Patents

Literature

446 results about "Electrical tape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrical tape (or insulating tape) is a type of pressure-sensitive tape used to insulate electrical wires and other materials that conduct electricity. It can be made of many plastics, but vinyl is most popular, as it stretches well and gives an effective and long lasting insulation. Electrical tape for class H insulation is made of fiberglass cloth.

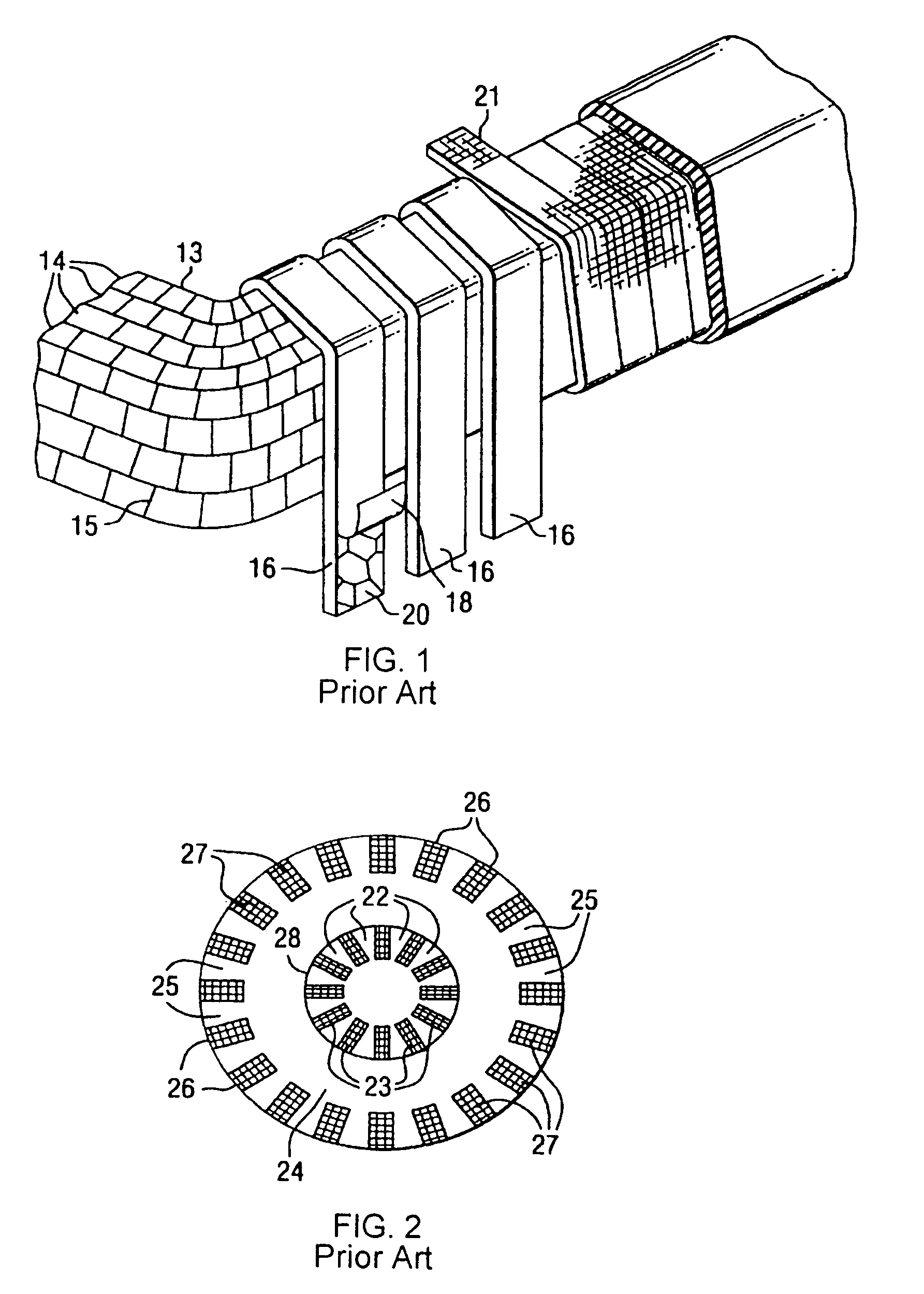

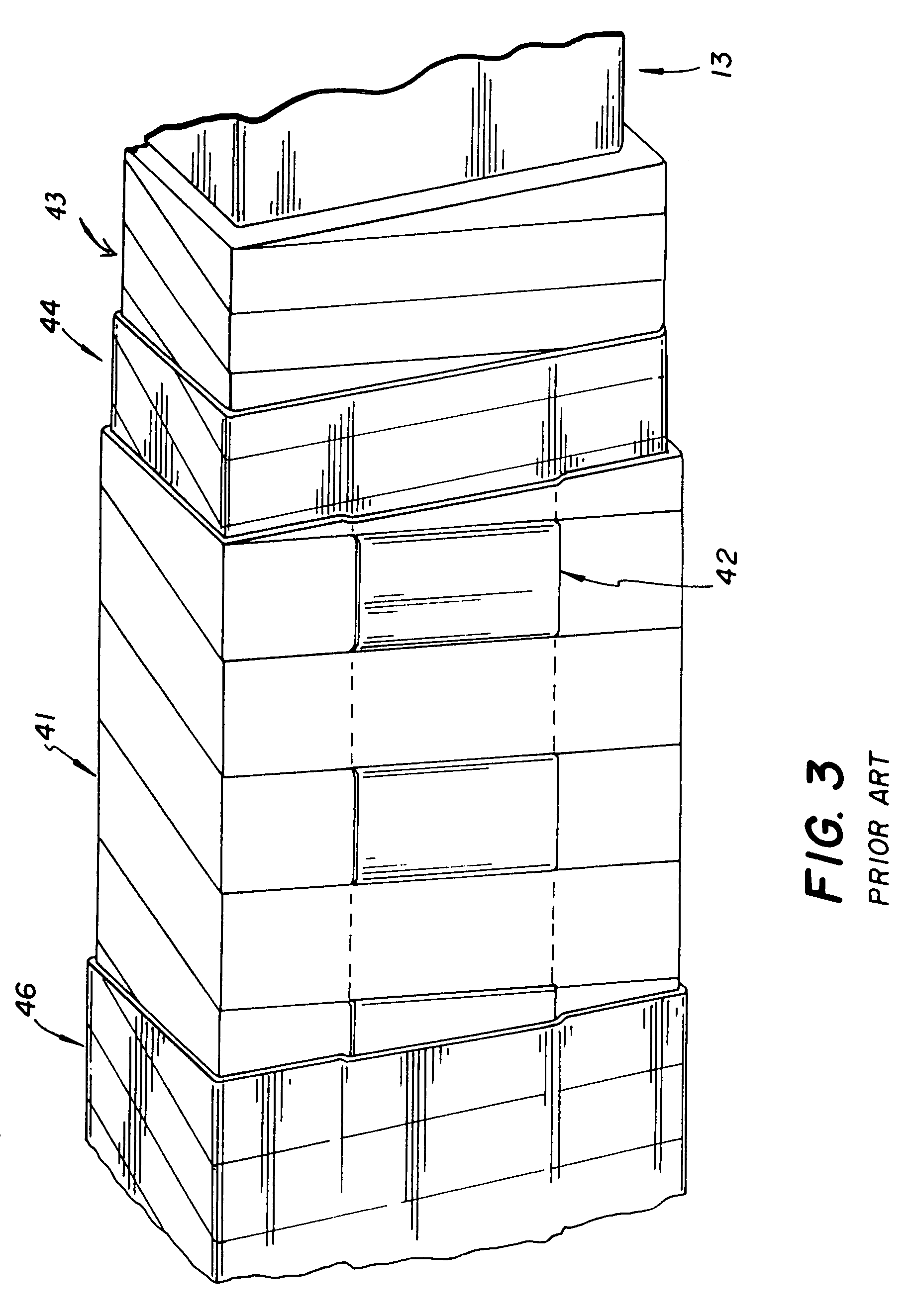

Surface coating of lapped insulation tape

ActiveUS20050274540A1Facilitates surface coatingImprove thermal conductivityWindings insulation materialWindings insulation shape/form/constructionHeat flowMagnetic tape

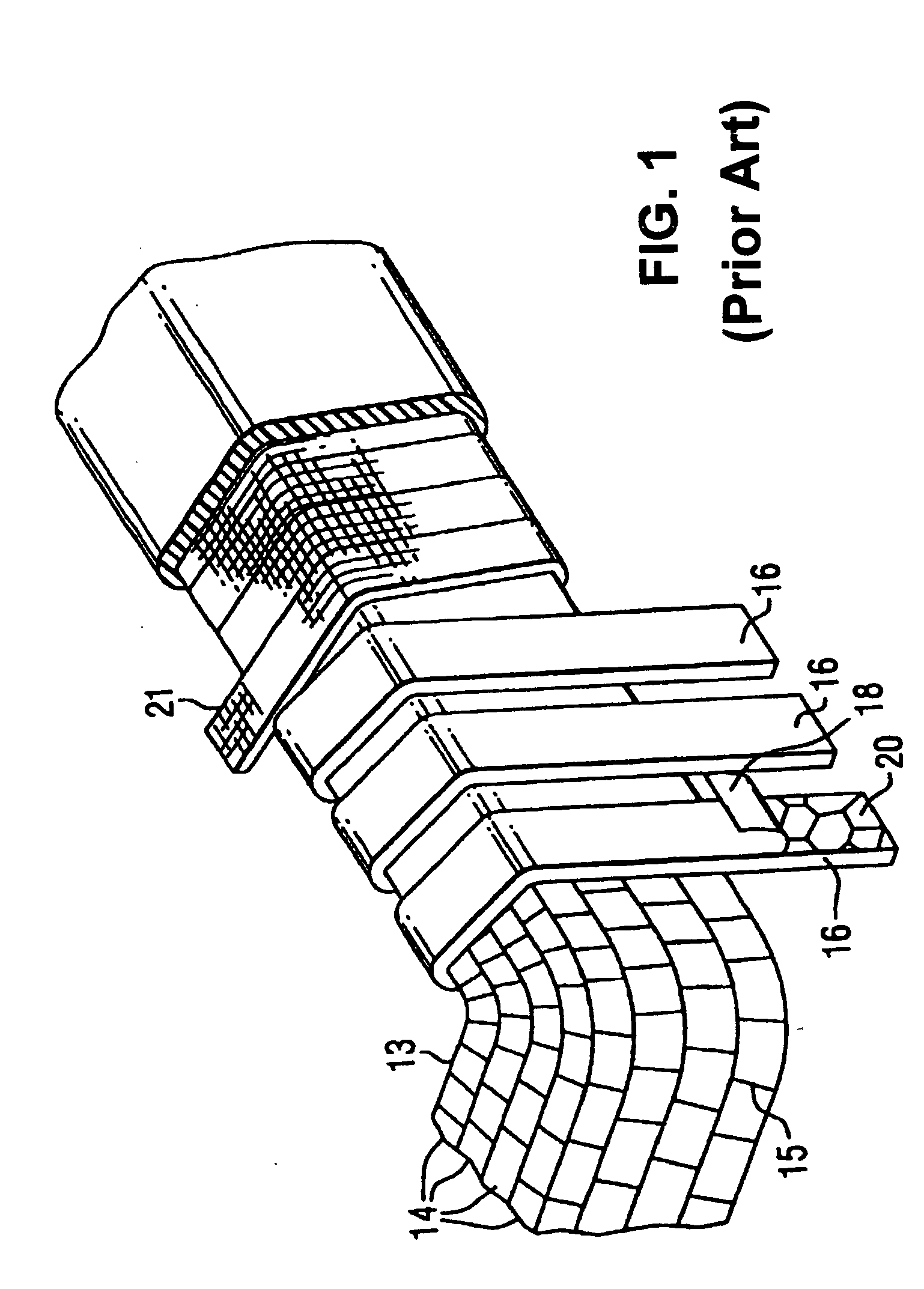

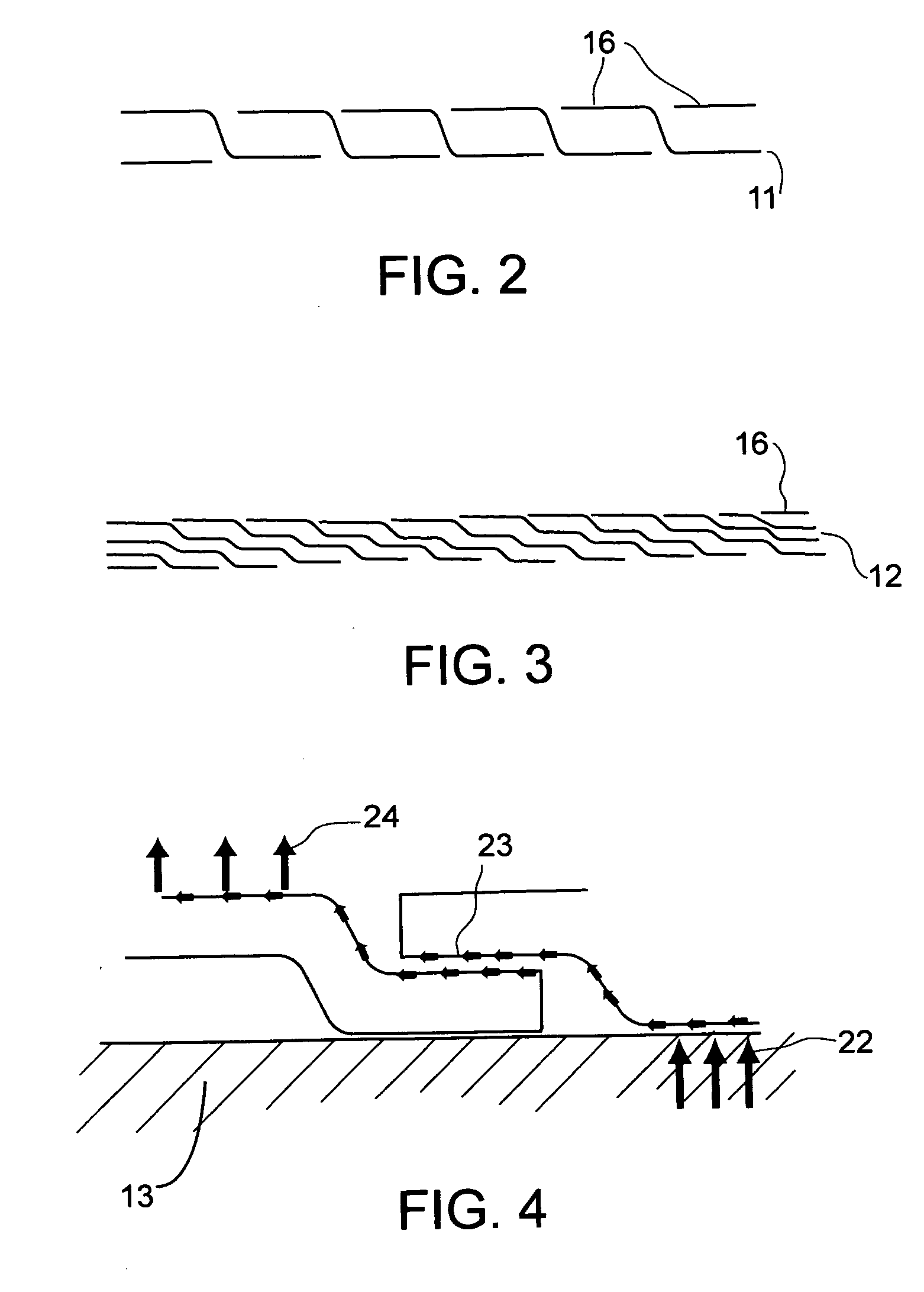

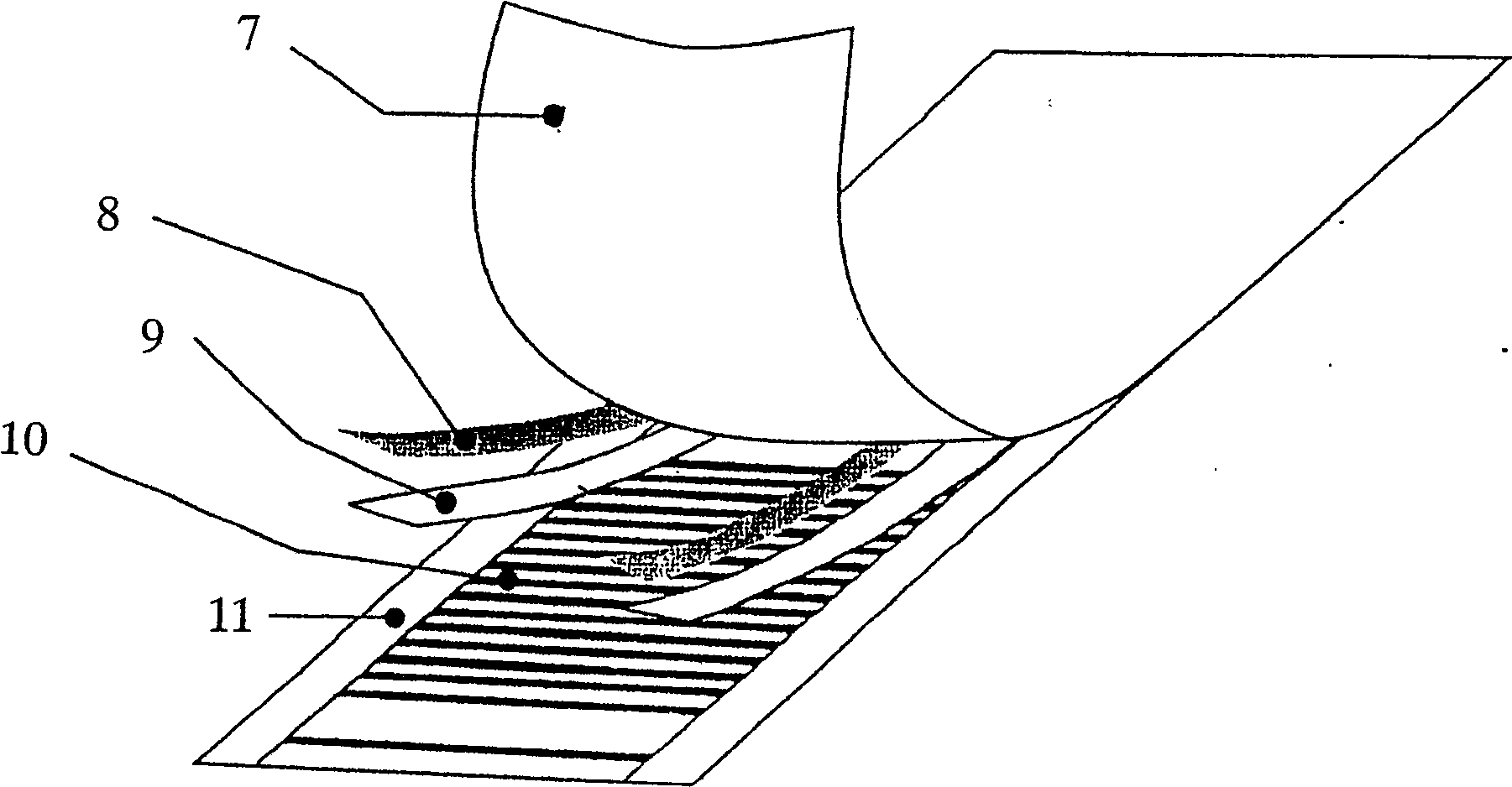

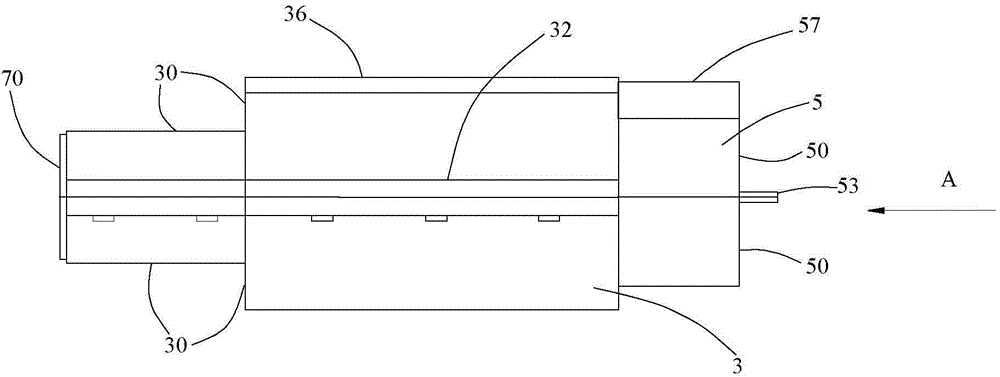

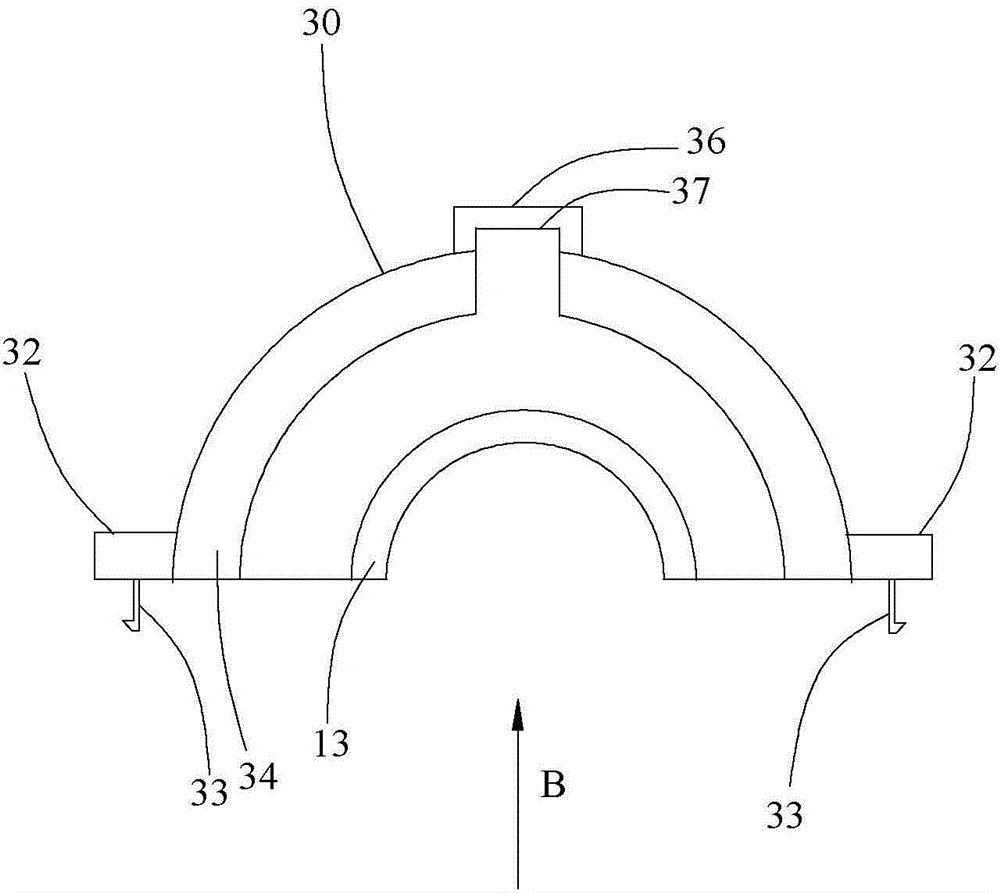

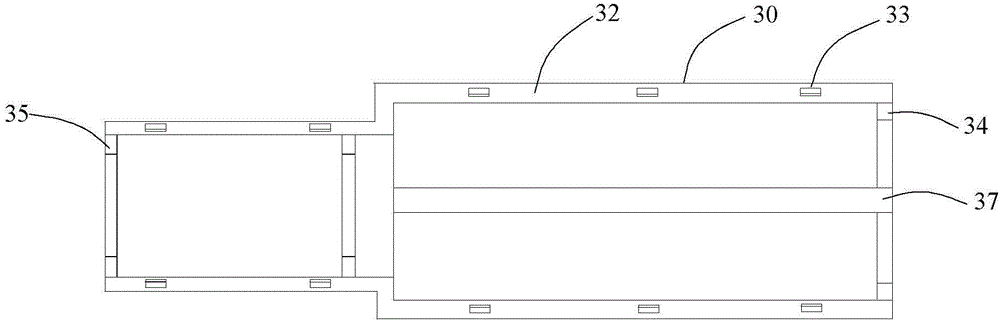

In one embodiment the present invention improves the heat flow from an electrically insulated object 13 by providing an enhanced conduit at the interface between the layers of insulating tape 16. The tape 16 has been surface coated with a high thermal conductivity (HTC) material, so that the interface between the layers of tape 23 provides a pathway for the heat to reach the environment 24. The radiation of heat through the tape layers is also increased by the surface coatings.

