Patents

Literature

540results about "Domestic seals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

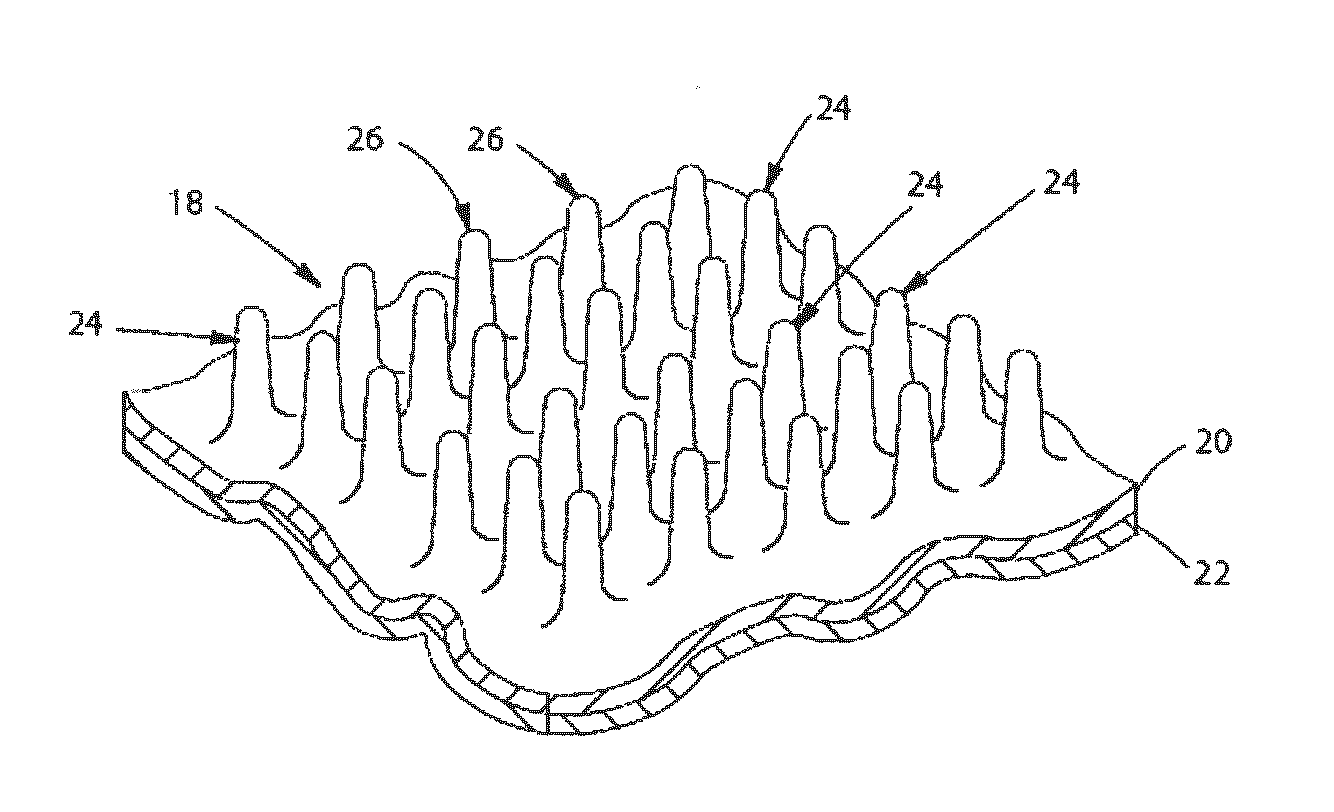

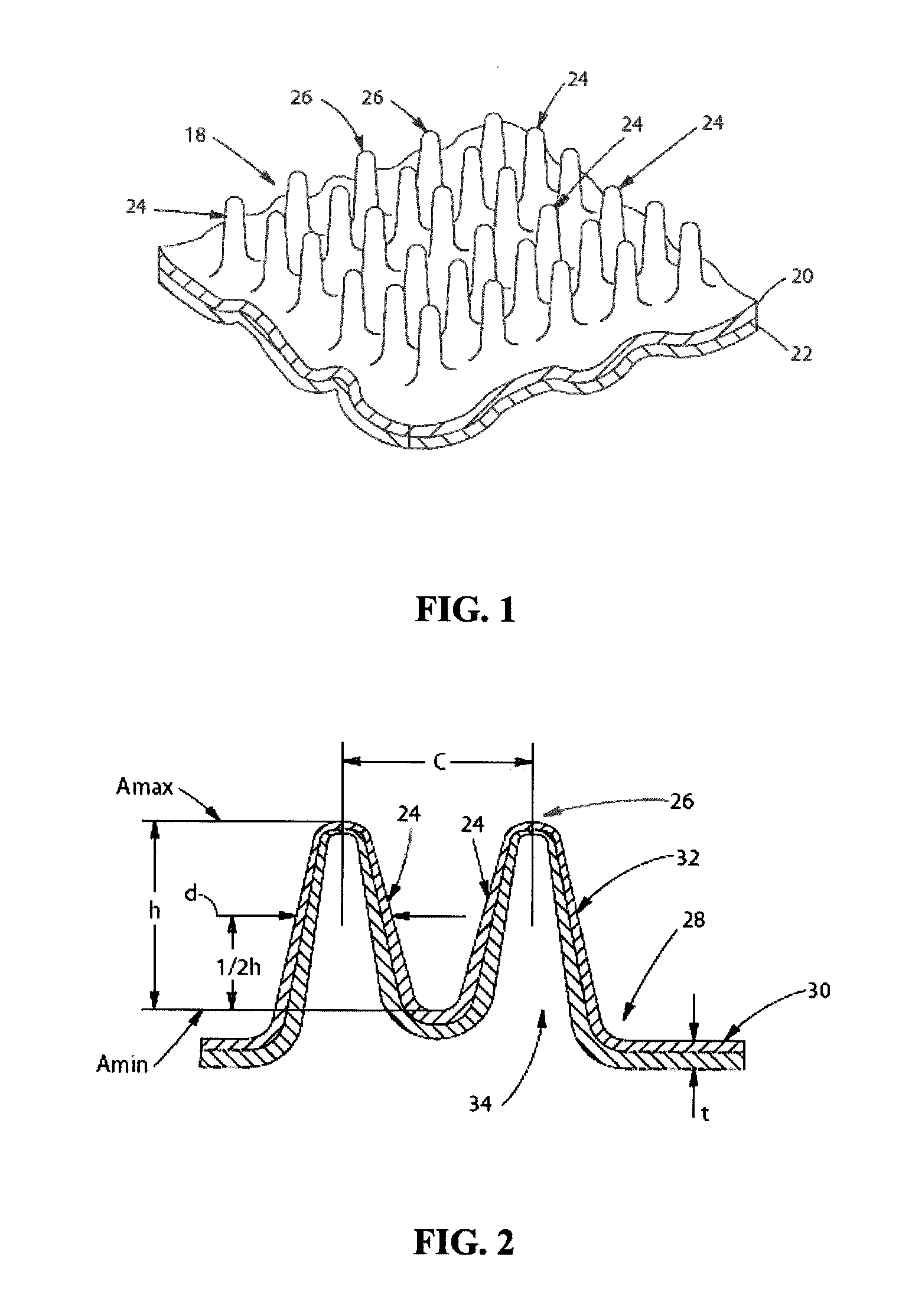

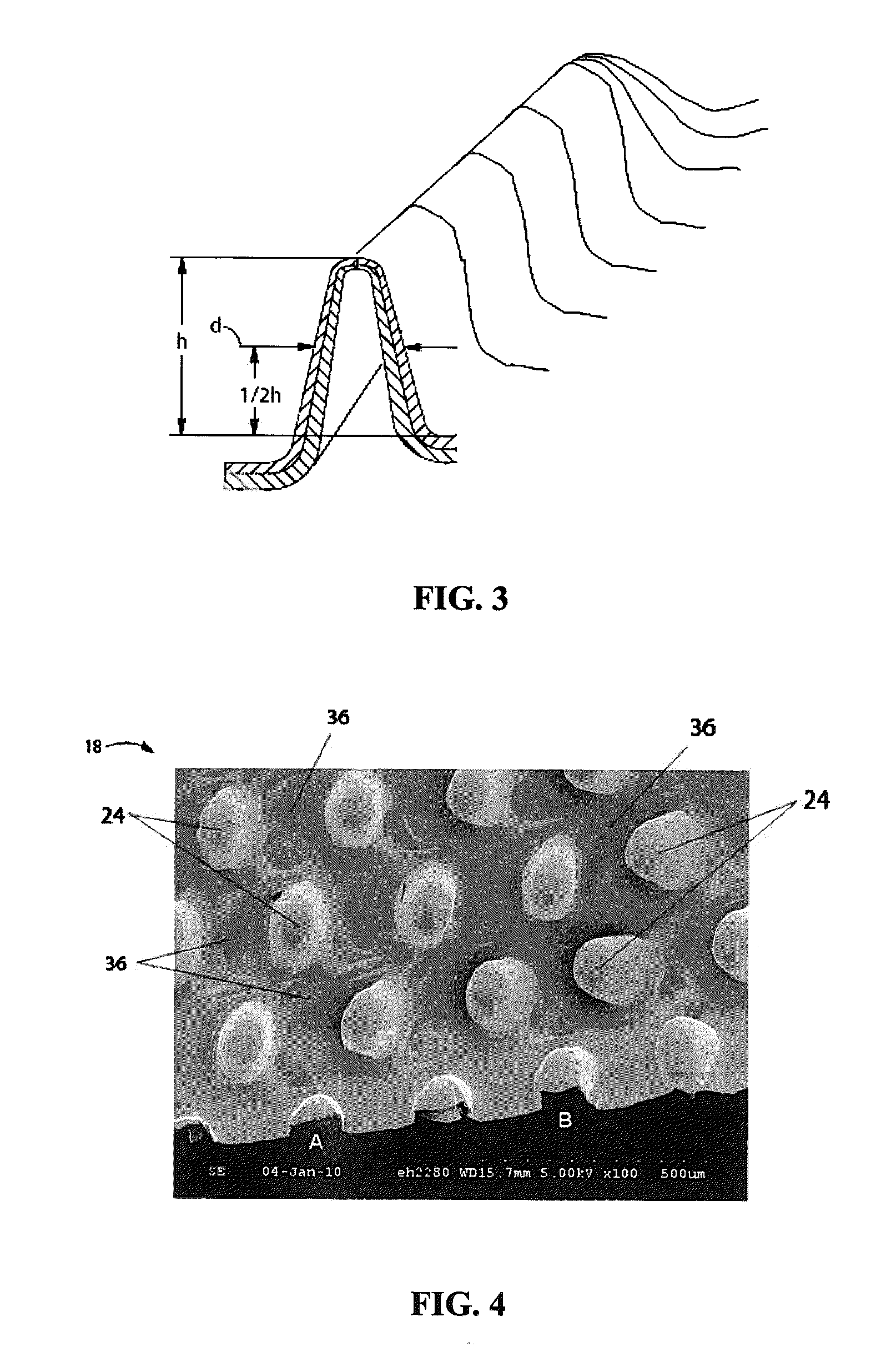

Colored web material comprising a plurality of discrete extended elements

A colored web material comprising a plurality of discrete extended elements. The colored web material comprises a colorant incorporated in the material itself or a colorant disposed on at least one surface of the web material. The discrete extended elements comprise thinned portions at the distal ends and / or along the sidewalls of the discrete extended elements. In one embodiment, the discrete extended elements have a diameter of less than about 500 microns. In one embodiment, the colored web material comprises at least about 95 discrete extended elements per square centimeter. In one embodiment, the discrete extended elements have an aspect ratio of at least about 0.2.

