Patents

Literature

8563 results about "Constant pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

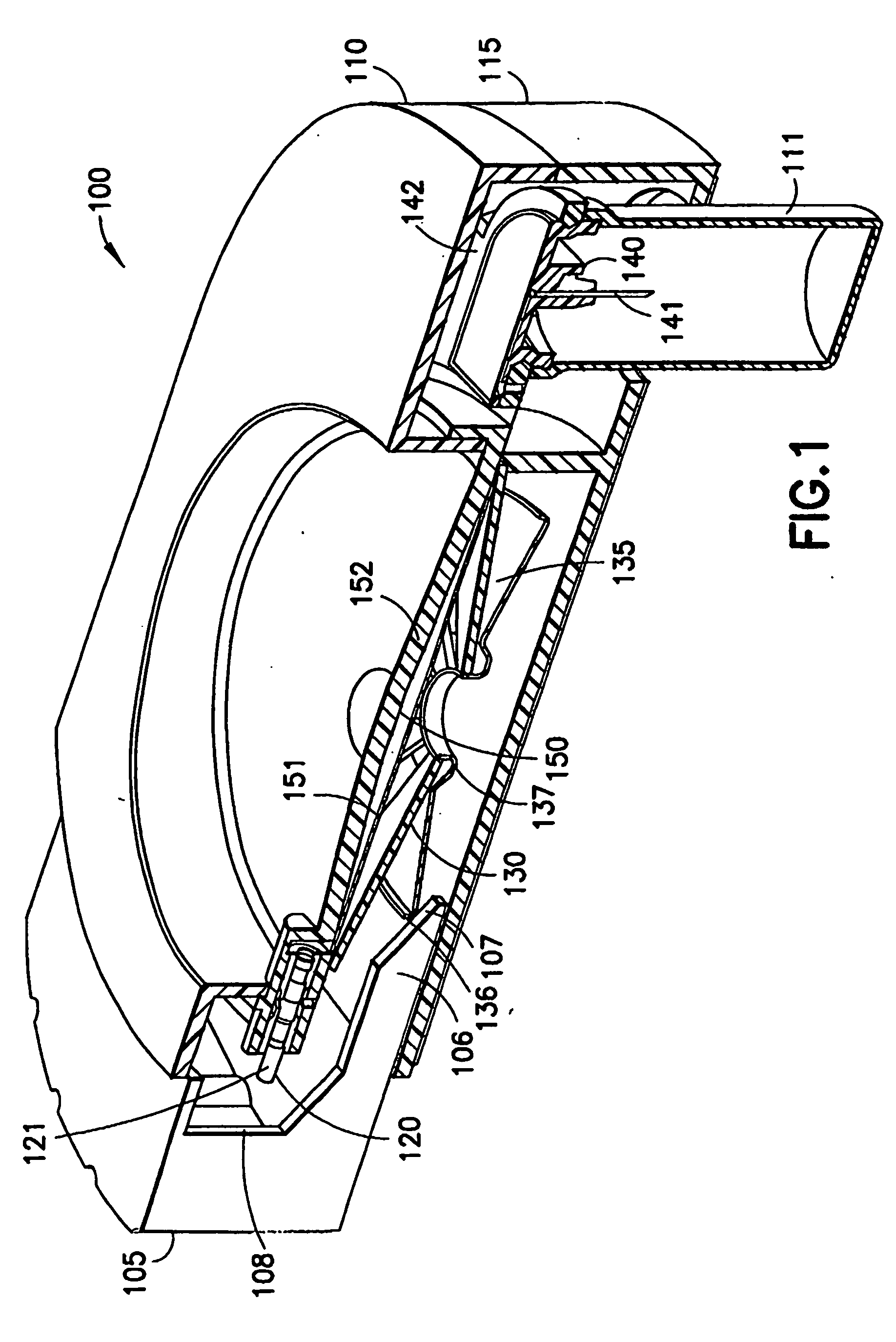

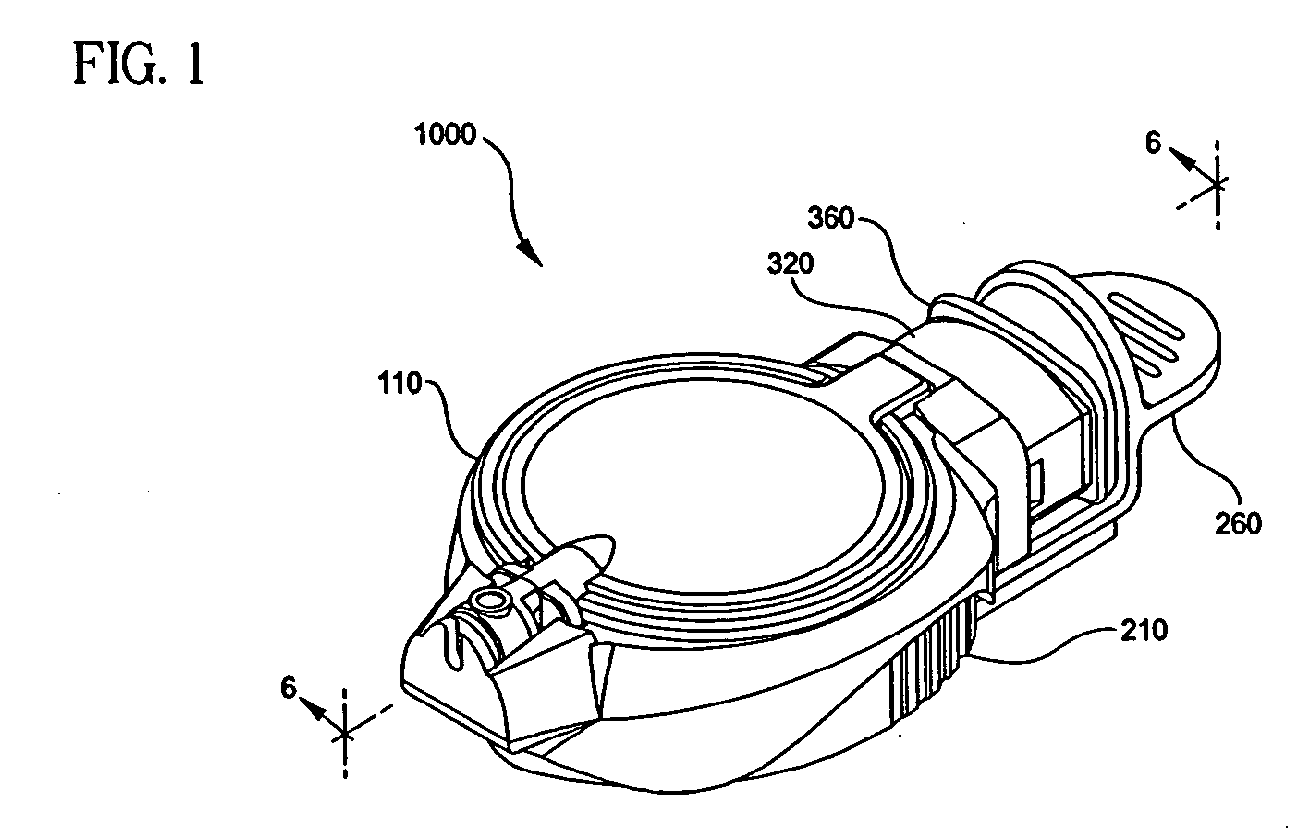

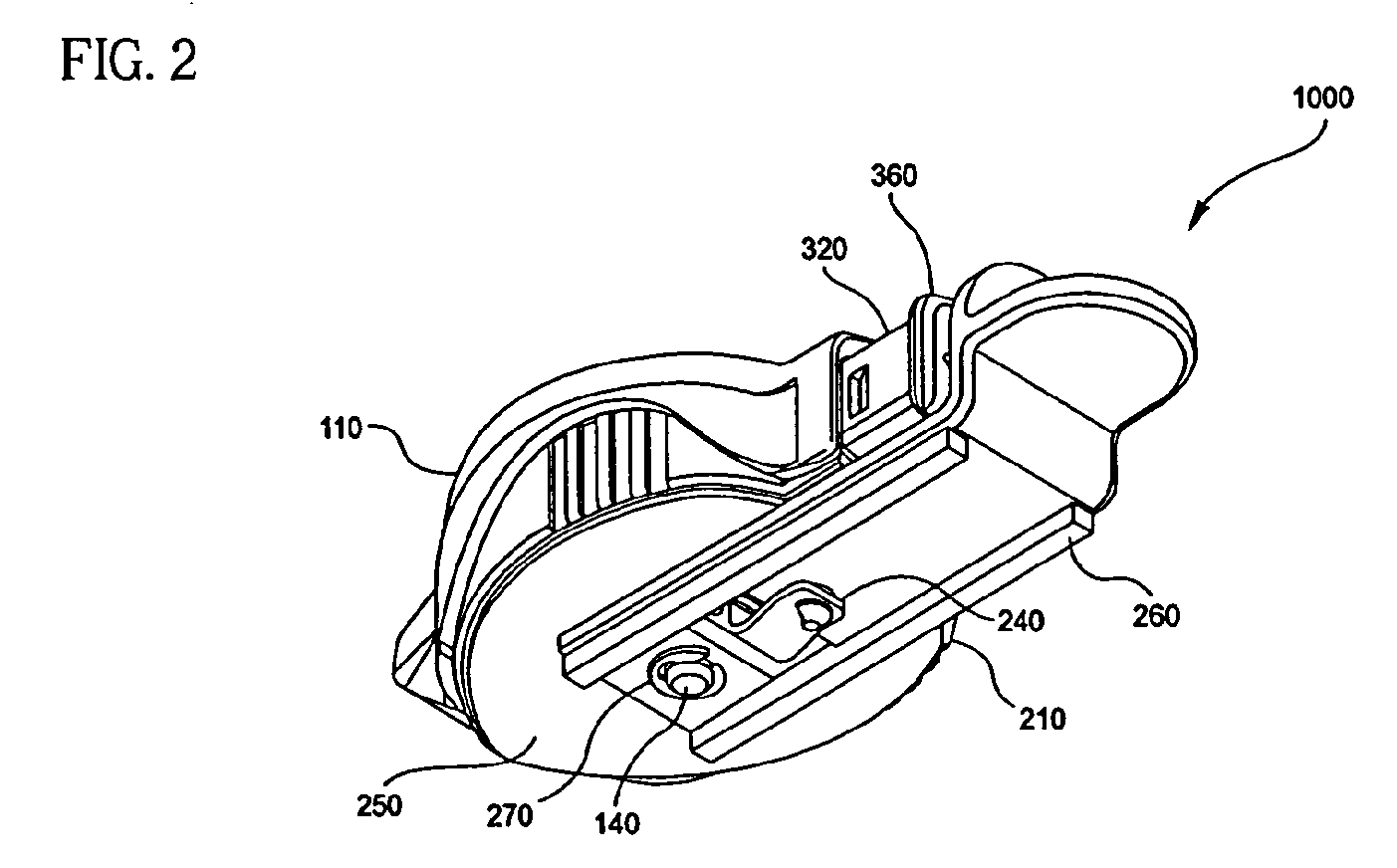

Patch-like infusion device

ActiveUS7250037B2Avoid accidental activationFacilitates self-injectionAutomatic syringesMedical devicesSkin surfaceInfusion set