Owner:SIEMENS ENERGY INC

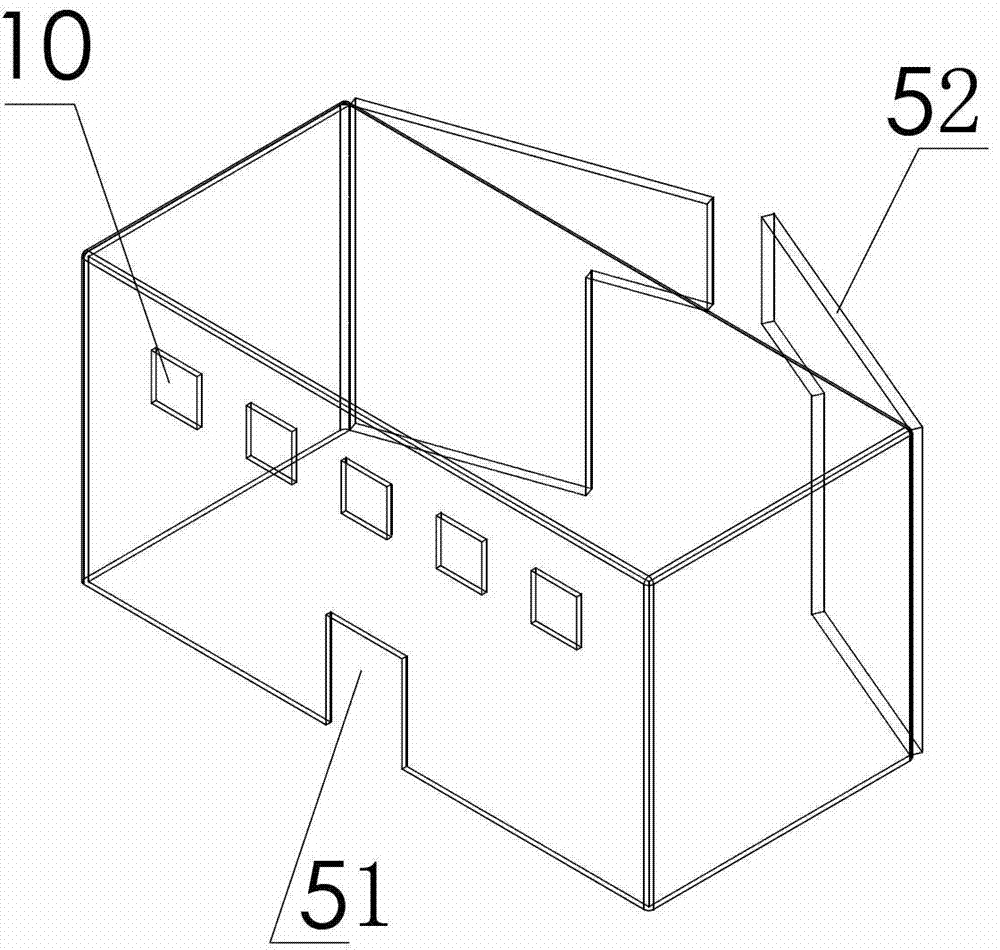

Composite insulation tape with loaded HTC materials

InactiveUS20060231201A1Improve thermal conductivityHigh materialLiquid surface applicatorsDomestic sealsElectrical tapeMaterials science

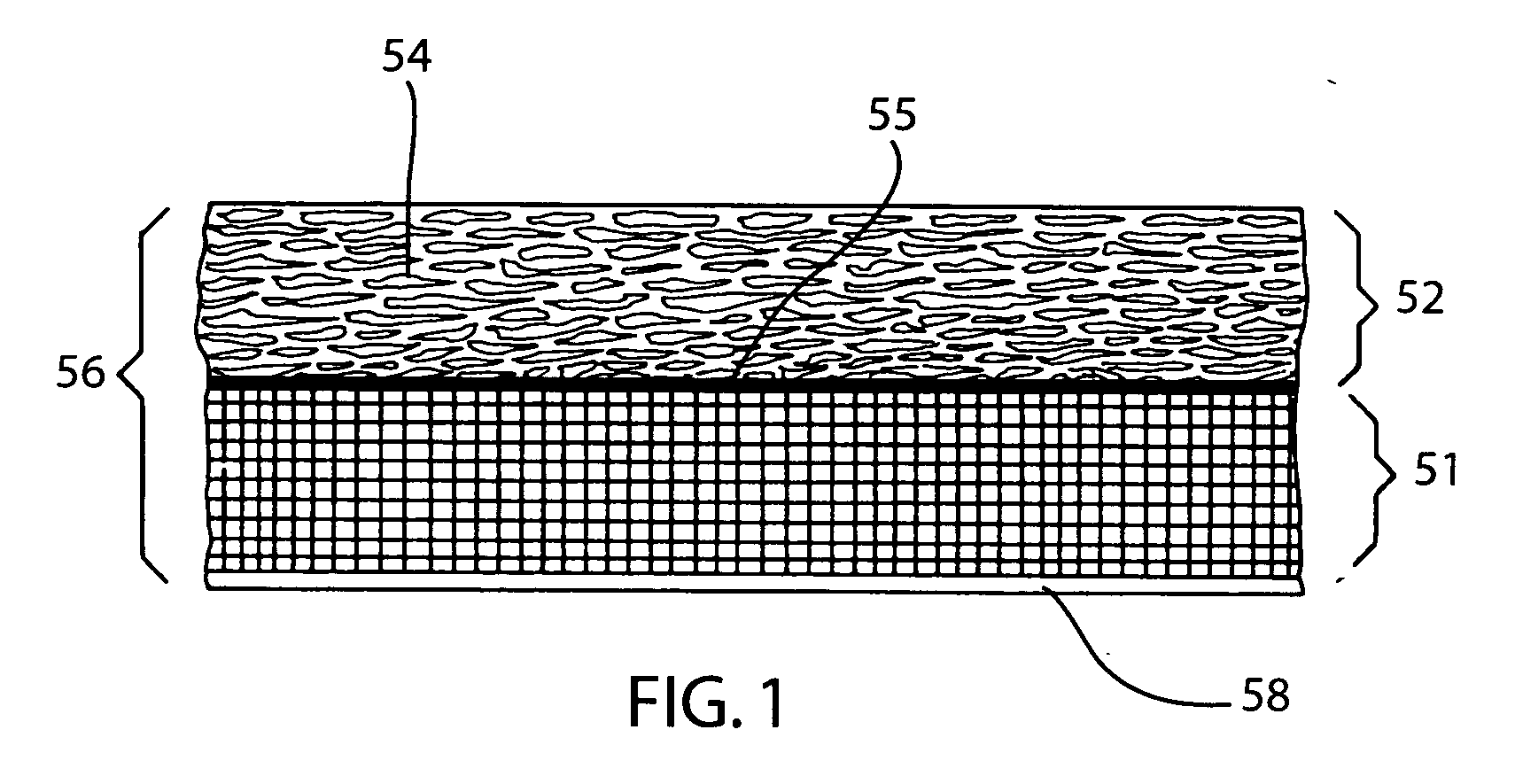

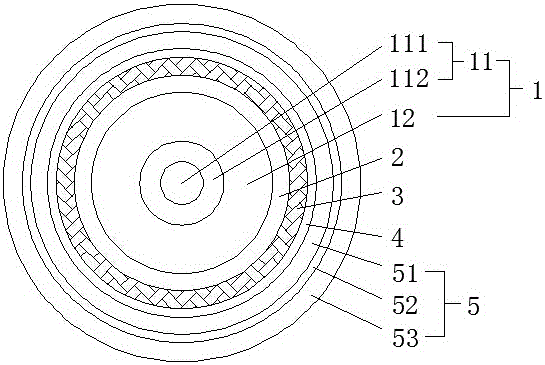

In one embodiment of the present invention as used for impregnating a composite tape (56) with HTC particles provides for permeating a fabric layer (51) of the composite tape with HTC particles and impregnating an impregnating resin into the composite tape through the fabric layer (51). At least 5% of the HTC particles permeated into the fabric layer are carried out of the fabric layer and into a mica layer (52) bound to the fabric layer by the impregnating resin. In some embodiments the impregnating resin itself contains HTC particles.

Owner:SIEMENS ENERGY INC

Heat-conductive insulated adhesive tape for large-power light-emitting diode (LED) and preparation method thereof

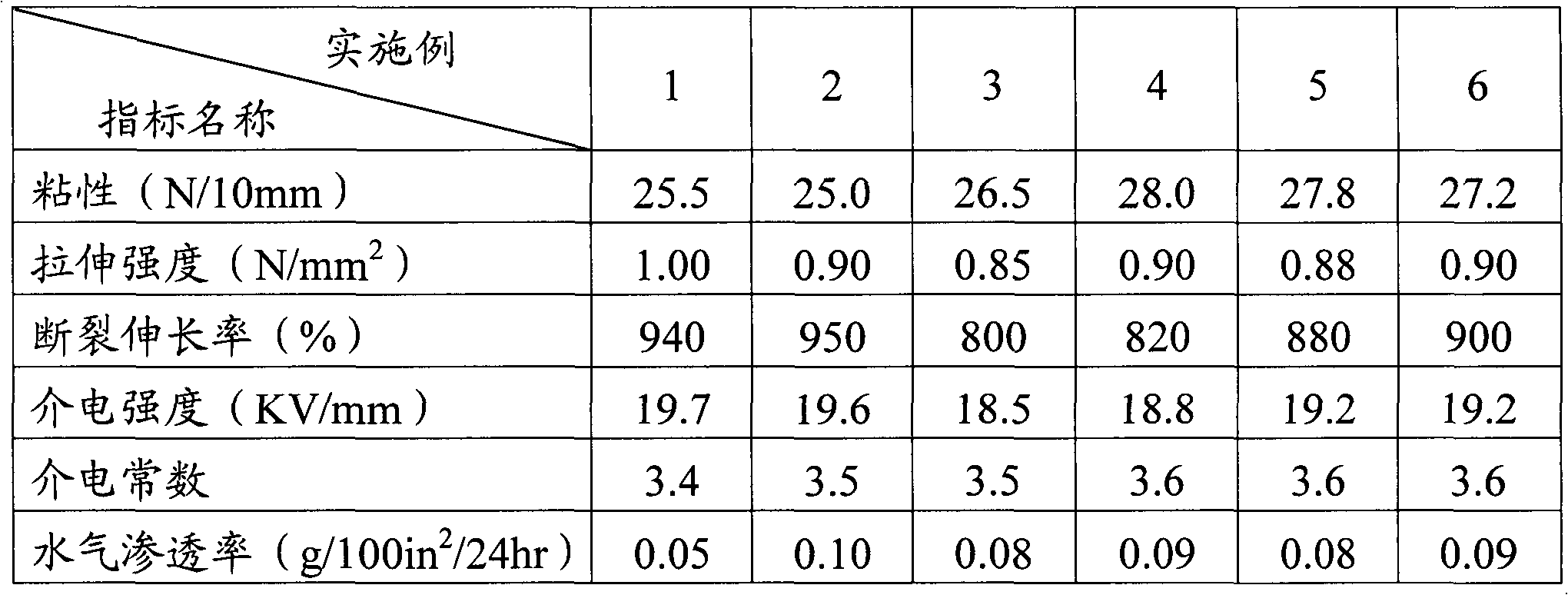

InactiveCN102161871AImprove thermal conductivityHigh bonding strengthLiquid surface applicatorsFilm/foil adhesivesFirming agentMoisture absorption

The invention discloses a heat-conductive insulated adhesive tape for a large-power light-emitting diode (LED) and a preparation method thereof. The preparation process comprises the following steps: mixing 5-10 parts by weight of mixture consisting of epoxy resin and toughening resin at a weight ratio of 1:1, 5-10 parts by weight of curing agent, 0-3 parts by weight of flexibilizer, 0.5 part by weight of accelerator and 0.5-1.5 parts of coupling agent; dissolving the obtained mixture in a solvent, wherein the weight ratio of the solvent to the mixture is 1:5; stirring for 1 hour, then adding 75-89 parts by weight of heat conductive filling material, and evenly mixing; and coating the obtained mixture on a substrate and carrying out graded curing, wherein the first-stage curing temperature is 80 DEG C, the first-stage curing time is 0.5 hour, the second-stage curing temperature is 120 DEG C, and the second-stage curing time is 1 hour, so that a semi-cured adhesive film is obtained. The heat-conductive insulated adhesive tape has the advantages of high heat conductive coefficient, high bonding strength, low moisture absorption, good room-low temperature storage and the like.

Owner:YANTAI DARBOND TECH

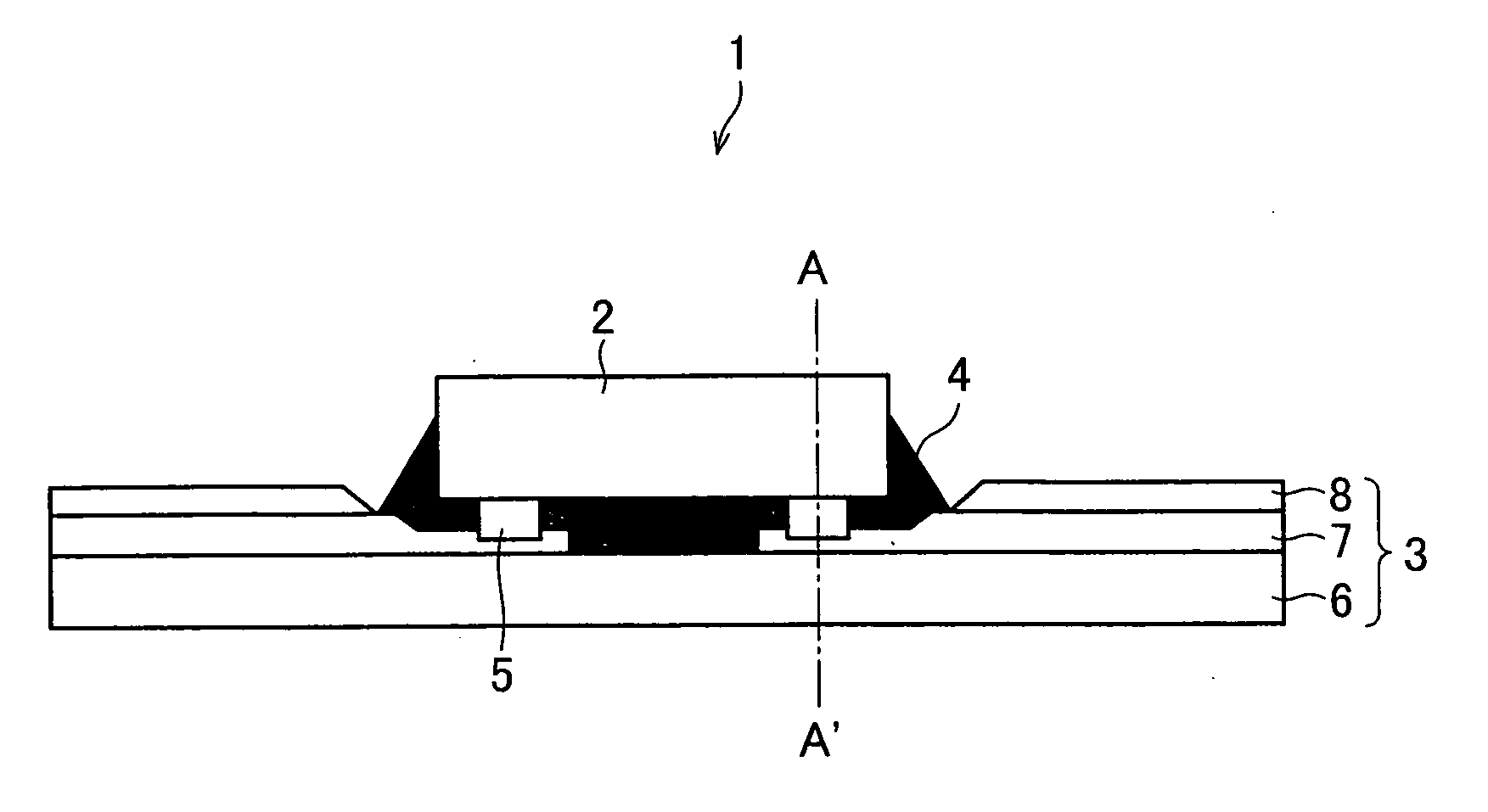

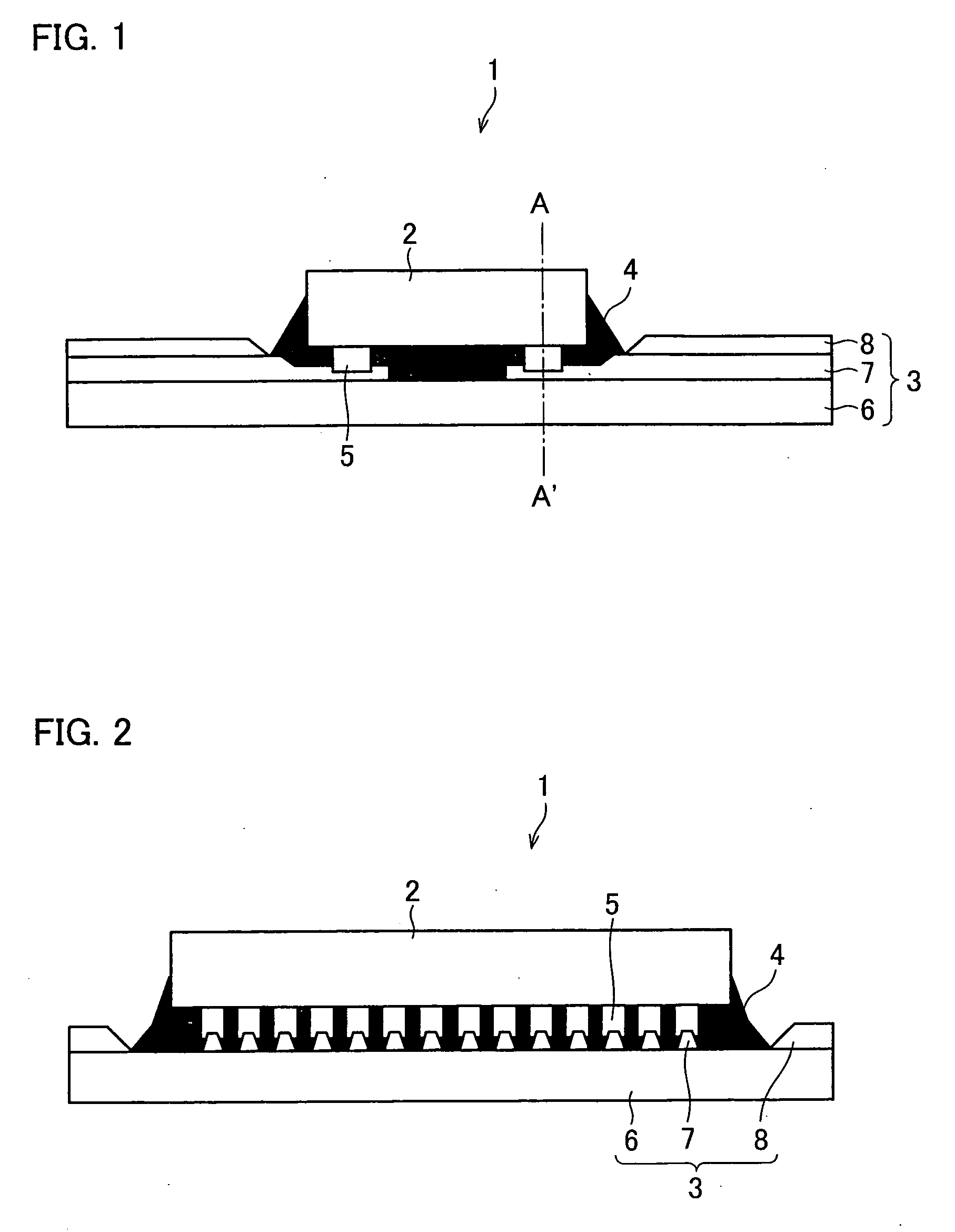

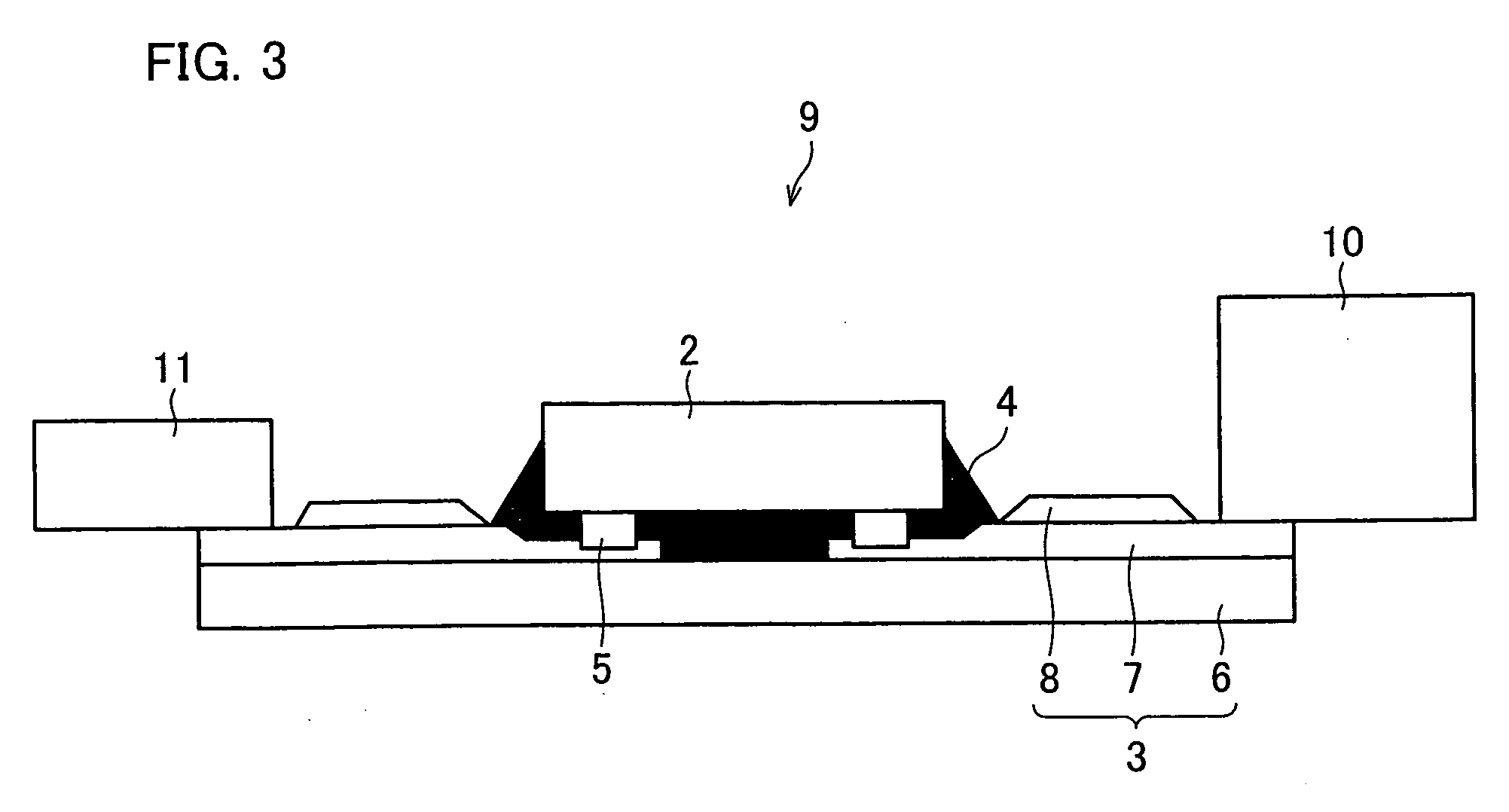

Flexible wiring substrate, semiconductor device and electronic device using flexible wiring substrate, and fabricating method of flexible wiring substrate

ActiveUS20060097368A1Good body shapeReduce variationFinal product manufactureSemiconductor/solid-state device detailsDevice materialEngineering

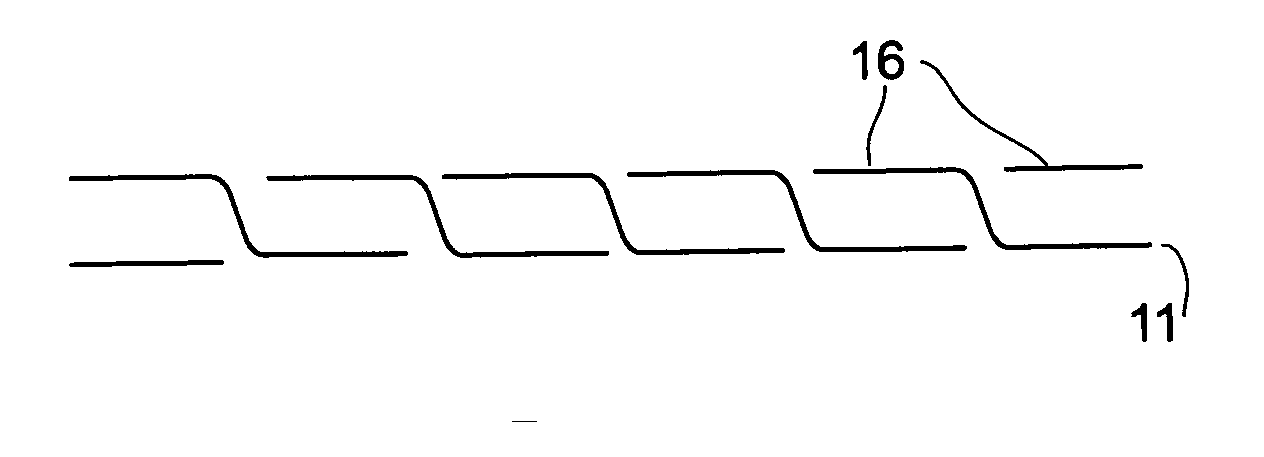

A flexible wiring substrate is provided which realizes a fine pitch of a wiring pattern and improves mechanical strength of the wiring pattern so as to prevent breaks or exfoliation of the wiring pattern. A flexible wiring substrate 3 of the present invention includes an insulation tape 6, and a wiring pattern 7 formed on the insulation tape 6. A thickness of the wiring pattern 7 is made thinner in a mounting region, where a semiconductor element is connected to, than in a non-mounting region.

