Patents

Literature

10743 results about "Cylinder (engine)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cylinder is the central working part of a reciprocating engine or pump, the space in which a piston travels. Multiple cylinders are commonly arranged side by side in a bank, or engine block, which is typically cast from aluminum or cast iron before receiving precision machine work. Cylinders may be sleeved (lined with a harder metal) or sleeveless (with a wear-resistant coating such as Nikasil).

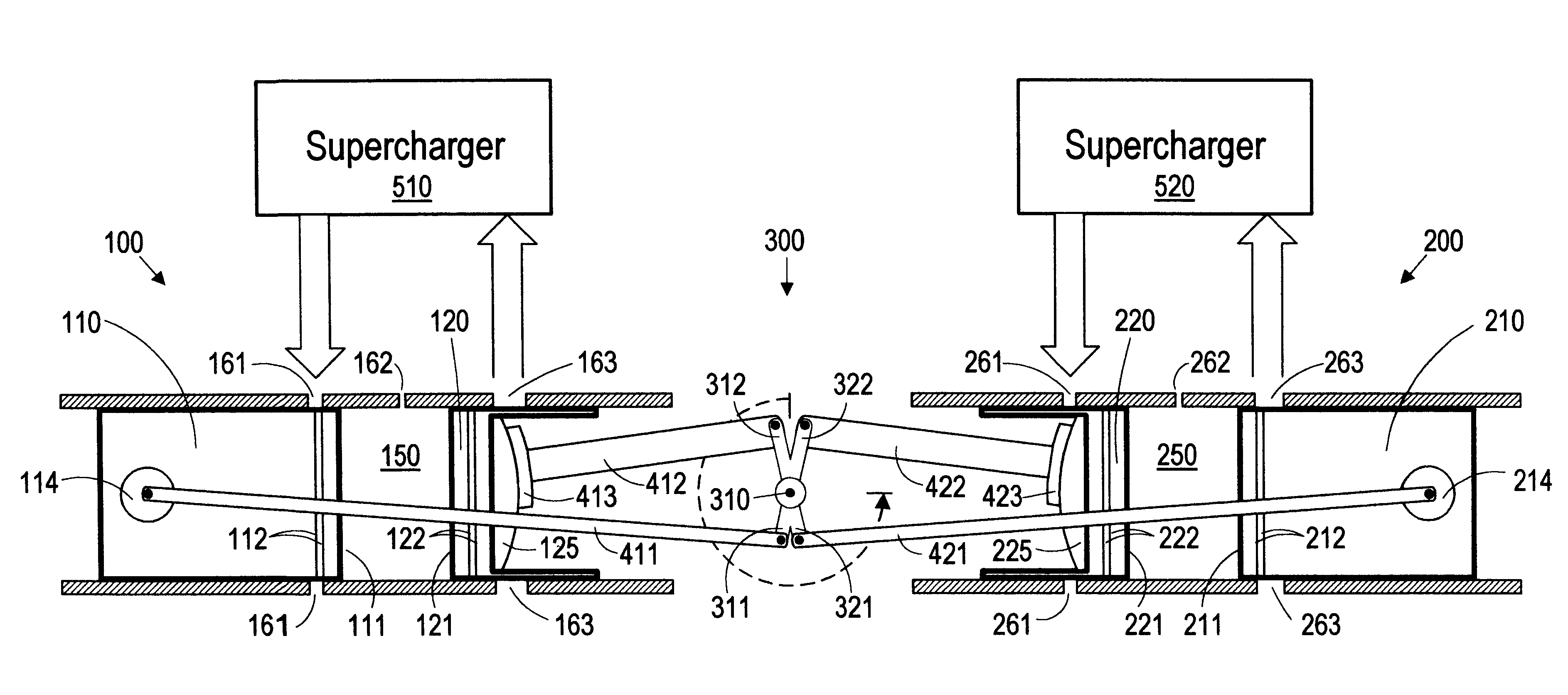

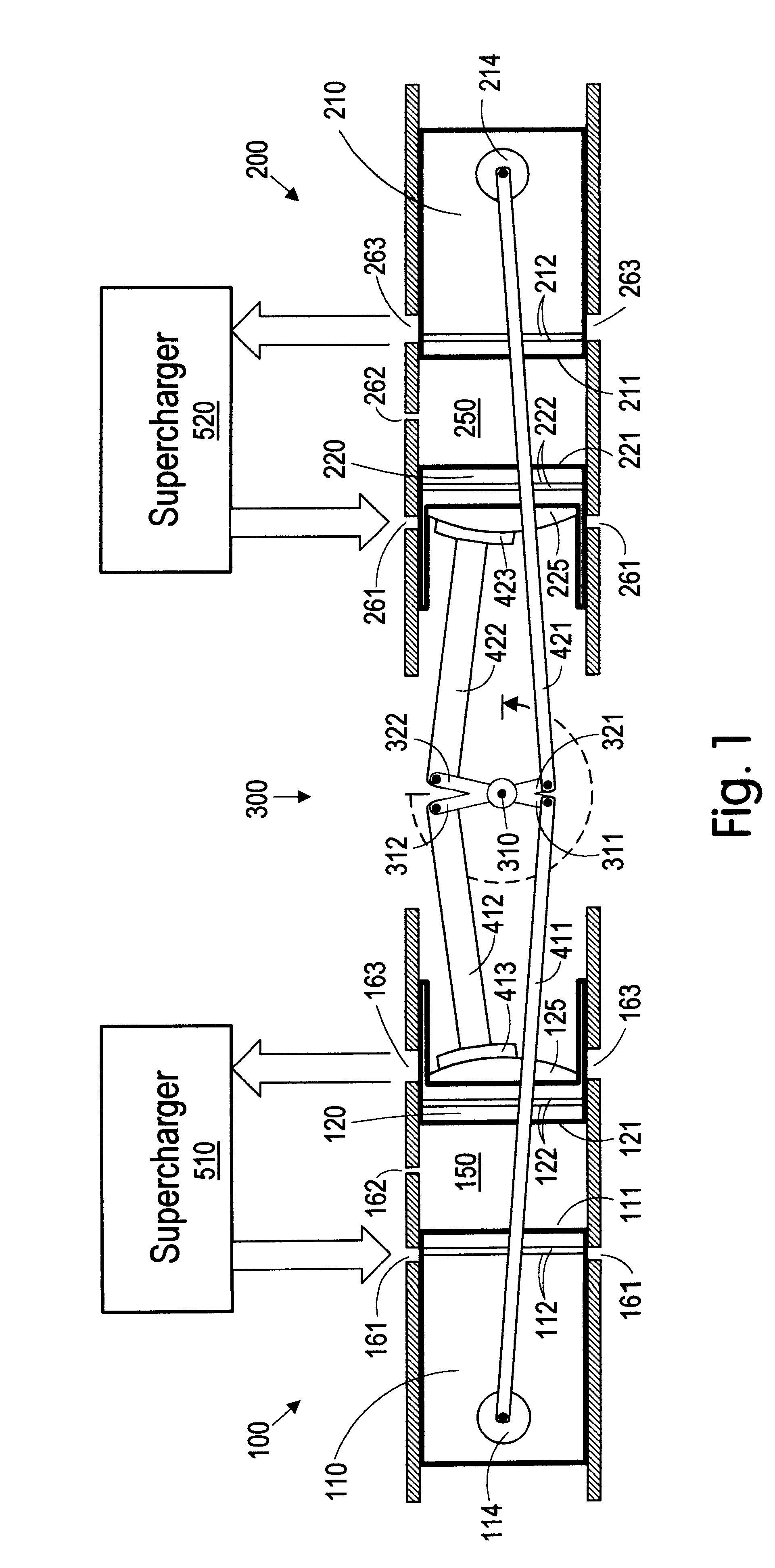

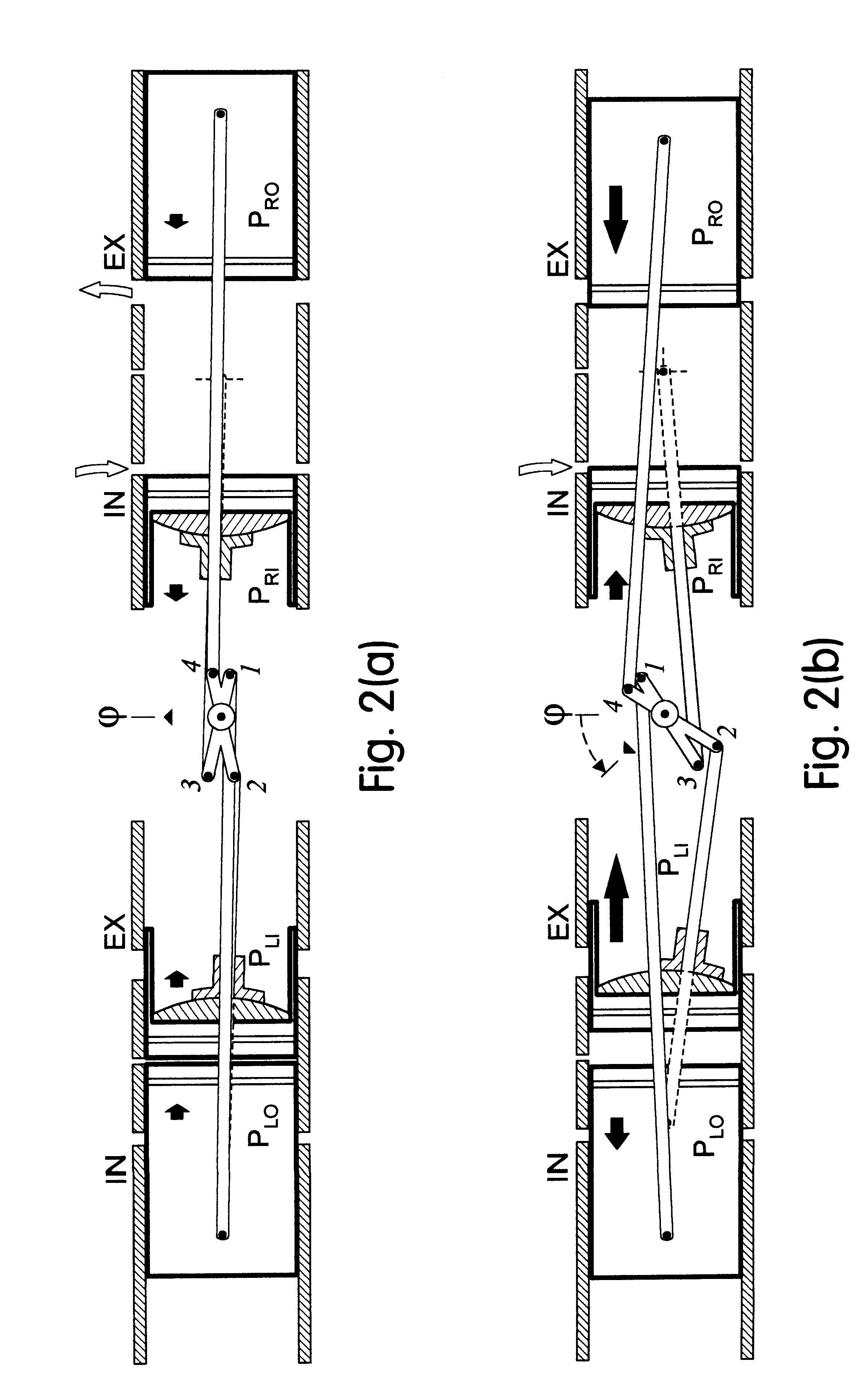

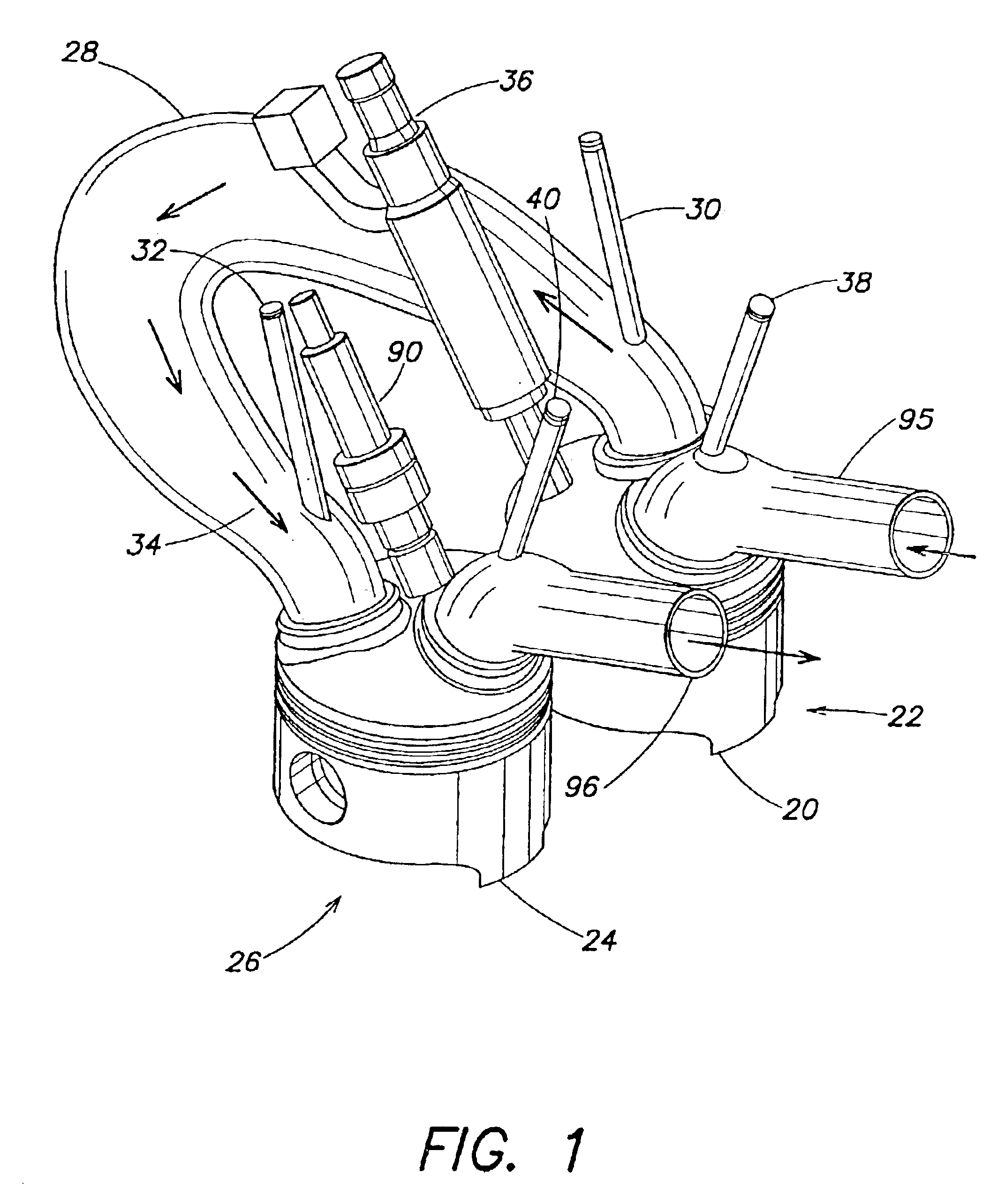

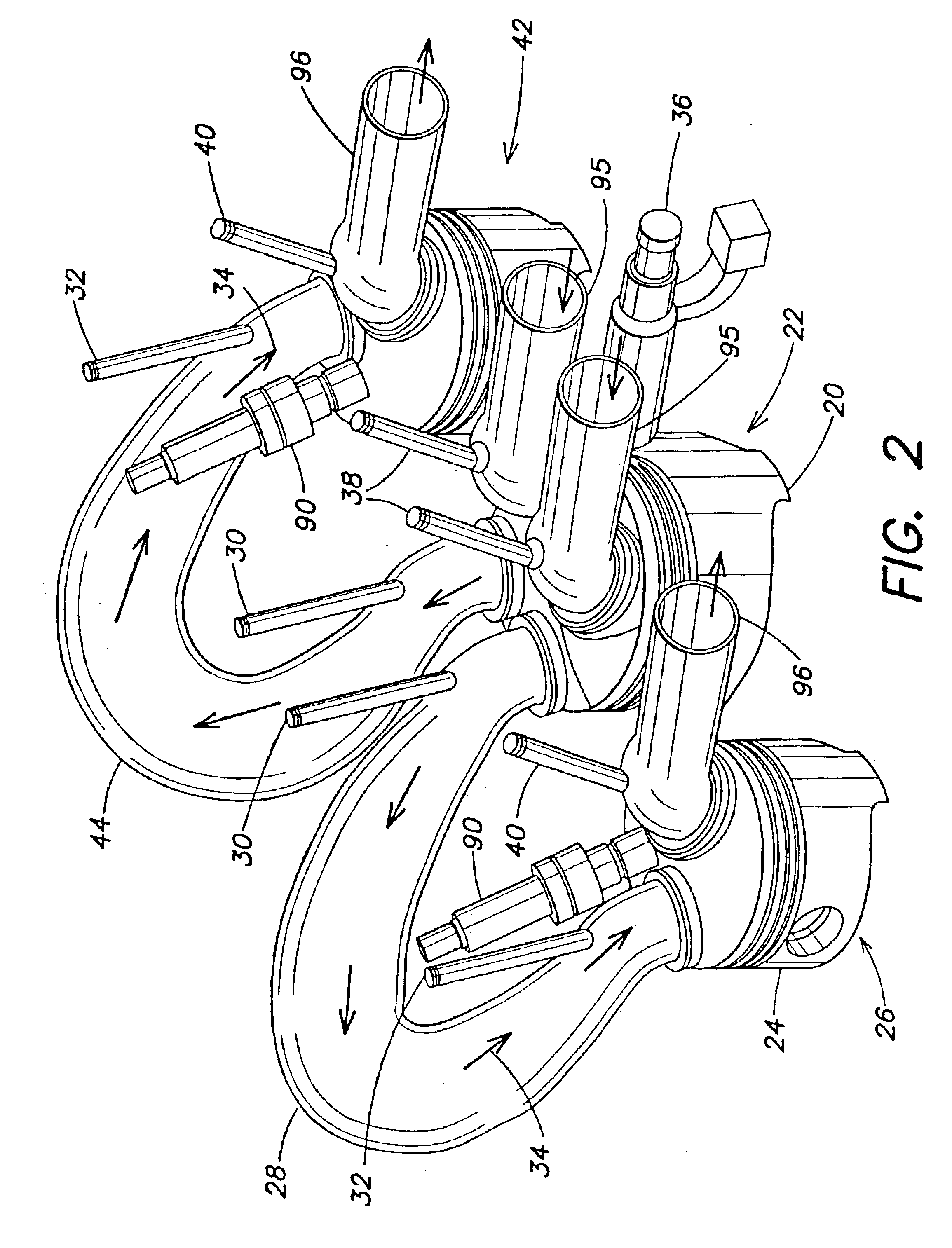

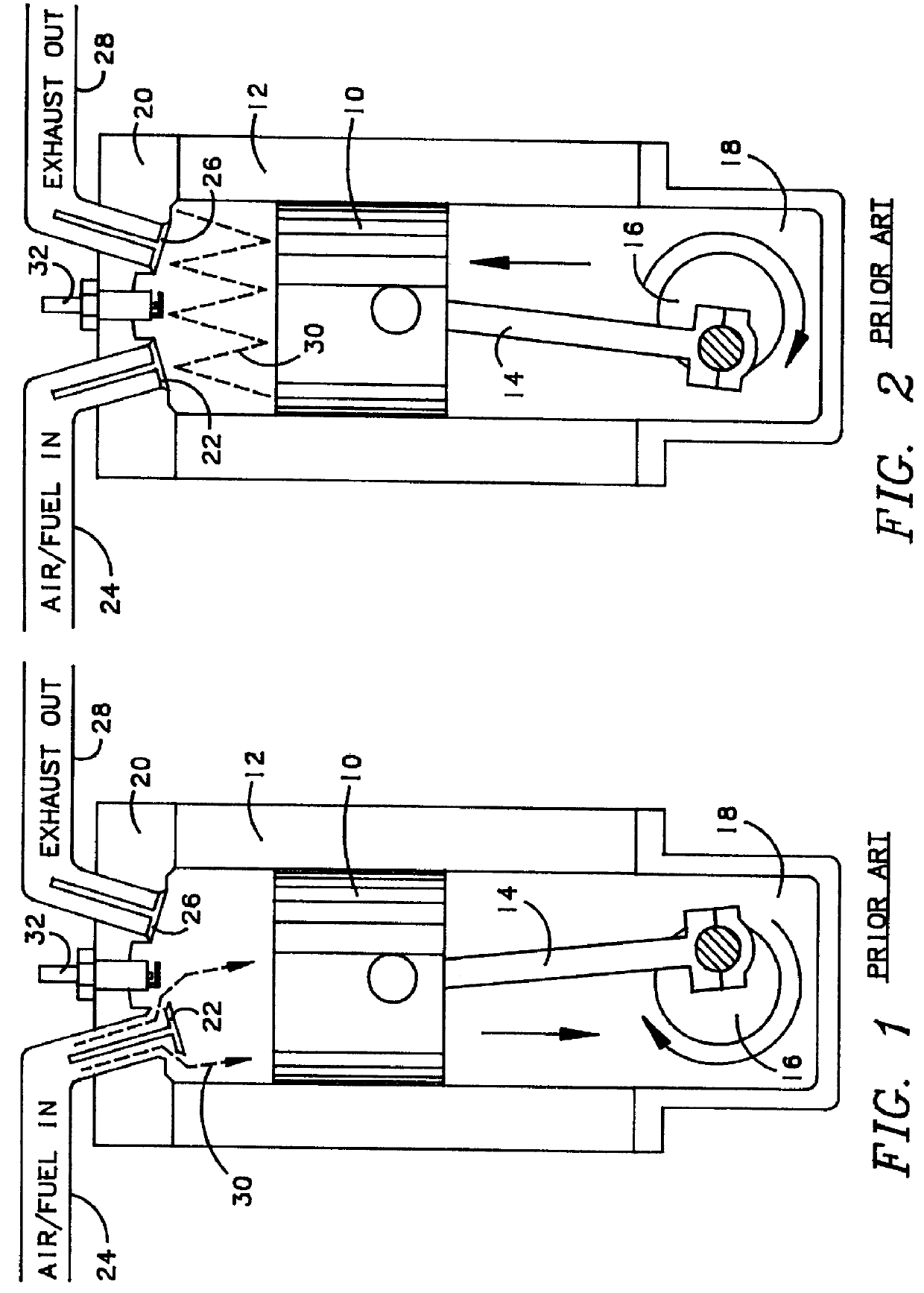

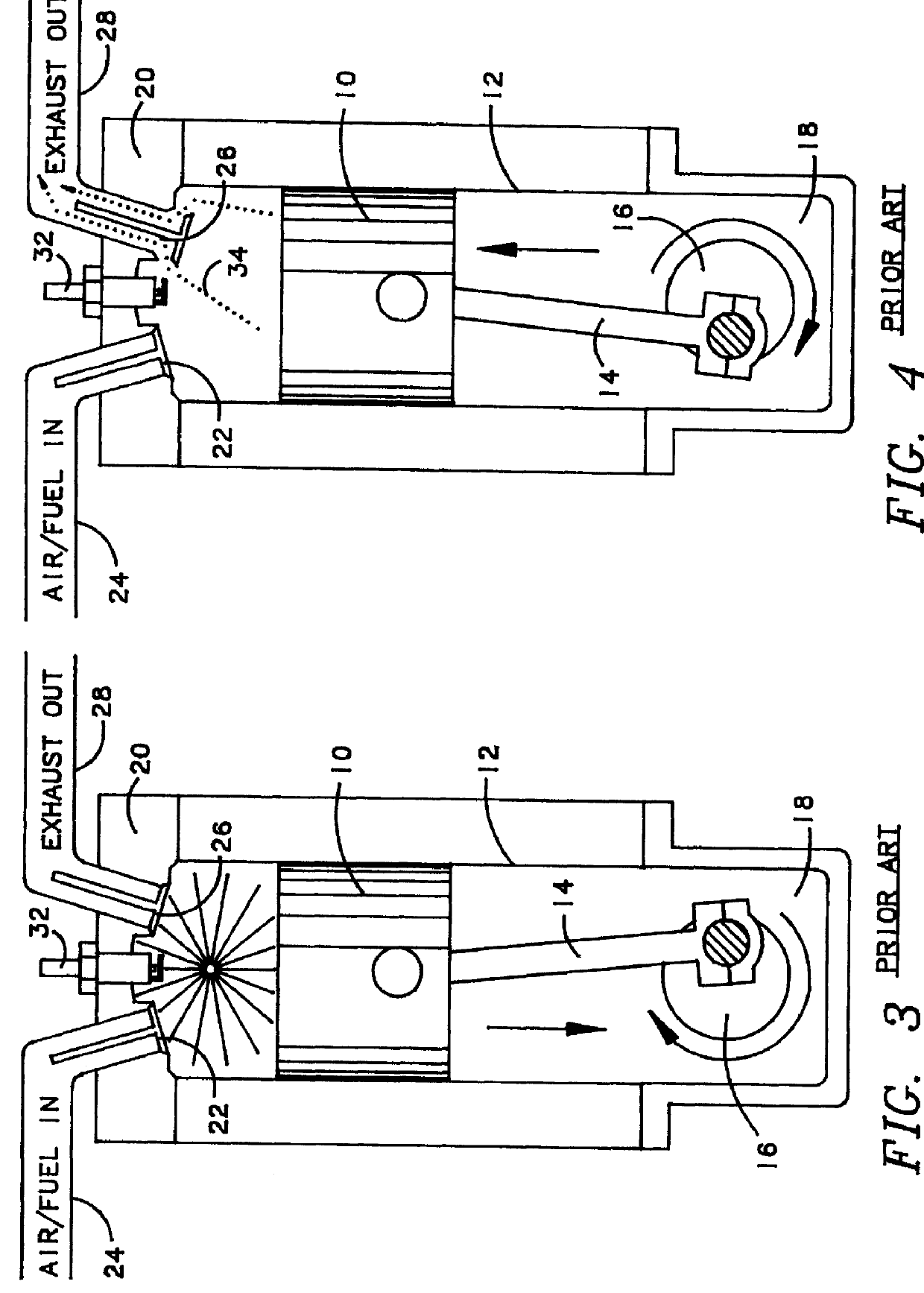

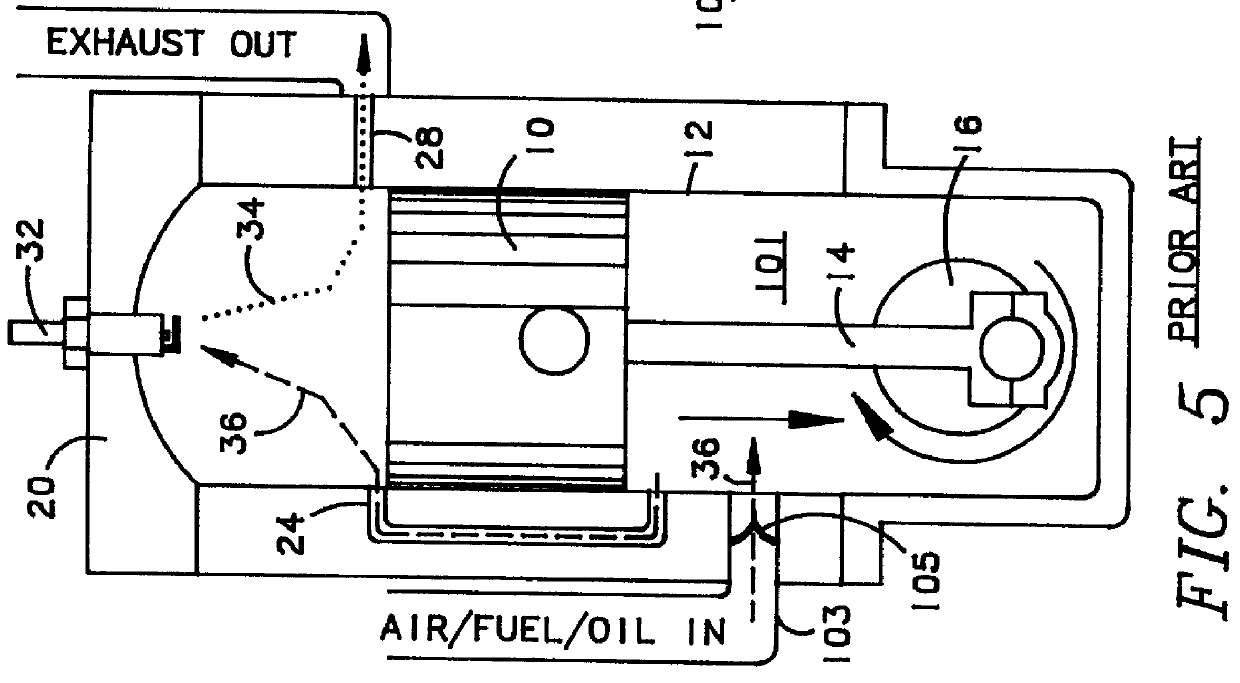

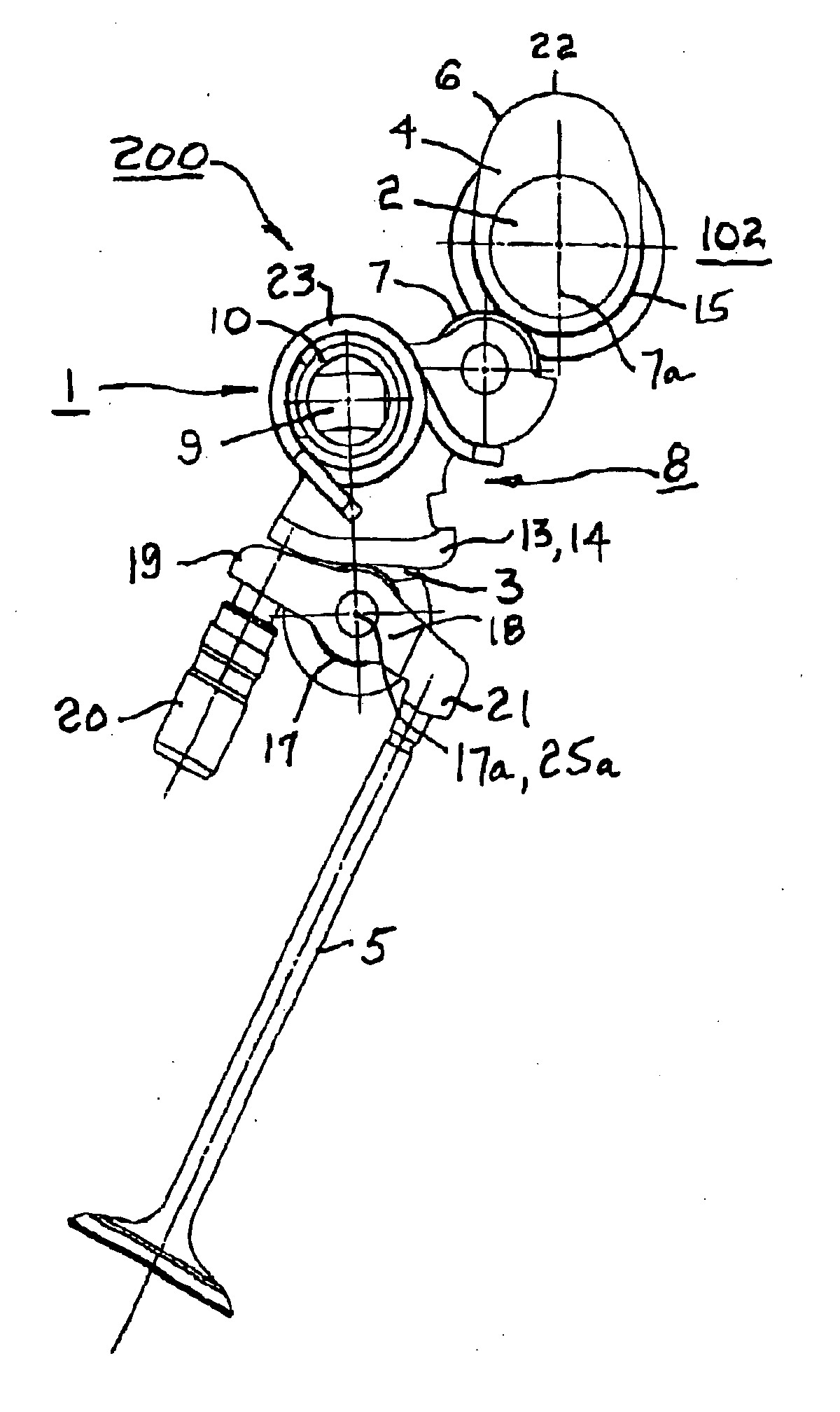

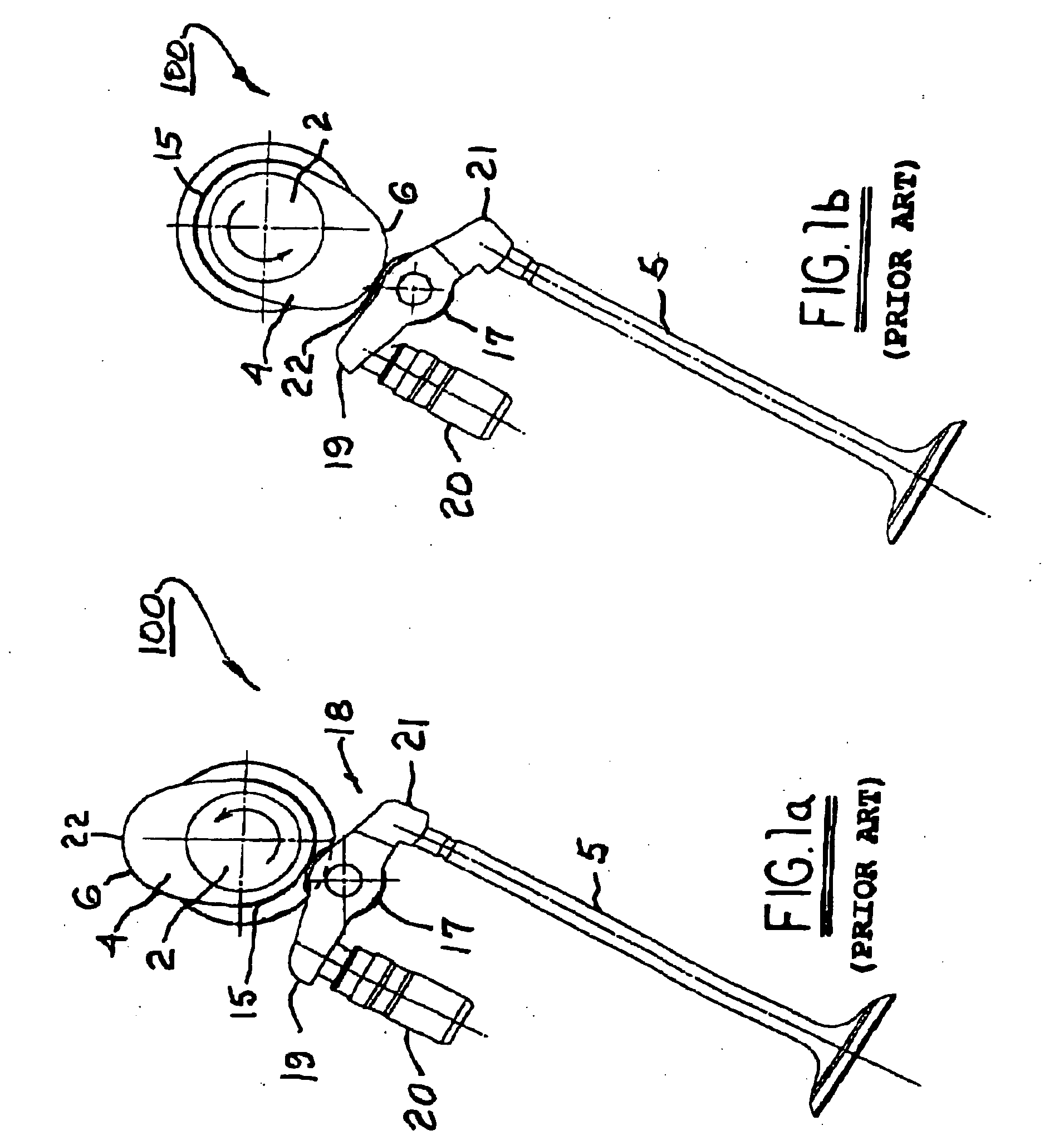

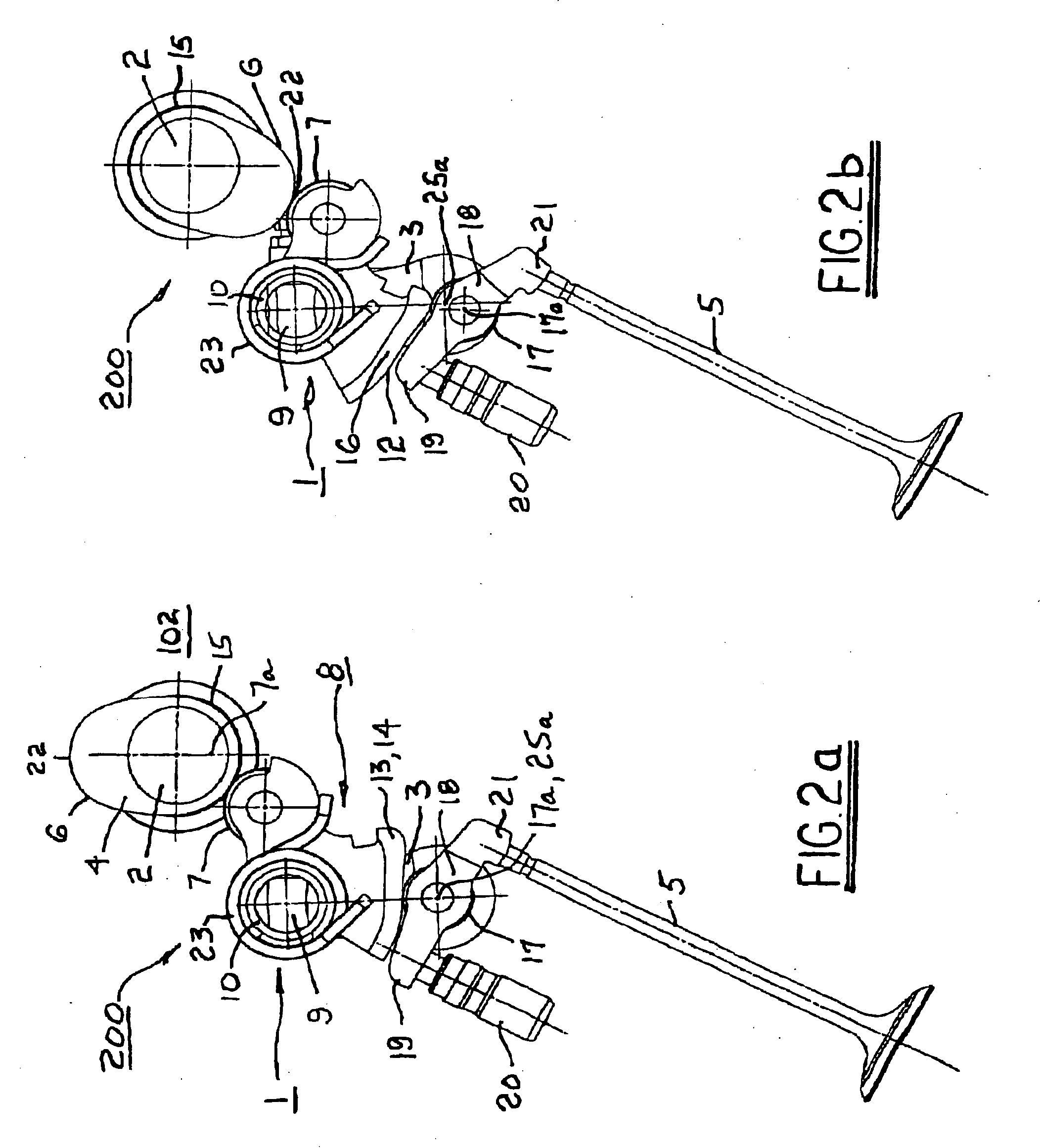

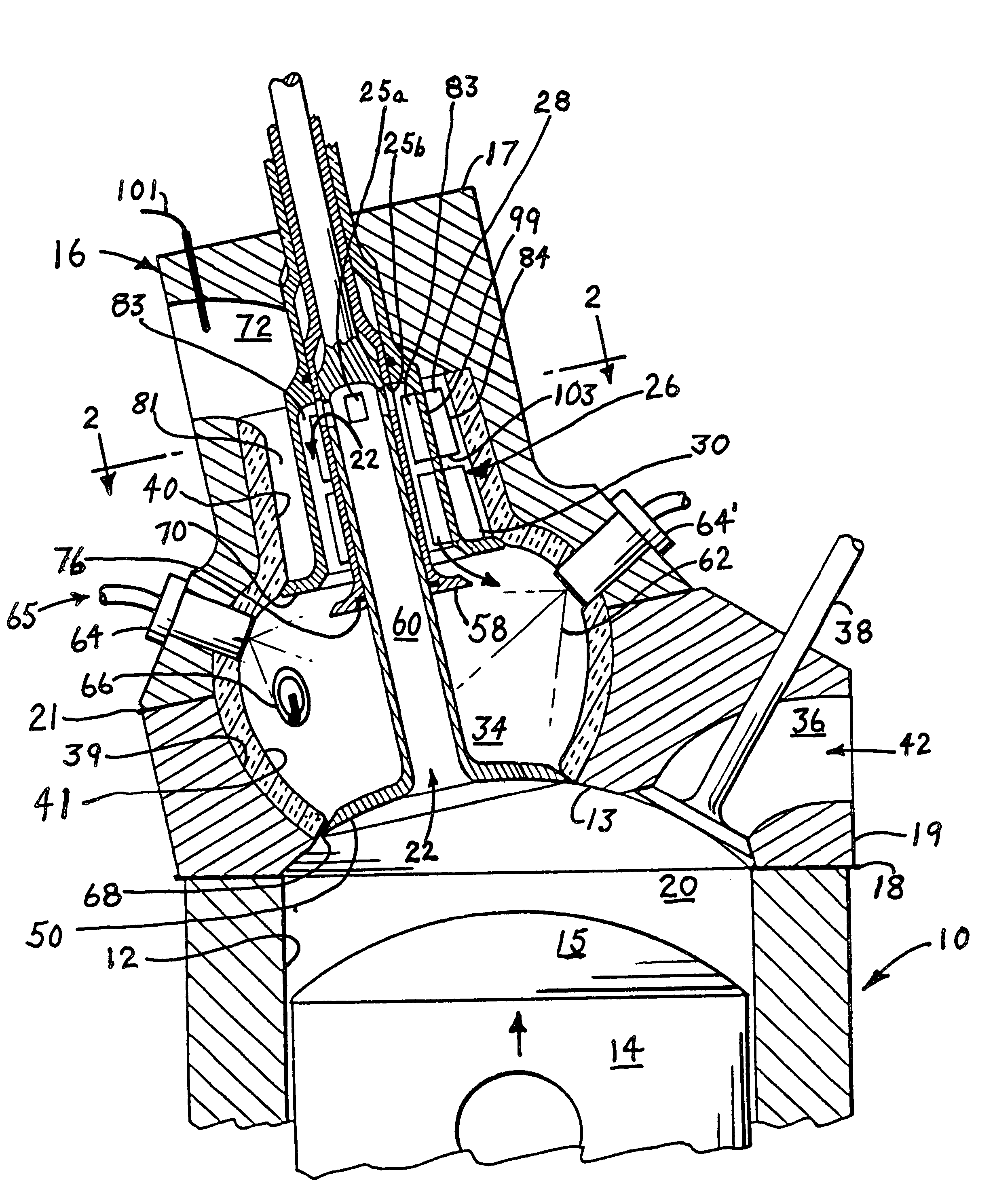

Internal combustion engine with a single crankshaft and having opposed cylinders with opposed pistons