Owner:THE PROCTER & GAMBLE COMPANY

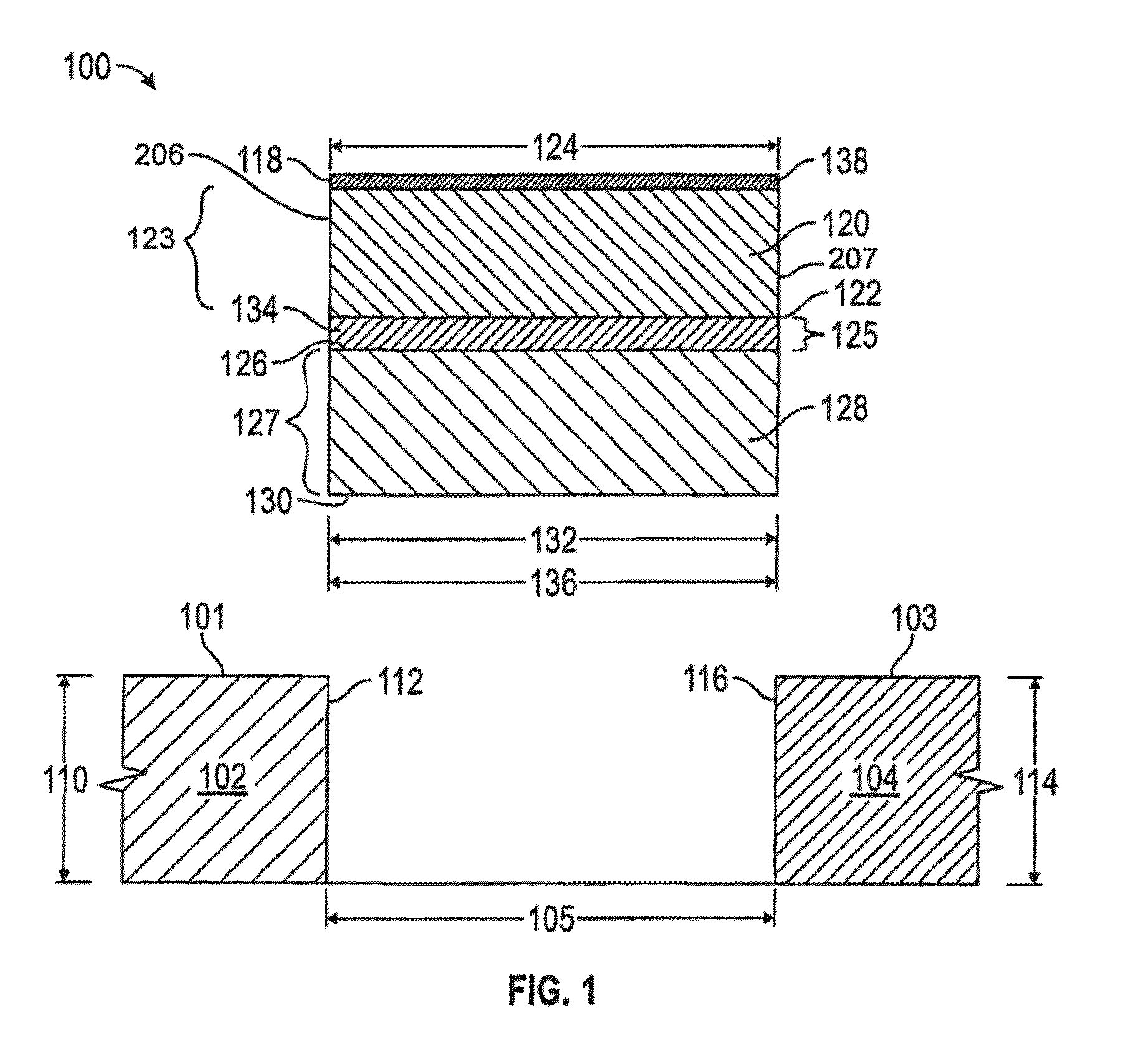

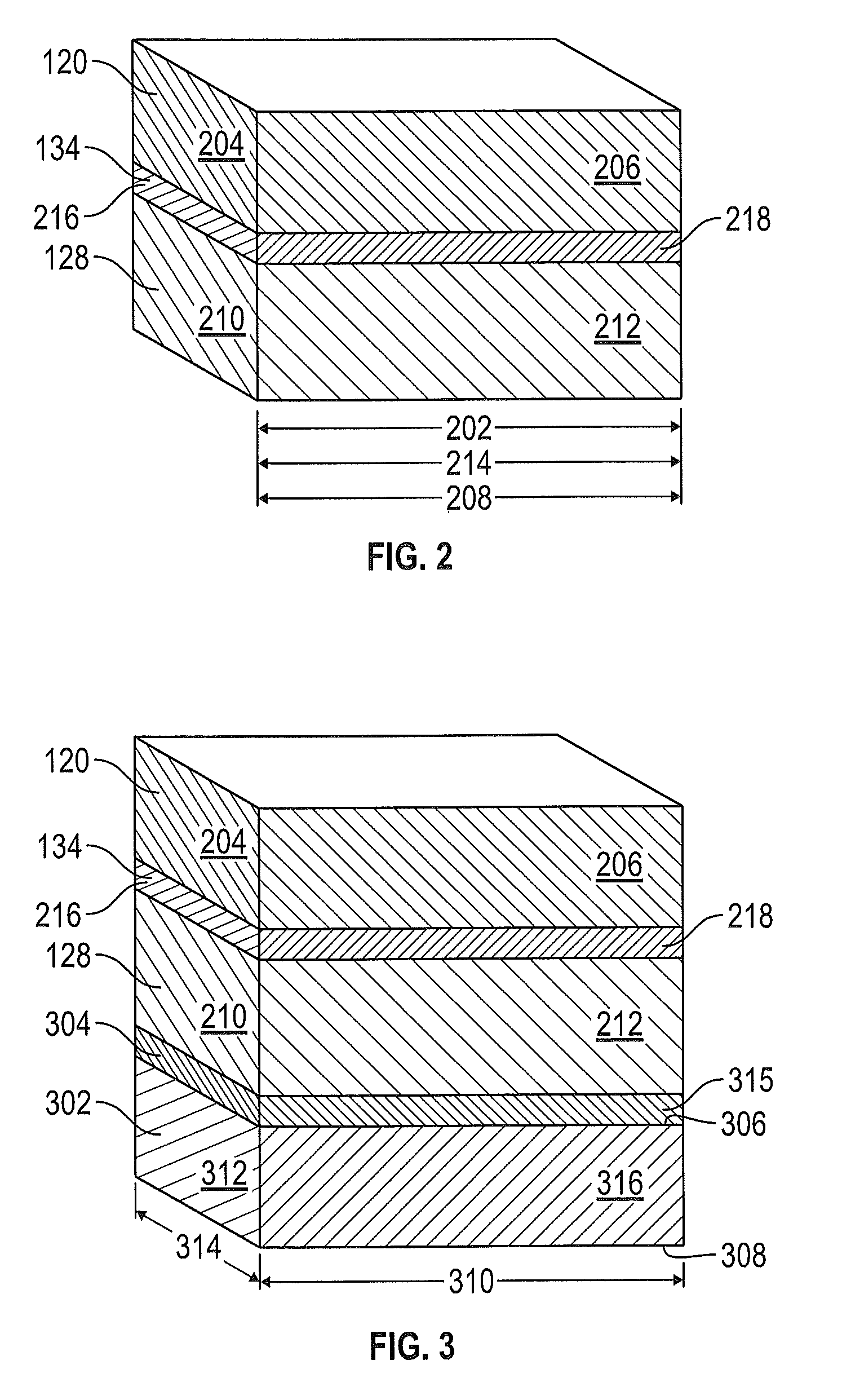

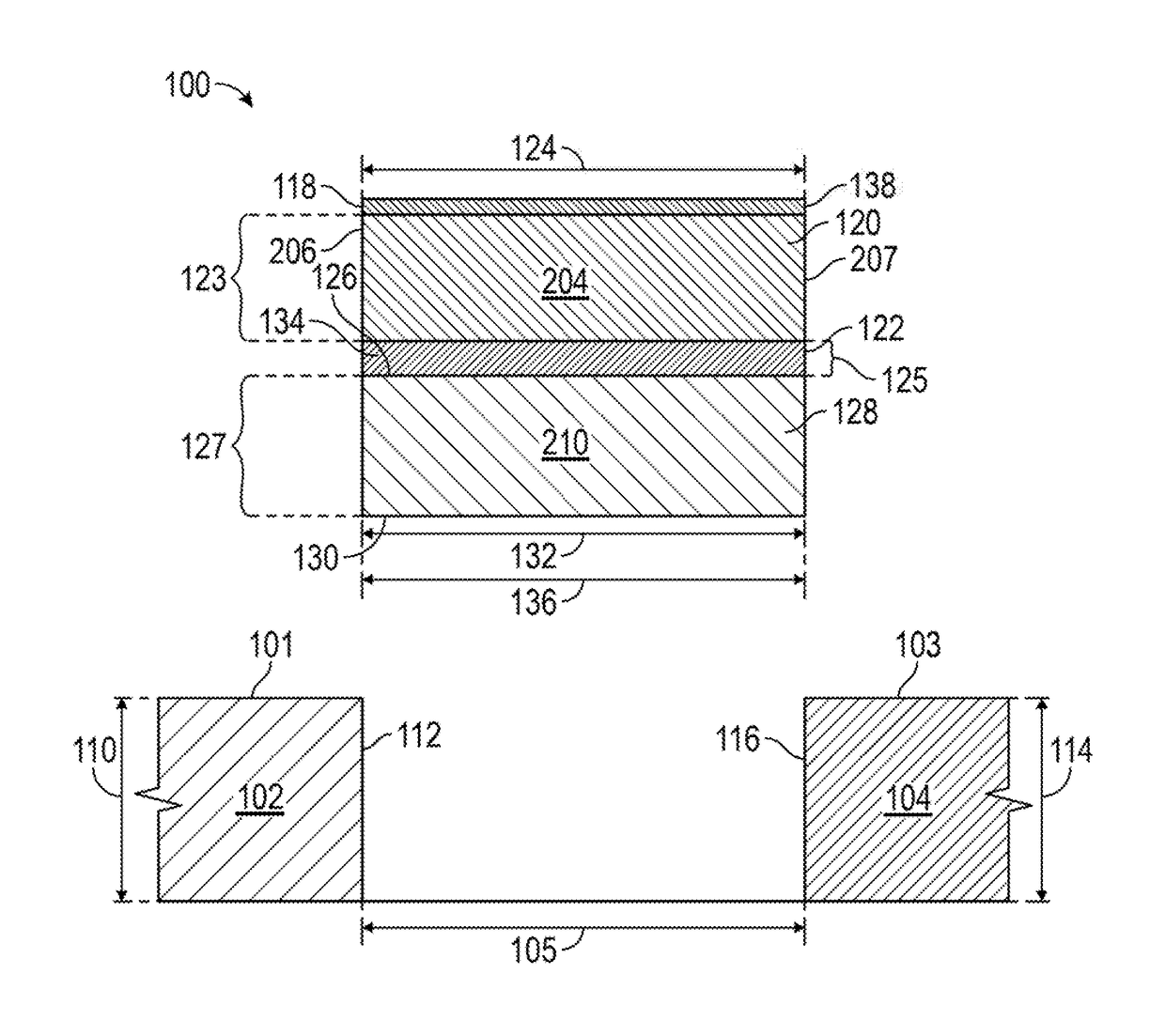

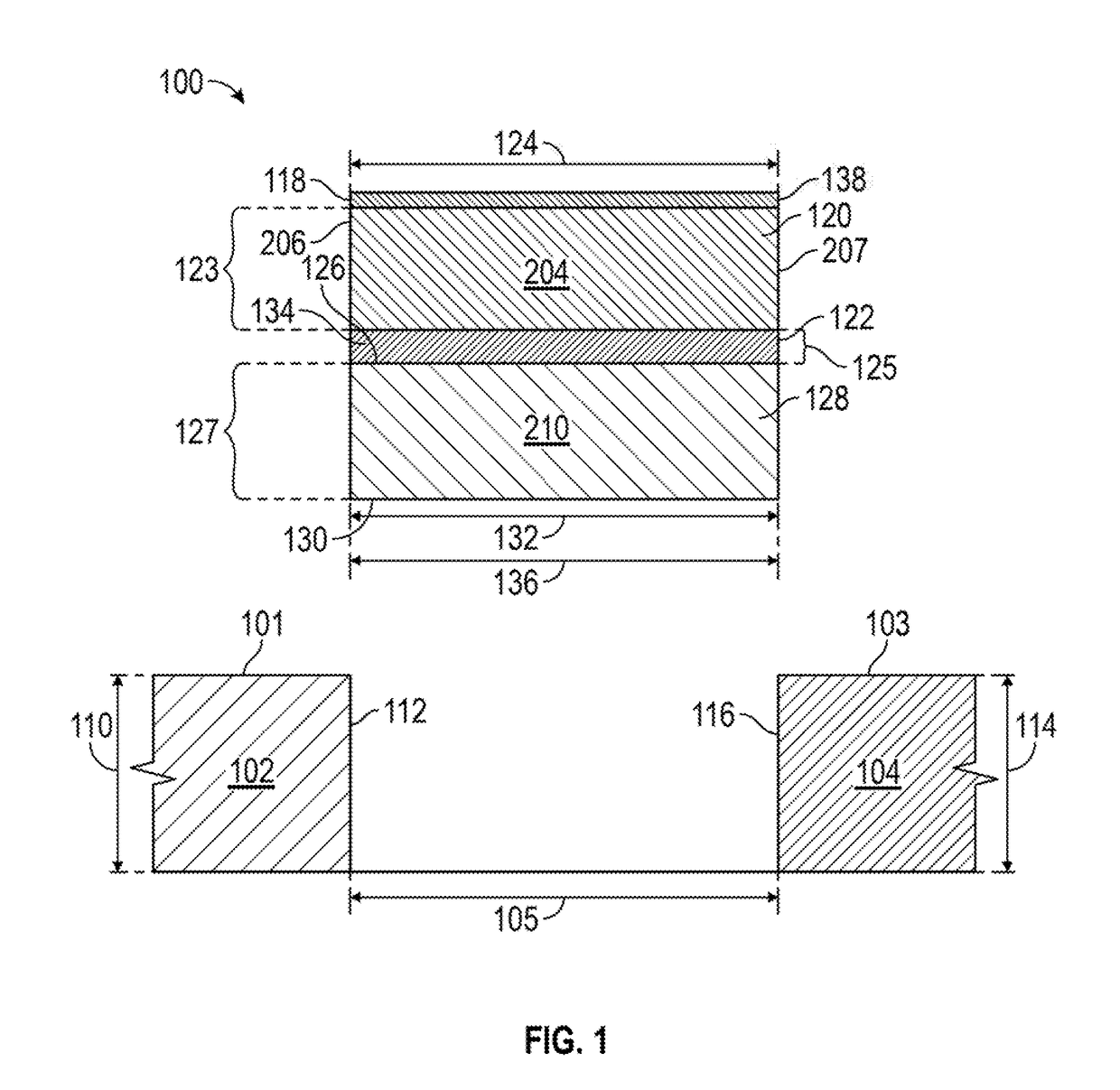

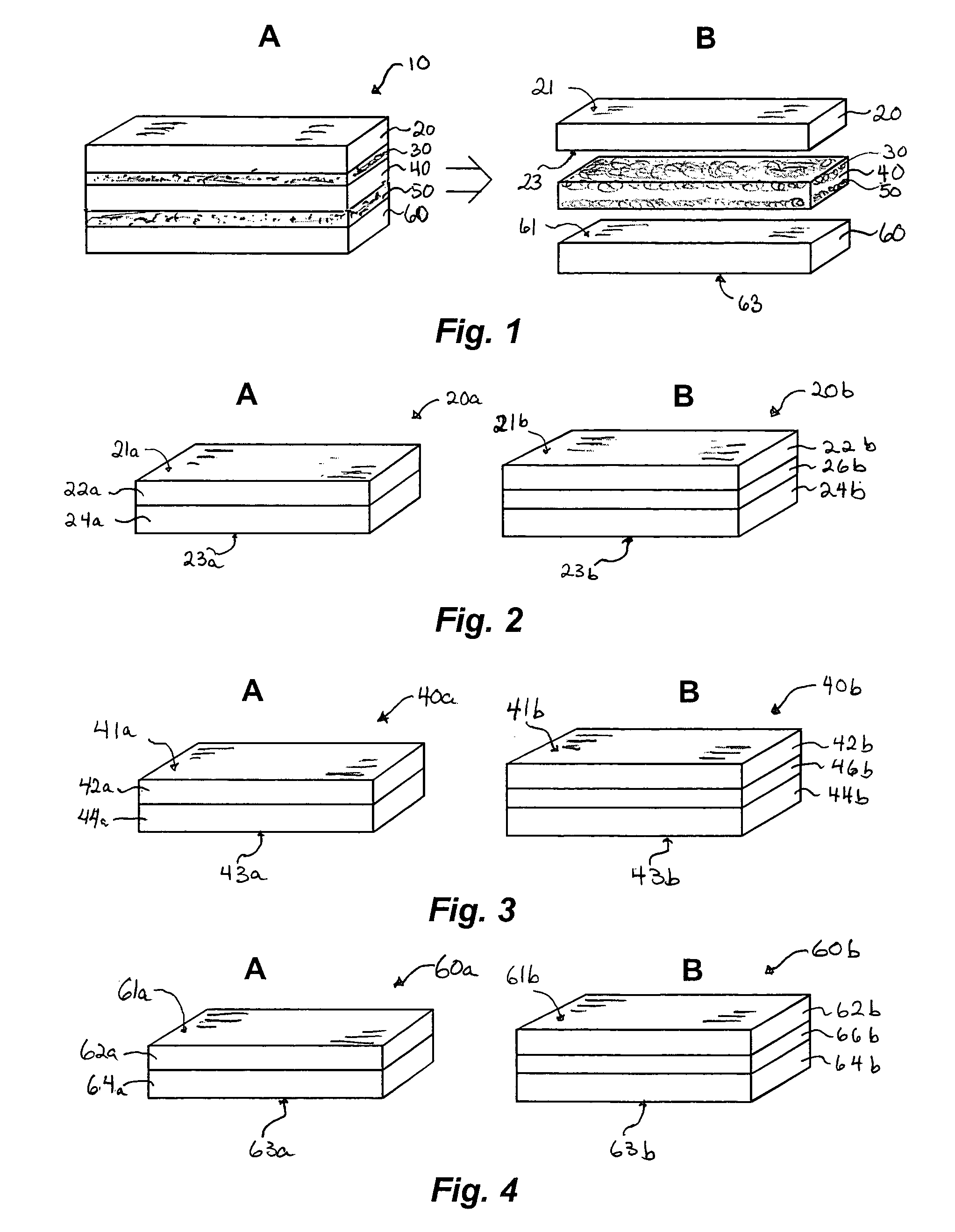

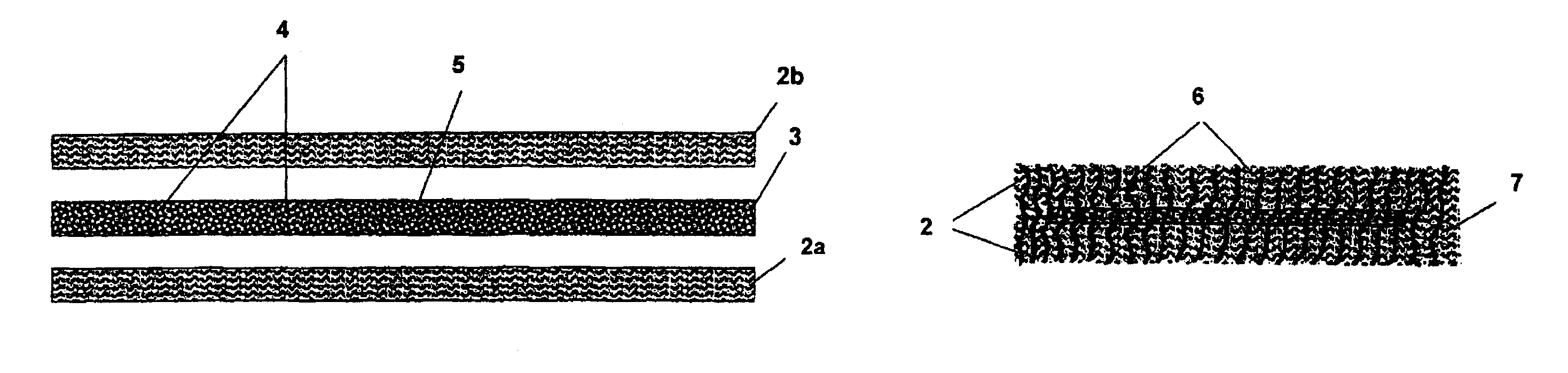

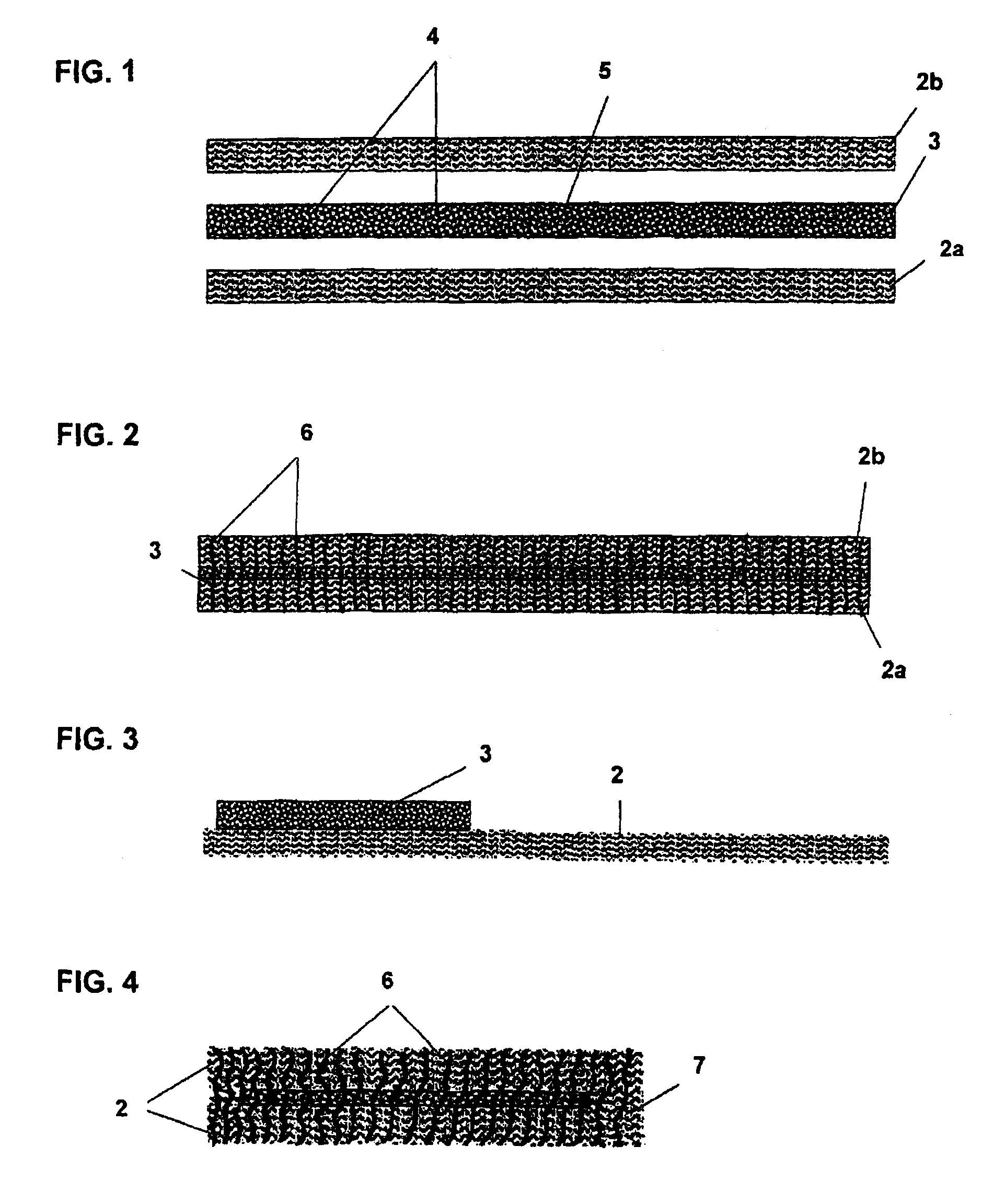

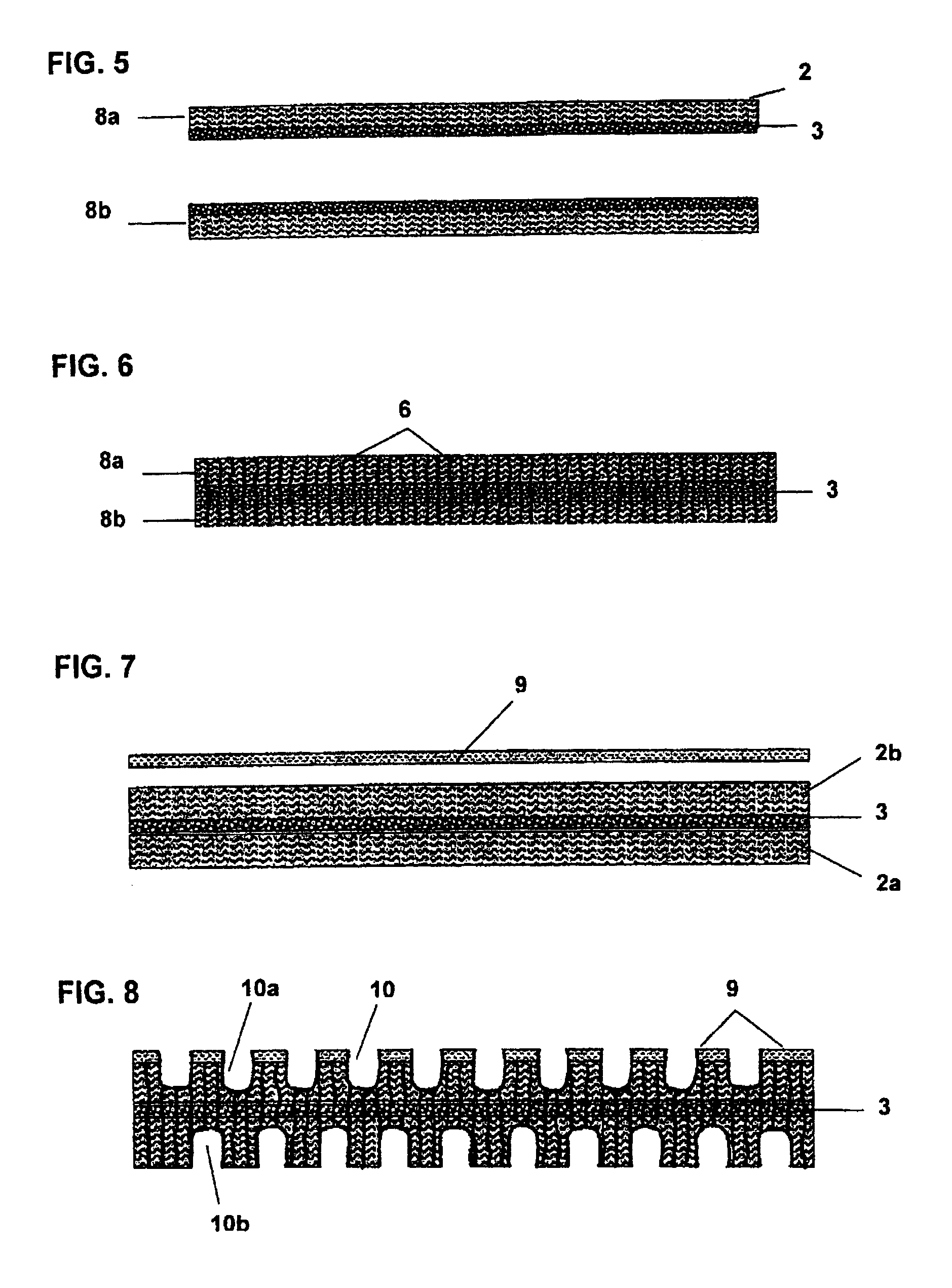

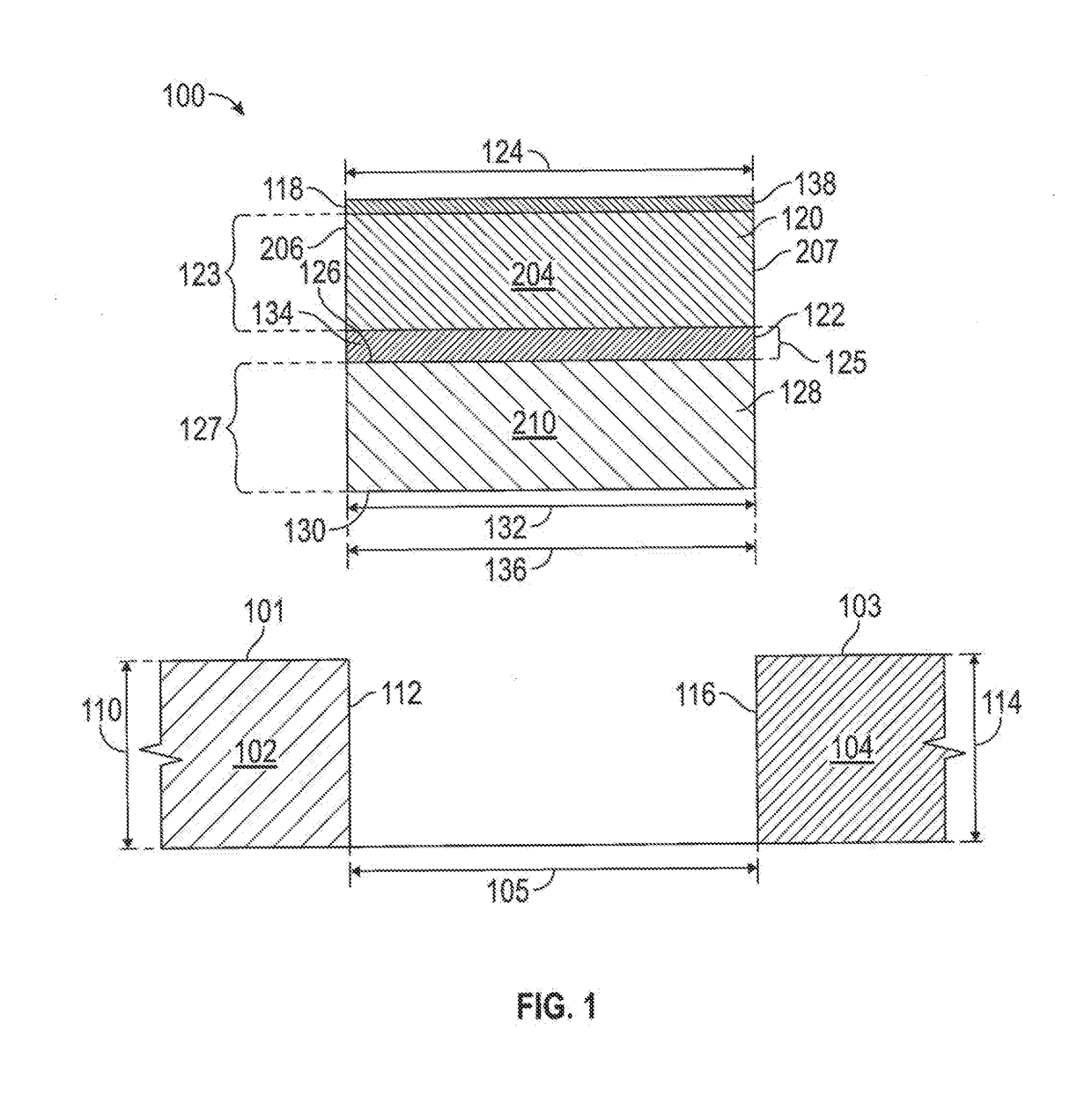

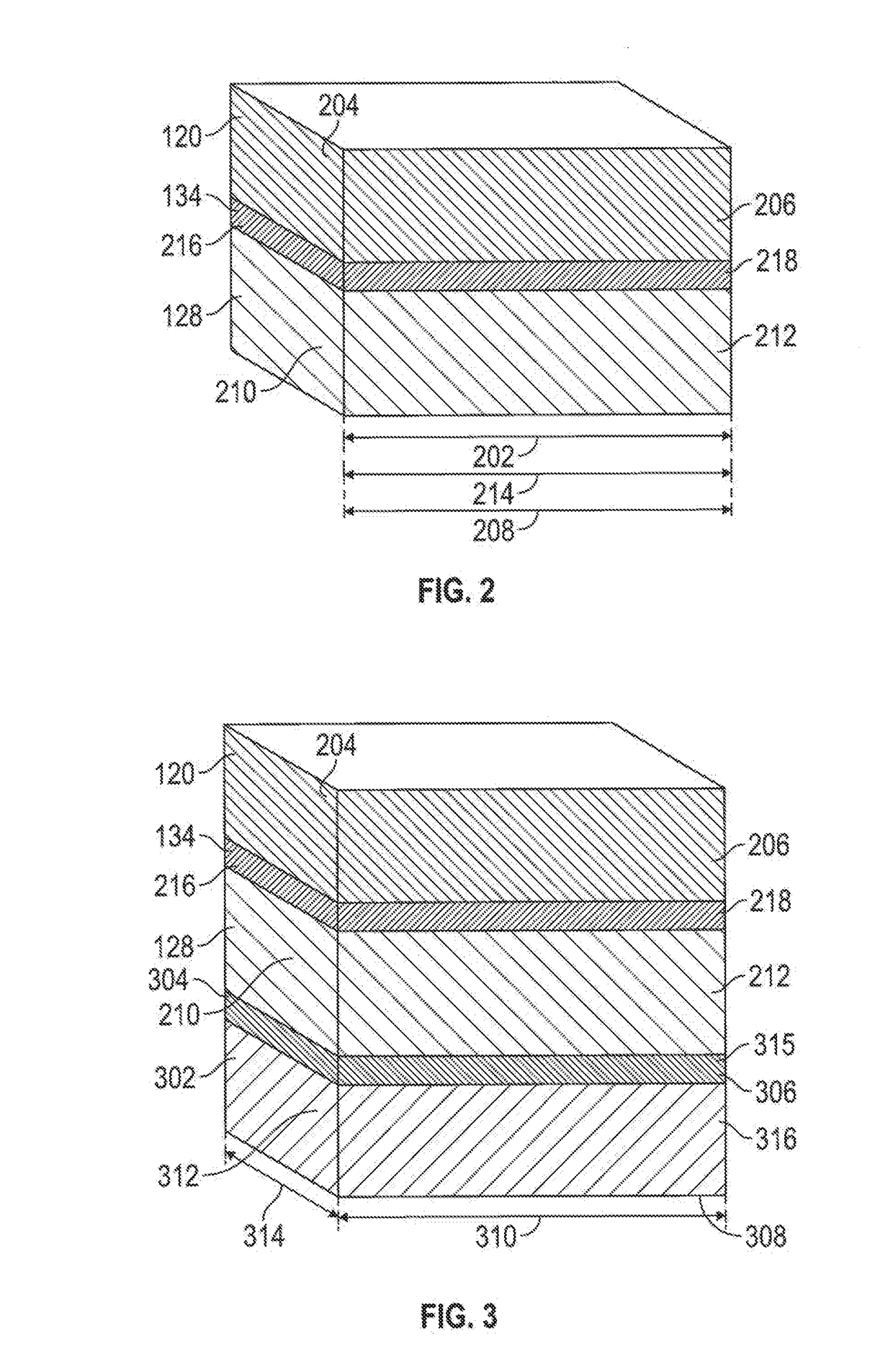

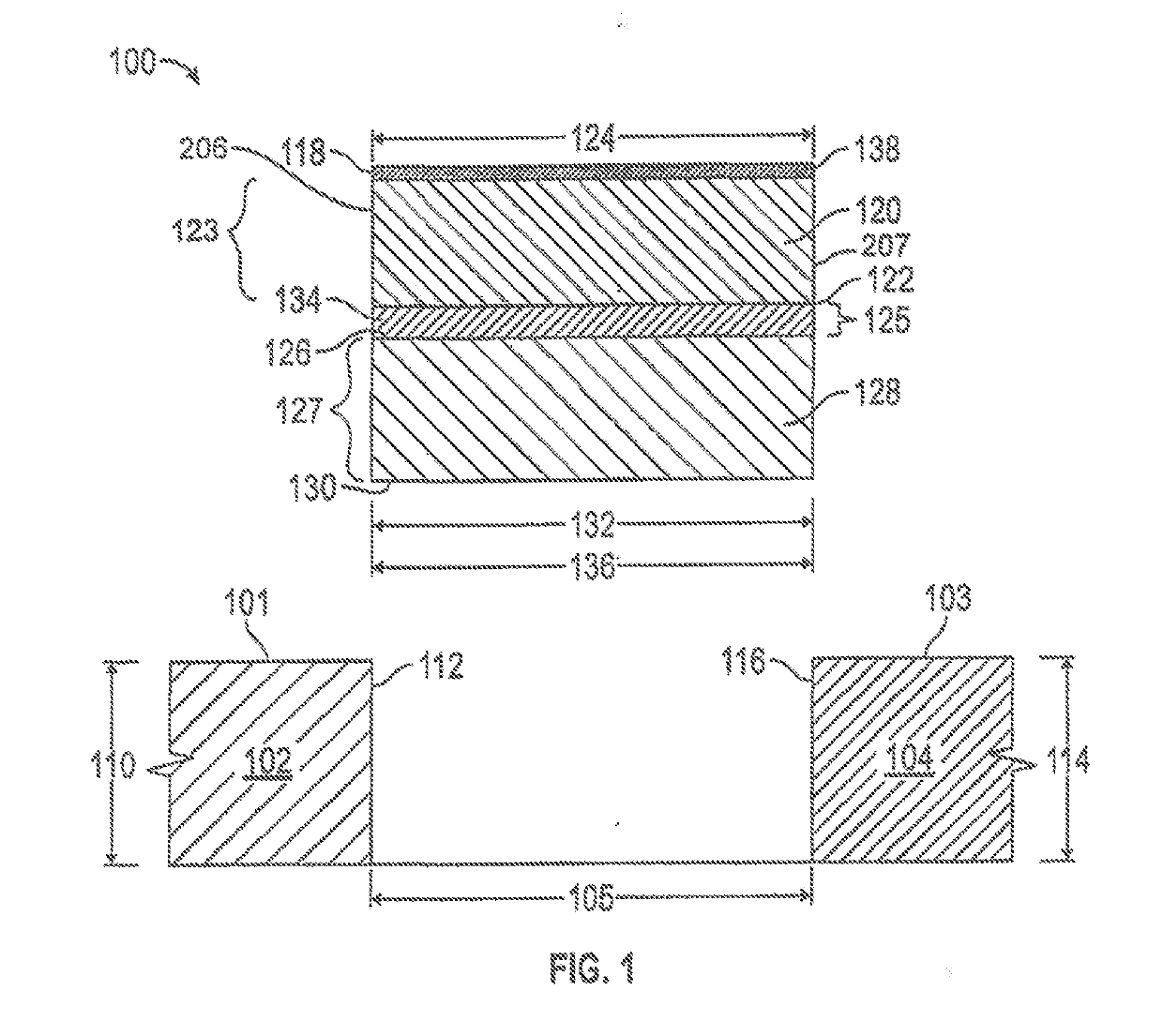

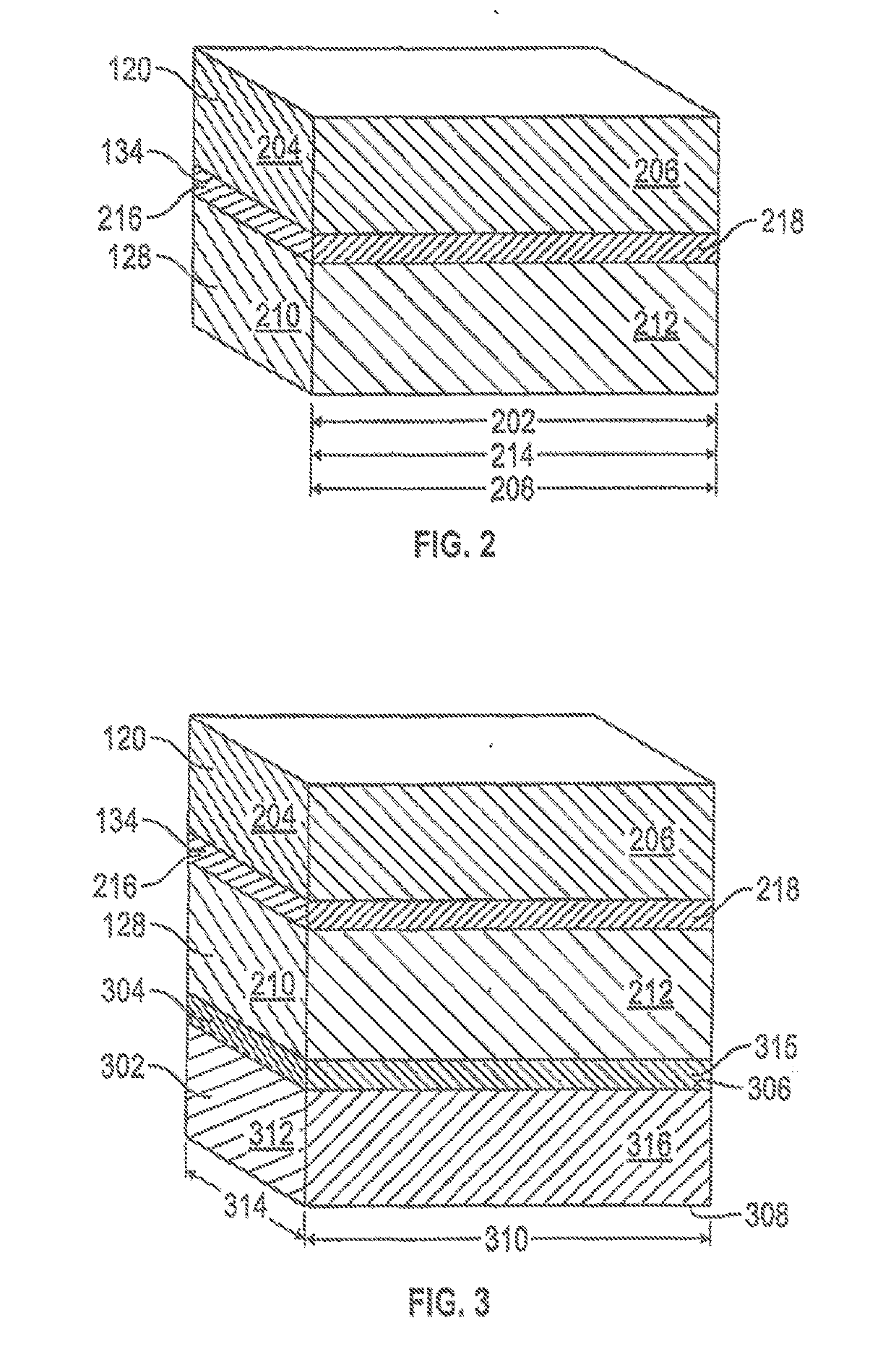

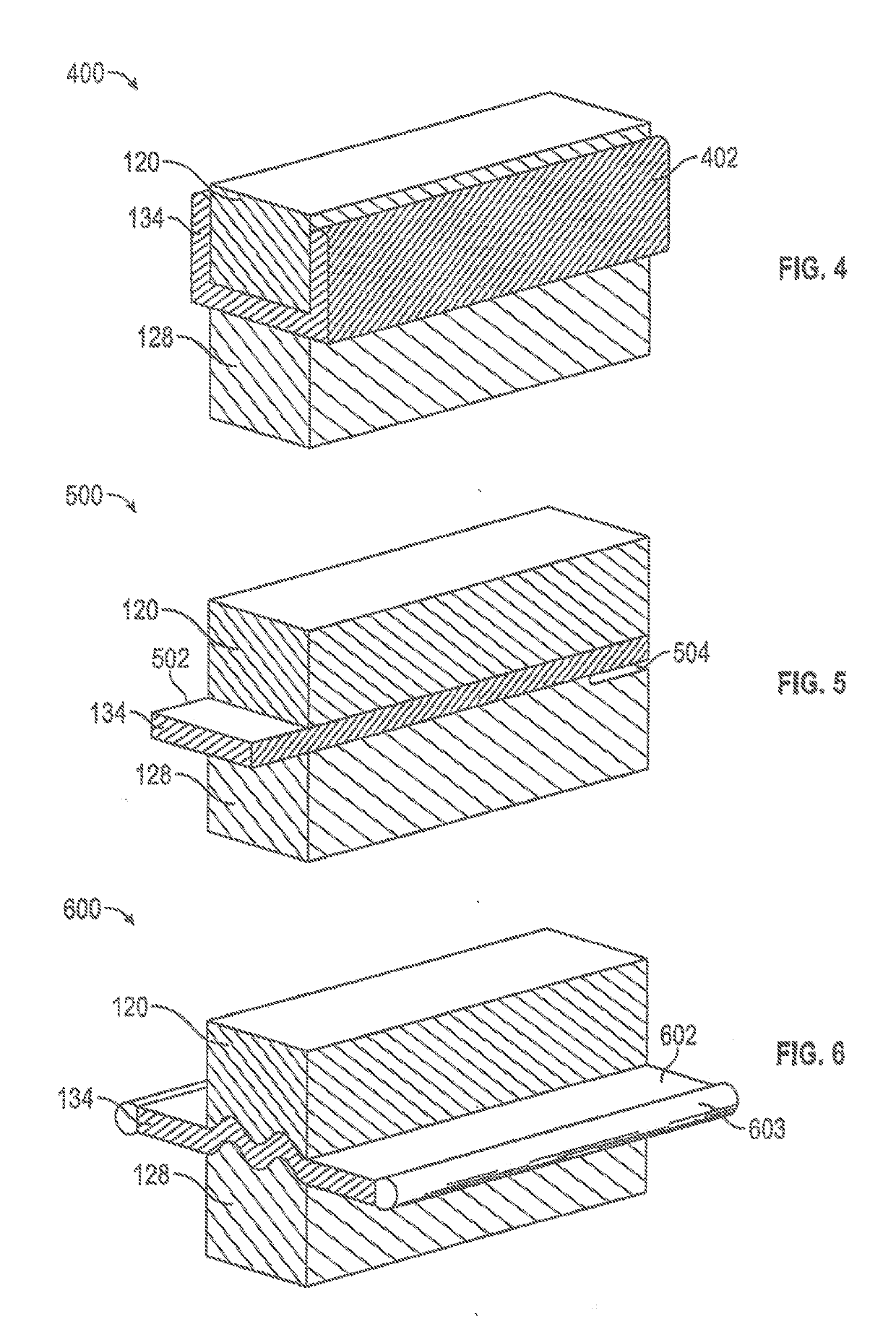

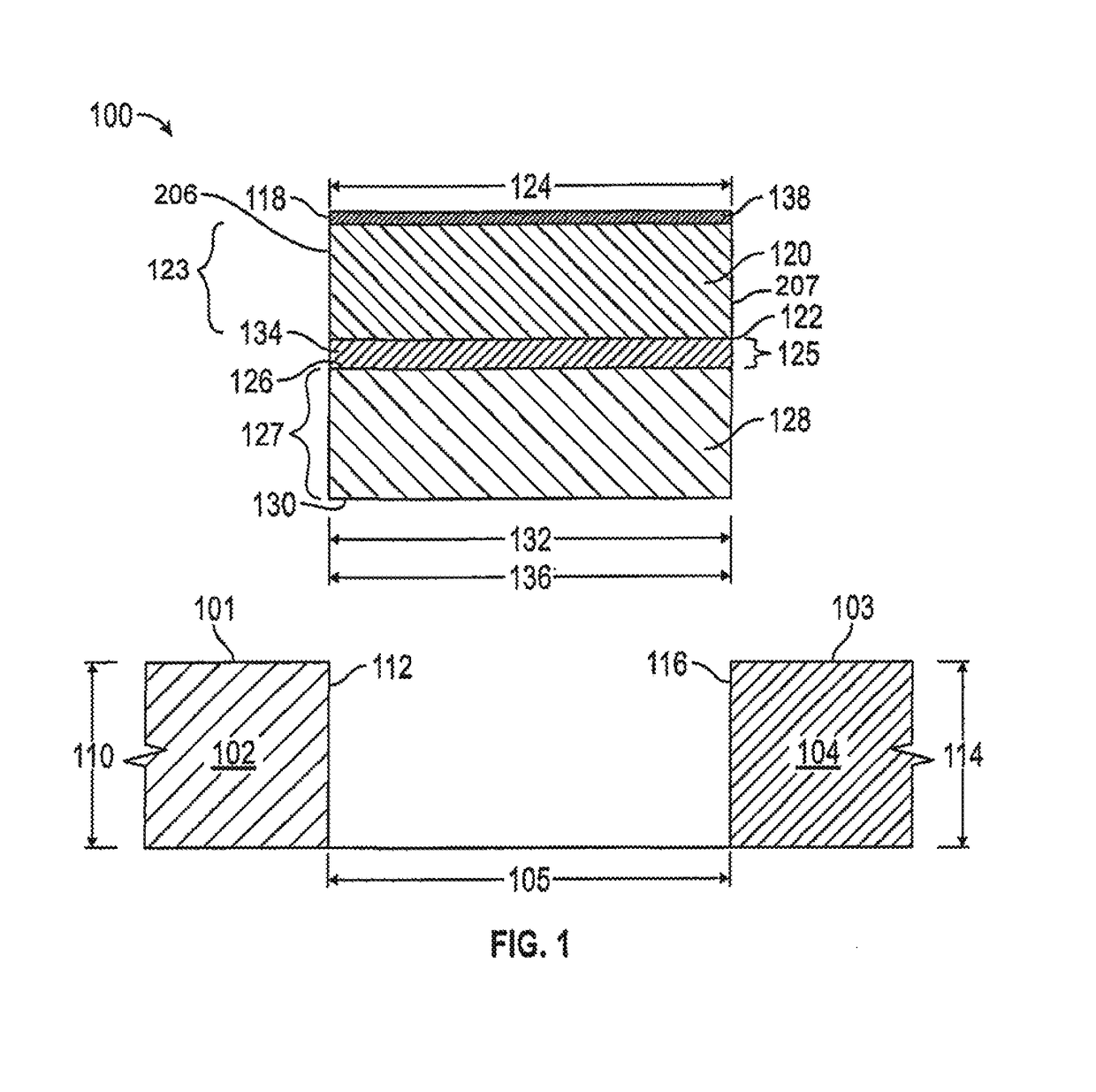

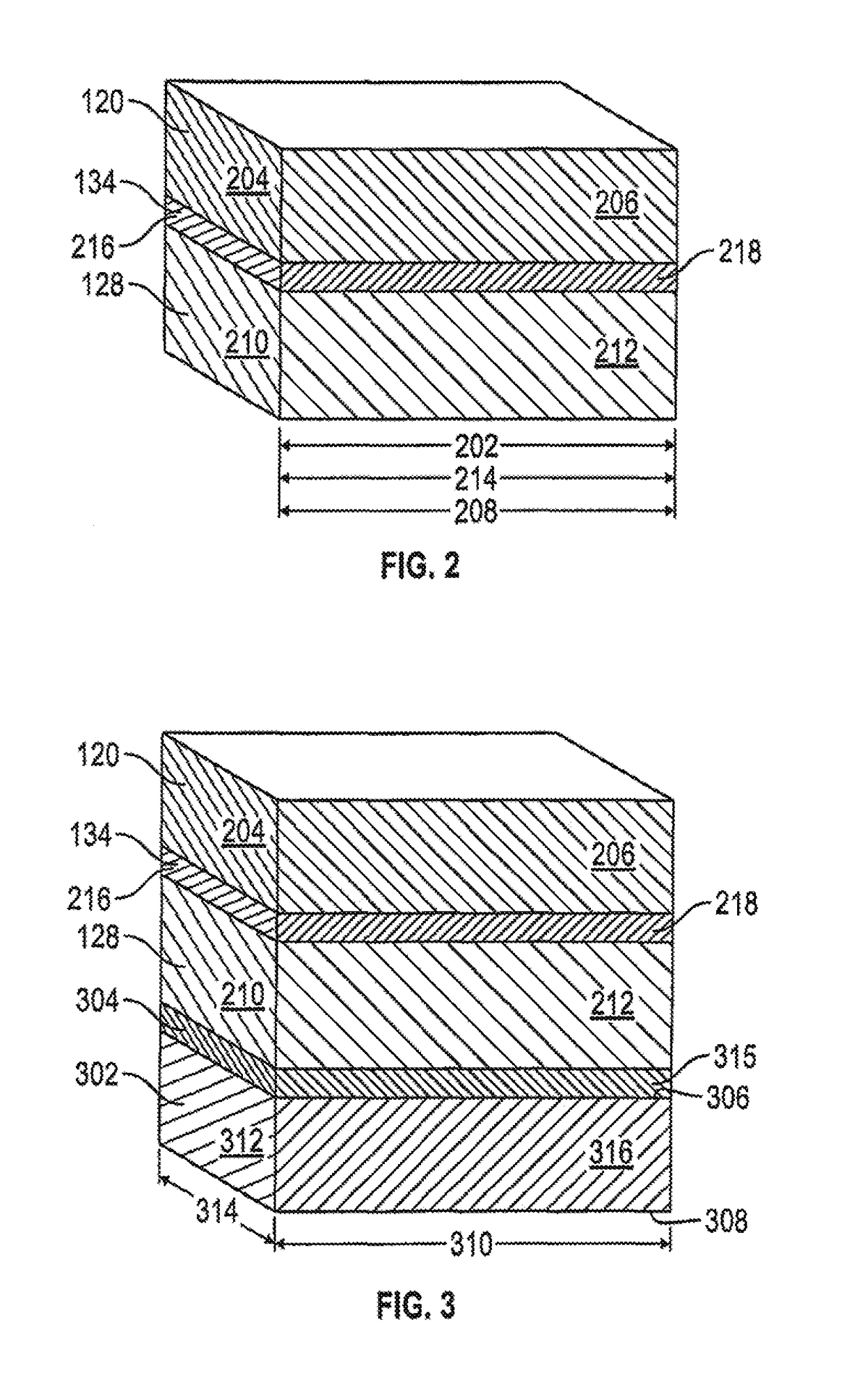

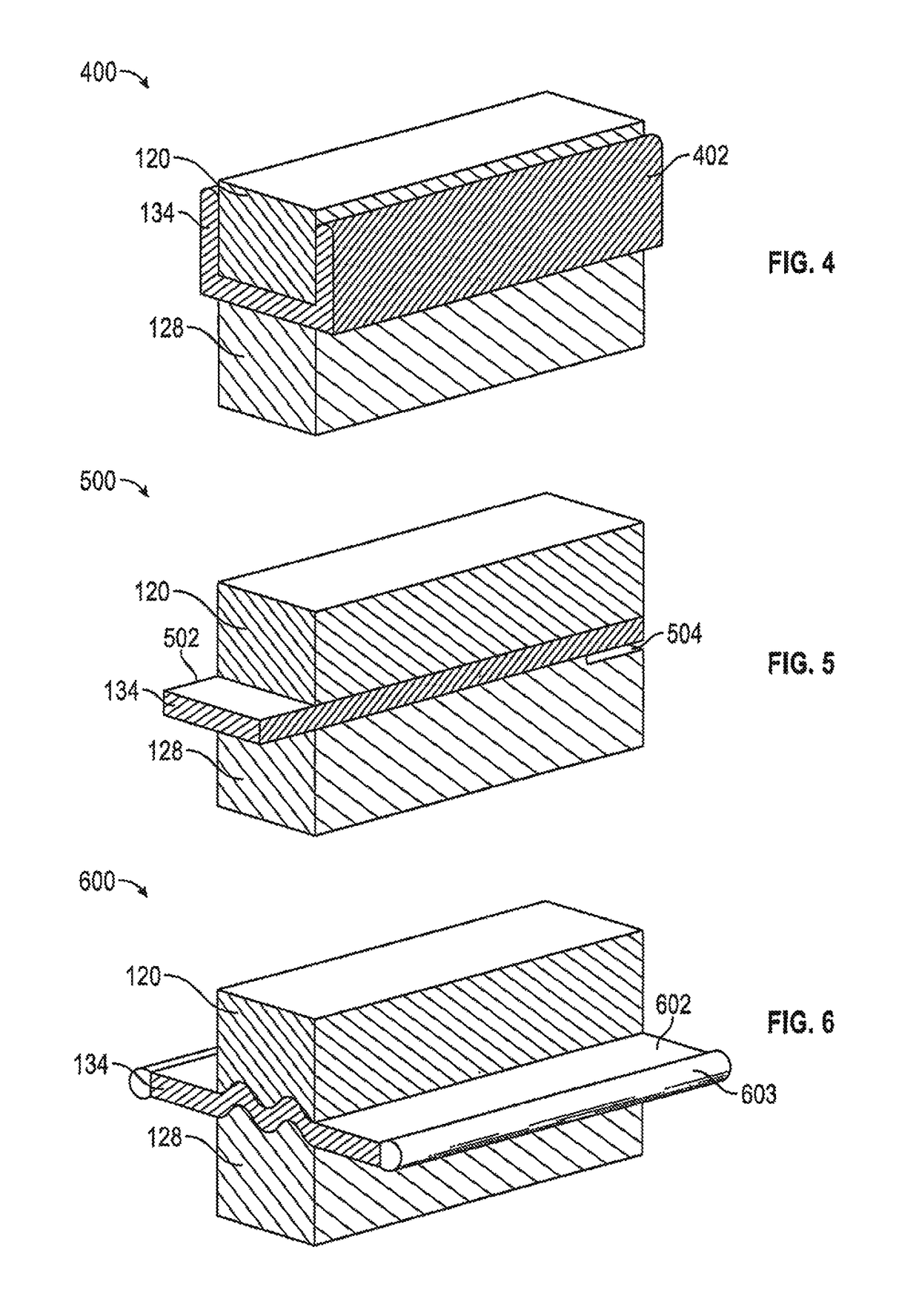

Joint seal system

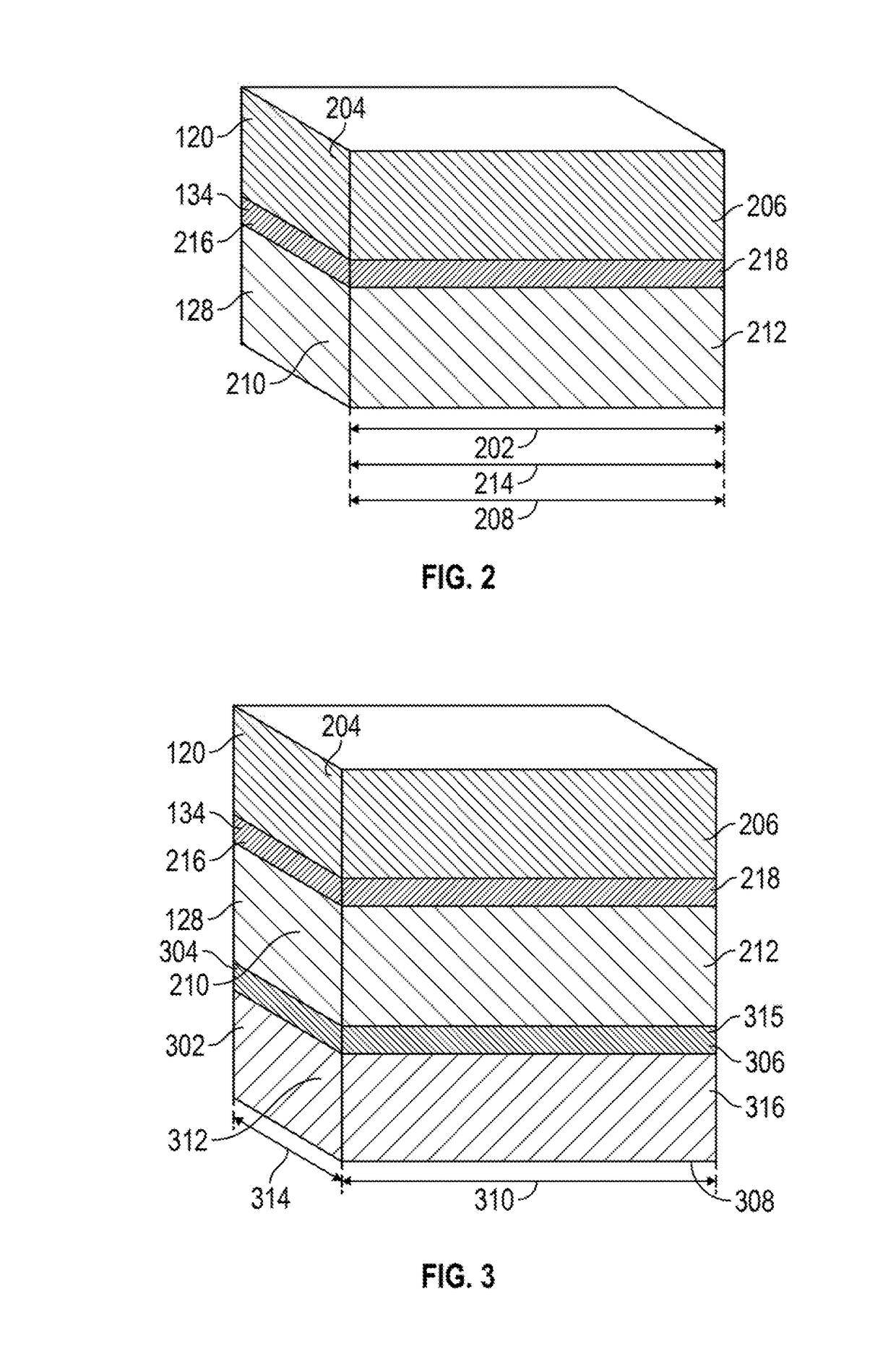

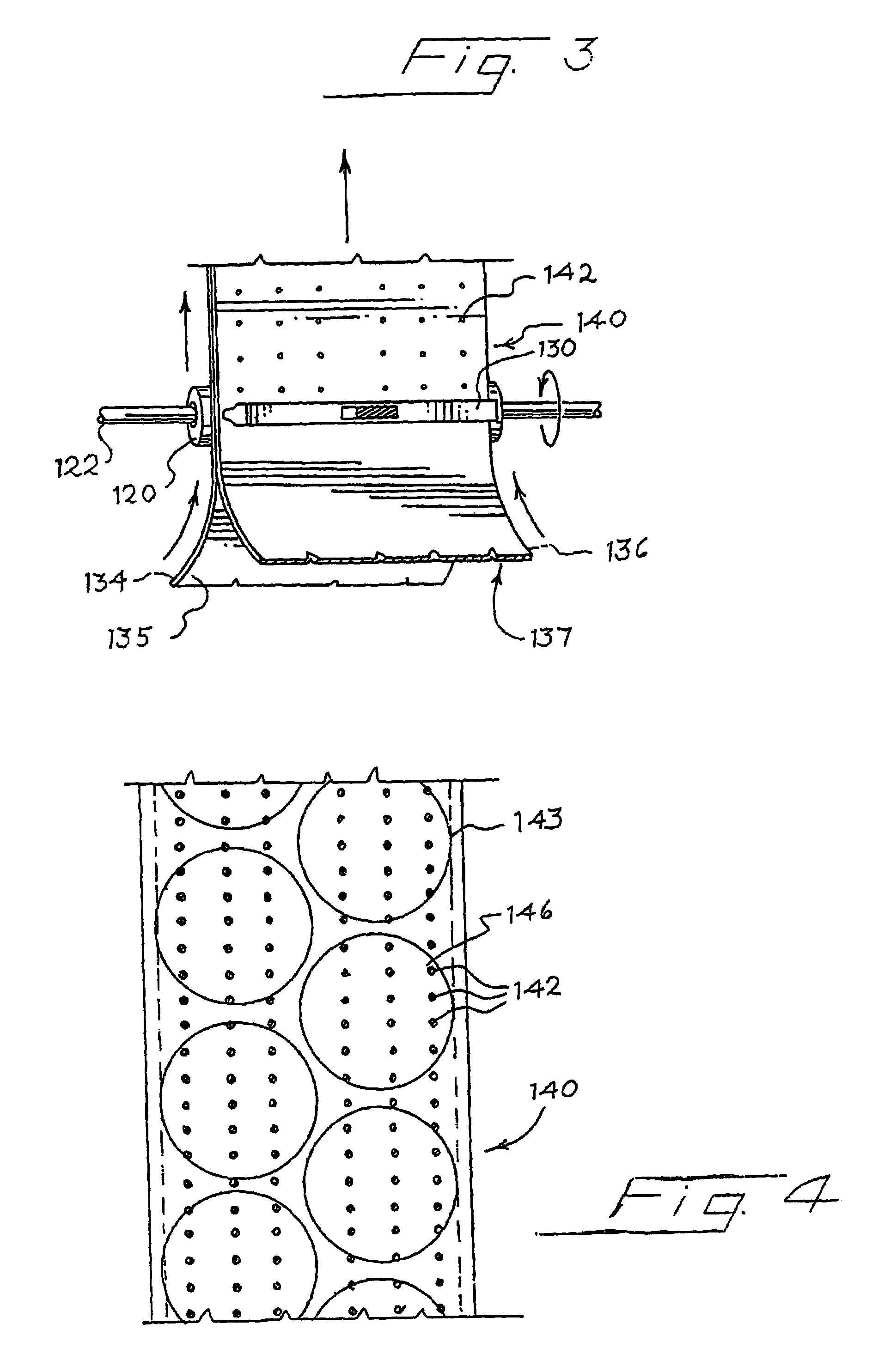

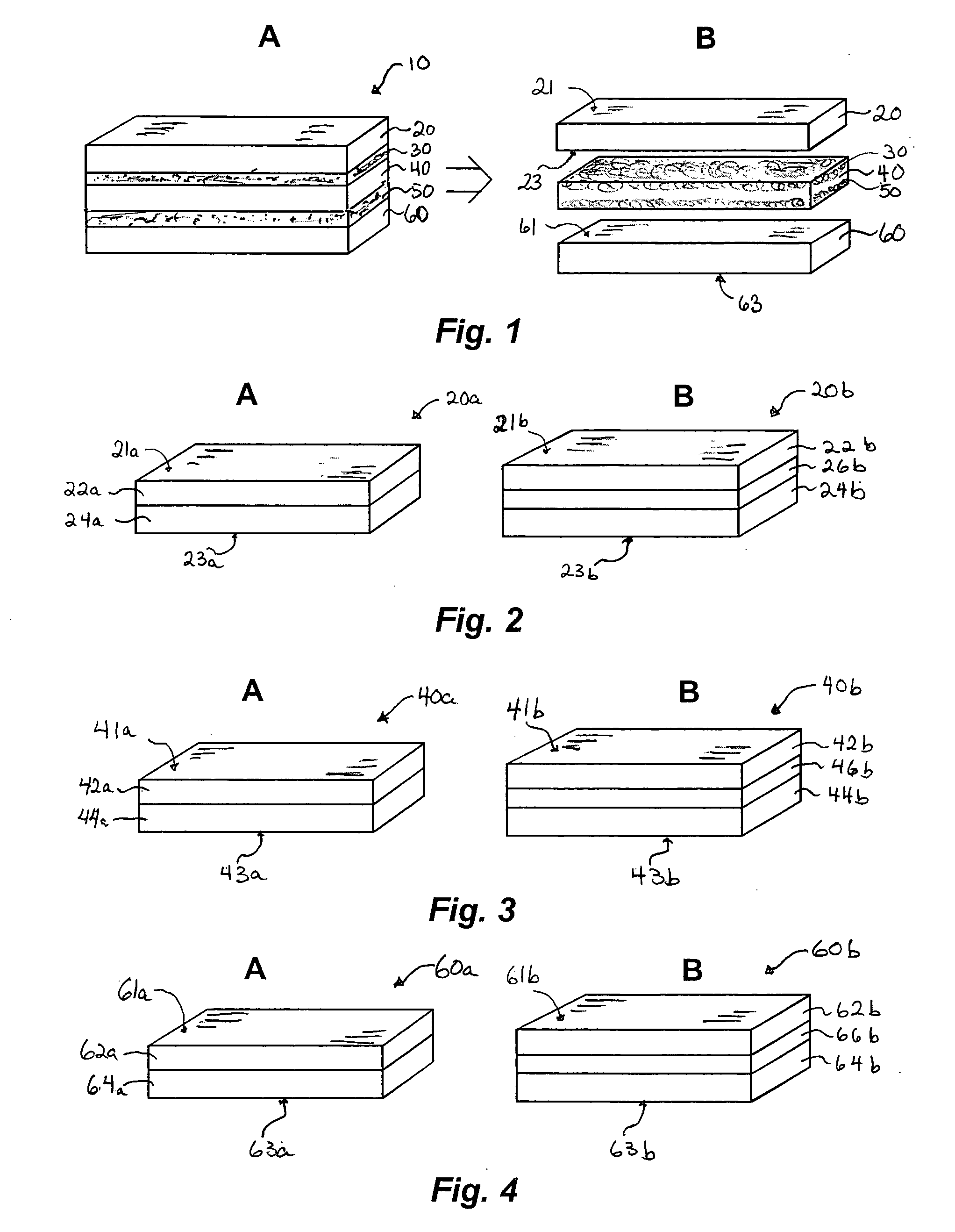

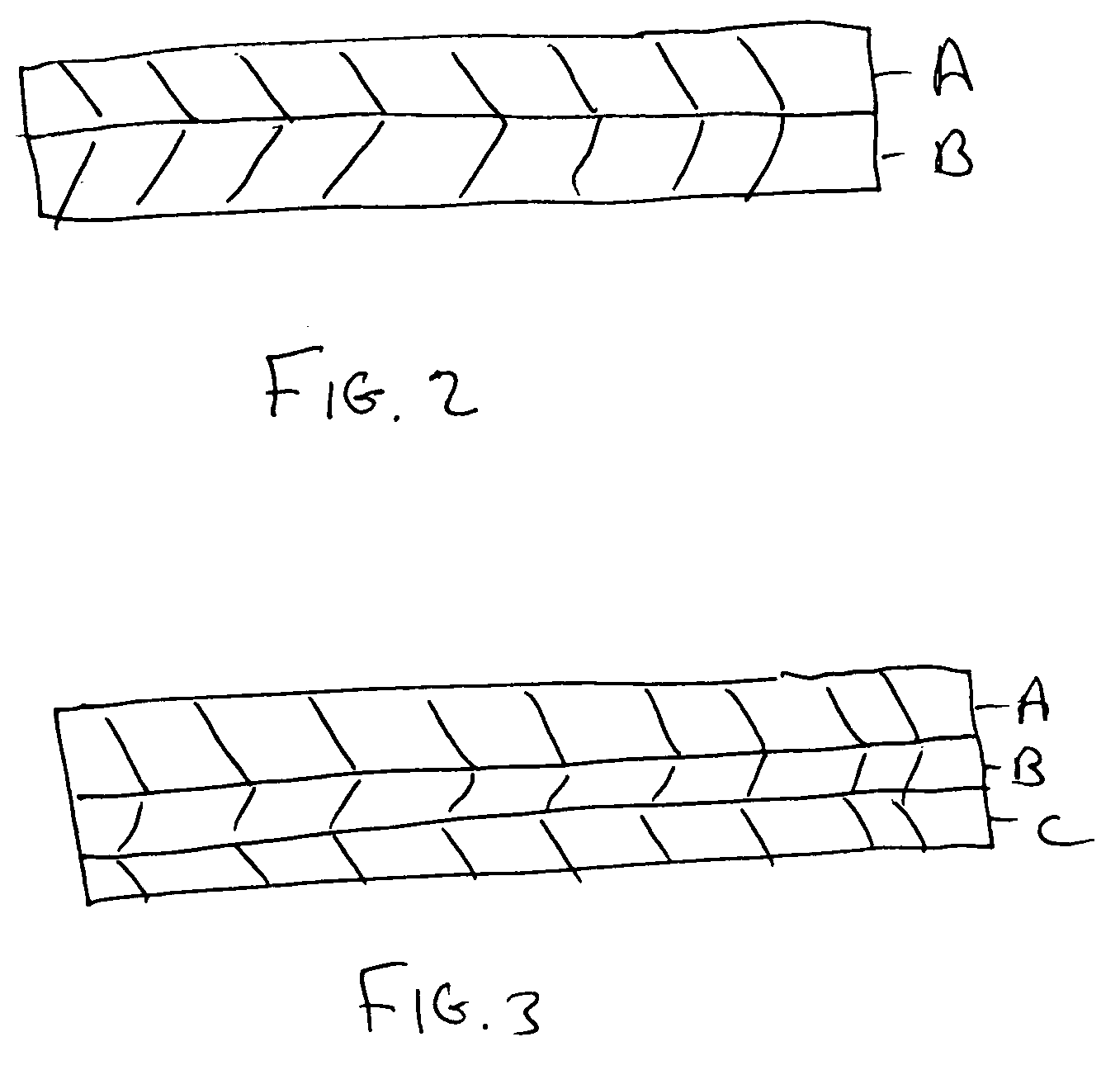

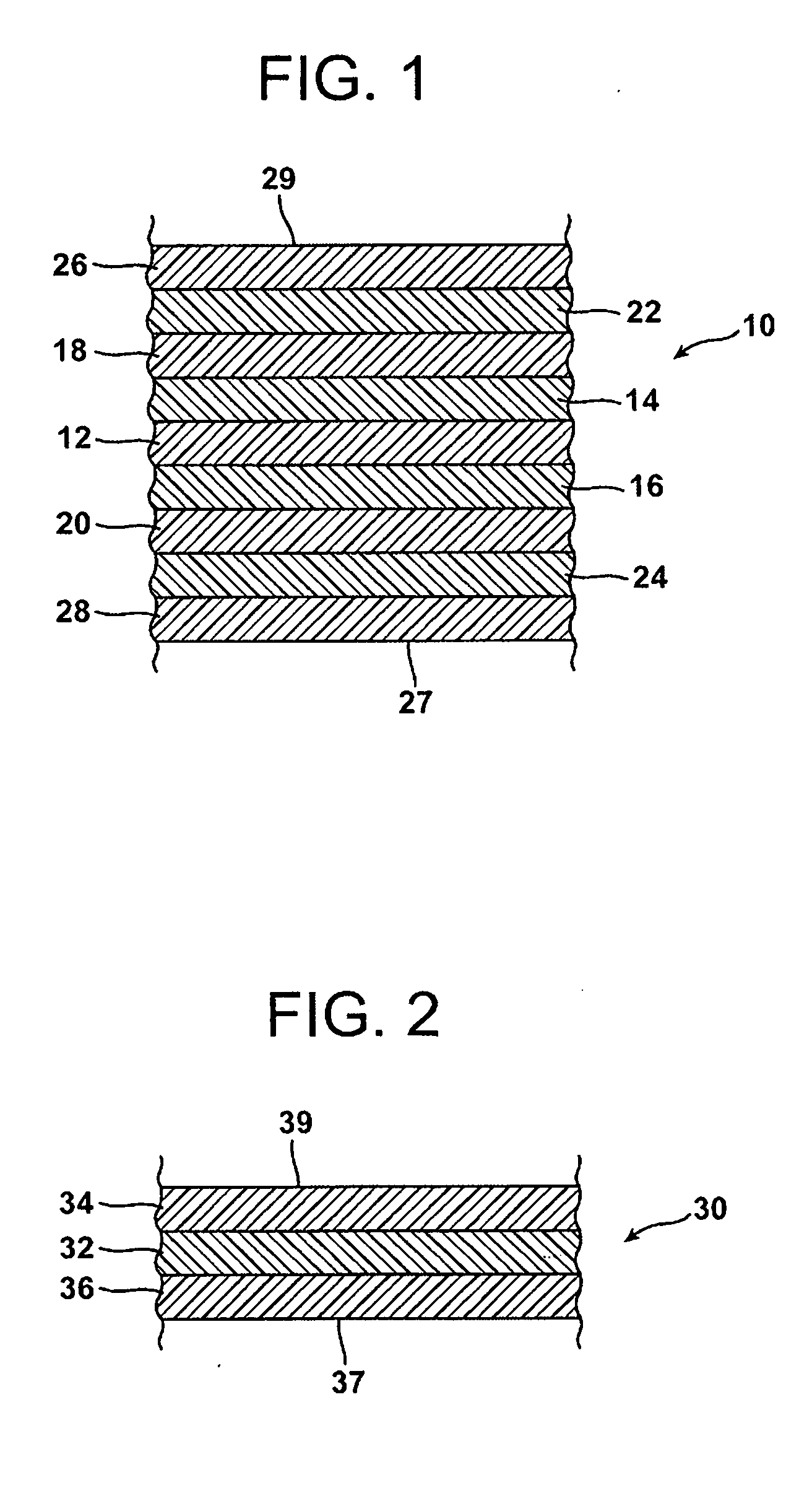

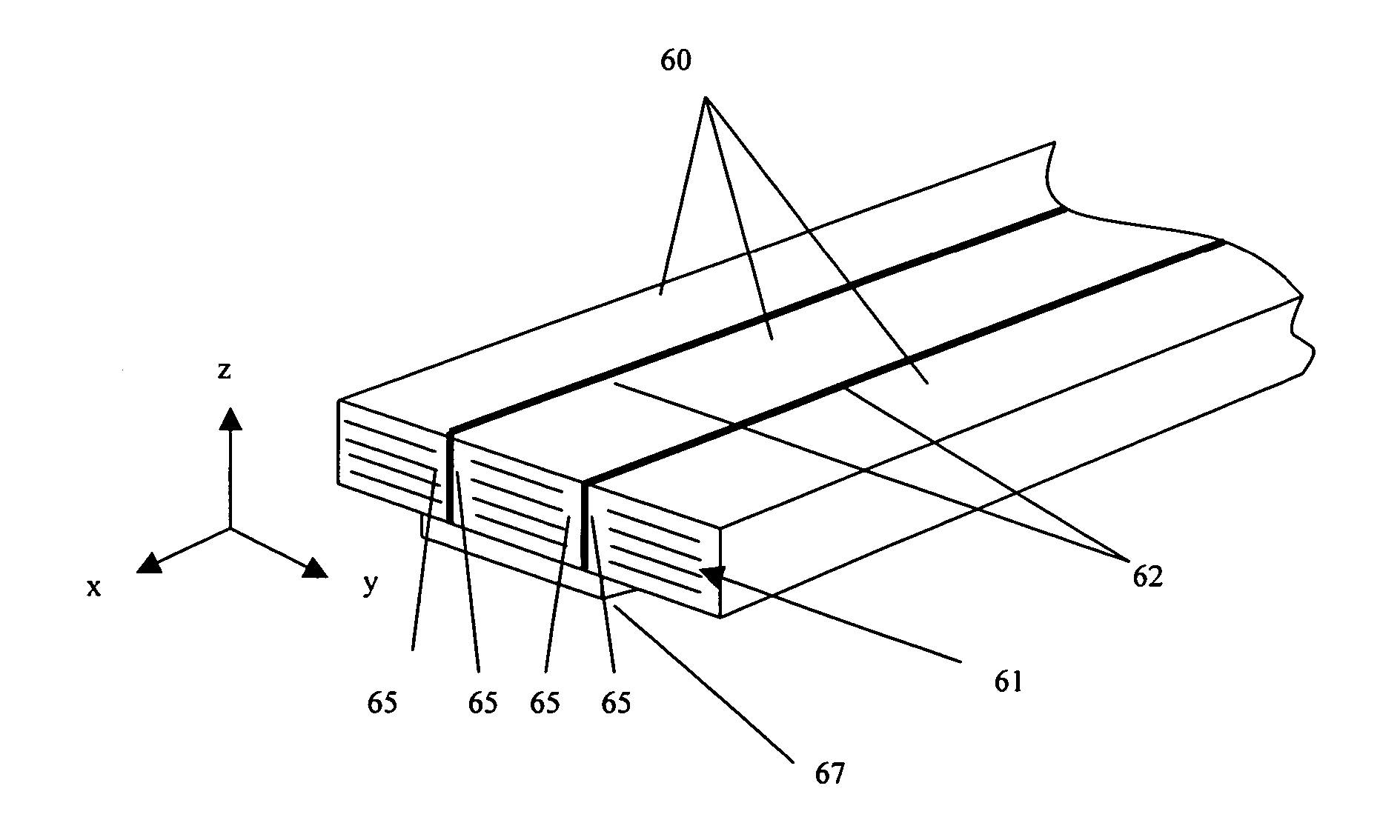

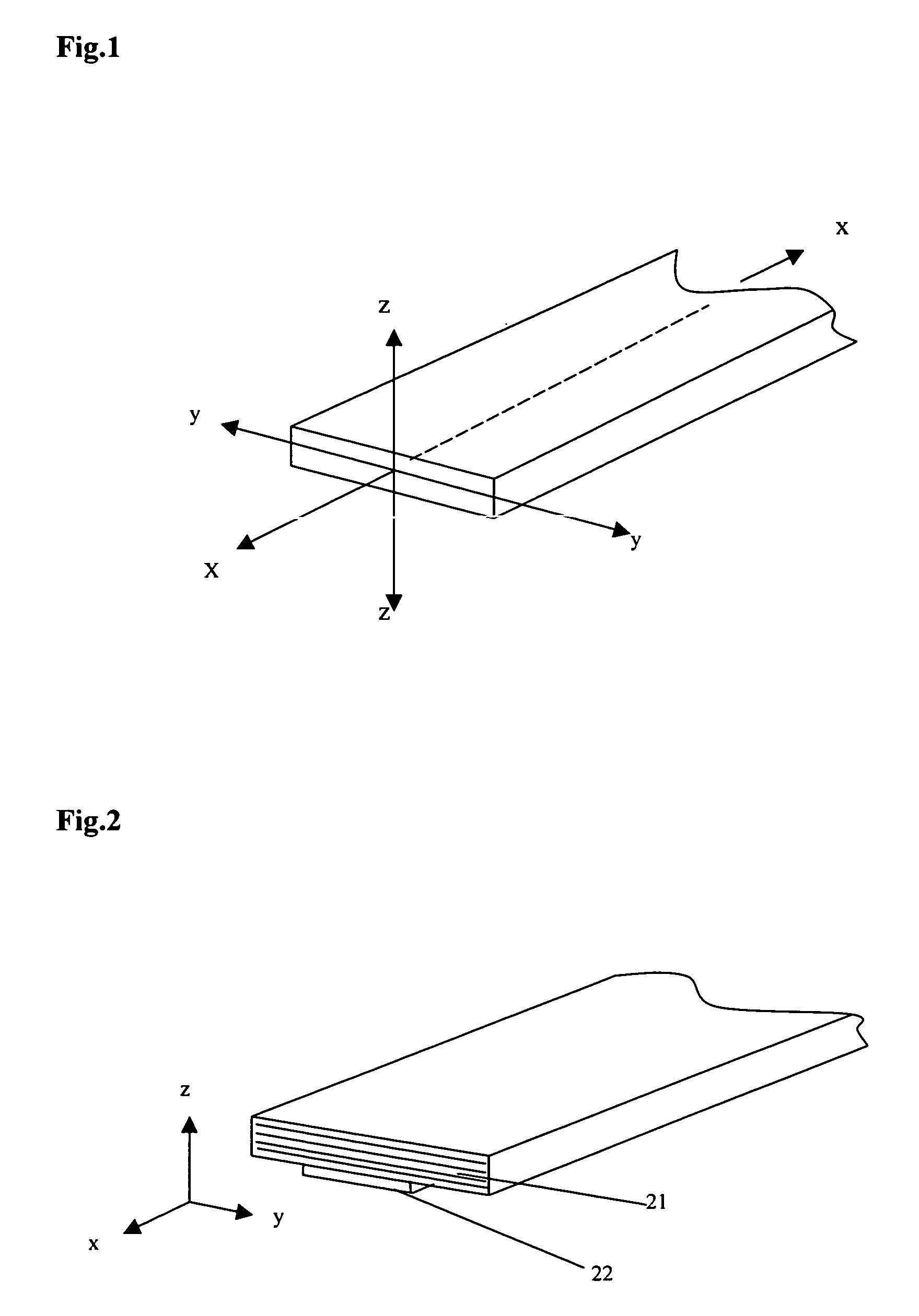

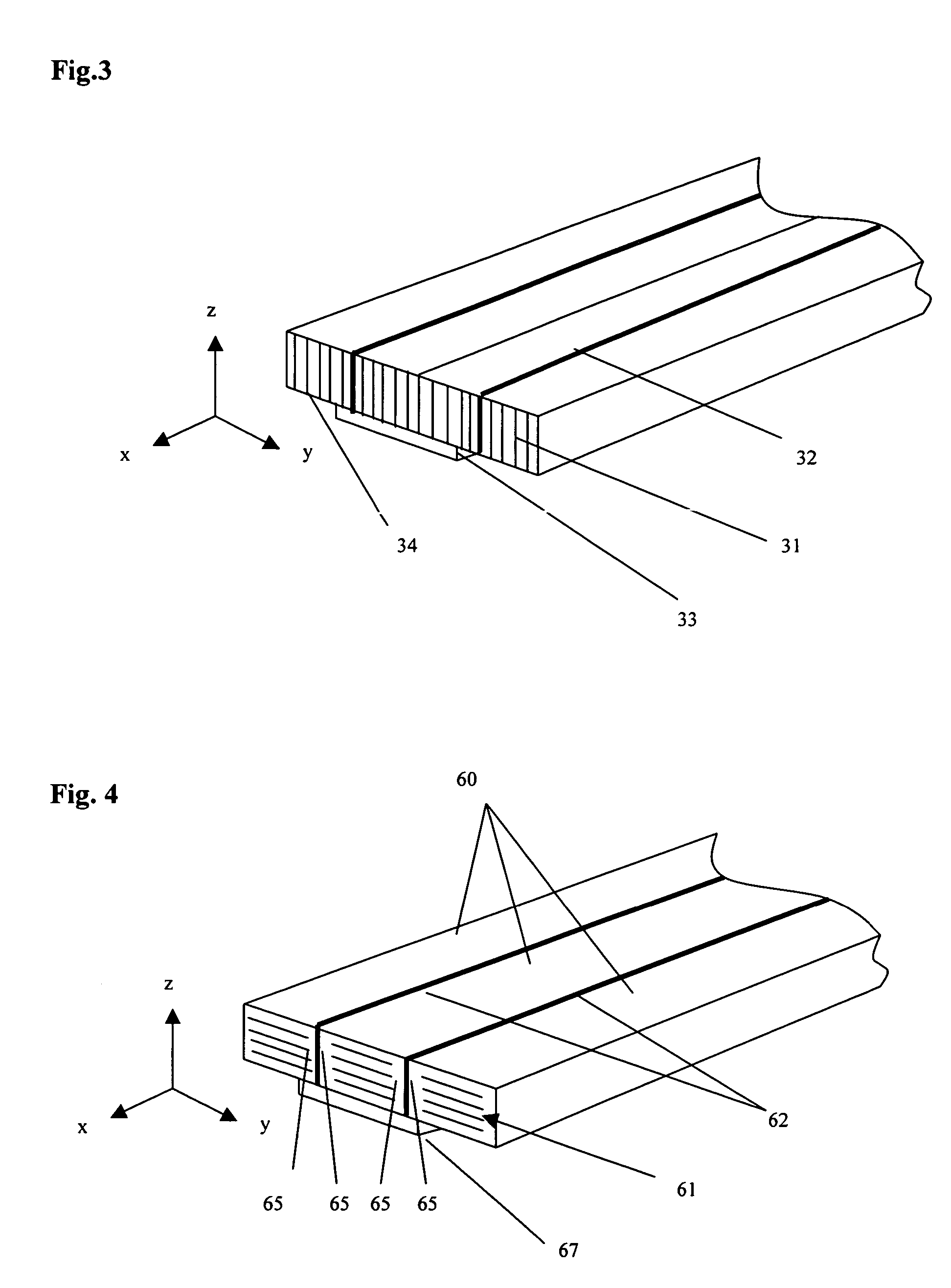

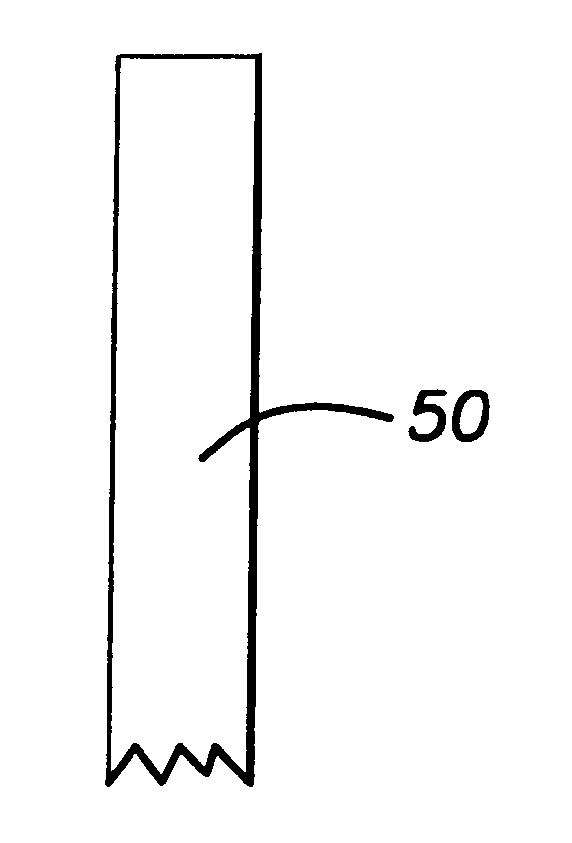

An integral multilayer joint seal system. Layers of foam, layered co-planar to the adjacent surface, are interspersed with a barrier layer. The foam layers may be uncompressed or partially compressed at the time of joint formation and may be composed