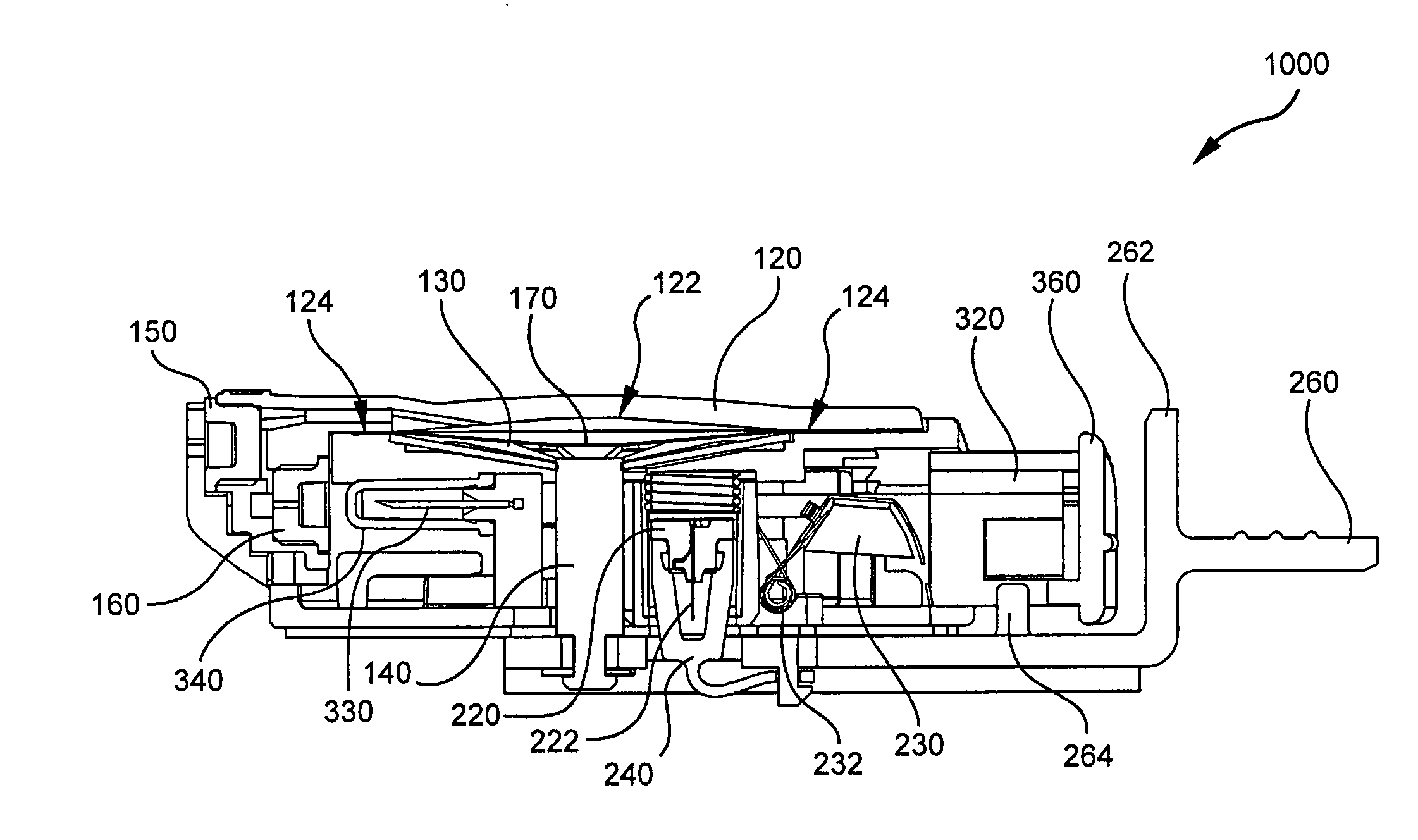

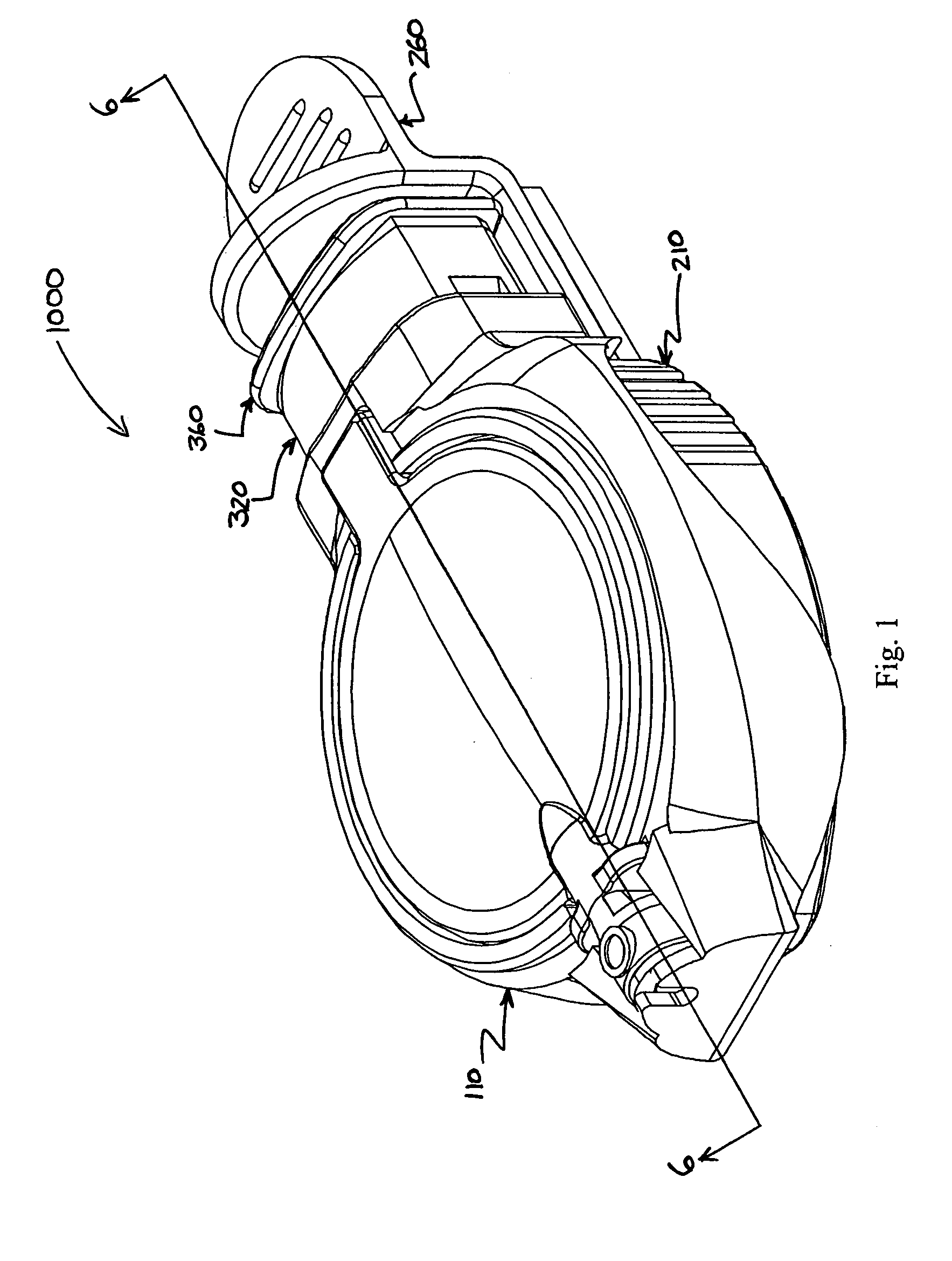

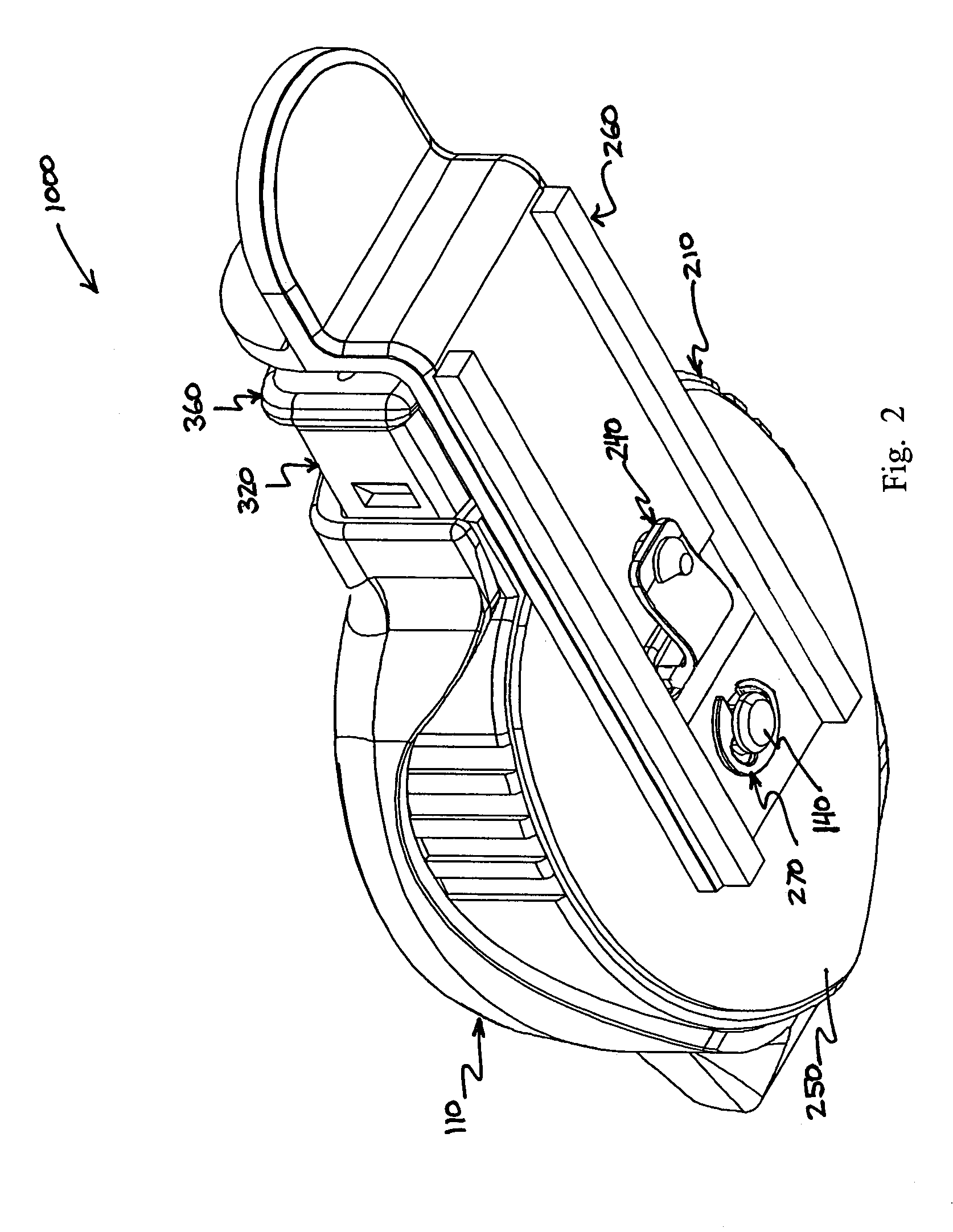

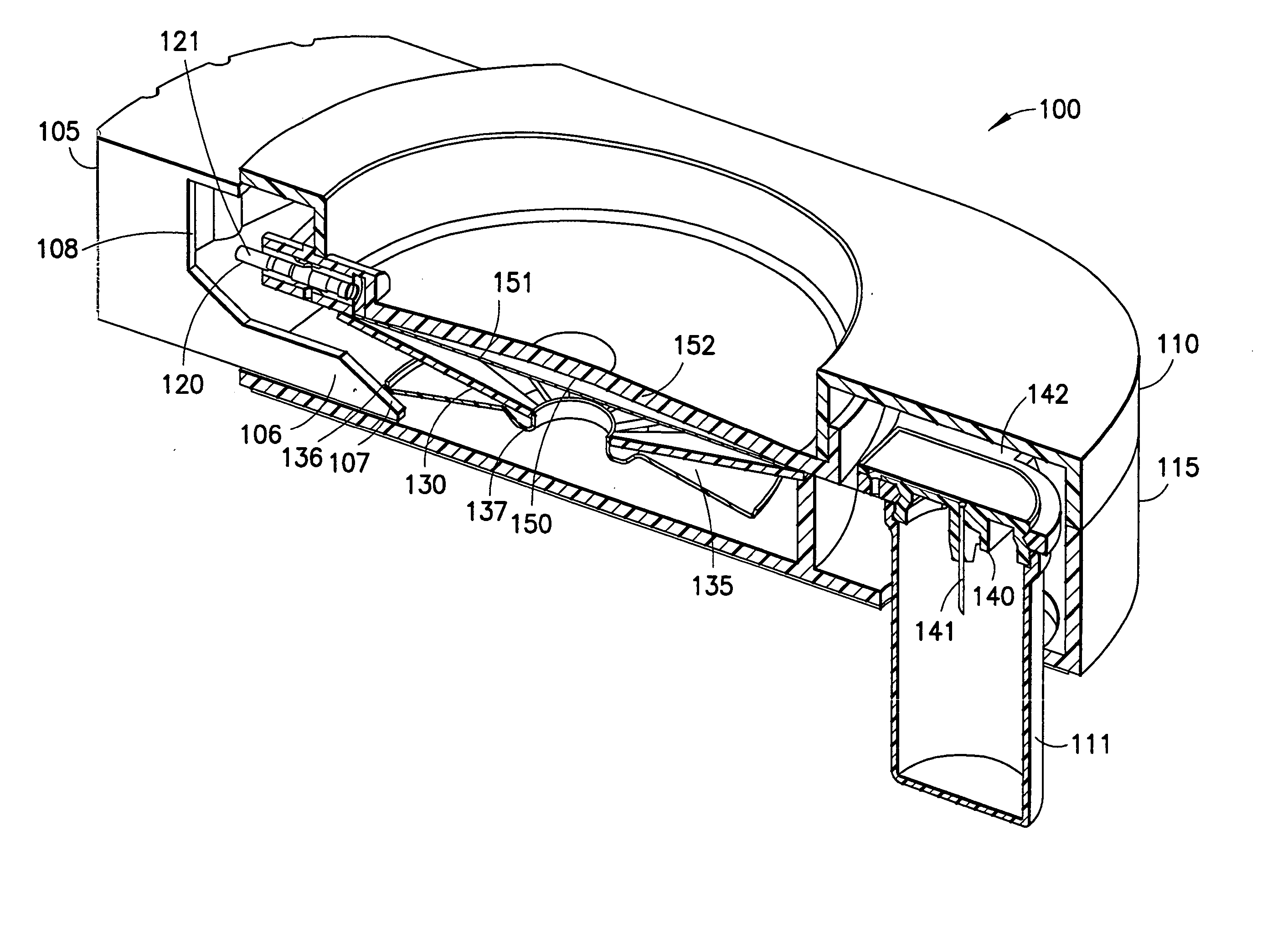

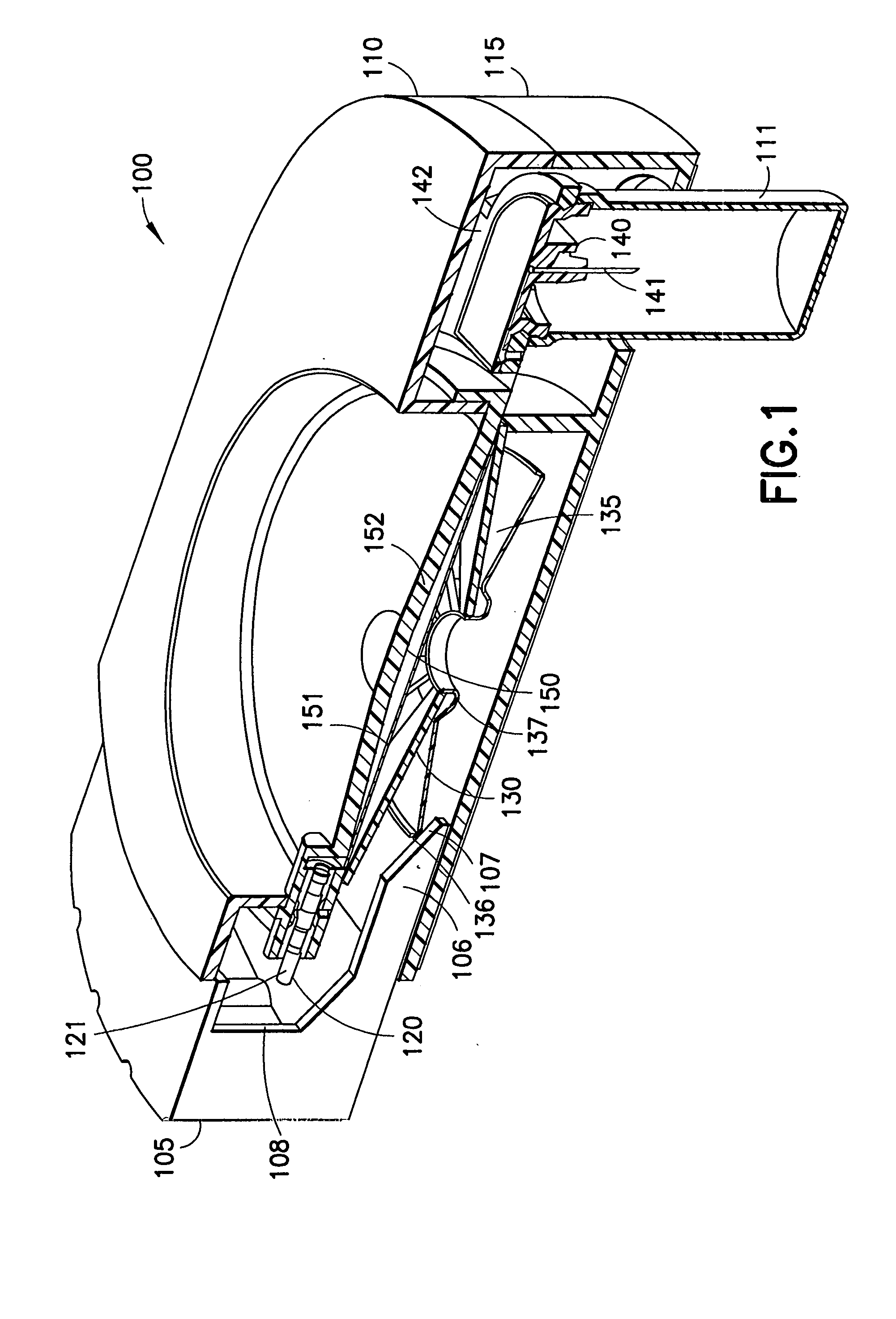

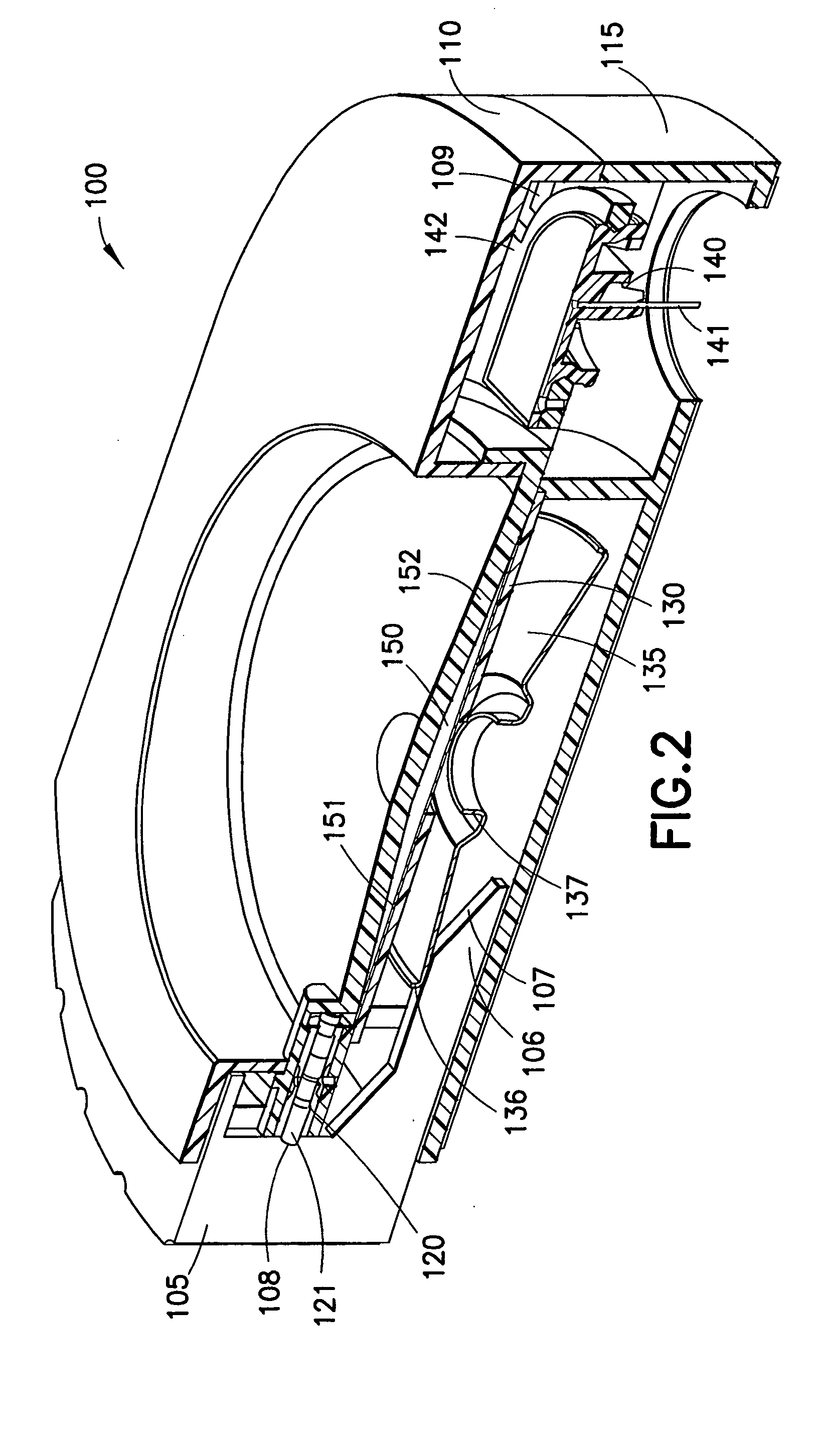

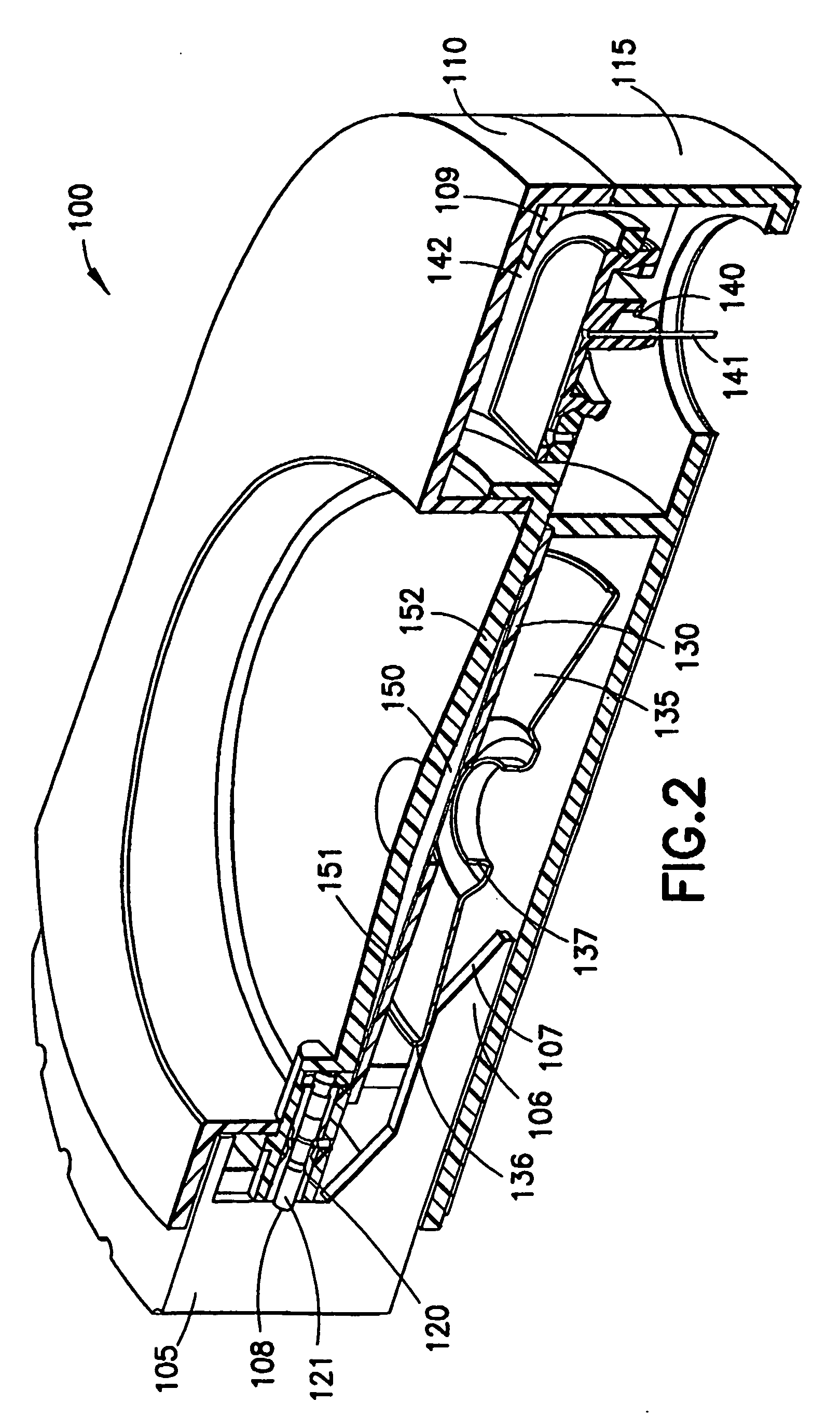

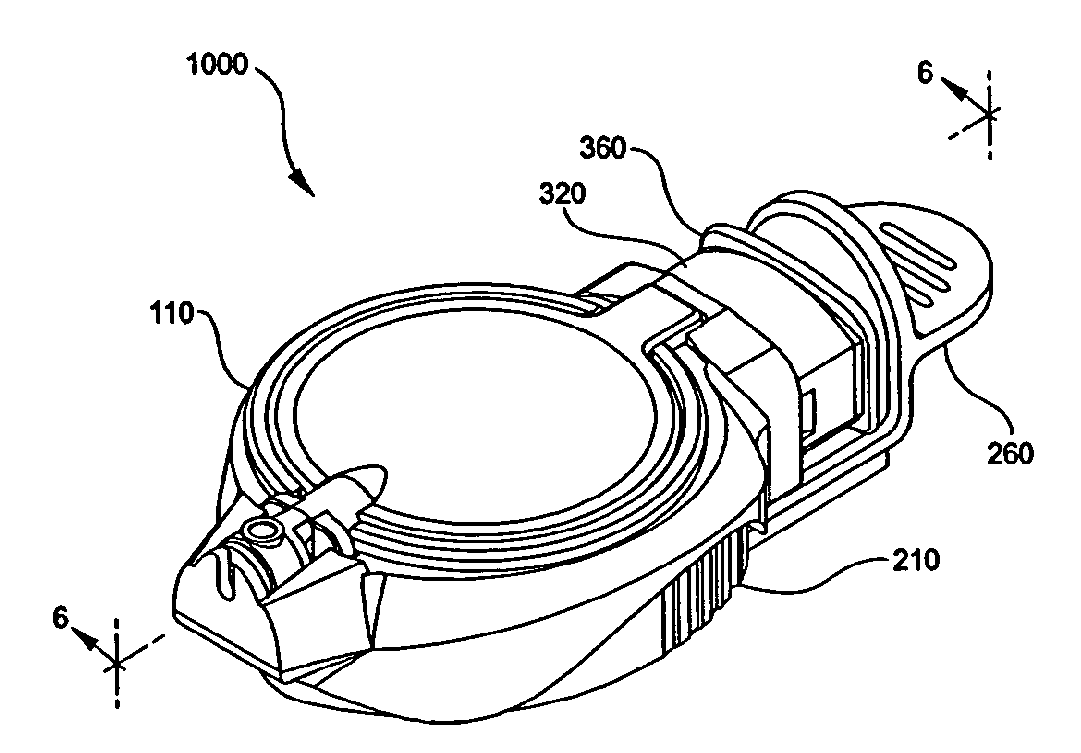

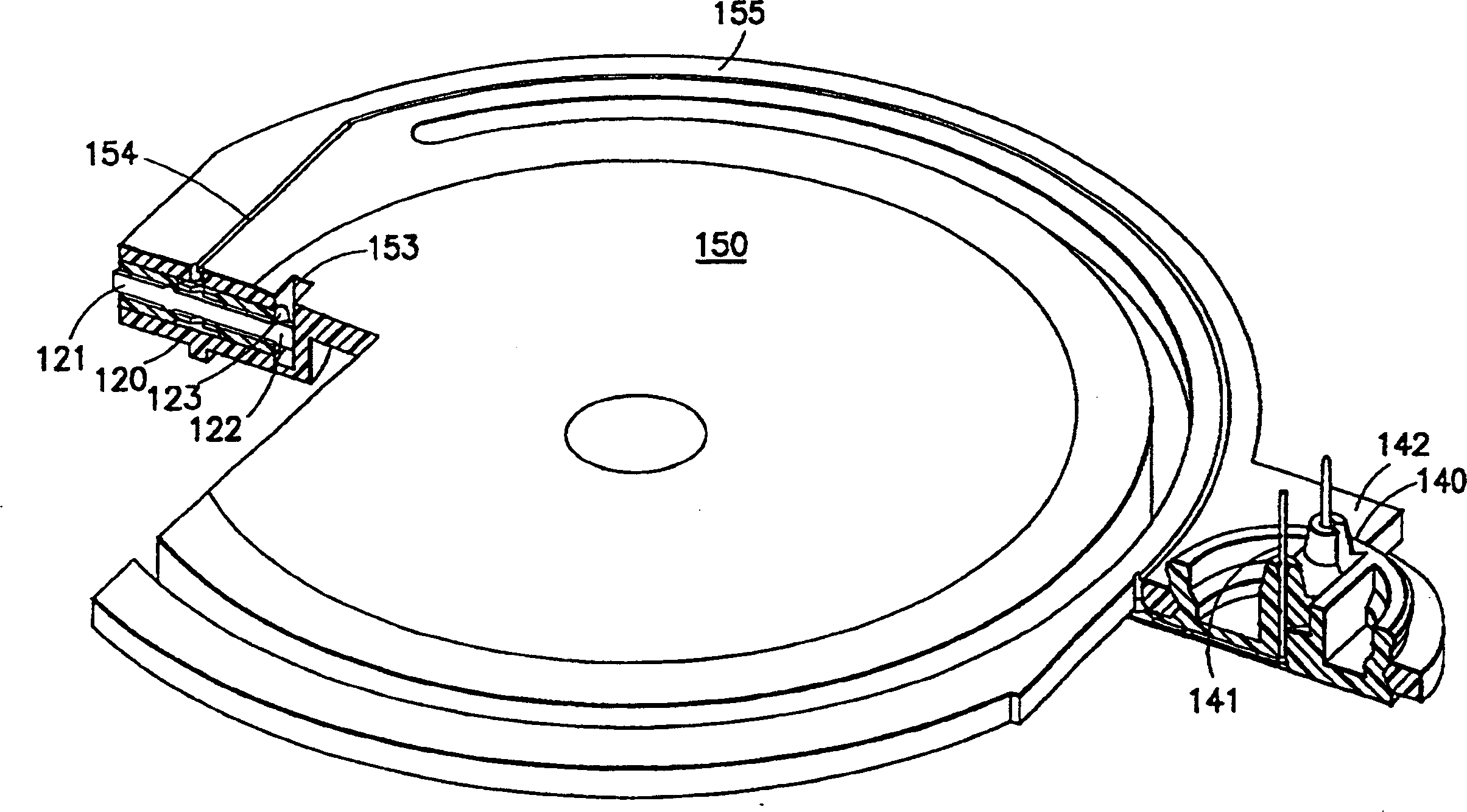

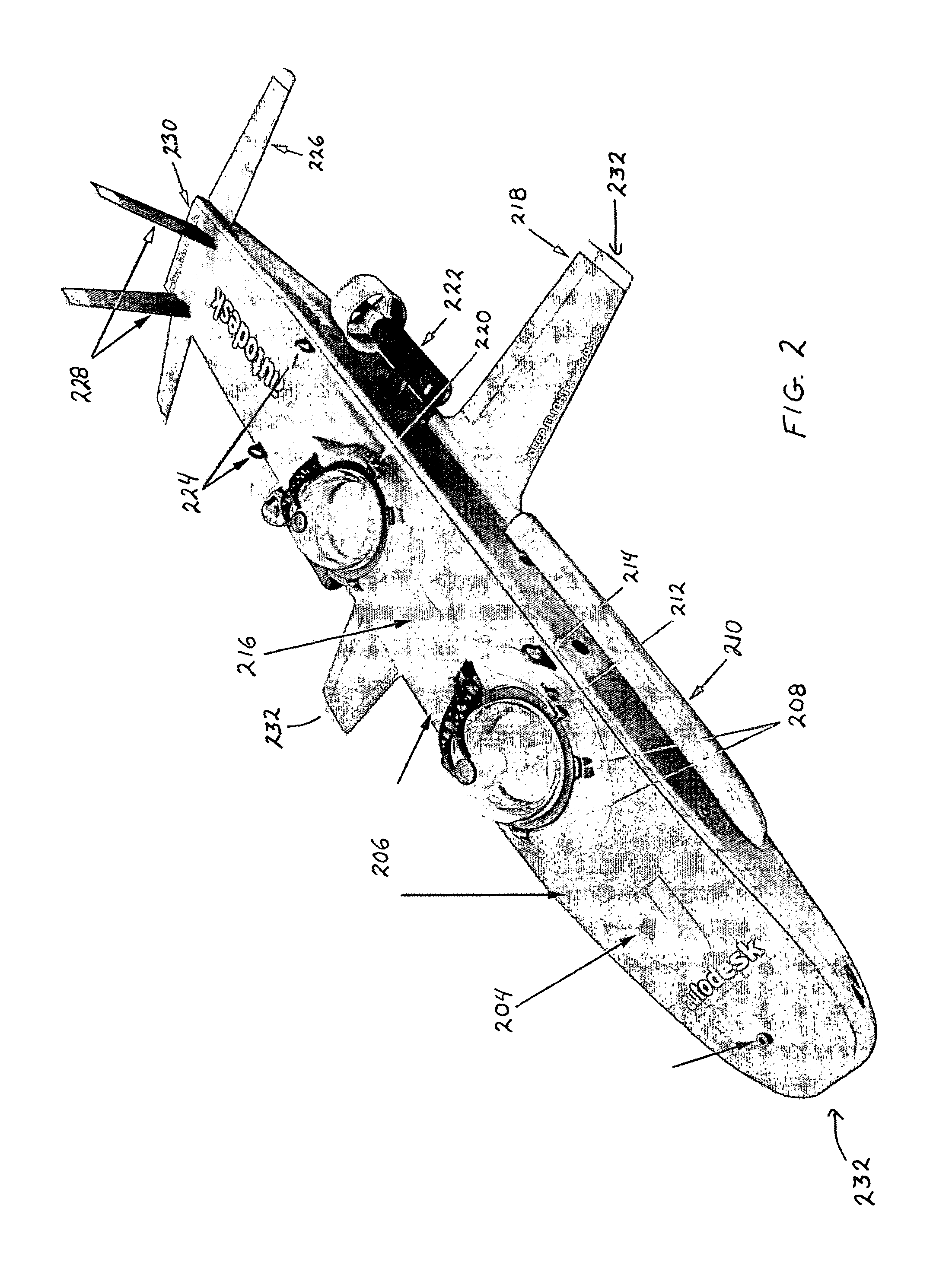

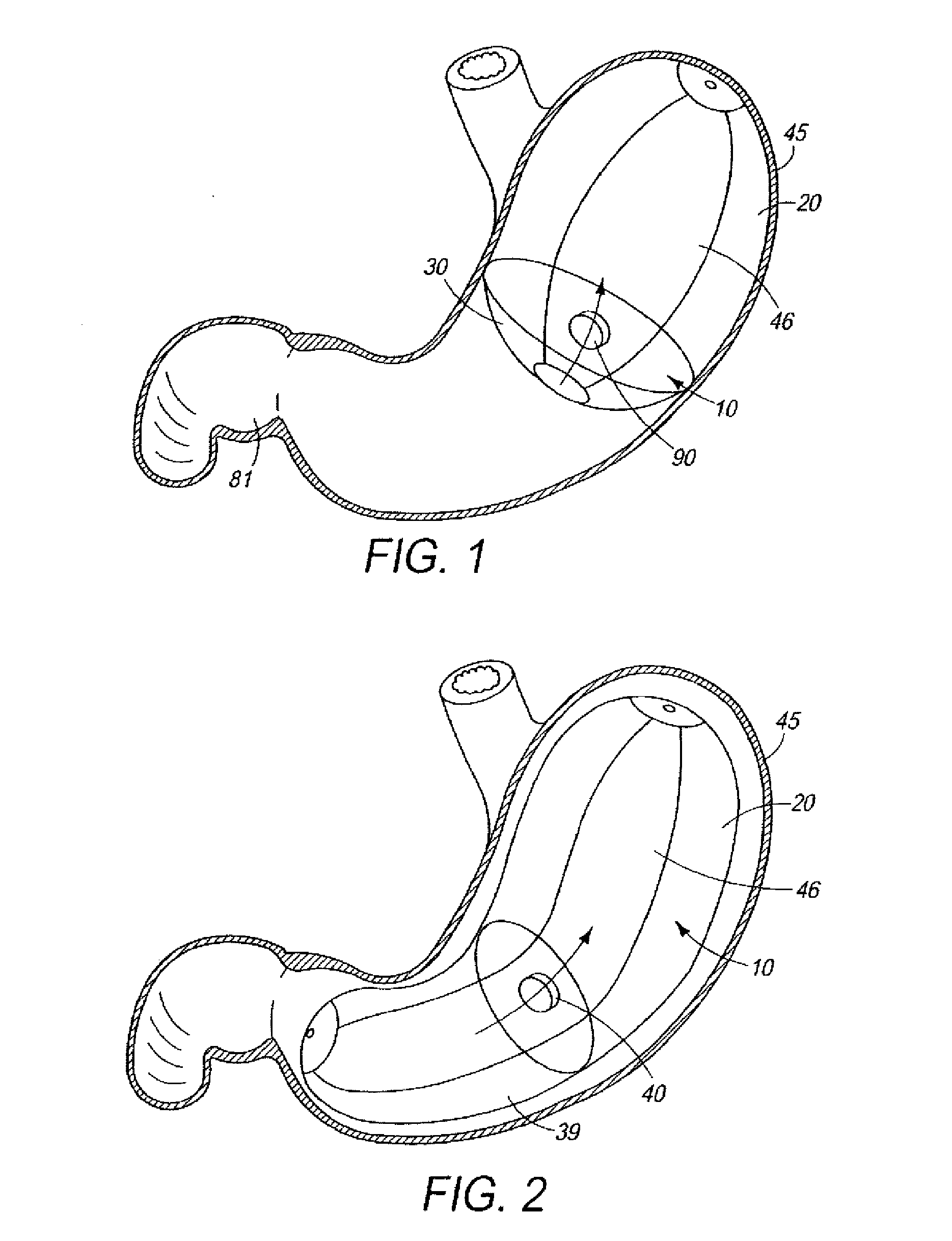

A system and method for a patch-like, self-contained substance infusion device which provides one or more substantially hidden patient needles which can be placed in fluid communication with a fluid reservoir subassembly that includes a rigid bladder portion used in conjunction with a non-distensible bladder film, such as a metallized film. Simple removal of an interlock allows a disk, or Belleville spring assembly to apply an essentially even and constant pressure to the contents of the fluid reservoir assembly, and allows the device to then be attached to a skin surface via an adhesive contact surface. A push button activation assembly is provided which can then be used to release and seat one or more spring-loaded patient needles into the skin surface, and establish a fluid communication path between the patient needles and the pressurized fluid reservoir contents thereby delivering an infusion into the skin.

Owner:BECTON DICKINSON & CO

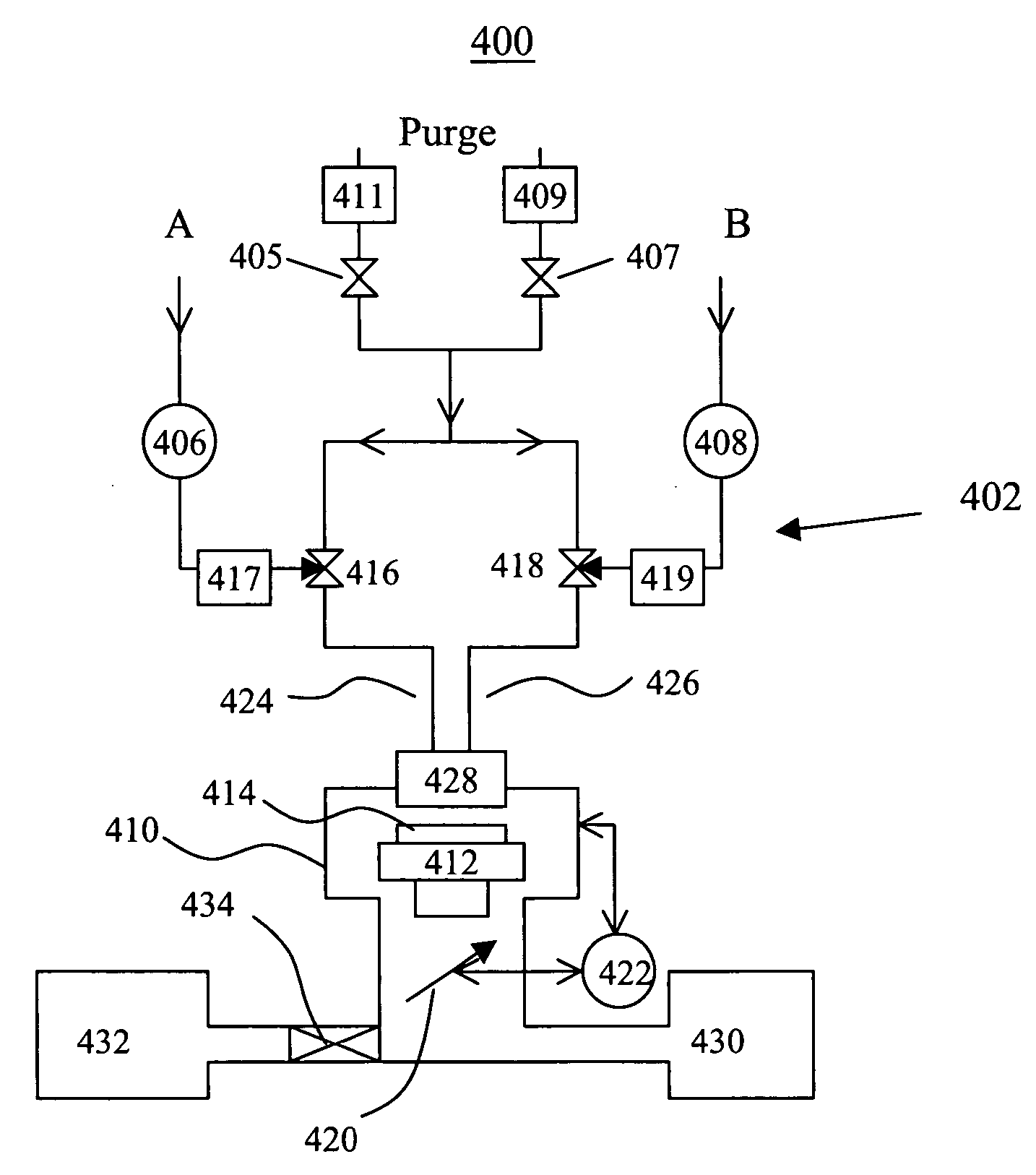

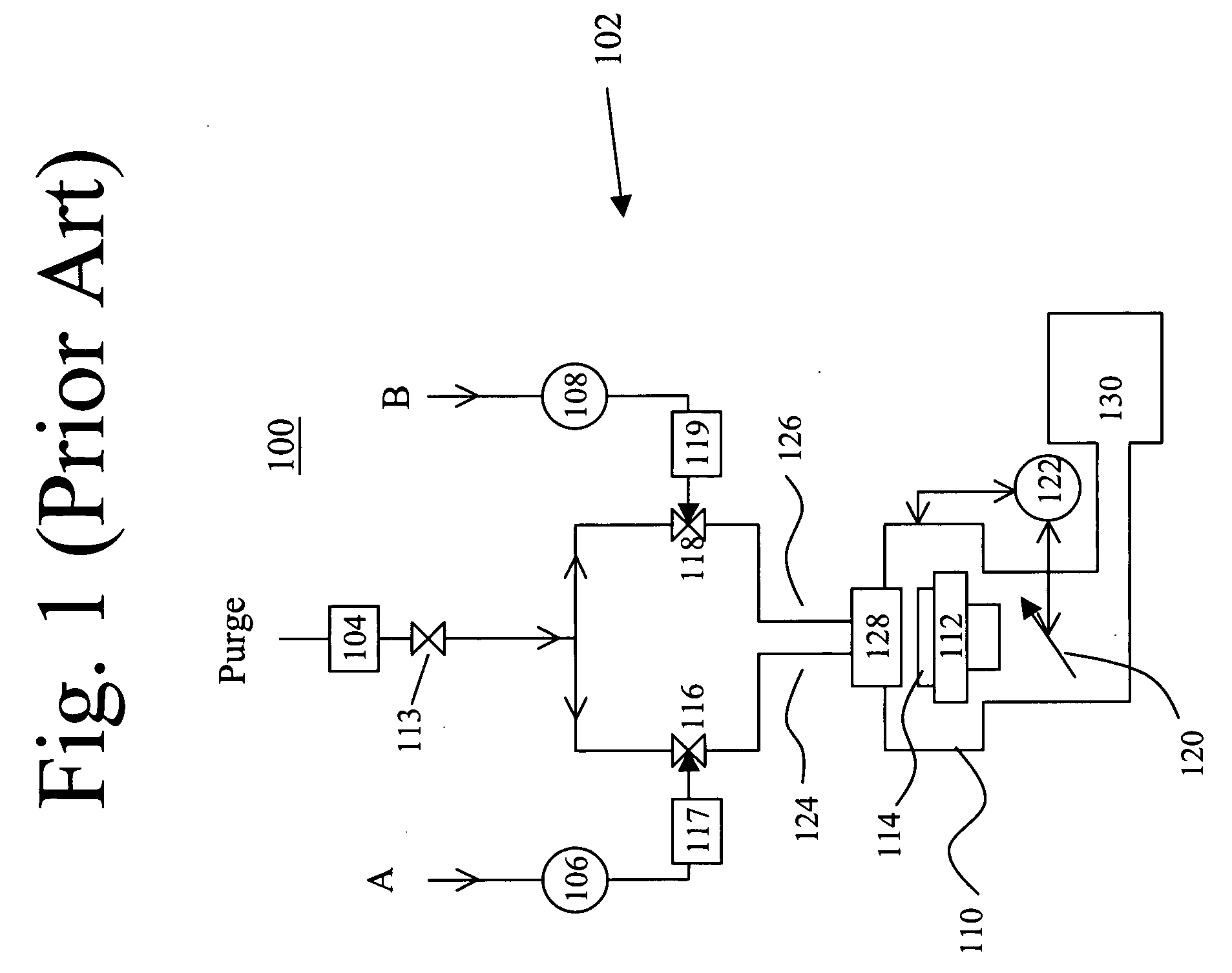

Methods and apparatus for cycle time improvements for atomic layer deposition

InactiveUS20050016956A1Decorative surface effectsFrom chemically reactive gasesProcess engineeringCycle time

Different periods of an ALD cycle are performed using different purge flows and, in some cases, different pumping capacities, while maintaining the reactor chamber at a nominally constant pressure. The purge flows may, in some cases, utilize different gasses and / or may be provided through different flow paths. These operations provide for ALD cycle time improvements and economical operation with respect to consumables usage. In some embodiments the use of an annular throttle valve provides a means for controlling downstream flow limiting conductances in a gas flow path from the reactor chamber.

Owner:AIXTRON INC

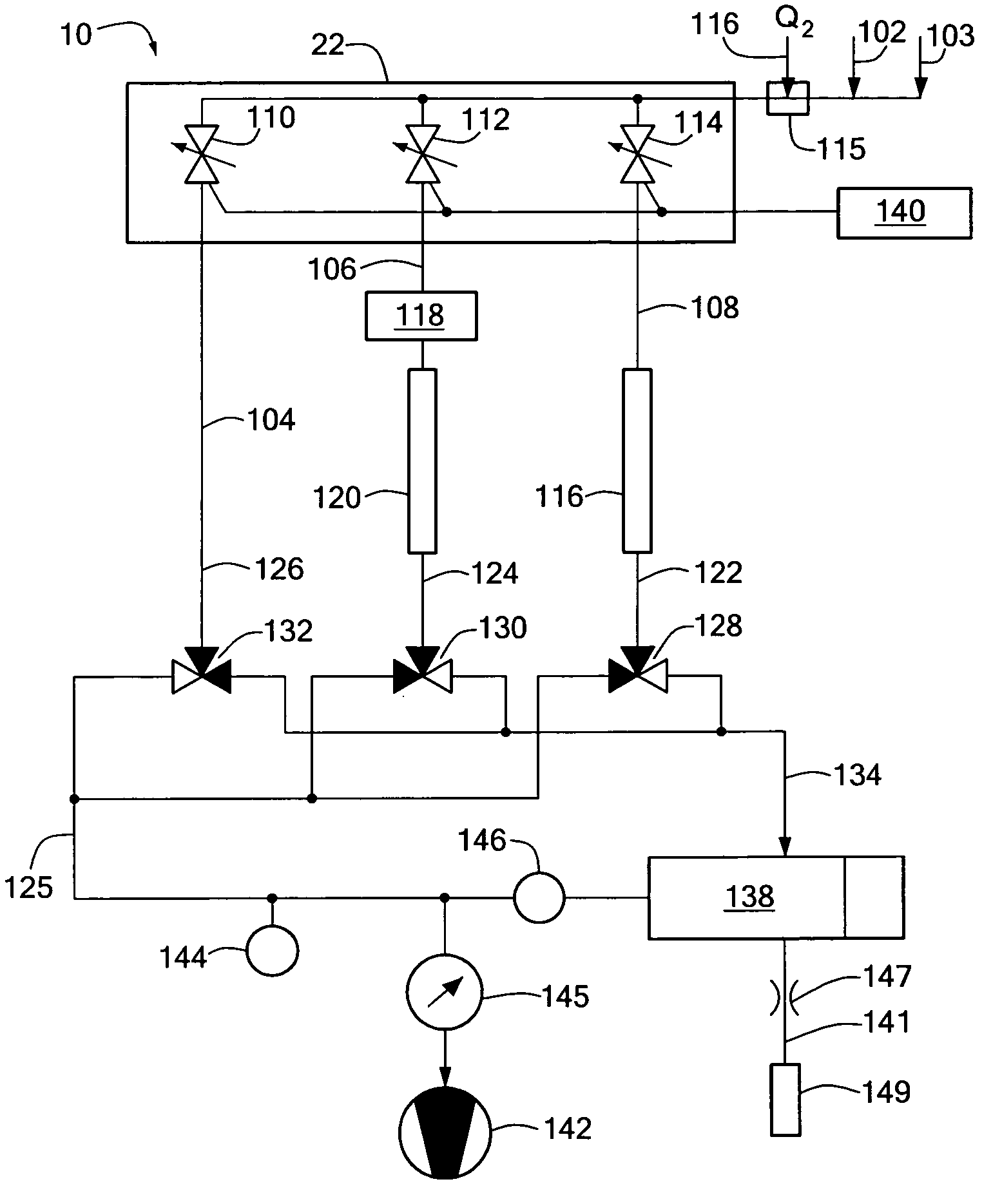

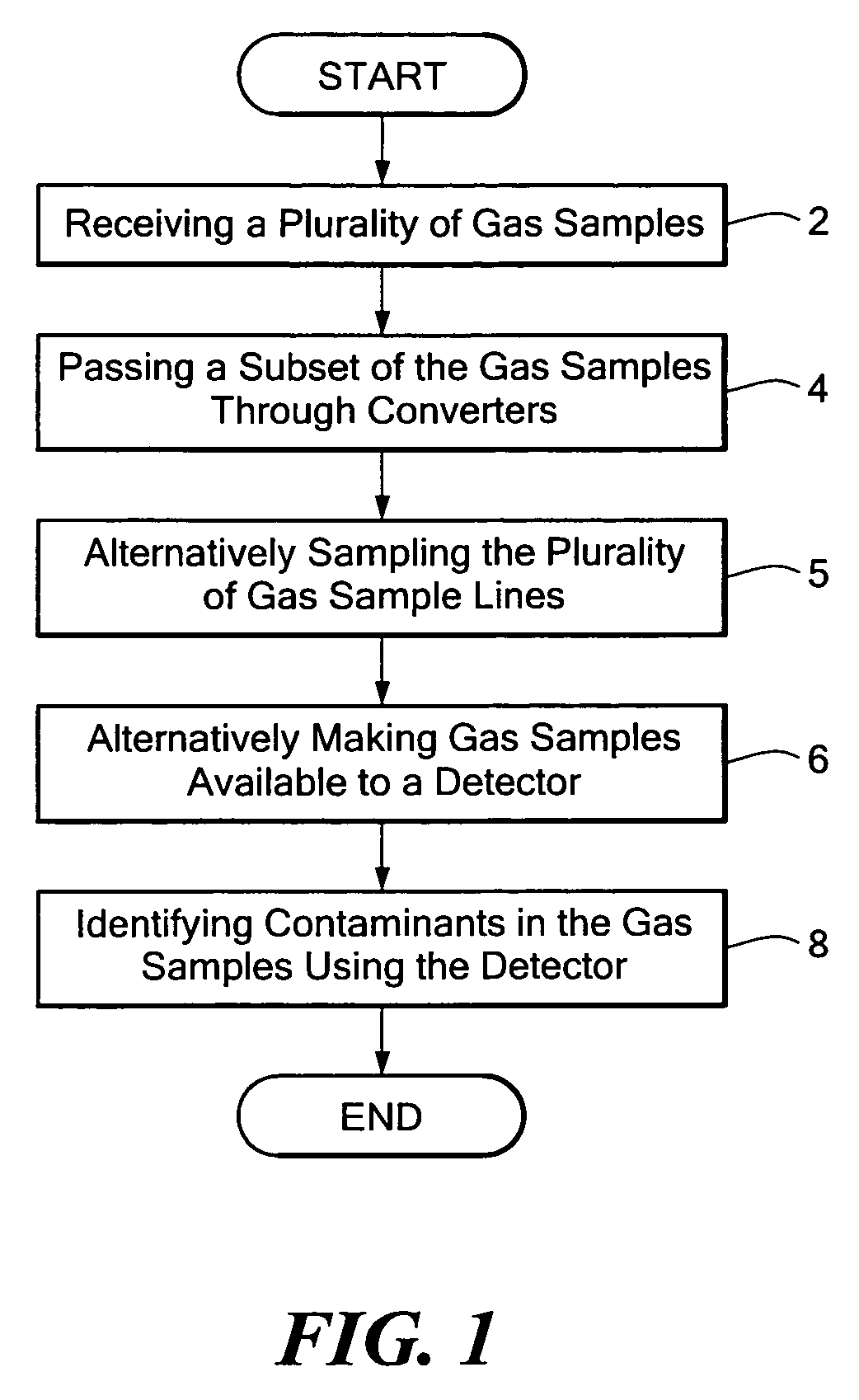

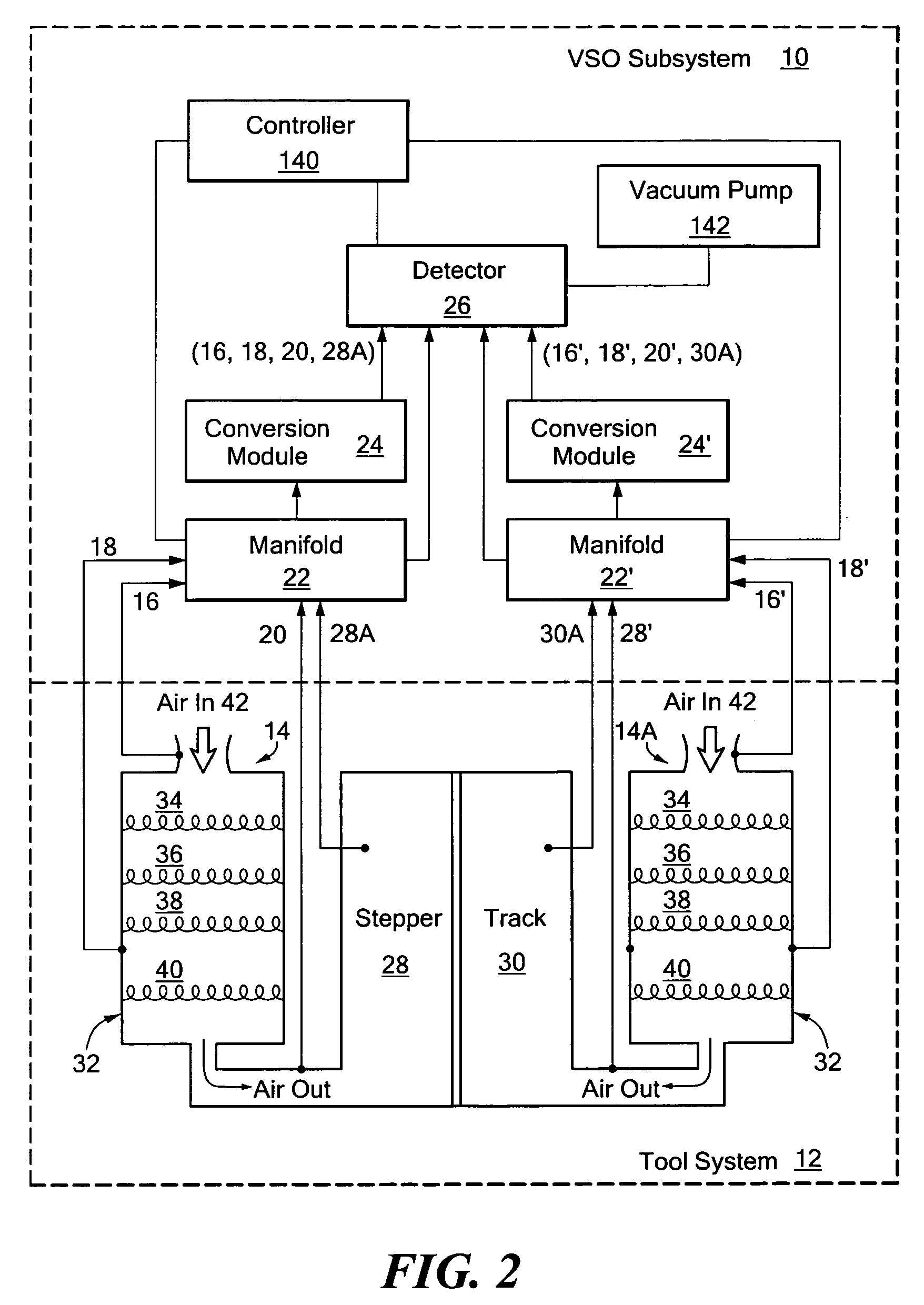

Method and apparatus for improving measuring accuracy in gas monitoring systems

InactiveUS20060108221A1Accurate and repeatable measurementFacilitate the monitoring of such speciesGas analyser construction detailsMaterial electrochemical variablesLine tubingEngineering

A method and apparatus for improving measurement accuracy in a gas monitoring system is provided. The apparatus can be connected to a plurality of gas sample lines each containing a gas sample. The gas samples are routed through a number of delivery channels which are fewer in number than the plurality of sample lines. Each delivery channel is alternatively coupled to a detector which identifies contaminants present in the gas samples. Each delivery channel includes a voltage sensitive orifice (VSO). The VSO's are operated by a controller and provide gas samples at a constant flow and a constant pressure to the detector independent of the length of the gas sample line being measured.

Owner:ENTEGRIS INC

Patch-like infusion device

ActiveUS20050065466A1Conveniently worn against skinMinimal discomfortDispensing apparatusDiagnosticsCircular discInfusion set

A packaging system and method which provides at least one tray or nest, having a number of wells and ribs to position and secure a patch-like, self-contained substance infusion device having one or more patient needles which can be placed in fluid communication with a fluid reservoir assembly within the device and upon which a disk, or Belleville spring assembly applies an essentially even and constant pressure to the contents. The device further provides for the release of one or more spring-loaded patient needles a patient's skin surface to establish a fluid communication path between the patient needles and the pressurized fluid reservoir contents.

Owner:BECTON DICKINSON & CO

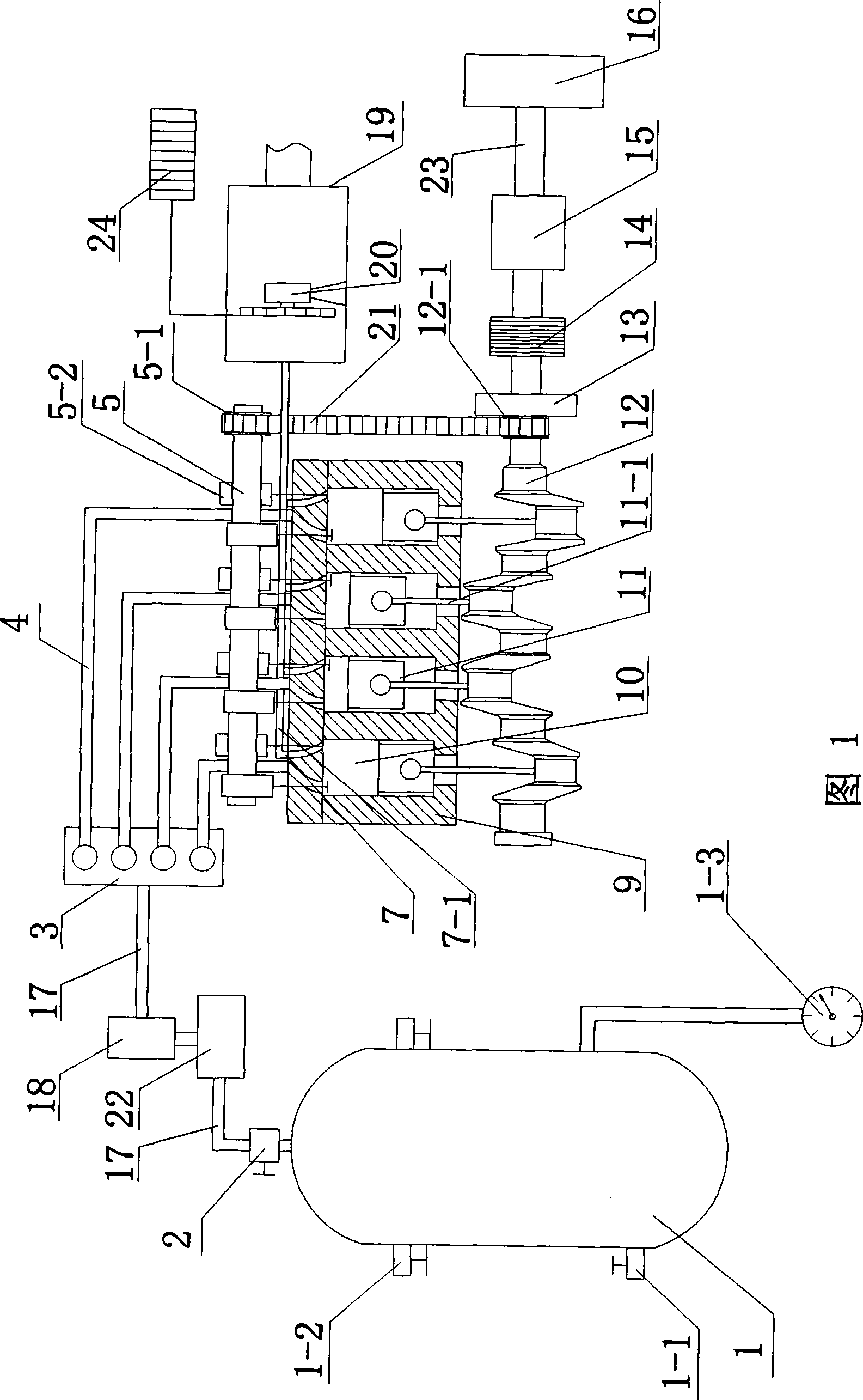

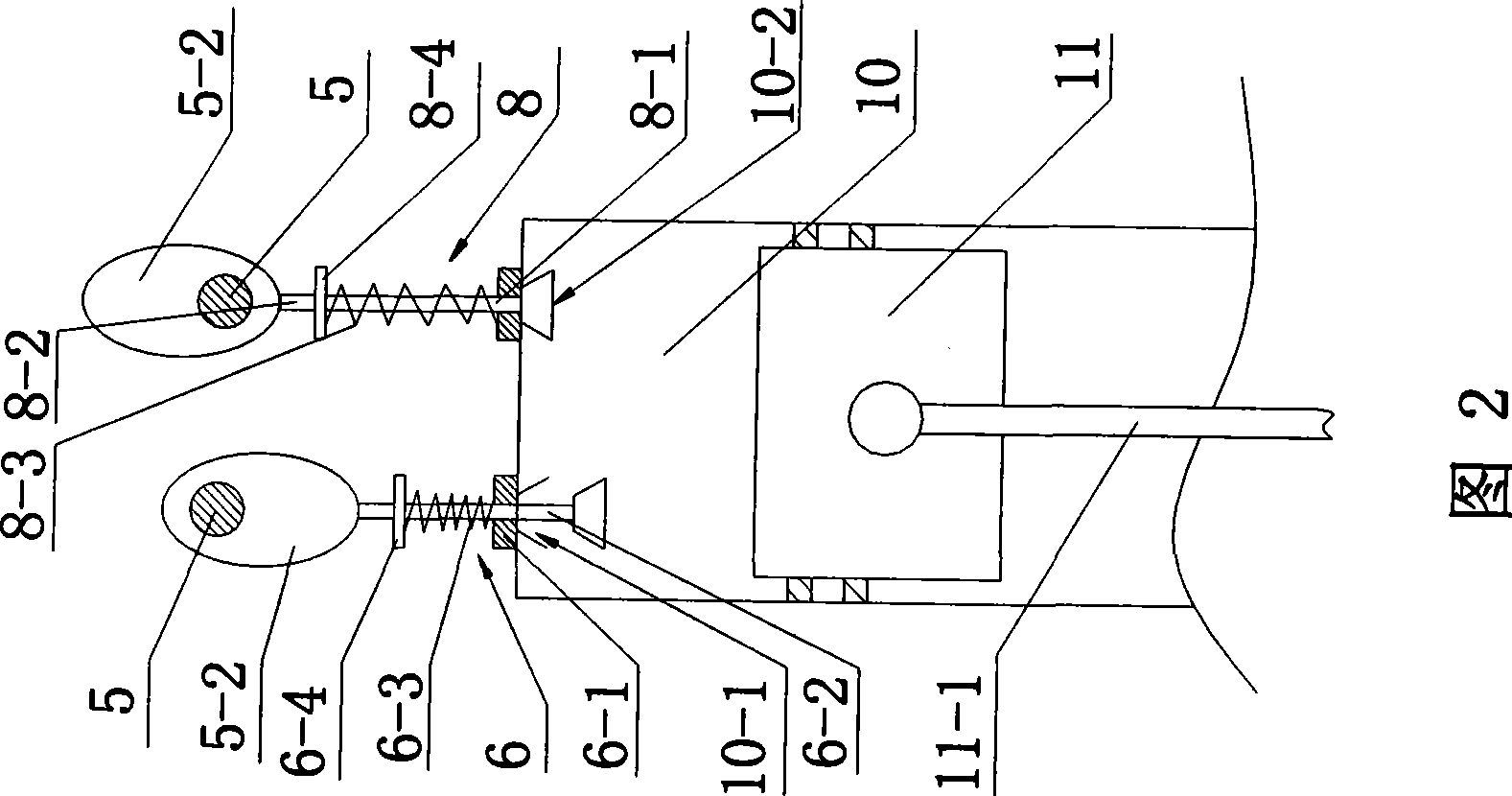

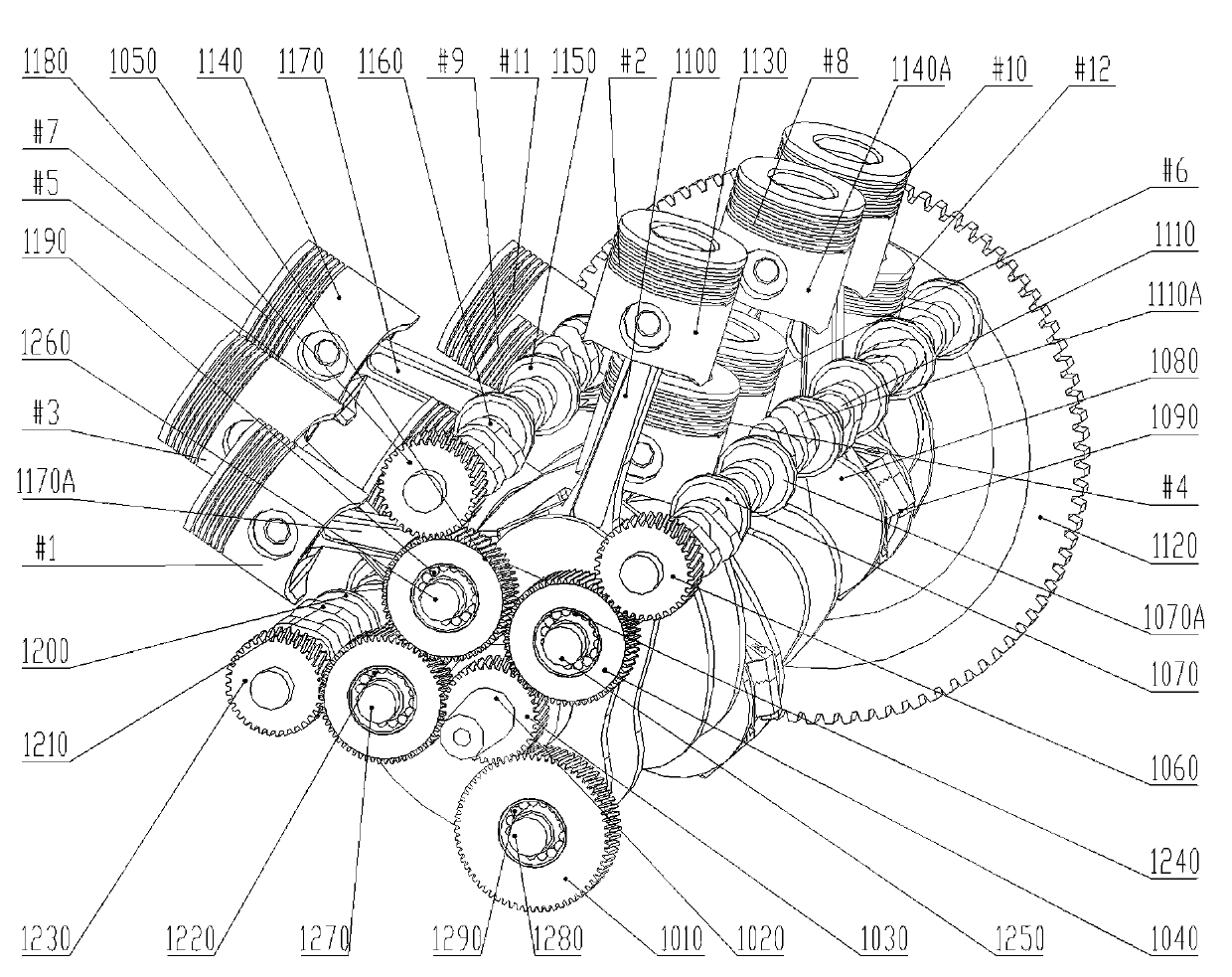

Air power engine assembly

InactiveCN101413403ALow costNo pollutionMechanical power devicesEngines characterised by uniflow principleDistributorPiston

The invention relates to an air-powered engine assembly, which comprises an air tank, an air valve, an air distributor, an intake pipe, camshafts, an intake duct, an exhaust control device, air cylinders, pistons, crankshafts, couplers, clutches, automatic gearboxes and differentials connected with the outside. The assembly is characterized in that the air valve, a constant pressure chamber and a pressure controller are arranged between the air tank and the air distributor; the air distributor is connected with a plurality of air cylinders on an air cylinder gasket; each air cylinder is connected with an exhaust chamber through an exhaust manifold; the exhaust chamber is provided with a turbine generator which is connected with a storage batter; the air cylinders are provided with the camshafts for controlling the air intake and exhaust of the air cylinders; the air cylinders are provided inside with the pistons for driving the crankshafts to rotate; the camshafts and the crankshafts are connected by chains; and the crankshafts are connected with the differentials through the couplers, the clutches and the gearboxes in turn. Therefore, doing work through air compression rather than fuel, the air-powered engine assembly has the advantages of avoiding waste gas discharge and air pollution, along with reliable operation, convenient operation, economical efficiency, practicality and so on. In addition, due to recycle of the waste gas for power generation, the air-powered engine assembly saves energy and reduces costs.

