Patents

Literature

15567 results about "Mixed materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mixed Materials. This mix of materials is undeniably elegant. Mixed metals combined with natural materials like marble and cork up the sophistication level of any space.

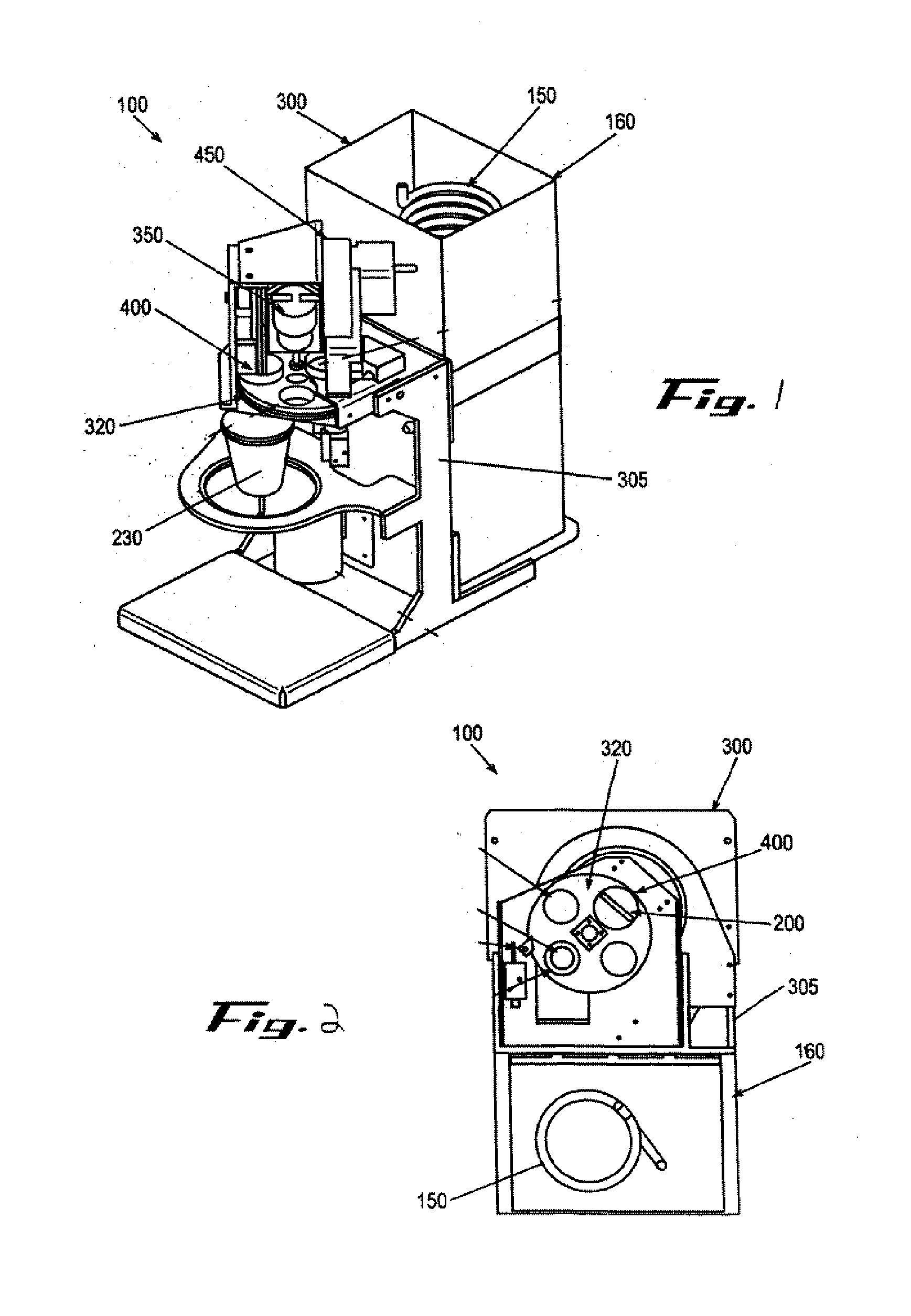

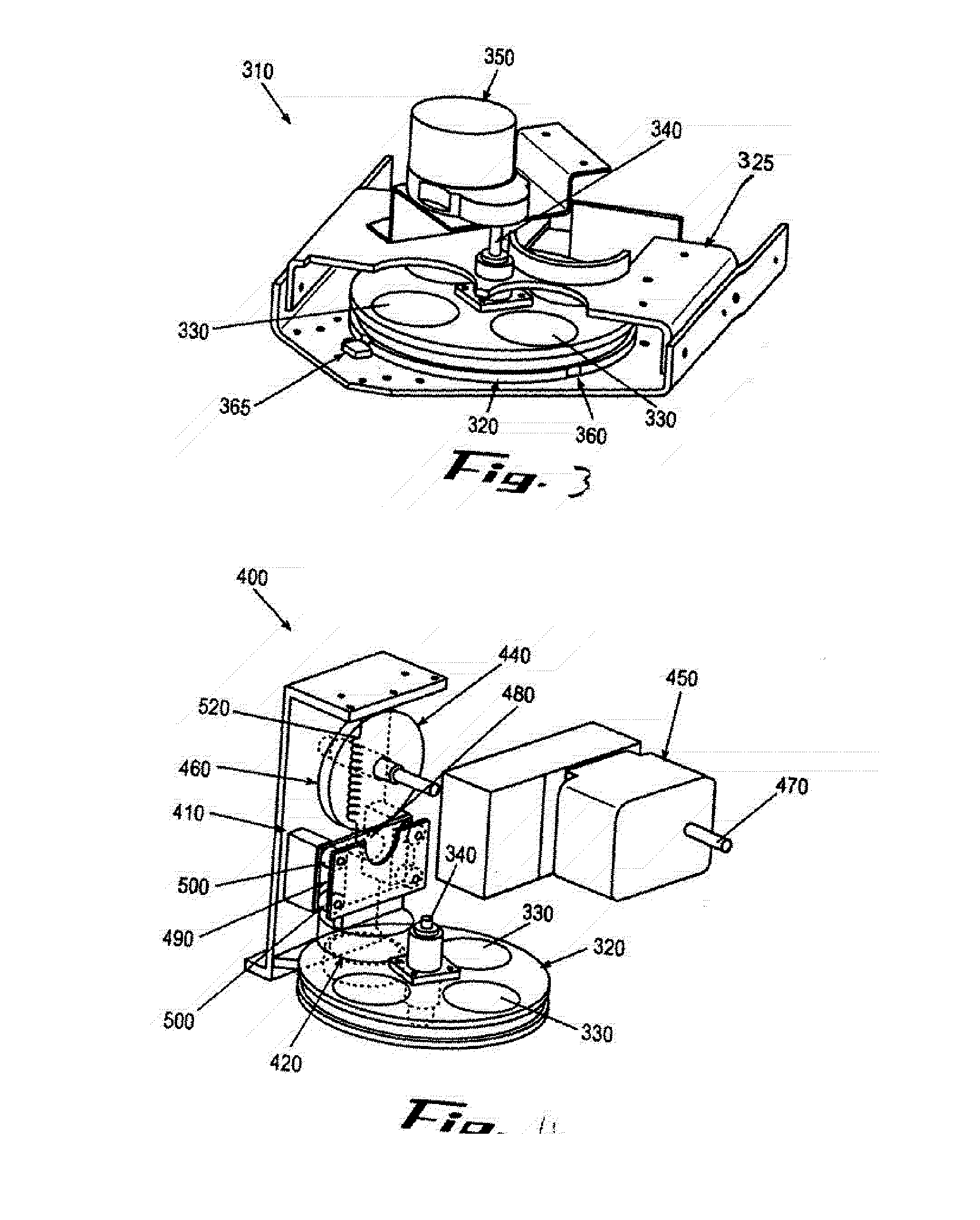

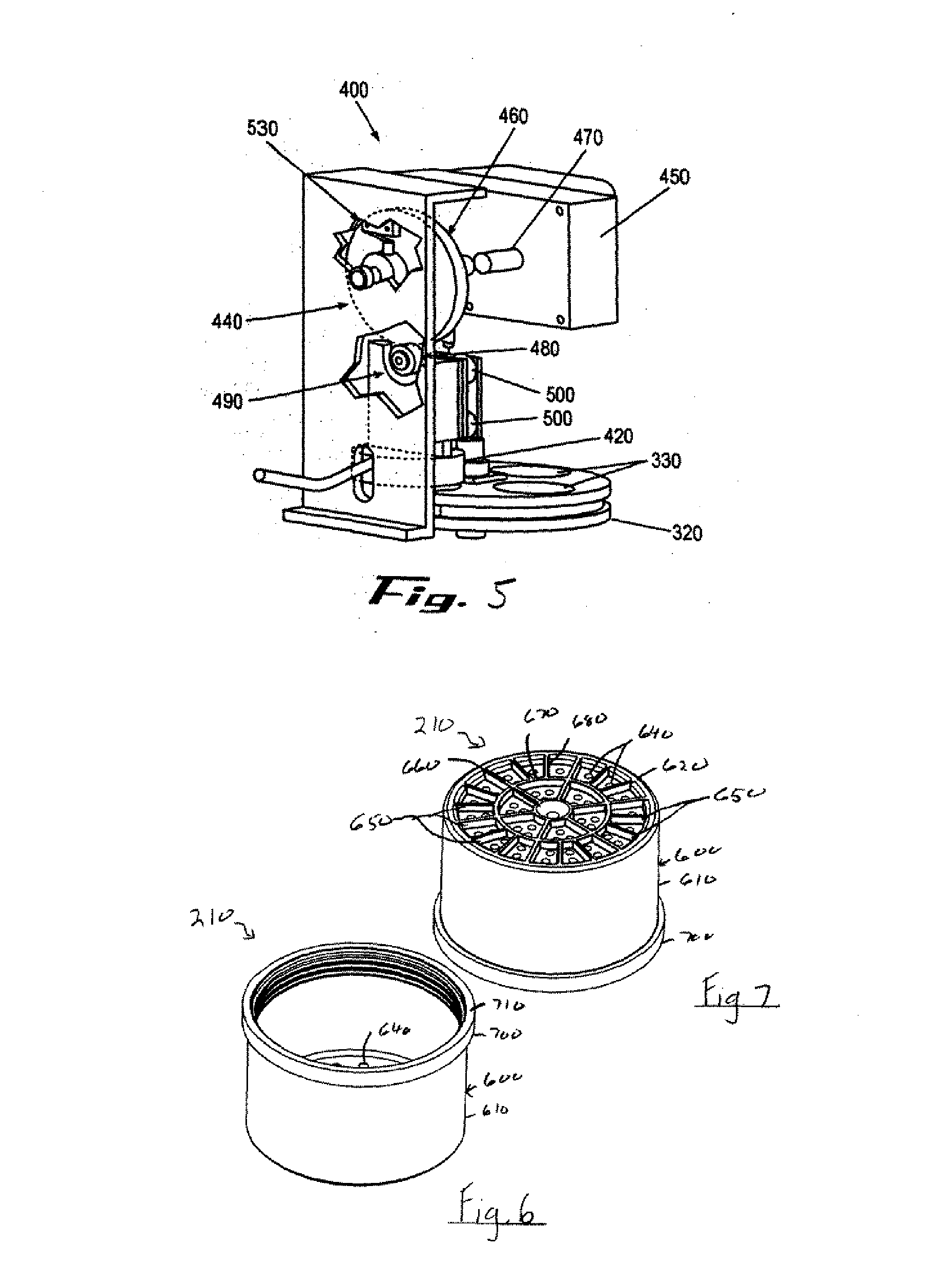

Coffee and tea pod

A pod for holding an amount of mixable material. The pod may include a circular sidewall and a base. The base may include a number of apertures. A substantially stiff filter paper may be positioned about the base.

Owner:THE COCA-COLA CO

Magnetic biological carrier and preparation method thereof

InactiveCN102225806APromote recoveryRealize dynamic regenerationSustainable biological treatmentBiological water/sewage treatmentResource utilizationEngineering

The invention discloses a magnetic biological carrier and a preparation method thereof. The raw materials of the magnetic biological carrier comprise aggregate, iron oxide, a binder and a reducing agent. The preparation method of the magnetic biological carrier comprises the following steps of: mixing the aggregate, iron oxide and the reducing agent, crushing, screening with a 60-mesh sieve to obtain a mixed material, adding water which is 30-60% of the mixed material by weight to the binder, stirring for dissolving the binder to obtain a binder solution, then mixing the binder solution with the mixed material, uniformly stirring, granulating and shaping to obtain 2-10 mm granules, drying the granules till the water content of the granules is less than 10%, and calcining at the temperature of 350-1100 DEG C for 0.2-10 hours to obtain the magnetic biological carrier. The magnetic biological carrier provided by the invention can be applied to the deep treatment of secondary treatment water of domestic sewage, meets the requirements of landscape water replenishing and circulating cooling water treatment, and can be used for realizing the deep treatment and resource utilization of industrial wastewater.