of open or closed, or hybrid, cell foam. The foam may be impregnated with a fire retardant or may be composed of a fire retardant material, if desired. The barrier may have a tensile strength greater than the adjacent foam and may be different in dimensions from the layers of foam. The joint may have an elastomer, such as silicone, at its top and / or bottom, and may even include an elastomer layer within or about the barrier.

Owner:SCHUL INT COMPANY

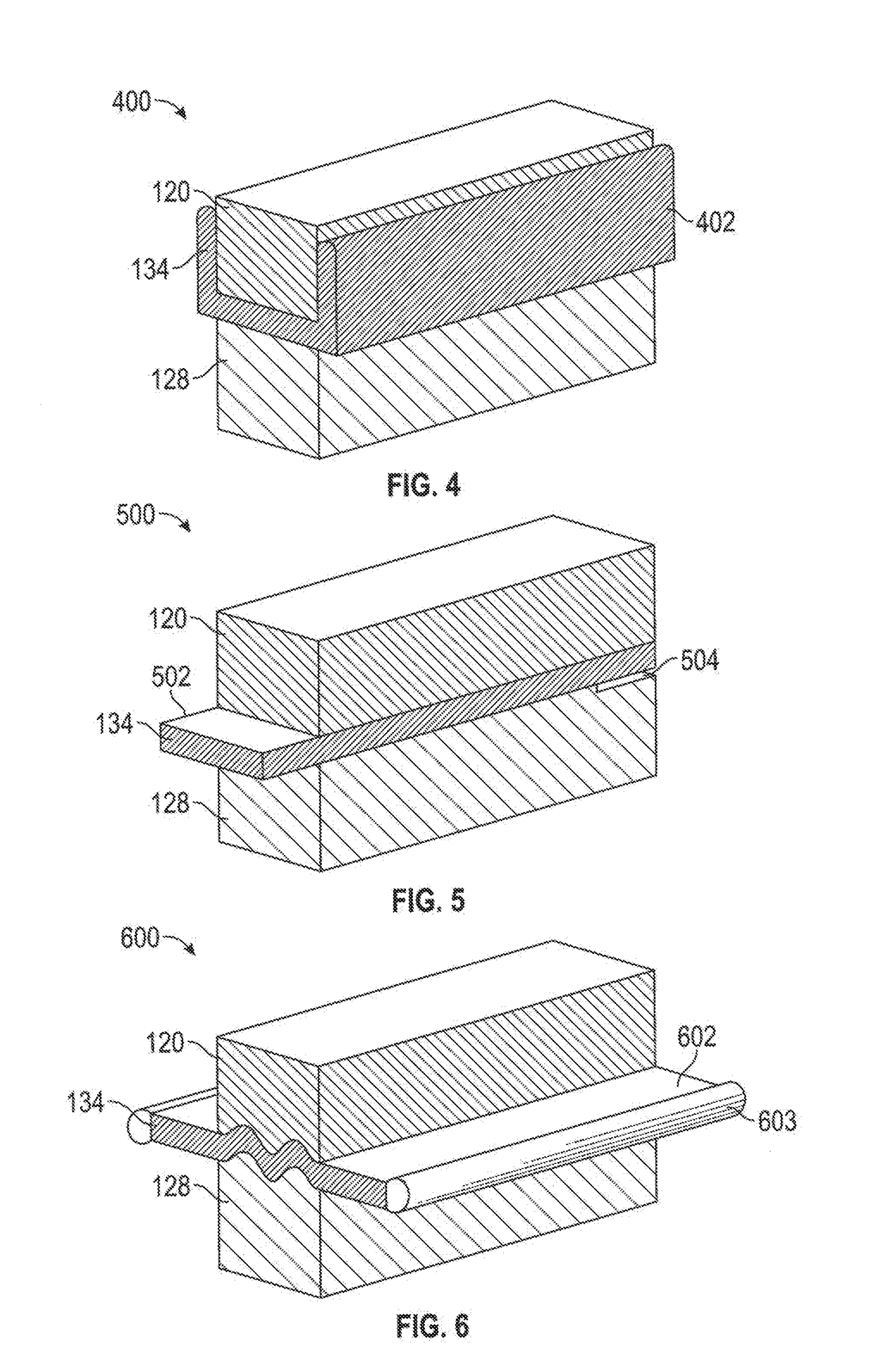

Joint seal system having internal barrier and external wings

An integral multilayer joint seal. Layers of foam, layered co-planar to the adjacent surface, are interspersed with a barrier layer which extends beyond the foam layers to provide a protective surface, a surface for attachment atop adjacent substrates, or a connecting tab for use with adjacent joint seals. The foam layers may be uncompressed or partially compressed at the time of joint formation and may be composed of open or closed, or hybrid, cell foam. The foam may be impregnated with a fire retardant or lay be composed of a fire retardant material, if desired. The barrier may have a tensile strength greater than the adjacent foam. The joint seal may have an elastomer, such as silicone, at its top and / or bottom, and may even include an elastomer layer within or about the barrier.