Owner:SHENZHEN TOREY MICROELECTRONIC TECH CO LTD

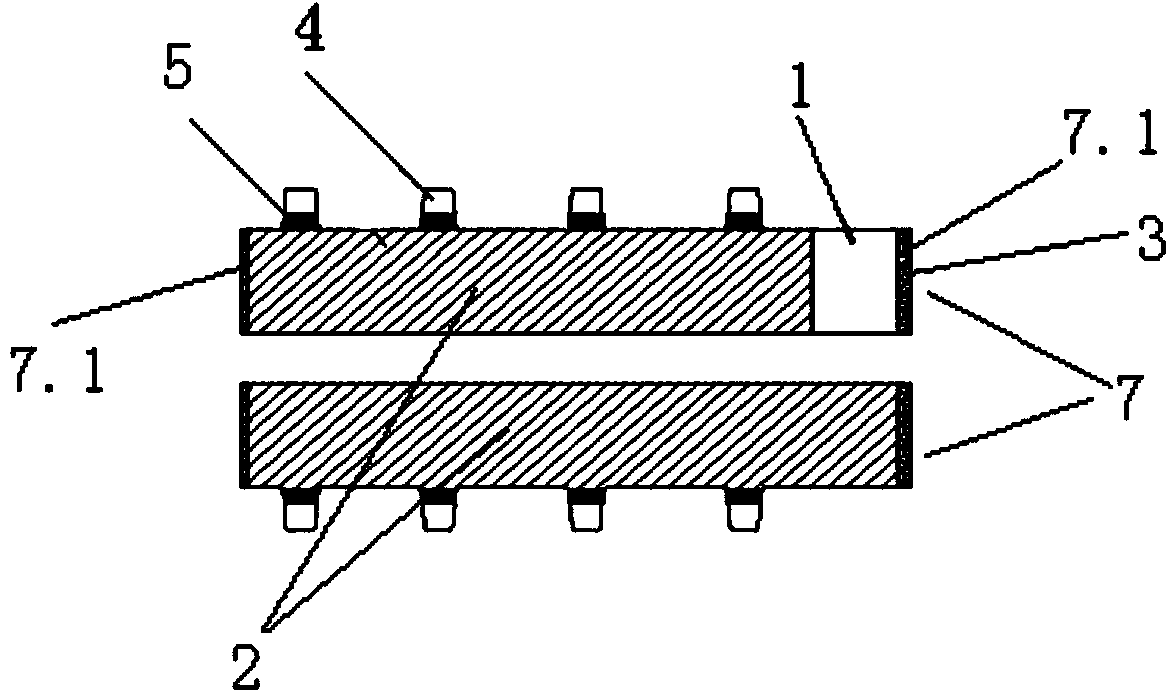

Reinforced type silicon rubber self-adhesion insulated rubber tape

InactiveCN102965048AHigh strengthImprove safe operationNon-macromolecular adhesive additivesFilm/foil adhesivesFiberPolymer science

The invention discloses a reinforced type silicon rubber self-adhesion insulated rubber tape. Cotton fiber cloth is taken as a base material and adhesive layers are respectively coated on upper and lower faces. Each adhesive layer comprises the following materials in parts by weight: 30-60 parts of silicon rubber, 10-25 parts of gas-phase white carbon black, 0-5 parts of silicone oil softening agent, 5-20 parts of silicon-boron tackifier, 0.2-0.5 part of coloring agent and 0.5-5 parts of vulcanizing agent. According to the reinforced type silicon rubber self-adhesion insulated rubber tape, the breaking strength is more than or equal to 5 MPa and the definite elongation strength is more than or equal to 3 MPa; when the reinforced type silicon rubber self-adhesion insulated rubber tape is used for an insulating, sealing and winding process of various cable connectors under 35 kV or below, the safety operation capability, the anti-cracking capability, the anti-fouling capability and the wear-resisting capability of cables are improved, the winding is more tight and the sealing waterproof effect is better; and the use is safe and reliable at a temperature rangoffing from -40 DEG C to 260 DEG C, and the anti-current-leakage capability is further improved.

Owner:吴孟怀

Square winding type battery pole piece and manufacturing technology thereof

ActiveCN104167553ALarge amount of dressingIncrease capacityElectrode carriers/collectorsElectrode collector coatingManufacturing technologyElectrical battery

The invention belongs to the technical field of battery structures, and discloses a square winding type battery pole piece. One edges of positive and negative current collectors are provided with convex electrode lugs; the roots of the convex electrode lugs are provided with insulation rubber coatings; two side edges of the positive current collector are provided with positive electrode small white spaces; two side edges of the negative current collectors are provided with negative electrode small white spaces; the positive electrode small white spaces and the negative electrode small white spaces are oppositely adhered with insulation tapes; a big white space is arranged between a positive electrode coating region and the positive electrode small white space at one side edge; the big white space provides larger coating amount of positive active substances, increases capacity of the battery, and reduces cost of the battery. The insulation rubber coatings are tightly combined with the coating material on the convex electrode lugs, thereby increasing the strength of the electrode lugs and playing a role of preventing shore-circuit situation during a pole-lug folding process. By cutting in the position where the insulation tapes are oppositely adhered during a winding process, powder off caused by cutting the material and burr short circuit caused by a cutter can be prevented effectively.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

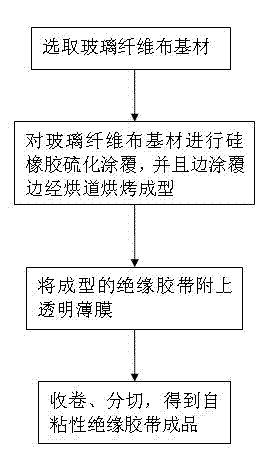

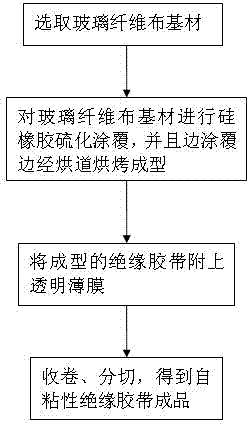

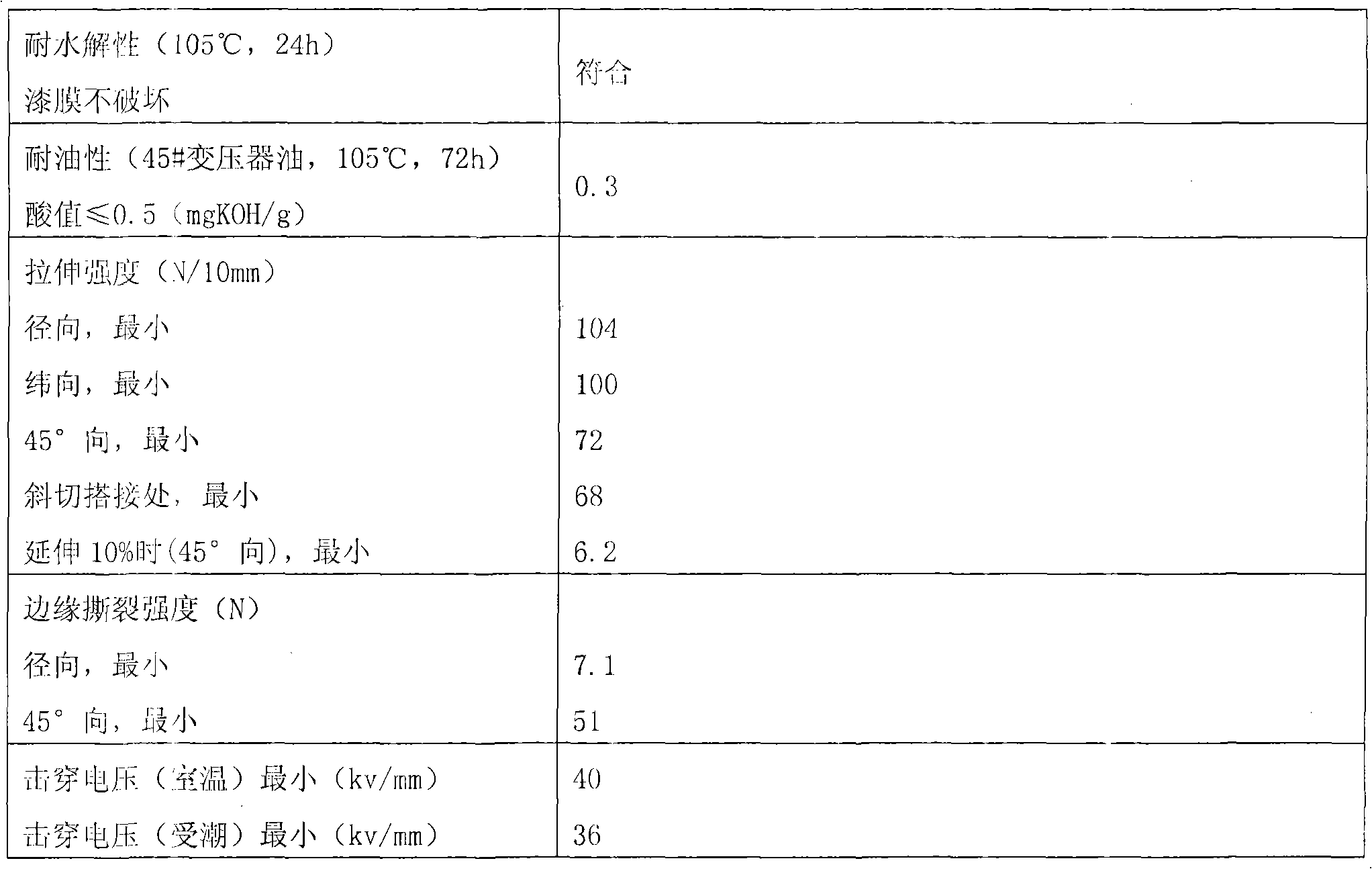

Method for making self-adhesive insulating tape

InactiveCN102516895ASimple processReduce energy consumptionNon-macromolecular adhesive additivesFilm/foil adhesivesGlass fiberVulcanization

The invention discloses a method for making a self-adhesive insulating tape. The method comprises the following steps of: selecting a glass fiber cloth base material; performing silicon rubber vulcanization and coating on the glass fiber cloth base material, and baking in an oven while coating; sticking a transparent film to the formed insulating tape; and rolling, cutting, and thus obtaining a self-adhesive insulating tape finished product. The self-adhesive insulating tape is formed by coating an insulating self-adhesive material on two sides of the glass fiber cloth base material and then compounding the two sides, so the method is simple and low in energy consumption; and the self-adhesive insulating tape has excellent properties of high temperature resistance, ageing resistance, tensile strength, viscosity and the like.

Owner:常熟市富邦胶带有限责任公司

Electric insulating tape

ActiveCN101921556AImprove insulation performanceSmall water absorptionFilm/foil adhesivesWeather resistanceEngineering

The invention discloses an electric insulating tape which is characterized by comprising the following components in parts by weight: 12-18 parts of butyl rubber, 17-25 parts of polyisobutene, 25-33 parts of nano calcium carbonate, 26-34 parts of superfine talcum powder, 0.5-1.2 parts of stearic acid, 0.8-1.5 parts of tackifying resin, 1.0-2.0 parts of carbon black and 1.0-2.0 parts of plasticiser. The electric insulating tape has great well weather resistance, high temperature resistance and insulativity when used for a cable connector, thereby enabling the cable and the optical cable to have no energy consumption and signal loss.

Owner:科建高分子材料(上海)股份有限公司

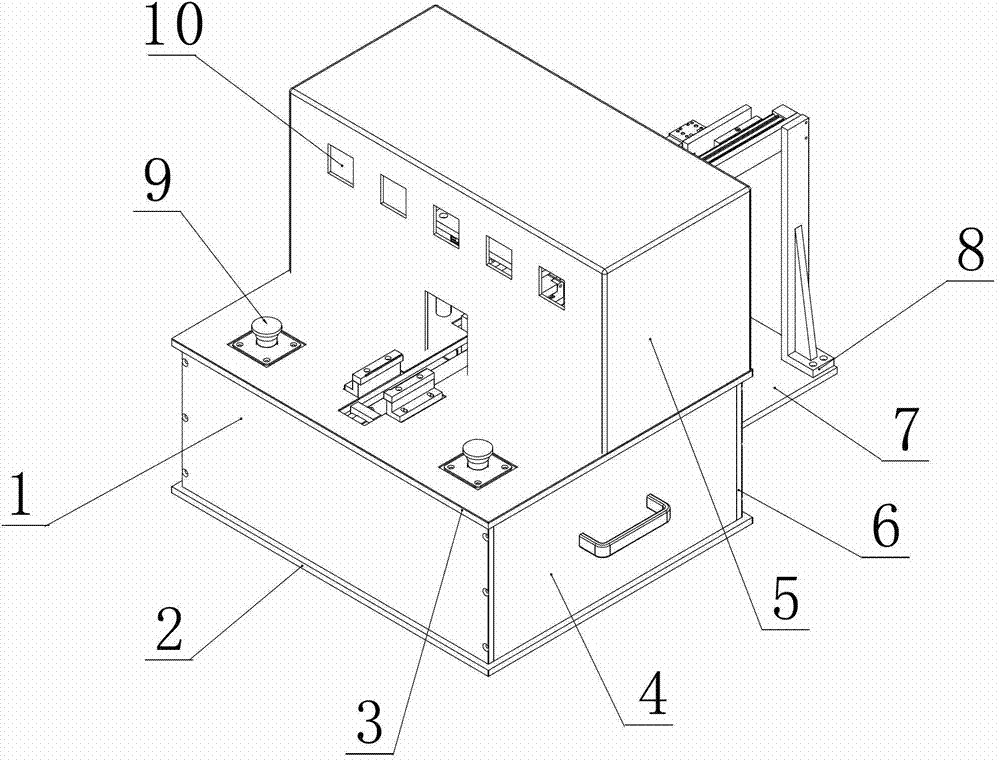

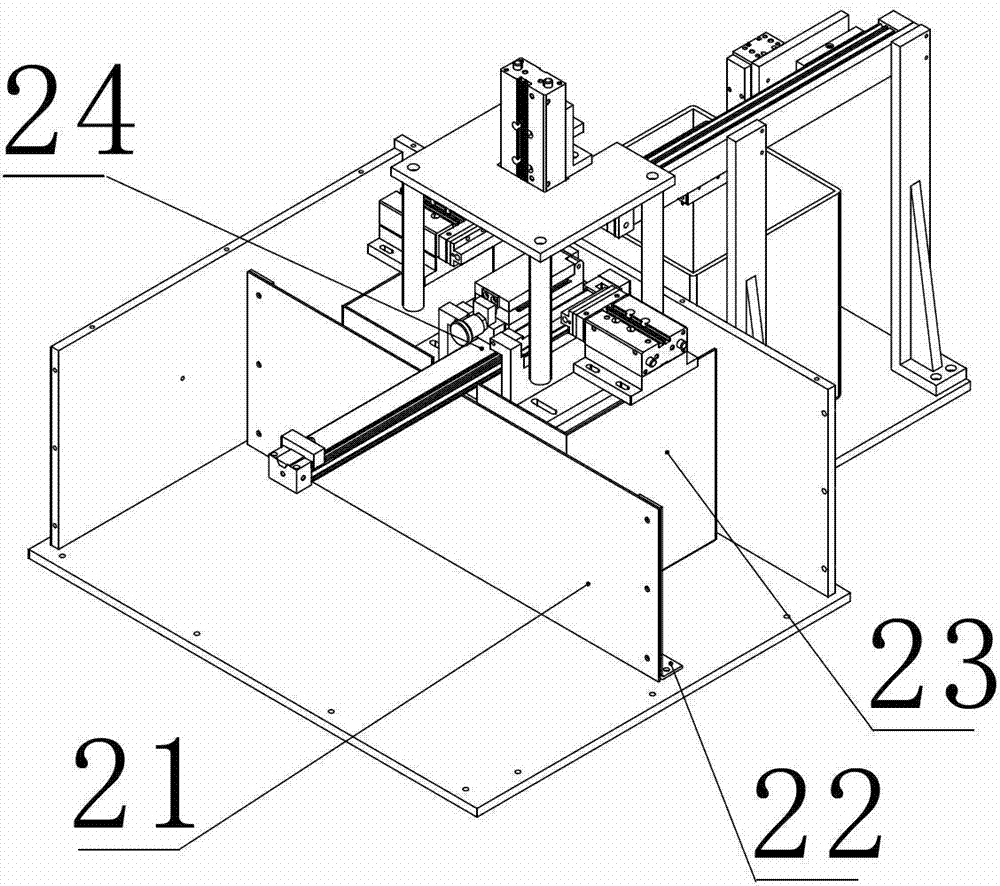

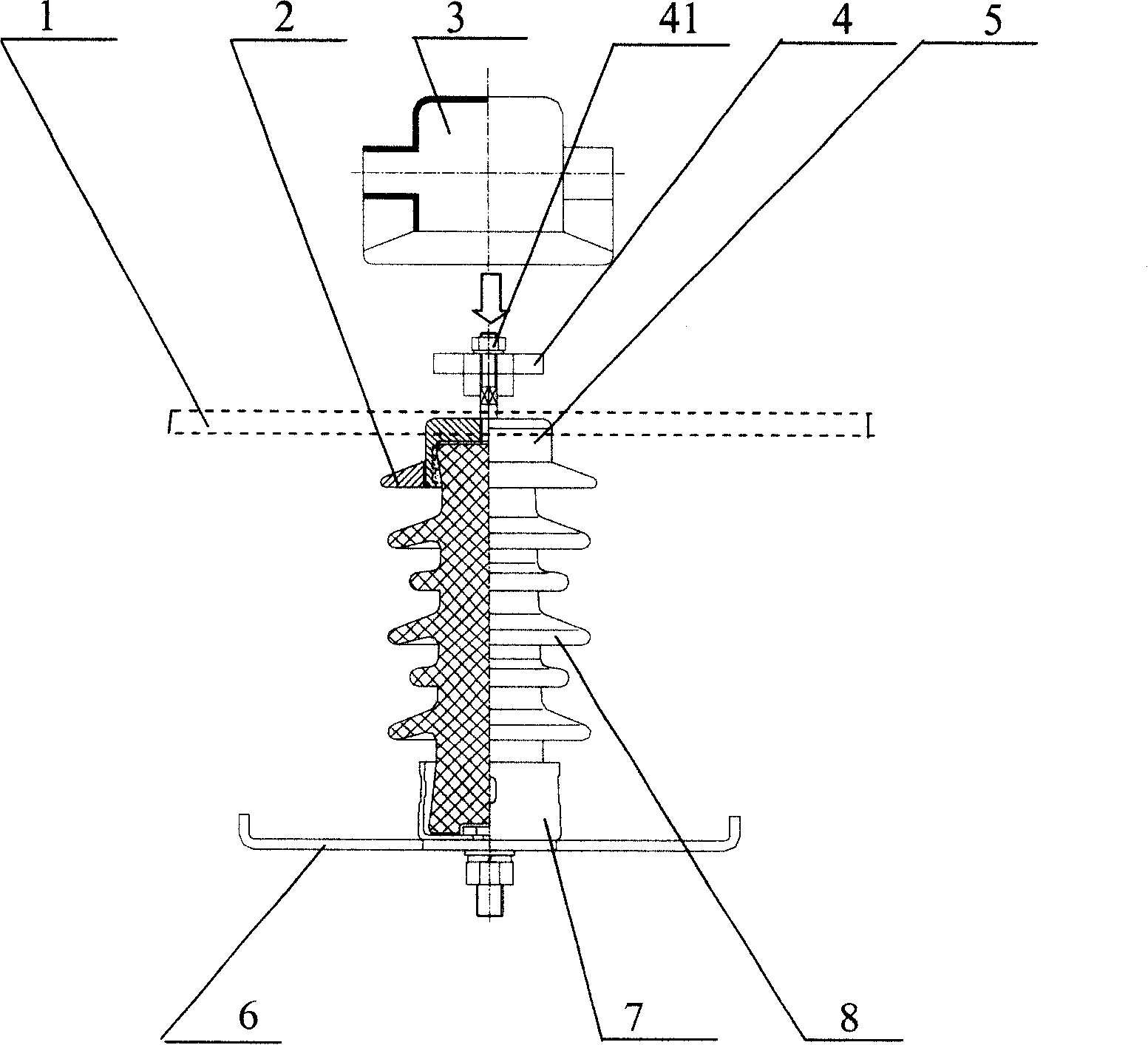

Full-automatic lithium ion polymer battery four-in-one device with bent side edges

ActiveCN102832413AFit to meetGuaranteed appearanceFinal product manufactureElectrolyte accumulators manufactureLithiumElectrical control

The invention discloses a full-automatic lithium ion polymer battery four-in-one device with bent side edges. The full-automatic lithium ion polymer battery four-in-one device comprises a rack, a material loading / unloading mechanism, a preheating mechanism, a release paper tearing mechanism, a side edge bending mechanism, a constant-temperature reforming mechanism and an electrical control device which are connected together through the rack, wherein the material loading and unloading mechanism is used for locating a battery, which is pasted with insulation tapes at the side edges, and sending the battery to a processing position after the battery is located, the upper surfaces and the lower surfaces of the side edges of the battery are simultaneously preheated by the preheating mechanism, the release paper tearing mechanism is used for tearing preheated release paper which is adhered on the insulation tapes at the side edges of the battery, the side edge bending mechanism is used for inwards bending two side edges of the battery simultaneously, and the constant-temperature mechanism is used for inwards squeezing the bent side edges of the battery simultaneously and enabling the side edges of the battery to be integrated with a battery body. According to the full-automatic lithium ion polymer battery four-in-one device disclosed by the invention, the generation of base angle fracturing due to the bending of the side edges of the battery can be reduced, the side edges can be in firm and reliable bending adhesion, and the consistency of the appearance and the size of a product is increased as well.

Owner:TIANJIN JUYUAN NEW ENERGY TECH CO LTD

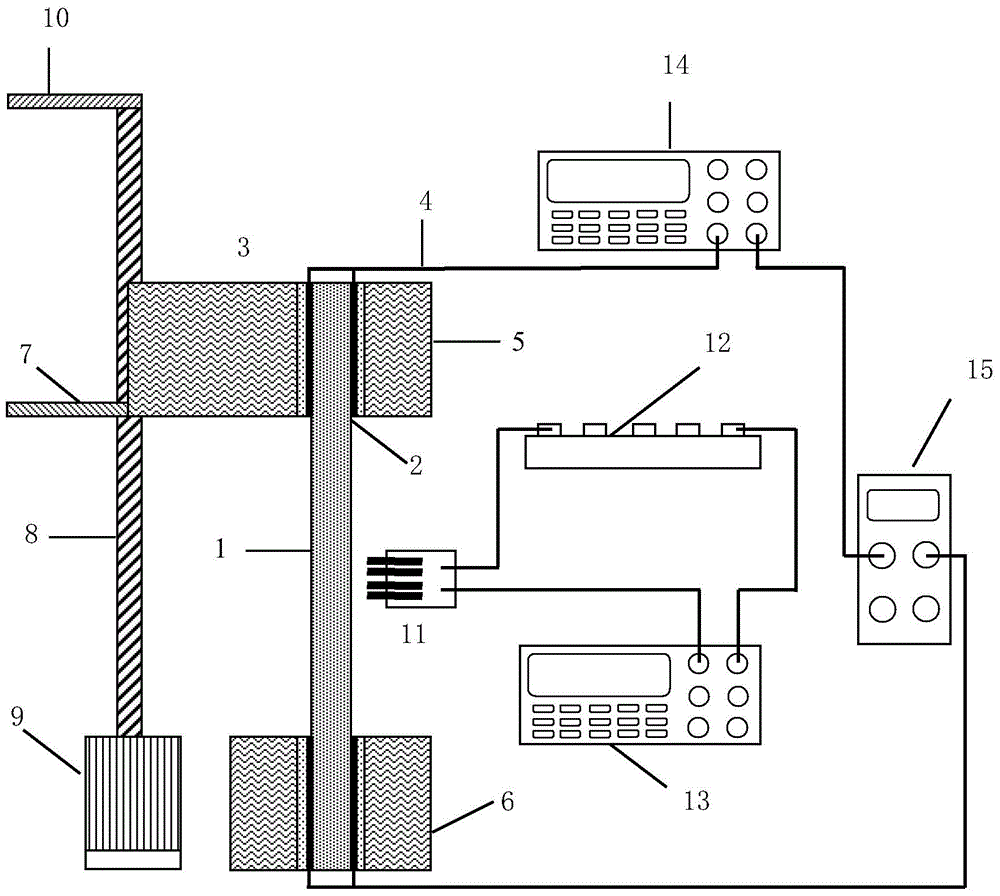

System and method for testing mechanical-electrical coupling effect of electrical conducting functional material

InactiveCN104931335ARealize measurementRealize analysisResistance/reactance/impedenceStrength propertiesHand heldDrive motor

The invention discloses a system and a method for testing the mechanical-electrical coupling effect of an electrical conducting functional material . The system comprises an electrical conducting functional material sample, a sample electrode, an insulation tape, an external wire on the electrode, a sample clamping device, a displacement sensor, a transmission shaft, a driving motor, a force sensor, a handheld four-point probe, a digital source meter B, a digital source meter A and a DC power supply, wherein an integral load-displacement curve can be obtained through accurate control of parameters such as voltage strength, conduction time and loading speed; mechanical and electrical properties such as elasticity modulus, tensile strength, elongation at break, yield strength, integral volume resistivity and micro-area volume resistivity distribution of a material under the action of different force fields and electric fields can be obtained through further calculation. Therefore, measurement and analysis of the mechanical-electrical coupling effect of the electrical conducting functional material can be realized accurately and reliably, and the system and the method are suitable for electrical conducting functional materials such as conductive macromolecule, piezoceramics, a polymer-matrix composite, a ceramics-matrix composite, and a metal-matrix composite.

