Patents

Literature

945 results about "Barrel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A barrel or cask is a hollow cylindrical container with a bulging center, longer than it is wide. They are traditionally made of wooden staves and bound by wood or metal hoops. Modern wooden barrels for wine-making are made of French common oak (Quercus robur) or white oak (Quercus petraea) or from American white oak (Quercus alba) and typically have standard sizes: "Bordeaux type" 225 litres (59 US gal; 49 imp gal), "Burgundy type" 228 litres (60 US gal; 50 imp gal) and "Cognac type" 300 litres (79 US gal; 66 imp gal). Modern barrels and casks can also be made of aluminum, stainless steel, and different types of plastic, such as HDPE.

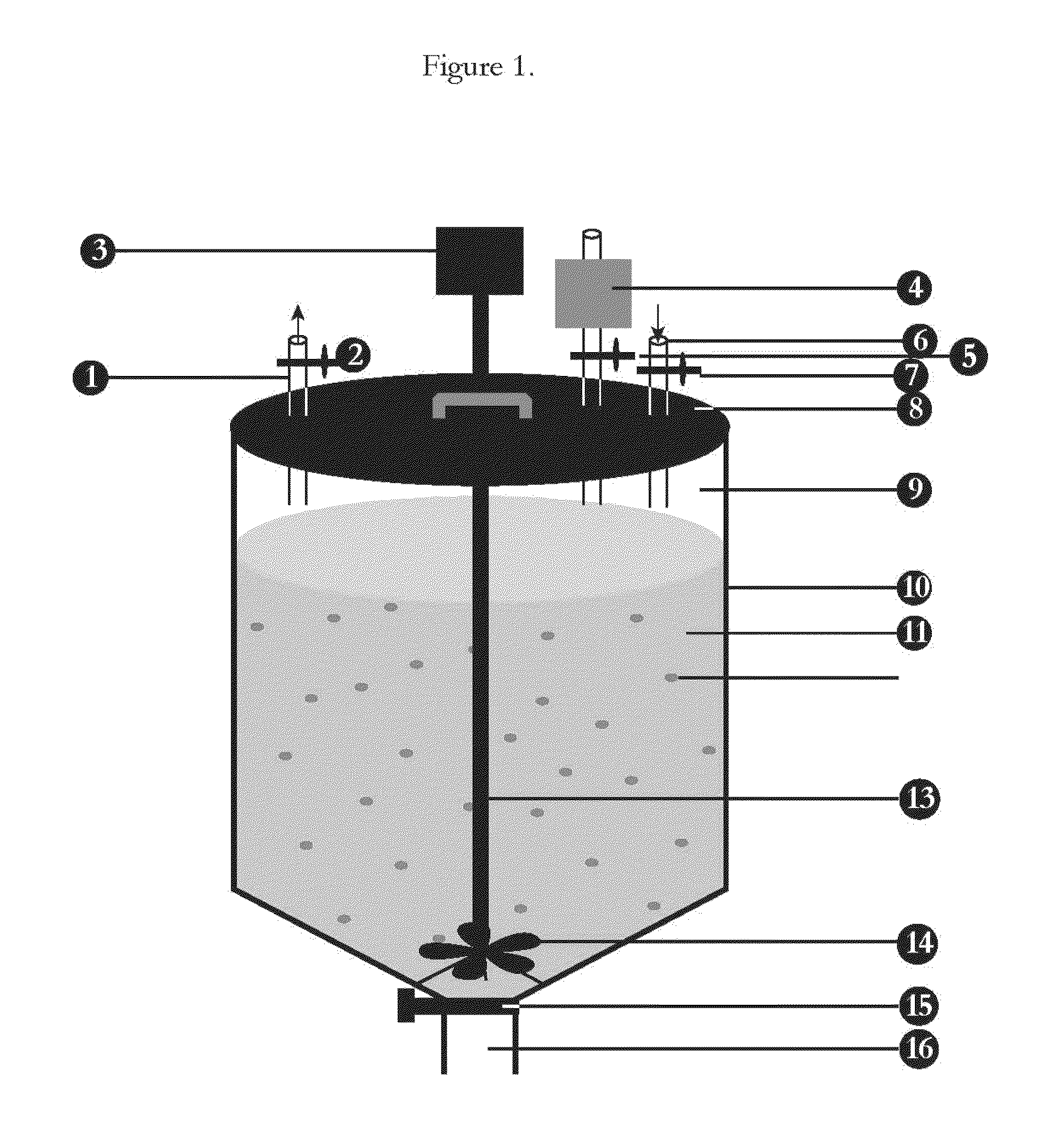

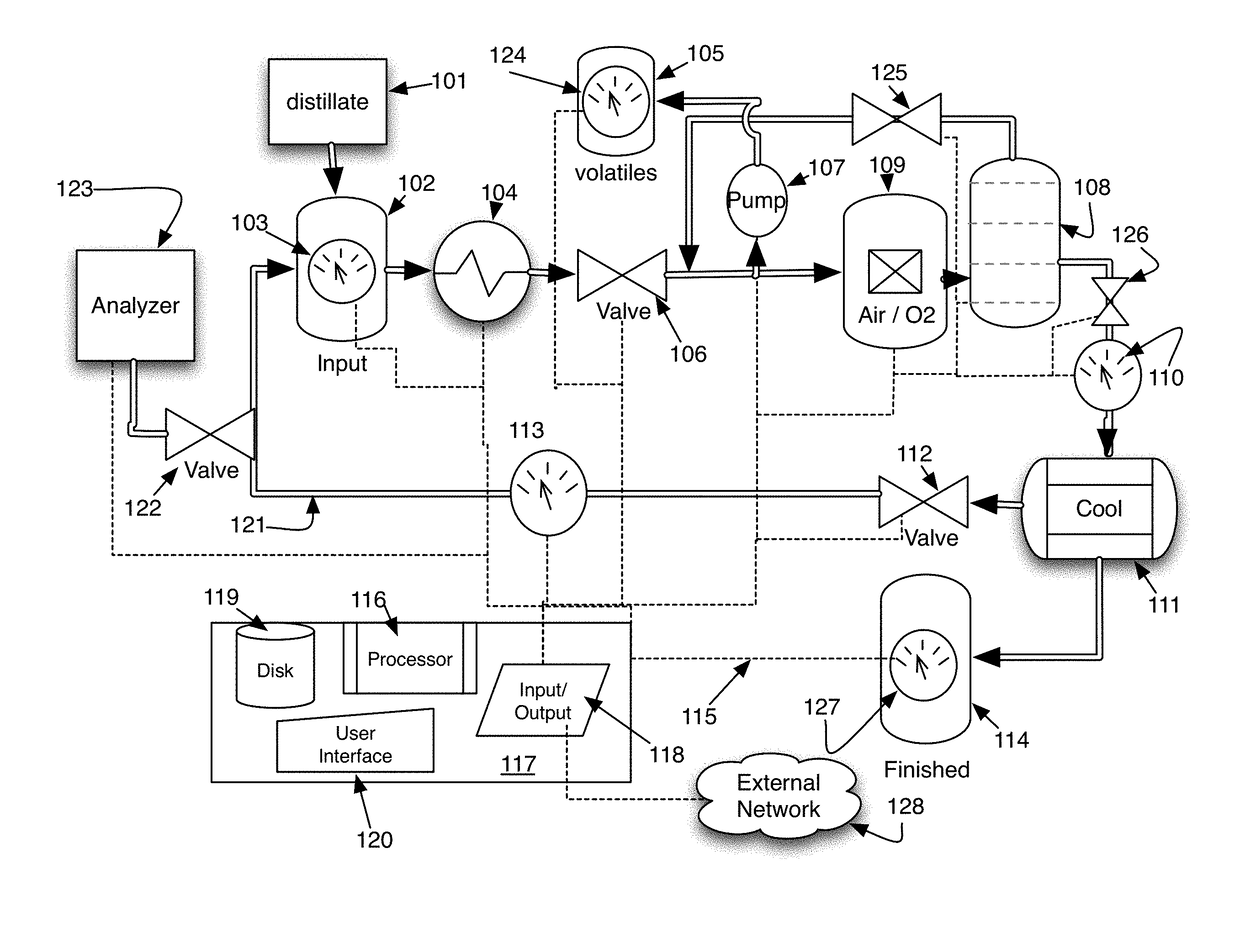

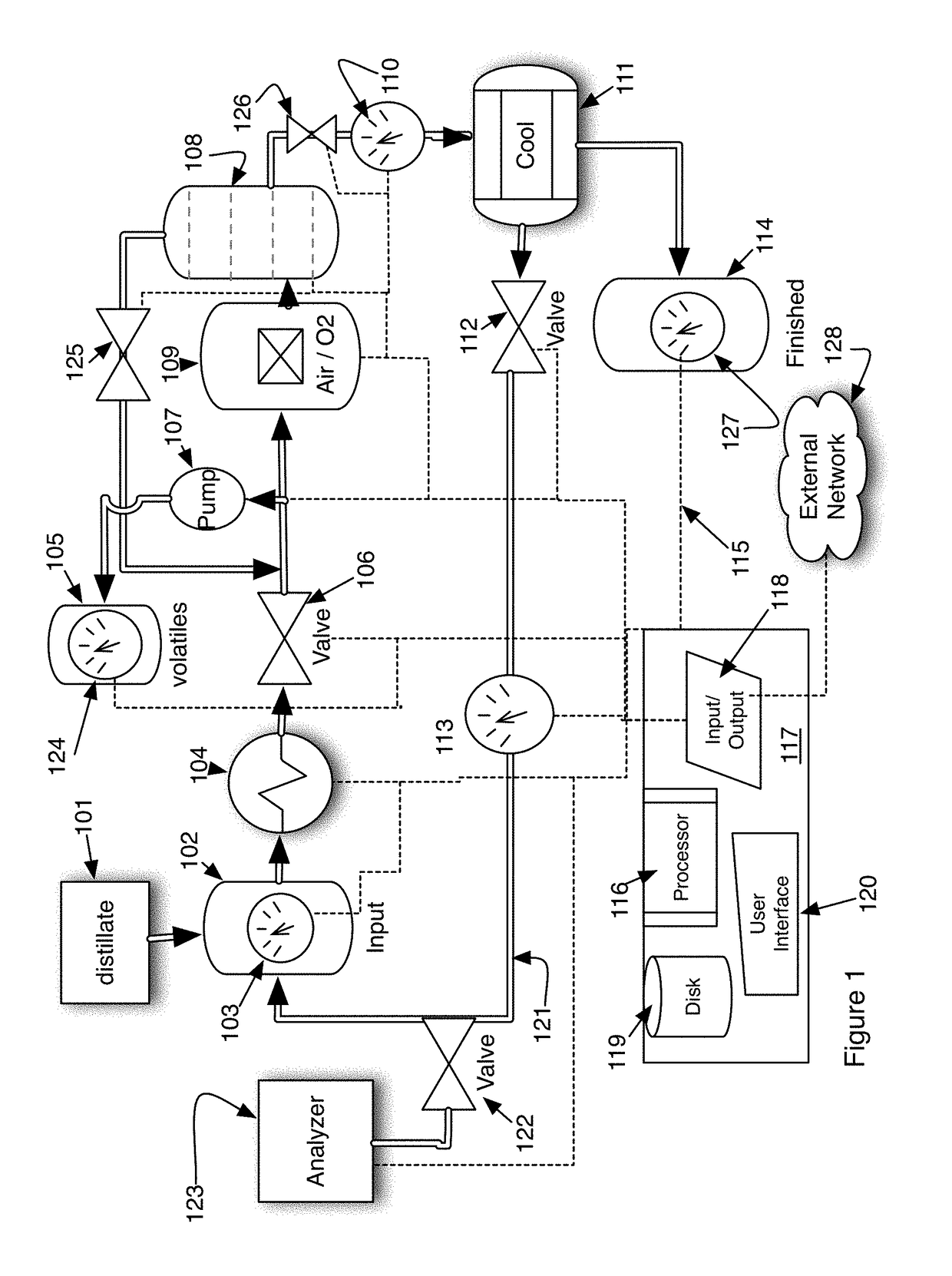

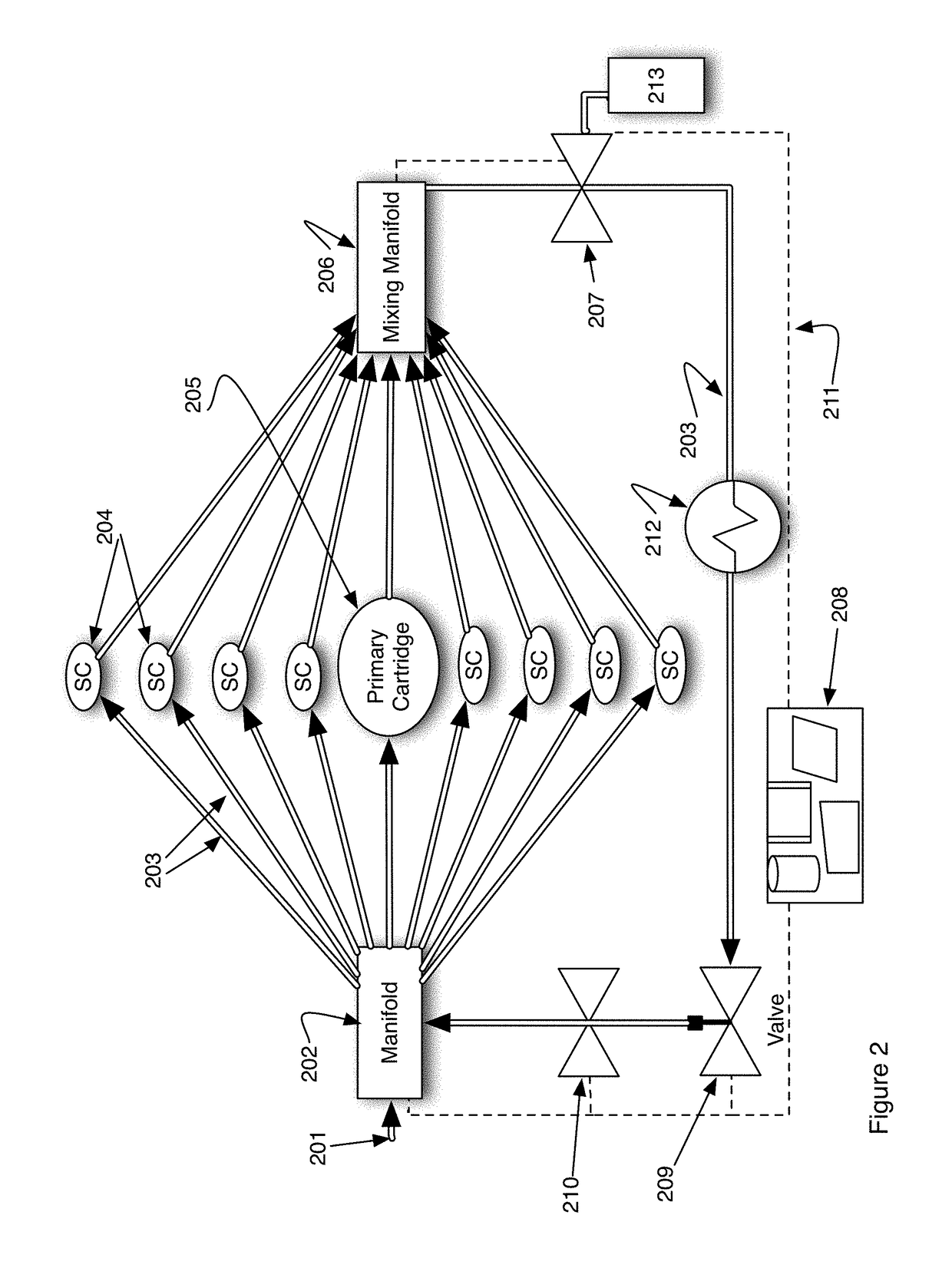

Accelerated Aging of Wines and Sprits

InactiveUS20120164300A1Avoid excessive oxidationLow costWine preparationAccelerated agingEngineering

