Graded high-nickel ternary anode material, and preparation method and application thereof

A positive electrode material and high-nickel technology, applied in the field of graded high-nickel ternary positive electrode material and its preparation, can solve the problems of phase change, service life and safety reduction, cost increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

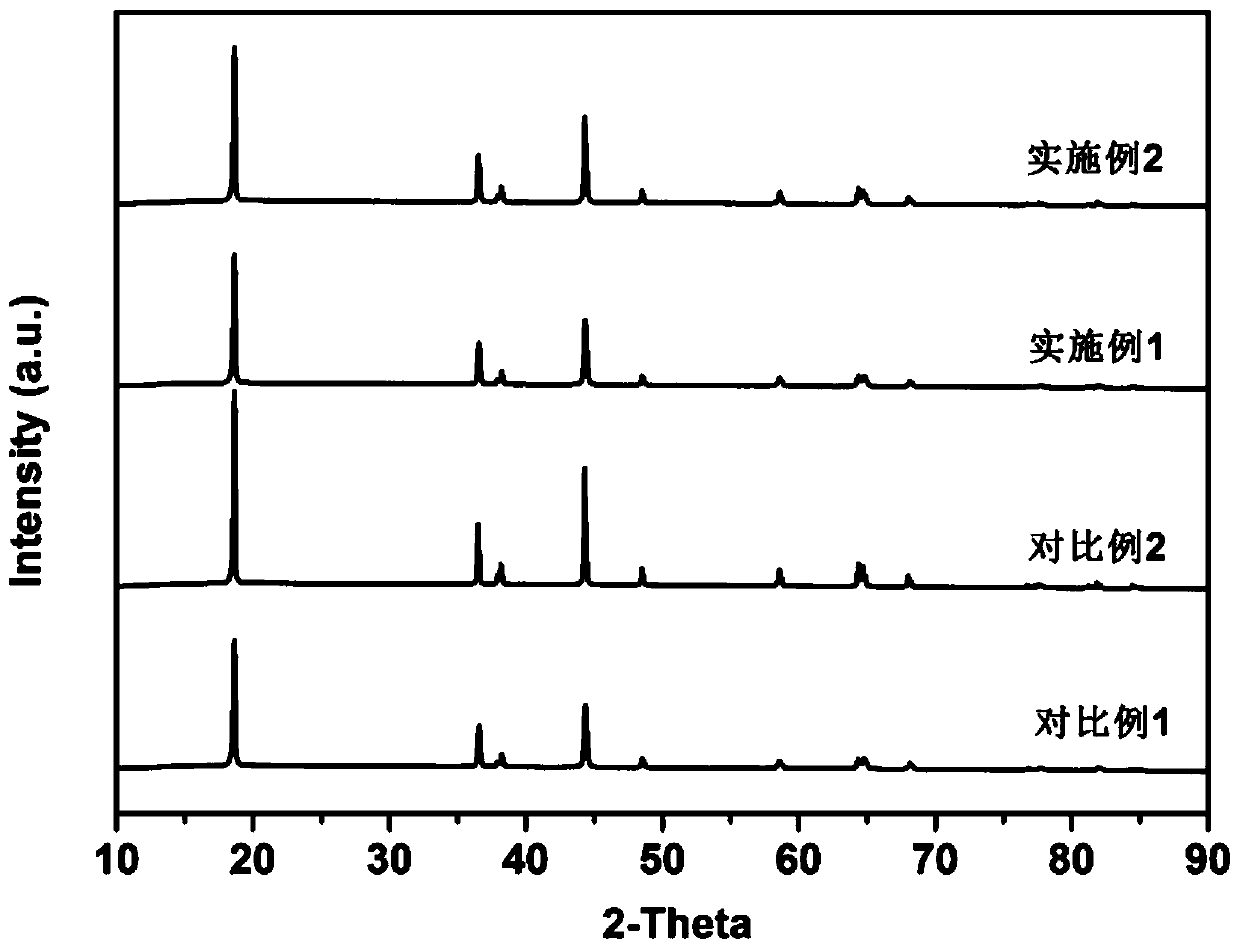

Embodiment 1

[0058] The preparation method of the graded high-nickel ternary cathode material in this example is as follows:

[0059] S1: First select the micropowder LiOH·H with a volume particle size distribution D50 of 15 μm 2 O, dehydrate and dry in a rake vacuum dryer at 150°C for 3 hours to obtain anhydrous LiOH with a D50 of 24 μm;

[0060] S2: Use Ni with a particle size D50 of 12 μm 0.8 co 0.1 mn 0.1 (OH) 2 Anhydrous LiOH obtained from precursor and S1 and 1500ppm additive ZrO 2 Mixed, and at 750°C, 150m 3 Sintered in a roller kiln with oxygen flow rate of / h for 18 hours, then crushed by a mechanical mill, washed with water, centrifuged, dried, and then mixed with 2000ppm additive Al 2 o 3 Mix, and carry out sintering coating at 600°C for 6 hours to obtain polycrystalline LiNi with a secondary average particle size of 12 μm 0.8 co 0.1 mn 0.1 o 2 Material;

[0061] S3: another Ni with D50 at 4μm 0.8 co 0.1 mn 0.1 (OH) 2 Anhydrous LiOH obtained from precursor and S1...

Embodiment 2

[0064] The preparation method of the graded high-nickel ternary cathode material in this example is as follows:

[0065] S1: First select the micropowder LiOH·H with a volume particle size distribution D50 of 12 μm 2 O, dehydrate and dry in a rake vacuum dryer at 160°C for 2 hours to obtain anhydrous LiOH with a D50 of 22 μm;

[0066] S2: Use Ni with a particle size D50 of 10 μm 0.9 co 0.05 mn 0.05 (OH) 2 Anhydrous LiOH obtained from precursor and S1 and 2000ppm additive Sb 2 o 5 Mixed, and at 770°C, 200m 3 Sintered in roller kiln with oxygen flow rate of / h for 16h, then crushed by mechanical mill, washed with water, centrifuged, dried, and added with 1500ppm TiO 2 Mix, and carry out 5h dicalcination coating at 580°C to obtain polycrystalline LiNi with a secondary average particle size of 10μm 0.90 co 0.05 mn 0.05 o 2 Material;

[0067] S3: another Ni with D50 at 4μm 0.5 co 0.2 mn 0.3 (OH) 2 Precursors and Li 2 CO 3 And 1000ppm additive TiO 2 Mixed, and at ...

Embodiment 3

[0070] The preparation method of the graded high-nickel ternary cathode material in this example is as follows:

[0071] S1: First select fine powder LiOH·H with a volume particle size distribution D50 of 13 μm 2 O, dehydrate and dry in a rake vacuum dryer at 150°C for 3 hours to obtain anhydrous LiOH with a D50 of 23 μm;

[0072] S2: Use Ni with a particle size D50 of 12 μm 0.8 co 0.15 Al 0.05 (OH) 2 Anhydrous LiOH obtained from precursor and S1 and 1500ppm additive Y 2 o 3 Mixed, and at 760°C, 100m 3 Sintered in roller kiln with oxygen flow rate of / h for 14h, then crushed by mechanical mill, washed with water, centrifuged, dried, and mixed with 1000ppm additive Al(OH) 3 Mixed and covered with dicalcin at 650°C for 8 hours to obtain polycrystalline LiNi with an average particle size of secondary aggregates of 12 μm 0.8 co 0.15 Al 0.05 o 2 Material;

[0073] S3: Another Ni with D50 at 4.5μm 0.65 co 0.15 mn 0.2 (OH) 2 The precursor was mixed with anhydrous LiOH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com