Patents

Literature

1241 results about "Quality assurance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quality assurance (QA) is a way of preventing mistakes and defects in manufactured products and avoiding problems when delivering products or services to customers; which ISO 9000 defines as "part of quality management focused on providing confidence that quality requirements will be fulfilled". This defect prevention in quality assurance differs subtly from defect detection and rejection in quality control and has been referred to as a shift left since it focuses on quality earlier in the process (i.e., to the left of a linear process diagram reading left to right).

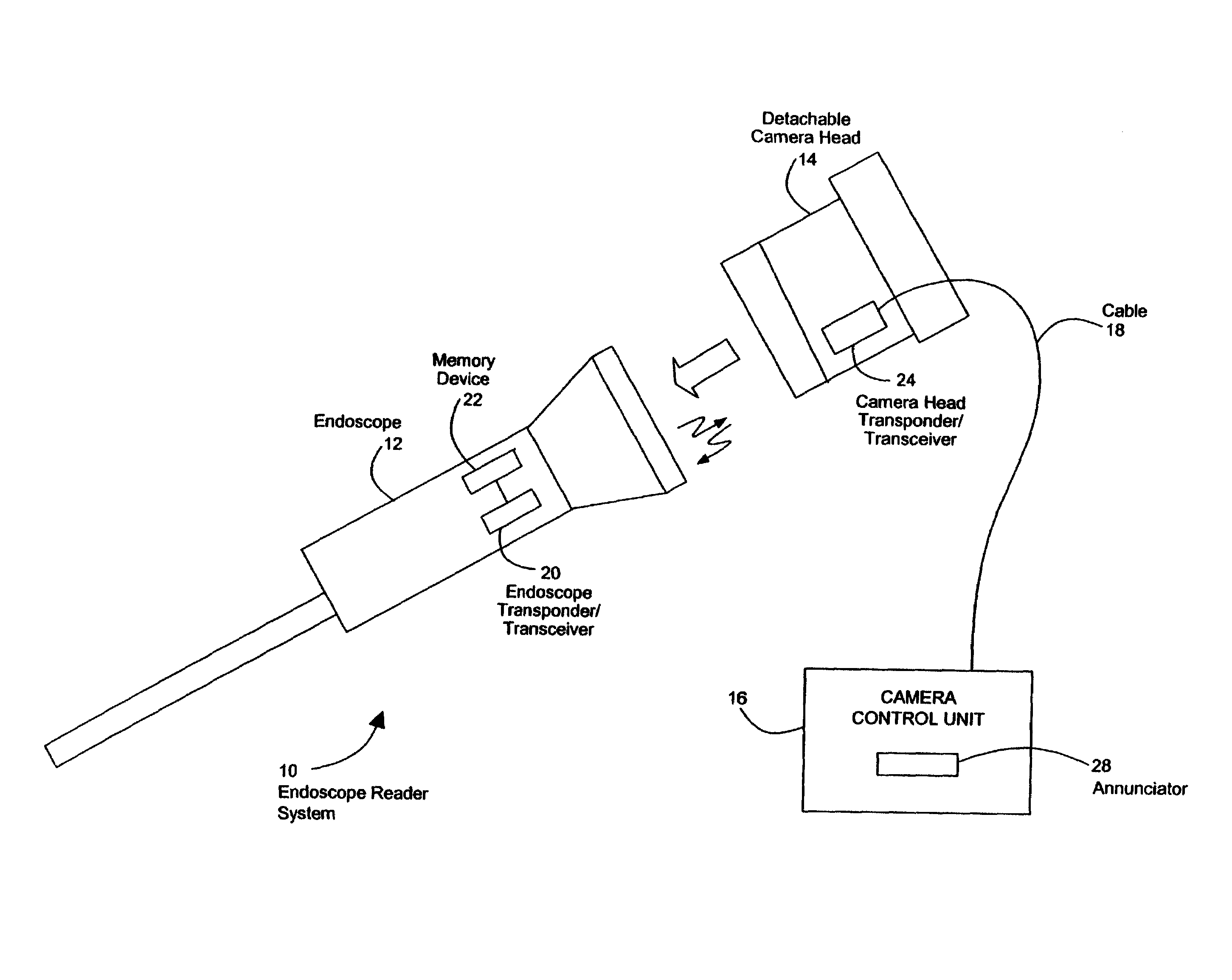

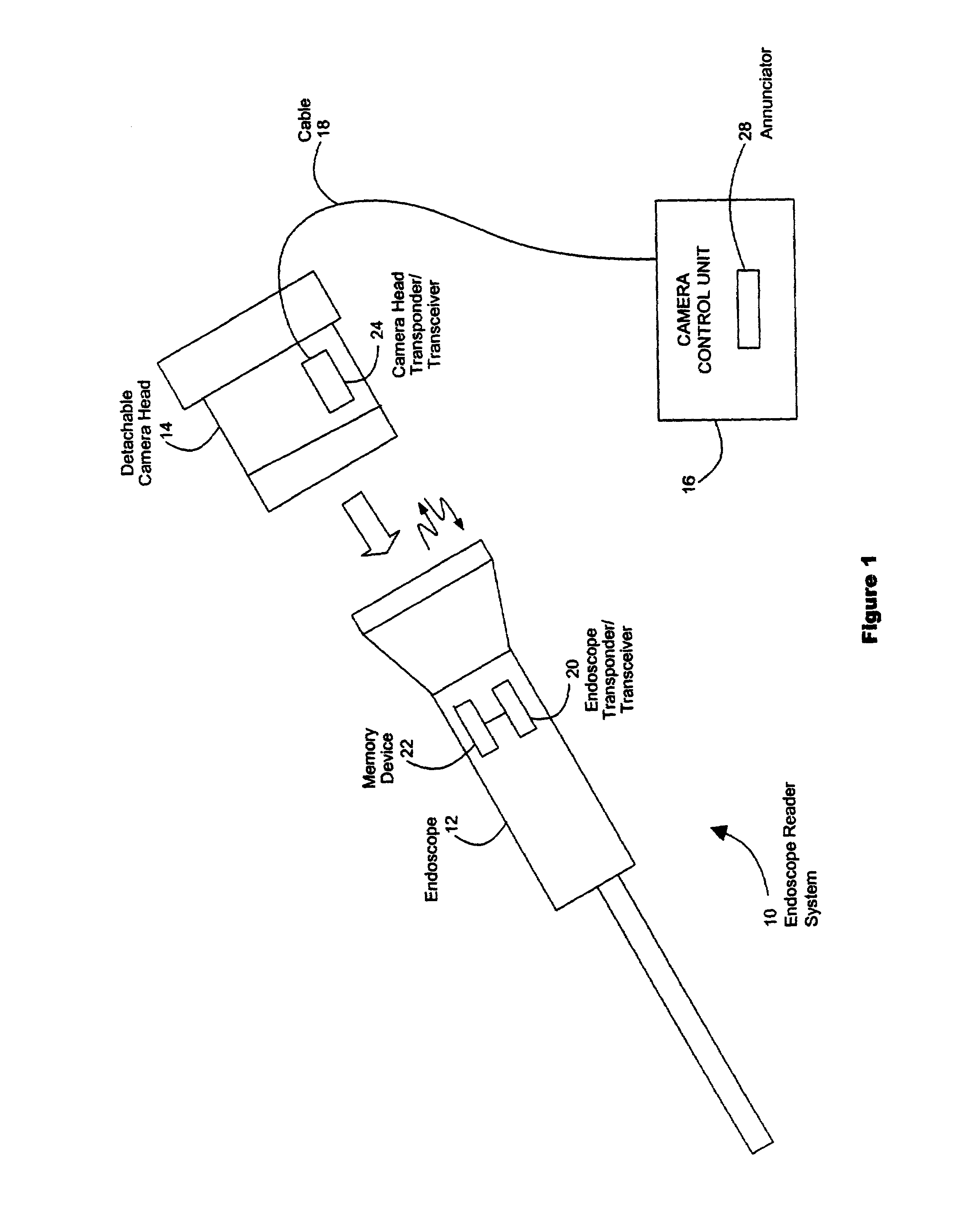

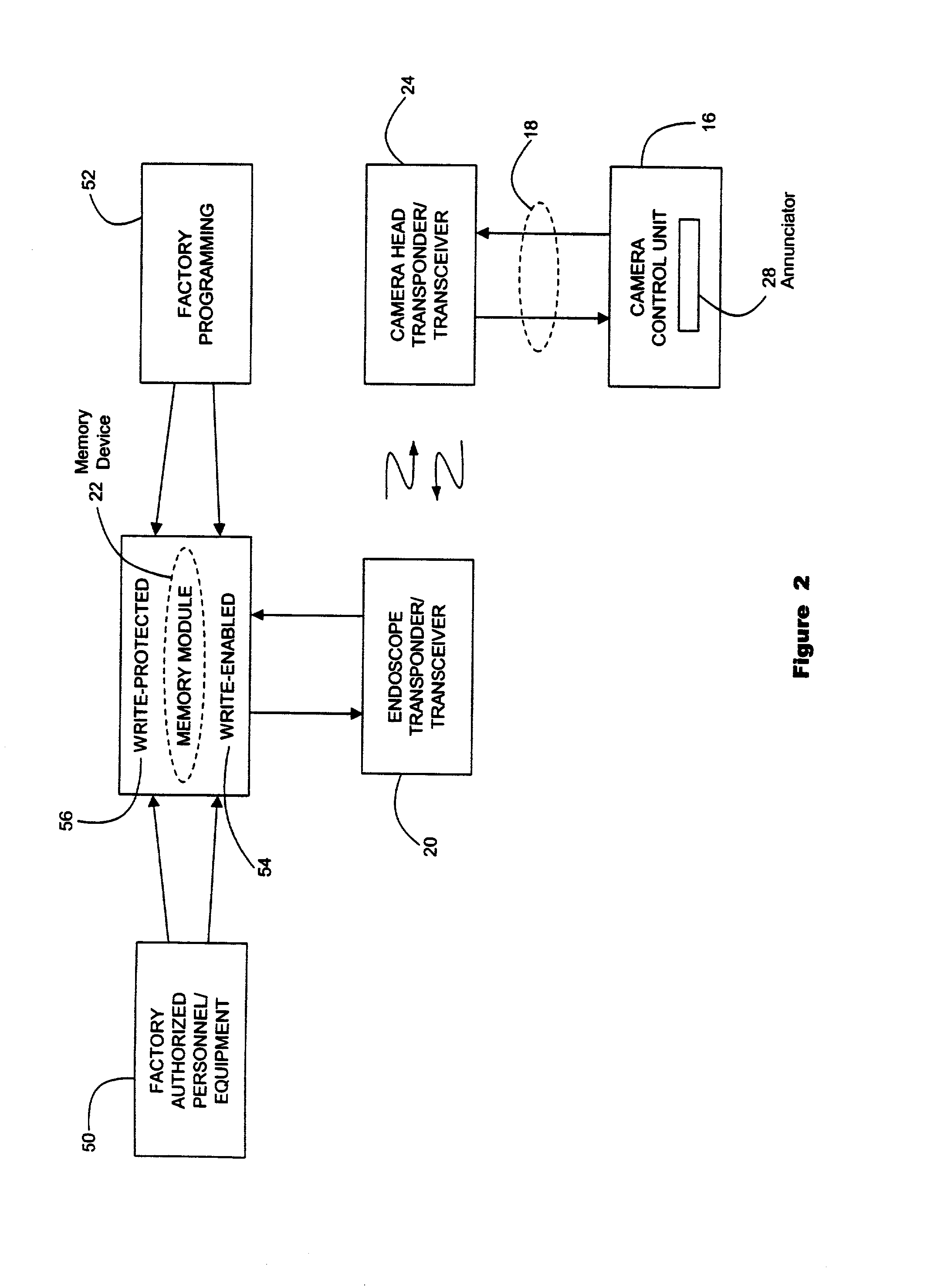

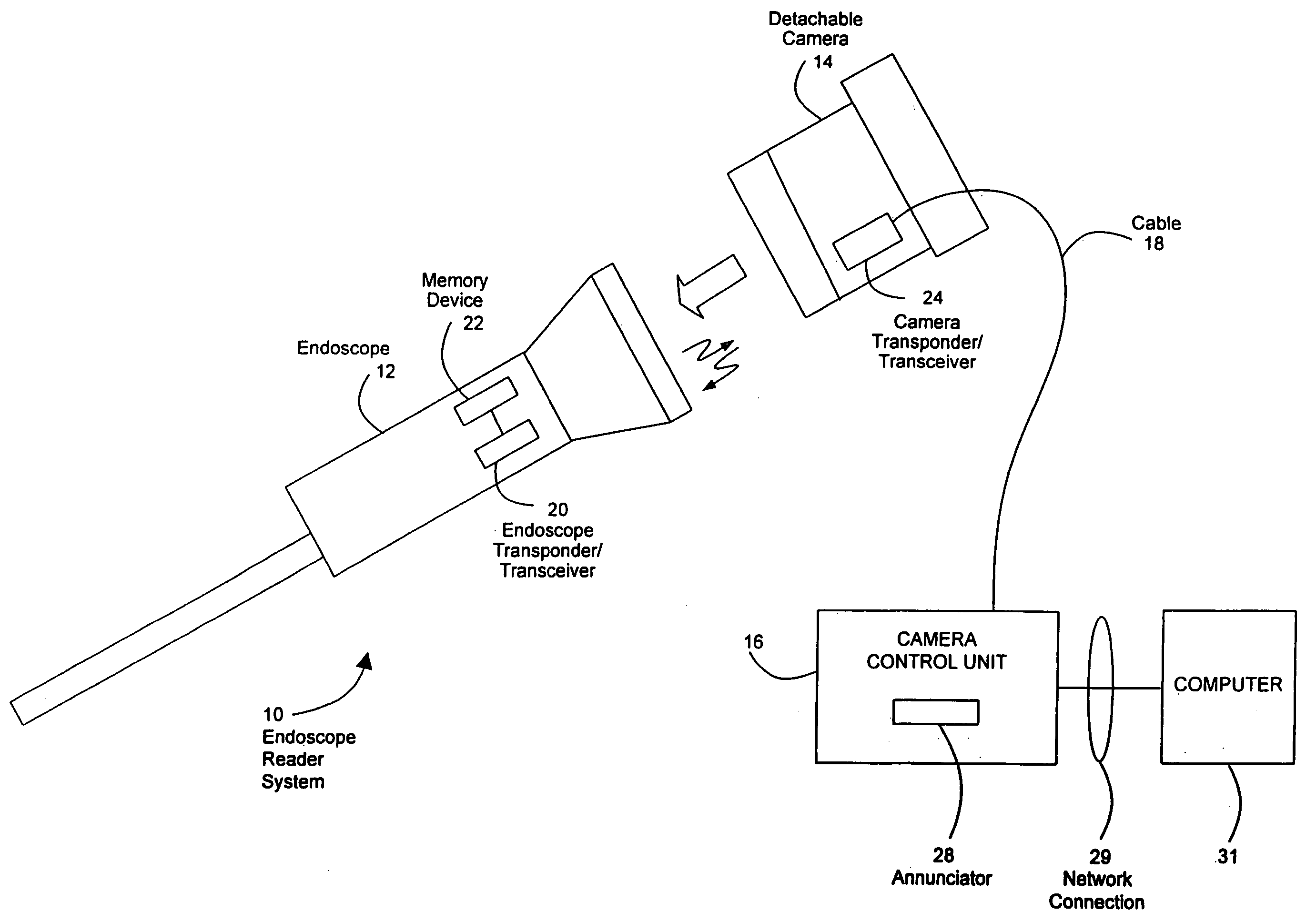

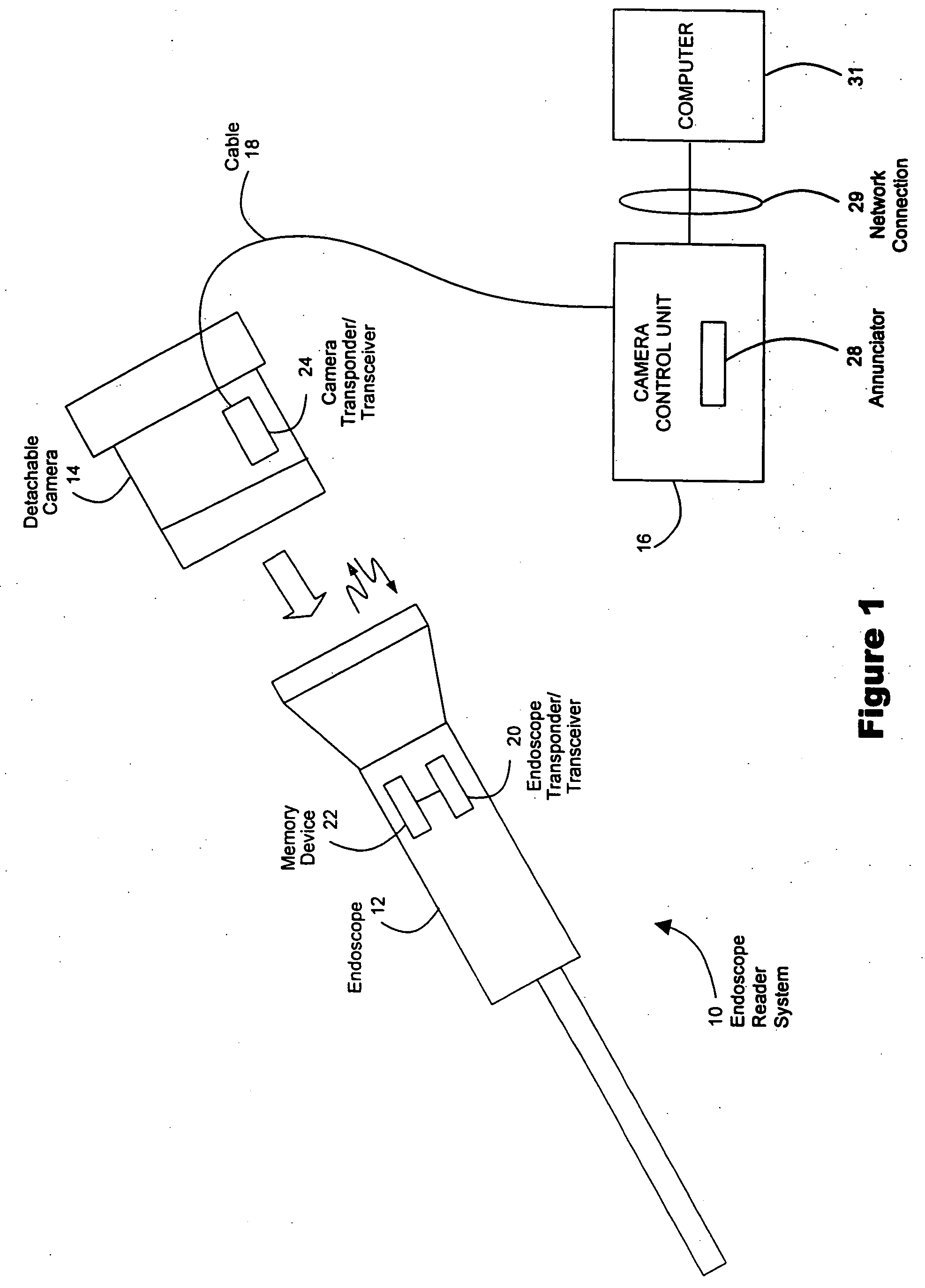

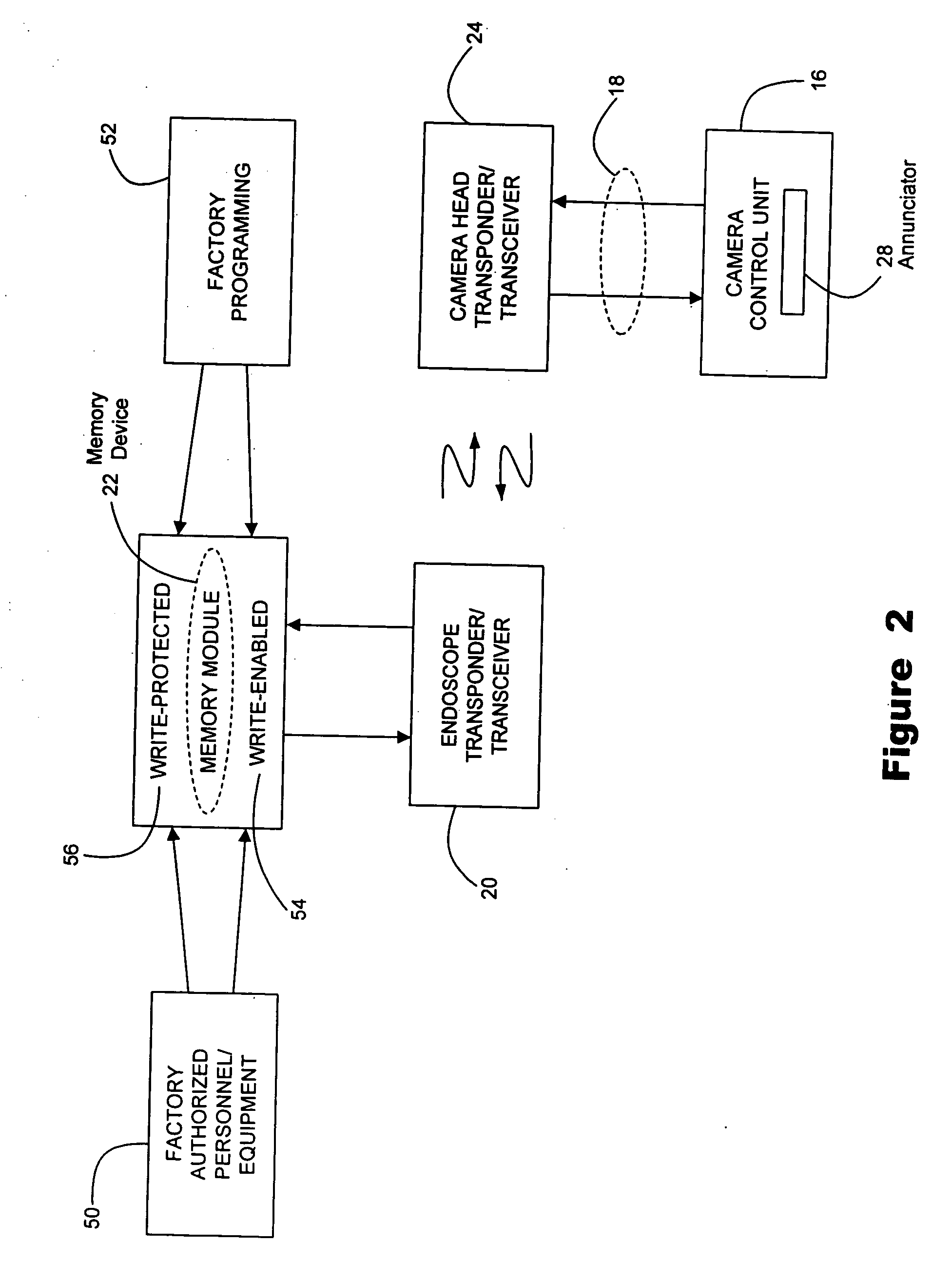

Endoscope reader

ActiveUS7289139B2Realize automatic adjustmentTelevision system detailsSurgeryQuality assuranceComputer graphics (images)

A system for automatically setting video signal processing parameters for an endoscopic video camera system based upon characteristics of an attached endoscope, with reduced EMI and improved inventory tracking, maintenance and quality assurance, and reducing the necessity for adjustment and alignment of the endoscope and camera to achieve the data transfer.

Owner:KARL STORZ IMAGING INC

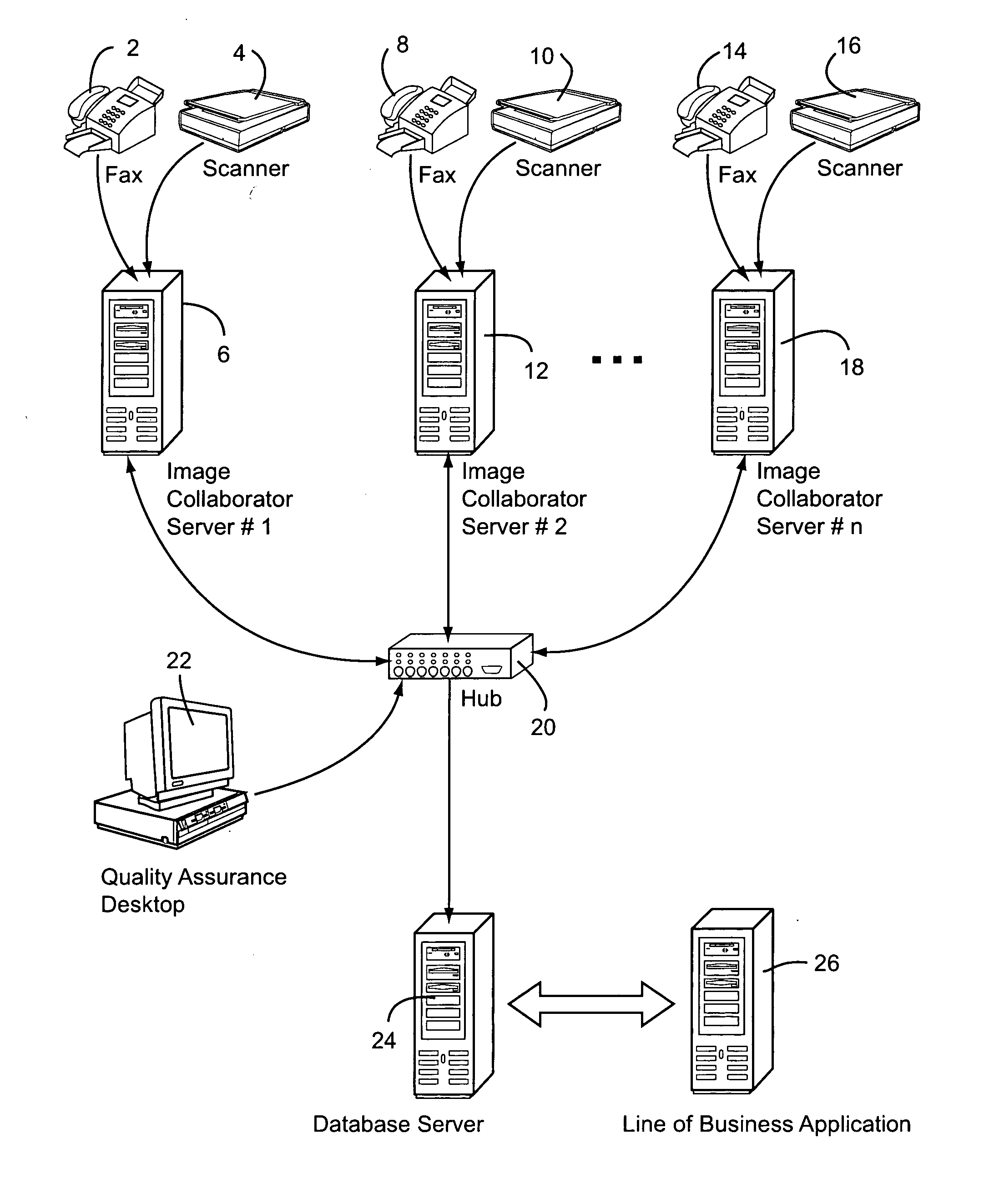

Document management system with enhanced intelligent document recognition capabilities

InactiveUS20050289182A1Enhances document management qualityImprove efficiencyCharacter and pattern recognitionOffice automationXMLData extraction

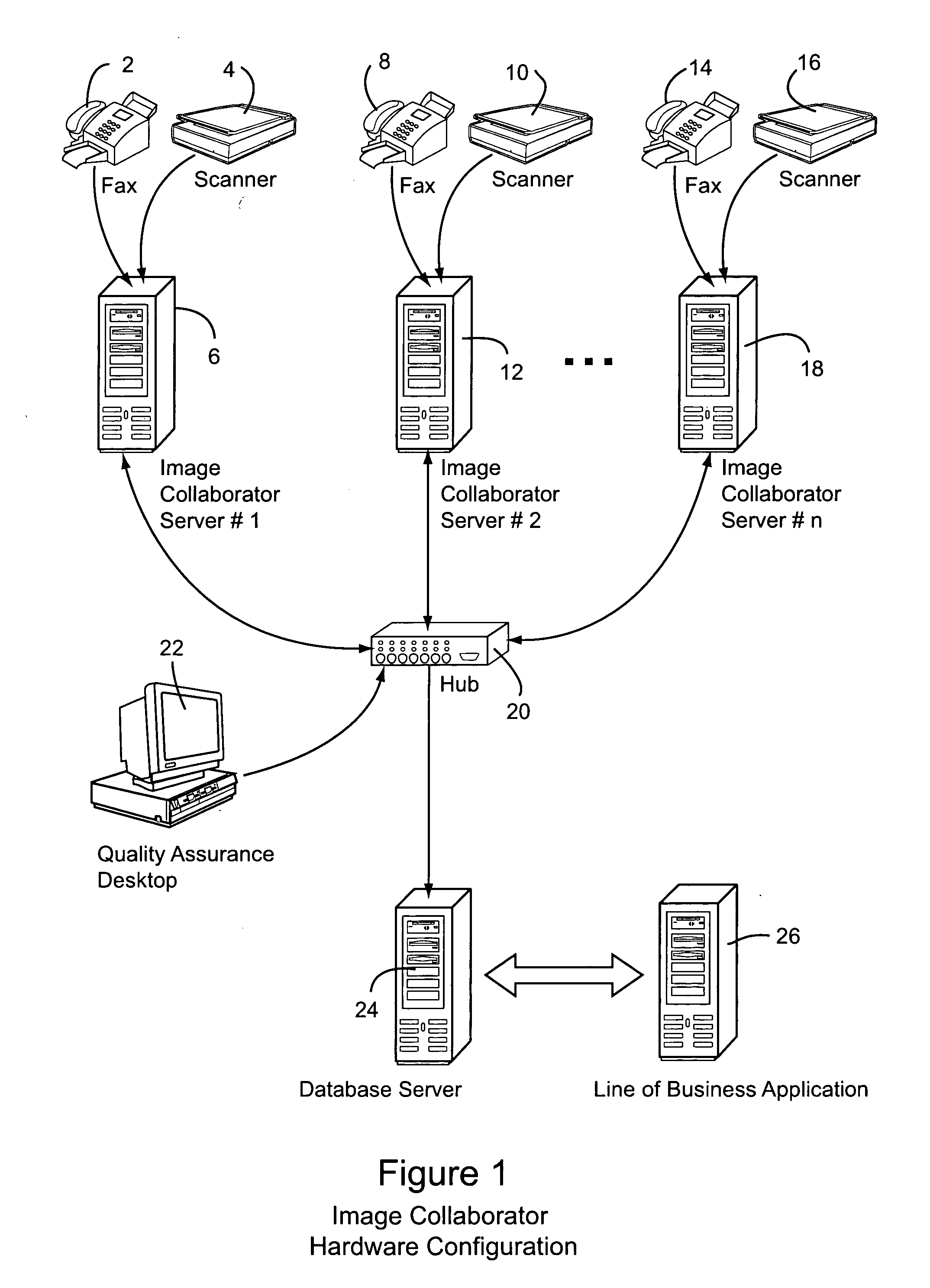

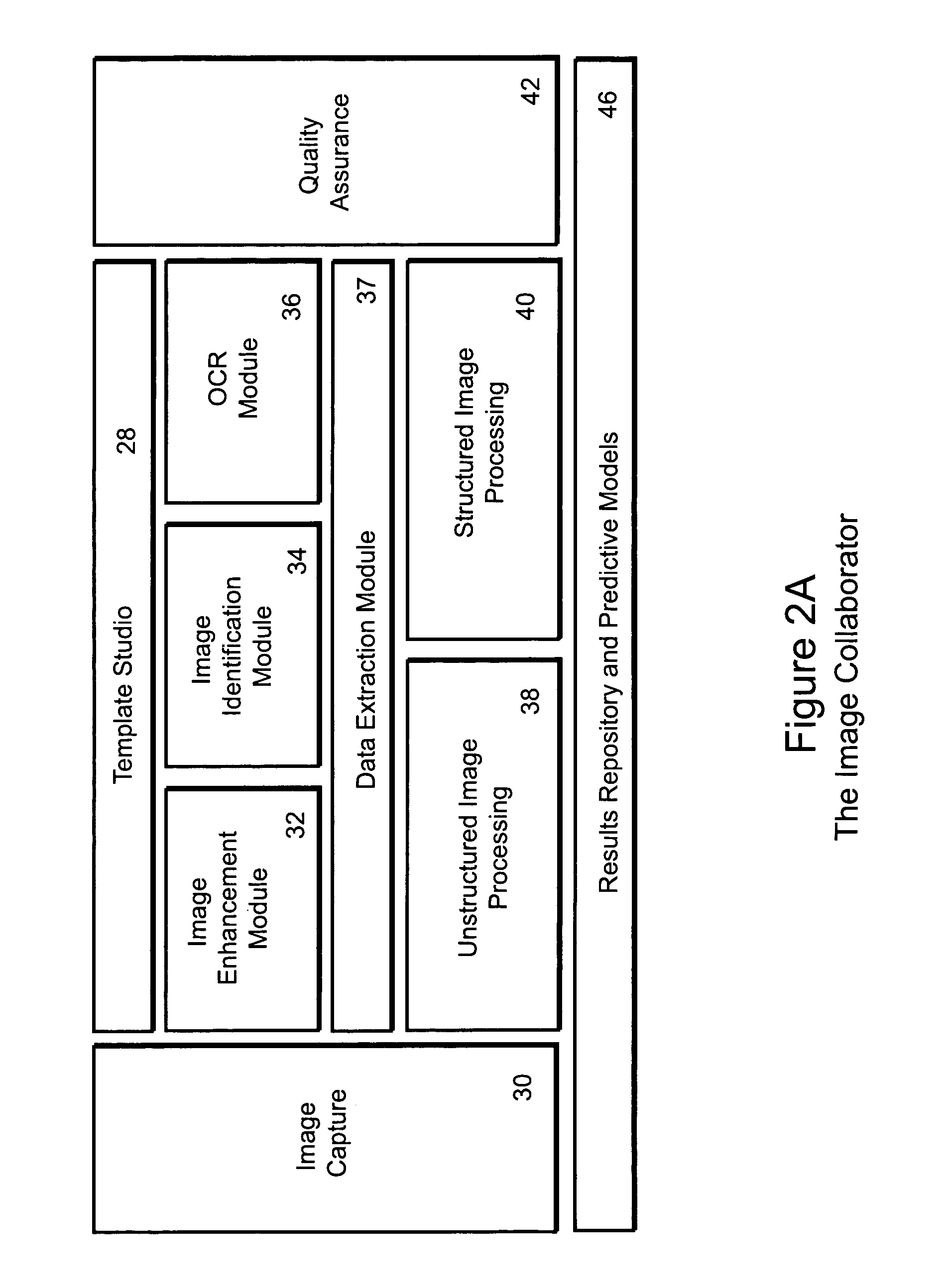

An intelligent document recognition-based document management system includes modules for image capture, image enhancement, image identification, optical character recognition, data extraction and quality assurance. The system captures data from electronic documents as diverse as facsimile images, scanned images and images from document management systems. It processes these images and presents the data in, for example, a standard XML format. The document management system processes both structured document images (ones which have a standard format) and unstructured document images (ones which do not have a standard format). The system can extract images directly from a facsimile machine, a scanner or a document management system for processing.

Owner:SAND HILL SYST

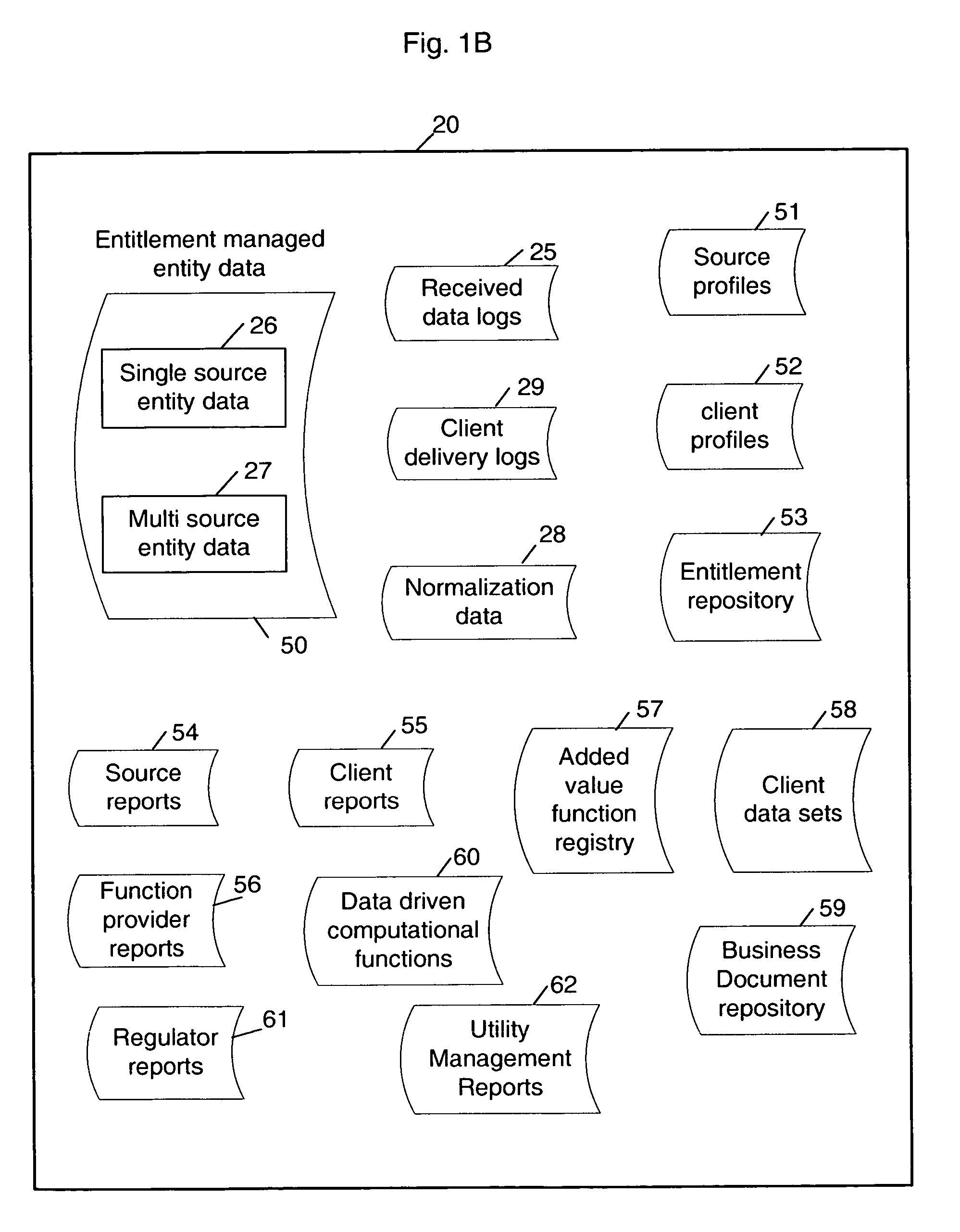

Sharable multi-tenant reference data utility and methods of operation of same

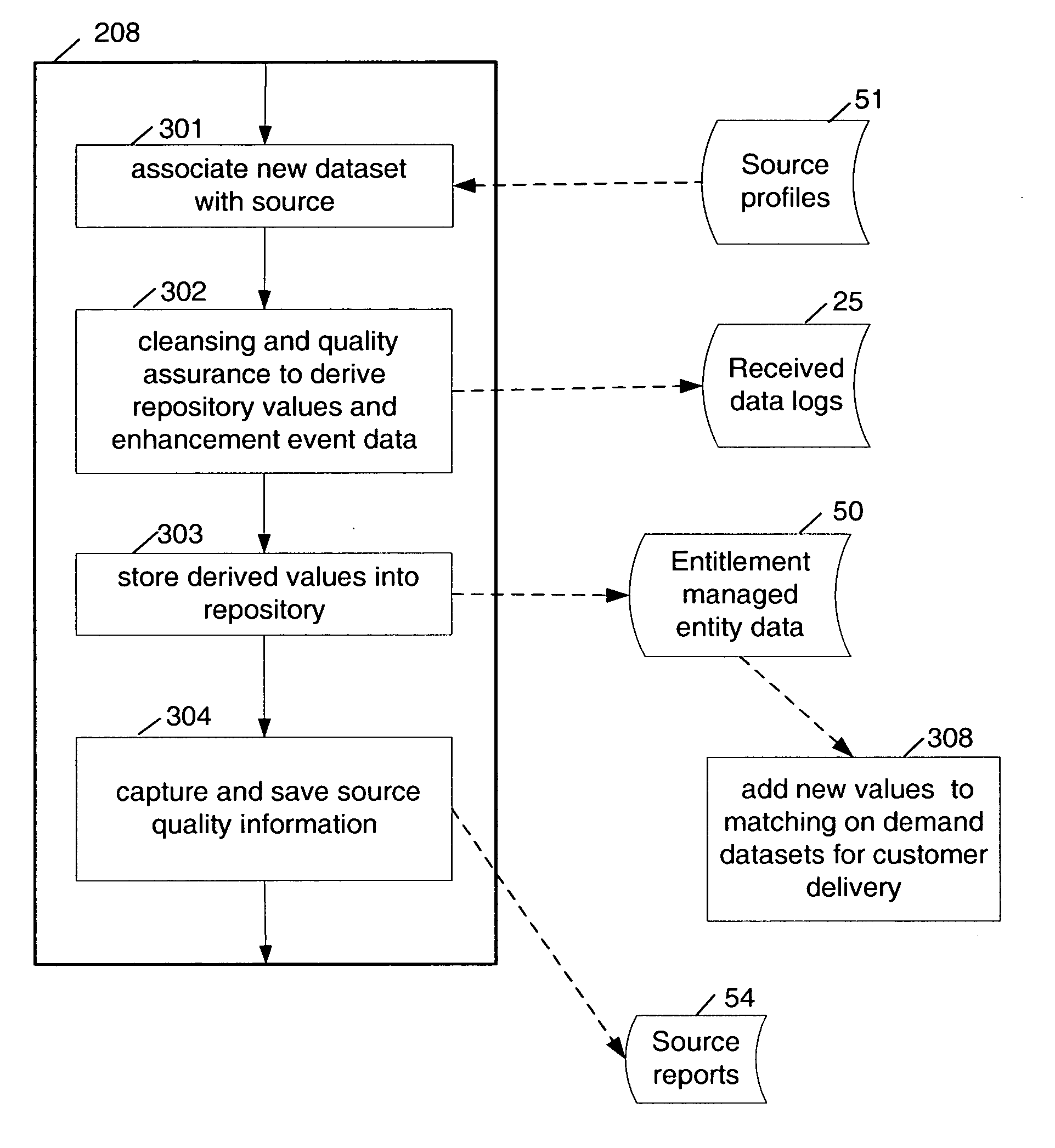

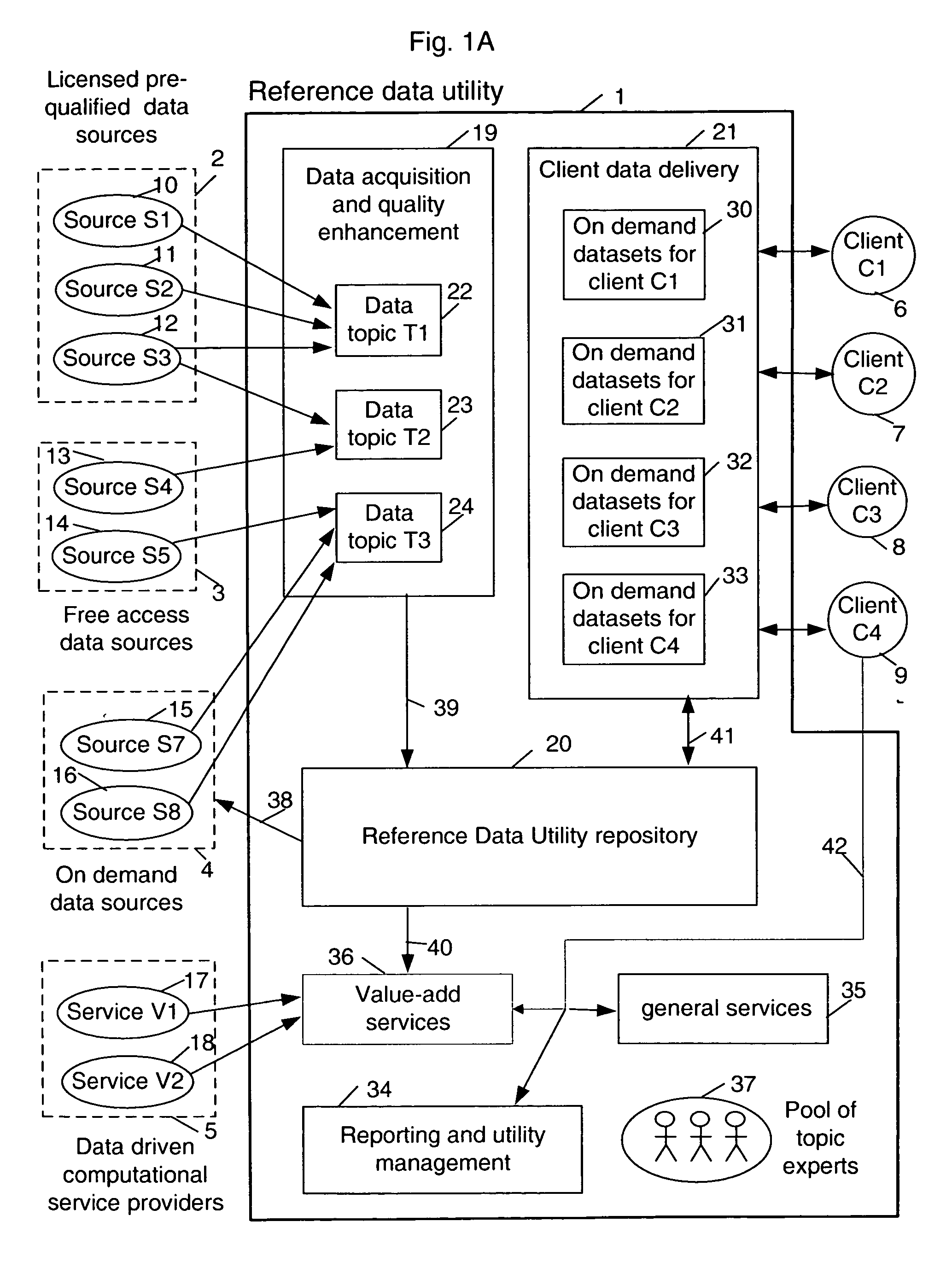

A multi-source multi-tenant reference data utility and methods for forming and maintaining the same, delivering high quality reference data in response to requests from clients, implemented using a shared infrastructure, and also providing added value services using the client's reference data. Included are data cleansing and quality assurance of the received data with full tracking of the sourcing of each value, storage of resulting entity values in a repository which allows retrievals and enforces source based entitlements, and delivery of retrieved data in the form of on demand datasets supporting a wide range of client application needs. An advantageous implementation has additional services for reporting on data quality and usage, a selection of value adding data driven computations and business document storage. By using a shared infrastructure and amortizing the costs of data quality assurance across a plurality of clients, while ensuring that clients only receive values from data sources to which they are licensed, better quality data at lower cost is delivered.