Owner:NIAZI SARFARAZ K

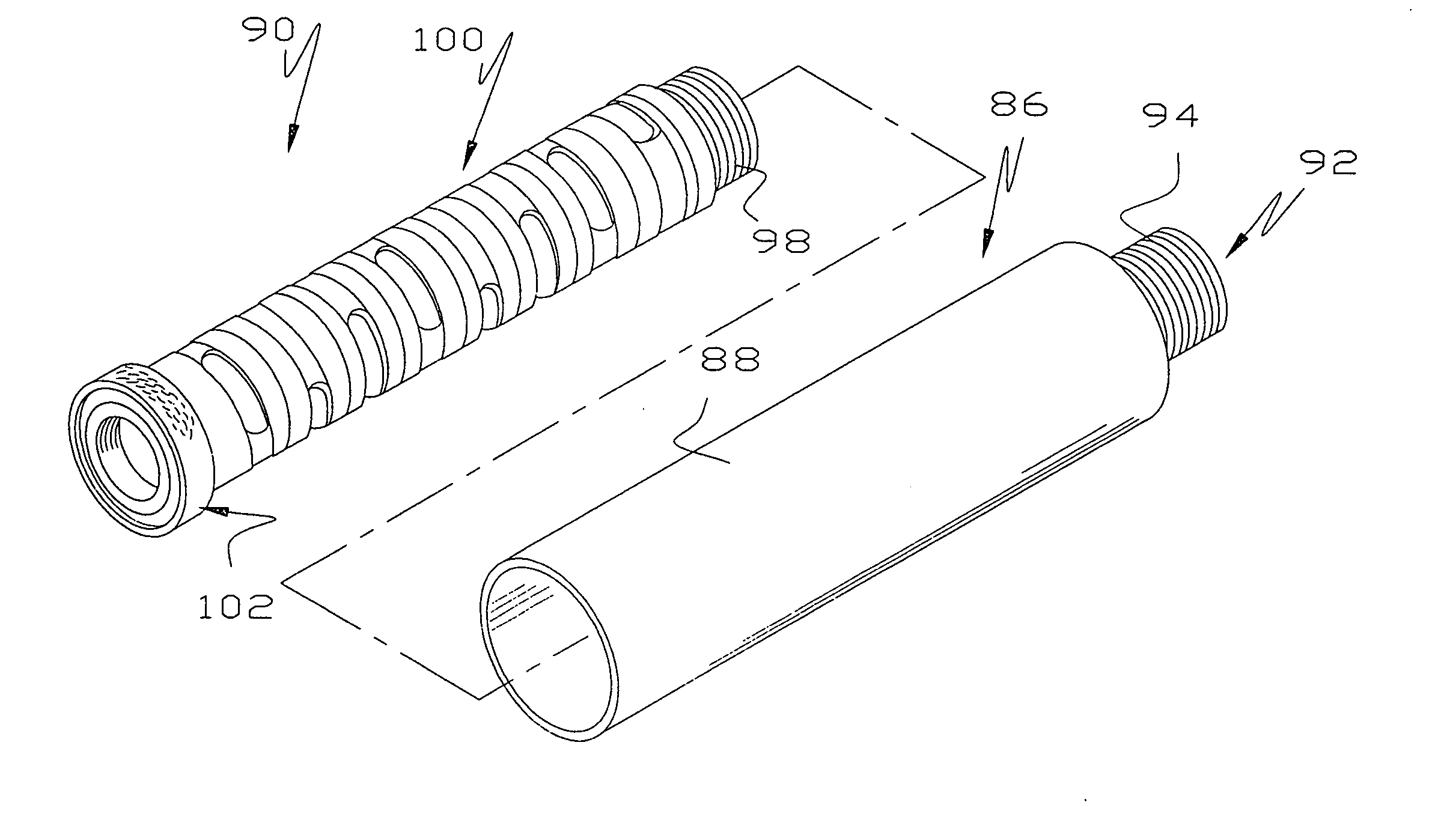

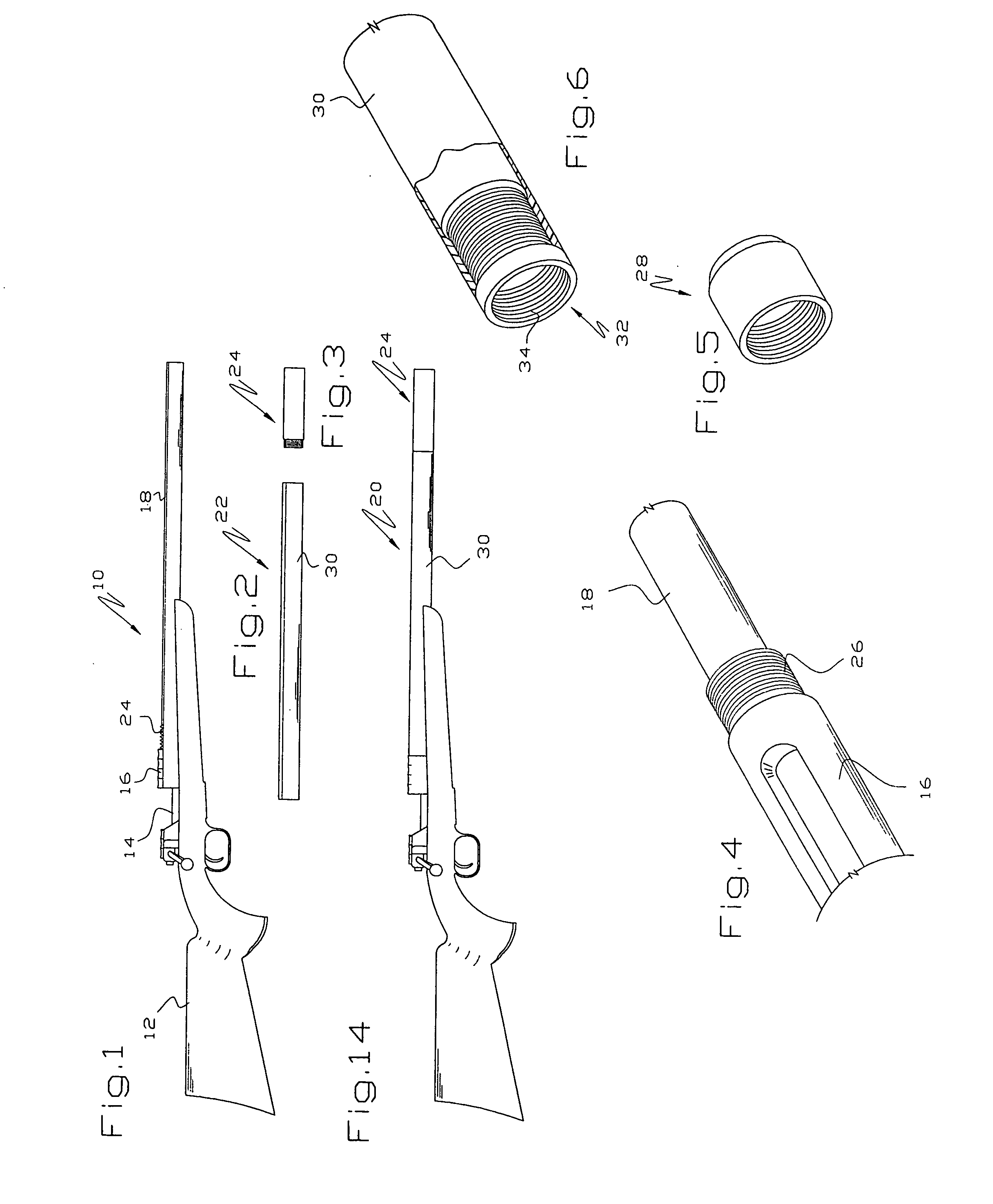

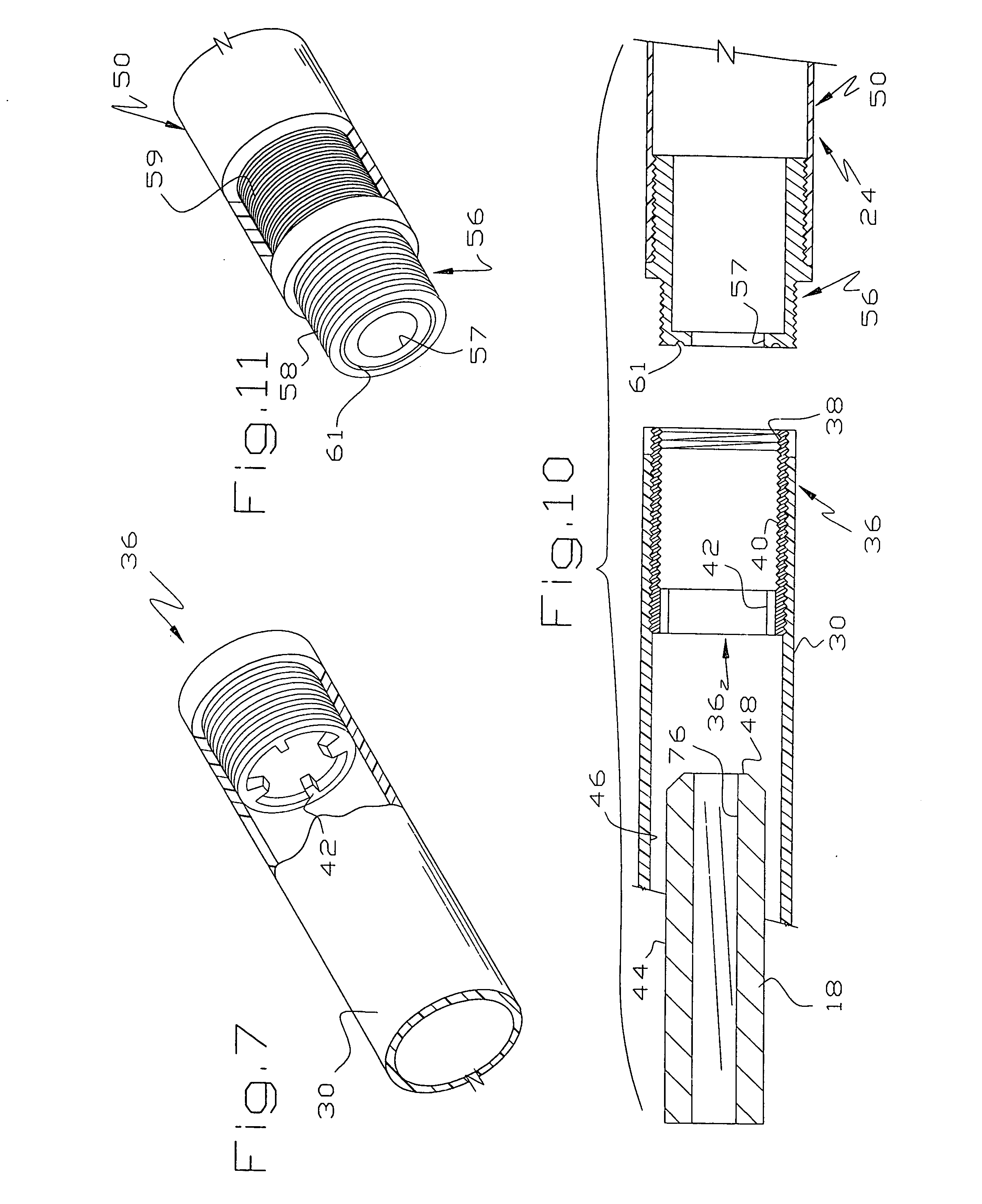

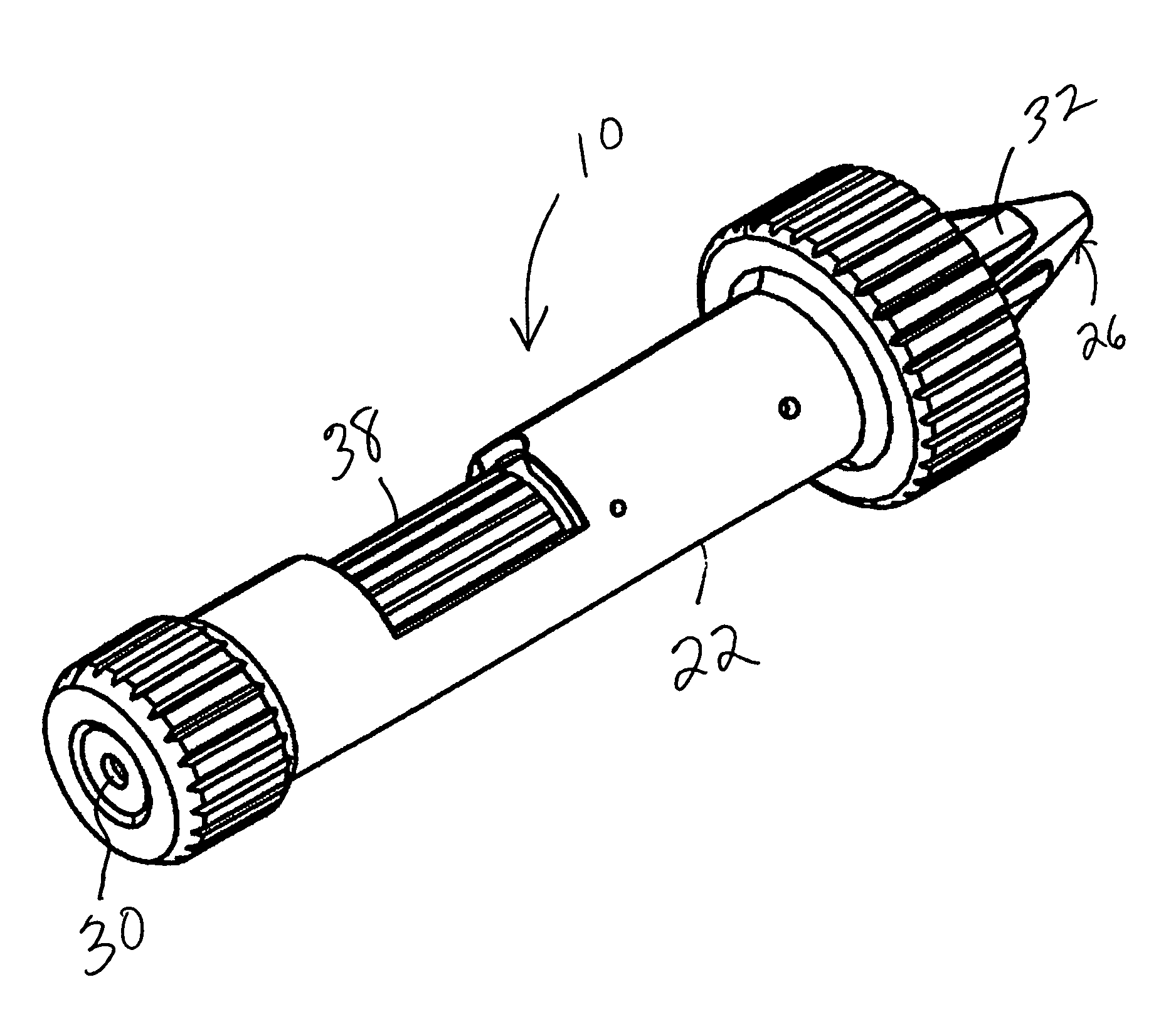

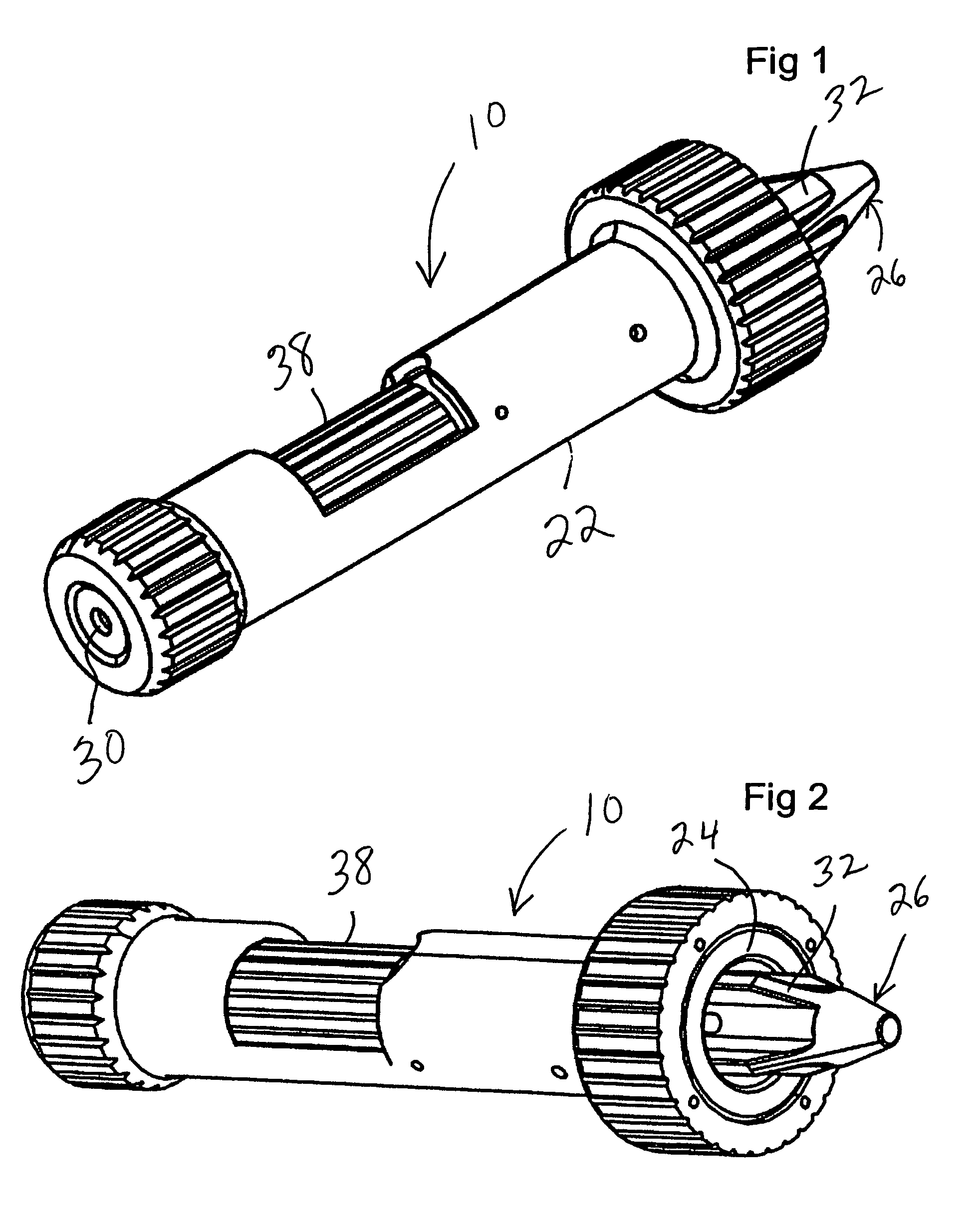

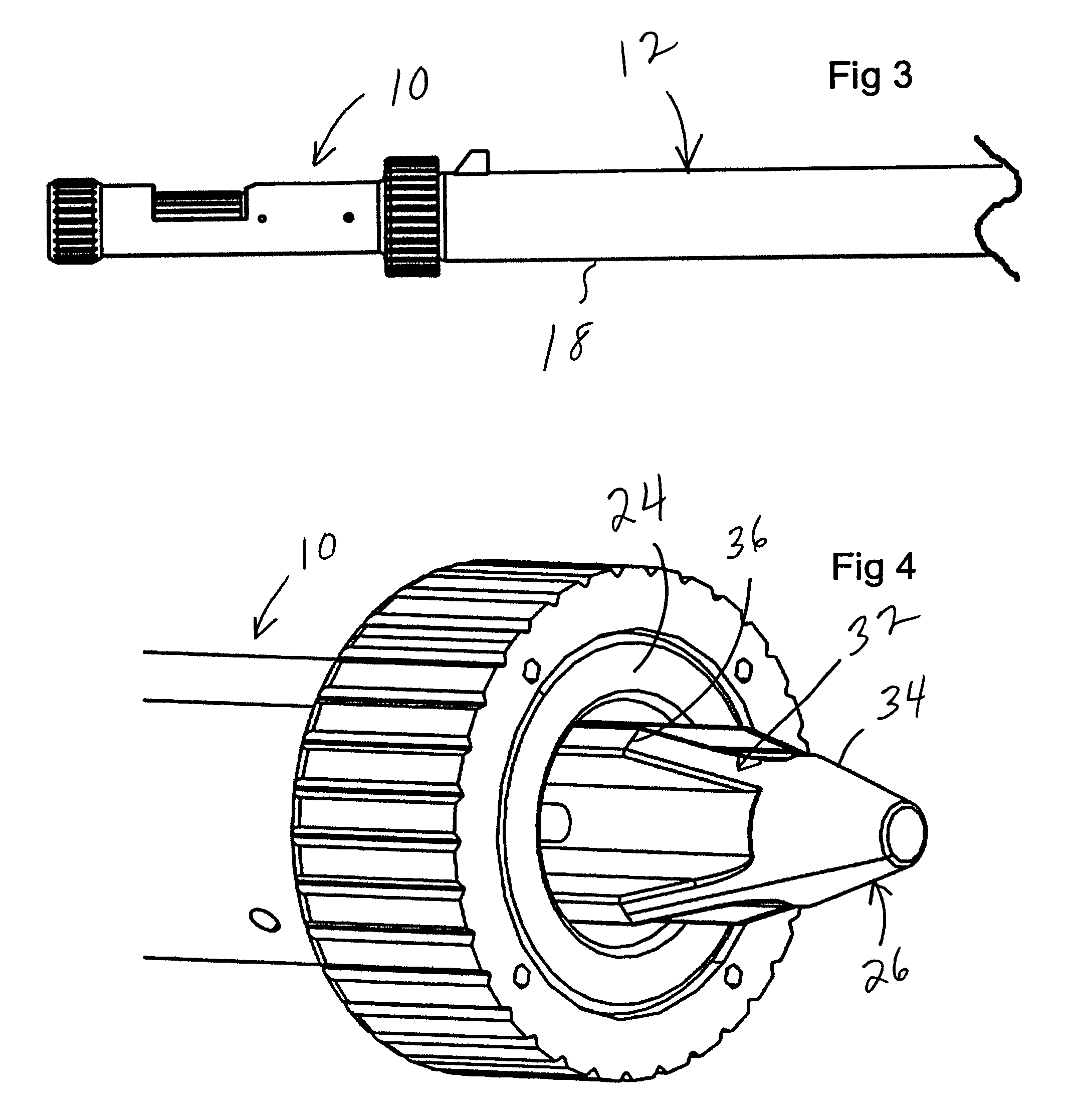

Assembly and noise suppressor for firearms

InactiveUS20110297477A1Does not affect accuracyImprove abilitiesMuzzle attachmentSuppressorEngineering

An assembly for a firearm (10) includes a sleeve (22) connected to the receiver or receiver end of the barrel (18). The sleeve (22) extends beyond the discharge end of the barrel (18) and includes inwardly extending projections (42) abutting or juxtaposed to a peripheral section (44) of the discharge end of the barrel (18). A noise suppressor (24, 50) threads onto the sleeve (22) . Some of the propellant gases are redirected and cooled by the noise suppressor (24, 50) in a conventional manner. Some of the propellant gases are redirected into an annulus (46) between the barrel (18) and sleeve (22) where they are cooled and some of their volume is reduced thereby increasing the efficiency of the noise suppressor (24, 50).

Owner:KOUMBIS GEORGE

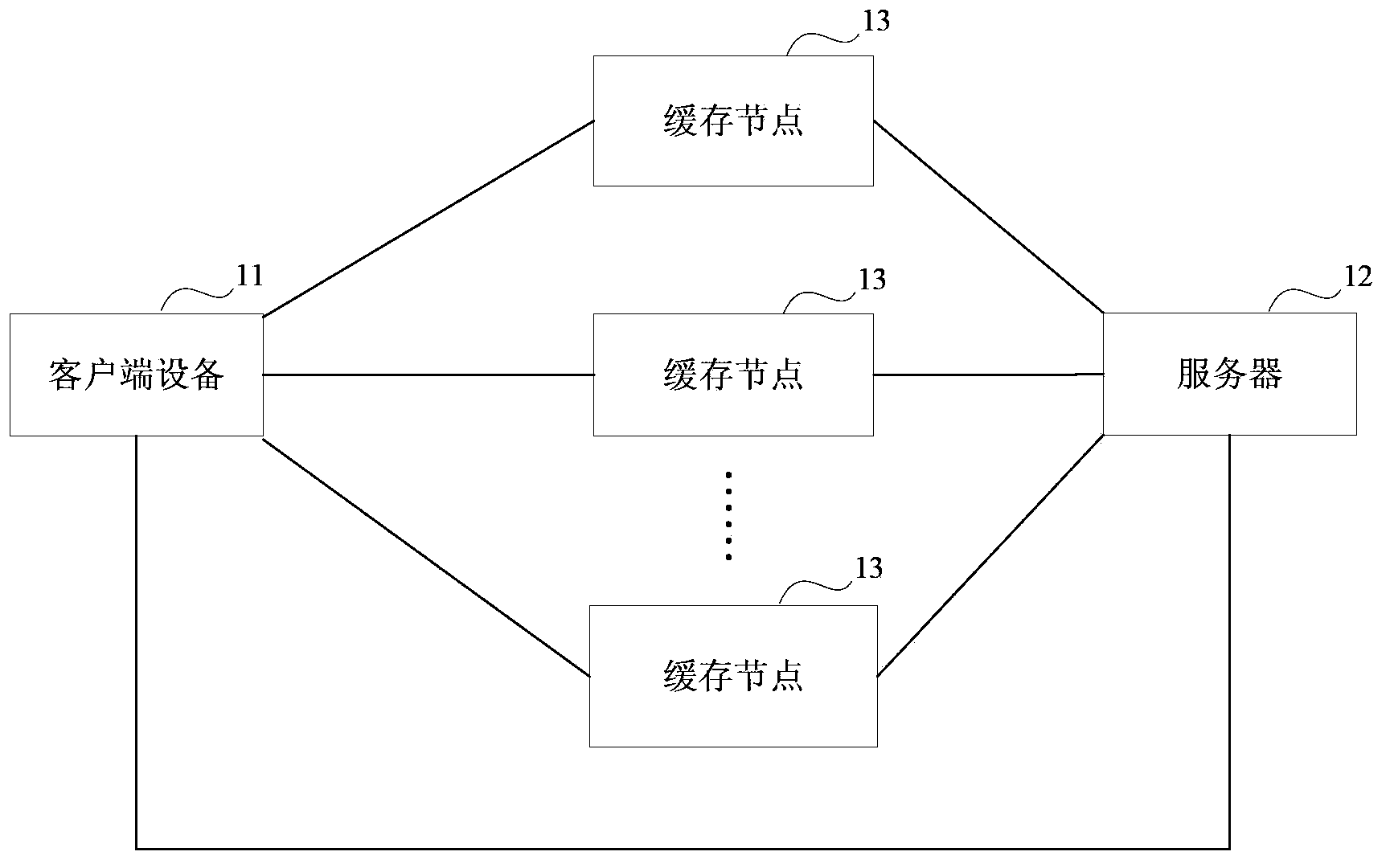

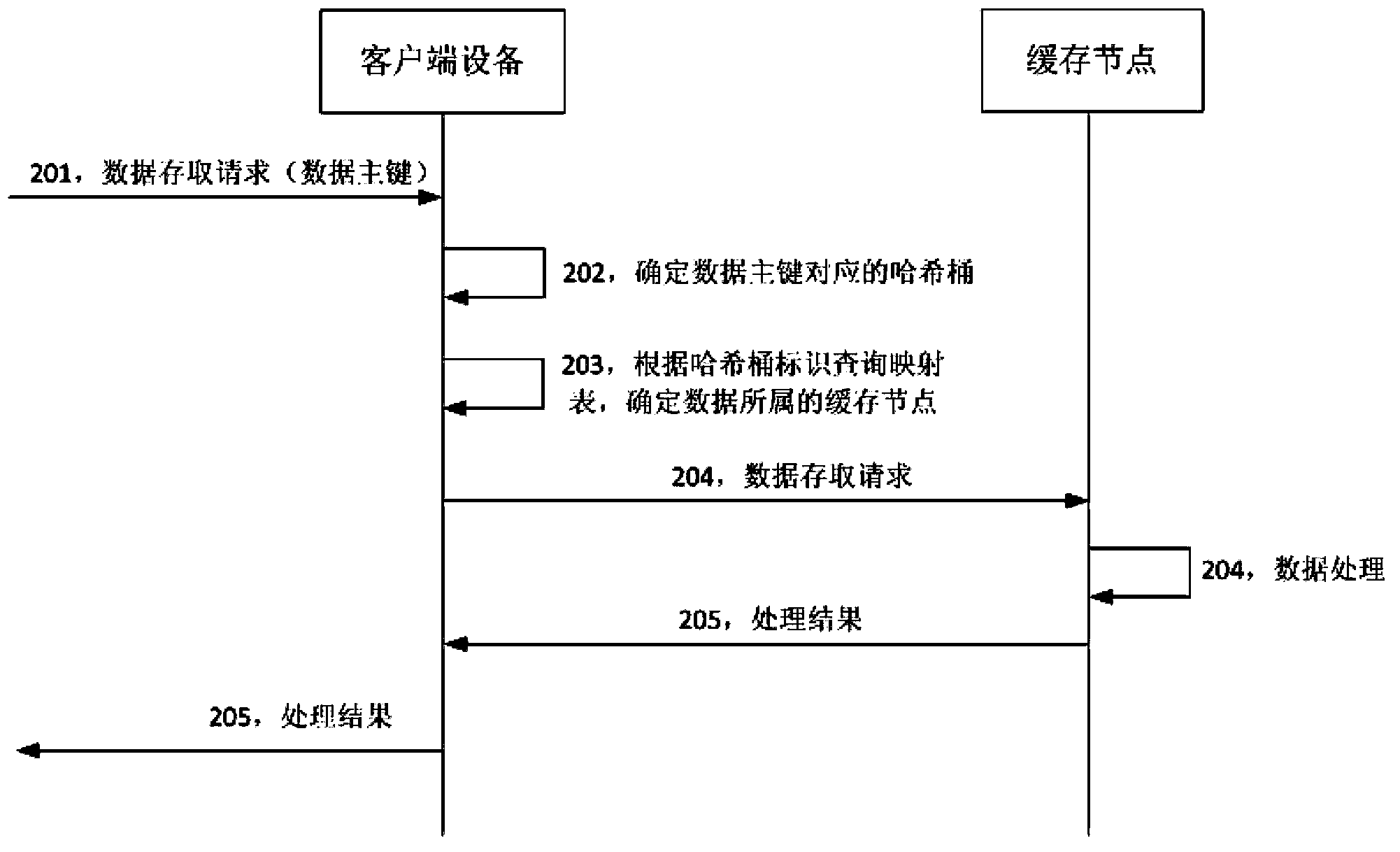

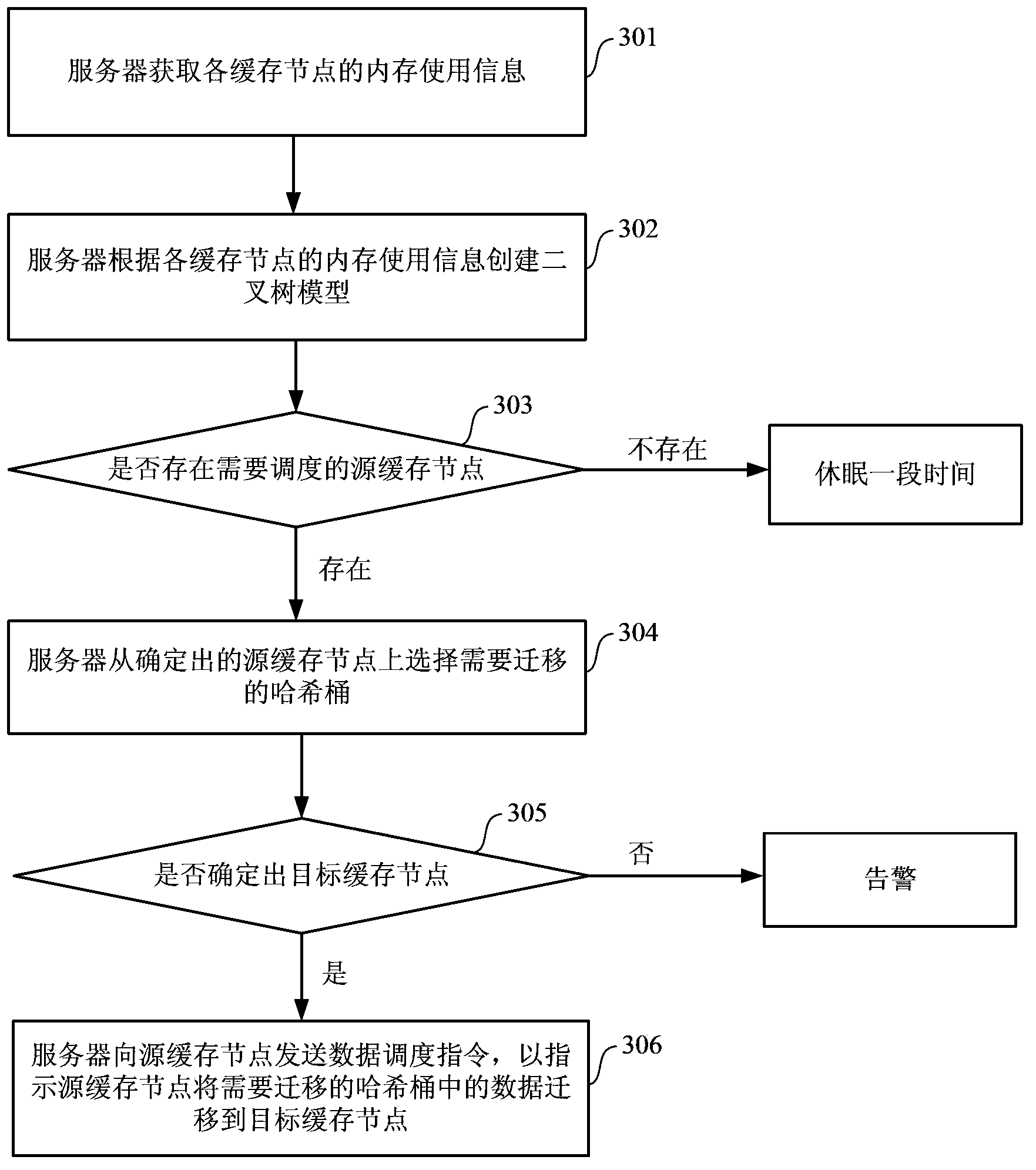

Data storage method, data scheduling method, device and system

ActiveCN103905503ASimplify the access processProcessing speedTransmissionScheduling instructionsDistributed cache

The invention discloses a data storage method, a data scheduling method, a device and a system. The data scheduling method comprises: the server of a distributed cache system obtaining memory use information of each cache node; the server, according to the memory use information of each cache node, determining a source cache node needing data migration, and determining a Hash barrel needing migration on the source cache node and a target cache node capable of accommodating data in the Hash barrel after the source cache node needing the data migration is determined; the server sending a data scheduling instruction to the source cache node so as to instruct the source cache node to migrate the data needing the migration in the Hash barrel to the target cache node; and the server sending a mapping relation updating instruction to a client which the migrated Hash barrel belongs to so as to instruct the client to update the mapping relation between the Hash barrel and the cache nodes according to data migration of this time.

Owner:CHINA MOBILE COMM GRP CO LTD

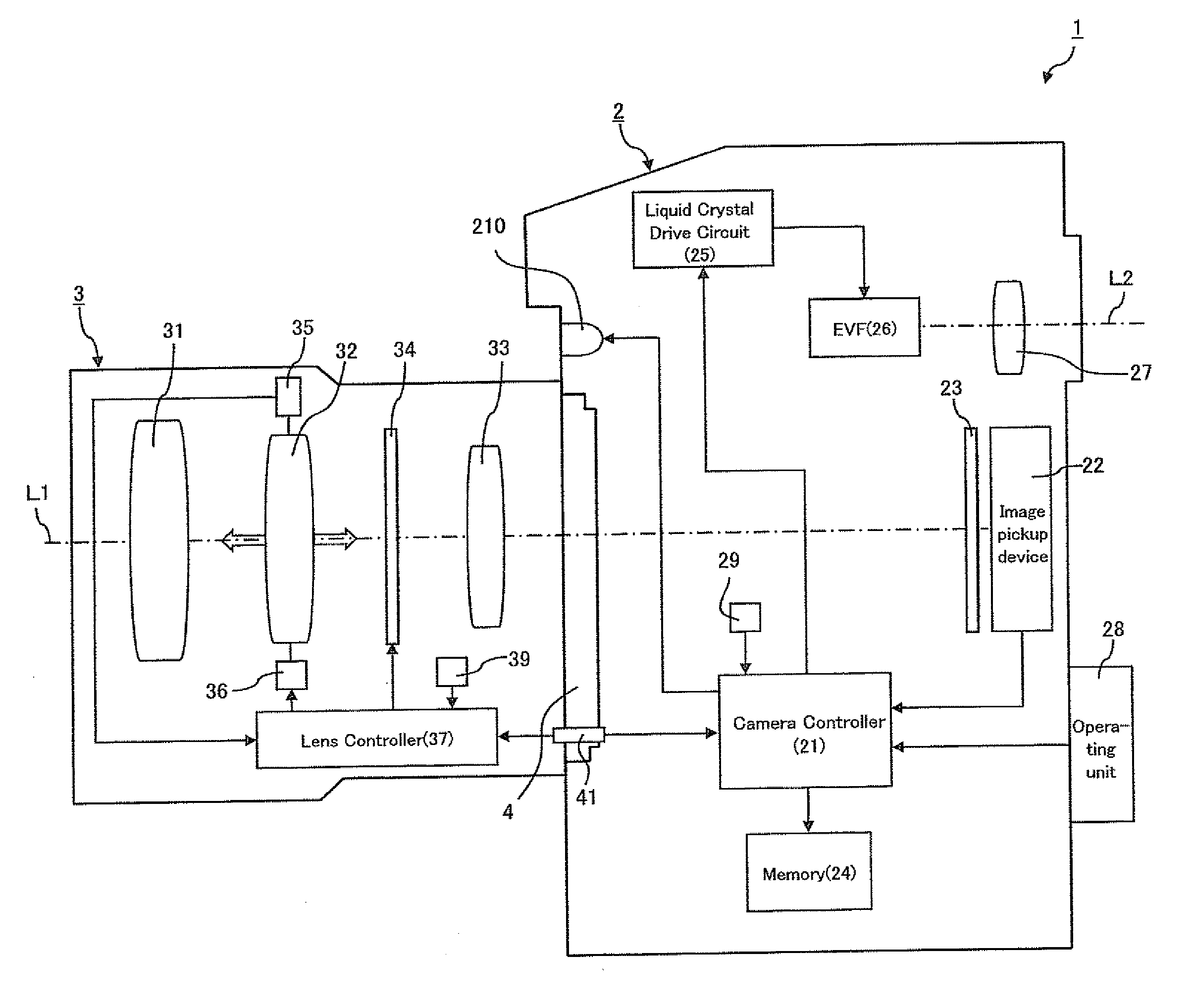

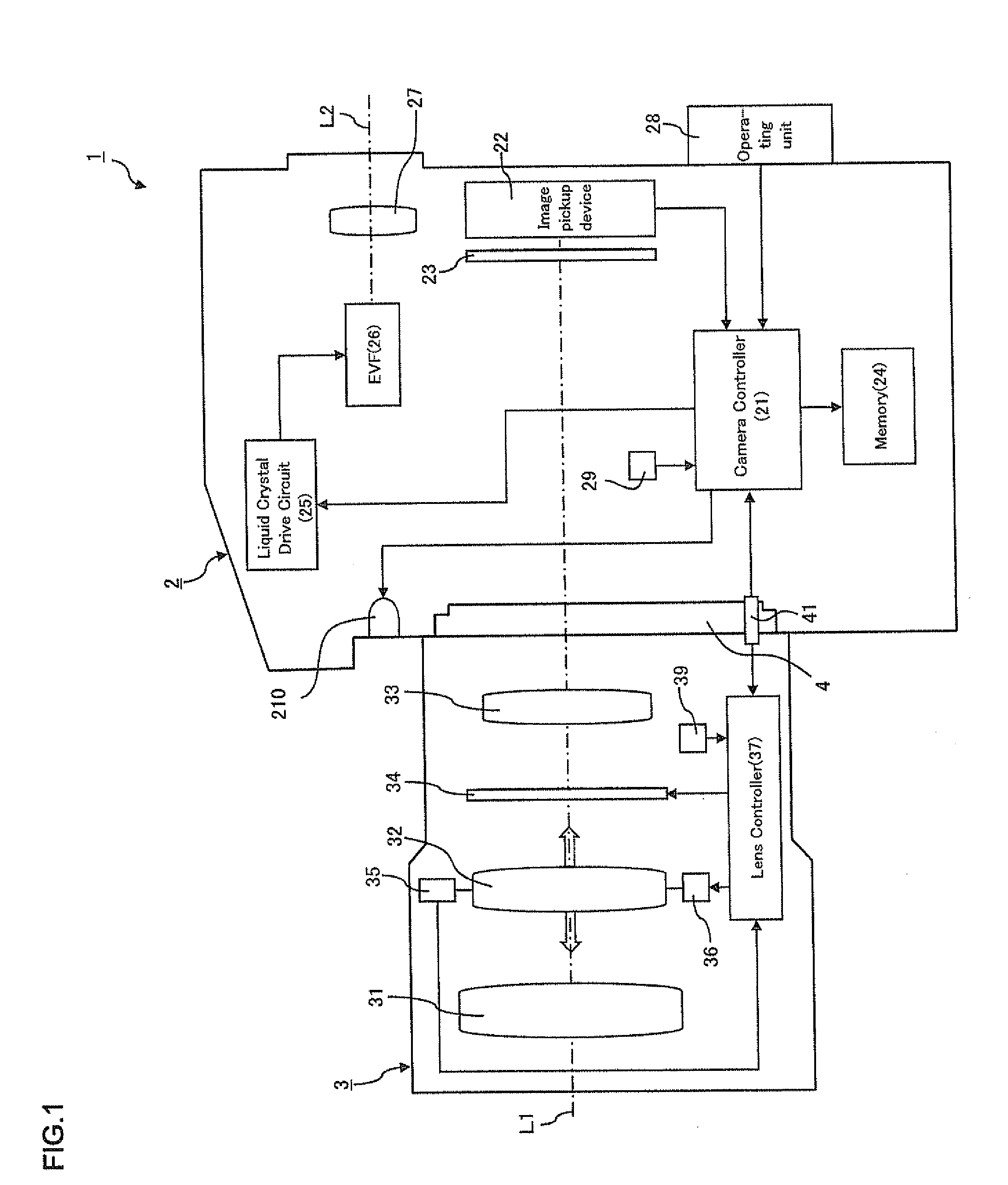

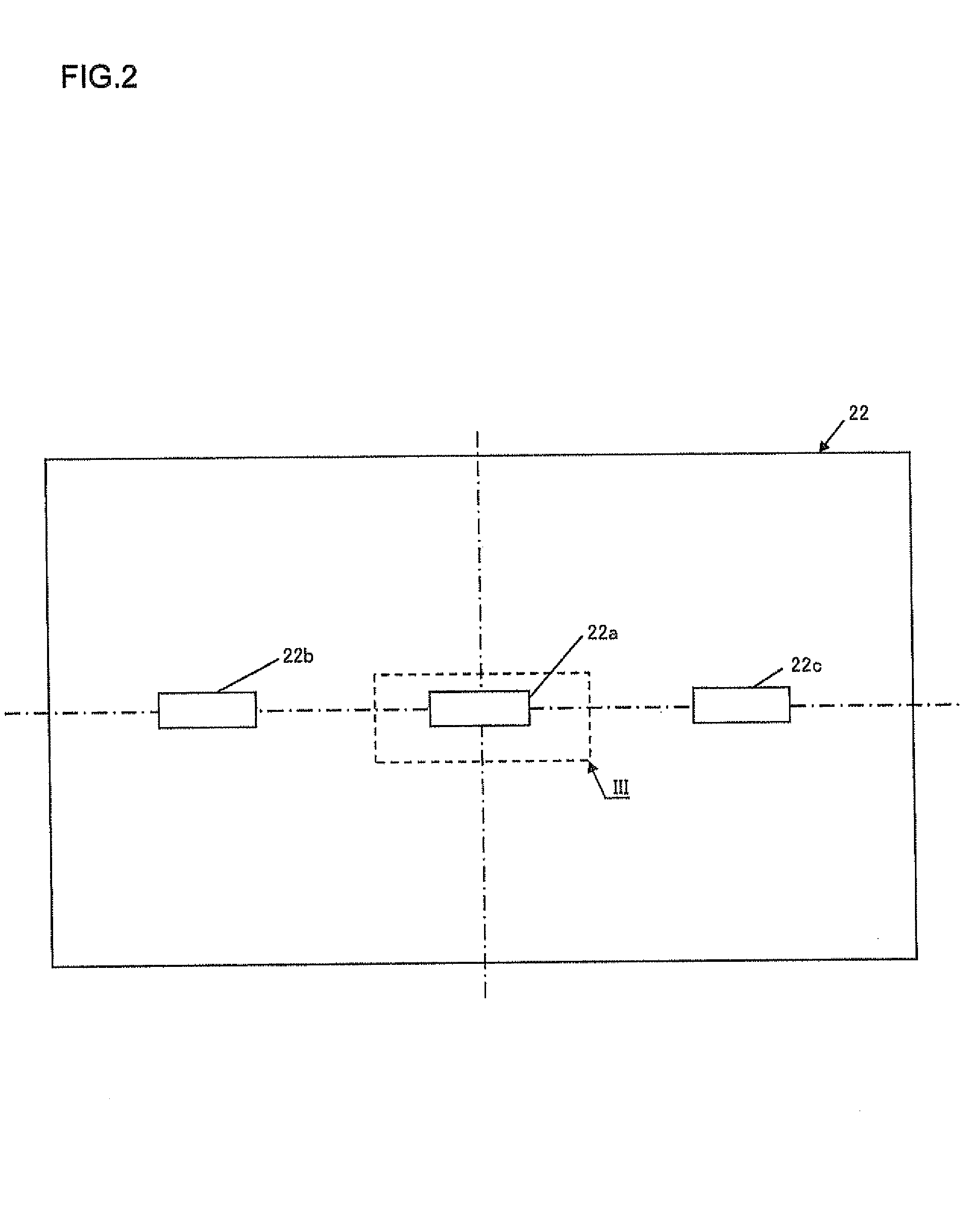

Lens barrel and camera body

ActiveUS20120327267A1Capture image wellEasy to captureTelevision system detailsProjector focusing arrangementLight beamTransmitter

A lens barrel comprising: an optical system which includes a focus adjustment optical system 32; an aperture 34 which limits the light beam which pass through the optical system to predetermined range at the time of detection of the focus state of the optical system; a drive 36 which drives the focus adjustment optical system 32; a memory 37 which stores a first predetermined value which is a aperture value within the predetermined range; and a transmitter 37 which sends the first predetermined value to the camera body 2.

