Patents

Literature

2695 results about "Computer Aided Design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Computer-aided design (CAD) is the use of computers (or workstations) to aid in the creation, modification, analysis, or optimization of a design. CAD software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The term CADD (for Computer Aided Design and Drafting) is also used.

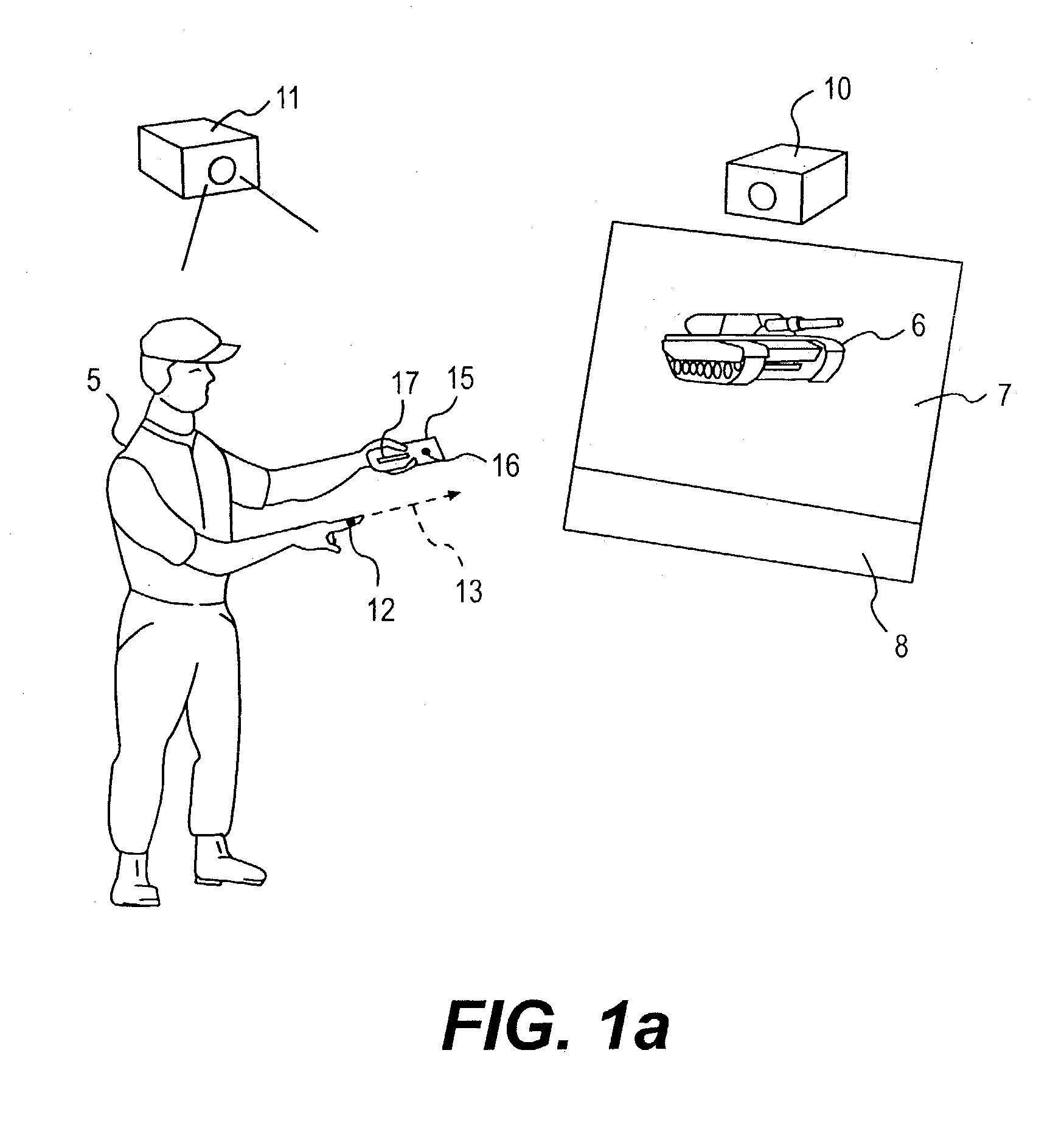

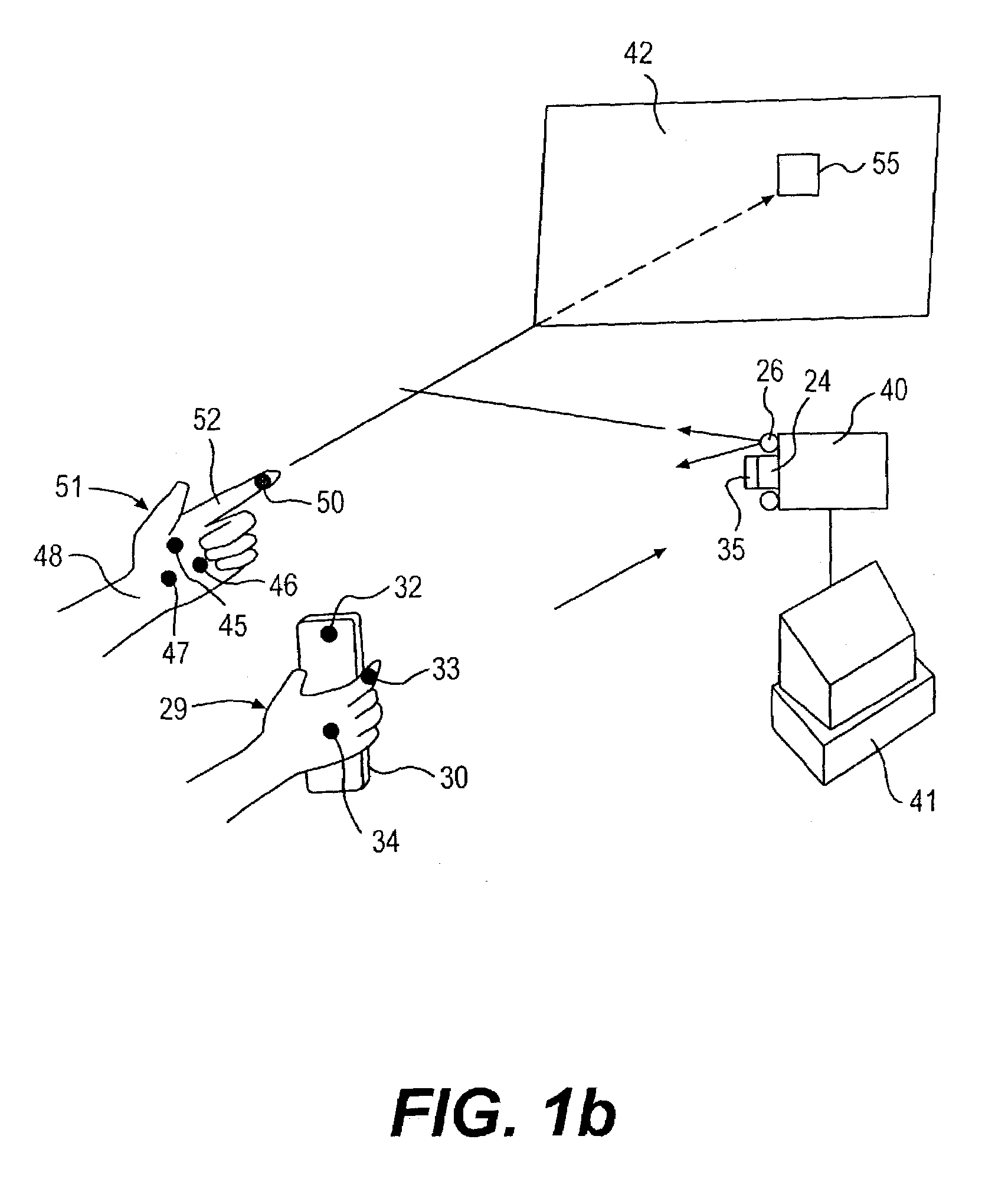

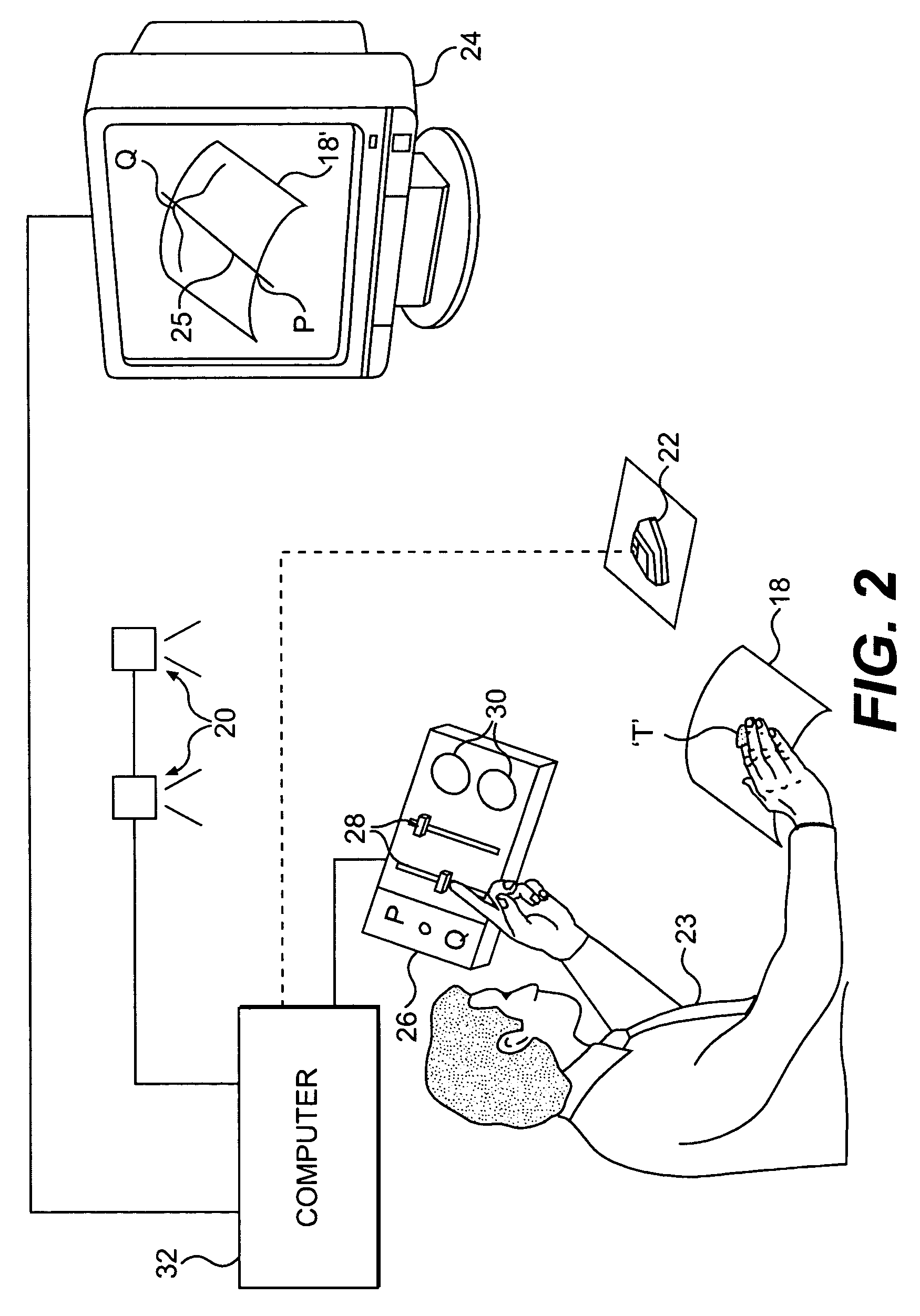

Man machine interfaces and applications

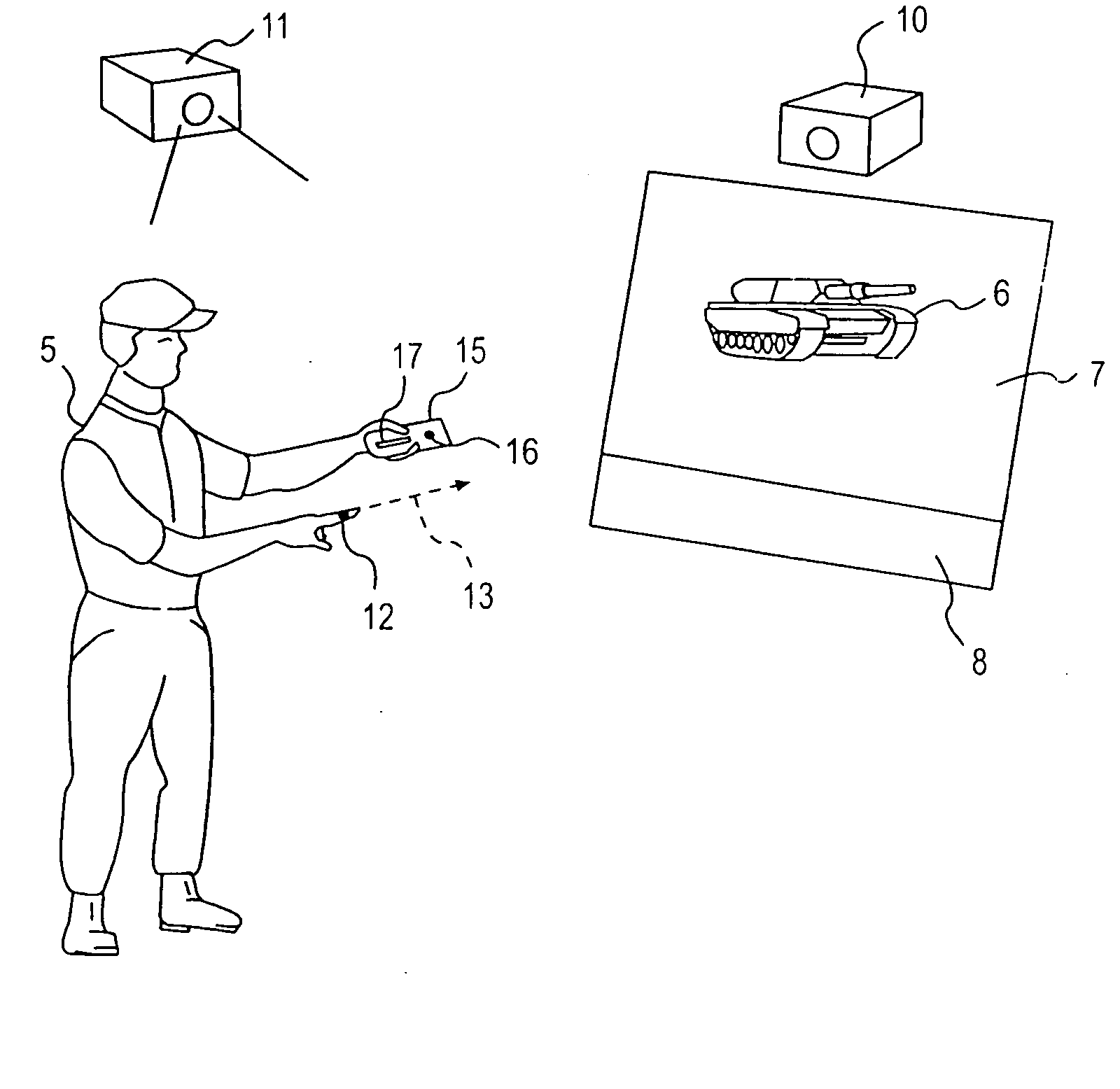

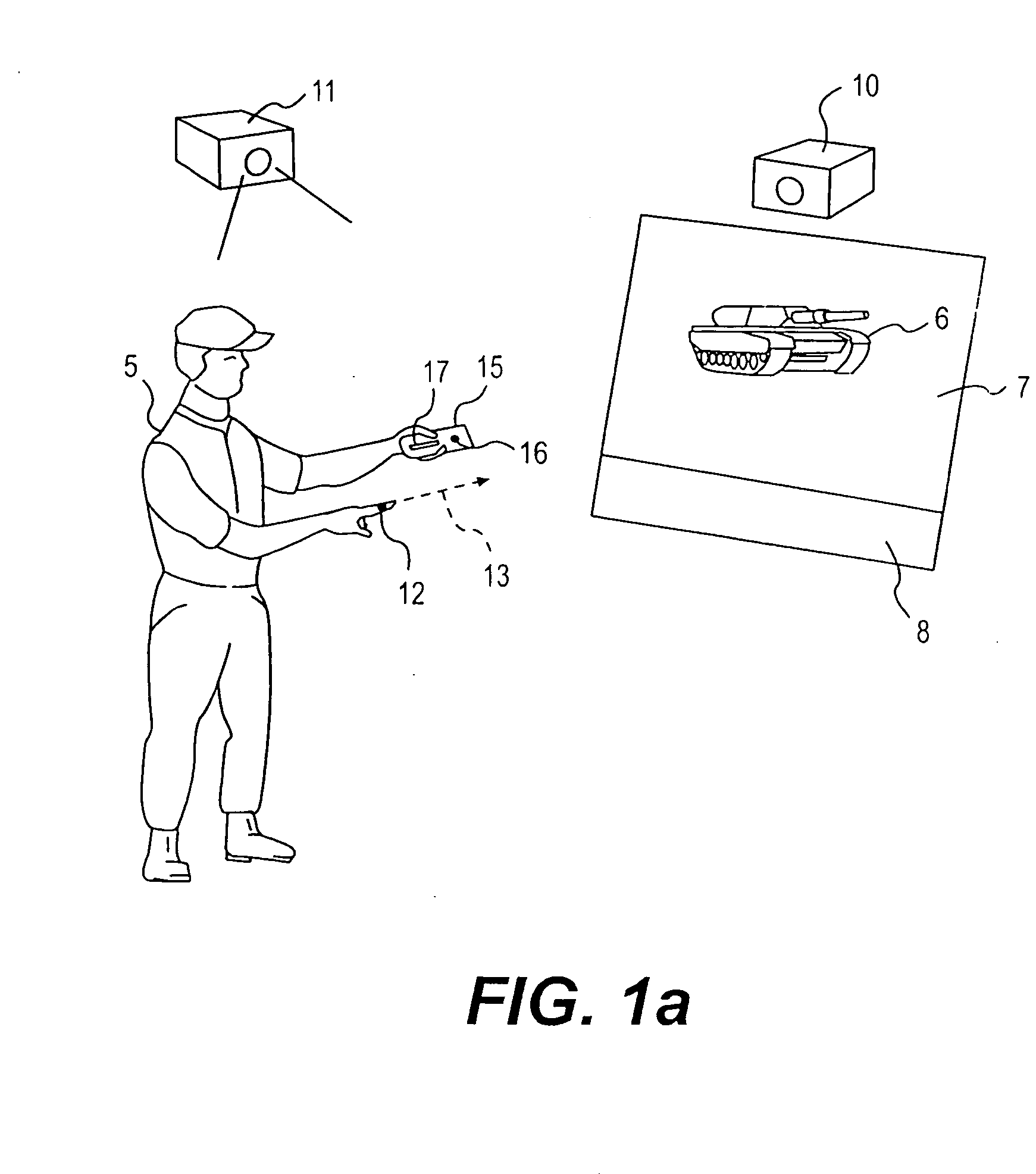

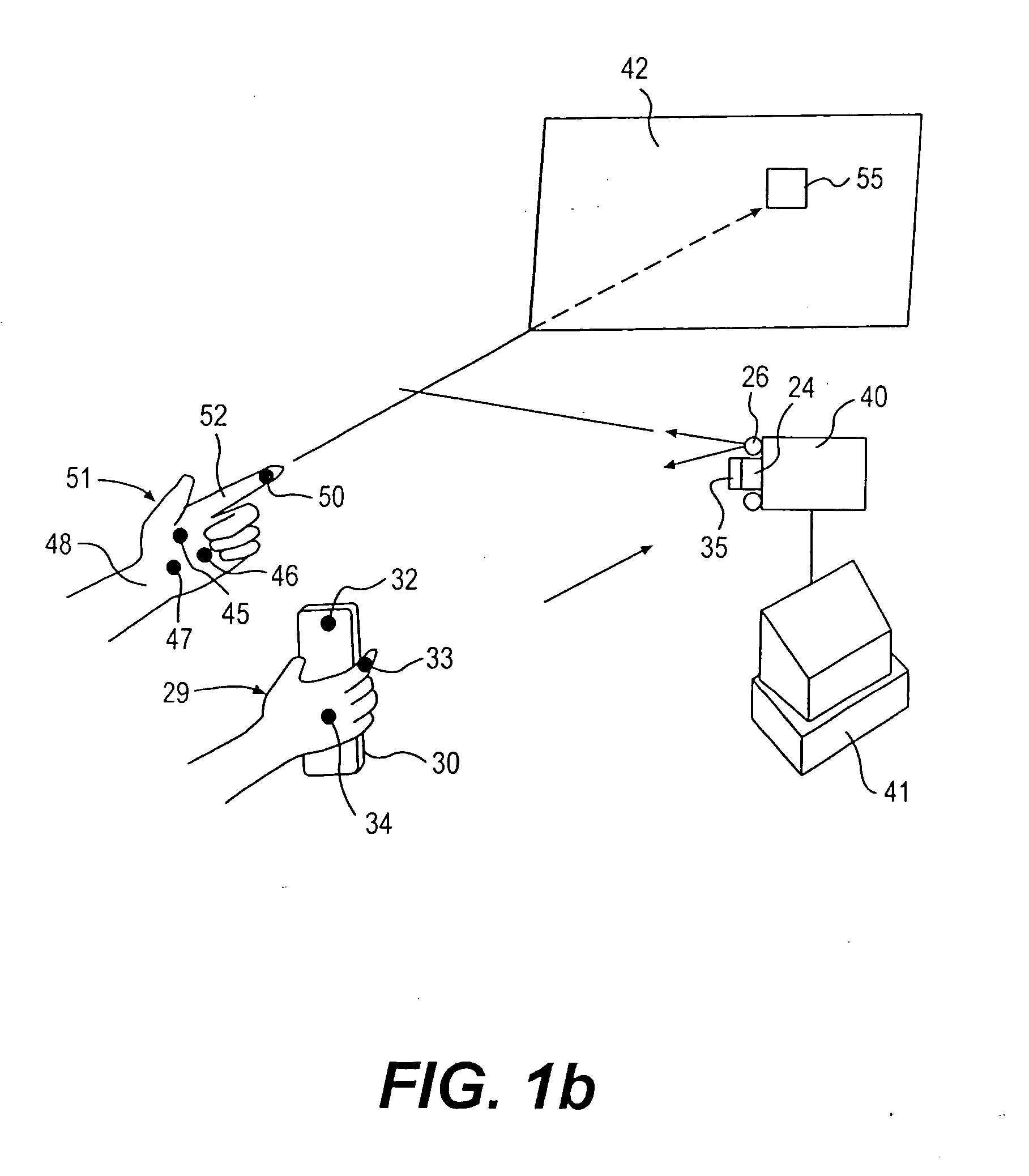

InactiveUS7042440B2Avoid carpal tunnel syndromeImprove efficiencyInput/output for user-computer interactionElectrophonic musical instrumentsComputer Aided DesignHuman–machine interface

Affordable methods and apparatus are disclosed for inputting position, attitude (orientation) or other object characteristic data to computers for the purpose of Computer Aided Design, Painting, Medicine, Teaching, Gaming, Toys, Simulations, Aids to the disabled, and internet or other experiences. Preferred embodiments of the invention utilize electro-optical sensors, and particularly TV Cameras, providing optically inputted data from specialized datum's on objects and / or natural features of objects. Objects can be both static and in motion, from which individual datum positions and movements can be derived, also with respect to other objects both fixed and moving. Real-time photogrammetry is preferably used to determine relationships of portions of one or more datums with respect to a plurality of cameras or a single camera processed by a conventional PC.

