Patents

Literature

706results about How to "Quick correction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

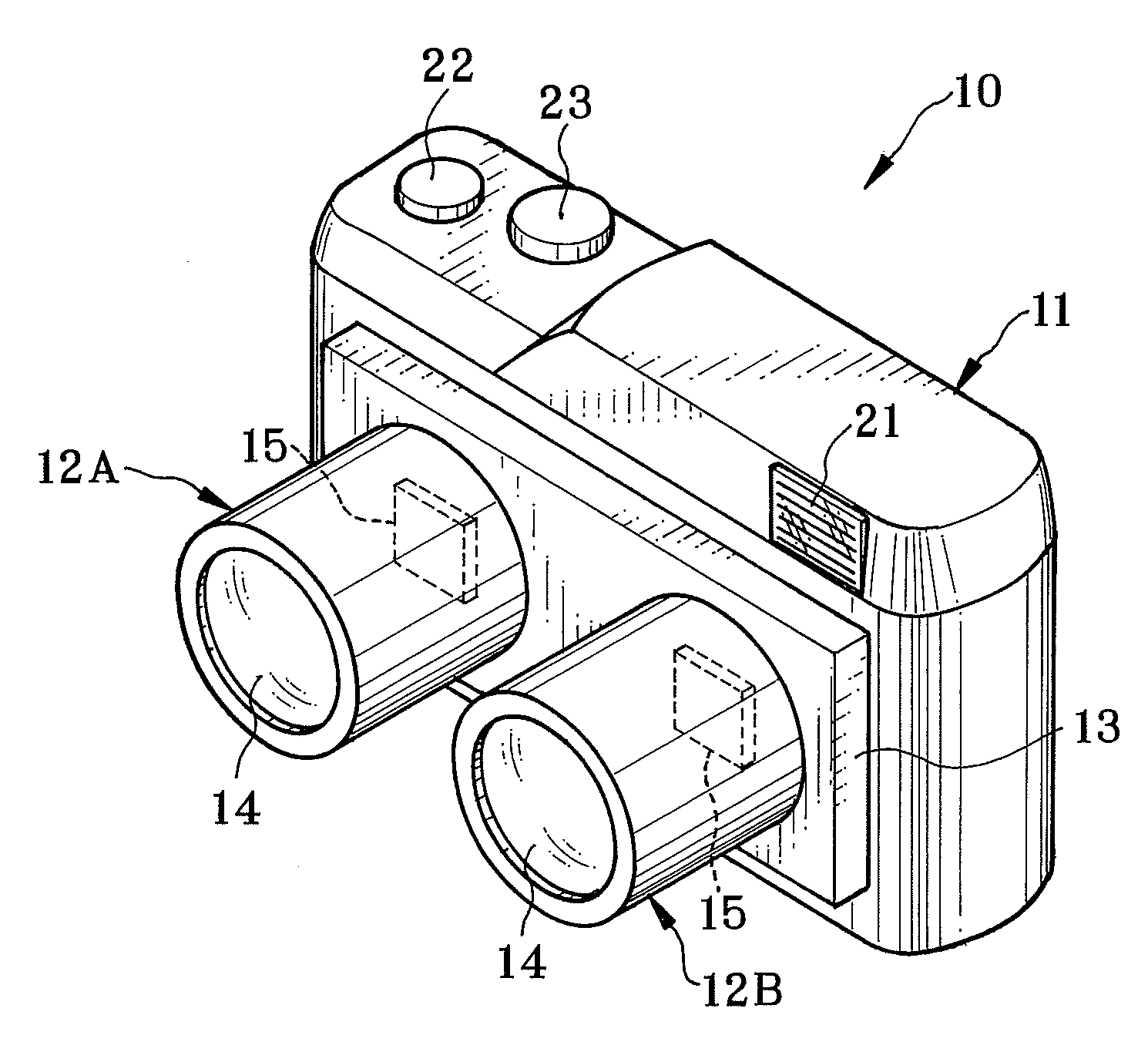

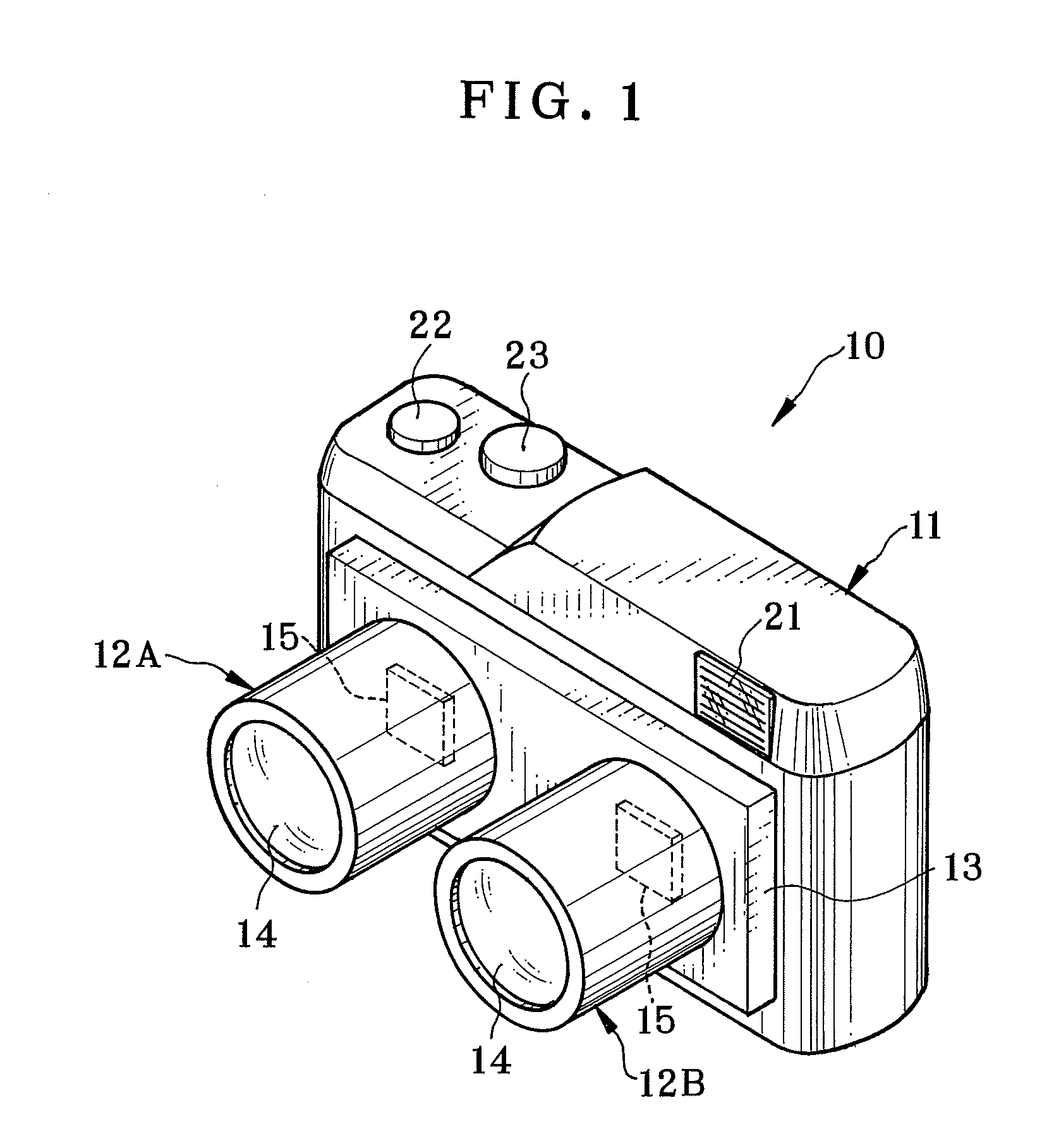

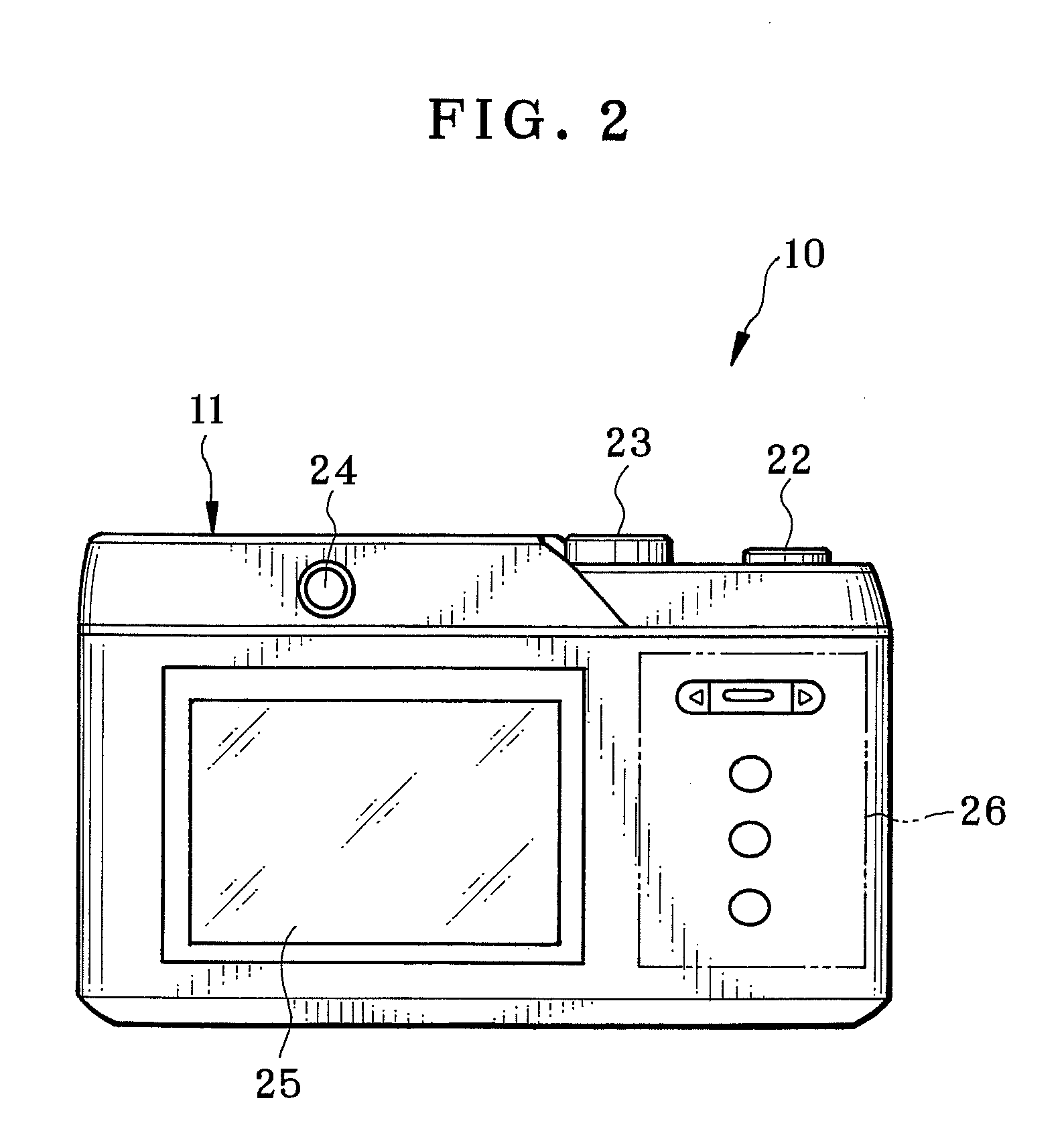

Stereoscopic image pickup apparatus and method of adjusting optical axis

InactiveUS20080239064A1Simple structureQuick correctionSteroscopic systemsFace detectionStereo camera

A stereoscopic camera includes first and second image pickup units, having respectively first and second optical axes, for photographing an object to form two image frames. Two angle adjusters make angle adjustment of the optical axes. An object detector detects a human face as a principal object in the two image frames. An arithmetic processor obtains a shift amount of the face between two image frames, and determines an axial correction angle according to the shift amount for the angle adjustment in consideration of the face. A checker checks whether the angle adjustment should be made for both optical axes or for one thereof. A controller operates at least one of the two angle adjusters according to the axial correction angle and in response to information from the checker, for positioning the face equally between the two image frames optically by adjusting the first and / or second optical axis.

Owner:FUJIFILM CORP

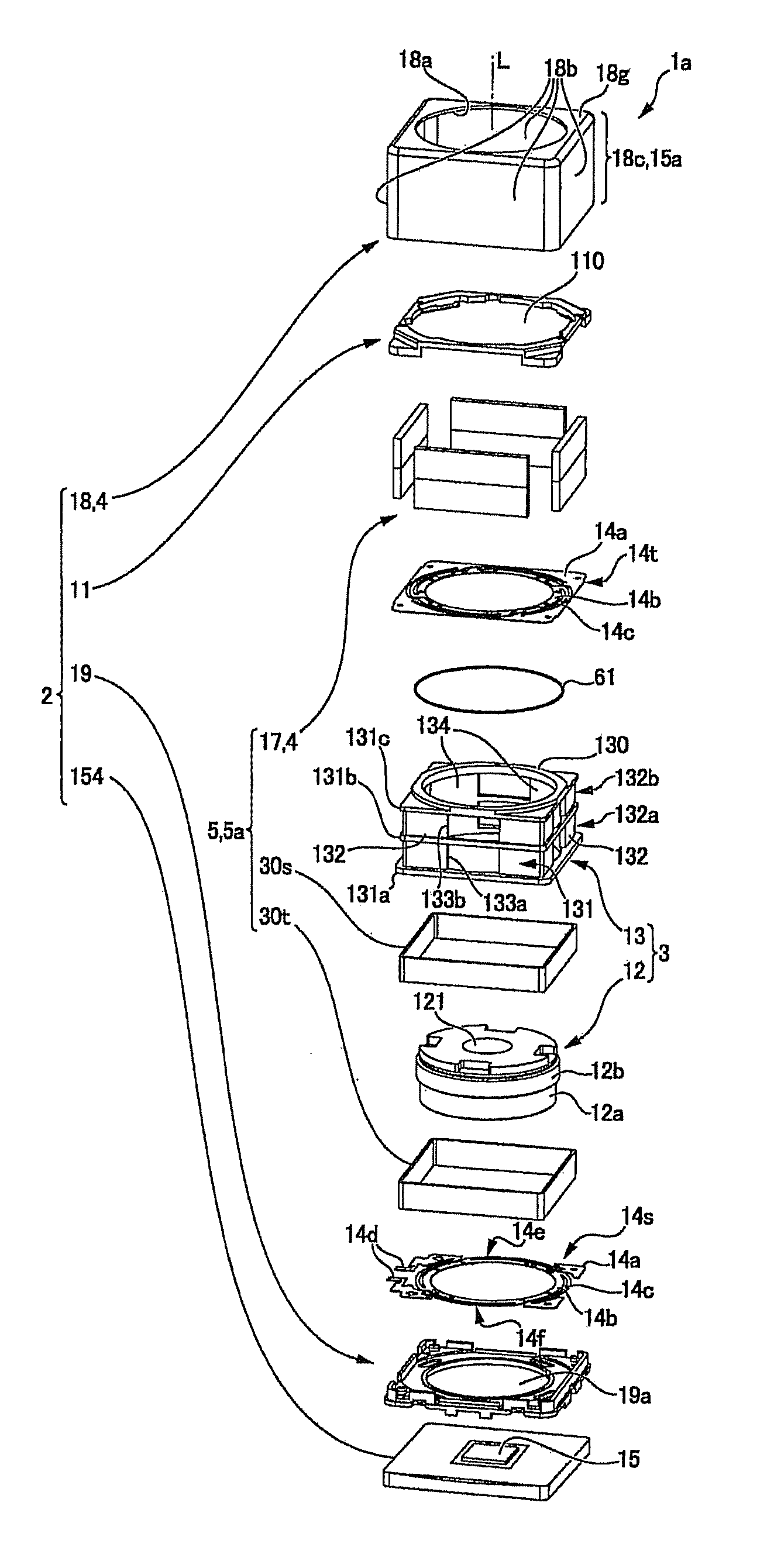

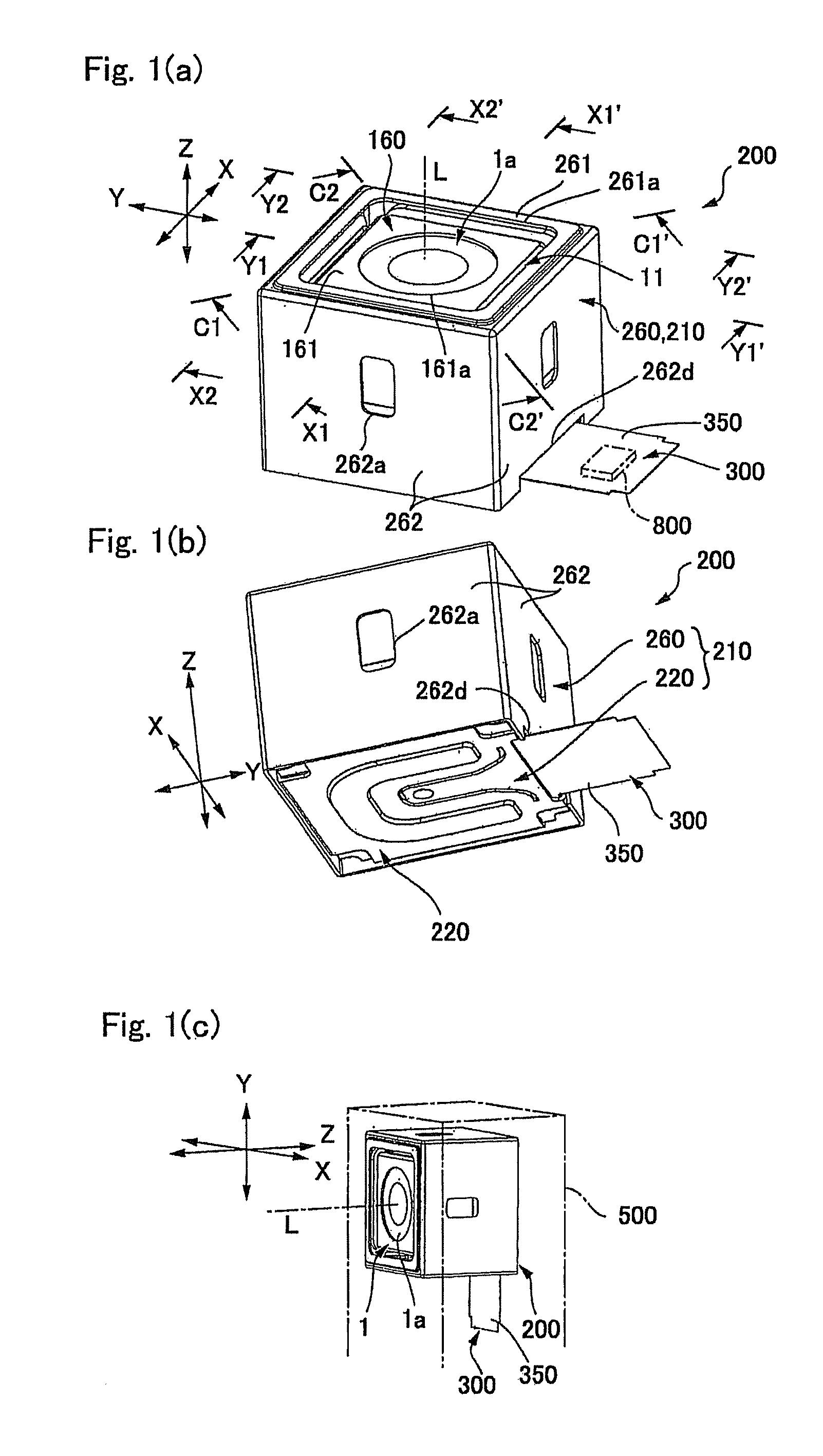

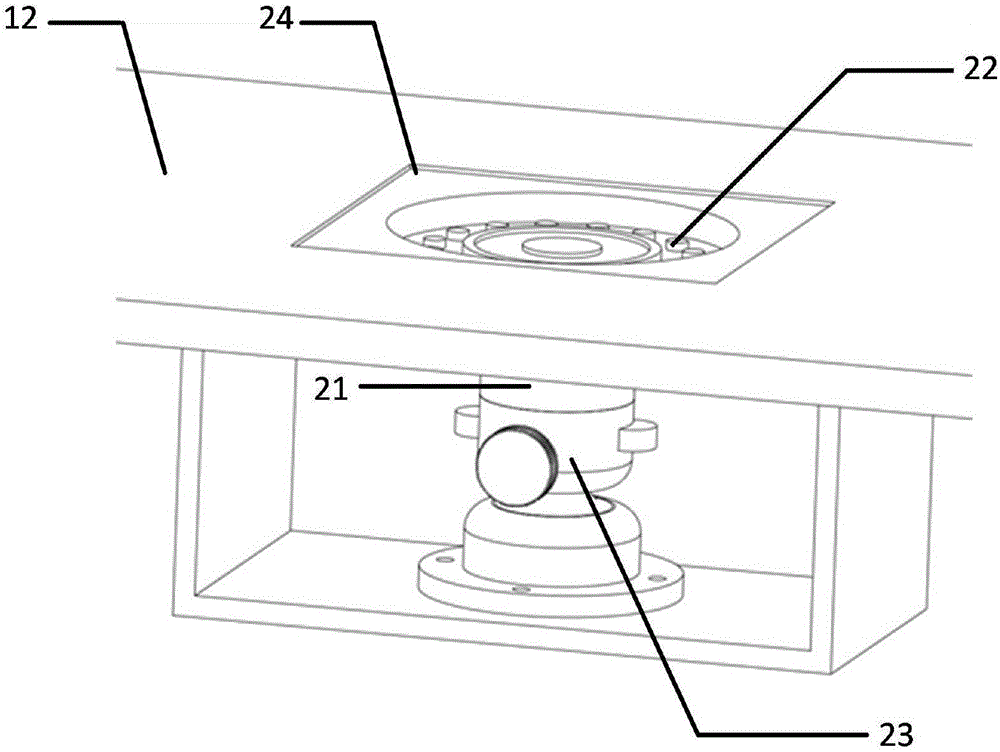

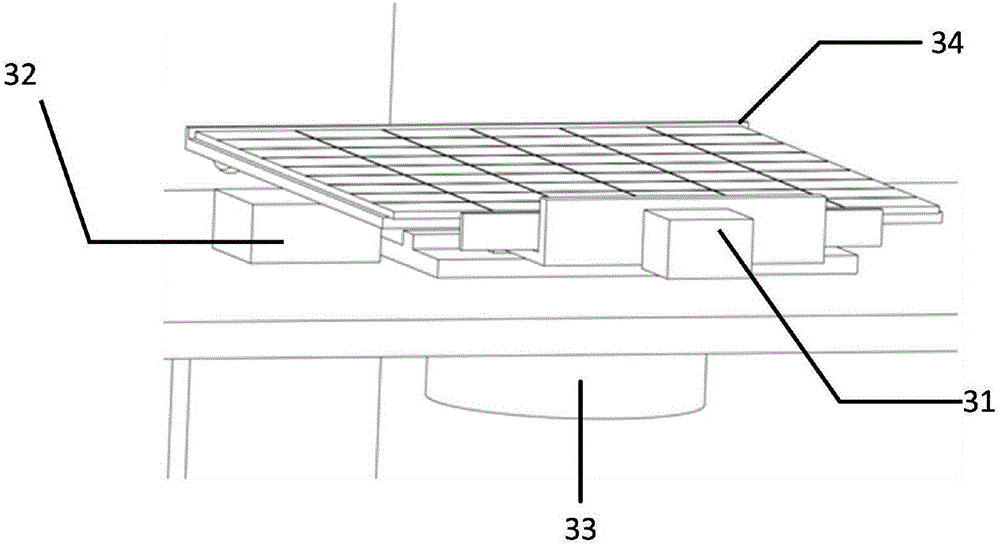

Optical unit with shake correcting function and shake correction control method therefor

InactiveUS20100098394A1Quick correctionSimple processTelevision system detailsCamera body detailsGyroscopeEngineering

An optical unit with shake correcting function may include a movable module on which at least an optical element is mounted, a fixed body which supports the movable module, a shake detection sensor which detects a shake of the movable module, a drive mechanism for shake correction for swinging the movable module on the fixed body on the basis of a detection result of the shake detection sensor to correct the shake of the movable module, and a control section which controls the drive mechanism for shake correction on the basis of the detection result of the shake detection sensor. The shake detection sensor is a gyroscope mounted on the movable module and the control section controls the drive mechanism for shake correction so as to cancel the shake detected by the gyroscope.

