Patents

Literature

2426 results about "Particle beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A particle beam is a stream of charged or neutral particles, in many cases moving at near the speed of light. There is a difference between the creation and control of charged particle beams and neutral particle beams, as only the first type can be manipulated to a sufficient extent by devices based on electromagnetism. The manipulation and diagnostics of charged particle beams at high kinetic energies using particle accelerators are main topics of accelerator physics.

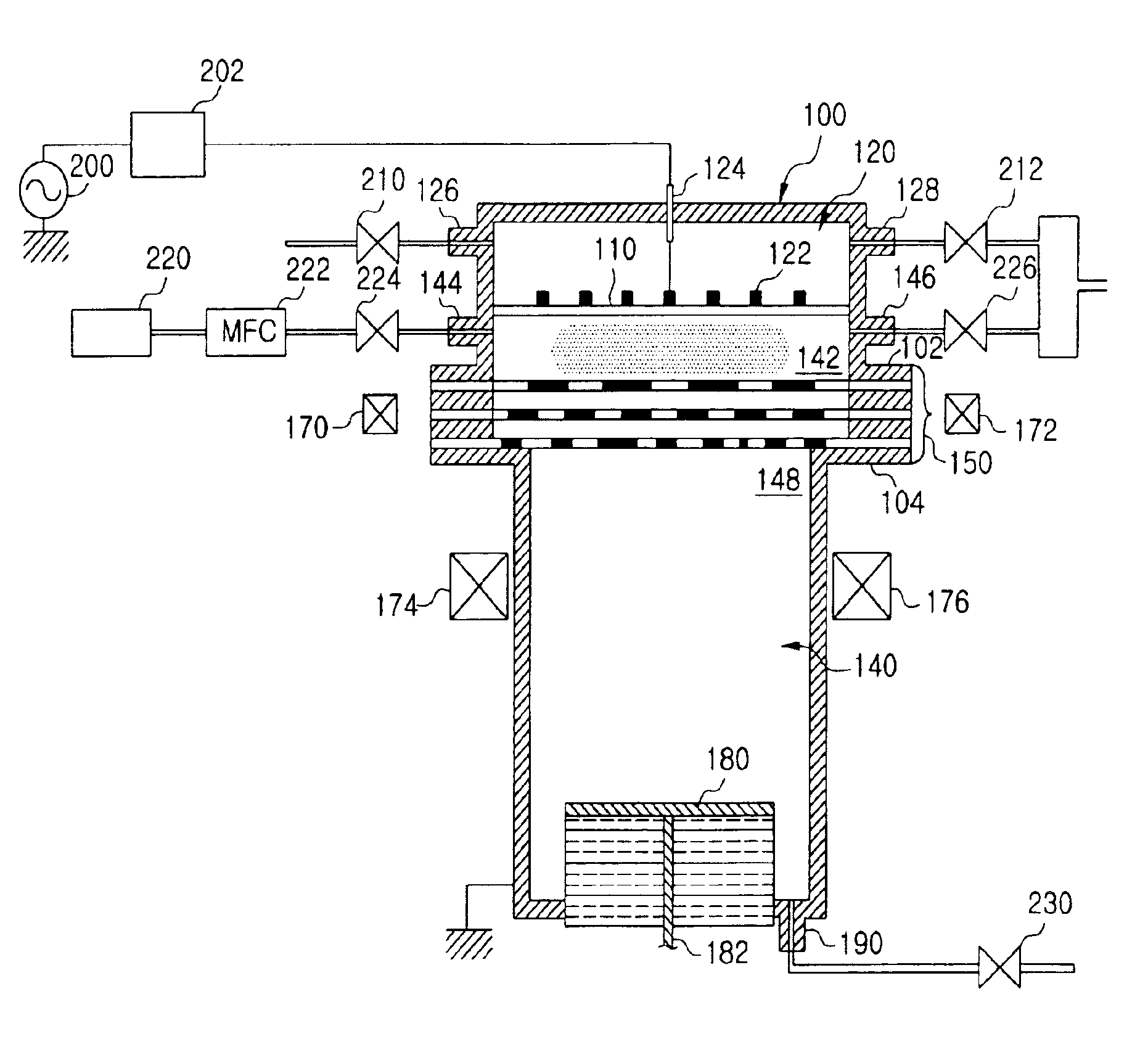

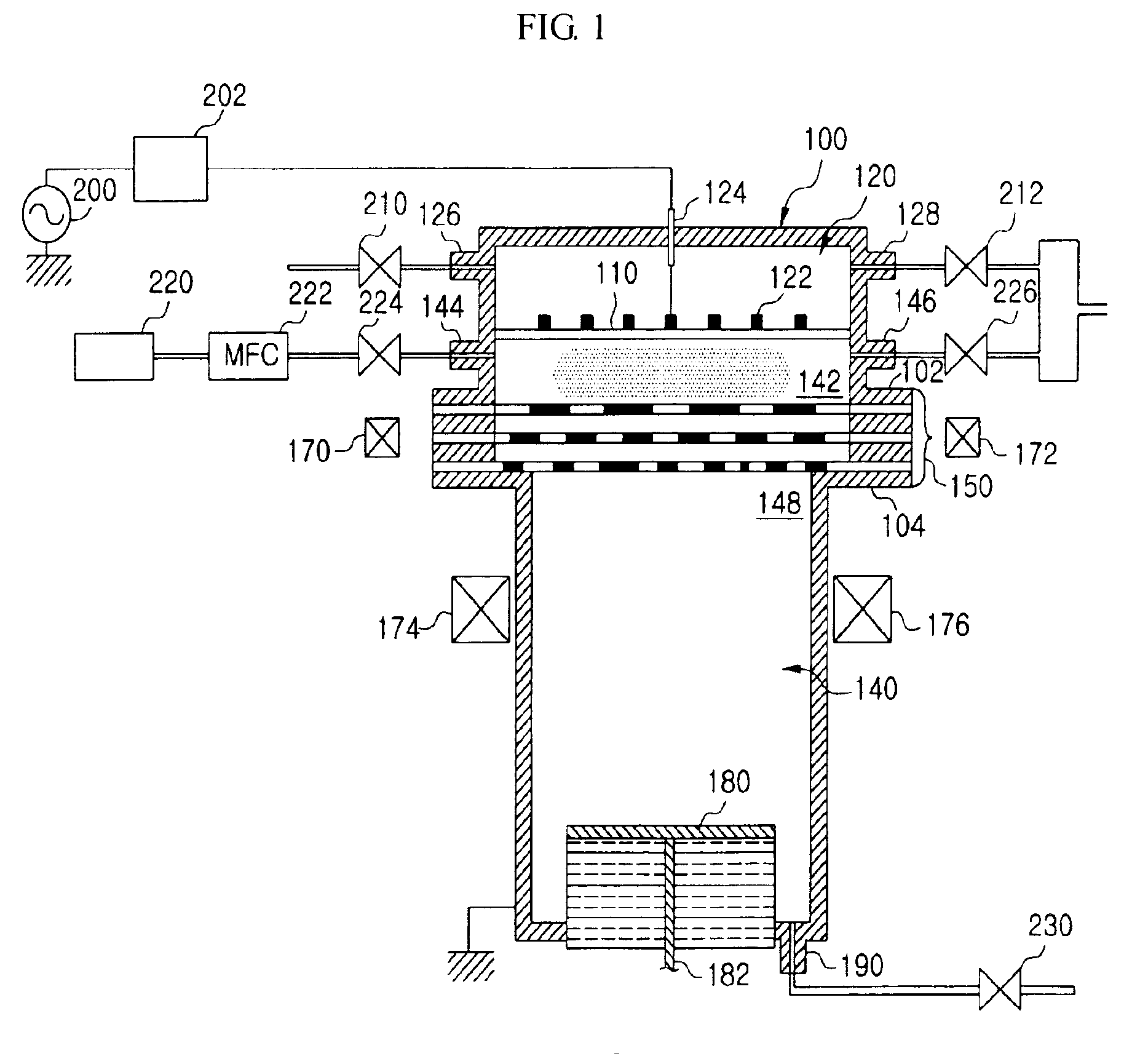

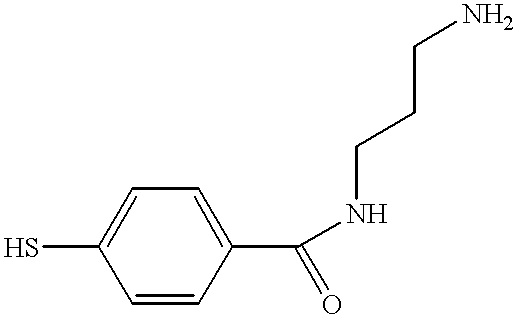

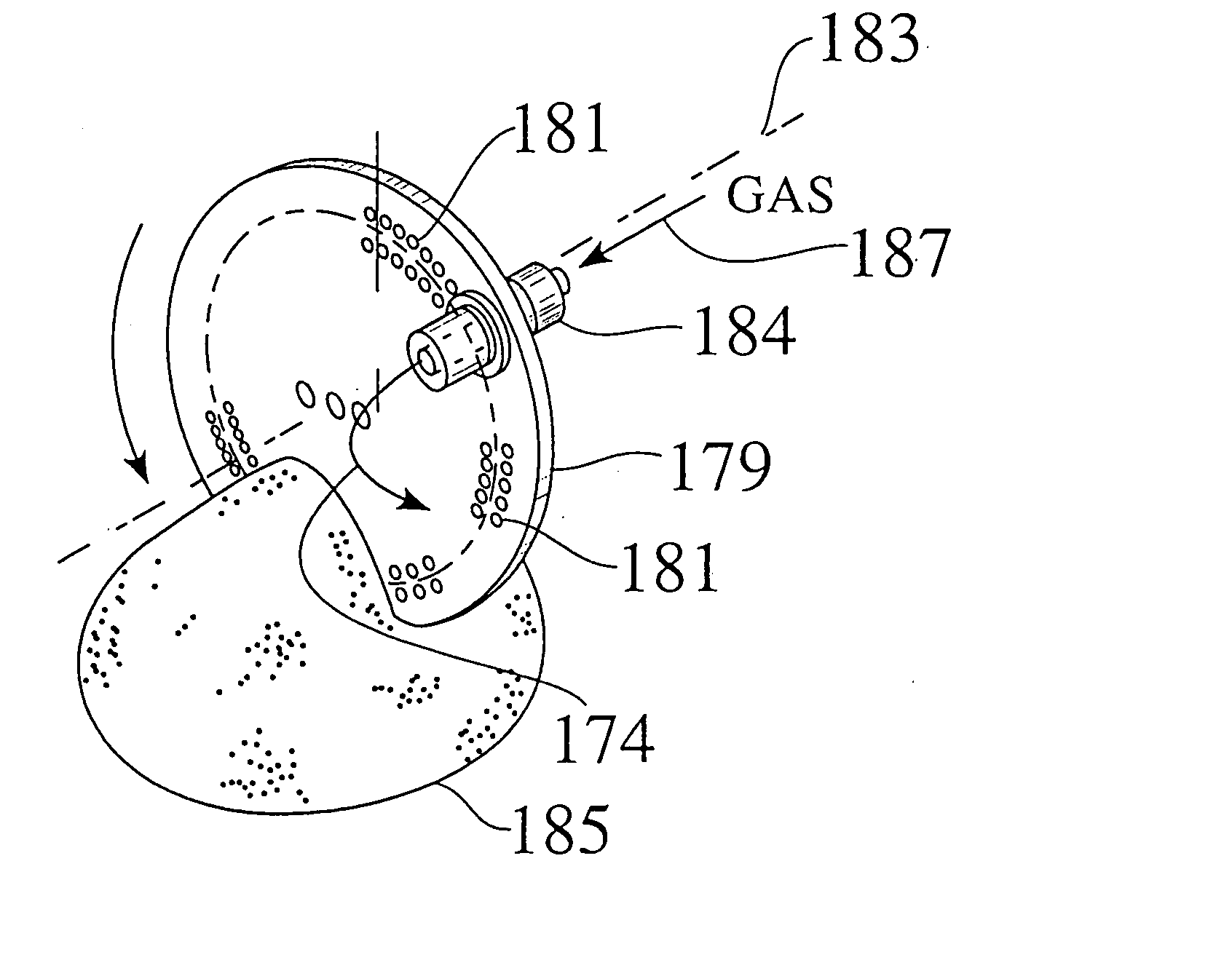

Apparatus for treating the surface with neutral particle beams

InactiveUS6935269B2Wide effective cross sectionImprove throughputRadiation/particle handlingElectric discharge tubesTarget surfaceMetal

The present invention relates to an apparatus for treating the surface with neutral particle beams comprising an antenna container, a plasma generating part, a neutral particle beam generating part and a treating part, wherein the antenna container comprises antennas connected to high frequency electric power supply through which high frequency electric power supplies, the plasma generating part transfers gases from a gas injector into plasmas with the supplied power, the neutral particle beam generating part reverts the obtained plasmas to neutral particle beams via the collision thereof with metal plates, and the treating part treats the surface of a target with the neutral particle beams.

Owner:SEM TECH CO LTD +1

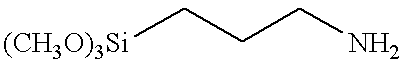

Organo luminescent semiconductor nanocrystal probes for biological applications and process for making and using such probes