Owner:HEFEI UNIV OF TECH

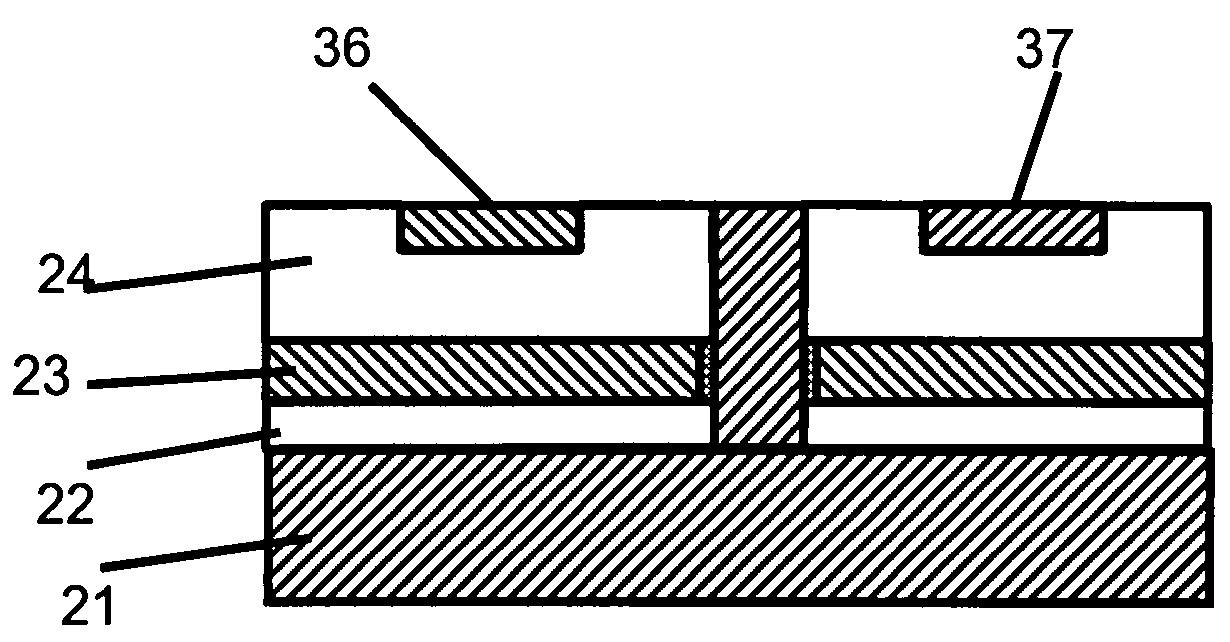

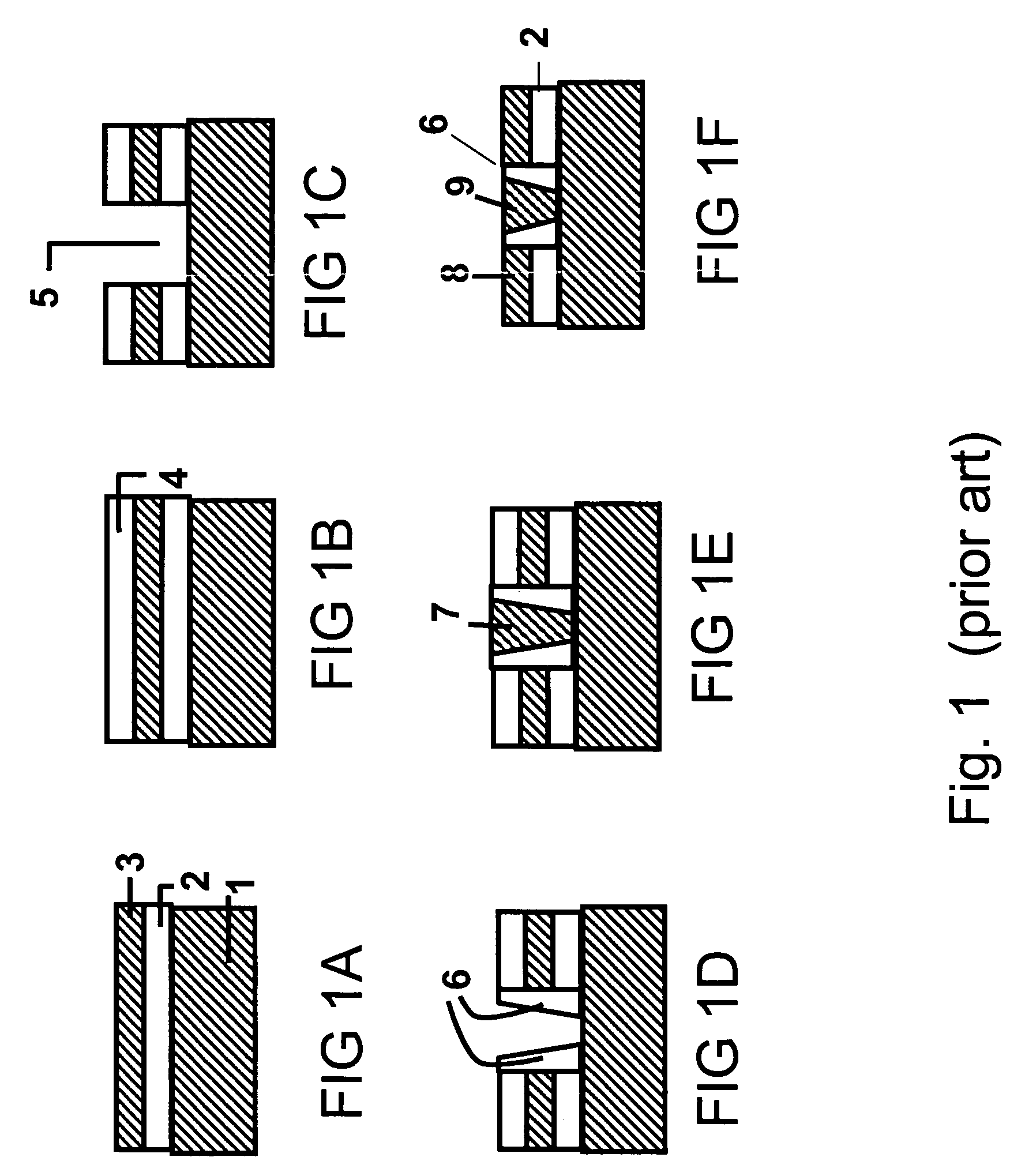

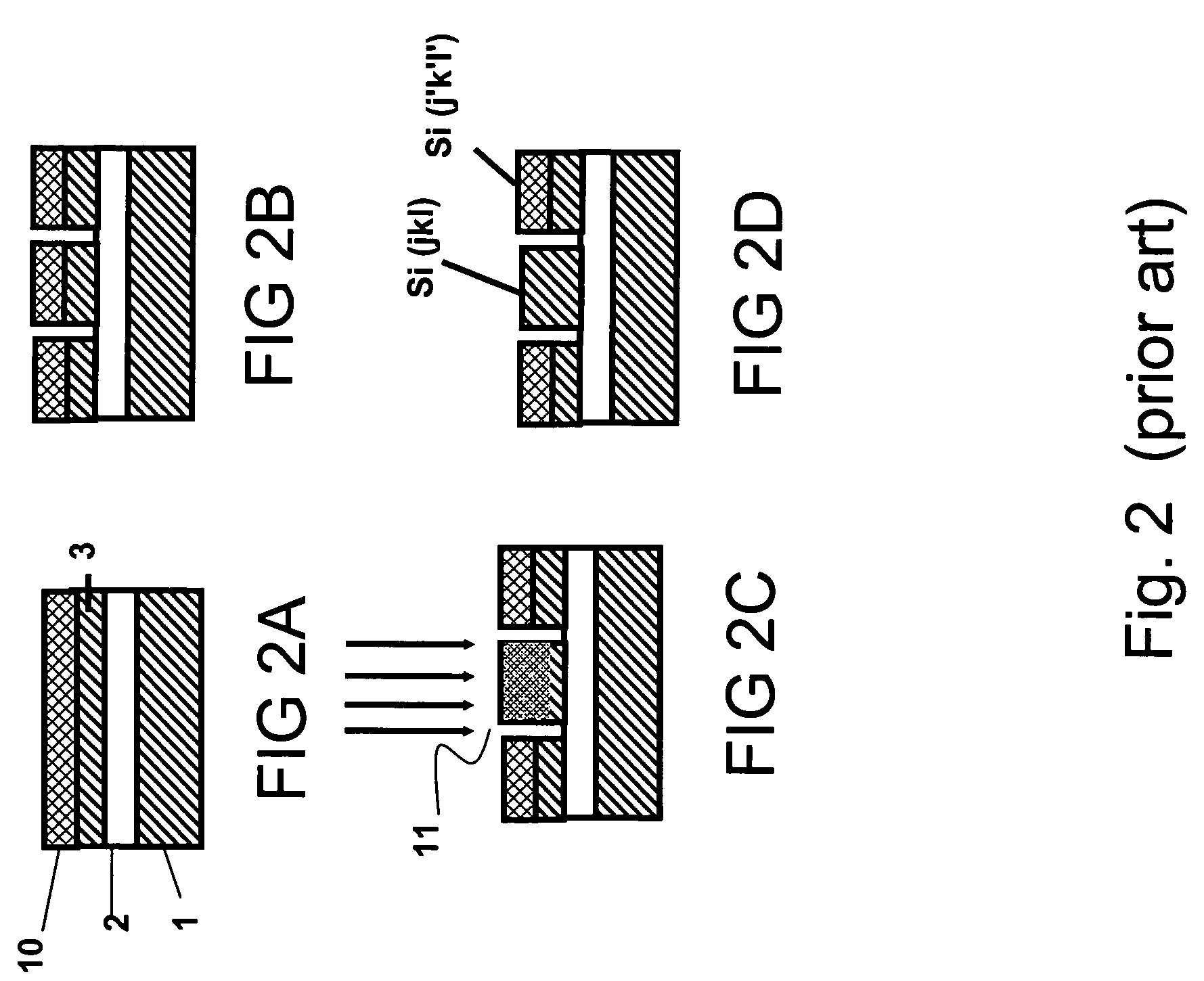

Mixed orientation and mixed material semiconductor-on-insulator wafer

The present disclosure relates, generally, to a semiconductor substrate with a planarized surface comprising mixed single-crystal orientation regions and / or mixed single-crystal semiconductor material regions, where each region is electrically isolated. In accordance with one embodiment of the disclosure CMOS devices on SOI regions are manufactured on semiconductors having different orientations. According to another embodiment, an SOI device is contemplated as having a plurality of semiconductor regions having at least one of a different semiconductor material, crystalline lattice constant or lattice strain. Methods and processes for fabricating the different embodiments of the invention is also disclosed.

Owner:GLOBALFOUNDRIES INC

Golf balls comprising glass ionomers, ormocers, or other hybrid organic/inorganic compositions

A golf ball comprising a core and a cover layer, wherein at least one of the core or cover layer comprises a hybrid material that contains fatty acid-modified glass ionomers, an ormocer or other inorganic-organic materials.

Owner:ACUSHNET CO

Method of manufacturing composite board

InactiveUS7022756B2Improve flow characteristicsIncreased flexural modulusSynthetic resin layered productsWood working apparatusThermoplasticFiber

A composite board is made from waste medium density fiber (MDF) board or waste particle board that includes solid urea formaldehyde. The waste board is chopped and milled into particles having a size between 20 mesh and 150 mesh, creating a waste flour. After removing moisture from the waste flour, the dried waste flour is mixed with a thermoplastic to bind and encapsulate the waste flour. Internal lubricants are added to improve the flow characteristics of the blended material, and external lubricants are added to present sticking of the mixture to an extruder or mold. Mineral fillers are added to improve the flexural modules of the composite board, and a plasticizer can be added to improve the physical properties or mechanical characteristics of the mixture. An ultraviolet absorber, a biocide, and a pigment can also be added. The blended material is extruded or molded into a desired shape. When cooled, the thermoplastic hardens to form a solid composite board.

Owner:MASCO RETAIL CABINET GROUP

Manufacturing method for crystallized fruit

The invention relates to a manufacturing method for crystallized fruit, which comprises the following steps: (1) preparing the following raw materials by weight percent: 20-67.7% of fruit embryos, 32.05-53.0% of sugar crops, 0.1-5% of filling materials, 0-5% of medicinal and food homologous traditional Chinese medicines, 0.05-10% of seasoning spices, 0.1-2.0% of preservatives and 0-5% of pigments; (2) pre-treating the raw materials by preparing liquid sugar, filling material liquid, traditional Chinese medicine extracts and preservative solution; (3) soaking: adding the liquid sugar material,the seasoning spices, the pigments, the liquid sugar, the filling material liquid and the traditional Chinese medicine extracts into a soaking cylinder and mixing uniformly to form the mixed materialliquid, adding the fruit embryos into the soaking cylinder, increasing the temperature of the mixed material liquid to 50-60 DEG C and keeping the temperature for 10-15 hours; (4) leaching and drying; and (5) drying to obtain the crystallized fruit. The manufacturing method for crystallized fruit is easily performed, the full utilization of fruit resource is realized, and the manufactured crystallized fruit is full of nutrition and tastes fresh and cool.

Owner:汕头市天悦轻工技术科技有限公司 +3

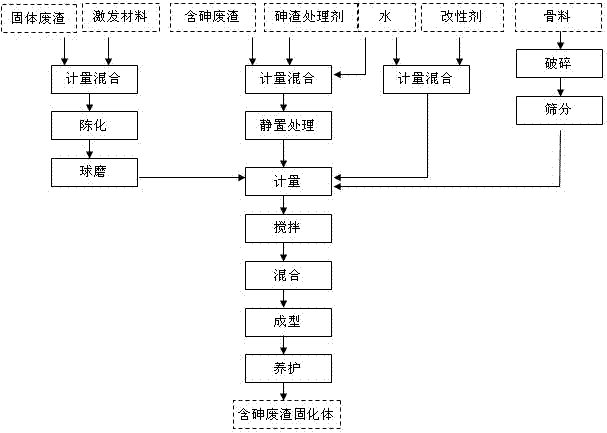

Arsenic-containing waste slag solidified body and preparation method thereof

InactiveCN102249609ASimple curing processLow costSolid waste managementSolid waste disposalArsenic pollutionSlag

The invention relates to an arsenic-containing waste slag solidified body and a preparation method thereof, and belongs to the technical field of environmental protection. The preparation method comprises the following steps of: treating arsenic-containing waste slag, mixing the treated arsenic-containing waste slag and a curing agent prepared from industrial waste slag and a mineral activated material, a modifying agent, aggregates, water and the like, and stirring, forming and curing the mixed materials to obtain the solidified body with high strength and low arsenic leaching rate. Comparedwith the prior art, the solidification process is simple, low in cost, safe and reliable, and solves the problem of arsenic pollution of the arsenic-containing waste slag.

Owner:KUNMING UNIV OF SCI & TECH +1

Material system for use in three dimensional printing

InactiveUS7049363B2High form stabilityHigh strengthAdditive manufacturing apparatusOrganic dyesPolyelectrolyteCross-link

A material system for use in a 3D-printing, which exhibits a higher form stability. The material system contains binder and solvent as well as optional filler materials. The binder is soluble in the solvent, as well as two complementary polyelectrolytes, and / or an initiator for a cross linking reaction of the binder. The advantage of such a mixed material system is comprised in the essentially higher binder force between the individual particles. This enhanced binder force results either from the acid-base linkages, which form between the complementary polyelectrolytes, or from the supplemental networking initiated by the initiators, or from both. Substantially higher binding forces between the individual particles means at the same time a substantially higher shape stability of the 3D-printing product.

Owner:DAIMLER AG

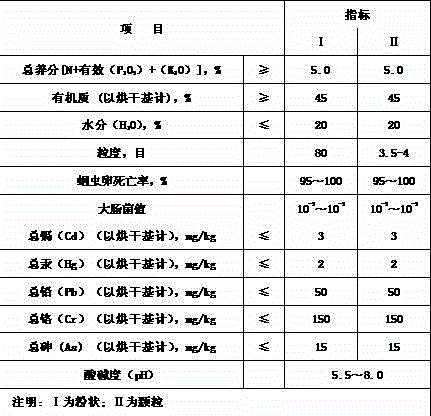

Organic fertilizer with livestock and poultry manure and preparation method thereof

InactiveCN103145463ANo pollution in the processImprove fertilizer efficiencyBio-organic fraction processingOrganic fertiliser preparationEffective microorganismMixed materials

The invention provides an organic fertilizer with livestock and poultry manure and a preparation method thereof. The organic fertilizer comprises cow manure, edible mushroom dregs, pig manure, chicken manure, maize straw powder and an Em (effective microorganisms) stock solution. The specific formula of the organic fertilizer comprises 19.7 percent of edible mushroom dregs, 10 percent of pig manure, 10 percent of chicken manure, 20 percent of maize straw powder, 0.3 percent of Em stock solution, and the balance of cow manure. The preparation method of the organic fertilizer is characterized in that a production technology of the organic fertilizer with the livestock and poultry manure mainly adopts a shallow pool type fermentation technology, namely the cow manure, the pig manure, the chicken manure, the edible mushroom dregs, the maize straw powder and the Em stock solution are poured into a mixer in proportion and are evenly mixed and stirred, the evenly mixed and stirred materials are sent into a shallow layer pool type fermentation pool, and the organic fertilizer fermentation environment temperature is controlled to be above 15 DEG C. Firstly, various raw materials including the livestock and poultry manure, the edible mushroom dregs, the straw powder and a fermentation bactericide are mixed, and then the mixed materials are put into a mixing and stirring machine to be evenly stirred, are sent into the material fermentation pool to be fermented for 8 days and are discharged from the pool to enter a secondary aerobic fermentation procedure. The organic fertilizer has the advantages of low cost and high yield and can improve the quality of crops.

