Patents

Literature

109 results about "Gas constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The gas constant is also known as the molar, universal, or ideal gas constant, denoted by the symbol R or R and is equivalent to the Boltzmann constant, but expressed in units of energy per temperature increment per mole, i.e. the pressure–volume product, rather than energy per temperature increment per particle. The constant is also a combination of the constants from Boyle's law, Charles's law, Avogadro's law, and Gay-Lussac's law.

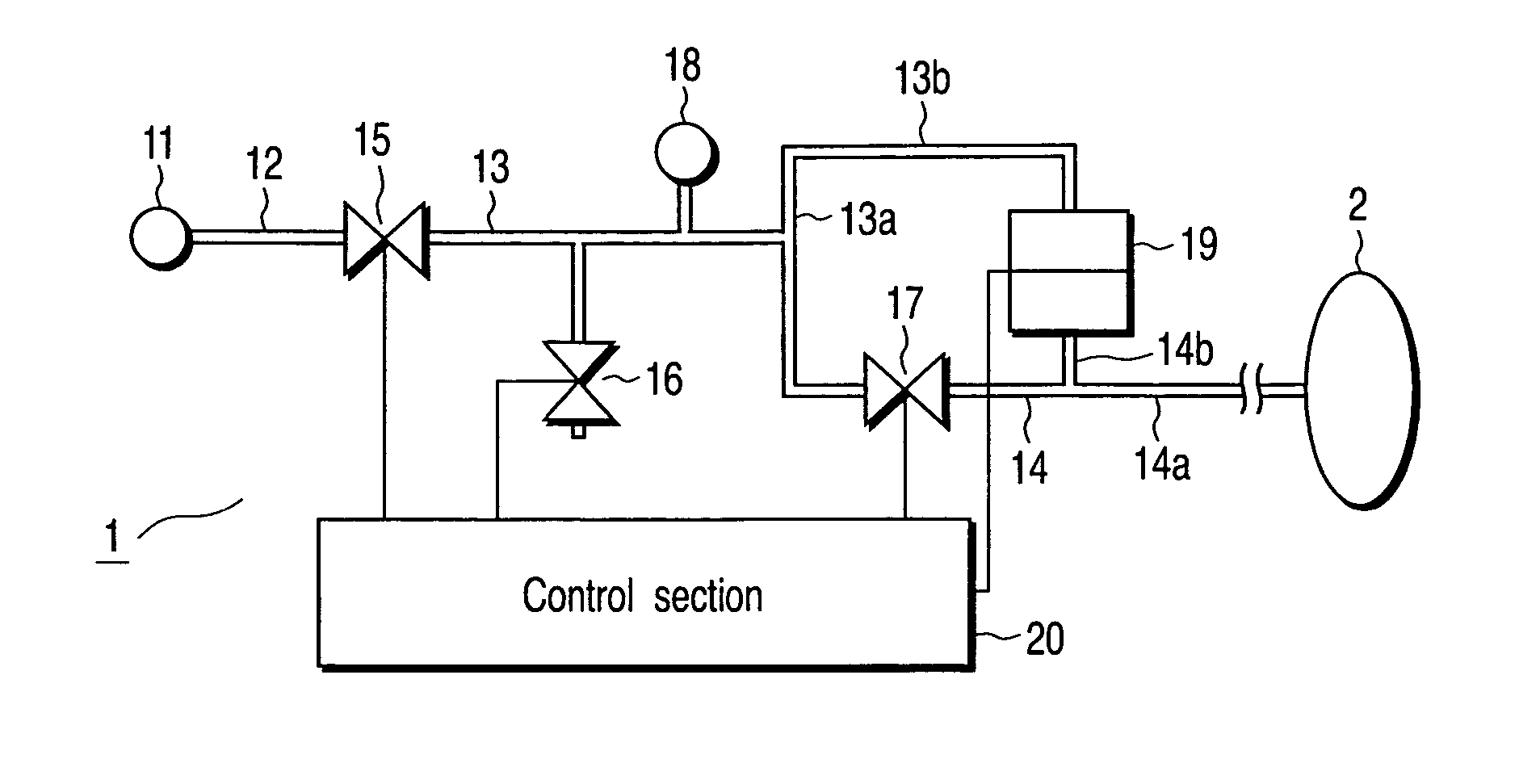

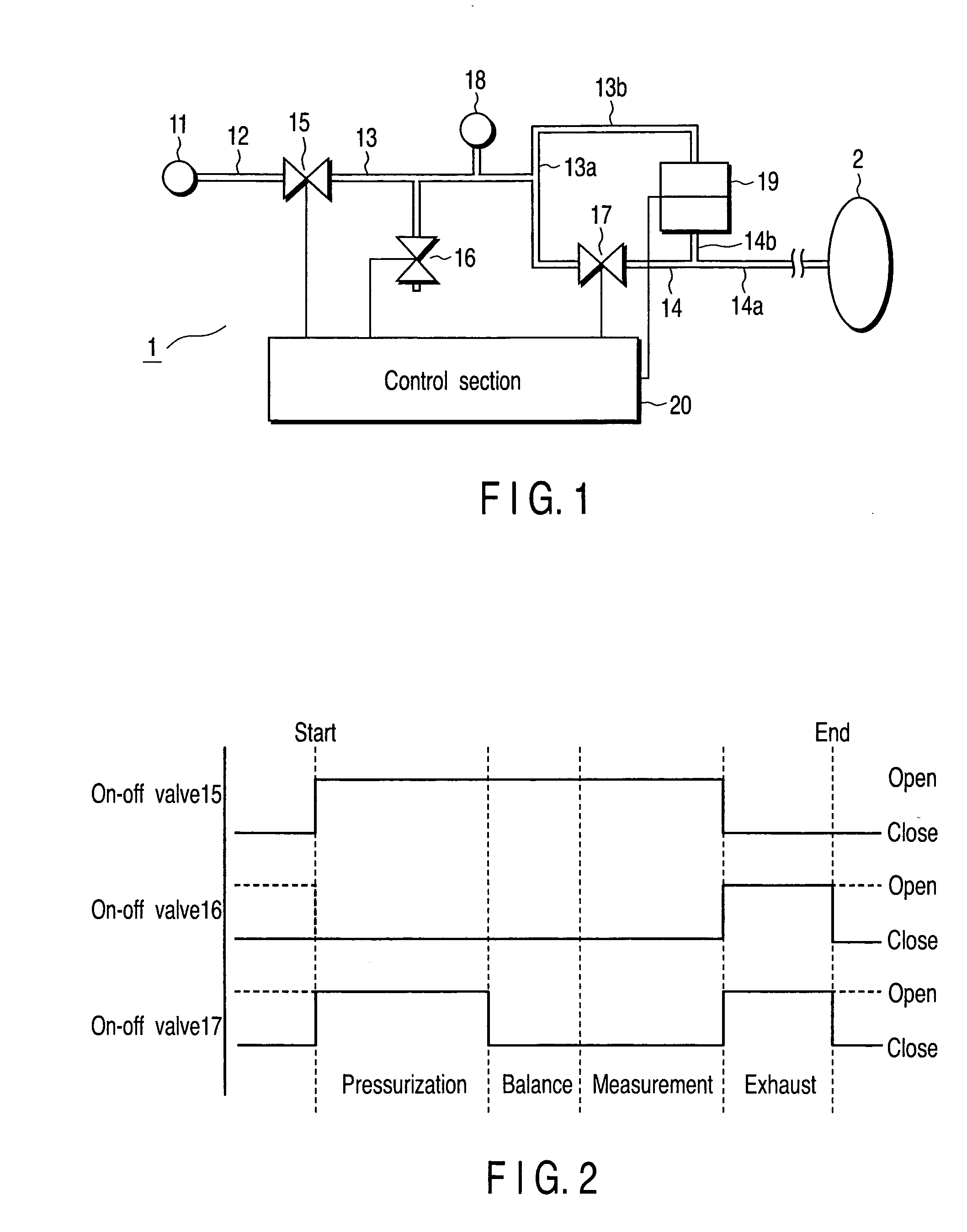

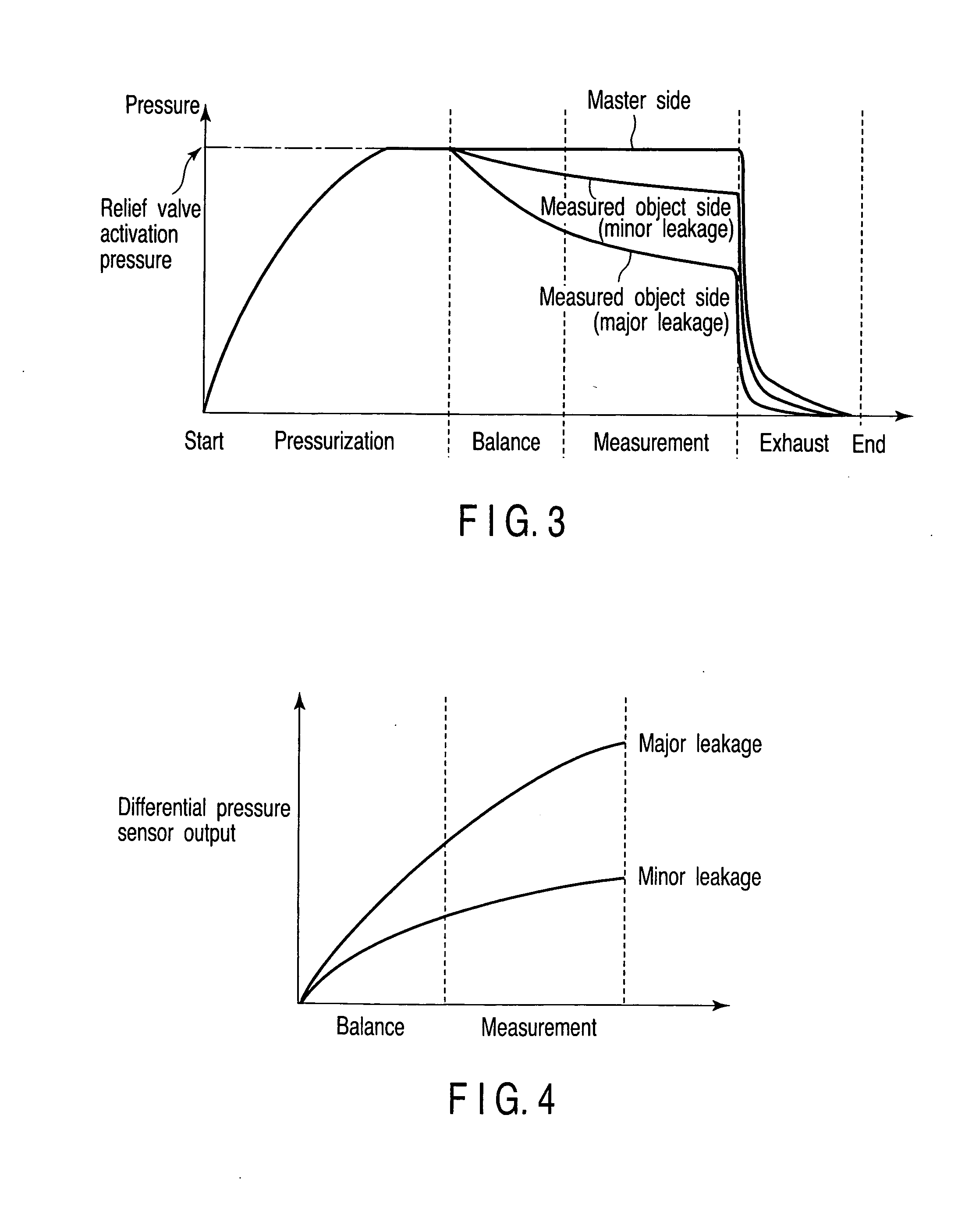

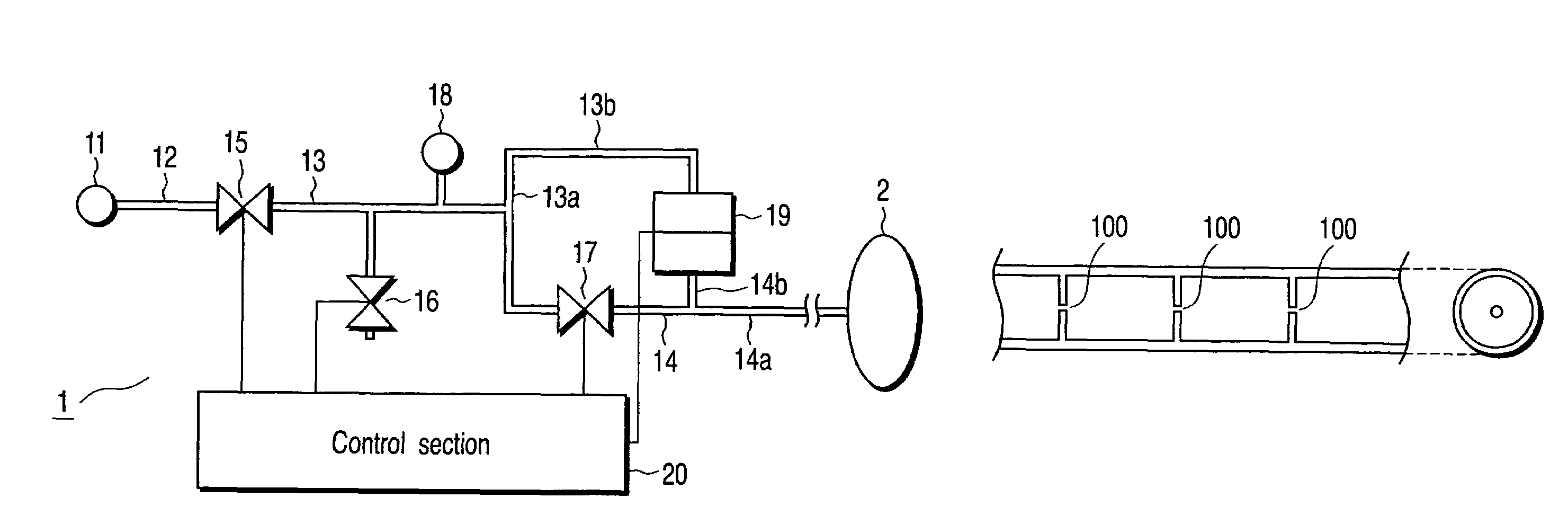

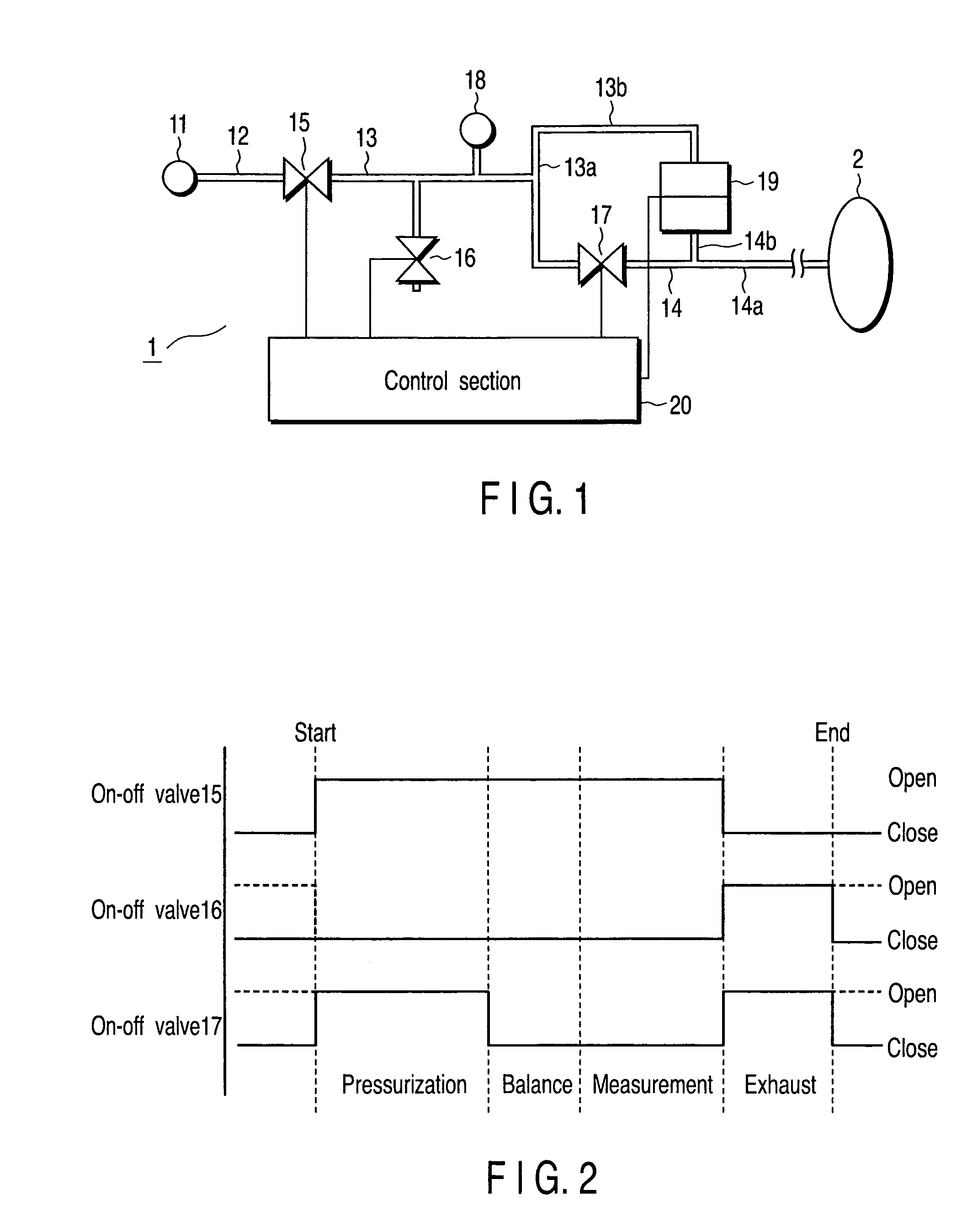

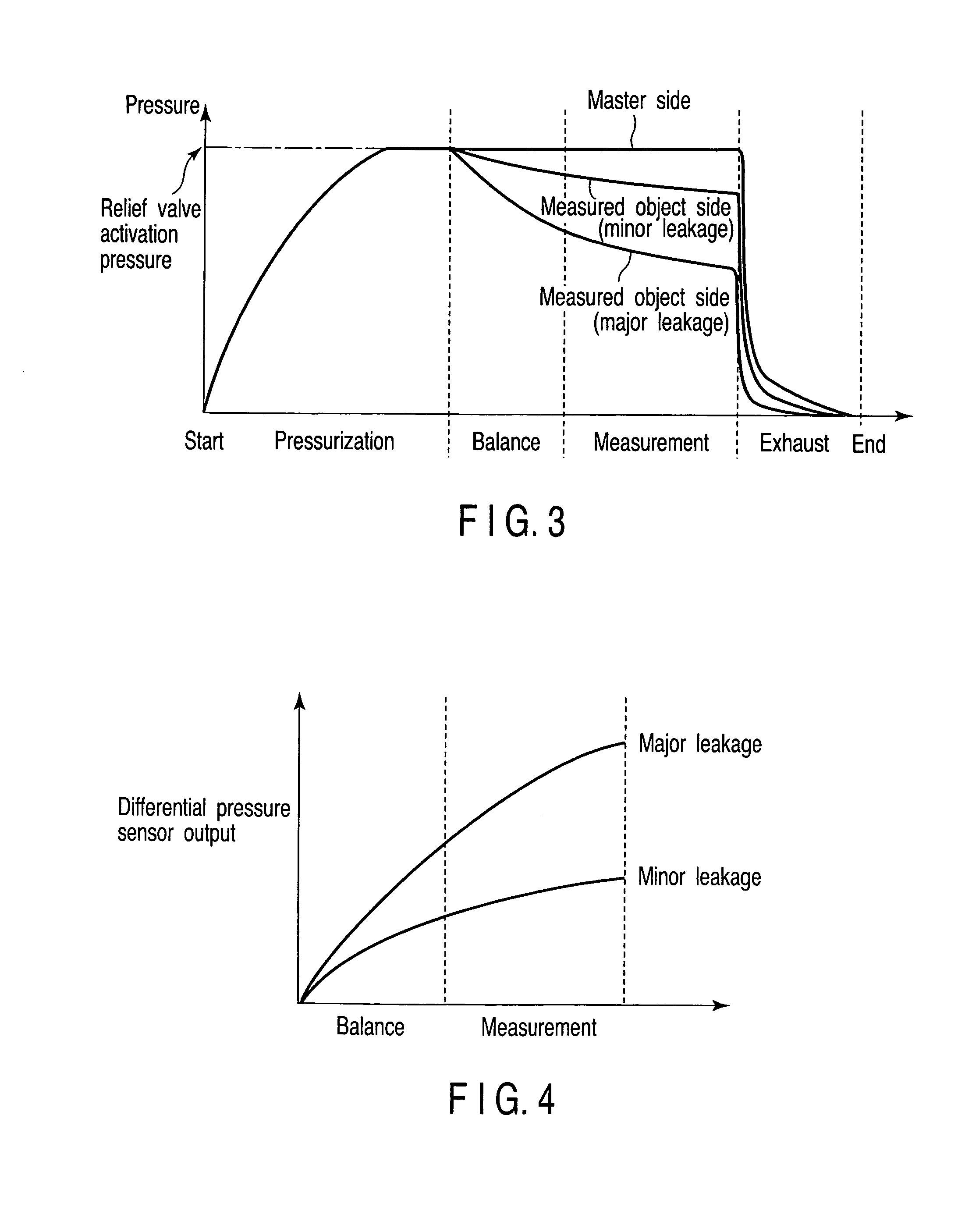

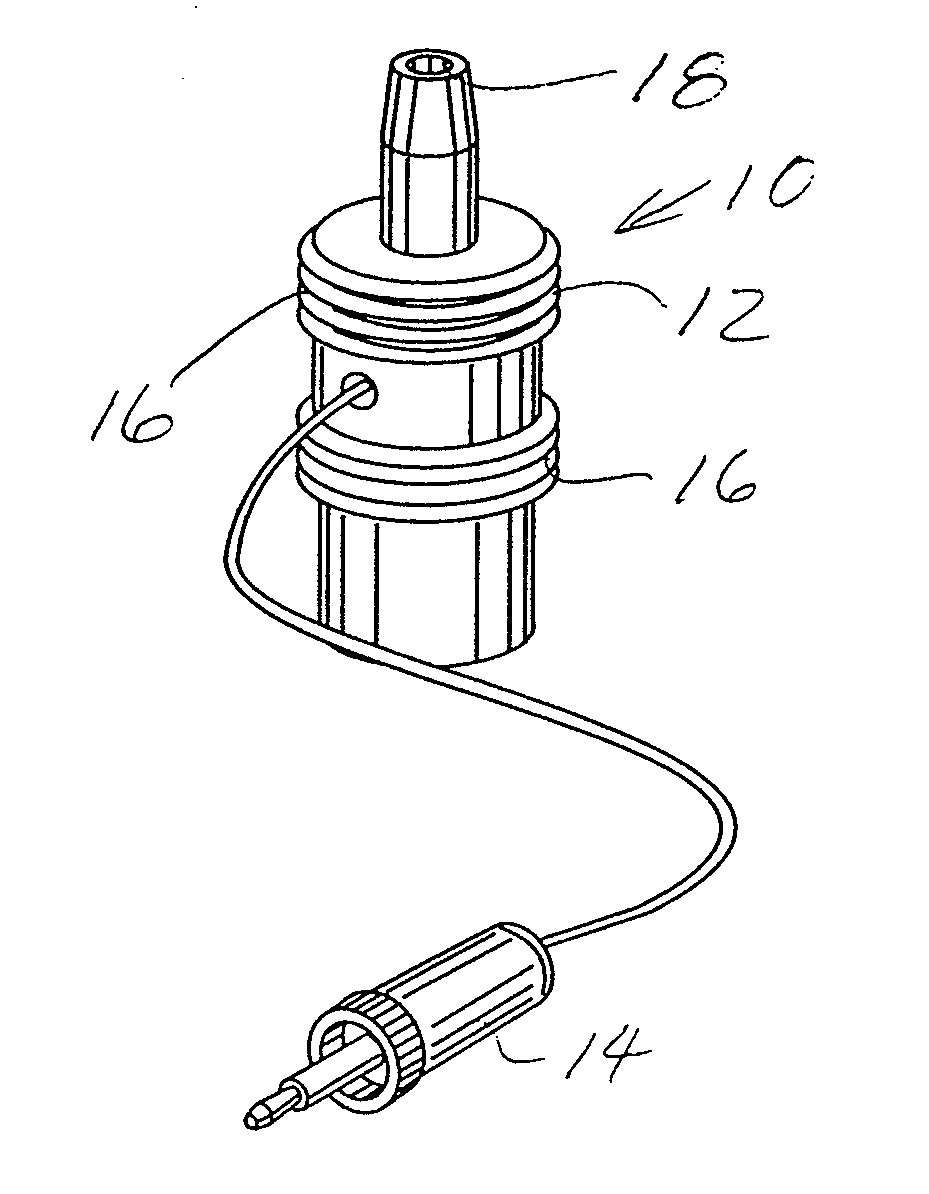

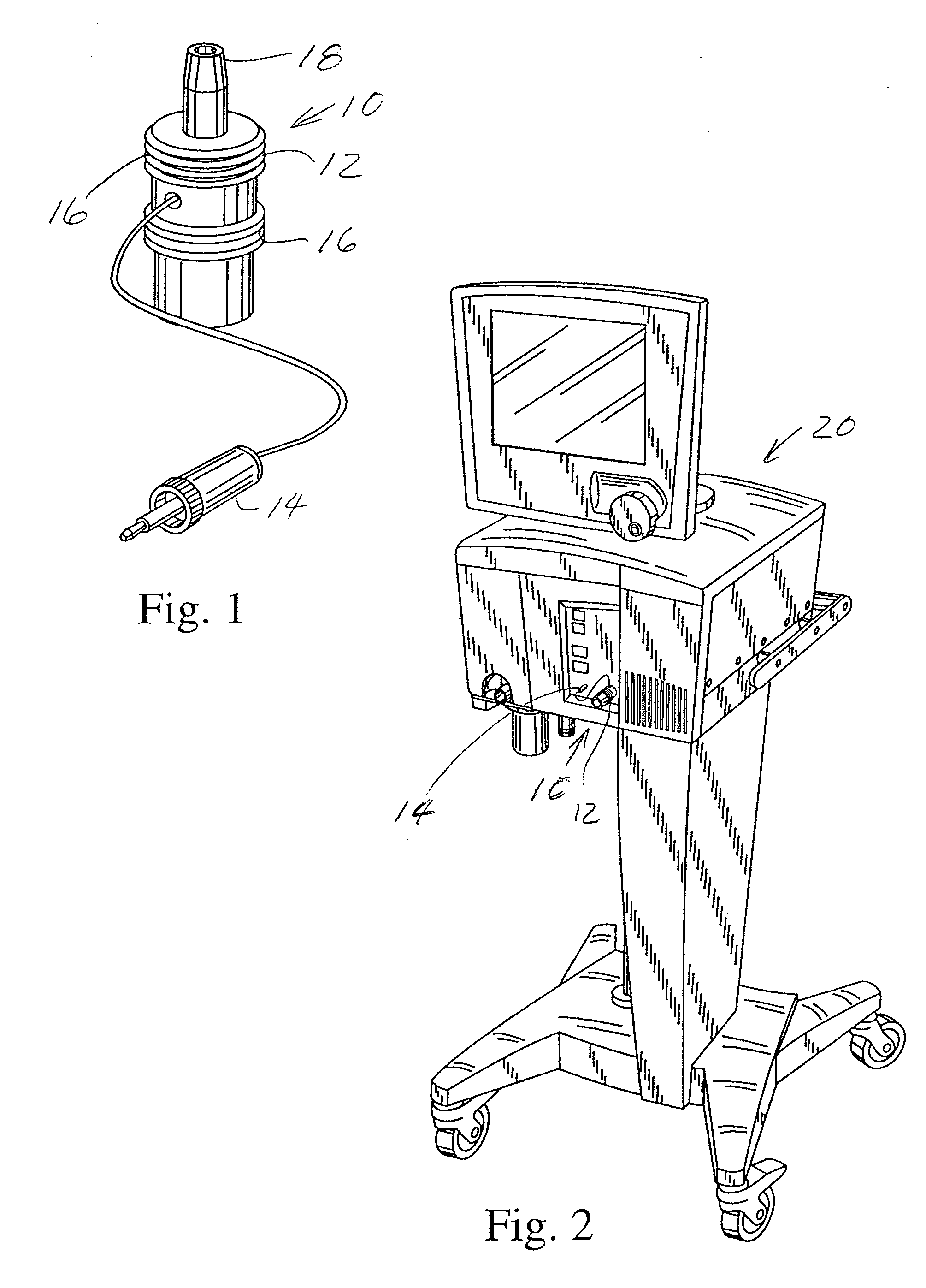

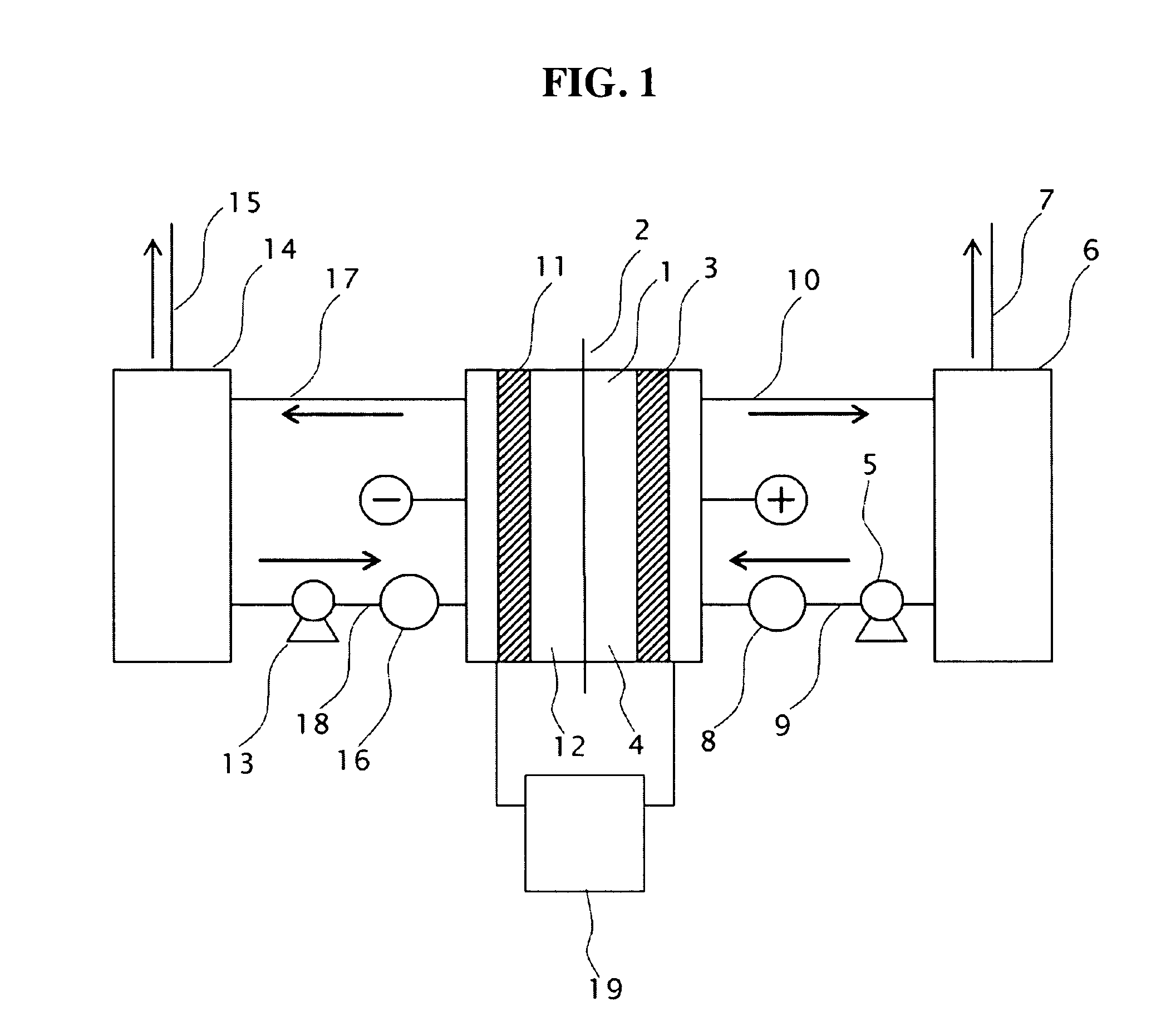

Leak tester

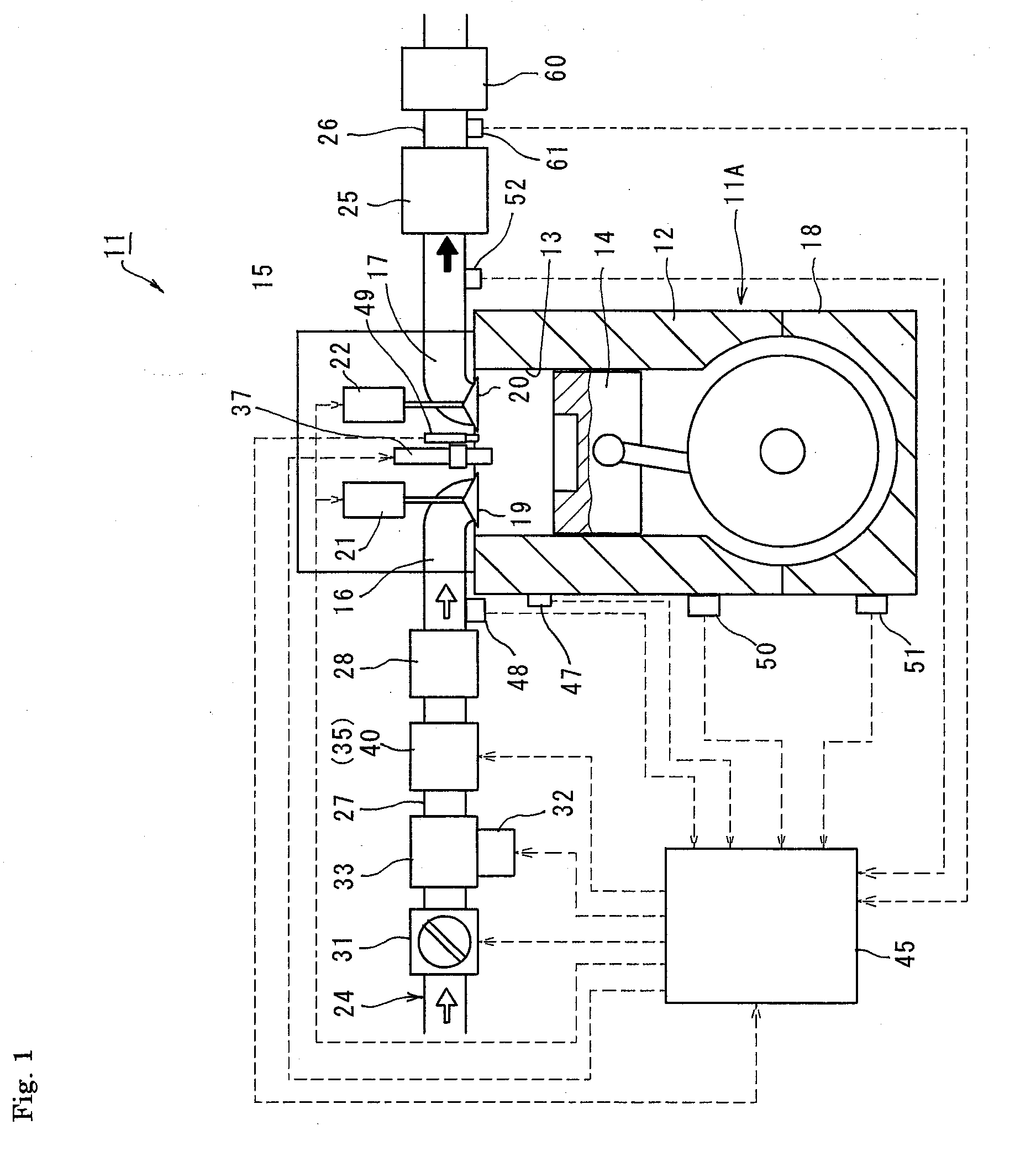

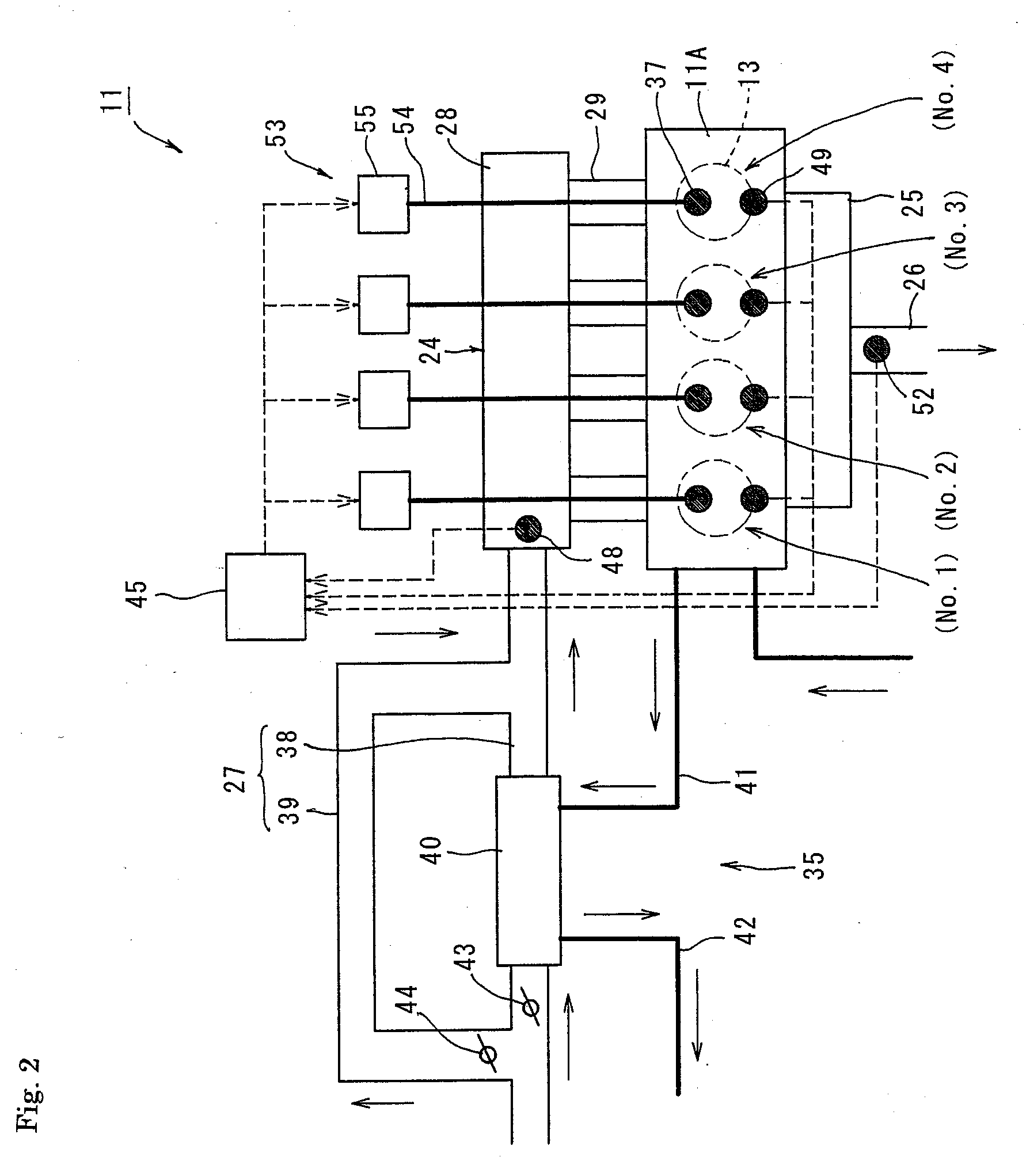

InactiveUS20050056081A1Detection of fluid at leakage pointMeasurement of fluid loss/gain rateDifferential pressureGas leak

A leak tester which detects leakage of a gas from a measured object, the leak tester including a source of a pressurized gas which supplies the pressurized gas, a differential pressure detecting section which detects a pressure difference between the pressure of a gas in the measured object and the pressure of a pressurized gas supplied by the source of the pressurized gas, and a pressure adjusting section which makes the pressure of the pressurized gas supplied by the source of the pressurized gas constant.