Owner:周登荣 +1

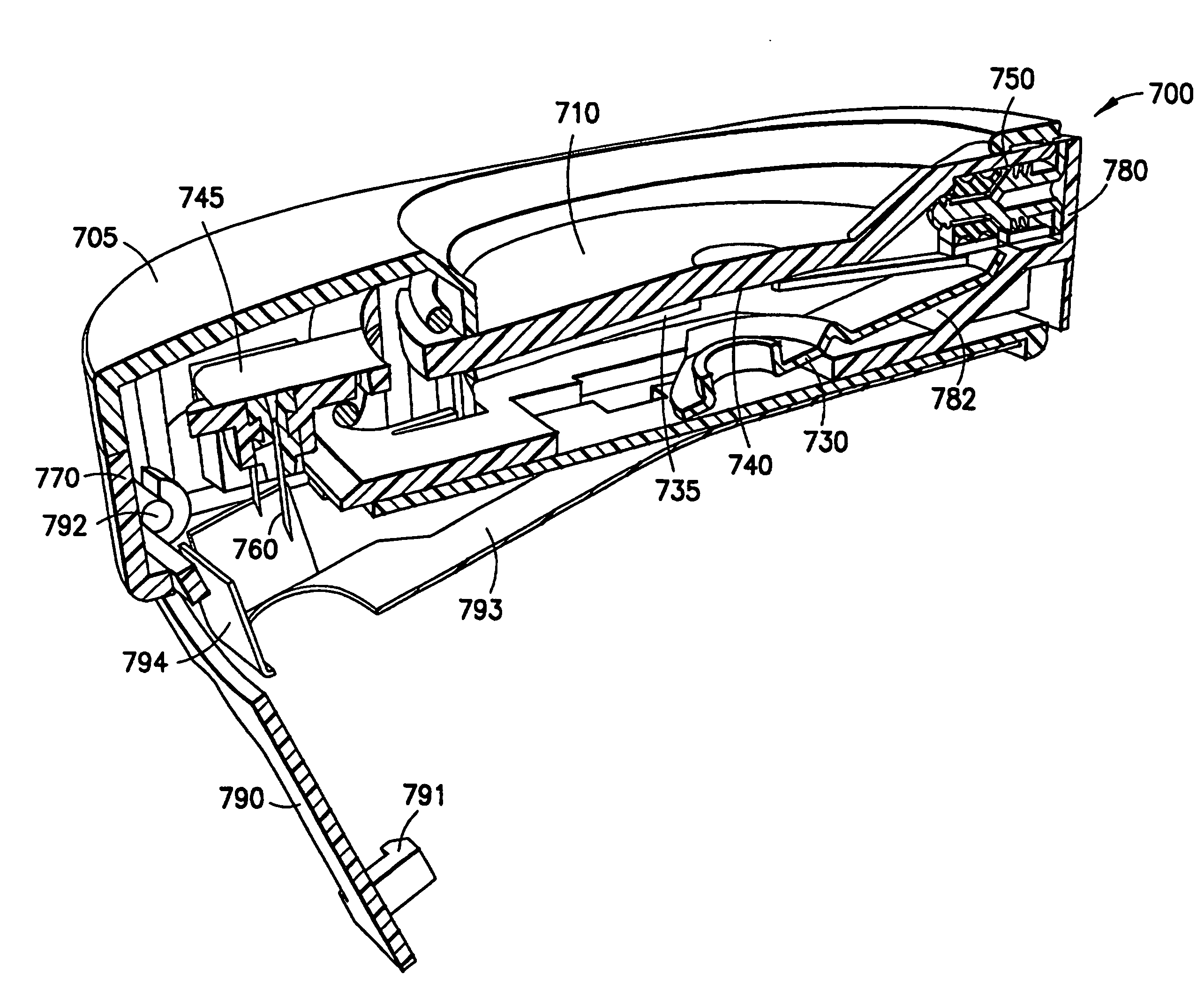

Patch-Like Infusion Device

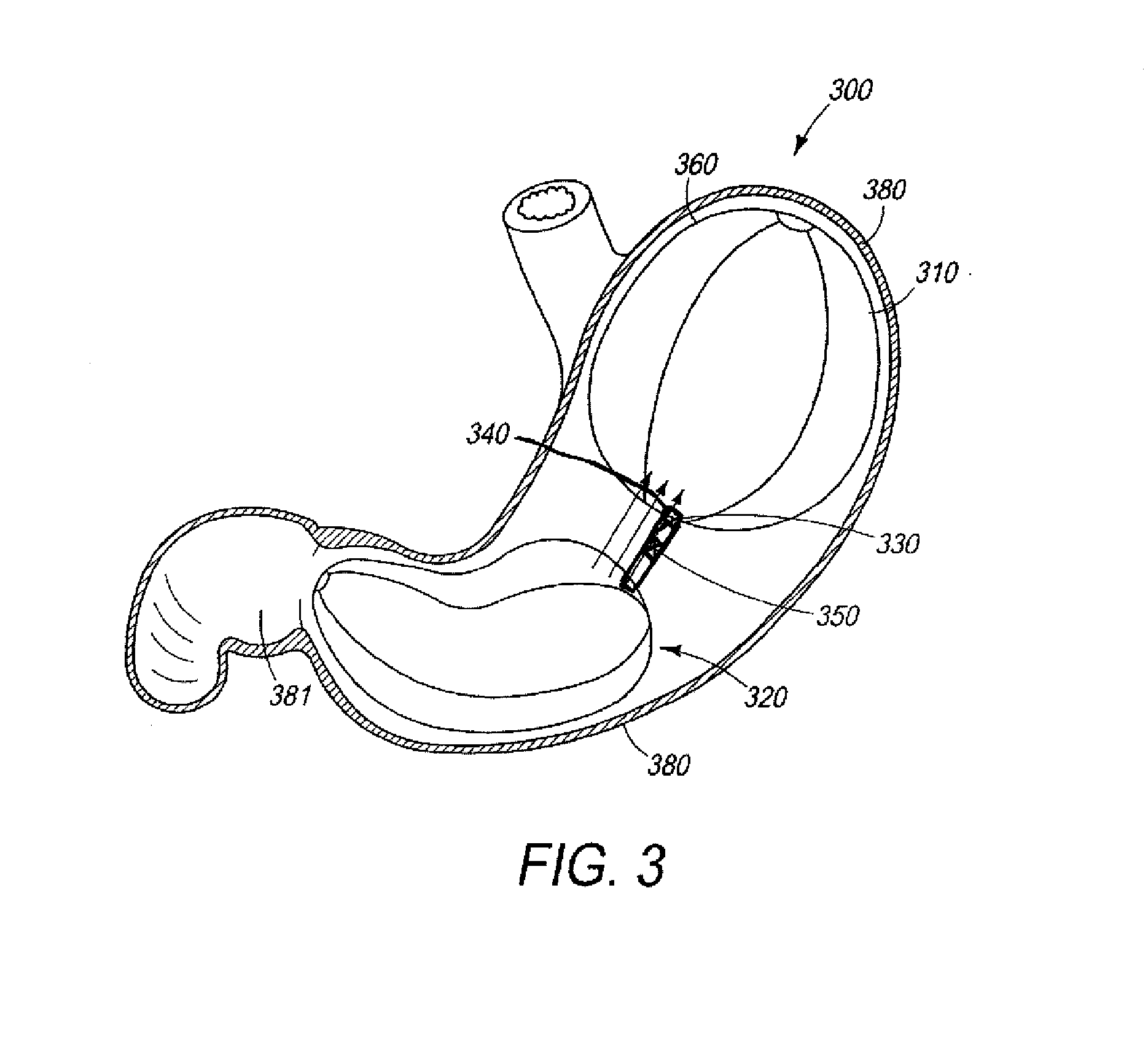

ActiveUS20080215015A1Conveniently worn against skinMinimal discomfortAmpoule syringesAutomatic syringesSkin surfaceCombined use

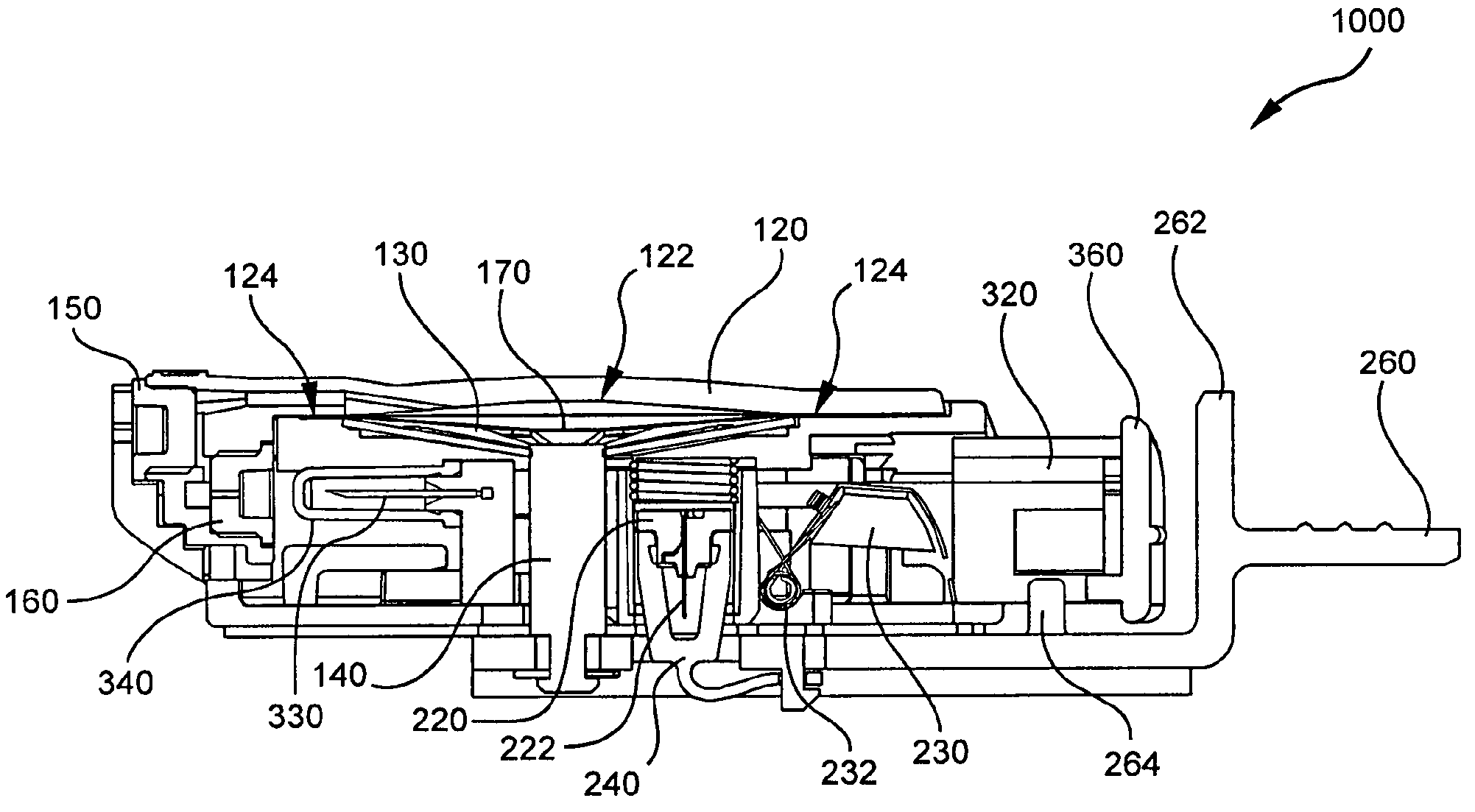

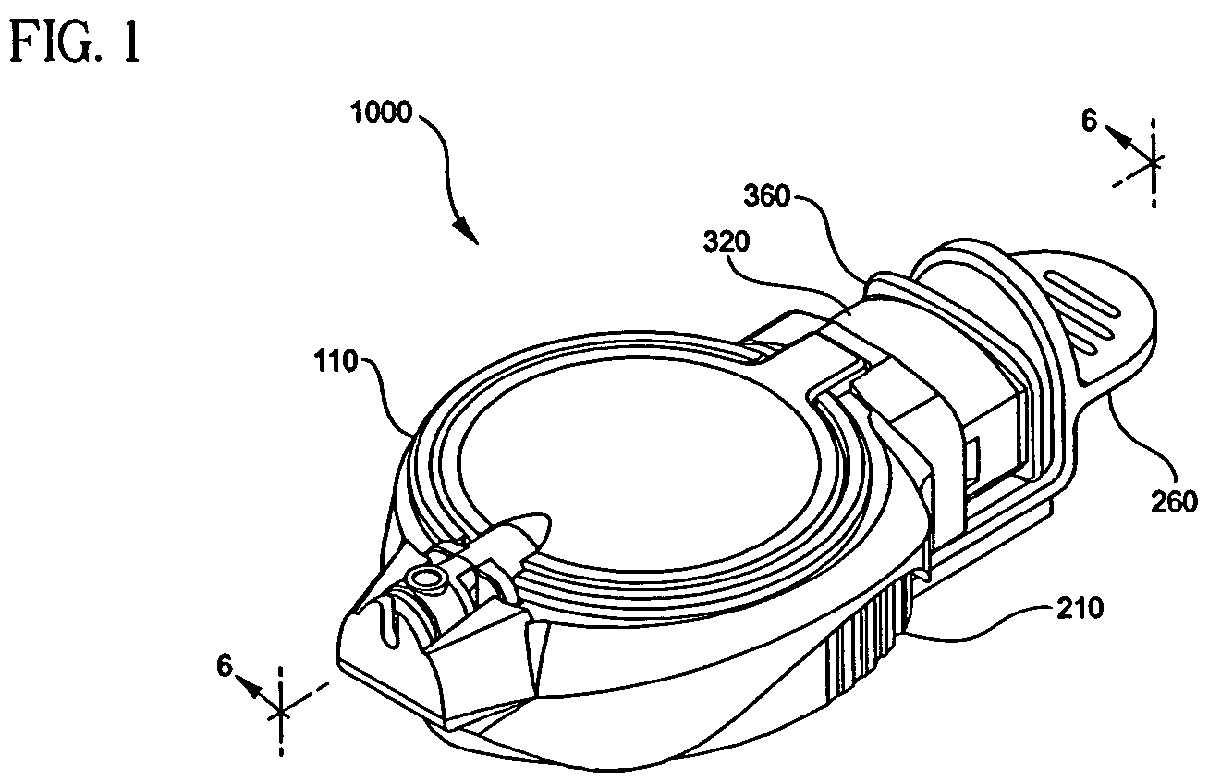

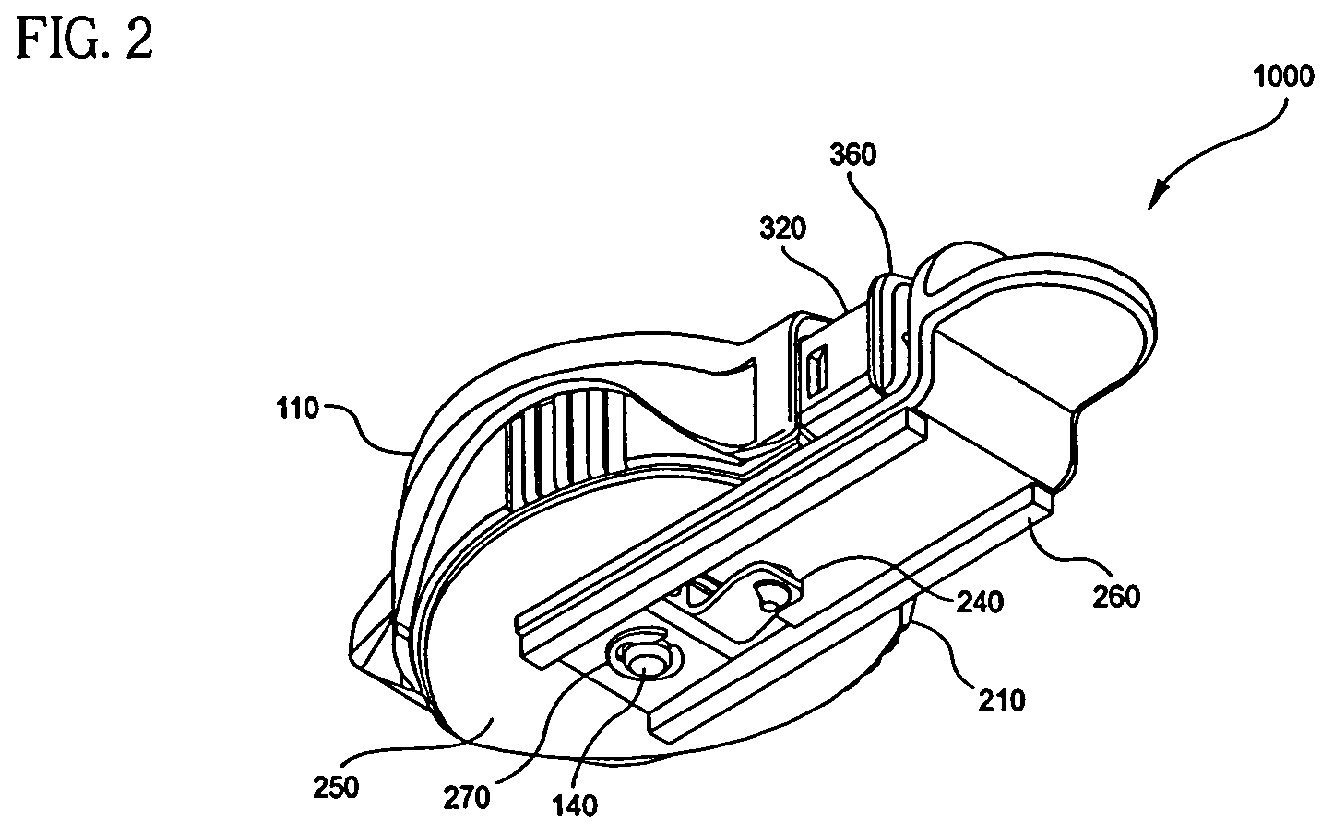

A system and method for a patch-like, self-contained substance infusion device (700) which provides one or more substantially hidden patient needles (760) which can be placed in fluid communication with a fluid reservoir assembly (710) that includes a rigid bladder portion (712) used in conjunction with a non-distensible bladder film (740), such as a metallized film. The device (700) can be attached to a skin surface via an adhesive contact surface and a push button (780) activation assembly can then be used to remove an interlock (730), allowing a disk, or Belleville spring (735) assembly to apply an essentially even and constant pressure to the contents of a fluid reservoir assembly (710). The push button (780) activation assembly further allows the release of one or more spring-loaded patient needles (760) into the skin surface, and establishes a fluid communication path between the patient needles (760) and the pressurized fluid reservoir contents thereby delivering an infusion into the skin. The push button (780) activation assembly further allows the release of one or more improved safety mechanisms (794) after use which are driven by spring (793) and released by trap-door (790).

Owner:BECTON DICKINSON & CO

Patch-like infusion device

InactiveUS7678079B2Conveniently worn against skinAutomatic syringesMedical devicesSkin surfaceCombined use

Owner:BECTON DICKINSON & CO

Direct write process and apparatus

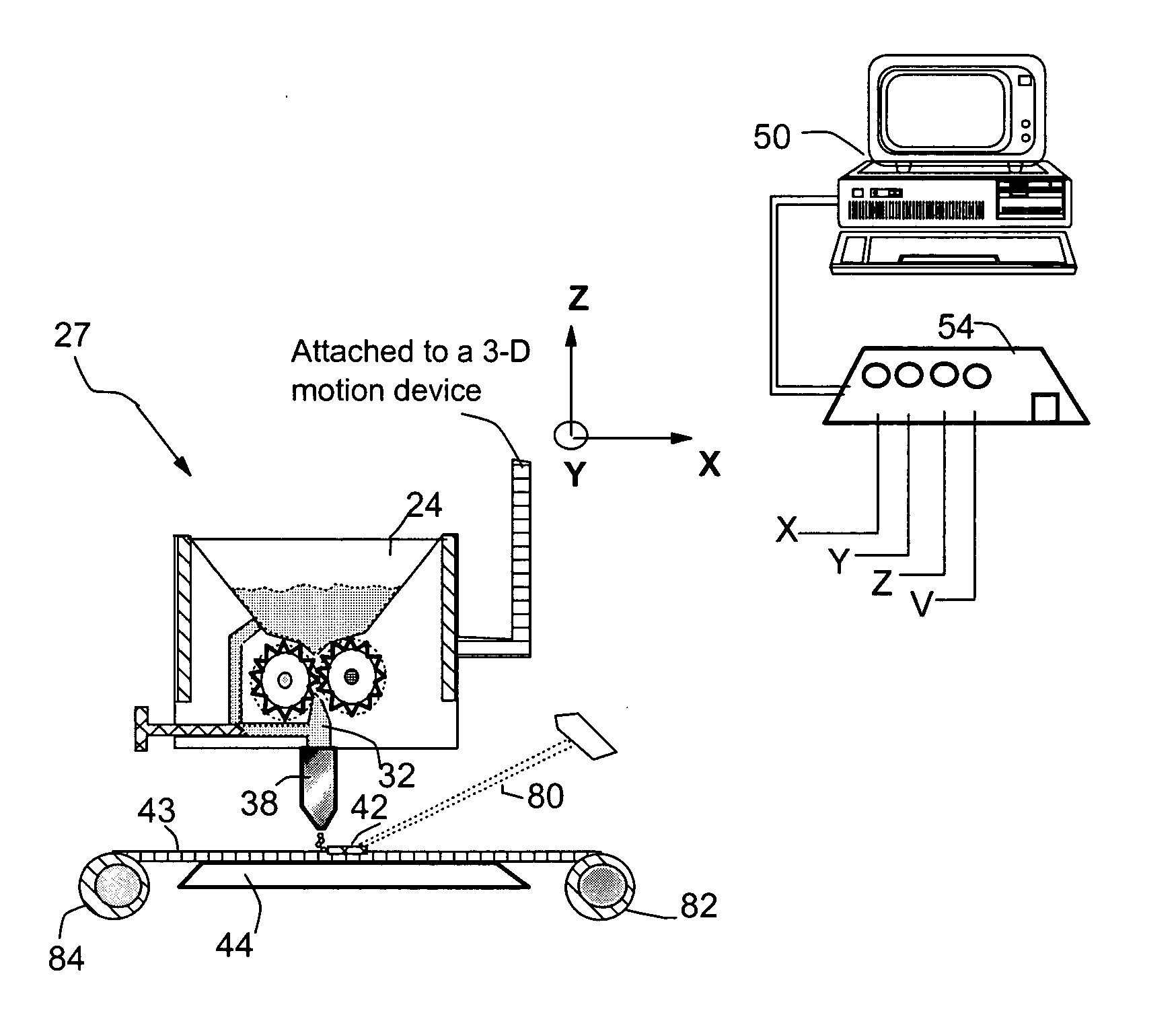

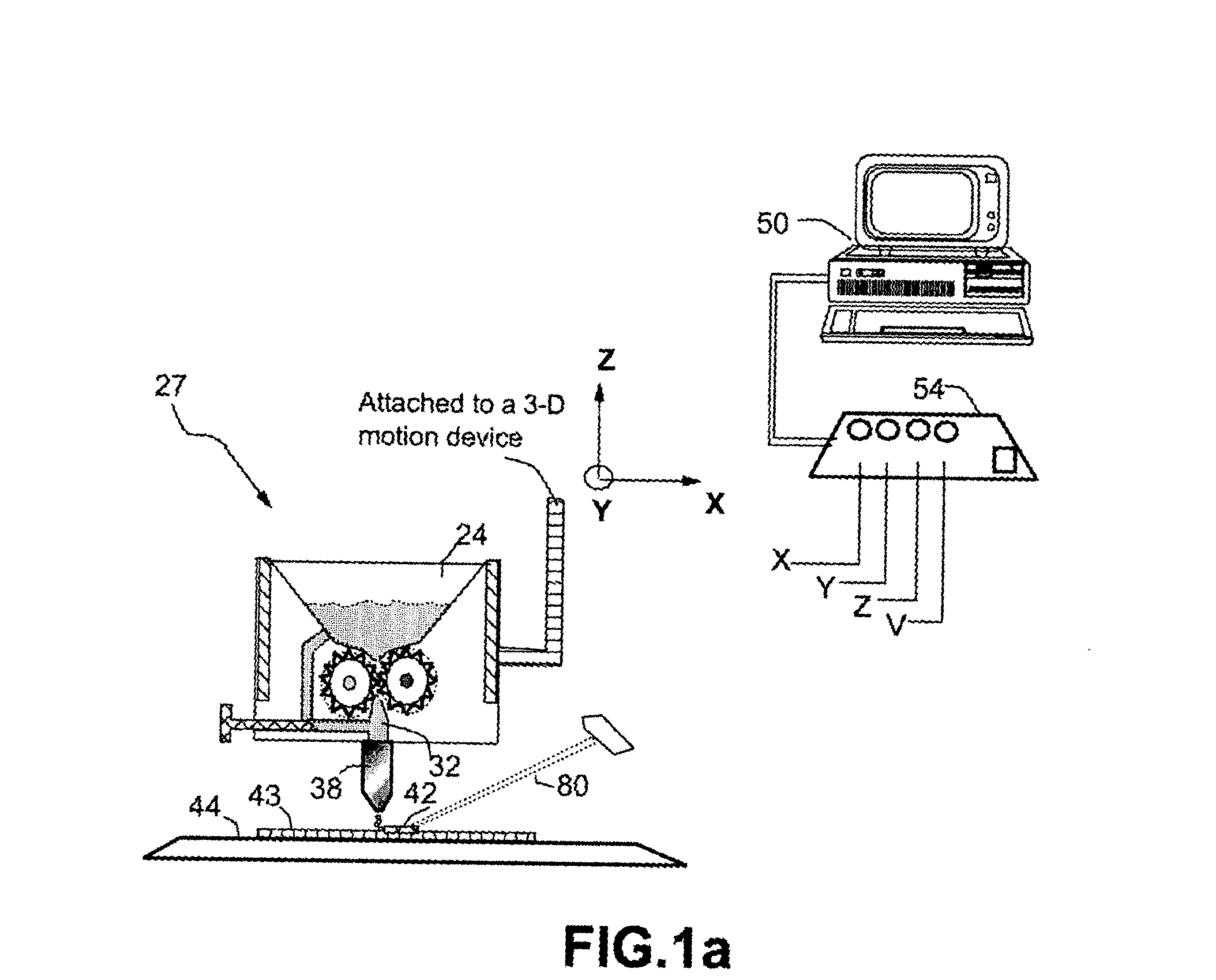

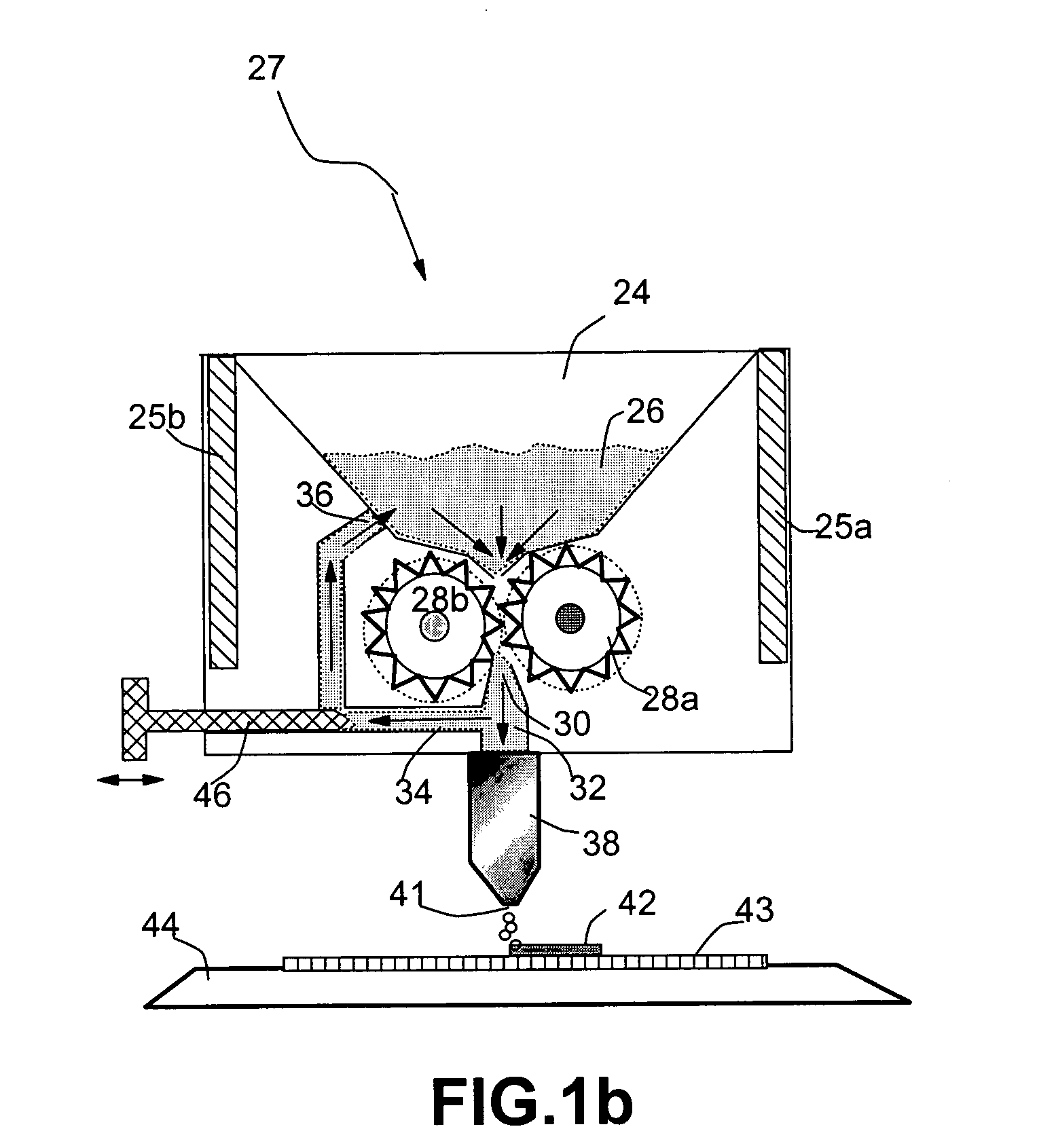

ActiveUS20050015175A1Fast preparationIncrease back pressureRecording apparatusAdditive manufacturing apparatusDielectricControl signal

A direct write process and apparatus for fabricating a desired circuit component onto a substrate surface of a microelectronic device according to a computer-aided design (CAD). The process includes (a) providing a support member by which the device is supported while being fabricated; (b) providing a chamber for containing a precursor fluid material under a substantially constant pressure differential relative to the ambient pressure, with the precursor fluid material having a viscosity no less than 10 cps; (c) operating an inkjet-based dispensing head with a control valve or actuator for dispensing and depositing minute droplets of the precursor fluid material onto the substrate surface; (d) energy- or heat-treat the deposited precursor fluid material for converting it to the desired active or passive component; and (e) operating a machine controller for generating control signals in response to the CAD coordinates for controlling the position of the dispensing head relative to the support member in response to the control signals to control dispensing and depositing of the precursor material to form the desired component. The process is useful for depositing a wide range of component materials onto an electronic device, including conductor, resistor, capacitor, dielectric, inductor, antenna, solar cell electrode, battery electrode, interconnect, superconductor, sensor, and actuator element materials.

Owner:NANOTEK INSTR GRP LLC

Patch-Like Infusion Device

InactiveUS20070203454A1Conveniently worn against skinAutomatic syringesMedical devicesInfusion setInfusion solution

A system and method for a patch-like, self-contained substance infusion device which provides one or more substantially hidden patient needles which can be placed in fluid communication with a fluid reservoir subassembly that includes a rigid bladder portion used in conjunction with a non-distensible bladder film, such as a metallized film. Simple removal of an interlock allows a disk, or Belleville spring assembly to apply an essentially even and constant pressure to the contents of the fluid reservoir assembly, and allows the device to then be attached to a skin surface via an adhesive contact surface. A push button activation assembly is provided which can then be used to release and seat one or more spring-loaded patient needles into the skin surface, and establish a fluid communication path between the patient needles and the pressurized fluid reservoir contents thereby delivering an infusion into the skin.

Owner:BECTON DICKINSON & CO

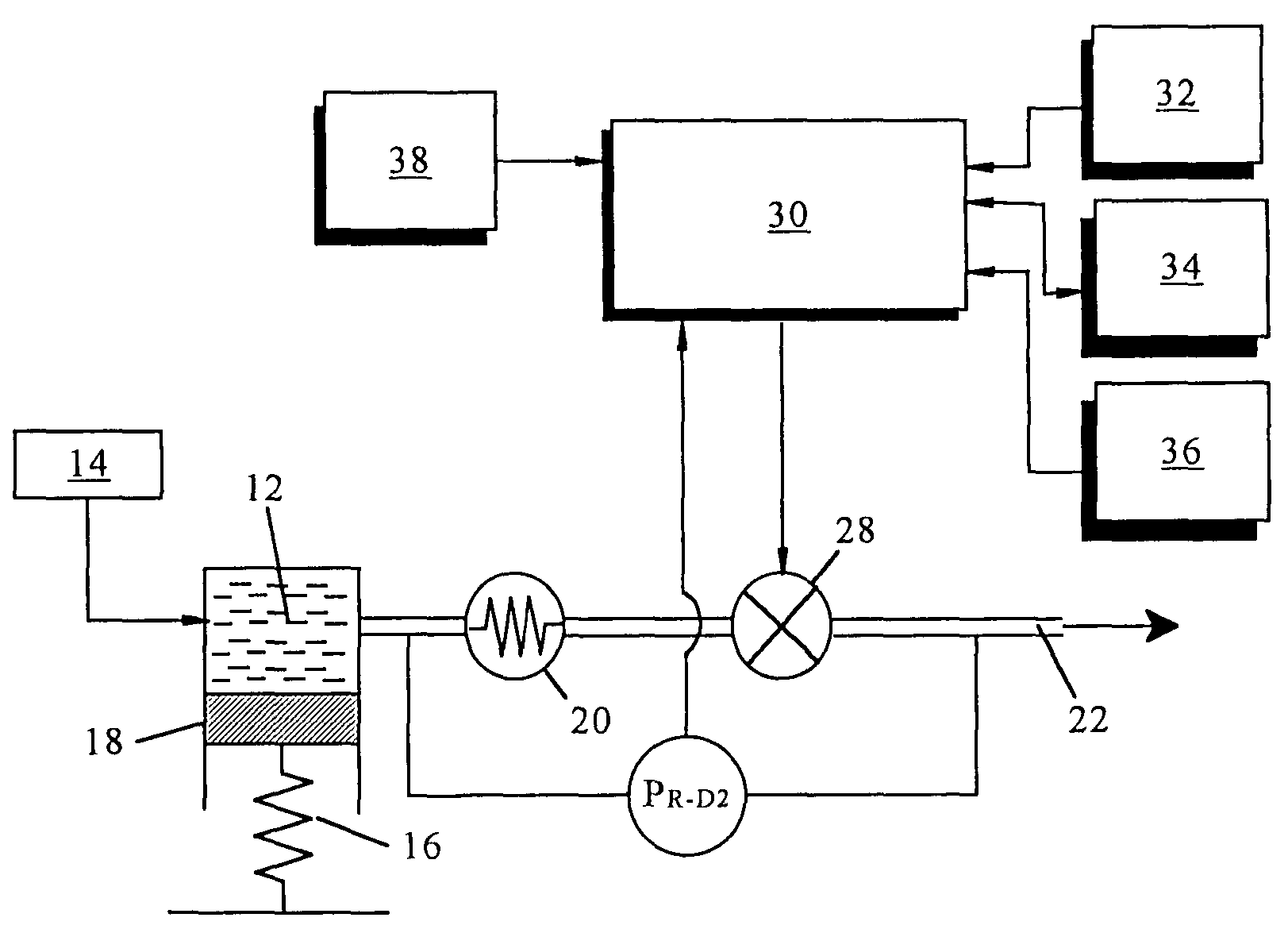

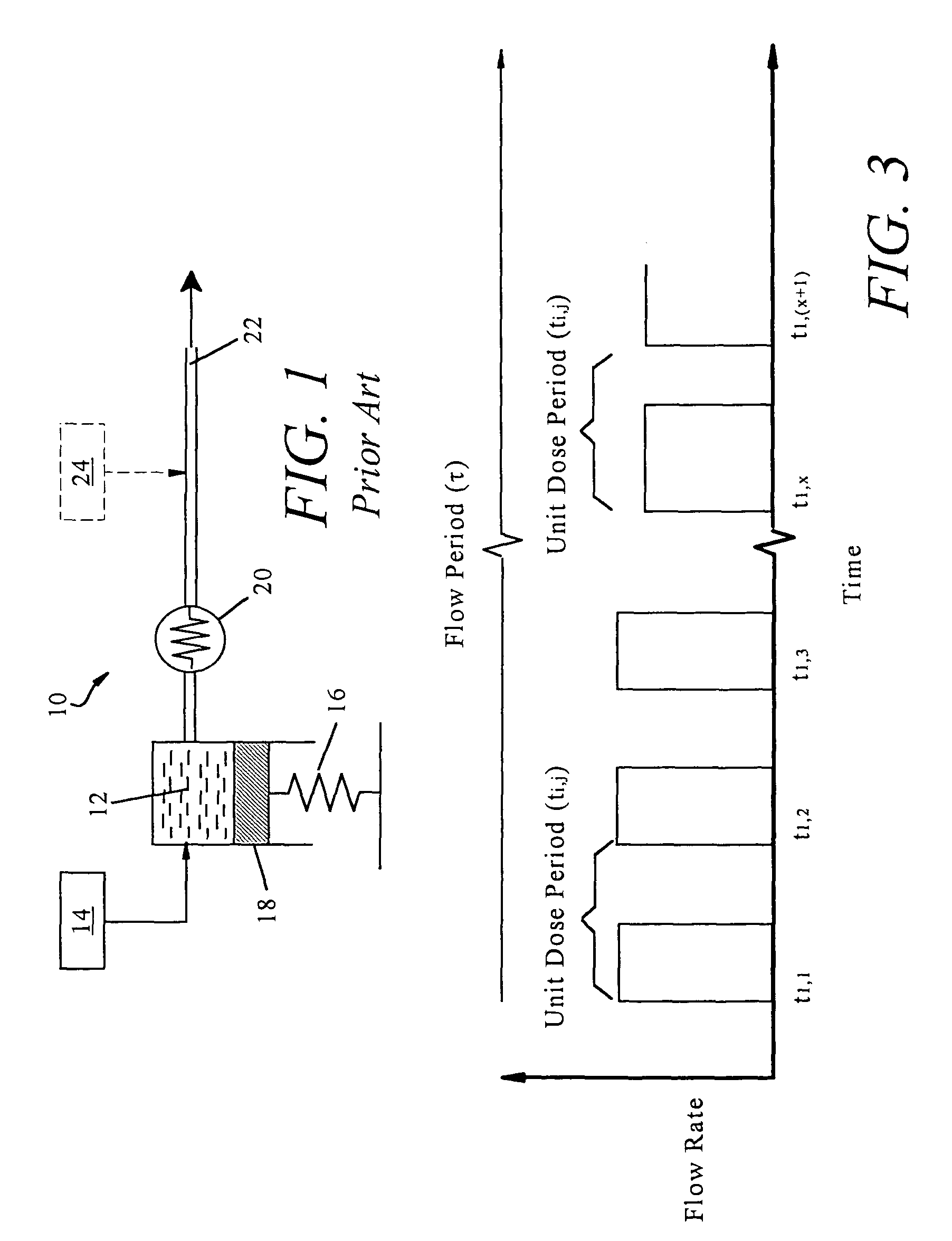

Non-constant pressure infusion pump

InactiveUS7338464B2Easy constructionPharmaceutical delivery mechanismMedical devicesPeriod effectsBiomedical engineering

The present invention relates to an implantable infusion pump having a refillable infusate reservoir in fluid communication with a delivery site via a flow path. This flow path includes a flow resistance. The infusion pump includes a sensing device(s), positioned relative to the flow path, to provide data regarding a flow rate along the flow path. The infusion pump effects a division of a total flow period into at least a plurality of unit dose periods, each unit dose period effecting delivery of a unit dose of infusate. The cumulative effect of delivering the total number of unit dose periods is the delivery of a desired dose over the total flow period. The present invention permits a reservoir pressure to vary over any portion of total flow period but effects a constant-pressure state over each unit dose cycle.