Owner:PEKING UNIV

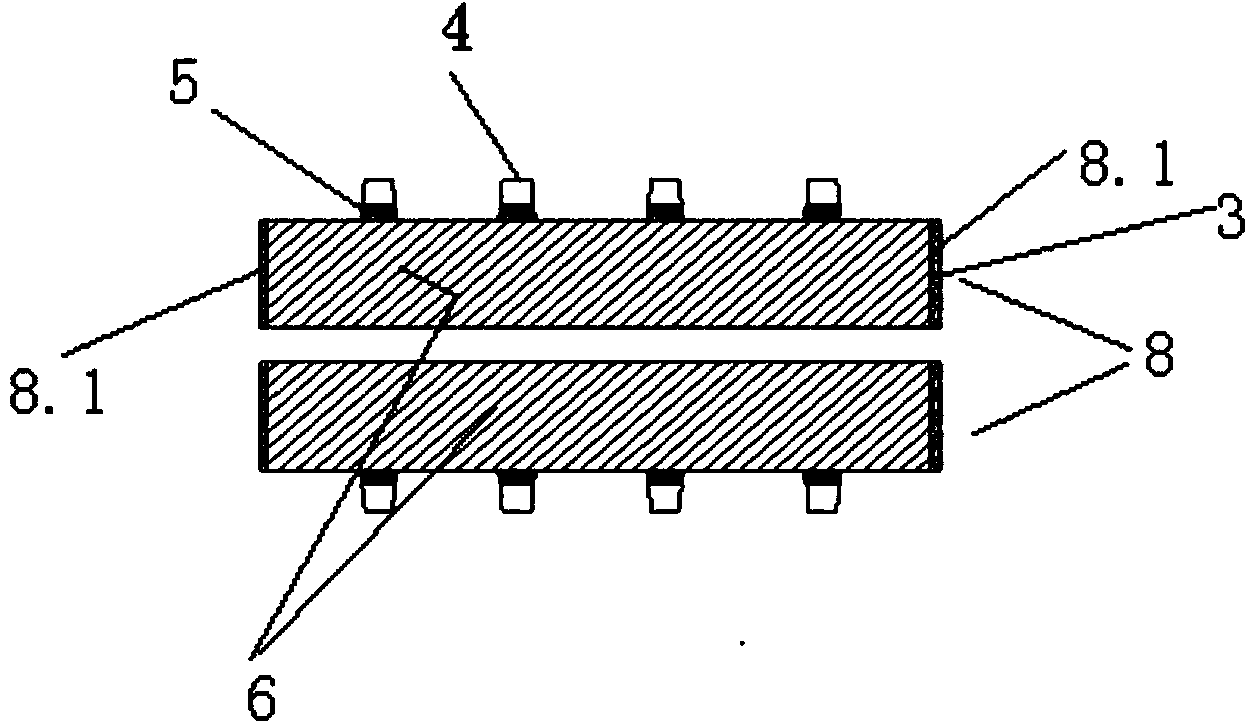

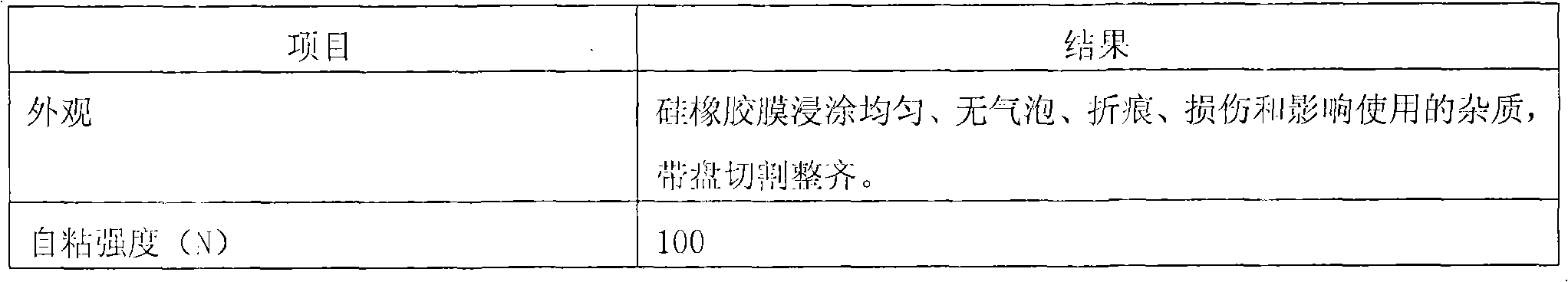

Insulating tape and preparation method thereof

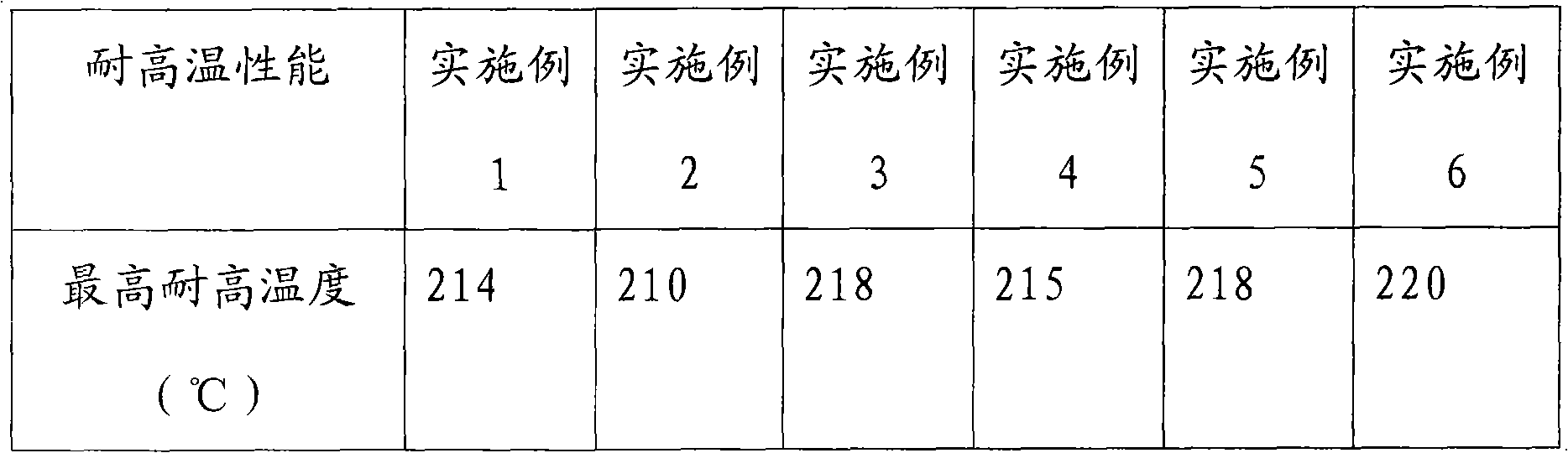

InactiveCN101987951AImprove heat resistanceMaintain insulation functionFilm/foil adhesivesPolymer scienceSolvent

The invention discloses a silicone rubber insulating tape and a coating-method production process thereof. The insulating tape is manufactured by combining glass fiber cloth belts with two sides coated with insulating viscous materials. The insulating viscous materials comprise the following components in part by weight: 65 to 75 parts of silicone rubber 110-2, 8 to 14 parts of silicone rubber 107, 1 to 2 parts of alkaline acid, 10 to 18 parts of white carbon black A200, 1 to 4 parts of hydroxy silicone oil GY2009-3, 1 to 4 parts of ferric oxide, 1 to 4 parts of vulcanizing agent, and the balance of xylene serving as a solvent. The insulating tape has advantages in the aspects of high-temperature resistance and ageing resistance, and instead of the conventional calendaring process, the process for coating silicone rubber paste on the glass fiber belts is adopted to simplify production process, reduce energy consumption and consequently reduce production cost.

Owner:常州俊科绝缘材料有限公司

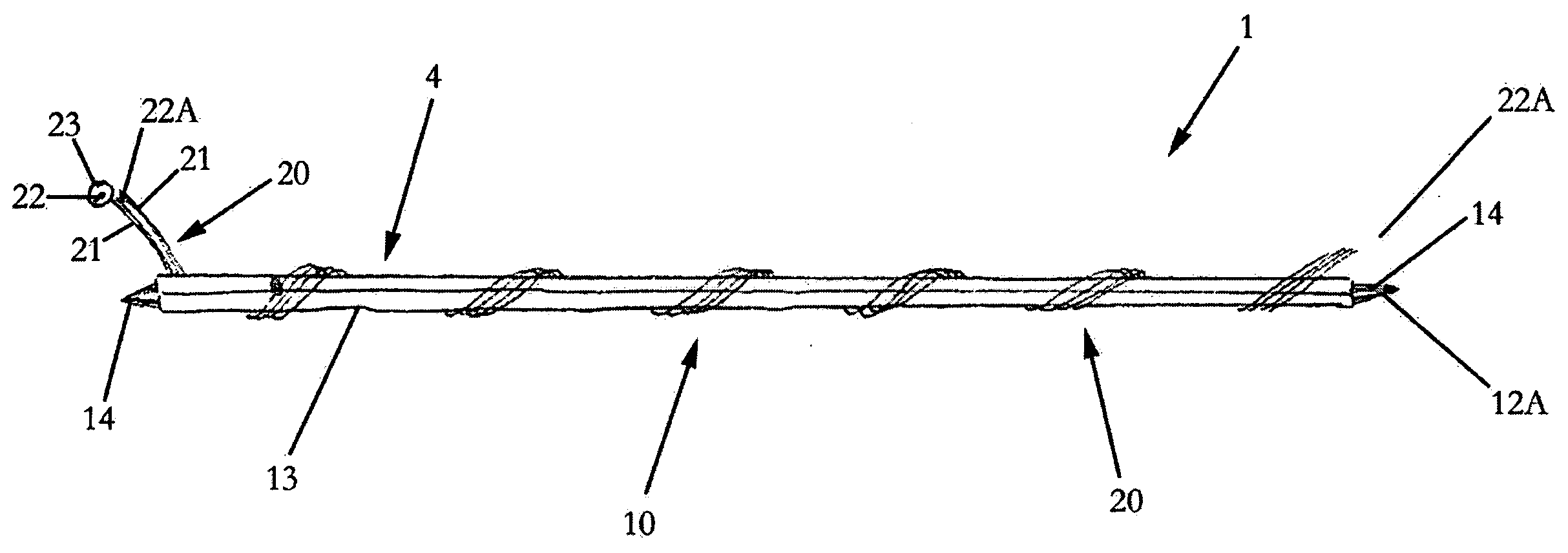

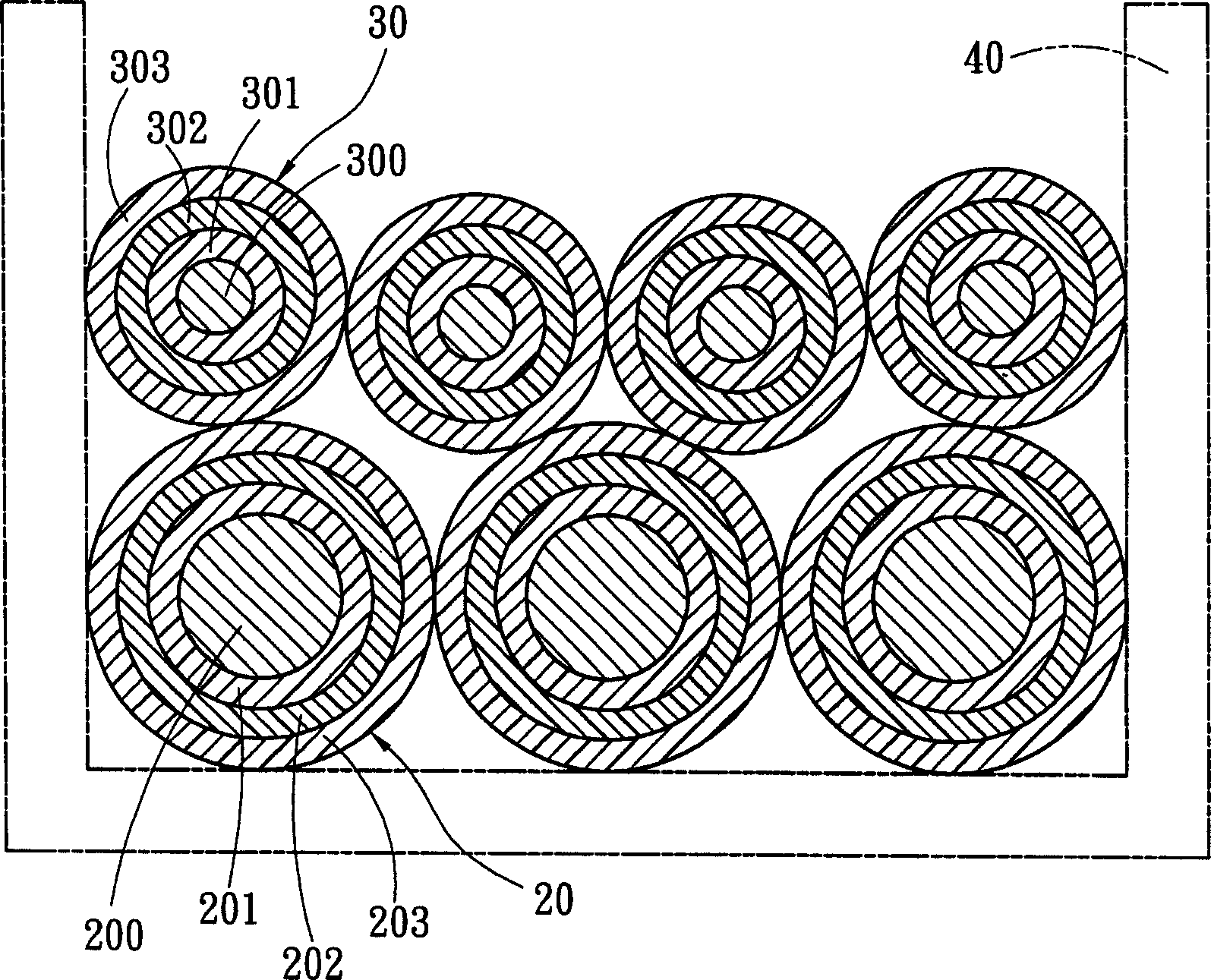

Electrical wiring device system

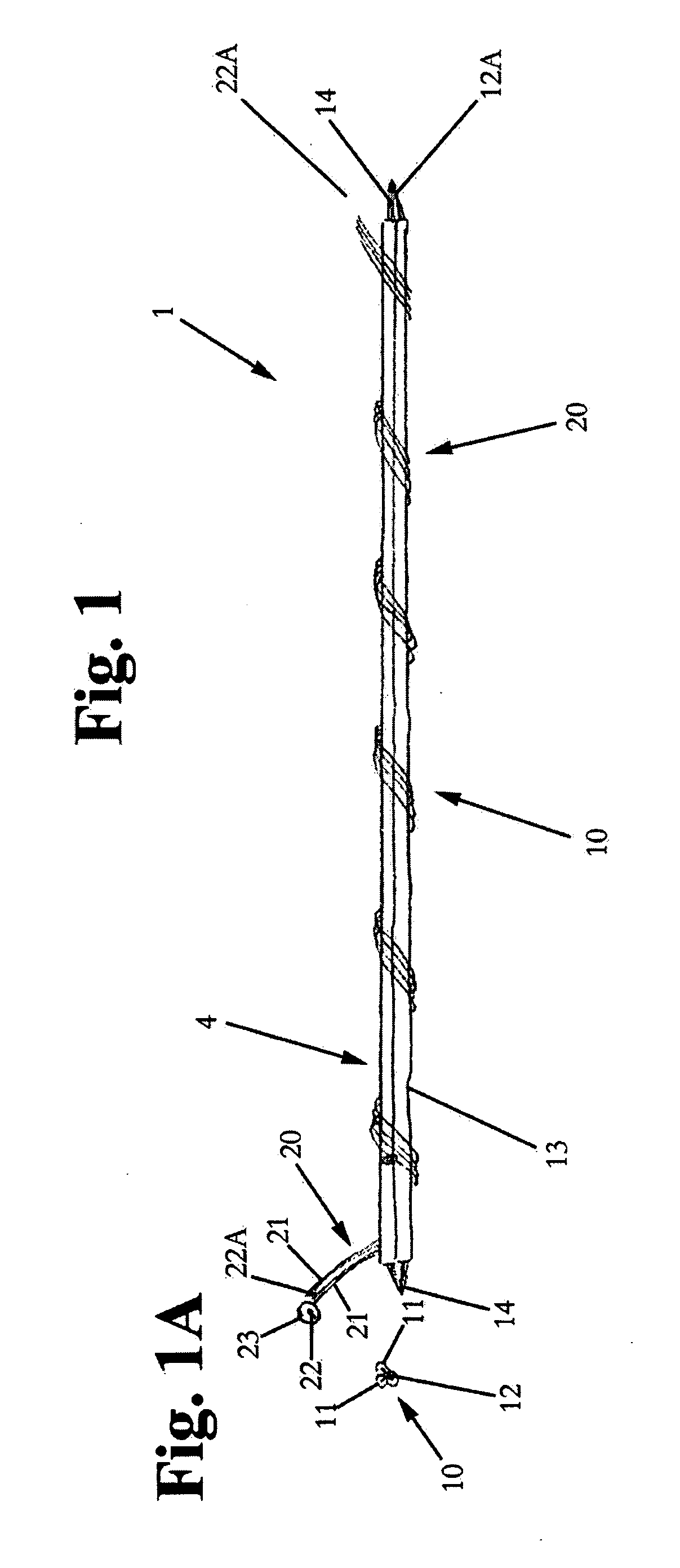

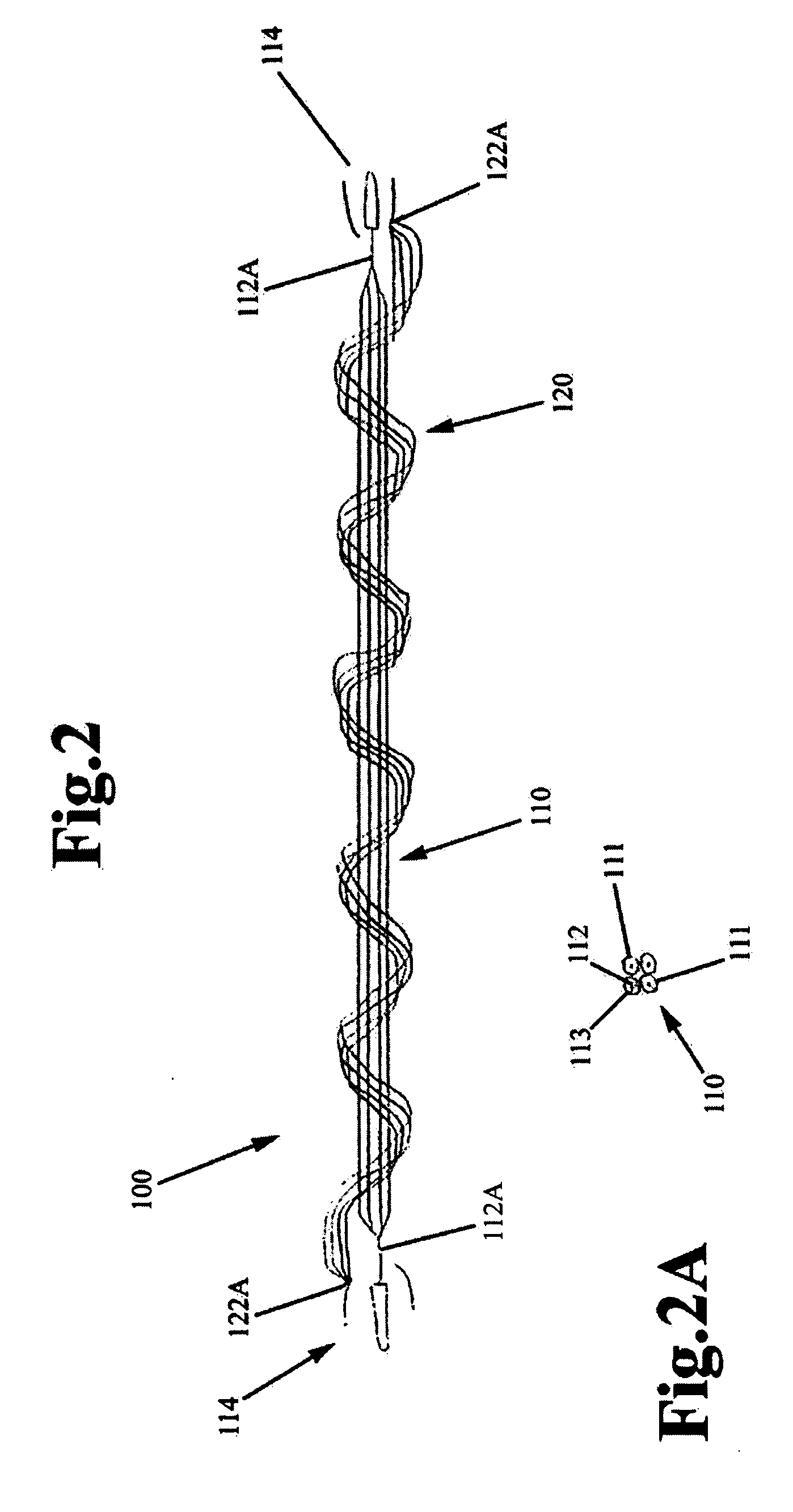

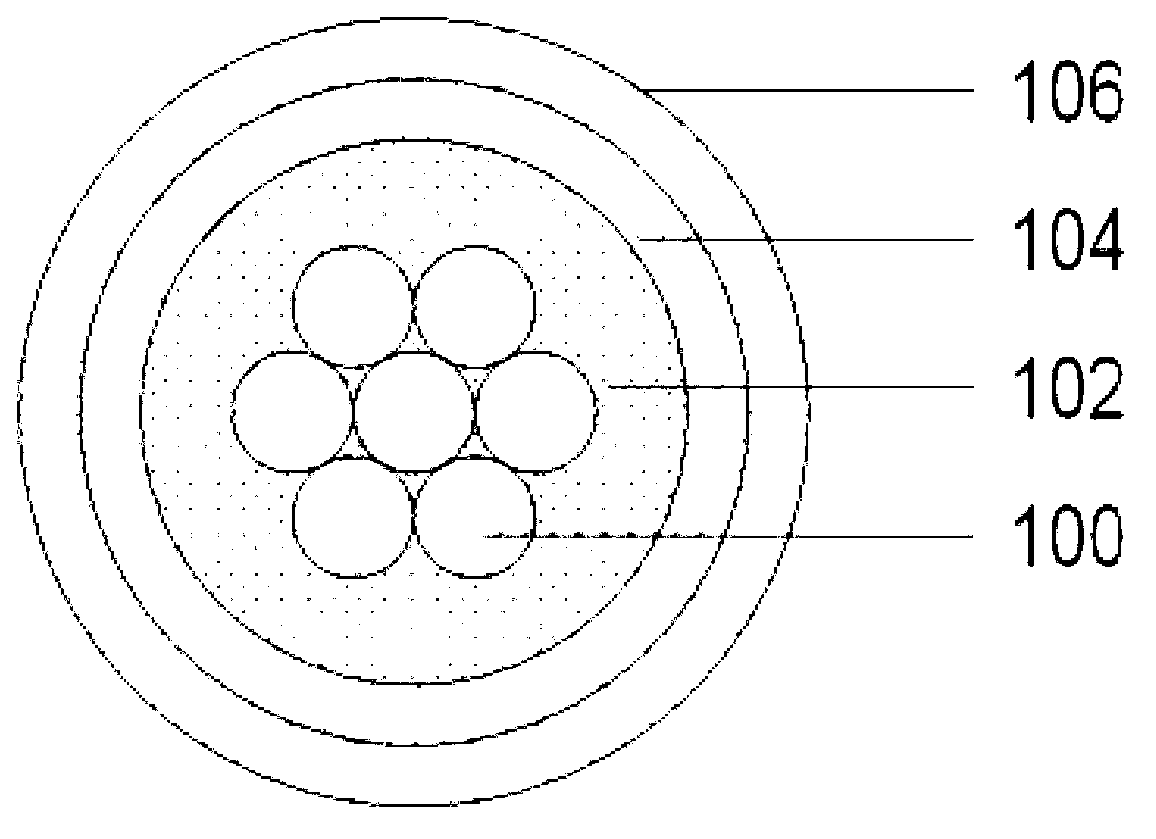

InactiveUS20050072594A1Power cables including communication wiresPower cables with screens/conductive layersPower cablePaper tape

Electrical wiring devices for audio / video systems, such as, for example, audio speaker cables (FIG. 1), audio / video component interconnect cables (FIG. 2) and power cables (FIG. 3) and the like, and more particularly the structure thereof using, preferably, a series of four, inner, parallel, longitudinally extended or straightly-laid, individually insulated, core wires (11 / 111 / 211) surrounded by at least one set [two 220 & 230 for a power cord (200)] of four, spiral wound, outer, individually insulated wires (21 / 121 / 221), typically with an initial covering of electrical tape type or paper tape material covered by aesthetic silk or cotton cloth or other material(s), in which the inner, core wires are signal carrying wires and the spiral wound wires are the ground / neutral wires, each type combined at their ends (12A / 112A / 221A) at terminating end elements, such as twisted ends, RCA-connectors or A / C power plug ends (14 / 114 / 214, respectively).

Owner:RICHARD GRAYS POWER CO

Liquid insulating glue for cable joint

InactiveCN101962519AVolatile fastHigh elongationRubber derivative adhesivesConnection insulationEngineeringCopper

The invention belongs to electric wire and cable protection and electric insulating adhesive tapes, and particularly relates to liquid insulating glue for a cable joint. The liquid insulating glue contains modified rubber and non-polar solvent and also can contain oil-soluble resin and / or copper corrosion inhibitor, wherein the consumption of the modified rubber is 10 to 40 percent of the total mass; and a formed insulating protective layer has excellent insulating performance and properties of resisting moisture, water, oxidation and acid and alkali corrosion. The liquid insulating glue can be used for joint coating and insulation of a metal lead, and also can be used for repair of cable outer sheaths and waterproof seal of embedded electric wires and cables.