Owner:PRYOR TIMOTHY R +1

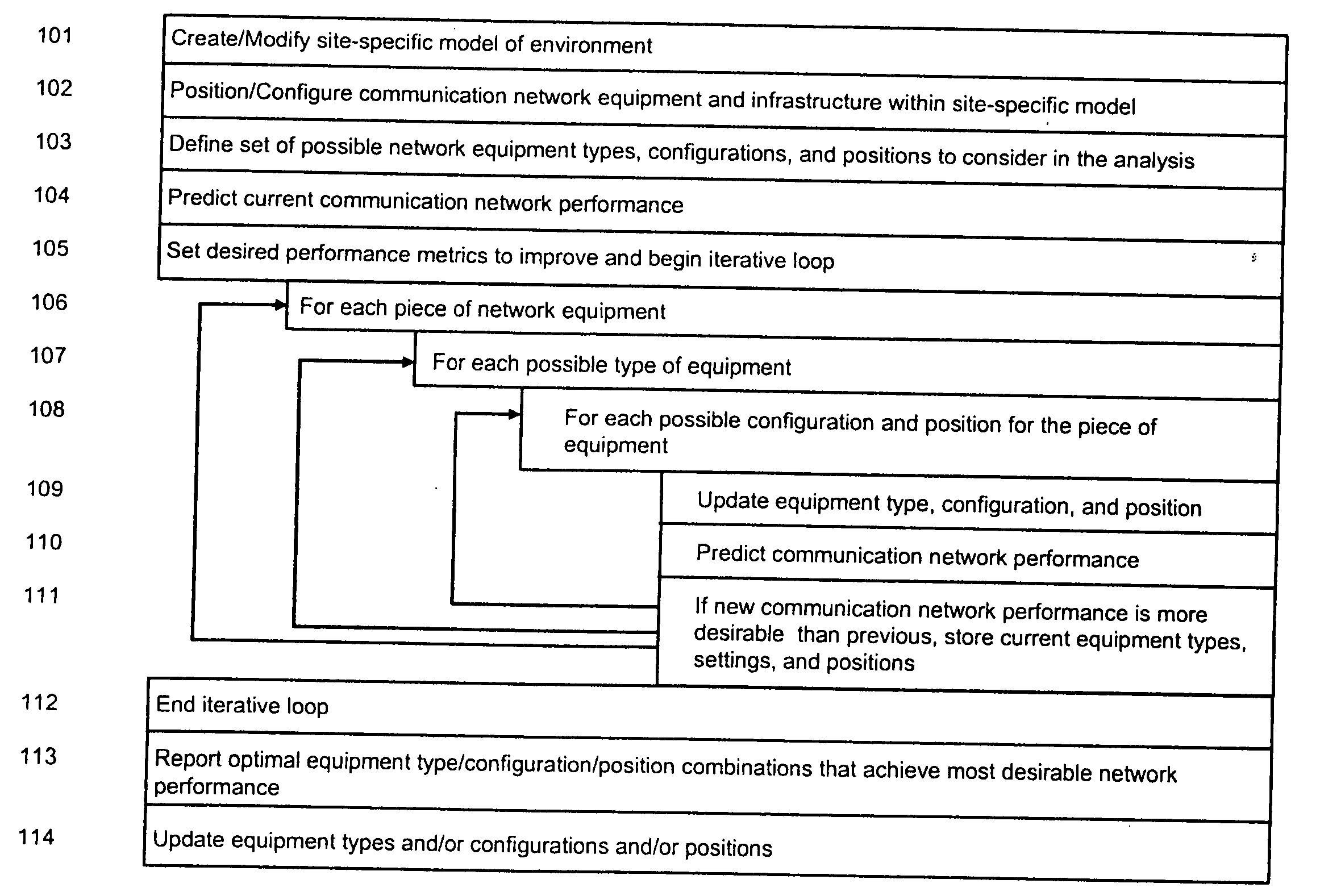

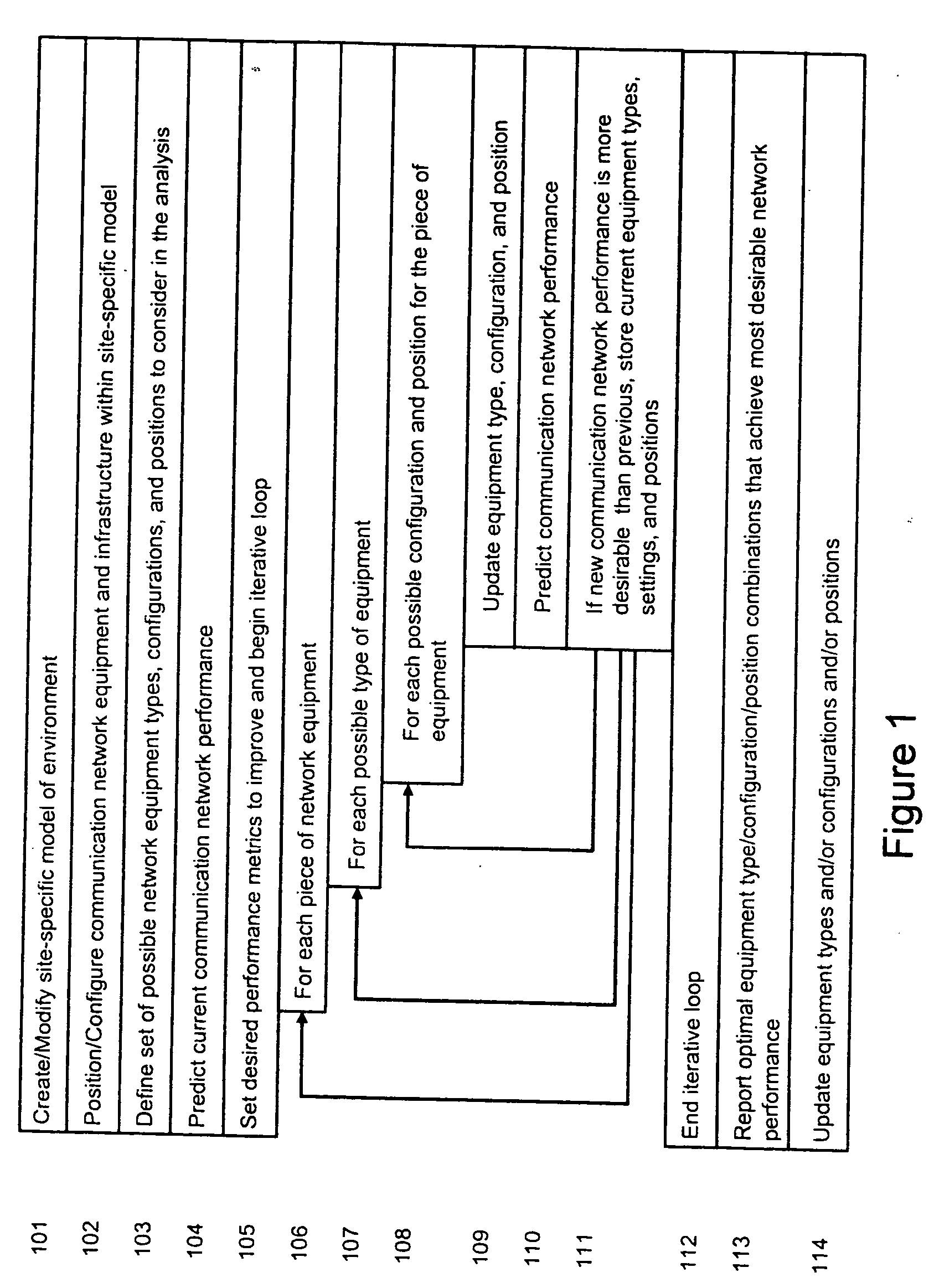

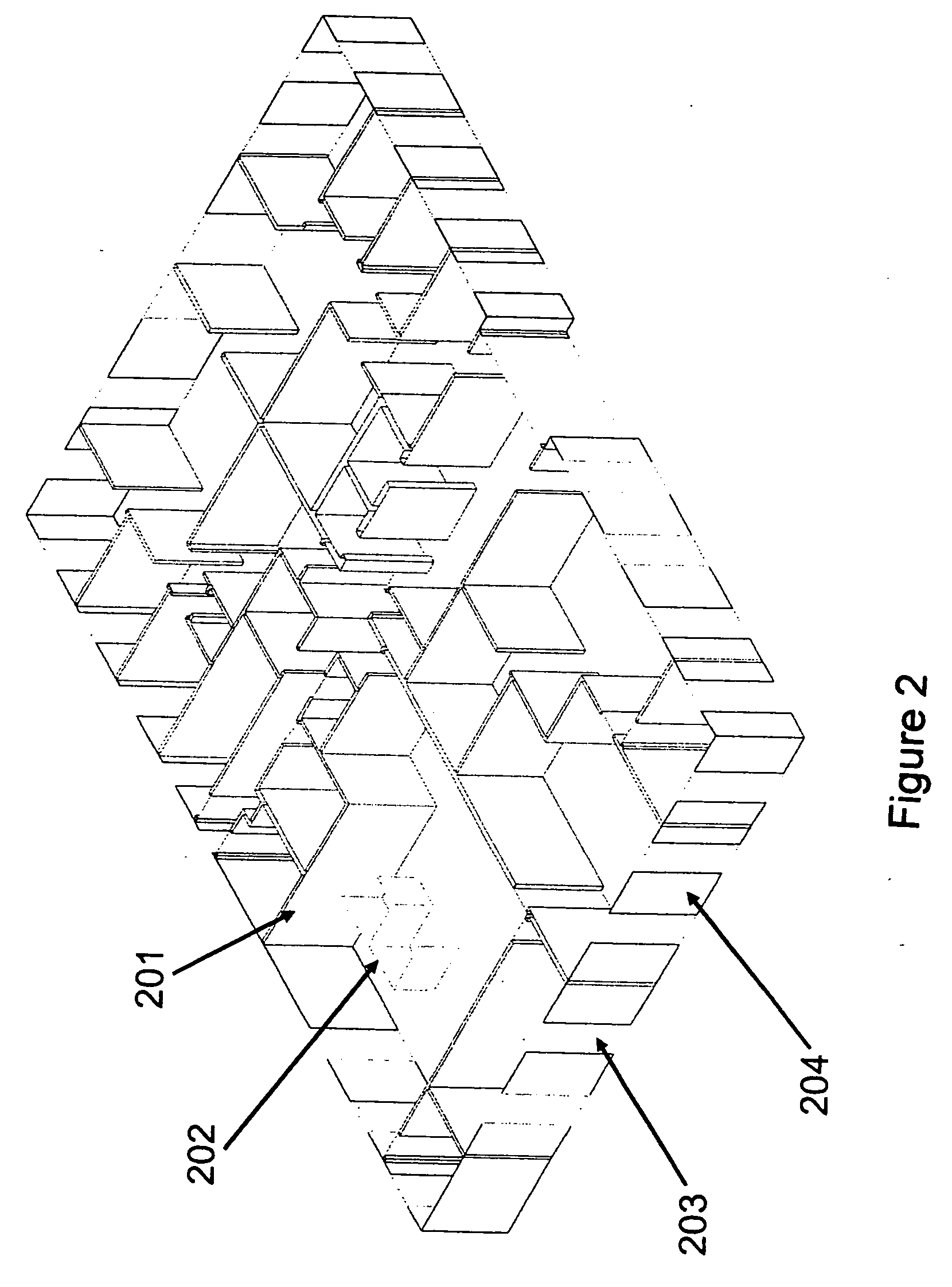

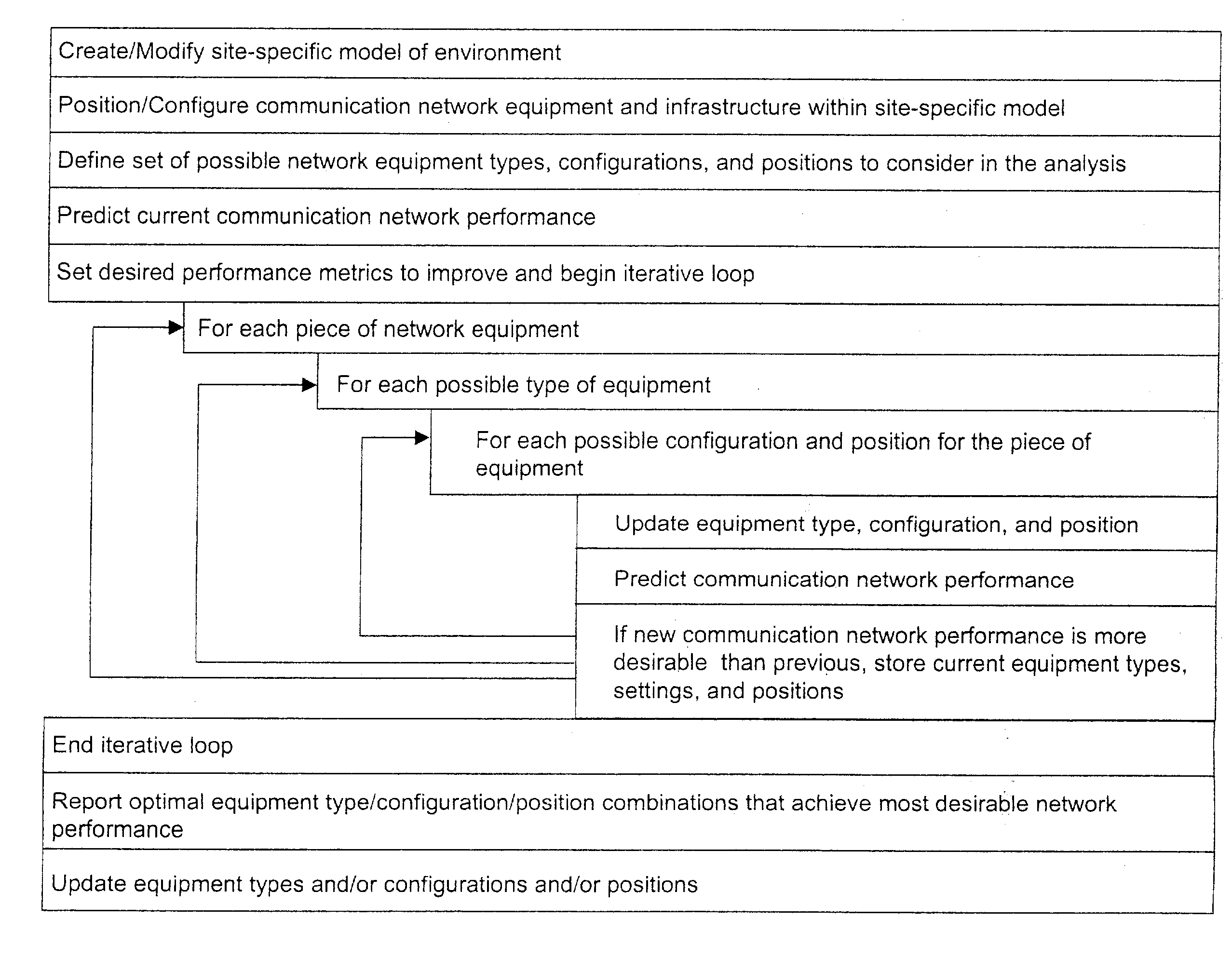

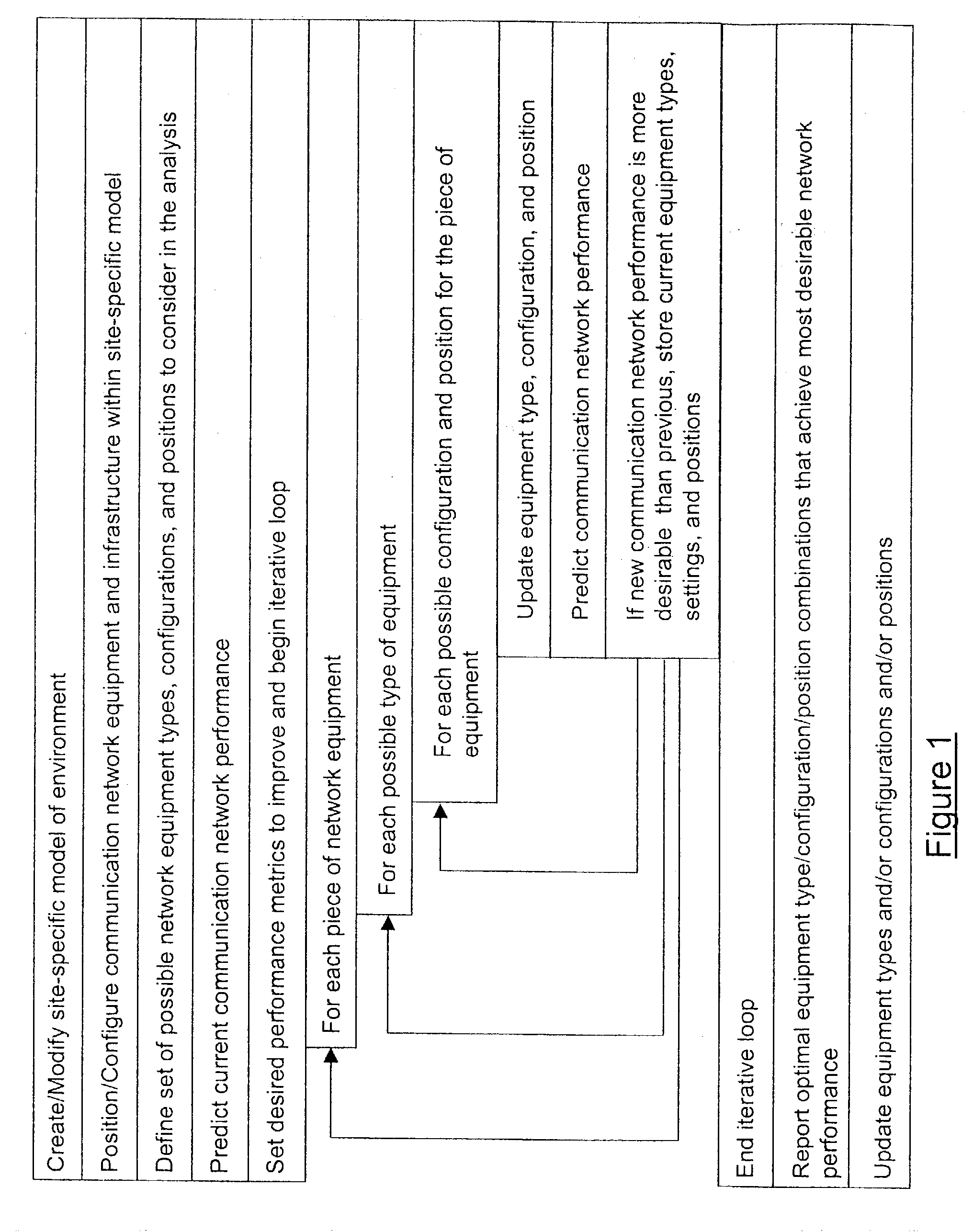

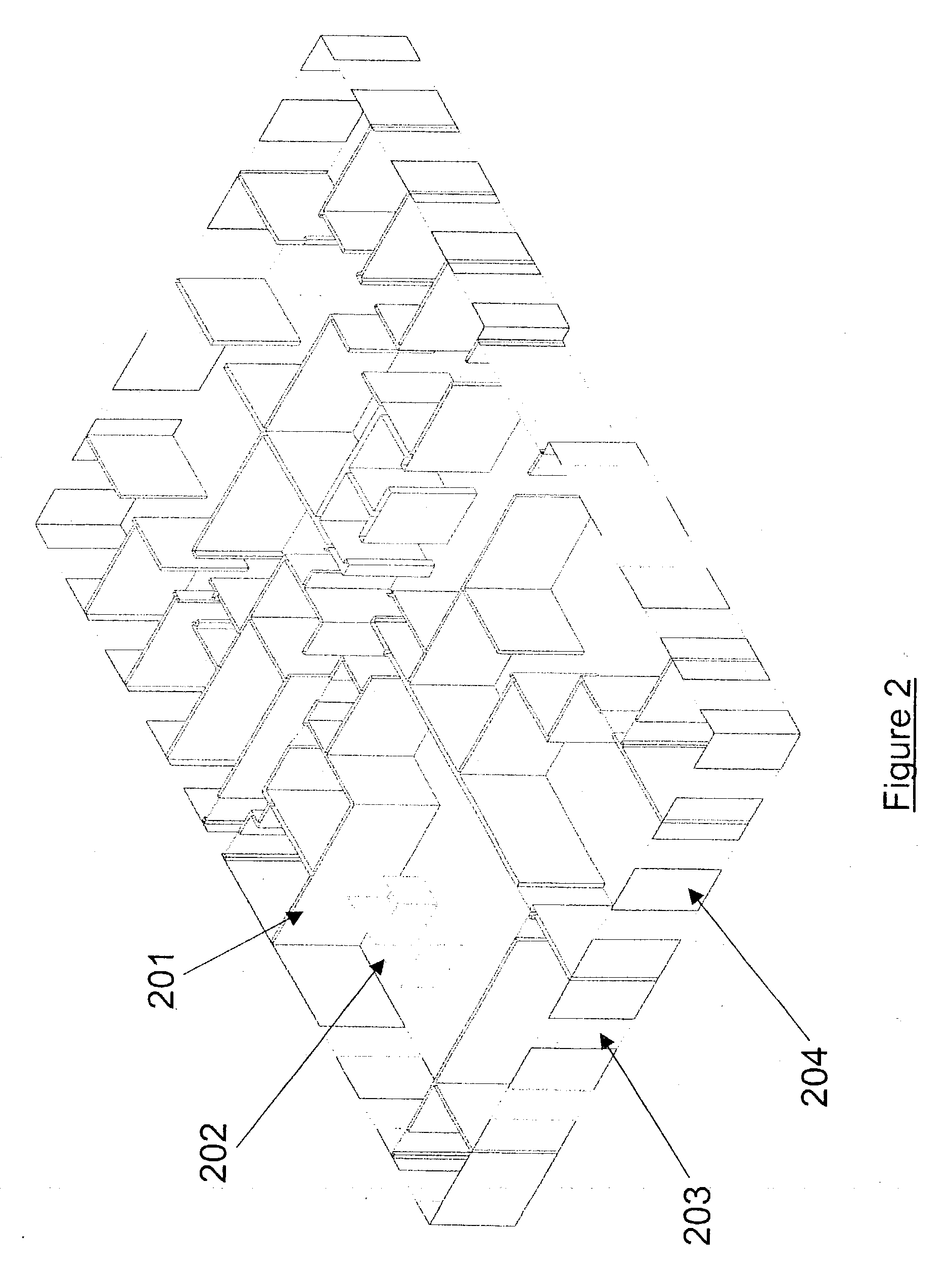

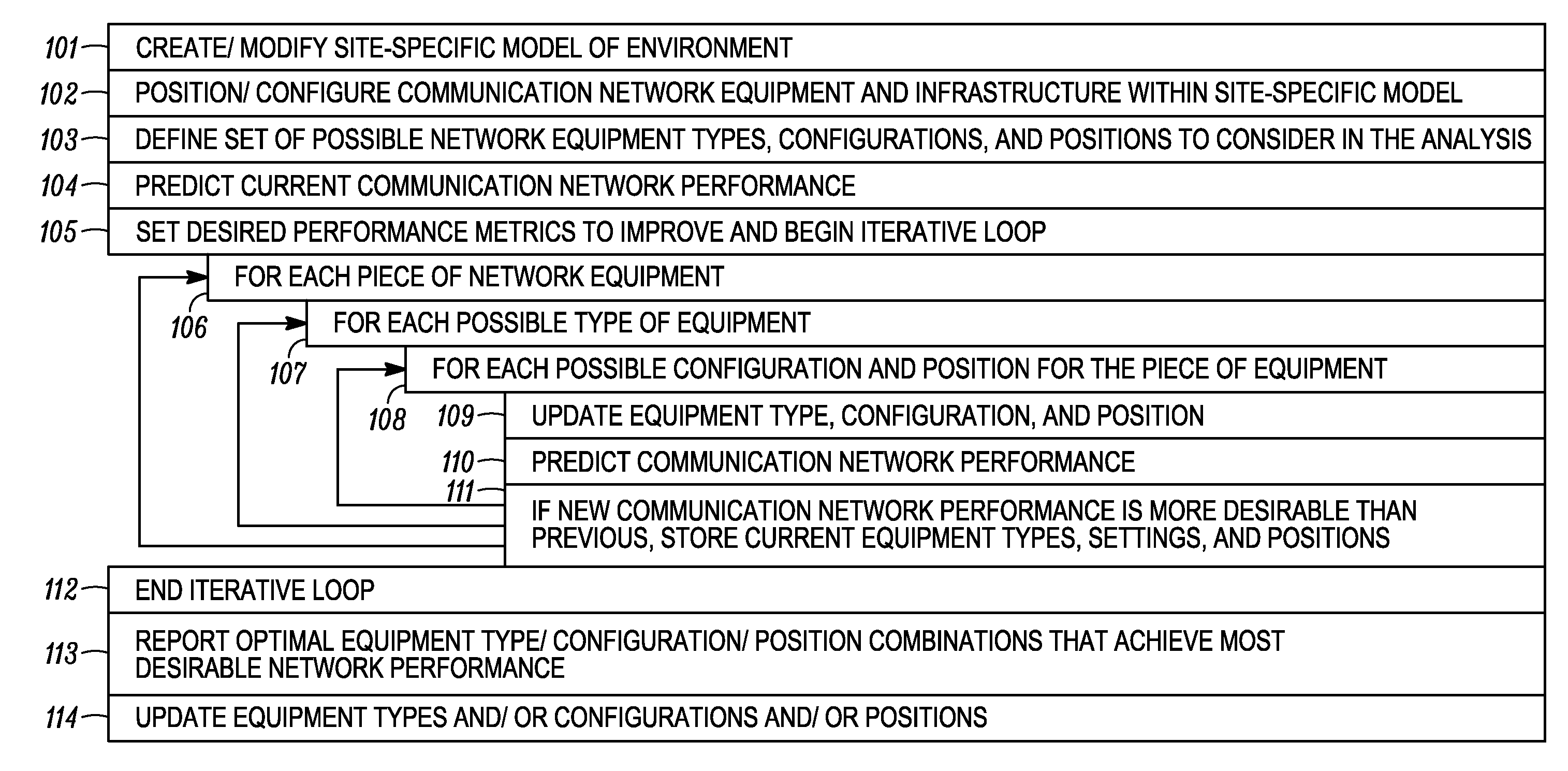

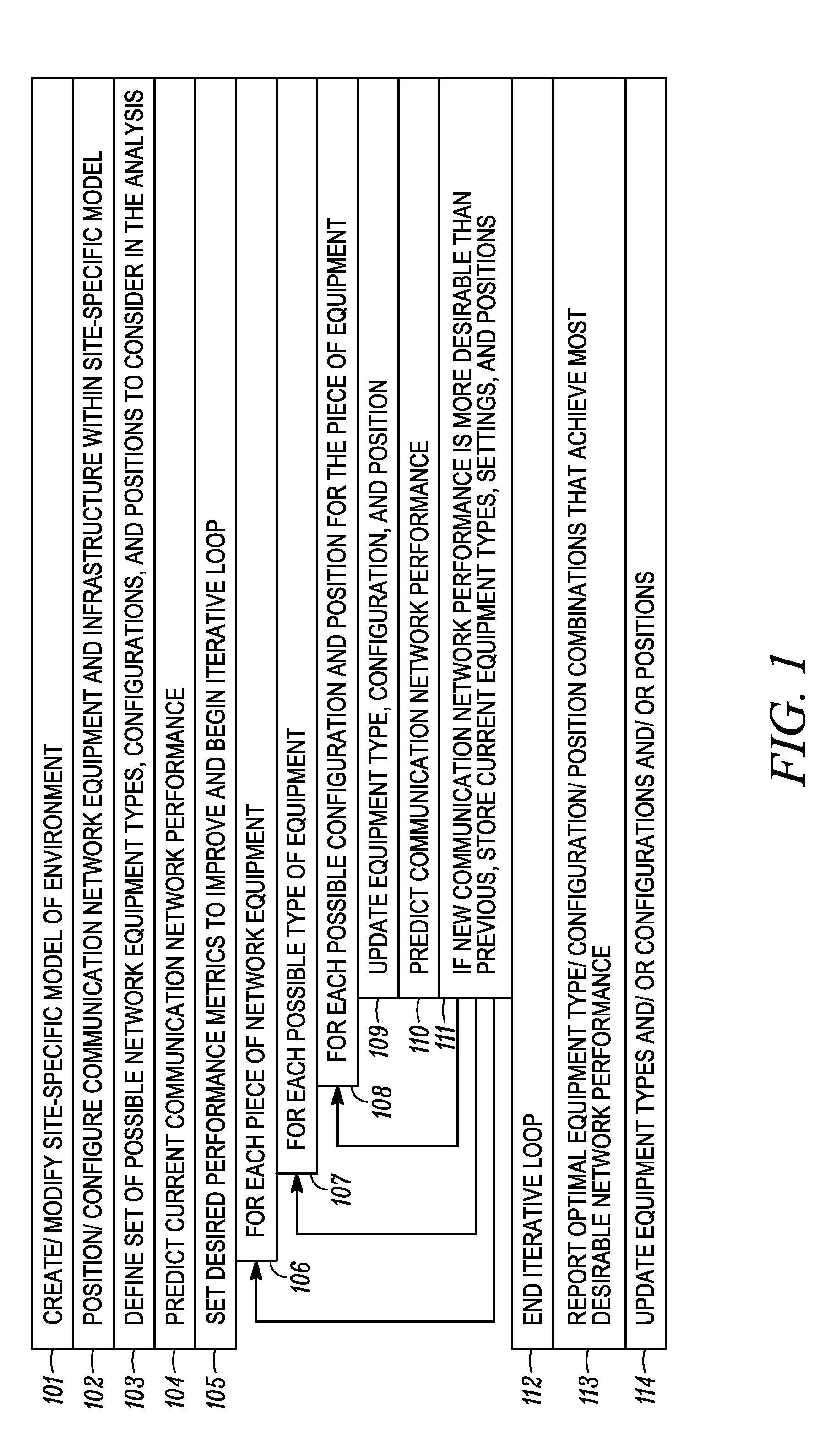

System and method for automated placement or configuration of equipment for obtaining desired network performance objectives and for security, RF tags, and bandwidth provisioning

ActiveUS20040236547A1Significant valueEasy to explainGeometric CADData taking preventionHard disc driveThe Internet

A method is presented for determining optimal or preferred configuration settings for wireless or wired network equipment in order to obtain a desirable level of network performance. A site-specific network model is used with adaptive processing to perform efficient design and on-going management of network performance. The invention iteratively determines overall network performance and cost, and further iterates equipment settings, locations and orientations. Real time control is between a site-specific Computer Aided Design (CAD) software application and the physical components of the network allows the invention to display, store, and iteratively adapt any network to constantly varying traffic and interference conditions. Alarms provide rapid adaptation of network parameters, and alerts and preprogrammed network shutdown actions may be taken autonomously. A wireless post-it note device and network allows massive data such as book contents or hard drive memory to be accessed within a room by a wide bandwidth reader device, and this can further be interconnected to the internet or Ethernet backbone in order to provide worldwide access and remote retrieval to wireless post-it devices.

Owner:EXTREME NETWORKS INC

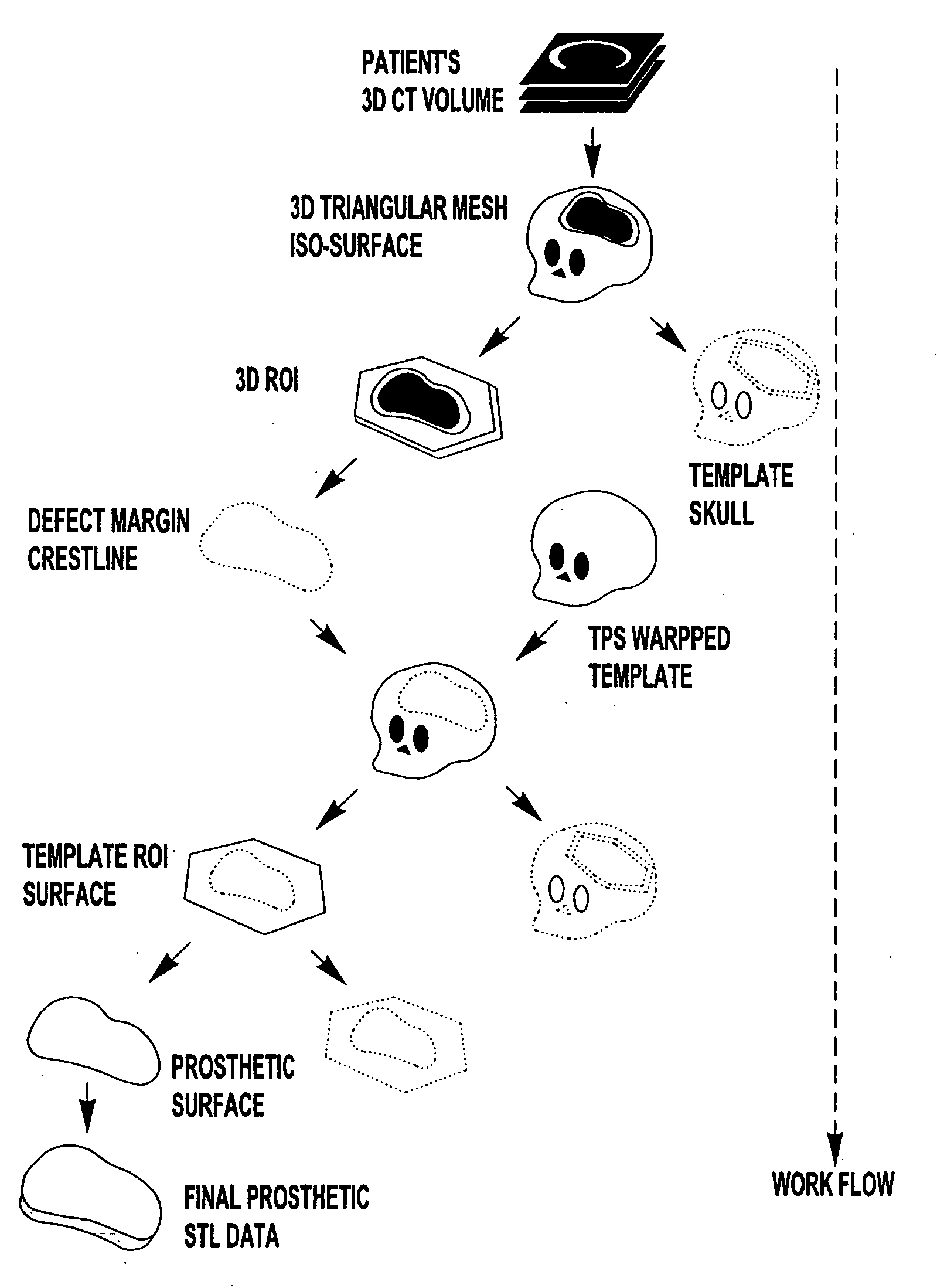

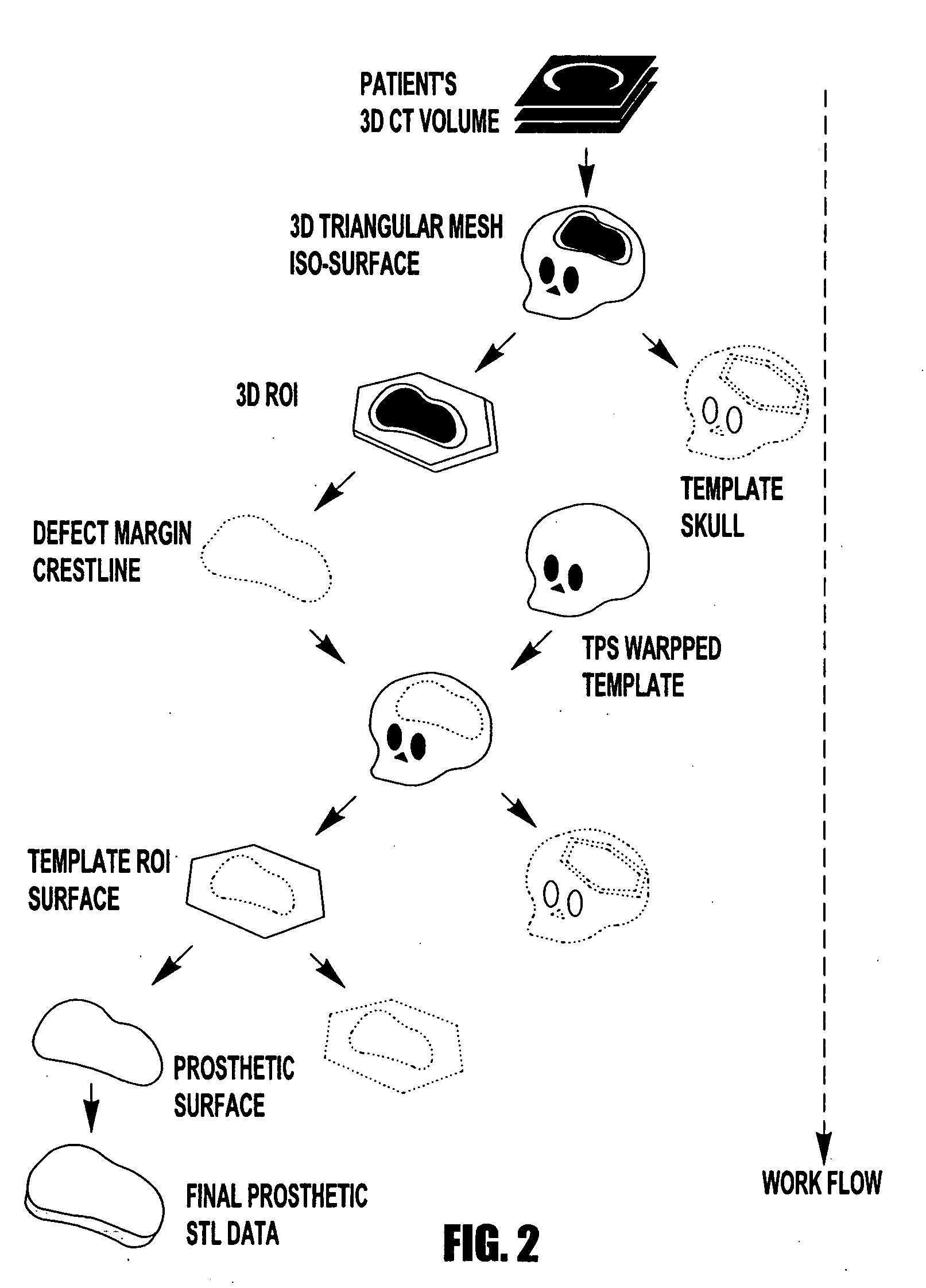

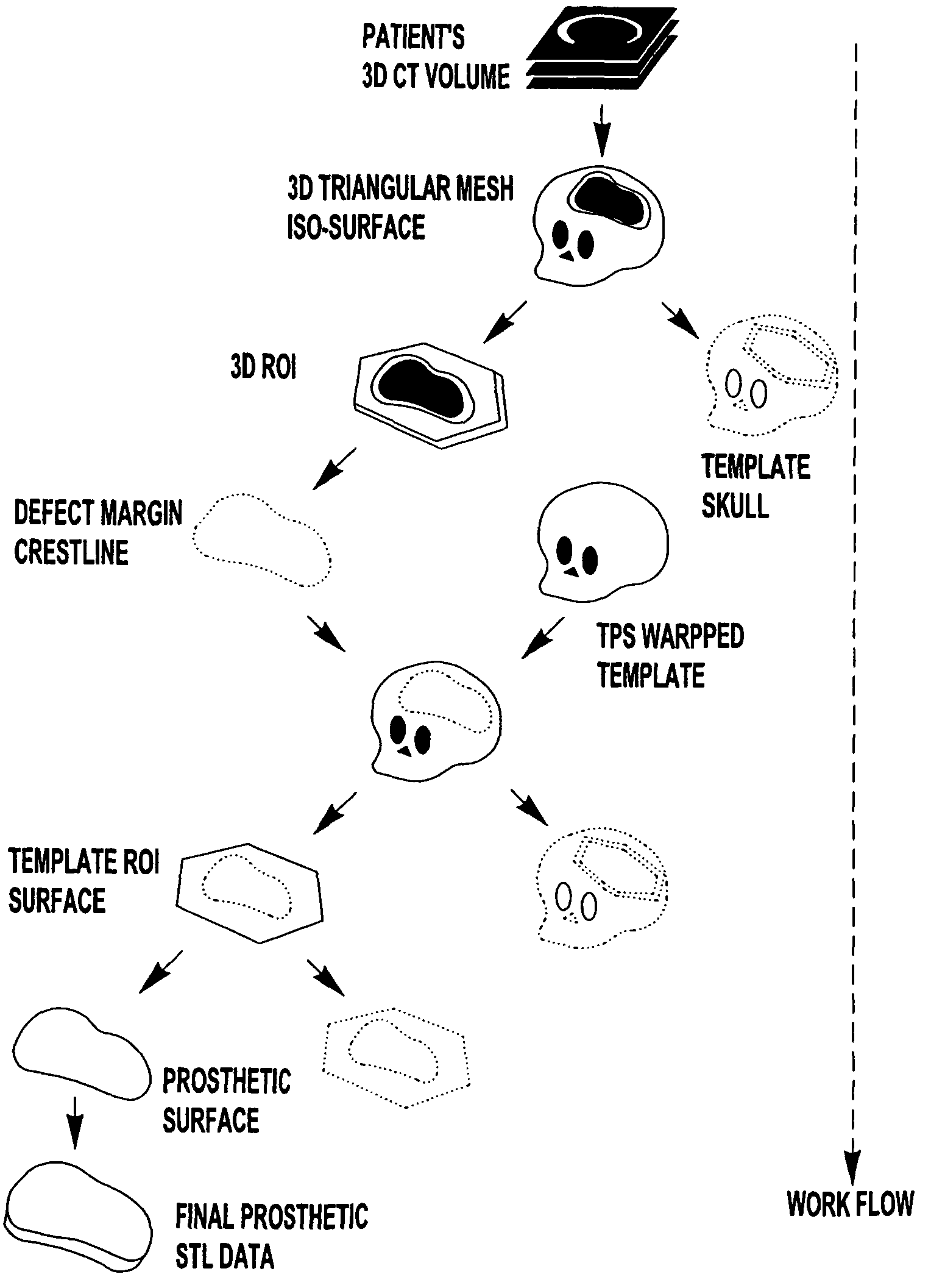

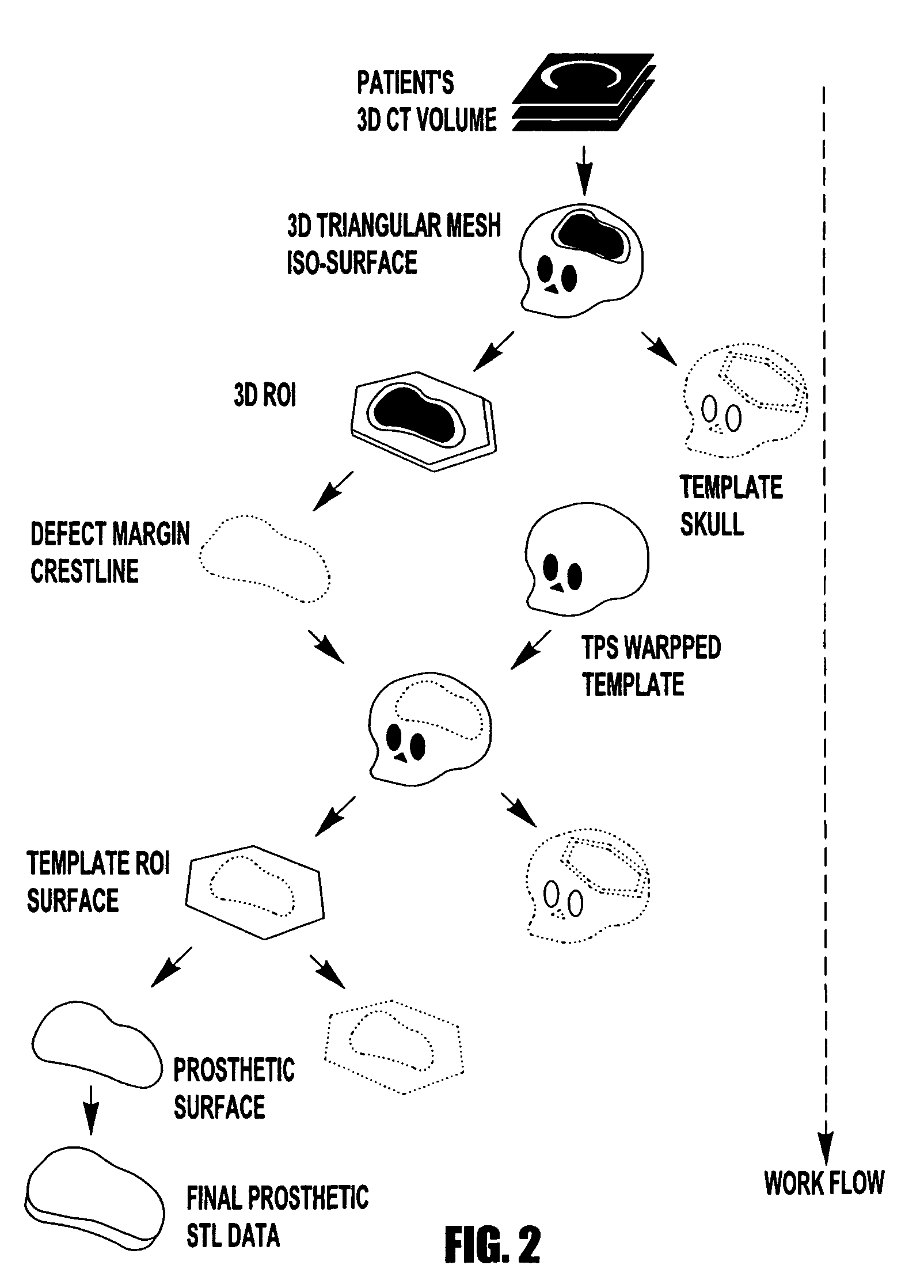

Computer-aided-design of skeletal implants

InactiveUS20060094951A1ContrastMaintain continuityProgramme controlMedical simulationComputer Aided DesignDigital data

The present invention is directed to a computer aided design method for producing an implant for a patient prior to operation comprising the steps of: generating data with a non-invasive 3D (3-dimensional) scan of the patient's defect site that digitally represents the area that will receive the implant; designing and validating an implant on a computer based on digital data generated from a volume image of the patient; and fabricating the implant based solely on the implant design data generated on computer.

Owner:OSTEOPLASTICS

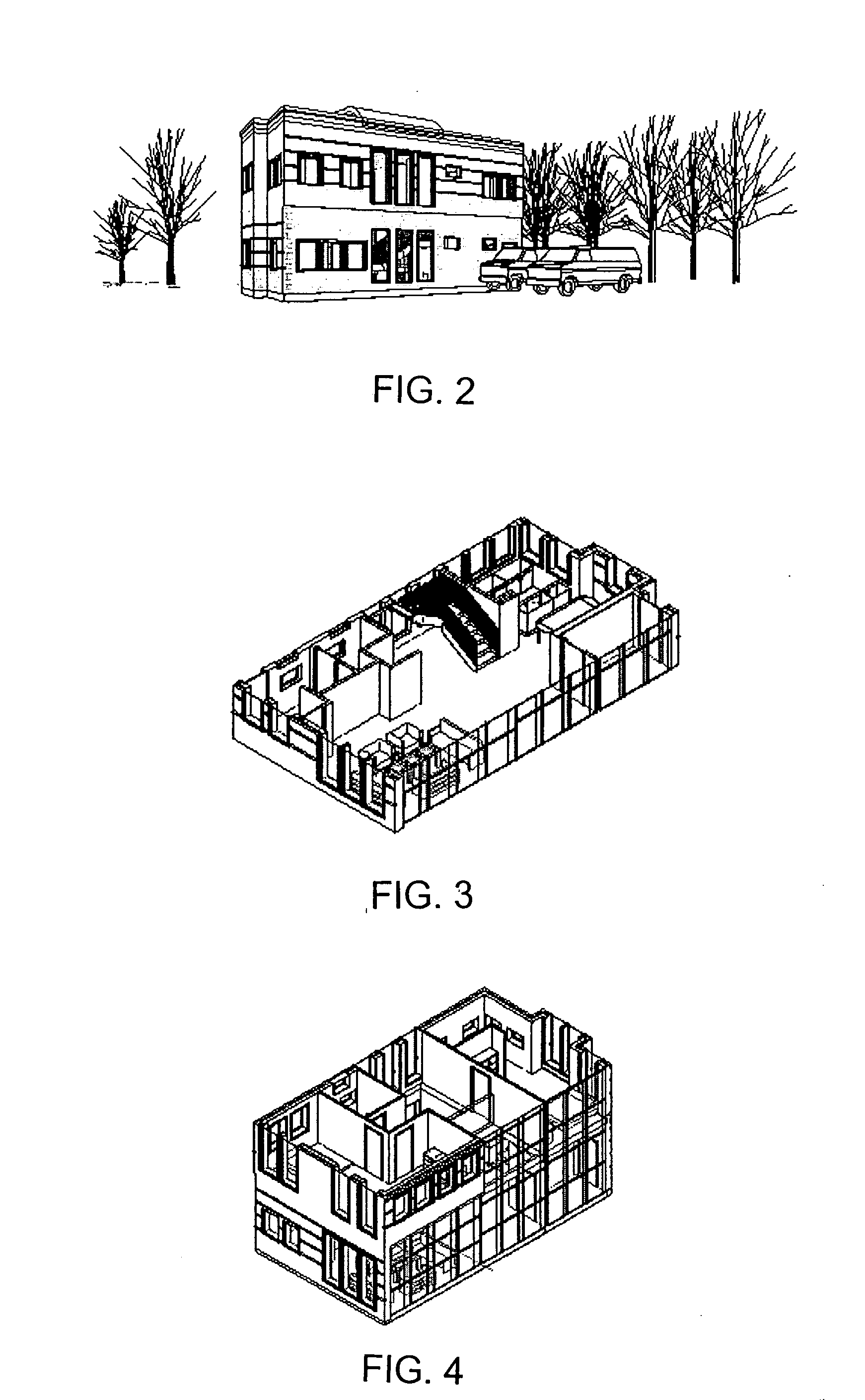

System and method for automated placement or configuration of equipment for obtaining desired network performance objectives

ActiveUS20040143428A1Significant valueEasy to explainGeometric CADProgram controlHard disc driveThe Internet

A method is presented for determining optimal or preferred configuration settings for wireless or wired network equipment in order to obtain a desirable level of network performance. A site-specific network model is used with adaptive processing to perform efficient design and on-going management of network performance. The invention iteratively determines overall network performance and cost, and further iterates equipment settings, locations and orientations. Real time control is between a site-specific Computer Aided Design (CAD) software application and the physical components of the network allows the invention to display, store, and iteratively adapt any network to constantly varying traffic and interference conditions. Alarms provide rapid adaptation of network parameters, and alerts and preprogrammed network shutdown actions may be taken autonomously. A wireless post-it note device and network allows massive data such as book contents or hard drive memory to be accessed within a room by a wide bandwidth reader device, and this can further be interconnected to the internet or Ethernet backbone in order to provide worldwide access and remote retrieval to wireless post-it devices.

Owner:EXTREME NETWORKS INC

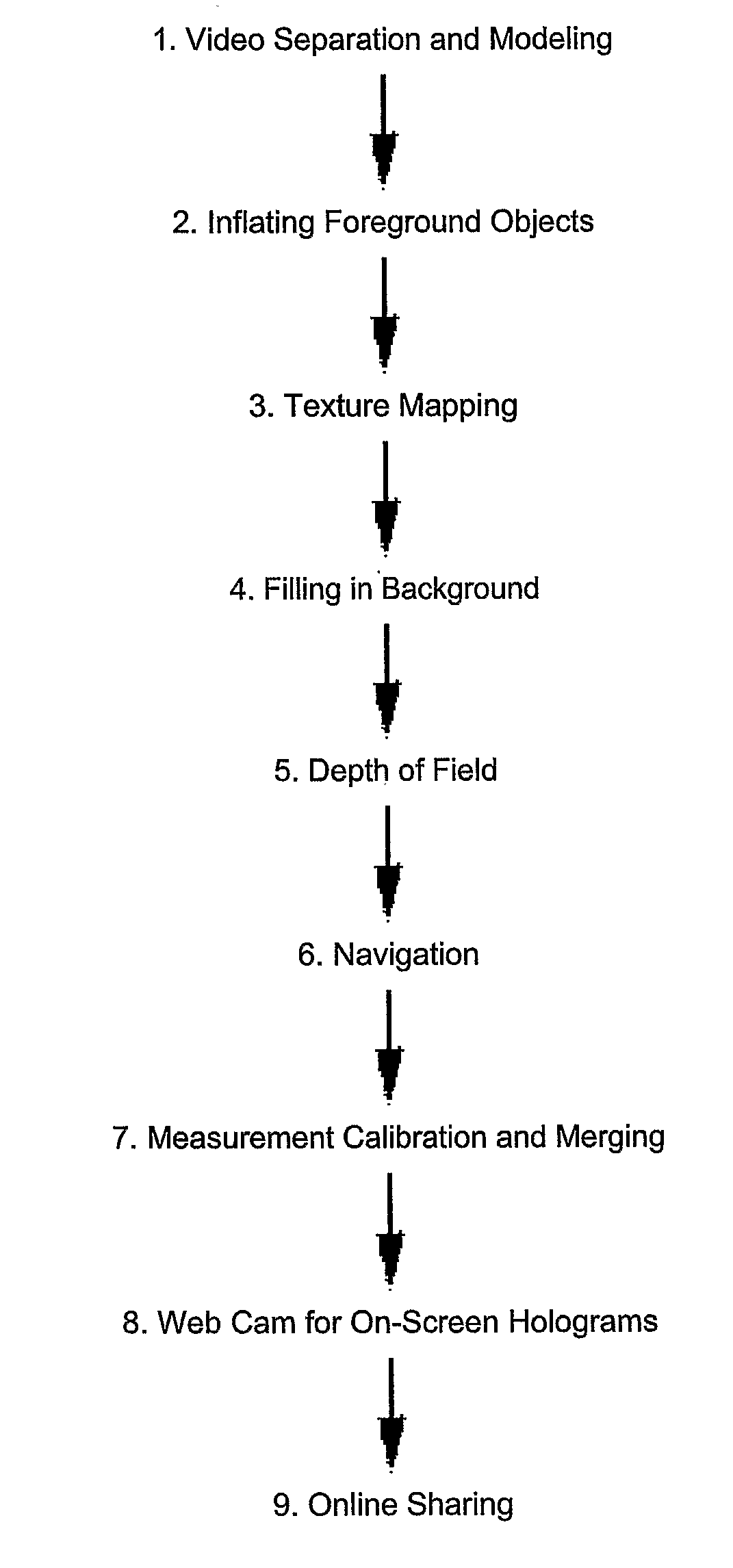

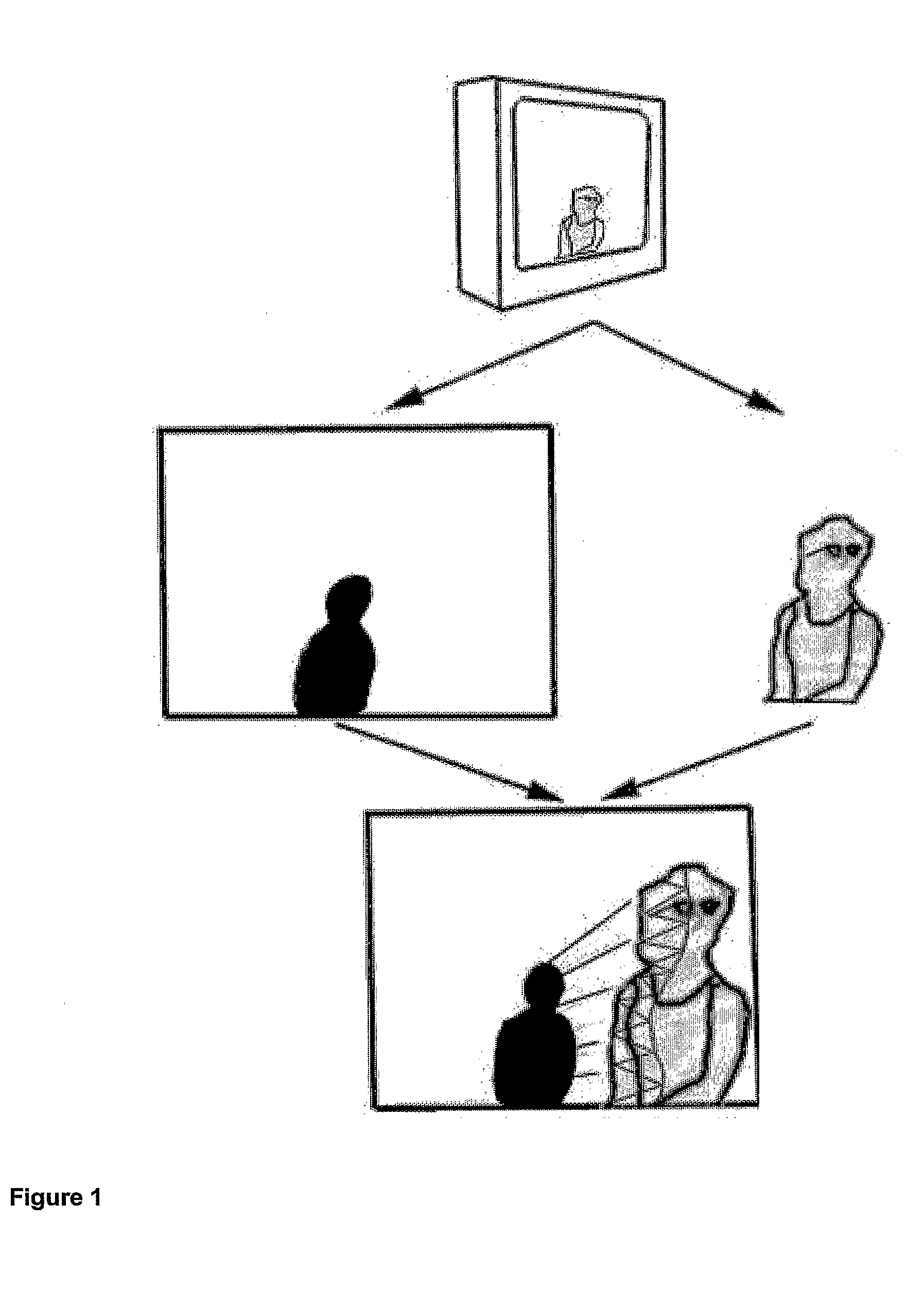

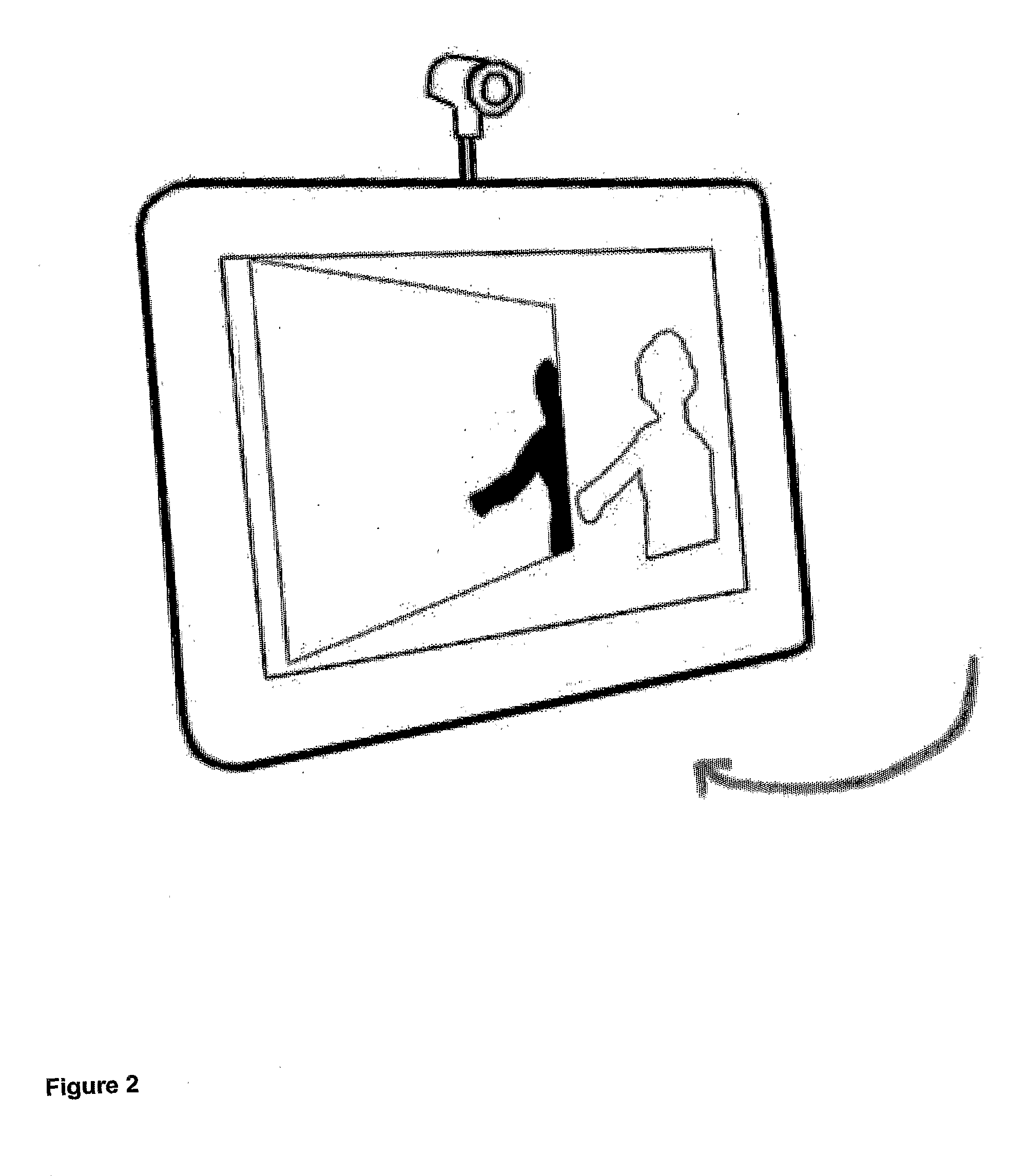

Automatic Scene Modeling for the 3D Camera and 3D Video

InactiveUS20080246759A1Reduce video bandwidthIncrease frame rateTelevision system detailsImage enhancementAutomatic controlViewpoints

Single-camera image processing methods are disclosed for 3D navigation within ordinary moving video. Along with color and brightness, XYZ coordinates can be defined for every pixel. The resulting geometric models can be used to obtain measurements from digital images, as an alternative to on-site surveying and equipment such as laser range-finders. Motion parallax is used to separate foreground objects from the background. This provides a convenient method for placing video elements within different backgrounds, for product placement, and for merging video elements with computer-aided design (CAD) models and point clouds from other sources. If home users can save video fly-throughs or specific 3D elements from video, this method provides an opportunity for proactive, branded media sharing. When this image processing is used with a videoconferencing camera, the user's movements can automatically control the viewpoint, creating 3D hologram effects on ordinary televisions and computer screens.