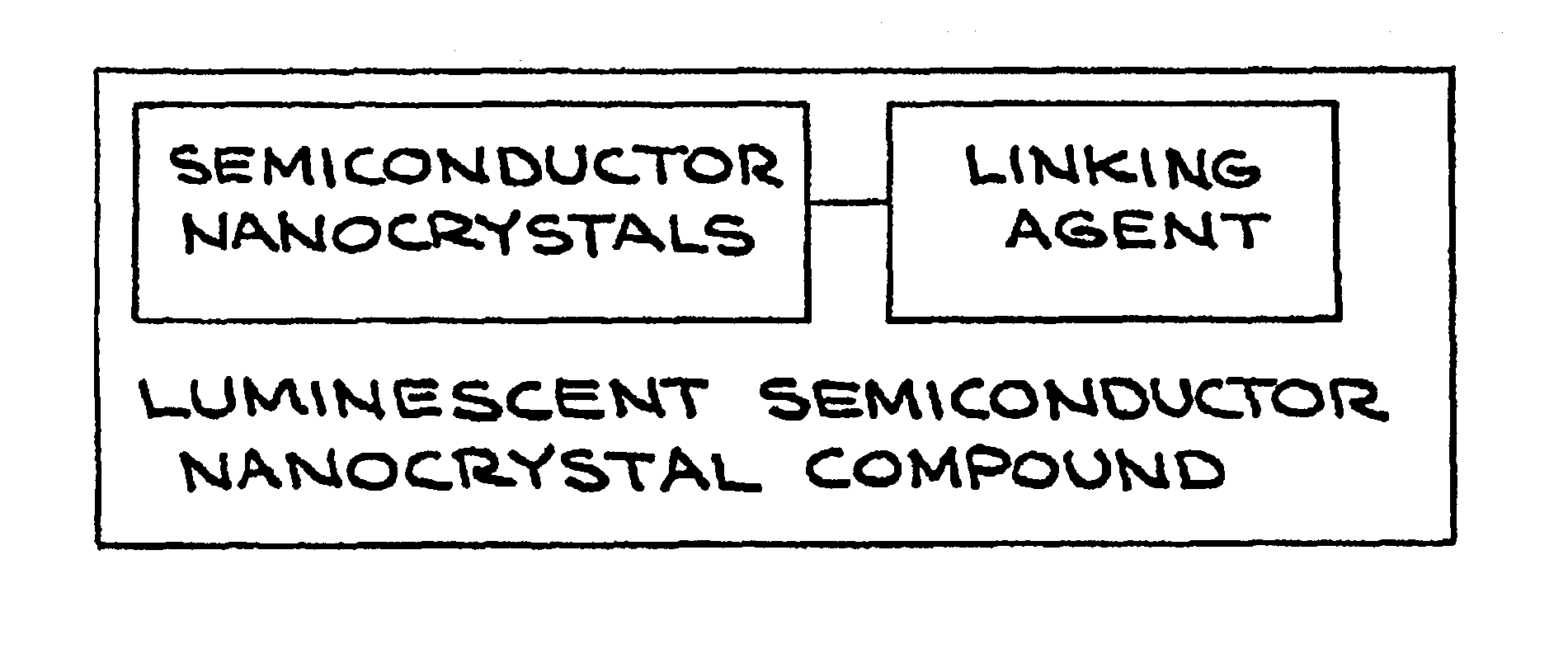

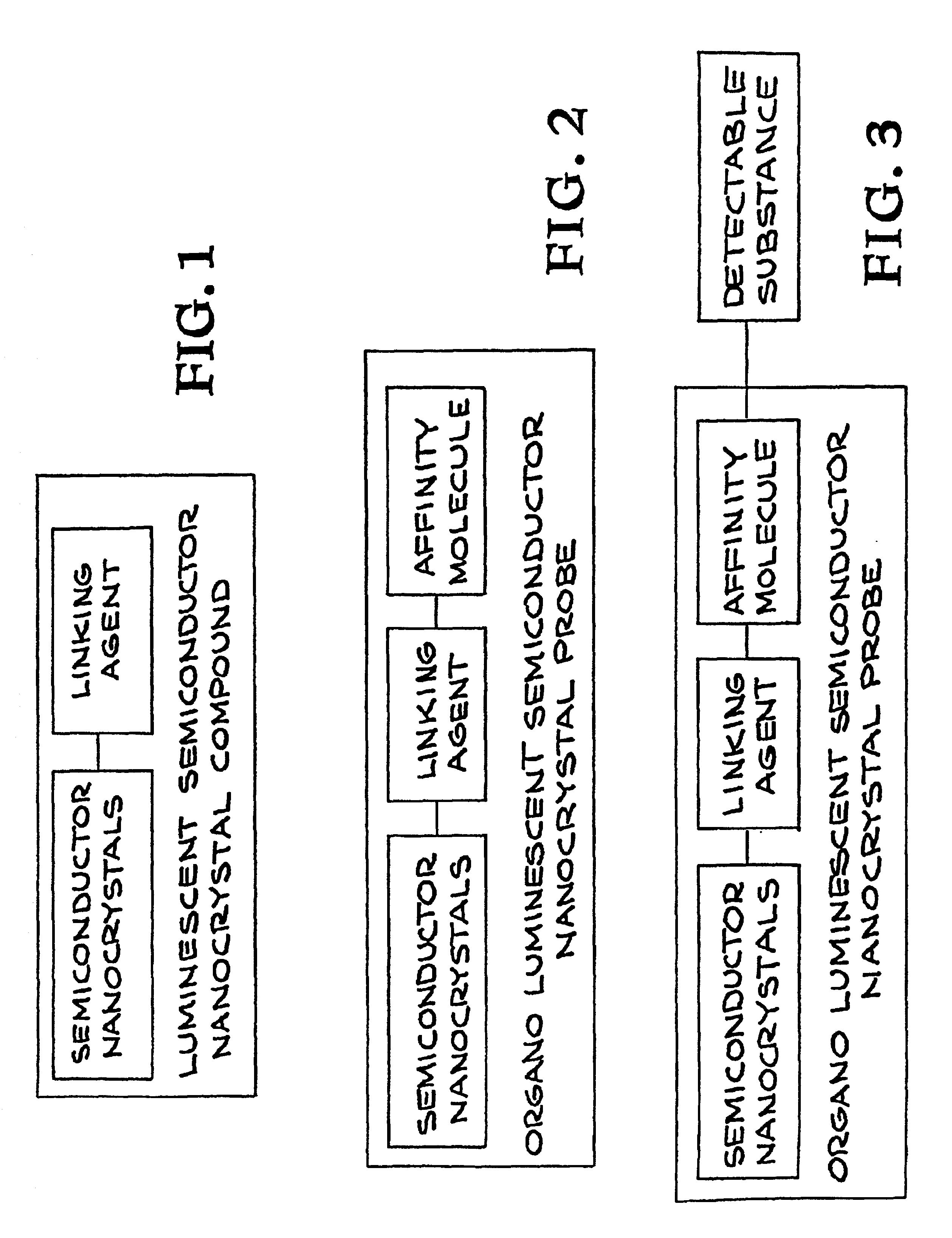

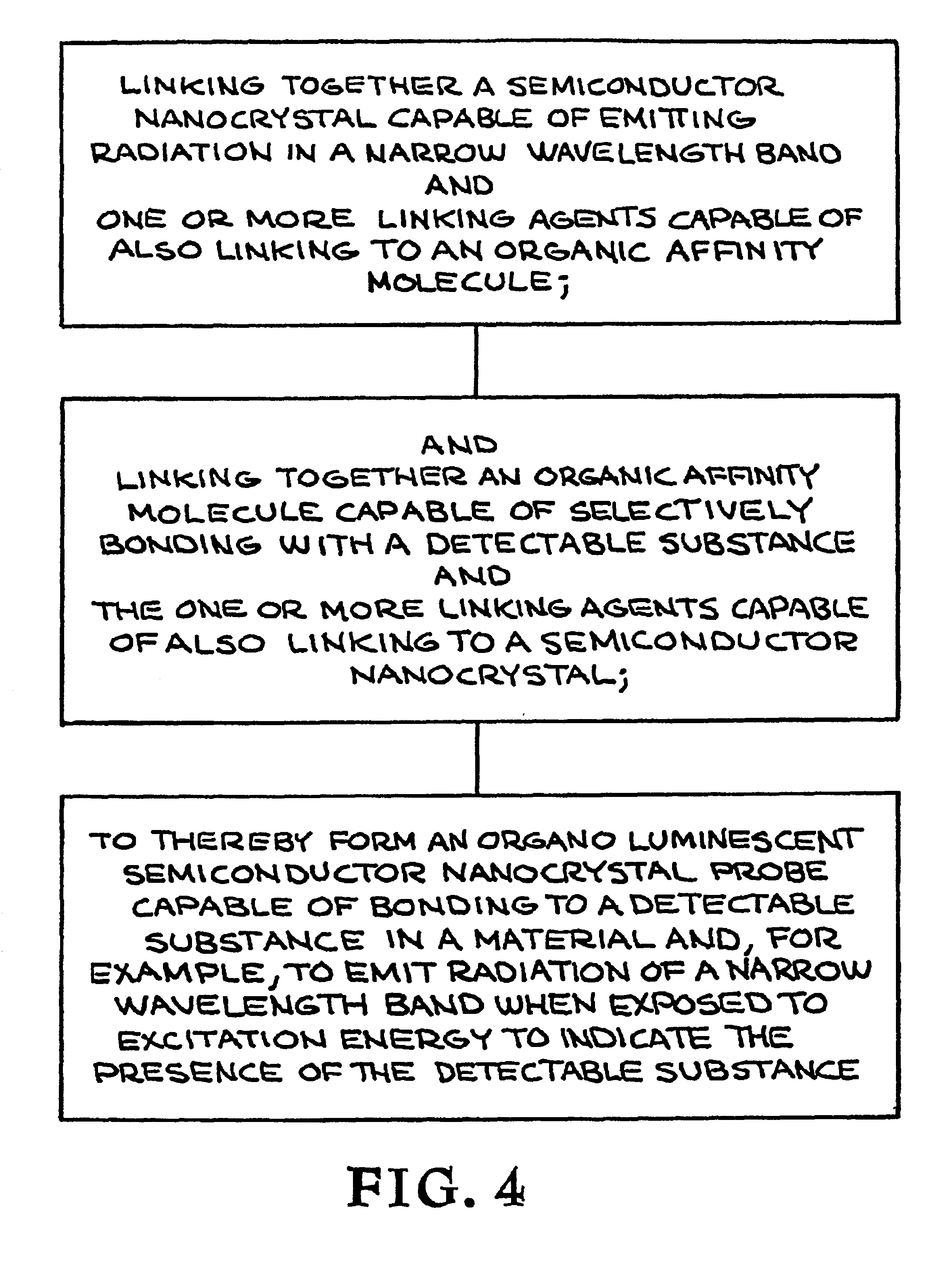

A semiconductor nanocrystal compound is described capable of linking to an affinity molecule. The compound comprises (1) a semiconductor nanocrystal capable of emitting electromagnetic radiation and / or absorbing energy, and / or scattering or diffracting electromagnetic radiation-when excited by an electromagnetic radiation source or a particle beam; and (2) at least one linking agent, having a first portion linked to the semiconductor nanocrystal and a second portion capable of linking to an affity molecule. The compound is linked to an affinity molecule to form a semiconductor nanocrystal probe capable of bonding with a detectable substance. Subsequent exposure to excitation energy will excite the semiconductor nanocrystal in he probe, causing the emission of electromagnetic radiation. Further described are processes for respectively: making the semiconductor nanocrystal compound; making the semiconductor nanocrystal probe; and using the probe to determine the presence of a detectable substance in a material.

Owner:RGT UNIV OF CALIFORNIA

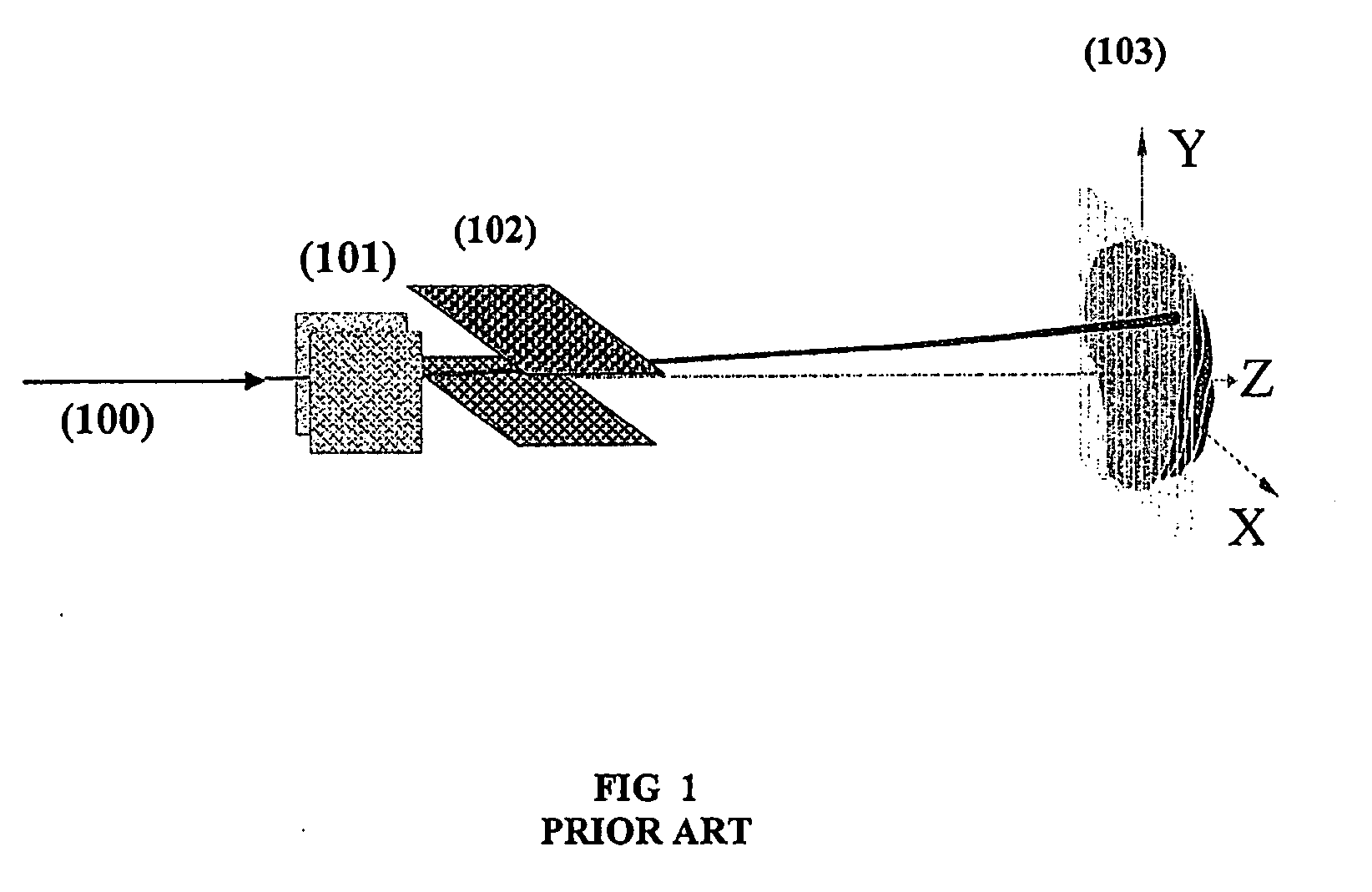

Method for treating a target volume with a particle beam and device implementing same

InactiveUS6717162B1Good flexibilityPossible to obtainRadiation/particle handlingElectrode and associated part arrangementsParticle beamParticle physics

The invention concerns a method for treating a target volume with a particle beam, in particular a proton beam, which consists in generating said particle beam using an accelerator and in producing from said beam a narrow spot directed towards the target volume, characterized in that said spot sweeping speed and the particle beam intensity are simultaneously varied.

