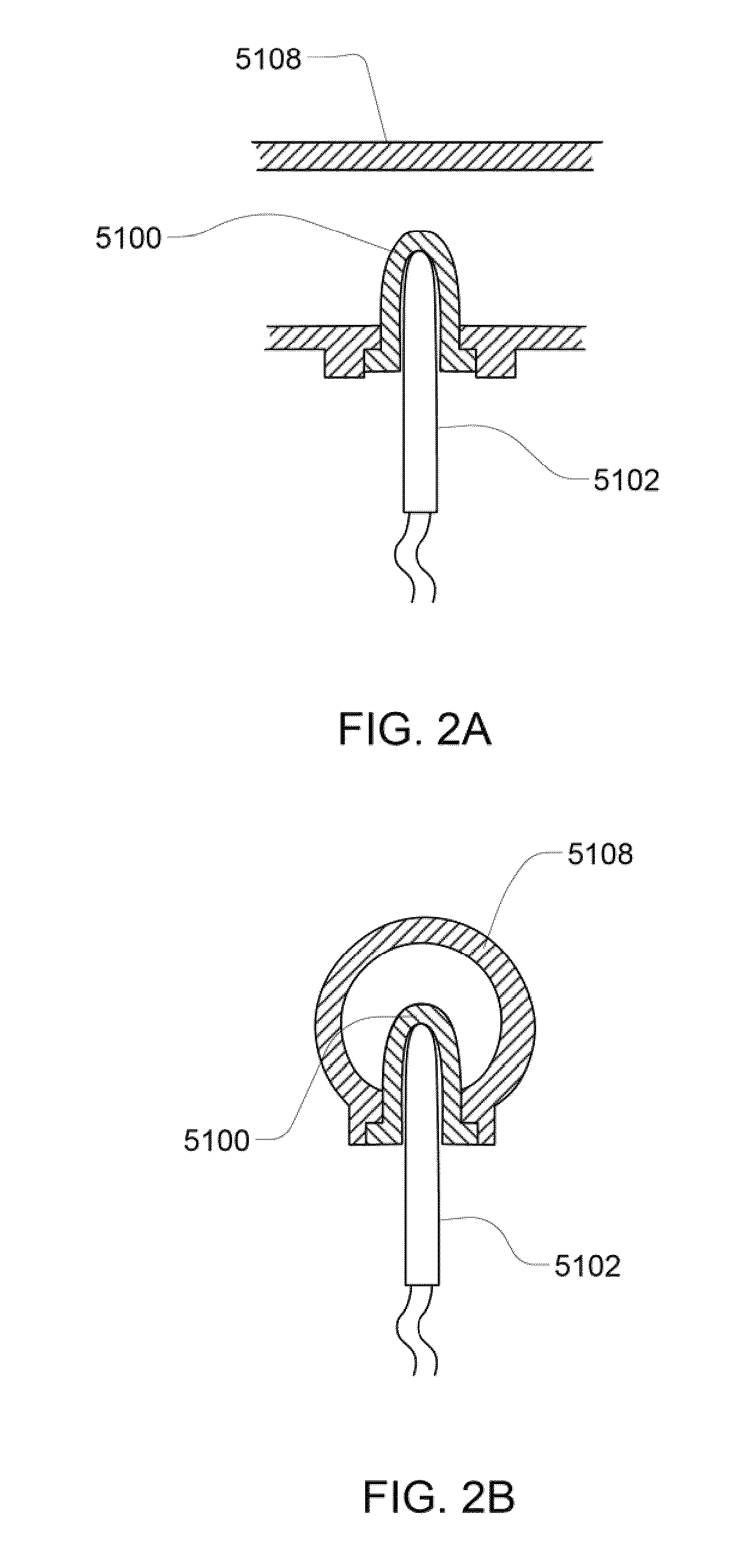

ActiveUS20080253427A1Provide flexibilitySolvent extractionFlexible member pumpsCombined useConductive materials

A sensor apparatus and sensor apparatus system for use in conjunction with a cassette, including a disposable or replaceable cassette. In some embodiments, the cassette includes a thermal well for permitting the sensing of various properties of a subject media. The thermal well includes a hollow housing of a thermally conductive material. In other embodiments, the cassette includes sensor leads for sensing of various properties of a subject media. The thermal well has an inner surface shaped so as to form a mating relationship with a sensing probe. The mating thermally couples the inner surface with a sensing probe. In some embodiments, the thermal well is located on a disposable portion and the sensing probe on a reusable portion.

Owner:DEKA PROD LLP

Implants and delivery system for treating defects in articulating surfaces

InactiveUS20060178748A1Precise positioningPrevent rotationDiagnosticsBone implantArticular surfacesTissue defect

The invention provides implant plugs having a complex clinically acceptable proximal surface. The invention also provides multi-phase implant plugs which have a nonplanar proximal surface. Suitable implant proximal surface shapes include, but are not limited to, concave surfaces, convex surfaces, faceted domes and angled surfaces formed by the convergence of two facets. The implants of the invention are suitable for repair of tissue defects in articulating surfaces. The invention also provides delivery devices and methods for delivering the implants of the invention. The invention also provides methods for creating defects suitable for use with the implants of the invention.

Owner:OSTEOBIOLOGICS

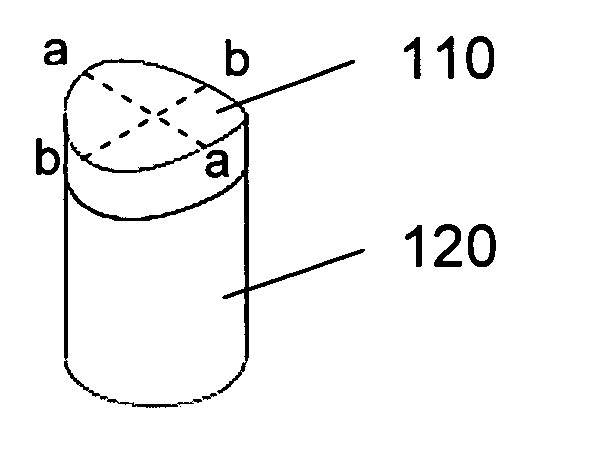

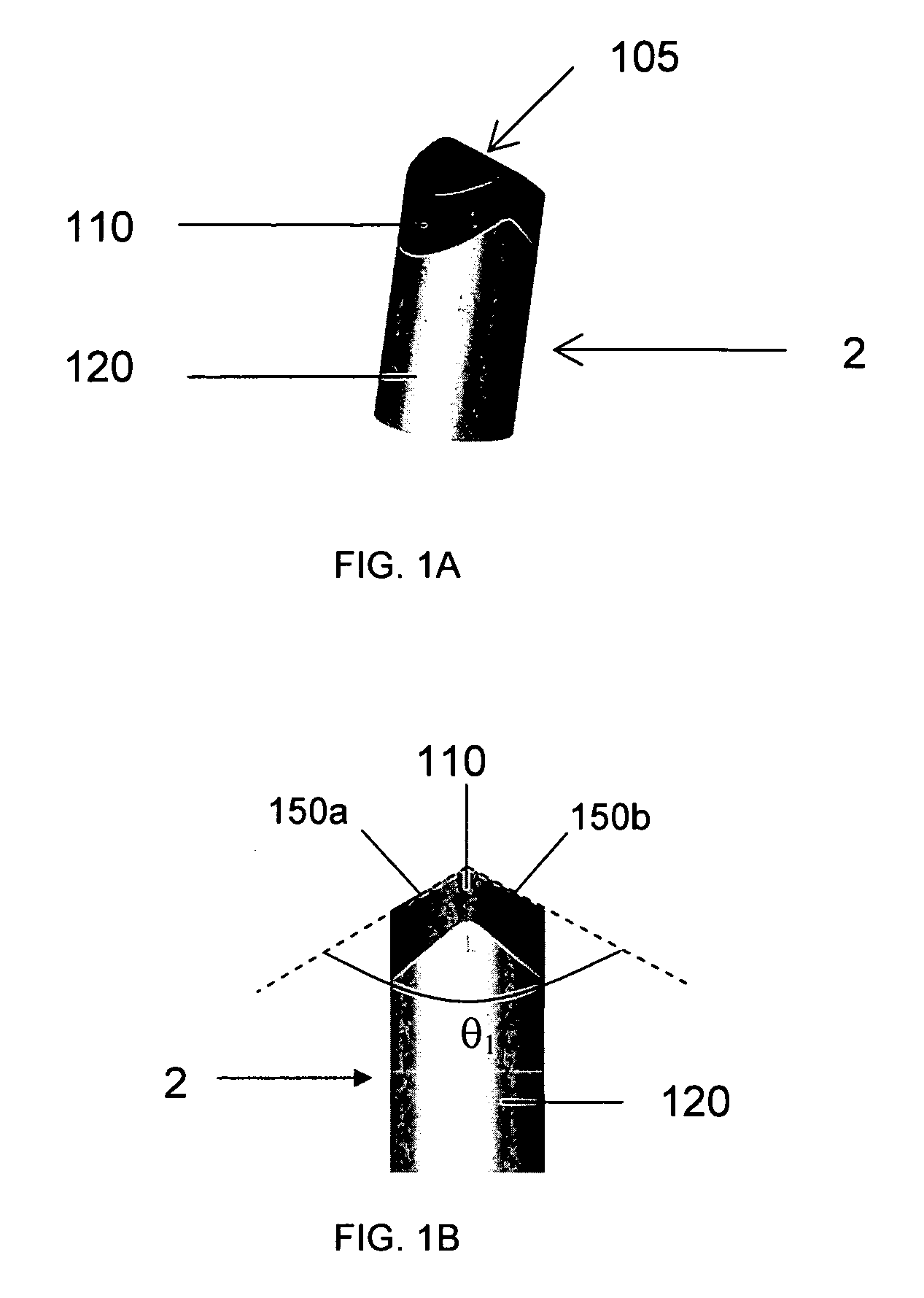

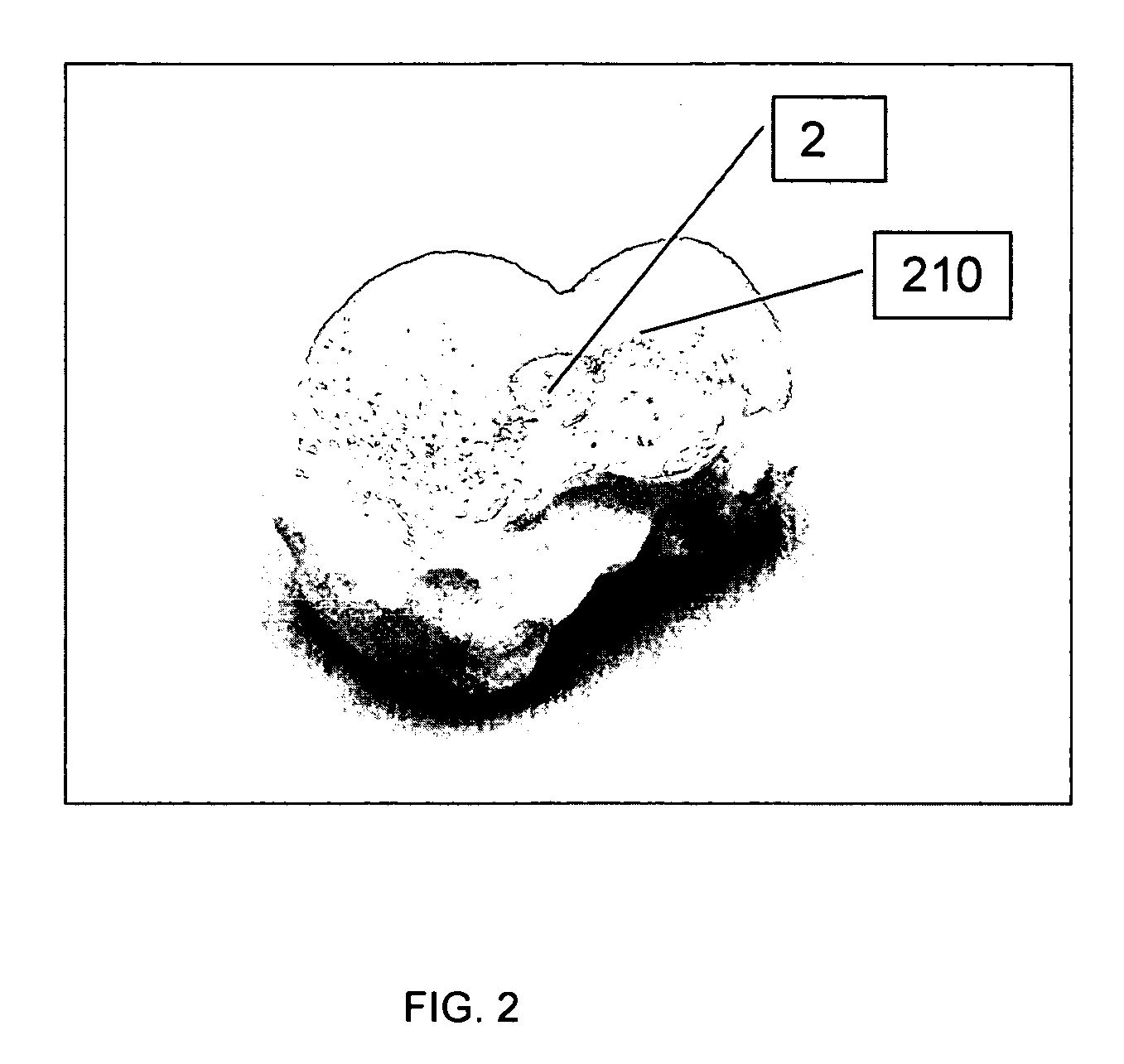

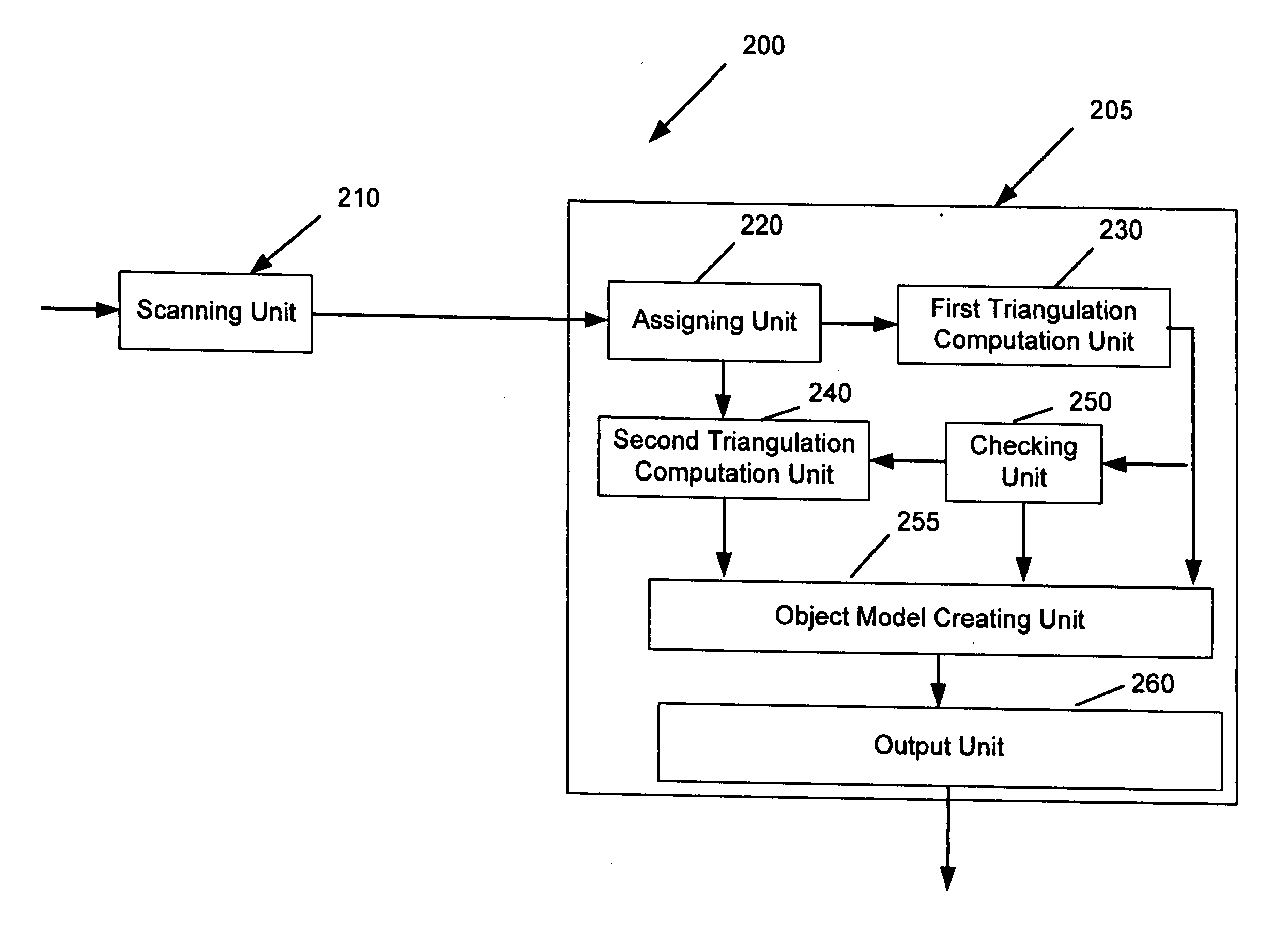

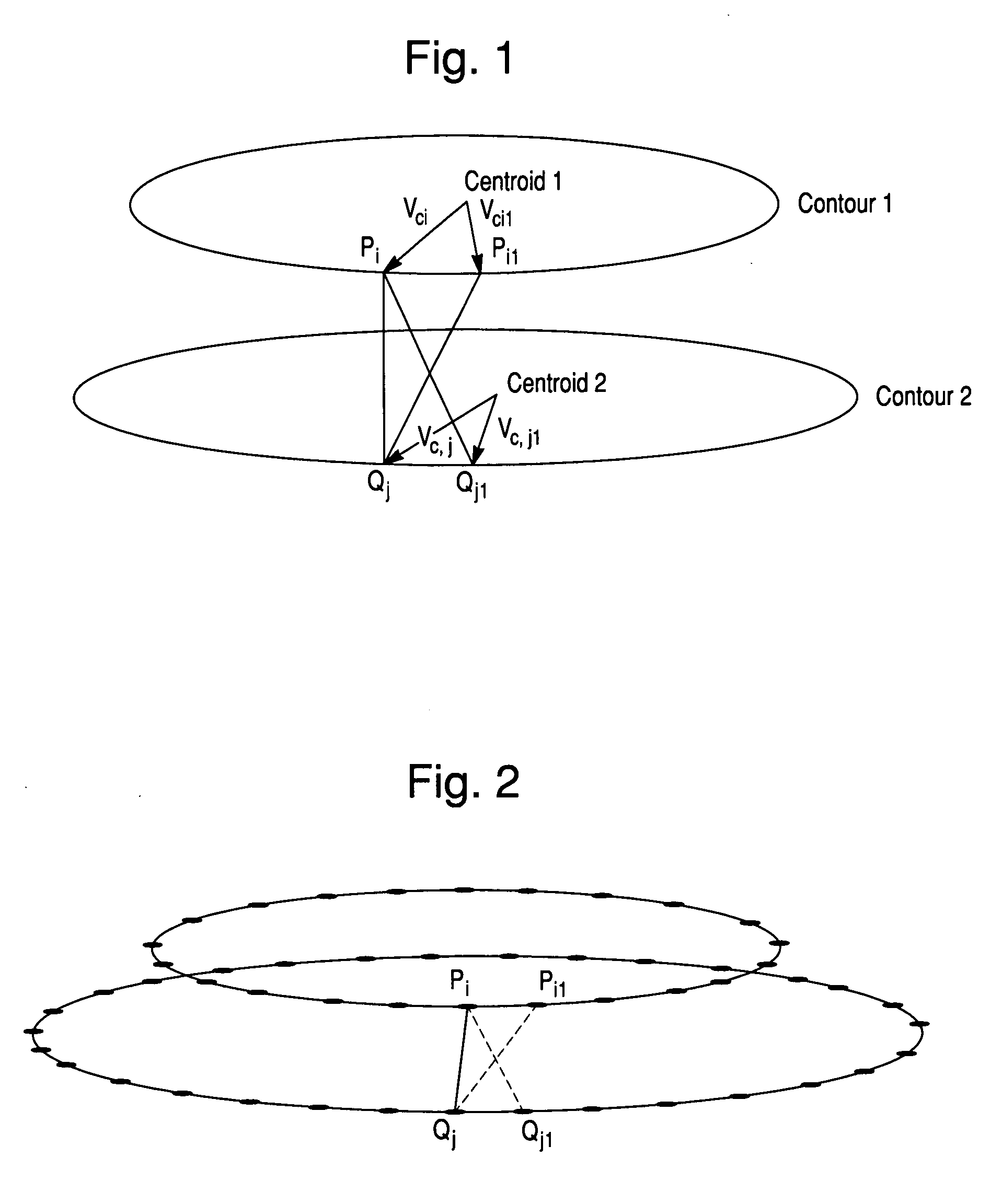

Contour triangulation system and method

ActiveUS20070253617A1Investigating moving sheetsCharacter and pattern recognitionTriangulationComputer vision

A method and apparatus for reconstructing a surface shape of an object having contour lines, includes assigning points to each contour line. A first triangulation scheme is performed with respect to respective points on two adjacently-positioned contour lines, to determine a first surface shape for a portion of the object corresponding to the two contour lines. The first surface shape is checked to determine if the first surface shape is in error. If the first surface shape is not in error, the first surface shape is outputted for the portion of the object as determined by the first triangulation scheme, as a reconstructed surface shape for that portion of the object. If the first surface shape is in error, a second triangulation scheme is performed with respect to the respective points on the two contour lines, to determine a second surface shape for that portion of the object, and the second surface shape is outputted for that portion of the object as determined by the second triangulation scheme, as a reconstructed surface shape.

Owner:MAKO SURGICAL CORP

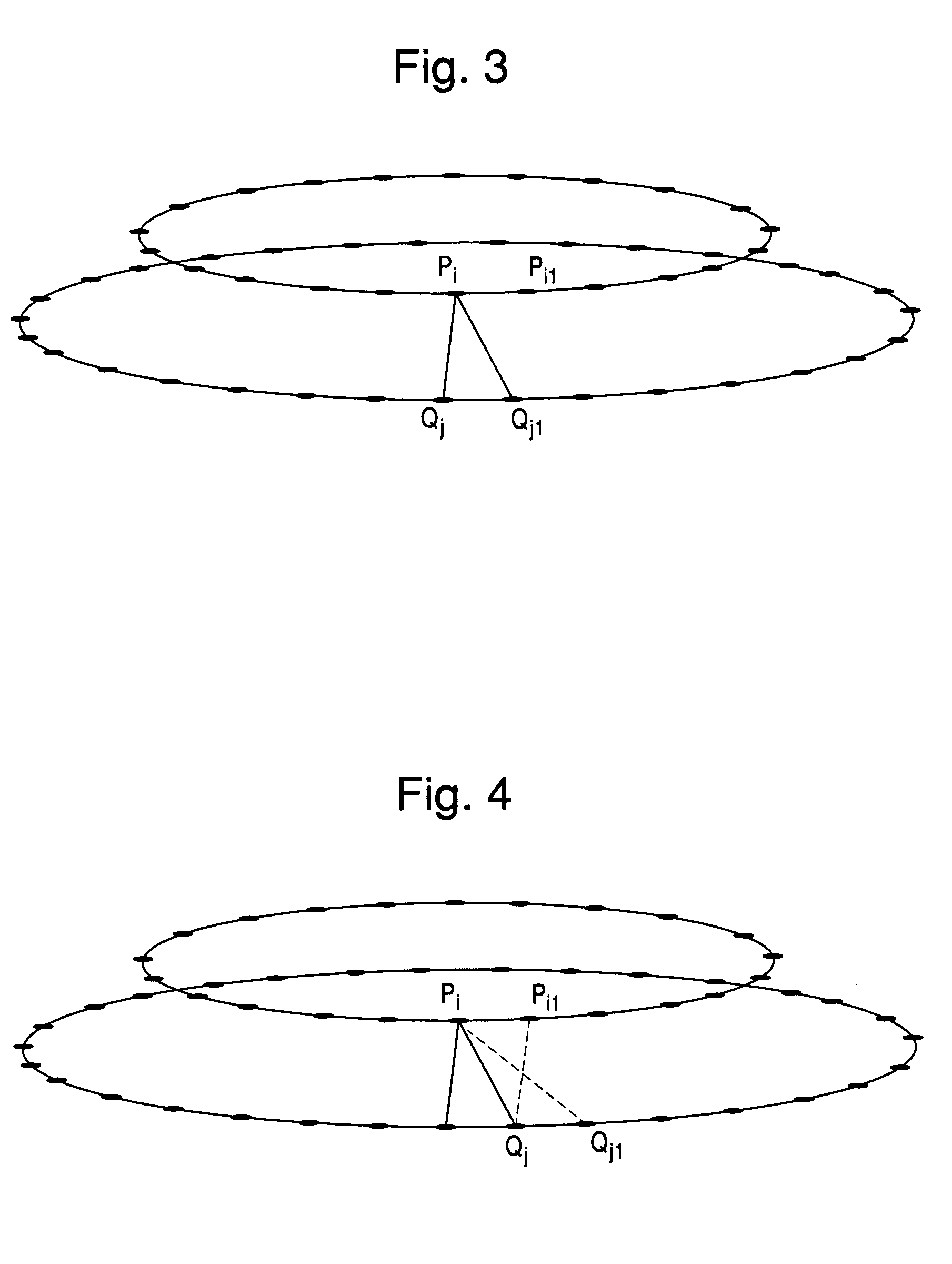

Pumping Cassette

InactiveUS20080240929A1Fluid parameterPositive displacement pump componentsCombined useConductive materials

A sensor apparatus and sensor apparatus system for use in conjunction with a cassette, including a disposable or replaceable cassette. In some embodiments, the cassette includes a thermal well for permitting the sensing of various properties of a subject media. The thermal well includes a hollow housing of a thermally conductive material. In other embodiments, the cassette includes sensor leads for sensing of various properties of a subject media. The thermal well has an inner surface shaped so as to form a mating relationship with a sensing probe. The mating thermally couples the inner surface with a sensing probe. In some embodiments, the thermal well is located on a disposable portion and the sensing probe on a reusable portion.