Owner:SANKYO SEIKI MFG CO LTD

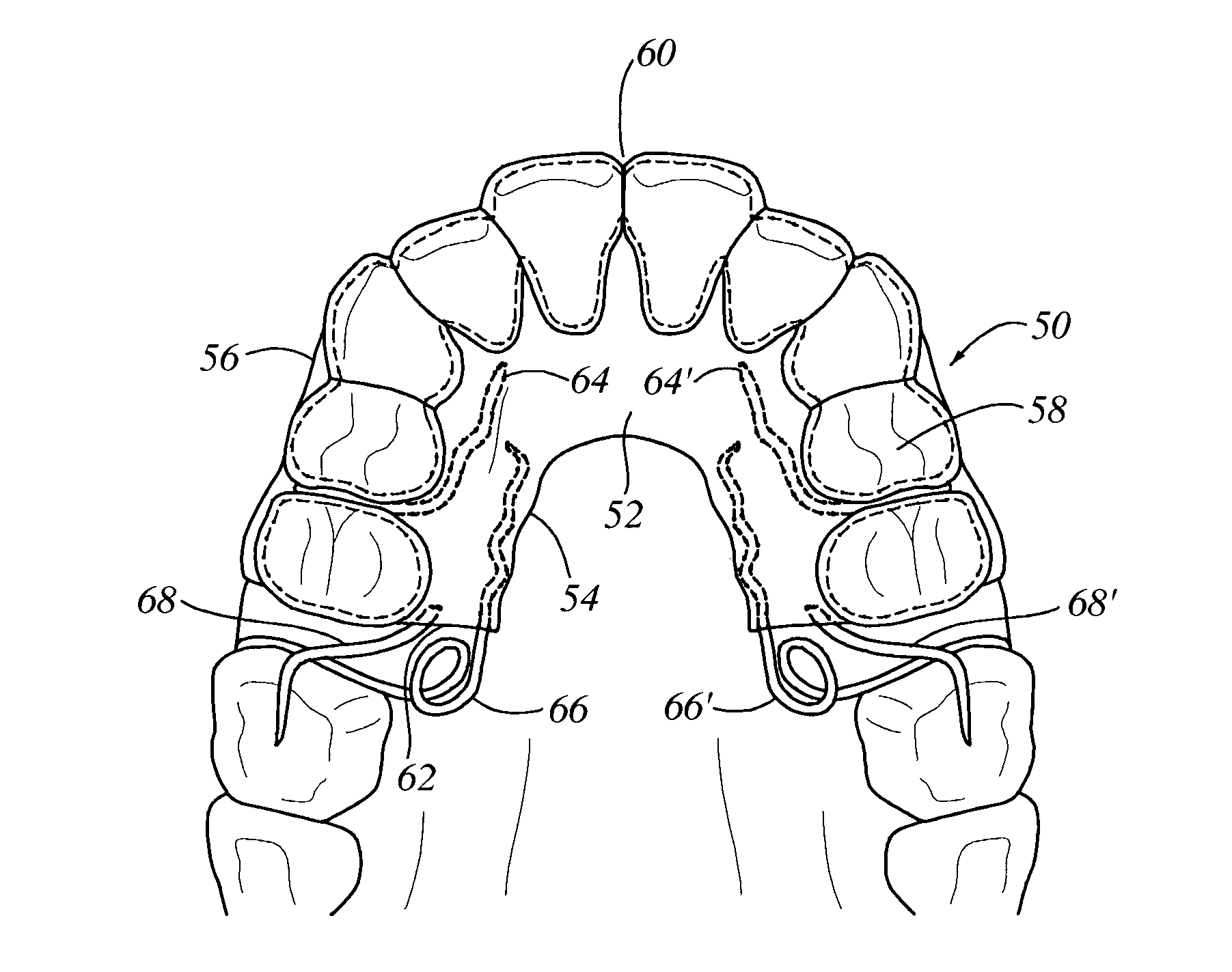

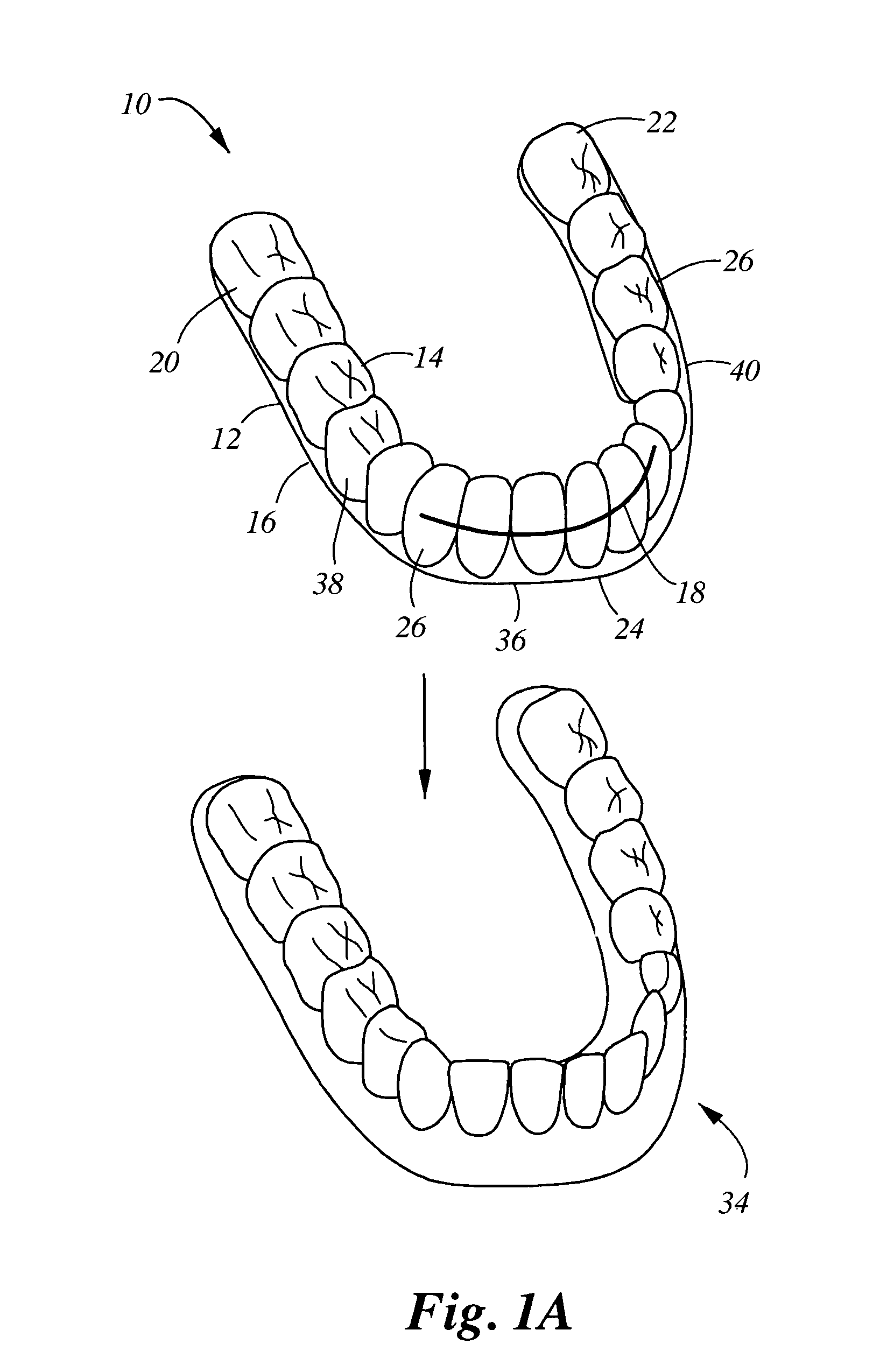

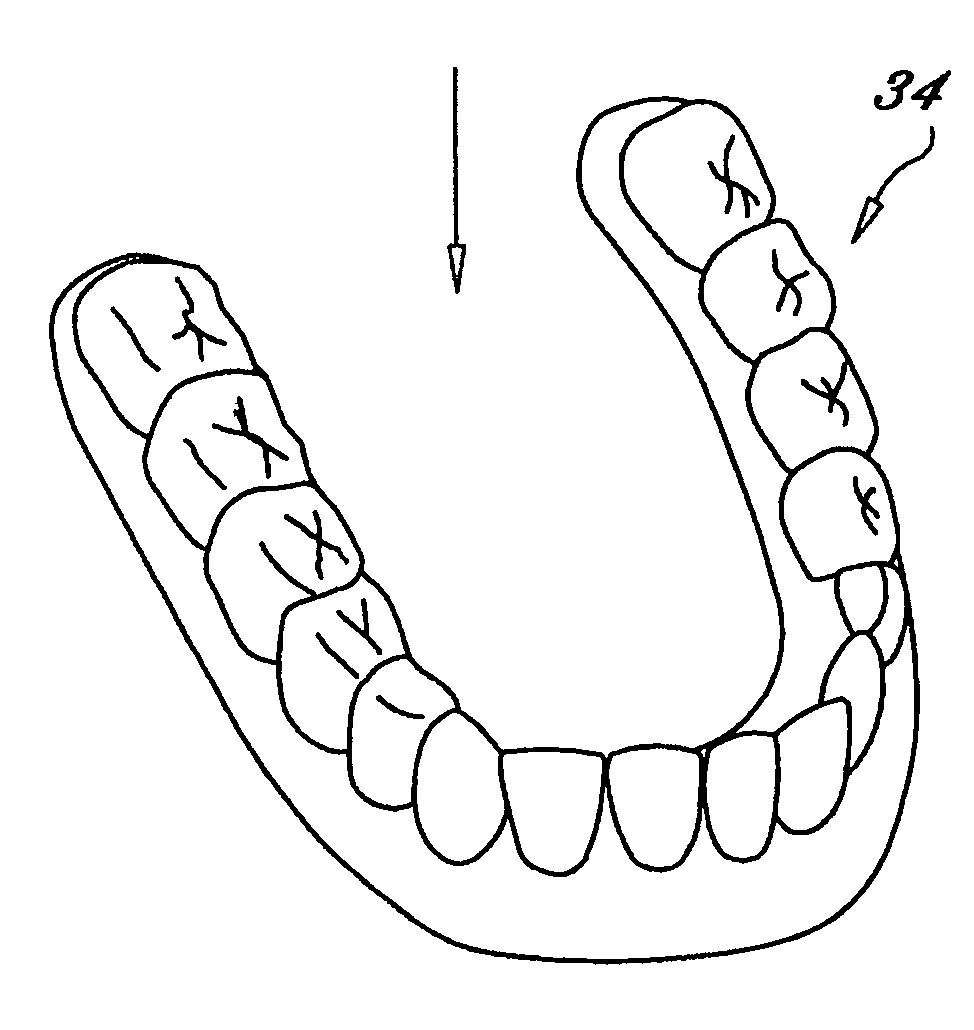

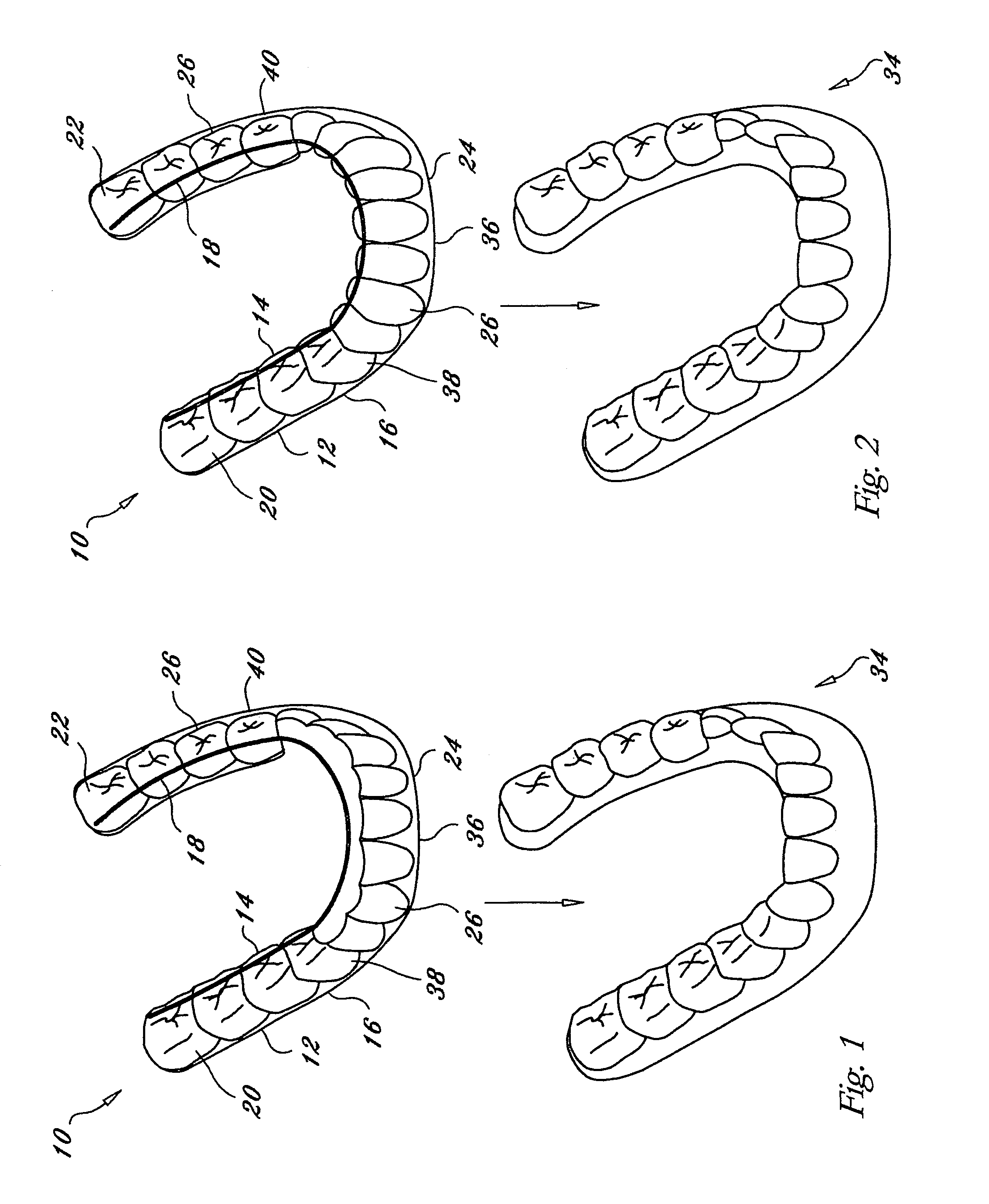

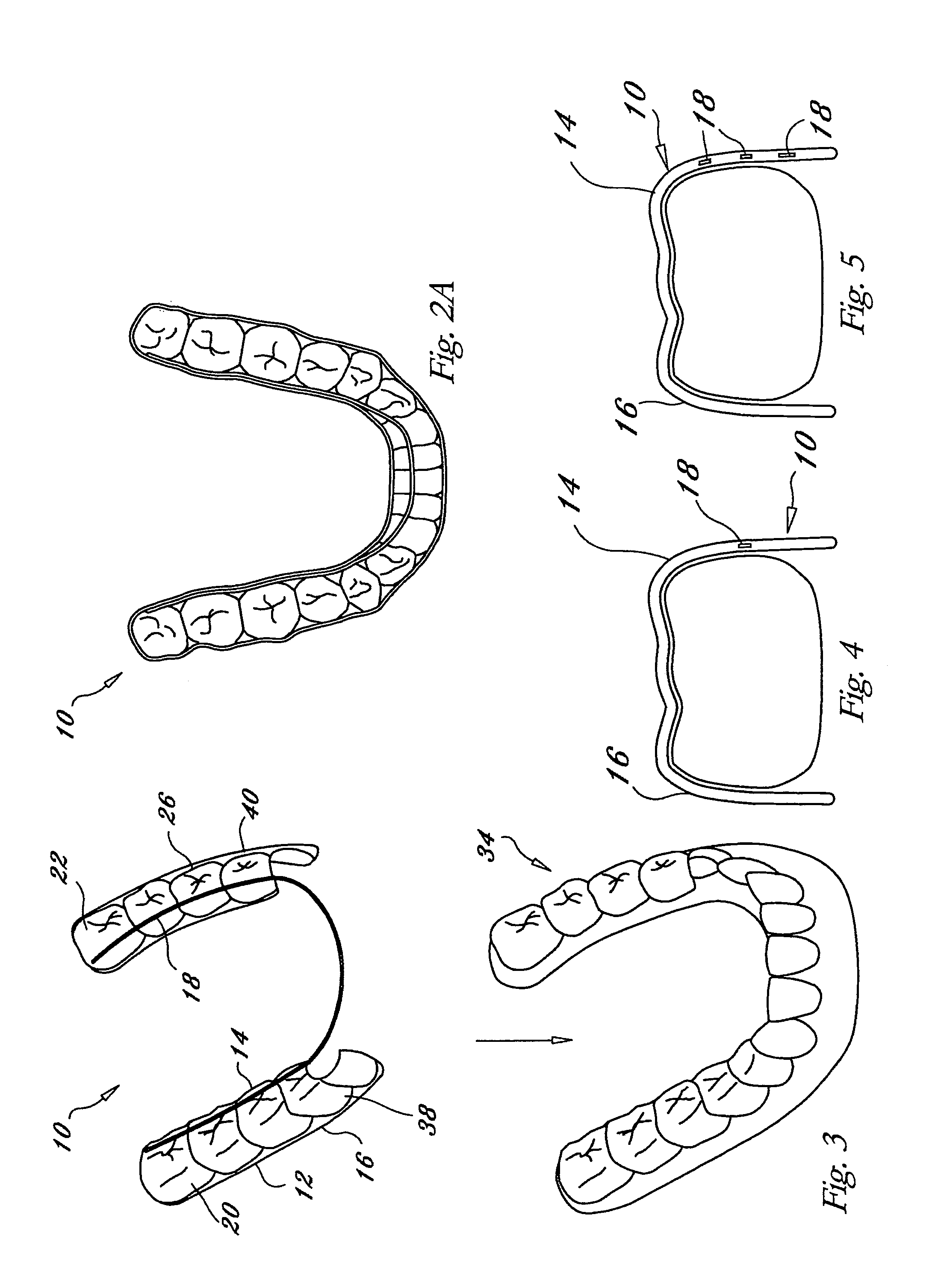

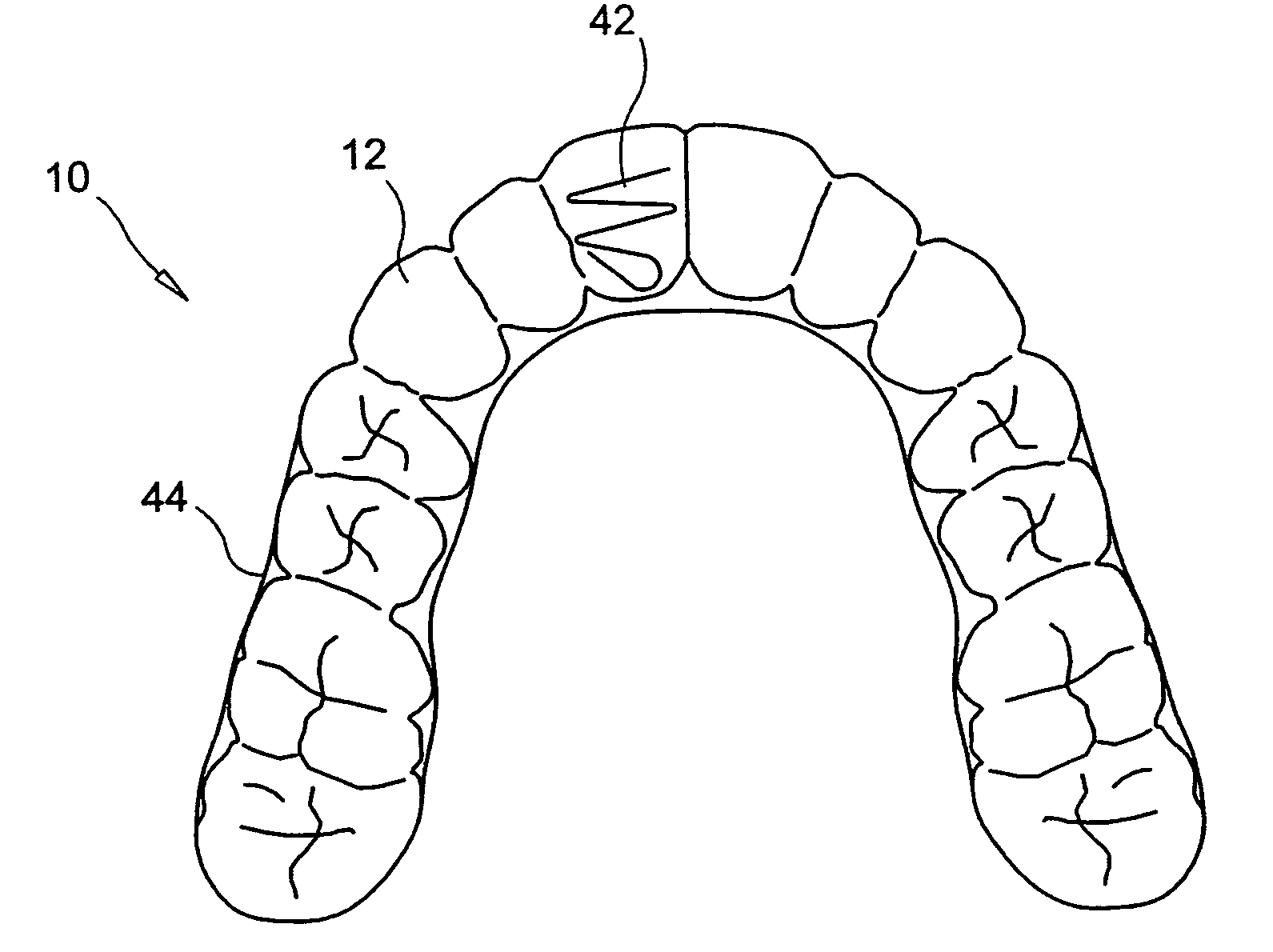

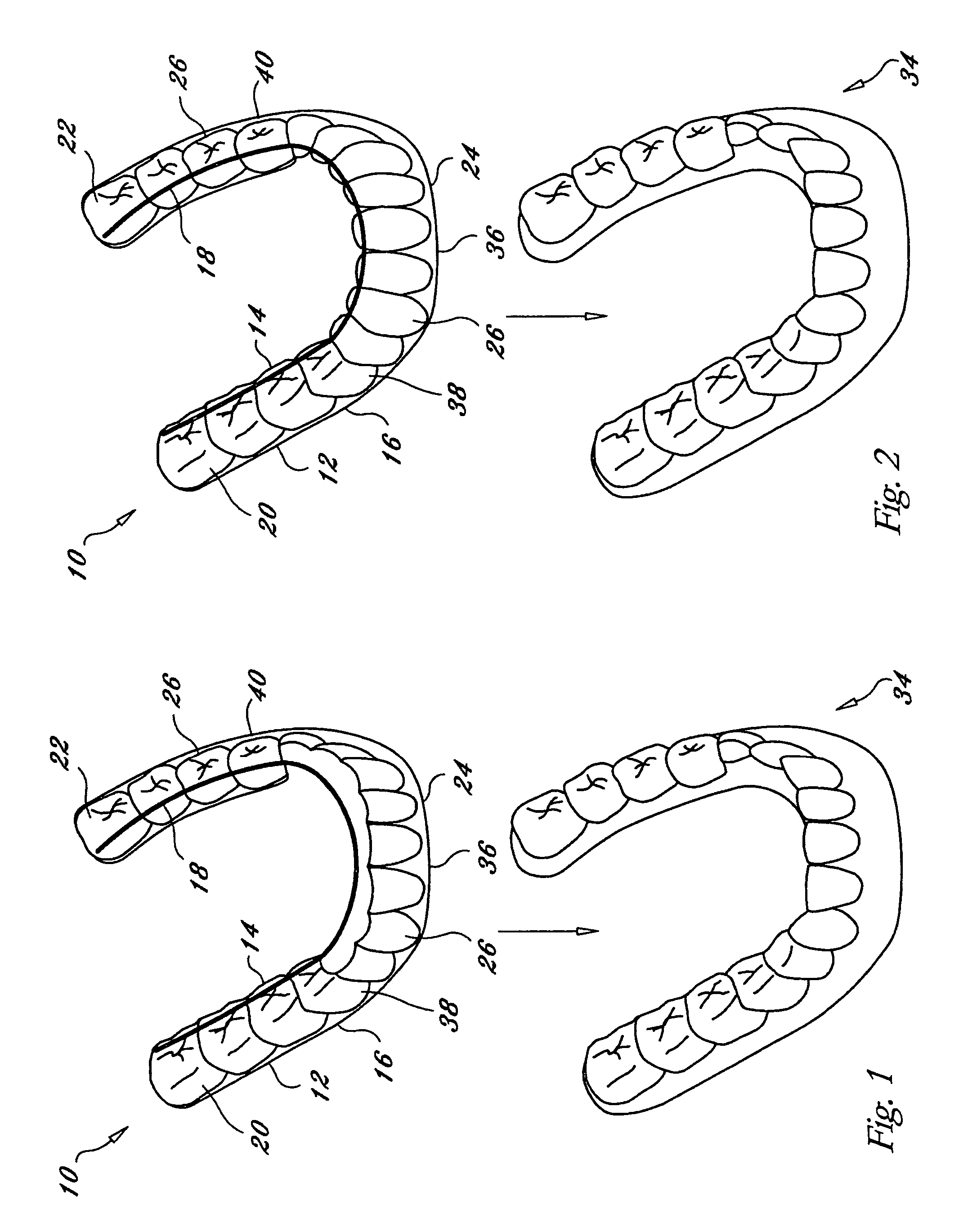

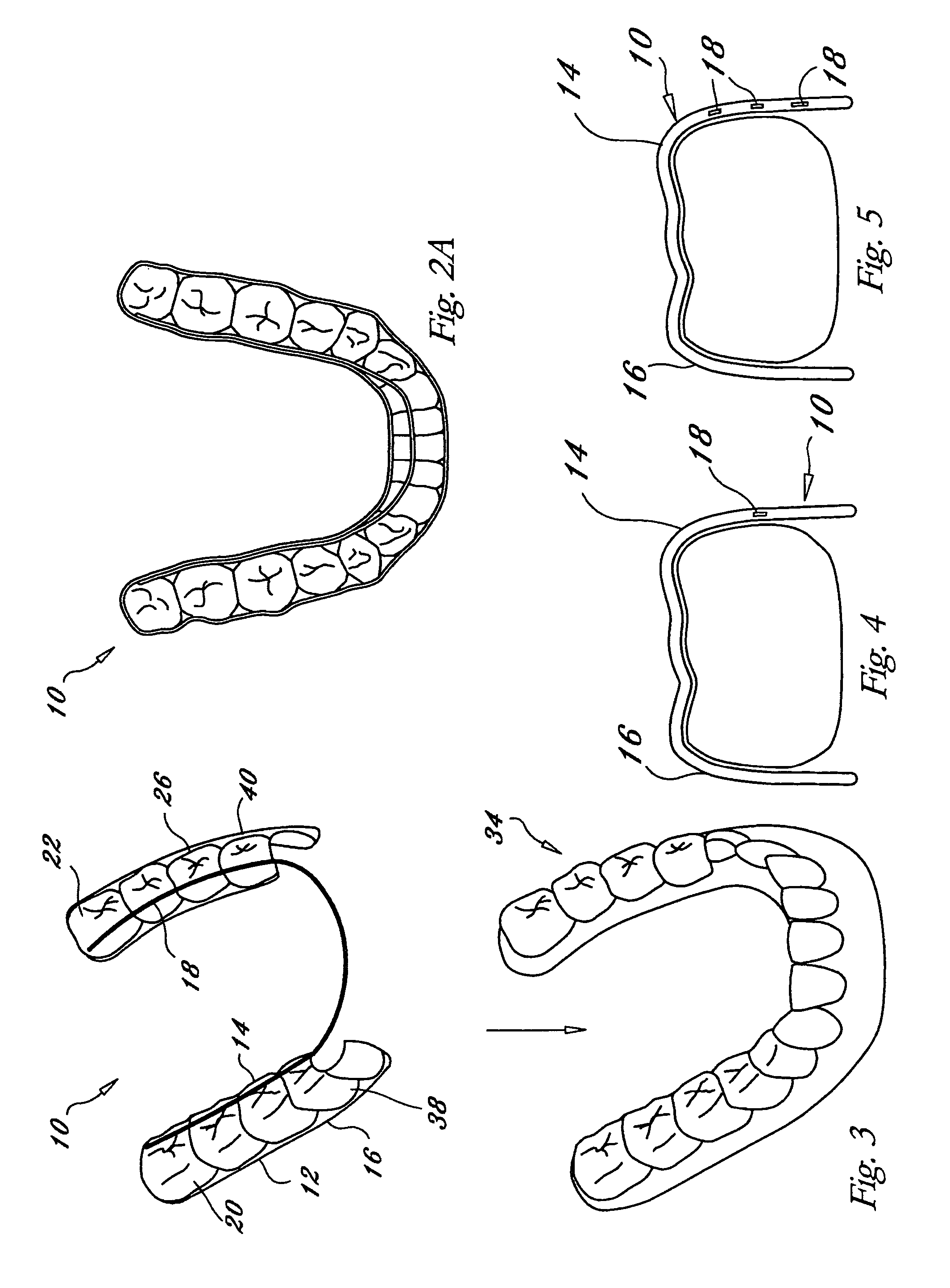

Orthodontic appliance with embedded wire for moving teeth

ActiveUS7963766B2Easy to manufactureIncreasingly forceful and less obtrusive movementArch wiresDental toolsDental flossBite registration

The present invention provides an orthodontic appliance including a unitary appliance body positionable about a portion of a single dental arch, where the appliance body may define a lingual portion, a labial-buccal portion, and a contoured portion therebetween. The appliance body may further define an anterior portion and a posterior portion, as well as a first wire coupled to the appliance body, with the first wire extending from the lingual portion of the appliance body to the labial-buccal portion of the appliance body. In addition, a first portion of the first wire may be embedded in the appliance body while a second portion of the first wire extends from the posterior portion of the appliance body. The appliance may further include a second wire disposed about the appliance body between the first wire and the anterior portion of the appliance body. A series of appliances may be used to shift a patient's bite to proper bite orientation.

Owner:CRONAUER EDWARD A

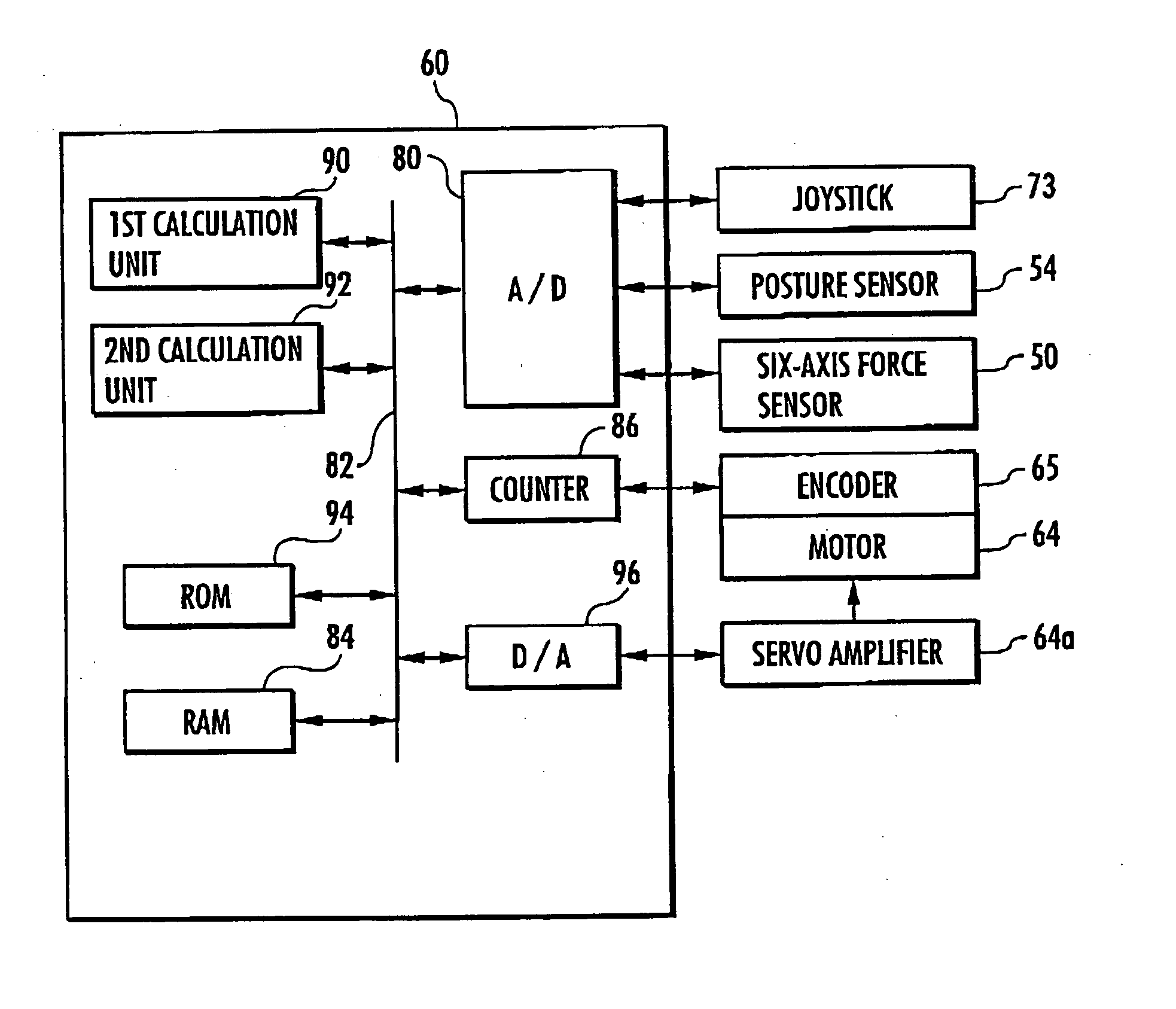

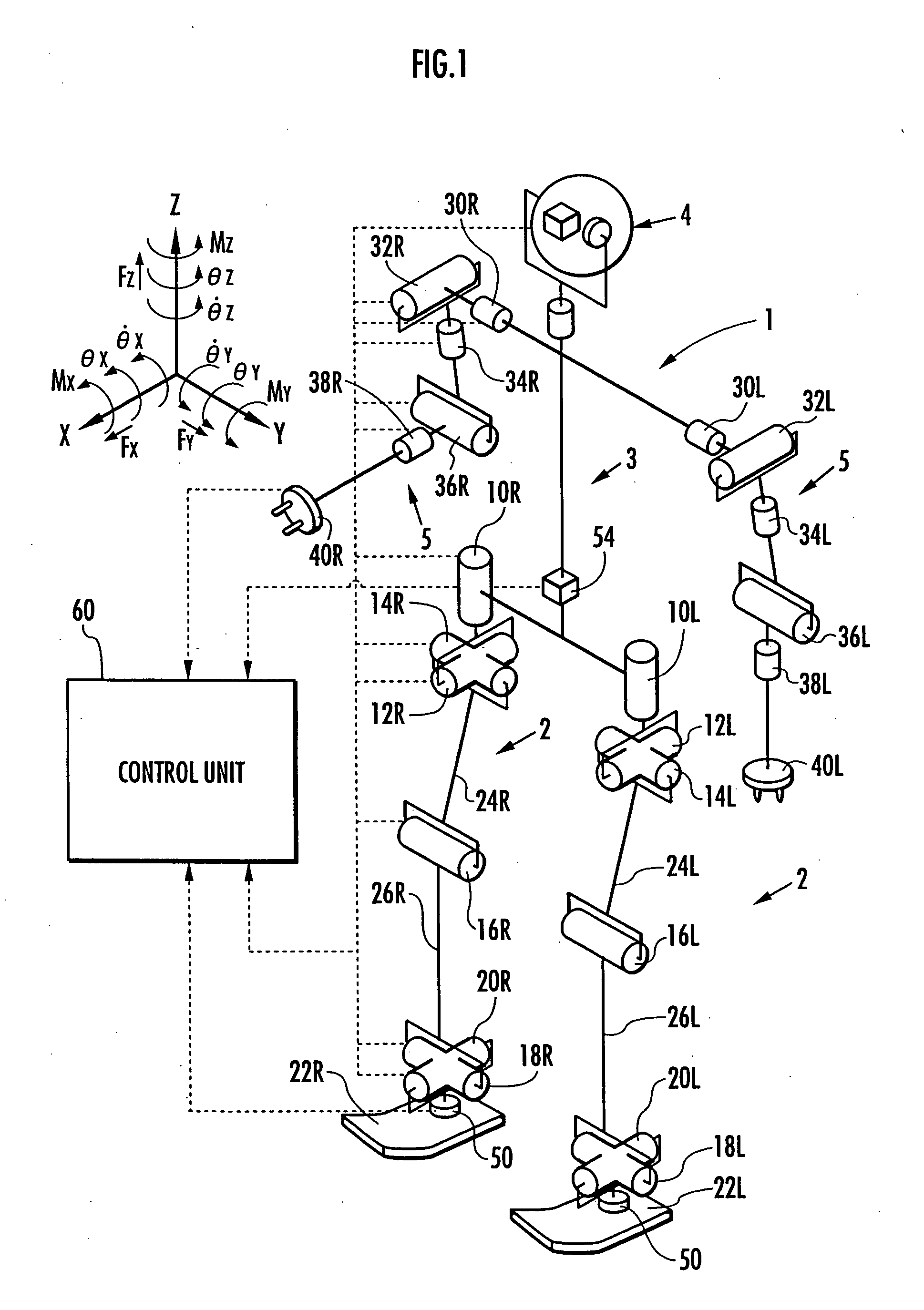

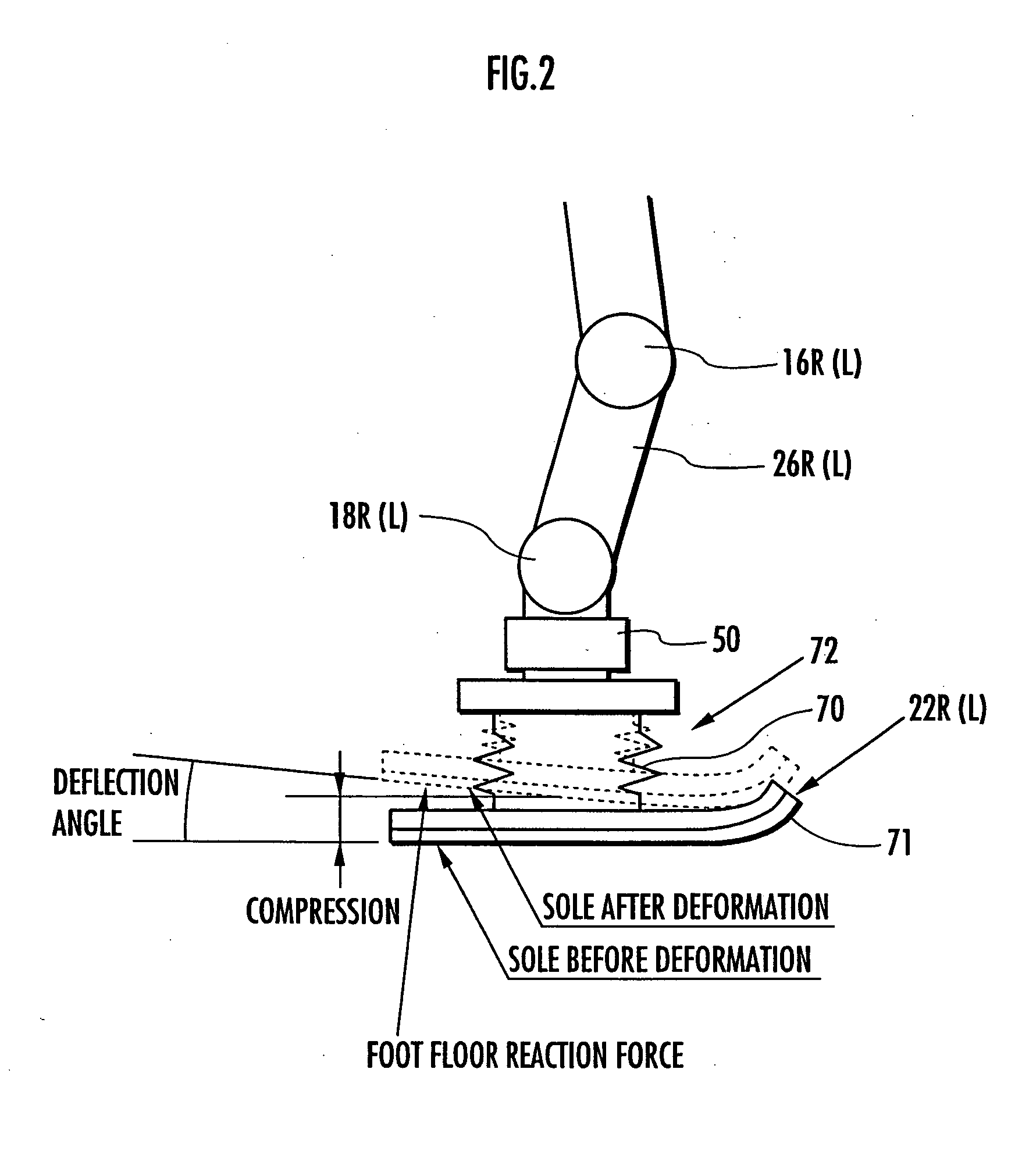

Controller of legged mobile robot

InactiveUS20060173578A1Inhibition is effectiveQuick fixProgramme-controlled manipulatorComputer controlMobile robot controlMomentum

The occurrence of a slippage of a robot in operation, following a desired gait, is determined, and the permissible range of a restriction object amount, such as a floor reaction force horizontal component or a floor reaction force moment vertical component to be applied to the robot, is variably set according to a slippage determination result. A provisional motion of a desired gait is determined using a dynamic model, and if the restriction object amount defined by the provisional motion deviates from the permissible range, then the motion of a desired gait is determined by correcting the provisional motion by changing the changing rate of the angular momentum of the robot from the provisional motion so as to limit the restriction object amount to the permissible range, while satisfying a dynamic balance condition.