Owner:NIKON CORP

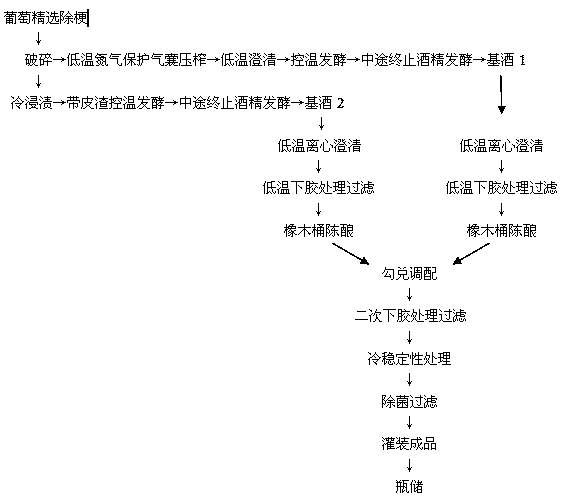

Ageing sweet-white wine and brewing process of ageing sweet-white wine

ActiveCN103911242ABroaden sources of raw materialsEnrich market product typesMicroorganism based processesWine preparationSweet white wineBottle

The invention relates to an ageing sweet-white wine and a brewing process of the ageing sweet-white wine, belonging to the technical field of brewing of wines. The physicochemical indexes of the ageing sweet-white wine disclosed by the invention are as follows: the content of reducing sugar is 80-90 g / L; the total acidity is 7.0-8.5 g / L; the alcoholic strength is 10.0-12.0%vol; the content of free sulphur dioxide is 30-45 mg / L; the total content of sulphur dioxide is less than or equal to 250 mg / L; the content of volatile acid is less than or equal to 1.0 g / L. The brewing process of the ageing sweet-white wine disclosed by the invention comprises the following steps of: (1) finely selecting grapes and removing stems; (2) crushing; (3) technically dividing; (4) centrifuging and clarifying at low temperature; (5) fining at low temperature, and filtering; (6) ageing by using an oak barrel; (7) blending and mixing; (8) fining for the second time, and filtering; (9) coldly processing stability; (10) sterilizing and filtering; (11) filling finished goods; (12) storing in a bottle. The ageing sweet-white wine disclosed by the invention is full-bodied in fragrance, graceful, lasting and plump in mouth feel; the brewing process of the ageing sweet-white wine disclosed by the invention is simple, scientific and convenient to operate; the production cost can be effectively reduced; the scale production of high-end sweet-white wines is realized.

Owner:COFCO GREAT WALL WINE YANTAI

Low-alcohol ice wine and brewing process thereof

The invention discloses low-alcohol ice wine. The brewing process comprises the following steps of: harvesting grapes, sorting, squeezing, diluting, fermenting, clarifying, resisting oxidation, freezing, degerming, filtering and filling. The invention adopts a temperature-controlled oak barrel fermentation process, converts part of glucose into gluconic acid at the initial period of fermentation by adding GOX, and lowers the generation quantity of ethanol, thereby lowering the alcoholic strength of the wine. After wine liquor is clarified, SO2 and EDTA are adopted to carry out synergic anti-oxidation processing, which reduces the use quantity of the SO2 greatly, lowers the influence of sulfite on the quality of the wine and also lowers the browning degree of the wine liquor effectively. The invention has the advantages that the color and the taste of the wine are enhanced, the wine has full-bodied wine fragrance and oak fragrance and more conforms to the healthy drinking requirements of modern people, and the alcoholic strength is also lowered.

Owner:山东中科生物创新产业园管理有限公司

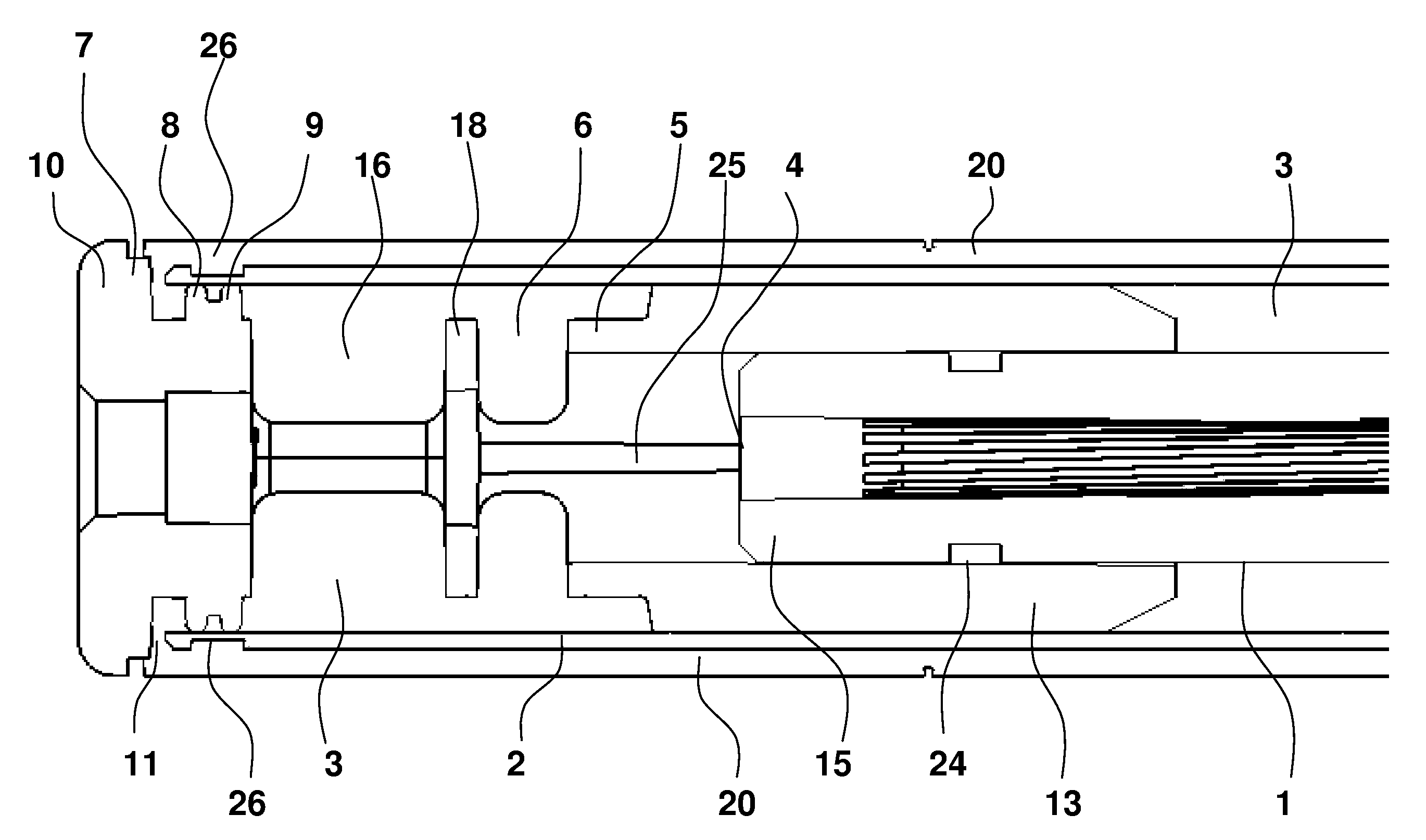

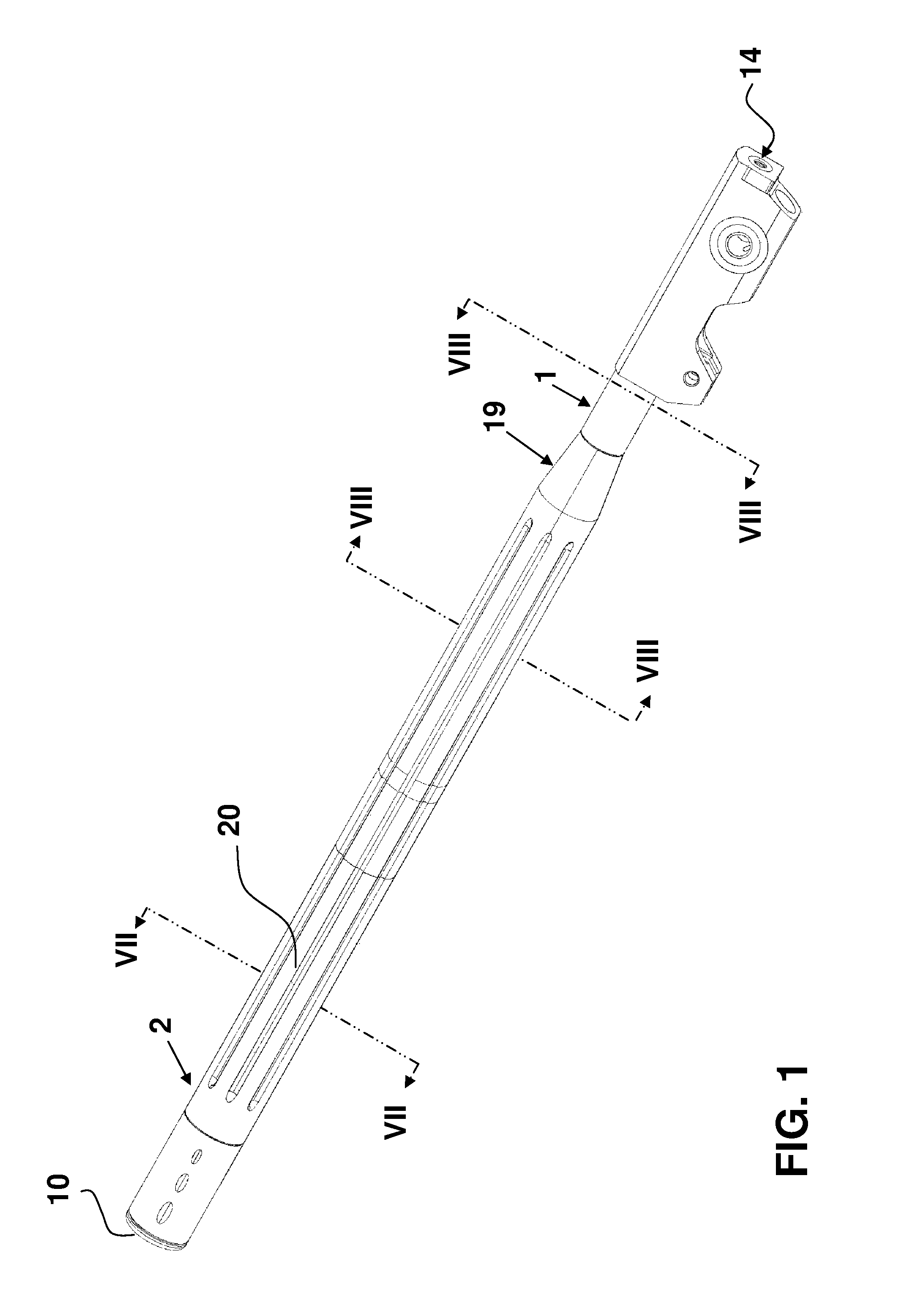

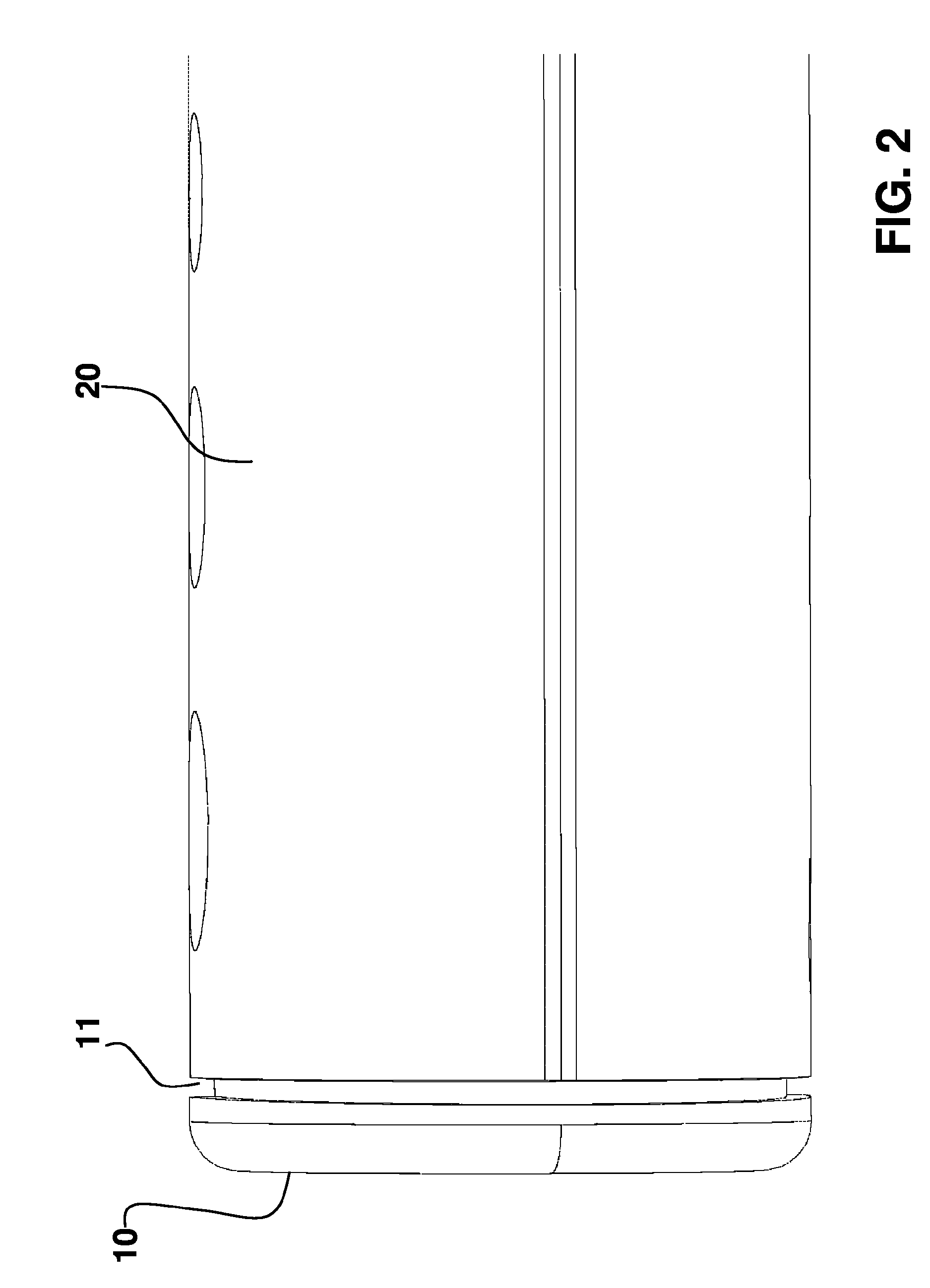

Method for manufacturing a bull barrel equipped with a silencer and silencer-equipped bull barrel thus obtained

A manufacturing procedure for a “bull barrel” model with silencer and “model bull barrel” with obtained silencer.It comprises the following stages: a first stage in which a tube (2), which defines two ends, a first (21) and a second (22), with an interior diameter that exceeds the outer diameter of the barrel (1), fixed to a wedge (19) by its first end (21), a second stage in which a muzzle (5) that ends in a hood (10) is fixed to the second end (22) of tube (2), with said muzzle (5) comprising at least one lateral aperture (6) and at least one first hoop (8) that fits inside the tube (2) sealing the second end (22), similarly with stops (7) that define channels (11) in the hood (10) that connect the exterior with the inside of the muzzle (5), with the mentioned stops (7) forming the end of travel for the referred tube (2), a third stage in which the barrel (1) is fixed to the muzzle (5) and to the wedge (19), thus defining a space or cavity (3) between the tube (2) and barrel (1) and a fourth stage in which the third stage configuration is inserted into a molding machine for over-molding, except for the barrel entrance end (14), giving it the desired shape, with said end penetrating said over-molding (20) towards the inside of the tube (2) by the channels (11) up to the referred first hoop (8).

Owner:GAMO OUTDOOR SL

Universal bore sight

Owner:SELLMARK CORP

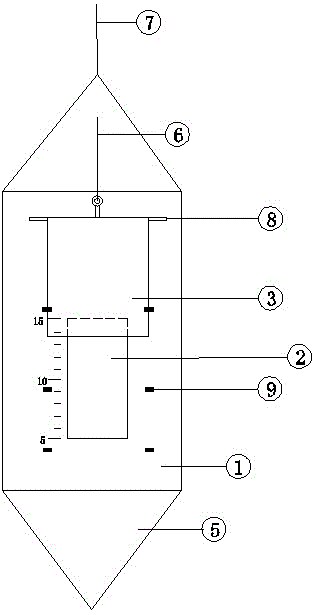

Device for measuring sediment thickness of pile base of cast-in-situ bored pile

InactiveCN102979111AQuick measurementAccurate measurementFoundation testingStructural engineeringSlurry

Owner:CHINA MCC17 GRP

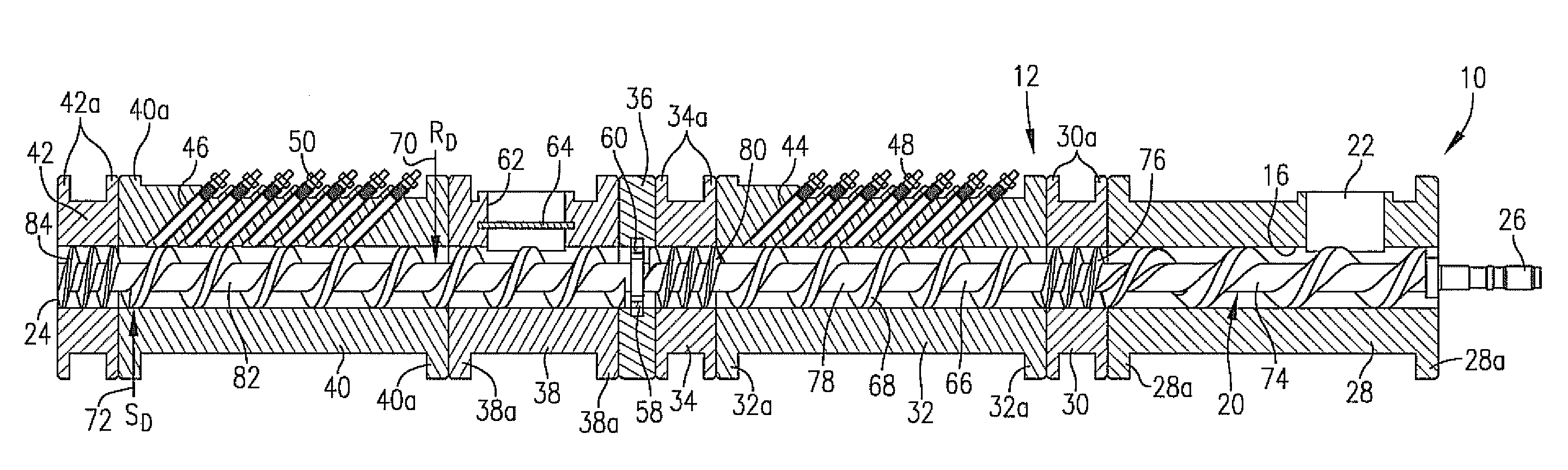

Cooking extruder with enhanced steam injection properties

ActiveUS7987774B2A large amountFeeding-stuffMeat/fish preservation by heatingEngineeringPitch length

An improved extruder (10) is provided which permits successful introduction of very high quantities of injected steam into material being processed, on the order of 6-8% or more by weight steam. The extruder (10) includes an elongated extruder barrel (12) having at least one elongated, axially rotatable, helically flighted extrusion screw (16,18) therein. The barrel (12) is equipped with obliquely oriented steam injection ports (44, 46) along the length thereof, housing steam injectors (48, 50). The barrel (12) includes relatively high free volume steam injection heads (32 and 38, 40) having therein screw sections (78, 82) of relatively long pitch length, together with steam restriction heads (30, 34, and 42) on opposite sides of the injection heads (32, and 38, 40) having therein relatively short pitch length screw sections (76, 80, 84).

Owner:WENGER MFG LLC

Persimmon brandy and brewing method thereof

InactiveCN101798556ALess suspended particlesSimple filterMicroorganism based processesAlcoholic beverage preparationPectinaseFruit wine

Persimmon brandy and a brewing method belong to the technical field of brewing science and engineering. The invention aims to solve the technical problem of providing the persimmon brandy keeping the original flavor of persimmons and a brewing method of the persimmon brandy. The process is as follows: 1. raw material treatment; 2. primary fermentation; 3. principal fermentation; 4. distillation; 5. ageing; and 6. blending and filling. The invention has the following advantages: 1. full persimmon juice is adopted for fermentation, without adding water; 2. pectinase is not added in the processes of juice extraction and fruit wine brewing, astringency removal process is omitted and the content of methanol is extremely low; 3. methode charantaise is adopted; and 4. oak barrels are adopted during ageing. The invention plays important roles in promoting reasonable processing and utilization of the persimmon resources, forming the post-harvest processing industrial chain and adjusting the fruit processing industrial structure.

Owner:HEBEI AGRICULTURAL UNIV.