Owner:DEKA PROD LLP

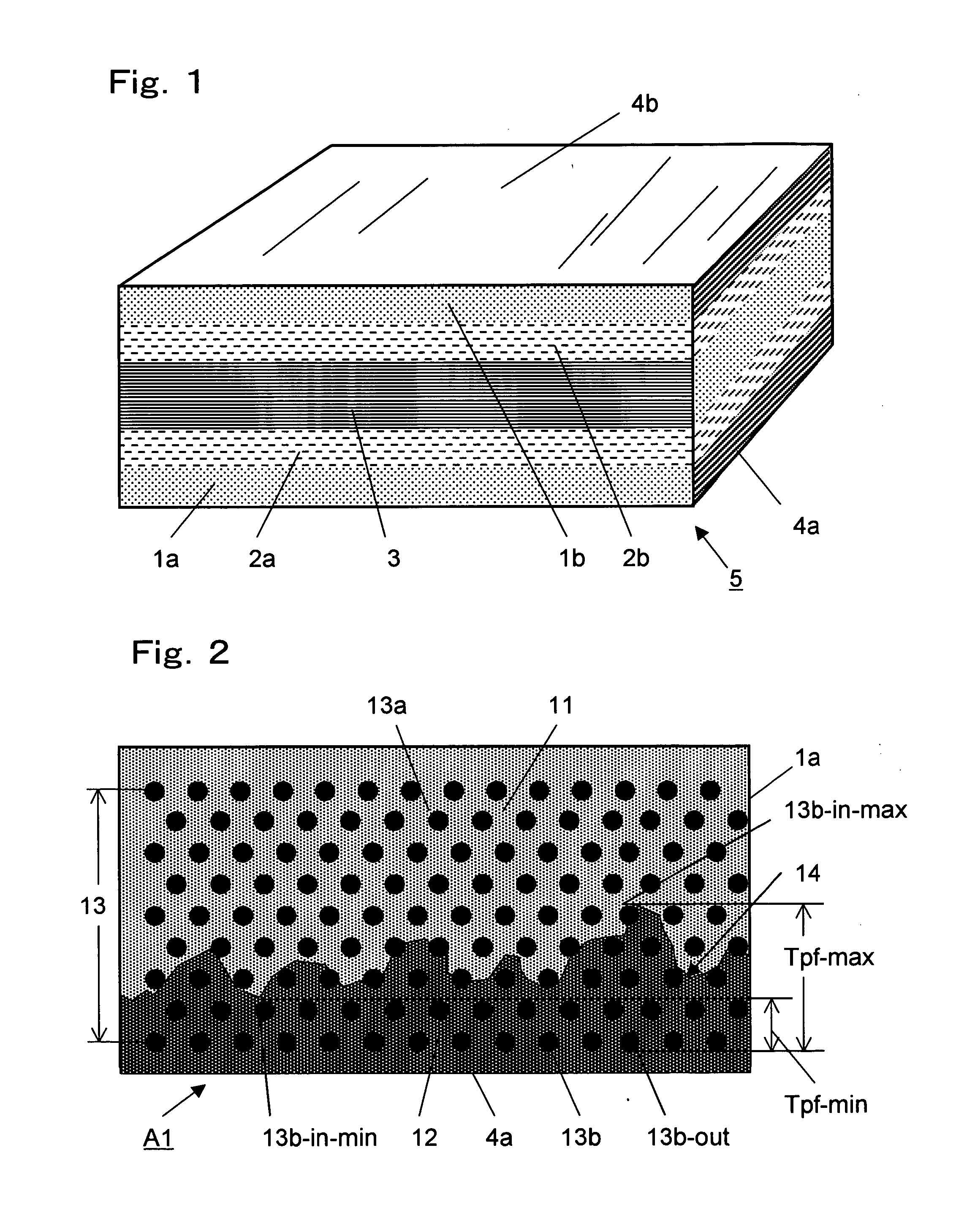

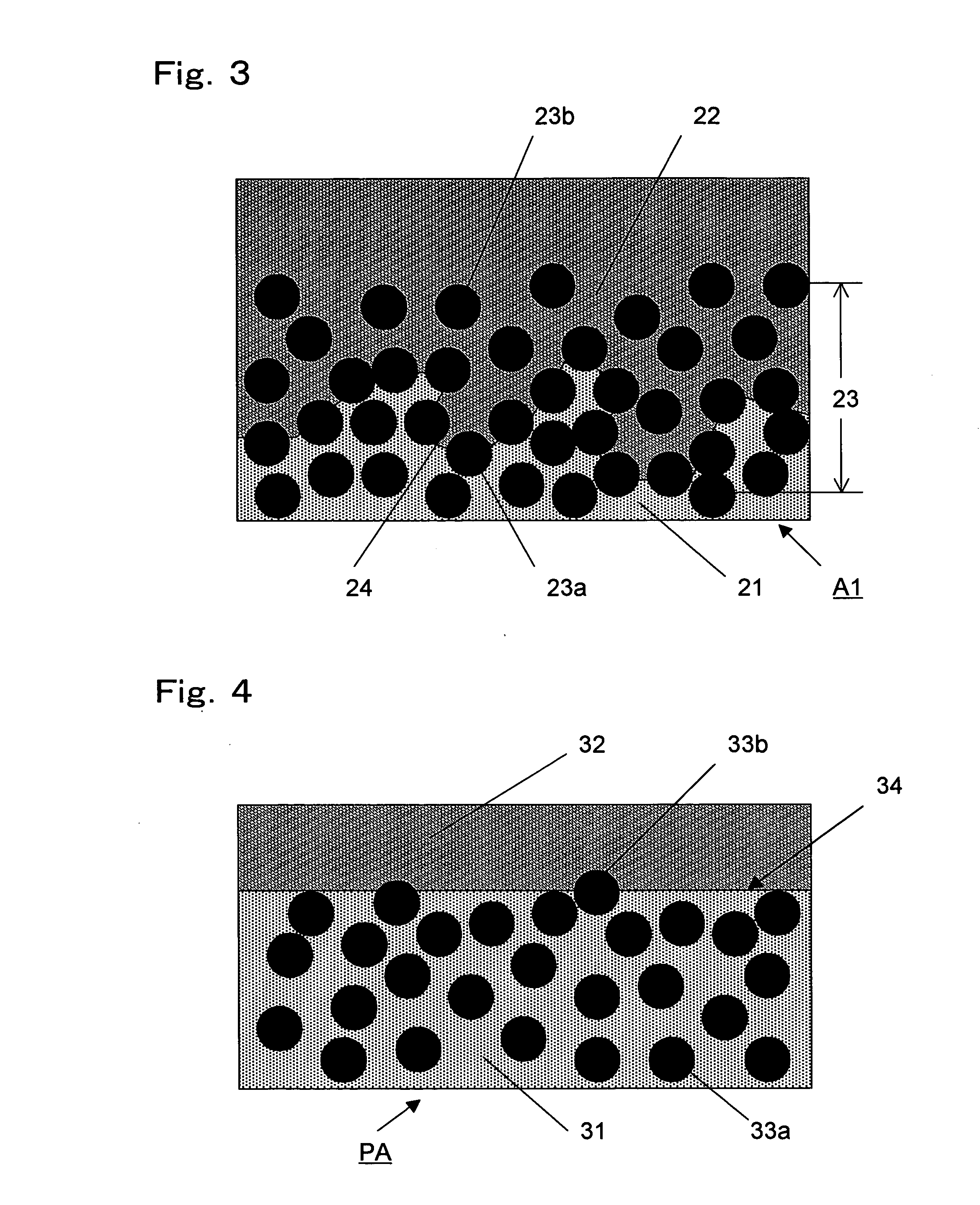

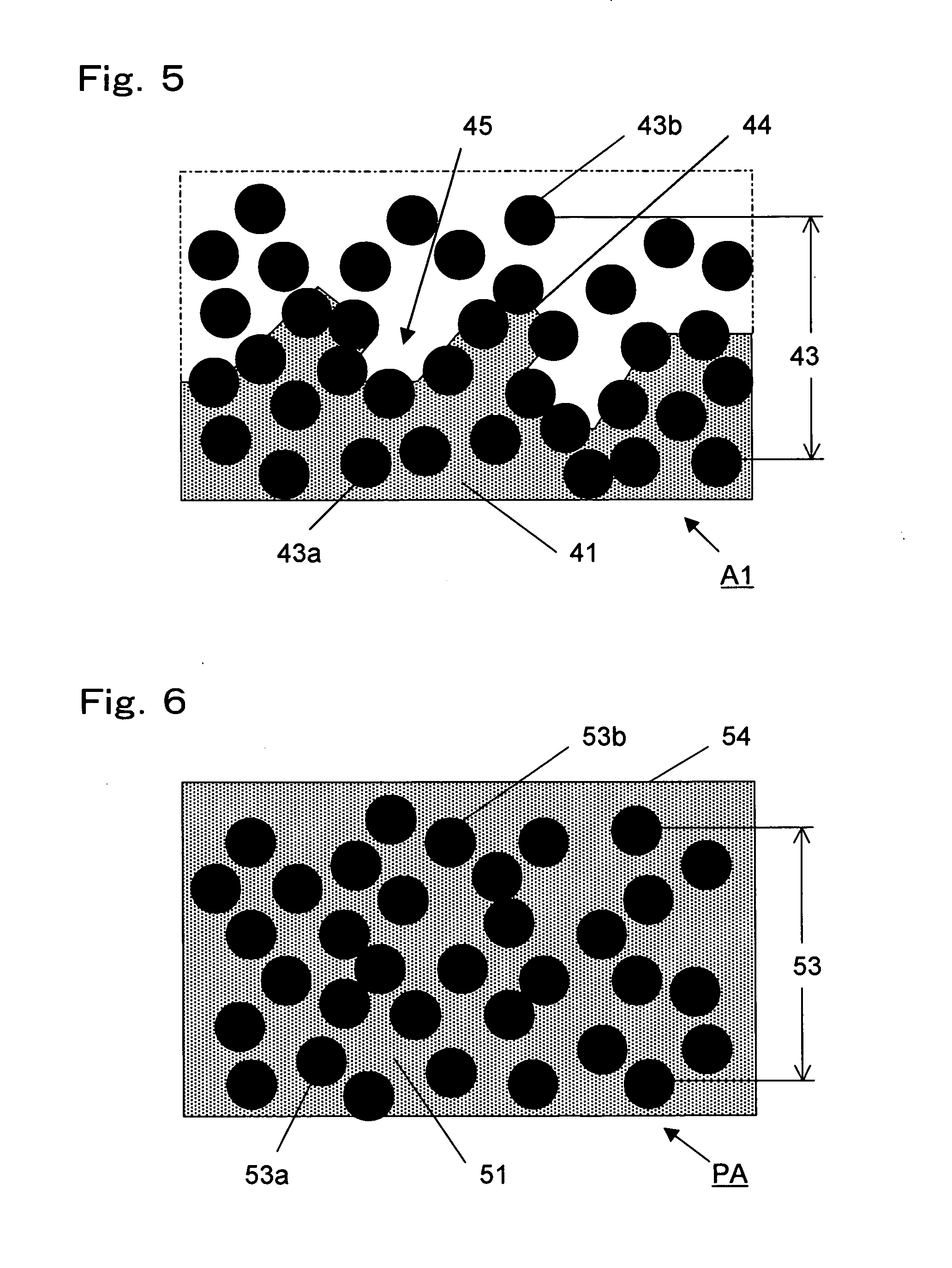

Layered product, electromagnetic-shielding molded object, and processes for producing these

ActiveUS20060110599A1Reduce thicknessReduce weightShielding materialsSynthetic resin layered productsFiberElectromagnetic shielding

A layered product which is a molded object comprising a thermoset resin layer, a thermoplastic resin layer, and reinforcing fibers comprising many continuous filaments, wherein the thremoset resin layer has been united with the thermoplastic resin layer at the interface between these layers, the resin of the thermoset resin layer and the resin of the thermoplastic resin layer each having an irregular surface shape at the interface, and a group of filaments among the reinforcing fibers are in contact with at least the resin of the thermoset resin layer and the other group of filaments among the reinforcing fibers are in contact with at least the resin of the thermoplastic resin layer, that side of the thermoplastic resin layer which is opposite to the interface being a surface of the molded object.

Owner:TORAY IND INC

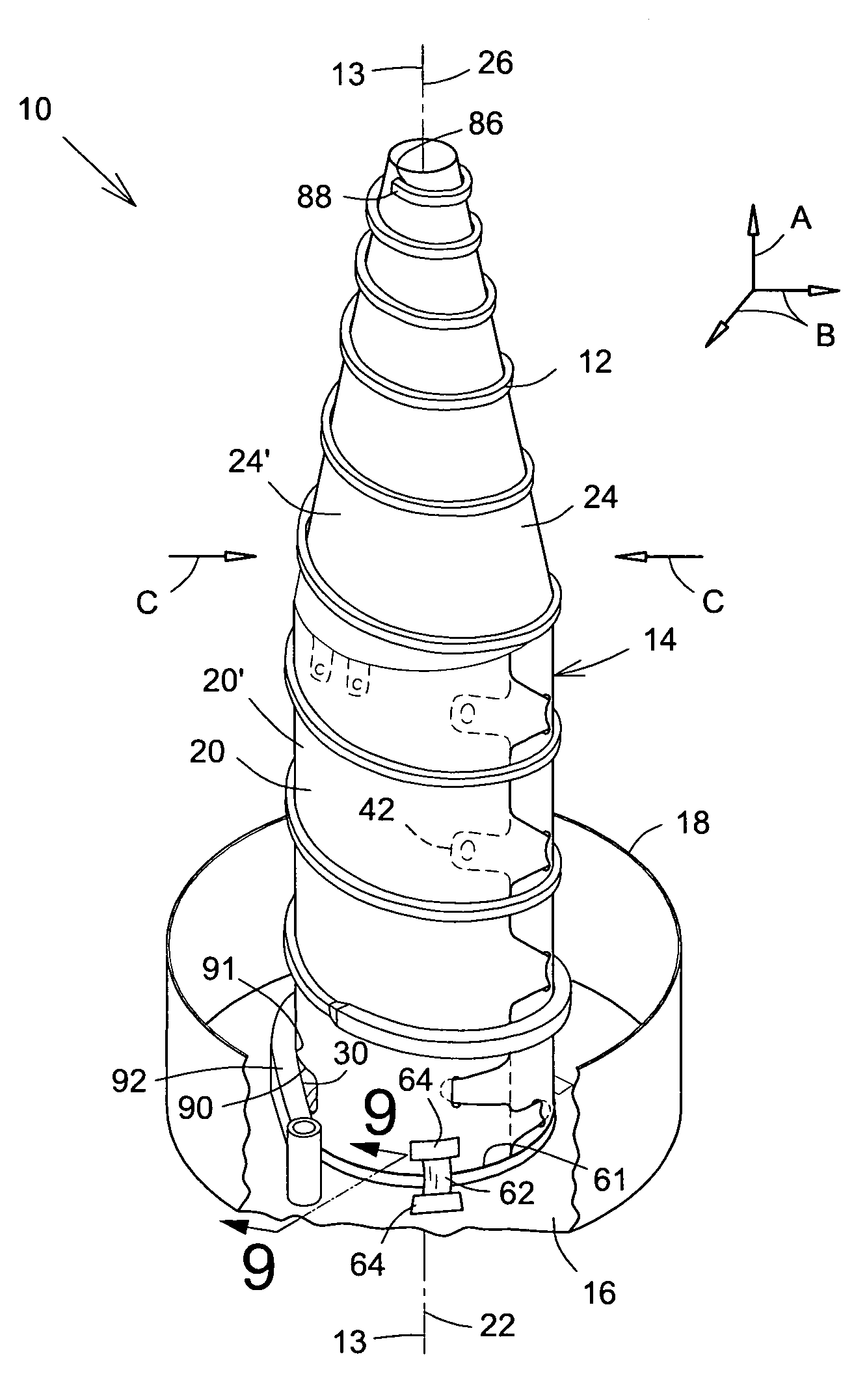

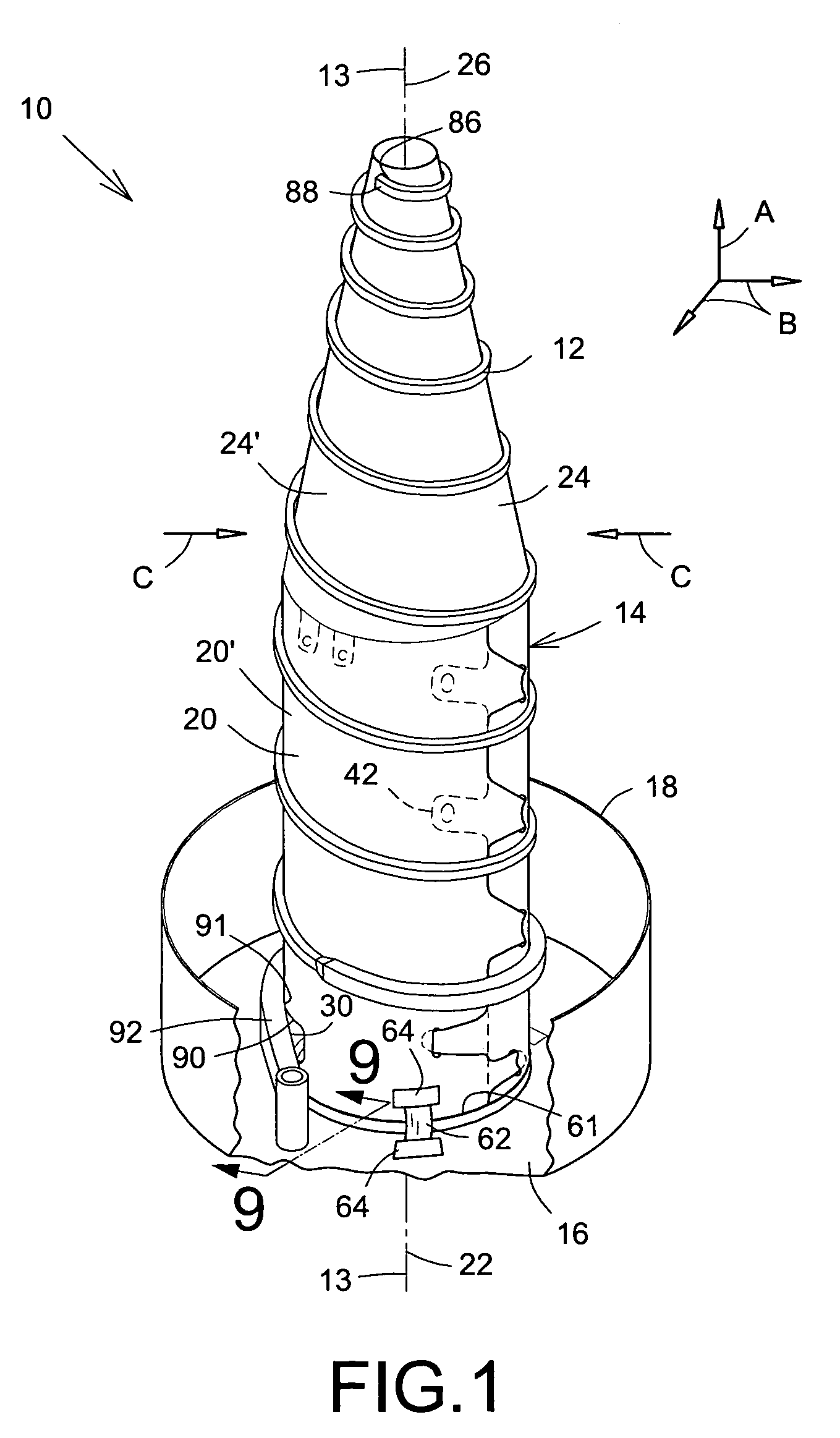

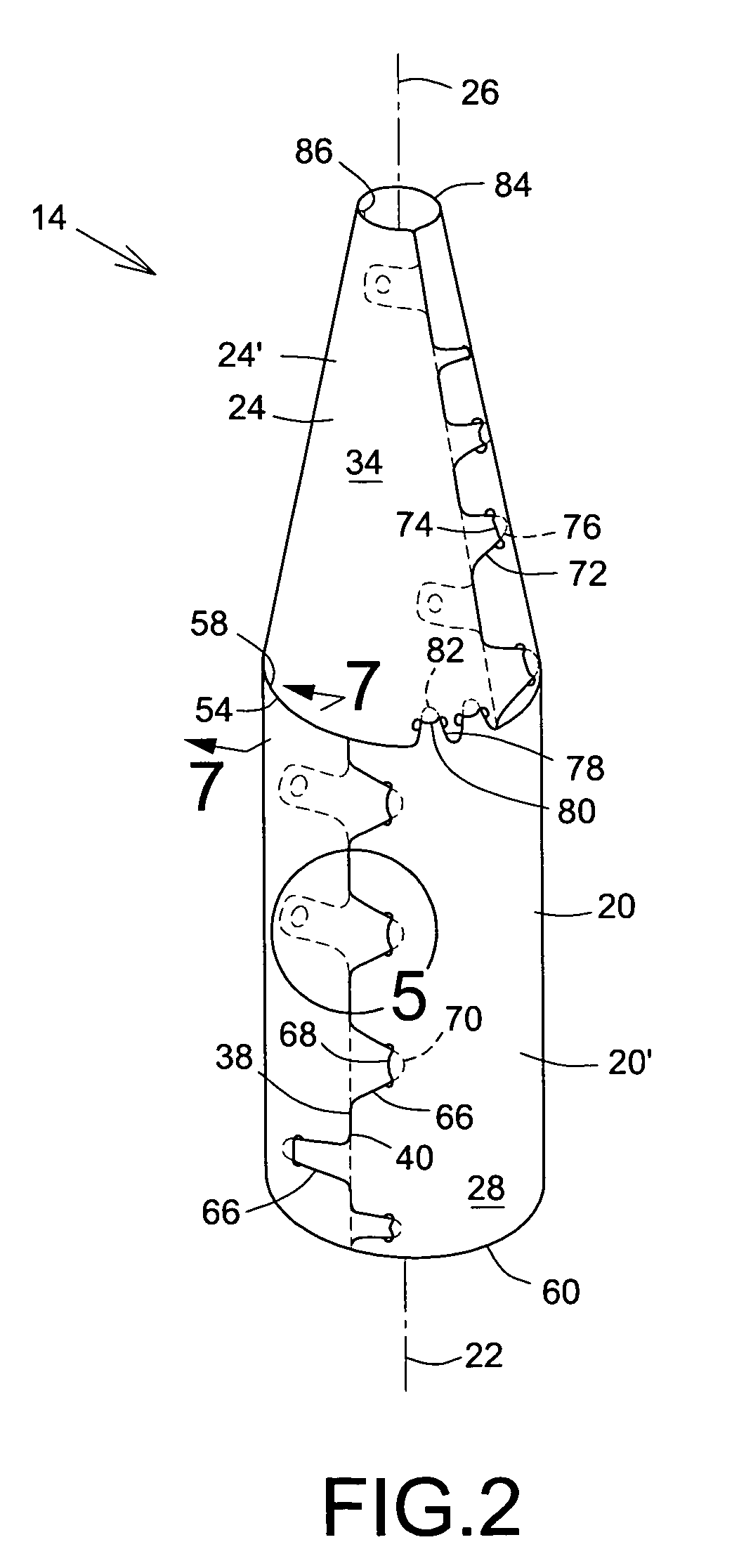

Helical antenna

ActiveUS7038636B2Light weightReduces dielectric lossLogperiodic antennasAntenna supports/mountingsLocking mechanismEngineering

A helical antenna has a helix supported by a helix support. The helix support includes at least one piece of flexible sheet having its two surfaces covered with a layer antistatic material. The flexible sheet is curlable into a revolution surface configuration to form a revolution surface-shaped support section for at least partially supporting a portion of the helix component there around. A grounding mechanism electrically grounds the external sheet surface to the helix and the two sheet surfaces to one another when in the revolution surface configuration while a locking mechanism locks the flexible sheet in the revolution surface configuration. The combination of the helix and the flexible support renders the antenna structurally relatively rigid in all directions.