Owner:HONDA MOTOR CO LTD

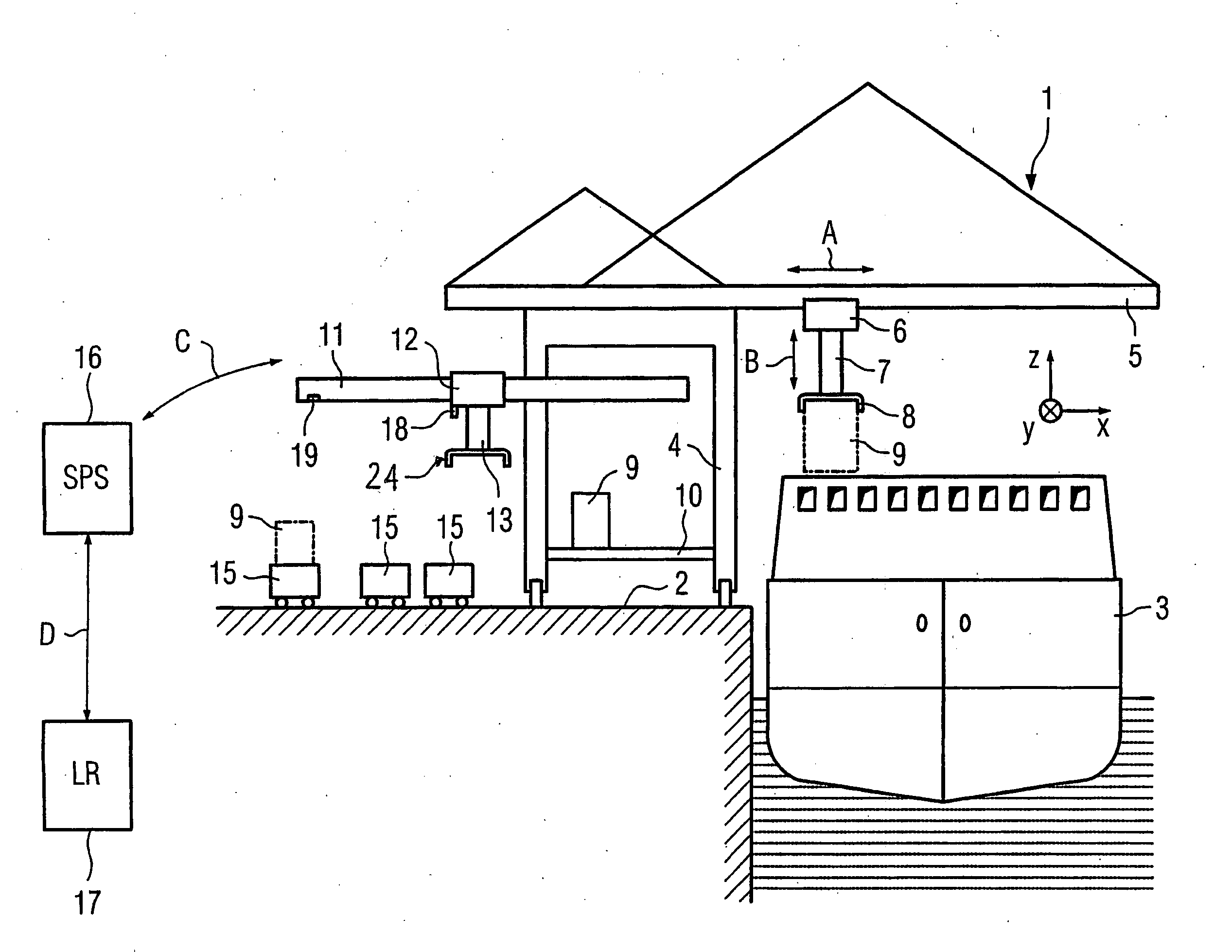

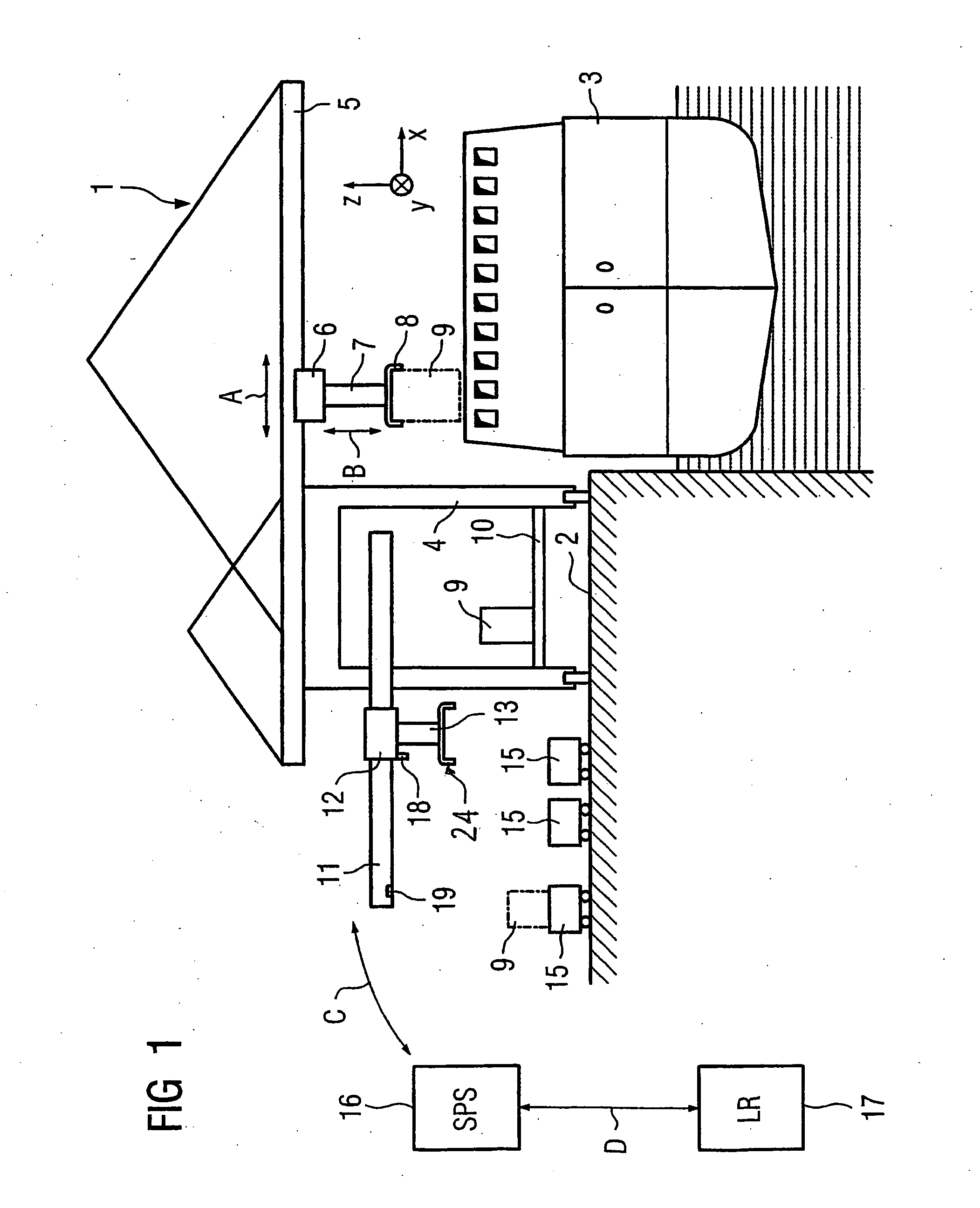

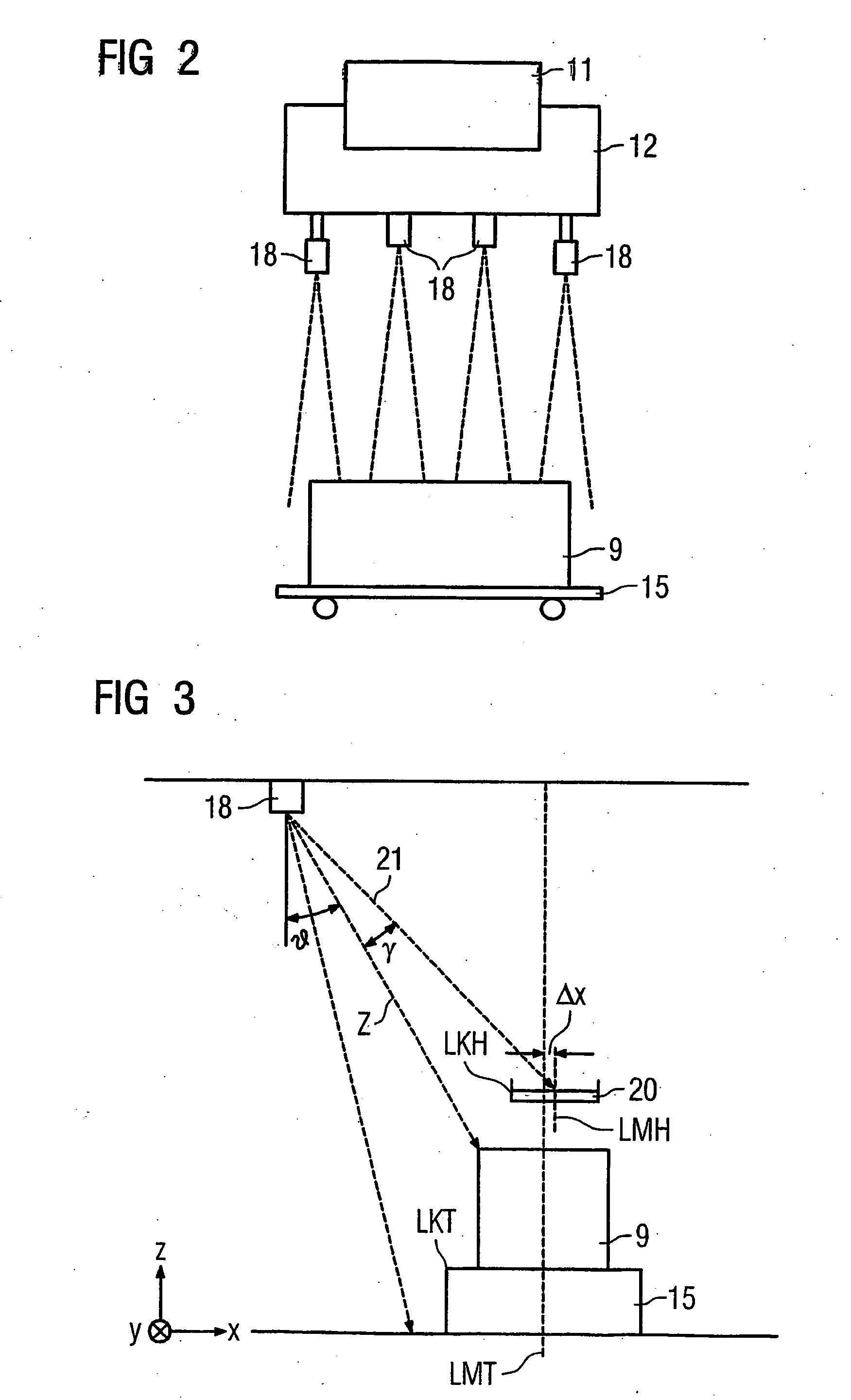

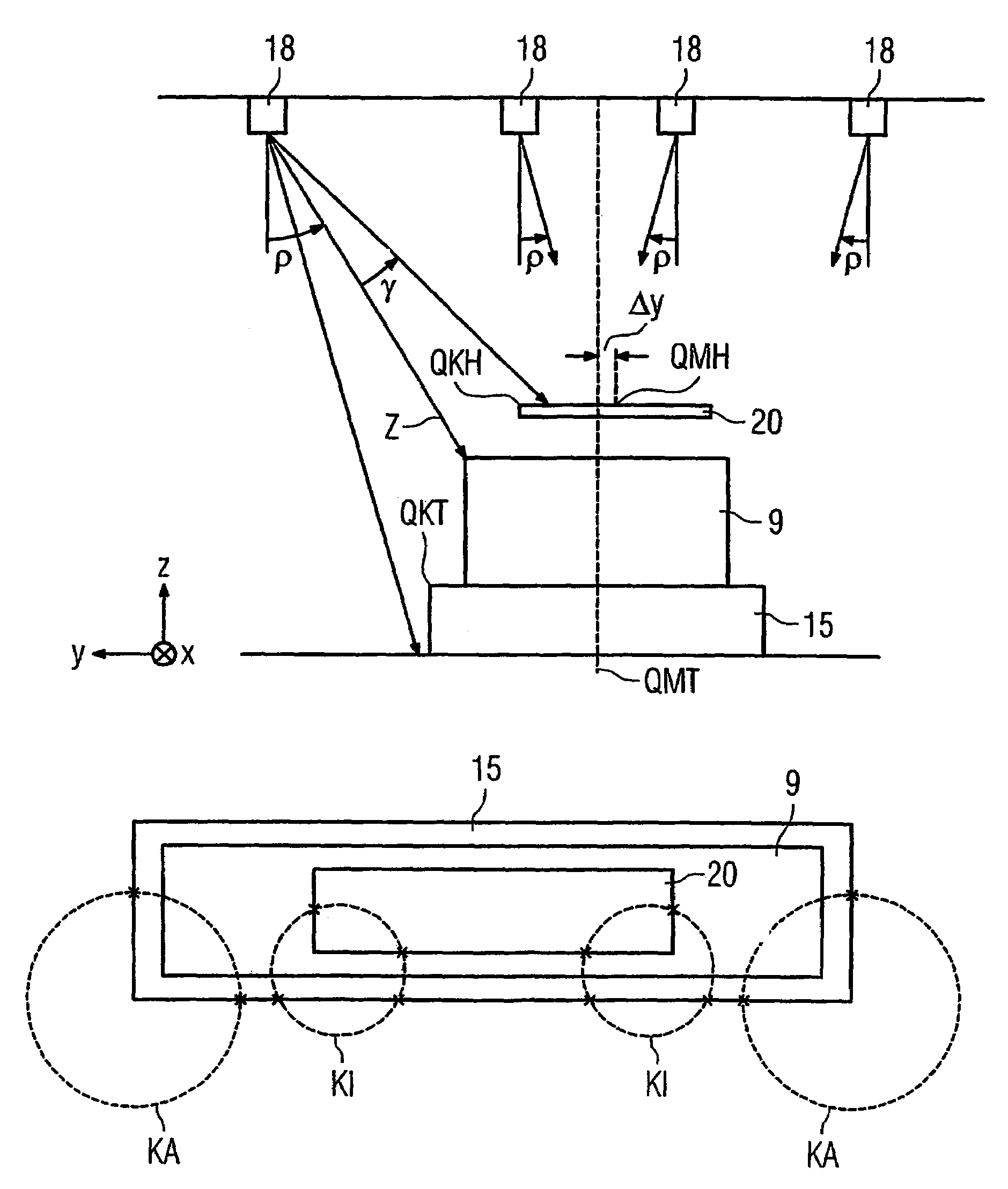

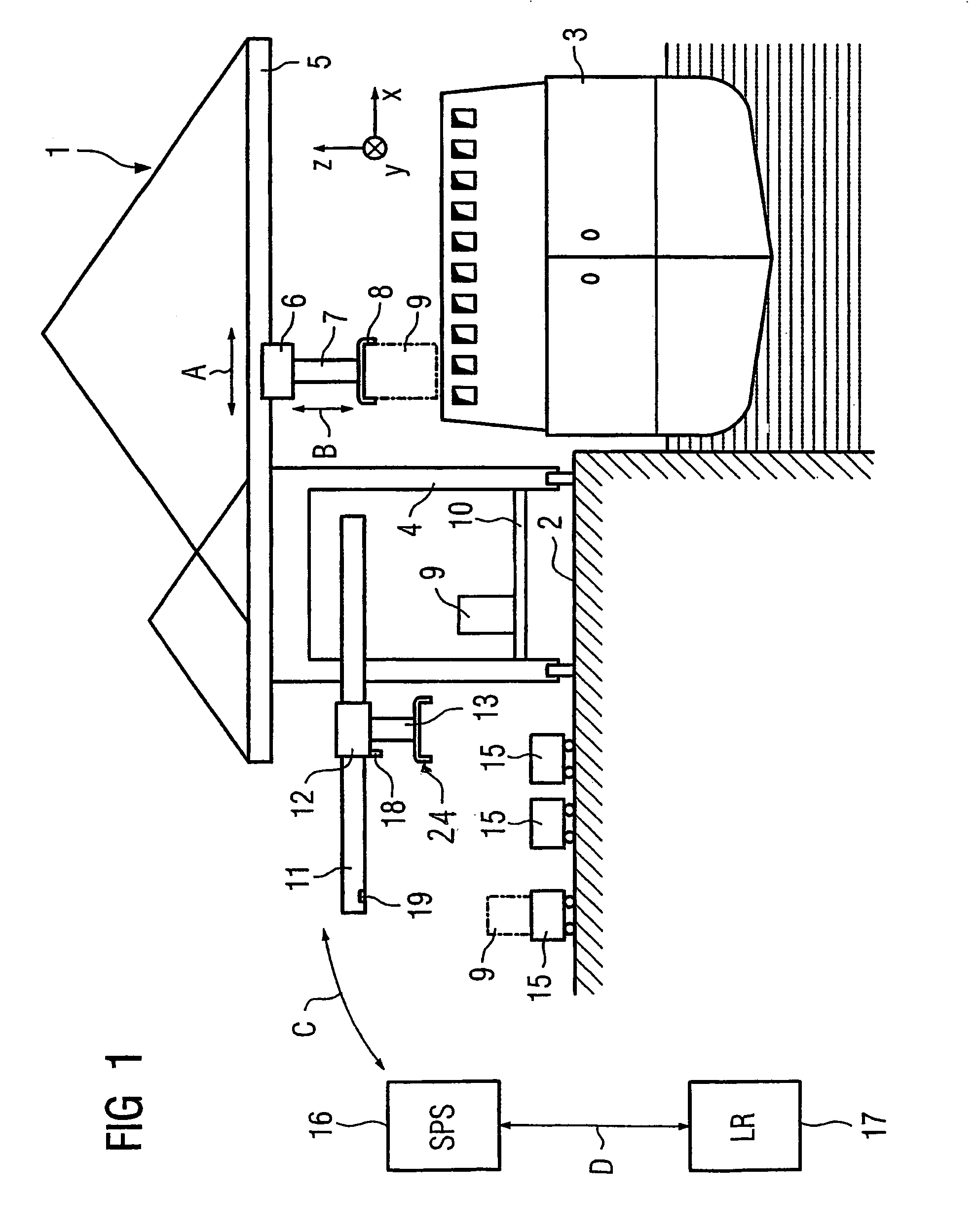

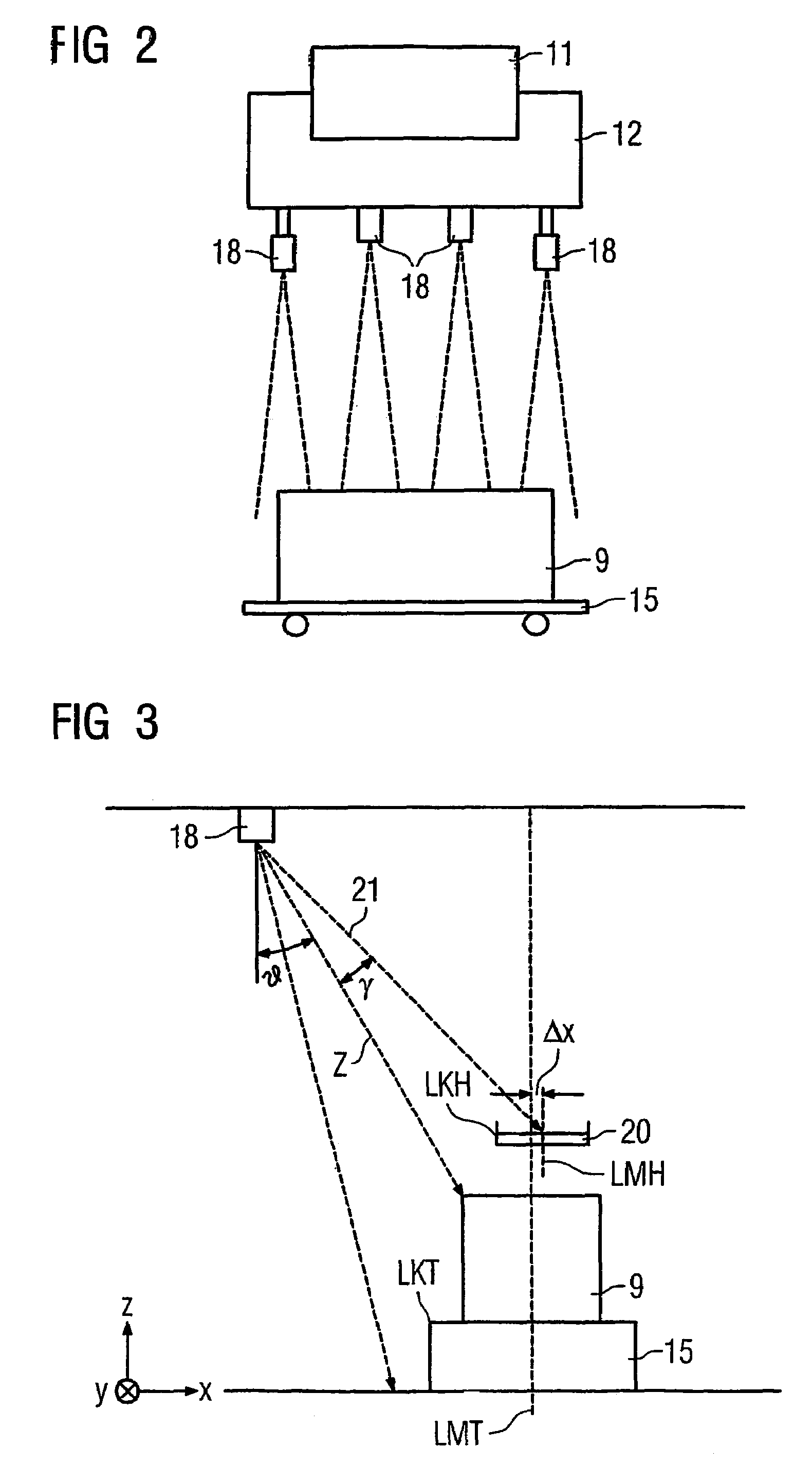

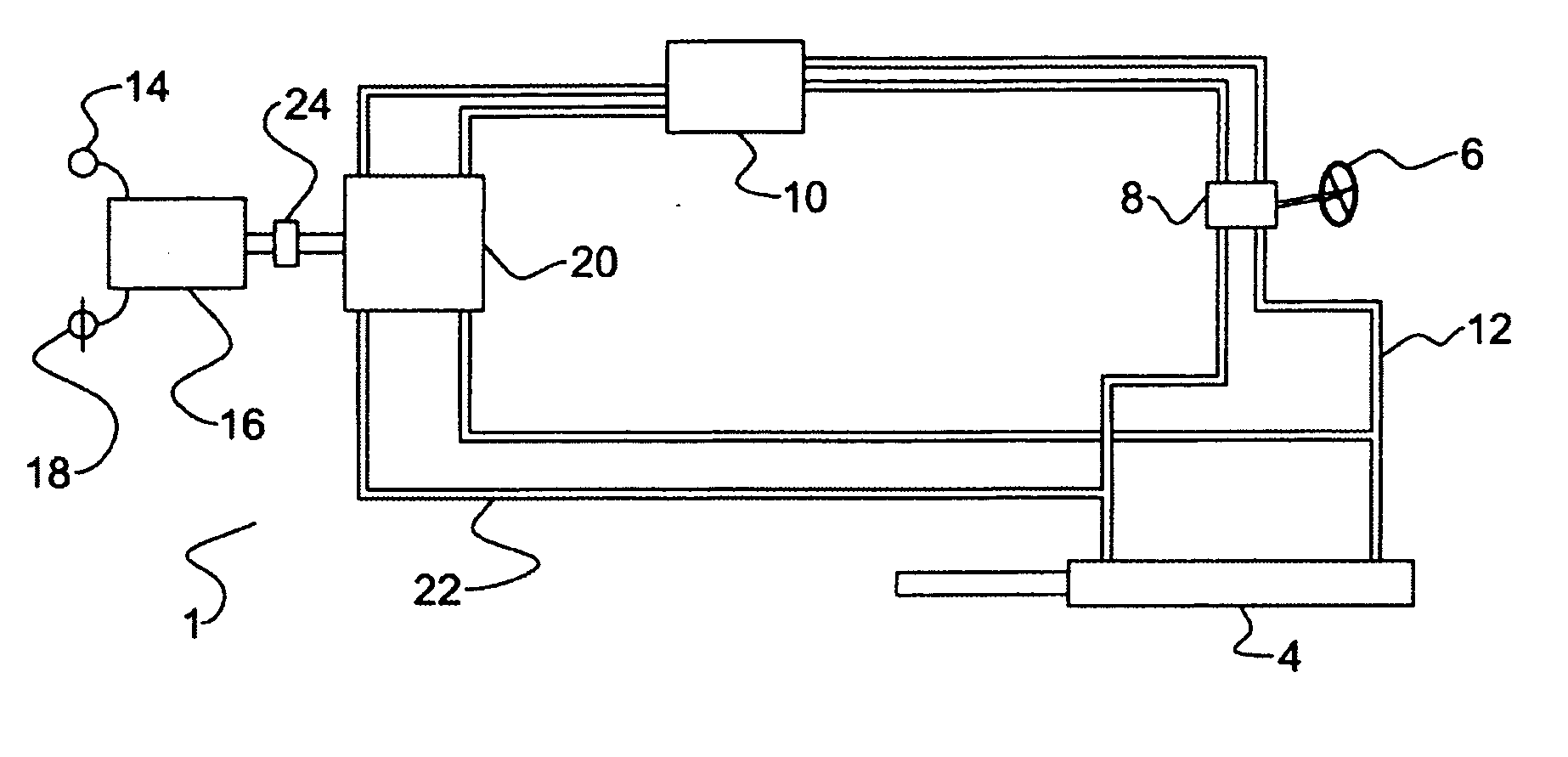

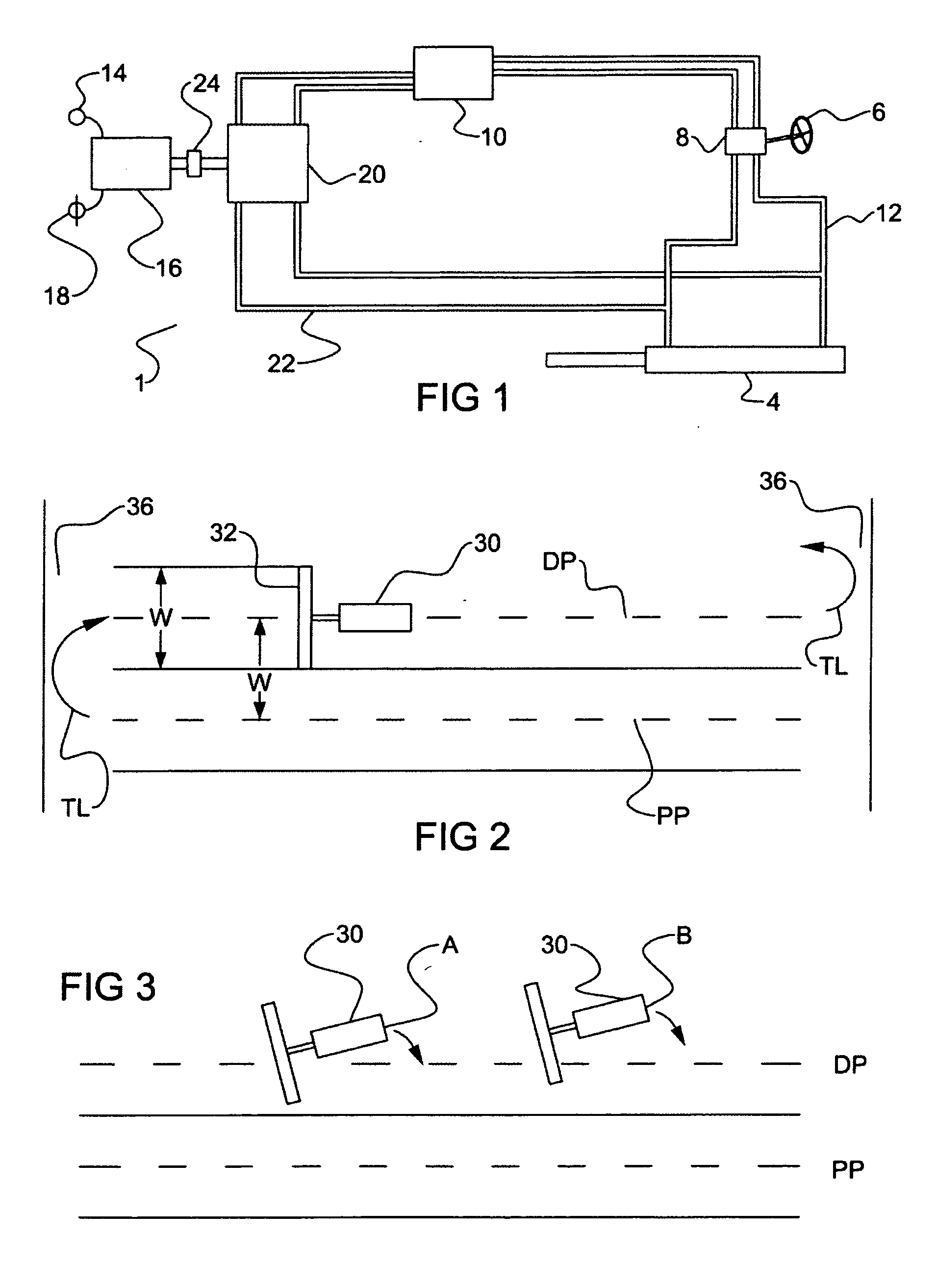

Container crane, and method of determining and correcting a misalignment between a load-carrying frame and a transport vehicle

ActiveUS20050281644A1Large enough scanning areaEnough recording areaDigital data processing detailsArticle unpackingContainer craneEngineering

A container crane includes a movable trolley and a load-carrying frame pendantly connected to the trolley and comprised of a spreader and a head block, for transfer of a container from or to a transport vehicle. Plural optical detectors are mounted on the trolley for identifying longitudinal and transversal edges of the head block or spreader and the transport vehicle. Operatively connected to the detectors is a processing device for determining a spatial position of the edges and calculating a position of longitudinal and transversal center lines of the head block or spreader and the transport vehicle and their spatial positions in relation to one another. In this way a possible offset of the center lines of the head block or spreader with regard to those of the transport vehicle in longitudinal and transversal directions as well as a rotation angle of the center lines can be determined, whereby a detected offset or rotation angle is compensated by displacing the spreader relative to the head block.

Owner:SIEMENS AG

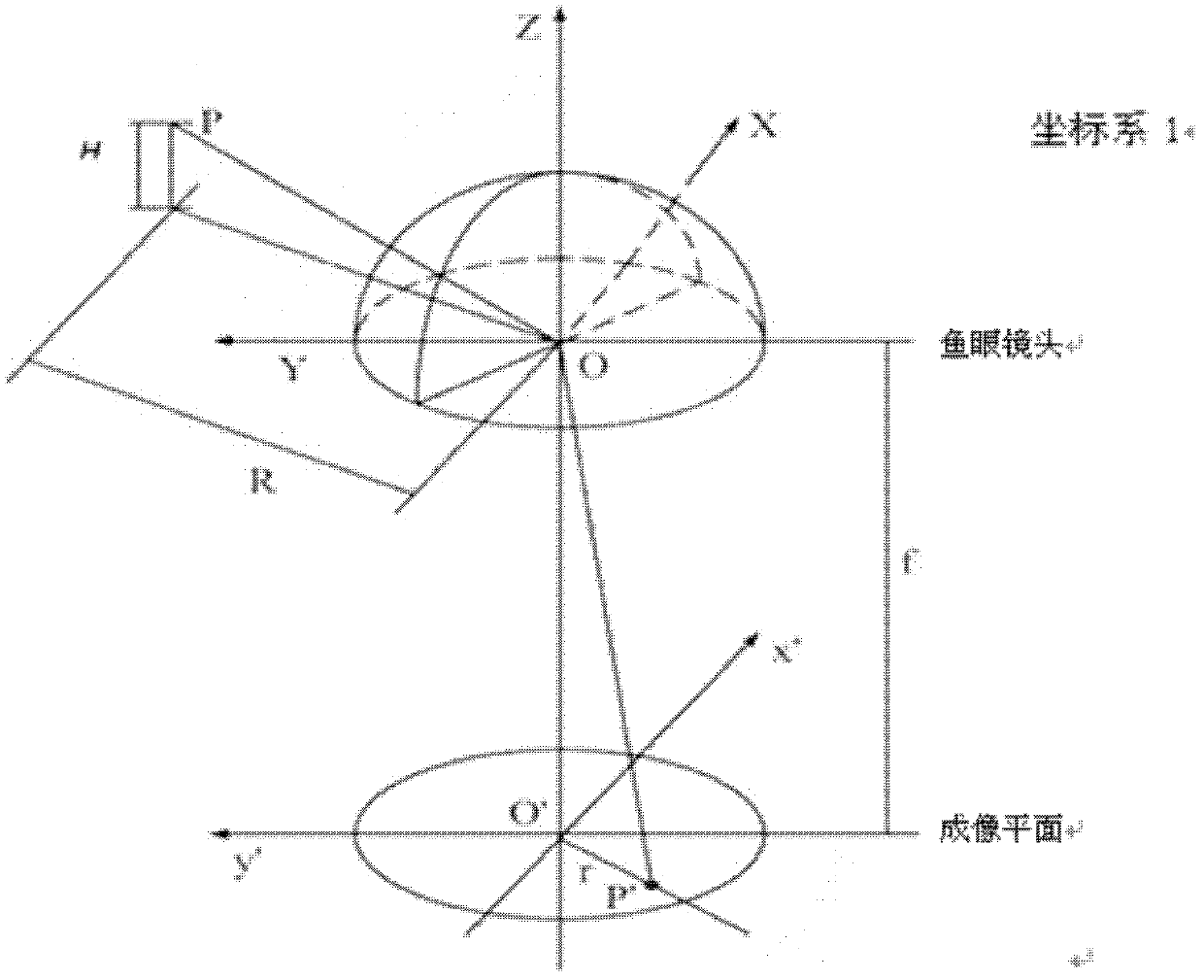

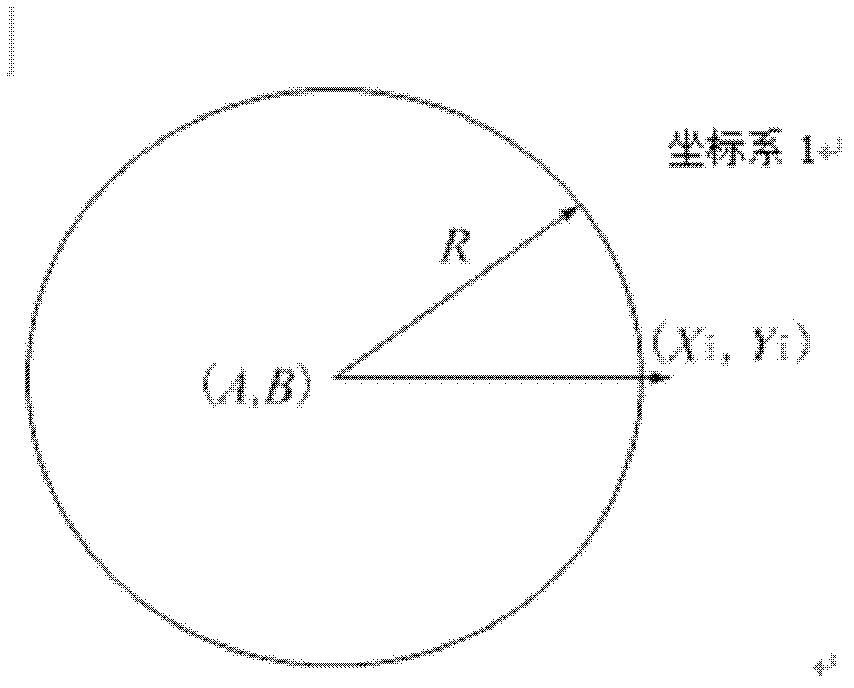

Fish eye lens calibration and fish eye image distortion correction method

InactiveCN102663734AQuick correctionPromote recoveryImage enhancementImage analysisDigital signal processingVertical projection

The invention relates to a fish eye lens calibration and fish eye image distortion correction method which belongs to the field of digital image processing and is very suitable for occasions of vision navigation, mobile monitoring and so on. Since imaging using a large wide angle will cause serious distortion, generally, imaging correction is needed to facilitate human eye observation. The method provided by the invention is mainly technically characterized by establishing a space coordinate system 1 and employing a least square curve-fitting method to calibrate a fish eye image to determine the center andthe radius of a fish eye lens, establishing a cylindrical projection model in a space coordinate system UV, and setting one-to-one relationships among an image point q2 of the fish eye image, a point q1 on object sphere and a point q projected on a cylinder, wherein q1 is in vertical projection relation with a bottom plane on which q2 is located and line q1q parallels to line oq2, thus achieving the purpose of fish eye image correction.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

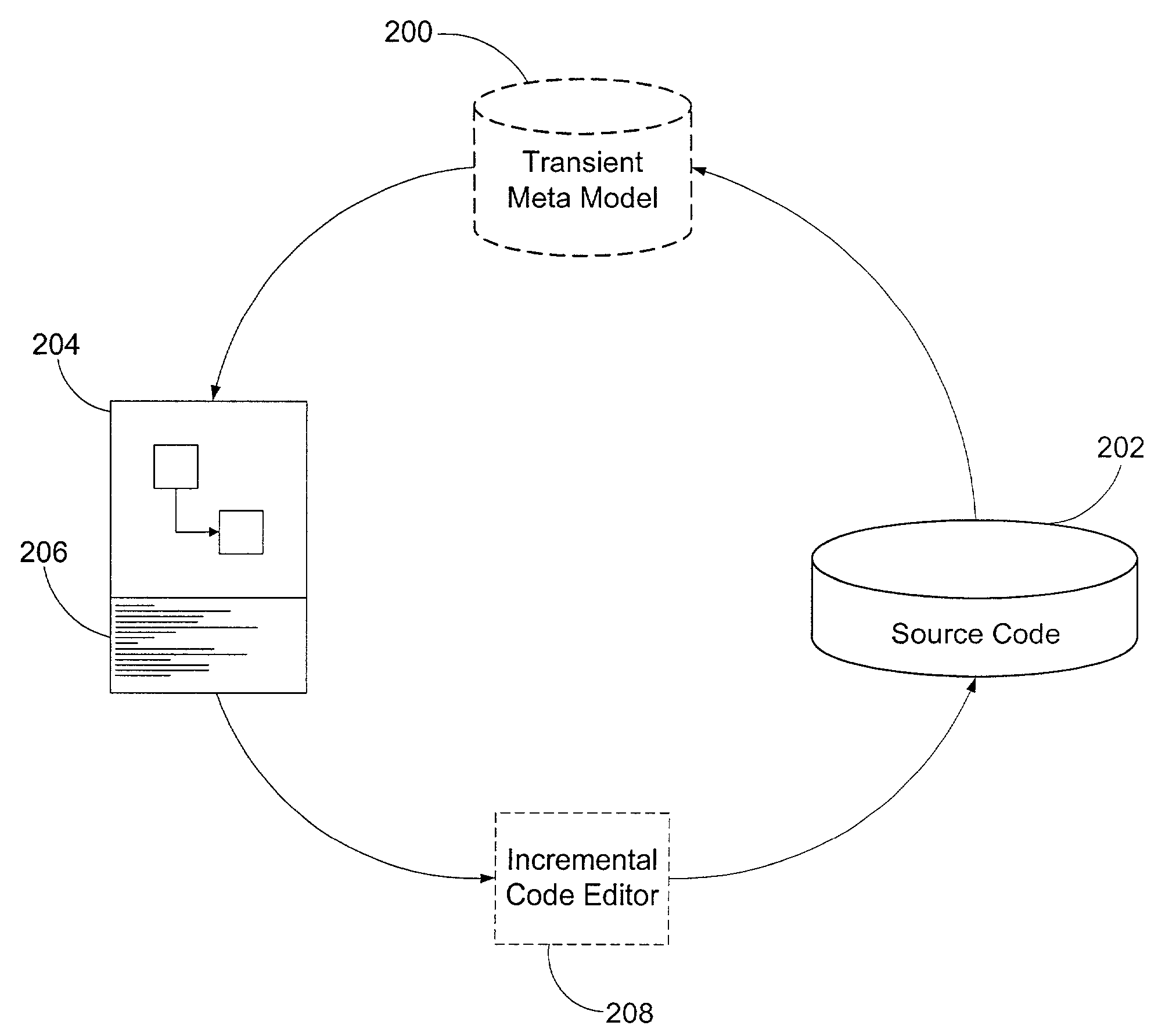

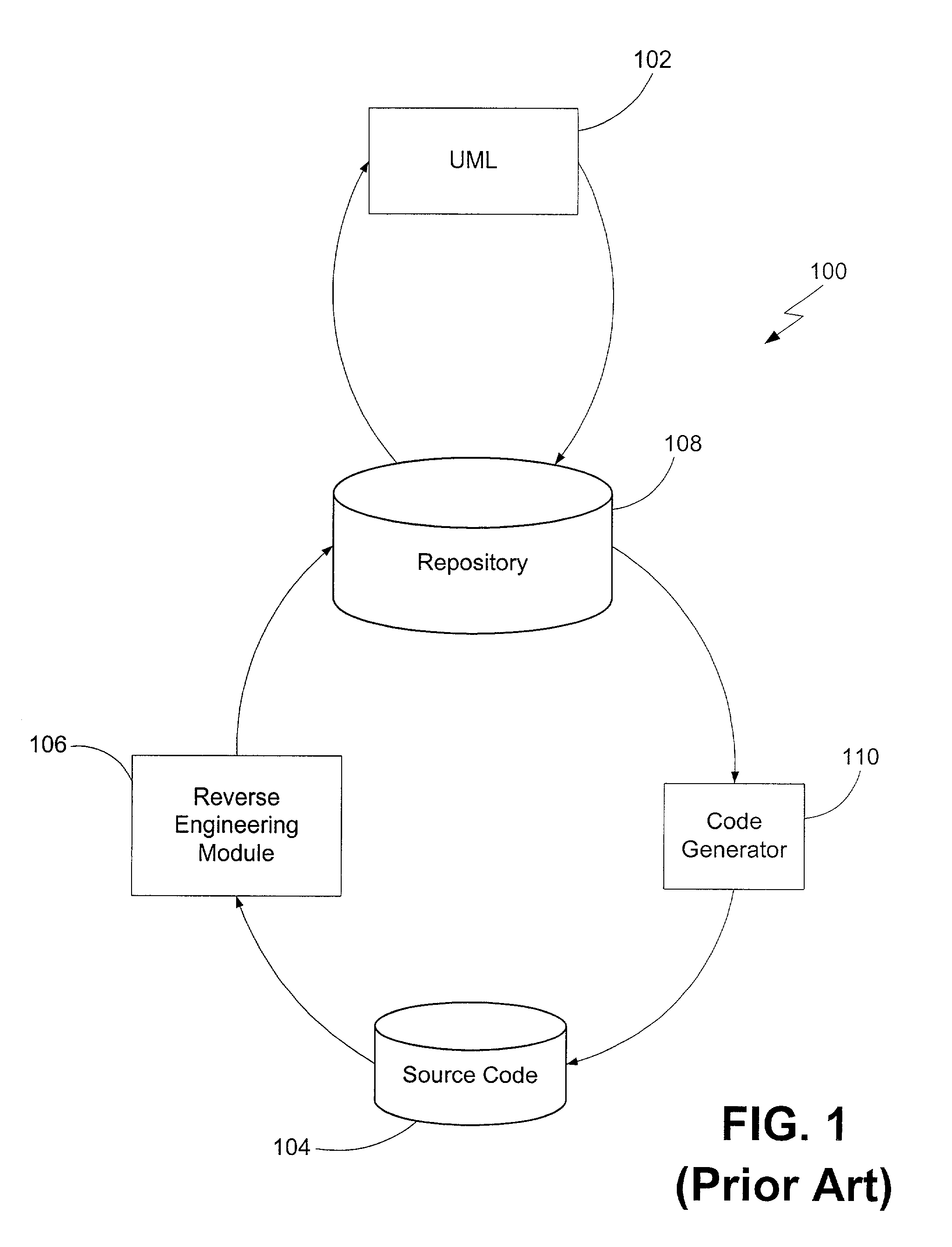

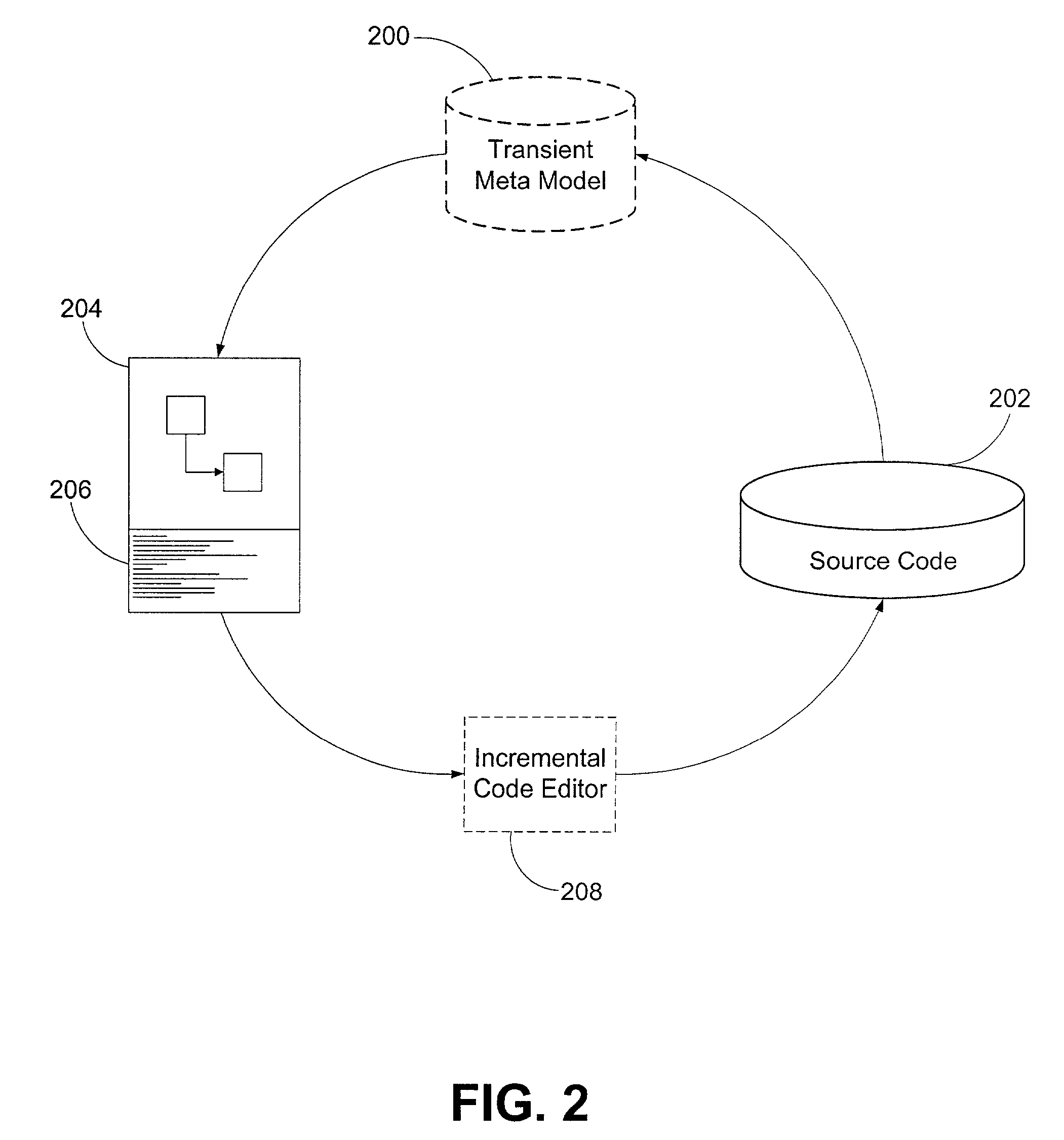

Methods and systems for relating a data definition file and a data model for distributed computing

InactiveUS7188332B2Overcome limitationsShorten development timeVersion controlReverse engineeringSoftware developmentData element

Methods and systems consistent with the present invention provide an improved software development tool which allows a developer to visually depict an existing data definition file containing data elements and relationships between the data elements by generating an XML structure diagram from the existing data definition file. Using methods and systems consistent with the present invention, the improved software development tool also allows the developer to generate a data definition file from an existing XML structure diagram.

Owner:BORLAND

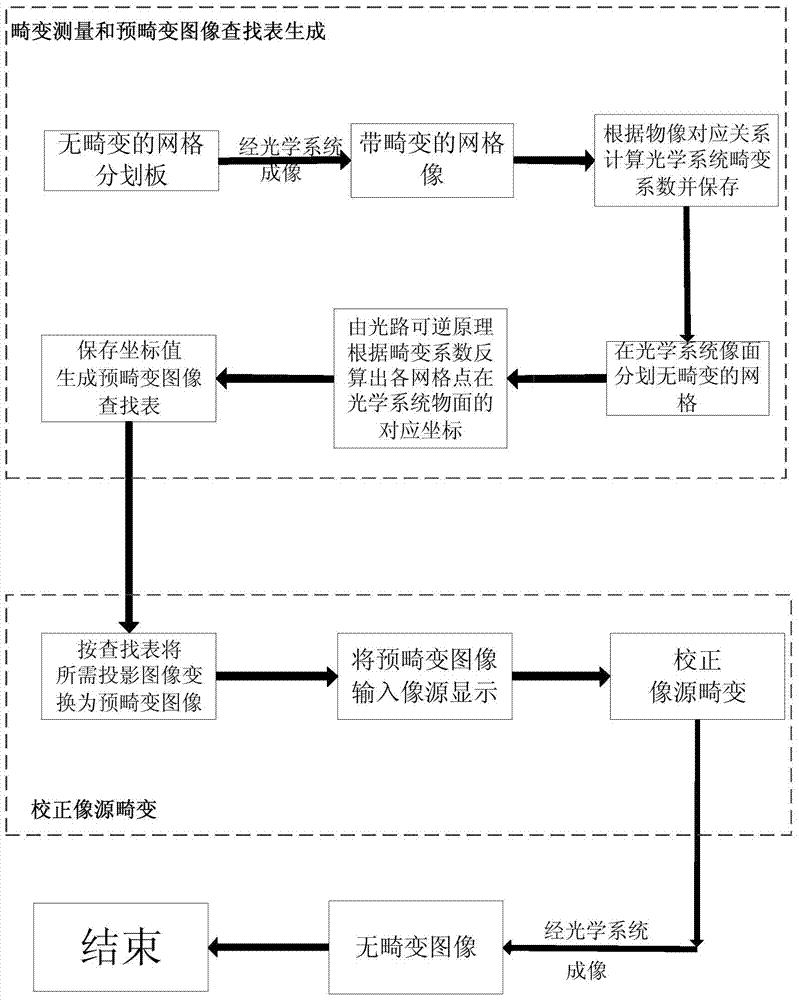

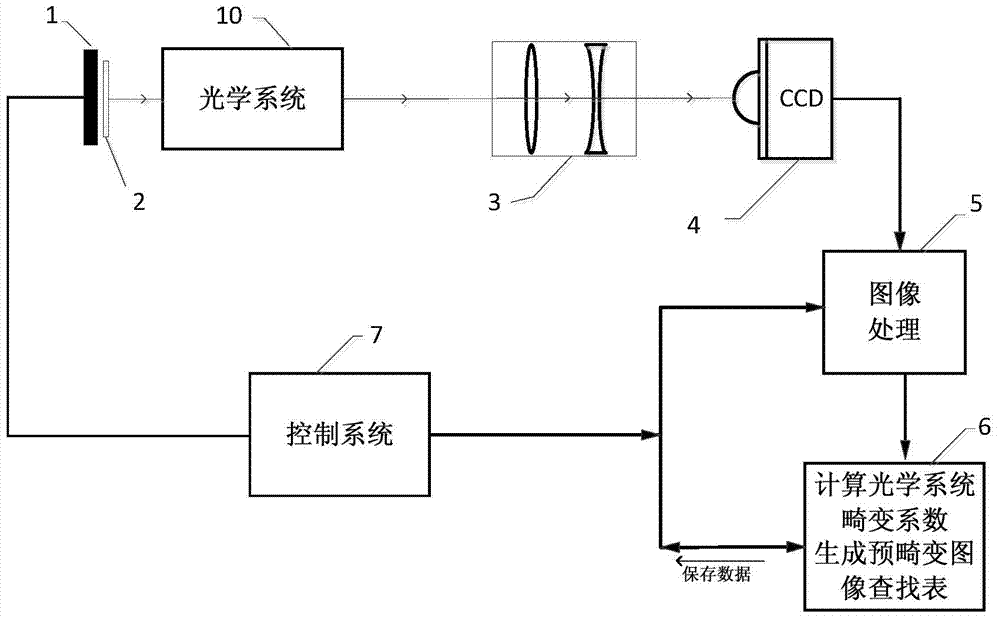

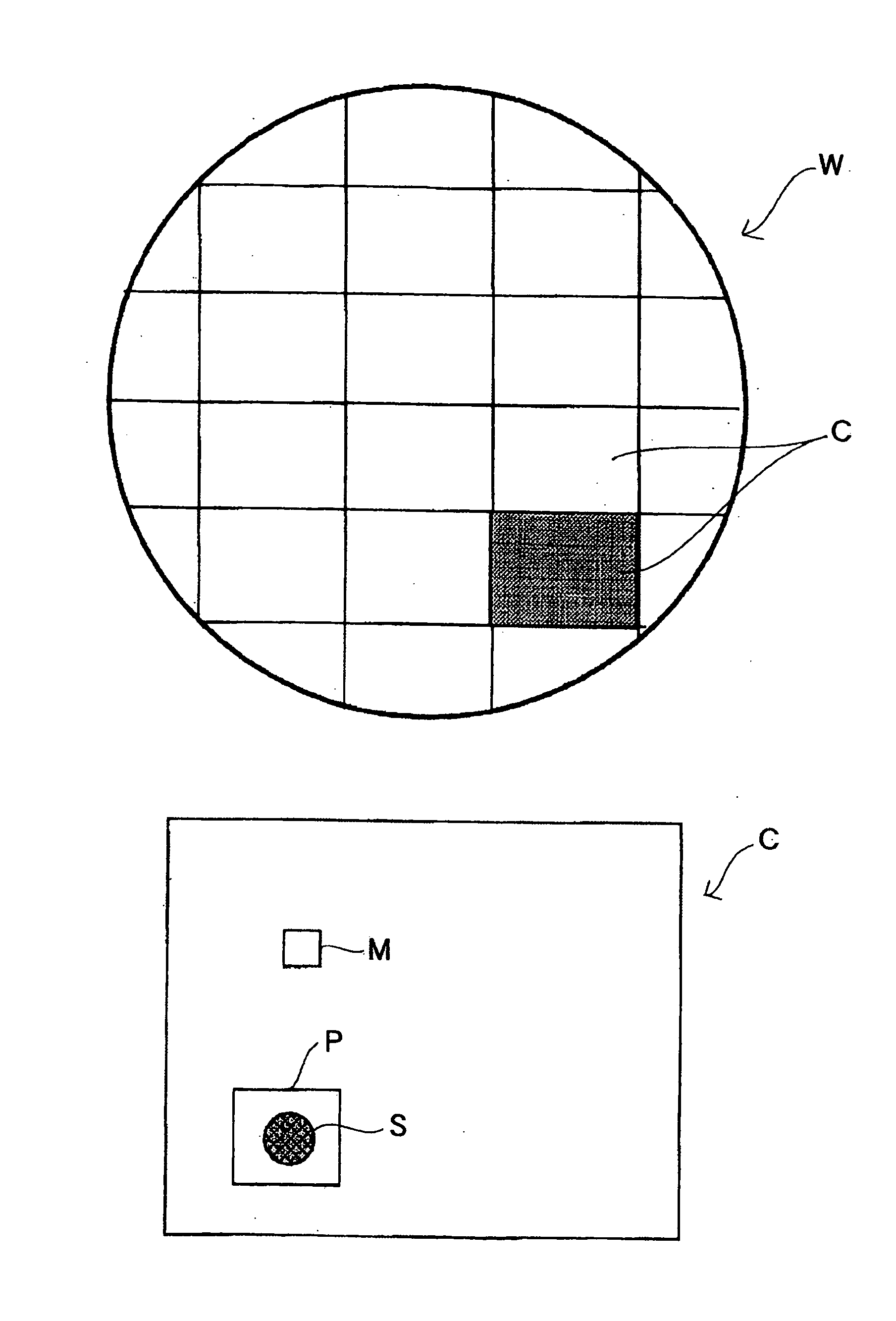

Device and method for measuring and correcting distortion of virtual reality displayer

The invention discloses a method for measuring and correcting distortion of a virtual reality displayer. The method includes the following steps that reticle imaging is carried out through an optical system to obtain a distortion grid image; a distortion coefficient of each grid is obtained through calculation according to the corresponding relationship between a vertex coordinate of the corresponding grid and a vertex coordinate of each distortion grid; non-distortion grids A are marked out on the distortion grid image, according to an optical path reversible principle, an object face of the optical system has distortion grids A' corresponding to the grids A, then vertex coordinates of the distortion grids A' are calculated by means of the distortion coefficients and the vertex coordinates of the grids A, and a coordinate look-up table is generated by means of the vertex coordinates of the distortion grids A'; an image to be projected is converted into a pre-distortion image by means of the coordinate look-up table, an image source is input, a pre-distortion image displayed by the image source is imaged, an imaging image is obtained, the imaging image is compared with the pre-distortion image, the image source is adjusted, and correcting of the image source is completed. The invention further discloses a device for measuring and correcting distortion of the virtual reality displayer.

