Patents

Literature

15685 results about "Manufacturing line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A production line is a traditional method which people associate with manufacturing. The production line is arranged so that the product is moved sequentially along the line and stops at work centers along the line where an operation is performed.

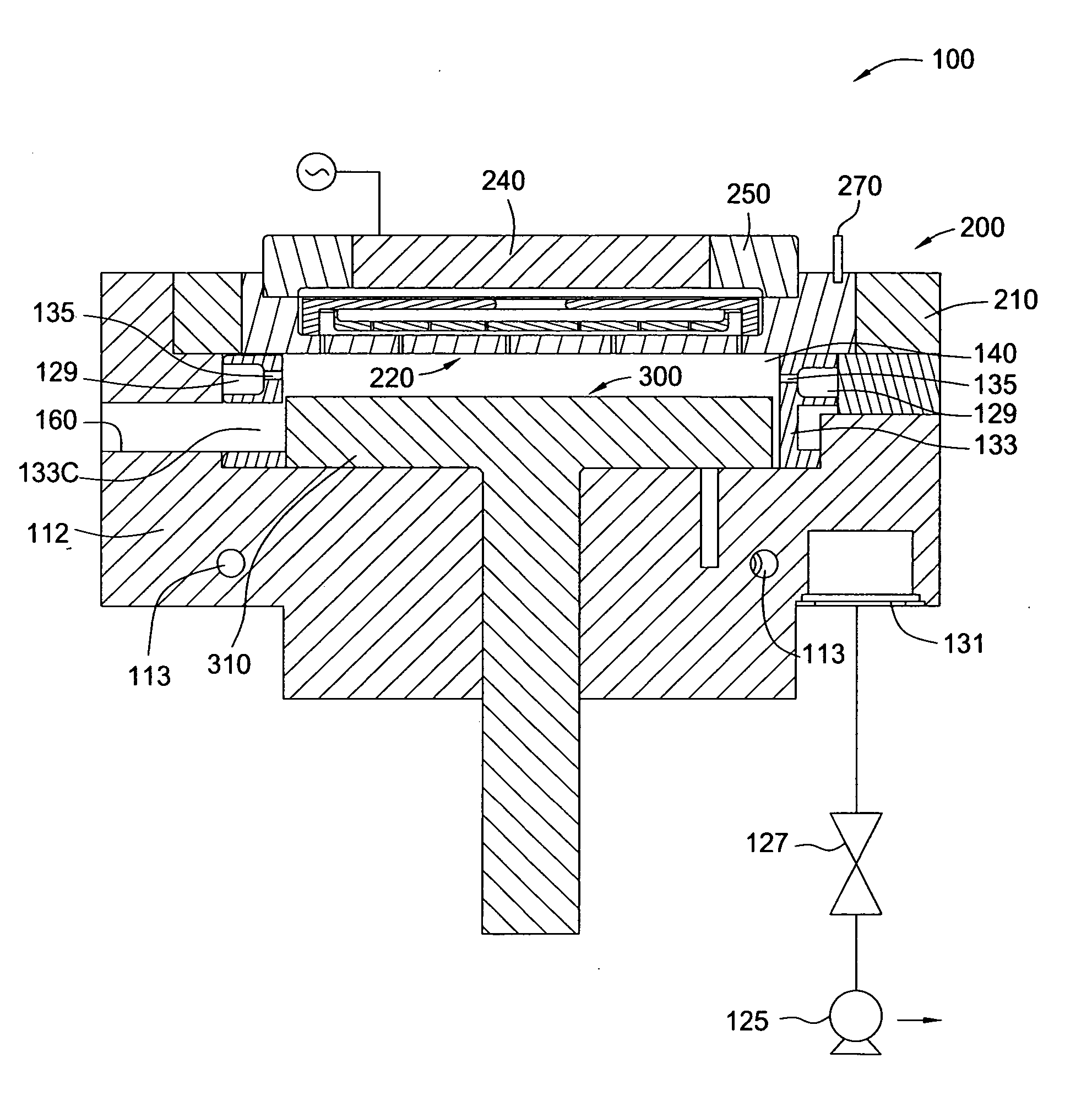

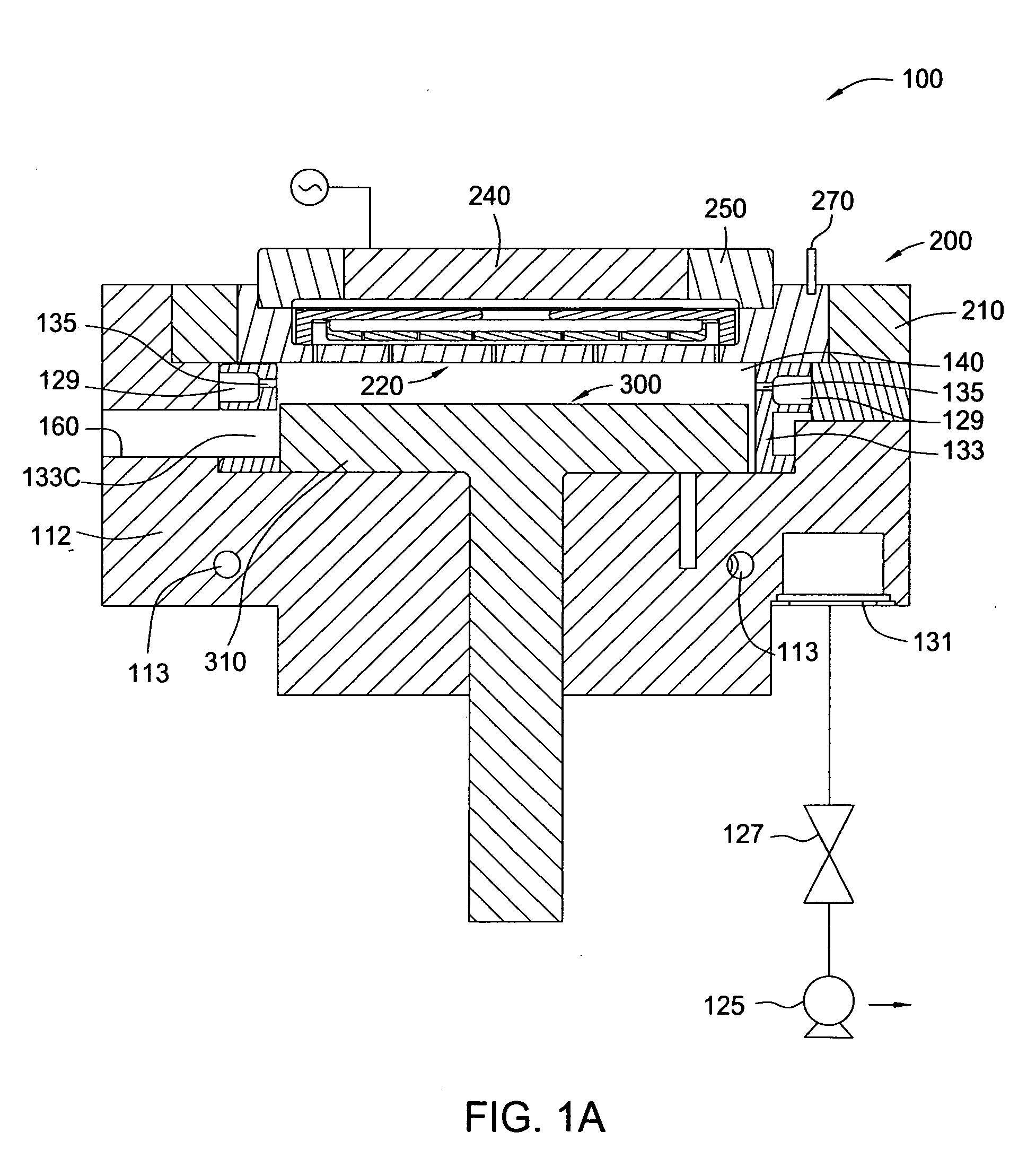

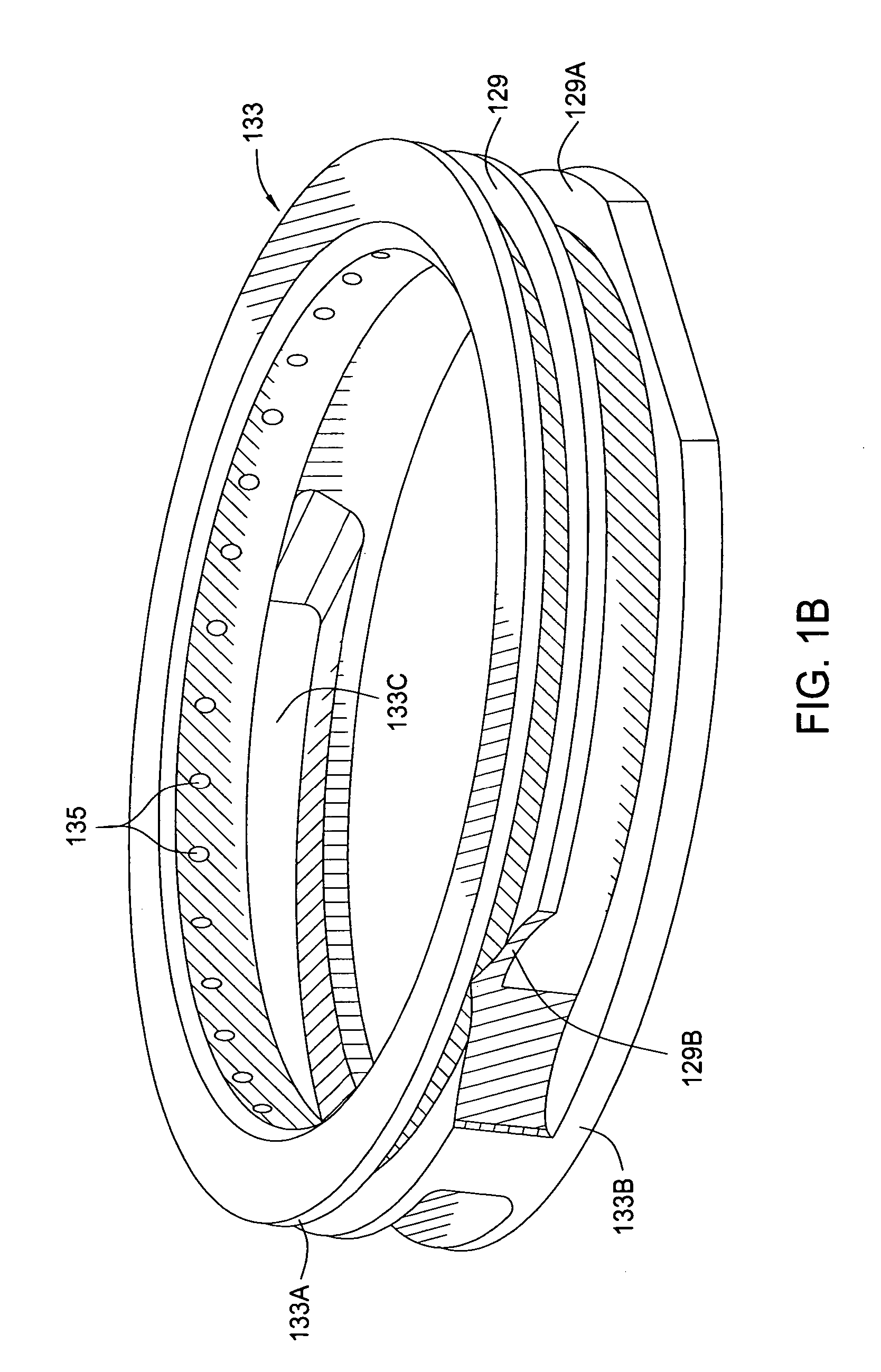

Substrate support for in-situ dry clean chamber for front end of line fabrication

InactiveUS20050221552A1Electric discharge tubesSemiconductor/solid-state device detailsFront end of lineBiomedical engineering

Owner:APPLIED MATERIALS INC

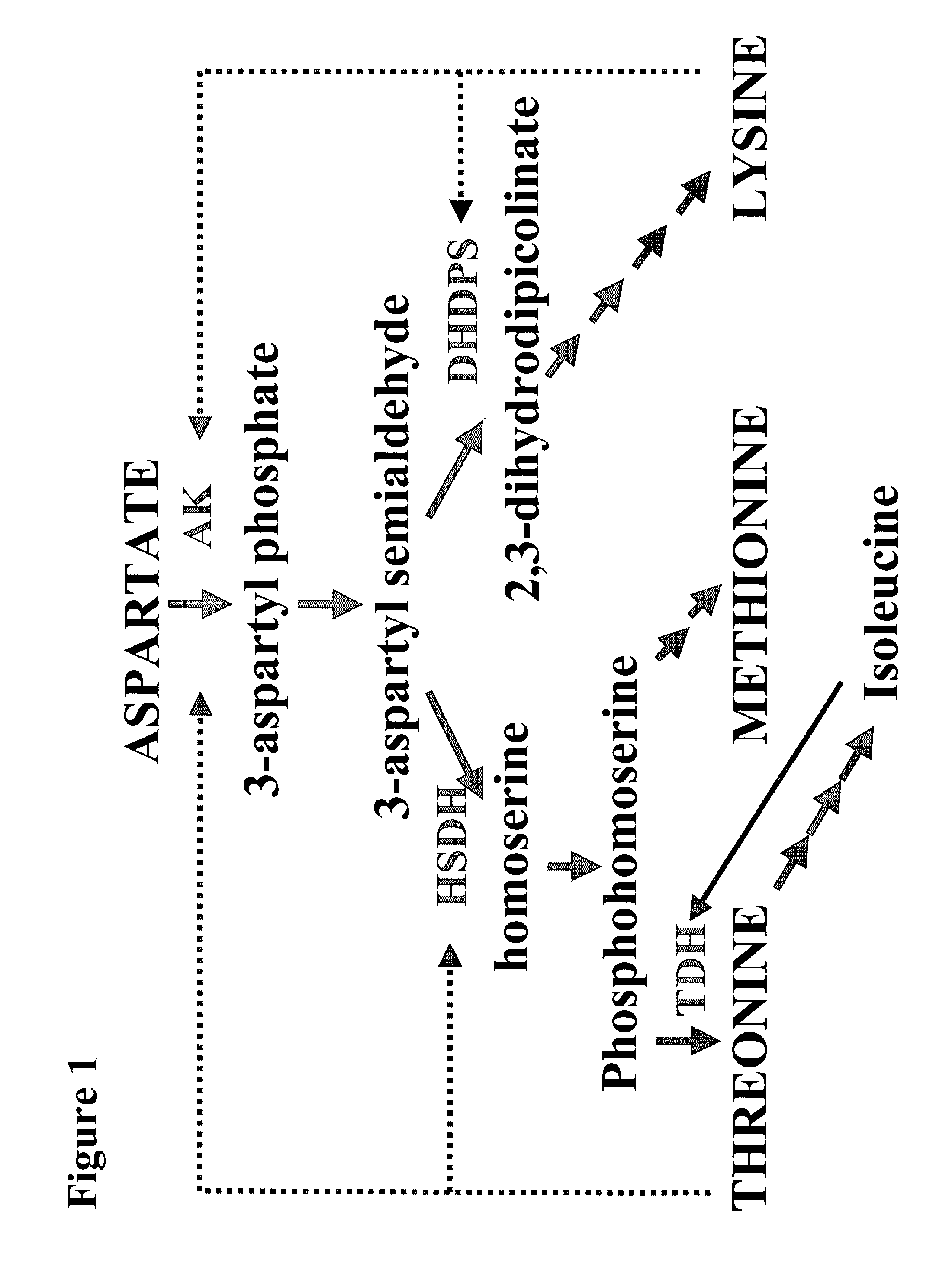

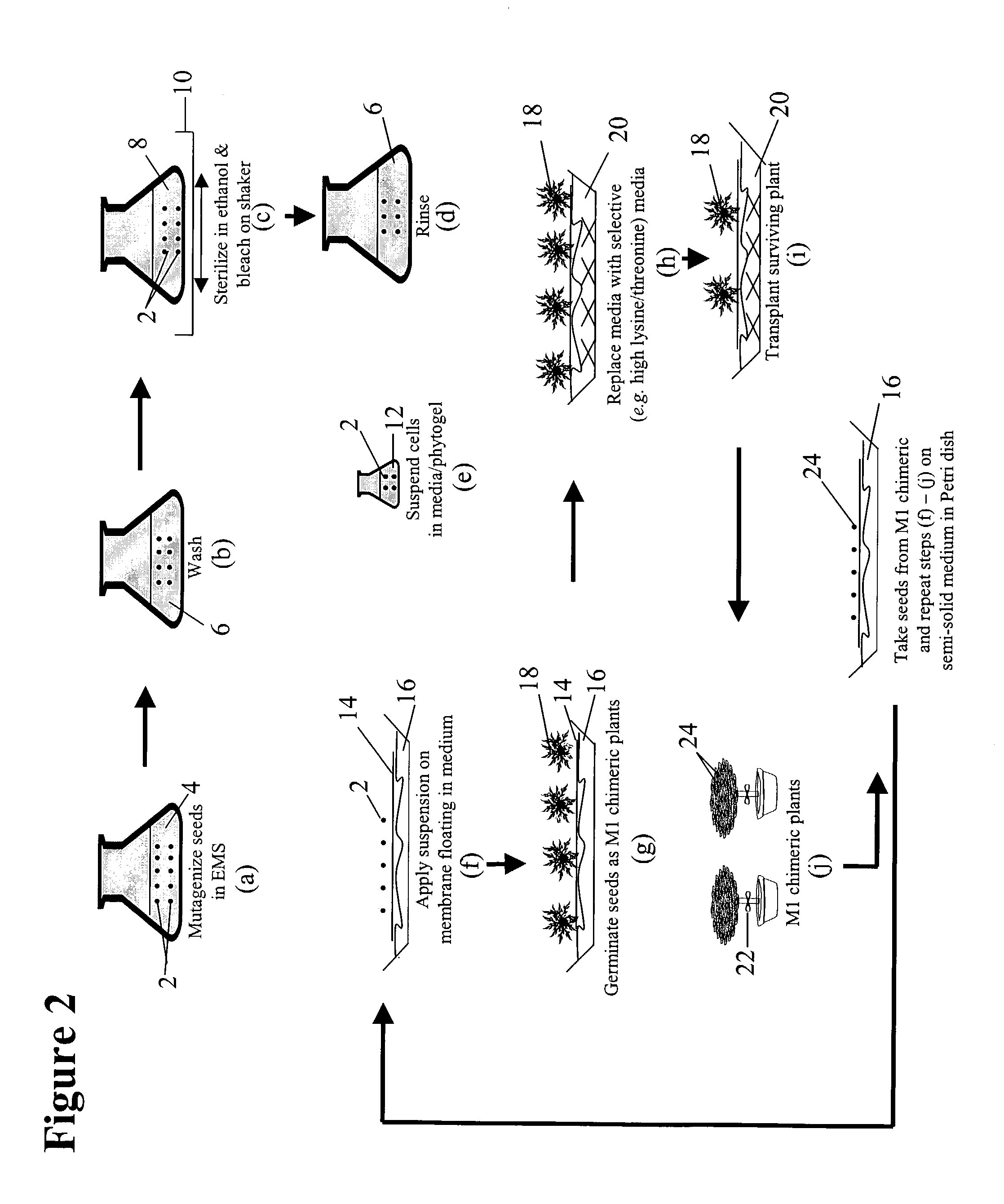

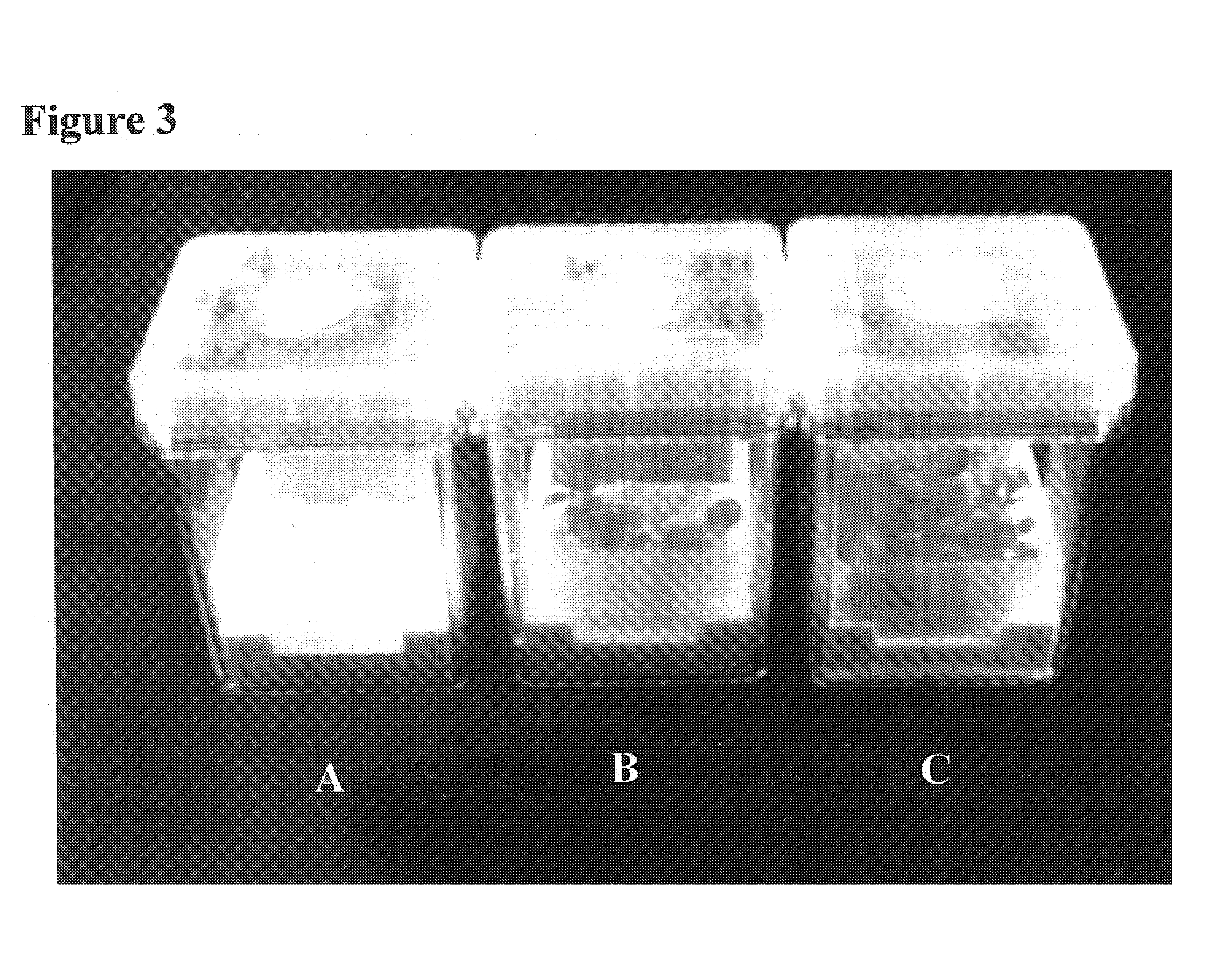

High threonine producing lines of Nicotiana tobacum and methods of producing

InactiveUS7173170B2Improve the level ofImproved taste and aromaMutant preparationFermentationNicotiana tabacumThreonine

The present invention provides a method for producing plants with a desired phenotypic trait which comprises subjecting plants to mutagenesis, screening chimeric progeny for plants having the desired phenotypic trait, and propagating the survivors. In an embodiment, the phenotypic trait comprises an altered amino acid content. Preferably, the technique is used to generate Nicotiana tobacum plant lines having an increase in at least one amino acid. In a preferred embodiment, the invention provides improved Nicotiana tobacum plant lines producing at least 1.35 nmole of threonine per milligram of dry plant weight. These plants are useful for improving the flavor and aroma of the tobacco.

Owner:REYNOLDS TECH

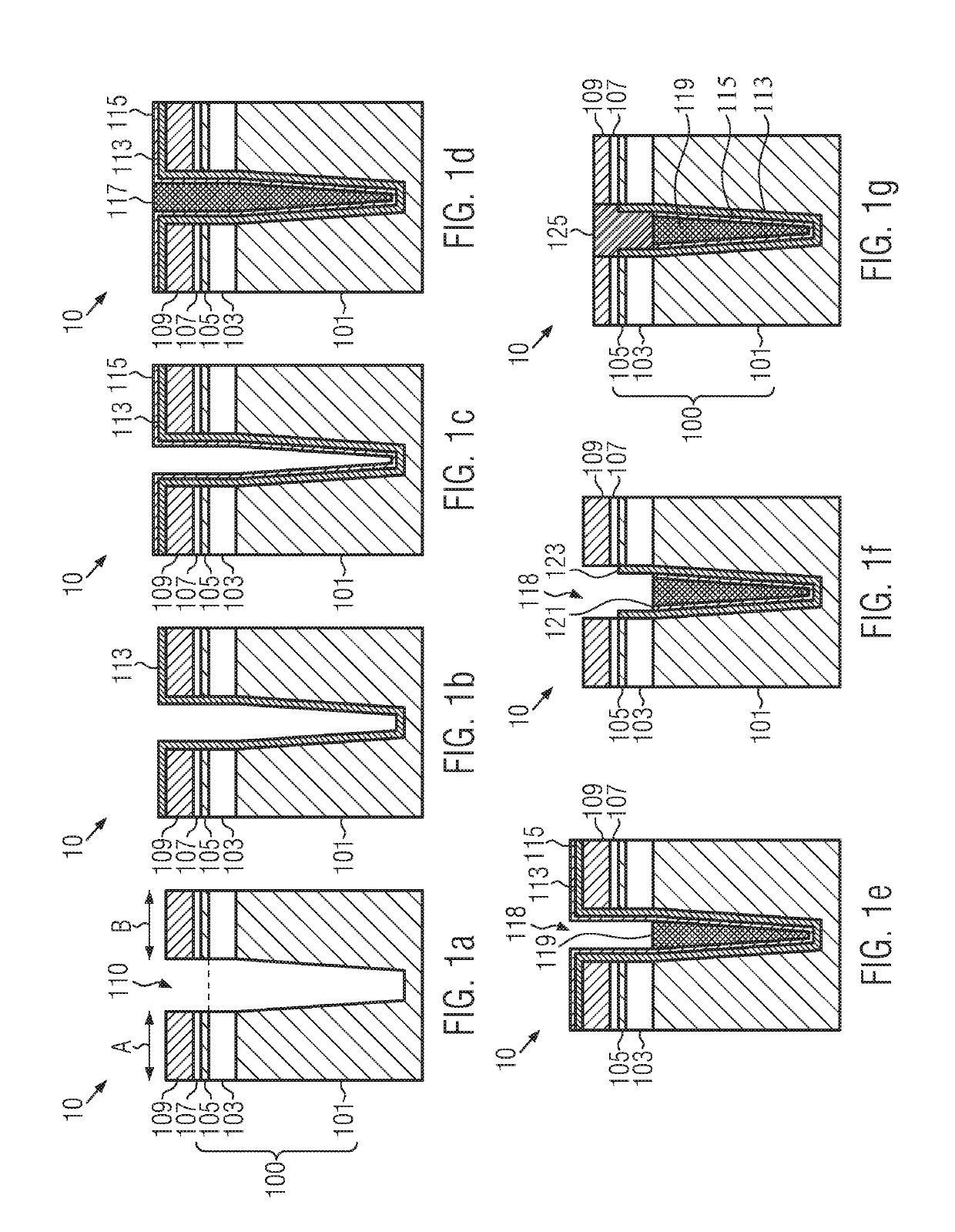

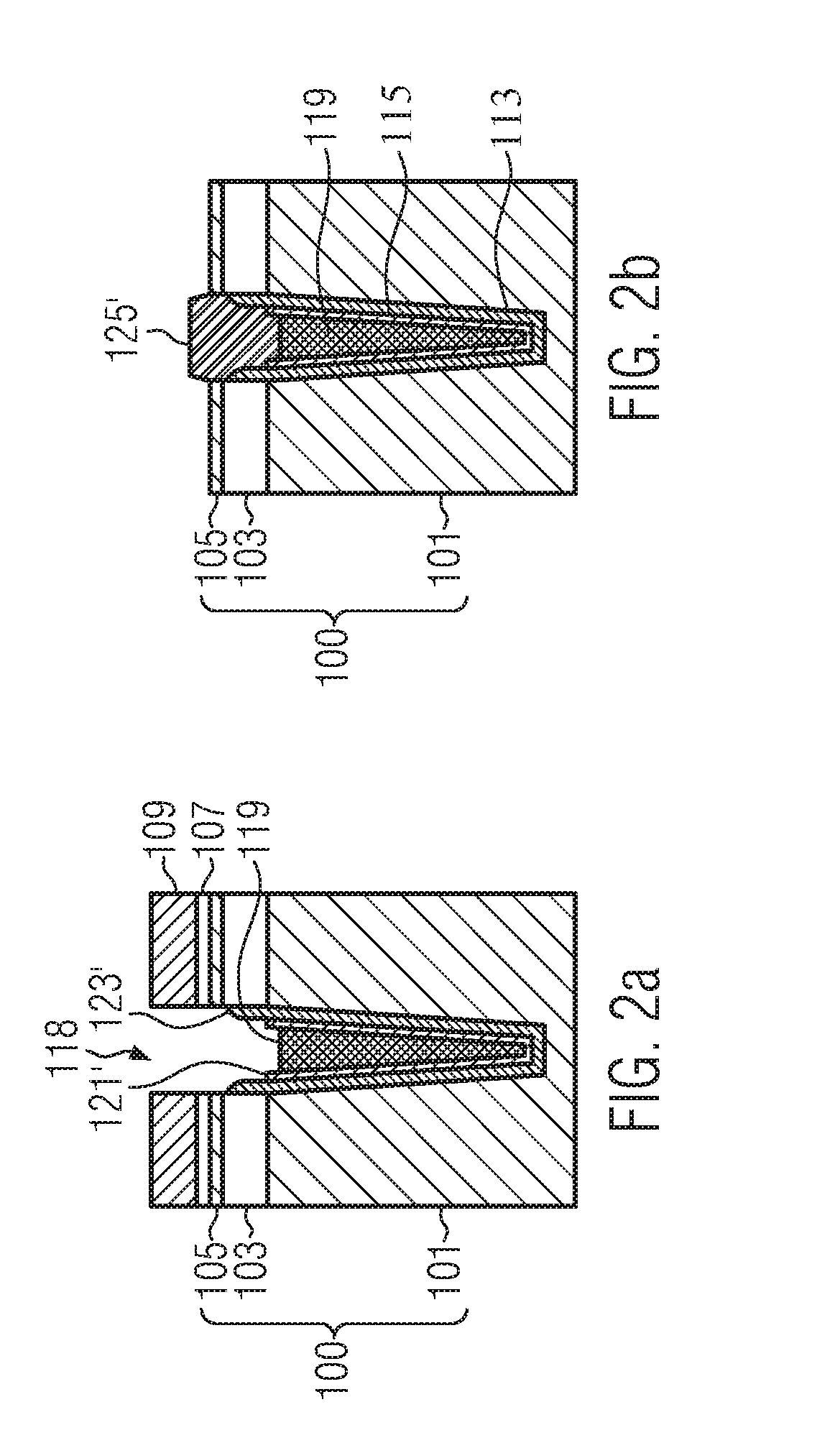

Front-end-of-line device structure and method of forming such a front-end-of-line device structure

ActiveUS10483154B1Well formedSemiconductor/solid-state device manufacturingSemiconductor devicesFilling materialsFront end of line

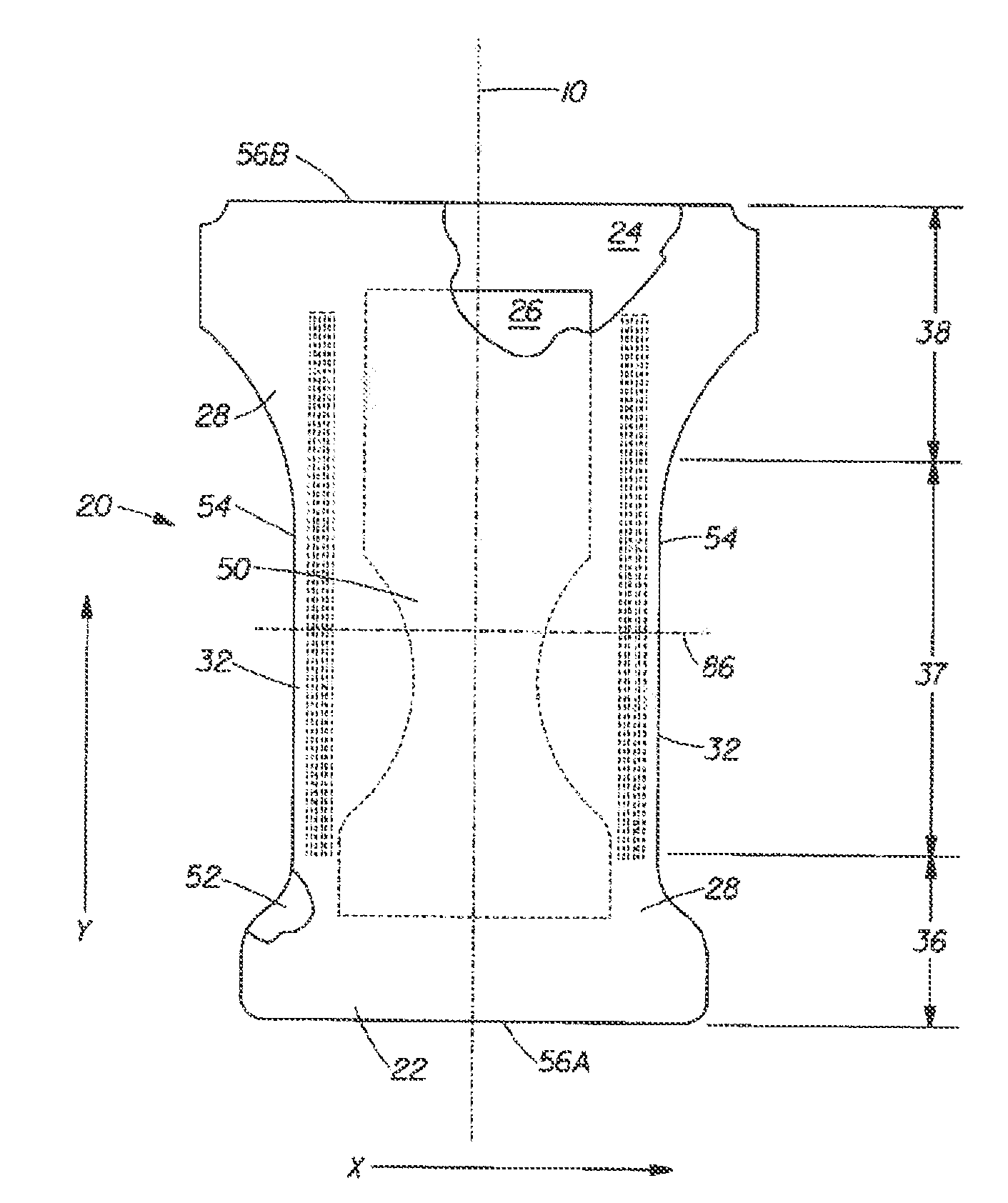

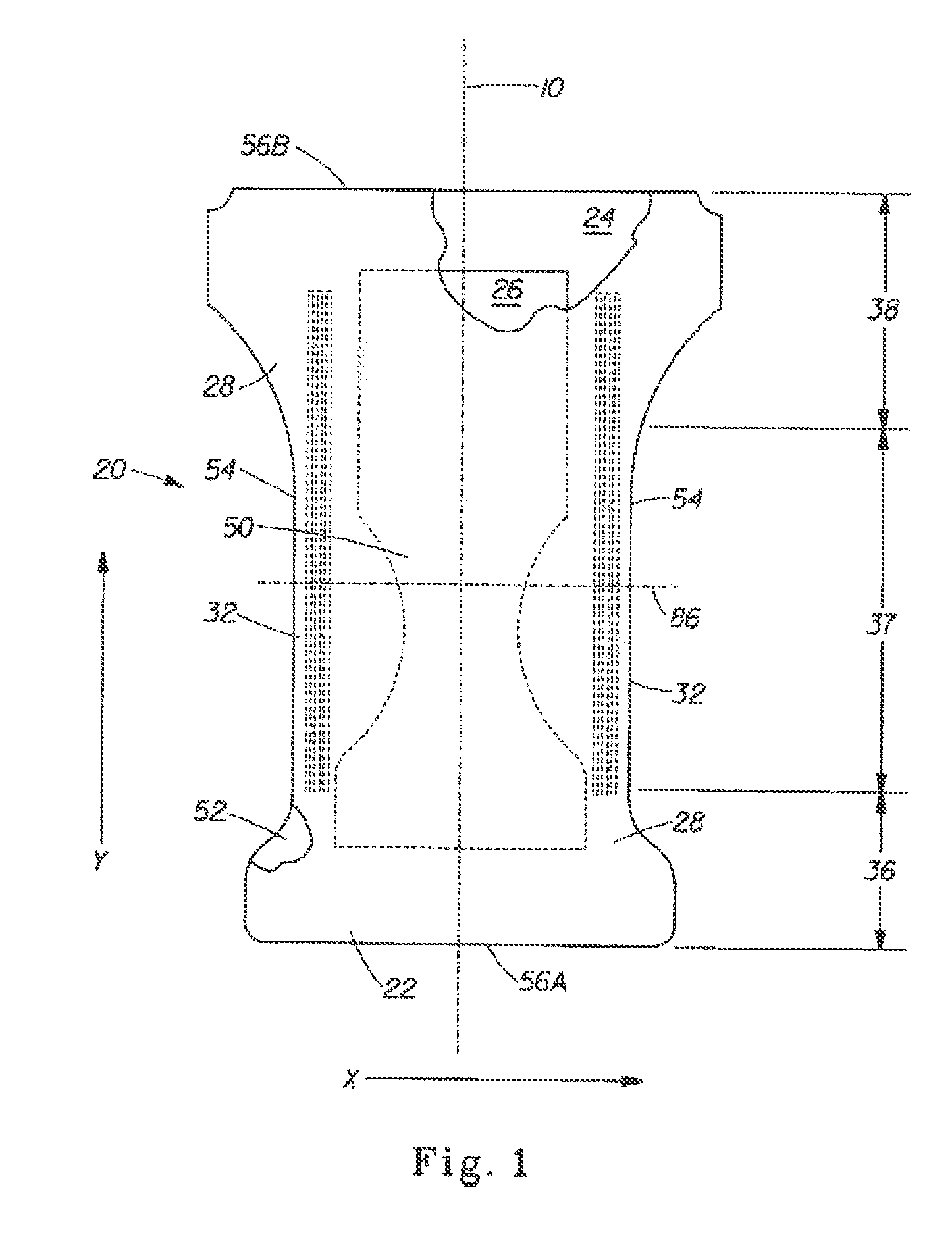

In various aspects, the present disclosure relates to device structures and a method of forming such a device structure. In some illustrative embodiments herein, a device is provided, including a semiconductor substrate having a first trench formed therein, and a first trench isolation structure formed in the first trench. The first trench isolation structure includes first and second insulating liners formed adjacent inner surfaces of the first trench, wherein the first insulating liner is in direct contact with inner surfaces of the first trench and the second insulating liner is formed directly on the first insulating liner, and a first insulating filling material which at least partially fills the first trench. In some aspects, a thickness of the first insulating liner is greater than a thickness of the second insulating liner.