Owner:IBM CORP

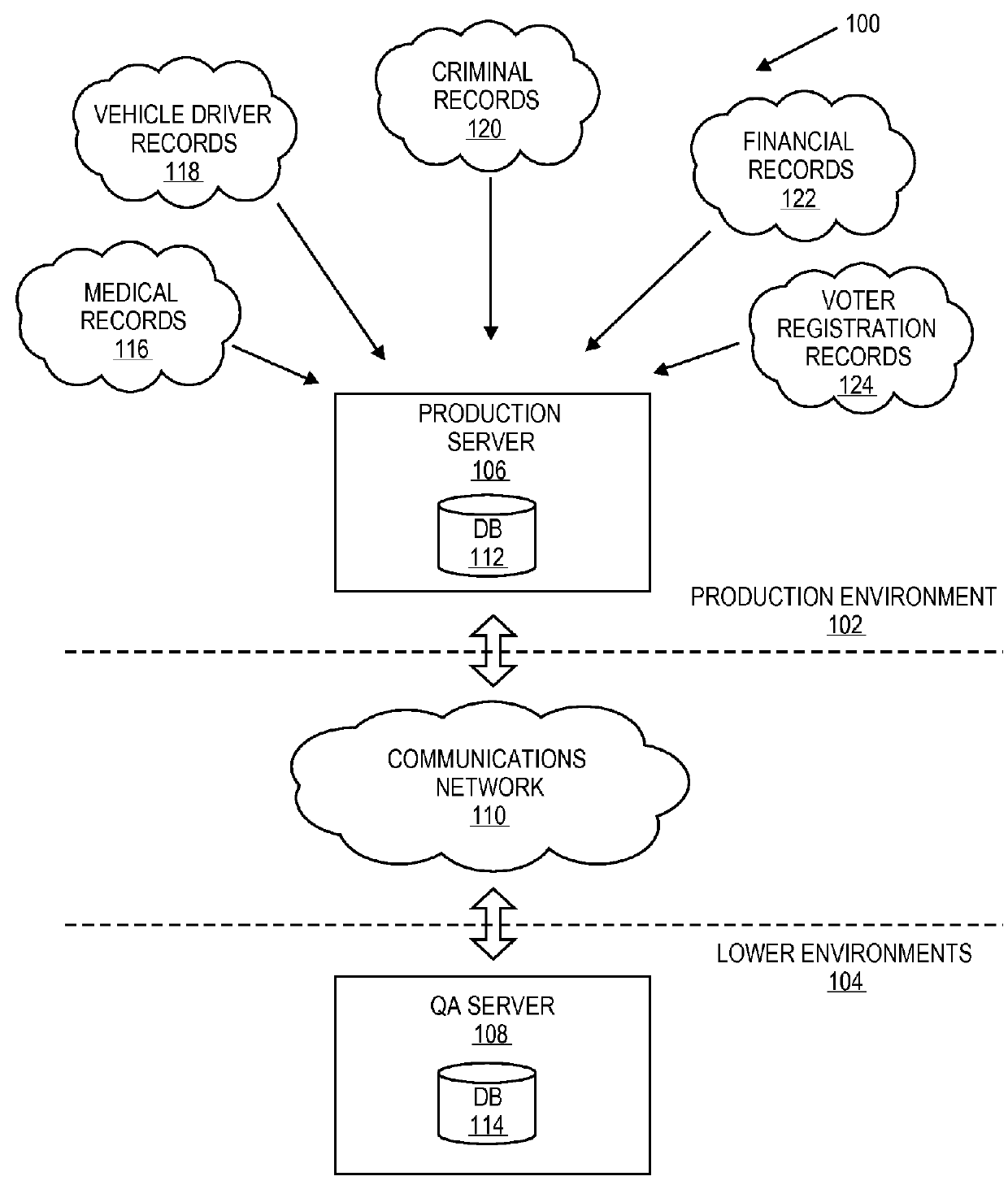

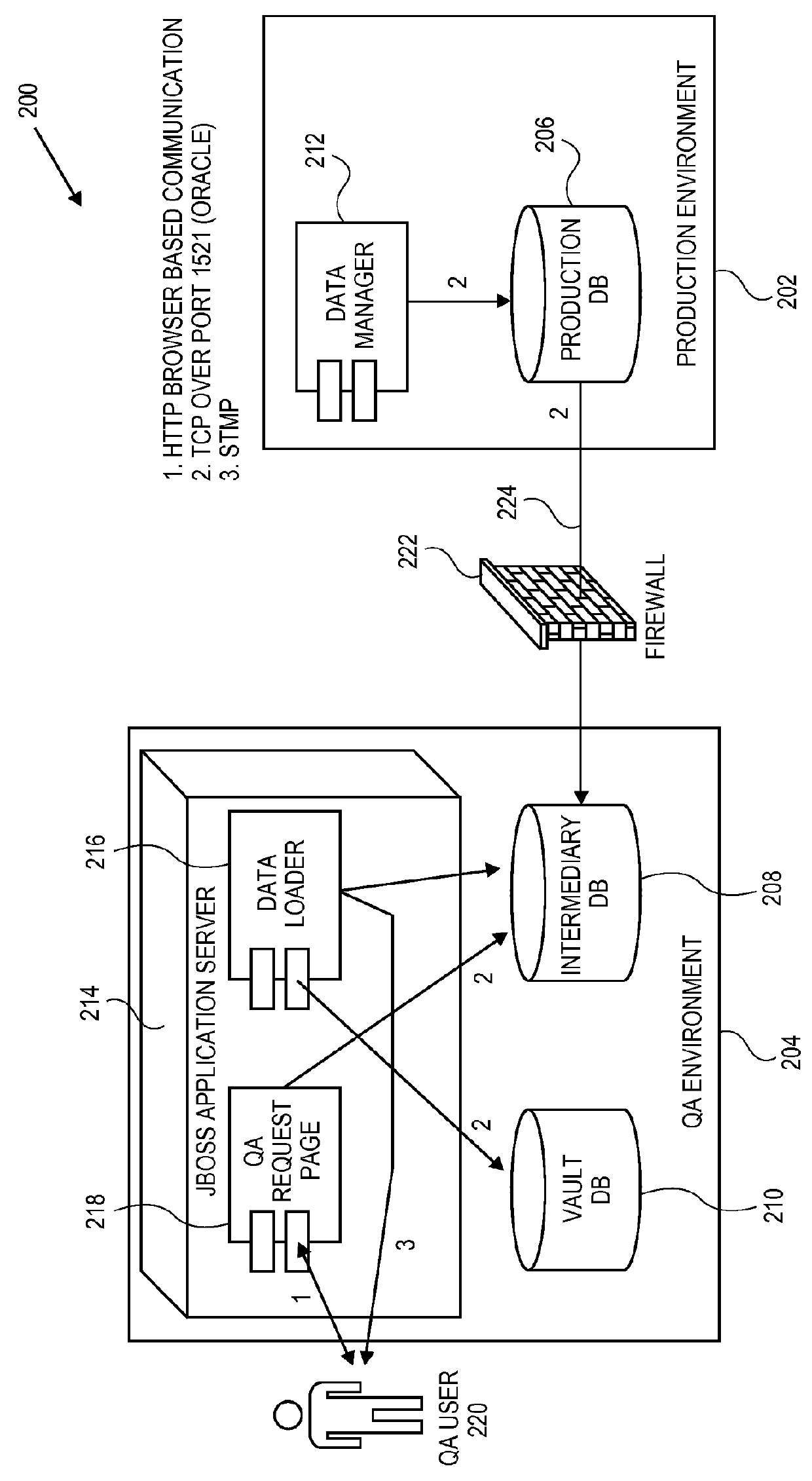

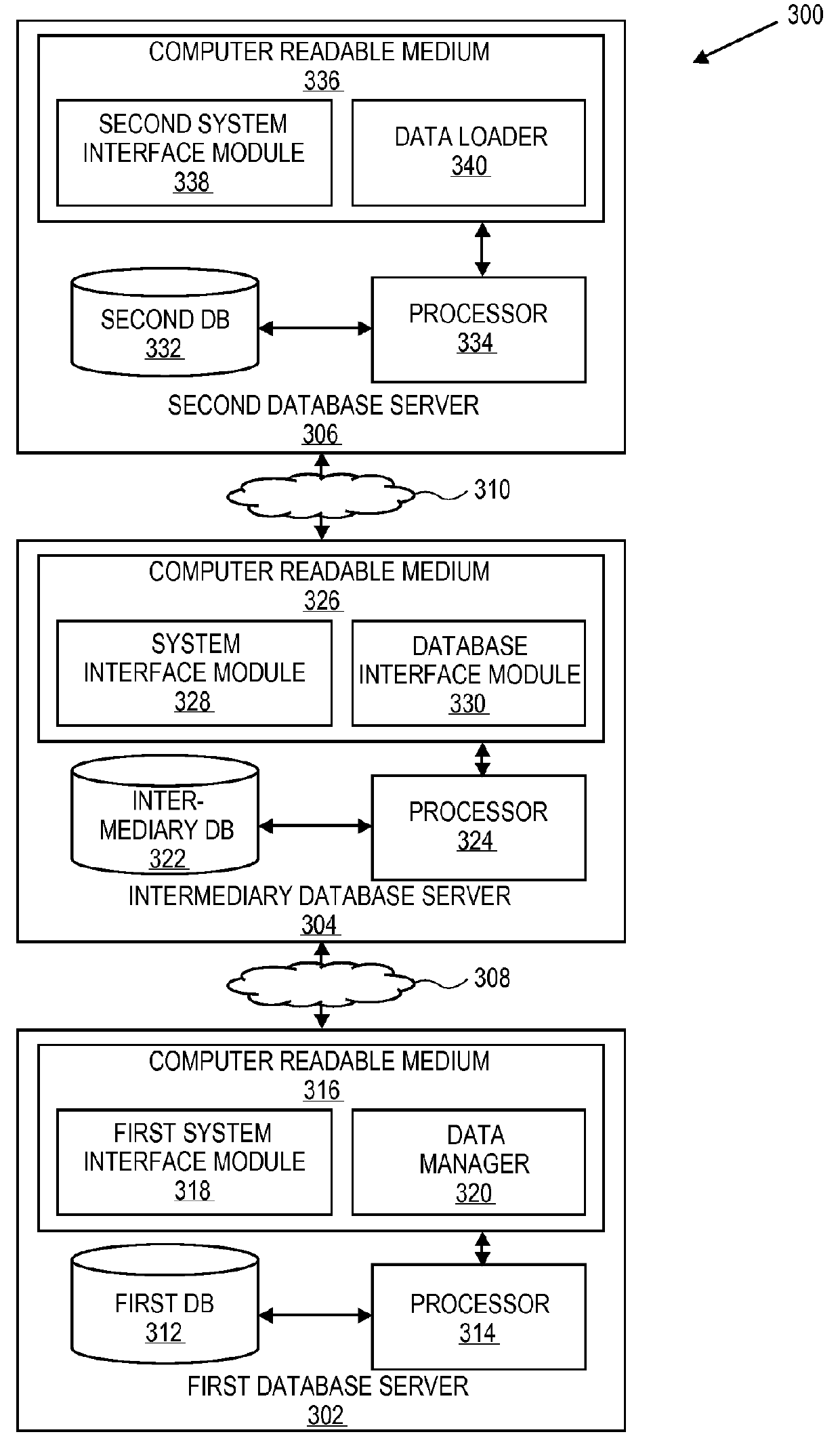

Database cloning and migration for quality assurance

ActiveUS9229964B2Data processing applicationsDigital data information retrievalPaymentQuality assurance

Embodiments of the invention relate to systems and methods for cloning a production database for quality assurance (QA) by the merchant users. A QA user may request tokens, card types and other data associated with a payment device for quality assurance purposes. The payment network redirects the QA request to a go-between database that is present between the QA user and the production environment of the payment network rather than pull the information directly from the production environment. As a result, the merchant is able to use tokens for testing, without violating consumer privacy and security rules and regulations (e.g., PCI rules). The QA user does not have to create a customized testing solution.

Owner:VISA INT SERVICE ASSOC

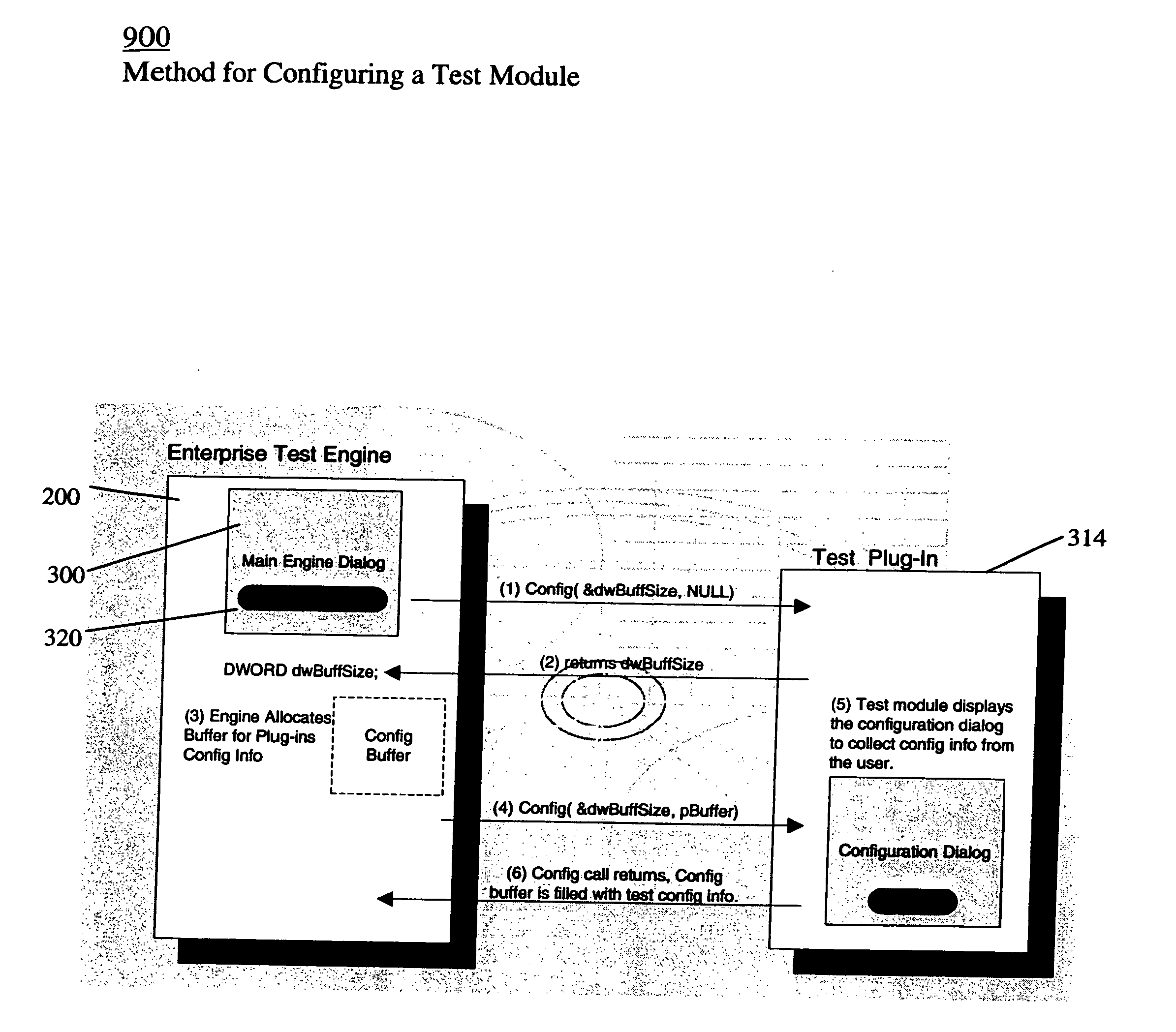

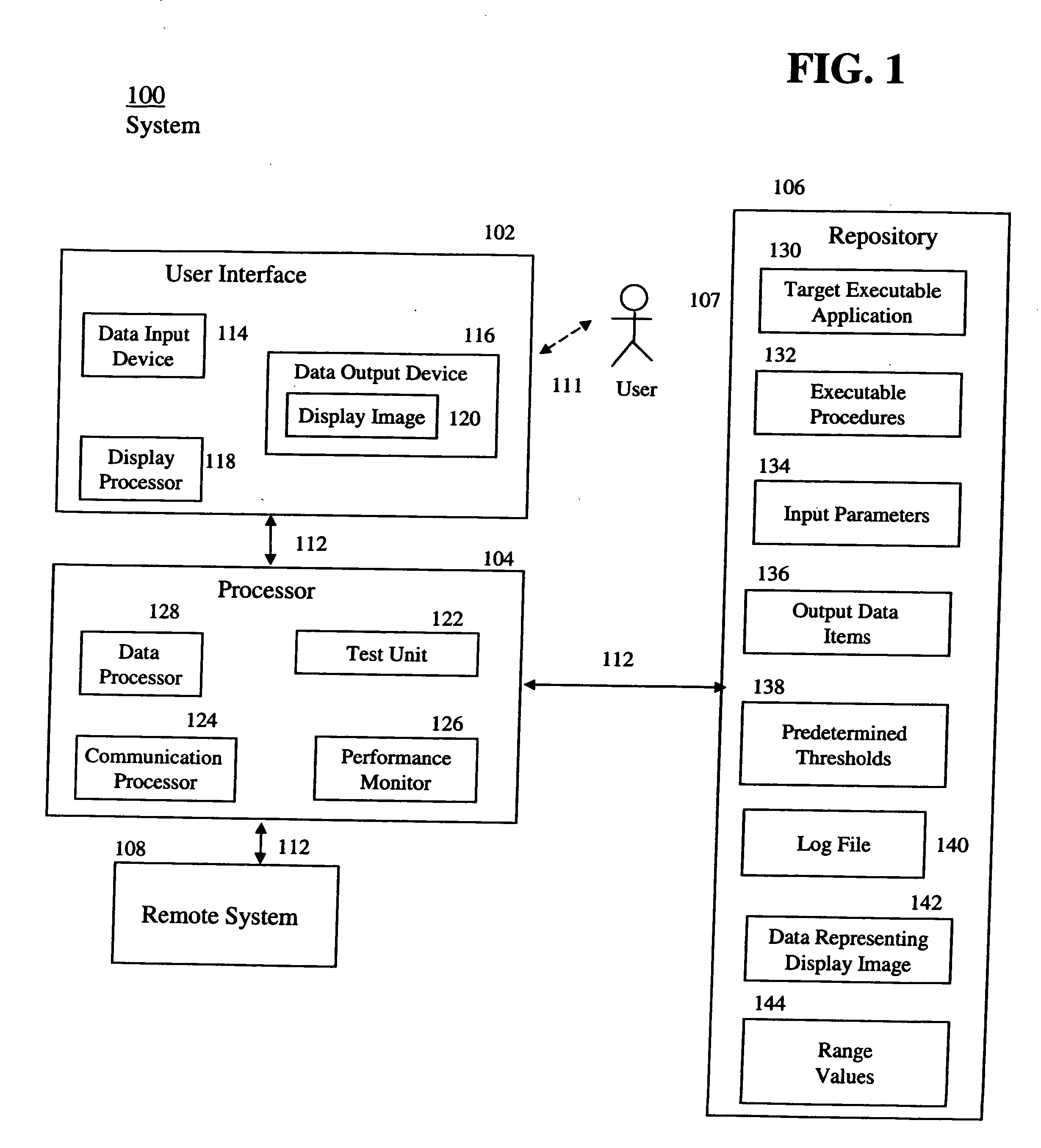

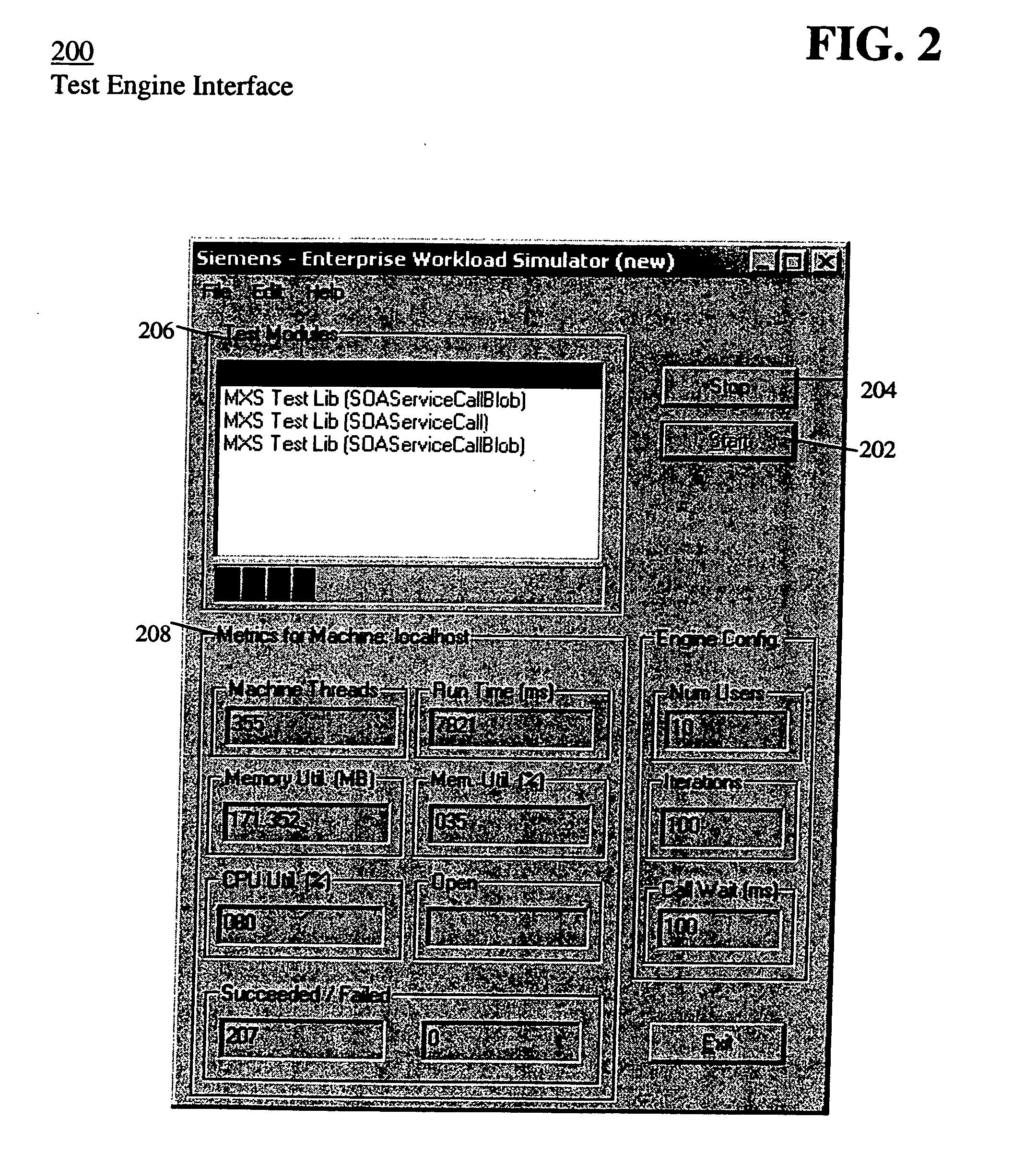

Software test and performance monitoring system

InactiveUS20060129992A1Error detection/correctionSpecific program execution arrangementsExtensibilityRegression testing

A quality assurance benchmark system tests a target executable application under load stress conditions over an extended period of time. The system has user-controlled parameters to benchmark performance, scalability, and regression testing before deploying the application to customers. The system includes a display processor and a test unit. The display processor generates data representing a display image enabling a user to select: input parameters to be provided to the target executable application, and output data items to be received from the target executable application and associated expected range values of the data items. The test unit provides multiple concurrently operating executable procedures for interfacing with the target executable application to provide the input parameters to the target executable application, and to determine whether data items received from the target executable application are within corresponding associated expected range values of the data items.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

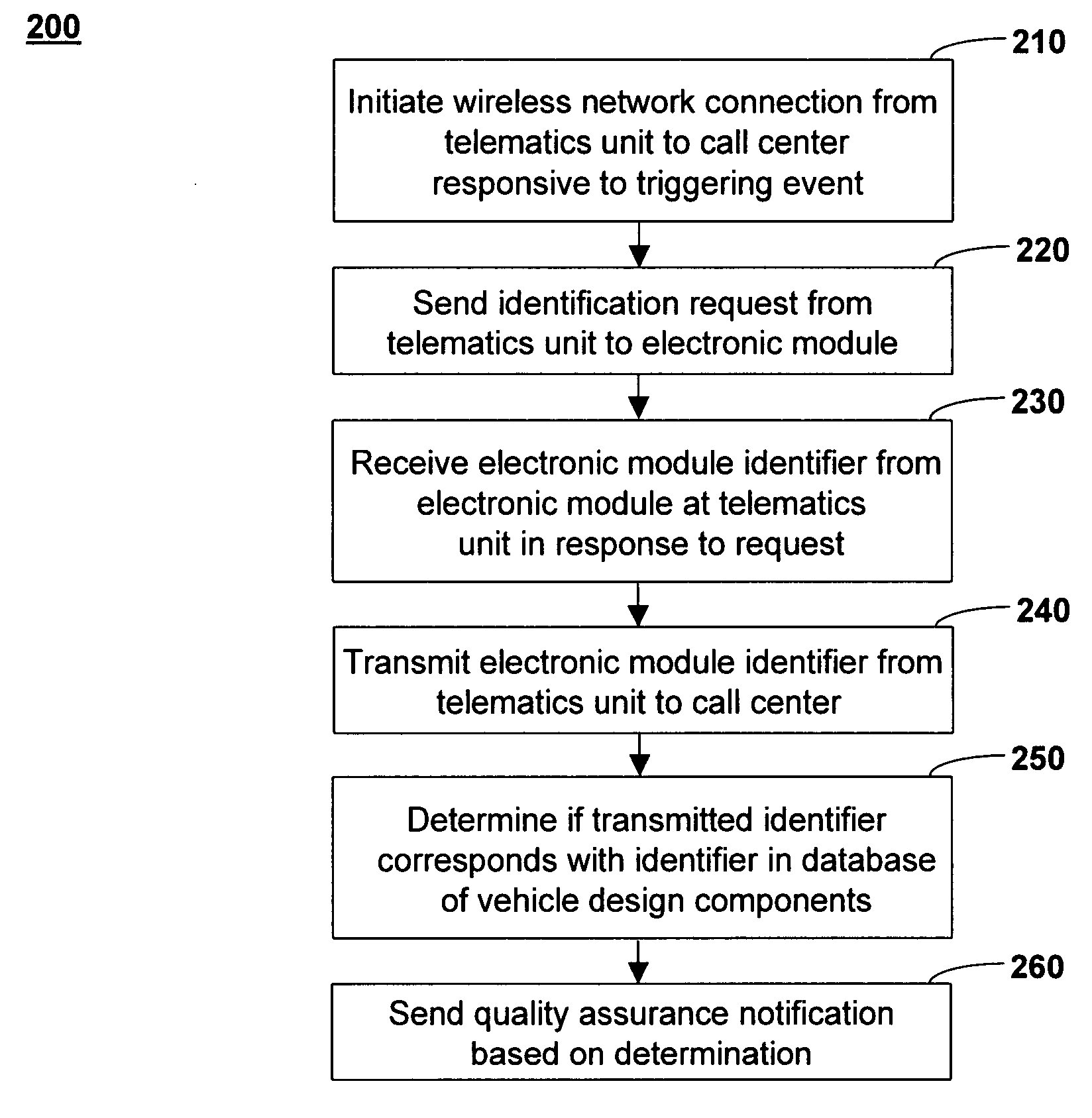

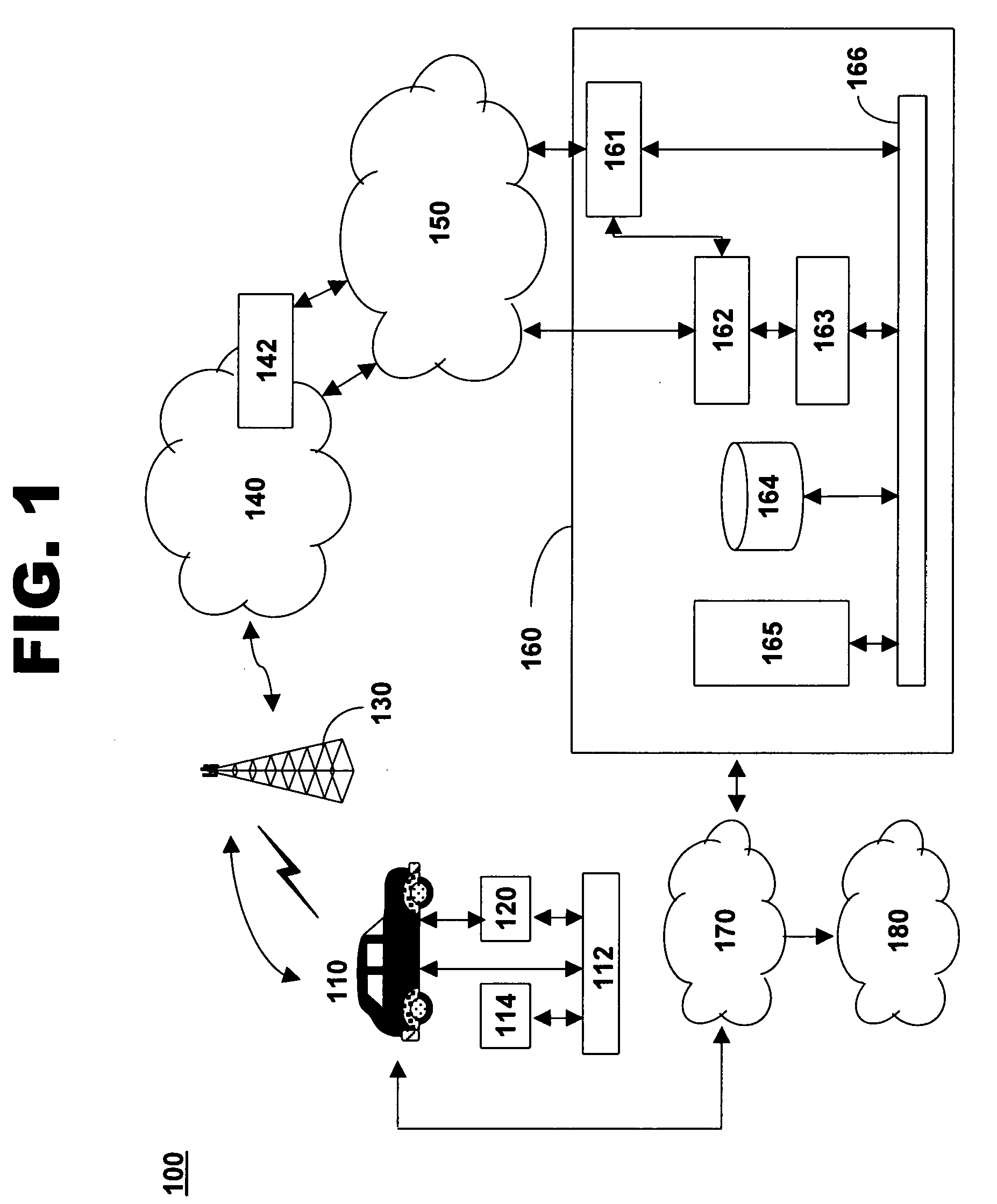

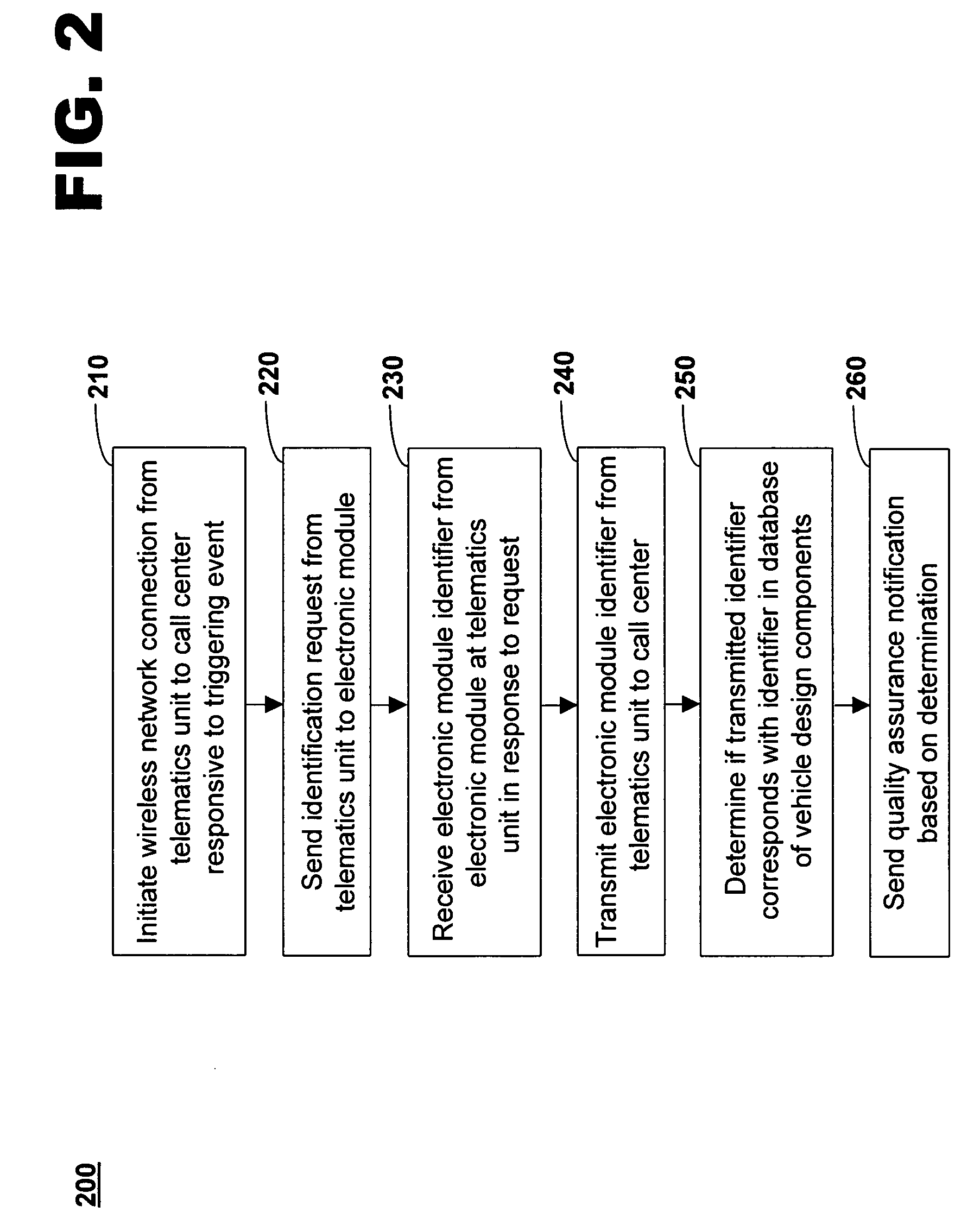

Method and system for remotely inventorying electronic modules installed in a vehicle

ActiveUS20050080519A1Vehicle testingRegistering/indicating working of vehiclesInformation processingQuality assurance

The invention provides a method and system for remotely inventorying electronic modules installed in a vehicle. A vehicle telematics unit sends an identification request to at least one electronic module. The telematics unit receives at least one electronic module identifier in response to the request. The identifier includes the serial number and software revision for the electronic module. The received identifier is transmitted from the telematics unit to a call center. The call center, or a quality center to which the call center sends the transmitted identifier, determines if the transmitted identifier corresponds with an identifier included in an electronic module identifier database. The database includes an identifier for each module that is intended to be installed in the vehicle. A quality assurance notice is sent based on the determination, indicating either that the correct module is installed in the vehicle or that an incorrect module must be replaced.