Owner:OLYMPUS CORP

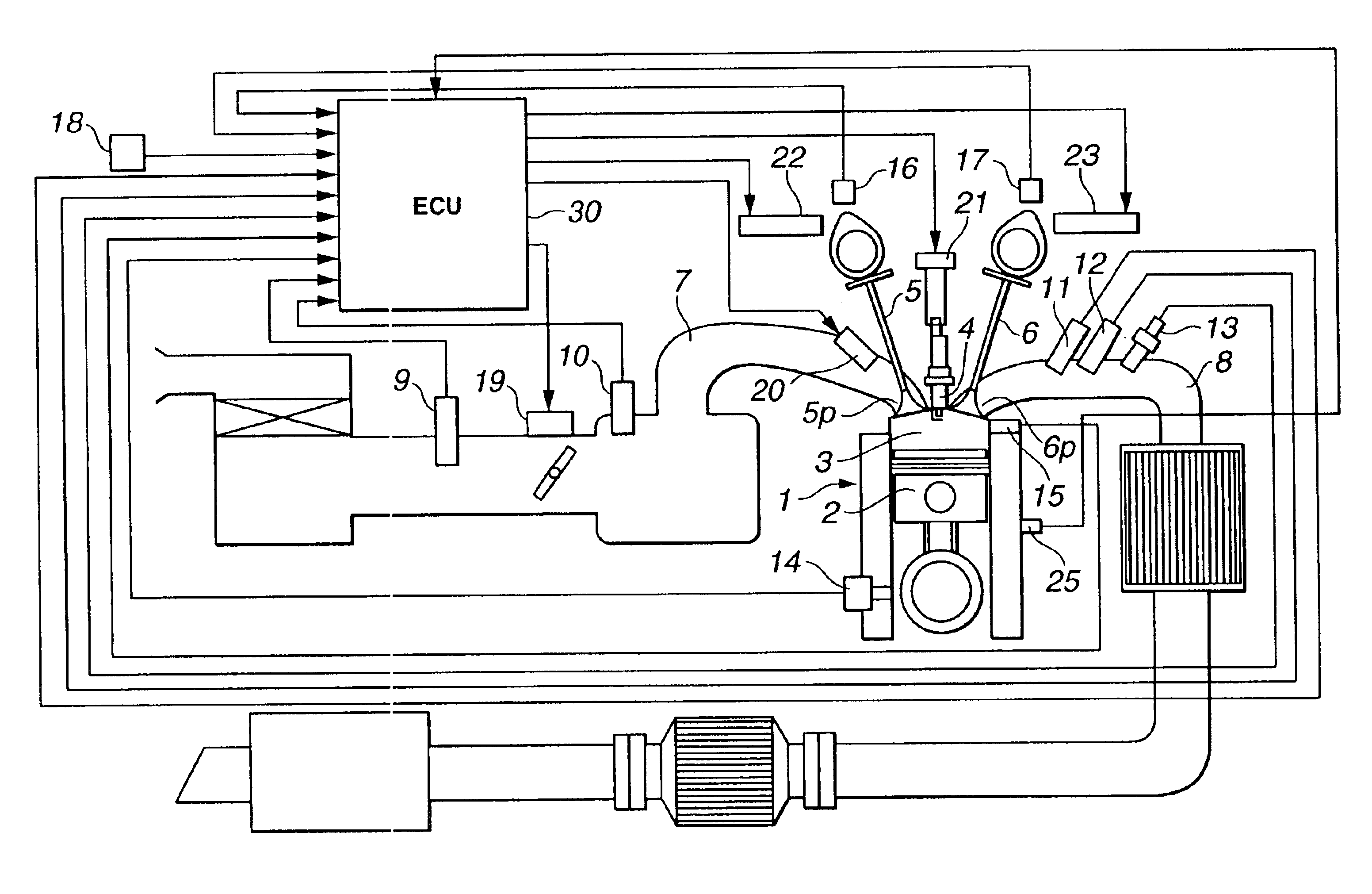

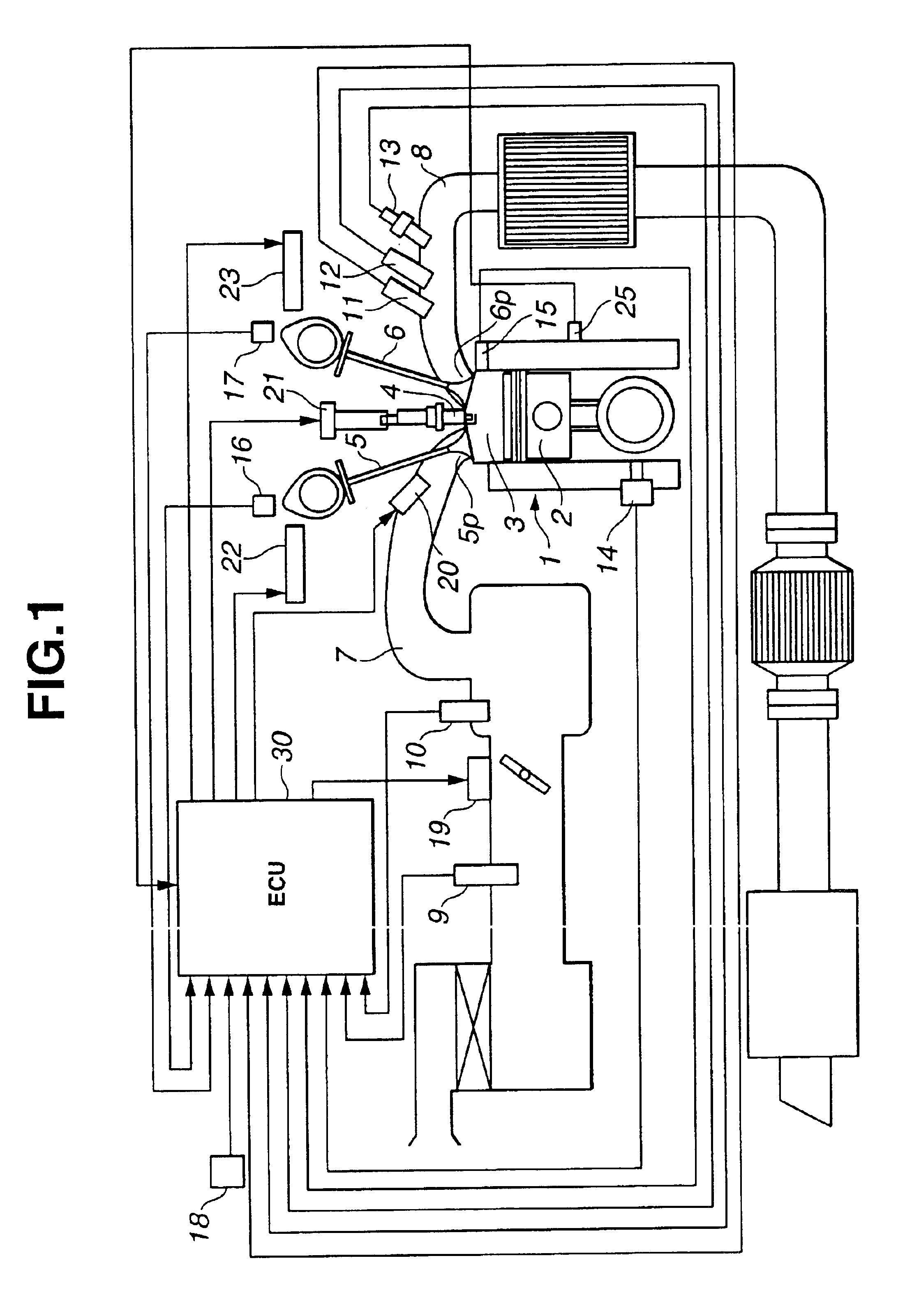

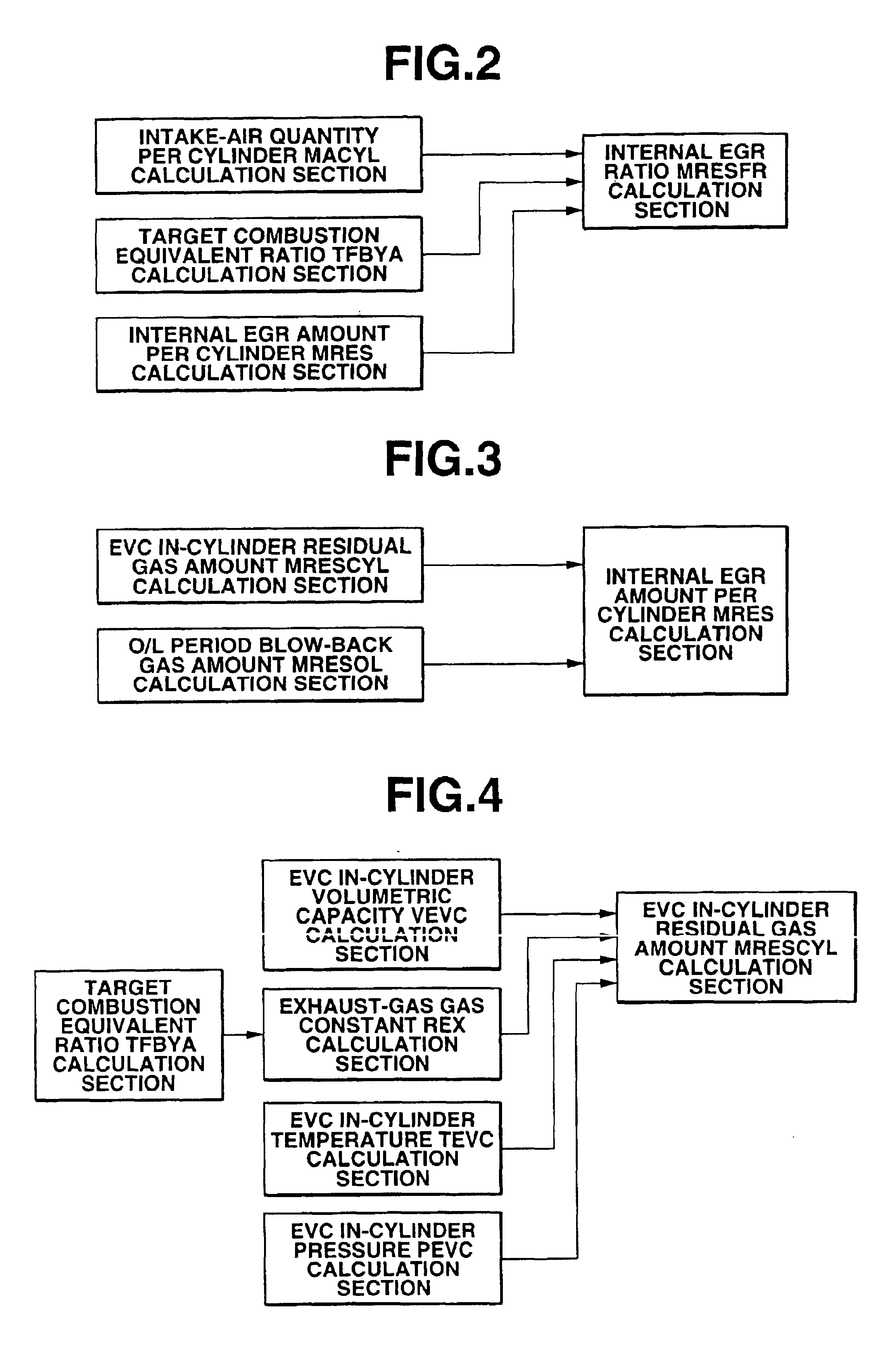

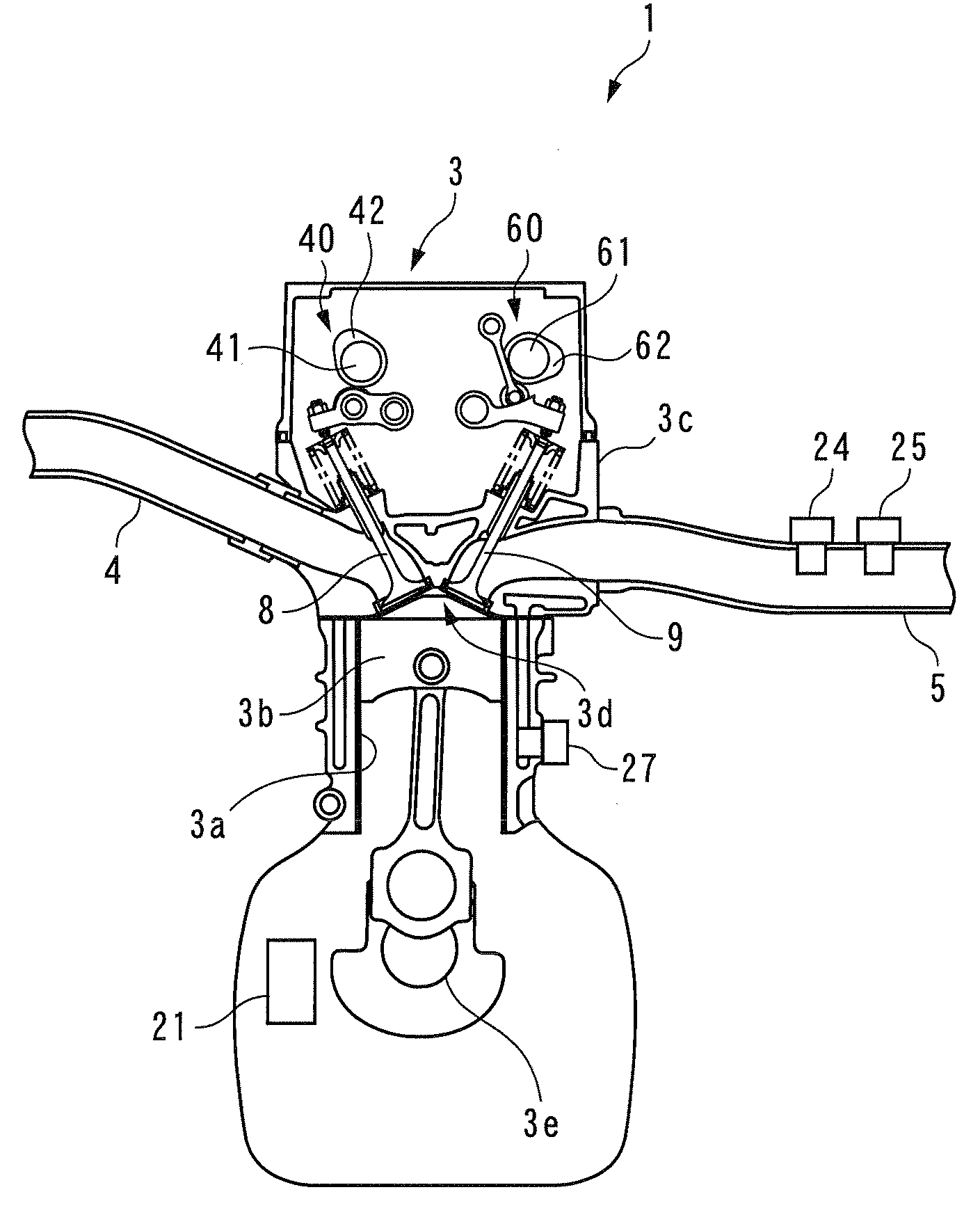

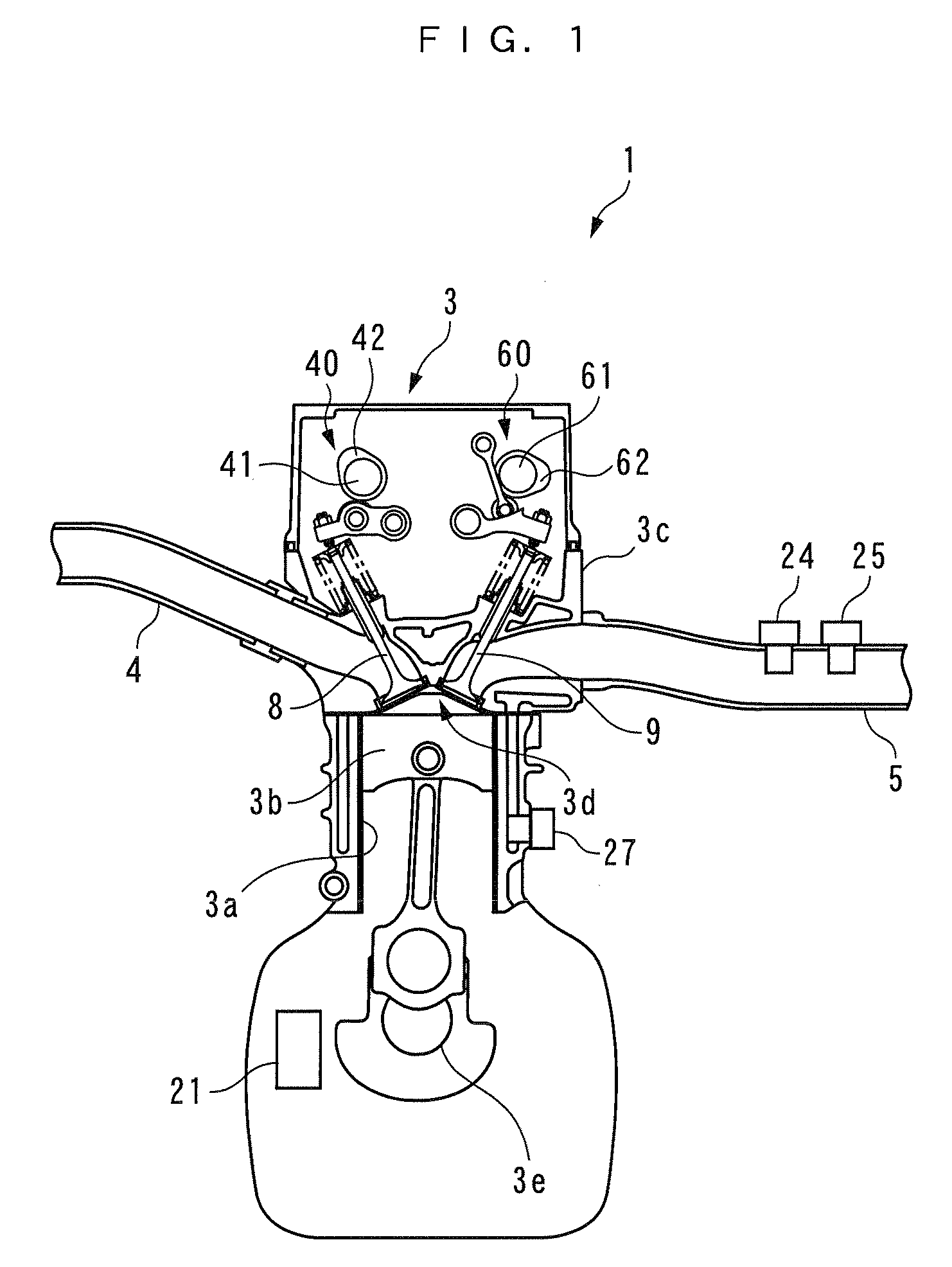

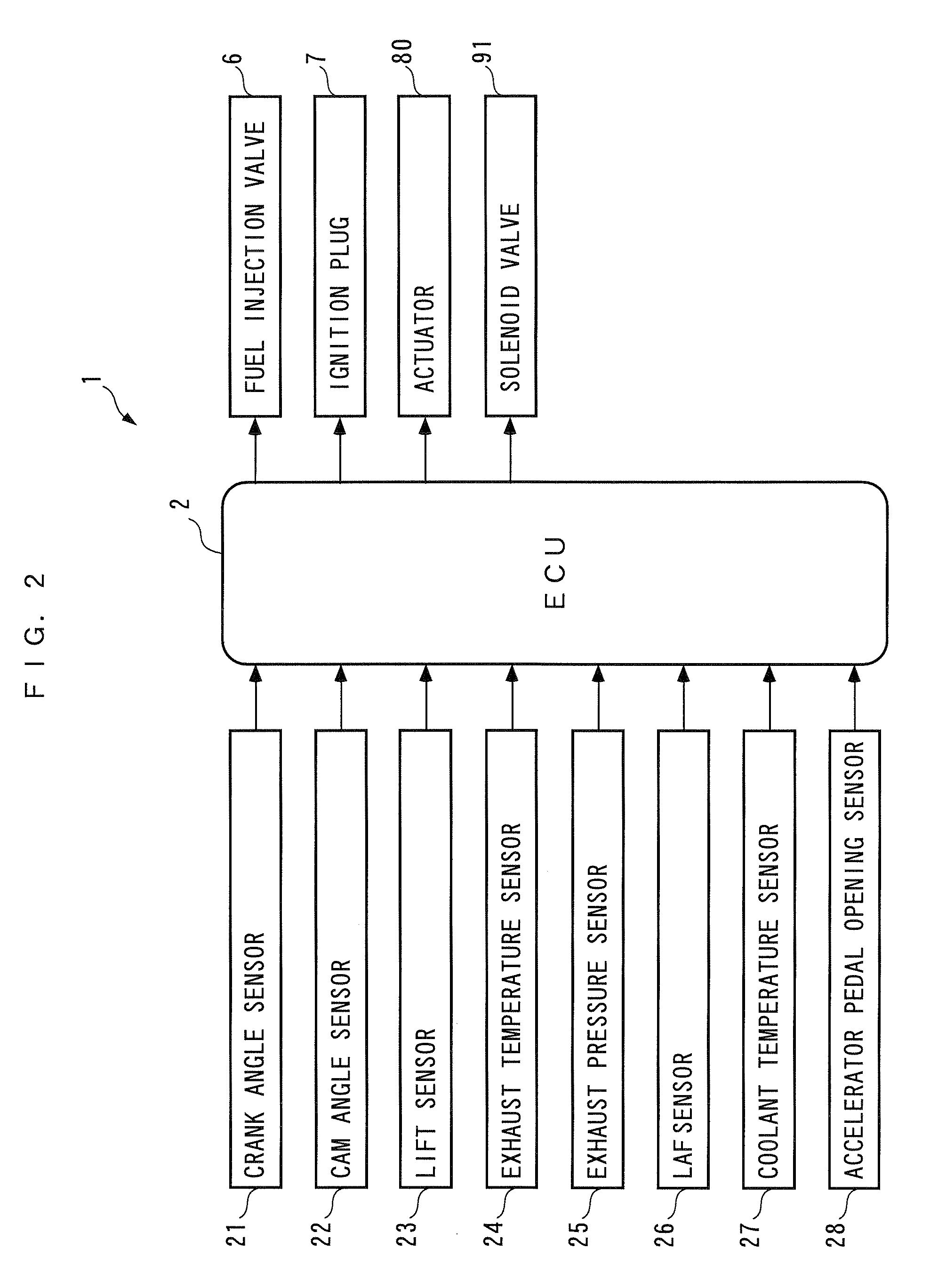

Internal exhaust gas recirculation amount estimation system of internal combustion engines

ActiveUS6840235B2Accurate estimateThe right amountValve arrangementsElectrical controlExhaust fumesGas constant

An internal exhaust gas recirculation amount estimation system calculates an in-cylinder temperature at an exhaust valve closure timing, an in-cylinder pressure at the exhaust valve closure timing, and a gas constant corresponding to a change in a composition of exhaust gas, based on an air-fuel mixture ratio. An exhaust valve closure timing in-cylinder residual gas amount is calculated based on at least the in-cylinder temperature, the in-cylinder pressure, and the gas constant. Also calculated is a valve overlap period blow-back gas amount, which is defined as a quantity of gas flow from one of intake and exhaust ports via a combustion chamber to the other port during a valve overlap period. An internal exhaust gas recirculation amount is calculated based on the exhaust valve closure timing in-cylinder residual gas amount and the valve overlap period blow-back gas amount.