Owner:SCHUL INT COMPANY

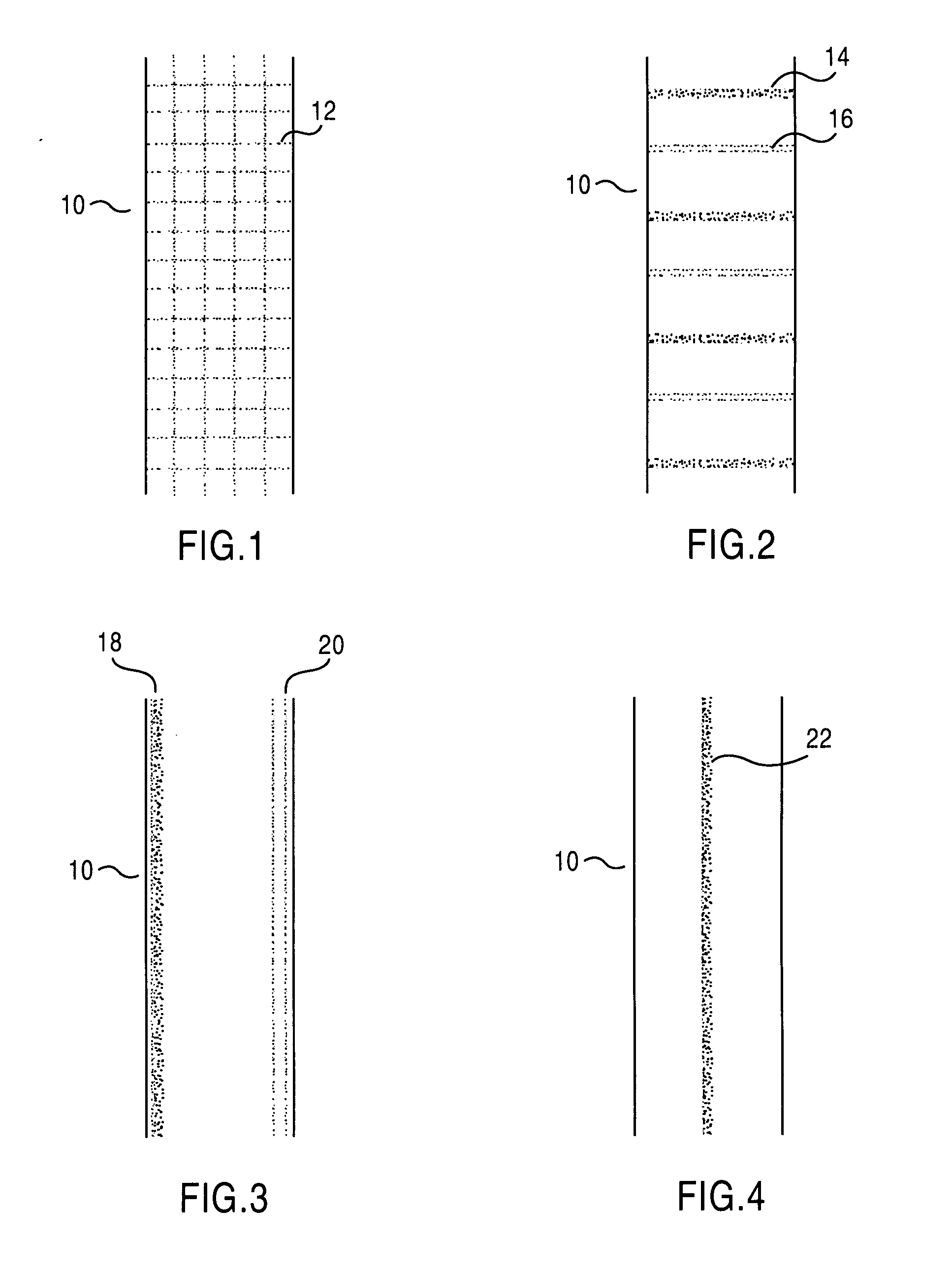

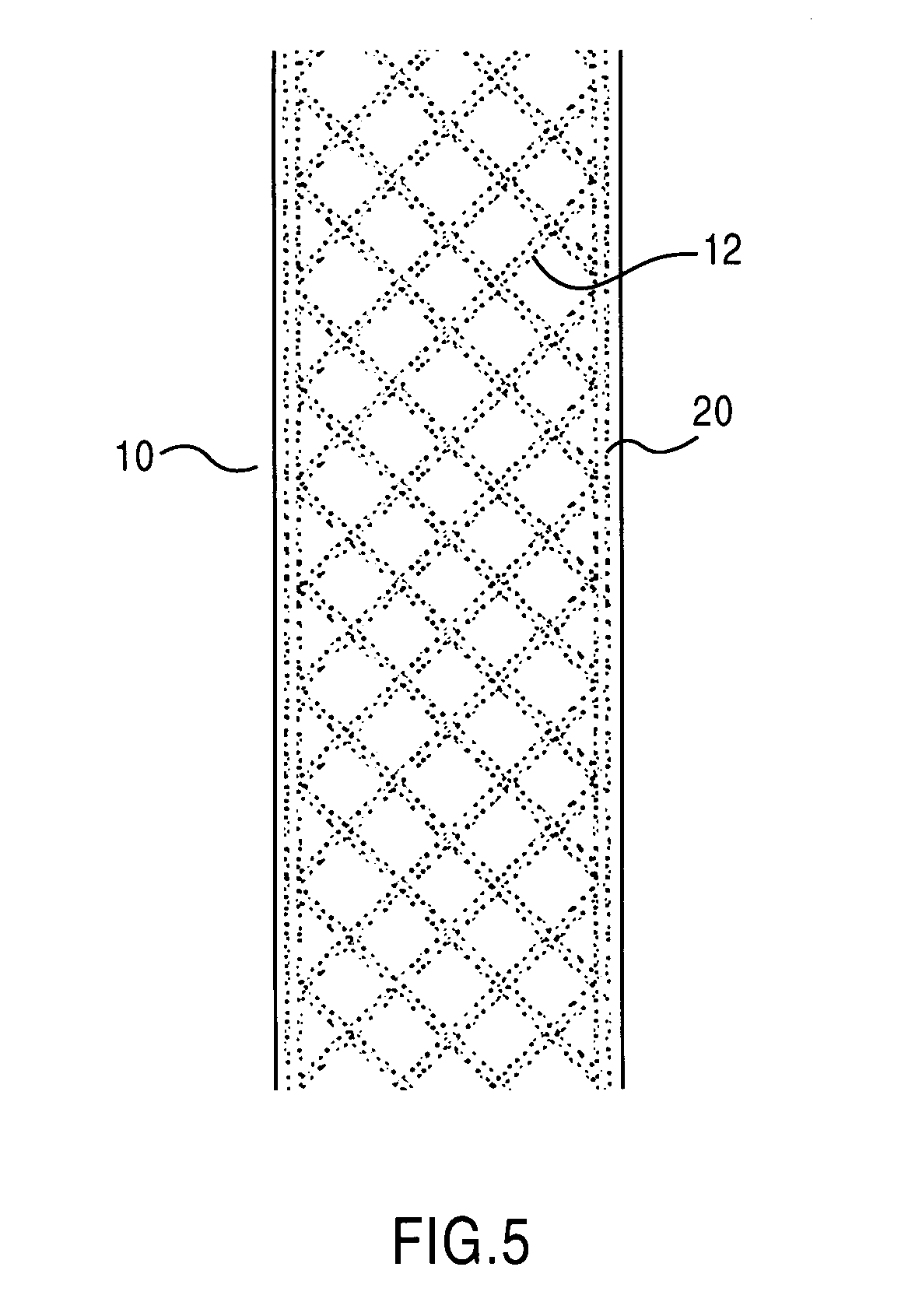

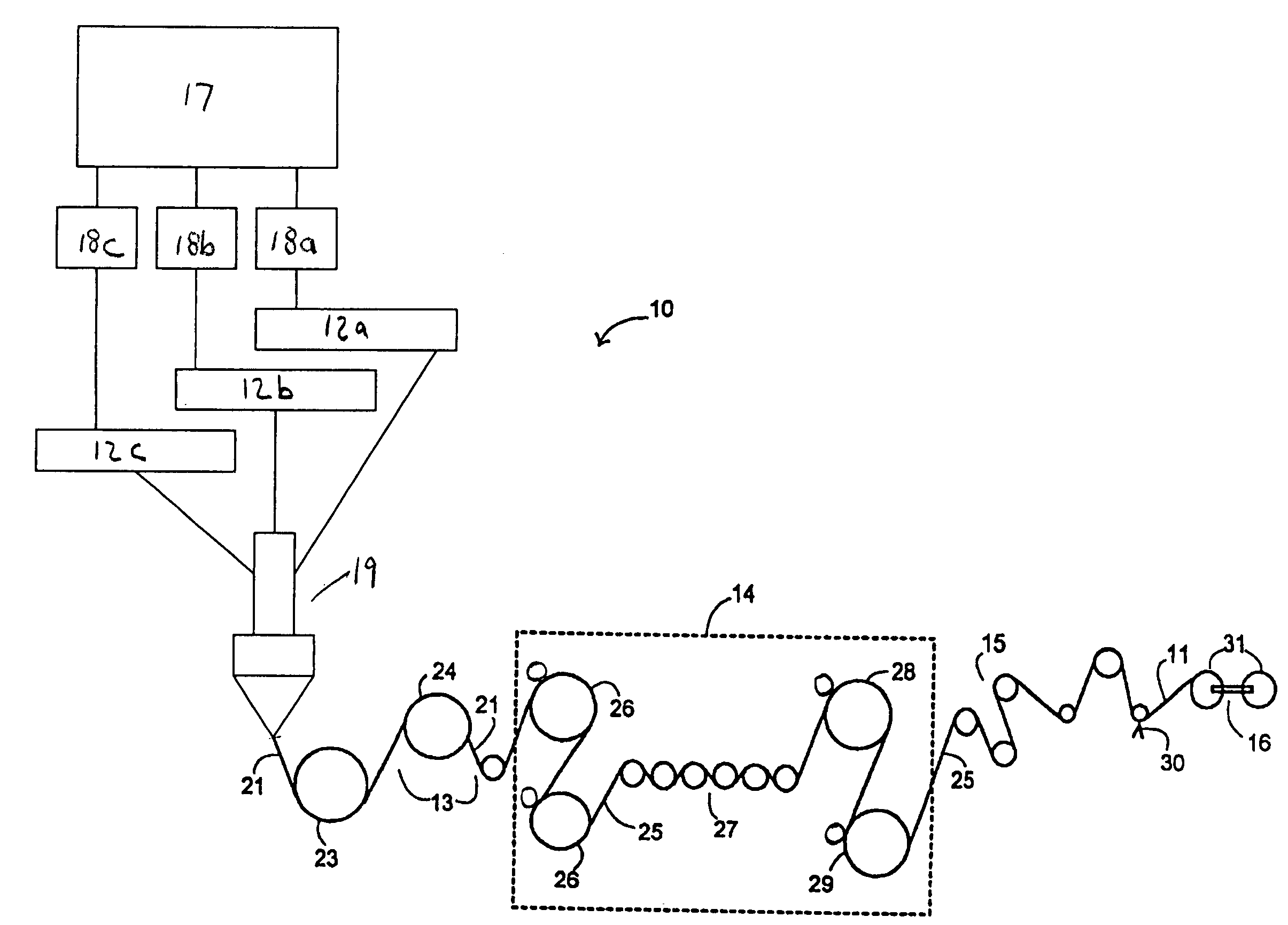

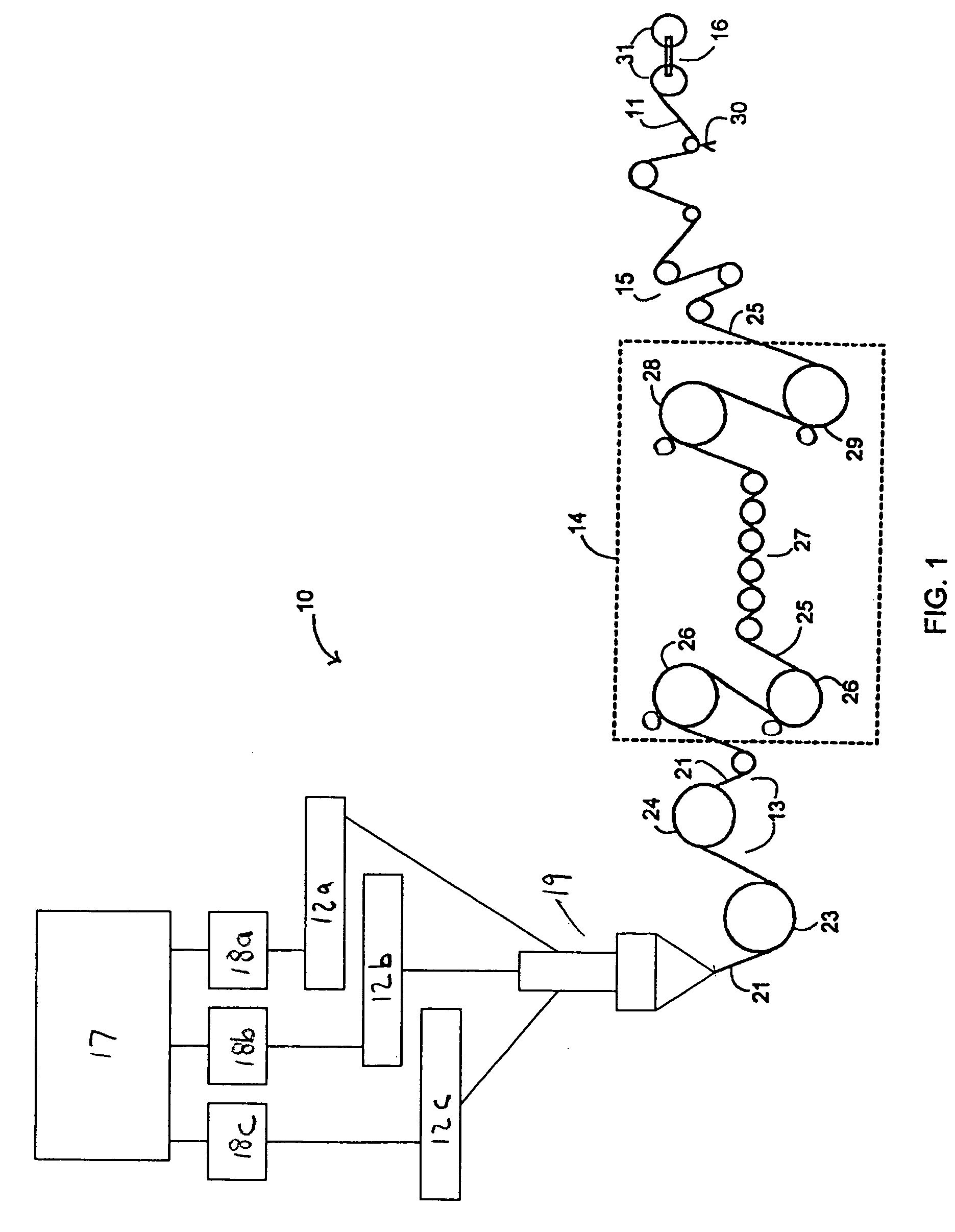

Patterning on surface with high thermal conductivity materials

ActiveUS20060234576A1Improve thermal conductivityHigh resistivityAdhesive articlesPaper/cardboardNanometreThermal transmittance

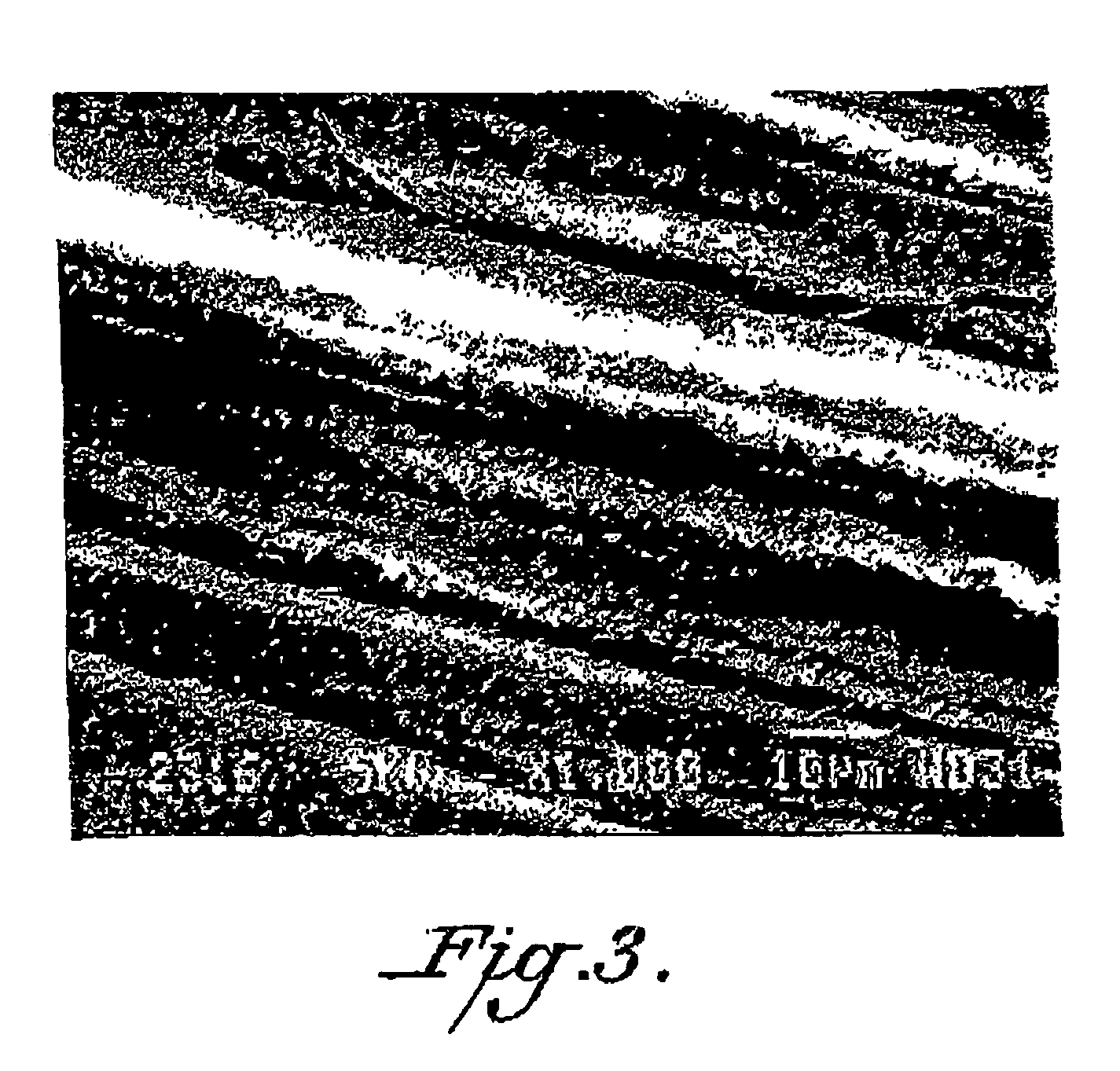

The present invention provides for high thermal conductivity paper that comprises a host matrix (10), and high thermal conductivity materials (12) added to a surface of the host matrix in a specific pattern (12). The high thermal conductivity materials are comprised of one or more of nanofillers, diamond like coatings directly on the host matrix, and diamond like coatings on the nanofillers. In particular embodiments the specific pattern comprises one or more of a grid, edging, banding centering and combinations thereof and the high thermal conductivity materials cover 15-55% of the surface of the host matrix. Multiple surfaces, including sub layers my have patterning.

Owner:SIEMENS ENERGY INC

Advanced body armor utilizing shear thickening fluids

InactiveUS20060234577A1High strengthNot impede fabric flexibilityWarp knittingCircular knitting machinesPuncture resistanceBody armor

An armor composite material has been invented which contains a fabric which has been impregnated with shear thickening fluid. This invention offers a ballistic resistant material that is more flexible and less bulky than comparable, conventional ballistic fabric. The material in the alternative can be puncture resistant. The invented material offers superior ballistic performance and / or puncture resistance compared to conventional ballistic fabric-based materials of equal thickness. The invented material can be applied to applications requiring armor that is compact and / or flexible, such as body armor, protective clothing and flexible protective devices and shields, and stab resistant clothing and devices.

Owner:UNIVERSITY OF DELAWARE

Advanced body armor utilizing shear thickening fluids

ActiveUS20050266748A1High strengthNot impede fabric flexibilityPersonal protection gearBeltsEngineeringBody armor

An armor composite material has been invented which contains a ballistic fabric which has been impregnated with shear thickening fluid. This invention offers a ballistic resistant material that is more flexible and less bulky than comparable, conventional ballistic fabric. The invented material offers superior ballistic performance compared to conventional ballistic fabric-based materials of equal thickness. The invented material can be applied to applications requiring armor that is compact and / or flexible, such as body armor, protective clothing and flexible protective devices and shields, and stab resistant clothing and devices.

Owner:UNIVERSITY OF DELAWARE

Web material exhibiting viewing-angle dependent color and comprising a plurality of discrete extended elements

A colored web material exhibiting viewing-angle dependent color and comprising a plurality of discrete extended elements. In one embodiment, the colored web material comprises a first web material and a second web material, wherein the first web material comprises a first polymer having first refractive properties and the second web material comprises a second polymer having second refractive properties, wherein said first refractive properties of said first polymer are different than said second refractive properties of said second polymer. In one embodiment, the colored web material comprises an interference pigment incorporated in at least one layer of the colored web material. In one embodiment, the discrete extended elements have a diameter of less than about 500 microns. In one embodiment, the colored web material comprises at least about 95 discrete extended elements per square centimeter. In one embodiment, the discrete extended elements have an aspect ratio of at least about 0.2.