Owner:GENERA MOTORS LLC

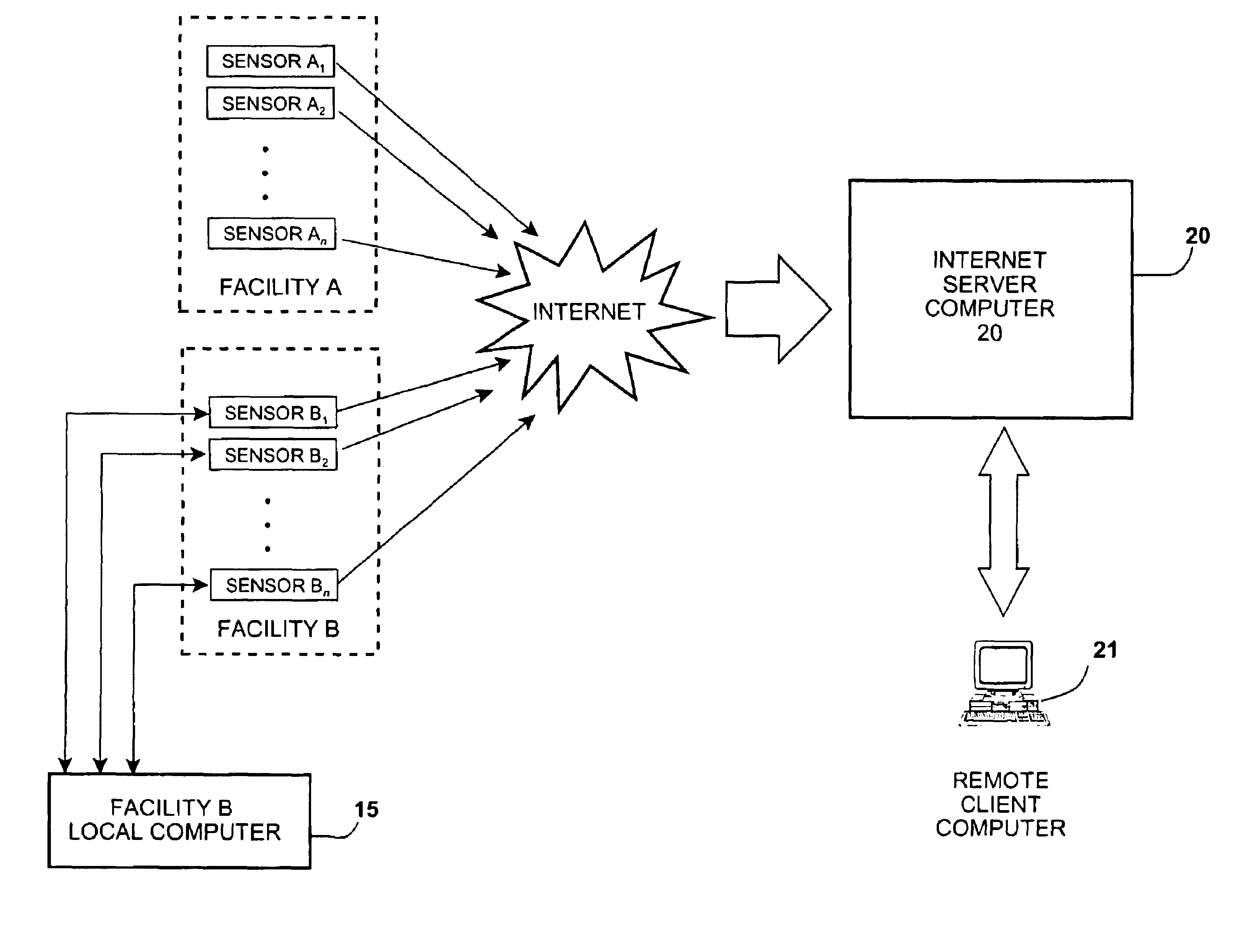

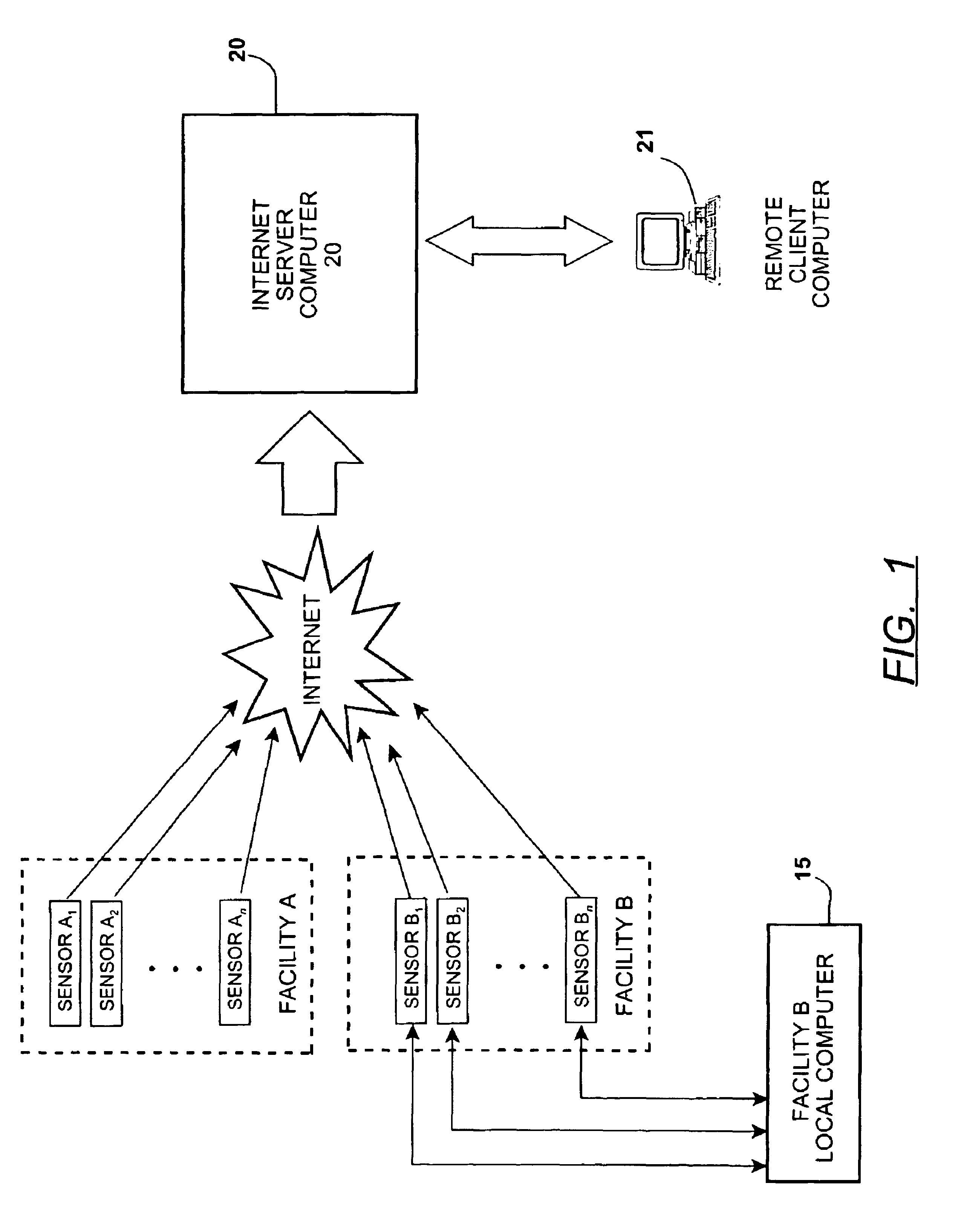

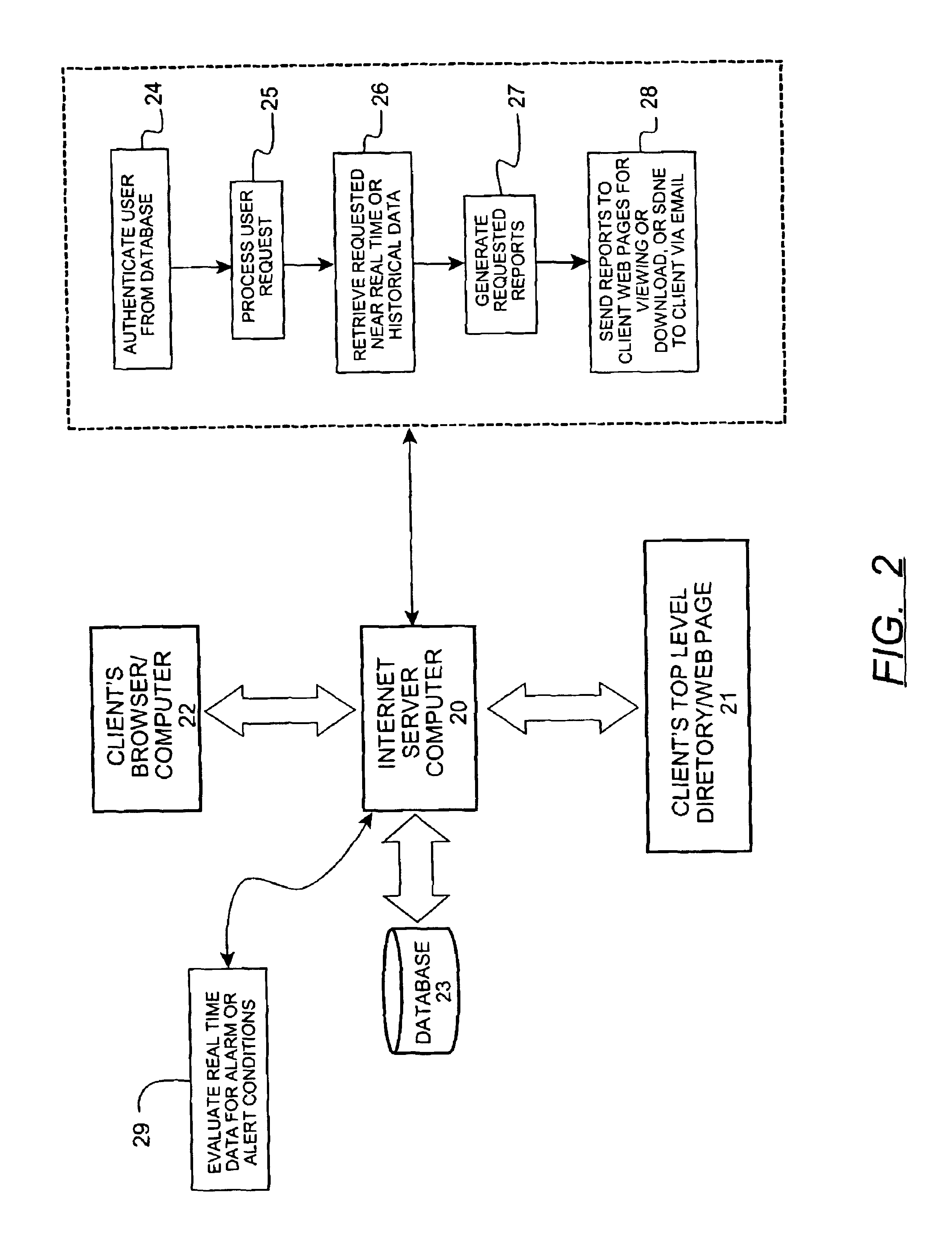

Method for remote monitoring of water treatment systems

InactiveUS6954701B2Rule out the possibilityNegating human error or tamperingUltrafiltrationSolid sorbent liquid separationWater treatment systemQuality assurance

A method of monitoring the daily operating performance parameters for water treatment processes through the collection of localized data. The data is manipulated to generate preconfigured performance, maintenance, and quality assurance reports and further provide automatic submission of data as required for regulatory review of certain water treatment systems such as potable water treatment. The data is collected from sensors located at an equipment site and transferred to a remote computer located by use of the Internet, further all data received and used for generation of reports is also accessible by Internet connection and be delivered directly to the regulatory agency without additional process.

Owner:WATEREYE +1

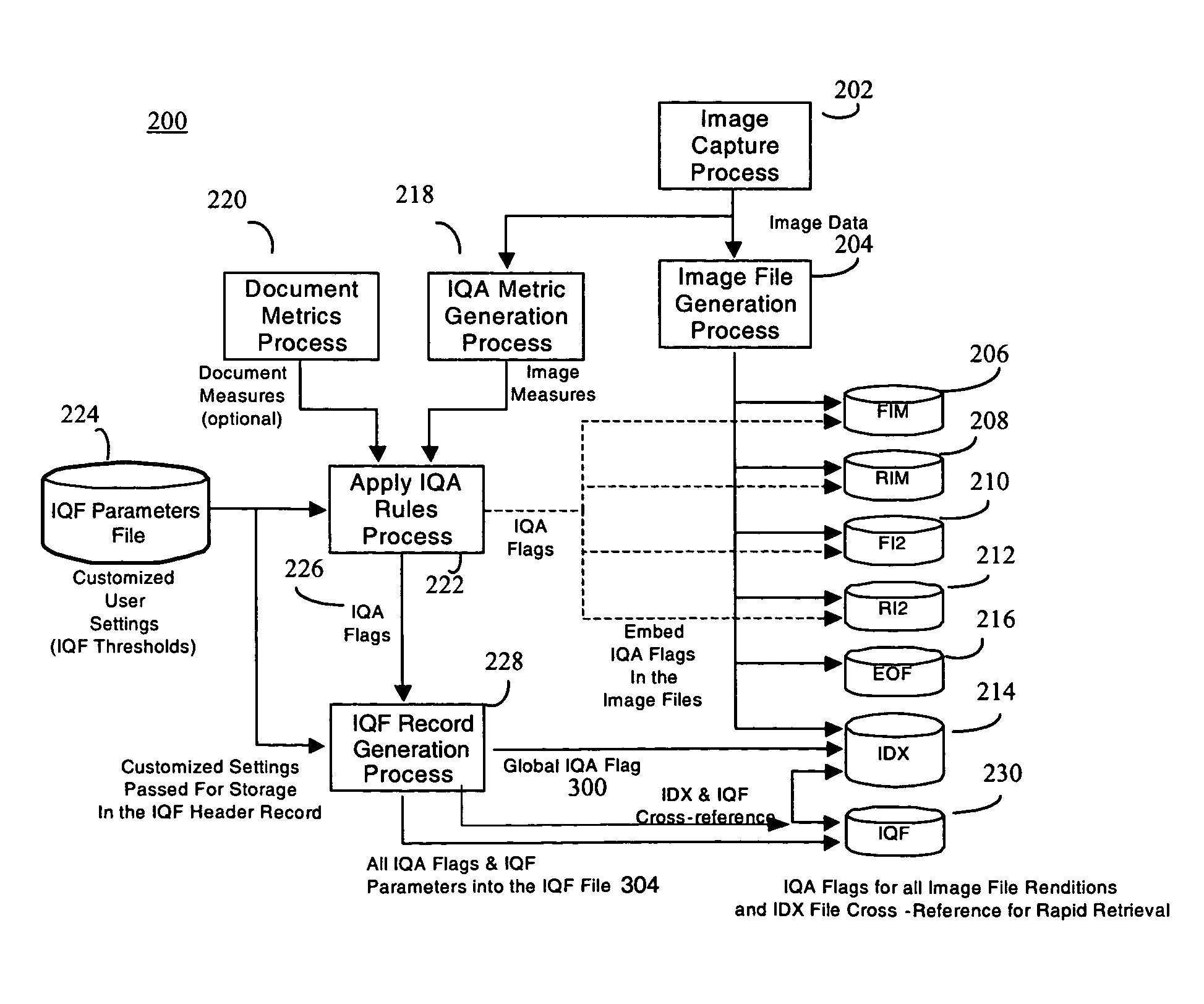

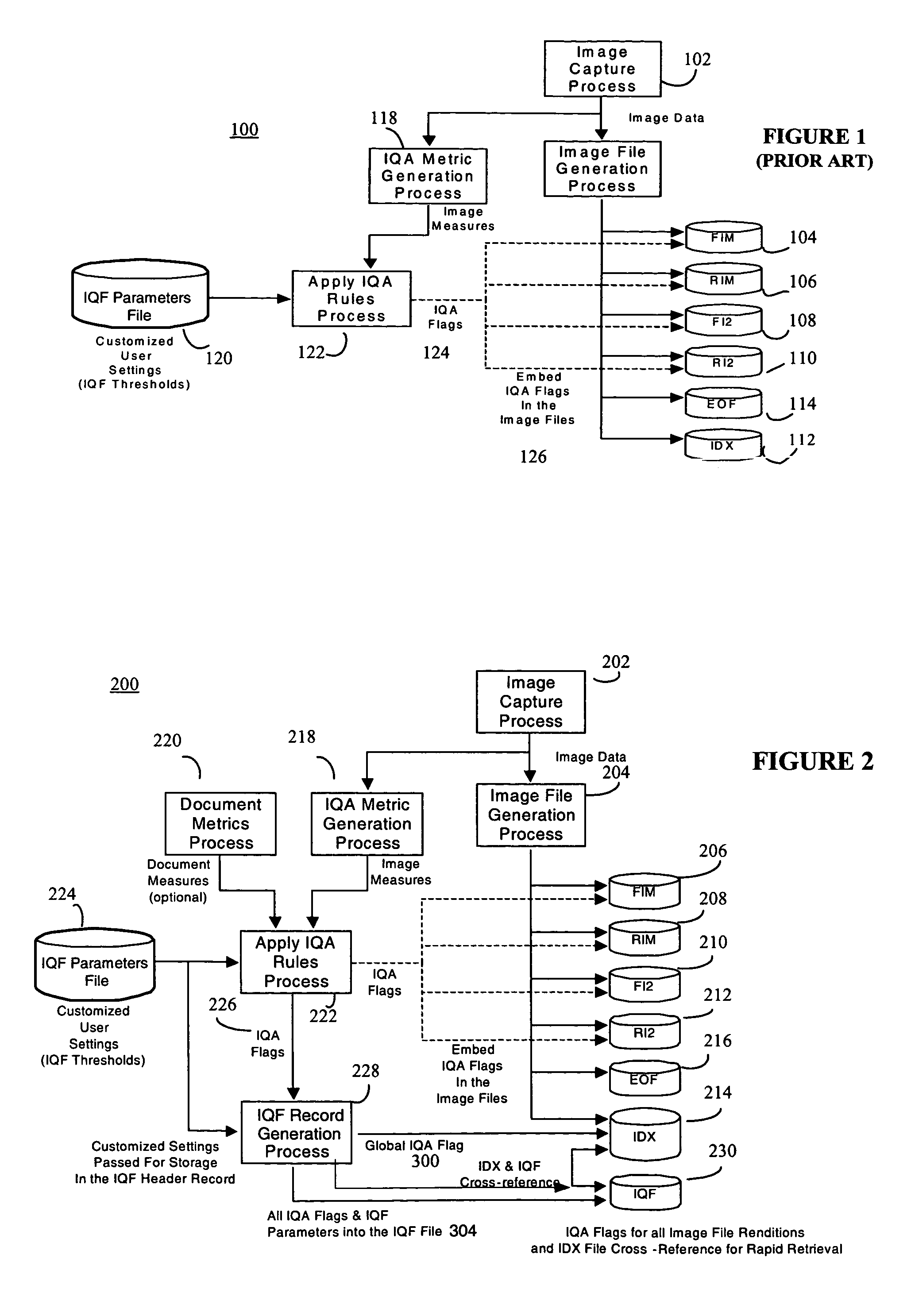

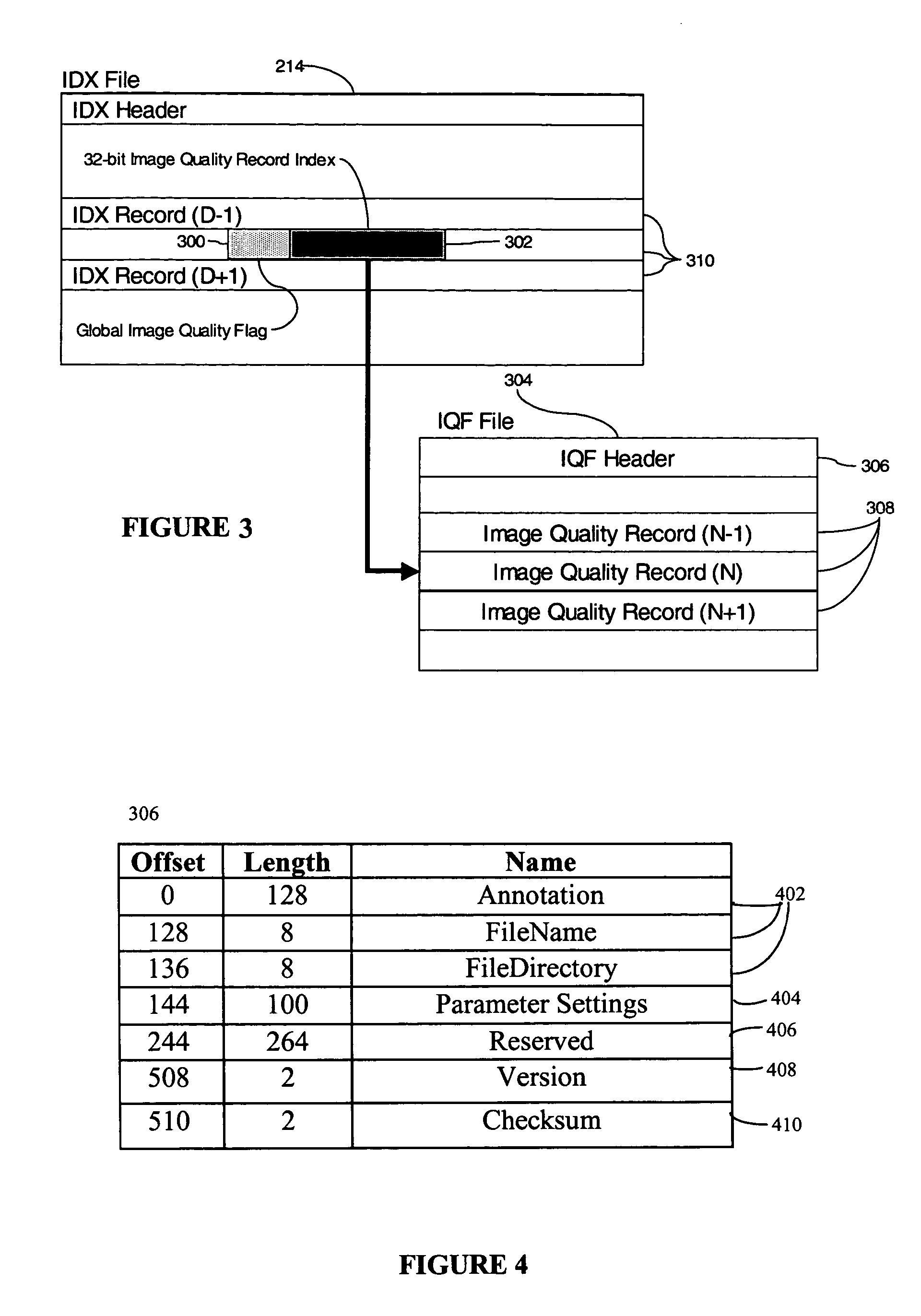

Document processing system with improved image quality assurance

ActiveUS7433098B2Improve image qualityEasy to identifyComplete banking machinesImage enhancementQuality assuranceComputer graphics (images)

A document processing system comprising an image capture subsystem for capturing selected image metrics and at least one image rendition from a plurality of documents and for determining if at least one of the selected image metrics for any of the at least one image rendition does not successfully compare against preselected image quality metric threshold values. An image quality flag is generated for any of the at least one image rendition if it does not successfully compare, and a record entry for each imaged document having at least one flagged image rendition is created in an image quality flag file. An image index file for individually accessing the image renditions is modified to include a reference to the corresponding image quality flag file record entry The document processing system may optionally compare selected document metrics against preselected document metrics in a similar manner. Image defects in the plurality of documents can be identified by examining the record entries in the image quality flag file.

Owner:DIGITAL CHECK CORP

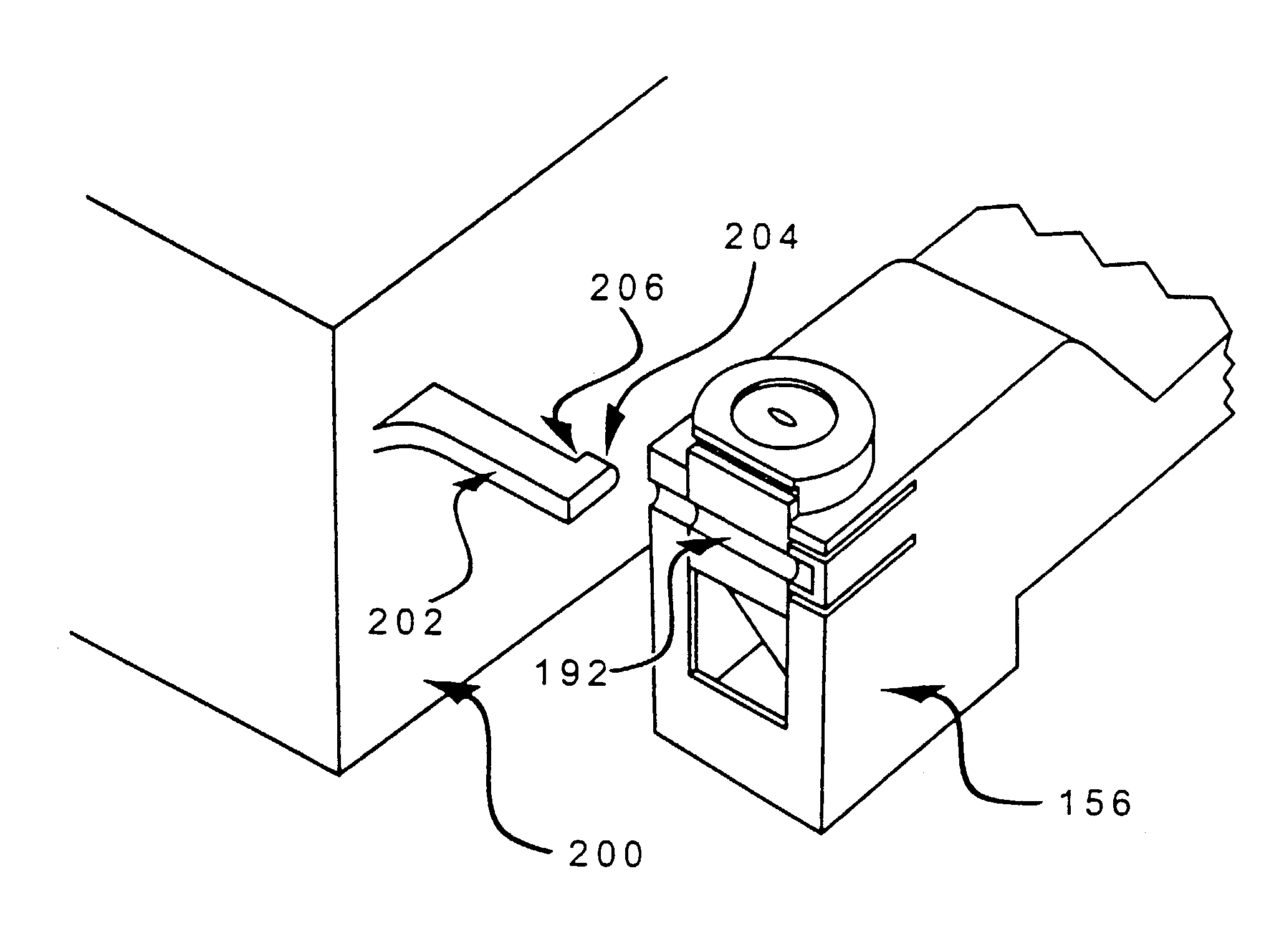

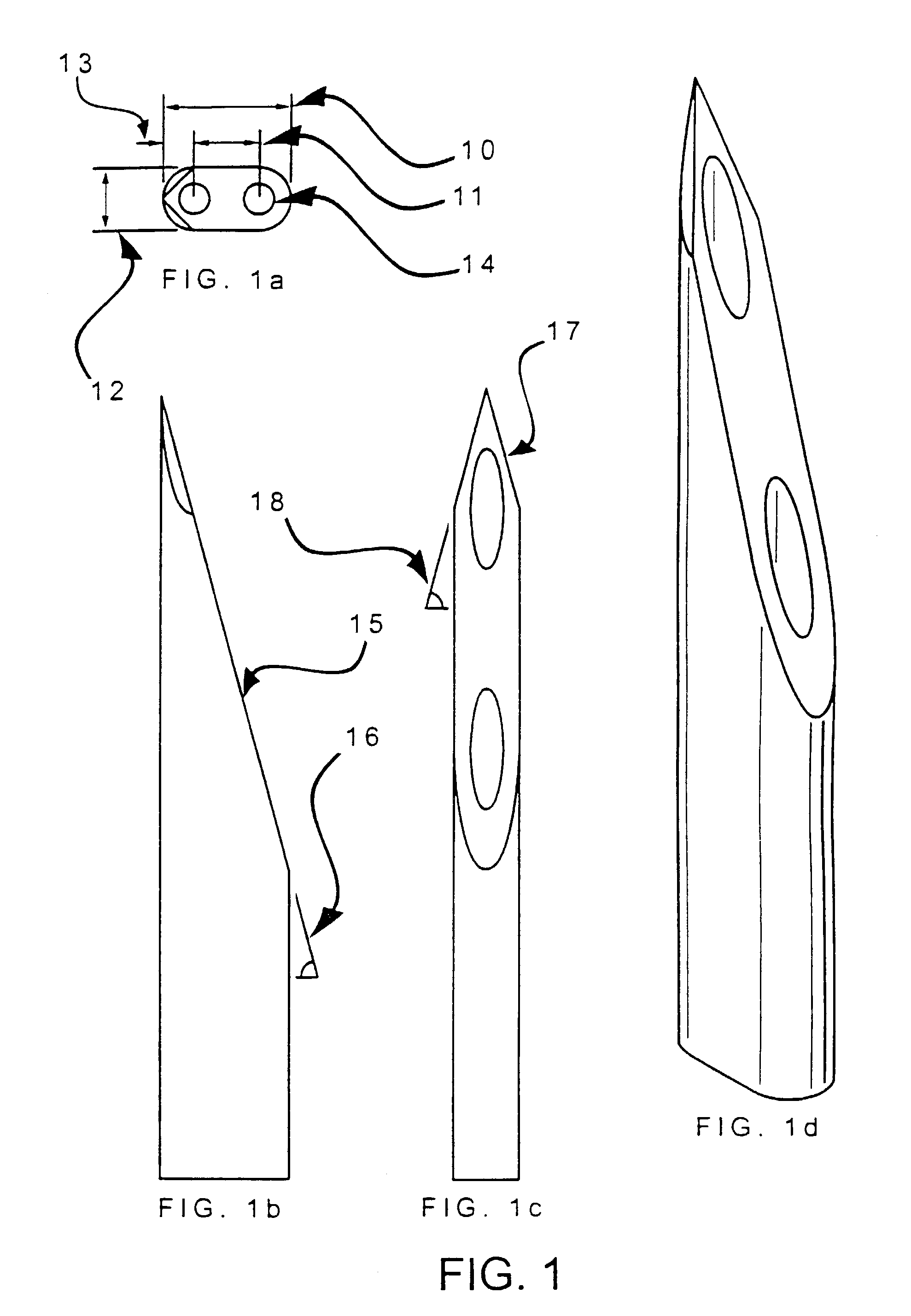

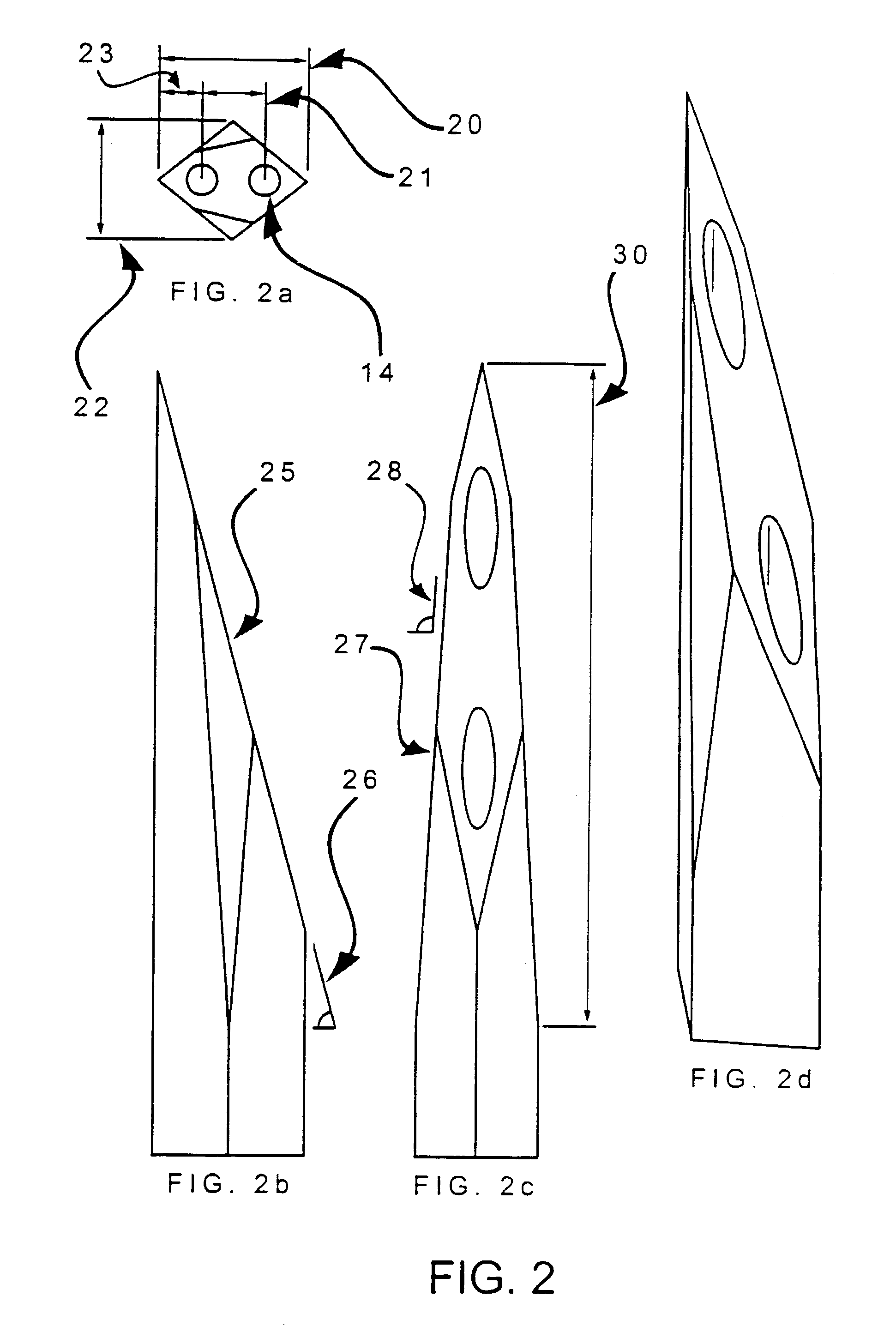

Universal scope reader

ActiveUS20070030345A1Realize automatic adjustmentTelevision system detailsSurgeryQuality assuranceComputer graphics (images)

A system for automatically setting video signal processing parameters for an endoscopic video camera system based upon characteristics of an attached endoscope, with reduced EMI and improved inventory tracking, maintenance and quality assurance, and reducing the necessity for adjustment and alignment of the endoscope and camera to achieve the data transfer.

Owner:KARL STORZ IMAGING INC

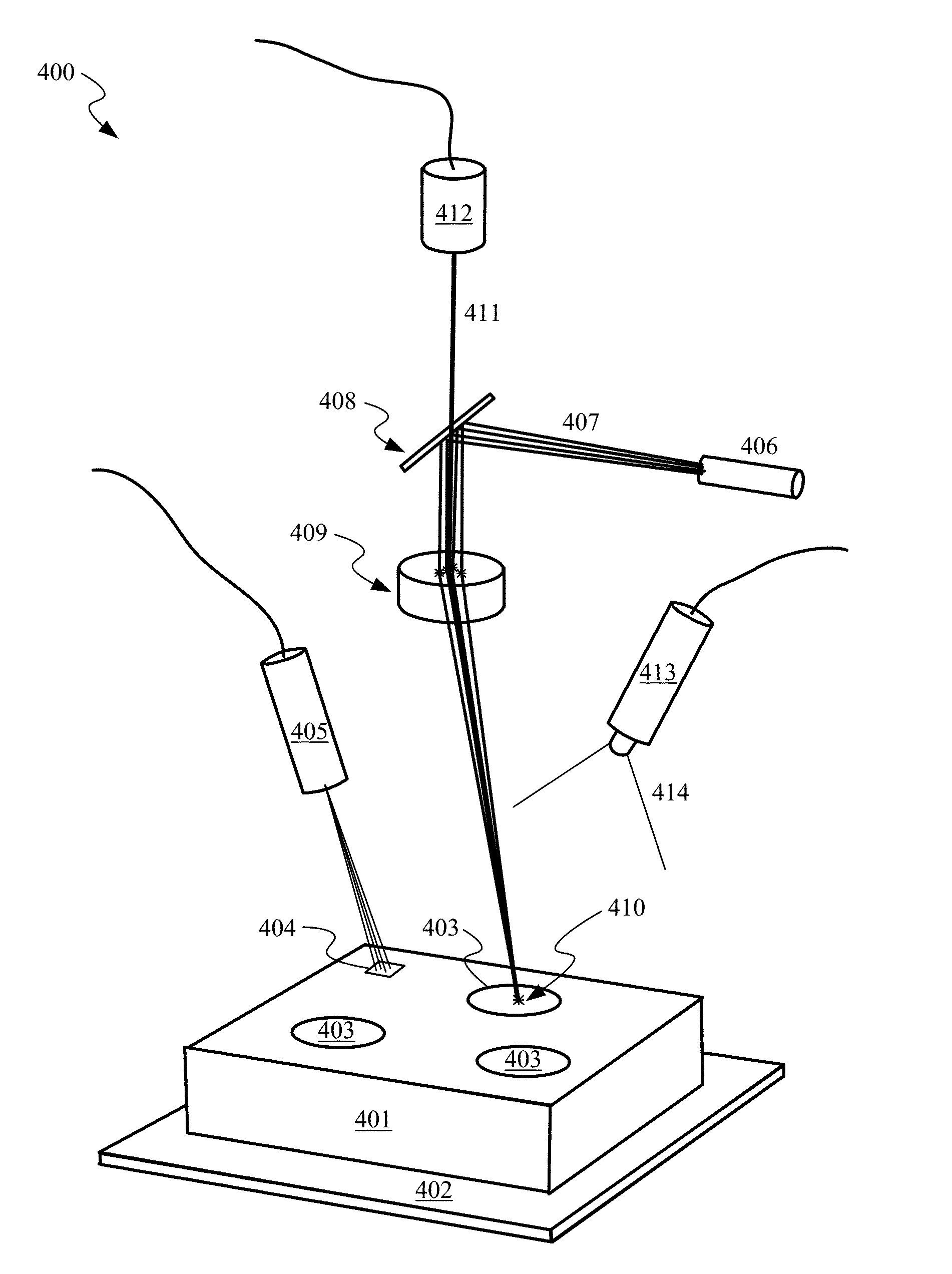

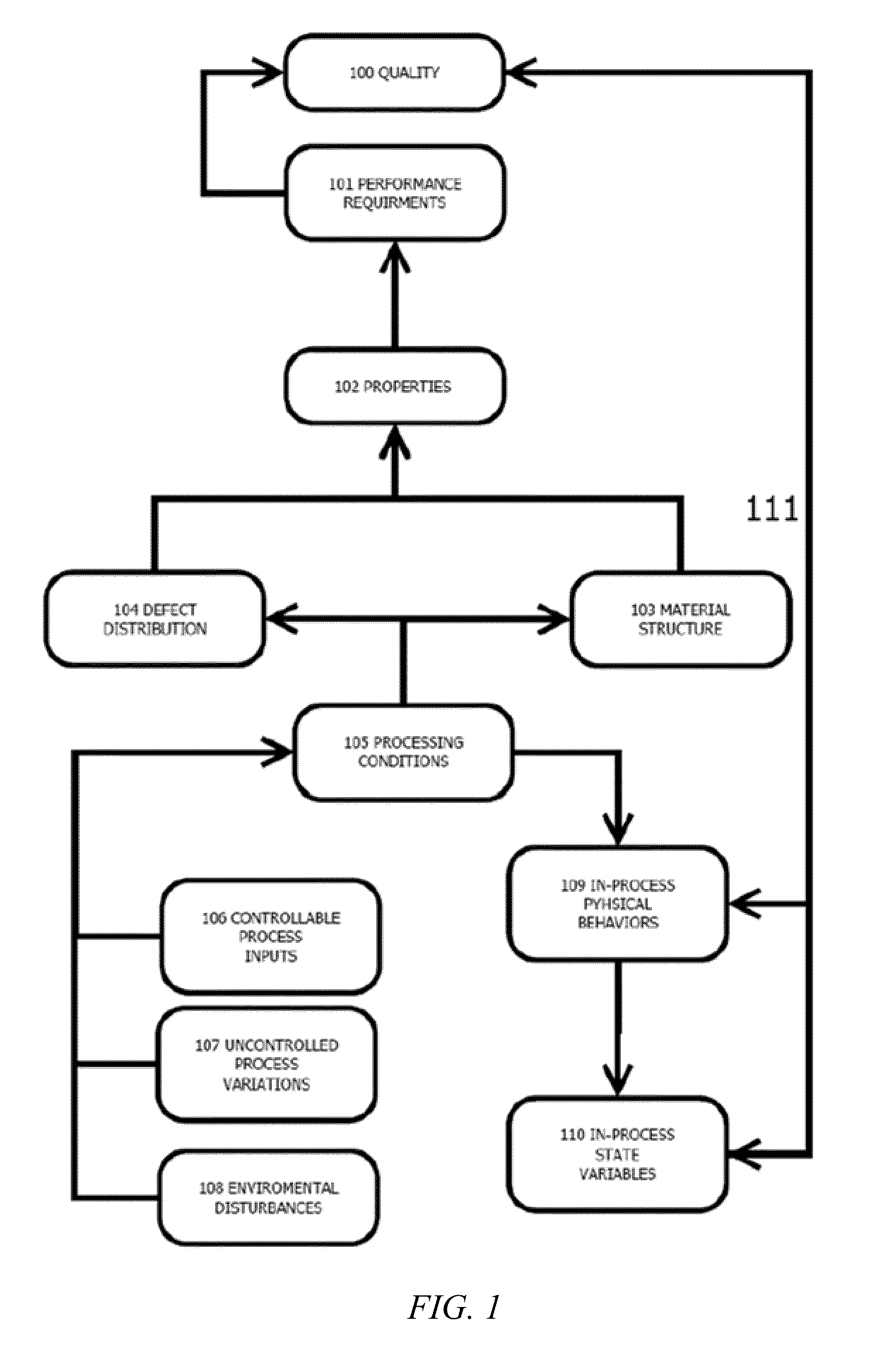

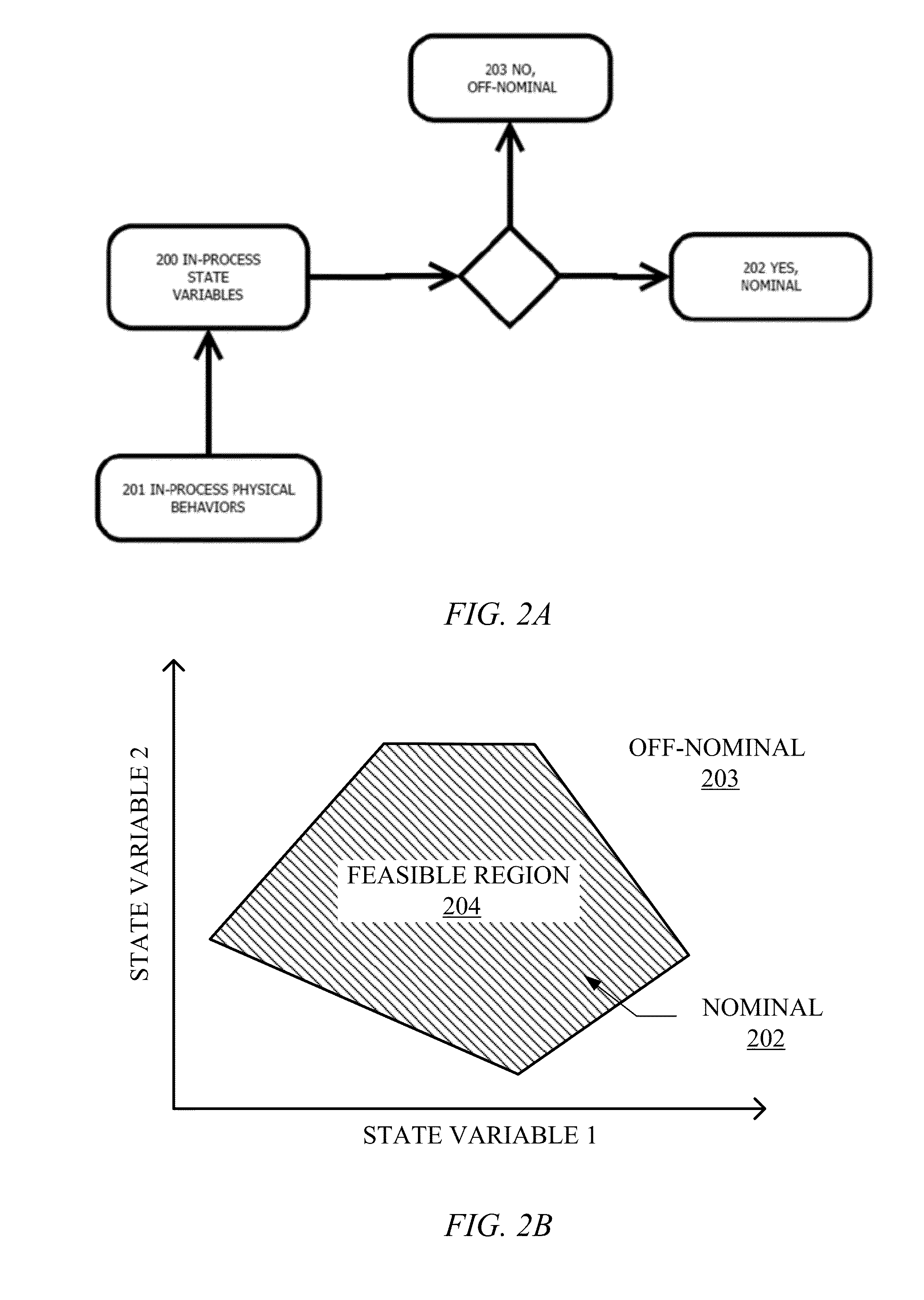

Method and system for monitoring additive manufacturing processes

ActiveUS20160184893A1Additive manufacturing apparatusIncreasing energy efficiencyQuality assuranceLagrangian eulerian

This invention teaches a quality assurance system for additive manufacturing. This invention teaches a multi-sensor, real-time quality system including sensors, affiliated hardware, and data processing algorithms that are Lagrangian-Eulerian with respect to the reference frames of its associated input measurements. The quality system for Additive Manufacturing is capable of measuring true in-process state variables associated with an additive manufacturing process, i.e. those in-process variables that define a feasible process space within which the process is deemed nominal. The in-process state variables can also be correlated to the part structure or microstructure and can then be useful in identifying particular locations within the part likely to include defects.