Owner:MACDONALD DETTWILER & ASSOC CORP

Sensor apparatus systems, devices and methods

A sensor apparatus and sensor apparatus system for use in conjunction with a cassette, including a disposable or replaceable cassette. In some embodiments, the cassette includes a thermal well for permitting the sensing of various properties of a subject media. The thermal well includes a hollow housing of a thermally conductive material. In other embodiments, the cassette includes sensor leads for sensing of various properties of a subject media. The thermal well has an inner surface shaped so as to form a mating relationship with a sensing probe. The mating thermally couples the inner surface with a sensing probe. In some embodiments, the thermal well is located on a disposable portion and the sensing probe on a reusable portion.

Owner:DEKA PROD LLP

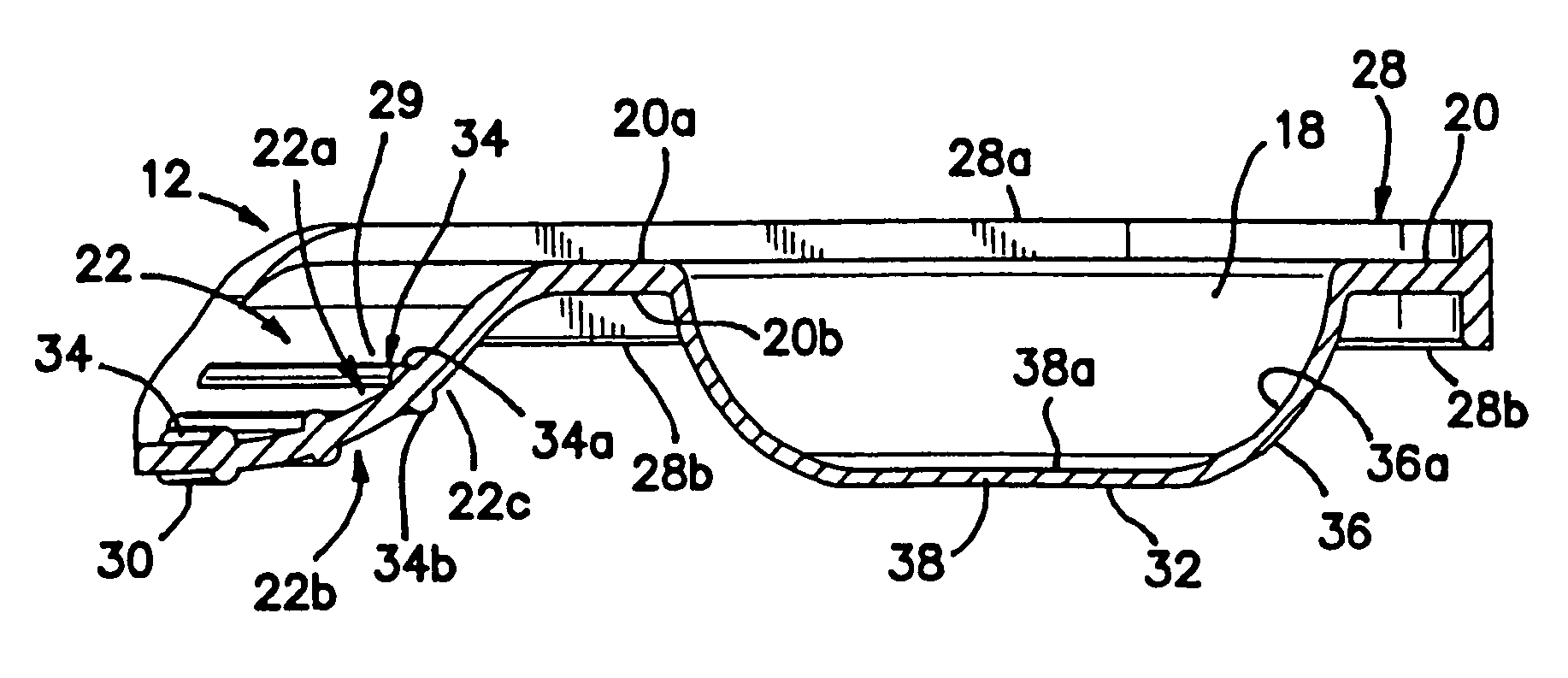

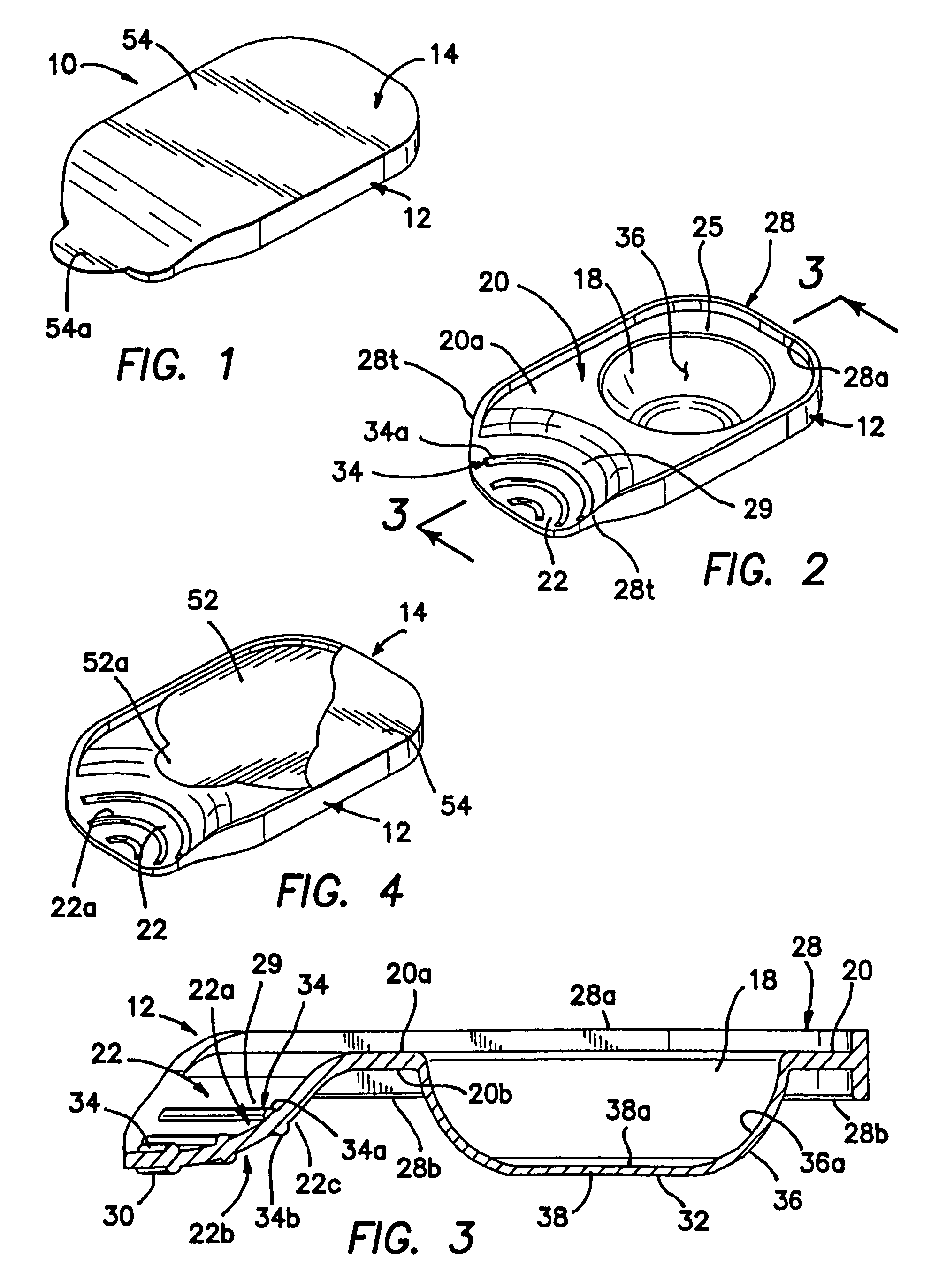

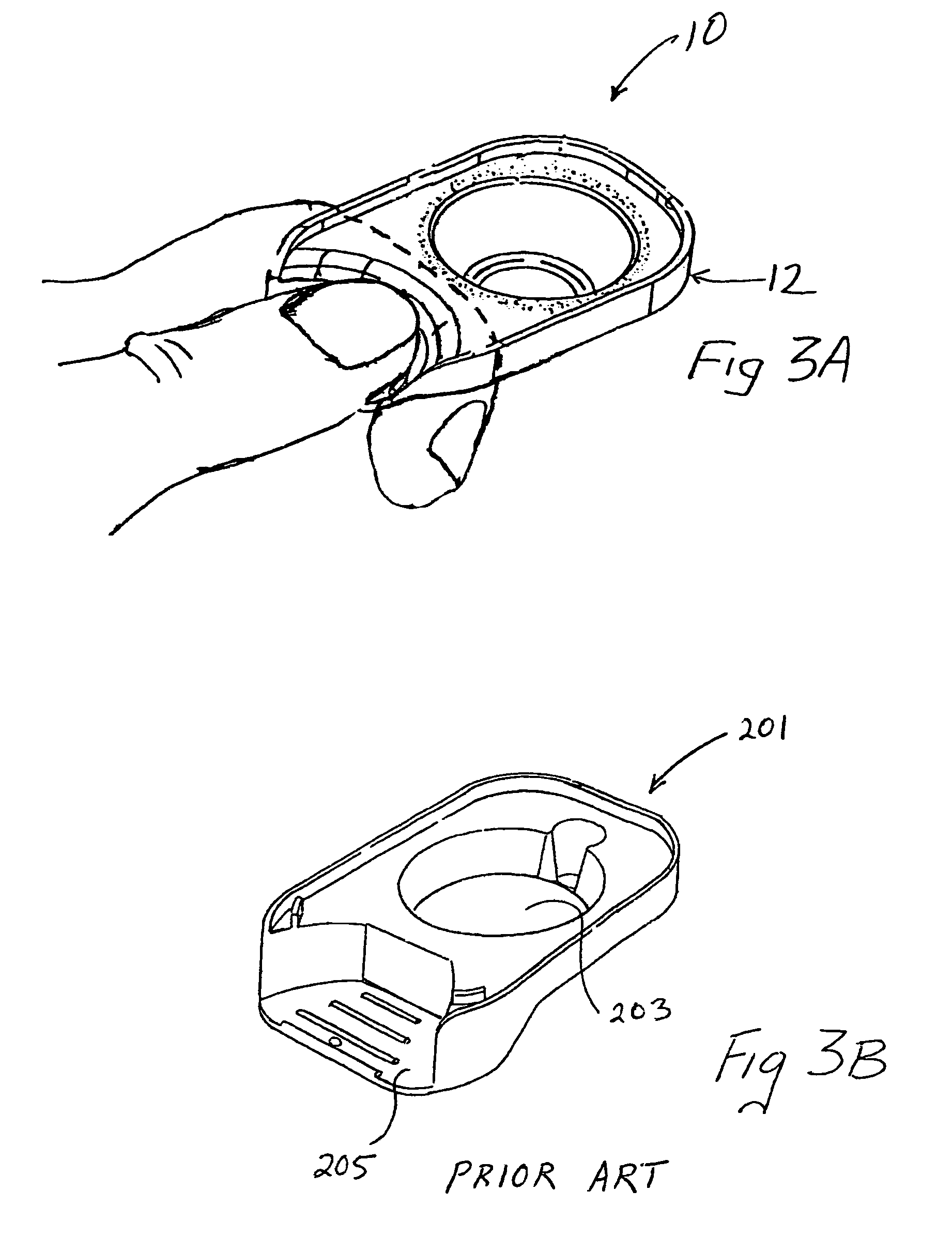

Contact lens package

ActiveUS7426993B2Reduced tendency to stick togetherReduce effortOther accessoriesContainer/bottle contructionLiquid mediumEngineering