Owner:THE PROCTER & GAMBLE COMPANY

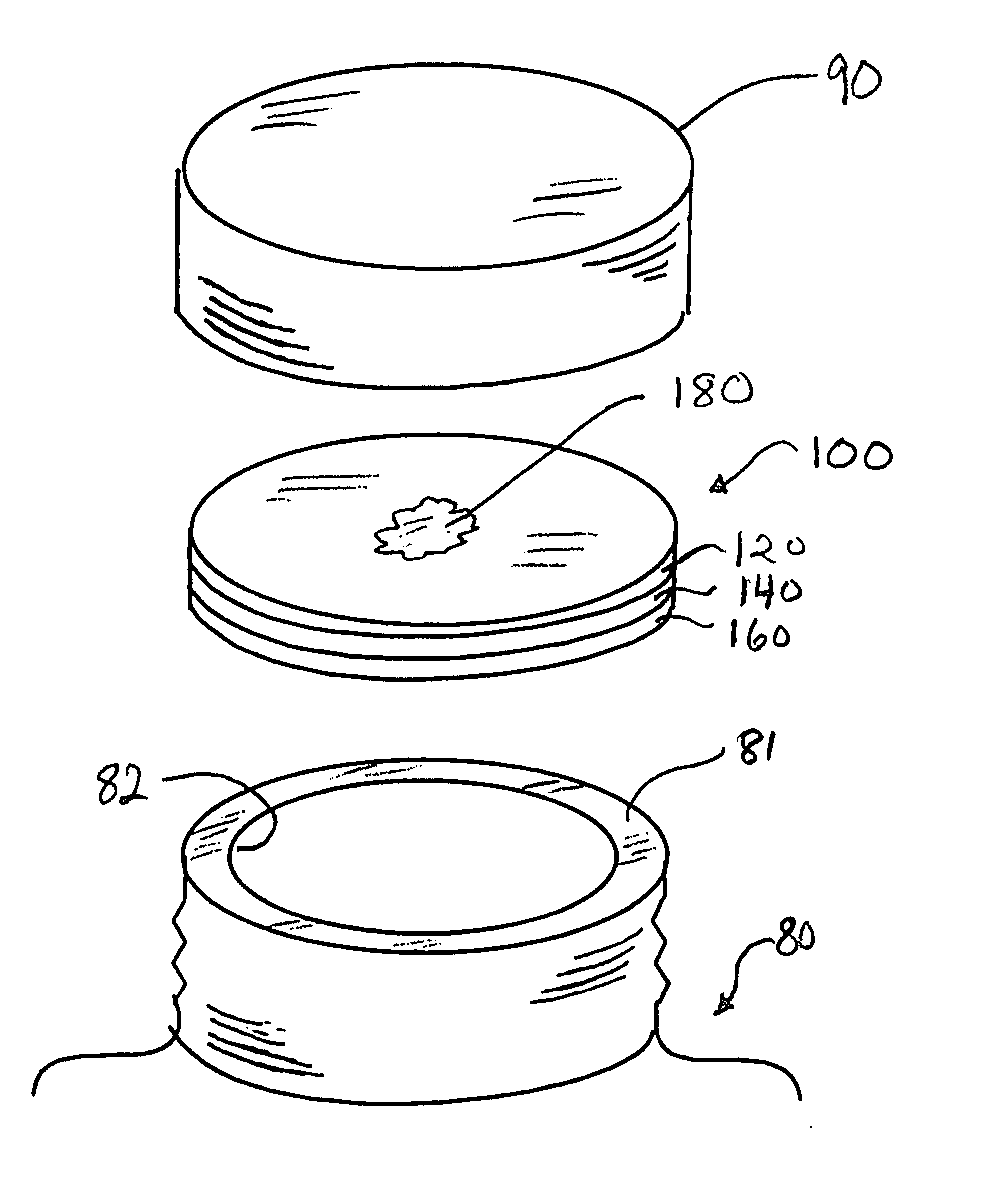

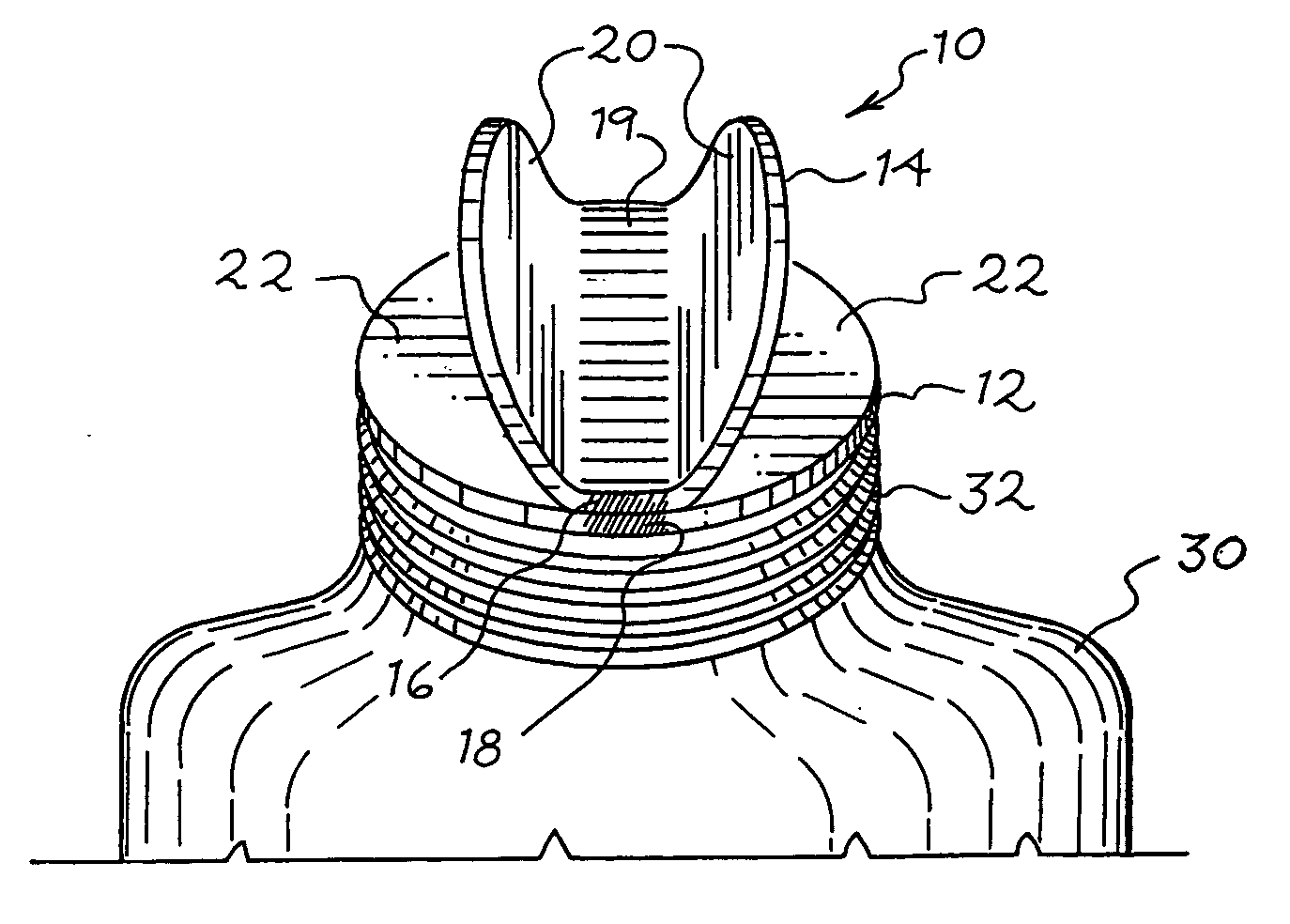

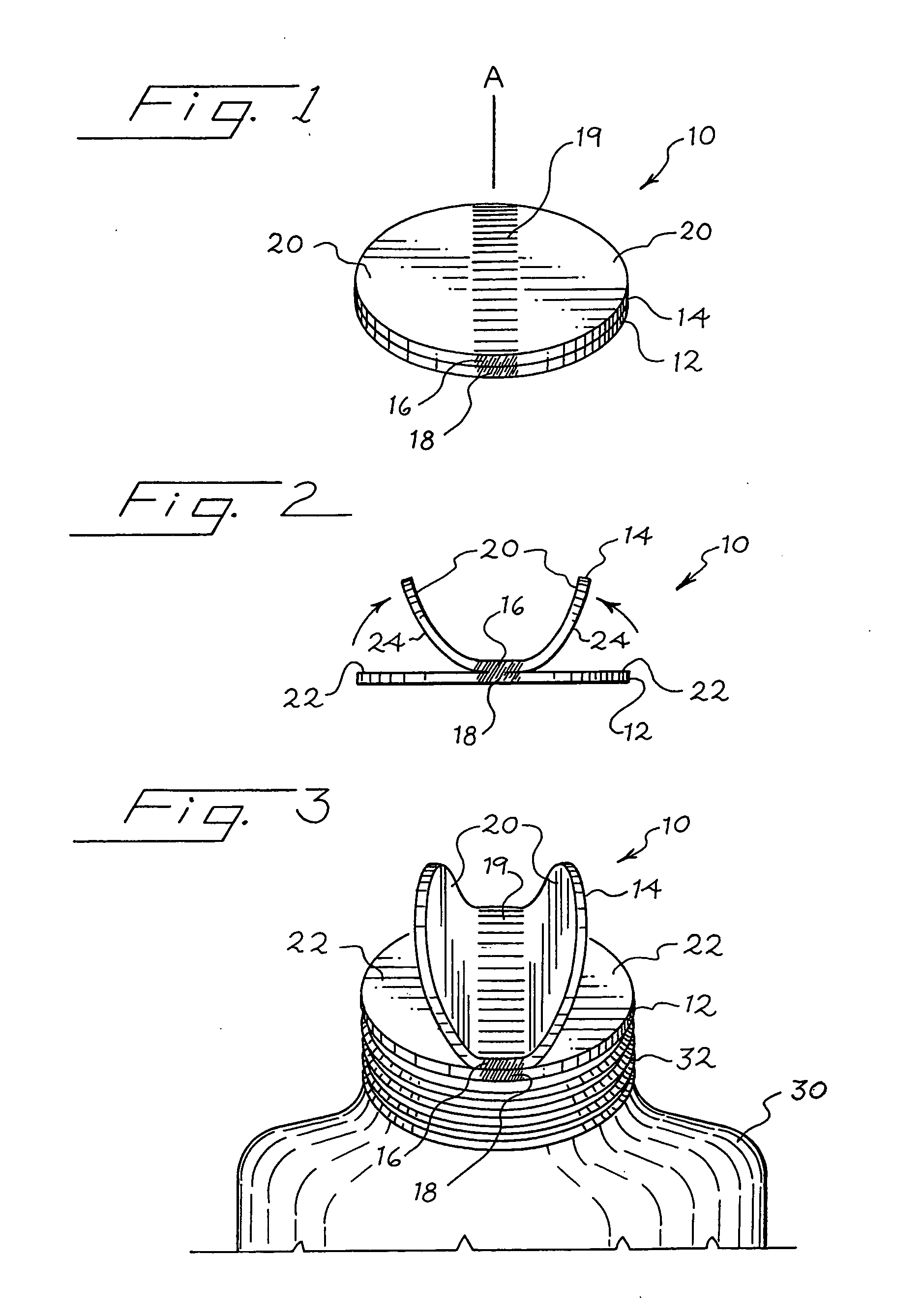

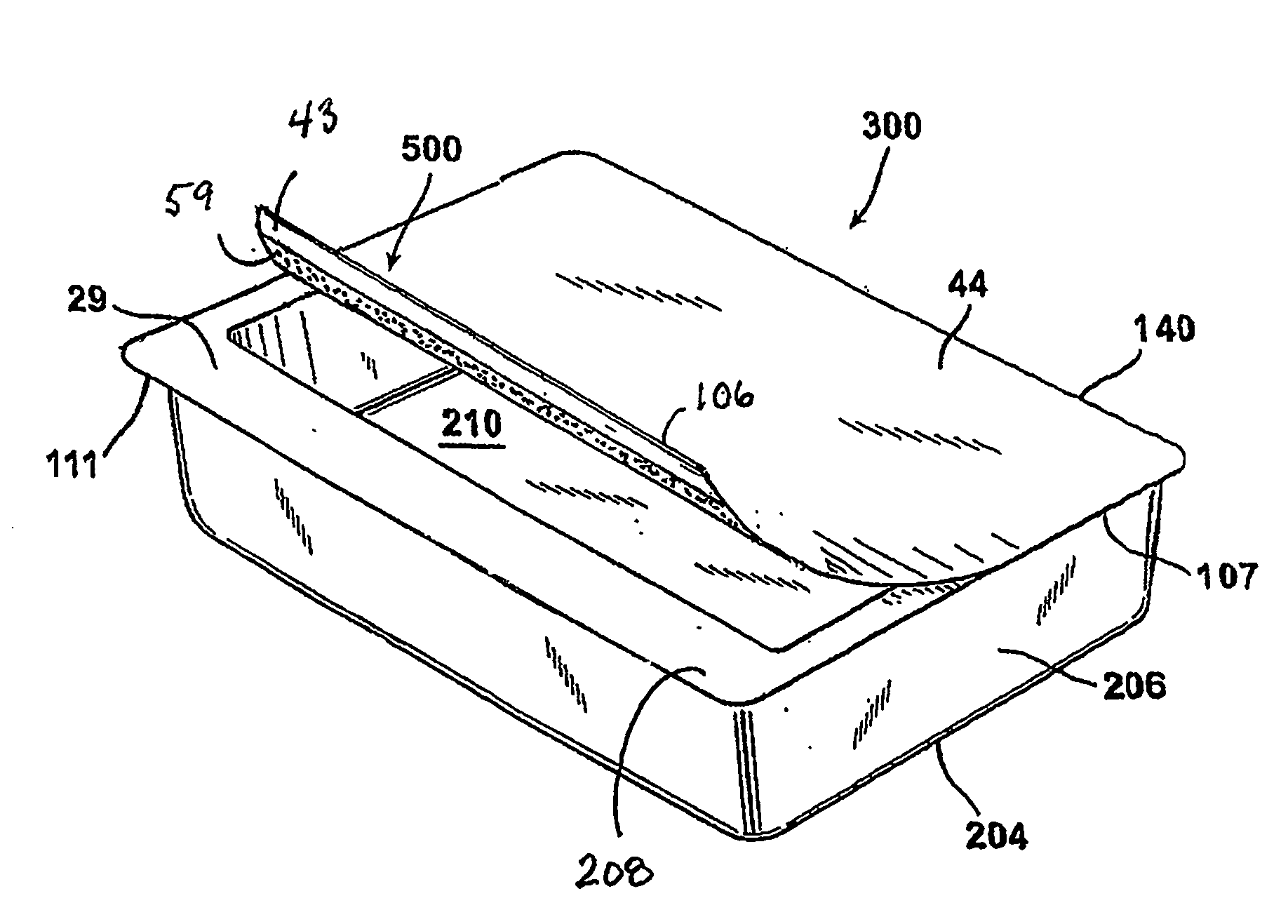

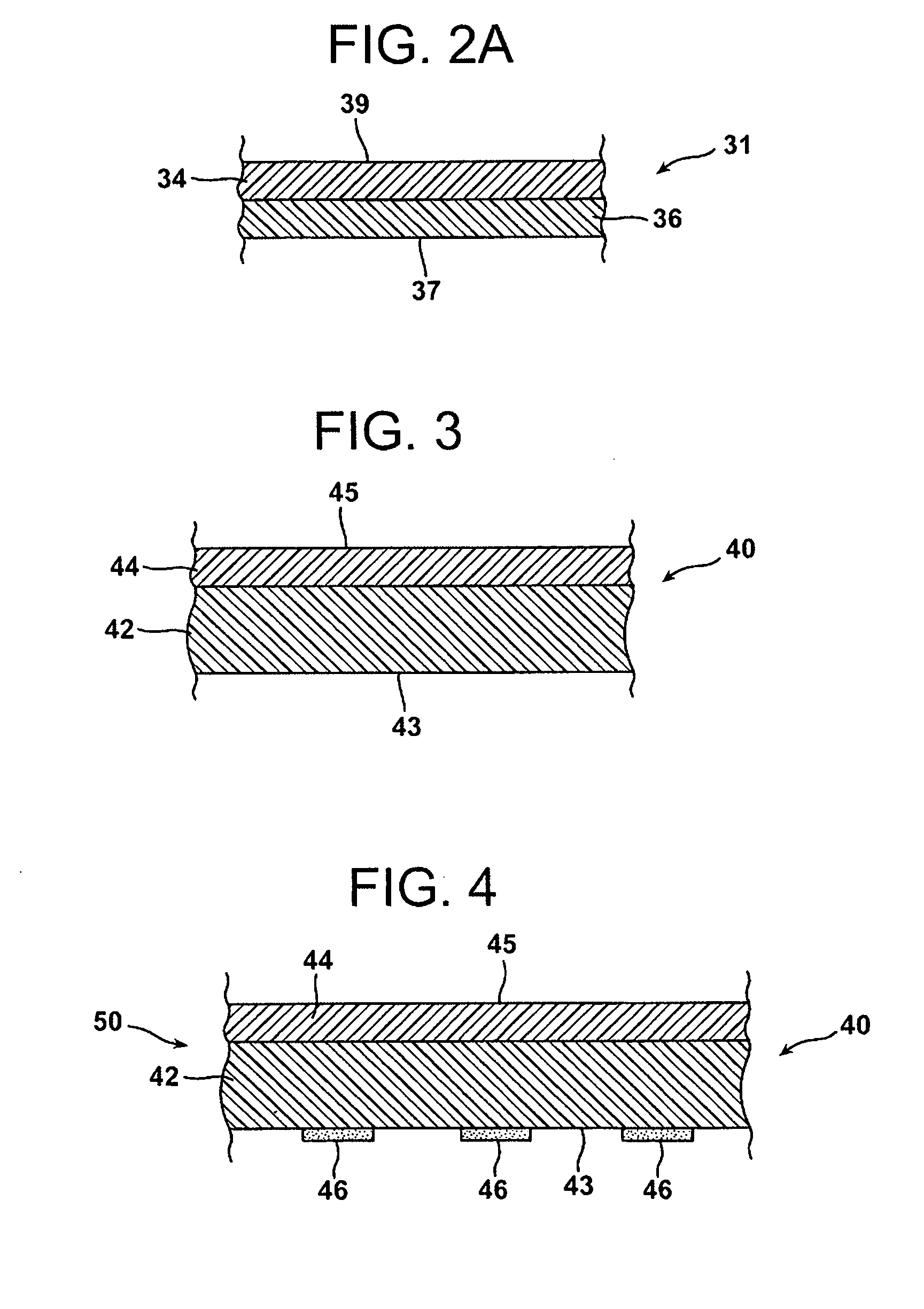

Two-piece container seal and method of manufacture

InactiveUS7648764B2Easy to manufactureImproved separation mechanismCapsSealingFree interfaceEngineering

An improved two-piece container seal suitable for sealing a container having a removable closure and for lining the closure comprises a flexible sealant sheet and a flexible liner sheet bonded thereto. The sealant sheet and liner sheet are of the same size and shape. The sealant sheet has a sealing surface and a first thermoplastic surface, and the liner sheet has an outer surface and a second thermoplastic surface. The first and second thermoplastic surfaces are in opposed, congruent contact with each other, and the first thermoplastic surface is ultrasonically welded to the second thermoplastic surface by an array of spaced, frangible ultrasonic welds, forming an adhesive-free interface therebetween. A method of manufacturing a two-piece container seal and a sealed container comprising a two-piece container seal are also described.

Owner:TEKNI PLEX

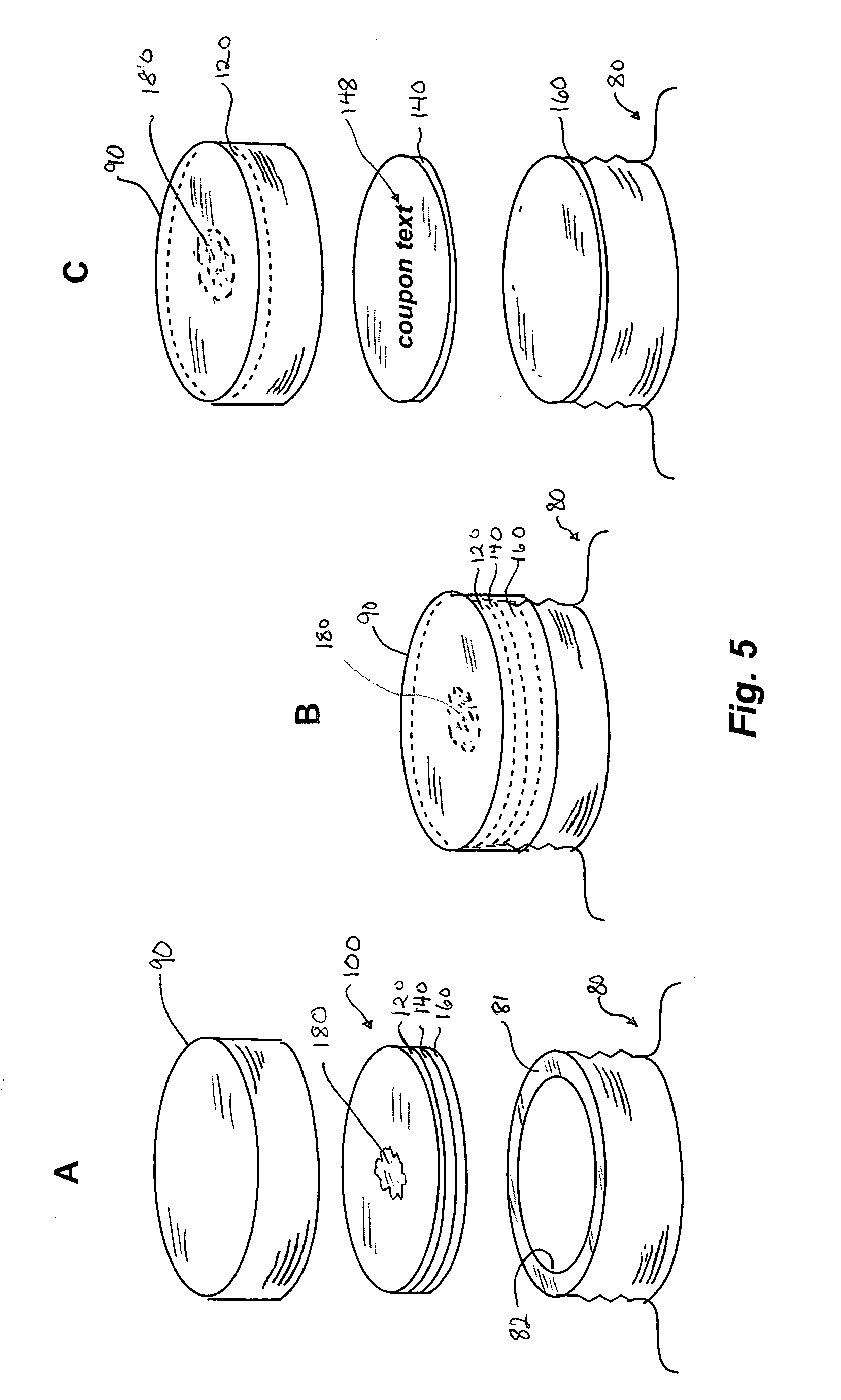

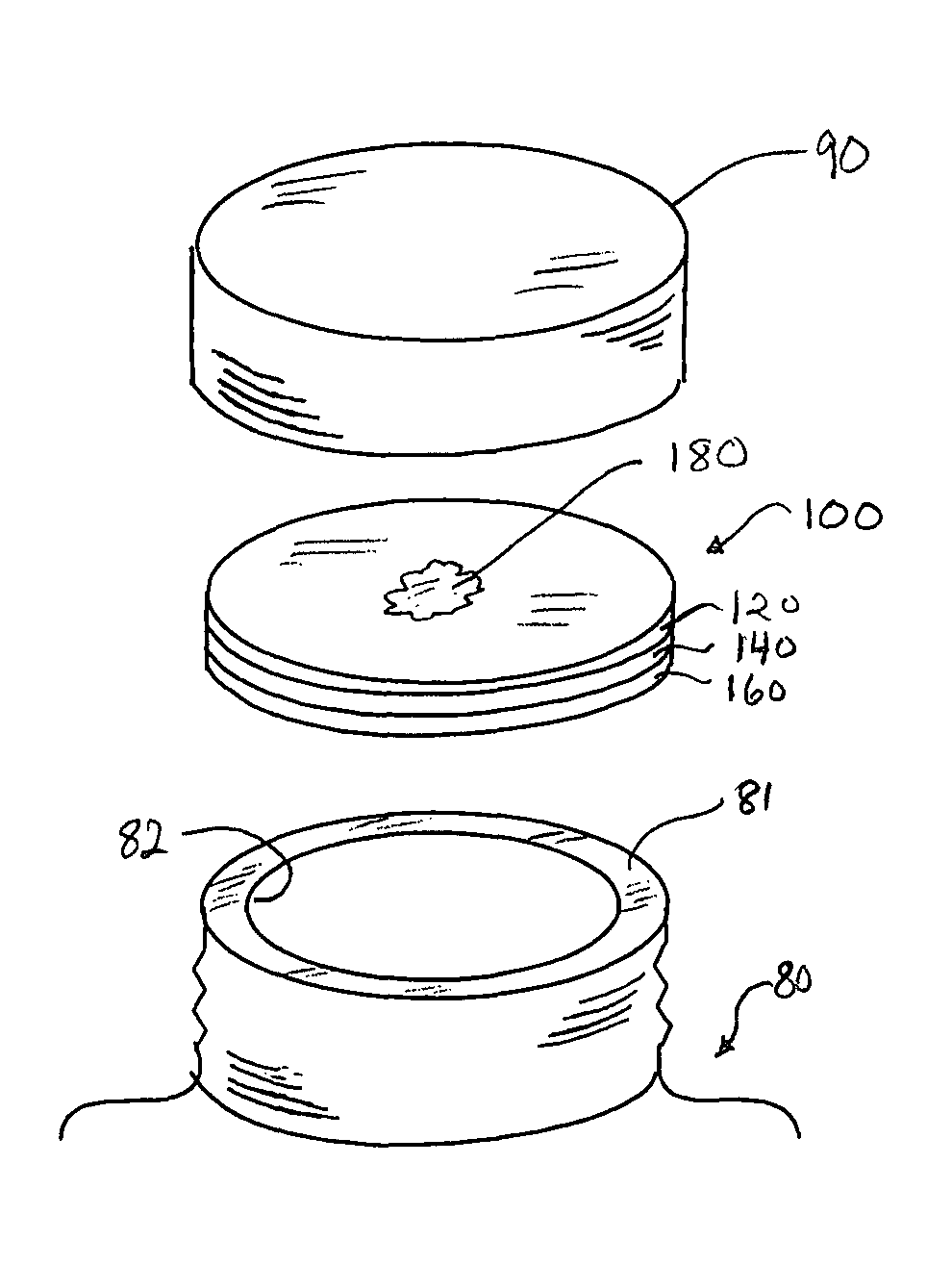

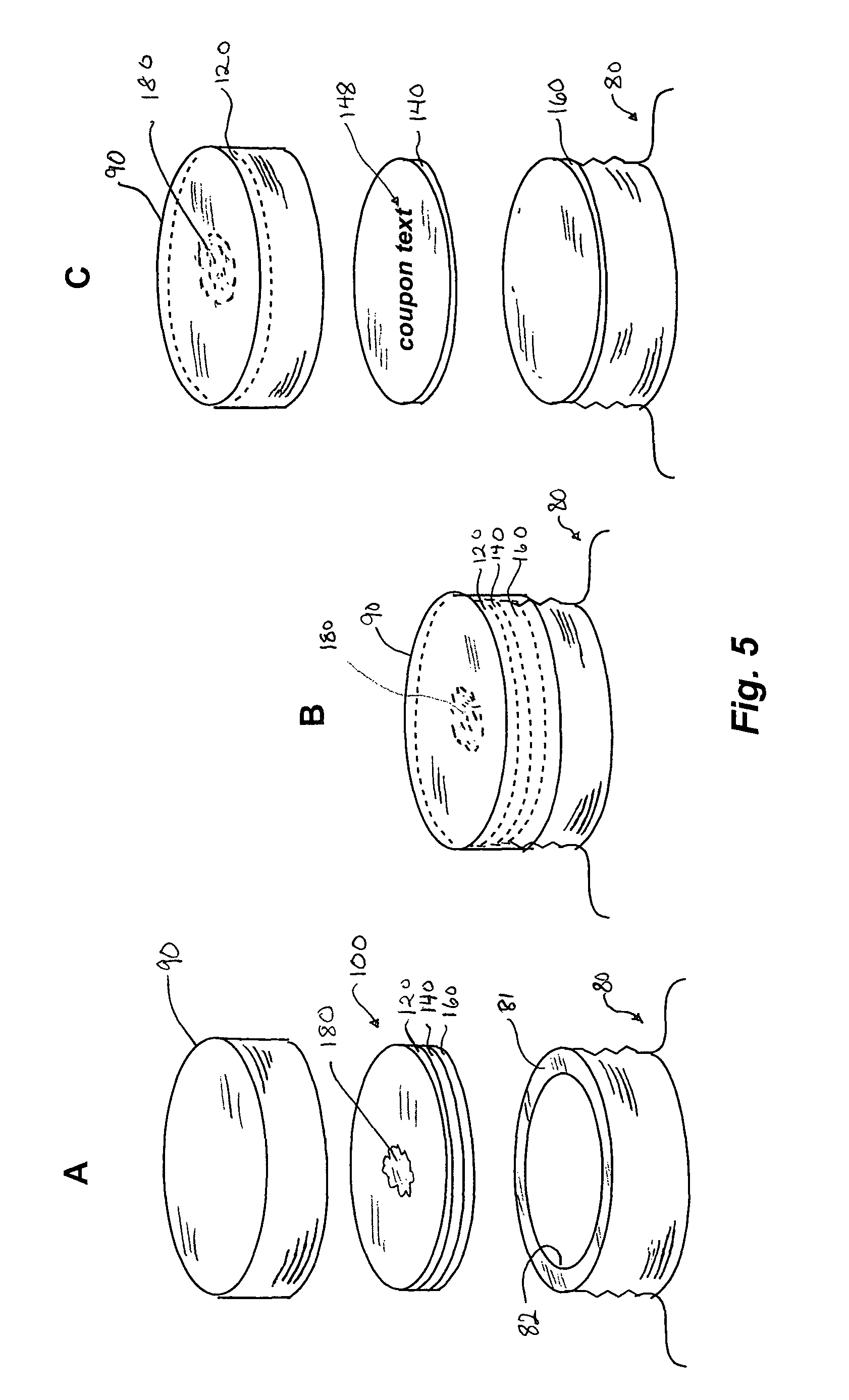

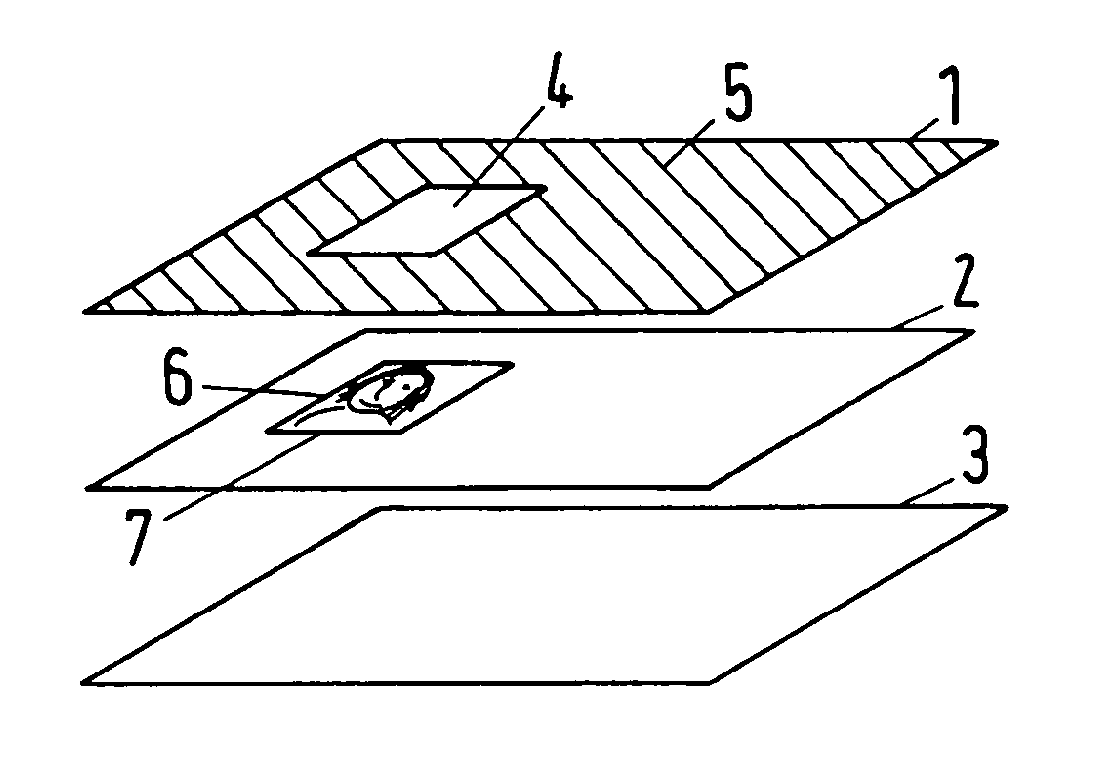

Container sealing material having a heat-releasable interlayer

An container sealing material suitable for sealing a container comprises a liner sheet (liner), a sealant sheet, and an interlayer portion (interlayer) bound between the liner and the sealant sheet by individual layers of wax. The material has a closure-contacting surface and a heat-sealable surface. At least one of the surfaces of the liner and the interlayer that contacts a layer of wax is capable of absorbing liquid wax when the layer of wax is melted. At least one of the surfaces of the sealant sheet and interlayer which contacts a layer of wax is capable of absorbing liquid wax when the layer of wax is melted. The liner and the sealant sheet each release from the interlayer when sufficient heat is applied to the container sealing material to melt the layers of wax. The interlayer can include printed matter visible on one or both of its surfaces (e.g., a logo, proof-of-purchase indicator, and the like). The printed matter can include promotional indica for a product, a service, a game and the like. Accordingly, the container sealing material provides a means for including a promotional token, such as a redeemable coupon within a container closure between the liner and the sealant sheet.

Owner:TEKNI PLEX

Container sealing material having a heat-releasable interlayer

An container sealing material suitable for sealing a container comprises a liner sheet (liner), a sealant sheet, and an interlayer portion (interlayer) bound between the liner and the sealant sheet by individual layers of wax. The material has a closure-contacting surface and a heat-sealable surface. At least one of the surfaces of the liner and the interlayer that contacts a layer of wax is capable of absorbing liquid wax when the layer of wax is melted. At least one of the surfaces of the sealant sheet and interlayer which contacts a layer of wax is capable of absorbing liquid wax when the layer of wax is melted. The liner and the sealant sheet each release from the interlayer when sufficient heat is applied to the container sealing material to melt the layers of wax. The interlayer can include printed matter visible on one or both of its surfaces (e.g., a logo, proof-of-purchase indicator, and the like). The printed matter can include promotional indica for a product, a service, a game and the like. Accordingly, the container sealing material provides a means for including a promotional token, such as a redeemable coupon within a container closure between the liner and the sealant sheet.

Owner:TEKNI PLEX

High Thermal Conductivity Mica Paper Tape

InactiveUS20080050580A1Improve thermal conductivityHigh materialDomestic sealsAdhesive articlesPaper tapeOptoelectronics

Owner:SIEMENS ENERGY INC

Tabbed container seal and method of manufacture

InactiveUS20070003725A1Easy to manufactureReliable removal mechanismStampsWrappersThermoplasticEngineering

An improved container seal comprises a flexible sealant sheet and a flexible tab sheet bonded thereto. The sealant sheet and tab sheet are of the same size and shape. The sealant sheet has a sealing surface and a first thermoplastic surface, and the tab sheet has an outer surface and a second thermoplastic surface. The first and second thermoplastic surfaces are in opposed, congruent contact with each other, and a portion of the first thermoplastic surface is ultrasonically welded to an opposed portion of the second thermoplastic surface. The ultrasonically welded portions of the thermoplastic surfaces are positioned on the sealant sheet and tab sheet in a manner that allows at least one edge portion of the tab sheet to be lifted away from the sealant sheet, providing a tab member for removing the seal from a container.