Owner:SUMMERS

Computer-aided-design of skeletal implants

InactiveUS7747305B2ContrastMaintain continuityMedical simulationProgramme controlDigital dataComputer Aided Design

The present invention is directed to a computer aided design method for producing an implant for a patient prior to operation comprising the steps of: generating data with a non-invasive 3D (3-dimensional) scan of the patient's defect site that digitally represents the area that will receive the implant; designing and validating an implant on a computer based on digital data generated from a volume image of the patient; and fabricating the implant based solely on the implant design data generated on computer.

Owner:OSTEOPLASTICS

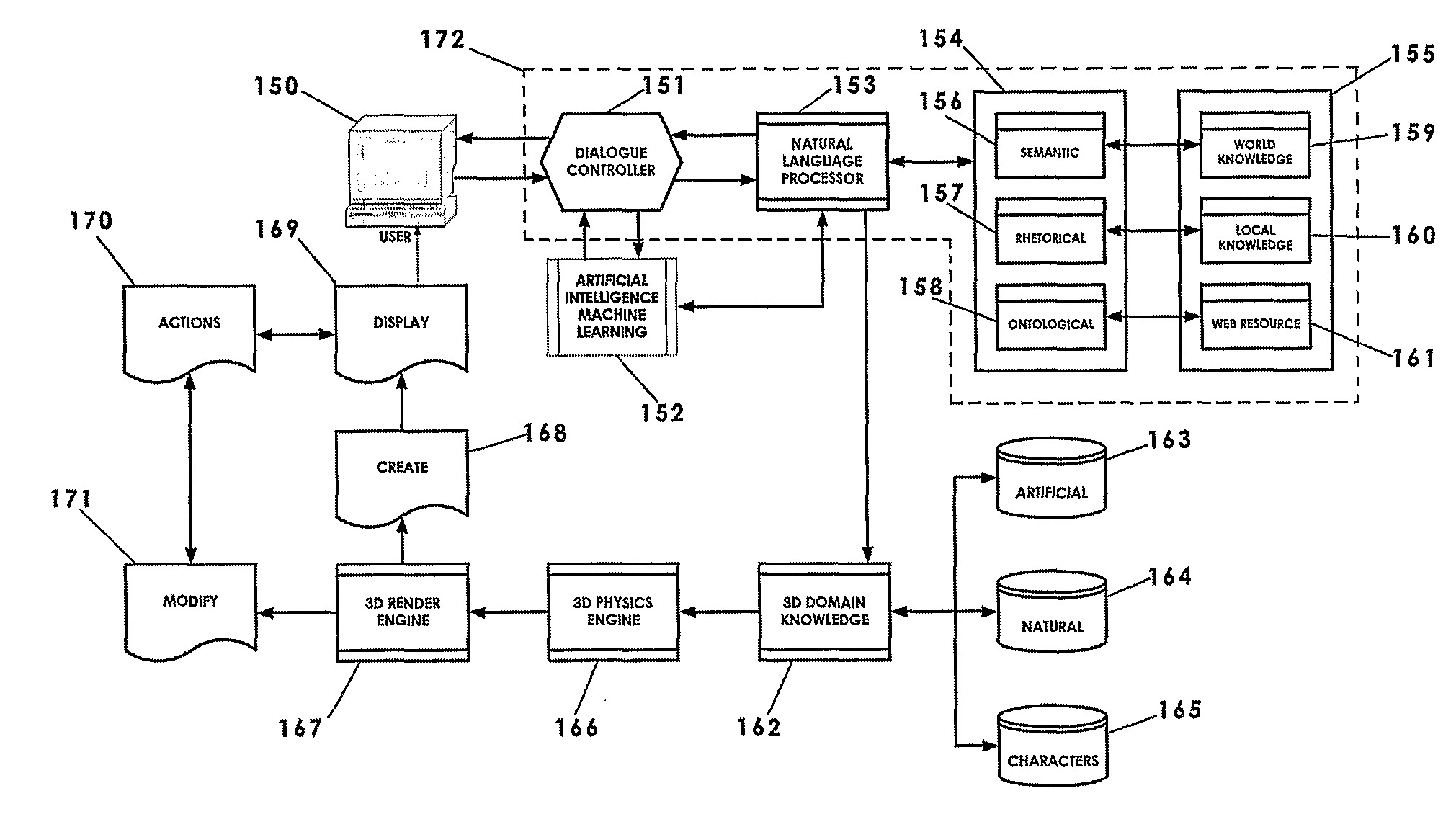

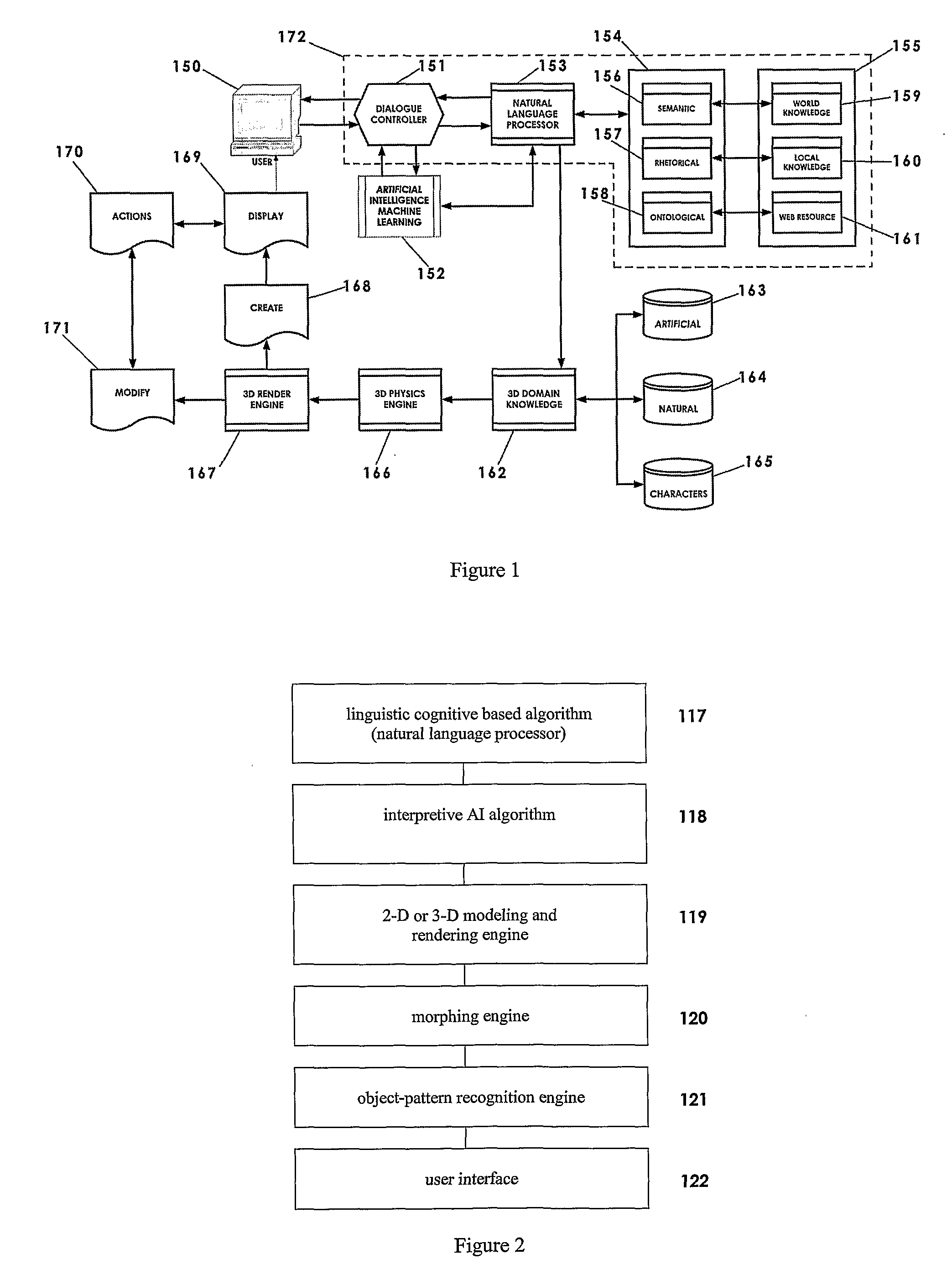

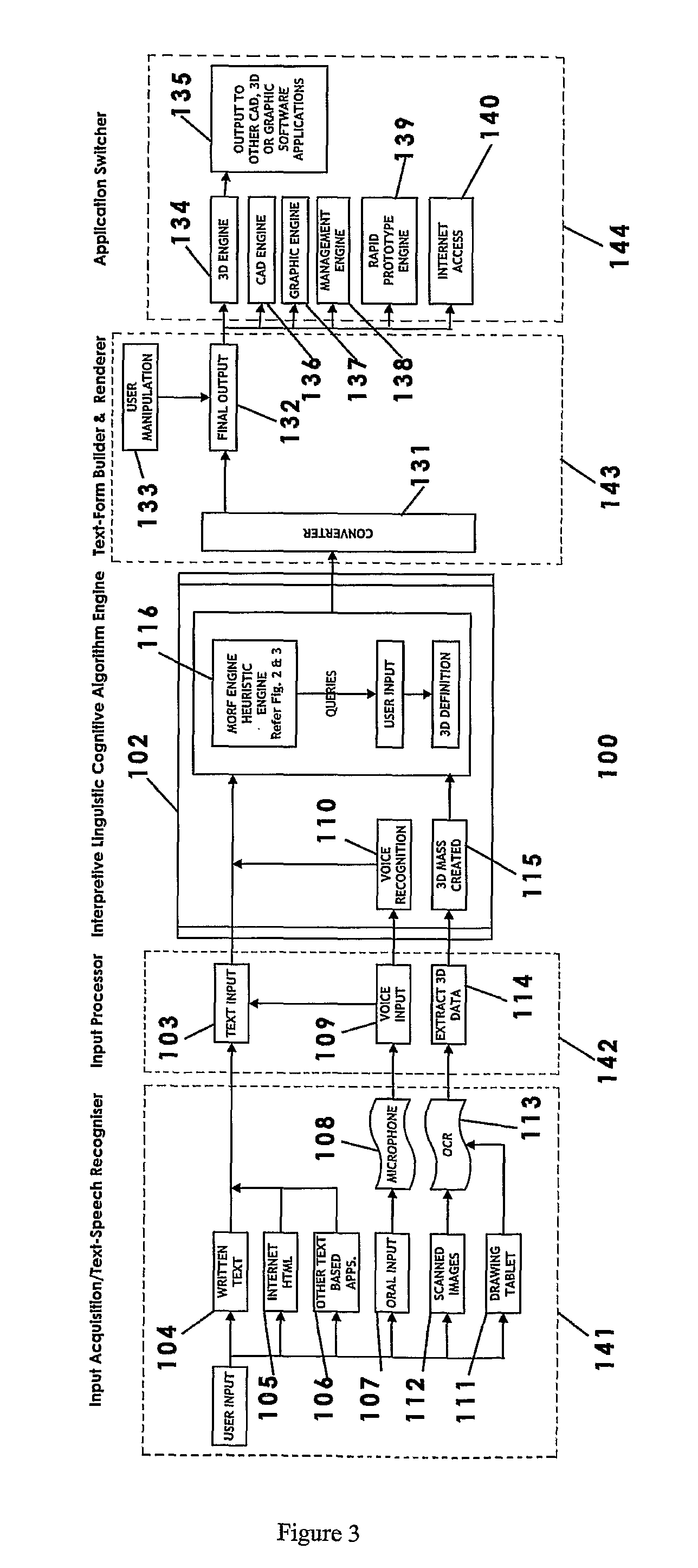

Method for Transforming Language Into a Visual Form

InactiveUS20090058860A1Easy to understandNatural language analysis2D-image generationComputer Aided DesignSpoken language

A computer assisted design system (100) that includes a computer system (102) and text input device (103) that may be provided with text elements from a keyboard (104). A user may also provide oral input (107) to the text input device (103) or to a voice recognition software with in-built artificial intelligence algorithms (110) which can convert spoken language into text elements. The computer system (102) includes an interaction design heuristic engine (116) that acts to understand and translate text and language into a visual form for display to the end user.

Owner:MOR F DYNAMICS

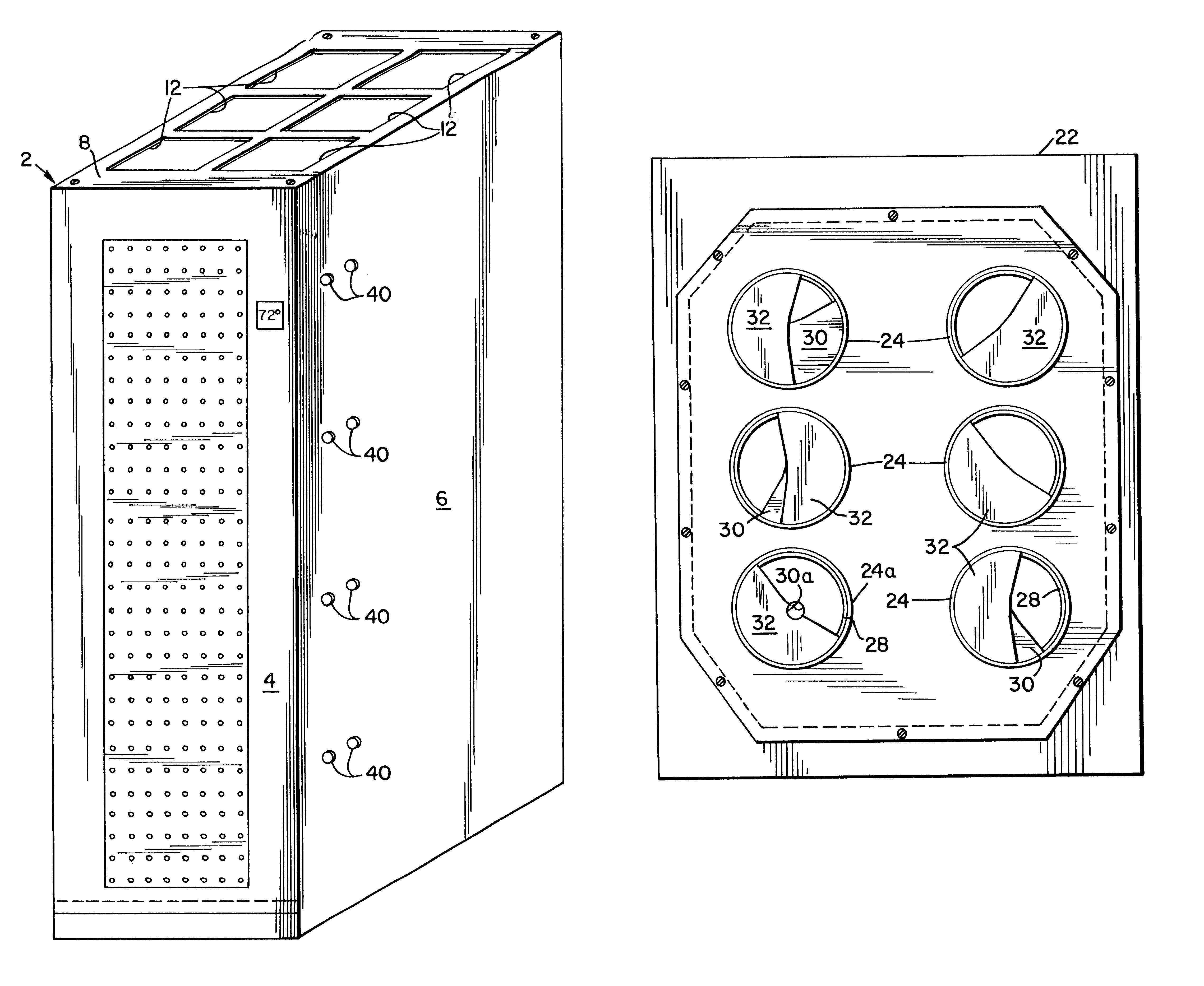

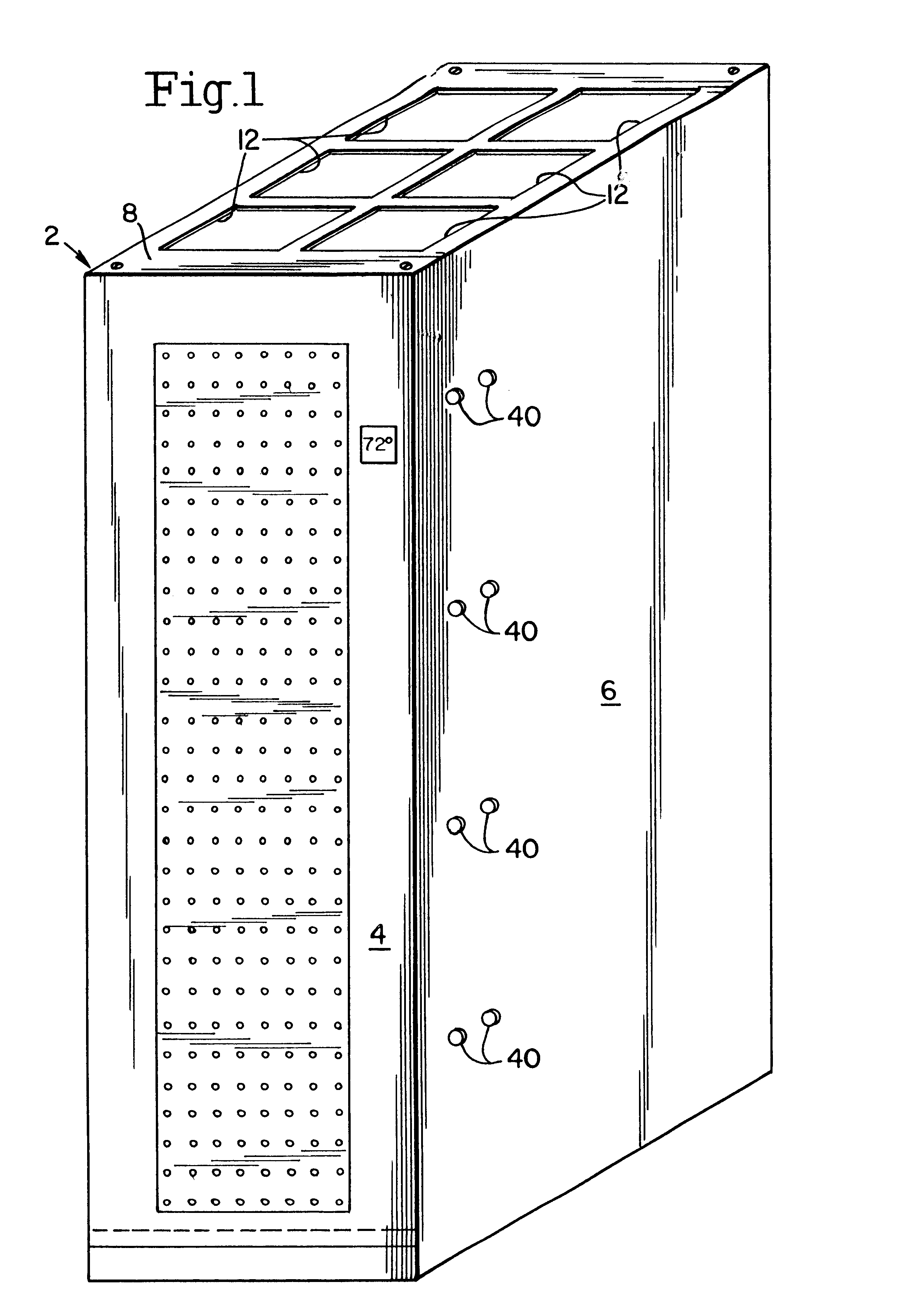

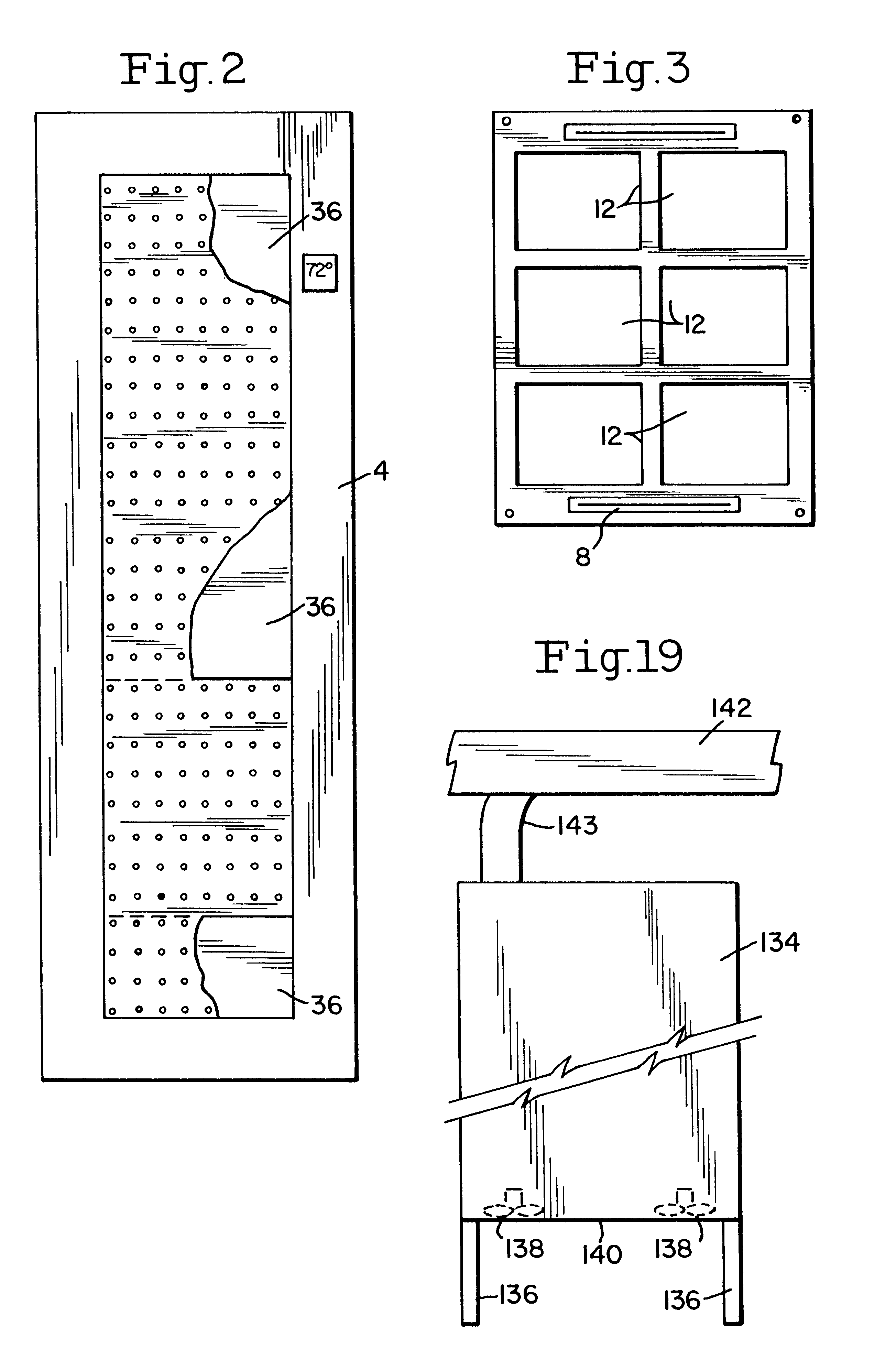

Computer cabinet design

InactiveUS6554697B1Avoid necessityEasy to adjustDigital processing power distributionCooling/ventilation/heating modificationsComputer Aided DesignEngineering

Cabinets or enclosures are provided having heat generating elements stored therein cooled by locating the cabinets on tiles of an elevated floor having cool air provided under the tiles, the cabinets having variable size openings in their bottom surface located over openings in the tiles, openings in the top surface of the cabinets, which openings may have fans located in the openings, highly perforated shelves and a highly perforated front door. By controlling the size of the various openings, and the number, if any, of fans and air flow through the door the temperature in the cabinet may be controlled. A number of cabinets may be located side-by-side with side walls in contact and with wires introduced into one cabinet from under the tiles through an opening in its bottom wall being passed from cabinet-to-cabinet through aligned openings in the side walls of the cabinets. The air flow within the cabinets may be reversed in air conditioned rooms not having cooling air under the floor on which the cabinet is situated.

Owner:ENG EQUIP & SERVICE

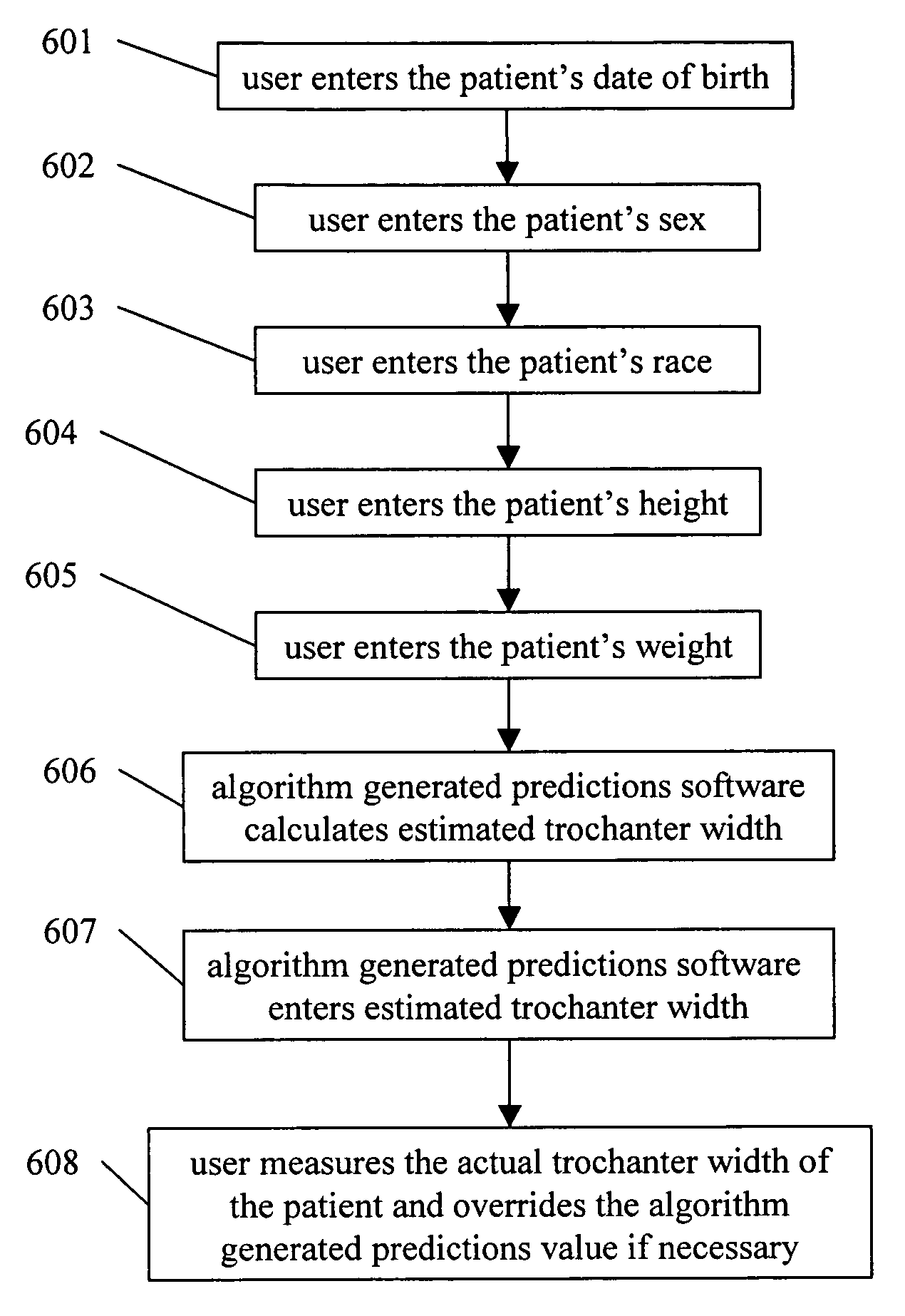

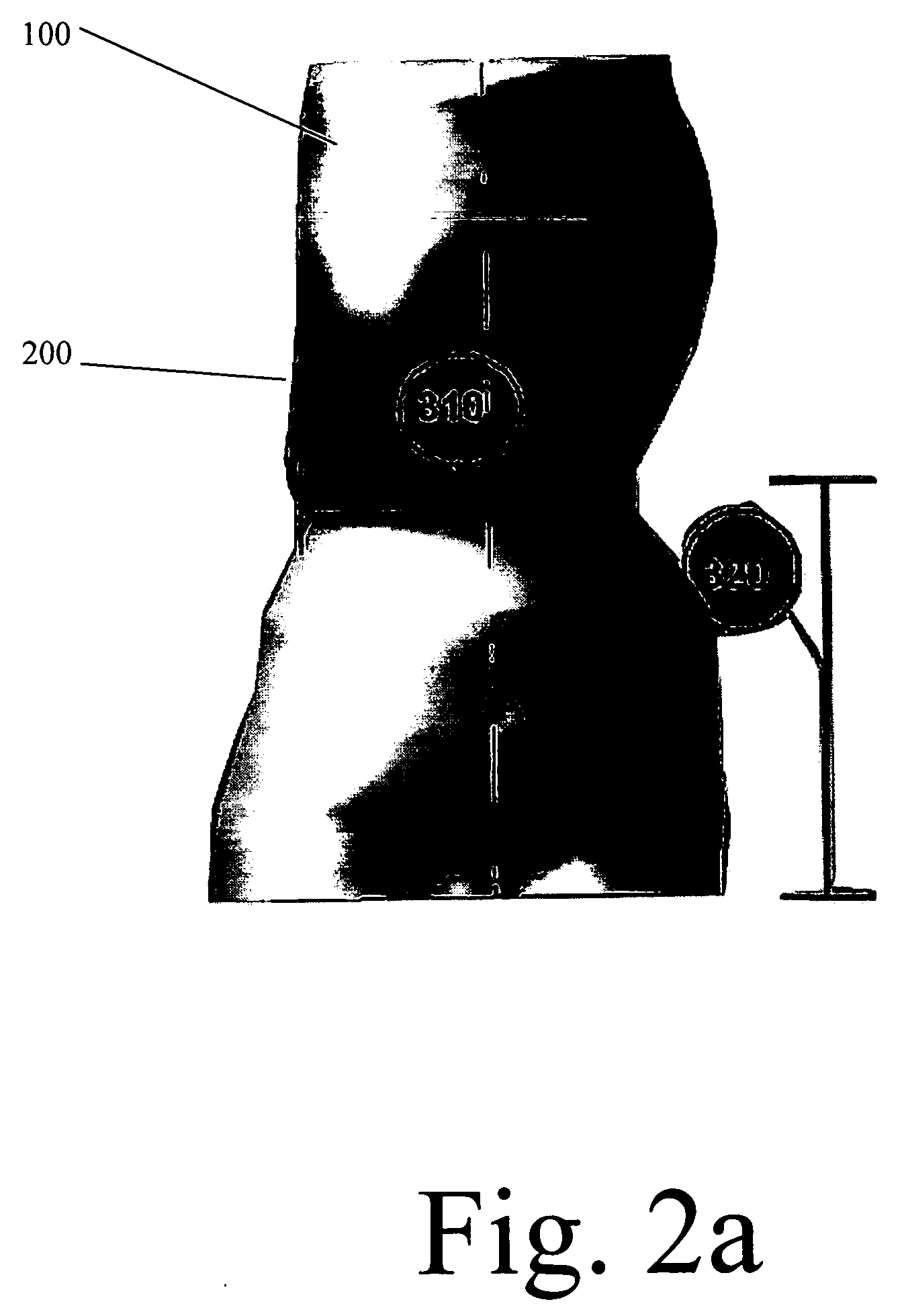

Method a designing, engineering modeling and manufacturing orthotics and prosthetics integrating algorithm generated predictions

InactiveUS20060100832A1More accurateMore scientificComputation using non-denominational number representationProsthesisComputer Aided DesignPhysical model

The present invention represents an advancement on the current processes involved in designing, engineering, modeling and manufacturing of orthotic and prosthetic devices. Orthotic and prosthetic computer aided design software has the option to apply measurements to a template to create a patient specific model. The use of algorithm generated predictions (also referred to as “AGP”) software takes this functionality and makes it more scientific. Algorithm generated predictions is the process of predicting the appropriate size and shape data through the use of complex algorithms. Certain key pieces of data are entered into the software that then calculates the appropriate dimensions and the appropriate computer aided design template. The dimensions are then applied to the computer aided design template. The computer aided design software modifies the templates by reducing and enlarging areas as necessary and a custom computer aided design model is created that can then be transformed into a physical model for the manufacture of the device.