Owner:ION BEAM APPL

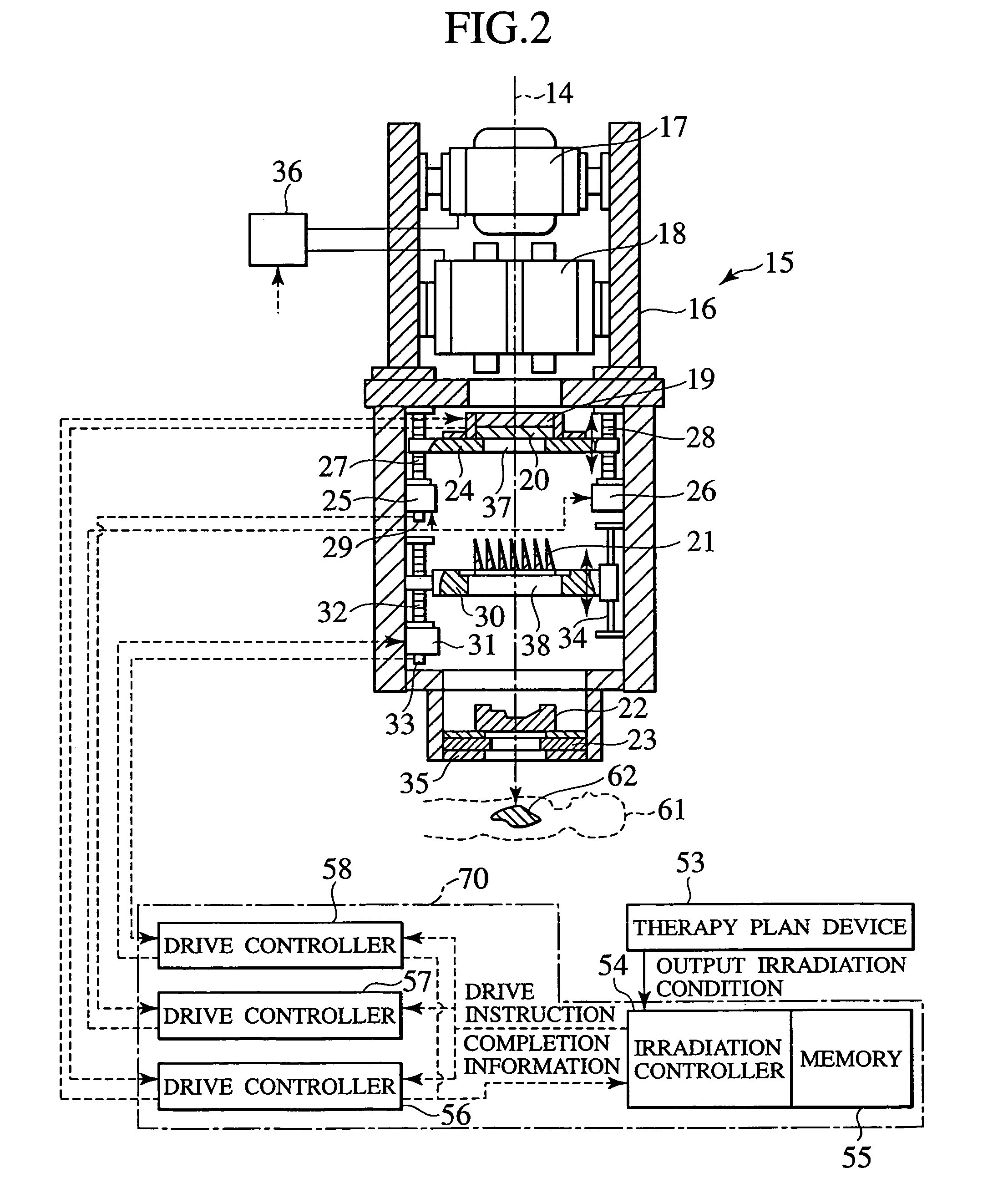

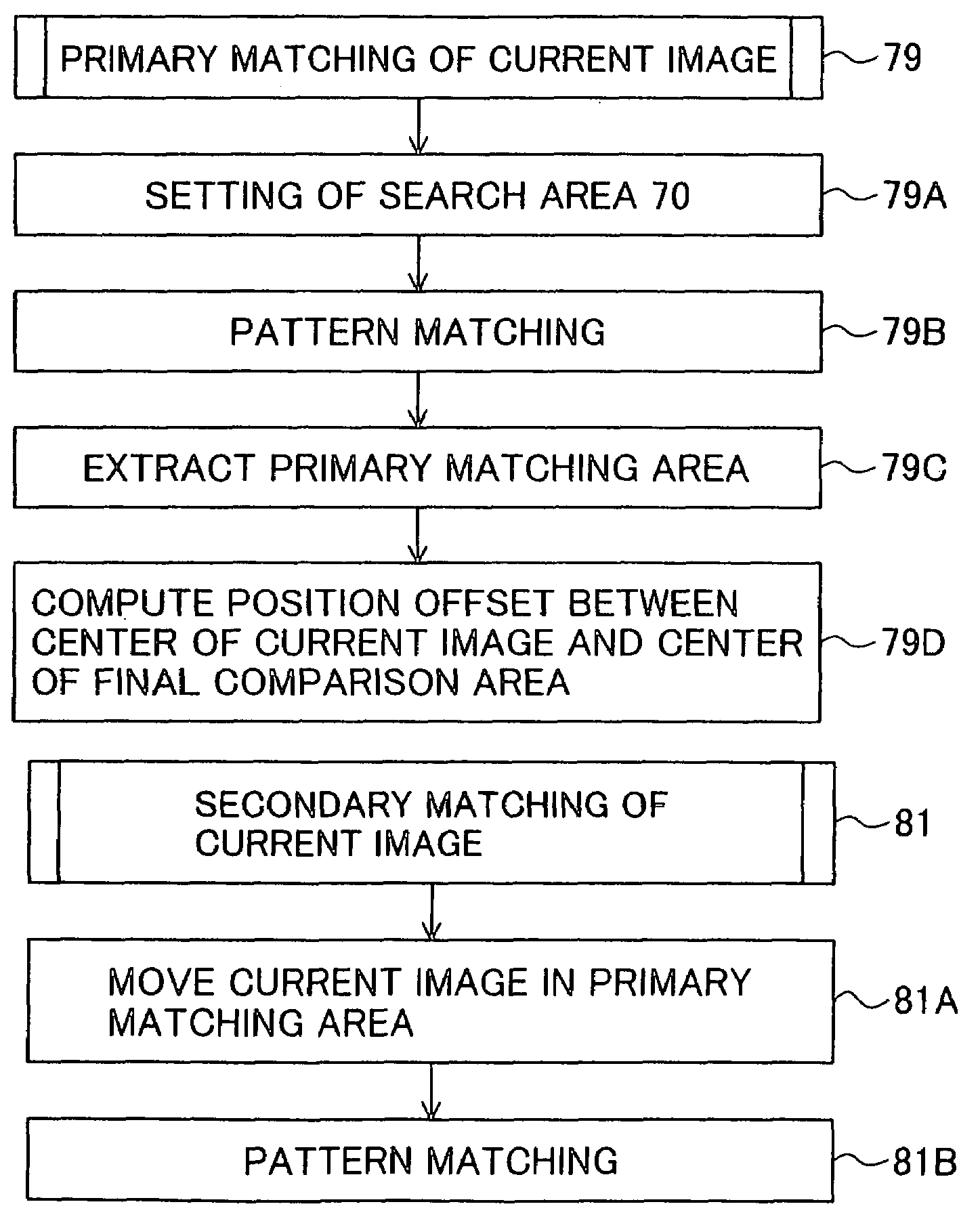

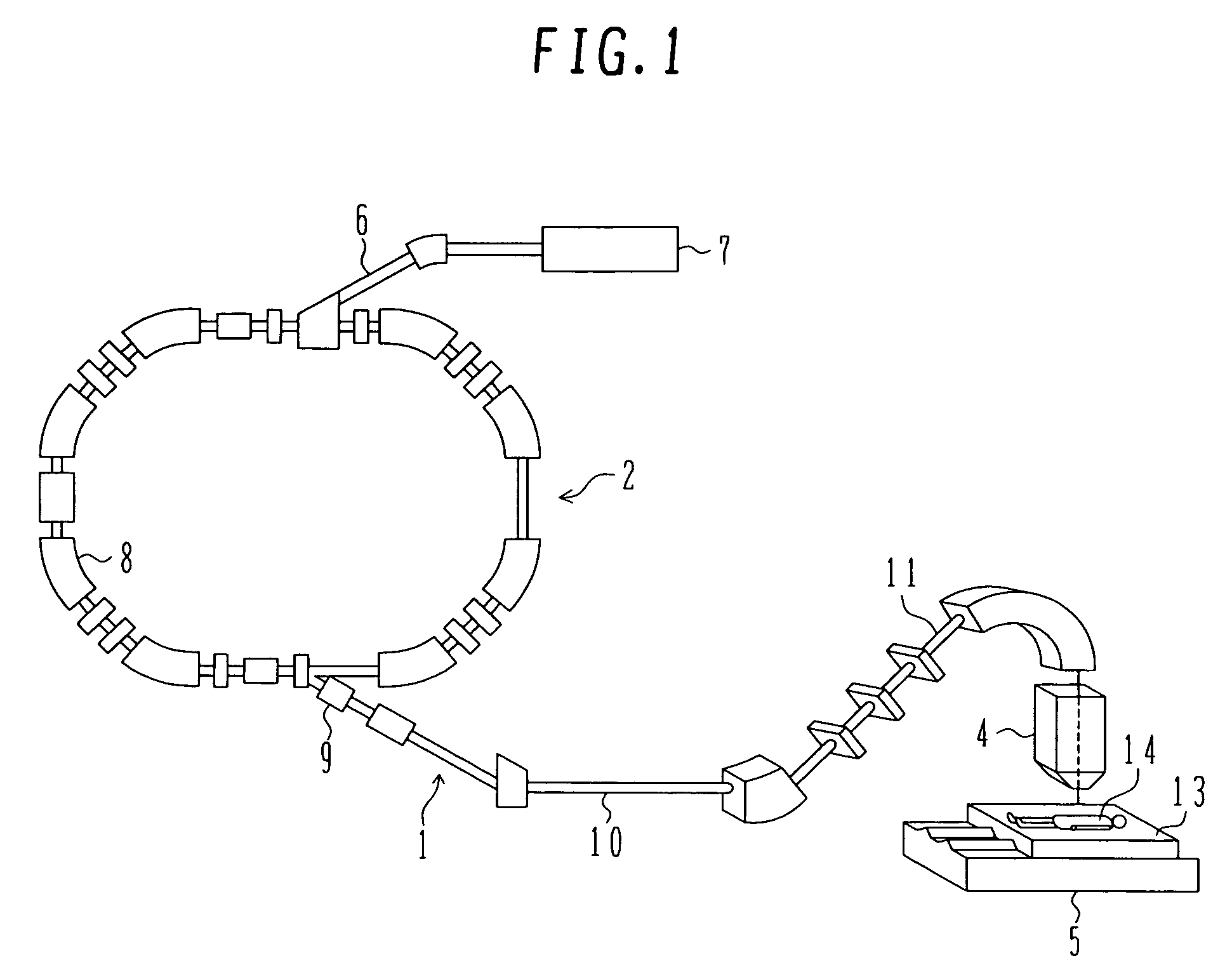

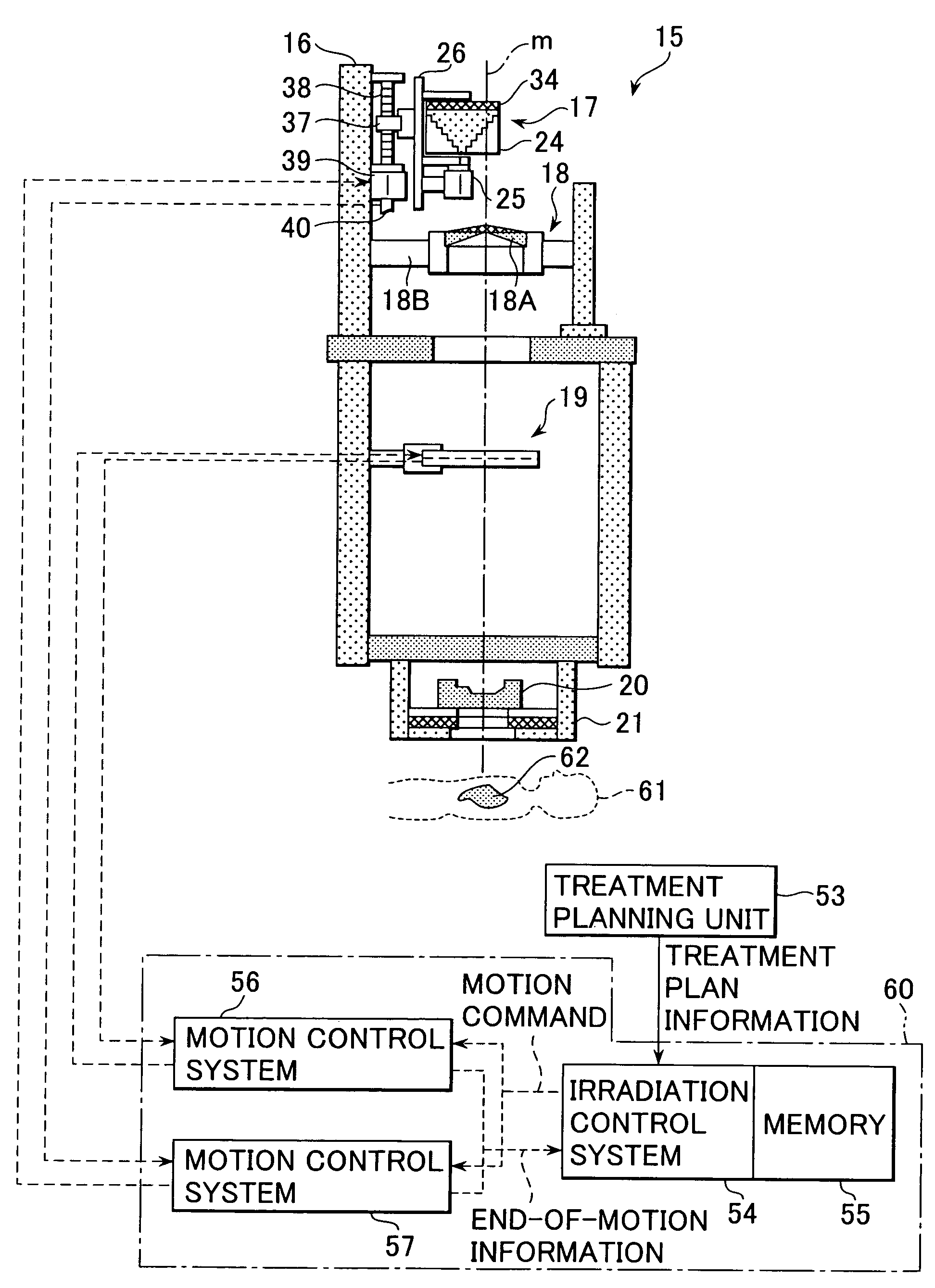

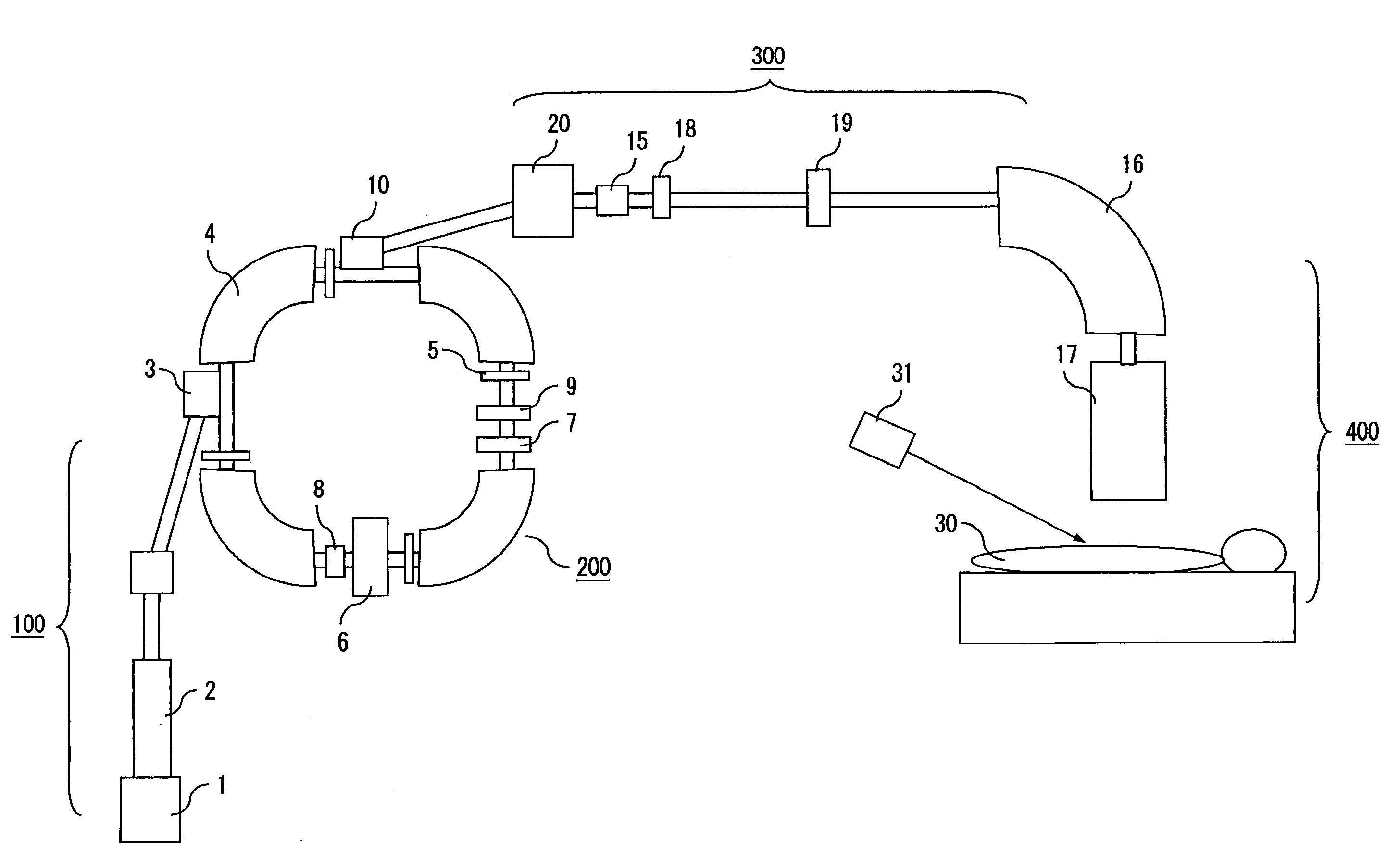

Patient positioning device and patient positioning method

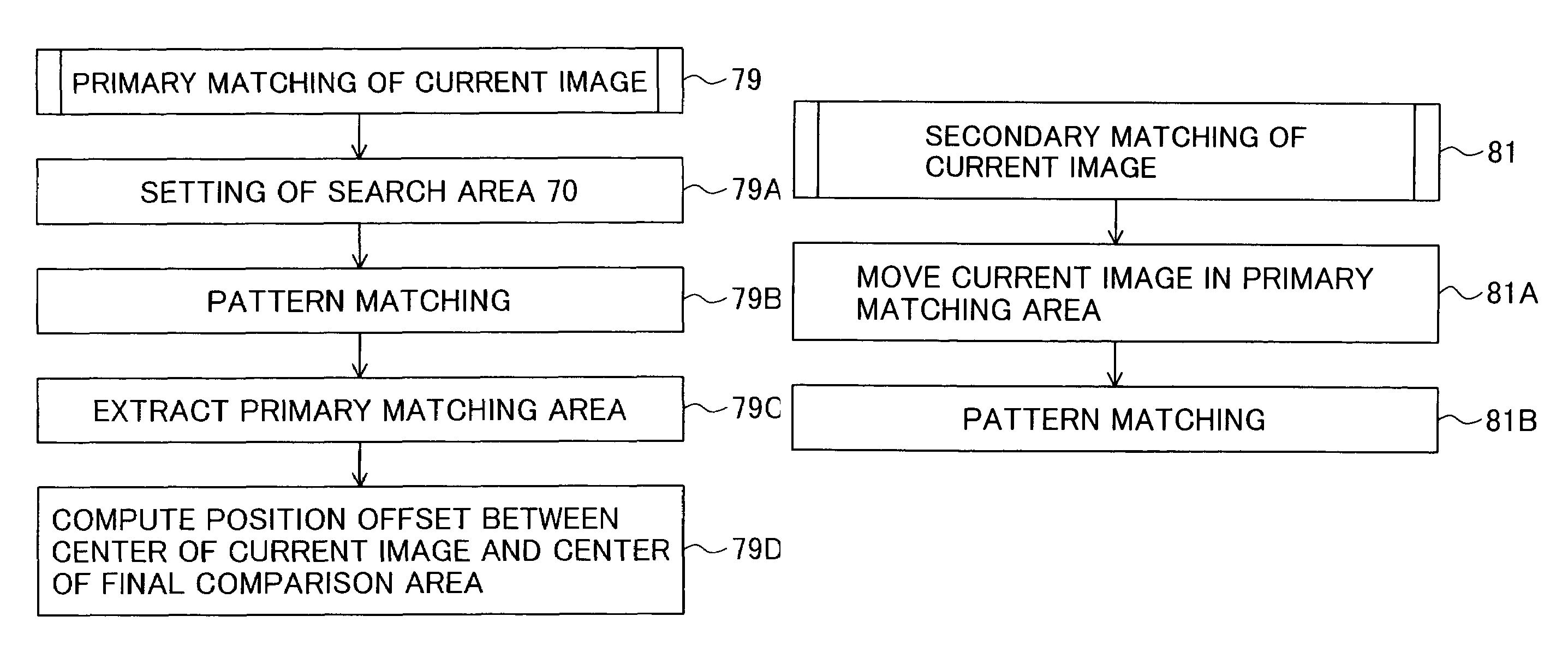

InactiveUS7212608B2Improve accuracyAvoid accuracyBuilding locksPatient positioning for diagnosticsPattern matchingX-ray

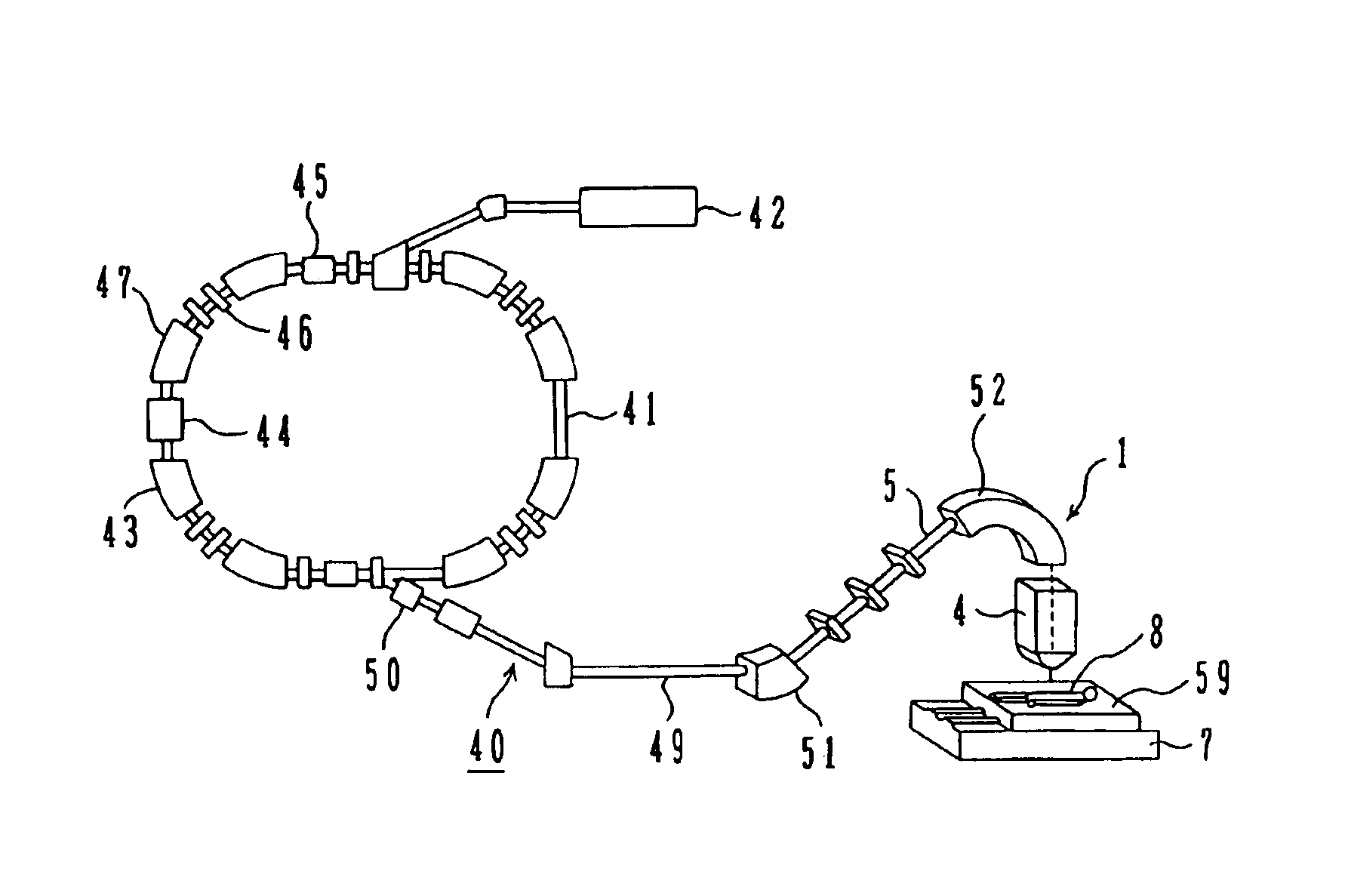

The invention is intended to always ensure a sufficient level of patient positioning accuracy regardless of the skills of individual operators. In a patient positioning device for positioning a patient couch 59 and irradiating an ion beam toward a tumor in the body of a patient 8 from a particle beam irradiation section 4, the patient positioning device comprises an X-ray emission device 26 for emitting an X-ray along a beam line m from the particle beam irradiation section 4, an X-ray image capturing device 29 for receiving the X-ray and processing an X-ray image, a display unit 39B for displaying a current image of the tumor in accordance with a processed image signal, a display unit 39A for displaying a reference X-ray image of the tumor which is prepared in advance, and a positioning data generator 37 for executing pattern matching between a comparison area A being a part of the reference X-ray image and including an isocenter and a comparison area B or a final comparison area B in the current image, thereby producing data used for positioning of the patient couch 59 during irradiation.