Owner:SIGMA LAB OF ARIZONA

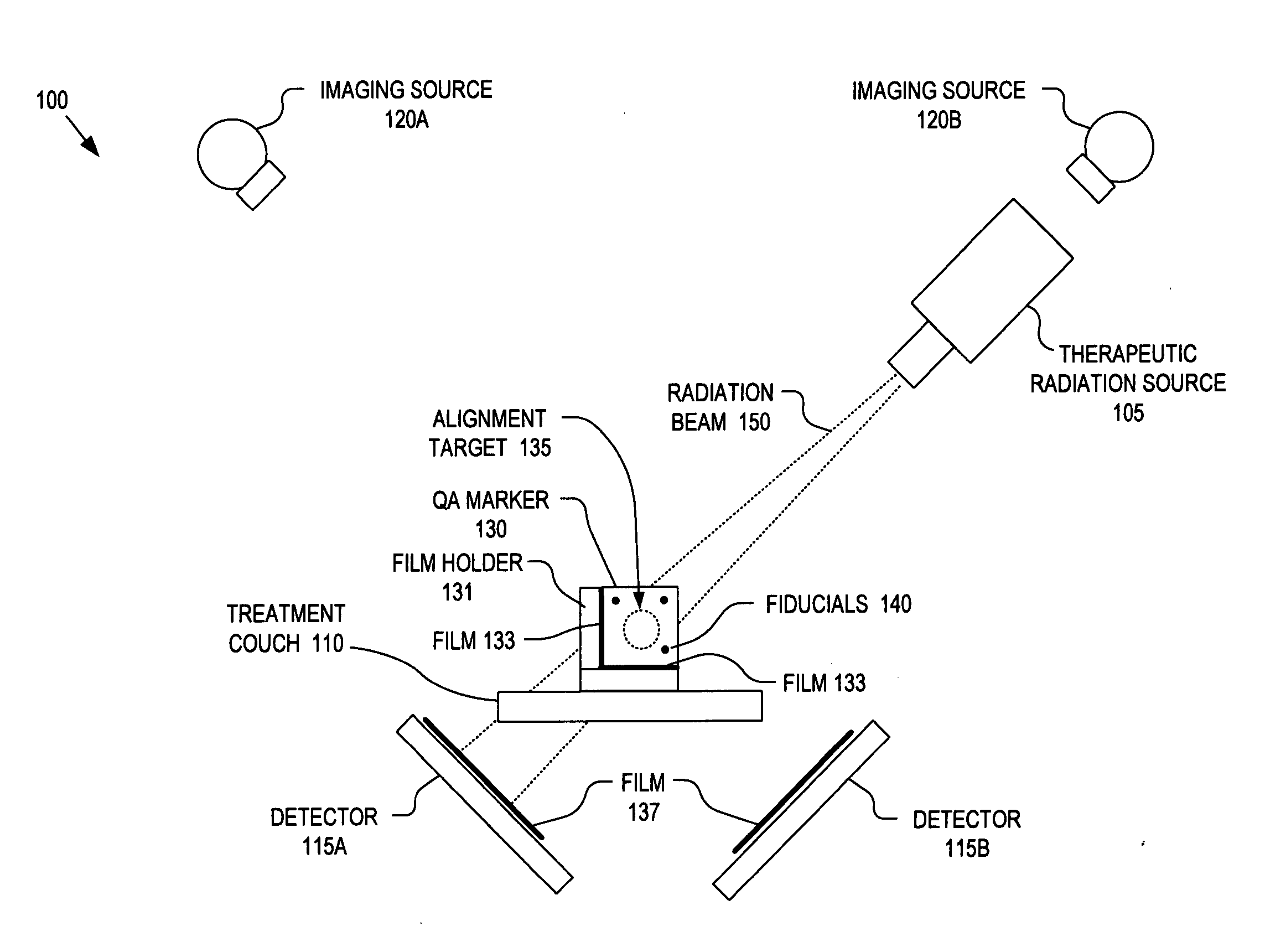

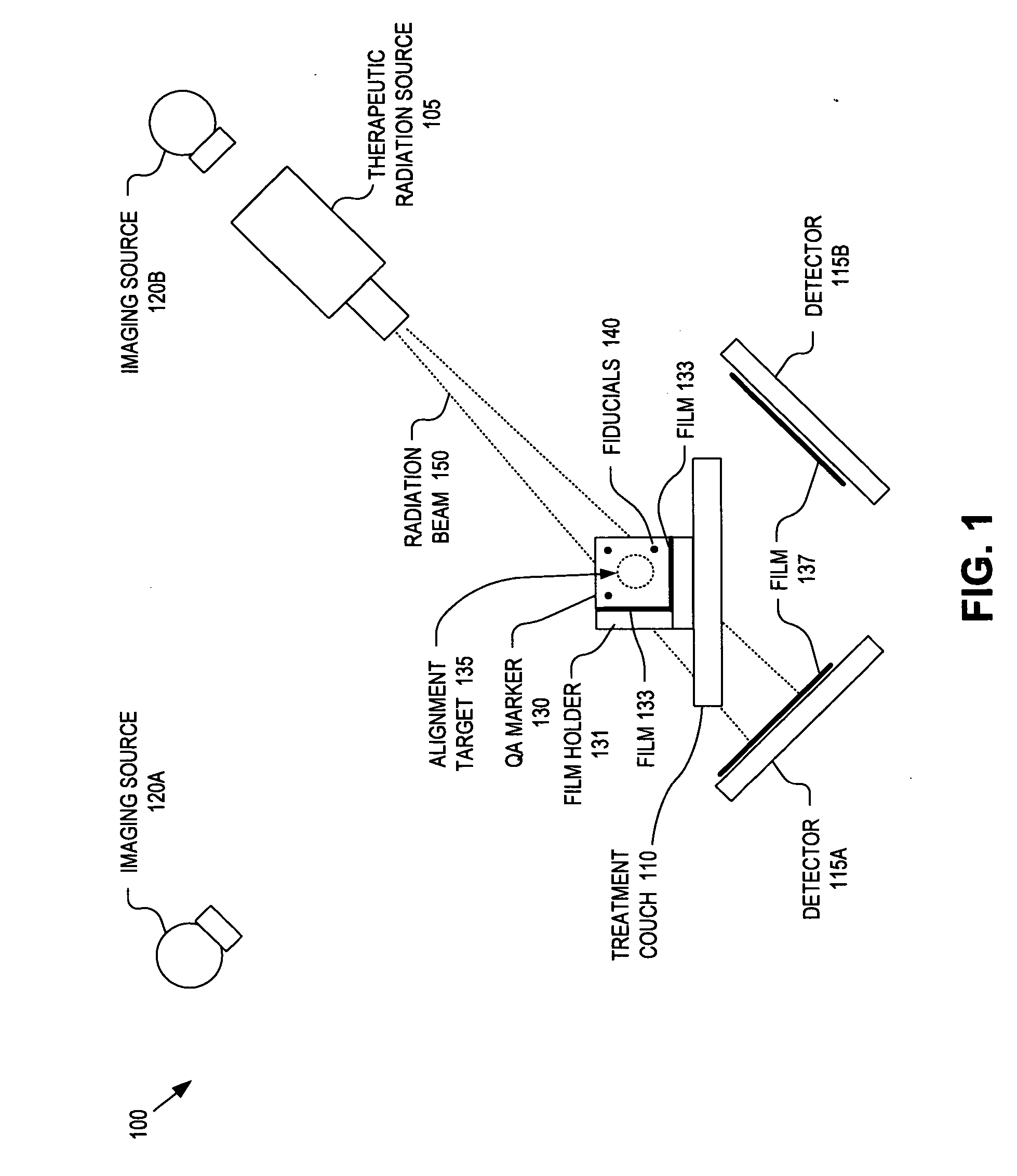

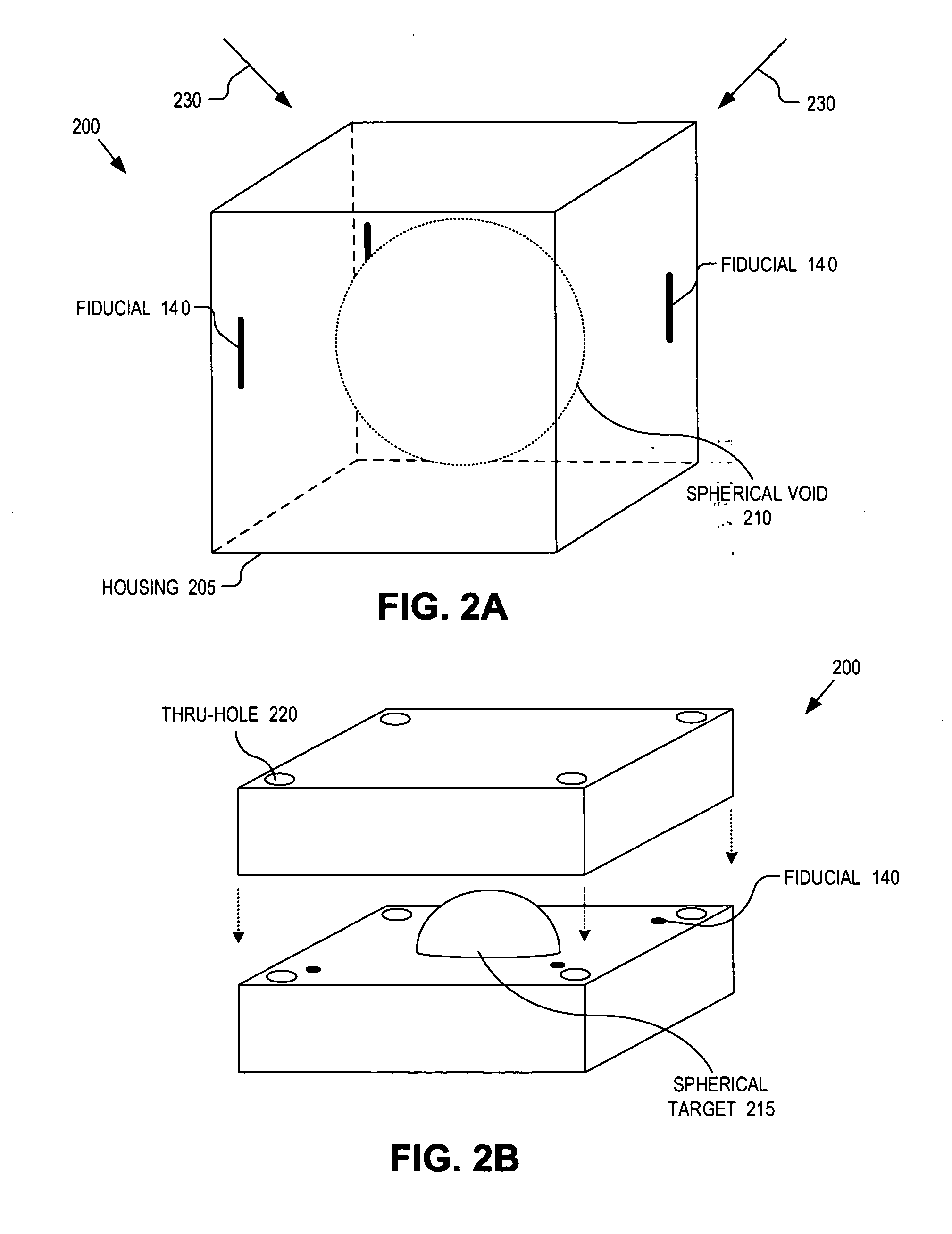

Integrated quality assurance for an image guided radiation treatment delivery system

ActiveUS20070071176A1Calibration apparatusRadiation beam directing meansQuality assuranceImage-guided radiation therapy

A method and apparatus for quality assurance of an image guided radiation treatment delivery system. A quality assurance (“QA”) marker is positioned at a preset position under guidance of an imaging guidance system of a radiation treatment delivery system. A radiation beam is emitted from a radiation source of the radiation treatment delivery system at the QA marker. An exposure image of the QA marker due to the radiation beam is generated. The exposure image is then analyzed to determine whether the radiation treatment delivery system is aligned.

Owner:ACCURAY

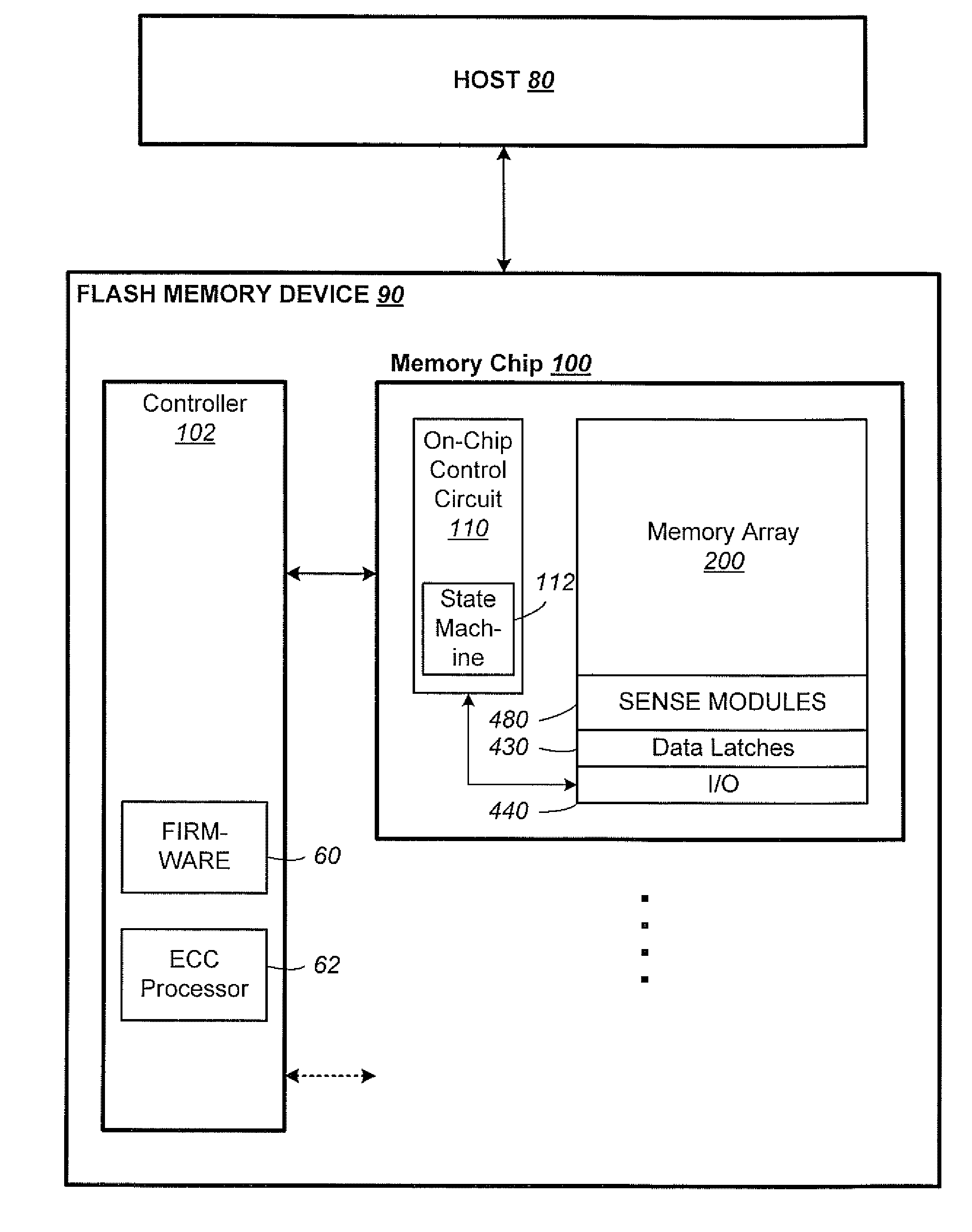

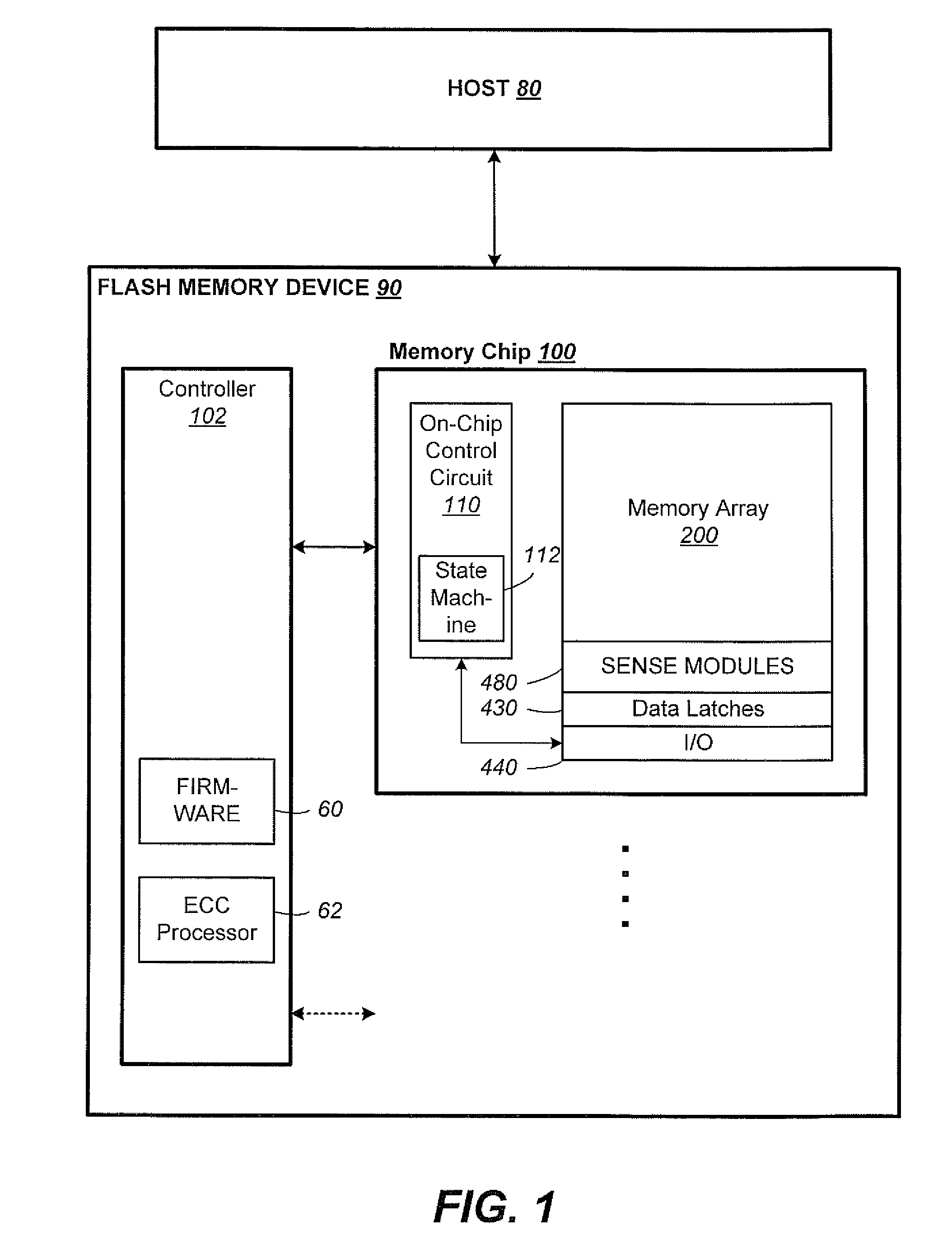

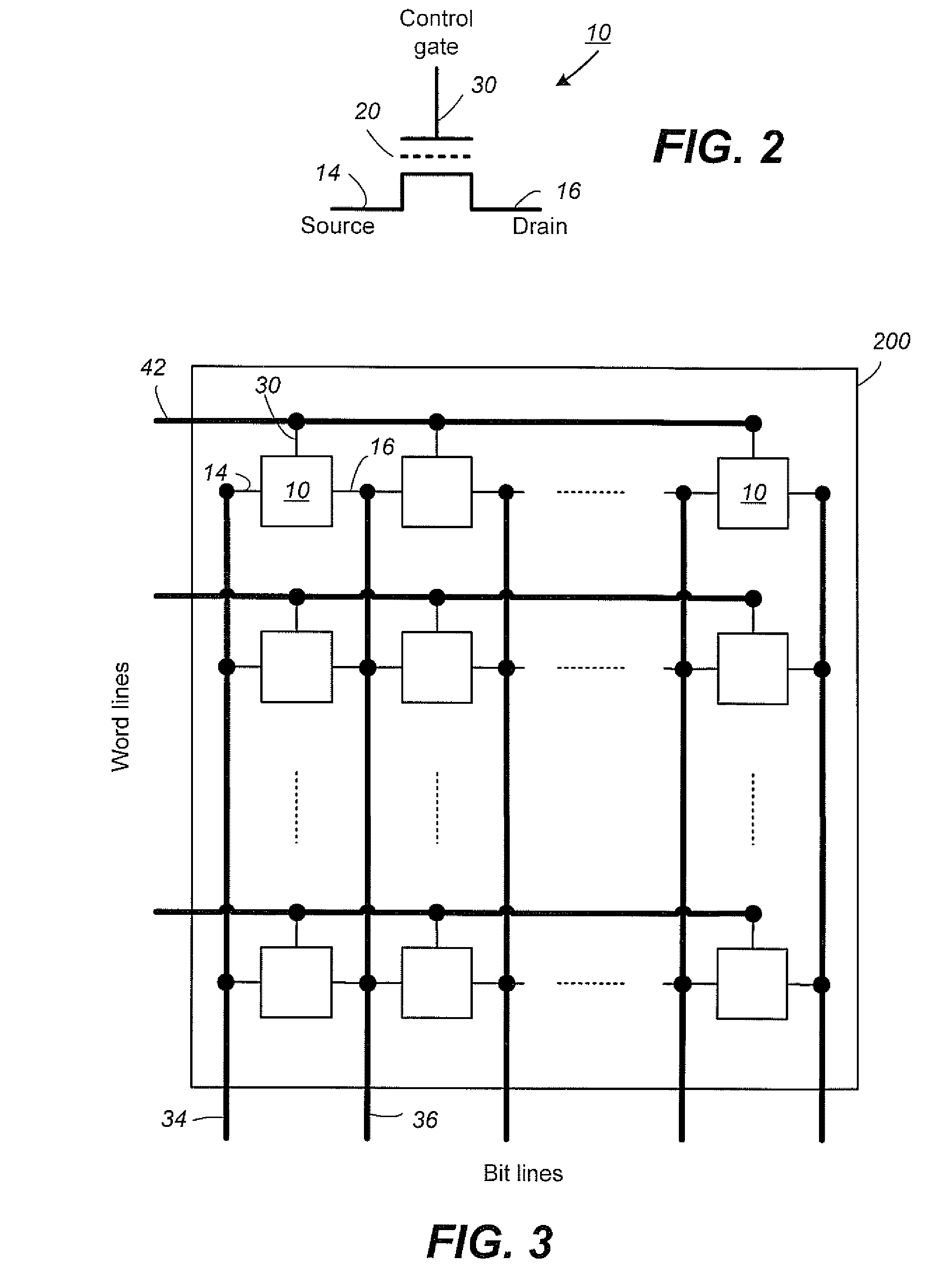

Non-Volatile Memory And Method With Post-Write Read And Adaptive Re-Write To Manage Errors

ActiveUS20110099418A1Small marginReduce memory costMemory adressing/allocation/relocationRead-only memoriesHigh densityQuality assurance

Data errors in non-volatile memory inevitably increase with usage and with higher density of bits stored per cell. For acceptable quality assurance, conventional error correction codes (“ECC”) have to correct a maximum number of error bits up to the far tail end of a statistical population. The present memory is configured to have a first portion operating with less error but of lower density storage, and a second portion operating with a higher density but less robust storage. If excessive error bits (at the far tail-end) occur after writing a group of data to the second portion, the data is adaptively rewritten to the first portion which will produce less error bits. Preferably, the data is initially written to a cache also in the first portion to provide source data for any rewrites. Thus, a more efficient ECC not requiring to correcting for the far tail end can be used.

Owner:SANDISK TECH LLC

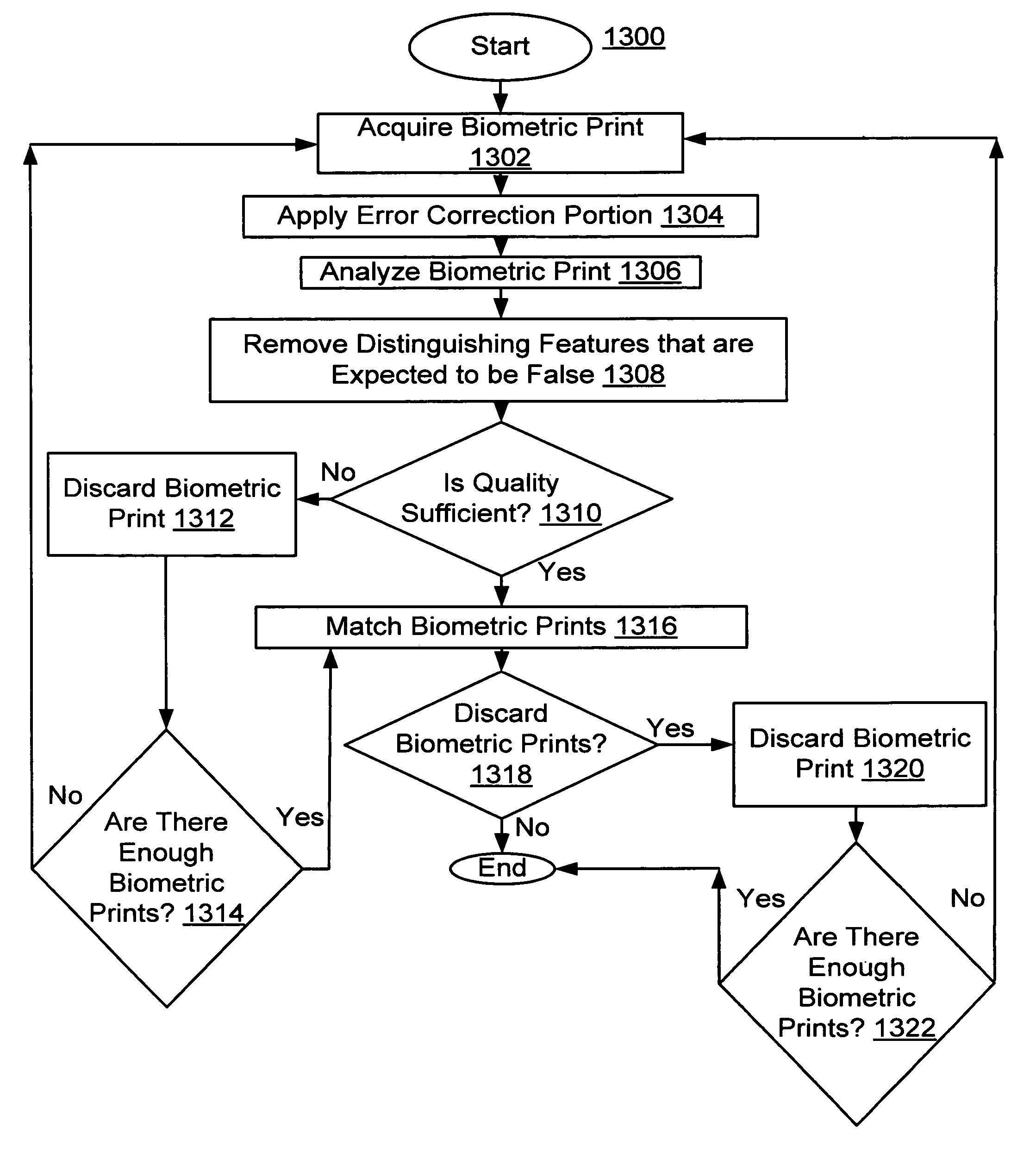

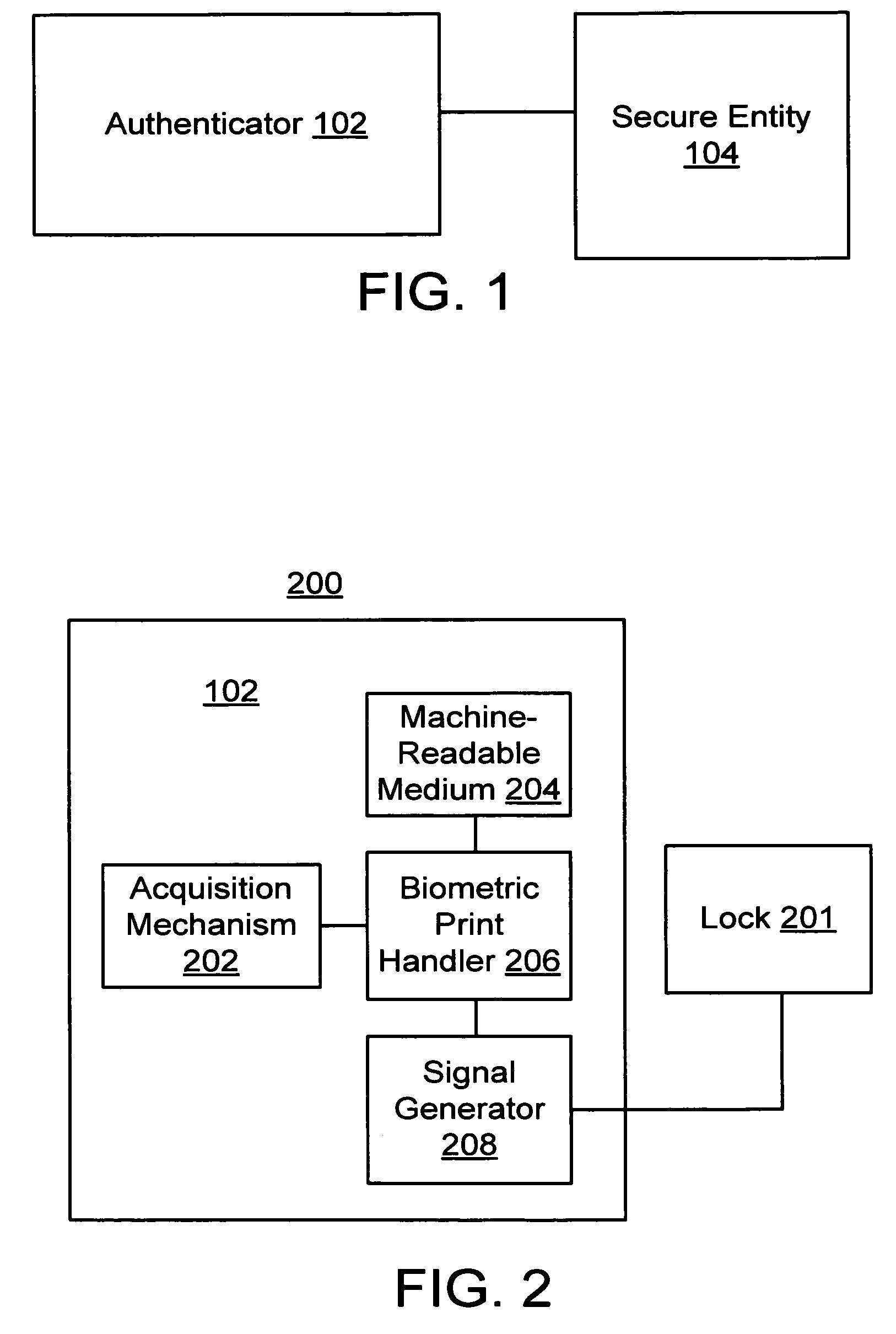

Biometric print quality assurance

ActiveUS7565548B2Character and pattern recognitionDigital data authenticationQuality assuranceInternet privacy

Quality of biometric prints is enhanced by any one of several different methods. In one embodiment, if a biometric print does not have a high enough quality, the biometric print is discarded. In another embodiment, a matching score is associated with the degree to which the two biometric prints match. In another embodiment, a ranking is associated with a biometric print, and the ranking is determined based upon two or more matching scores associated with the biometric print. In another embodiment, a variety of distinguishing features are derived from a given biometric print and are stored for authenticating a biometric print of a user requesting access to a secure entity. In an embodiment, a transformation is applied to at least a portion of a newly acquired biometric print to improve the match of the newly acquired biometric print to a stored biometric print.

Owner:BIOGY

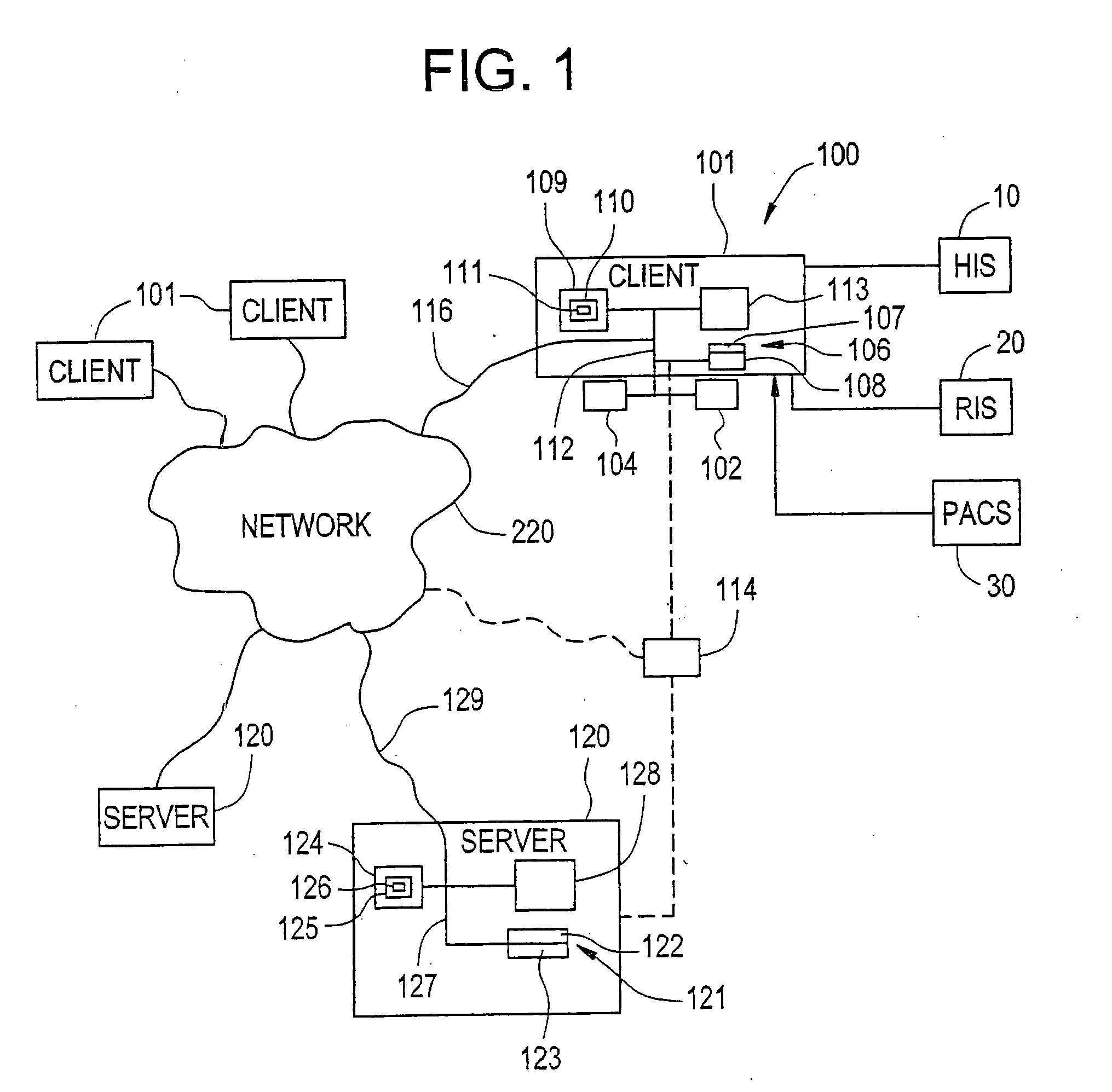

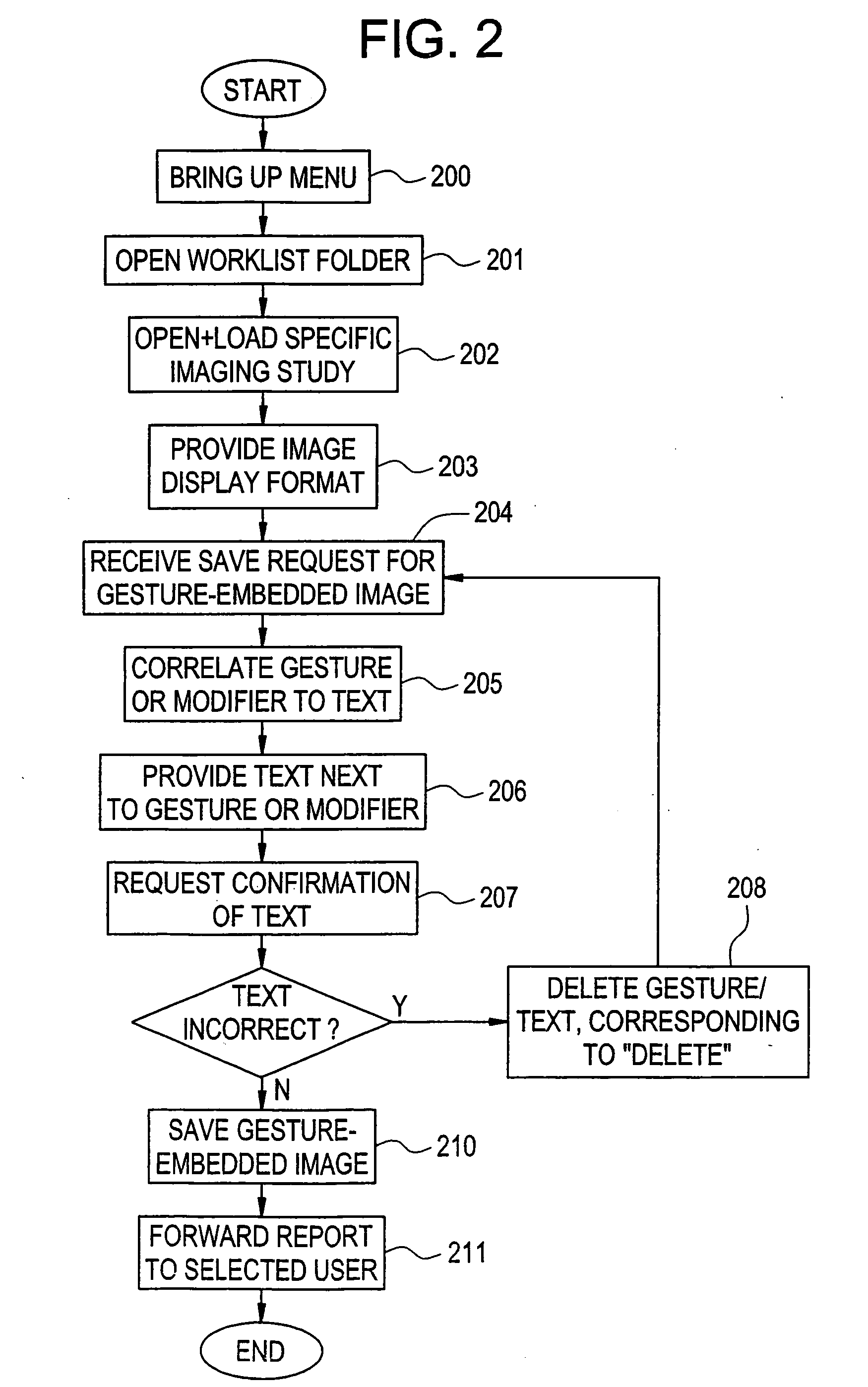

Gesture-based communication and reporting system

ActiveUS20090018867A1Avoid mistakesFacilitate communicationData processing applicationsMechanical/radiation/invasive therapiesData dredgingImaging quality

The present invention relates to a gesture-based reporting method and system, including a critical results reporting pathway, which is used to communicate critical findings to users according to predetermined methods (i.e., e-mail, facsimile, etc.), and create an electronic auditing trail to document receipt, understanding, bi-directional queries, and track clinical outcomes. Based on a predetermined rule set, predetermined data elements within the structured database could trigger the critical results reporting pathway. There is a quality assurance component to the invention, such that technical deficiencies in an imaging quality can be noted, analyzed, and tracked. There is a workflow and data analysis portion to the invention, wherein workflow is enhanced, and structured data is mapped to a standardized lexicon, such that data mining can be performed. Thus, the present invention extends beyond reporting alone and is a tool to facilitate electronic communication, consultation, education / training, and data mining for quality assurance.