Owner:BOWMAN GERALD DAVID

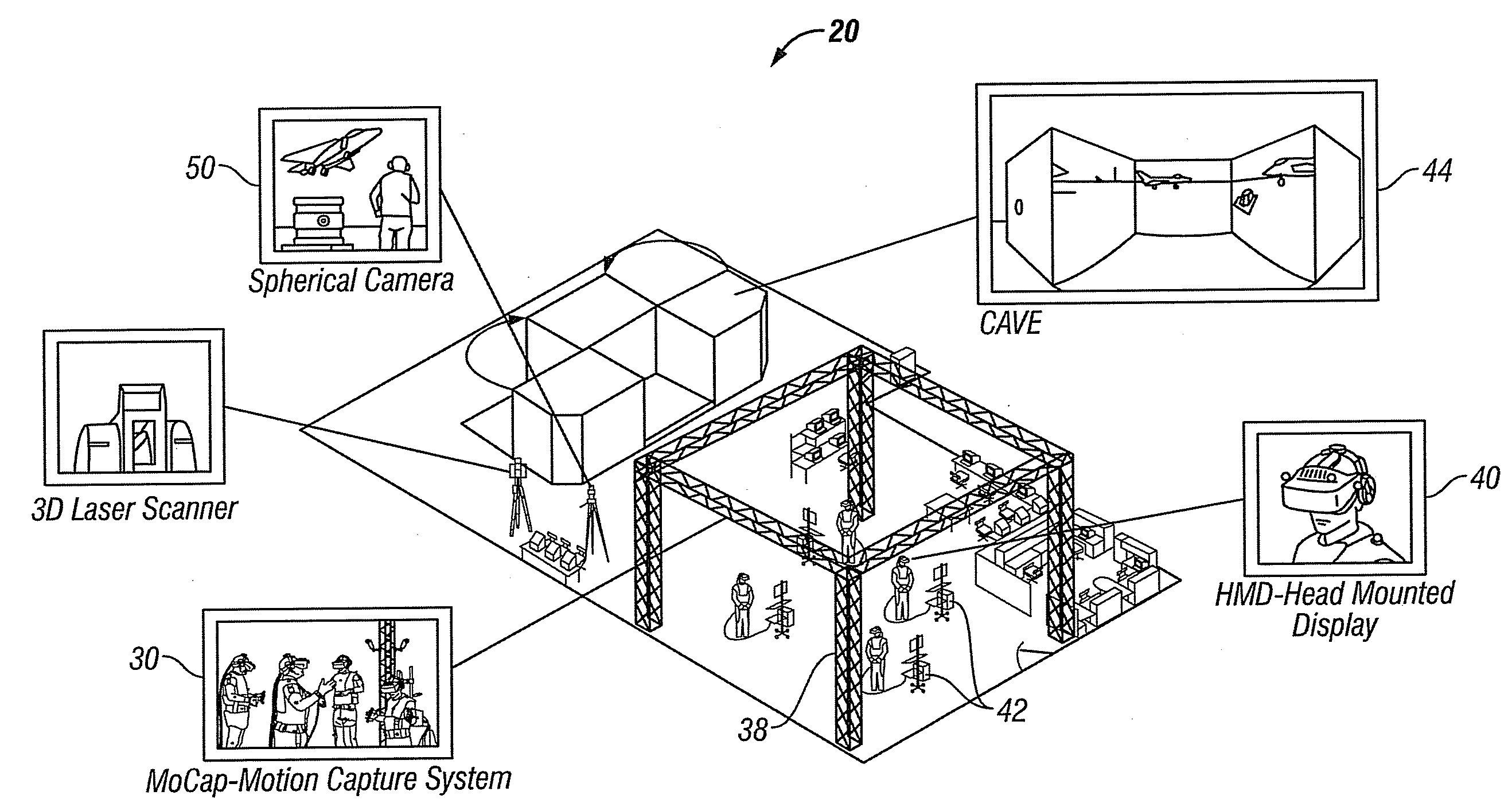

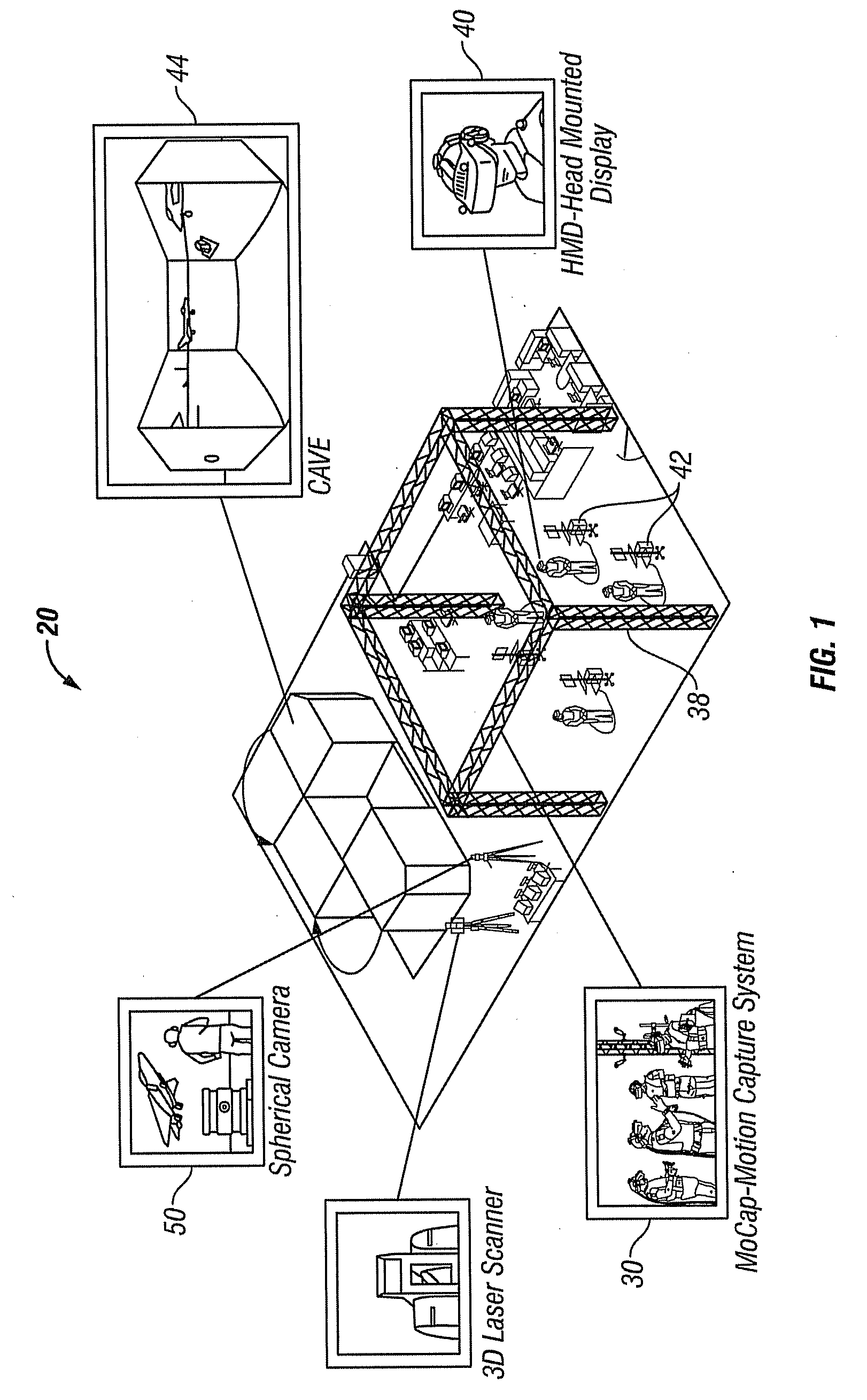

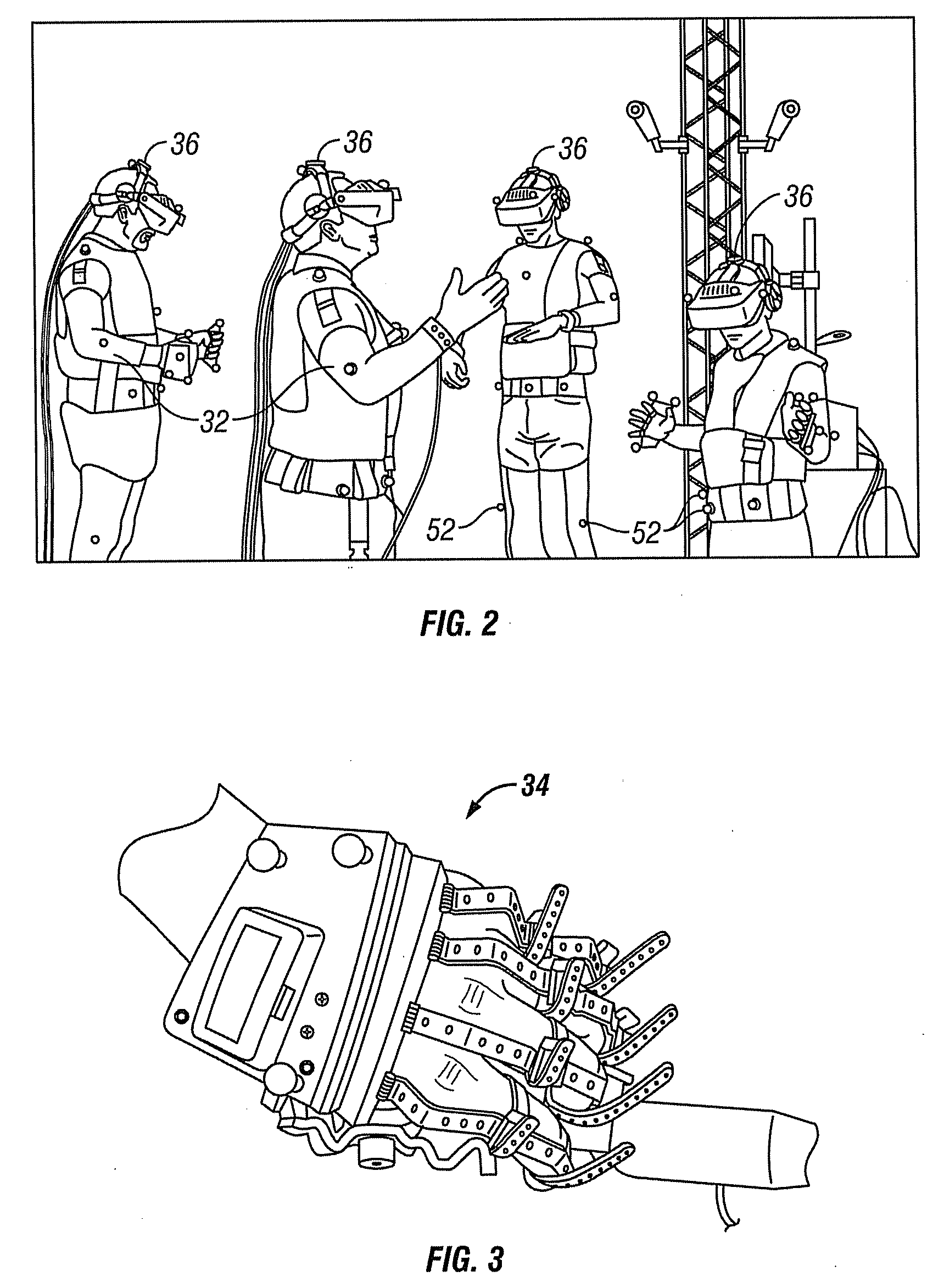

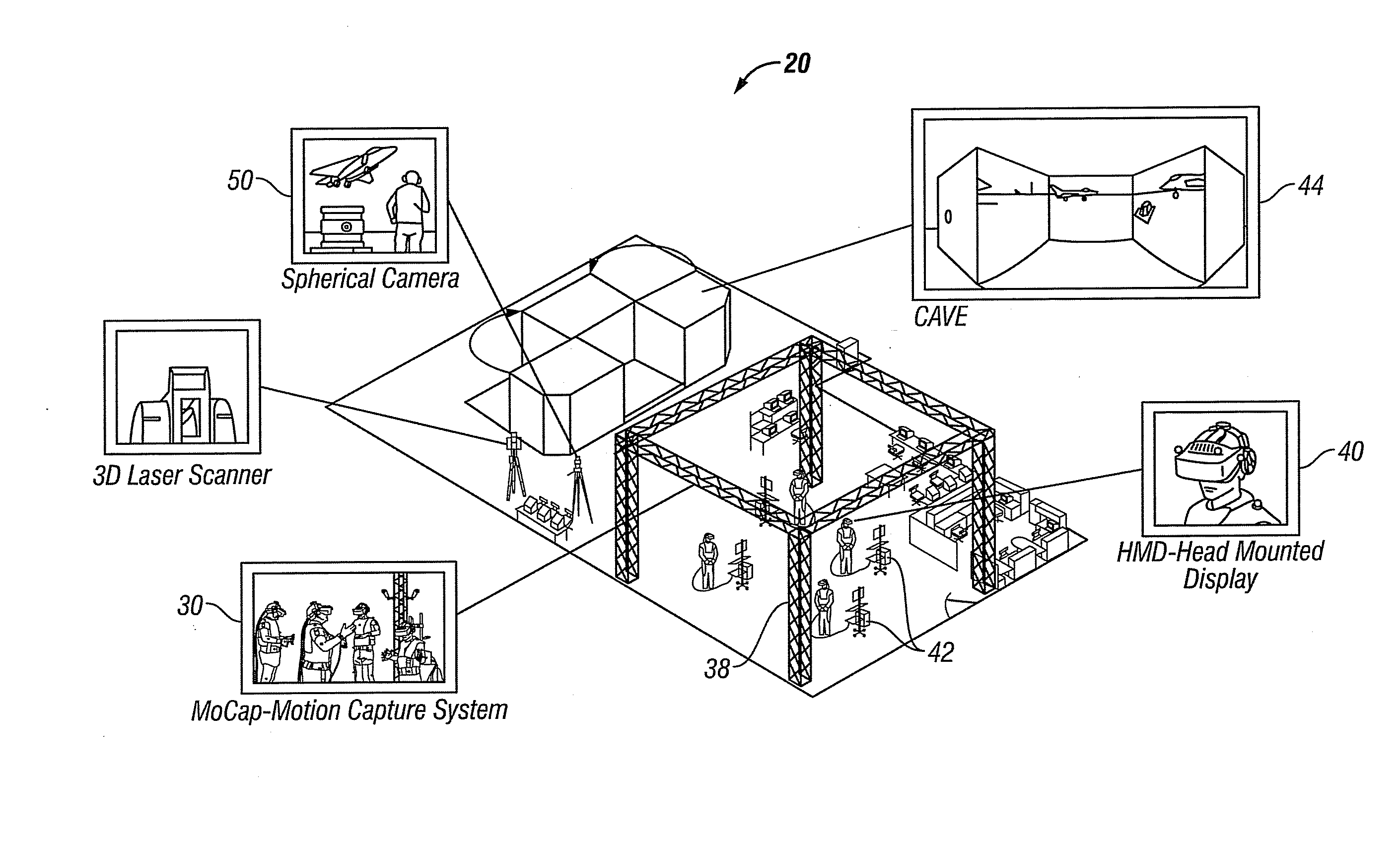

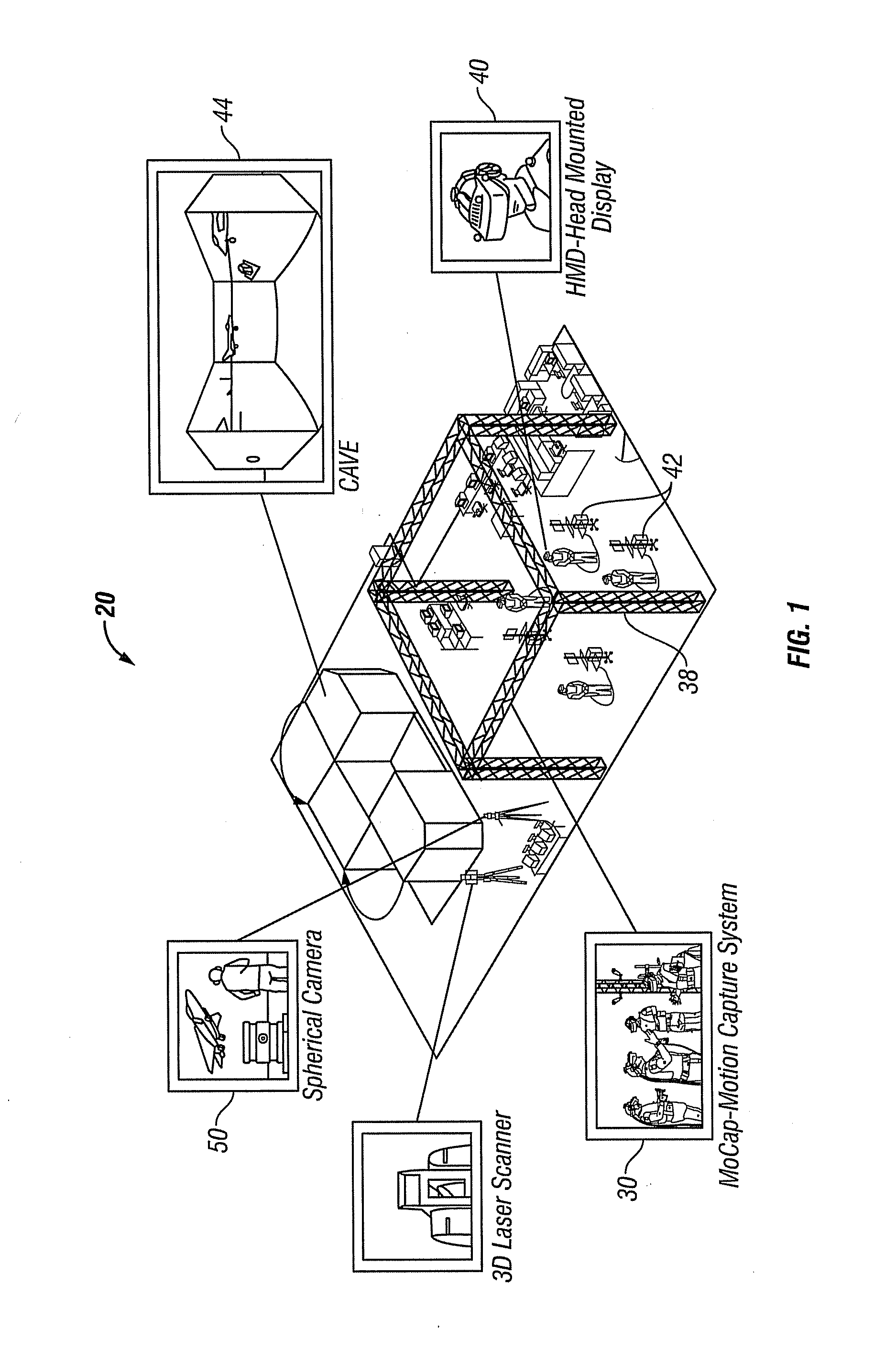

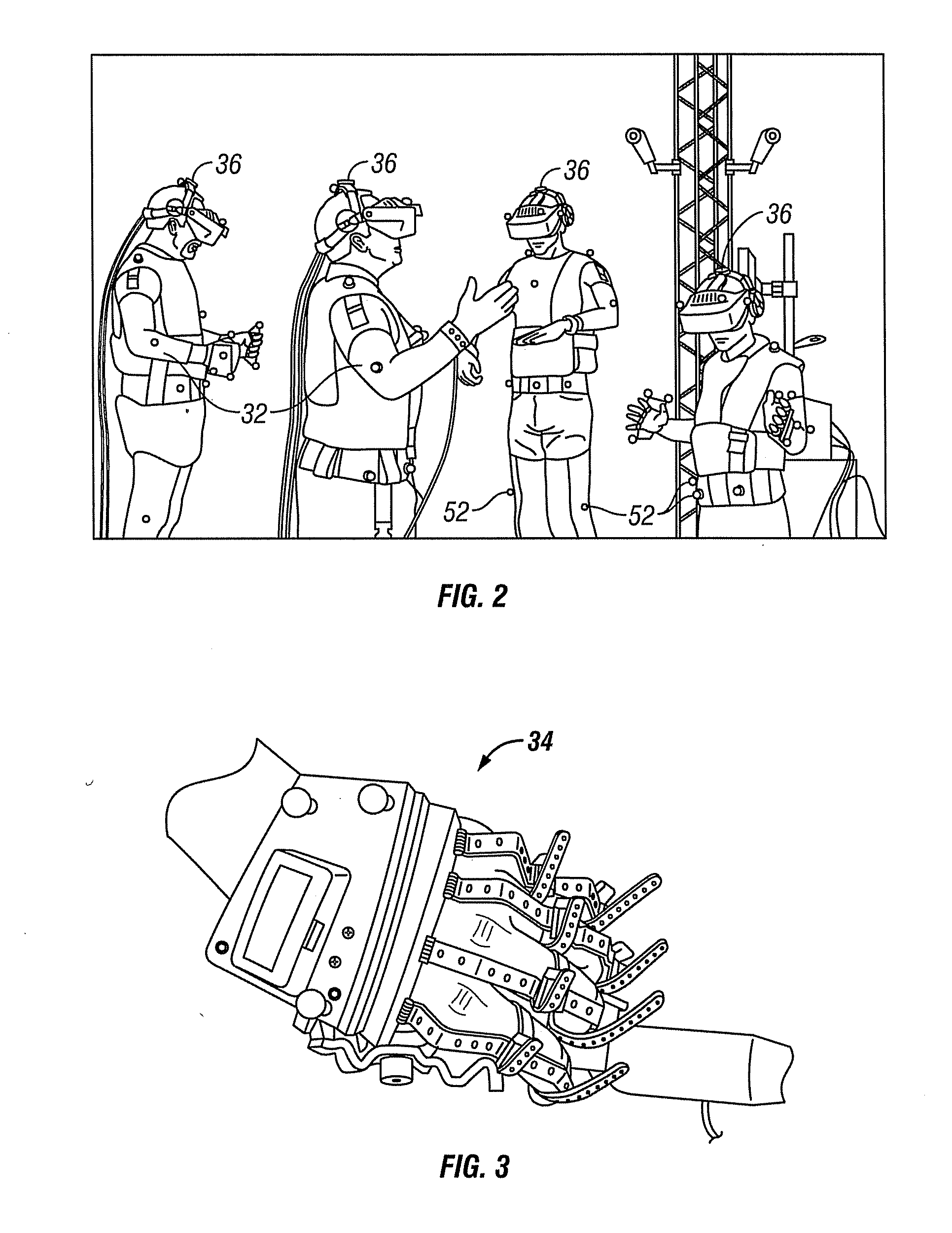

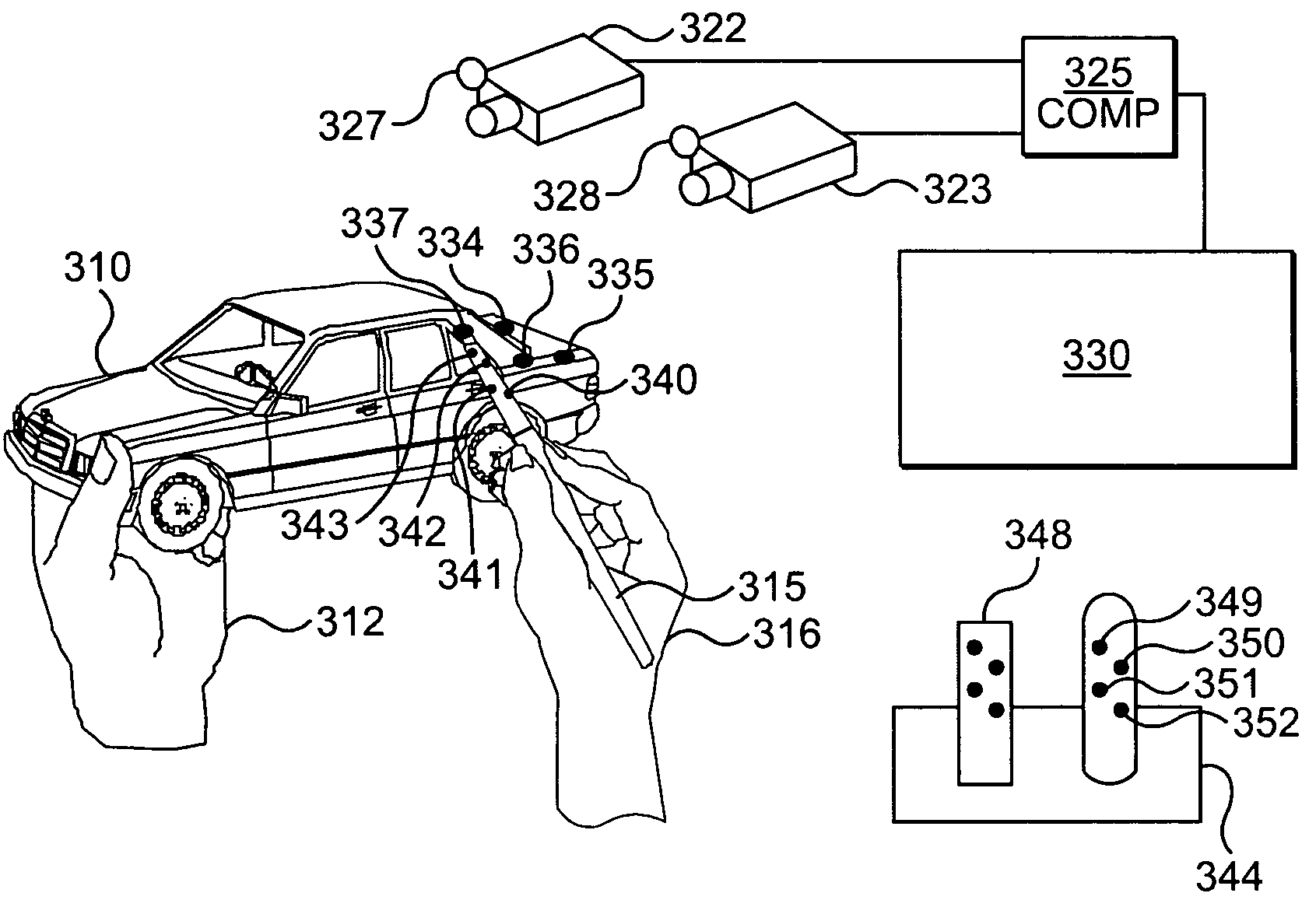

Immersive Collaborative Environment Using Motion Capture, Head Mounted Display, and Cave

ActiveUS20090187389A1Cathode-ray tube indicatorsSpecial data processing applicationsComputer Aided DesignKinematics

A collaborative visualization system integrates motion capture and virtual reality, along with kinematics and computer-aided design (CAD), for the purpose, for example, of evaluating an engineering design. A virtual reality simulator creates a full-scale, three-dimensional virtual reality simulation responsive to computer-aided design (CAD) data. Motion capture data is obtained from users simultaneously interacting with the virtual reality simulation. The virtual reality simulator animates in real time avatars responsive to motion capture data from the users. The virtual reality simulation, including the interactions of the one or more avatars and also objects, is displayed as a three-dimensional image in a common immersive environment using one or more head mounted displays so that the users can evaluate the CAD design to thereby verify that tasks associated with a product built according to the CAD design can be performed by a predetermined range of user sizes.

Owner:LOCKHEED MARTIN CORP

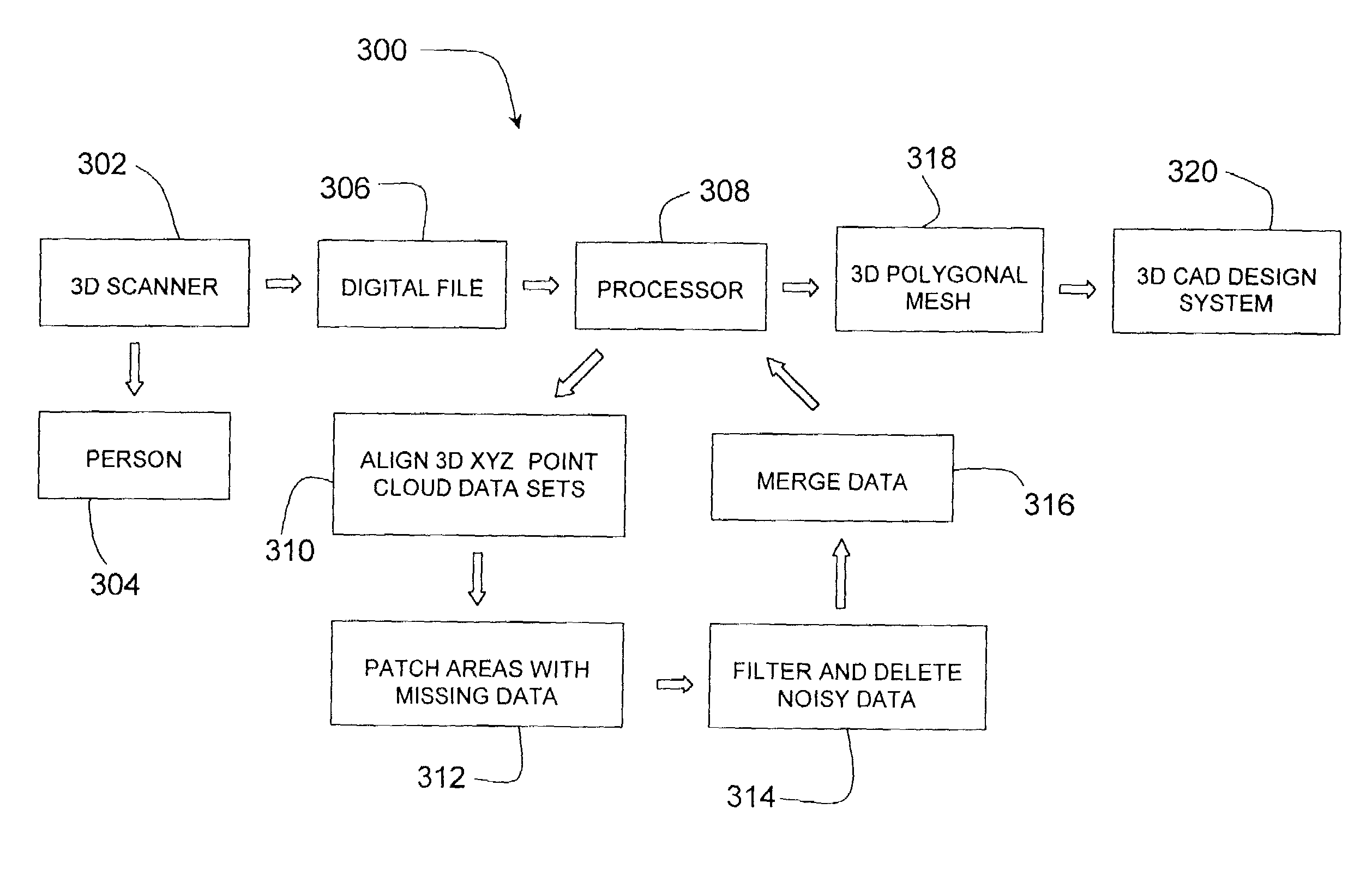

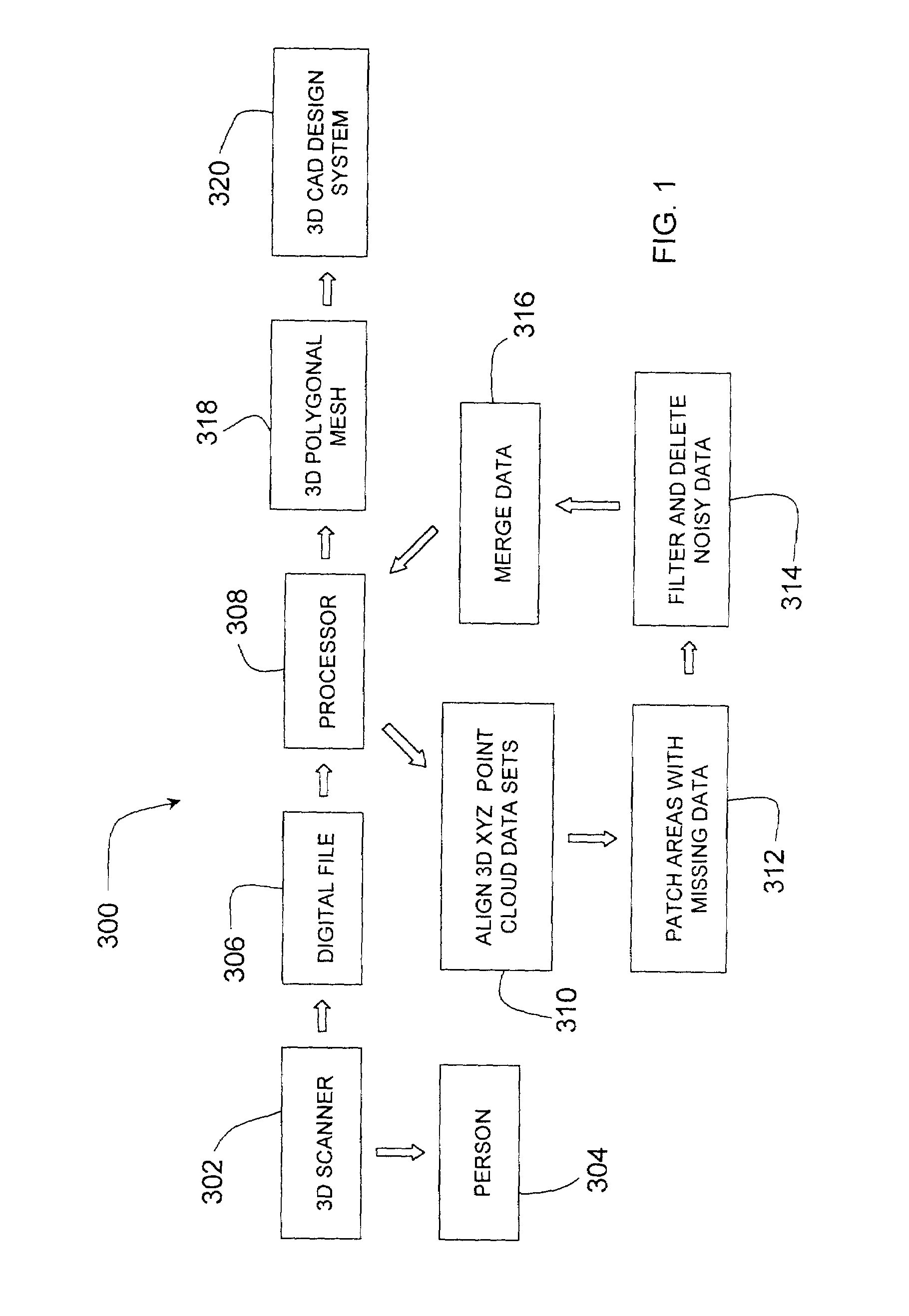

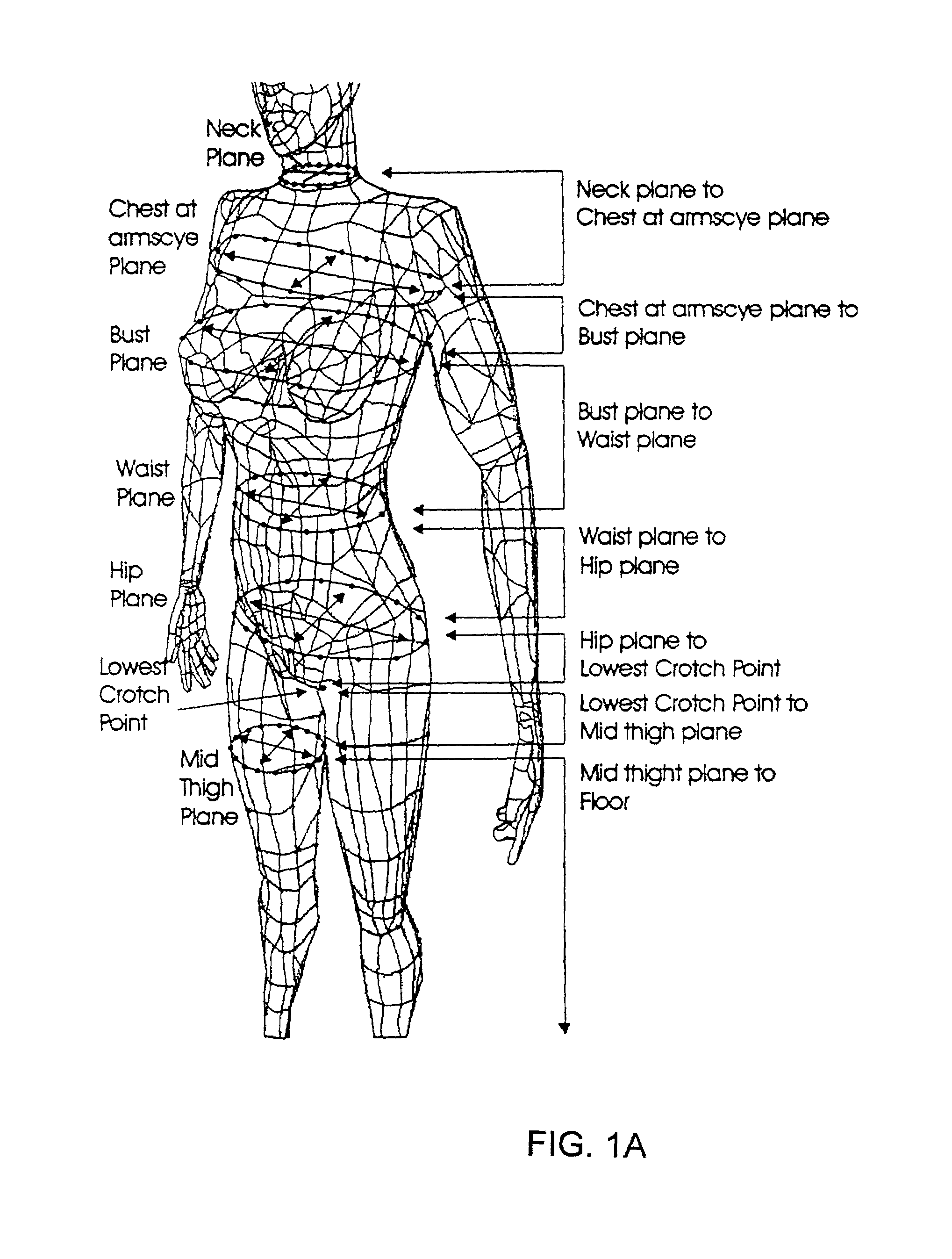

System and method for three-dimensional shape and size measurement

InactiveUS6968075B1Accurate measurementData augmentationData processing applicationsSpecial data processing applicationsComputer Aided DesignSize measurement

A method for three-dimensional shape and size measurement of a three-dimensional body surface comprising providing a three-dimensional scanner, providing a processor, providing a three-dimensional Computer Aided Design system, scanning in three dimensions with the three-dimensional scanner at least a portion of the three-dimensional body surface, creating a data file representative of the three-dimensional body surface, processing the data file with the processor, importing the data file into the three-dimensional Computer Aided Design System, employing the three-dimensional Computer Aided Design System relative to the data file to define and record three-dimensional measuring data relative to at least a portion of the three-dimensional body surface, A and employing the three-dimensional Computer Aided Design System to exploit the three-dimensional measuring data.

Owner:CHANG KURT C

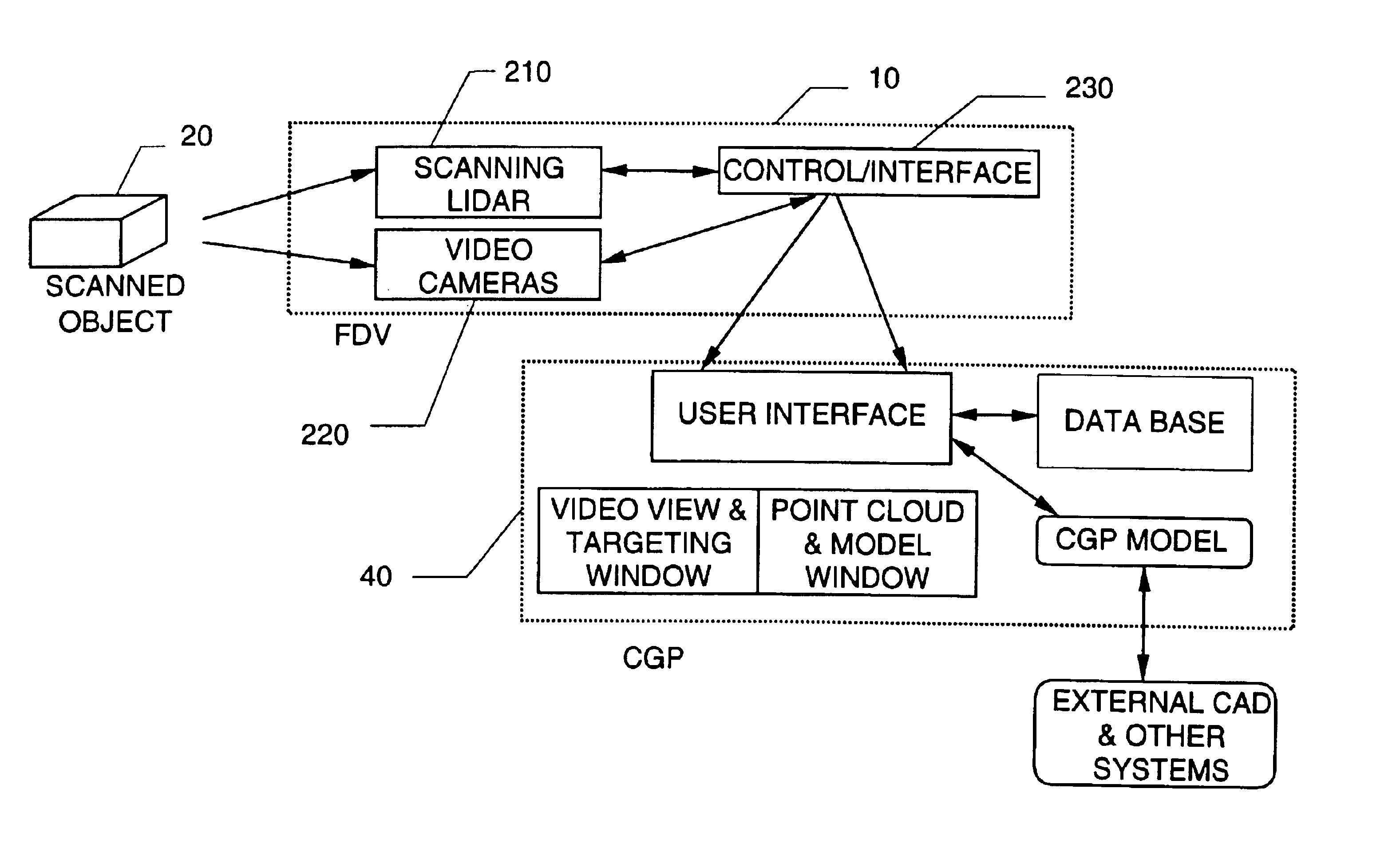

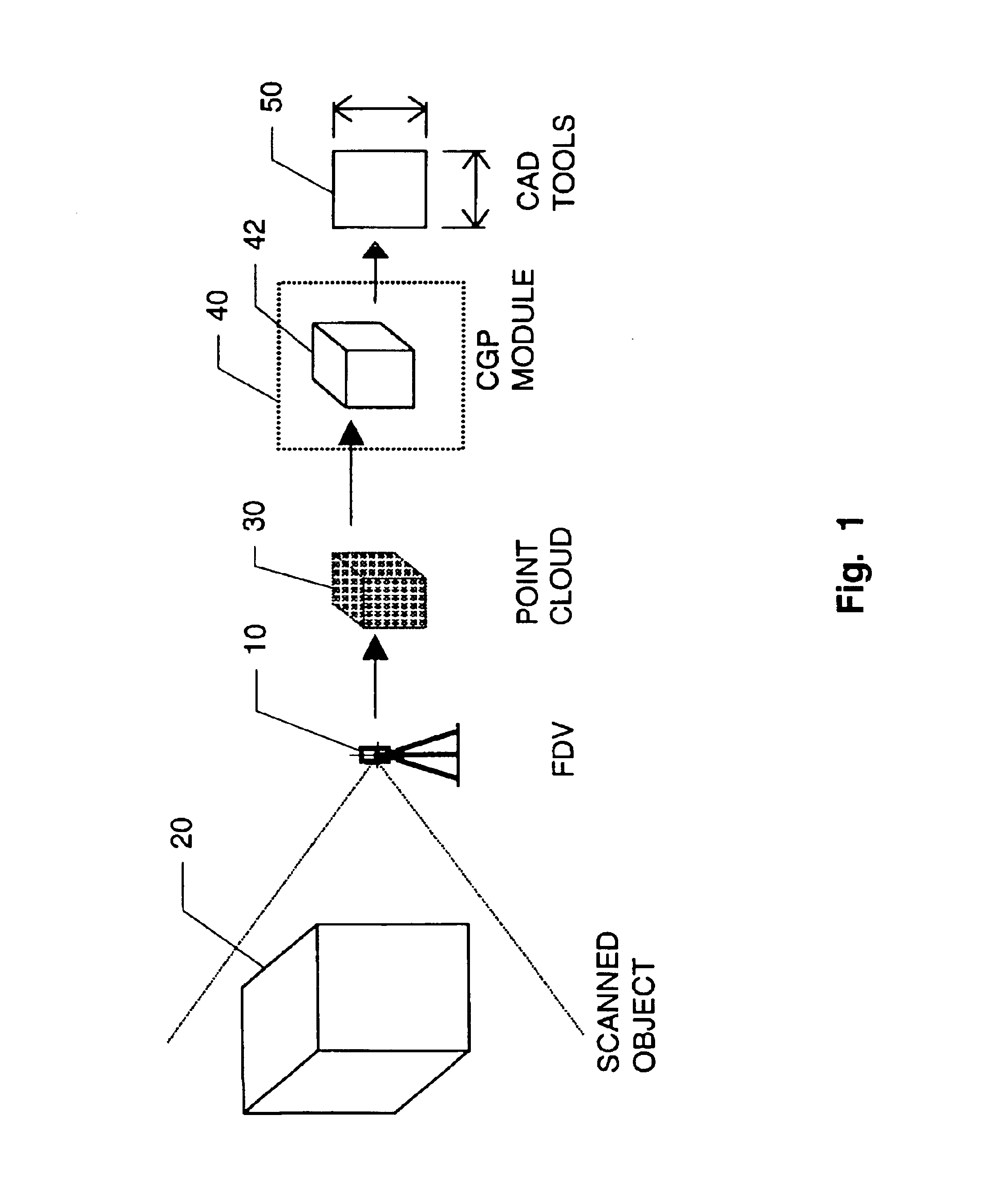

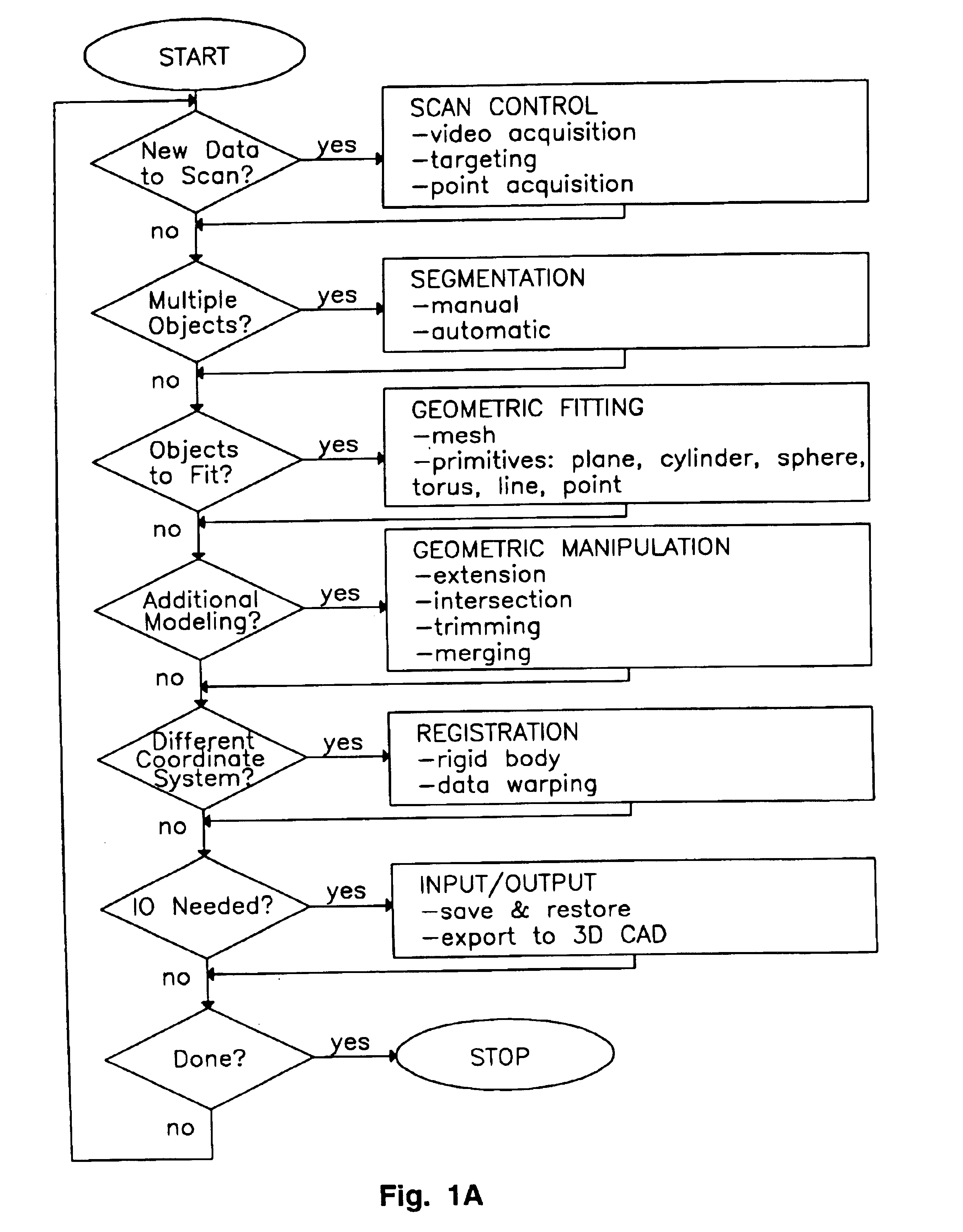

Integrated system for quickly and accurately imaging and modeling three-dimensional objects

InactiveUS6847462B1Improve fitOptical rangefindersBeam/ray focussing/reflecting arrangementsComputer Aided DesignPoint cloud

An integrated system generates a model of a three-dimensional object. A scanning laser device scans the three-dimensional object and generates a point cloud. The points of the point cloud each indicate a location of a corresponding point on a surface of the object. A first model is generated, responsive to the point cloud, that generates a first model representing constituent geometric shapes of the object. A data file is generated, responsive to the first model, that can be inputted to a computer-aided design system.