Owner:ADVANCED NEUROMODULATION SYST INC

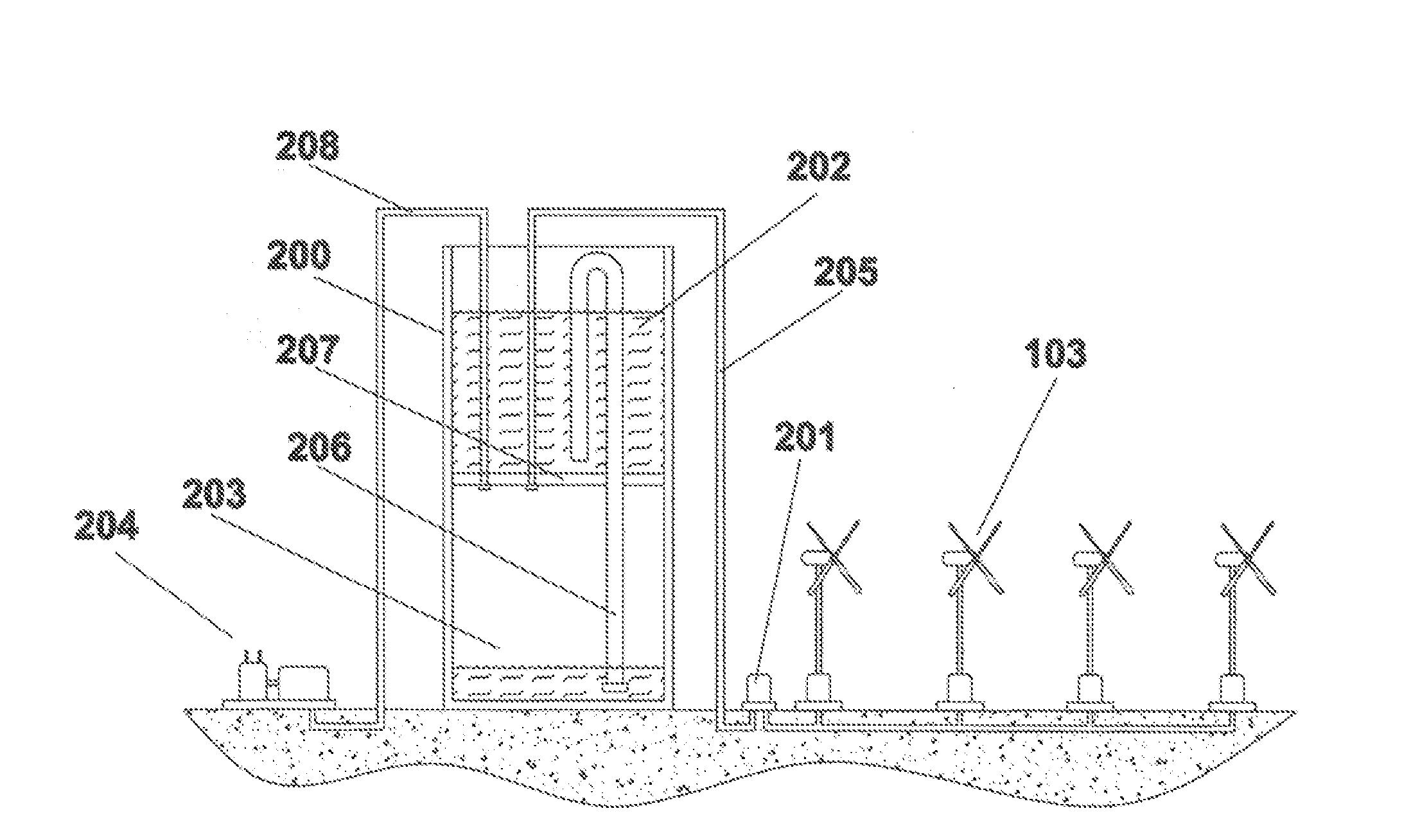

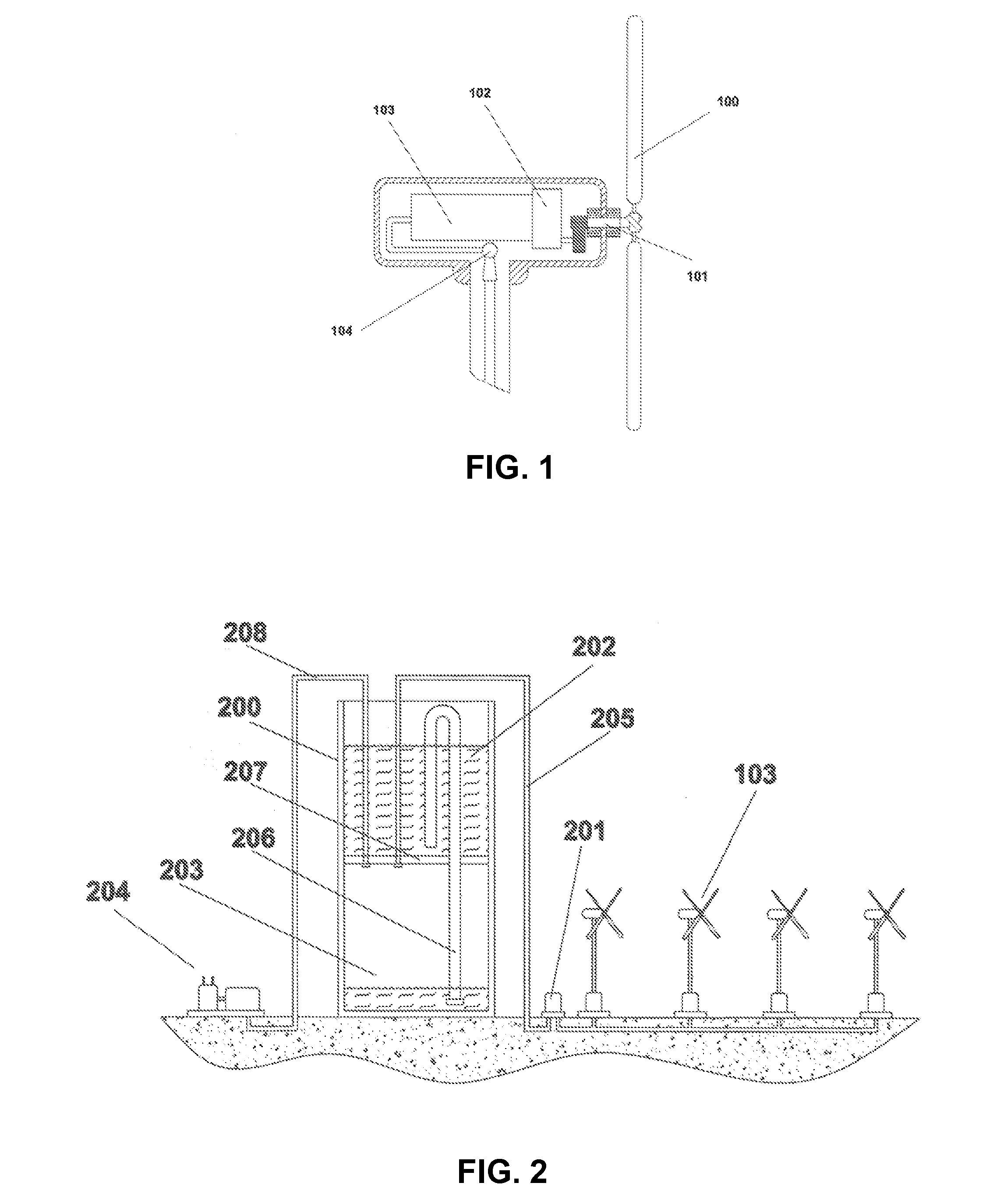

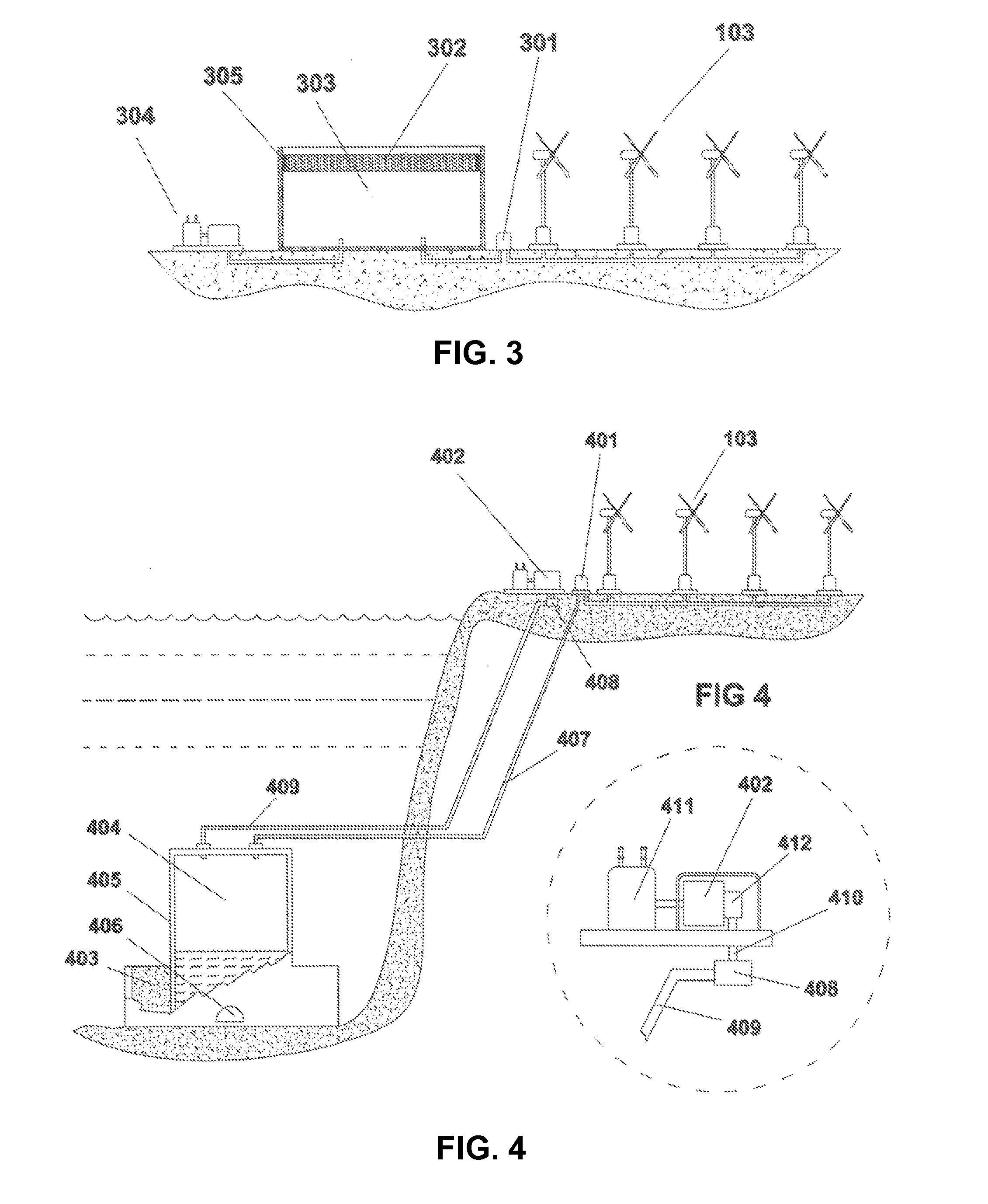

Integrated wind-power electrical generation and compressed air energy storage system

InactiveUS20090021012A1Prevent over-pressurization of the storage unitFrequency stabilityWind energy with garvitational potential energySteam accumulatorsThermal energy storageEngineering

The present invention relates to a method and apparatus for using wind energy to compress air or pressurize a fluid as a means of storing energy. Compressed air or pressurized fluid is generated directly by the wind turbines, thereby avoiding the energy losses that occur when wind power is used first to generate electricity to run an electrically powered air compressor. The compressed air or pressurized fluid is stored by means of expanding a volume at constant or nearly constant pressure. This method avoids energy losses that would otherwise result from compressional heating; while also allowing lower pressures to be employed, reducing the cost of the containment facility and avoiding the need to locate facilities in geographically favored locations where underground storage is available. The invention permits both large and small-scale storage at low cost per unit of energy stored, thereby avoiding the difficulty of using a highly variable and unreliable source of energy such as the wind for electrical power generation. The invention can be used for generation and storage on land, in shallow near-shore waters and in deep-water locations far from shore.

Owner:STULL MARK A +1

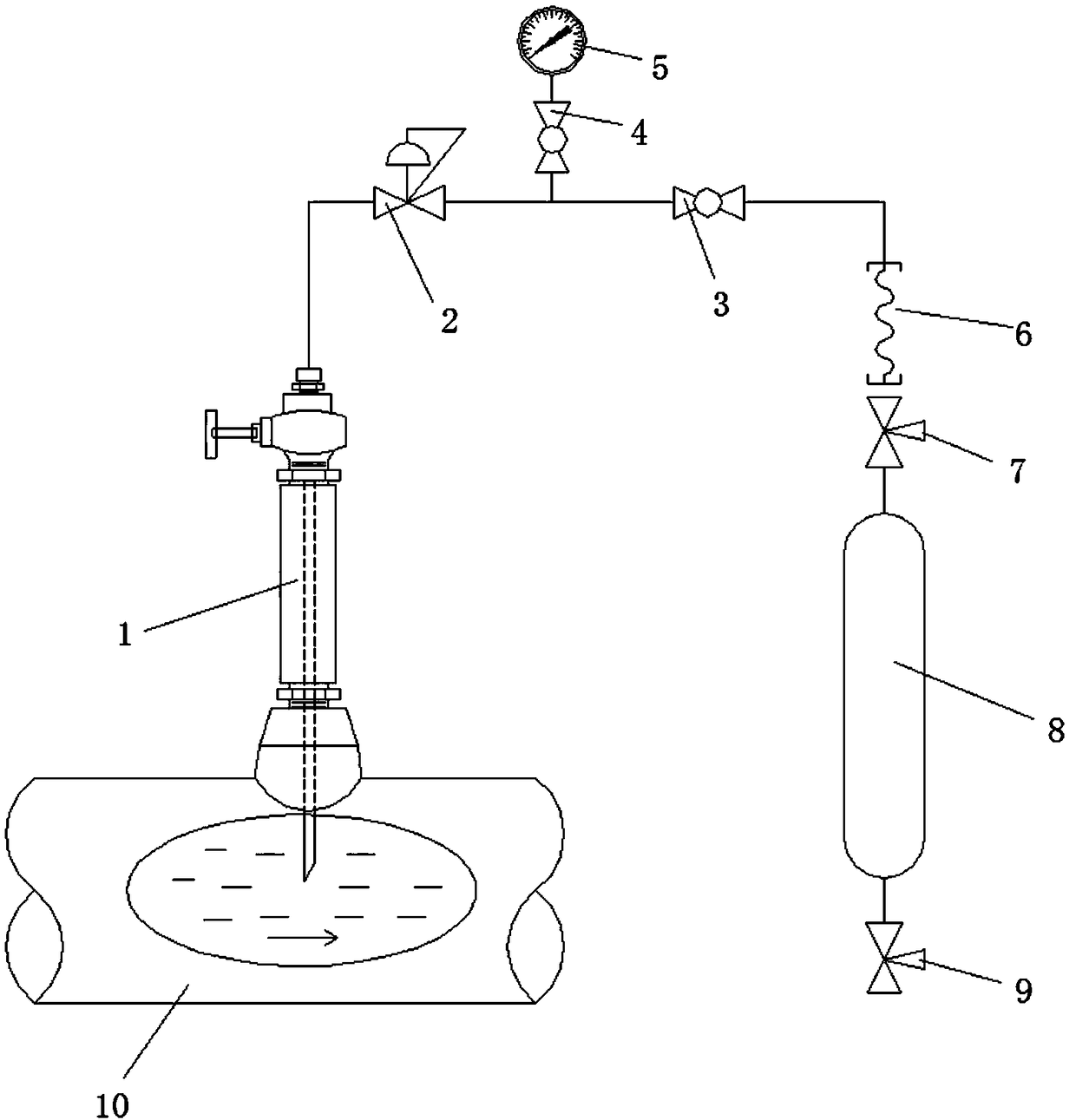

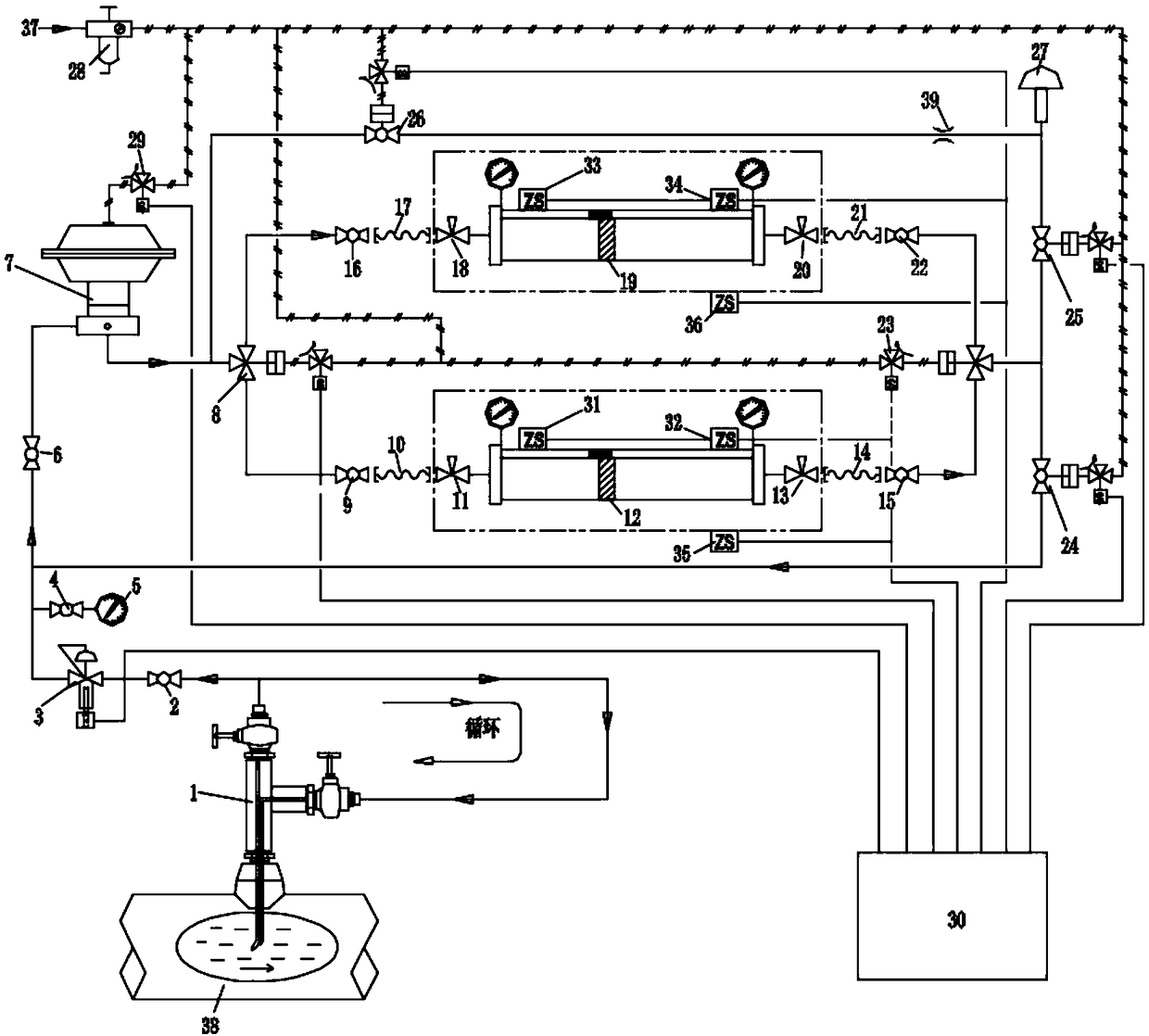

Automatic natural gas continuous-sampling control system

PendingCN109141990ARealize continuous samplingRepresentativeWithdrawing sample devicesControl systemProduct gas

The invention belongs to the technical field of natural gas detection and particularly relates to an automatic natural gas continuous-sampling control system. The system includes a reducing valve anda sampling probe connected with a natural gas pipe. An inlet of the reducing valve is connected with an outlet of the sampling probe, an outlet of the reducing valve is divided into two paths, one path is connected with a pneumatic membrane sampling pump, and the other path is connected with outlet ends of a first constant-pressure sampling steel bottle and second constant-pressure sampling steelbottle. The system also includes a full-automatic natural gas replacement system. The automatic natural gas continuous-sampling control system can achieve continuous sampling. Since sampling is conducted once every certain time interval until the constant-pressure sampling steel bottles are fully filled, sampled gas can completely represent a fluid medium in a whole production cycle and have representativeness.

Owner:JEREH TIANJIN PETROLEUM ENG & TECH

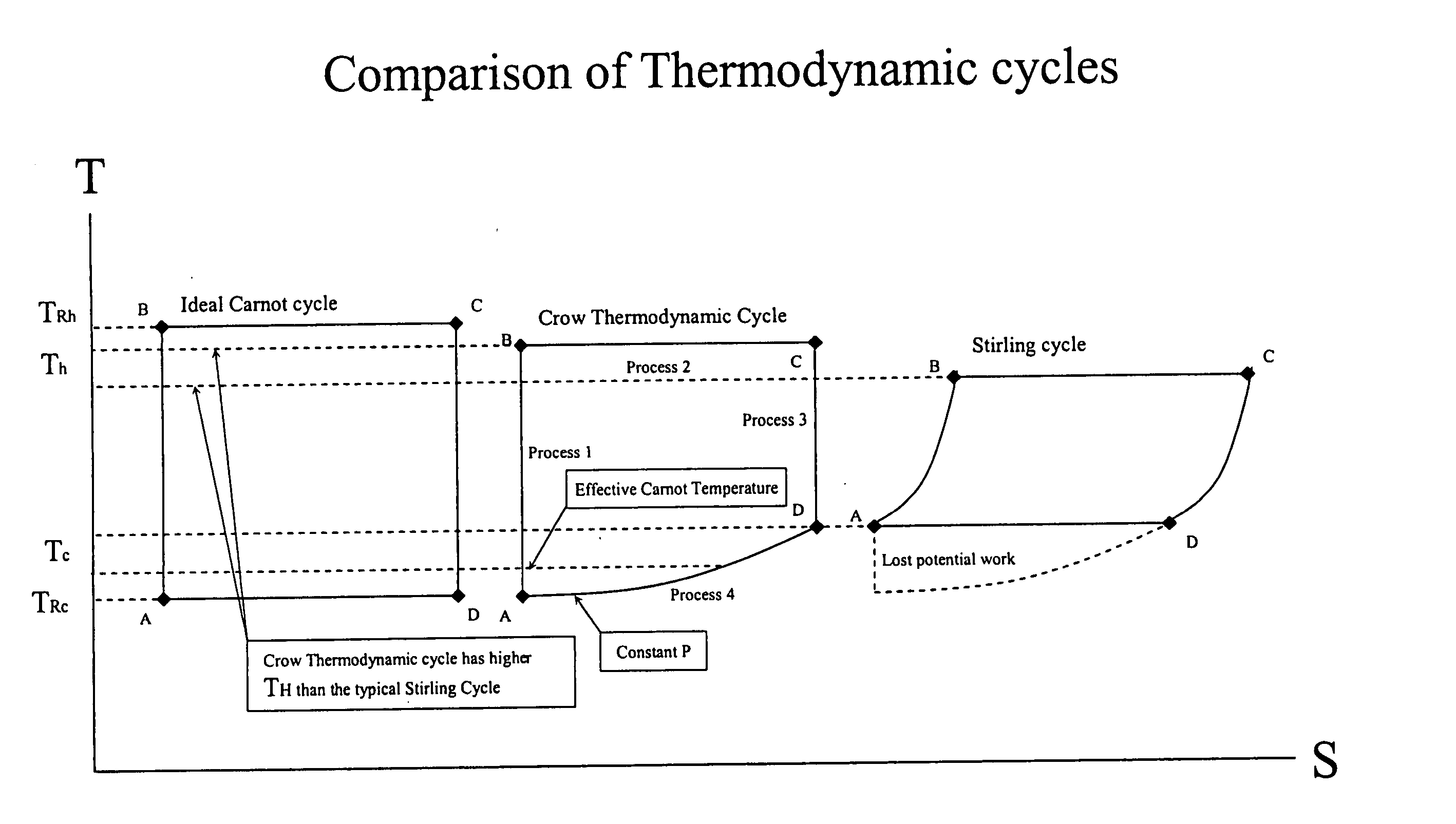

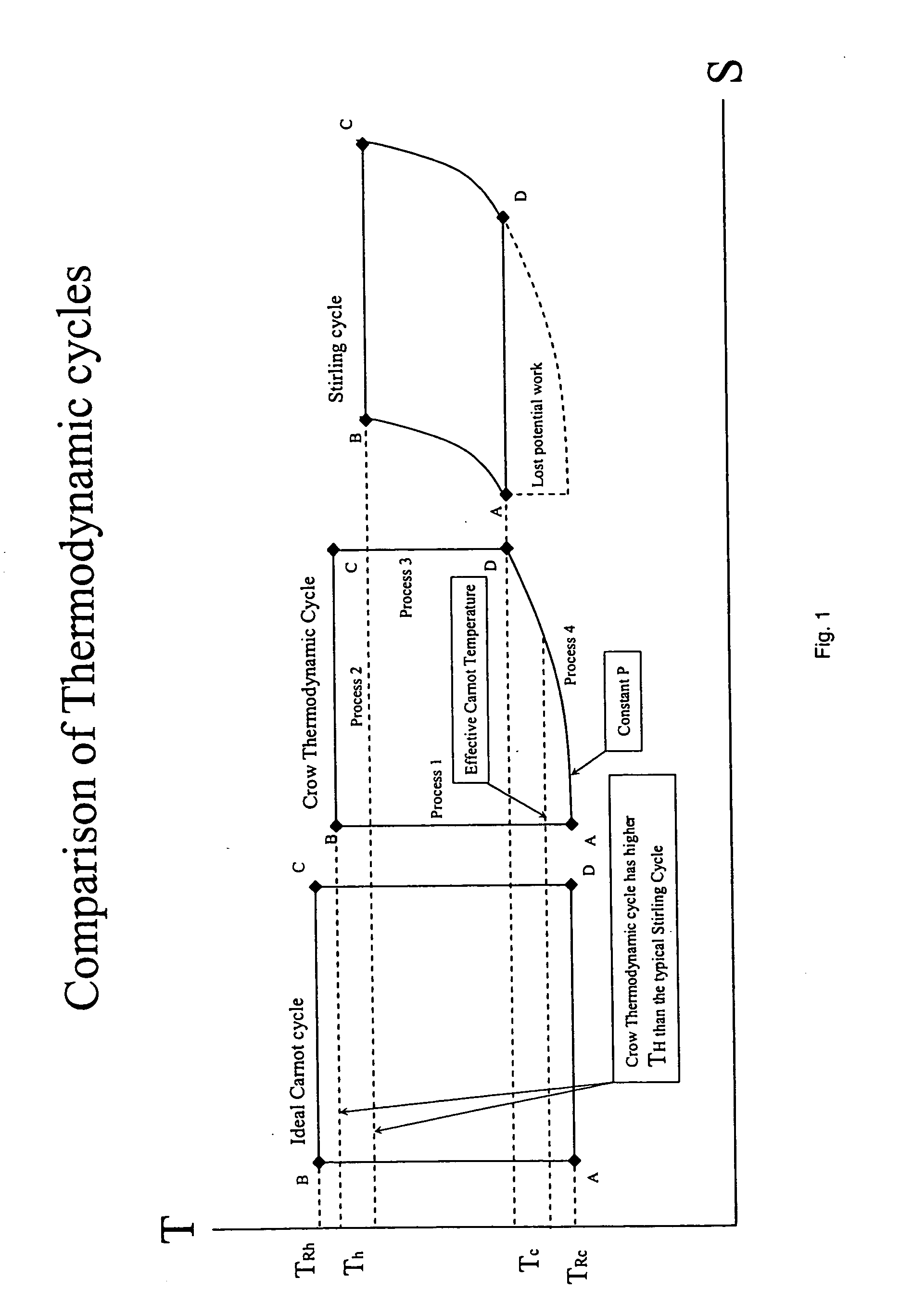

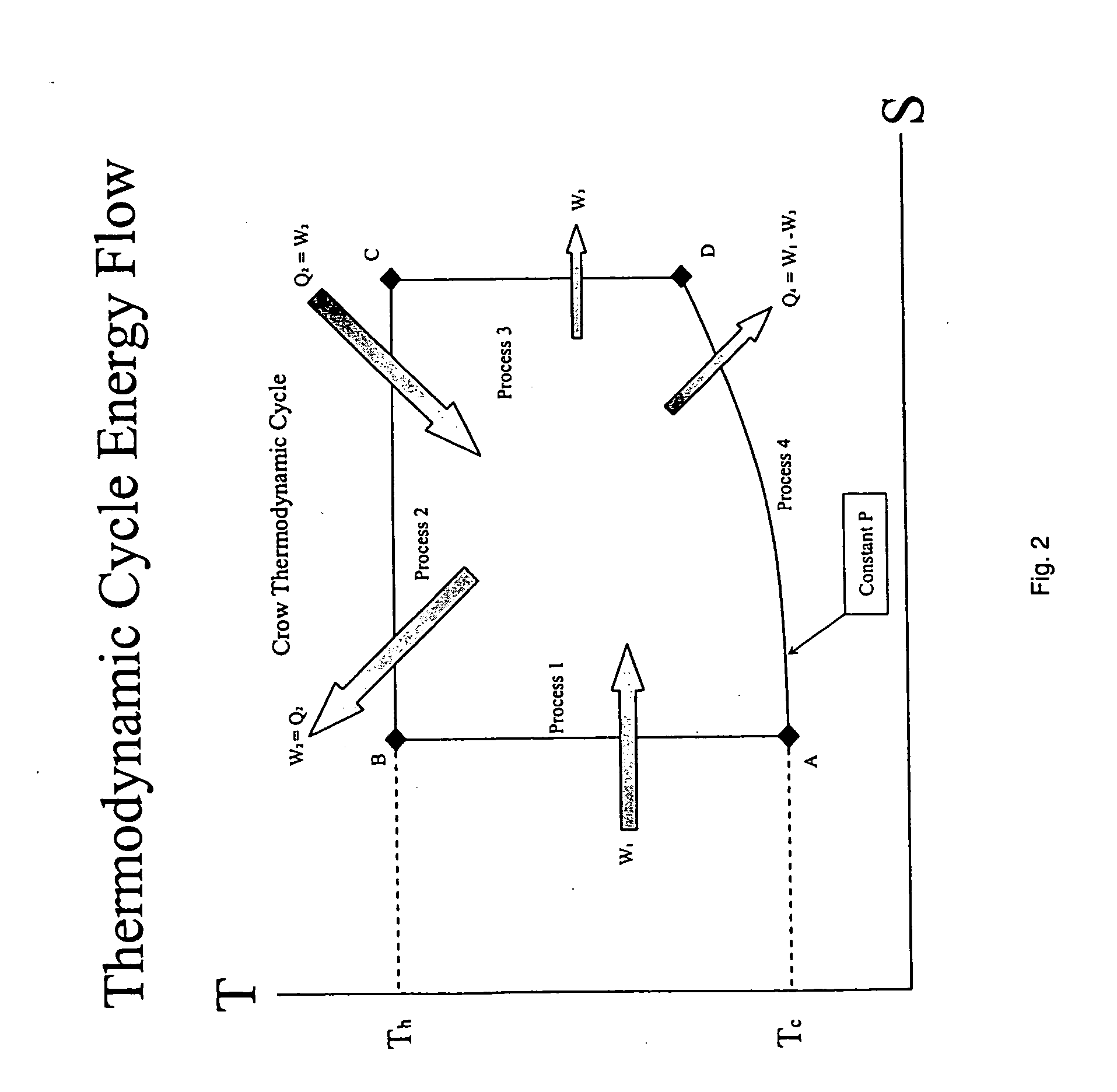

Method and apparatus for converting thermal energy to mechanical energy

InactiveUS20060090467A1Improve efficiencyEfficient regenerationEricsson type enginesSteam engine plantsThermal energyWorking fluid

A method and apparatus for converting thermal energy to mechanical energy which can use a wide range of fuels and perform with a high efficiency. Operating on a little utilized thermodynamic cycle of isentropic compression, isothermal expansion, isentropic expansion and finally constant pressure cooling and contraction. The external heat engine utilizes a heat exchanger carrying heat from the external energy source to the working parts of the engine. Pistons and cylinders are activated by appropriate means to adiabatically compress the working fluid, for example ambient air, to transfer the entire mass of the air through the heat exchanger to accomplish isothermal expansion followed by adiabatic expansion and, finally, exhaust the air to ambient to allow for constant pressure cooling and contraction. Valve pistons in conjunction with the cylinders form valves that allow for the exchange of working fluid with ambient. Energy is added to the engine during isothermal expansion, whereby the energy of compression is added by a flywheel or other appropriate energy storage means, said flywheel stores energy recovered during adiabatic expansion. The thermodynamic cycle described and the engine embodiments disclosed, when run in reverse, perform as a heat pump or refrigeration device.