Owner:深圳市安思疆科技有限公司

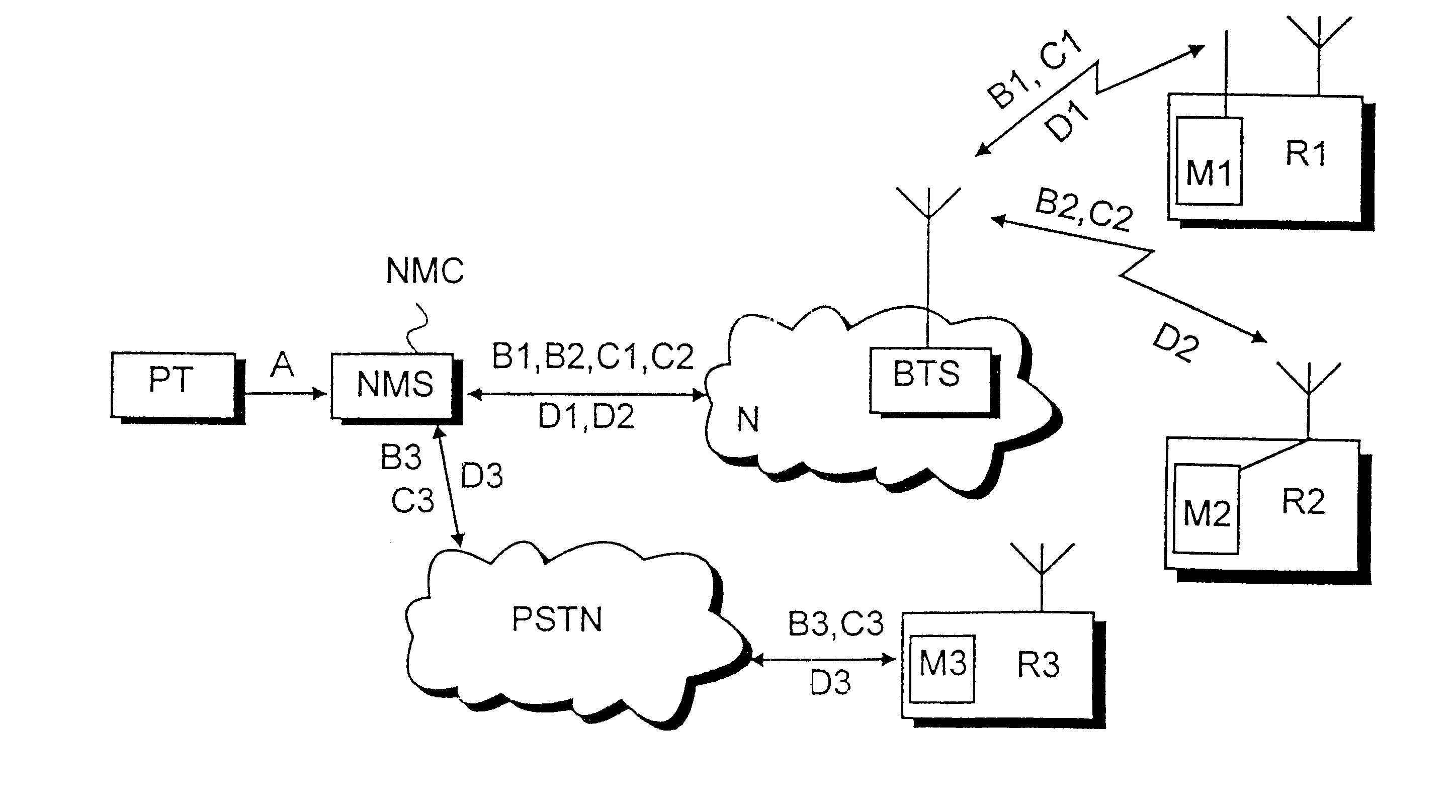

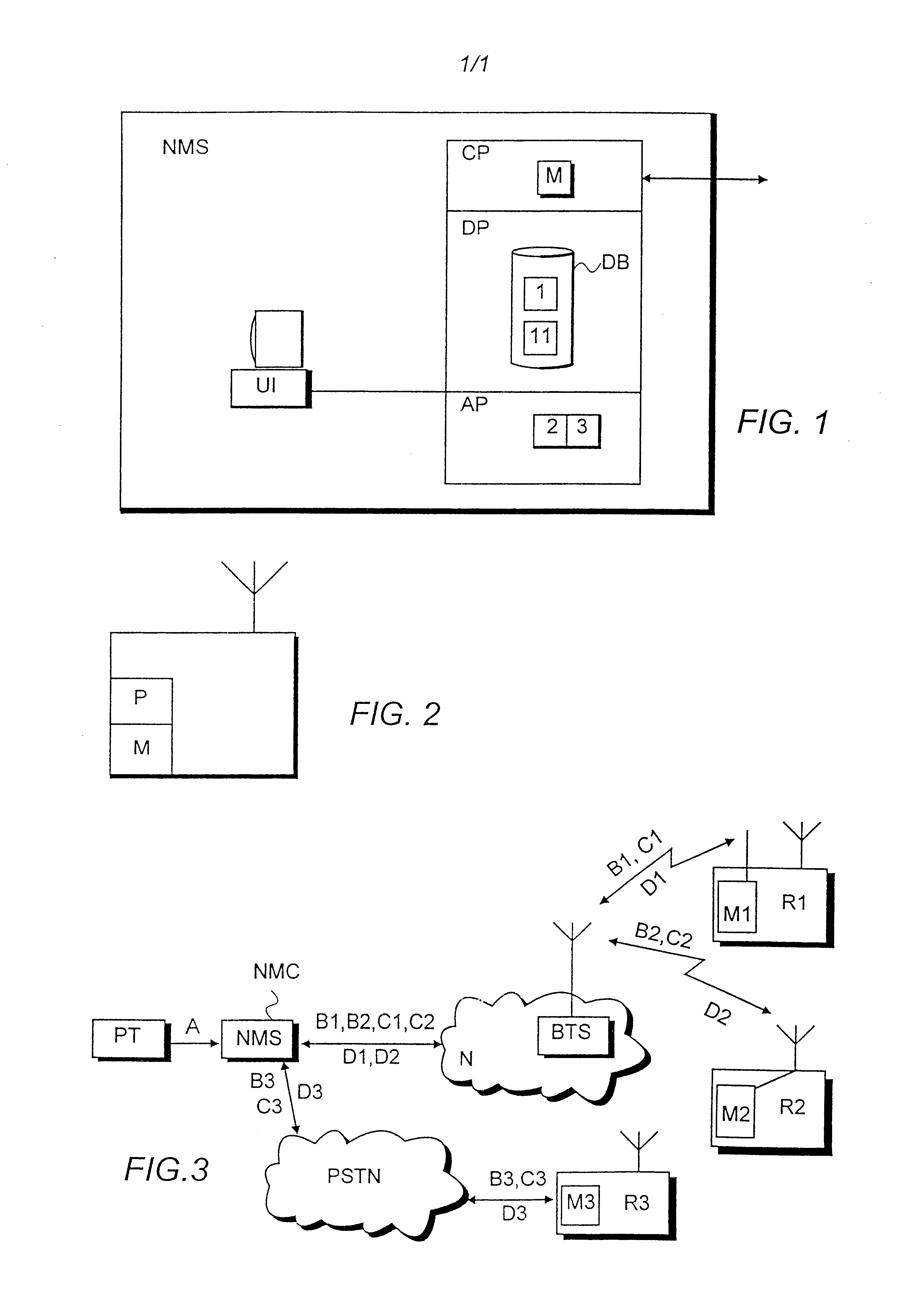

Method for repeater management

InactiveUS6571284B1Improve network reliabilityQuick updateError preventionFrequency-division multiplex detailsTelecommunications networkEngineering

In order to integrate repeater management with network management in a wireless telecommunication network, a database is added to the network management center (NMC), said database including the data on the network repeaters (R1, R2, R3), which include for each repeater (R1, R2, R3) at least the identifier of the base station (BTS) corresponding to the repeater concerned; a repeater plan is made for changing repeater parameters to correspond to the changed configuration of the base stations; and each repeater is sent an update message (B1, B2, B3) containing parameters for the reconfiguring of the repeater (R1, R2, R3) to correspond to the repeater plan. The invention also relates to a network management system in which the method of the invention can be applied. In addition, the invention relates to a repeater, which can be utilized in the method and system of the invention.

Owner:VRINGO INFRASTRUCTURE

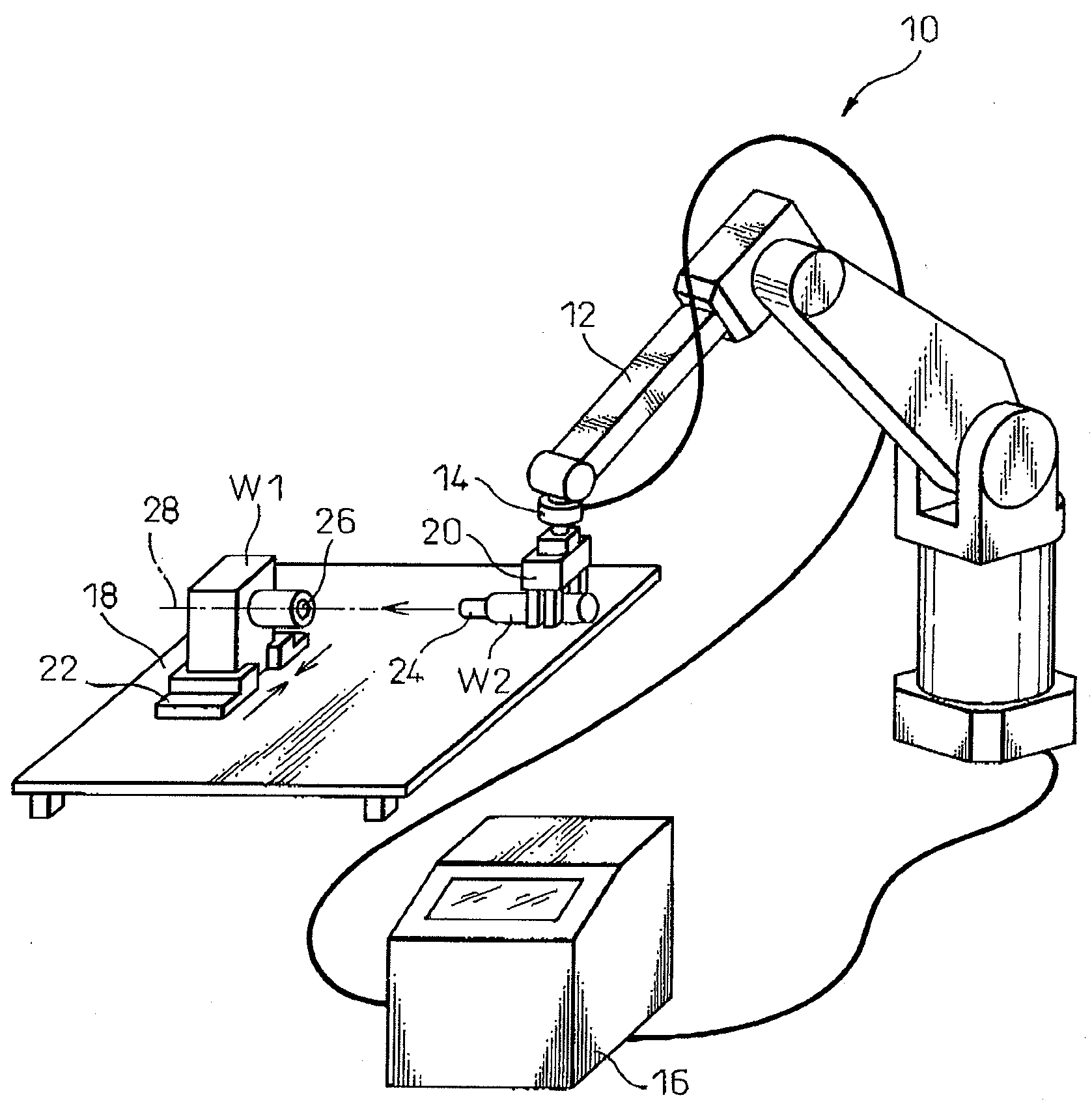

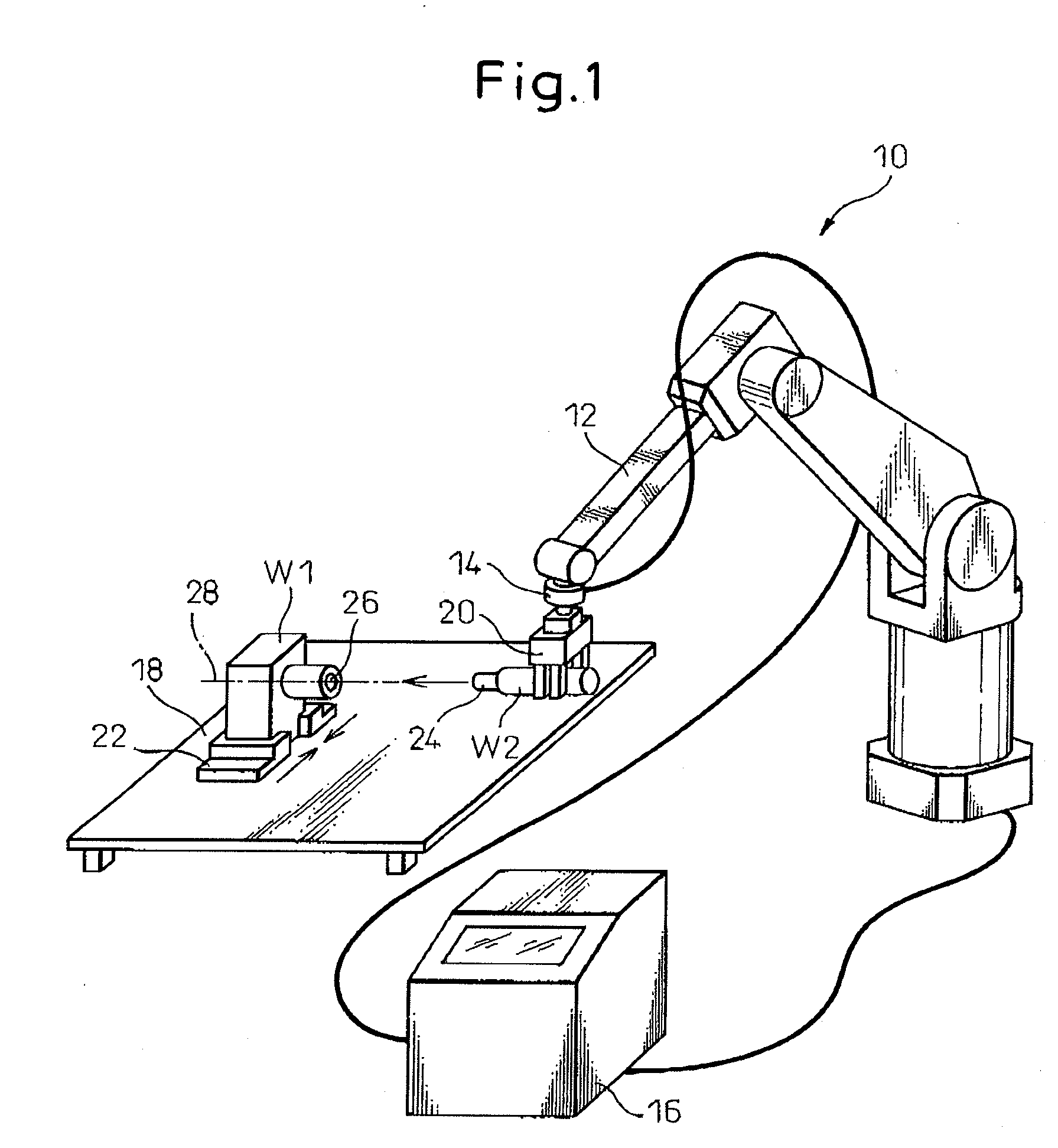

Fitting apparatus

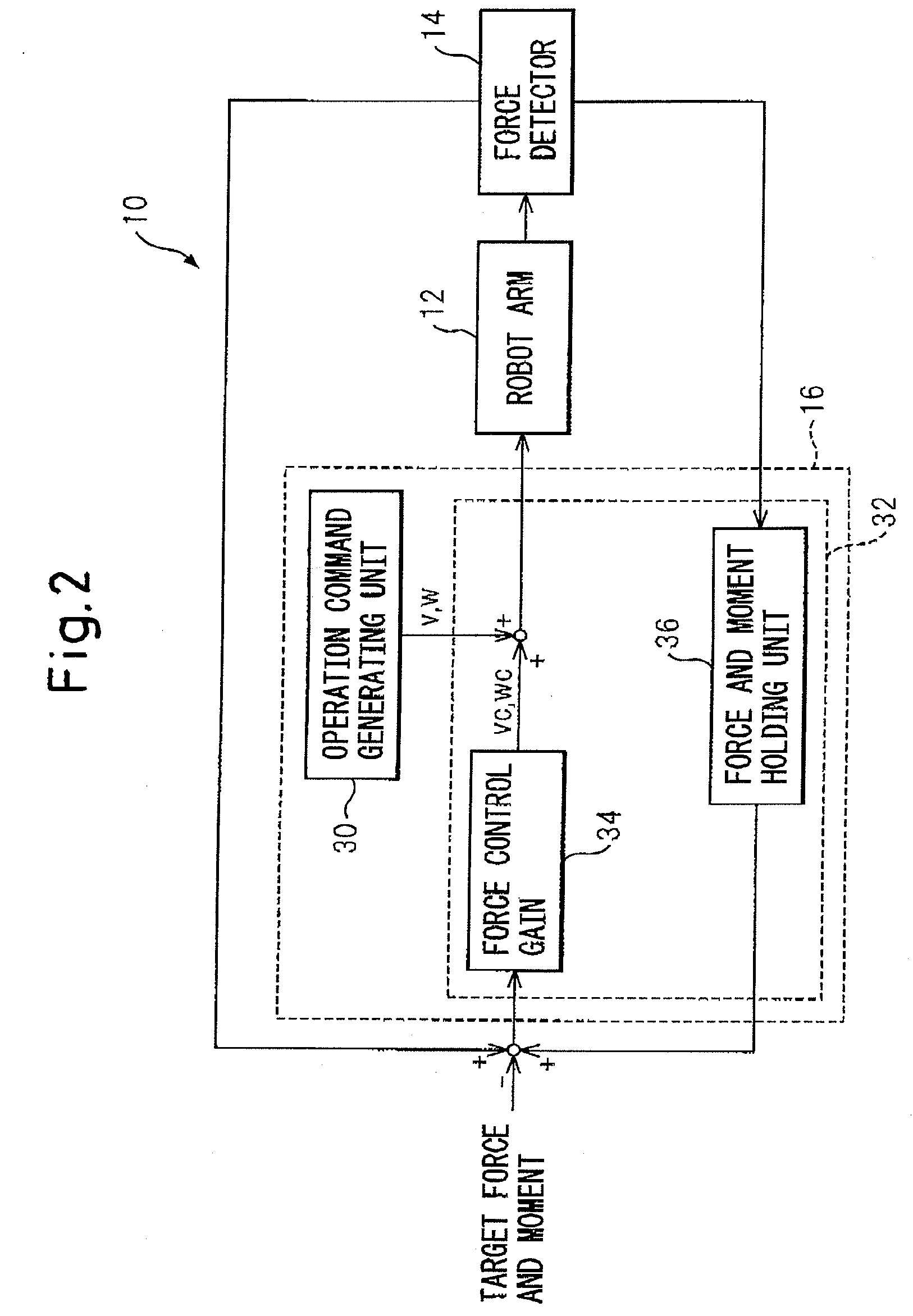

ActiveUS20080312769A1Quick and stable fitting operationCorrection errorProgramme-controlled manipulatorComputer controlEngineeringGenerating unit

A fitting apparatus includes a robot arm having, at the forward end thereof, a gripper for holding a workpiece, a force detector for detecting a force and moment received by the workpiece held by the gripper, and a controller for controlling an operation of the robot arm. The controller includes a motion command generating unit for generating an operation command to fit two workpieces to each other, and an operation command correcting unit for correcting the operation command so as to correct the position of the gripper in a direction perpendicular to the fitting direction and the orientation of the gripper around an axis perpendicular to the fitting direction until the detected force and moment become less than or equal to a threshold value, based on either maximum values of the force and moment detected by the force detector while the two workpieces are in contact with each other or the force and moment detected by the force detector when the two workpieces first come into contact with each other.