Owner:NISSAN MOTOR CO LTD

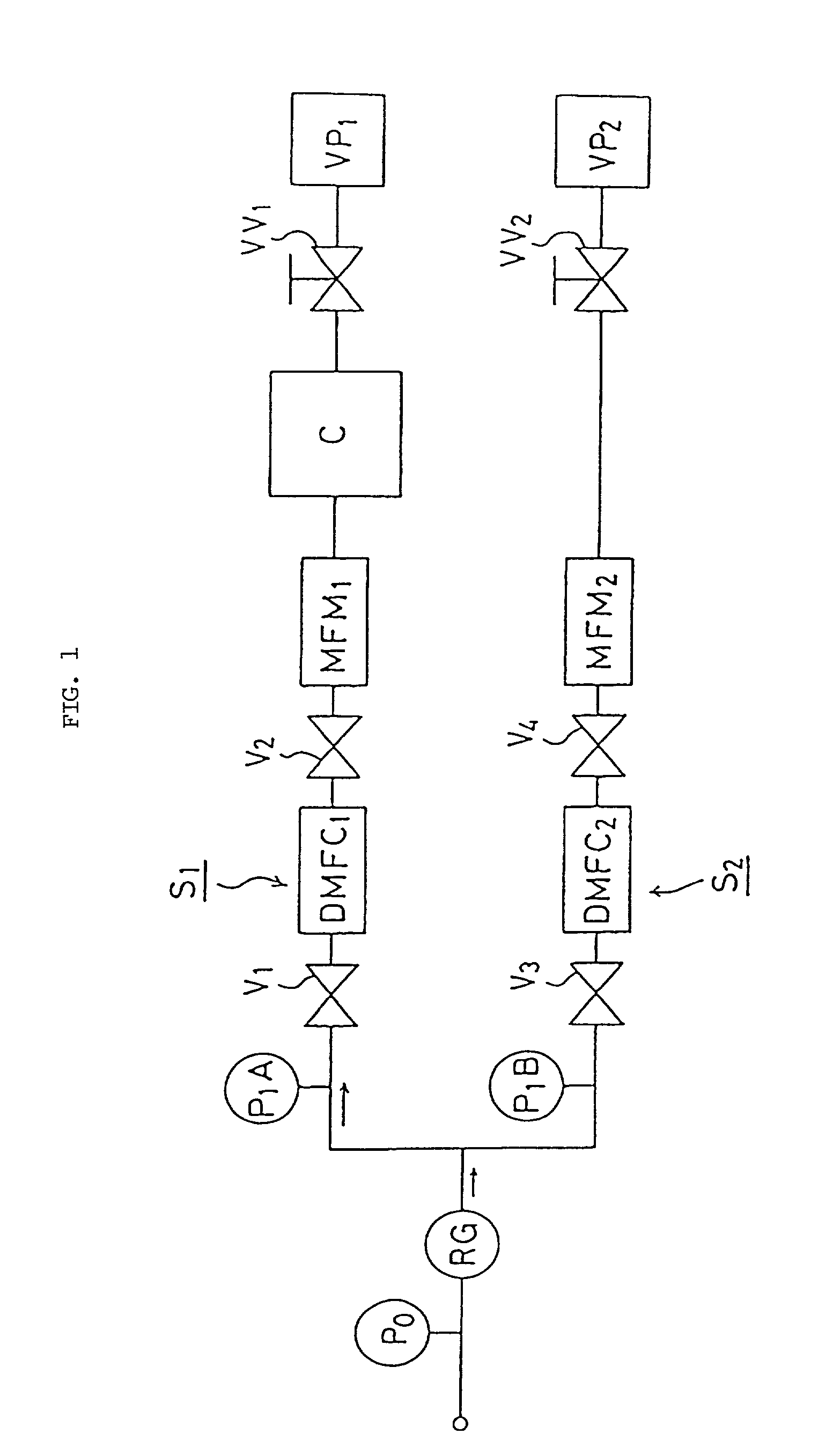

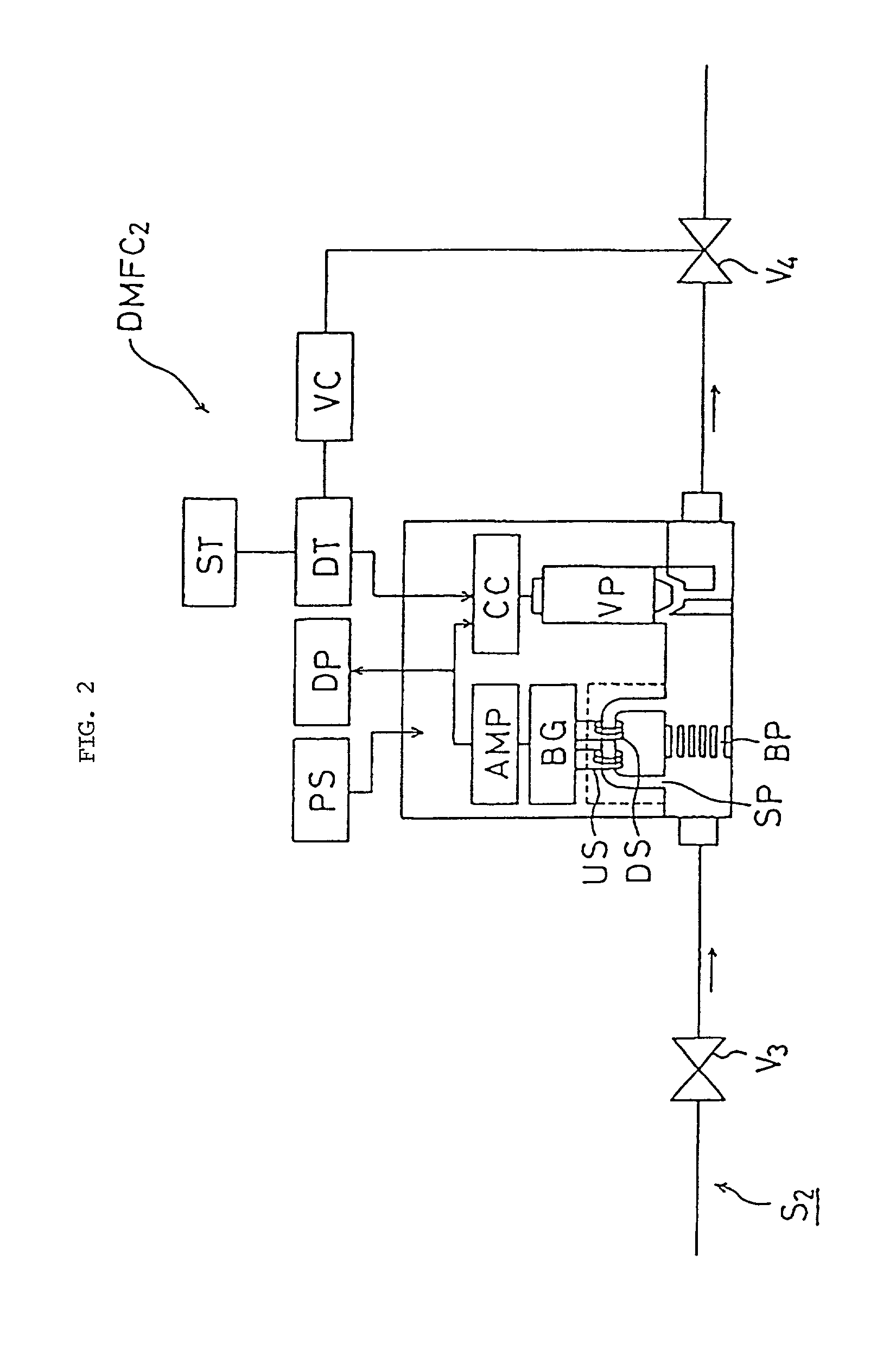

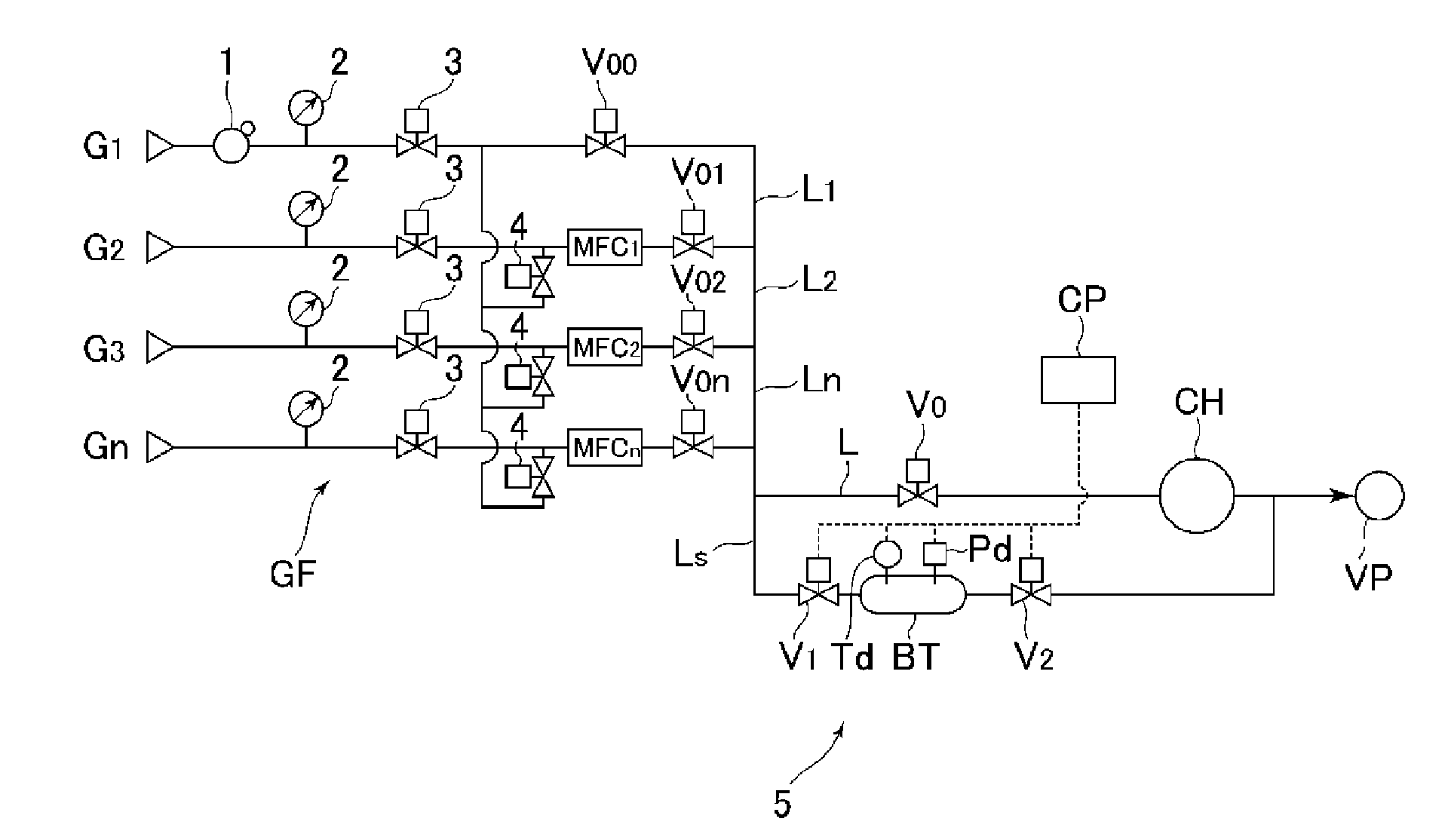

Parallel divided flow-type fluid supply apparatus, and fluid-switchable pressure-type flow control method and fluid-switchable pressure-type flow control system for the same fluid supply apparatus

InactiveUS20010004903A1Operating means/releasing devices for valvesTime-programme switchesStandard stateControl system

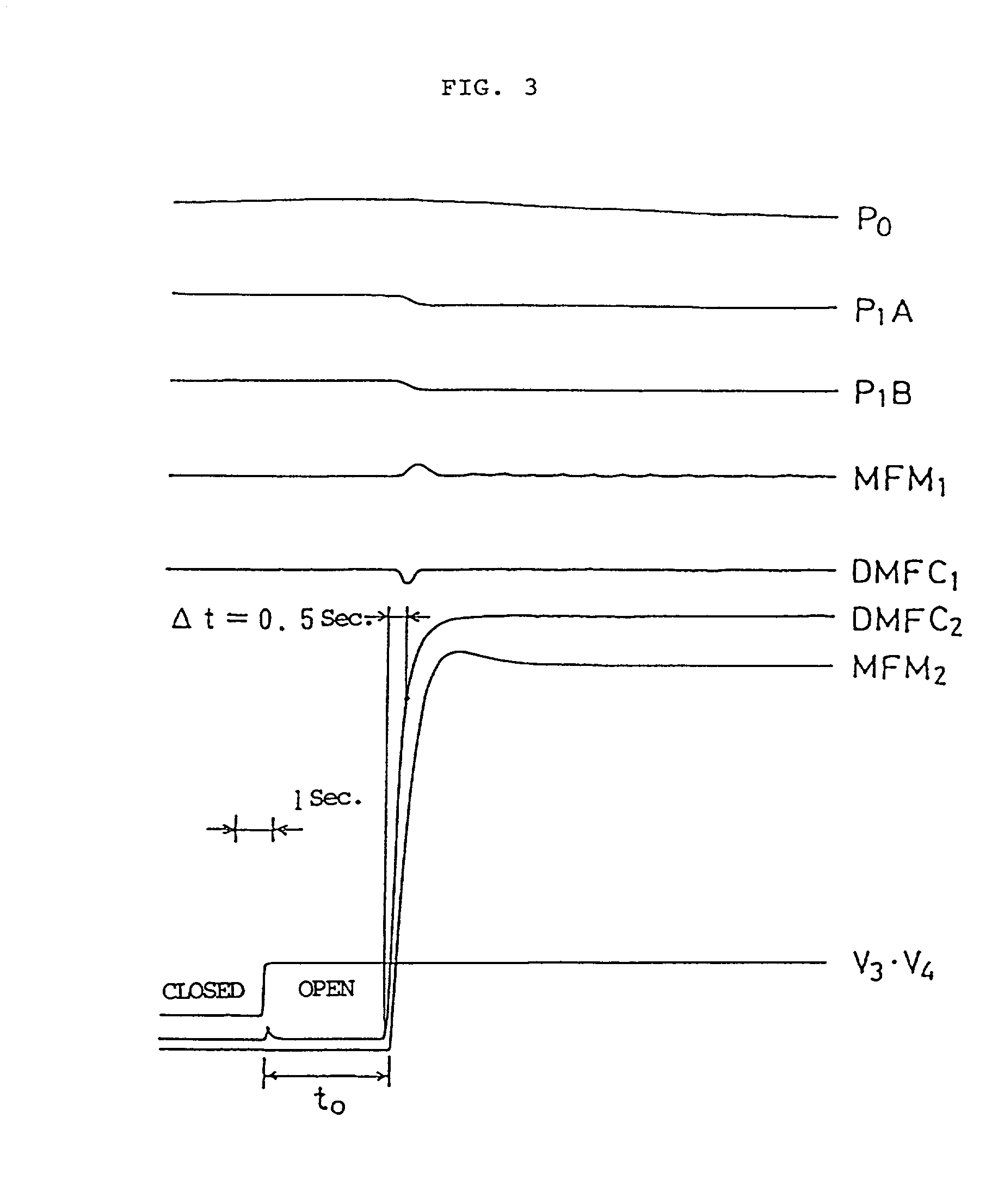

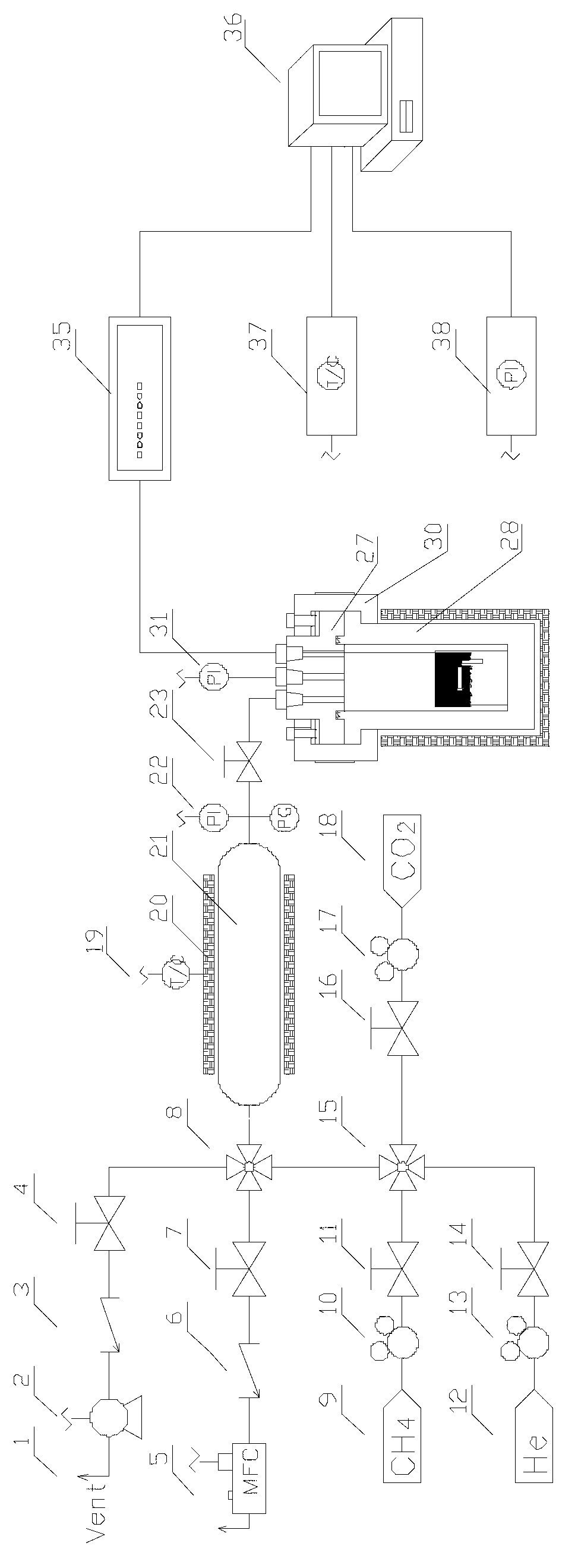

A fluid supply apparatus with a plurality of flow lines branching out from one regulator for adjustment of pressure, the flow lines being arranged in parallel, wherein a measure is taken that the operation, that is, opening or closing of one flow passage will have no transient effect on the steady flow of the other flow passages. For this purpose, each flow passage is provided with a time delay-type mass flow controller MFC so that when one closed fluid passage is opened, the mass flow controller on that flow passage reaches a set flow rate Qs in a specific delay time DELTAt from the starting point. Also provided are a method and an apparatus for the above in which a plurality of gas types can be controlled in flow rate with high precision by one pressure-type flow control system. To that end, a formula for calculating the flow rate of a gas is theoretically derived that flows with a pressure ratio not higher than the critical pressure ratio. From that formula, the flow factor is defined, so that the formula may be applied to a number of gas types using flow factors. The method includes calculating the flow rate Qc of a gas passing through an orifice according to formula Qc=KP1 (K=constant) with a pressure P1 on an upstream side of the orifice set at twice or more higher than pressure P2 on a downstream side, wherein the flow factor FF for each kind of gas is calculated as follows: <paragraph lvl="0"><in-line-formula>FF=(k / gammas){2 / (kappa+1)}1 / (kappa-1)[kappa / {(kappa+1)R}]½< / in-line-formula>and wherein, if the calculated flow rate of gas type A is QA, and, when gas type B is allowed to flow through the same orifice under the same pressure on the upstream side and at the same temperature on the upstream side, the flow rate QB is calculated as follows: <paragraph lvl="0"><in-line-formula>QB=(FFB / FFA)QA < / in-line-formula>where gammas=concentration of gas in standard state; kappa=ratio of specific heat of gas; R=constant of gas; K=proportional constant not depending on the type of gas; FFA=flow factor of gas type A; and FFB=flow factor of gas type B.

Owner:FUJIKIN INC +2

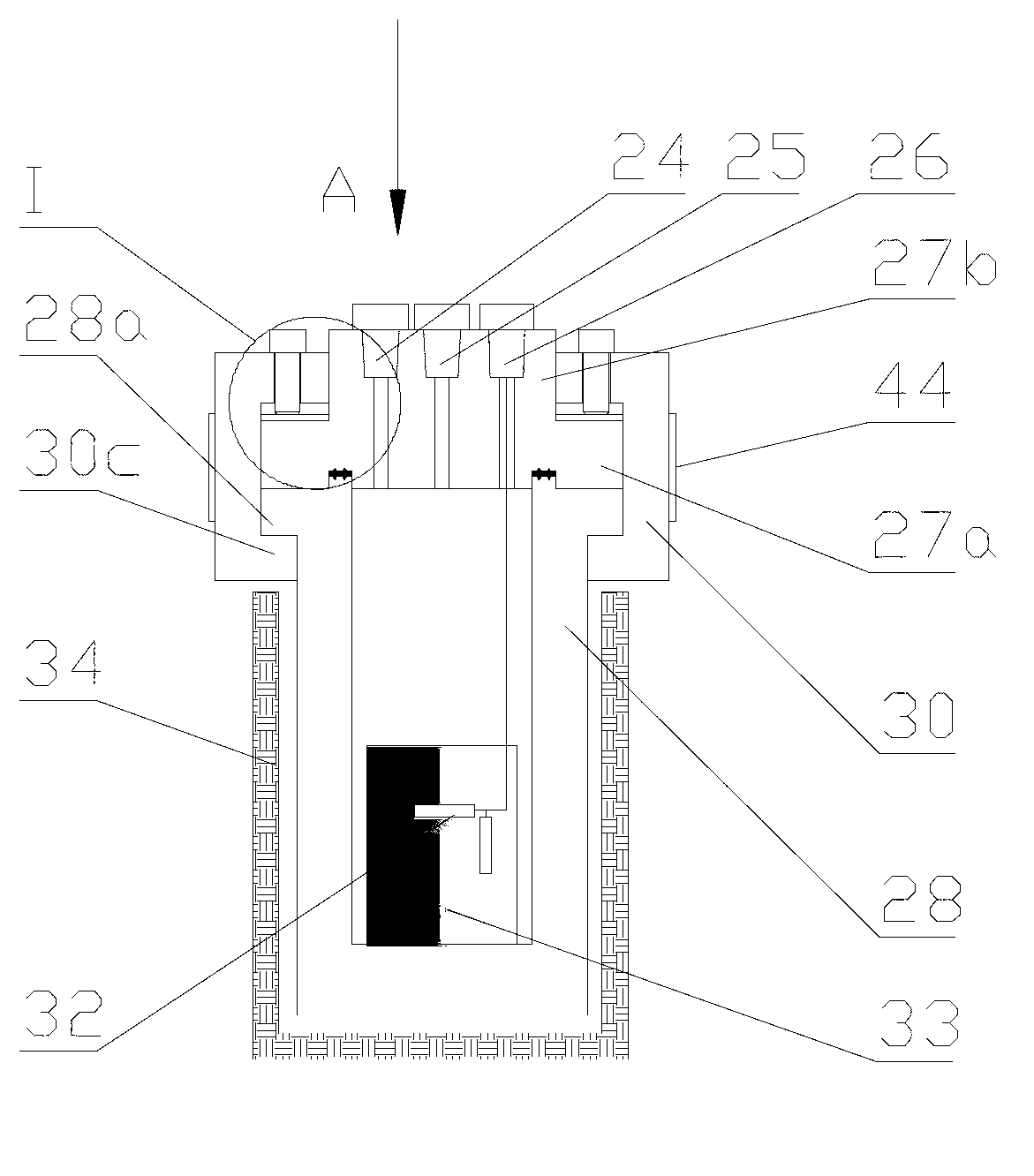

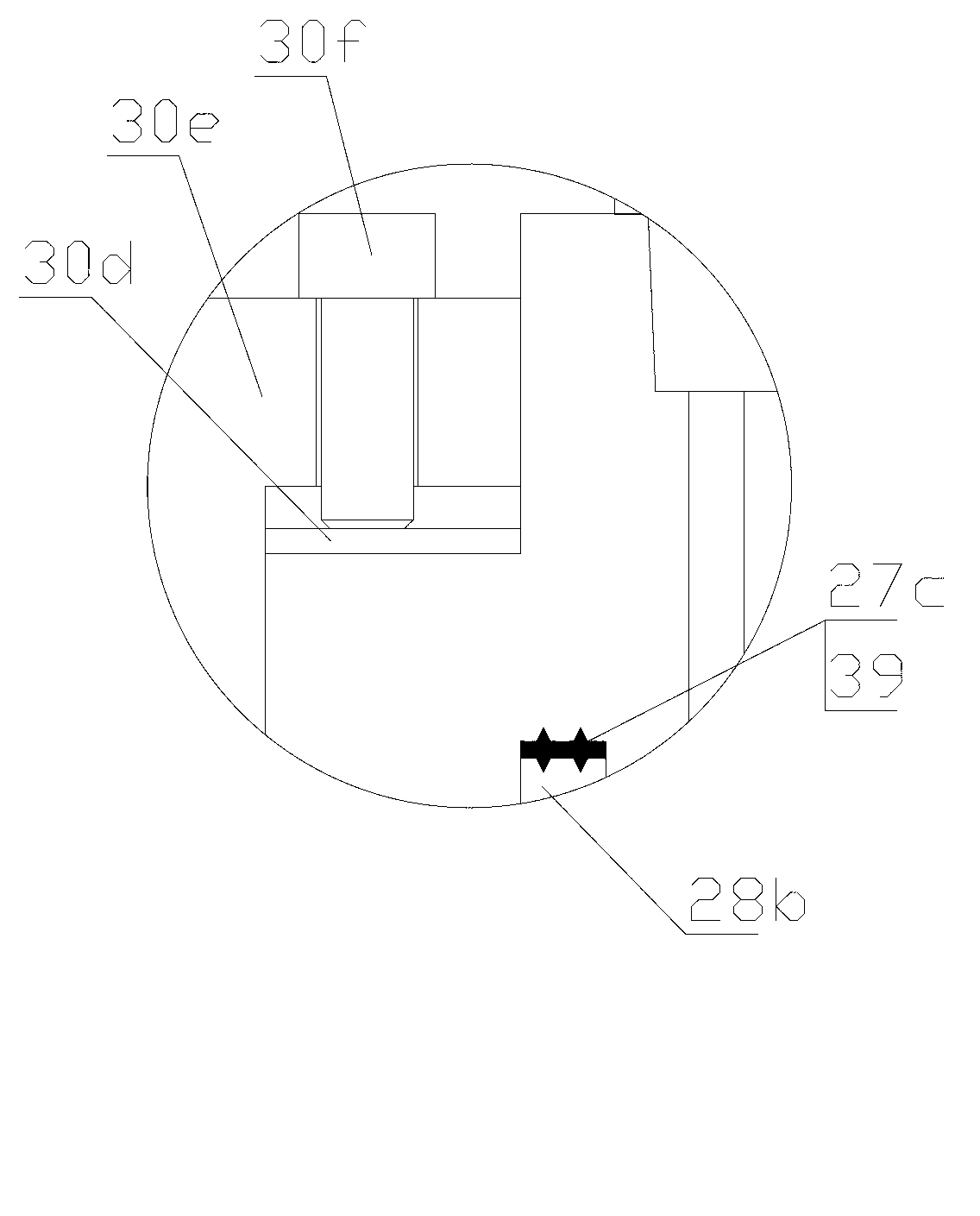

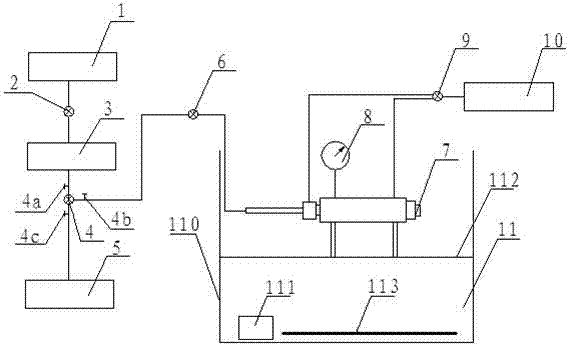

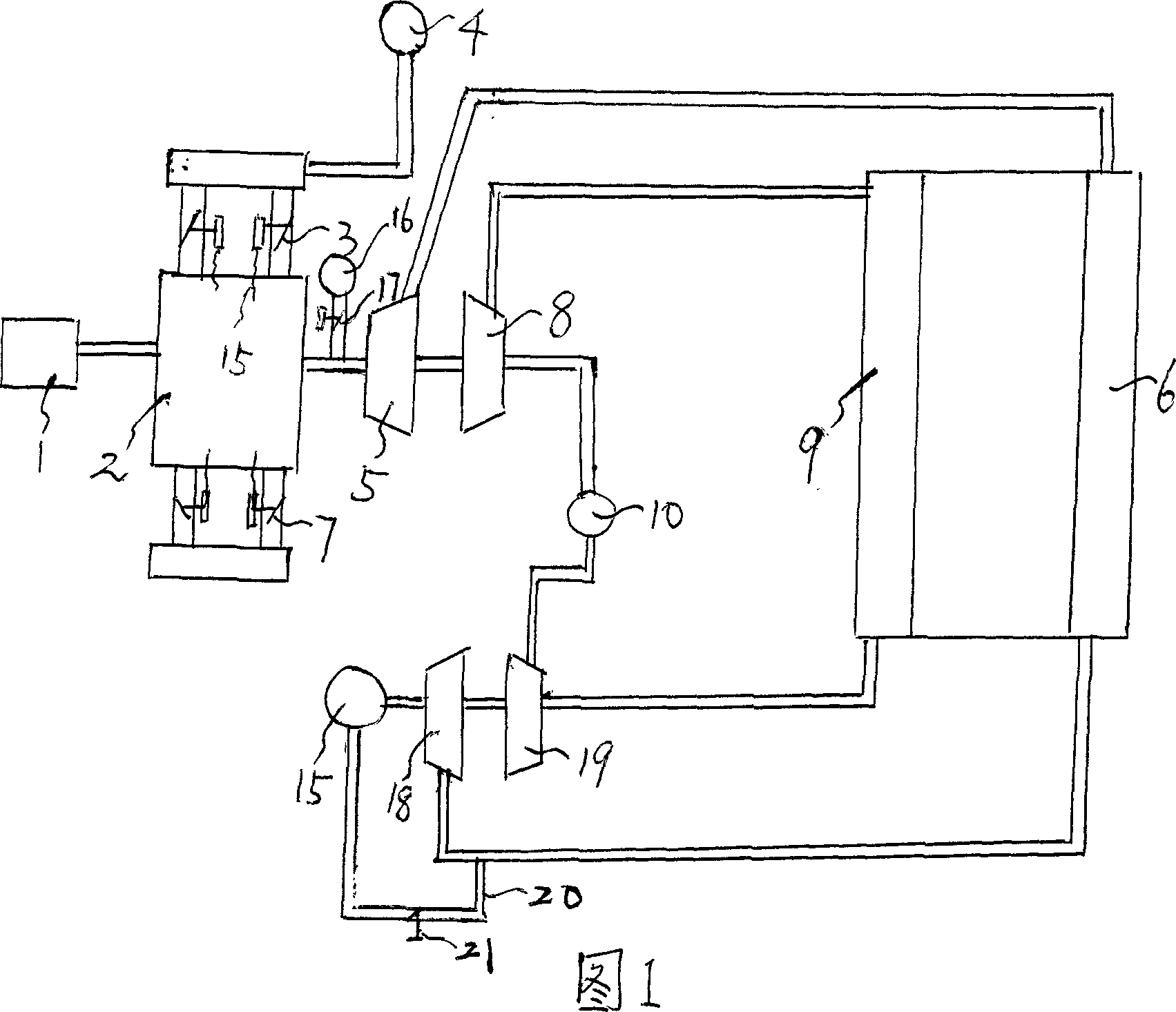

Coalbed gas high pressure desorption instrument

The invention relates to a coal bed gas high pressure desorption meter, while the prior coal bed gas high pressure constant temperature adsorption instruments utilizes coal powder samples to test coal bed gas constant temperature adsorption parameters, and the coal bed gas desorption test generally utilizes normal-pressure desorption instruments, to test the parameters of drilling well coal core, such as coal bed gas content and adsorption time and the like. The coal bed gas high pressure desorption meter comprises an automatic temperature control water bath apparatus, a stainless steel mechanical device, and an image and pressure data acquisition system, wherein the stainless steel mechanical device comprises a gas collection cylinder, a sample cylinder, a gas regulation cylinder, a frame, a high pressure pipeline and a valve, the cylinder is fixed on the frame, the frame and the cylinder are arranged in the automatic temperature control water bath device, and the frame is connected with a lifting machine. The invention can effectively simulate reservoir bed conditions and discharge-mining working systems, realize the switch between gas-solid two-phase system and gas-liquid-solid three-phase system under high pressure condition, the desorption, gas collection and measurement processes under high pressure water injection conditions, effectively observe the desorption of coal bed gas, and test the parameters such as desorption pressure, desorption quantity and lost gas quantity and the like.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Dynamic deformation characteristic testing method in coal absorption and desorption process

InactiveCN103018132ASolve the problem of simultaneous measurement of deformationImprove stabilityElectrical/magnetic solid deformation measurementMaterial analysisGas cylinderDesorption

The invention discloses a dynamic deformation characteristic testing method in a coal absorption and desorption process. The method comprises the following steps: (1) measuring empty volumes of a high-pressure air accumulation bottle and a high-pressure absorption and desorption tank; (2) mounting samples; (3) measuring the free space volume of the absorption and desorption tank; (4) implementing the dynamic coal evolutionary process test in a gas isothermal constant-volume absorption process; (5) implementing the dynamic coal evolutionary process test in a gas isothermal constant-pressure absorption process; (6) implementing the absorption-desorption dynamic evolution process test under the gas constant-volume and variable-temperature condition; (7) implementing the dynamic coal evolutionary process test in a gas competitive absorption process; and (8) implementing the dynamic coal evolutionary process test in a gas desorption process. The method is easy to operate; and the accuracy of test results is high.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