Owner:CROW DARBY

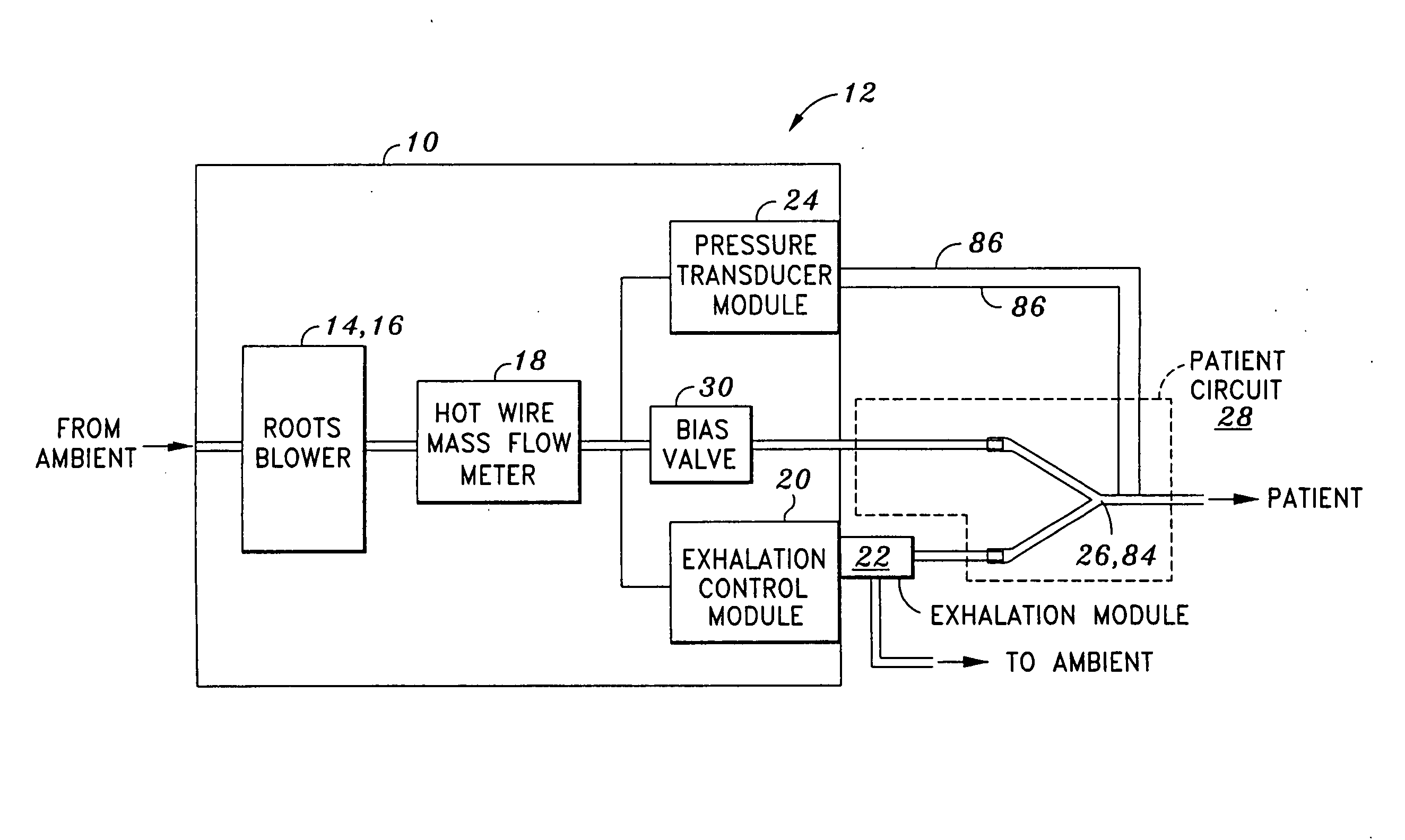

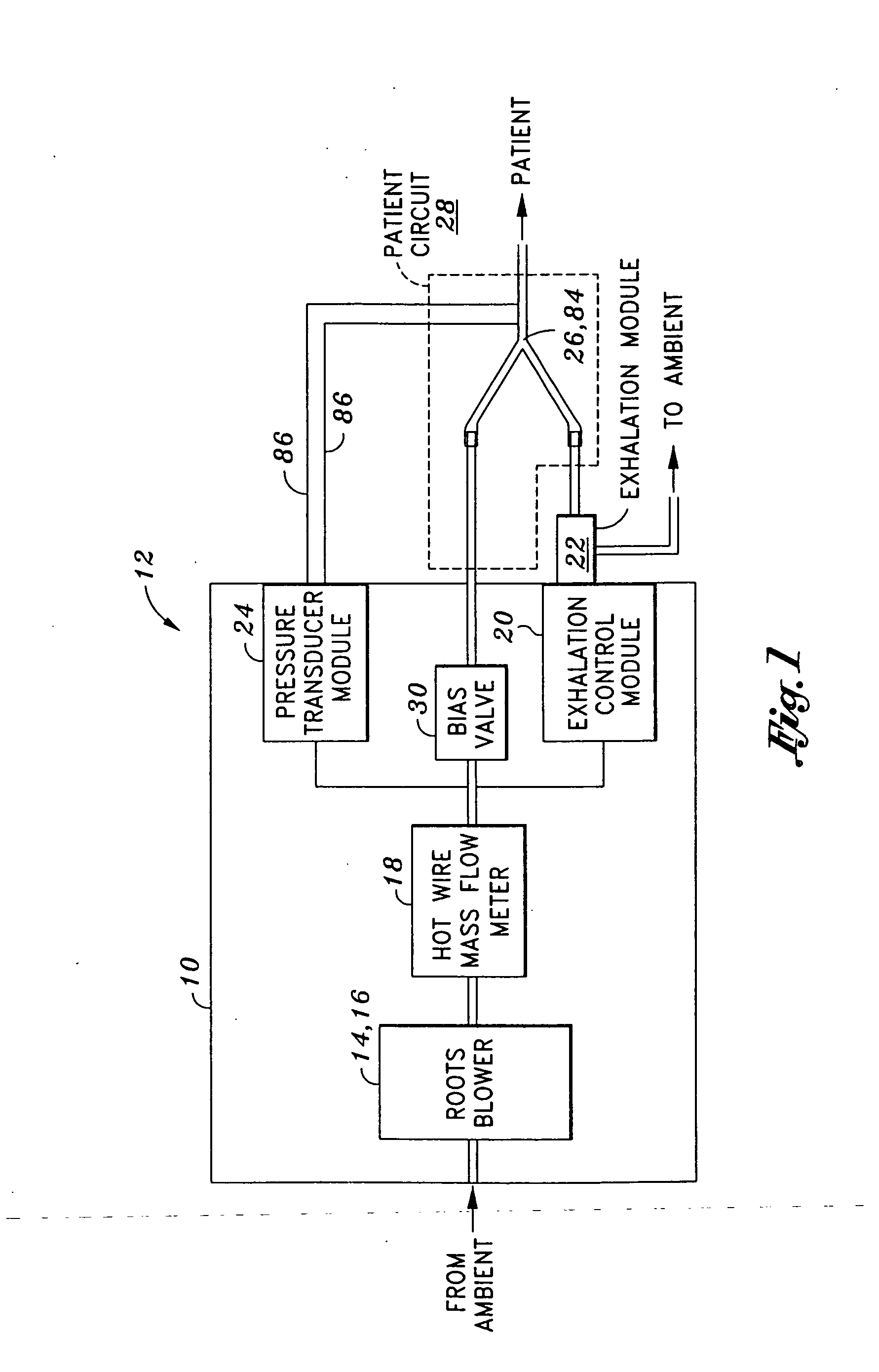

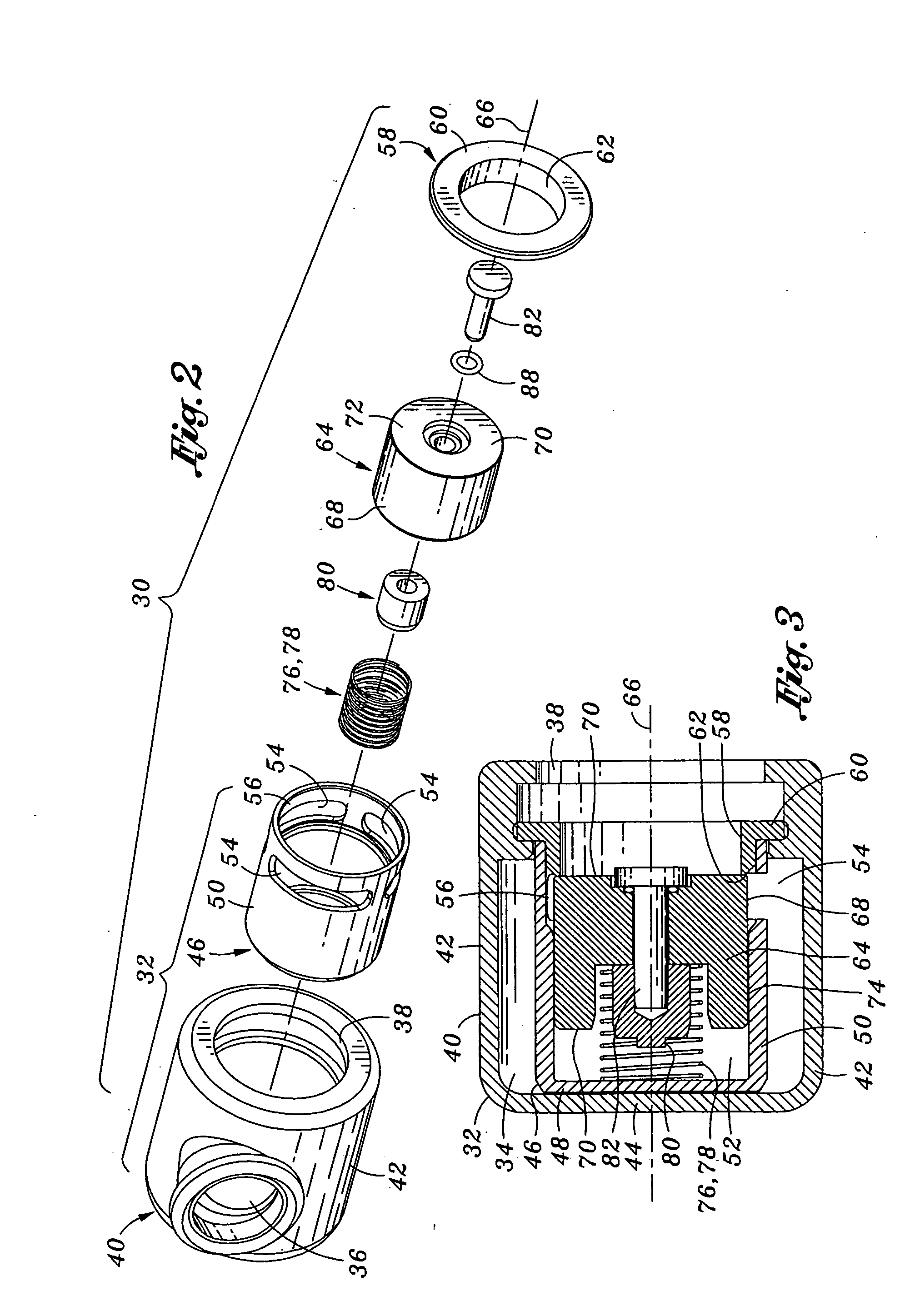

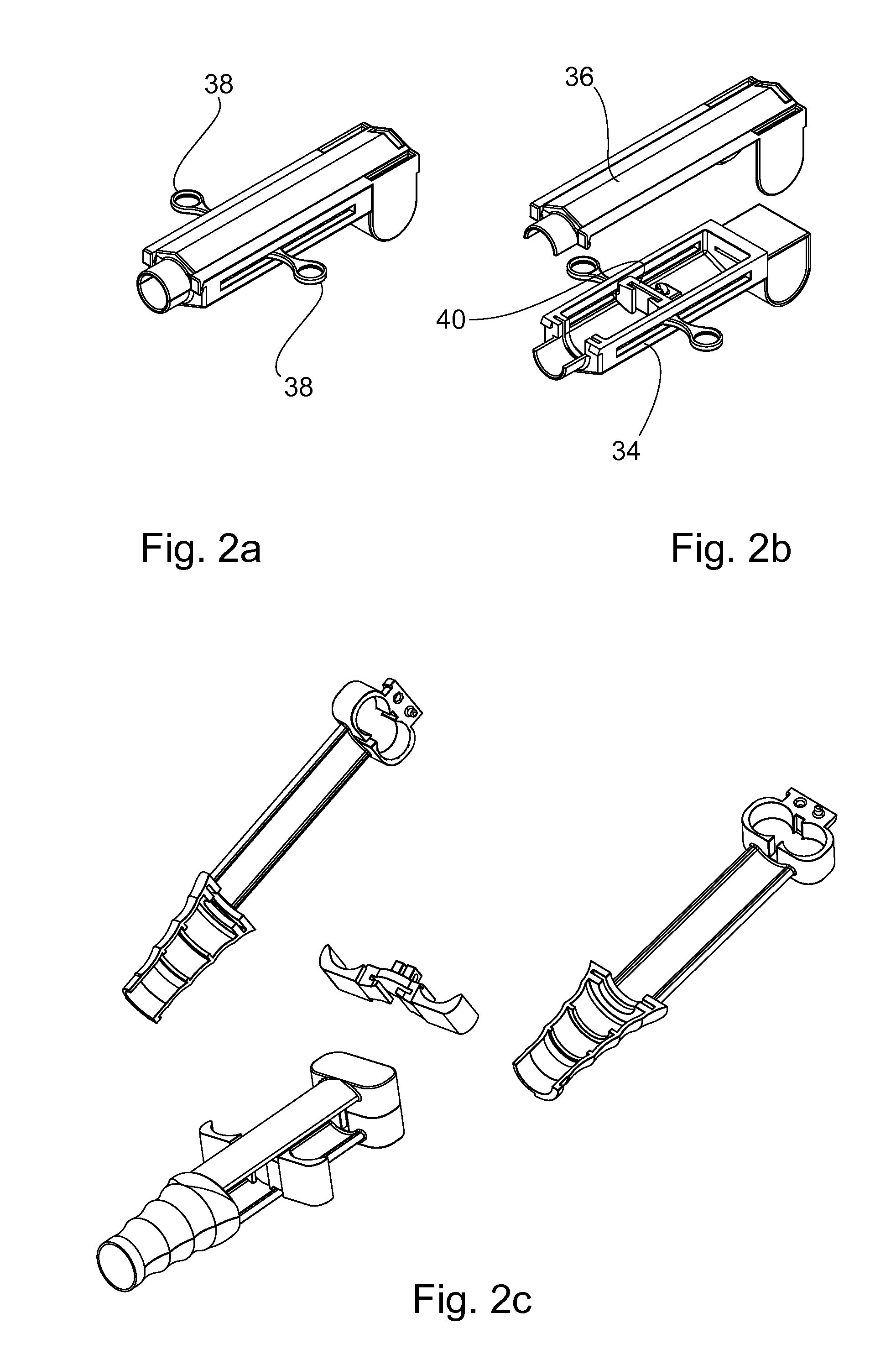

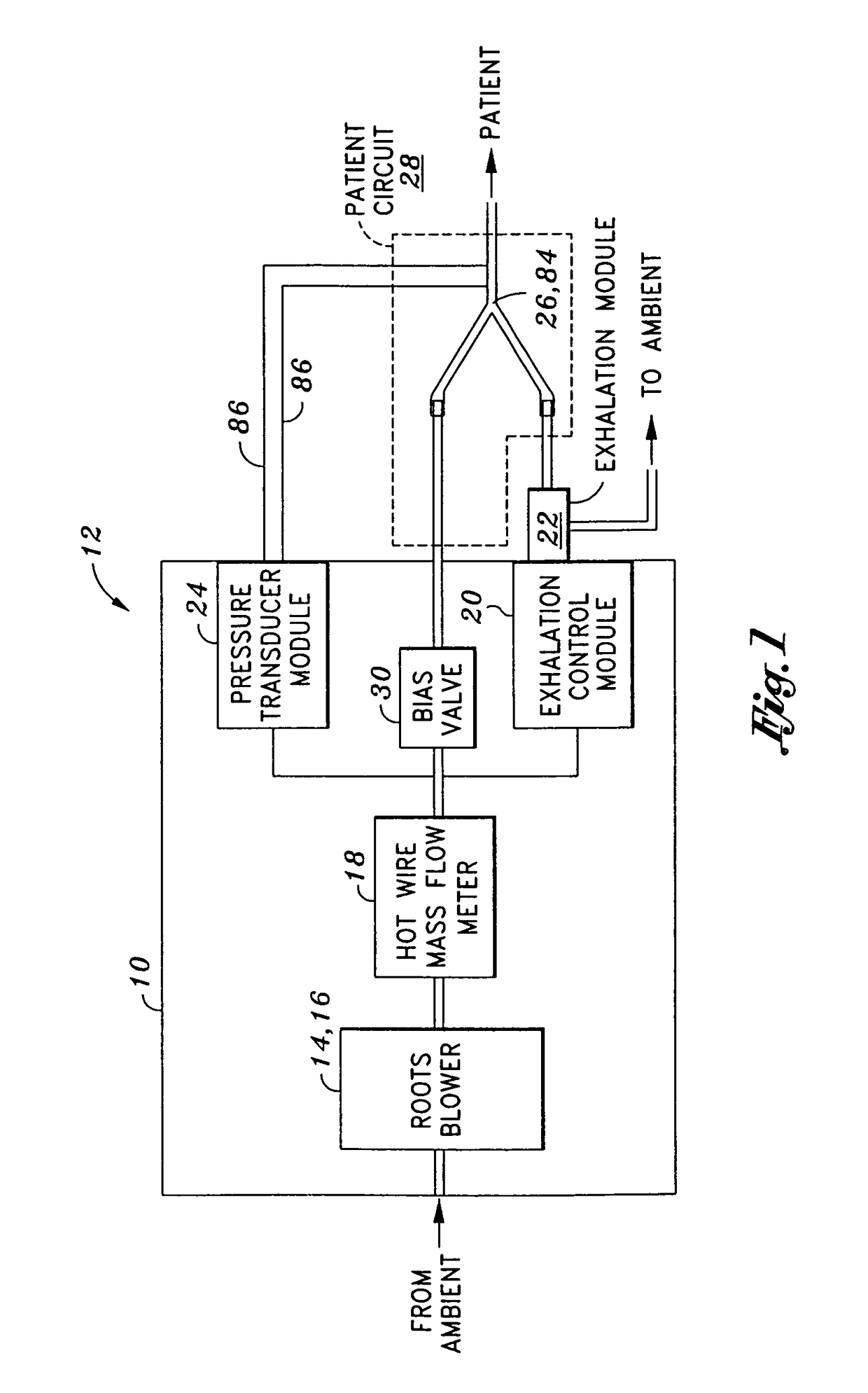

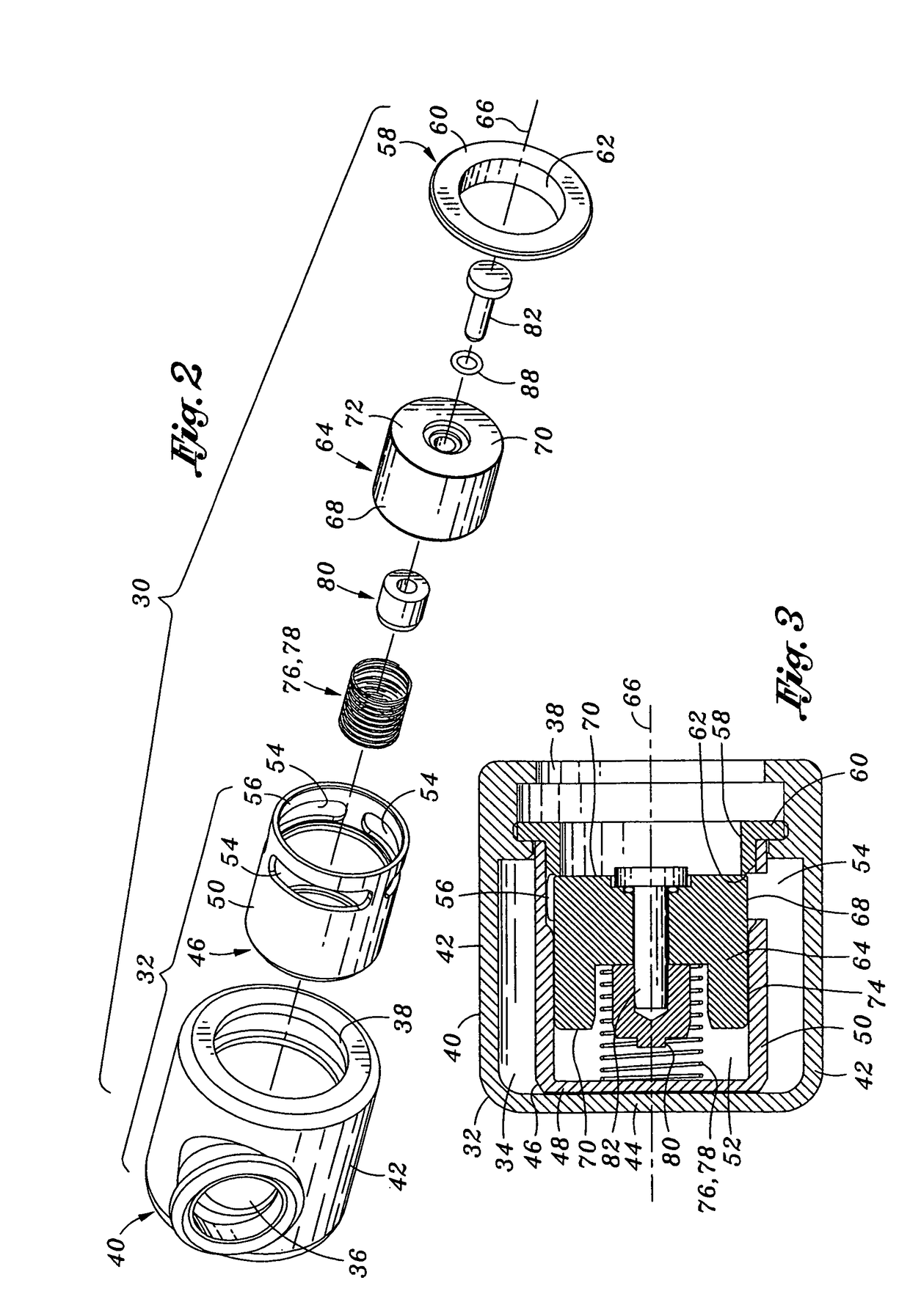

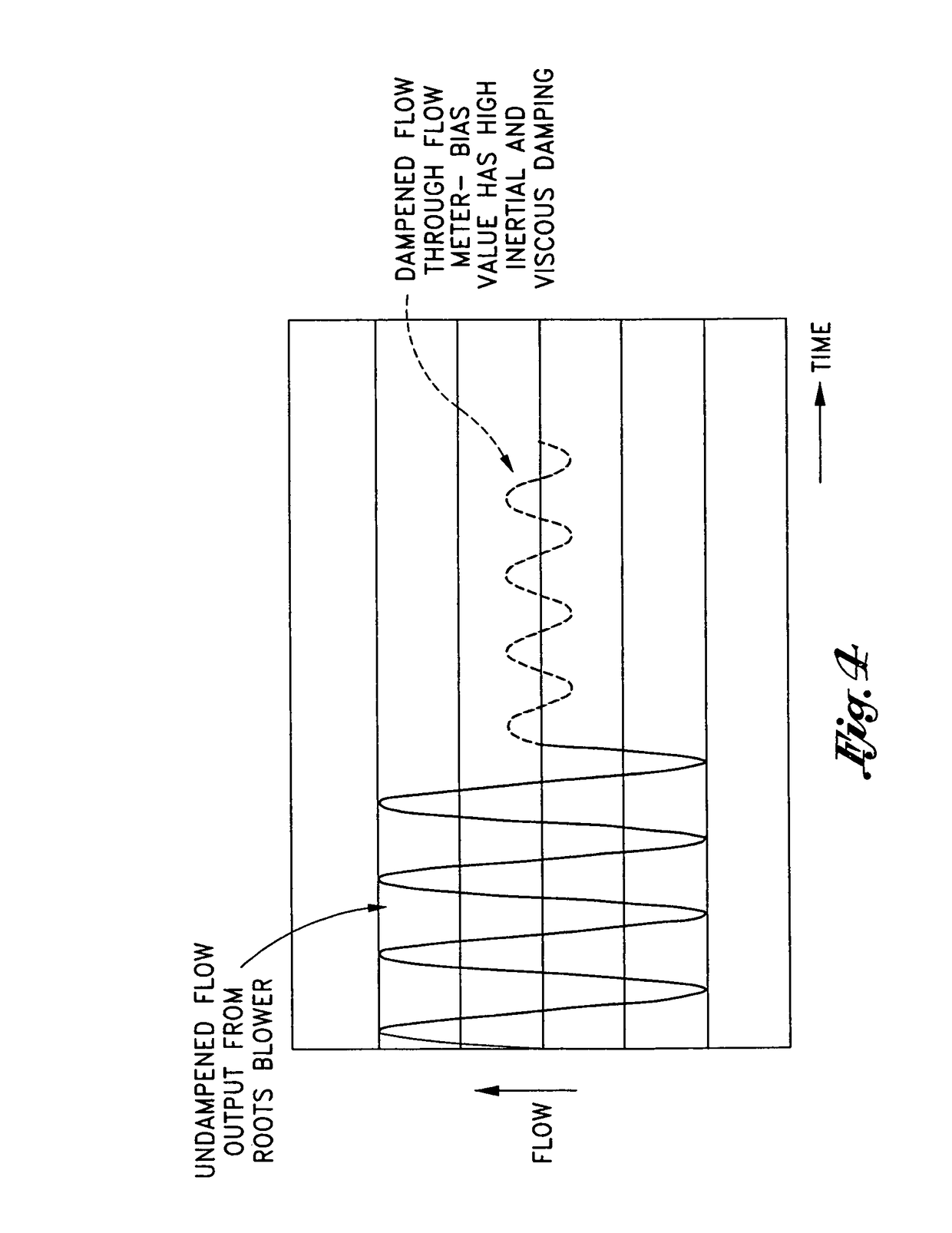

Mechanical ventilation system utilizing bias valve

ActiveUS20060249153A1Accurate measurementViscous dampingRespiratorsOperating means/releasing devices for valvesPositive pressureEngineering

A portable mechanical ventilator having a Roots blower is configured to provide a desired gas flow and pressure to a patient circuit. The mechanical ventilator includes a flow meter operative to measure gas flow produced by the Roots blower and an exhalation control module configured to operate an exhalation valve connected to the patient circuit. A bias valve connected between the Roots blower and the patient circuit is specifically configured to generate a bias pressure relative to the patient circuit pressure at the exhalation control module. The bias valve is further configured to attenuate pulsating gas flow produced by the Roots blower such that gas flowing to the mass flow meter exhibits a substantially constant pressure characteristic. The bias pressure facilitates closing of the exhalation valve at the start of inspiration, regulates positive end expiratory pressure during exhalation, and purges sense lines via a pressure transducer module.

Owner:VYAIRE MEDICAL 203 INC

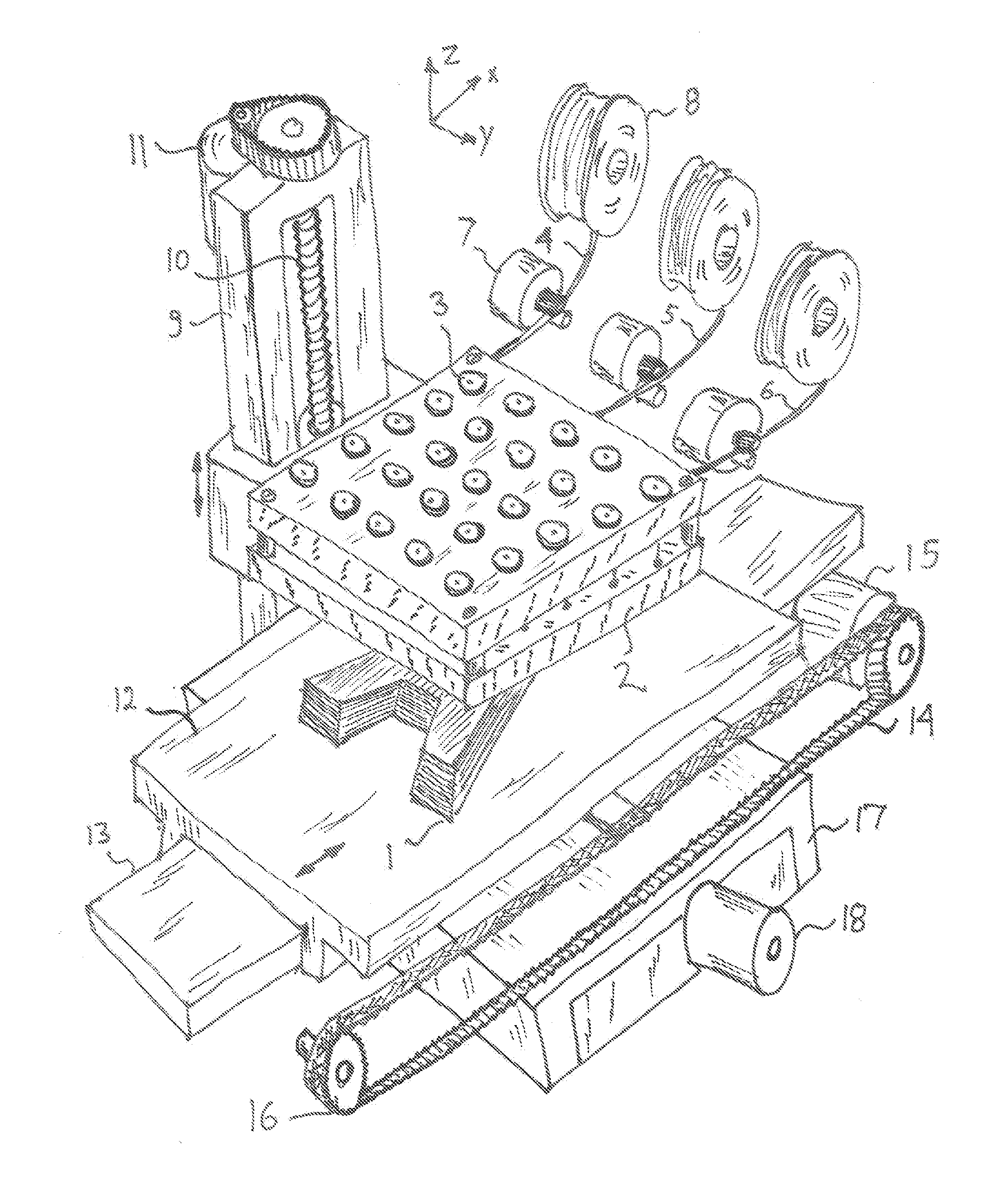

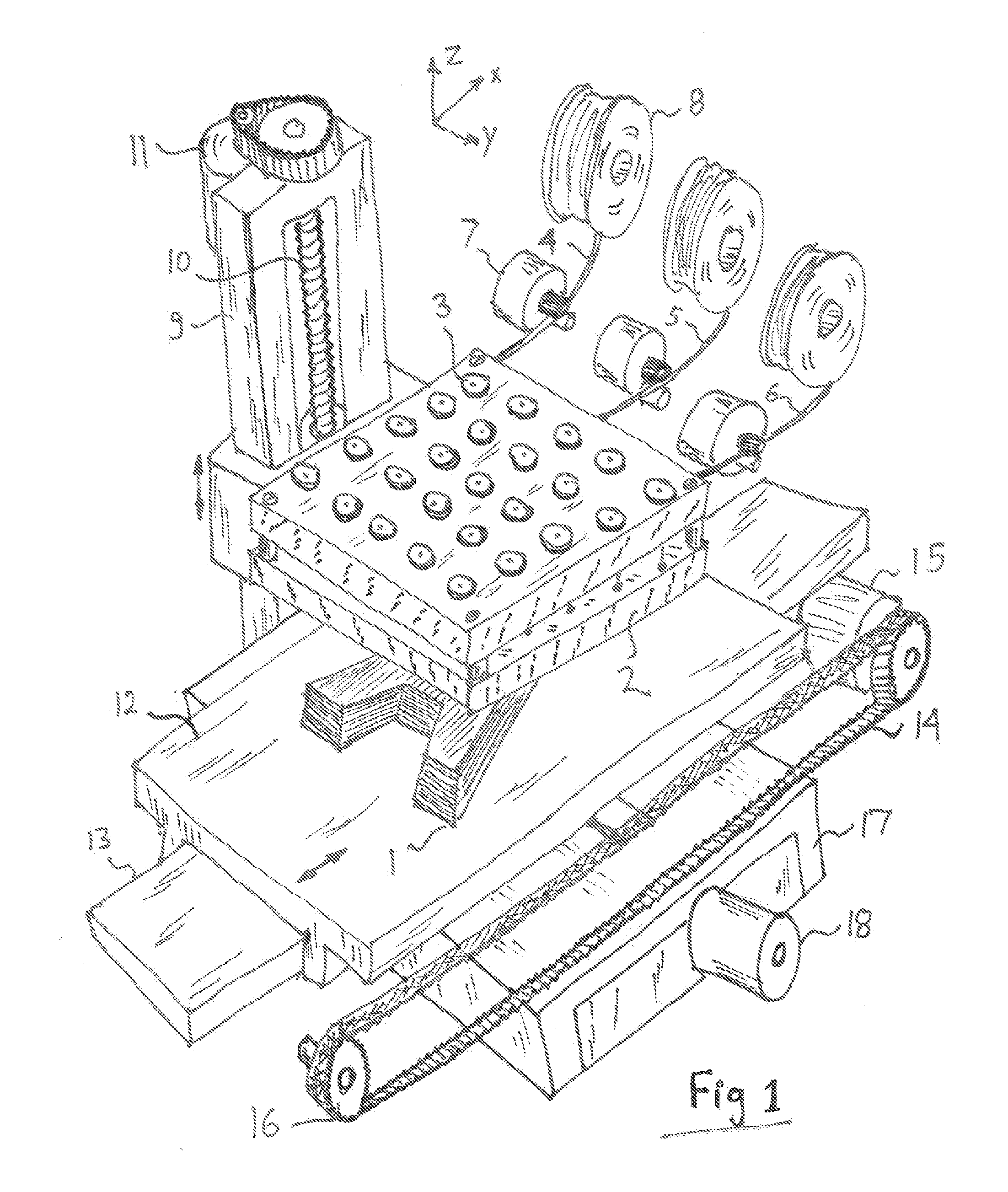

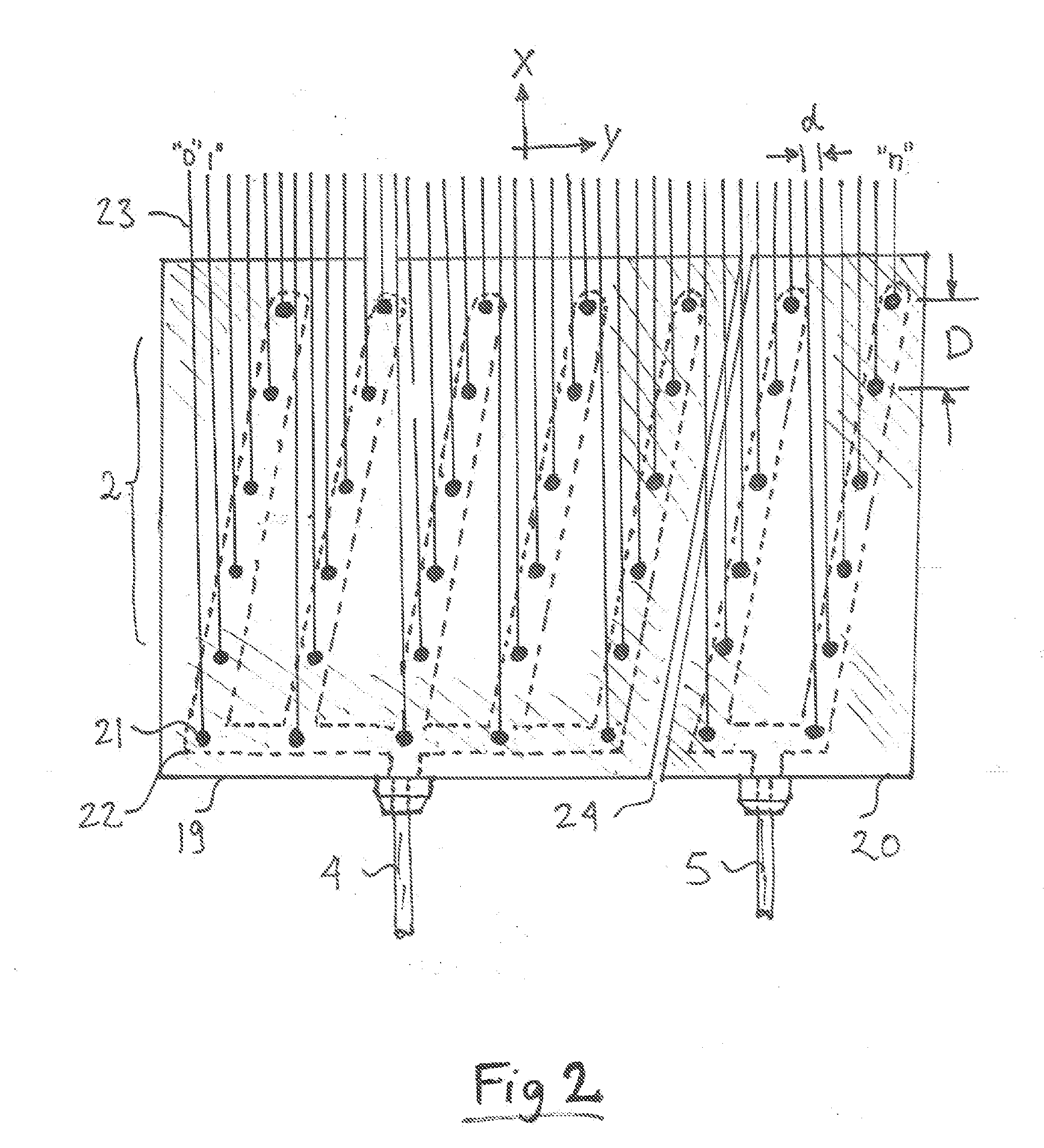

3D Printer Based on a Staggered Nozzle Array

InactiveUS20160325498A1Increase deposition rateIncrease pressureAdditive manufacturing with liquids3D object support structuresGratingEngineering

A 3D printer is based on a two dimensional staggered nozzle array, depositing each layer in a raster scan mode. Each nozzle contains an individually controlled mechanical high speed valve, and multiple nozzles are fed from a constant pressure reservoir, typically containing molten polymer.

Owner:GELBART DANIEL

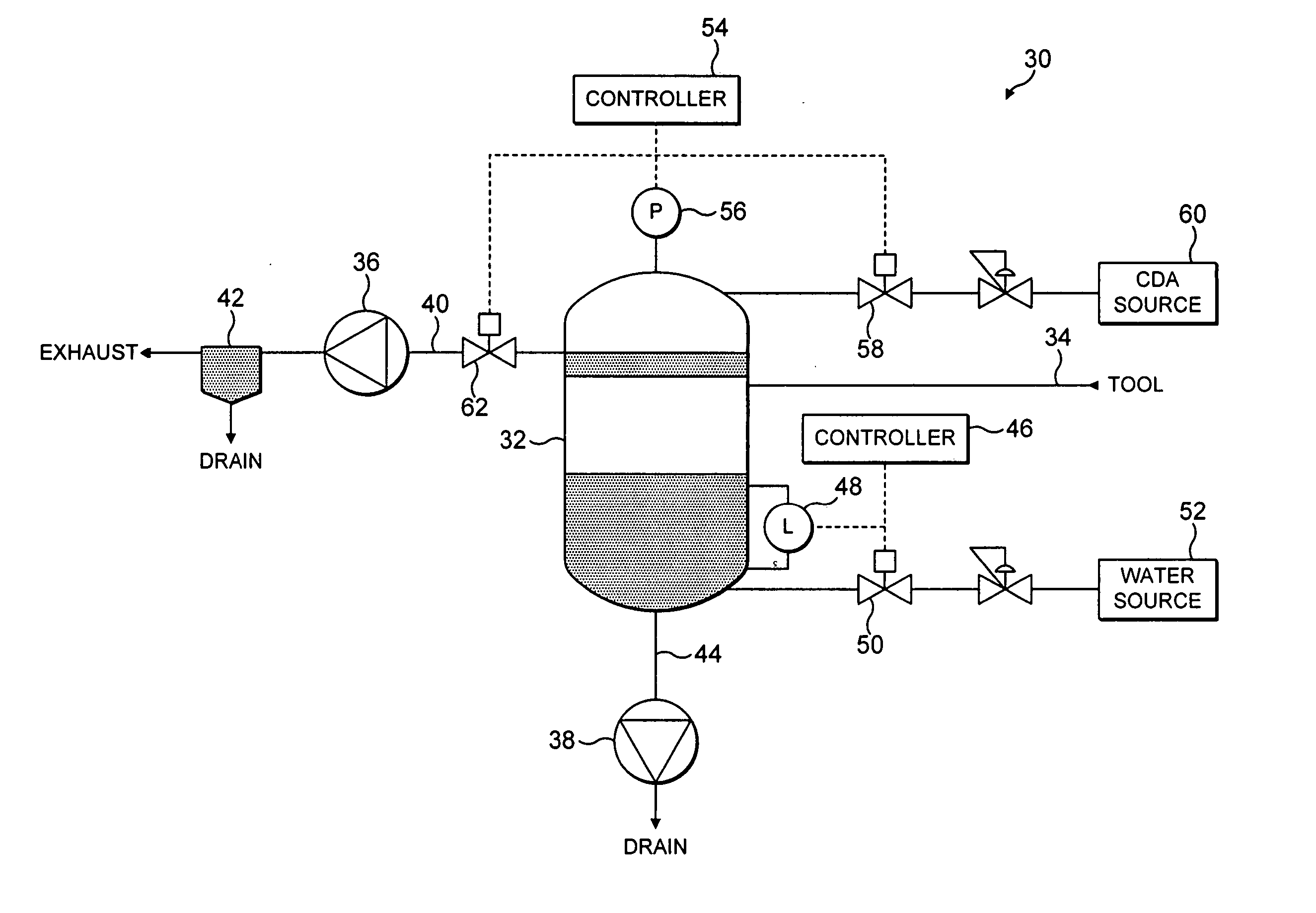

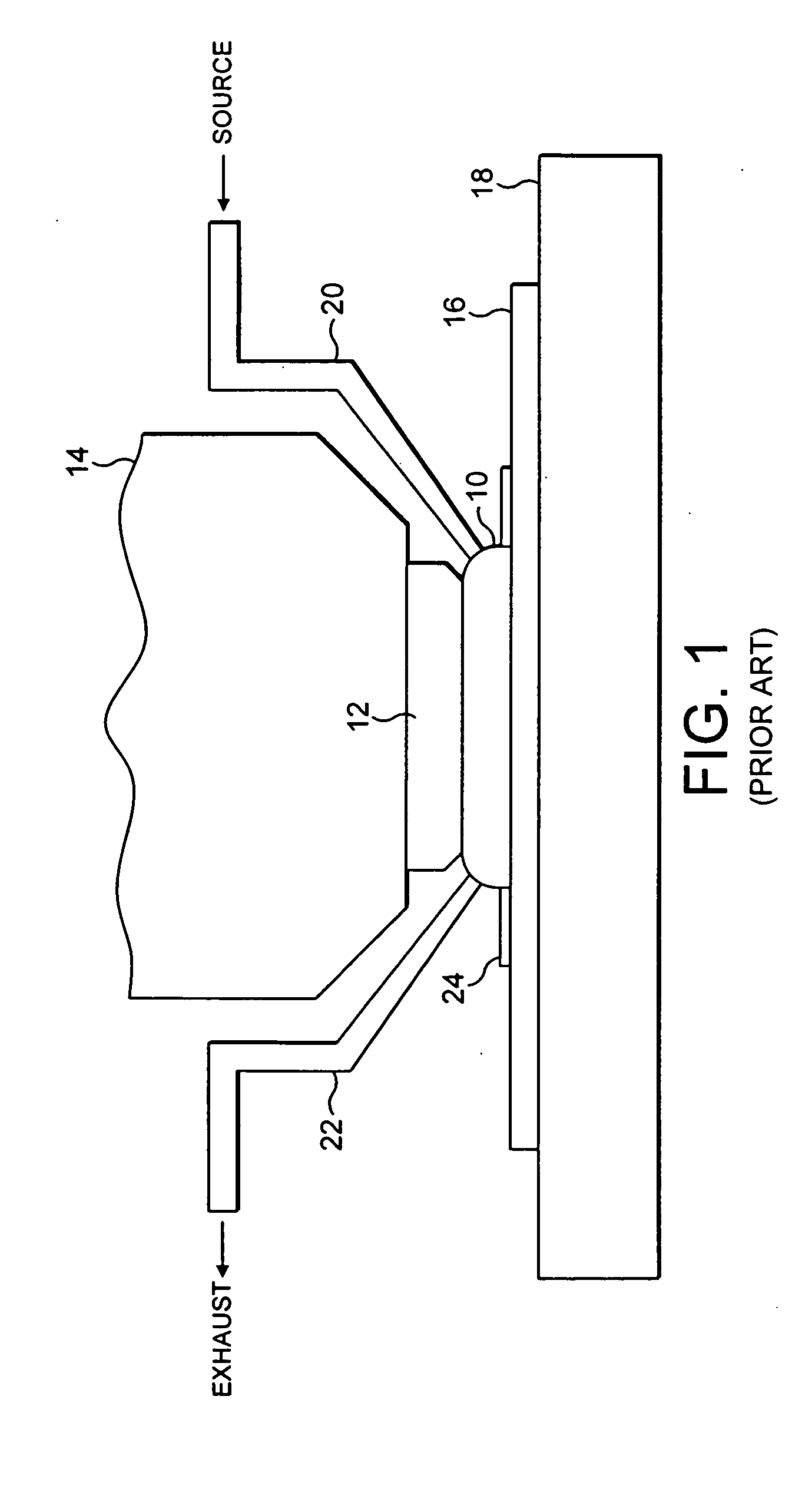

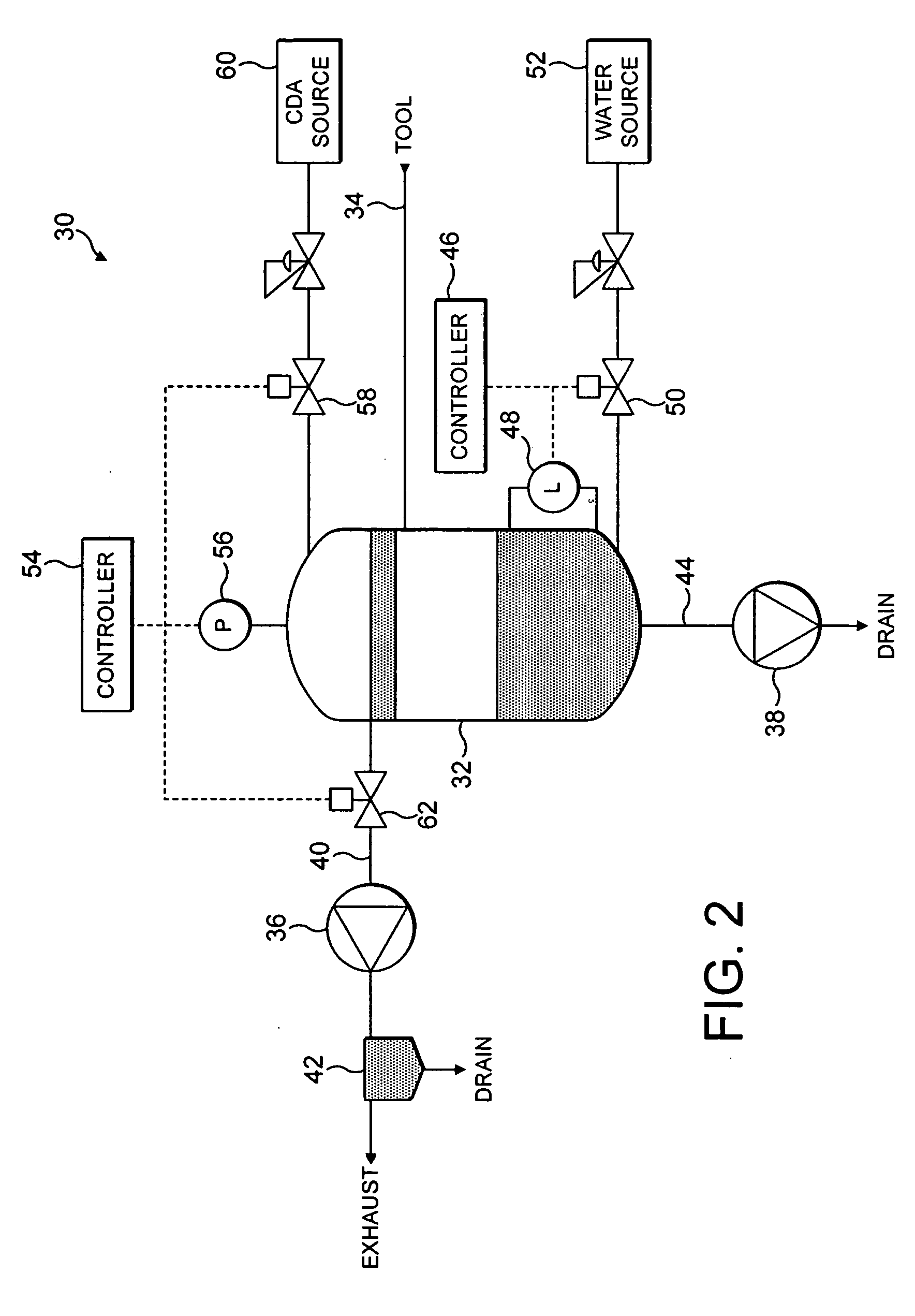

Vacuum system for immersion photolithography

InactiveUS20050282405A1Minimize transmissionLiquid degasificationDispersed particle separationControl systemEngineering