Owner:GLOBALFOUNDRIES US INC

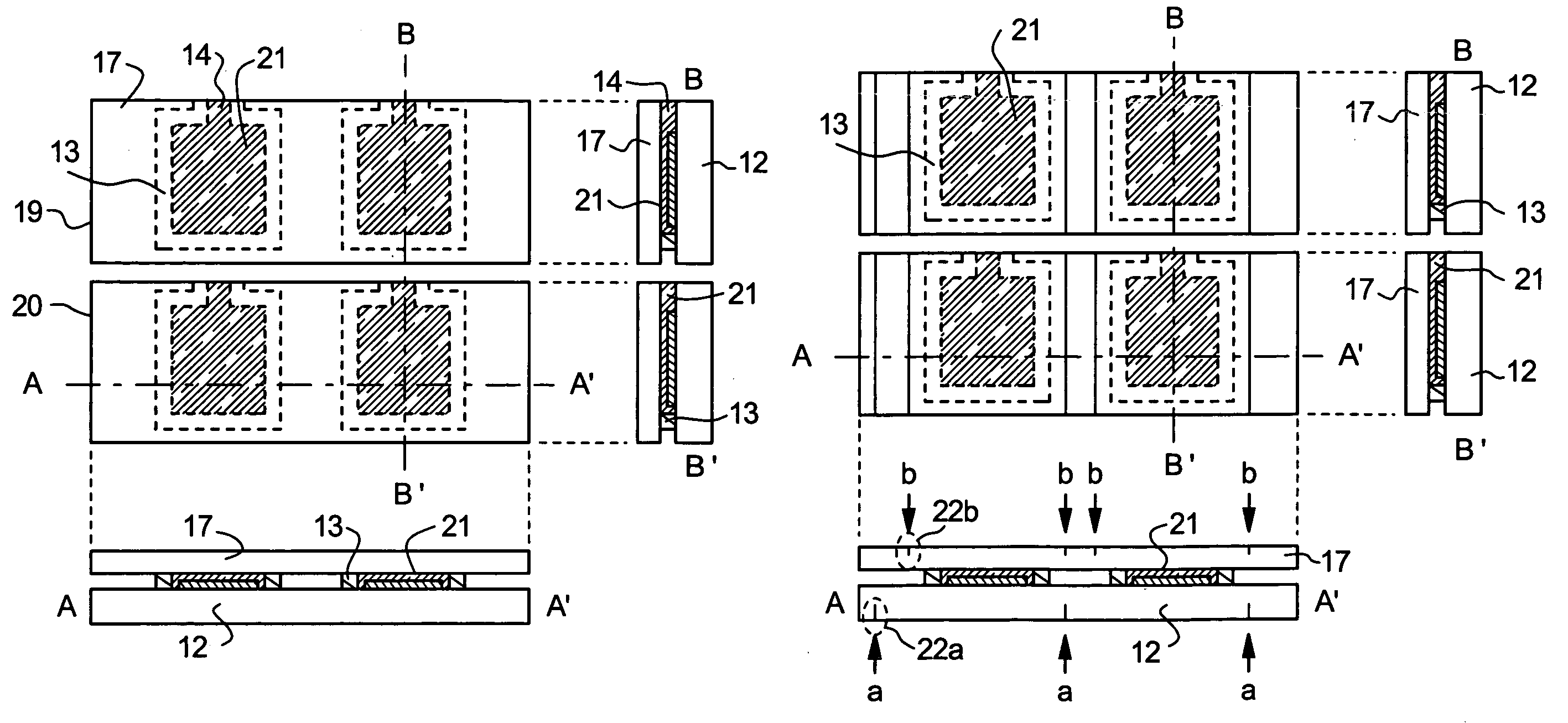

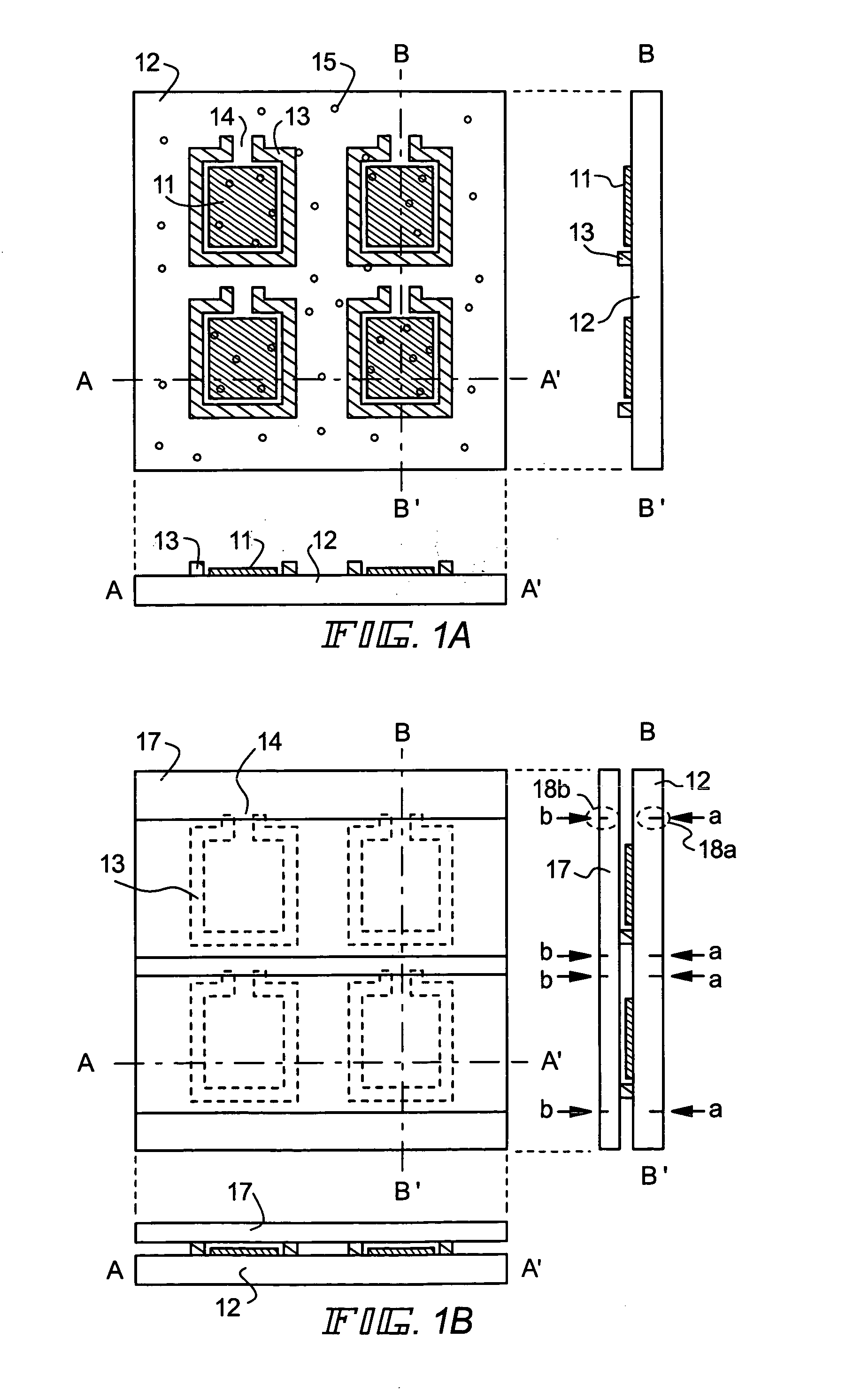

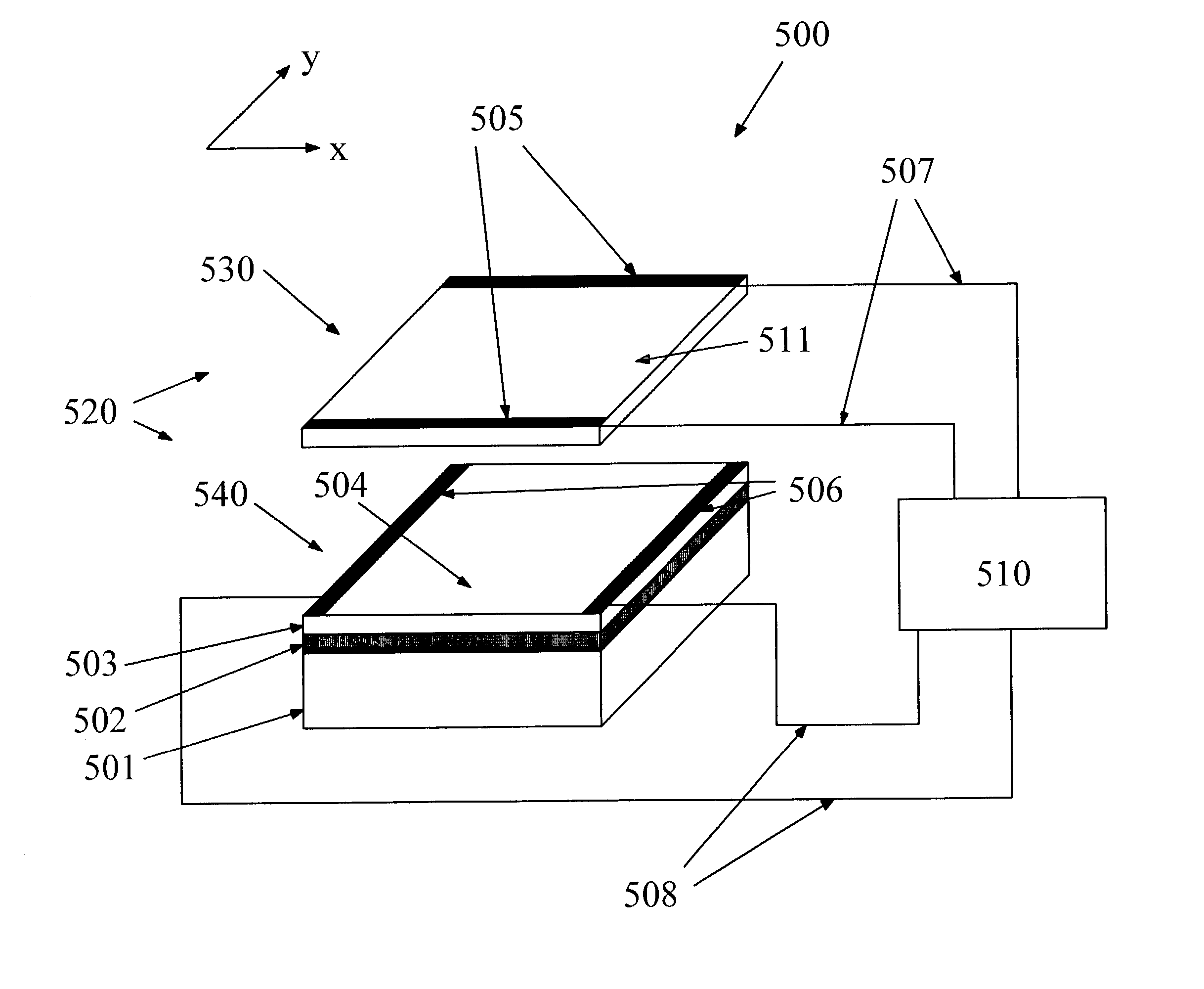

Light emitting device and method of manufacturing the same

ActiveUS7112115B1Improve throughputHigh yieldDischarge tube luminescnet screensElectroluminescent light sourcesManufacturing cost reductionEngineering

Technology to reduce the manufacturing cost of a manufacturing process of a light emitting device is provided. The manufacturing cost of a device using a light emitting element can be reduced by using a multilayout process for forming a plurality of light emitting devices from a large-sized substrate. In particular, an existing line for manufacturing liquid crystal cells can be diverted to a process of encapsulating light emitting elements, which can greatly reduce the manufacturing cost including the investment in plant and equipment.