Owner:海宁市科泰克金属表面技术有限公司

Far-infrared electrothermal film blanket

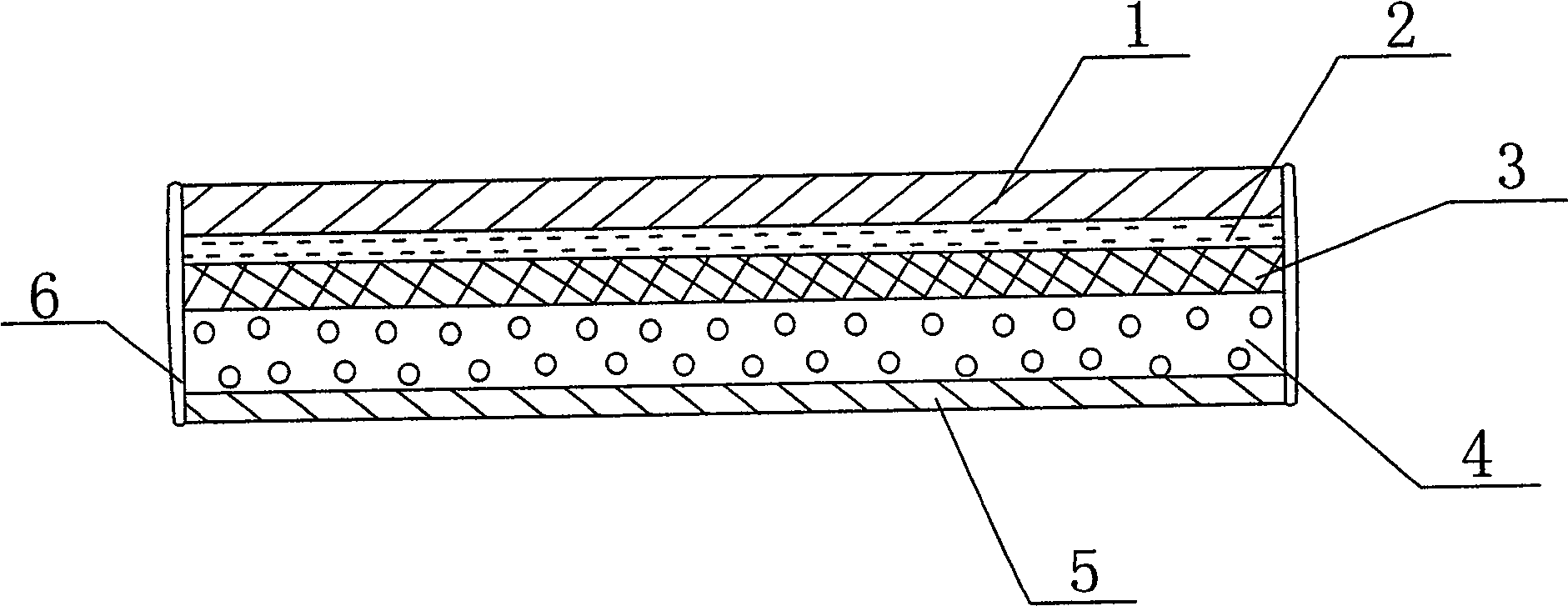

InactiveCN101534582ATo achieve the purpose of low temperature radiationStay fresh and pleasantSleeping rugTravelling rugTemperature controlInsulation layer

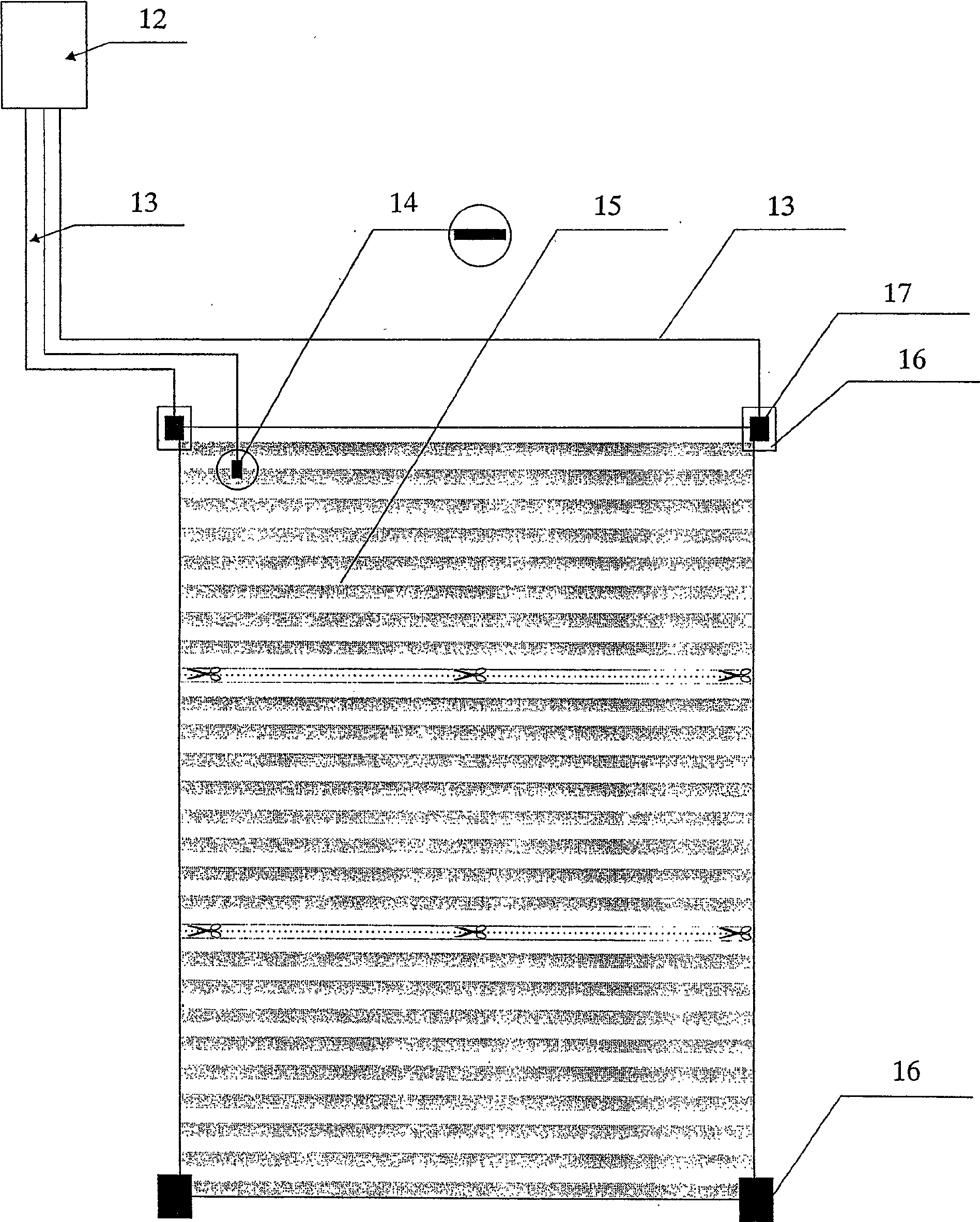

The invention discloses a far-infrared electrothermal film blanket, and relates to an indoor warming article. The far-infrared electrothermal film blanket consists of an electrothermal film blanket and a temperature control part; the structure of the electrothermal film blanket (15) comprises a leather layer (1), a protective layer (2), an electrothermal film (3), a heat insulation layer (4) and a waterproof layer (5) from top to bottom; the outside of the electrothermal film (3) is stuck with an insulated adhesive tape; the width of the electrothermal film blanket (15) is between 50 and 100 cm; the electrothermal film blanket (15) is provided with a cuttable part; two sides of the electrothermal film blanket (15) are provided with connecting clamping sheets (17); the outer layer of the connecting clamping sheet (17) is wrapped with an insulating cover (16); the temperature control part comprises: a sensor (14) is arranged on the electrothermal film blanket (15) and is connected with an intelligent temperature controller (12) through a conducting wire; and the intelligent temperature controller (12) is connected with the connecting clamping sheets of two sides of the electrothermal film blanket (15) respectively through the conducting wire (13). The far-infrared electrothermal film blanket can be applied to a mattress, a bed blanket, a carpet, and the like so as to adjust the temperature.

Owner:李昌浩

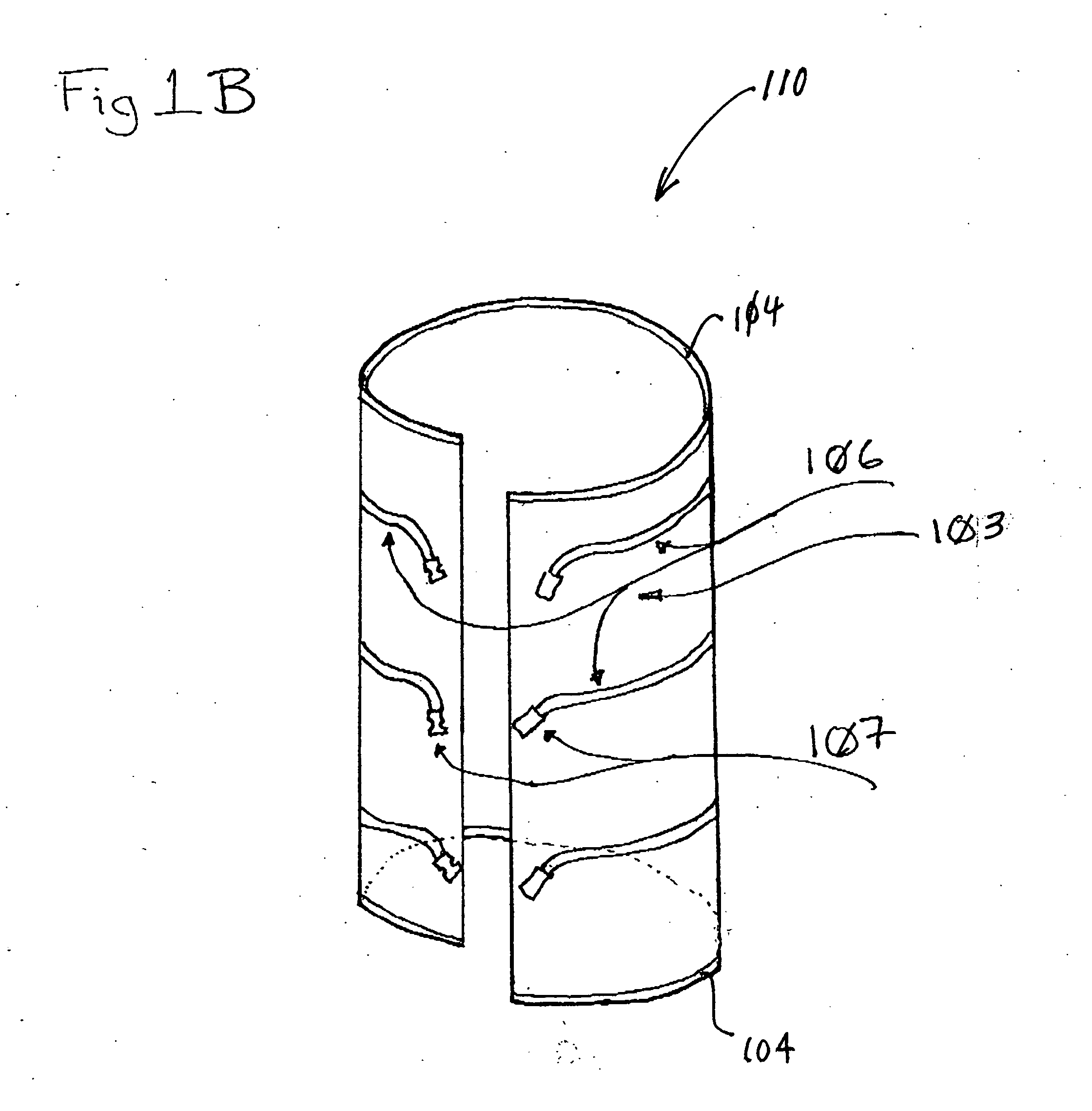

Insulating/protective covering for a container

InactiveUS20060231562A1Prevent heat transferAvoid conductionContainer/bottle contructionRigid containersHeat lossesElectrical tape

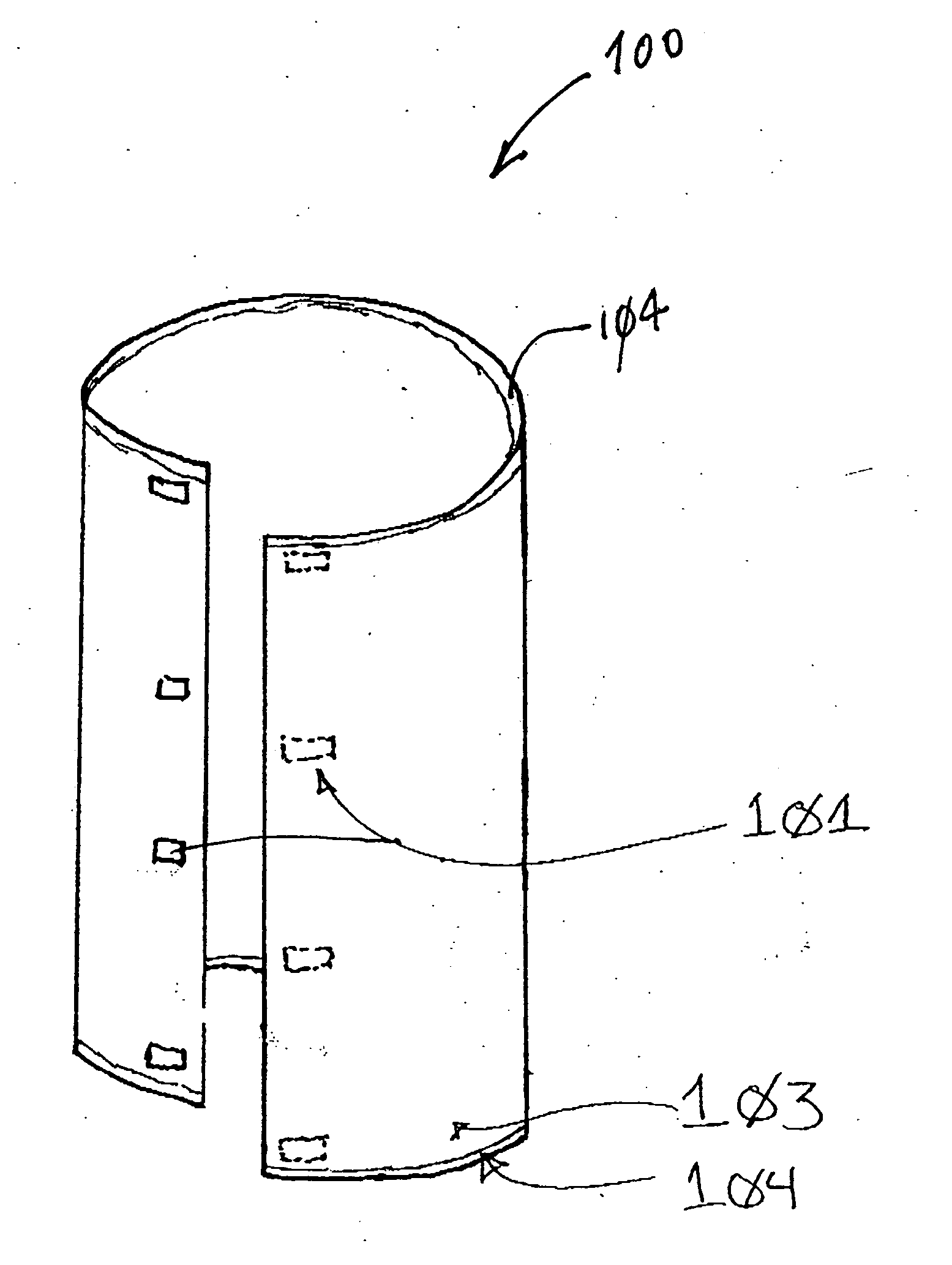

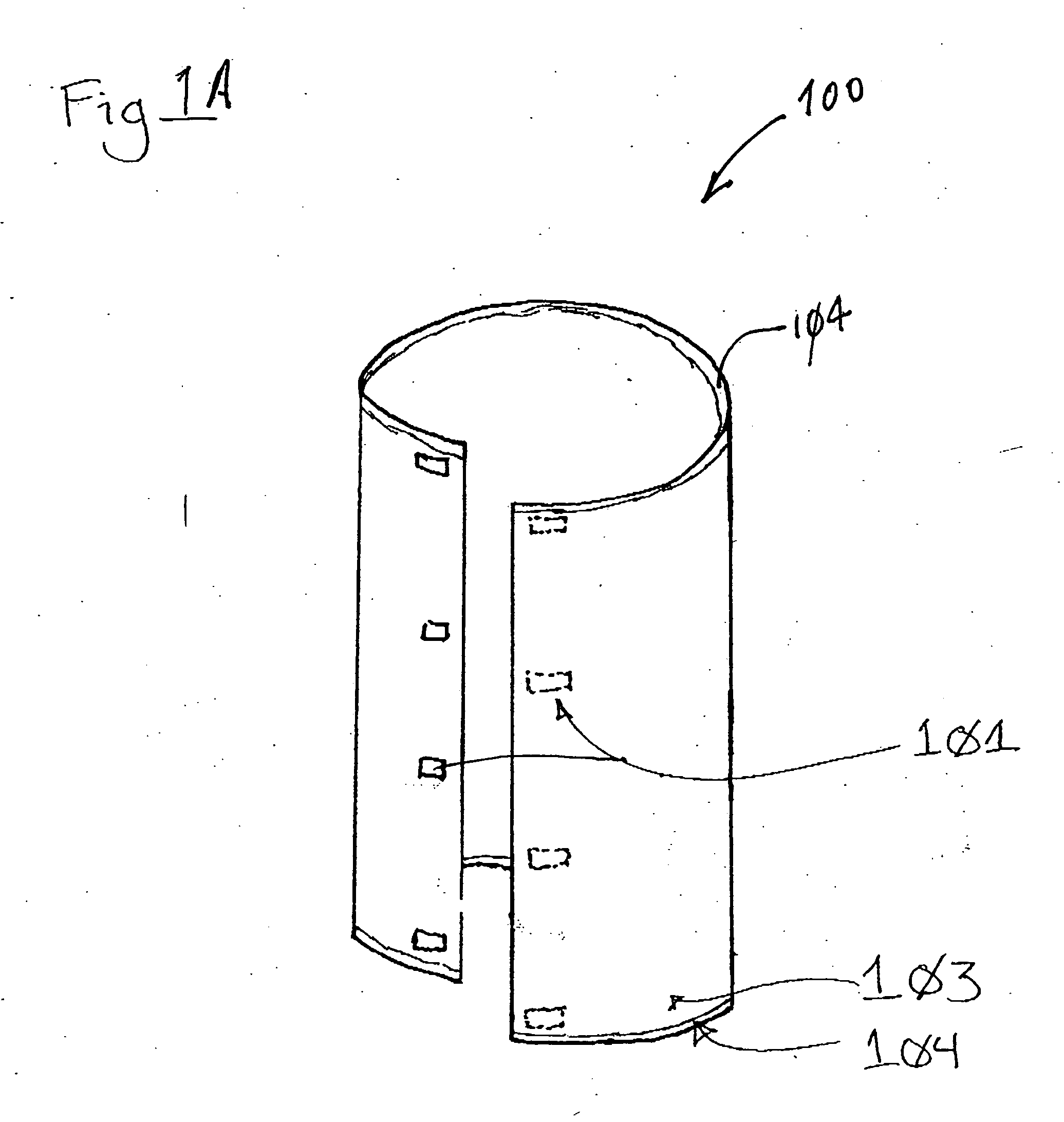

An insulating wrap for adding to containers to prevent heat adsorbsion or heat loss is composed of conductive insulation material as well as radian barrier material. The insulating wrap conforms to the container shape and has multiple attachment elements for closing and retaining the insulating wrap to the container. The insulating wrap may also have attachment elements for adding a top and / or a bottom insulating cover also comprising conductive insulation material as well as radian barrier material. The insulating wrap may employ insulating tape on the top and bottom edges to protect the edges as well as to further improve heat transfer at the interface between the top or bottom covers and the insulating wrap. In one embodiment the top cover may have an integrated handle piece where the top and bottom cover attachments have sufficient strength to allow a container to be lifted. This embodiment facilitates lifting of a insulated container.

Owner:MANNING ENVIRONMENTAL

Aerial insulation wire electrification repairing method

ActiveCN104009421ANon-stickReduce the temperatureApparatus for repairing insulation/armouring cablesSilicone tapeElectrical tape

The invention relates to an aerial insulation wire electrification overhauling method, in particular to an aerial insulation wire electrification repairing method. The method comprises the steps that polyimide adhesive tape is wrapped on the exposed part of an aerial insulation wire through a half fold packaging method, the outer side of the exposed part wrapped by the polyimide adhesive tape is coated with a layer of teflon coating film, an injection hole is formed in the middle of the teflon coating film, and a spray gun sprays a polyurethane foam joint mixture to the position between the teflon coating film and the polyimide adhesive tape through the injection hole for joint filling. According to the aerial insulation wire electrification repairing method, the problems that the insulation performance of the aerial wire is lowered, and a grounded short circuit accident is caused due to the facts that the aerial wire is exposed and the insulation adhesive tape is aged, unglued and chapped are effectively prevented, large-area power failure is avoided, power supply reliability is provided for reducing interphase short circuits and ground faults, and hidden dangers existing when workers work are avoided.