Owner:IMPRIVATA

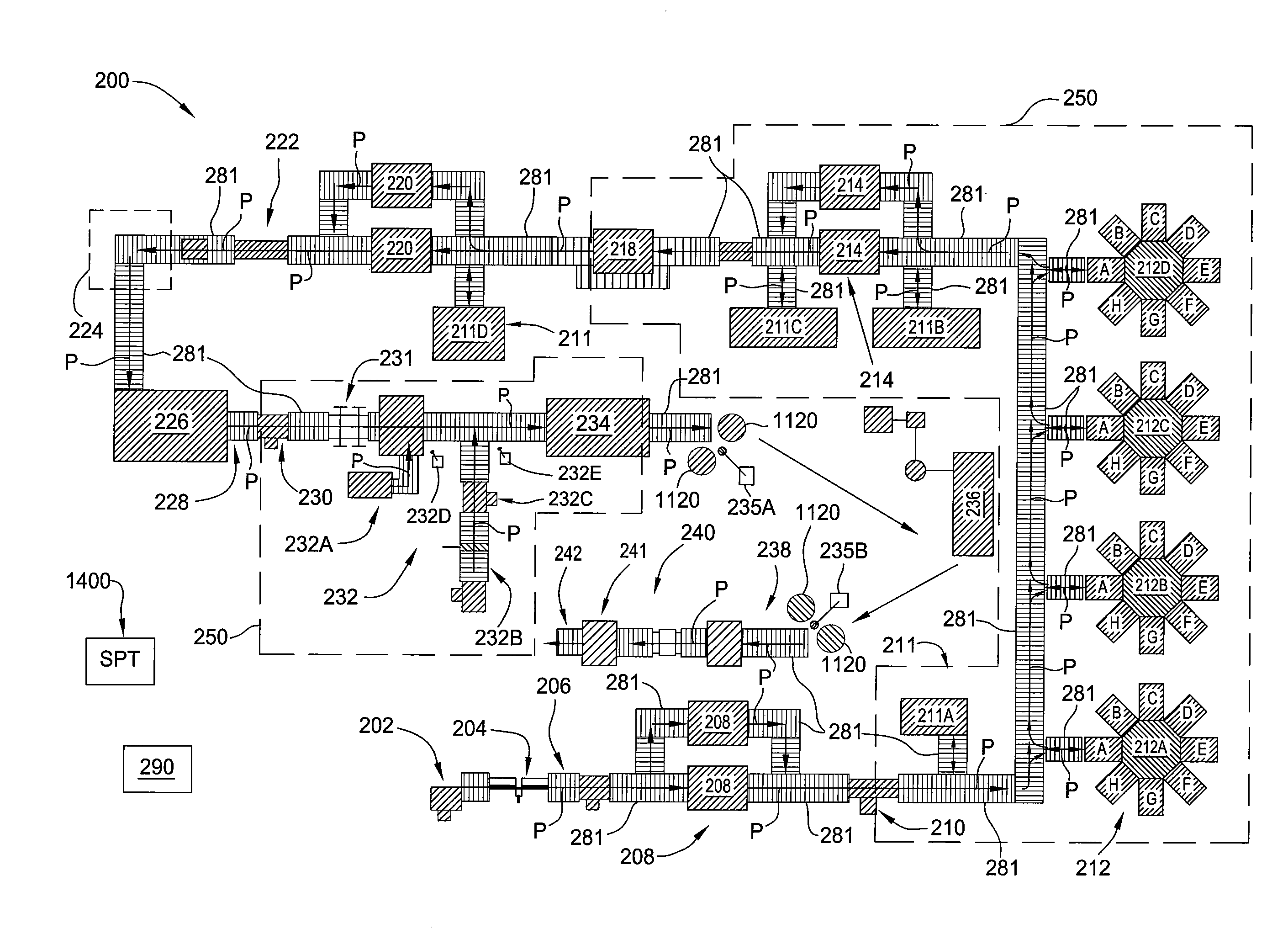

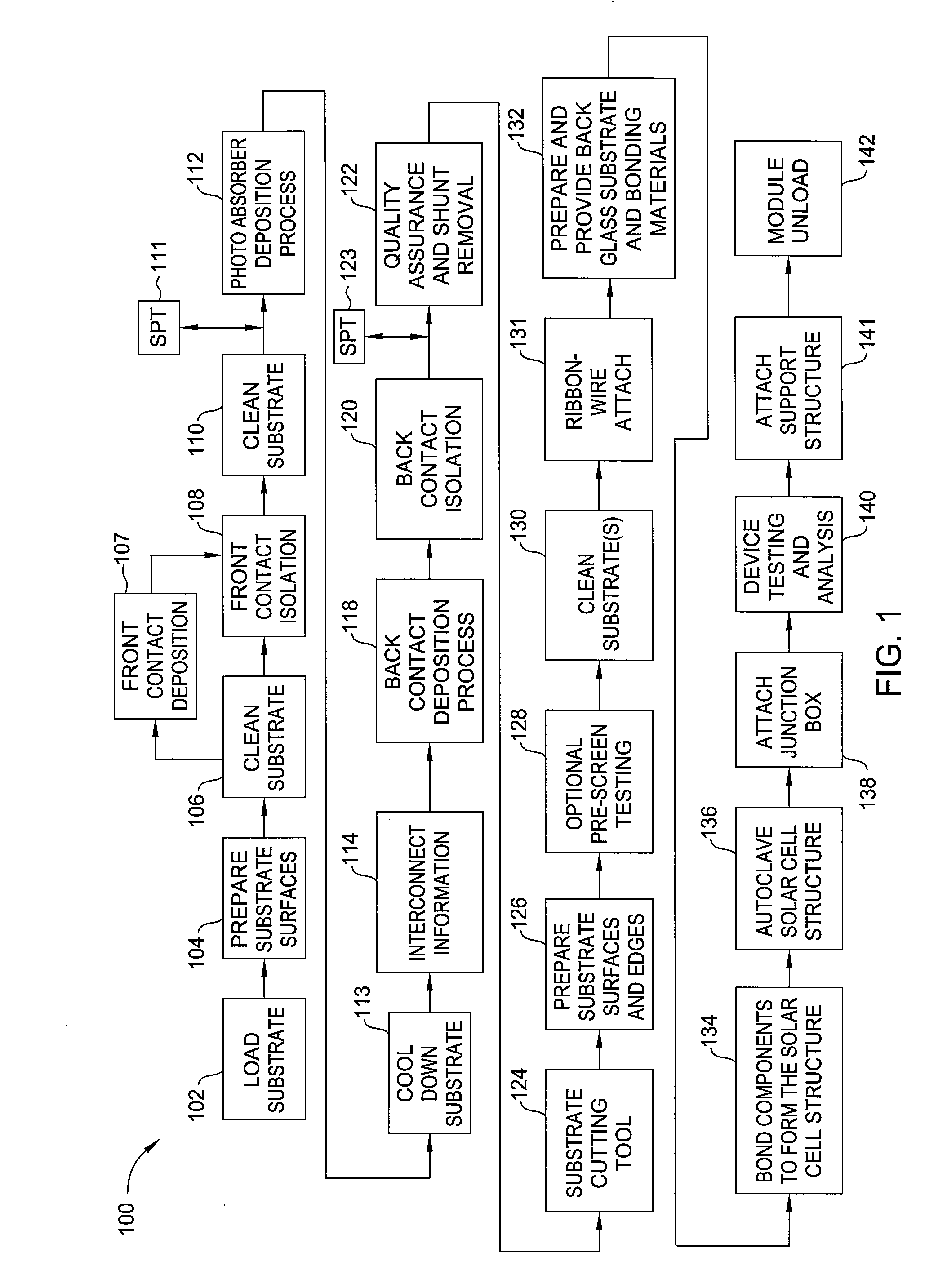

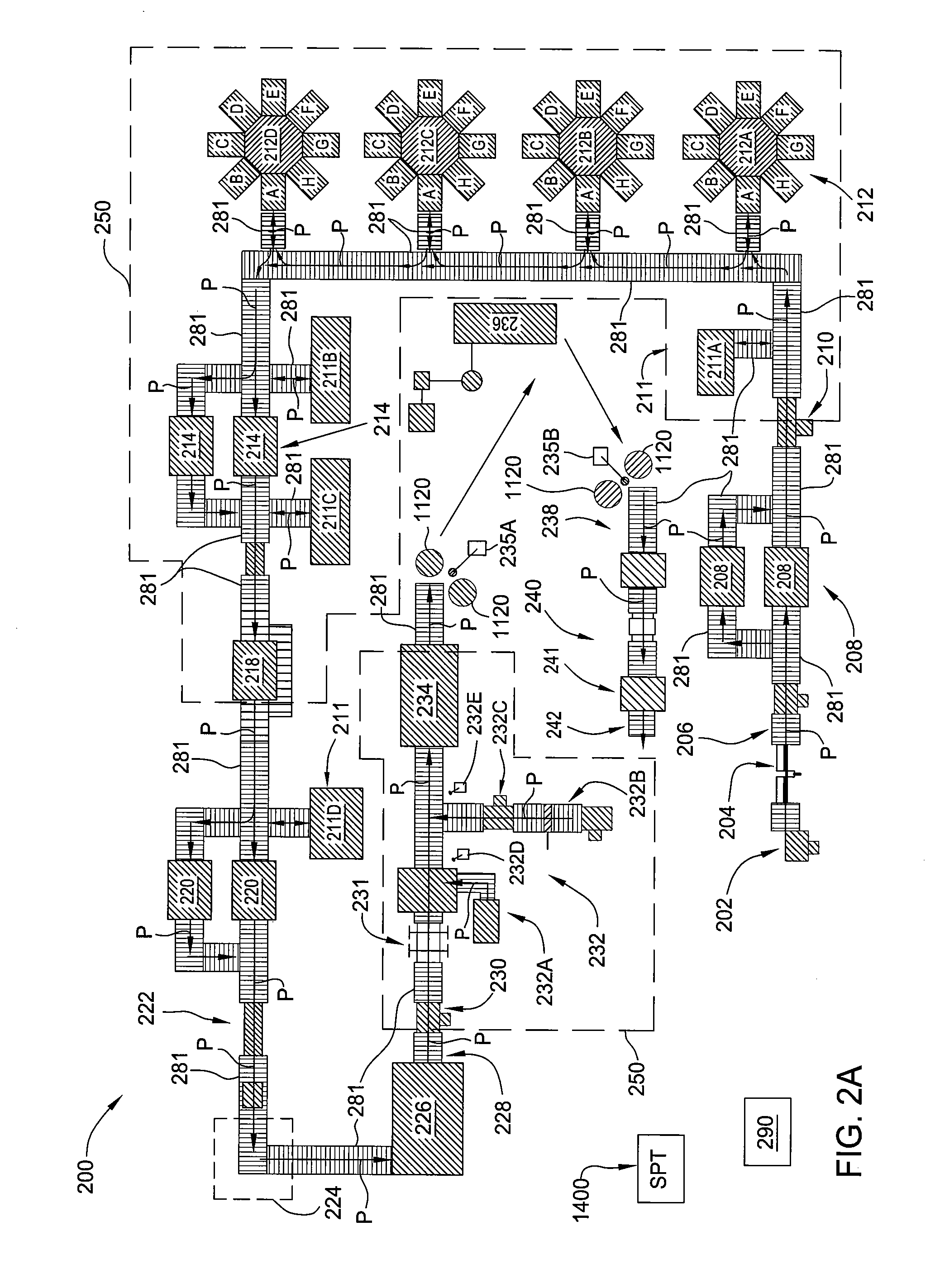

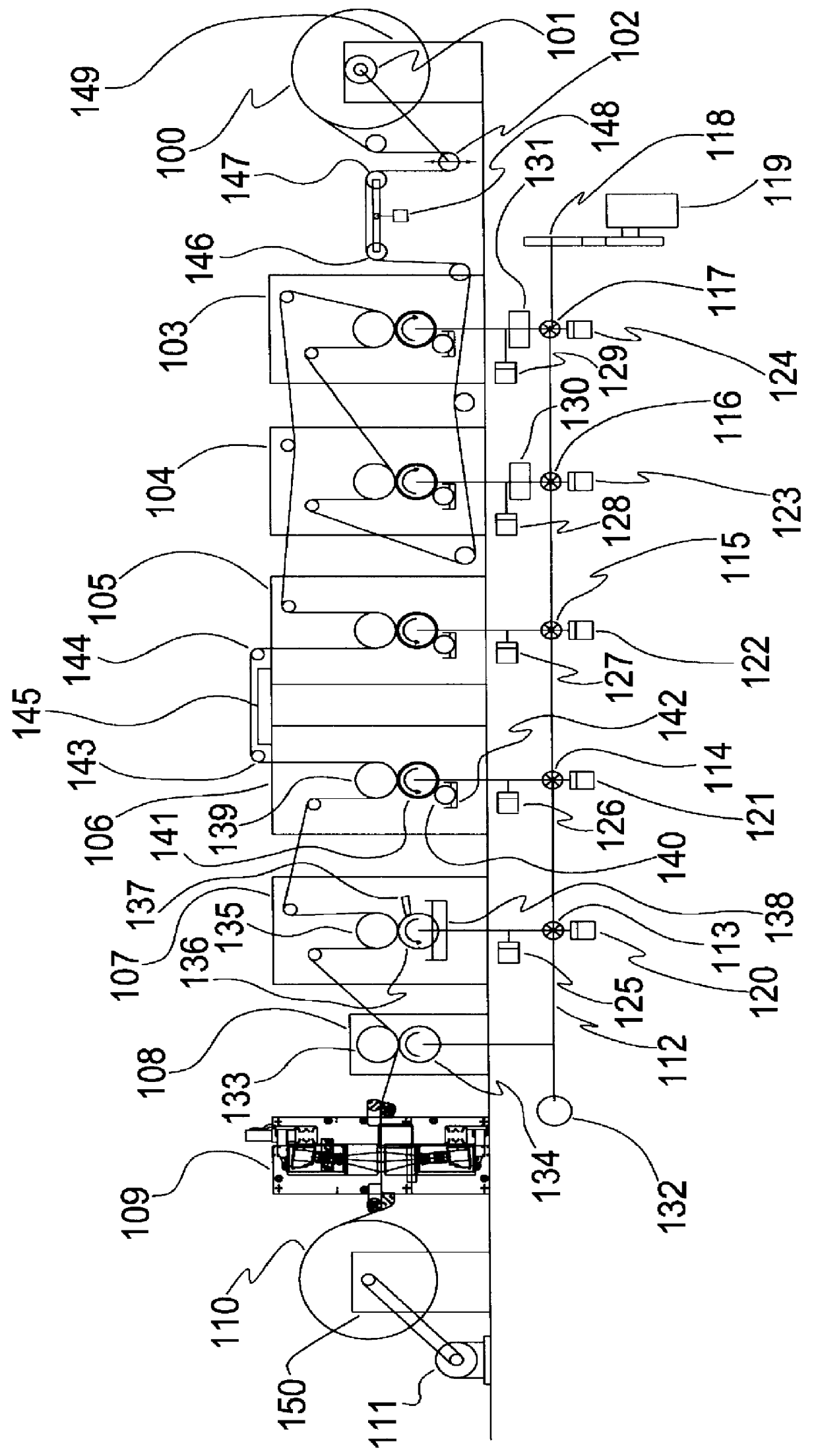

Photovoltaic production line

InactiveUS20090077805A1Improve bindingPhotovoltaic monitoringWave amplification devicesProduction lineQuality assurance

The present invention generally relates to a system that can be used to form a photovoltaic device, or solar cell, using processing modules that are adapted to perform one or more steps in the solar cell formation process. The automated solar cell fab is generally an arrangement of automated processing modules and automation equipment that is used to form solar cell devices. The automated solar fab will thus generally comprise a substrate receiving module that is adapted to receive a substrate, one or more absorbing layer deposition cluster tools having at least one processing chamber that is adapted to deposit a silicon-containing layer on a surface of the substrate, one or more back contact deposition chambers, one or more material removal chambers, a solar cell encapsulation device, an autoclave module, an automated junction box attaching module, and one or more quality assurance modules that are adapted to test and qualify the completely formed solar cell device.

Owner:APPLIED MATERIALS INC

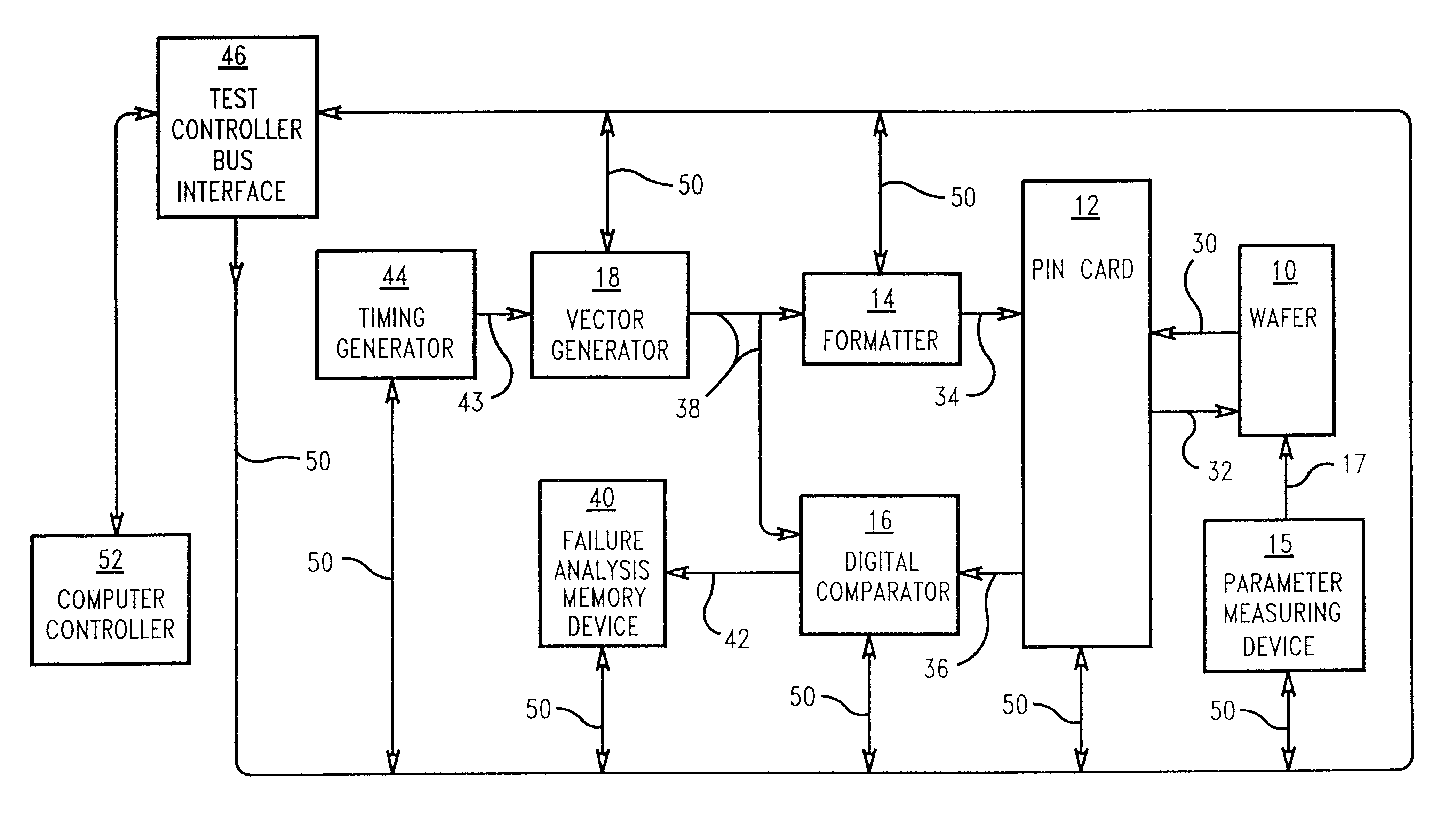

Method for testing semiconductor devices

InactiveUS6512392B2Quality improvementImprove reliabilityMeasurement leads/probesIndividual semiconductor device testingLow voltageQuality assurance

Method for determining a more efficient quality assurance or reliability test screen without falsely rejecting, i.e., over stressing, short channel length devices during voltage stress test screening. Short channel lengths devices fabricated on a semiconductor wafer have a higher tendency to fail at voltage levels that would otherwise not harm long channel length devices. The failures, however, are not related to device defects. Protection to the more vulnerable devices is provided by determining the speed of the die prior to the voltage test screen, thus, segregating the devices based on operational speed performance. Next, a lower voltage is effetively applied during wafer probe test to the faster devices, which directly correspond to the population of short channel devices.

Owner:MITSUBISHI ELECTRIC CORP +1

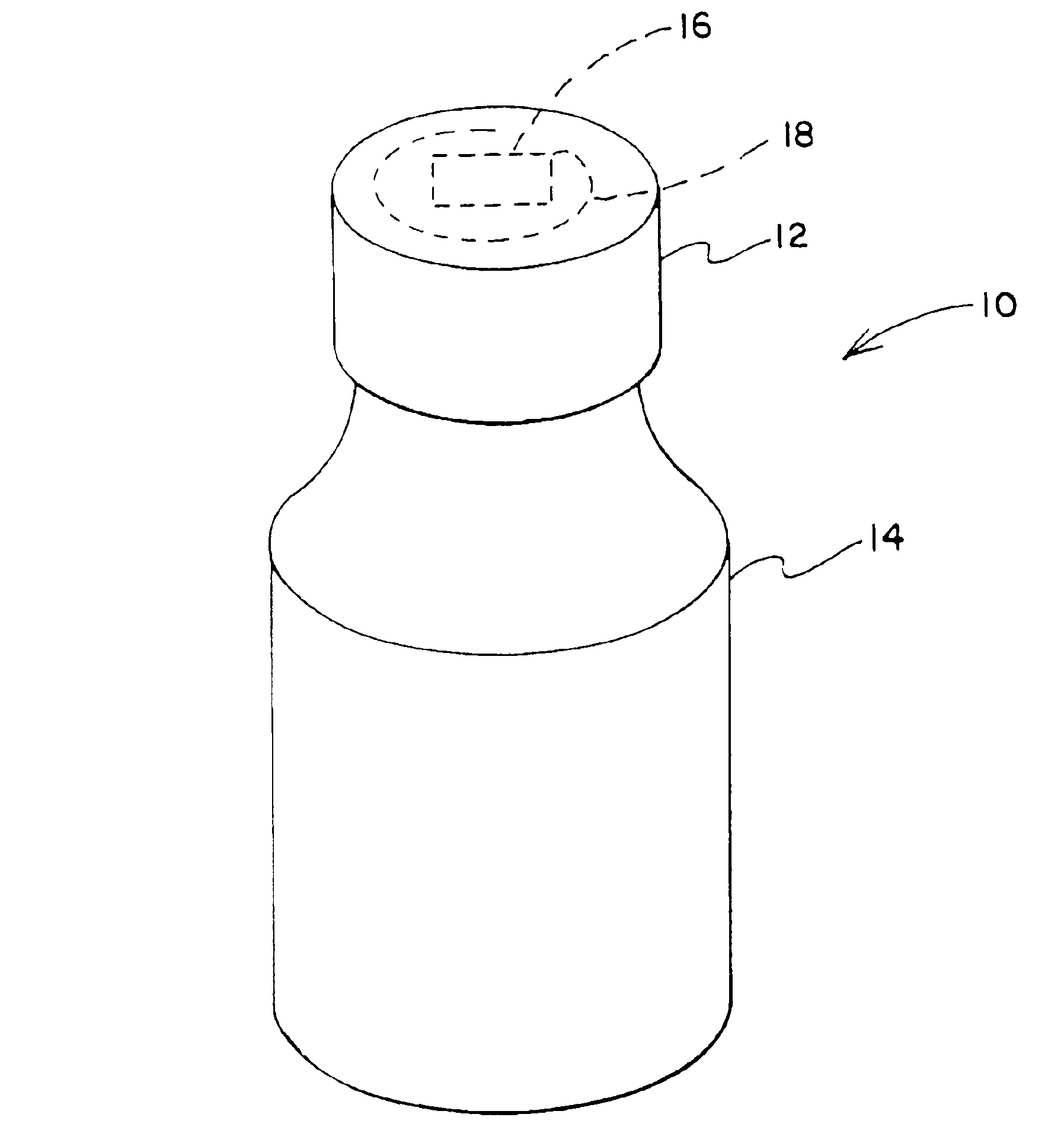

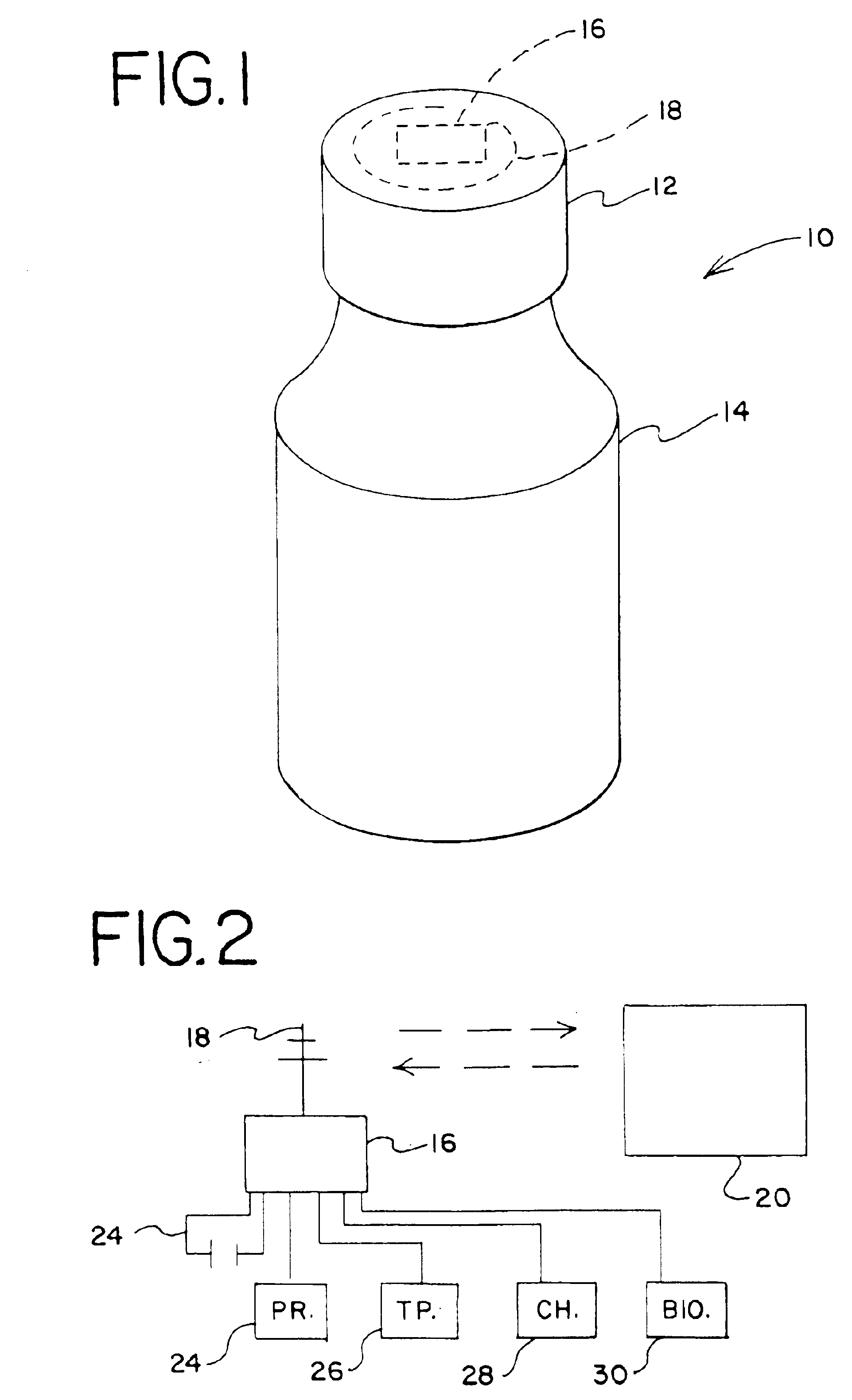

Drug container entry mechanisms and method

The invention of this application relates generally to intravenous (IV) infusion of drugs to patients, and more particularly to aspects of an IV infusion system comprising an infusate cassette and an infusate container. The present invention provides a drug infusion cassette that incorporates a strong vial spike that may be non-metal, a means for sheathing the spike when it is not in use, an anti-free flow device, and other beneficial features such as an air entrainment lockout mechanism, quality assurance tags, stopcocks made of soft materials and means of securing tubing to the cassette with a minimum of individual parts. The drug cassette can be used with an automated spiking mechanism comprising a motorized vial holder that holds a vial. The spike remains sheathed if the drug cassette is not fully engaged with a mating surface of devices such as a pumping unit or a sedation and analgesia delivery system.

Owner:SCOTT LAB

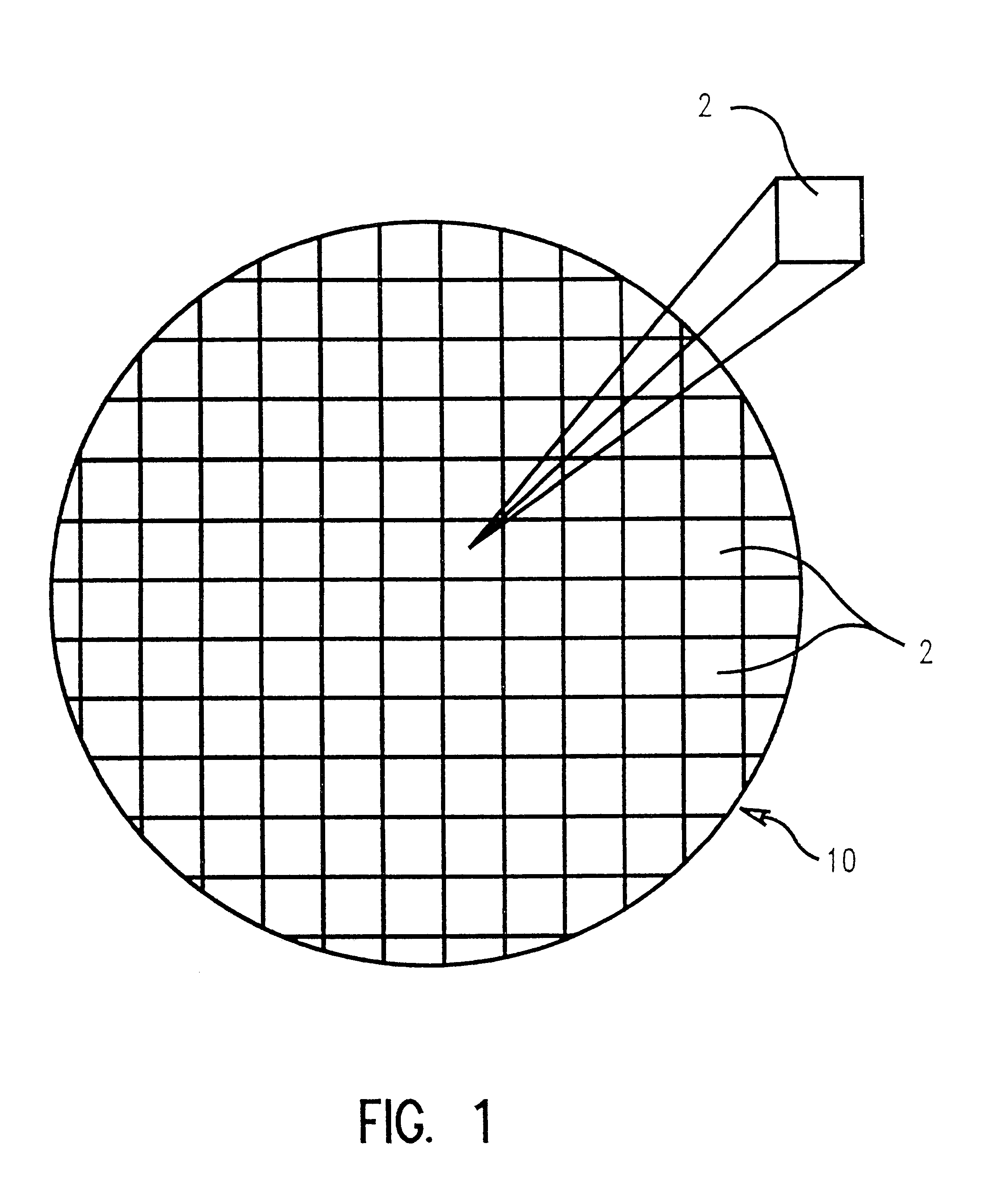

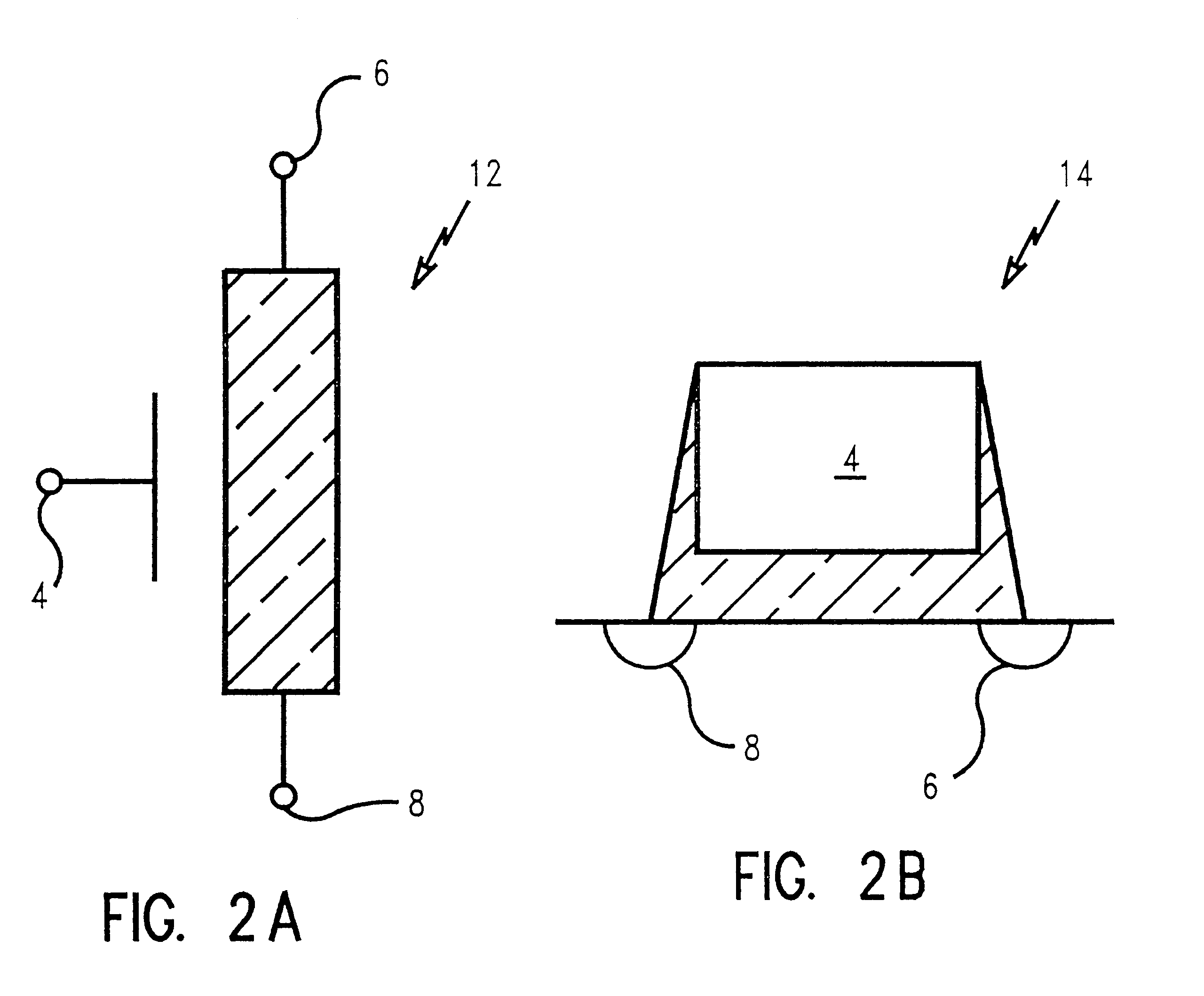

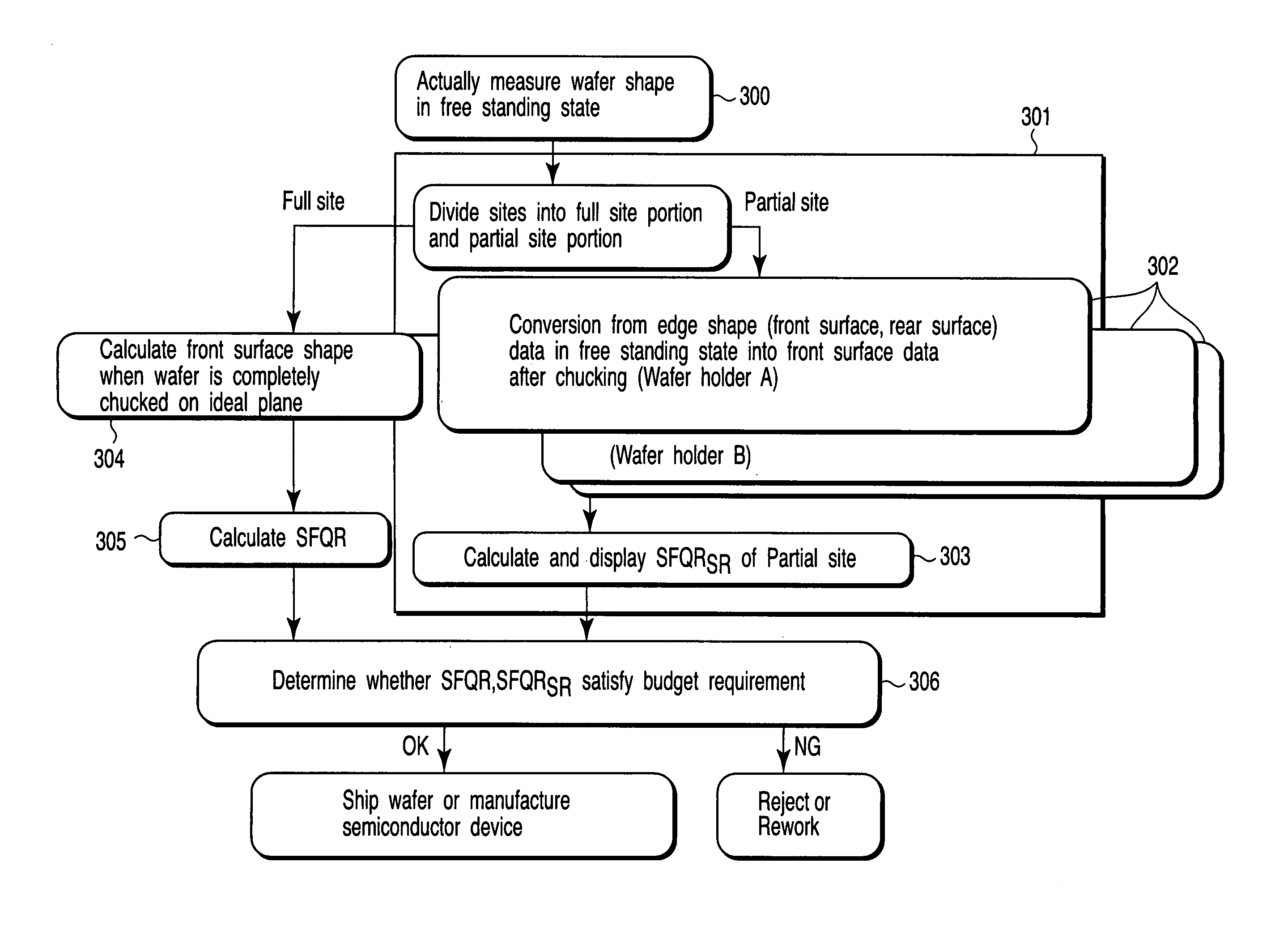

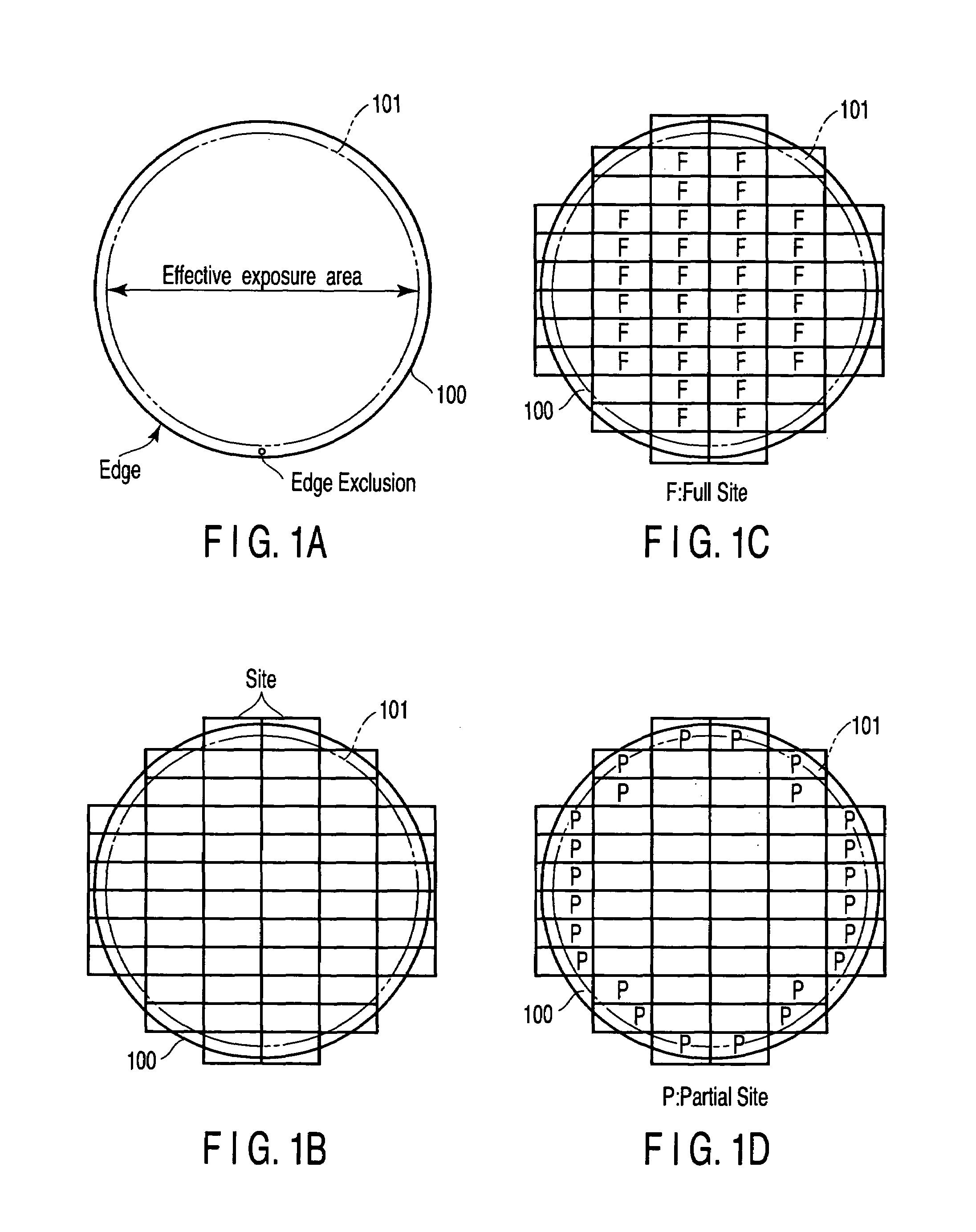

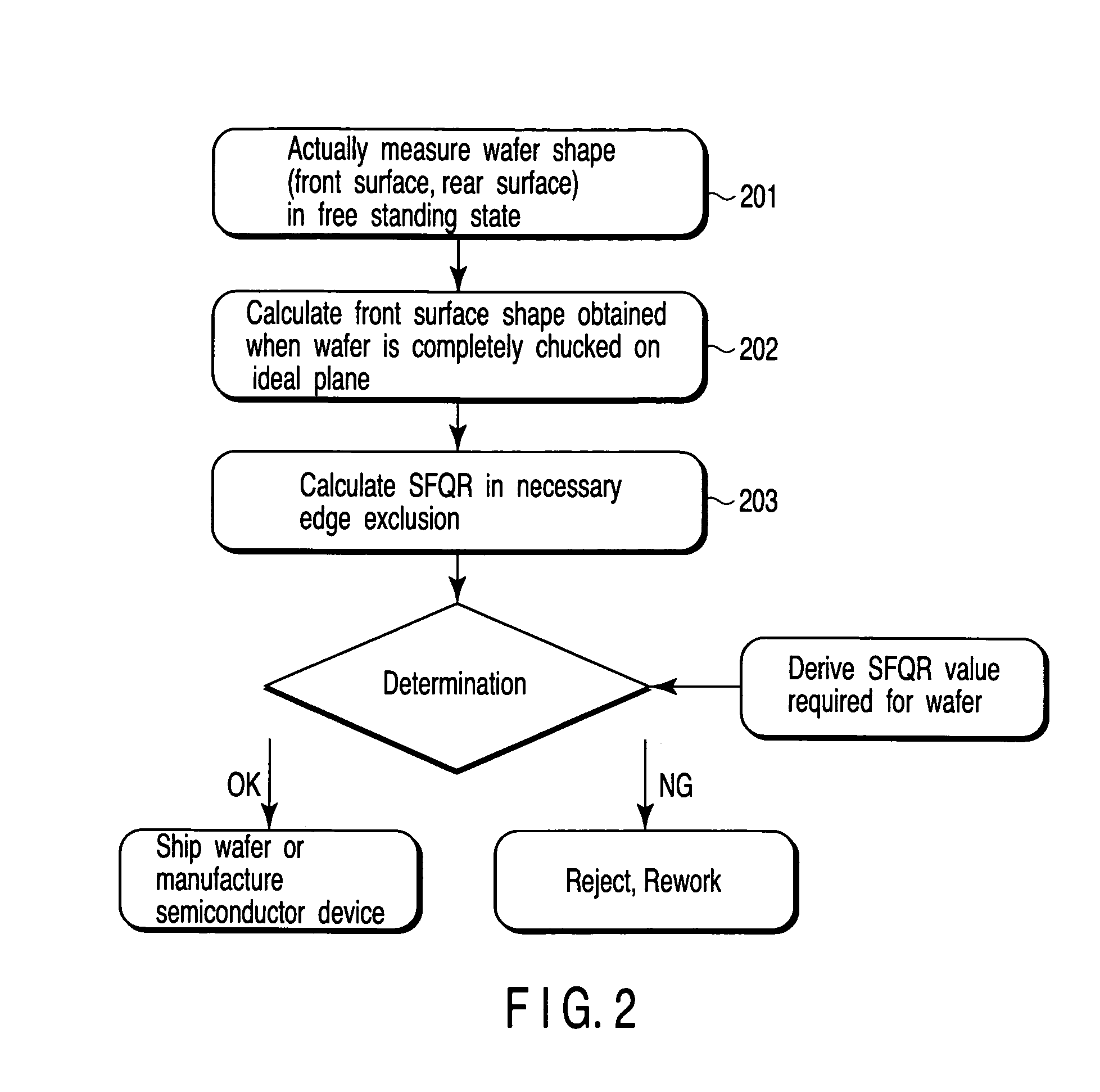

Wafer flatness evaluation method, wafer flatness evaluation apparatus carrying out the evaluation method, wafer manufacturing method using the evaluation method, wafer quality assurance method using the evaluation method, semiconductor device manufacturing method using the evaluation method and semiconductor device manufacturing method using a wafer evaluated by the evaluation method

ActiveUS7230680B2Semiconductor/solid-state device testing/measurementSolid-state devicesQuality assuranceCalculation methods

There is disclosed a wafer flatness evaluation method includes measuring front and rear surface shapes of a wafer. The wafer front surface measured is divided into sites. Then, a flatness calculating method is selected according to a position of the site to be evaluated and flatness in the wafer surface is acquired.