Owner:SEMICON ENERGY LAB CO LTD

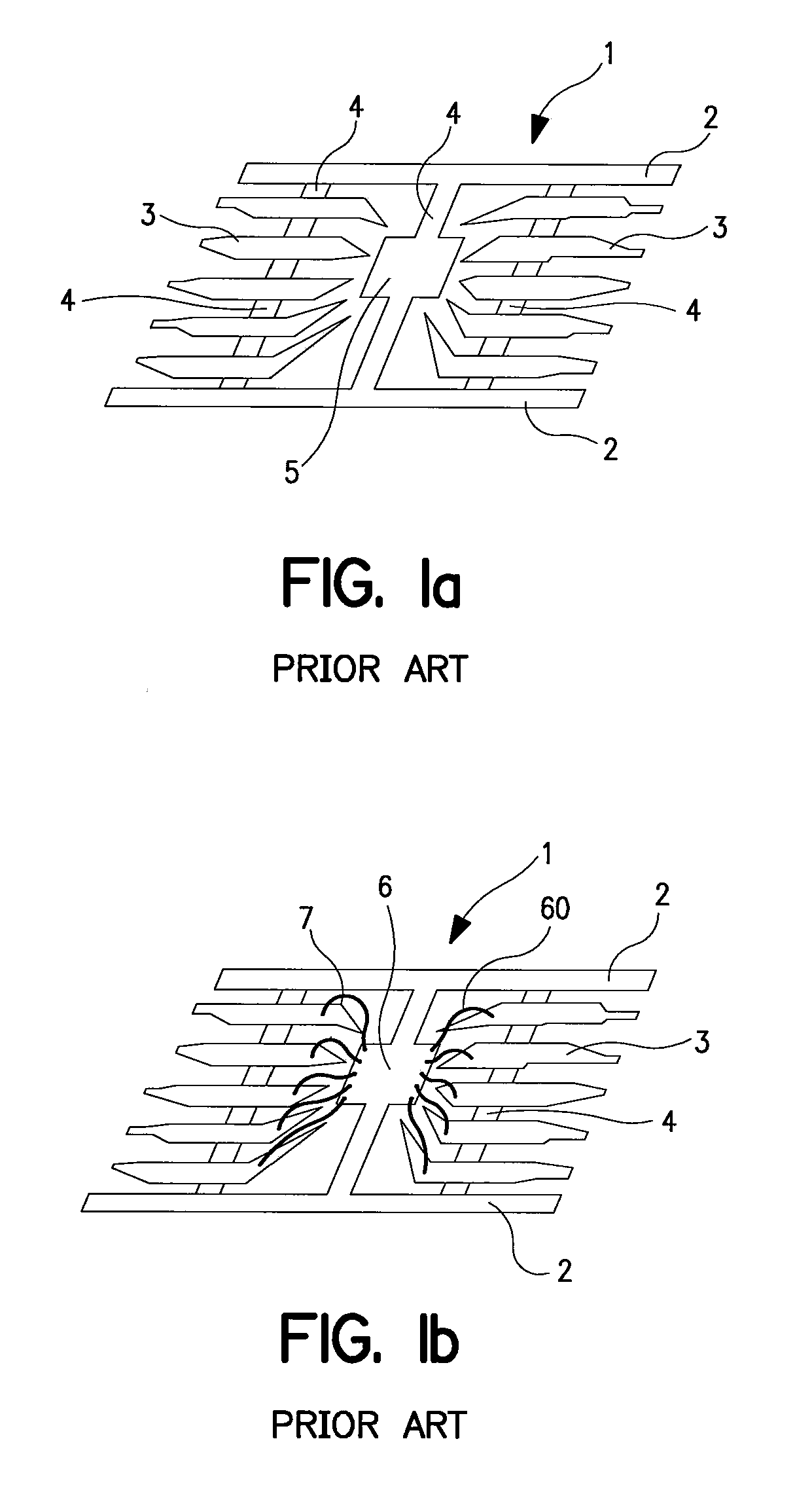

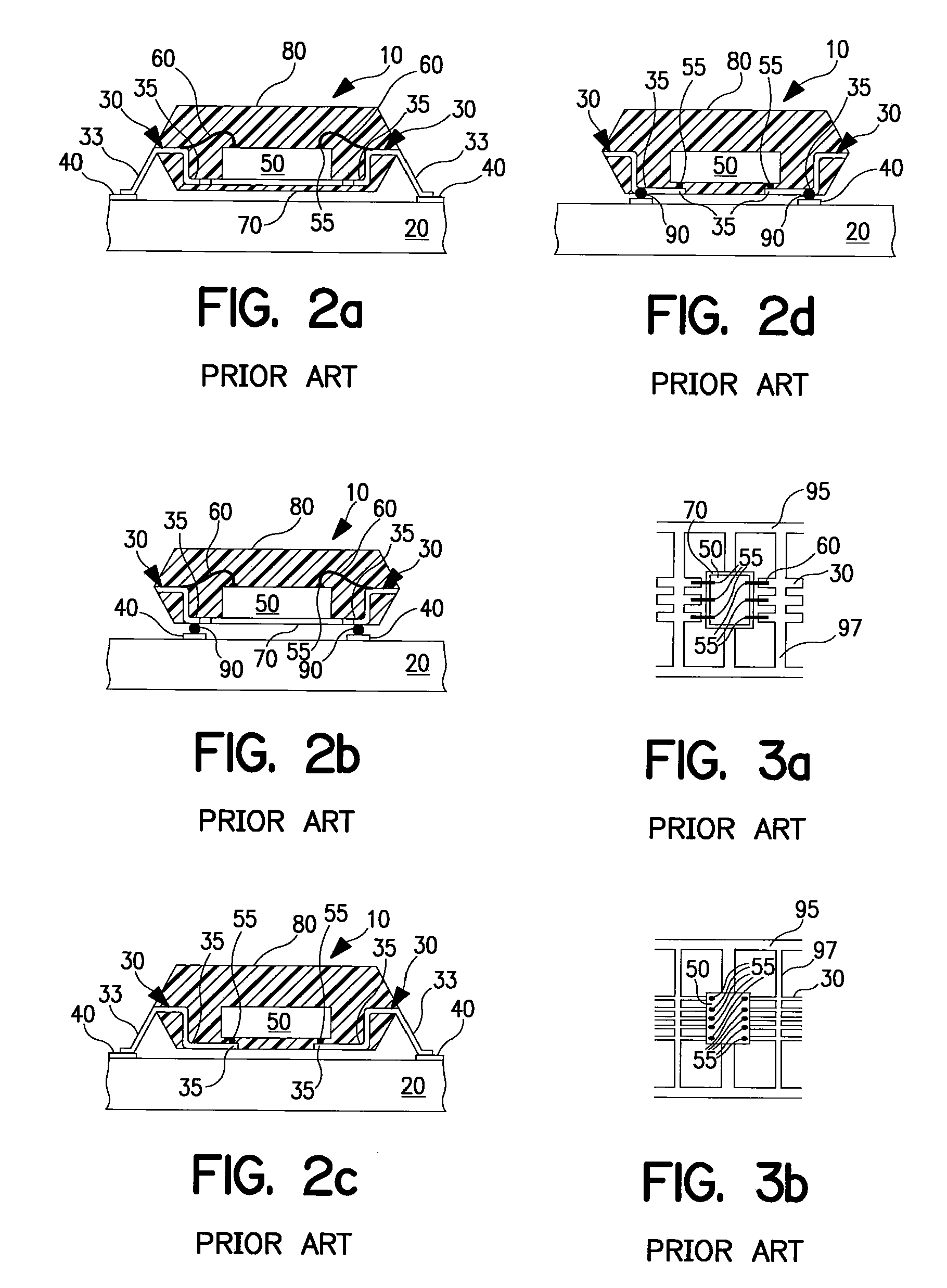

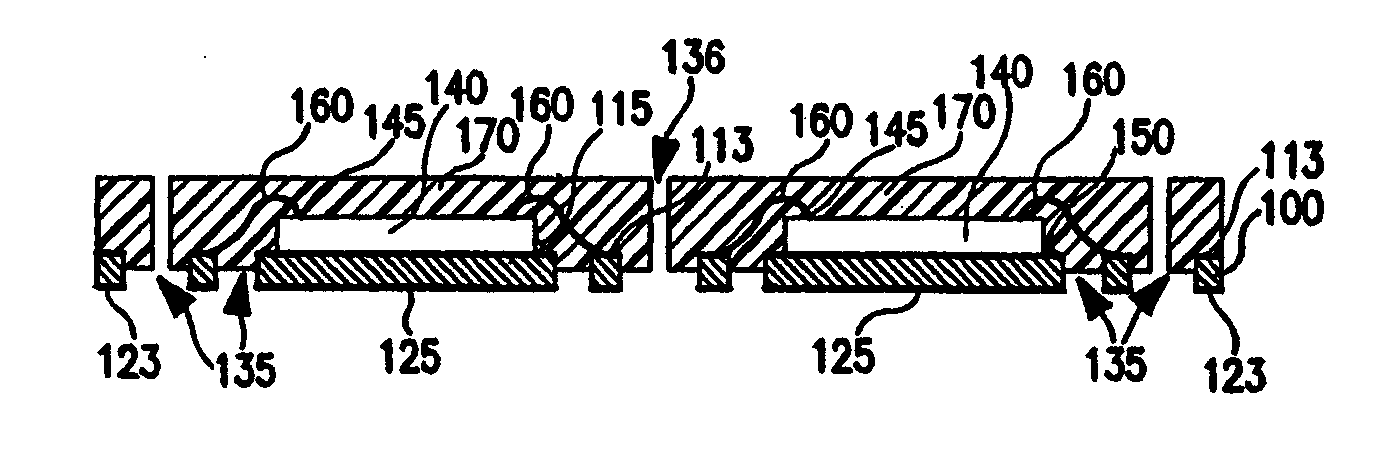

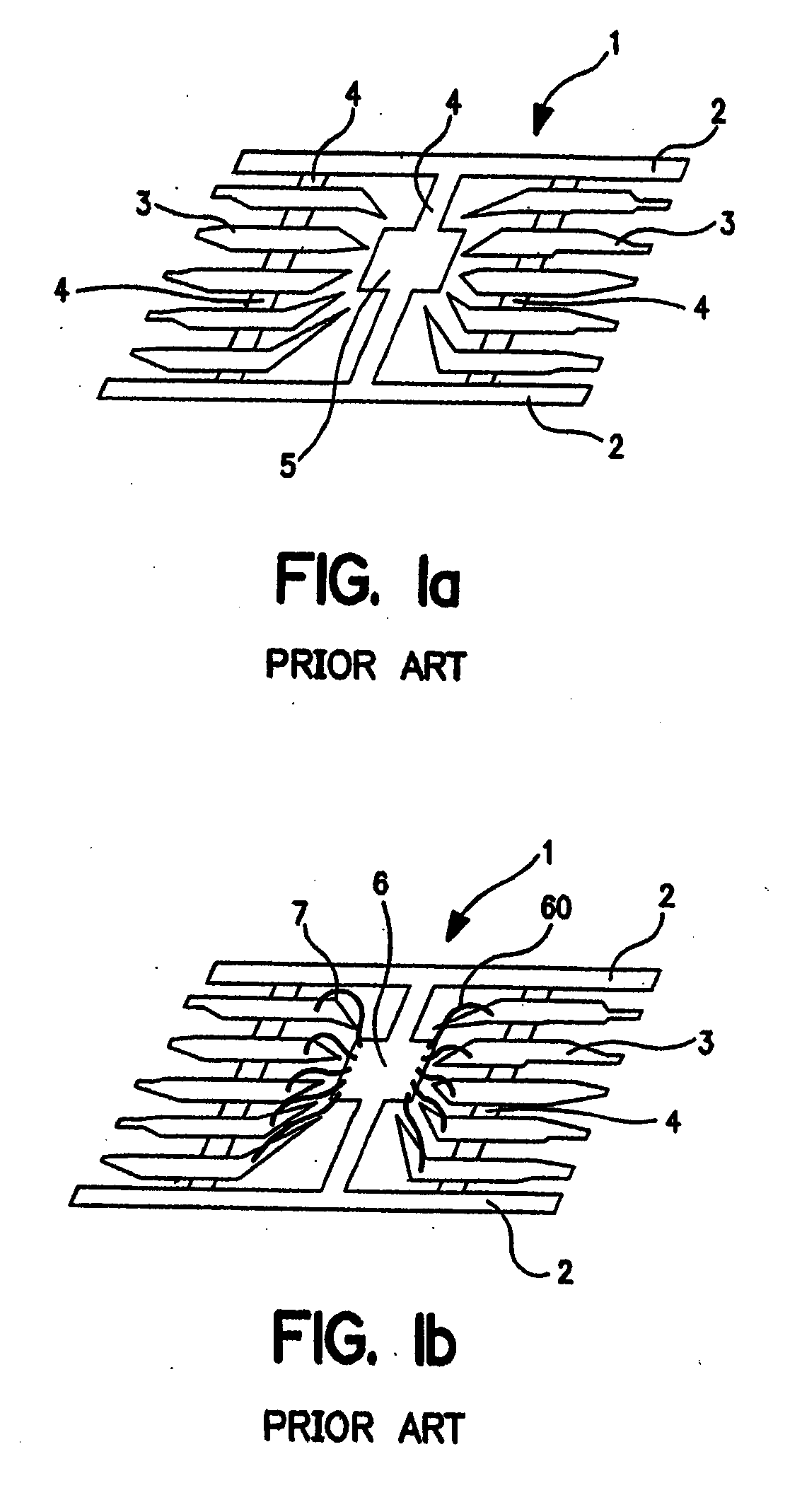

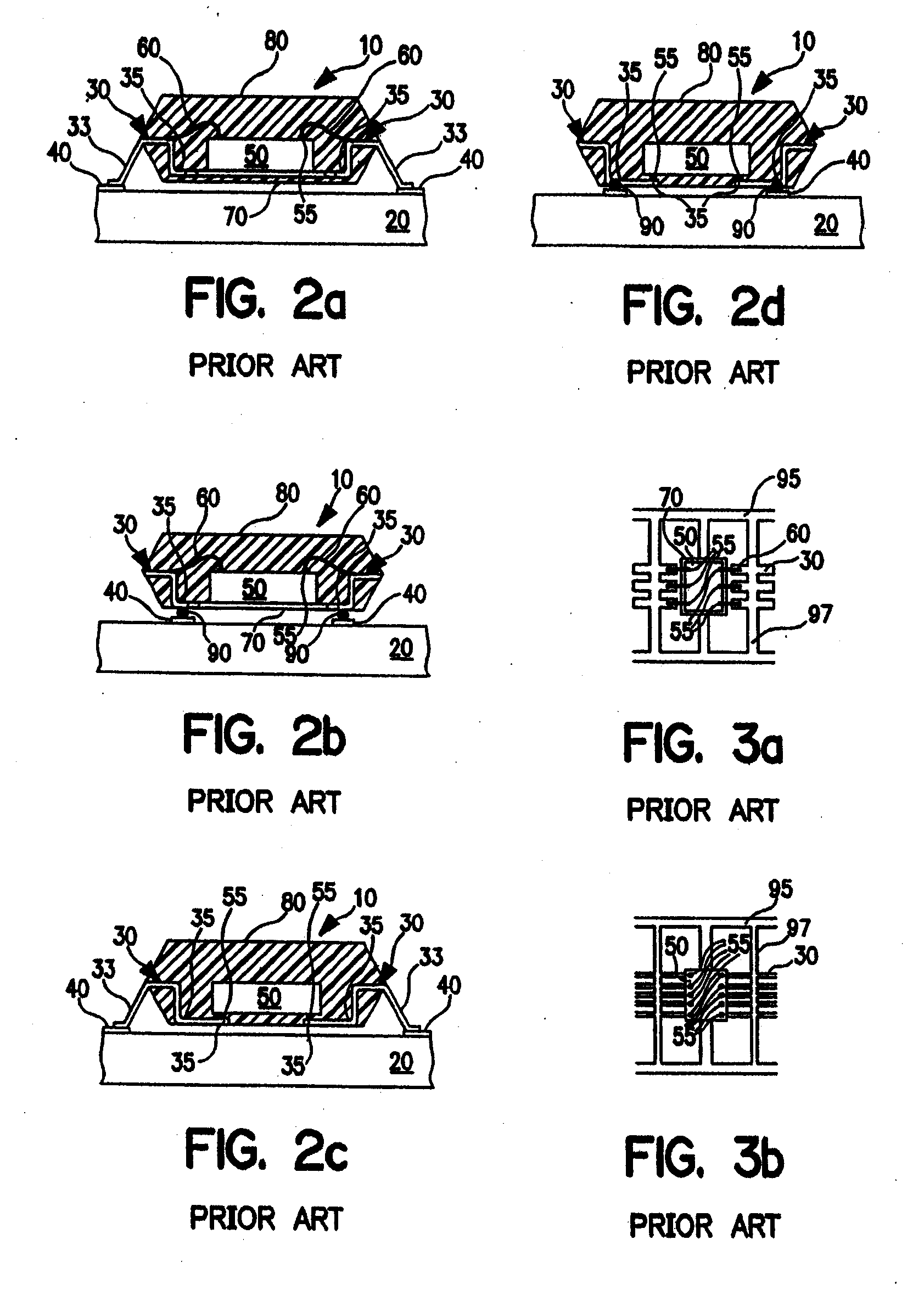

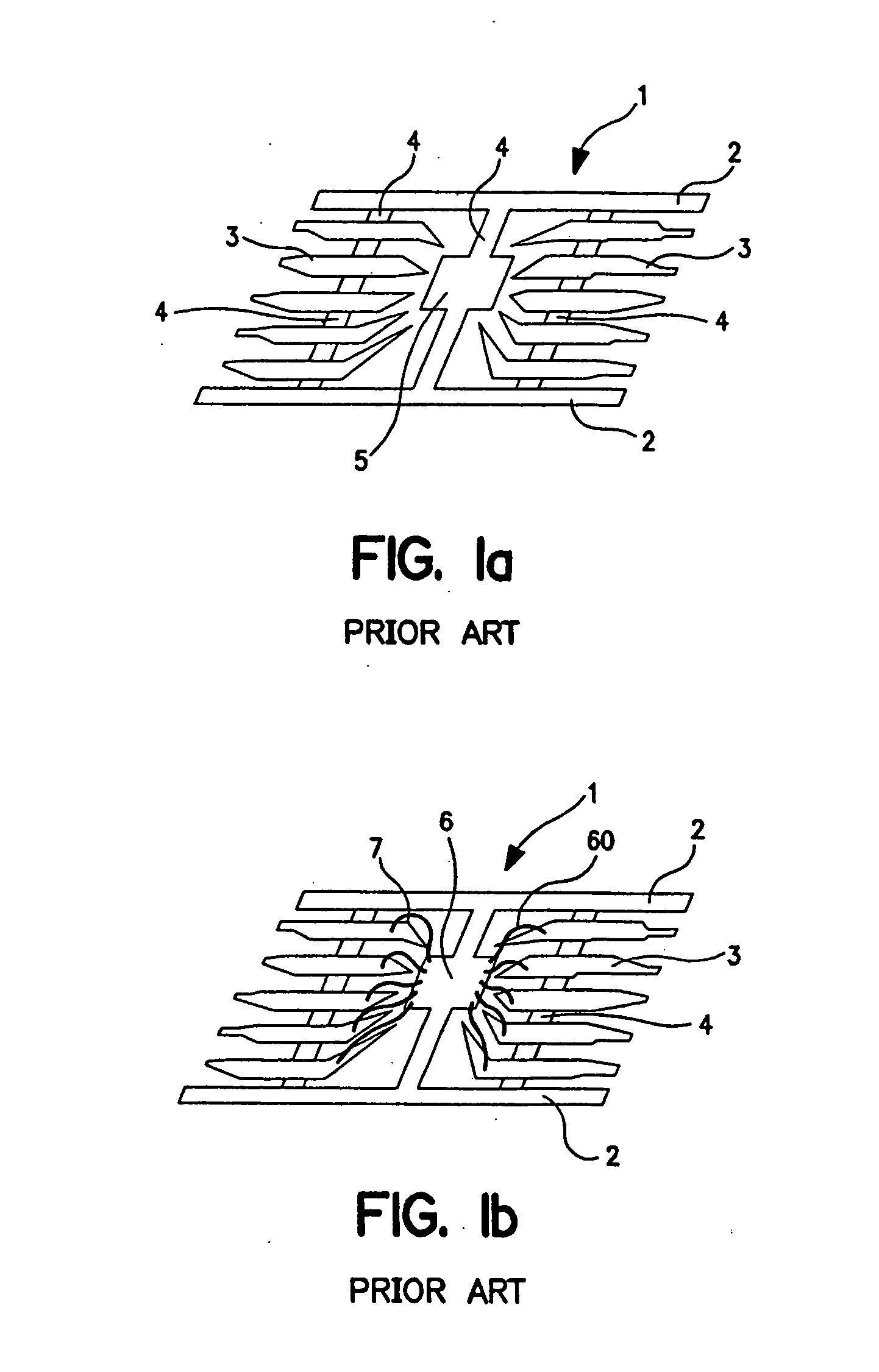

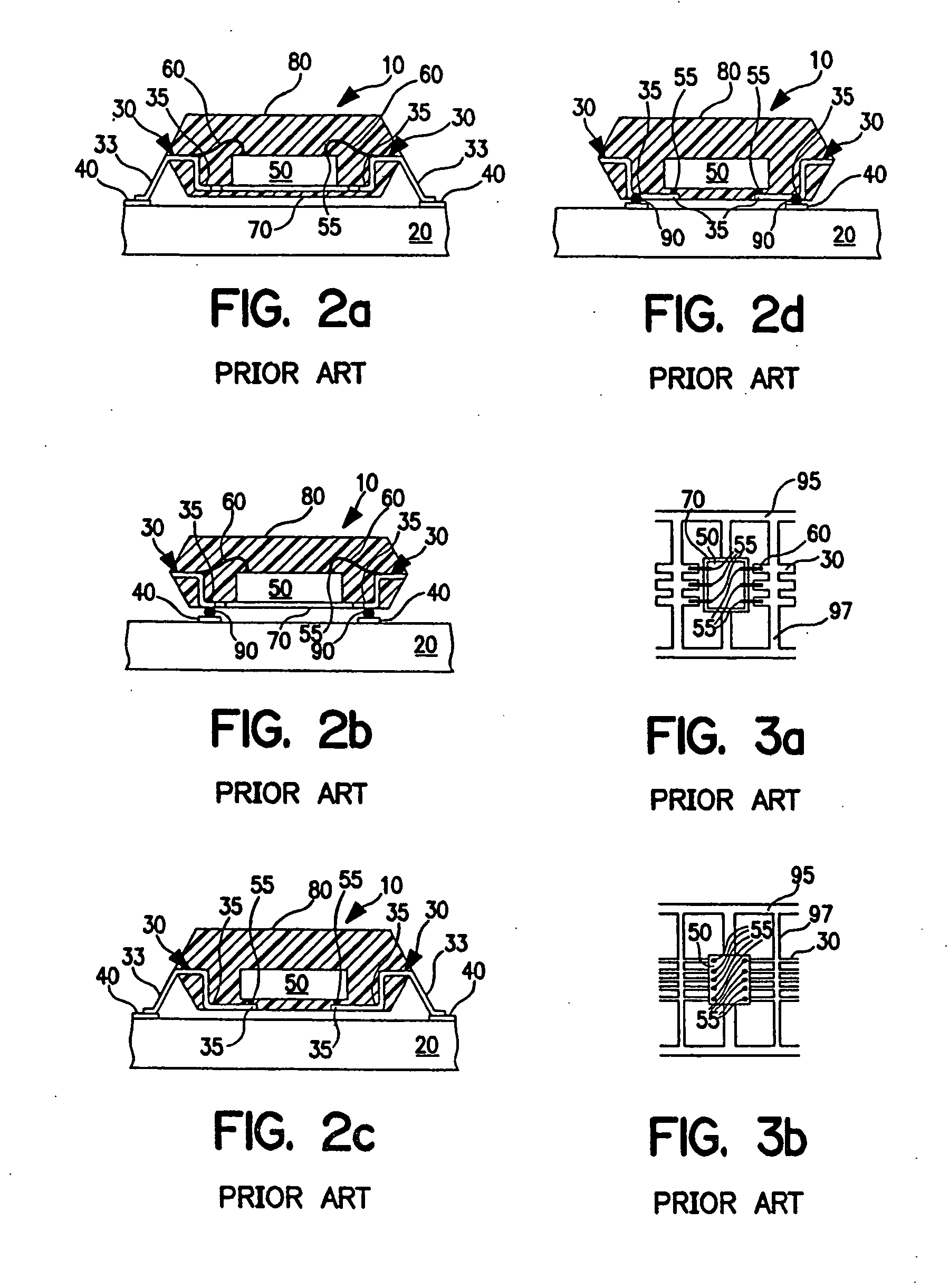

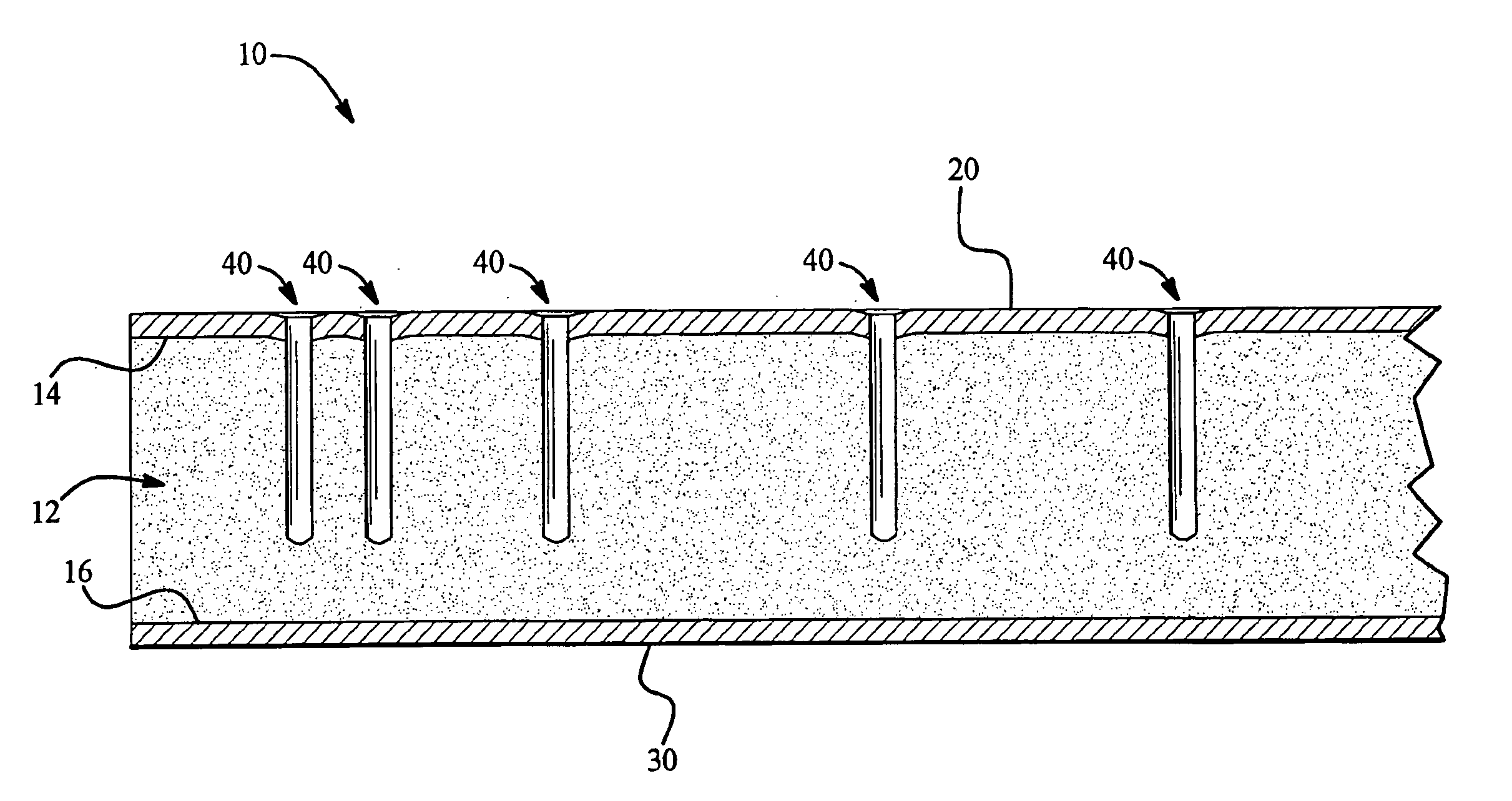

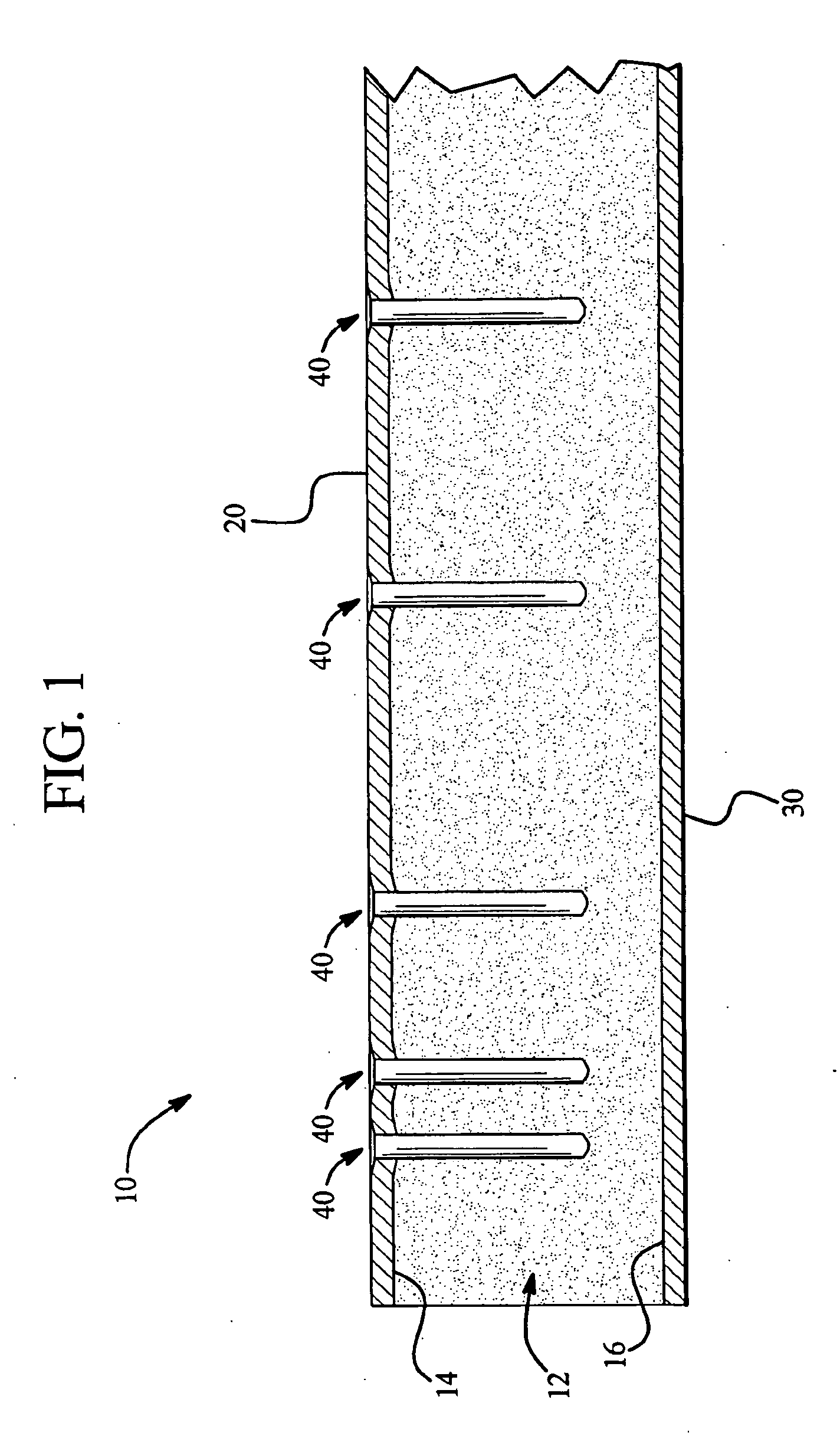

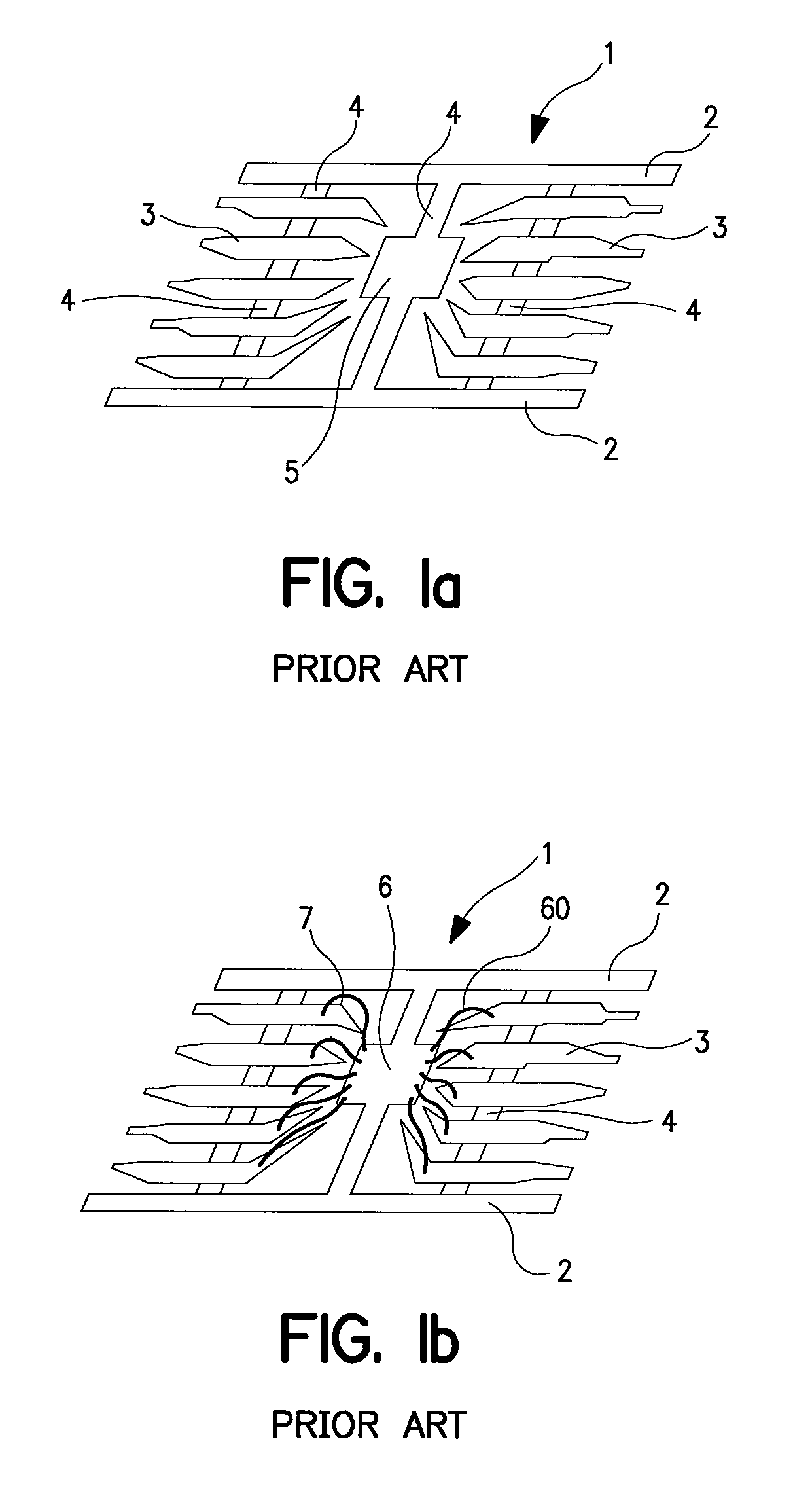

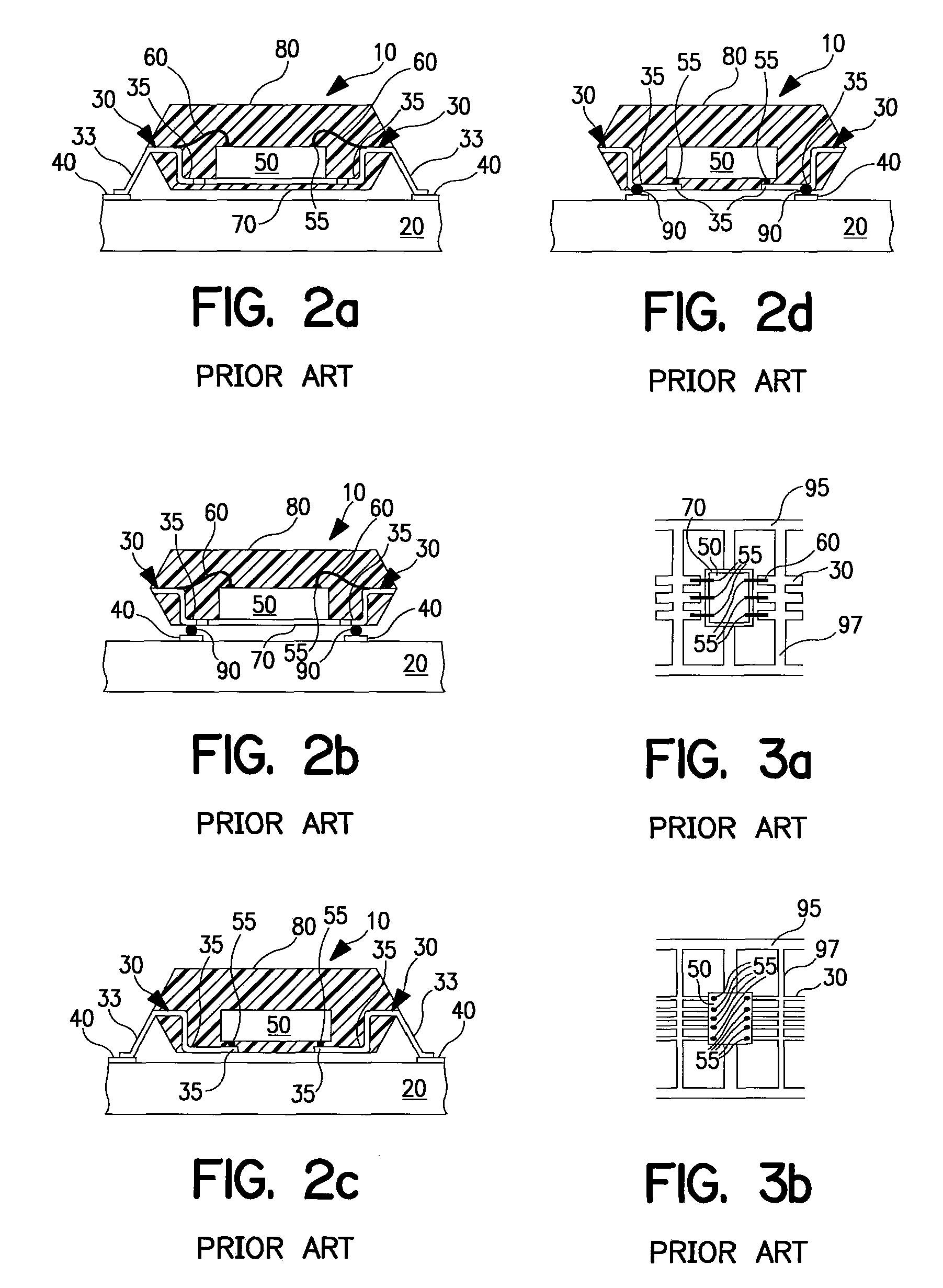

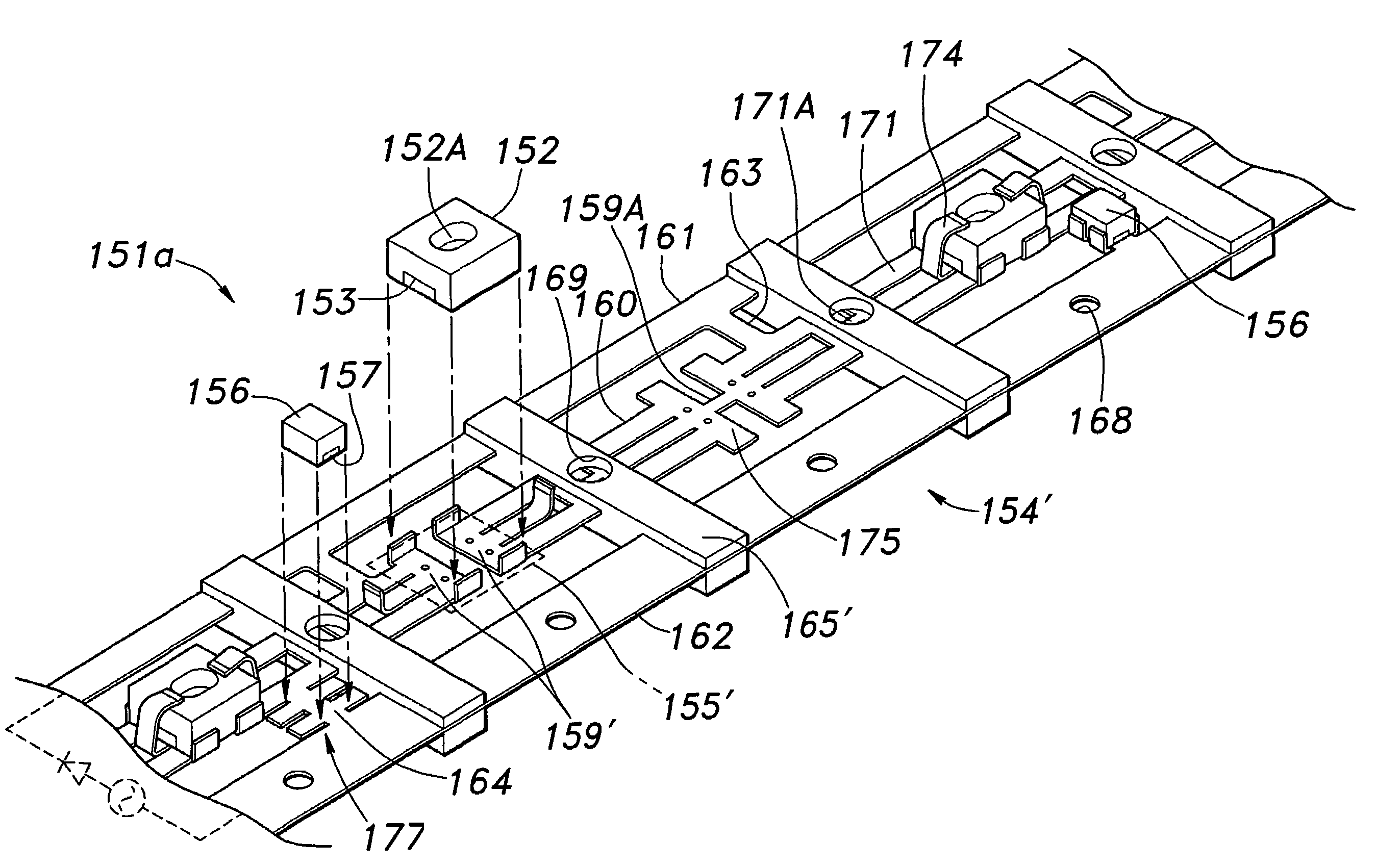

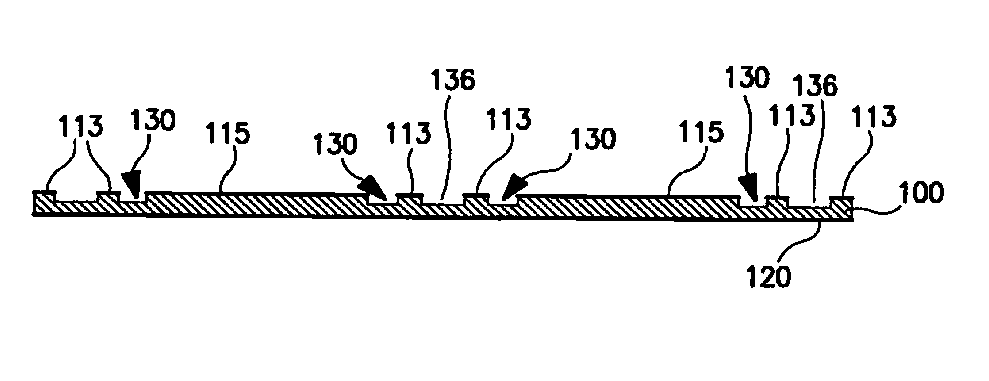

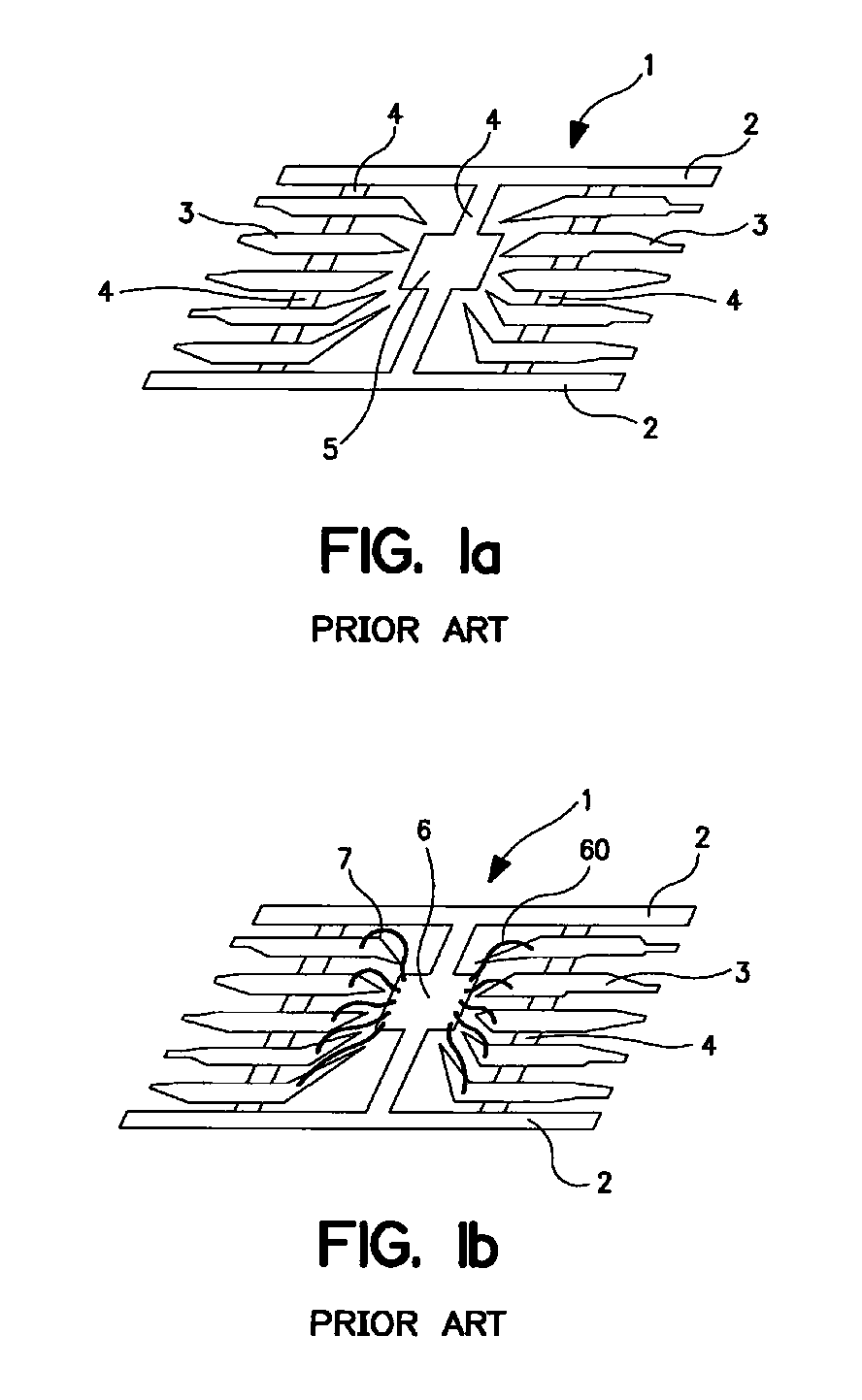

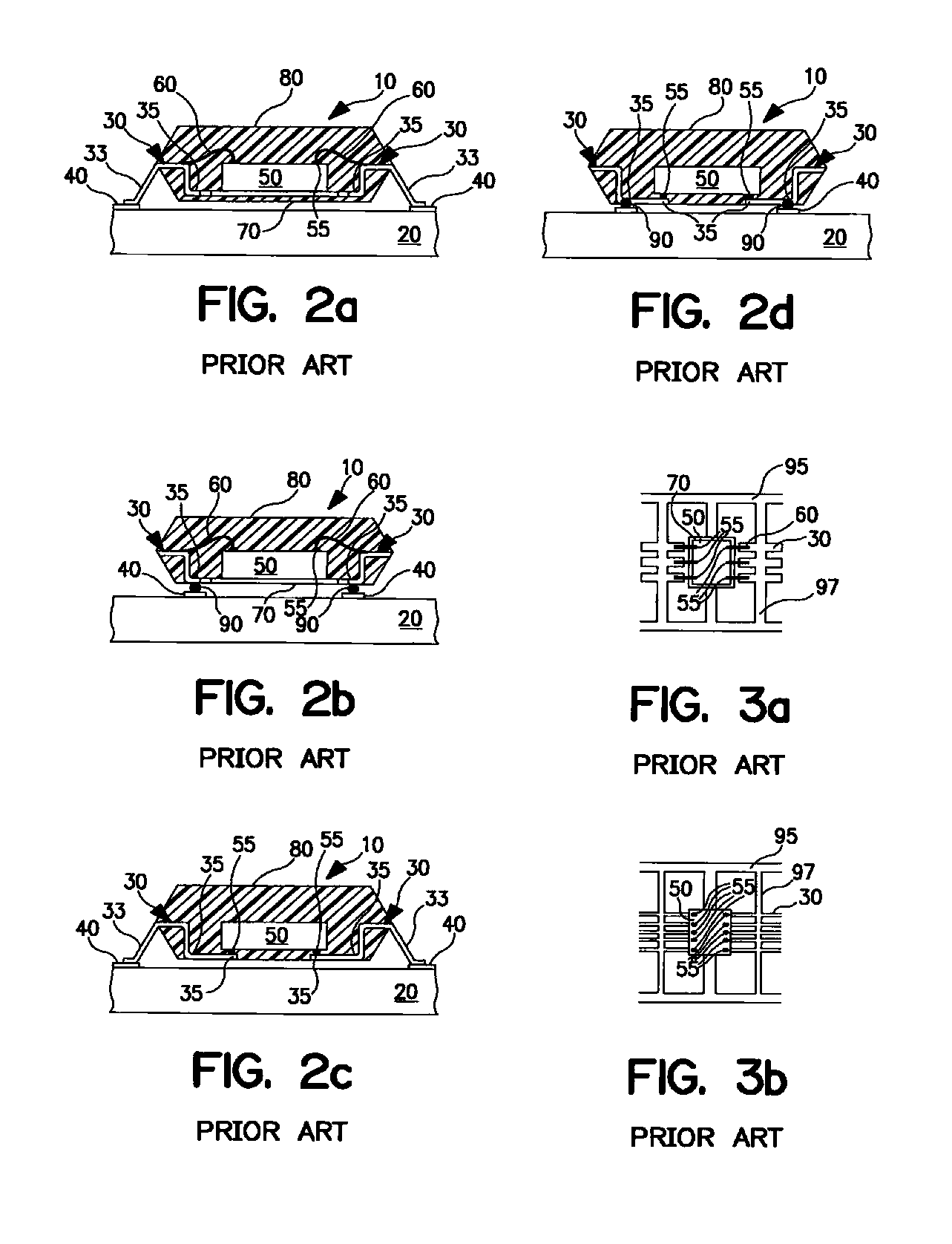

Partially patterned lead frames and methods of making and using the same in semiconductor packaging

InactiveUS20080258278A1Reduce thicknessImprove structural rigiditySemiconductor/solid-state device detailsSolid-state devicesLead bondingBonding process

A method of making a lead frame and a partially patterned lead frame package with near-chip scale packaging lead-count, wherein the method lends itself to better automation of the manufacturing line and improved quality and reliability of the packages produced therefrom. A major portion of the manufacturing process steps is performed with a partially patterned strip of metal formed into a web-like lead frame on one side so that the web-like lead frame is also rigid mechanically and robust thermally to perform without distortion or deformation during the chip-attach and wire bond processes, both at the chip level and the package level. The bottom side of the metal lead frame is patterned to isolate the chip-pad and the wire bond contacts only after the front side, including the chip and wires, is hermetically sealed with an encapsulant. The resultant package being electrically isolated enables strip testing and reliable singulation.

Owner:UNISEM M BERHAD

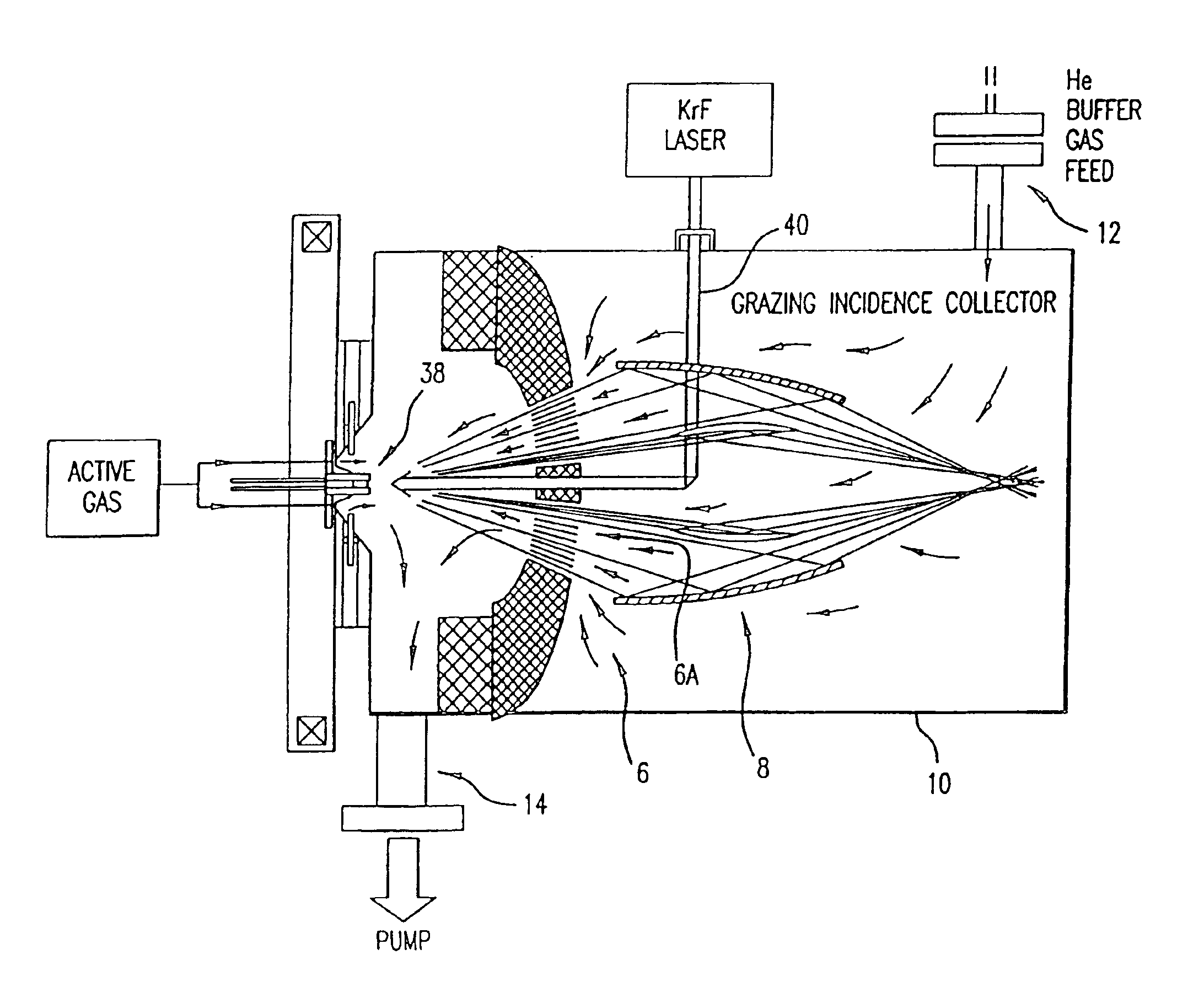

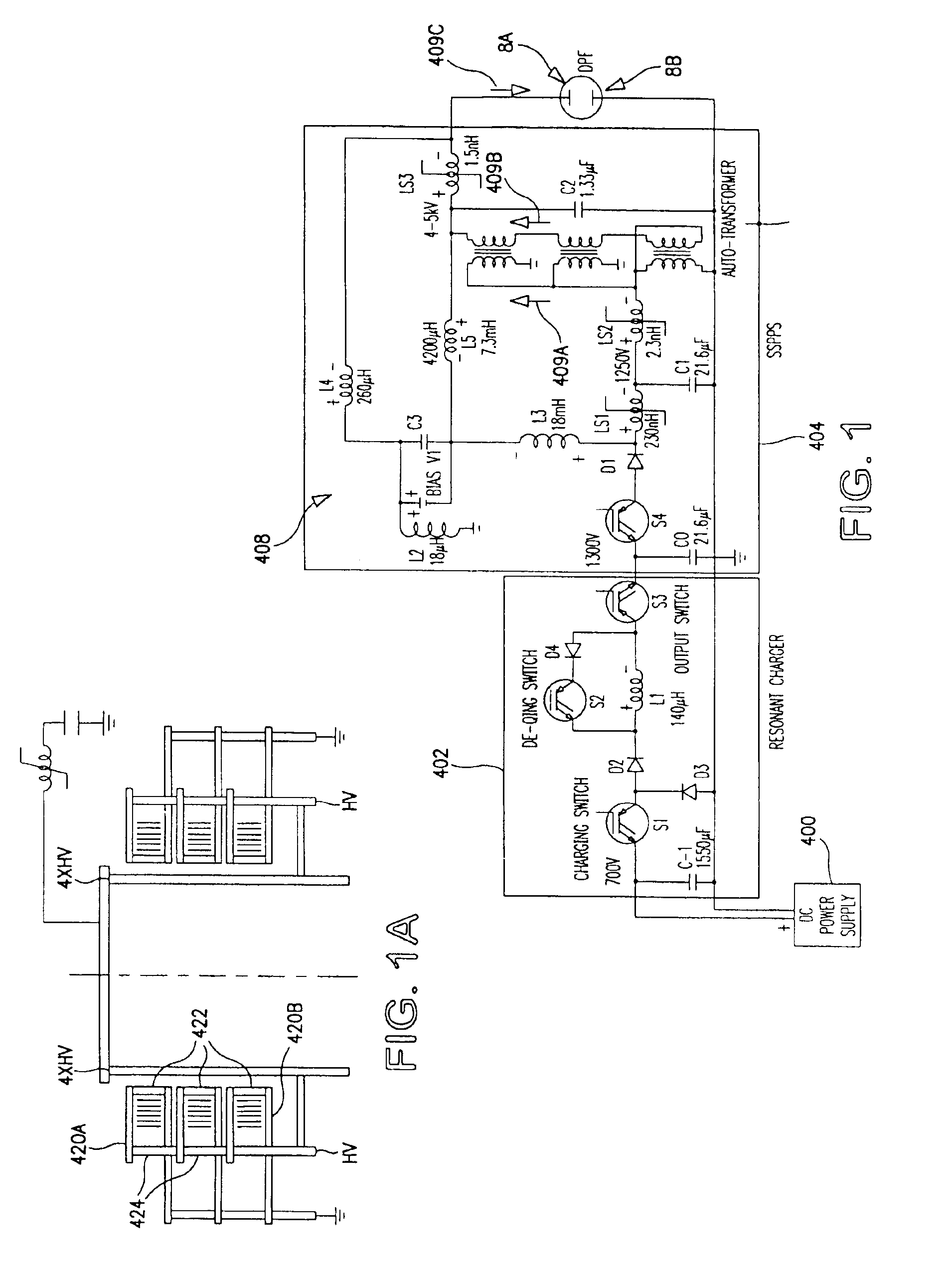

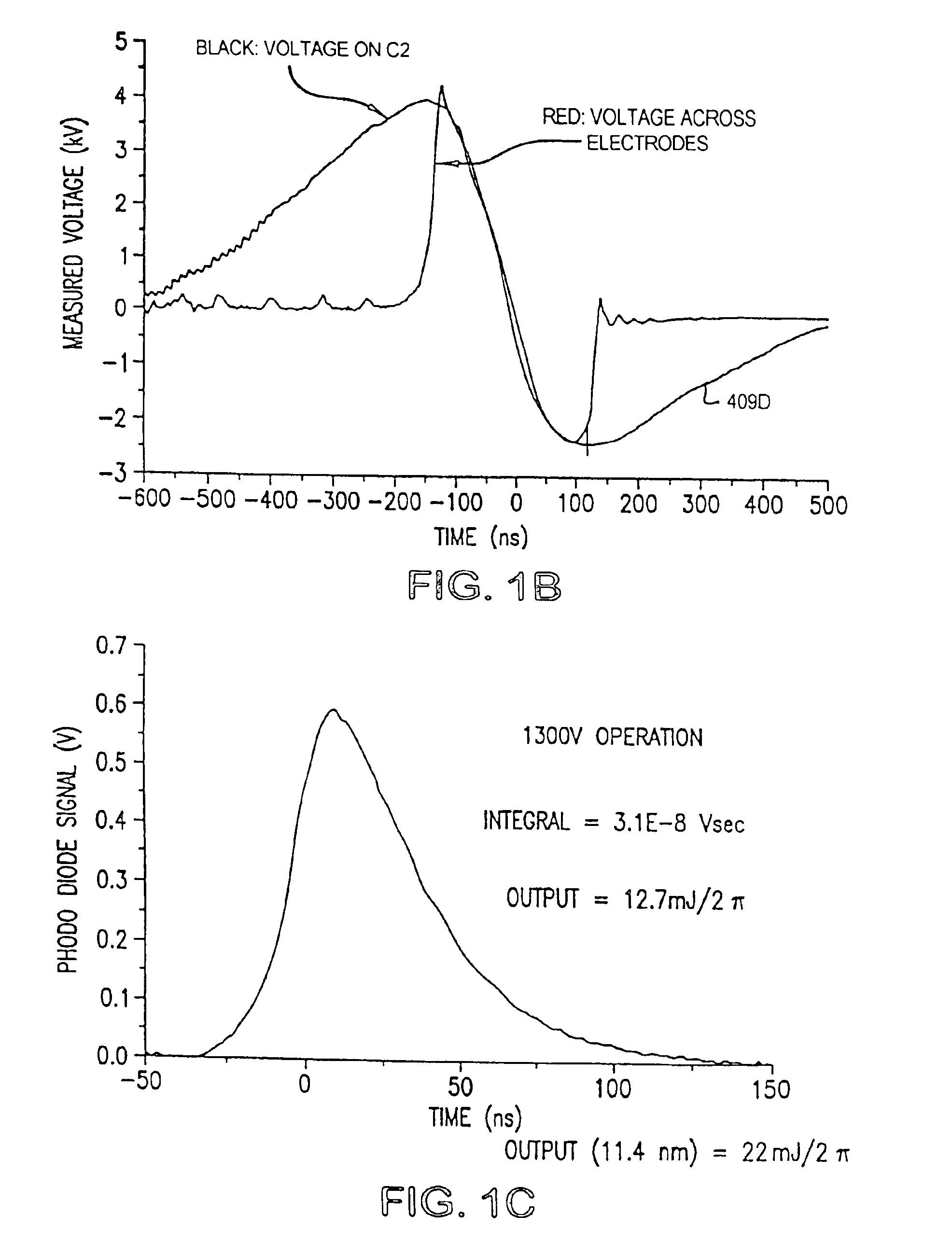

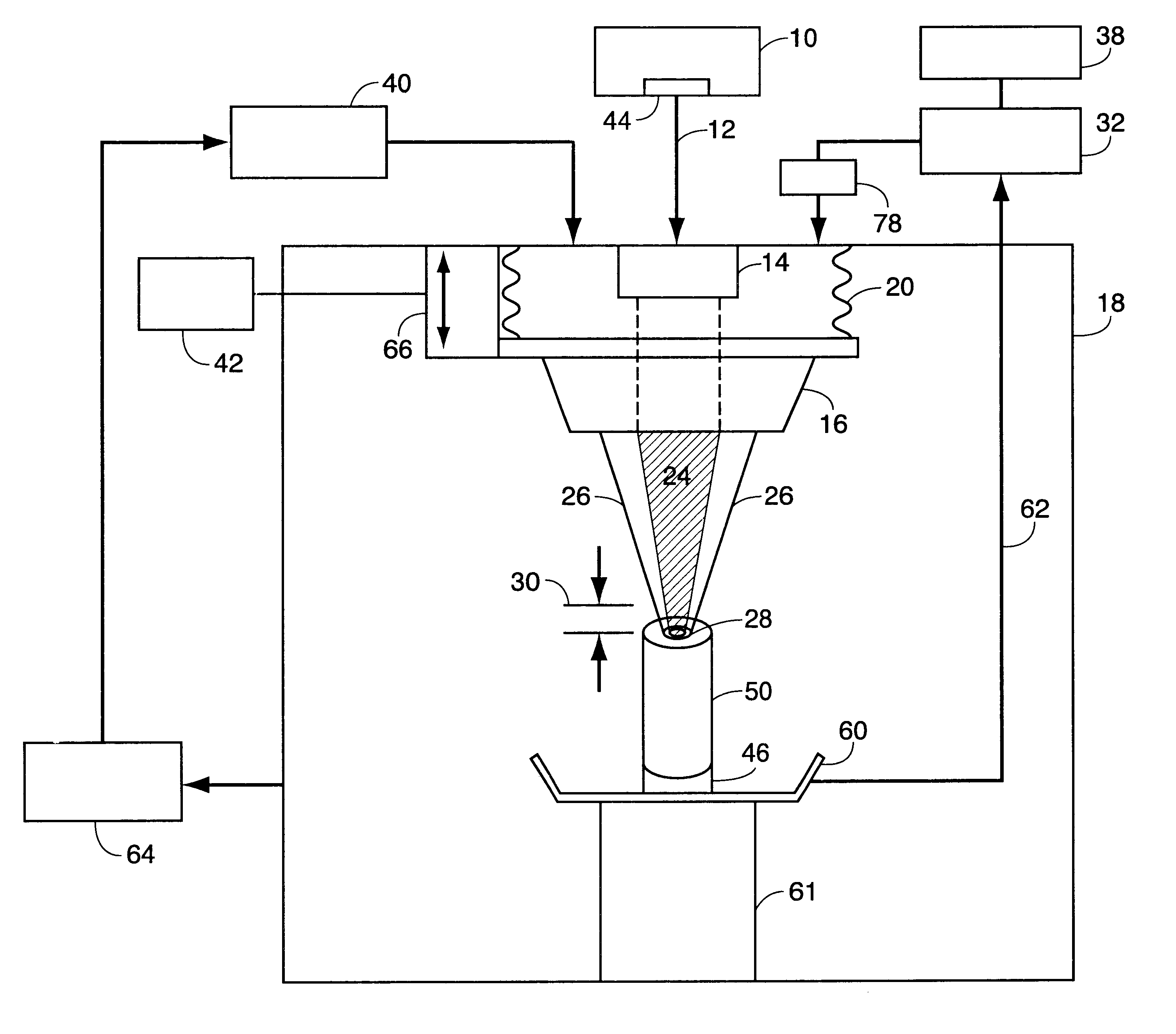

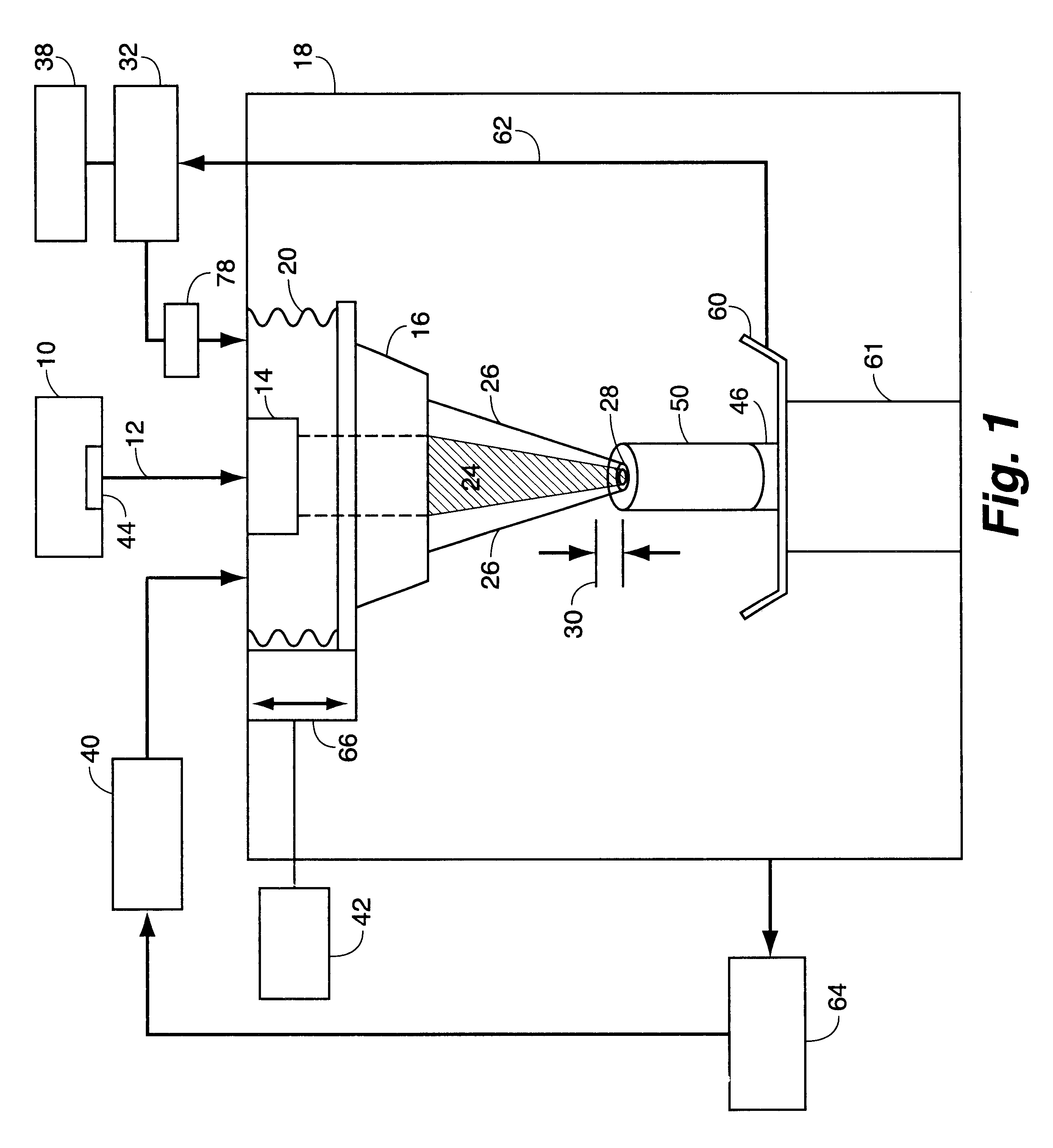

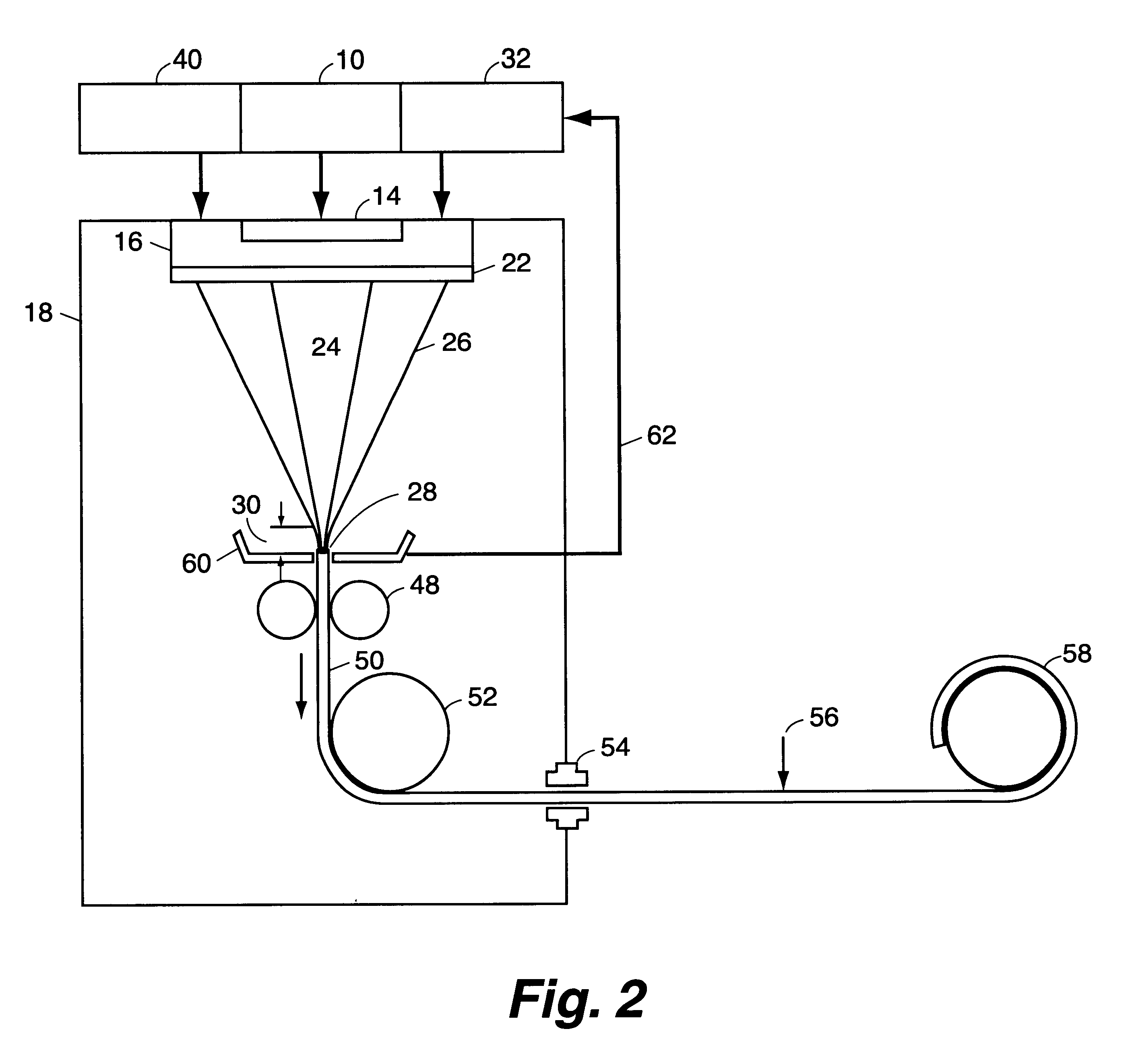

Extreme ultraviolet light source

InactiveUS6972421B2Improve efficiencyImprove performanceNanoinformaticsSemiconductor/solid-state device manufacturingAtomic elementLight energy

The present invention provides a reliable, high-repetition rate, production line compatible high energy photon source. A very hot plasma containing an active material is produced in vacuum chamber. The active material is an atomic element having an emission line within a desired extreme ultraviolet (EUV) range. A pulse power source comprising a charging capacitor and a magnetic compression circuit comprising a pulse transformer, provides electrical pulses having sufficient energy and electrical potential sufficient to produce the EUV light at an intermediate focus at rates in excess of 5 Watts. In preferred embodiments designed by Applicants in-band, EUV light energy at the intermediate focus is 45 Watts extendable to 105.8 Watts.