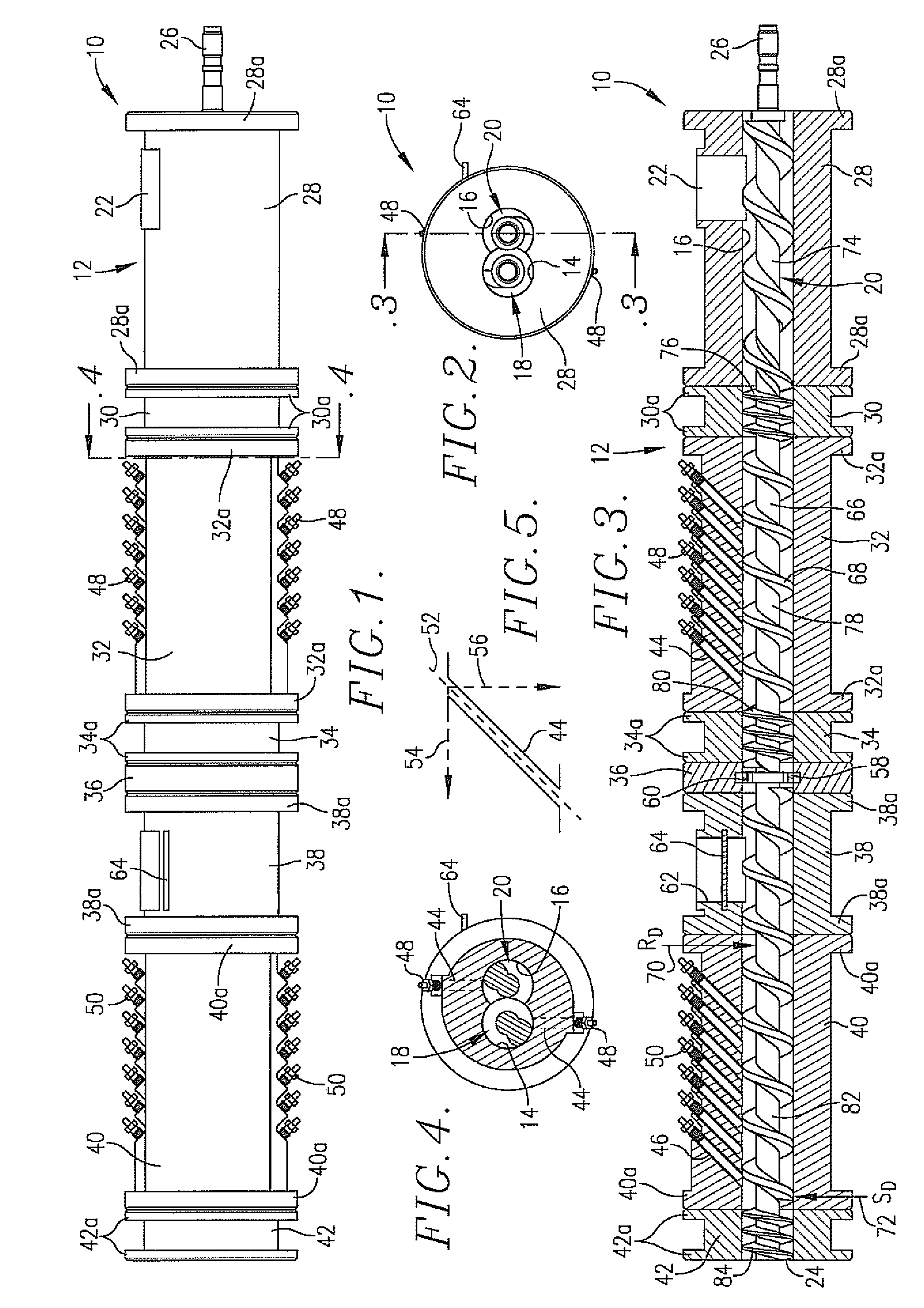

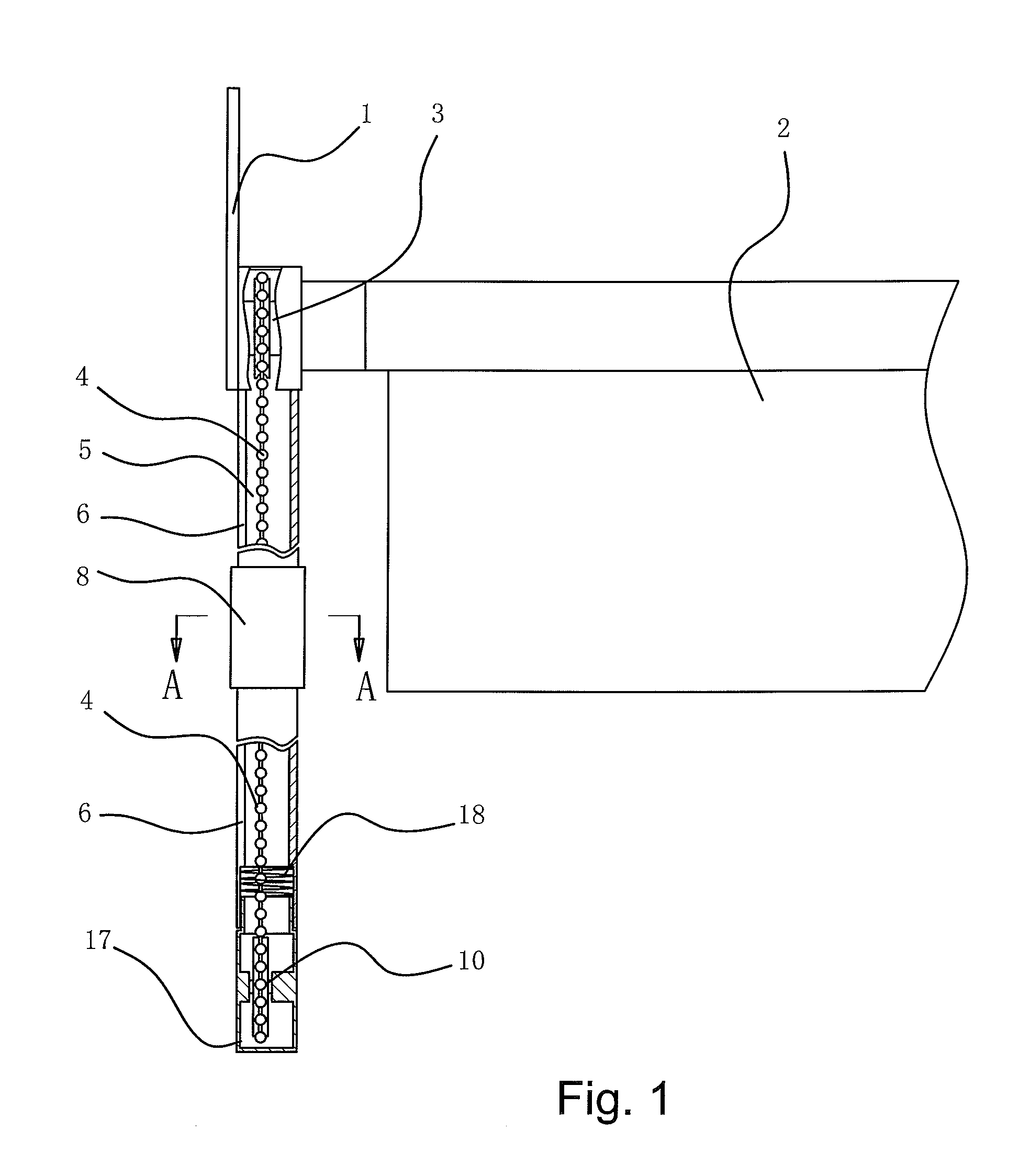

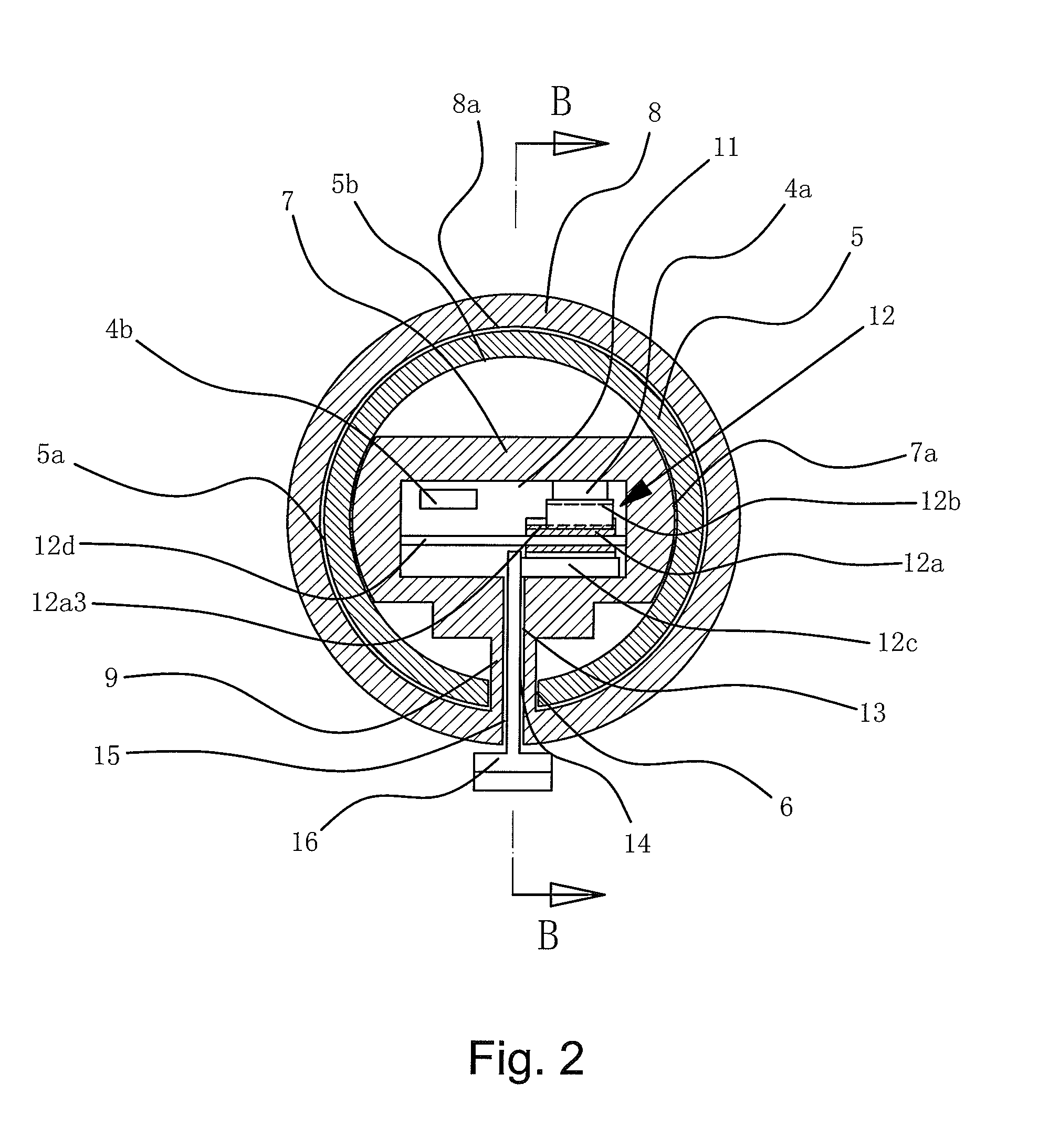

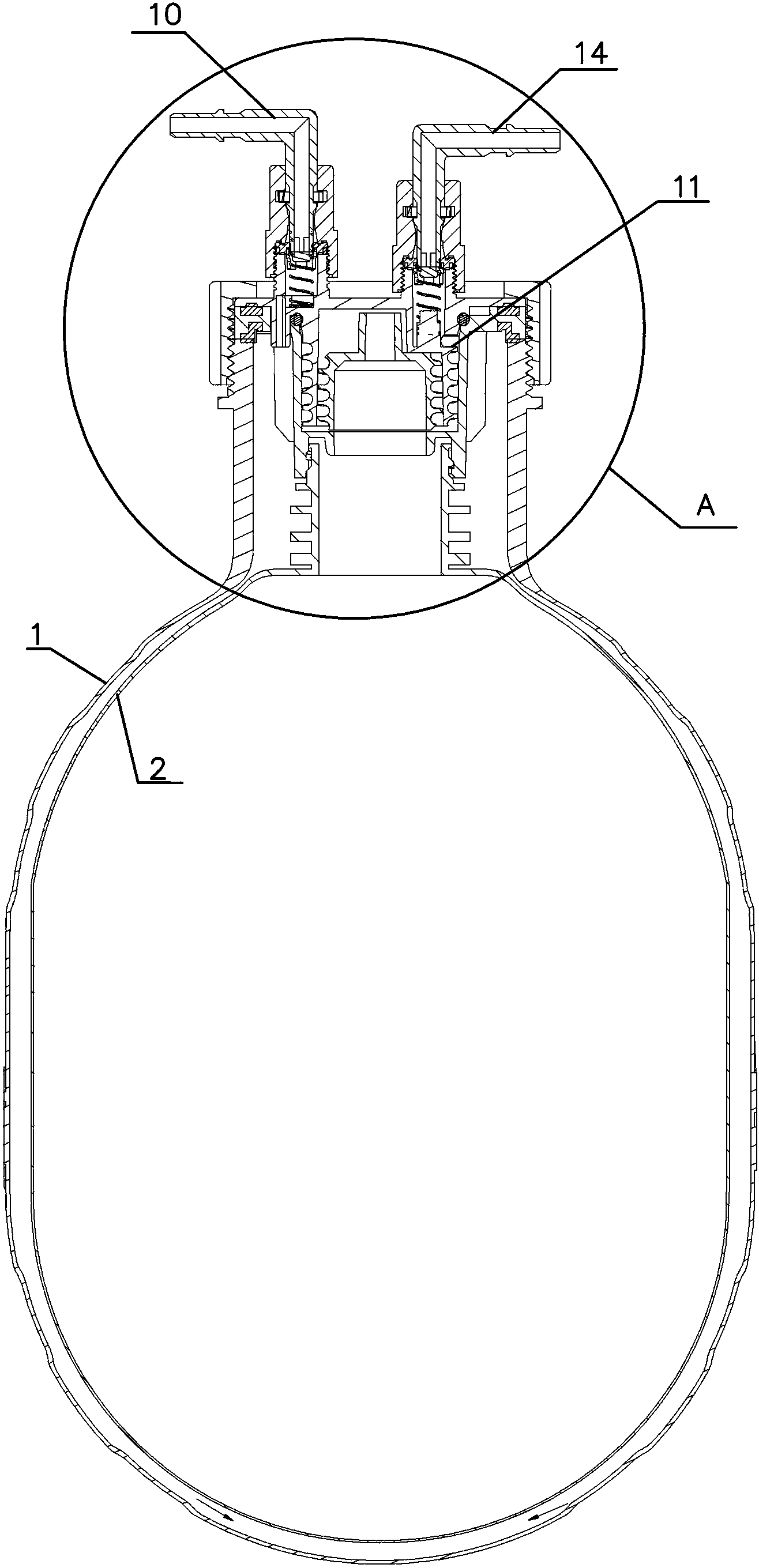

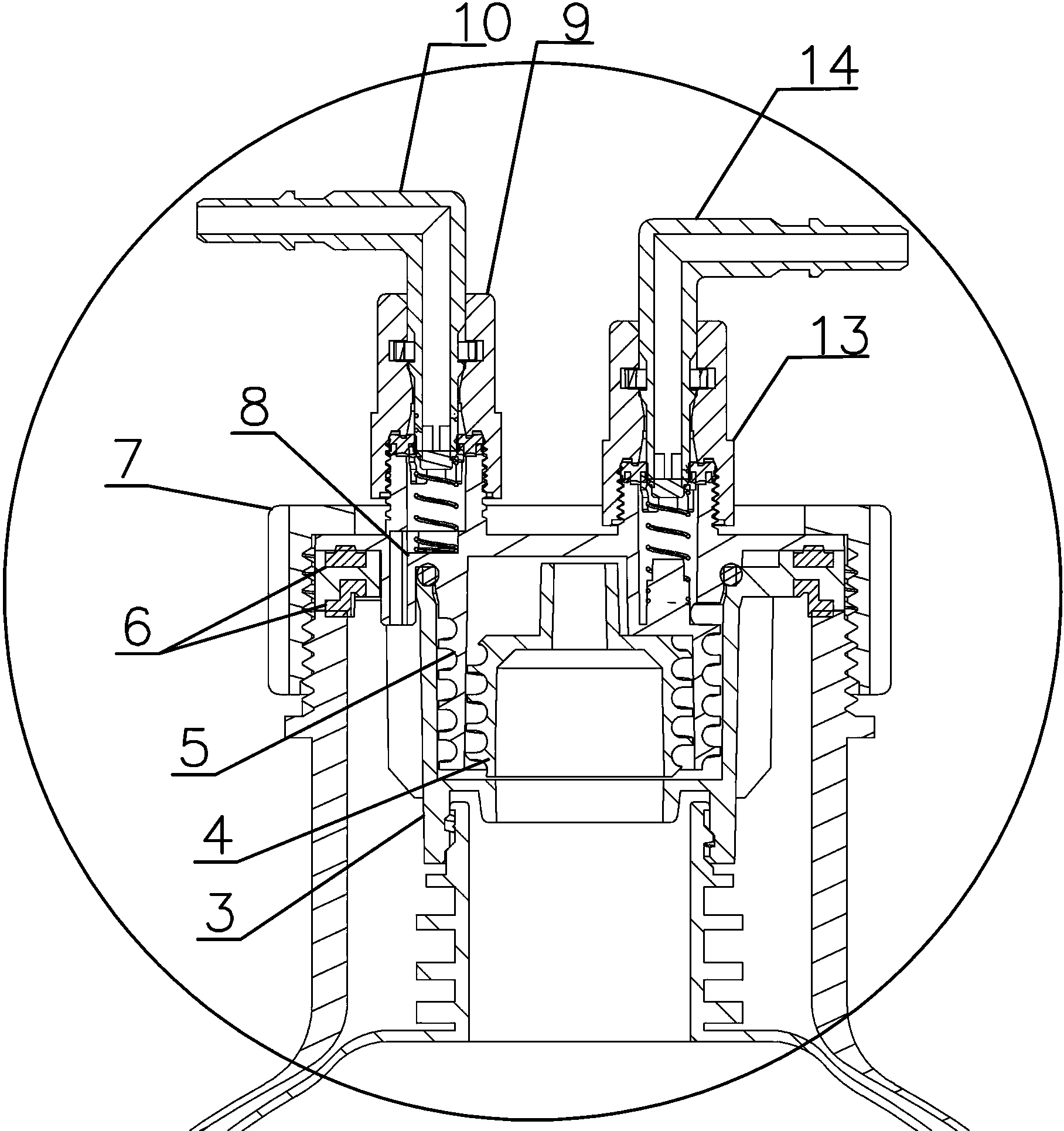

Bidirectionally operable/switchable pull cord mechanism for a window shade

InactiveUS8544525B2Effectively preventing the bead chain or pull cord from tangling a childEasy to adjustScreensDoor/window protective devicesEngineeringMechanical engineering

A pull cord mechanism for a window shade includes a frame (1), a shade (2), a shade driving mechanism (3), and a bead chain or pull cord (4) for driving the shade driving mechanism (3). A sliding block (7) is slideably received in a barrel (5) receiving the pull cord (4). A handle (8) is mounted outside of the barrel (5) and connected to the sliding block (7). A pivotal plate (12a) is pivotably supported in a passageway (11) of the sliding block (7). A recess is defined in one of a rear side (12a1) of the pivotal plate (12a) and a wall (11a) of the passageway (11) facing the rear side (12a1). A positioning block (12c) is located between the rear side (12a1) of the pivotal plate (12a) and the wall (11a) of the passageway (11). A gear (12b) is located between the section (4a) of the pull cord (4) and a front side (12a2) of the pivotal plate (12a) opposite to the rear side (12a1).

Owner:ZHU XIANG RONG

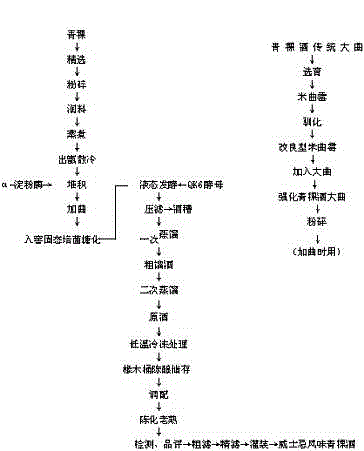

Highland barley wine with whisky flavor and preparation process thereof

InactiveCN104342339AHigh alcohol production capacityAdaptableAlcoholic beverage preparationMicroorganism based processesBiotechnologyChaptalization

The invention relates to wine making techniques and in particular relates to highland barley wine with a whisky flavor and a preparation process thereof. The highland barley wine with a whisky flavor is characterized by being made from Plateau crops ('Black crow' and sky blue highland barley) in high-attitude areas in high Qinghai-Tibet Plateau by process steps of fermentation distillation, oak barrel aging and blending according to a wine making technique combining granite slab cellar solid-state saccharification with a liquid-state fermentation process, thus obtaining the highland barley wine with whisky flavor. Adopted QK6 yeast can generate good-flavor substances, the contents of all the generated total acid, total acetate and total ethyl ester are high, the flavor complexity of the raw highland barley wine is improved, and the highland barley wine has unique product characteristics in terms of fragrance, flavor and style. The highland barley wine with whisky flavor is clear and transparent, is pale yellow to golden yellow, is free of suspended solids and sediment, has harmonious and strong aromatic odor endowed by cereal and oak barrels and is elegant and fine; the body of the highland barley wine is plump, pure, mild and sweet and has aromatic odor endowed by cereal and oak barrels.

Owner:青海互助天佑德青稞酒股份有限公司

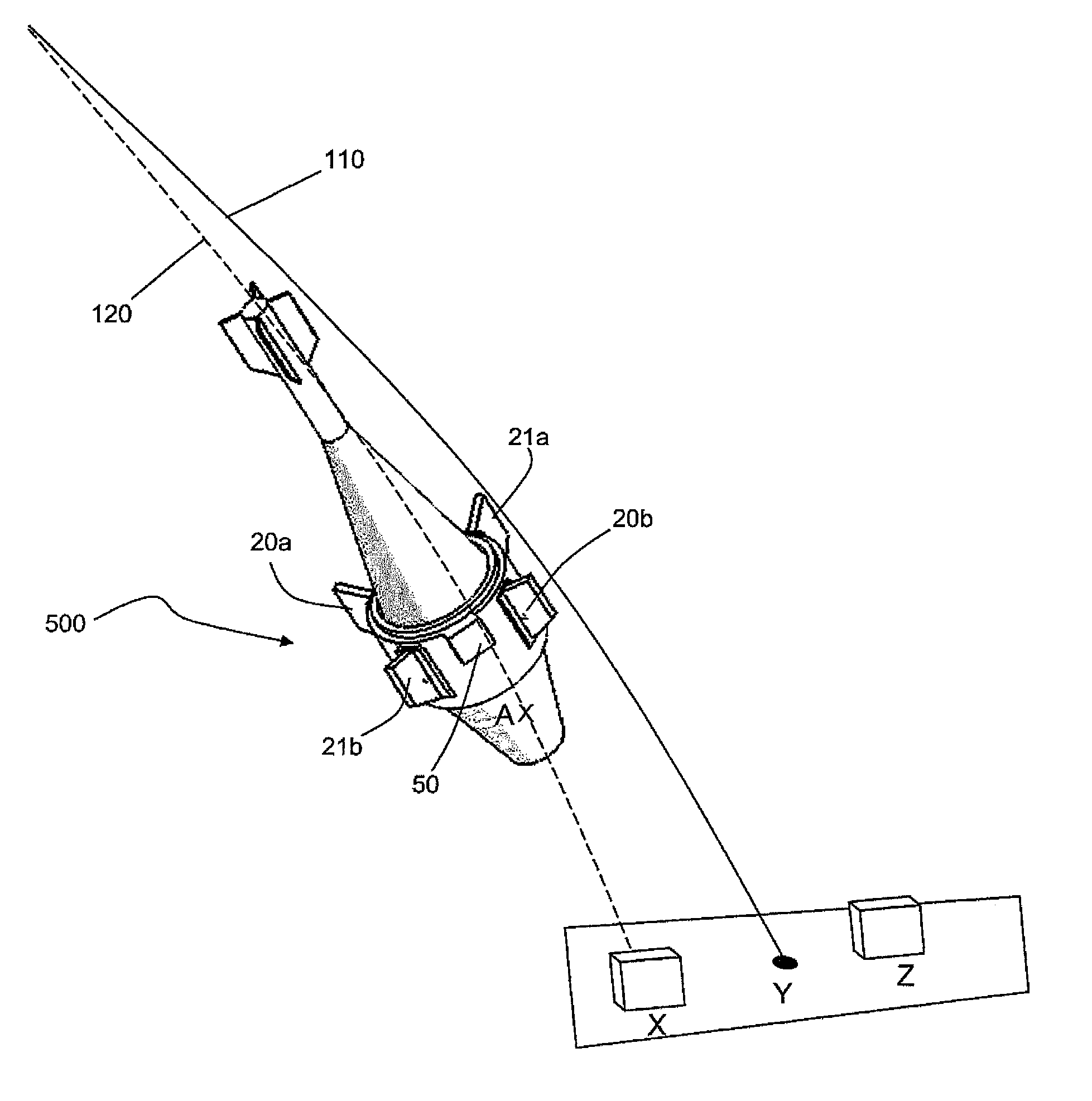

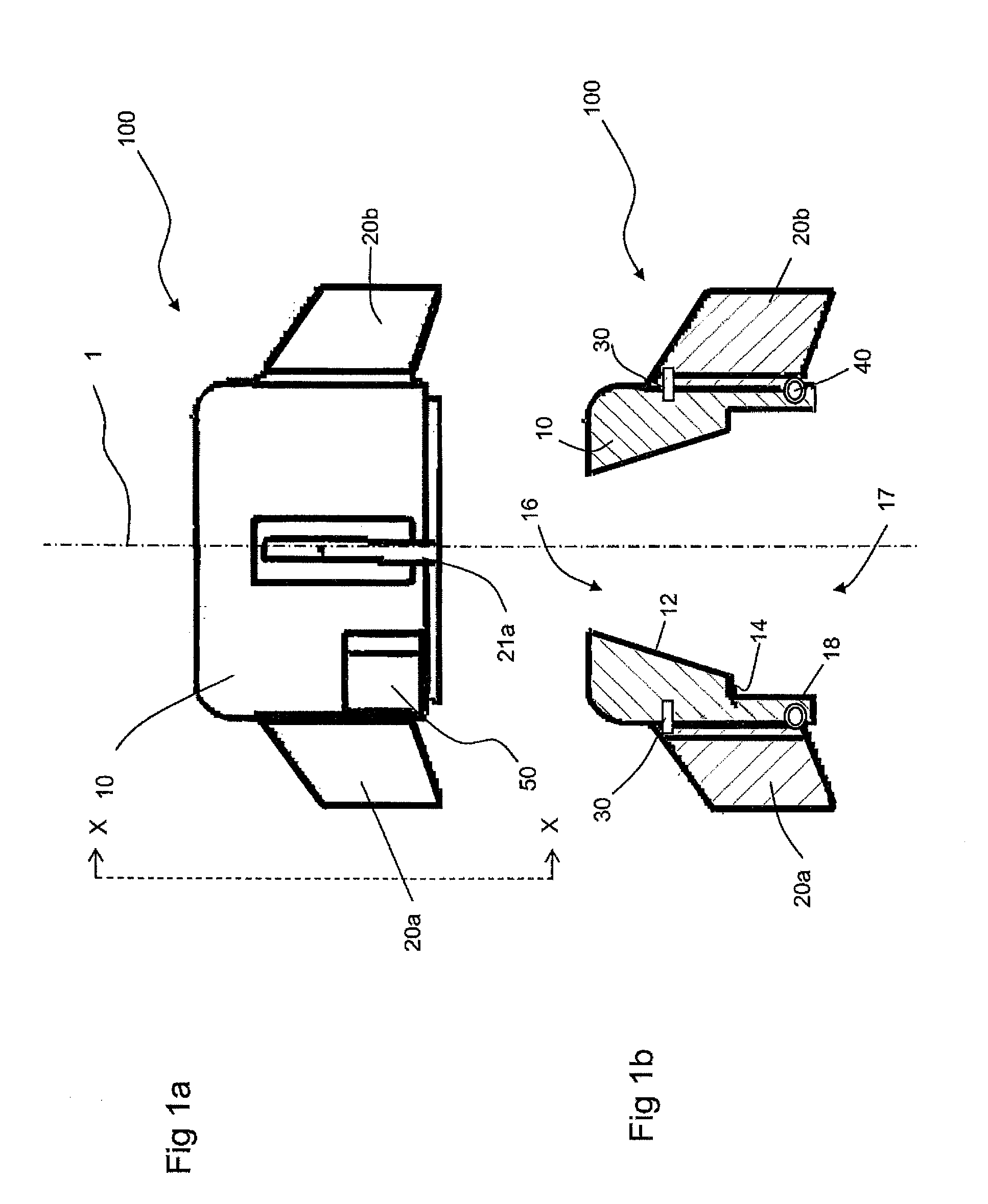

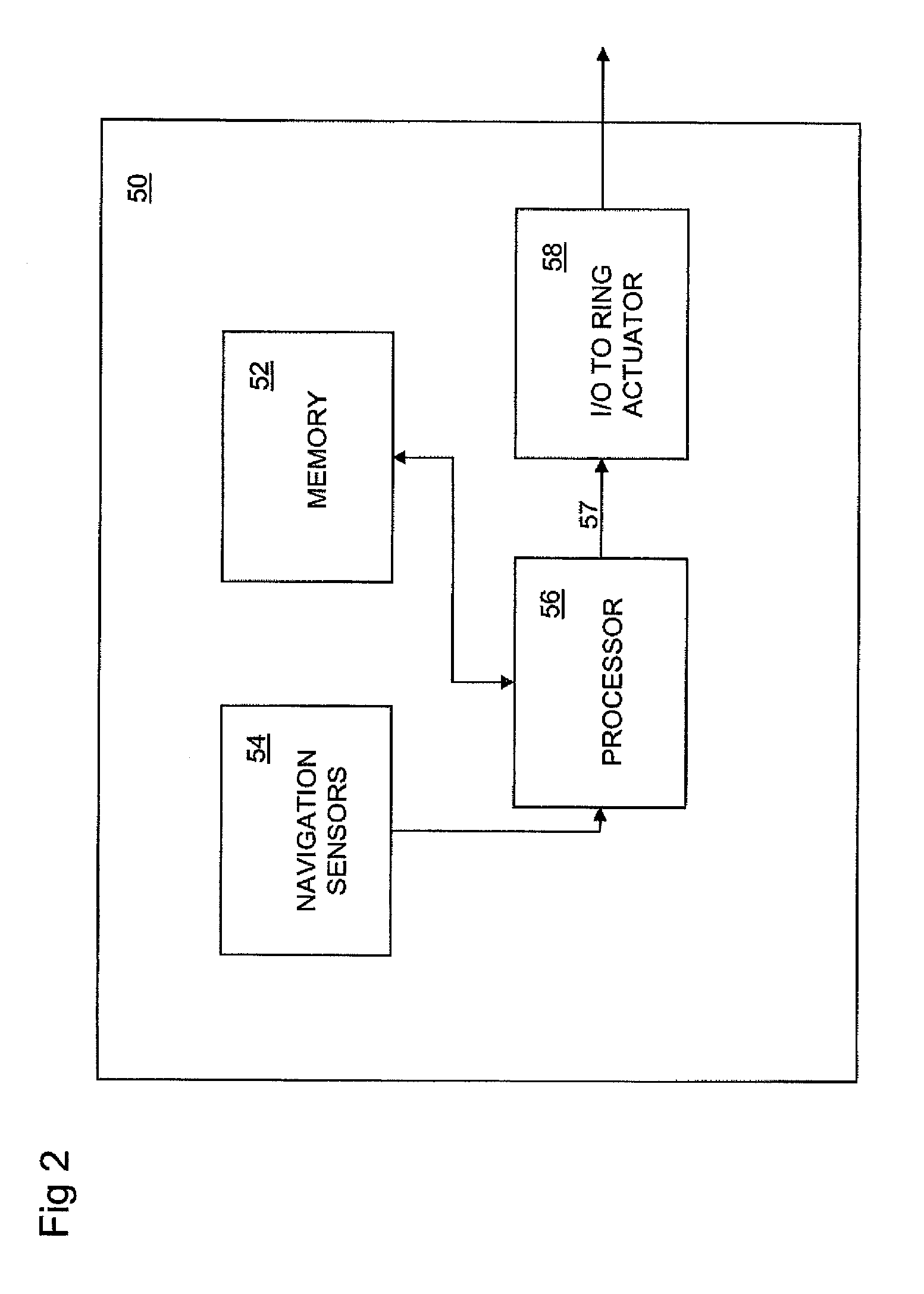

Guidance device

InactiveUS8674277B2Reduce disadvantagesAmmunition projectilesDirection controllersEngineeringProjectile

There is disclosed a collar (100) which may be attached to a munition in order to control the trajectory of the munition. The collar (100) has a collar body (10); a surface (12) for capturing the projectile as it leaves the barrel; a sill (14) for supporting the surface (12) at the muzzle of the barrel; and a guidance means (20a, 20b, 21a, 21b) for altering the flow of air around the collar (100). The collar (100) supports itself at the muzzle and may attach to the projectile at the surface (12) to integrate with the projectile as the projectile is fired. The collar (100) is particularly suited for attachment to mortar rounds. Such a collar (100) gives a weapon operator the option of increasing the precision of a munition without having to carry a plurality of munition types.

Owner:BAE SYSTEMS PLC

Beer barrel structure provided with valve

The invention discloses a beer barrel structure provided with a valve, relating to beverage retailing machines. The beer barrel structure provided with the valve comprises a barrel assembly and a valve assembly, wherein the barrel assembly comprises a hard outer barrel and a soft wine bag, and the wine bag is arranged inside the outer barrel; the valve assembly comprises an outer barrel sealing cover, the valve, an air inlet pipe and a wine outlet pipe, the valve is connected to the opening of the wine bag opening in a sealing way, and the outer barrel sealing cover seals and compresses the valve on the opening of the outer barrel opening; the valve is provided with an air inlet and a wine outlet, the air inlet is communicated with the outside of the valve and the inner cavity of the outer barrel, the wine outlet is communicated with the outside of the valve and the inner cavity of the wine bag, the air inlet pipe is connected to the air inlet, and the wine outlet pipe is connected to the wine outlet. The beer barrel structure provided with the valve, provided by the invention, effectively avoids the problem that gas in wine liquid escapes when the air space in the barrel becomes larger, and guarantees the quality of the liquid in the barrel in the storage process to be invariable.

Owner:ZHONGSHAN DONLIM WEILI ELECTRICAL APPLIANCES CO LTD

Litchi ice wine and production method thereof

ActiveCN101906365AIncrease Natural BrixHigh alcohol contentAlcoholic beverage preparationMicroorganism based processesLitchi fruitCold storage

The invention relates to the field of fruit wine brewing, particularly to a brewing method of litchi ice wine through freezing concentration and then low-temperature fermentation of litchis as raw materials. The method comprises the following steps of: processing the litchis as the raw materials, shelling and de-nucleating, pressing and extracting juice, clarifying, carrying out freezing concentration, carrying out temperature-controlled fermentation, ageing in an oak barrel, carrying out cold storage, clarifying for the second time, and filtering to finally obtain the litchi ice wine. The method has low cost and simple process. The alcohol (V / V) of the litchi ice wine is 10-15 percent; the total sugar (calculated by glucose) is 2.0-3.5g / L; the total acid (calculated by tartaric acid) is 6.0-7.5g / L; the volatile acid (calculated by acetic acid) is 0.45-0.75g / L; the litchi ice wine is golden in color and luster and is elegant and pleasant; the fragrance is mellow litchi fruit fragrance, and the fruit fragrance is coordinated with the wine fragrance; and the litchi ice wine has elegant and exquisite taste and a coordinated wine body.