Owner:郑晓华

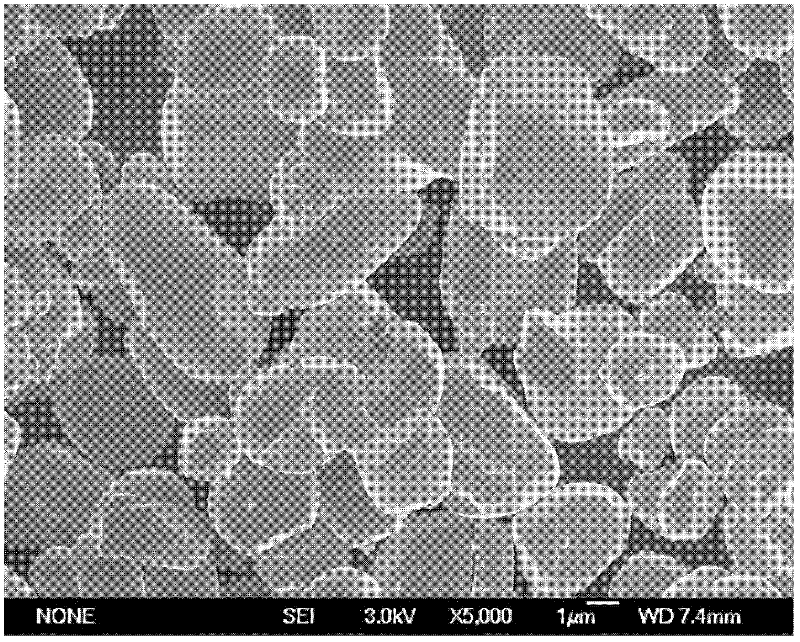

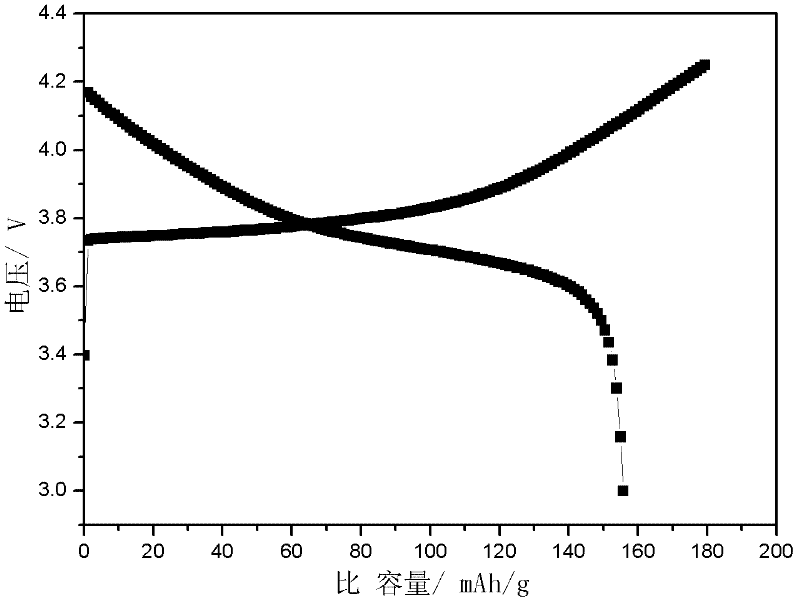

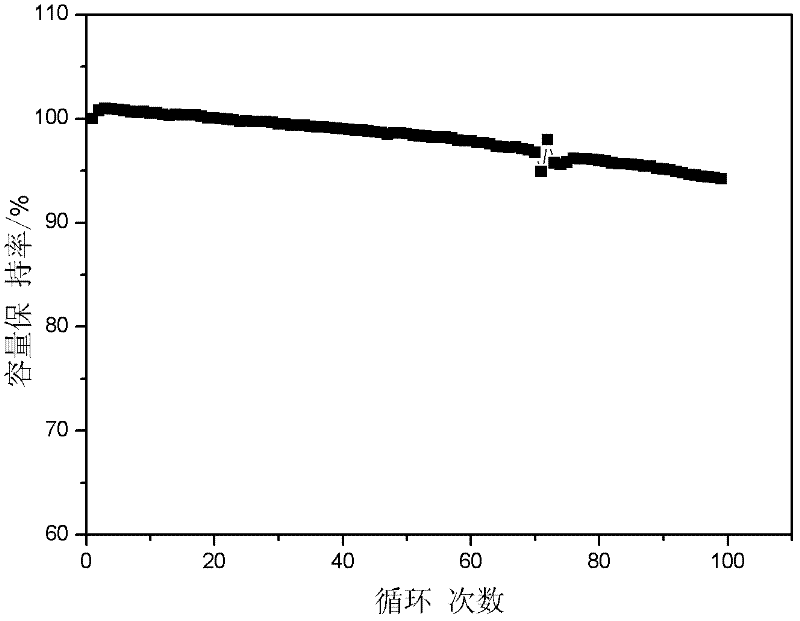

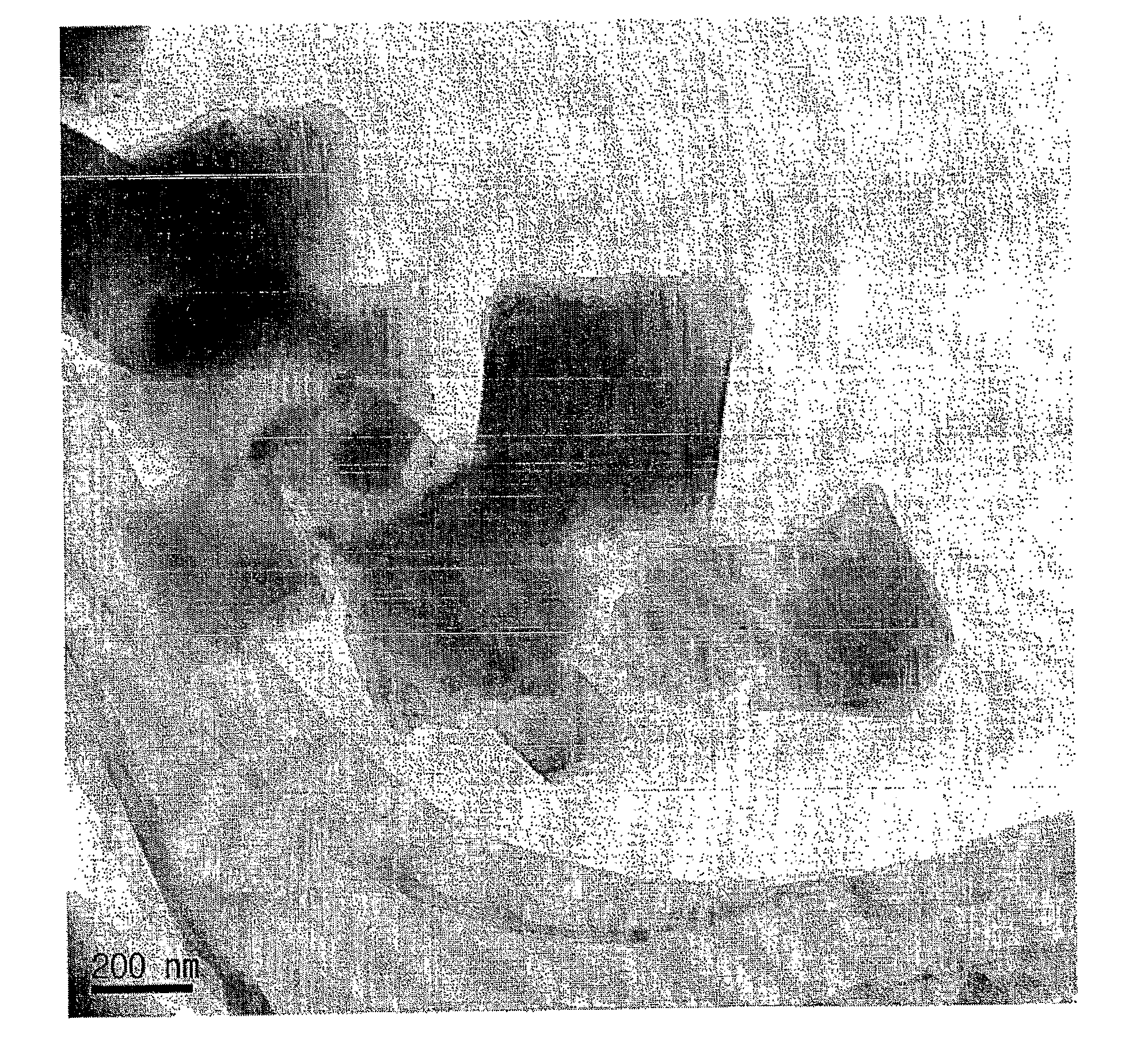

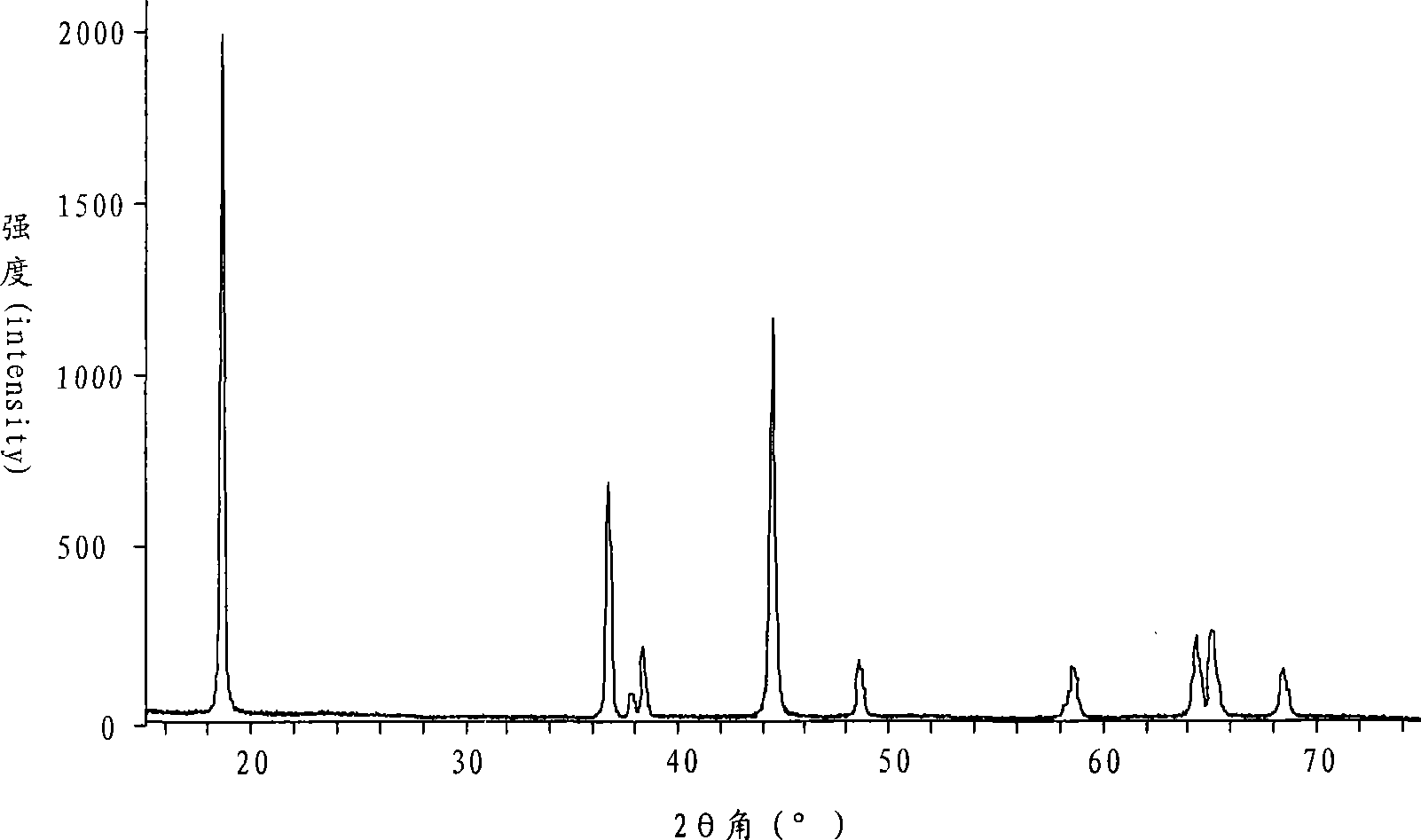

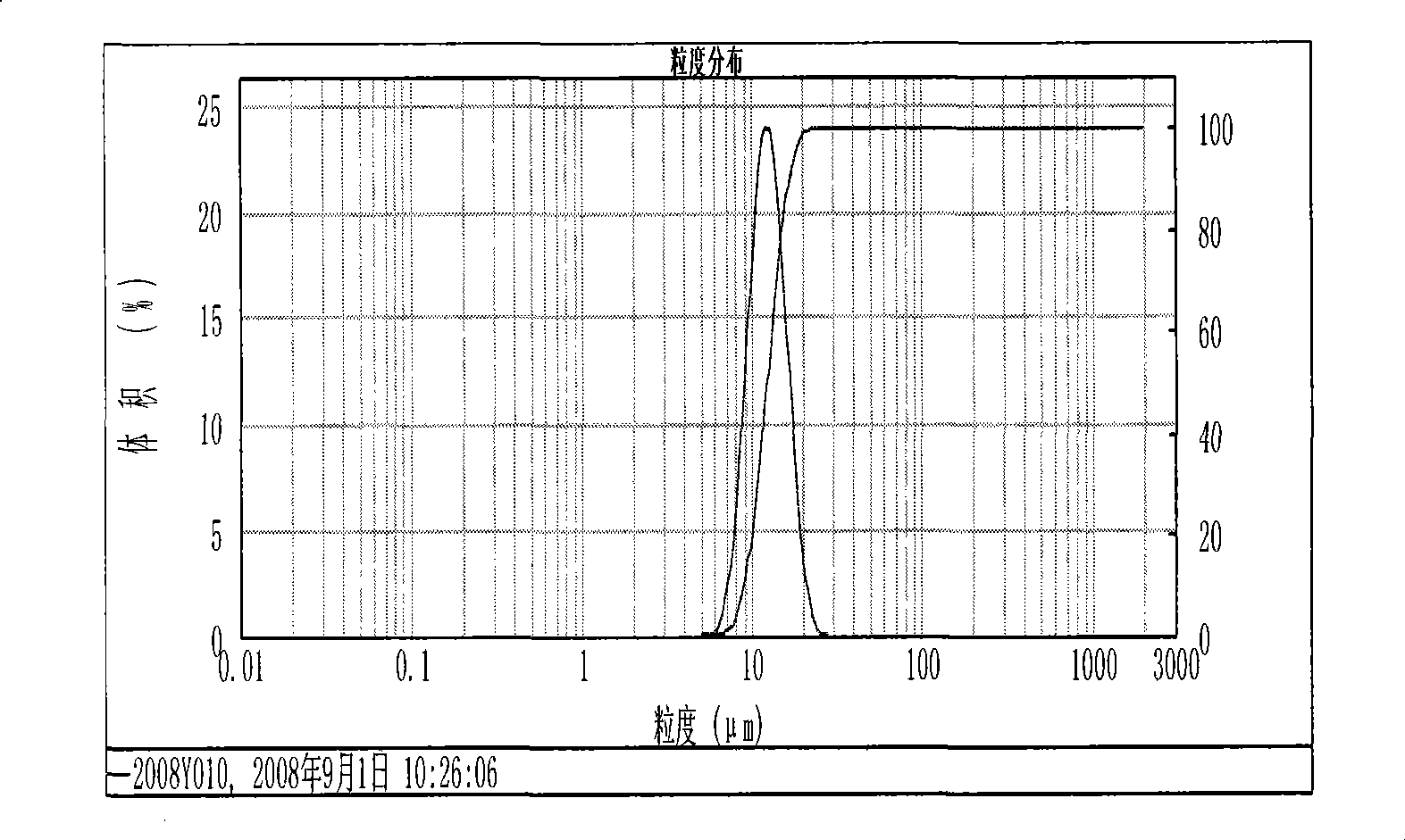

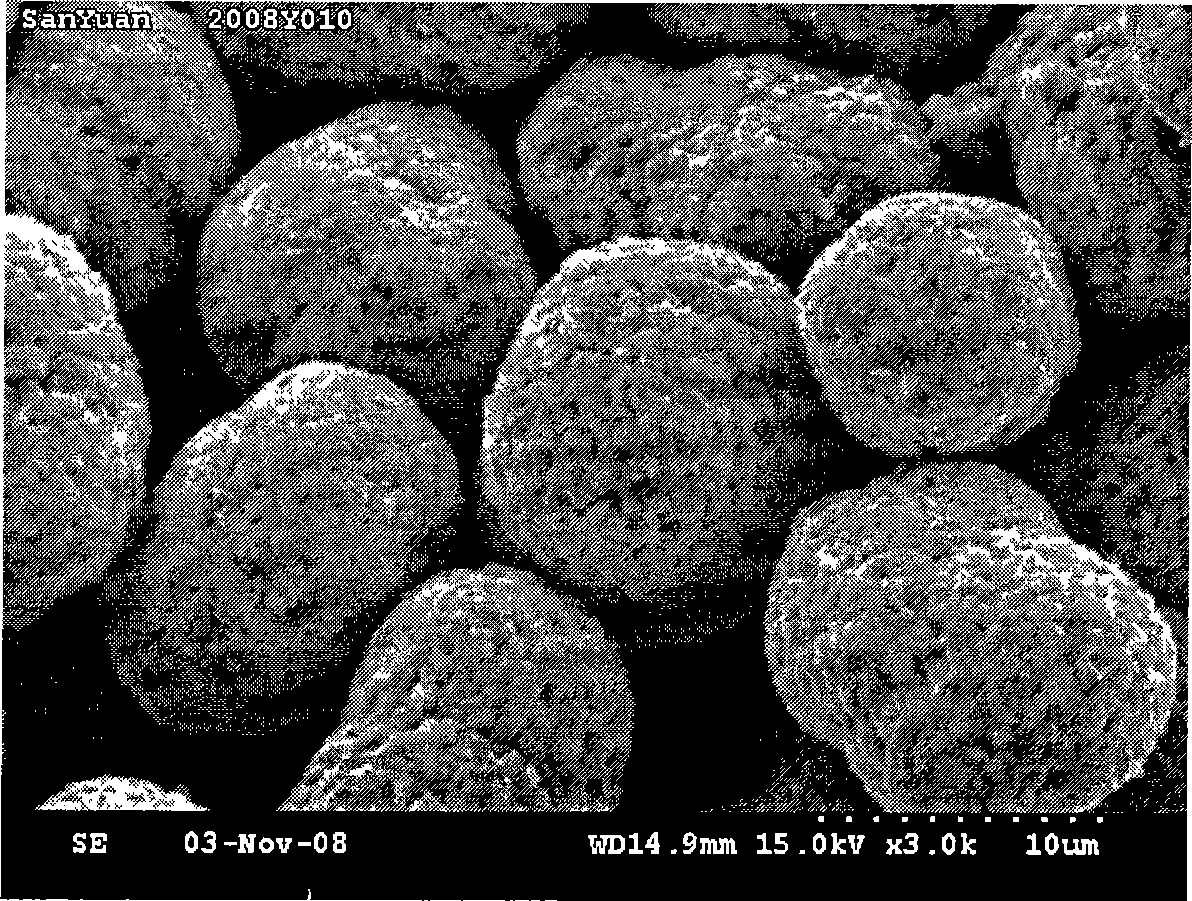

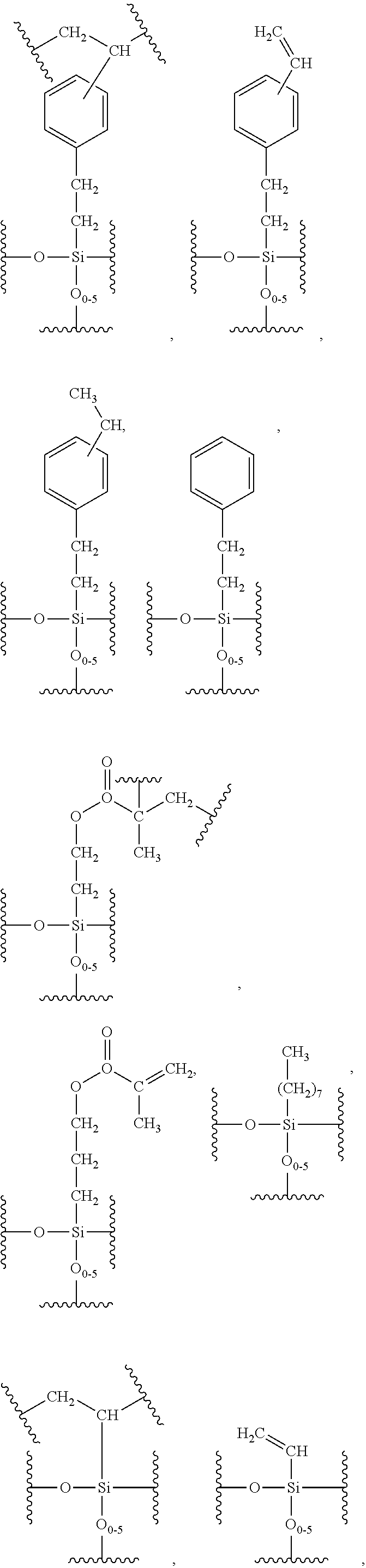

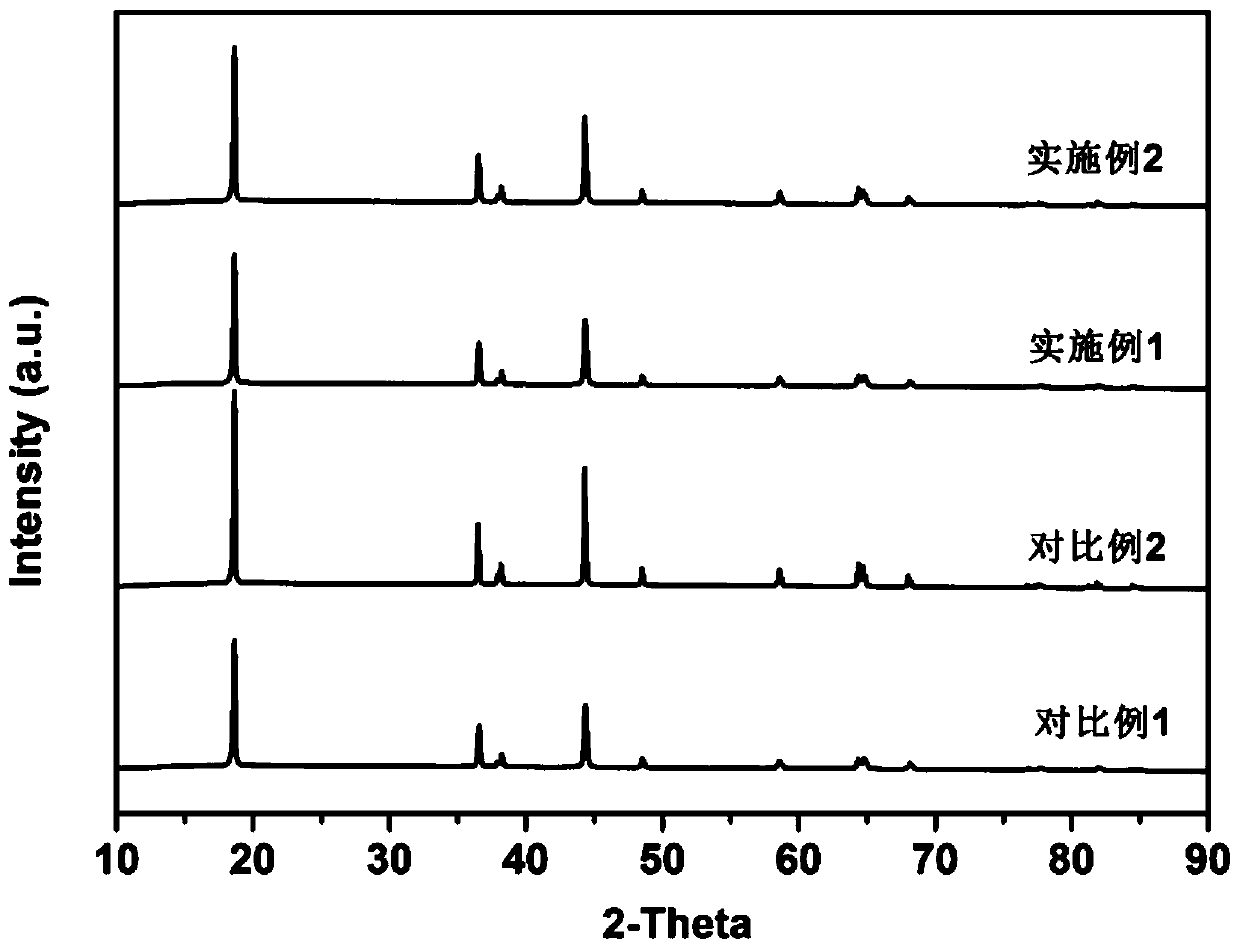

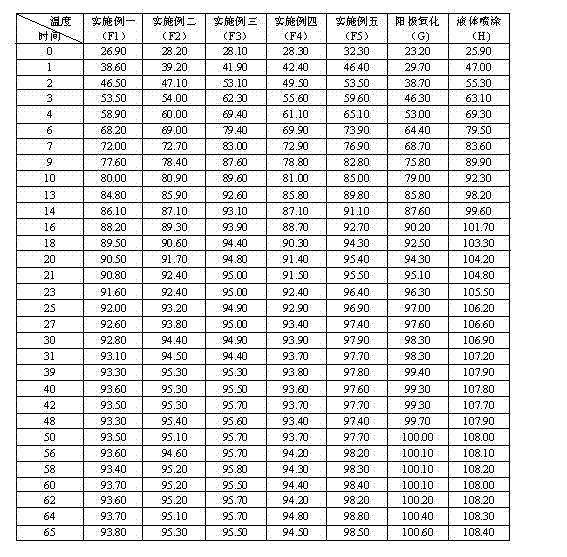

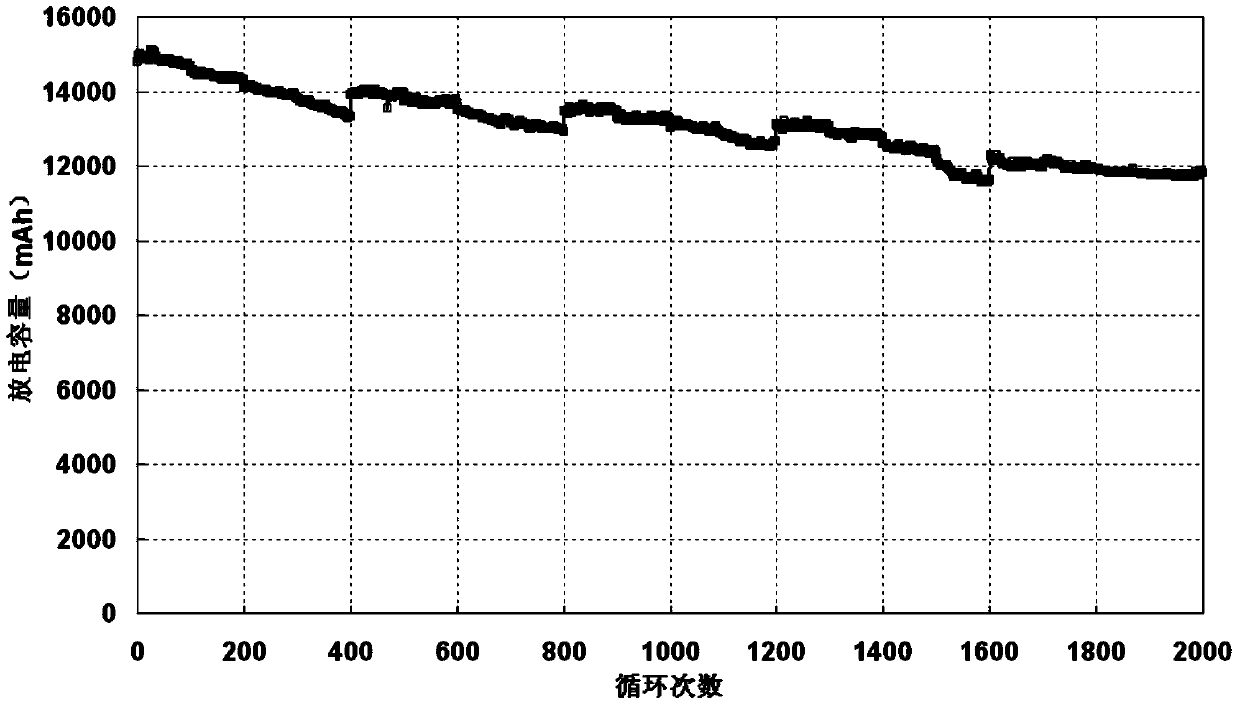

Preparation method of lithium ion battery ternary cathode material

The invention discloses a preparation method of a lithium ion battery ternary cathode material. According to the preparation method, full grinding is performed through a colloid mill to improve the reactivity of a precursor and a lithium salt and the uniformity of a mixed material; and a carbon chain organic additive is added in the process of grinding to improve the viscosity of a sizing material, inhibit raw material segregation in the process of drying, quickly balance the temperature of each part of a system in the process of high-temperature reaction and inhibit agglomeration among particles, so that a uniform-appearance and regular mono-crystal ternary cathode material is obtained. Meanwhile, the ternary cathode material is doped and subjected to surface coating modification, so that the structure of the material is stabilized, the side reaction between the material and electrolyte is inhibited, and the high-temperature cycle performance of the material is improved.