Owner:ASML NETHERLANDS BV

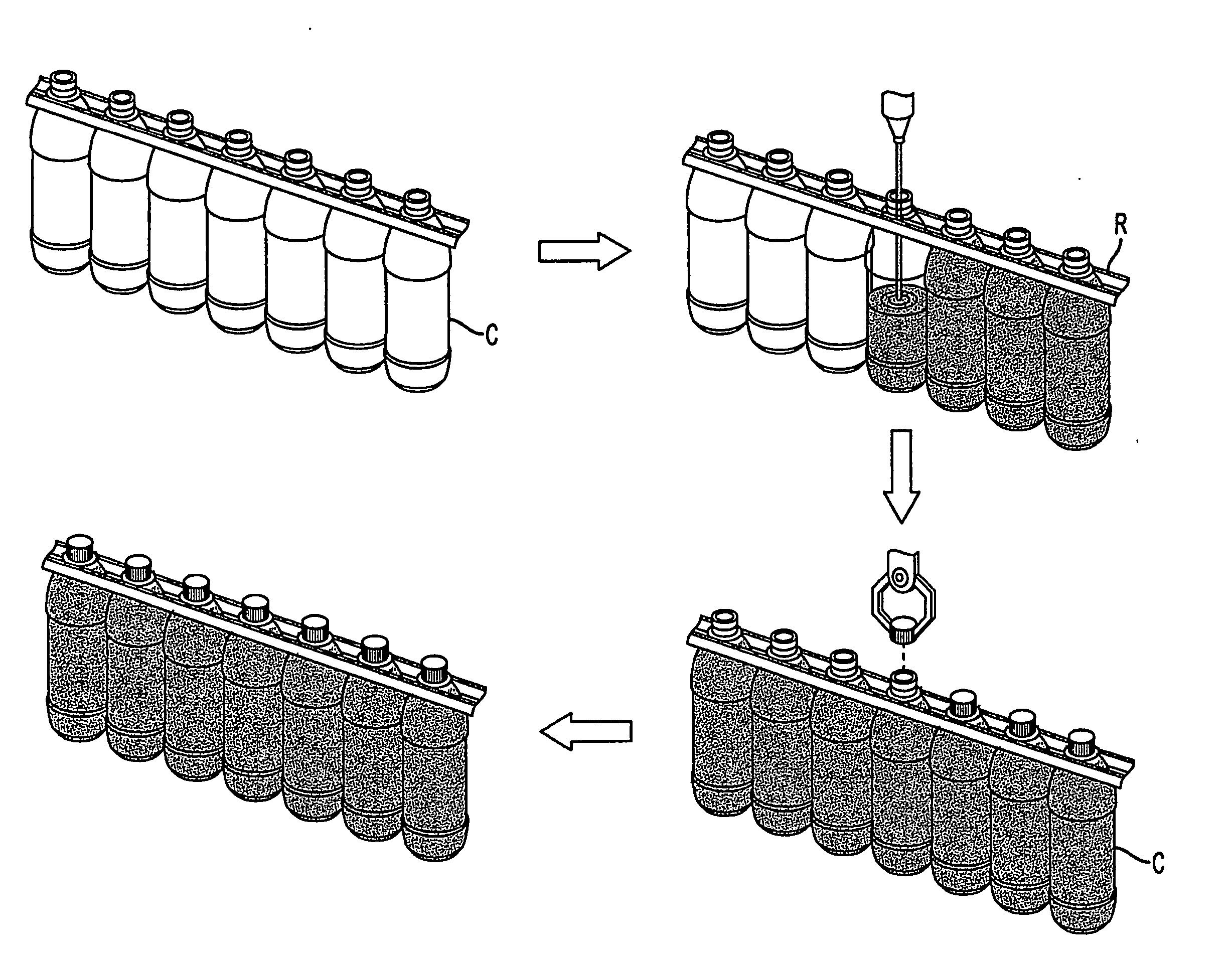

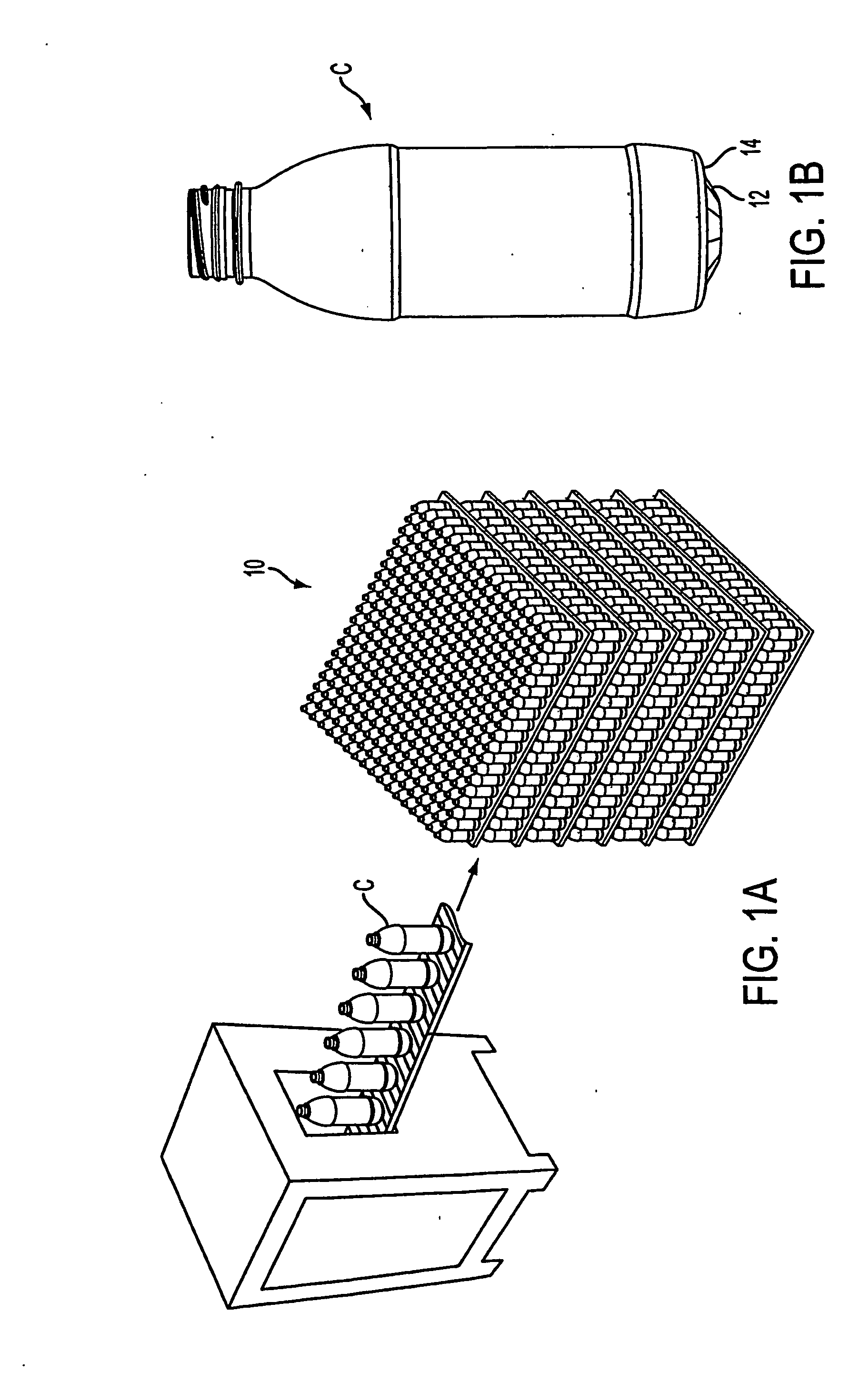

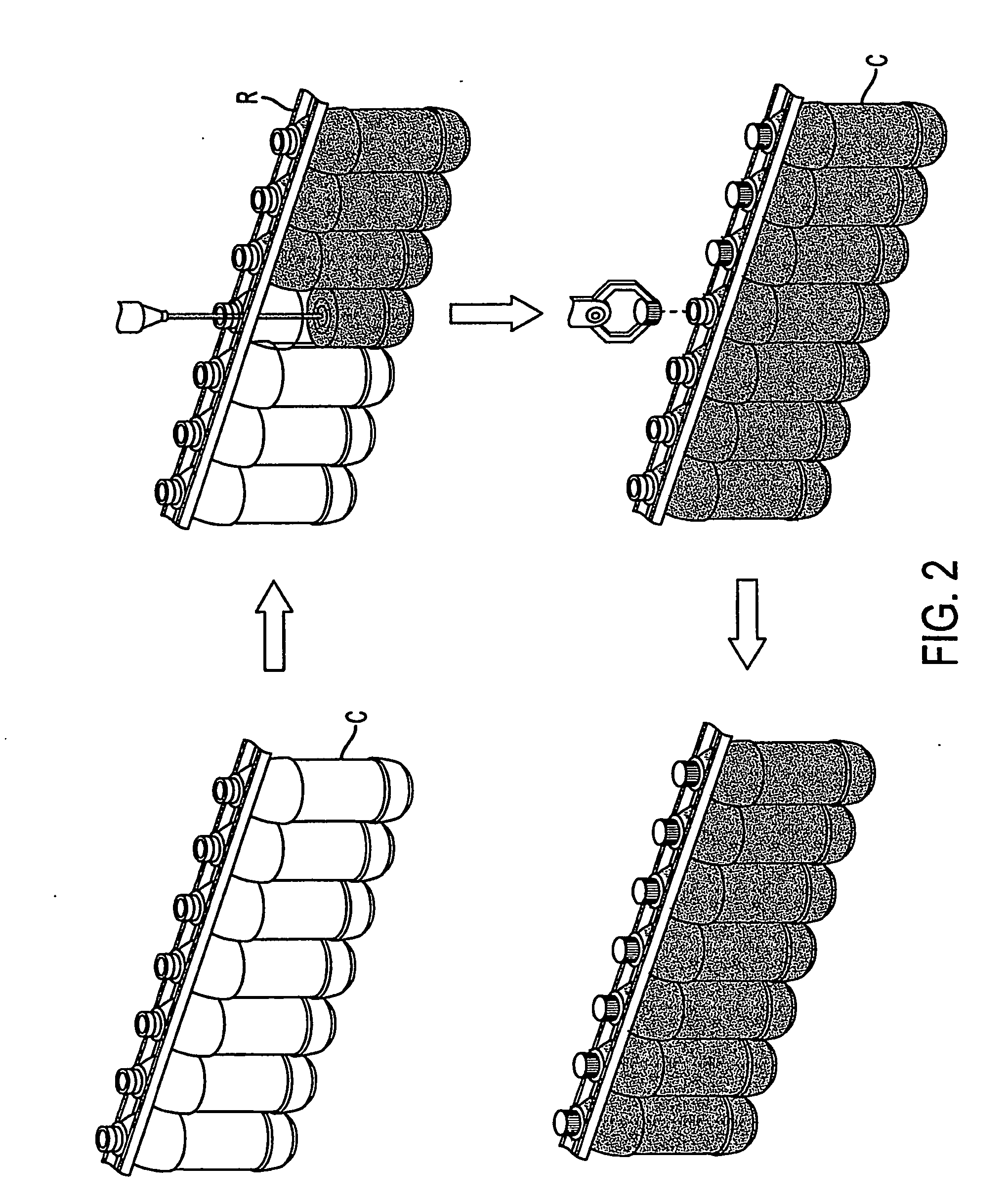

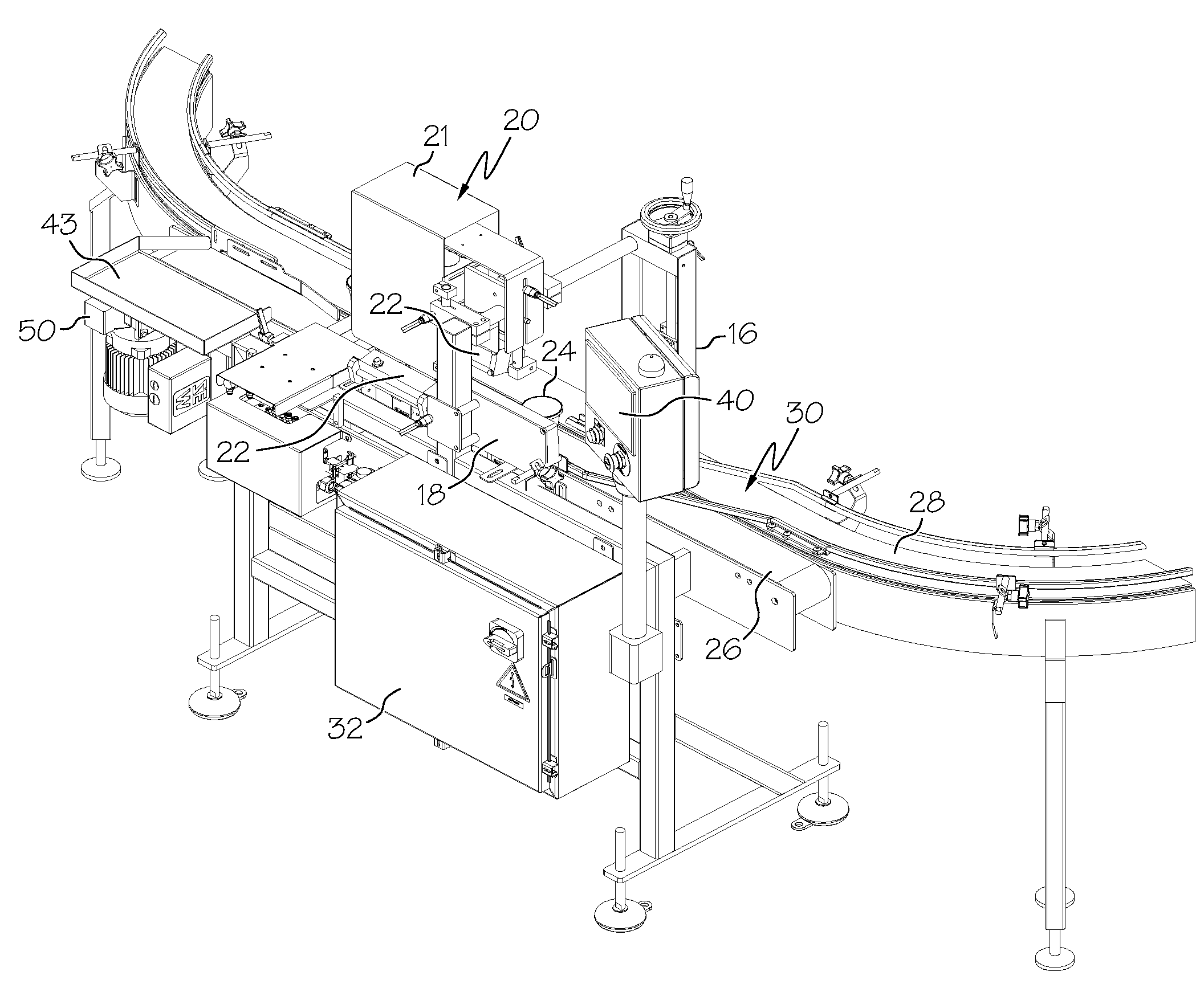

Container handling system

ActiveUS20070051073A1Smooth for label placementThorough removalCapsDecorative coversBlow moldingStructural geometry

A system for processing a simplified plastic container (C) that is to be filled with a hot product includes the step of blow-molding parison to form a container body, where the container body has a neck, a base, a side surface relatively free of structural geometry that surrounds an interior of the container body and, prior to being filled with the hot product, a projection (12) extending from the container body. After the container body is filled with a hot product in a production line, the neck of the filled container body is capped with a cap and then, the container body is cooled. During the cooling operation, the hot product is contracted so that the projection extending from the container can be pushed (P) into the container body like a traditional push-up so that the resultant, filled and cooled container body is relatively free of structural geometry.

Owner:CO2 PAC

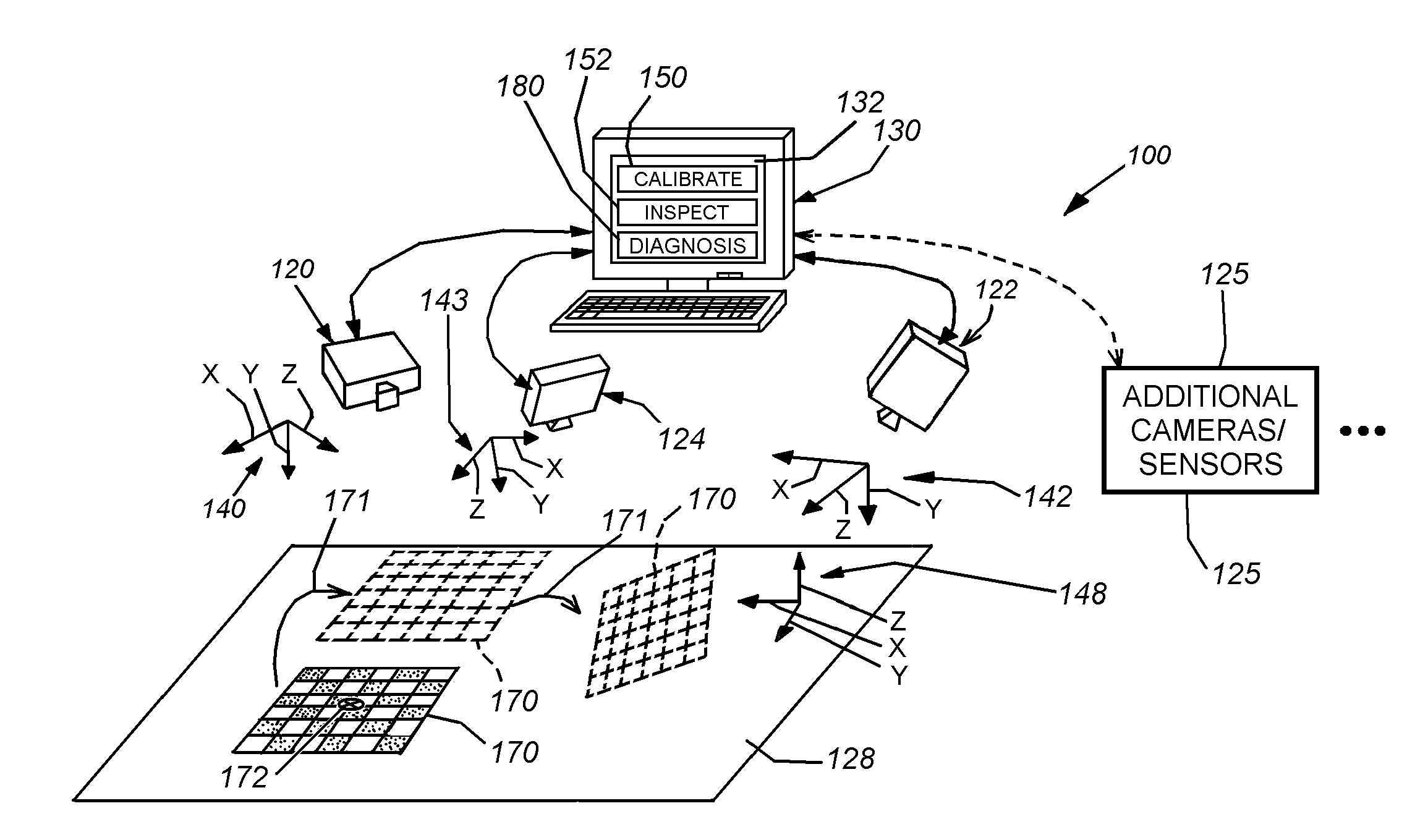

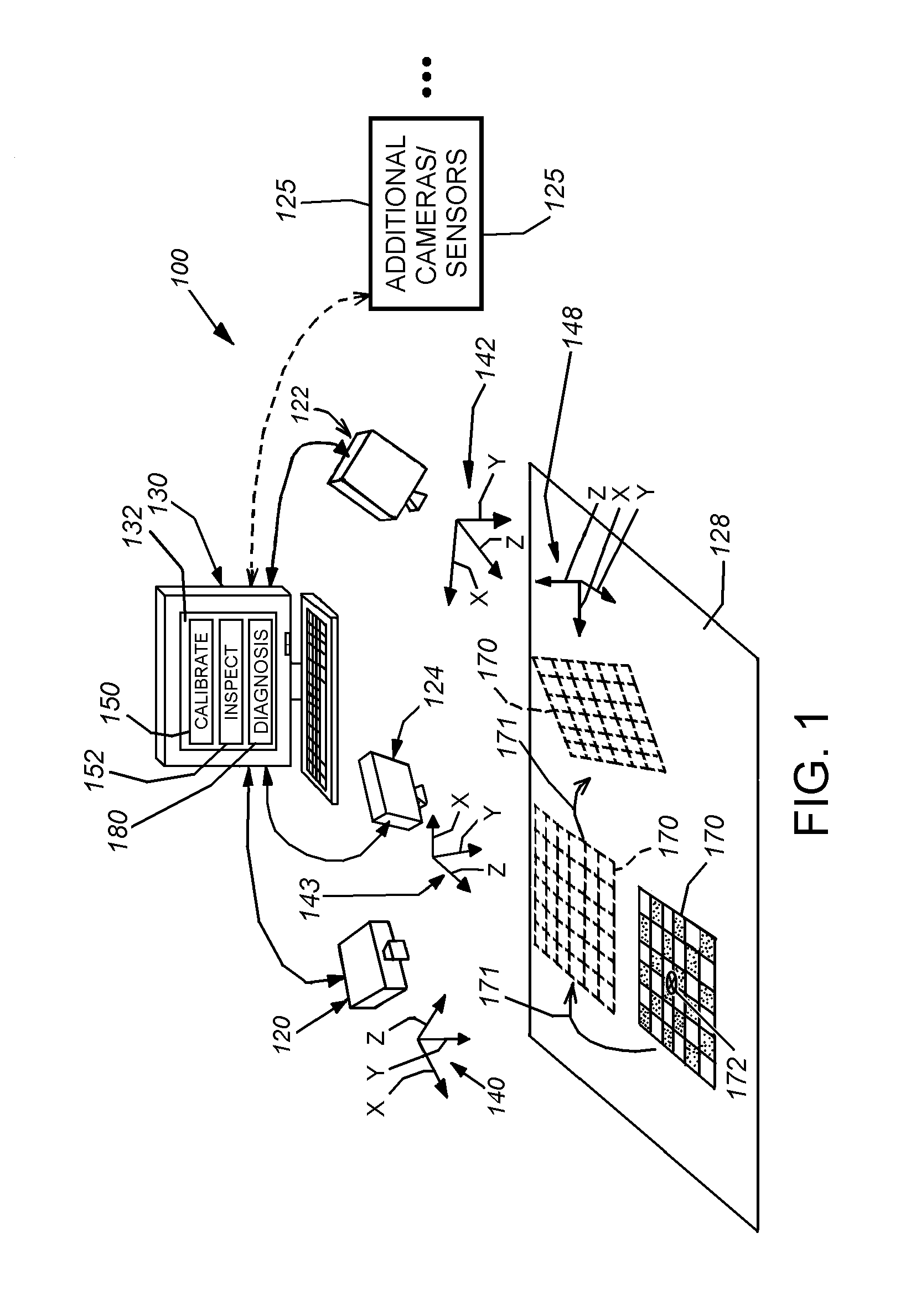

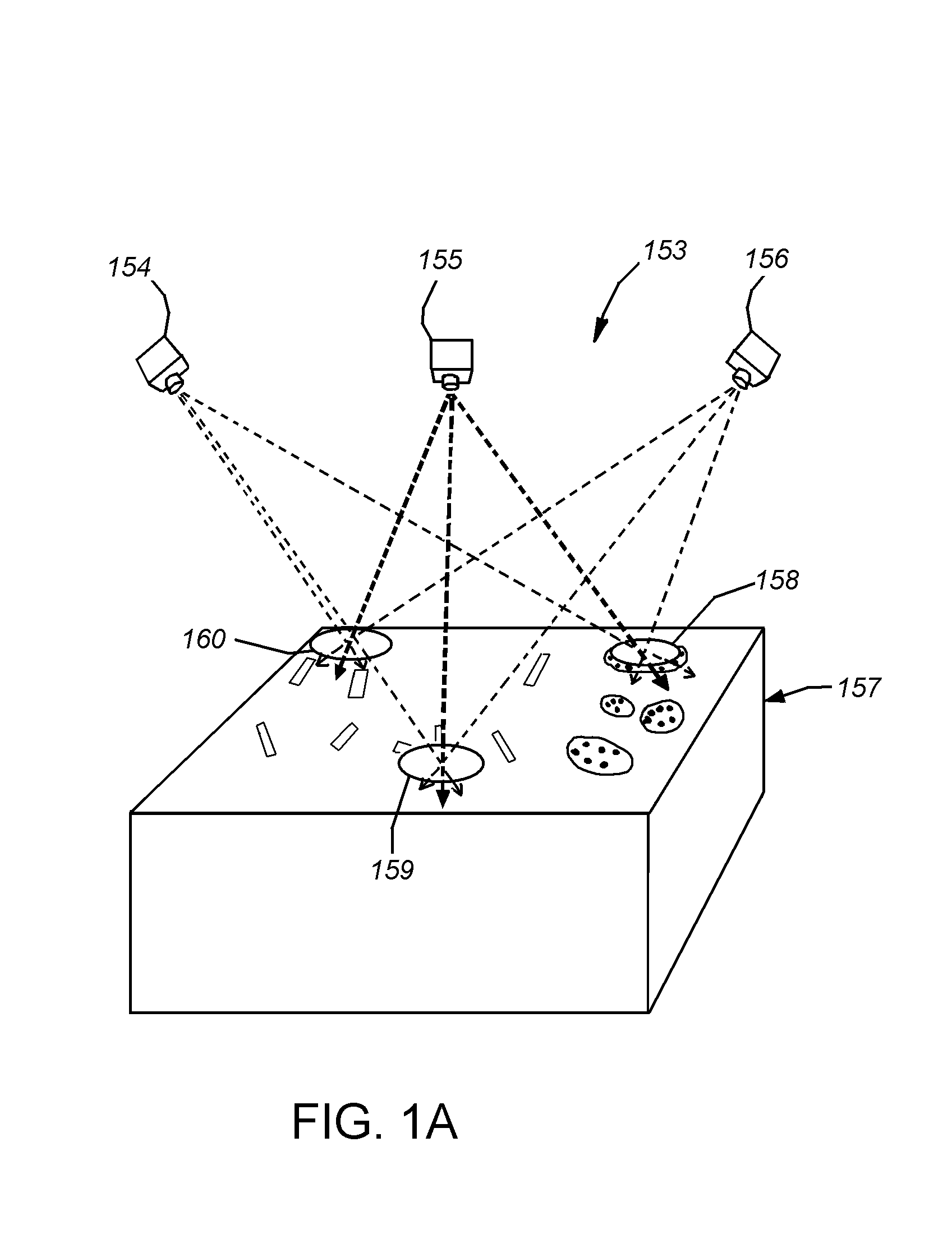

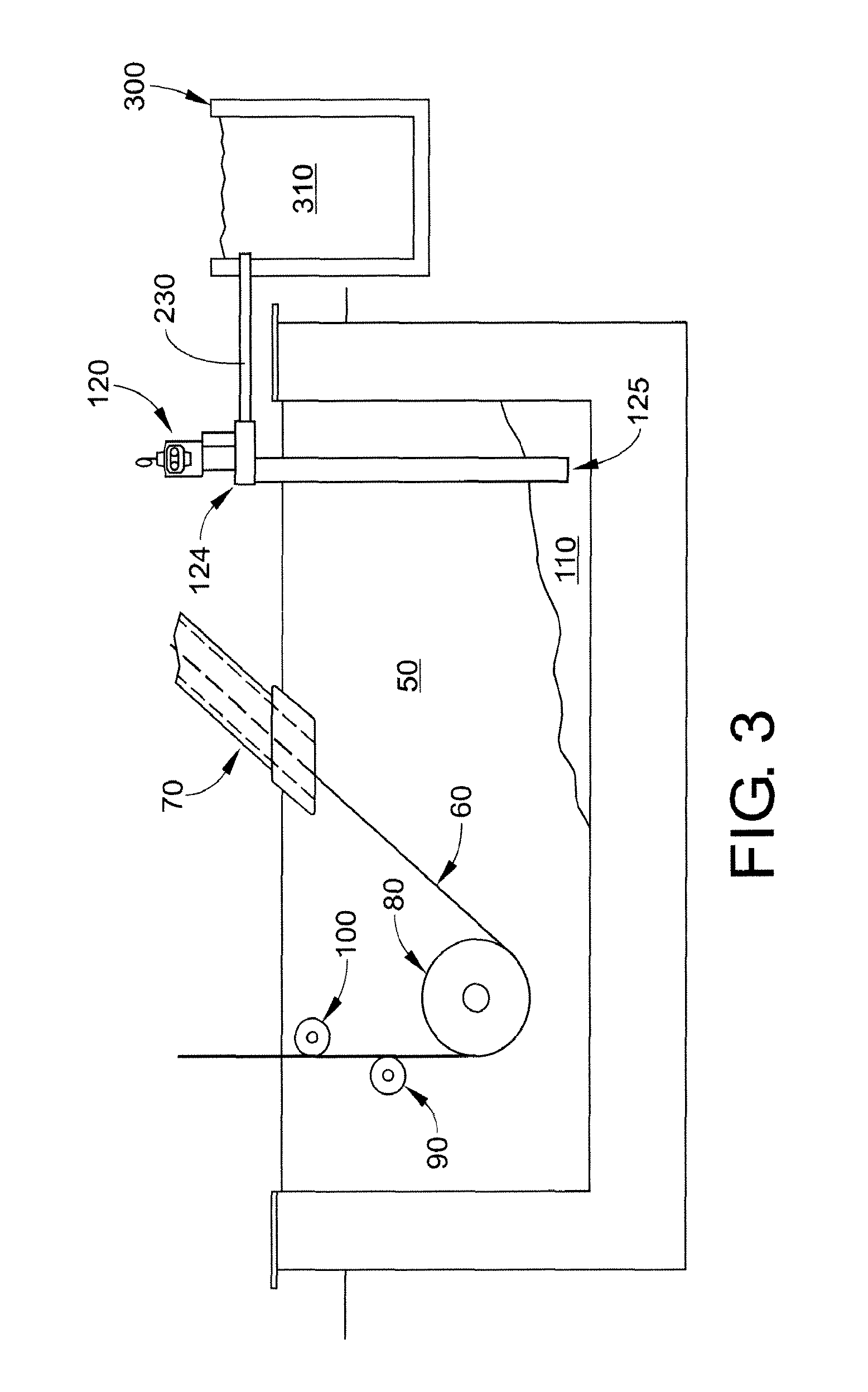

System and method for runtime determination of camera miscalibration

ActiveUS20110157373A1Faster and and diagnosisImage enhancementImage analysisMulti cameraCamera auto-calibration

This invention provides a system and method for runtime determination (self-diagnosis) of camera miscalibration (accuracy), typically related to camera extrinsics, based on historical statistics of runtime alignment scores for objects acquired in the scene, which are defined based on matching of observed and expected image data of trained object models. This arrangement avoids a need to cease runtime operation of the vision system and / or stop the production line that is served by the vision system to diagnose if the system's camera(s) remain calibrated. Under the assumption that objects or features inspected by the vision system over time are substantially the same, the vision system accumulates statistics of part alignment results and stores intermediate results to be used as indicator of current system accuracy. For multi-camera vision systems, cross validation is illustratively employed to identify individual problematic cameras. The system and method allows for faster, less-expensive and more-straightforward diagnosis of vision system failures related to deteriorating camera calibration.