Owner:GUANGDONG ZHENZHOU LYCHEE IND

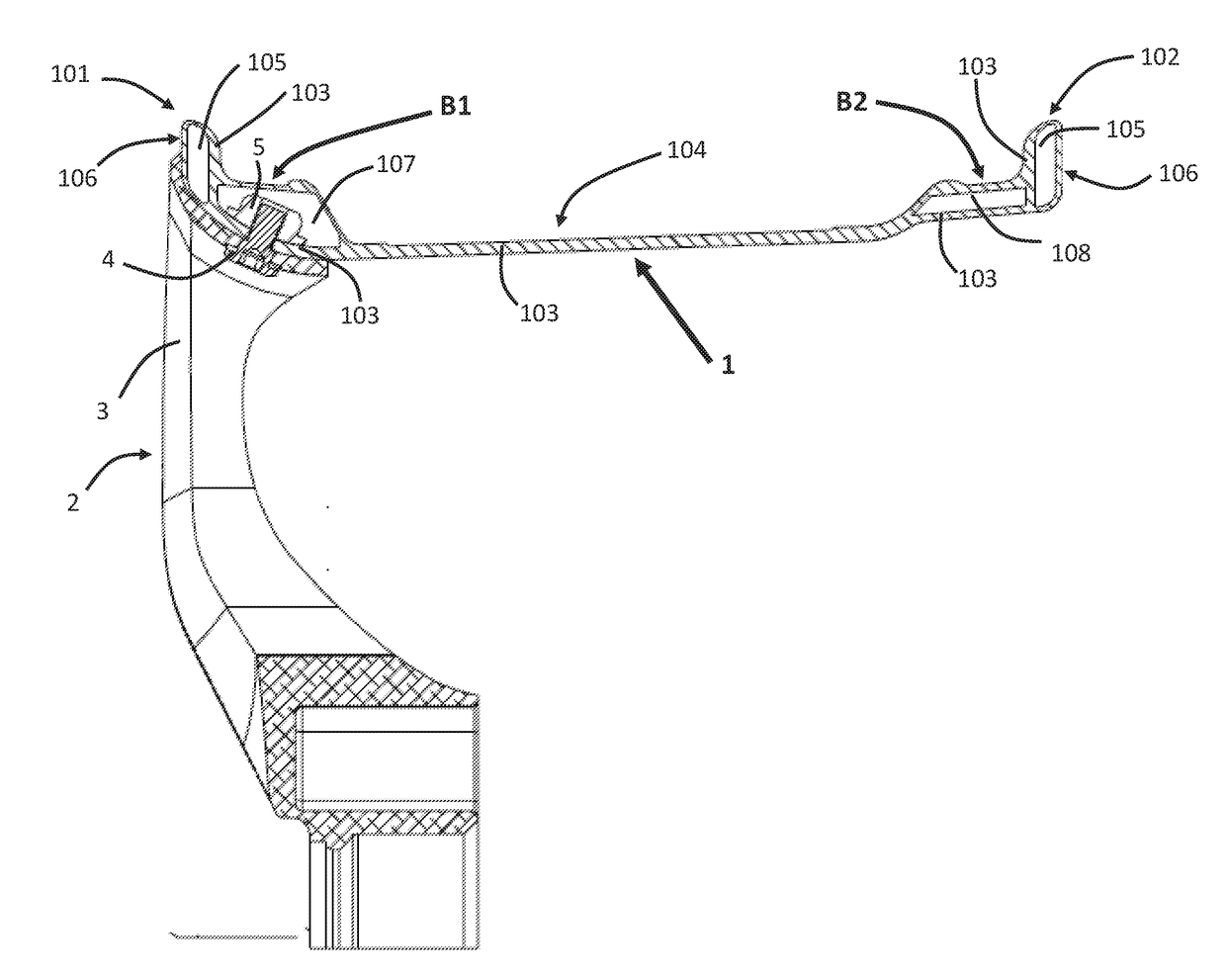

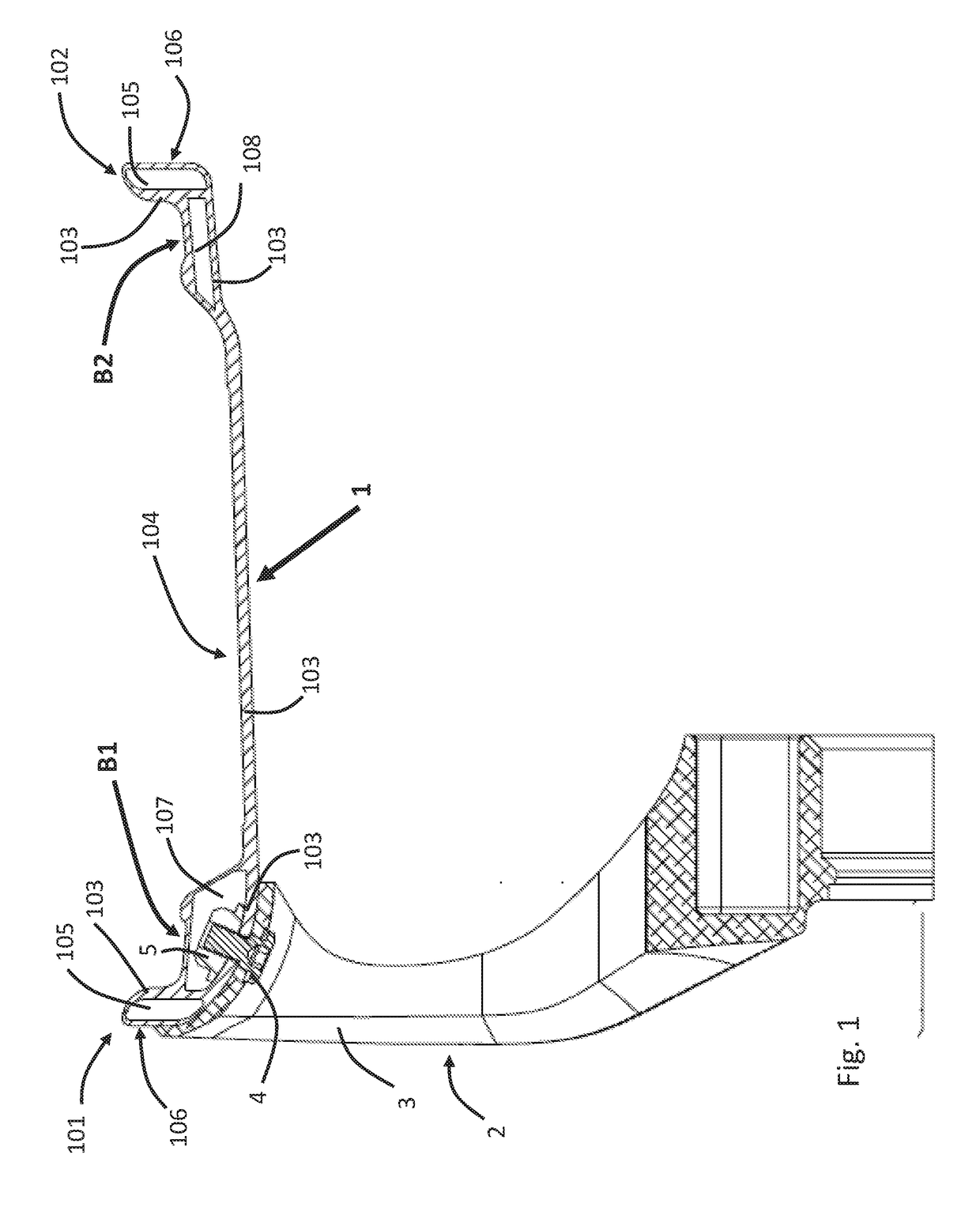

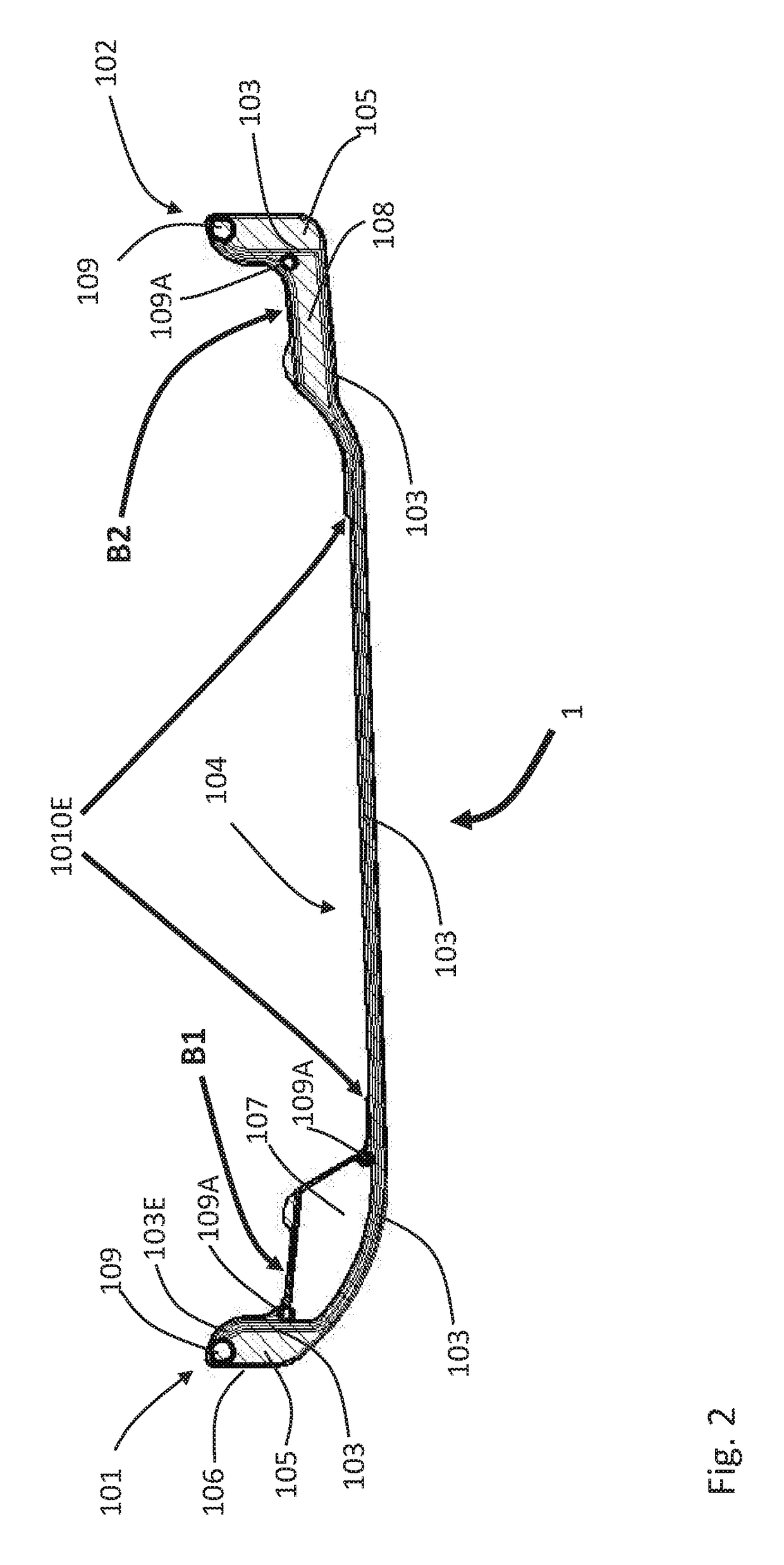

Rim for a wheel

ActiveUS20170087929A1Improve impact resistanceIncrease stiffnessRimsNon-metallic wheel bodyEngineeringPolymer

Herein is described a non-metallic rim for a wheel, the rim comprising:a barrel having first and second flanges extending radially outward from opposing edges of the barrel, and the barrel comprising a first bead seat and a second bead seat arranged axially inwardly, respectively, of the first and second flanges,whereina primary structural component extends at least through the first flange and the barrel, the primary structural component being capable of bearing the majority of the radial and / or lateral load that, in use, would be borne by the rima protective insert is disposed between an outer face of the first flange and the primary structural component and / orat least a portion of the first bead seat is spaced apart from the primary structural component andthe primary structural component, bead seat and, if present, the protective insert are bound by a polymer matrix.

Owner:DYMAG GRP LTD

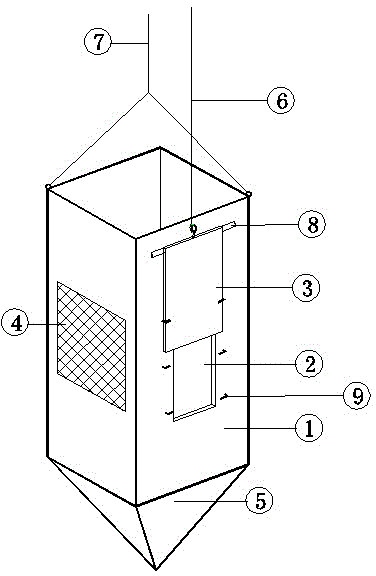

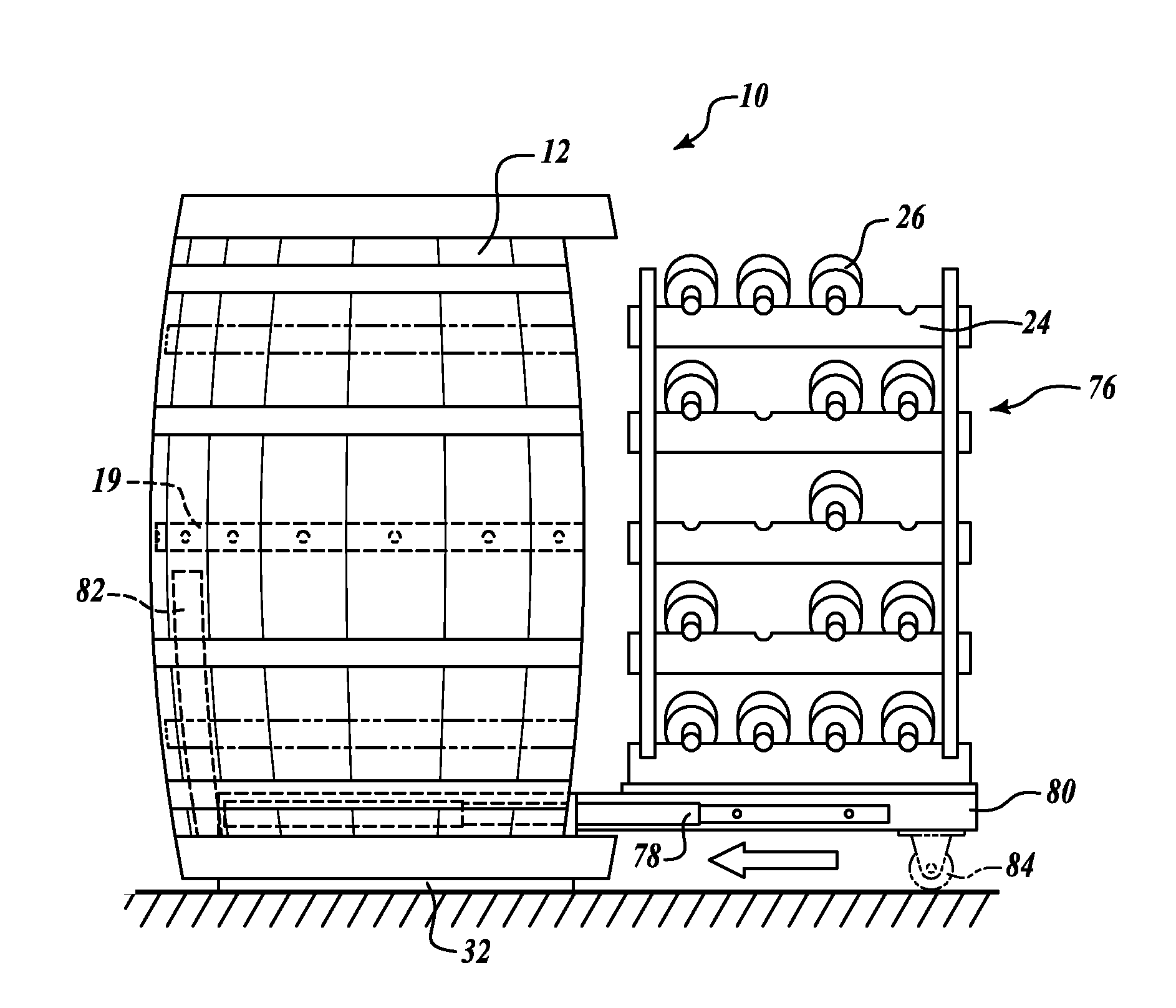

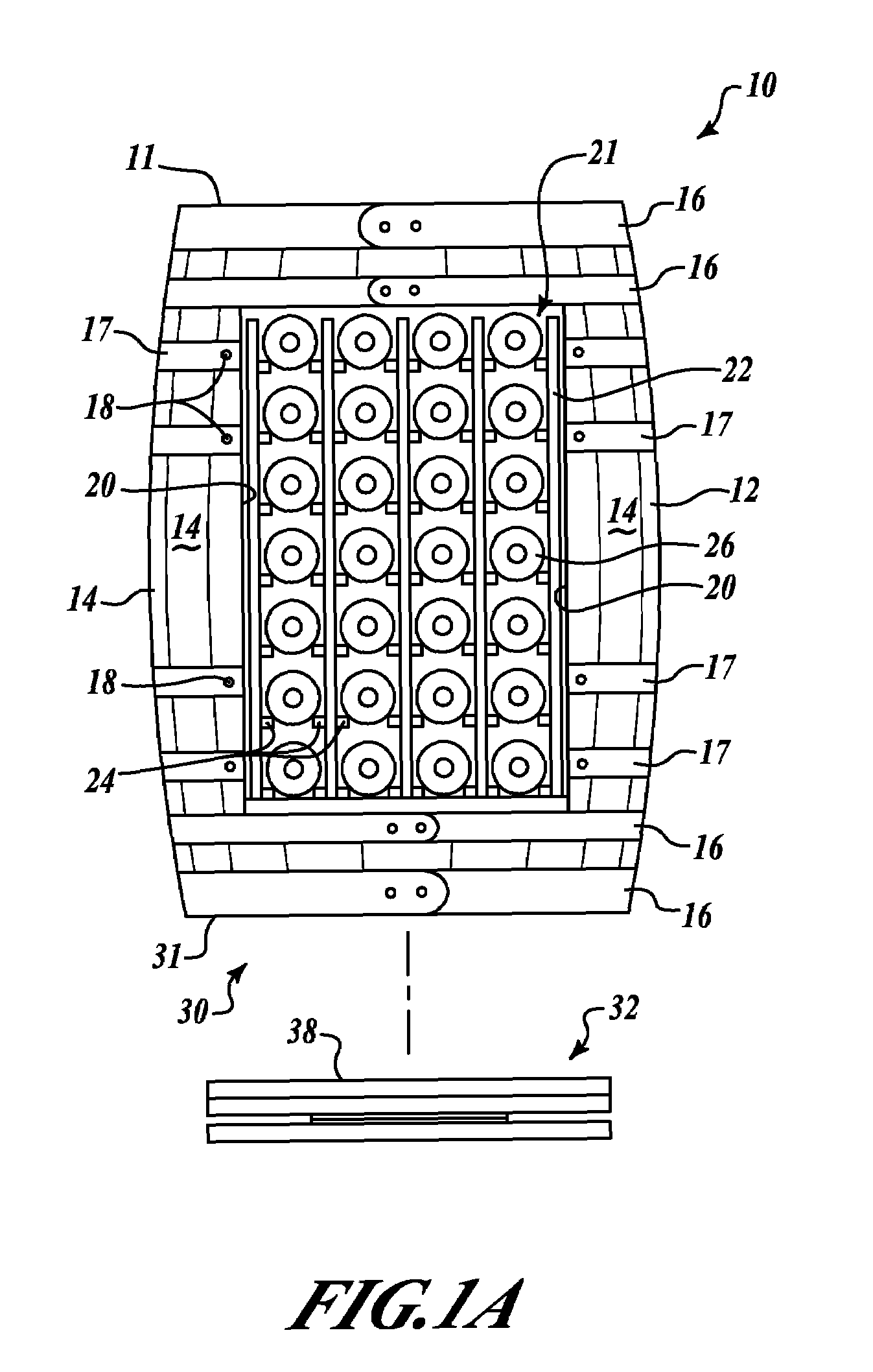

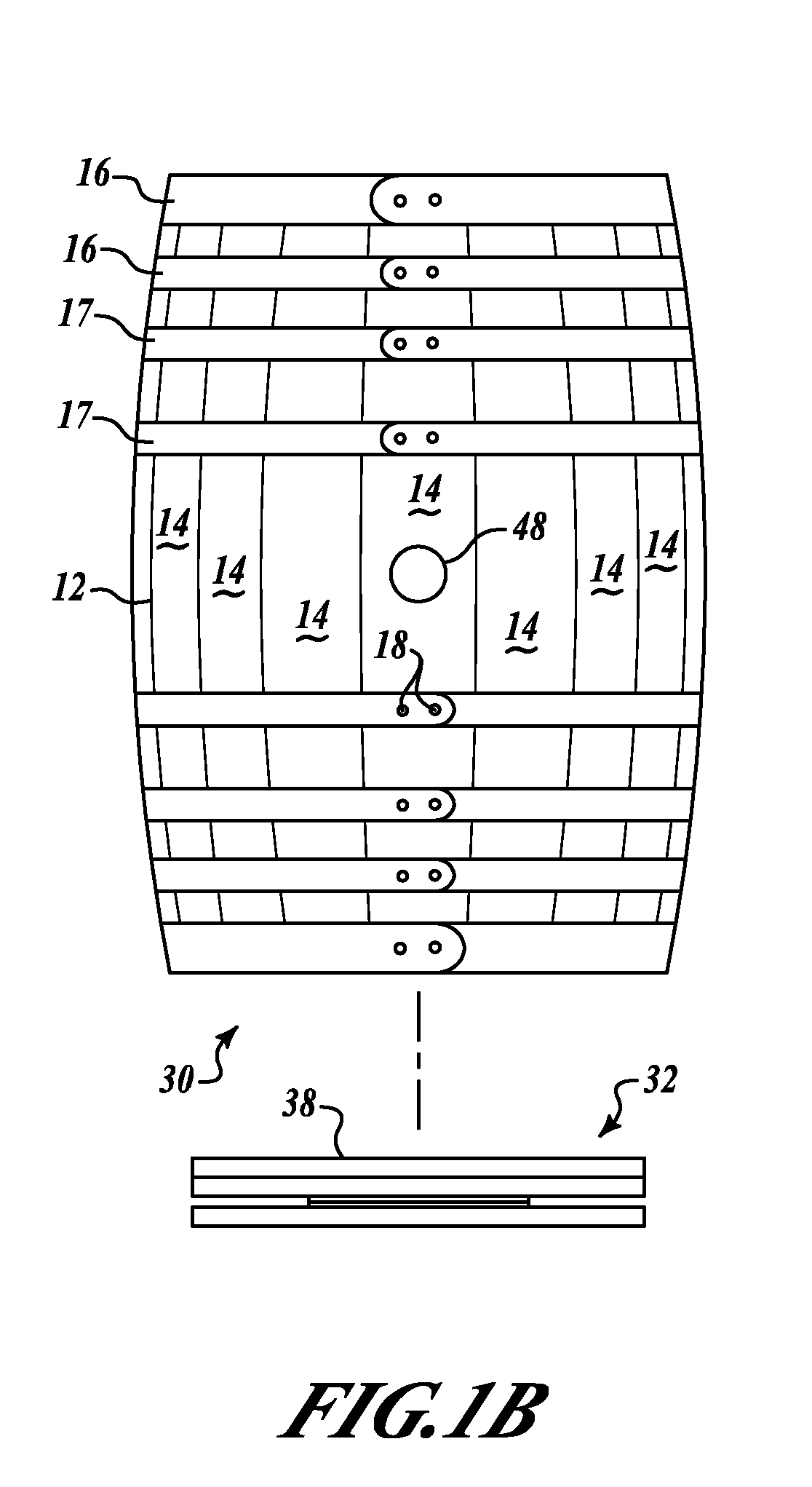

Rotating barrel storage system

Storage units of standard, new or used wood stave barrels, mounted on end on a rotating platform and having a side opening cut-out to the interior for access to shelving, drawers, wine racks or other storage devices fitted in the interior. The barrel is mounted on and secured to a rotatable platform that includes a turntable mechanism, the platform being specifically sized to fit inside the base recess of the barrel, so that it is hidden by the barrel lip, yet holds the barrel sufficiently off the ground to clear carpeting or other irregular flooring such as slate, brick or tile pavers, that might otherwise interfere with its rotation. The platform includes friction sliders so that the barrel rotates under hand pressure but does not spin freely. Selected feet or spacer disks are used to provide minimum needed clearance so the barrel appears to float just above the flooring surface.

Owner:MCNULTY JOHN M

Preparation method of red date brandy

ActiveCN101921687ARich jujube fragranceEntrance softMicroorganism based processesAlcoholic beverage preparationPectinaseAlcohol content

The invention relates to a preparation method of red date brandy, which comprises the following steps: boiling the high quality dried red dates in water to obtain red date liquor; adding composite enzyme for enzymolysis, and carrying out solid-liquid separation to extract red date juice; adding softened water and white granulated sugar, which account for 50 wt% of the date paste, to the residual red date paste, and controlling the sugar degree of the red date paste to be 20 degrees; respectively adding leaven into the red date juice and red date paste for fermentation; distilling the red date juice suspension and red date paste suspension by using a red copper pot to extract alcohol and flavored substances; leaving out the beginning and the end while flowing the brandy, and controlling the alcohol content of intermediate flow brandy to be 35-40 degrees; and storing the obtained brandy in an oak barrel for more than half a year to obtain the red date brandy. In the invention, organic red dates are used as the raw material; pulp enzyme, pectinase and amylase are mixed to carry out enzymolysis so as to extract the juice; the mixture of Danbaoli brewage active dry yeast and Angle wine active dry yeast is used as the leaven; the red date juice and the red date paste are respectively fermented; the red copper pot is used for distillation; and the oak barrel is used for storage. The red date brandy is slight yellow, has thick red date flavor and tastes soft and mellow.

Owner:佳县益民现代农业开发有限公司 +1

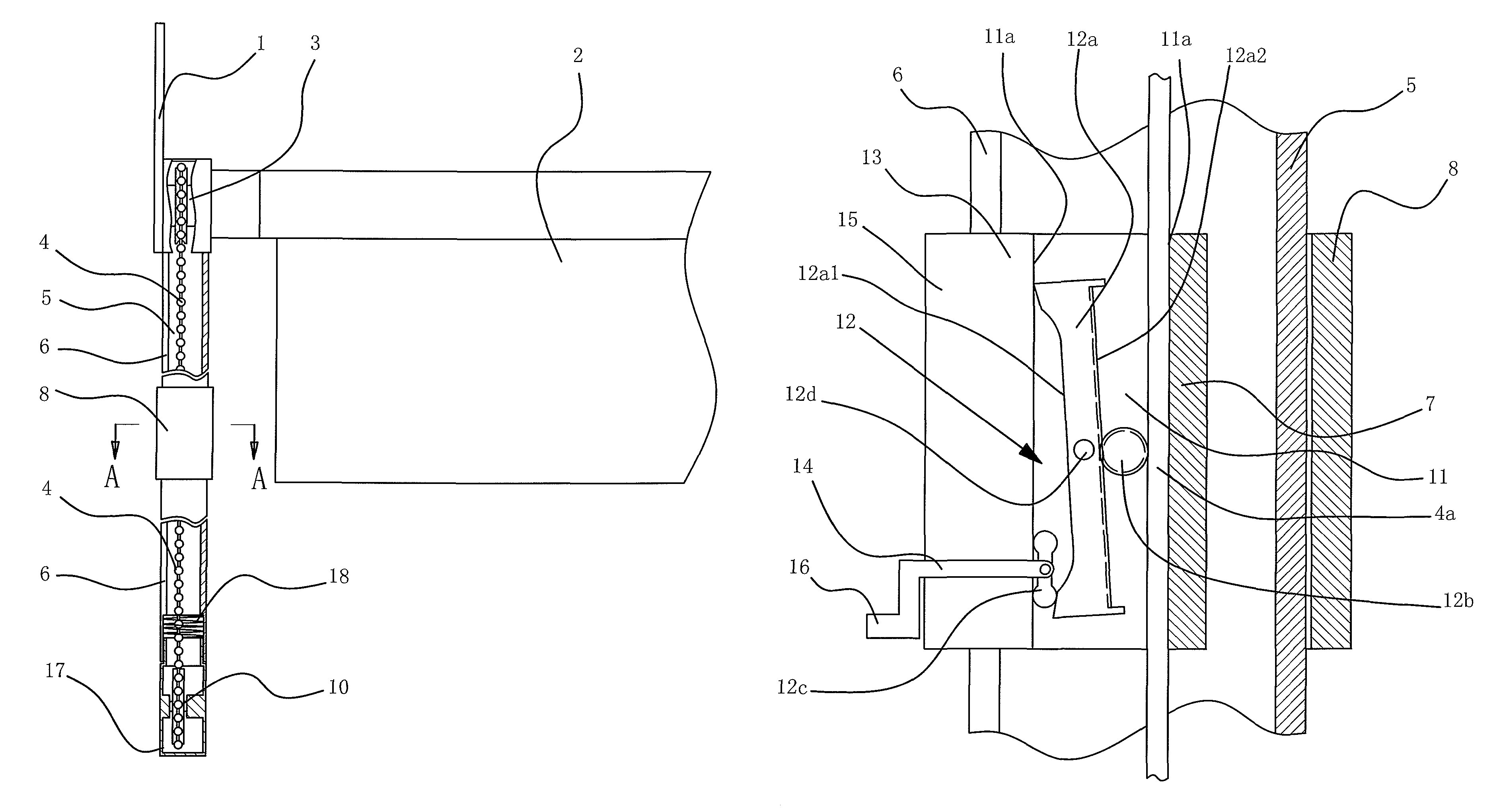

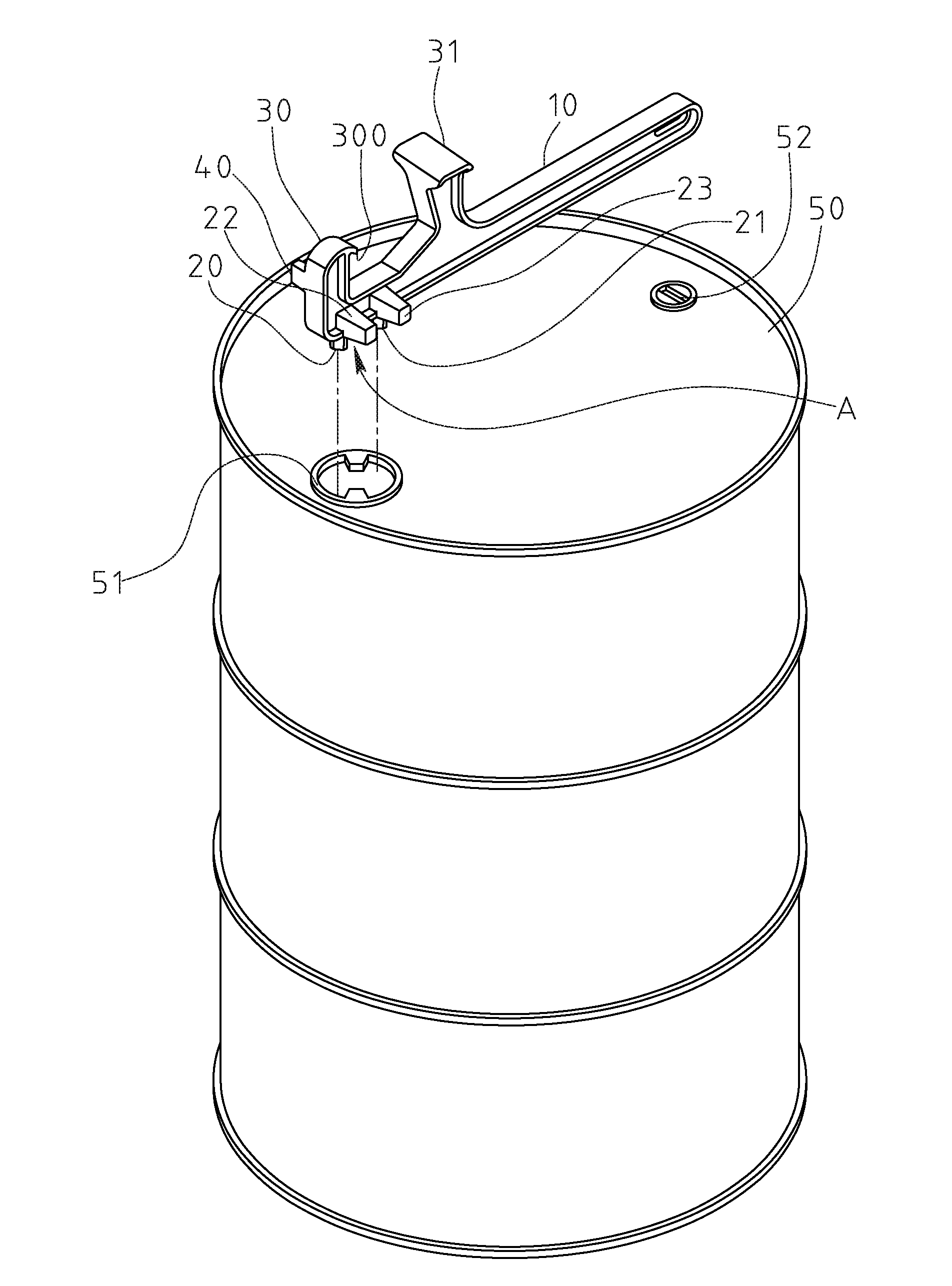

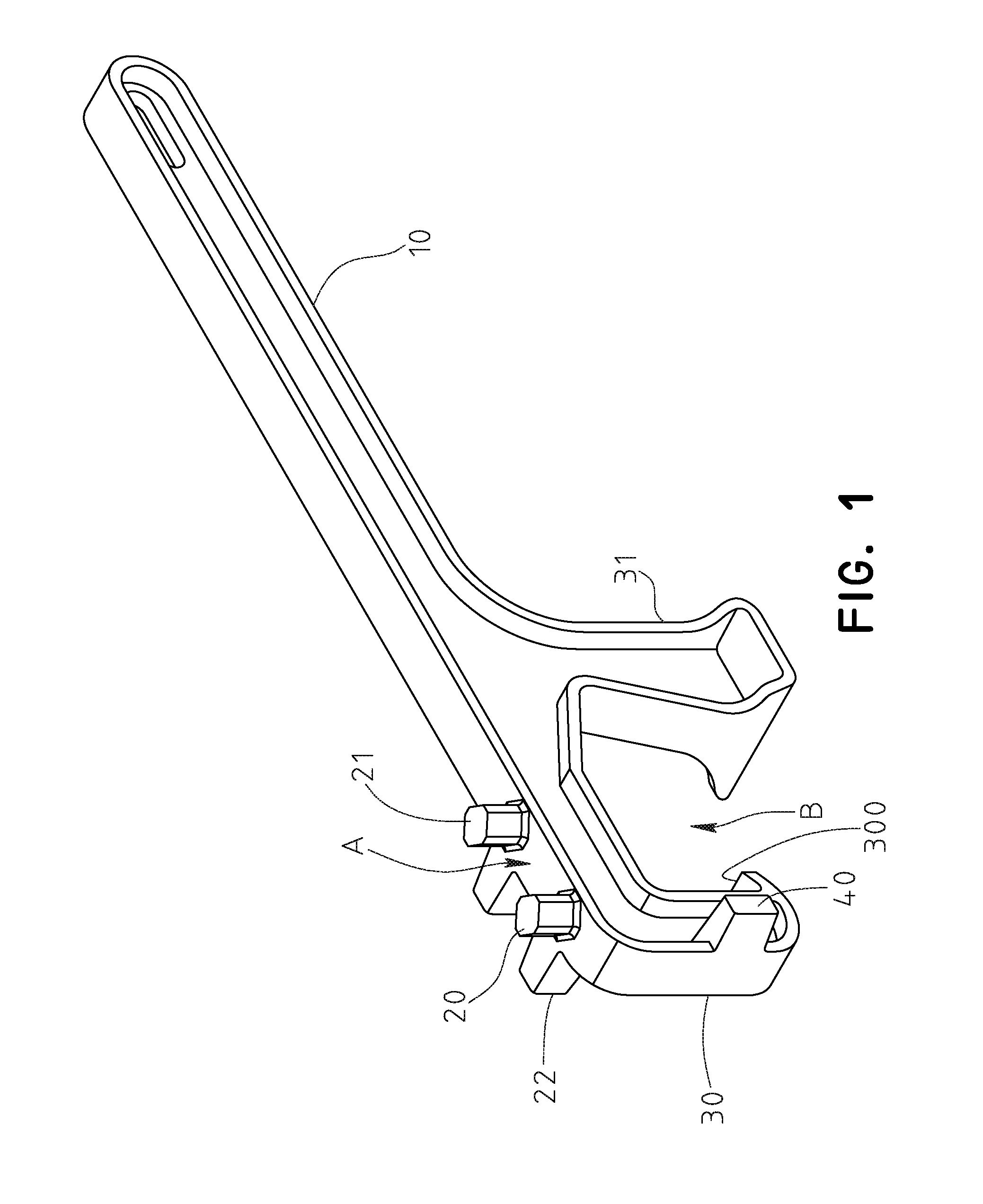

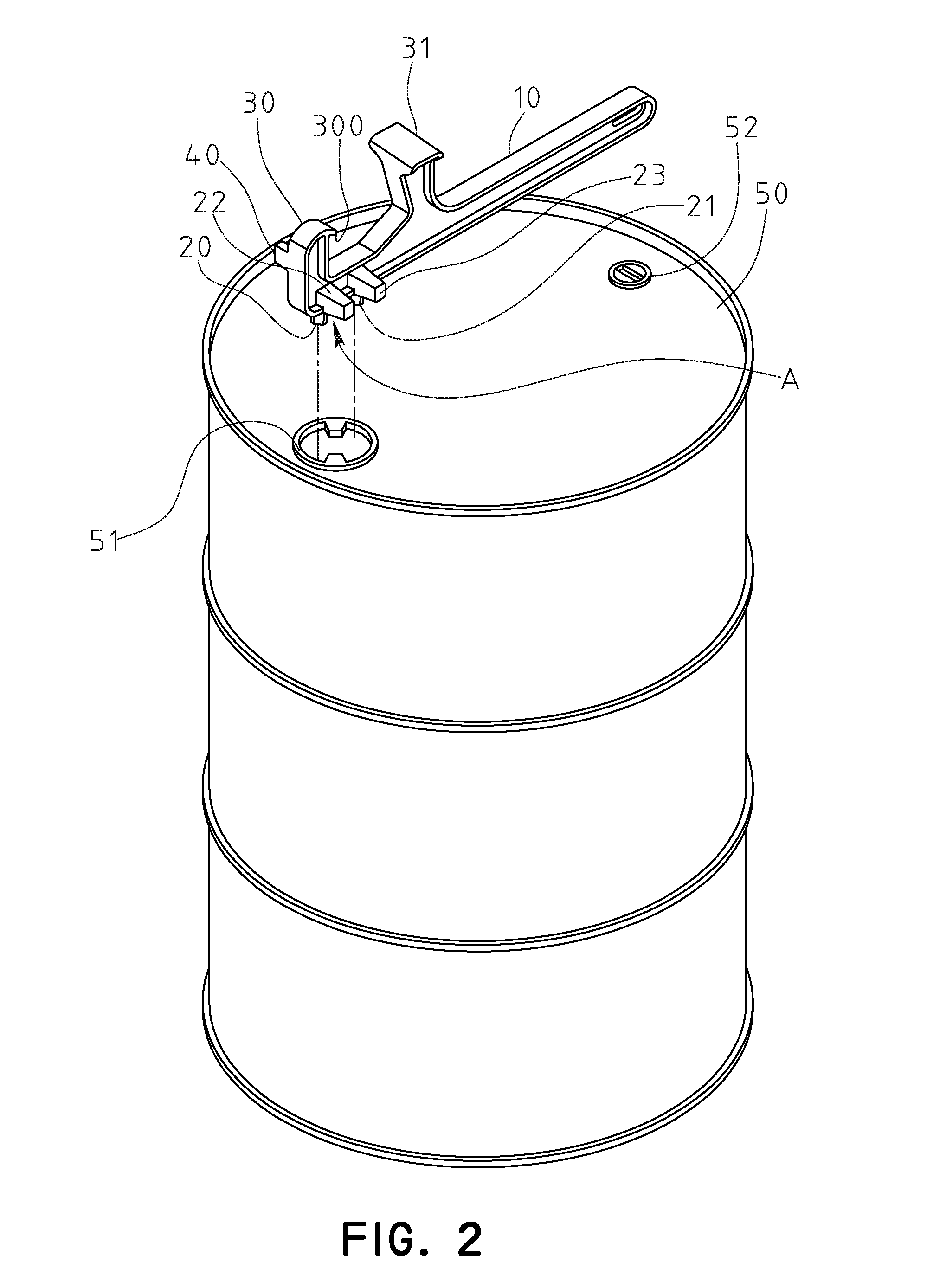

Universal barrel opener

A barrel opener includes a handle (10); a first projection (20) on a first surface of the handle (10); a second projection (21) parallel to the first projection (20) on the first surface of the handle (10); a first protrusion (22) on one side of the handle (10); a second protrusion (23) parallel to the first protrusion (22) on one side of the handle (10); a prying member (30) on a second surface of the handle (10) opposite the first surface of the handle (10), the prying member (30) having an end hook (300); a fulcrum (31) spaced from the prying member (30) and on the second surface of the handle (10); and a protuberance (40) on one side of the prying member (30) opposing both the first and second protrusions (22, 23). The open is operable to open one of a variety of barrel caps or barrel tops.