Owner:ASML NETHERLANDS BV

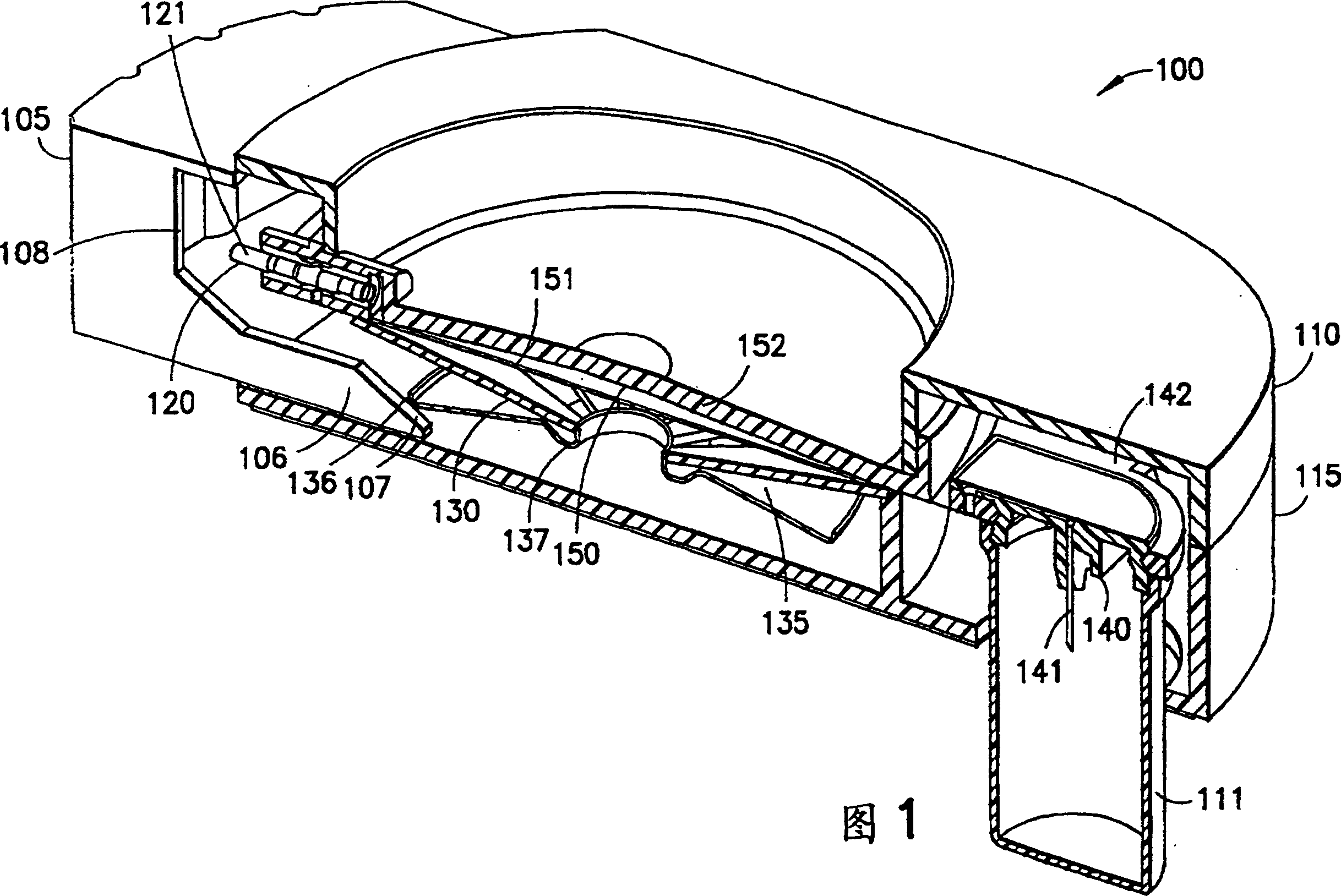

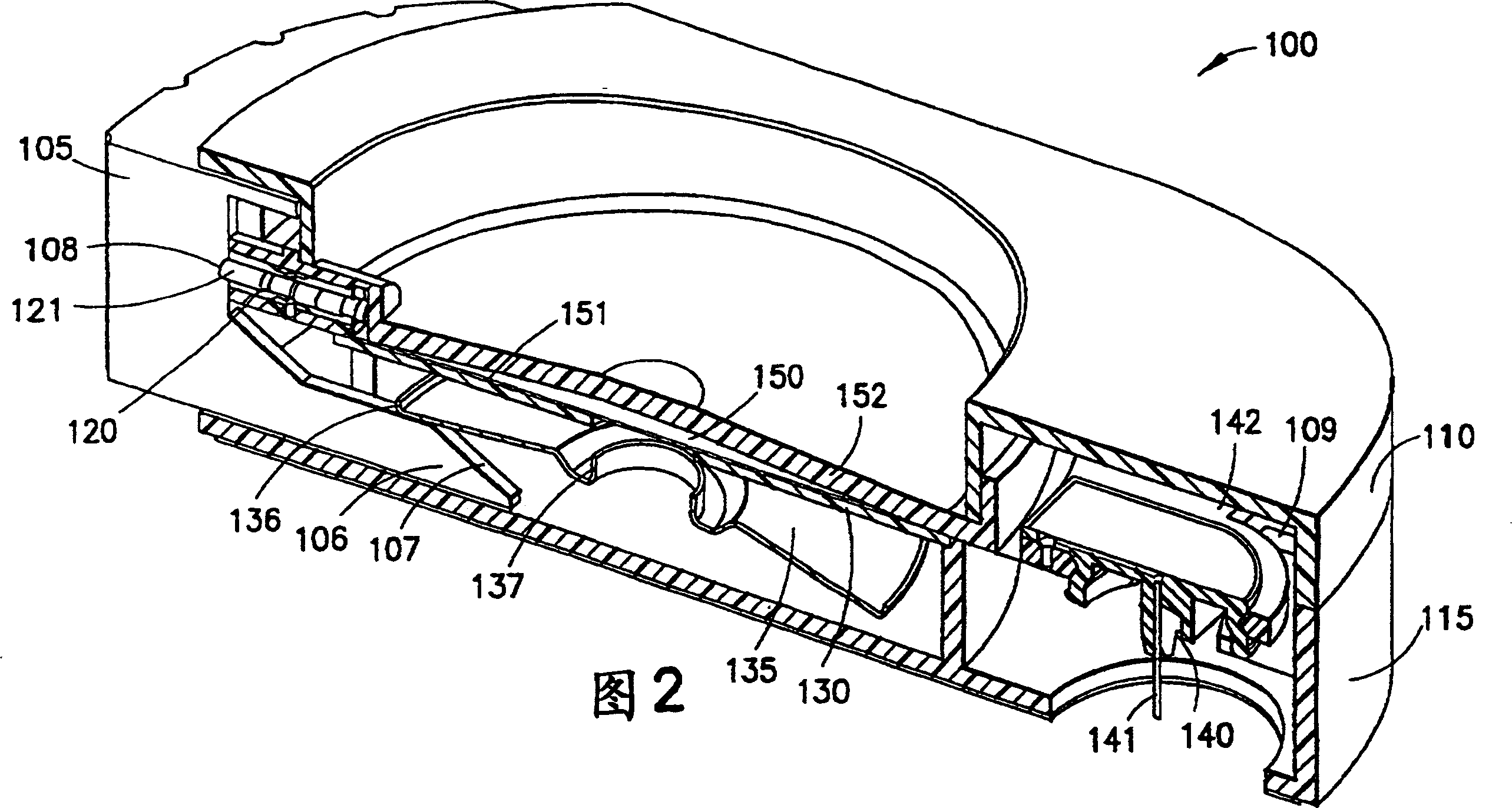

Patch-like infusion device

ActiveCN1863566AEasy to wearLess discomfortPressure infusionInfusion needlesSkin surfaceBiological activation

A system and method for a patch-like, self-contained substance infusion device (700) which provides hidden patient needles (760) that includes a rigid bladder (712) used with a non-distensible bladder film (740), such as a metallized film. The device (700) can be attached to skin via an adhesive surface and a push button (780) activation assembly can be used to remove an interlock (730), allowing a disk, or Belleville spring (735) assembly to apply constant pressure to a fluid reservoir assembly (710). The push button (780) assembly allows the release of one or more spring-loaded patient needles (760) into the skin, and establishes a fluid path between the patient needles (760) and the pressurized fluid reservoir thereby delivering an infusion into the skin. The push button (780) activation assembly further allows the release of safety mechanisms (794) which are driven by spring (793) and released by trap-door (790).

Owner:BECTON DICKINSON & CO

Closed System and Method for Atraumatic, Low Pressure, Continuous Harvesting, Processing, and Grafting of Lipoaspirate

ActiveUS20080167613A1Reduce excessFat graft survivalMelt-holding vesselsMedical devicesFat graftingEngineering

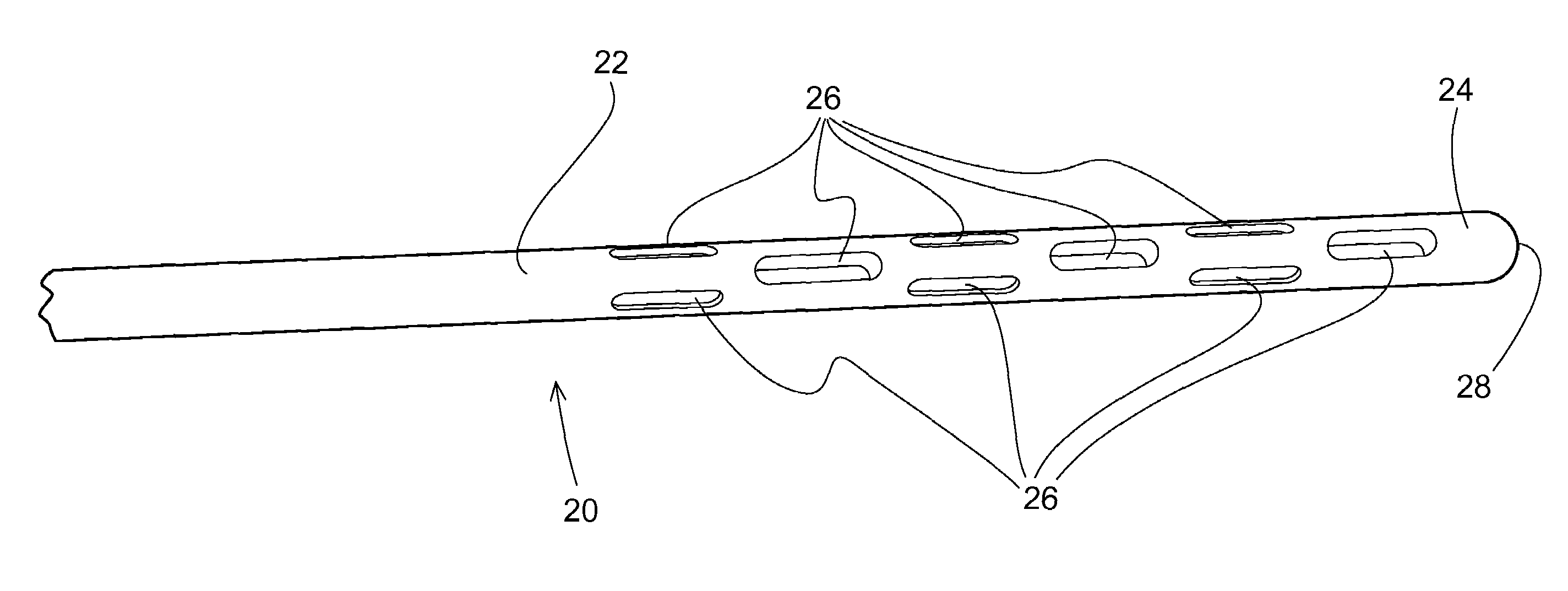

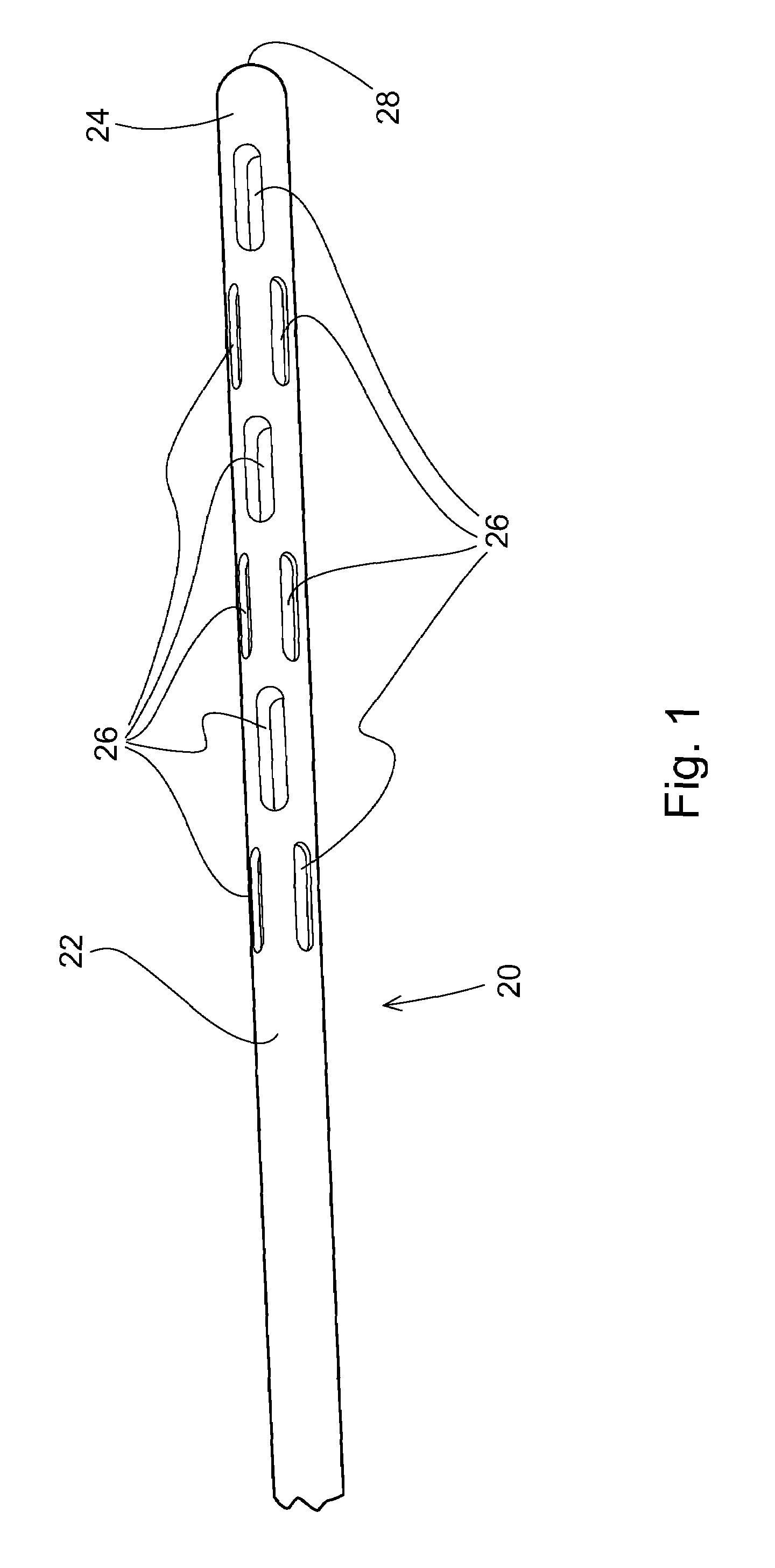

A closed system for harvesting fat through liposuction, concentrating the aspirate so obtained, and then re-injecting the concentrated fat into a patient comprises as its main components a low pressure cannula having between about 7 to 12 side holes of about 1-2 mm by 2.0 to 4.0 mm, a spring loaded syringe holder with a helicoidal spring to apply a substantially constant pressure over the full excursion of the plunger, and a preferably flexible collection bag which is also preferably graduated, cylindrical over most of its body and funnel shaped at its bottom, all of which are connected through flexible tubings to a multi-port valve. The multi-port valve has two flutter / duck bill valves which restrict the fluid flow to a one way direction which effectively allows the syringe to be used to pump fat out of a patient and into a collection bag in a continuous manner. After the bags are centrifuged to concentrate the fat, the excess fluids are separated and the valve is re-connected to permit the syringe pump to reverse fluid flow to graft the concentrated fat back into the patient.

