Waterproof insulation epoxy resin composition, adhesive tape and preparation method thereof

A technology of epoxy resin and composition, which is applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems that the initial adhesion of the surface cannot meet the requirements, the product is too soft, and the product cannot be repaired. Achieve good re-peeling performance, good lamination followability, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

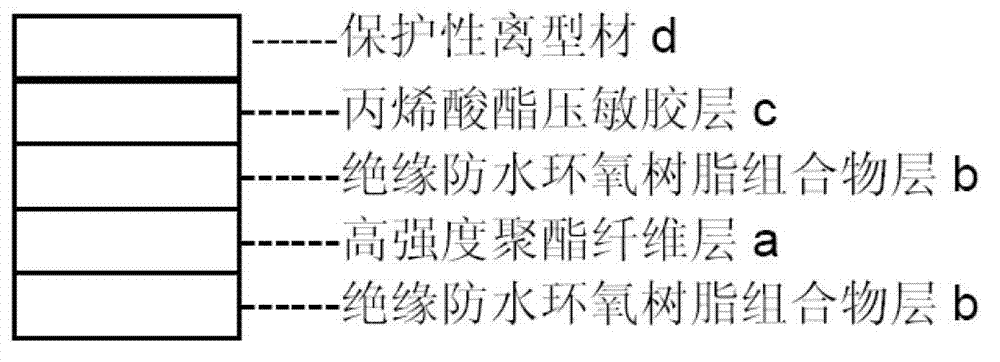

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

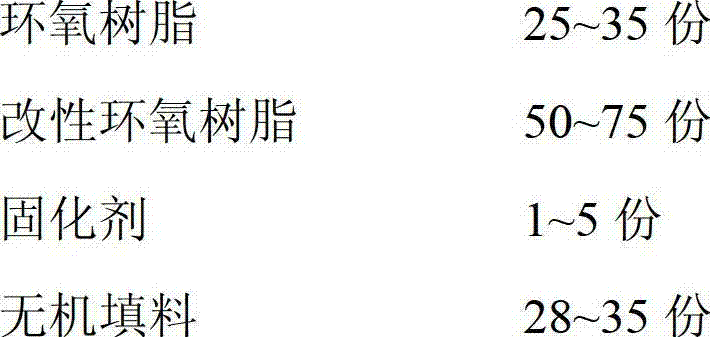

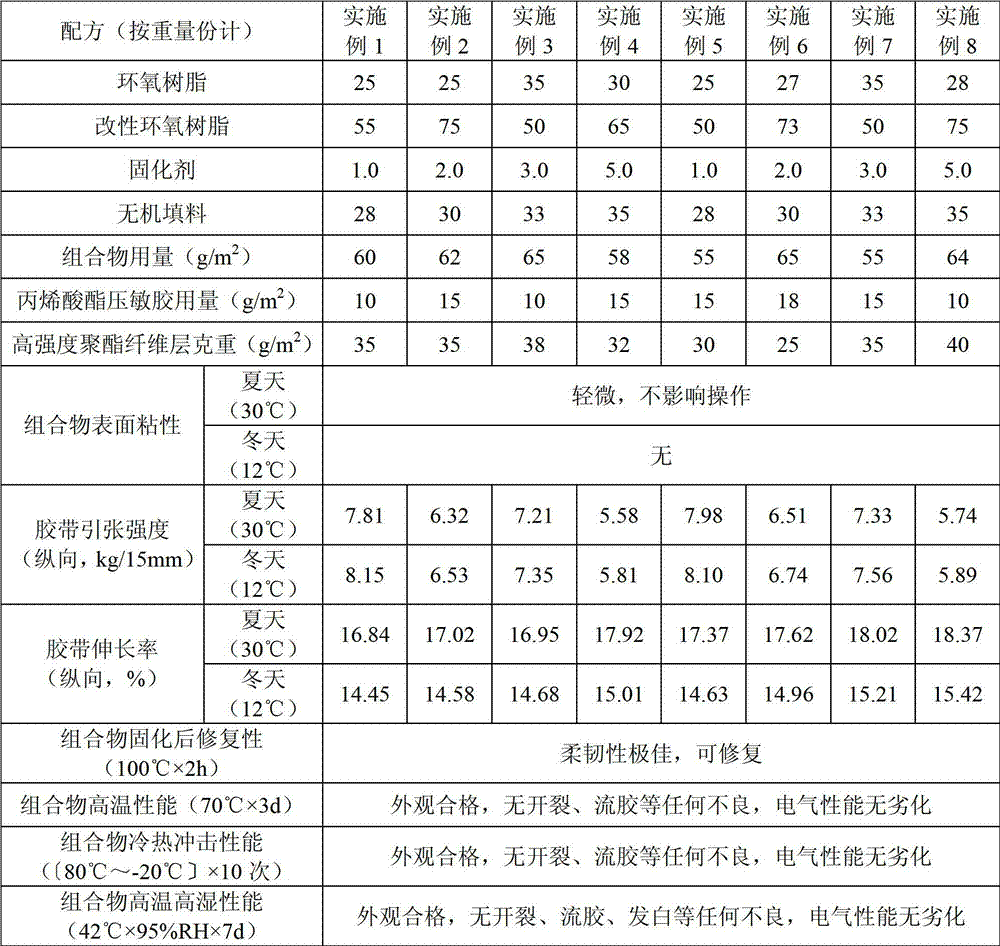

[0034] The formulations of the insulating and waterproof epoxy resin compositions of Examples 1 to 8 are shown in Table 1, and the insulating and waterproof epoxy resin compositions and electrical insulating tapes of Examples 1 to 8 were prepared respectively.

[0035] 1. Preparation of insulating and waterproof epoxy resin composition:

[0036] 1) Prepare various raw materials according to the weight components in Table 1, and prepare a certain amount of organic solvent at the same time, and the weight ratio of the total weight of various raw materials to the organic solvent is 2;

[0037] 2) After mixing the curing agent with some organic solvents, stir at high speed for 30 minutes to obtain a uniform mixture;

[0038] 3) Add epoxy resin, modified epoxy resin and inorganic filler to the remaining organic solvent, stir at high speed for 2 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com