InactiveUS6170443B1MiniaturizationEliminates dynamic imbalanceCombustion enginesReciprocating piston enginesExternal combustion engineEngineering

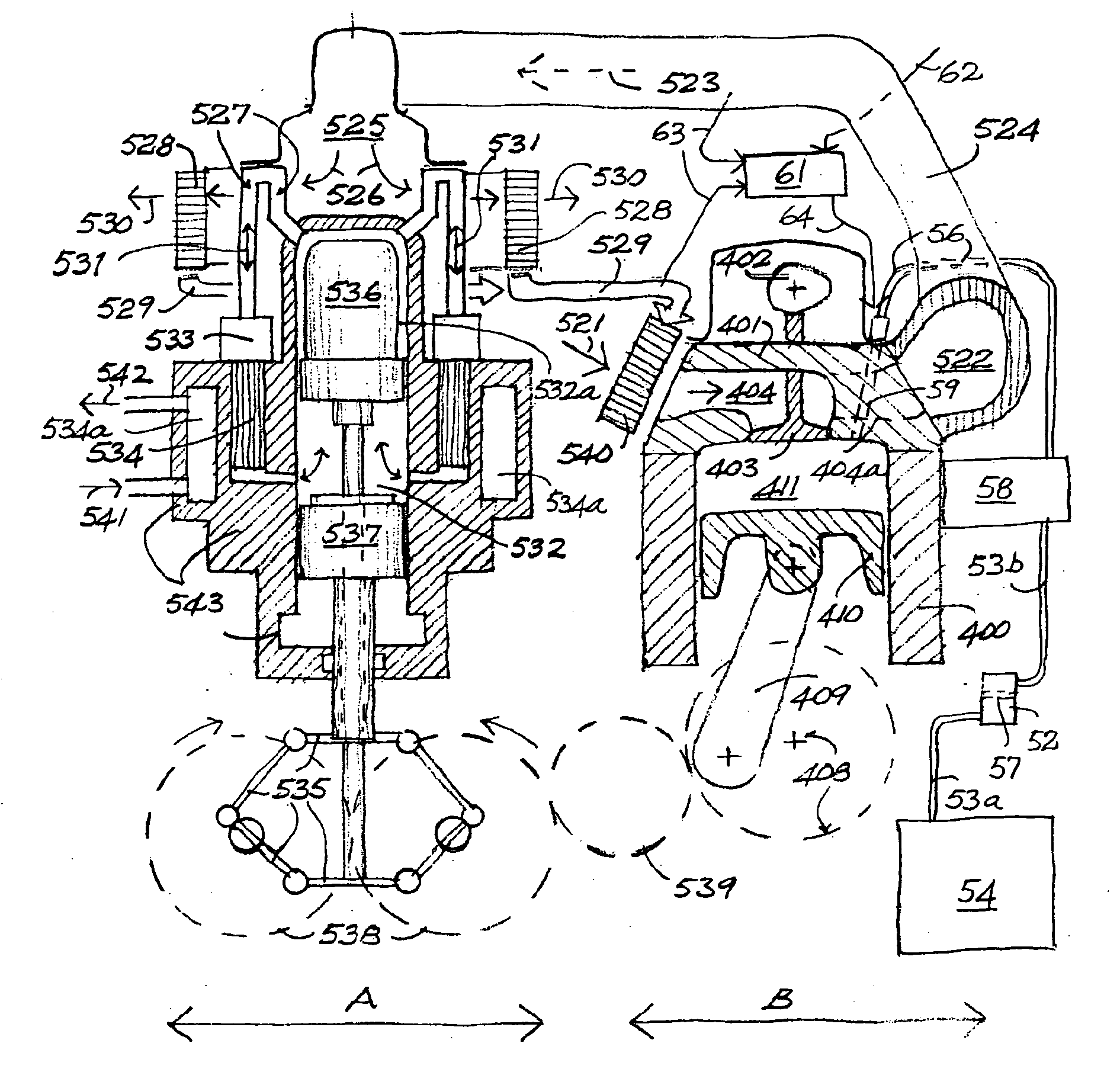

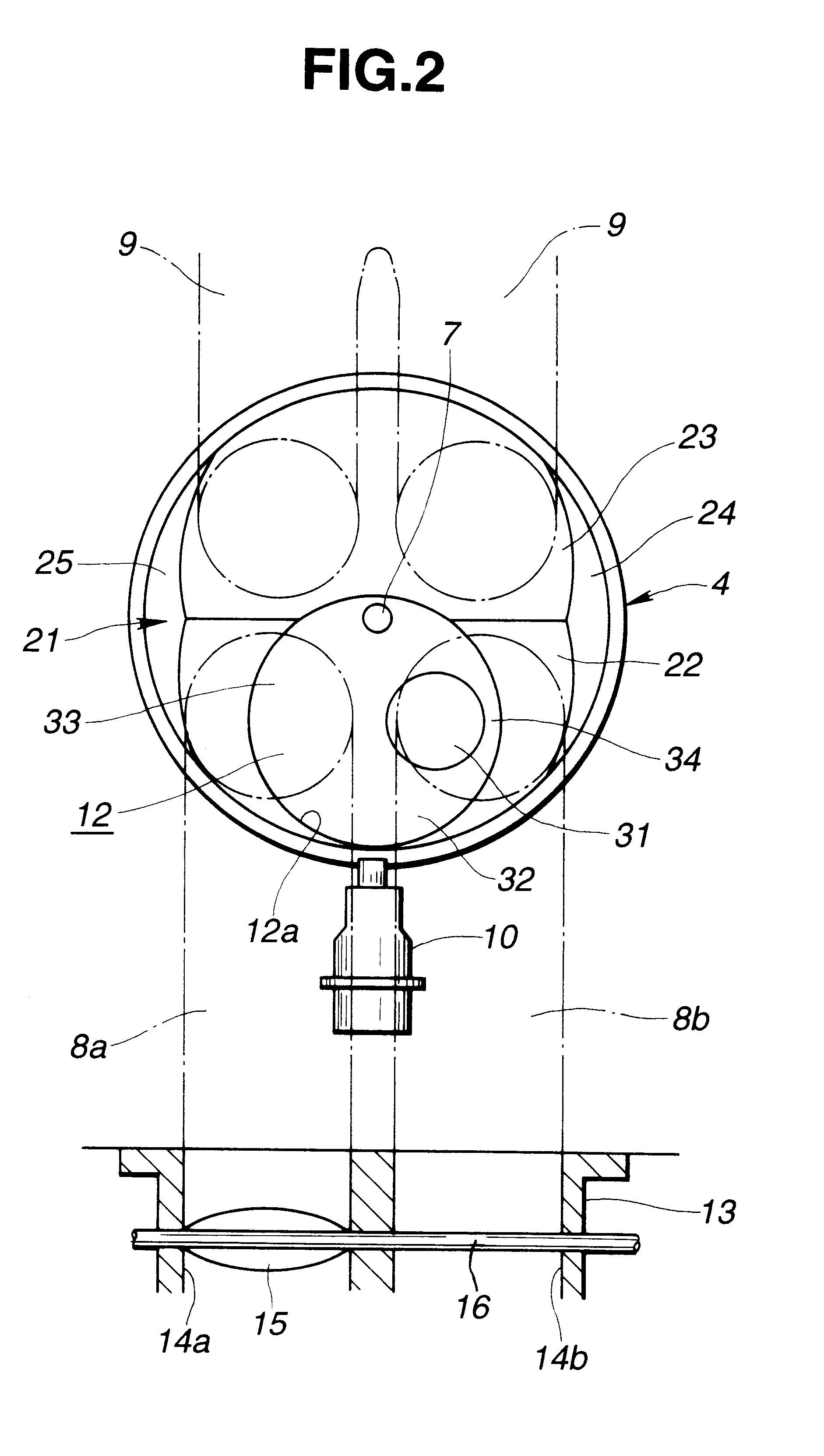

A two-stroke internal combustion engine is disclosed having opposed cylinders, each cylinder having a pair of opposed pistons, with all the pistons connected to a common central crankshaft. The inboard pistons of each cylinder are connected to the crankshaft with pushrods and the outboard pistons are connected to the crankshaft with pullrods. This configuration results in a compact engine with a very low profile, in which the free mass forces can be essentially totally balanced. The engine configuration also allows for asymmetrical timing of the intake and exhaust ports through independent angular positioning of the eccentrics on the crankshaft, making the engine suitable for supercharging.

Owner:ADVANCED PROPULSION TECH +1

Differential torque operation for internal combustion engine

InactiveUS7503312B2Improve internal efficiencyImprove fuel efficiencyElectrical controlInternal combustion piston enginesInternal combustion engineControl theory

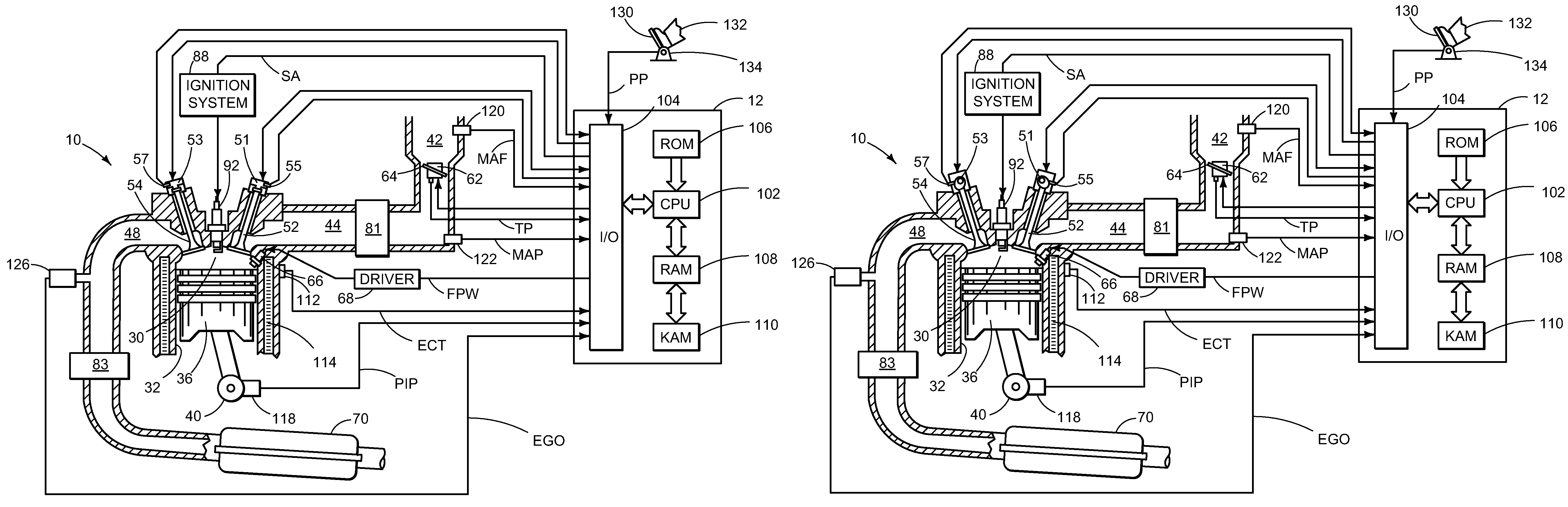

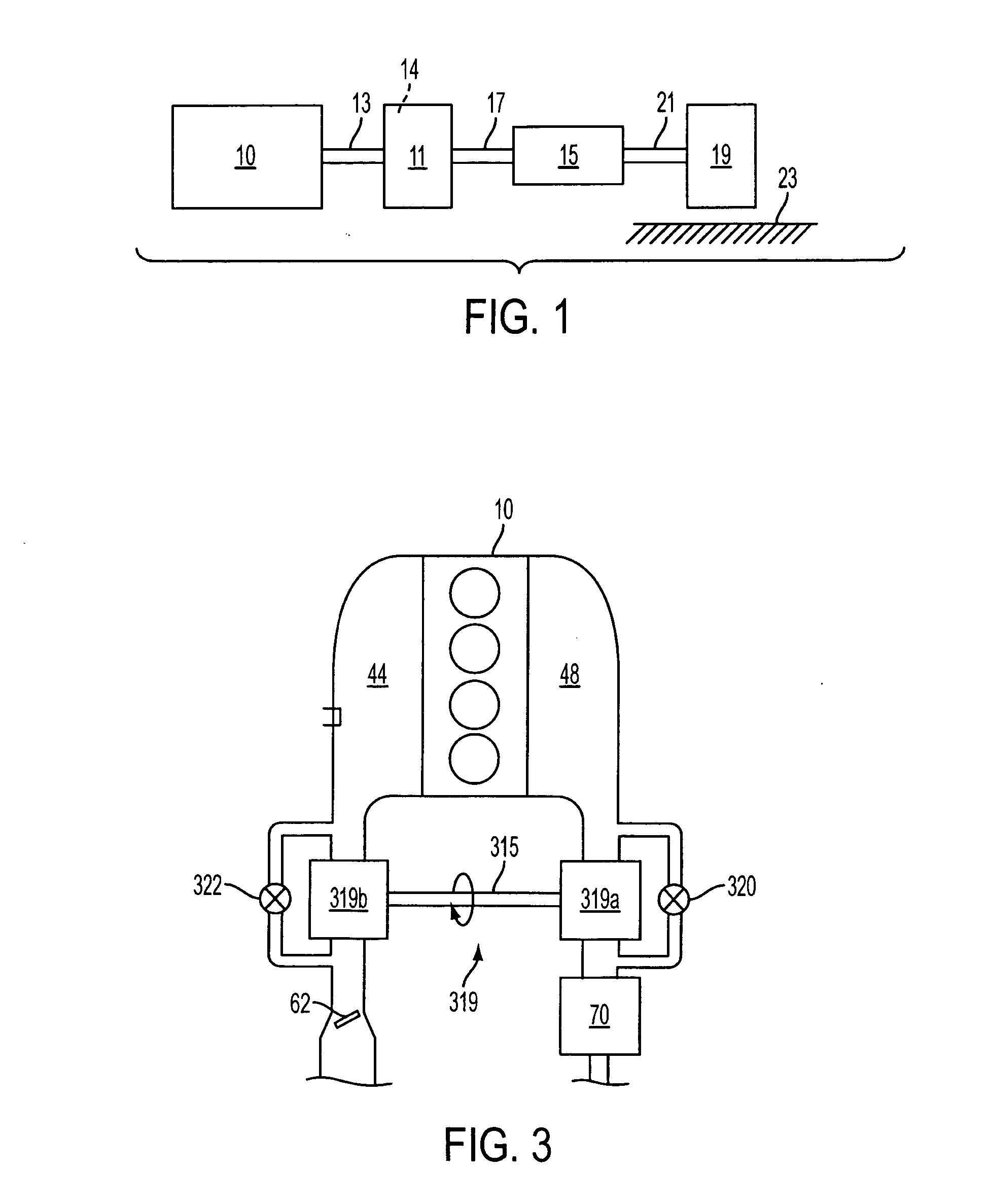

A method of operating an internal combustion engine having a plurality of cylinders including at least a first cylinder and a second cylinder, the method comprising firing the first cylinder and the second cylinder in an alternating sequence; during a first mode, adjusting an operating parameter of the engine to produce a first difference between an amount of torque produced by the firing of the first cylinder and an amount of torque produced by the firing of the second cylinder; during a second mode, adjusting the operating parameter of the engine to produce a second difference between an amount of torque produced by the firing of the first cylinder and an amount of torque produced by the firing of the second cylinder; and performing the first mode at a higher engine speed than the second mode; wherein the first difference is greater than the second difference.

Owner:FORD GLOBAL TECH LLC

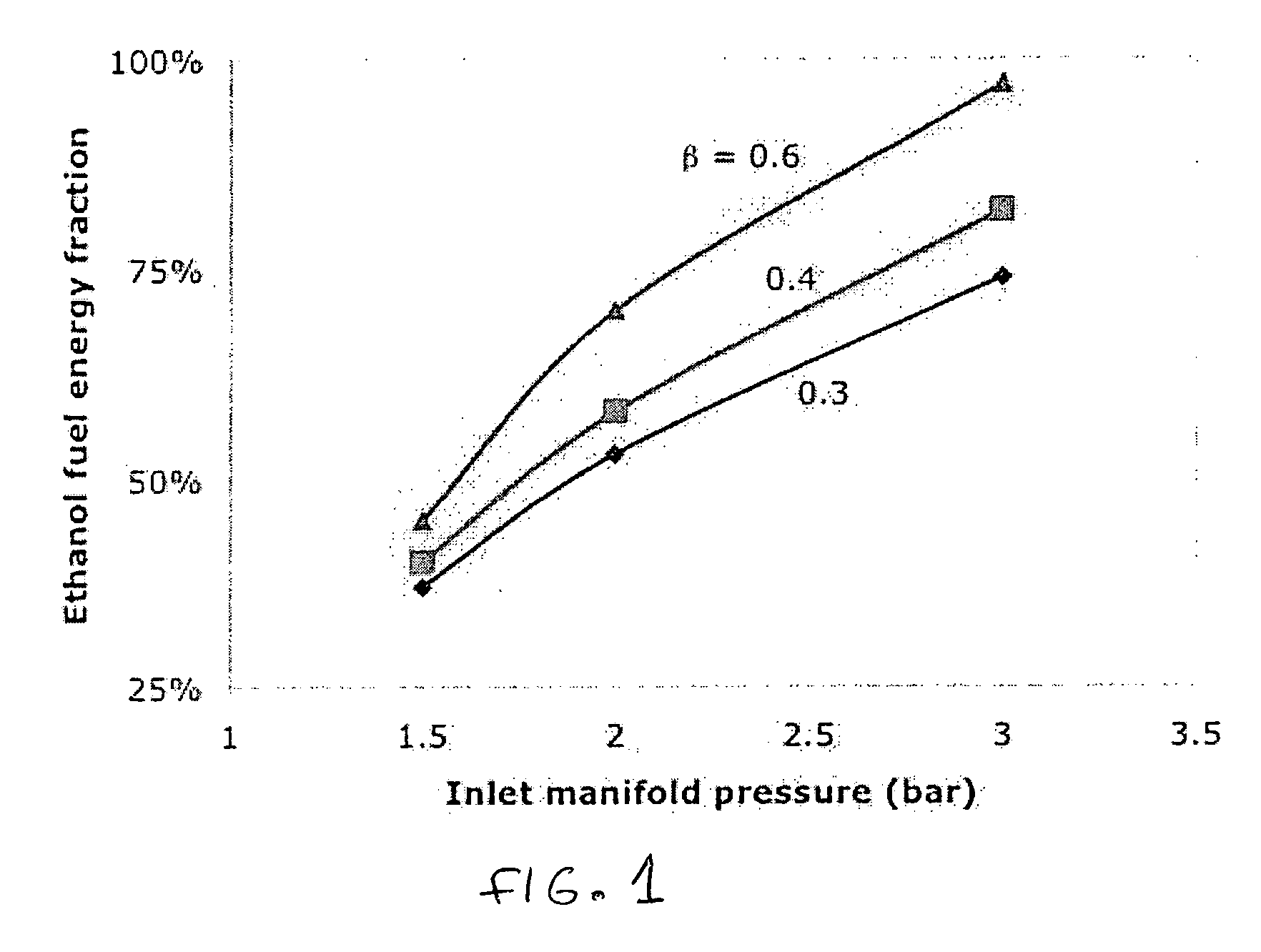

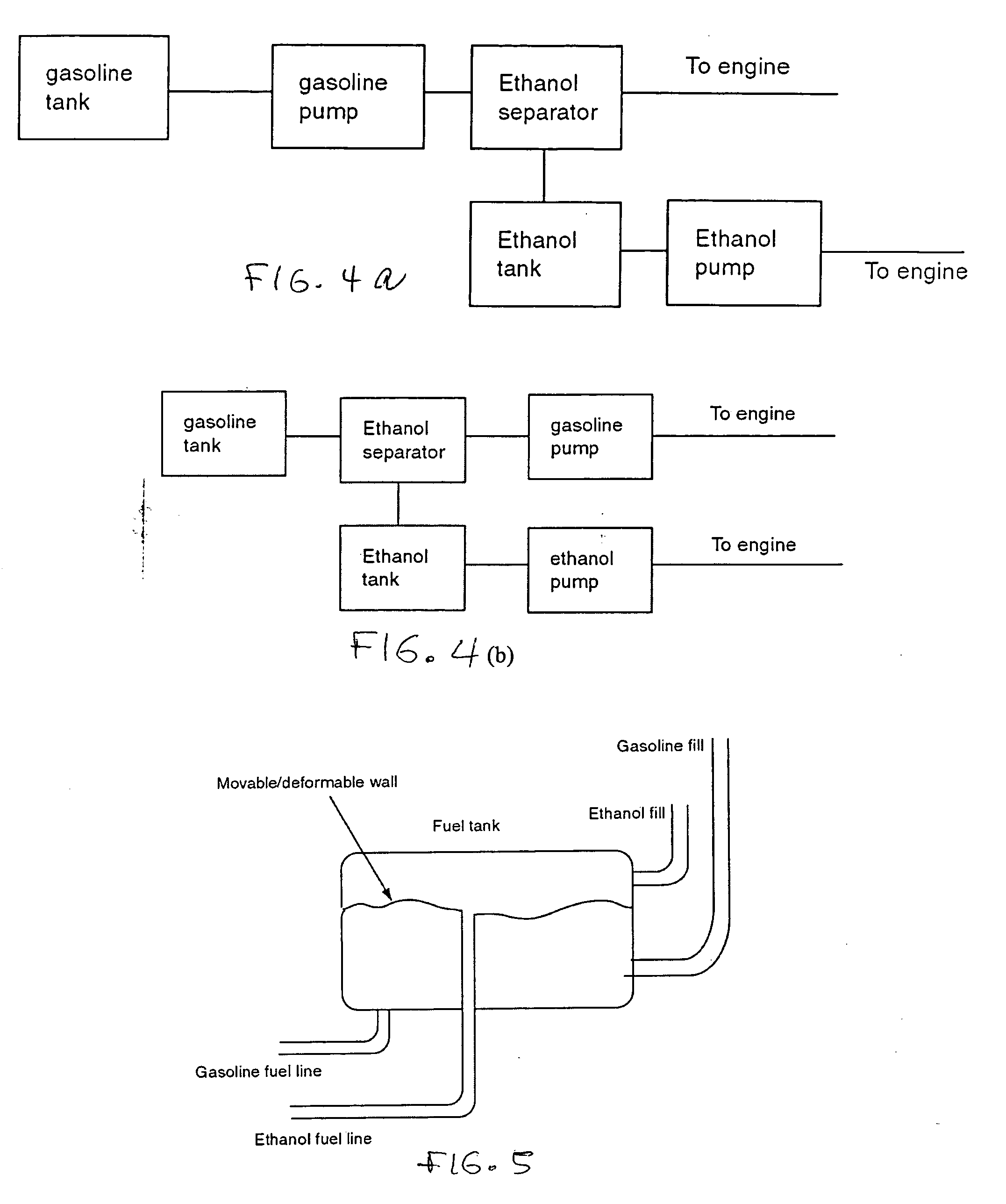

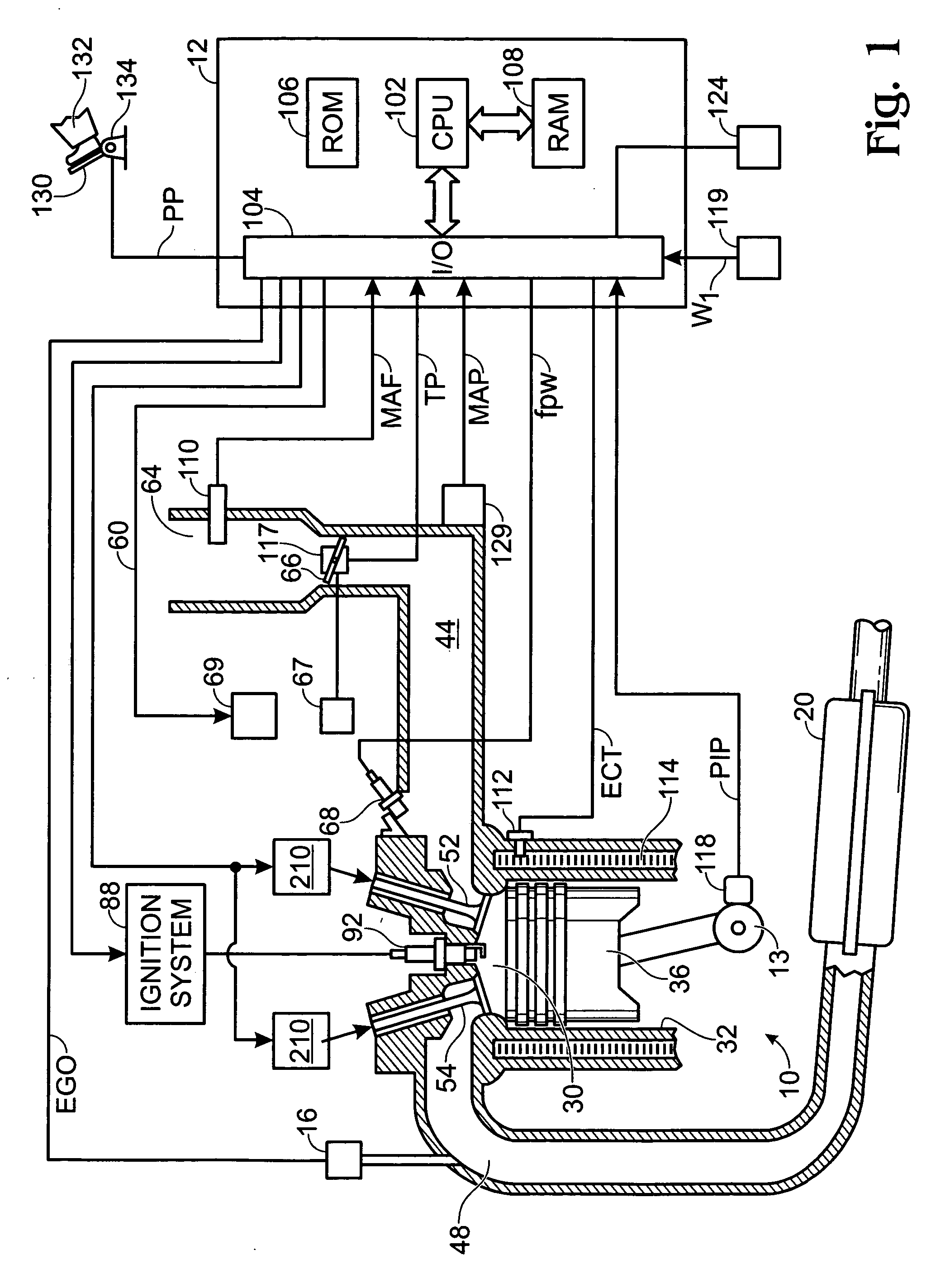

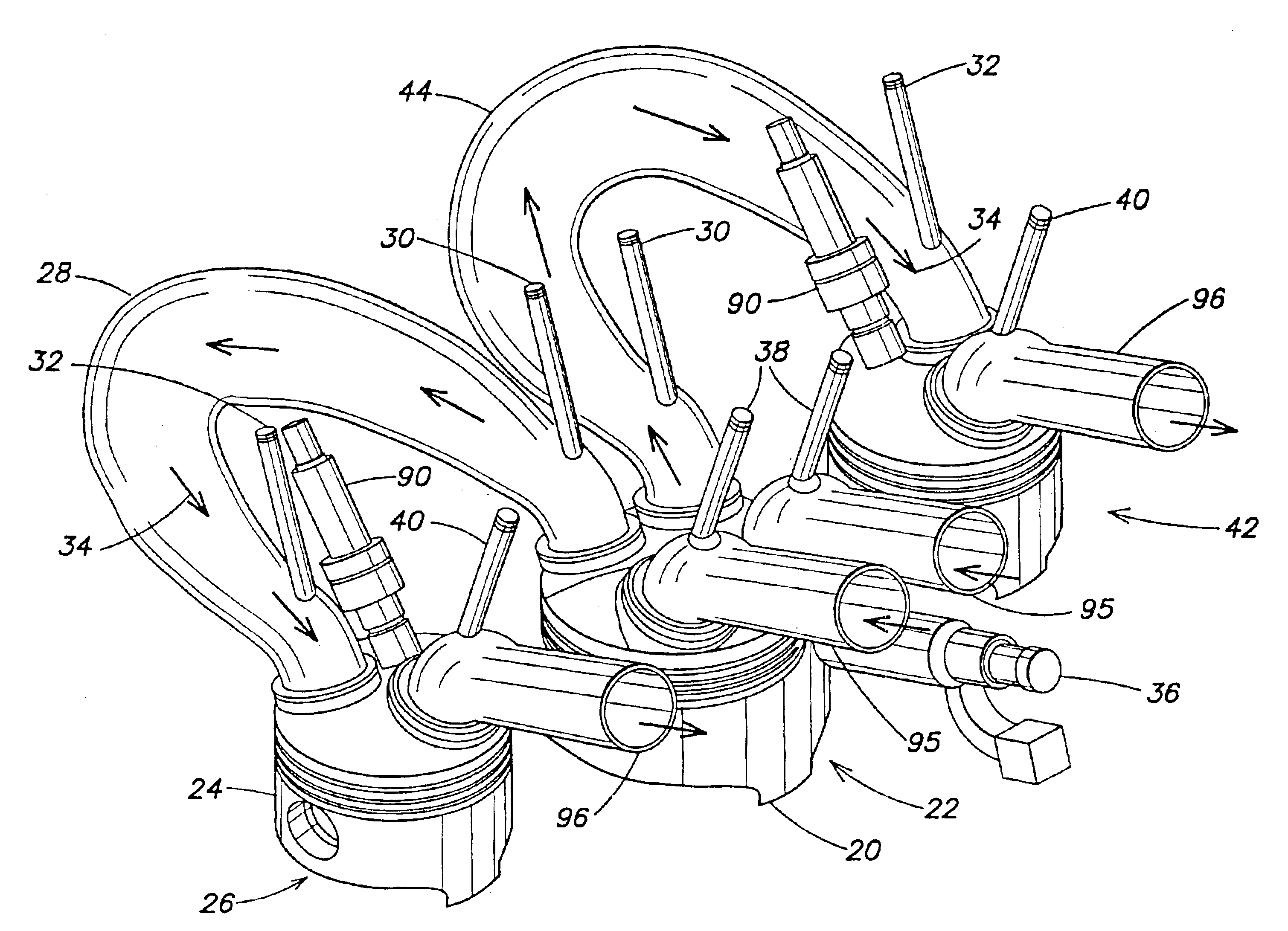

Optimized fuel management system for direct injection ethanol enhancement of gasoline engines

InactiveUS20060102136A1Improve engine efficiencySave gasElectrical controlNon-fuel substance addition to fuelProcess engineeringVaporization

Fuel management system for enhanced operation of a spark ignition gasoline engine. Injectors inject an anti-knock agent such as ethanol directly into a cylinder. It is preferred that the direct injection occur after the inlet valve is closed. It is also preferred that stoichiometric operation with a three way catalyst be used to minimize emissions. In addition, it is also preferred that the anti-knock agents have a heat of vaporization per unit of combustion energy that is at least three times that of gasoline.

Owner:MASSACHUSETTS INST OF TECH

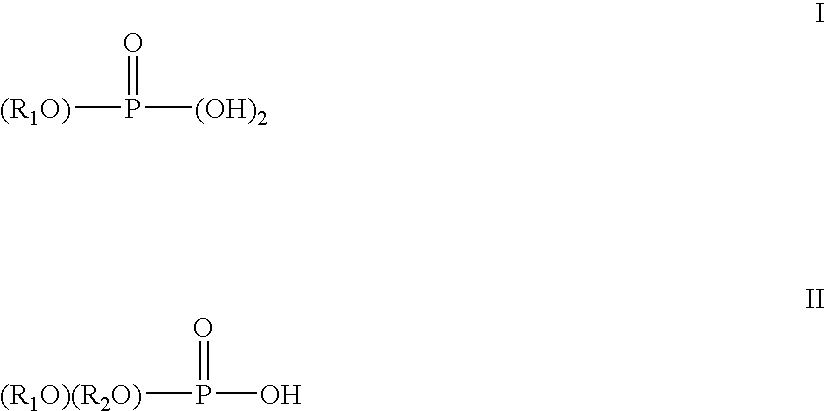

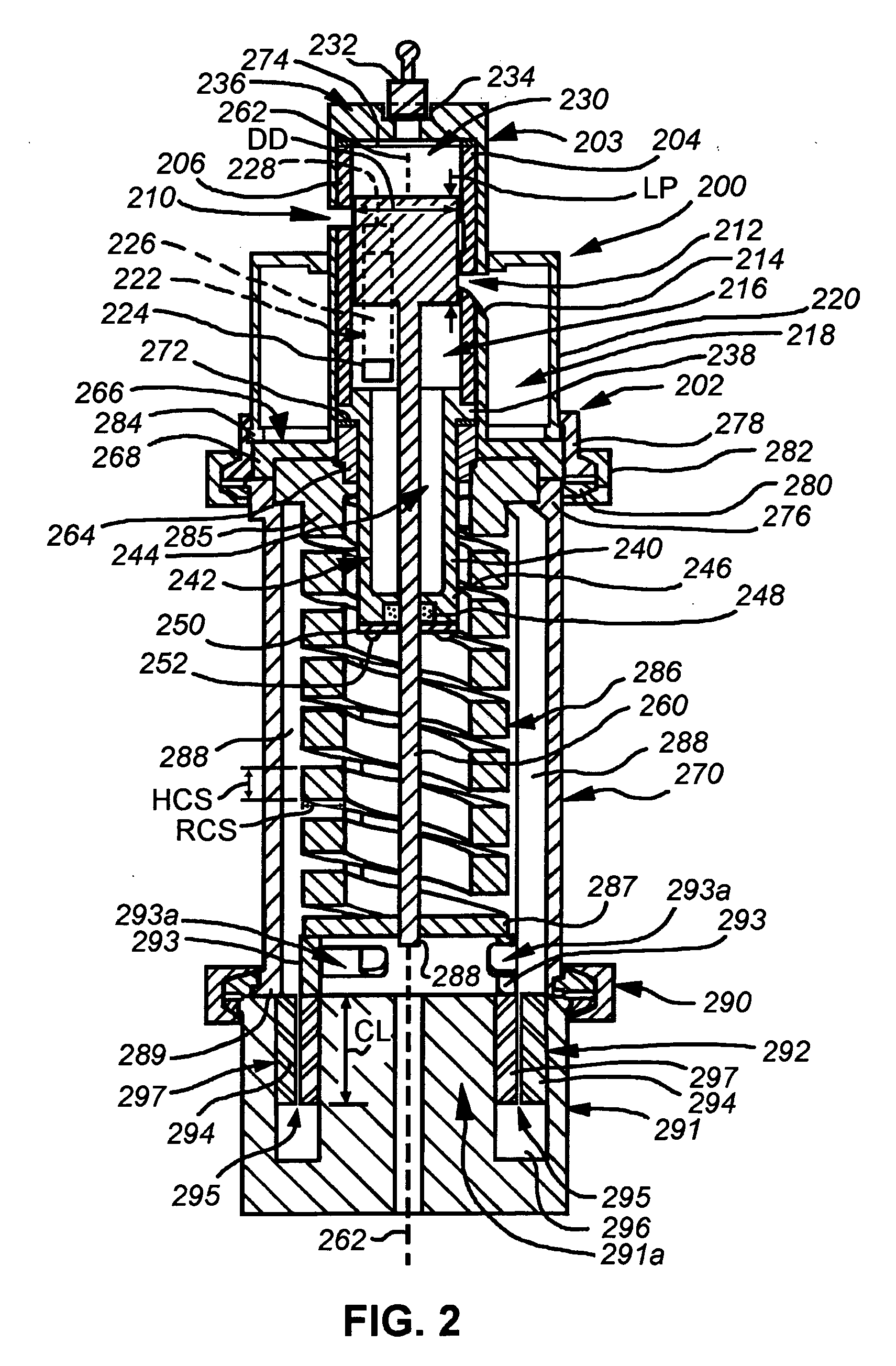

Reciprocating machine & other devices

InactiveUS20120227389A1Improve power densityImprove efficiencyLiquid coolingCasingsCombustionReciprocating motion