Owner:COGNEX CORP

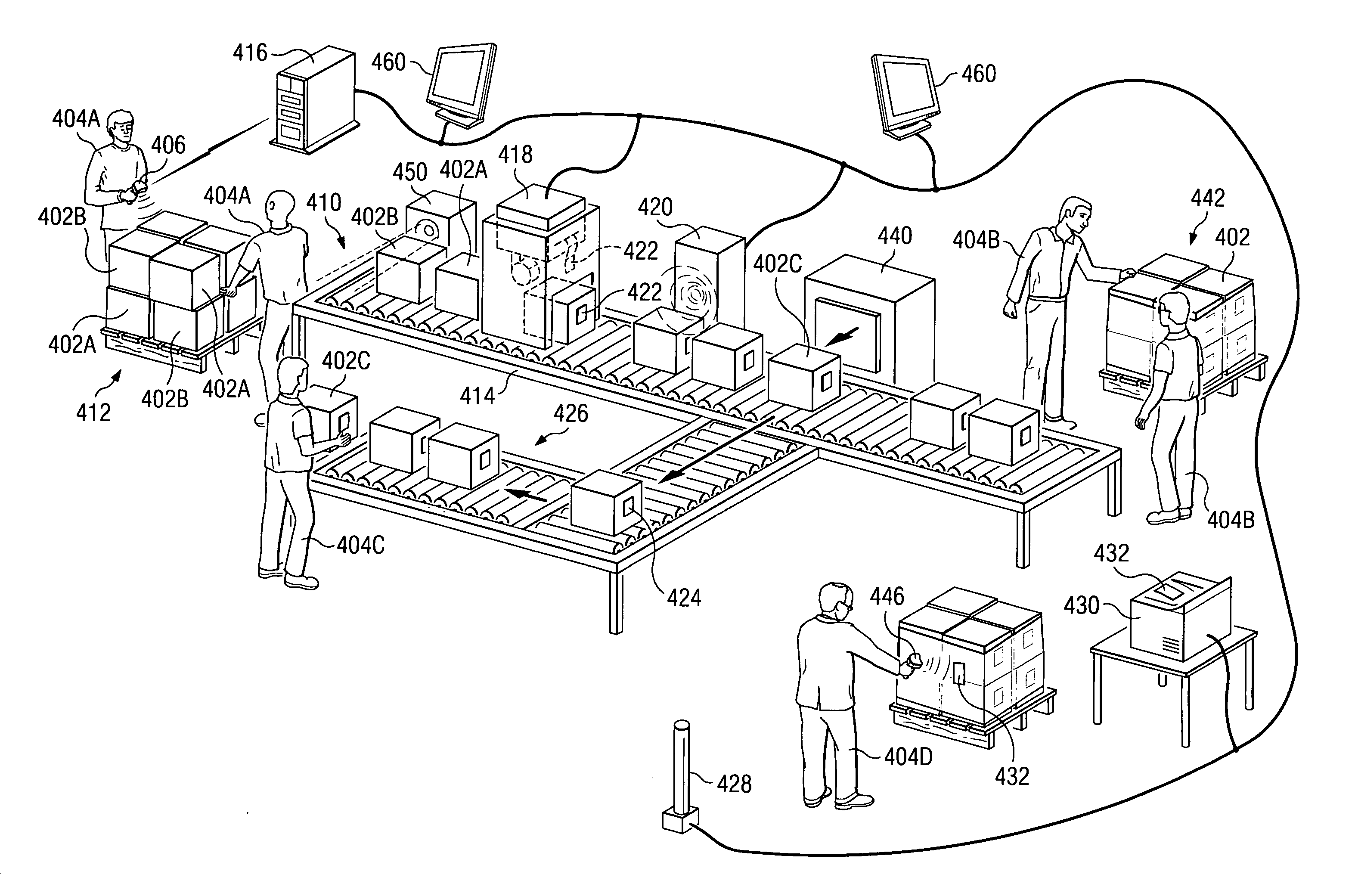

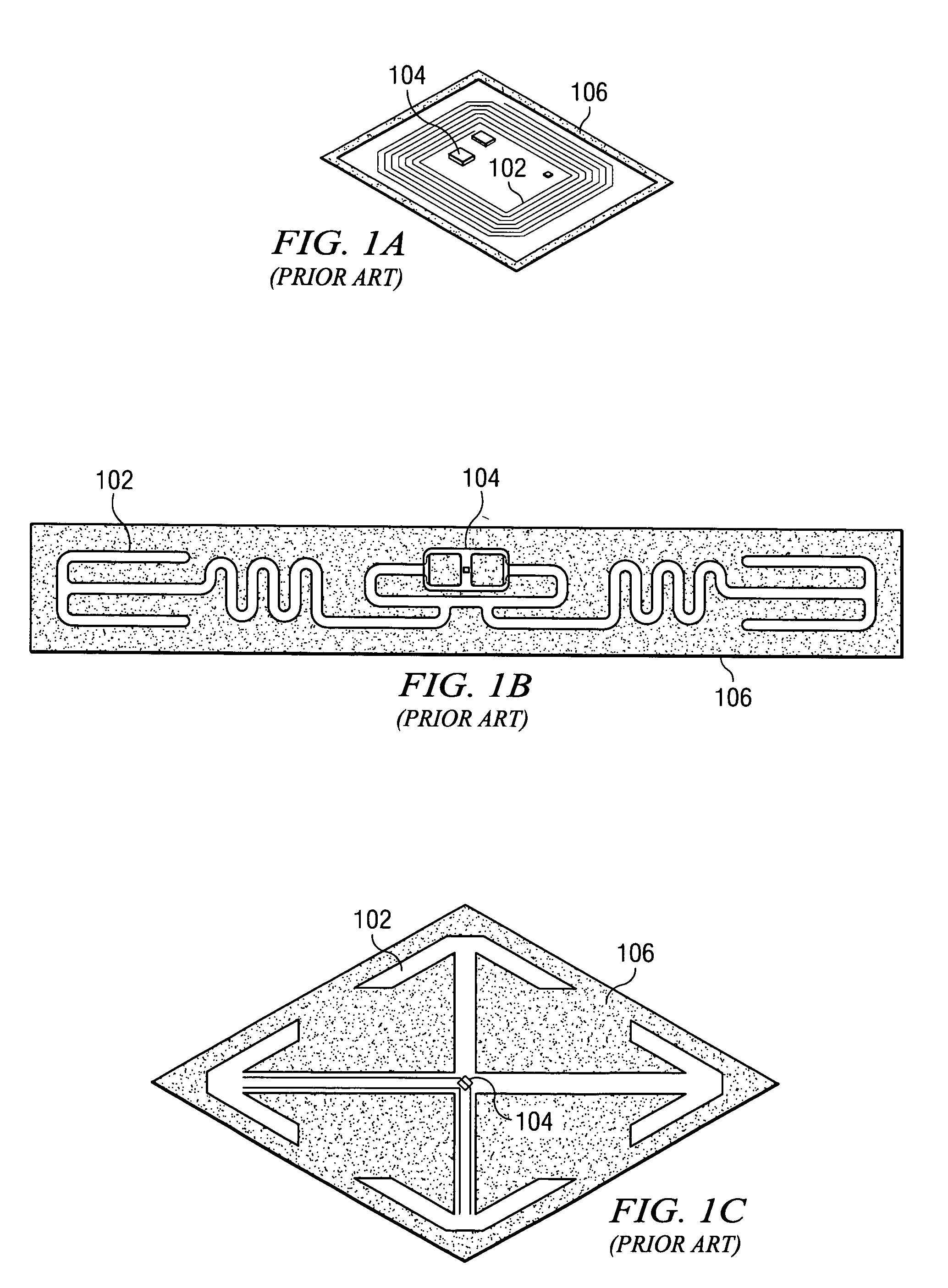

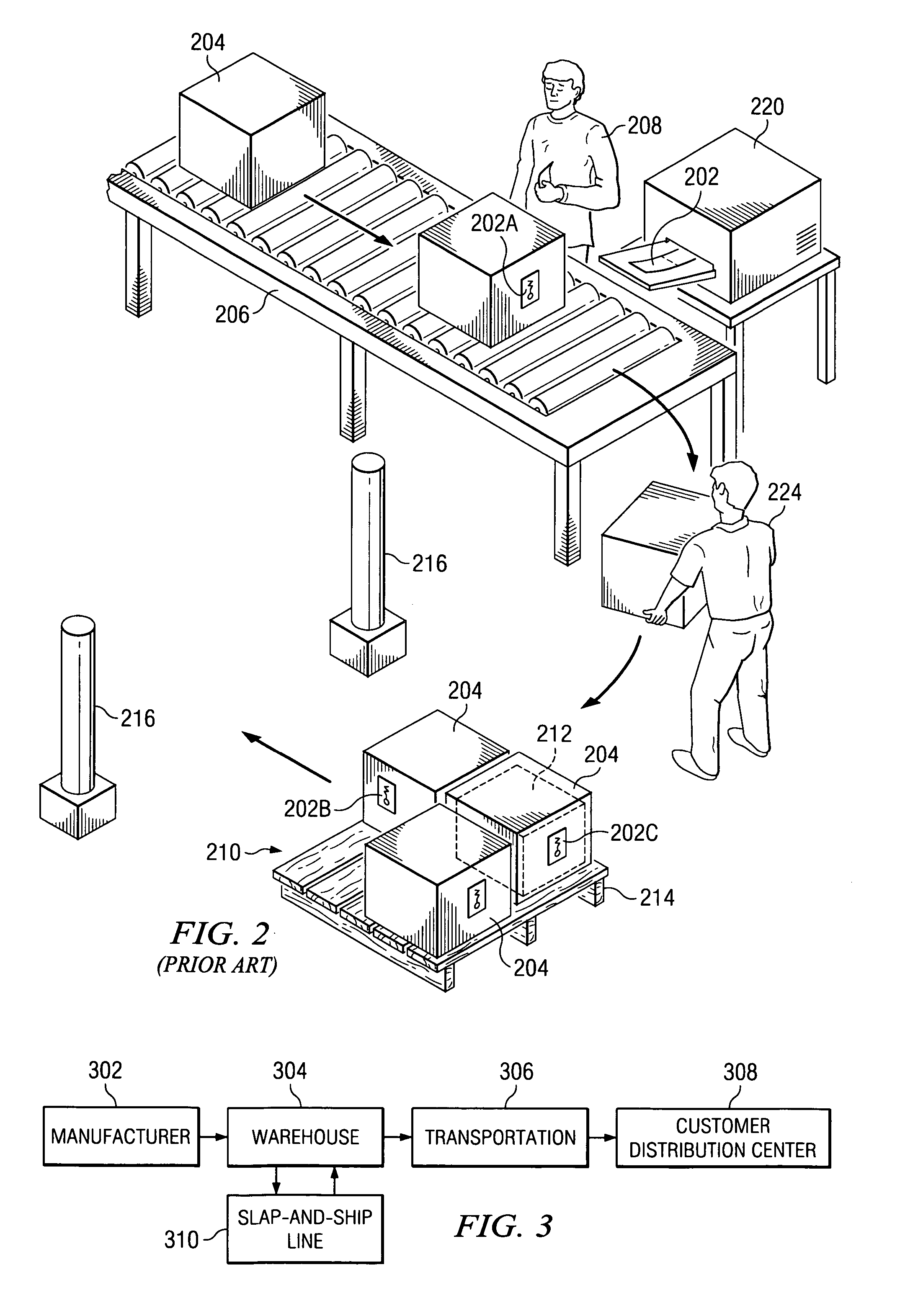

Method for slap-and-ship RFID labeling

ActiveUS20070126578A1Function can be ensuredEasy to placeDigital data processing detailsCo-operative working arrangementsCrateEmbedded system

A method for applying at least one RFID product tag to each of a plurality of products and to a product-containing container. Each product, case, or box is first unloaded from a container (e.g. pallet, tote, crate) or passed directly from manufacturing onto a conveyor whereon each item receives at least one RFID tag. Each RFID tag is then verified. Multiple items are then re-stacked in a container. An RFID tag is applied to the container and then the RFID tags are verified again before the container is shipped. Serialized numbers corresponding to products and containers are assigned and tracked. EPC data is stored on, or associated with, each RFID tag. RFID tags are verified to detect faulty placement and non-functionality. Non-functioning and poorly placed RFID tags are replaced before passing verification. The slap-and-ship line can handle execute-and-record methods and synchronized execution methods of handling product and associated data.

Owner:FRITO LAY NORTH AMERICA INC

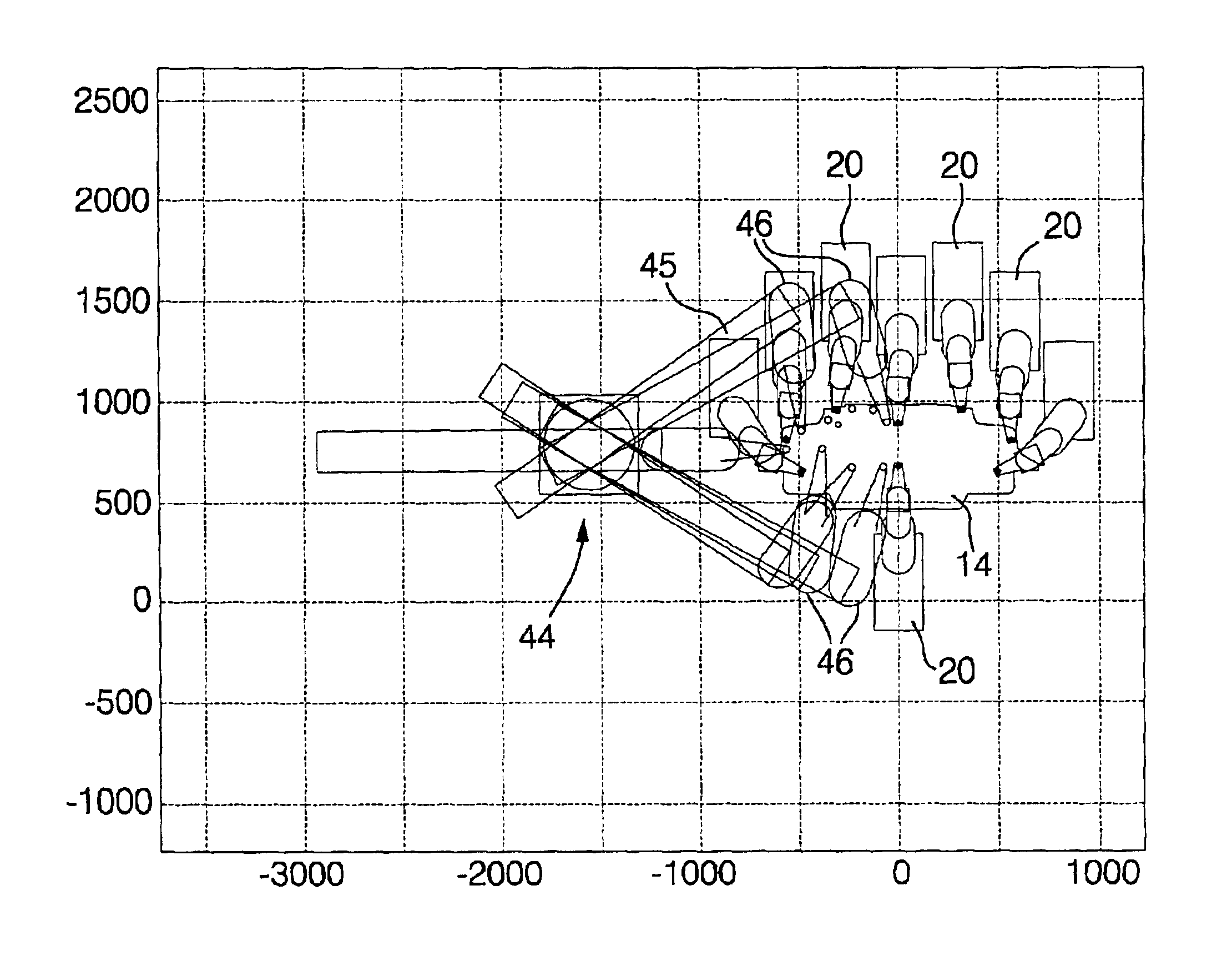

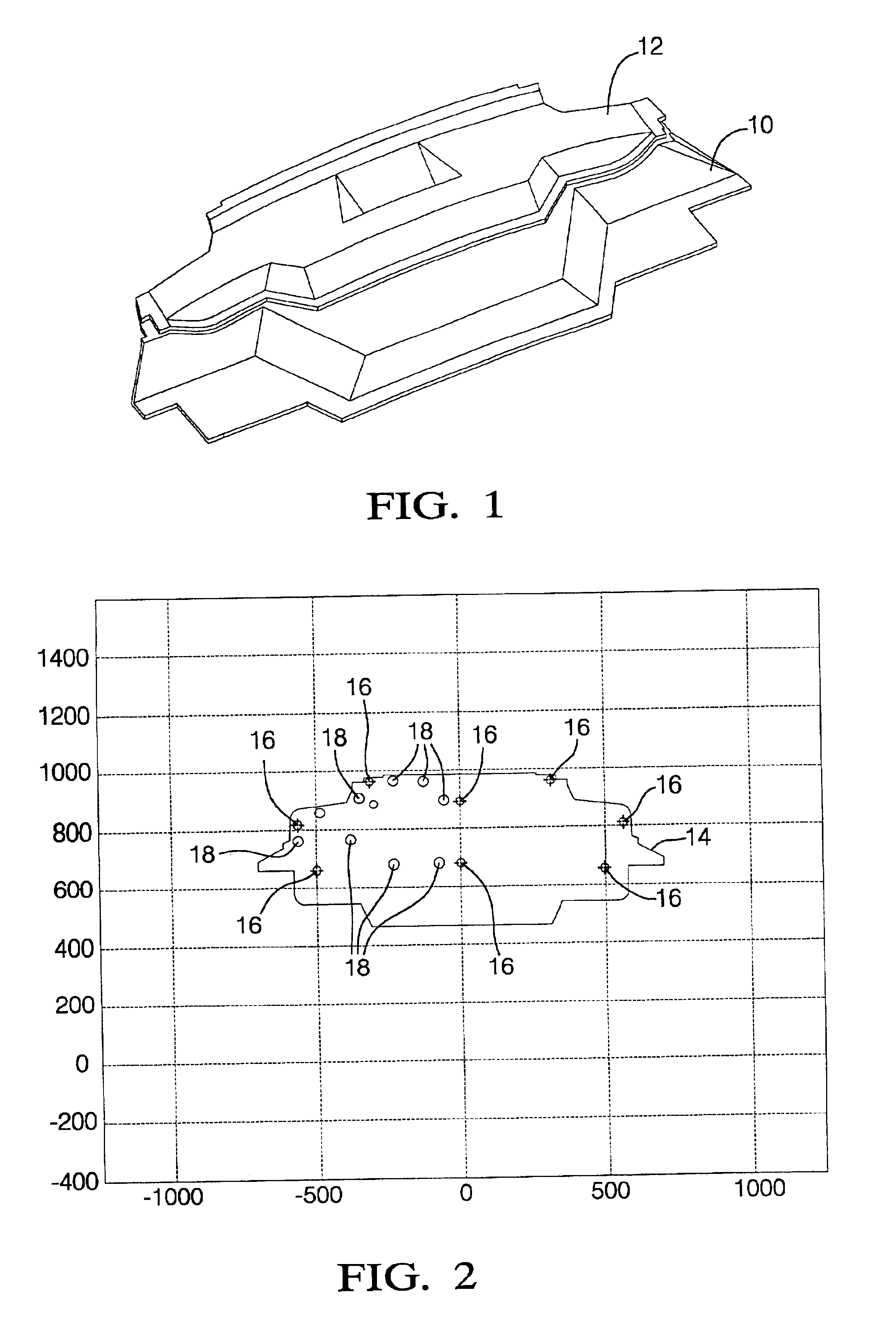

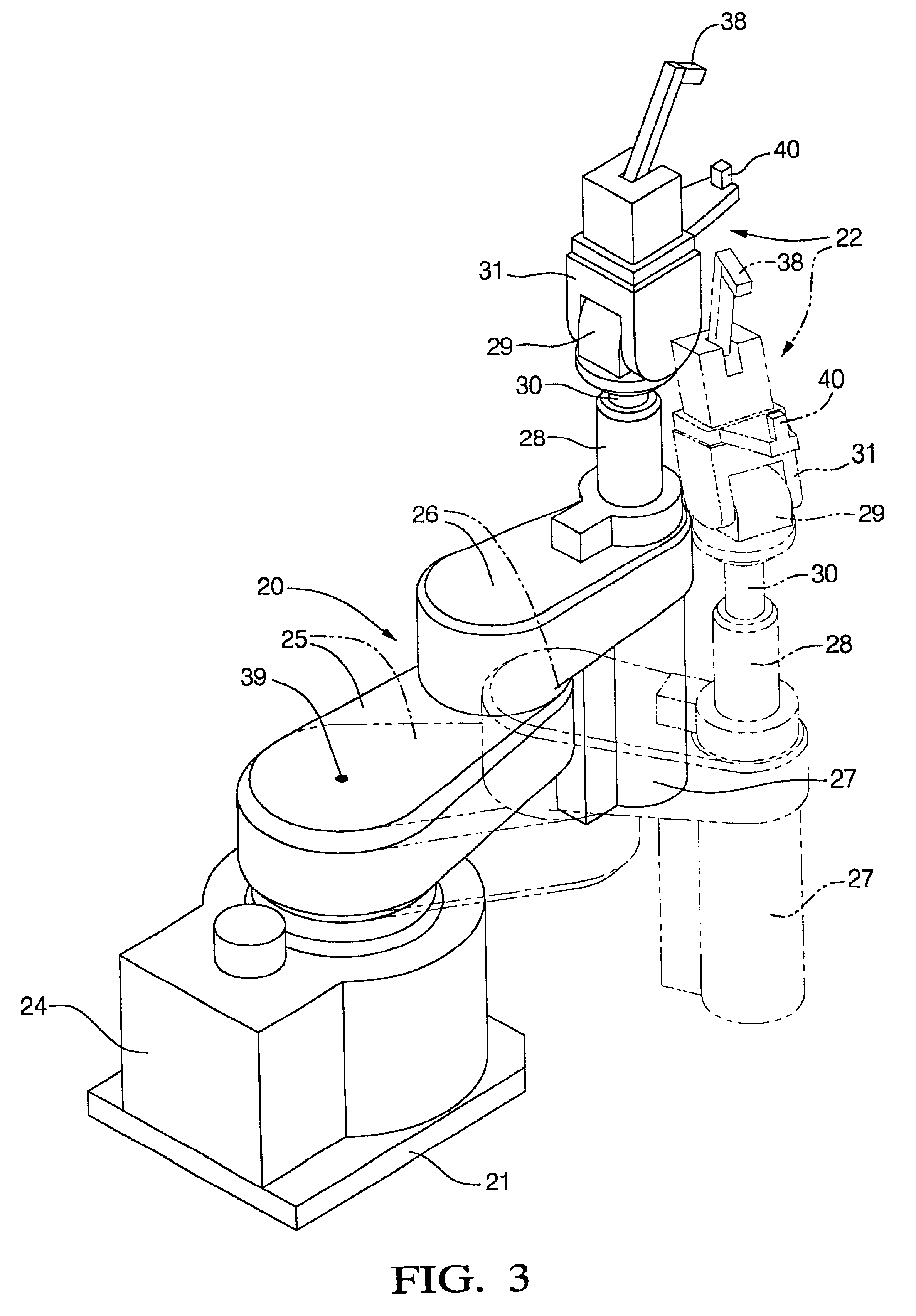

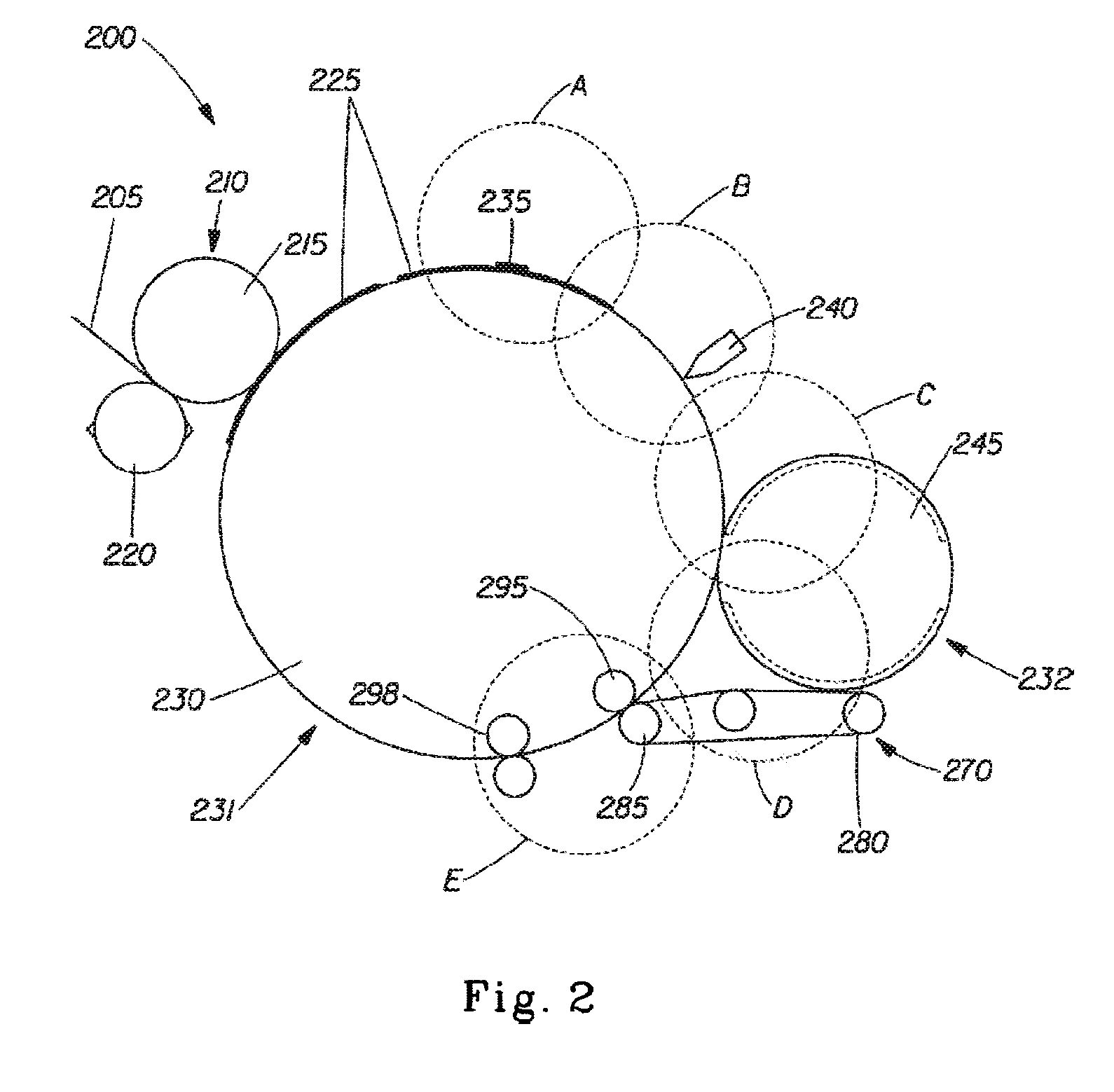

Method for computer-aided layout of manufacturing cells

A computer assisted method is disclosed for making an optimized layout of a manufacturing cell to be used, for example, to locate, hold and process workpieces, such as in robotic welding of an assembly of stamped sheet metal parts. The items to be processed and employed in the cell are identified by physical structure and kinematic characteristics and given an initial location to start the process. Further movements of the parts toward attraction points and away from repelling points are evaluated on the computer by an optimization program to arrive at an optimized cell layout.

Owner:GM GLOBAL TECH OPERATIONS LLC

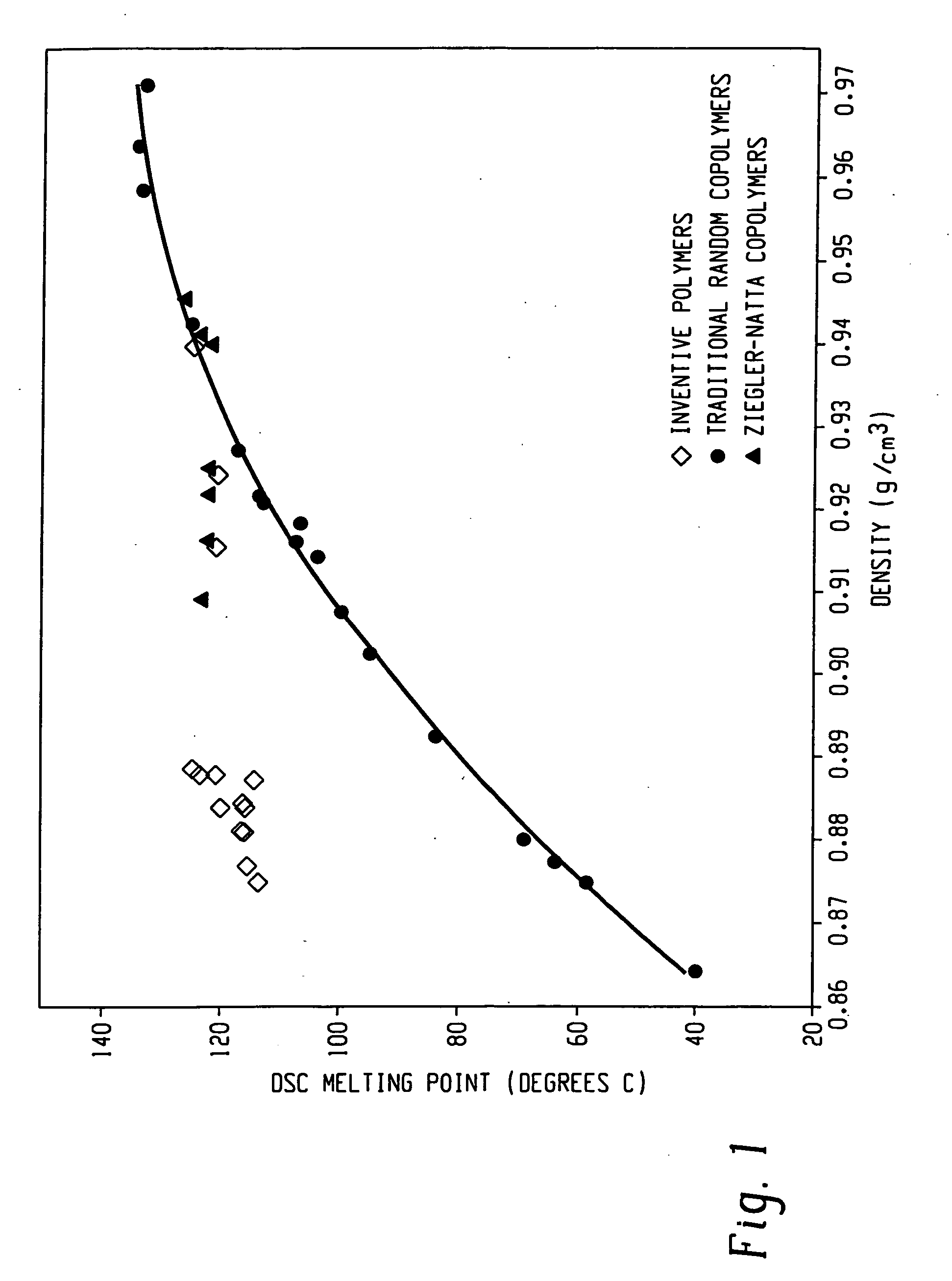

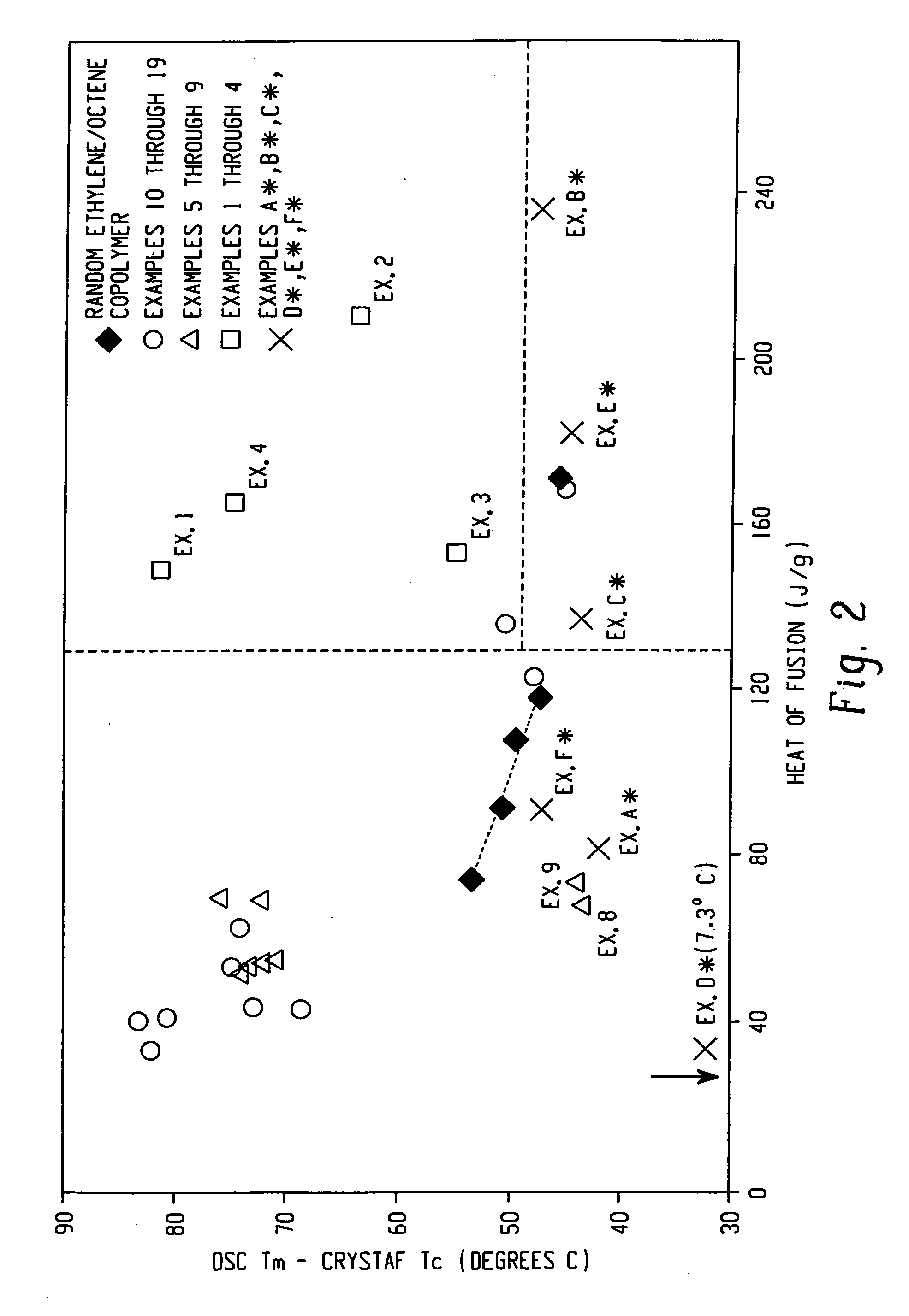

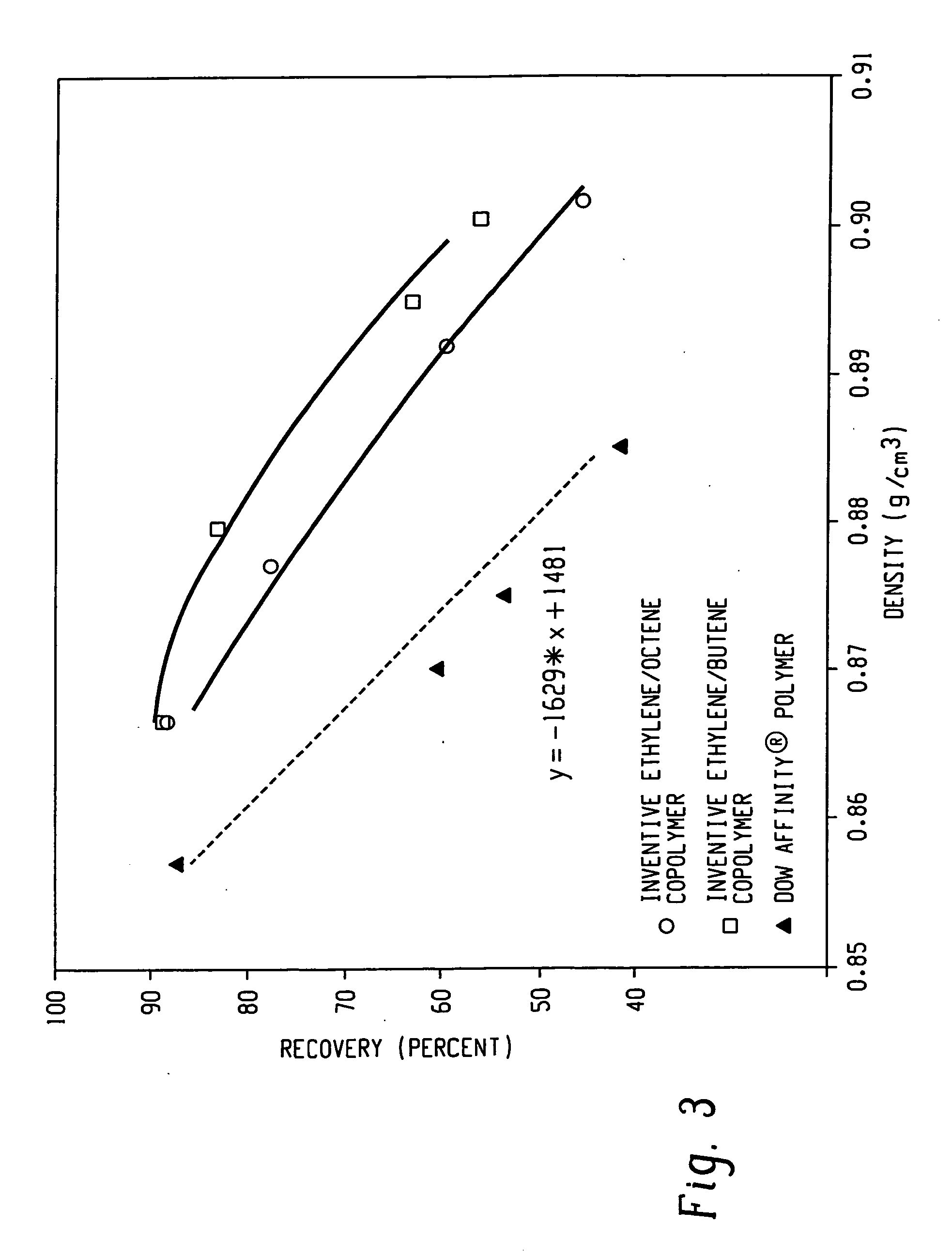

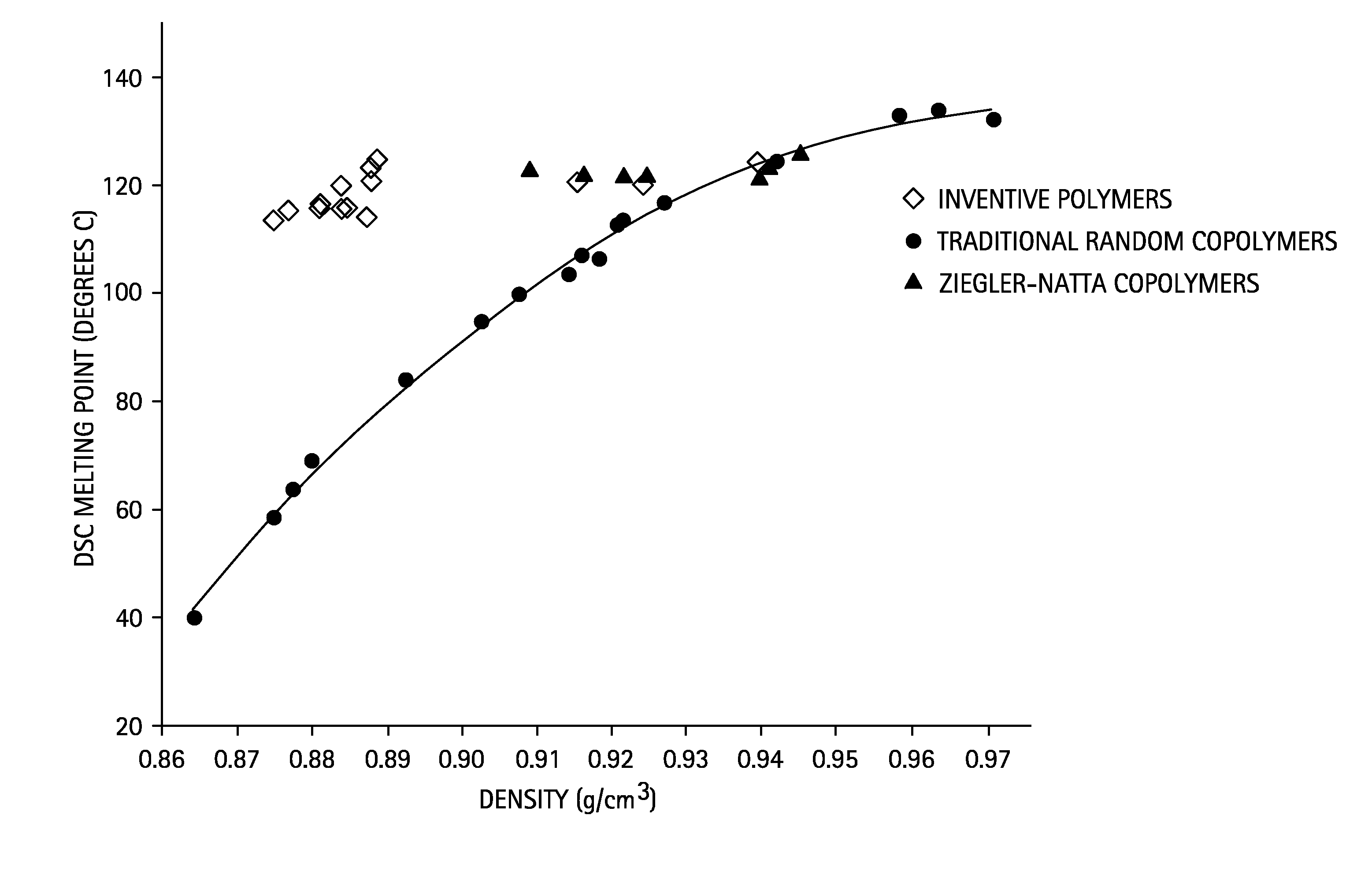

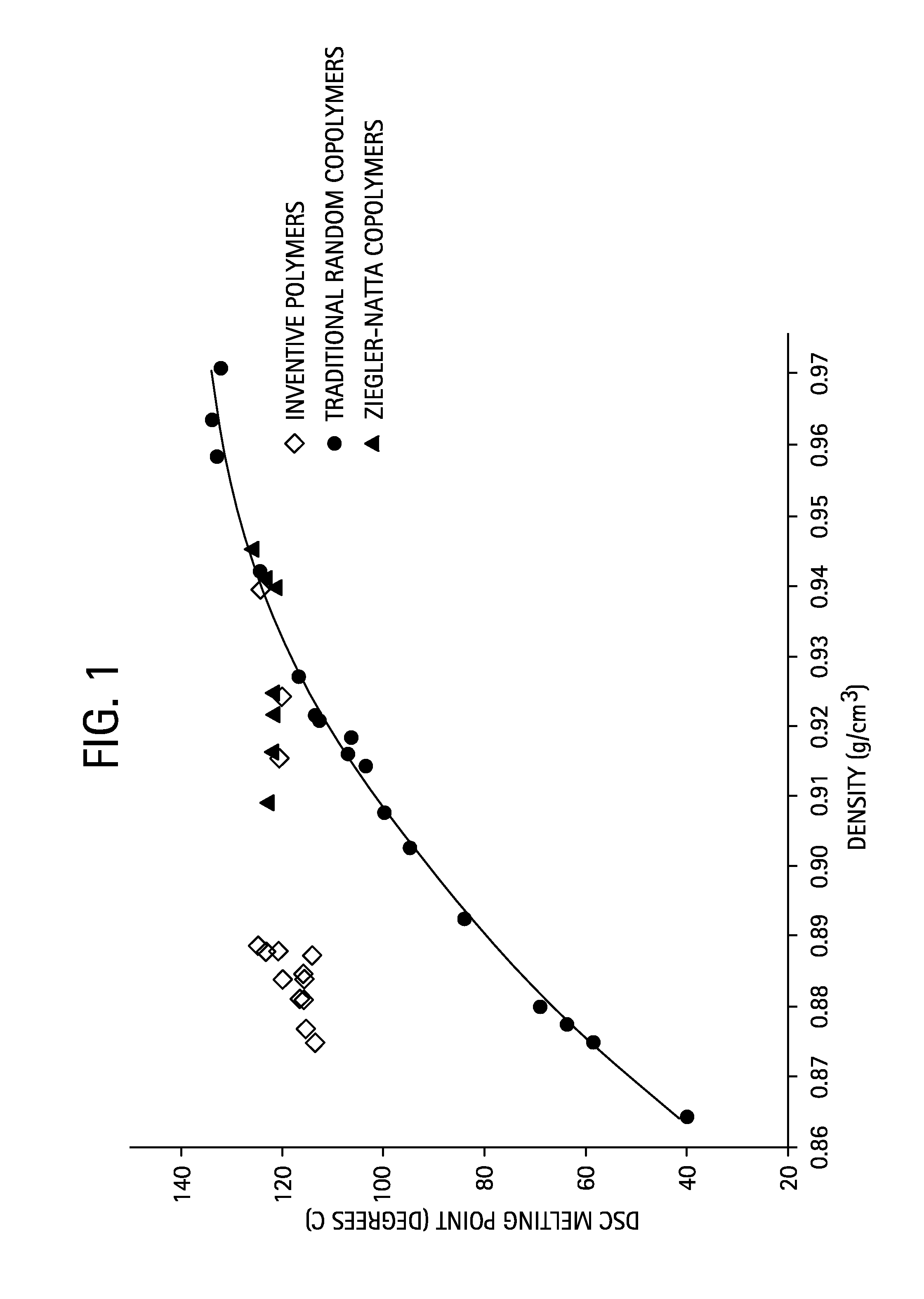

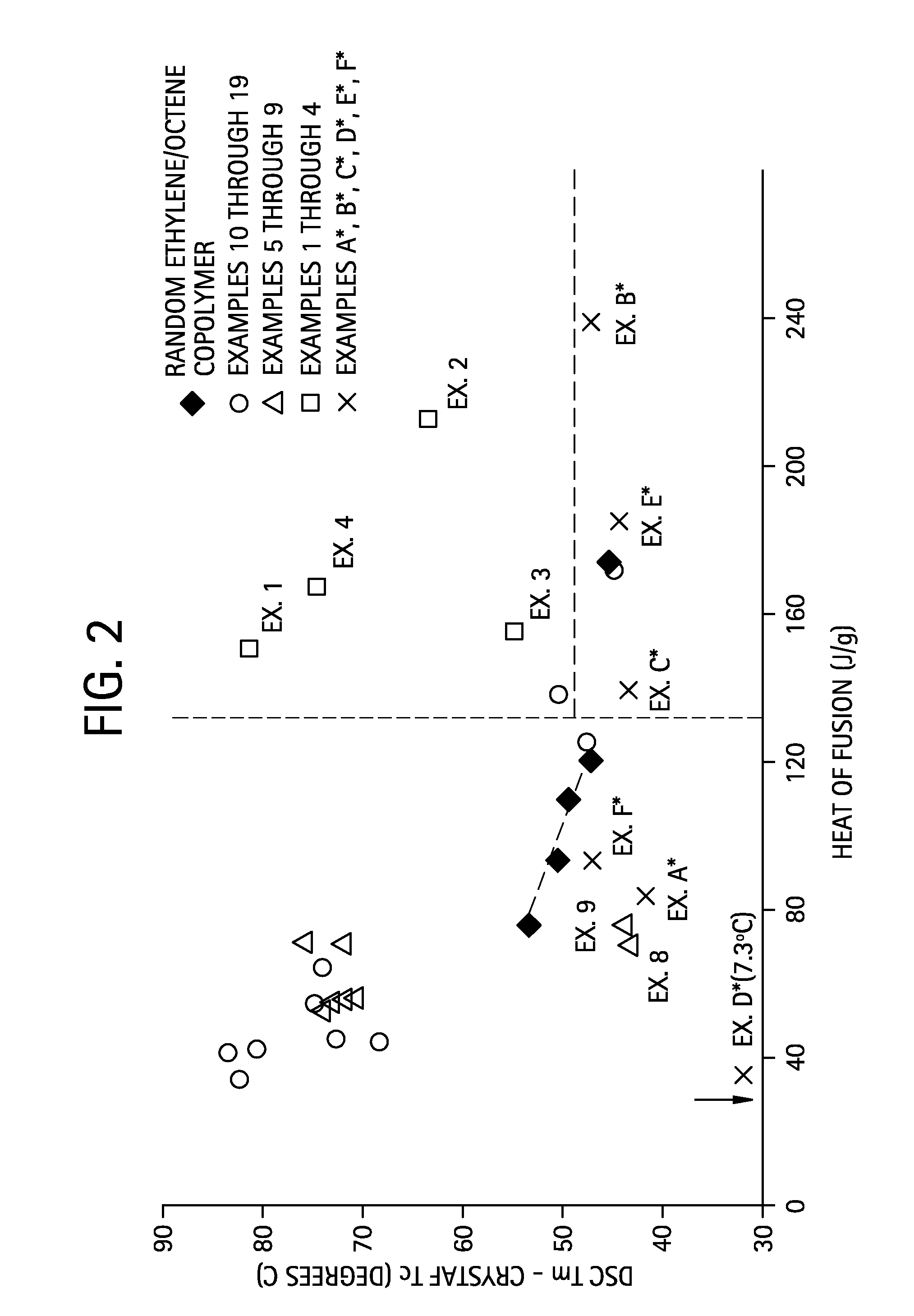

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

ActiveUS20070078222A1Easy to processHigh tensile strengthPersonal careSynthetic resin layered productsPolyolefinHigh pressure