Owner:HITACHI LTD

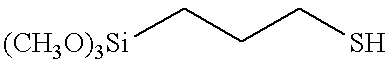

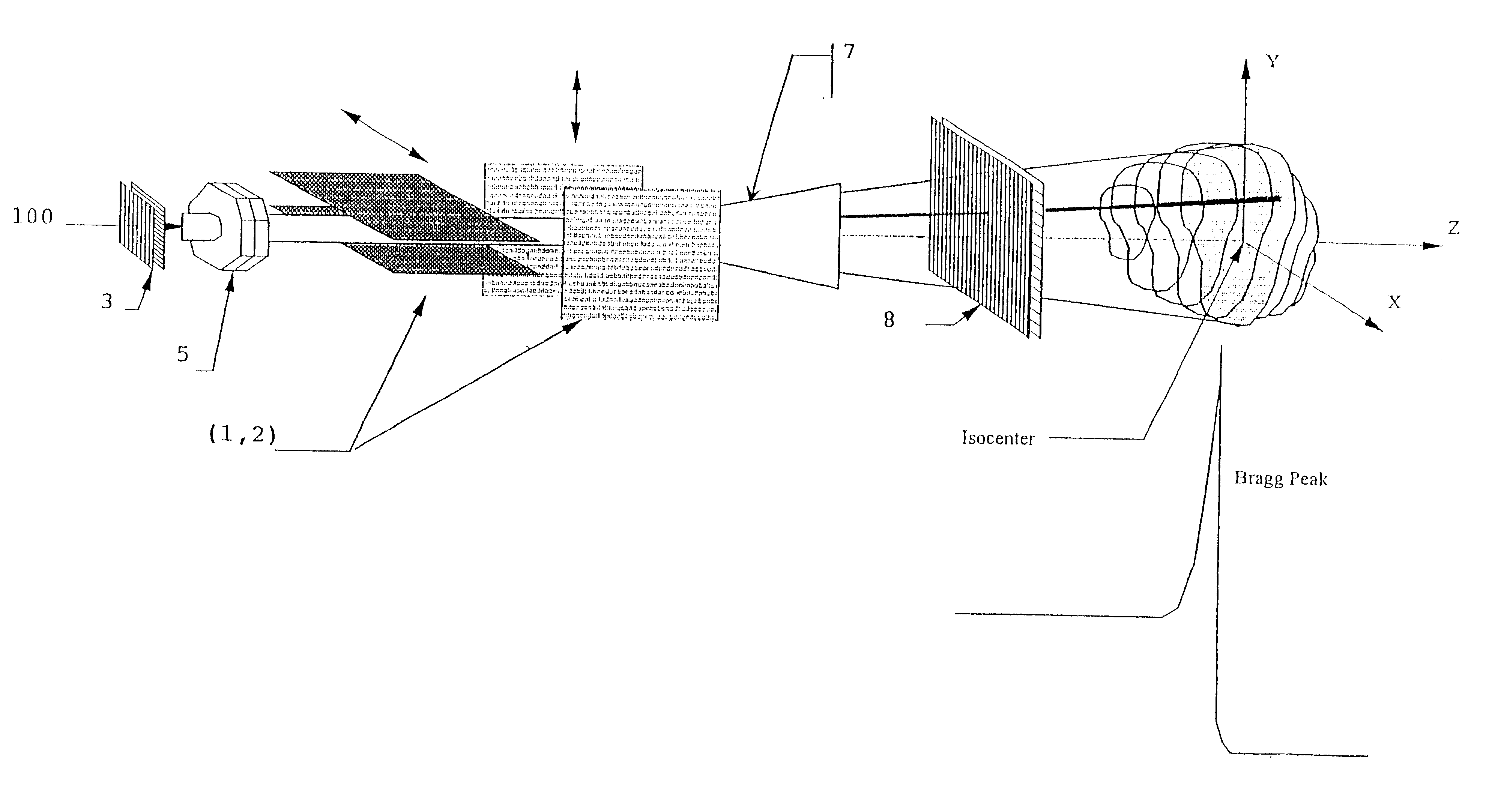

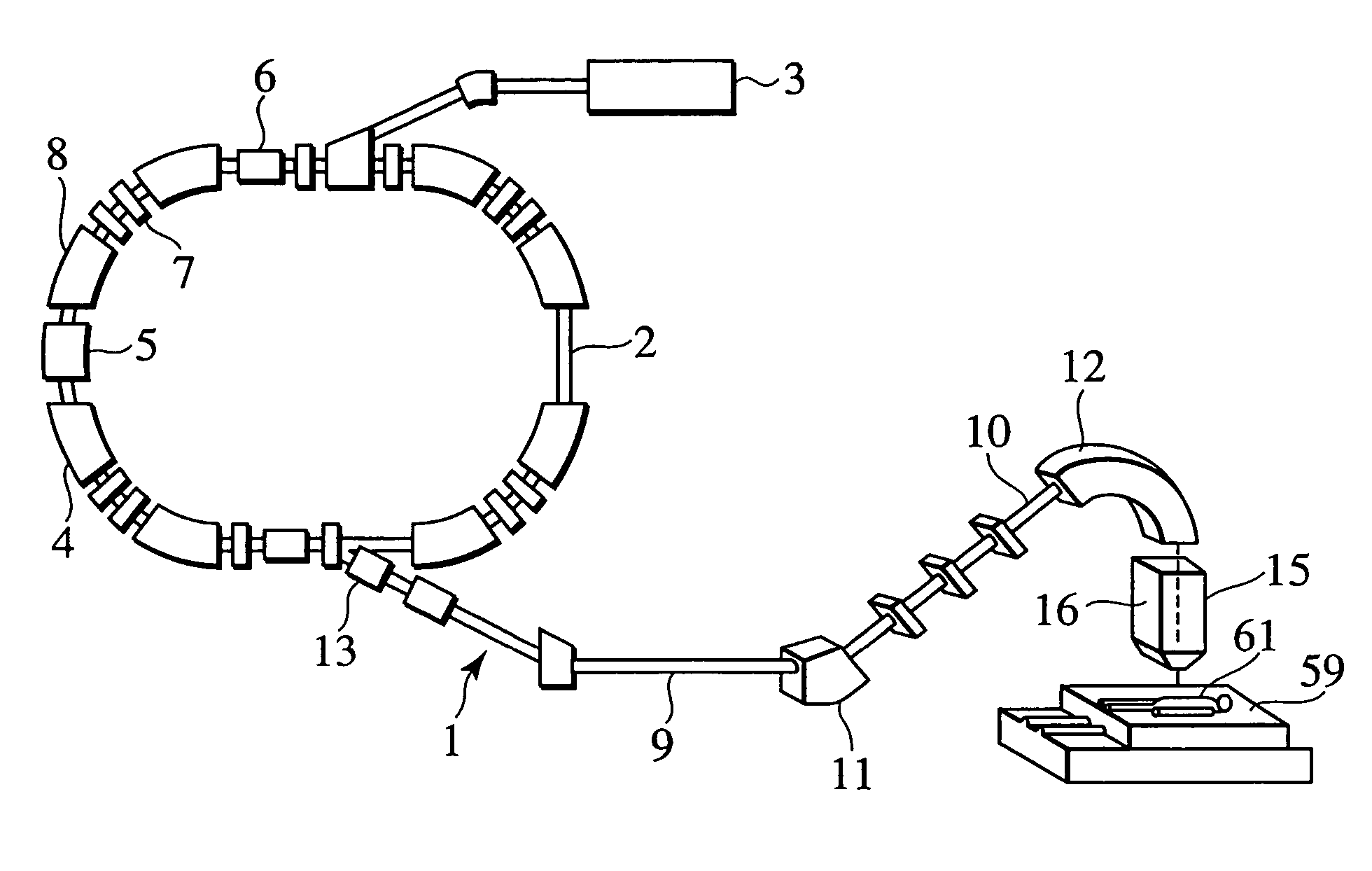

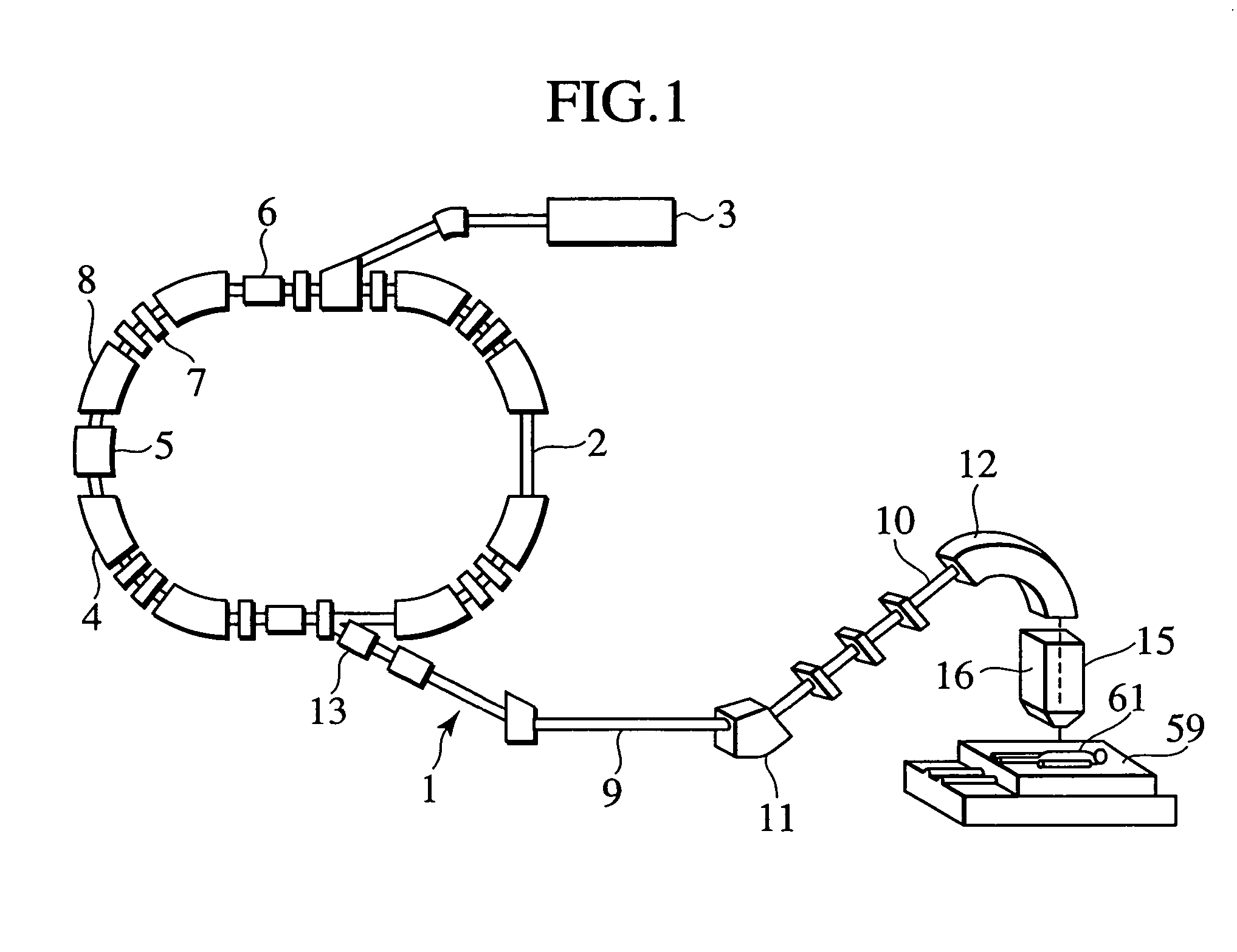

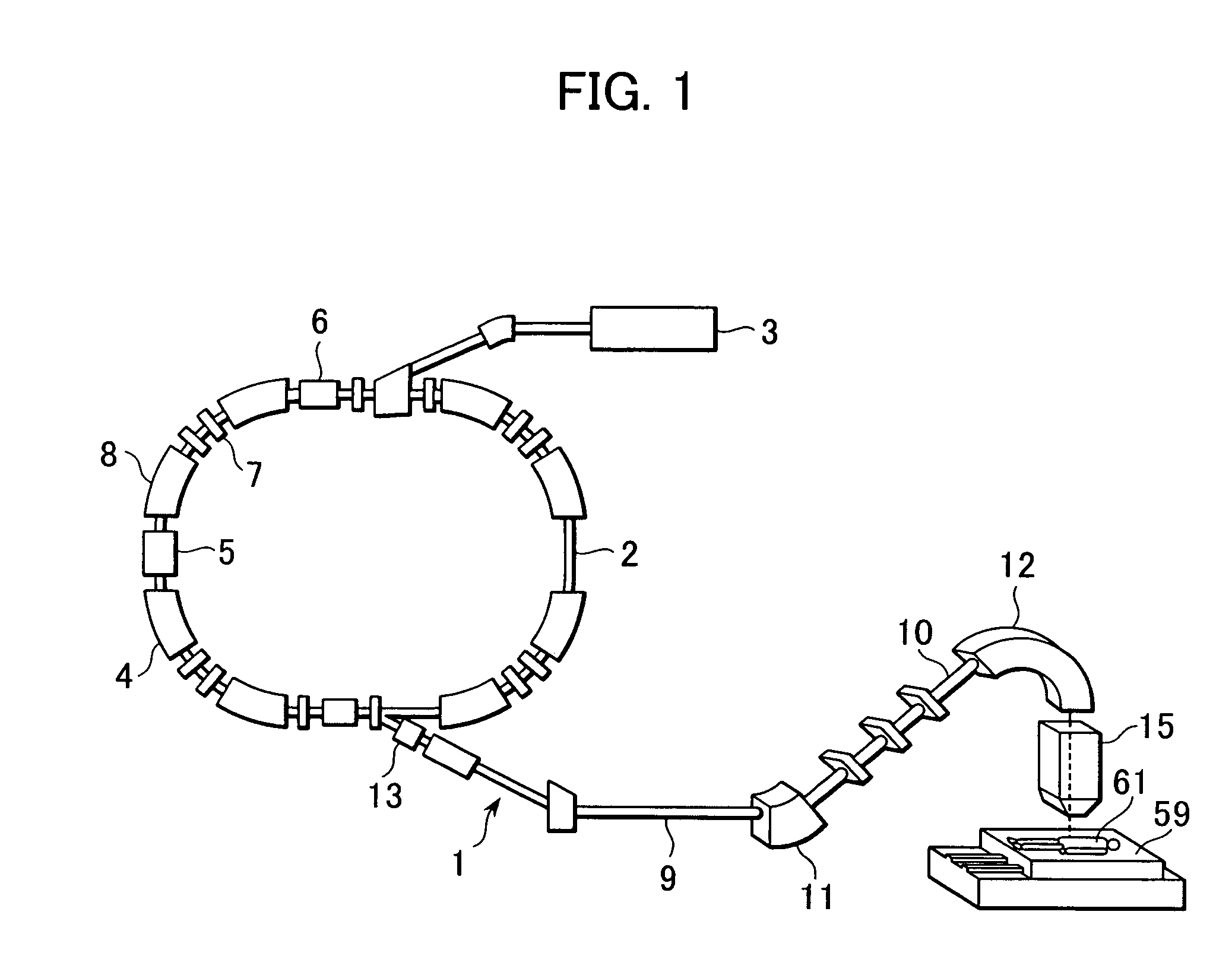

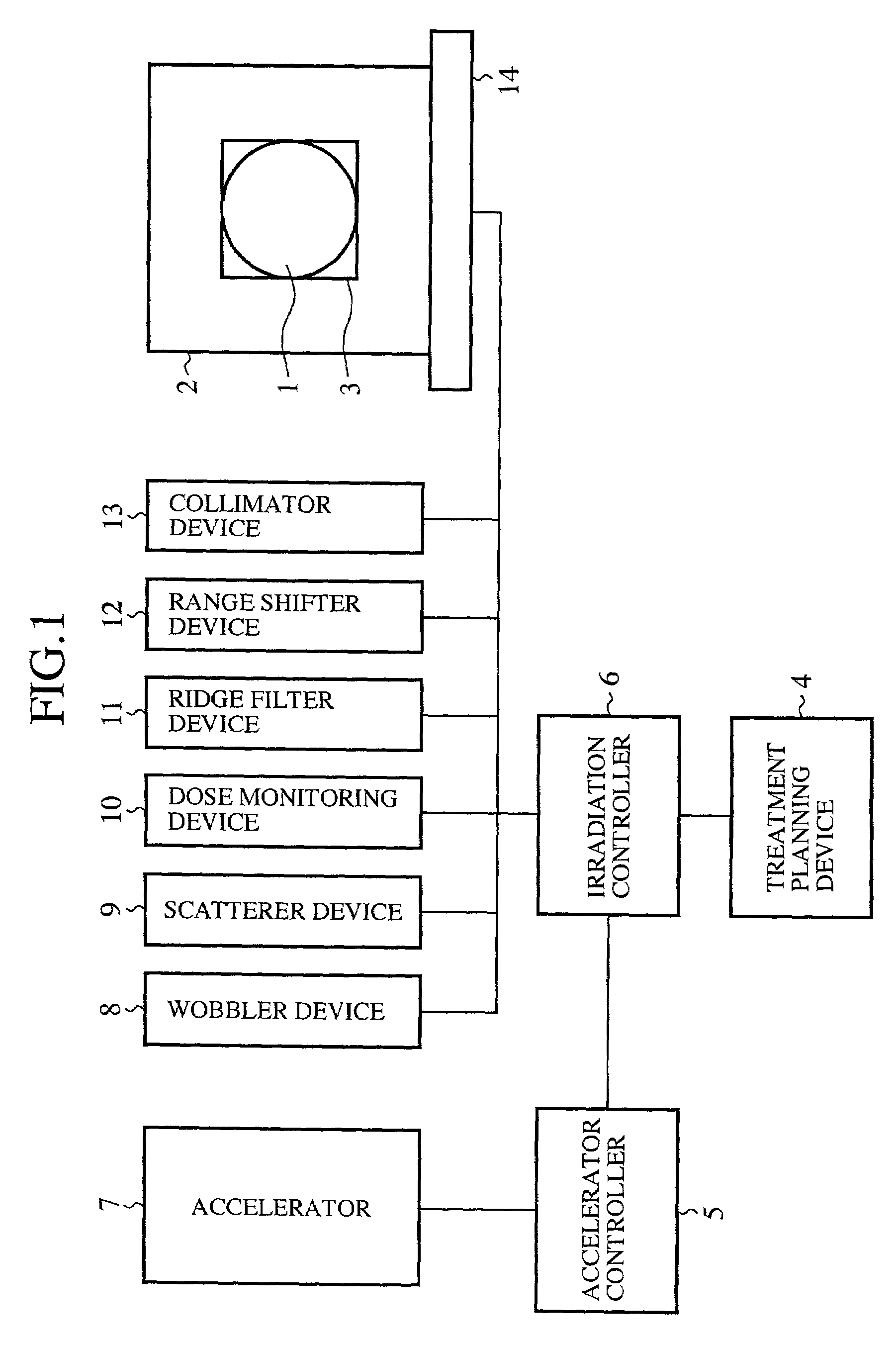

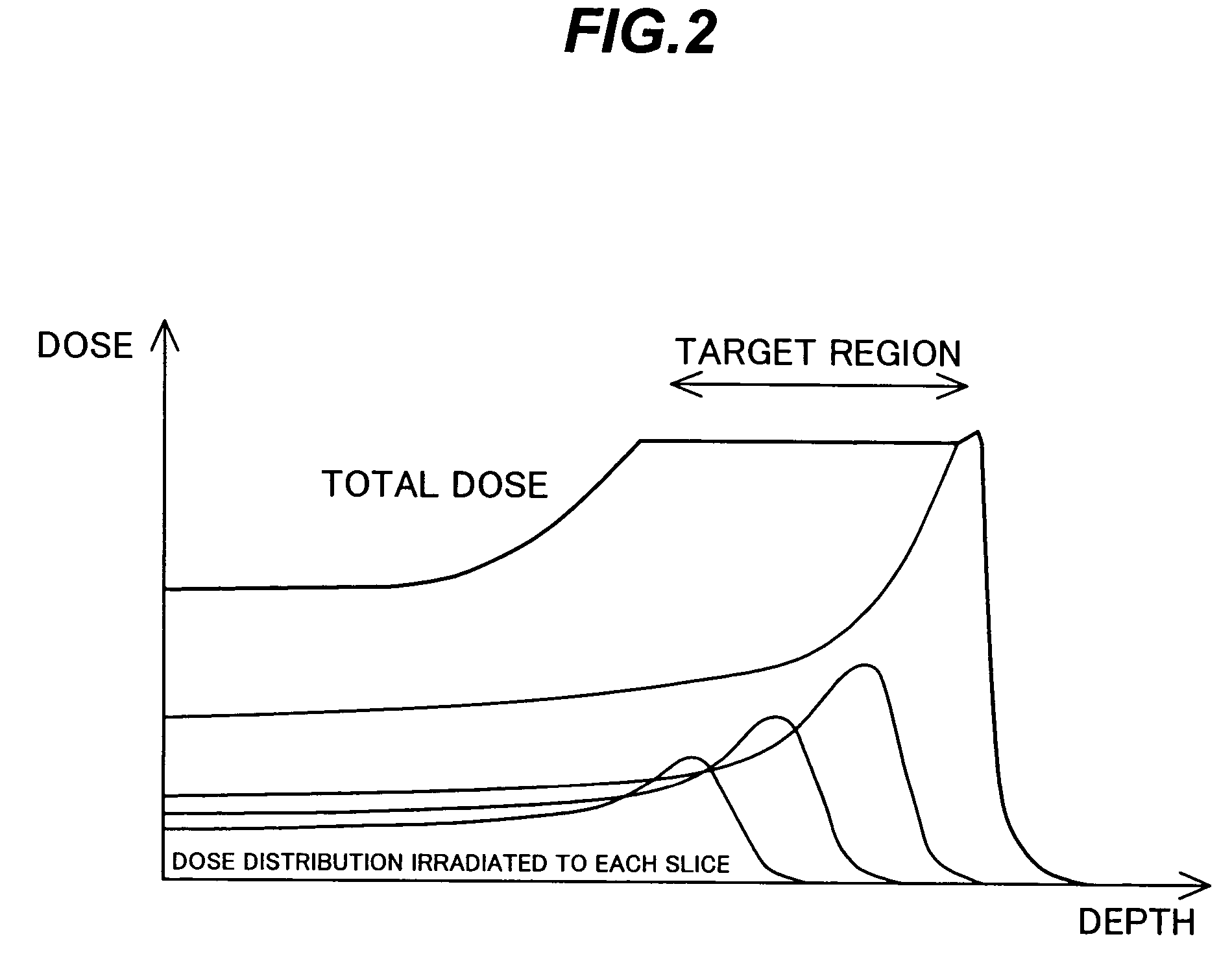

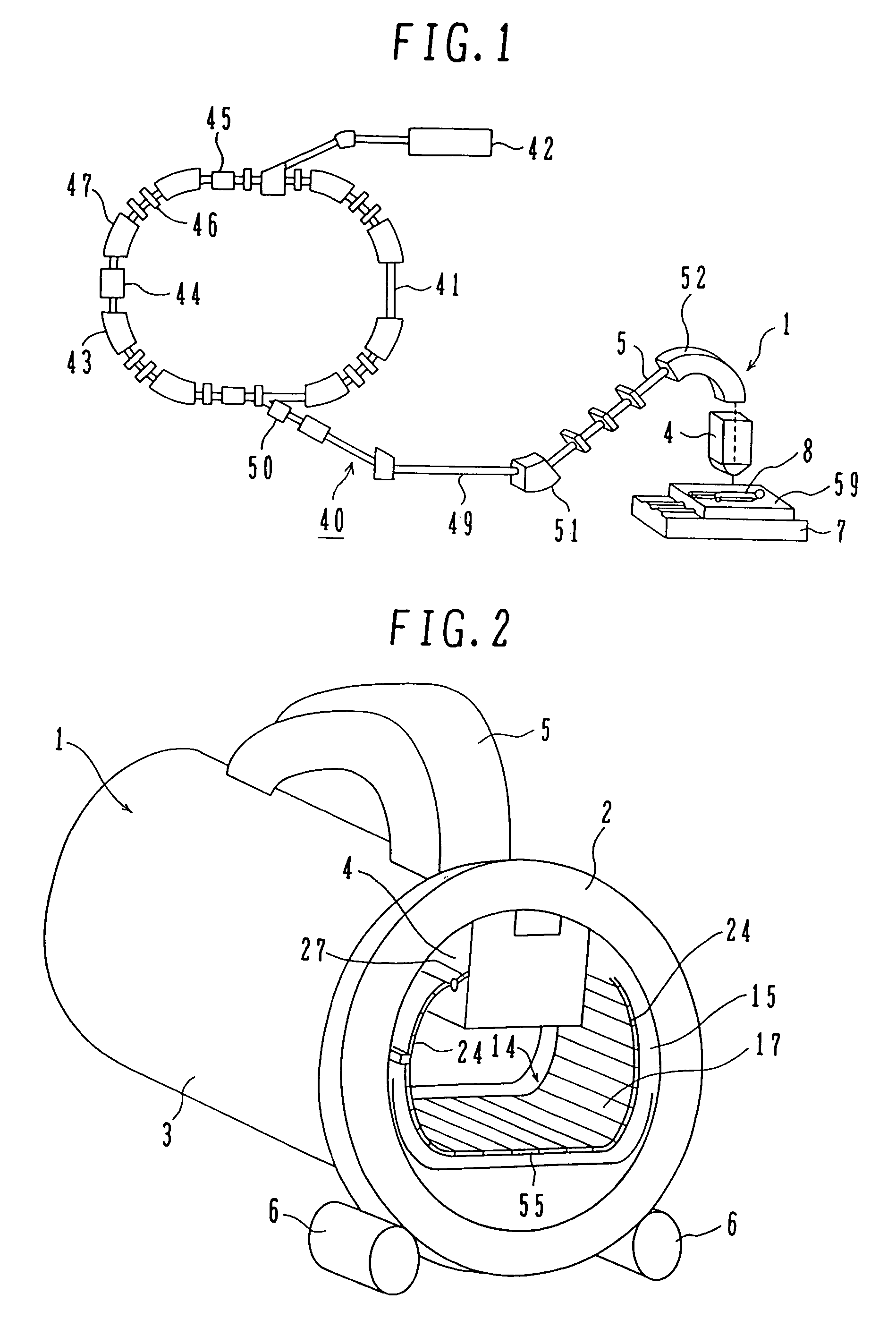