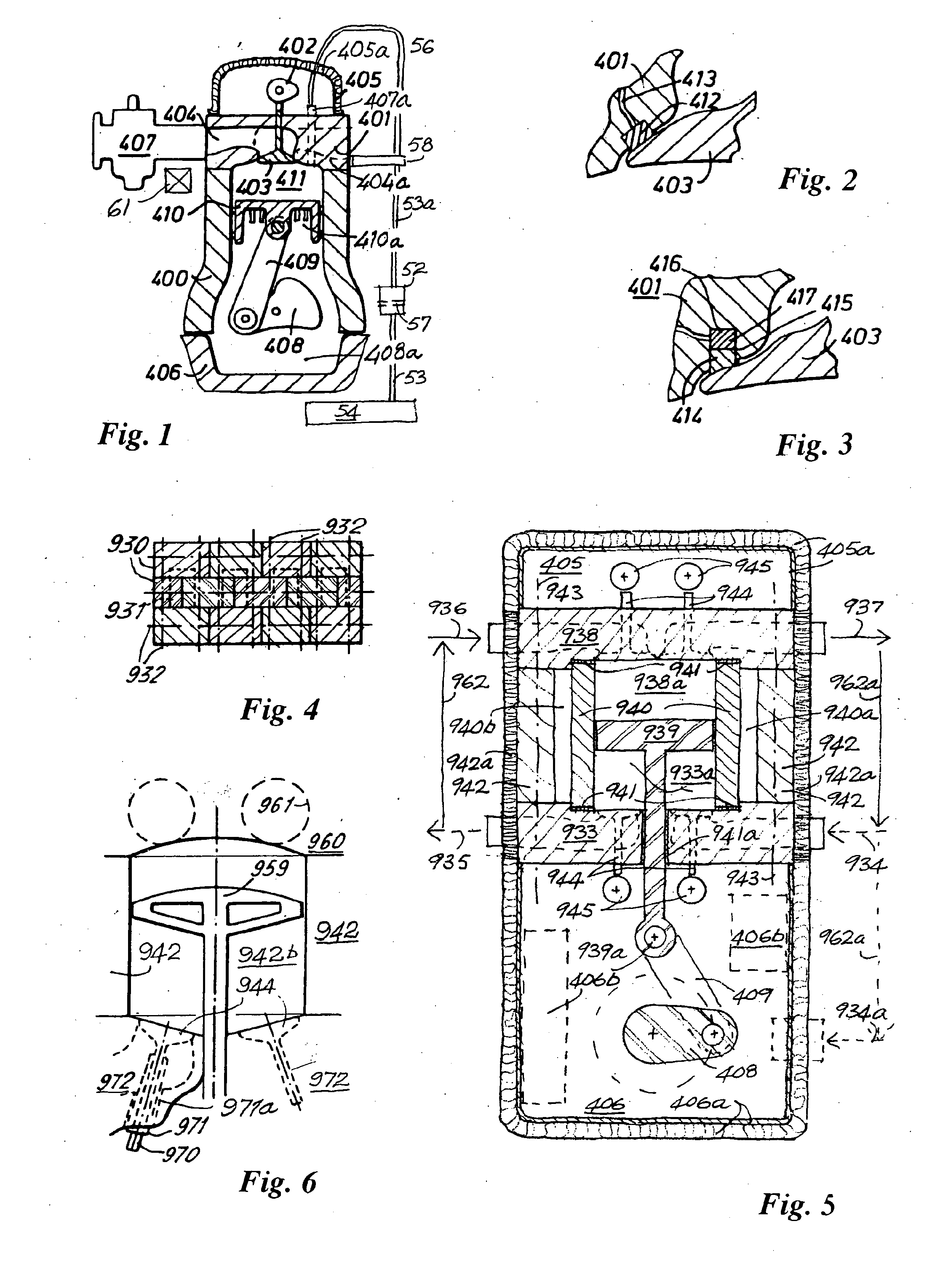

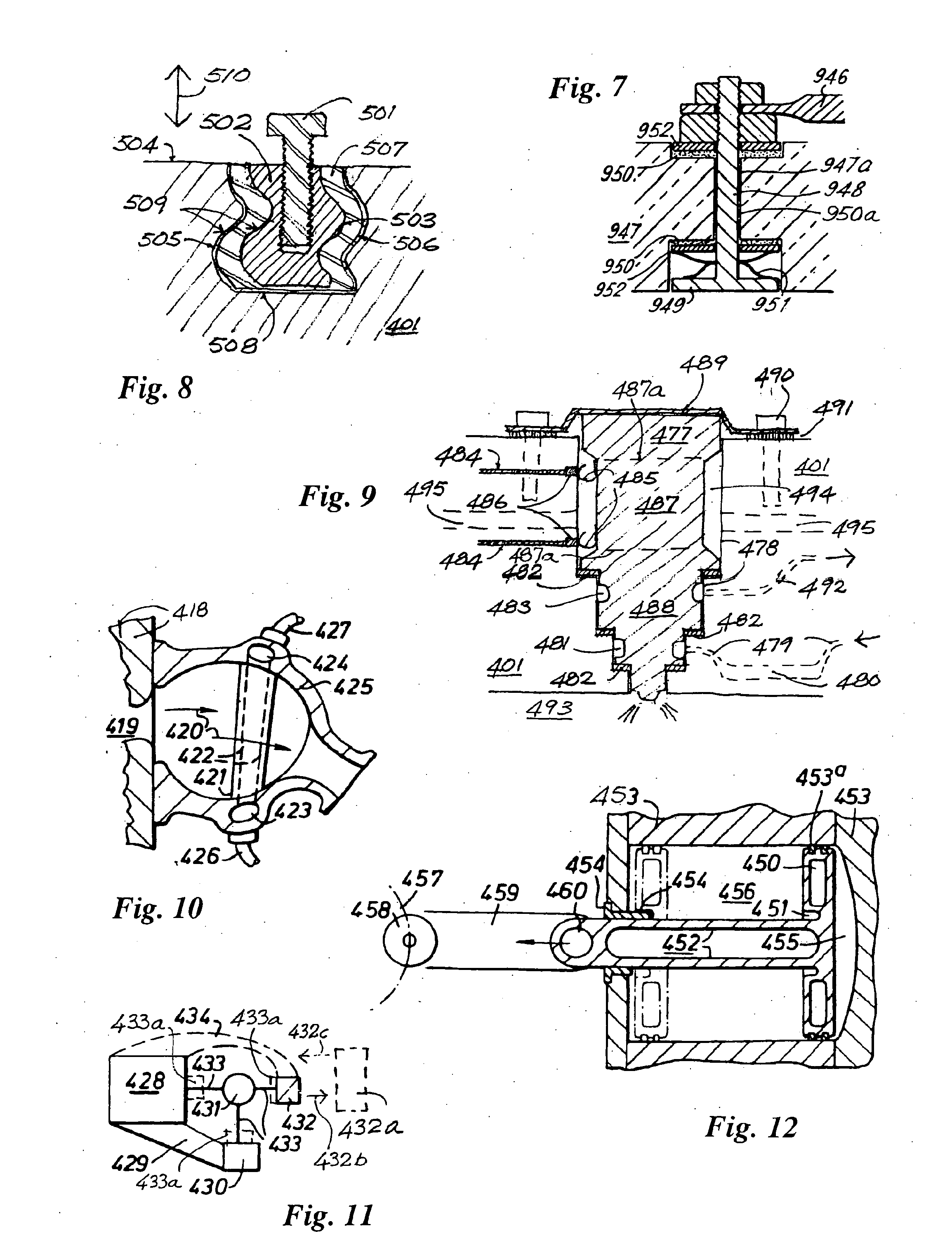

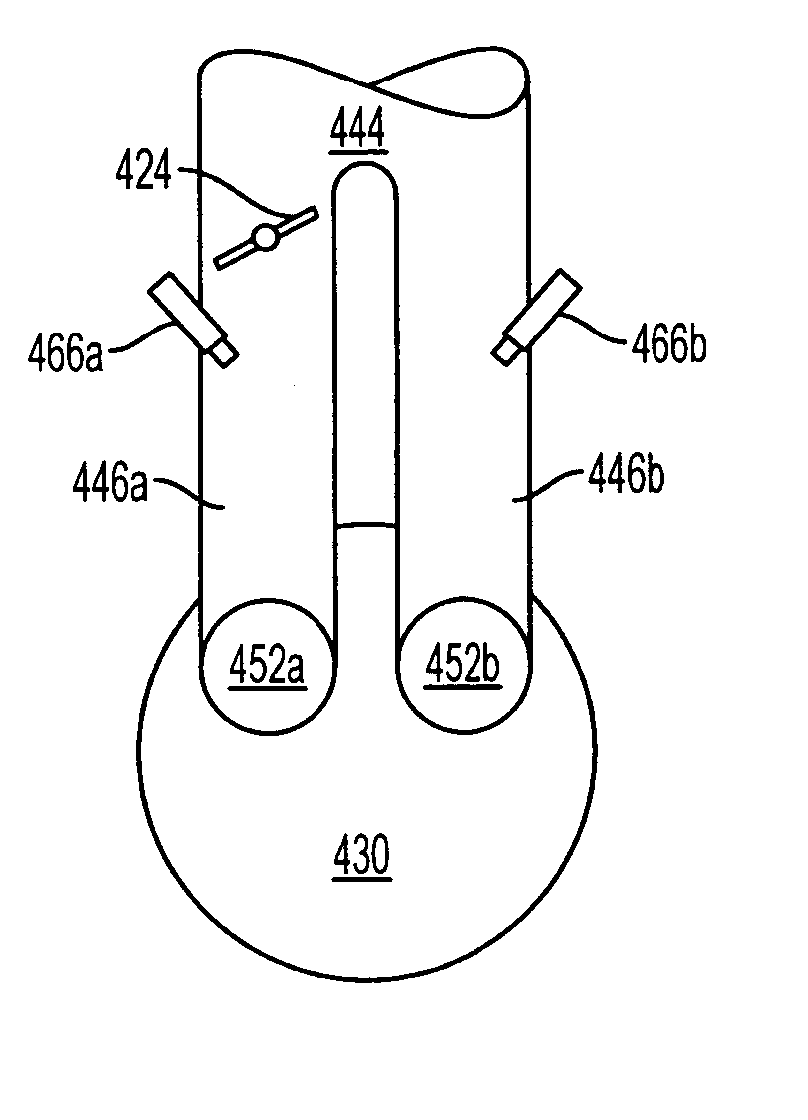

The disclosure relates to reciprocating fluid working devices including internal combustion engines, compressors and pumps. A number of arrangements for pistons and cylinders of unconventional configuration are described, mostly intended for use in IC engines operating without cooling. Included are toroidal combustion or working chambers, some with fluid flow through the core of the toroid, a single piston reciprocating between a pair of working chambers, tensile valve actuation, tensile links between piston and crankshaft, energy absorbing piston-crank links, crankshafts supported on gas bearings, cylinders rotating in housings, injectors having components which reciprocate or rotate during fuel delivery. In some embodiments pistons mare rotate while reciprocating. High temperature exhaust emissions systems are described, including those containing filamentary material, as are procedures for reducing emissions during cold start by means of valves at reaction volume exit. Also disclosed are improved vehicles, aircraft, marine craft, transmissions and exhaust emission systems suited to the engines of the invention.

Owner:HINDERKS MITJA VICTOR

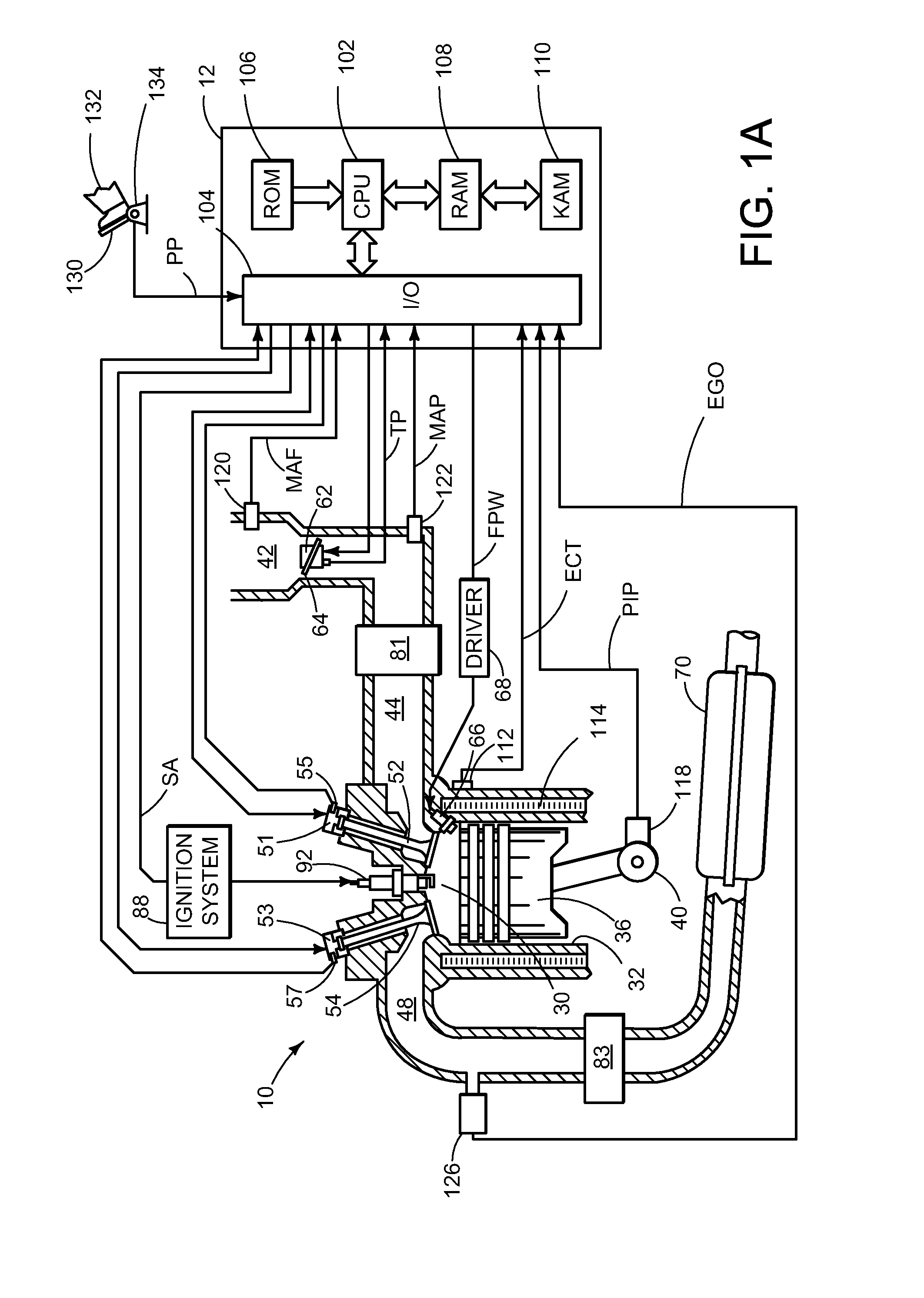

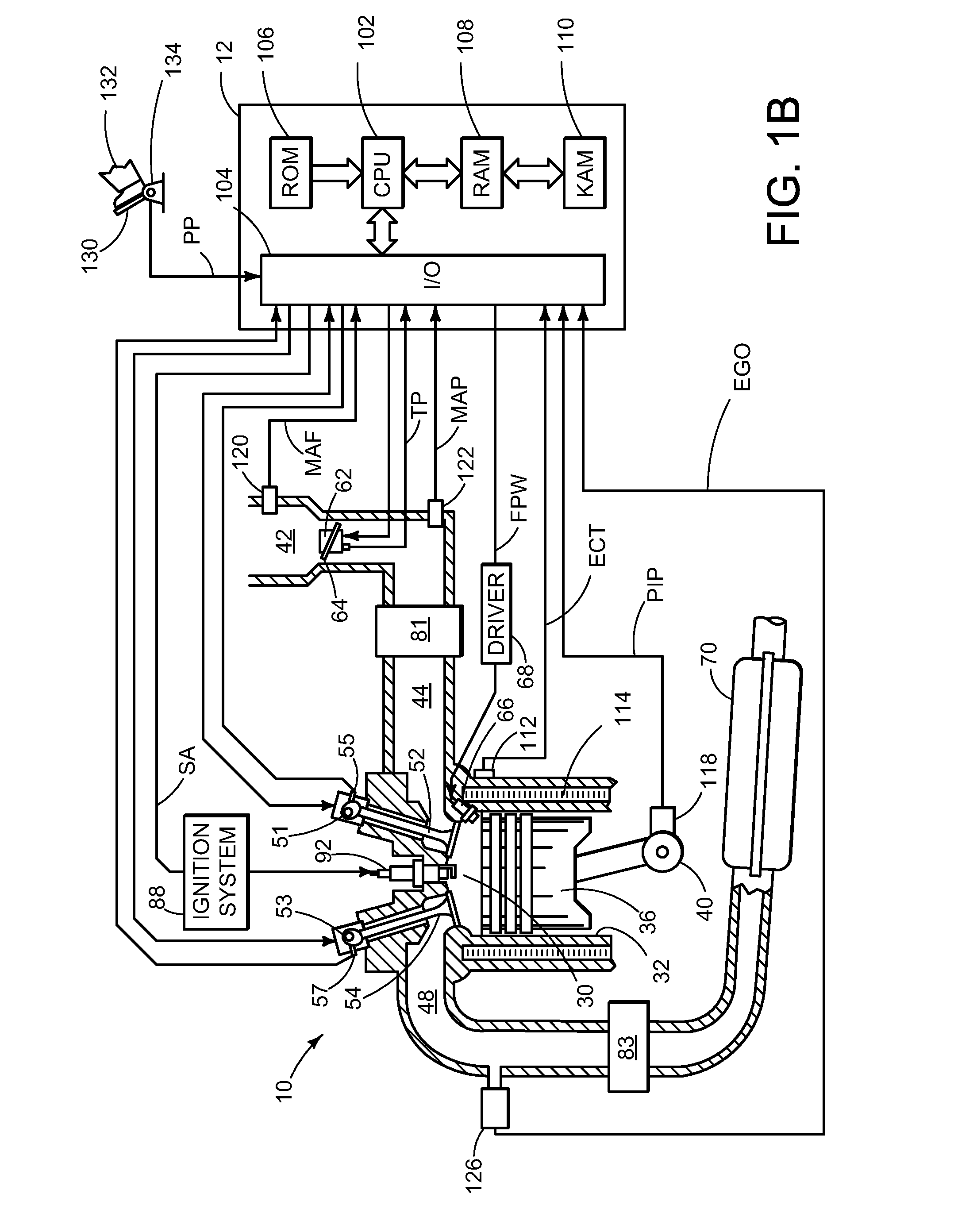

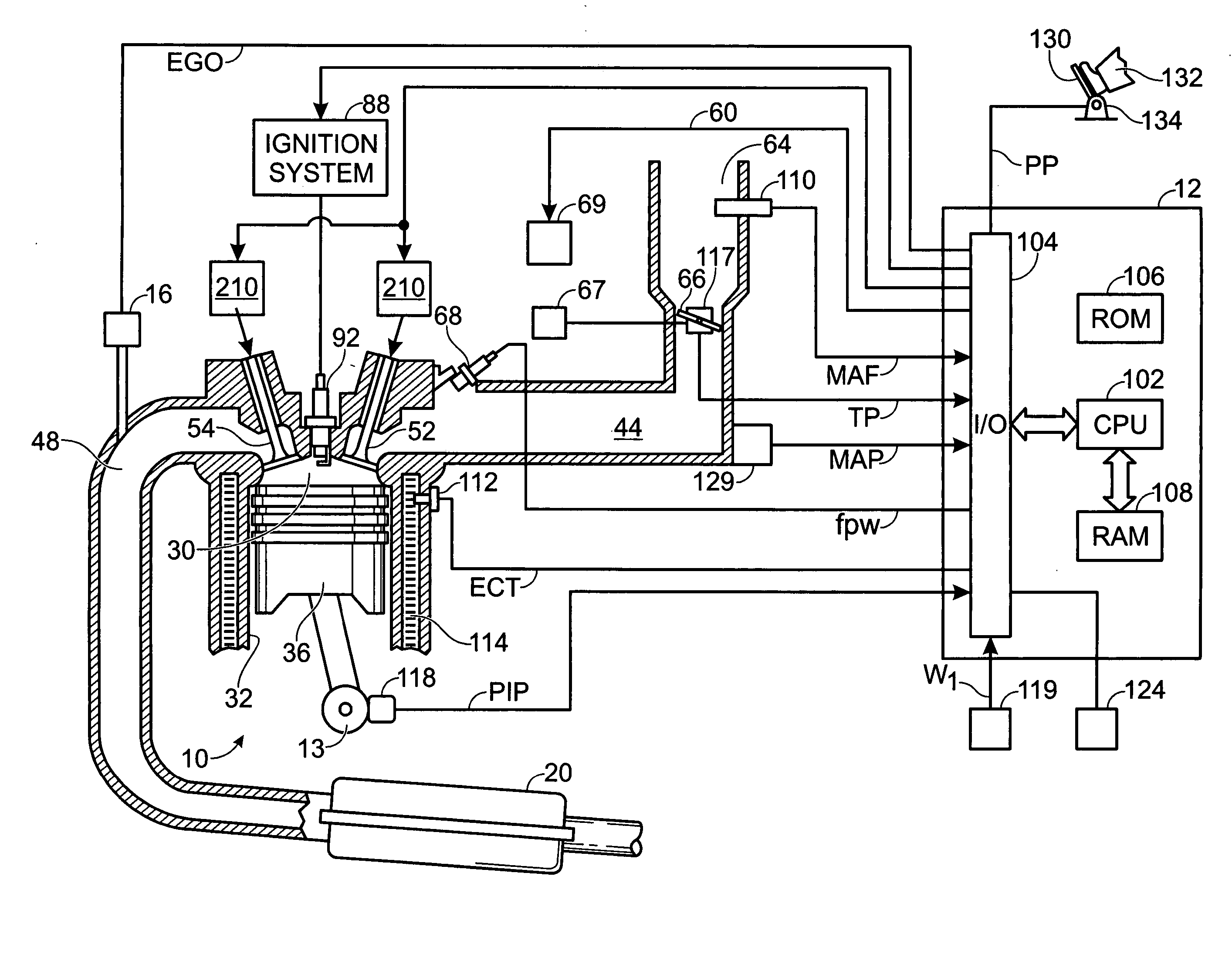

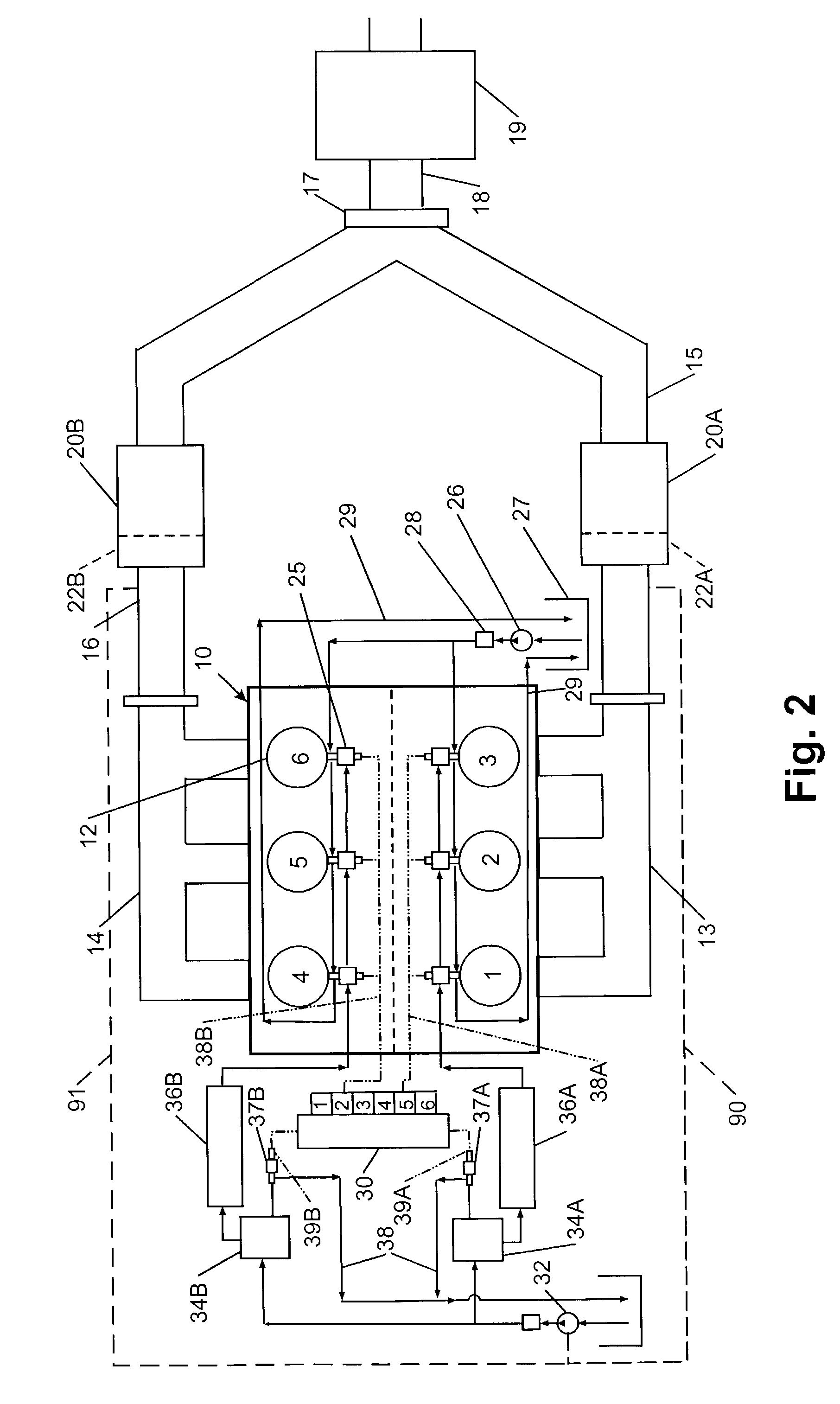

Control strategy for engine employing multiple injection types

ActiveUS20070215110A1Improve engine performanceLow costElectrical controlInternal combustion piston enginesMultiple injectionAutomotive engineering

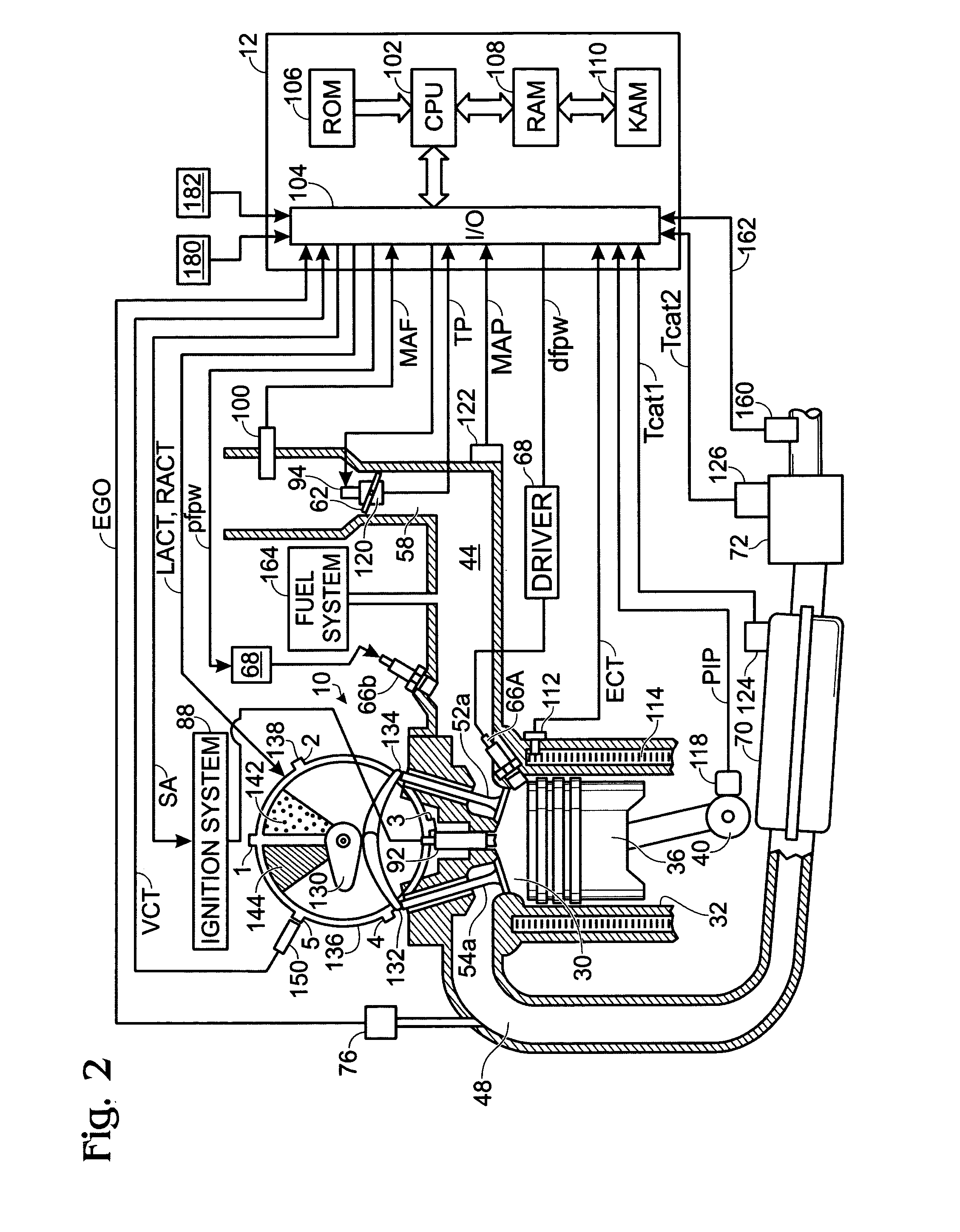

A system for an engine, comprising a cylinder, a first injection subsystem for injecting a first substance into the cylinder, a second injection subsystem for injecting a second substance into the cylinder, and an electronic engine controller configured to control a plurality of operating parameters of the engine, where the electronic engine controller is configured to cause variation of at least one of the operating parameters in response to a shortfall condition of the second injection subsystem.

Owner:FORD GLOBAL TECH LLC

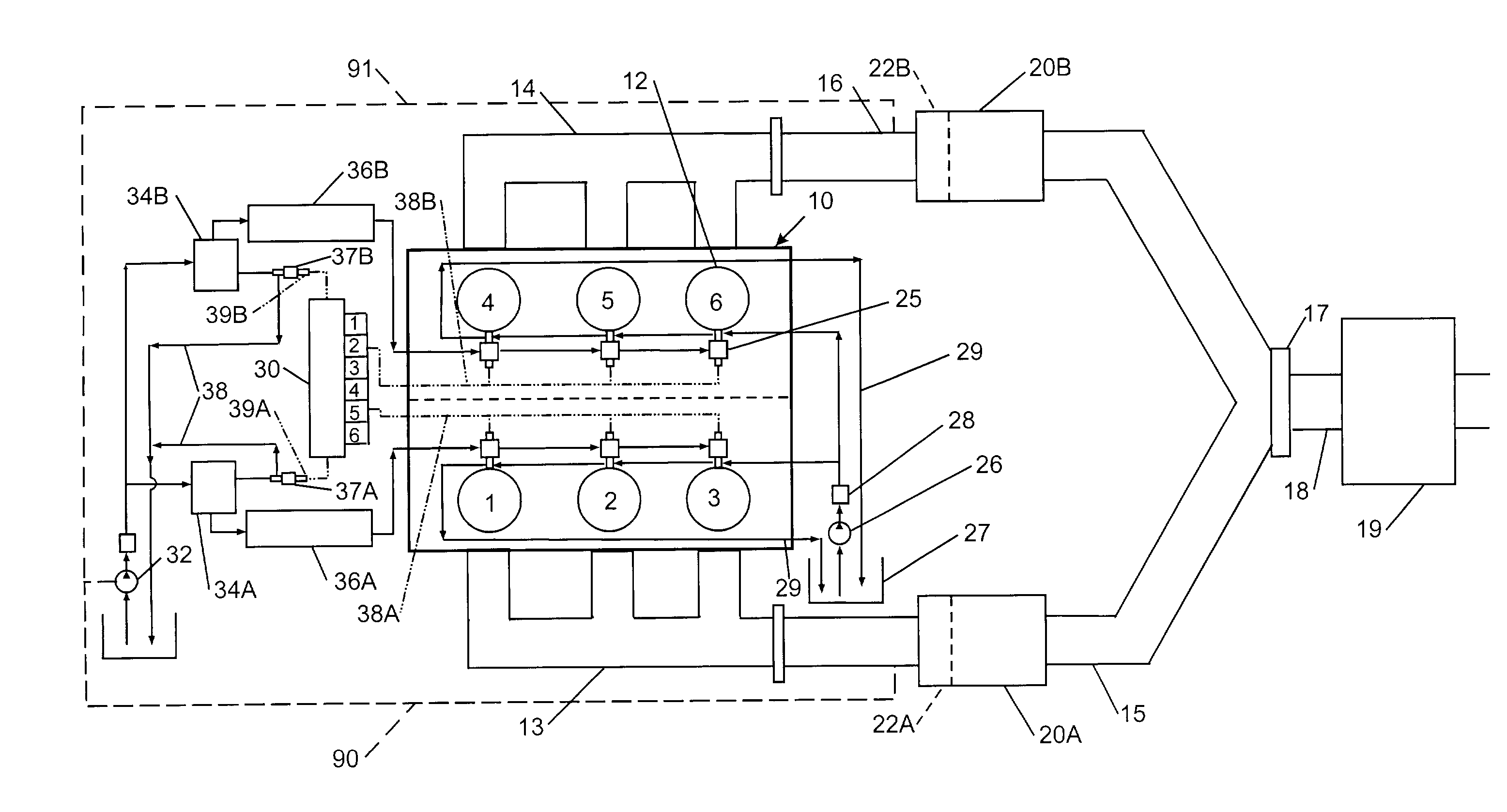

Methods and systems for operating an engine

ActiveUS20110253113A1Increase exhaust temperatureIncrease in temperatureElectrical controlNon-fuel substance addition to fuelExhaust gas recirculationCylinder (engine)

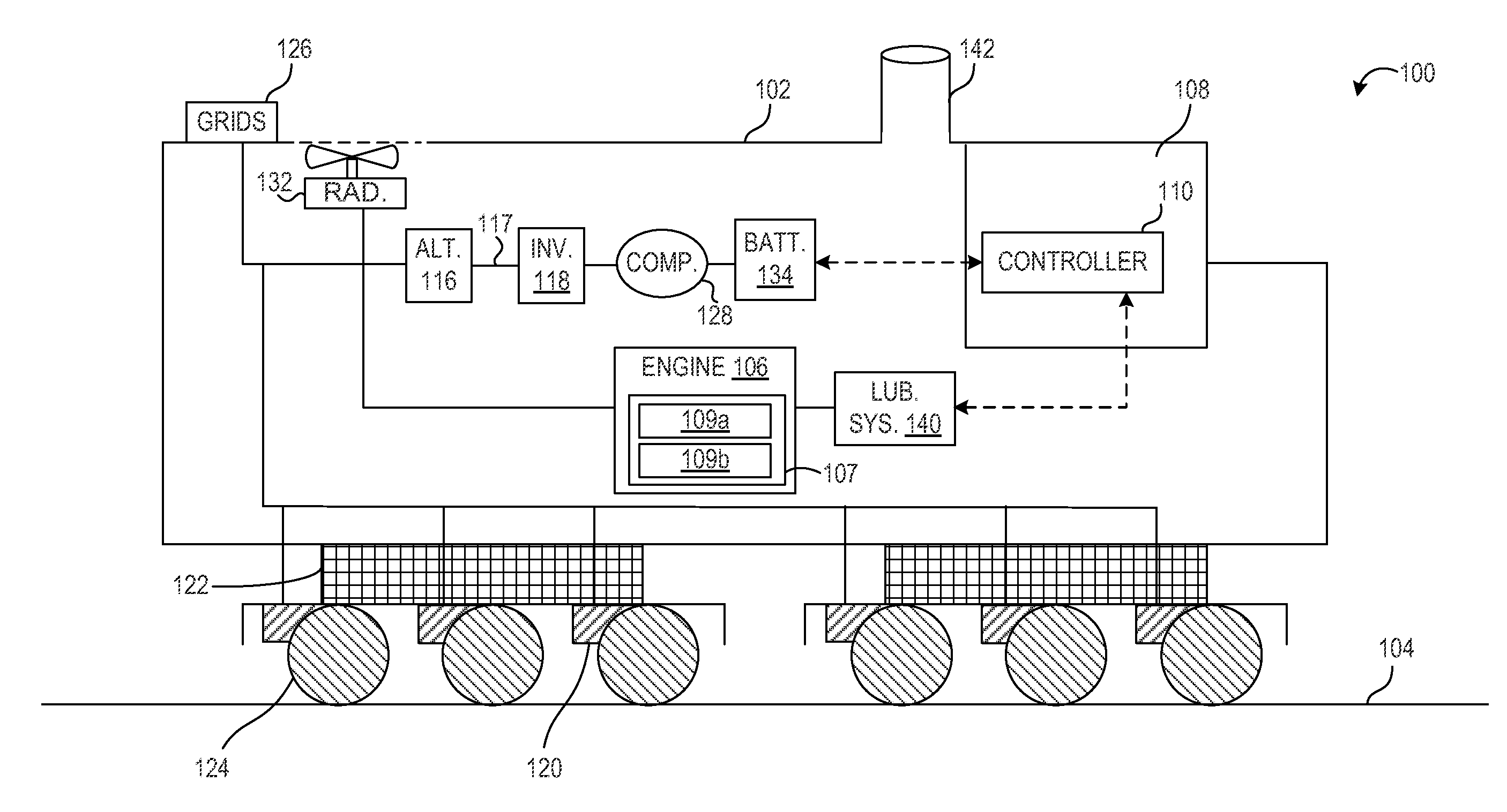

Various methods and systems are provided for operating an internal combustion engine, the engine having a plurality of cylinders including one or more donor cylinders and one or more non-donor cylinders. In one example, a method includes, during an exhaust gas recirculation cooler heating mode, operating at least one of the donor cylinders at a cylinder load sufficient to increase an exhaust temperature for regenerating an exhaust gas recirculation cooler, and operating at least one of the non-donor cylinders in a low- or no-fuel mode.

Owner:GE GLOBAL SOURCING LLC

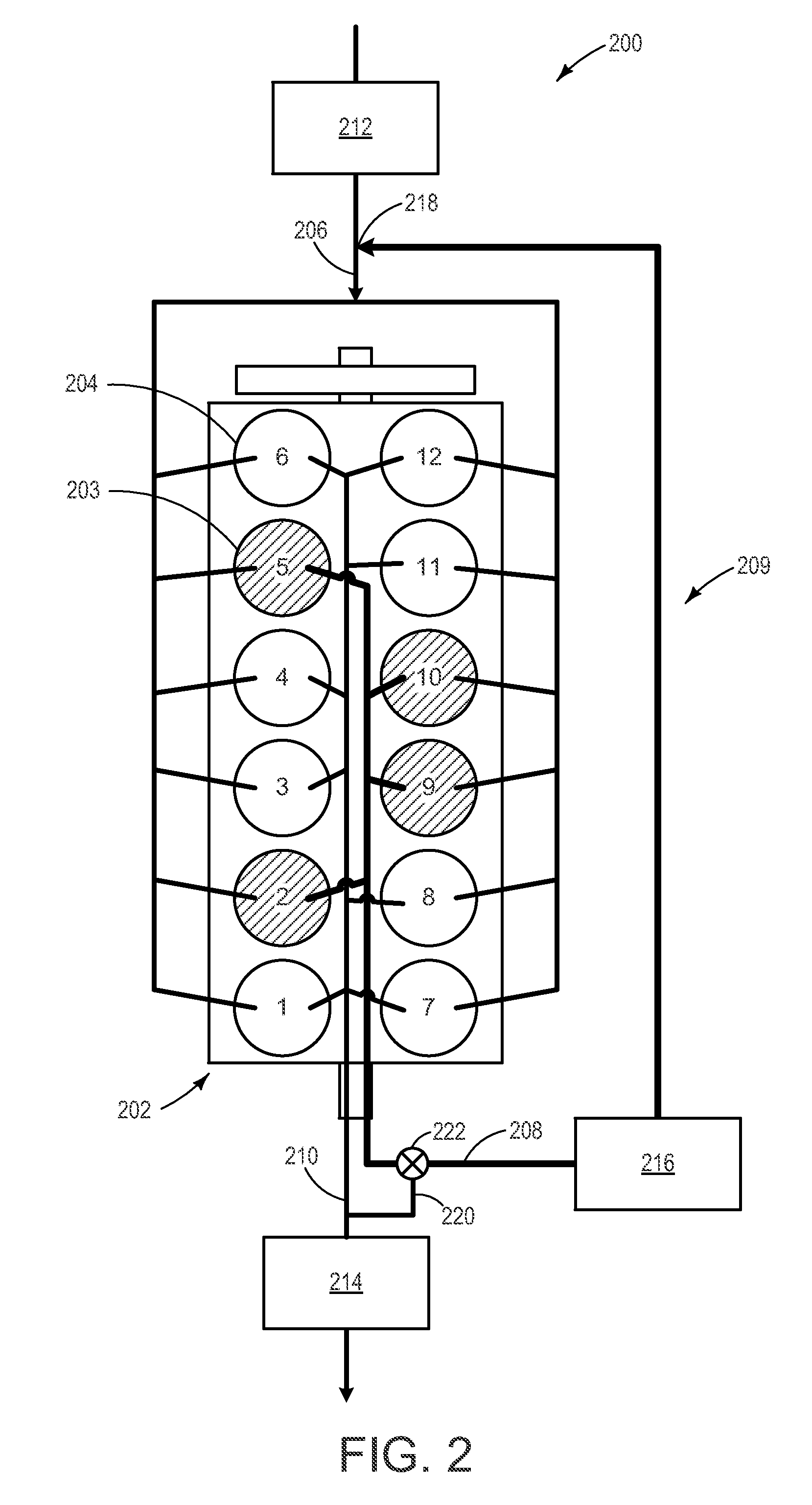

Cylinder deactivation method to minimize drivetrain torsional disturbances

ActiveUS20050131618A1Reduce engine vibrationImprove fuel economyAnalogue computers for vehiclesElectrical controlDriver/operatorDrivetrain

Owner:FORD GLOBAL TECH LLC

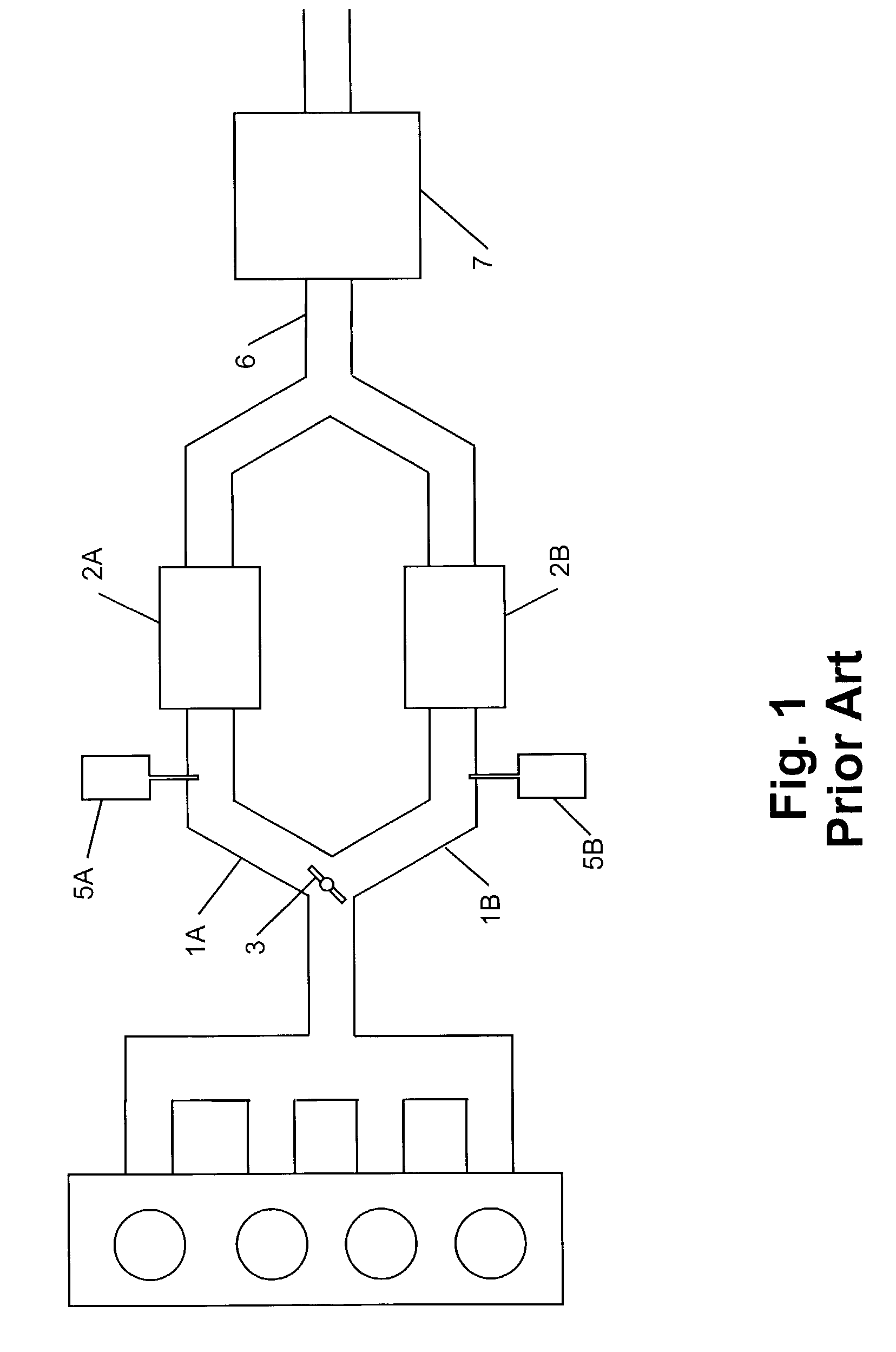

Emission control system for vehicles powered by diesel engines

InactiveUS7055311B2Increase efficiencyStrong affinityElectrical controlInternal combustion piston enginesExhaust gasExhaust fumes

An NOx emission system for diesel powered vehicles has a “Y” exhaust system with an NOx adsorber catalyst in each leg and an oxidation catalyst in the combined leg. One bank of cylinders sends exhaust gases to one of the “Y” legs while a second bank of cylinders send exhaust gases to the other “Y” leg. Composition of the exhaust gases in each leg is independently controlled by the engine's ECU so that exhaust gases in one leg are rich for regenerating the NOx adsorber catalyst in that leg while exhaust gas composition in the other leg is lean so that the combined gas stream is always lean and reductant slip is oxidized in the oxidation catalyst.