Owner:LIPOCOSM LLC

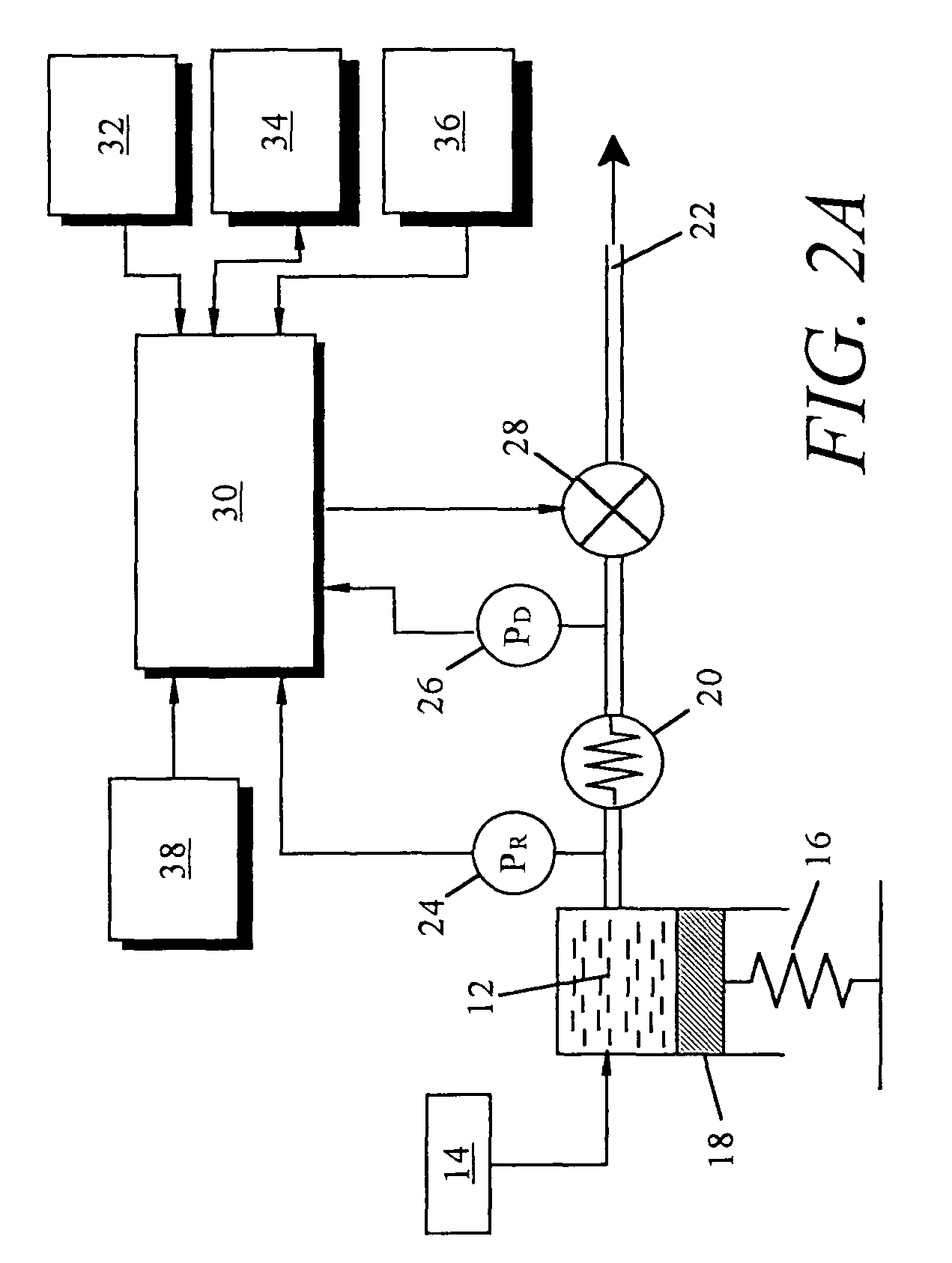

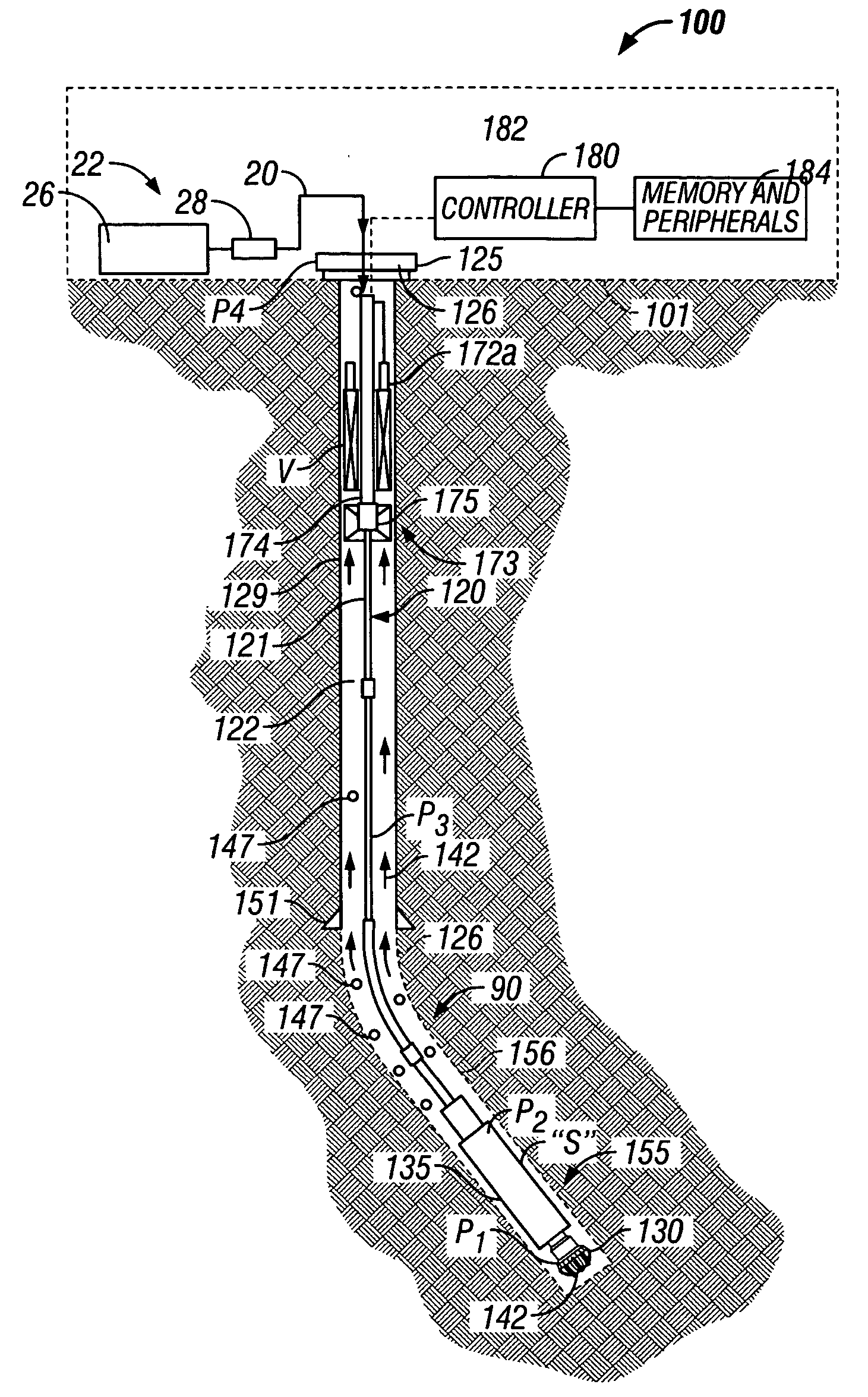

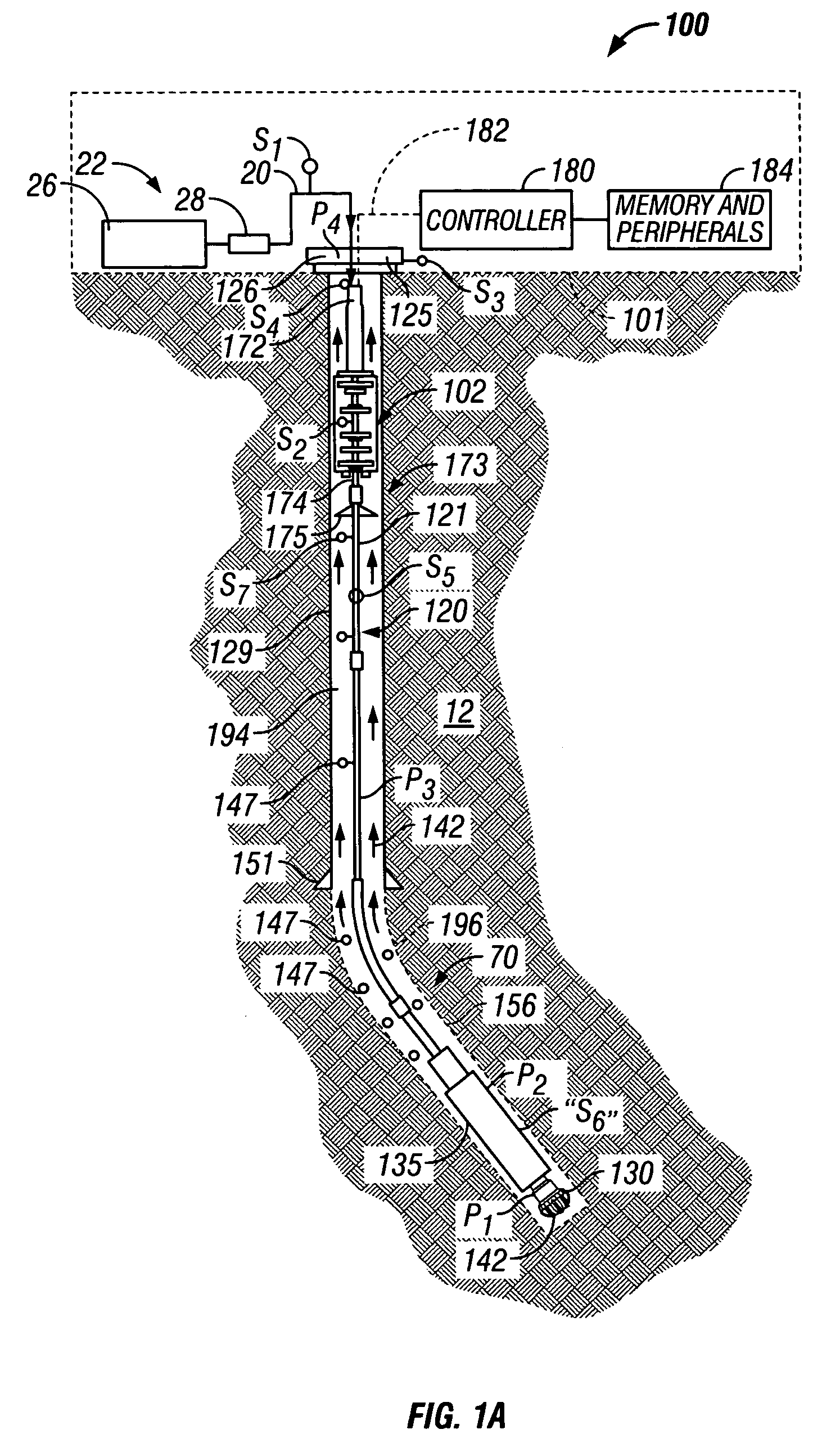

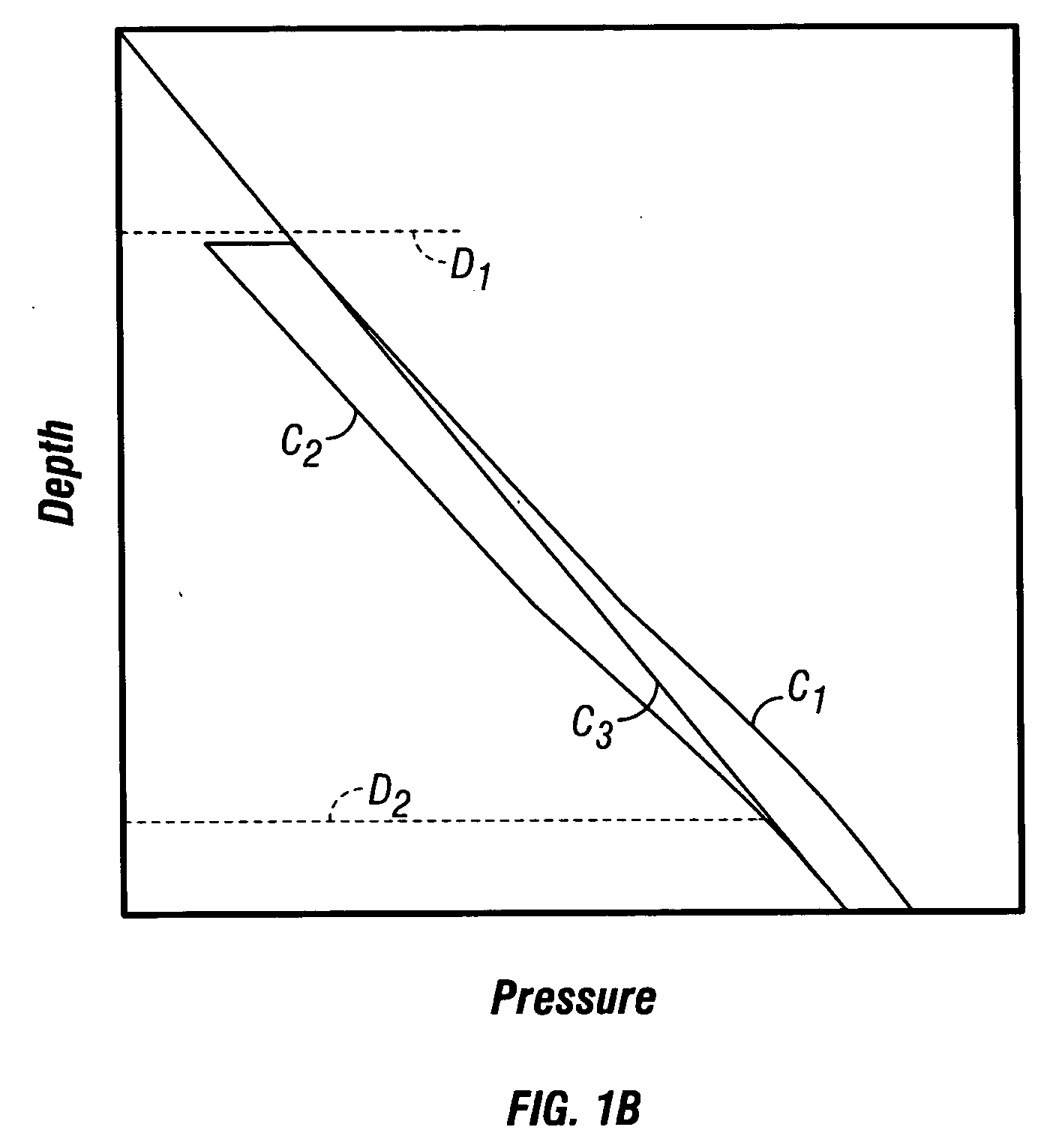

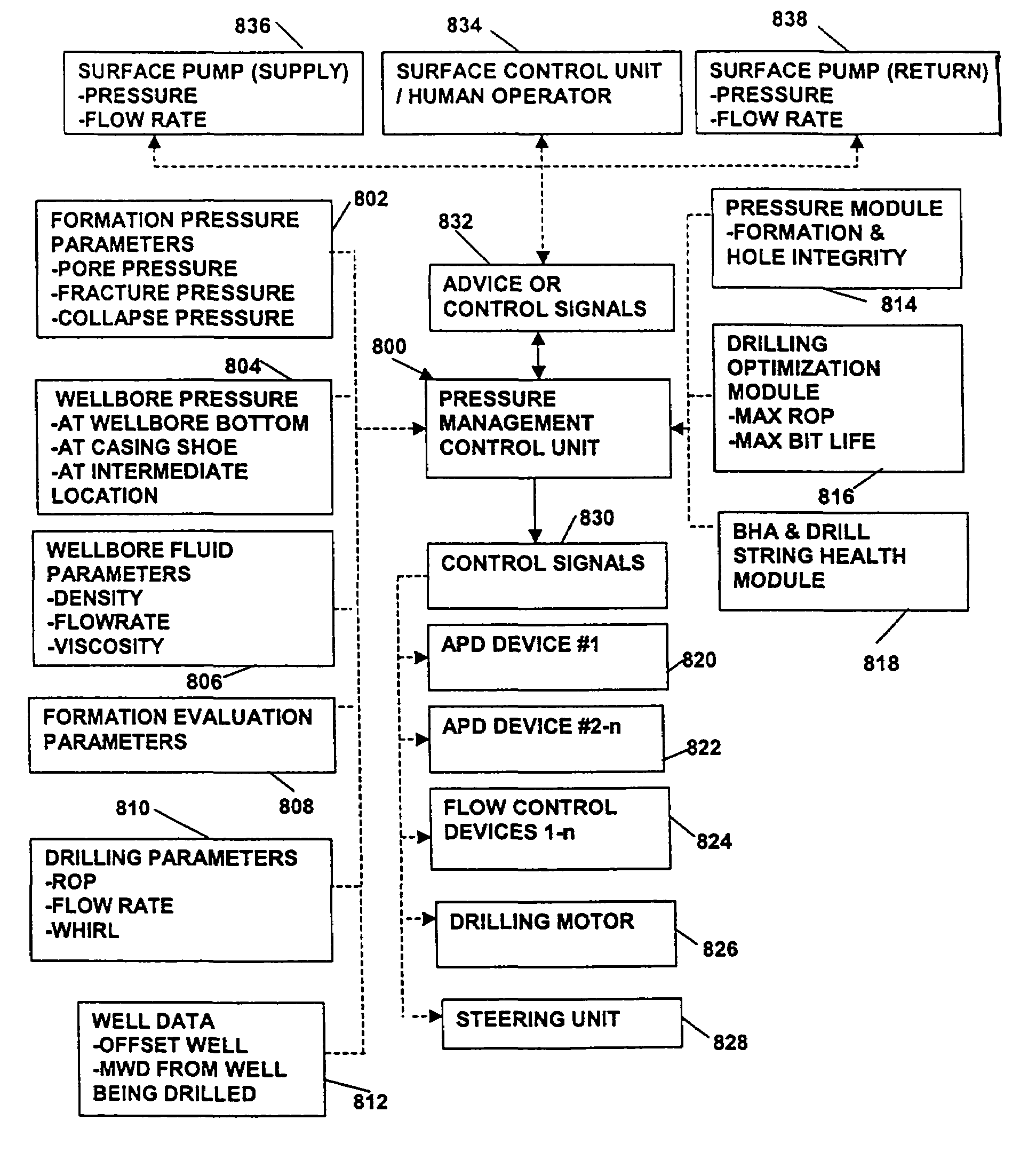

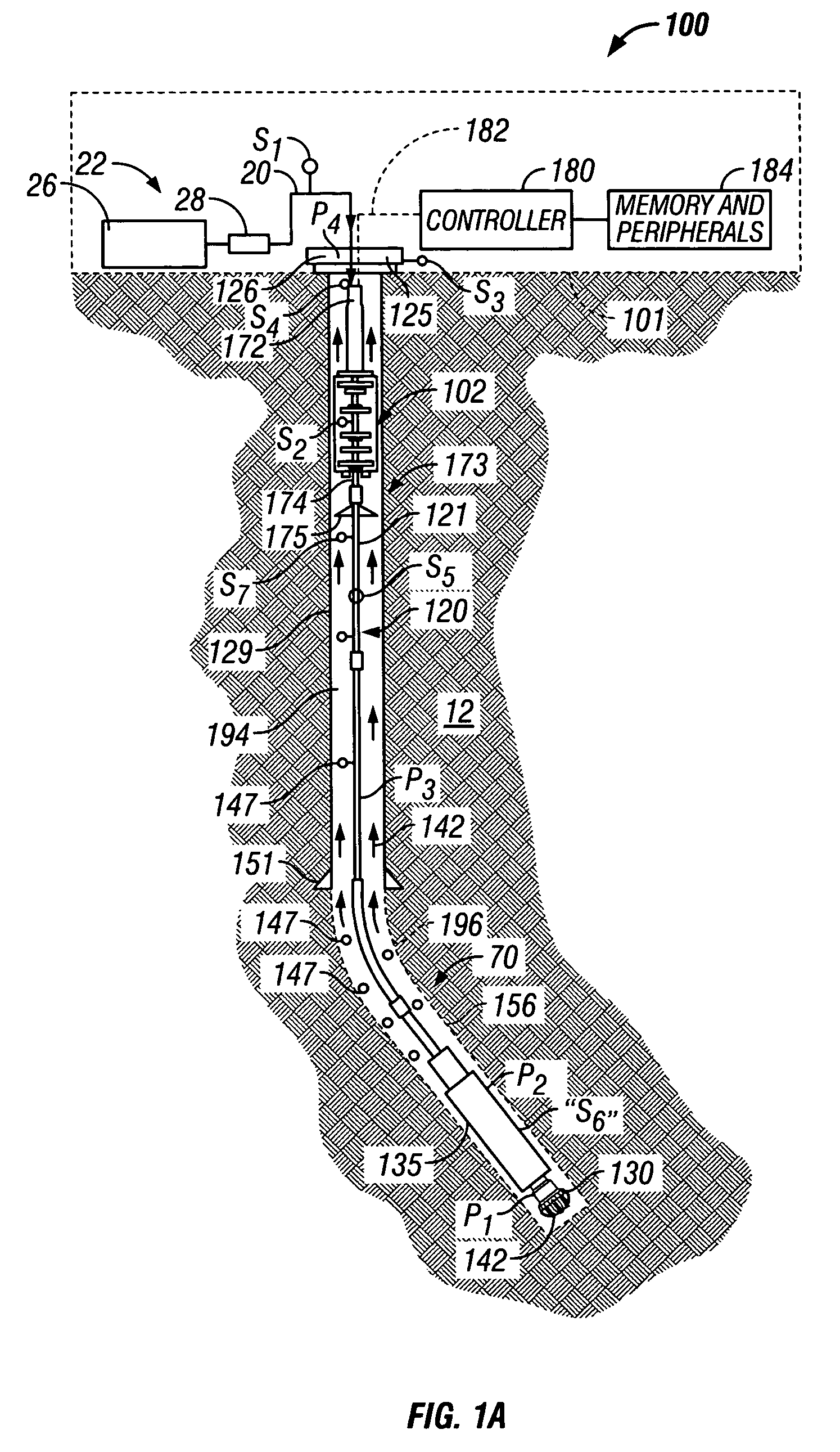

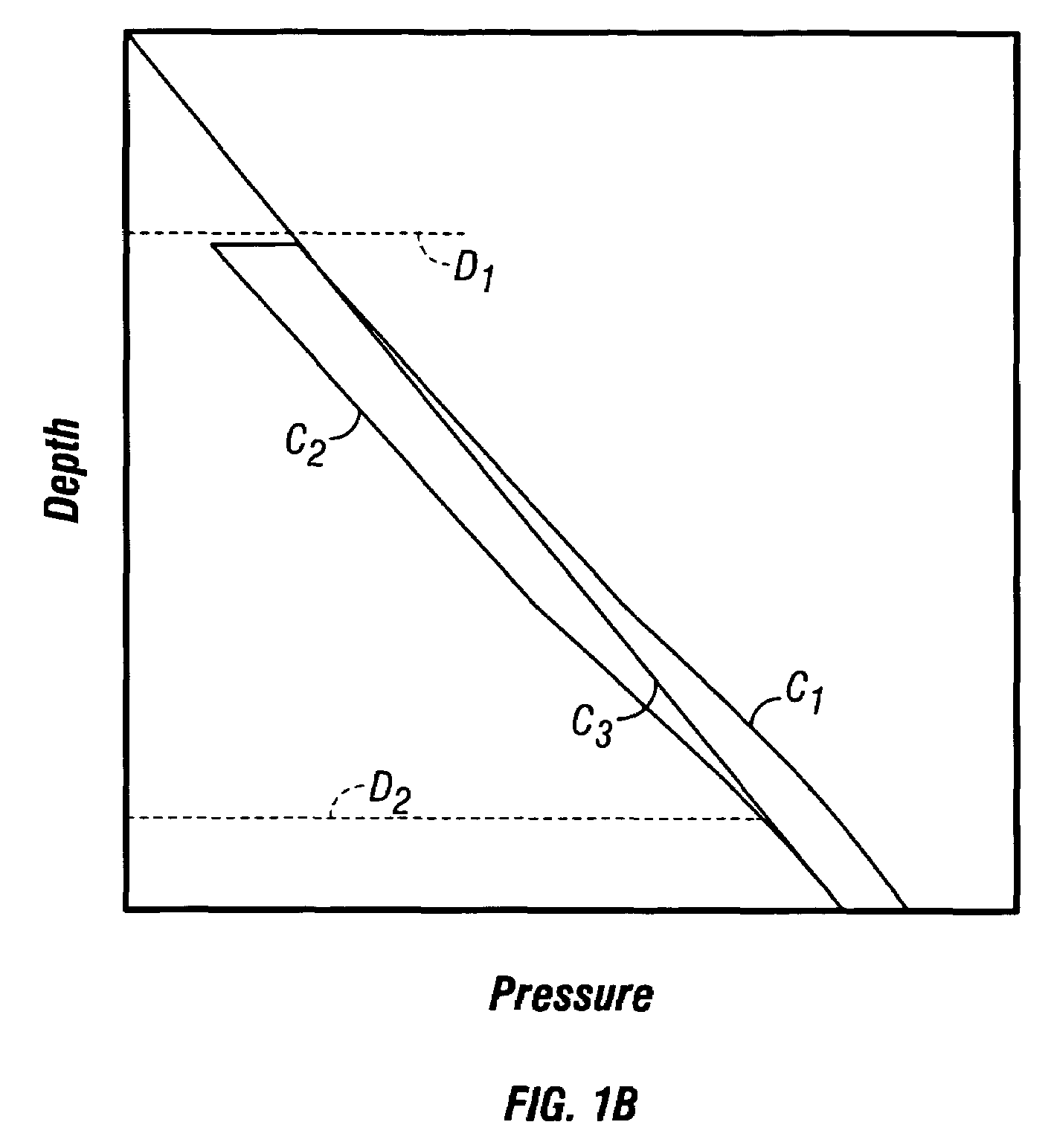

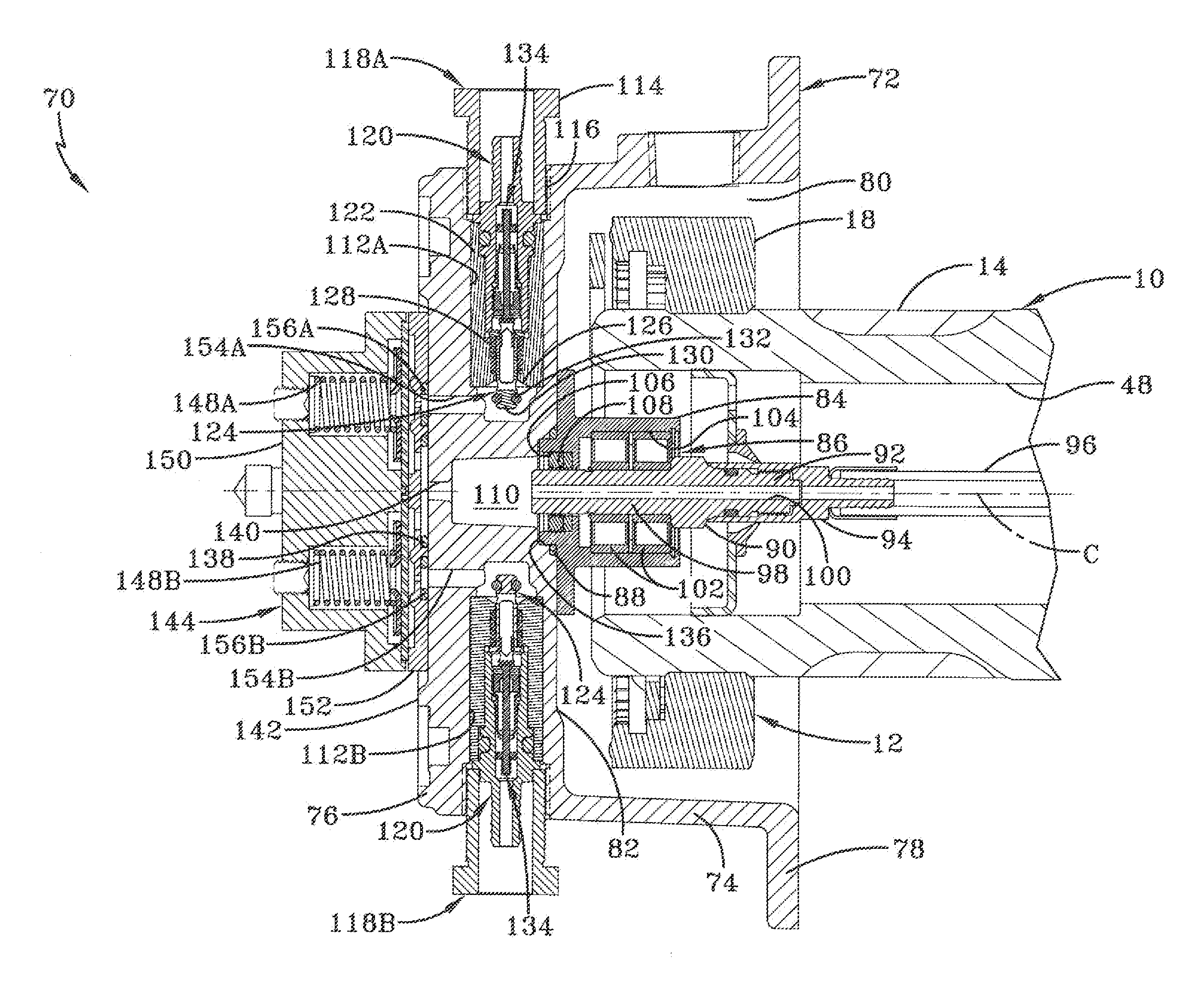

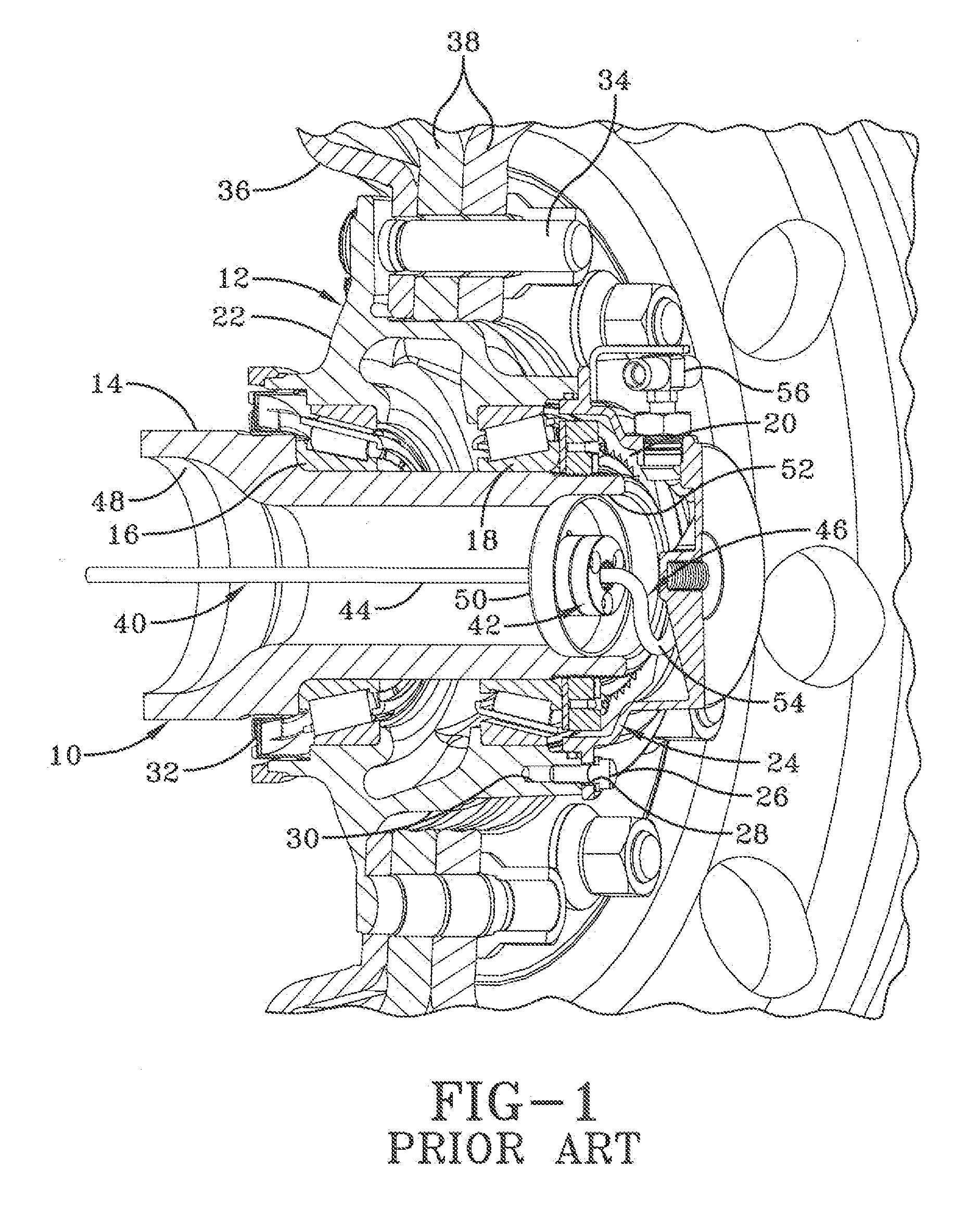

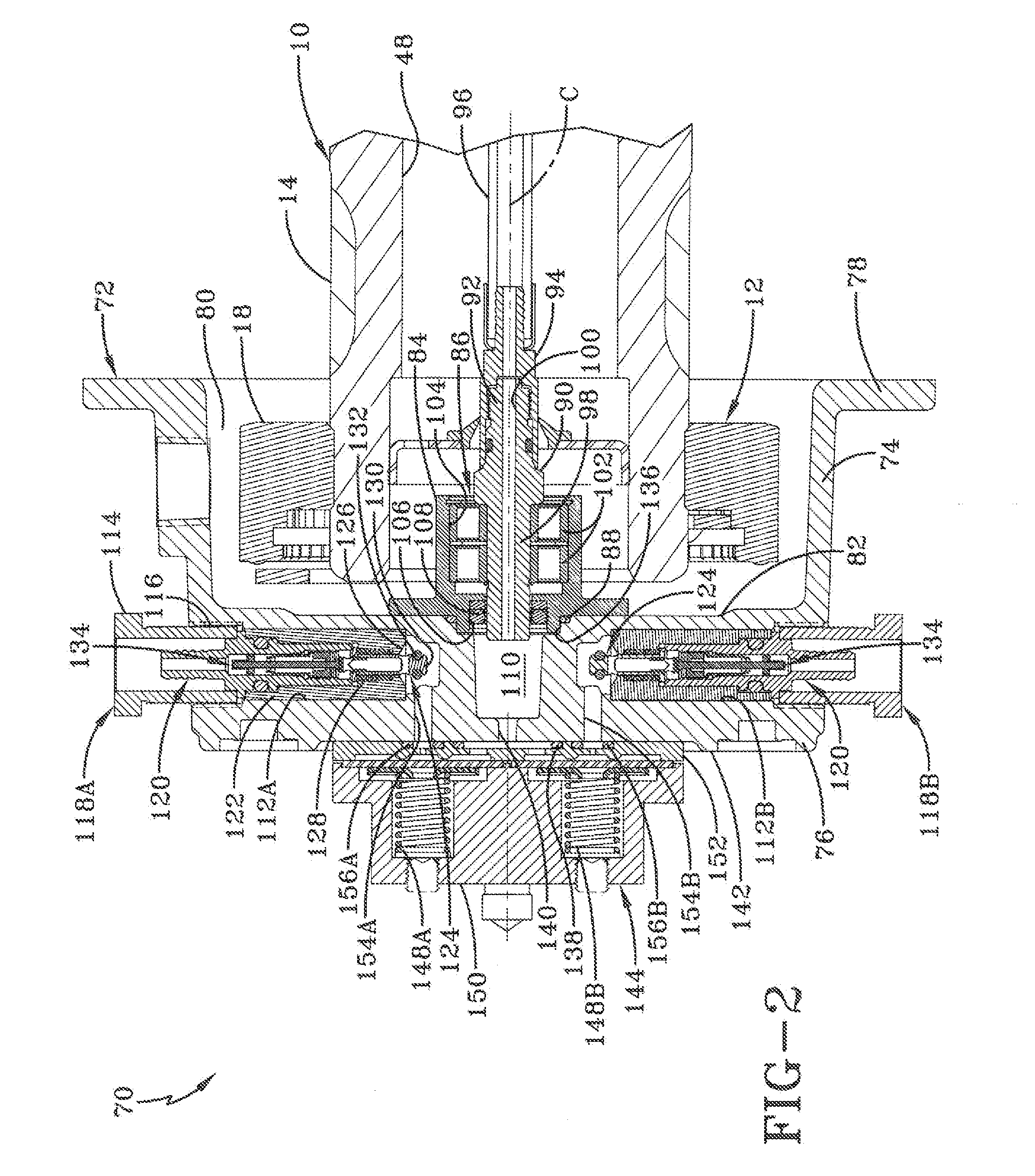

Control systems and methods for active controlled bottomhole pressure systems

InactiveUS20050098349A1Eliminate needCertain applicationDrilling rodsConstructionsPressure systemControl system

Methods and control systems are provided for a wellbore drilling system having an active differential pressure device (APD device) in fluid communication with a returning fluid. The APD Device creates a differential pressure across the device, which reduces the pressure below or downhole of the device. In embodiments, a control unit controls the APD Device to provide a selected pressure differential at a wellbore bottom, adjacent a casing shoe, in an intermediate wellbore location, or in a casing. In one arrangement, the control system is pre-set at the surface such that the APD Device provides a substantially constant pressure differential. In other arrangements, the control system measures one or more parameters (e.g., wellbore pressure, formation parameters, BHA parameters, etc.) and adjusts an operating parameter of the APD Device to provide a desired pressure differential. Devices such as an adjustable bypass can be used to control the APD Device.

Owner:BAKER HUGHES INC

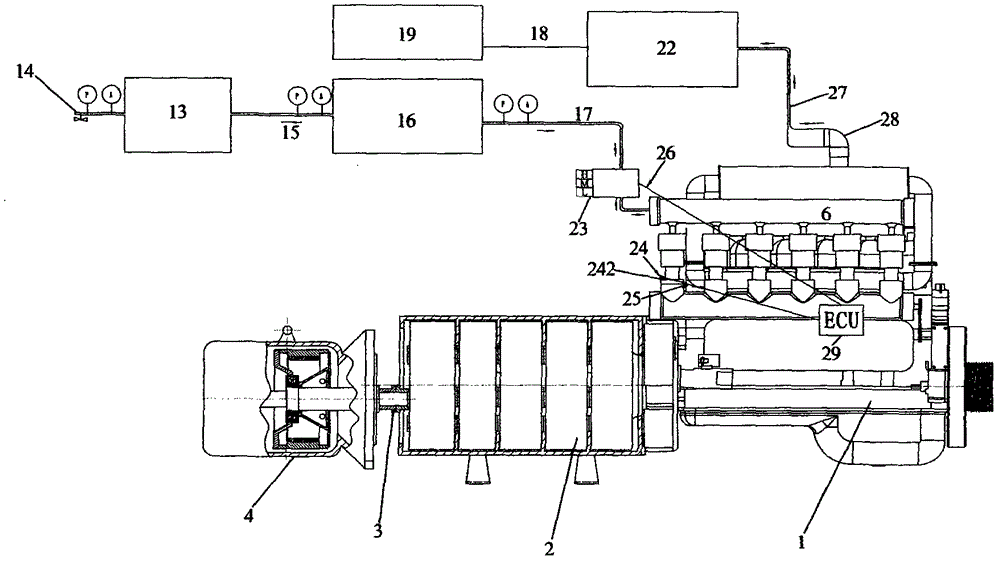

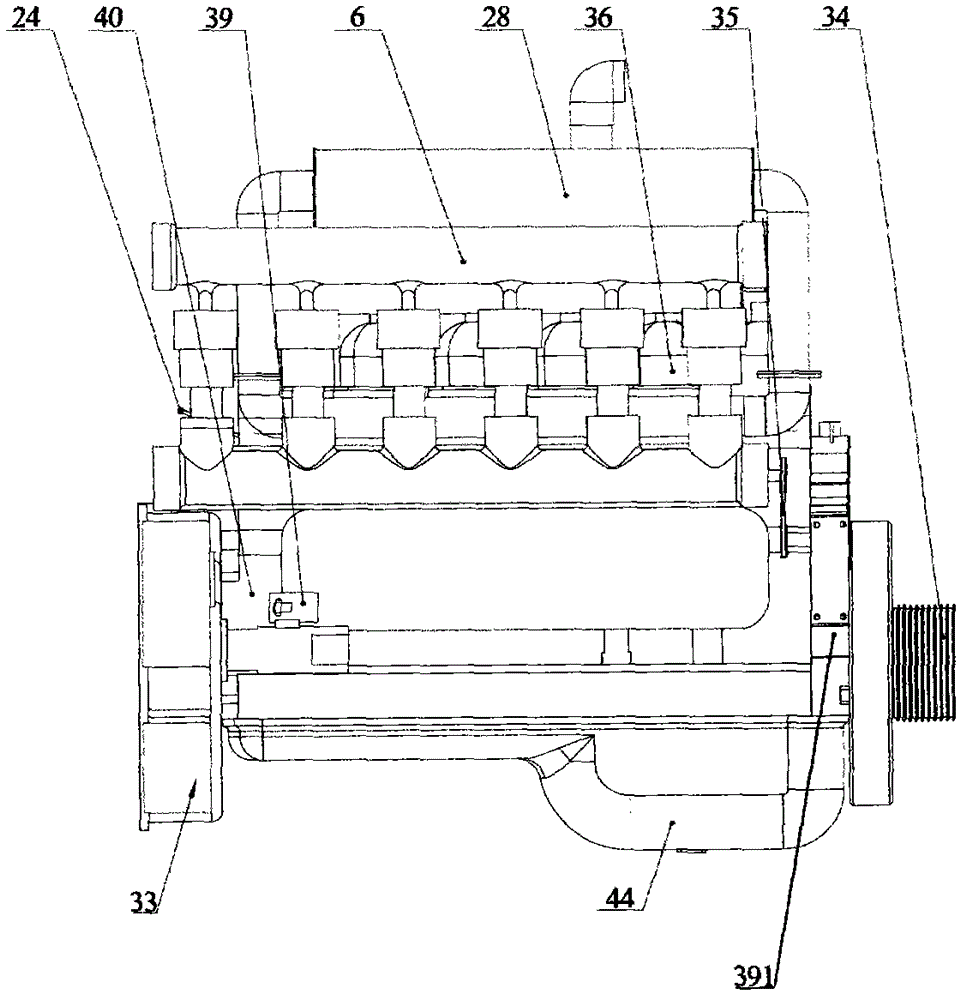

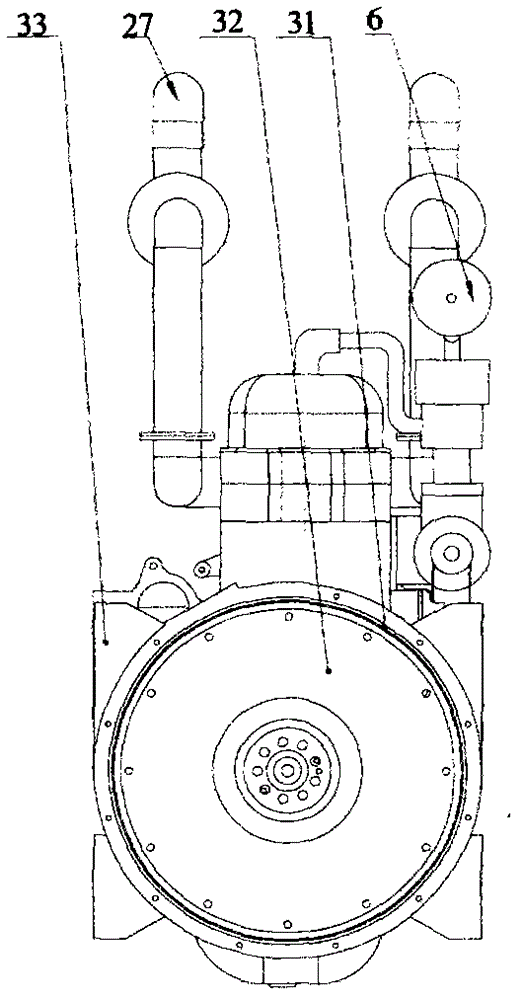

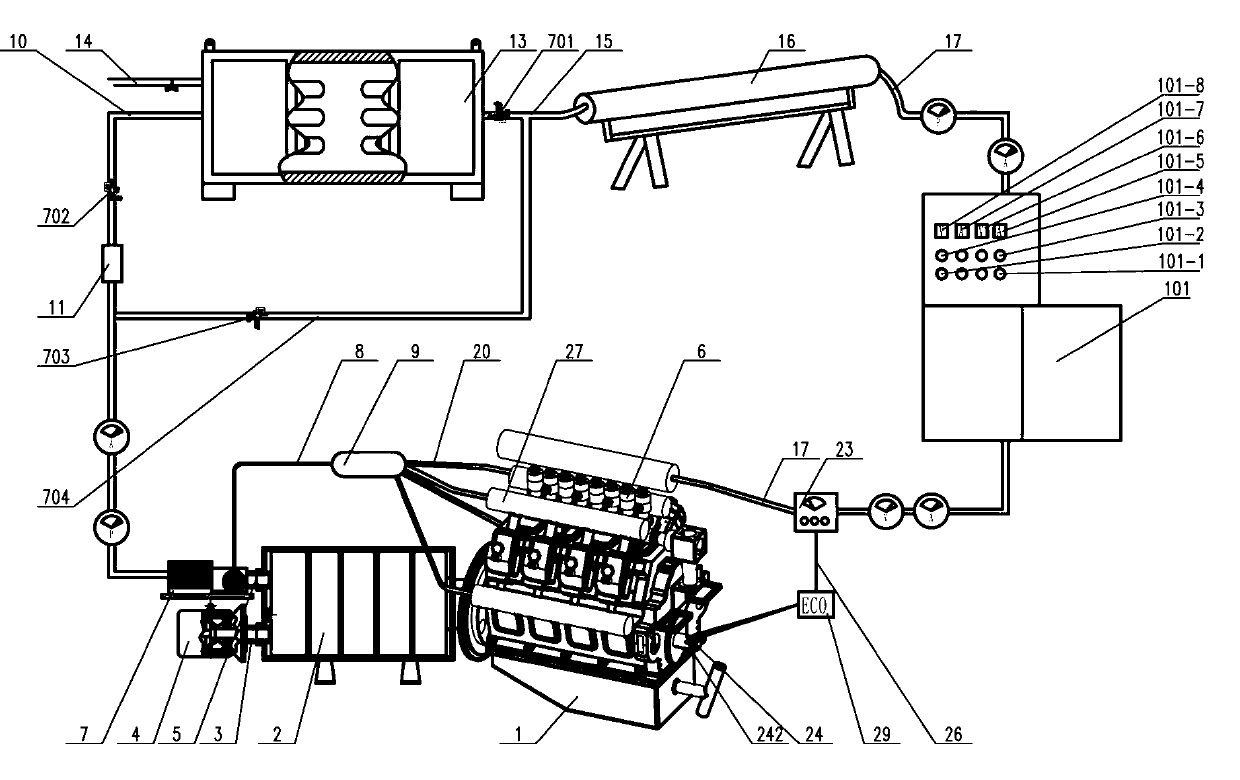

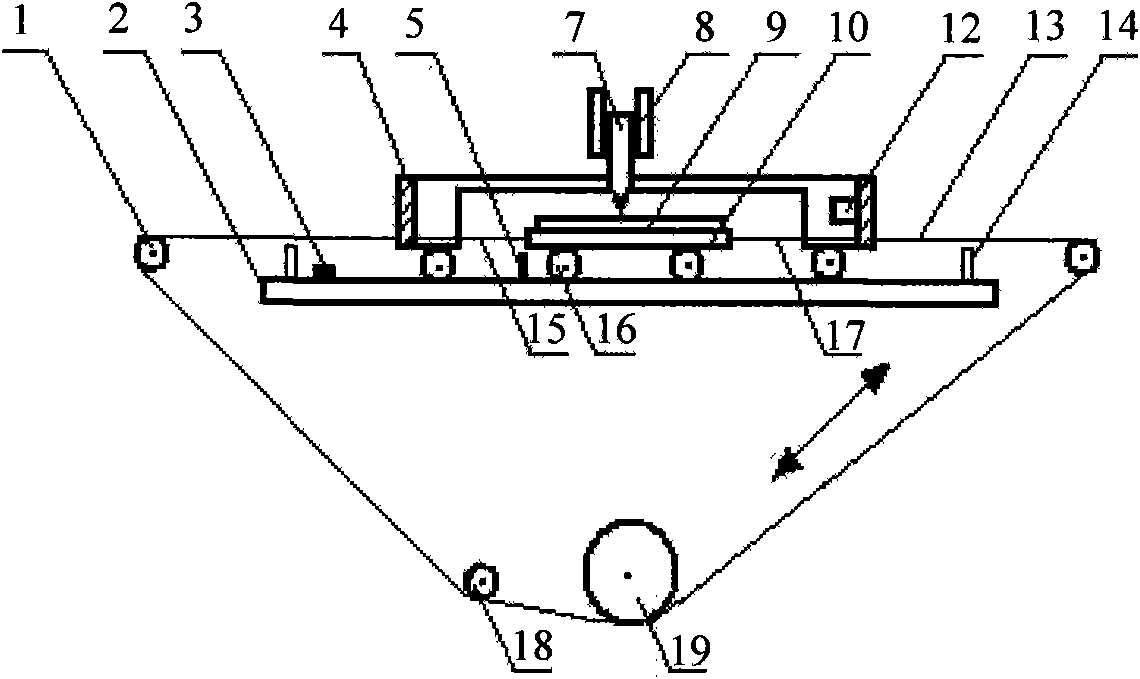

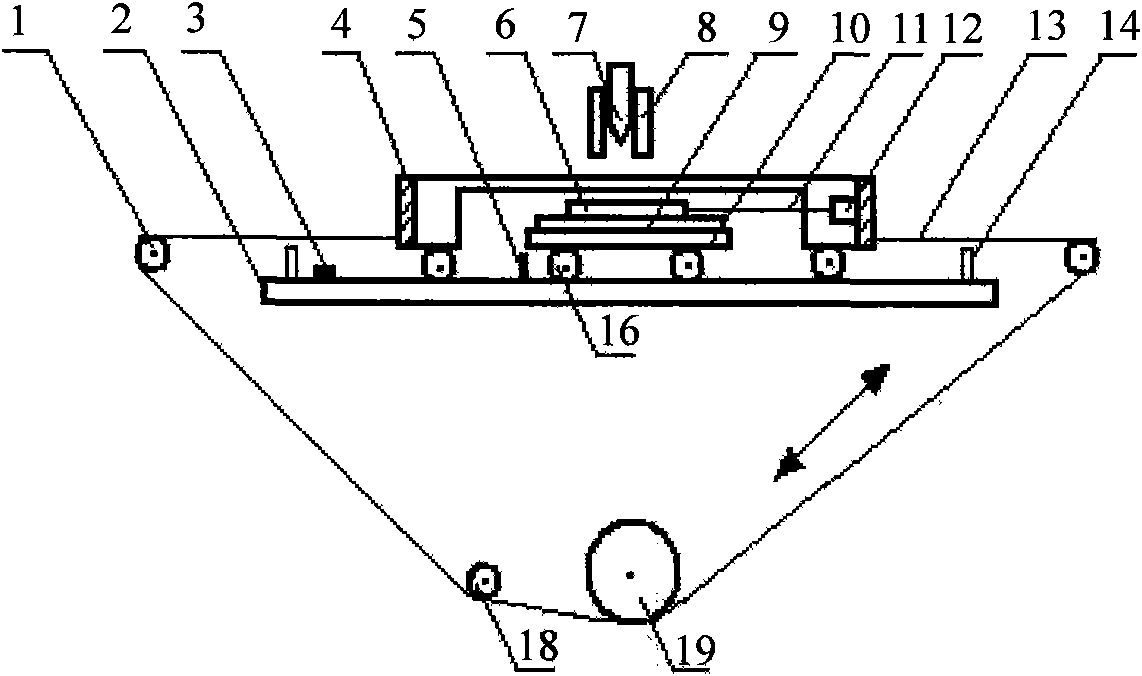

Compressed air engine assembly with tail gas recovery loop

The invention relates to a two-stroke engine, in particular to a two-strike compressed air engine assembly which takes compressed air as a power source. The compressed air engine assembly comprises an engine body (1), a multi-cylinder power divider (2), a power plant (4), a controller system (6), an air inlet control and speed regulation valve (23), a high-pressure gas tank group (13), a constant-pressure tank (16), an electronic control unit (ECU) (29) and a tail gas recovery loop. The tail gas recovery loop comprises an air compressor (7), a condenser (11), a tail gas recovery tank (9), an electric turbine one-way air pump (19) and a tail gas noise deadener (22).

Owner:周登荣 +1

Control systems and methods for active controlled bottomhole pressure systems

InactiveUS7174975B2Increase pressureEliminate needDrilling rodsConstructionsPressure systemDifferential pressure

Methods and control systems are provided for a wellbore drilling system having an active differential pressure device (APD device) in fluid communication with a returning fluid. The APD Device creates a differential pressure across the device, which reduces the pressure below or downhole of the device. In embodiments, a control unit controls the APD Device to provide a selected pressure differential at a wellbore bottom, adjacent a casing shoe, in an intermediate wellbore location, or in a casing. In one arrangement, the control system is pre-set at the surface such that the APD Device provides a substantially constant pressure differential. In other arrangements, the control system measures one or more parameters (e.g., wellbore pressure, formation parameters, BHA parameters, etc.) and adjusts an operating parameter of the APD Device to provide a desired pressure differential. Devices such as an adjustable bypass can be used to control the APD Device.

Owner:BAKER HUGHES HLDG LLC

Mechanical ventilation system utilizing bias valve

ActiveUS8118024B2Small powerSmall sizeRespiratorsOperating means/releasing devices for valvesTransducerEngineering

A portable mechanical ventilator having a ROOTS® blower is configured to provide a desired gas flow and pressure to a patient circuit. The mechanical ventilator includes a flow meter operative to measure gas flow produced by the ROOTS® blower and an exhalation control module configured to operate an exhalation valve connected to the patient circuit. A bias valve connected between the ROOTS® blower and the patient circuit is specifically configured to generate a bias pressure relative to the patient circuit pressure at the exhalation control module. The bias valve is further configured to attenuate pulsating gas flow produced by the ROOTS® blower such that gas flowing to the mass flow meter exhibits a substantially constant pressure characteristic. The bias pressure facilitates closing of the exhalation valve at the start of inspiration, regulates positive end expiratory pressure during exhalation, and purges sense lines via a pressure transducer module.

Owner:VYAIRE MEDICAL 203 INC

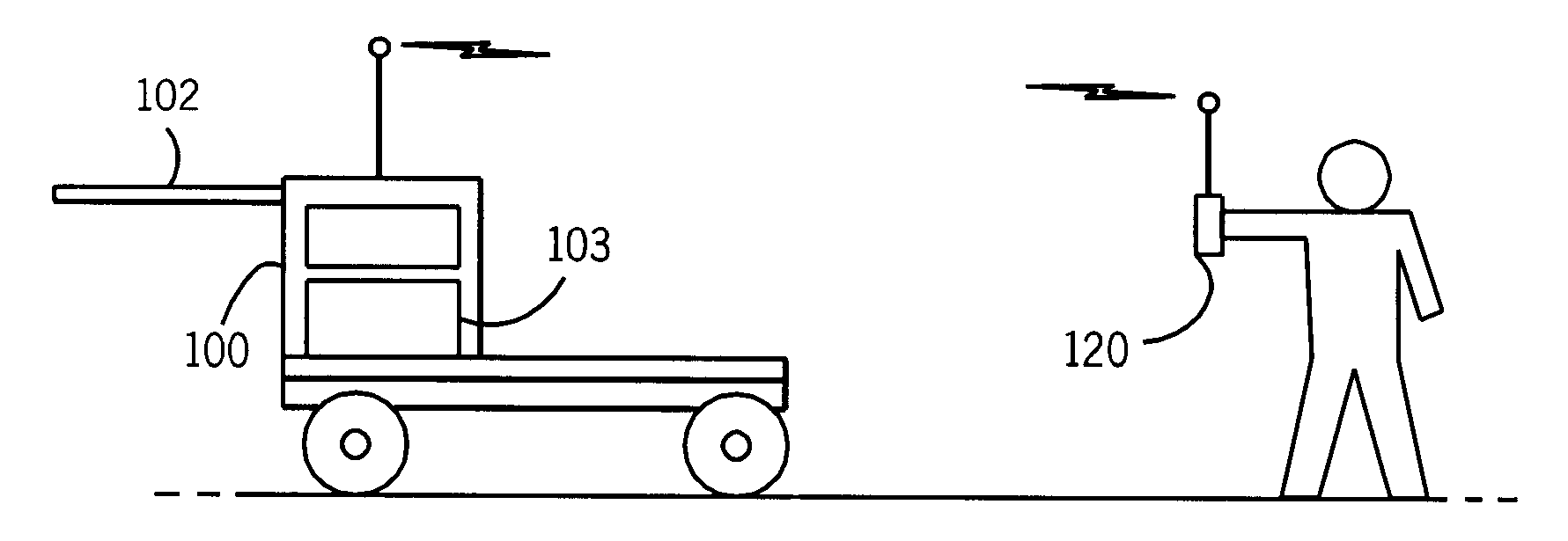

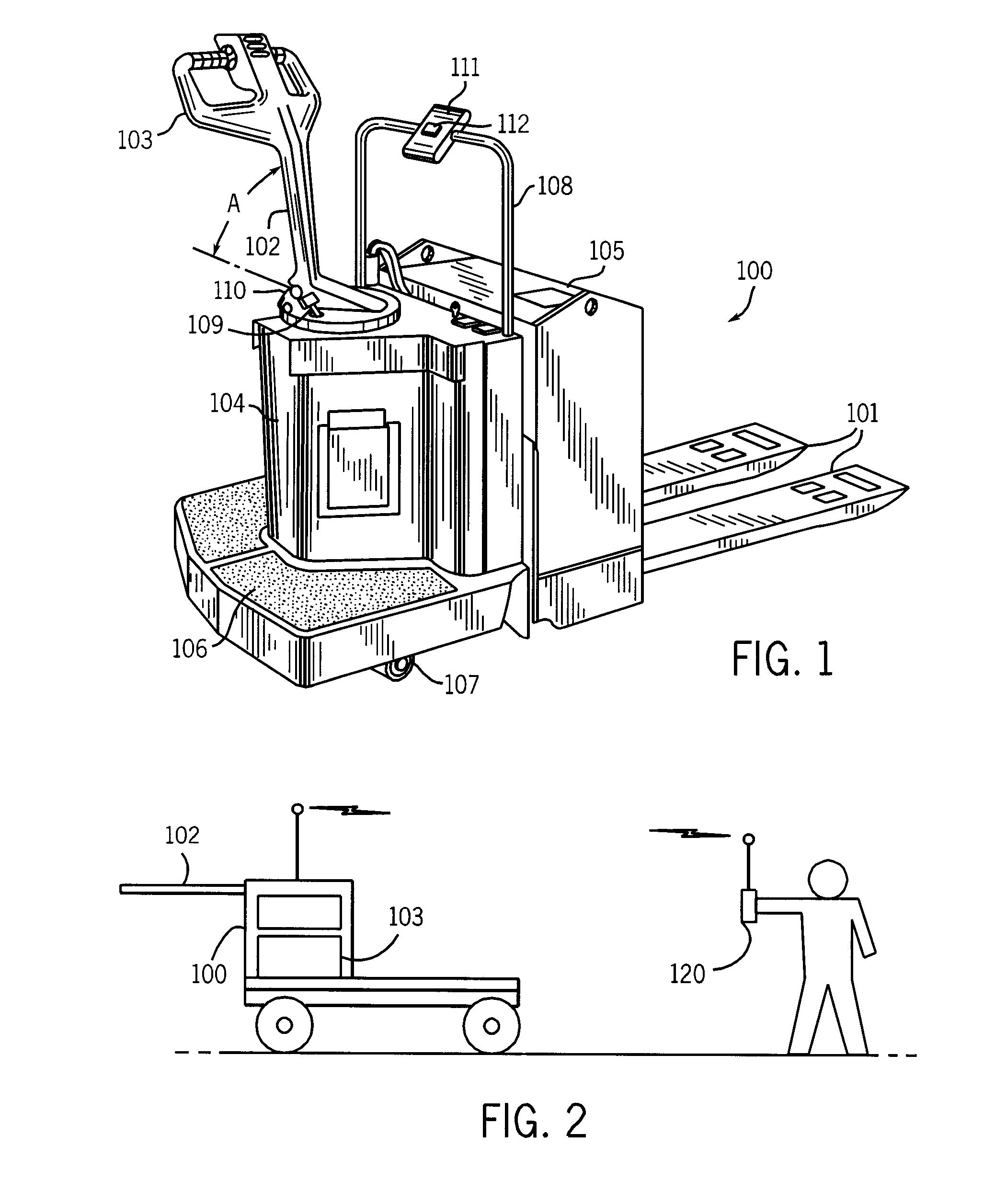

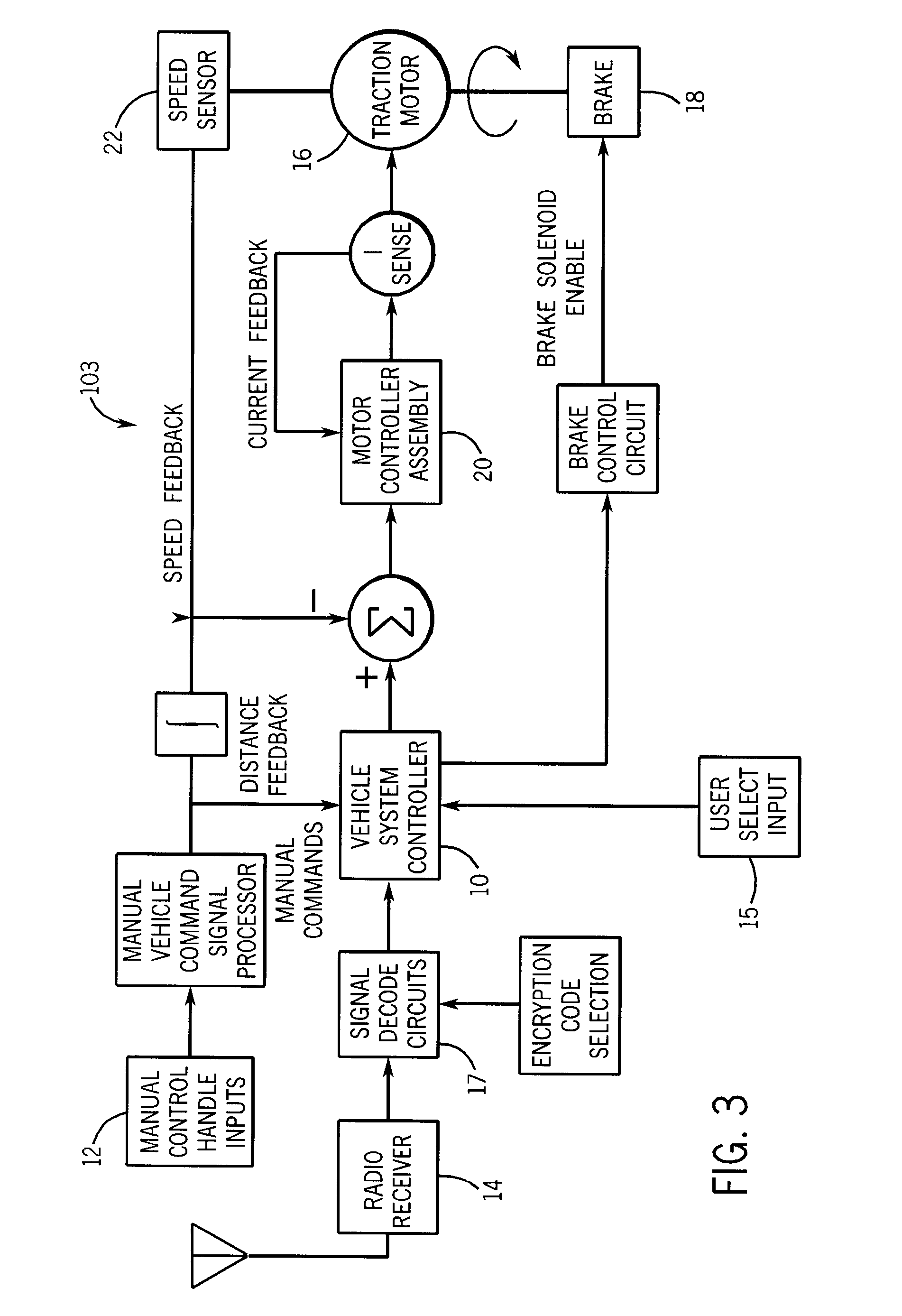

Control system for a pallet truck

A control system for controlling motion of a pallet truck vehicle includes three modes of operation for controlling coasting of the vehicle. In a first, constant pressure mode, the vehicle coasts for as long as an activation button is depressed. In a second, time controlled mode, the vehicle coasts for a predetermined period of time. In the third, distance controlled mode, the vehicle coasts for a predetermined distance. Each of these functions can be activated from a remote location using a remote activation device.