Owner:TEKNI PLEX

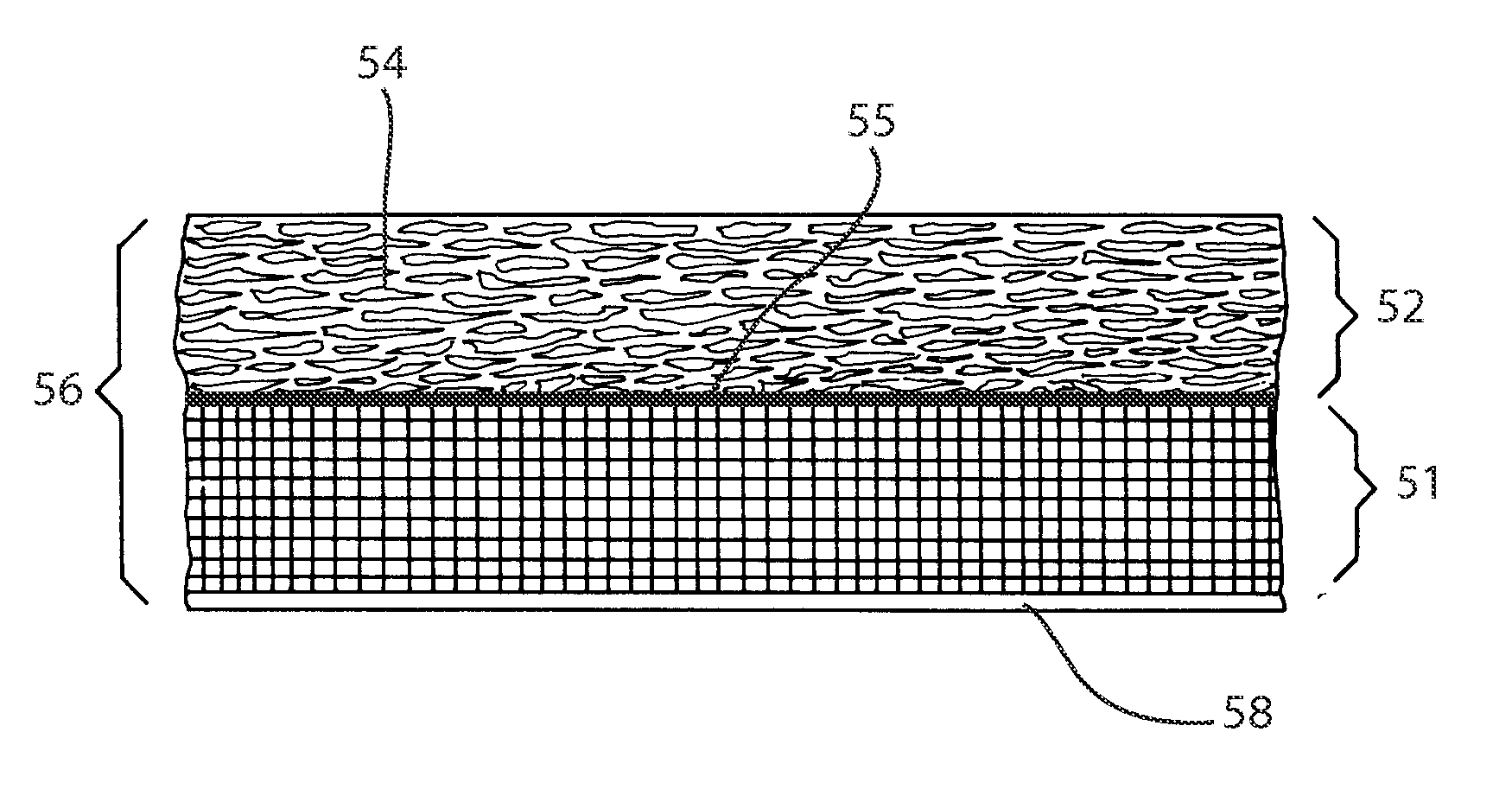

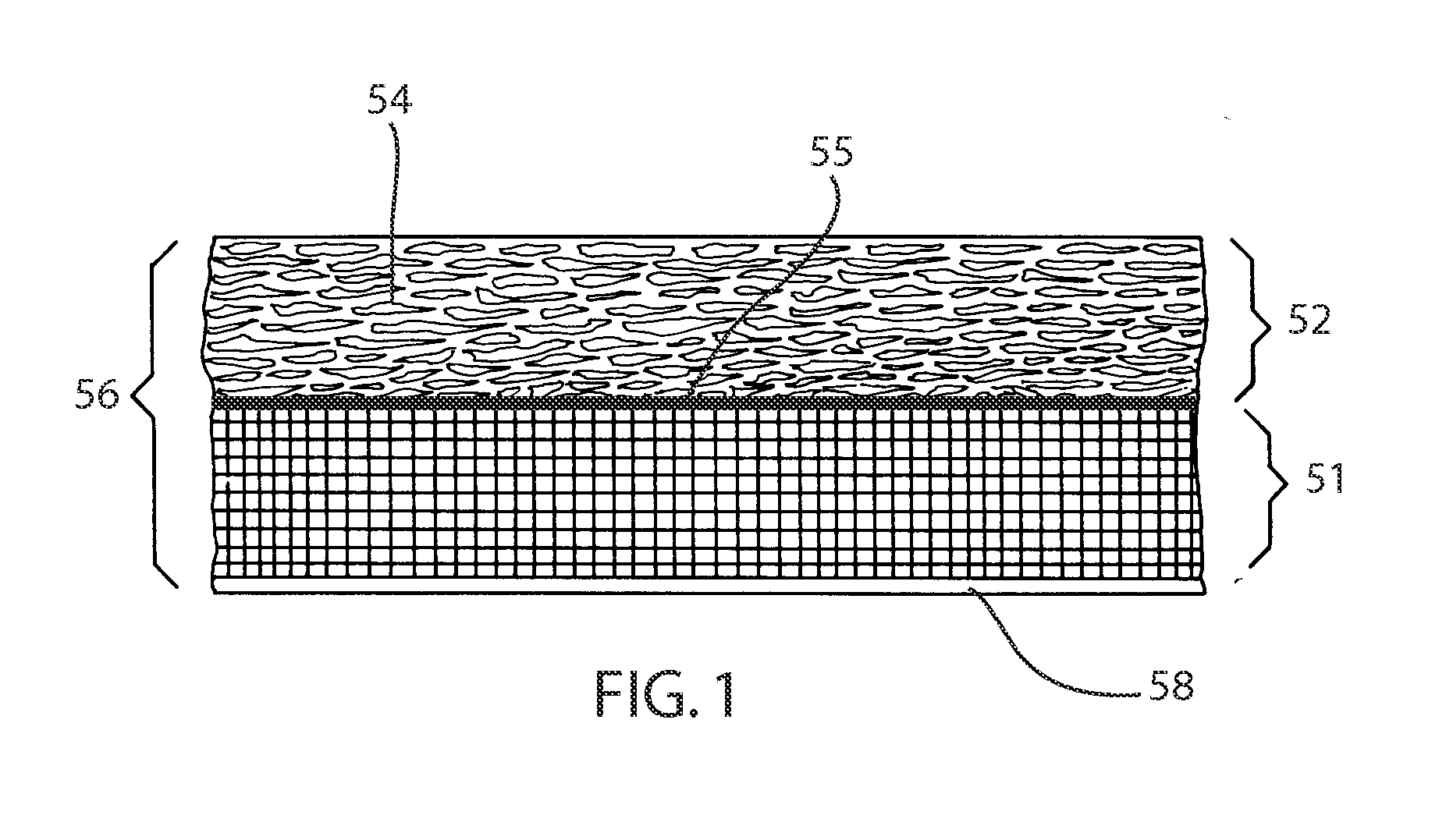

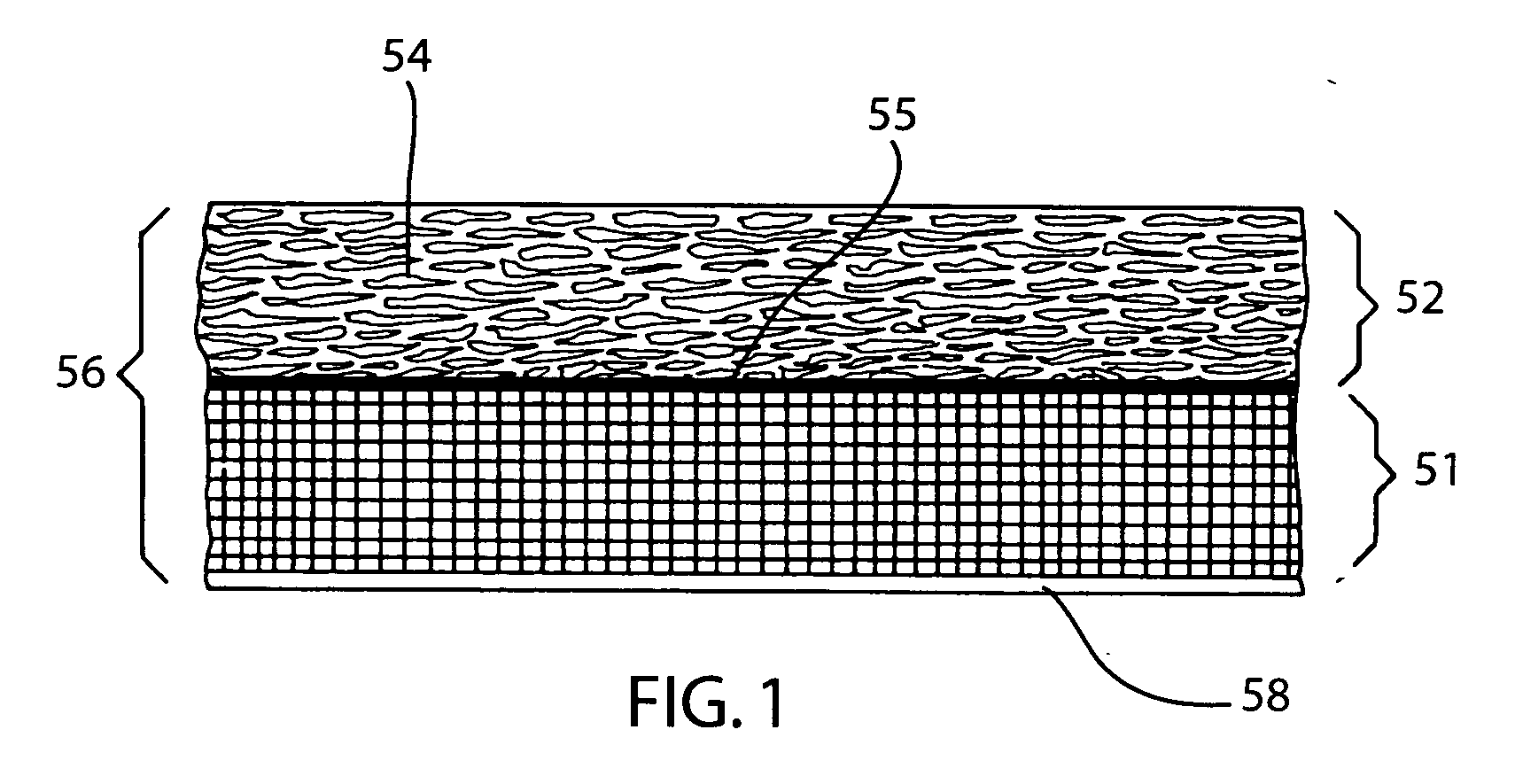

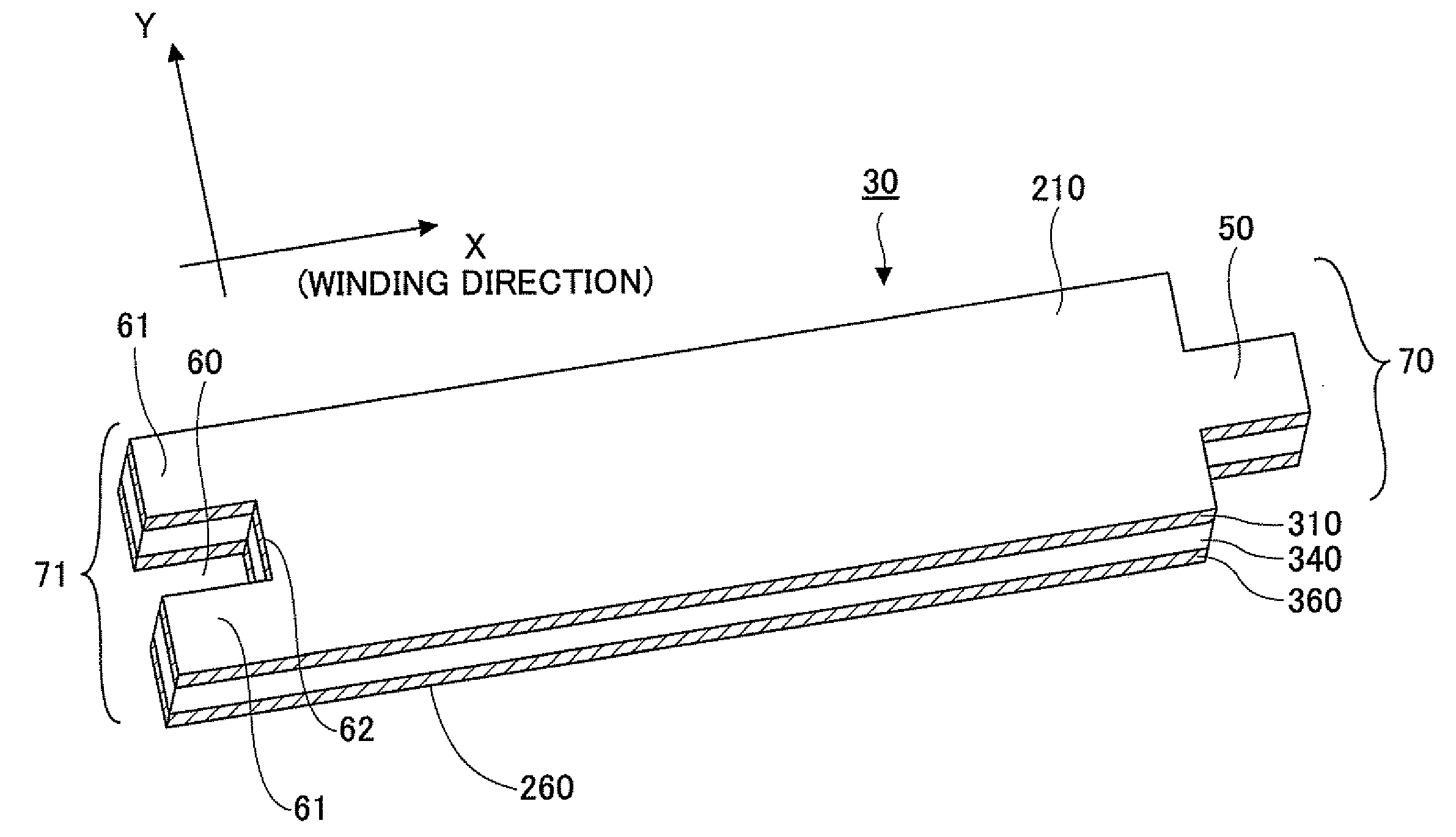

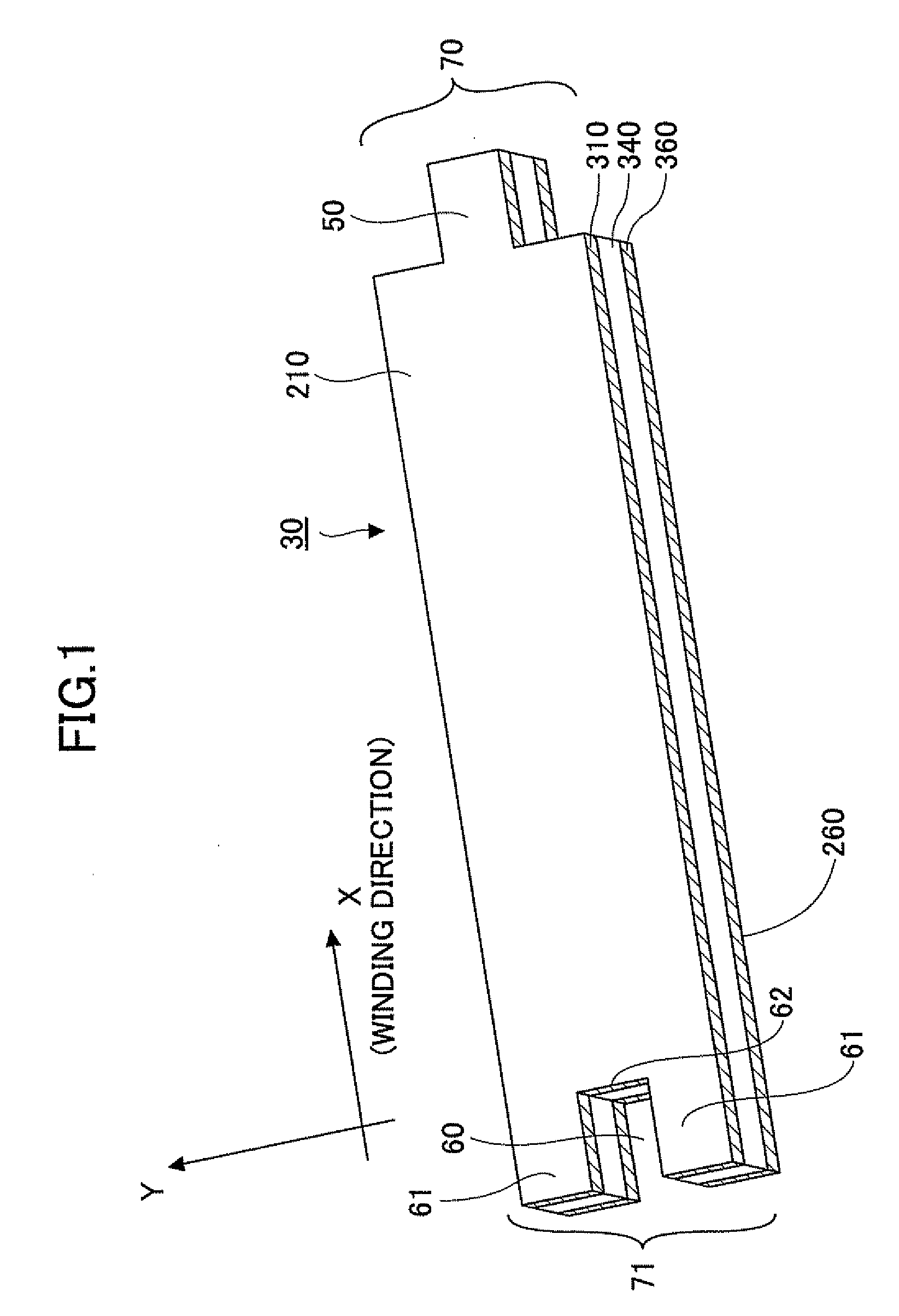

Composite insulation tape with loaded HTC materials

InactiveUS20060231201A1Improve thermal conductivityHigh materialLiquid surface applicatorsDomestic sealsElectrical tapeMaterials science

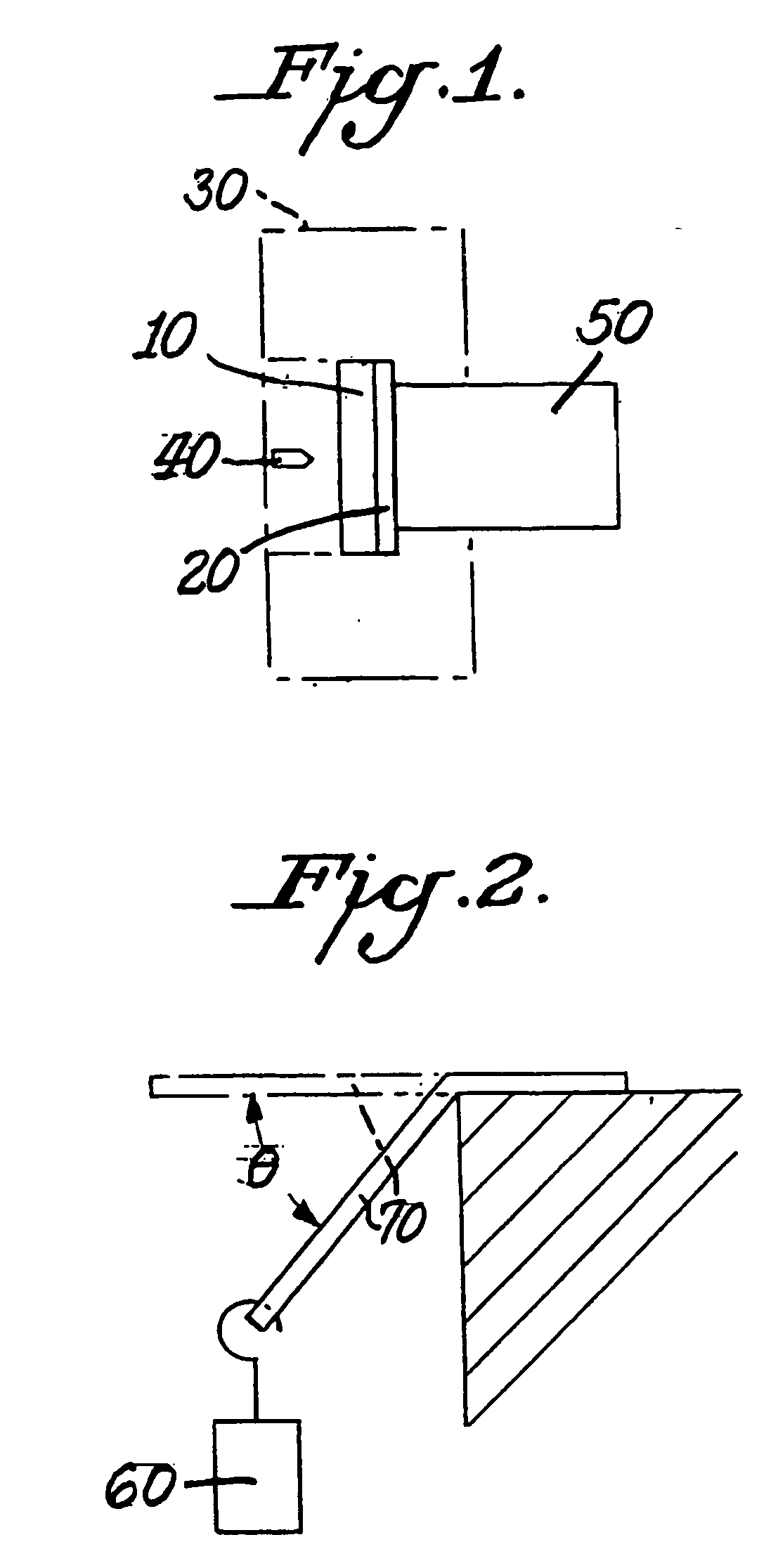

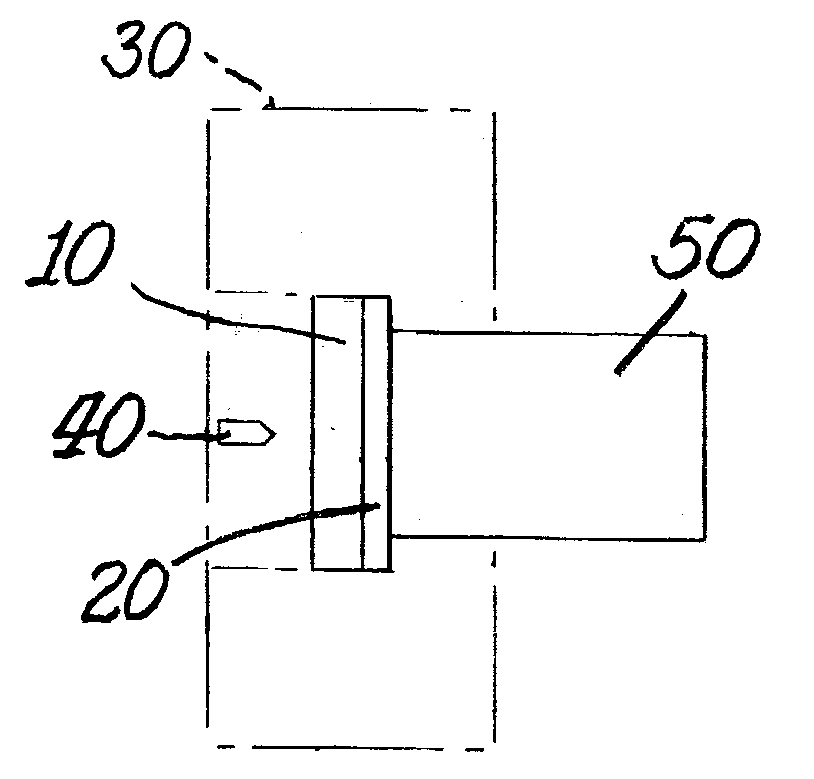

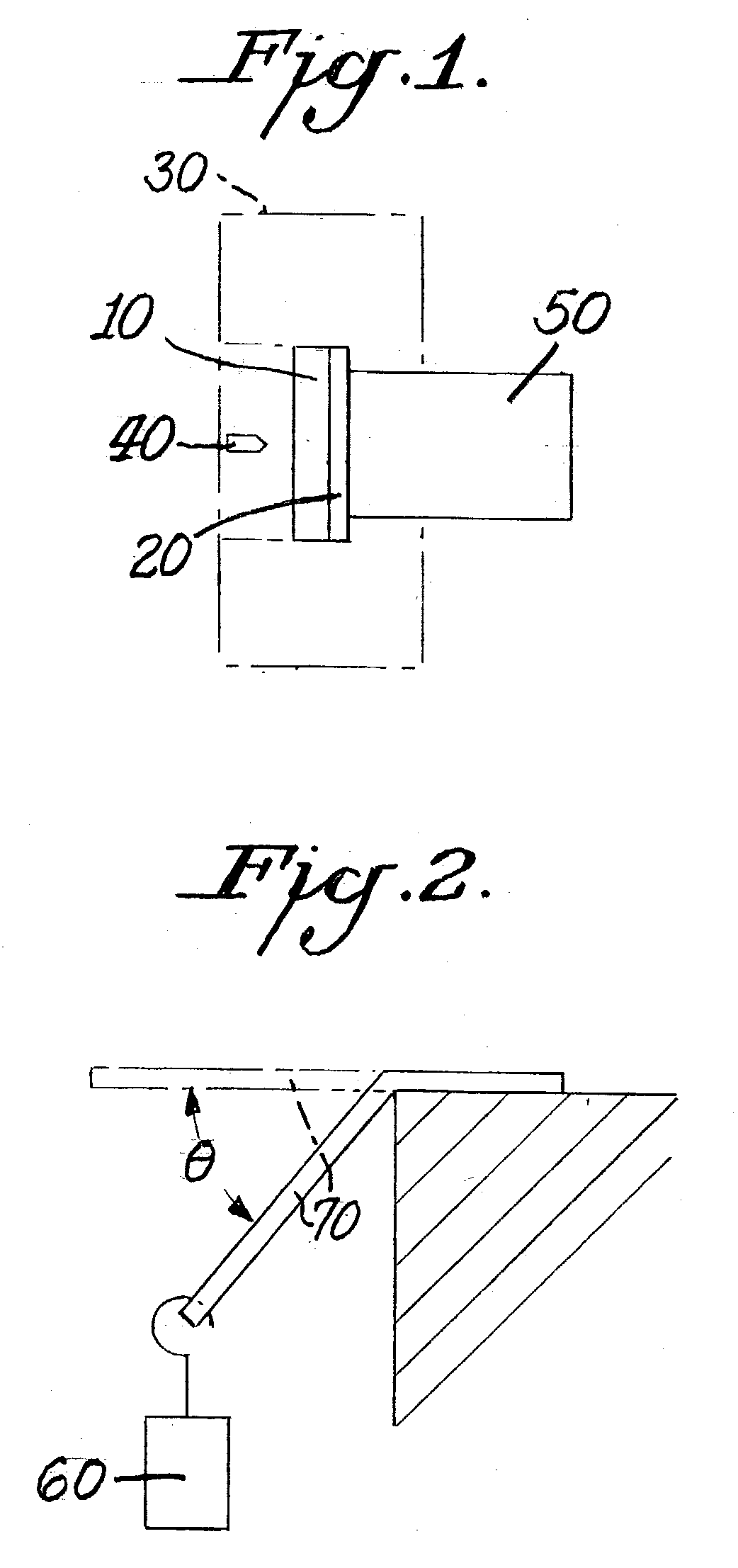

In one embodiment of the present invention as used for impregnating a composite tape (56) with HTC particles provides for permeating a fabric layer (51) of the composite tape with HTC particles and impregnating an impregnating resin into the composite tape through the fabric layer (51). At least 5% of the HTC particles permeated into the fabric layer are carried out of the fabric layer and into a mica layer (52) bound to the fabric layer by the impregnating resin. In some embodiments the impregnating resin itself contains HTC particles.

Owner:SIEMENS ENERGY INC

Multilayer separable film or sheet

InactiveUS20060088695A1Low production costSaveDomestic sealsProtective equipmentElectrical and Electronics engineeringSheet material

A multilayer film having two or more separable adjacent layers. The multilayer film includes adjacent layers formed of compositions of dissimilar primary materials. Optionally, at least one of the layers contains a slip additive to change the release tension between adjacent layers. The multilayer film may include an adhesive layer between layers, with the adhesive layer more adhesion compatible with one of the layers than the other. The multilayer film may be a relatively inexpensive means to produce labels, films, sheets, containers, etc., requiring protection or isolation of one surface without the additional processes of gluing together individual dissimilar layers. Applications include, but are not limited to, the multilayer film being used as a seal to secure containers, including envelopes, and being imprinted and used as a multilayer labeling system. In one preferred embodiment, at least one layer of the multilayer film undergoes a visibly observable change when the at least one layer is released from at least one other layer; the visibly observable change is useful for many purposes, including, but not limited to, serving as a security mechanism within a container seal which, when the seal is broken, provides evidence that the container was opened.

Owner:COBURN THEODORE

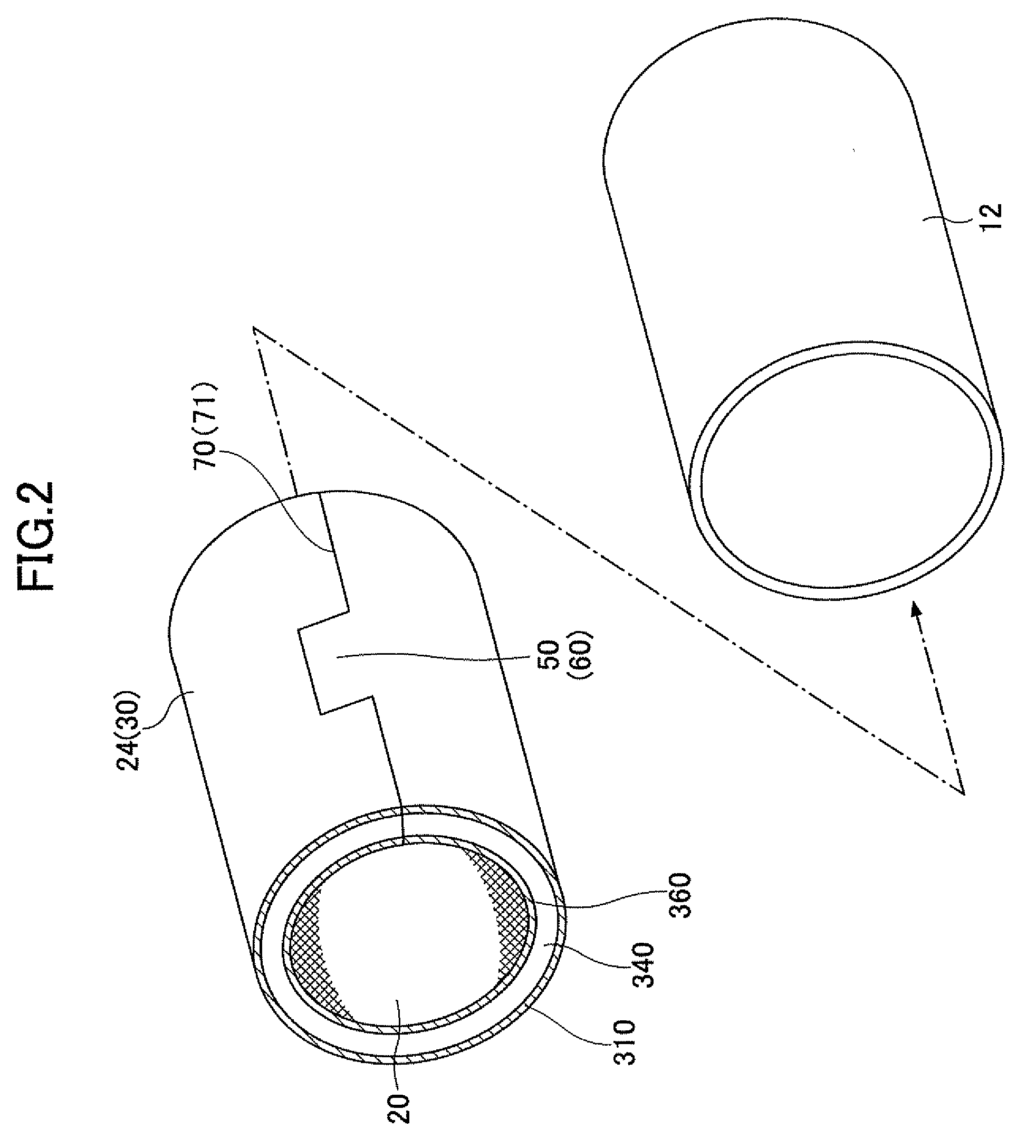

Mat material and exhaust gas treatment device

ActiveUS20090114097A1Improves its winding propertyHigh positioning accuracyDomestic sealsSynthetic resin layered productsFiberExhaust fumes

A mat material includes an inorganic fiber, a first sheet material and a second sheet material. The first sheet material is provided on a first surface of the mat material. The second sheet material is provided on a second surface of the mat material. The first sheet material and the second sheet material show a different elongation amount in a longitudinal direction of the mat material under a same tensile load.

Owner:IBIDEN CO LTD

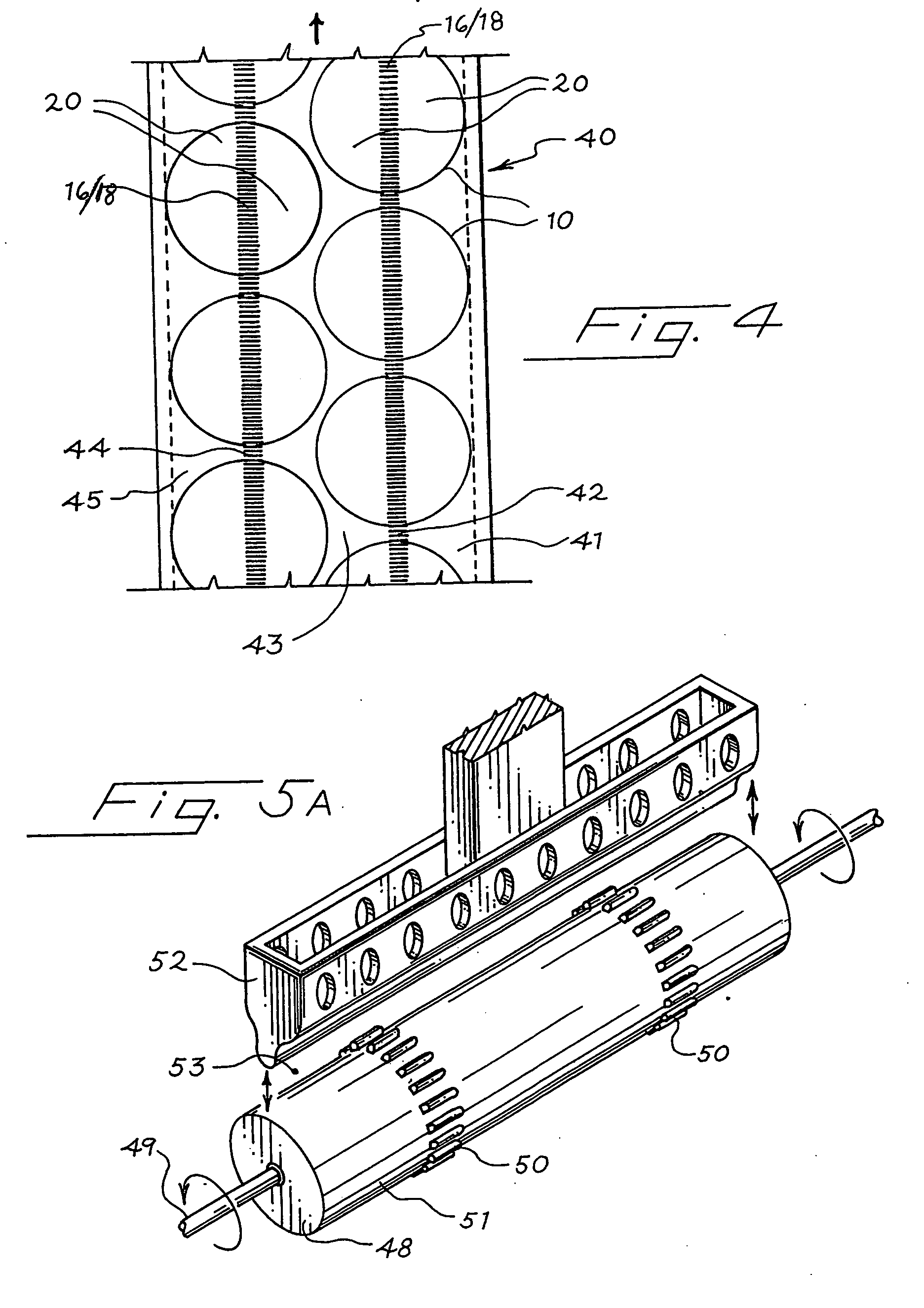

Exterior sheathing weather barrier construction and method of manufacture

InactiveUS20050159057A1Diminish or eliminate the possible leak path at the board jointsObstruct passageLiquid surface applicatorsDomestic sealsEdge surfaceFace sheet

A gypsum board panel having two facing main surfaces and machine edge surfaces, the board including an outer gypsum layer in which a polymer additive has been entrained, and the machine edges being shaped to have a three-dimensional feature, such that the features are complementary, and one machine edge surface can engage the complementary surface of the machine edge of an adjacent gypsum board panel. The three-dimensional features may include a triangular, in cross-section, ridge, or a rectangular ledge, or a concave edge, with a corresponding complementary groove or depression on the opposed edge for engagement with the edge of an adjacent board. A plurality of fastener plugs, taking the form of, for example strips or dots, can be disposed on the outer facing surface of the board to provide an entry point for penetration of a fastener, such as a nail or screw, and a layer of sheathing material, for example a covering polymeric coating, is optionally disposed over the outer board panel surface to further enhance the moisture repellent properties of the board.

Owner:BPB LTD

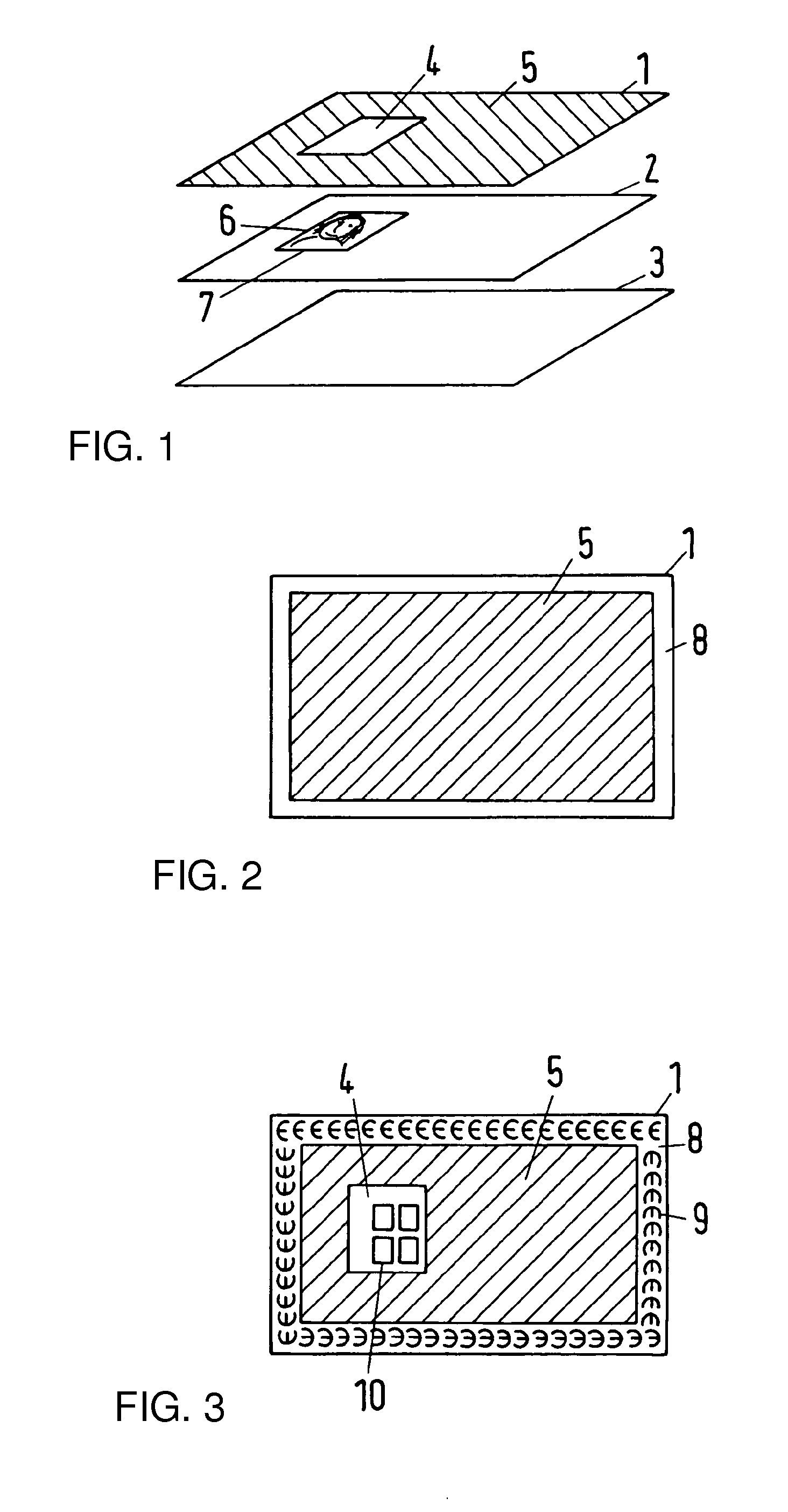

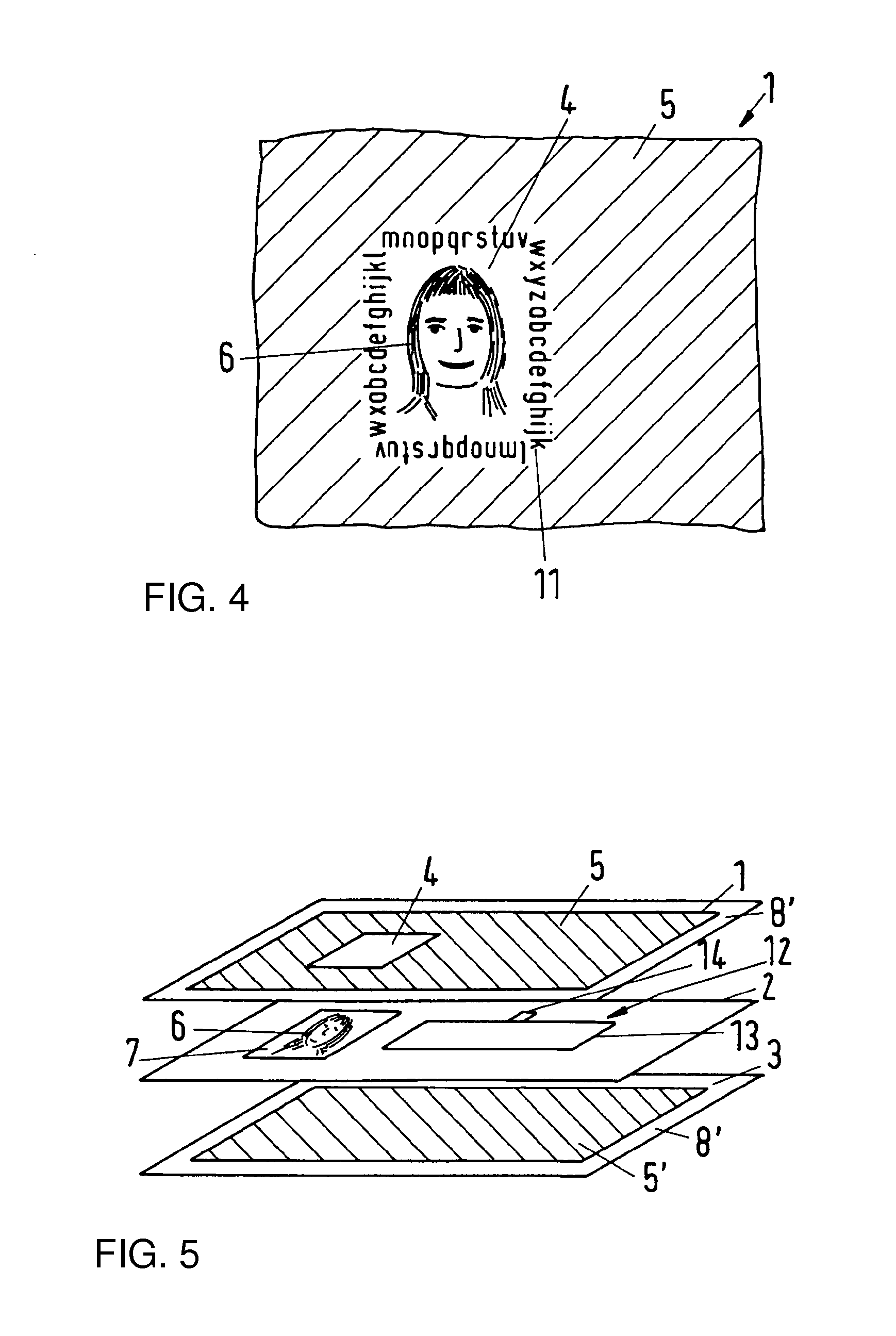

Polymer laminate for a security and/or valuable document and method for the production thereof

ActiveUS20100295290A1Easily delaminatedEasy to splitRecord carriersDecorative surface effectsEngineeringPolymer

In order to create novel security features in secure and / or valuable documents, a polymer layer composite, which has at least two polymer layers that are bonded to each other in a material fit is provided. At least one surface is printed with an absorbing printed layer within a visible region in and / or on the composite located on a polymer layer of the composite. The absorbing printed layer forms at least one printed region, and all printed regions of the printed surface of the polymer layer have a total surface area of at least 50% and not more than 95%.