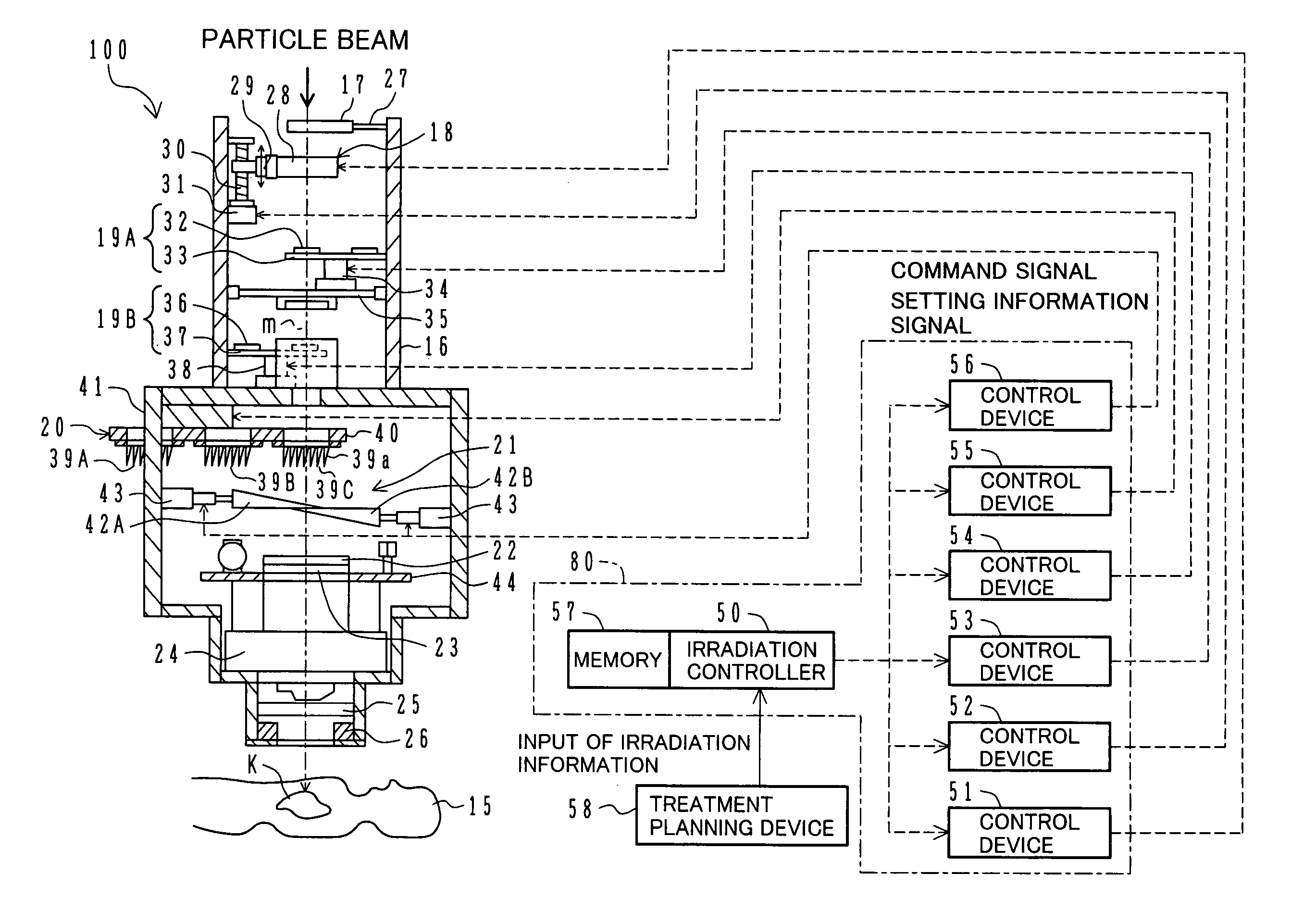

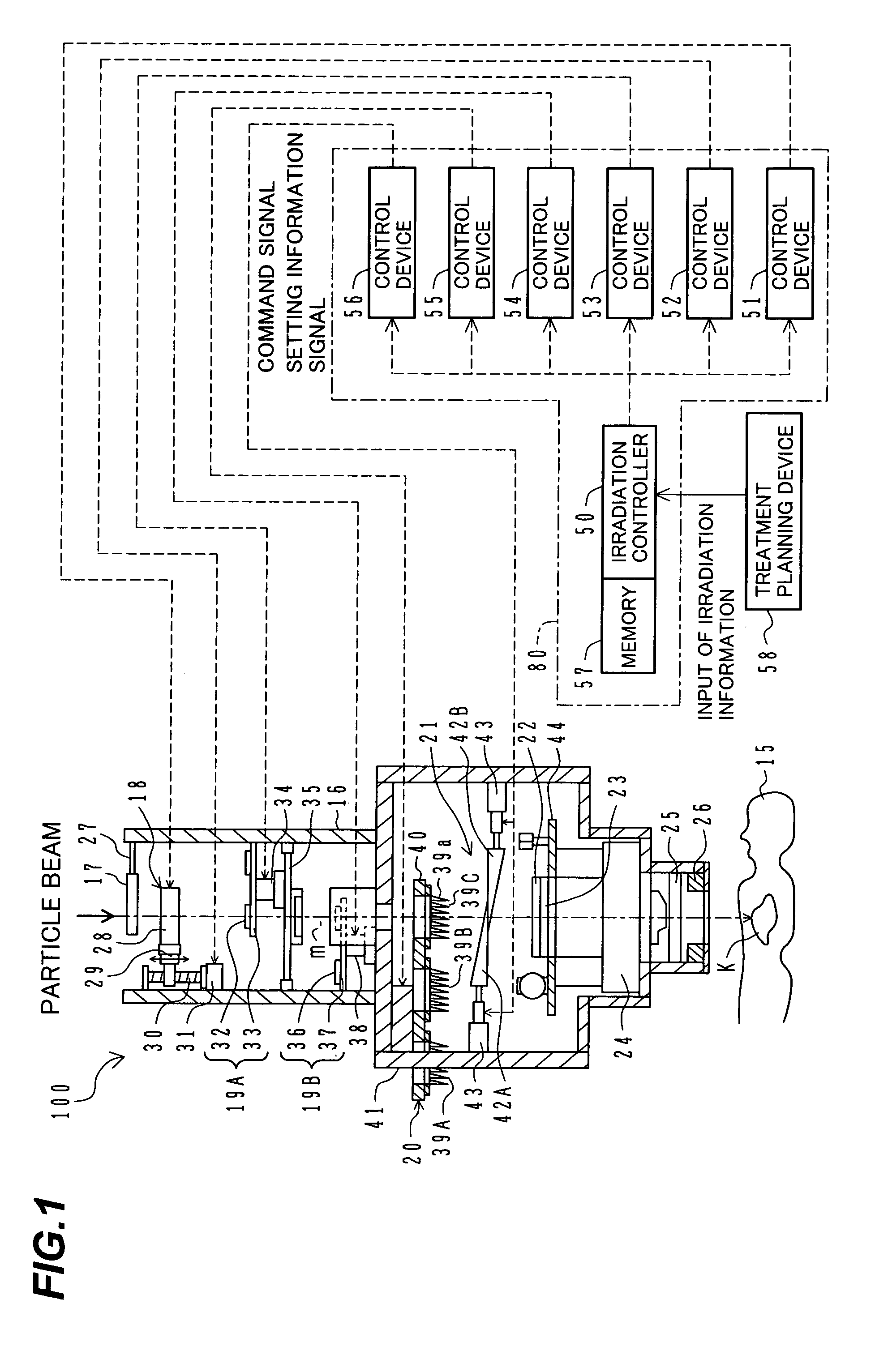

Particle beam irradiation system and method of adjusting irradiation apparatus

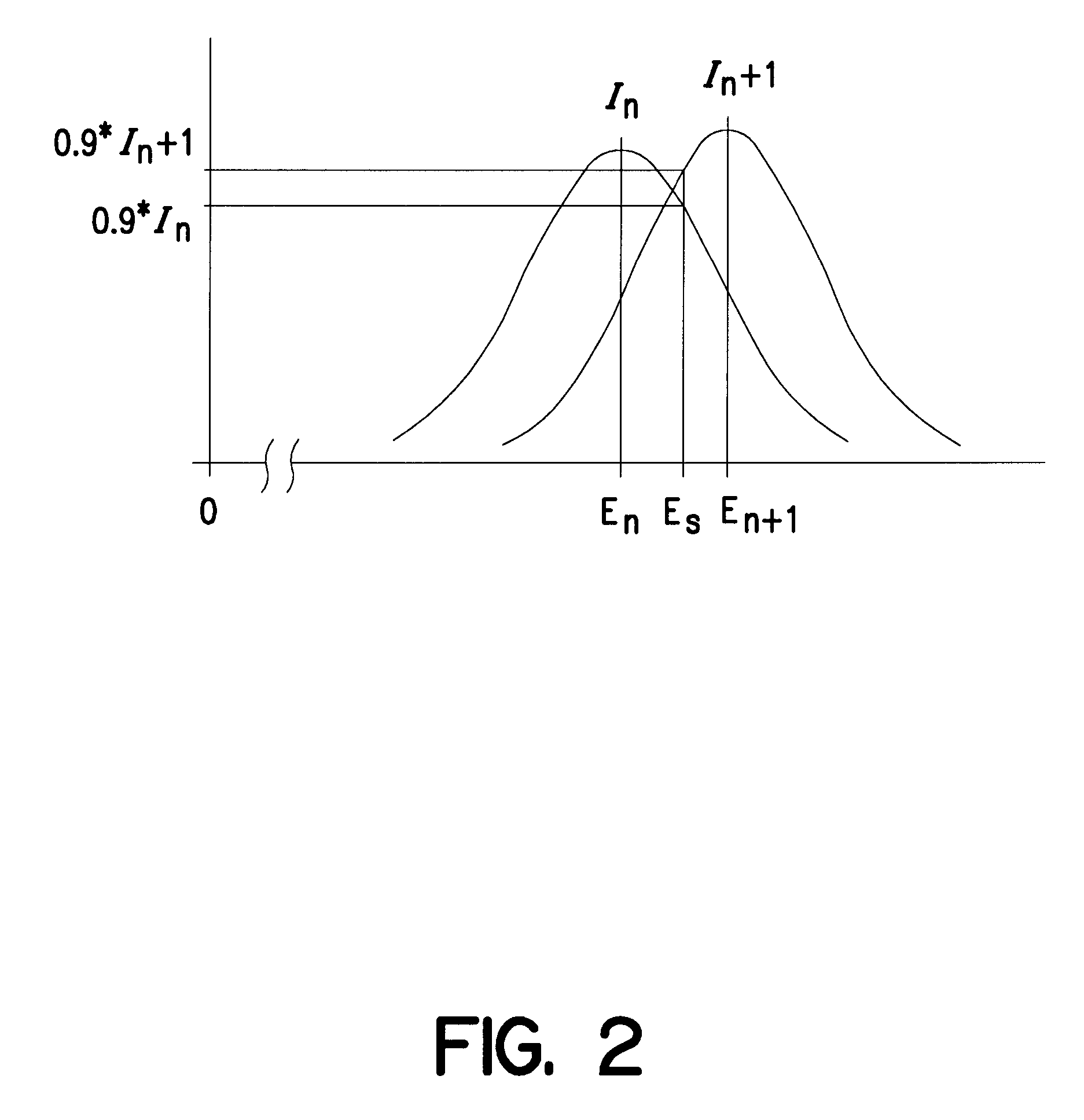

InactiveUS7026636B2Improve uniformityRadiation/particle handlingMagnetic resonance acceleratorsBragg peakParticle beam