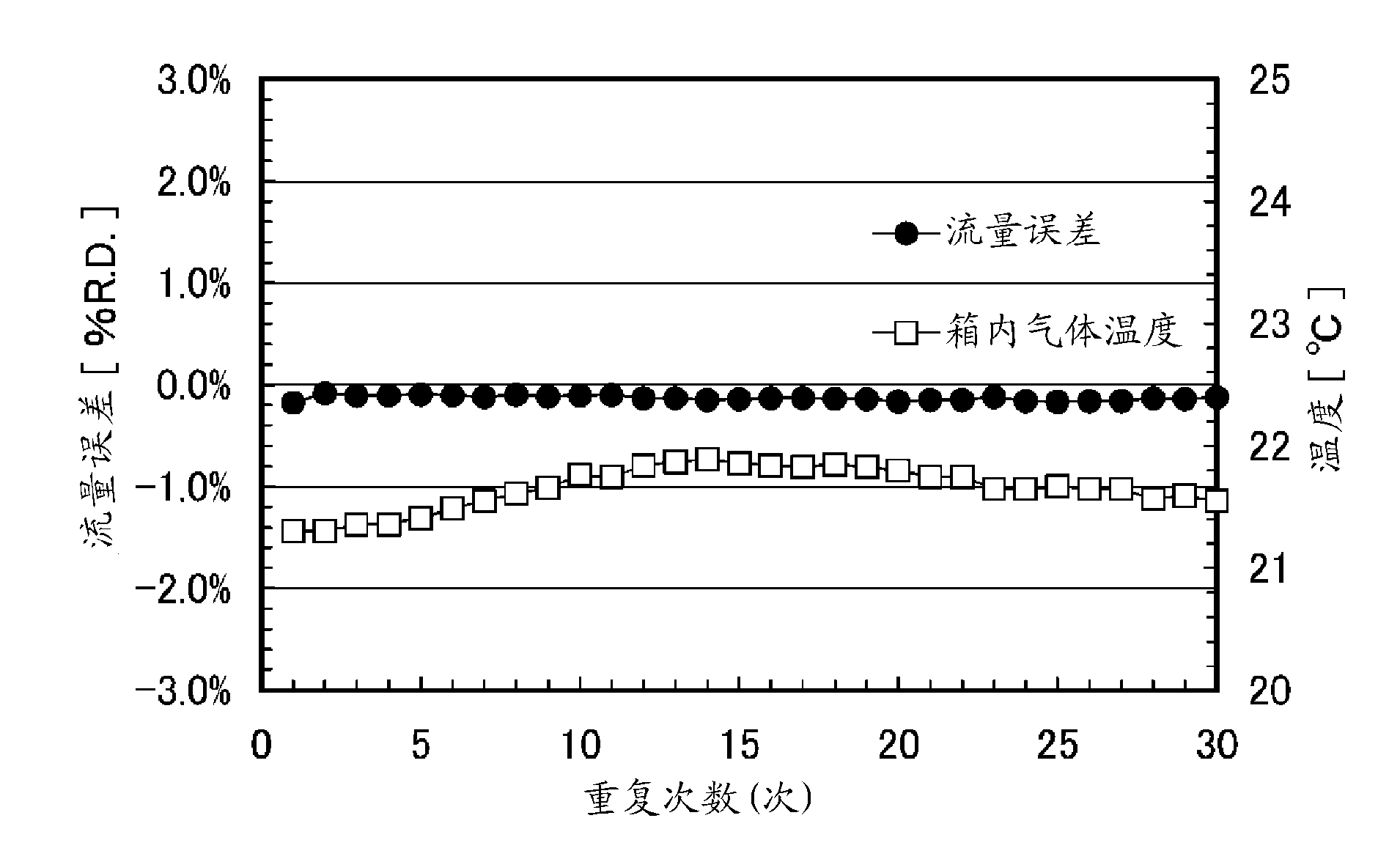

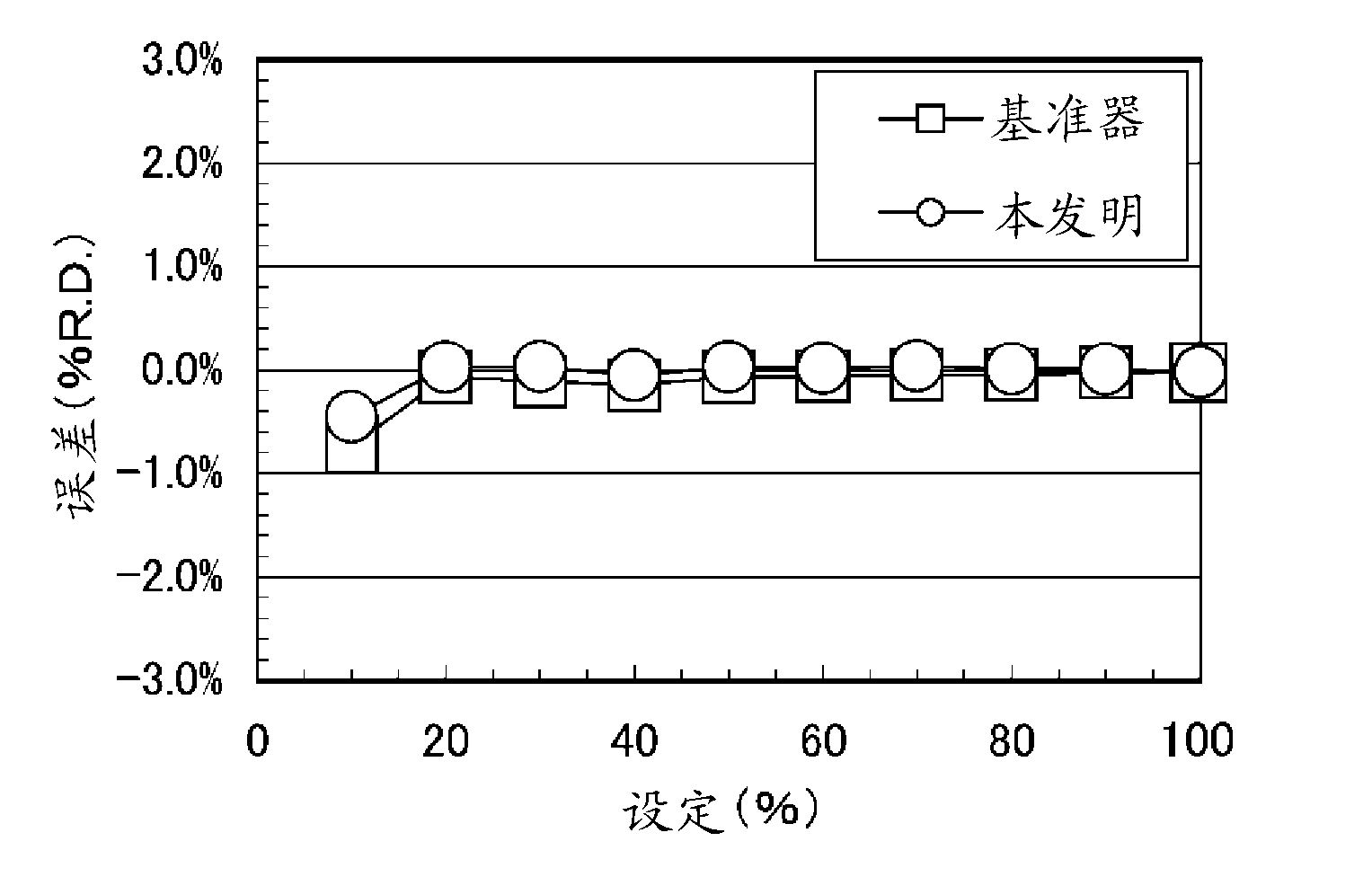

Calibration method and flow-rate measurement method for flow-rate controller of gas supplying apparatus

ActiveCN103003766AEasy CalibrationQuick correctionTesting/calibration apparatusFlow control using electric meansProcess engineeringGas supply

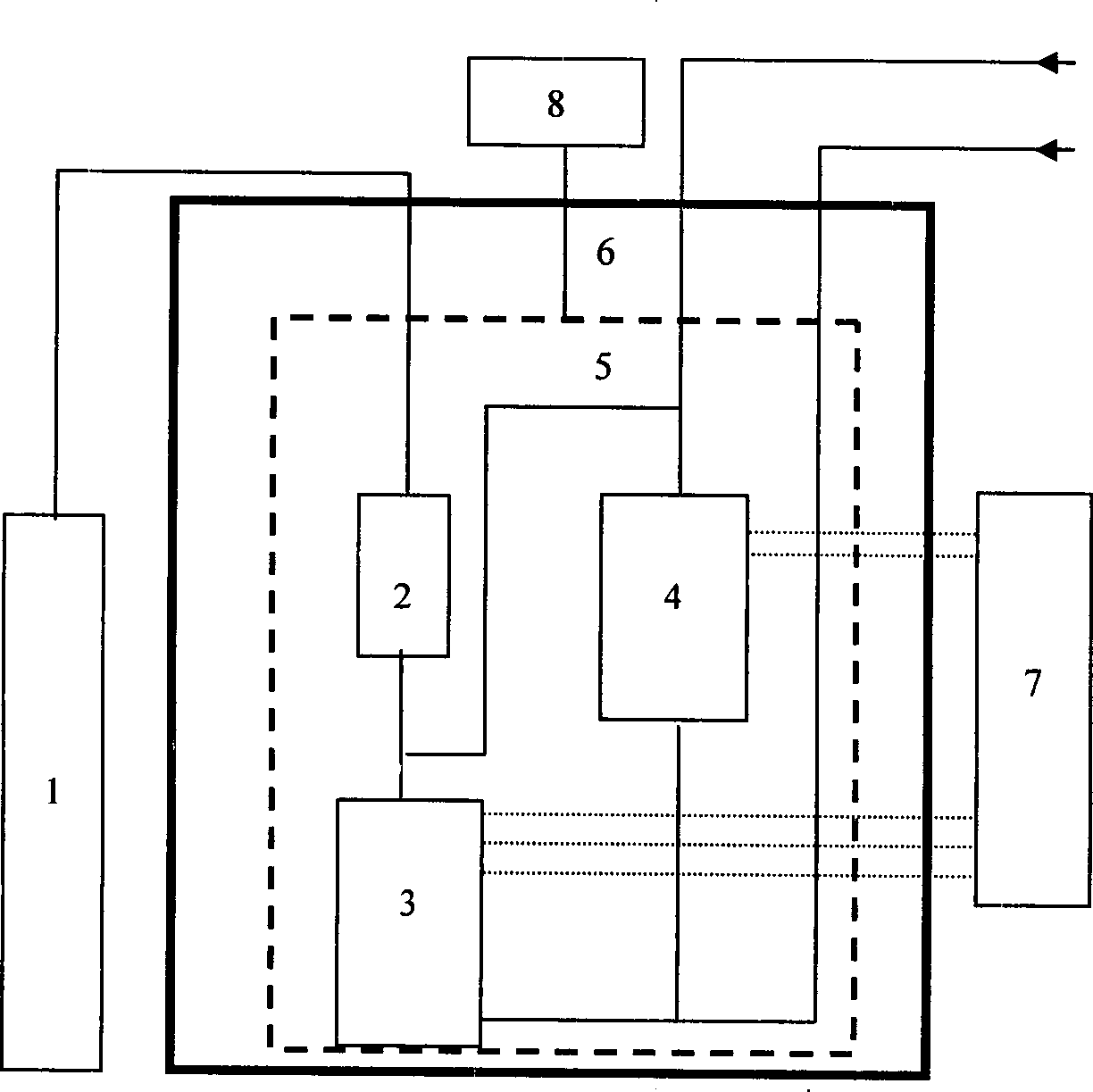

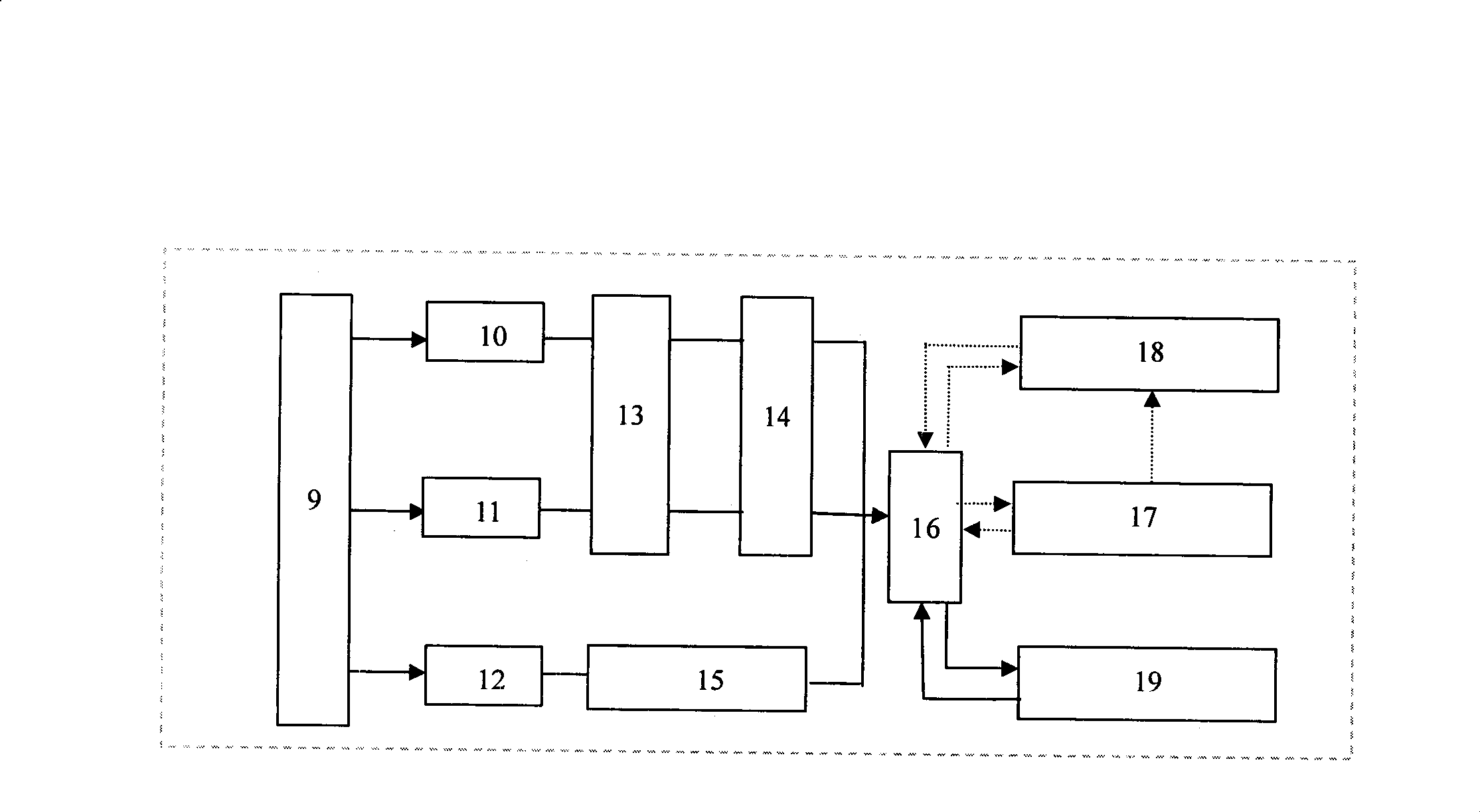

Flow-rate calibration is executed, by opening just an exit-side opening / closing valve of a flow-rate controller to be calibrated and letting gas with a set flow-rate flow into a calibration unit (5), measuring, at time (t0) when gas temperature and gas pressure within a tank (BT) has stabilized, the gas temperature (T0) and the gas pressure (P0) within the tank (BT) for the first time, then closing an exit-side opening / closing valve (V2) of the calibration unit (5) to build up gas within the tank (BT), closing an entrance-side opening / closing valve (V1) of the calibration unit (5) at time (t1) and measuring the gas temperature (T2) and the gas pressure (P2) within the tank for the second time at time (t2), which is subsequent to the closing of the entrance-side opening / closing valve (V1), calculating the gas flow-rate (Q) from the measured values with a formula of Q = (22.4V / R DEG.t); (P2 / T2-P0 / T0) (wherein V is the internal volume of the tank (BT), R is the gas constant, and t is the build-up time (t1 - t0)), and comparing the gas flow rate that was set and the calculated as flow rate (Q).

Owner:FUJIKIN INC

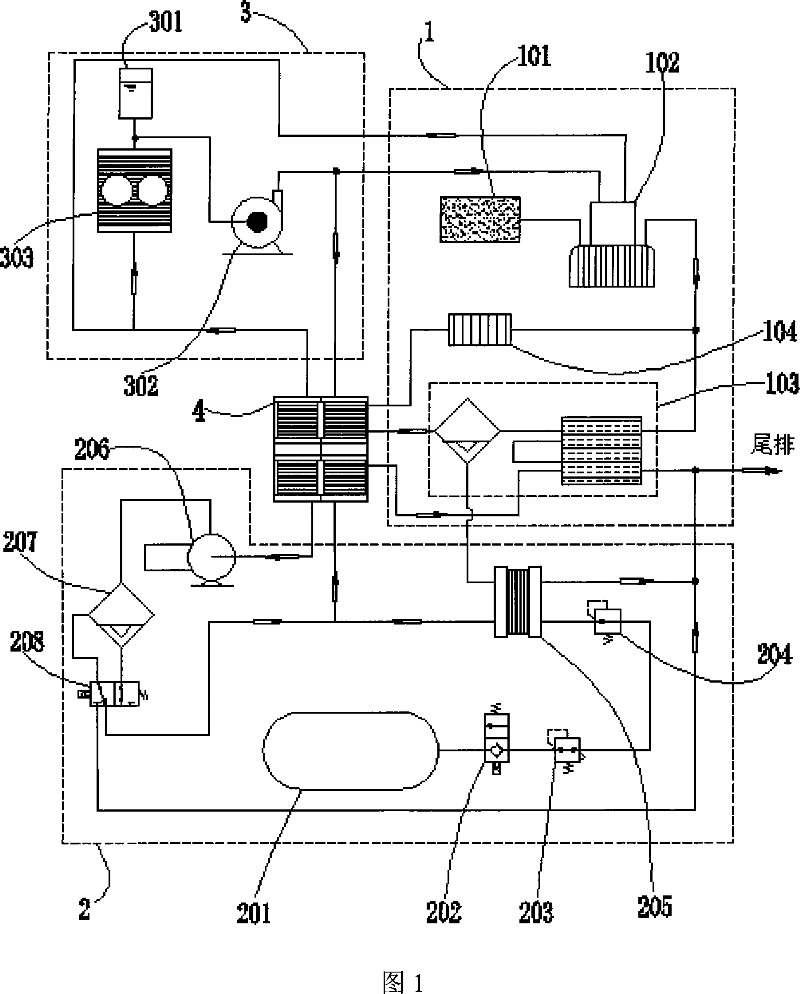

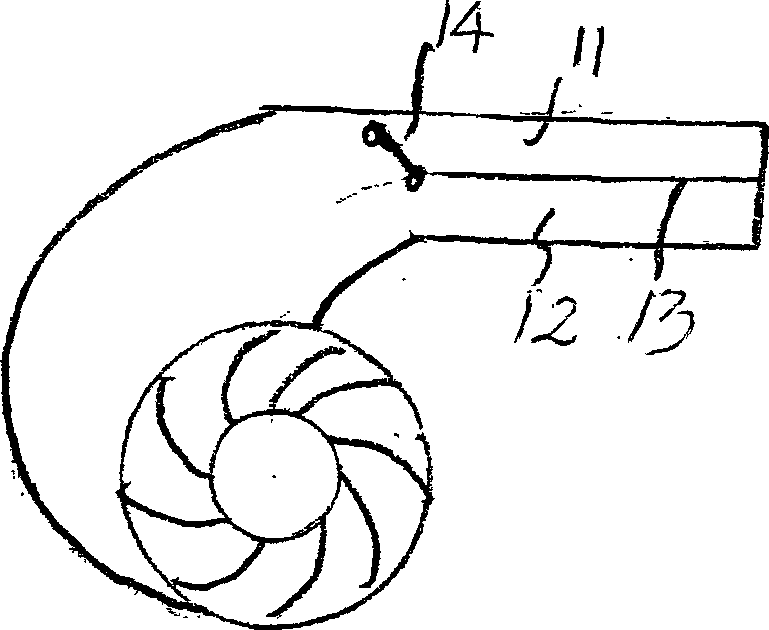

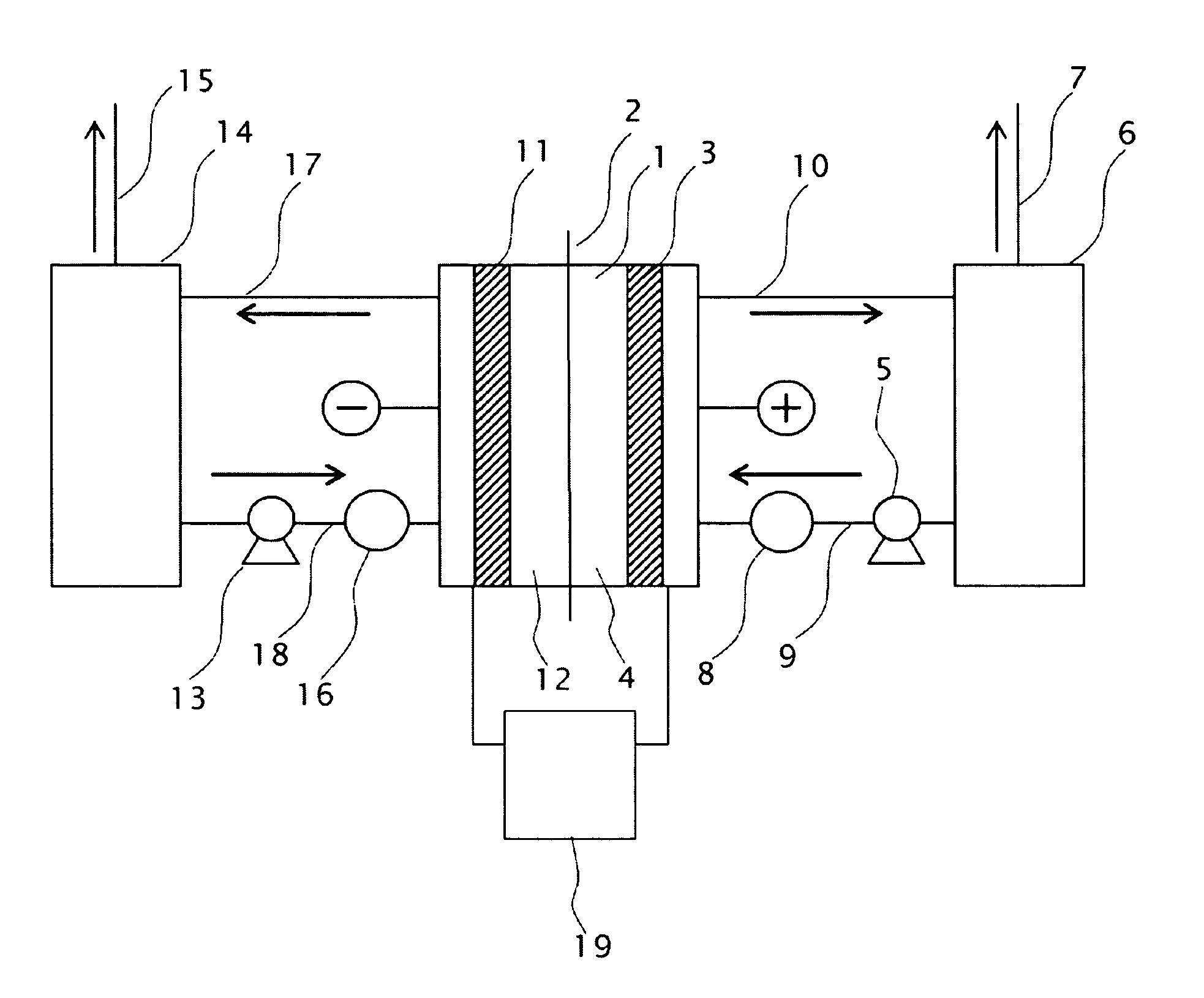

Fuel batter system with proton exchange film used for high-performance vehicle and ship

ActiveCN101043082ALow oxygenAccelerated corrosionFuel cell heat exchangeSolid electrolyte fuel cellsAir filterSolenoid valve

A high-performance proton exchanging film fuel battery system flow which is used in vehicle and ship includes fuel battery, air system flow, hydrogen gas system flow and cooling part flow. The air system flow element includes: air filter, air supply arrangement (direct current speed governing fan or air compressor), air damp conversion device equipped with water separater, radiator; the hydrogen gas system flow includes: high-pressure hydrogen gas tank, normally closed two-position two-way solenoid valve, hydrogen gas high-pressure decompressor, hydrogen gas constant pressure arrangement, hydrogen gas humidifying device, hydrogen gas reflux pump, hydrogen gas water separater, two-position three-way solenoid valve; the cooling system element includes: water tank, direct current speed governing pump and radiator. The structure of the invention is simple, the efficiency is high, service life is long, and it fits for proton exchanging film fuel battery system flow which is used in vehicle and ship.

Owner:SUNRISE POWER CO LTD

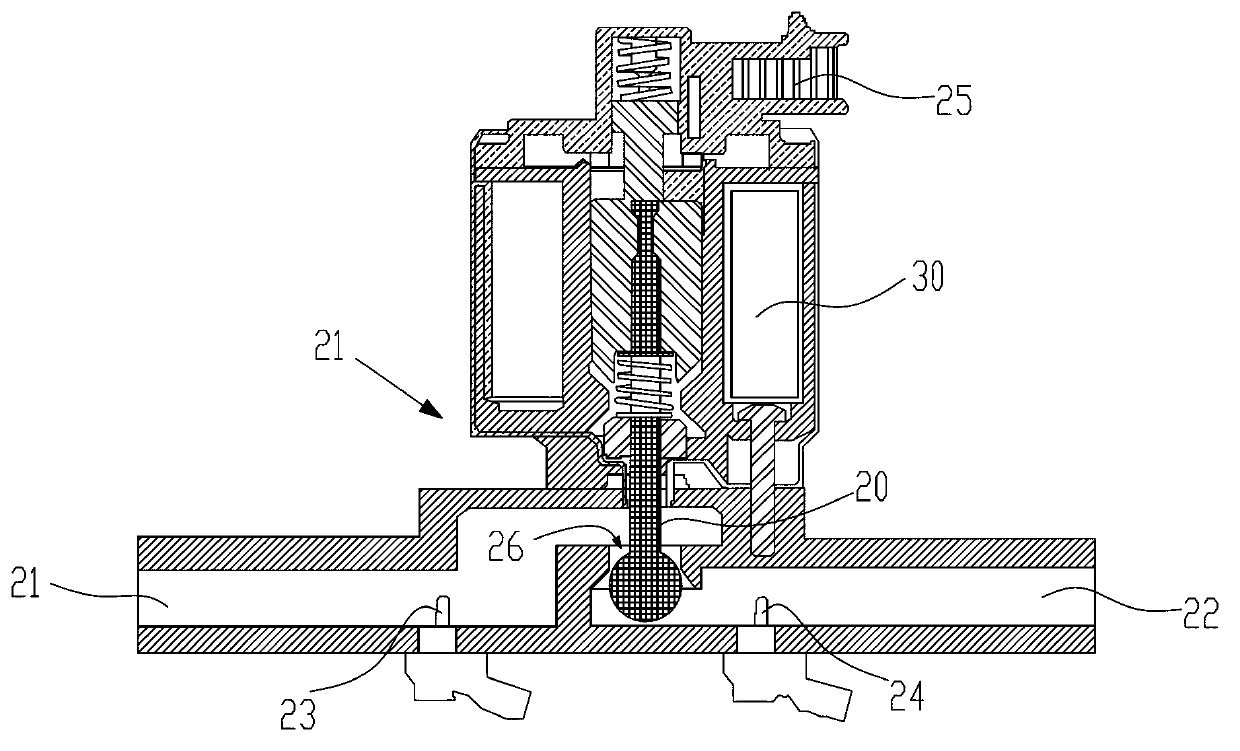

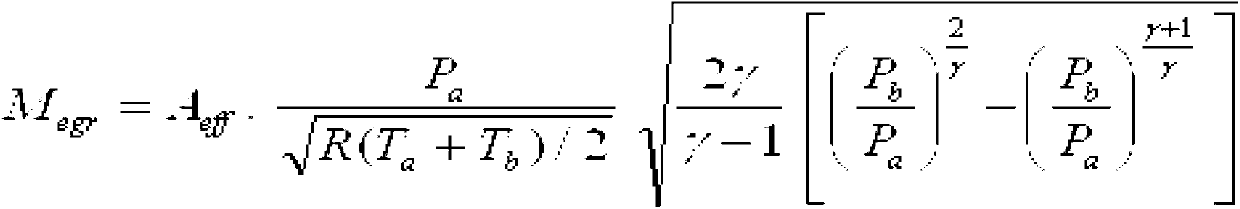

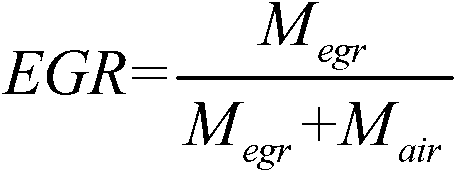

Direct measurement method of engine exhaust gas recirculation (EGR) rate and engine EGR valve

InactiveCN103105297AAccurate measurementReduce mistakesInternal-combustion engine testingInternal combustion piston enginesEngineeringExhaust gas recirculation

The invention relates to the filed of engine exhaust emission recirculation rate measurement, in particular to a direct measurement method of engine exhaust gas recirculation (EGR) rate. The direct measurement method of engine exhaust gas recirculation (EGR) rate comprises the following steps: a. measuring a fuel consumption meter and an air-fuel ratio analysis meter of the engine to obtain fuel consumption Bfuel and an excess air coefficient phi under a current working condition, calculating and obtaining the mass flow rate Mair of refresh air burning in a cylinder of the engine through the following relation: Mair=Bfuel*phi*14.5, b. measuring the pressure Pa and the temperature Ta in an exhaust gas inlet of an EGR valve and the pressure Pb and the temperature Tb in an exhaust gas outlet of the EGR valve, c. measuring the section area of an exhaust duct of an EGR valve Ao, d. calculating and obtaining an exhaust gas mass flow rate Megr of the EGR valve according to the following relation: Aeff=Ao*CFF, wherein Aeff is the actual flow section area of the EGR valve, CFF is the theoretical flow coefficient of the EGR valve, R is gas constant and gamma is specific heat ratio, and e. calculating and obtaining the engine EGR rate through the following relation: EGR=Meger / (Megr plus Mair). According to the direct measurement method of EGR rate and engine EGR valve, the EGR rate is directly measured and obtained according to the temperature and the pressure of the exhaust gas inlet and the exhaust gas outlet of the EGR valve, measurement results are precise and reflect the engine EGR rate intuitively.

Owner:CHERY AUTOMOBILE CO LTD

Leak tester

InactiveUS7290440B2Detection of fluid at leakage pointMeasurement of fluid loss/gain rateDifferential pressureGas leak

A leak tester which detects leakage of a gas from a measured object, the leak tester including a source of a pressurized gas which supplies the pressurized gas, a differential pressure detecting section which detects a pressure difference between the pressure of a gas in the measured object and the pressure of a pressurized gas supplied by the source of the pressurized gas, and a pressure adjusting section which makes the pressure of the pressurized gas supplied by the source of the pressurized gas constant.