Owner:STATE GRID CORP OF CHINA +1

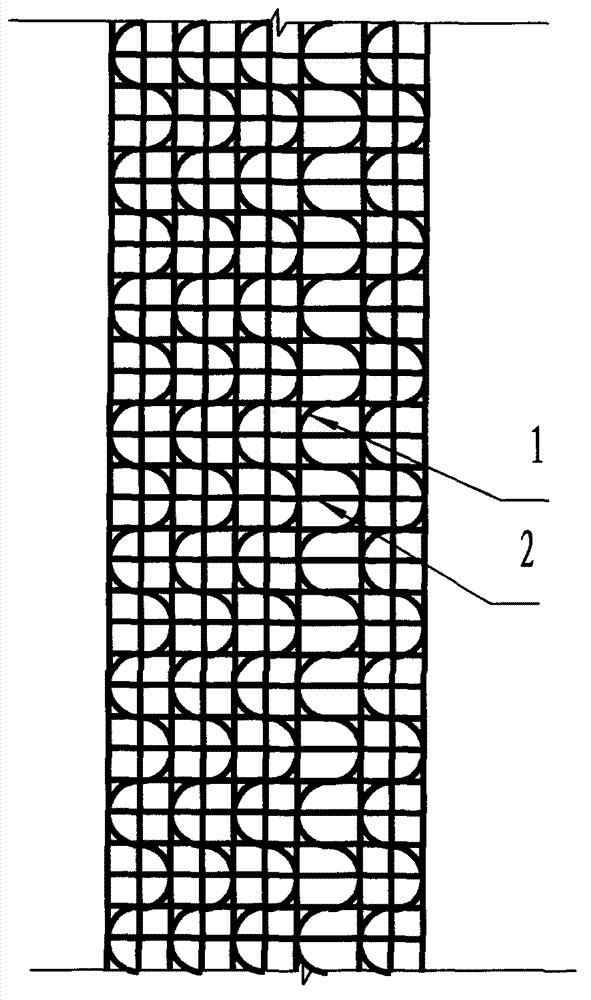

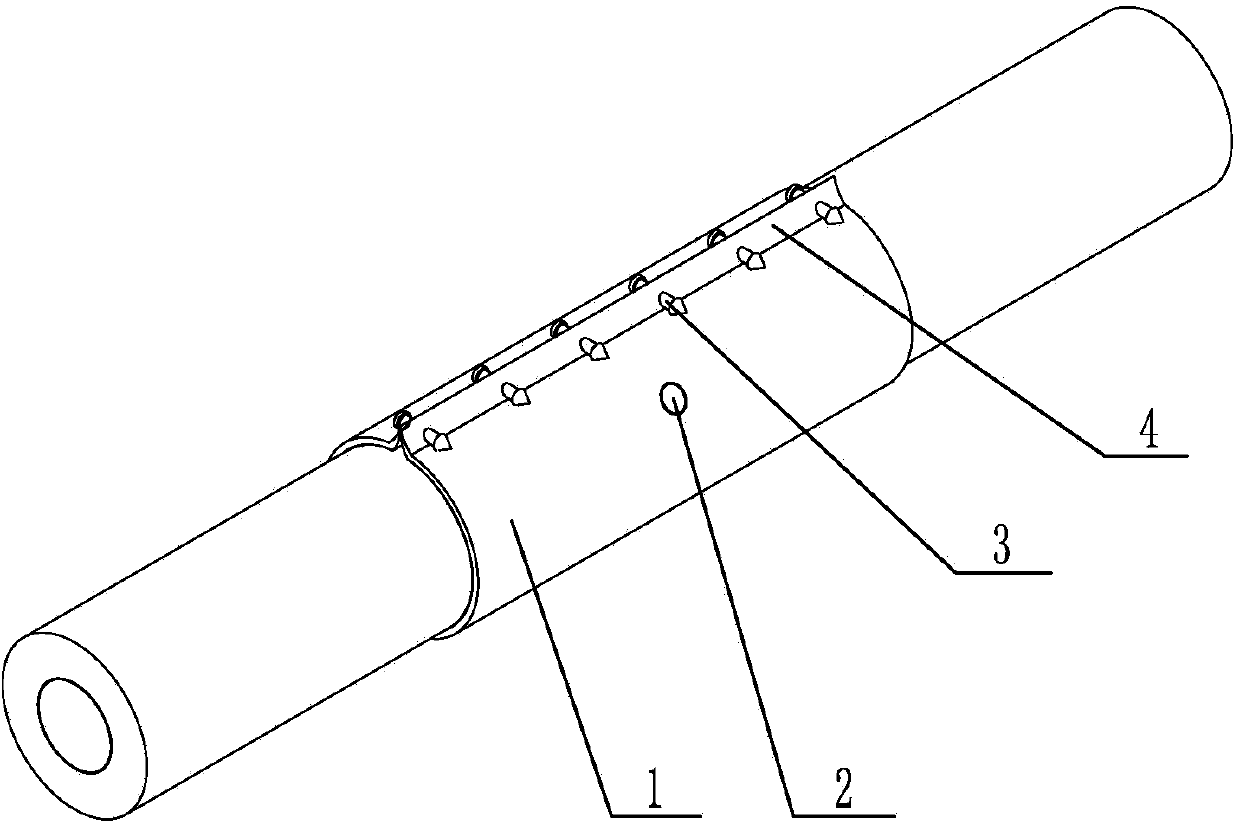

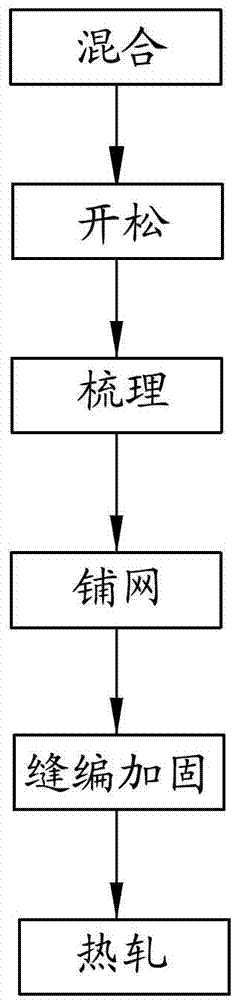

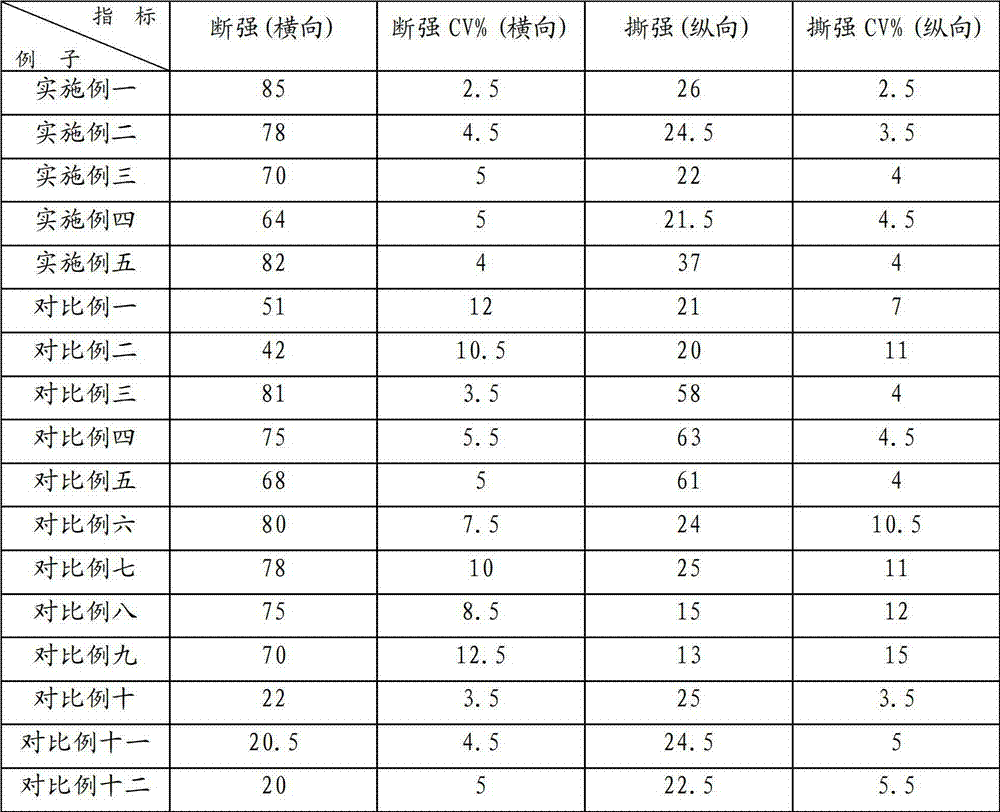

Stitch knitting non-weaving cloth for electrical tape base cloth and production method thereof

InactiveCN102965852AImprove transverse breaking strengthEasy to processNon-woven fabricsBreaking strengthGram

The invention discloses stitch knitting non-weaving cloth for electrical tape base cloth and a production method thereof. The production method comprises the following steps of: oploosening and carding polyester staple fibers with specified fineness and paving and laminating the carded polyester staple fibers to form a fiber web with specified monomer gram weight; reinforcing stitches with fine denier polyester filaments formed by a specified warping mode by adopting an active warp let-off mode; and carrying out stitching knitting and reinforcing on a stitch knitting machine adjusted by a process and then carrying out hot pressing to form the stitch knitting non-weaving cloth. Compared with a general product, the stitch knitting non-weaving cloth produced by adopting the production method disclosed by the invention has the characteristics that transverse breaking strength is great so as to facilitate the next coating processing of the product; longitudinal tearing strength is small so as to ensure the advantage of convenience for tearing with hand in actual application of next terminal product; the service performance of products is greatly improved; and the stitch knitting non-weaving cloth can be widely applied to base cloth of electrical tapes and the like of various cables and electronic elements and has wide popularization significance.

Owner:海东青非织工业(福建)有限公司 +1

Crosslinked polyethylene welding type insulated cable joint and manufacturing and installation processes thereof

InactiveCN106024133AThe preparation process is simple and convenientIncrease success ratePlastic/resin/waxes insulatorsPower cables with screens/conductive layersElectrical conductorEngineering

The invention relates to a cross-linked polyethylene fusion-bonded insulated cable joint and its manufacturing and installation process, belonging to the technical field of the electrical industry. It includes a cable, a shielding layer, an inner sheath and an outer sheath from the inside to the outside, the cable includes a conductive layer and an insulating layer from the inside to the outside, and the conductive layer includes a conductor layer and an inner sheath from the inside to the outside. The semiconductor layer, the insulating layer is a cross-linked polyethylene insulating layer formed by melting cross-linked polyethylene insulating tape; the shielding layer is a semi-conductive paint layer; the outer protective layer includes a steel armor, a waterproof layer from the inside to the outside and armor belt. The invention adopts the method of directly melting the cross-linked polyethylene insulating layer with the cross-linked polyethylene tape, so that the manufacturing and installation process of the cross-linked polyethylene fusion-bonded insulating cable joint is very simple and convenient, and the success rate and efficiency are improved .

Owner:HANGZHOU LINAN KEMA ELECTRIC POWER TECH CO LTD

Process for fixing resin impregnated adhesive tapes for rotor

ActiveCN102468718AFacilitate conductionGood magnetic performanceManufacturing stator/rotor bodiesMagnetic circuit characterised by insulating materialsNon magneticElectrical tape

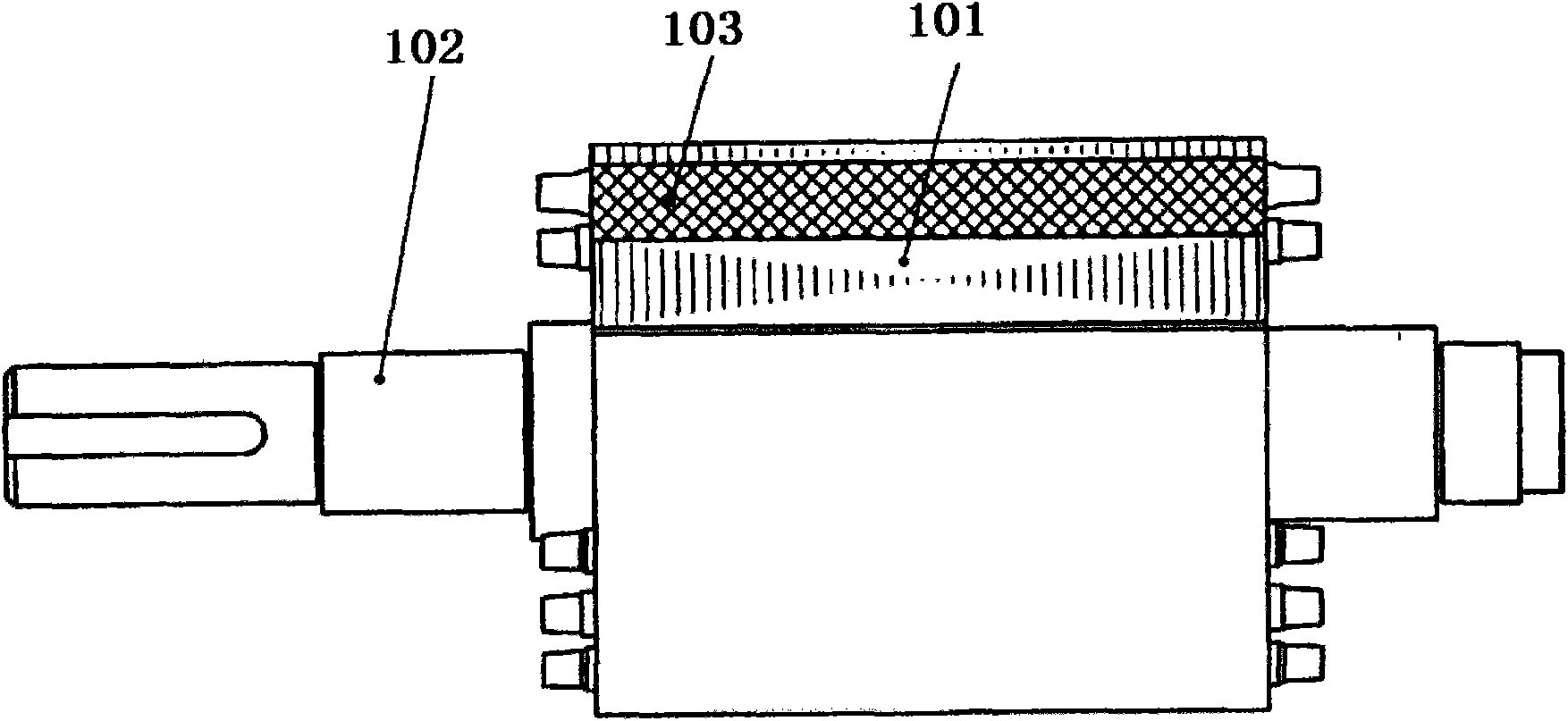

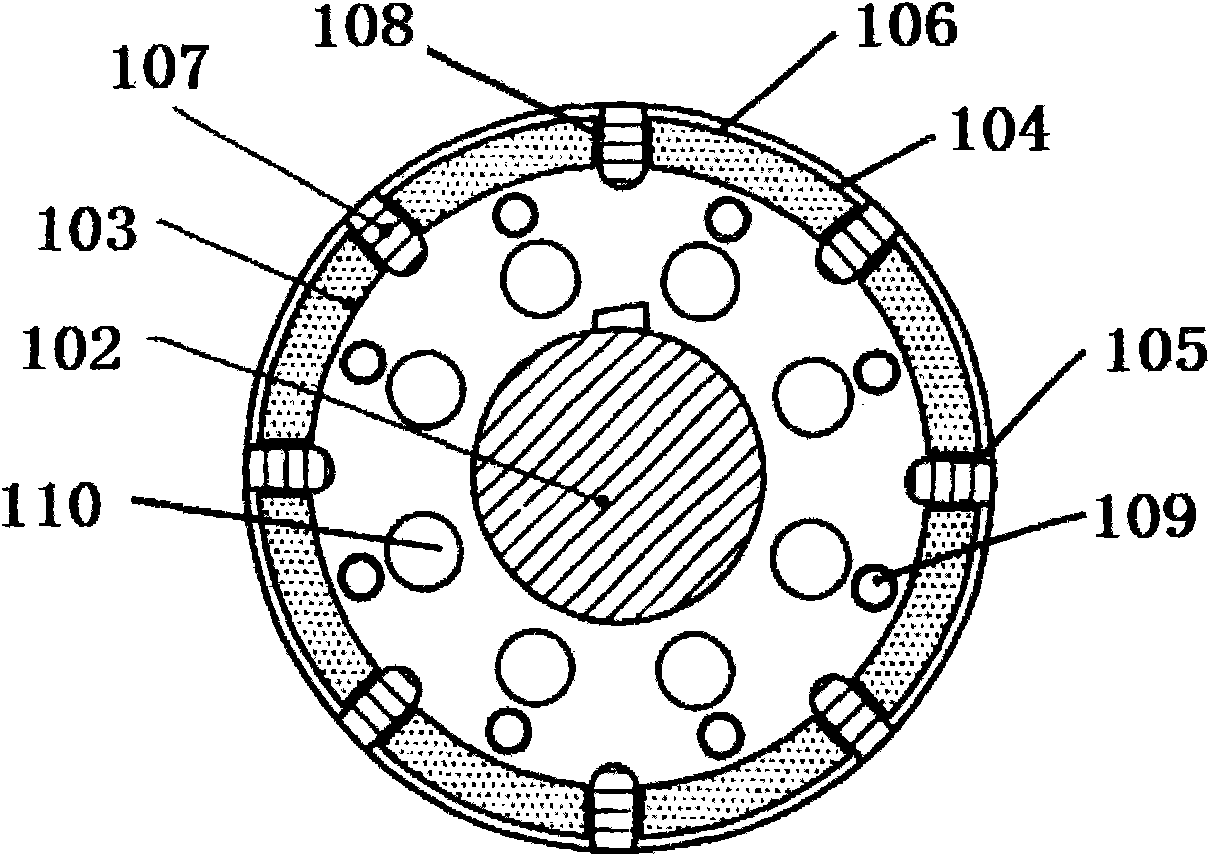

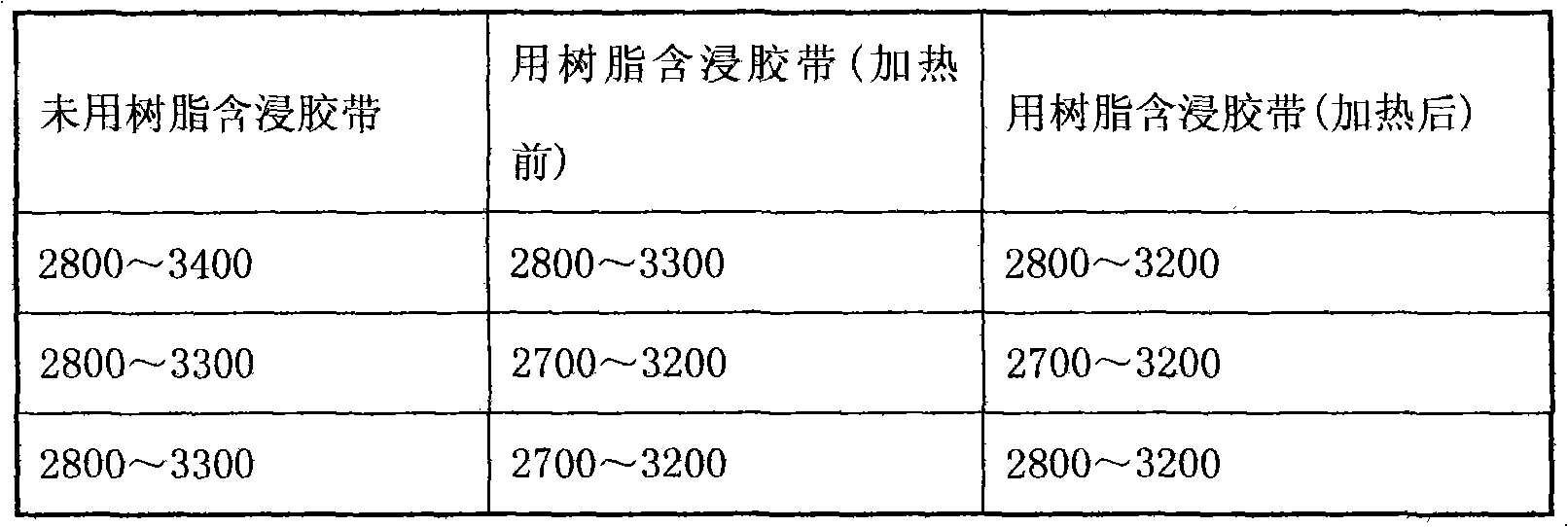

The invention discloses a process for fixing resin impregnated adhesive tapes for a rotor. In the process, a rotor iron core, a rotary shaft and magnets are adopted, wherein the rotor iron core is formed by laminating a plurality of rotor blades; and a plurality of magnet grooves and non-magnetic grooves are formed on the circumferential surface of the rotor iron core. The process comprises the following steps of: firstly, putting the rotor iron core into a baking oven, and pre-heating the rotor iron core; secondly, uniformly coating glue on the surface of the rotor iron core, and inlaying the magnets into the magnet grooves; thirdly, winding the resin impregnated adhesive tape on the surface of each magnet, and winding an insulating adhesive tape outside the resin impregnated adhesive tape; and finally, putting the rotor iron core into the baking box again, baking the rotor iron core to make the resin impregnated adhesive tape tightly wrap on the surface of the magnet, and thus obtaining a finished product for fixing the resin impregnated adhesive tapes for the rotor. The process for fixing the resin impregnated adhesive tapes for the rotor has the advantages that: the thickness of each resin impregnated adhesive tape can be a fraction of that of metal; an interval between the adhesive tape and the magnet can be quite smaller than the interval between a metal annular ring and the magnet; the friction between the rotor and a stator is greatly reduced; the conduction conversion rate of a magnetic field of a motor is higher; and the rotor can be polished and shaped.

Owner:腾禾精密电机(苏州)有限公司

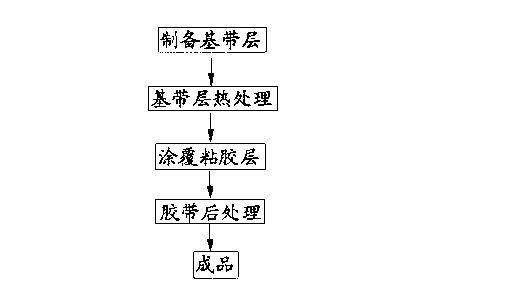

Preparation method of novel insulated rubber tape

InactiveCN103275640AHigh strengthIncrease elasticityFilm/foil adhesivesHeating/cooling textile fabricsFiberElectrical tape

The invention discloses a preparation method of a novel insulated rubber tape. The preparation method comprises the following steps of: a) preparing a base band layer; b) thermally treating the base band layer; c) coating an adhering layer; and d) post-treating the tape. The invention discloses the preparation method of the novel insulated rubber tape. The preparation method is reasonable in step arrangement and simple and convenient in preparation process. The base band layer in the tape has unique fiber constitution and structure, so that the prepared tape has more excellent strength, elasticity and insulating performance. Meanwhile, the tape is moderate in thickness, and the sealing and insulating demands can be satisfied by winding the tape by two layers generally, therefore, the practical value of the tape can be effectively enhanced.

Owner:KUNSHAN HANBAO TAPE TECH

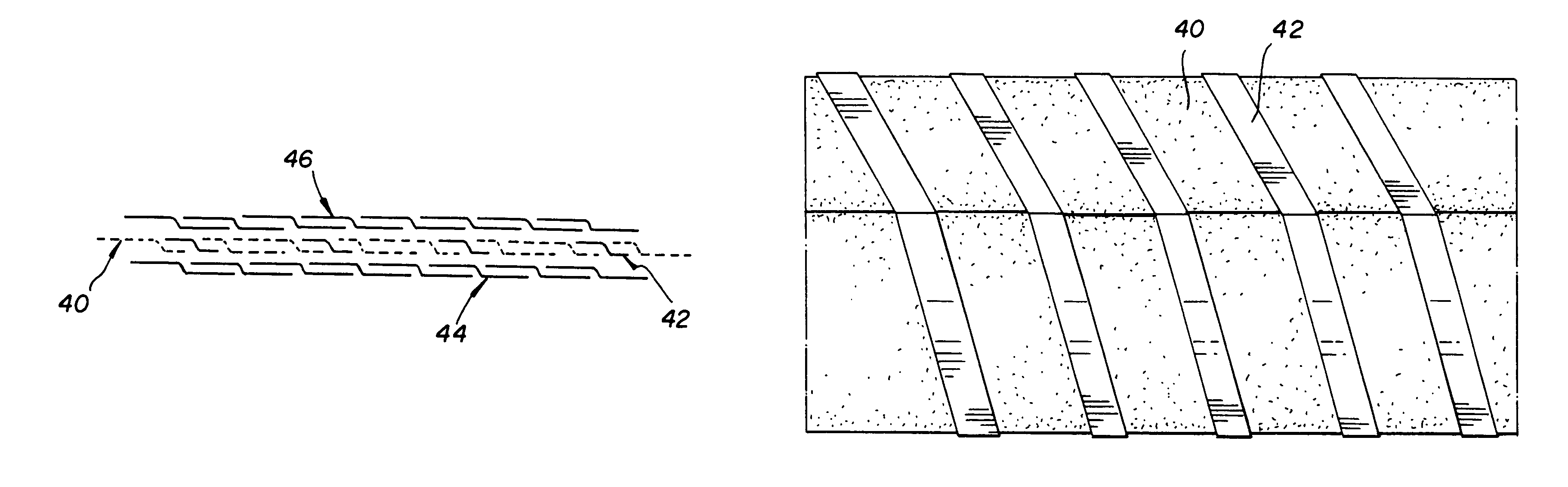

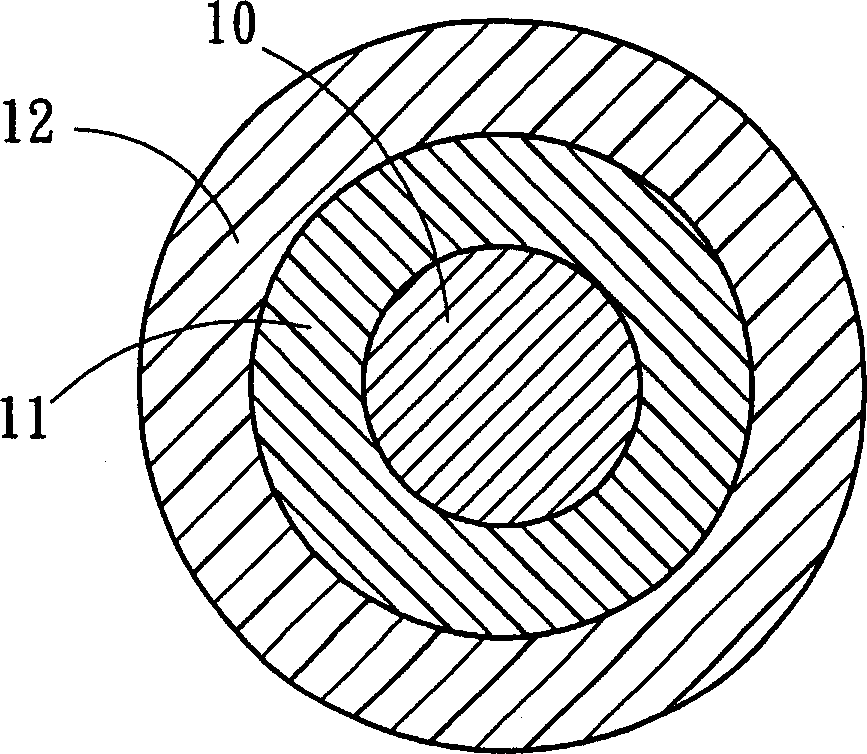

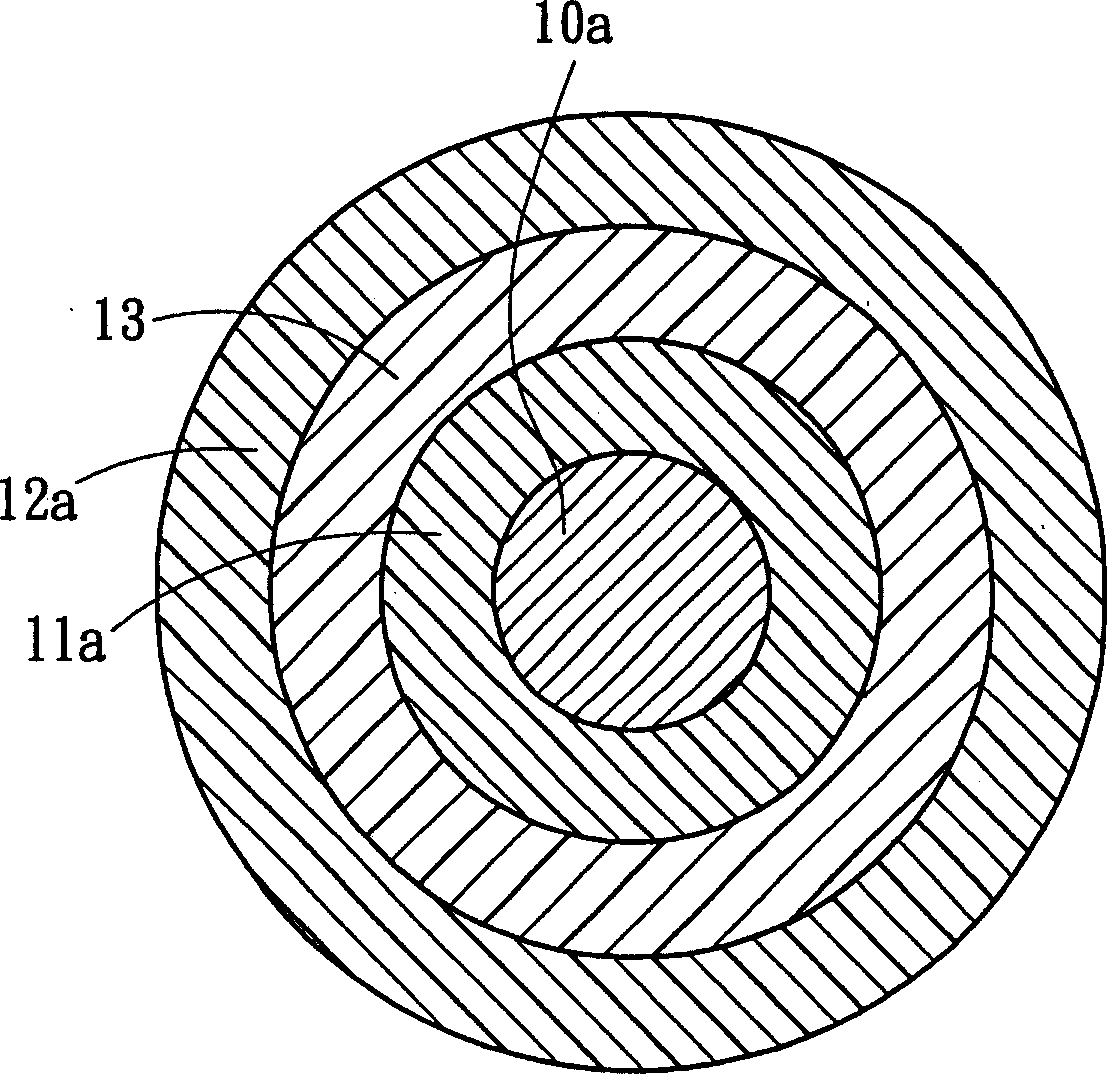

Integral slip layer for insulating tape

ActiveUS7135639B2Windings insulation shape/form/constructionPlastic/resin/waxes insulatorsElectrical conductorEngineering

A non-stick material coated glass slip layer for use in insulating tapes for electrical conductors. A conductive glass tape is interwoven with a non-stick material coated glass tape to form the slip layer. The slip layer is sandwiched between and inner conductive layer that is in contact with and electrical conductor, and an cater conductive layer that is in contact with machinery, such as a generator. The slip layer allows for a difference of movement between the inner conductive layer and the outer conductive layer without damage to the insulating tape.