Owner:COOPERVISION INT LTD

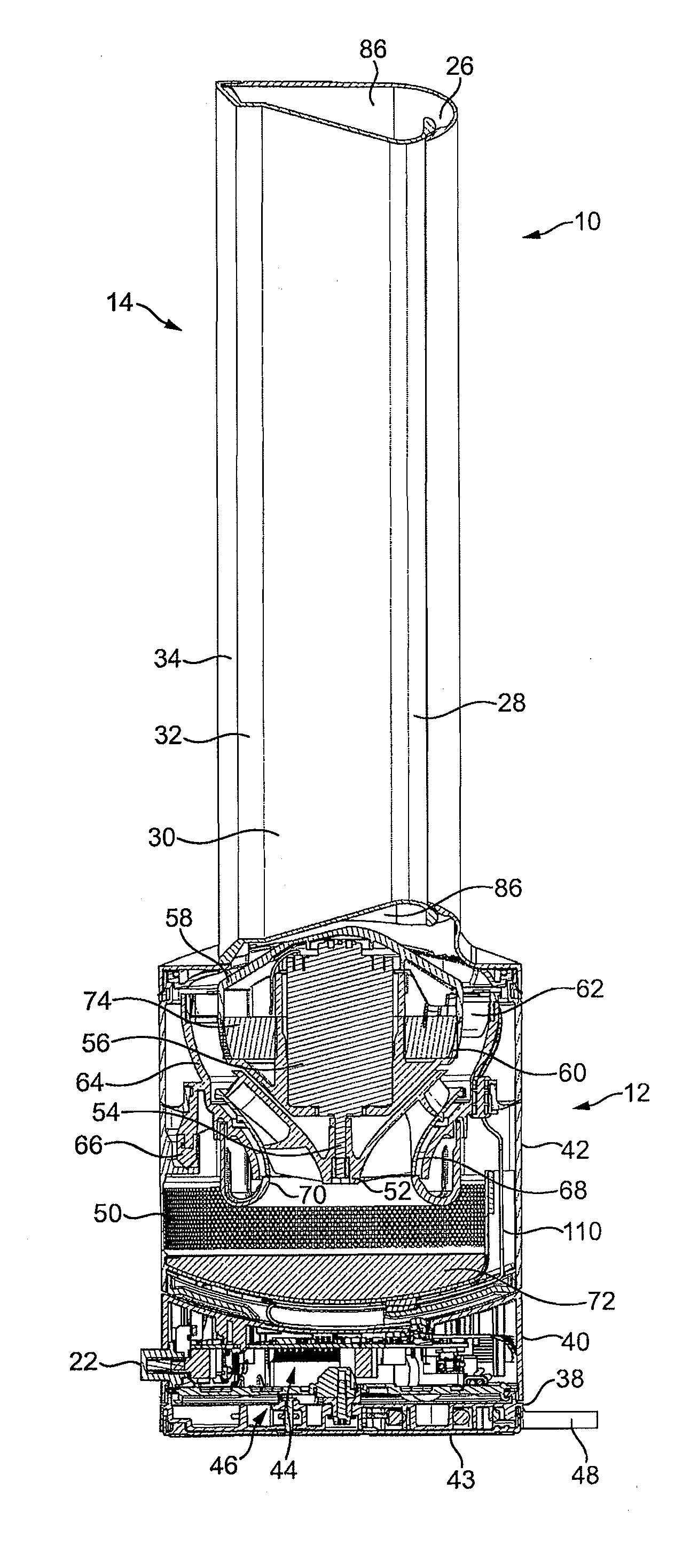

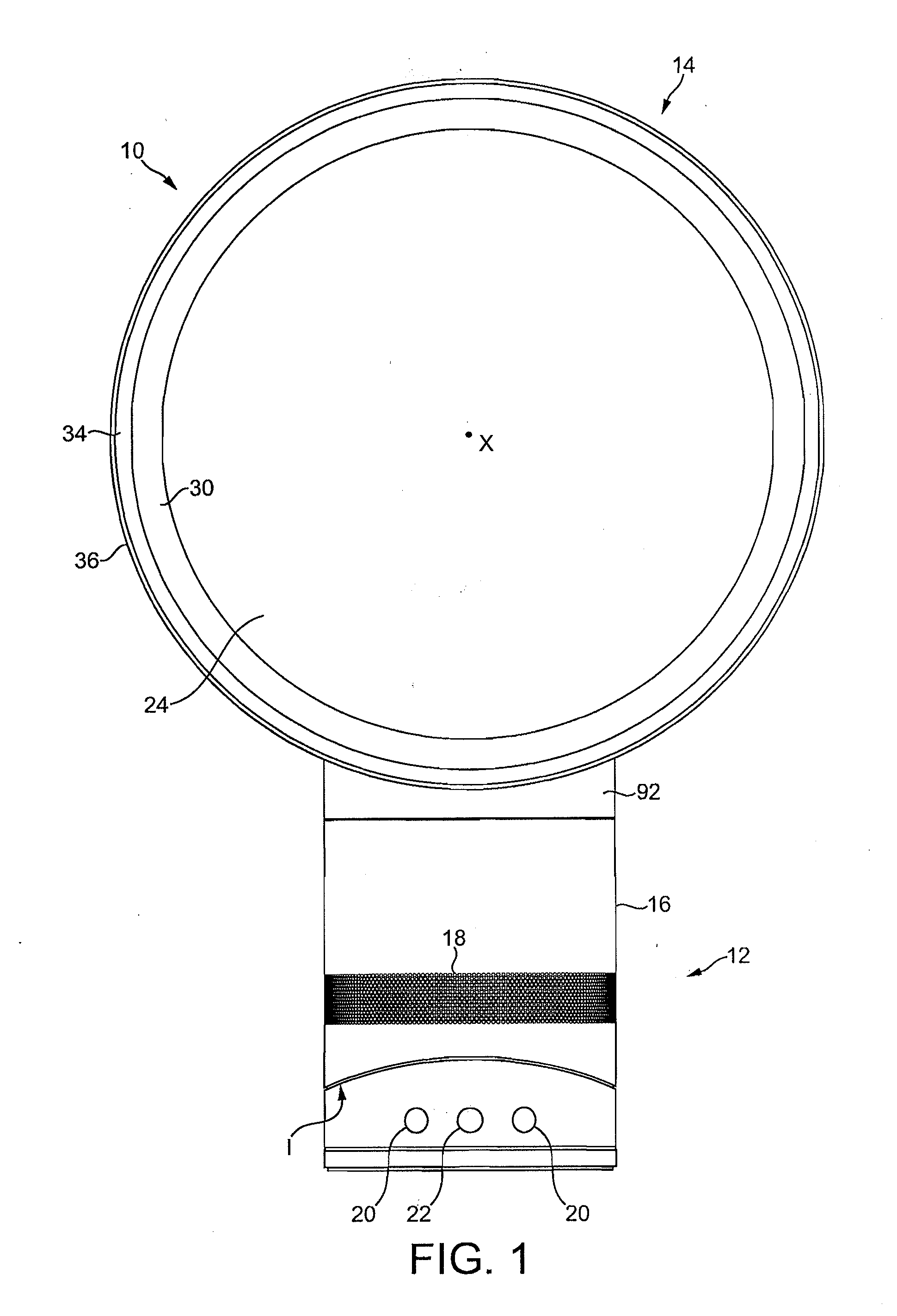

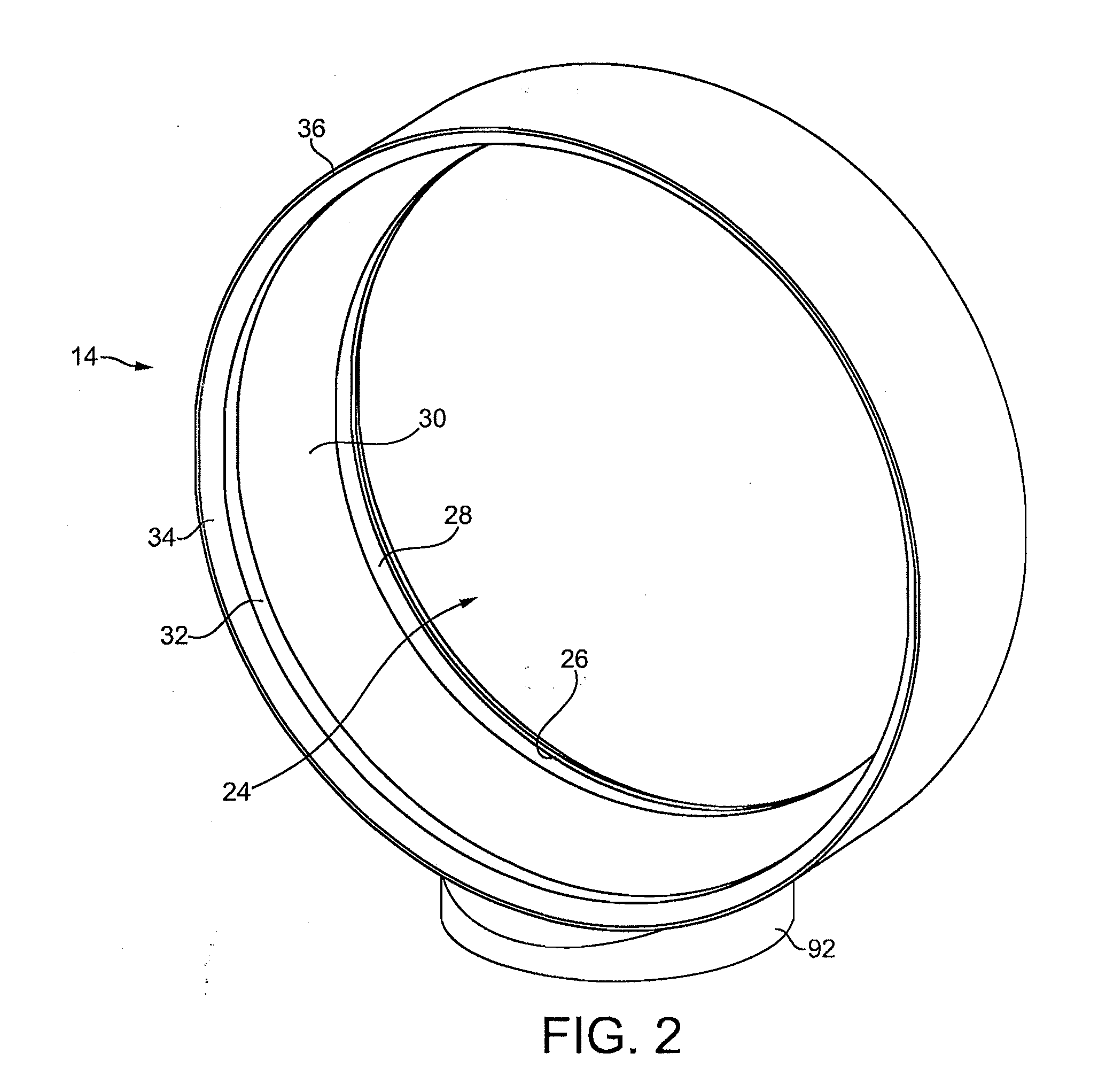

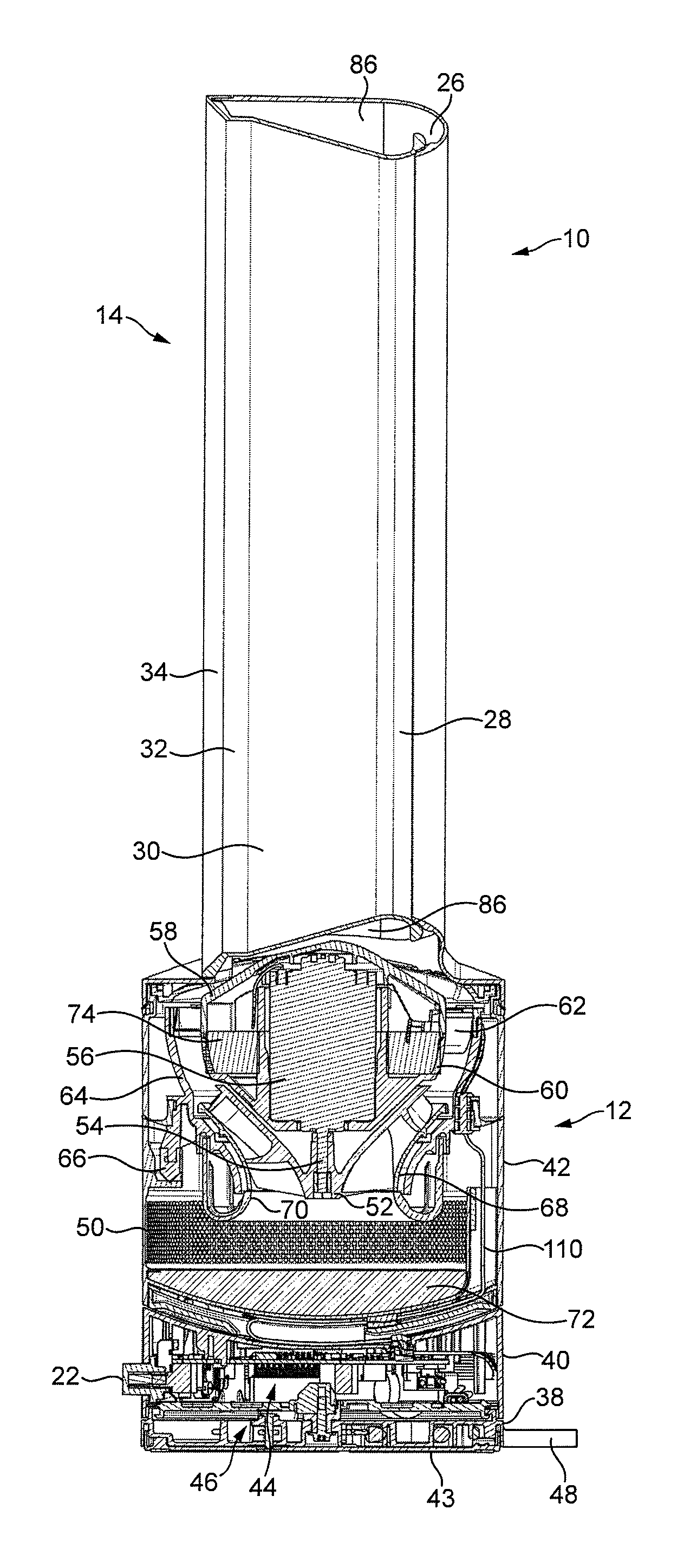

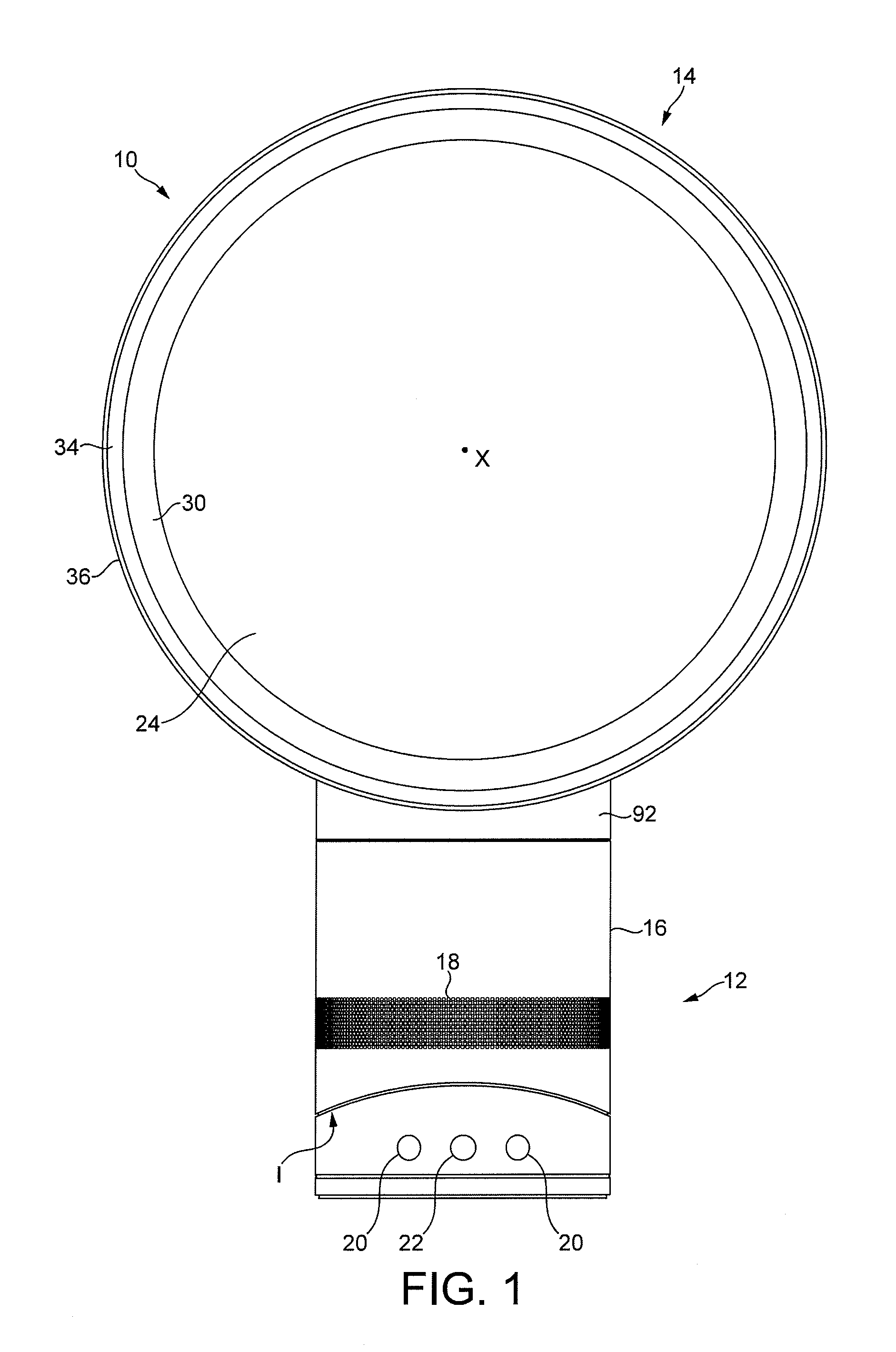

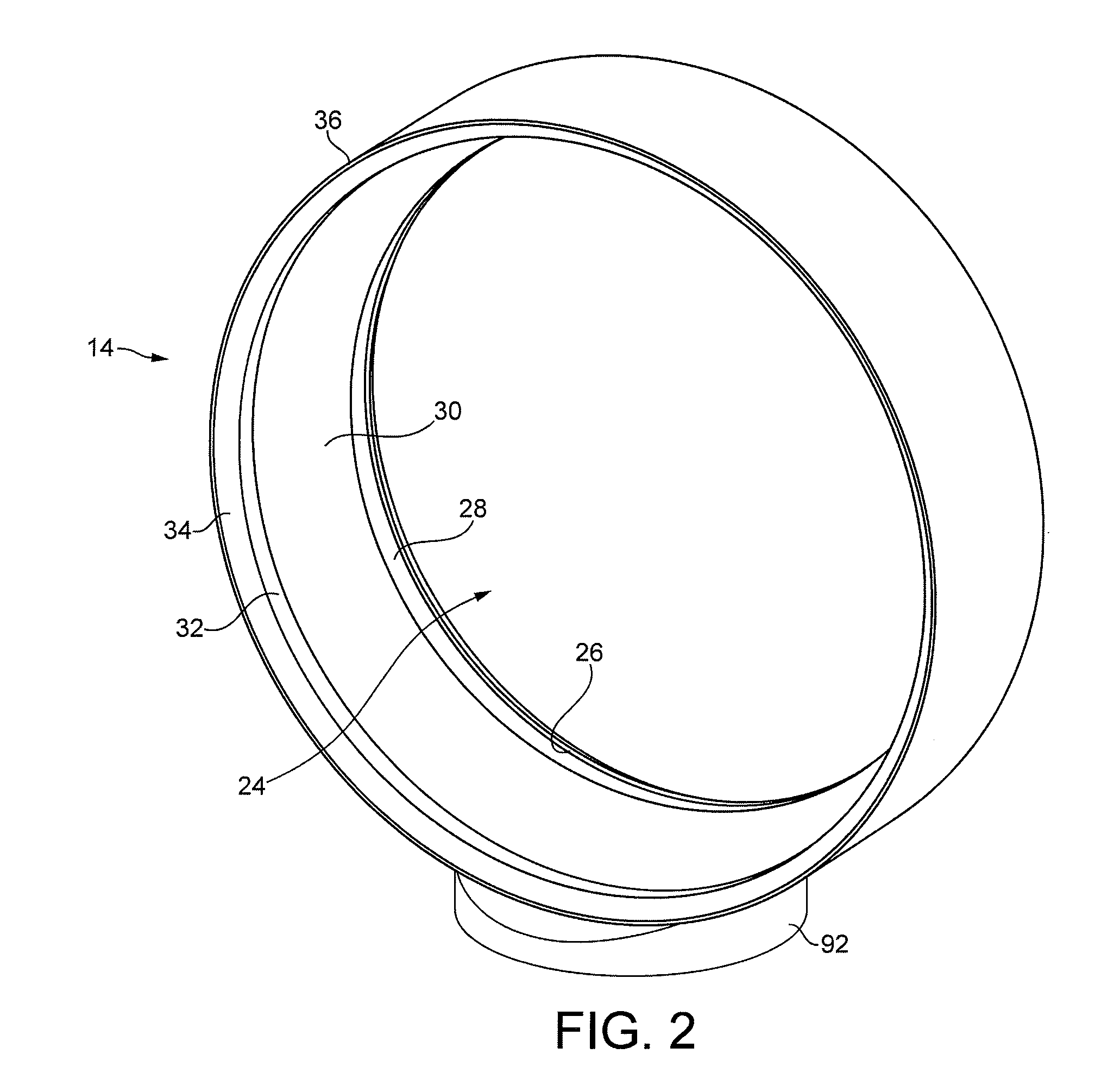

Fan assembly

InactiveUS20100226787A1Emission reductionWide operating speed rangePump componentsLighting and heating apparatusEngineeringSurface shape

A fan assembly for creating an air current includes an air outlet mounted on a stand. The stand includes a base and a body tiltable relative to the base. Each of the base and the body has an outer surface shaped so that adjoining portions of the outer surfaces are substantially flush when the body is in the untilted position.

Owner:DYSON TECH LTD

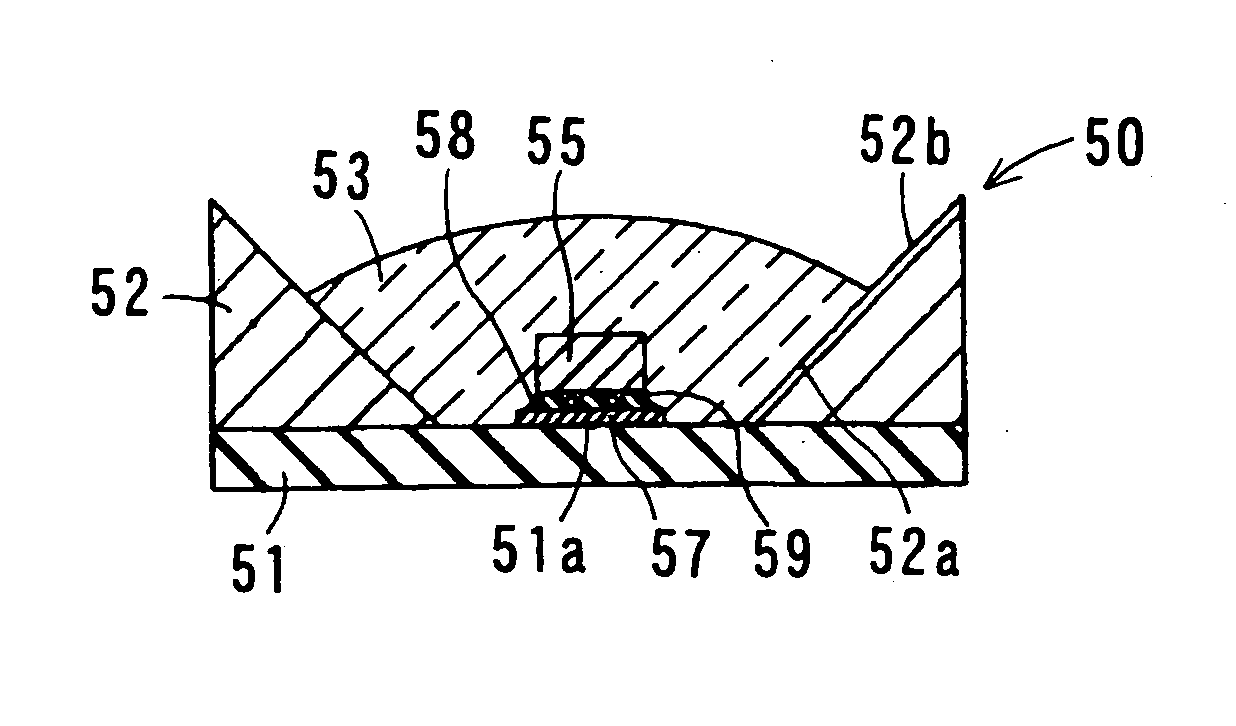

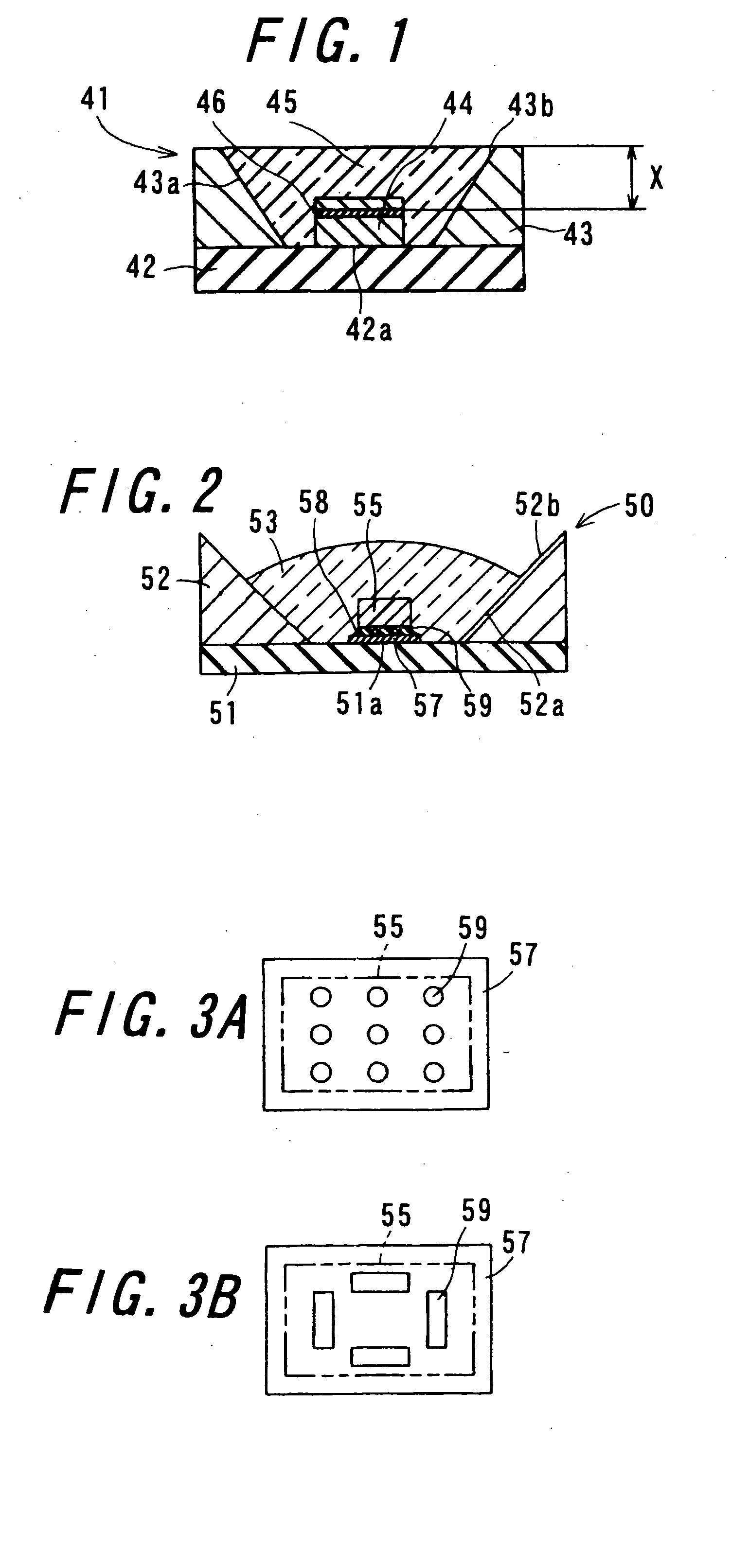

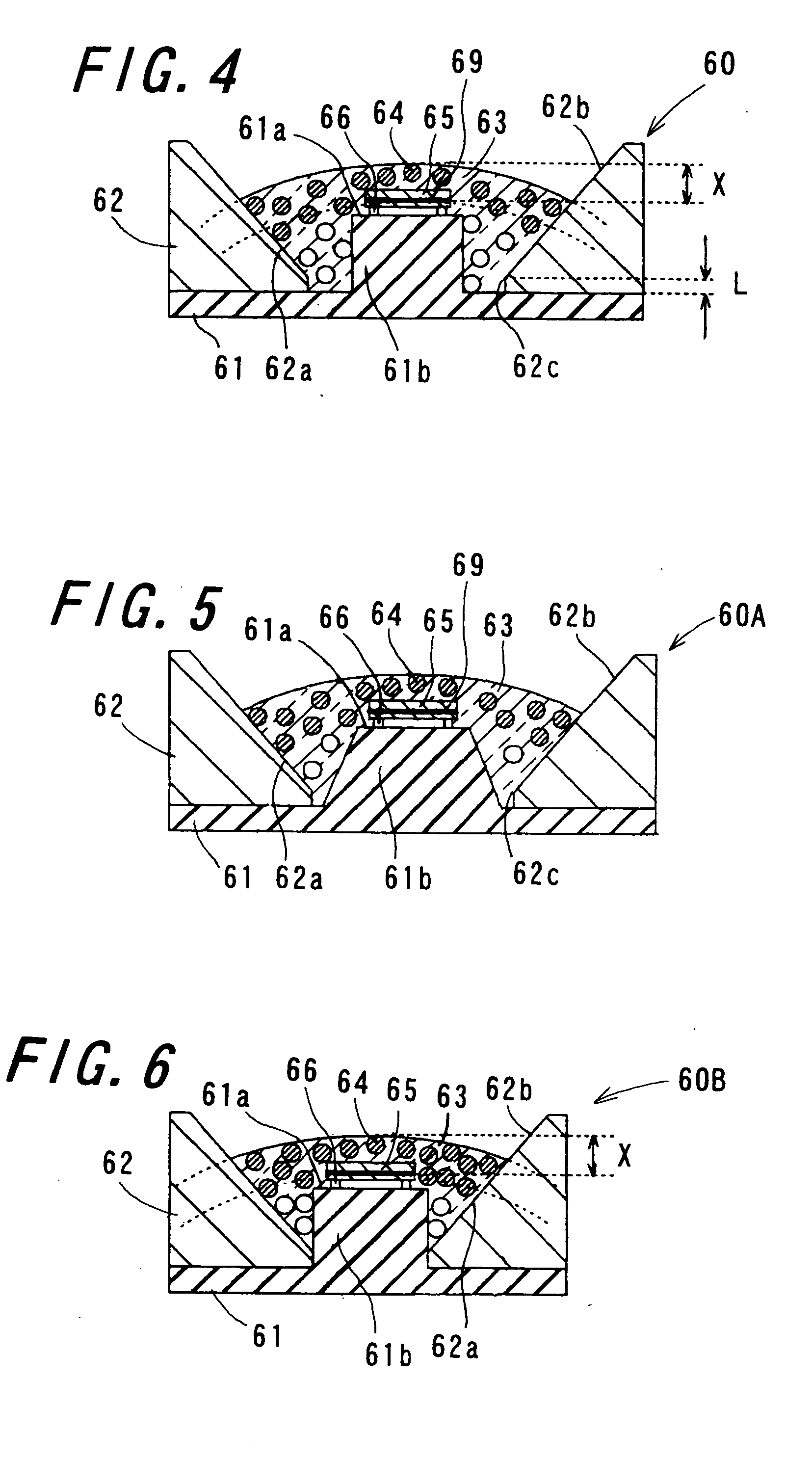

Package for housing light-emitting element, light-emitting apparatus and illumination apparatus

InactiveUS20050133808A1Increasing radiation light intensityImprove cooling effectSolid-state devicesPrintingElectrical conductorEngineering

A light-emitting apparatus provides a ceramic-made base body, a frame body, a light-emitting element, a conductor layer and a light-transmitting member. The base body has on its upper surface a mounting portion for the light-emitting element. The frame body is joined to the upper surface of the base body so as to surround the mounting portion, with its inner peripheral surface shaped into a reflection surface. The wiring conductor has its one end formed on the upper surface of the base body and electrically connected to the light-emitting element, and has another end led to a side or lower surface of the base body. The light-transmitting member is disposed inside the frame body so as to cover the light-emitting element, which contains fluorescent materials for performing wavelength conversion. The base body is so designed that ceramic crystal grains range in average particle diameter from 1 to 5 μm.

Owner:KYOCERA CORP

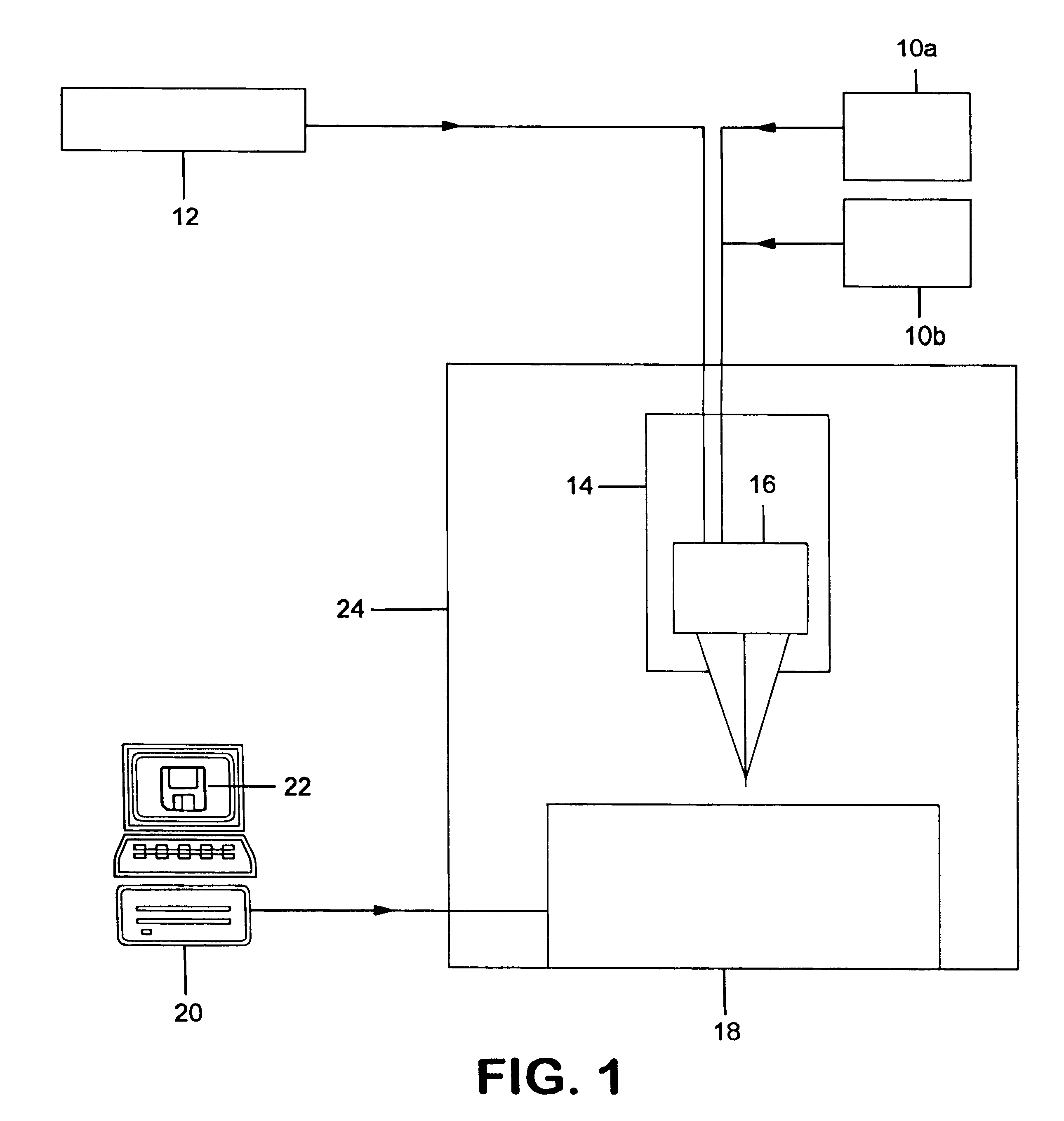

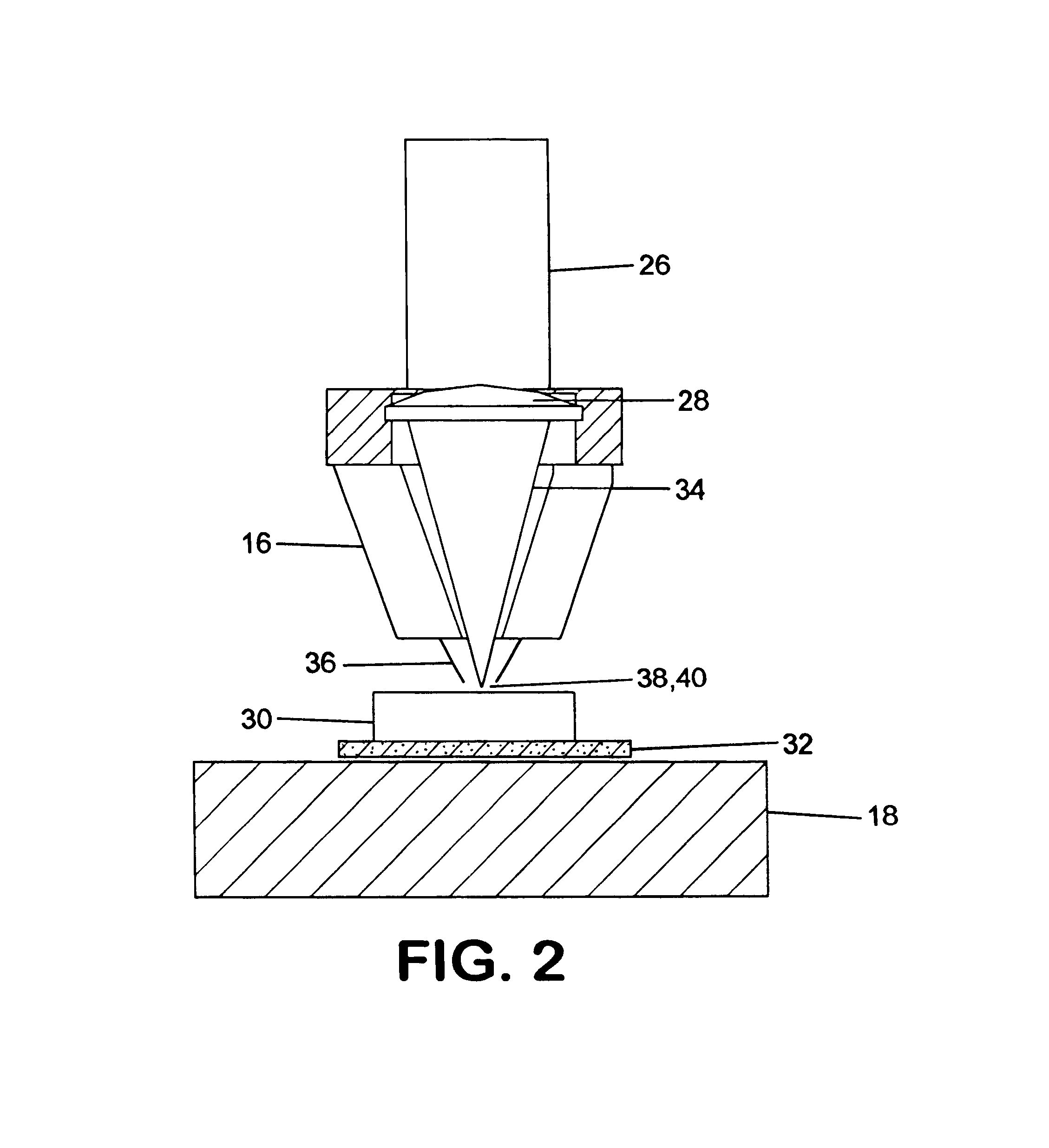

Manufacturable geometries for thermal management of complex three-dimensional shapes