Owner:OLYMPUS CORP

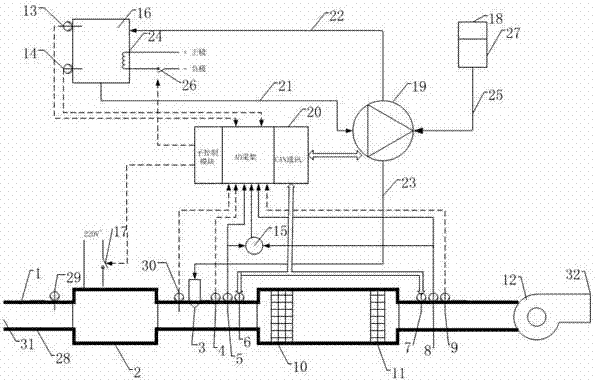

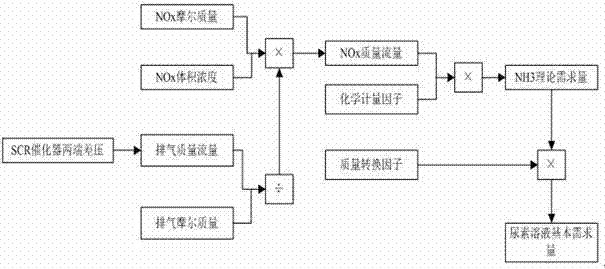

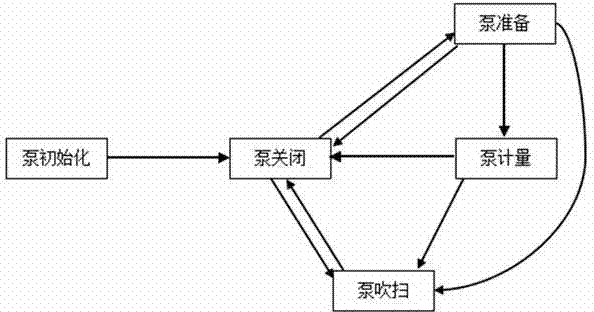

Exhaust smoke passage integrated purification system for plurality of diesel engine test table frames

InactiveCN104775876AStrong technical sustainabilityReduce contentInternal-combustion engine testingInternal combustion piston enginesParticulatesEngineering

The invention relates to an engine exhaust smoke passage integrated purification treatment technology for diesel engine test table frames, in particular to an exhaust smoke passage integrated purification system for a plurality of diesel engine test table frames. The exhaust smoke passage integrated purification system comprises a smoke gas constant-temperature pre-heating system, a urea metering spraying system, a urea water solution storage system, a compressed air purification system, a catalysis system, a control system and a monitoring system. An SCR (selective catalytic reduction) technology is used, the content of nitric oxides in the smoke gas can be effectively reduced, and the conversion efficiency can be higher than 90 percent; meanwhile, a DOC technology is used, HC in the smoke gas, CO, volatile organic compounds adsorbed on the surfaces of particles and the like can be oxidized into CO2, H2O and the like, so that the goal of lowering the particle exhaust total quantity is achieved, the harmful gas removing rate can reach 90 percent, and the total quantity of the particles can be reduced by 20 percent to 30 percent. The technology continuity of the whole set of smoke gas integrated purification system is high.

Owner:JIANGSU UNIV

Cellulose acetate propionate film, process for producing cellulose acetate propionate film, optical compensation sheet, polarizing plate and liquid crystal display device

InactiveUS20080227881A1High elastic modulusHigh mechanical strengthNon-linear opticsOptical elementsCrystallographyDynamic viscoelasticity

A cellulose acetate propionate film has a density νe of entanglement points of a polymer chain of cellulose acetate propionate represented by the following expression (A) of from 0.3 to 2.0 moles / dm3:νe=ER′ / 3RTR (A)wherein R represents a gas constant; ER′ represents a storage elastic modulus in a rubbery state plateau upon measurement of a dynamic viscoelasticity; and TR represents a temperature in the rubbery state plateau.

Owner:FUJIFILM CORP

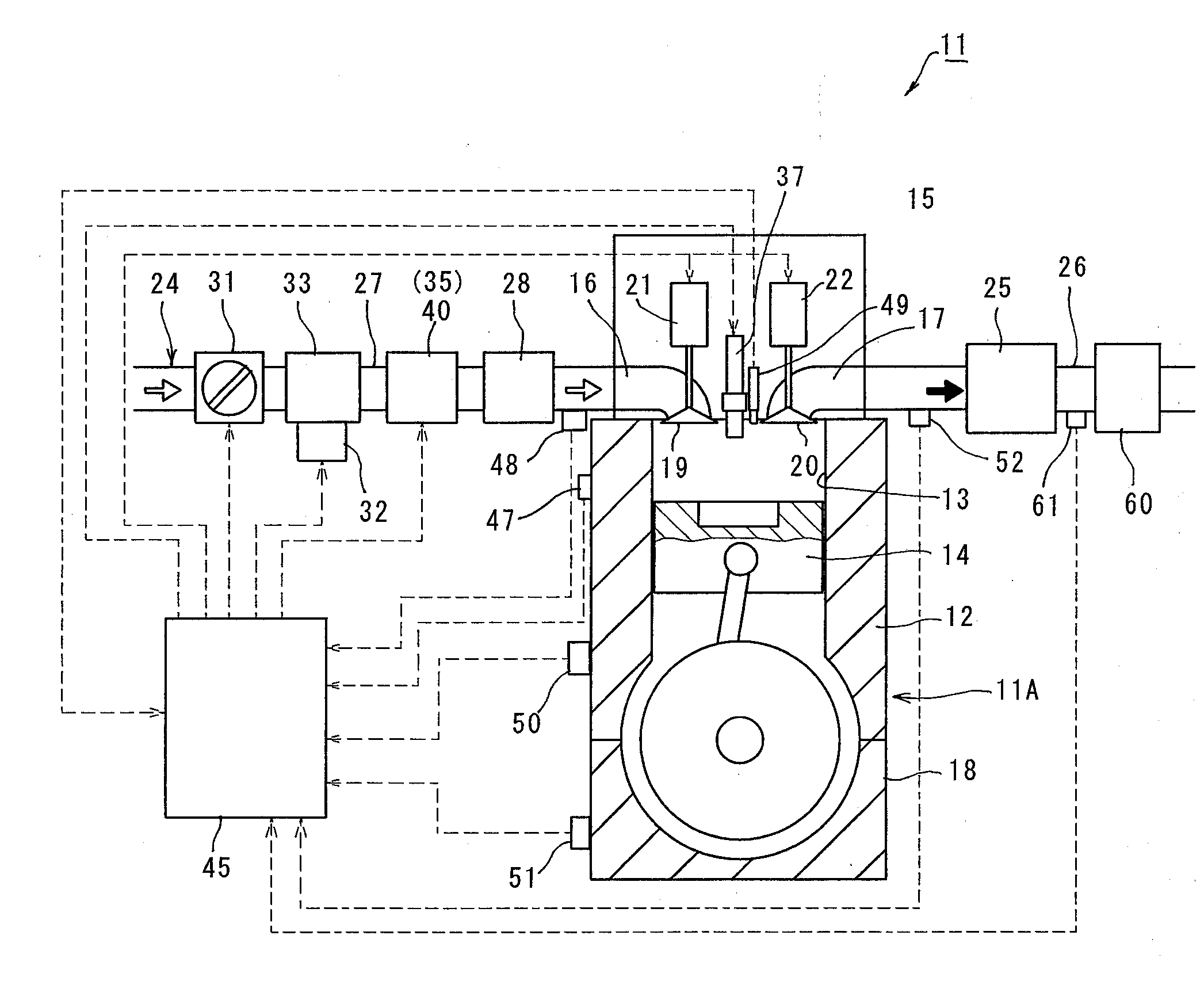

Homogeneous Charge Compressed Ignition Engine Operating Method

InactiveUS20100012079A1Expand the scope of operationPromote generationElectrical controlAutomatic controlHomogeneous charge compression ignitionTemperature control

An aspect of the invention provides a method for operating a workable homogeneous charge compressed ignition engine in which a compression ignition operation is performed by spark ignition to shorten a load input time and a load cutoff time. In the homogeneous charge compressed ignition engine operating method, a mixture gas is burned by compression ignition in a combustion chamber, and fuel and air are previously mixed to produce the mixture gas. The homogeneous charge compressed ignition engine includes a spark ignition device 53 which performs spark ignition to the mixture gas. A temperature controller 35 substantially keeps an intake air temperature of the mixture gas constant. A spark ignition operation, a spark-assist compression ignition operation in which spark ignition is supplementarily used, and a non-spark compression ignition operation in which the spark ignition is not used are switched according to magnitude of a load.

Owner:YANMAR POWER TECHNOLOGY CO LTD

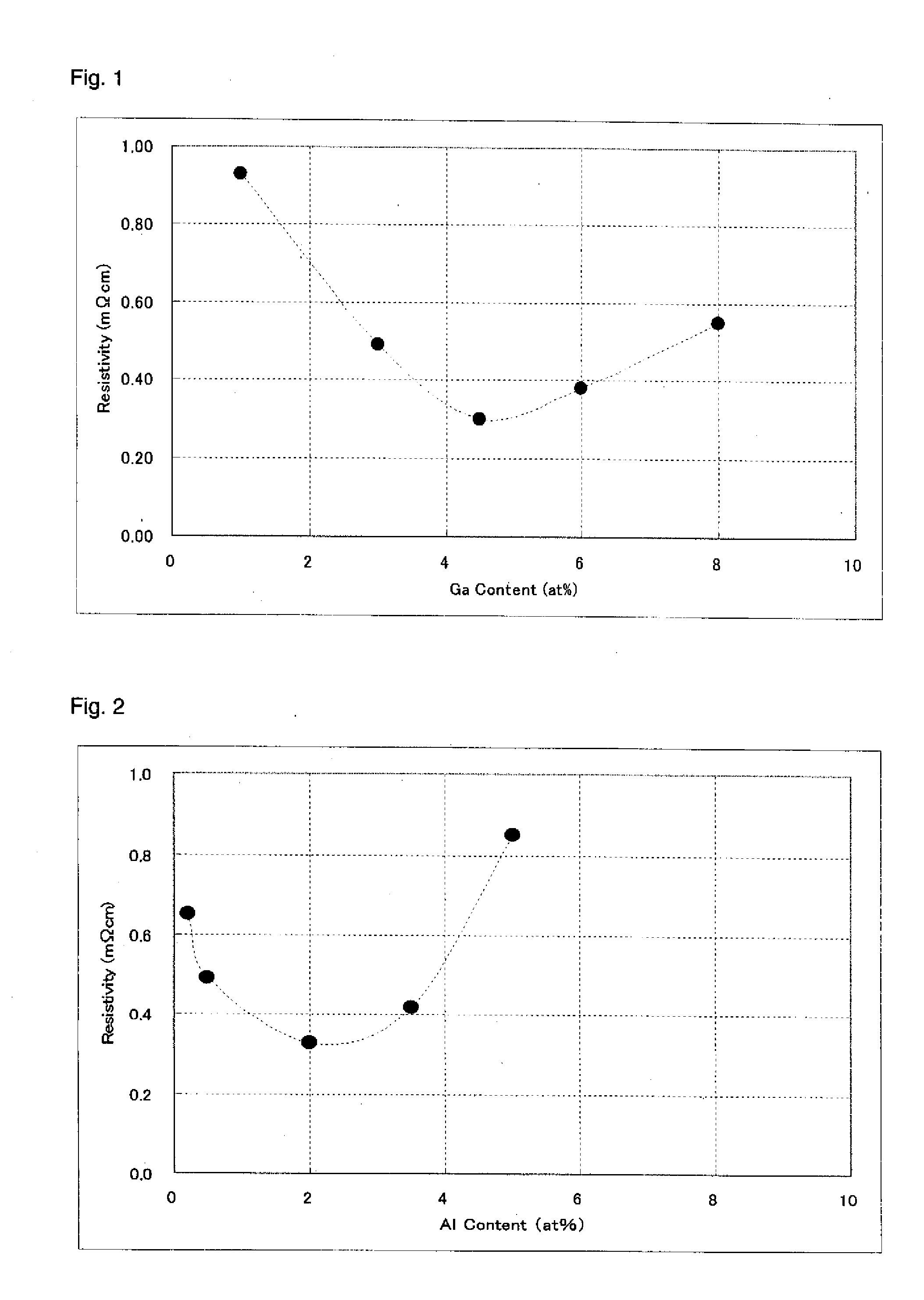

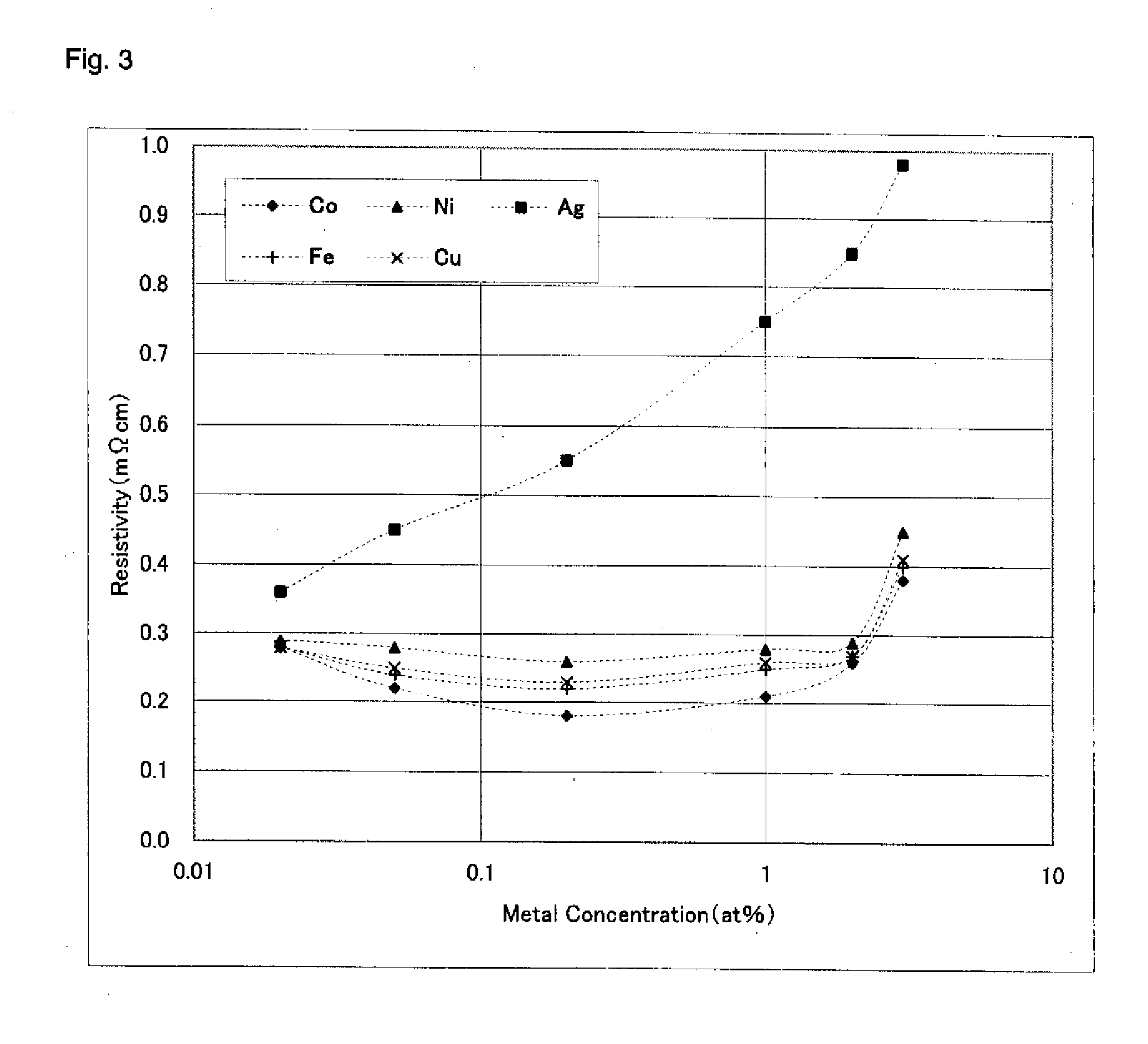

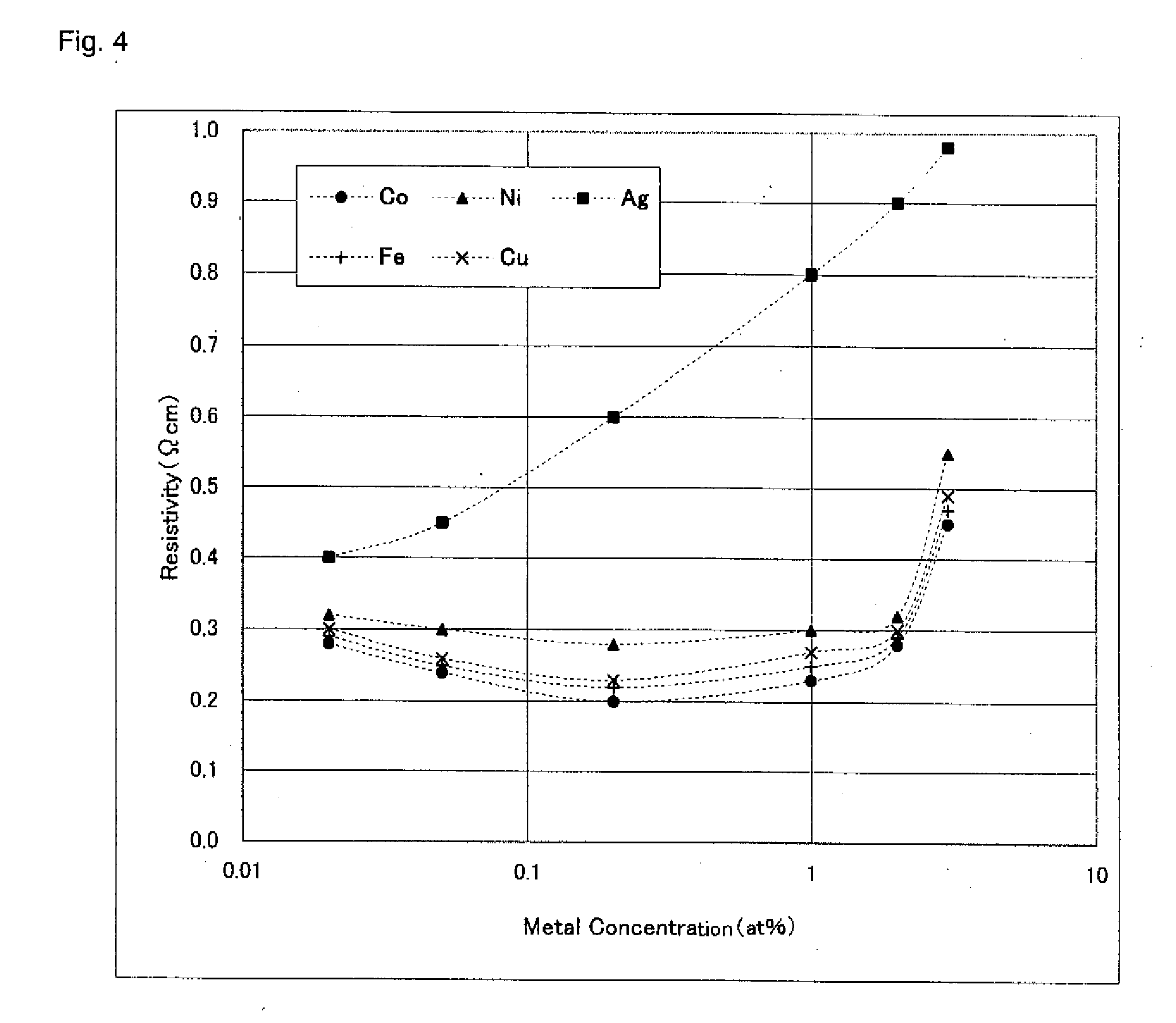

Zinc Oxide Based Transparent Electric Conductor, Sputtering Target for Forming of the Conductor and Process for Producing the Target

ActiveUS20090200525A1Low resistivityDeteriorates mobilityCellsConductive layers on insulating-supportsResource depletionGibbs free energy

Provided is a zinc oxide transparent electric conductor having zinc oxide (ZnO) as its principal component, containing an element to become an n-type dopant to zinc oxide, containing metal M in which P(P=(G+H mix) / RT, wherein G is the Gibbs free energy at temperature T of the metal, H mix is the mixing enthalpy at temperature T of zinc oxide and the metal, R is the gas constant, and T is the temperature) as a parameter showing the wettability with zinc oxide is 6 or less and in which its resistivity is smaller than the resistivity of zinc oxide added with the n-type dopant, and wherein concentration of metal M in relation to the total atomicity of zinc and the n-type dopant and metal M, which are all metal atoms configuring the zinc oxide transparent electric conductor, is 0.05 to 2.0 at %. In the development of a transparent electric conductor that does not contain raw material In which is expensive and with concern of resource depletion, provided is a low resistivity transparent electric conductor by exceeding the limits of the conventional development technique of the single dopant method, presenting guidelines for selecting a secondary additive material effective in achieving low resistivity, and indicating types of specific materials and the appropriate concentration range.

Owner:JX NIPPON MINING & METALS CO LTD

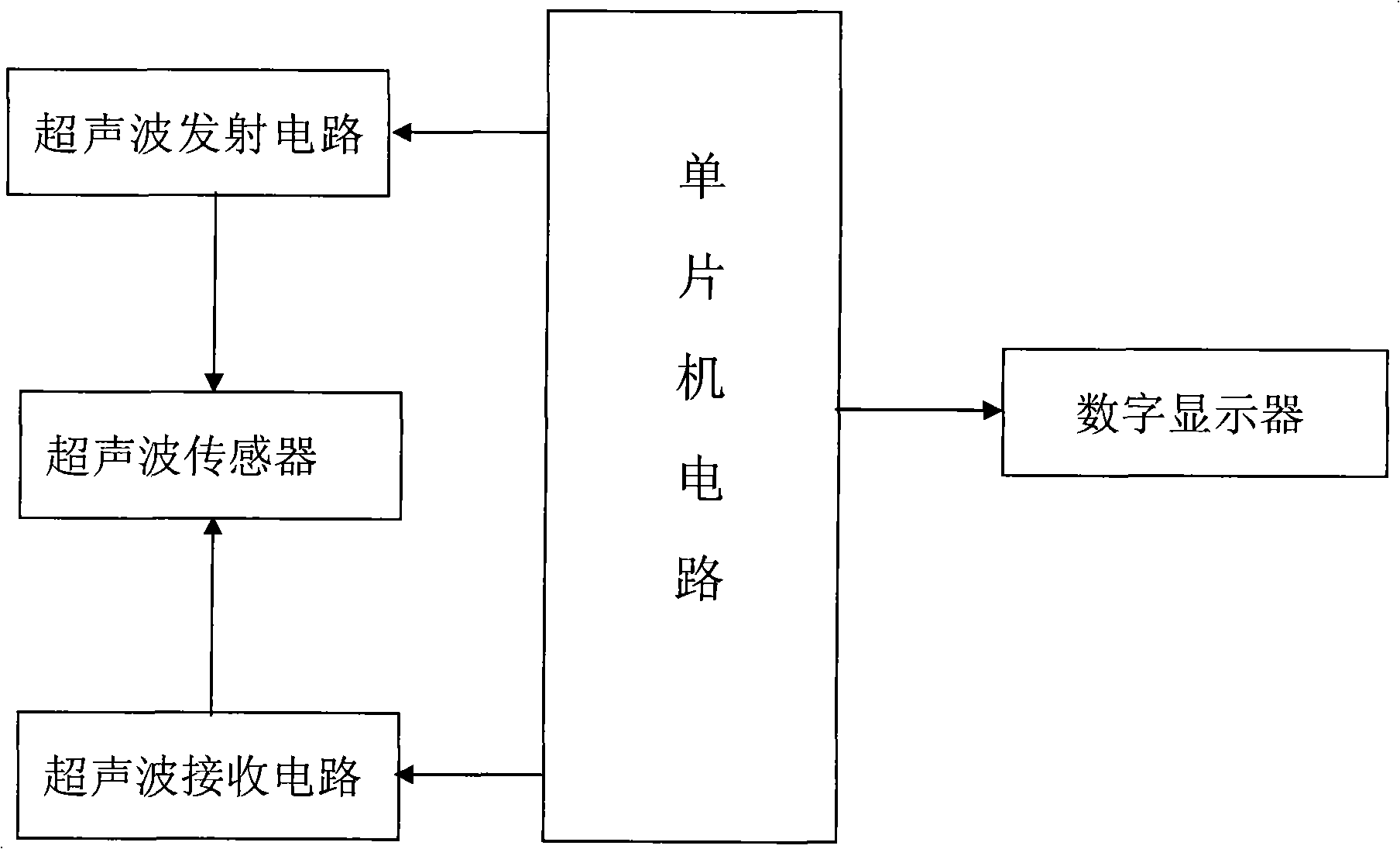

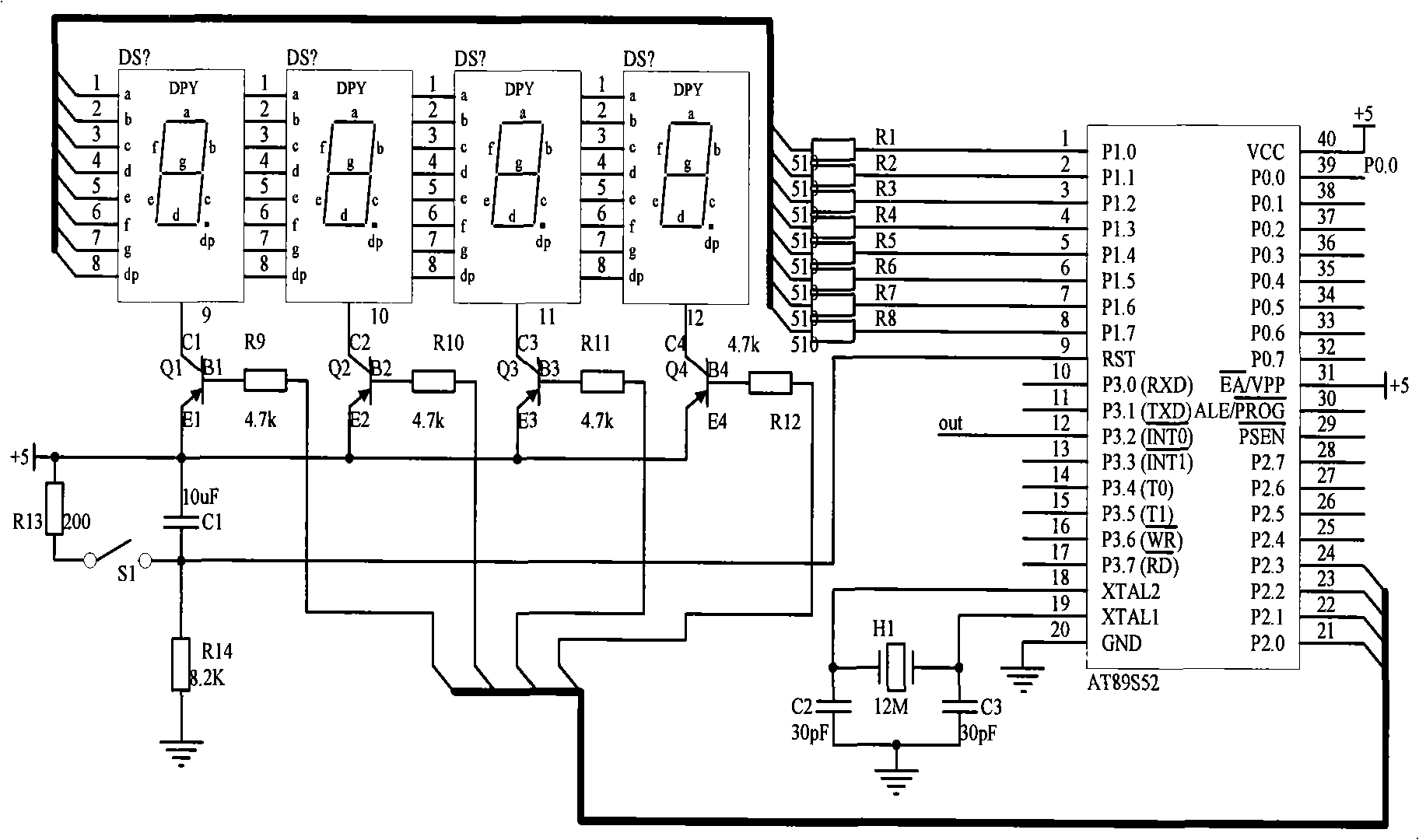

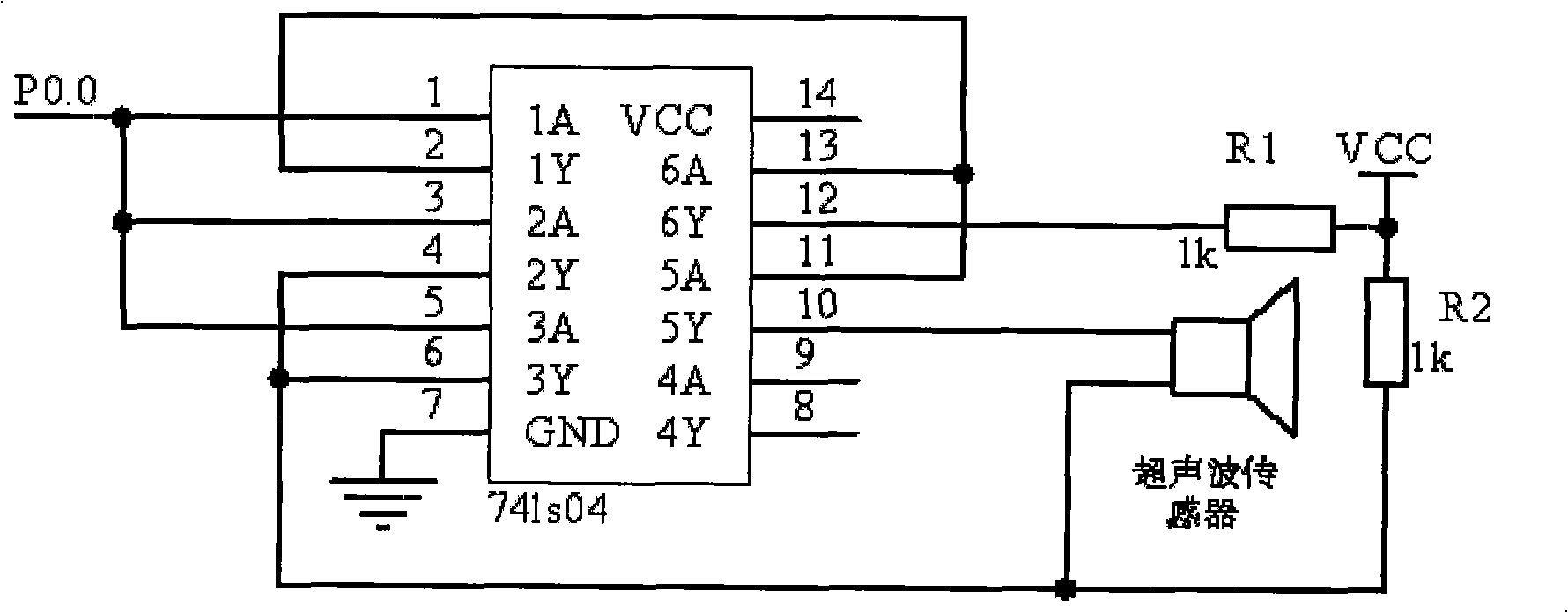

Method and device for measuring ultrasonic wave coal wall temperature

InactiveCN101408462AShort wavelengthBeamyThermometers using physical/chemical changesMicrocontrollerMicrocomputer

The invention relates to an ultrasonic coal wall temperature measurement method and a device thereof. An ultrasonic sensor is arranged at a designated point of a coal mine, a single-chip microcomputer circuit is utilized to control the ultrasonic sensor to transmit ultrasonic signals, and the sensor also receives the reflected signals and triggers the external interrupt of a single-chip microcomputer by an ultrasonic receiving circuit to obtain the time of flight of the ultrasonic signals between the round trip. On the premise of knowing the coal wall distance, data are processed by the single-chip microcomputer according to a gas constant and an adiabatic exponent of the signal flight environment to obtain the measurement result of the coal wall temperature, and the result is displayed by a digital display. The measurement device is composed of the ultrasonic sensor, the single-chip microcomputer circuit, the ultrasonic transmitting circuit, the ultrasonic receiving circuit and the digital display. The ultrasonic sensor is connected with the ultrasonic transmitting circuit and the ultrasonic receiving circuit simultaneously, an external interrupt port of the single-chip microcomputer circuit is connected with the ultrasonic receiving circuit, and an output interface of the single-chip microcomputer circuit is connected with the digital display.