Owner:SHIN-ETSU HANDOTAI CO LTD +2

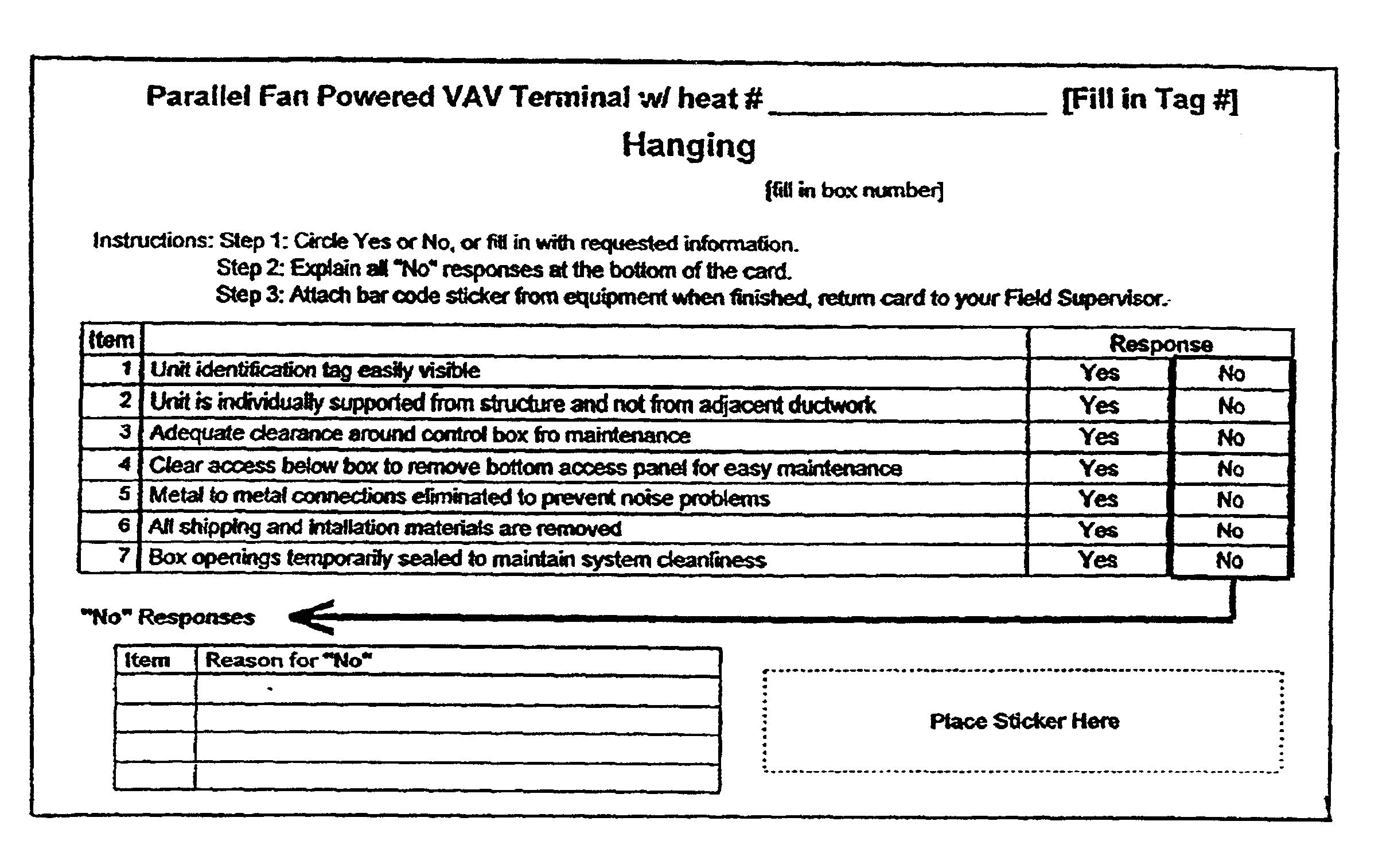

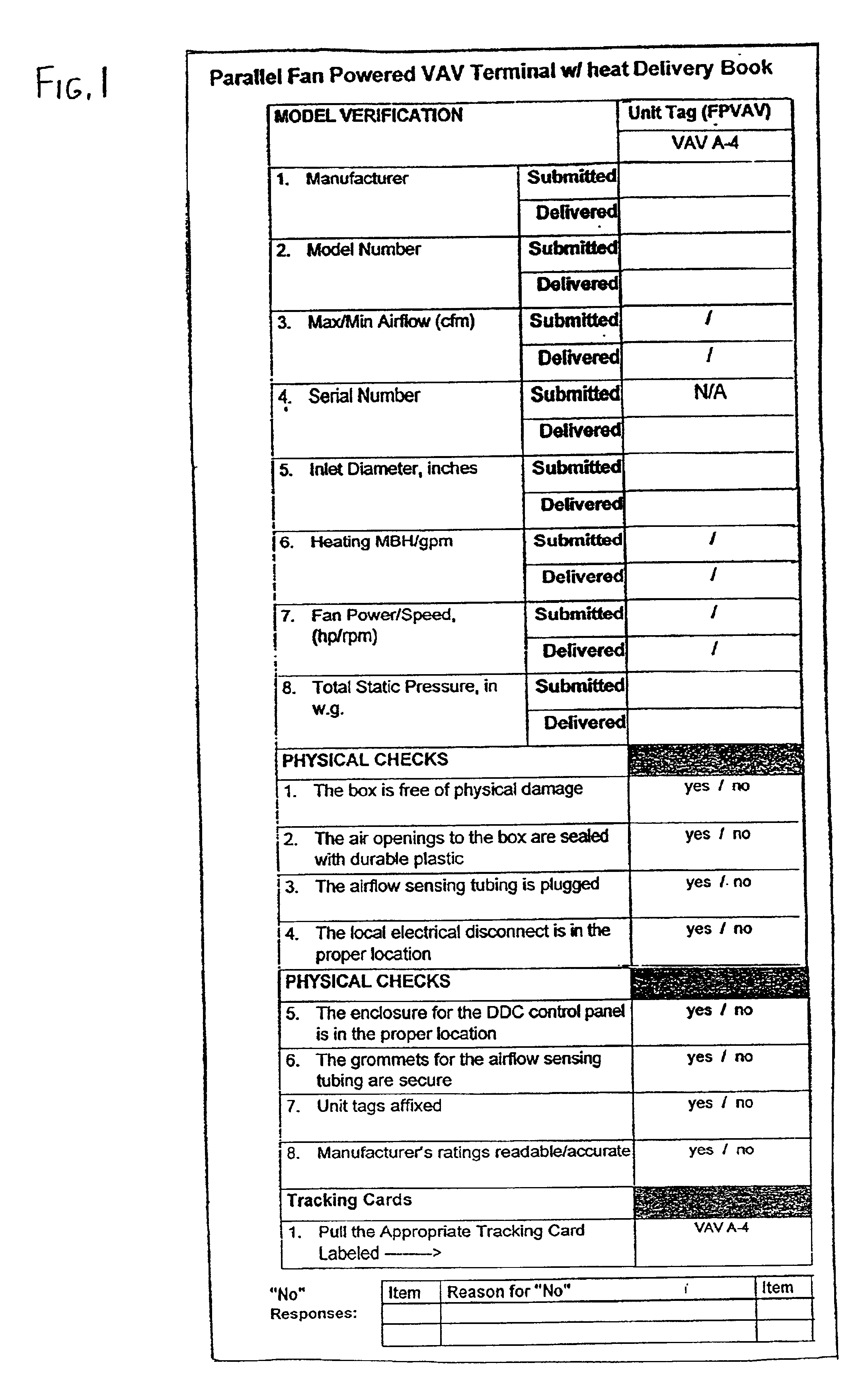

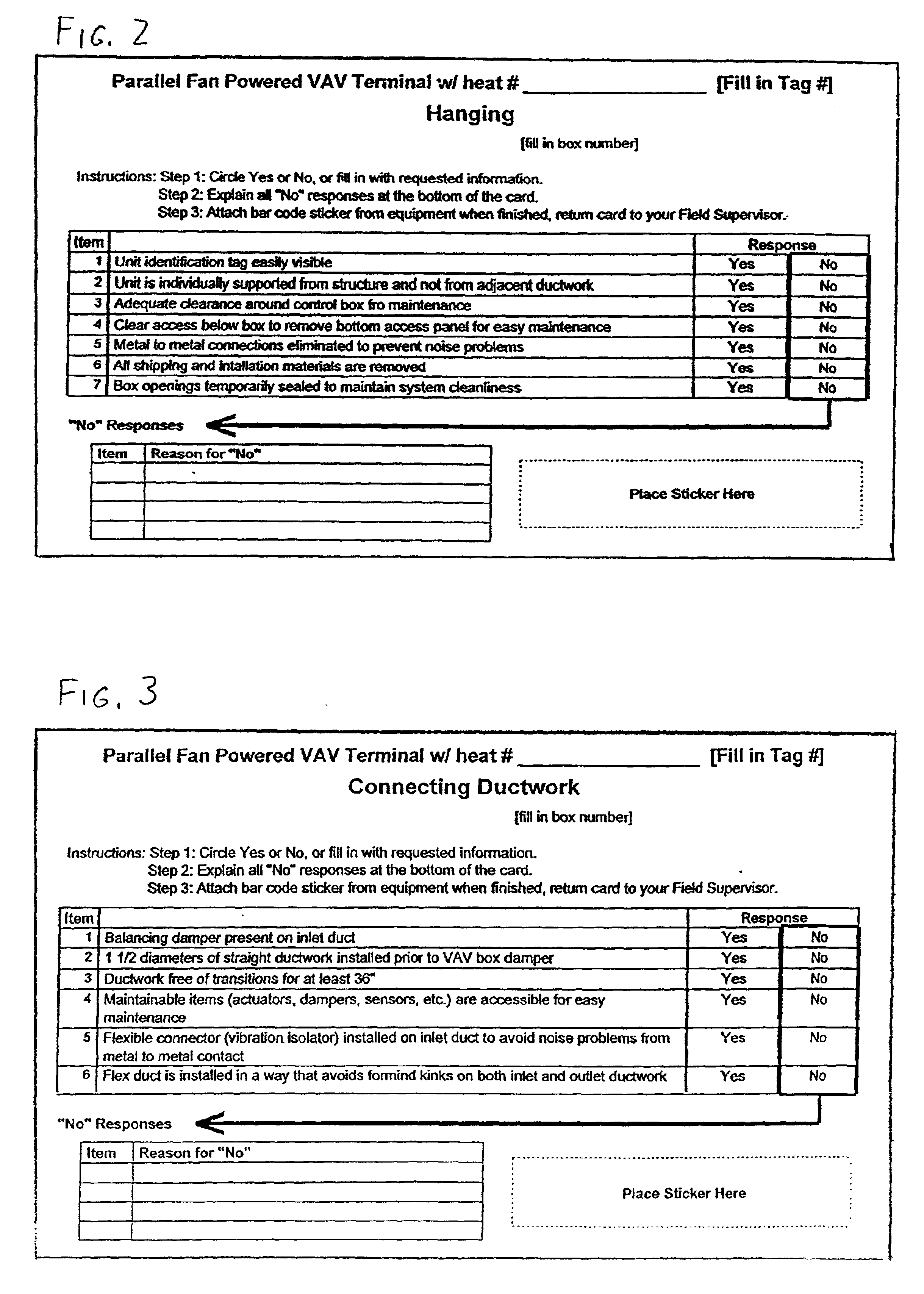

Methods and apparata for highly automated quality assurance of building construction projects

InactiveUS6842760B1Optimize schedulingQuality is determinedResourcesSpecial data processing applicationsCompletion StatusMilestone

Tracking forms allow tracking of the completion status and implemented quality standards of a building construction project. A tracking form is prepared for one or more tasks requiring completion at the construction site. Each task is assigned two components on its tracking form: a quality control indicator form, which contains one or more quality control indicators indicating whether certain quality standards are met; and a completion indicator, which indicates the completion status of a task. The completion status may be a discrete binary value, or may instead be a continuous value. Preferably, the workers performing the tasks complete each task's quality control indicator form and completion indicator during design and construction as milestones relating to the task are completed, or at the end of some predetermined time period. The completion indicators relating to the tasks are logged so that the completion status of the project may be monitored, and the information recorded on the quality control indicator forms may be sampled and checked to verify that construction quality standards are being met.

Owner:DORGAN CHAD BARRY +1

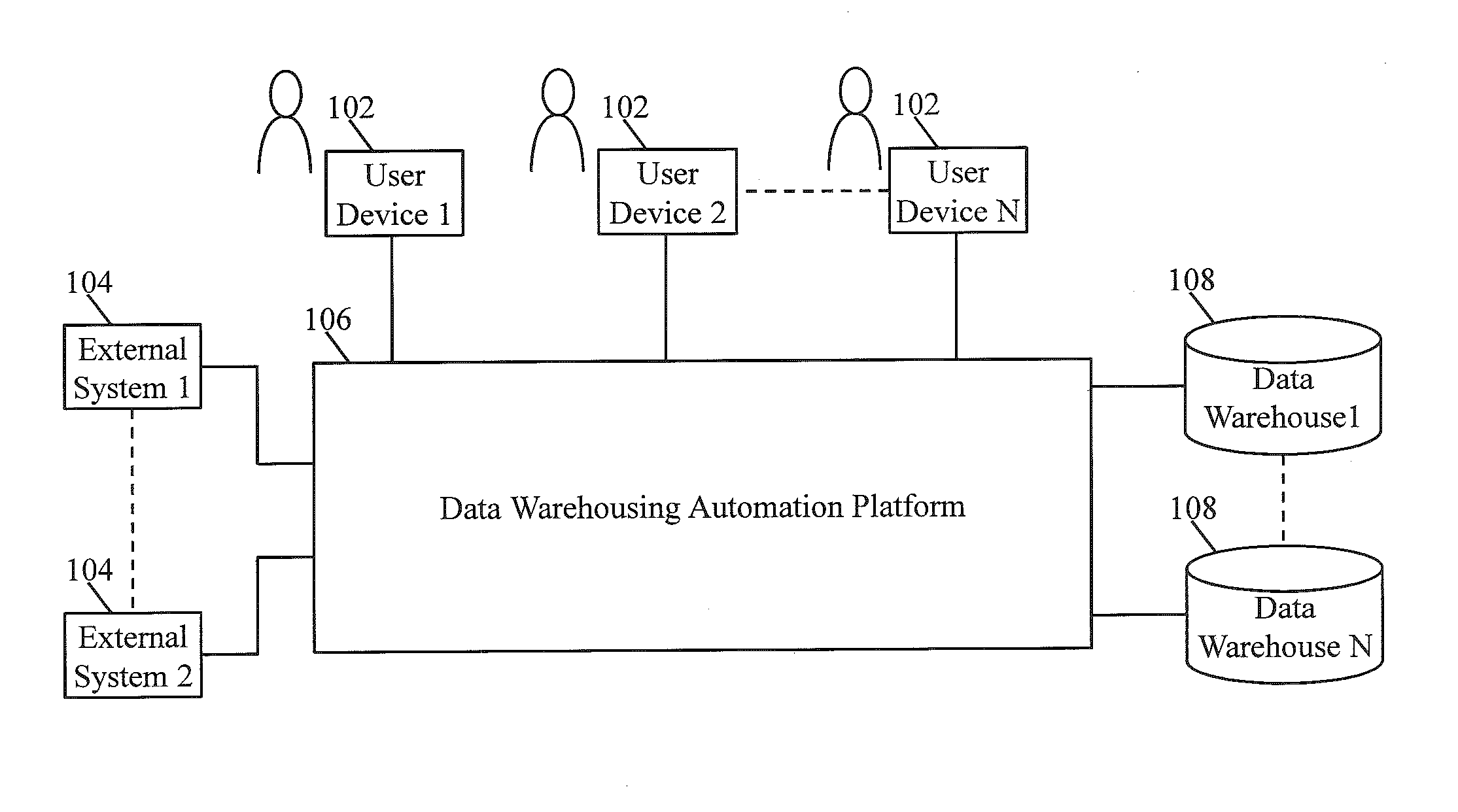

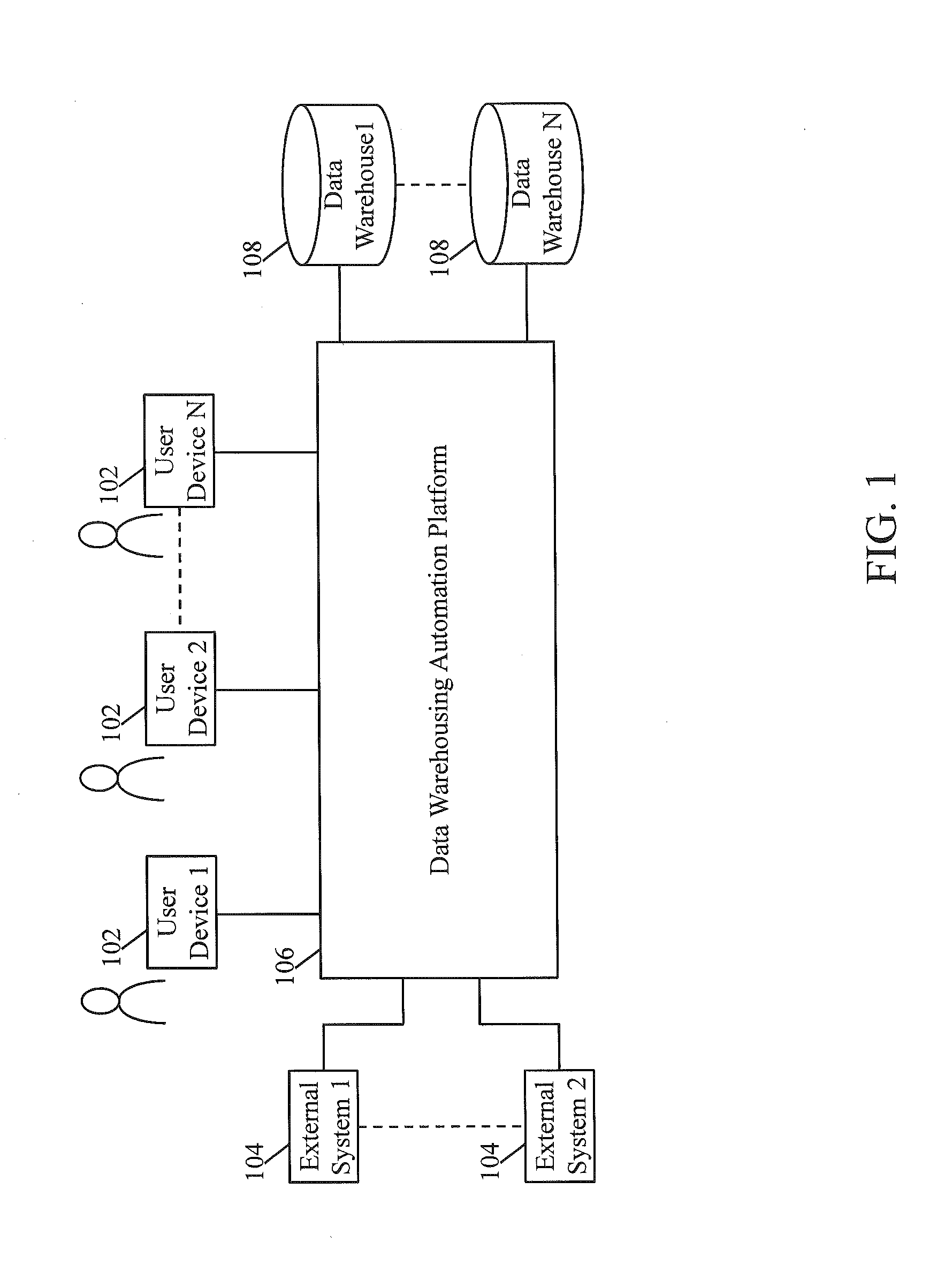

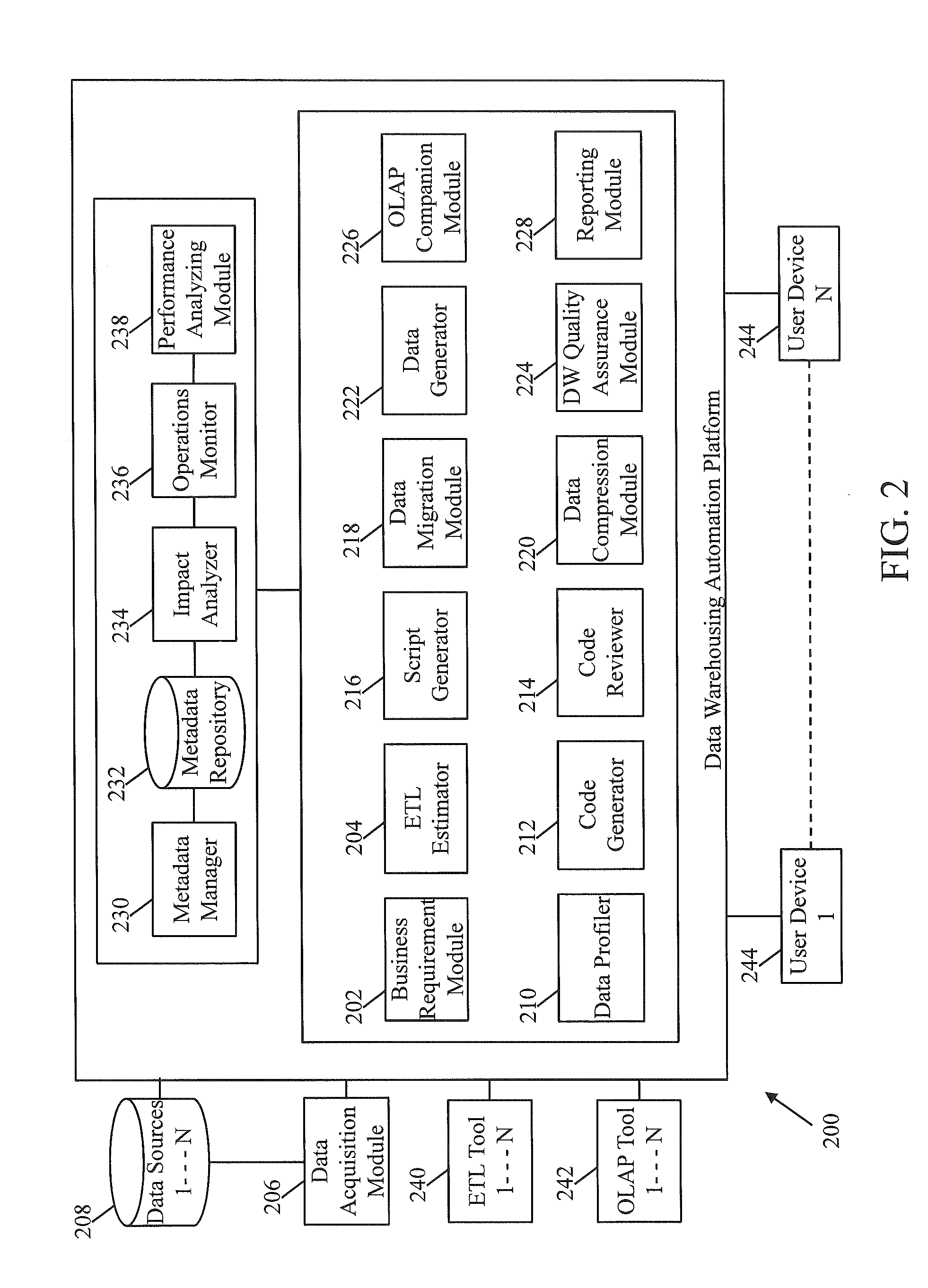

System and method for automating data warehousing processes

ActiveUS20140310231A1Easy extractionEasy to transformDigital data information retrievalDigital data processing detailsData warehouseQuality assurance

A system and computer-implemented method for automating data warehousing processes is provided. The system comprises a code generator configured to generate codes for Extract, Transform and Load (ETL) tools, wherein the codes facilitate the ETL tools in extracting, transforming and loading data read from data sources. The system further comprises a code reviewer configured to review and analyze the generated codes. Furthermore, the system comprises a data migration module configured to facilitate migrating the data read from the data sources to one or more data warehouses. Also, the system comprises a data generator configured to mask the data read from the data sources to generate processed data. In addition, the system comprises a Data Warehouse Quality Assurance module configured to facilitate testing the read and the processed data. The system further comprises a reporting module configured to provide status reports on the data warehousing processes.

Owner:COGNIZANT TECH SOLUTIONS INDIA PVT

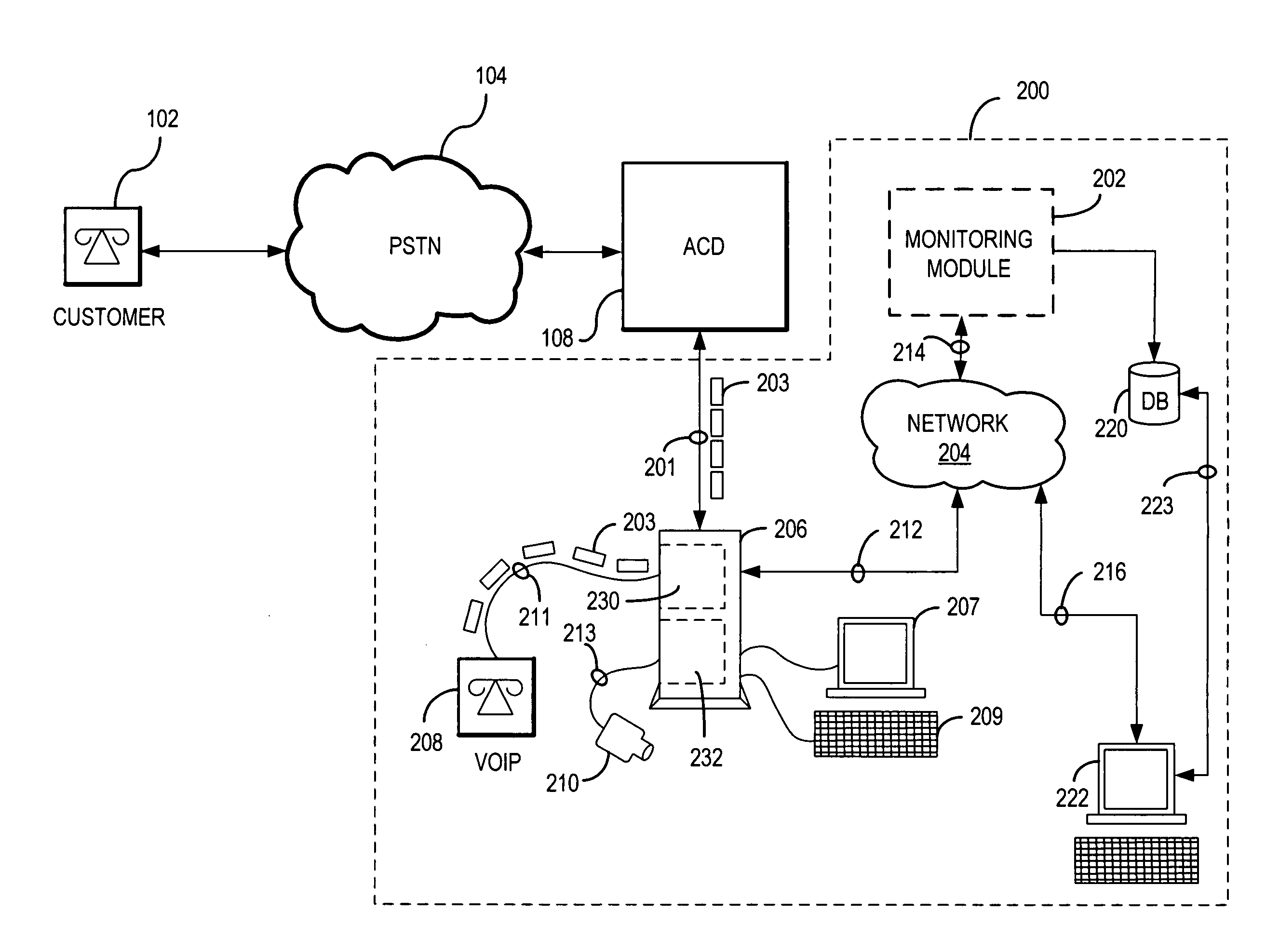

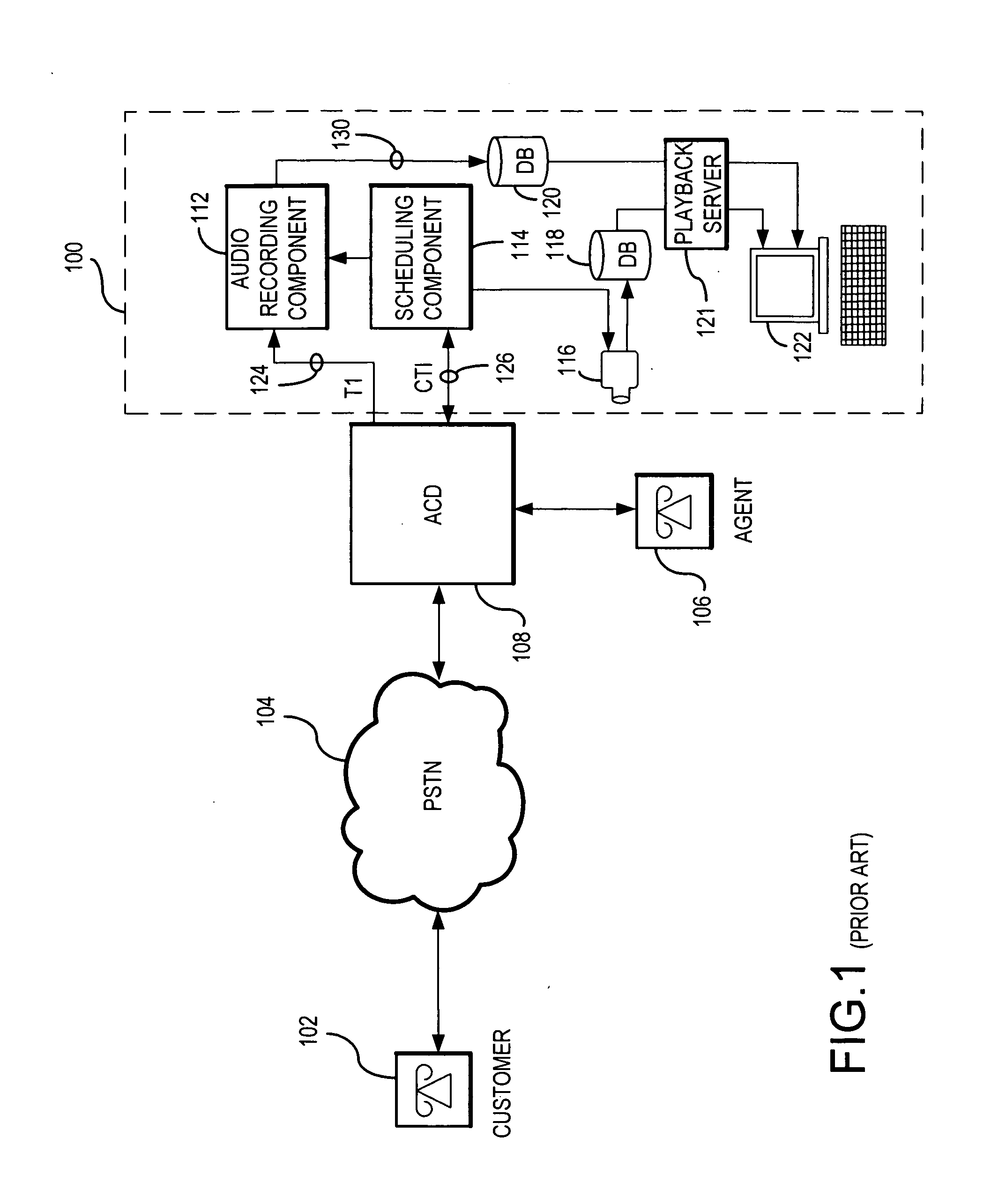

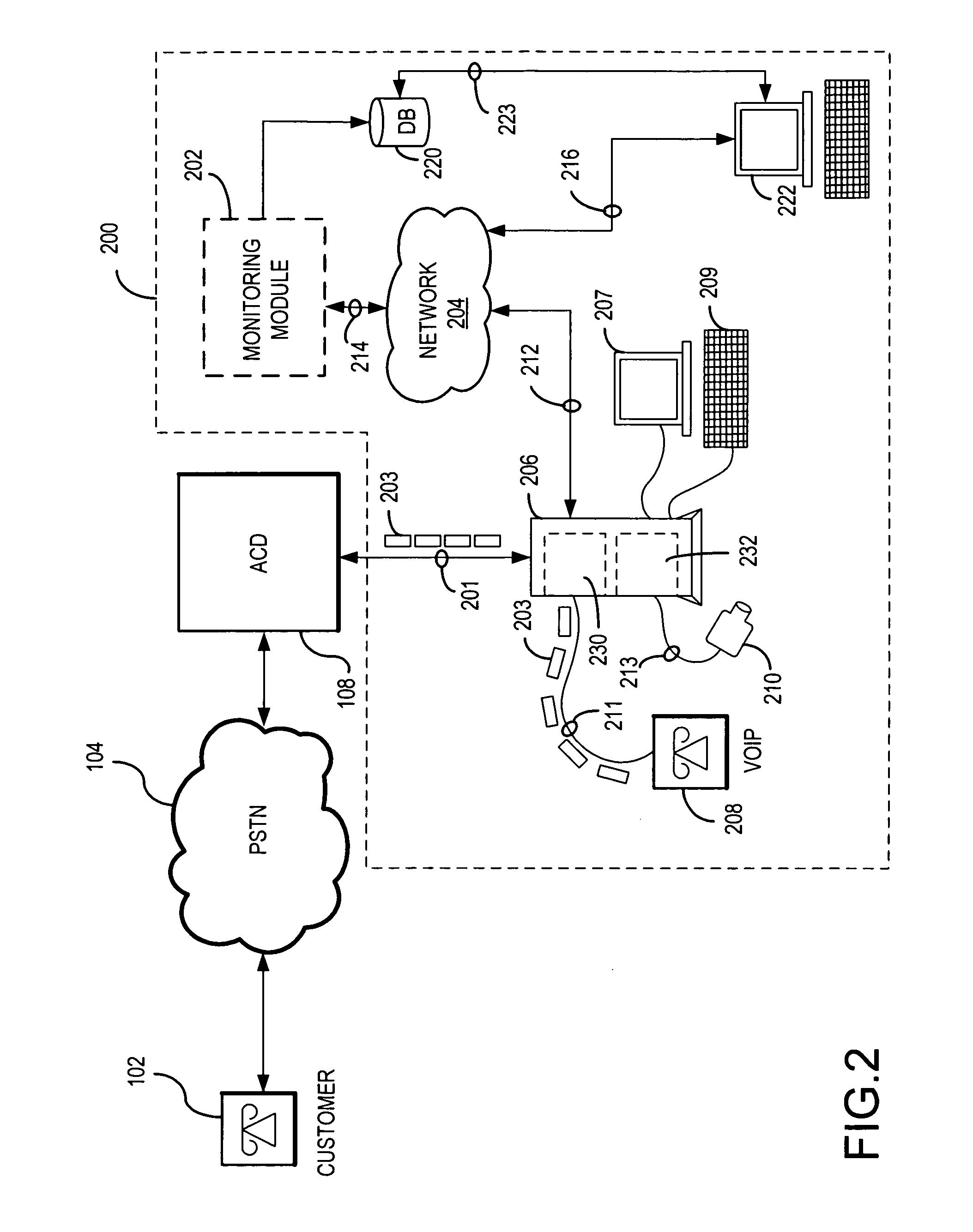

Monitoring service personnel

An approach for monitoring interaction between individuals engaged in a communication session is disclosed. The individuals are described herein as a customer service representative and a customer and the communication session is accomplished over a communication network. Audio data embodying the communication session is copied and stored to a media file in conjunction with video data captured by a video capture device monitoring the customer service representative. The media file is a data structure in which the audio data and the video data are stored in segmented fashion. Each segment of audio data is associated with a segment of video data based on a common time reference, thereby providing synchronized documentation of the communication session. The media file is stored on a database and available to a supervisor using a server computer to monitor the communication session for quality assurance or other evaluation purposes.