Owner:SIEMENS ENERGY INC

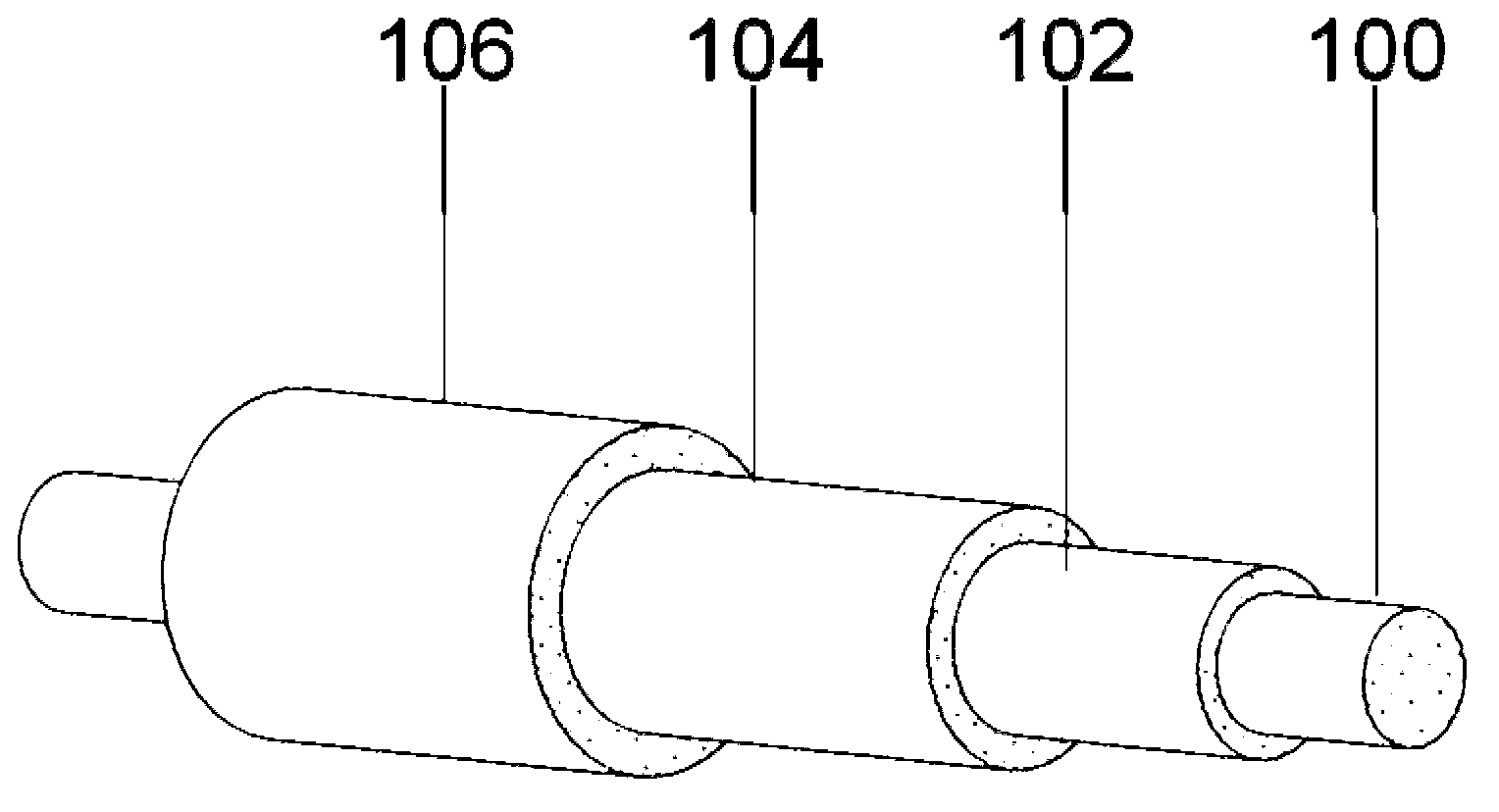

Multi-layer insulated electrical wire

InactiveCN1767081AHeat resistantWith pressurePlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsElectrical conductorEngineering

The invention discloses a multi-layer insulating wire which is formed by a conductor and at least two insulating layers which coats the conductor; it uses heat plasticity with fluorine to form the insulating layers; any two adjacent layers are formed by the heat plasticity with different fluorine so as to form inter-strip insulating layers.

Owner:国光电子线股份有限公司

Method for forming insulating layer on overhead power transmission line

ActiveCN103310915APromote formationImprove insulation performancePolyurea/polyurethane coatingsEpoxy resin coatingsElectrical tapePower transmission

The invention provides a method for forming an insulating layer on an overhead power transmission line. The method includes painting solventless coatings on the power transmission line to form a first coating, winding an electric insulating rubber tape on the first coating to form a rubber tape layer after the first coating is half-dry or dry, and painting the solventless coatings on the rubber tape layer to form a second coating. Gaps among guide lines of the overhead power transmission line are filled, and the rubber tape and the coatings are provided to form the insulating layer, so that good insulating and waterproof effects are realized.

Owner:3M CHINA

Insulating protection tube

ActiveCN104575880AEasy to disassembleEasy to assemble and disassembleInsulating bodiesConnection insulationForeign matterElectrical tape

The invention provides an insulating protection tube which comprises a first sleeve (3), wherein the first sleeve (3) is provided with a first axial through hole and comprises two first half sleeves (30) which are detachably connected with each other; each first half sleeve (30) is provided with two first edges extending along the axial line of the first axial through hole; cable fixing pieces are arranged on both the first half sleeves (30). According to the insulating protection tube, insulation of a metal wire at the cracked position on an insulating wire can be recovered conveniently and quickly, and the metal wire at the cracked position can be exposed if necessary; furthermore, foreign matters cannot be retained on the metal wire at the cracked position on the insulating wire, so that the problems that an insulating rubber tape needs to be frequently wound and eliminated and the time and the labor are wasted in the prior art are effectively solved.

Owner:STATE GRID CORP OF CHINA +2

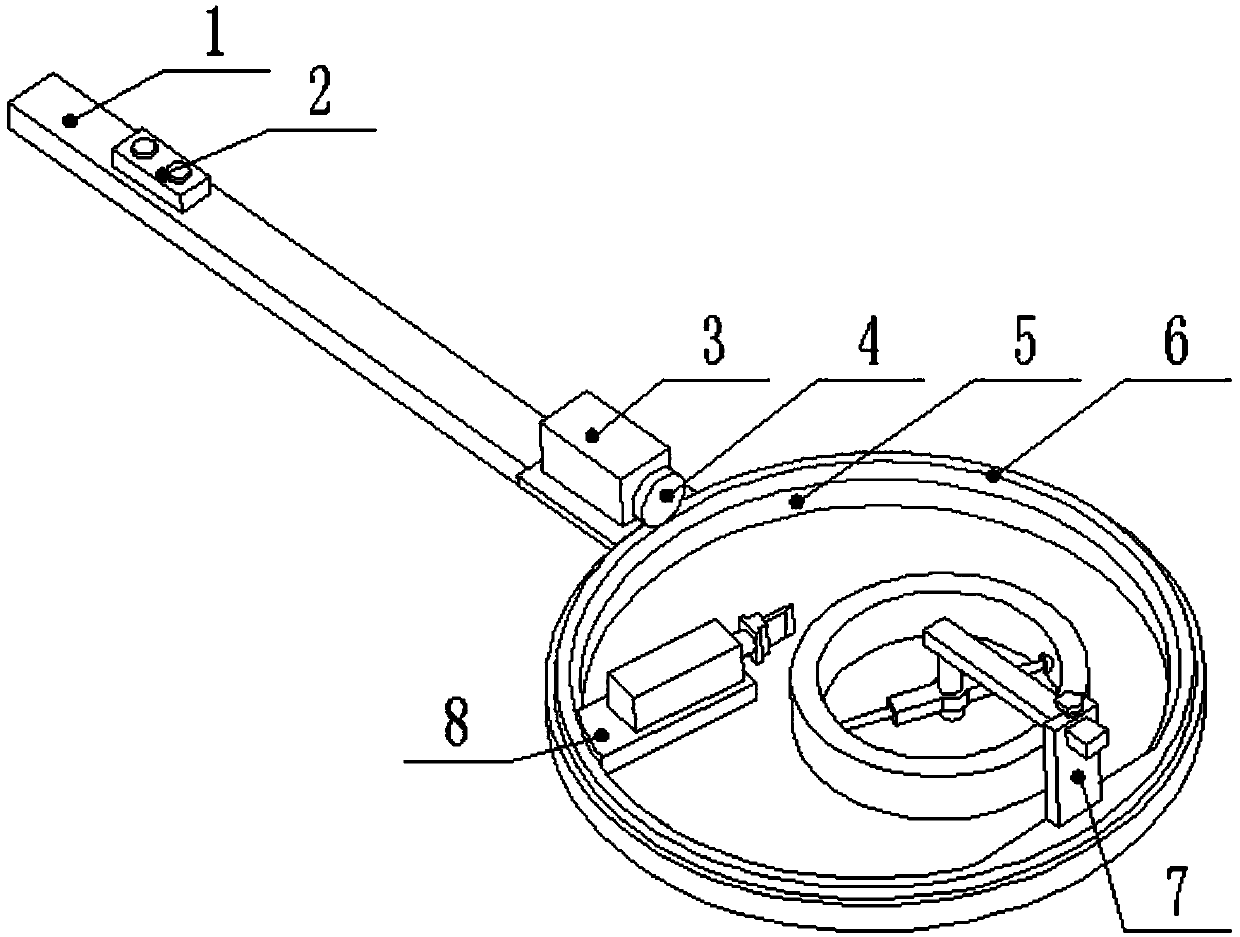

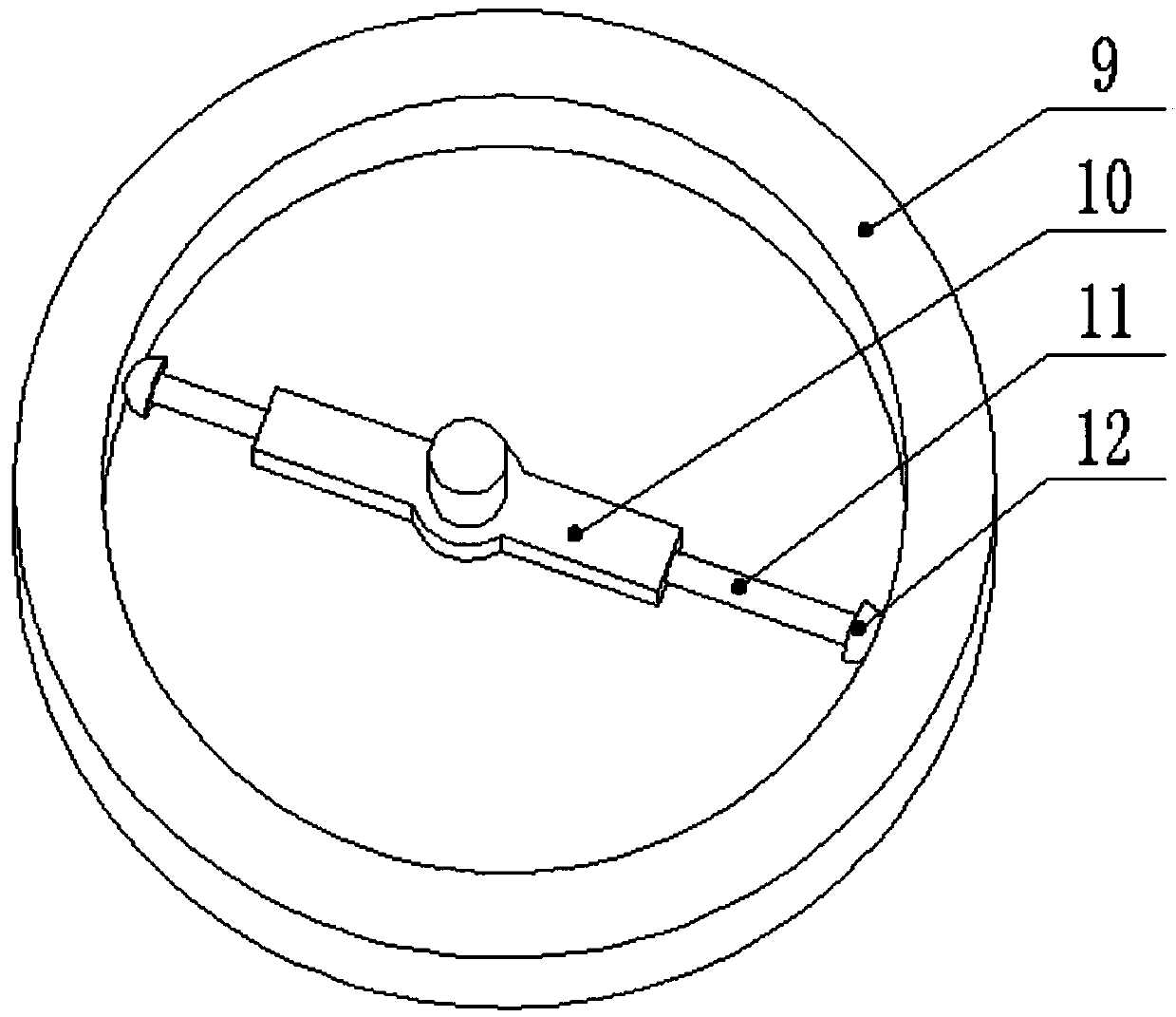

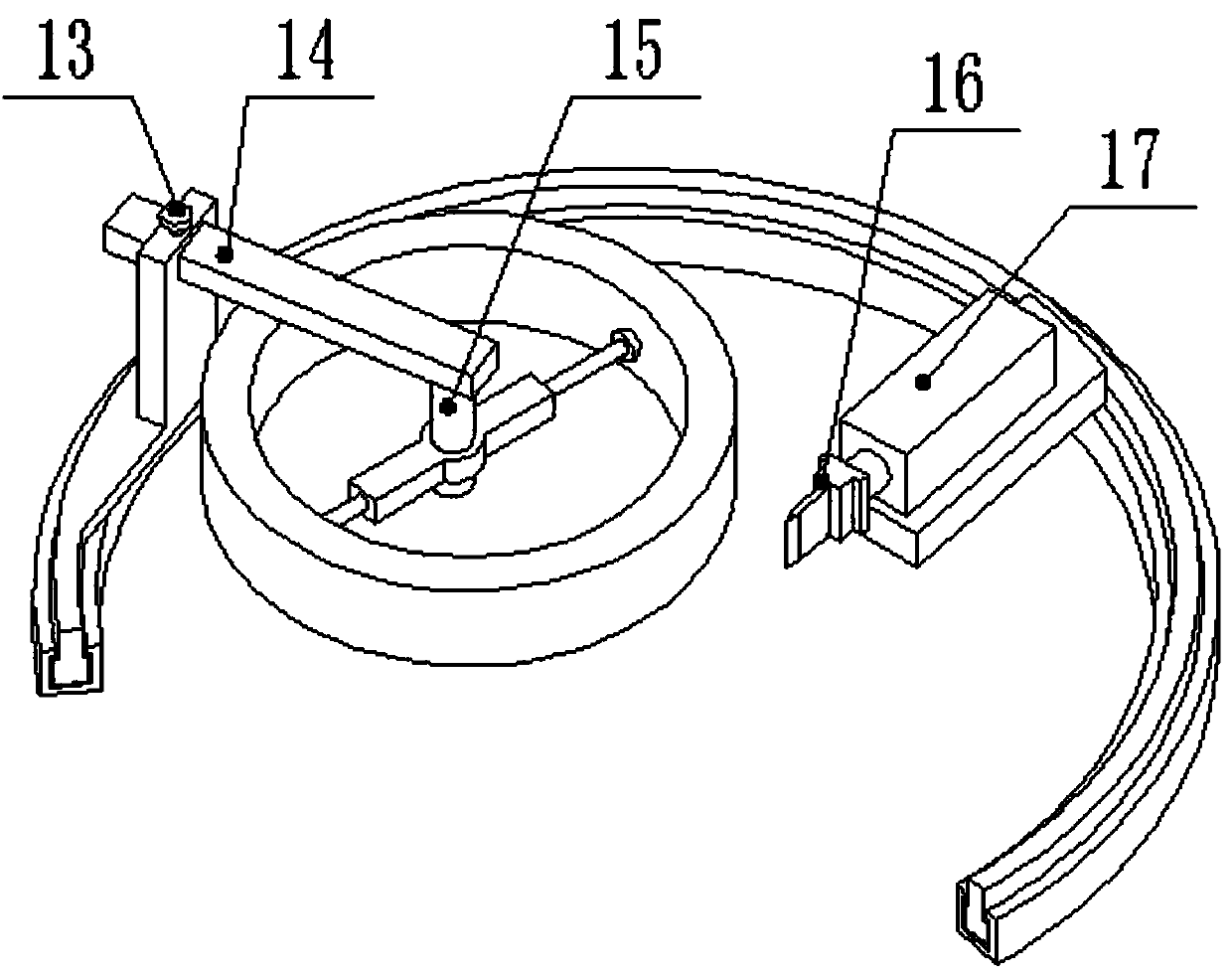

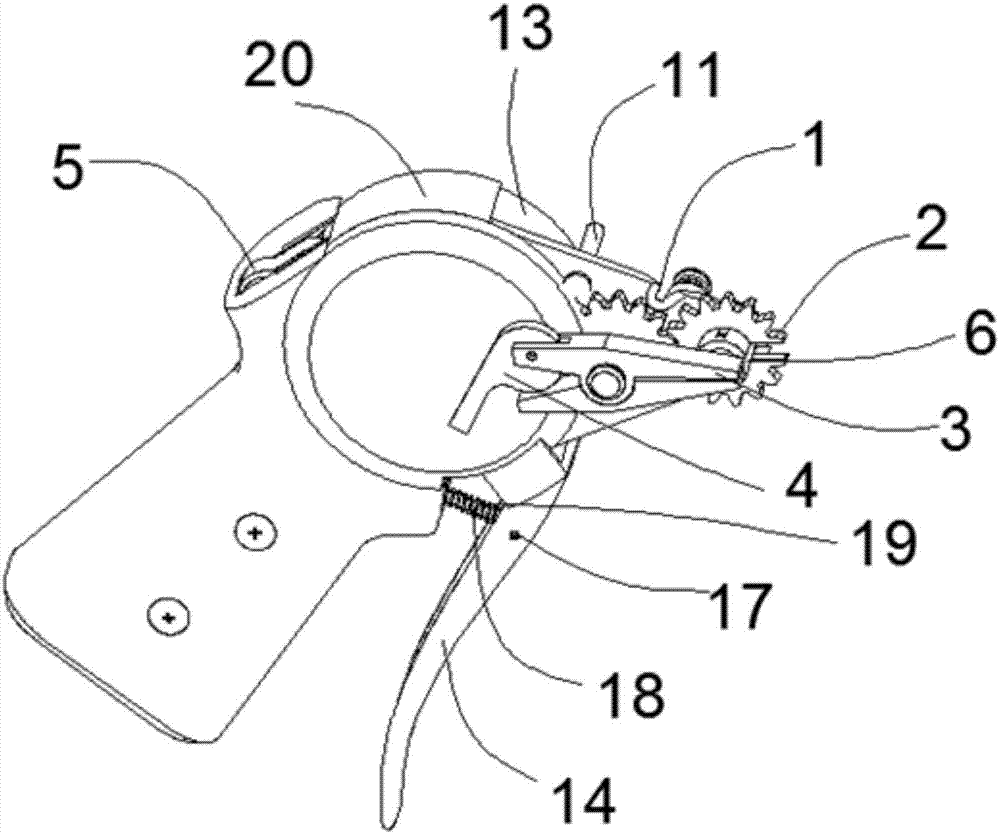

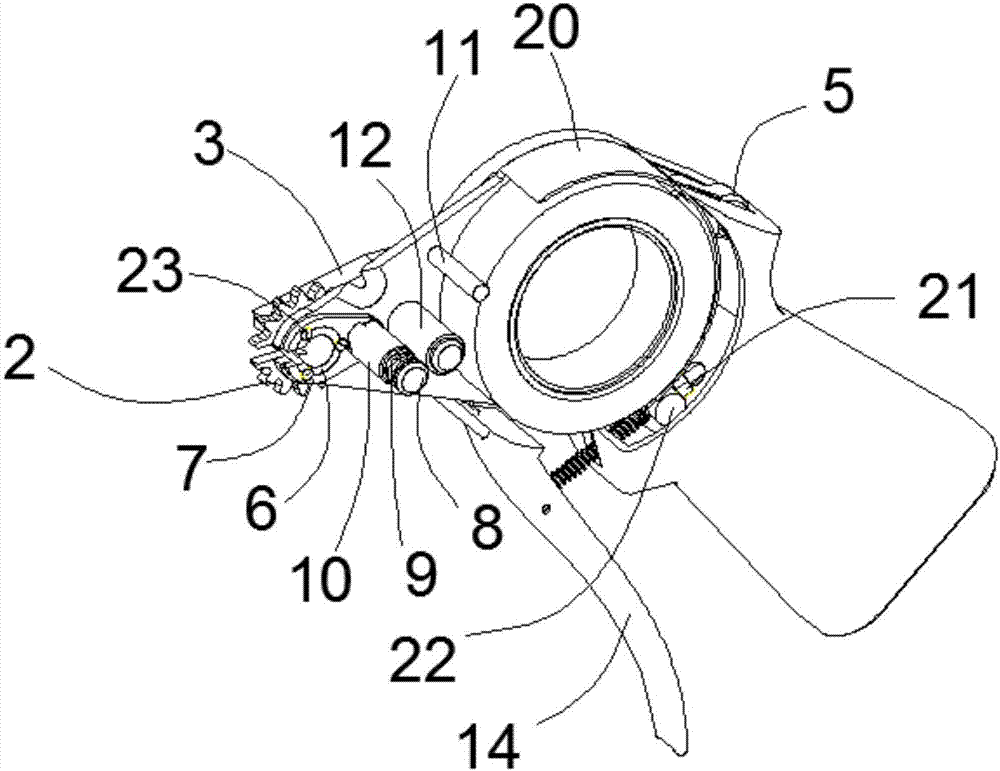

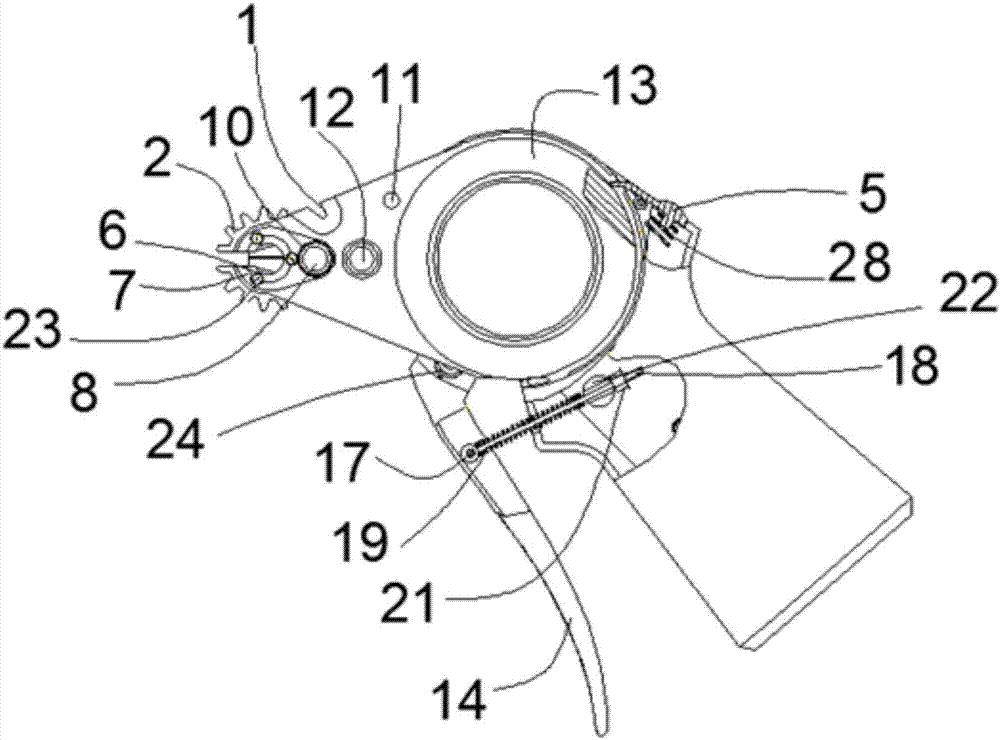

Terminal electric tape automatic winding apparatus

InactiveCN108054687AGuaranteed reliabilityThe same degree of elastic deformationApparatus for joining/termination cablesArticle deliveryEngineeringConductor Coil

The invention discloses a terminal electric tape automatic winding apparatus, and belongs to the field of engineering daily tools. A handheld base frame is connected with a sliding rail, a controlleris installed on the handheld base frame, and a friction wheel is installed on a motor. A rotating ring is arranged in the sliding rail, and an insulating tape roll is fixed on an anti-slip ball. A fixed screw rod is installed on the two sides of a damping wheel, an anti-skid ball is arranged at one end of the fixed screw rod, a damping shaft is installed below one end of a third support, and an electromagnet is installed above a second support. The friction wheel is driven to rotate through rotation of the motor, so that the friction wheel drives the rotating ring to rotate, and the process ofmanual winding of workers is replaced. Damping rotation is carried out through the damping wheel and the damping shaft, so that the insulation adhesive tape wound on the wire core is ensured to havethe same elastic deformation degree, and the winding stress of the adhesive tape is uniform. The work of workers is replaced, and the winding quality and efficiency of the adhesive tape are improved.