Owner:ENGELHARD CORP

Internal combustion engine

InactiveUS6880501B2Easy to implementLower emission levelsCombustion enginesEngineeringInternal combustion engine

An internal combustion engine that has a pair of cylinders each having a reciprocating piston connected to a crank shaft by a connecting rod. One of the cylinders is adapted for an air and fuel intake and a compression strokes only, and the other of the cylinders adapted for at least power and exhaust strokes. A conduit exists for transfer of gases from the one into the other cylinder after the compression stroke. The conduit has means for isolating gases in the conduit intermediate the compression and power strokes. Furthermore, the conduit is designed to prevent the transfer of liquefied fuel from the one cylinder to the other.

Owner:MASSACHUSETTS INST OF TECH

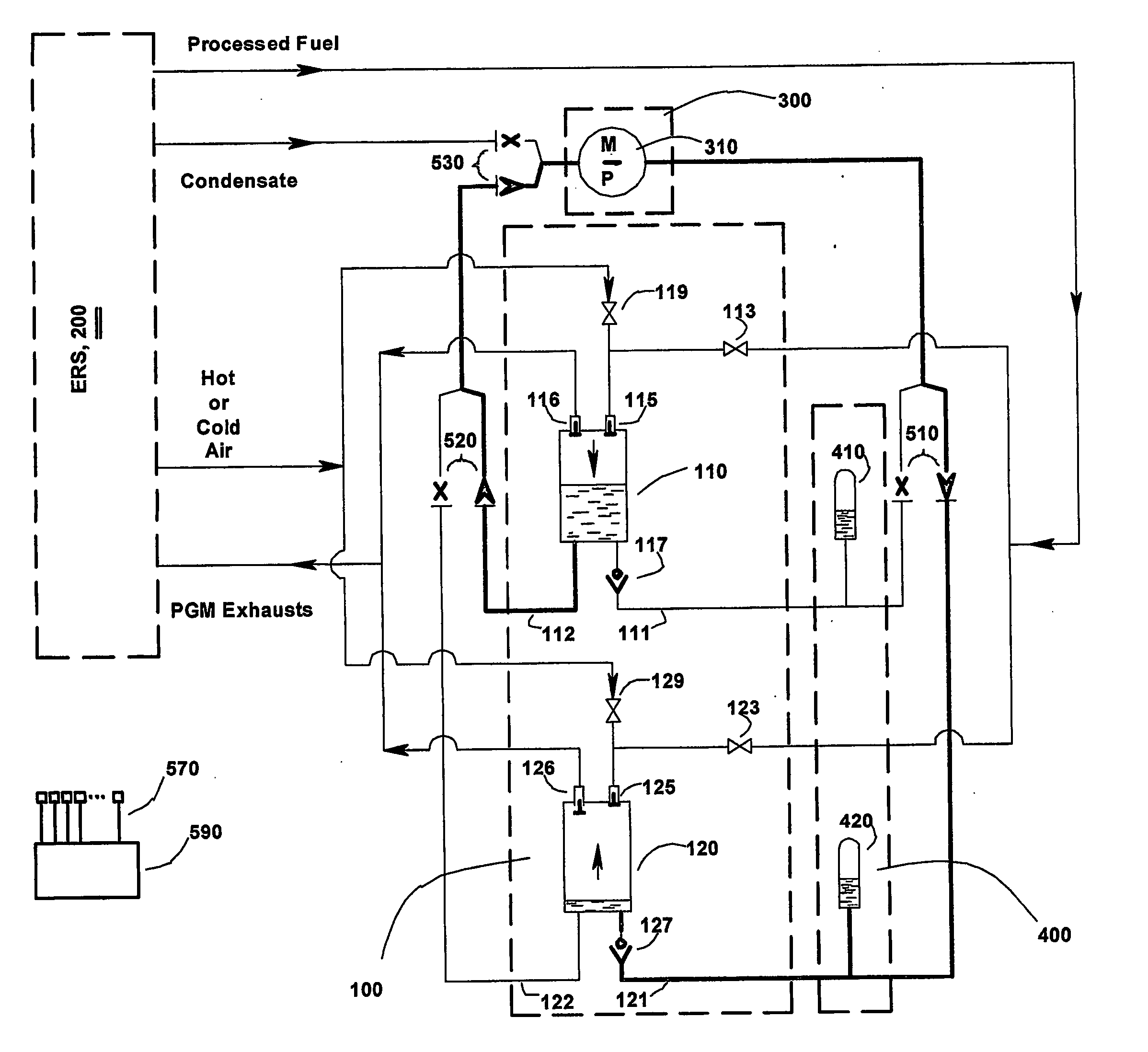

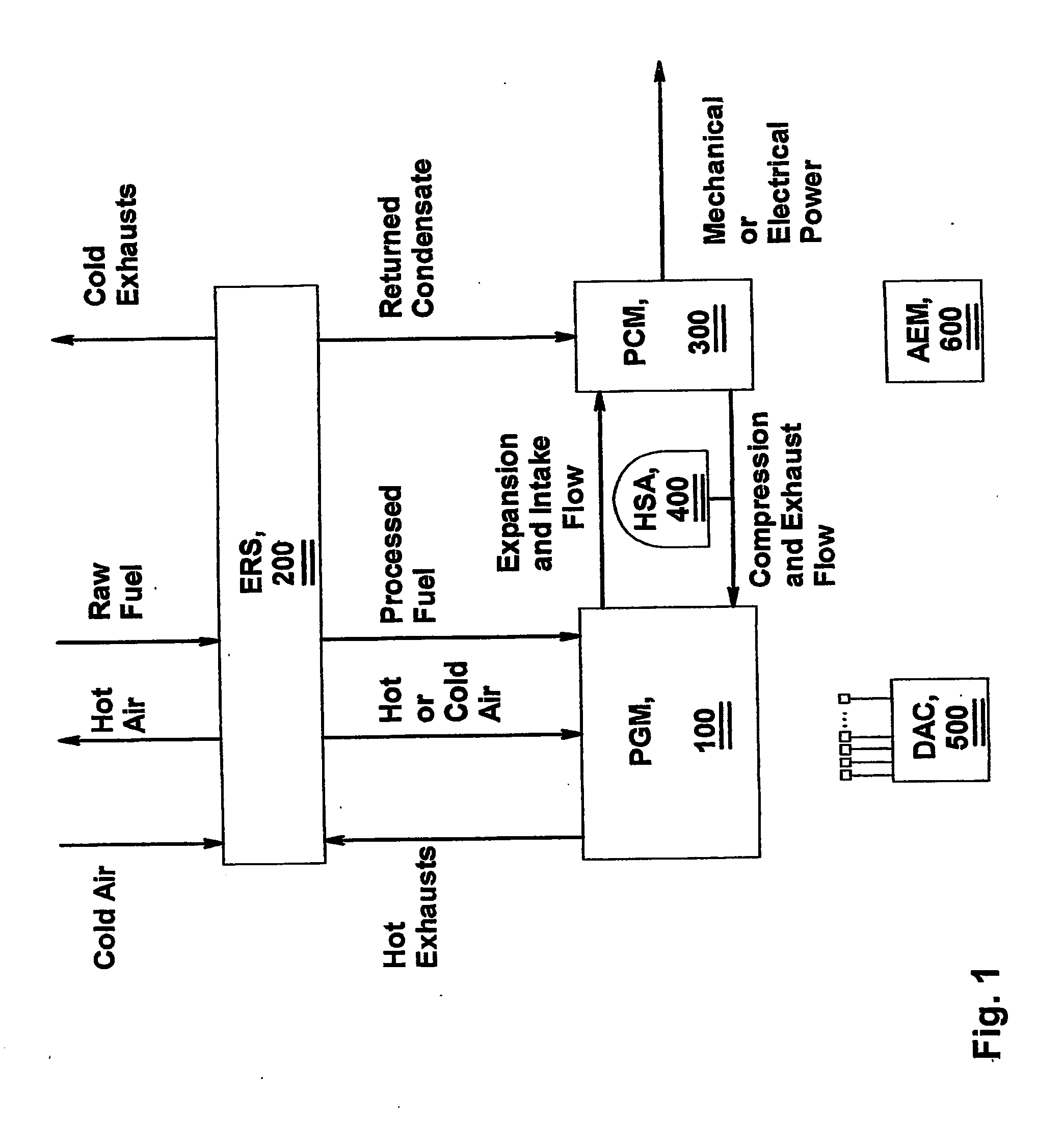

Liquid piston internal combustion power system

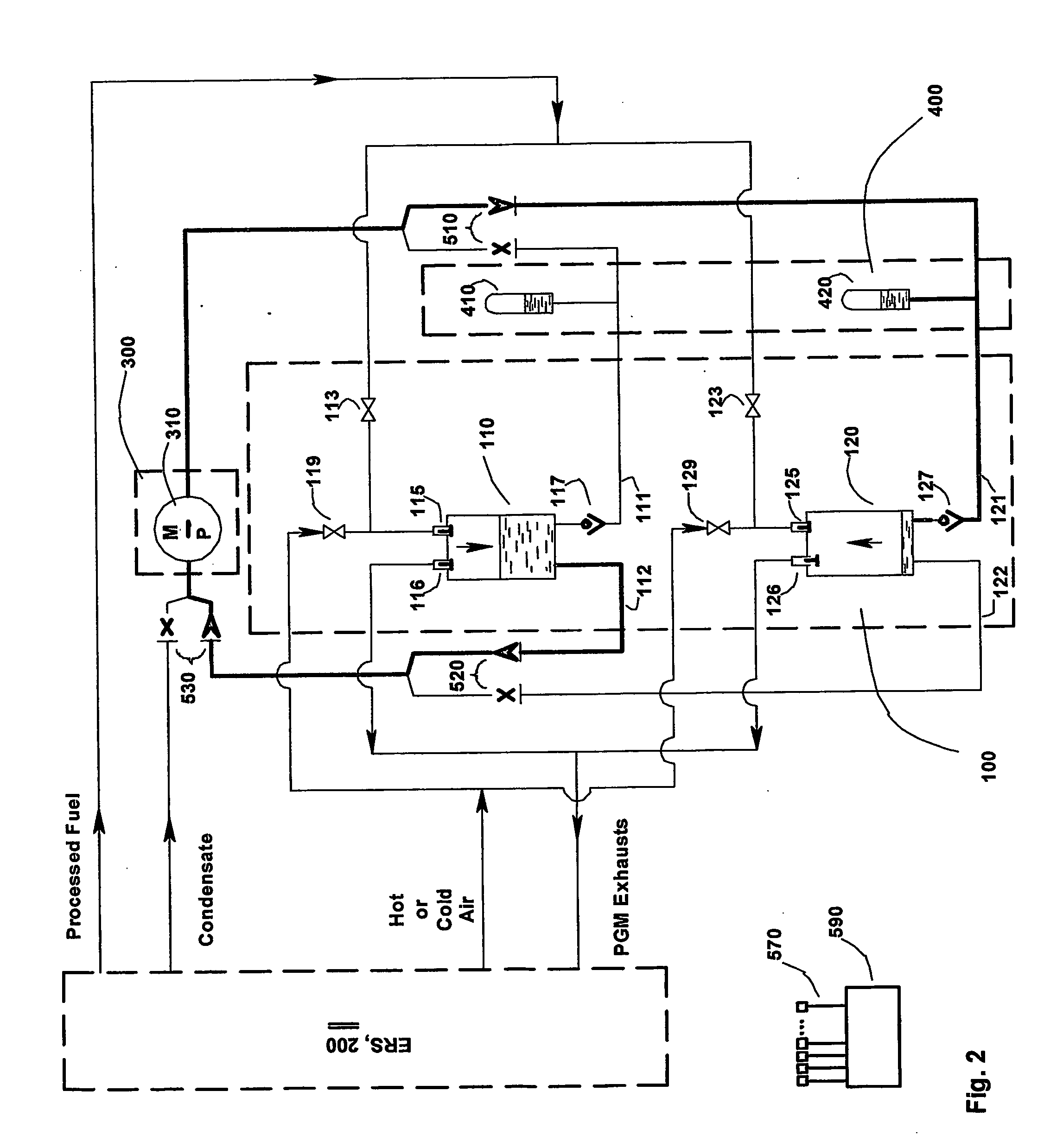

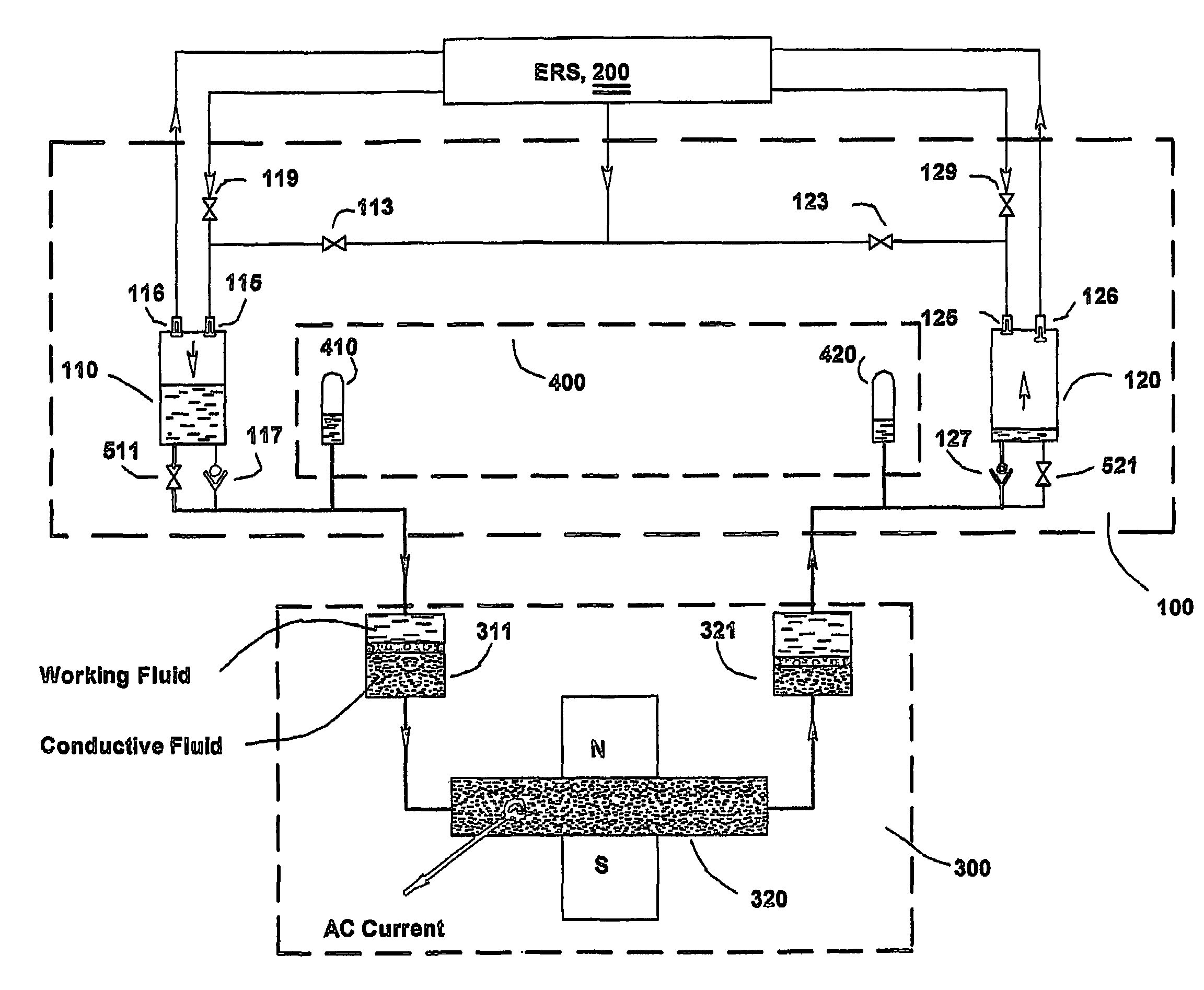

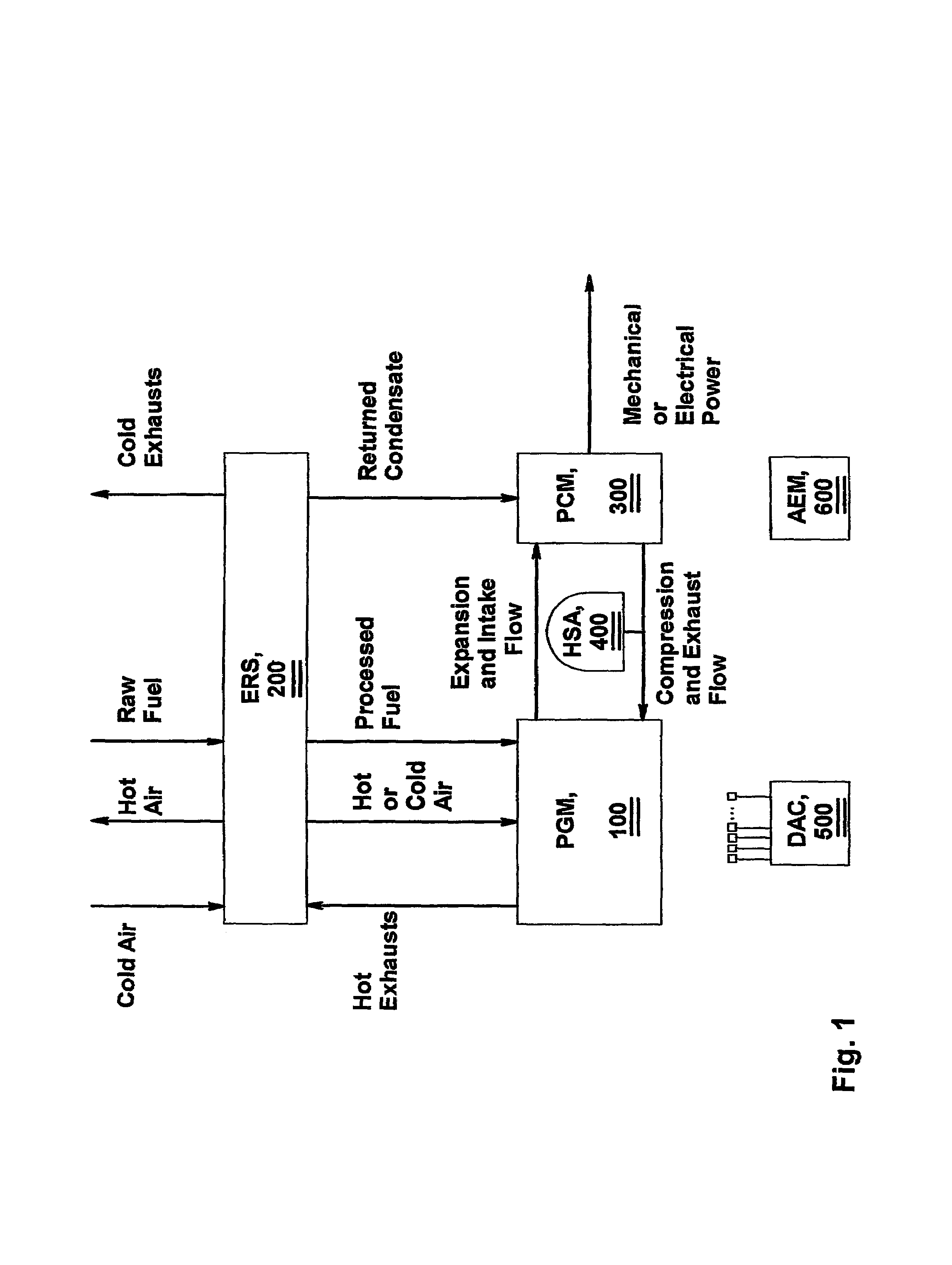

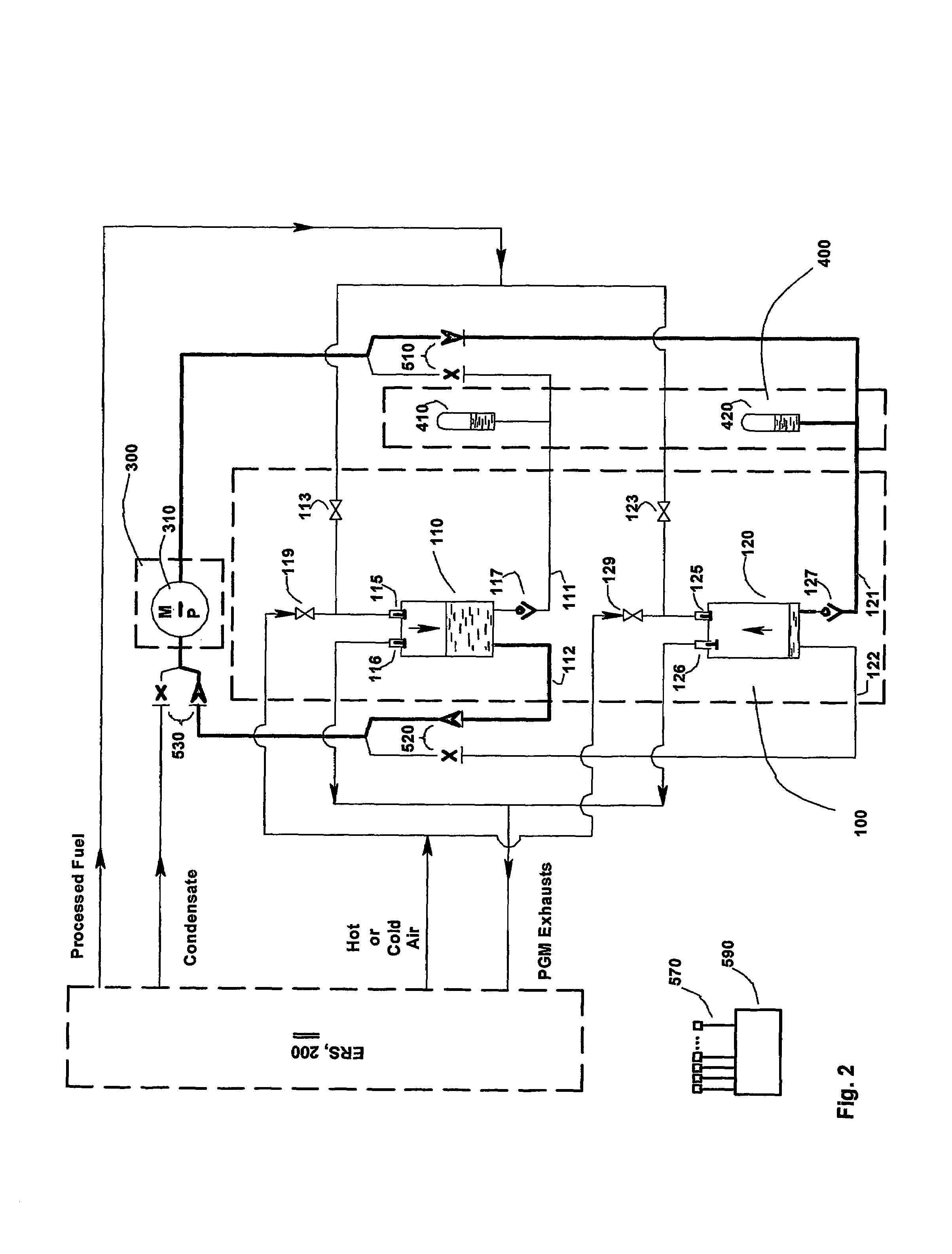

InactiveUS20050166869A1Reduce pollutionRotary slide valveSteam engine plantsLiquid pistonEnergy recovery

Methods, devices and systems for power generation through liquid piston internal combustion engine. The liquid piston internal combustion engine of the invention, utilizes a novel, synergetic combination of internal combustion and steam piston engines within the framework of one and the same system. The engine may comprise or a plurality of cylinders, each having a liquid piston. The ICE (Internal Combustion Engine) system comprises six modules viz PGM (Power Generating Module) (100), ERS (Energy Recovery System) (200), PCM (Power Conversion Module) (300), HAS (Hydraulic Shock Absorbers Module) (400), DAC (Data Acquisition & Control Module) (500) and AEM (Auxiliary Equipment Module) (600).

Owner:LIQUIDPISTON INC

Liquid piston internal combustion power system

InactiveUS7191738B2Reduce pollutionRotary slide valveSteam engine plantsFree-piston engineCombustion

Methods, devices, and systems for power generation through liquid piston internal combustion engine. The liquid piston internal combustion engine of the invention utilizes a novel, synergetic combination of internal combustion and steam piston engines within the framework of one and the same system. The engine may comprise a plurality of cylinders, each having a liquid piston.

Owner:LIQUIDPISTON INC

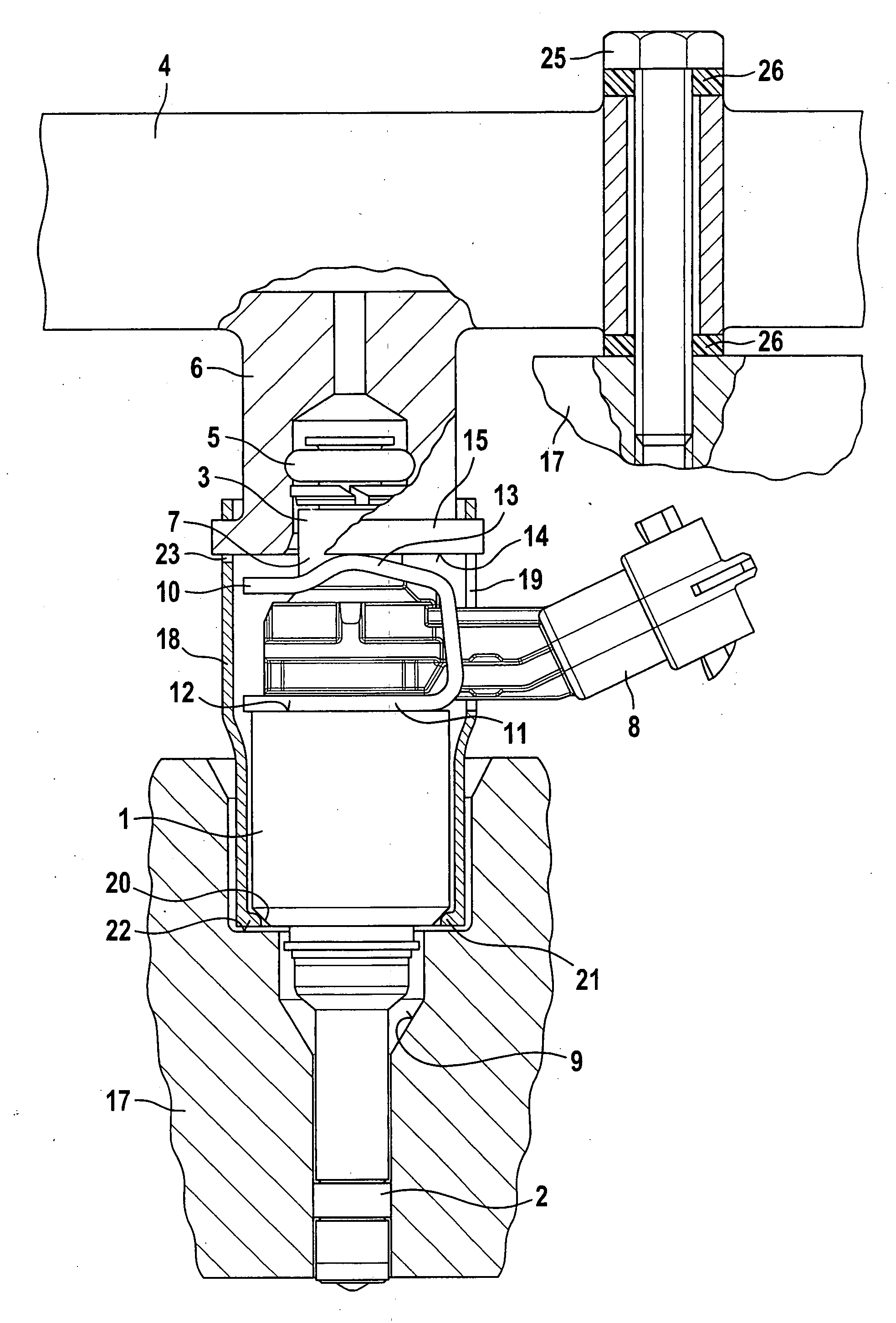

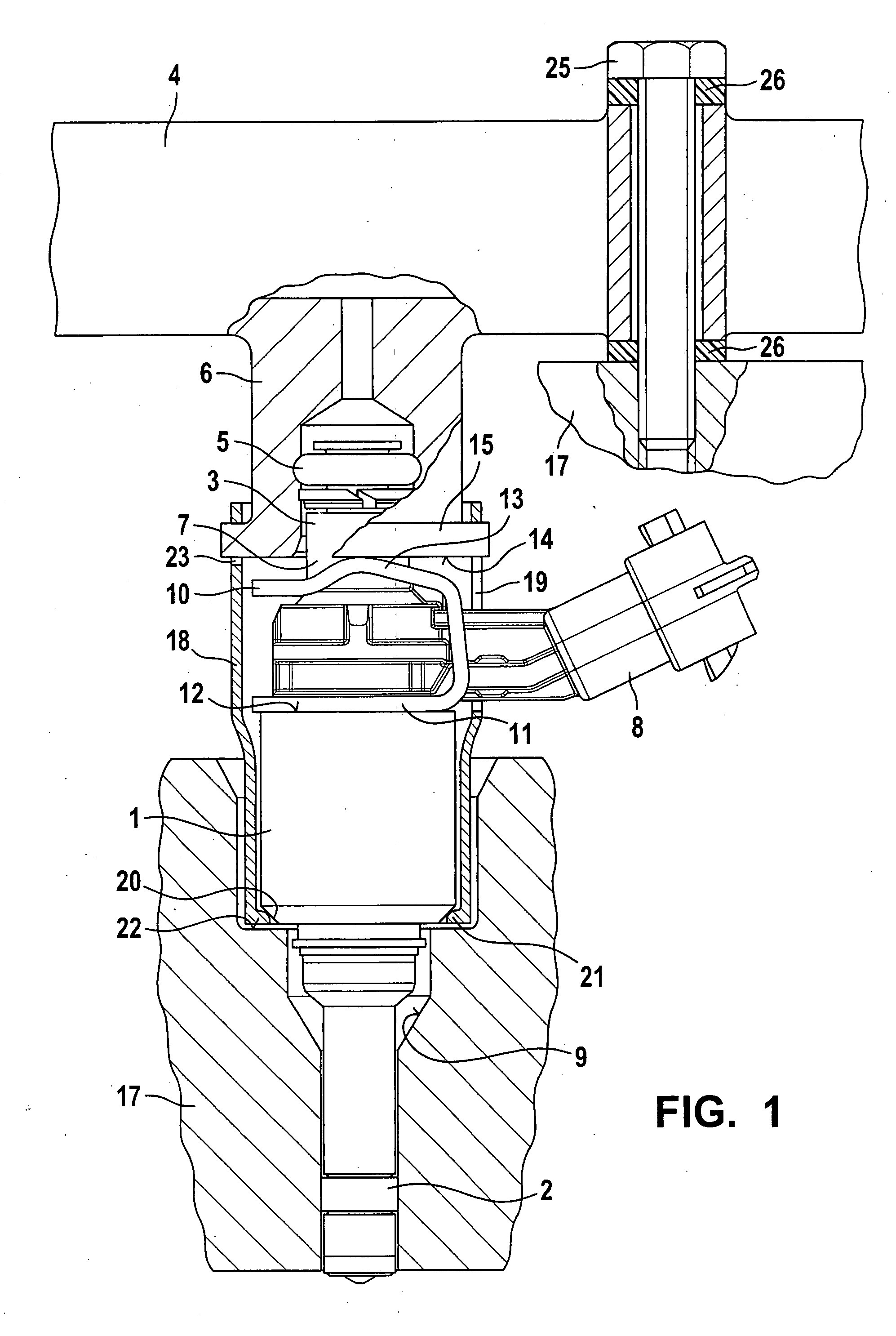

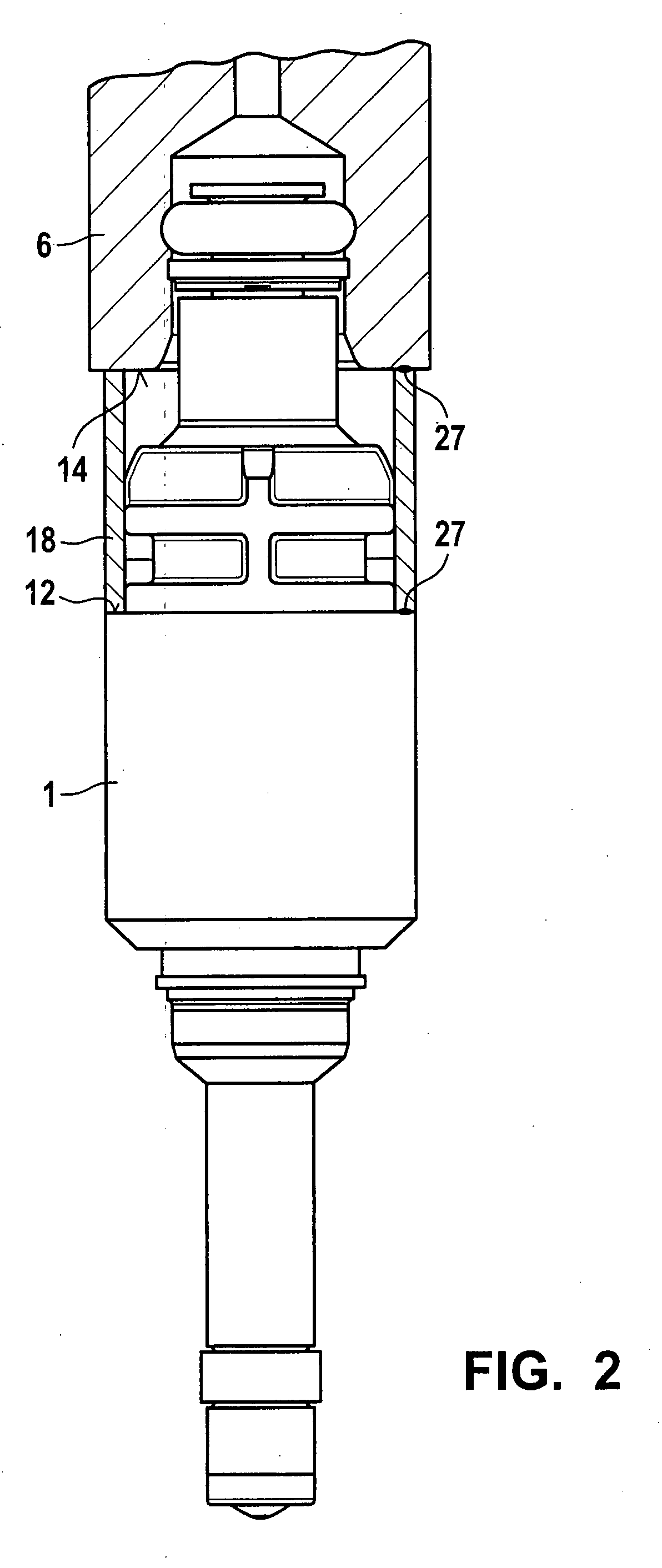

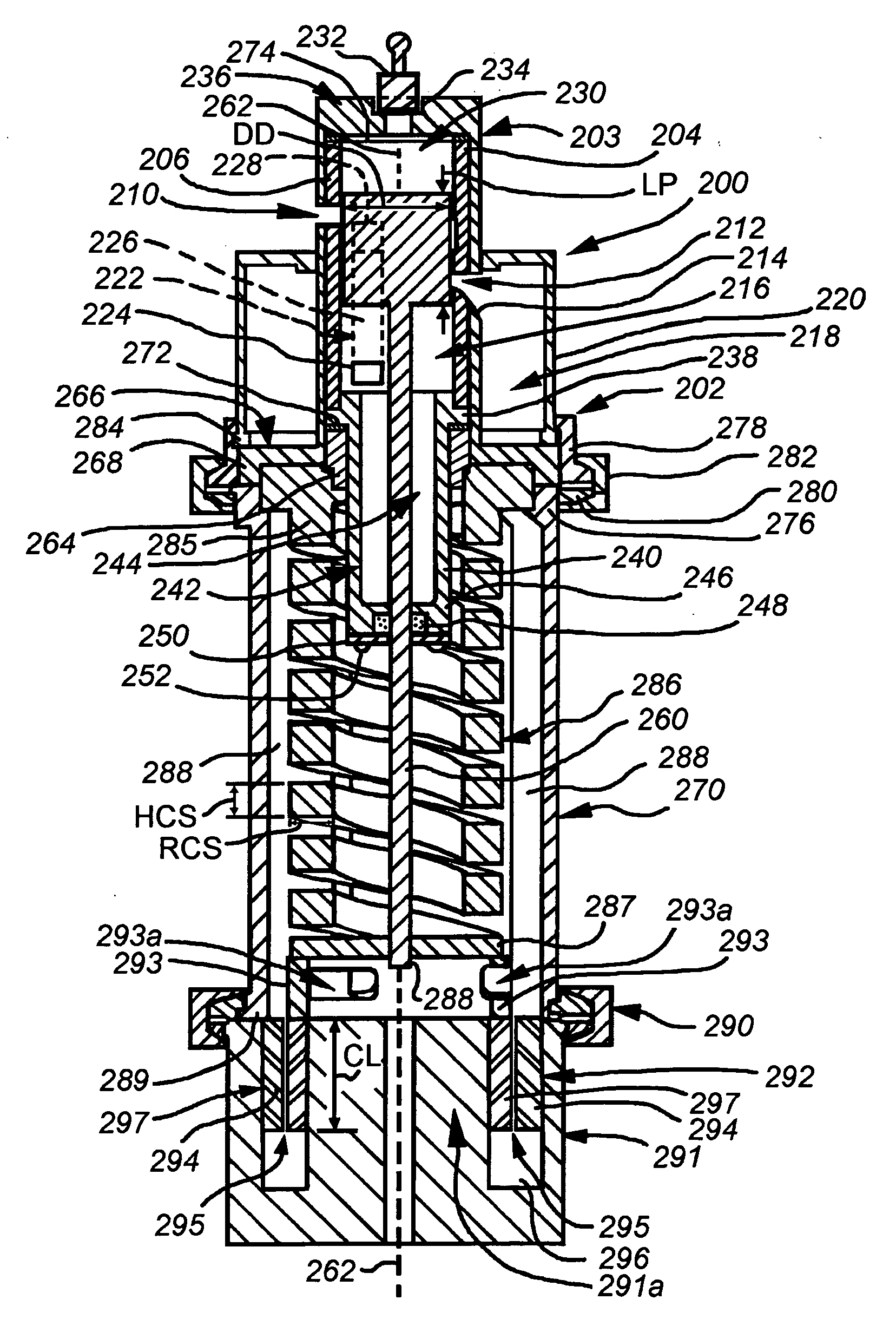

Fuel Injection Valve

InactiveUS20080302336A1Reduce sound transmissionReduce transmissionLow pressure fuel injectionMachines/enginesCombustionCylinder head

The fuel injection device provides a particularly effective sound-decoupling construction. The fuel injection device has at least one fuel injection valve, a receptacle bore for the fuel injection valve in a cylinder head, and a fuel distributor line having a fitting in which the fuel injection valve is placed in partially overlapping fashion. A connecting element is situated in the receptacle bore such that the fuel injection valve is held in the connecting element such that the fuel injection valve and the connecting element are held so that they do not contact any surfaces or walls of the receptacle bore of the cylinder head that do not run axially parallel to the fuel injection valve. For this purpose, the connecting element is attached immediately on the fitting of the fuel distributor line.The fuel injection valve is particularly well-suited for use in fuel injection systems of mixture-compressing externally ignited internal combustion engines.