Owner:TELETECH HLDG

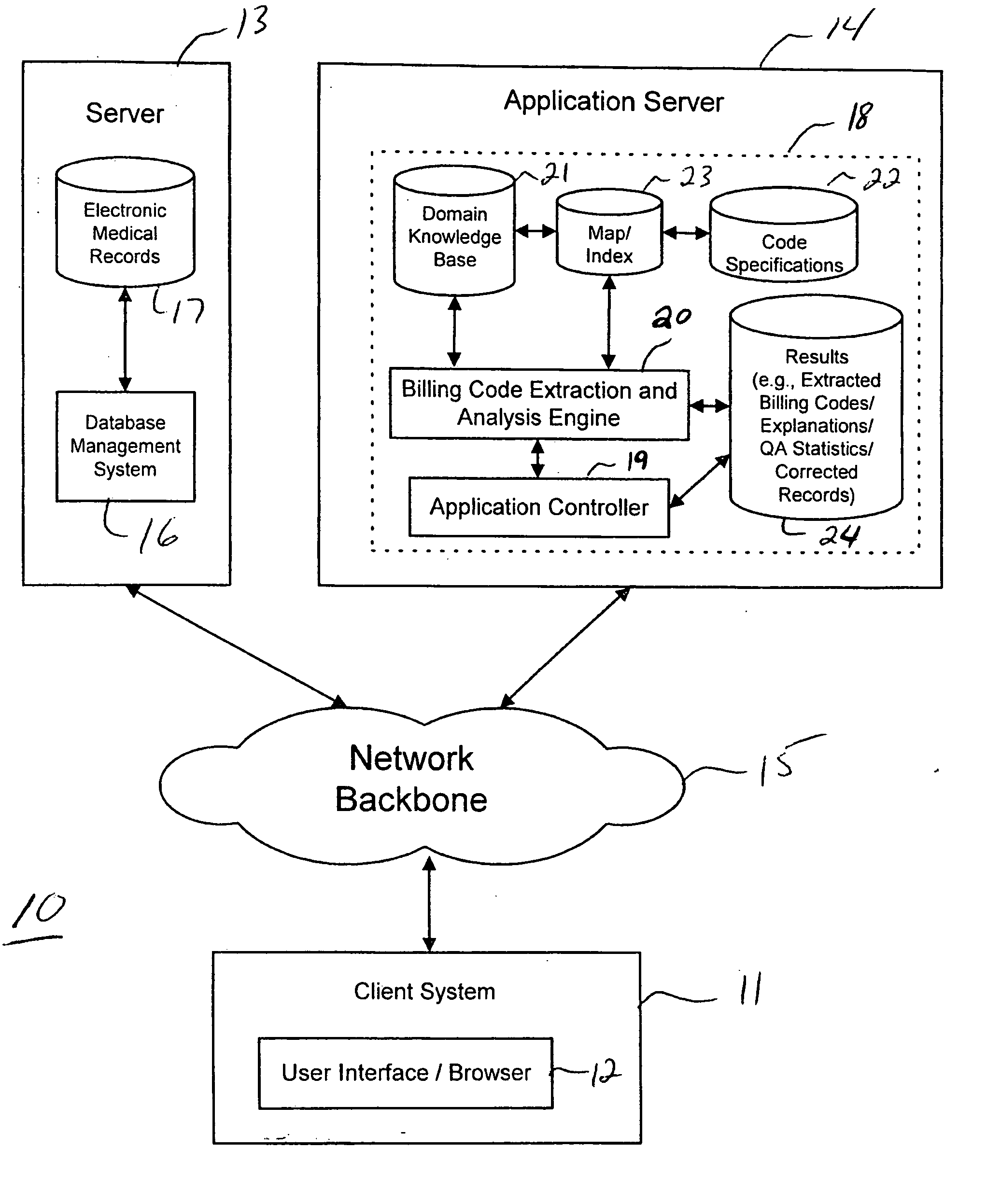

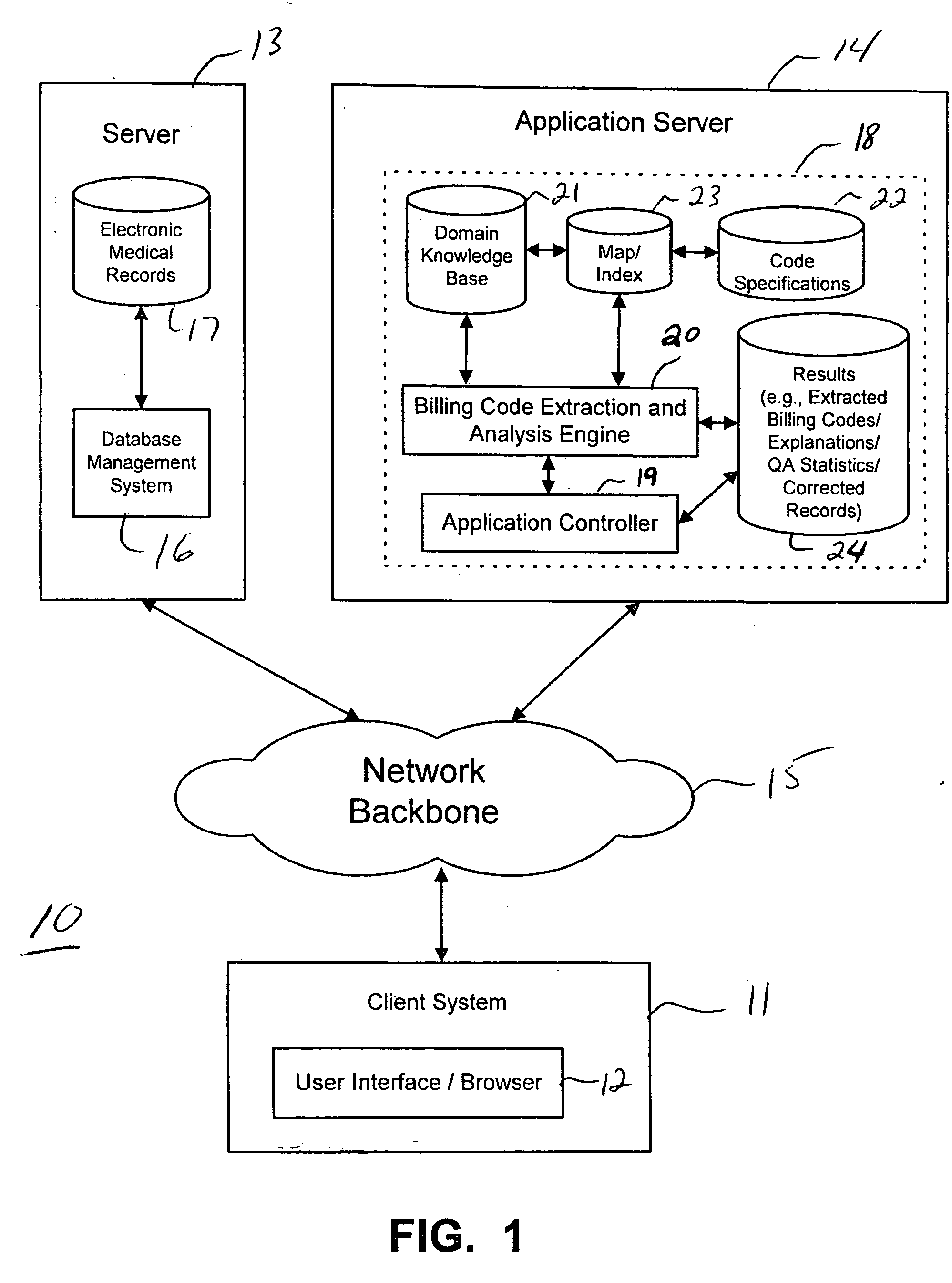

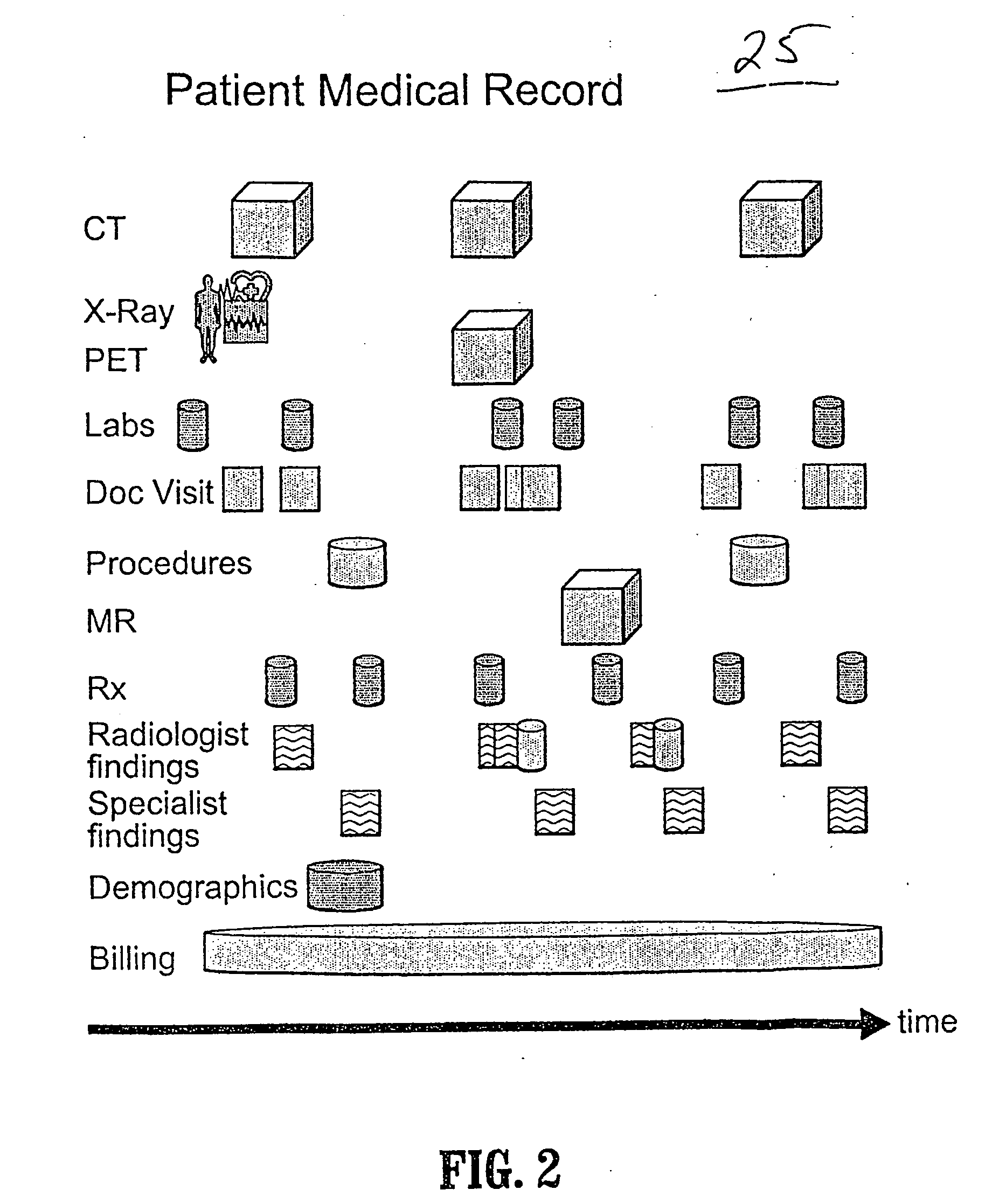

Systems and methods for automated extraction and processing of billing information in patient records

Systems and methods for automated processing of medical information in electronic patient medical record databases, wherein billing information (e.g., diagnosis codes, procedural codes) is automatically extracted from electronic patient medical records through comprehensive analysis of clinical information included in the patient medical records using a knowledge base of domain-specific criteria. The extracted billing information can be automatically processed for purposes of, e.g., medical claims correction, medical claims billing, quality assurance of recorded billing information, or claim reimbursement tracking.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

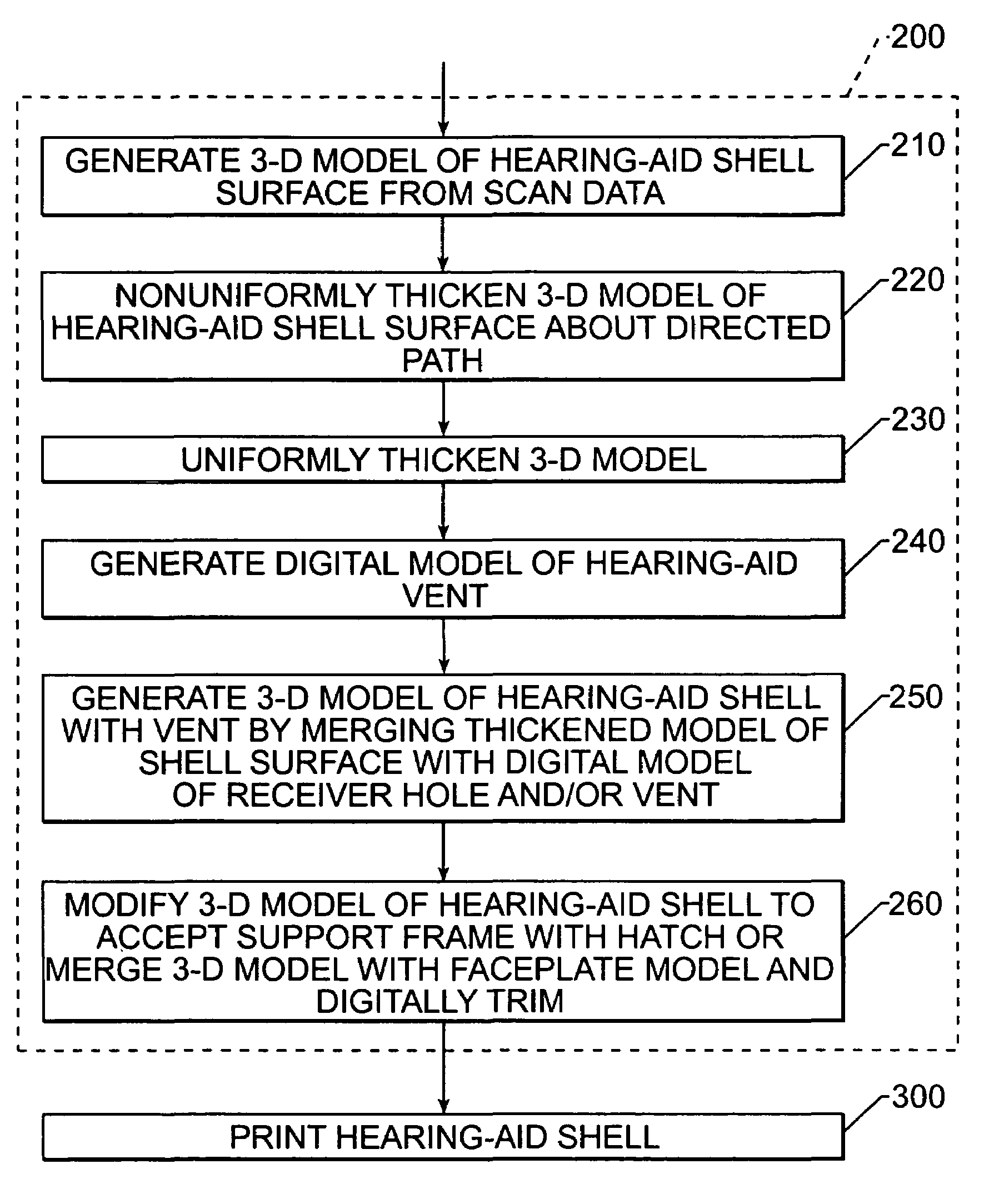

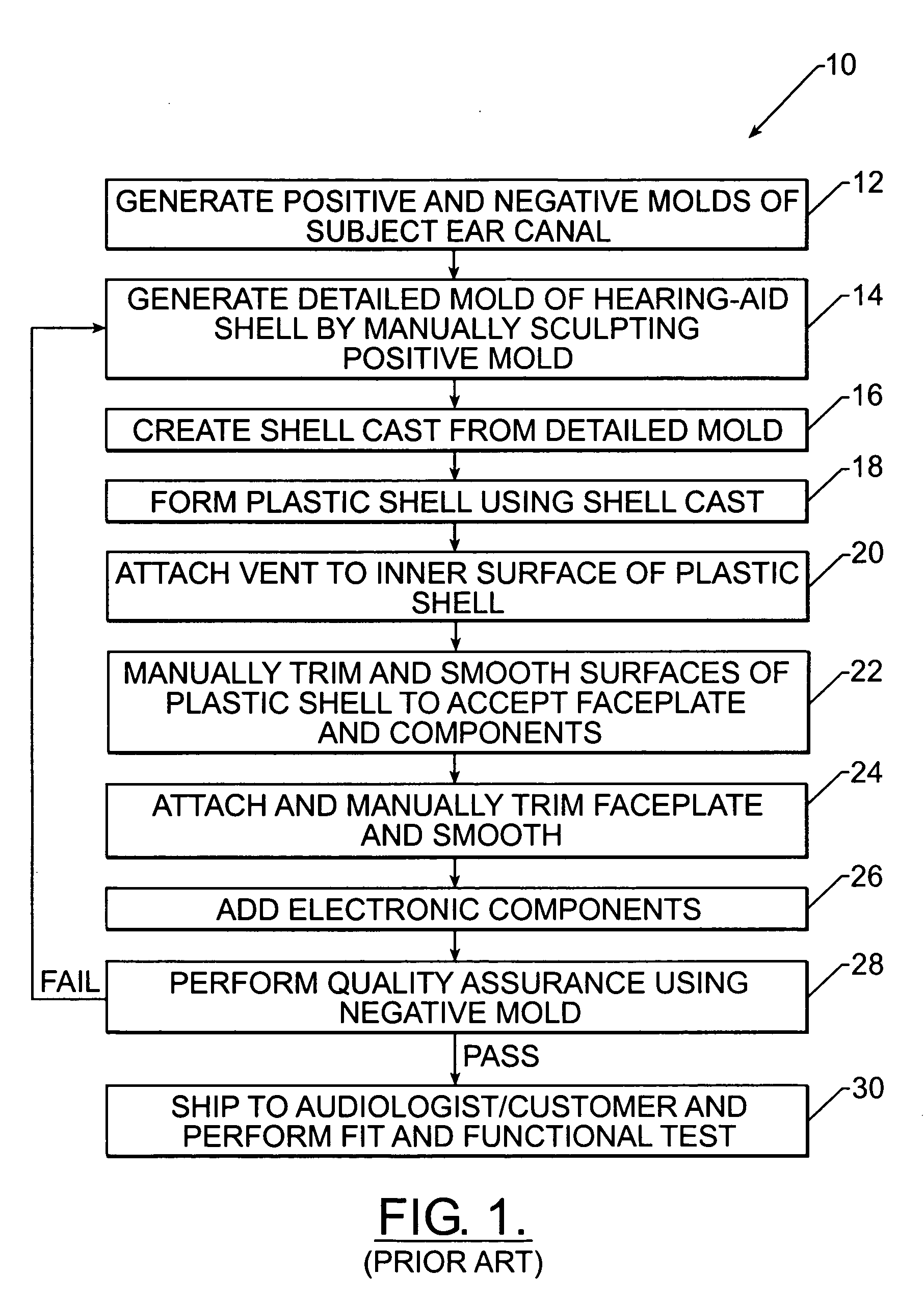

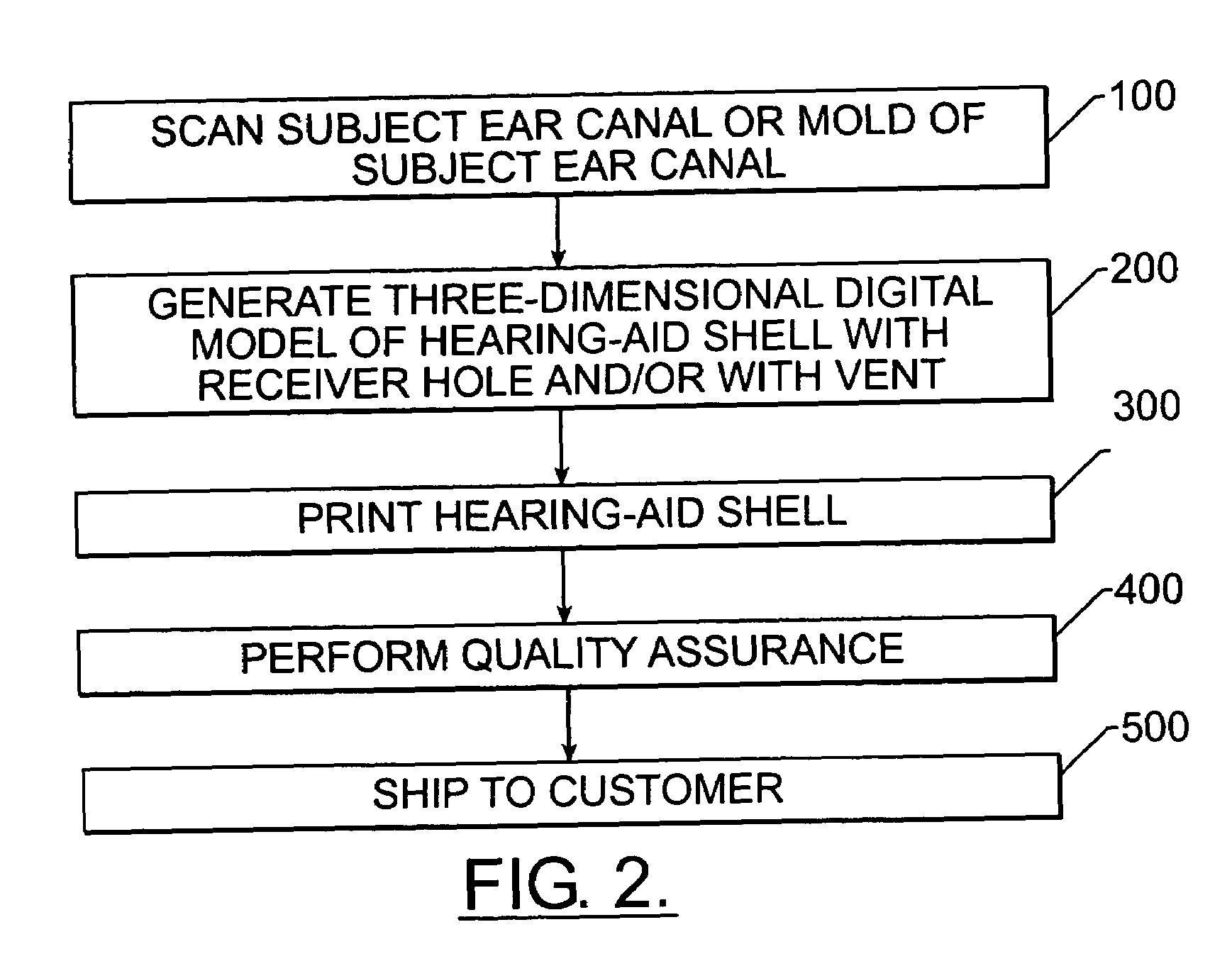

Manufacturing methods and systems for rapid production of hearing-aid shells

ActiveUS7050876B1High degree of qualityImprove reliabilityProgramme controlElectrical transducersComputer Aided DesignQuality assurance

Methods, apparatus and computer program products provide efficient techniques for designing and printing shells of hearing-aid devices with a high degree of quality assurance and reliability and with a reduced number of manual and time consuming production steps and operations. These techniques also preferably provide hearing-aid shells having internal volumes that can approach a maximum allowable ratio of internal volume relative to external volume. These high internal volumes facilitate the inclusion of hearing-aid electrical components having higher degrees of functionality and / or the use of smaller and less conspicuous hearing-aid shells. A preferred method includes operations to generate a watertight digital model of a hearing-aid shell by thickening a three-dimensional digital model of a shell surface in a manner that eliminates self-intersections and results in a thickened model having an internal volume that is a high percentage of an external volume of the model. This thickening operation preferably includes nonuniformly thickening the digital model of a shell surface about a directed path that identifies a location of an undersurface hearing-aid vent. This directed path may be drawn on the shell surface by a technician (e.g., audiologist) or computer-aided design operator, for example. Operations are then preferably performed to generate a digital model of an undersurface hearing-aid vent in the thickened model of the shell surface, at a location proximate the directed path.

Owner:PHONAK

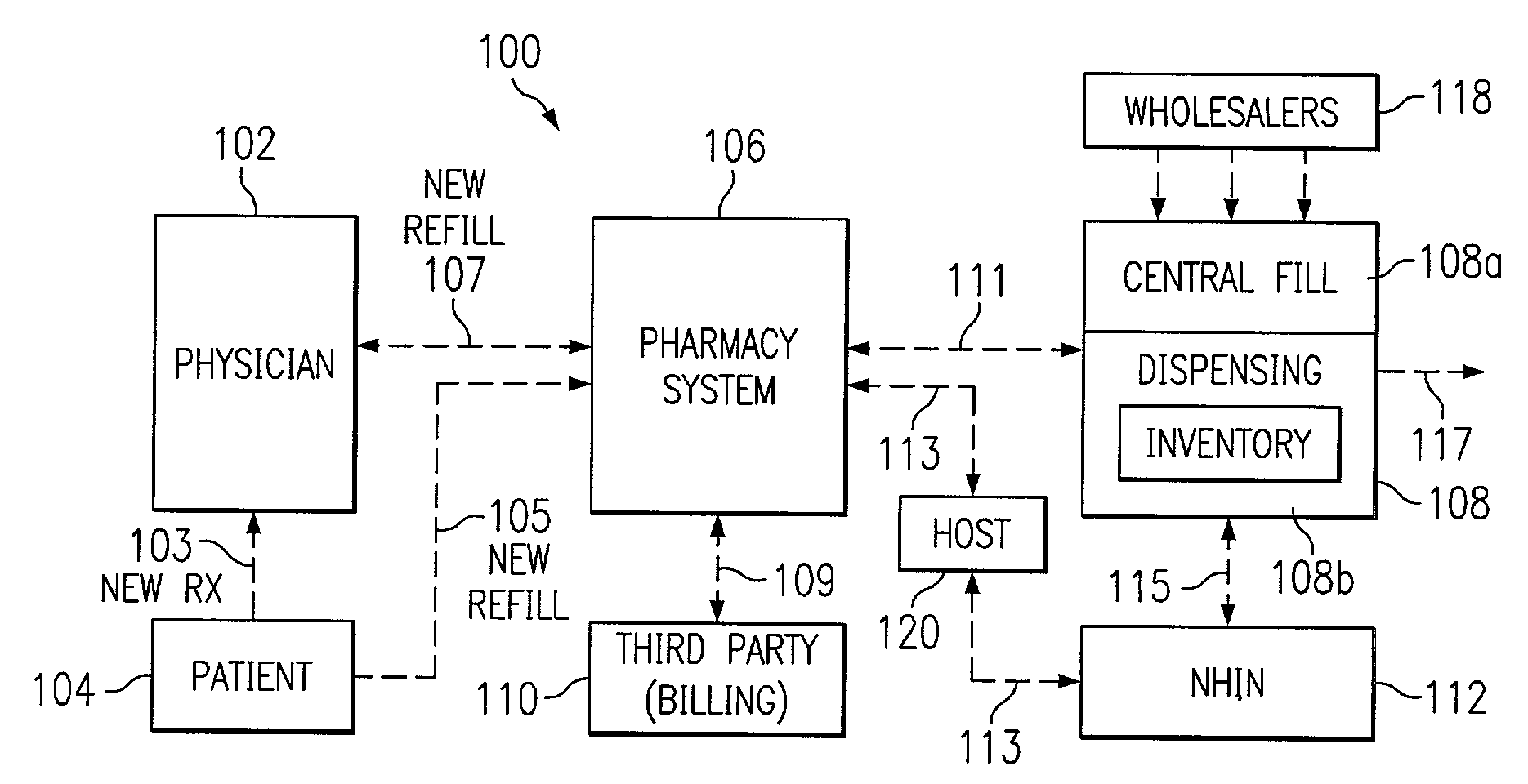

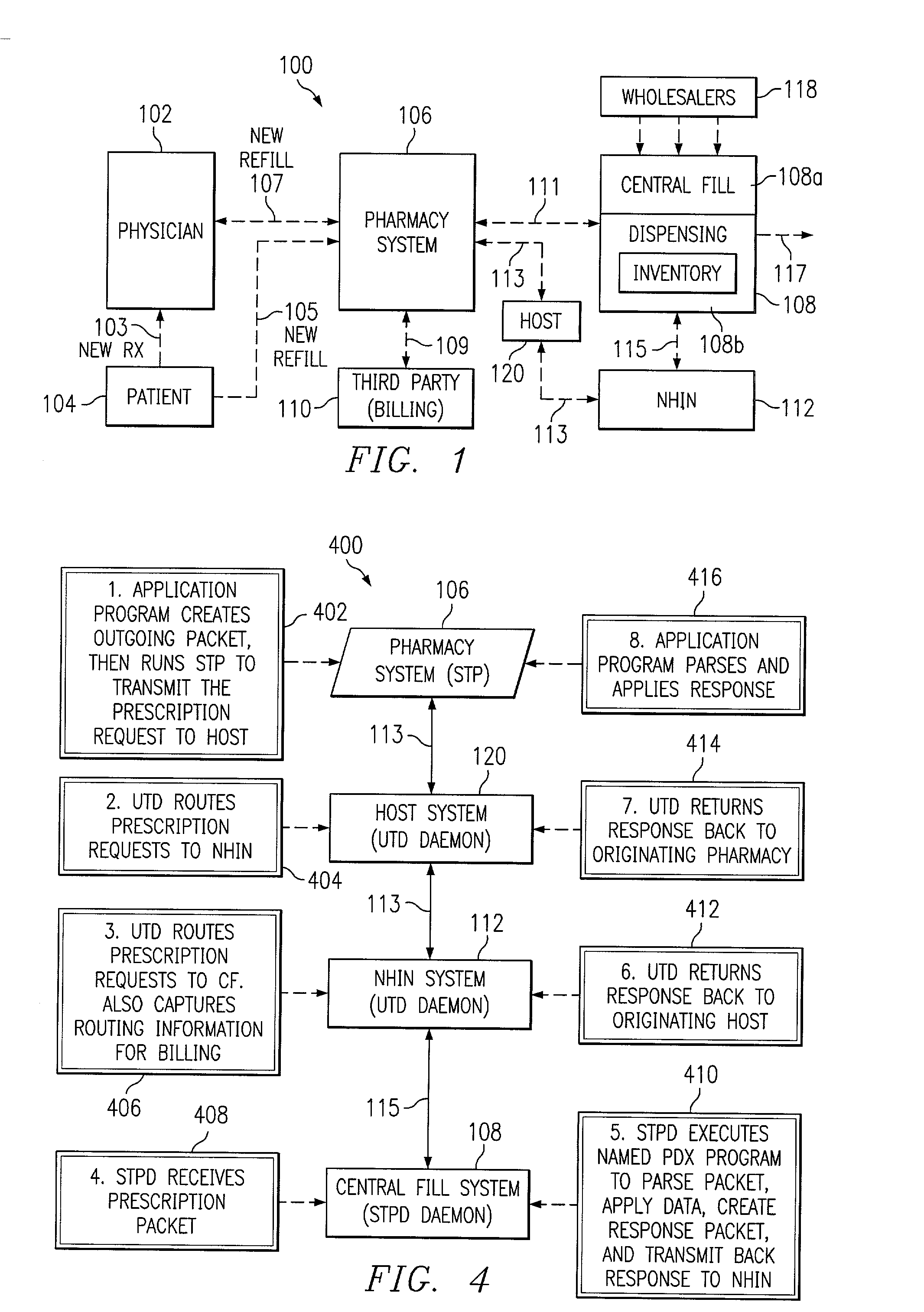

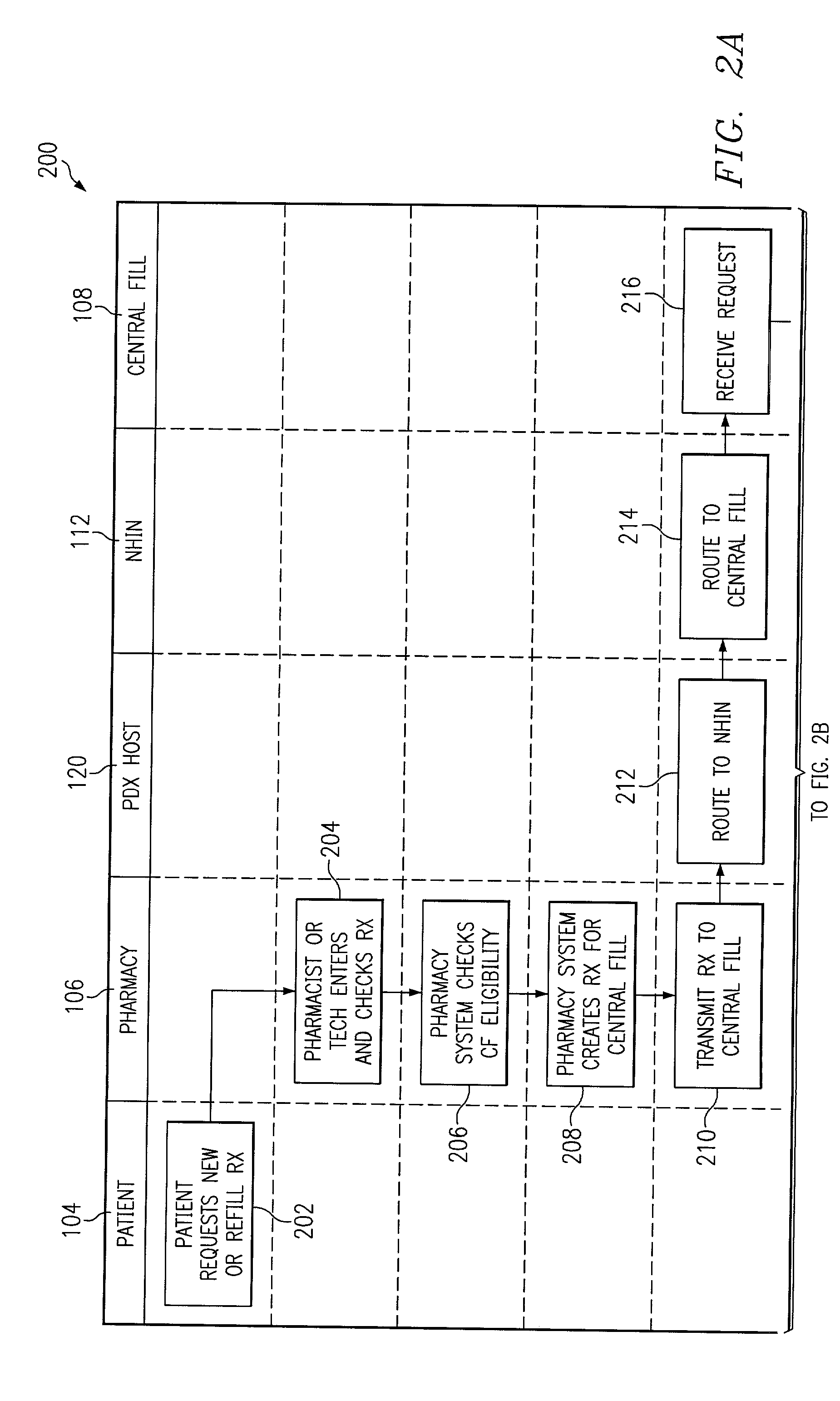

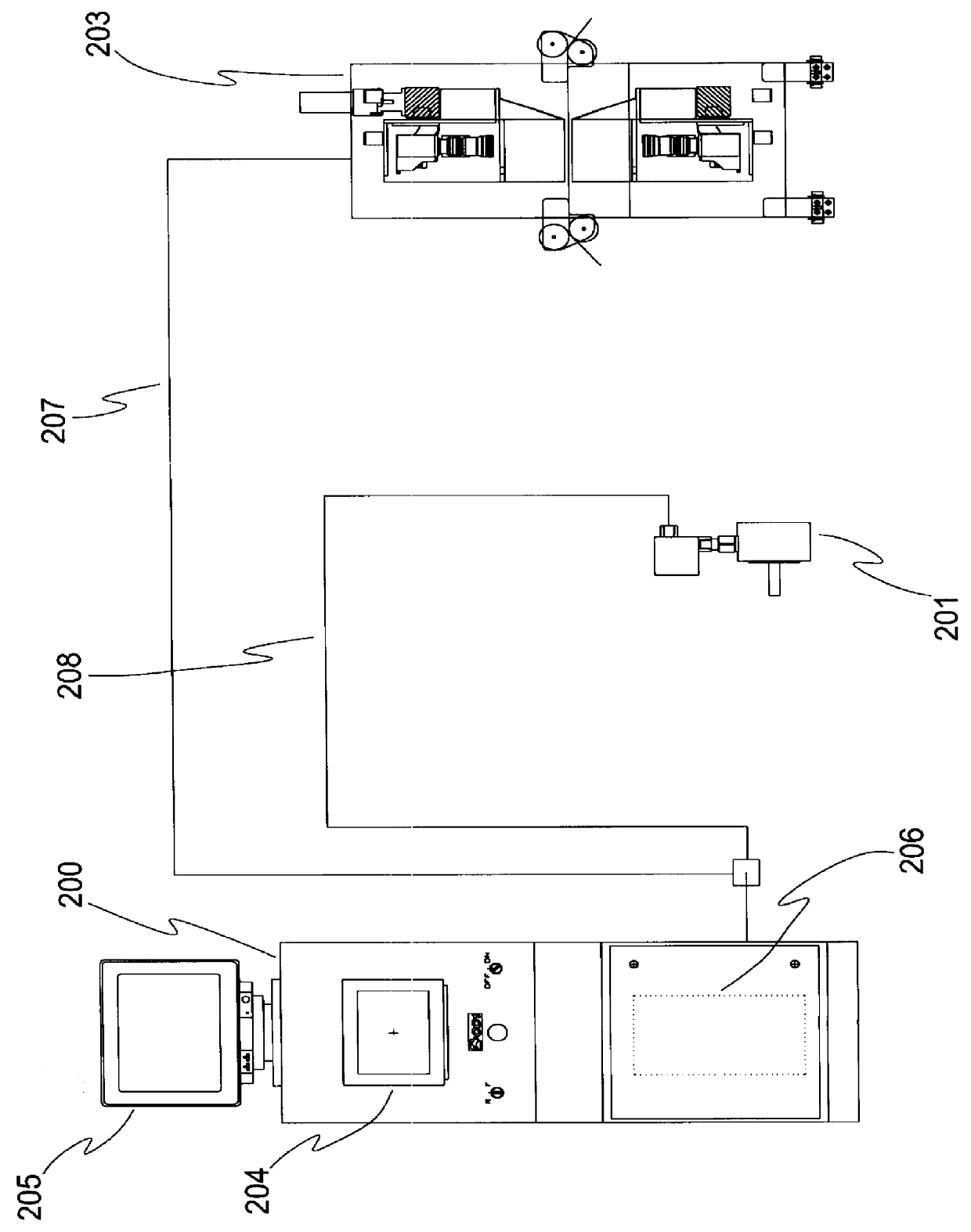

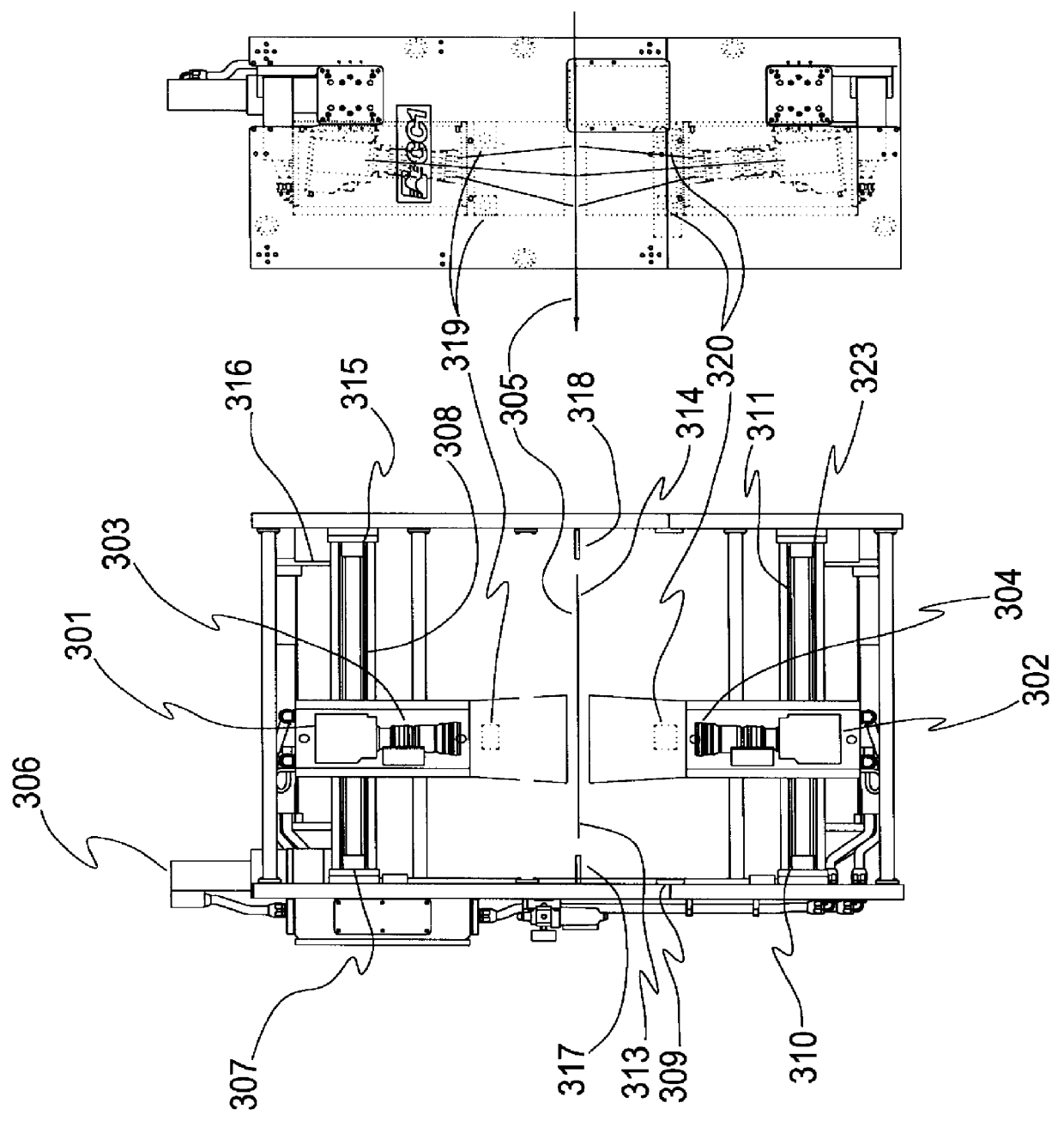

Automated system and method for processing prescriptions

InactiveUS20060149587A1Previous techniques for filling prescriptions are substantially reduced or eliminatedEasy to handleDrug and medicationsDiagnostic recording/measuringQuality assurancePhysician roles

An automated system and method for processing prescription requests is disclosed, whereby a patient or physician enters a prescription request to an automated pharmacy prescription processing system. For example, a request for a new or refill prescription can be transmitted from a physician's office to the prescription processing system as a digital file or facsimile message, or using keypad or voice commands in an Interactive Voice Response (IVR) system running in the prescription processing system. A request for a prescription refill can also be entered by a patient using an IVR system, or the patient can physically carry the refill prescription request to a pharmacy for entry to the prescription processing system by a technician. The automated pharmacy system determines whether the new or refill prescription request can be filled by a central fill inventory. The automated pharmacy prescription processing system sends eligible, pending prescription requests to an automated central fill prescription request processing system. The automated central fill processing system processes and fills each valid prescription request from a central fill inventory, initiates a quality assurance procedure to double-check each prescription to be filled, labels the double-checked, approved prescriptions, and routes them to a staging area for shipment to the appropriate pharmacy stores.

Owner:PDX

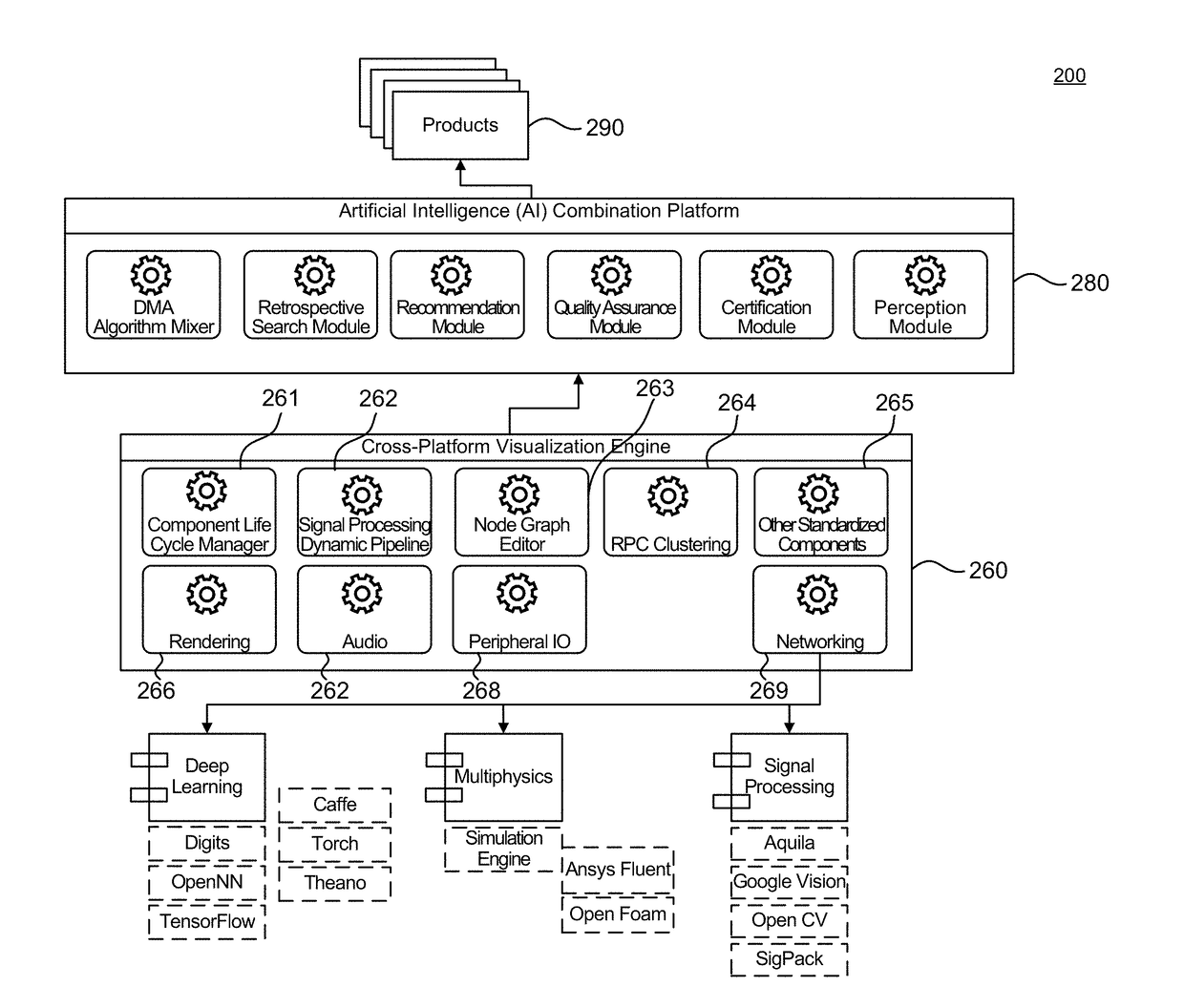

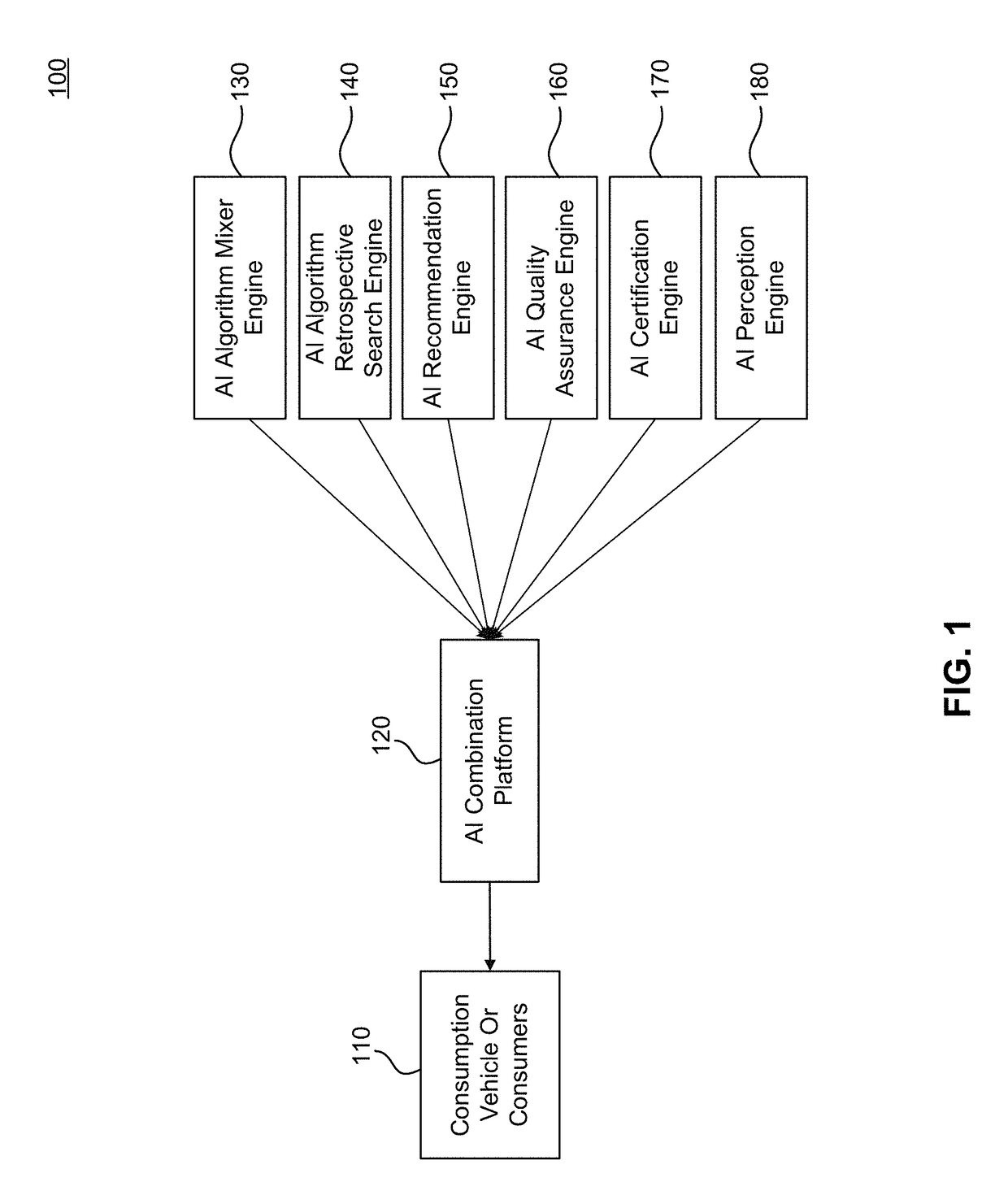

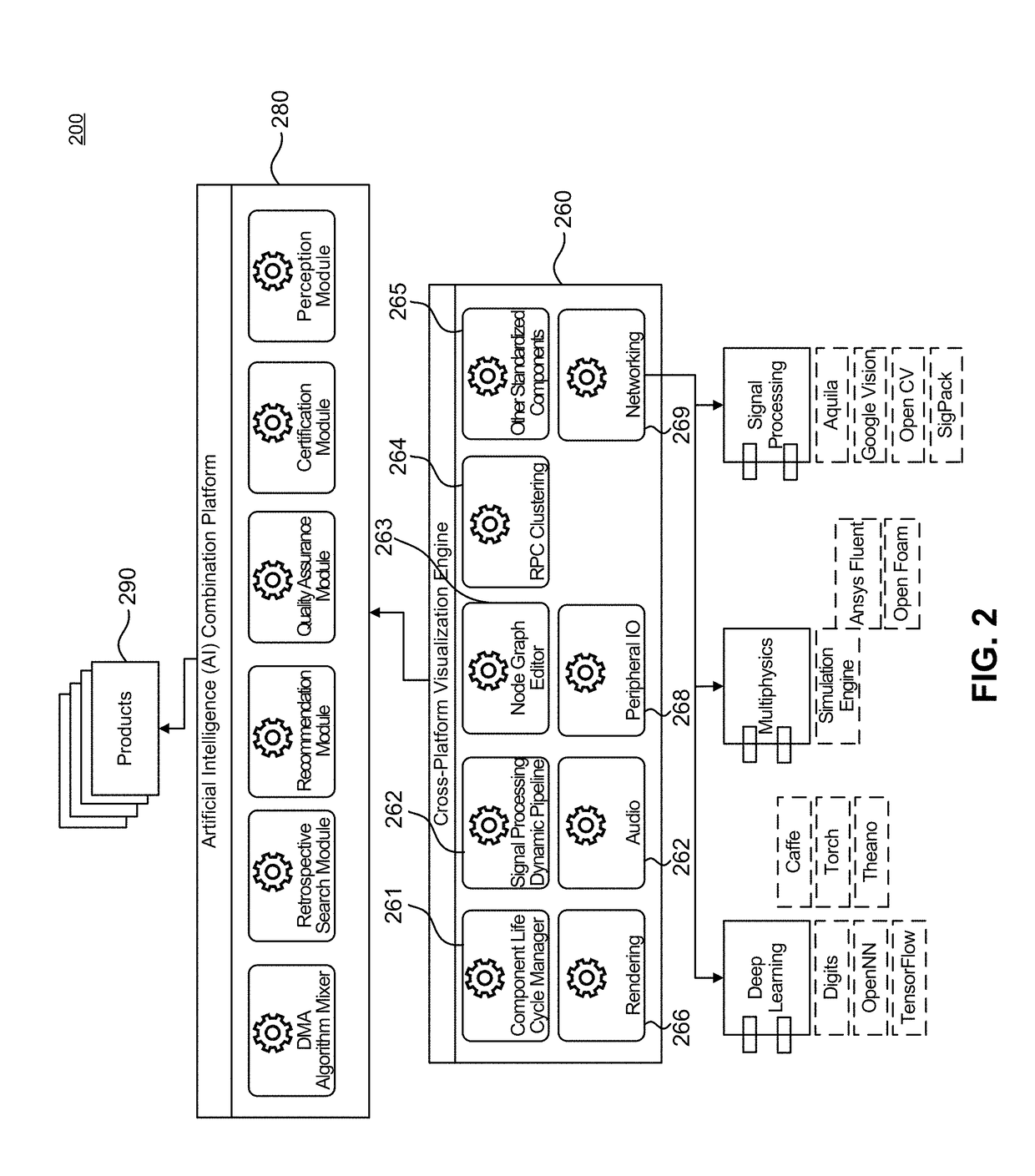

Interchangeable Artificial Intelligence Perception Systems and Methods

InactiveUS20170308800A1Avoid obscuring purposeEfficient use ofProcessor architectures/configurationMachine learningQuality assurancePerception system

An artificial intelligence (AI) combination platform or orchestration module is described that orchestrates and automates the processes of selecting, building, testing, and delivering new or integrated computer vision, detection, sensor and perception algorithms that can be published or leveraged in near real time by sensors, hardware or applications. The AI combination platform includes one or more of the following engines: algorithm mixer engine, retrospective search engine, algorithm recommendation engine, quality assurance engine, certification engine, and perception engine.