Owner:LEICA GEOSYSTEMS AG

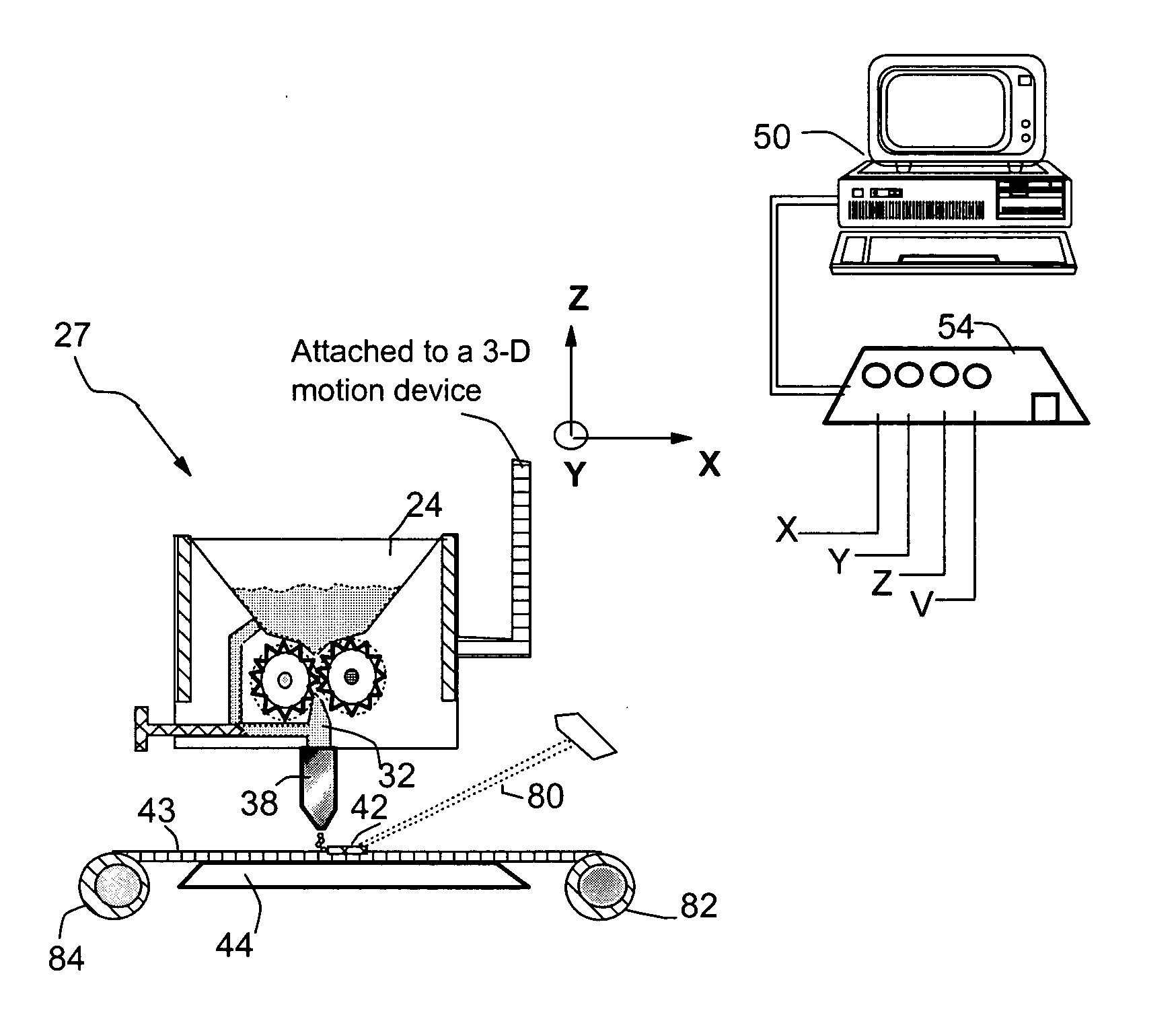

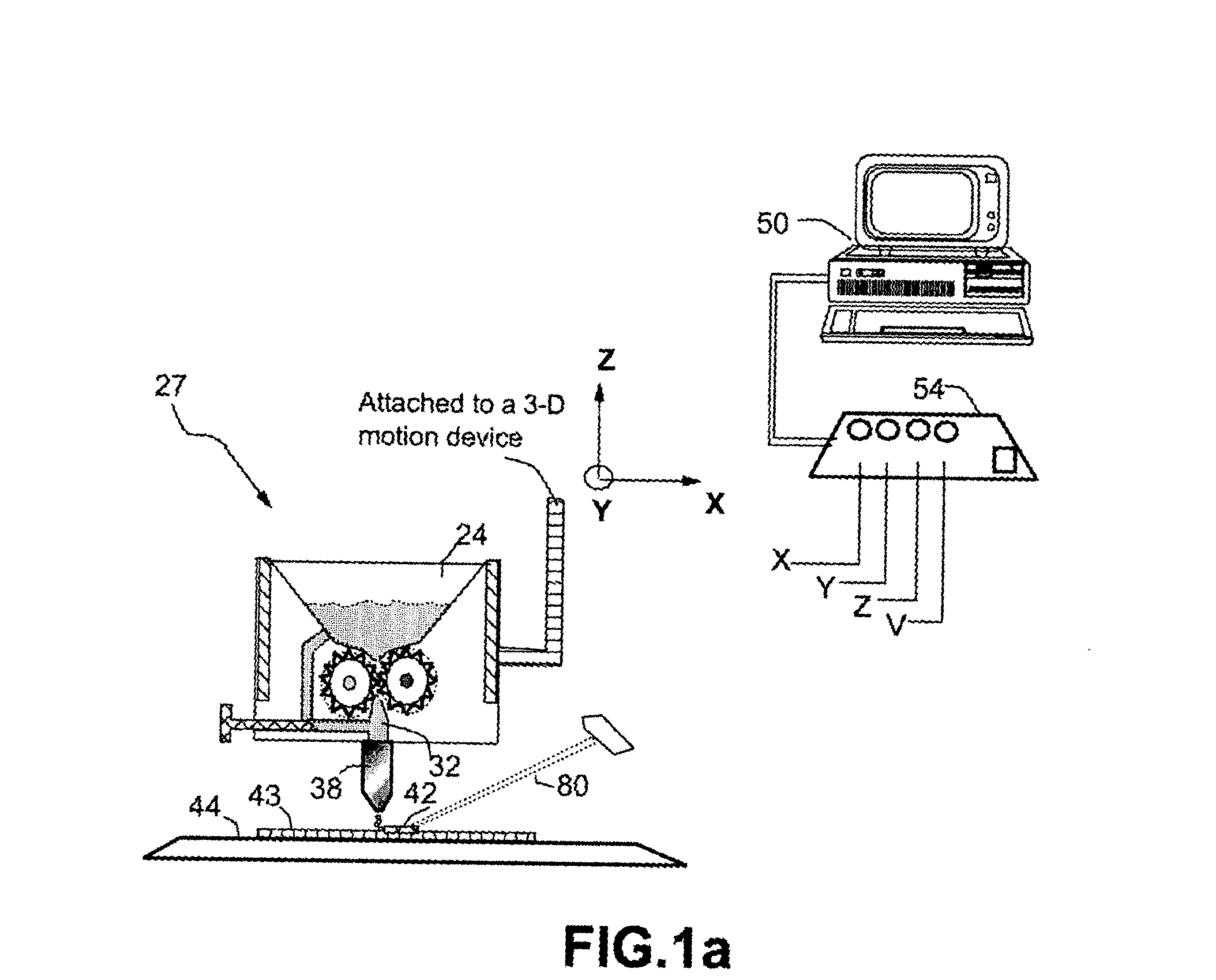

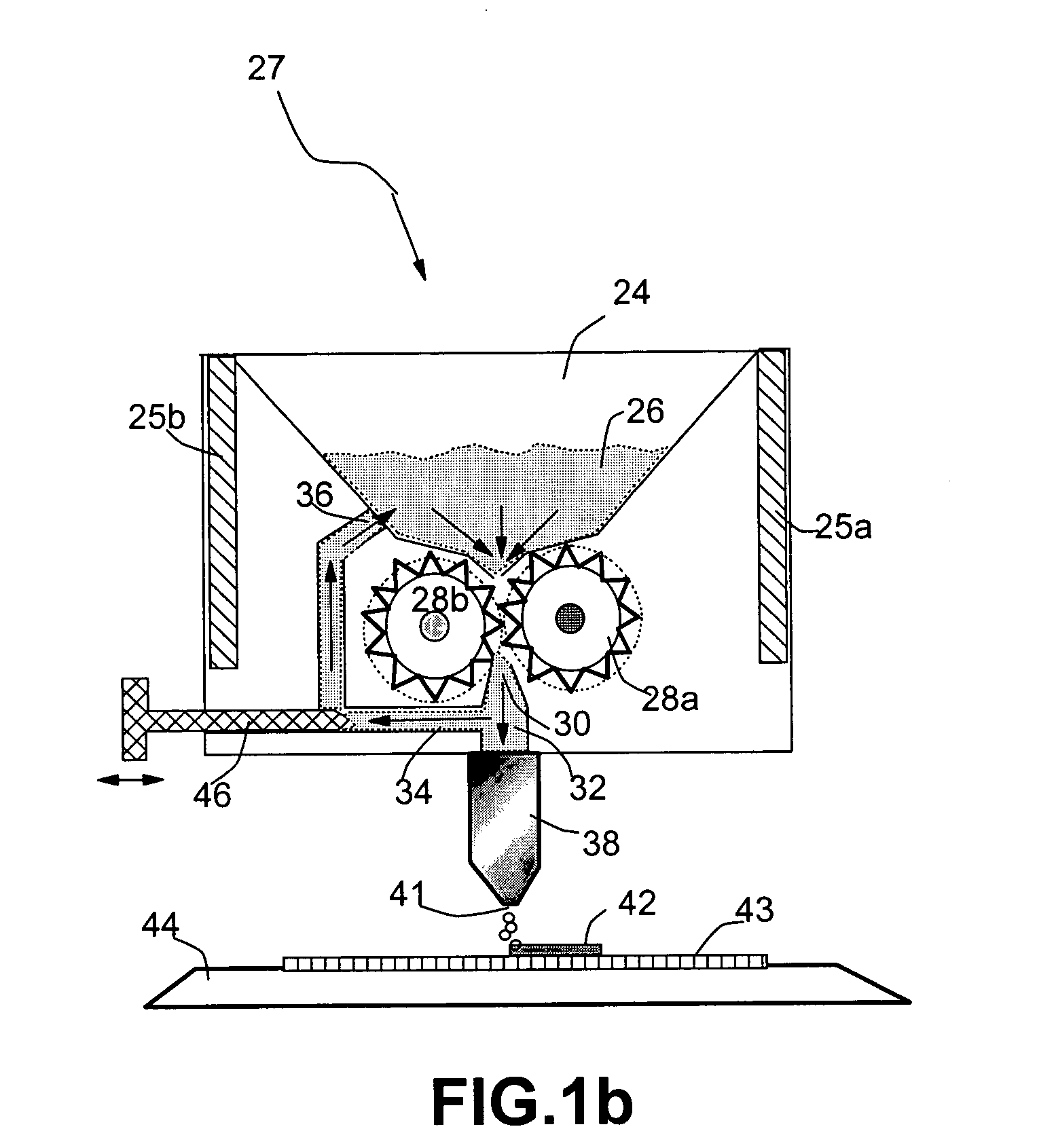

Direct write process and apparatus

ActiveUS20050015175A1Fast preparationIncrease back pressureRecording apparatusAdditive manufacturing apparatusDielectricControl signal

A direct write process and apparatus for fabricating a desired circuit component onto a substrate surface of a microelectronic device according to a computer-aided design (CAD). The process includes (a) providing a support member by which the device is supported while being fabricated; (b) providing a chamber for containing a precursor fluid material under a substantially constant pressure differential relative to the ambient pressure, with the precursor fluid material having a viscosity no less than 10 cps; (c) operating an inkjet-based dispensing head with a control valve or actuator for dispensing and depositing minute droplets of the precursor fluid material onto the substrate surface; (d) energy- or heat-treat the deposited precursor fluid material for converting it to the desired active or passive component; and (e) operating a machine controller for generating control signals in response to the CAD coordinates for controlling the position of the dispensing head relative to the support member in response to the control signals to control dispensing and depositing of the precursor material to form the desired component. The process is useful for depositing a wide range of component materials onto an electronic device, including conductor, resistor, capacitor, dielectric, inductor, antenna, solar cell electrode, battery electrode, interconnect, superconductor, sensor, and actuator element materials.

Owner:NANOTEK INSTR GRP LLC

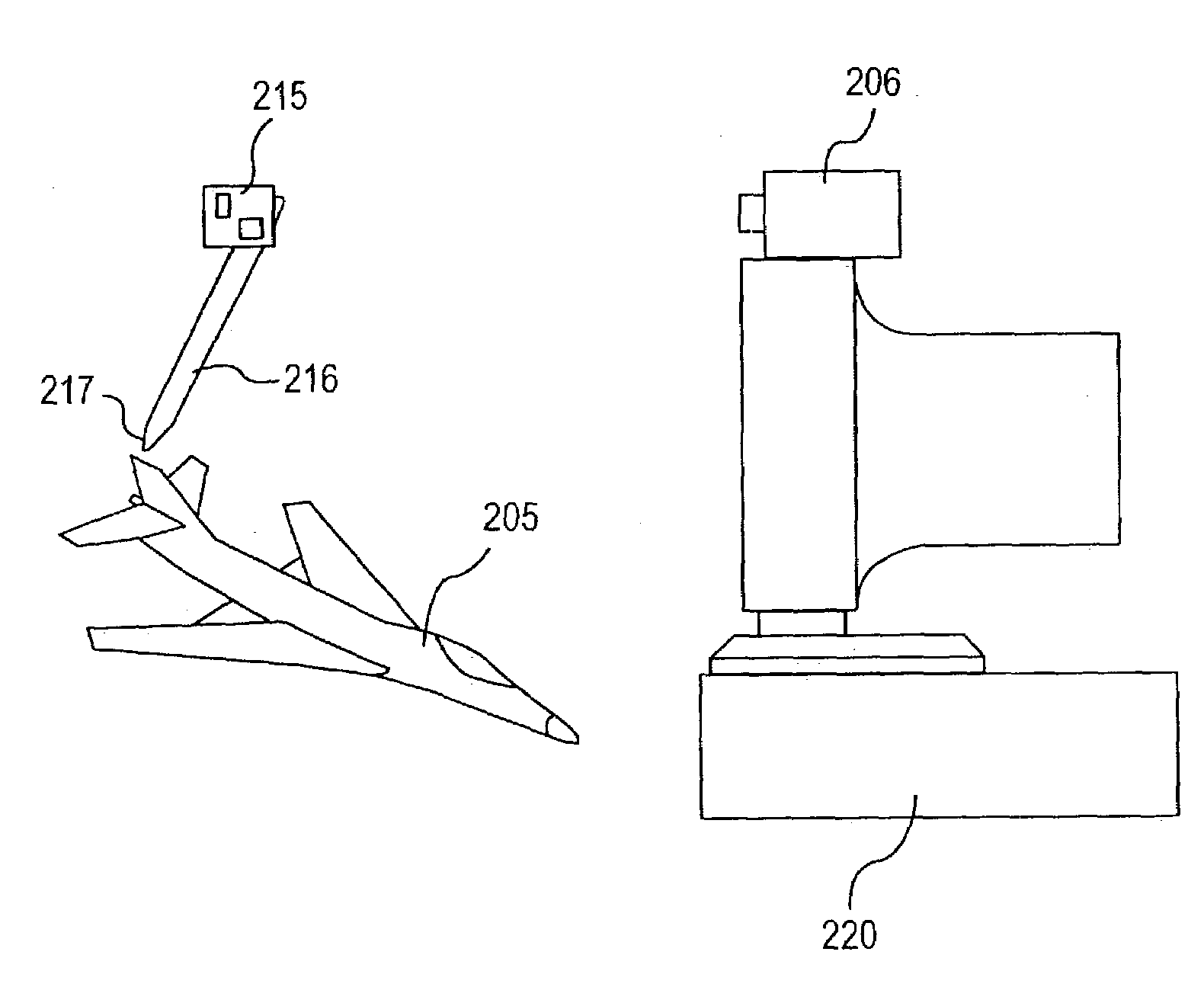

Novel man machine interfaces and applications

InactiveUS20060202953A1Good adhesionIncrease brightnessInput/output for user-computer interactionElectrophonic musical instrumentsComputer Aided DesignHuman–machine interface

Affordable methods and apparatus are disclosed for inputting position, attitude (orientation) or other object characteristic data to computers for the purpose of Computer Aided Design, Painting, Medicine, Teaching, Gaming, Toys, Simulations, Aids to the disabled, and internet or other experiences. Preferred embodiments of the invention utilize electro-optical sensors, and particularly TV Cameras, providing optically inputted data from specialized datum's on objects and / or natural features of objects. Objects can be both static and in motion, from which individual datum positions and movements can be derived, also with respect to other objects both fixed and moving. Real-time photogrammetry is preferably used to determine relationships of portions of one or more datums with respect to a plurality of cameras or a single camera processed by a conventional PC.