Owner:ROBERT BOSCH GMBH

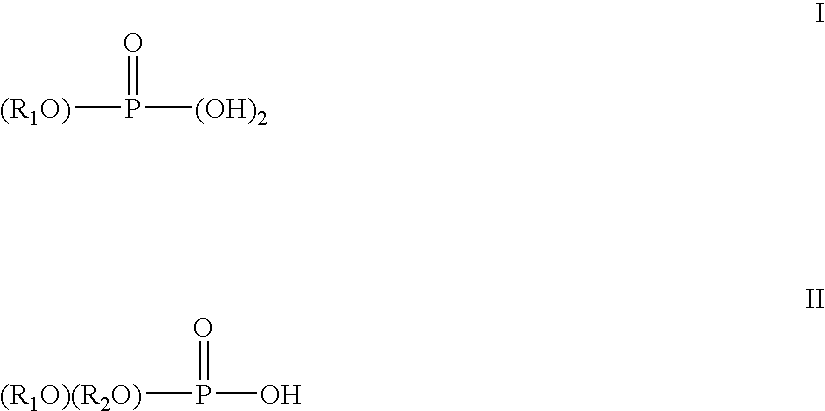

Modification of lubricant properties in an operating all loss lubricating system

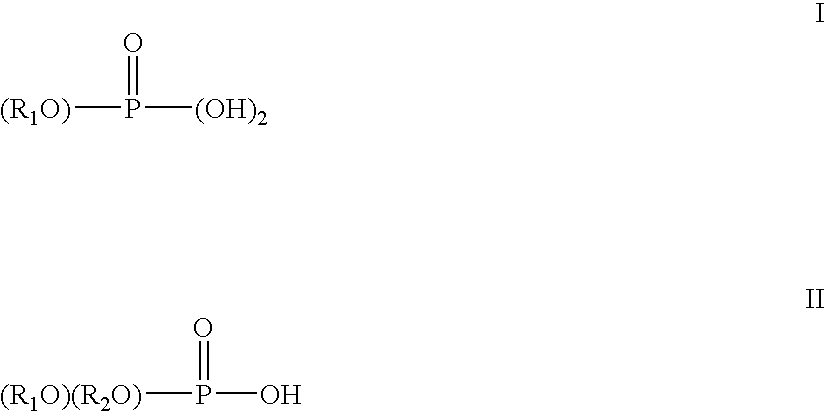

ActiveUS20040144355A1Lubrication of auxillariesLubricant conduit arrangementsSulfonateAlkylphosphate

A marine diesel engine system includes a diesel engine having a plurality of cylinders. The system also includes, proximate the engine, a primary engine lubricant and an additive selected from certain alkylamine-alkylphosphates, 500 TBN calcium sulfonate and mixtures thereof. A means for blending the lubricant and additives into a mixture for introduction into a cylinder is provided. Thus lubricant properties may be modified depending upon engine conditions.

Owner:EXXOMOBIL RES & EINGIEERING

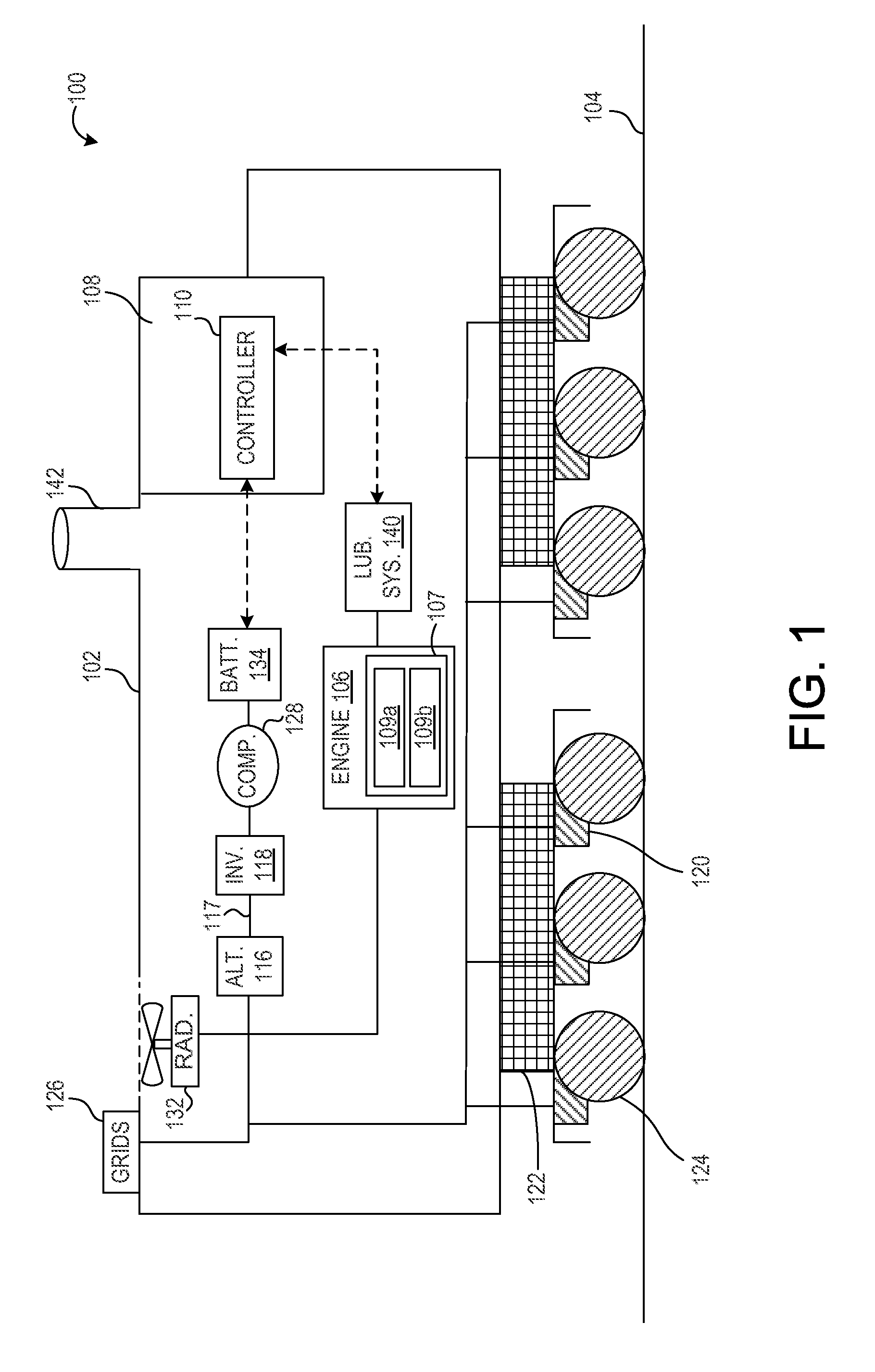

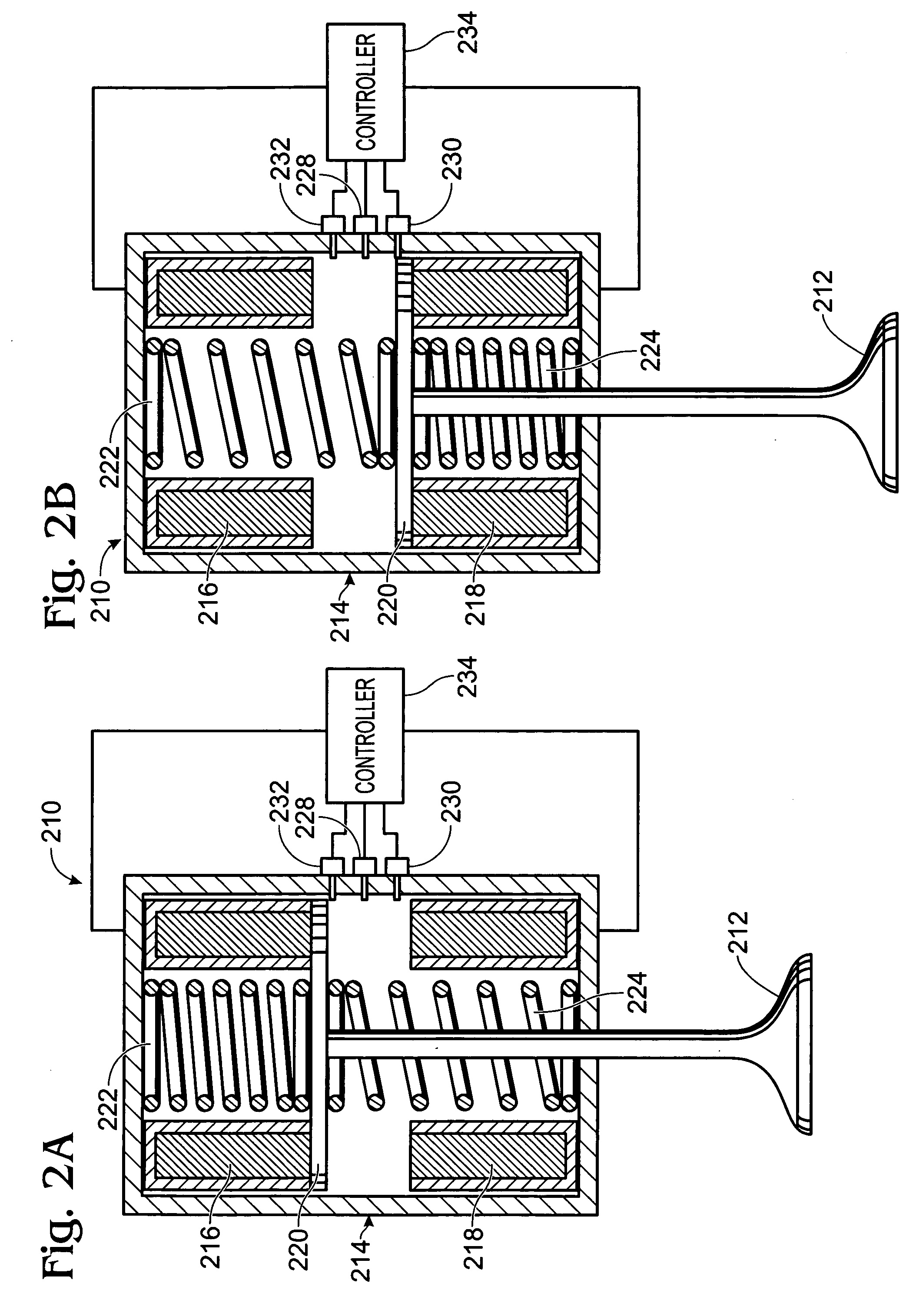

Power generating system

ActiveUS20070158946A1Reduce lateral movementControl moreCombustion enginesGaseous engine fuelsCircular discEngineering

This invention overcomes the disadvantages of the prior art by providing a power generating system particularly suitable for field use in remote locations, which is fuel-efficient, relatively quiet, tolerant of dust, capable of operating on low grade logistics and diesel-like fuels and capable of generating between 500 W and 2 KW of continuous electrical power. This generator employs a miniature internal combustion engine / generator (MICE) having a piston moving within a cylinder arranged for two-cycle operation, and an interconnected, axially arranged piston shaft that oscillates an alternator coil within a magnetic core. The piston shaft is opposed by a strong, multiple-helix spring. The cylinder head, in which the piston operates, is cooled by moving (electrically pumped) fluid in a cooling head, or by another heat-transfer mechanism. The MICE generator's intake arrangement includes a preheater heated by a heated fluid flow thereon. The MICE generator is vibration-isolated using a base that supports the MICE on a plurality of soft coil springs. The MICE generator is encased in an acoustic enclosure having a shell composed of sheet metal or another stiff material extending from the base plate and being covered by a top side. Holes in the enclosure top are covered by porous discs that allow exhaust gasses from the internal muffler to pass therethrough. The acoustic enclosure resides in a large, typically portable, external package enclosure.

Owner:AERODYNE RES

High efficiency low-pollution engine

InactiveUS6026568AEliminate needCasingsInternal combustion piston enginesExternal combustion engineCylinder head

An internal combustion engine of either two-cycle or four-cycle construction including a block having at least one cylinder bore therein having sidewalls carrying a liner of a structural fiber reinforced ceramic matrix composite material disposed in sealed fiber reinforced sliding relationship within the cylinder bore, and a cylinder head sealing atop end of the cylinder bore to form a closed combustion chamber in combination with the piston. The cylinder head also has the structural fiber reinforced ceramic matrix composite material disposed on an inner surface thereof facing the combustion chamber. The preferred engine is a two-cycle engine having an externally scavenged intake system and an oil sump lubricating system thereby eliminating the need to separately mix or inject lubricating oil. Higher operating temperatures and closer tolerances allow higher fuel efficiency and less pollutant production. A preferred structural fiber reinforced ceramic matrix composite material and the method of making same is also disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

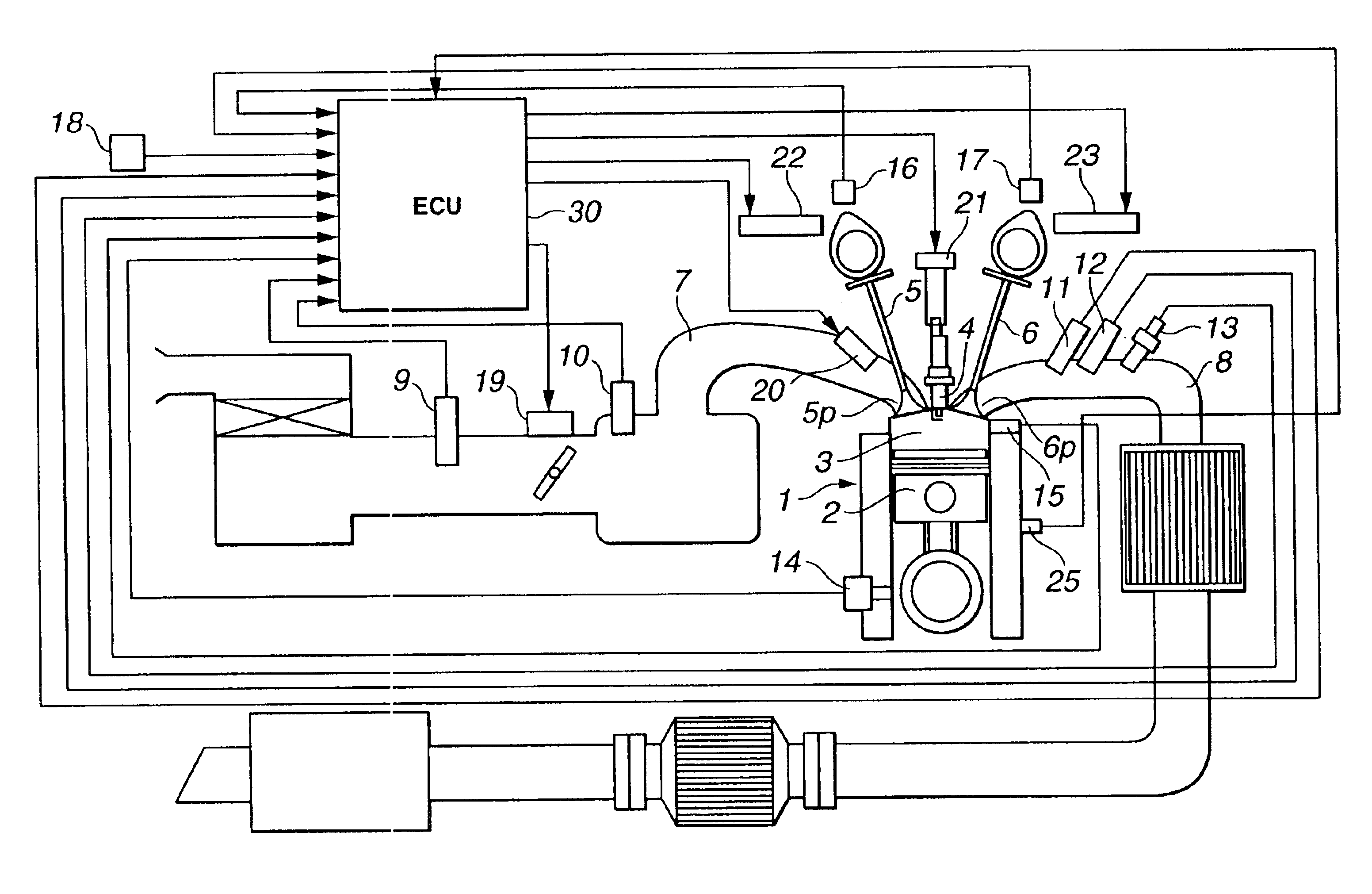

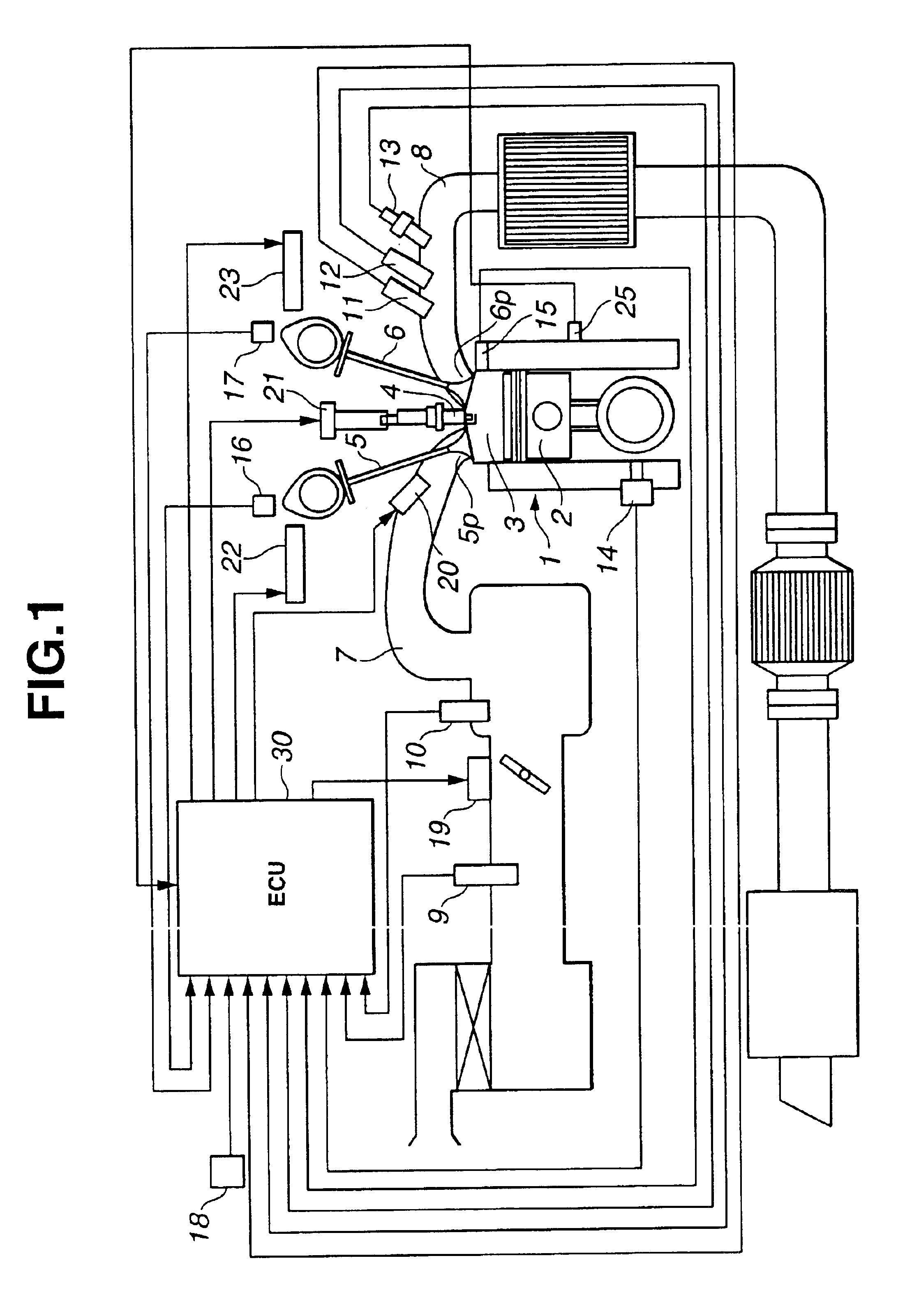

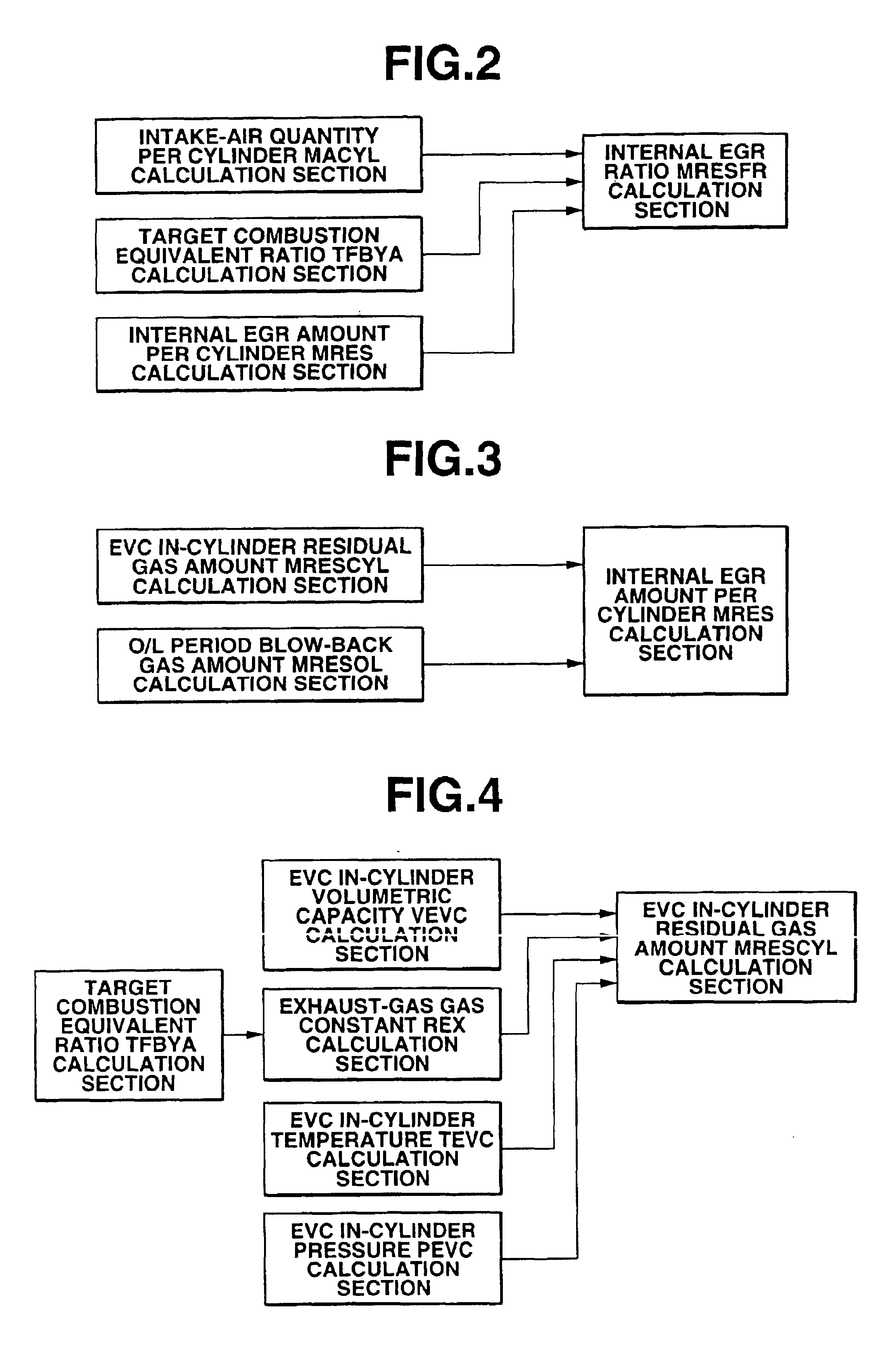

Internal exhaust gas recirculation amount estimation system of internal combustion engines

ActiveUS6840235B2Accurate estimateThe right amountValve arrangementsElectrical controlExhaust fumesGas constant

An internal exhaust gas recirculation amount estimation system calculates an in-cylinder temperature at an exhaust valve closure timing, an in-cylinder pressure at the exhaust valve closure timing, and a gas constant corresponding to a change in a composition of exhaust gas, based on an air-fuel mixture ratio. An exhaust valve closure timing in-cylinder residual gas amount is calculated based on at least the in-cylinder temperature, the in-cylinder pressure, and the gas constant. Also calculated is a valve overlap period blow-back gas amount, which is defined as a quantity of gas flow from one of intake and exhaust ports via a combustion chamber to the other port during a valve overlap period. An internal exhaust gas recirculation amount is calculated based on the exhaust valve closure timing in-cylinder residual gas amount and the valve overlap period blow-back gas amount.

Owner:NISSAN MOTOR CO LTD

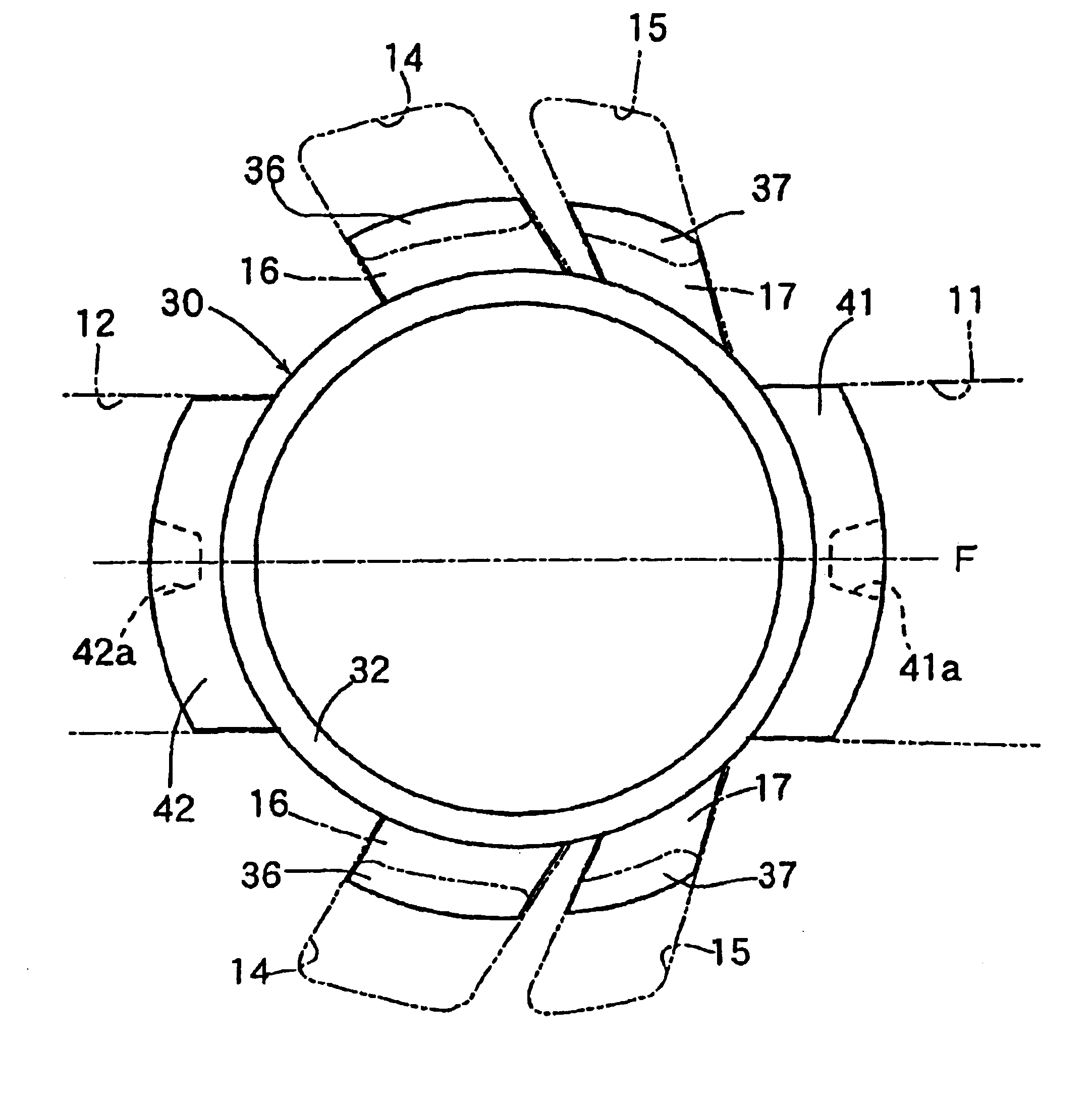

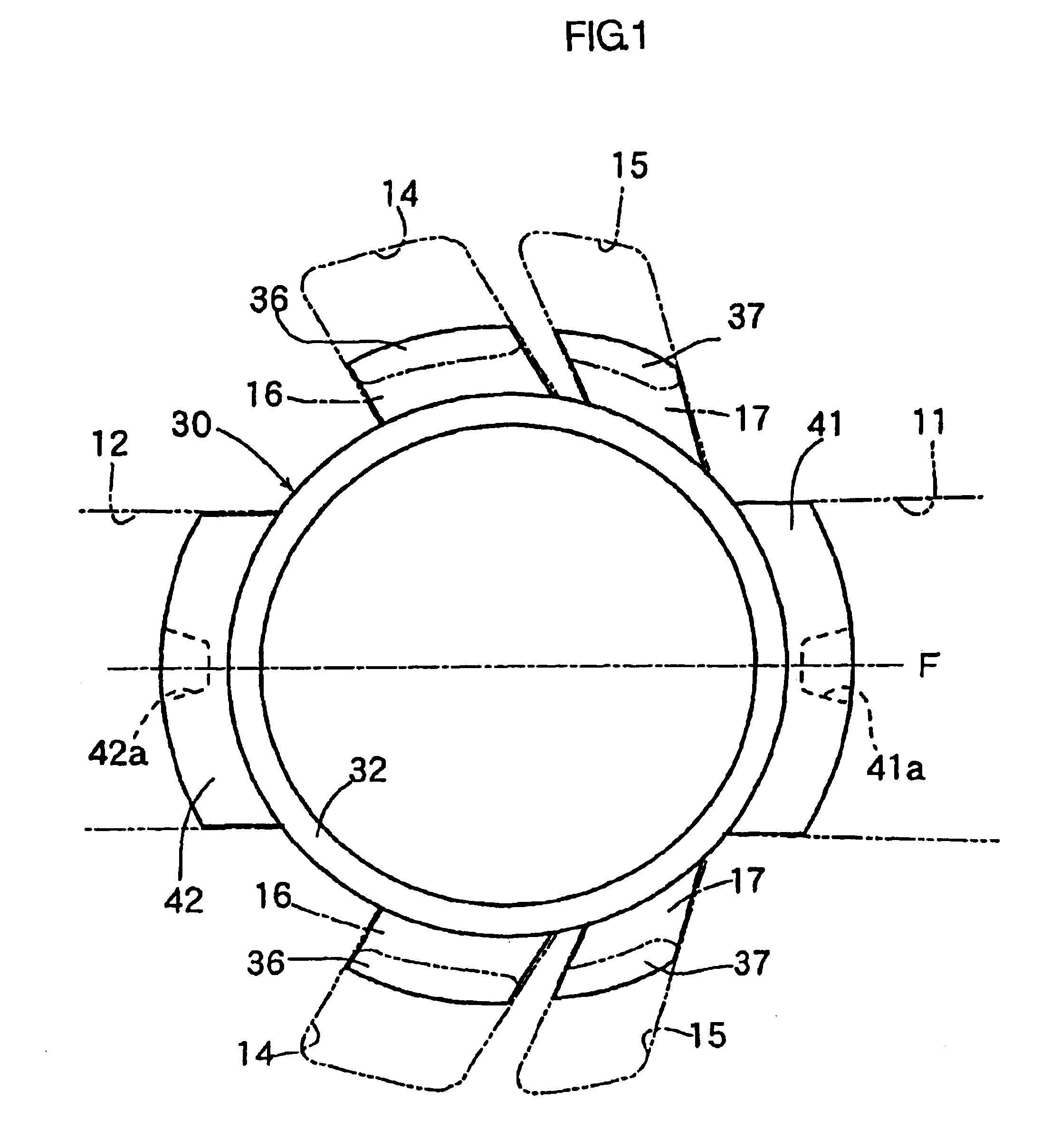

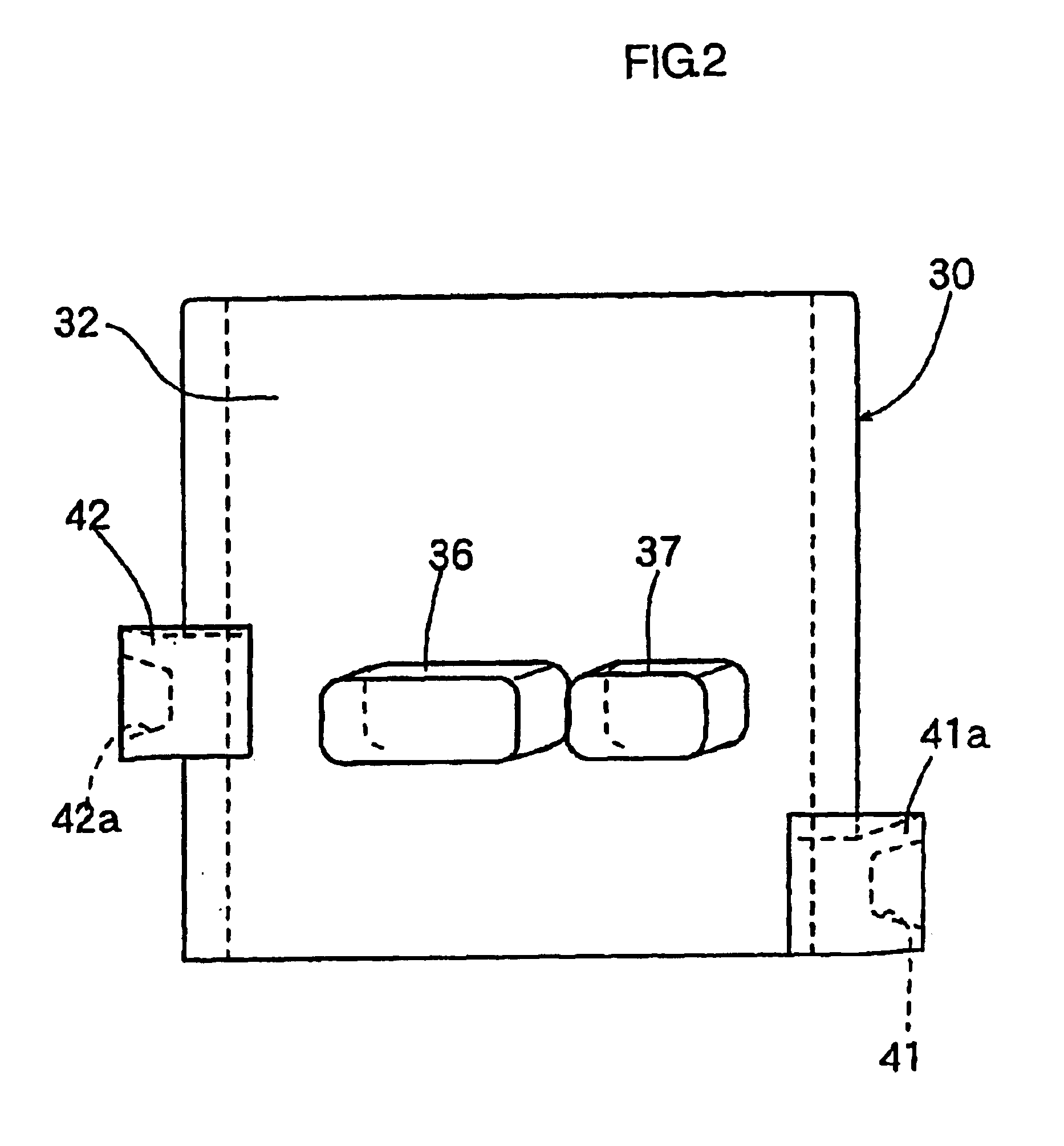

Insert core and method for manufacturing a cylinder for internal combustion engine by making use of the insert core

There is provided a method for manufacturing a cylinder for an internal combustion engine by making use of an insert core, which makes it possible to manufacture the cylinder by a die casting method such as a high-pressure die casting method at low cost and in high accuracy. The insert core to be employed herein includes: a cylindrical body having substantially the same outer diameter as the diameter of bore of the cylinder to be obtained; a scavenging port-forming portion projecting radially outward from the cylindrical body and having substantially the same cross-sectional configuration as that of the scavenging port; a suction port-forming portion projecting radially outward from the cylindrical body and having substantially the same cross-sectional configuration as that of at least the cylinder bore-side end portion of a suction port; and an exhaust port-forming portion projecting radially outward from the cylindrical body and having substantially the same cross-sectional configuration as that of at least the cylinder bore-side end portion of an exhaust port.