Uniform cooling of complex surface shapes in injection mold tooling can be accomplished with cooling channels that conform to the shapes of the mold cavity or mold cone. By conventional methods this can be very difficult to accomplish. By applying methods of material deposition or material sintering, which include but are not limited to, laser metal deposition, where material is deposited on a layer by layer basis, certain cooling or heating passages could be integrated into the manufactured component that follow the contours and profiles of the mold's complex surfaces. These passages would act as internal heat sinks with a much higher surface area for heat transfer than traditional drilled and plugged straight passages. These geometries could also be incorporated into complex geometries such as, but not limited to, turbine blades where the cooling passages can follow the contour of the outer shape, provide a more uniform or controlled heat transfer from the component. Multiple loops of cooling or heating channels could be designed and manufactured into solid objects for small-scale heat exchanger technologies.

Owner:OPTOMEC DESIGN CO

Sensor apparatus systems, devices and methods

A sensor apparatus and sensor apparatus system for use in conjunction with a cassette, including a disposable or replaceable cassette. In some embodiments, the cassette includes a thermal well for permitting the sensing of various properties of a subject media. The thermal well includes a hollow housing of a thermally conductive material. In other embodiments, the cassette includes sensor leads for sensing of various properties of a subject media. The thermal well has an inner surface shaped so as to form a mating relationship with a sensing probe. The mating thermally couples the inner surface with a sensing probe. In some embodiments, the thermal well is located on a disposable portion and the sensing probe on a reusable portion.

Owner:DEKA PROD LLP

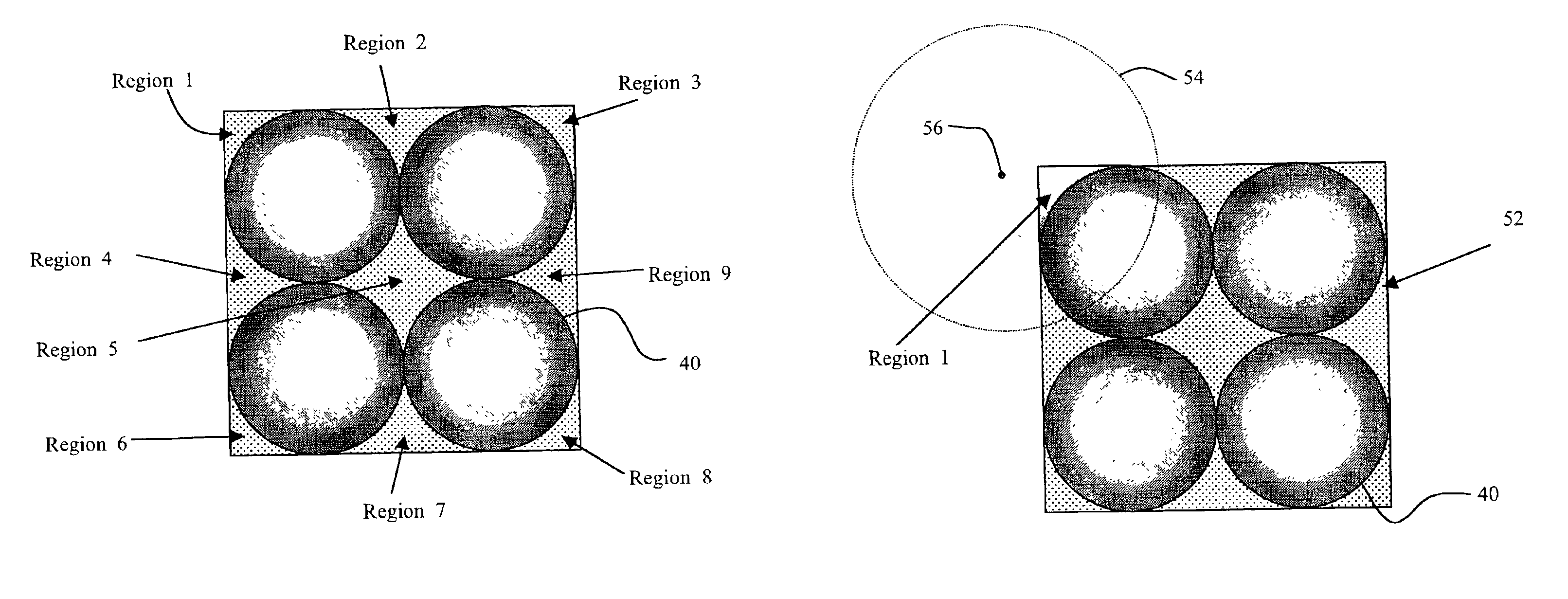

Random microlens array for optical beam shaping and homogenization

Microlens arrays are defined with microlens elements that differ from each other in accordance with a probability distribution for shaping an optical beam having a prescribed intensity profile within a desired far-field scatter pattern. The differences include random variations in a sag profile corresponding to a surface shape of the microlenses, a boundary profile corresponding to a boundary of the microlenses, and a spatial distribution corresponding to the relative position of the microlenses within the array. The sag profile variations can be used to homogenize an intensity profile of the optical beam. The boundary profile variations within an irregular spatial distribution can be used to apply the prescribed intensity profile of the optical beam within the desired scatter pattern.

Owner:CORNING INC

Lens system and method for power adjustment using externally actuated micropumps

An intraocular lens is provided that having optical parameters that may be adjusted in-situ, and is particularly useful in cataract patients that require an adjustment in the optical power of the lens post-implantation. The lens body carries an array of interior fluid-filled cells in which fluid is controllably moved by micropumps upon application of energy from an external source to move a fluid media into the cells to thereby alter the lens surface shape.

Owner:ALCON INC

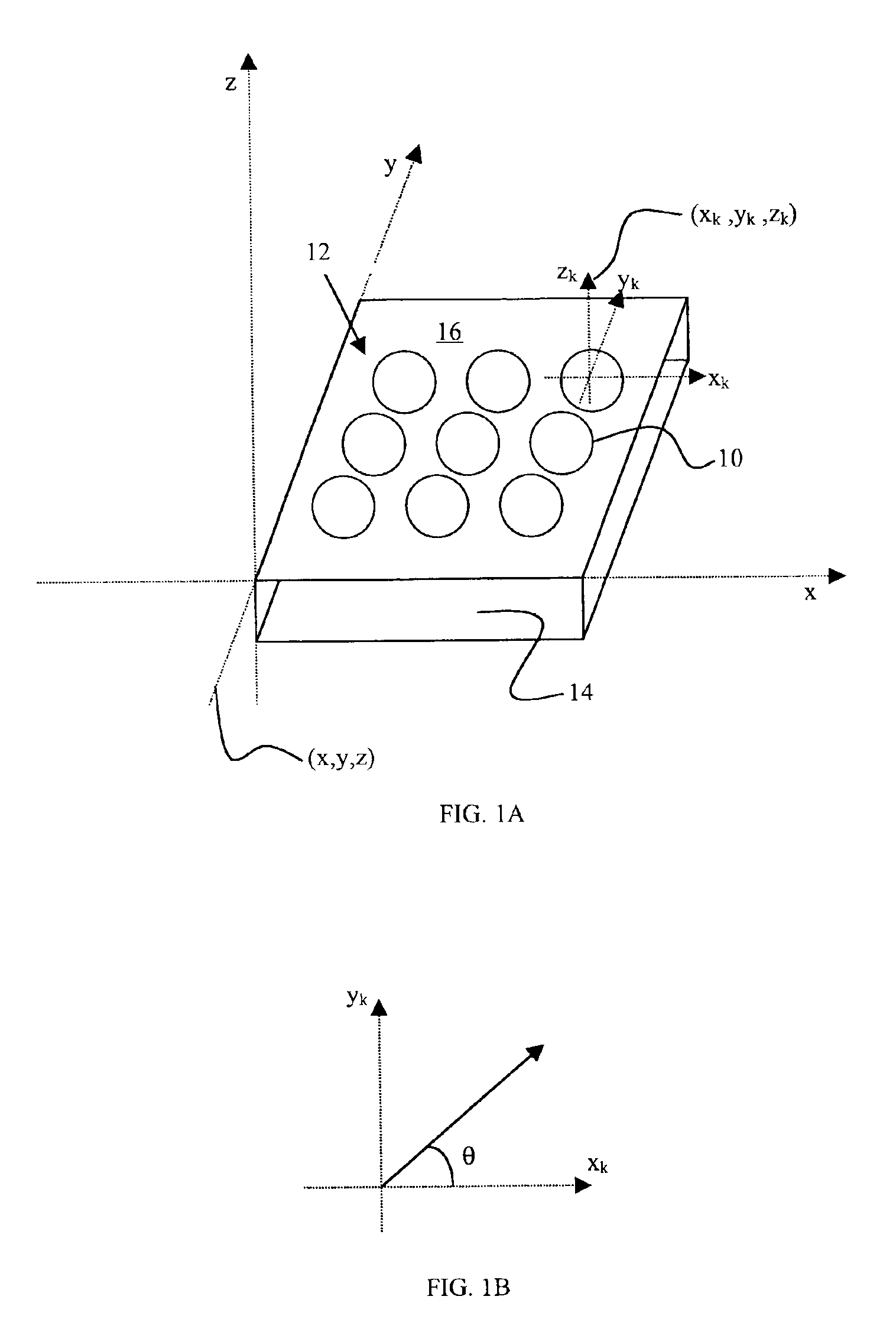

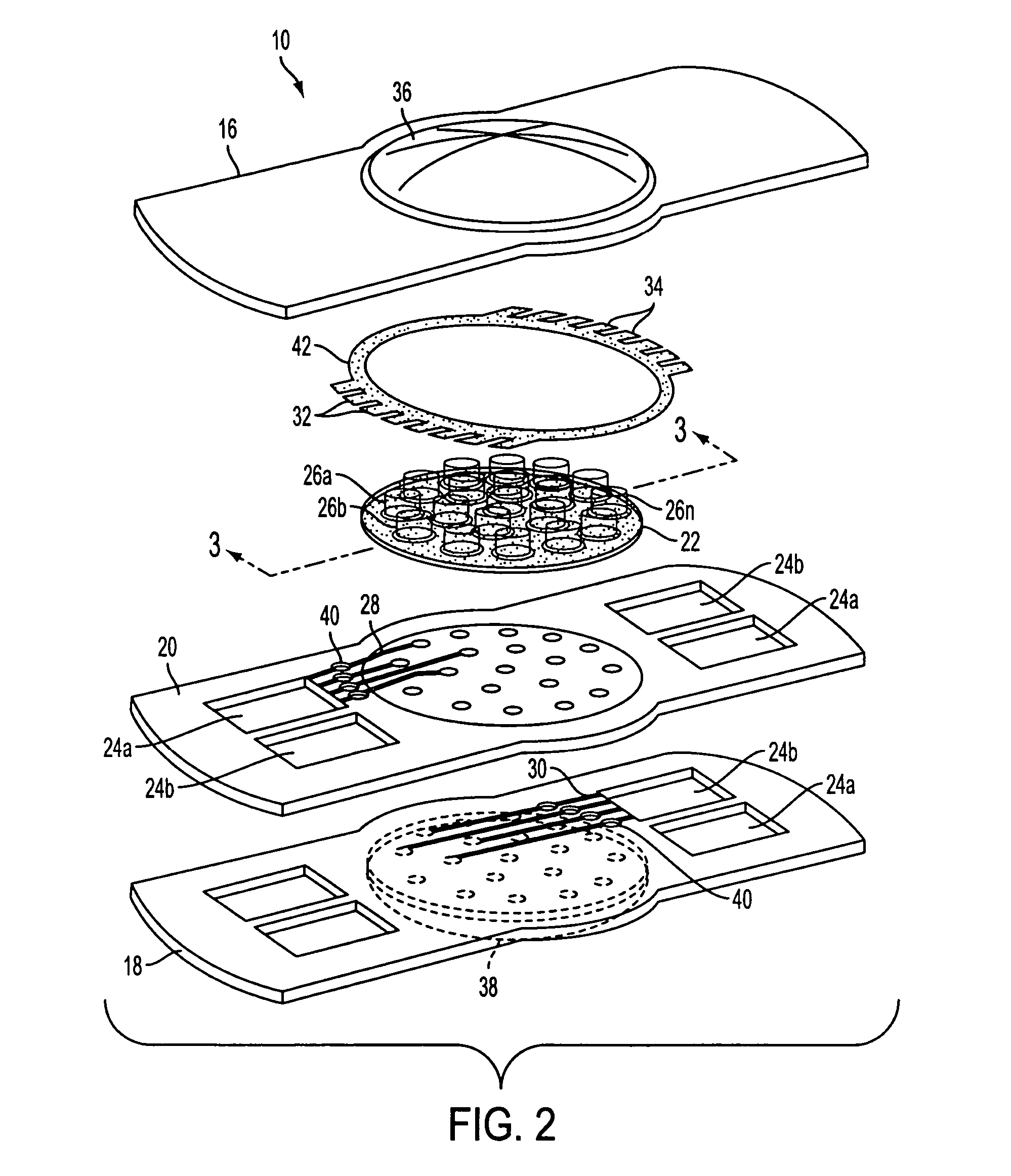

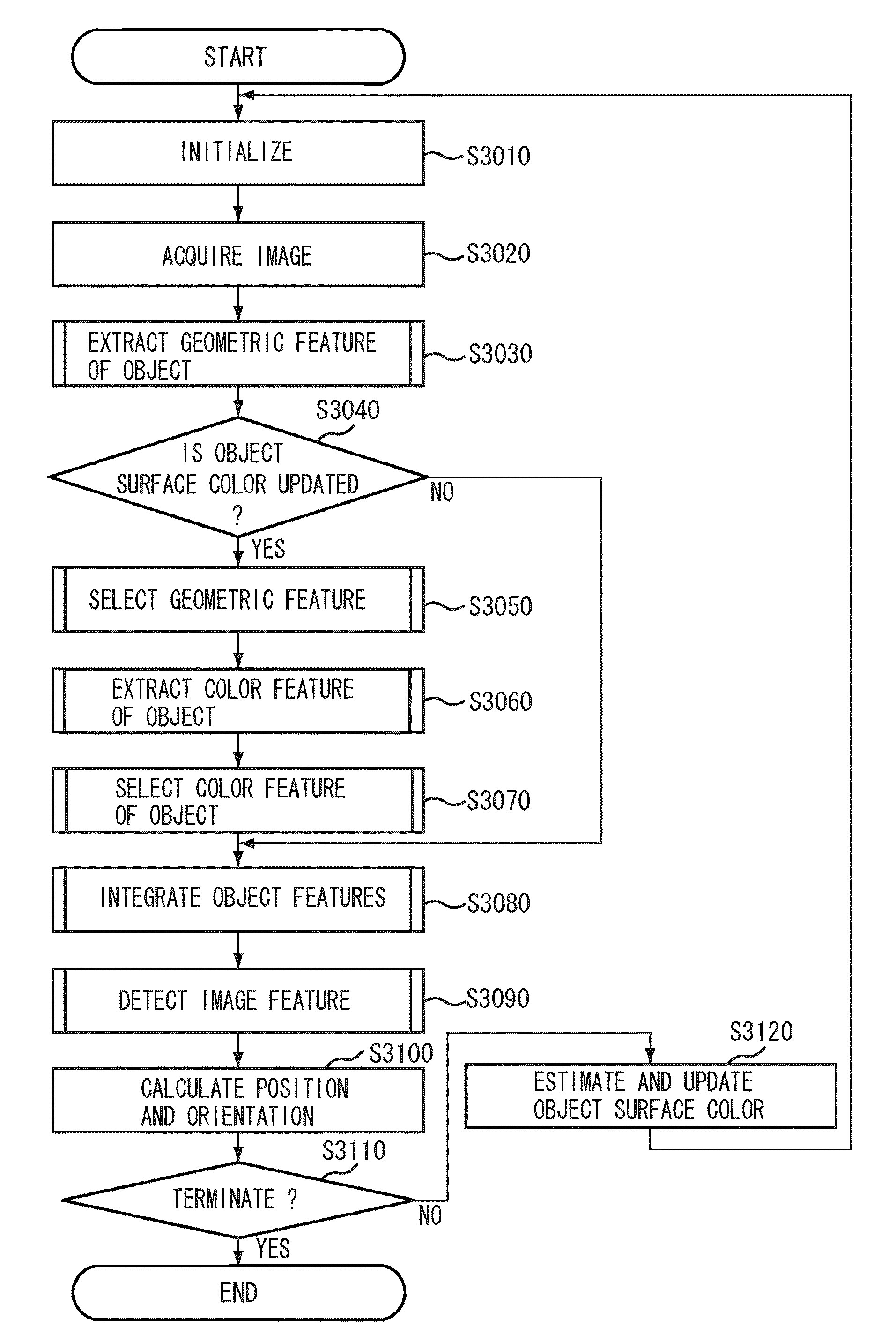

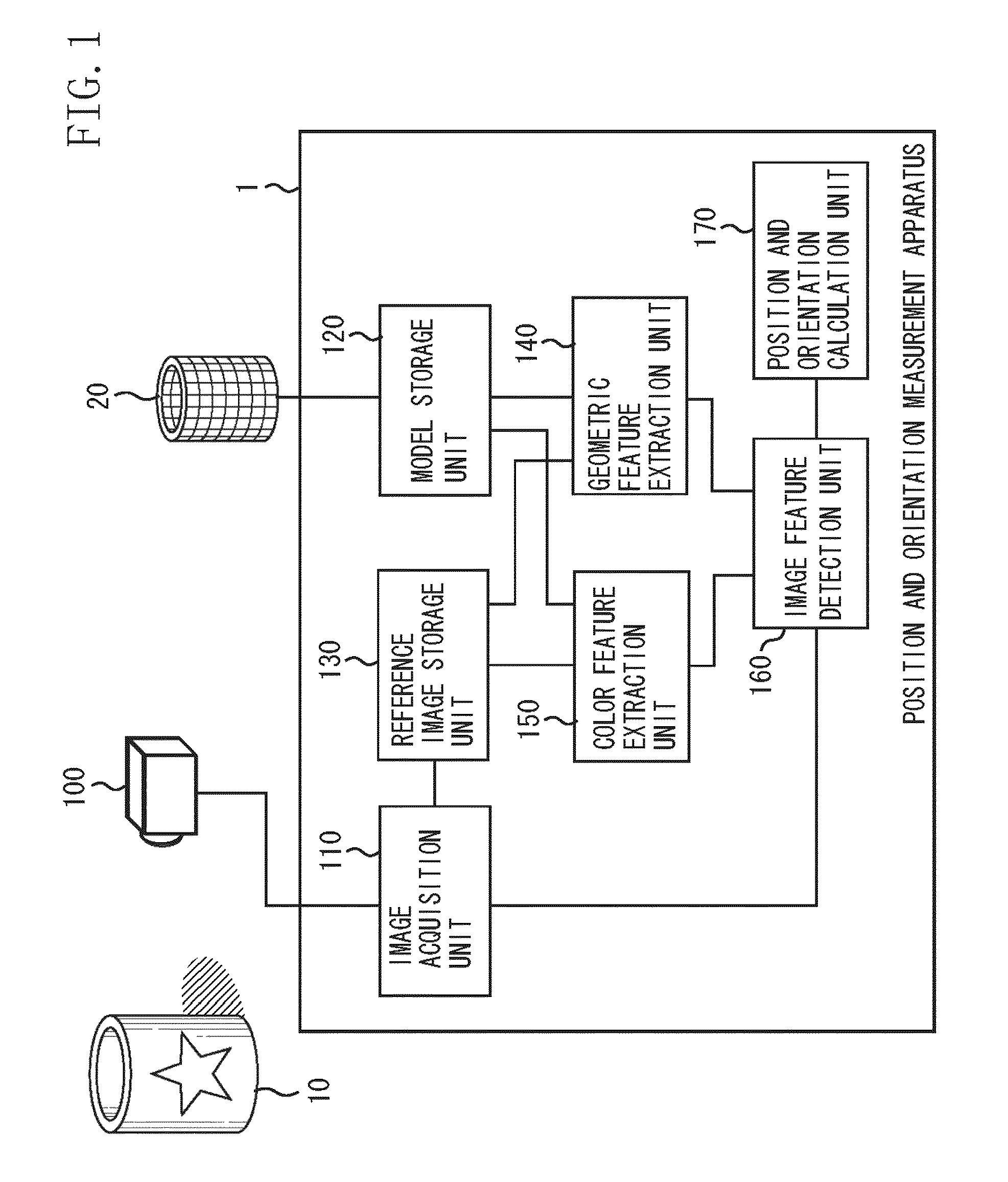

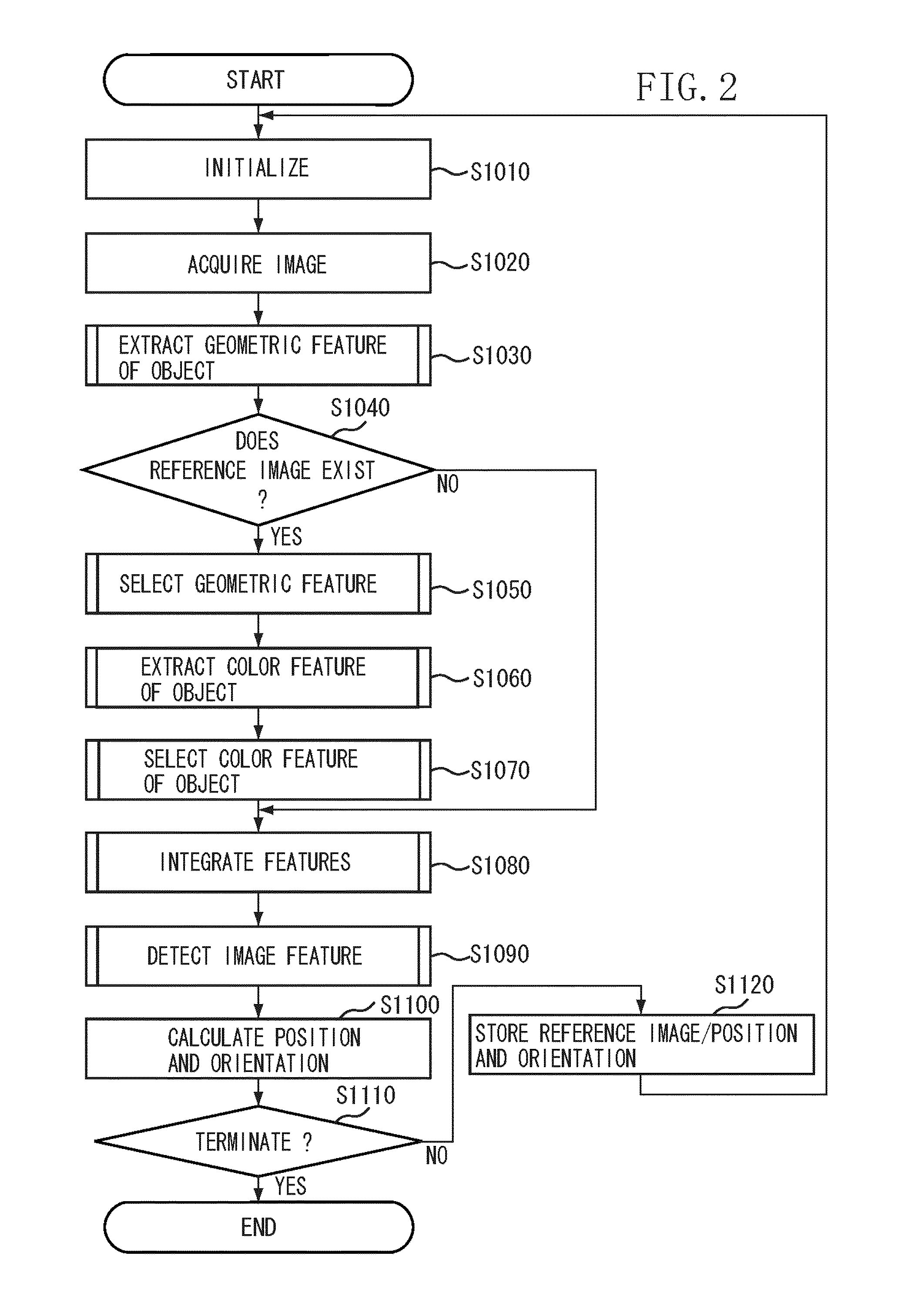

Position and orientation measurement apparatus and method thereof

ActiveUS8520931B2Stably estimatePrecise positioningImage analysisUsing optical meansReference imageImaging Feature

Owner:CANON KK

Fan assembly

InactiveUS20120082561A1Tidy and uniform appearanceQuickly and easily wiped cleanPump componentsLighting and heating apparatusEngineeringSurface shape

A fan assembly for creating an air current includes an air outlet mounted on a stand. The stand includes a base and a body tiltable relative to the base. Each of the base and the body has an outer surface shaped so that adjoining portions of the outer surfaces are substantially flush when the body is in the untilted position.