Owner:MOTION GAMES

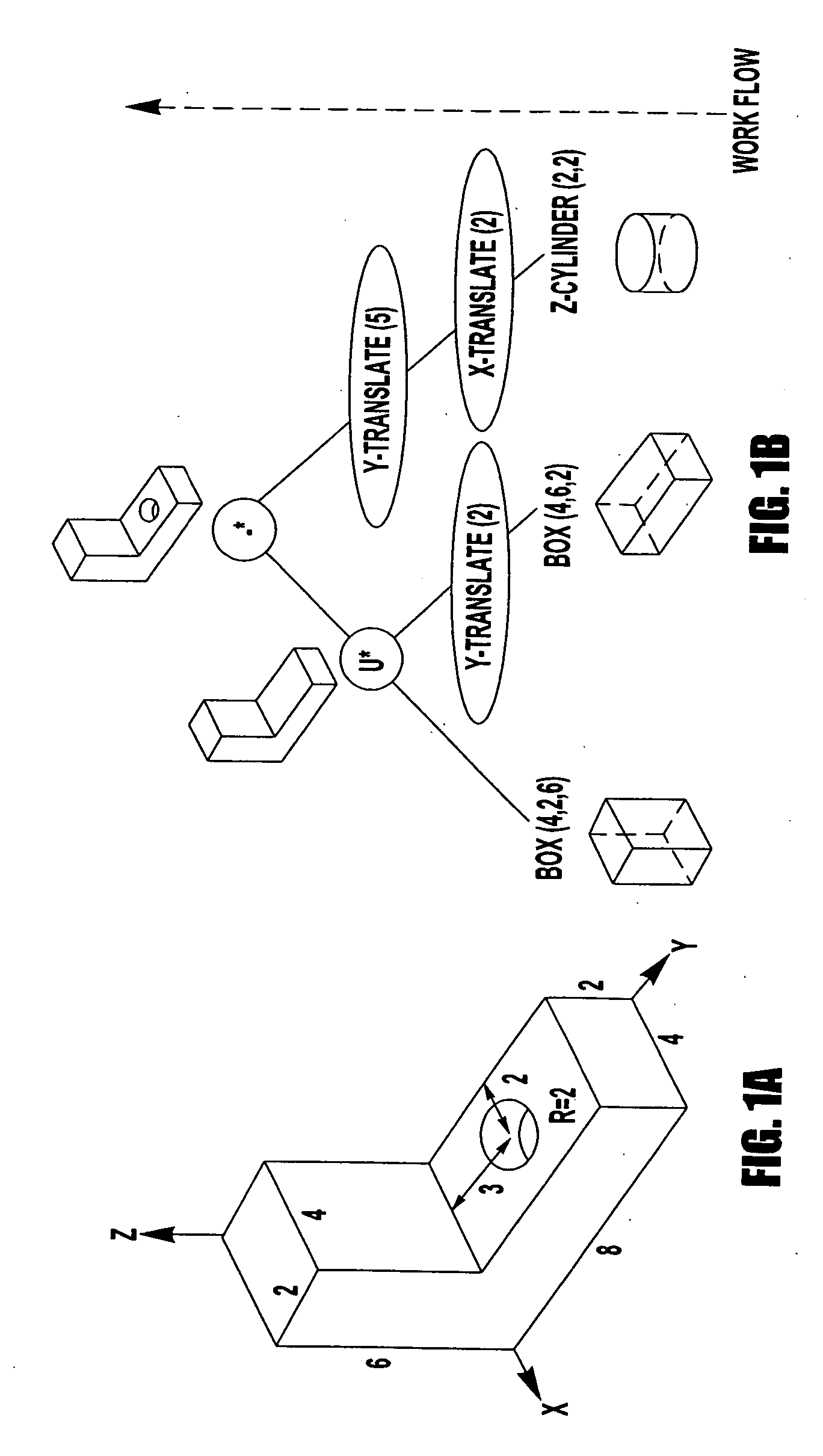

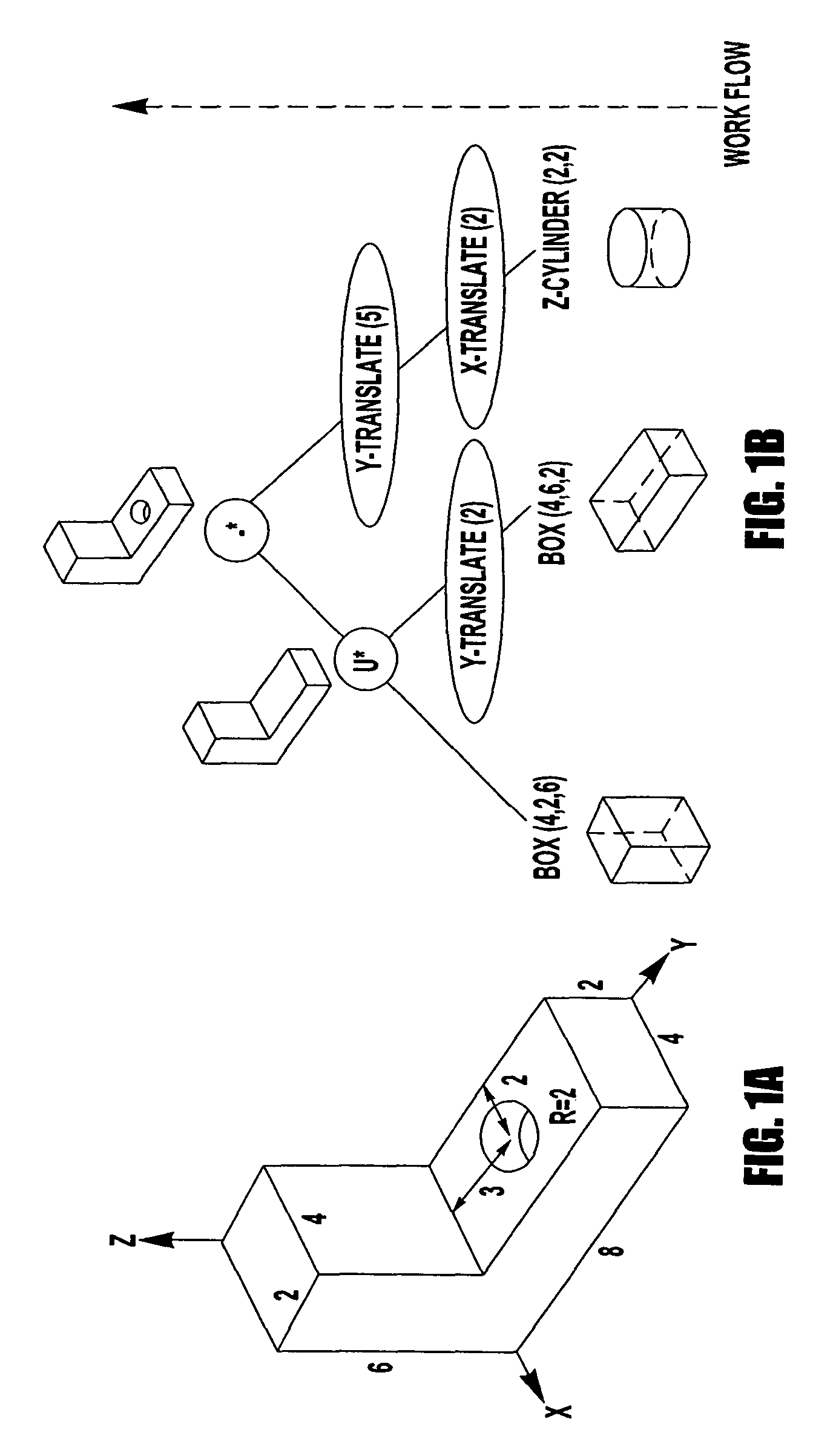

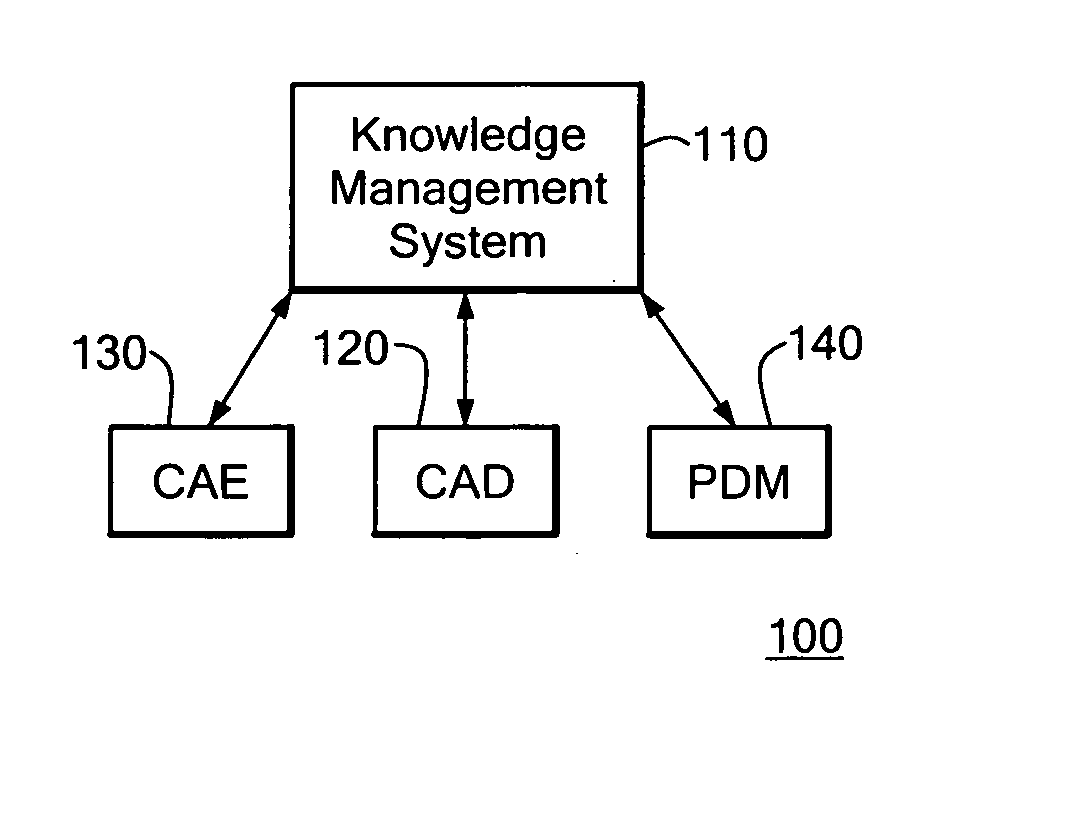

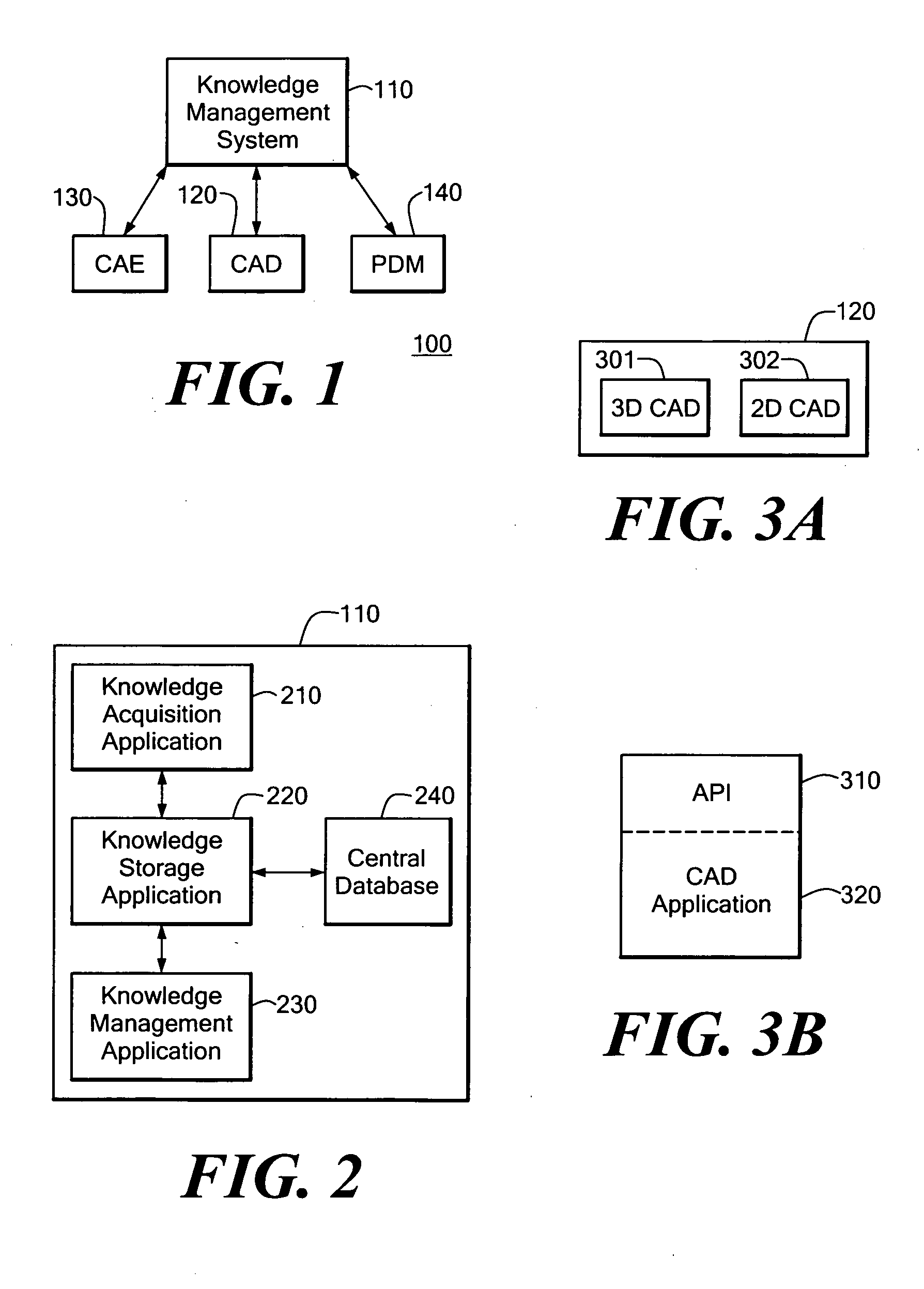

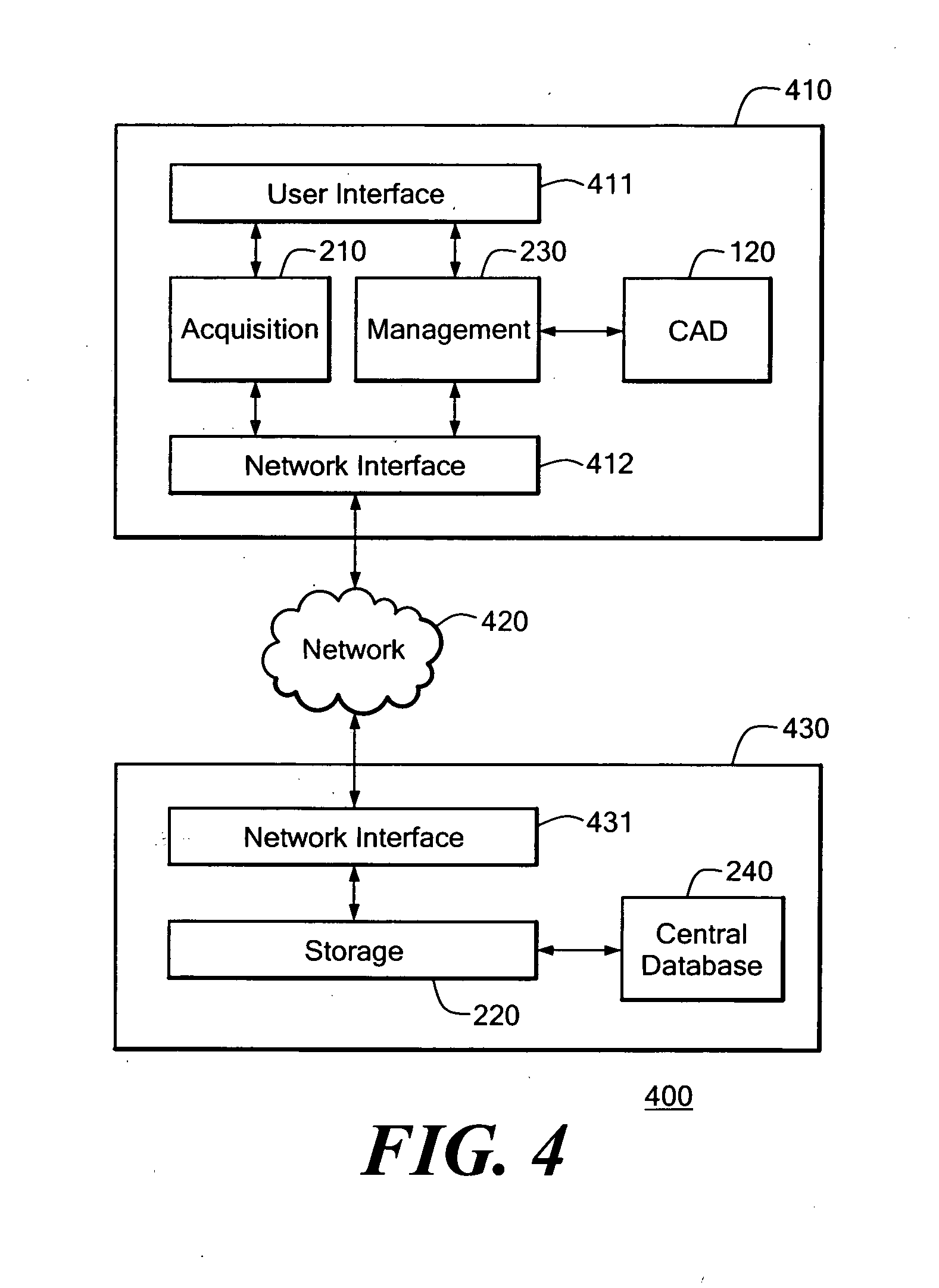

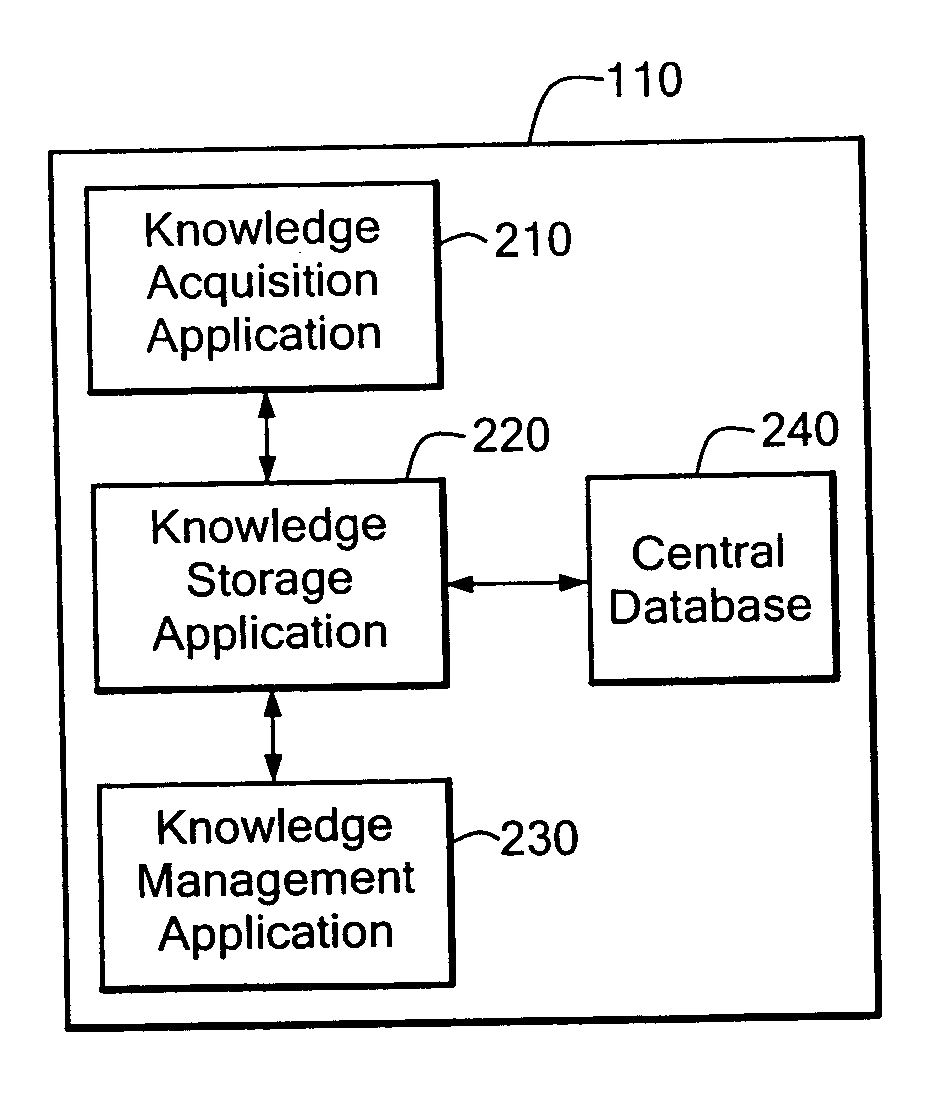

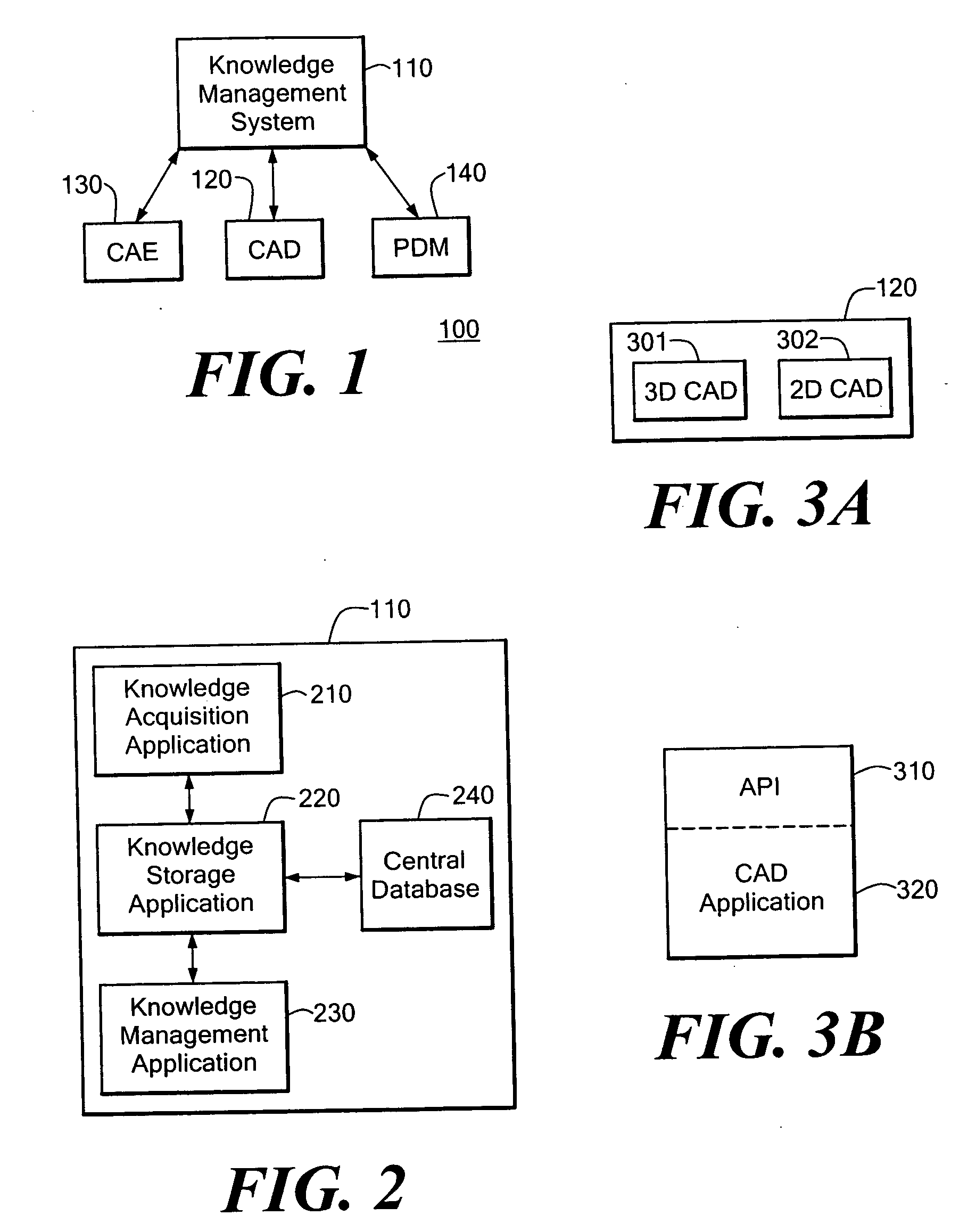

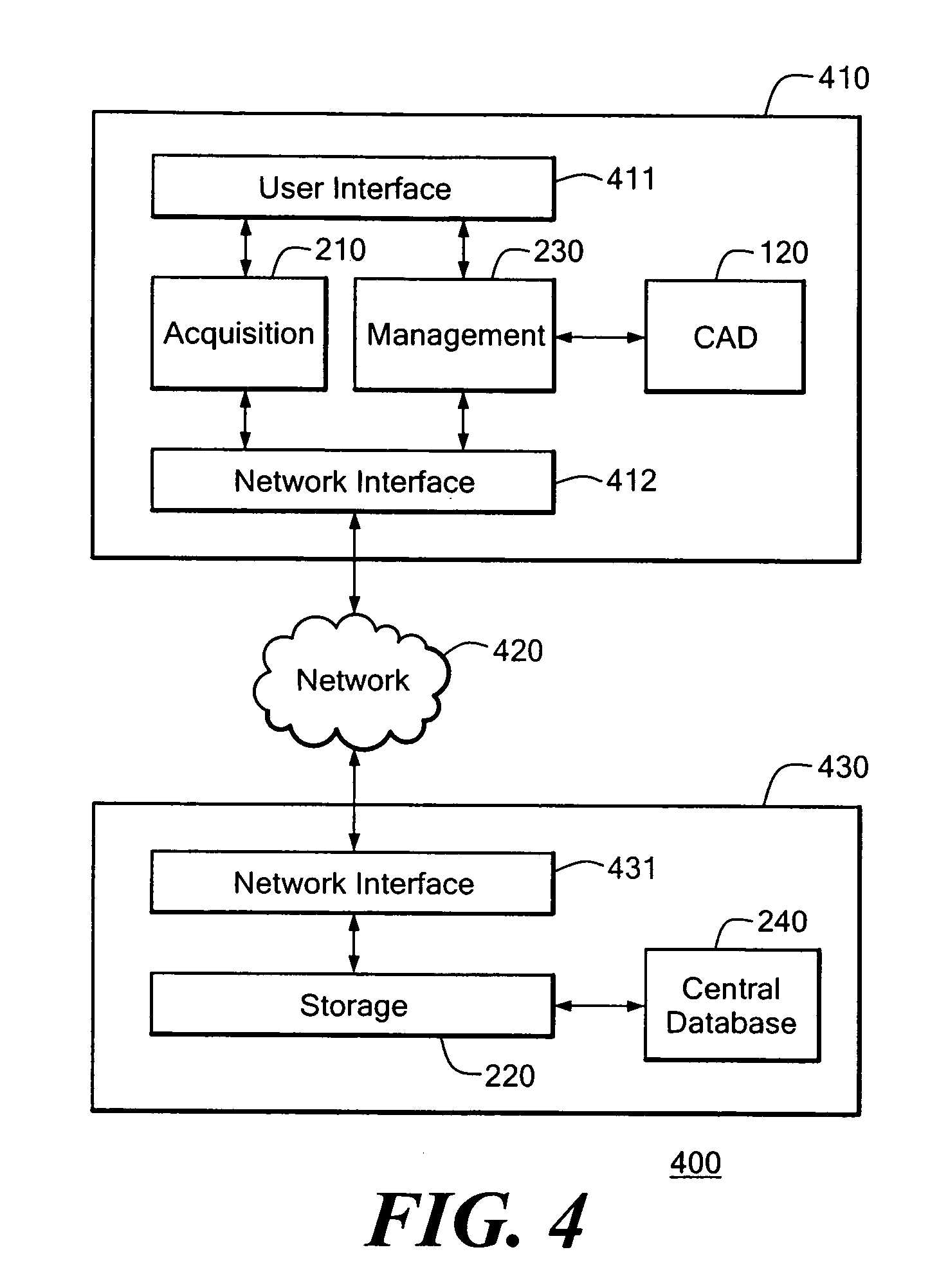

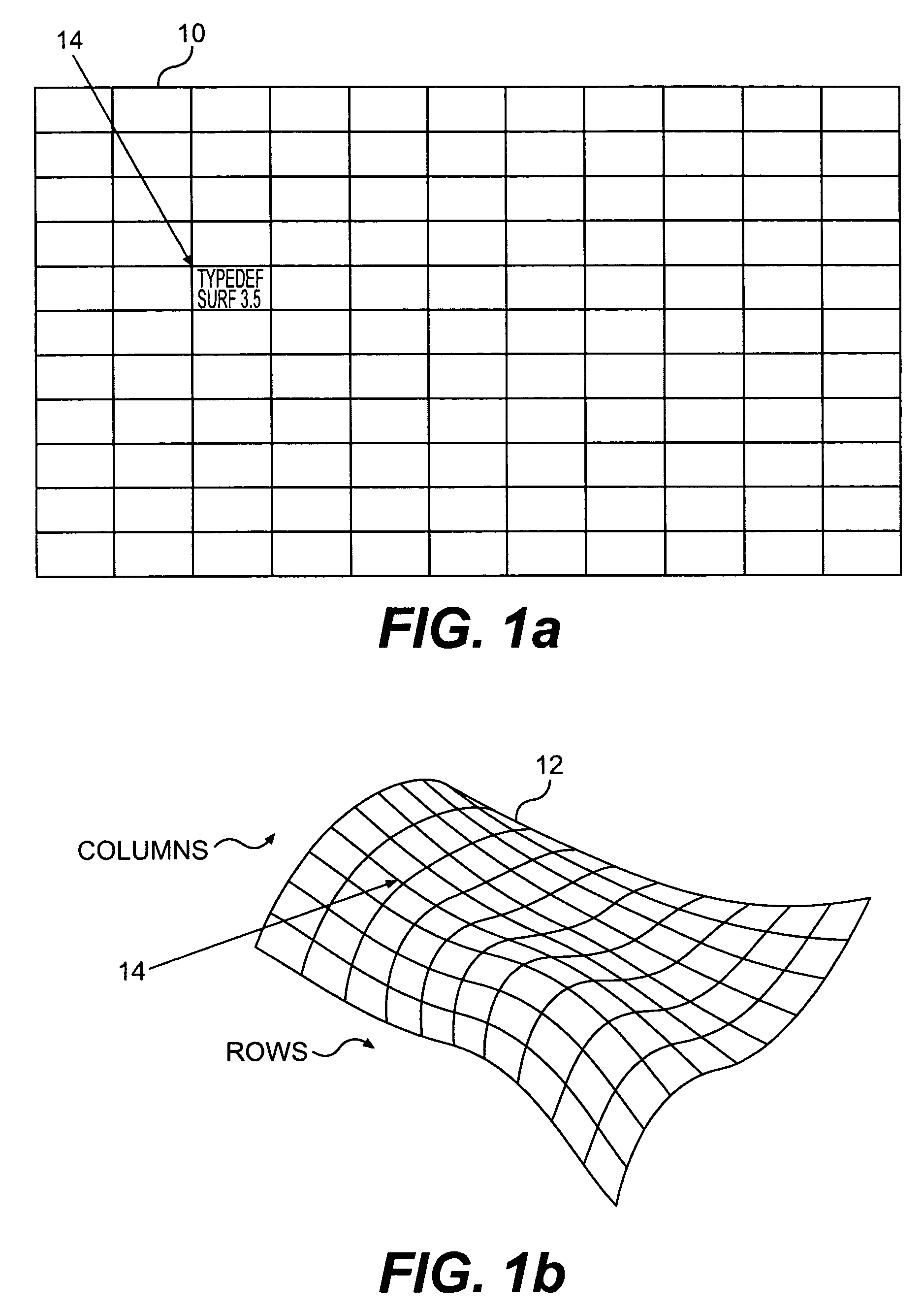

Knowledge management system for computer-aided design modeling

A knowledge management system captures, stores, manages, and applies rules for modeling geometric objects and related non-geometric attributes. The knowledge management system controls a computer-aided design system for modeling a geometric structure. The knowledge management system includes a knowledge management application in communication with the computer-aided design system through an application program interface. The knowledge management system also includes a central database managed by a knowledge storage application for maintaining rules and other related information. The knowledge management system also includes a knowledge acquisition application for generating rule programs for storage in the central database. The rules can relate to geometric and non-geometric attributes of the model.

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

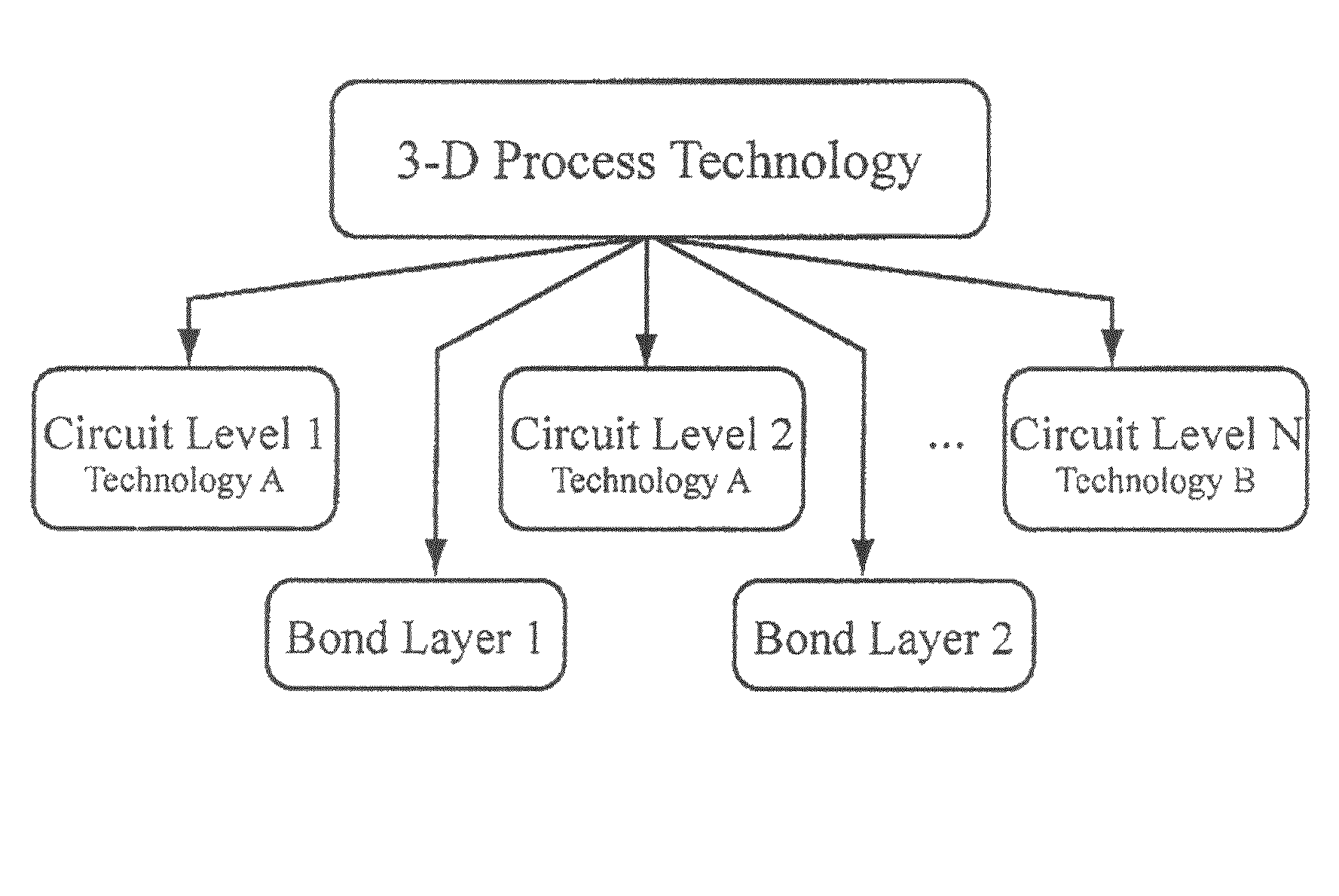

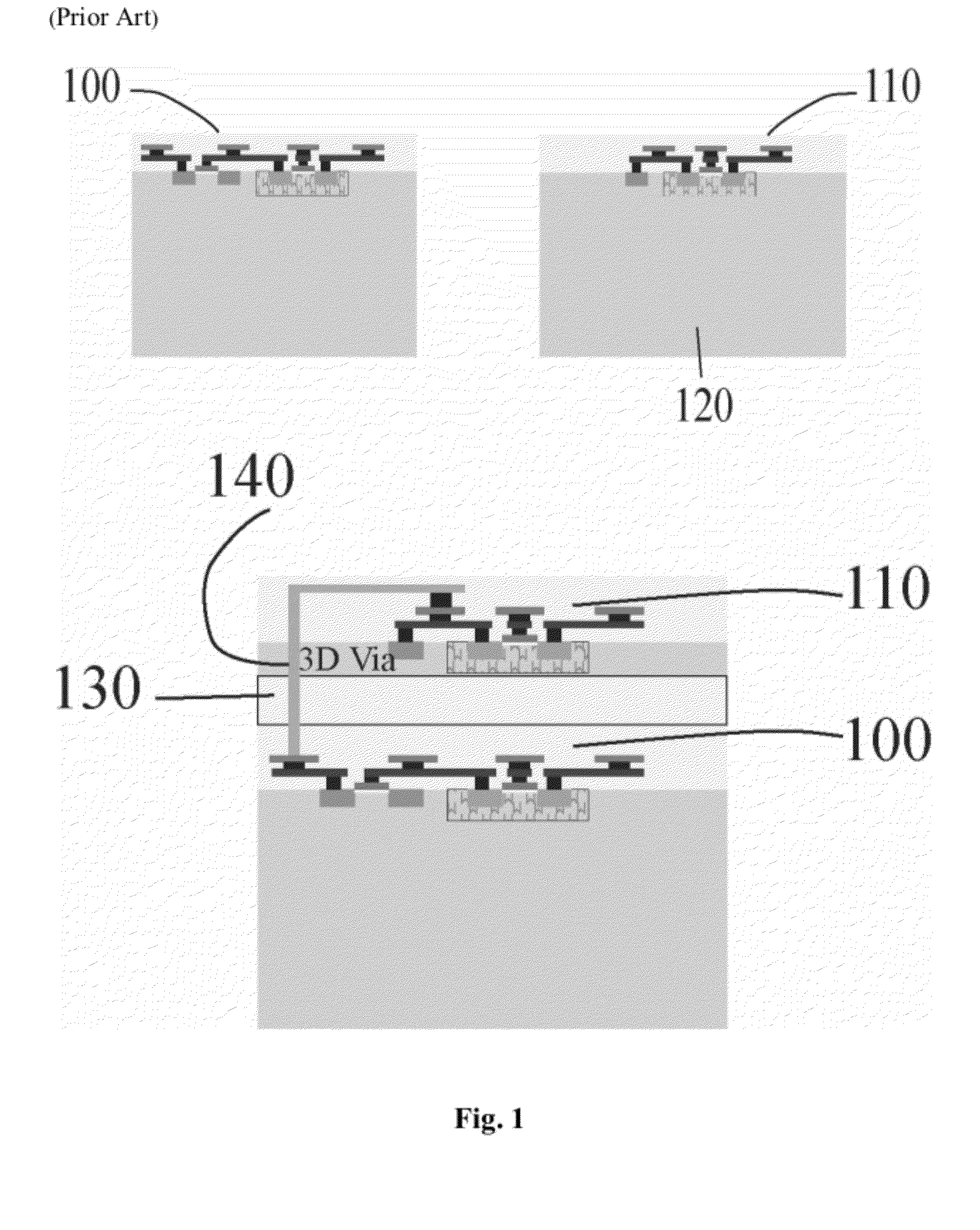

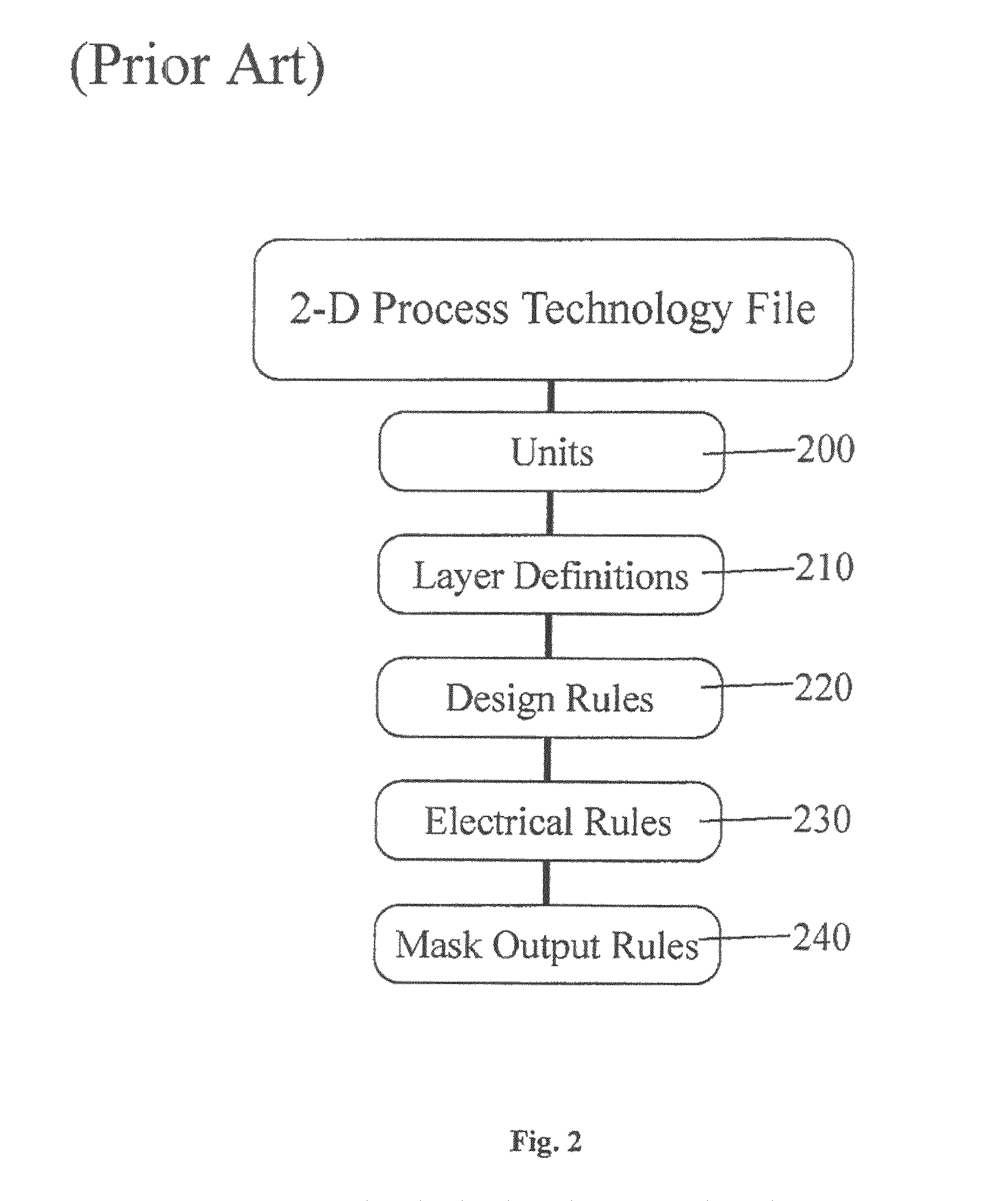

Methods and systems for computer aided design of 3D integrated circuits

ActiveUS8209649B2Computer programmed simultaneously with data introductionCAD circuit design3d integrated circuitComputer Aided Design

Owner:R3 LOGIC

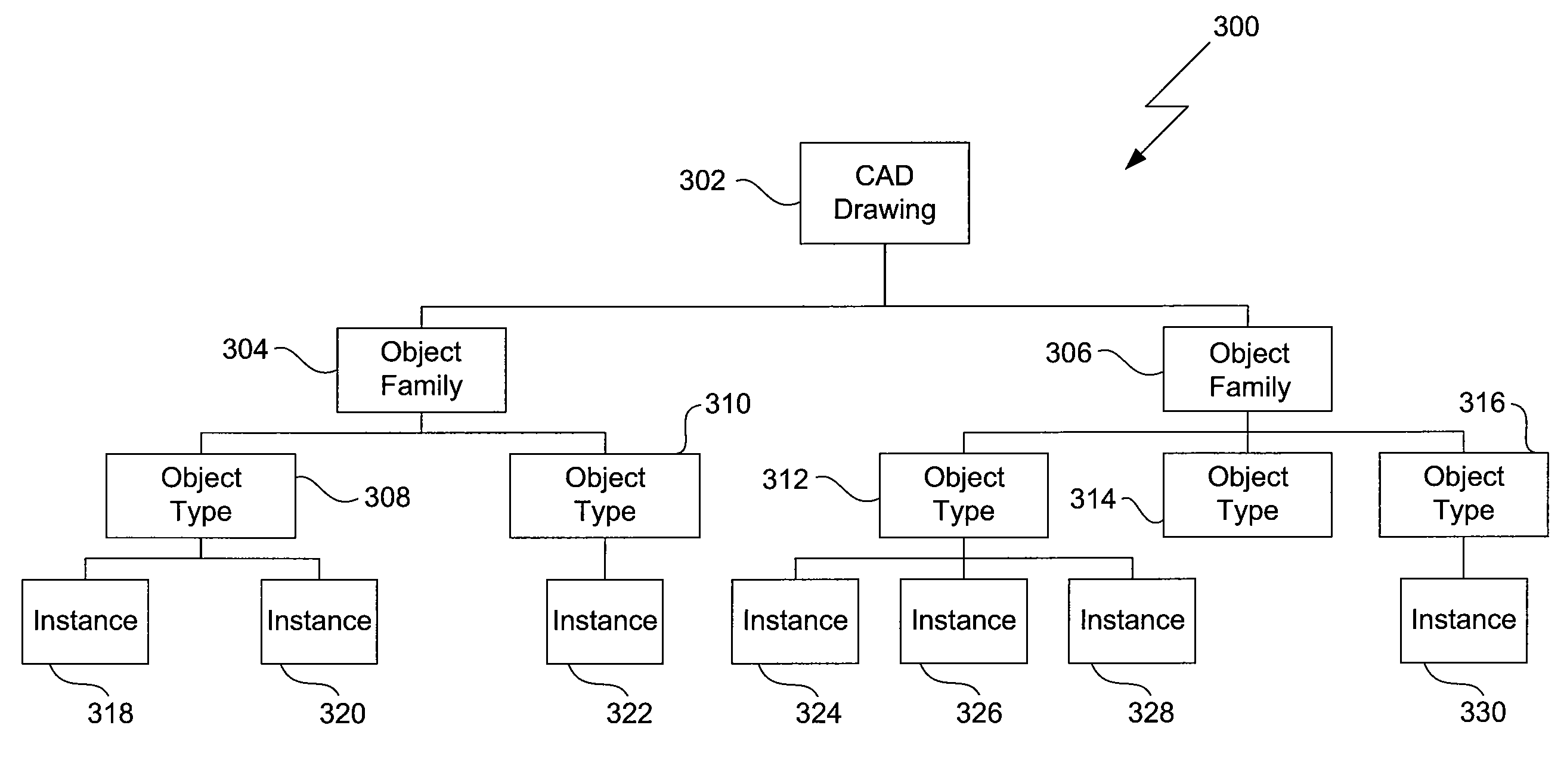

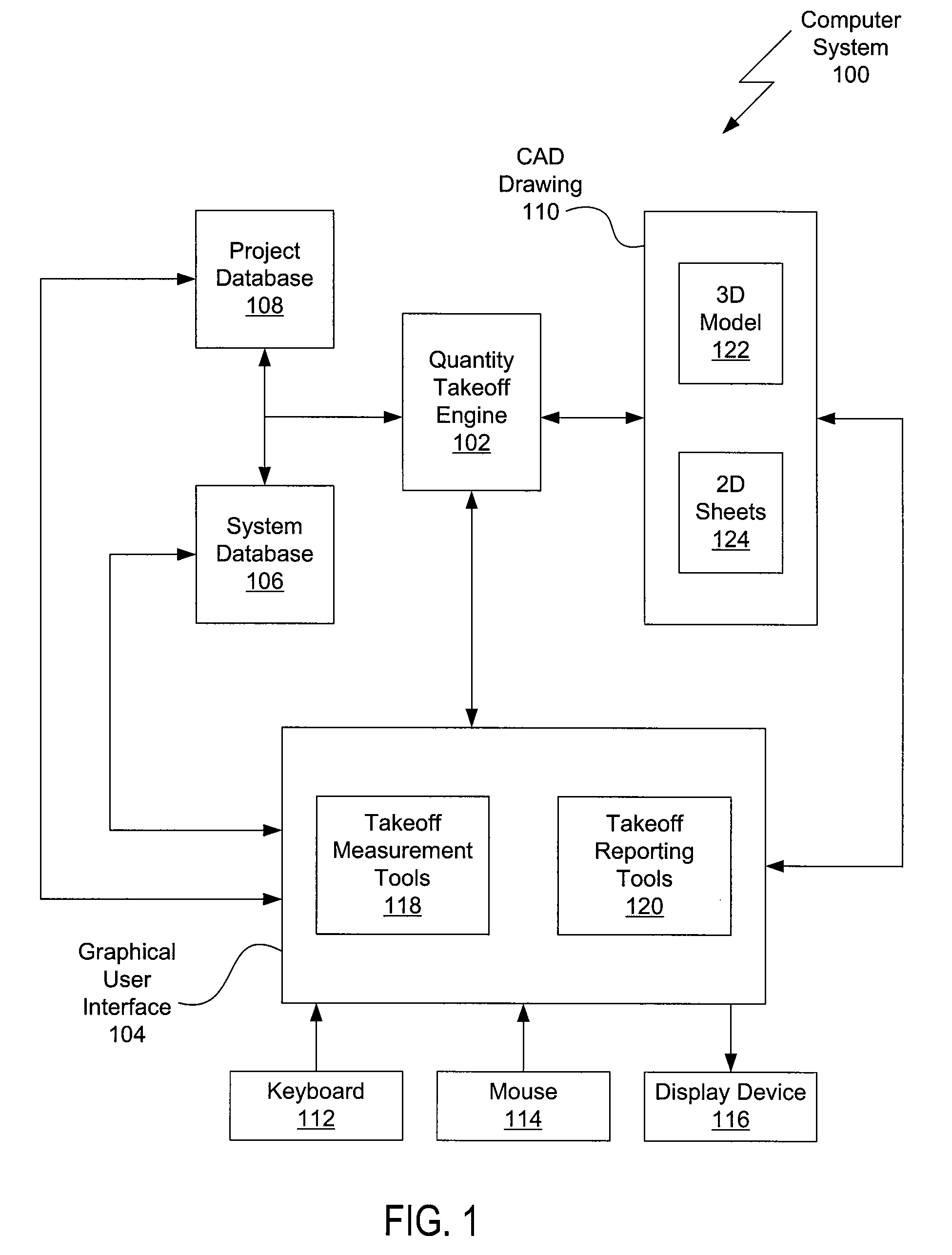

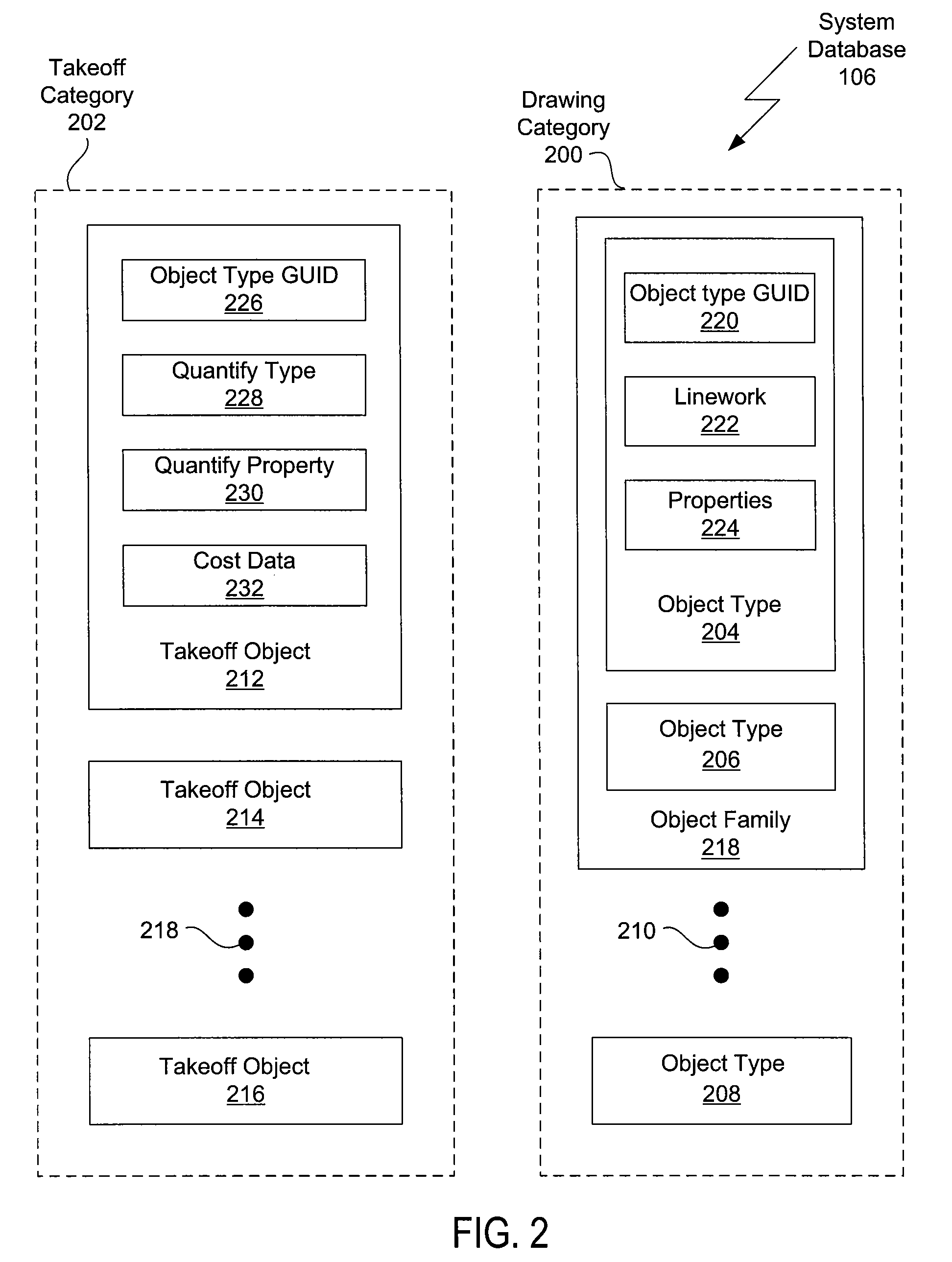

Selective quantity takeoff from computer aided design drawings

ActiveUS20090240730A1Estimated costQuickly and easily costObject oriented databasesSpecial data processing applicationsComputer Aided DesignApplication software

One embodiment of the invention sets forth a CAD application configured to perform quantity takeoff computations. The CAD application is further configured to organize a CAD drawing into a hierarchical representation of object families and associated object types, where instances of the object types represent drawing objects present in the CAD drawing. The CAD application is further configured to receive a selection of an object family and to parse the selection to determine the object types associated with the selection. The CAD application then creates a takeoff object for each of the object types associated with the selection and identifies instances, associated with object properties, of each of the object types of the selection. The CAD application quantifies the instances and associated properties to produce a quantity takeoff value. Advantageously, users are able to more quickly and easily estimate the cost of a design project associated with the CAD drawing.

Owner:AUTODESK INC

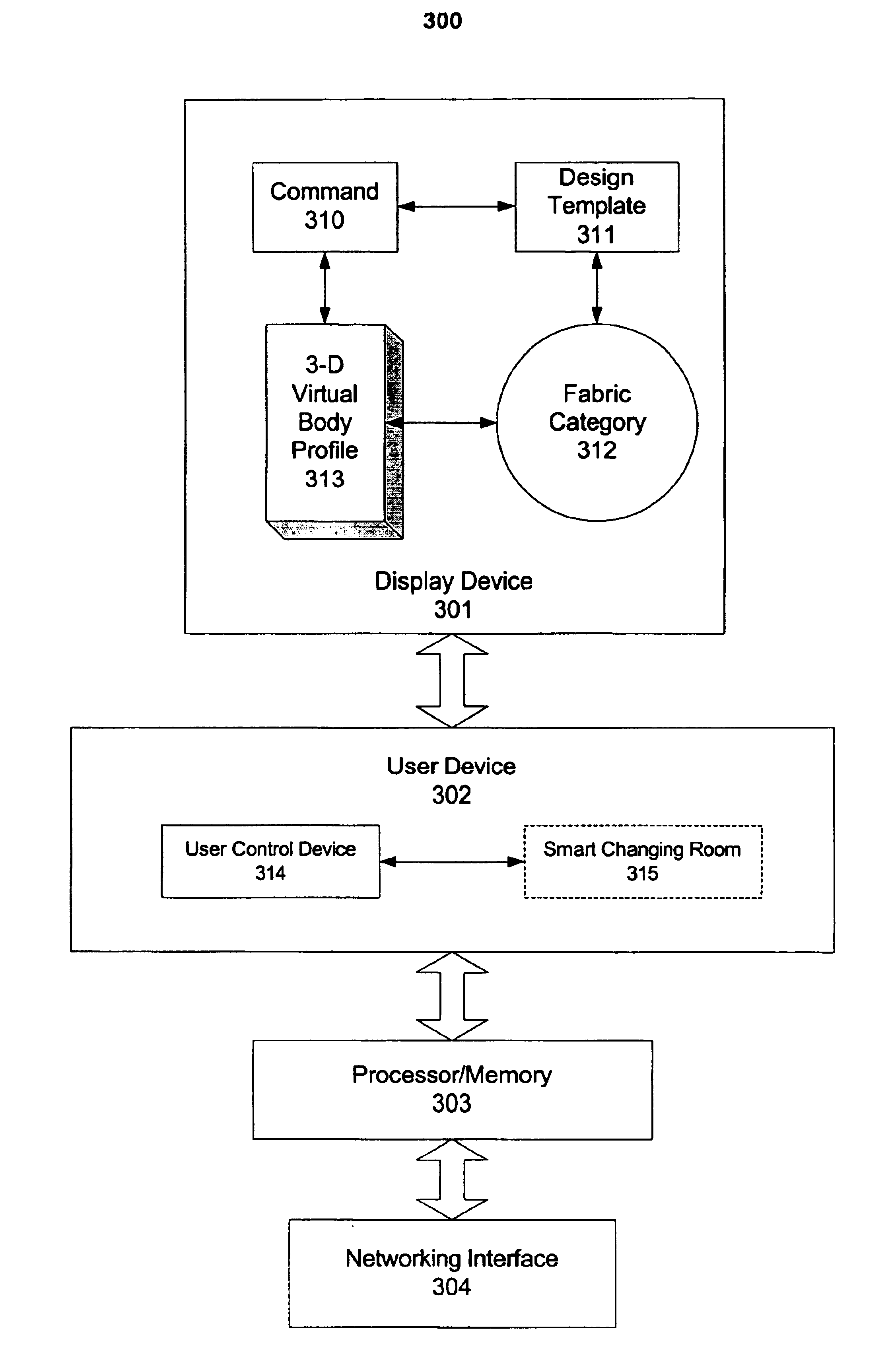

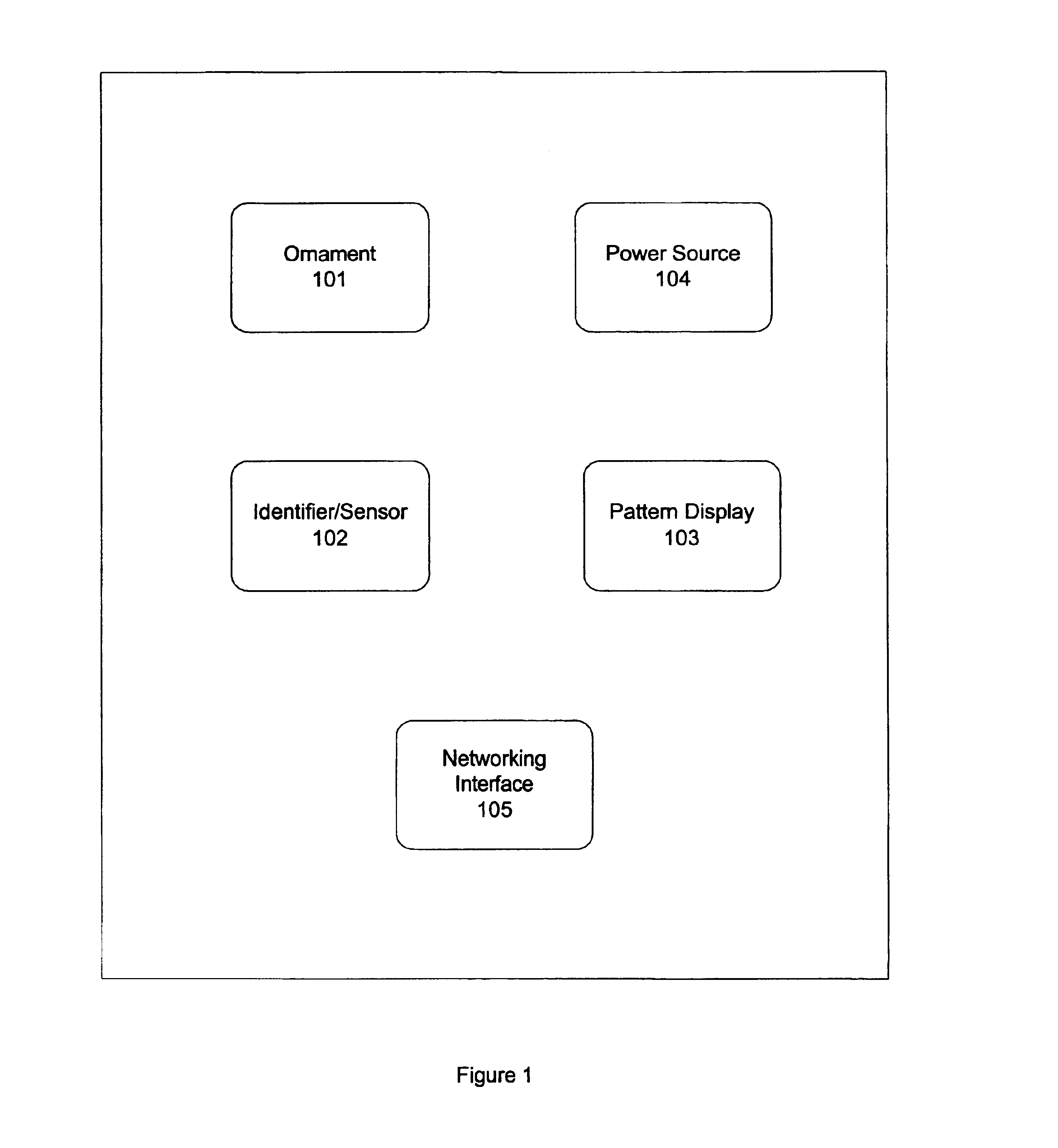

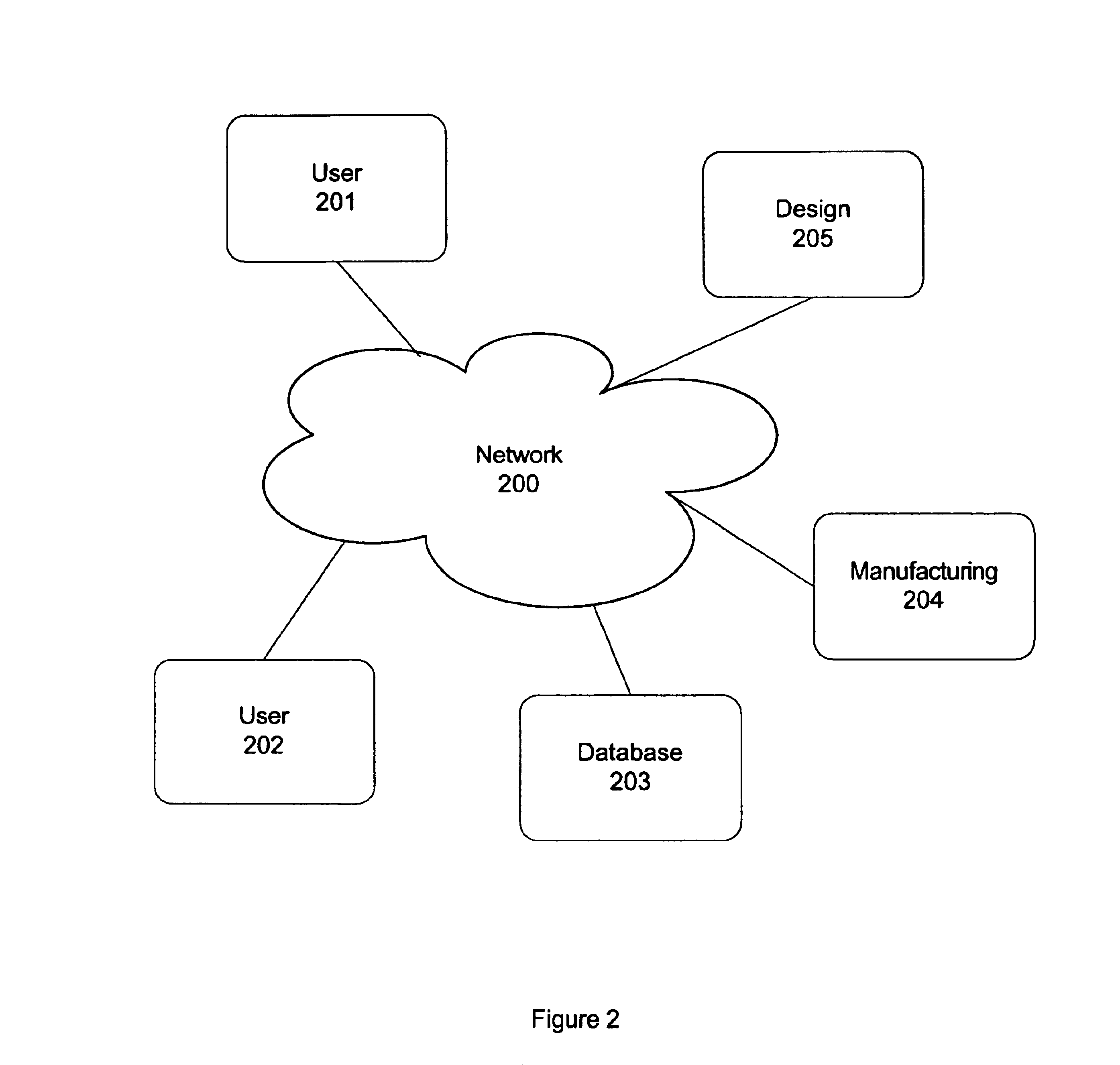

Reconfigurable garment definition and production method

InactiveUS6882897B1Efficient integrationSimple designGarmentsSurgeryLine sensorComputer Aided Design

Computer-aided design and manufacture software and hardware automate garment and fashion definition and production. Configurable garment includes ornamental element, pattern display, and personal identifier and wireless sensor electronics.