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

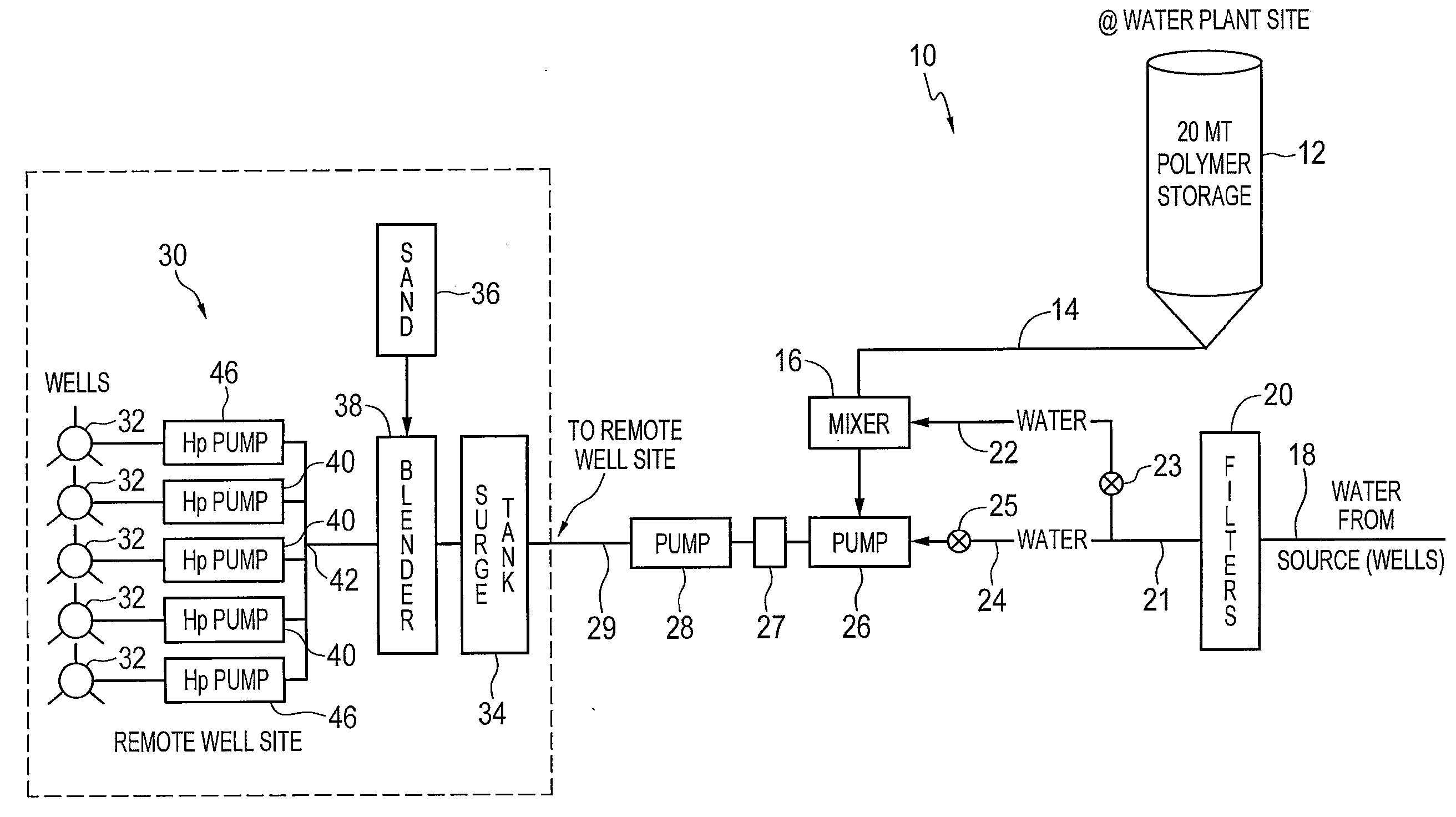

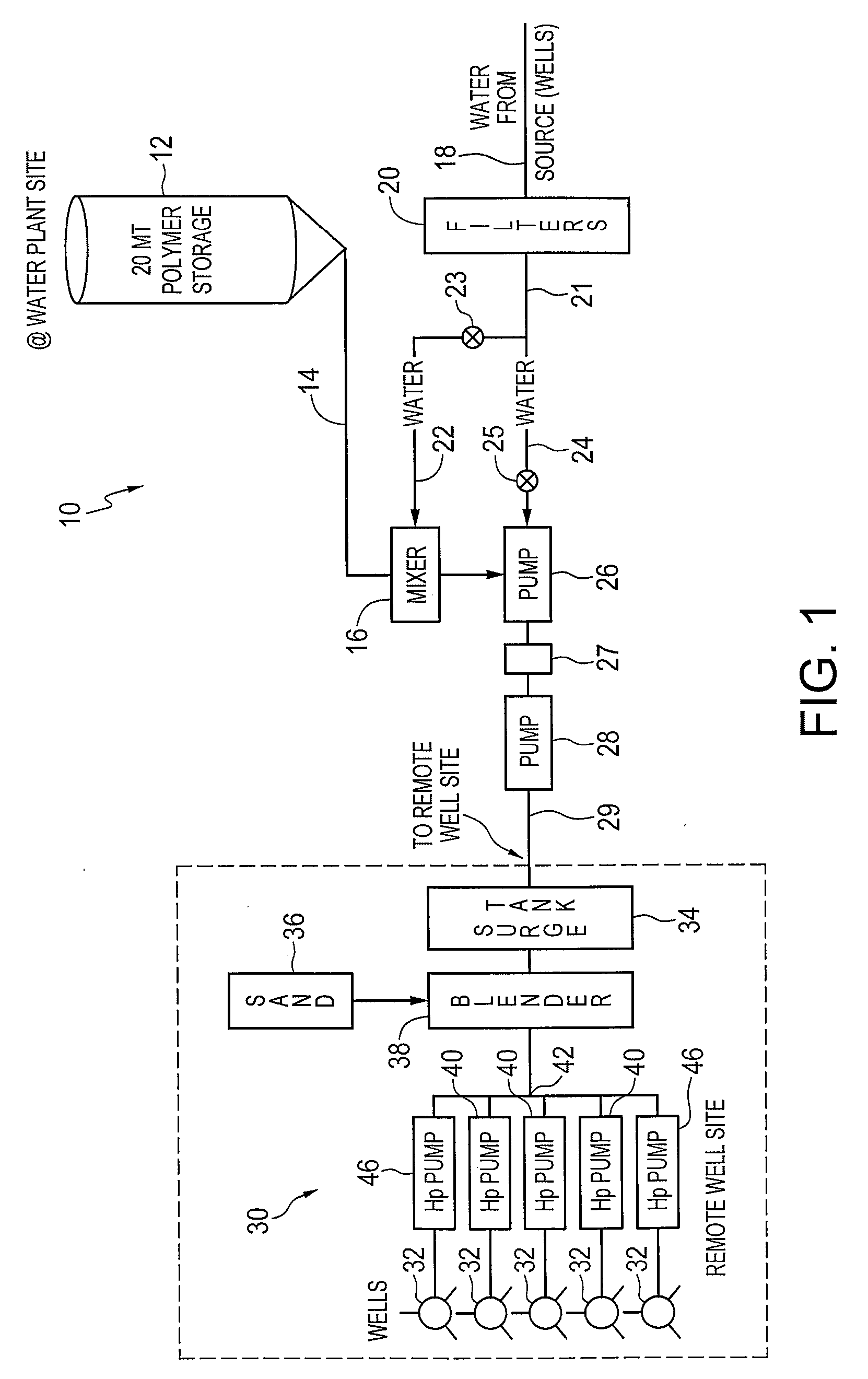

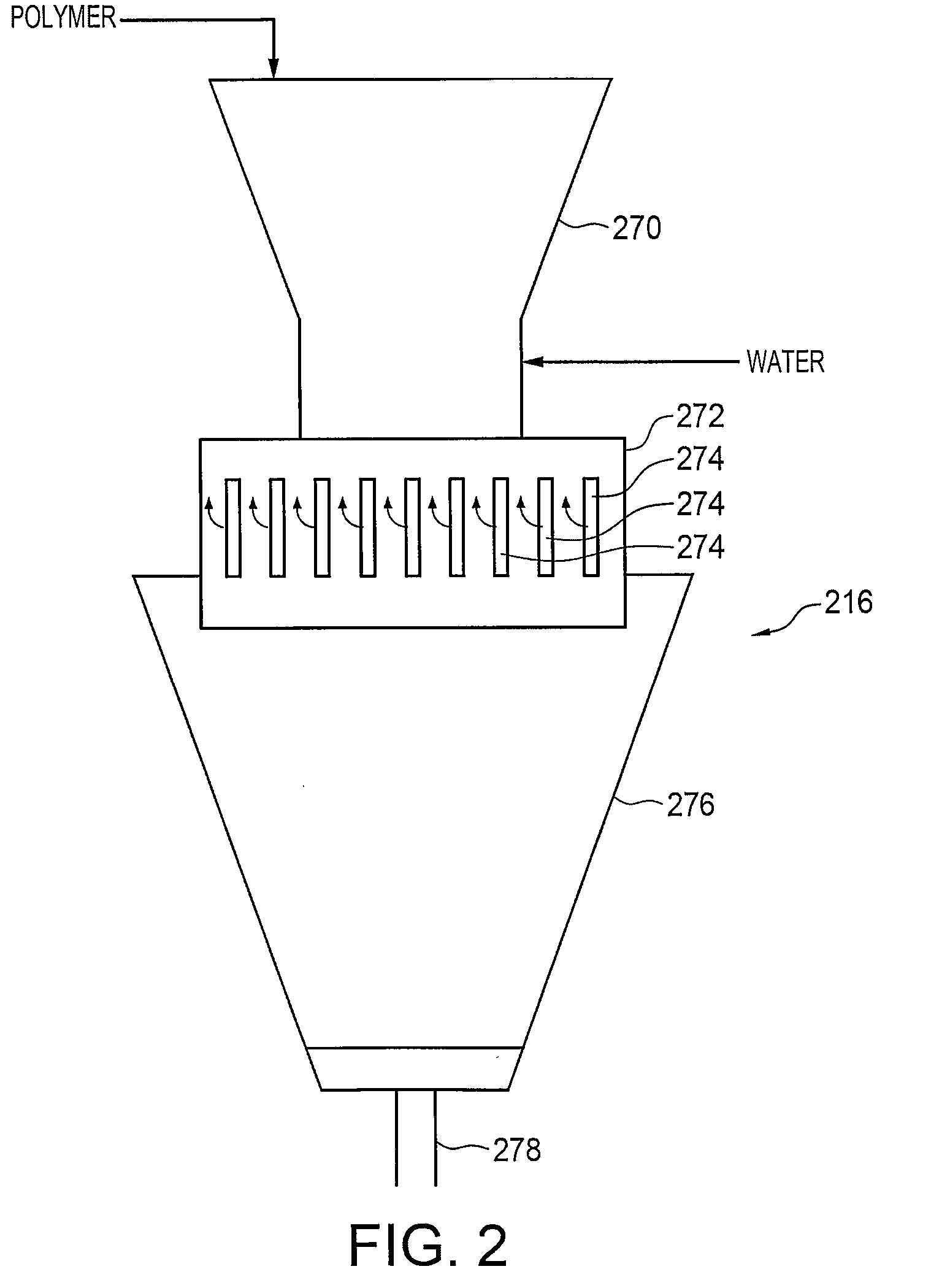

Process and process line for the preparation of hydraulic fracturing fluid

InactiveUS20100132949A1Drilling rodsTransportation and packagingFracturing fluidHydraulic fracturing

A process and process line is provided for preparing a friction-reduced hydraulic fracturing fluid at a central location which can be readily transported to an oil or gas well in a formation at a well site, comprising: preparing a mixture of polymer and water at the central location by shearing the polymer in the water in a high shear environment to create the friction-reduced hydraulic fracturing fluid; pumping the friction-reduced hydraulic fracturing fluid through a series of pumps and pipelines to the well site; and injecting the hydraulic fracturing fluid into the oil or gas well at a pressure sufficient to cause fracturing of the formation.

Owner:OVINTIV CANADA ULC

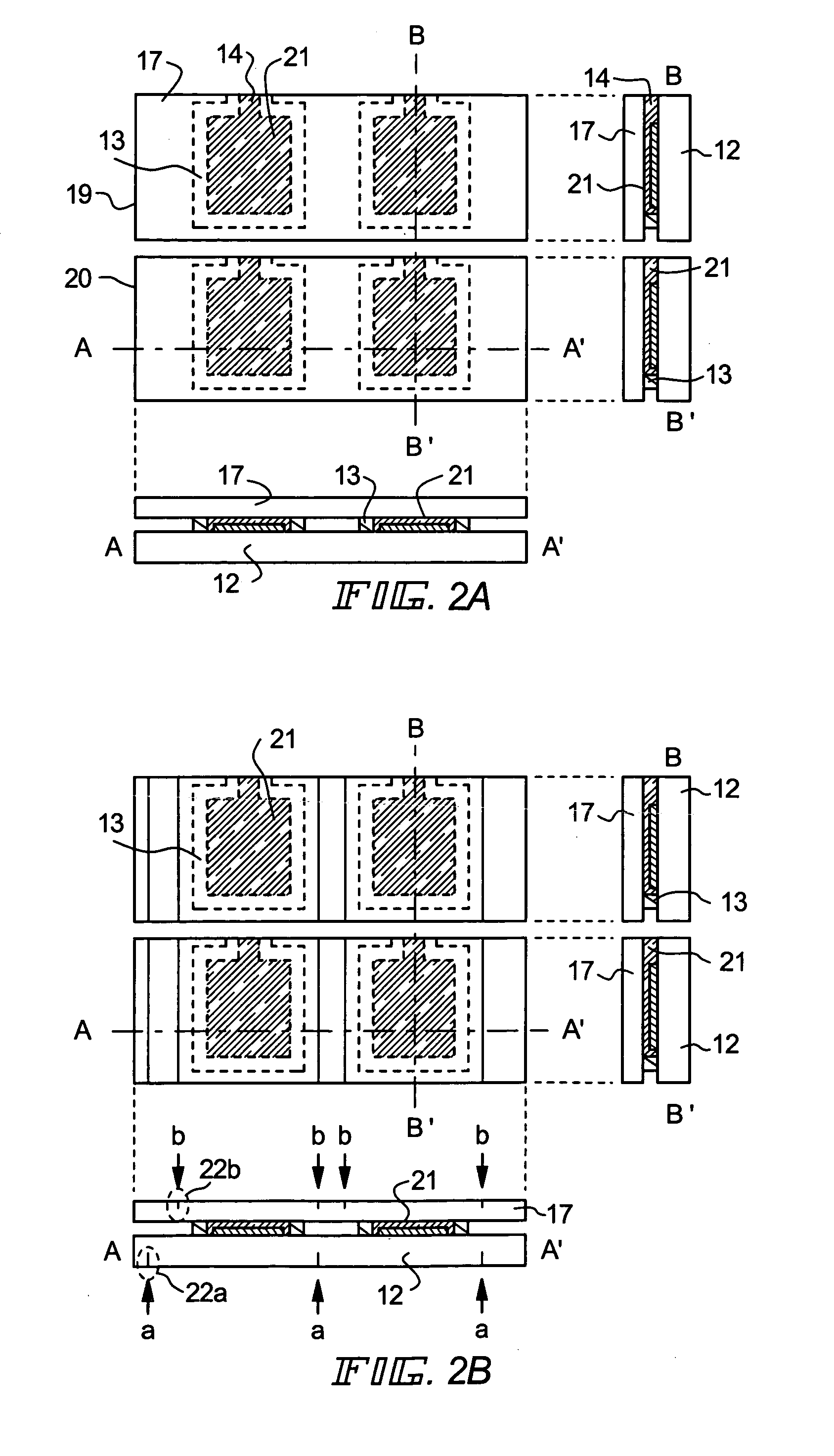

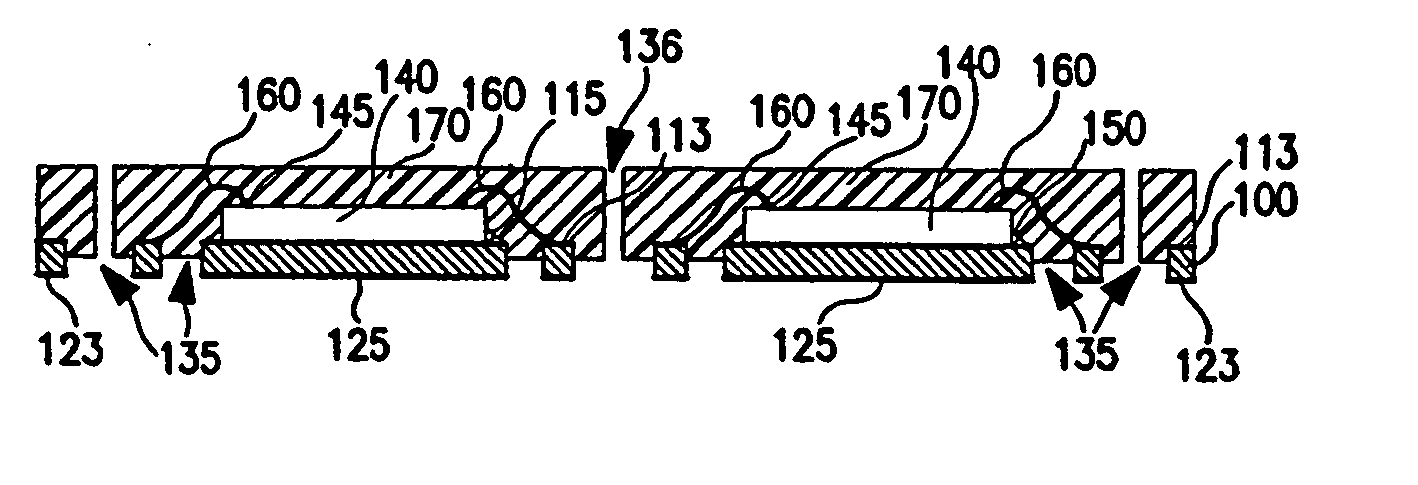

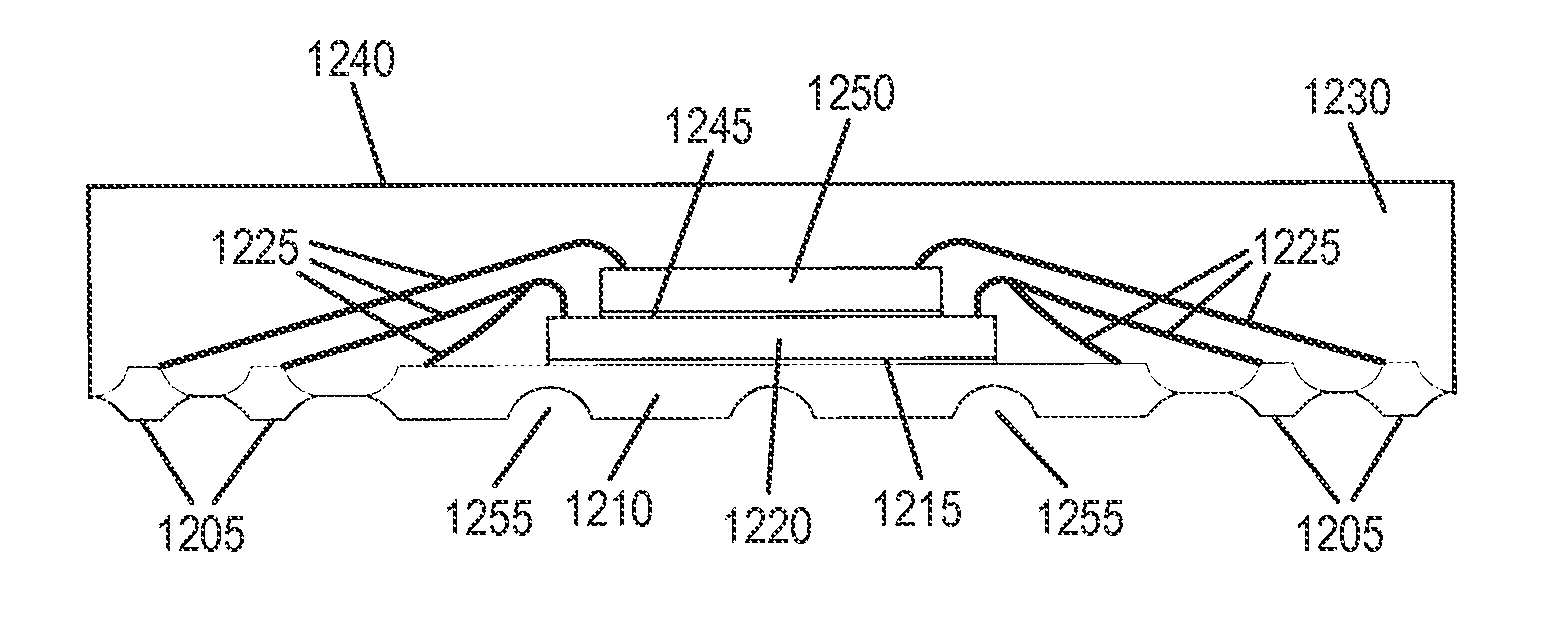

Partially Patterned Lead Frames and Methods of Making and Using the Same in Semiconductor Packaging

ActiveUS20070052076A1Increase surface areaImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyLead bonding

A method of making a lead frame and a partially patterned lead frame package with near-chip scale packaging (CSP) lead-counts is disclosed, wherein the method lends itself to better automation of the manufacturing line as well as to improving the quality and reliability of the packages produced therefrom. This is accomplished by performing a major portion of the manufacturing process steps with a partially patterned strip of metal formed into a web-like lead frame on one side, in contrast with the conventional fully etched stencil-like lead frames, so that the web-like lead frame, which is solid and flat on the other side is also rigid mechanically and robust thermally to perform without distortion or deformation during the chip-attach and wire bond processes, both at the chip level and the package level. The bottom side of the metal lead frame is patterned to isolate the chip-pad and the wire bond contacts only after the front side, including the chip and wires, is hermetically sealed with an encapsulant. The resultant package being electrically isolated enables strip testing and reliable singulation without having to cut into any additional metal. The use of the instant partially patterned lead frame in making ELP, ELPF and ELGA-type CSPs is also disclosed.

Owner:UNISEM M BERHAD

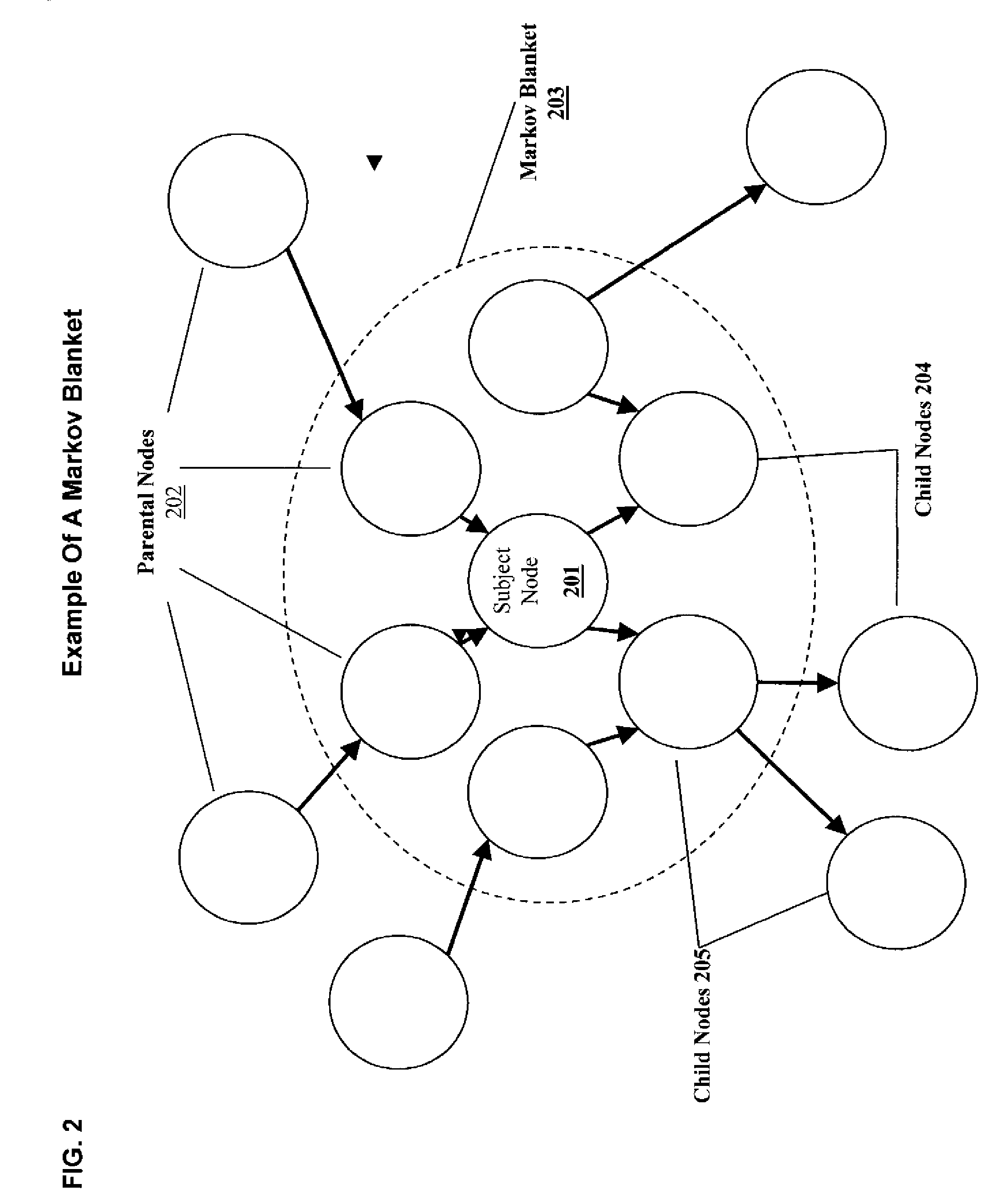

Extensible bayesian network editor with inferencing capabilities

A system for the representation, editing, evaluation, and inference of graphical models is disclosed which can be used to construct and evaluate a graphical model or graphical network and to calculate inference values. An efficient method of updating graphical models is demonstrated, and provides the basis for an improved system for manipulation and evaluation of probabilistic models. The graphical network editor is useful in the construction of graphical modes such as Bayesian Networks. The graphical network and network graphical user interface (GUI) are used in conjunction with each other to model a system wherein failure probabilities and the current state of components are taken into account to monitor the health and progress of a system for an engineer or engineering software to evaluate and monitor. The evaluation is useful in the monitoring of assets and other real systems having multiple, dependent, and independently operating components such as a pump, a manufacturing plant, a production line, an assembly line, where asset health and quality control is a concern. The asset components each influencing some overall outcome of a system or situation. Success or failure or probability of success, probability of failure and health of the system can be monitored and manipulated by altering the values of prior probability and posterior probability values. Failure correlation between components can be evaluated wherein failure rates of asset is unknown. Production and quality can be monitored and altered.

Owner:QUANTUM LEAP RES

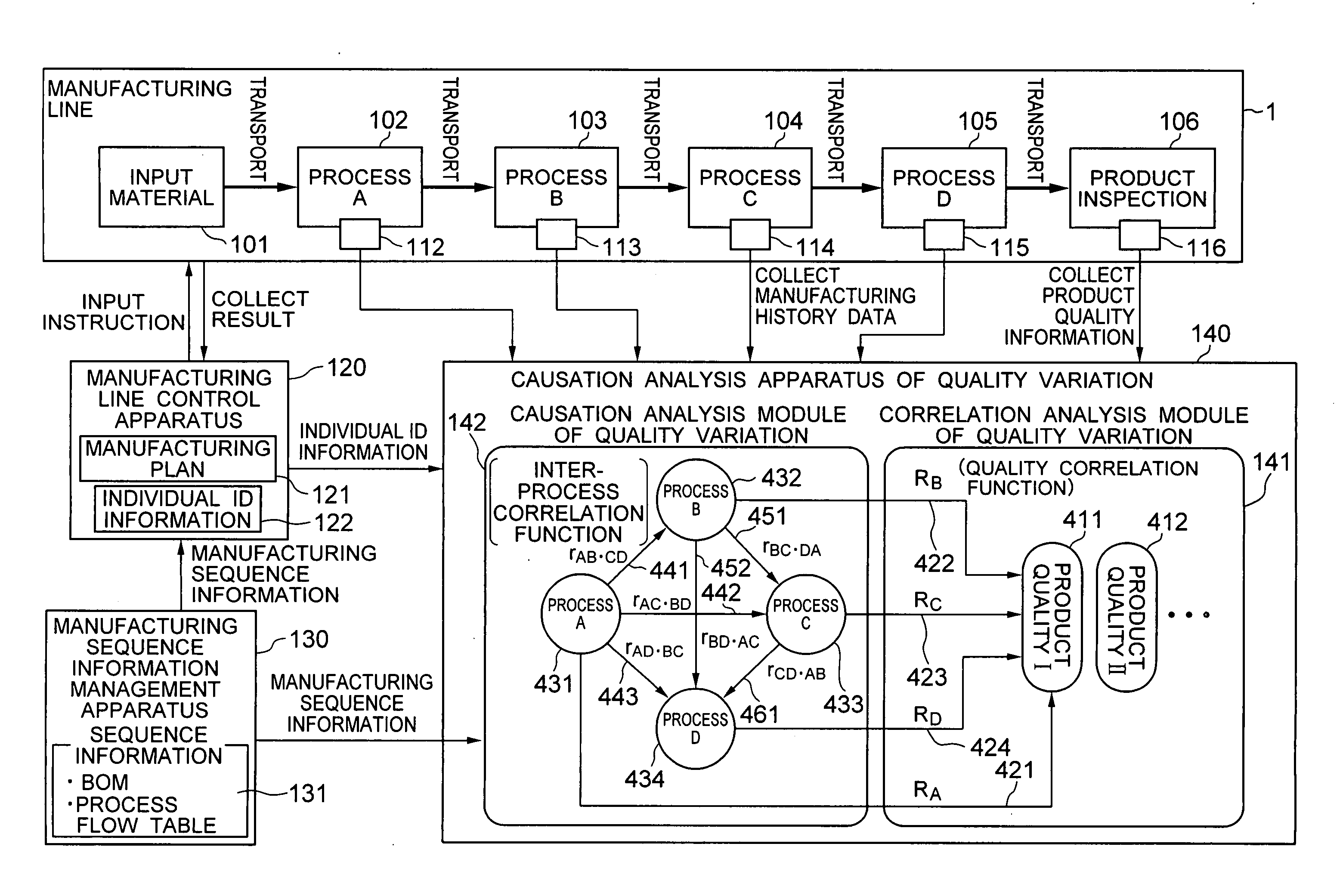

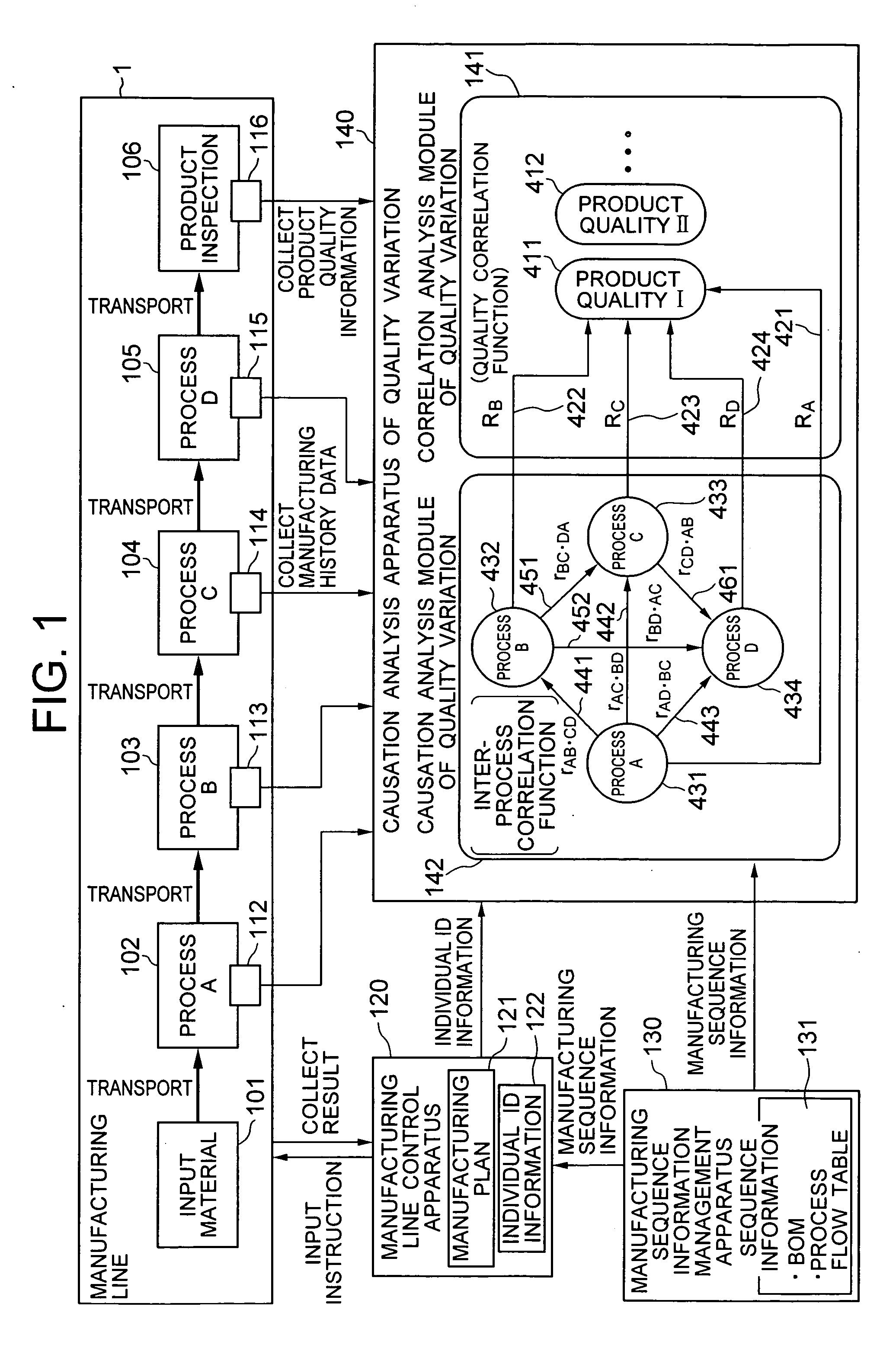

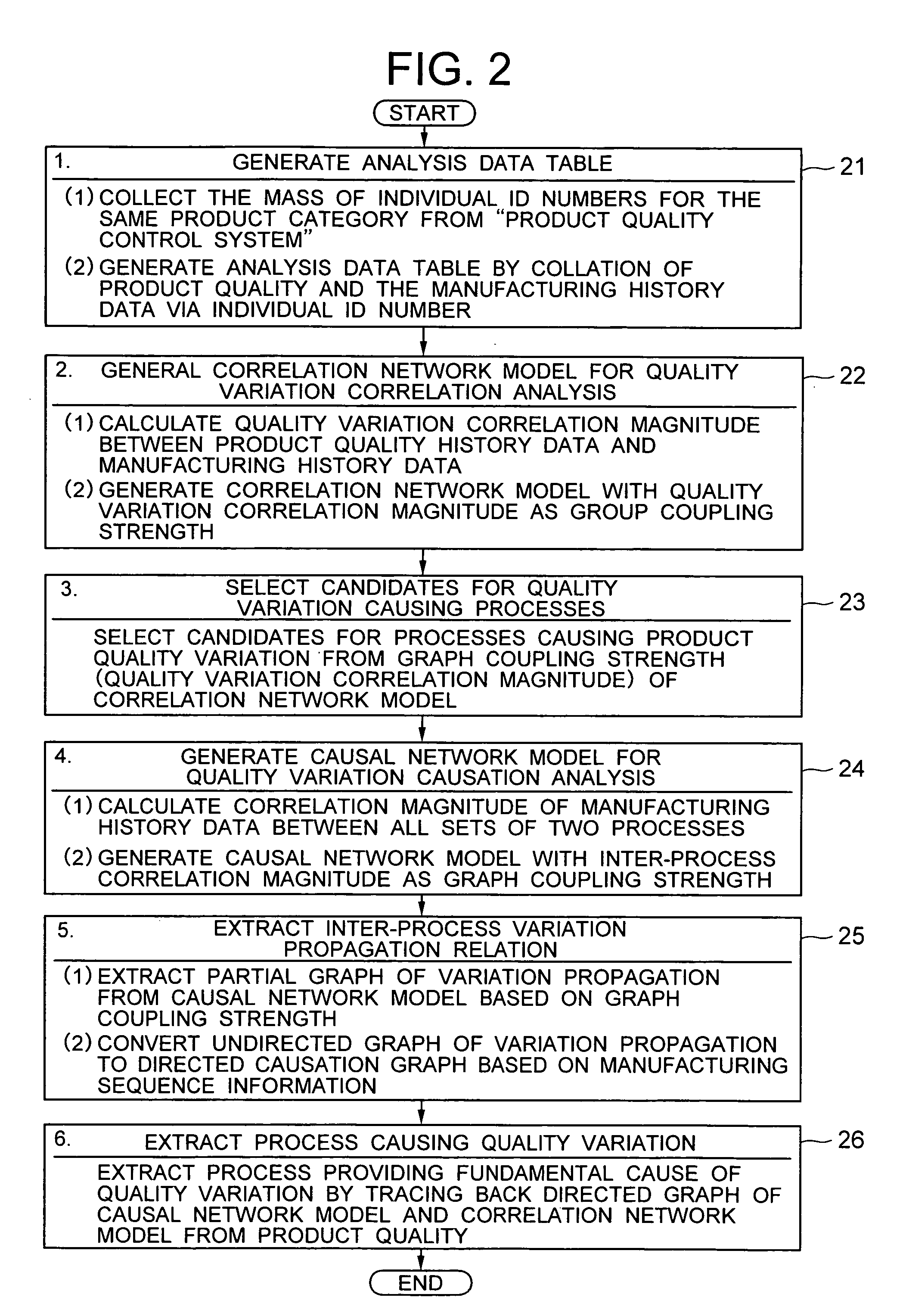

Quality control system for manufacturing industrial products

InactiveUS20060047454A1Quality improvementResourcesSpecial data processing applicationsManufacturing technologyProgram planning

In a quality control system for manufacturing industrial products, the product quality history and the manufacturing process history are collected and collated to calculate the correlation magnitude between the two histories. The candidates for the cause of quality variation hidden in the manufacturing processes are listed, and the correlation magnitude between all combinations of the variates of the manufacturing process history are calculated. Further, by utilizing the manufacturing sequence history used for an input plan, a causation connecting structure model between the manufacturing processes of the manufacturing line is automatically generated and automatically analyzed thereby to automatically extract the fundamental cause of quality variation from the candidates for the cause of quality variation. By doing so, the cause of quality variation of industrial products manufactured through a complicated process can be traced in a complicated connecting structure in the manufacturing history data.