Owner:PULEAD TAIAN TECH IND

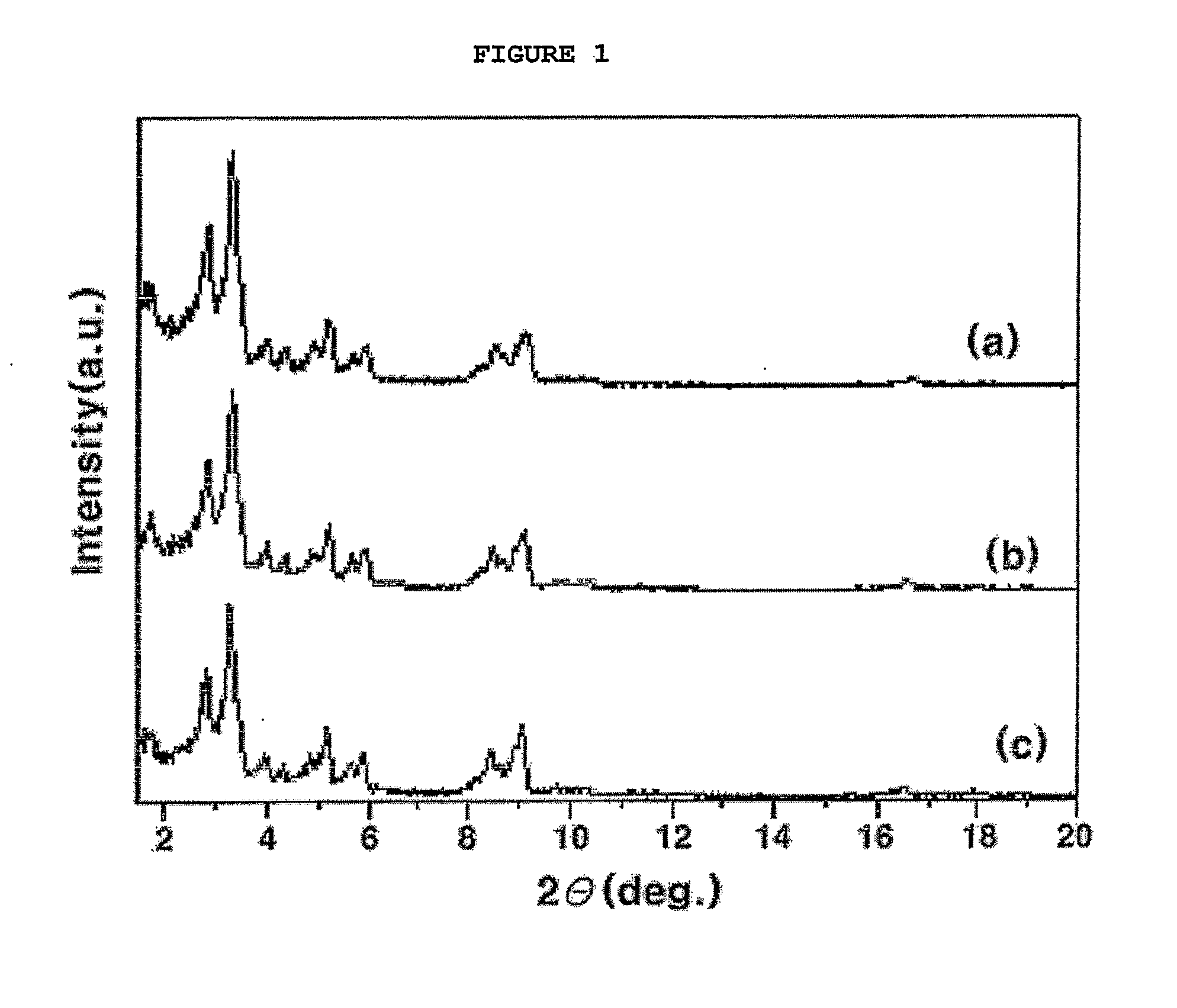

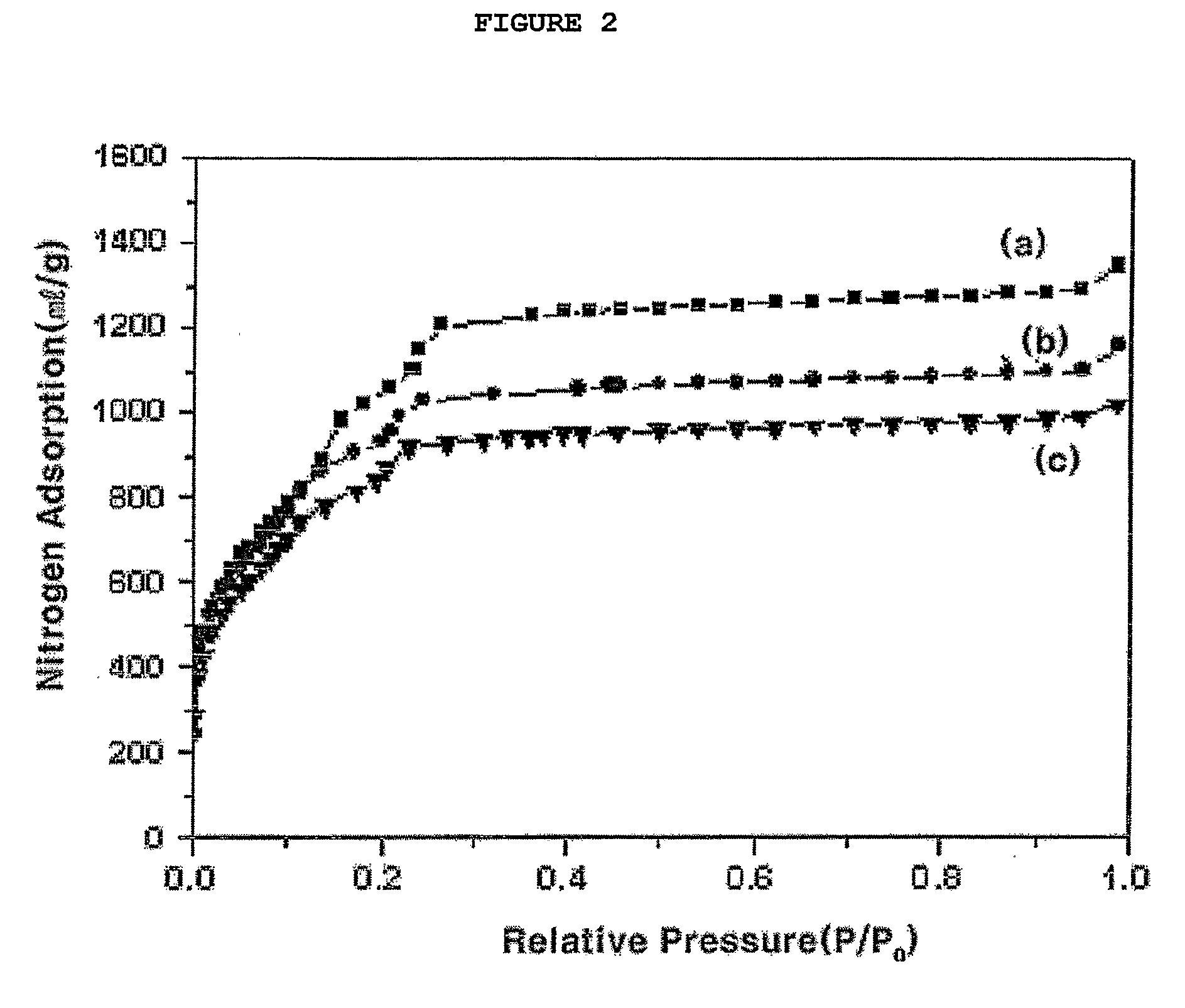

Preparation of surface functionalized porous organic-inorganic hybrid materials or mesoporous materials with coordinatively unsaturated metal sites and catalytic applications thereof

ActiveUS20100273642A1Improve adhesionHigh catalytic activityMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsSorbentHybrid material

Disclosed herein is a method of surface-functionalizing a porous organic-inorganic hybrid material or a organic-inorganic mesoporous material, in which organic substances, inorganic substances, ionic liquids and organic-inorganic hybrid substances are selectively functionalized on the coordinatively unsaturated metal sites of a porous organic-inorganic hybrid material or organic-inorganic mesoporous material, and thus the porous organic-inorganic hybrid material can be used for adsorbents, gas storage devices, sensors, membranes, functional thin films, catalysts, catalytic supports, and the like, and the applications of the surface-functionalized porous organic-inorganic hybrid material prepared using the method to catalytic reactions.

Owner:KOREA RES INST OF CHEM TECH

Lightweight wall plaster

InactiveCN101691292AReduce lossWith thermal insulationSolid waste managementPlasterworkThermal insulation

The invention discloses a lightweight wall plaster which comprises the following components by weight percent: 65-90% of inorganic cementing material, 5-30% of lightweight aggregate, 0-30% of filler and 0-10% of functional additive, wherein the inorganic cementing material is a desulfurized plaster or a building plaster. The lightweight wall plaster is a single-component dry mixed material produced by a factory and can be used on a construction site by only adding water for stirring, the lightweight wall plaster has a certain thermal insulation function and excellent fire prevention performance, the bonding performance is good, and the compressive strength is high, thereby being capable of replacing the traditional plastering mortar to be plastered on inner sides of external walls, partition walls, room separating walls, ceilings and other occasions and further improving the thermal insulation performance of wall bodies.

Owner:谢日清

Multi-element composite positive pole material for lithium secondary battery and preparation thereof

ActiveCN101478044AEnsure mixing uniformityAvoid destructionElectrode manufacturing processesSecondary cellsManganeseSpherical shaped

Owner:XTC NEW ENERGY MATERIALS(XIAMEN) LTD

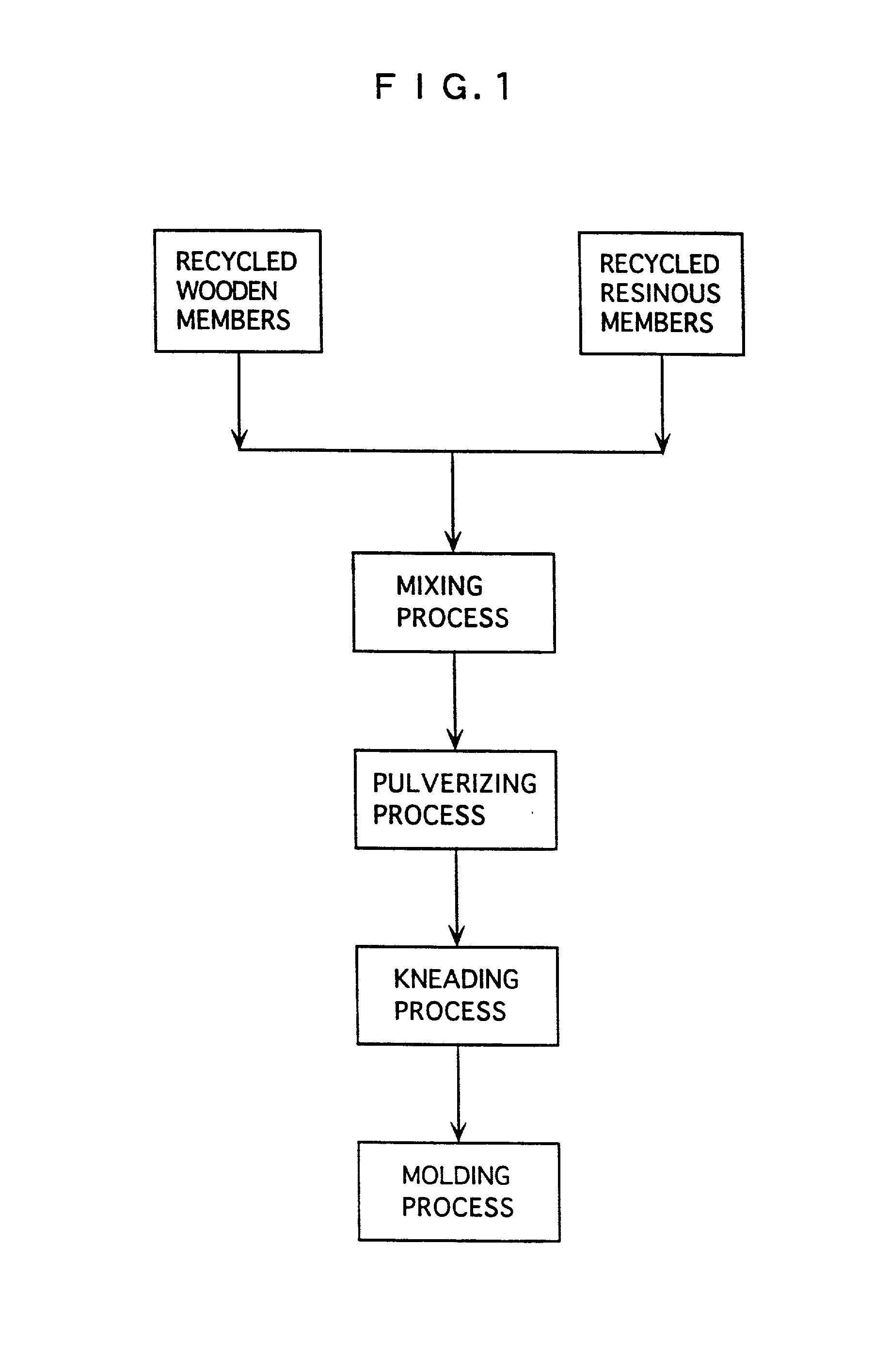

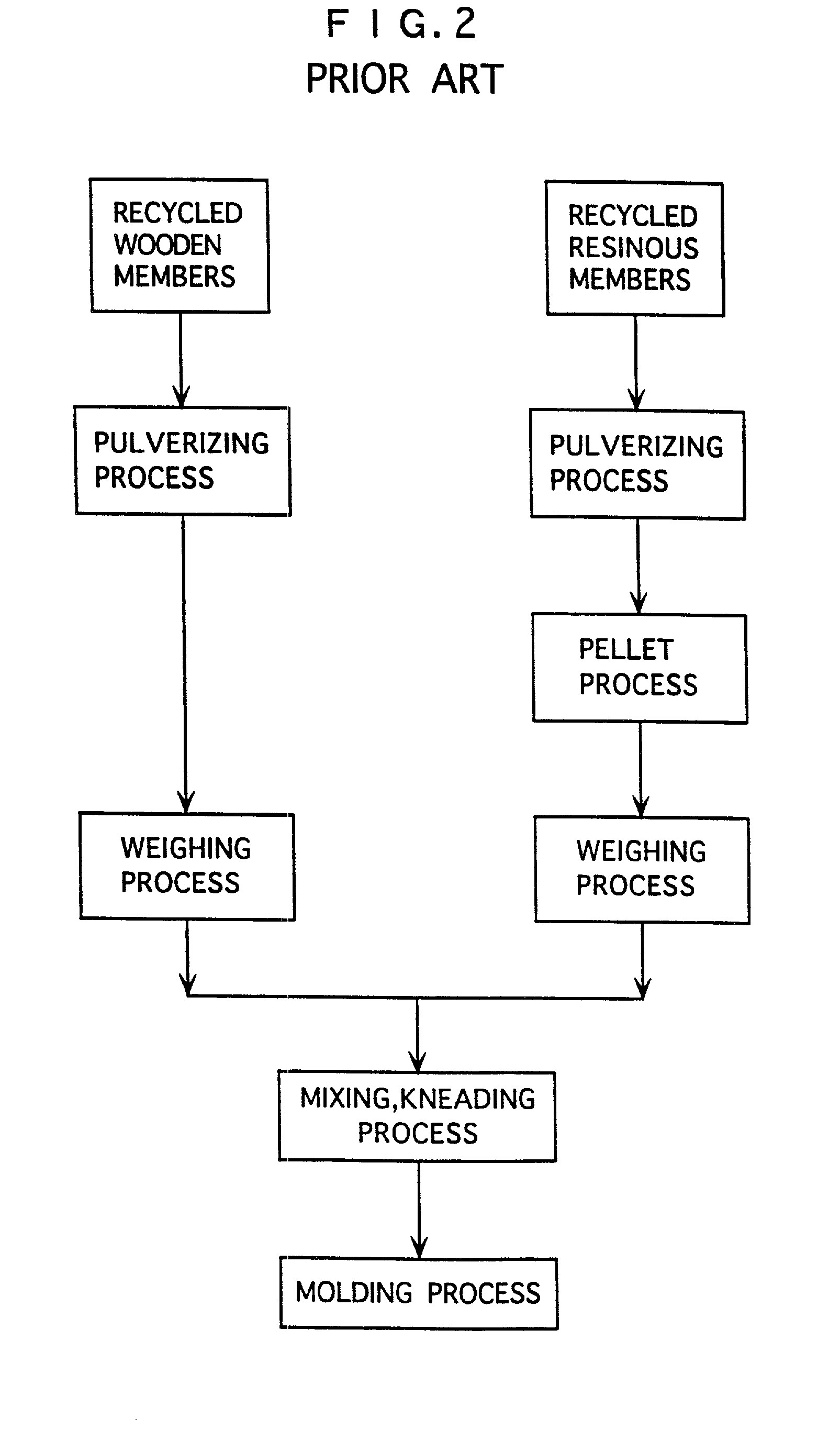

Cement bonded wood chip product, resin bonded wood chip product, simulated wood product

InactiveUS20010009309A1Reduce the numberReduce processFlat articlesDomestic articlesMixed materialsInjection moulding

A manufacturing method for providing a cement bonded wood chip product, a resin bonded wood chip product and a simulated wood product, in which recycled wooden members and recycled resinous members are pulverized after having been mixed. Accordingly, a mixing process and a pulverizing process can be integrated into one single line, reducing the space as well as laborious work and efficient operation in a plant. A manufacturing method of a simulated wood product utilizing pulverized powders obtained from recycled building members as raw material, in which the building members comprise recycled wooden members made of wooden materials and resinous members made of resinous materials, the manufacturing method further comprising a mixing process for mixing the recycled wooden members, a pulverization process for pulverizing the mixed materials obtained in the mixing process to form pulverized powder, a kneading process for kneading the pulverized powders obtained by the pulverizing process, and a molding process for molding the kneaded materials obtained in the kneading process either by an extrusion or injection molding.