Owner:FERNANDEZ DENNIS S

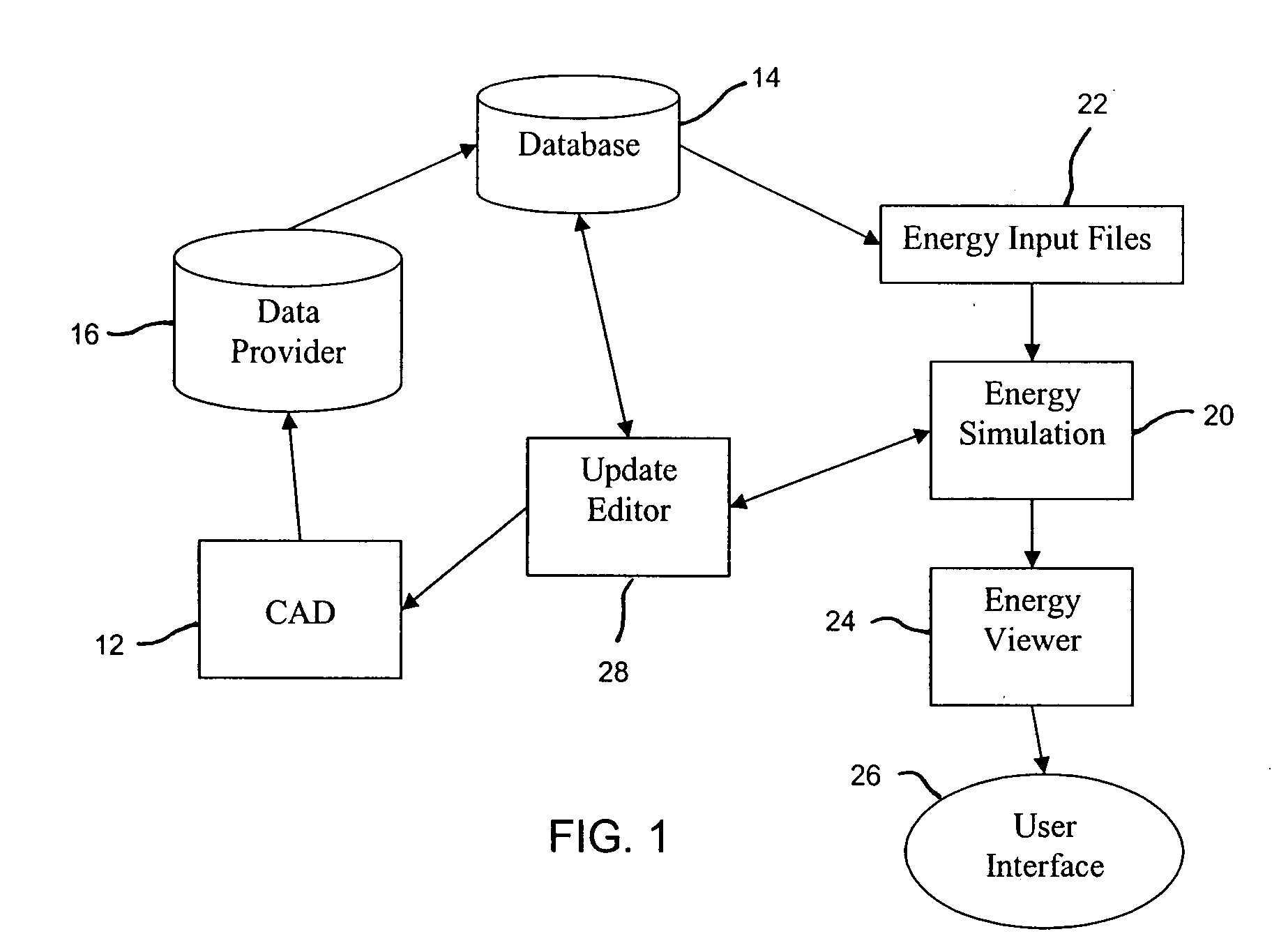

Method and system for integrating computer aided design and energy simulation

InactiveUS20080249756A1Shorten the timeReduce effortGeometric CADAnalogue computers for electric apparatusComputer Aided DesignSoftware system

A software system and method for providing interoperability between computer aided design and energy simulation. The method includes preparing an electronic construction plan, extracting structure information from the electronic construction plan, executing an energy simulation using at least a portion of the structure information, and displaying an energy efficiency analysis of the construction plan through a user interface.

Owner:CHAISUPARASMIKUL PONGSAK

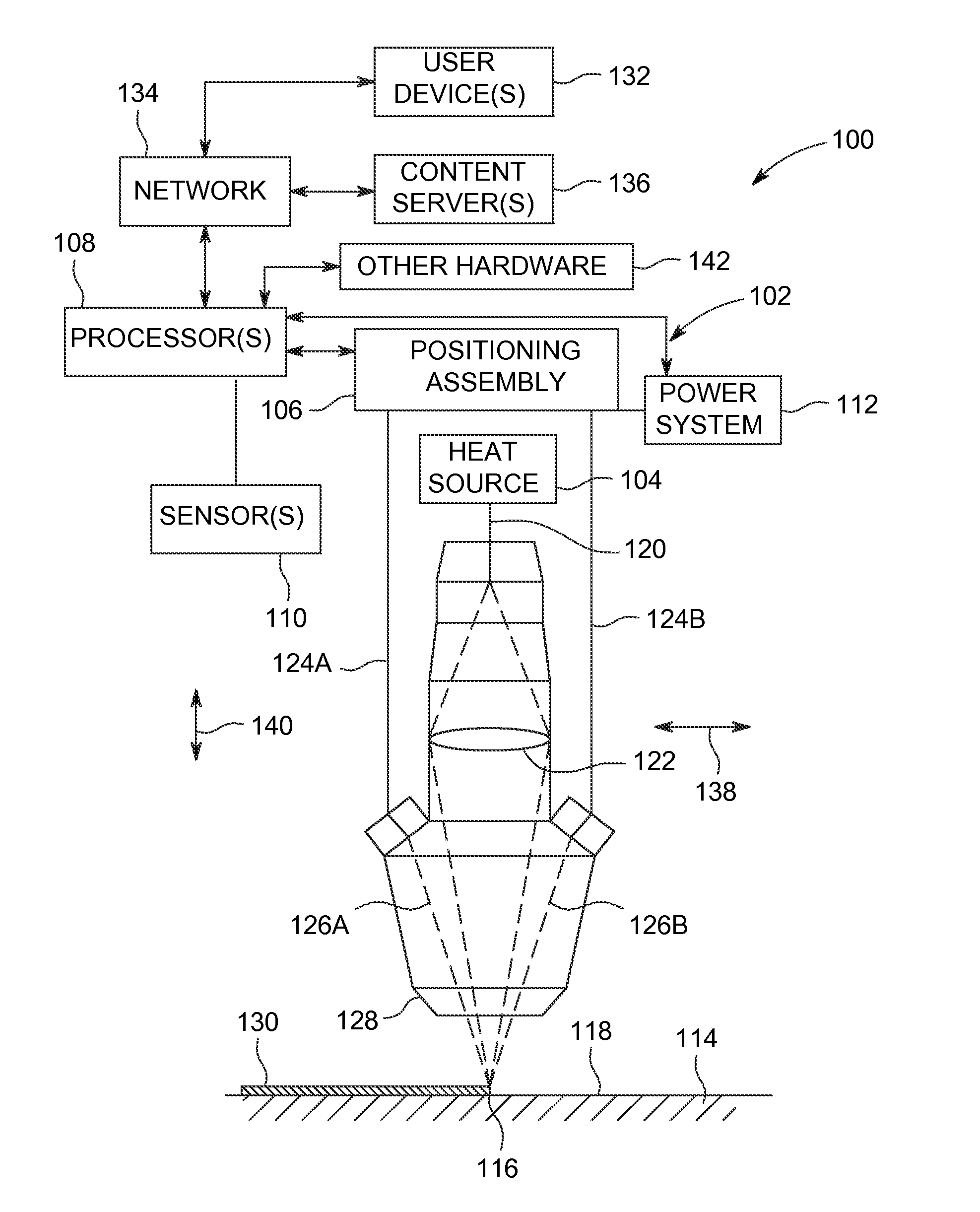

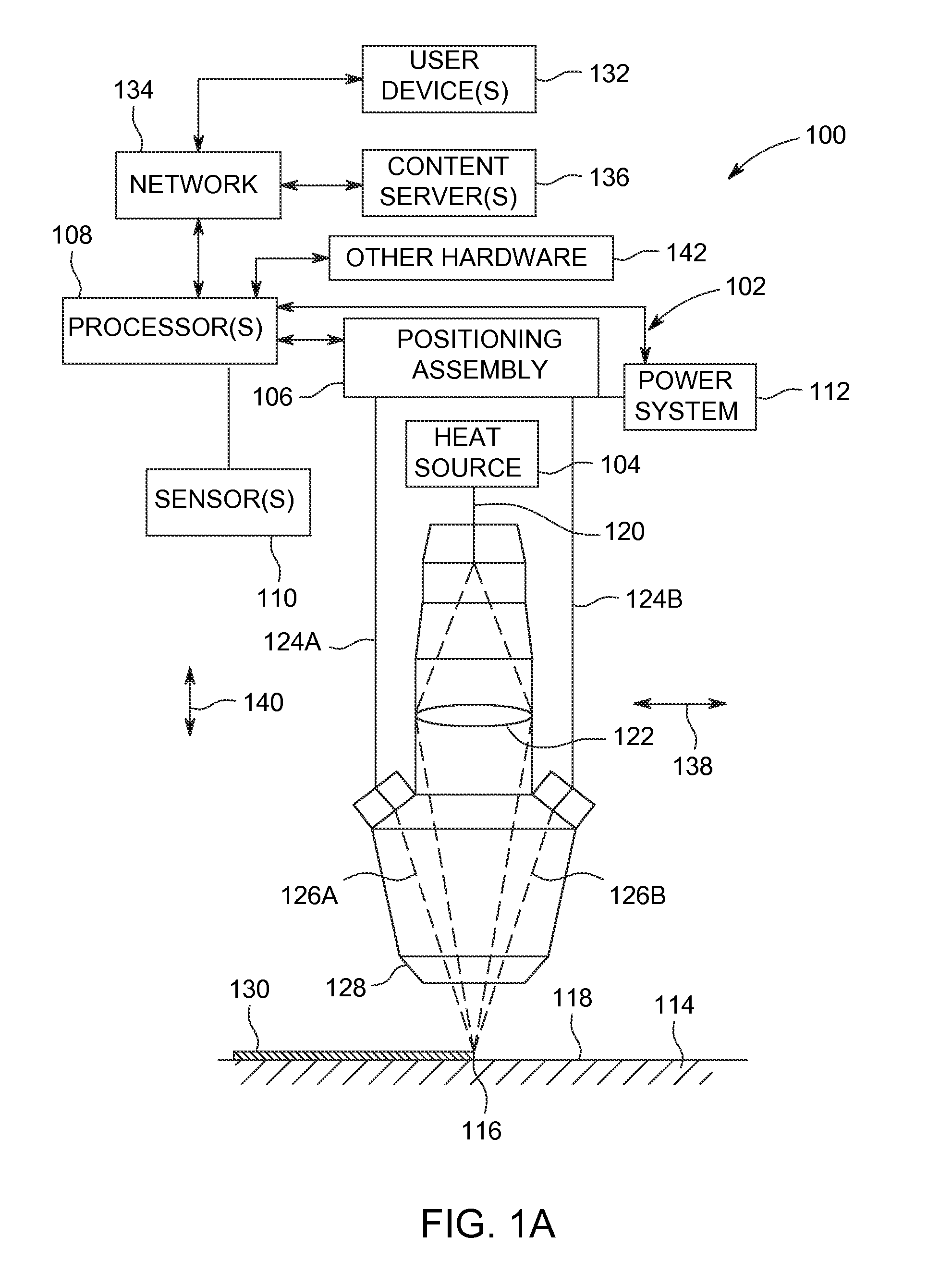

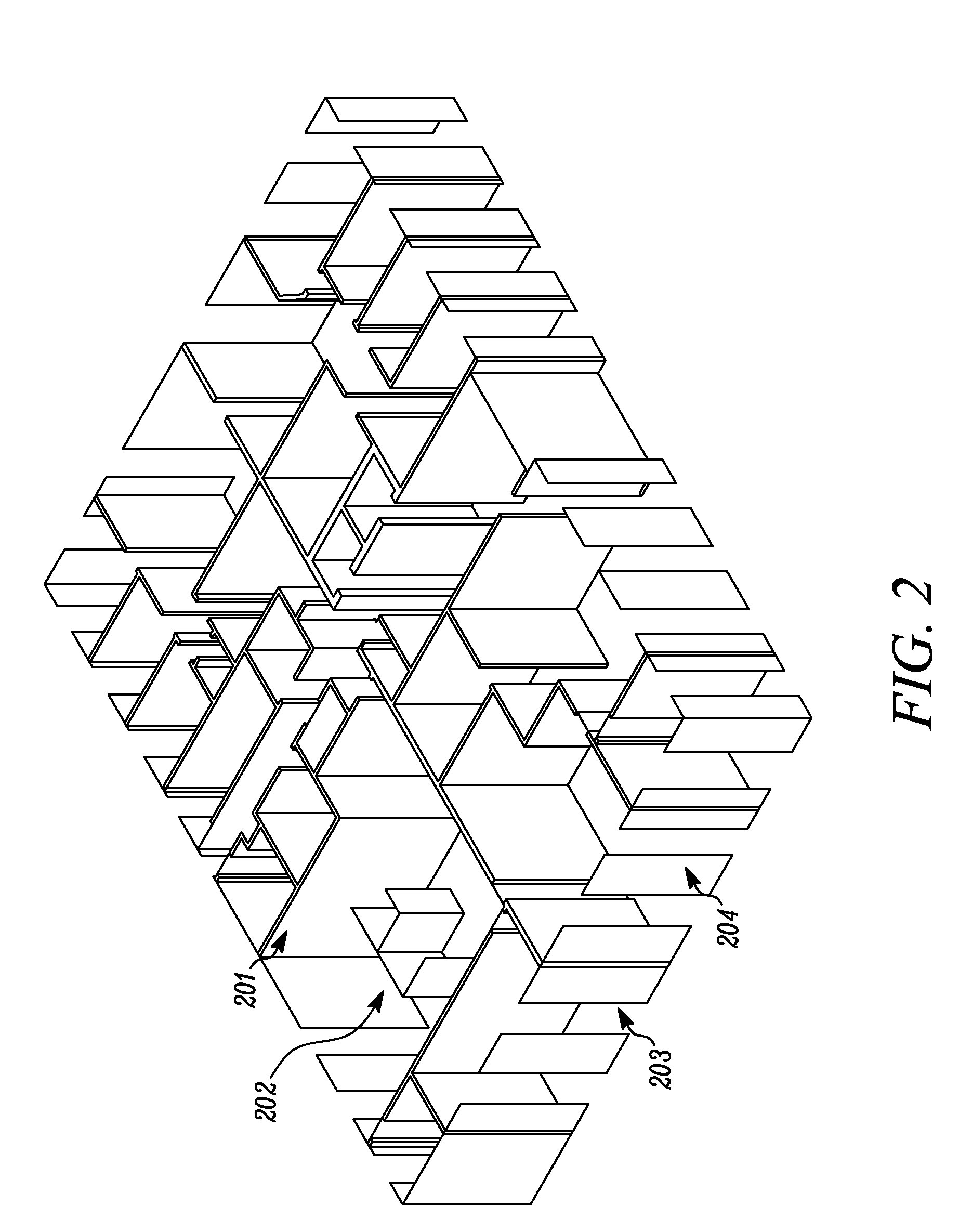

Visualization of additive manufacturing process data

ActiveUS20160179064A1Programme controlAdditive manufacturing apparatusComputer Aided DesignUser device

Systems, apparatus and methods provide a visual representation to users of data collected from a three dimensional manufacturing process, such as an additive manufacturing (AM) process. In an embodiment, a user device receives process data associated with a three dimensional manufacturing process, transforms the process data into visualization data compatible with a computer-aided design specification, receives a Boolean query, and then renders, in response to the Boolean query, a visual depiction on a display screen of at least one aspect of the three dimensional manufacturing process and / or the three dimensional manufacturing apparatus and / or a object being manufactured.

Owner:GENERAL ELECTRIC CO

Providing A Collaborative Immersive Environment Using A Spherical Camera and Motion Capture

ActiveUS20090278917A1Color television detailsCathode-ray tube indicatorsComputer Aided DesignKinematics

Embodiments of the present invention provide a collaborative visualization system, which integrates motion capture and virtual reality, along with kinematics and computer-aided design (CAD), for the purpose of, for example, validating a simulation with a real-world video. A spherical camera captures real-world video at a first location. At a second location, one or more head-mounted display devices display the captured real-world video and also display a simulation corresponding to the real-world video. A motion capture system captures head rotation information for one or more users to thereby to control a pan, tilt, and zoom of the real-world video so that when a position of a user's head changes, the portion of the real-world video displayed in the head-mounted display changes accordingly. Upon user input, a computer program product selects between displaying the real-world video and the simulation in the head-mounted display.

Owner:LOCKHEED MARTIN CORP

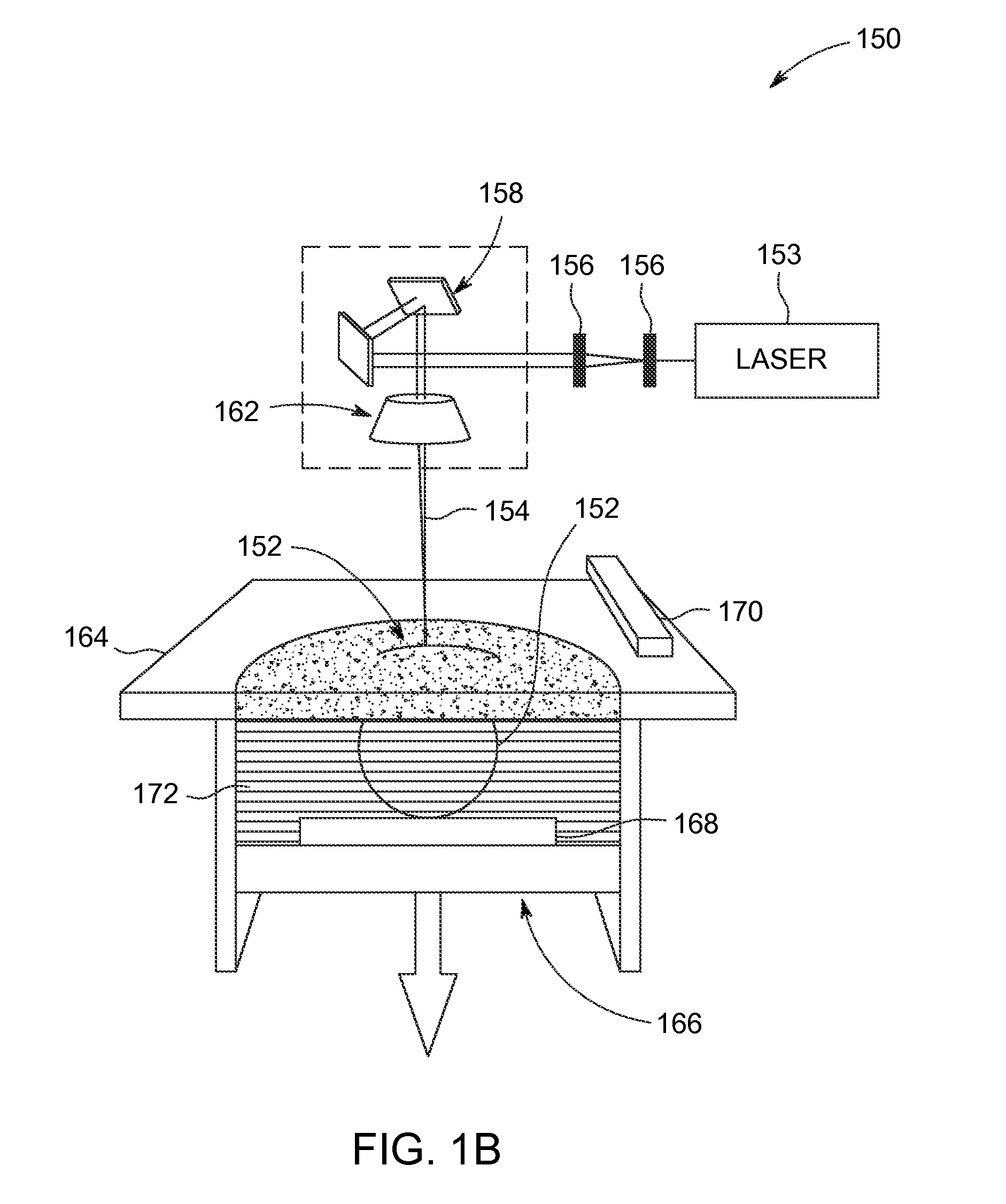

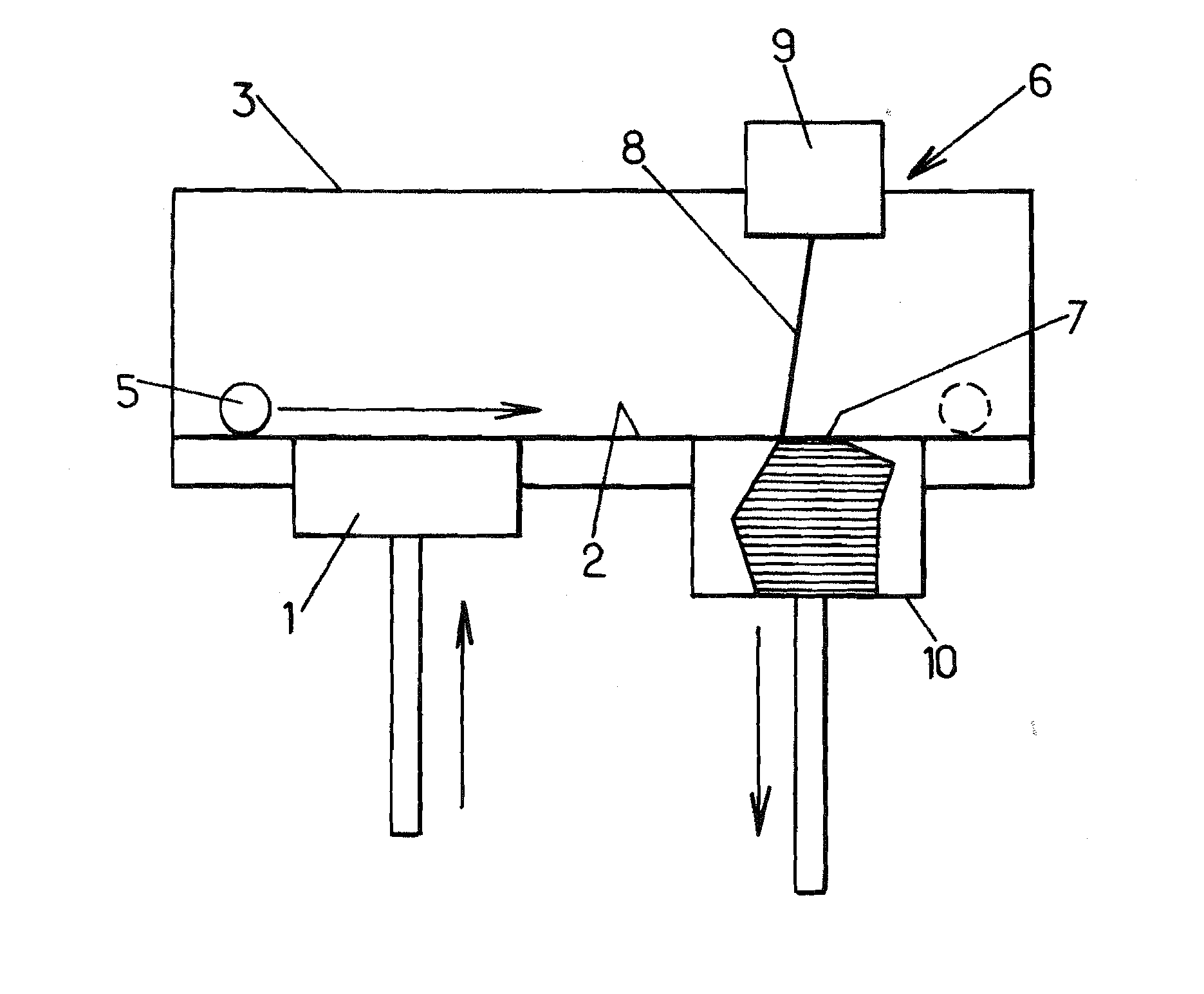

Biomedical device, method for manufacturing the same and use thereof

InactiveUS20120165954A1Reduce usageEasy to processBone implantCeramic shaping apparatusLead zirconate titanatePorosity

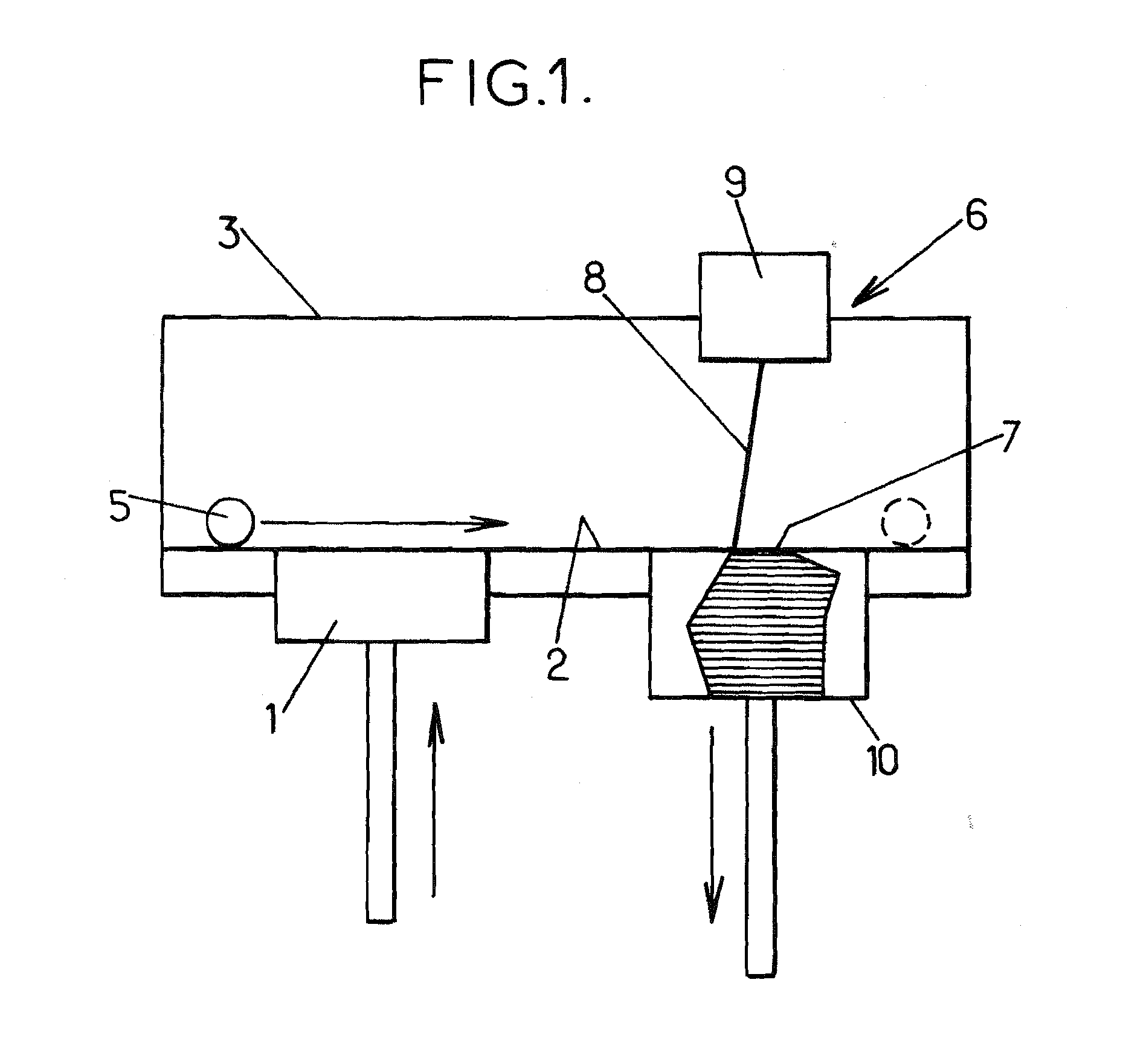

A three-dimensional biomedical device having an osteoinductive first area with a controlled porosity and a second area, which is produced by laser technology from a powder including one of ceramics, metals, metal alloys, bioactive glasses, lead zirconate titanate and biocompatible polymers, or mixtures thereof. The ratio of the porosities from the second area to the first area is equal or less than one, preferably from 0.001 to 0.9. A method for manufacturing the device for fitting in a bone defect, wherein a virtual object is designed with a computer-aid designed software, and the device is manufactured by laser technology including layering a powder onto a plate (7) so that a layer of a predetermined thickness is formed; the laser beam (8) selectively processes the powder to produce a processed layer, and, thus, layer after layer, the layers are joined together until the biomedical device is formed.

Owner:NIMAL DIDIER

Knowledge management system with integrated product document management for computer-aided design modeling

InactiveUS20050203718A1Knowledge representationComputer aided designComputer Aided DesignThird party

A knowledge management system captures, stores, manages, and applies rules for modeling geometric objects and related non-geometric attributes, and includes integrated support for one or more third party product document management systems. The knowledge management system can store documents in the product document management system, such as templates for generated computer-aided design system components. An add-in program may be executed by the computer-aided design system for creating and managing template documents in the product document management system for use by the knowledge management system.

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

Interactive methods for design of automobiles

InactiveUS7079114B1Modifies flowHigh expressionGeometric CADAdditive manufacturing apparatusDisplay deviceEngineering

The invention concerns new computer aided methods and apparatus for designing objects, particularly 3D objects, and especially those having a sculpted form such as found in automobiles, boats, planes, furniture and certain fashion apparel items. Preferred embodiments employ optical sensing of the designers' hands, fingers, or styling implements, or his sketches, in conjunction with large screen displays and several novel software based methods which have the further advantage of direct interface to conventional CAD (Computer Aided design) systems which are then used to physically manifest the results as models, tooling or whatever. Use of the invention not only saves time and cost, but allows, in a “natural” way, much greater freedom of expression for the artist / designer than any known computer based system.

Owner:SMITH PETER +1

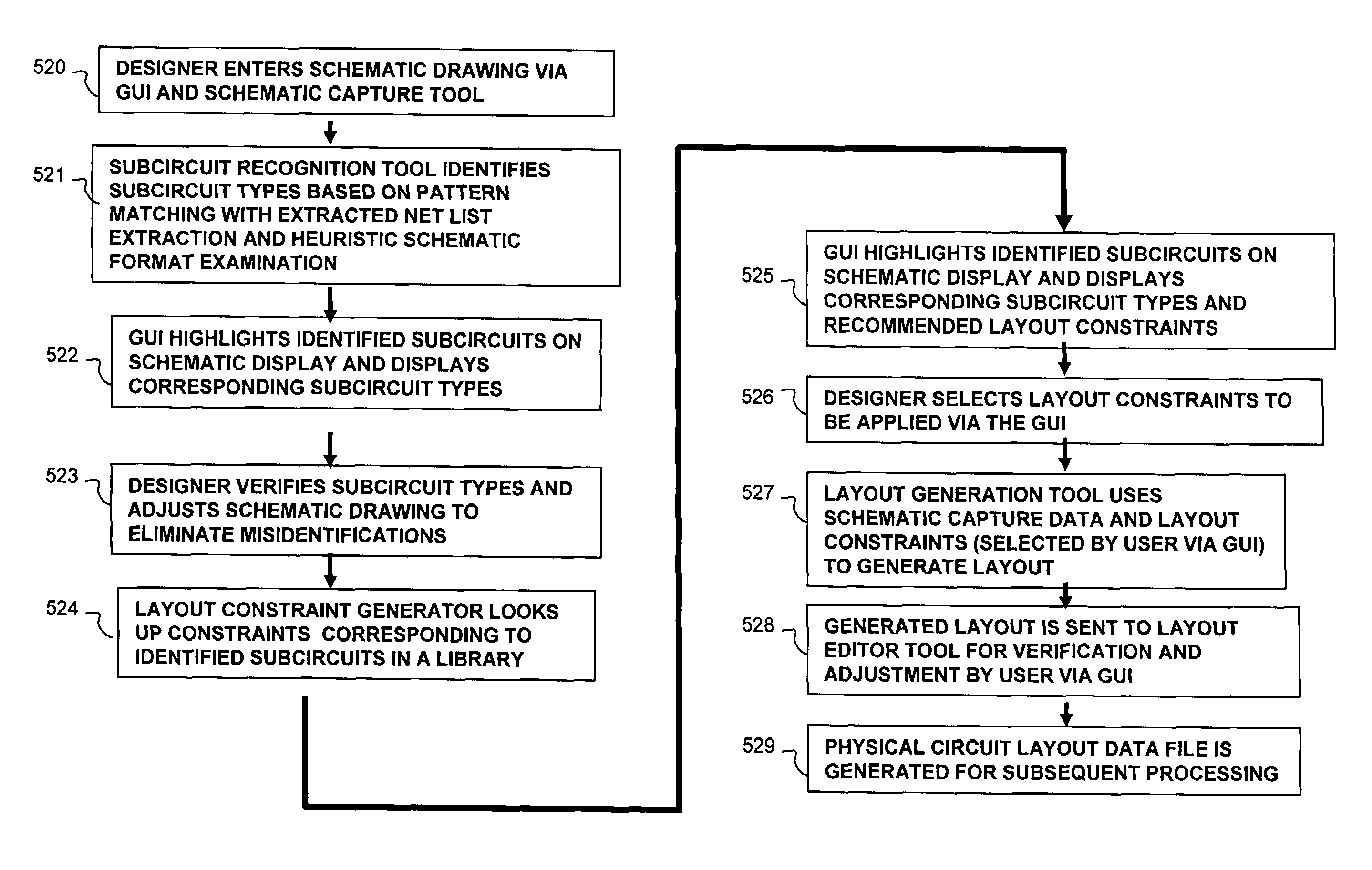

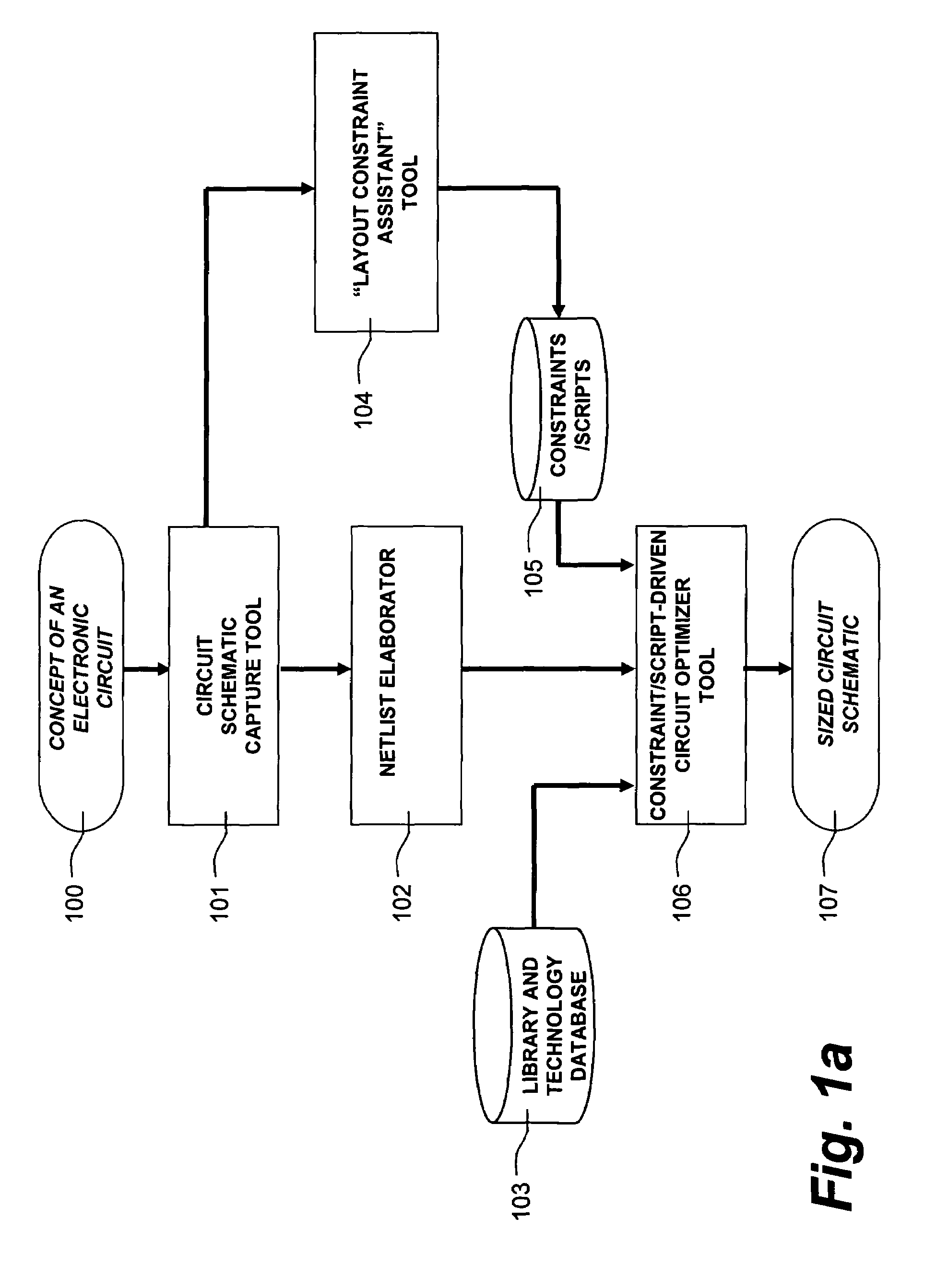

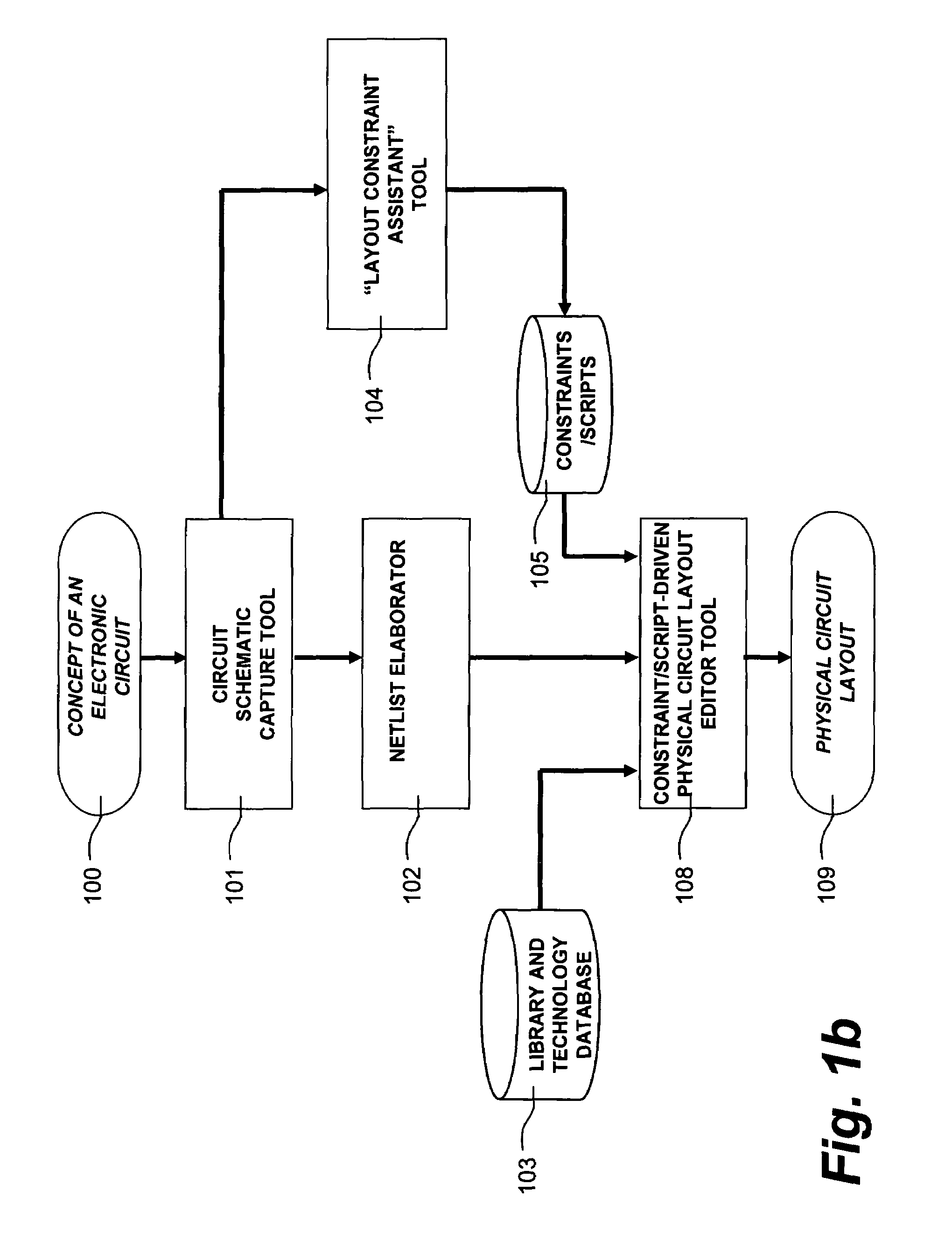

Constraint assistant for circuit design

InactiveUS7418683B1Less likelyAvoid wasting timeSpecial data processing applicationsSymbolic schematicsComputer Aided DesignEngineering

A computer aided design tool and method for designing IC layouts by recommending subcircuit layout constraints based upon an automated identification from a circuit schematic of subcircuit types requiring special IC layout constraints. Subcircuit types are identified on the basis of netlist examination, as well as cues from the layout of the circuit schematic.

Owner:CADENCE DESIGN SYST INC

System and method for automated placement or configuration of equipment for obtaining desired network performance objectives

InactiveUS7295960B2Significant valueEasy to explainGeometric CADAnalogue computers for electric apparatusHard disc driveThe Internet

A method is presented for determining optimal or preferred configuration settings for wireless or wired network equipment in order to obtain a desirable level of network performance. A site-specific network model is used with adaptive processing to perform efficient design and on-going management of network performance. The invention iteratively determines overall network performance and cost, and further iterates equipment settings, locations and orientations. Real time control is between a site-specific Computer Aided Design (CAD) software application and the physical components of the network allows the invention to display, store, and iteratively adapt any network to constantly varying traffic and interference conditions. Alarms provide rapid adaptation of network parameters, and alerts and preprogrammed network shutdown actions may be taken autonomously. A wireless post-it note device and network allows massive data such as book contents or hard drive memory to be accessed within a room by a wide bandwidth reader device, and this can further be interconnected to the internet or Ethernet backbone in order to provide worldwide access and remote retrieval to wireless post-it devices.