Owner:RAYMOND LTD

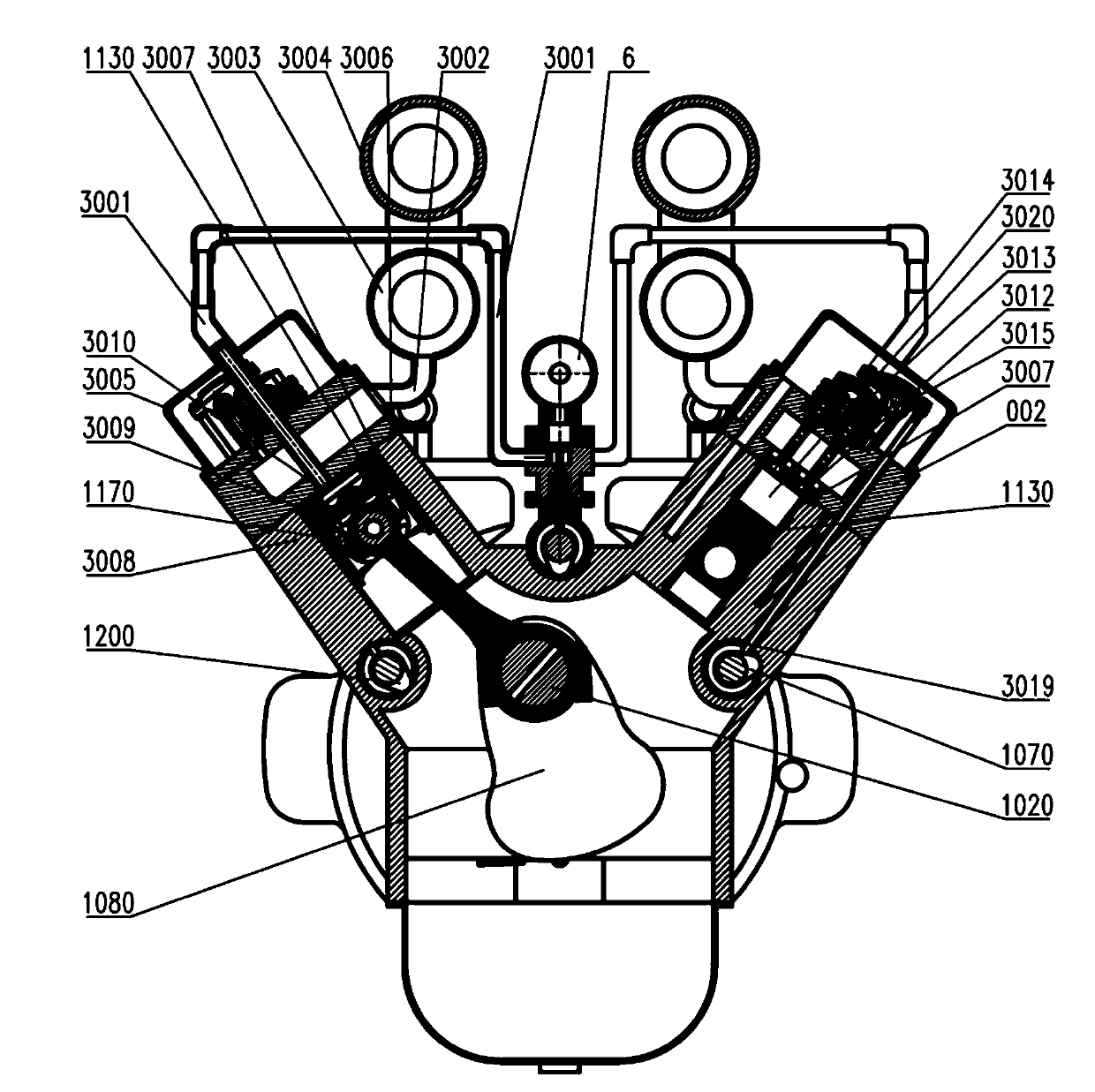

V-shaped multi-cylinder aerodynamic engine

InactiveCN103306728ASafety/regulatory devicesReciprocating piston enginesAir compressorHigh pressure

The invention relates to an engine, in particular to a V-shaped multi-cylinder aerodynamic engine assembly adopting compressed air as motive power. The V-shaped multi-cylinder aerodynamic engine assembly comprises a multi-cylinder engine body (1), a multi-column motive power distributor (2), motive power equipment (4), a controller system (6), an air inlet control speed regulating valve (23), a high-pressure gas tank group (13), a constant pressure tank (16), an electronic control unit (ECU) (29), a compressed air heating device (101) and an optional second gas supply loop. The second gas supply loop comprises an air compressor (7), a condenser (11), a pressure limiting valve (702), a sequence valve (705) and a tail gas recovery tank (9).

Owner:周登荣 +1

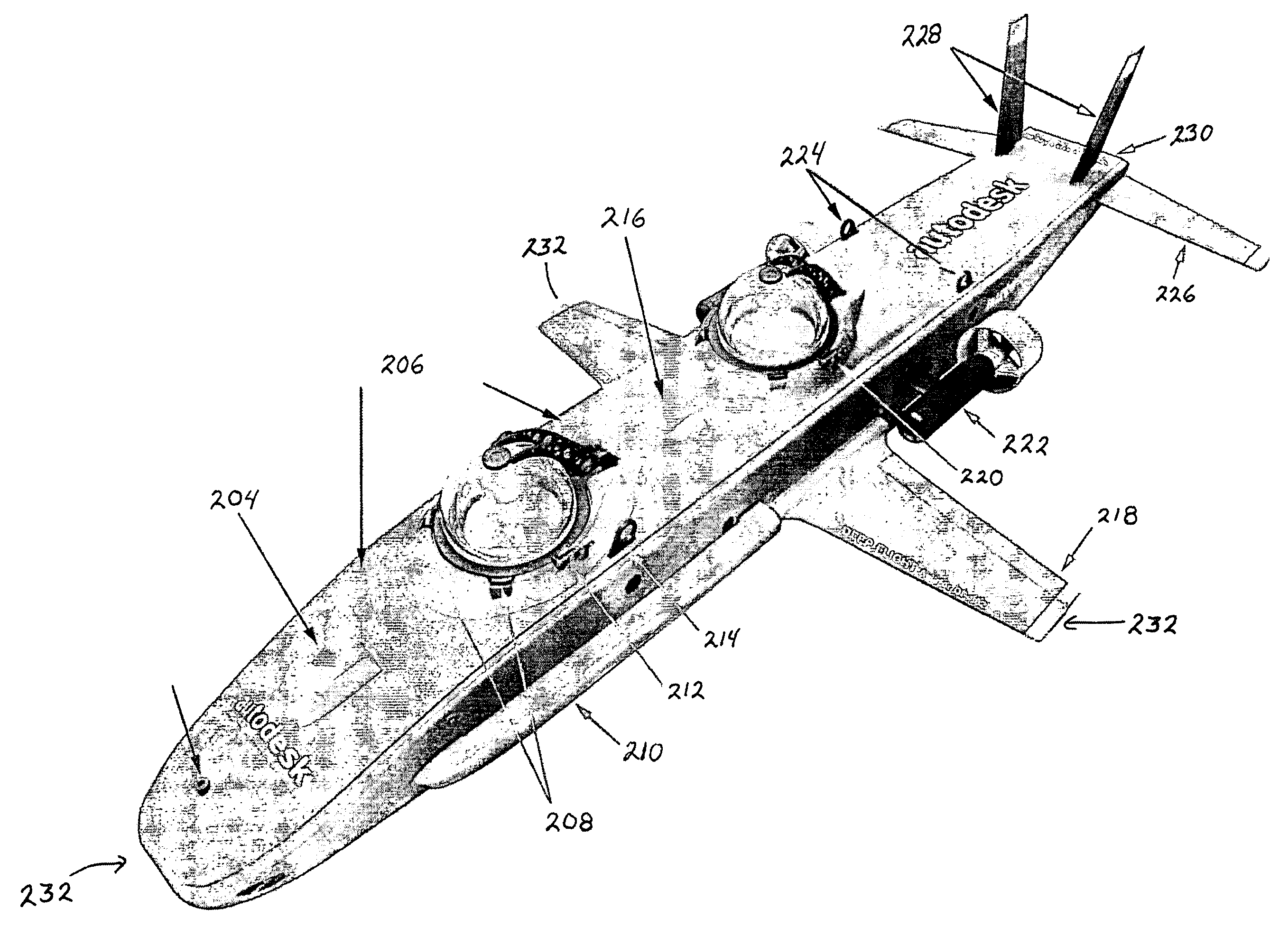

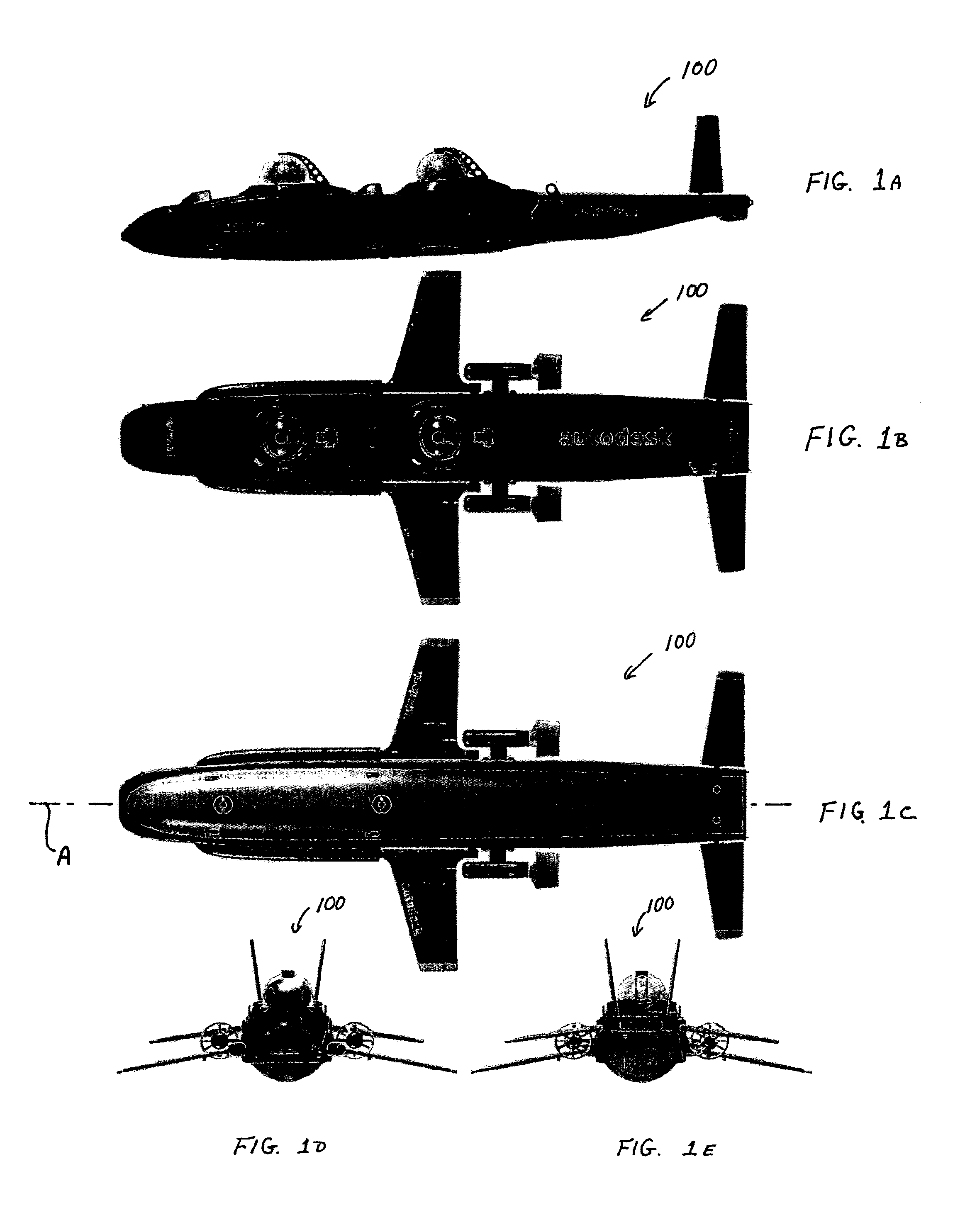

Submersible

ActiveUS7131389B1Positive buoyancyUnderwater vesselsUnderwater equipmentInternal pressureLife support

A winged submersible having a neutral to positive buoyancy utilizes an inverted wing structure to allow the wings to create downward force on the submersible in response to forward movement. Internal pressure pods are provided to allow an occupant to maintain a recumbent sitting position. The pressure pods are maintained at a constant pressure with life support systems, while the remainder of the hull is not pressurized. Acrylic domes are positioned to allow access to each internal pressure pod and when closed, the occupant's head is positioned within the center of the dome for optimal optics under water. Wings with adjustable control surfaces provide the submersible with the ability to roll about a longitudinal axis 0–360 degrees in either direction.

Owner:DEEPFLIGHT ASSIGNMENT FOR THE BENEFIT OF CREDITORS LLC

Constant pressure pneumatic balancing tire inflation system

A constant pressure vehicle tire inflation system includes an air supply source. A first wheel valve is in fluid communication with a first tire of the vehicle, and a second wheel valve is in fluid communication with a second tire of the vehicle. A pneumatic conduit extends between and is in fluid communication with the air supply source and the wheel valves. At least a portion of the pneumatic conduit remains charged with air from at least one of the supply source and the tires. The system includes means for distributing air flow between the pneumatic conduit and the first and second wheel valves, in which the wheel valves and the means selectively maintain fluid communication between the first and second tires and the pneumatic conduit to provide pneumatic balancing between the tires, and the wheel valves provide emergency protection when a tire experiences significant pressure loss.

Owner:HENDRICKSON USA L L C

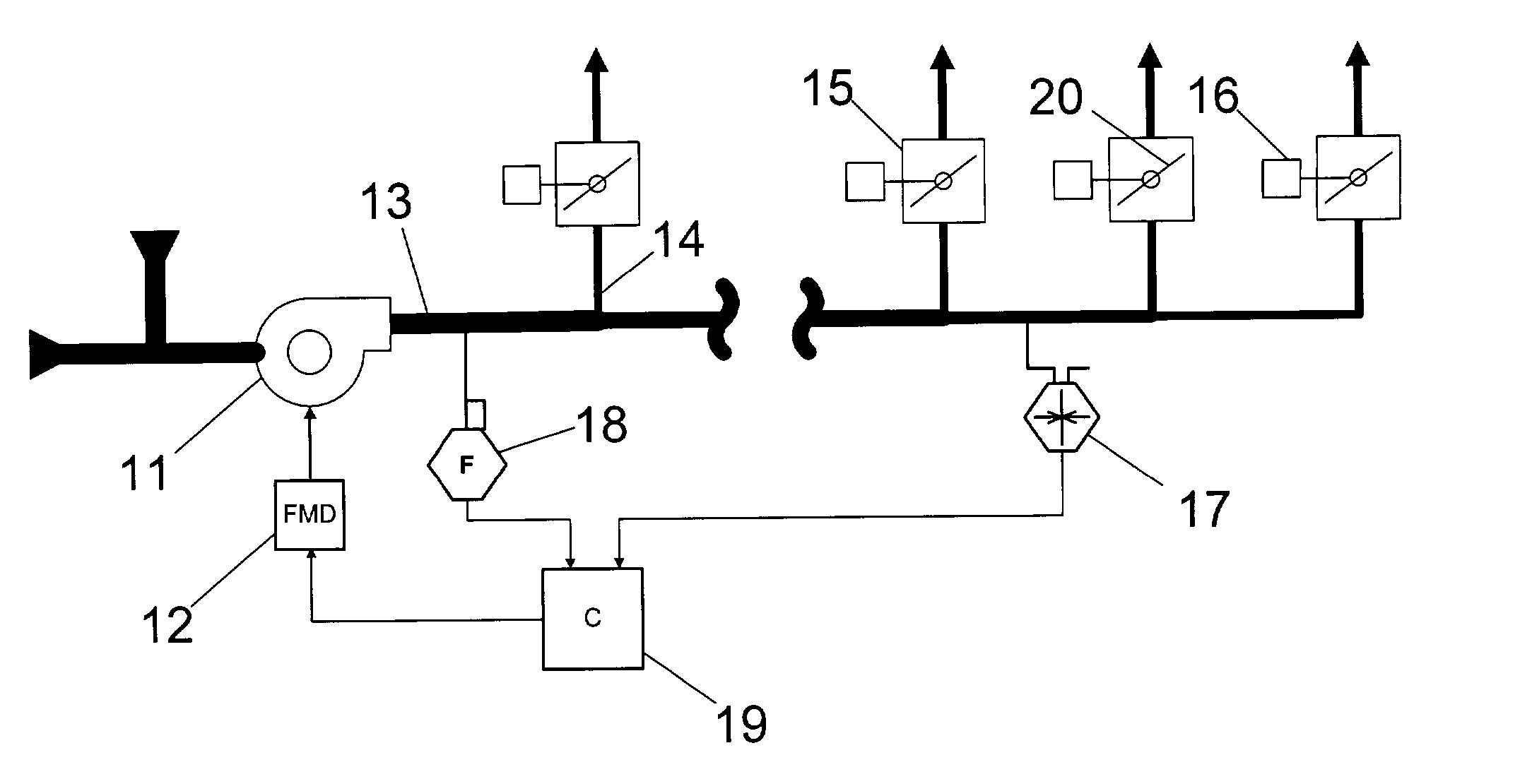

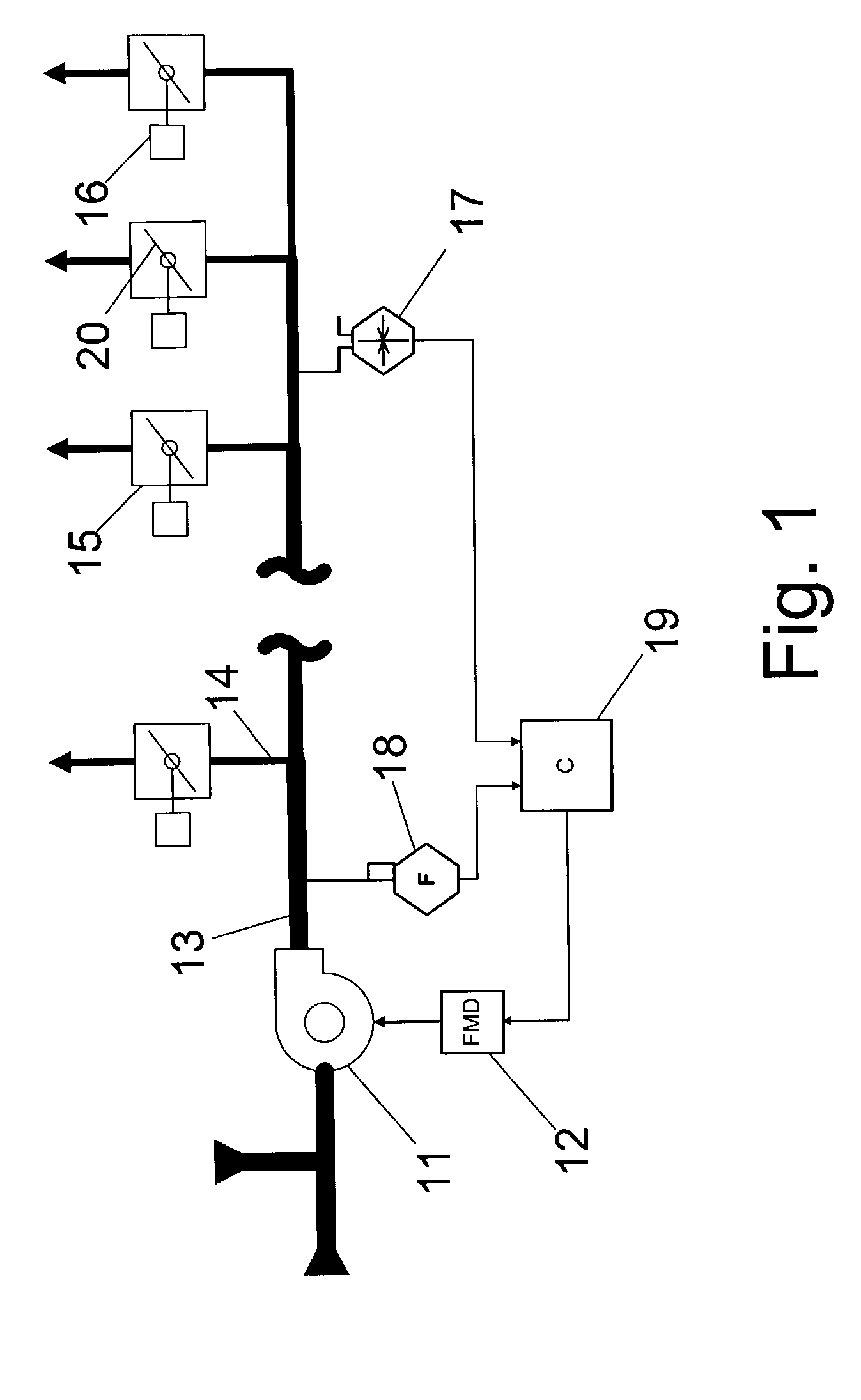

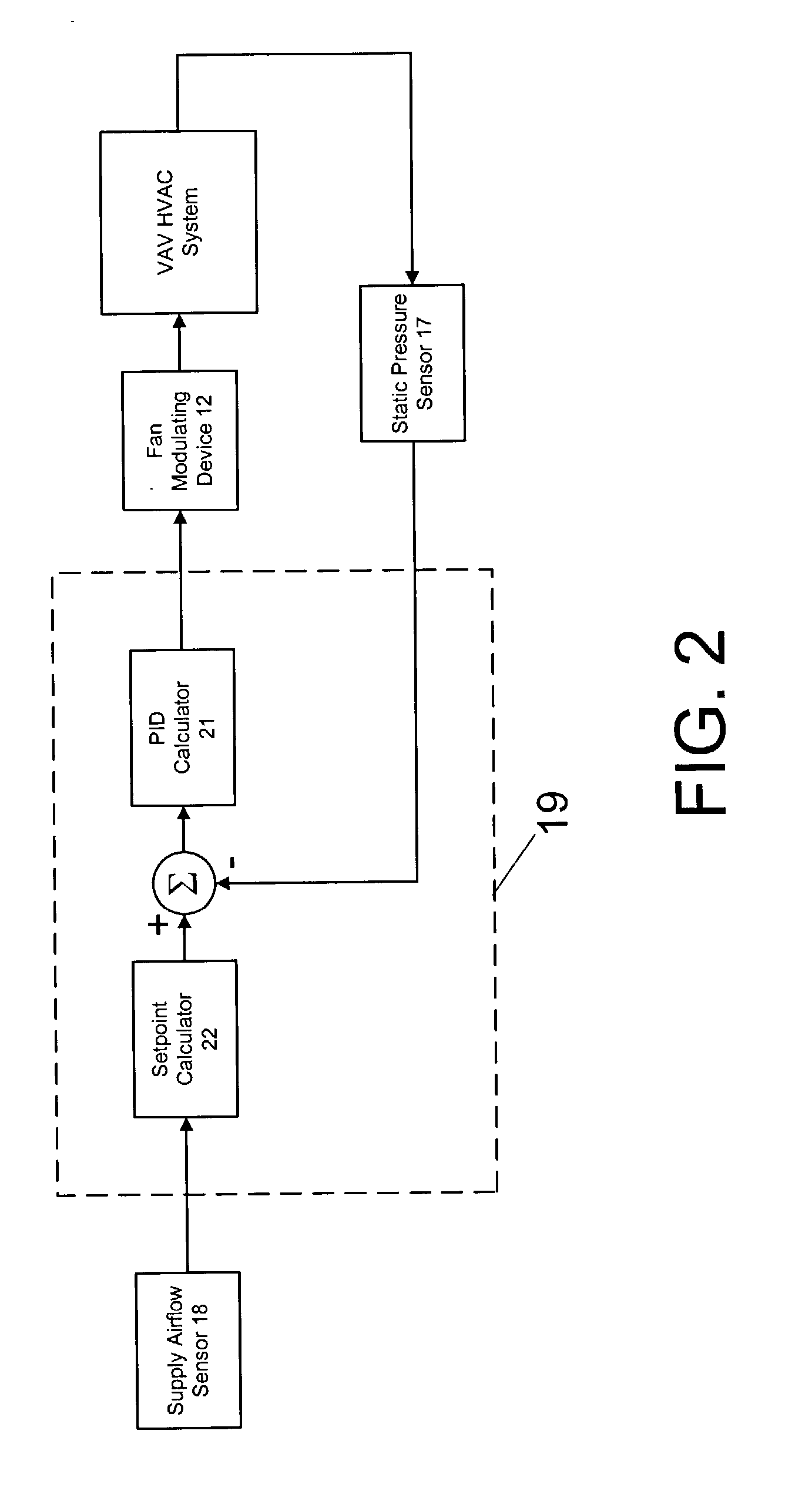

Method and apparatus for controlling variable air volume supply fans in heating, ventilating, and air-conditioning systems

InactiveUS20030064676A1Improve energy efficiencyEasy to adjustDucting arrangementsAuxillariesVariable air volumeAir volume

A control strategy for supply fans in variable-air-volume heating, ventilating, and air-conditioning systems that reduces the static pressure at part-load conditions. The invention consists of a static pressure sensor, an airflow sensor, a supply fan, a fan modulating device, and a controller coupled to the static pressure sensor and the airflow sensor. The controller includes a calculator that calculates the static pressure setpoint as a function of the airflow rate. The static pressure setpoint is lower when the airflow rate is lower. The controller compares the static pressure setpoint with the static pressure, and it commands the fan modulating device so that the static pressure remains close to the static pressure setpoint. Alternatively, the controller includes a calculator that calculates a loss coefficient as a function of the static pressure and the supply rate. The controller compares the loss coefficient with a loss coefficient setpoint, and it commands the fan modulating device so that the loss coefficient remains close to the loss coefficient setpoint. When the airflow rate is sufficiently high, the alternative embodiment switches to a constant-pressure controller.

Owner:VIGILENT CORP

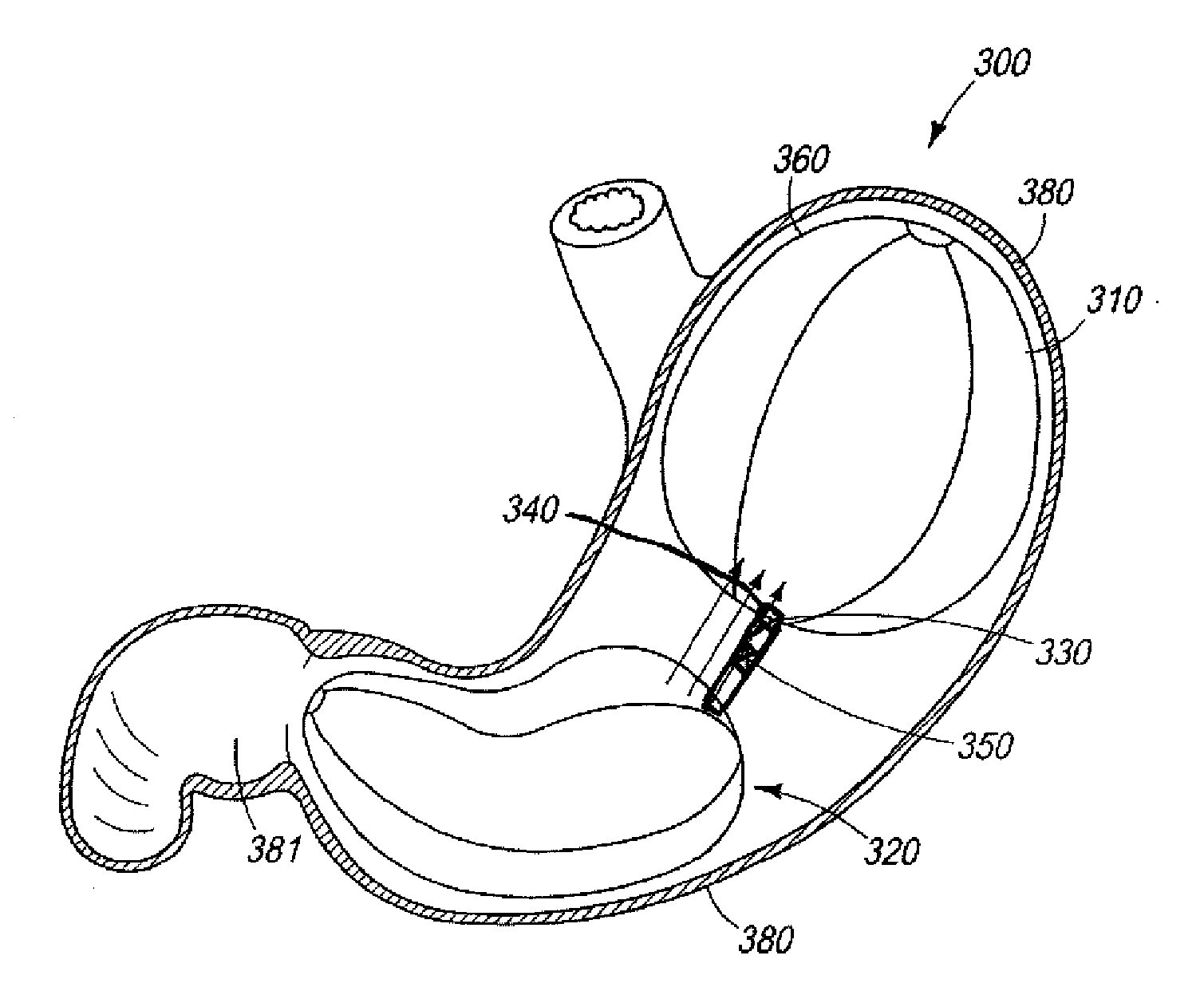

Dynamic volume displacement weight loss device

An intragastric device and method of use thereof are provided. The device is actuated to change its volume based on one or parameters detected in the gastric lumen. The device comprises an expandable reservoir that is adapted to distend one or more walls of the gastric lumen for a predetermined time. The device may also be actuated based on a pressure control system in which the reservoir maintains a constant pressure against the walls of the gastric lumen.

Owner:DILLON TRAVIS E

Device and method for testing linear reciprocating sliding friction and abrasion

InactiveCN101556238AAdjustable sliding speedAdjustable loadUsing mechanical meansMaterial weighingPositive pressurePeak value

The invention discloses a device and a method for testing linear reciprocating sliding friction and abrasion; the device consists of a transducer, a workbench, a sample table, a dragging frame, a force sensor, a changeover switch, a counter, a locking device, a guideway, a baffle, a cable wire, a reducer, a peak value stabilizer, a control part and an auxiliary component; the equipment can automatically complete the abrasion test of an arranged period and can manually complete the test to friction coefficient. The testing method comprises the following steps of: leading the friction block and the sample to reciprocate to slide horizontally with constant pressure, obtaining an abrasion weight loss rate after abrading, keeping a certain positive pressure and leading the sliding block to move from stillness to uniform movement, thus obtaining the maximum static friction coefficient and the sliding friction coefficient. The device and the method can realize uniformly linear and reciprocating relative sliding abrasion in long unidirectional journey, test the maximum static friction coefficient between two bodies and the maximum static friction coefficient, the speed, the load and the adjustable journey with other materials, and can be widely applied to the detection of various samples of different materials and different structural forms.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

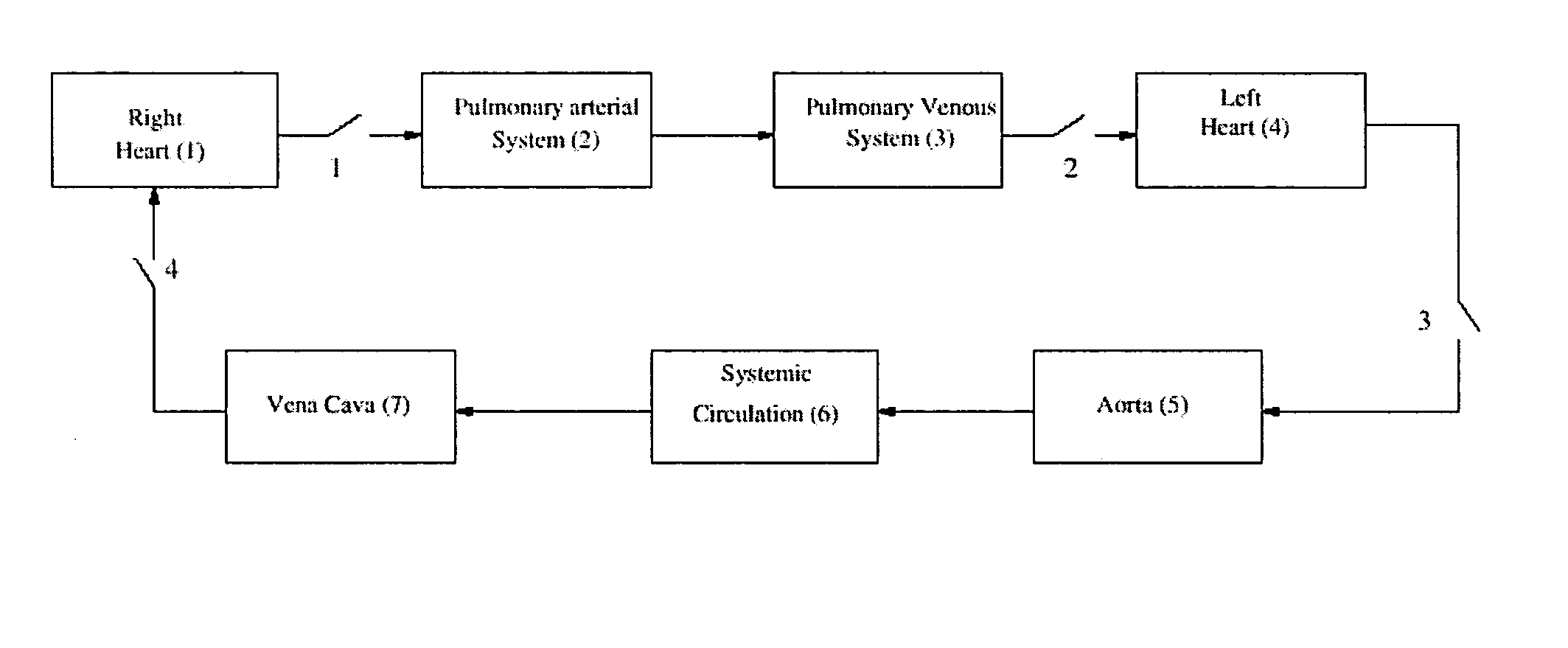

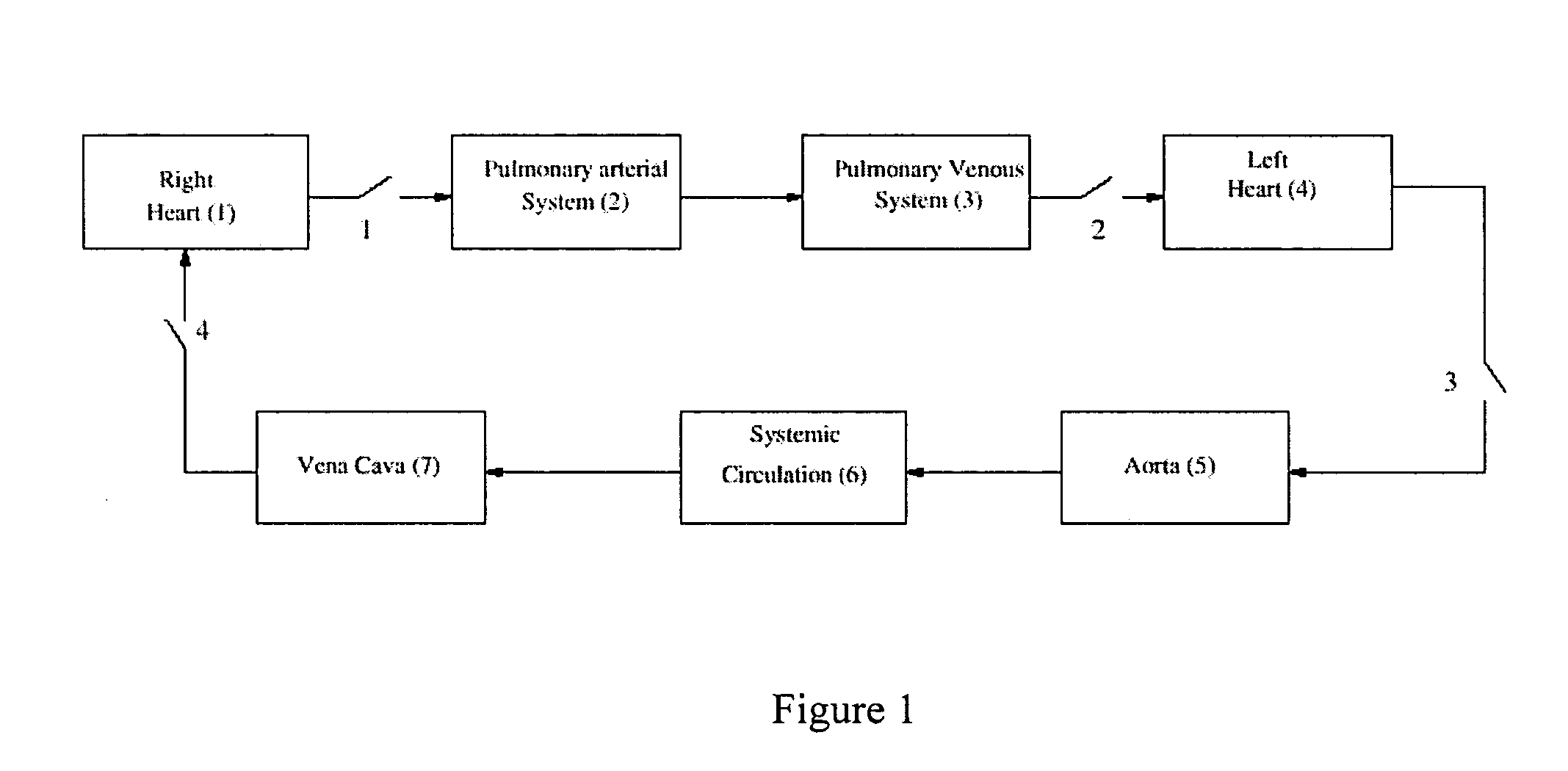

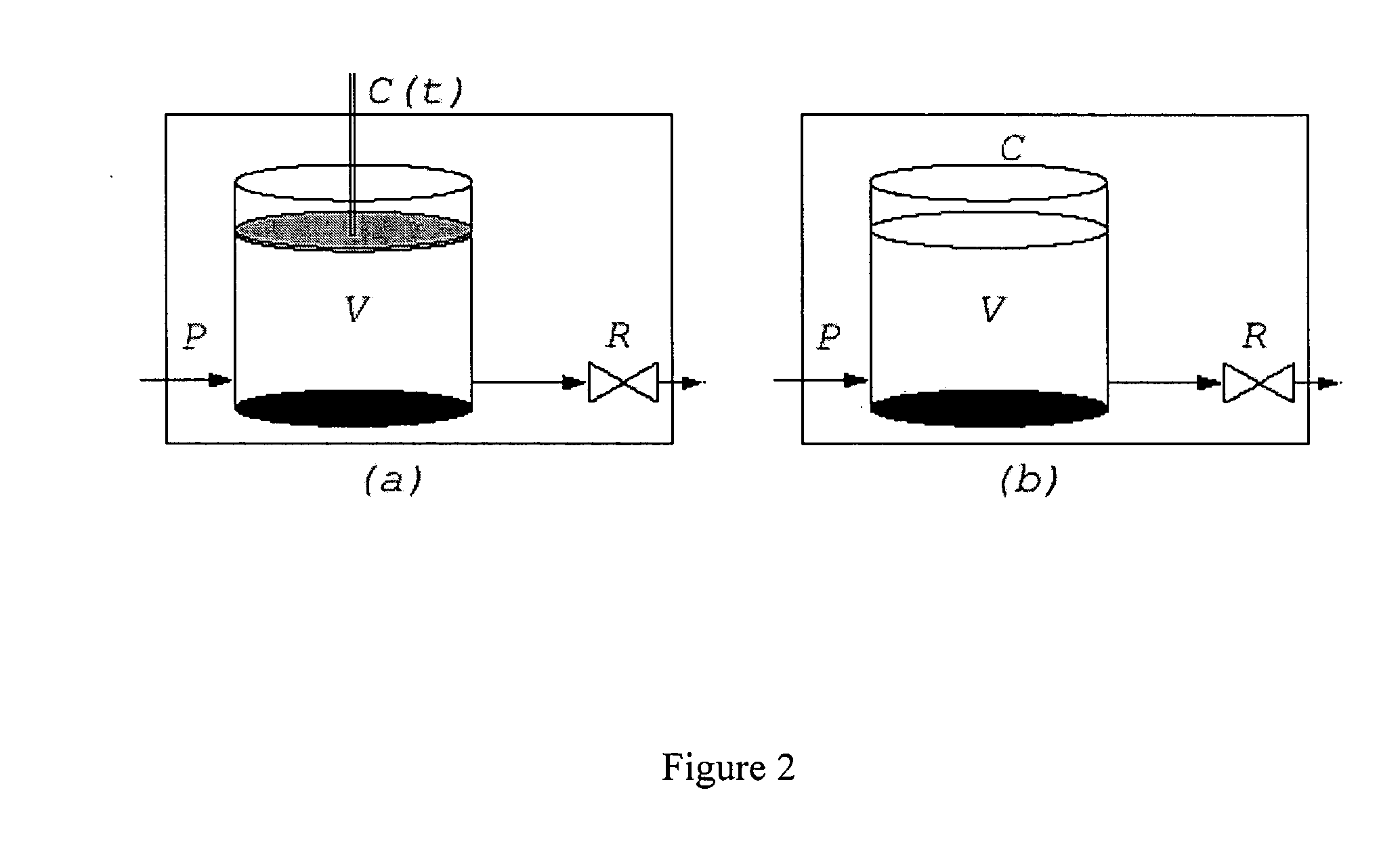

Physiologically based control system and method for using the same

InactiveUS20050159639A1Avoid inhalationMinimizing back flowControl devicesBlood pumpsControl systemEngineering

A device and method for maintaining a constant average pressure difference between the inlet and outlet of a pump for a body fluid, leading to an adequate flow for different pathological and physiological conditions, is described. The device and method allow for automatic adjustment of the pump operation to increase or decrease the flow rate of a body fluid to meet the physiological demand of the patient. The device and method also allow the physiological constraints on the pump to be accounted for, preventing suction and minimizing back flow of the body fluid. The device and method allow implicit synchronization of the pump with the natural regulatory mechanism for meeting patient's demand. The natural regulatory system continuously adjusts the parameters of the circulatory system to meet physiological demand for a body fluid. Maintaining constant pressure differential between the inlet and outlet of a pump, or a part of the body leads to the adaptation of the flow rate of the body fluid to physiological changes in response to the patient's clinical or physiological conditions.

Owner:UNIV OF UTAH RES FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com