Owner:MISAWA HOMES CO LTD

Lightweight leveling mortar

The invention discloses a lightweight leveling mortar material for a variety of wall surfaces and floors inside and outside buildings, and the lightweight leveling mortar material comprises the following components by weight percent: 65-90% of inorganic cementing material, 5-30% of lightweight aggregate, 0-30% of filler and 0-10% of functional additive. The lightweight leveling mortar material is a single-component dry-mixed material produced by a factory and can be used on a construction site by only adding water for stirring. The lightweight leveling mortar has a certain thermal insulation function and excellent fire prevention performance, the bonding performance is good, and the compressive strength is high, thereby being capable of replacing the traditional mortar to be plastered on a variety of wall surfaces and floors of buildings and further improving the thermal insulation performance of wall bodies.

Owner:谢日清

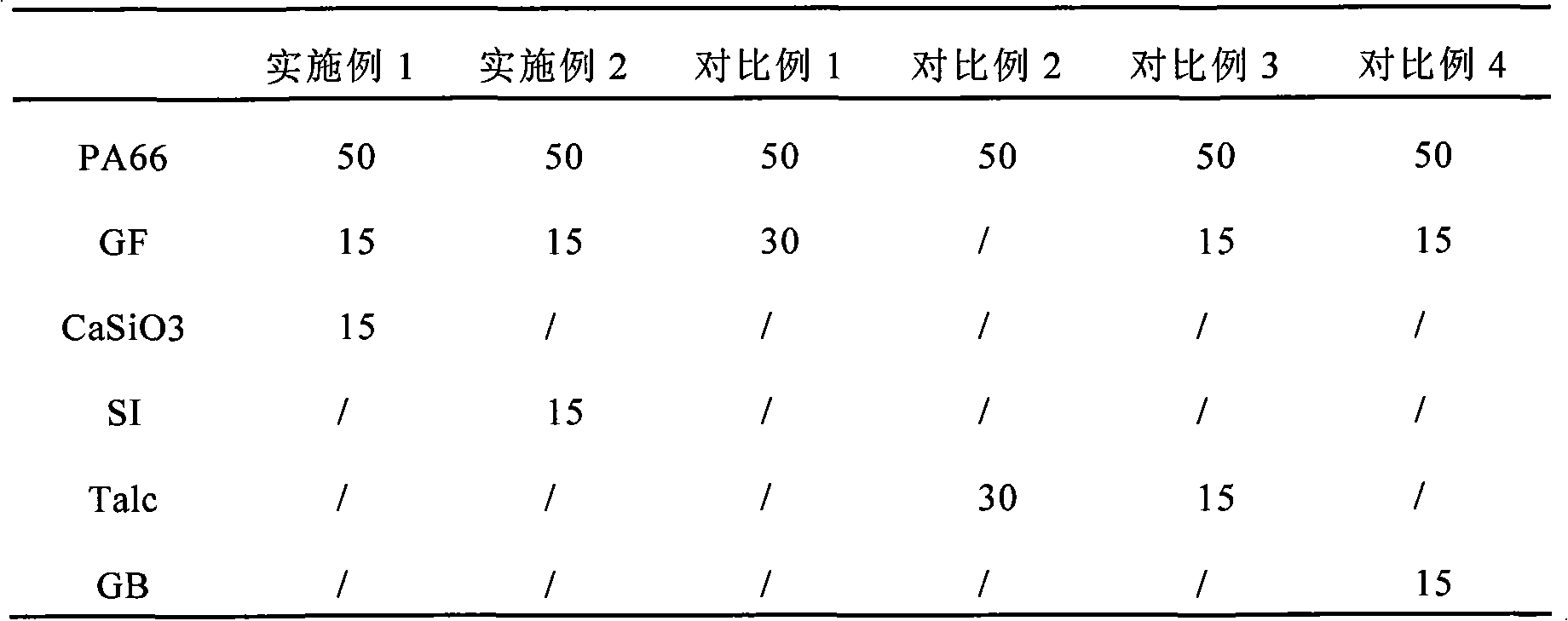

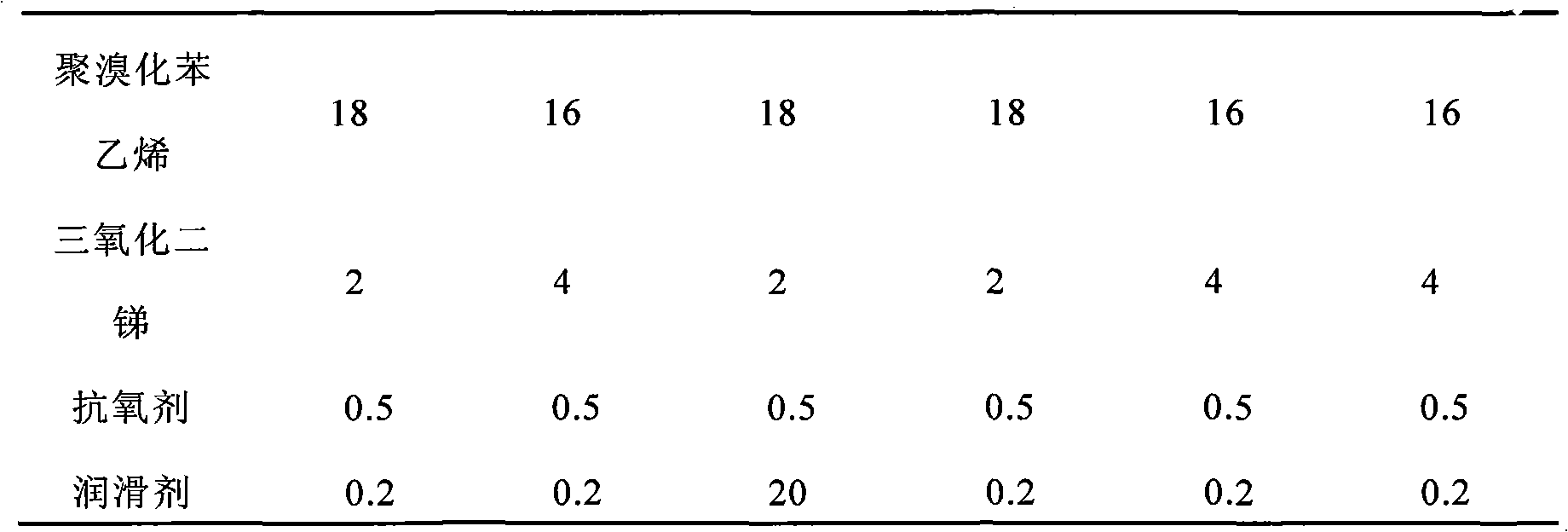

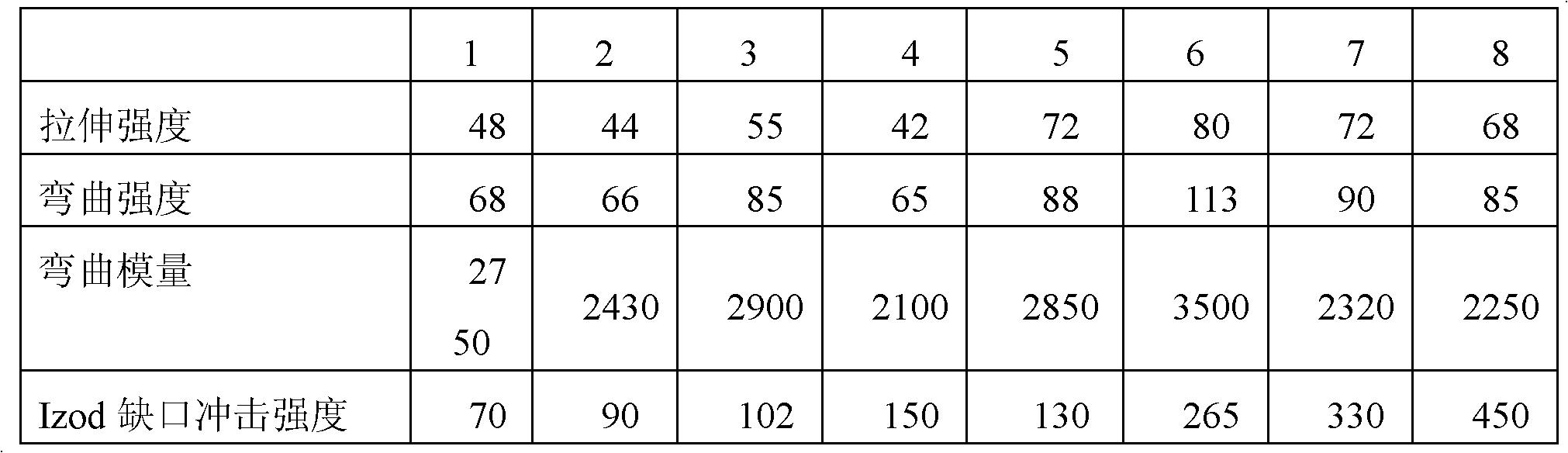

Plastic case material for breaker and preparation method thereof

ActiveCN102108204ASolve the problem of exposureHigh strengthProtective switch detailsBreaking strengthGlass fiber

The invention relates to a plastic case material for a breaker and a preparation method thereof. The material comprises the following components in parts by weight: 22-80 parts of nylon, 5-25 parts of glass fiber, 5-25 parts of needle-like filling material, 8-20 parts of fire retardant, 2-6 parts of auxiliary fire retardant and 0.1-2 parts of other auxiliaries. The preparation method comprises the following steps: evenly mixing the raw materials with a high-speed mixer at a high speed; and then bracing and pelleting the mixed materials with a screw extruder at the temperature of 220 DEG C-290DEG C to obtain the plastic case material. Compared with the prior art, the plastic case material has high breaking strength and elastic modulus, the strength of a compound material is barely influenced by a proper addition of the raw materials, and the obtained product has the advantages of no glass fiber rich surface, no buckling deformation, high strength and good heat resistance.