Owner:FANUC LTD

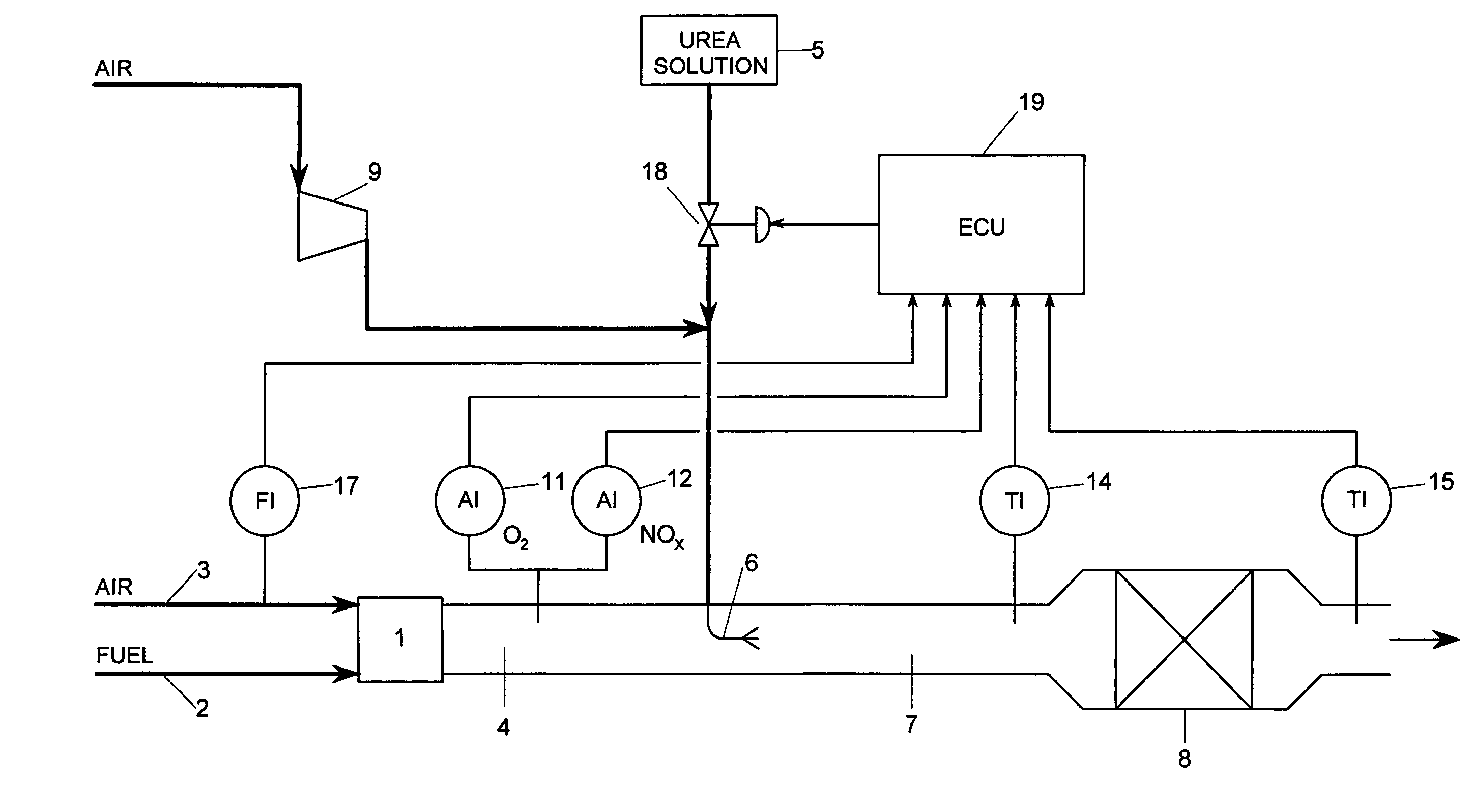

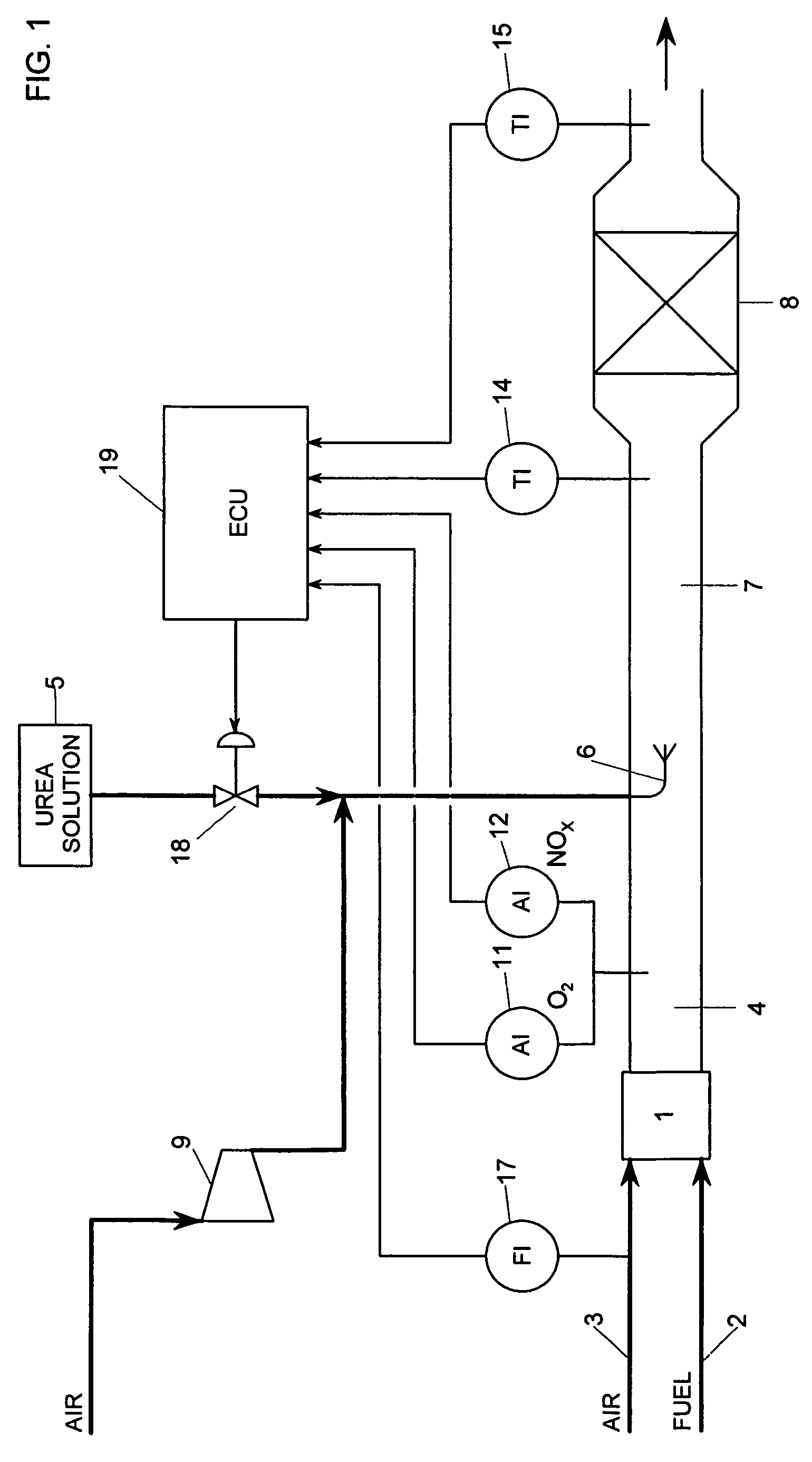

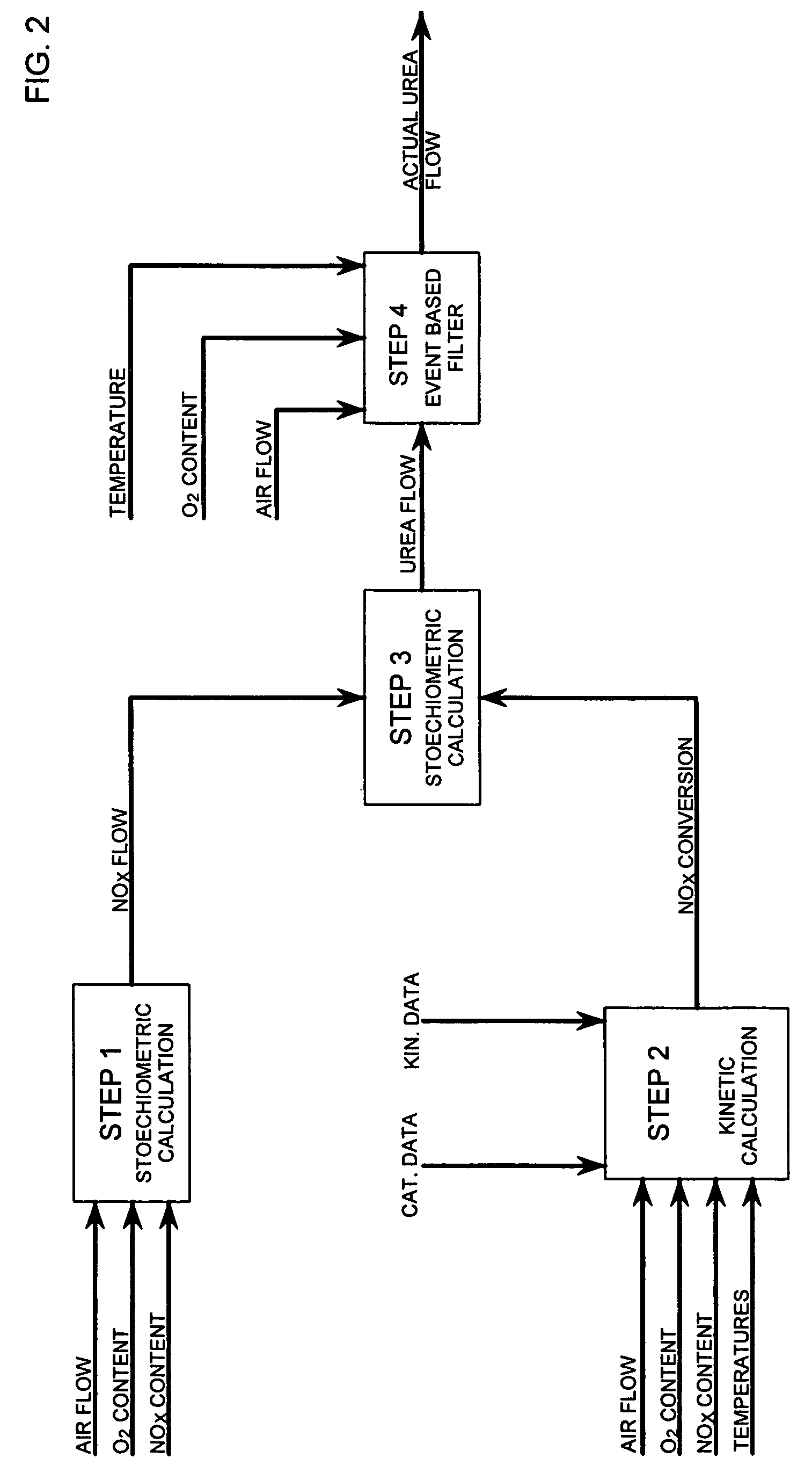

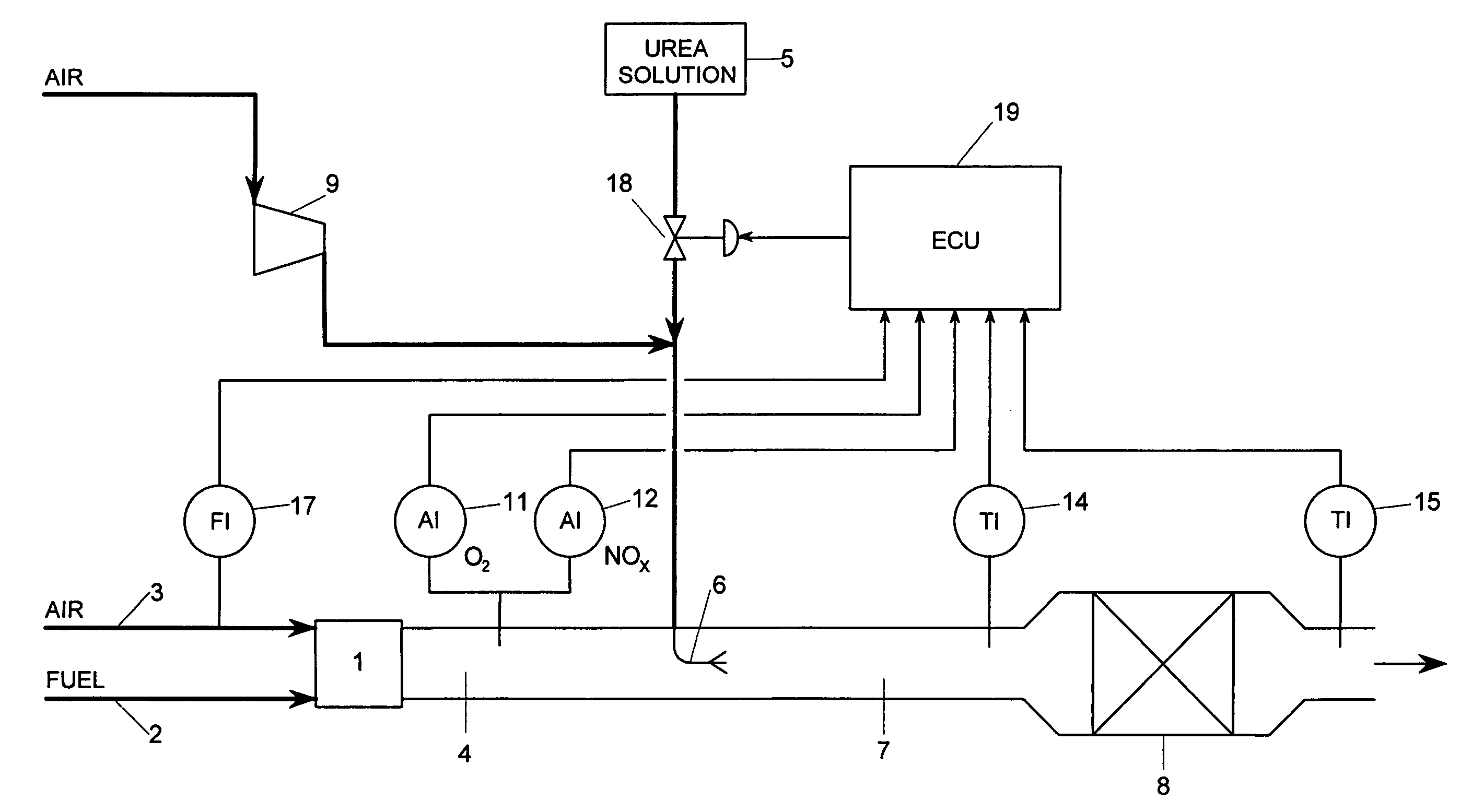

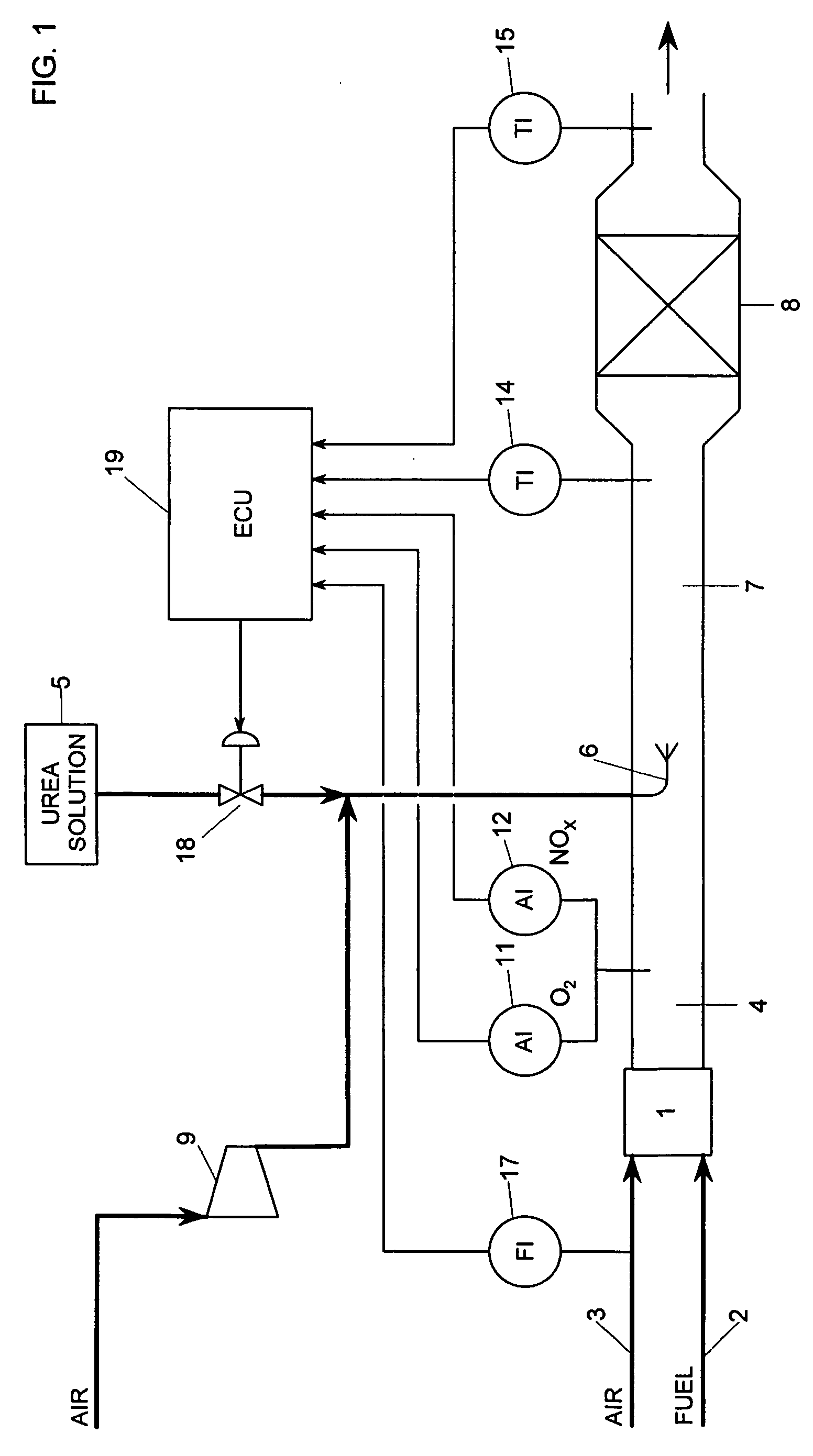

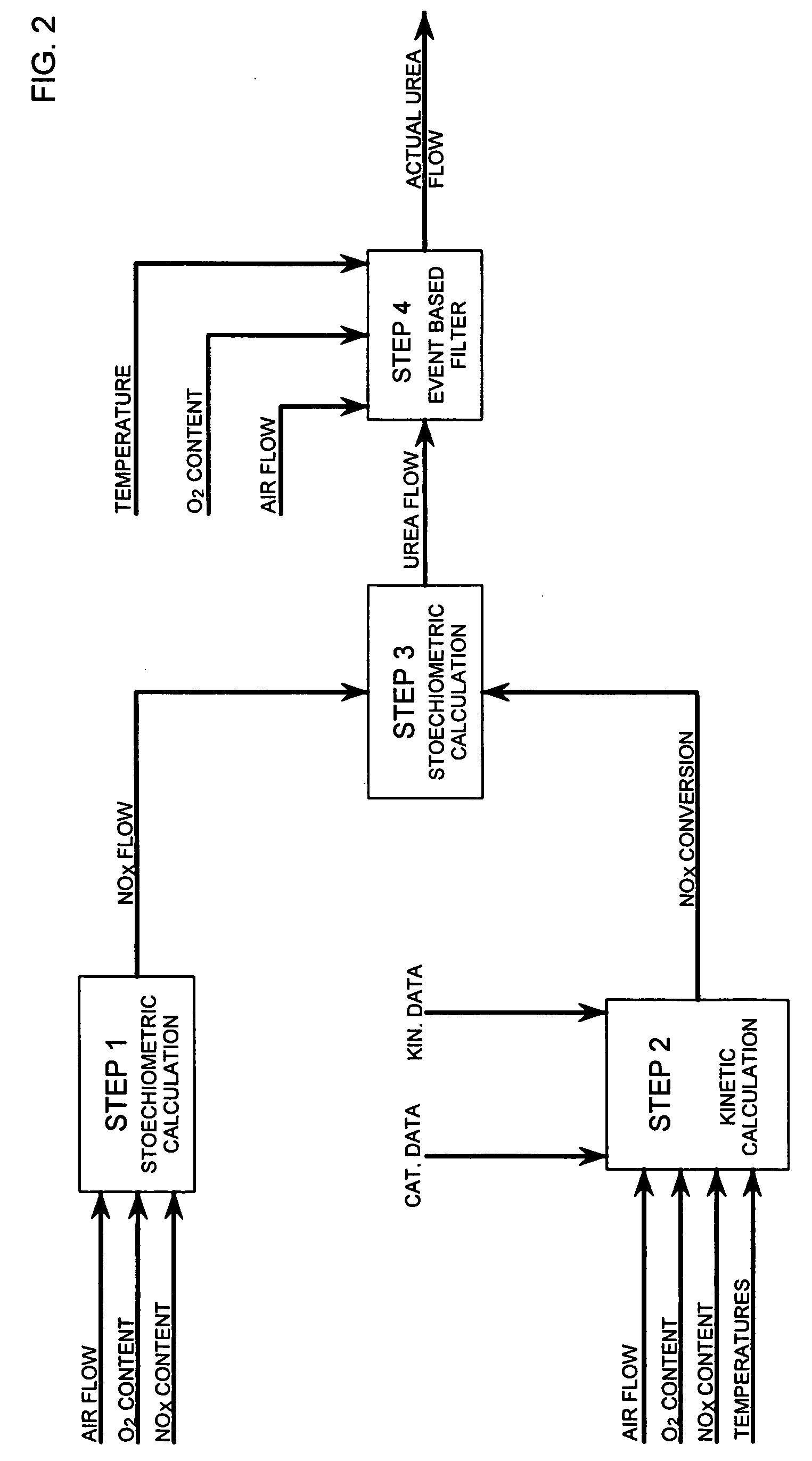

Method for controlling injection of reducing agent in exhaust gas from a combustion engine

ActiveUS7200990B2Easy to measureQuick correctionInternal combustion piston enginesExhaust apparatusCombustionExhaust fumes

The invention relates to a method for controlling injection of a reductant into a NOx containing exhaust gas stream from a combustion engine, where combustion of a known fuel takes place and where the NOx is reduced by selective catalytic reduction, SCR, in the presence of a SCR catalyst, comprising establishing signals related to exhaust gas flow, HOx concentration in the exhaust gas stream upstream of the catalyst, exhaust gas temperature upstream of the SCR catalyst, exhaust gas temperature downstream of the SCR catalyst and to input data for catalyst characteristics. From the signals an adjusted amount of the reductant is calculated by using a calculated amount of reductant and a value d(E*T) / dt, where E is the exhaust gas flow, T is the exhaust gas temperature upstream of the catalyst and t is time.

Owner:UMICORE AG & CO KG

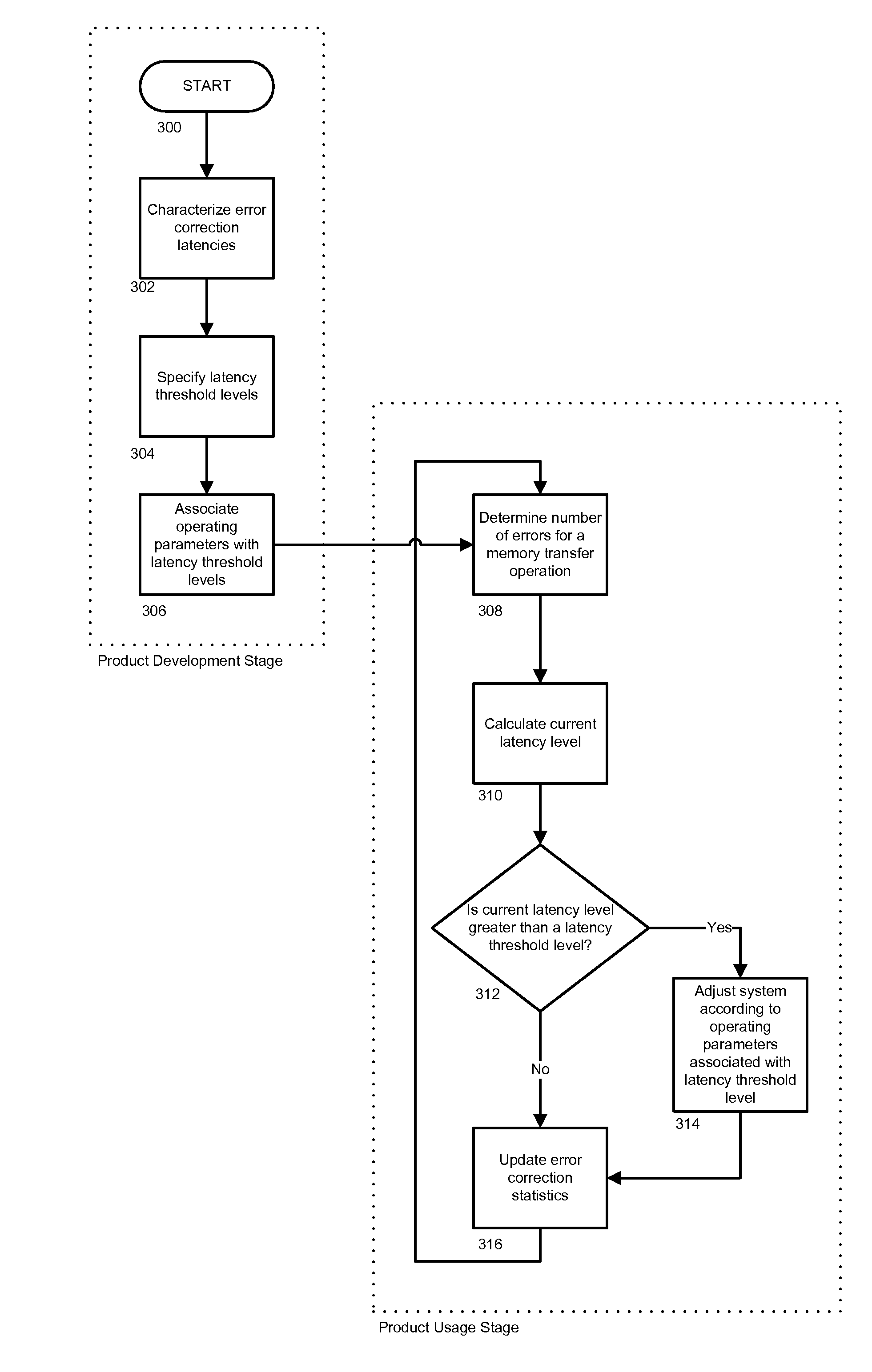

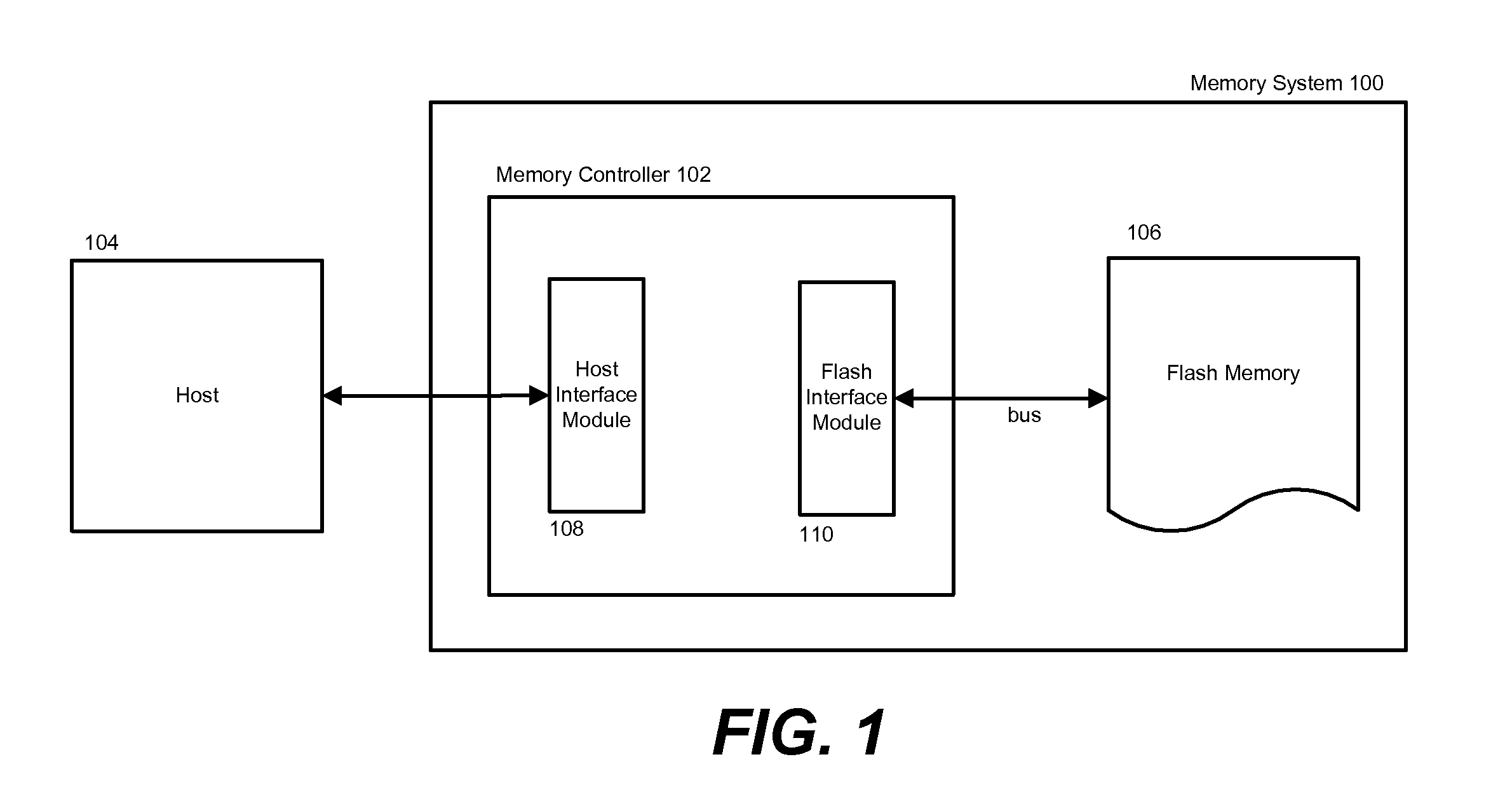

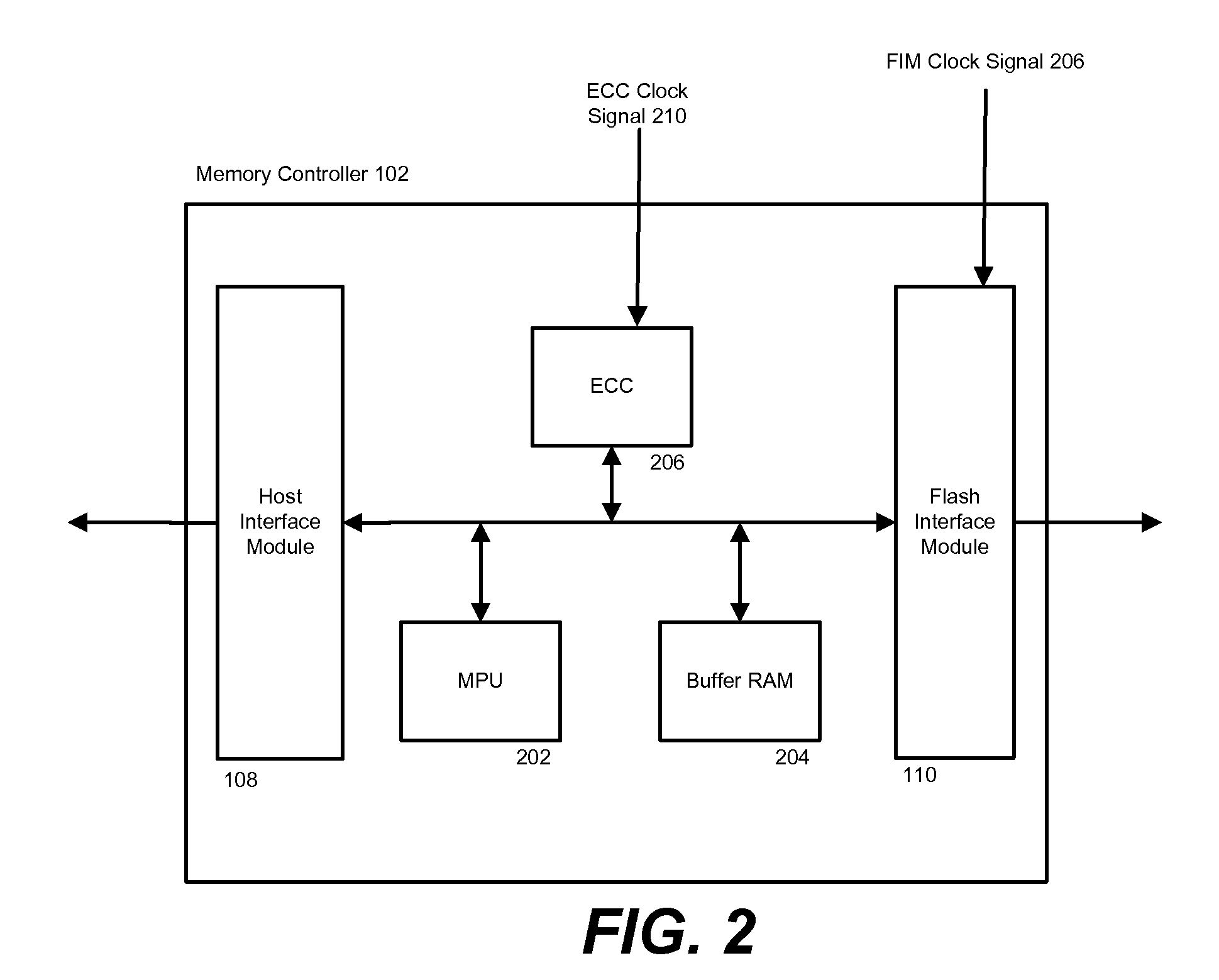

Guaranteed memory card performance to end-of-life

ActiveUS20090276570A1Quick correctionFast speedError detection/correctionMemory systemsReal-time computingMemory cards

In order to maintain a memory system's performance levels to its end-of-life, latency threshold level(s) are specified and associated with different memory system operating parameters. In one embodiment, the memory system monitors and gathers performance statistics in real time, and in accordance with specific memory transfer sizes. A current latency level can be dynamically calculated using the performance statistics and compared to previously established latency threshold levels. If the current latency level is greater than or equal to a specific latency threshold level, the memory system's configuration setting can be adjusted according to the operating parameters associated with the latency threshold level to offset the increased latency.

Owner:SANDISK TECH LLC

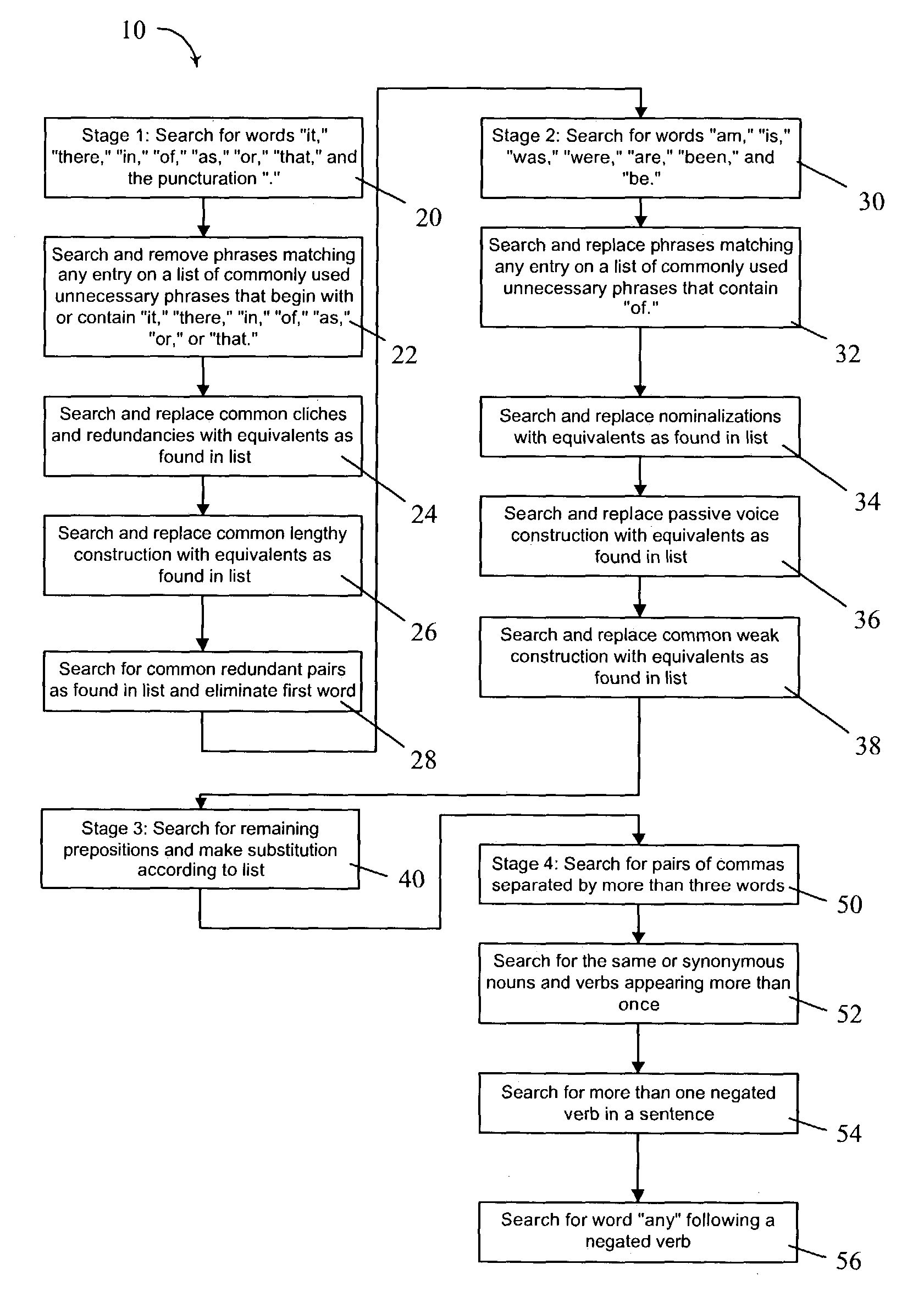

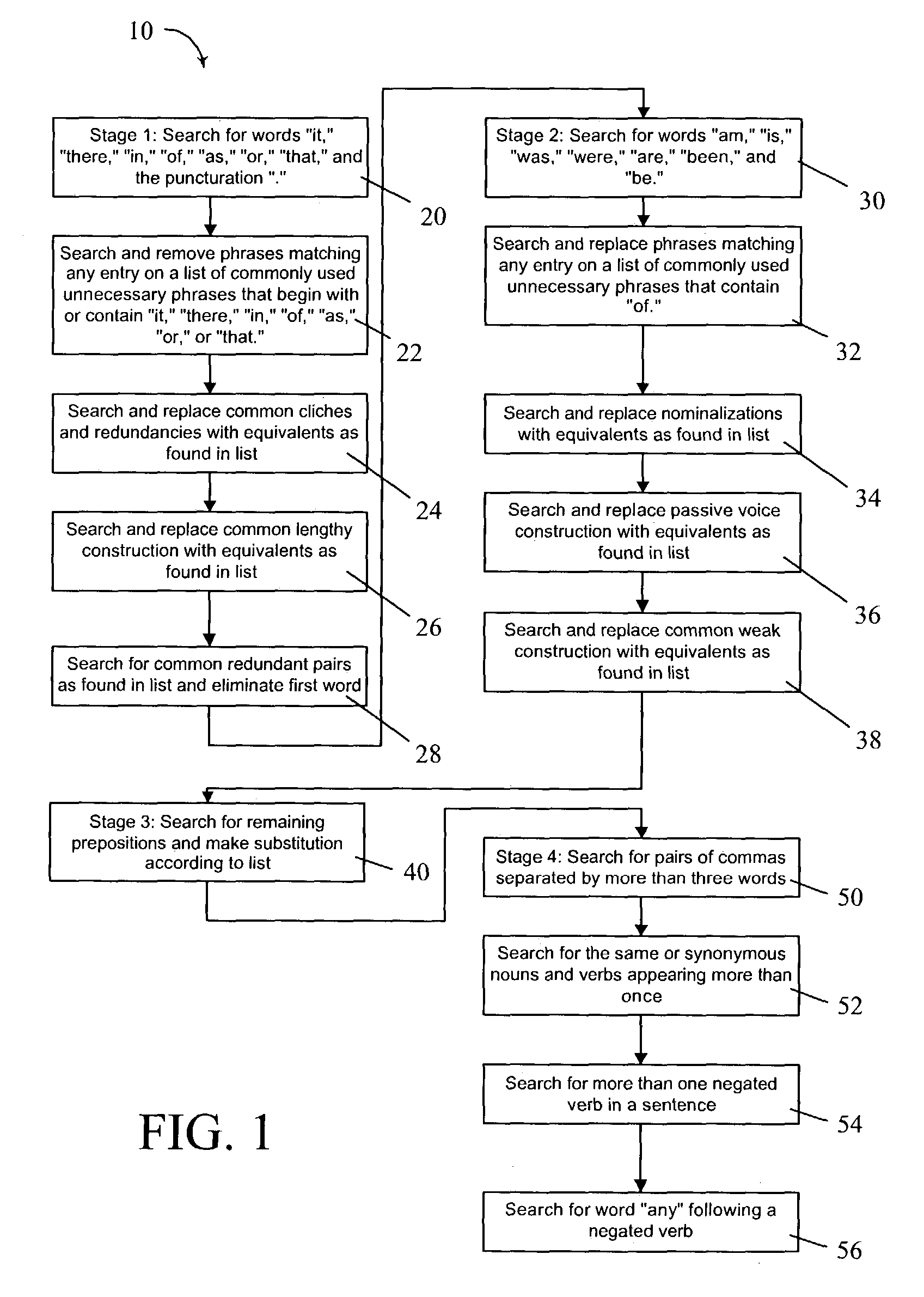

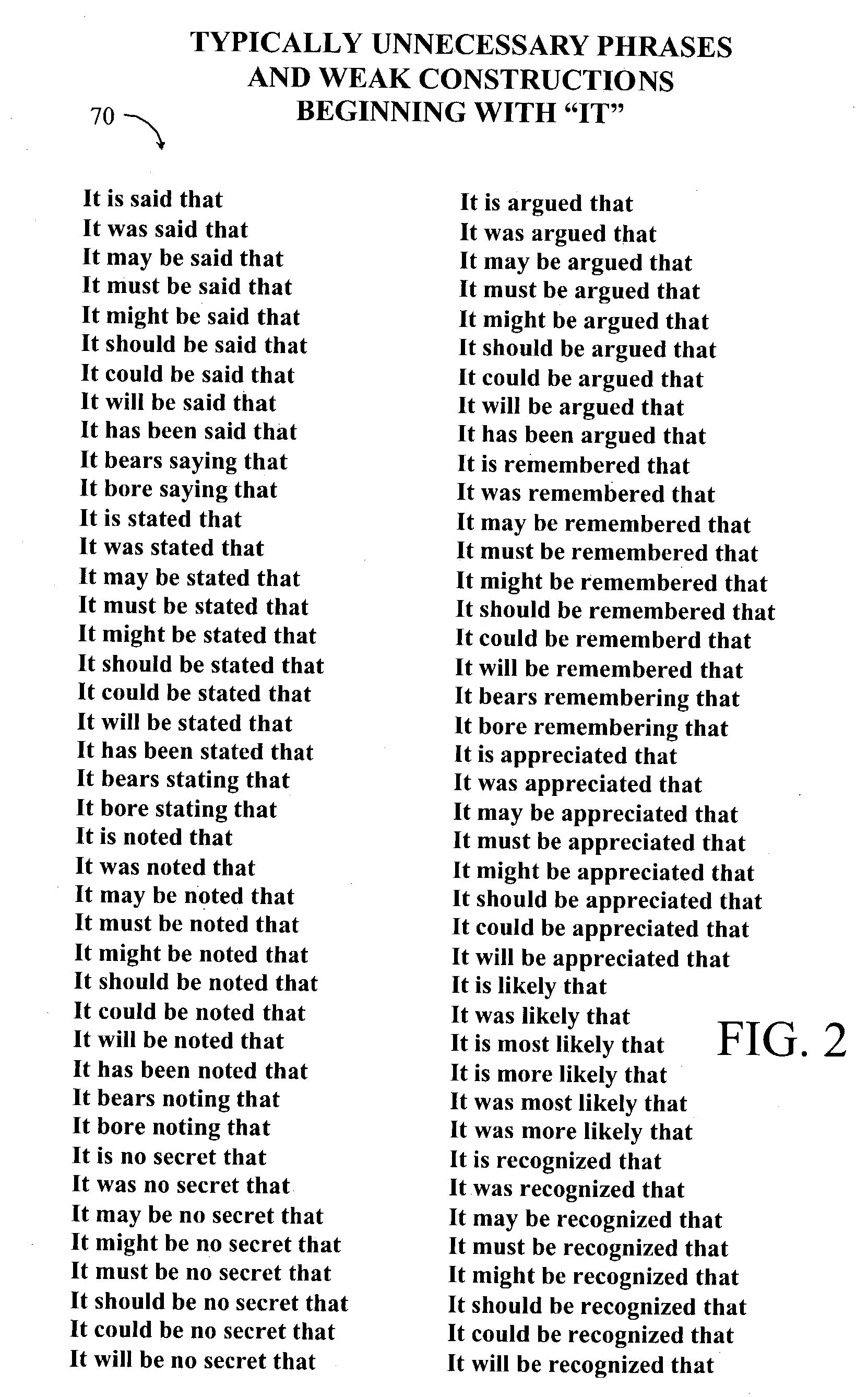

Method for editing and enhancing readability of authored documents

ActiveUS7313513B2Work lessMore informationNatural language analysisReadingNatural language processingDocument preparation

Various methods are disclosed for improving the readability of authored documents. The methods generally involve scanning a sentence to check for specific signs of potential writing problems, and applying associated sign-dependent decision logic to assess whether particular writing problems exist. The methods may be implemented in a computer program that makes editing suggestions to a user and / or makes edits automatically. The program may, in some cases, dim unnecessary language to reveal how the sentence will read with such language removed.