Owner:DYSON TECH LTD

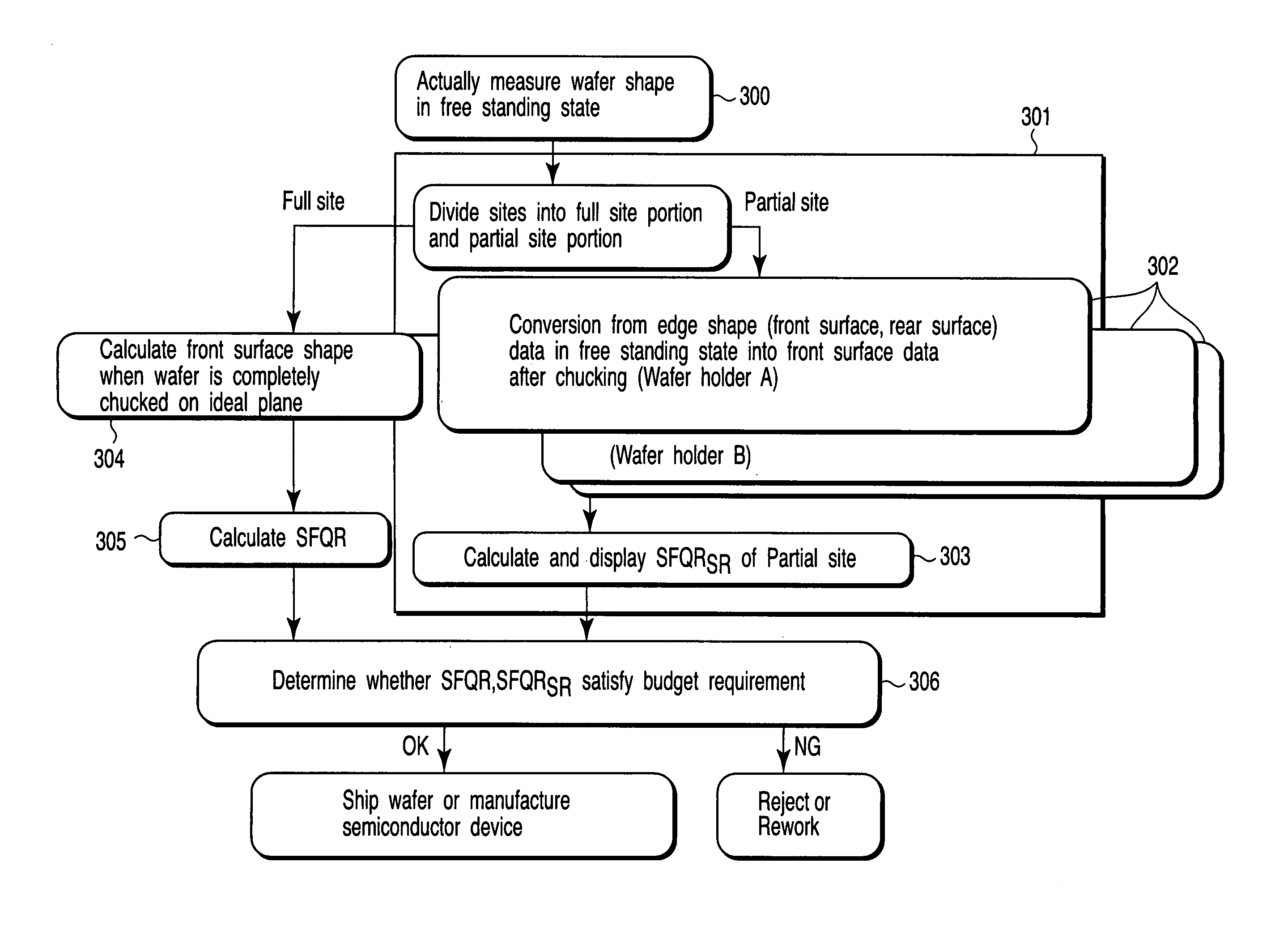

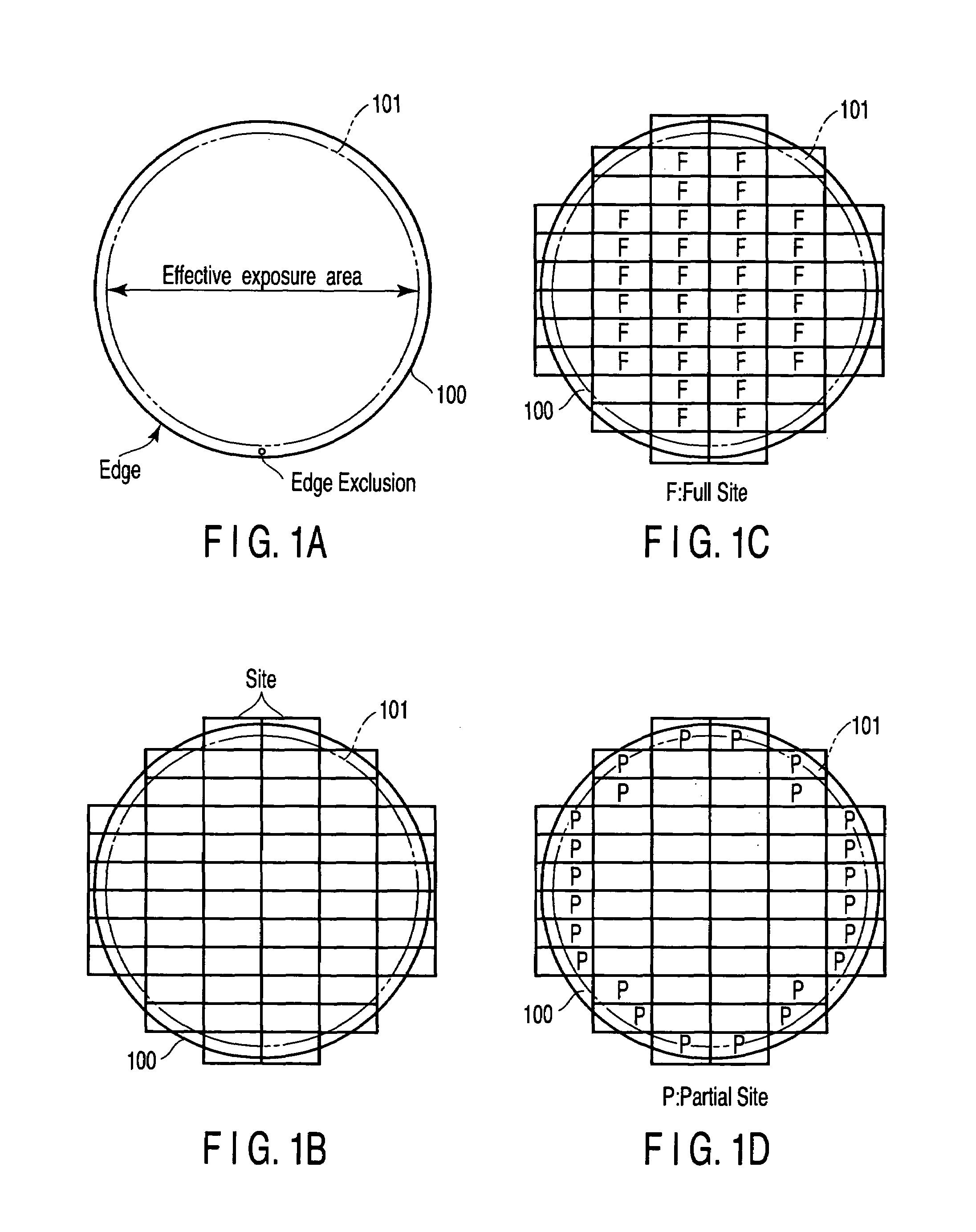

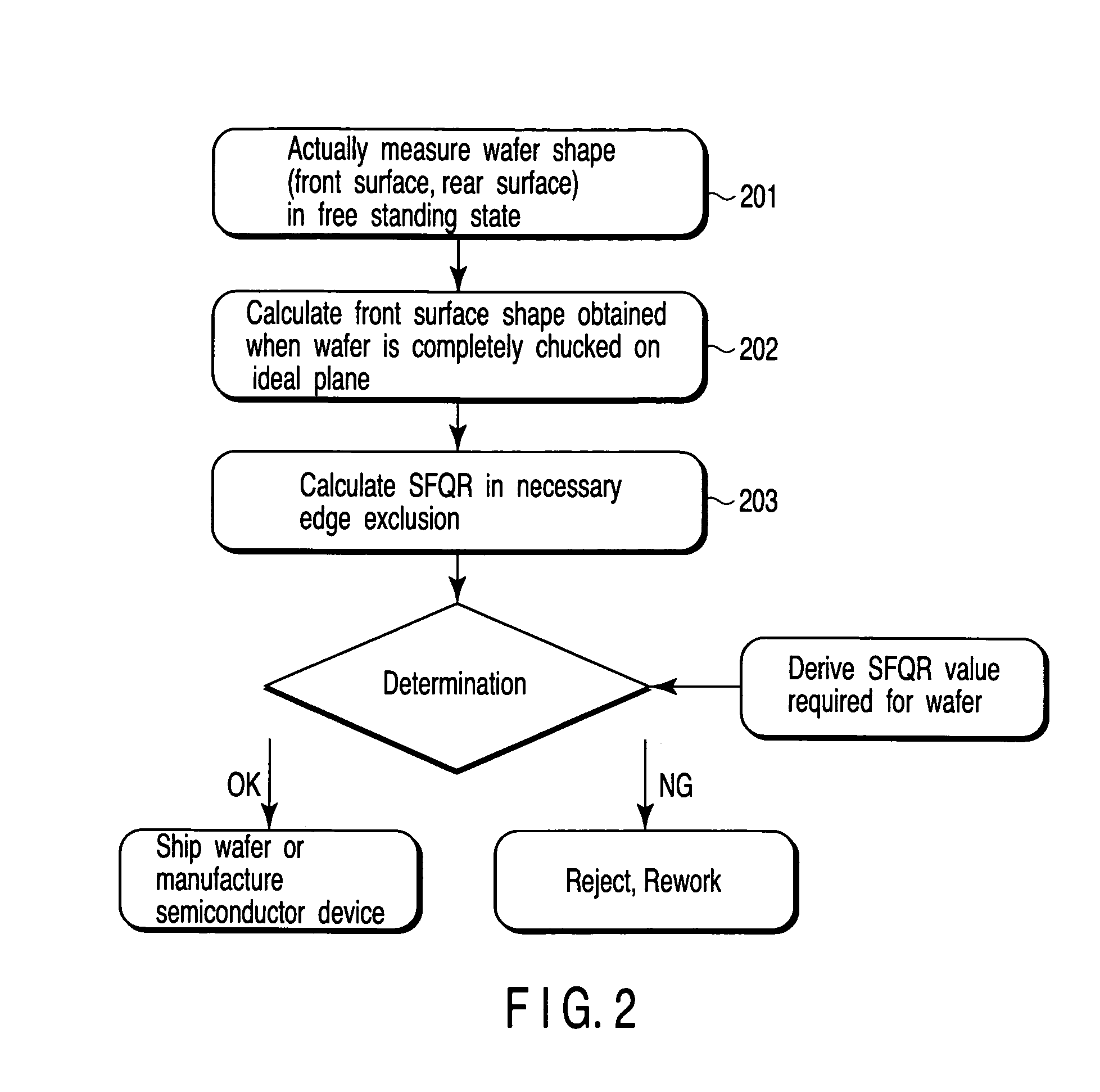

Wafer flatness evaluation method, wafer flatness evaluation apparatus carrying out the evaluation method, wafer manufacturing method using the evaluation method, wafer quality assurance method using the evaluation method, semiconductor device manufacturing method using the evaluation method and semiconductor device manufacturing method using a wafer evaluated by the evaluation method

ActiveUS7230680B2Semiconductor/solid-state device testing/measurementSolid-state devicesQuality assuranceCalculation methods

There is disclosed a wafer flatness evaluation method includes measuring front and rear surface shapes of a wafer. The wafer front surface measured is divided into sites. Then, a flatness calculating method is selected according to a position of the site to be evaluated and flatness in the wafer surface is acquired.