Owner:HEFEI GENIUS NEW MATERIALS

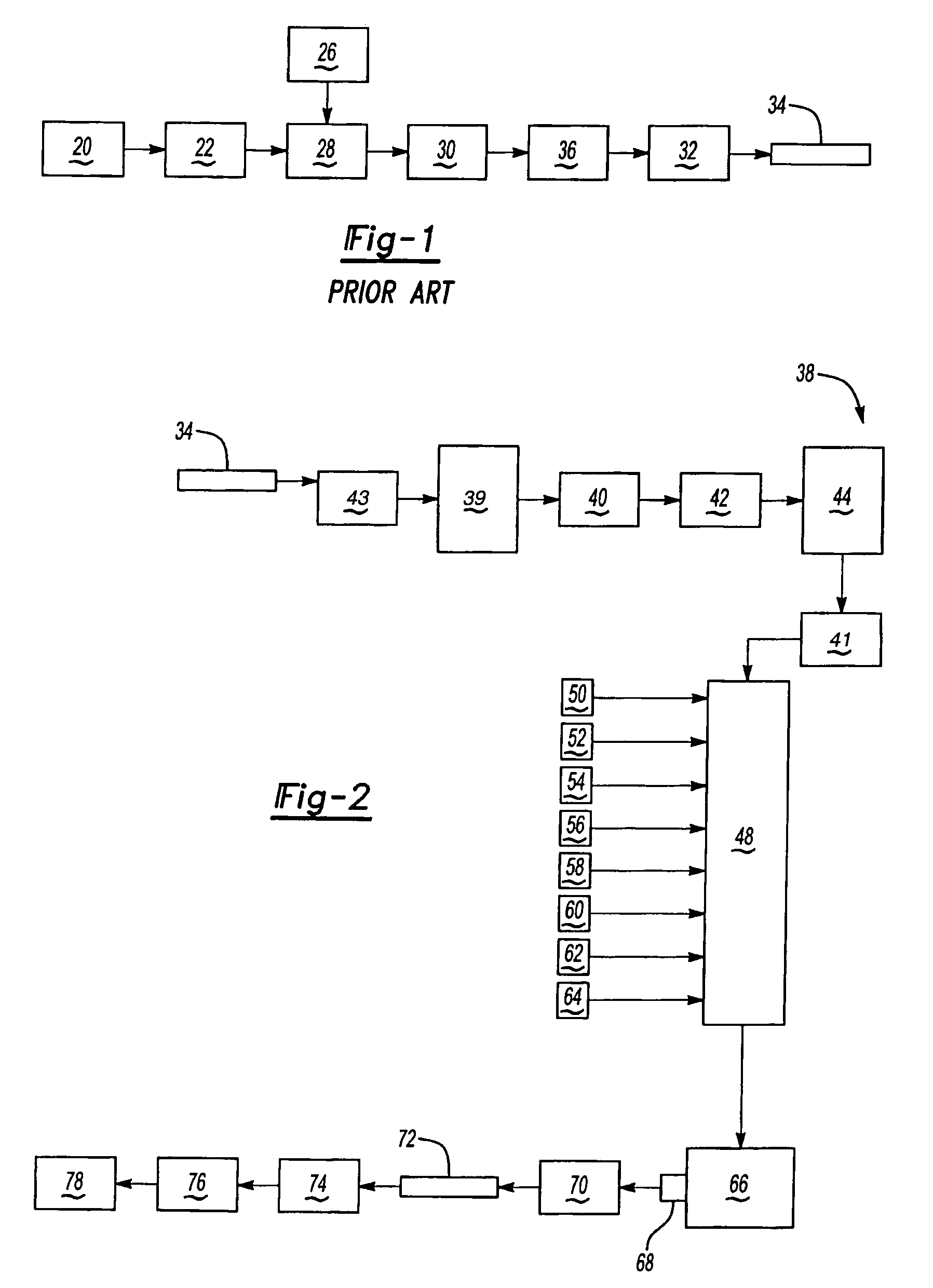

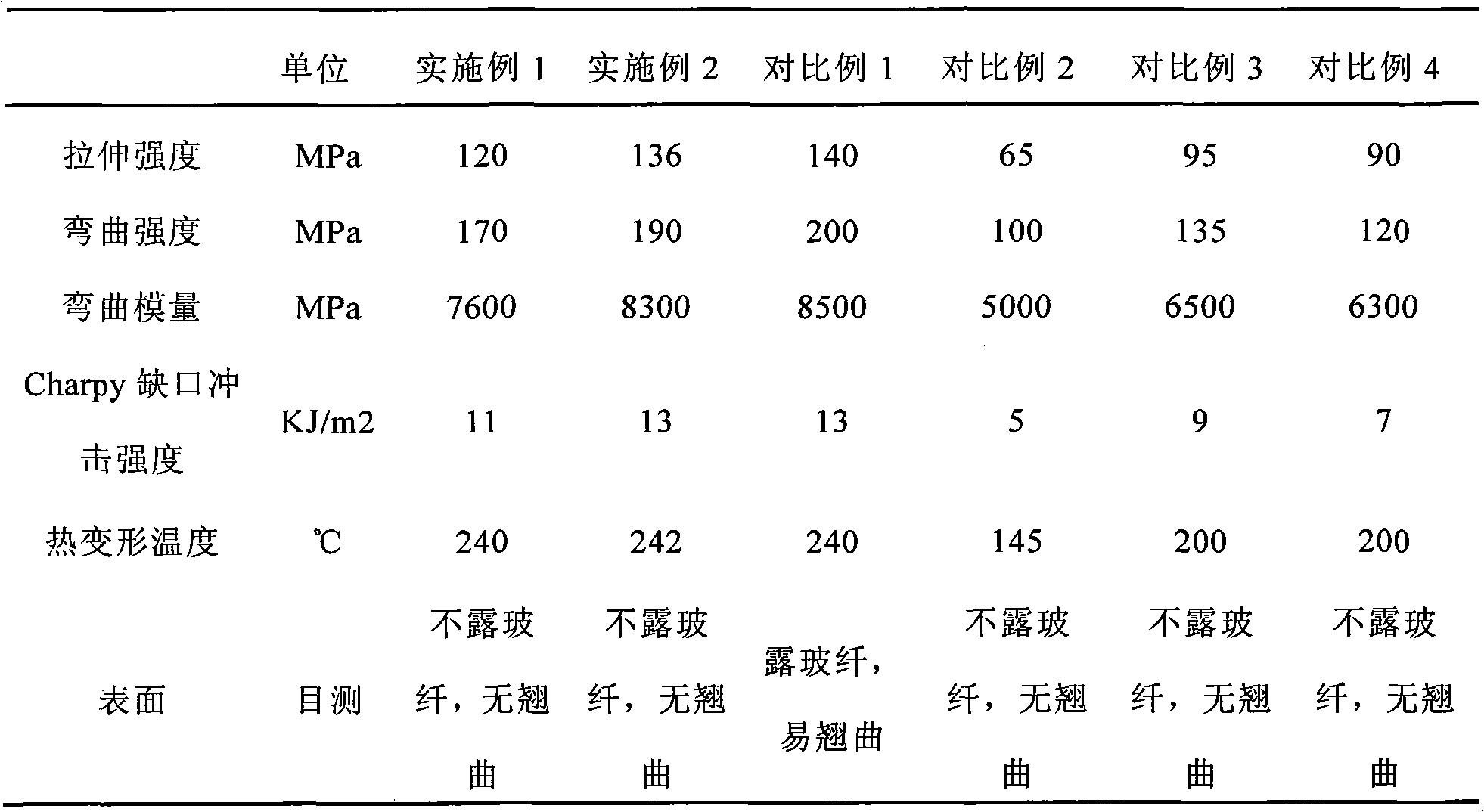

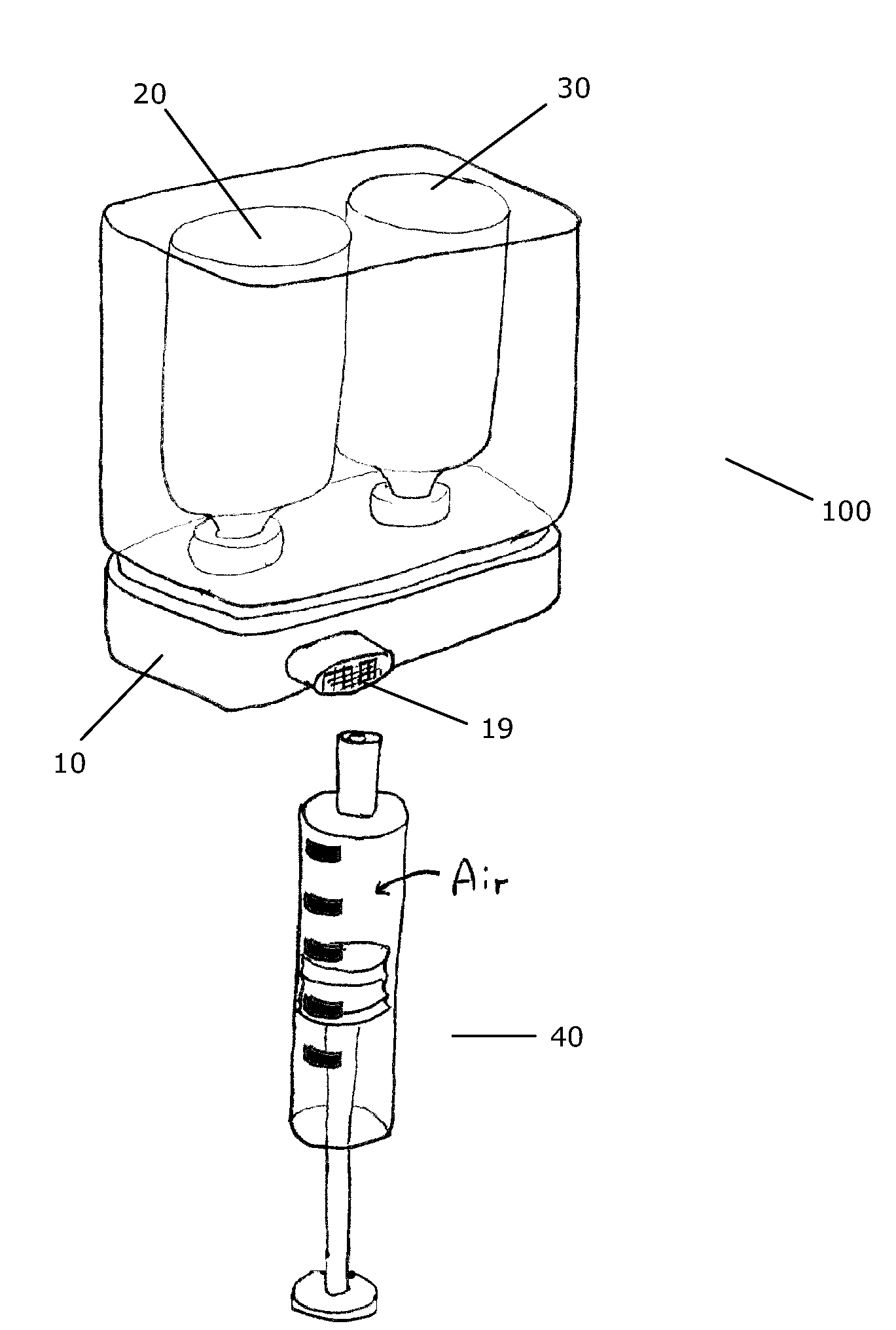

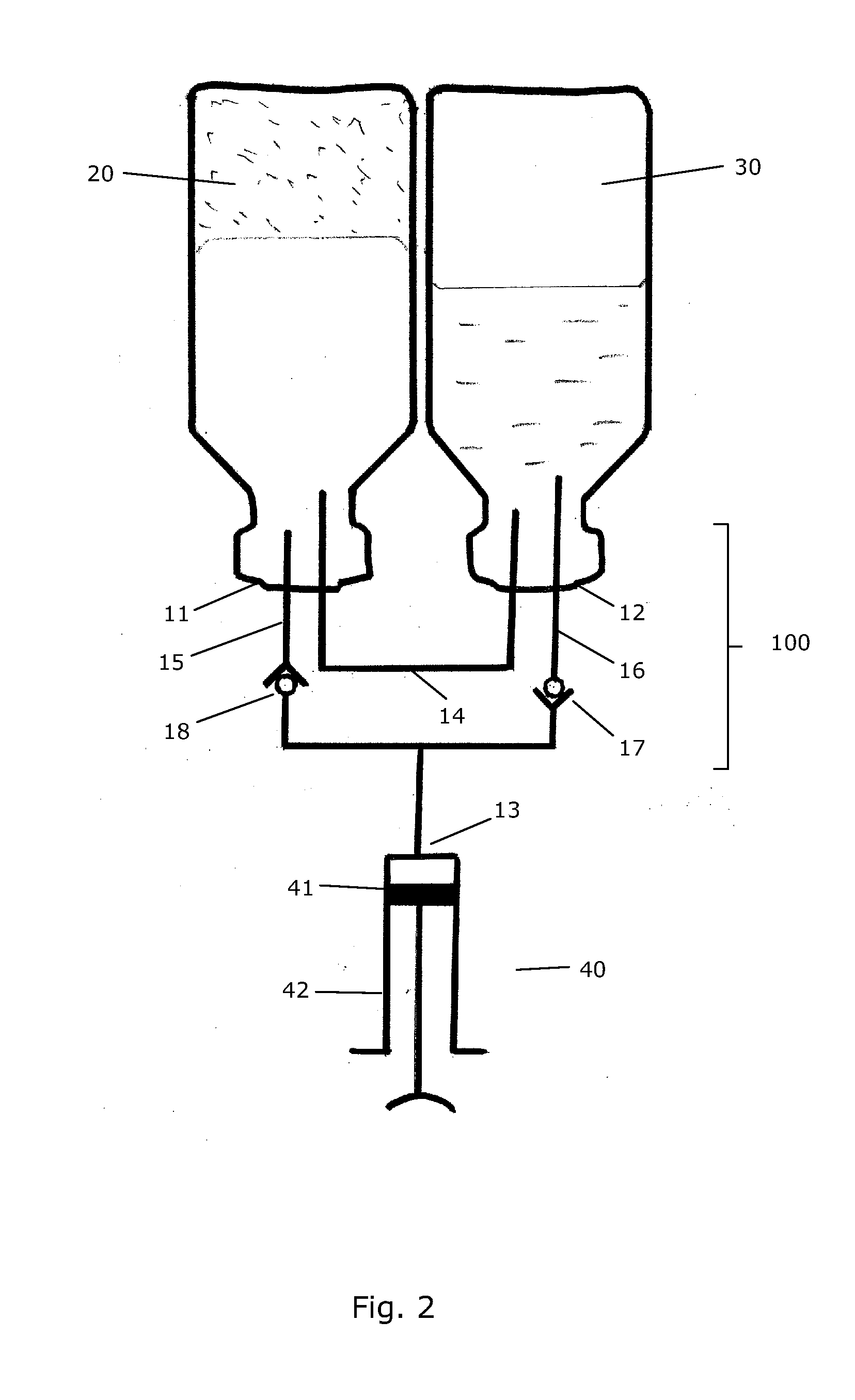

Transfer System for Forming a Drug Solution from a Lyophilized Drug

InactiveUS20090099547A1Simple but efficientInfusion syringesPharmaceutical containersDrugs solutionTransfer system

A transfer system (100, 100′, 100″) adapted to allow first contents of a first container (20) and second contents of a second container (30) to mix to form a material. The mixed material is retrieved to a syringe (40). The transfer system (100, 100′, 100″) comprises first (17) and second (18) flow control members for controlling fluid flow between the containers (20, 30) and the syringe (40). The invention further relates to a drug mixing kit comprising a container unit containing first and second containers, and a transfer unit comprising ports for receiving the containers and a syringe and a number of flow channels. The container unit and the transfer unit are adapted to be coupled together to form a drug mixing kit.

Owner:NOVO NORDISK AS

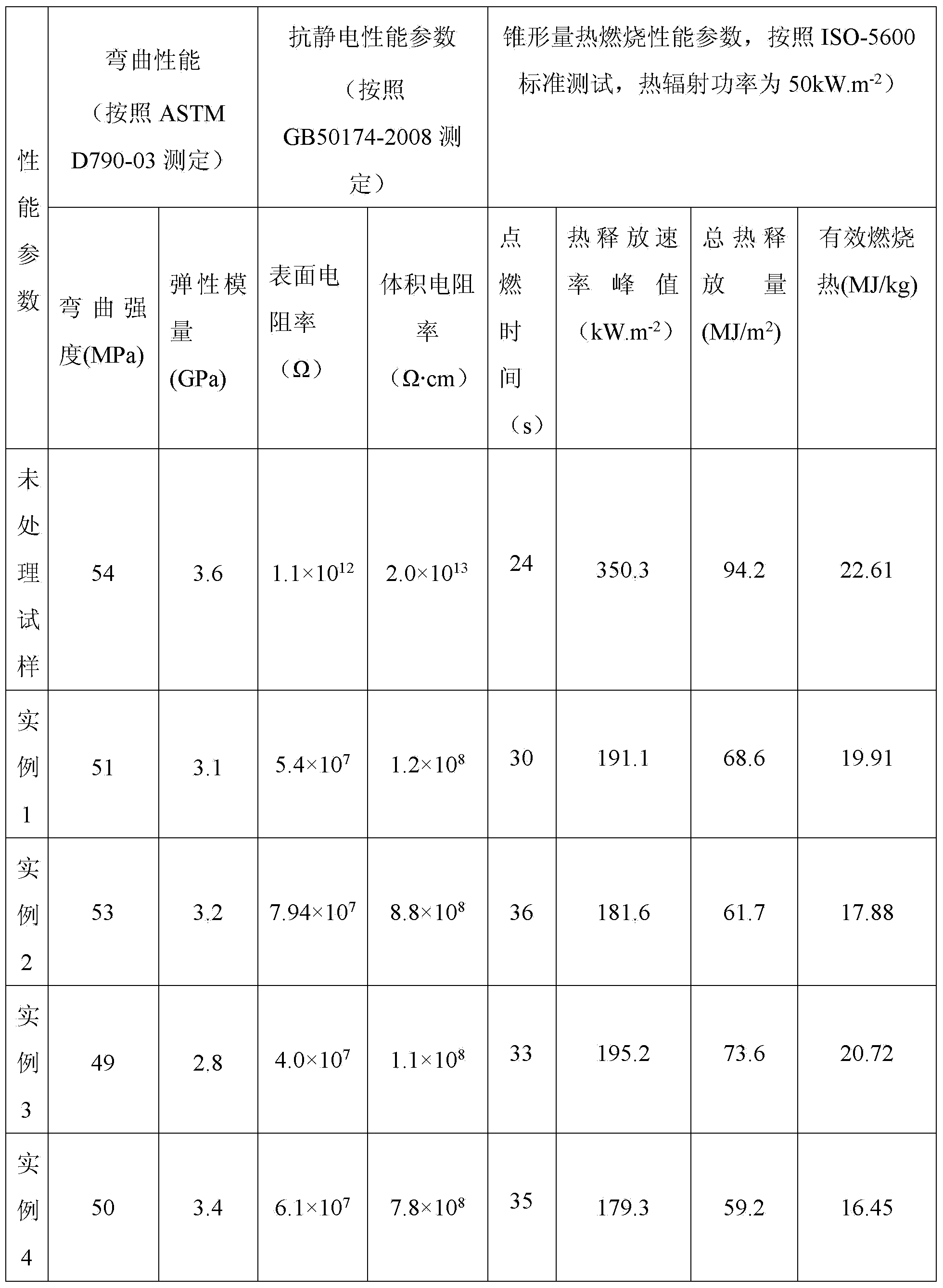

Flame-retardant and antistatic wood-plastic composite material and preparation method thereof

ActiveCN104327530AAchieve flame retardant and antistatic effectImprove flame retardant performanceThermoplasticFiber

The invention discloses a flame-retardant and antistatic wood-plastic composite material and a preparation method thereof and relates to a wood-plastic composite material and a preparation method thereof. The invention aims at solving the problems of relatively poor flame retardance and relatively high cost of the existing antistatic wood-plastic composite material. The wood-plastic composite material is prepared from the following components in parts by weight: a lignocellulosic material, thermoplastic, a lubricant, an antistatic agent, a flame retardant, a coupling agent and an inorganic filler. The method comprises the following steps: 1) performing hot mixing on the lignocellulosic material, the thermoplastic and the lubricant to obtain a hot-mixed material; 2) putting the hot-mixed material into a cold mixing machine for cold mixing, and adding the weighed antistatic agent, the flame retardant, the coupling agent and the inorganic filler into the cold mixing machine for re-mixing when the temperature is lowered to 40-60 DEG C to obtain a premix; 3) putting the premix into a twin-screw extruder to perform melting, mixing and granulation; and 4) performing extrusion molding or thermoforming to prepare the flame-retardant and antistatic wood-plastic composite material. The flame-retardant and antistatic wood-plastic composite material is used in the fields of indoor buildings, decorations, decoration materials and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

High thermal conducting composite material and preparation method thereof

InactiveCN101775213AImprove thermal conductivityEasy to processHeat-exchange elementsGlass fiberMixed materials

This invention relates to a high thermal conducting composite material for injecting or extrusion molding, which is prepared from the following components in parts by weight: 100 parts of plastic substrate, 30 to 100 parts of thermal conducting filler with a diameter between 50 to 300 microns, 0 to 50 parts of thermal conducting filler with a small diameter between 1 to 10 microns, 10 to 50 parts of fiberglass or silicon whisker, 0 to 5 parts of coupling agent and 0 to 8 parts of additive. The preparation of the high thermal conducting composite material comprises the following steps: adding the coupling agent to the thermal conducting filler with a small diameter and the thermal conducting filler with a big diameter respectively to do surface treatment for later use; putting the plastic substrate material, the processed thermal conducting filler with a big diameter and other additives to a super mixer to mix for 1 to 5 minutes; adding the processed thermal conducting filler with a small diameter into the super mixer to mix for 2 to 3 minutes; putting the mixed material into a feeding bucket of a twin screw extruder; adding the fiberglass into a glass fiber orifice; and pelleting after melting and extruding. The composite material prepared by the invention has good thermal conducting property and processing property.

Owner:黄晓峰

3D printing material having self-cleaning antibacterial function as well as preparation method and application of 3D printing material

The invention discloses a 3D printing material having a self-cleaning antibacterial function as well as a preparation method and an application of the 3D printing material. The 3D printing material consists of the following components: 70-85 parts of a high-molecular polymer, 1-5 parts of pigment powder, 1-5 parts of inorganic filler, 0.5-1.5 parts of a nanometer antibacterial agent and 10-20 parts of a binding material. The 3D printing material having the self-cleaning antibacterial function is prepared by the following steps: uniformly mixing the components; adding the uniformly mixed materials to a single-screw plastic extruder, extruding, cooling and shaping, drying, drawing and winding. The 3D printing material disclosed by the invention is excellent in toughness and mechanical property, and furthermore the 3D printing material is good in self-cleaning and antifouling properties; and the 3D printing material has high application potential.