Owner:HITACHI LTD

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

ActiveUS20080177242A1Good physical propertiesElasticityCosmetic preparationsToilet preparationsElastomerPolyolefin

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

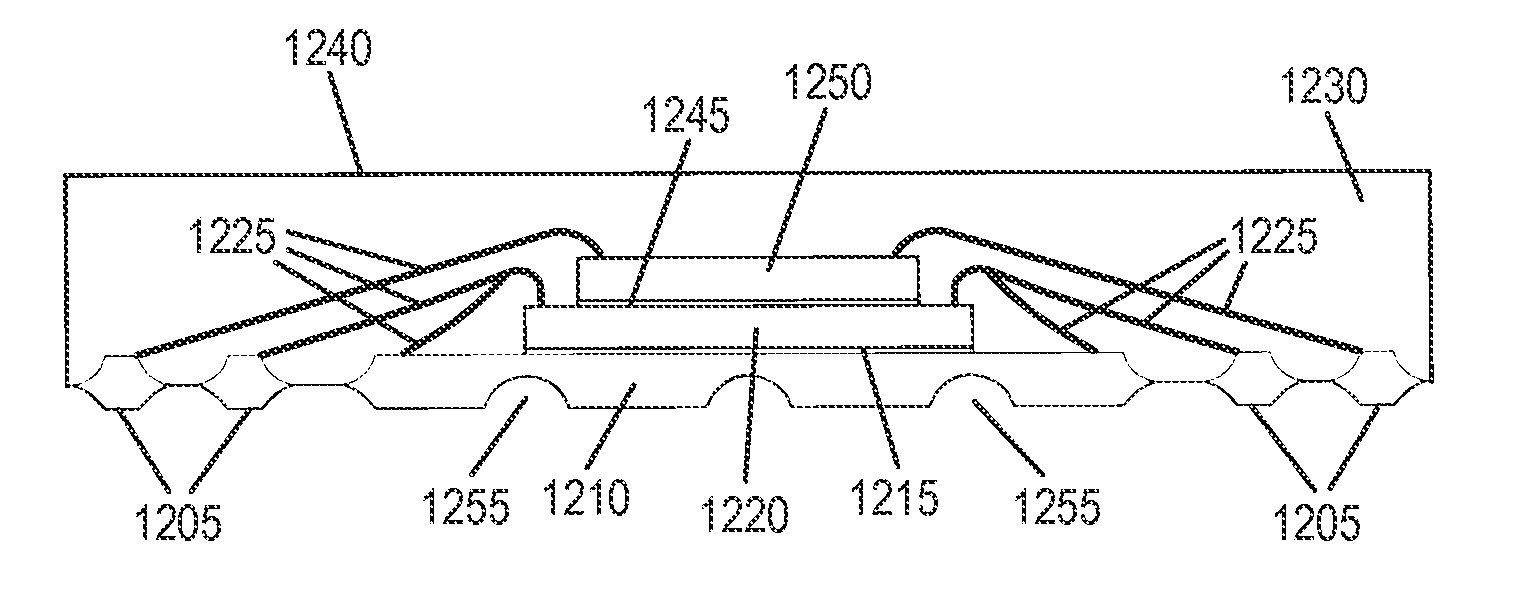

Partially patterned lead frames and methods of making and using the same in semiconductor packaging

InactiveUS20050263864A1Improve structural rigidityProcess stabilityLine/current collector detailsSemiconductor/solid-state device detailsLead bondingBonding process

A method of making a lead frame and a partially patterned lead frame package with near-chip scale packaging (CSP) lead-counts is disclosed, wherein the method lends itself to better automation of the manufacturing line as well as to improving the quality and reliability of the packages produced therefrom. This is accomplished by performing a major portion of the manufacturing process steps with a partially patterned strip of metal formed into a web-like lead frame on one side, in contrast with the conventional fully etched stencil-like lead frames, so that the web-like lead frame, which is solid and flat on the other side is also rigid mechanically and robust thermally to perform without distortion or deformation during the chip-attach and wire bond processes. The bottom side of the metal lead frame is patterned to isolate the chip-pad and the wire bond contacts only after the front side, including the chip and wires, is hermetically sealed with an encapsulant. The resultant package being electrically isolated enables strip testing and reliable singulation without having to cut into any additional metal. The use of the instant partially patterned lead frame in making ELP, ELPF and ELGA-type CSPs is also disclosed.

Owner:UNISEM M BERHAD

Acoustical gypsum board for ceiling panel

Low density acoustical gypsum boards having a perforated cover sheet that have good sound absorption properties and are generally clear of falling gypsum dust. The invention optionally provides a cover sheet having a pattern producing a textured visual effect particularly when viewed from a distance. The acoustical gypsum boards can be produced on modified existing gypsum board lines.

Owner:USG INTERIORS INC

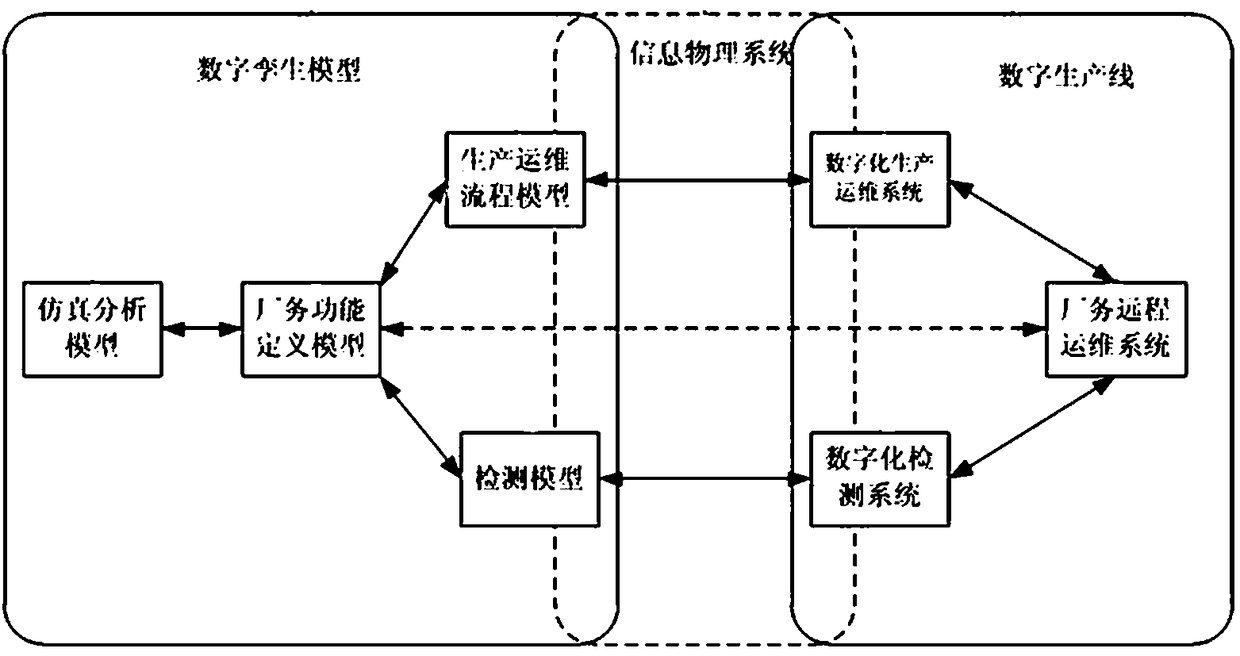

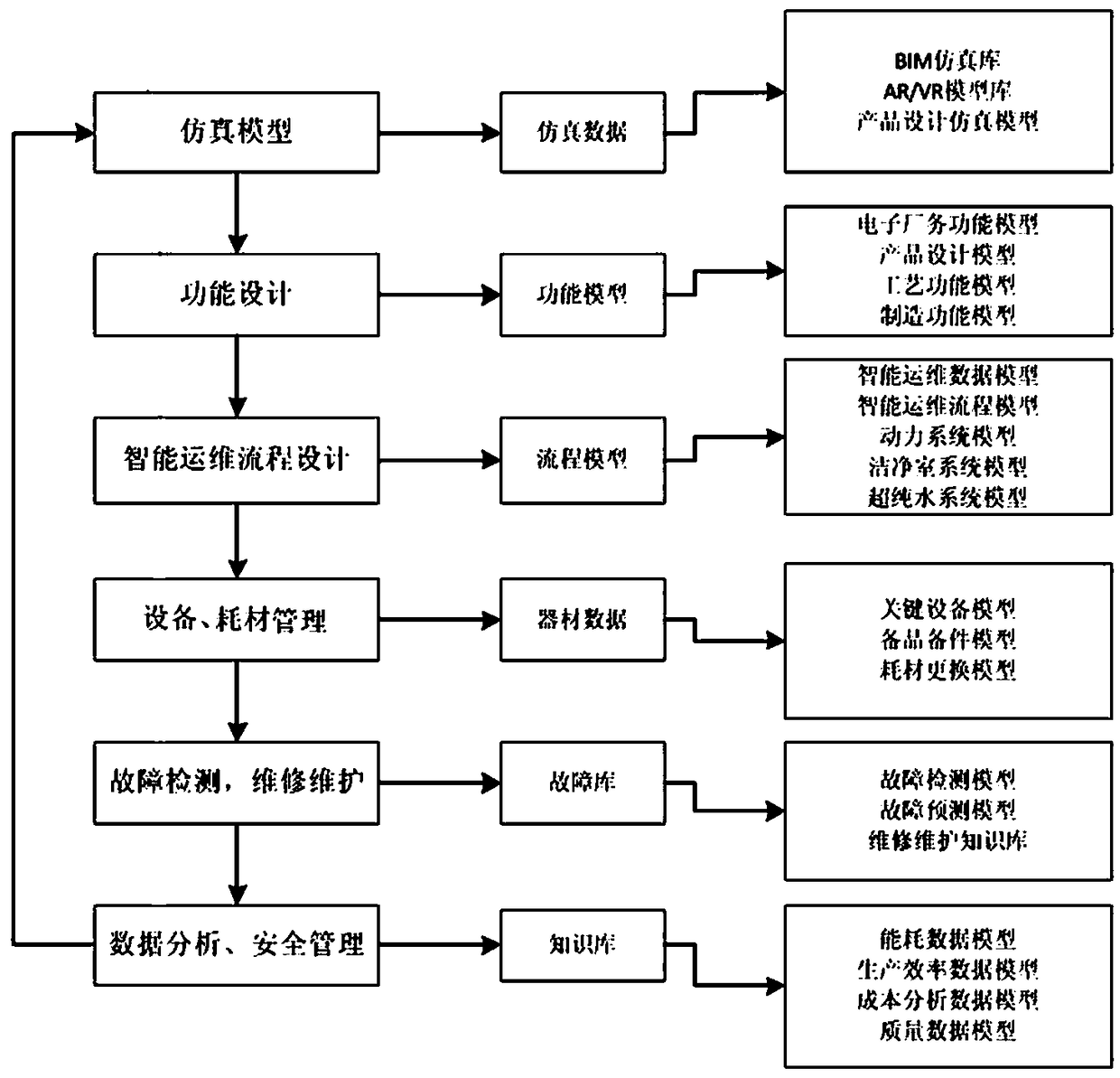

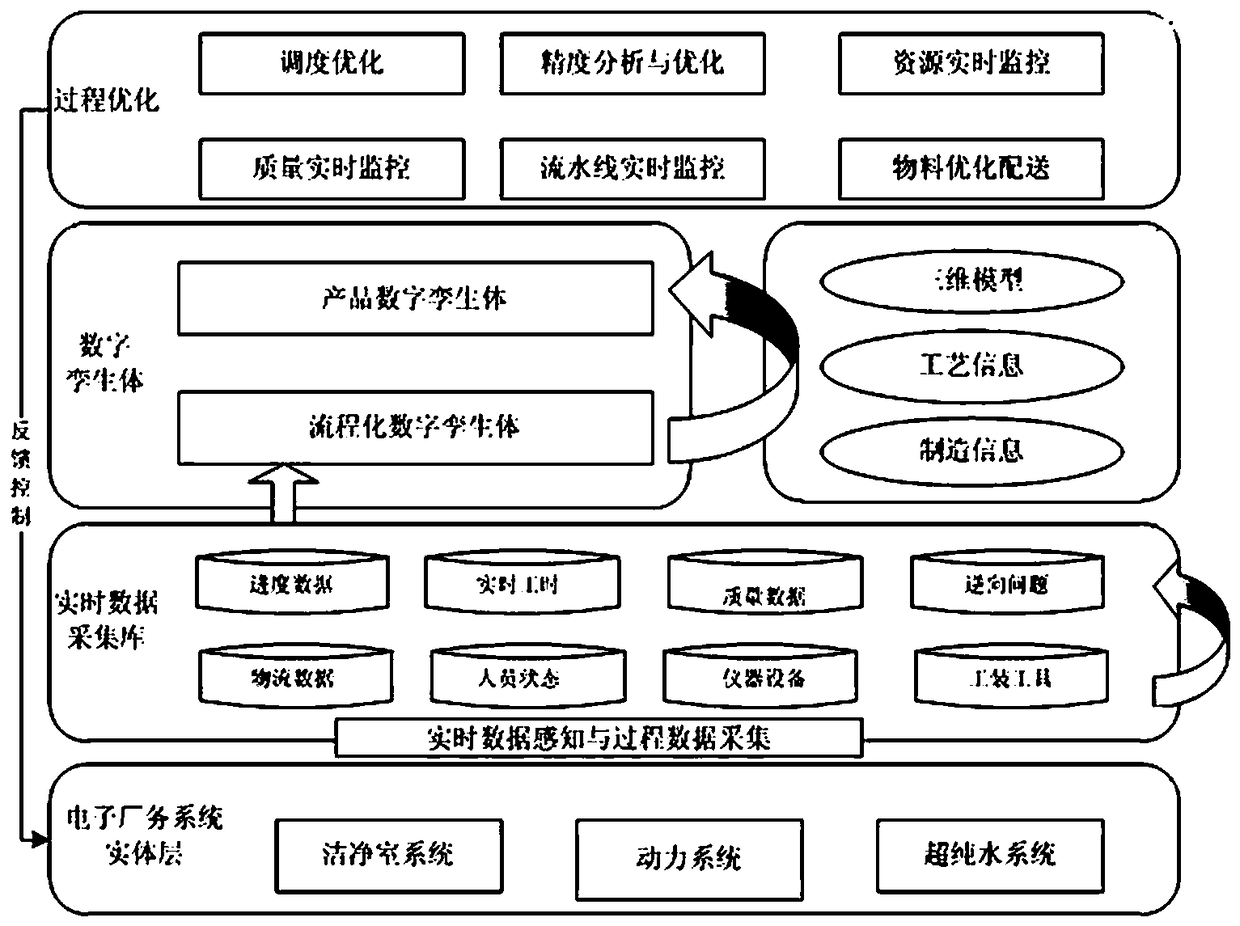

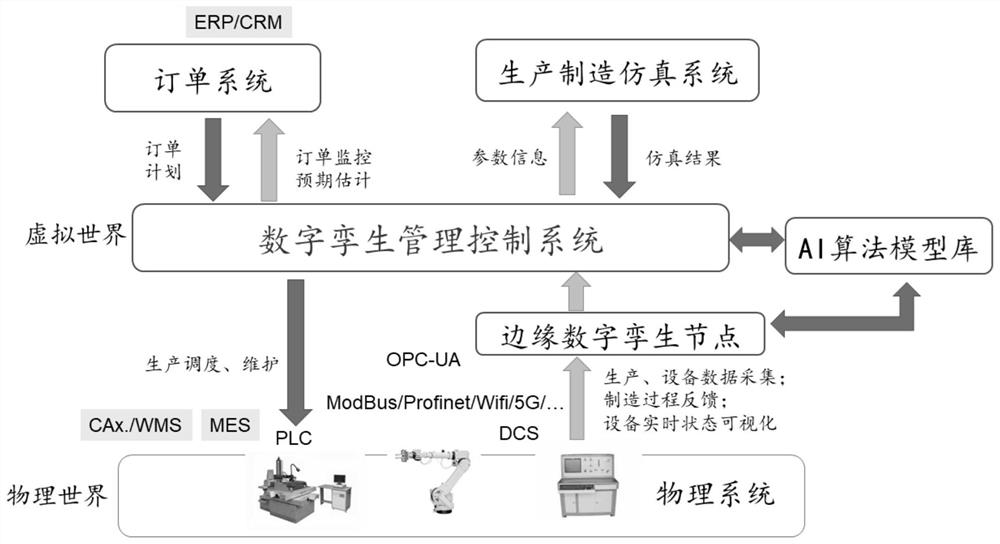

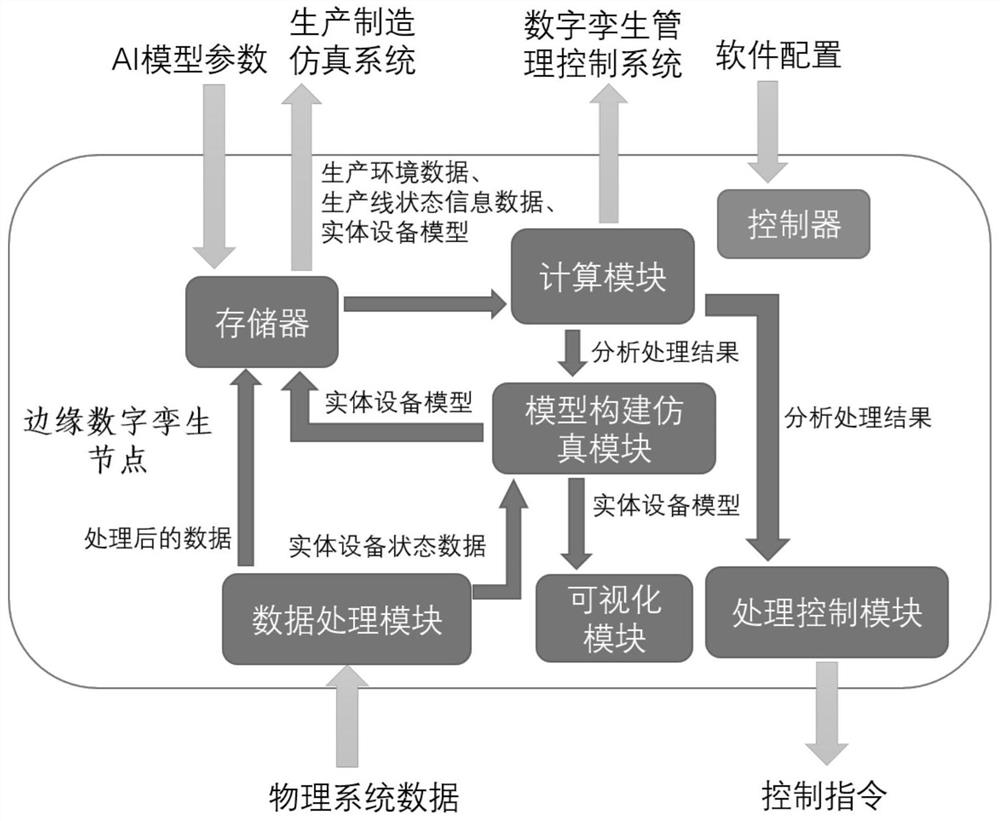

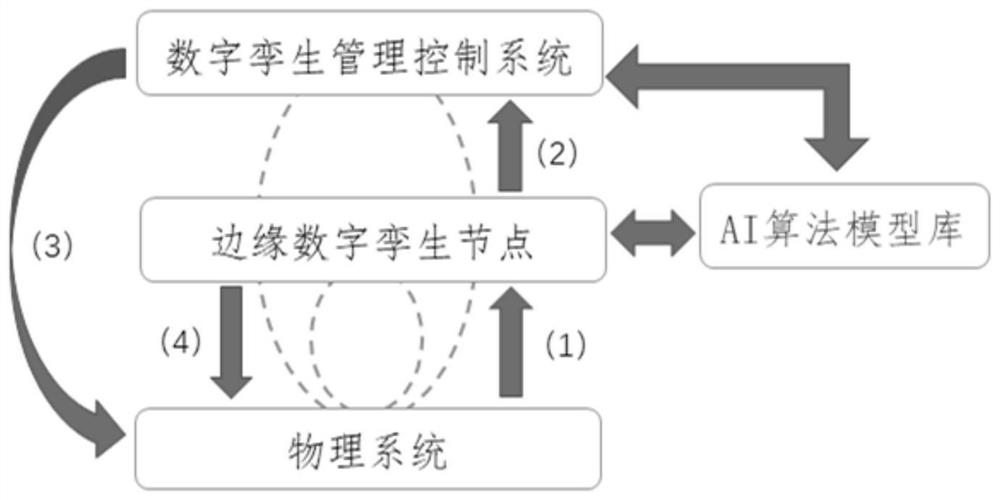

Digital twinning system applied to industrial production and forming method thereof

PendingCN109343496AIntelligent controlTesting/monitoring control systemsTechnology managementProduction lineProcess optimization

The invention discloses a digital twinning system applied to industrial production and a forming method thereof. The digital twinning system applied to industrial production is arranged on the basis of an industrialized intelligent production system, and includes a physical entity layer, a data collection layer, a layer of digital twinning and an information model thereof and a process optimization layer which are sequentially connected. The process optimization layer is also connected with the physical entity layer through feedback control to form a closed loop. The digital twinning system can more intelligently control production, and is suitable for all production and factory affair systems (production equipment and production lines) and monitoring and prediction management systems in use and maintenance.

Owner:CHINA ELECTRONICS ENG DESIGN INST

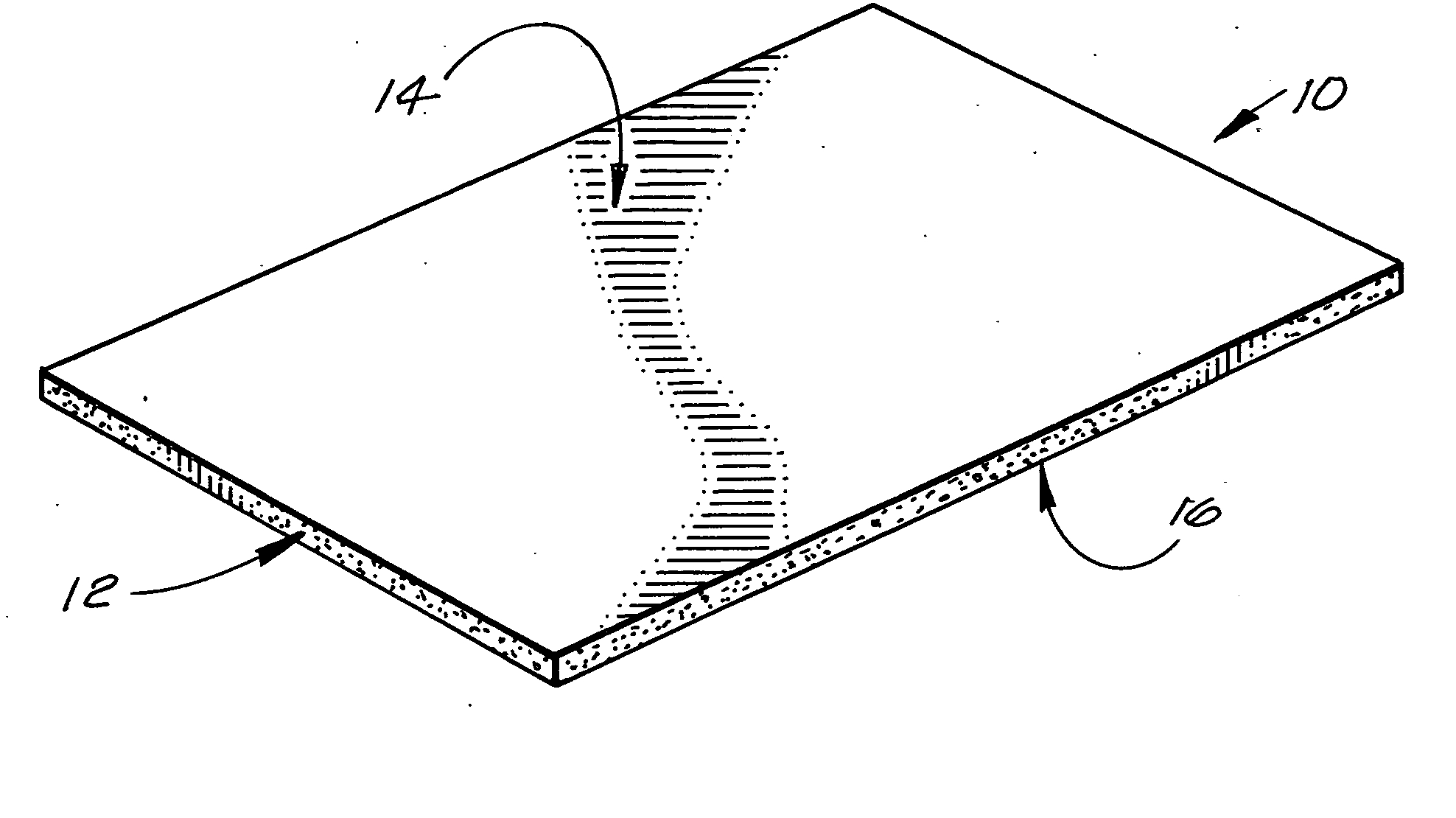

Controlled laser production of elongated articles from particulates

It has been discovered that wires and small diameter rods can be produced using laser deposition technology in a novel way. An elongated article such as a wire or rod is constructed by melting and depositing particulate material into a deposition zone which has been designed to yield the desired article shape and dimensions. The article is withdrawn from the deposition zone as it is formed, thus enabling formation of the article in a continuous process. Alternatively, the deposition zone is moved along any of numerous deposition paths away from the article being formed.

Owner:LOS ALAMOS NATIONAL SECURITY

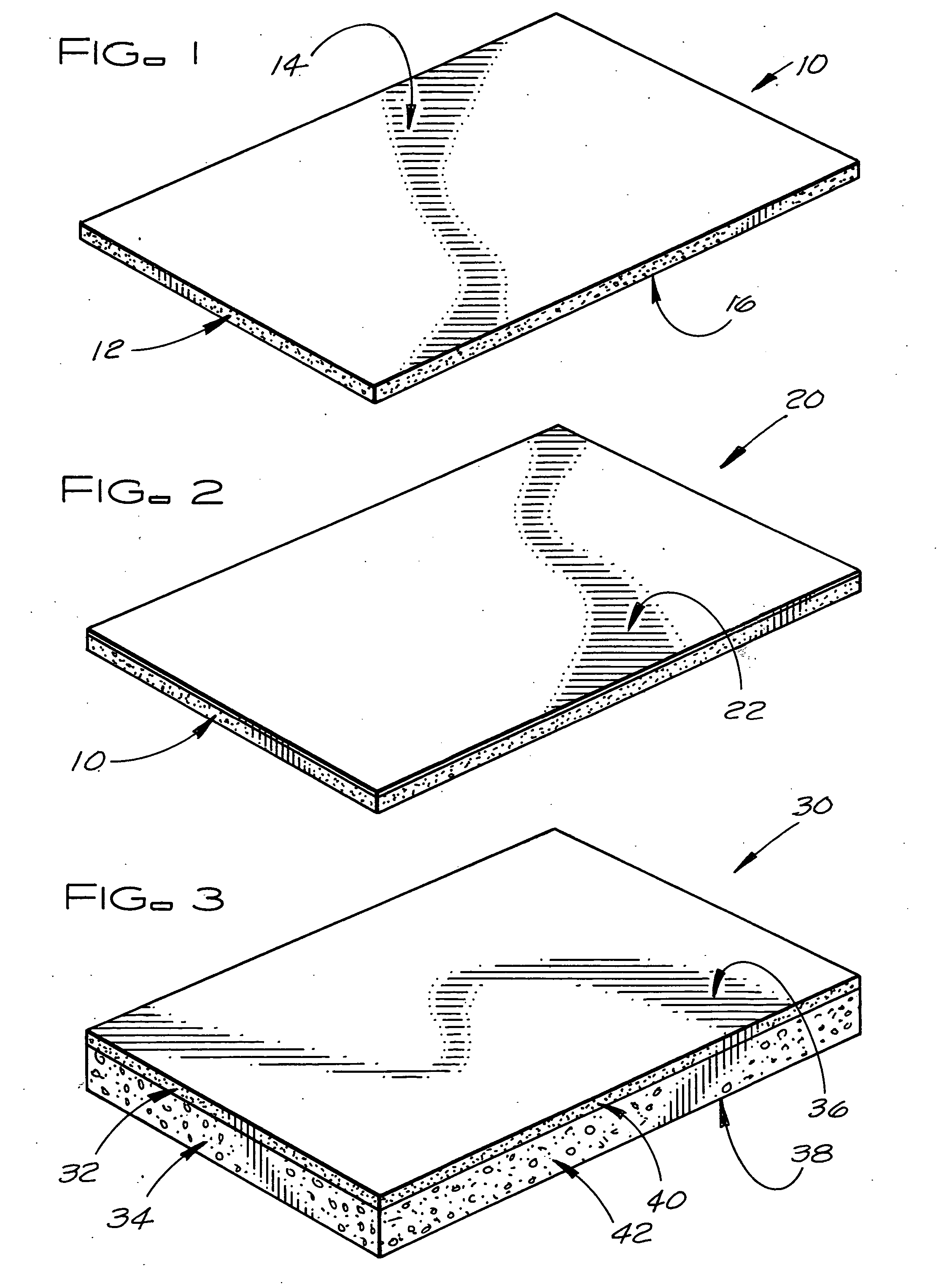

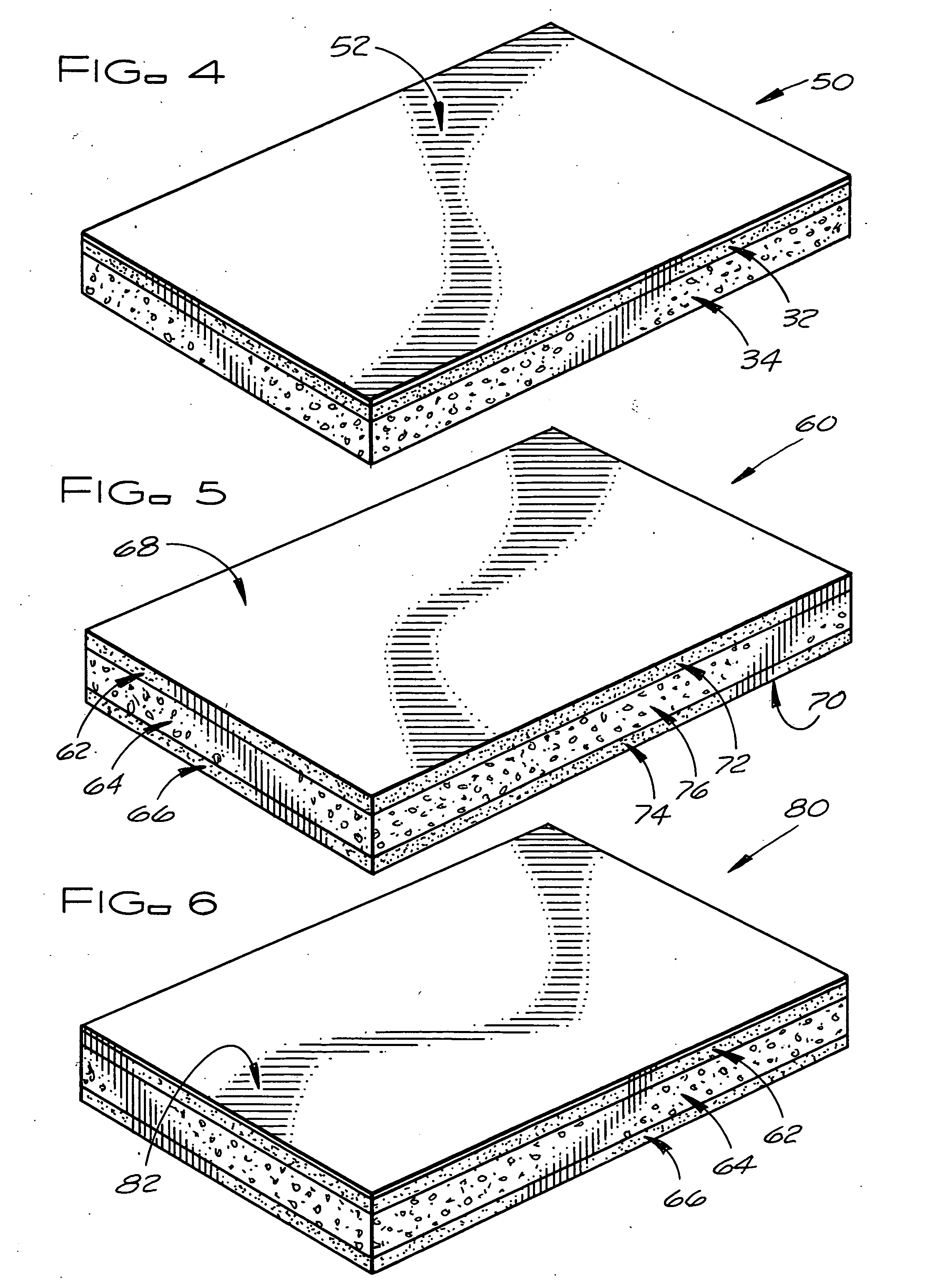

Roofing cover board, roofing panel composite, and method

InactiveUS20060096205A1Improve bindingEasy to cutRoof covering using slabs/sheetsSynthetic resin layered productsHigh densityLow density

A prefabricated cover board has a high-density polymer or predominantly polymer material core layer having a density between 6 lbs / ft3 and 25 lbs / ft3. A prefabricated roofing panel composite includes the cover board and an insulation board that has a low-density polymer or predominantly polymer material foam core layer having a density less than 6 lbs / ft3. The cover board may have a waterproofing membrane forming the top major surface of the cover board. When making the roofing panel composite, the low-density foam core layer of the insulation board may be formed with the high-density core layer of the cover board being currently or subsequently formed over and bonded to a top major surface of the low-density foam core layer in the same operation or preformed insulation boards may be fed into a production line with the high-density core layer of the cover board being formed over and bonded to top major surfaces of the low-density foam core layers of the insulation boards.

Owner:MANVILLE JOHNS

Partially patterned lead frames and methods of making and using the same in semiconductor packaging

InactiveUS7790500B2Improve structural rigiditySemiconductor/solid-state device detailsSolid-state devicesLead bondingBonding process

A method of making a lead frame and a partially patterned lead frame package with near-chip scale packaging lead-count, wherein the method lends itself to better automation of the manufacturing line and improved quality and reliability of the packages produced therefrom. A major portion of the manufacturing process steps is performed with a partially patterned strip of metal formed into a web-like lead frame on one side so that the web-like lead frame is also rigid mechanically and robust thermally to perform without distortion or deformation during the chip-attach and wire bond processes, both at the chip level and the package level. The bottom side of the metal lead frame is patterned to isolate the chip-pad and the wire bond contacts only after the front side, including the chip and wires, is hermetically sealed with an encapsulant. The resultant package being electrically isolated enables strip testing and reliable singulation.