Owner:SHIN-ETSU HANDOTAI CO LTD +2

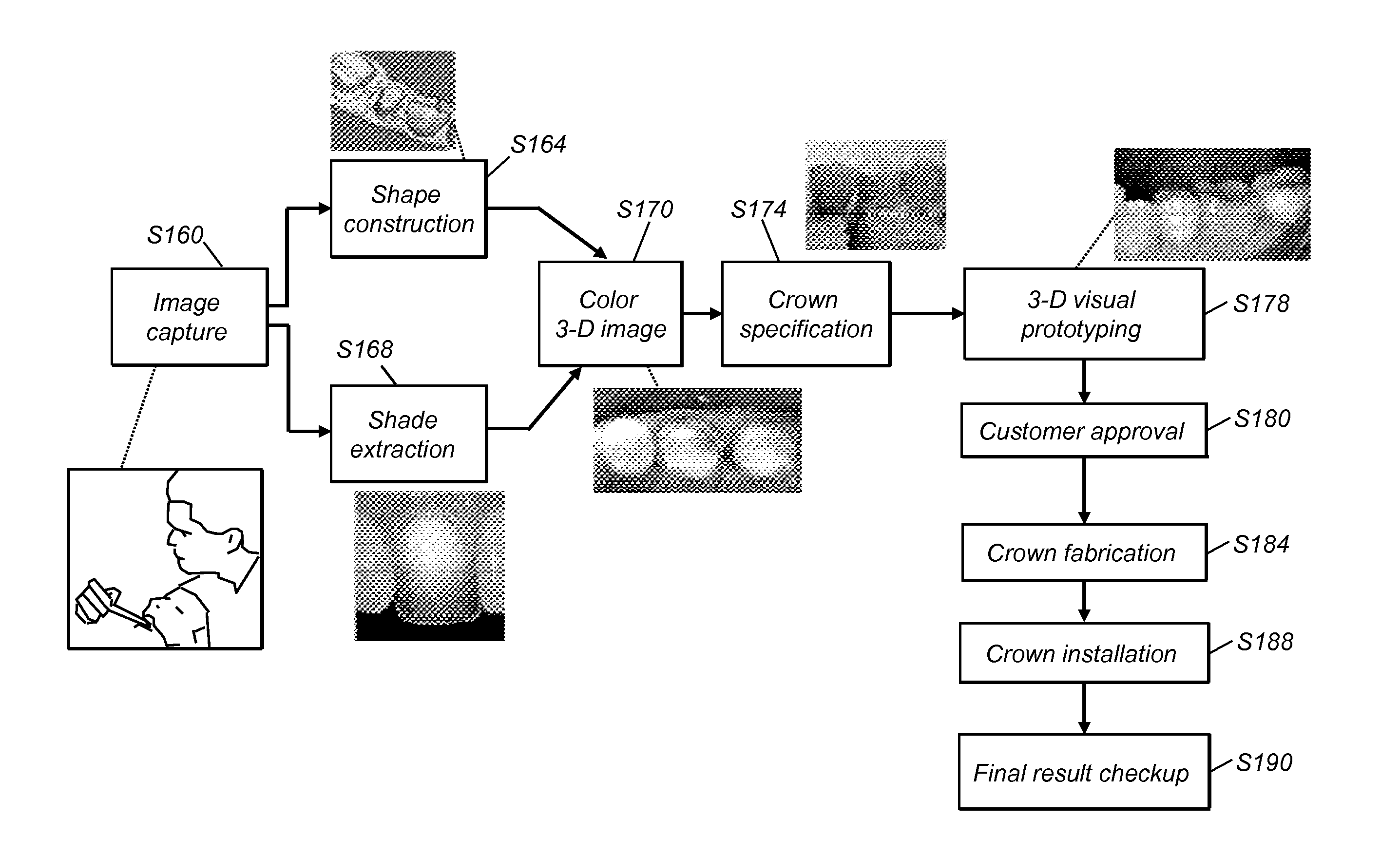

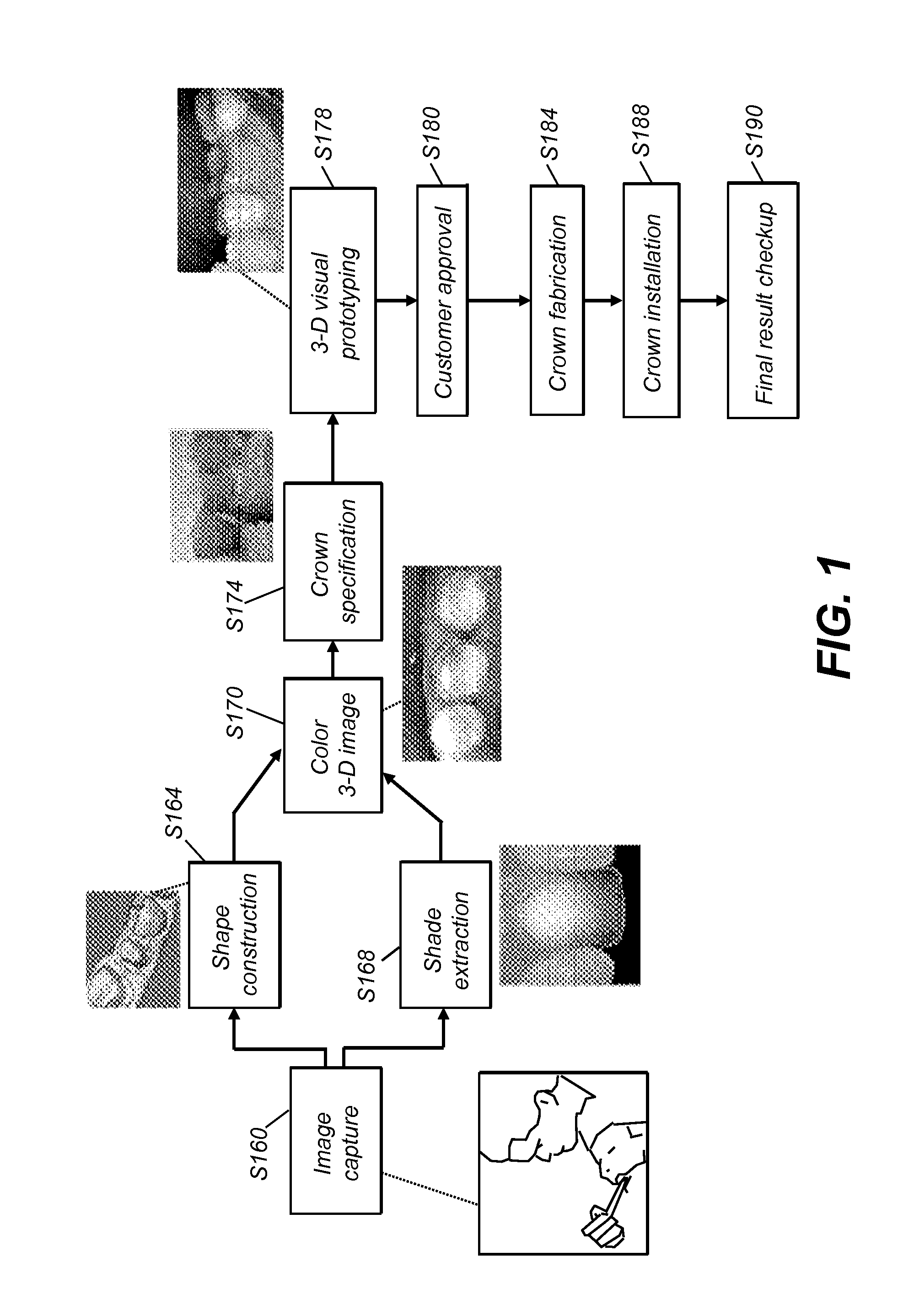

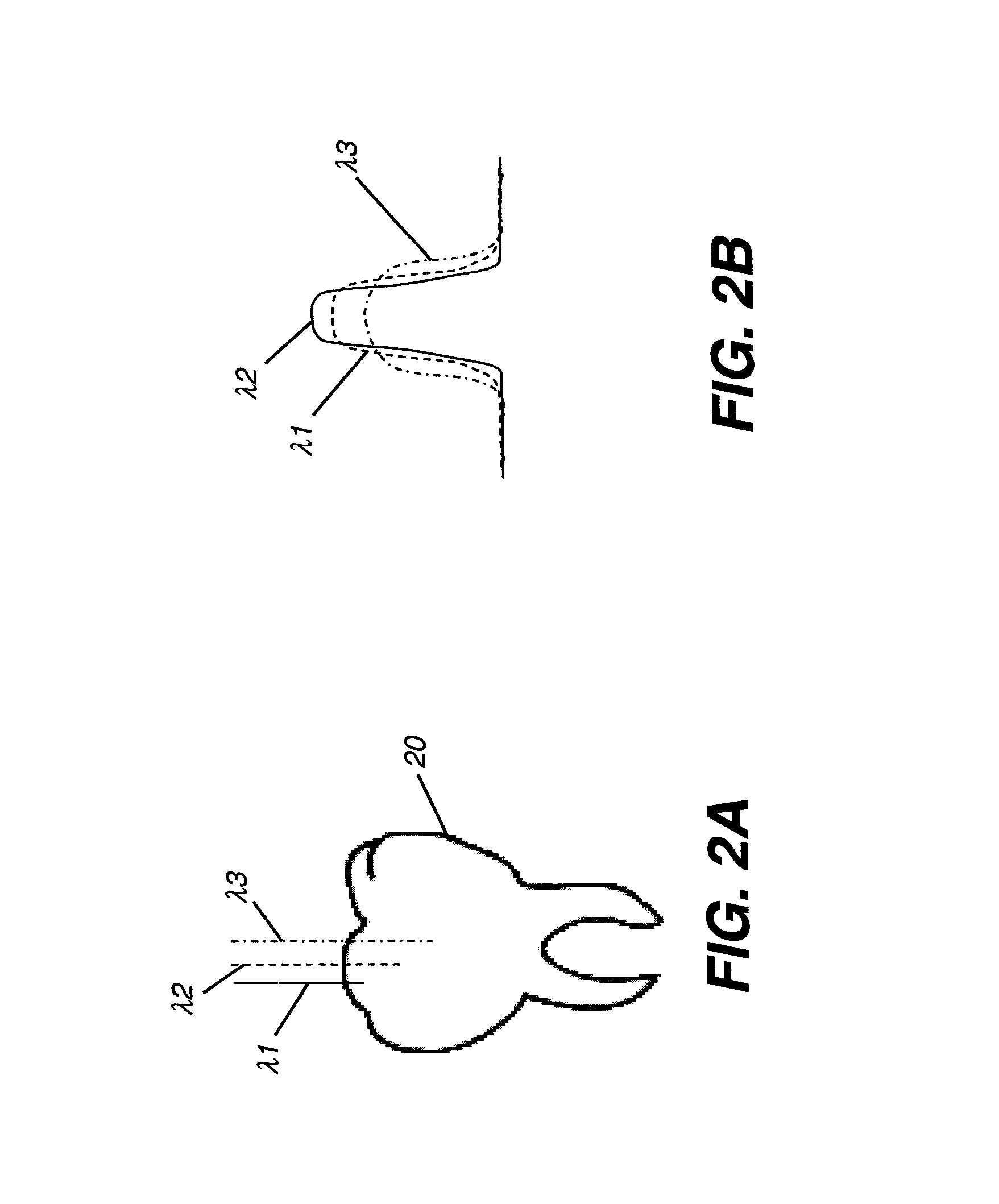

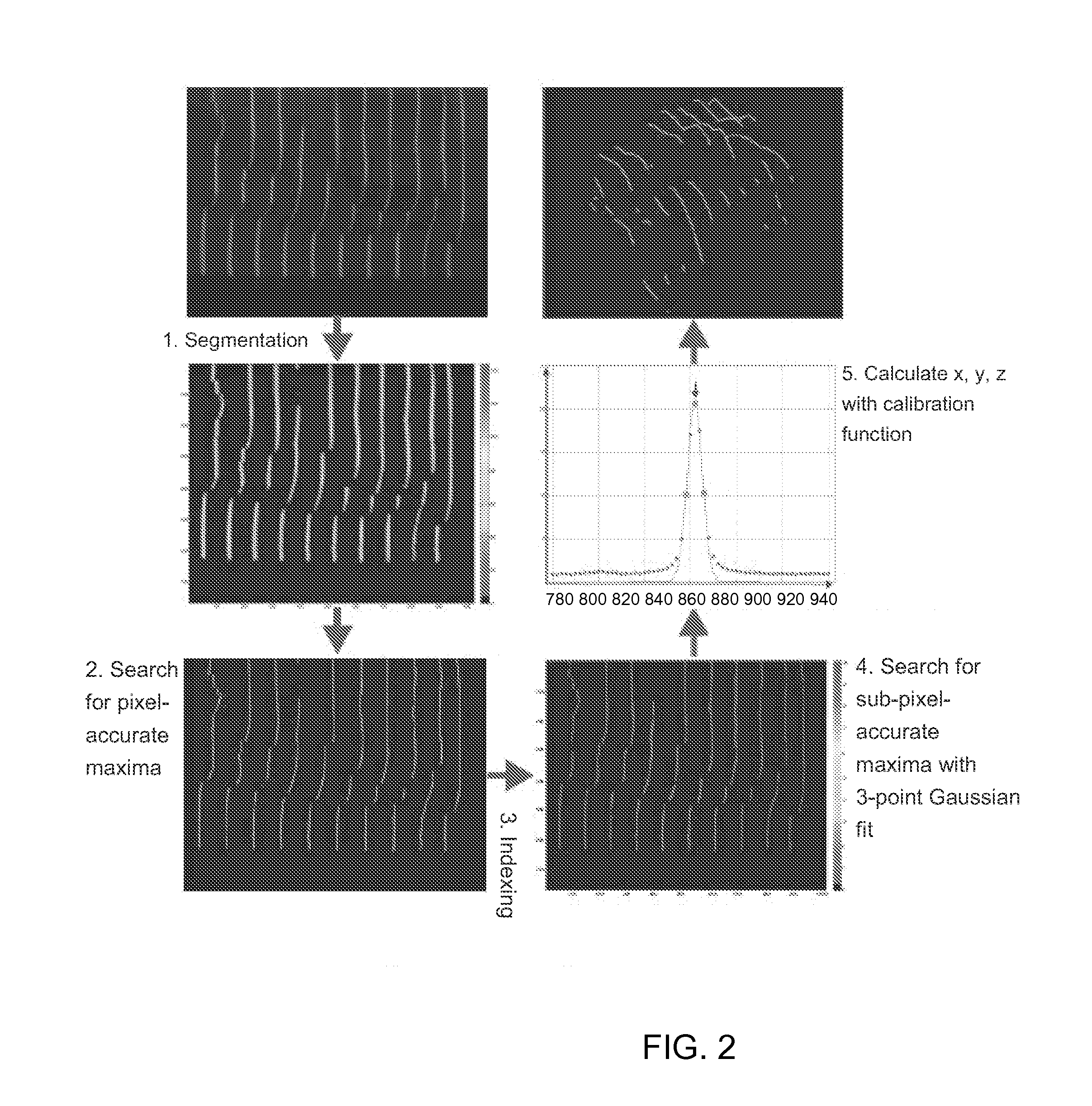

Apparatus for dental surface shape and shade imaging

An intra-oral imaging apparatus having an illumination field generator that forms an illumination beam having a contour fringe projection pattern when receiving light from a first light source and having a substantially uniform illumination field when receiving light from a second light source. A polarizer in the path of the illumination beam has a first polarization transmission axis. A projection lens directs the polarized illumination beam toward a tooth surface and an imaging lens directs at least a portion of the light from the tooth surface along a detection path. A polarization-selective element disposed along the detection path has a second polarization transmission axis. At least one detector obtains image data from the light provided through the polarization-selective element. A control logic processor responds to programmed instructions for alternately energizing the first and second light sources in a sequence and obtaining both contour fringe projection data and color image data.

Owner:CARESTREAM DENTAL LLC

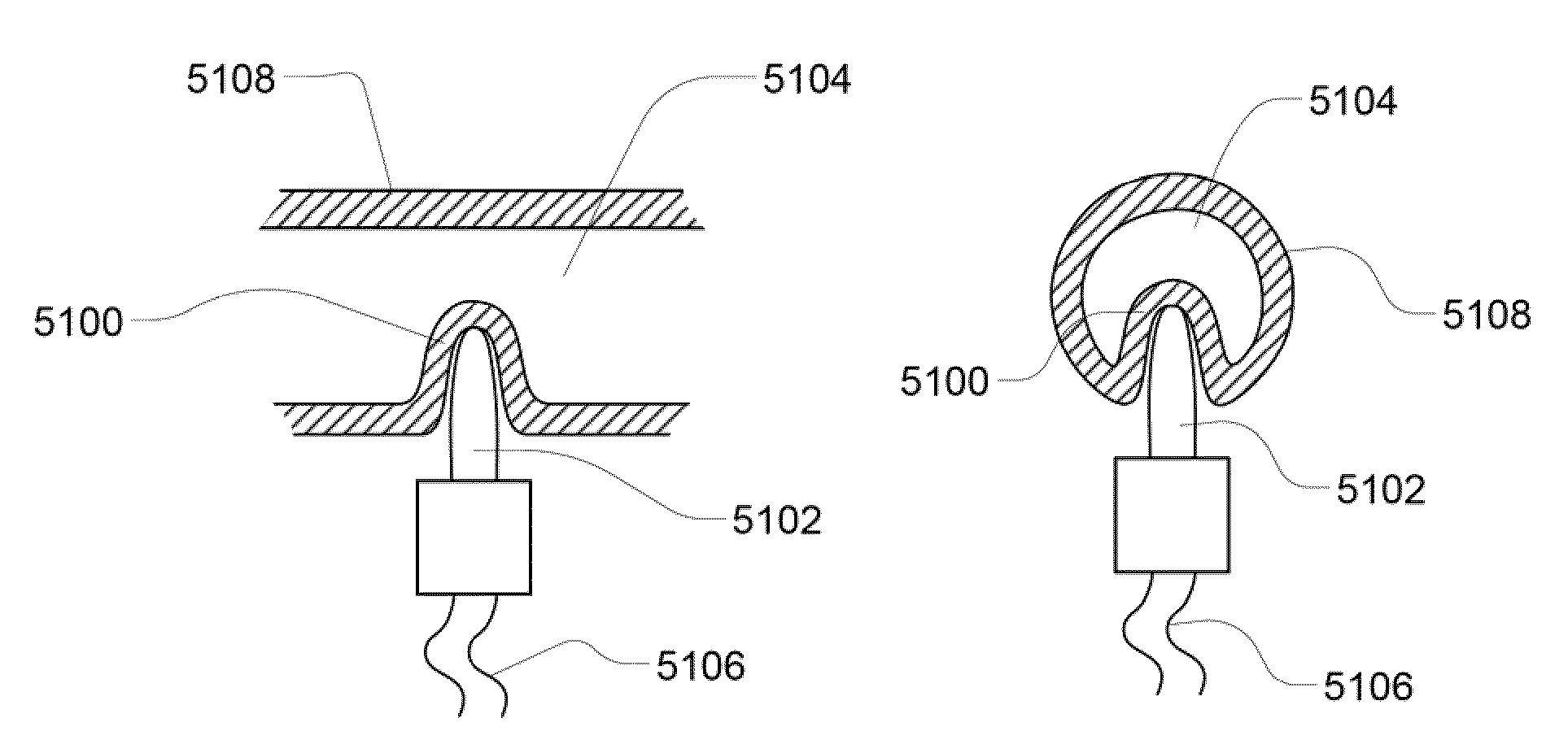

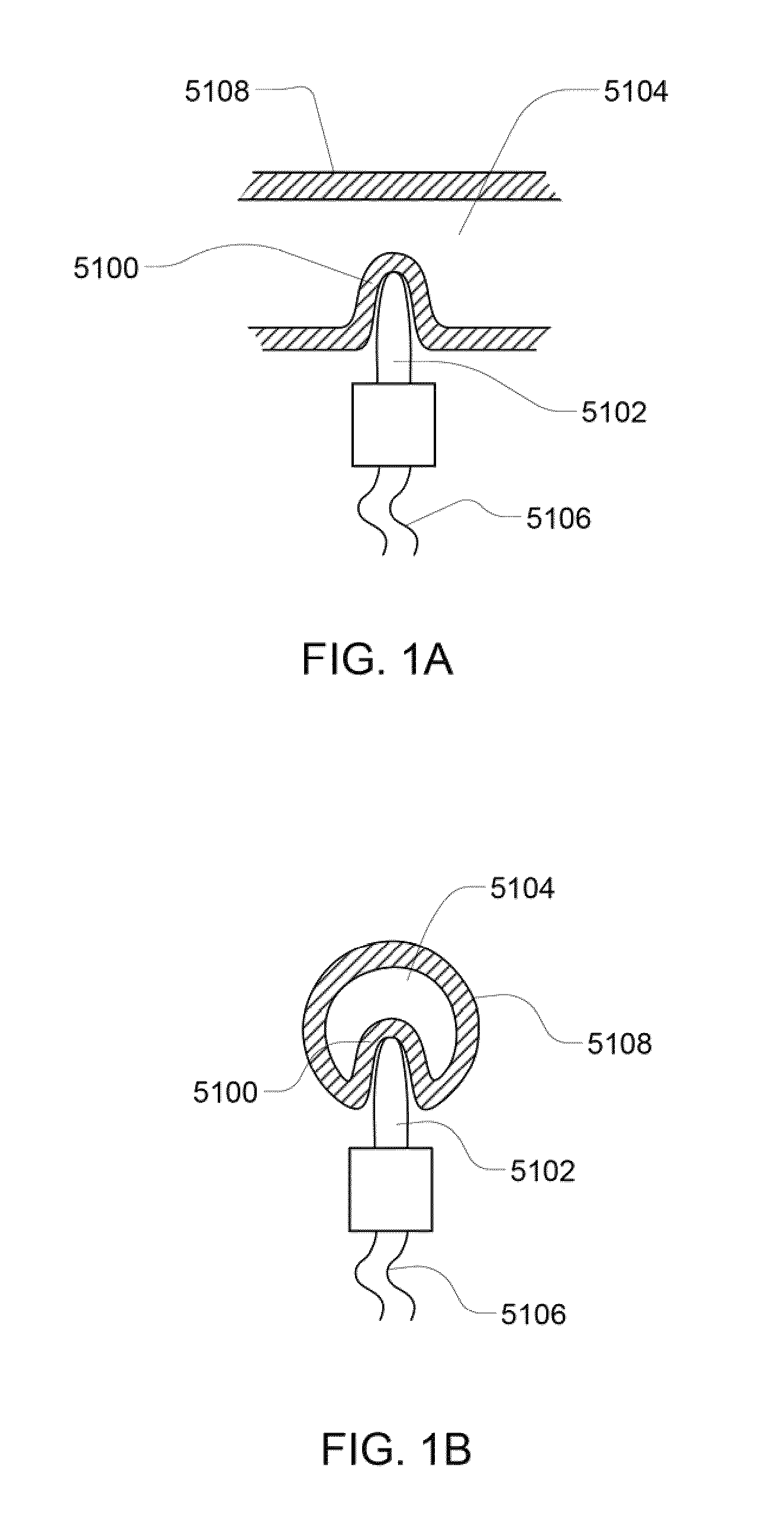

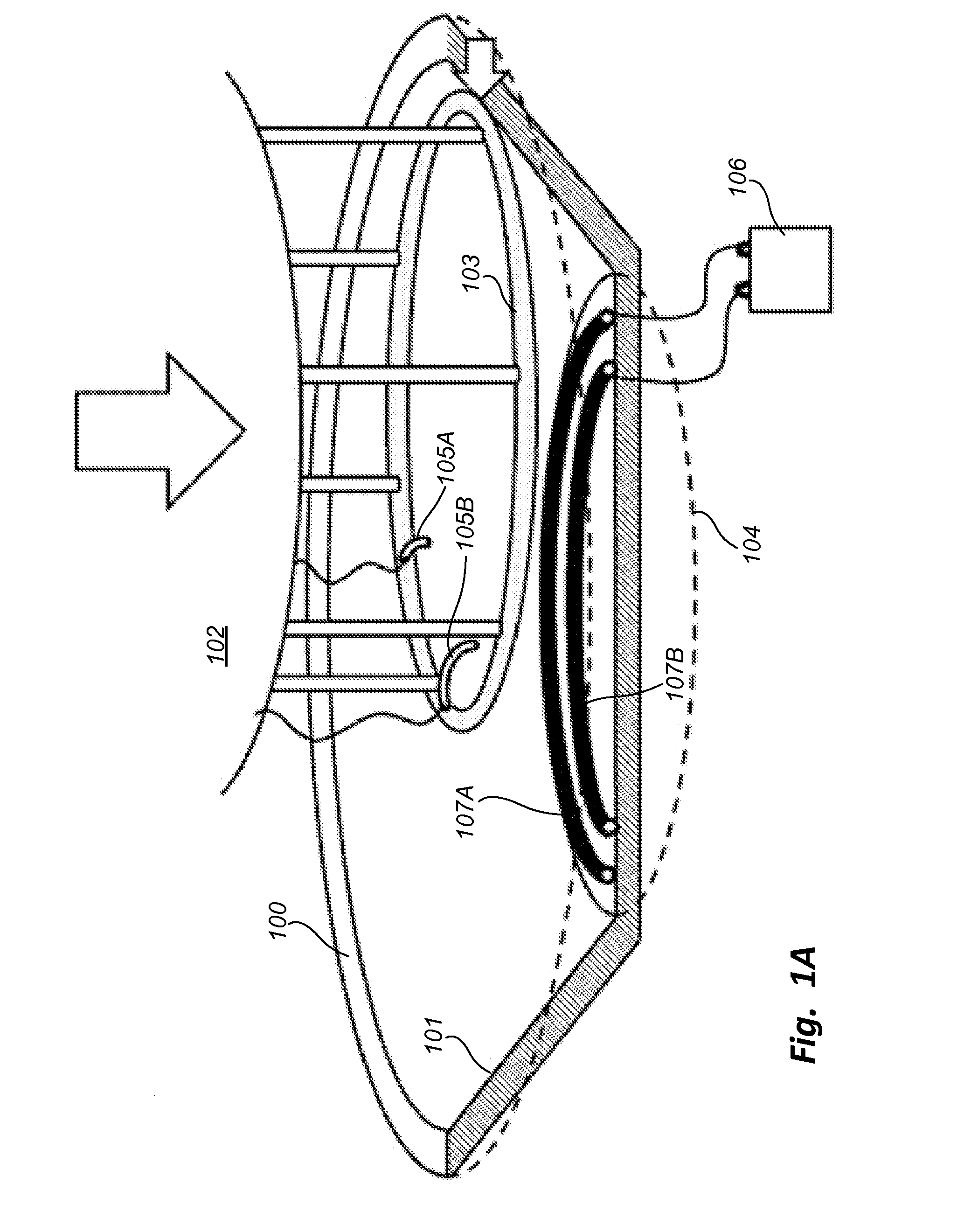

Vehicle replenishment

The present invention extends to methods, systems, devices, and apparatus for replenishing vehicle resources. Vehicles can be aligned with and docked to replenishment devices. In one aspect, a flying vehicle (e.g., an unmanned aerial vehicle (UAV)) is aligned onto electrical recharging contacts. The flying vehicles fuel level or battery charge can be replenished with minimal, if any, human intervention. Vehicle docking (e.g., landing), alignment, and replenishment can be performed automatically. A circular ring or shaped surface of a vehicle can engage with a conical sloping surface of a docking apparatus as a vehicle moves towards and / or into the docking apparatus. The conical sloping surface shape aligns the vehicle with recharge contacts or a refueling probe at the base of the docking apparatus.