Owner:杨雪锋

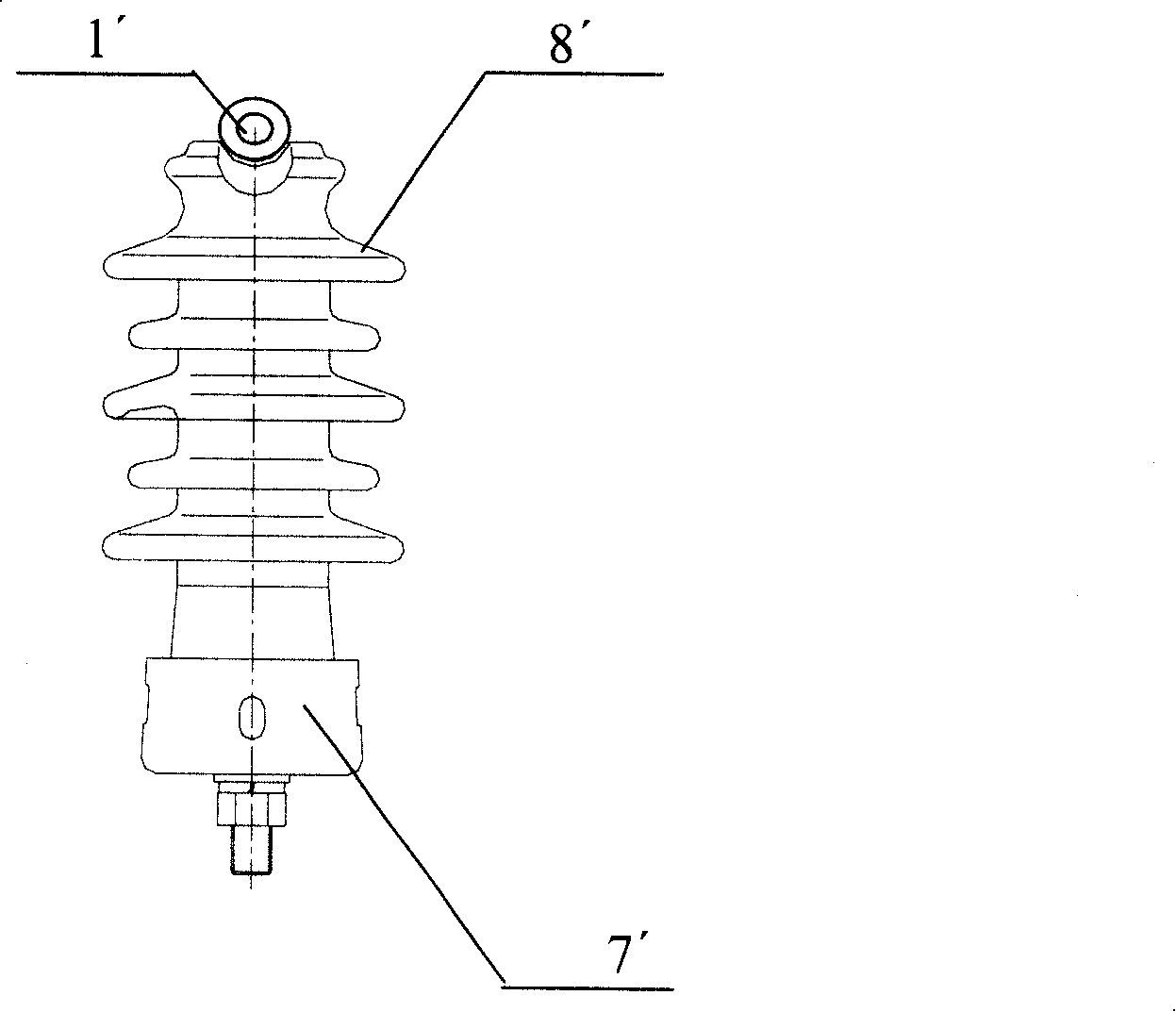

Lightning protection supporting insulator and insulated cable used with it

InactiveCN101174497AProtected from lightning damageGuaranteed safe operationInsulated cablesSupporting insulatorsElectric arcEngineering

The invention relates to a lightning-proof post insulator and a matching insulated cable, wherein, the lightning-proof post insulator comprises an insulator body, an upper flange, a lower flange, a discharge ring, a run-on tab, a built-in clip and an insulating boot. The invention is characterized in that the built-in clip is arranged at the top of the upper flange via a bolt with a pressure spring, enabling the insulated cable to be tightly pressed between the bottom of the built-in clip and the upper flange, and arranged on the discharge ring via the insulating boot from a top boot; part of the insulated cable arranged on the post insulator is bare, two insulated adhesive tapes are arranged at two ends of the bare cable and an aluminum armor tape is arranged in the middle. The invention has the advantages that part of the insulated cable close to the insulator is bared according to lightening breaking mechanism to the insulated cable; an arc root of a power frequency electric arc is transferred or fixed between the electric arc and the run-on tab via the discharge ring on the upper flange and the run-on tab on the lower flange of the lightning-proof post insulator; the electric arc energy of lightening short circuit is transferred away from the cable in a short time, thereby preventing the insulated cable from being damaged by lightening and ensuring safe operation of overhead insulated distribution network.

Owner:SHANGHAI ELECTRIC PORCELAIN WORKS CO LTD

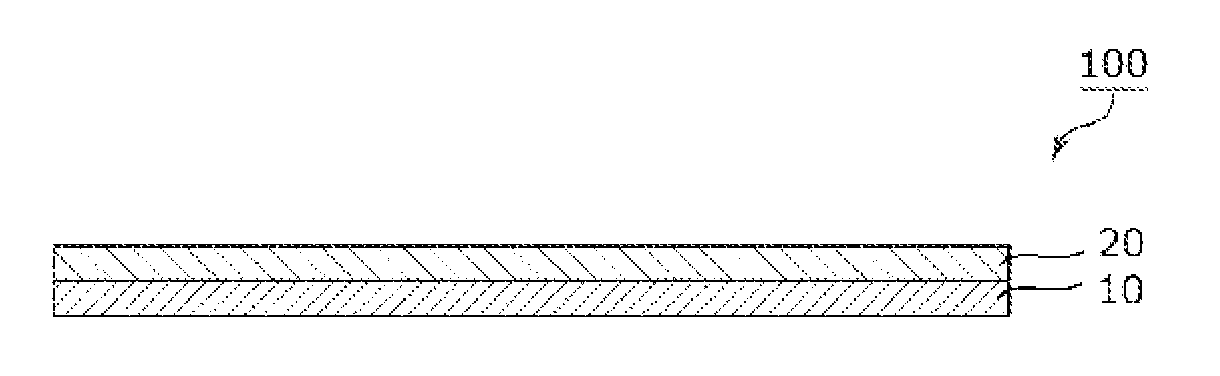

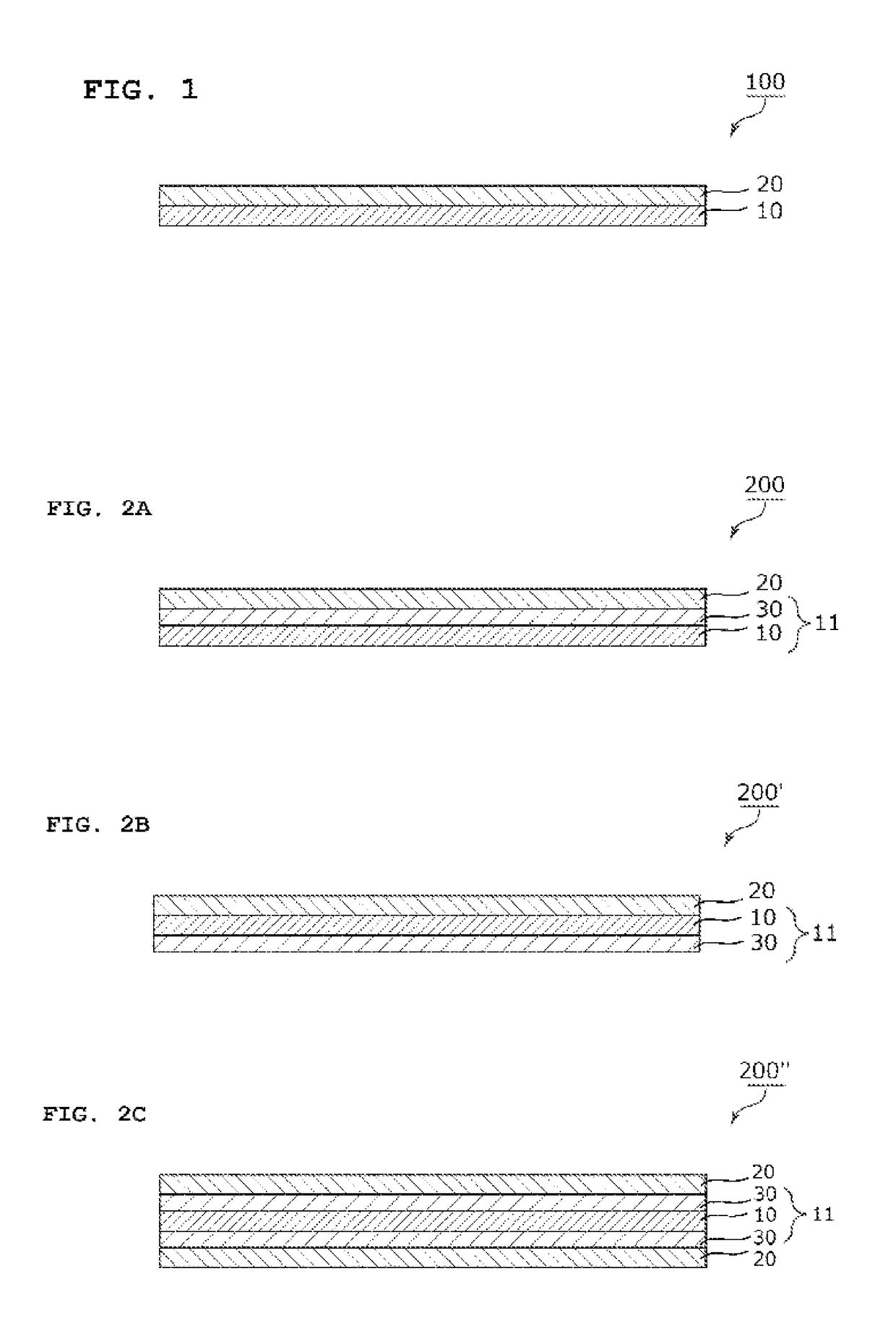

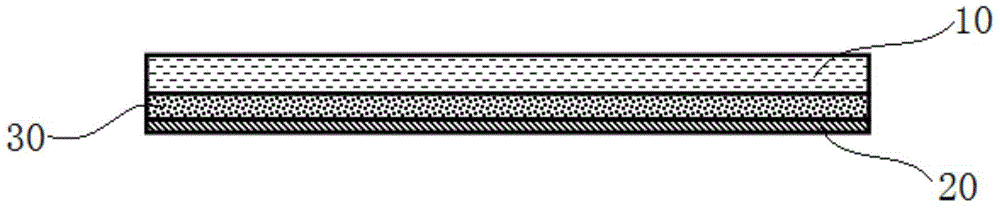

Insulating tape

PendingUS20170244087A1Improve securityMaintain insulation propertiesNon-macromolecular adhesive additivesFinal product manufactureEngineeringElectrical tape

Provided is an insulating tape to be used in a nonaqueous secondary battery, the insulating tape being capable of maintaining its insulating property even under a severe environment, e.g., even when being heated, and being capable of improving the safety of the nonaqueous secondary battery. Specifically, provided is an insulating tape for a nonaqueous battery, including a base material, and a pressure-sensitive adhesive layer arranged on one side, or each of both sides, of the base material, in which the base material and / or the pressure-sensitive adhesive layer each contain / contains an insulating inorganic filler. Also provided is an insulating tape for a nonaqueous battery, including a base material with an insulating layer, and a pressure-sensitive adhesive layer arranged on one side, or each of both sides, of the base material with the insulating layer, in which the insulating layer contains an insulating inorganic filler.

Owner:NITTO DENKO CORP

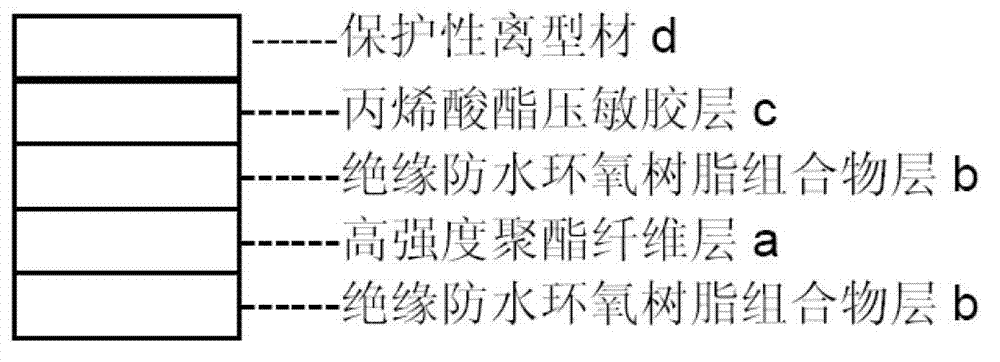

Waterproof insulation epoxy resin composition, adhesive tape and preparation method thereof

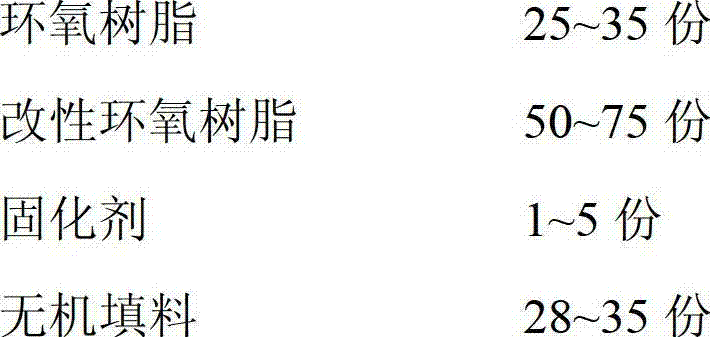

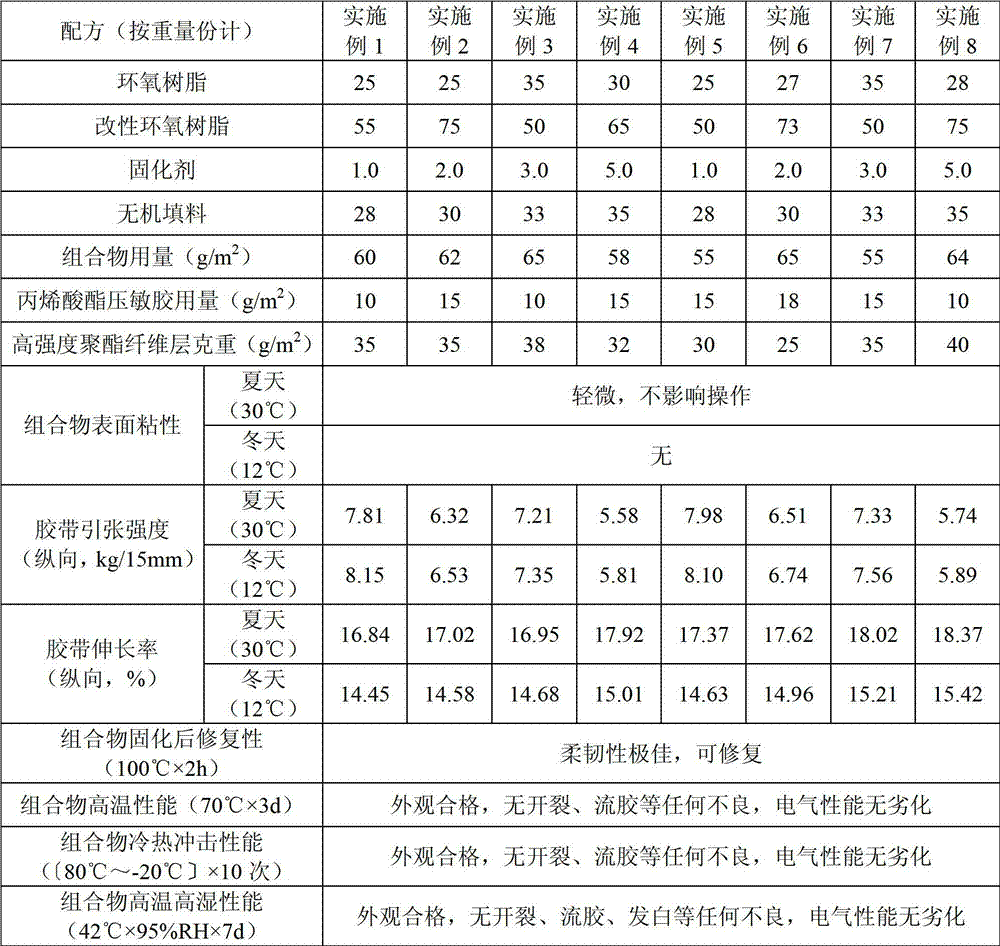

InactiveCN103044859AGood flexibilityImprove low temperature resistanceFilm/foil adhesivesEster polymer adhesivesEpoxyHeat resistance

The invention discloses a waterproof insulation epoxy resin composition, an electrician insulation adhesive tape prepared by using the composition and a preparation method for the composition and the adhesive tape, wherein the composition comprises the following components in parts by weight: 25 to 35 parts of epoxy resin, 50 to 75 parts of modified epoxy resin, 1 to 5 parts of curing agent and 28 to 35 parts of inorganic fillers. The waterproof insulation epoxy resin composition has good flexibility, can be recovered after being cured at the high temperature, has high impact strength, stripping strength and stretch shearing strength, and has good low-temperature resistance and heat resistance; the flexibility of the composition is not influenced by the seasonal climate, so that the problem of excessively brittle in winter and excessively soft in summer in the existing products is solved; the preparation cost is low; and the finished product yield is high. The electrician insulation adhesive tape has the excellent performances of tightness, insulation, heat resistance, water prevention, high mechanical strength and good gloss, has excellent early bonding performance and restripping performance, has good bonding following characteristic, and can be widely applied in the coil winding protection and associated industries.

Owner:NINGBO SOKEN CHEM

Electric wire connector

ActiveCN107317205AGuaranteed contact effectWind evenlyLine/current collector detailsStructural engineeringWire fixation

The invention discloses an electric wire connector that can reduce the labor intensity and has relatively good wiring quality. The electric wire connector comprises a wire connector main body, a wiring mechanism, a driving mechanism and an electric wire fixing device; the wiring mechanism comprises a wiring shaft rotatably arranged on the wire connector main body, and the driving mechanism is arranged on the wire connector main body and is in transmission connection with the wiring shaft; and the electric wire fixing device is arranged on the wire connector main body, and a clamping and fixing position of the electric wire fixing device corresponds to one end of the wiring shaft. The electric wire connector is used for connecting power lines, the thread residues are uniformly twined, the compactness is proper, and the lapping parts are sufficient, thereby being conducive to guaranteeing the contact performance of electric wires, meanwhile, the labor intensity is reduced, the wiring efficiency is improved, and moreover, the quality and efficiency of twining insulating tapes are improved.

Owner:PANZHIHUA UNIV

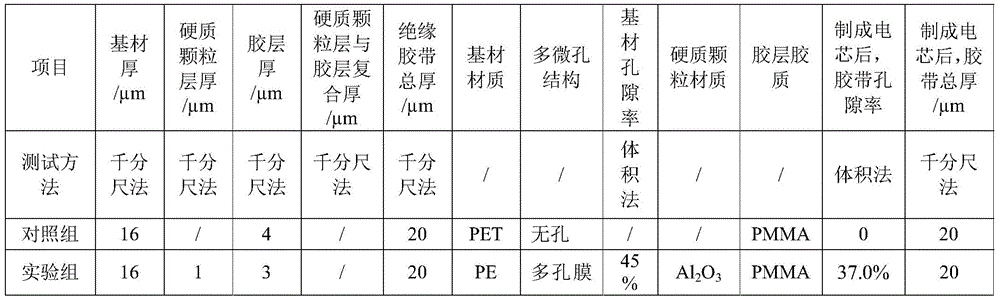

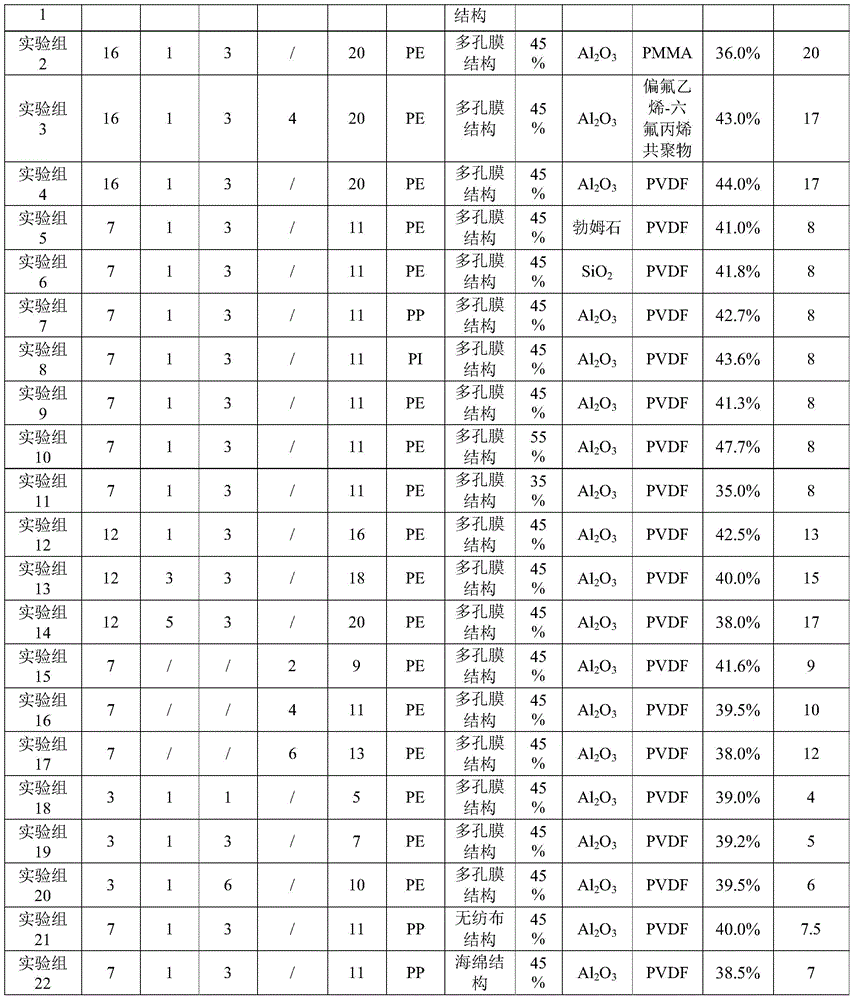

Insulated rubber tape and lithium ion battery using insulated rubber tape

ActiveCN105690894AReduce thicknessAvoid punctureLayered productsSecondary cellsElectrical tapeLithium-ion battery

Owner:DONGGUAN AMPEREX TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com