The present invention provides an increased degree of uniformity of radiation dose distribution for the interior of a diseased part. A particle beam therapy system includes a charged particle beam generation apparatus and an irradiation apparatus. An ion beam is generated by the charged particle beam generation apparatus. The irradiation apparatus exposes a diseased part to the generated ion beam. A scattering device, a range adjustment device, and a Bragg peak spreading device are installed upstream of a first scanning magnet and a second scanning magnet. The scattering device and the range adjustment device are combined together and moved along a beam axis, whereas the Bragg peak spreading device is moved independently along the beam axis. The scattering device moves to adjust the degree of ion beam scattering. The range adjustment device moves to adjust ion beam scatter changes caused by an absorber thickness adjustment. The Bragg peak spreading device moves to adjust ion beam scatter changes arising out of an SOBP device. These adjustments provide uniformity of radiation dose distribution for the diseased part.

Owner:HITACHI LTD

Patient positioning device and patient positioning method

InactiveUS7212609B2Improve accuracyAvoid accuracyMaterial analysis using wave/particle radiationRadiation/particle handlingPattern matchingX-ray

The invention is intended to always ensure a sufficient level of patient positioning accuracy regardless of the skills of individual operators. In a patient positioning device for positioning a patient couch 59 and irradiating an ion beam toward a tumor in the body of a patient 8 from a particle beam irradiation section 4, the patient positioning device comprises an X-ray emission device 26 for emitting an X-ray along a beam line m from the particle beam irradiation section 4, an X-ray image capturing device 29 for receiving the X-ray and processing an X-ray image, a display unit 39B for displaying a current image of the tumor in accordance with a processed image signal, a display unit 39A for displaying a reference X-ray image of the tumor which is prepared in advance, and a positioning data generator 37 for executing pattern matching between a comparison area A being a part of the reference X-ray image and including an isocenter and a comparison area B or a final comparison area B in the current image, thereby producing data used for positioning of the patient couch 59 during irradiation.

Owner:HITACHI LTD

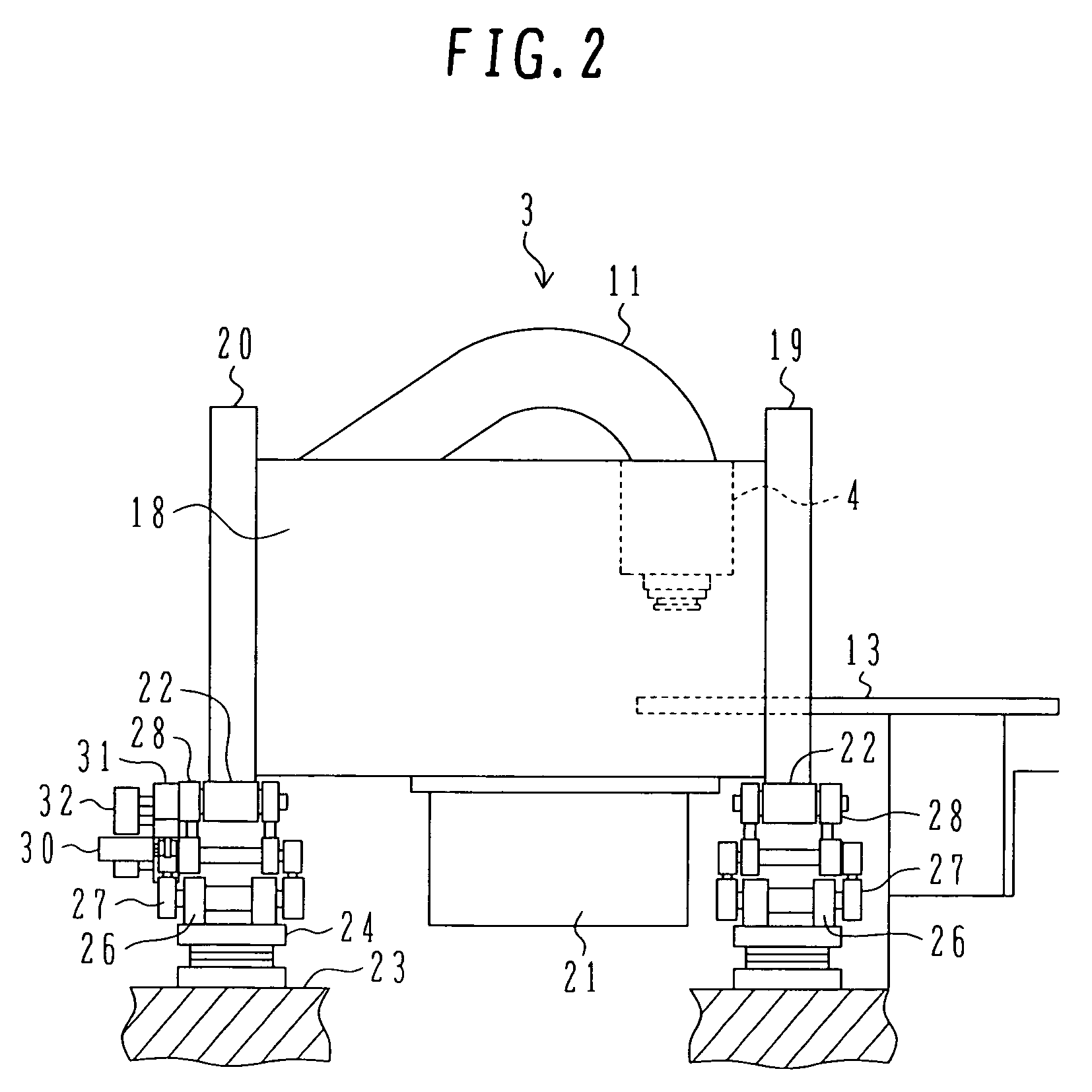

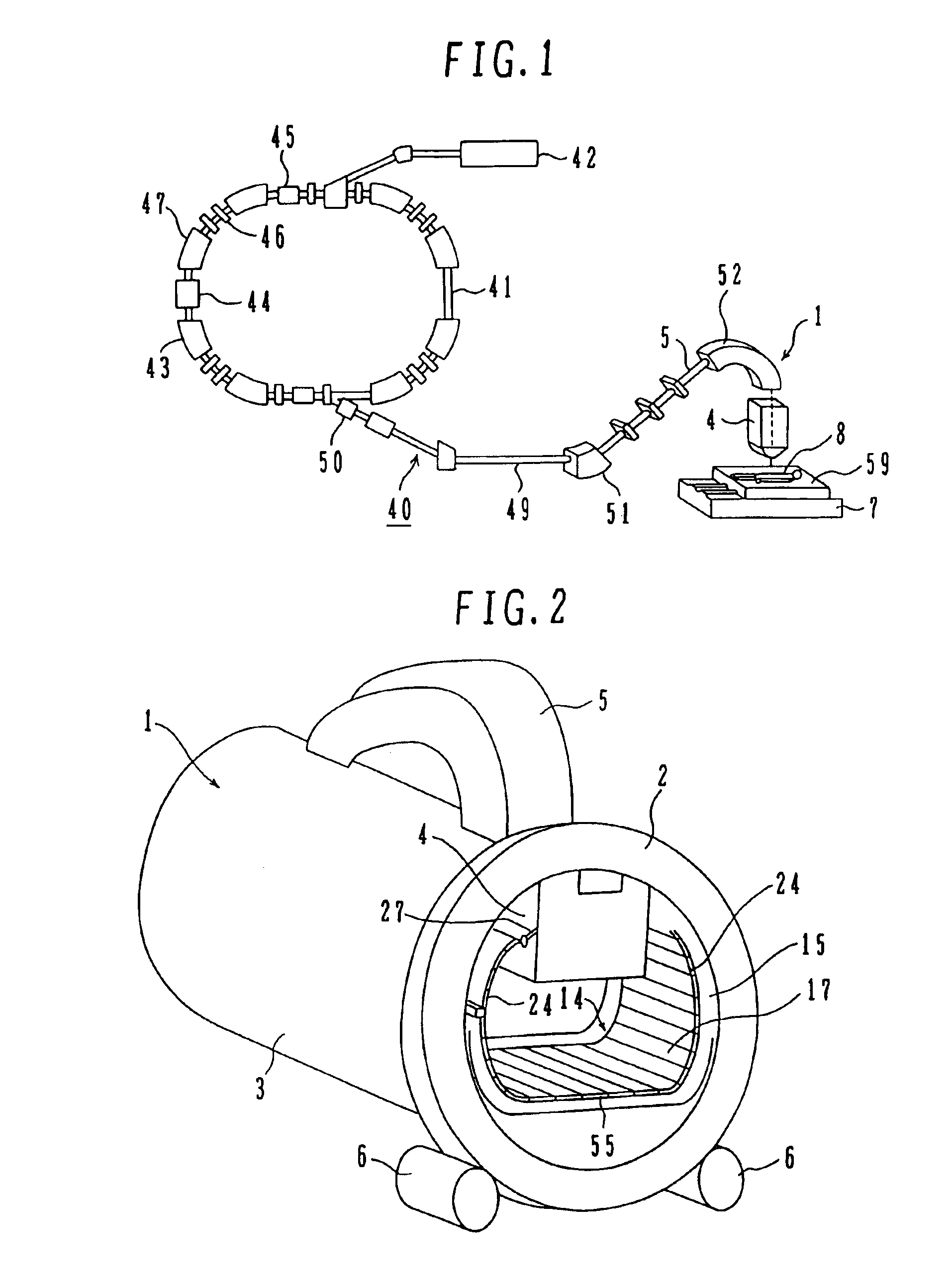

Rotating gantry of particle beam therapy system

ActiveUS7372053B2Improve rigidityVariation can be suppressedThermometer detailsFluid actuated brakesSolenoid valveParticle beam

A rotating gantry includes a link frame for supporting a plurality of rollers which rotatably support the rotating gantry, a brake for releasing a braking force applied to at least one of the rollers upon supply of air and applying the braking force to the one roller upon discharge of air, and a solenoid valve for sealing the supplied air in the brake when closed, and discharging the air from the brake when opened. The solenoid valve is supported by a solenoid valve support member mounted to the link frame such that the solenoid valve is positioned just near the brake. The rotating gantry can be more quickly braked and stopped while maintaining high irradiation accuracy.

Owner:HITACHI LTD +1

Particle beam irradiation system and method of adjusting irradiation field forming apparatus

ActiveUS7049613B2Increase in sizePenumbra can be reducedElectrotherapyRadiation/particle handlingParticle beamLight beam

A particle therapy system, as one example of a particle beam irradiation system, comprises a charged particle beam generator and an irradiation field forming apparatus. An ion beam from the charged particle beam generator is irradiated to a diseased part in the body of a patient through the irradiation field forming apparatus. A scattering compensator and a range modulation wheel (RMW) are disposed on the upstream side in a direction of beam advance and are movable along a beam axis. The movement of the scattering compensator and the RMW adjusts a size of the ion beam entering a scatterer device, whereby a change in scattering intensity of the ion beam in the scatterer device is adjusted. As a result, a penumbra in dose distribution is reduced and a more uniform dose distribution in a direction perpendicular to the direction of beam advance is obtained in the diseased part.