Owner:GUANGZHOU FEISHENG HIGH POLYMER MATERIAL CO LTD +1

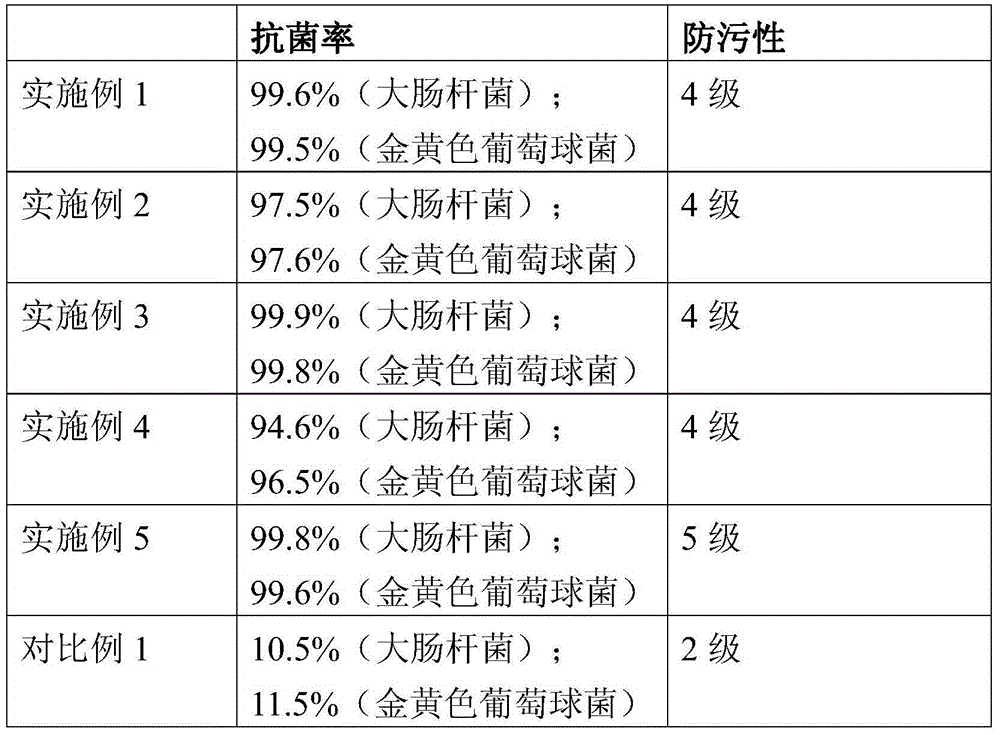

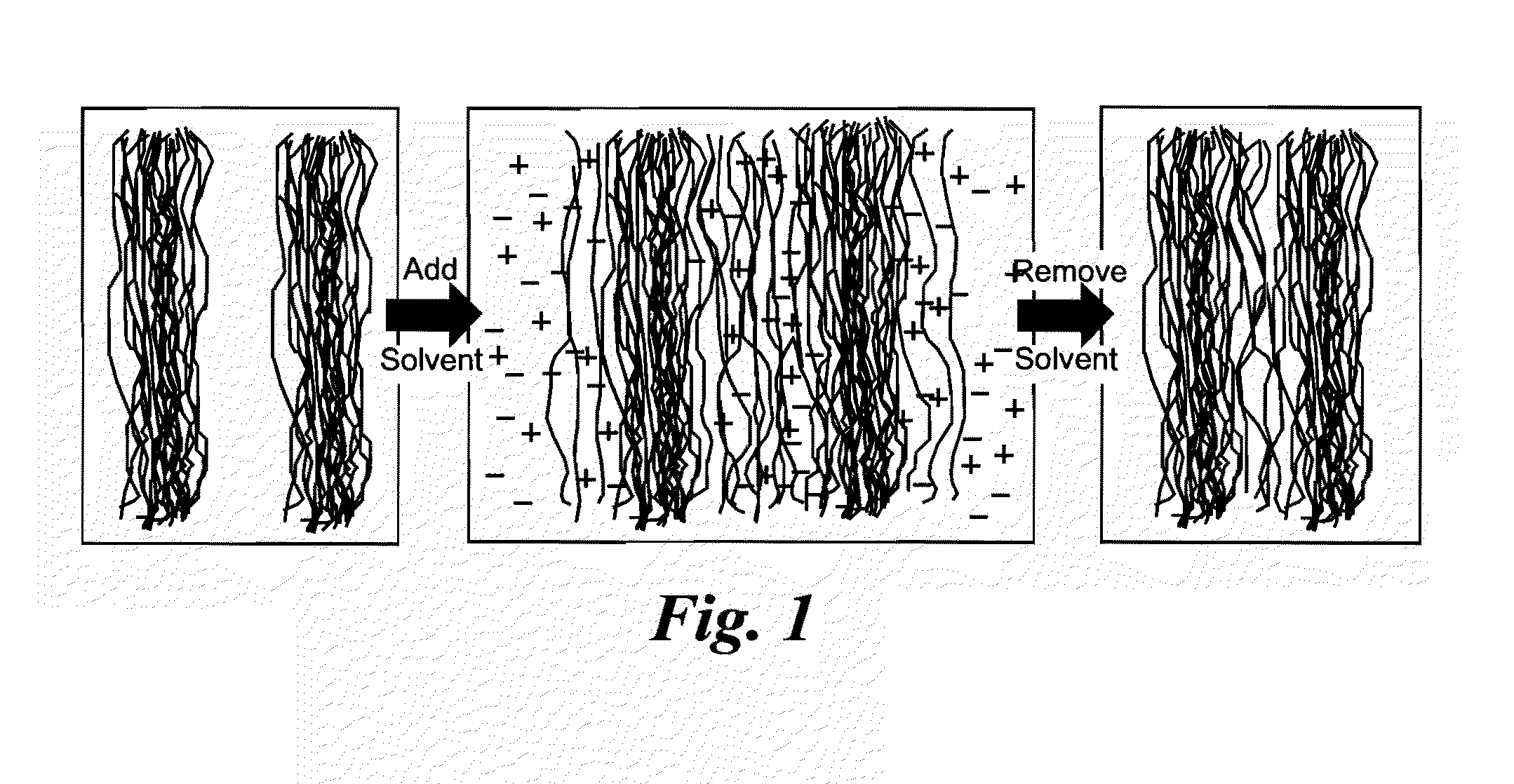

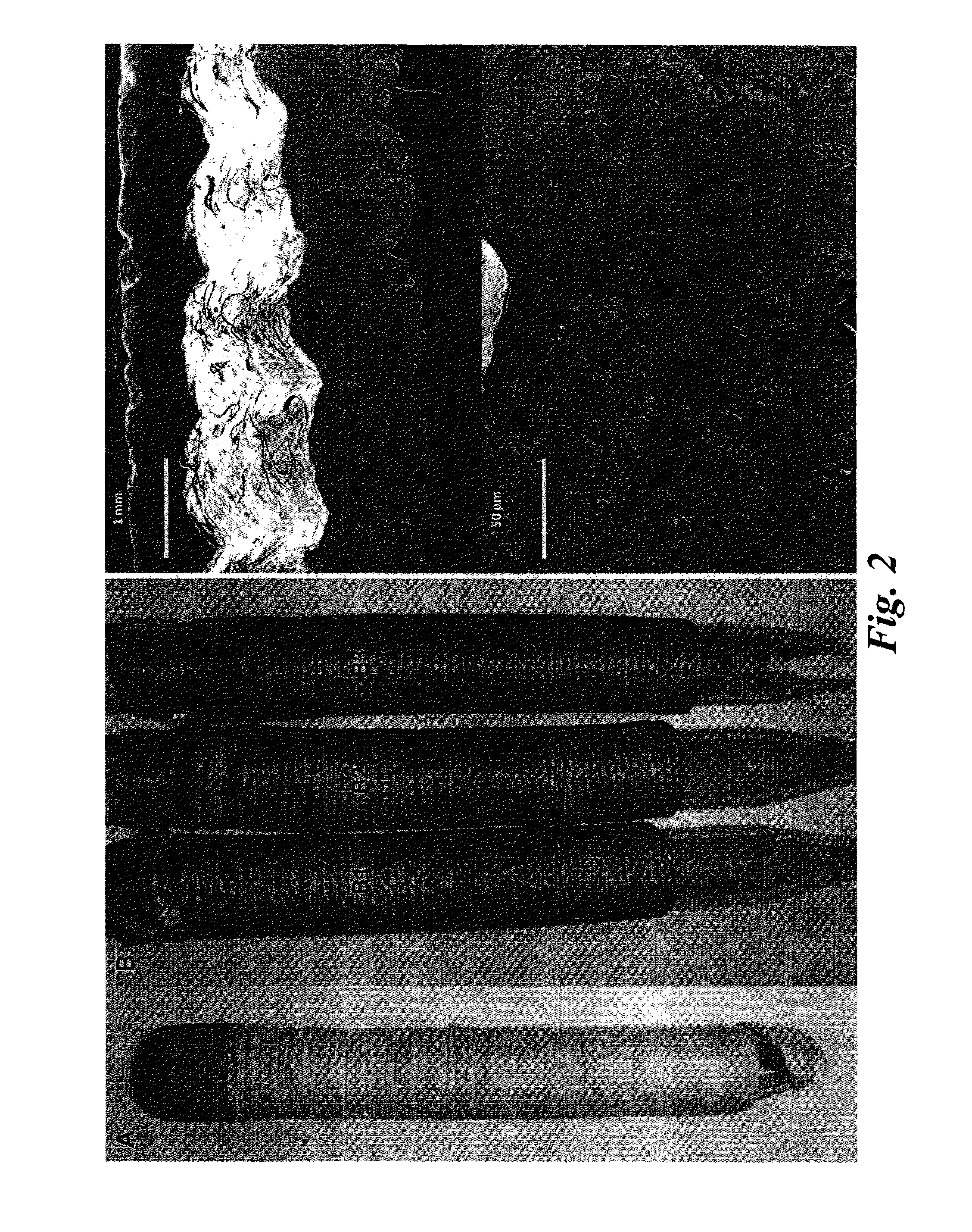

Natural fiber welding

ActiveUS8202379B1Increase material densitySmall surface areaAdhesive processesLaminationPolymer scienceMixed materials

Natural fiber welding is a process by which individual fibers are swollen by an appropriate ionic liquid-based solvent system to form a congealed network. Manipulated fibrous materials may be either composed of natural polymers such as cellulose, hemicellulose, silk, et cetera, or synthetic polymers, or mixed materials. The process is principally controlled by the composition of the solvent system which includes an ionic liquid solvent plus additives such as water, methanol, et cetera. Other conditions such as the amount and placement of solvent, as well as time, temperature, and pressure control the extent to which neighboring fibers are fused. Only the material at the outer surface of fibers need be sufficiently mobile to merge with that of neighboring fibers. Material in the fiber core may be left in the native state by controlling process variables. Fibers form a congealed network upon removal of the ionic liquid-based solvent.

Owner:US SEC THE AIR FORCE THE

Cement-base dual-liquid slip-casting material

The invention relates to a kind of pair-slurry affusing material prepared with cement as basic raw material. It is comprised of two kinds of dry powdery mixed materials A and B of affusing slurry pair-liquid formed after adding water. Their weight percents are respectively: mixed material A: sulfur aluminate cement 30% - 98.1%, retarder citric acid 0.1% - 0.5%, flocculant polyacrylamide 0% - 0.8%, water-reducing agent FDN 0.6% - 1.5% and inorganic padding pulverized coal ash 0% - 69.1%; mixed material B: Portland cement 20% - 88%, land plaster 6% - 15%, flocculant UWN 0% - 0.7%, accelerator lithium carbonate 0.4% - 1.0%, water-reducing agent FDN 0.5% - 1.3%, calcareousness 2.0% - 5.0% and inorganic padding pulverized coal ash 0% - 70.8%.

Owner:张振秋

Compound amino acid organic fertilizer and production method of compound amino acid organic fertilizer

The invention disclose a compound amino acid organic fertilizer, which is characterized in that the compound amino acid organic fertilizer consists of the following ingredients in parts by weight: 5 to 10 of compound amino acid, 0.3 to 0.5 of microbial yeasts, 16 to 29 of inorganic fertilizers, 5 to 10 of humic acid fertilizers and 0.2 to 1 of trace elements. A production method of the compound amino acid organic fertilizer comprises the following steps that: firstly, compound amino acid water solution, the microbial yeasts and the humic acid fertilizers are respectively prepared, then, inorganic compounds containing boron, copper, iron, manganese and zinc are added into the compound amino acid water solution, and the chelation is carried out at a temperature being 80 to 110 DEG C so that the mixture becomes free-state chelated amino acid salt; after the metering, 10 to 50kg of raw materials are added into each ton of farmyard manure to be mixed, then, the mixed materials are placed into a warehouse for natural stacking and curing for 3 to 5 days and can be pelletized and packed to leave factories. The compound amino acid organic fertilizer can be used as a base fertilizer and an additional fertilizer and belongs to a compound organic fertilizer capable of improving the amino acid content of high-quality fragrant rice and fruit and vegetables, improving the fruit and vegetable quality and improving the sugar content of sugarcanes.

Owner:GUANGXI YUXIN BIOLOGICAL TECH

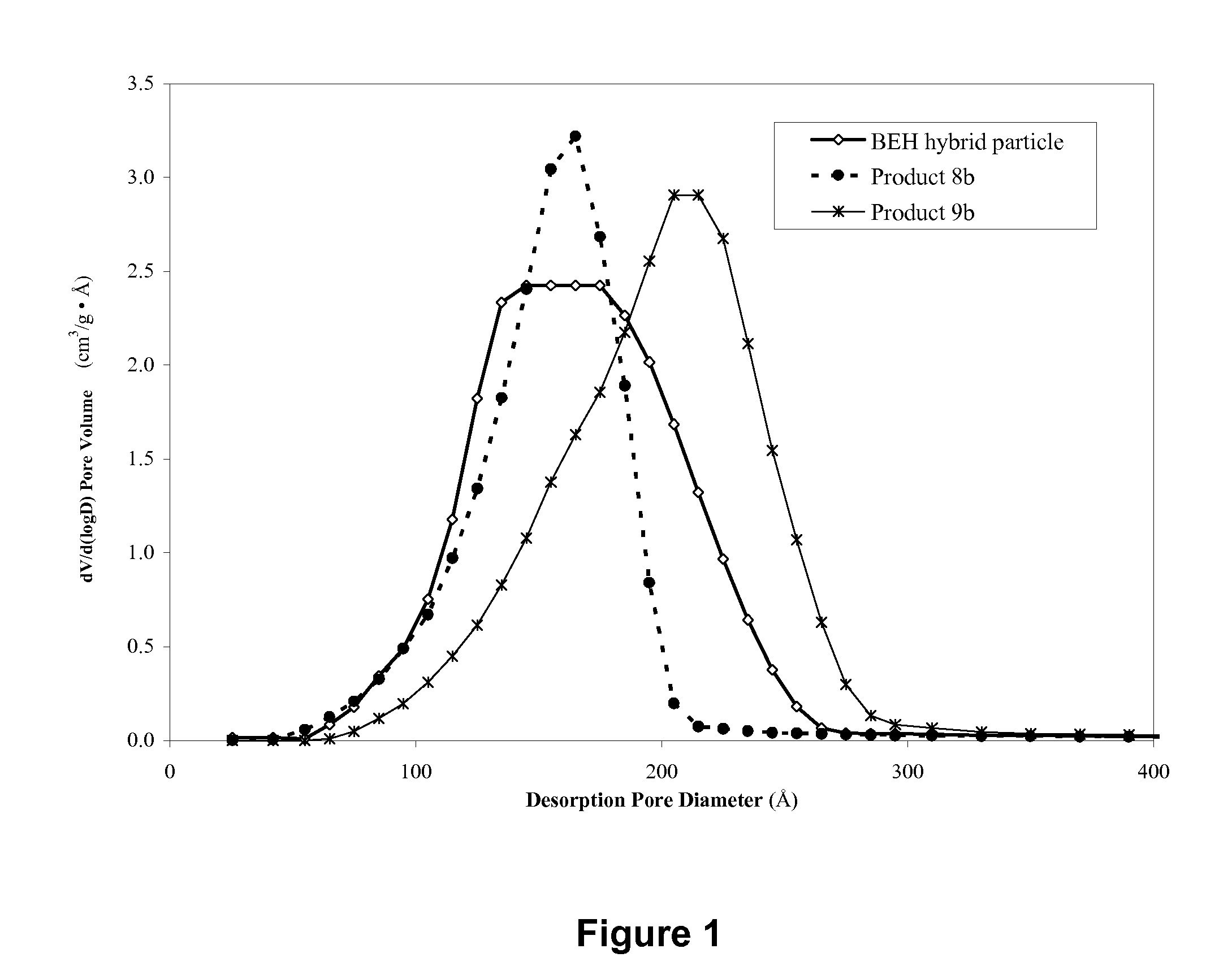

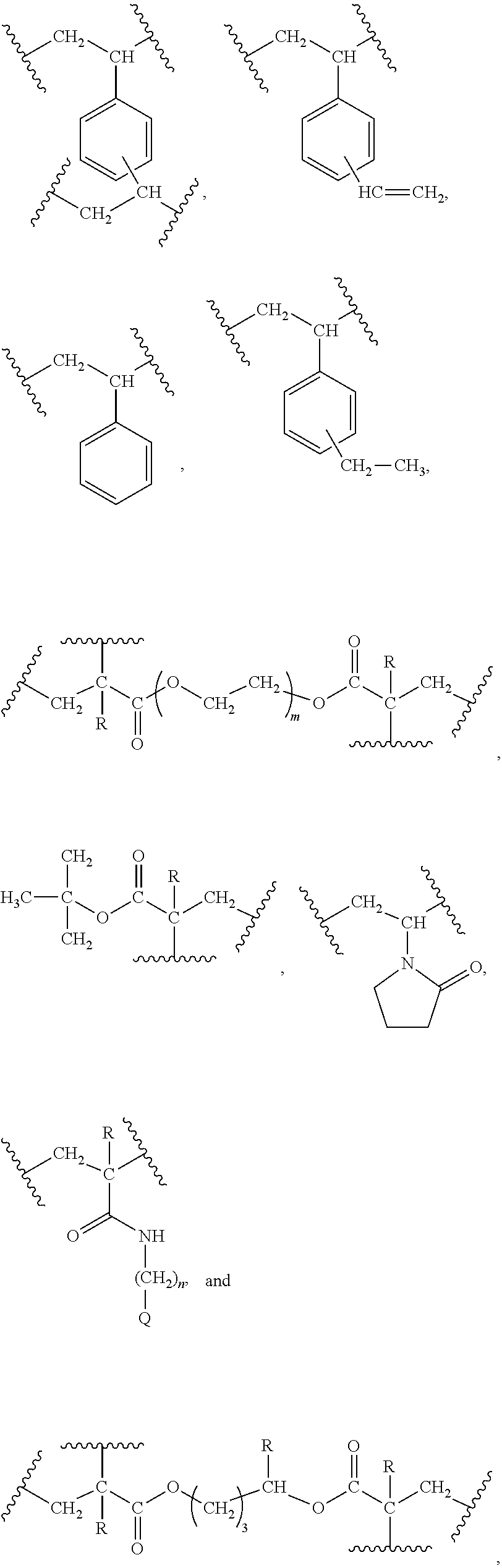

Hybrid inorganic/organic materials having novel surface modification; process for the preparation of inorganic/organic hybrid materials; and use of said particles for chromatographic separations

ActiveUS20120055860A1Enhancing oneMany of characteristicIon-exchange process apparatusSemi-permeable membranesChromatographic separationIon exchange

The present invention provides novel chromatographic materials, e.g., for chromatographic separations, processes for their preparation and separations devices containing the chromatographic materials. The preparation of the inorganic / organic hybrid materials of the invention wherein a surrounding material is condensed on a porous hybrid core material will allow for families of different hybrid packing materials to be prepared from a single core hybrid material. Differences in hydrophobicity, ion-exchange capacity, surface charge or silanol activity of the surrounding material may be used for unique chromatographic separations of small molecules, carbohydrates, antibodies, whole proteins, peptides, and / or DNA.

Owner:WATERS TECH CORP

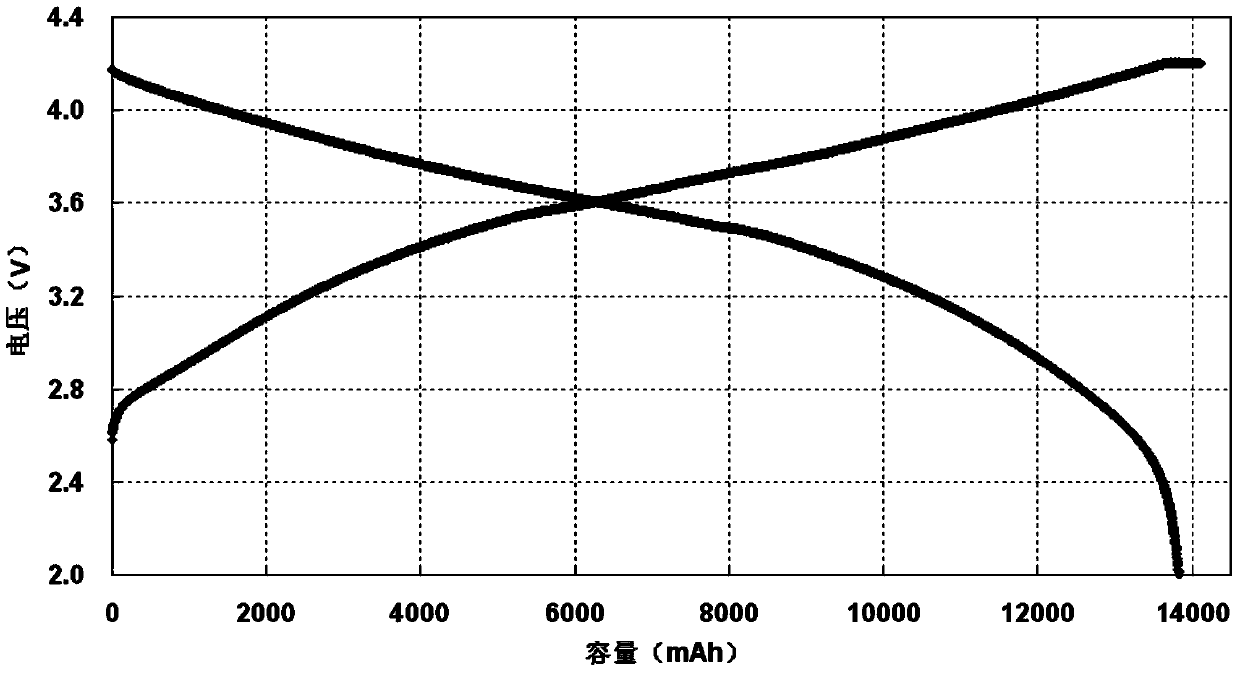

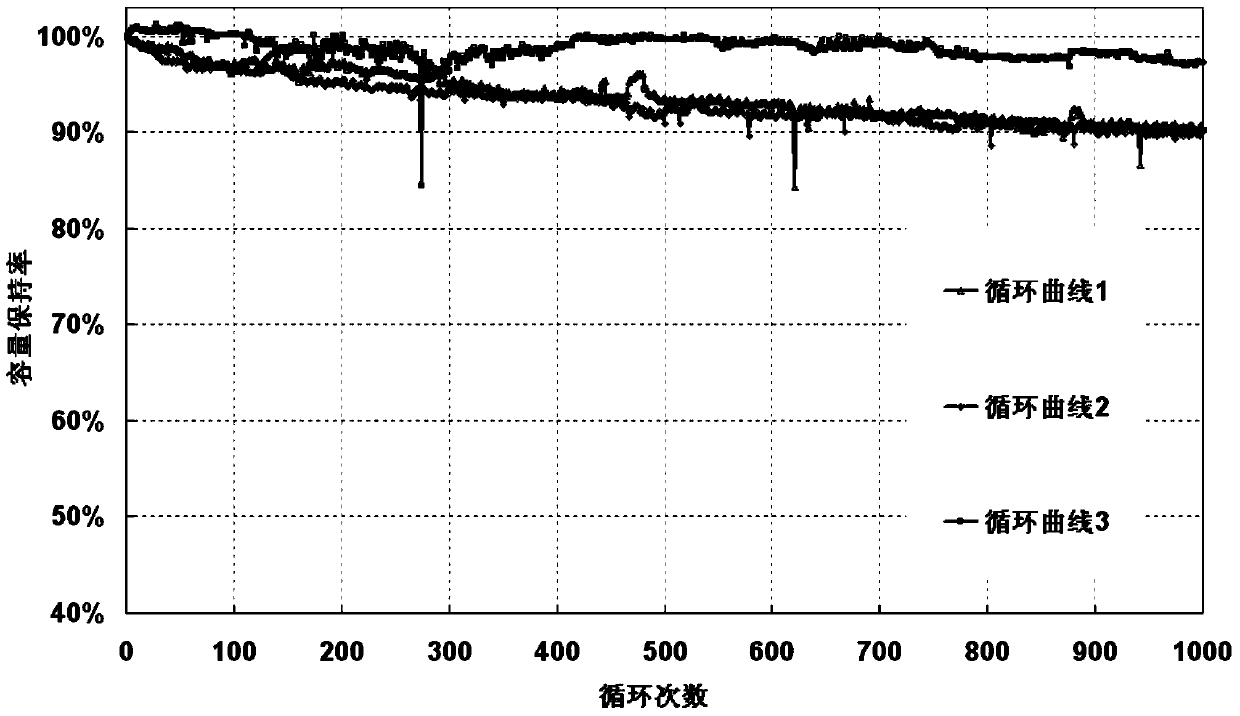

Graded high-nickel ternary anode material, and preparation method and application thereof