Owner:WORDRAKE

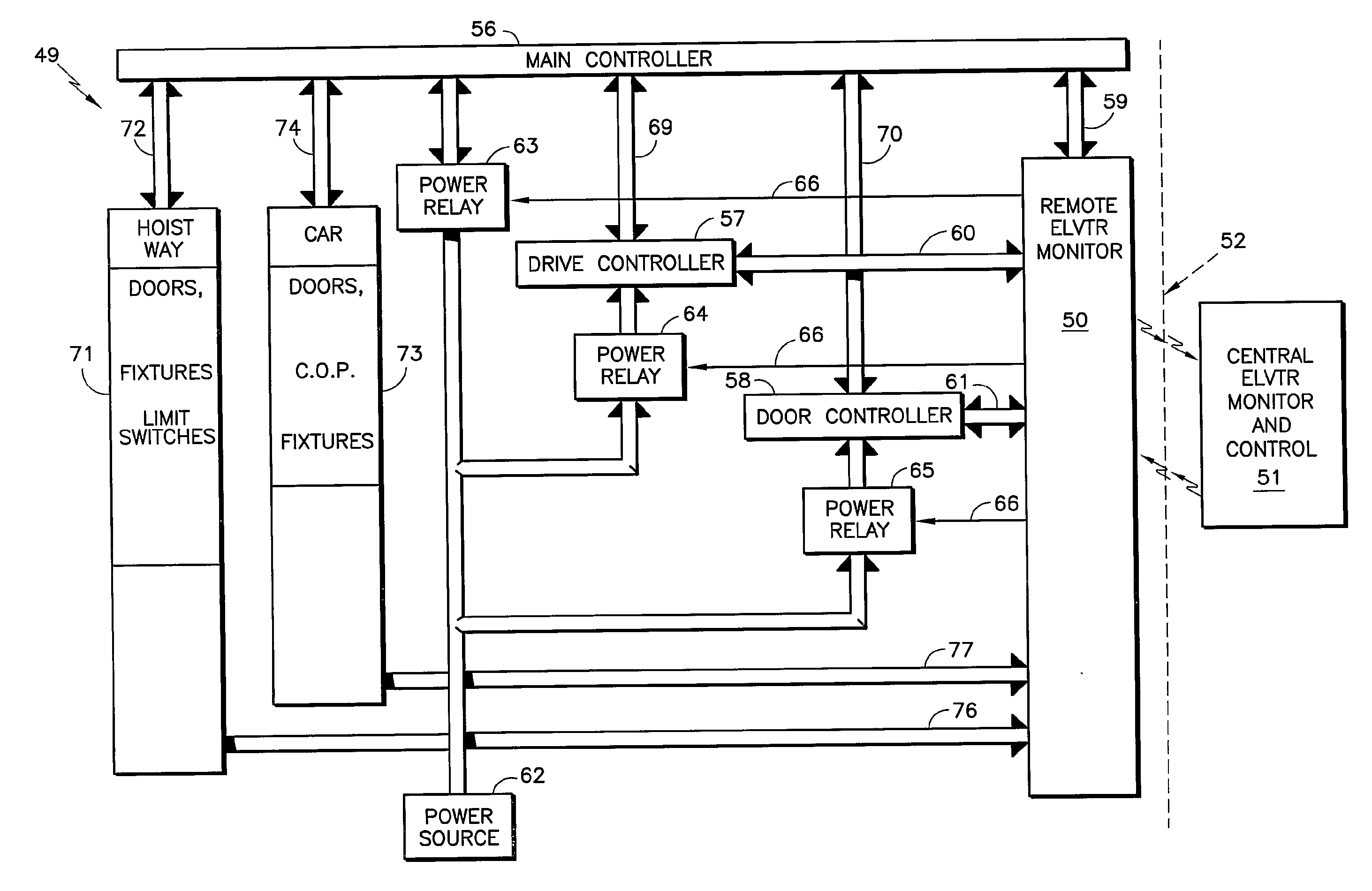

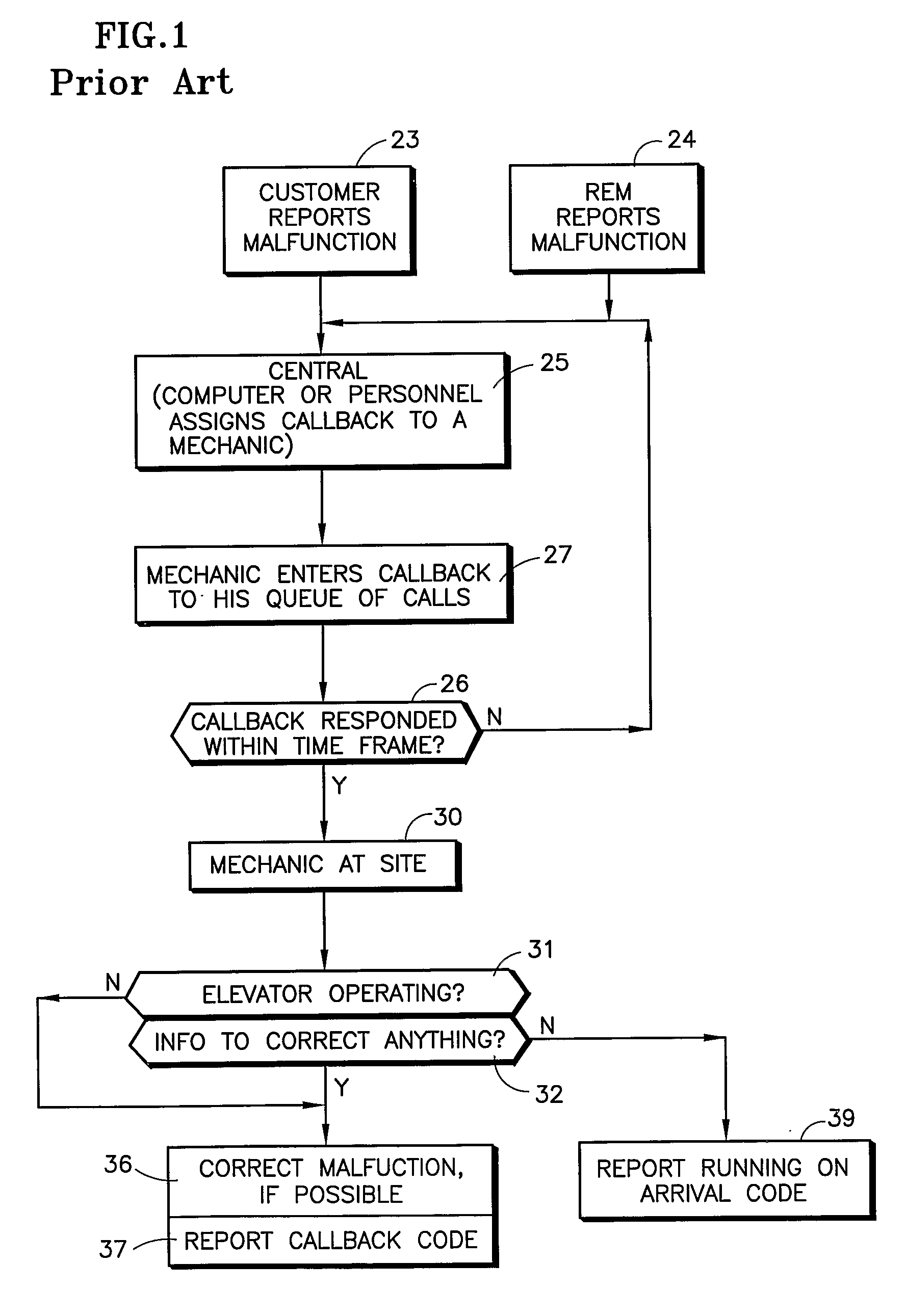

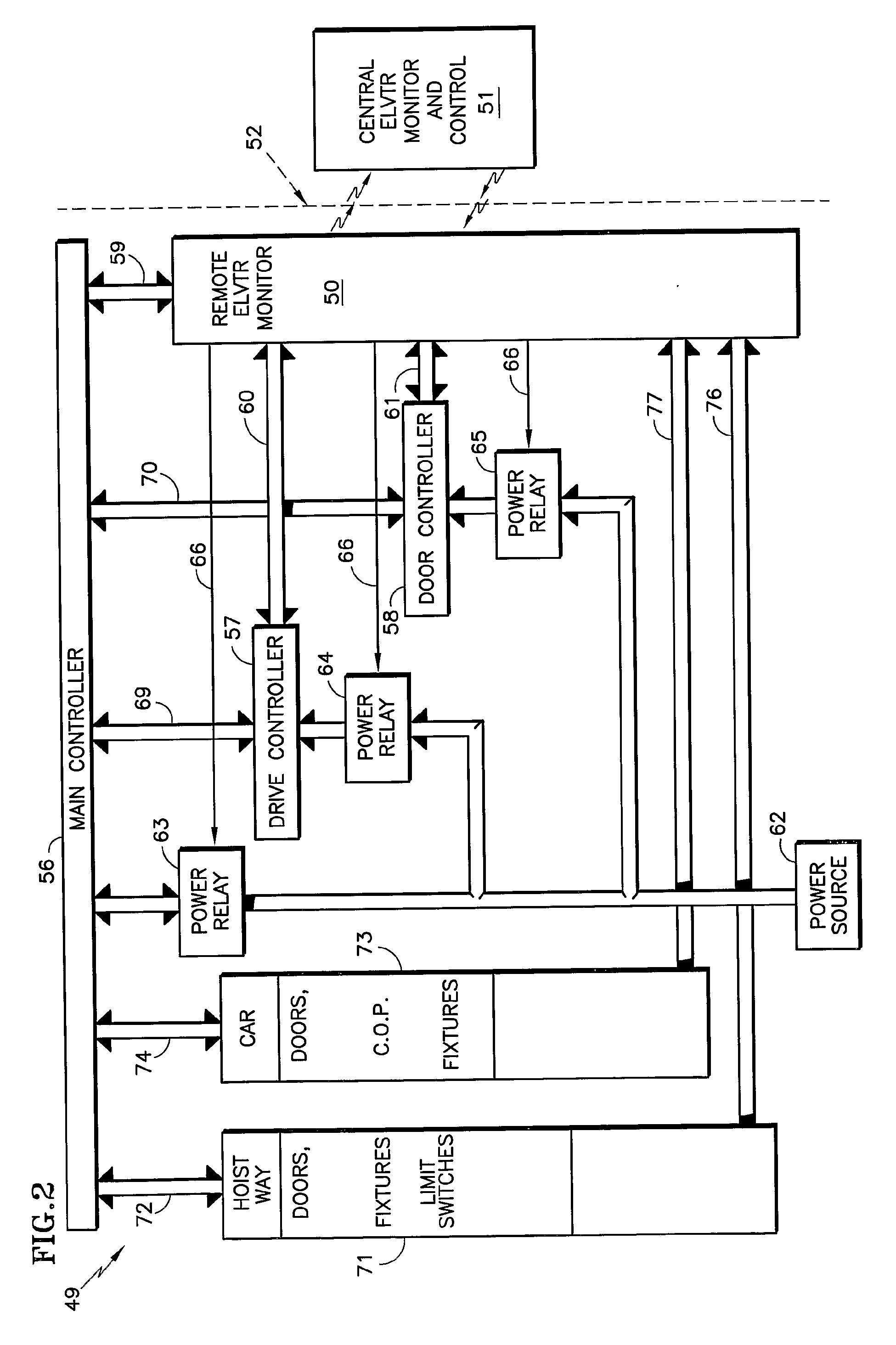

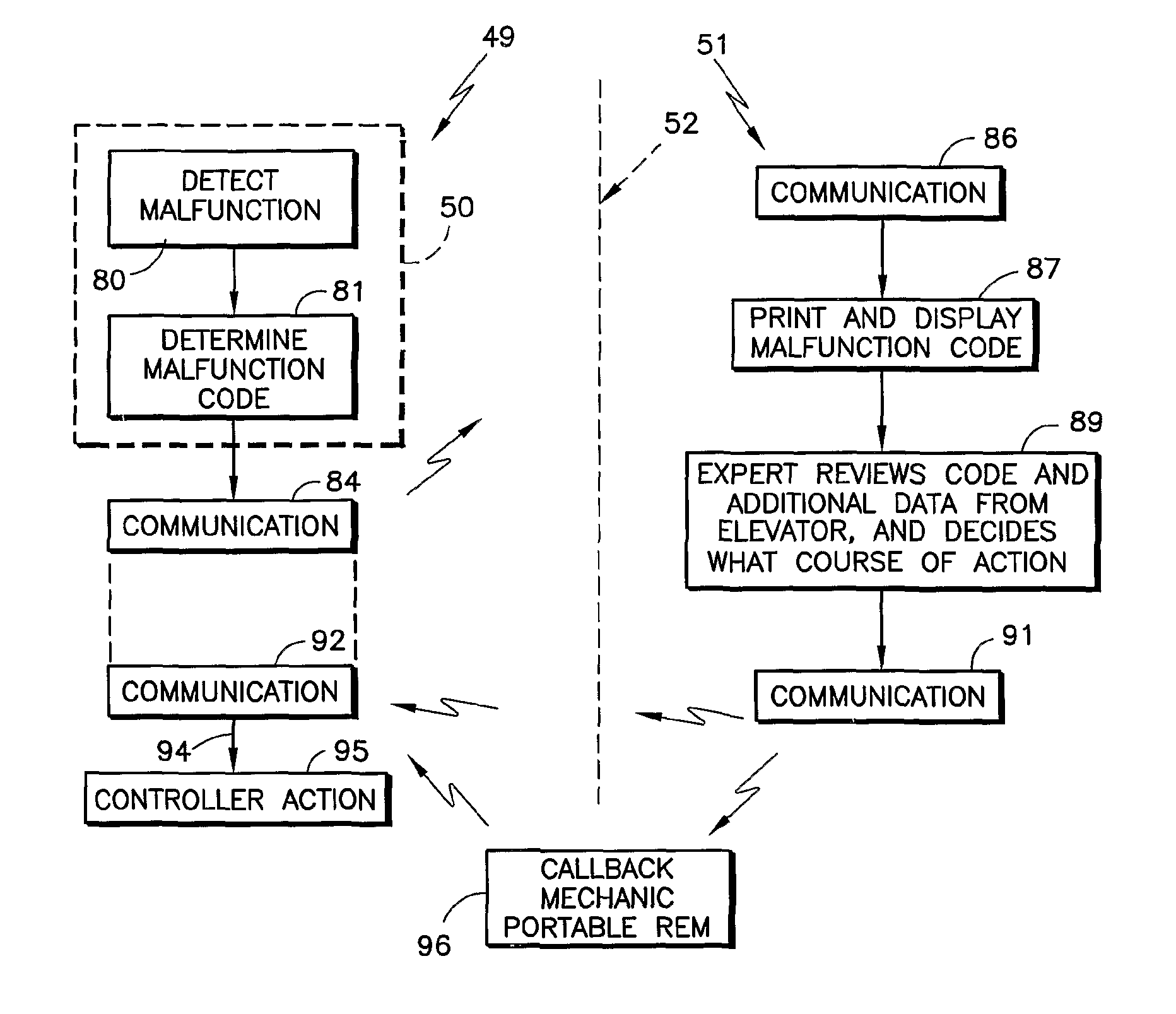

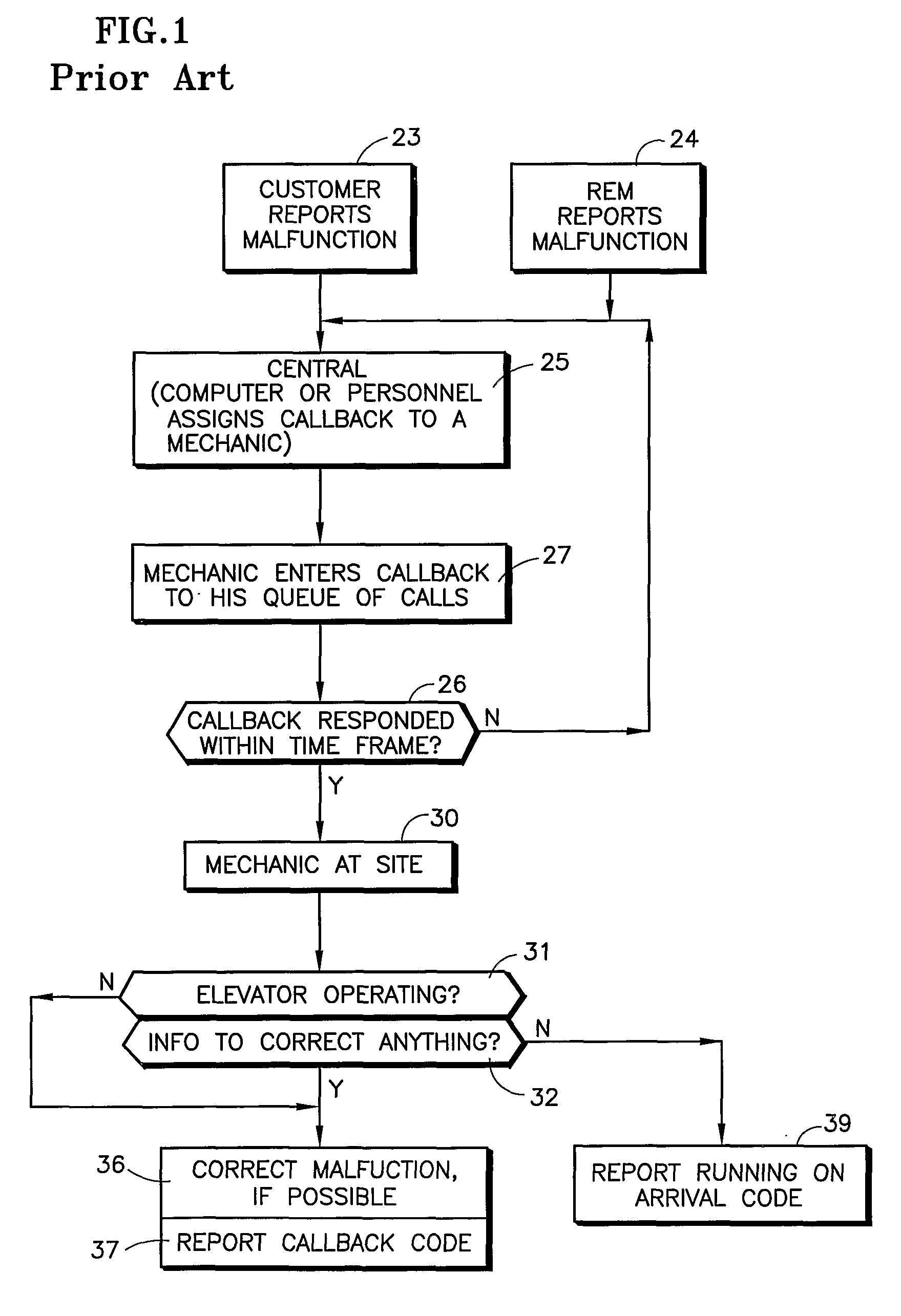

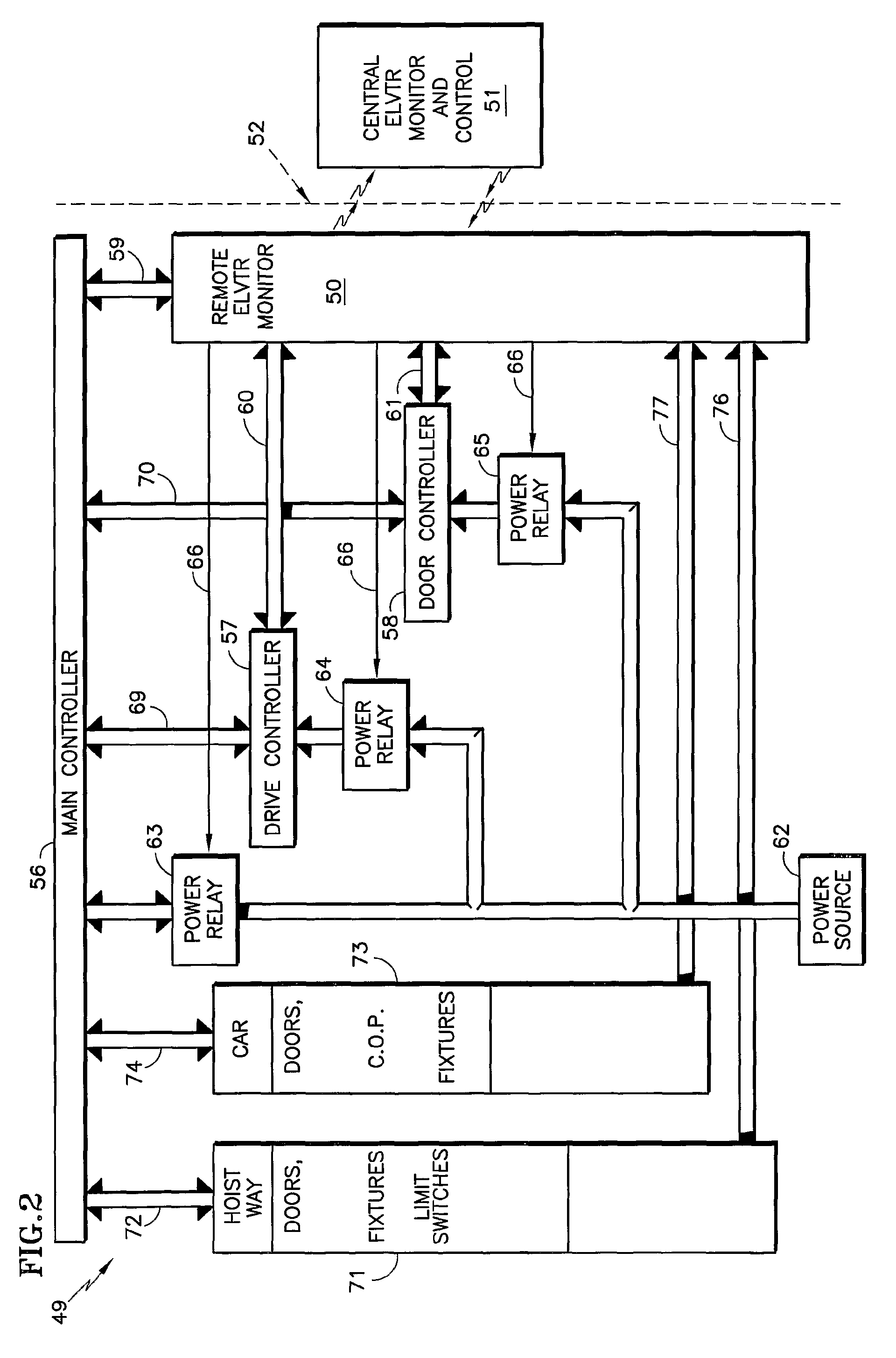

Remotely Performed and/or Assisted Restoration of Elevator Service

ActiveUS20090218178A1Avoiding unnecessary service callReduce in quantityComputer controlElevatorsPower-on resetStation

An elevator (49) includes remote elevator monitoring equipment (50) (REM) connected by a communication linkage (52) to a central elevator monitoring and control station (51). Main, drive, and door controllers (56-58) are interconnected (5961) with the REM. Power-on-reset (POR) of controllers is caused internally (150) or by remotely-operable relays (63-65). An elevator expert at the remote station may order a POR (108), disable components (120), try various fixes (124), and / or order maintenance (115, 135) with instructions. In another embodiment, the controller (56a, 56b) includes elevator diagnostics (150) which can recognize an elevator malfunction and either cause a relay (63) to interrupt power for an interval or cause a reboot.

Owner:OTIS ELEVATOR CO

Method for controlling injection of reducing agent in exhaust gas from a combustion engine

ActiveUS20060130461A1Simple and reliable measurementEasy to measureInternal combustion piston enginesExhaust apparatusExhaust gasExhaust fumes

The invention relates to a method for controlling injection of a reductant into a NOx containing exhaust gas stream from a combustion engine, where combustion of a known fuel takes place and where the HOx is reduced by selective catalytic reduction, SCR, in the presence of a SCR catalyst, comprising establishing signals related to exhaust gas flow, HOx concentration in the exhaust gas stream upstream of the catalyst, exhaust gas temperature upstream of the SCR catalyst, exhaust gas temperature downstream of the SCR catalyst and to input data for catalyst characteristics. From the signals an adjusted amount of the reductant is calculated by using a calculated amount of reductant and a value d(E*T) / dt, where E is the exhaust gas flow, T is the exhaust gas temperature upstream of the catalyst and t is time.

Owner:UMICORE AG & CO KG

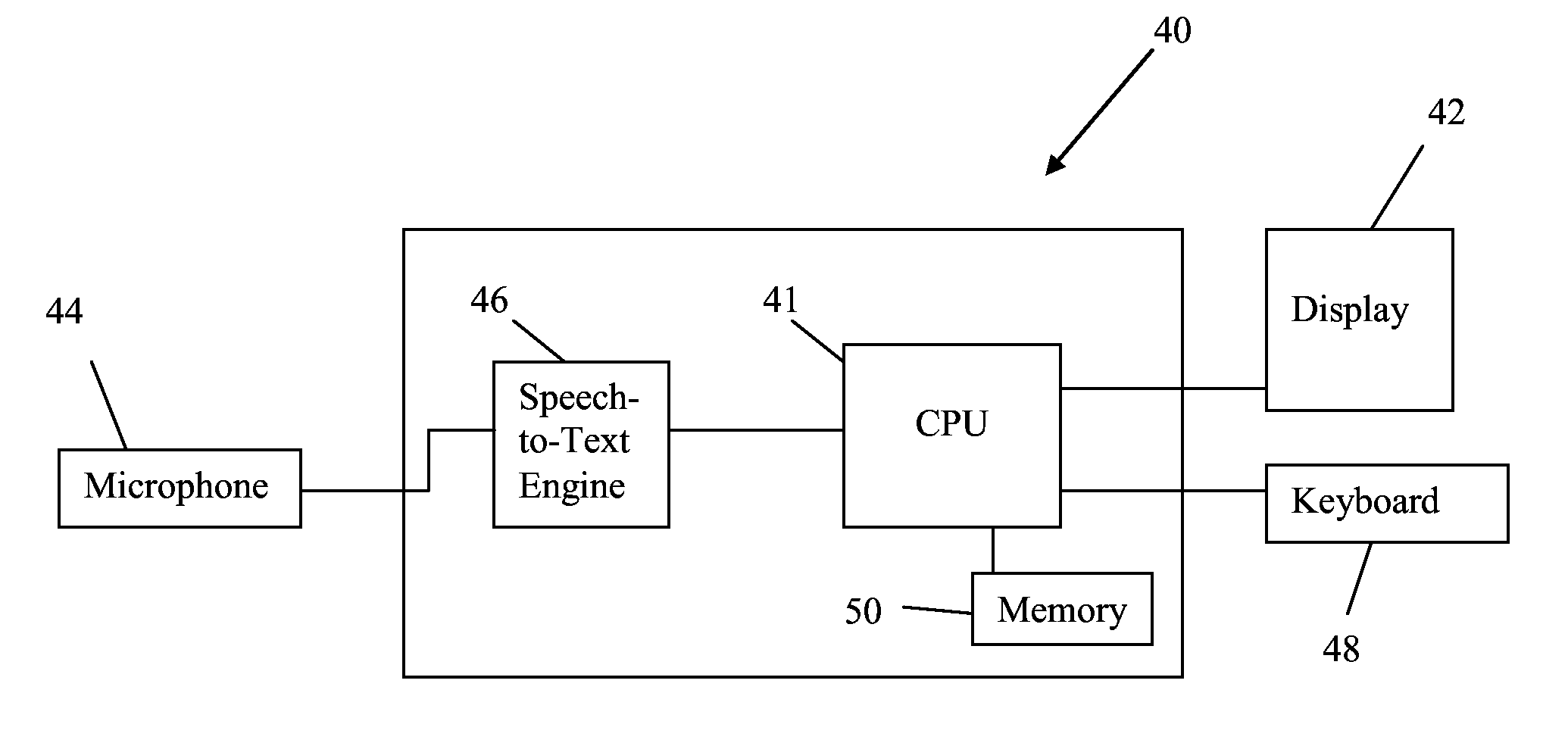

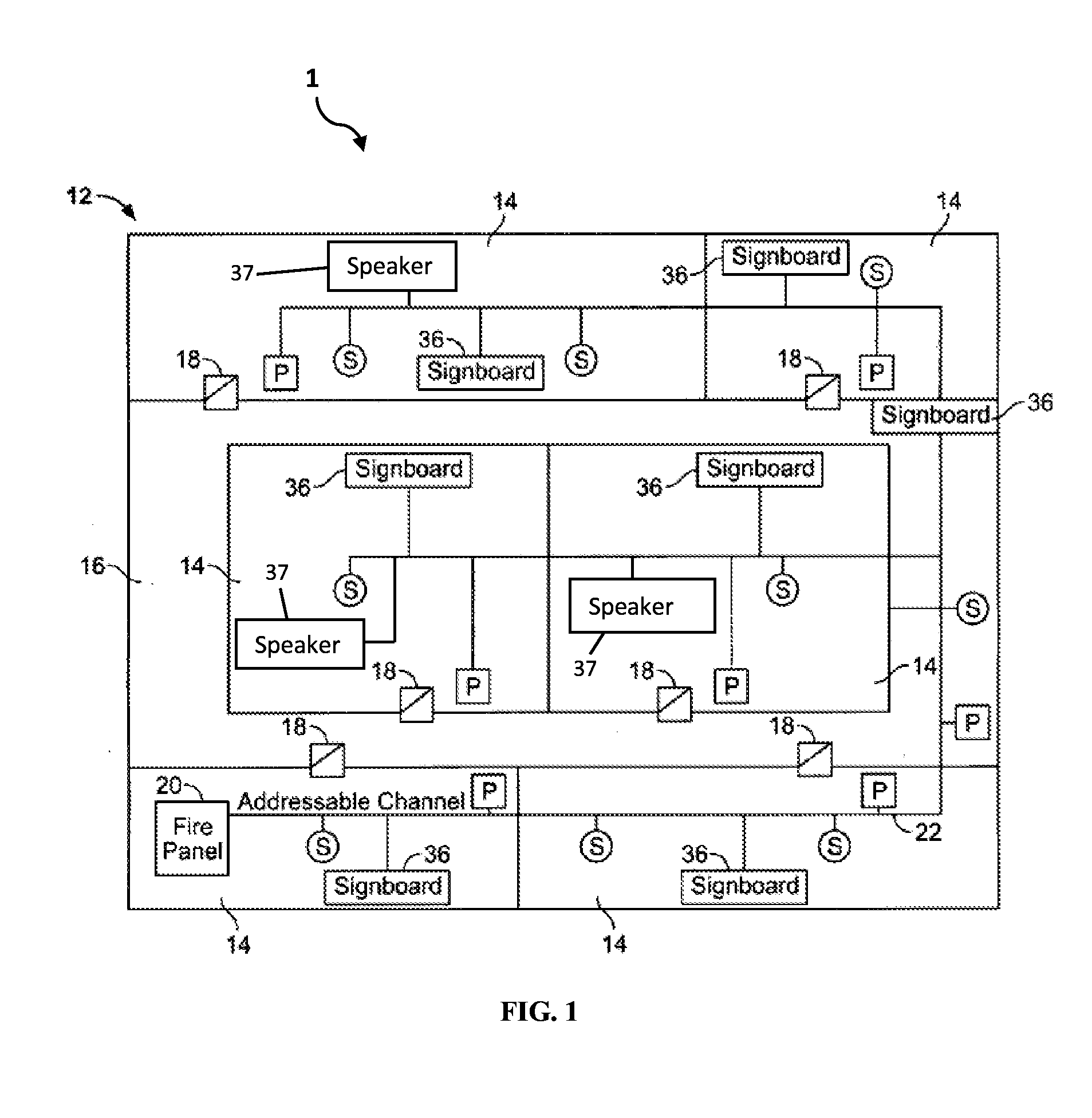

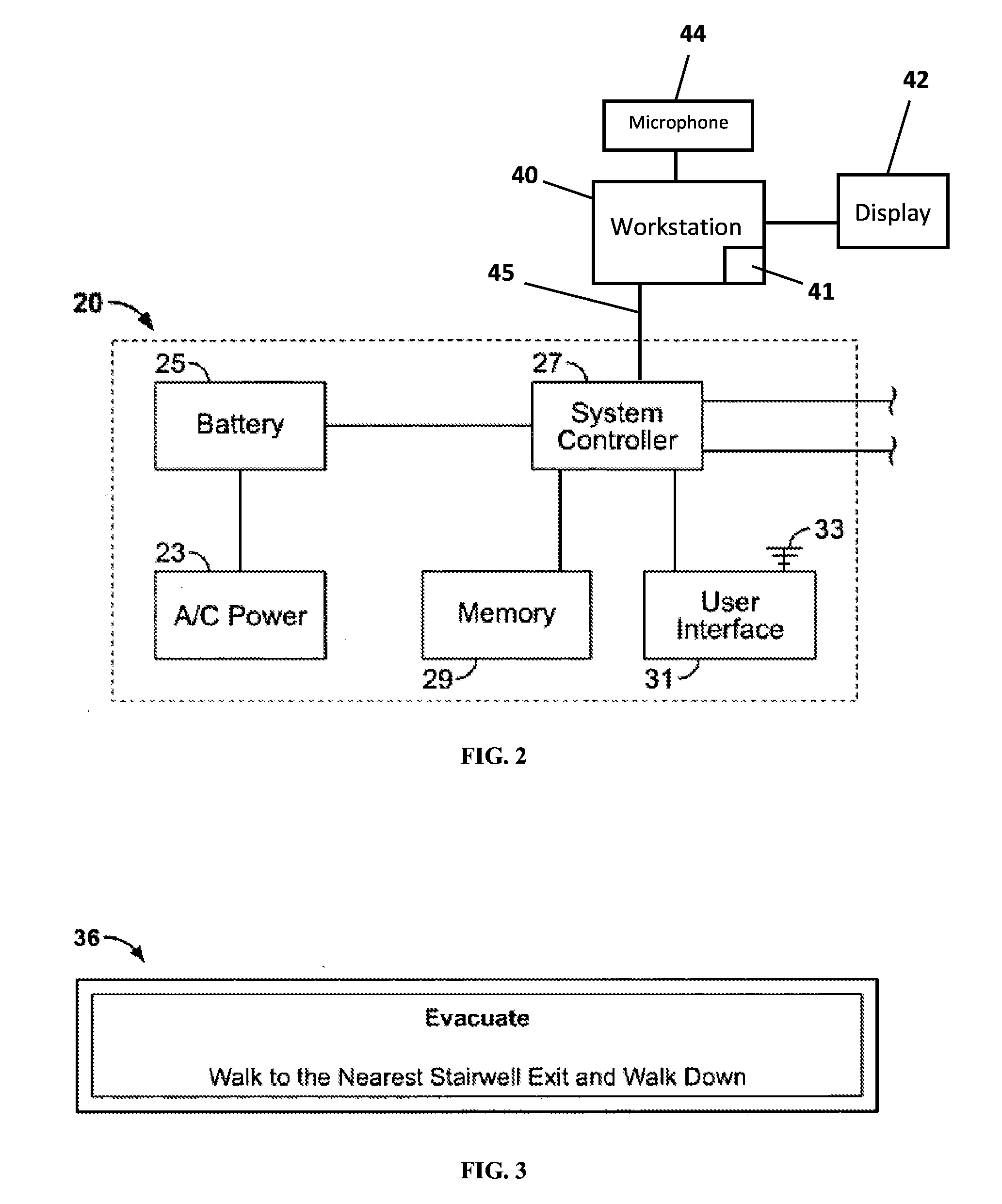

System and method for emergency message preview and transmission

InactiveUS20130041646A1Improve communication performanceEasy to identifyAlarmsSpeech recognitionData displayDisplay device

In accordance with the embodiments of the present invention, a system and method for enabling preview, editing, and transmission of emergency notification messages is provided. The system includes a controller, a microphone, and a speech-to-text engine for receiving an audio message input to the microphone and for convert the audio message to a text message. The resulting text message is displayed on a local display, where a user can edit the message via a text editor. Text and / or audio notification devices are provided for displaying the edited text data as a text message. Other embodiments are disclosed and claimed.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

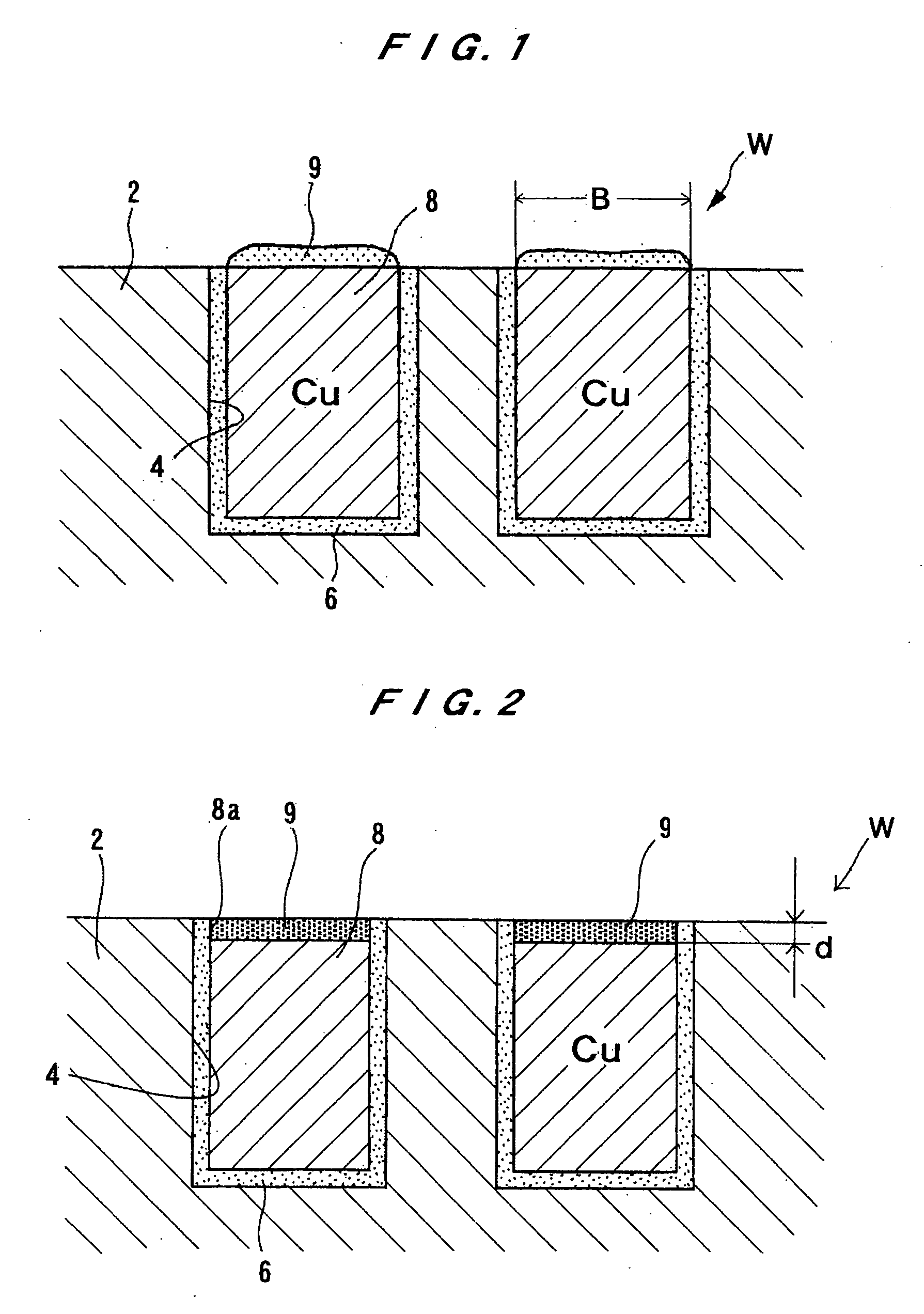

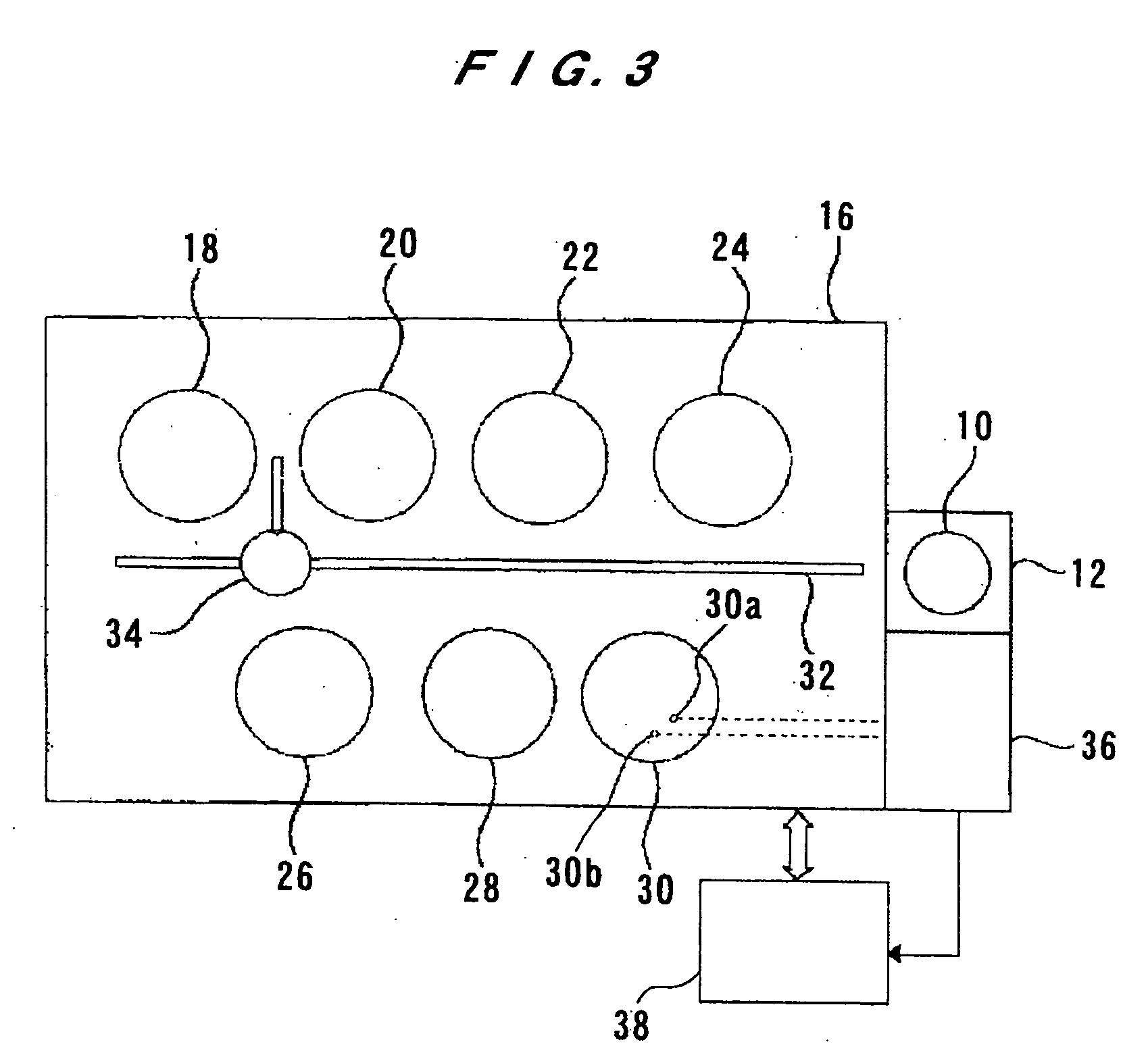

Substrate processing method and apparatus

ActiveUS20050009213A1Variation in qualitySuppress mutationSemiconductor/solid-state device testing/measurementSolid-state devicesProcess conditionsMetal

There is provided a substrate processing method and apparatus which can measure and monitor the thickness and / or properties of a film formed on a substrate as needed, and quickly correct a deviation in the process conditions, and which can therefore stably provide a product of constant quality. A substrate processing method for processing a substrate with a metal and an insulating material exposed on its surface in such a manner that the film thickness of the metal portion with the exposed surface of the metal as a reference plane is selectively or preferentially changed, including measuring a change in the film thickness and / or a film property of the metal portion during and / or immediately after processing, and monitoring the processing and adjusting the processing conditions based on the results of measurement.