Owner:KIORITZ

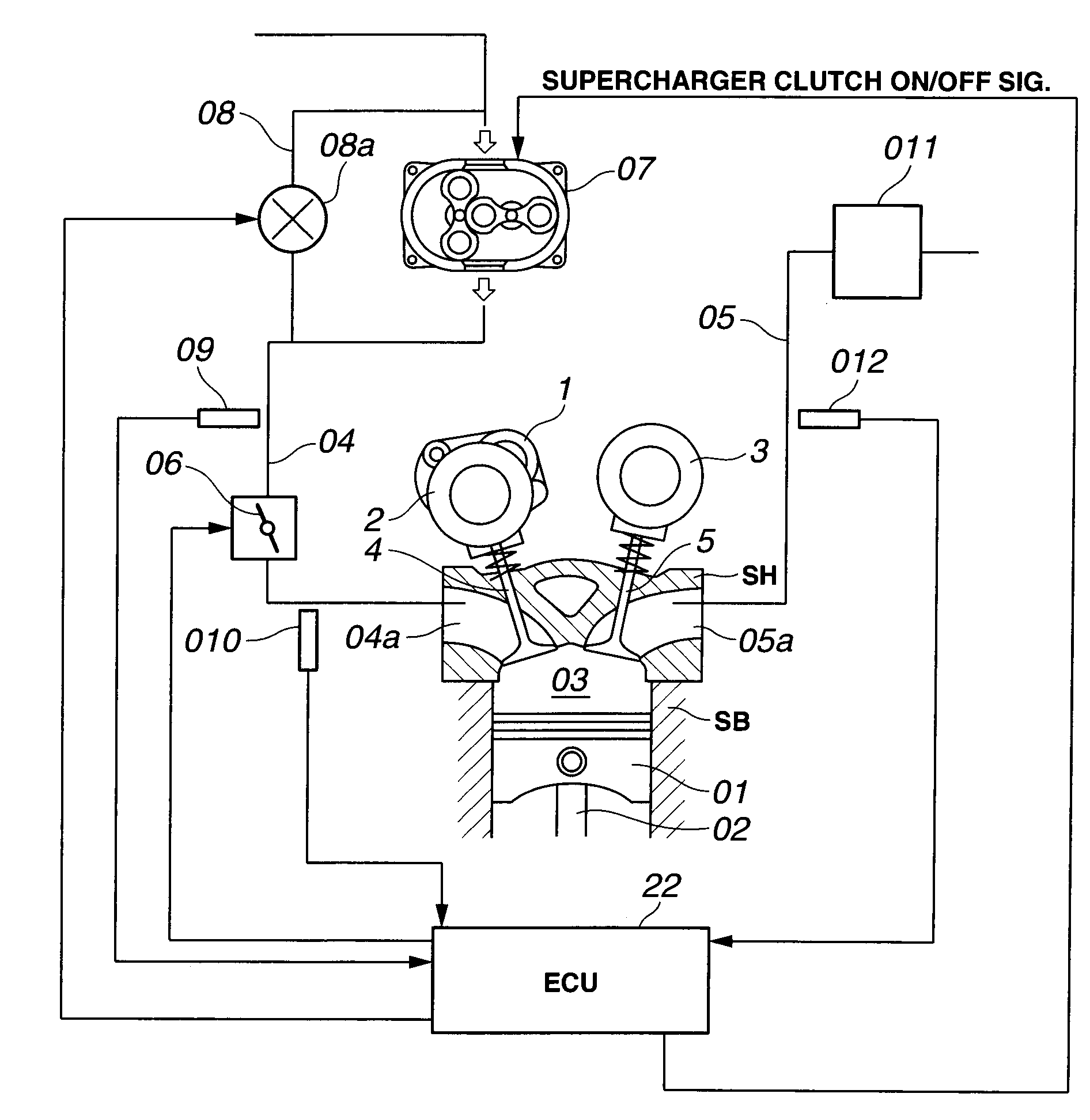

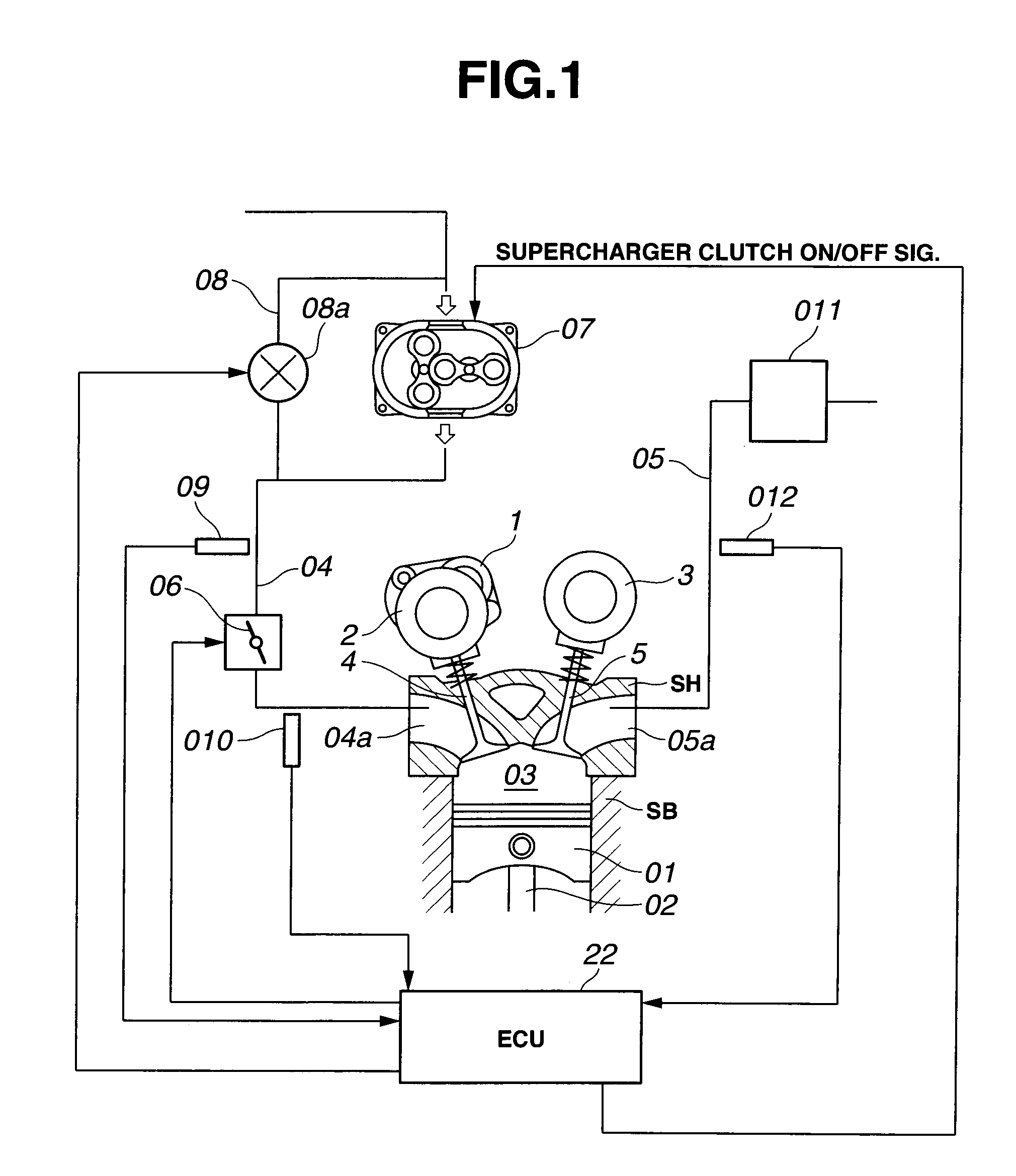

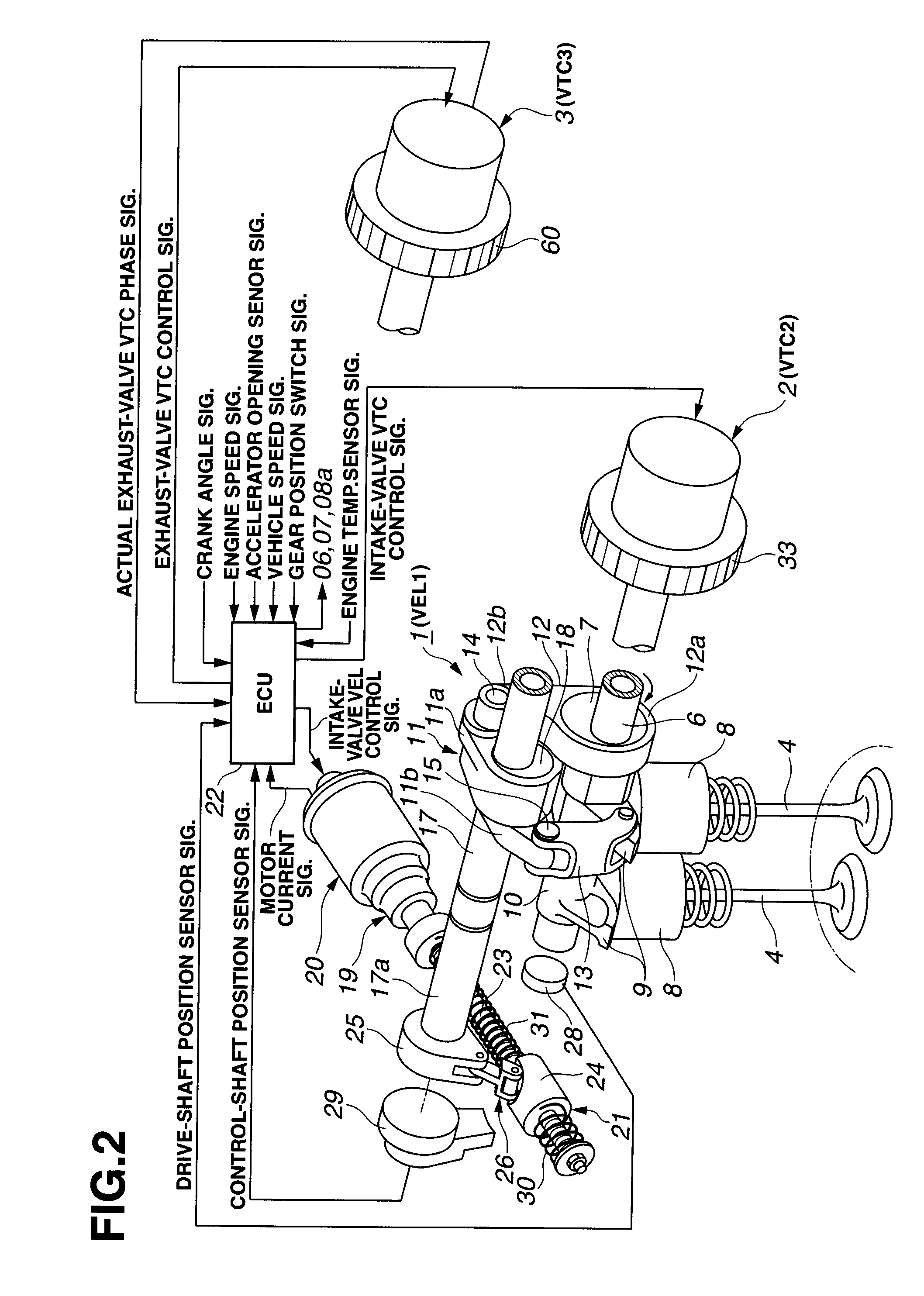

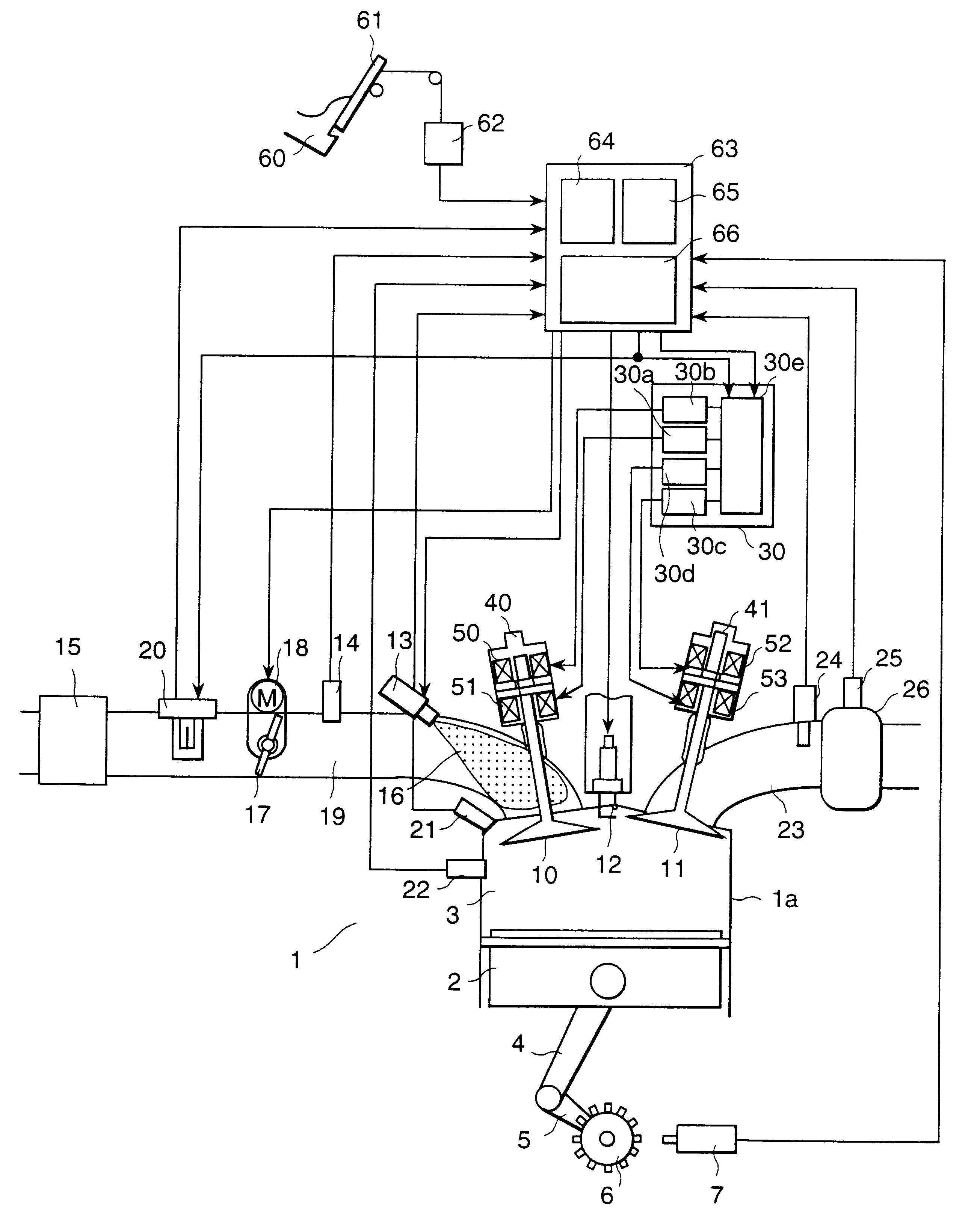

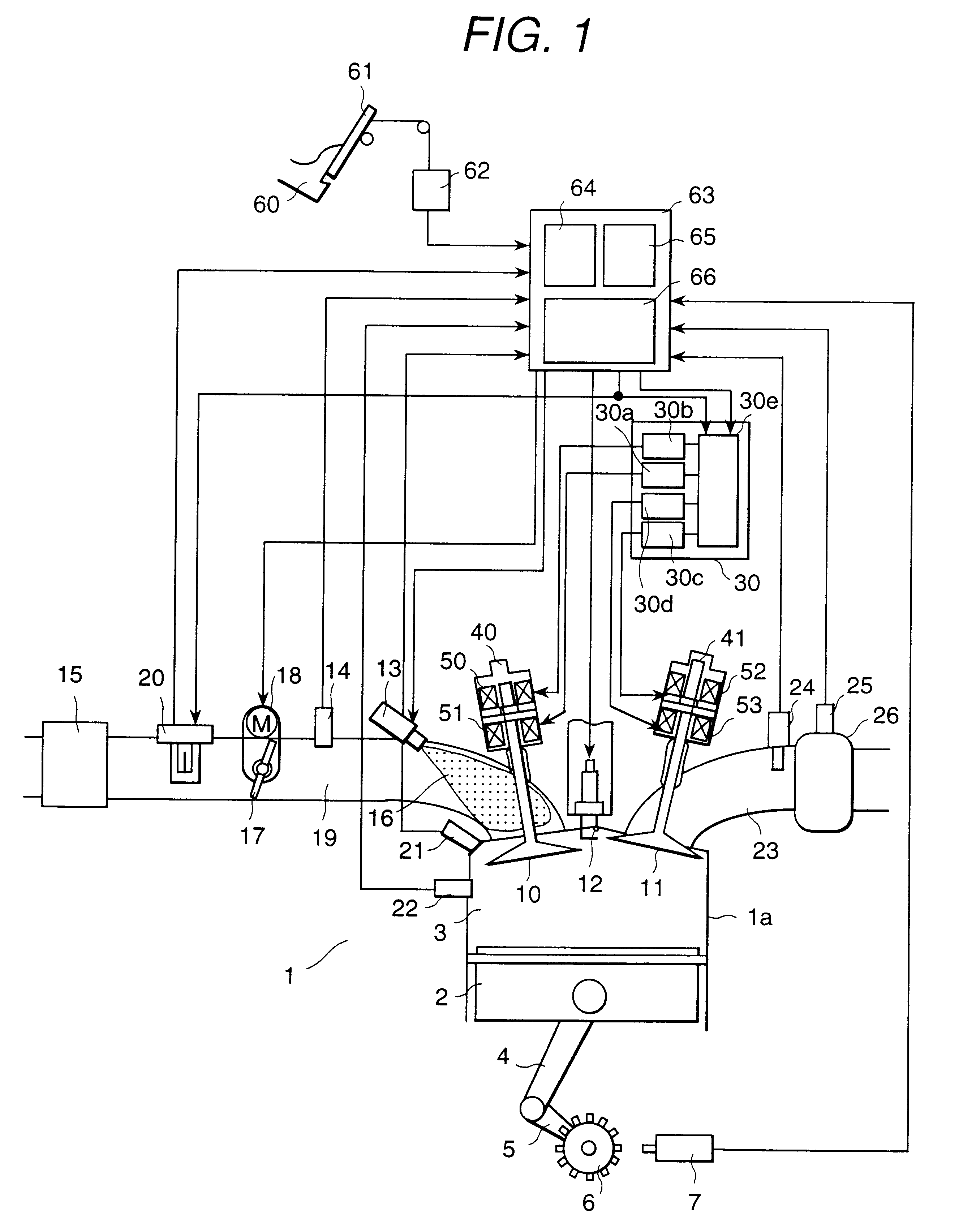

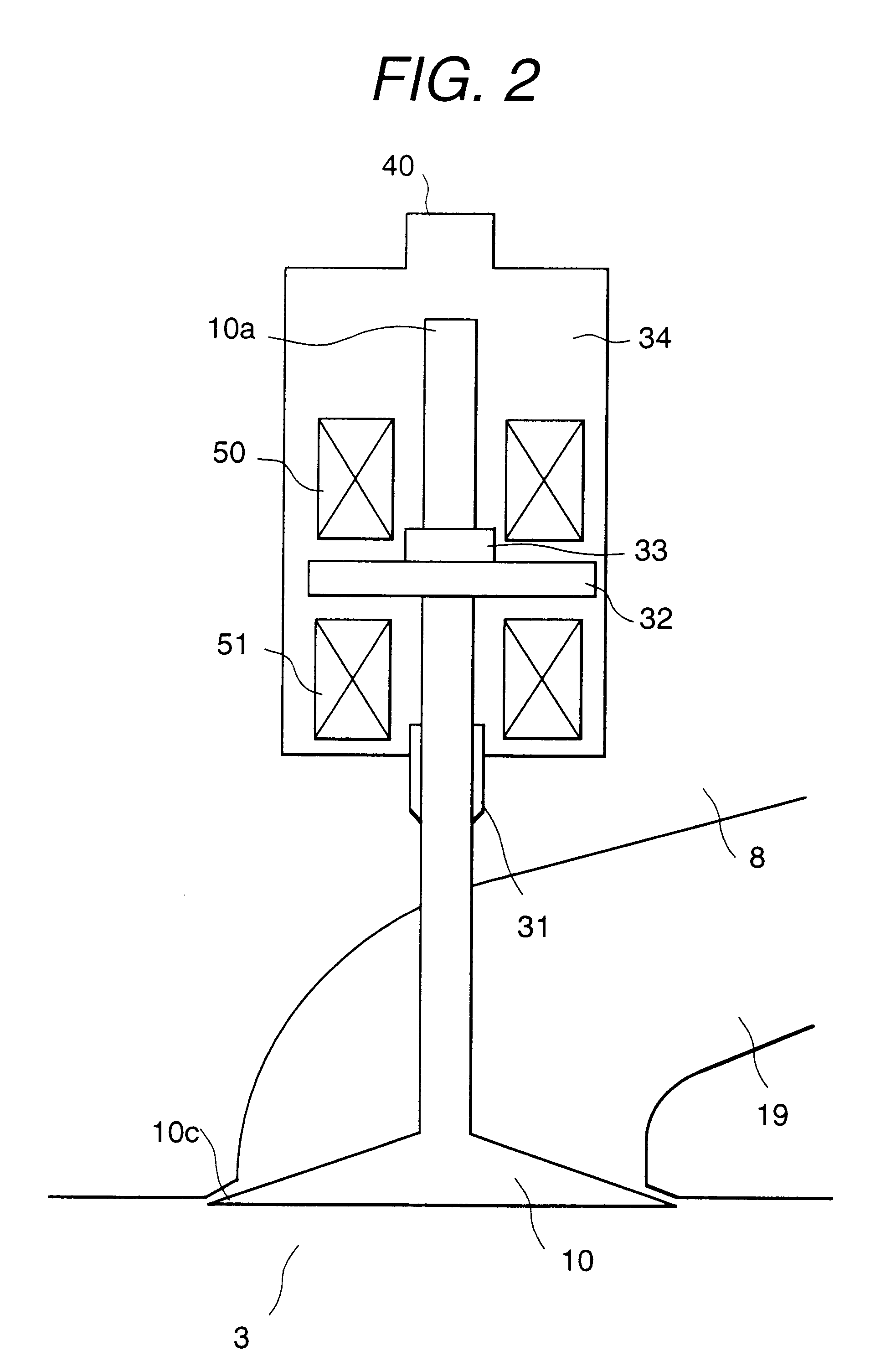

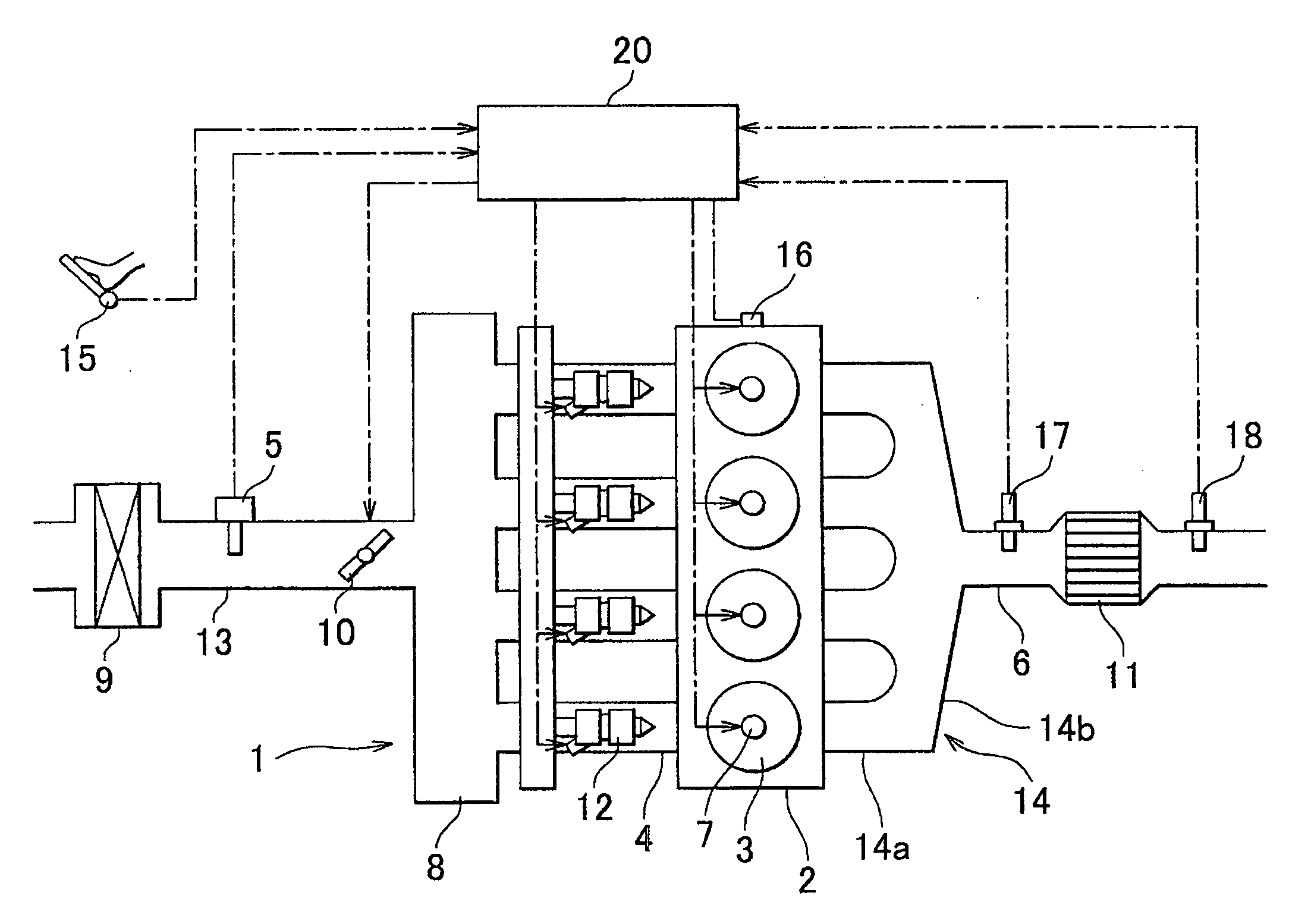

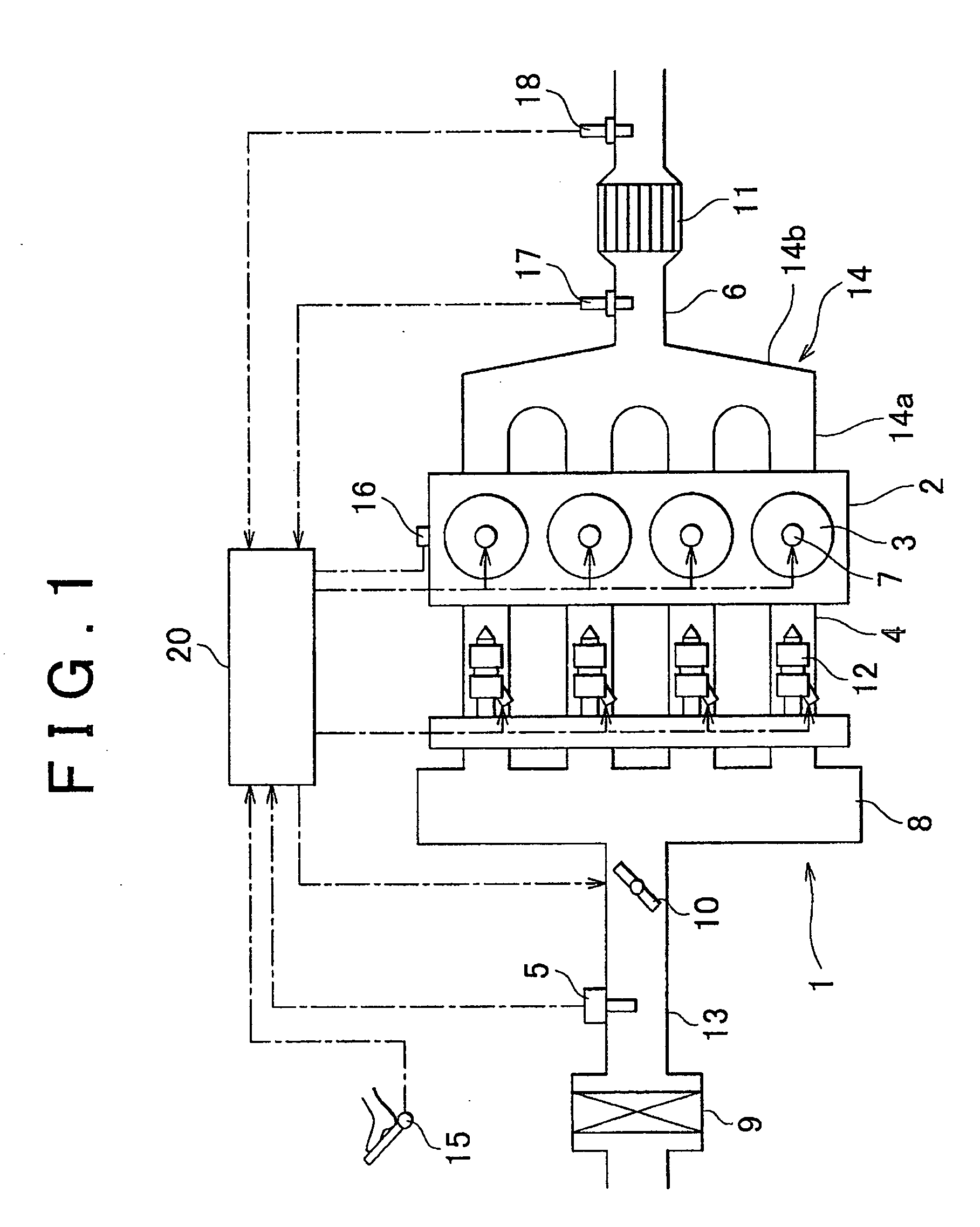

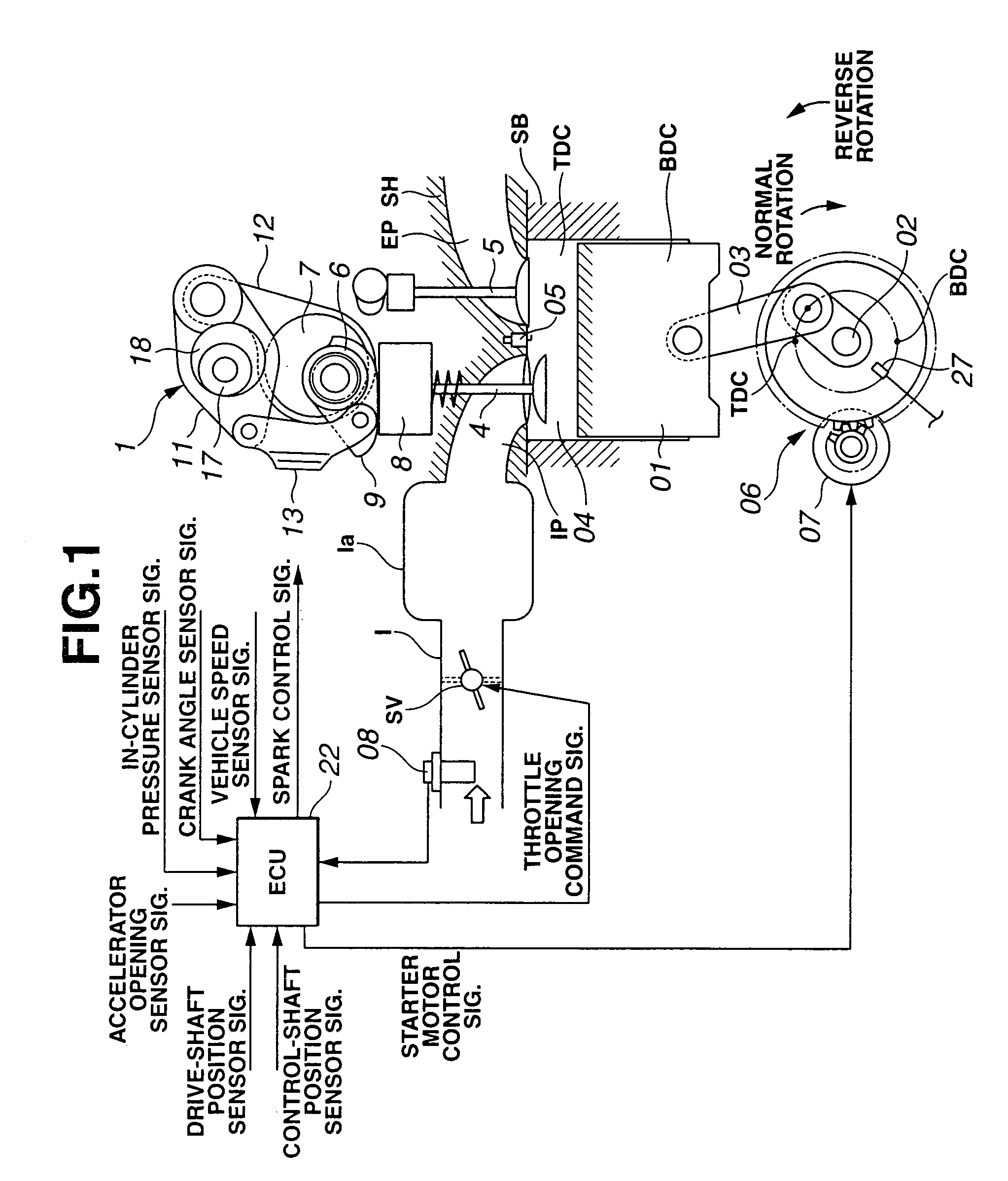

Variable valve actuation system of internal combustion engine and control apparatus of internal combustion engine

ActiveUS20090228187A1Improve responsivenessEngine-torque-increase responsivenessAnalogue computers for vehiclesValve arrangementsExhaust valvePhase shifted

In a control apparatus of a supercharged internal combustion engine, a variable valve actuation system interacts with an engine control system. A controller is configured or programmed to increase an intake-valve lift by a variable valve lift mechanism, which is provided for variably controlling at least the intake-valve lift of engine valves, when starting from a vehicle stand-still state or when accelerating from an idling state or a light load state. The controller is further configured or programmed to increase a valve overlap of intake and exhaust valves by a variable phase control mechanism, which is provided for variably phase-shifting a central phase angle of a valve lift characteristic curve of at least one of the intake and exhaust valves, while increasing a boost pressure of intake air introduced into an engine cylinder by a supercharging device, after the intake-valve lift has been increased.

Owner:HITACHI ASTEMO LTD

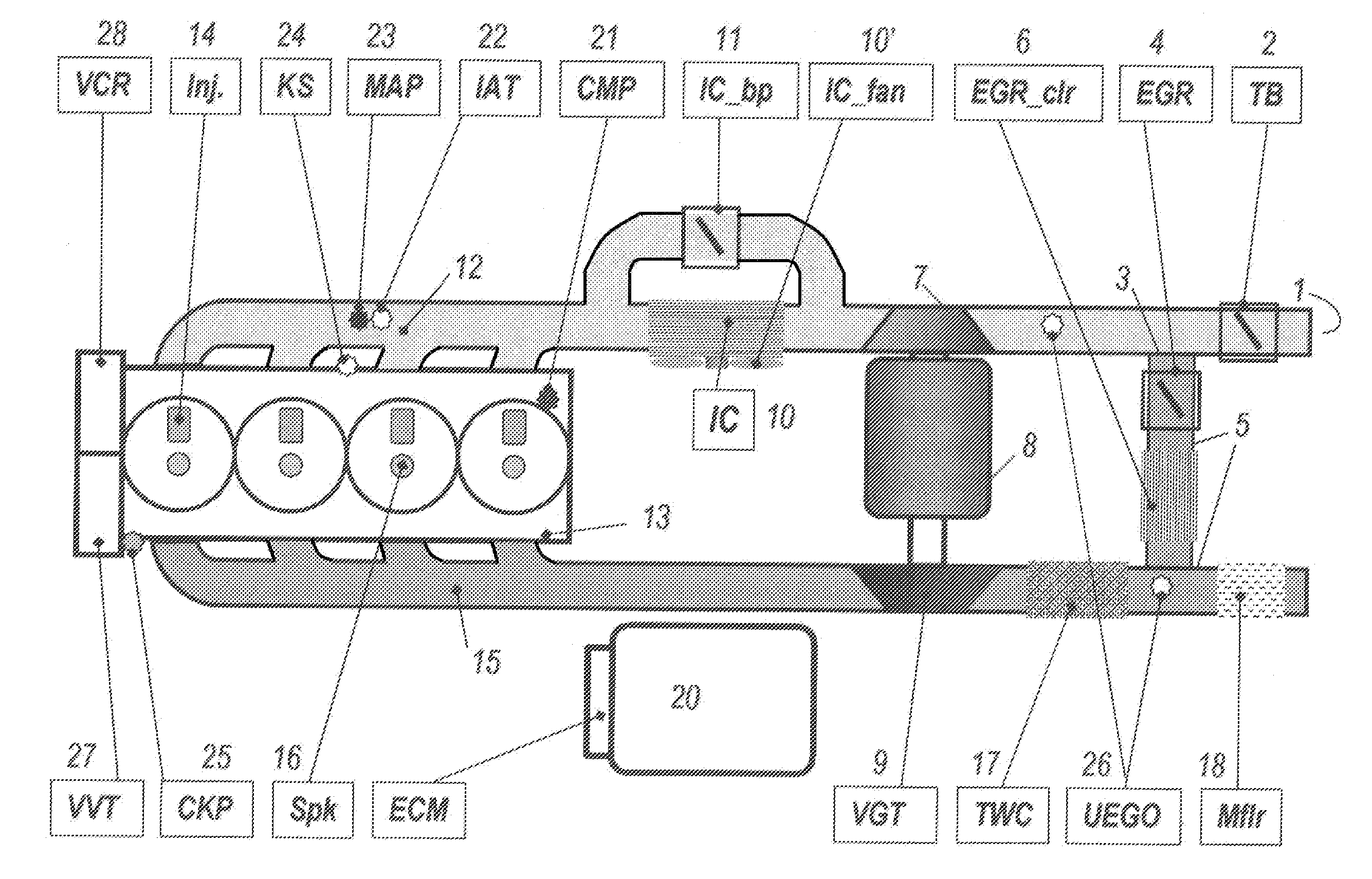

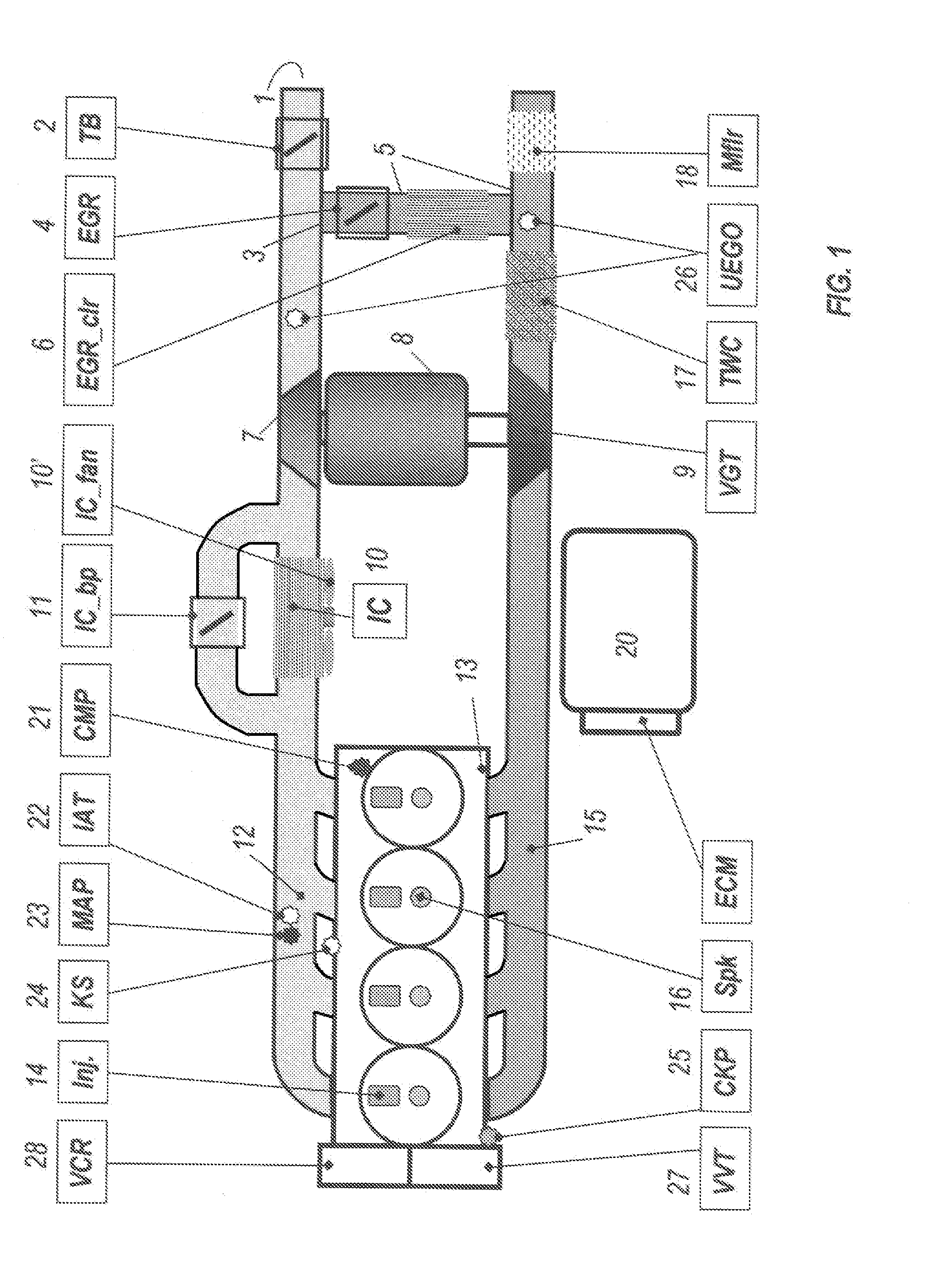

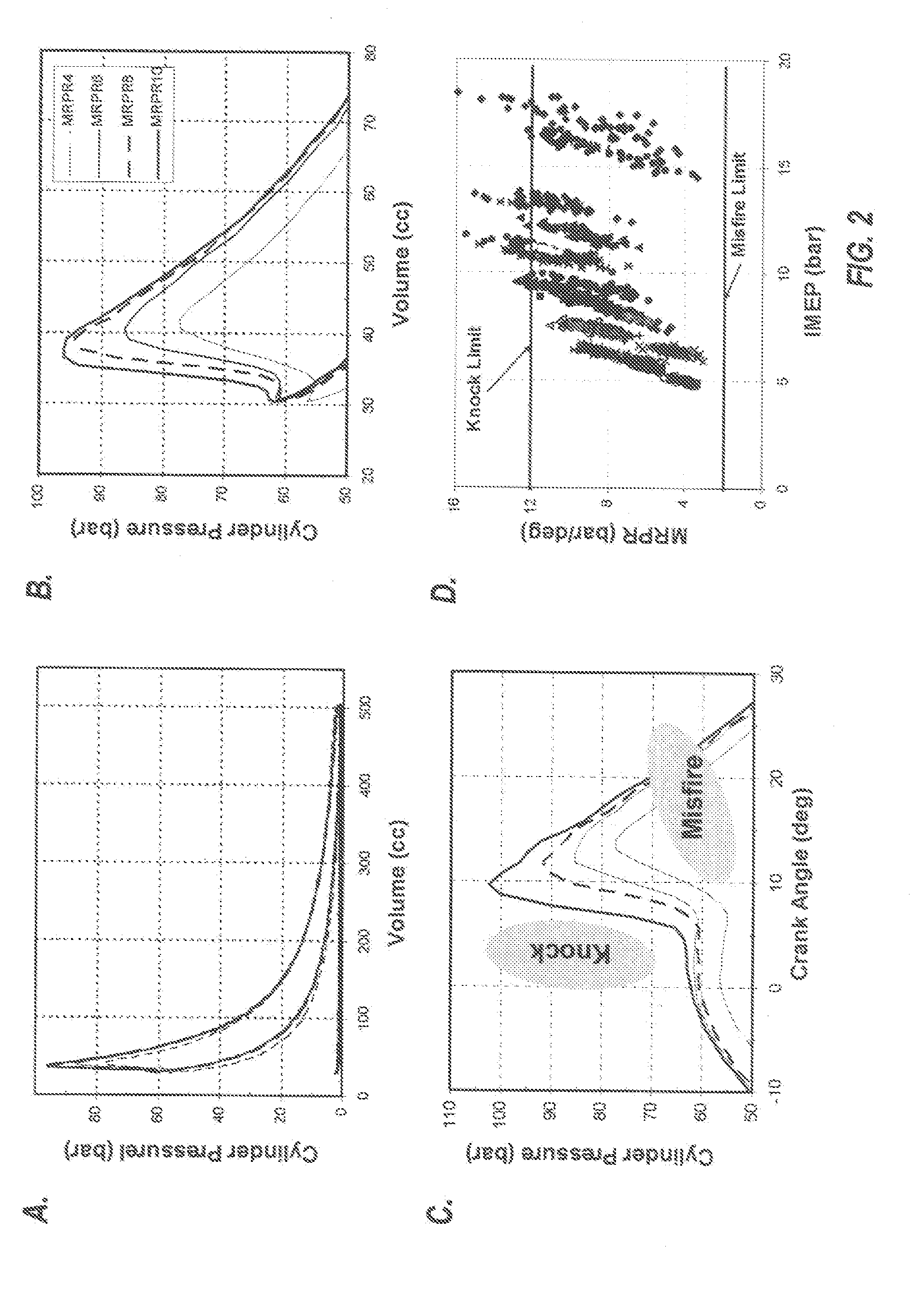

Method and system of transient control for homogeneous charge compression ignition (HCCI) engines

InactiveUS20100031924A1Reduce computing loadRobust engine controlElectrical controlInternal combustion piston enginesApplying knowledgeHcci combustion

A HCCI engine with a model reference adaptive feedback control system maintains stable HCCI combustion during speed / load transitions by: (1) estimating the maximum rate of pressure rise (MRPR), for each cycle, from an extra-cylinder sensor metric, such as a crankshaft dynamics or knock sensor metric, via statistical vector-to-vector correlation; (2) periodically self-tuning the vector-to-vector correlation; (3) applying knowledge base models to guide cycle-to-cycle adjustments of fuel quantity and other engine parameters, to maintain a target MRPR value.