Owner:LUO A FA

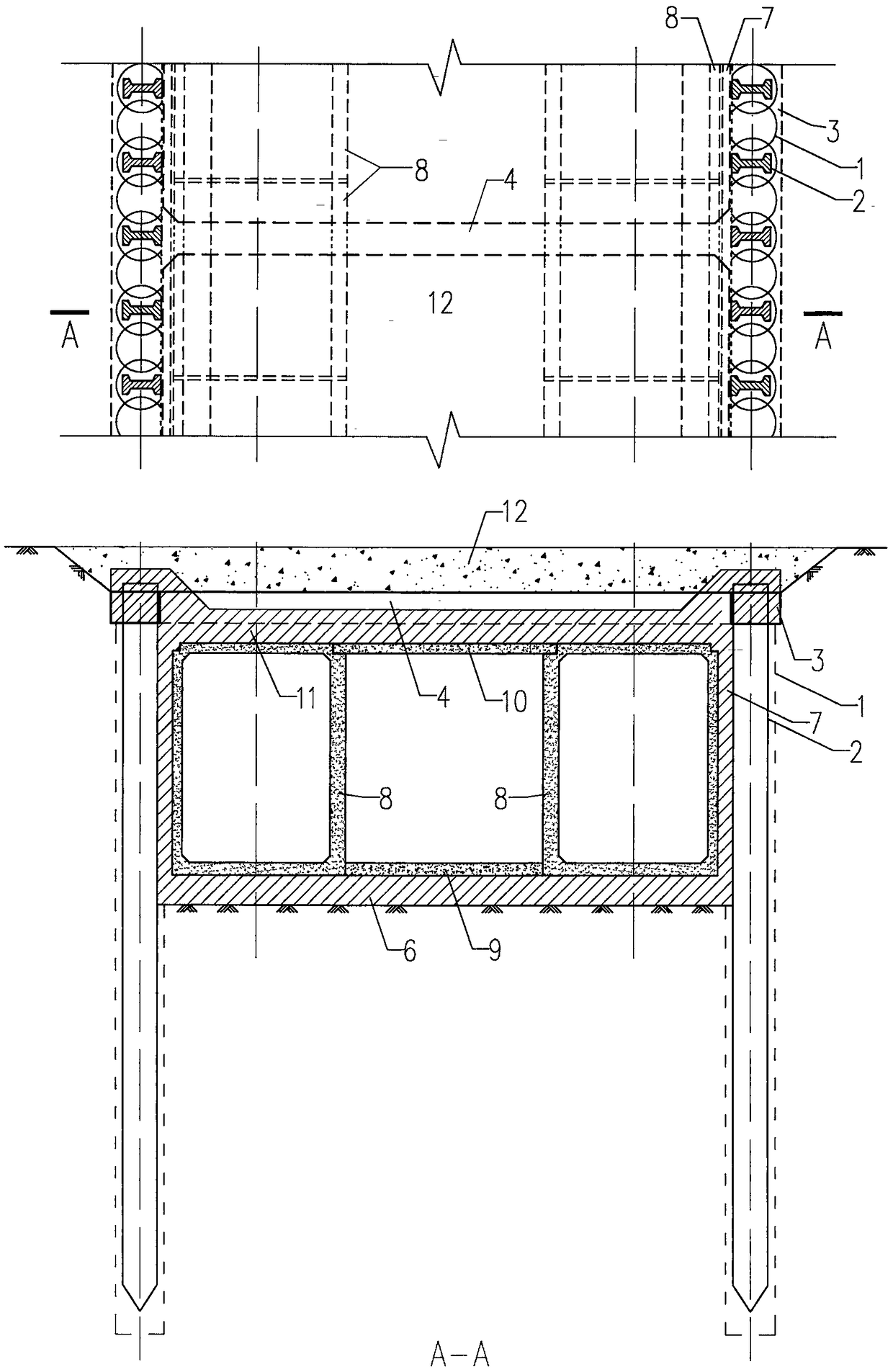

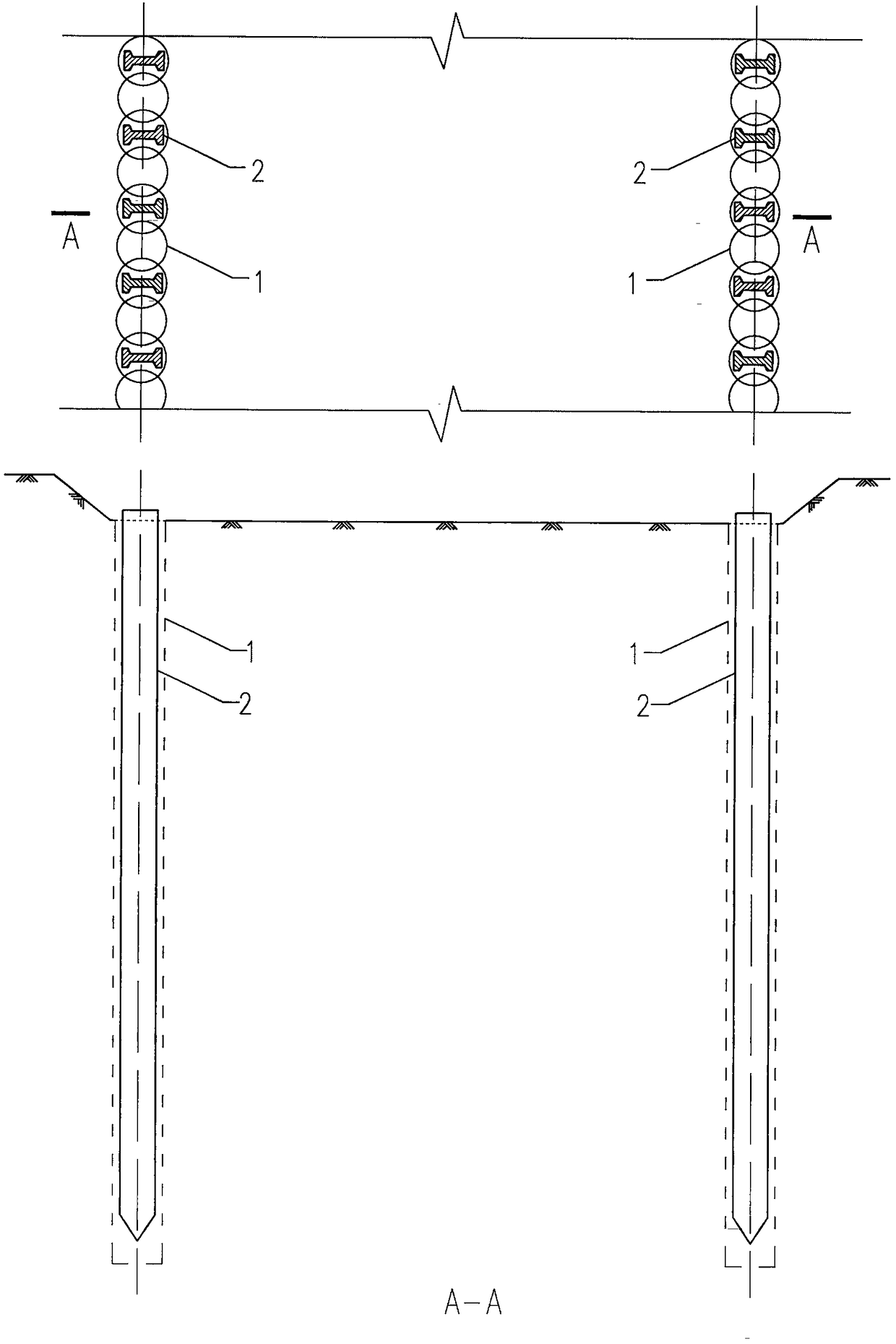

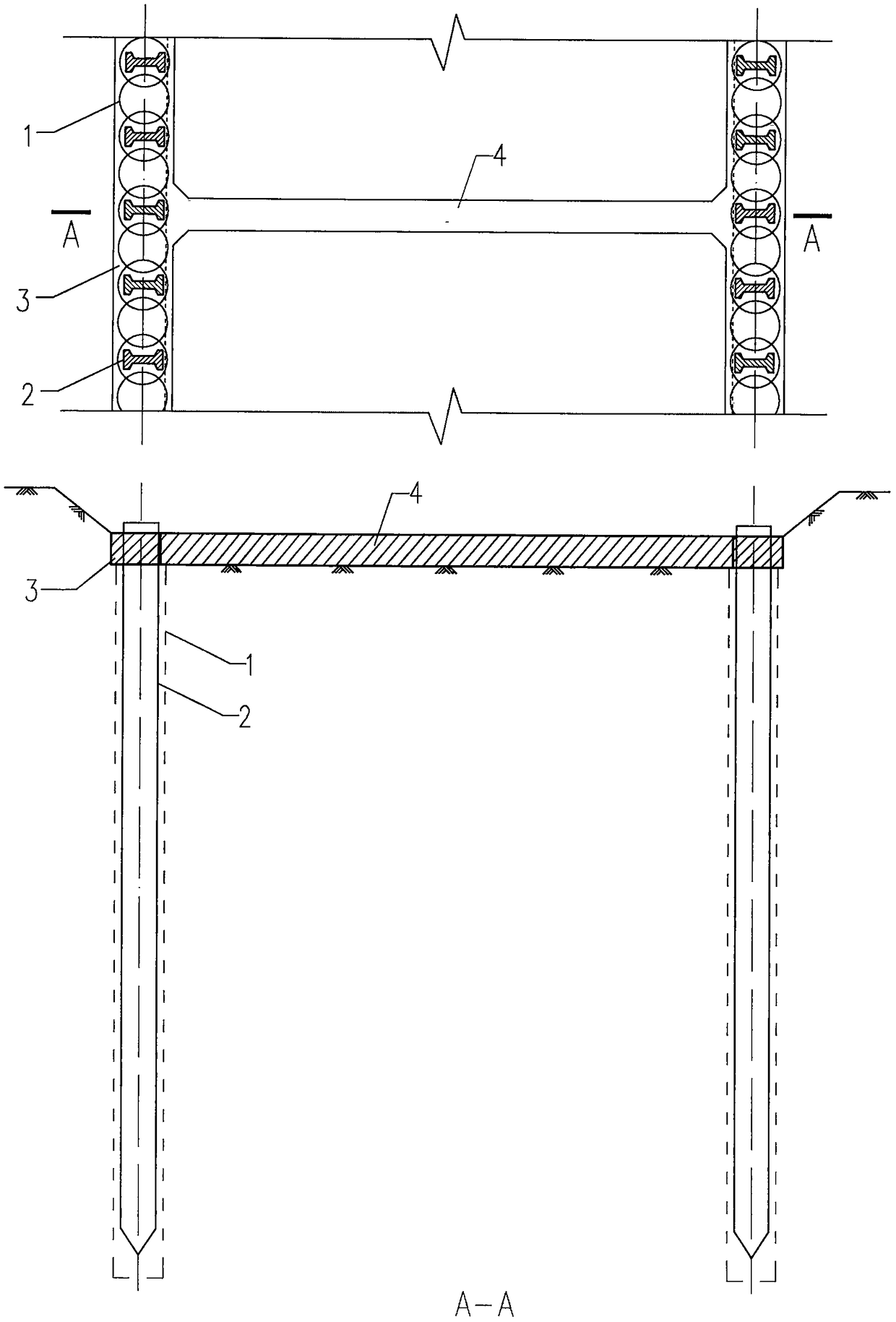

Semi-reverse construction method for combining two walls into one of combined prefabricated pipe barrels of underground comprehensive pipe gallery

InactiveCN108343059ALow costIncrease stiffnessExcavationsBuilding material handlingReinforced concreteUtility tunnel

The invention discloses a semi-reverse construction method for combining two walls into one of combined prefabricated pipe barrels of an underground comprehensive pipe gallery. In the construction ofthe urban underground comprehensive pipe gallery, cement mixed with soil is implanted into prefabricated reinforced concrete I-shaped piles with pile bodies provided with embedded parts, and the prefabricated reinforced concrete I-shaped piles are used as an enclosure pile wall in the excavation process of a pipe gallery foundation pit; and the I-shaped piles and a pipe gallery outer lining wall are connected through the pile body embedded parts or pile body main ribs, and are subjected to cast-in-place to be cast into a whole, so that the structural mode that the enclosure pile wall and the pipe gallery outer lining wall are combined into the whole is formed. According to the method, a longitudinally extending pipe gallery channel is formed by splicing the prefabricated pipe barrels on acast-in-place pipe gallery bottom plate, a prefabricated reinforced concrete horizontal plate is connected with the pipe barrels on the left side and the right side through the embedded parts at the tops of the pipe barrels, and a framework for pouring an underground pipe gallery top plate is formed; then the cast-in-place reinforced concrete is connected with an enclosure supporting beam throughthe embedded parts to form the underground pipe gallery reinforced concrete top plate with ribs; soil covering and backfilling are carried out, a roadbed pavement is built, and the civil engineering work of the underground comprehensive pipe gallery is completed; and the semi-reverse construction method for combining the two walls into one of the combined prefabricated pipe barrels of the underground comprehensive pipe gallery by slicing has the characteristics of being high in construction speed, low in construction cost, small in environmental pollution and the like, and the requirements ofenvironmental-friendly engineering construction for being low-carbon, environment-friendly and economic are met.

Owner:HANGZHOU NANLIAN BASE FOUND ENG +1

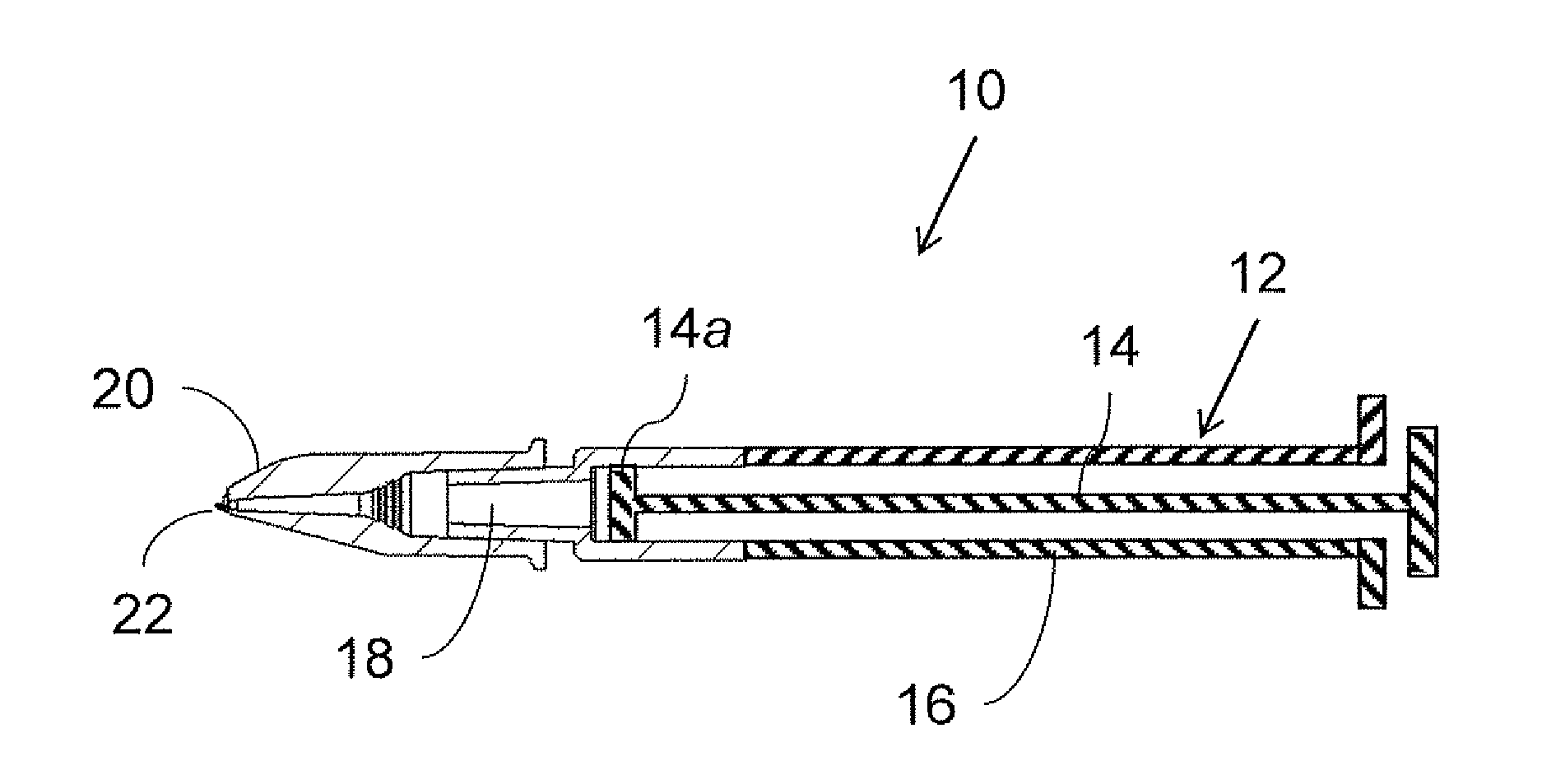

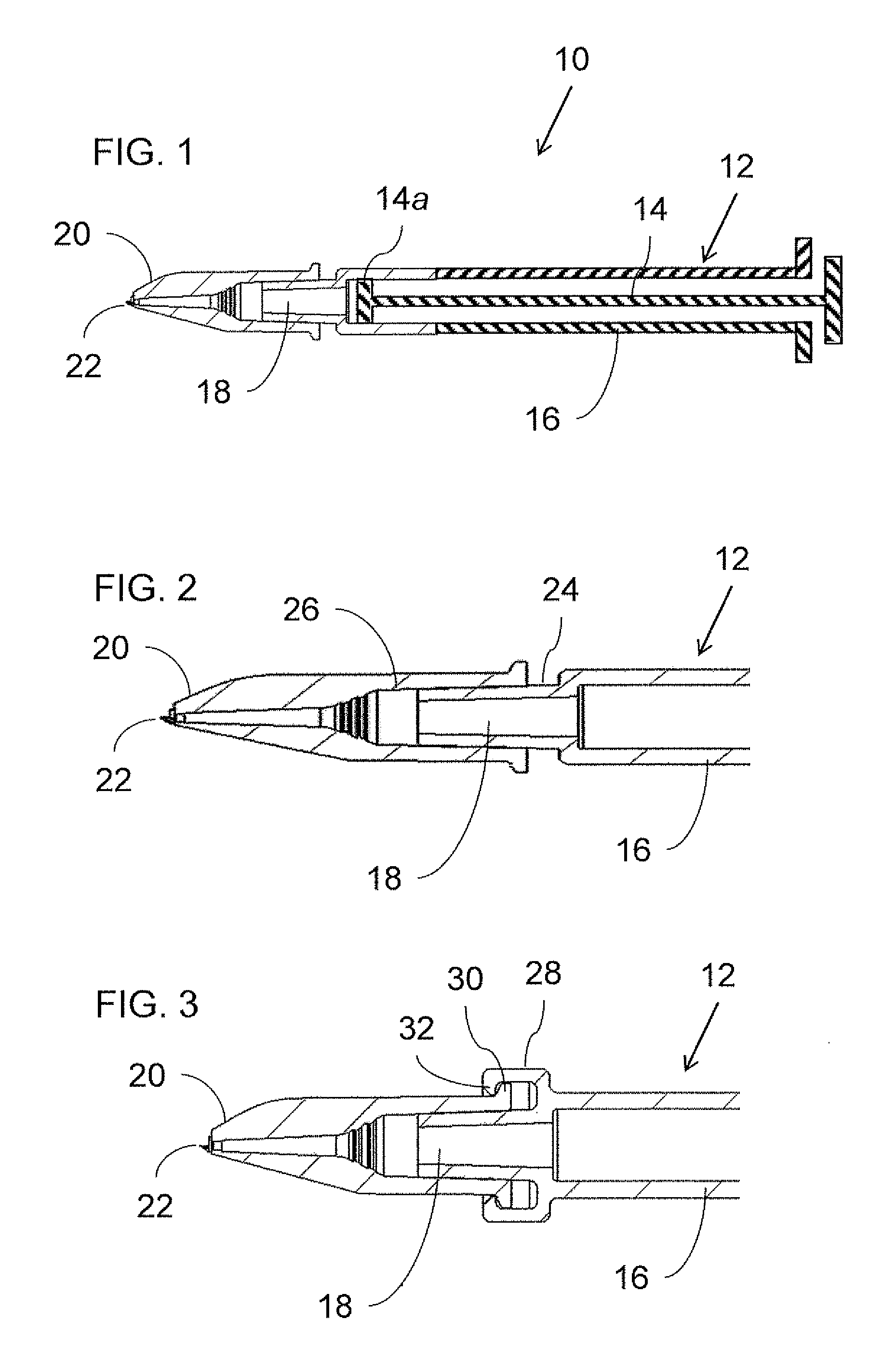

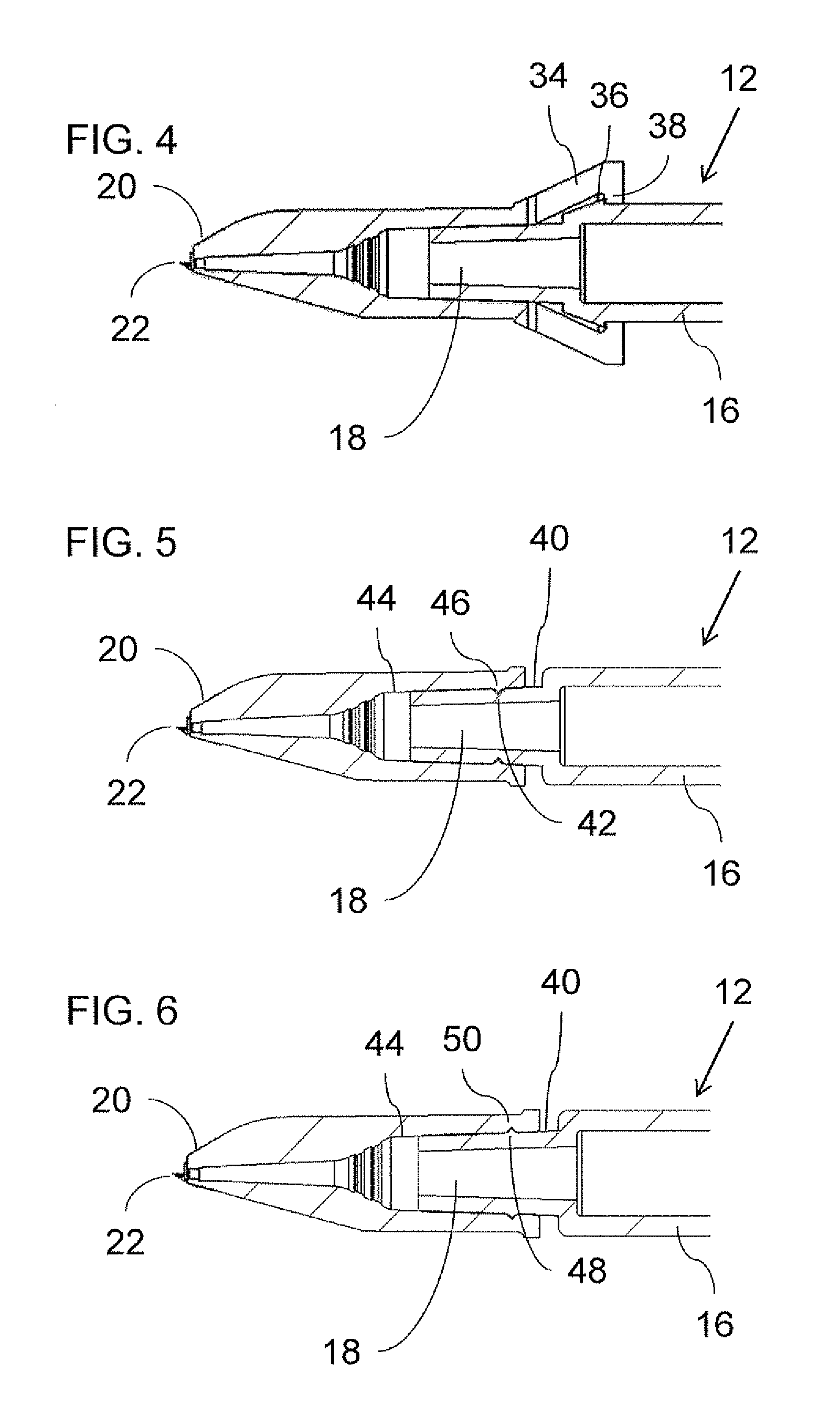

Microneedle Intradermal Drug Delivery Device with Auto-Disable Functionality

InactiveUS20130110043A1Reduce dead spacePrevent exitMicroneedlesNon destructiveBiomedical engineering

A microneedle intradermal drug delivery device with auto-disable functionality includes a syringe (12) having a plunger (14) displaceable along a barrel (16) and a microneedle adapter (20) with hollow microneedle(s) (22). The microneedle adapter (20) and the syringe (12) are configured for irreversible engagement such that, after attachment of the microneedle adapter (20) to the syringe (12), the microneedle adapter (20) is resistant to non-destructive manual removal from the syringe (12). Also provided are a self-locking plunger configuration (54, 56, 58) and a sliding safety shield (62).