Owner:BUNDESDRUCKEREI GMBH

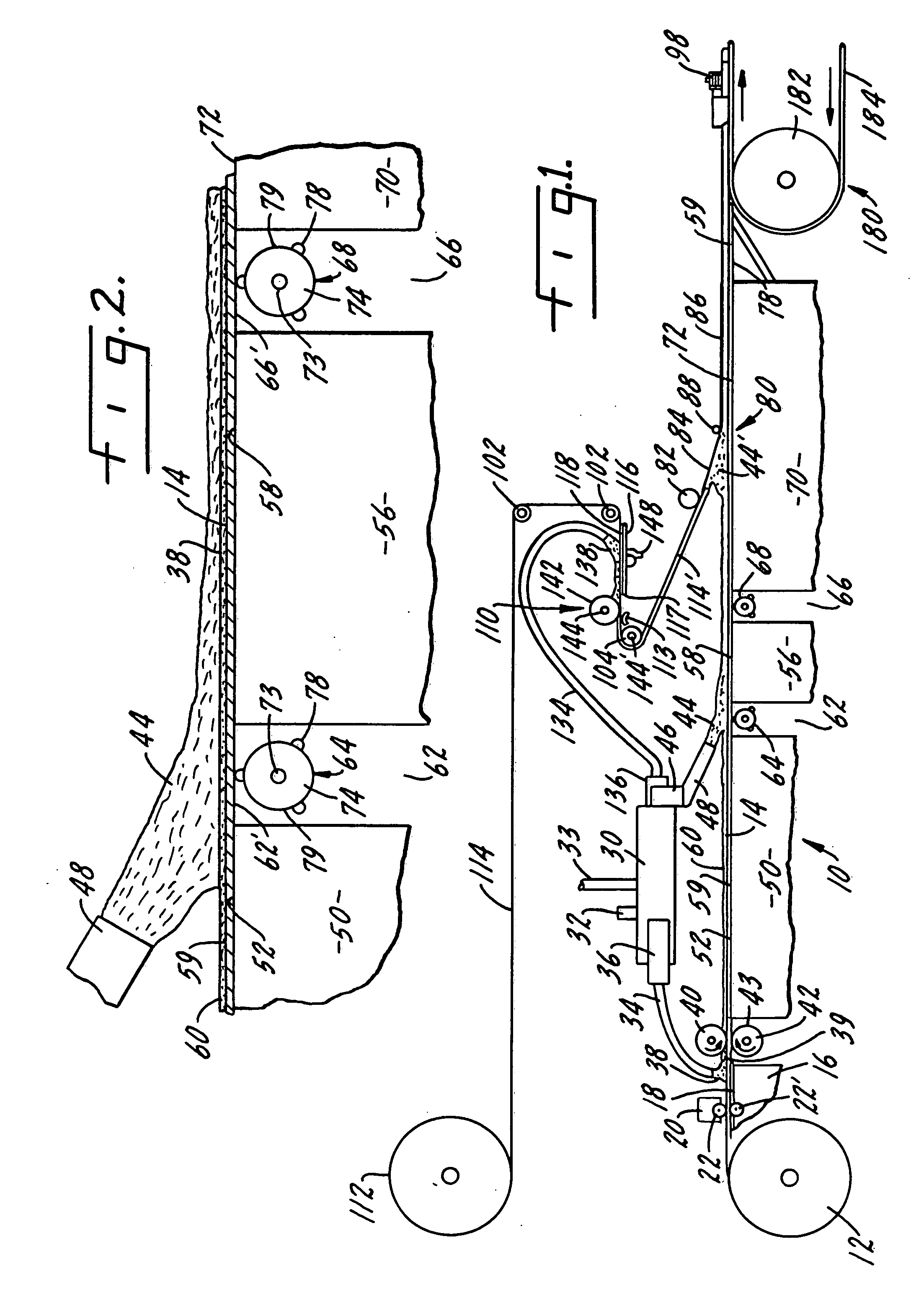

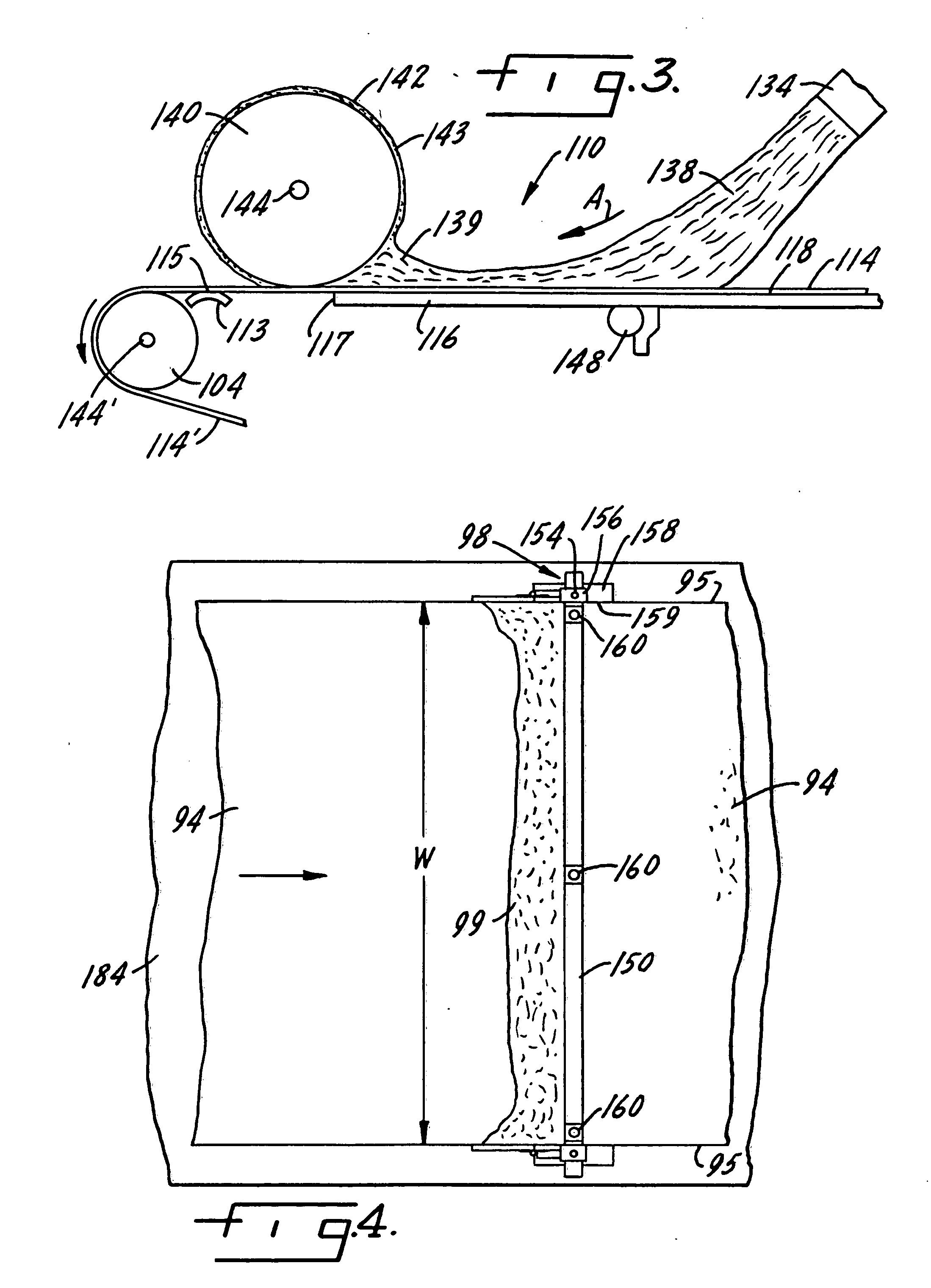

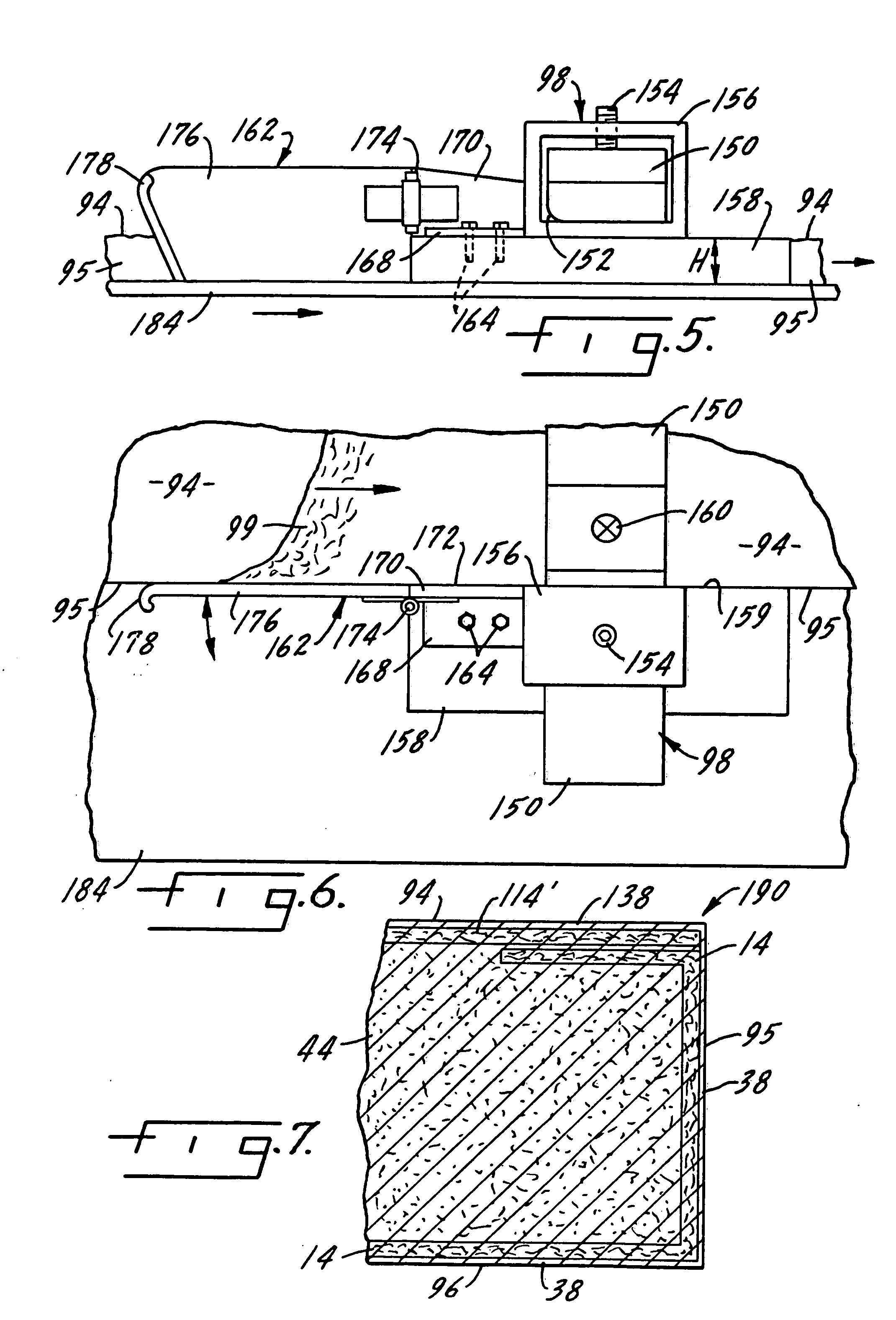

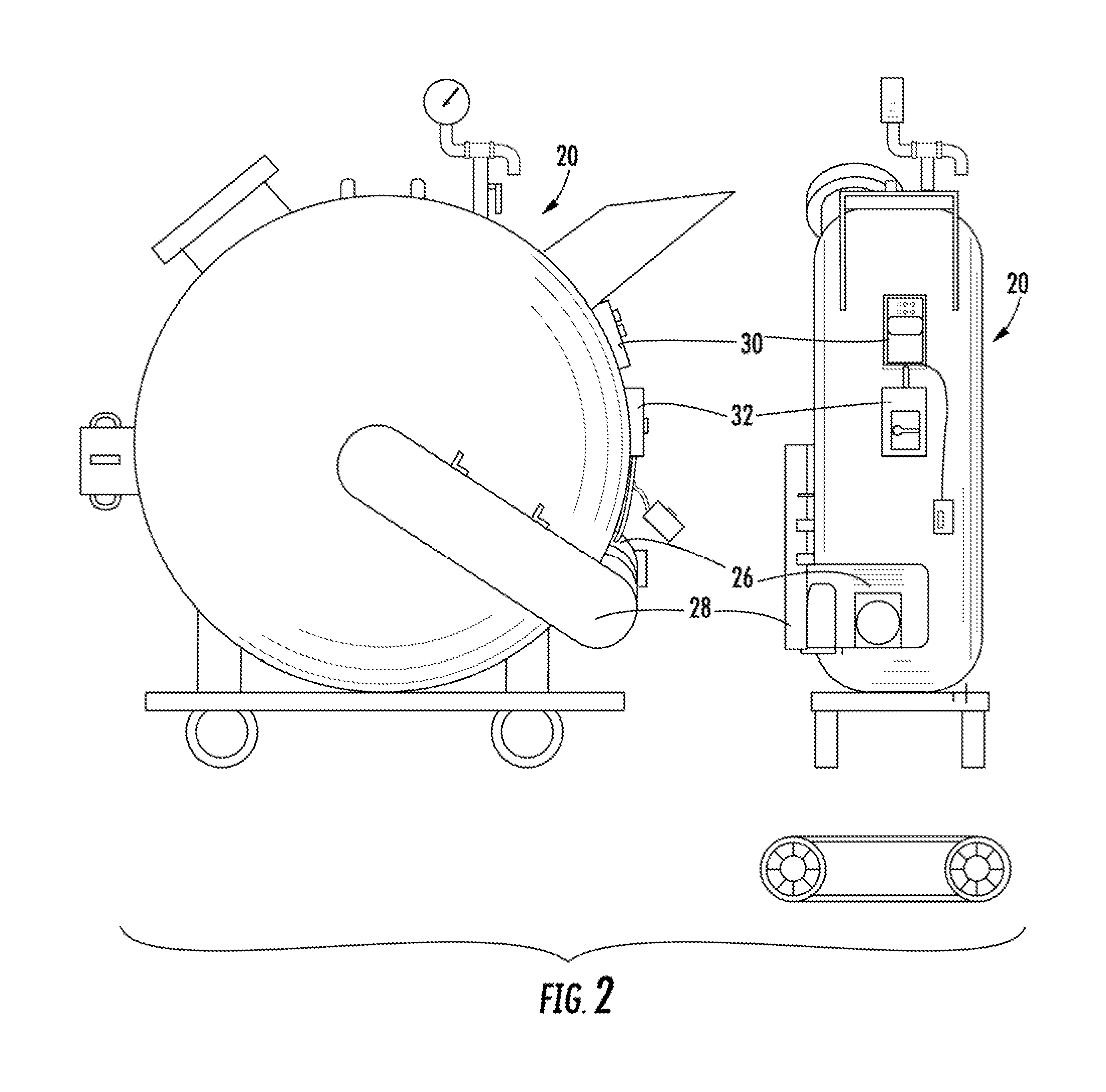

Pressure infusion lining system

InactiveUS20150020908A1Strong stickinessEffectively seal all crackDomestic sealsLayered productsInternal pressureEpoxy

A method and system for applying a liner to an underground utility structure is provided. First a layer of epoxy is applied to the interior surface of the host pipe using a machine such as a spincast machine. A dry liner is inverted into the pipe directly behind the coating application at a limited speed and pressure. A drag is set on the inversion equipment relative to the speed of the epoxy spinner unit to control inversion speed. Once the liner is completely inverted the internal pressure of the liner is raised and infused into the uncured epoxy.

Owner:WARREN ENVIRONMENTAL & COATING LLC

Super absorber polymer felt and method for the production thereof

InactiveUS8844158B2Simple and inexpensive methodAdhesive processesDrying using combination processesSpecial designMaterials science

The invention relates to a felt material comprising at least one felt layer and an absorbing layer, to a method for producing the felt material, and to the use of the felt material in textiles, shoes, technical application or medical applications. The felt material according to the invention has the advantages of conventional felt materials regarding the warming and damping properties and is permeable to air in the dry state. Due to the special design, however, it is waterproof in the wet state and thus it is suitable for sealing many materials. The felt material according to the invention binds more humidity or binds water in a different way than common felt materials.

Owner:IQTEX PATENTVERWALTUNG UG HAFTUNGSBESCHRANKT

Curable material comprising silylated polymers containing urethane groups, and use thereof in sealants and binders

Owner:EVONIK DEGUSSA GMBH

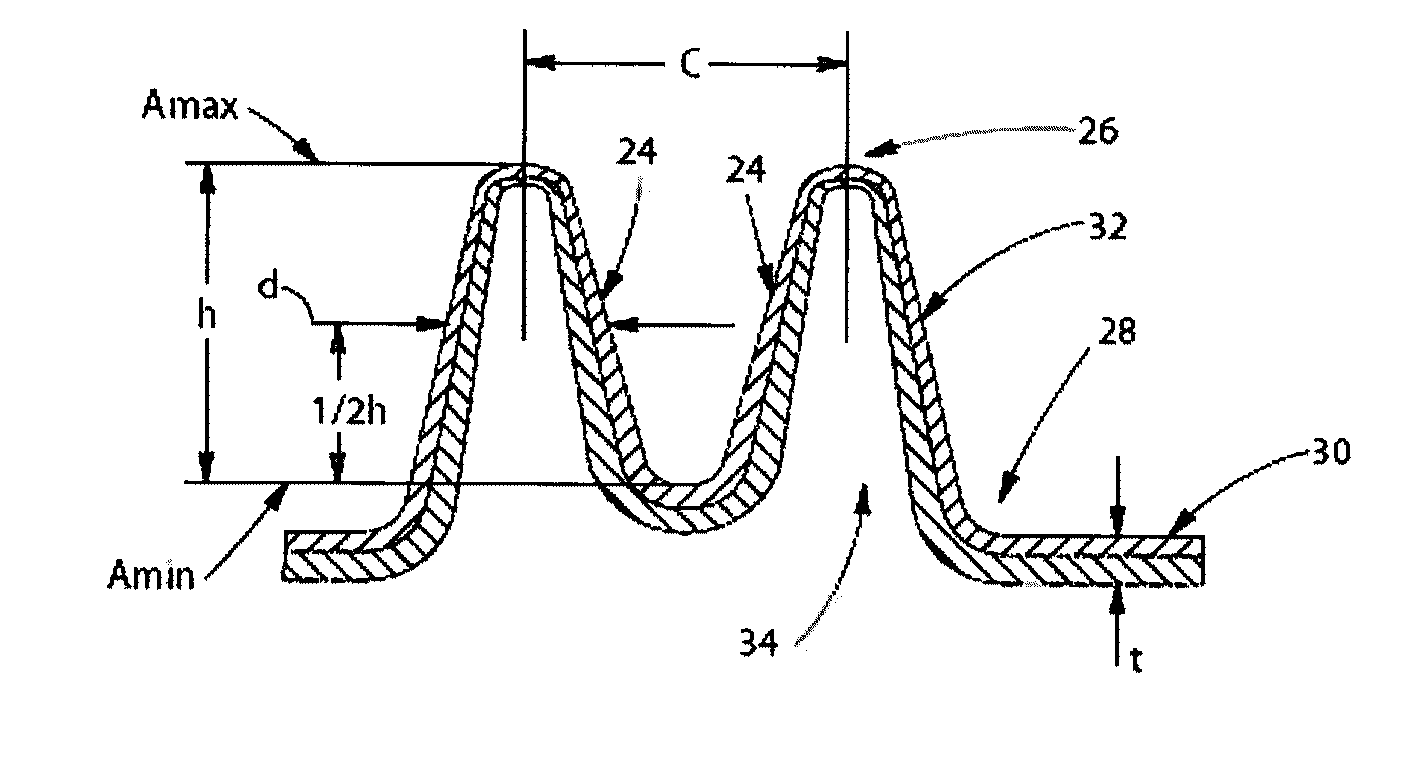

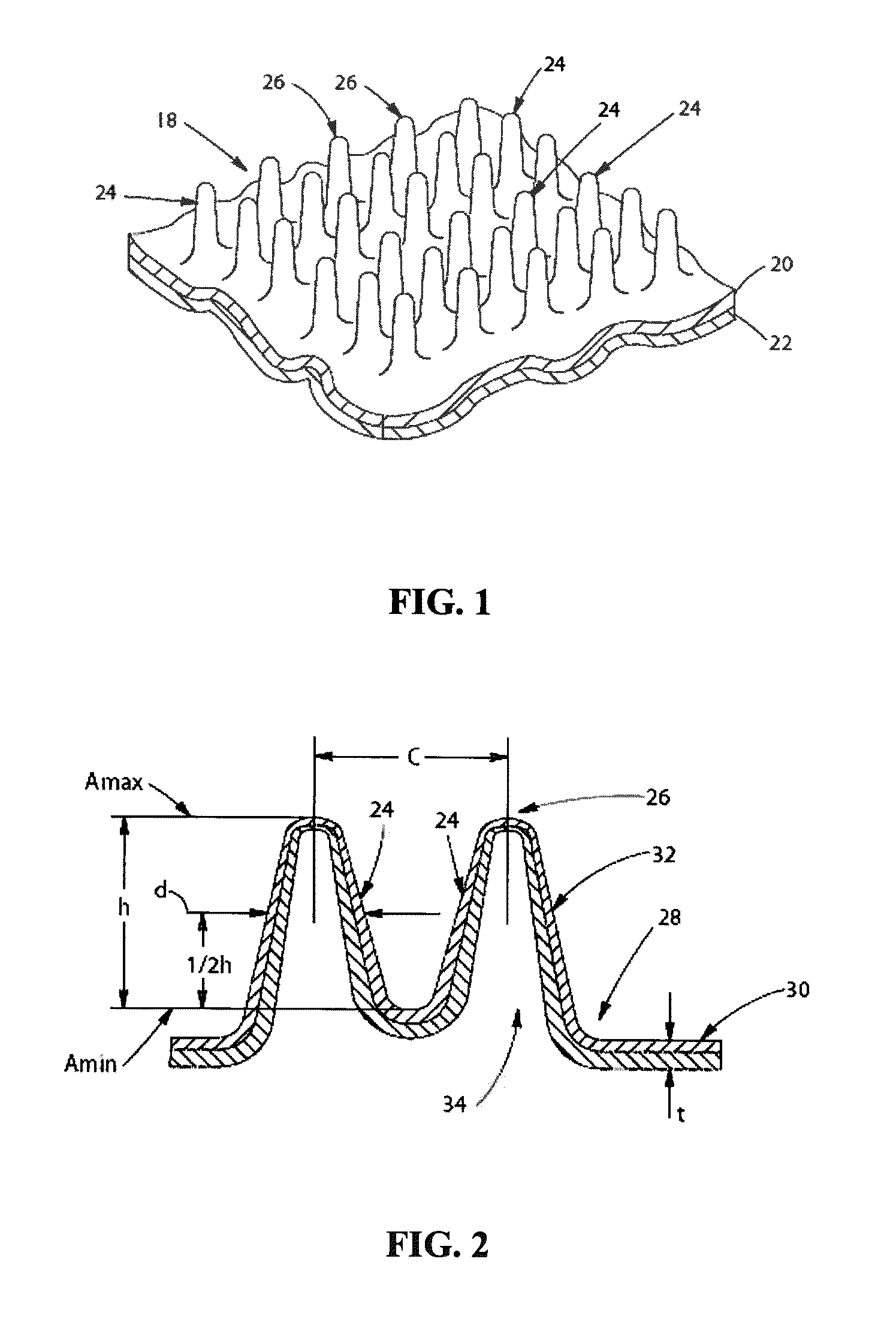

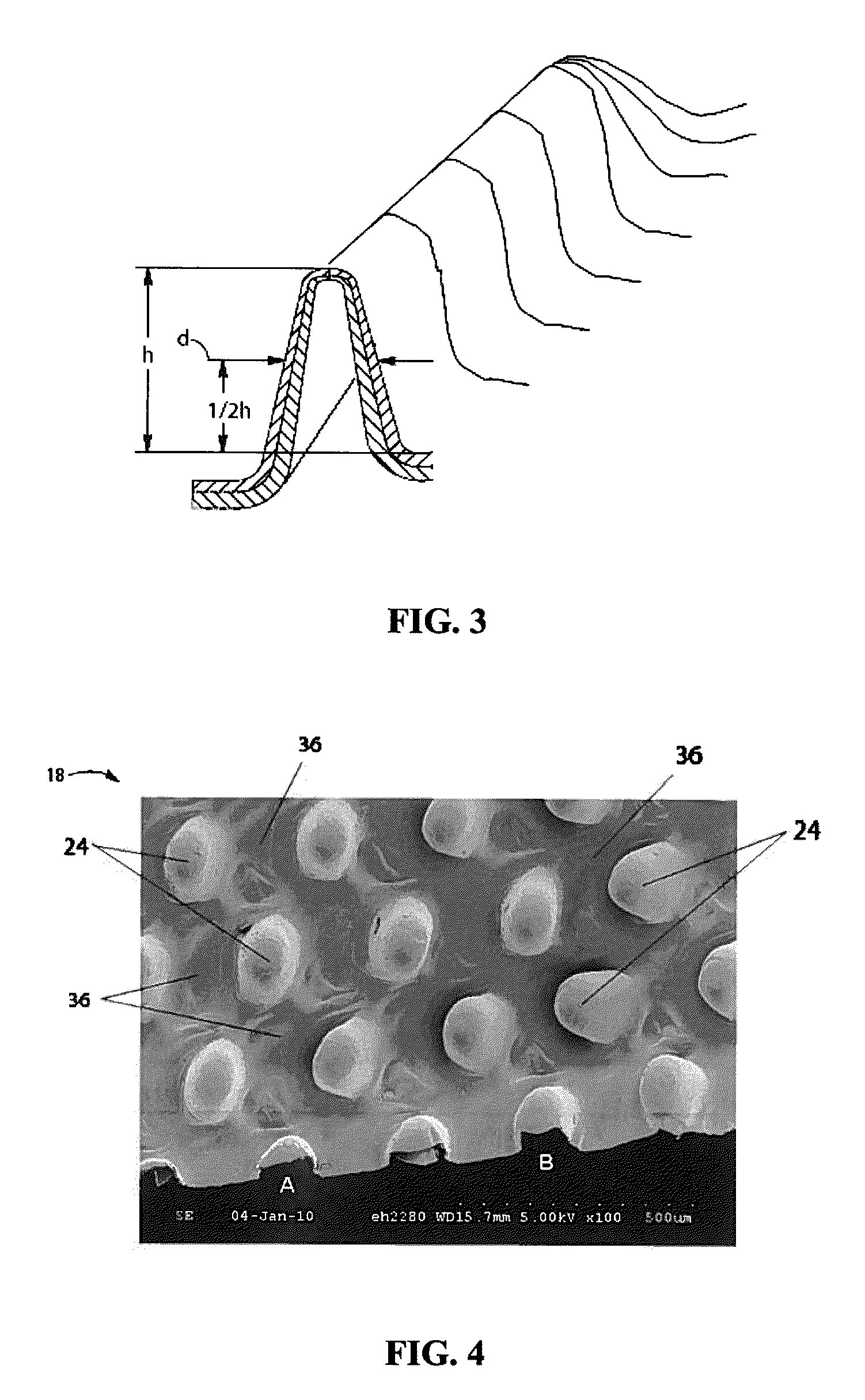

Joint seal system with shaped barrier and wings

An expansion joint seal proving a flexible barrier therethrough in a concave shape with a first body of compressible foam on one side and a second body of compressible foam on the other side, where the barrier extends laterally from the first body and second body and may be used to protect the sides of the expansion joint seal or may be used to provide contact on the surface of each adjacent substrate.

Owner:SCHUL INT COMPANY

Multi-layer films, methods of manufacture and articles made therefrom

InactiveUS20070082154A1Improve air tightnessEfficiently formedDomestic sealsSynthetic resin layered productsEngineeringUltimate tensile strength

Multi-layer films particularly suited for packaging applications, including a core layer, a tie layer made from at least 10 wt % of a first polymer and where the first polymer preferably is not present in the core layer are provided. Optionally, the multi-layer film may have a skin layer, a second tie layer and / or a second skin layer. Embodiments may have the advantage of improved seal strength, hermeticity, hot tack and reduced-temperature sealability.

Owner:JINDAL FILMS AMERICAS LLC

Joint seal system with winged barrier

An integral multilayer joint seal. Layers of foam, layered co-planar to the adjacent surface, are interspersed with a barrier layer which extends beyond the foam layers to provide a protective surface, a surface for attachment atop adjacent substrates, or a connecting tab for use with adjacent joint seals. The foam layers may be uncompressed or partially compressed at the time of joint formation and may be composed of open or closed, or hybrid, cell foam. The foam may be impregnated with a fire retardant or may be composed of a fire retardant material, if desired. The barrier may have a tensile strength greater than the adjacent foam. The joint seal may have an elastomer, such as silicone, at its top and / or bottom, and may even include an elastomer layer within or about the barrier.

Owner:SCHUL INT COMPANY

Joint seal system

An integral multilayer joint seal. Layers of foam, layered co-planar to the adjacent surface, are interspersed with a barrier layer which extends beyond the foam layers to provide a protective surface, a surface for attachment atop adjacent substrates, or a connecting tab for use with adjacent joint seals. The foam layers may be uncompressed or partially compressed at the time of joint formation and may be composed of open or closed, or hybrid, cell foam. The foam may be impregnated with a fire retardant or may be composed of a fire retardant material, if desired. The barrier may have a tensile strength greater than the adjacent foam. The joint seal may have an elastomer, such as silicone, at its top and / or bottom, and may even include an elastomer layer within or about the barrier.

Owner:SCHUL INT COMPANY

Protective articles

InactiveUS7141303B2Good solvent resistanceDomestic sealsPolyureas/polyurethane adhesivesPolymer scienceAdhesive

The invention provides protective articles comprising a backing that comprises a fluorinated polymer and a curable adhesive on at least one layer of the backing. The protective articles of the invention may be used to provide substrates or articles of the invention having a fluorinated surface. The invention also provides methods of preparing such articles, methods of repairing appliqués, and methods of edge sealing appliqués.