Owner:EL-SIGHT LTD

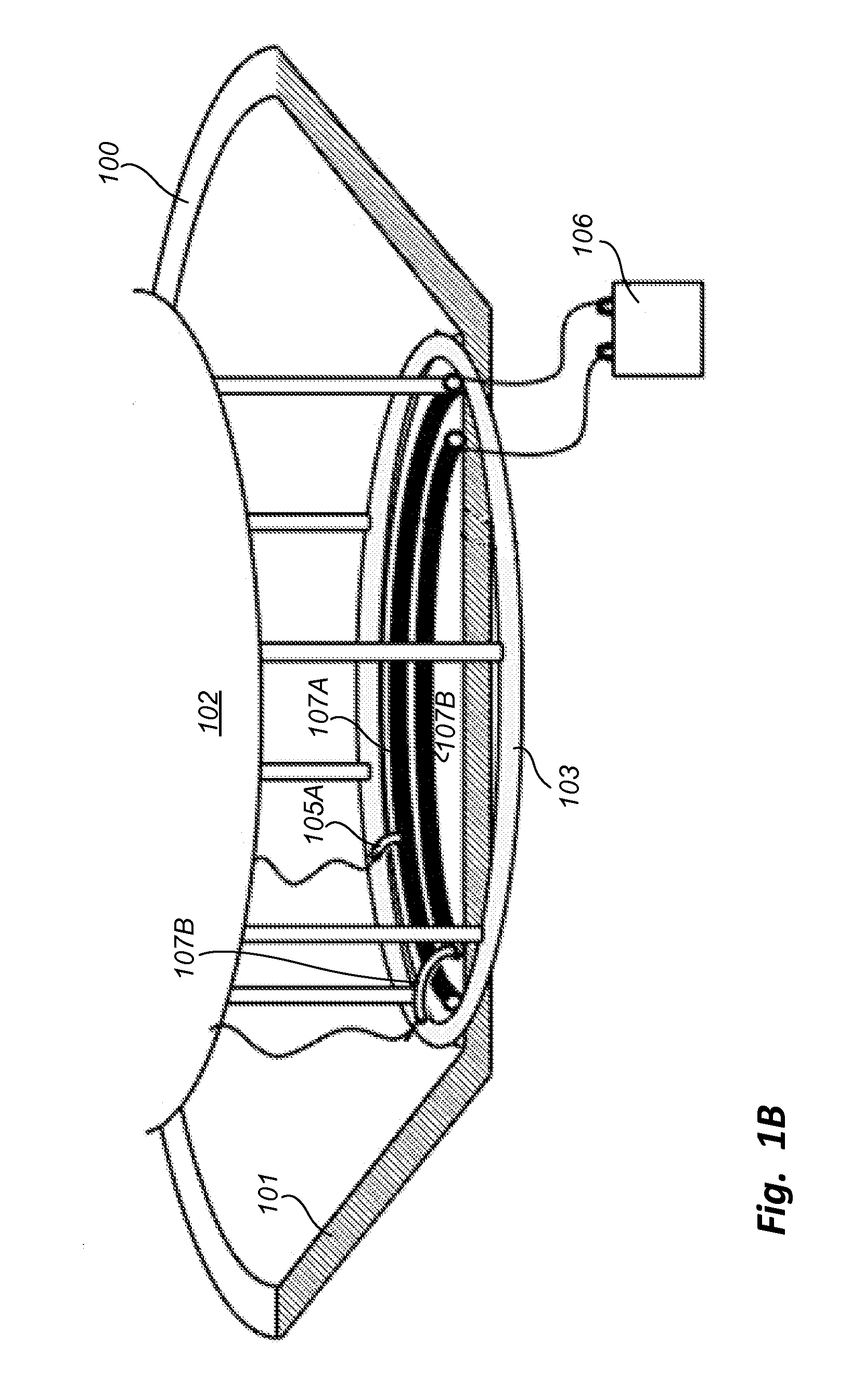

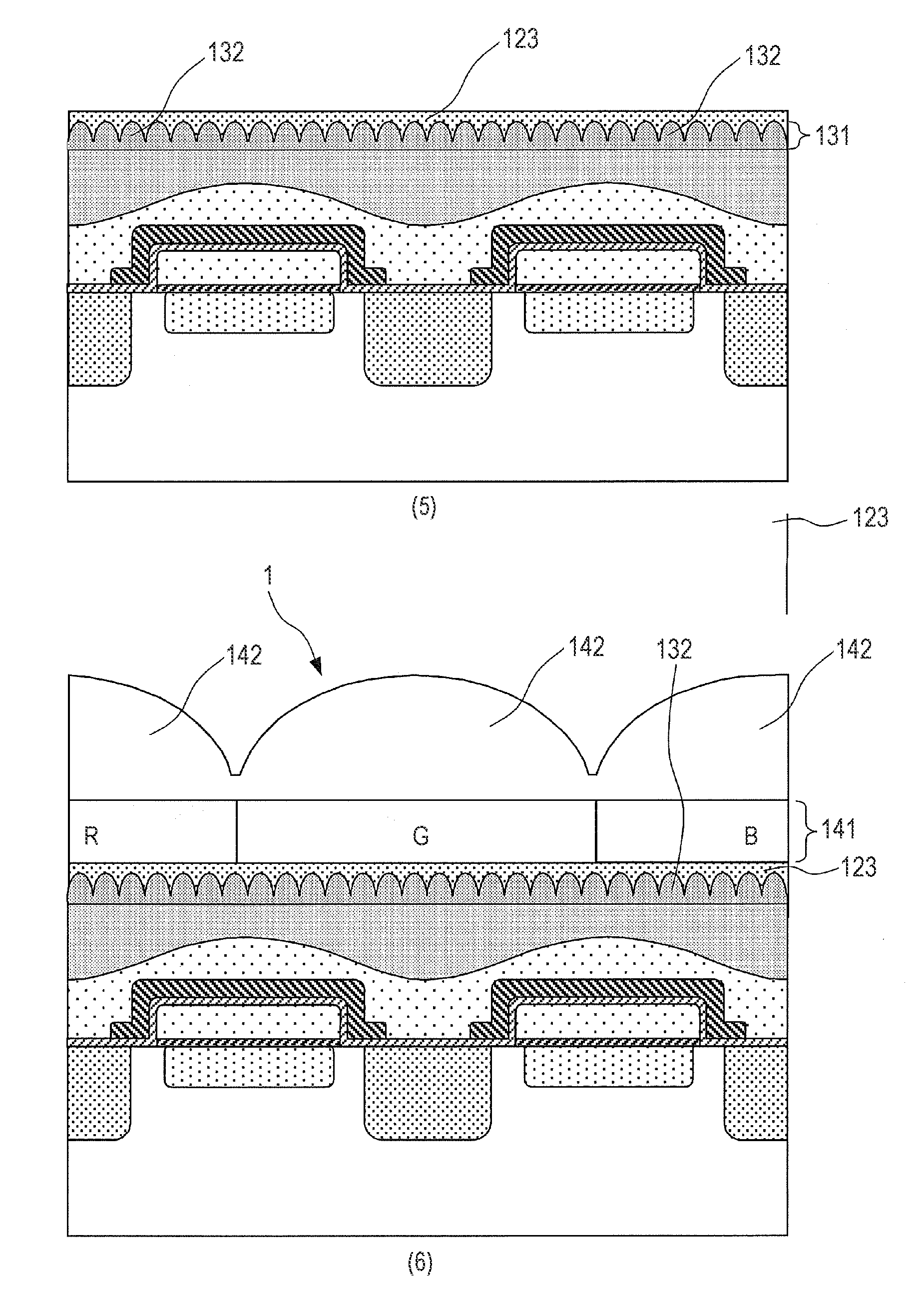

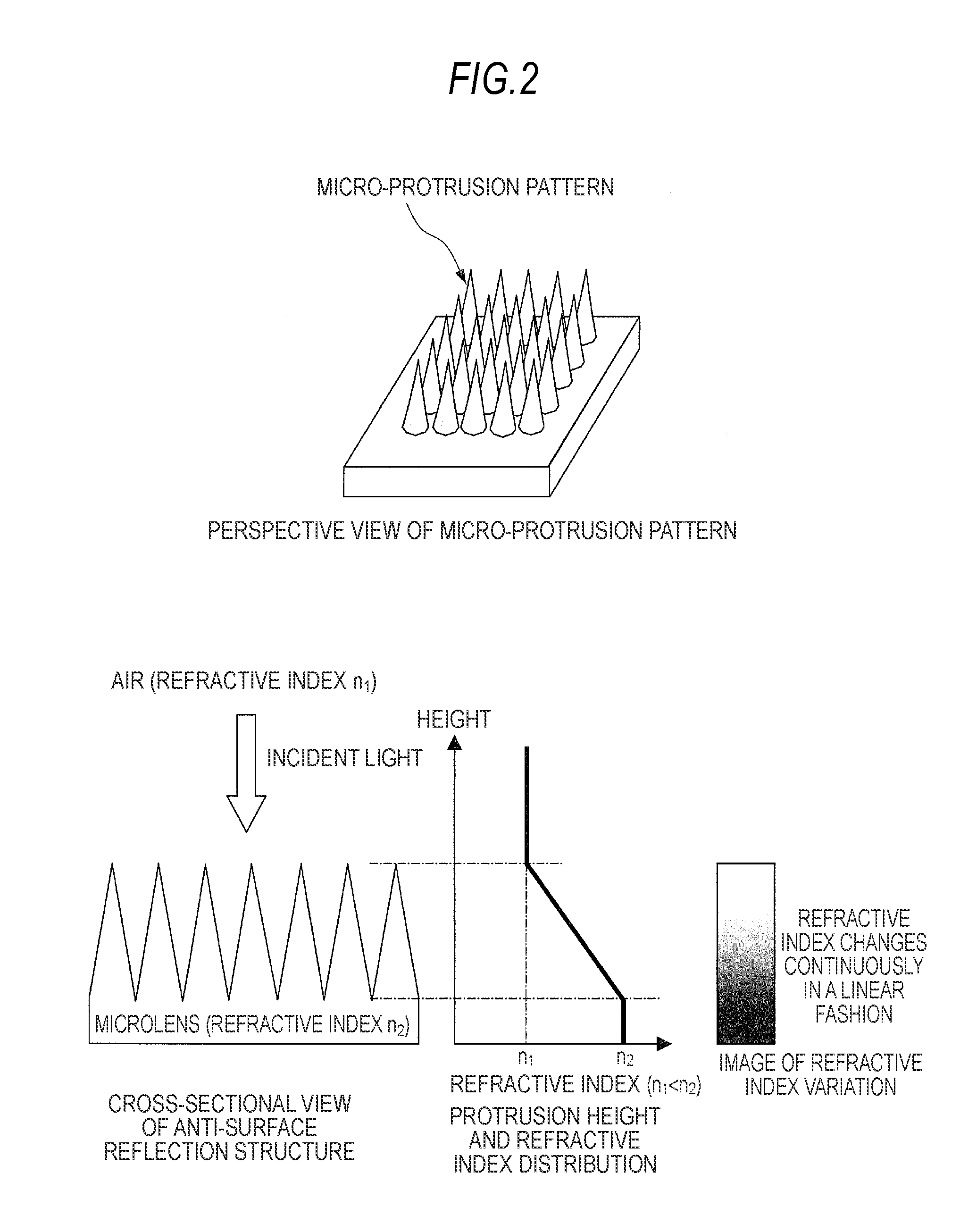

Solid-state imaging device, fabrication method thereof, imaging apparatus, and fabrication method of Anti-reflection structure

InactiveUS20100244169A1Avoid sensitivityHigh sensitivitySolid-state devicesSemiconductor/solid-state device manufacturingThin membraneSurface shape

A fabrication method of an anti-reflection structure includes the steps of: forming a resin film having micro-particles dispersed therein on a surface of a substrate; forming a protrusion dummy pattern on the resin film by etching the resin film using the micro-particles in the resin film as a mask while gradually etching the micro-particles; and forming a protrusion pattern on the surface of the substrate by etching back the surface of the substrate together with the resin film having the protrusion dummy pattern formed thereon, and transferring a surface shape of the protrusion dummy pattern formed on a surface of the resin film to the surface of the substrate.

Owner:SONY CORP

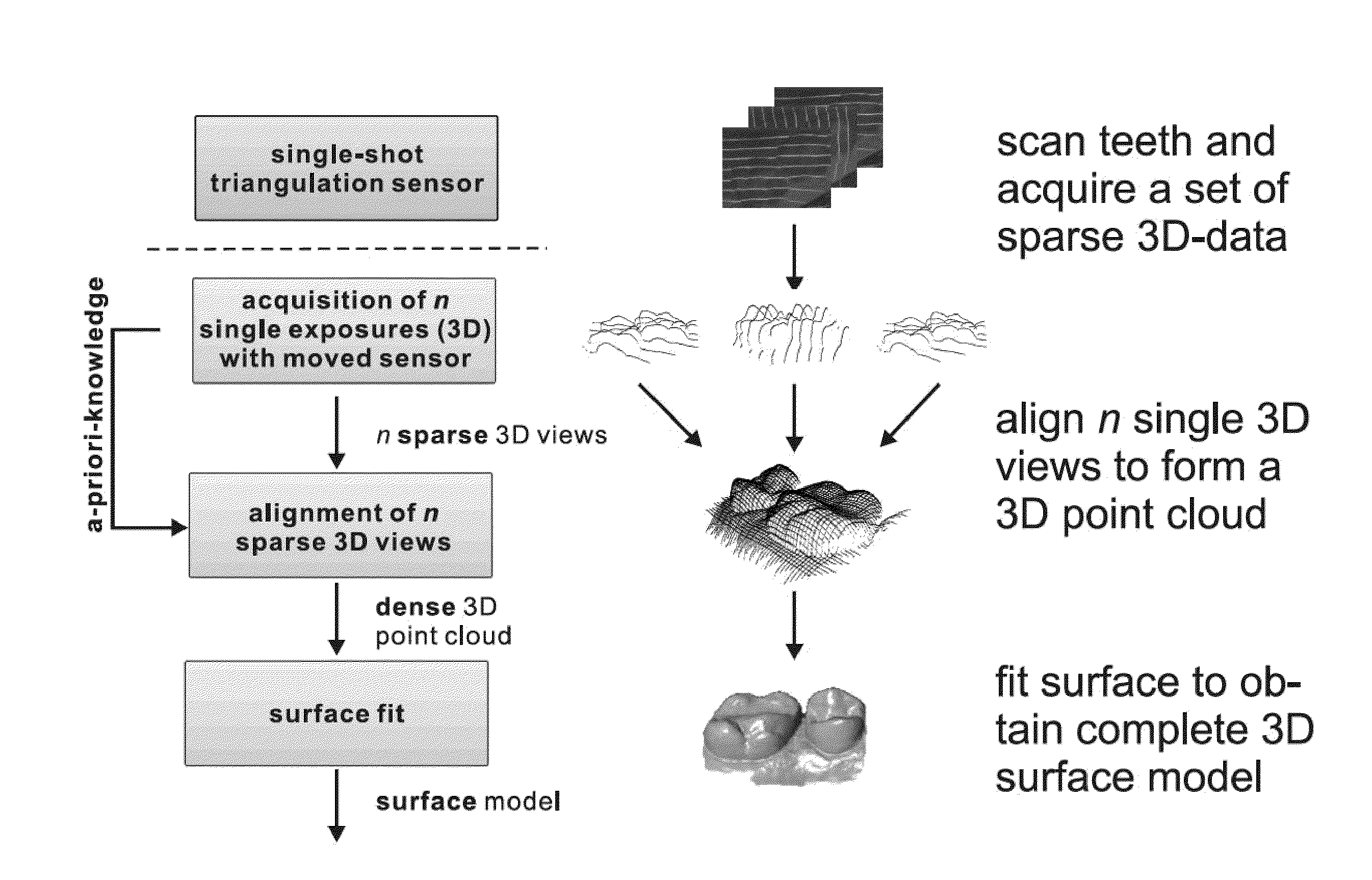

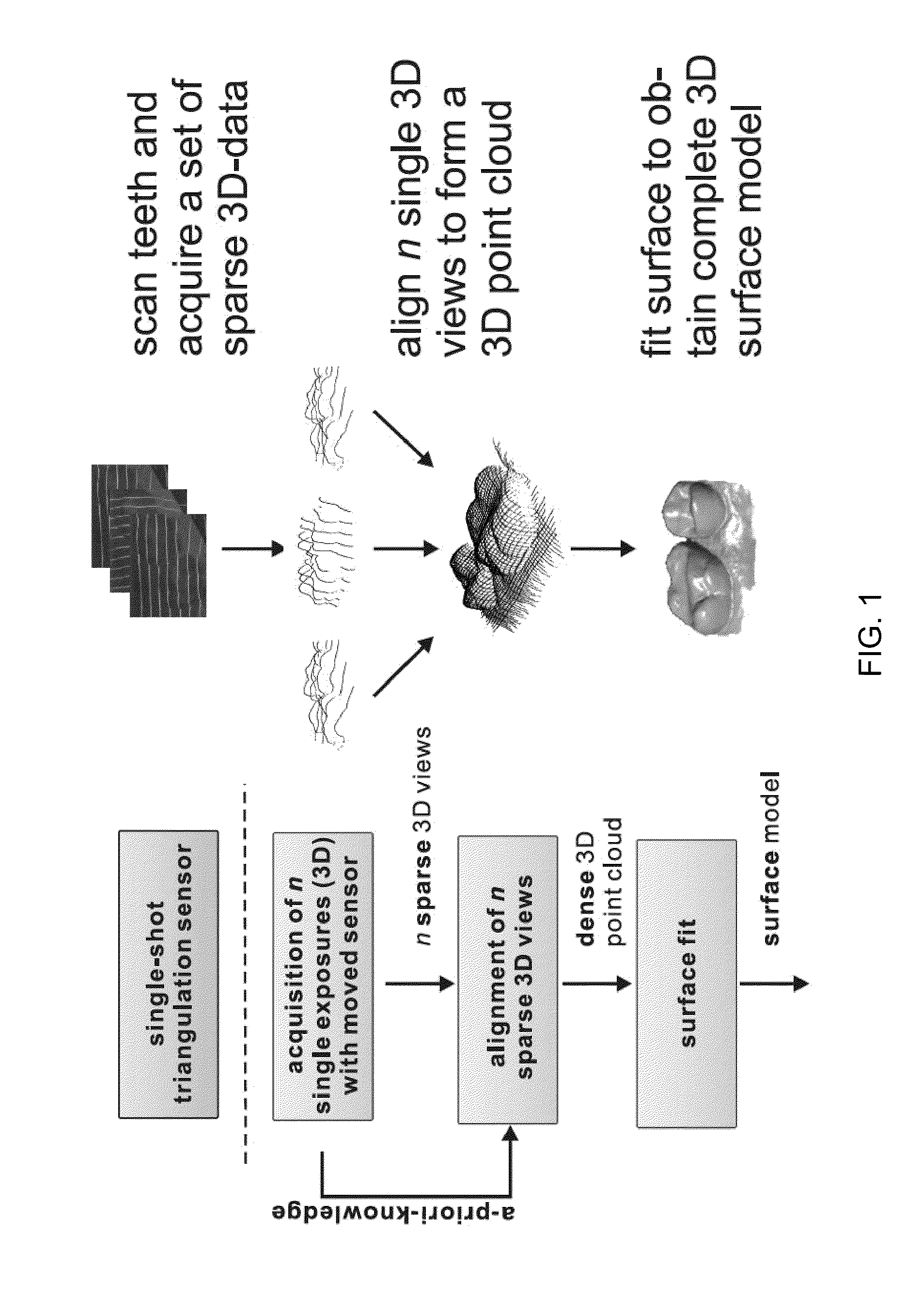

Method and device for three-dimensional surface detection with a dynamic reference frame

ActiveUS20100303341A1Simple and robust acquisitionImage enhancementImage analysisData setSingle exposure

The surface shape of a three-dimensional object is acquired with an optical sensor. The sensor, which has a projection device and a camera, is configured to generate three-dimensional data from a single exposure, and the sensor is moved relative to the three-dimensional object, or vice versa. A pattern is projected onto the three-dimensional object and a sequence of overlapping images of the projected pattern is recorded with the camera. A sequence of 3D data sets is determined from the recorded images and a registration is effected between subsequently obtained 3D data sets. This enables the sensor to be moved freely about the object, or vice versa, without tracking their relative position, and to determine a surface shape of the three-dimensional object on the fly.

Owner:DENTSPLY SIRONA INC

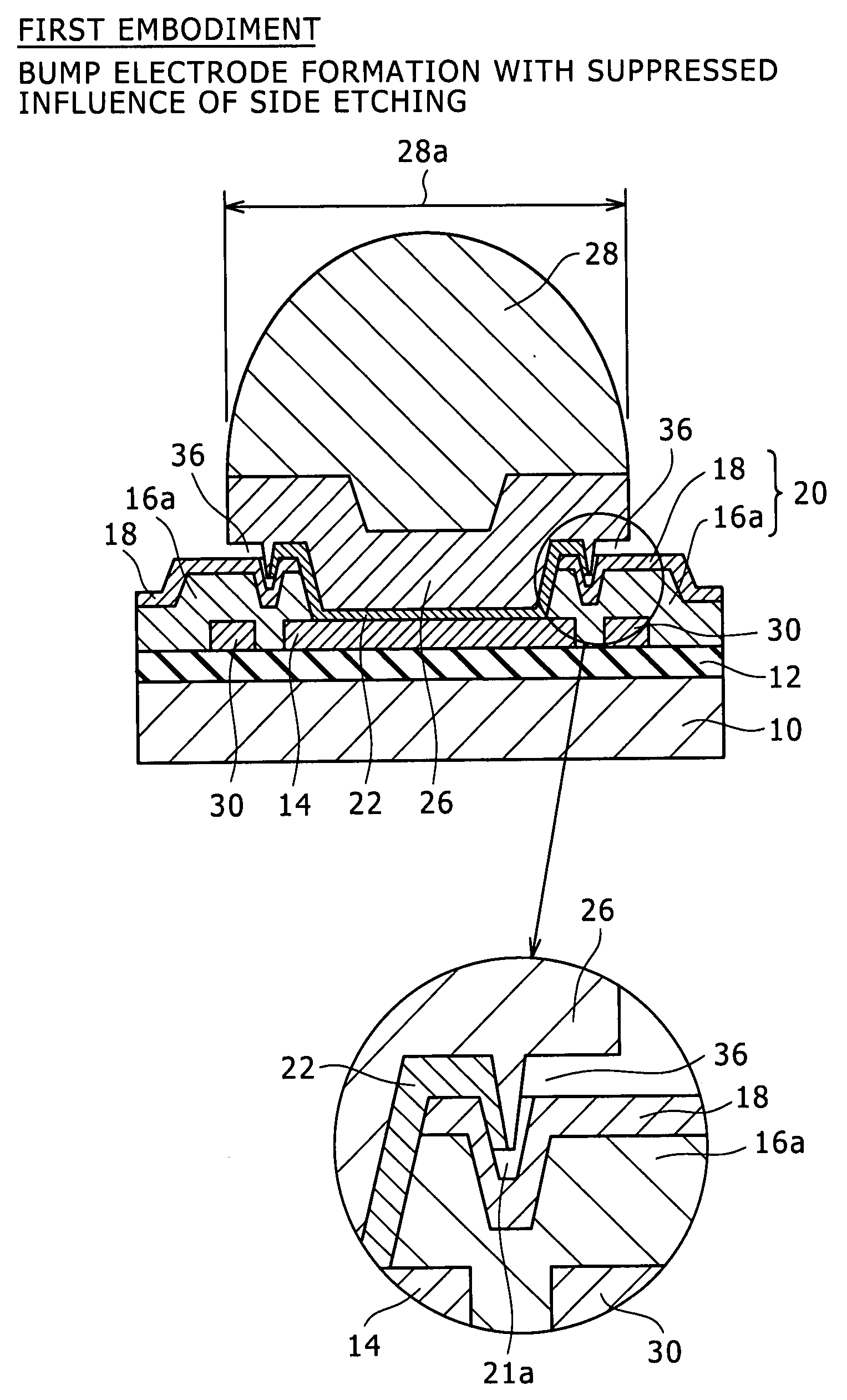

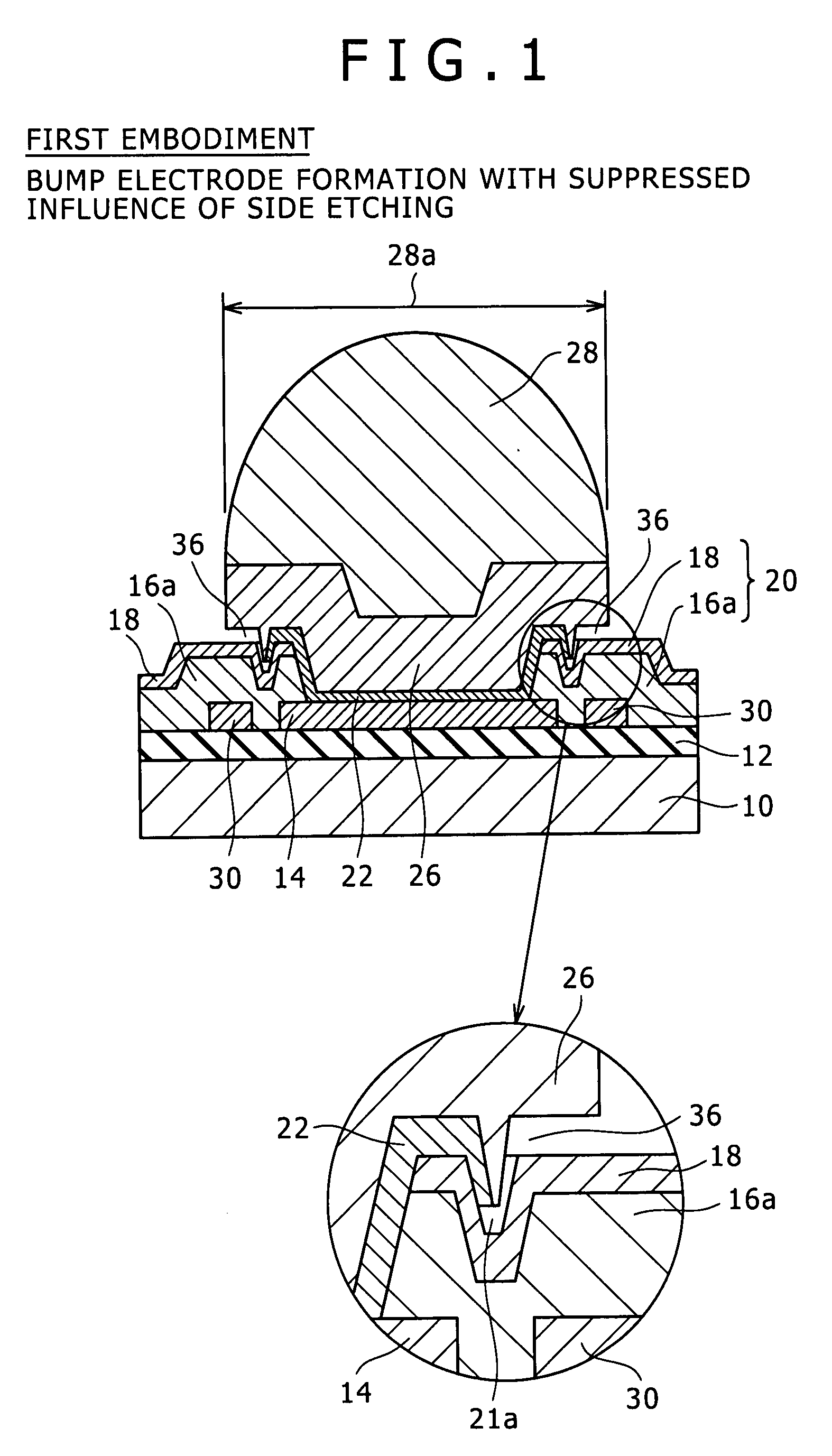

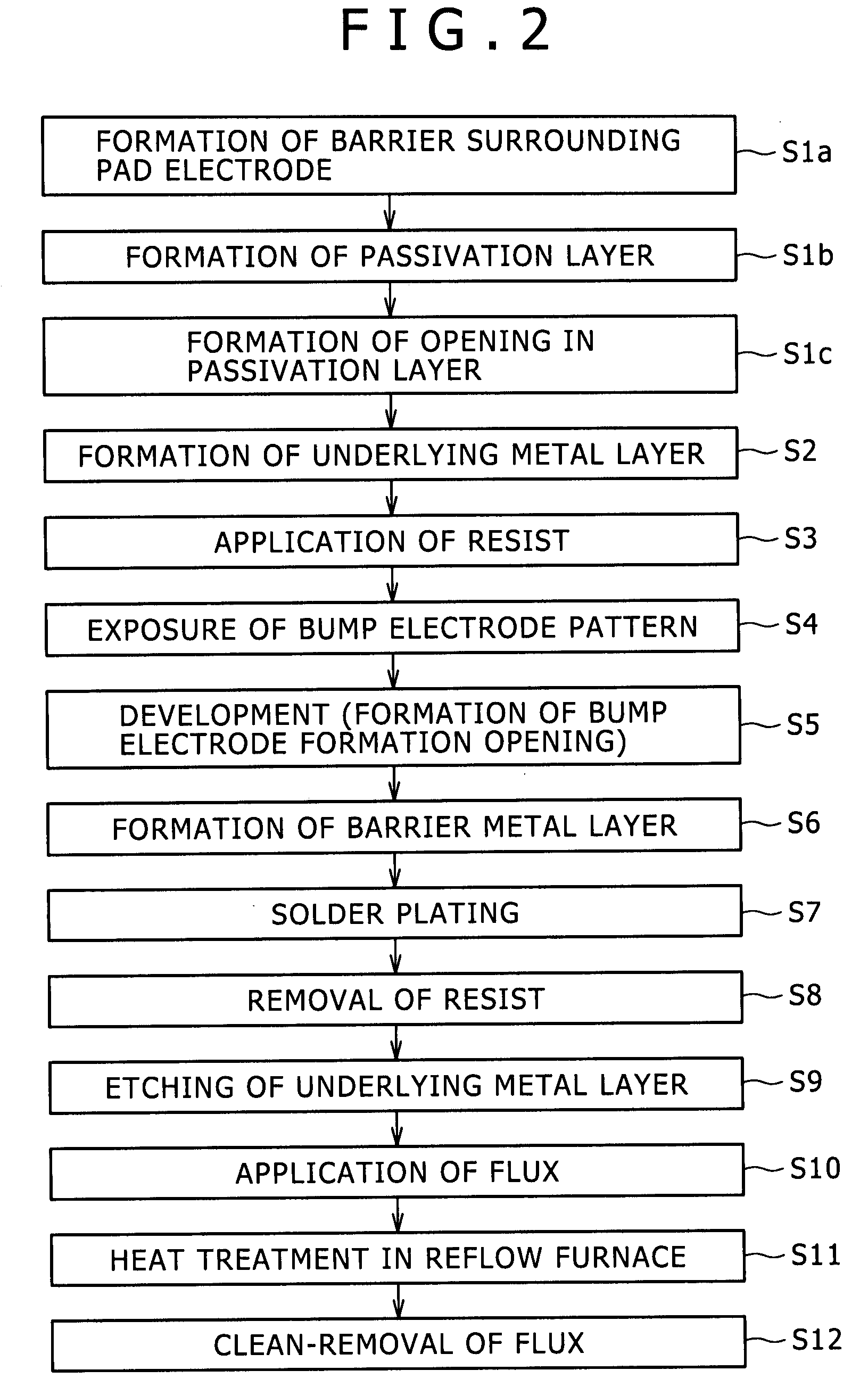

Electronic component, semiconductor device employing same, and method for manufacturing electronic component

ActiveUS20070290343A1Reduce bond strengthHighly reliable electric connectionSemiconductor/solid-state device detailsSolid-state devicesElectronic componentSemiconductor

Herein disclosed an electronic component having a passivation layer in which an opening that exposes a part of a pad electrode is formed, an underlying metal layer formed on the pad electrode and the passivation layer, and a barrier metal layer formed on the underlying metal layer for an external connection electrode, the electronic component including a recess or / and a projection configured to be provided under the barrier metal layer outside or / and inside the opening, the underlying metal layer being formed on the recess or / and the projection and having a surface shape that follows the recess or / and the projection.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com