Owner:U S ENVIRONMENTAL PROTECTION AGENCY UNITED STATES OF AMERICA AS REPRESENTED BY THE

Apparatus of diagnosing an internal combustion engine and a method of diagnosing of an internal combustion engine

InactiveUS6457353B1Assurance controlEnsure reliabilityElectrical controlInternal combustion piston enginesExhaust valveExternal combustion engine

By employing command value signals for controlling the opening timing of an exhaust valve or an intake valve and means for measuring flow rates of an intake air of a flow direction which flows through an intake manifold of an internal combustion engine, an air flow rate corresponding to the command value signal is measured. A valve mechanism includes the intake valve and the exhaust valve for each cylinder of the internal combustion engine and is controlled by a valve control means for controlling the valve mechanism. A failure diagnosis of an operating status of the valve mechanism can be performed.

Owner:HITACHI LTD

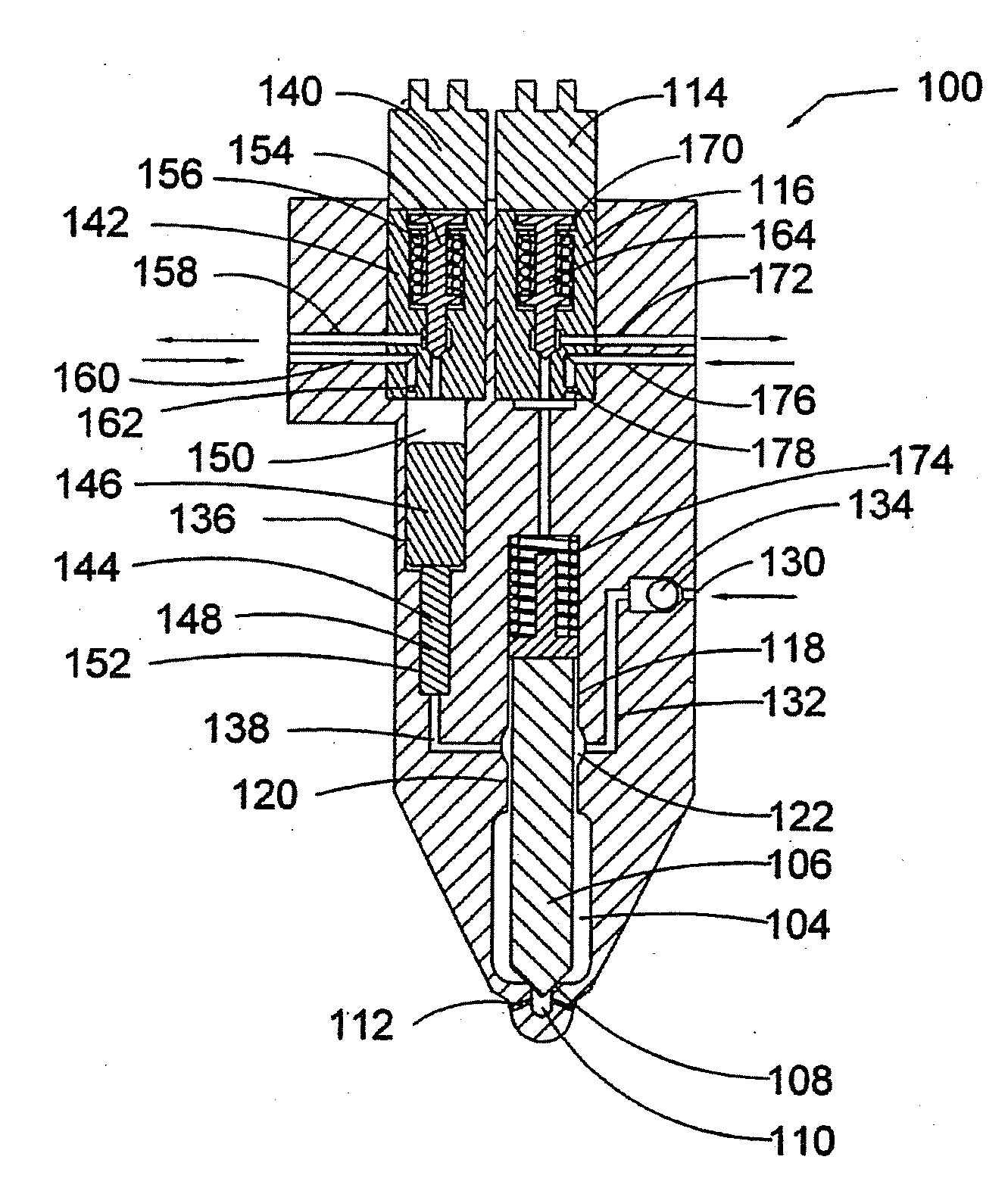

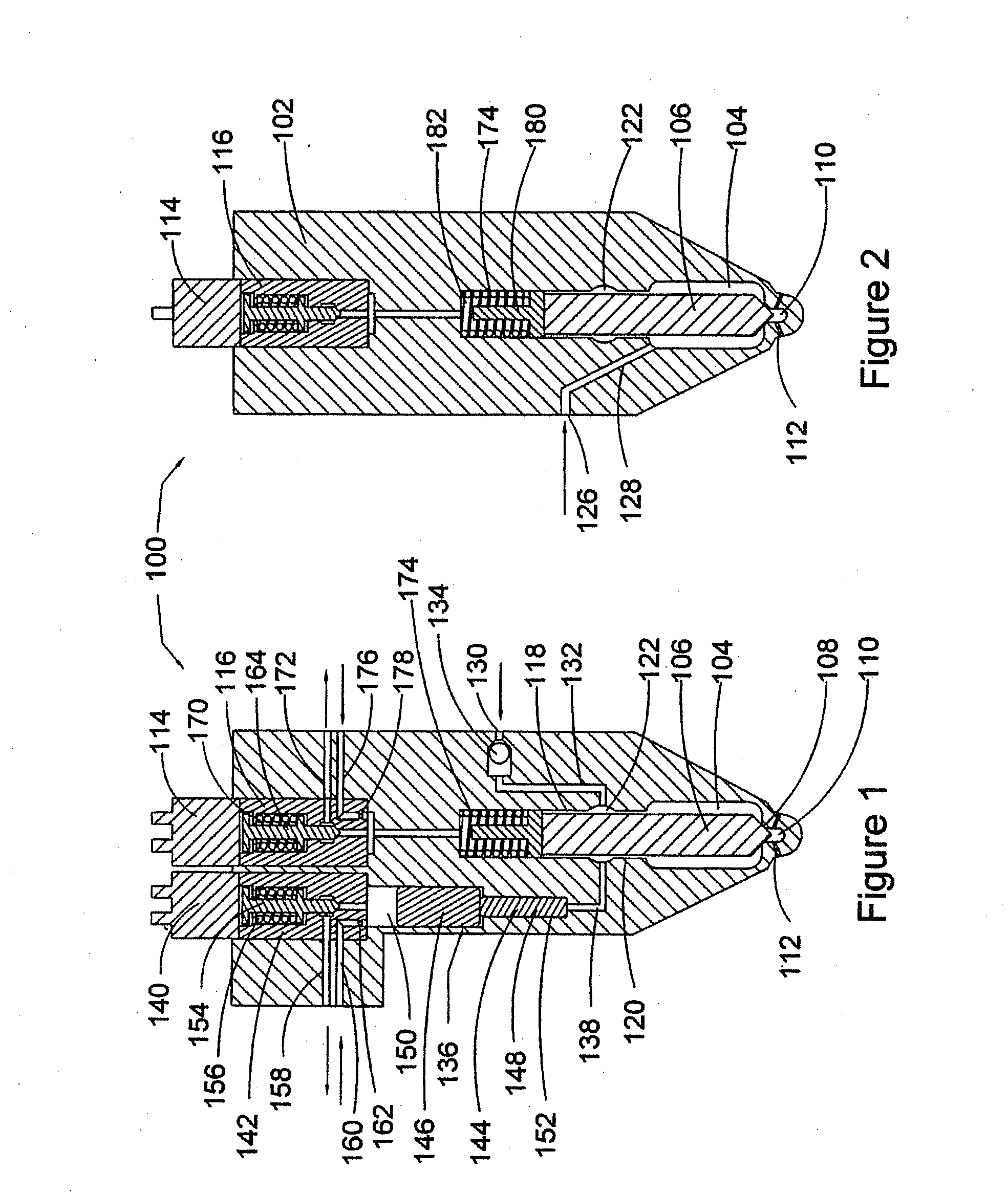

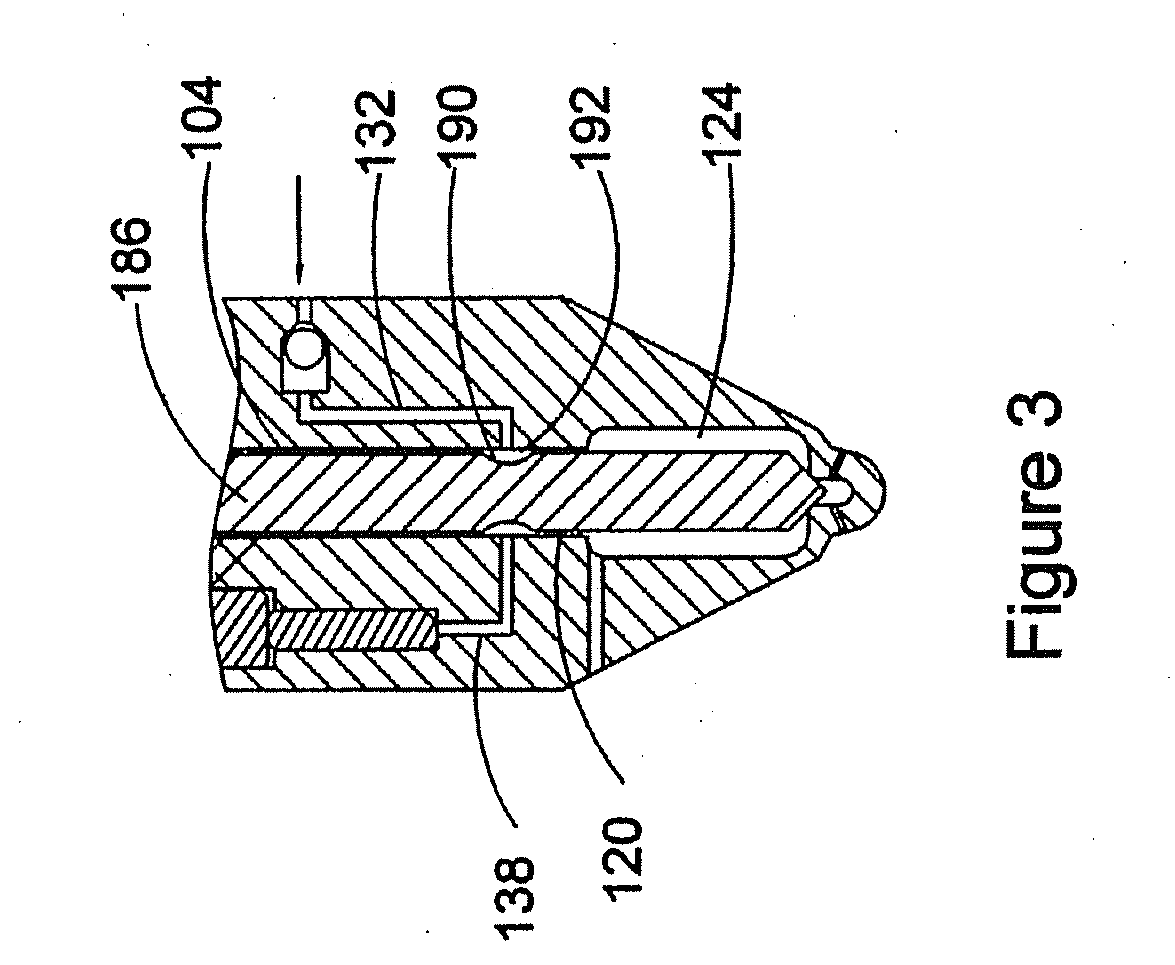

Fuel Injection Valve And Method For Co-Injecting A Liquid And A Gaseous Fuel Into The Combustion Chamber Of An Internal Combustion Engine

ActiveUS20110108631A1Prevent escapeInternal combustion piston enginesFuel supply apparatusIntensifierEngineering

A fuel injection valve co-injects a liquid and a gaseous fuel into the combustion chamber of an internal combustion engine. A solid needle regulates the injection of liquid and gaseous fuels from a cavity in the fuel injection valve into the combustion chamber when the needle is lifted to its open position. In preferred embodiments, liquid fuel is metered and pressurized in an intensifier's cylinder provided within the valve body and the liquid fuel is delivered through a restricted flow passage into the cavity where it mixes with the gaseous fuel. The restricted flow passage can be formed by a small passage formed in the valve body or an annular passage between the needle and the valve body.

Owner:WESTPORT FUEL SYST CANADA INC

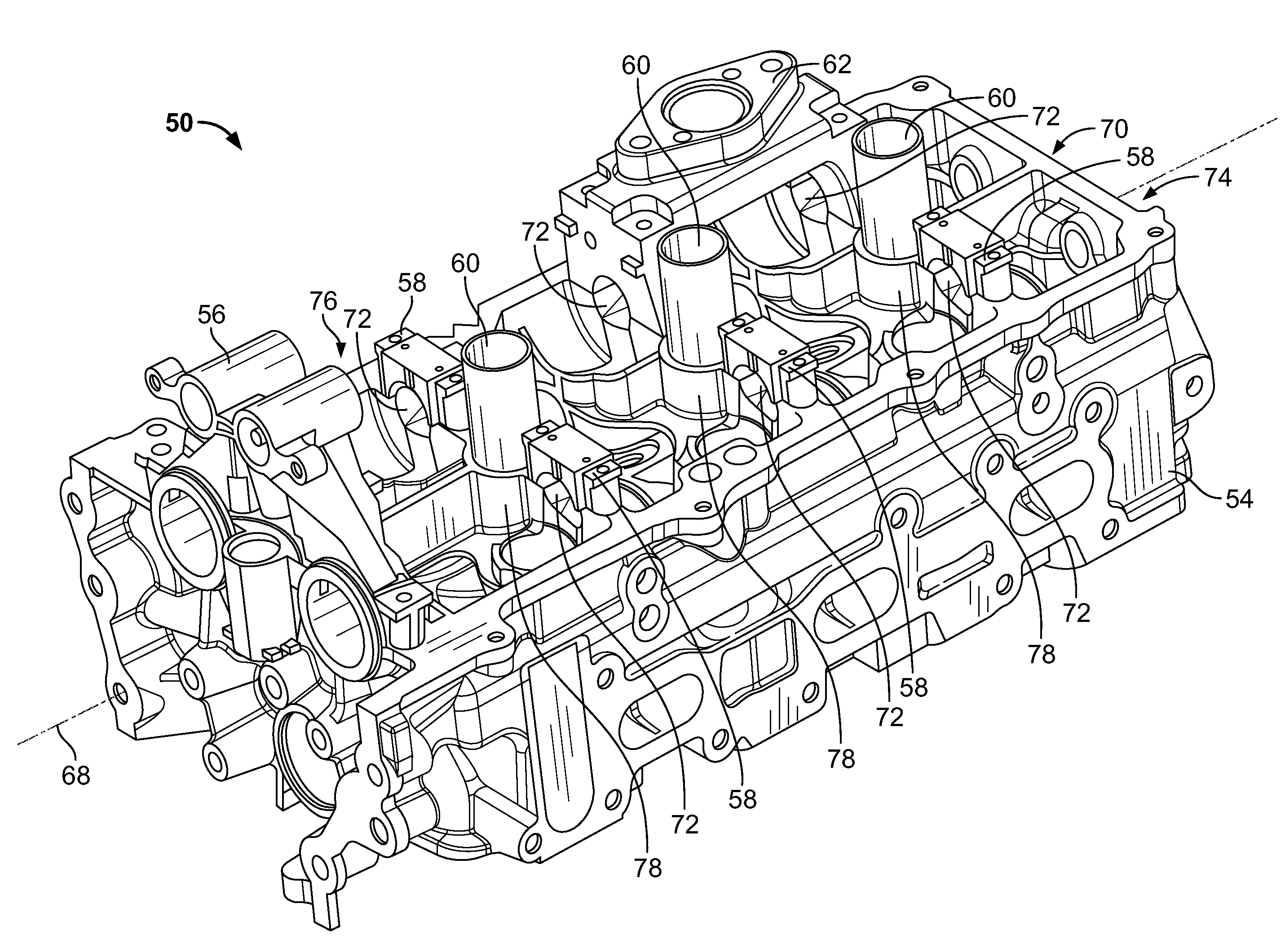

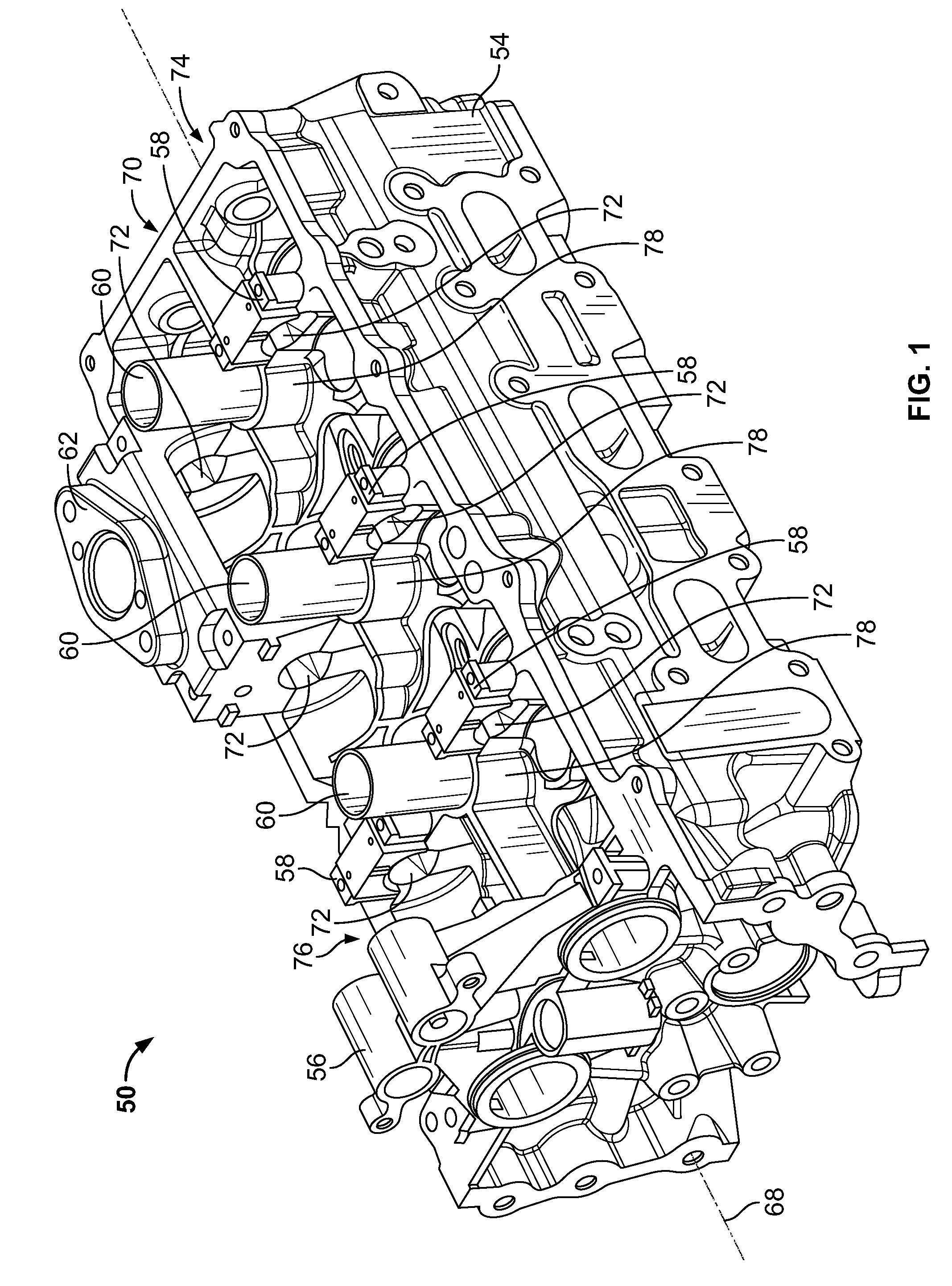

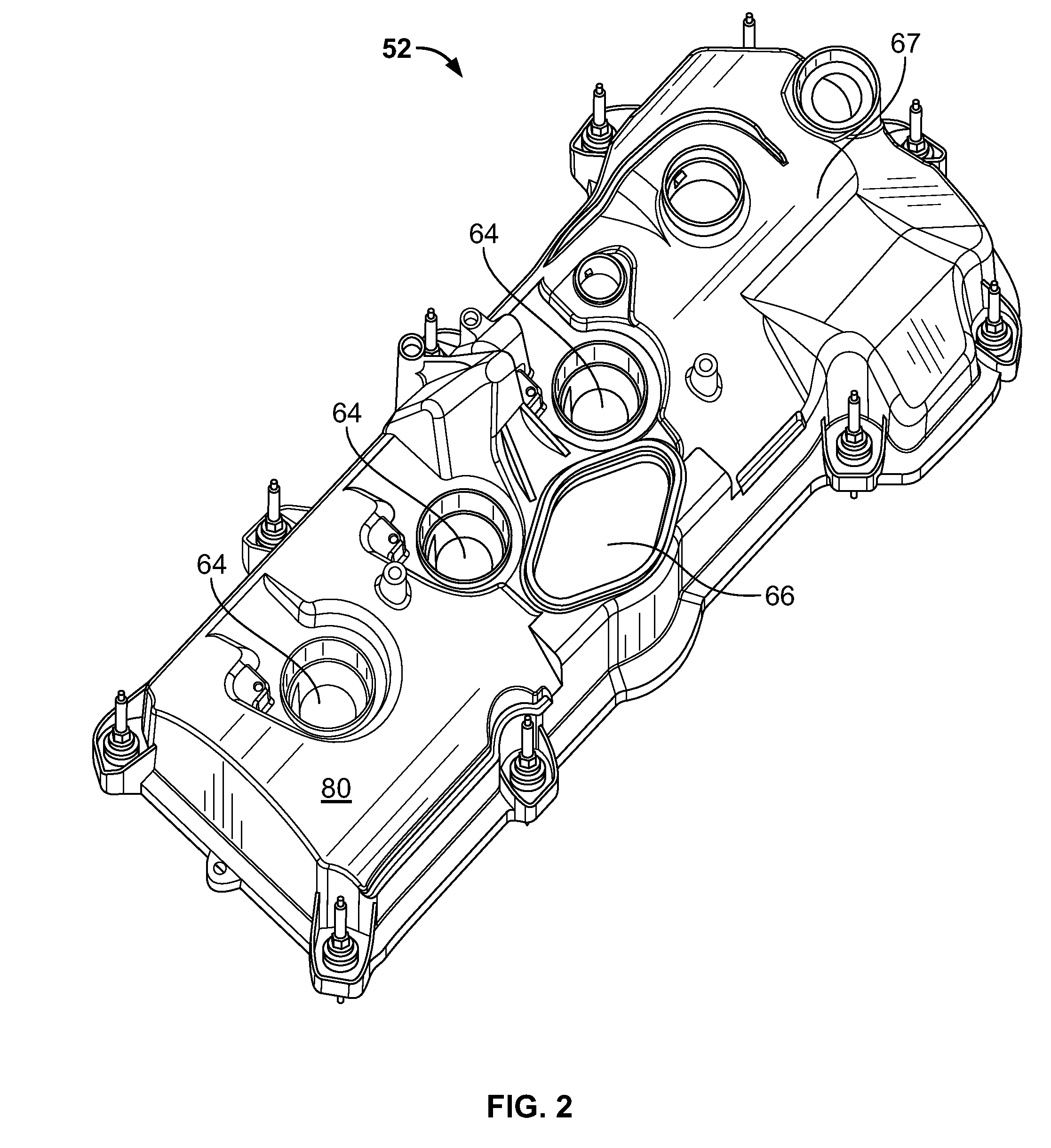

Upper cylinder head housing for use with an engine and method of making the same

An upper cylinder head (UCH) housing for use with a vehicle engine is provided. The UCH housing includes a cover body and a variable cam timing (VCT) valve body integrally formed with the cover body. The VCT valve body is configured to at least partially cover a VCT valve assembly coupled to the vehicle engine. The UCH housing further includes a plurality of cam caps integrally formed with the cover body. The plurality of cam caps is configured to receive at least a portion of a cam shaft for securing the cam shaft to a cylinder head.

Owner:SPARTAN LIGHT METAL PRODS

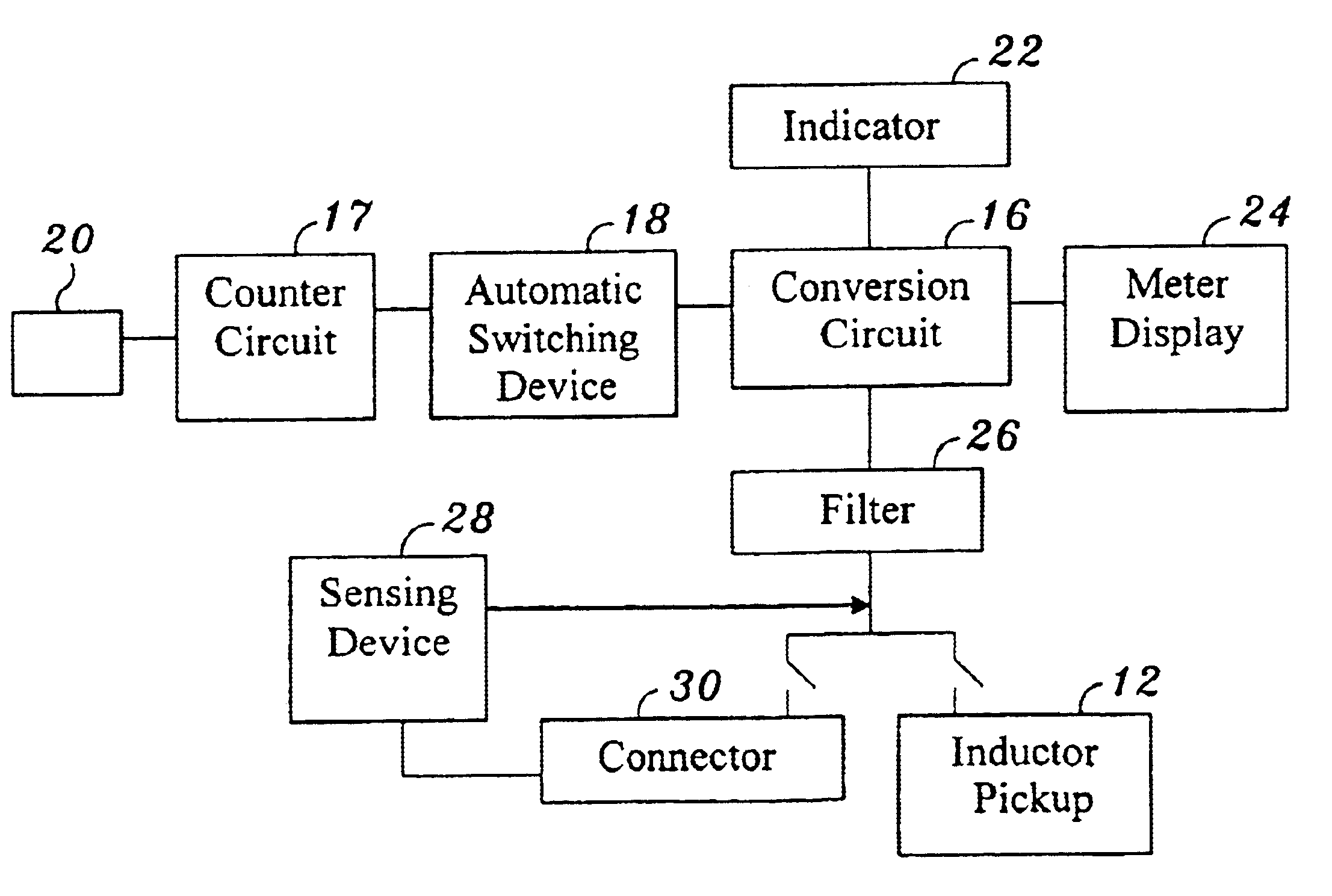

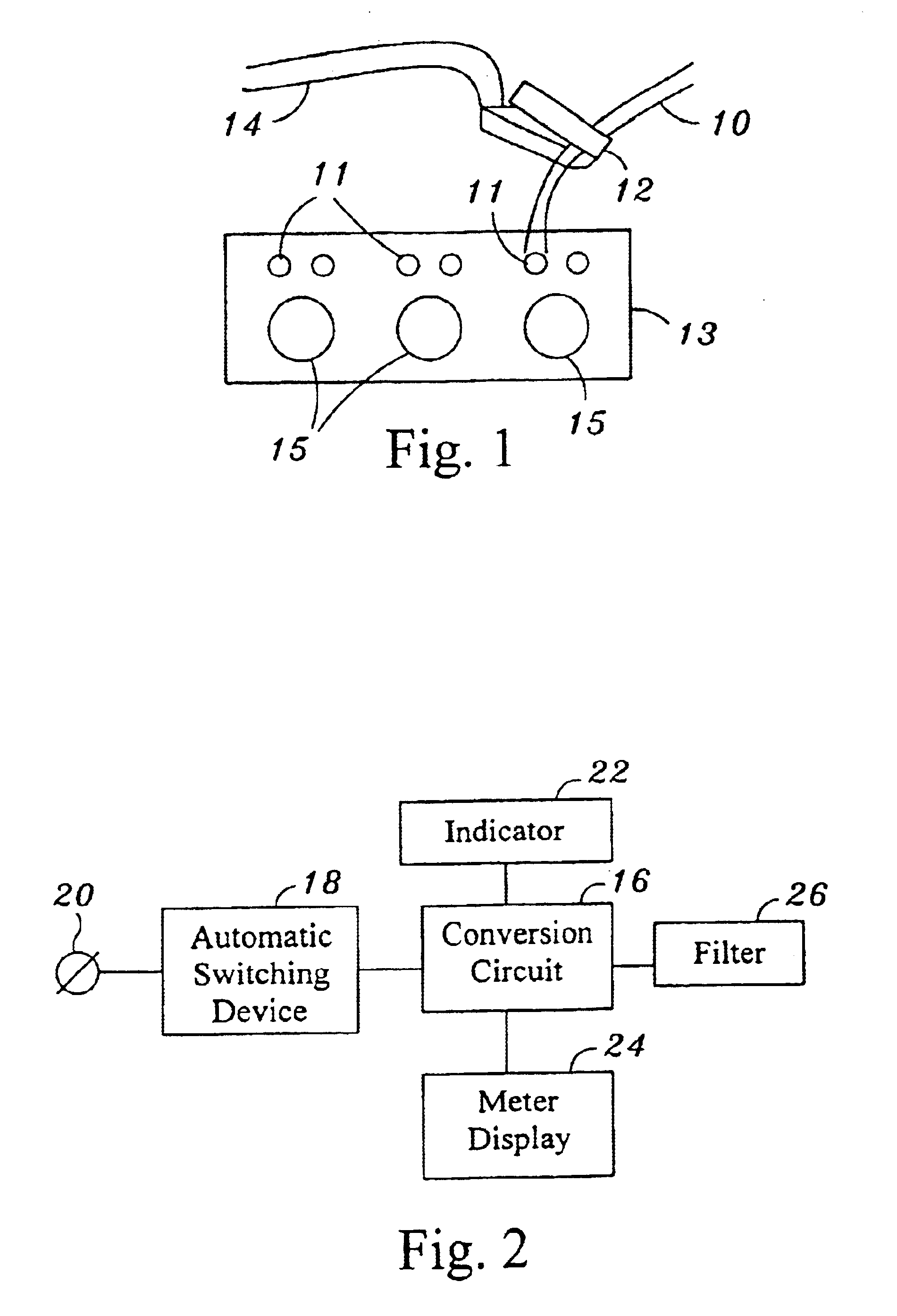

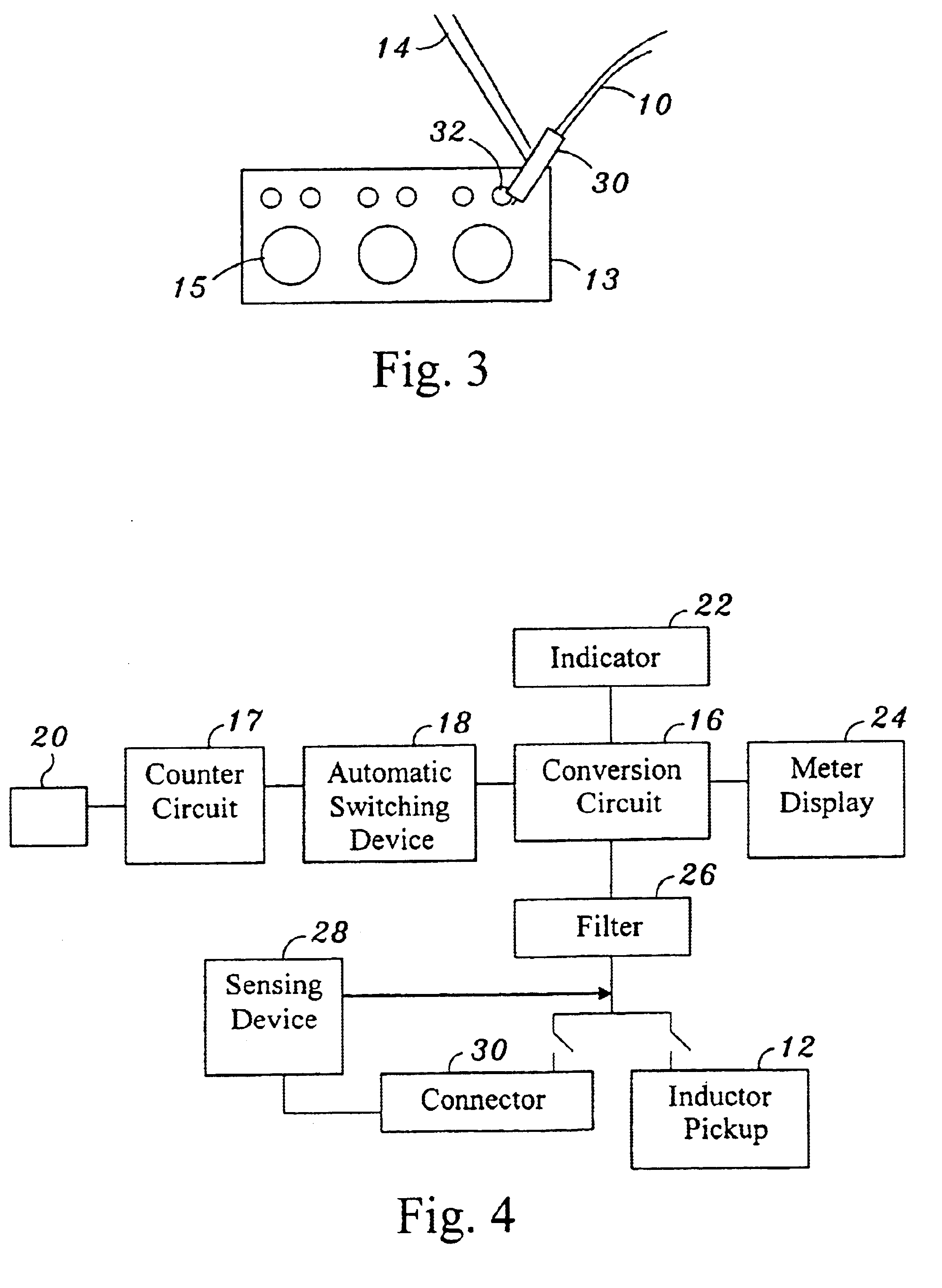

Tachometer

ActiveUS6868369B2Amplifier modifications to reduce noise influenceNuclear monitoringTachometerSpark plug

A tachometer used to measure a speed of an engine. The tachometer includes a pickup, a counter circuit, a conversion circuit, an automatic switching device, an indicator and a meter display. The inductive pickup may be disposed around a spark plug wire of the engine to generate a pulse signal in response to a current flowing through the spark plug wire. The pulse signals are then counted by the counter circuit and input to the conversion circuit therefrom. The conversion circuit typically includes a plurality of lookup tables, each having mapped information correlating the pulse signals to the engine speed for a particular number of engine cylinders. The automatic switching device is operative to call up alternate lookup tables, e.g. each time when the electrical system of the engine is turned on. The display may be display the number of engine cylinders called up by the automatic switching device and measured engine speed.

Owner:INNOVA ELECTRONICS +1

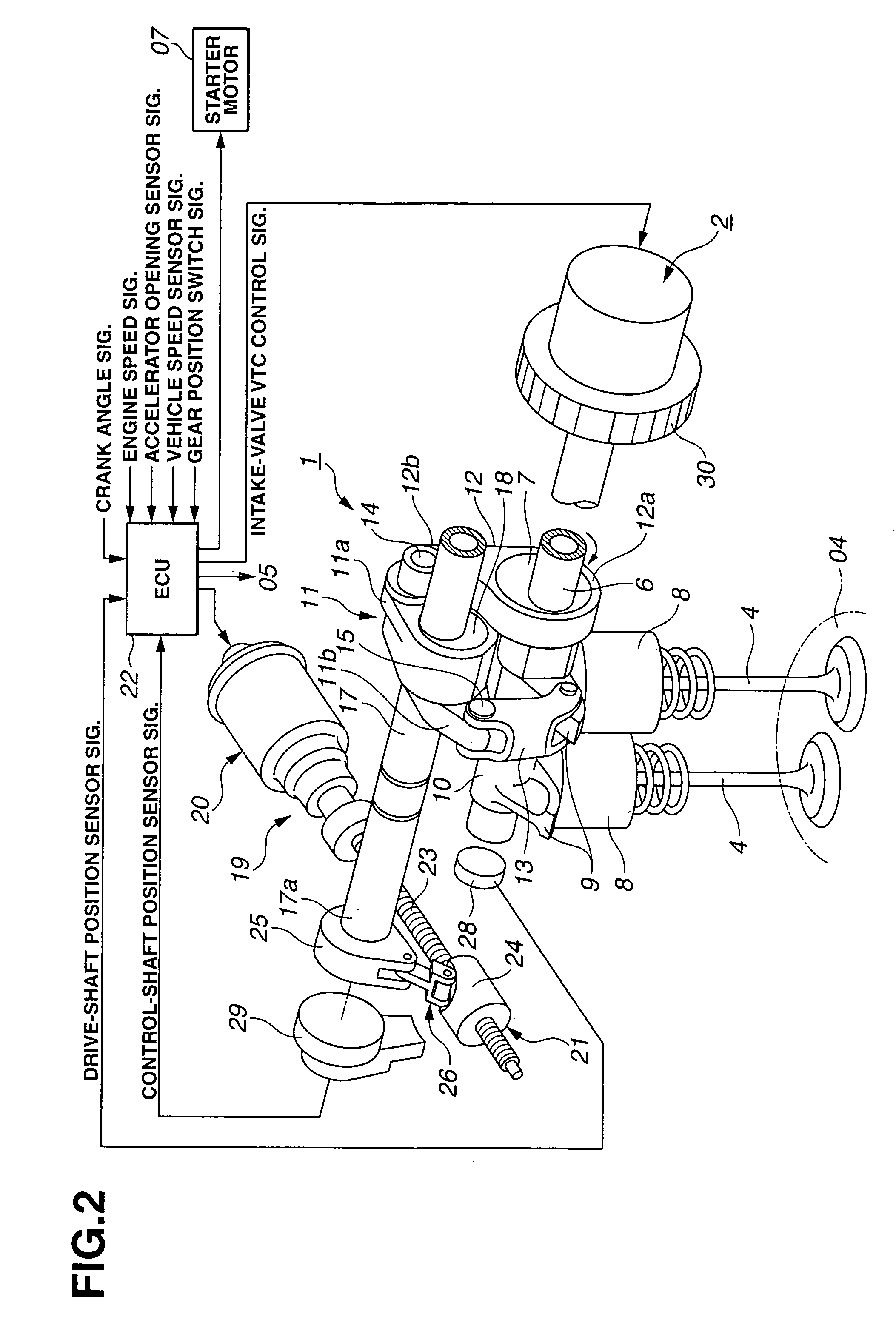

System for variable valvetrain actuation

InactiveUS20070125329A1Simple taskReduce in quantityValve drivesMachines/enginesCylinder headGasoline

An electromechanical VVA system for controlling the poppet valves in the cylinder head of an internal combustion engine. The system varies valve lift, duration, and phasing in a dependent manner for one or more banks of engine valves. A rocker subassembly for each valve or valve pair is pivotably disposed on a control shaft between the camshaft and the roller finger follower. The control shaft may be displaced about a pivot axis outside the control shaft to change the angular relationship of the rocker subassembly to the camshaft, thus changing the valve opening, closing, and lift. A plurality of control shafts for controlling all valvetrains in an engine bank defines a control shaft assembly. The angular positions of the individual control shafts may be tuned to optimize the valve timing of each cylinder. The system is applicable to the intake and exhaust camshafts of diesel and gasoline engines.

Owner:DELPHI TECH IP LTD

Four-stroke internal combustion engine with recuperator in cylinder head

InactiveUS6340013B1Prevent leakageQuick mixInternal combustion piston enginesCylinder headsThermal energyCommon Duct

A recuperating four-stroke internal combustion engine obtains improves Carnot efficiency by use of a new and novel cylinder head which captures thermal energy normally thrown away in the exhaust and re-introduces it to the working cycle. This result, long sought by others, has been achieved by incorporating within the head a compact internal recuperative heat exchanger in series with a combustion chamber or pre-chamber. A recuperator-protecting valve segregates the recuperator from hot combustion gases until the gases reach maximum expansion in the cylinder. Recuperators of both common-duct and seperated-duct design are described, the separated duct recuperator permitting higher recuperator temperature and increased efficiency and a reduction in the number of valves necessary to control gas flow. A preferred embodiment employs four valves per cylinder unit, a separated duct recuperator, and an insulating liner that surrounds both the combustion chamber and the recuperator. A similar prototype recuperative engine has demonstrated that recuperation can reduce exhaust temperature as much as 600° Rankine below that attainable in an equivalent Otto Cycle engine.