Owner:SMOKESCREEN INTELLIGENCE LLC

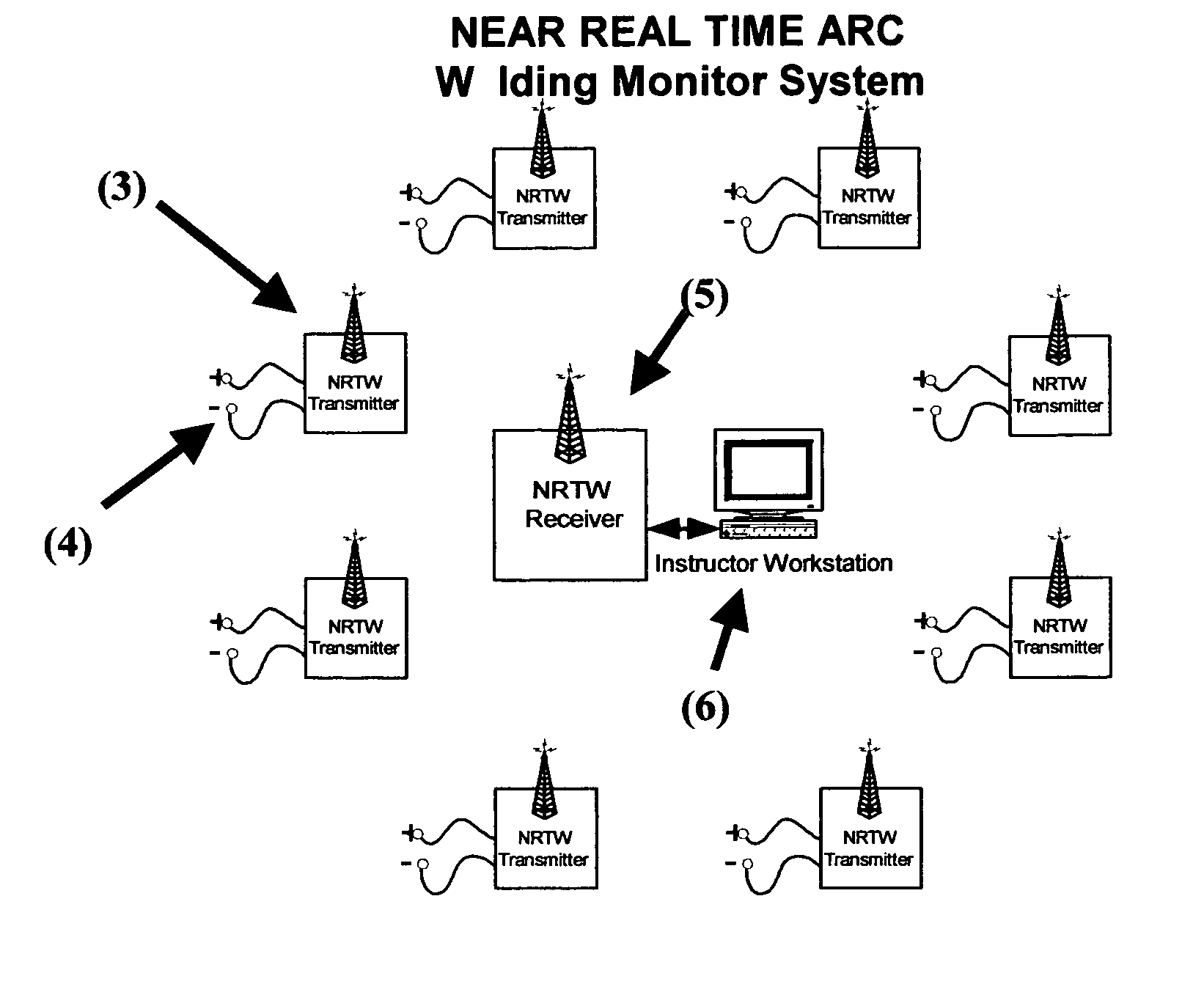

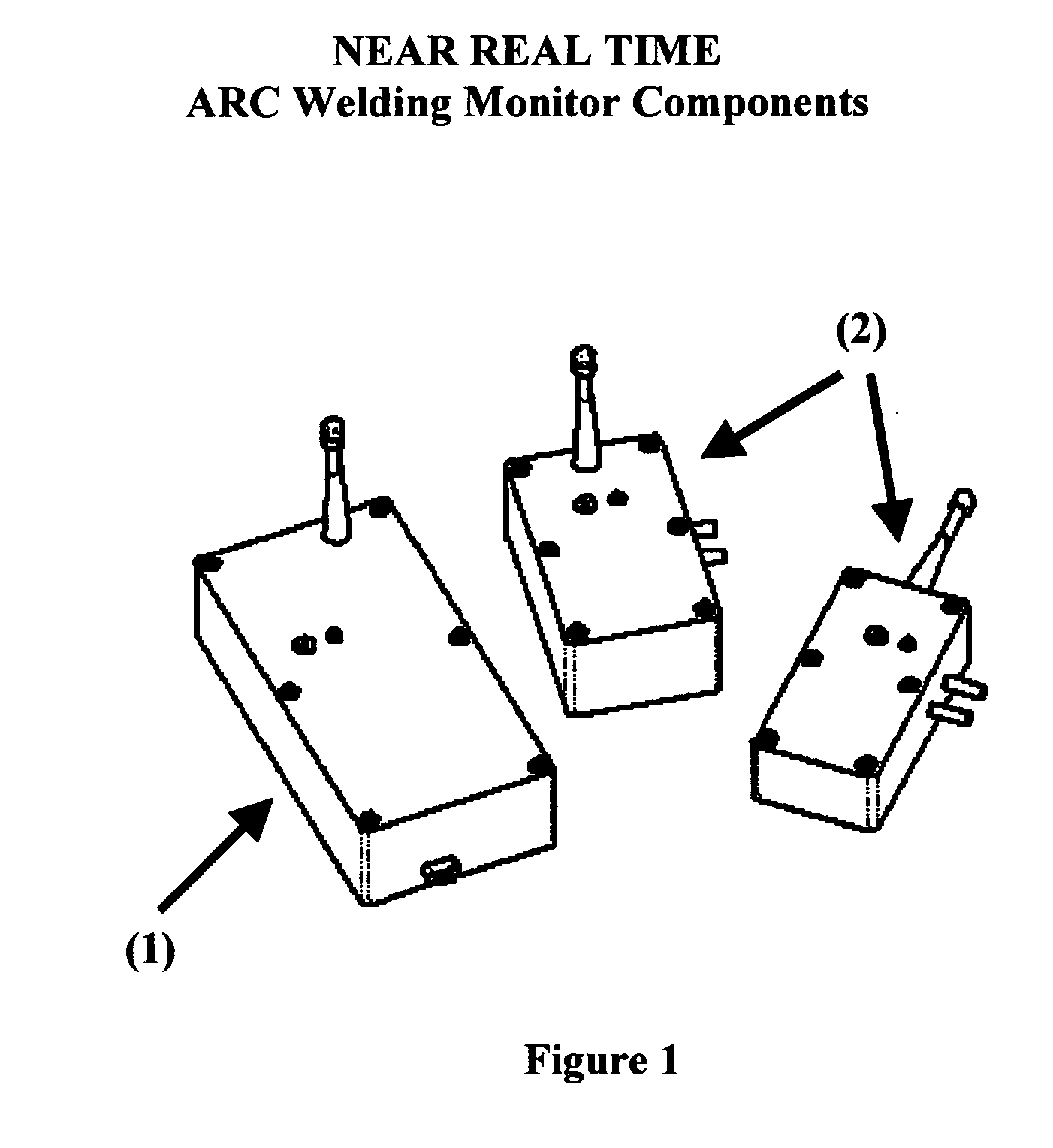

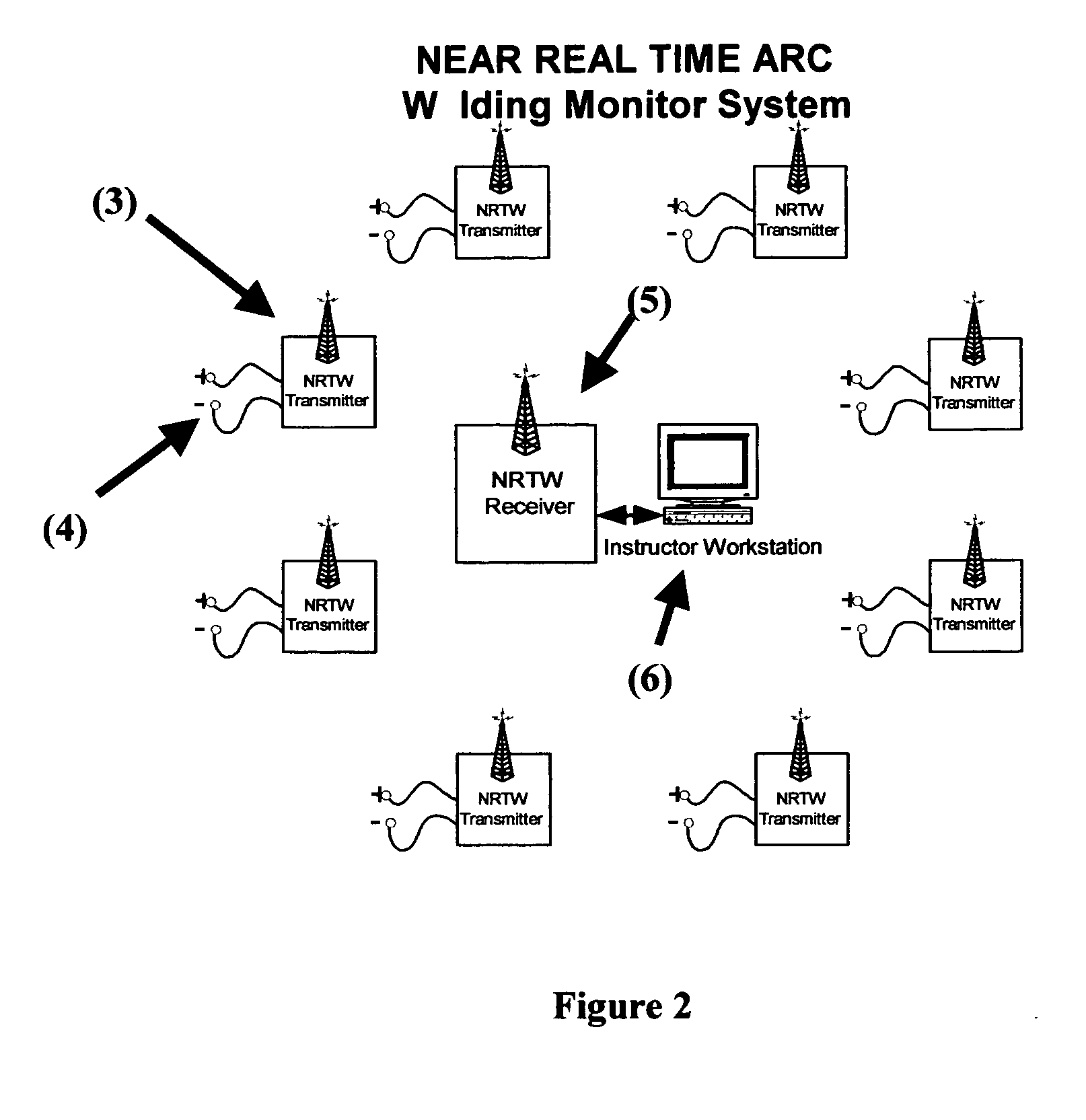

Near real time arc welding monitor

InactiveUS20050127052A1Improve learning experienceProduced economicallyWelding accessoriesGraphicsStatistical analysis

An arc welding monitor designed to aid in the instruction of electric arc welding, provide data that can be used for inspection and quality assurance of individual welds, and provide an archive record of the arc welding process for future reference and analysis. A sensor is used to unobtrusively measure the welding arc parameters. The measurements are transmitted in real-time from the welding station to an instructor / supervisor workstation via a radio frequency data link. The received data is graphically displayed in near-real-time on the instructor / supervisor workstation computer screen. The data can be analyzed by standard statistical analysis tools to qualitatively grade the weld, be stored on computer disk storage media for later retrieval and analysis, or printed in a graphic display. Interpretation of the graphical display and statistical analysis is used to critique and instruct welder operator technique or to indicate process flaws that warrant further inspection of suspected welds.

Owner:SPENCER MARK SCOTT

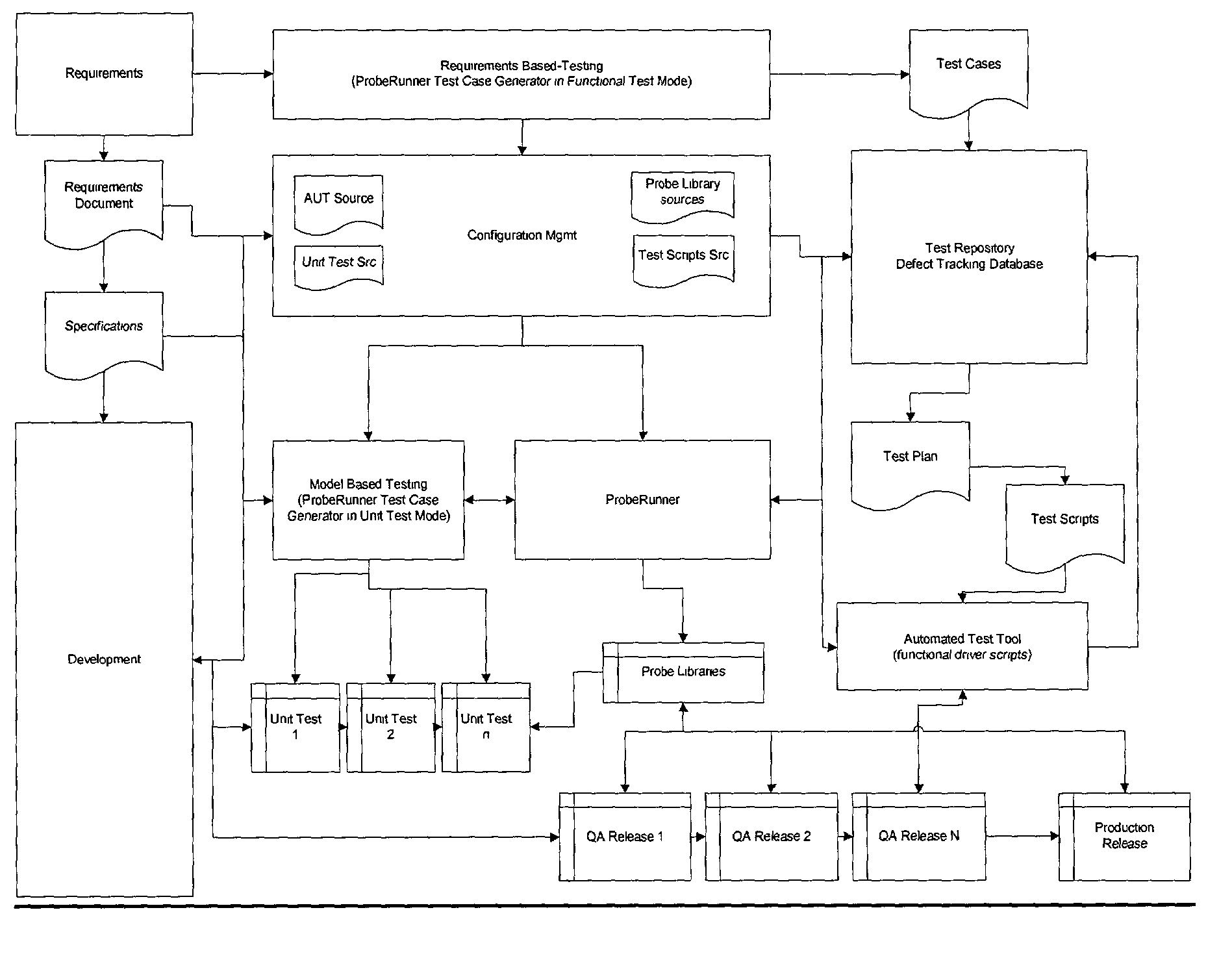

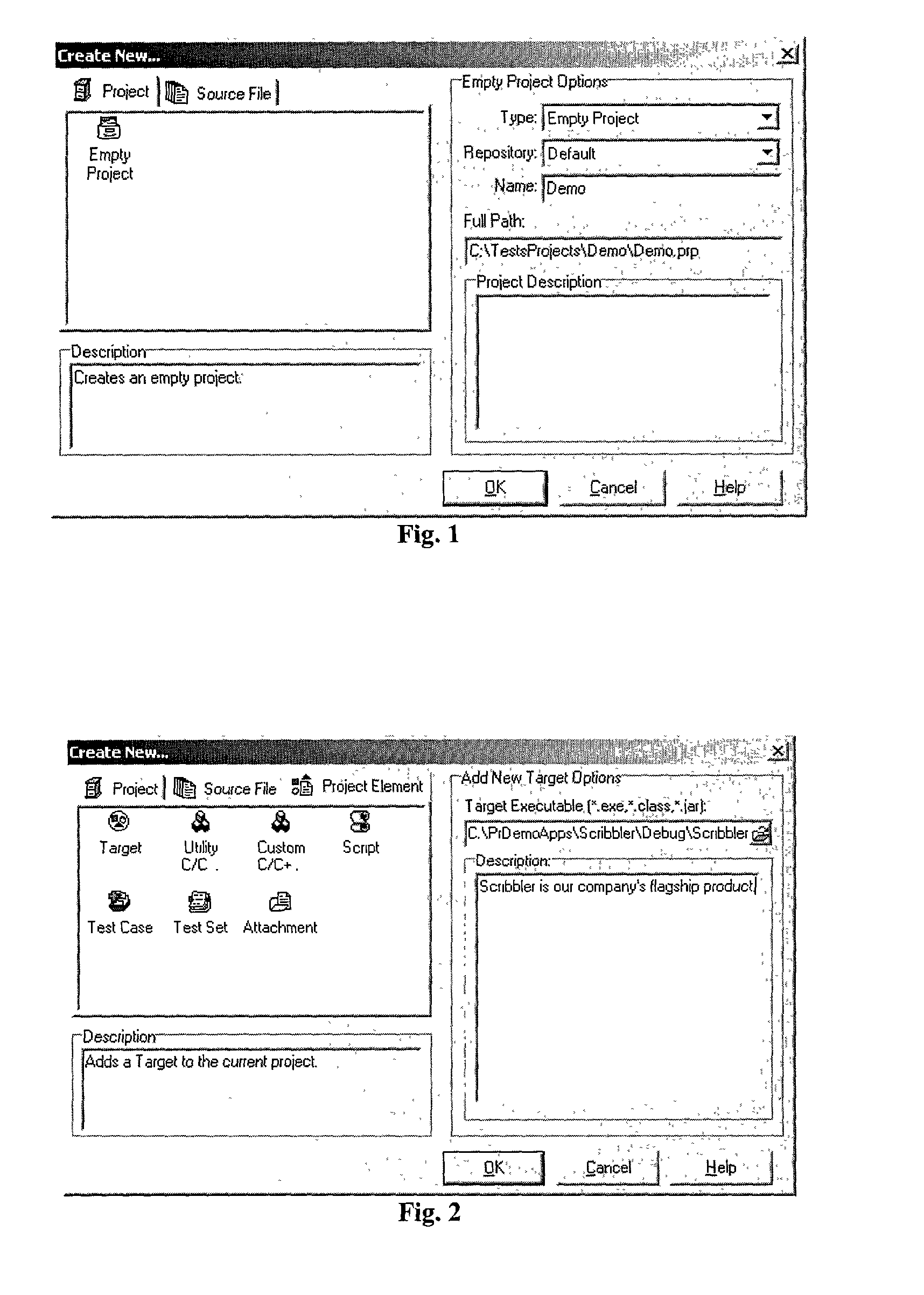

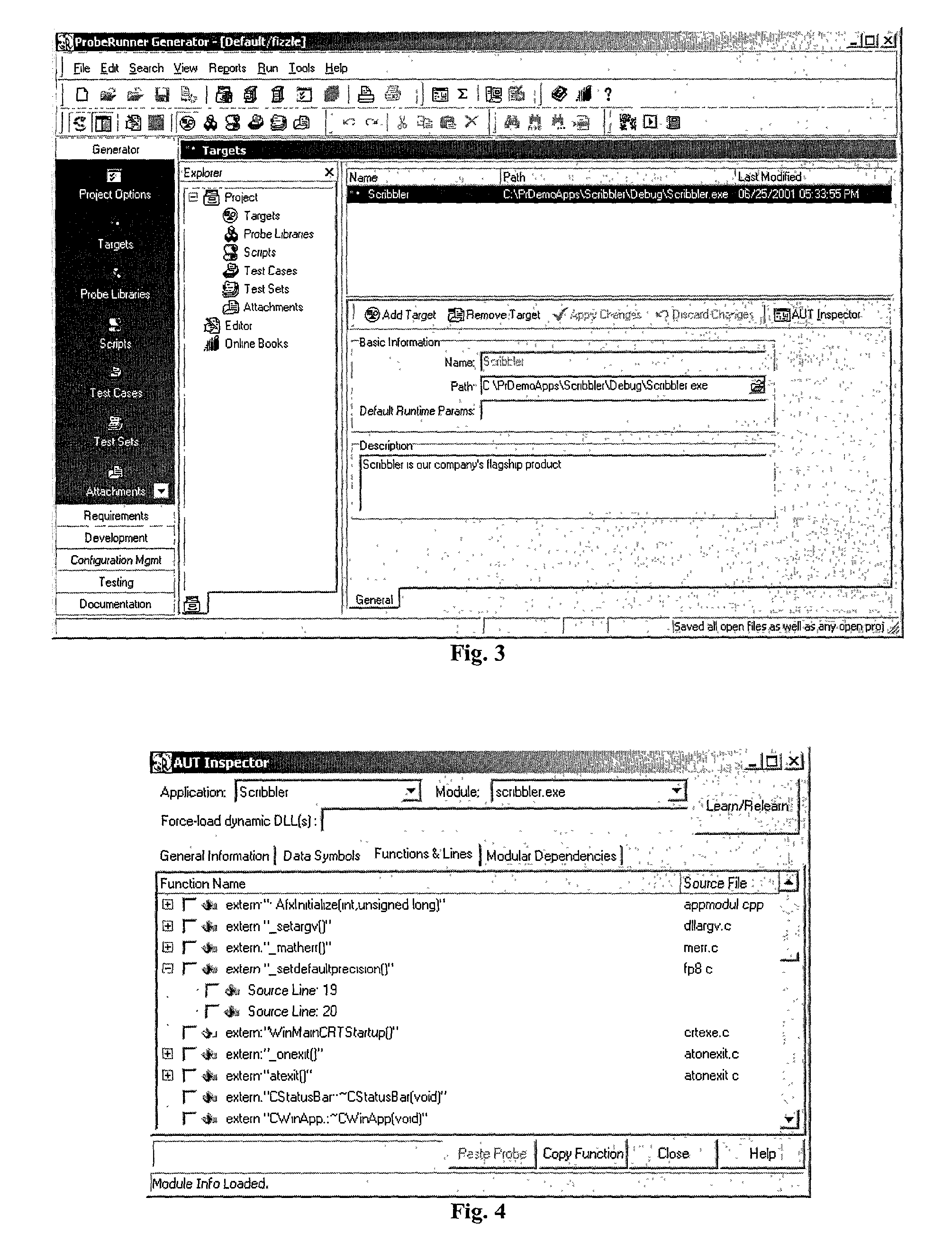

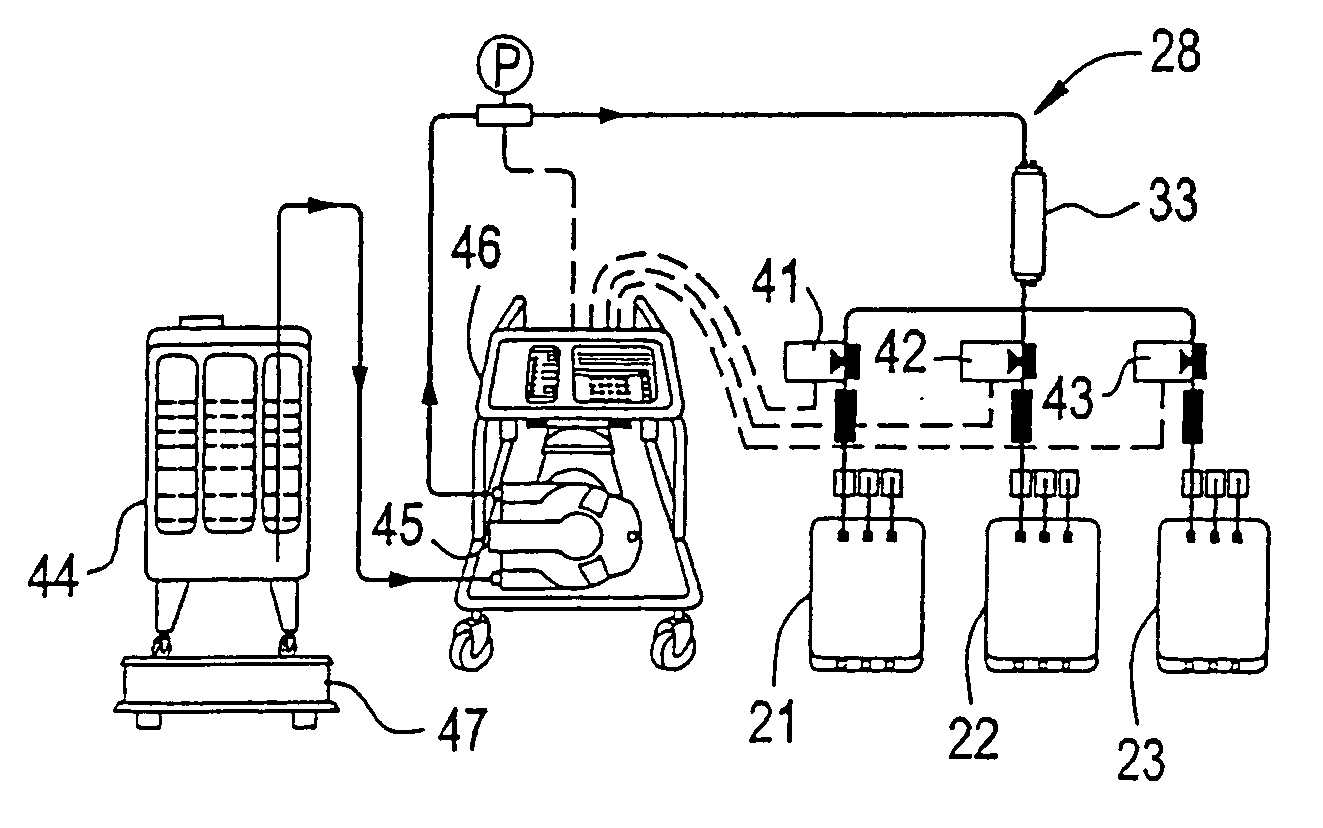

Method for merging white box and black box testing

InactiveUS20030046029A1Easy to optimizeSimple processNuclear monitoringDigital computer detailsFunctional testingQuality assurance

A method and process for developing and testing software applies runtime executable patching technology to enhance the quality assurance effort across all phases of the Software Development Life-Cycle in a "grey box" methodology. The system facilitates the creation of re-usable, Plug"n'Play Test Components, called Probe Libraries, that can be used again and again by testers as well as developers in unit and functional tests to add an extra safety net against the migration of low-level defects across Phases of the overall Software Development and Testing Life-Cycle. The new elements introduced in the Software Development Life-Cycle focus on bringing developers and testers together in the general quality assurance workflow and provide numerous tools, techniques and methods for making the technology both relatively easy to use and powerful for various test purposes.

Owner:CORTECHS LABS INC

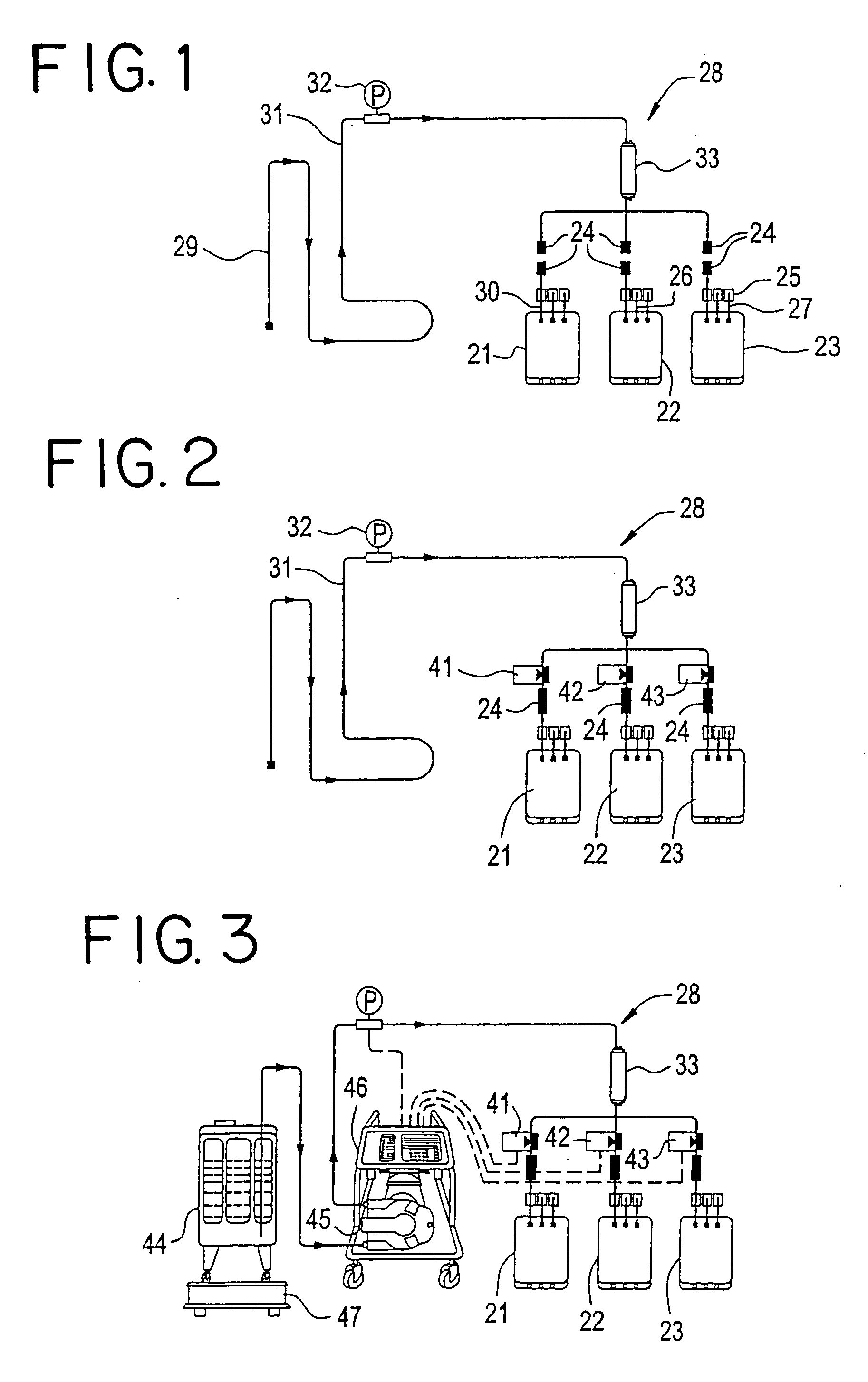

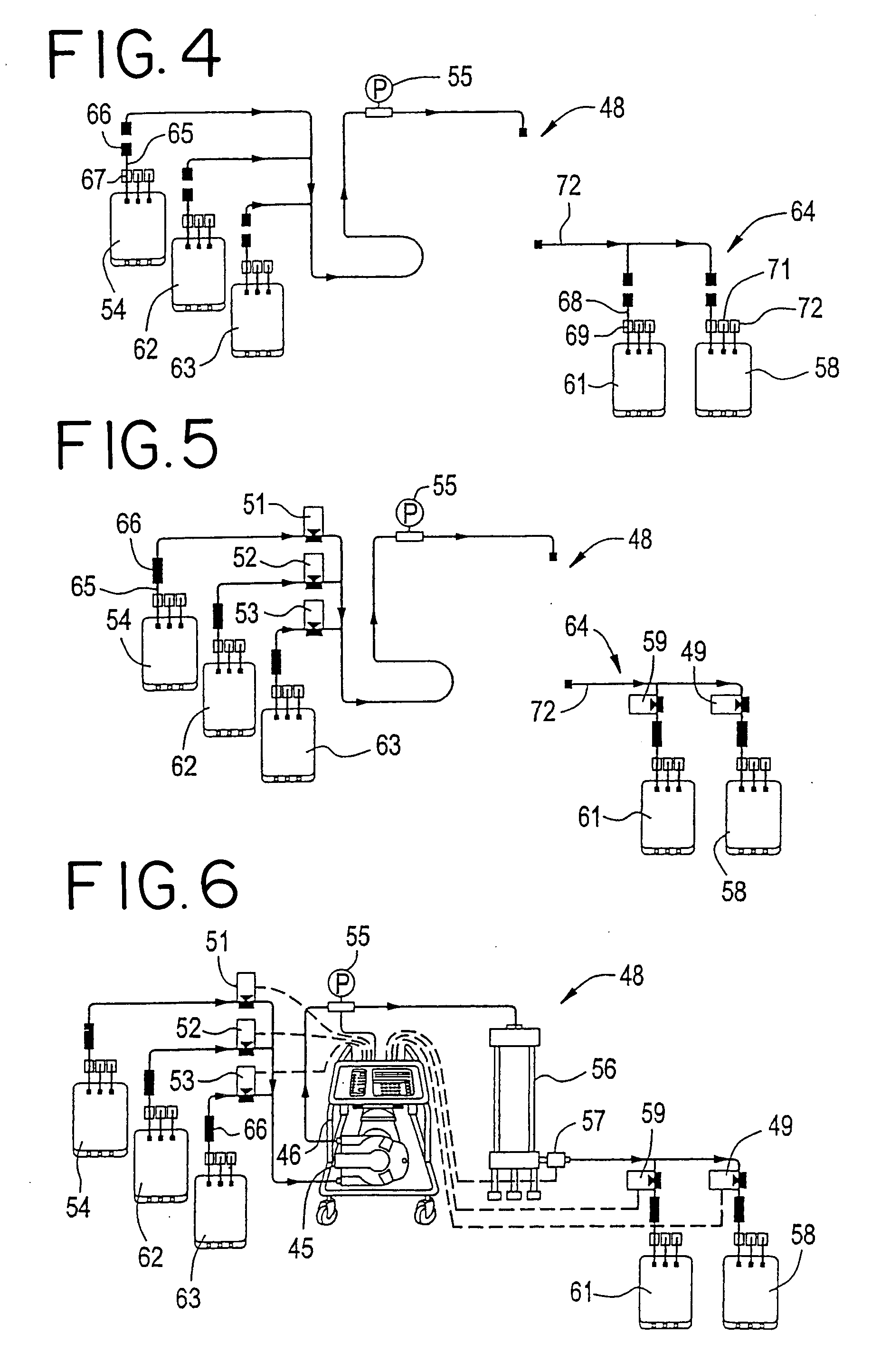

Single-use manifold and sensors for automated, aseptic transfer of solutions in bioprocessing applications

ActiveUS20060118472A1Reduce expenditure of resourceReduce time expenditureComponent separationIon-exchanger regenerationQuality assuranceCombined use

Presteralized manifolds are provided which are designed for sterile packaging and single-use approaches. Disposable tubing and flexible-wall containers are assembled via aseptic connectors. These manifolds interact with valves and pumping equipment which can be operated by a controller which provides automated and accurate delivery of biotechnology fluid. The manifold also being used in conjunction with one or more conductivity sensors used to measure the conductivity of the biotechnology fluid. Such sensors interact with the controller or are connected to a separate user interface. The combination of disposable tubing, flexible-wall containers, aseptic connectors, manifold, controller, and conductivity sensors provides an aseptic environment while avoiding or reducing cleaning and quality assurance procedures.

Owner:PARKER INTANGIBLES LLC

System and method for zoom lens calibration and method using same

Using marks of known dimensions and size, and spacing, a zoom lens may be calibrated in either or both the X and Y spatial directions. A system comprising an image capture device, positioning means, position encoder means, operator interface, and processing unit permits this method to be advantageously applied to a wide variety of web inspection / control functions, including but not limited to initial web registration, multiple color ink registration, lateral web positioning, repeat length calculations, image capture synchronization, thermal / mechanical differential compensation, and accurate registration of objects within an image to other objects within an image or to a mechanical reference on a machine. Since the Zoom Calibration method permits a system to be constructed with both wide / variable field of view and accurate distance measurement positioning and calibration, all of the web inspection / control functions traditionally used in the web printing industry may be implemented with a single inspection / control system using a multitasking approach with the same inspection / control hardware. This permits rapid implementation of old and new web inspection / control functions at a greatly reduced cost as compared to traditional fixed lens systems, as well as permitting a degree of automation, remote access, diagnostic control, quality assurance, and product quality control heretofore not possible with conventional web inspection / control systems.

Owner:CC1

Interactive information package

InactiveUS6859745B2Eliminate needEnhanced disseminationContainer decorationsLevel indicationsQuality assuranceRadio frequency

A product package embodying the principles of the present invention includes an integrated circuit device which is configured for radio frequency interfacing with associated equipment. The package is configured such that the integrated circuit device is disposed within the package, thus assuring that the device remains associated with the package's contents. Notably, this arrangement facilitates use of the device for applications apart from product tracking and inventory control, including product promotions, storage, and dissemination of product information, and quality assurance including tamper-indication. A packaging machine for writing information on, and or reading information from, the integrated circuit device is also disclosed.

Owner:CREDIT SUISSE SYDNEY BRANCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com