Owner:UNISEM M BERHAD

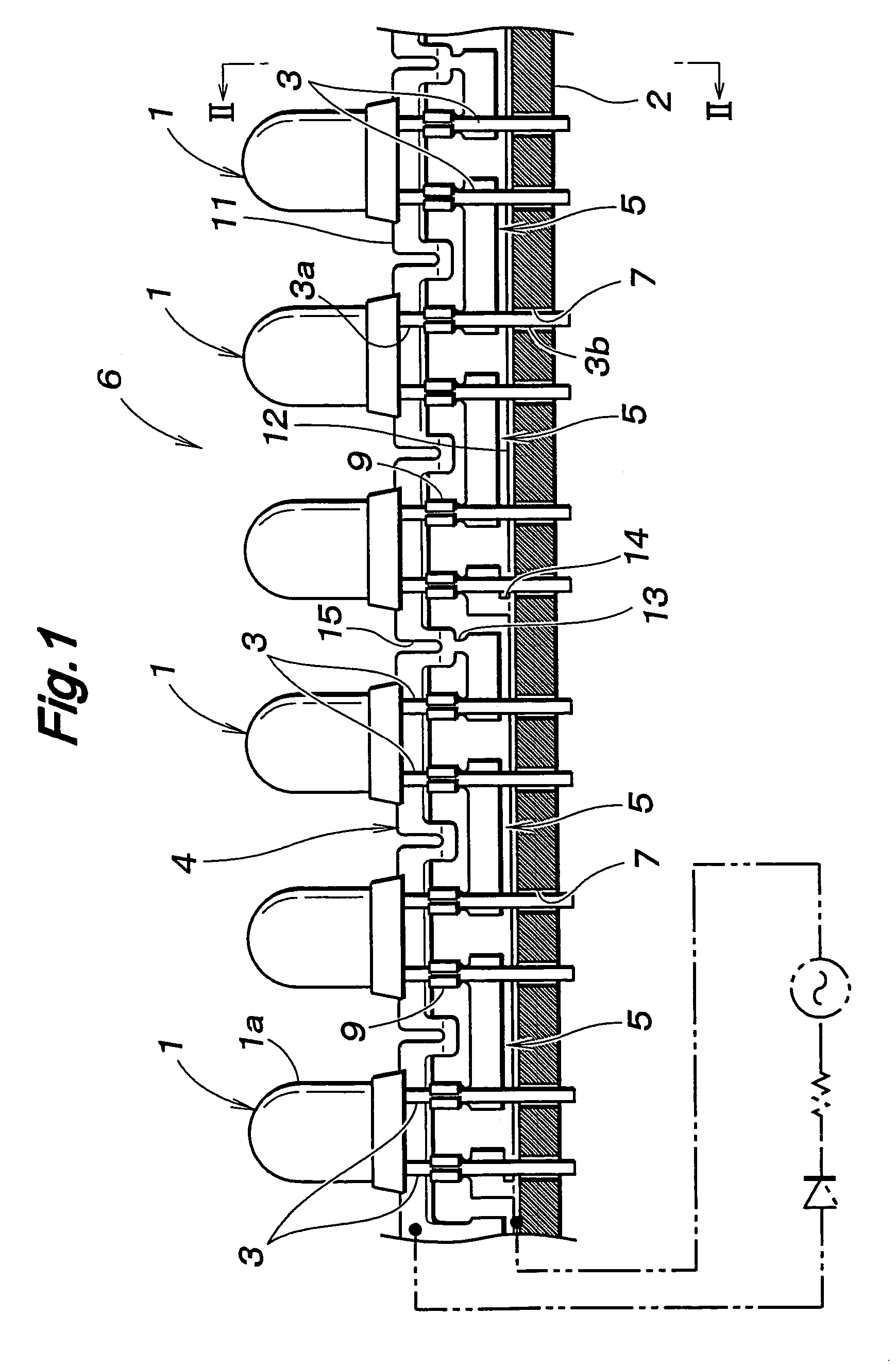

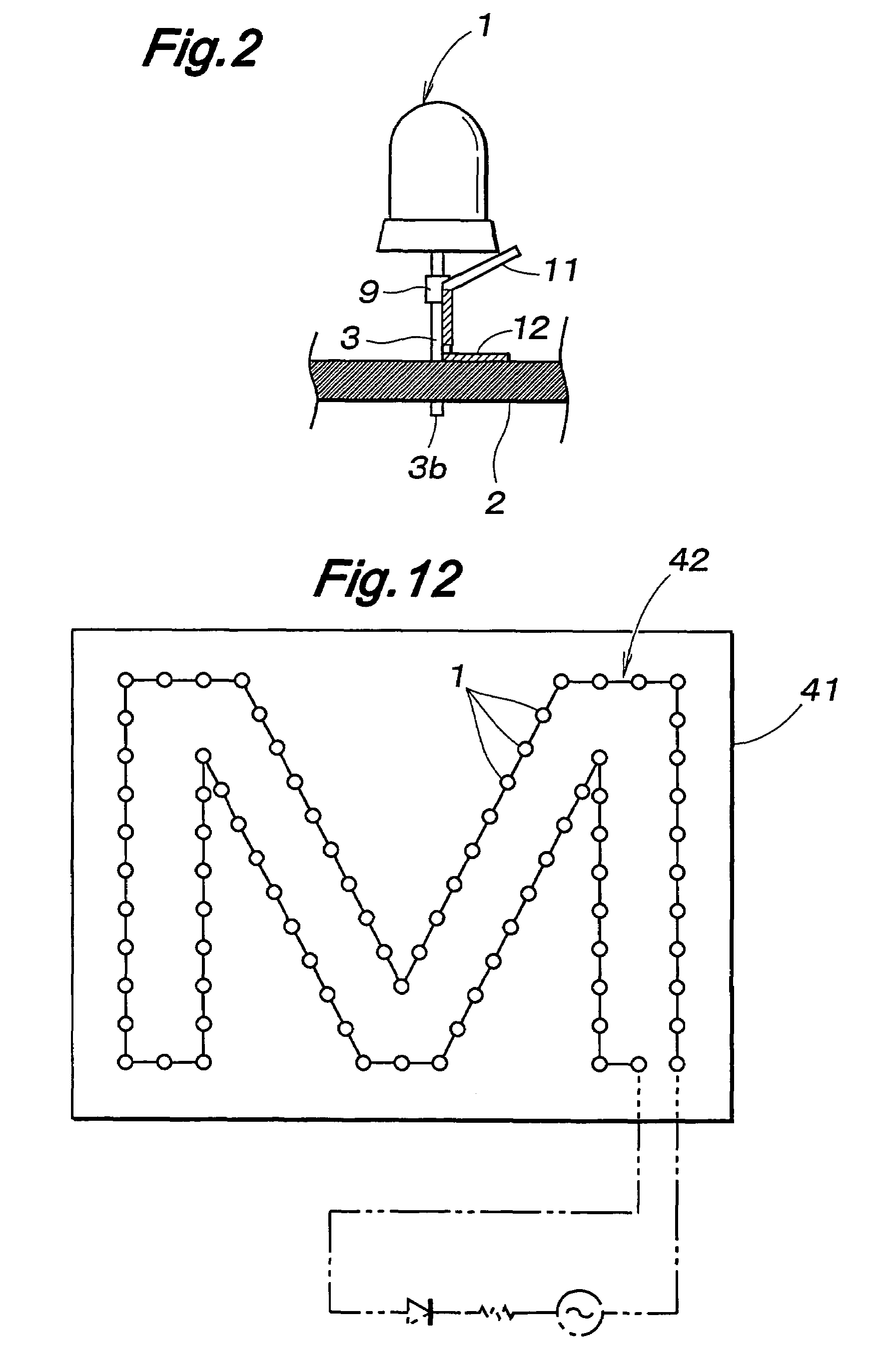

Light source coupler, illuminant device, patterned conductor, and method for manufacturing light source coupler

InactiveUS7380961B2Efficient preparationLow costCoupling device connectionsLighting support devicesElectrical conductorEngineering

To provide a light source assembly that does not use a printed circuit board and can be manufactured at a low cost even when produced in small quantities, a light source assembly according to the present invention comprises a plurality of light sources and a connective conductor structure extending in a direction of arrangement of the light sources to join the light sources, wherein the connective conductor structure is formed by cutting off parts of a substantially plate-like patterned conductor as required, the patterned conductor being provided with a prescribed pattern. Thus, by changing the parts to be cut off in the patterned conductor, it is possible to manufacture light source assemblies having various light source connection patterns in a single manufacturing line, allowing efficient and low cost manufacture of the light source assemblies to be achieved even when the light sources are manufactured in small quantities.

Owner:MORIYAMA SANGYO

Intelligent production system and method based on edge calculation and digital twinning

ActiveCN111857065ARealize nearby processingImplement extractionTechnology managementTotal factory controlPhysical systemReliability engineering

Owner:BEIJING UNIV OF POSTS & TELECOMM

Multifunctional multilayer optical film

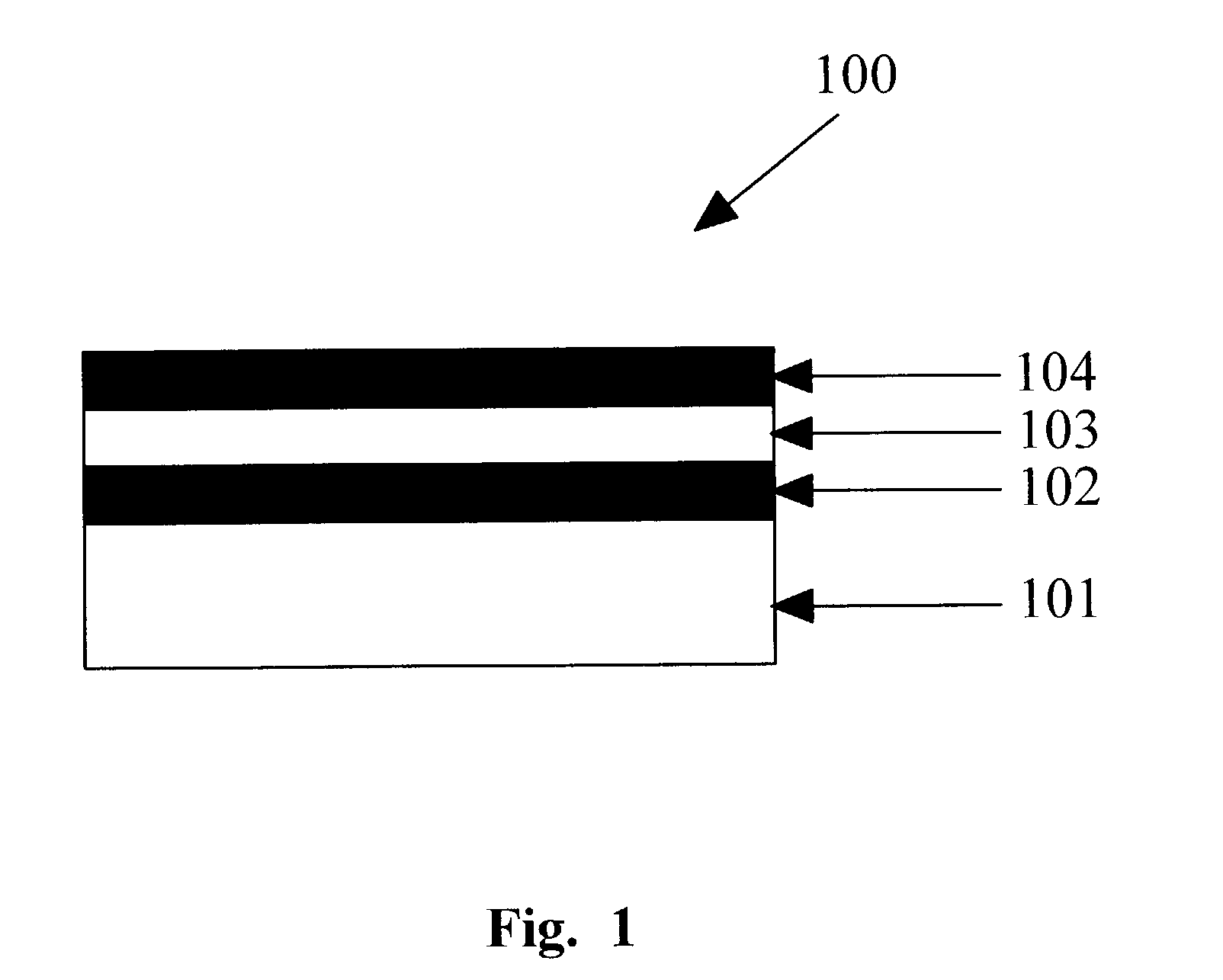

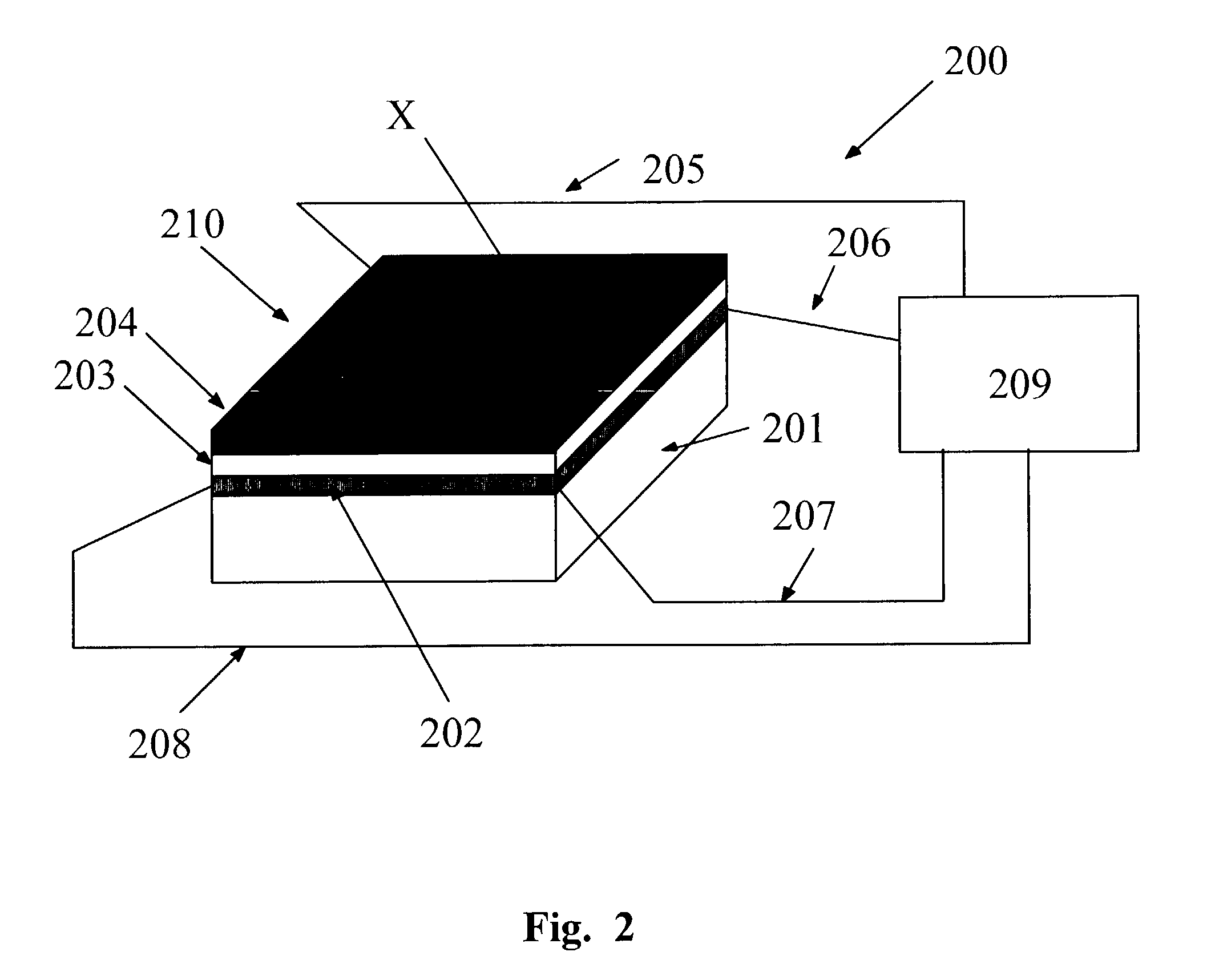

ActiveUS7151532B2Reduce glareReduce manufacturing costCathode-ray tube indicatorsInput/output processes for data processingOptical thin filmManufacturing line

Optical component for use in a touch sensor and method of fabrication of same are disclosed. Optical component includes a multilayer optical film at least some layers of which are fabricated on the same manufacturing line and using the same manufacturing method. Each layer of the multilayer optical film is designed primarily to provide a desired associated property.

Owner:3M INNOVATIVE PROPERTIES CO

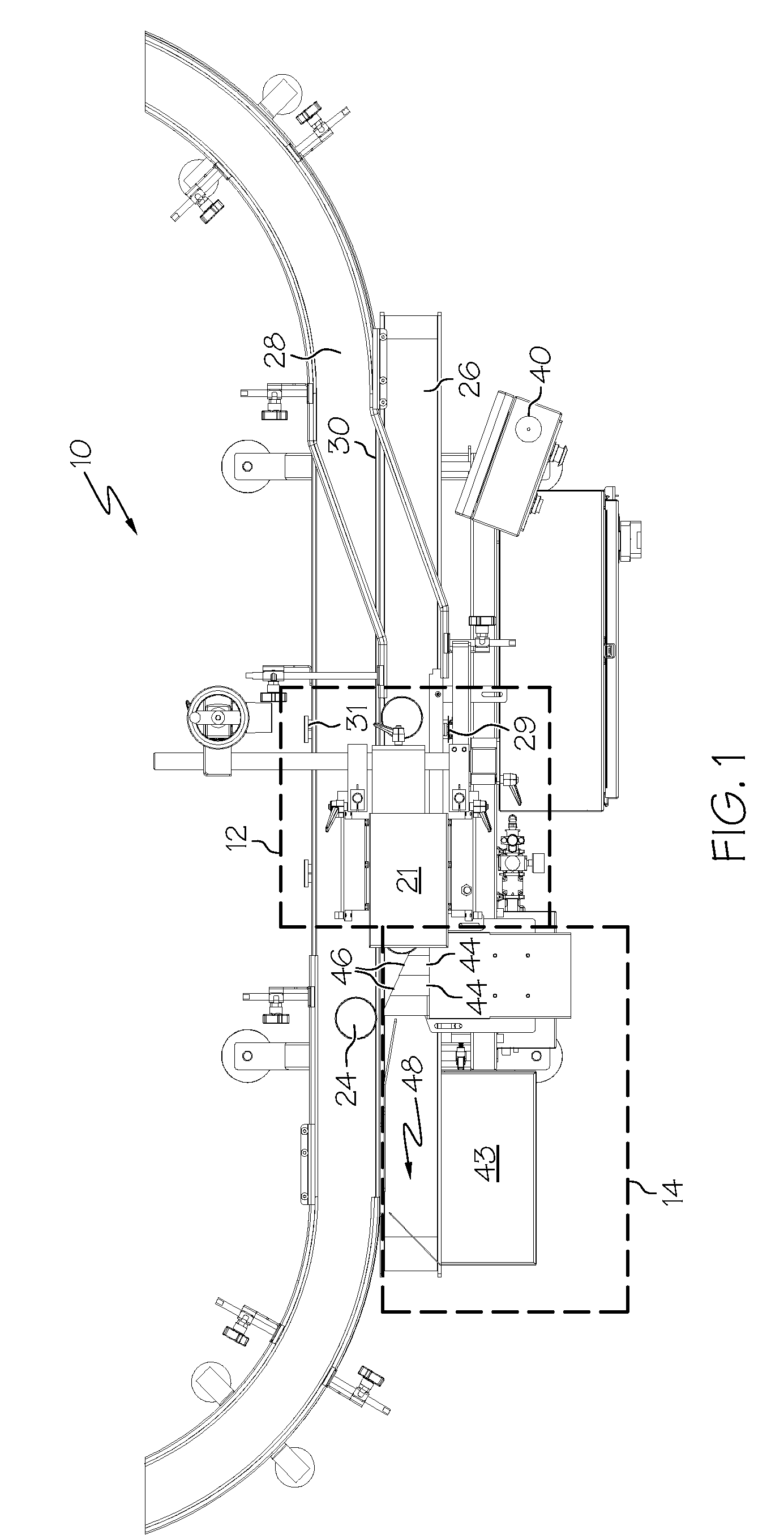

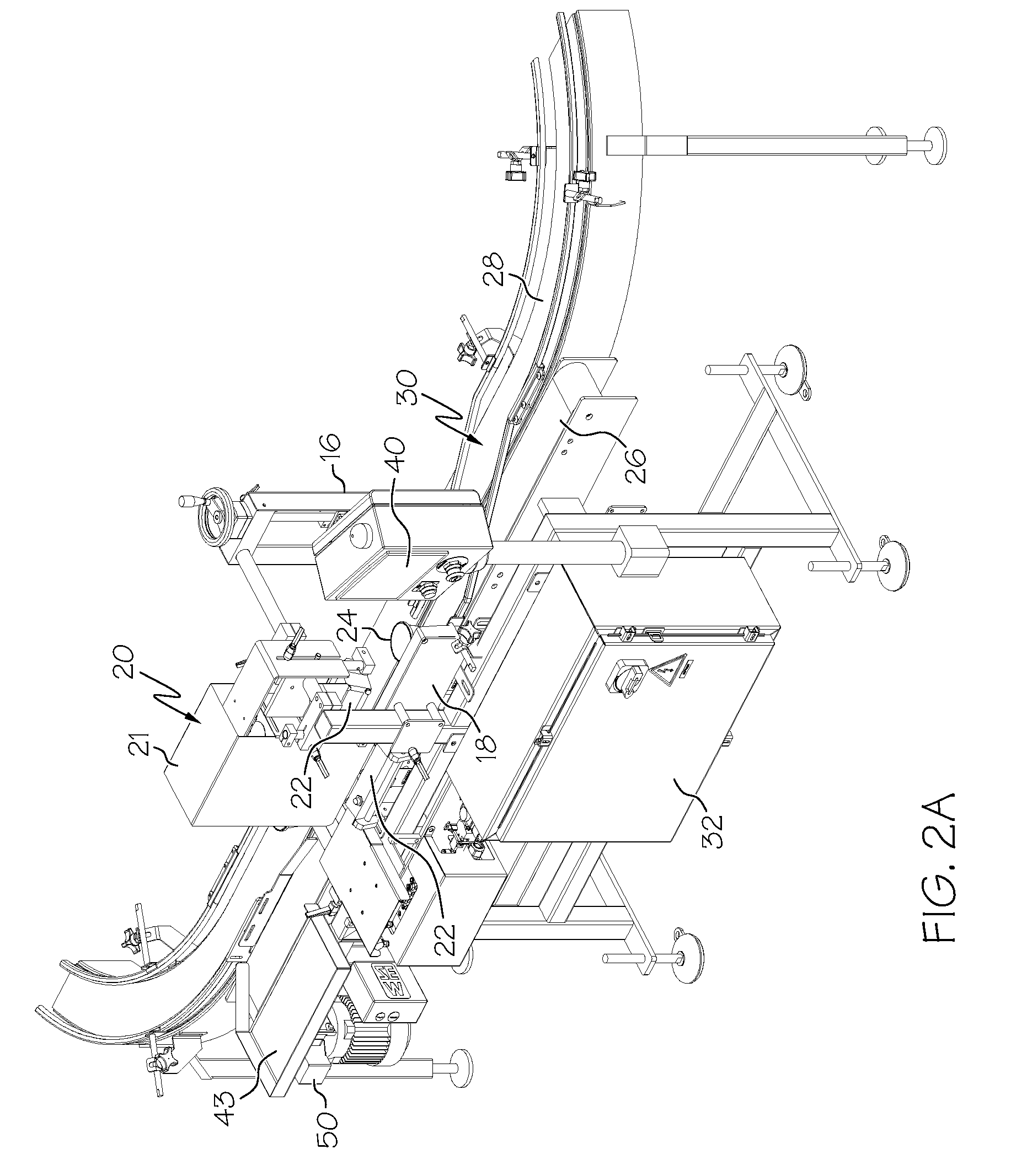

System for Bifolding an Absorbent Article

A system is provided for bifolding disposable absorbent articles on a high speed production line on which the disposable absorbent articles are moved along a predetermined path. The system includes the use of one or more vacuum conveyor assemblies to engage and transfer the leading end portion of the article from the surface of a peel-roll to a folding drum, thereby potentially reducing the occurrence of undesirable misalignment between opposing edges of an article during a bifolding process.

Owner:THE PROCTER & GAMBLE COMPANY

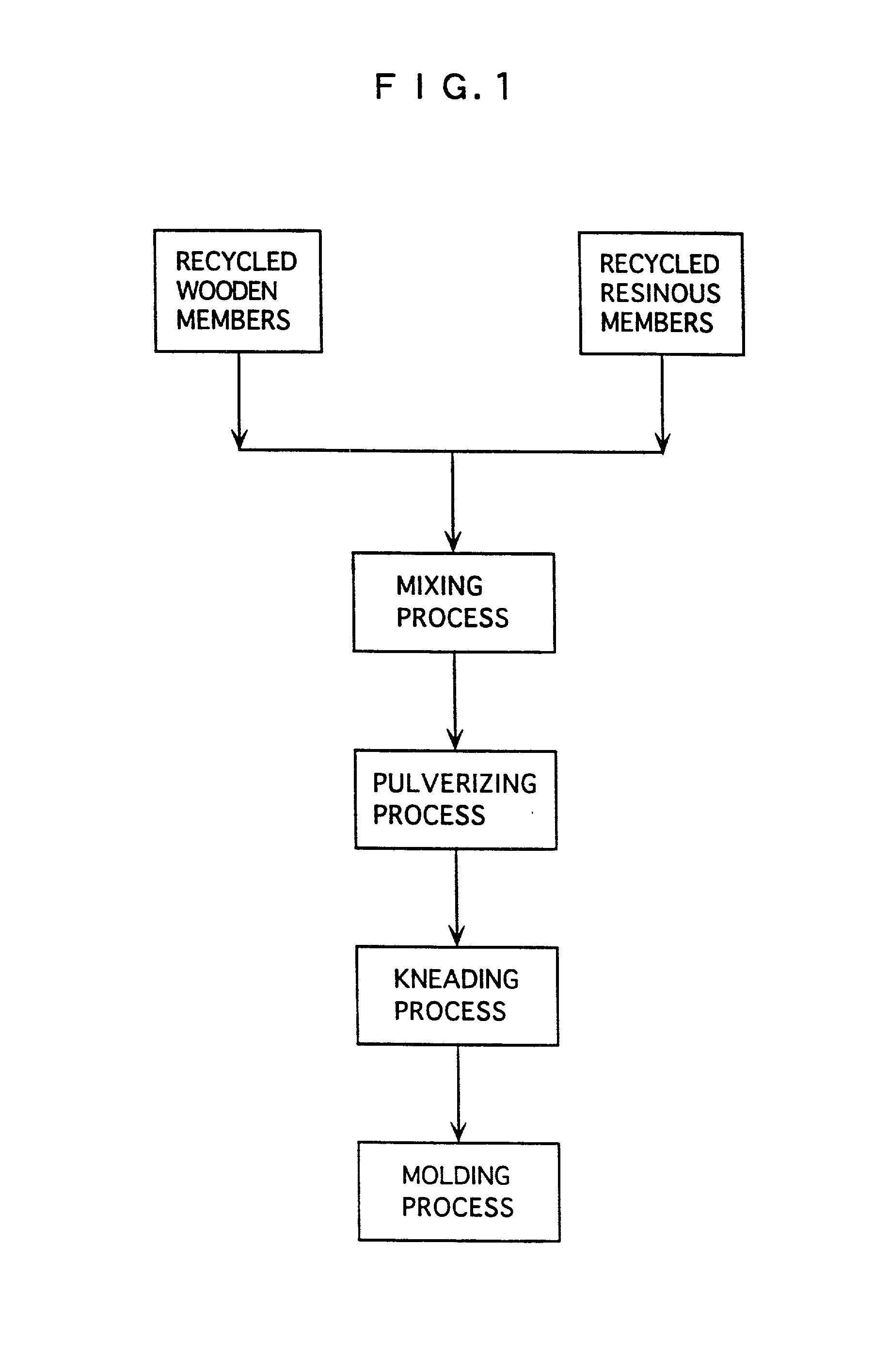

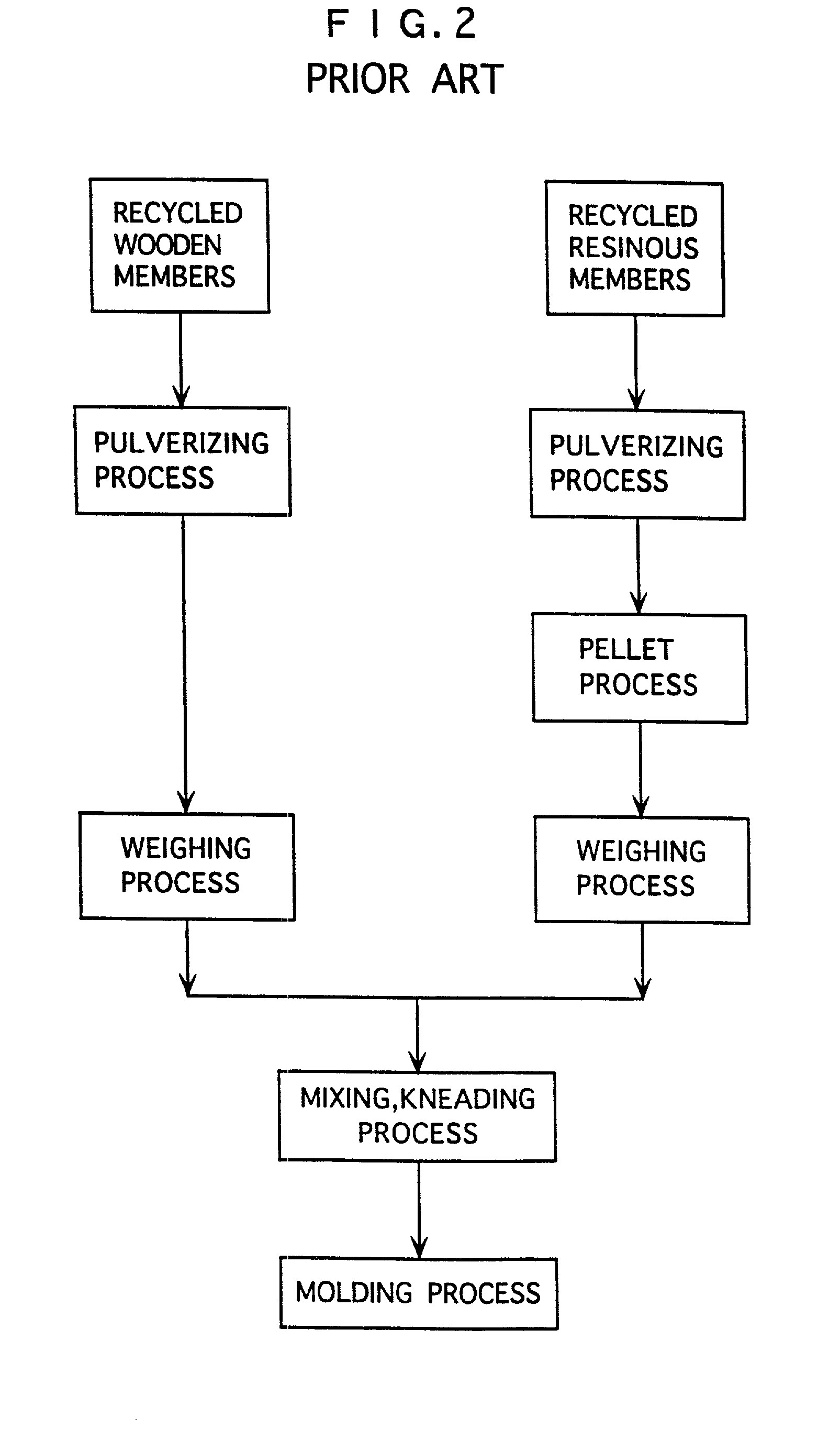

Cement bonded wood chip product, resin bonded wood chip product, simulated wood product

InactiveUS20010009309A1Reduce the numberReduce processFlat articlesDomestic articlesMixed materialsInjection moulding

A manufacturing method for providing a cement bonded wood chip product, a resin bonded wood chip product and a simulated wood product, in which recycled wooden members and recycled resinous members are pulverized after having been mixed. Accordingly, a mixing process and a pulverizing process can be integrated into one single line, reducing the space as well as laborious work and efficient operation in a plant. A manufacturing method of a simulated wood product utilizing pulverized powders obtained from recycled building members as raw material, in which the building members comprise recycled wooden members made of wooden materials and resinous members made of resinous materials, the manufacturing method further comprising a mixing process for mixing the recycled wooden members, a pulverization process for pulverizing the mixed materials obtained in the mixing process to form pulverized powder, a kneading process for kneading the pulverized powders obtained by the pulverizing process, and a molding process for molding the kneaded materials obtained in the kneading process either by an extrusion or injection molding.

Owner:MISAWA HOMES CO LTD

Detection System

A foil lid inspection system for detecting and separating defective foil lids on a container in a production line includes one or more light sources, an inspection camera, and inspection software. The light sources are positioned to direct light in an upward direction to illuminate the container. The inspection camera is positioned above the foil lid, and the camera includes one or more outputs. The inspection software is in communication with the inspection camera. The inspection software is constructed and arranged to determine if the foil lid on the container is defective. A reject signal is applied to an output if the software determines that the foil lid is defective.

Owner:DELKOR SYST

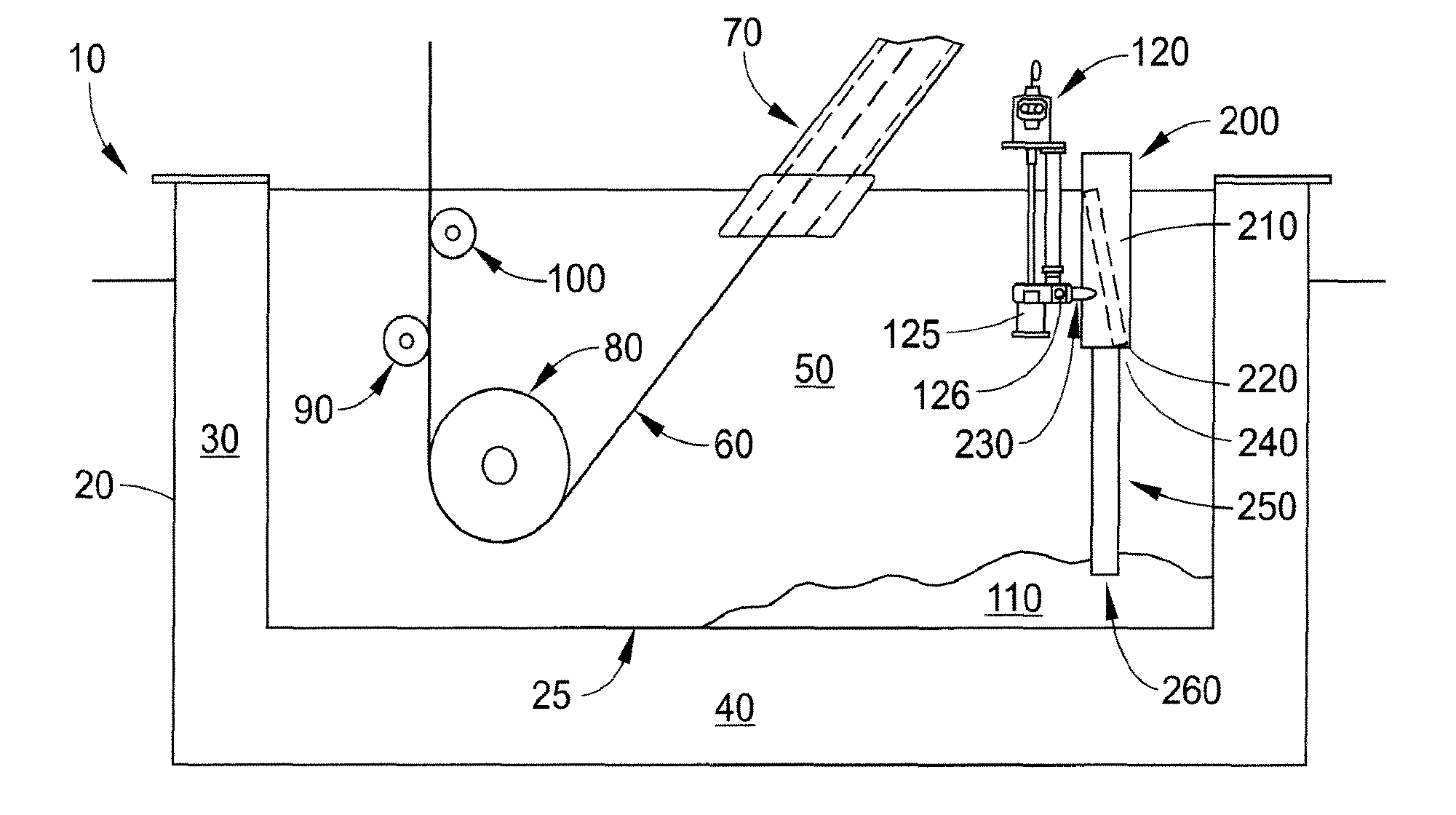

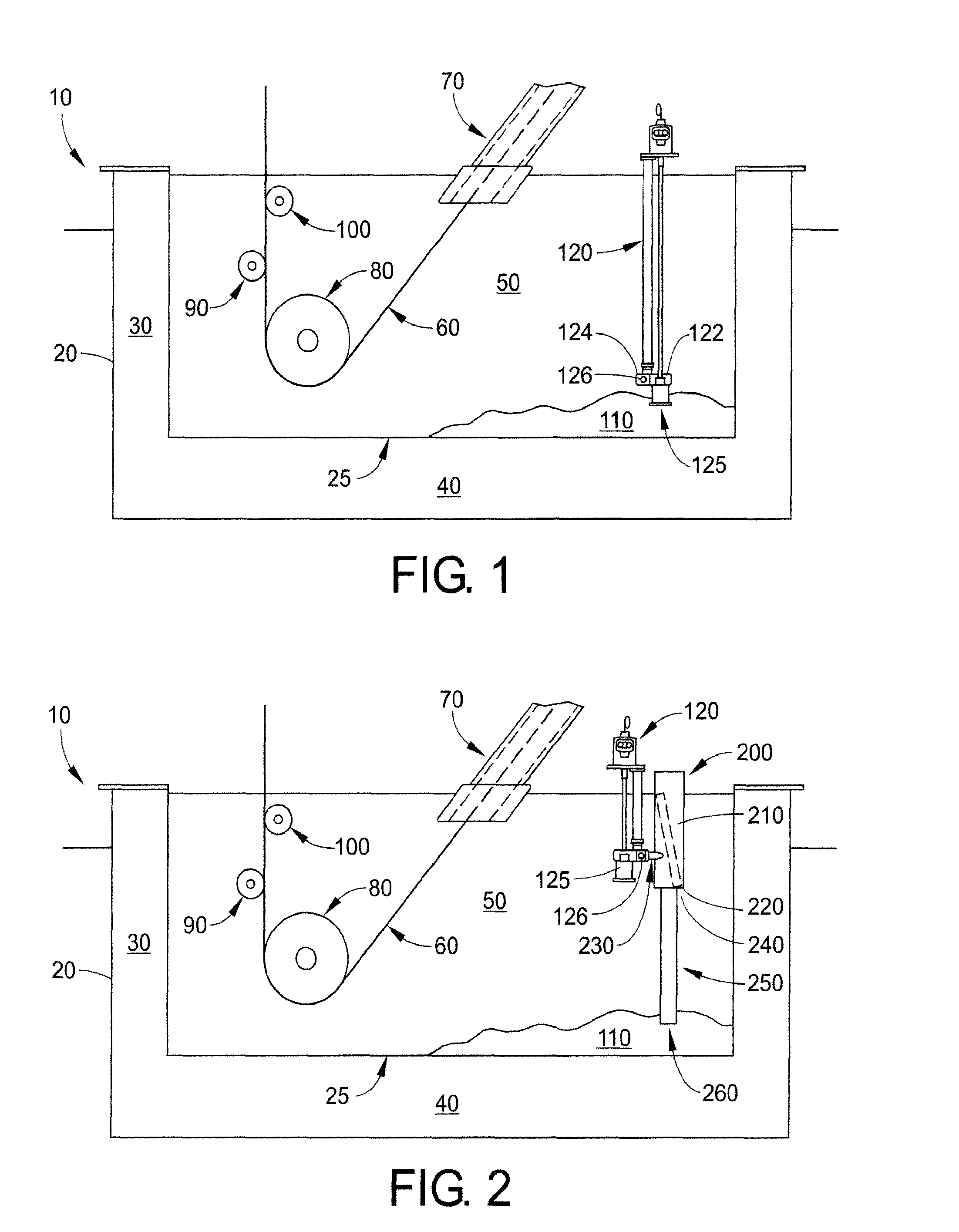

Galvanizing bath apparatus

InactiveUS8475594B2Reduce buildSpeed up the conversion processHot-dipping/immersion processesPretreated surfacesHigh concentrationDross

A continuous galvanizing line uses a coating pot containing a molten zinc bath having bottom dross and further comprises a pump. The pump agitates the bottom dross so the bottom dross interacts with aluminum and converts to top dross, which can be removed without needing to stop the galvanizing line. A reaction vessel may also be used to provide a higher concentration of aluminum to react with the bottom dross.

Owner:PYROTECK INC

Partially Patterned Lead Frames and Methods of Making and Using the Same in Semiconductor Packaging

InactiveUS20110111562A1Improve structural rigiditySemiconductor/solid-state device detailsSolid-state devicesLead bondingBonding process

A method of making a lead frame and a partially patterned lead frame package with near-chip scale packaging lead-count, wherein the method lends itself to better automation of the manufacturing line and improved quality and reliability of the packages produced therefrom. A major portion of the manufacturing process steps is performed with a partially patterned strip of metal formed into a web-like lead frame on one side so that the web-like lead frame is also rigid mechanically and robust thermally to perform without distortion or deformation during the chip-attach and wire bond processes, both at the chip level and the package level. The bottom side of the metal lead frame is patterned to isolate the chip-pad and the wire bond contacts only after the front side, including the chip and wires, is hermetically sealed with an encapsulant. The resultant package being electrically isolated enables strip testing and reliable singulation.

Owner:UNISEM M BERHAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com