Owner:EXTREME NETWORKS INC

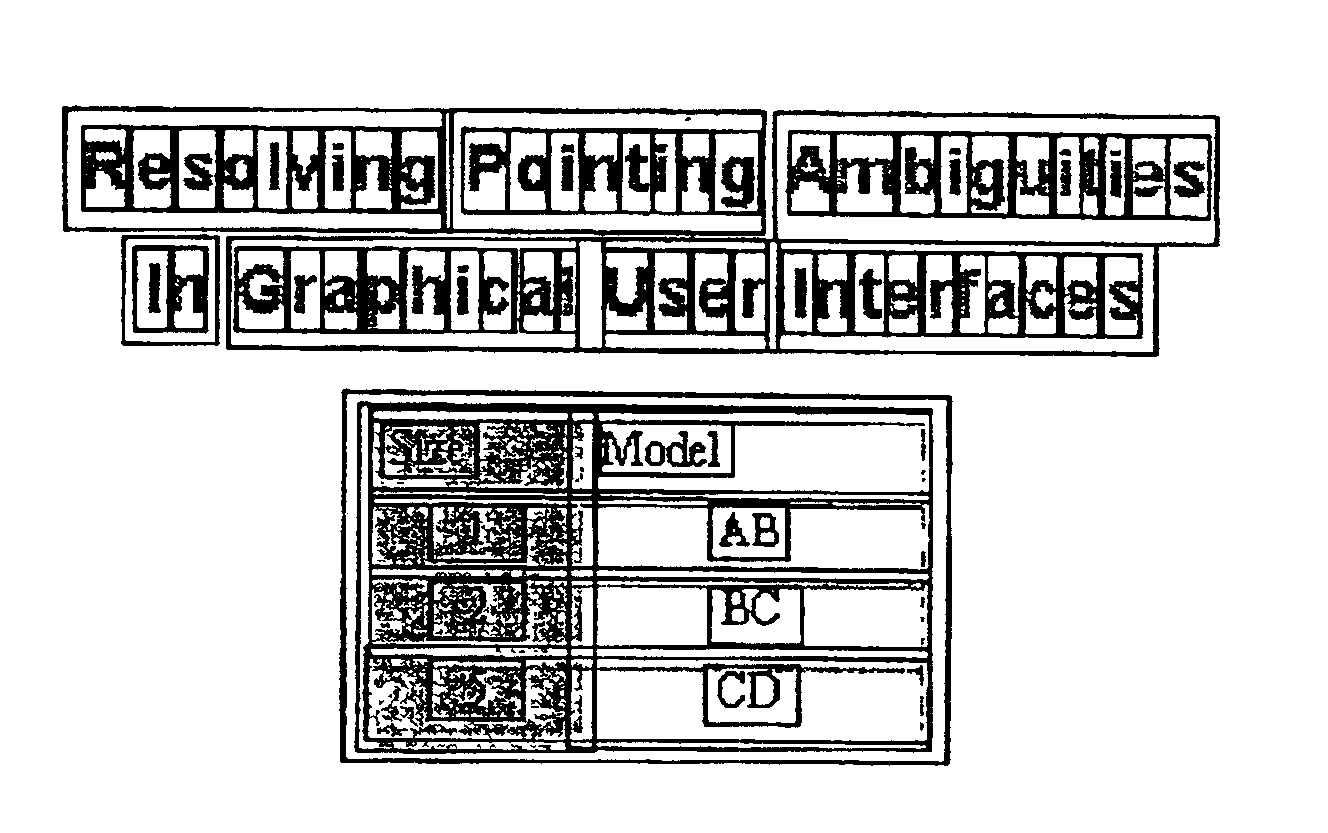

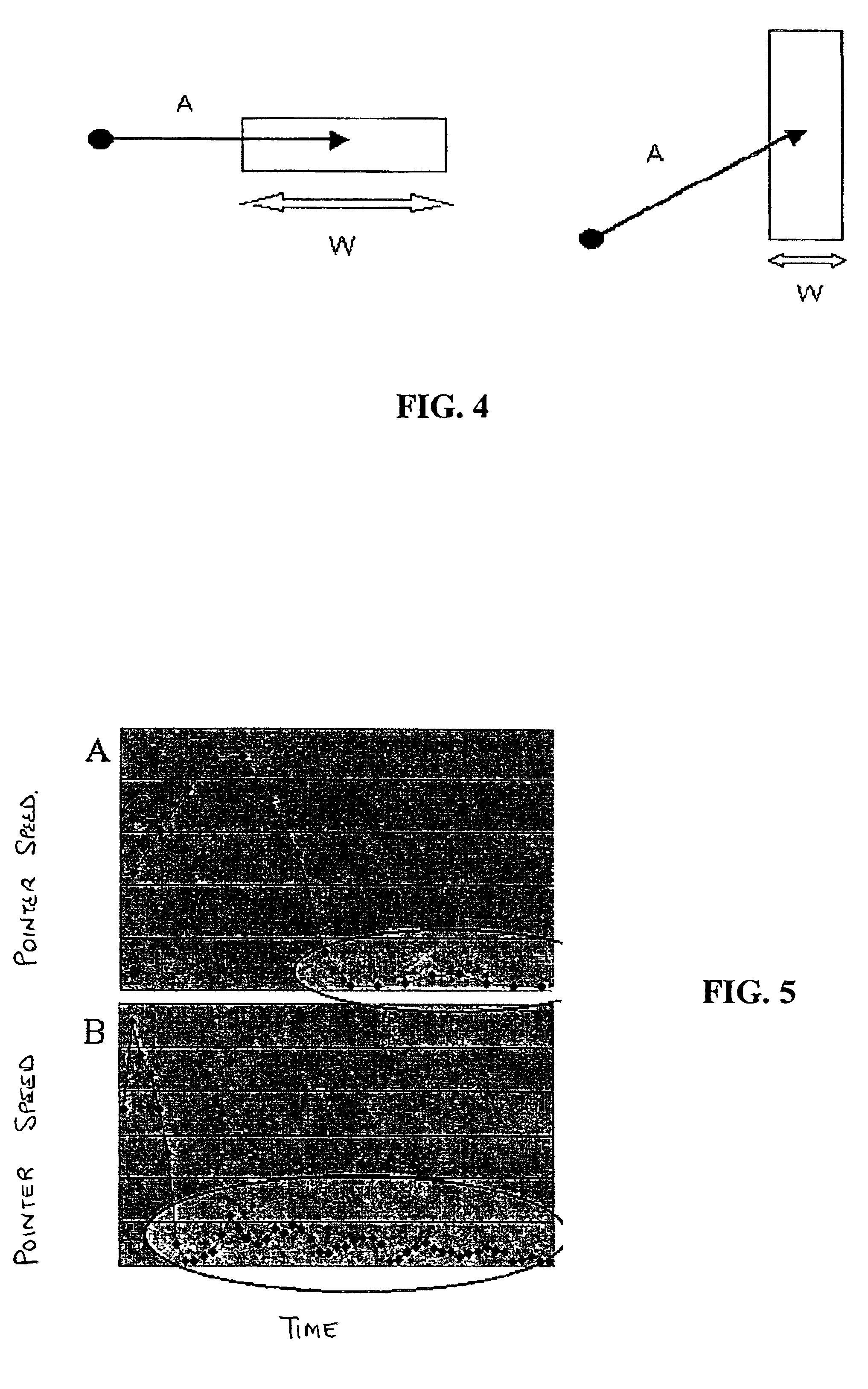

Method and system for implicitly resolving pointing ambiguities in human-computer interaction (HCI)

InactiveUS6907581B2Simple design and implementationEasy accessInput/output processes for data processingObject basedAmbiguity

Owner:RAMOT AT TEL AVIV UNIV LTD

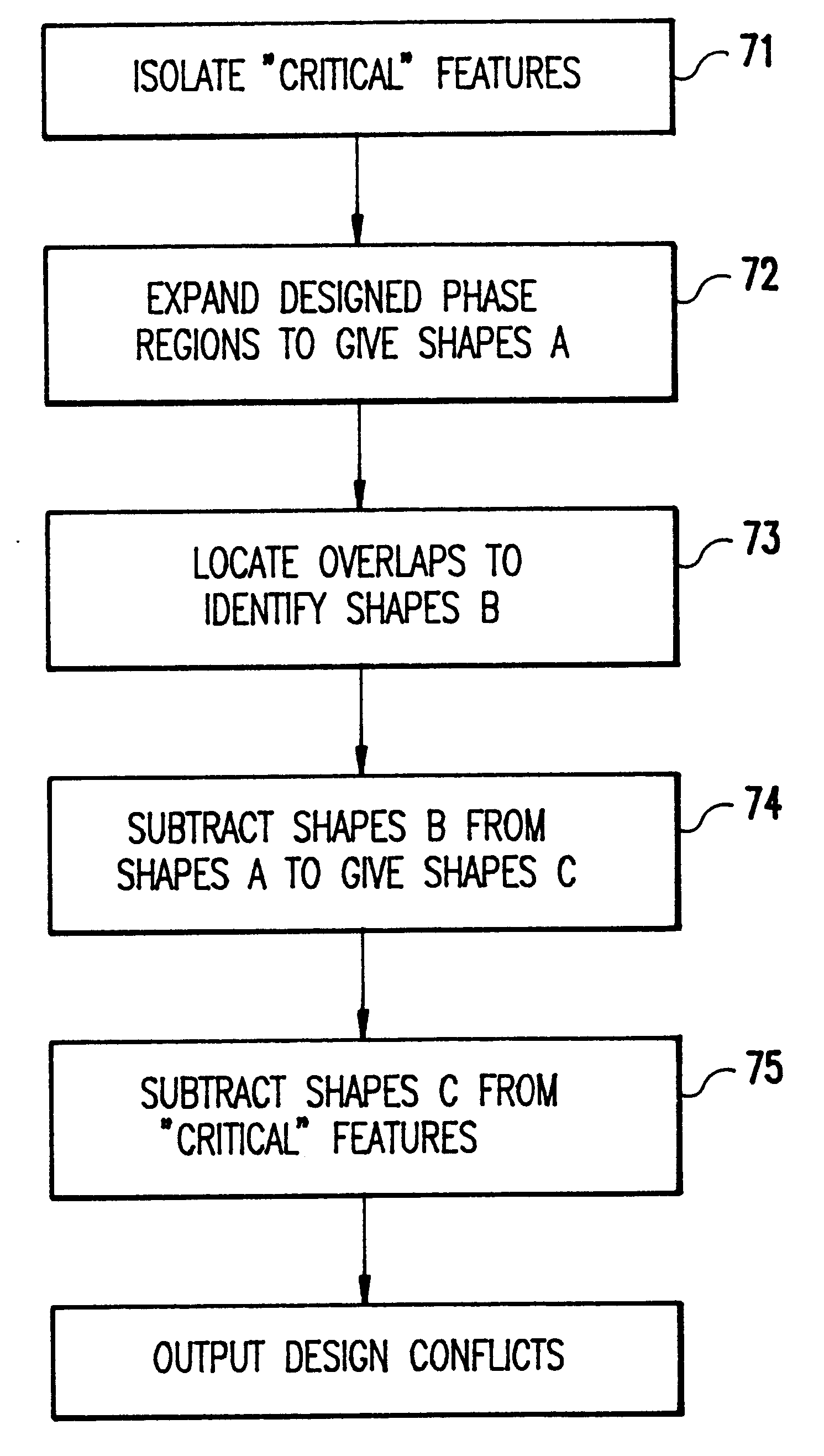

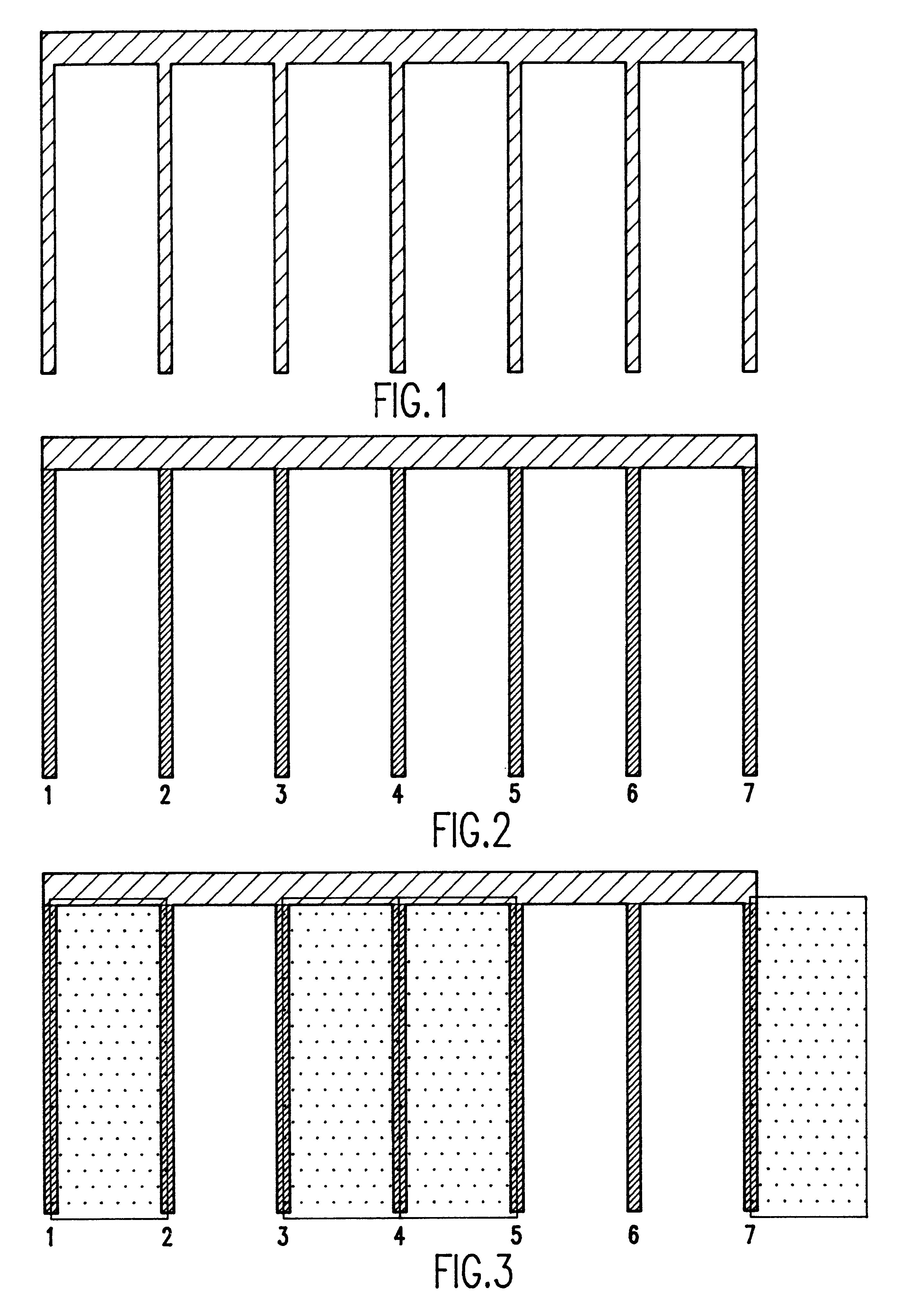

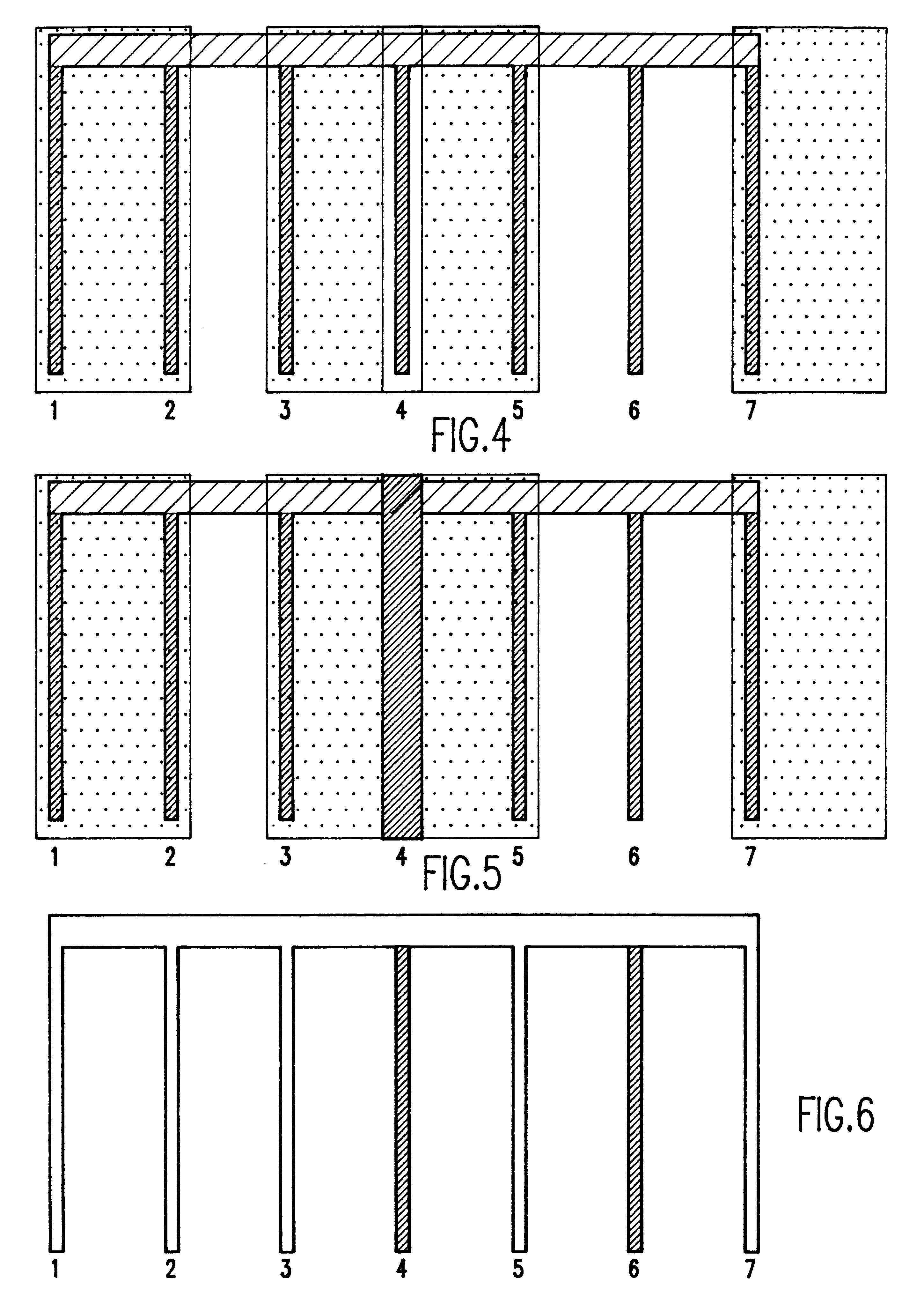

Design verification for asymmetric phase shift mask layouts

InactiveUS6185727B1Photo-taking processesOriginals for photomechanical treatmentComputer Aided DesignPhase shifted

A checking routine verifies a phase shifted mask (PSM) design based on fundamental principles of PSM and utilizing only basic shape manipulation functions and Boolean operations found in most computer aided design (CAD) systems. The design verification system checks complete chip designs for the two possible design errors that can cause defective masks by eliminating the phase transition; namely, placing a 180° phase region on both sides of a critical feature or completely omitting the phase region adjacent to certain critical features.

Owner:IBM CORP

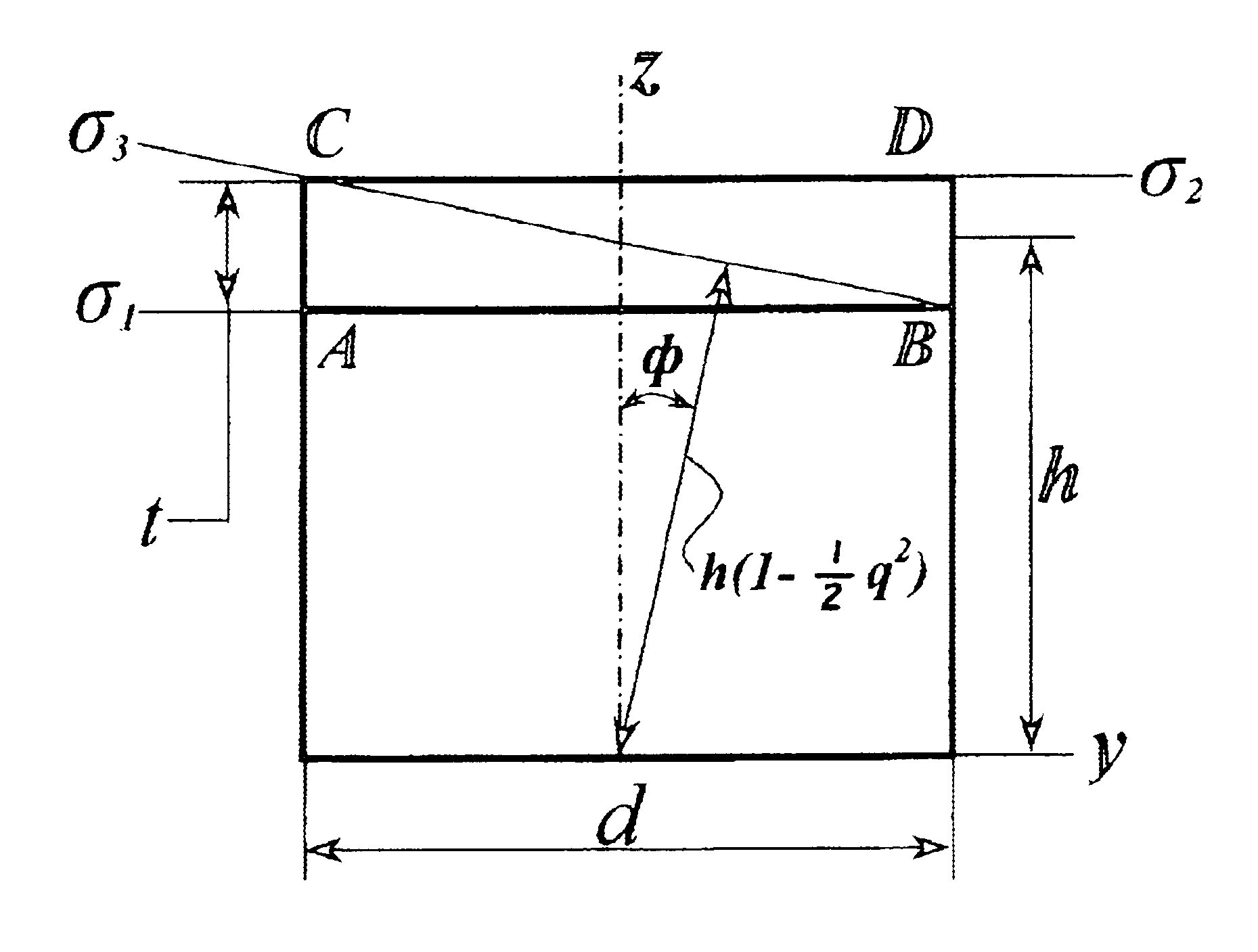

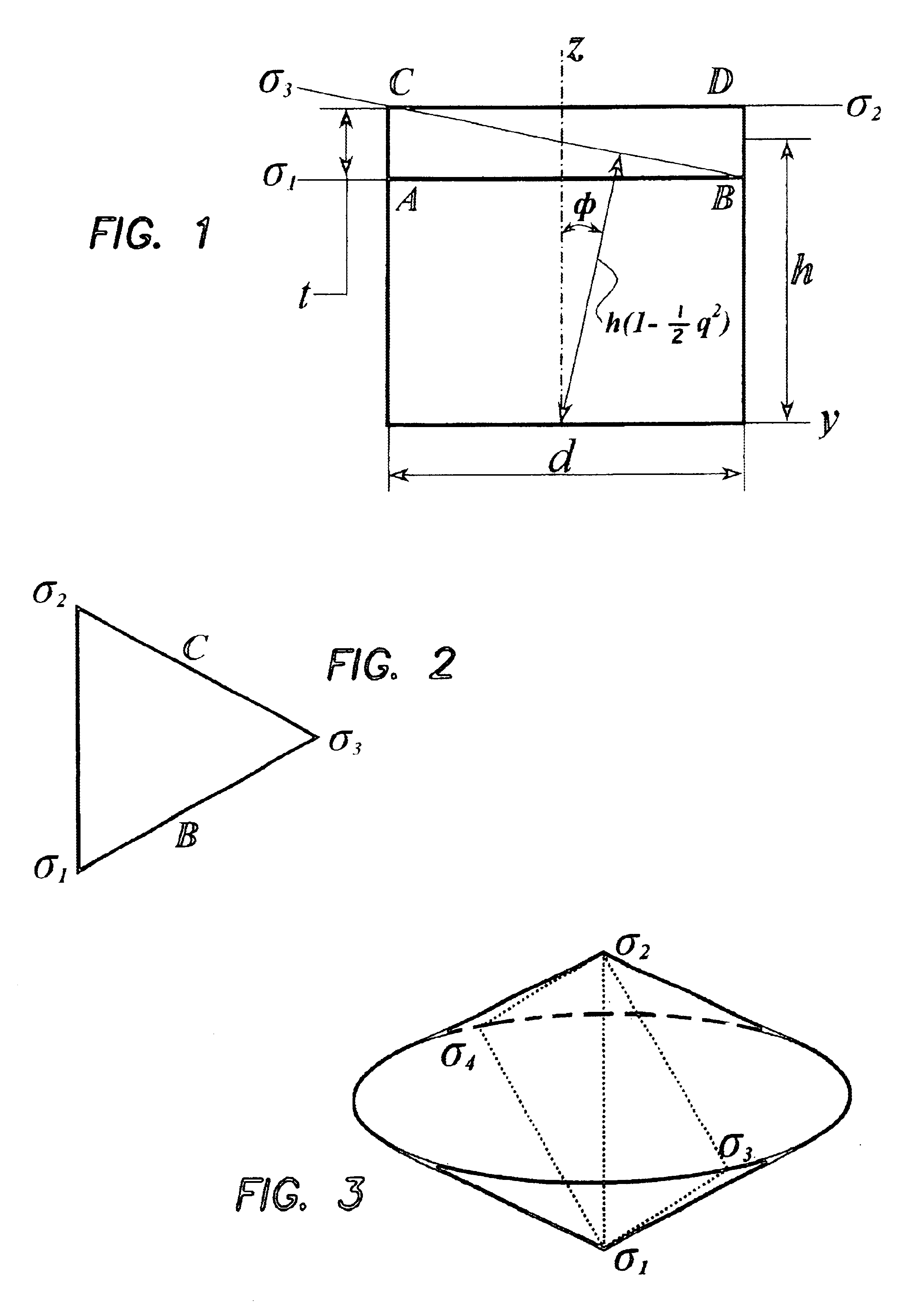

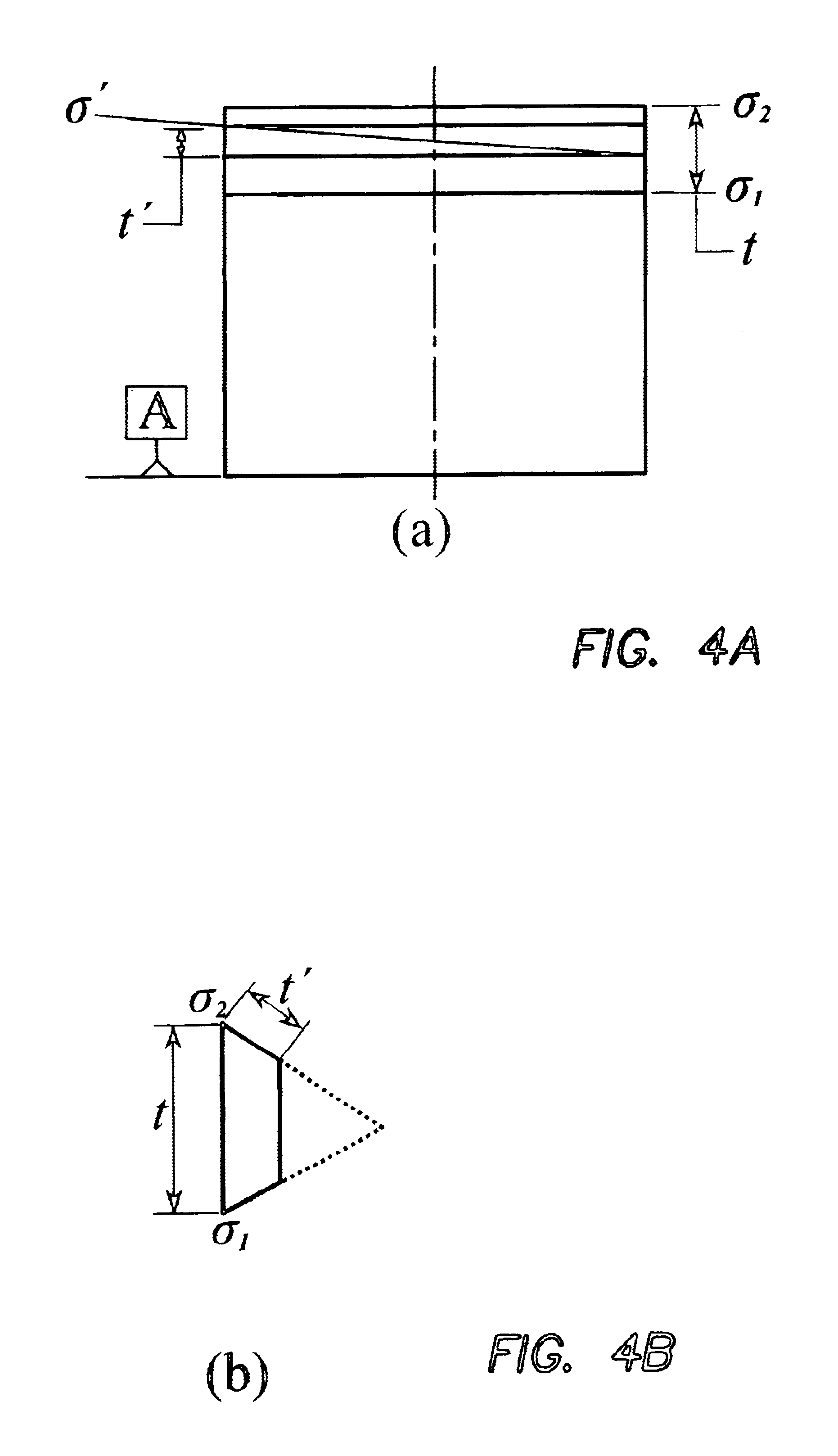

Method and apparatus for geometric variations to integrate parametric computer aided design with tolerance analyses and optimization

InactiveUS6963824B1Convenient investigationReadily apparentPosition fixationComputation using non-denominational number representationGraphicsComputer Aided Design

The objective of the invention is a bi-level method for modeling geometric tolerances compatible with the ANSI / ASME tolerance standard. At the local level, the model represents each tolerance-zone for a plane or an axis (line) as a tolerance map, and it includes the computational techniques that relate interdependencies between these regions and subregions within them. The model includes formulations for variations in size, form, orientation, position, and runout, and combinations of these, because all of these variations can be modeled using points, lines, and planes. Since variations in simple profiles that are formed from lines and circular arcs also can be described by such combinations, they too are includable in the formulation. The primary method is to overlay the geometry of tolerance-zones onto some traditional modes for representing planes, lines, and points. At the global level, the model inter-relates all frames of reference on a part or an assembly.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

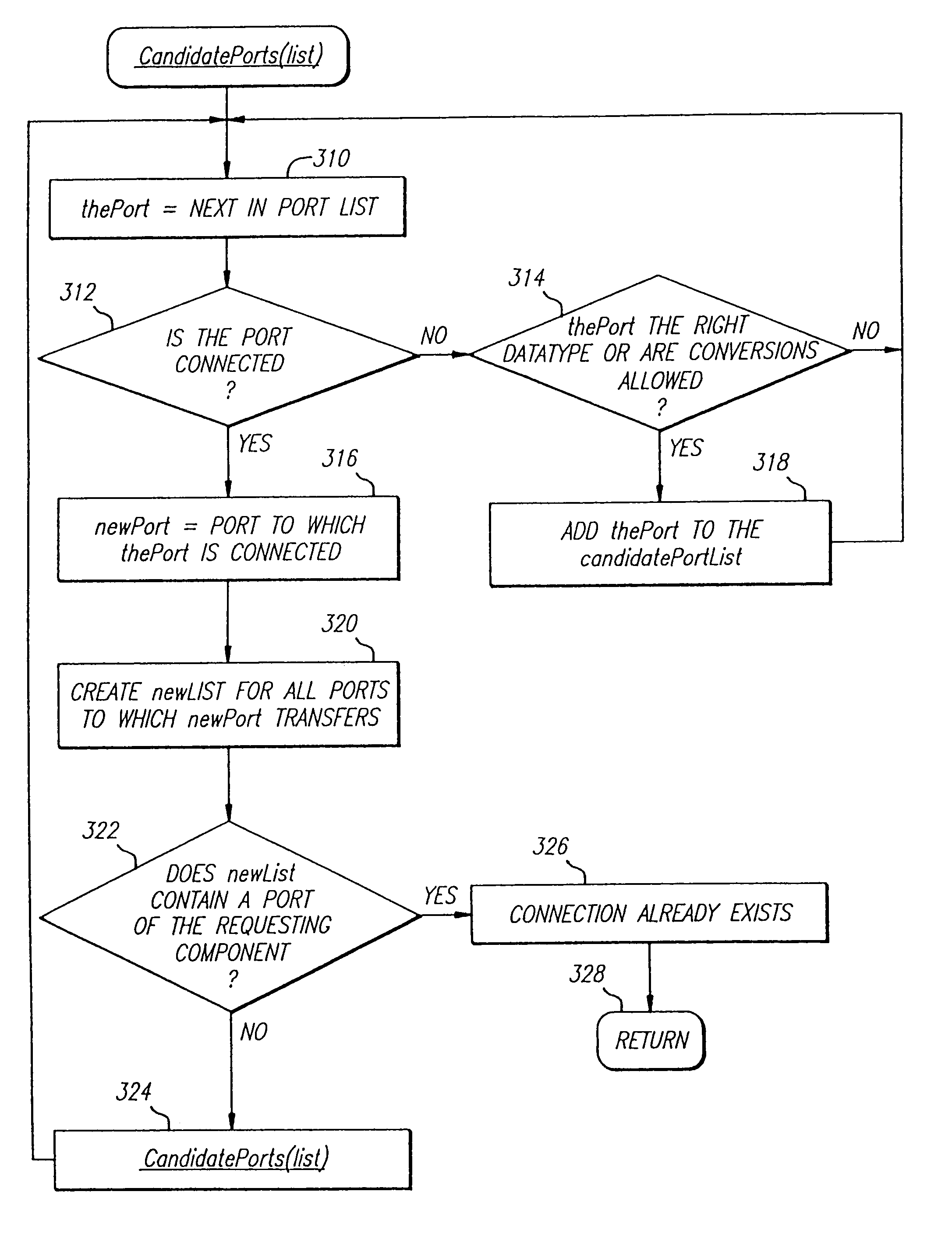

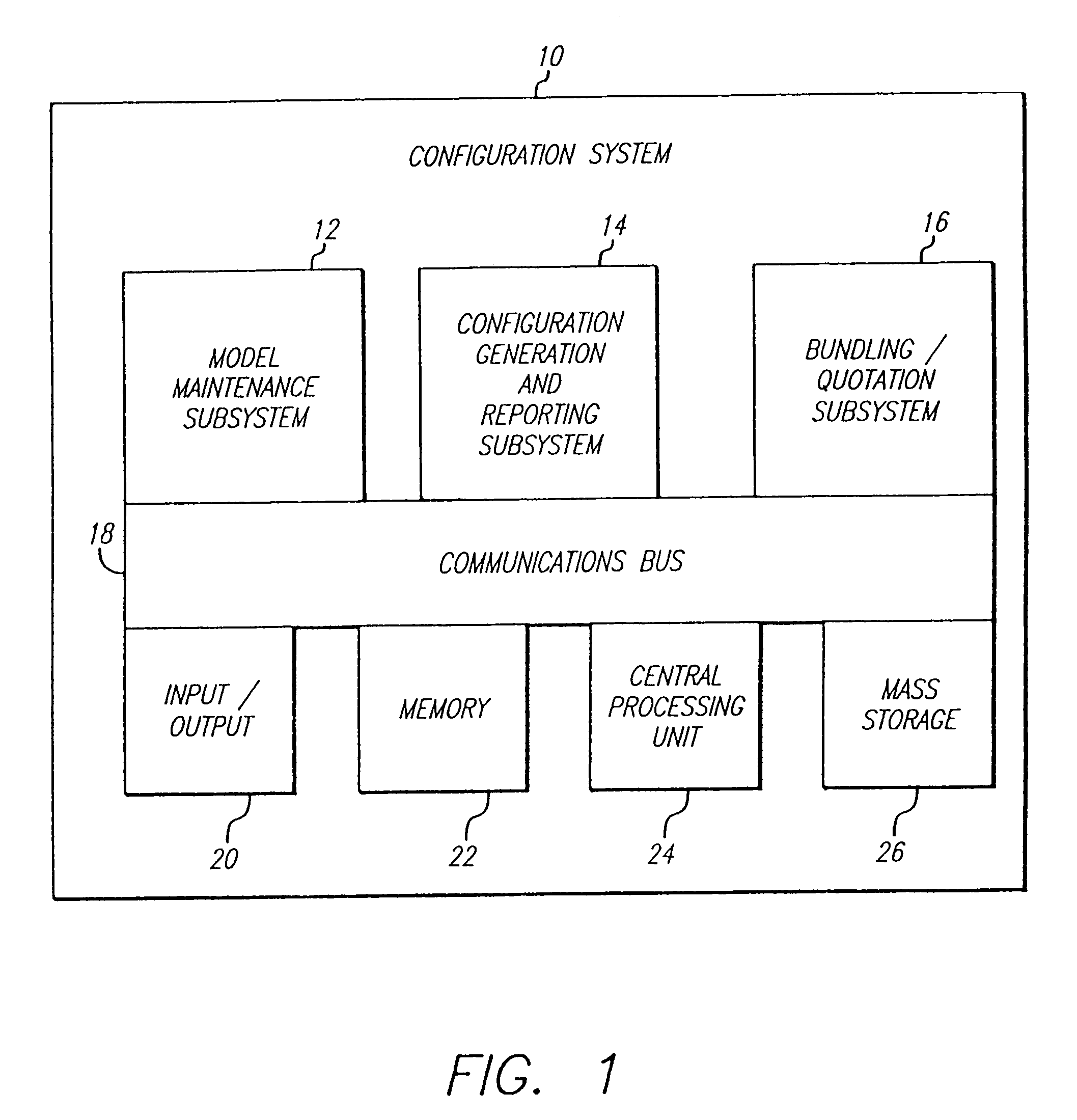

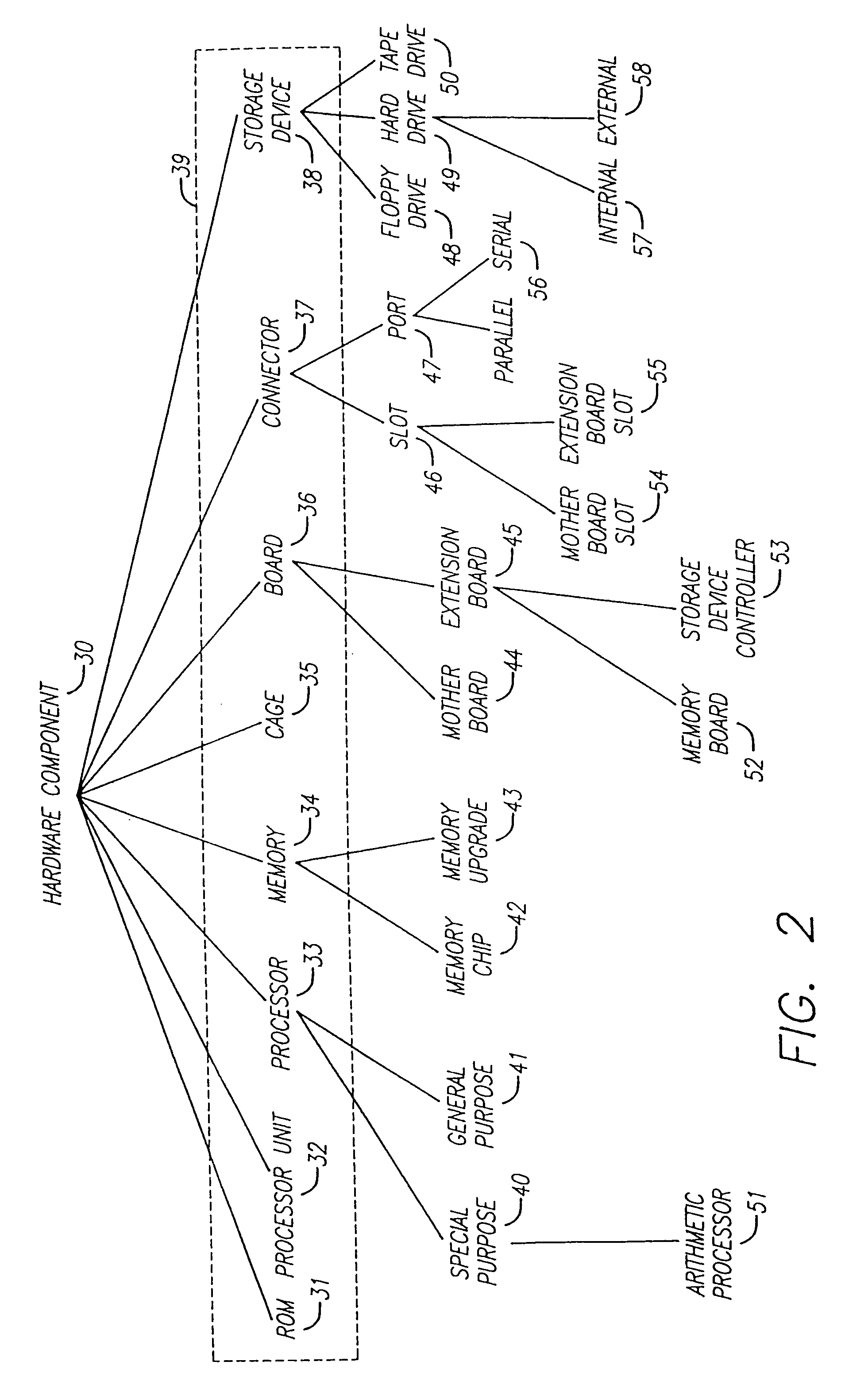

Method and apparatus for configuring systems

The present invention employs a generative approach for configuring systems such that a system may be configured based on component or resource requests, or input in the form of need. The present invention provides a constraint-based configuration system using a structural model hierarchy. The structural aspects of the model provide the ability to define a model element as being contained in, or by, another model element. In addition, the structural model provides the ability to identify logical datatype and physical interconnections between elements and establish connections between elements. To configure a system, the present invention accepts input in the form of requests (e.g., component or resource) or needs, such as an expression of a need for a desktop computer system to be used in a CAD (i.e., computer-aided design) environment. Using this information, the present invention configures a system by identifying the resource and component needs, constraints imposed on or by the resources or components identified, and the structural aspects of the system.

Owner:VERSATA DEV GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com