Owner:BRITTON RICHARD BERKELEY

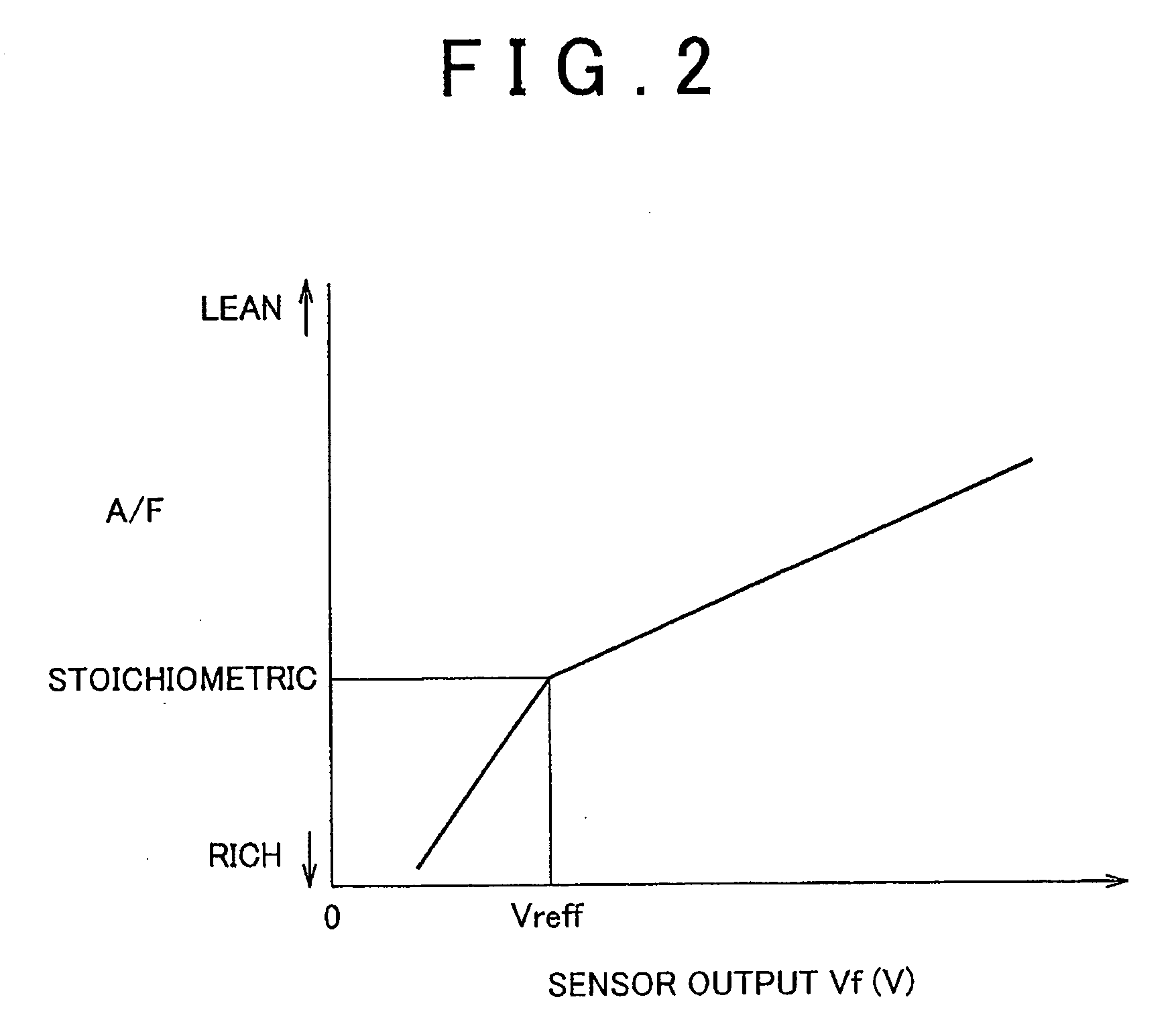

Apparatus and method for detecting abnormal air-fuel ratio variation among cylinders of multi-cylinder internal combustion engine

InactiveUS20100168986A1Accurate detectionIncrease volumeInternal-combustion engine testingElectrical controlHydrogenExternal combustion engine

An apparatus for detecting abnormal air-fuel ratio variation among cylinders of a multi-cylinder internal combustion engine includes: a catalyst element that oxidizes hydrogen contained in exhaust gas to remove the hydrogen; a first air-fuel ratio sensor that detects an air-fuel ratio of exhaust gas that has not passed through the catalyst element; a second air-fuel ratio sensor that detects an air-fuel ratio of exhaust gas that has passed through the catalyst element; and a unit that determines whether abnormal air-fuel ratio variation among the cylinders has occurred based on an amount by which a value detected by the second air-fuel ratio sensor is leaner than a value detected by the first air-fuel ratio sensor

Owner:TOYOTA JIDOSHA KK

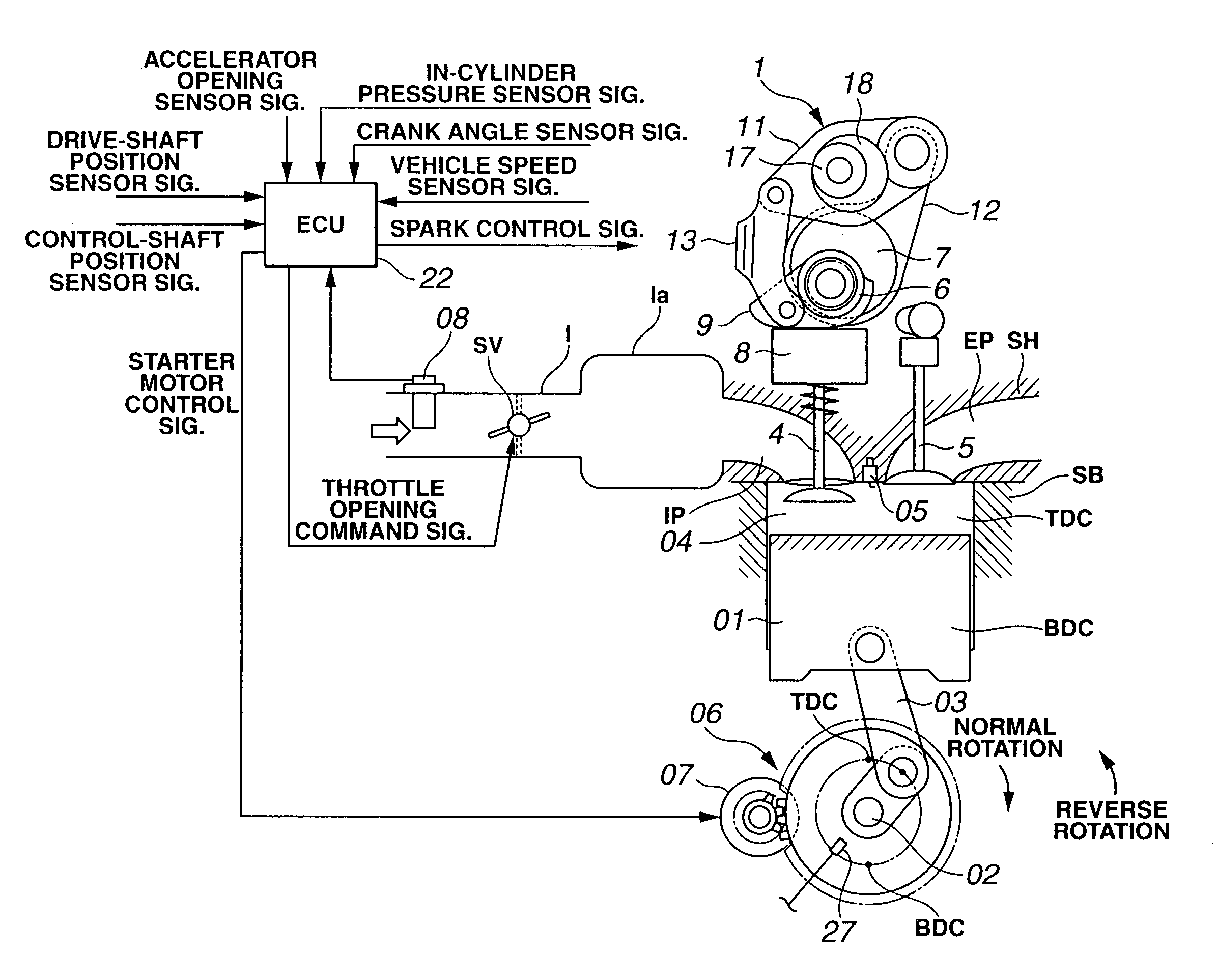

Engine start control apparatus

InactiveUS7191746B2Preventing an excessive in-cylinder pressure riseReduce electricity loadValve arrangementsElectrical controlInlet valveEngineering

Owner:HITACHI LTD

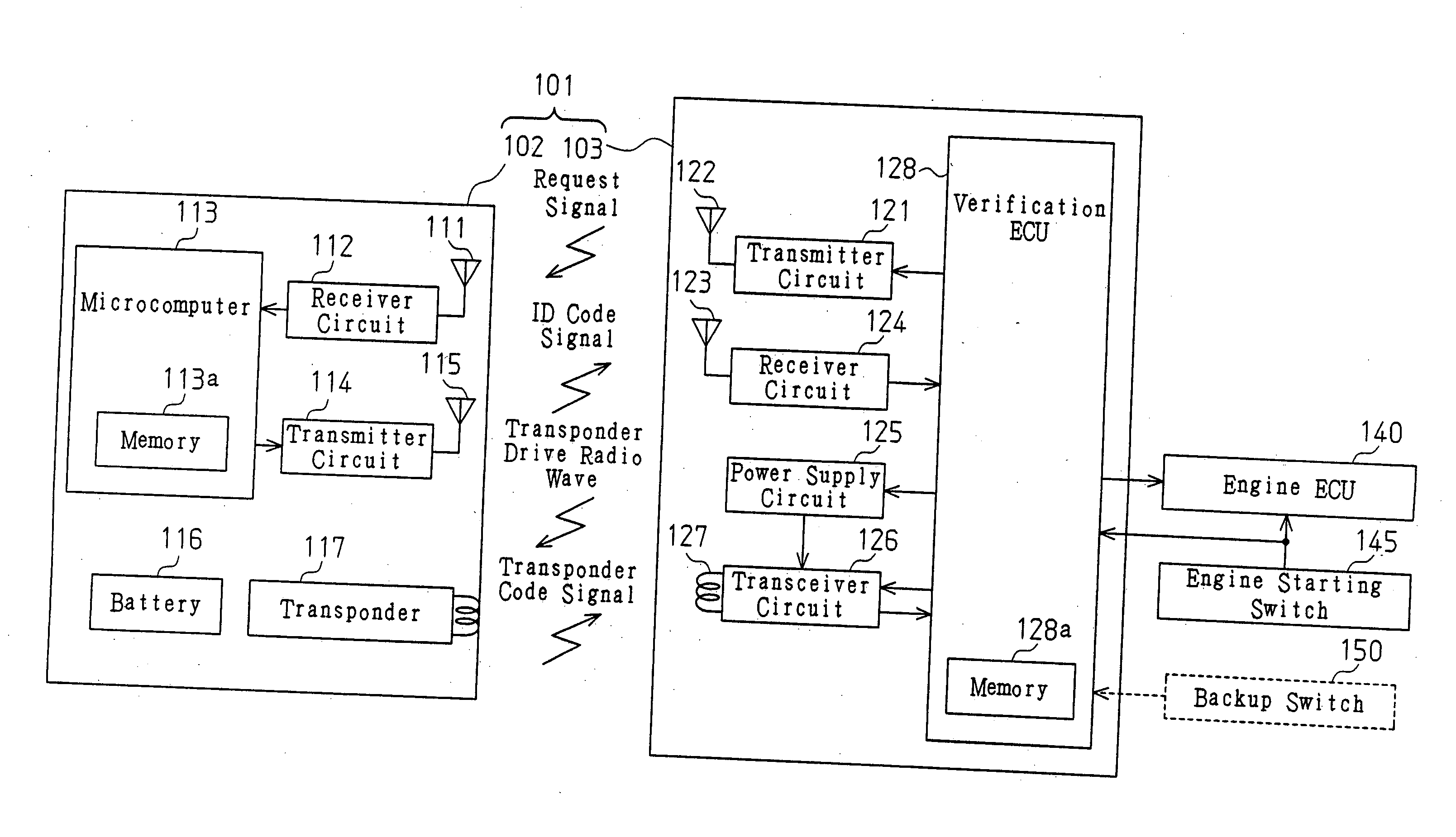

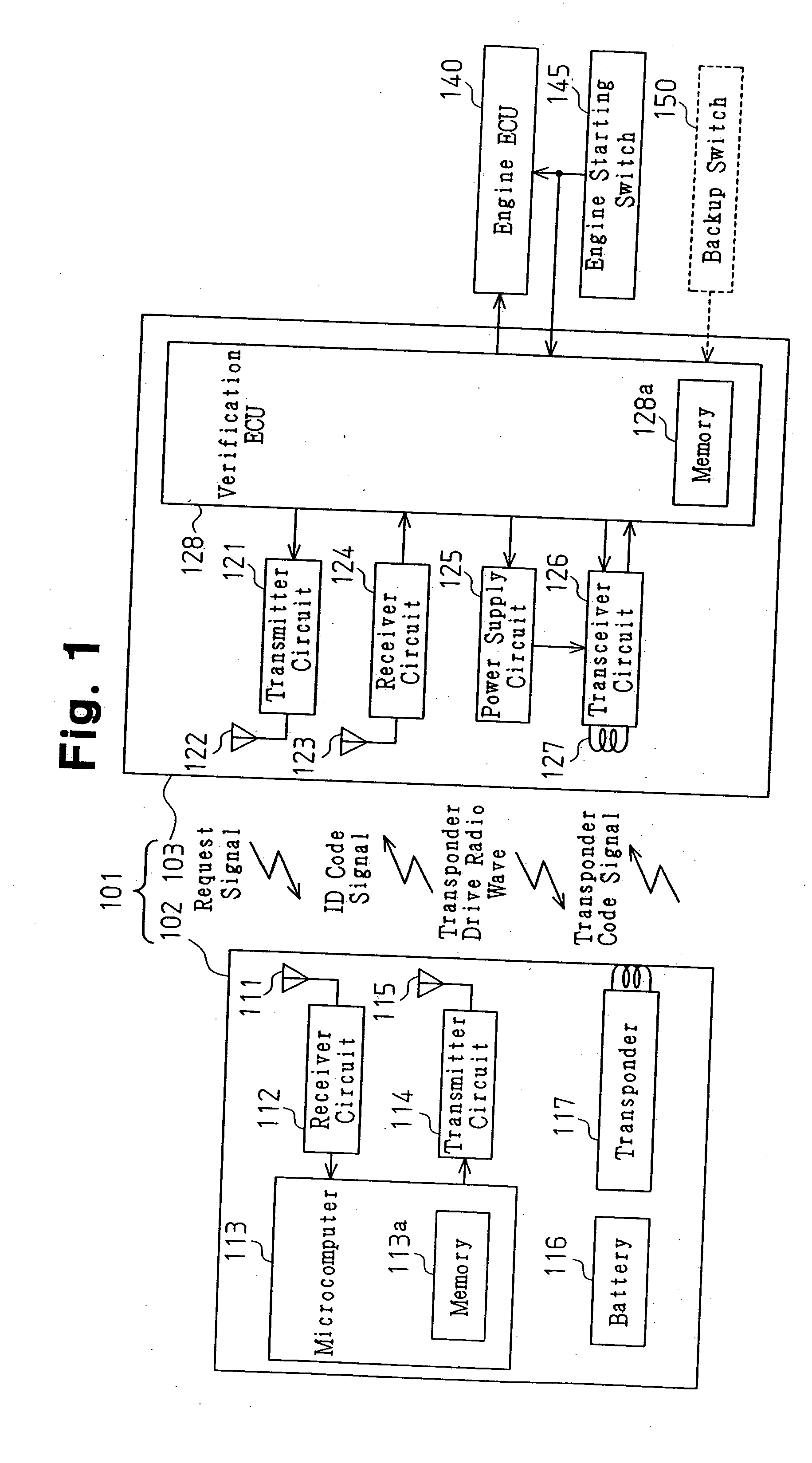

Controller for remote control system

ActiveUS20050020212A1Electric signal transmission systemsDigital data processing detailsDriver/operatorRemote control

A controller enabling switching between a smart function and an immobilizer function without using a key cylinder or a slot. The controller includes a verification ECU for transmitting a request signal to a first area and transmitting a transponder drive radio wave to a second area. The portable device transmits an ID code signal in response to the request signal or the transponder drive radio wave. The verification ECU enables the starting of an engine when the ID code transmitted from the portable device matches an ID code of the controller. The verification ECU transmits the drive radio wave when a driver operates a switch in a state in which the starting of the engine is not enabled after the request signal is transmitted.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO +1

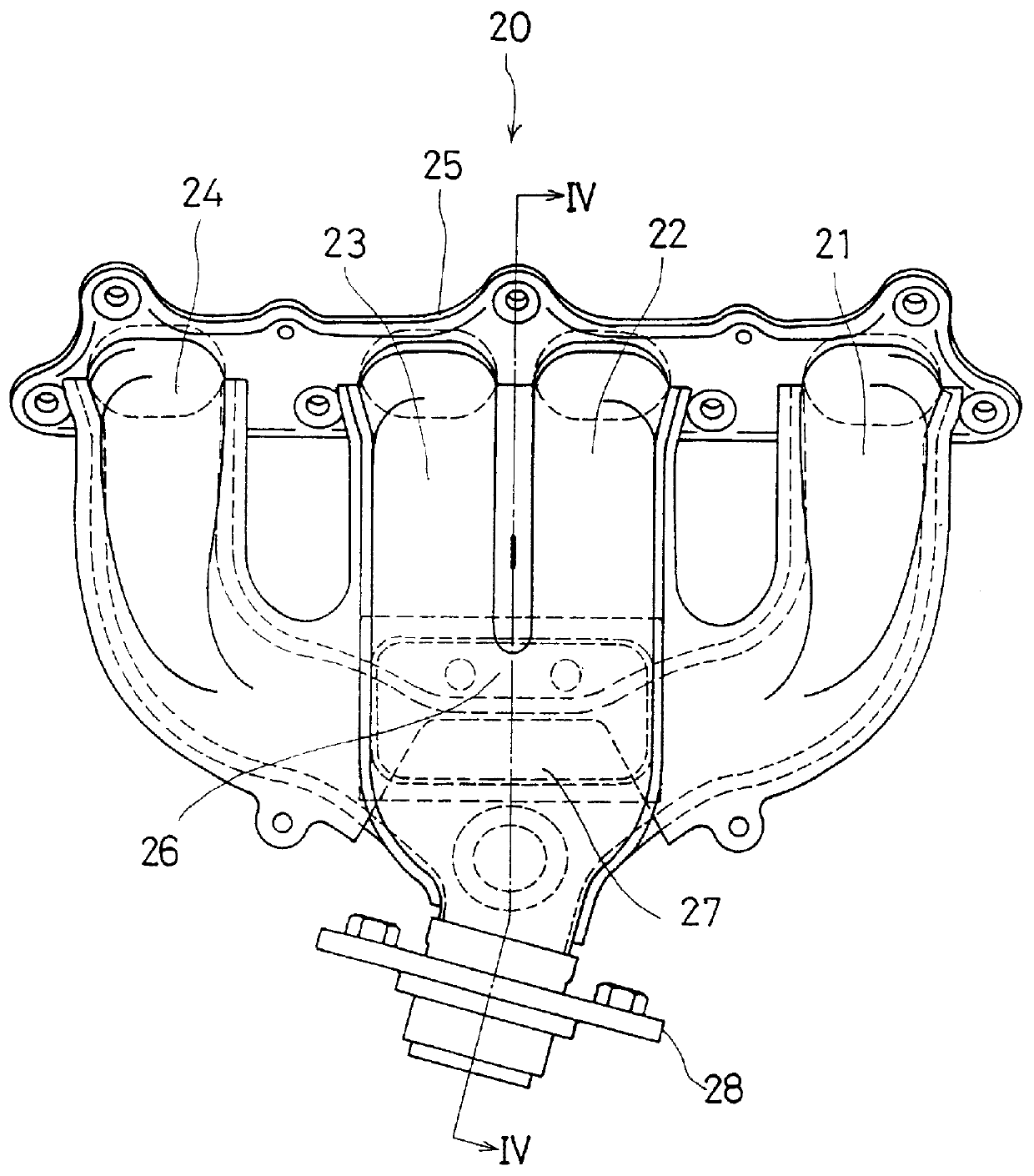

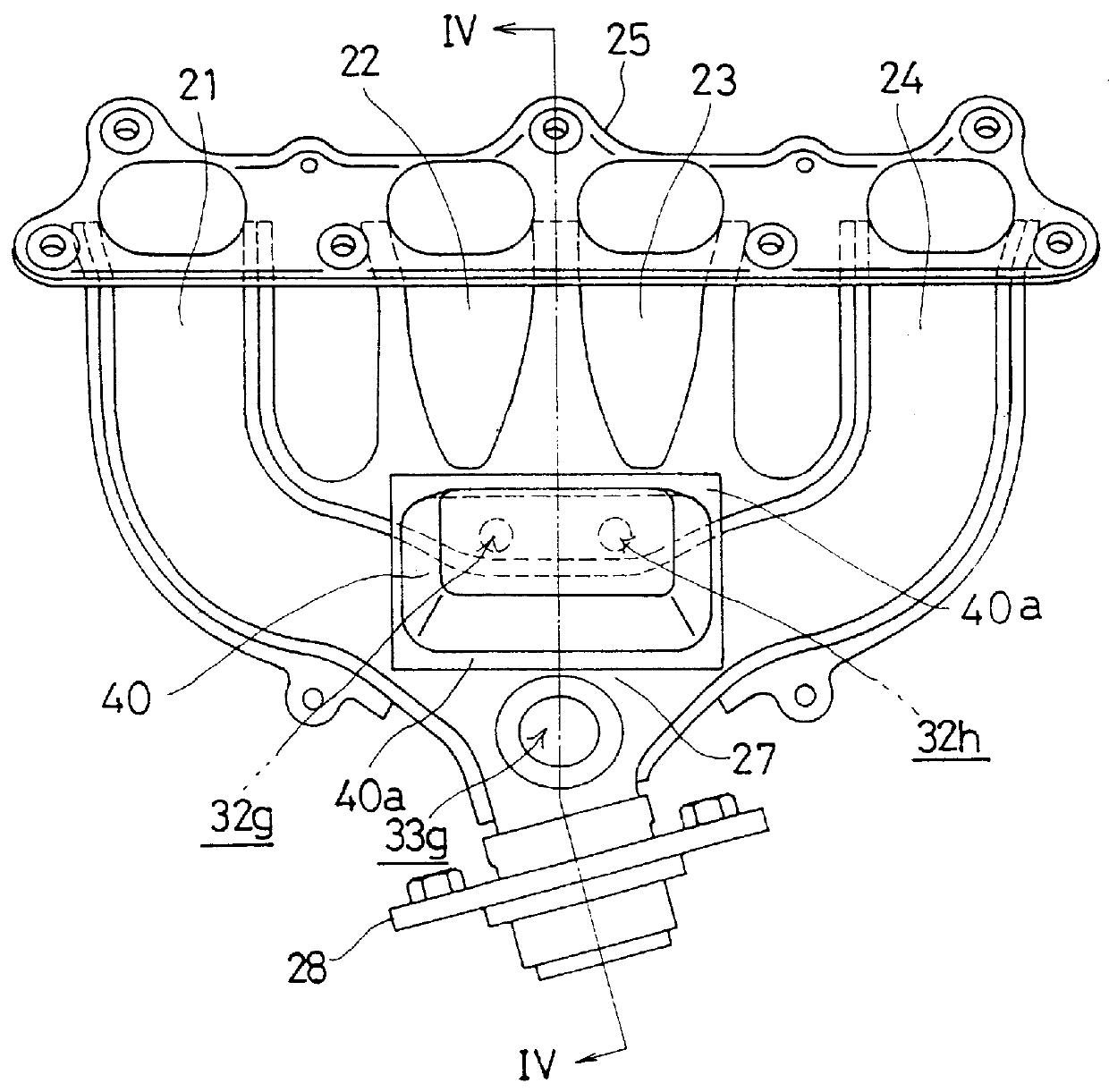

Exhaust manifold of multi-cylinder internal combustion engine

InactiveUS6018946AImprove space efficiencyAvoiding exhaust interferenceSilencing apparatusMachines/enginesExhaust pipeMechanics

An exhaust manifold made of plate metal in which sufficient strength and rigidity can be ensured, lightening of the weight is intended by making walls thin as a whole, and early activation of a catalyst is easy. The exhaust manifold is one for a multi-cylinder internal combustion engine having two groups of cylinders selected so that exhaust strokes are not successive. The exhaust manifold includes two exhaust pipe sections containing exhaust pipes communicating with the cylinders of one of the groups respectively, confluence sections where the exhaust pipes in each of the exhaust pipe sections join respectively, and a gathering section where the confluence sections join. Further, the exhaust manifold is constructed by an obverse half body, a partition body and a reverse half body made of plate metals and laid face to face with each other, the exhaust pipe sections and the confluence sections are formed by the partition body and one of the obverse and reverse half bodies, and the gathering section is formed by the obverse half body and the reverse half body.

Owner:HONDA MOTOR CO LTD

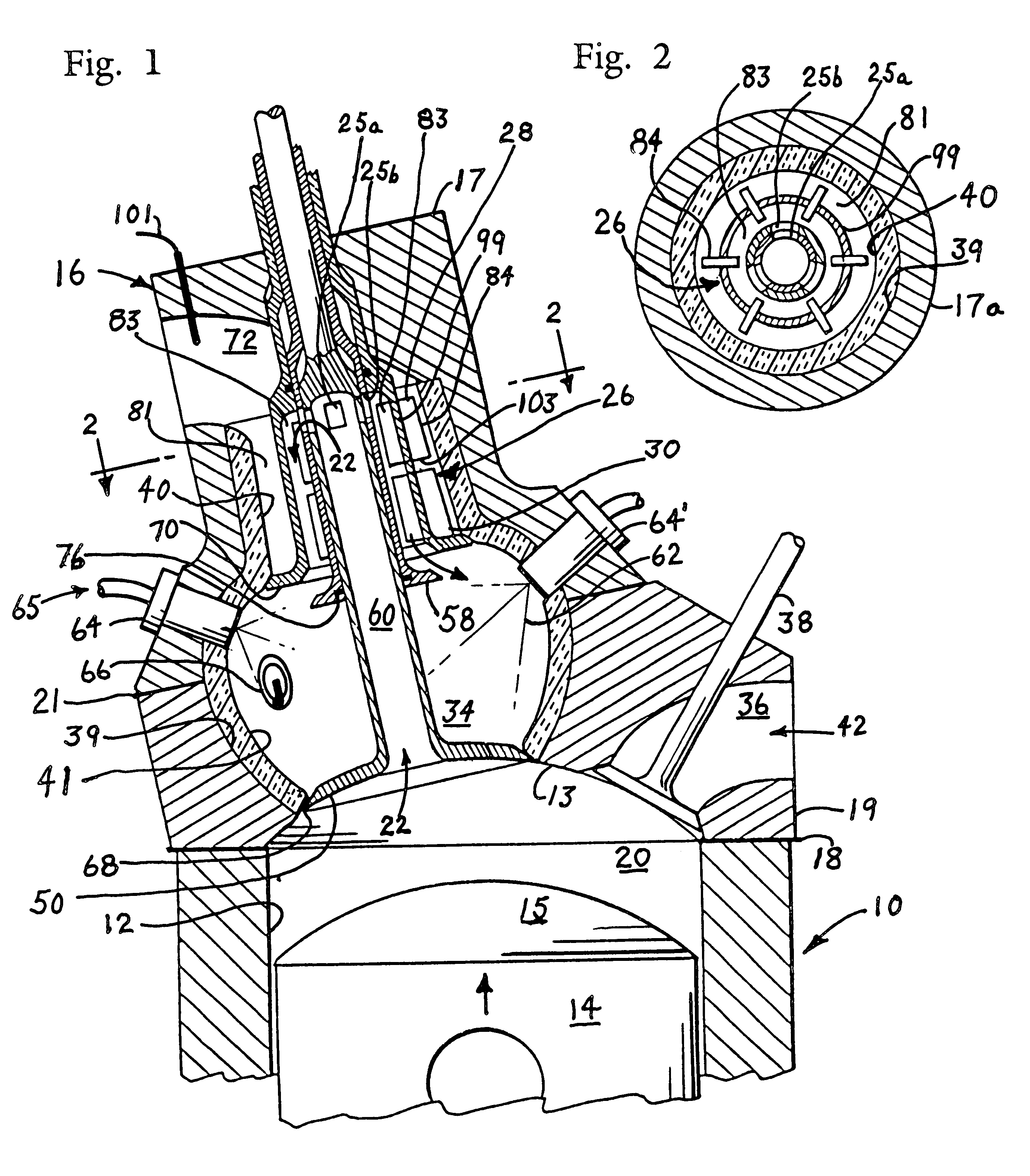

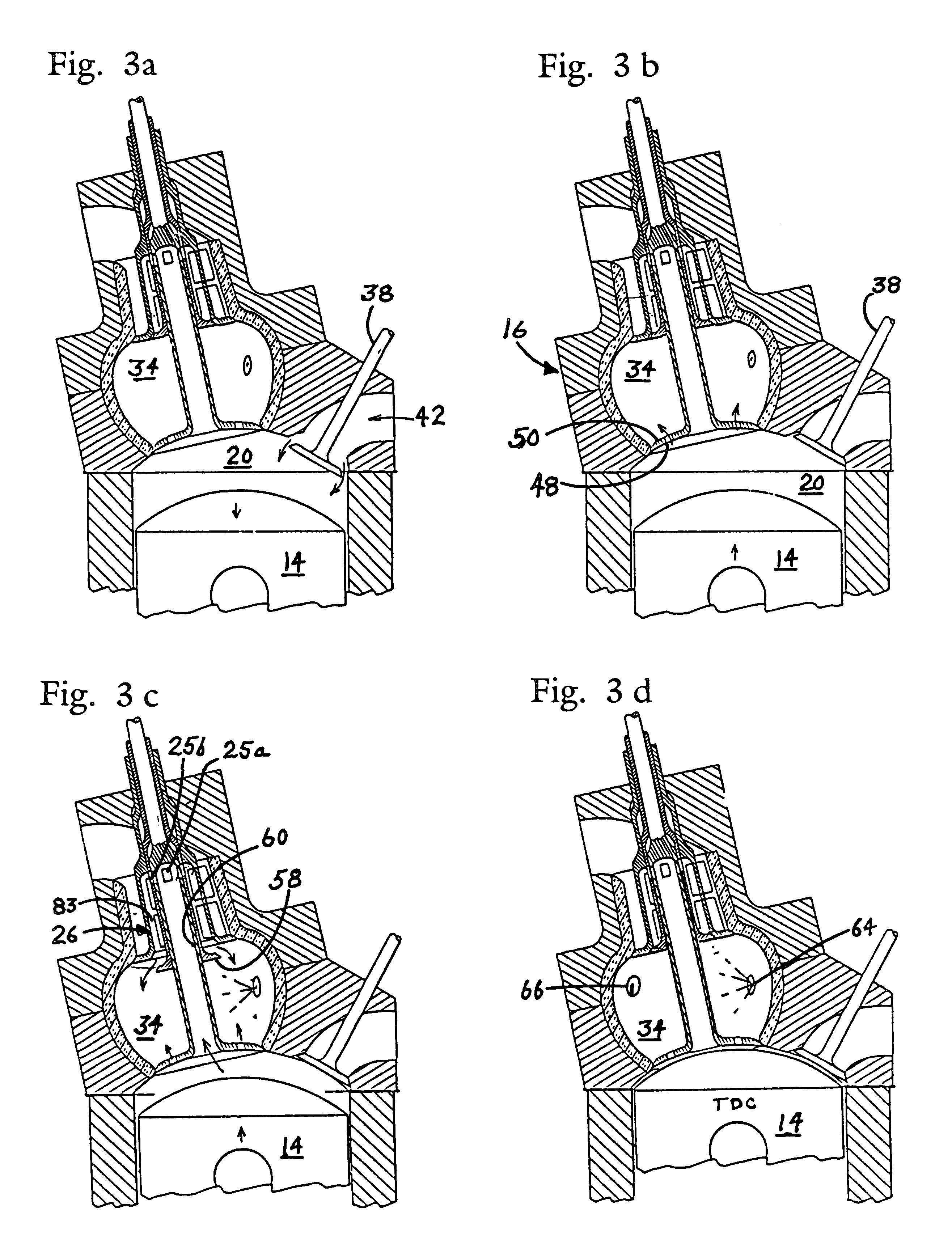

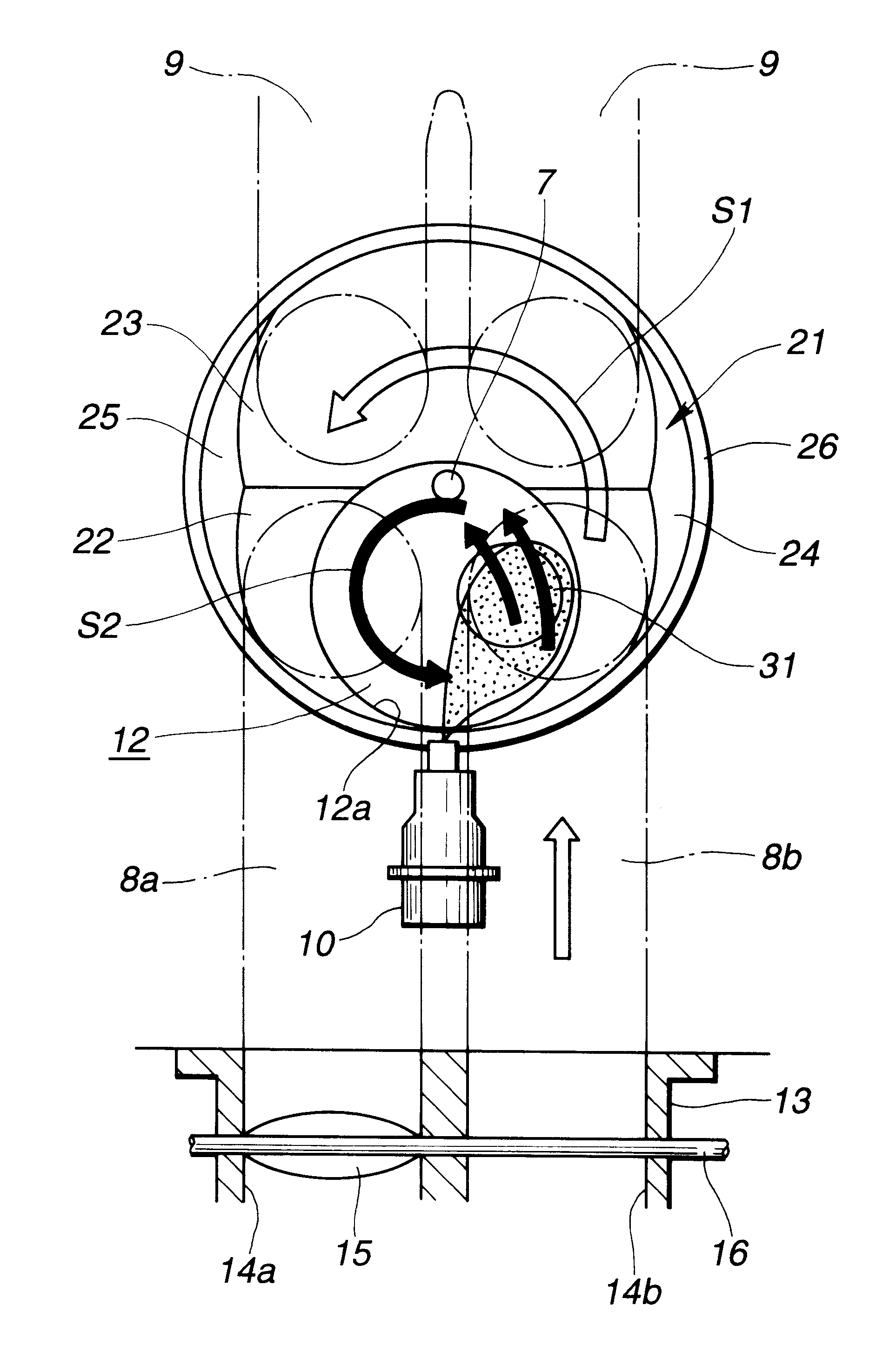

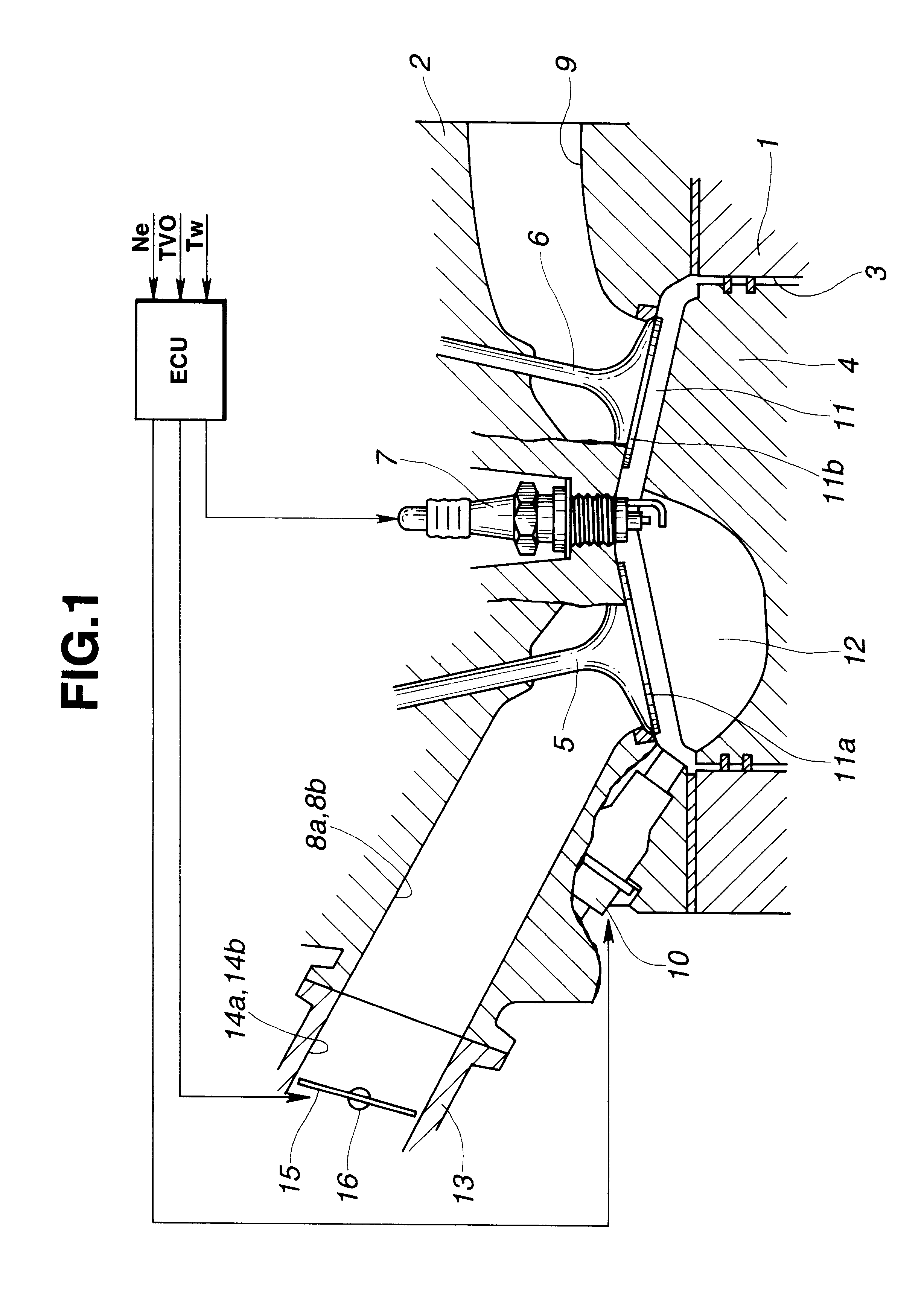

In-cylinder direct-injection spark-ignition engine

InactiveUS6173690B1Charge efficiency be reduceIncrease in airflow resistanceInternal combustion piston enginesCylinder headsPistonSpark-ignition engine

An in-cylinder direct-injection spark-ignition engine using at least a homogeneous combustion mode and a stratified combustion mode and equipped with a pentroof combustion chamber head having first and second shallow-angled surfaces, comprises intake valves disposed in the first shallow-angled surface, exhaust valves disposed in the second shallow-angled surface. A pair of substantially straight intake ports are formed in the cylinder head. A tumble-and-swirl control valve is disposed in a first intake port of the substantially straight intake ports for adjusting the amount of intake air passing through the first intake port. A piston crown comprises an intake-valve side inclined surface generally parallel to the first shallow-angled surface, an exhaust-valve side inclined surface generally parallel to the second shallow-angled surface, and a piston bowl having an opening of a substantially complete round and arranged in an eccentric position with respect to the outside circle of the upper portion of the piston toward the intake valves. The piston bowl has a deeply-recessed bowl cavity. The deeply-recessed bowl cavity is arranged eccentrically to the opening of the piston bowl toward a second intake port of the substantially straight intake ports.

Owner:NISSAN MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com