Owner:CHINA UNIV OF MINING & TECH

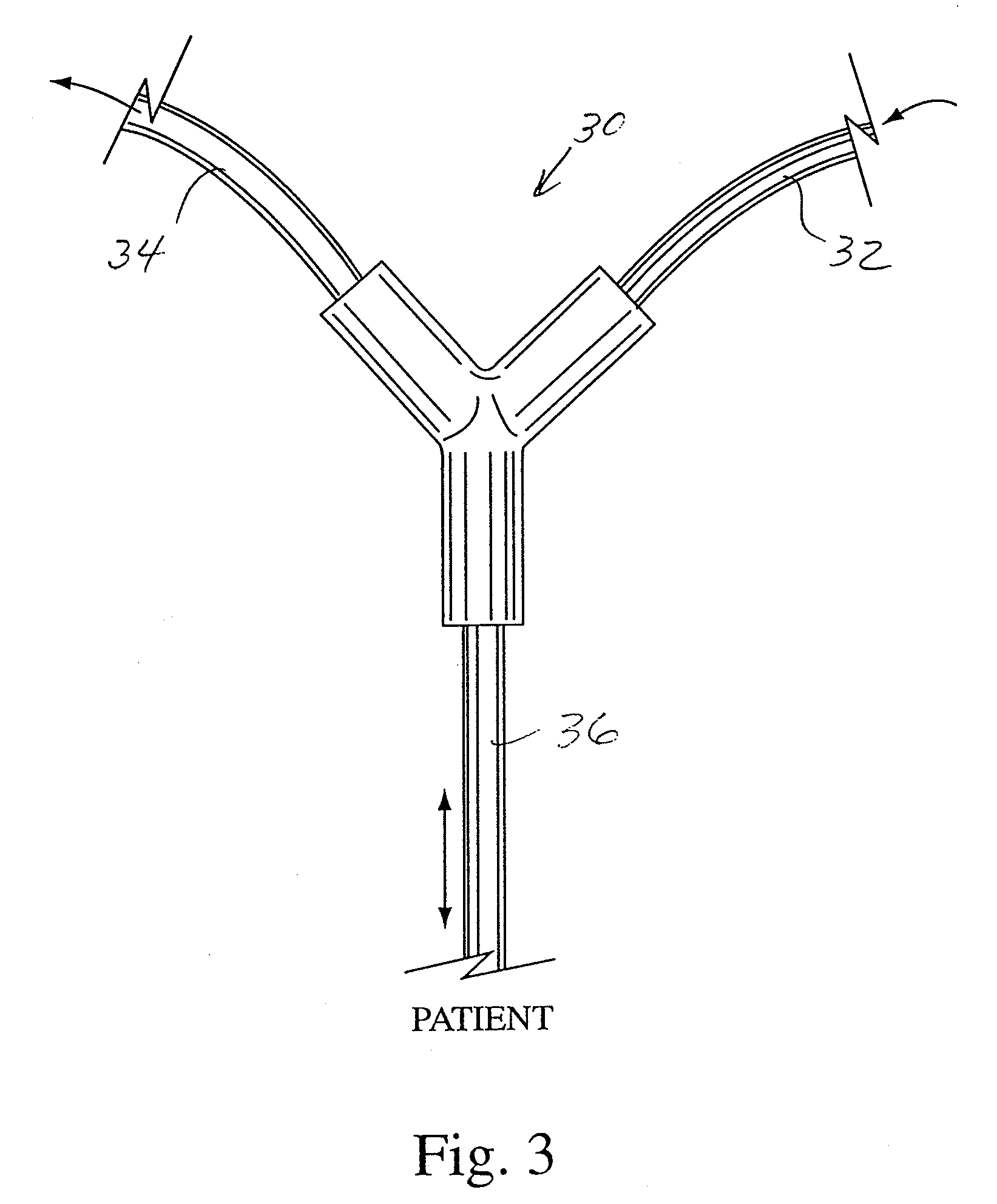

Gas identification system and respiratory technologies volumetrically corrected gas delivery system

A gas delivery system, having a gas identification, by which a gas supplied to the gas delivery system is identified, a blender, blending oxygen and the gas to provide a gas mixture with an oxygen flow rate set up by an operator, and at least one flow sensor, to measure a flow rate of the gas mixture. The blender is driven by an actuator motor to various blender positions with the blender positions being calibrated based on the specific heat ratio and the gas constant of the gas. The flow sensor can be installed at the inspiratory circuit, the proximal circuit and the expiratory circuit of the gas delivery system. The flow sensor output is corrected based on the actual conditions, including the temperature, pressure and humidity, and characteristics of the gas mixture.

Owner:VYAIRE MEDICAL 202 INC

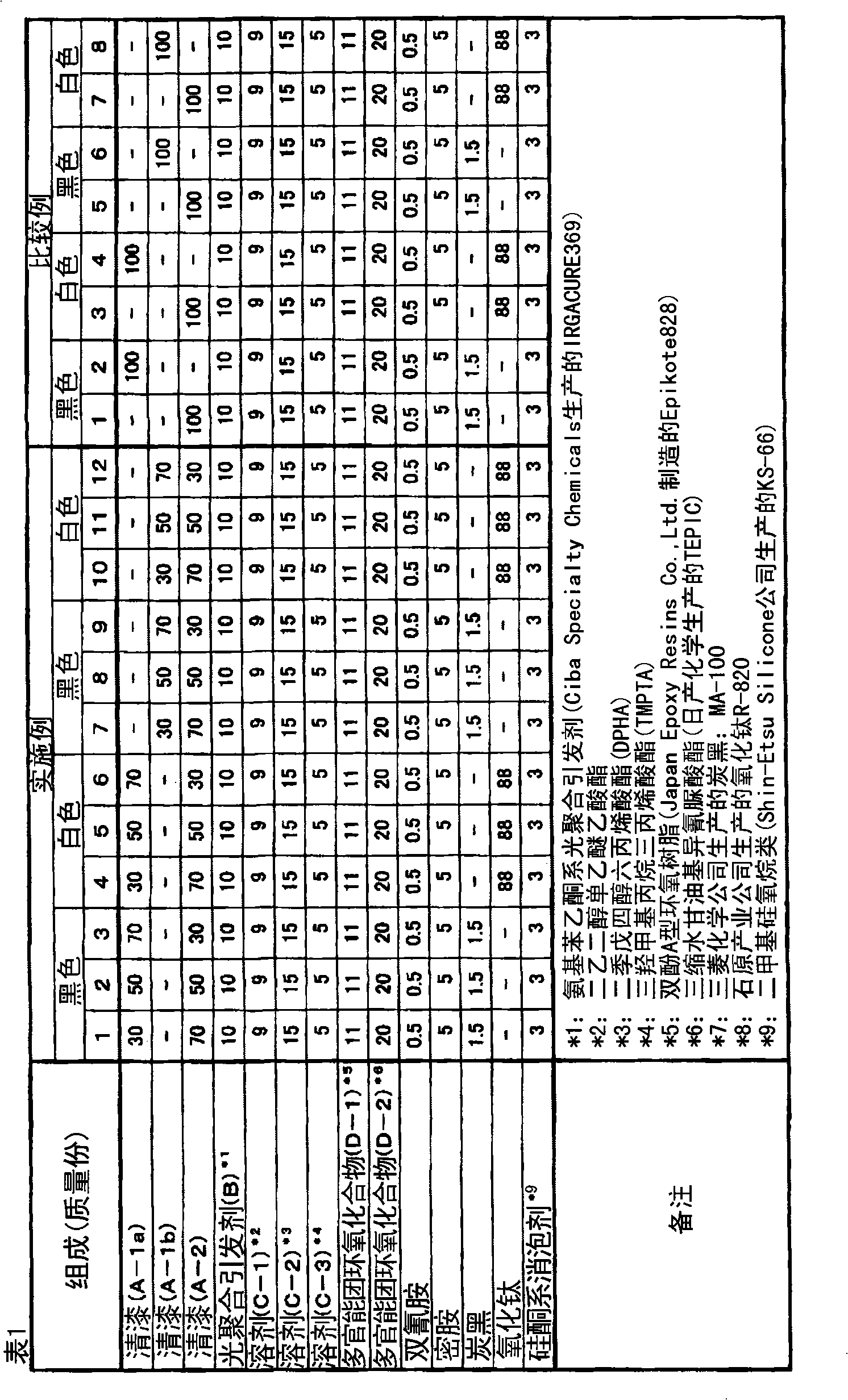

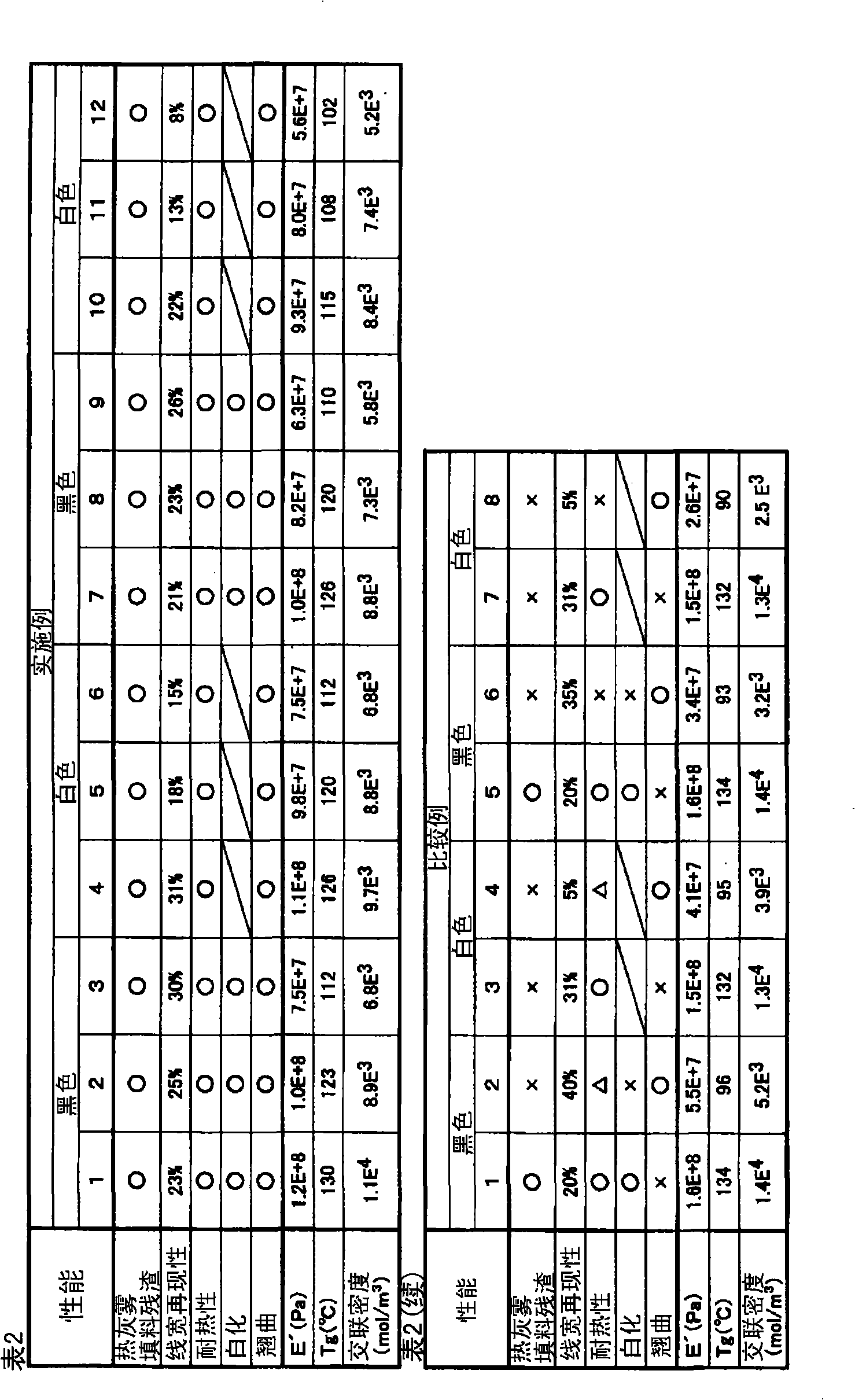

Solder resist compound and cured product thereof

ActiveCN101281367AExcellent developabilityHigh resolutionPhotosensitive materials for photomechanical apparatusNon-metallic protective coating applicationResistComputer module

The present invention provides a soldering inhibitor composition and condensate thereof, which has excellent developing performance, excellent resolving capability, excellent heat-resisting quantity and excellent resistance to plating needed by a pc board, a package substrate, a module base plate necessarily, and can provide a base plate with little curing shrinkage and no-warp.The soldering inhibitor composition is characterized in that: the solidified crosslink density computed by formula (1) being 2*103-1.2*104mol / m3, and glass transition temperature being more than 100 EDG C, n=E' min / 3 PhiRT(1).In the formula, n being crosslink density, E' min being minimum value of the storage elastic modulus E', Phi being modified coefficient approximate 1, R being gas constant, T being absolute temperature of E' min.

Owner:TAIYO INK MFG

Experiment device and method for gas adsorption and desorption of large rock samples with different sizes

The invention relates to an experiment device and method for the gas adsorption and desorption of large rock samples with different sizes. In the experiment device, a gas cylinder is communicated with a gas constant-pressure device, the gas constant-pressure device and a vacuum-pumping device are merged and connected to a main pipeline through a three-way valve, and the main pipeline is communicated with a gas inlet of a core holding unit through a core holding unit inlet valve; the core holding unit is arranged in a constant-temperature heating device; and a metering pump is connected with the core holding unit, and applies surrounding rock and axial compression to core samples in a core holding unit sample chamber. The experiment device not only implements the experiment requirements, but also achieves the effects of simple structure, low cost and easy operation; and when the experiment device is adopted for carrying out experiments, experiment results are more accurate and closer to the adsorption desorption of actual rock masses, and gas adsorption and desorption experiments of cores under the conditions of different sizes, different temperatures and different pressures can be performed in one experiment device.

Owner:CHONGQING UNIV

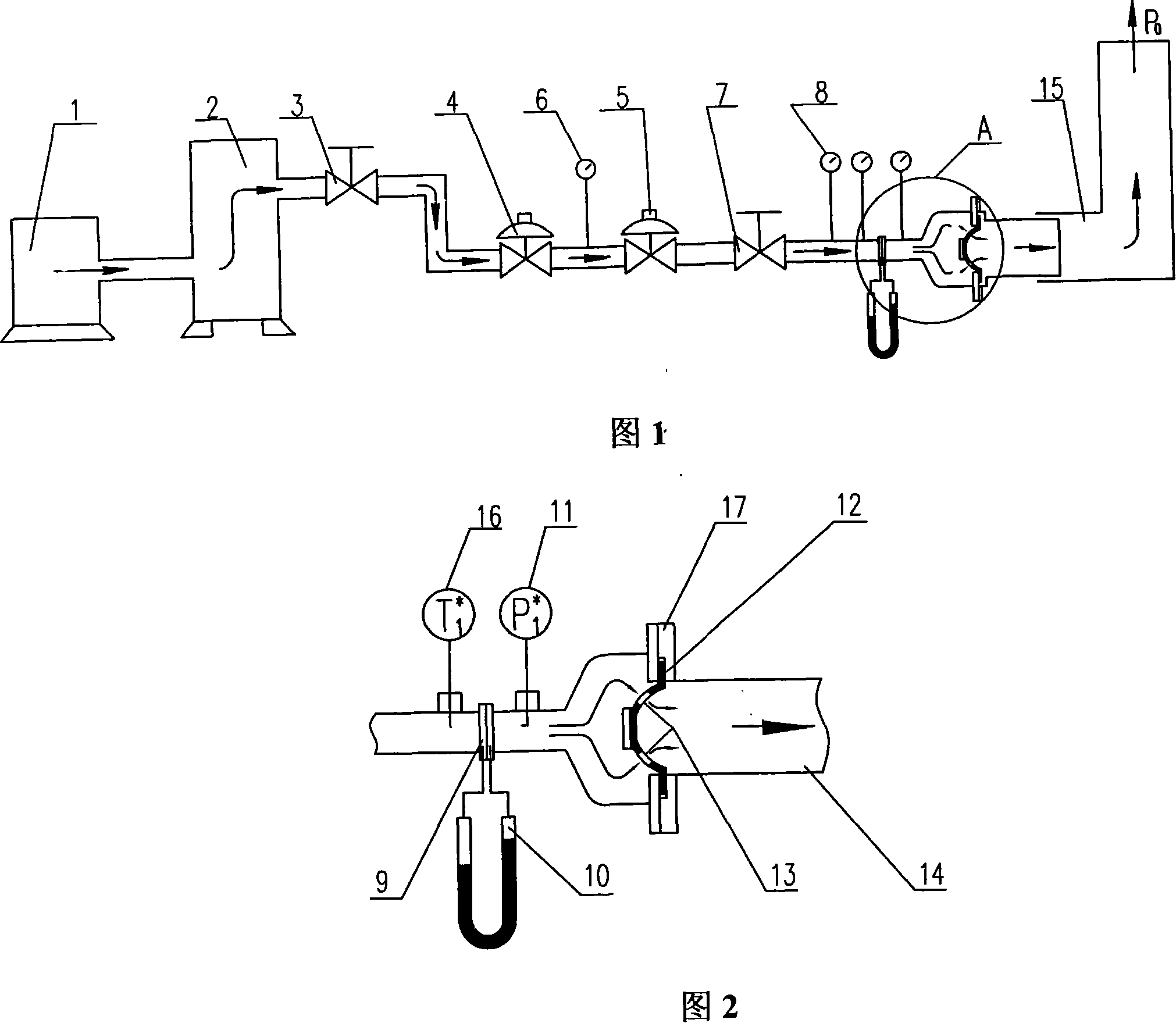

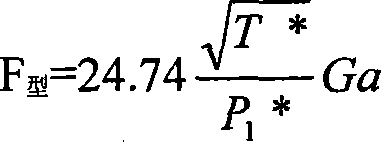

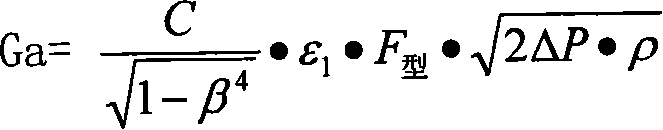

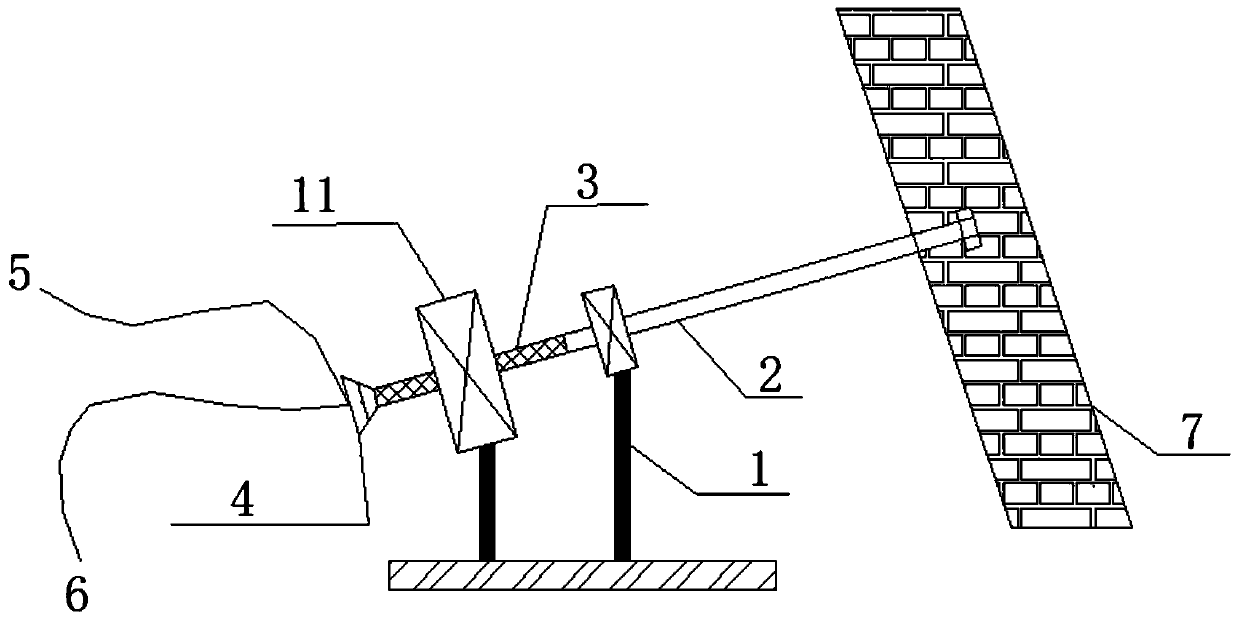

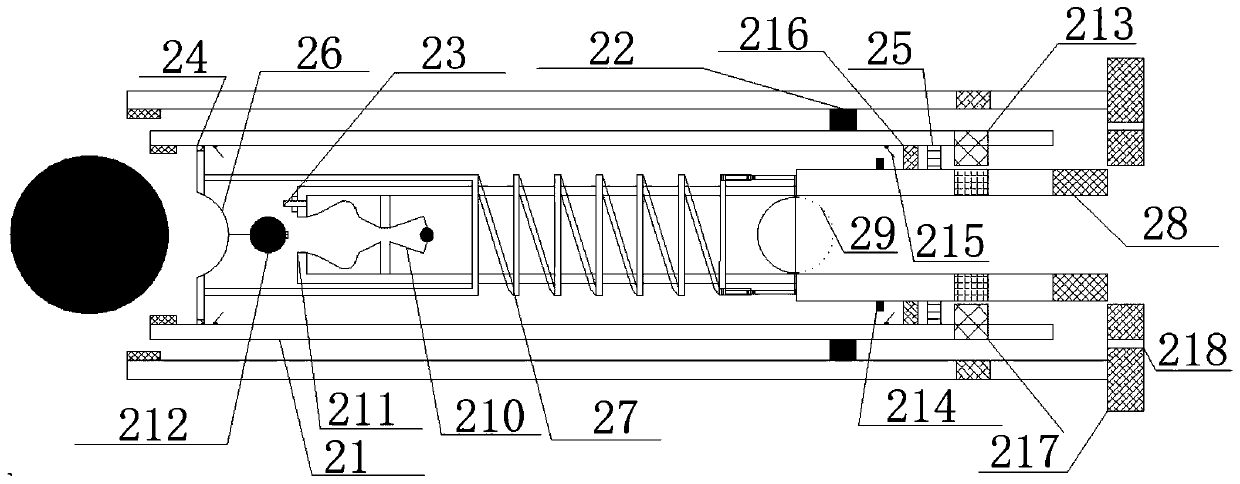

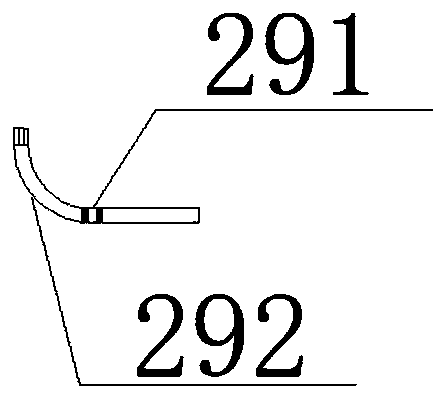

Method for measuring complicated type face flow area with supercritical pressure ratio

ActiveCN101140162AOutstanding advantagesHighlight positive effectsAerodynamic testingMeasurement deviceAtmospheric air

The invention discloses a method for measuring the circulation area of complex profile hole, main contents of which are that the air pressure P1* in front of the workpiece profile hole to be measured is adjusted to the supercritical pressure ratio, namely not less than 2 times of atmospheric pressure Po in order to ensure that air passes through the profile hole at a critical speed, and the air after further expansion is discharged into the atmosphere through an exhaust pipe. Measuring the air pressure P1* in front of the profile hole, the air temperature T1* and the air flow Ga through a pipeline, calculating the coefficient m of the air through the air adiabatic index K and the gas constant R, and substituting these data into the flow equation of compressible flow to calculate the circulation area of the complex profile hole to be measured. Compared with the prior art method of measuring the area of the profile hole with the air power, the method disclosed by the invention, which measures the circulation area of the complex profile hole with the supercritical pressure ratio, has the advantages of the high measurement precision, the large measurement range, the strong commonality of a measuring device and the convenient operation, and solves the problem of precise measurement of the circulation area of the complex profile hole with the small circulation area.

Owner:CHENGDU ENGINE GROUP

In-situ test system and method while drilling for coal seam gas content in underground coal mine

ActiveCN110454105AEliminate lossEliminate fugitiveComponent separationWithdrawing sample devicesPorosityHigh pressure water

The invention relates to an in-situ test system and method while drilling for coal seam gas content in an underground coal mine, and belongs to the technical field of coal mine safety. The in-situ test method while drilling comprises the steps that a special coring drill bit is connected with a coal core storage tube, and then connected with a special drill pipe and connected with a clamping device on a drilling rig; high-pressure water or compressed air is connected with a tail drill pipe through a special water tail, in the drilling process, the drill bit is replaced without removing the drill pipe, the coal core is directly drilled, and the coal core is cooled by the cold air, so that the internal moisture of the coal core is solidified, and gas dissipation of the coal core is prevented; and the coal core is sent to a laboratory, after the temperature of the coal core is raised, the solidified moisture is converted into a liquid state, the gas dissipates from the coal core storage tube, the natural gas content and the gas content after pulverization in the coal core storage tube are measured, and the gas content of the coal seam is calculated by combining industrial analysis, porosity and adsorption gas constants.

Owner:重庆安标检测研究院有限公司 +1

Electricity generating device utilizing constant ultra-low concentration transportation, purification and supercharging of gas

The invention relates to a gas constant ultra-low density transmission, purification, pressuring and generation device, which comprises a gas constant ultra-low density bank connecting the gas outlet. Wherein, the gas constant ultra-low density bank via the air adsorption control valve is connected to the air adsorption tube; the gas outlet of gas constant ultra-low density bank is connected to the compressor of dual-channel pressuring device; the upper channel of compressor is connected to the gas inlet tube of motor; and the lower channel of compressor via the gas inlet control valve is connected to the gas constant ultra-low density bank. The invention uses the under-well air and the reflux rare gas to adjust the gas density to under the burning point. It has safe transmission and via the dual-channel pressuring device, the gas has been purified before entering the motor and the density is high than 16%. And the gas is mixed inside the cylinder, than enters the motor to be burned to confirm the safe operation.