Owner:EBARA CORP

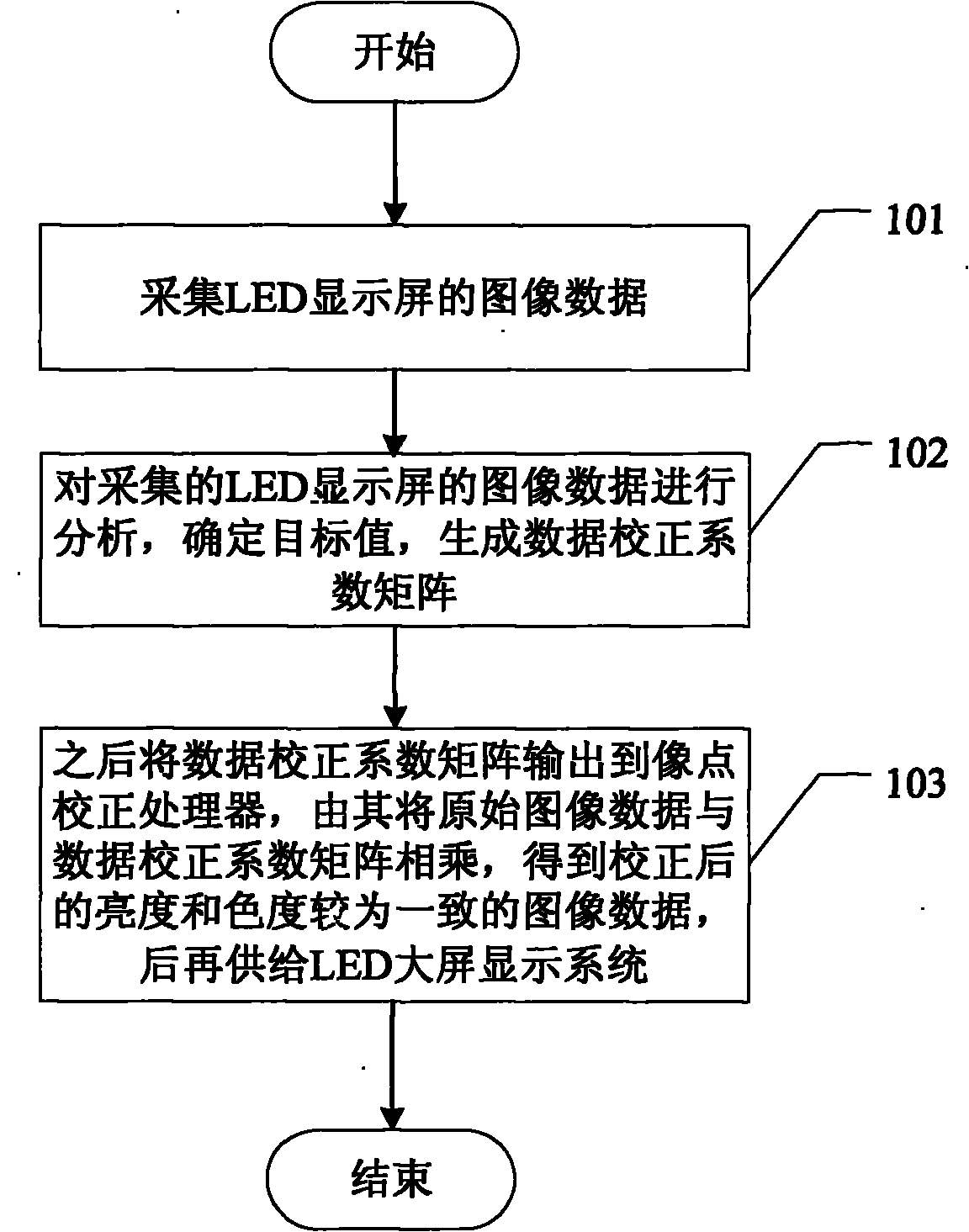

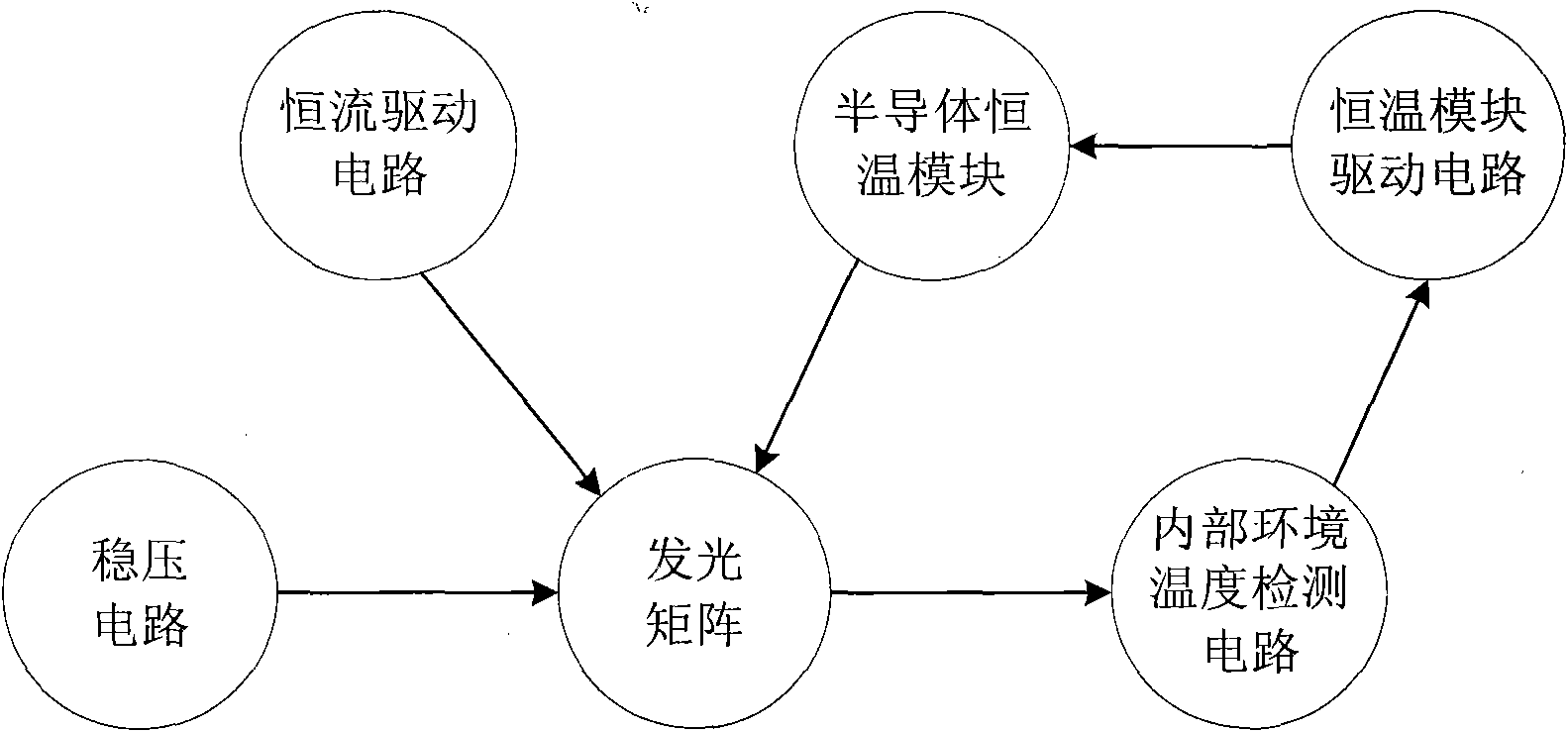

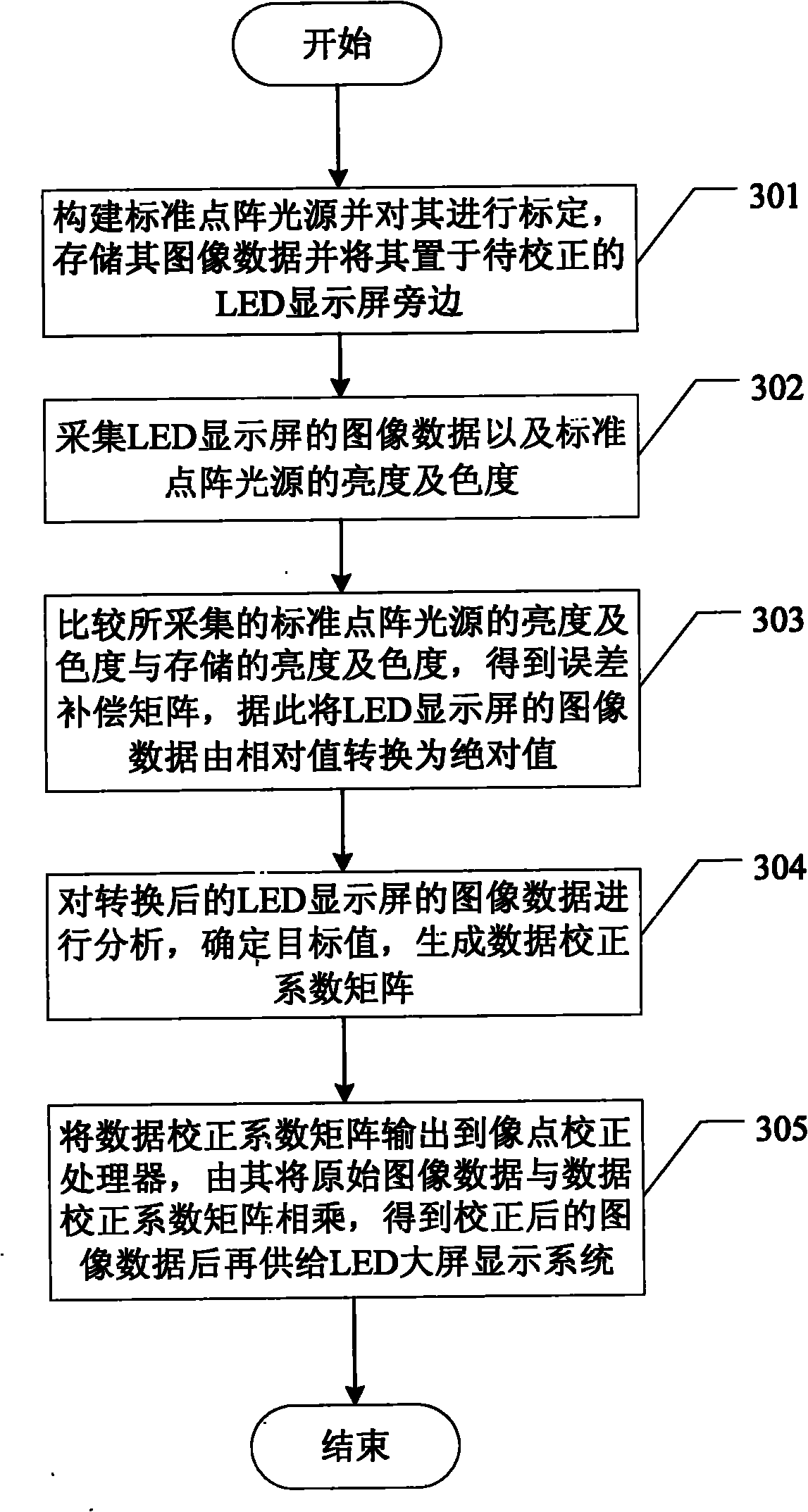

Standard dot matrix light source and image point correction method of LED display screen

InactiveCN102005181AImprove light color consistencyGood white balanceStatic indicating devicesElectric light circuit arrangementDot matrixLight-emitting diode

The invention discloses a standard dot matrix light source and an image point correction method of a light-emitting diode (LED) display screen. The method comprises the following steps of: A, constructing the standard dot matrix light source, and calibrating the brightness and the chroma of the standard dot matrix light source; B, acquiring image data of the LED display screen, and the brightness and the chroma of the standard dot matrix light source; C, comparing the acquired brightness and chroma of the standard dot matrix light source with a stored value to obtain an error compensation matrix, and converting the image data of the LED display screen from a relative value into an absolute value; D, analyzing the converted image data of the LED display screen to generate a data correction coefficient matrix; and E, outputting the data correction coefficient matrix to an image point correction processor to perform image data correction processing so as to obtain corrected image data according to the data correction coefficient matrix, and finally outputting the corrected image data to an LED large screen display system. The standard dot matrix light source and the image point correction method can overcome adverse effects caused by working condition drifting of a camera to ensure that the LED display screen has better light-color consistence and white balance after performing the image point correction; and an additional light colorimeter is not needed, and a plurality of times of tests are not performed any more.

Owner:GTEK GRP LTD

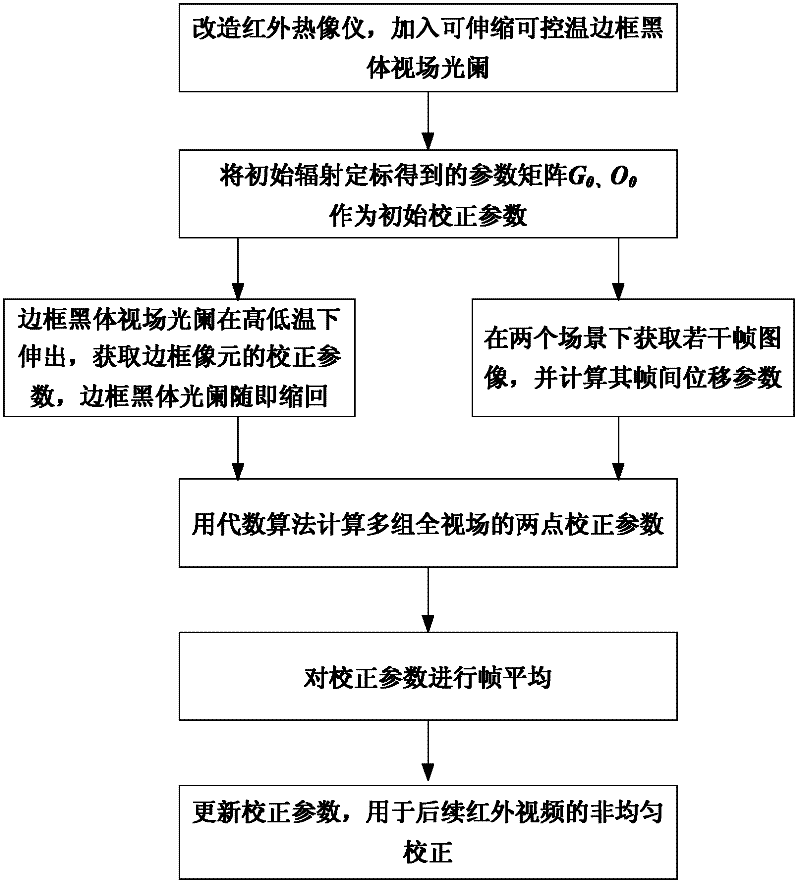

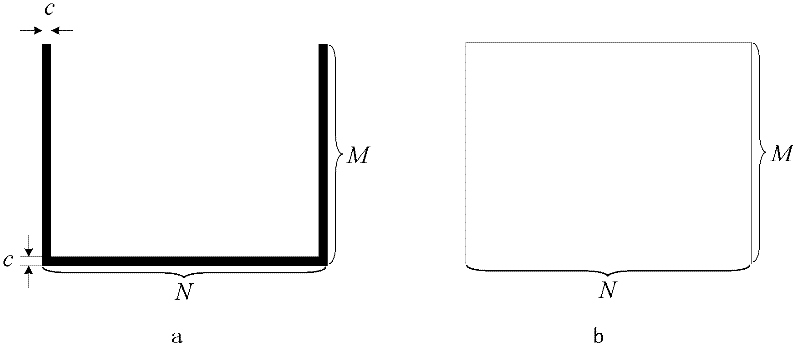

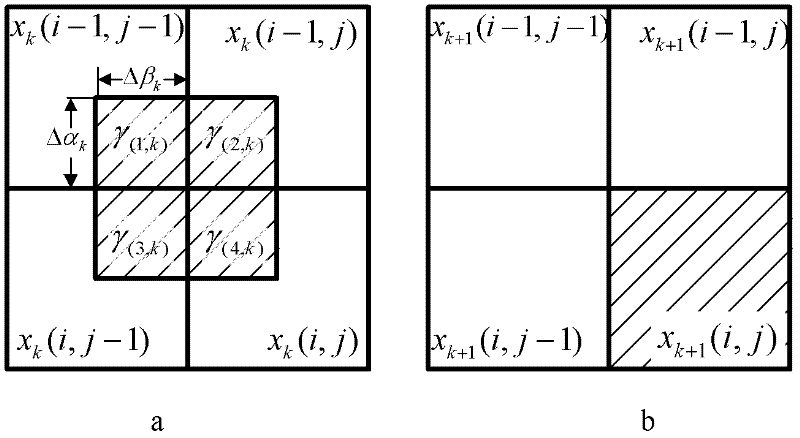

Infrared two-point non-uniform calibrating method based on frame black body field diaphragm

The invention relates to an infrared two-point non-uniform calibrating method based on a frame black body field diaphragm, belonging to the field of infrared thermal imaging. The method comprises the following steps of: arranging an automatically-telescopic frame black body field diaphragm on a diaphragm of an infrared thermal imager and performing two-point calibration under a frame to obtain a gain calibration factor and an offset calibration factor of a detection unit under the coverage of a frame black body; acquiring f frames of initially-calibrated images respectively on two scenes to obtain f-1 groups of inter-frame displacement parameters on every scene; and acquiring calibration parameters of f-1 groups of images with inter-frame displacement on an internal detection unit by adopting an algebraic method, and averaging the frames to obtain finial calibration matrixes G and 0 for calibrating the entire field of a subsequent infrared video. The method has the advantages of rapidness, self-adaption and system miniaturization, and can be applied to the fields of designing, production and manufacturing of refrigerating and non-refrigerating infrared focal plane detector thermalimaging systems, satellite infrared thermal imaging systems, infrared alarm systems, scientific researches and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

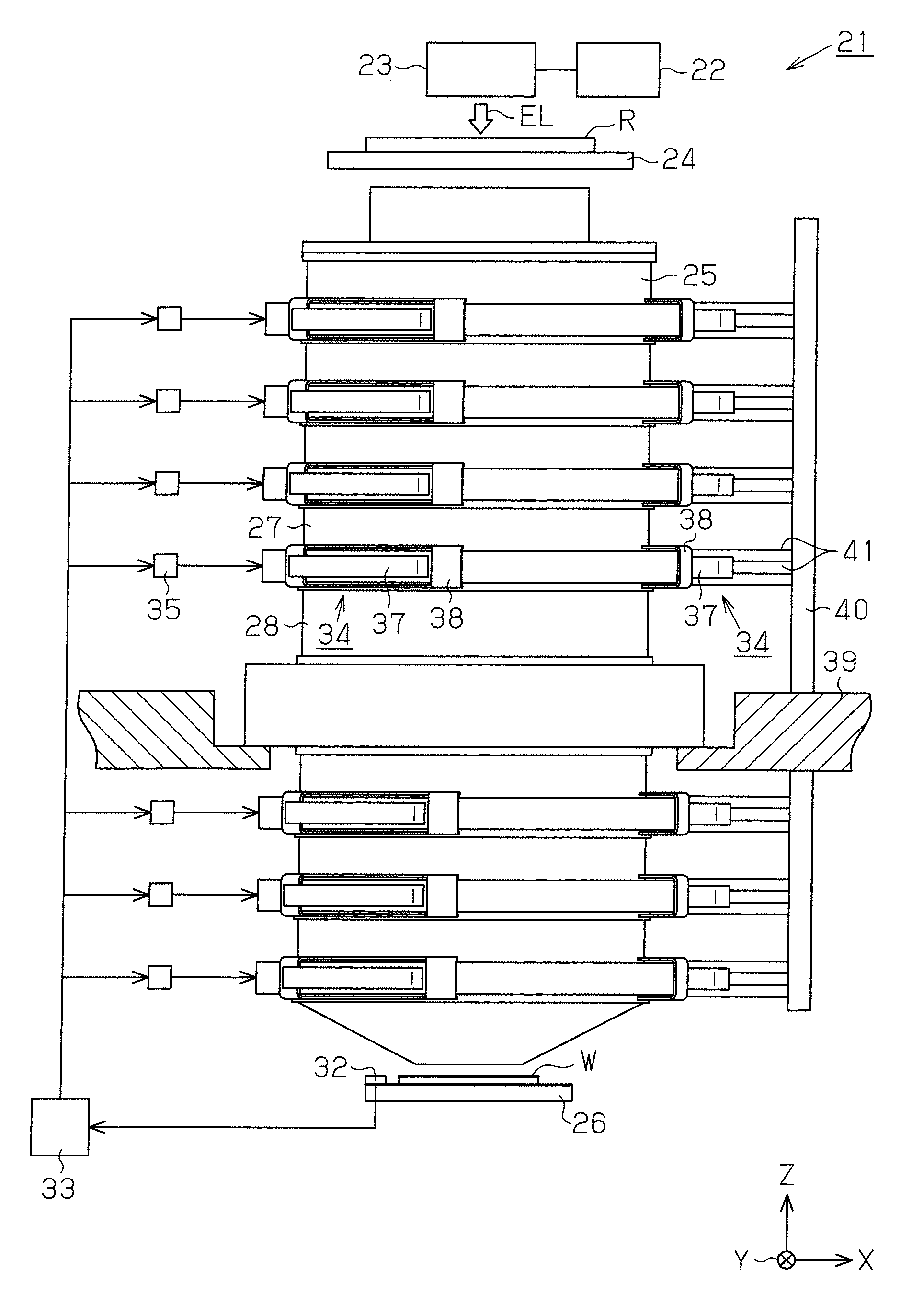

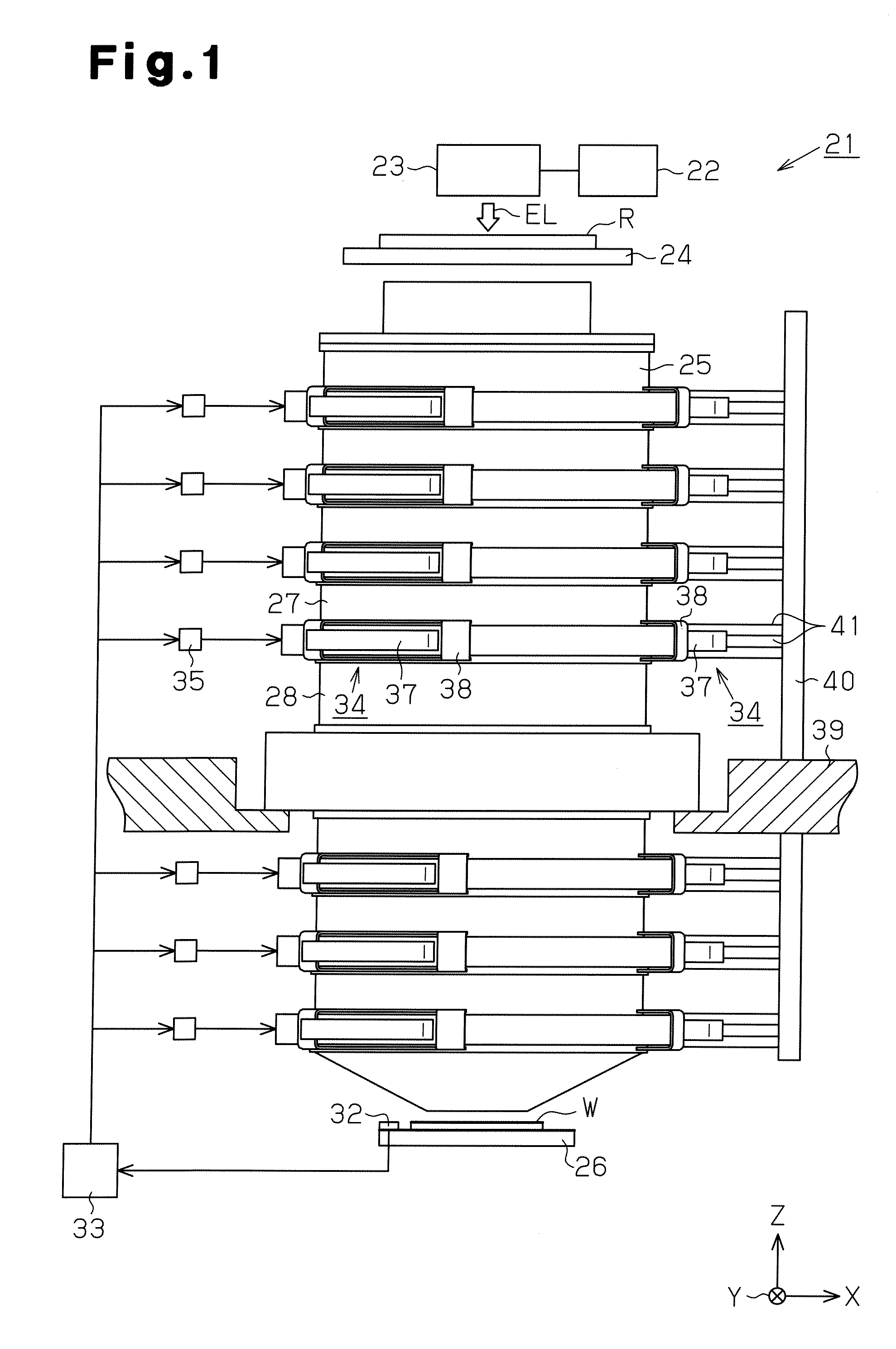

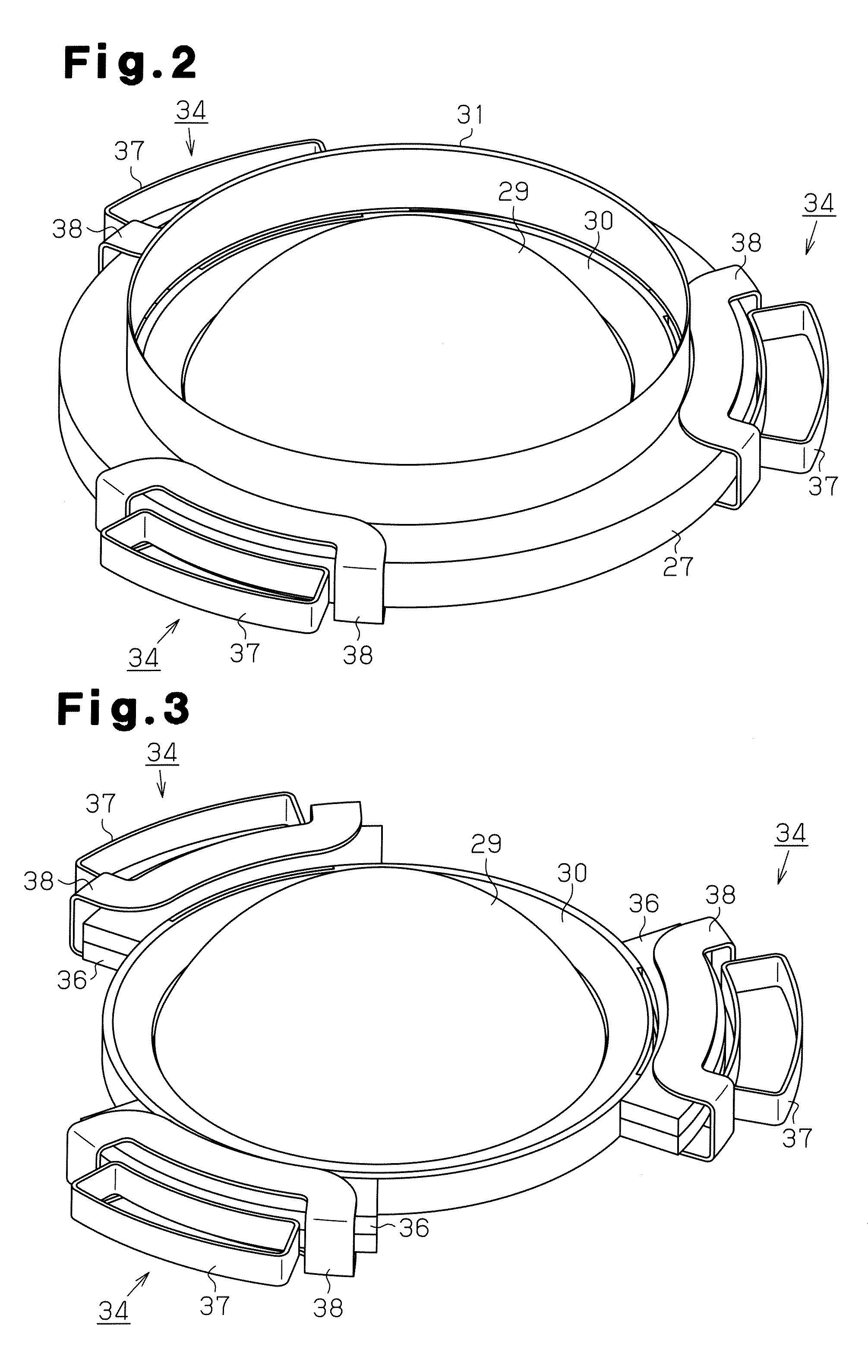

Optical element driving apparatus, barrel, exposure apparatus and device manufacturing method

InactiveUS20090009742A1Quick correctionAccurate transferPhotomechanical apparatusMountingsOptical axisElectrical current

A permanent magnet fixed to a peripheral portion of a lens cell includes two magnets that are joined together so that the north poles face each other and the south poles are exposed. A first driving coil is arranged to face toward exits for lines of magnetic force from the joining surfaces of the north poles of the permanent magnet, and a second driving coil is arranged to face toward entrances for lines of magnetic force in the permanent magnet. The orientation of the lens is adjusted by adjusting the currents supplied to the first driving coil and second driving coil to drive the lens cell in an optical axis direction and horizontal direction in a state in which the lens cell is levitated relative to the cover.

Owner:NIKON CORP

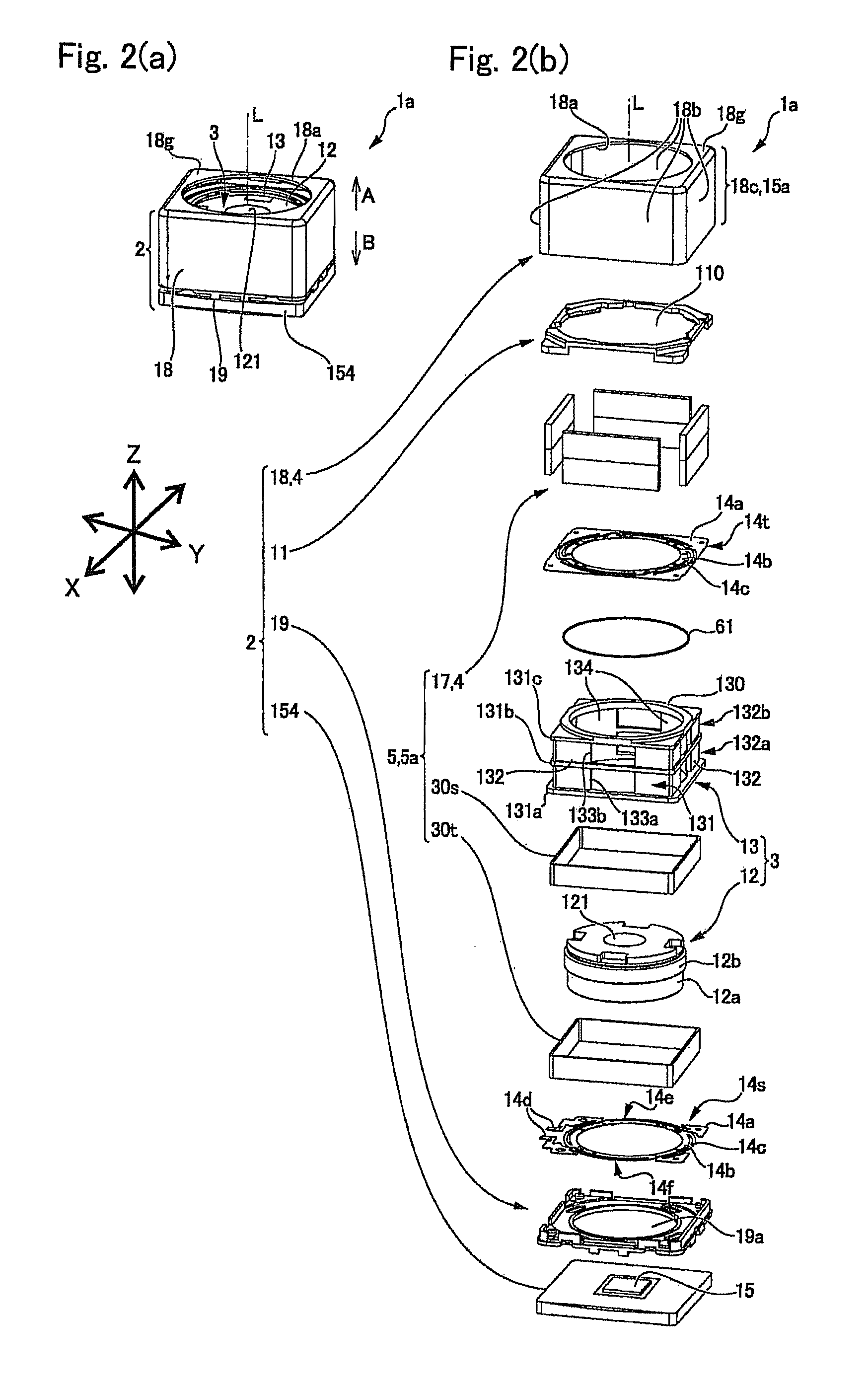

Orthodontic appliance with embedded wire for moving teeth and method

InactiveUS7104790B2Easily manufactureEasy to manufactureOthrodonticsDental toolsPlastic forming machinePlaster Casts

A generally horseshoe shaped clear flexible resilient plastic wire-imbedded orthodontic appliance is made with a plastic portion with contours on the lingual side and on the labial side, wherein the contours snugly cover the patient's teeth so that the appliance remains in place. One or more flexible wires are imbedded within the lingual side of the plastic portion from the left molar area to the right molar area of the plastic portion, whereby the wires apply force on the lingual side of the patient's bite. The appliance is formed by obtaining a plaster cast of the patient's teeth and gums, removing plaster teeth from the plaster cast of the gums, reattaching the plaster teeth to the plaster cast of the gums to form a cast of proper bite alignment, attaching one or more wires to the labial surface of the aligned plaster teeth so the wires become imbedded within thermosetting plastic placed over the cast, putting the cast in a thermosetting plastic molding machine, inserting thermosetting plastic in the machine, and heating the thermosetting plastic around the cast of the proper bite alignment, so the wires are imbedded within the formed appliance after the thermosetting plastic cools. A series of appliances may be used to shift a patient's bite to proper bite orientation.

Owner:CRONAUER EDWARD A

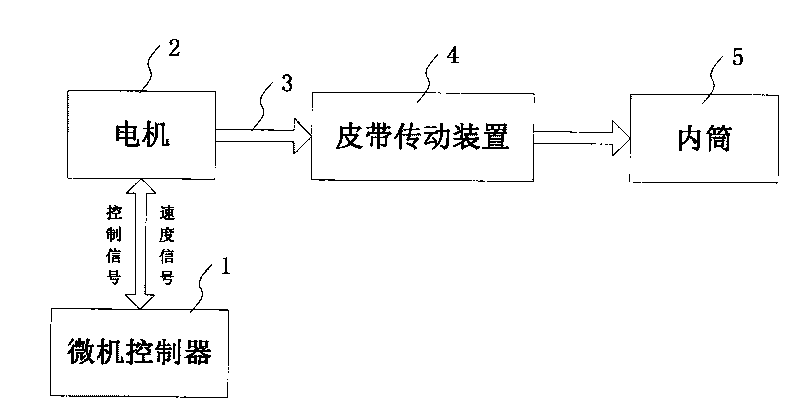

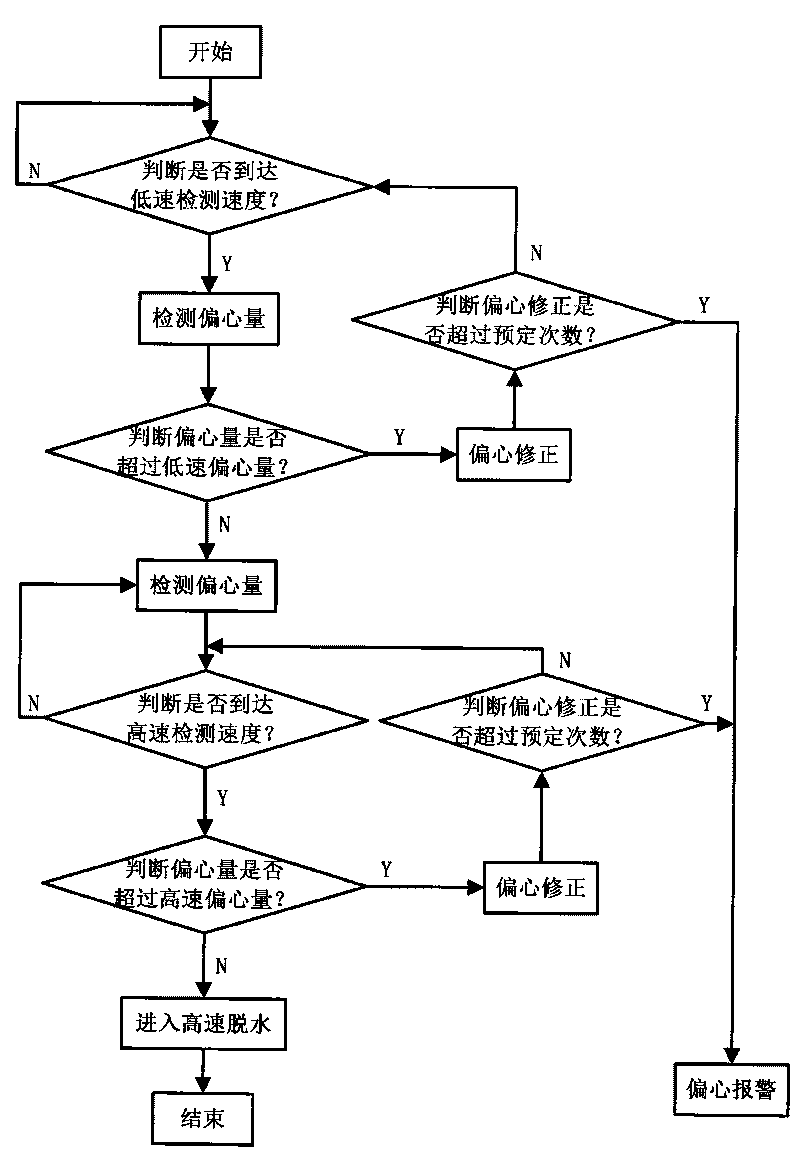

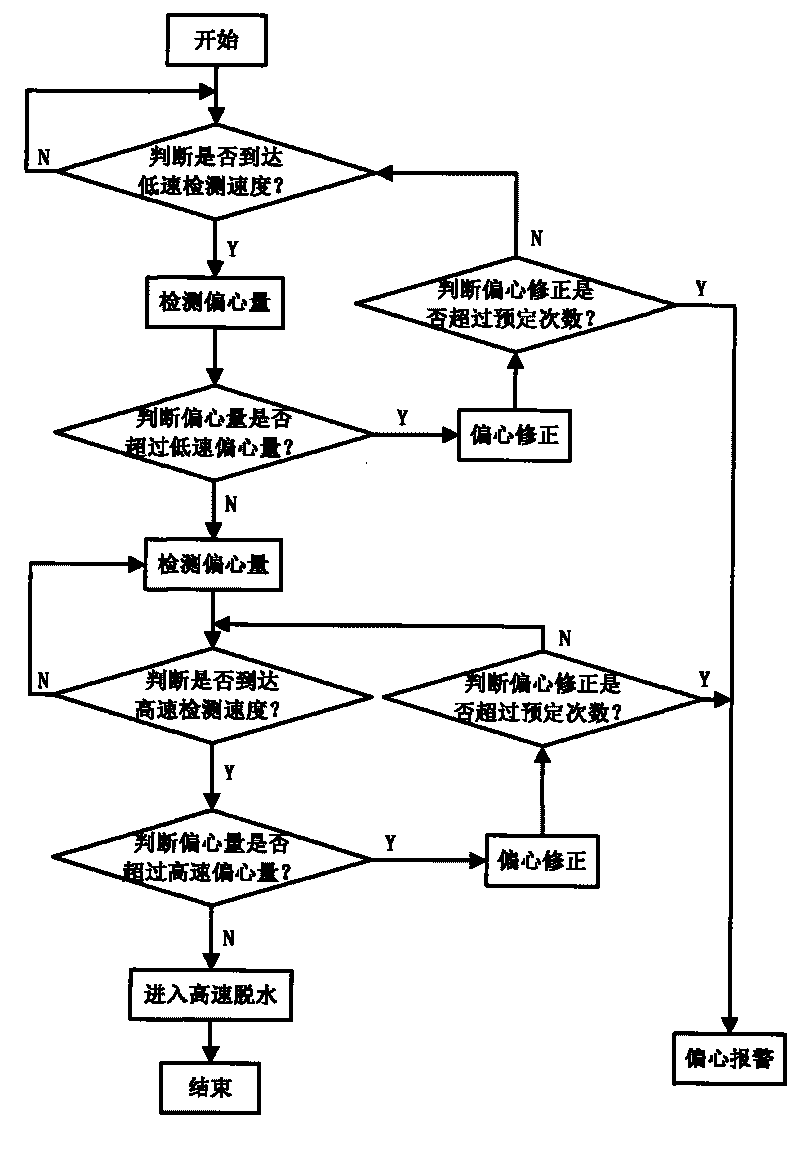

Method for detecting dehydration imbalance of inclined drum washing machine

InactiveCN101736553AHigh degree of intelligenceQuick correctionOther washing machinesControl devices for washing apparatusLow speedEngineering

The invention discloses a method for detecting dehydration imbalance of an inclined drum washing machine, which comprises the steps of (1) carrying out eccentricity detection on an inner barrel and judging whether the eccentricity exceeds the predetermined low-speed eccentricity when the rotational speed of the inner barrel achieves the low-speed detection speed, carrying out eccentricity correction when the judgment result is yes, otherwise, continuously detecting the eccentricity; and (2) carrying out the eccentricity detection on the inner barrel and judging whether the eccentricity exceeds the predetermined high-speed eccentricity when the rotational speed of the inner barrel achieves the high-speed detection speed, carrying out the eccentricity correction when the judgment result is yes, otherwise, entering into the high-speed dehydration. The method is divided into two detection stages of low-speed detection speed and high-speed detection speed, and the adoption of the unbalanced detection on a two-stage speed platform can accurately distinguish the eccentricity position and the eccentricity of clothes and adopt the different dehydration control methods and eccentricity correction strategies according to the eccentricity situations, thereby achieving the fast eccentricity correction and the smooth and high-efficient dehydration effect.

Owner:WHIRLPOOL CHINA

Container crane, and method of determining and correcting a misalignment between a load-carrying frame and a transport vehicle

ActiveUS7289876B2Quick correctionQuick identificationDigital data processing detailsArticle unpackingContainer craneEngineering

A container crane includes a movable trolley and a load-carrying frame pendantly connected to the trolley and comprised of a spreader and a head block, for transfer of a container from or to a transport vehicle. Plural optical detectors are mounted on the trolley for identifying longitudinal and transversal edges of the head block or spreader and the transport vehicle. Operatively connected to the detectors is a processing device for determining a spatial position of the edges and calculating a position of longitudinal and transversal center lines of the head block or spreader and the transport vehicle and their spatial positions in relation to one another. In this way a possible offset of the center lines of the head block or spreader with regard to those of the transport vehicle in longitudinal and transversal directions as well as a rotation angle of the center lines can be determined, whereby a detected offset or rotation angle is compensated by displacing the spreader relative to the head block.

Owner:SIEMENS AG

Orthodontic appliance with embedded wire for moving teeth and method

InactiveUS7416407B2Easy to manufactureMore forceful and less obtrusive movementOthrodonticsDental toolsPlastic forming machineWire rod

A generally horseshoe shaped clear flexible resilient plastic wire-imbedded orthodontic appliance is made with a plastic portion with contours on the lingual side and on the labial side, wherein the contours snugly cover the patient's teeth so that the appliance remains in place. One or more flexible wires are imbedded within the lingual side of the plastic portion from the left molar area to the right molar area of the plastic portion, whereby the wires apply force on the lingual side of the patient's bite. The appliance is formed by obtaining a plaster cast of the patient's teeth and gums, removing plaster teeth from the plaster cast of the gums, reattaching the plaster teeth to the plaster cast of the gums to form a cast of proper bite alignment, attaching one or more wires to the labial surface of the aligned plaster teeth so the wires become imbedded within thermosetting plastic placed over the cast, putting the cast in a thermosetting plastic molding machine, inserting thermosetting plastic in the machine, and heating the thermosetting plastic around the cast of the proper bite alignment, so the wires are imbedded within the formed appliance after the thermosetting plastic cools. A series of appliances may be used to shift a patient's bite to proper bite orientation.