Owner:NANOPASS TECH LTD

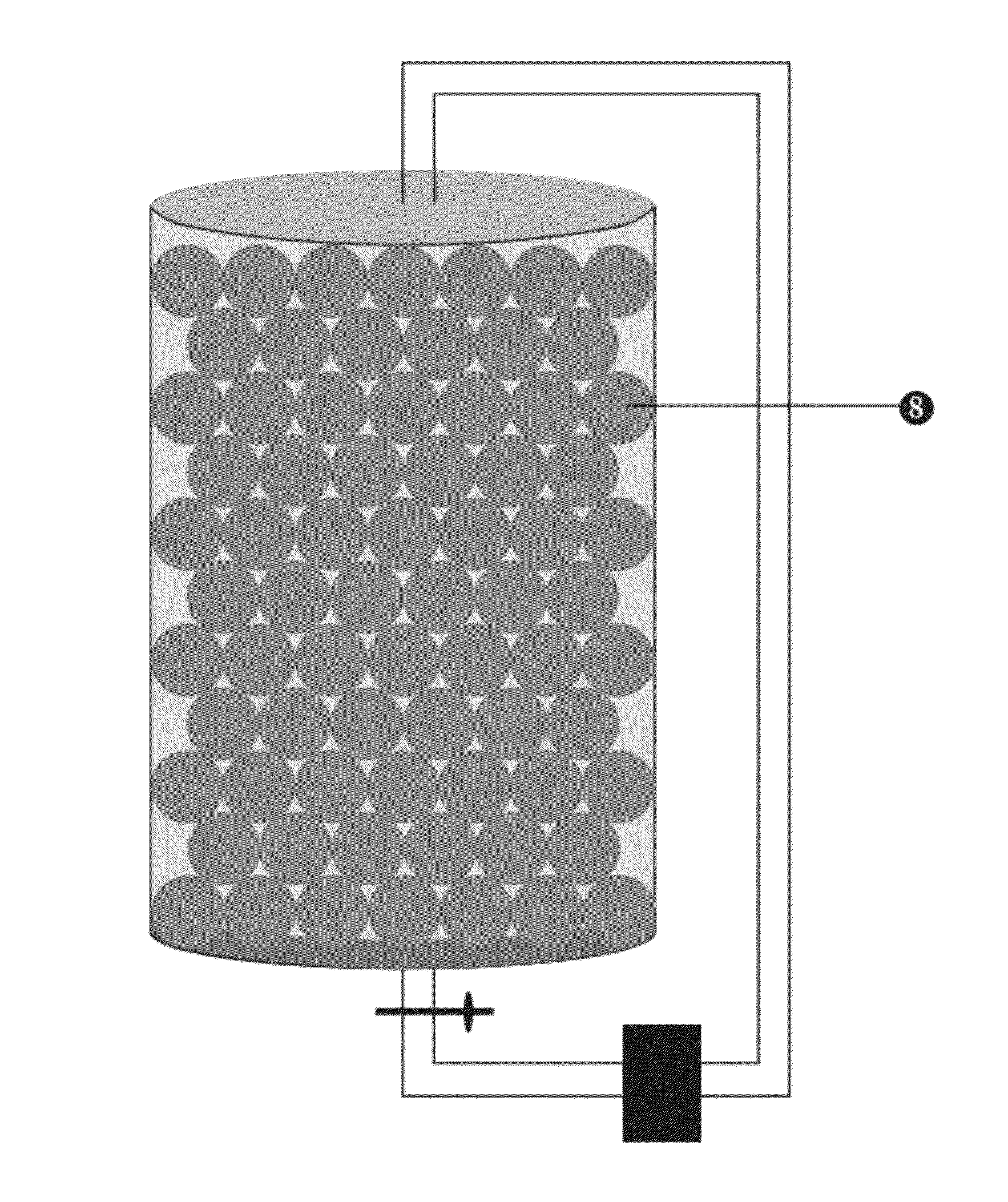

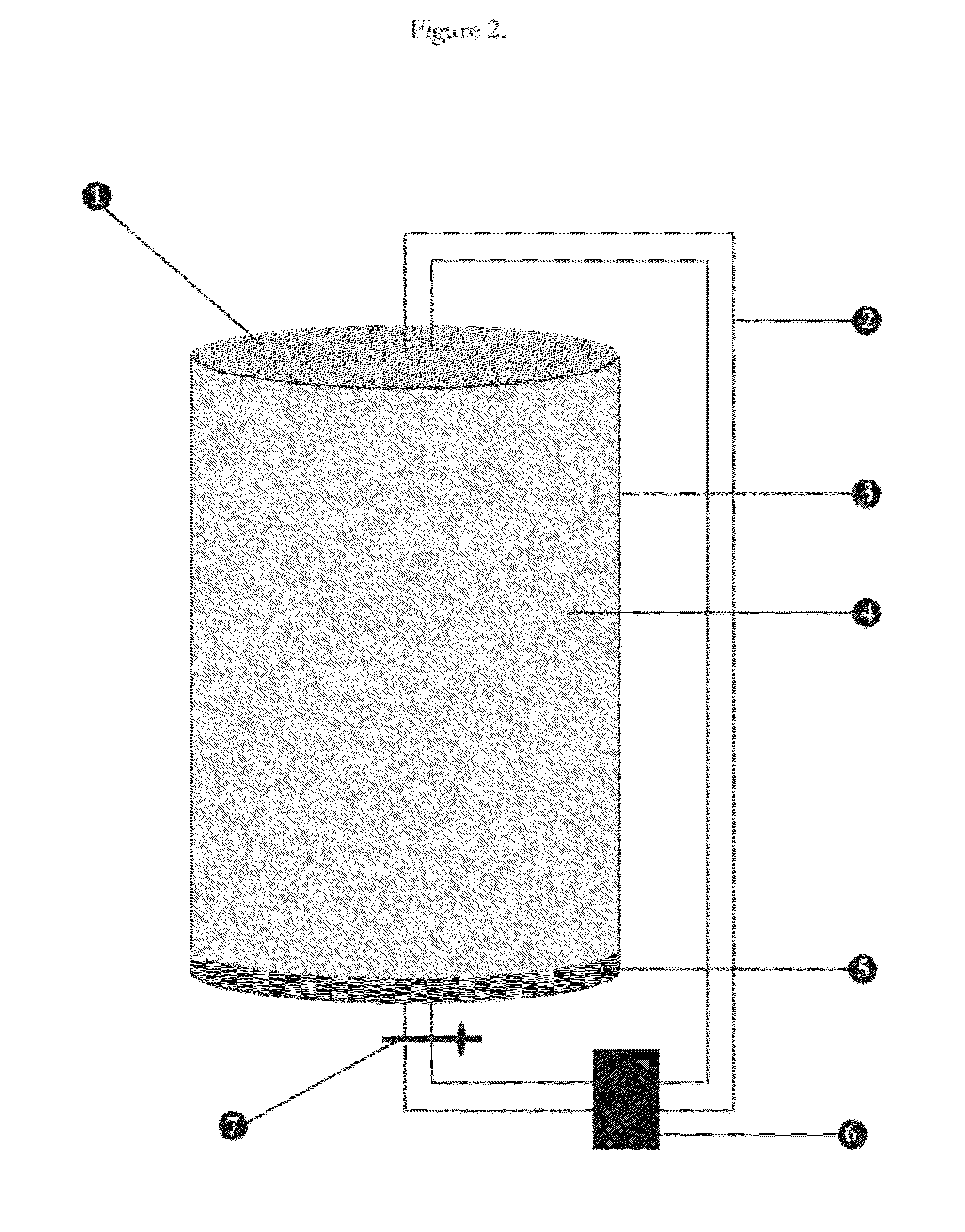

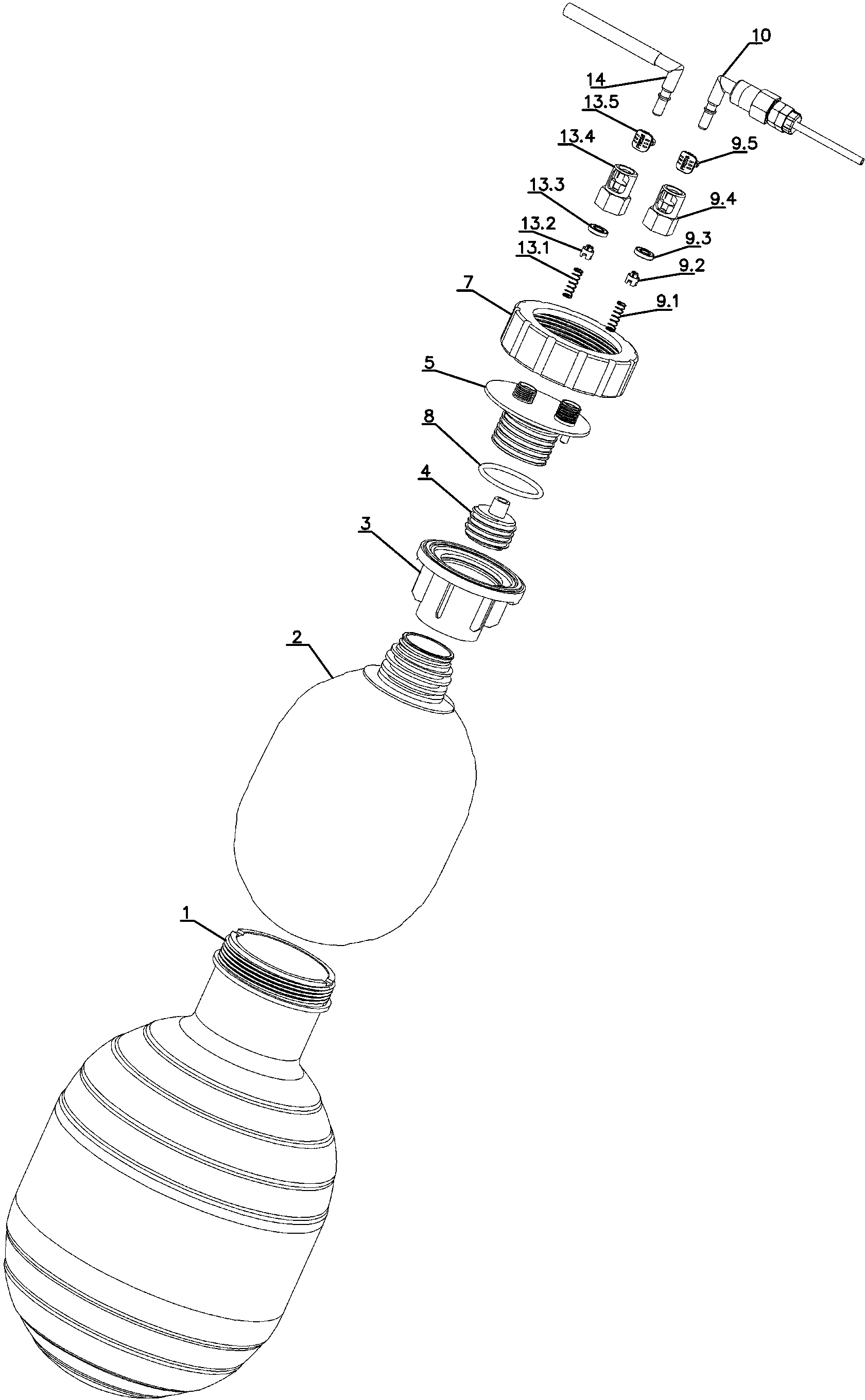

Accelerated Aging of Alcohol Drinks

InactiveUS20170292100A1Slow variation of pressureDesirable flavorAlcoholic beverage preparationAlcohol drinkAccelerated aging

Devices and methods are described that enable controlled, repeatable and accelerated aging and infusion of alcohol containing beverages. The devices include newly reaction canisters in a computer controlled environment of valves, pumps, interconnecting plumbing, sensors and mixing and dispersing manifolds. Embodiments include devices and infusing materials. The infusing materials include traditional aging / infusing materials such as oaks traditionally used to make barrels for aging and infusion as well as other woods and a variety of non-wood infusion materials such as citrus, beans and seeds. The combination of controls, sensor and computer interface allows for repeatable preparation of aged / infused drinks and for development of new aged / infused drinks.

Owner:BUTTE BRYAN

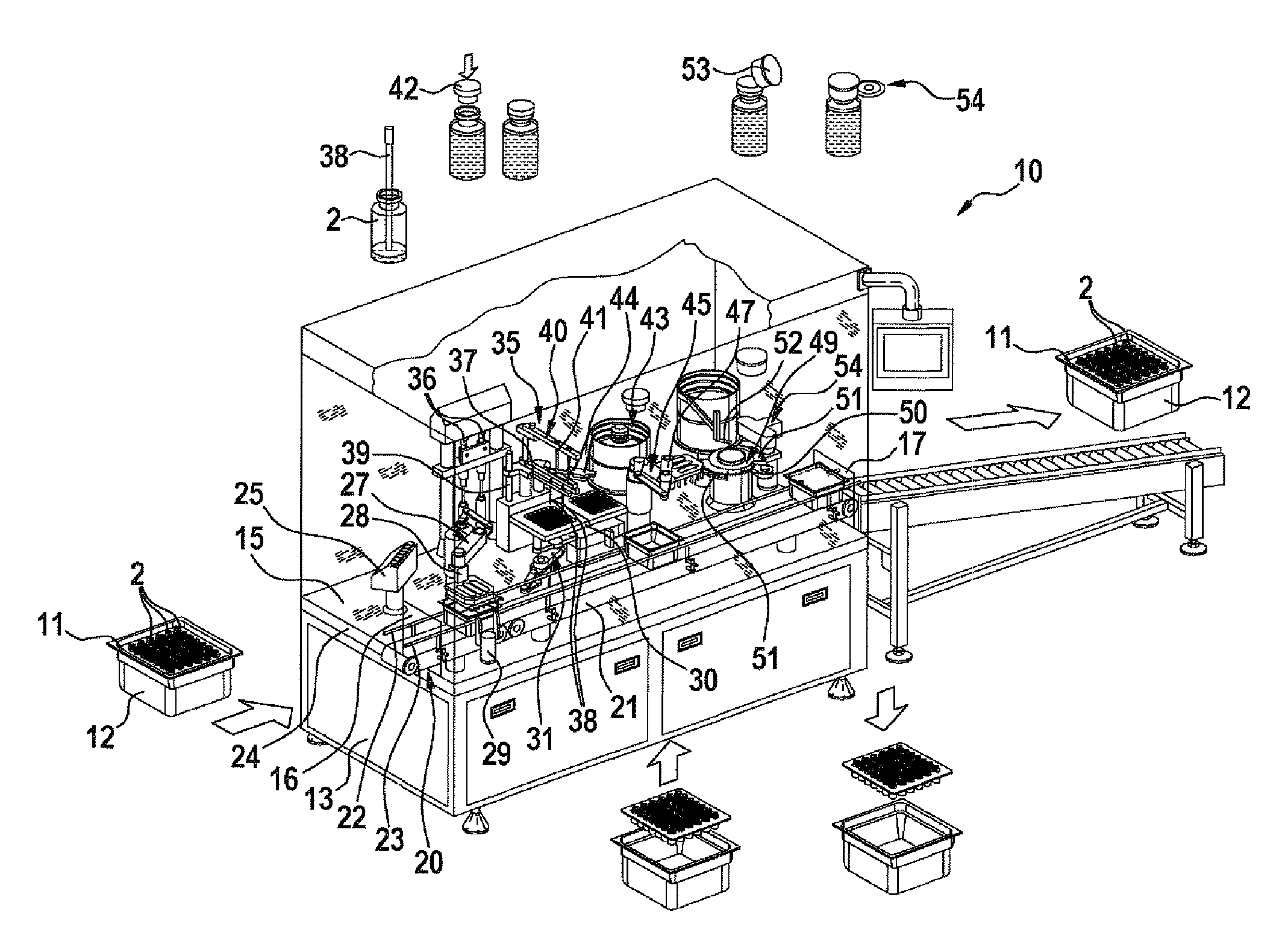

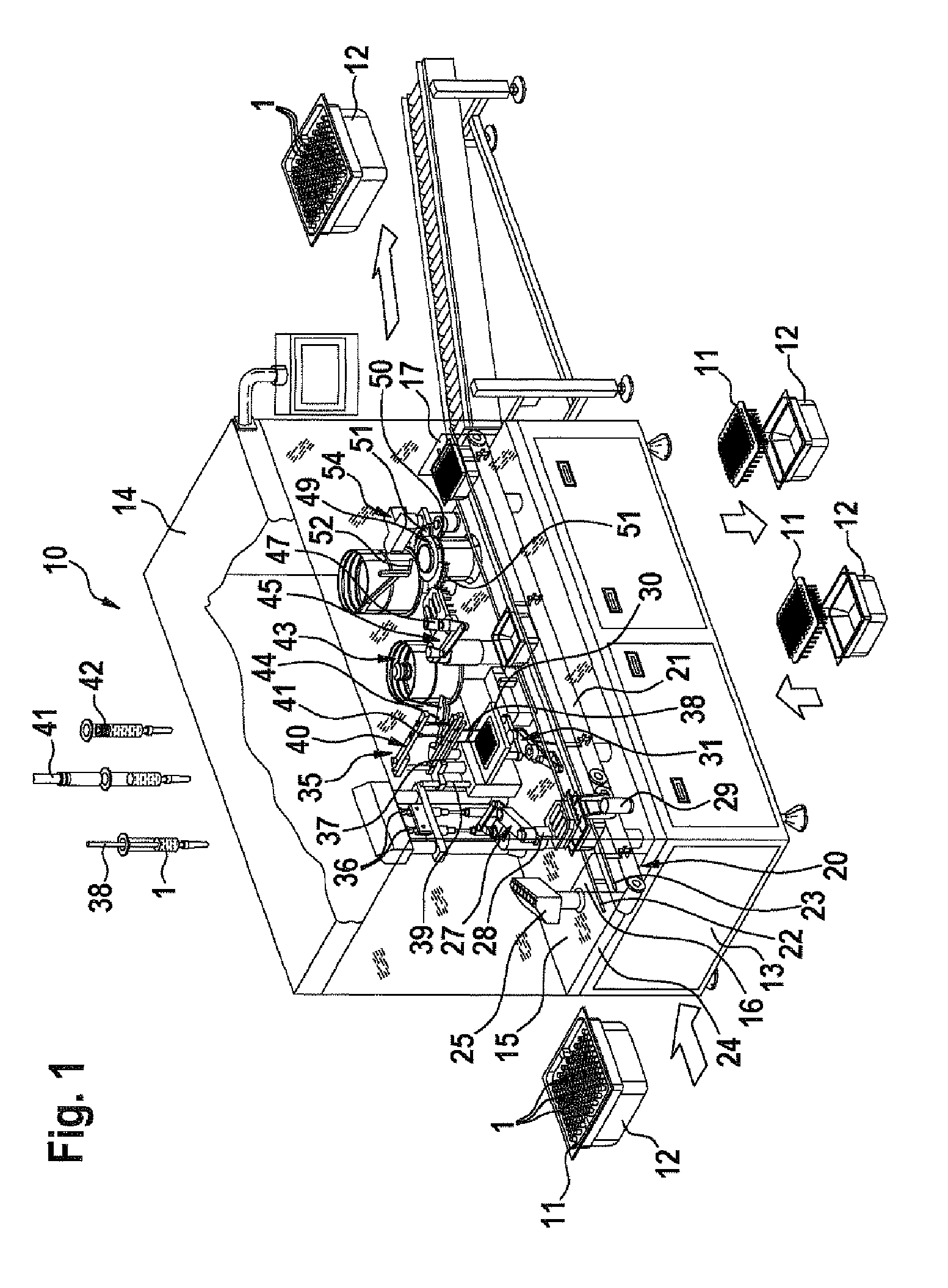

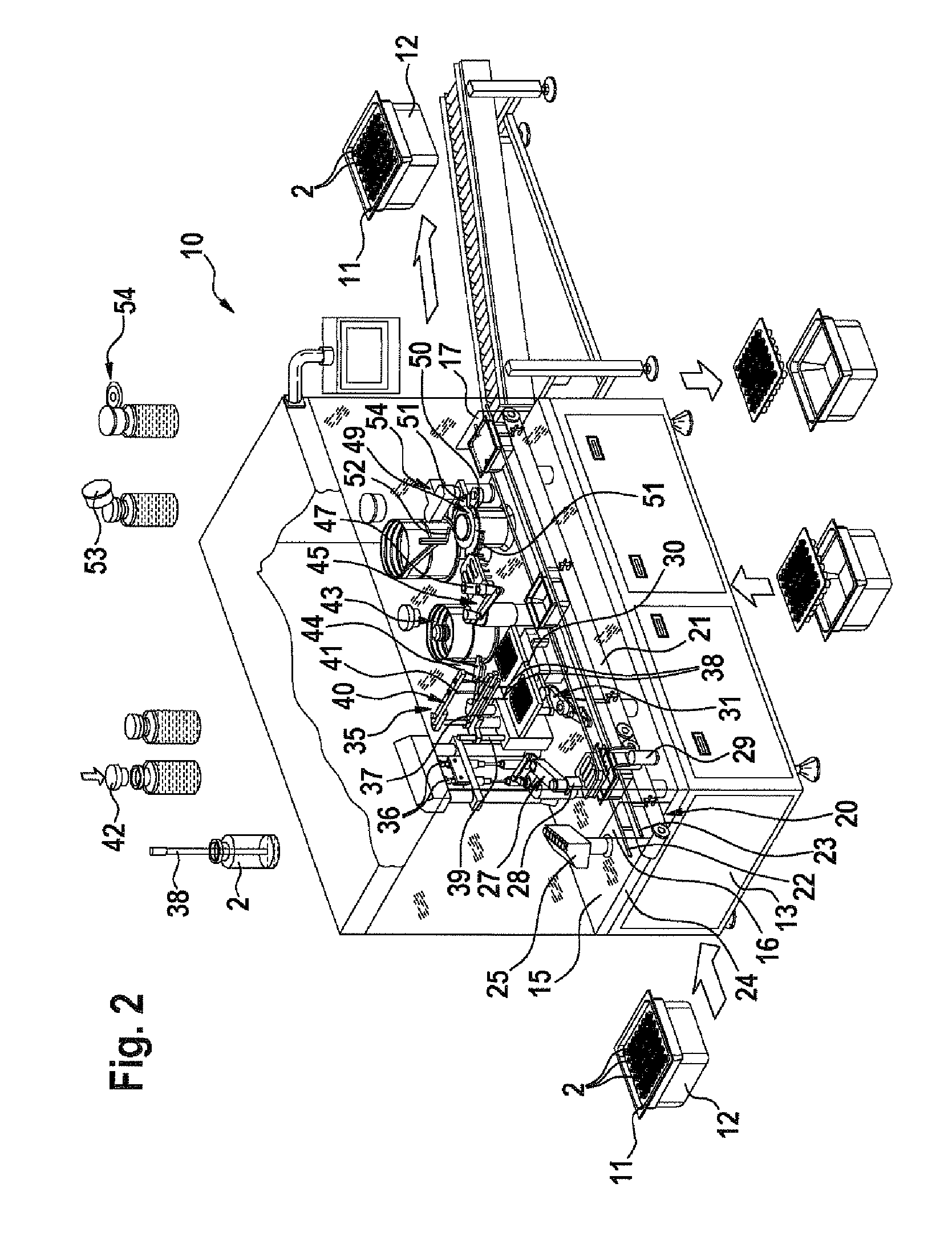

Device for filling and sealing pharmaceutical containers

ActiveUS8978344B2Chance is lostNo longer be conveyedIntravenous devicesSolid materialEngineeringBarrel

The invention is a device (10) for filling and sealing pharmaceutical containers. The containers are received in a receptacle (12), in which a carrier element (11) is inserted. The containers are arranged in receivers of the carrier element (11) in multiple rows. The device further includes a first handling unit (27) for removing the carrier element (11) from the receptacle (12), a filling and sealing device (35) for the containers, and a second handling unit (45) for reinserting the carrier element (11) into the receptacle (12) which is conveyed with the carrier element (11) on a conveying device (20). The containers are embodied as syringe barrels (1) or as containers which are to be provided with crimp caps (53), and the second handling device (45) is associated with a crimping device (54).