Owner:朱裕丰

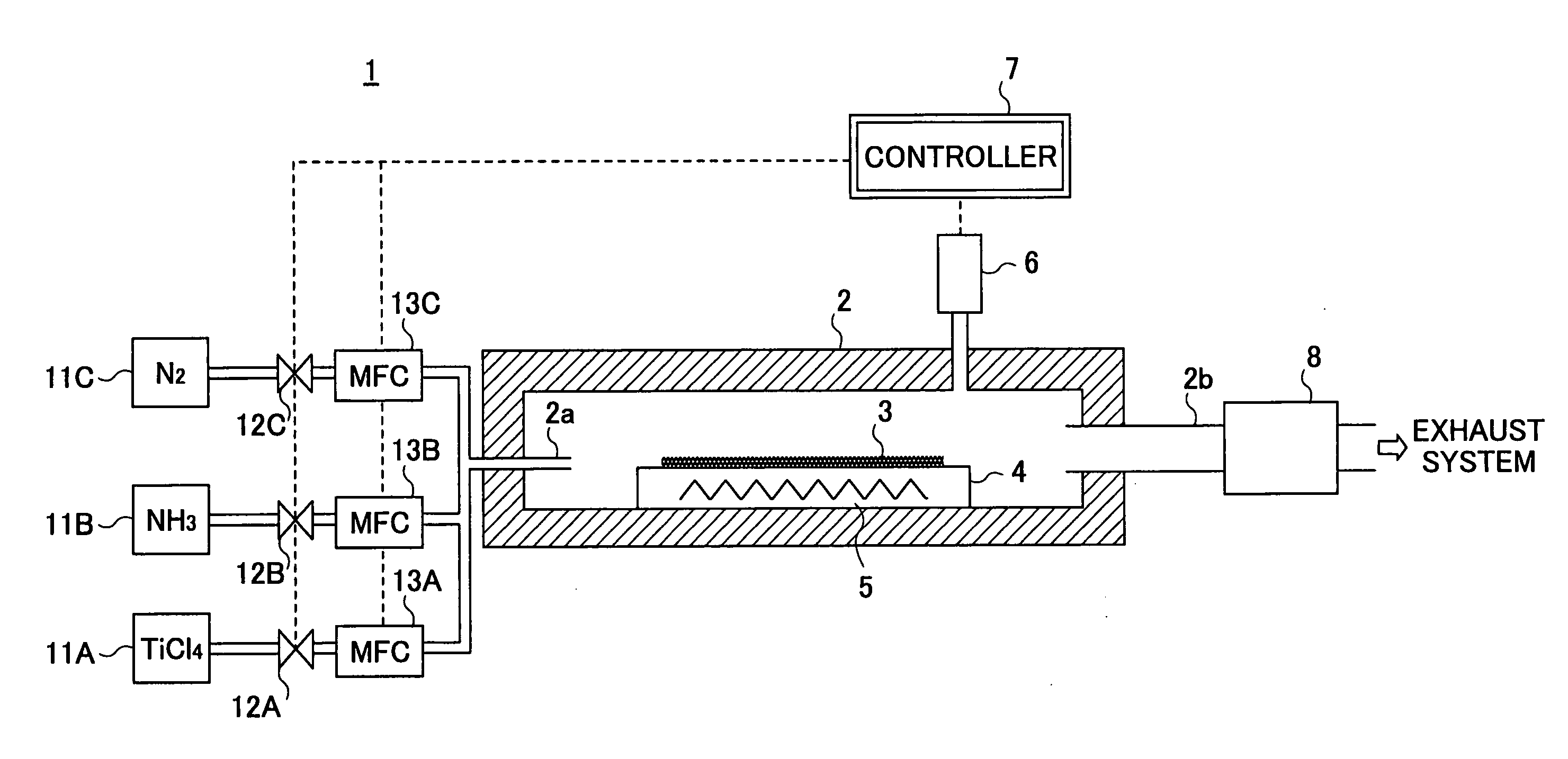

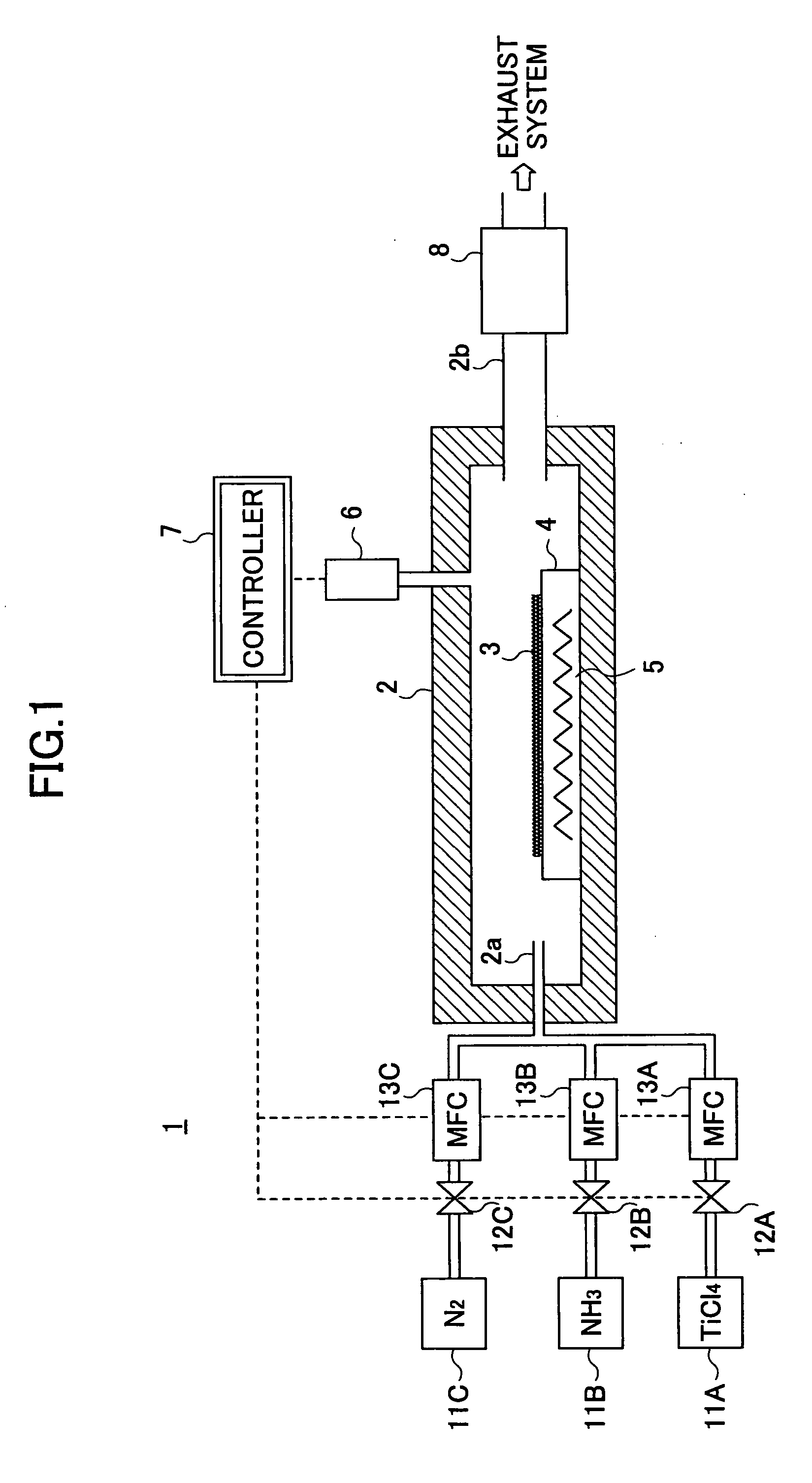

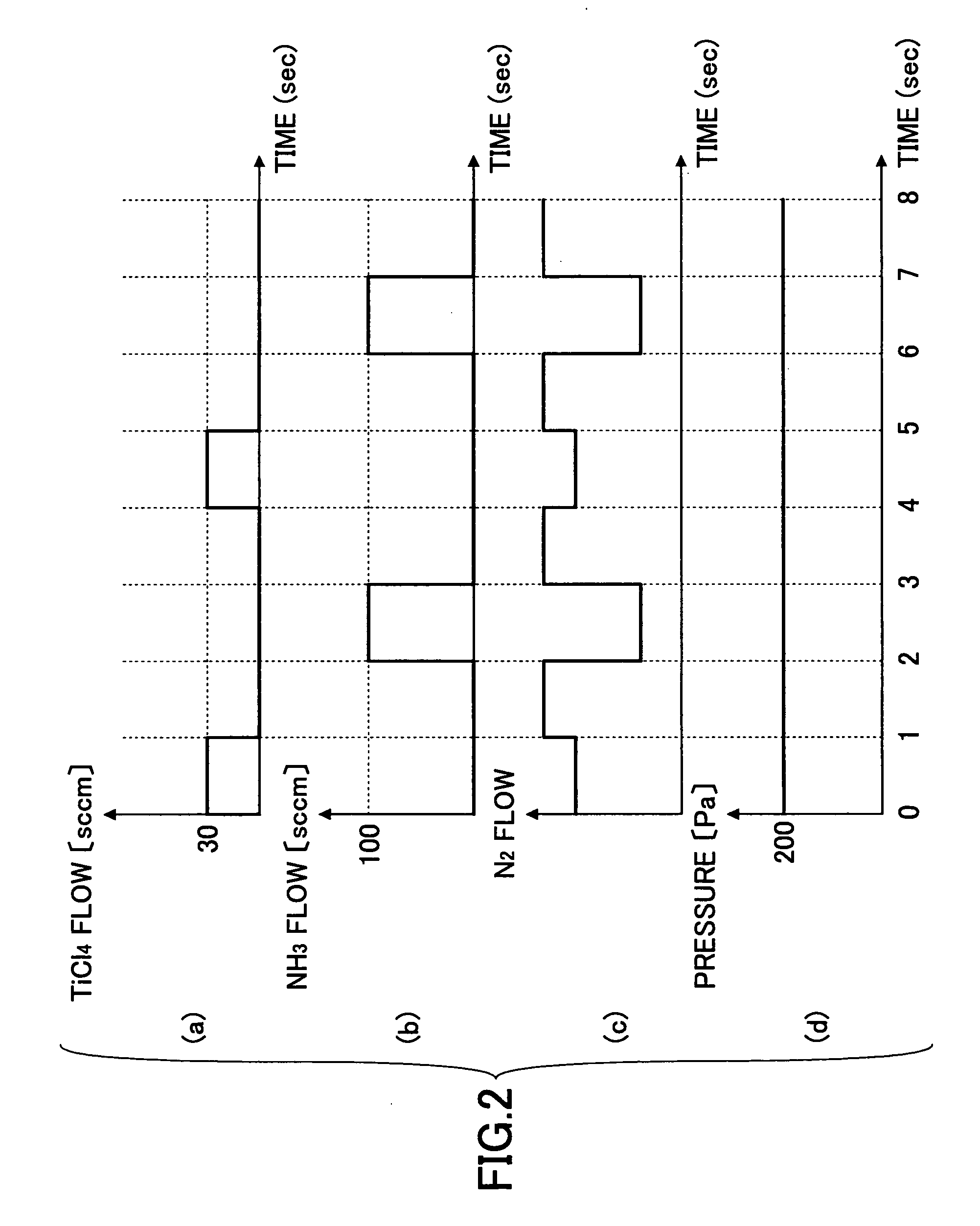

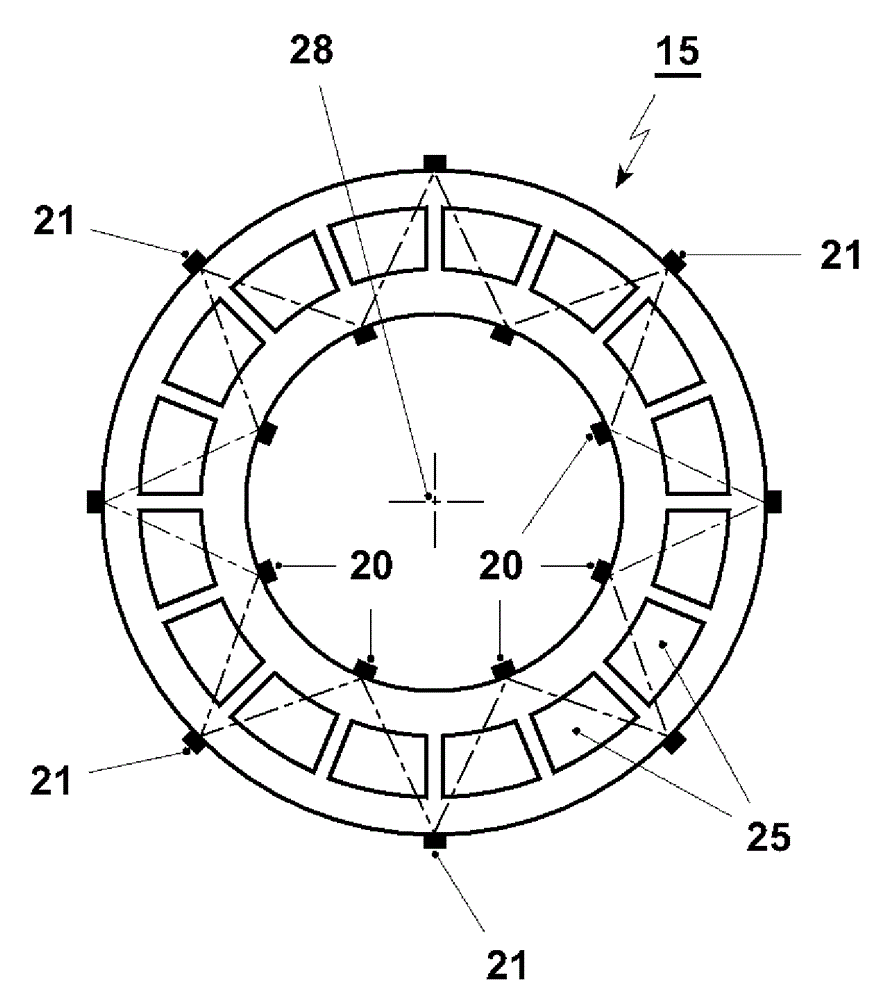

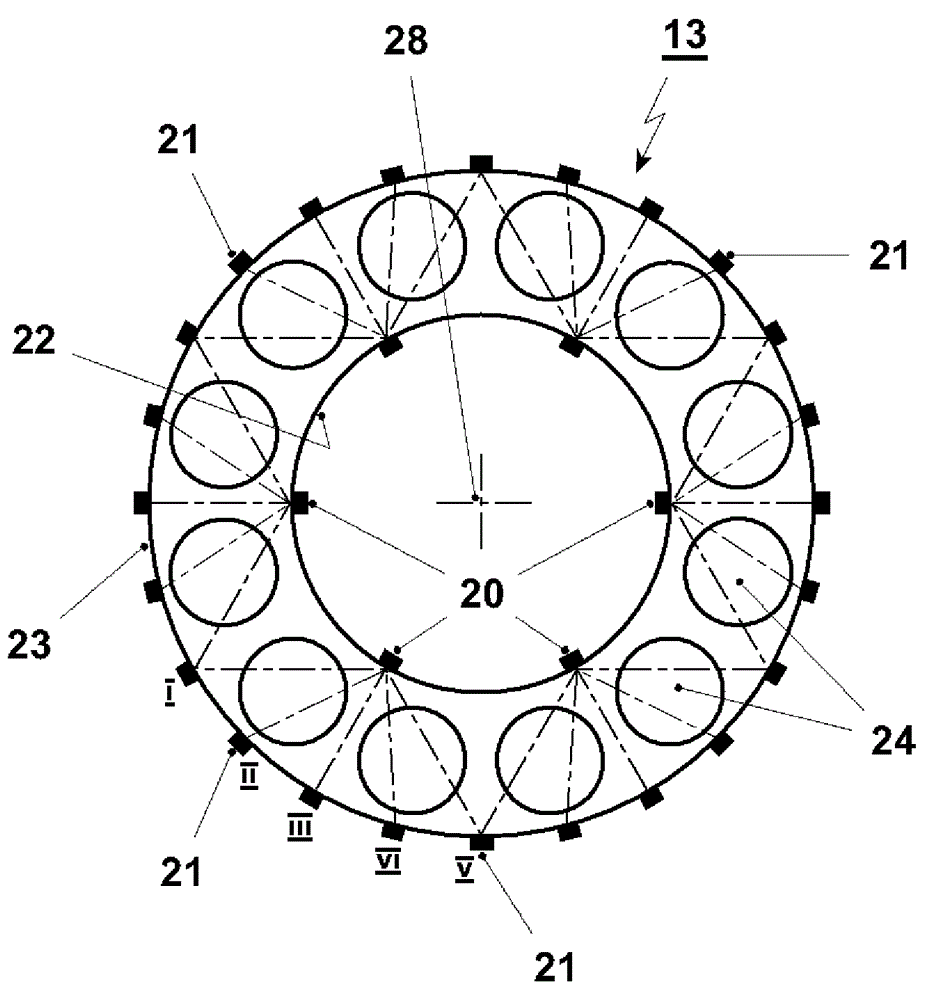

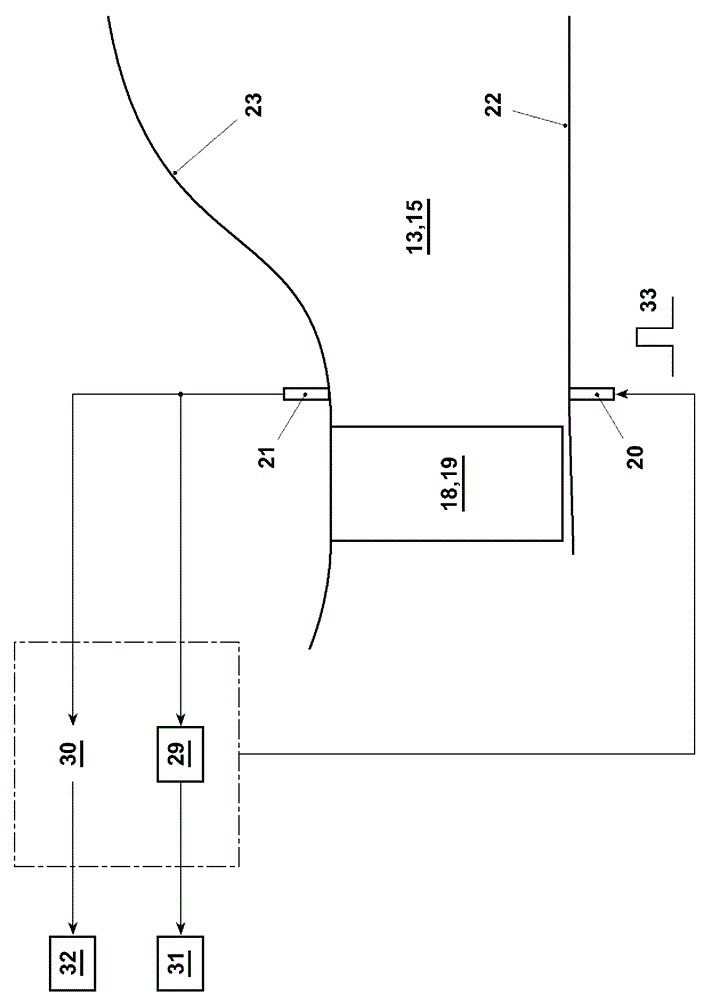

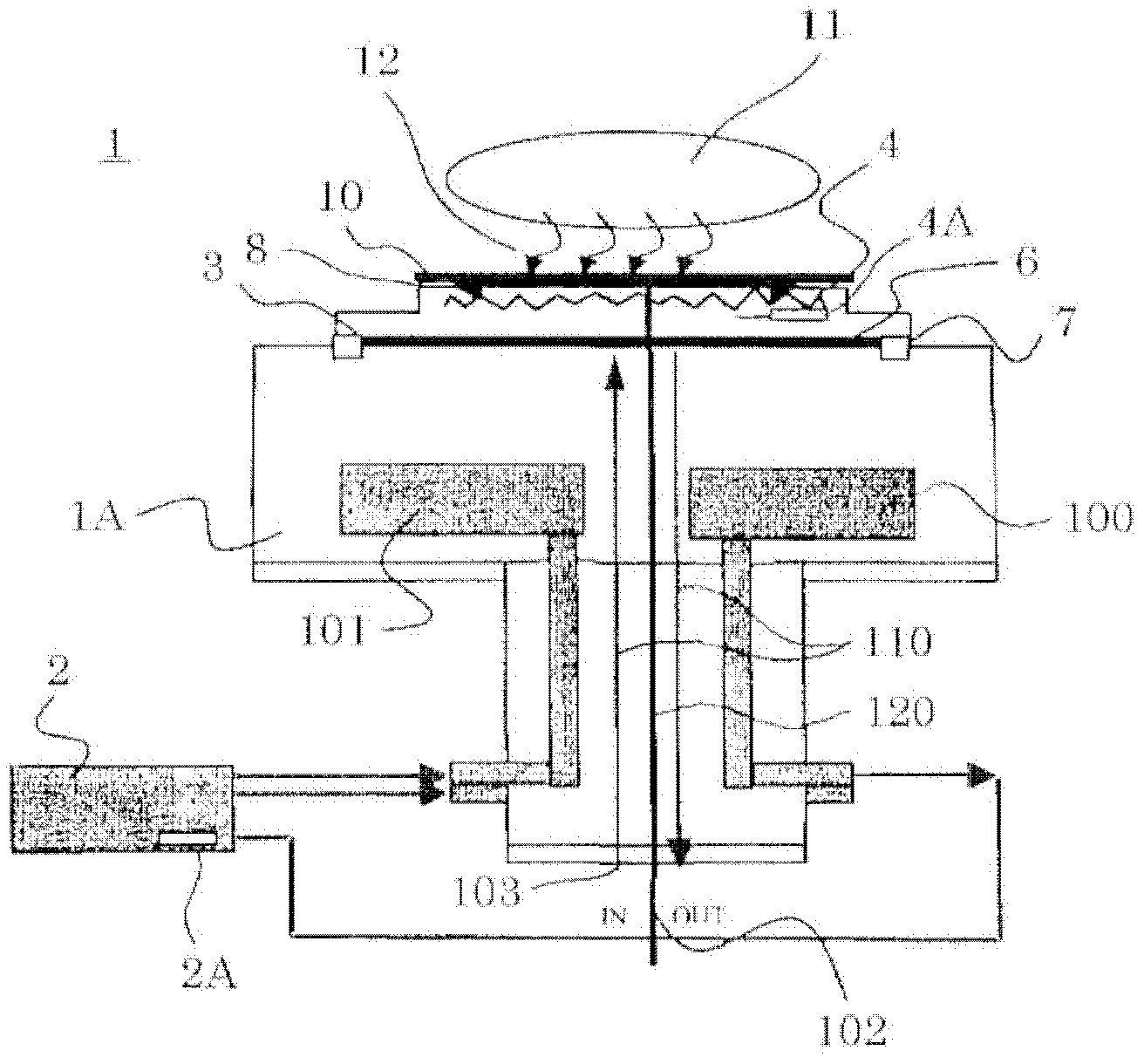

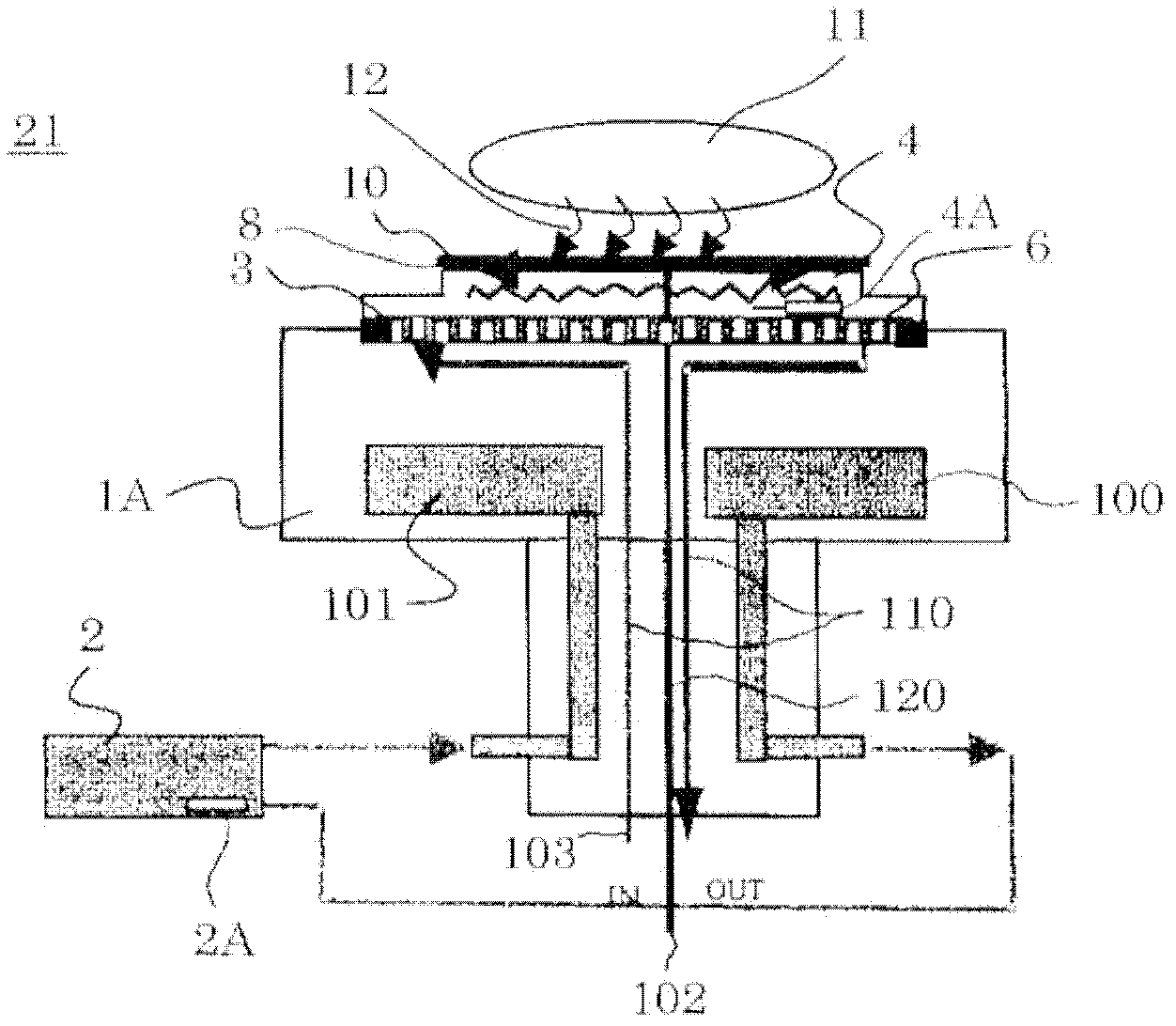

Processing apparatus and processing method

InactiveUS20060154383A1Lower the volumeShort timeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringGas supply

In a processing apparatus, a process gas including a source gas (TiCl4, NH3) and an inert gas (N2) is supplied into a process chamber (2). A pressure meter (6) detects a pressure in the process chamber (2) so as to control an amount of flow of the process gas supplied to the process chamber (2) based on a result of the detection. A source gas is purged by the inert gas. By maintaining the amount of flow of the source gas constant and controlling the amount of flow of the inert gas, an amount of flow the entire process gas is controlled so as to maintain a pressure in the process chamber (2) constant. Since a time spent on evacuation of the source gas is reduced, a time for switching the source gas is reduced. Additionally, a temperature of a surface of a substrate during processing can be maintained constant.

Owner:TOKYO ELECTRON LTD

Gas turbine temperature measurement

InactiveCN103850803AGood for distinguishing noiseGood for distinguishing pulsationGas-turbine engine testingGas turbine plantsTransducerHeat capacity ratio

Method for determining a temperature in a pressurized flow path of a gas turbine (10) comprising the steps of sending an acoustic signal from an acoustic signal emitting transducer (20, 21) across a section of the pressurized flow path, detecting the acoustic signal with a receiving transducer (20, 21), measuring the time needed by the acoustic signal to travel from the acoustic signal emitting transducer (20, 21) to the receiving transducer (20, 21), calculating the speed of sound, and calculating the temperature as a function of the speed of sound, the heat capacity ratio (kappa) and a specific gas constant (R spec ) of the gas flowing in the pressurized flow path. Gas turbine with a processor and transducers arranged to carry out such a method is disclosed.

Owner:ANSALDO ENERGIA SWITZERLAND AG

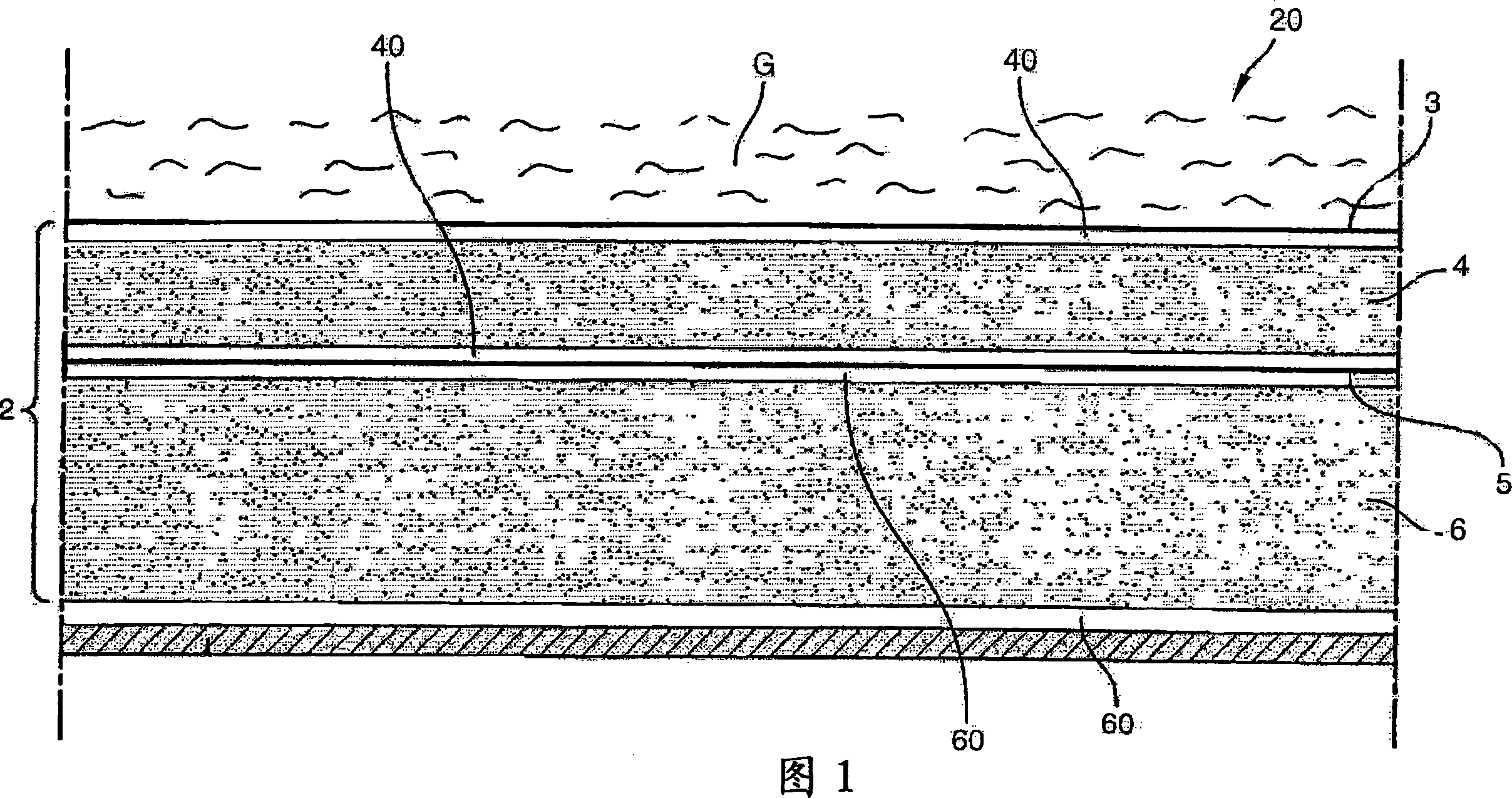

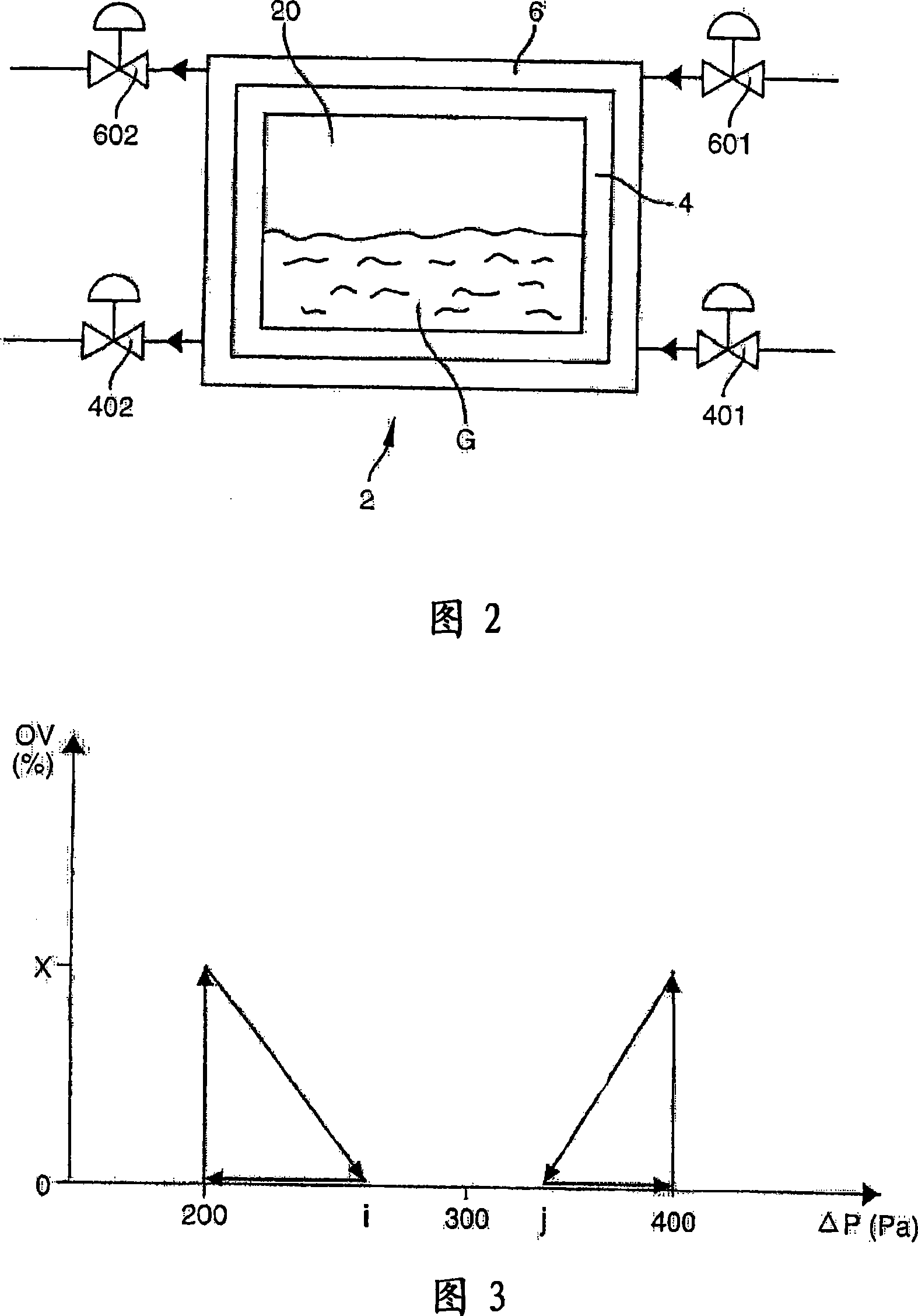

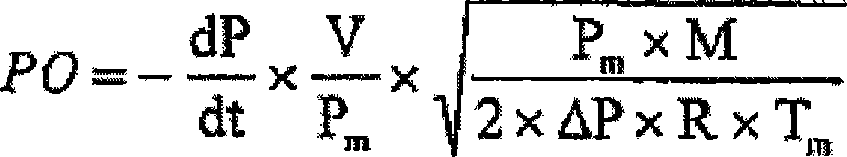

Method for measuring the actual porosity of the watertightness barrier of a fluid containment tank

The method involves measuring values of pressure and absolute temperature inside a free space (60) of a thermal insulation layer (6) at two instants during closing of inert gas i.e. nitrogen, intake and discharge valves (601, 602) or stable usage conditions of an insulated storage tank (20) e.g. membrane tank, to calculate layer's average pressure and temperature. Actual porosity of liquid / gas proof barrier is calculated based on specific formula comprising parameters such as rate of change of pressure inside the space, volume of the space, molar mass of inert gas and perfect gas constant.

Owner:STX EUROPE

Sulfuric acid electrolysis process

Sulfuric acid electrolysis process wherein;a temperature of electrolyte containing sulfuric acid to be supplied to an anode compartment and a cathode compartment is controlled to 30 degree Celsius or more;a flow rate F1 (L / min.) of the electrolyte containing sulfuric acid to be supplied to said anode compartment is controlled to 1.5 times or more (F1 / Fa≧1.5) a flow rate Fa (L / min.) of gas formed on an anode side as calculated from Equation (1) shown below and a flow rate F2(L / min.) of said electrolyte containing sulfuric acid to be supplied to said cathode compartment is controlled to 1.5 times or more (F2 / Fc≧1.5) a flow rate Fe (L / min.) of gas formed on a cathode side as calculated from Equation (2) shown below.Fa=(I×S×R×T) / (4×Faraday constant) Equation (I)Fe=(I×S×R×T) / (2×Faraday constant) Equation (2)I: Electrolytic current (A)S: Time: 60 second (Fixed)R: Gas constant (0.082 1·atm / K / mol)K: Absolute temperature (273.15 degree Celsius+T degree Celsius)T: Electrolysis temperature (degree Celsius)Faraday constant: (C / mol)

Owner:KK TOSHIBA +2

Internal egr control device for internal combustion engine

InactiveUS20090240422A1Easy to controlReduce concentrationValve arrangementsElectrical controlExhaust valveEngineering

An internal EGR control device for an internal combustion engine, which is capable of properly controlling an internal EGR amount, while causing conditions of burned gases to be reflected thereon in controlling the internal EGR by changing valve-closing timing of an exhaust valve. An internal EGR control device sets a target internal EGR amount EGRINCMD as a target of the internal EGR amount according to detected operating conditions of an internal combustion engine, and a target internal EGR amount EGRINC is determined by correcting the target internal EGR amount based on a gas state equation, using obtained temperature and pressure of exhaust gases, and a calculated gas constant R. Then, according to the corrected target internal EGR amount EGRINC, the valve-closing timing of an exhaust valve is calculated, and a variable valve mechanism is controlled based on the calculated valve-closing timing of the exhaust valve.