InactiveCN109888235AImprove compactionImprove cycle stabilityCell electrodesSecondary cellsSingle crystalMixed materials

The invention discloses a graded high-nickel ternary anode material, and a preparation method and an application thereof. The graded high-nickel ternary anode material is prepared by the following method: 1) mixing a high-nickel polycrystalline precursor with anhydrous LiOH and a doping additive, performing sintering, mixing the obtained product with a coating additive, and performing sintering toobtain a high-nickel polycrystalline material; 2) mixing a ternary monocrystalline silicon precursor with a lithium source and the doping additive, performing sintering, mixing the obtained product with the coating additive, and performing sintering to obtain a ternary monocrystalline silicon material; and 3) mixing the high-nickel polycrystalline material with the ternary monocrystalline siliconmaterial, or mixing the mixed material with the coating additive, and then performing sintering. The invention further discloses an application of the graded high-nickel ternary anode material in lithium batteries. The graded material prepared by the method provided by the invention has higher compaction and cycle stability than the single polycrystalline material, has higher capacity than the single monocrystalline silicon, and the gas production and service life problems of the battery can be effectively improved after the grading modification.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

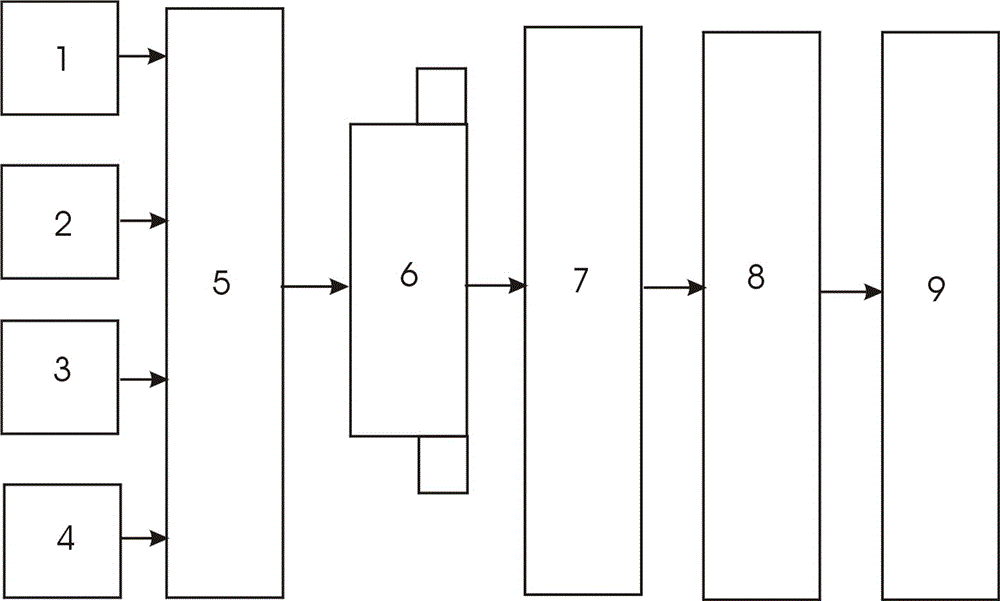

Method for forming fiber reinforced composite parts

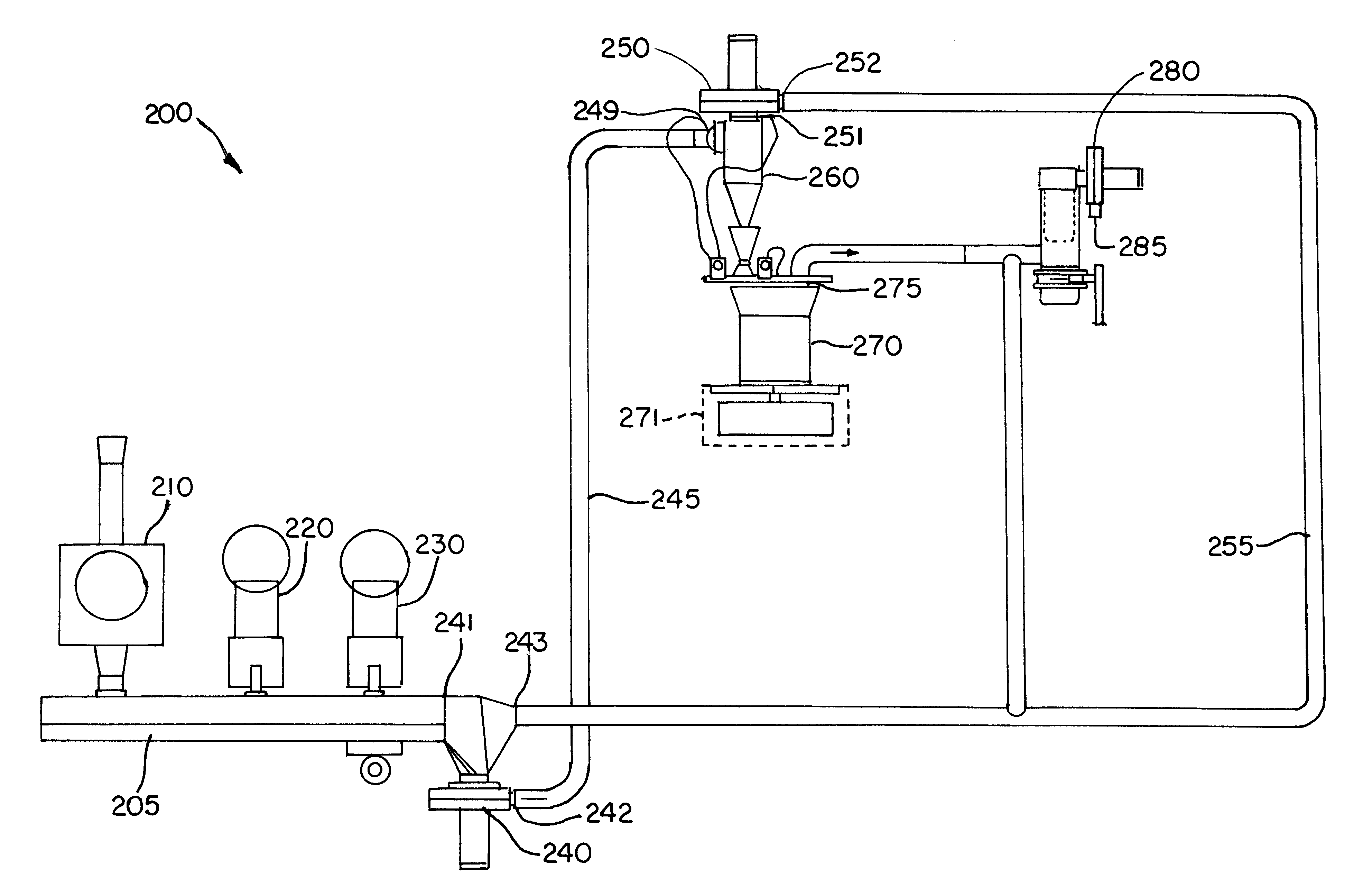

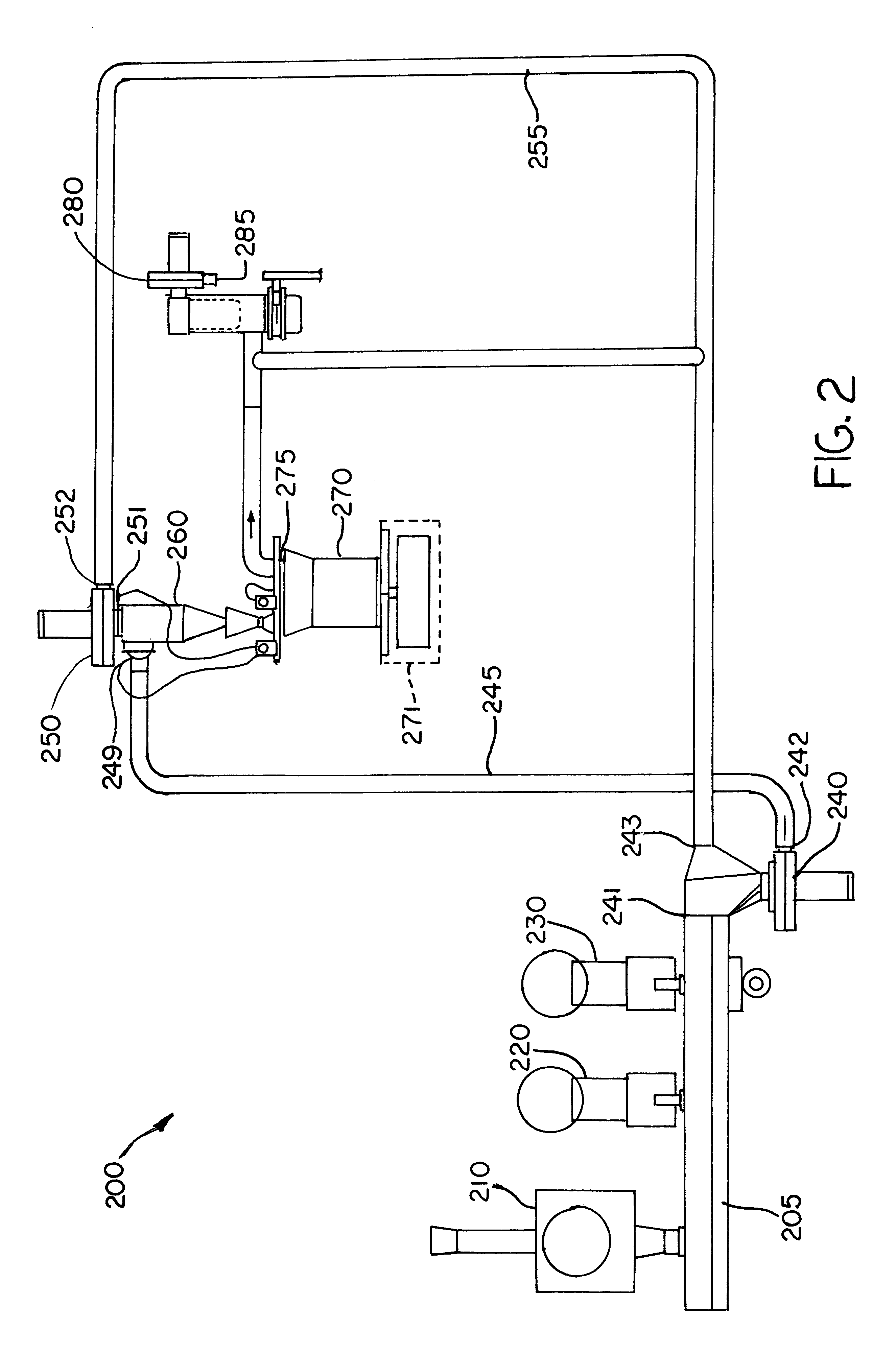

A method and apparatus for combining raw fibrous and binding materials in a single mixing step (Step S3), followed by consolidation (Step S5) so as to greatly shorten the overall cycle time to a finished fiber-reinforced composite part. Chopped fibrous materials and binder materials are deposited sequentially onto a belt conveyor (Step S2) so that the materials are successively layered, one on top of each other in a predetermined ratio, and subsequently mixed (Step S3) to achieve uniform dispersion throughout. The mixed materials are then deposited into a rotating mold (Step S4) to further ensure uniform dispersion of fibrous and binder materials. Impregnation of the fibrous materials with the binder material occur in-situ as the uniformly mixed materials are heated and subsequently compacted in the mold (Step S5) to obtain the desired shape of the fiber-reinforced composite part.

Owner:HONEYWELL INT INC

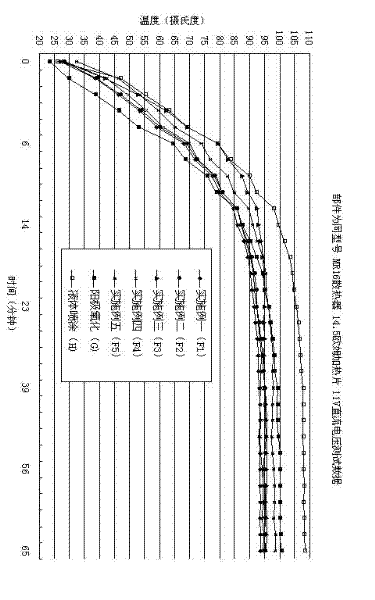

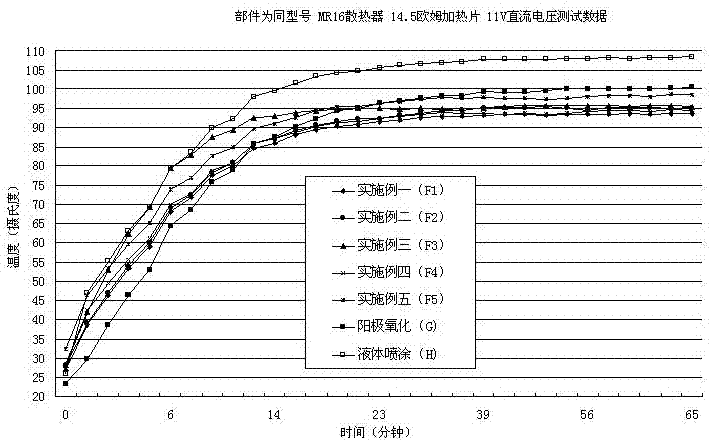

Radiating material and preparation method of radiating material

InactiveCN102181212AImprove cooling effectNo dead endsElectrophoretic coatingsPolyurea/polyurethane coatingsThermal insulationMixed materials

The invention discloses a radiating material and a preparation method of the radiating material. The radiating material comprises a component A and a component B, wherein the component A is an ionic modified resin, or a mixture of more than one ionic modified resin, or a composite of more than one ionic modified resin; and the component B is one or more mixed material with the far infrared emission rate greater than 0.80 or thermal conduction coefficient greater than 5W / m.K, and grain size smaller than 30mu. In use, the radiating material can not only improve the radiating performance of metal parts, but also achieve certain other special functions (for example, self-cleaning, infrared stealth, thermal insulation, corrosion resistance, thermostability, self-lubricating, insulation and other properties), and can be prepared into most needed color according to requirement.

Owner:东莞市中科智恒新材料有限公司

Power and energy storage lithium-ion battery and preparation method thereof

ActiveCN103441305AImproved gram capacity playIncrease capacityFinal product manufactureElectrolyte accumulators manufactureGramEngineering

The invention relates to a preparation method of a power and energy storage lithium-ion battery. A negative active substance of the power and energy storage lithium-ion battery comprises soft carbon, hard carbon, a mixed material of soft carbon and graphite and a mixed material of hard carbon and graphite. The designing method of the battery comprises the steps of designing the gram volume of the negative active substance as the primary lithium-embedding gram volume, designing the gram volume of the positive active substance as the primary lithium-removal gram volume, designing the ratio of the capacity of the positive electrode and the capacity of the negative electrode to be (1: 1) to (1.5: 1). By adopting the designing method, the capacity and comprehensive performance of the battery can be remarkably improved, and excellent lithium-embedding and lithium-removal capacity of the soft carbon material and the hard carbon material can be adequately exerted. Compared with the existing lithium battery technology, the prepared power lithium battery has long service life, high multiplying power, high safety performance and excellent low-temperature performance and can be widely applied to the fields such as electric tools, various portable devices, spaceflight, starting power supply and the like.

Owner:BTR NEW MATERIAL GRP CO LTD

Resin material, preparation method and applications of resin material

The invention belongs to the technical field of high-polymer materials and discloses a resin material, a preparation method and applications of the resin material. The resin material disclosed by the invention comprises the following components in parts by weight: 70-95 parts of high-polymer resin, 1-15 parts of conducting material, 3-14 parts of compatilizer, 0.5-1 part of antioxidation aid and 0.5-1 part of processing aid. The preparation method for the resin material disclosed by the invention comprises the following steps of: weighing 70-95 parts of high-polymer resin, 1-15 parts of conducting material, 3-14 parts of compatilizer, 0.5-1 part of antioxidation aid and 0.5-1 part of processing aid; putting in a high-speed mixing machine and fully mixing; delivering a mixed material into a twin-screw extruder by using a metering material conveying device; fully mixing the material under the shearing actions of screws; performing extrusion, bracing, cooling and grain cutting on a molten blend; and packaging into a finished product. The resin material disclosed by the invention has an anti-static dustproof effect, is excellent in surface effect and can be used for manufacturing card readers or electrical equipment enclosures and the like.

Owner:HEFEI GENIUS NEW MATERIALS

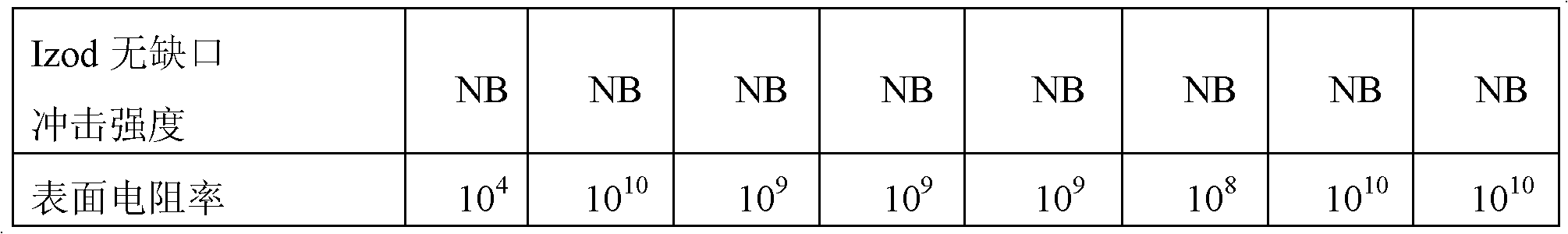

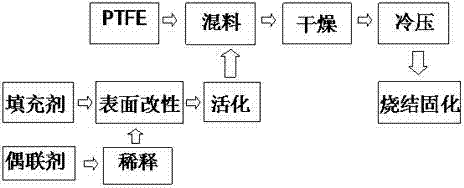

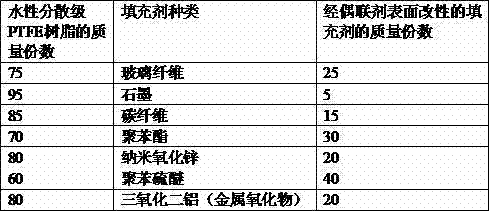

Fluorine-containing polymer mixing material and method for preparing bulb buffer ball keyway by same

InactiveCN102952360AGood chemical stabilityGood self-lubricating performanceControl armMixed materials

The invention discloses a fluorine-containing polymer mixing material and a method for preparing a bulb buffer ball keyway by the same. The fluorine-containing polymer mixing material is prepared by mixing fluorine-containing polymer resin with filler modified by a coupler, and comprises the materials in parts by mass as follows: 60-99 parts of fluorine-containing polymer resin and 1-40 parts of modified filler. The filler meets the condition that the filler is stably sintered at a temperature above the melting temperature of the resin and the granularity is smaller than or equal to 150 microns; the filler does not absorb moisture; and the filler is not clustered under the sintering condition and is not reacted with the polymer. The coupler accounts for 5-40% of the filler by mass percentage. The material has excellent chemical stability, self-lubricating property, noninflammability, resistance to atmospheric aging and high and low temperature adaptability and the like as well as higher mechanical strength. The hardness can be improved through modification and the material is used to prepare wear-resisting products. The bulb buffer ball keyway is prepared from the material so that a suspension type direction control arm assembly of an automobile with high mechanical strength, good wear-resistance and a long service life is further obtained.

Owner:浙江国威汽车配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com