Owner:SYNTEGON TECHNOLOGY GMBH

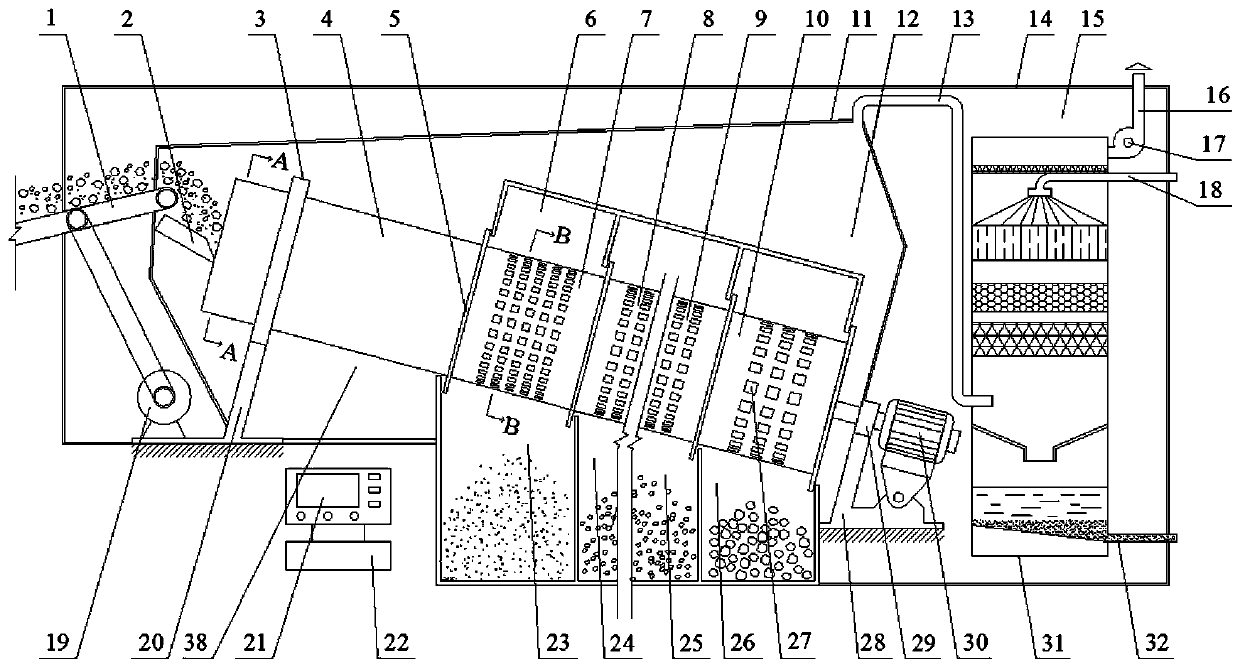

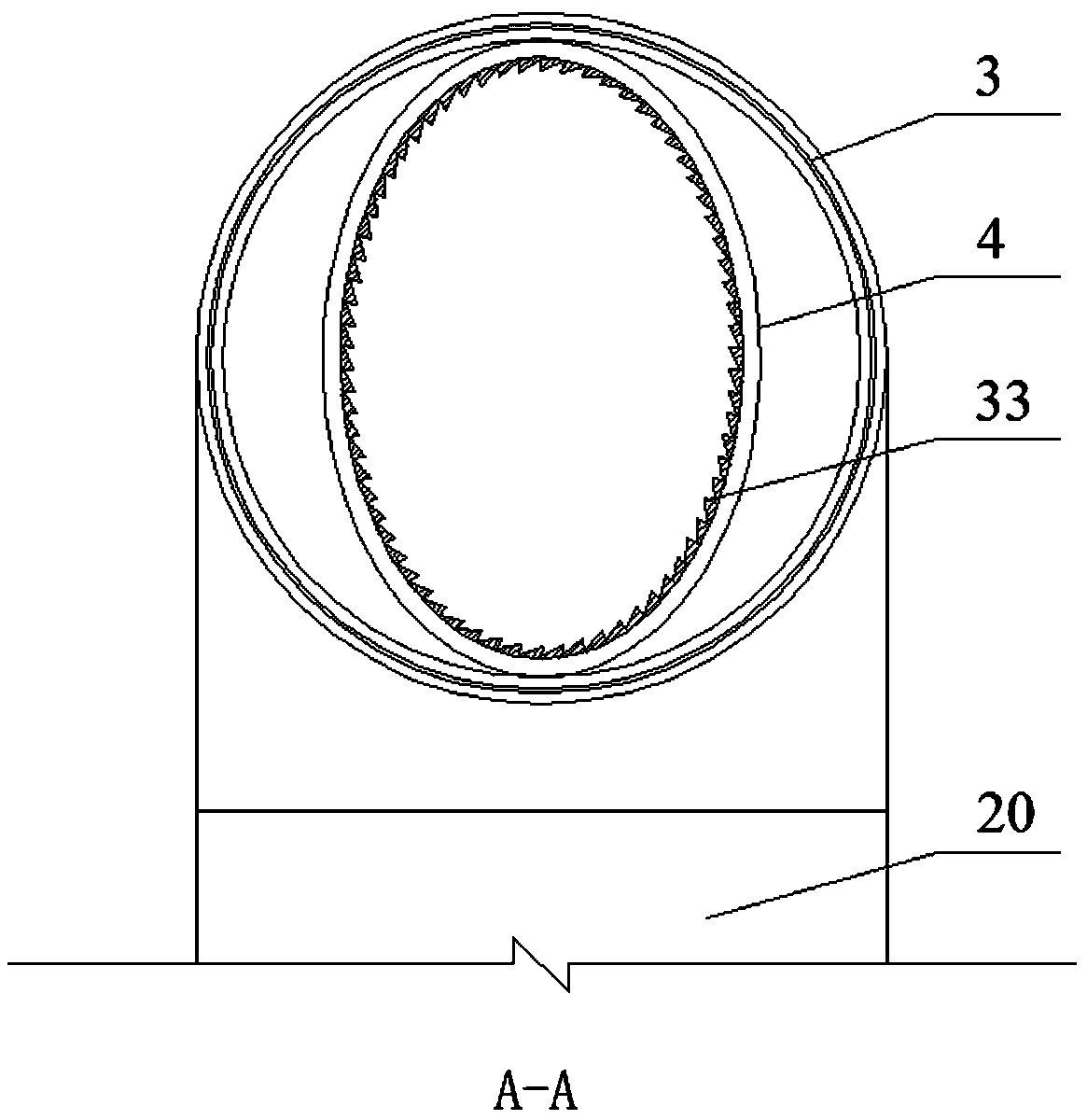

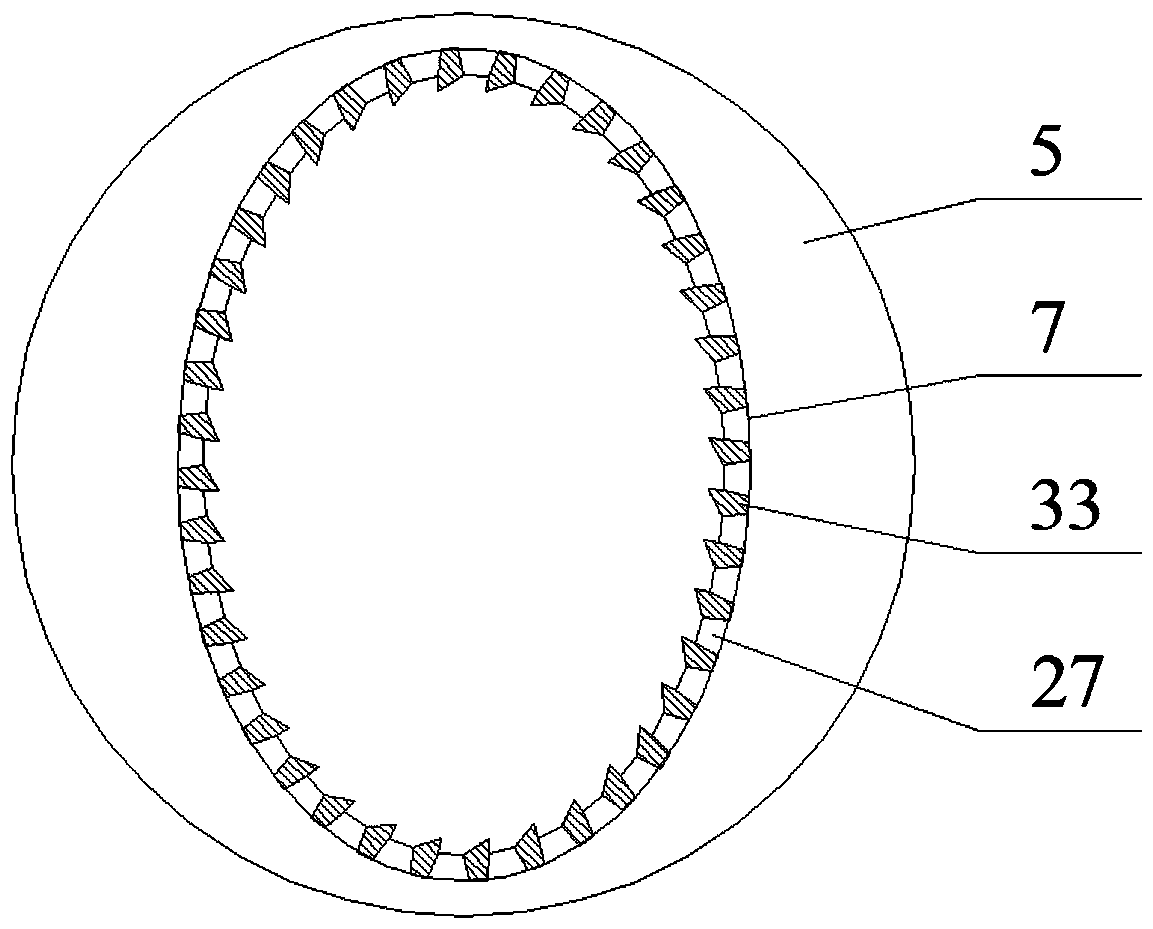

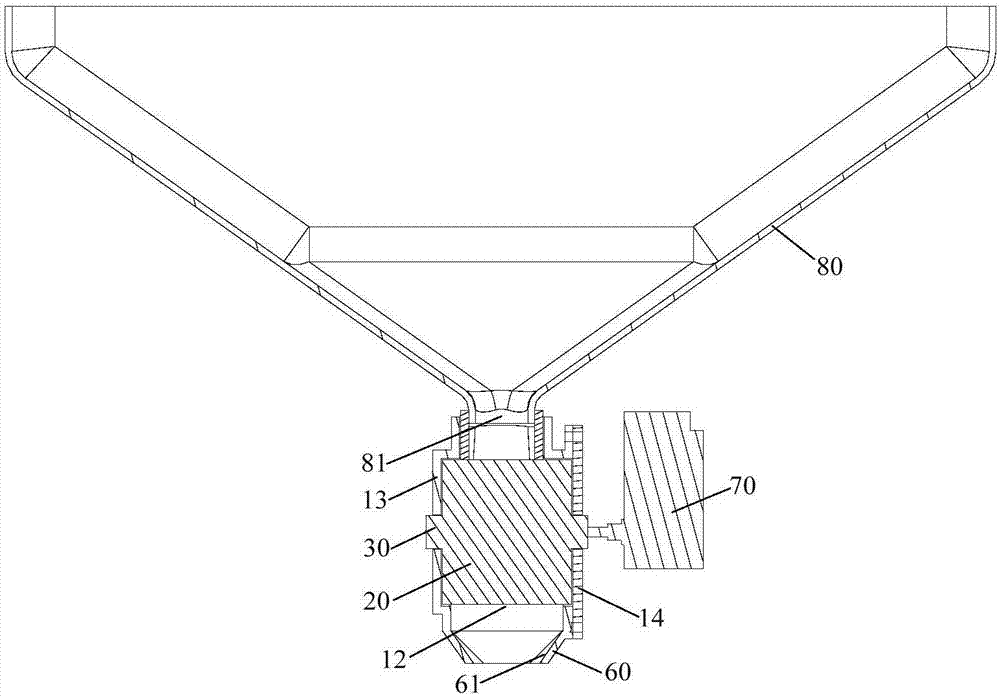

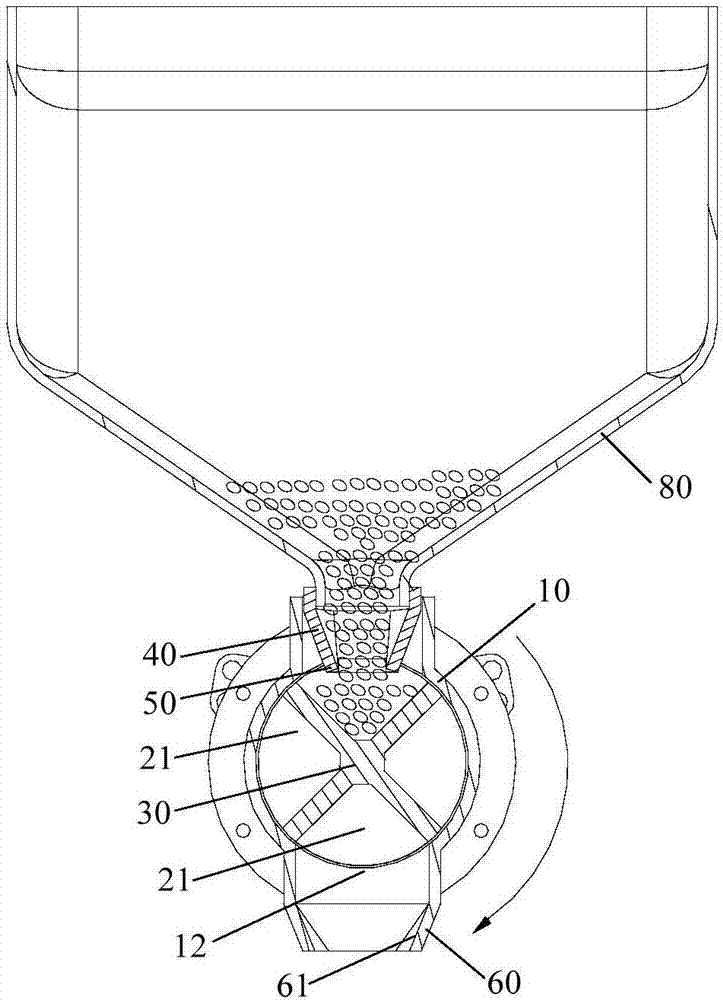

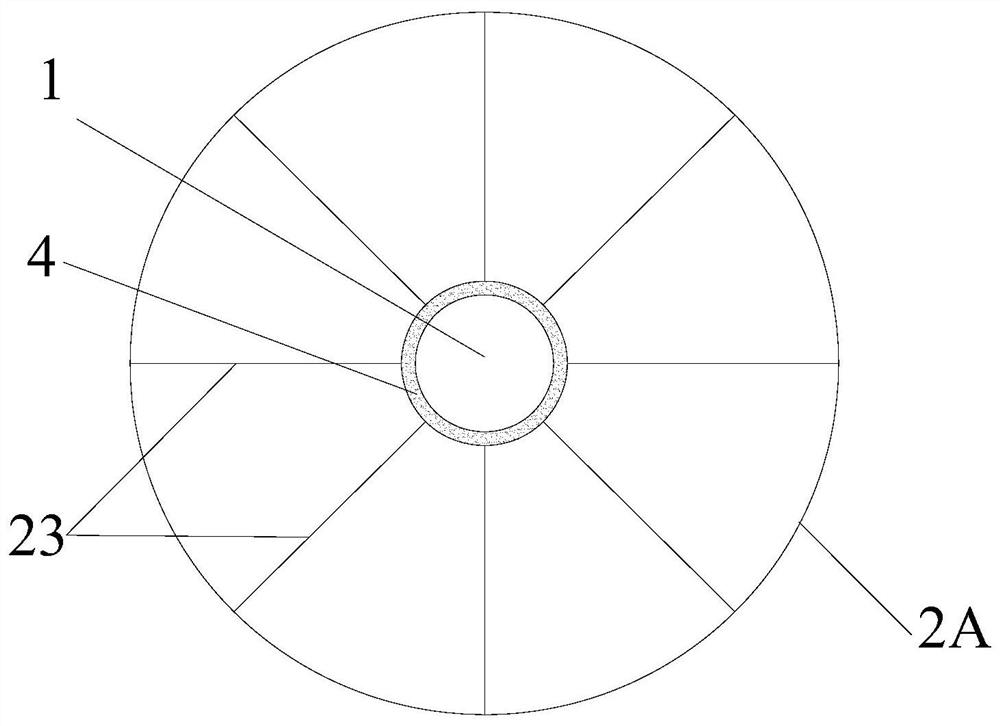

Recycled aggregate shaping barrel and recycled aggregate shaping equipment using shaping barrel

The invention relates to a recycled aggregate shaping barrel and recycled aggregate shaping equipment using the shaping barrel. The recycled aggregate shaping barrel comprises a barrel body which is provided with a shaping section and a feeding hole, wherein support parts which are in rotating and supporting fit with corresponding support seats are arranged on the barrel body; and the cross section of the shaping section is in an elliptical shape. When recycled aggregates are shaped, the barrel body is driven by a driving mechanism to rotate, and back-and-forth rollover and impact of the innerpart of the barrel body is driven by the elliptical shaping section, so that through the arrangement of the elliptical shaping section, increment on impact force of an inner wall to particles and gyratory motion amplitude and frequency of the particles in the barrel body are facilitated, so that a mortar weak layer on the surfaces of the recycled aggregates is effectively abraded and removed; andin addition, because of the elliptical structure, excessive acting force on the recycled aggregates is avoided, and the recycled aggregates are prevented from being broken, so that the shapes of theparticles of the shaped recycled aggregates are close to squircle, damage to internal structures of the aggregates is reduced to a maximum extent while the good shaping effect is realized at the sametime, and a desired shaping reinforcement effect is achieved.

Owner:ZHENGZHOU UNIV

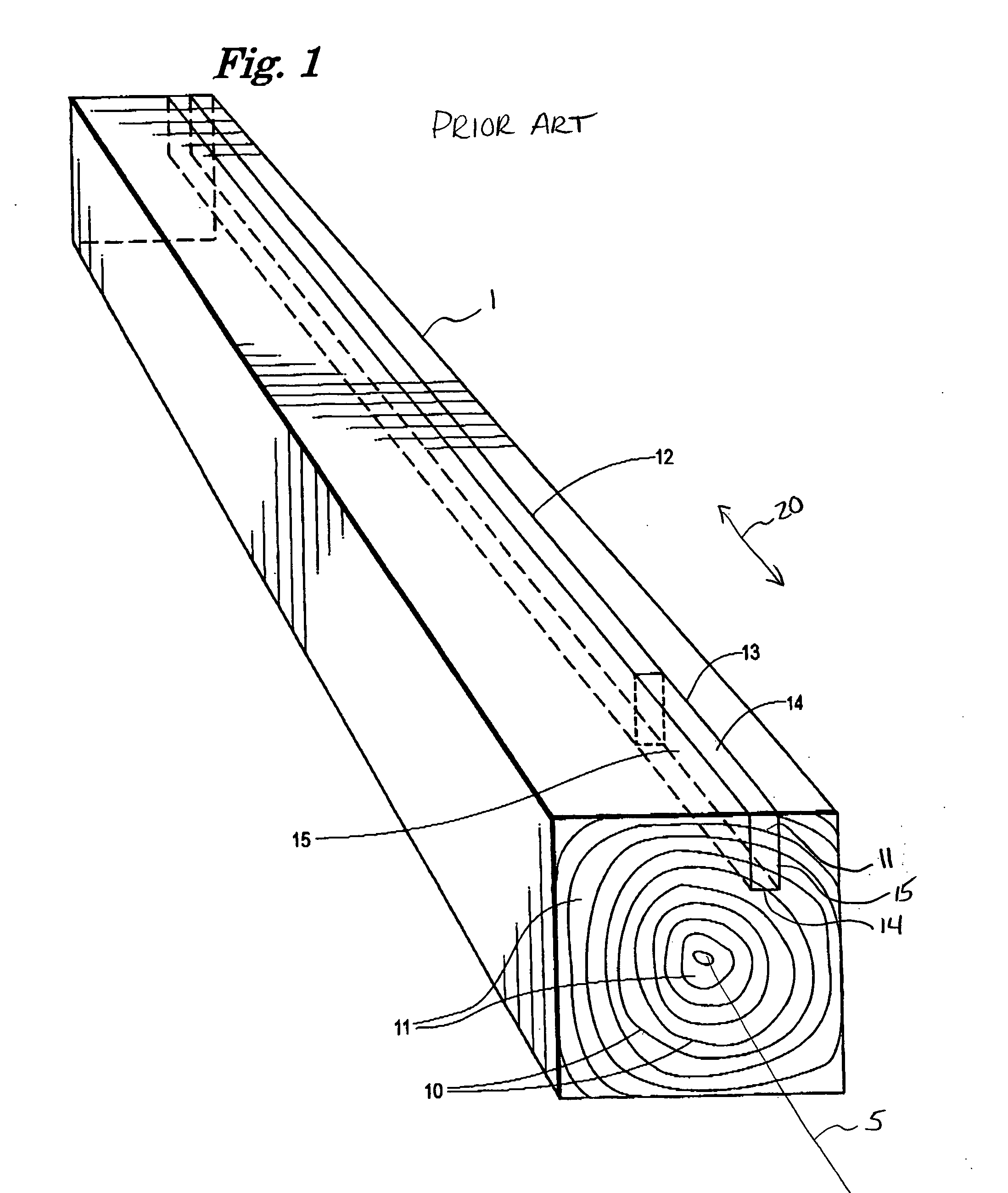

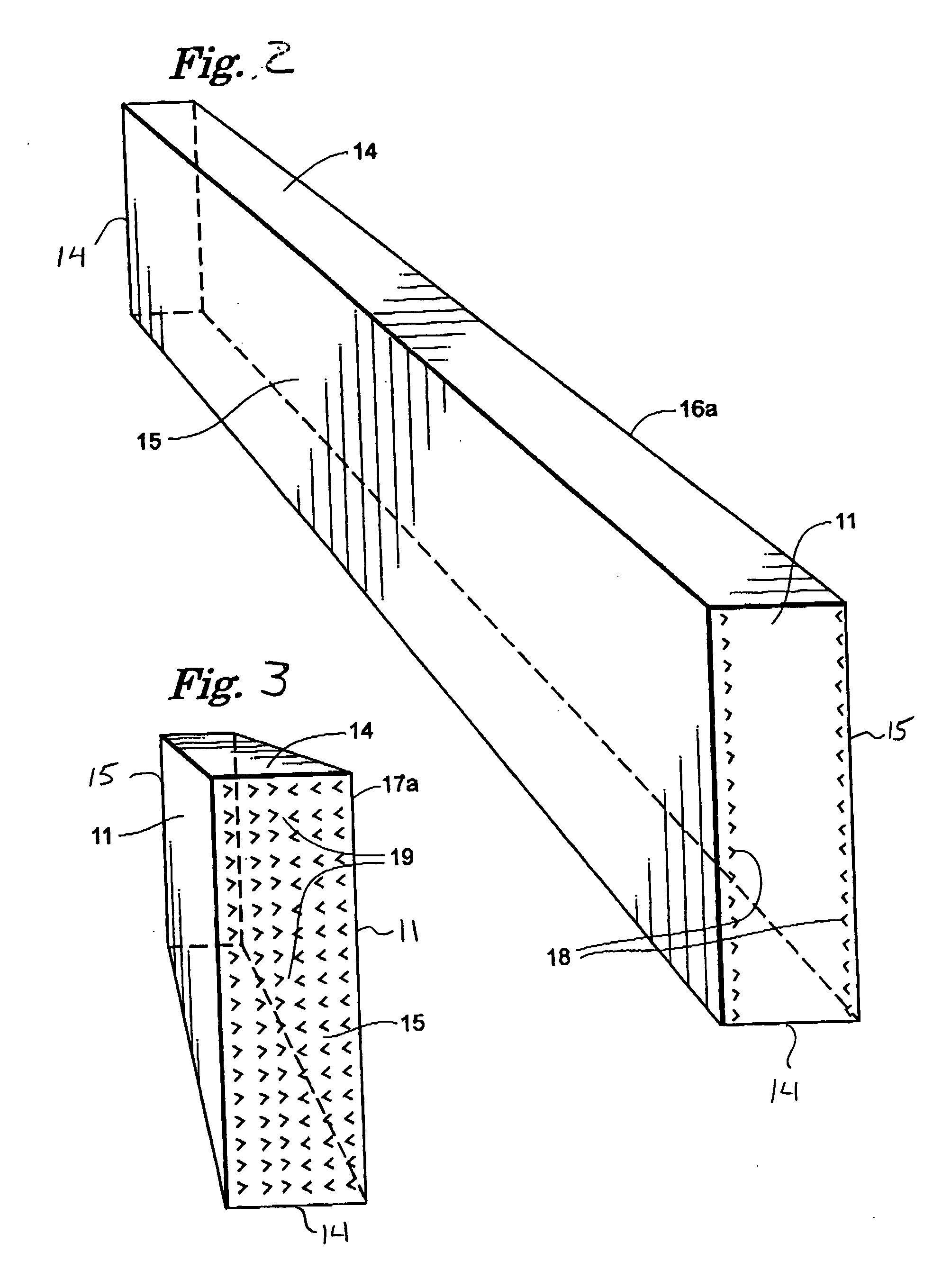

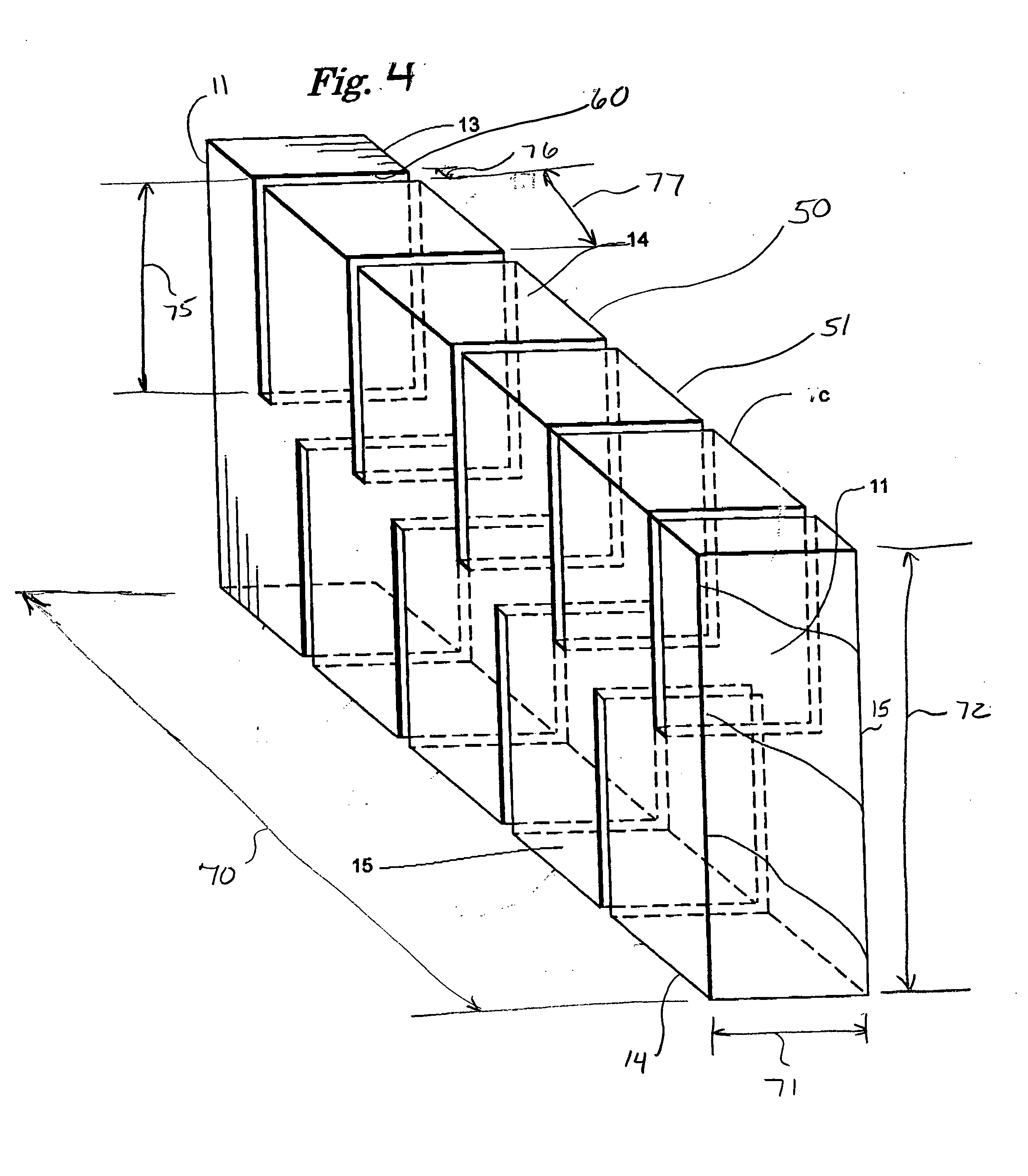

Barrel alternative for flavoring wine

A barrel alternative is a wood member cut or formed to expose a significant amount of longitudinal surface area in relation to the volume or length of the wood member. Because the longitudinal face is more permeable than other faces of the wood, extraction time is reduced and the barrel alternative can be produced in a cost effective manner.

Owner:PLUMB DAVID C

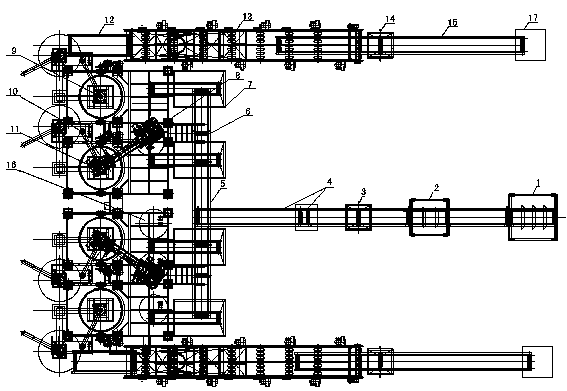

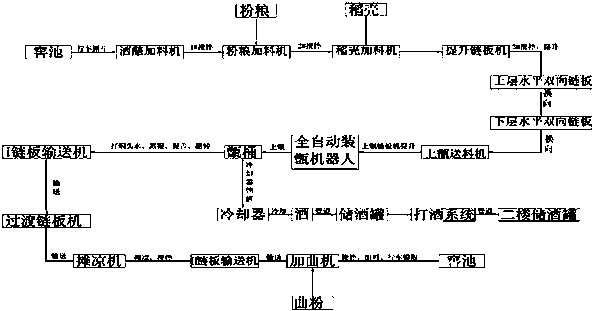

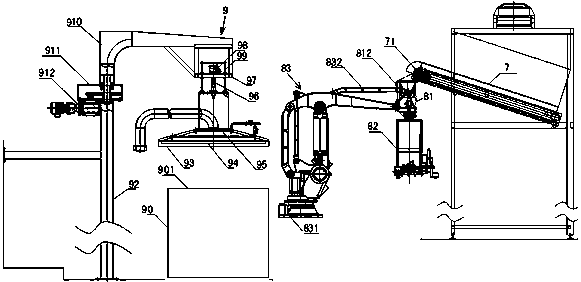

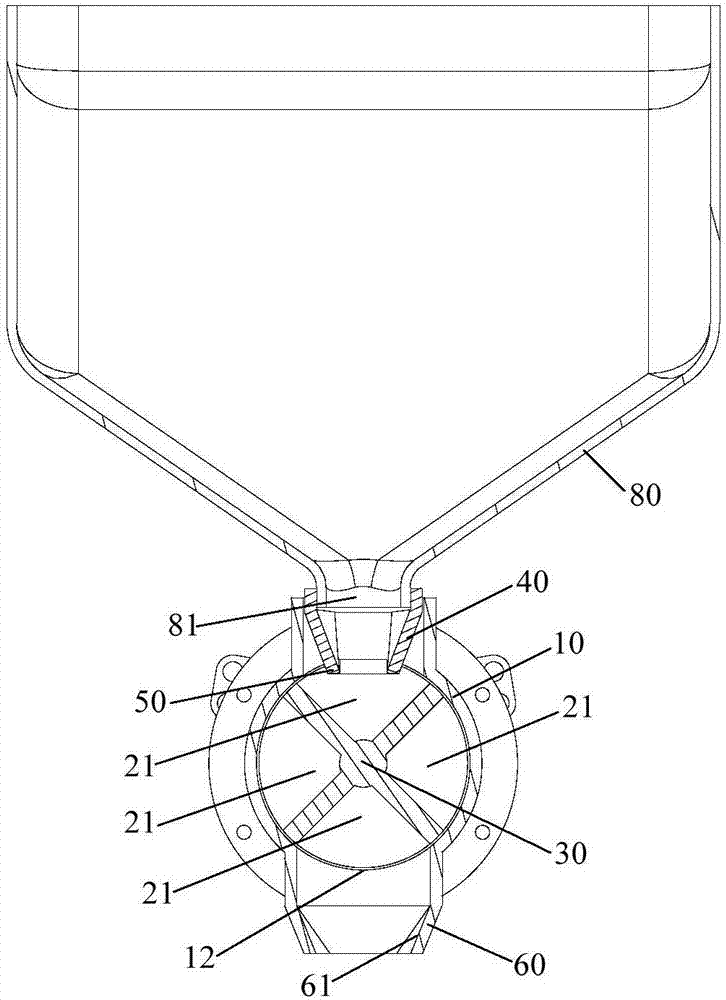

Automatic wine-making production line with full-automatic steaming robot

ActiveCN103911261ASimple structureReasonable layoutAlcoholic beverage preparationProcess engineeringManufacturing line

The invention discloses an automatic wine-making production line with a full-automatic steaming robot. The automatic production line comprises a fermented grain charger, a powder grain charger, a rice husk charger, a lifting chain plate machine, an upper horizontal double-layer chain plate machine, a lower horizontal double-layer chain plate machine, a steamer charger, a full-automatic steaming robot, a steaming barrel, a cooler, a chain plate conveyor I, a transition chain plate machine, a cooling machine, a distiller's yeast charger, a chain plate conveyor II and a wine storage tank. The production line is reasonable in layout, full-automatic in mechanical operation, low in labor intensity and good in production environment conditions, and energy is saved.

Owner:JIANGSU KINGS LUCK BREWERY +1

Preparation method of red wine rich in resveratrol

ActiveCN102634429AIncrease vitalityEasy to useMicroorganism based processesWine preparationFiltrationFreeze-drying

The invention provides a preparation method of red wine rich in resveratrol. According to the method, the red wine with resveratrol content of 125.2-168.5mg / L is prepared by the following steps of: firstly preparing four freeze-dried powder leavening agent of the following four strains: saccharomyces cerevisiae, saccharomyces loges, saccharomyces willianus and an aspergillus niger; and then preparing grape with color on peels, carrying out the processes of cleaning, stem removal, pulp preparation, primary fermentation at 25-28 DEG C, secondary fermentation at 18-20 DEG C, filtration by a plate filter, ageing, first barrel change after 8 and10 days, second barrel change after 50 and 60 days, third barrel change after 80 and 90 days, fourth barrel change after 170 and180 days, sealed storage for 2-3 years, mixing with wine base according to the dosage being above 65% and the like.

Owner:黑龙江省谷醴传奇健康酒业有限公司

Quantifying device and cooking utensil

PendingCN107960921ANo failureGuaranteed Quantitative AccuracyCooking vesselsRotational axisQuantitative accuracy

The invention provides a quantifying device and a cooking utensil. The quantifying device comprises an outer barrel and a rotation part, wherein a material inlet hole and a material discharge hole areformed in the outer barrel; the rotation part is positioned in the outer barrel, and is provided with quantifying grooves with one ends provided with openings, a rotation shaft is connected to the rotation part, the rotation part can perform fixed-axis rotation by adopting the rotation shaft as the center, so that the openings of the quantifying grooves perform movement along the circumferentialdirection of the rotation shaft; a feeding position and a discharging position are arranged on the movement locus of the opening of each quantifying groove, when at the feeding position, the opening of each quantifying groove communicates with the material inlet hole and is isolated from the material discharge hole, when at the discharging position, the opening of each quantifying groove communicates with the material discharge hole and is isolated from the material inlet hole. For the quantifying device provided by the technical scheme of the invention, volume quantifying is carried out on materials by utilizing the quantifying grooves, compared with the weighing quantifying manner, the volume quantifying manner has the advantages that the influences of the measurement precision are eliminated, meanwhile, the phenomenon of efficacy loss is avoided, and thus the quantifying accuracy and reliability of the product are guaranteed.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

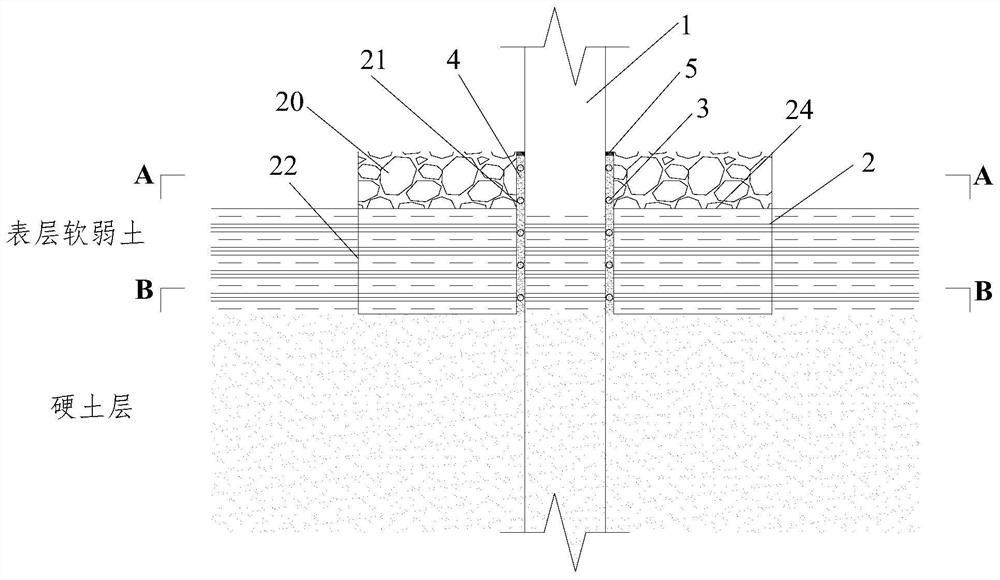

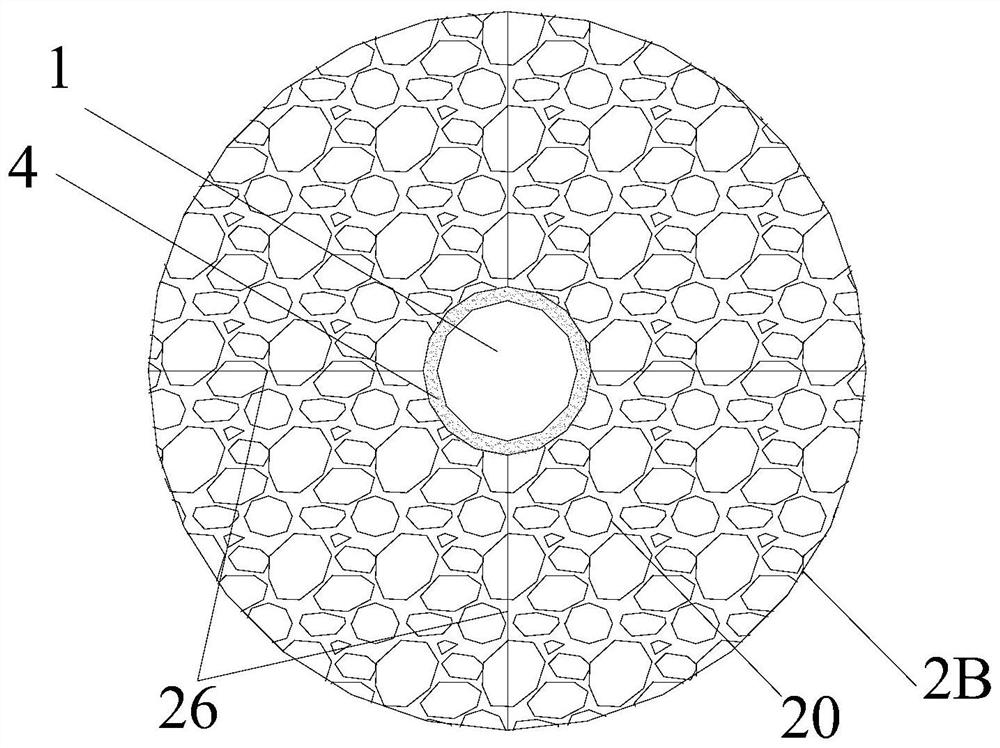

Pile box barrel composite foundation for offshore wind power and construction method thereof

The invention discloses a pile box barrel composite foundation for offshore wind power. The pile box barrel composite foundation comprises a single pile and a barrel body, wherein the barrel body comprises an inner barrel body, an outer barrel body, a negative pressure barrel top plate and a plurality of negative pressure barrel partition plates; the inner barrel body is coaxially arranged in an inner cavity of the outer barrel body and arranged on the single pile in a sleeving mode; the inner barrel body and the single pile are connected into a whole through grouting; the negative pressure barrel top plate is arranged between the upper portion of the inner barrel body and the upper portion of the outer barrel body in a sealing and covering mode, so that a negative pressure barrel is formed on the lower portion of the negative pressure barrel top plate, an open box barrel is reserved on the upper portion of the negative pressure barrel top plate, and the interior of the open box barrelis divided into a plurality of weight areas through a plurality of rib plates; the plurality of negative pressure barrel partition plates are evenly connected into the negative pressure barrel in theradial direction to divide the negative pressure barrel into a plurality of negative pressure cabins; and after the barrel body penetrates into seabed soil and the negative pressure barrel top platereaches the designed elevation, the weight areas of the open box barrel are filled with riprap weights, and the box-shaped foundation is formed. The invention further discloses a construction method of the pile box barrel composite foundation for offshore wind power. By means of the pile box barrel composite foundation for offshore wind power and the construction method thereof, the anti-overturning bearing capacity can be improved, and the buried depth of the single pile is reduced.

Owner:CCCC THIRD HARBOR ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com