Owner:HONDA MOTOR CO LTD

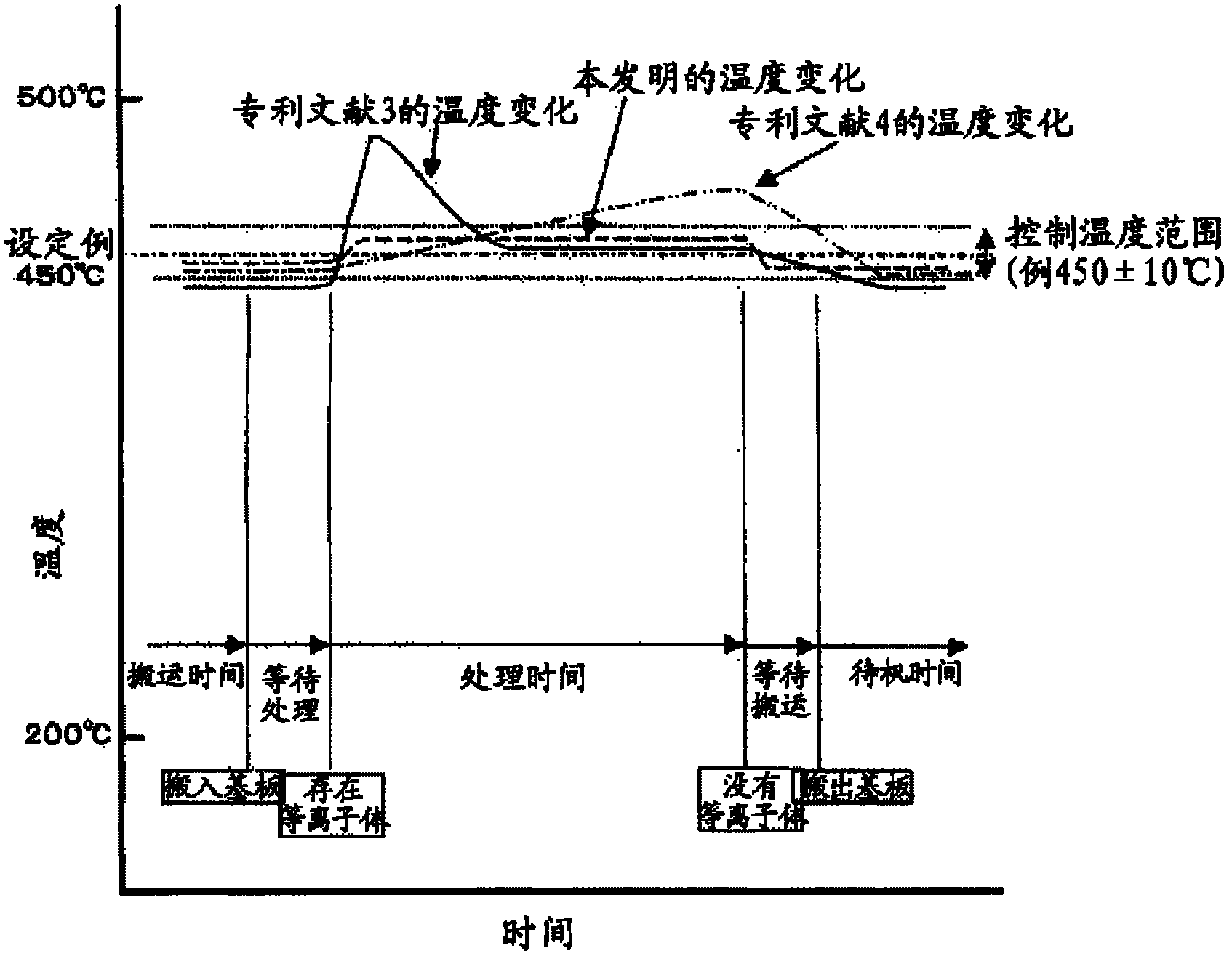

Substrate temperature control method

InactiveCN102354673AVacuum evaporation coatingSemiconductor/solid-state device manufacturingTemperature controlProcess engineering

The invention provides a substrate temperature control method using a substrate holder. The substrate temperature control method comprises: (1) the first step of, before the start of a process, heating a substrate to a set temperature by using a heating unit in an electrostatic chuck and keeping the temperature constant at the set temperature until the process is started, without supplying the sealed gas into the gap between the holder and the electrostatic chuck; (2) the second step of, after the start of the process, when the temperature of the substrate is increased by a heat input from a plasma, supplying the sealed gas into the gap between the holder main body and the electrostatic chuck, maintaining the pressure of the sealed gas constant and deceasing the substrate temperature to the set temperature; and (3) the third step of, also after the start of the process, after the substrate temperature reaches the set temperature, adjusting the pressure of the sealed gas for heating the heating unit and the sealed gas supplied into the gap between the holder main body and the electrostatic chuck, and maintaining the substrate temperature at the set temperature.

Owner:CANON ANELVA CORP

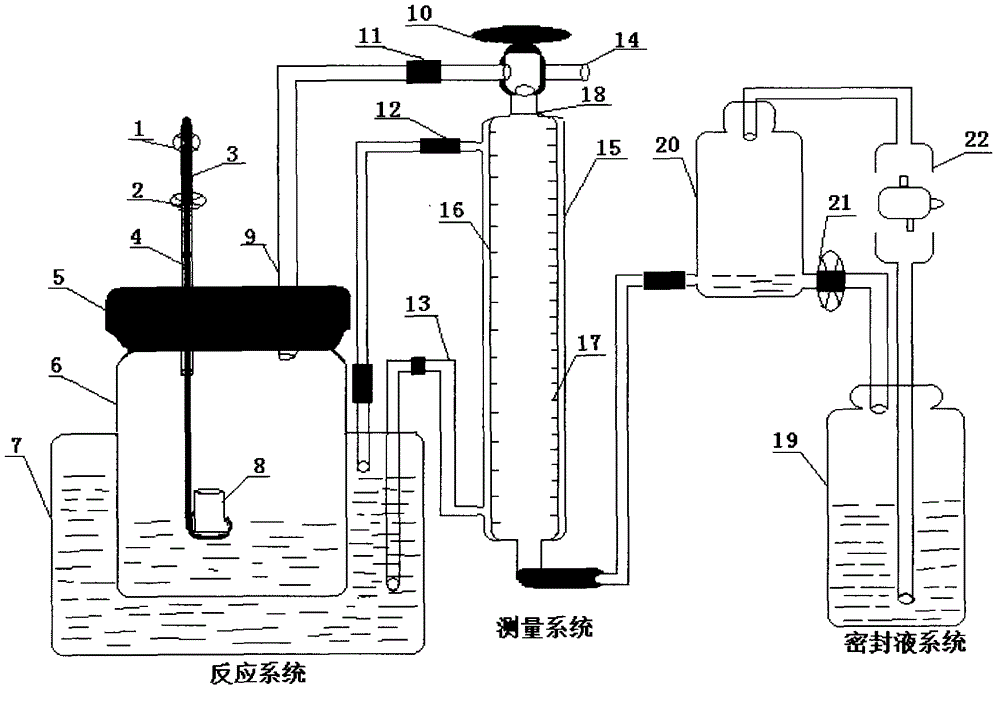

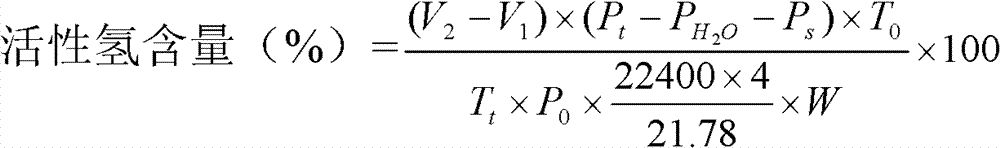

Instrument for analyzing active calcium in calcium-series auxiliary agent for steelmaking

ActiveCN103149122AGood constant temperature effectEliminate Volume EffectsMaterial weighingSteelmakingScale unit

The invention discloses an instrument for analyzing active calcium in a calcium-series auxiliary agent for steelmaking; the instrument comprises a reaction system device, a measuring system and a sealing liquid system device, and is characterized in that a controllable sampling rod in a reaction system can be used for controlling the reaction speed of a sample and a solution, and the sealing property is good; a gas burette has a double-layer structure, thus being good in thermostatical effect and eliminating the influence of environment to gas volume; the gas burette has two reading ways due to two scale units; and the bottom of a leveling bottle in the sealing liquid system is provided with an overflow hole, so that reverse acting force influence to the gas volume caused by the discharged liquid stored in the leveling bottle can be eliminated, and the accuracy of gas volume measurement is guaranteed. Furthermore, the instrument is also used for series experiments such as molar gas constant determination and the like of physics and chemical laboratories in colleges and universities; and the instrument has the characteristics of being wide in applicability, easy to popularize in the metallurgical industry, low in analysis cost, simple, convenient and rapid to operate, etc.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Density calculation method of plasmas in gun barrel in gunpowder combustion process

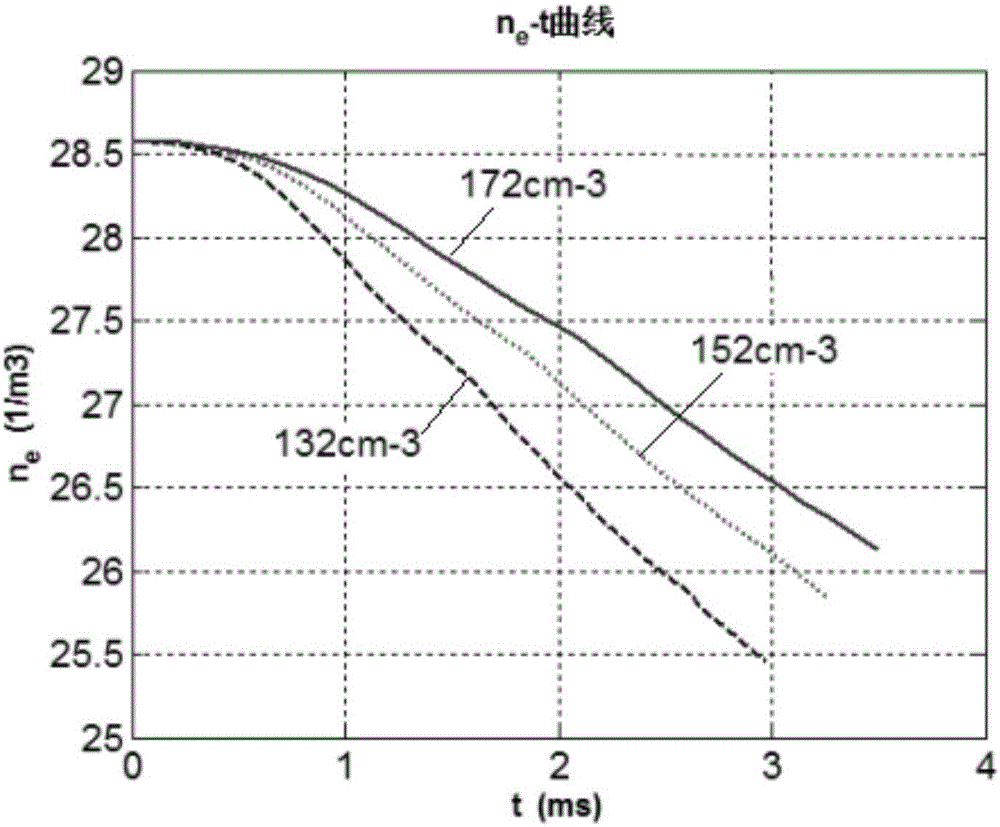

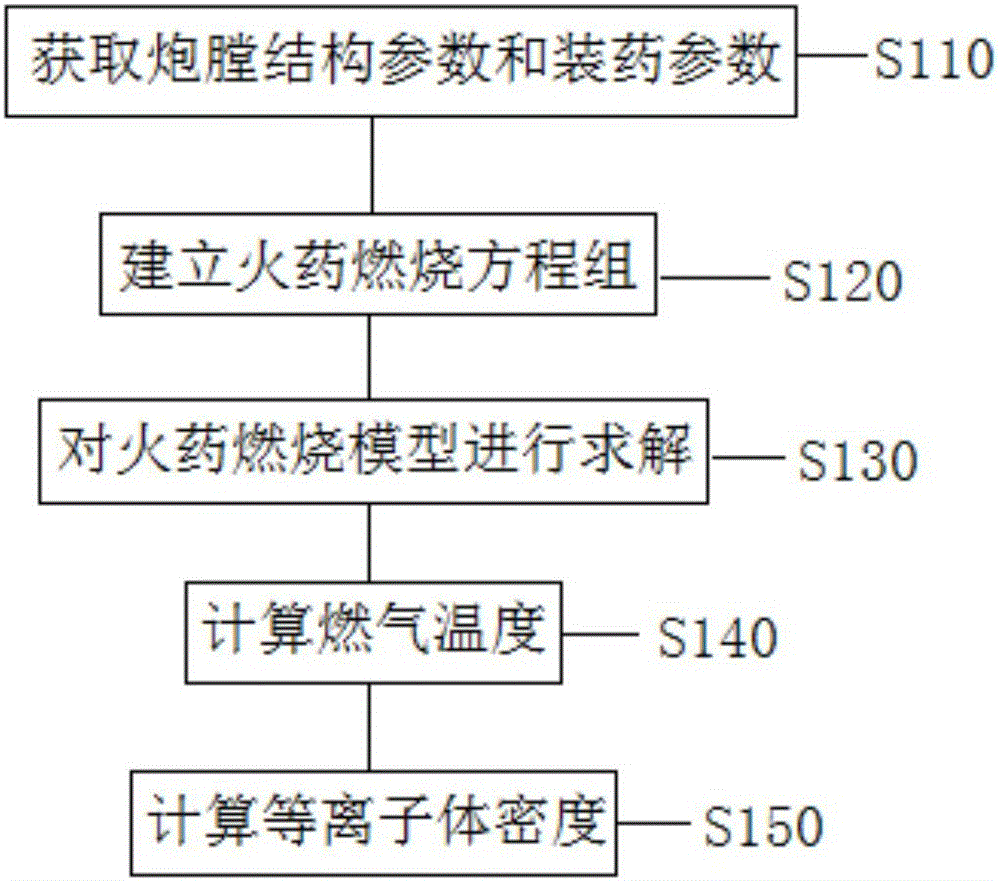

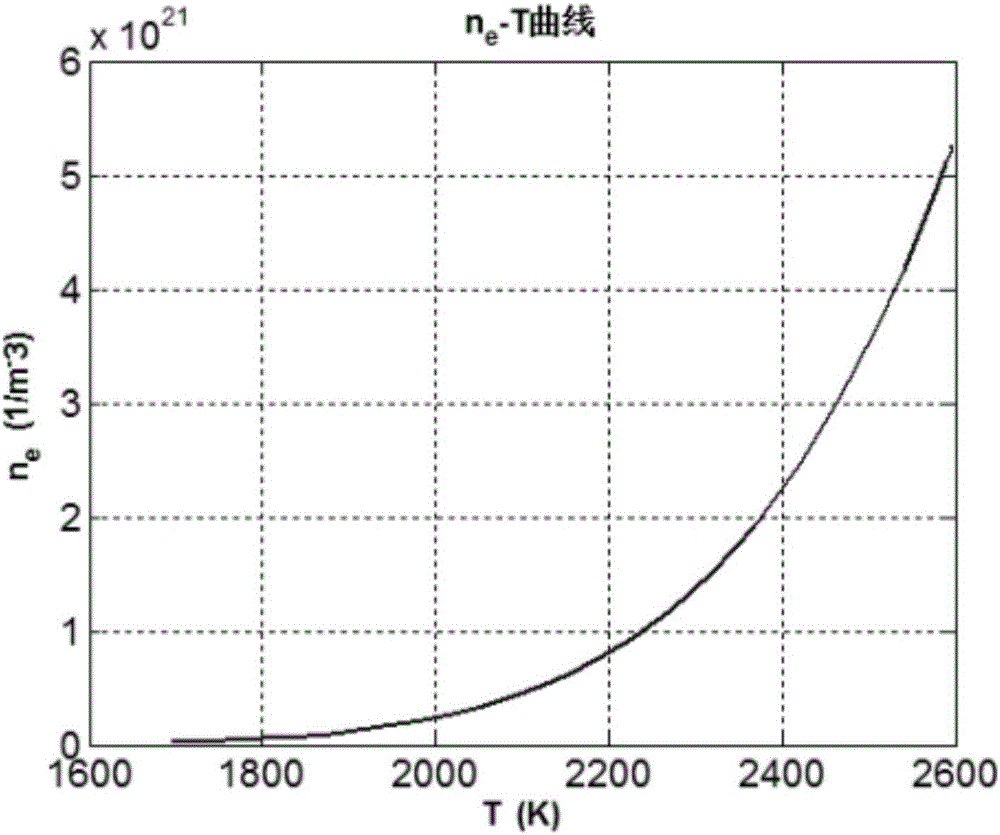

InactiveCN106202797AAccurate calculation of densityHigh densityDesign optimisation/simulationSpecial data processing applicationsPlasma densityEngineering

The invention discloses a density calculation method of plasmas in a gun barrel in a gunpowder combustion process. The density calculation method comprises the following steps: step 1, obtaining gun bore structure parameters and explosive filling parameters; step 2, establishing a gunpowder combustion equation set; step 3, solving the gunpowder combustion equation set; obtaining functions of p, l and phi relative to t by taking the t as an independent variable; step 4, calculating a gas temperature T: T=Sp(l+lphi) / omegaphiR, wherein R is a gas constant; and step 5, calculating a plasma density ne: ne=no / ni*(2mnokT)<1.5> / h<3>*2gi / g0exp(-eEi / kT), wherein Ei is an ionization potential of ions, go is a statistical weight of an atomic ground state, gi is a statistical weight of an ion ground state, me is the mass of electrons, ni is the ion density and no is the atom density. The density calculation method of the plasmas in the gun barrel in the gunpowder combustion process, disclosed by the invention, can accurately calculate the density of the plasmas in the gun barrel, and provides theoretical supports for the density of the plasmas in the gun barrel.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

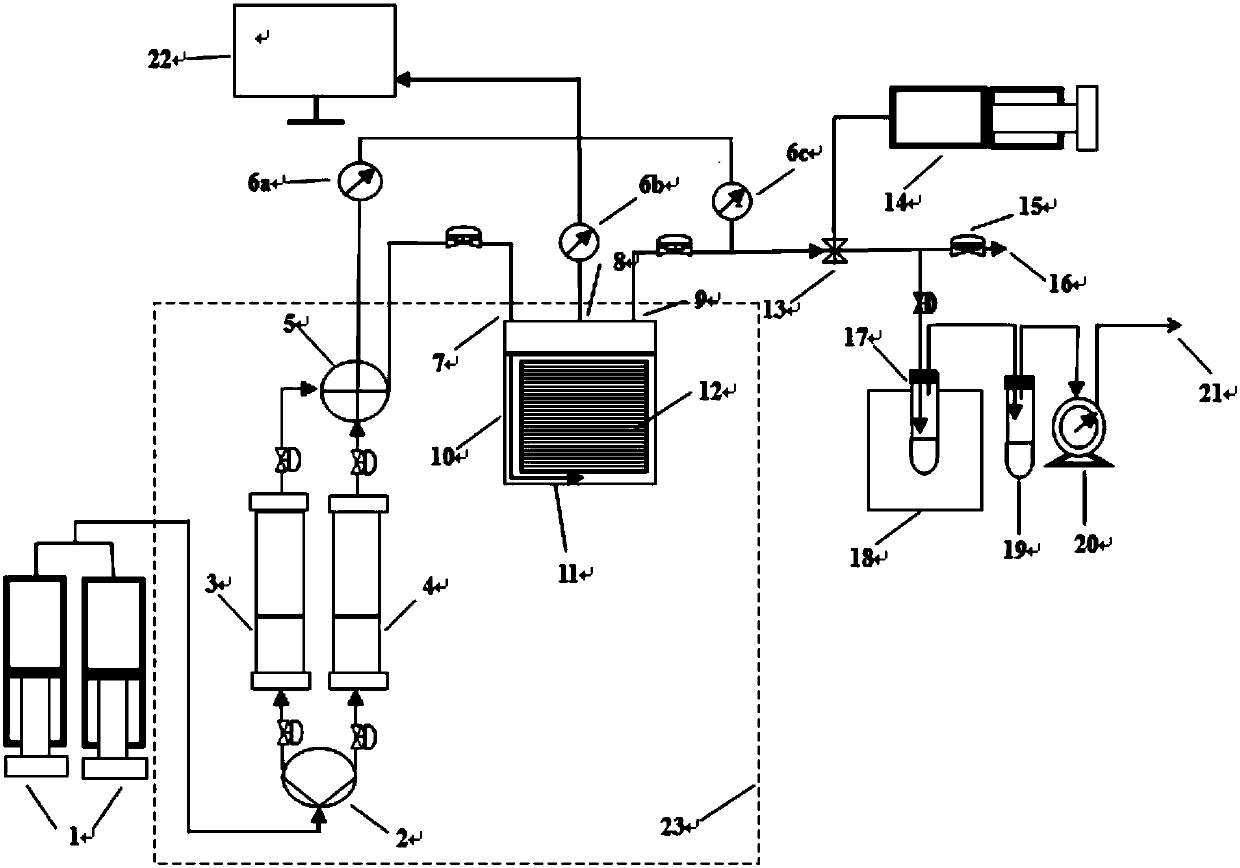

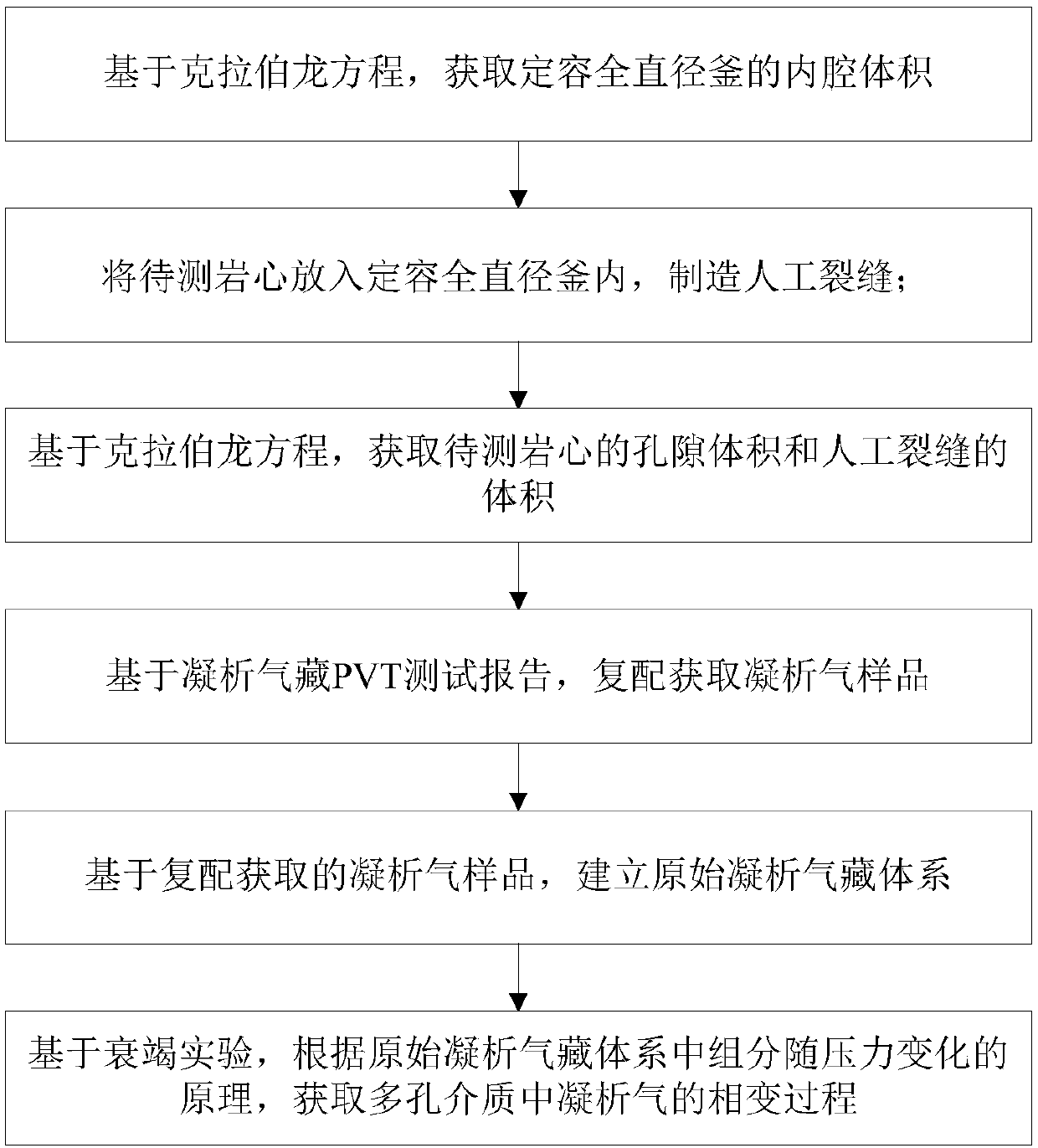

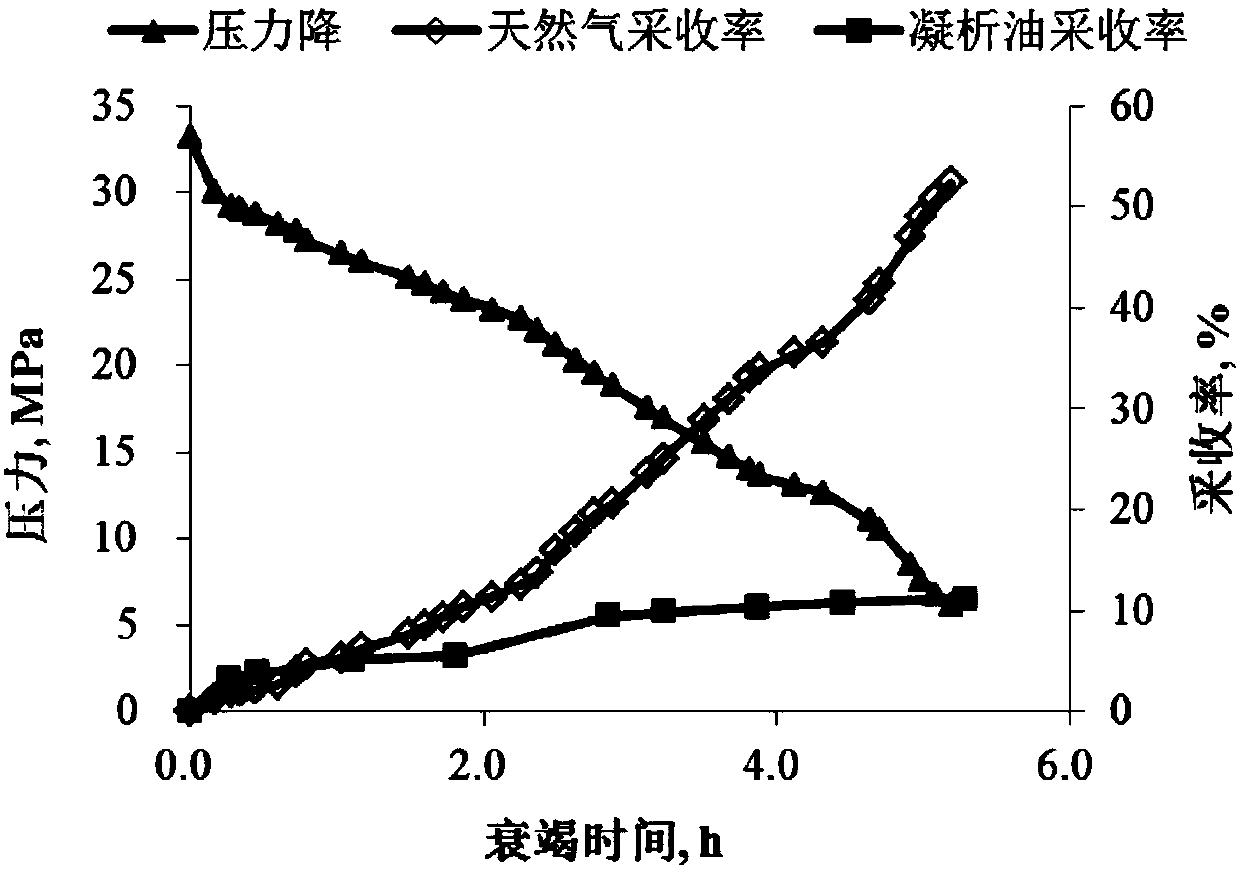

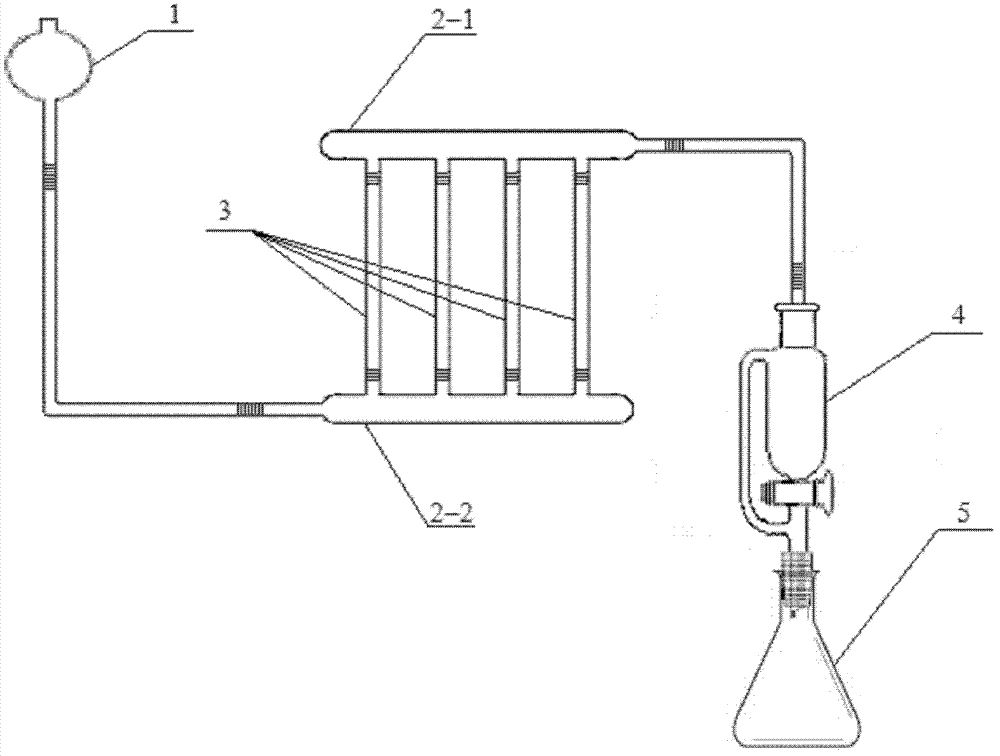

Simulation device of condensate gas constant volume depletion in dense porous medium and experiment method

InactiveCN110261571AClarify the degree of influenceReliable principleEarth material testingGas phasePorous medium

The invention discloses a simulation device of condensate gas constant volume depletion in a dense porous medium and an experiment method. The device comprises a constant volume condensate gas reservoir module, a pressure supply module and an oil and gas separation module, wherein in the constant volume condensate gas reservoir module, a core to be tested is placed in a constant volume full diameter kettle, an end cap is provided with an inlet hole, an outlet hole and a pressure monitoring hole, and a first connecting pipe line is connected to the inlet hole and a center of a circle of a bottom surface of the core to be tested; the pressure supply module includes a constant pressure constant speed displacement pump which is connected to one ends of a condensate gas intermediate container and a high pressure separator gas intermediate container, and the other ends of the condensate gas intermediate container and the high pressure separator gas intermediate container are connected to the inlet hole through the first connecting pipe line; and the oil and gas separation module includes a back pressure pump, a back pressure valve, an oil and gas separator and a gas meter which are connected successively, and an inlet end of the back pressure valve is connected to the outlet hole through a second connecting pipe line. The device and the method have advantages that changes of an oil and gas phase in a depletion process of a condensate gas reservoir in fractured tight reservoir can be simulated, and an oil and gas state under a condensate gas reservoir condition can be maximumly restored.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gas constant pressure capacity tester

InactiveCN102901796AEasy to manufactureImprove accuracyVolume measurement apparatus/methodsChemical microanalysisEngineeringRepeatability

The invention relates to a gas constant pressure capacity tester used for hydride quantitative analysis. The gas constant pressure capacity tester includes a constant pressure controller, a comb tube, graduated tubes, a constant pressure funnel and a reaction container. Specifically, the comb tube includes an upper comb tube and a lower comb tube that are vertically symmetrical and are connected by the graduated tubes. The upper comb tube and the lower comb tube are respectively connected to the constant pressure funnel and the constant pressure controller. The constant pressure funnel and the reaction container are in sealed connection so as to form a sealed system. The gas constant pressure capacity tester provided in the invention has the advantages of easy manufacturing, high accuracy, convenient operation, and good repeatability, etc., and can make a hydride quantitative analysis method simple, accurate, and rapid.

Owner:车瀛照

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com