Owner:3M INNOVATIVE PROPERTIES CO

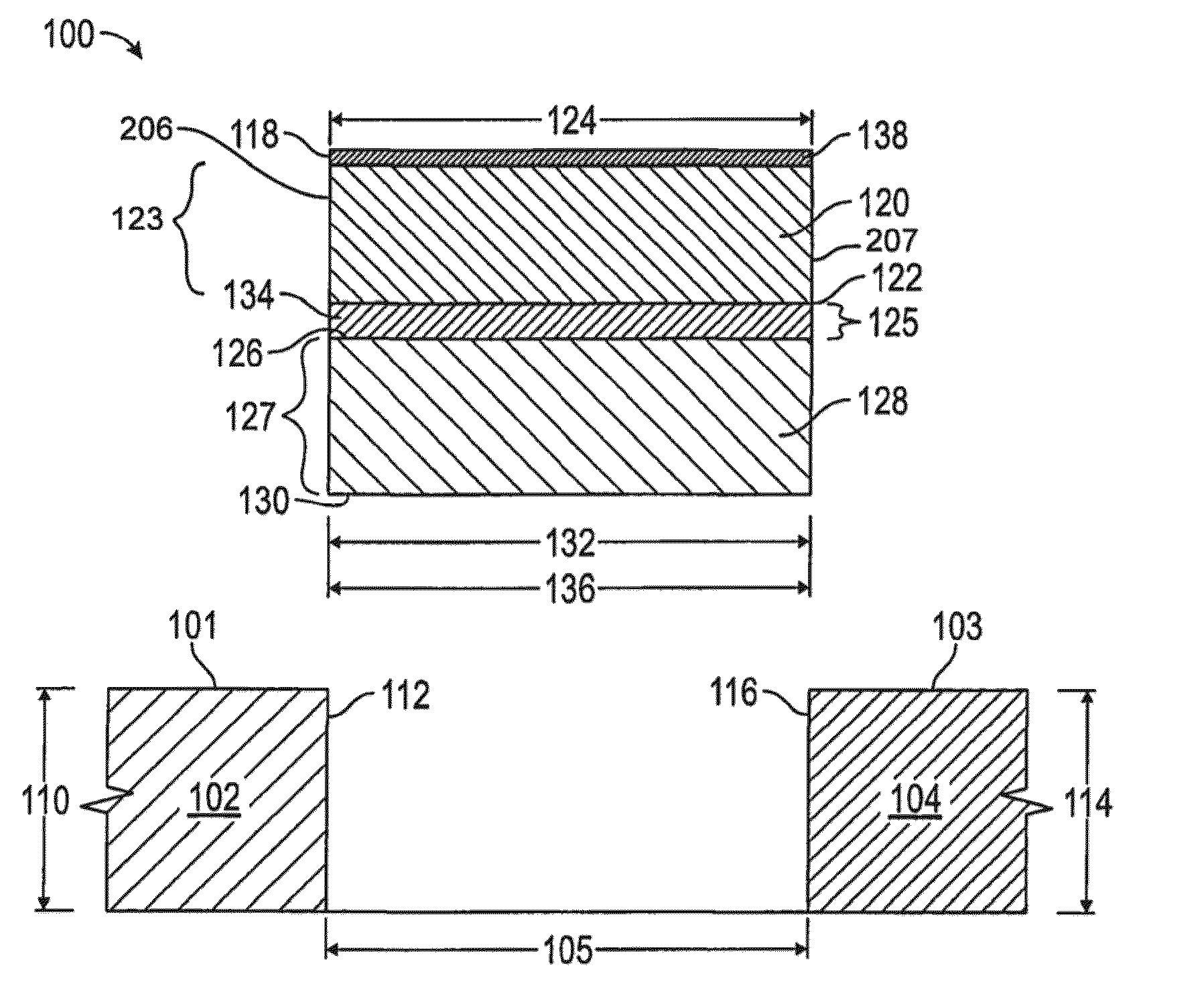

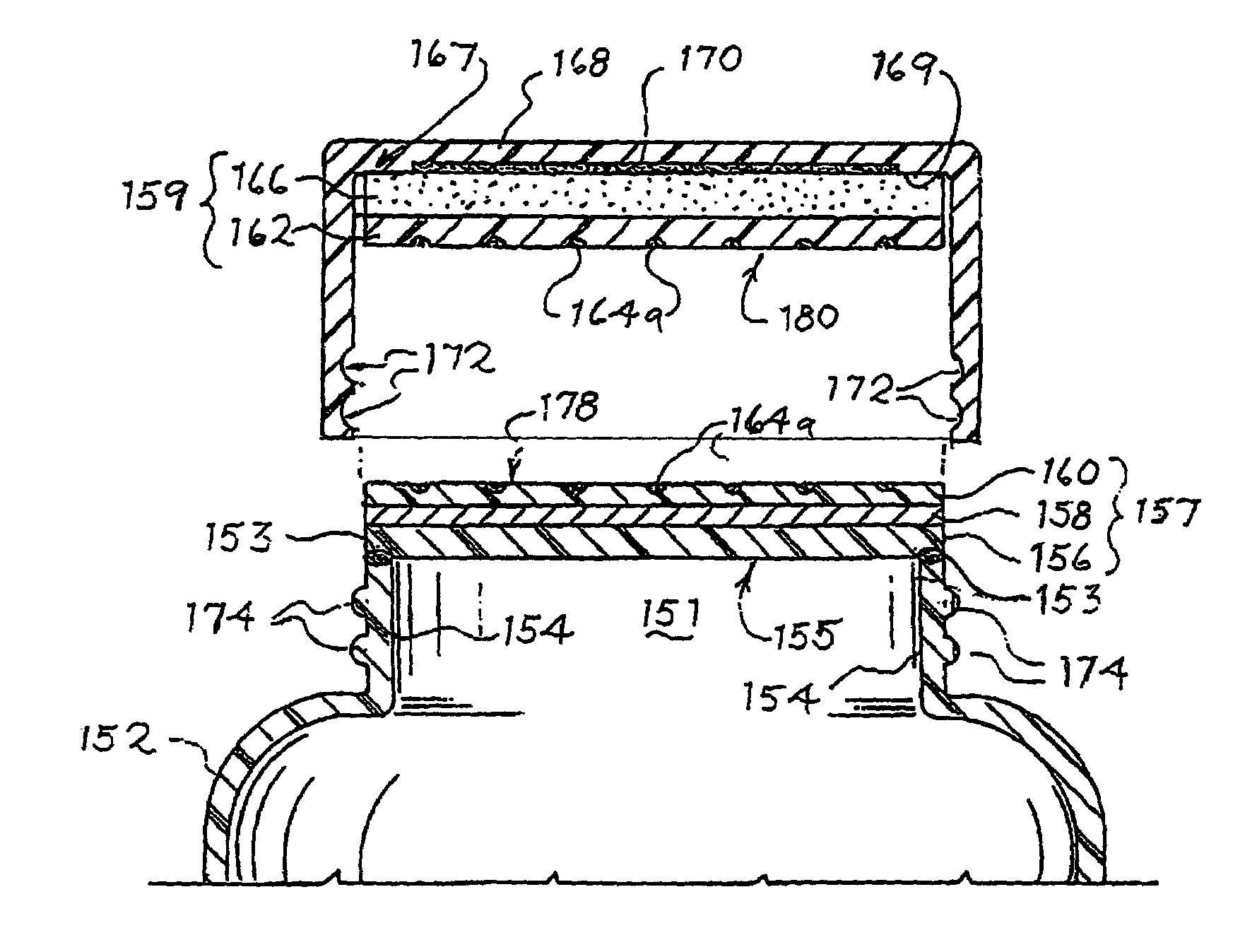

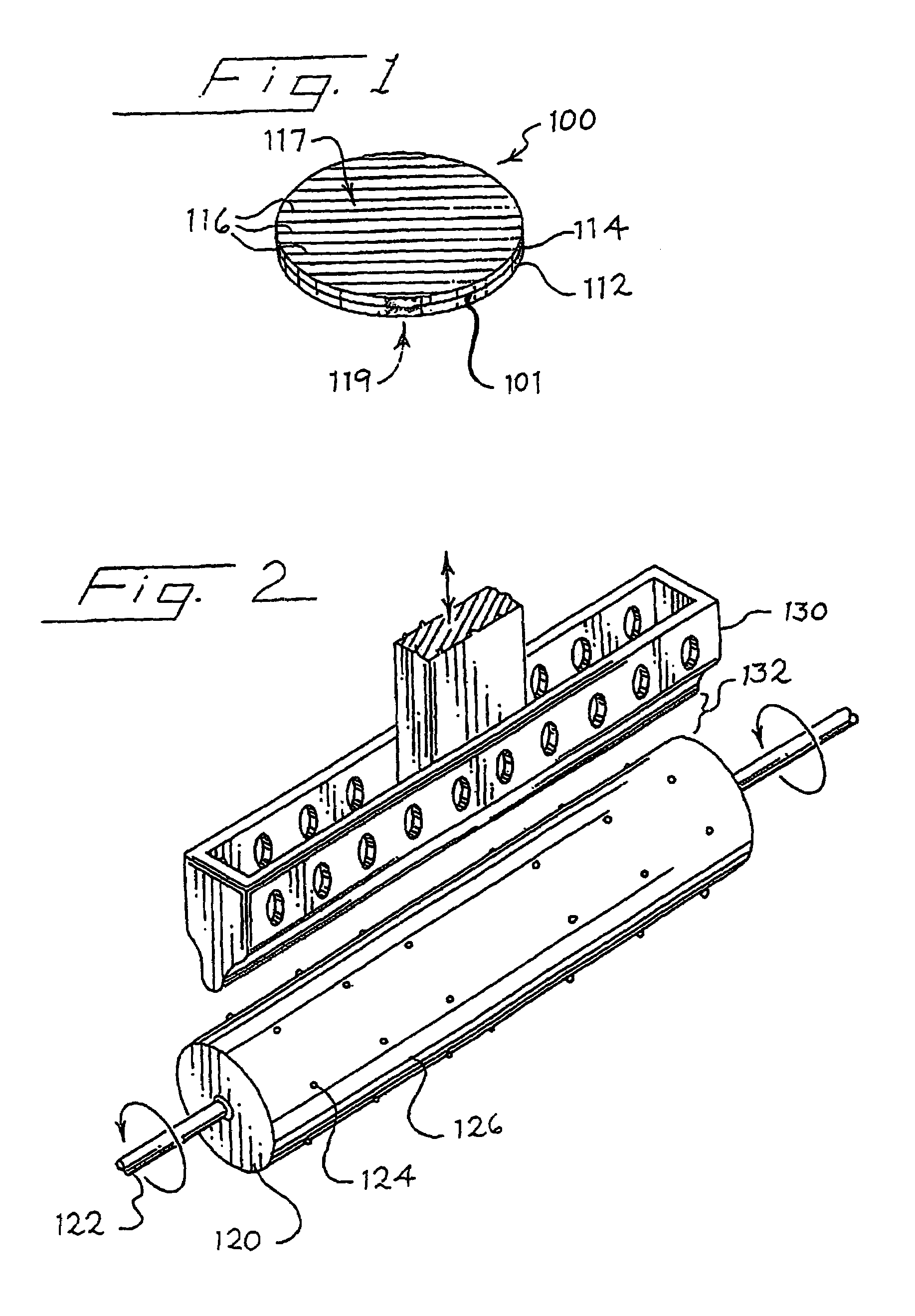

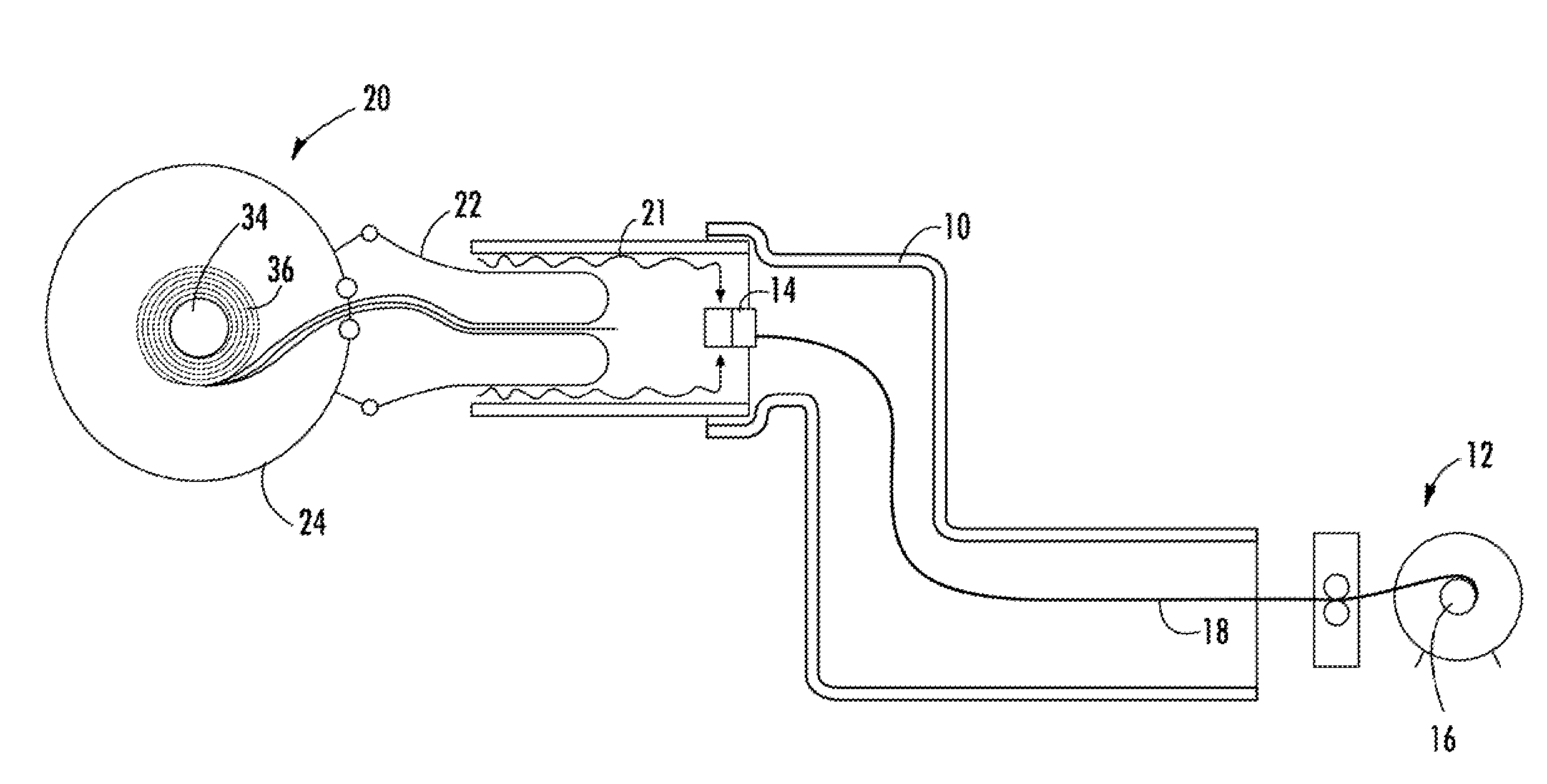

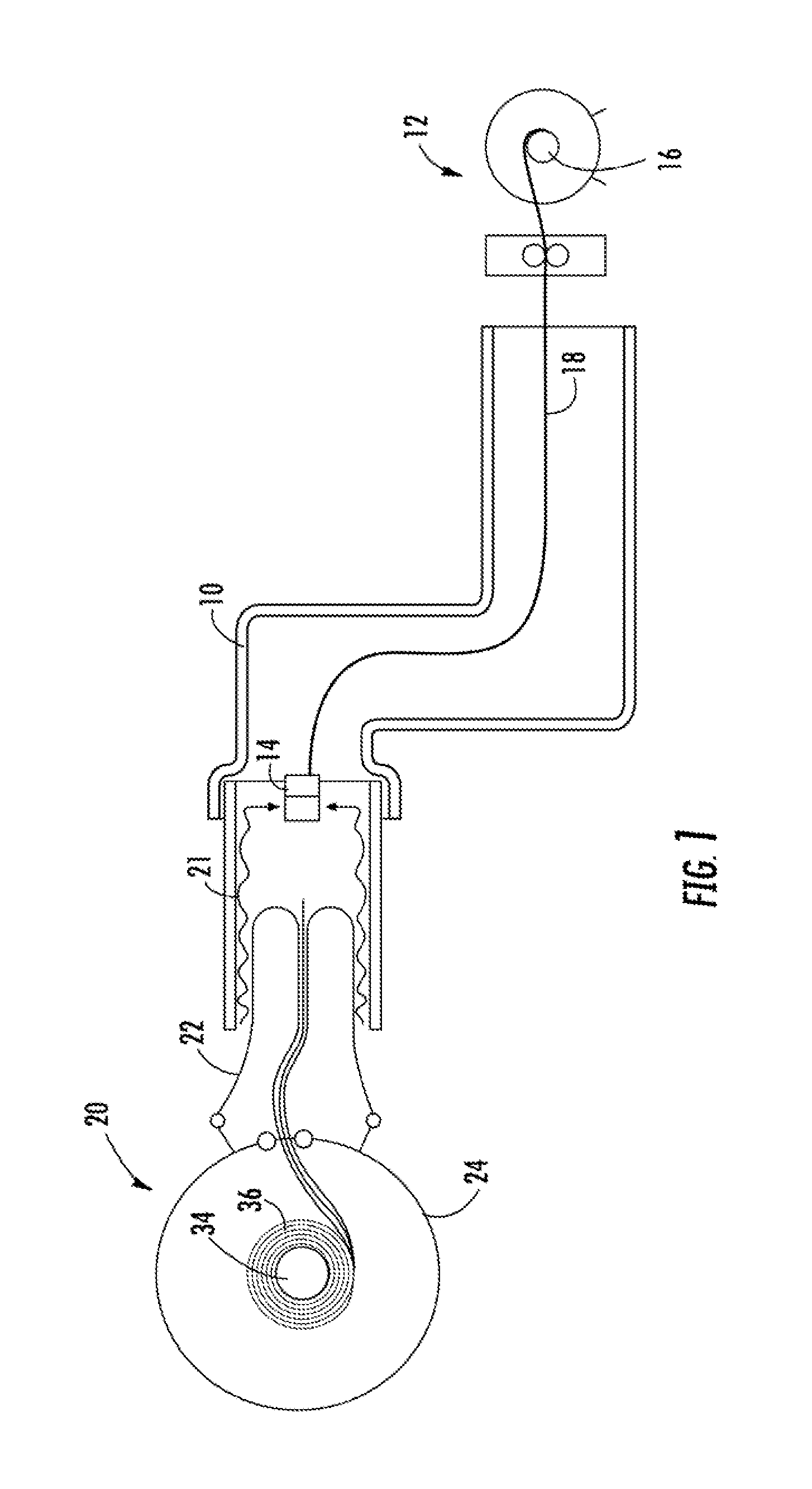

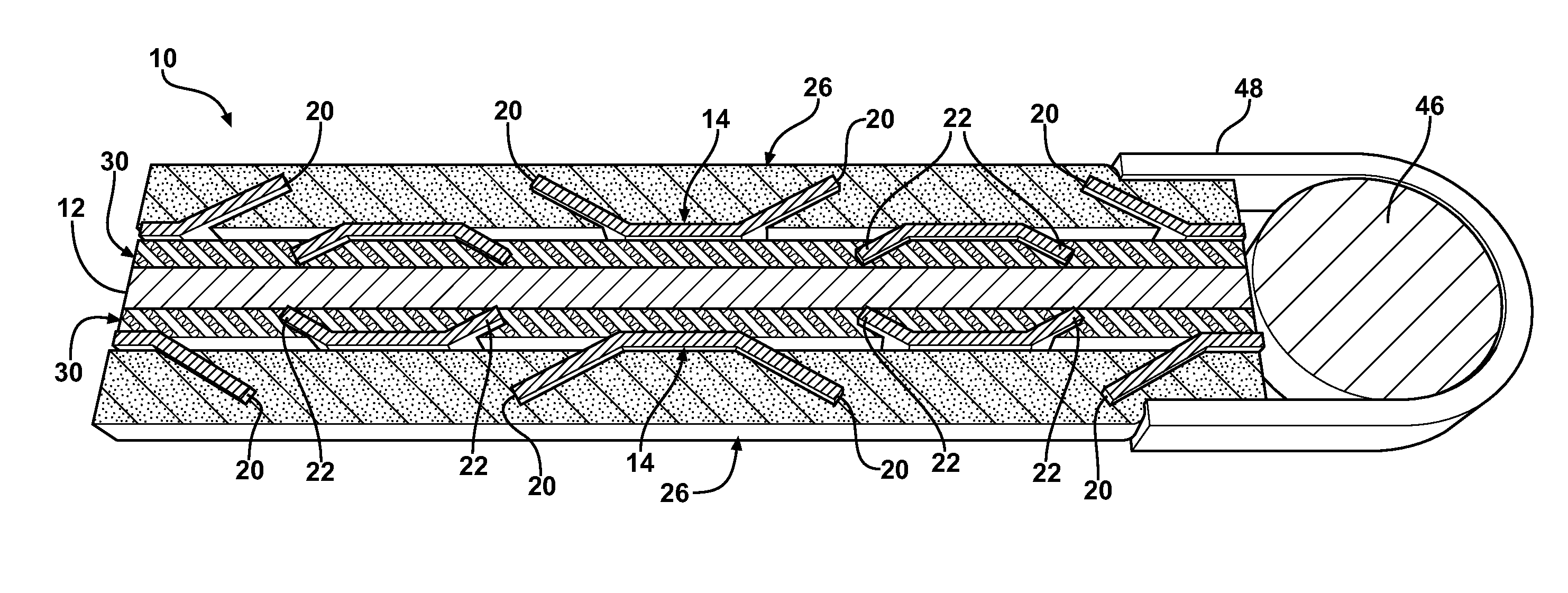

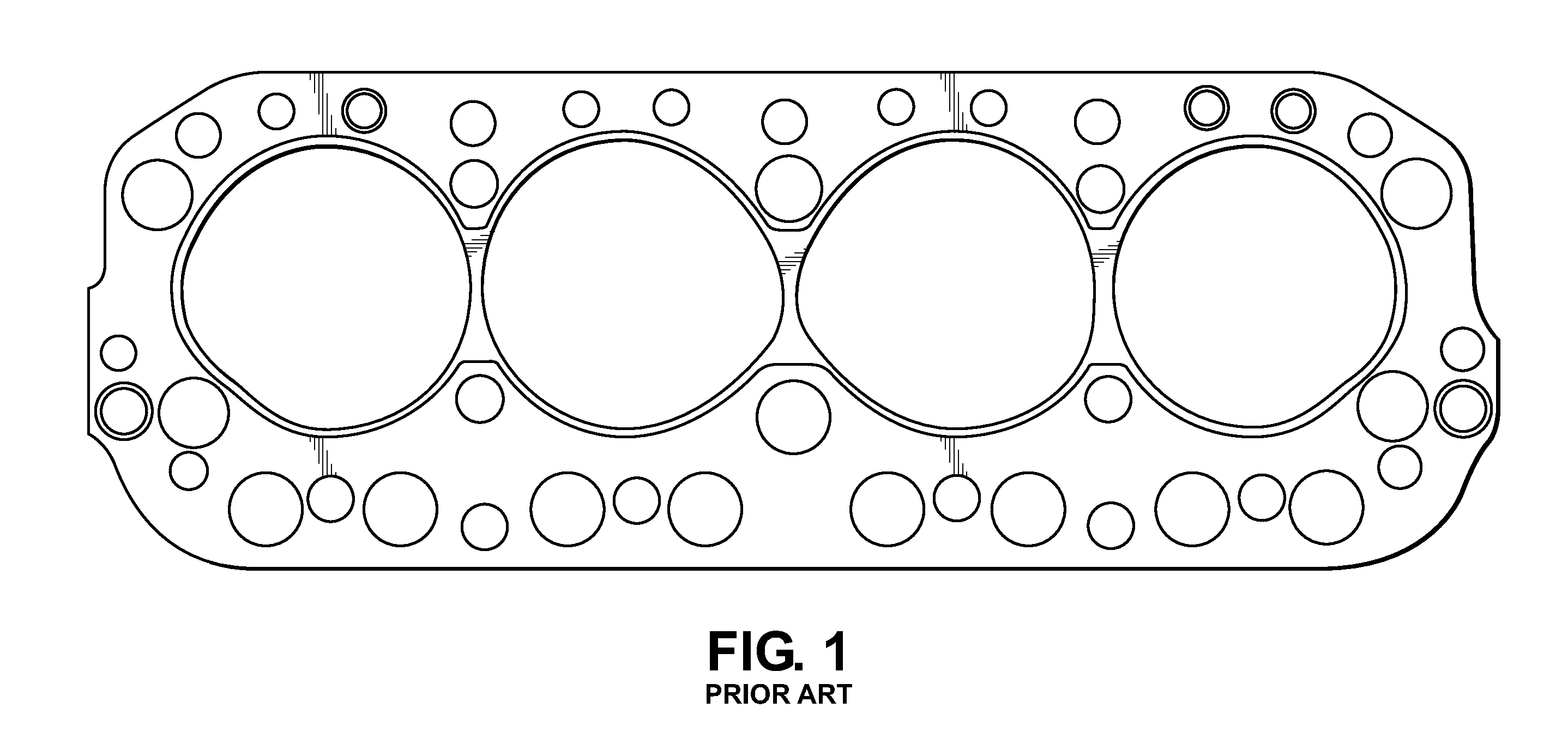

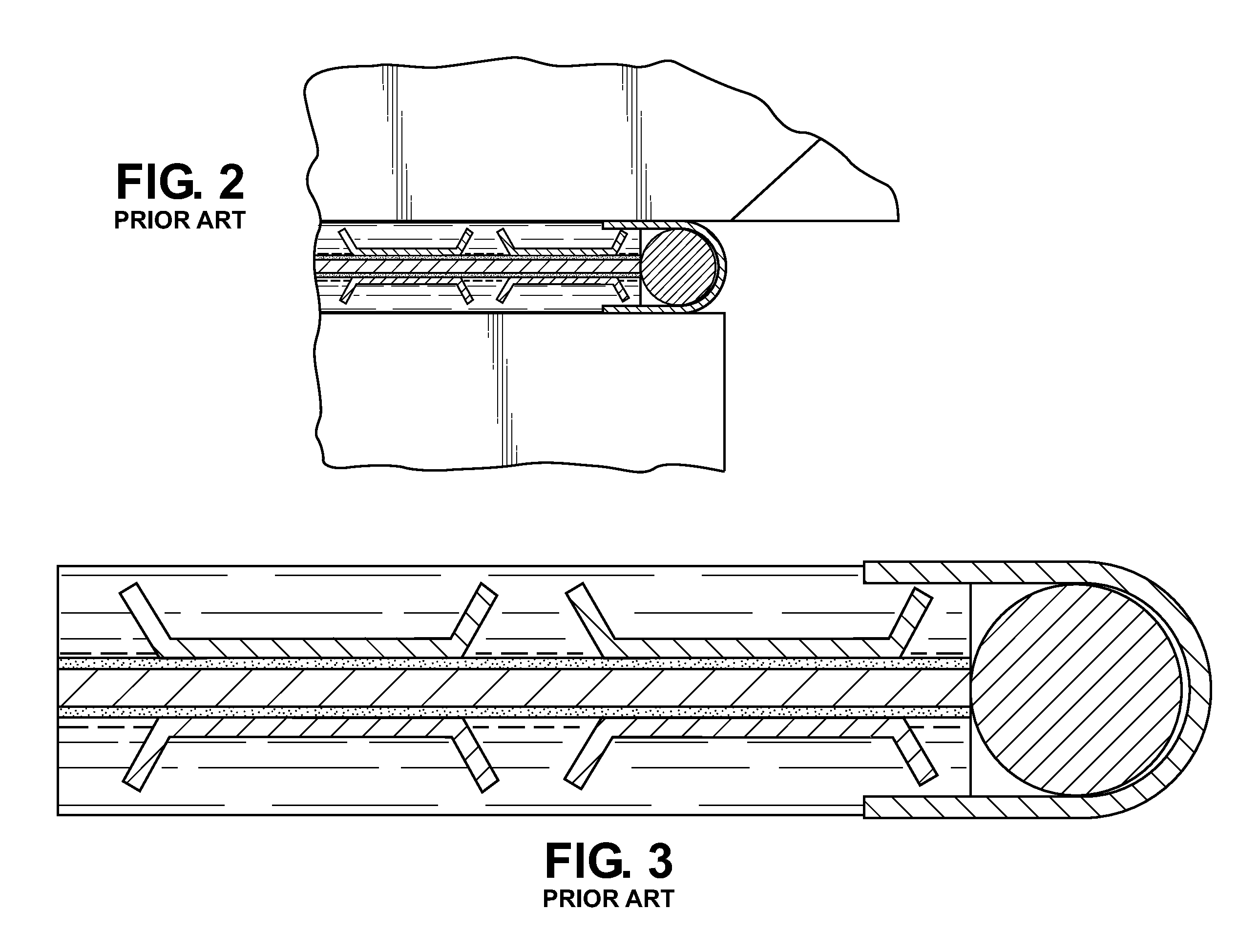

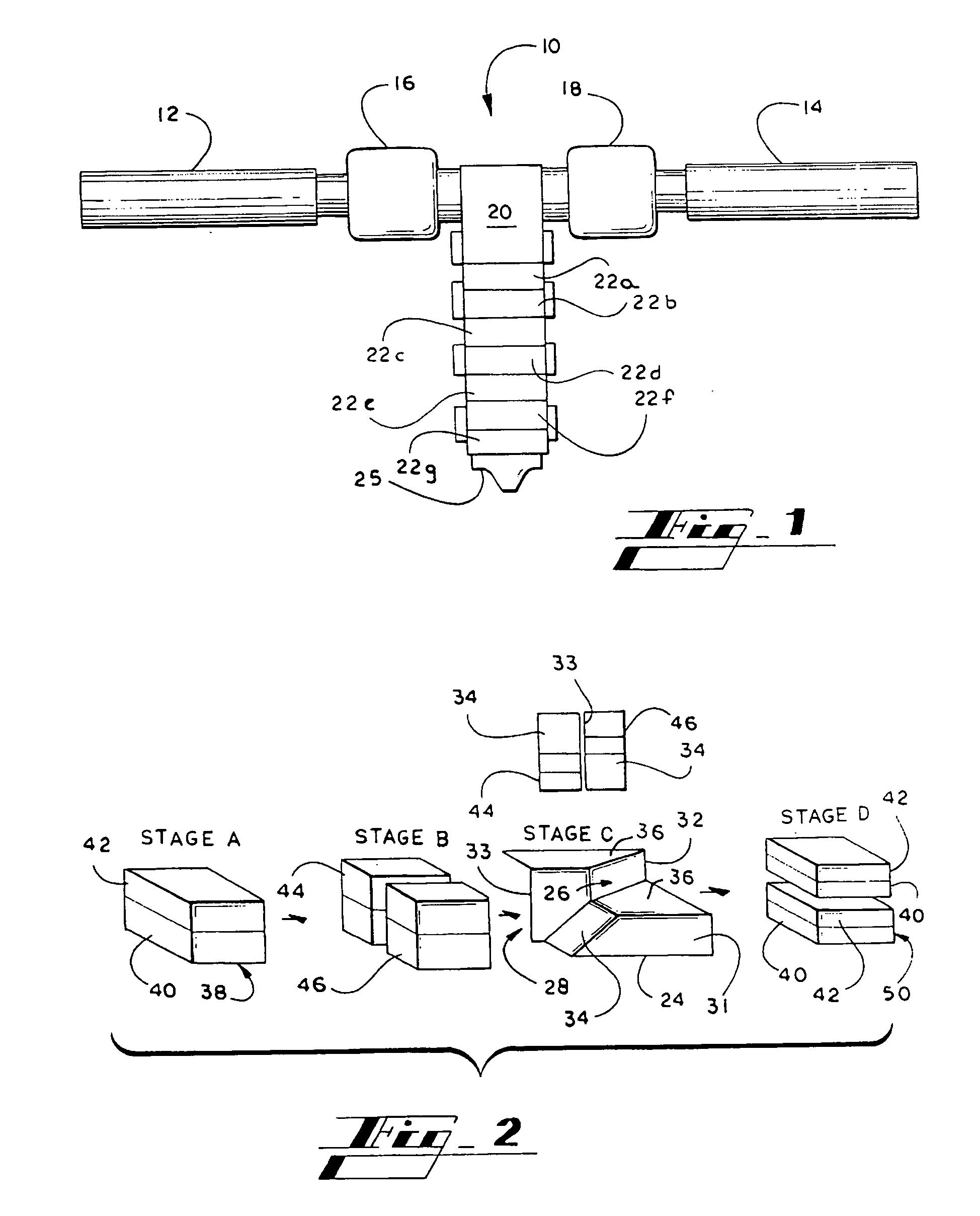

Multi-layered composite gasket

A multi-layered composite gasket (10) includes three, preferably metallic cores (12, 14). A solid center core (12) is flanked on both sides by bonded paper layers (30). Perforated cores (14) mechanically interlock with each paper layer (30) through inwardly directed tangs (22). Graphite layers (26) are disposed outside of each perforated core (14) and are mechanically interlocked thereto by outwardly directed tangs (20) extending from the perforated cores (14). When using the gasket (10) material for sealing cylinder heads in internal combustion engines, a fire ring (46) may be affixed with a fire ring holder (48). The gasket (10) can be manufactured by making first and second preform sheets (32) comprised of one perforated core (14) sided with one paper layer (30) and one graphite layer (26). The preform sheets (32) are then bonded to a center core (12) using a heat activated adhesive. Combining rollers (42) compress and densify the layers to form the completed material set which can be stored on a coil (44) or cut into sheets.

Owner:TENNECO

Laminated lidstock with pull tab

A laminated lidstock includes a substrate film, a support web; a pressure sensitive adhesive disposed between the substrate and support webs, and covering the substrate film and support web except for a clear area at one end of the lidstock; a product die cut disposed in the substrate film; and a pull tab disposed at a first end of the laminated lidstock, wherein at least one of the substrate film and the support web carries a registration device. A method of making the lidstock, and a package, are also disclosed.

Owner:CRYOVAC INC

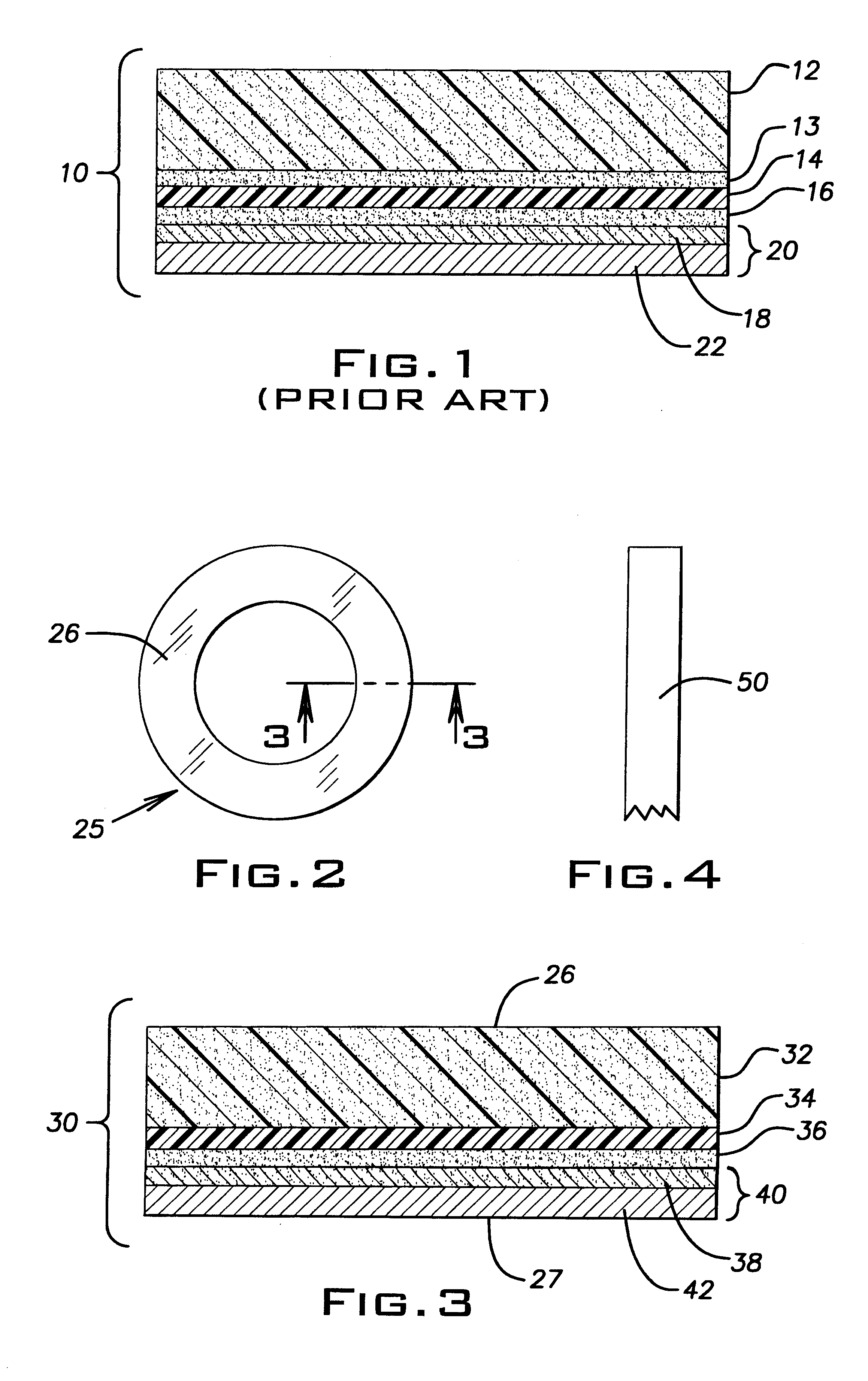

Low stress to seal expanded PTFE gasket tape

ActiveUS7179525B2Reduce loadReduce stressDomestic sealsEngine sealsUltimate tensile strengthExpanded PTFE

A low stress to seal, unitary gasket tape is provided that is particularly suited for use in form-in-place gaskets. The gasket tape preferably comprises at least two joined porous expanded polytetrafluoroethylene (ePTFE) tapes aligned along tape side surfaces and a substantially air impermeable layer there between. The plane of expansion of the ePTFE is substantially parallel to the flange surface providing longitudinal and transverse strength. The substantially air impermeable layer prevents fluid from permeating through the gasket in the radial direction.

Owner:WL GORE & ASSOC INC

Self-adhesive reinforced foam gasket

A self-adhesive reinforced foam gasket comprising a release liner having an upper surface which is a release surface, a layer of pressure sensitive adhesive applied to the release surface, a layer of flexible polymeric film, preferably polyester film, applied to the pressure sensitive adhesive layer, and a layer of flexible foam, preferably closed cell PVC flexible foam, thermally bonded to the flexible polymeric film layer. A length of material for die-cutting the gasket therefrom is provided. The gasket may be used in automobiles and other applications.

Owner:SYLVESTER MICHAEL S

Degradable breathable multilayer film with improved properties and method of making same

A multilayer film includes a plastic layer and an elastomeric layer. The plastic layer and / or the elastomeric layer can contain filler particles, and may be present as a well bonded bilayer laminate. The plastic layer and a filled elastomeric layer can also be combined with an unfilled elastomeric layer to form a tri-layer laminate. The film has an average roughness of about 500 to about 1,000 nanometers. The multilayer films can provide breathable films with improved degradability, stretchability and recoverability, and tactile feel.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com