Owner:CRONAUER EDWARD A

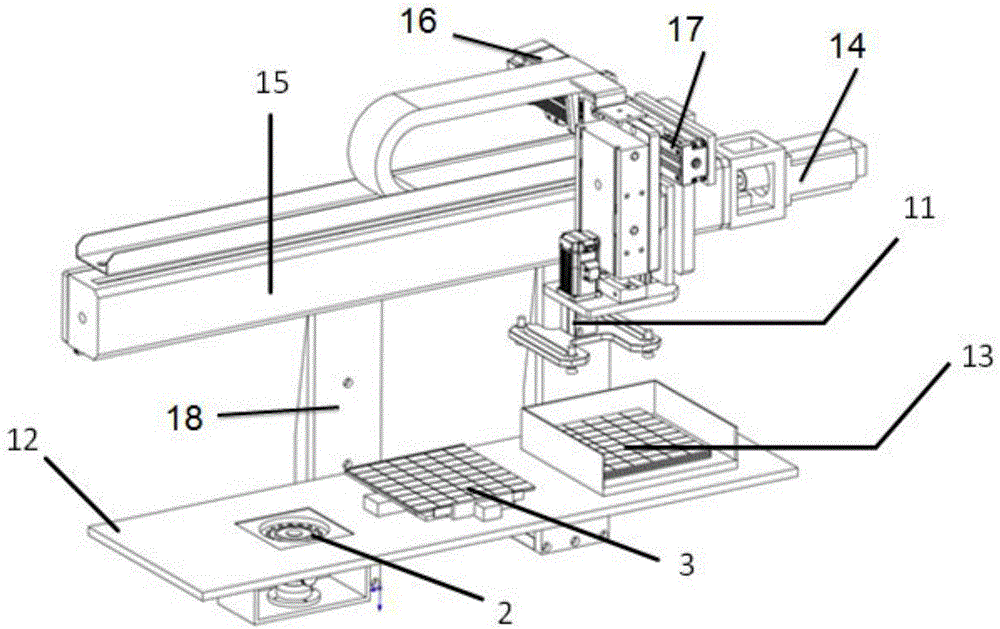

Equipment used for visual positioning and angle detection of solar cells before series welding

ActiveCN106272426AIncrease productivityIncrease production capacityProgramme-controlled manipulatorProduction lineEngineering

The invention provides equipment used for visual positioning and angle detection of solar cells before series welding. The equipment comprises a support rack, a Y-axis slide rail, an X-axis slide rail, a manipulator, a bracket bedplate, an imaging mechanism, a cell correction mechanism, and a feeding plate, wherein the Y-axis slide rail is fixed at the top end of the support rack; the X-axis slide rail is mounted on the Y-axis slide rail and can move along the Y-axis slide rail; the manipulator is mounted on the X-axis slide rail and can move along the X-axis slide rail; the bracket bedplate is mounted below the Y-axis slide rail; the imaging mechanism is mounted on the bracket bedplate; the cell correction mechanism is mounted at the right side of the imaging mechanism; and the feeding plate is mounted at the right side of the cell correction mechanism. According to the equipment, the position and angle correction of the solar cells can be realized automatically in a moving process, so that the production efficiency and the production line flexibility are improved. The invention further provides a method for used for visual positioning and angle detection of the solar cells before series welding. According to the method adopting visual correction, the correction process of solar cell workpieces can be performed fast and accurately, and the series welding efficiency and precision of the solar cells are improved.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

Automatic steering system

InactiveUS20060064216A1Quick checkQuick correctionAuxillary drivesDigital data processing detailsAutomatic steeringGyroscope

An automatic steering system for an agricultural vehicle comprises a steering actuator operative to steer the vehicle in response to a steering signal, and a steering wheel operative to generate and send a manual steering signal to the steering actuator when the steering wheel is turned. A microprocessor is operative to generate and send an automatic steering signal to the steering actuator. A global positioning sensor is operative to determine a sensed location of the vehicle and send a corresponding location signal to the microprocessor, and a gyroscope is operative to determine lateral movement of the vehicle and send a corresponding movement signal to the microprocessor. The microprocessor receives the location signal and the movement signal and compares the sensed location and lateral movement with a desired vehicle path and generates the automatic steering signal. The steering actuator steers the vehicle in response to one of the steering signals.

Owner:ACCUTRAK SYST

Handling failures in processing natural language queries

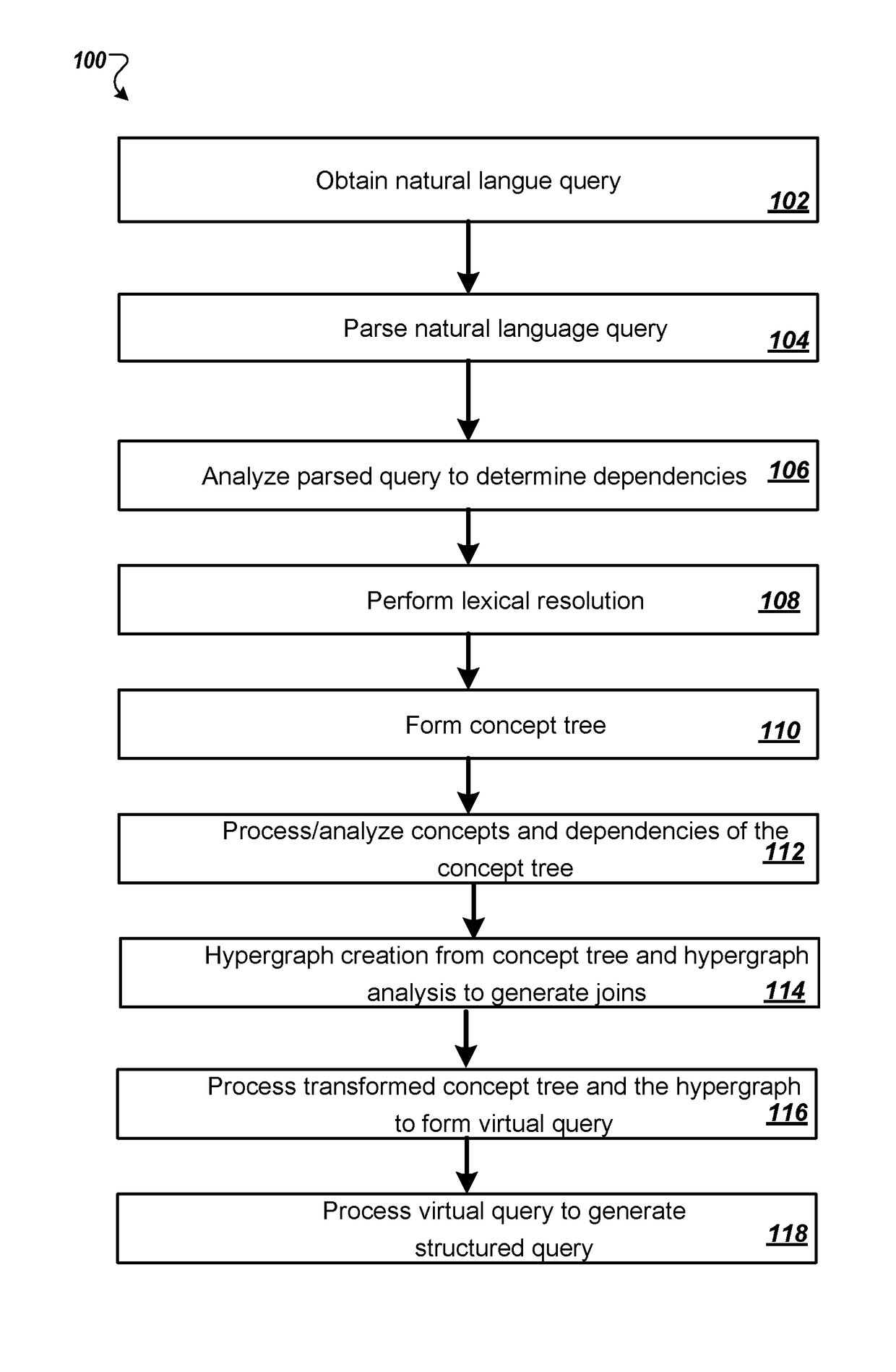

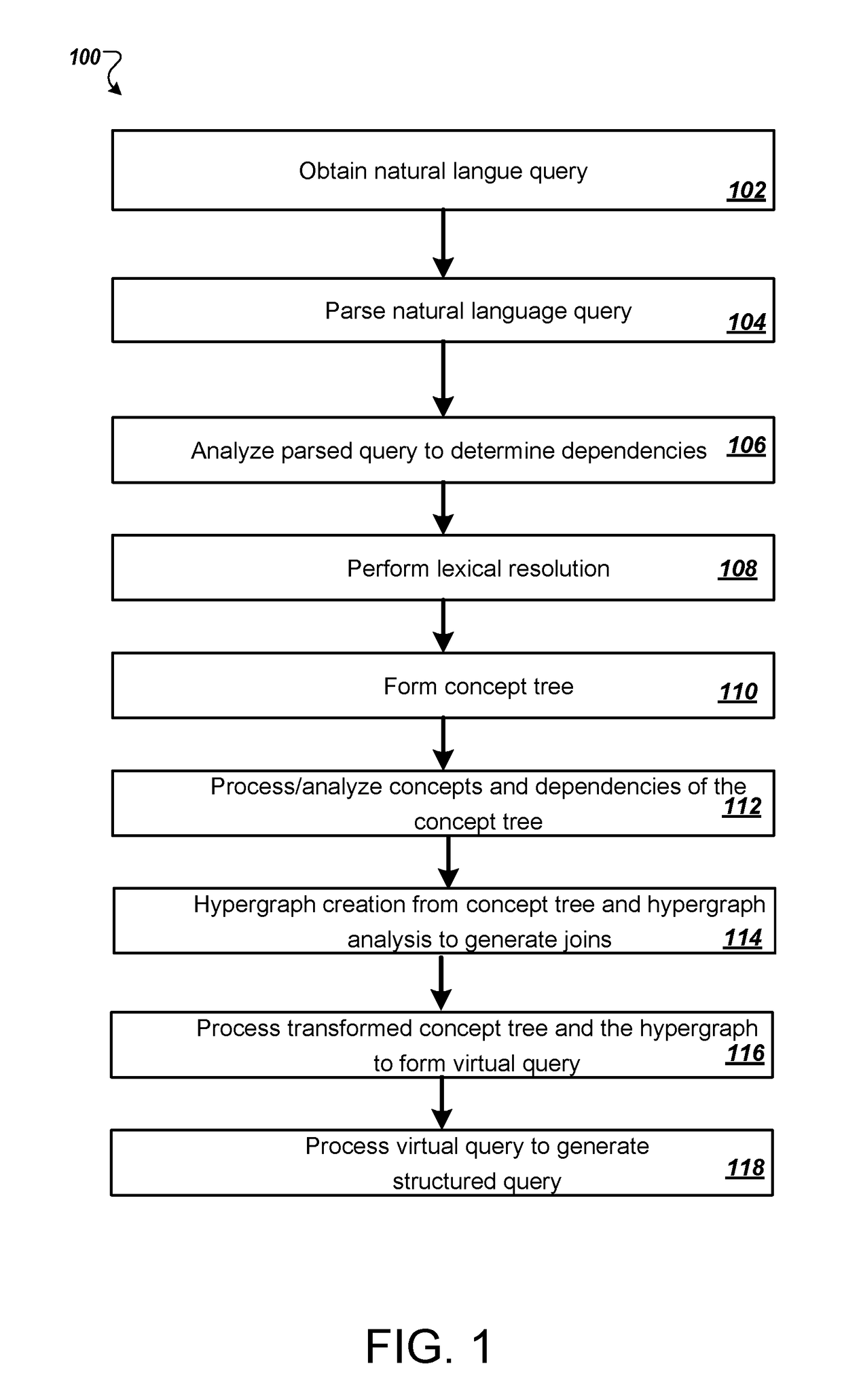

InactiveUS20170075953A1Reduce needEliminate needDigital data information retrievalNatural language data processingApplication programming interfaceHypergraph

Systems, methods, and computer storage media for handling failures in generating structured queries from natural language queries. One of the methods includes obtaining, through a natural language front end, a natural language query from a user; converting the natural language query into structured operations to be performed on structured application programming interfaces (APIs) of a knowledge base, comprising: parsing the natural language query, analyzing the parsed query to determine dependencies, performing lexical resolution, forming a concept tree based on the dependencies and lexical resolution; analyzing the concept tree to generate a hypergraph, generate virtual query based on the hypergraph, and processing the virtual query to generate one or more structured operations; performing the one or more structured operations on the structured APIs of the knowledge base; and returning search results matching the natural language query to the user.

Owner:GOOGLE LLC

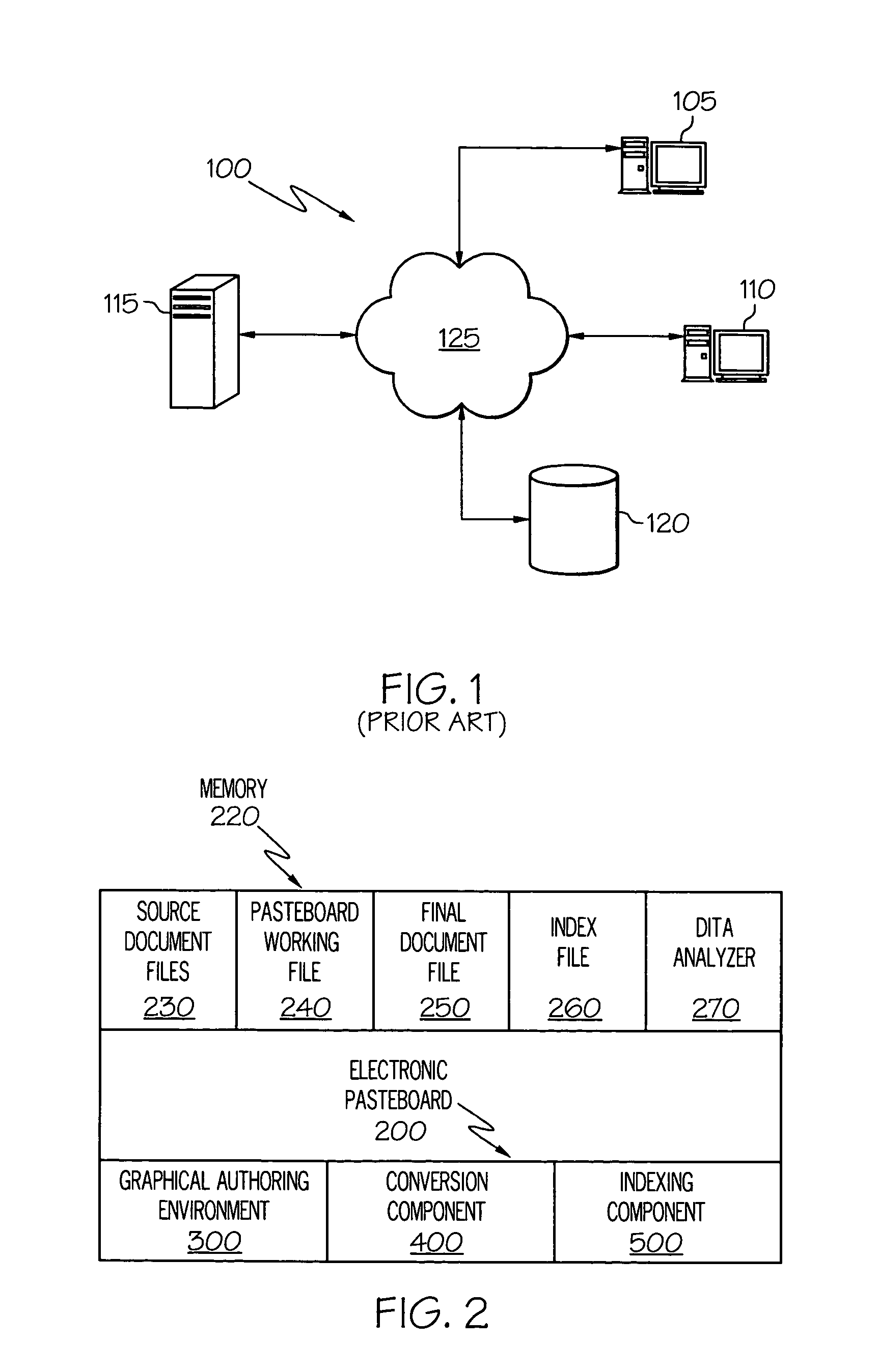

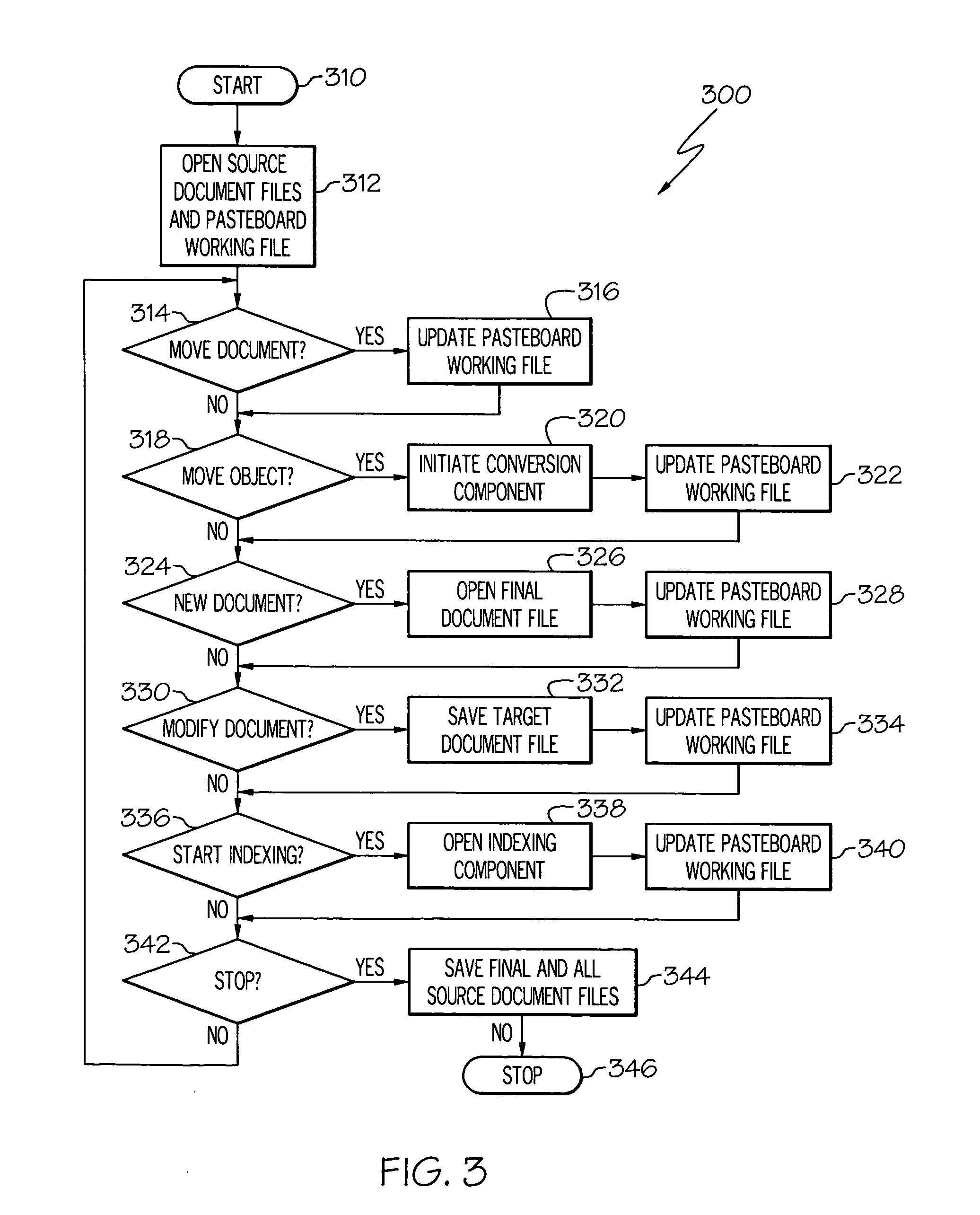

System and method for dynamic organization of information sets

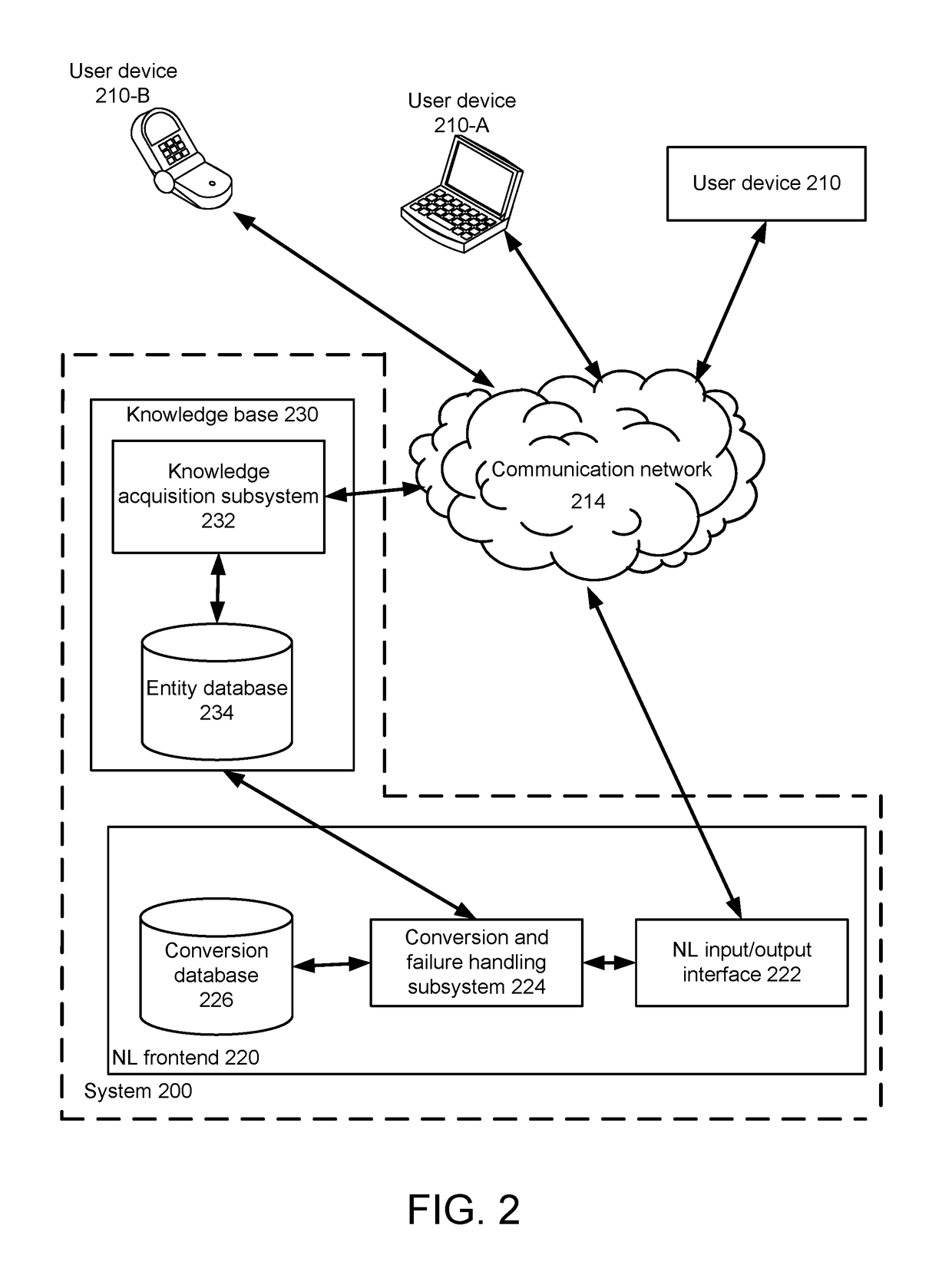

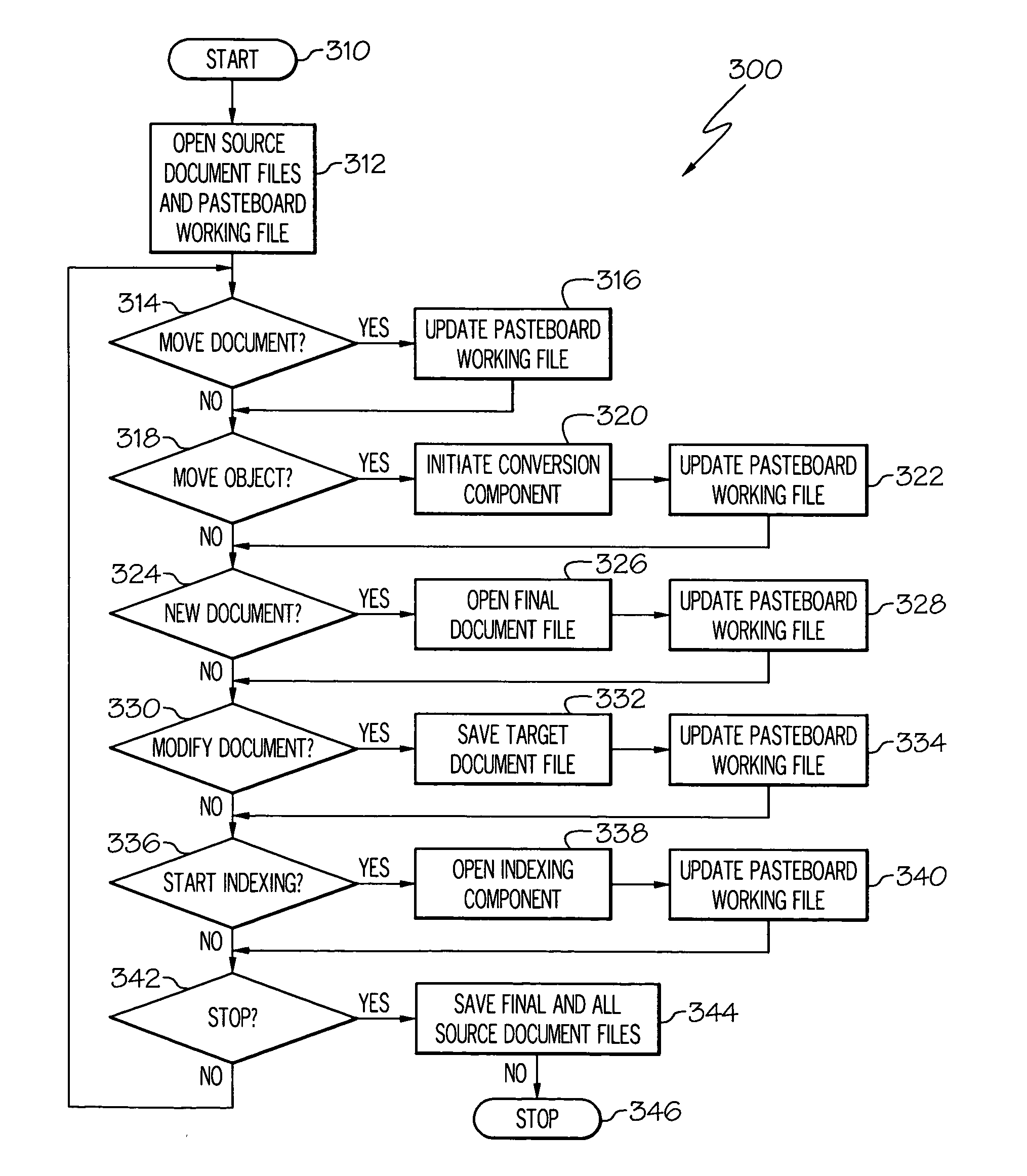

ActiveUS20070277101A1Quick identificationQuick correctionMetadata text retrievalNatural language data processingGraphicsDrag and drop

An electronic pasteboard allows users to organize multiple documents in a single visual interface. After placing documents on the pasteboard, users can drag and drop portions (paragraphs, words, figures, images, graphs) from one document to another document, or create a new document combining elements from several source documents. Users can create tables or an index for grouping together individual documents, or elements of documents. Each original source document can be saved individually, with tags added related to the user defined groupings. The entire pasteboard with content from all the source documents can be saved or printed out. Likewise, selected groupings on the pasteboard can also be saved or printed out.

Owner:IBM CORP

Elevator system and method including a controller and remote elevator monitor for remotely performed and/or assisted restoration of elevator service

ActiveUS8069958B2Avoiding unnecessary service callReduce in quantityComputer controlElevatorsPower-on resetElevator system

An elevator (49) includes remote elevator monitoring equipment (50) (REM) connected by a communication linkage (52) to a central elevator monitoring and control station (51). Main, drive, and door controllers (56-58) are interconnected (5961) with the REM. Power-on-reset (POR) of controllers is caused internally (150) or by remotely-operable relays (63-65). An elevator expert at the remote station may order a POR (108), disable components (120), try various fixes (124), and / or order maintenance (115, 135) with instructions. In another embodiment, the controller (56a, 56b) includes elevator diagnostics (150) which can recognize an elevator malfunction and either cause a relay (63) to interrupt power for an interval or cause a reboot.

Owner:OTIS ELEVATOR CO

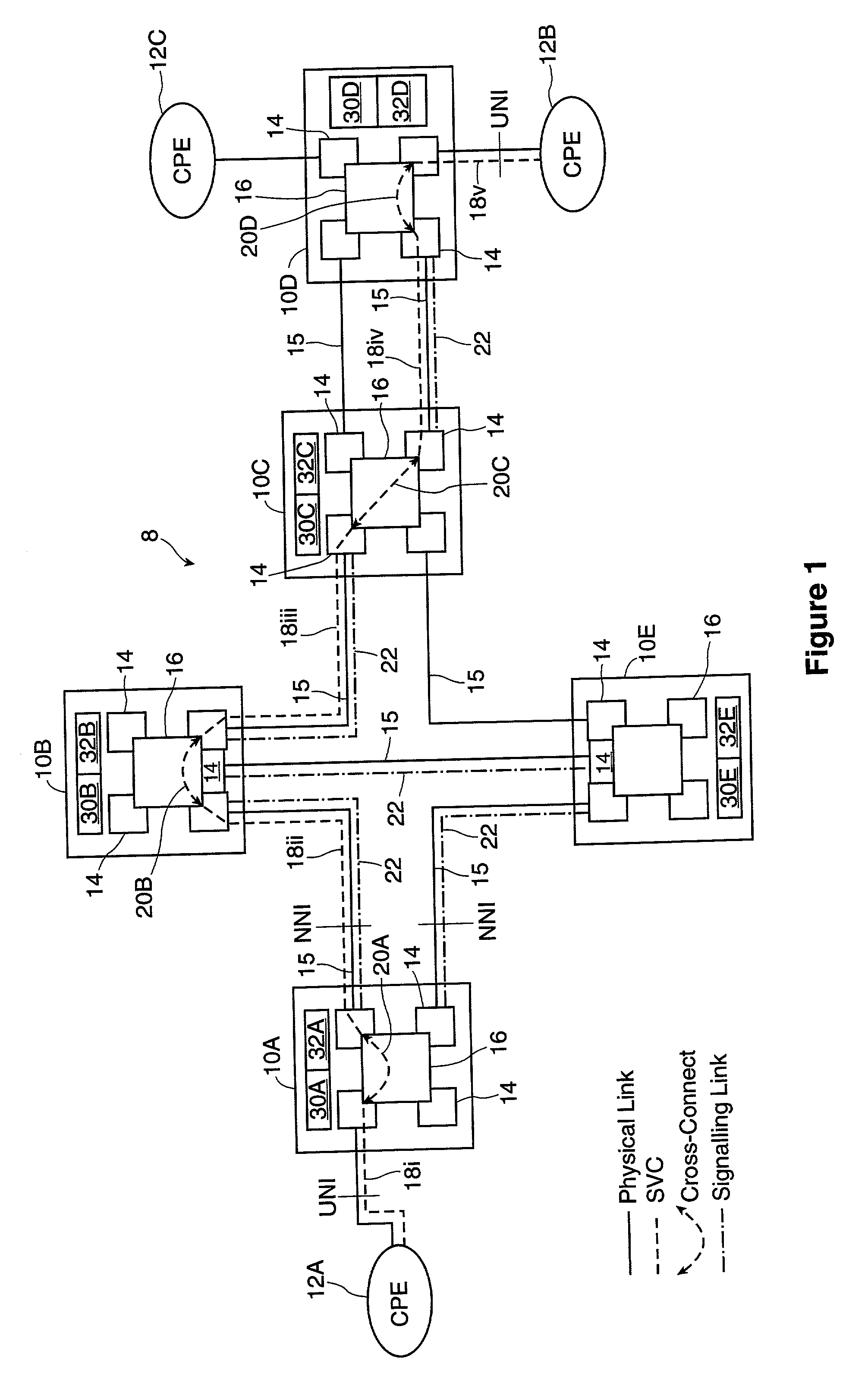

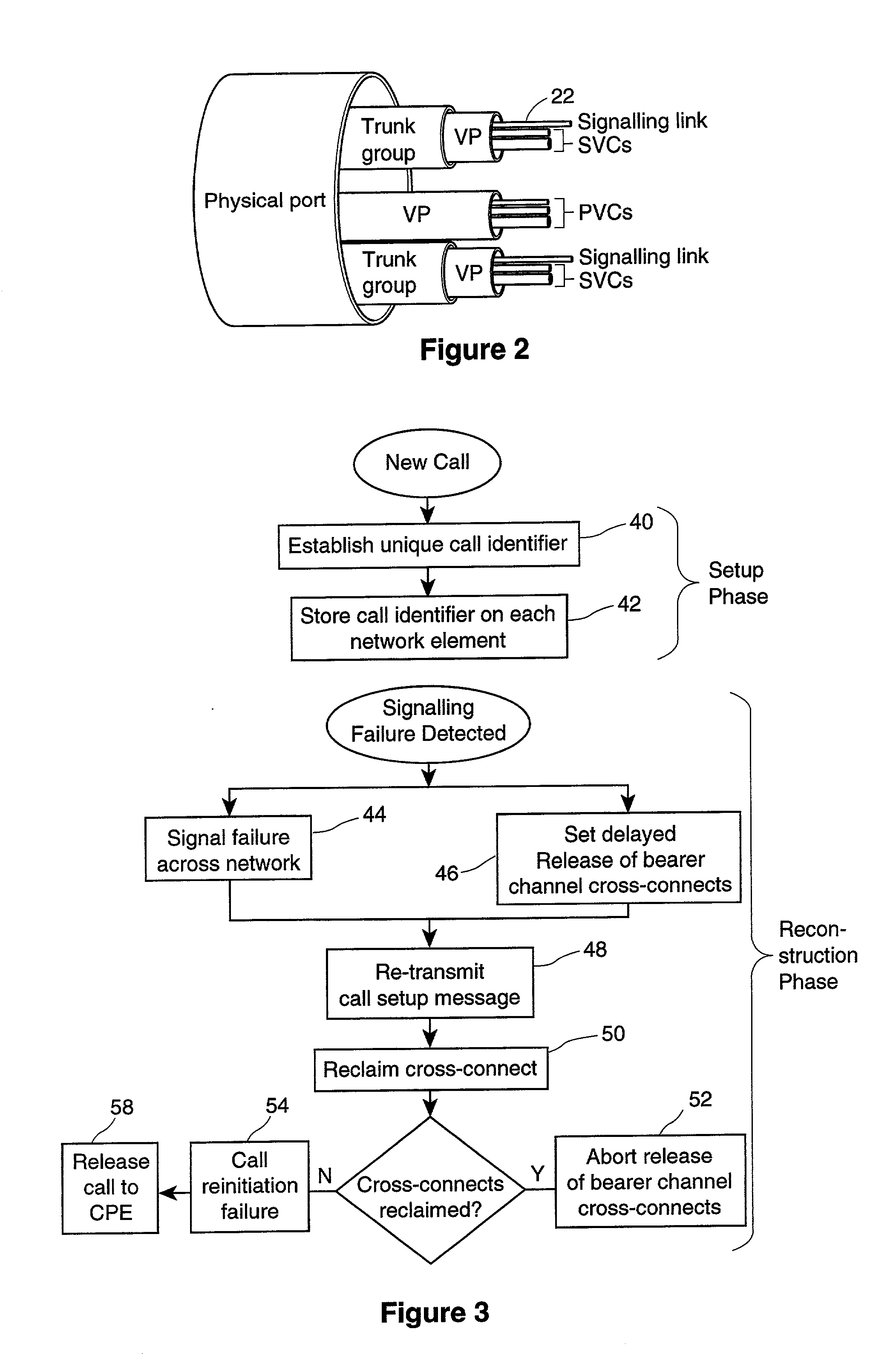

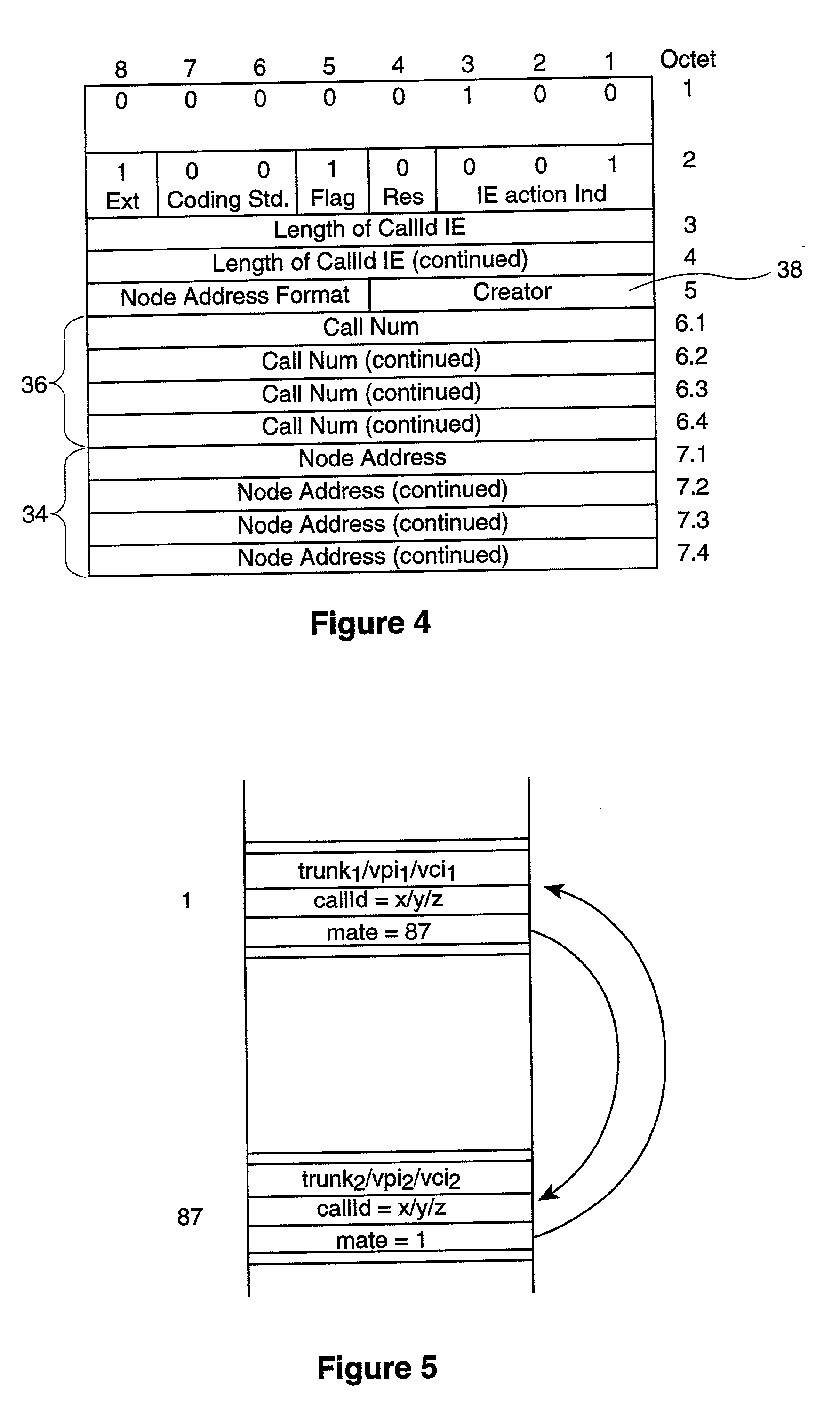

Method and apparatus for recovering from a signalling failure in a switched connection data transmission network

InactiveUS20010043561A1Not to wasteQuick correctionError preventionFrequency-division multiplex detailsCross connectionUnique identifier

The method of potentially recovering from a short term signalling failure in a switched connection data transmission network comprises the steps of: (a) establishing a unique, network-wide, identifier for each call; (b) incorporating the unique identifier in a call setup message transmitted to each network element in the path of the call; (c) linking the unique call identifier with each bearer channel cross-connect associated with the call; and (d) upon detection of a failure in a signalling network which affects the call, (i) actuating a timed release of the cross-connects, (ii) re-transmitting the call setup message, including the unique call identifier, to each network element involved in placing the call, (iii) re-linking the unique call identifier with the surviving cross-connects thereby reclaiming the cross-connects, and (iv) aborting the release of the cross-connects provided they have all been timely reclaimed.

Owner:ALCATEL CANADA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com