Owner:HITACHI LTD

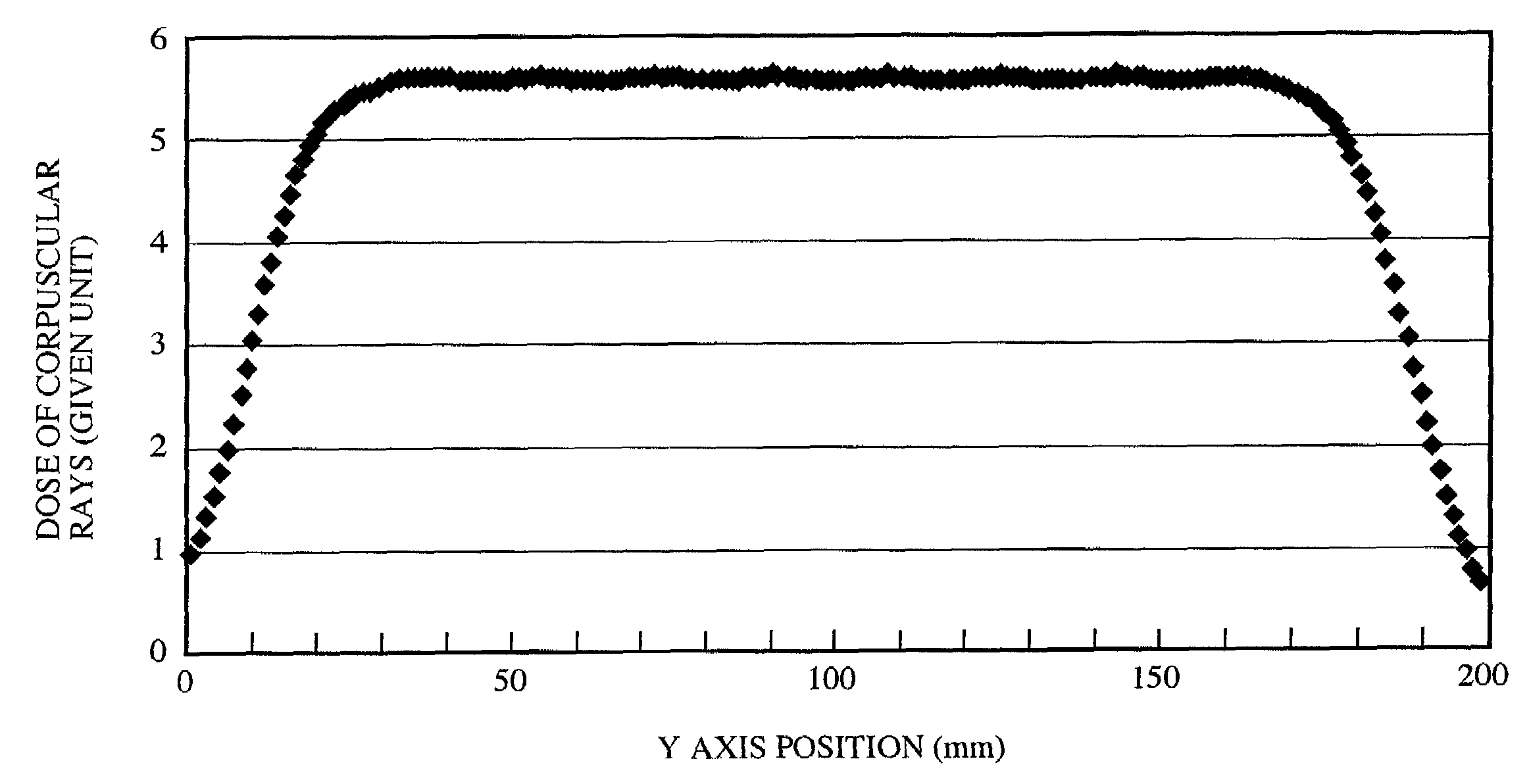

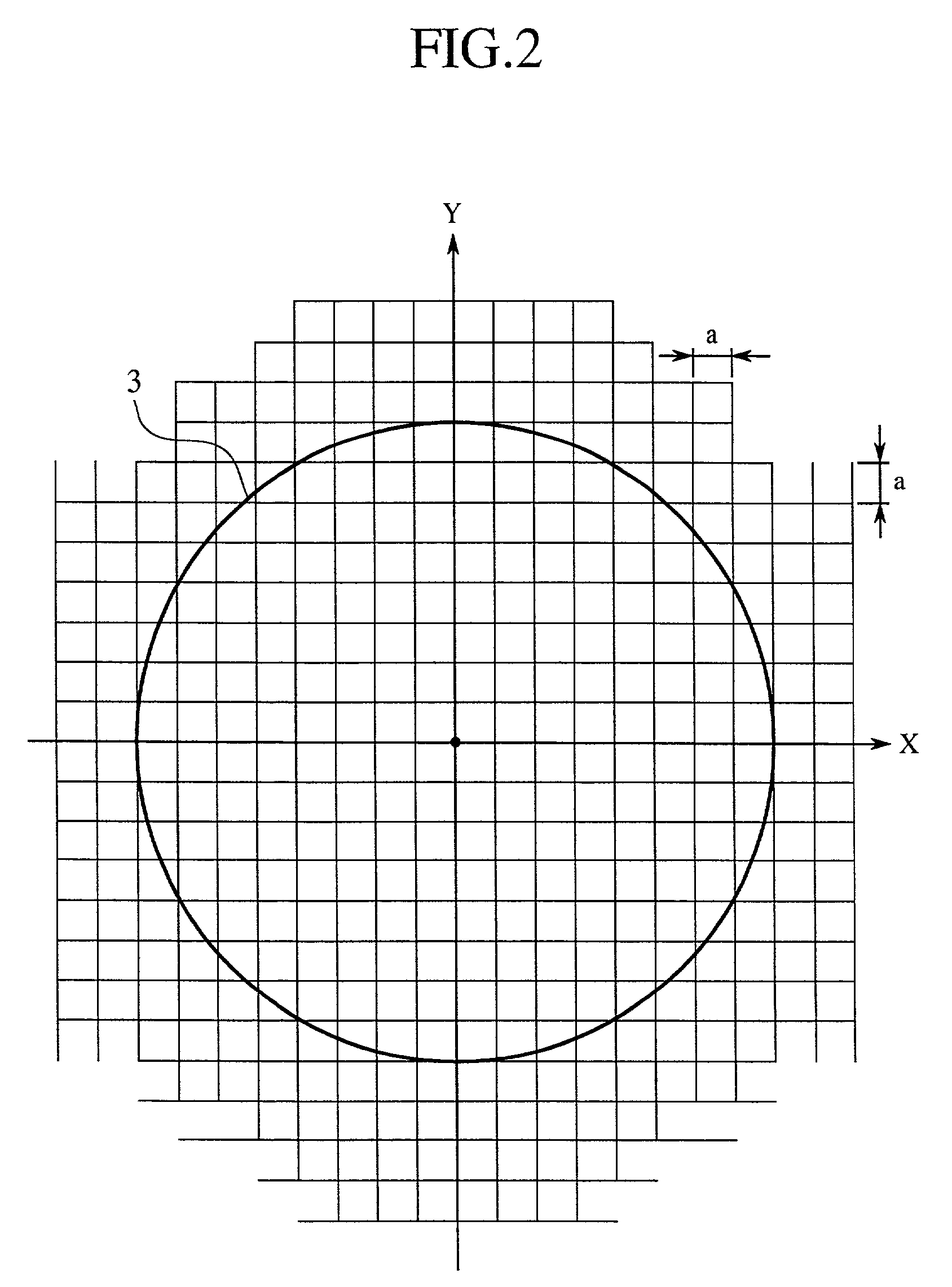

Radiation treatment plan making system and method

InactiveUS7054801B2Improve efficiencyImprove flatnessAnalogue computers for electric apparatusAnalogue computers for chemical processesParticle beamRadiation exposure

A radiation exposure region to be irradiated with particle beams and a peripheral region thereof are respectively divided into pluralities of exposure regions, radiation treatment simulation for applying particle beams according to the shape of each divided exposure region is performed, and a radiation treatment condition is obtained for causing the flatness of the radiation exposure region to be in a desired range, and a dose of particle beams applied to the unit exposure region of the peripheral region to be minimum. Thus, the problem of low efficiency of radiation is solved.

Owner:MITSUBISHI ELECTRIC CORP

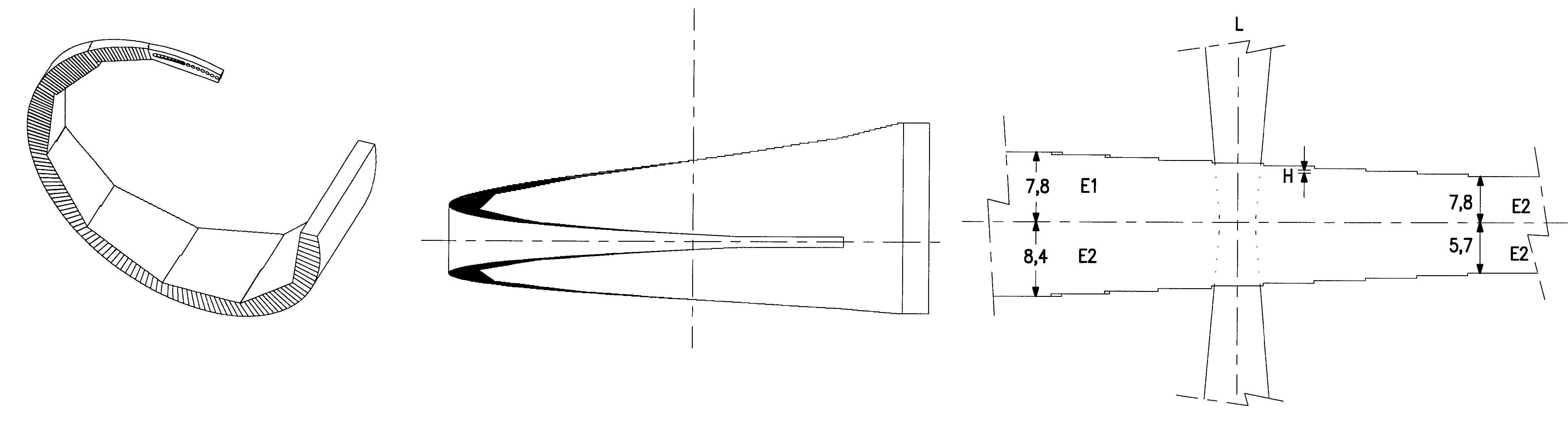

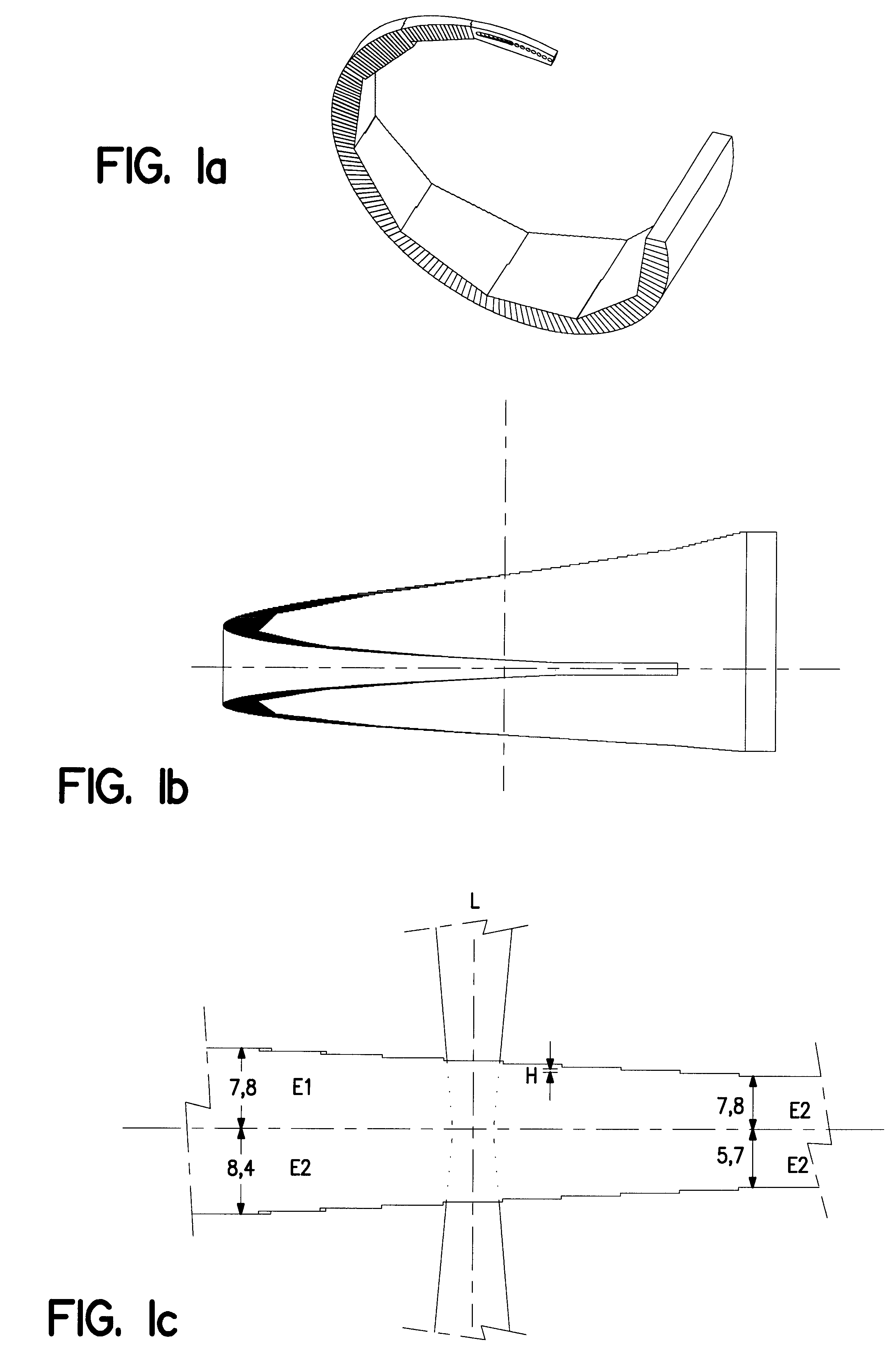

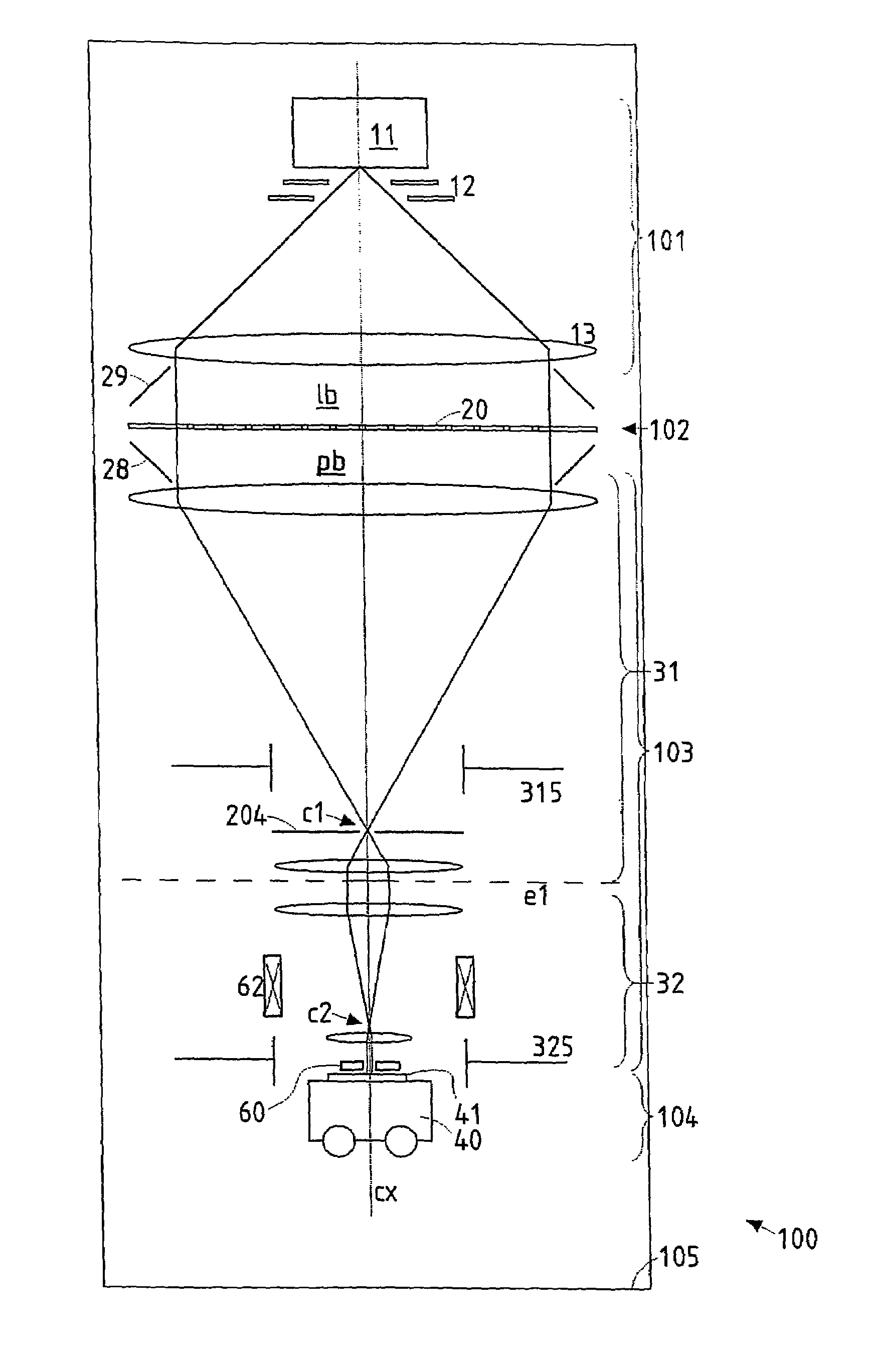

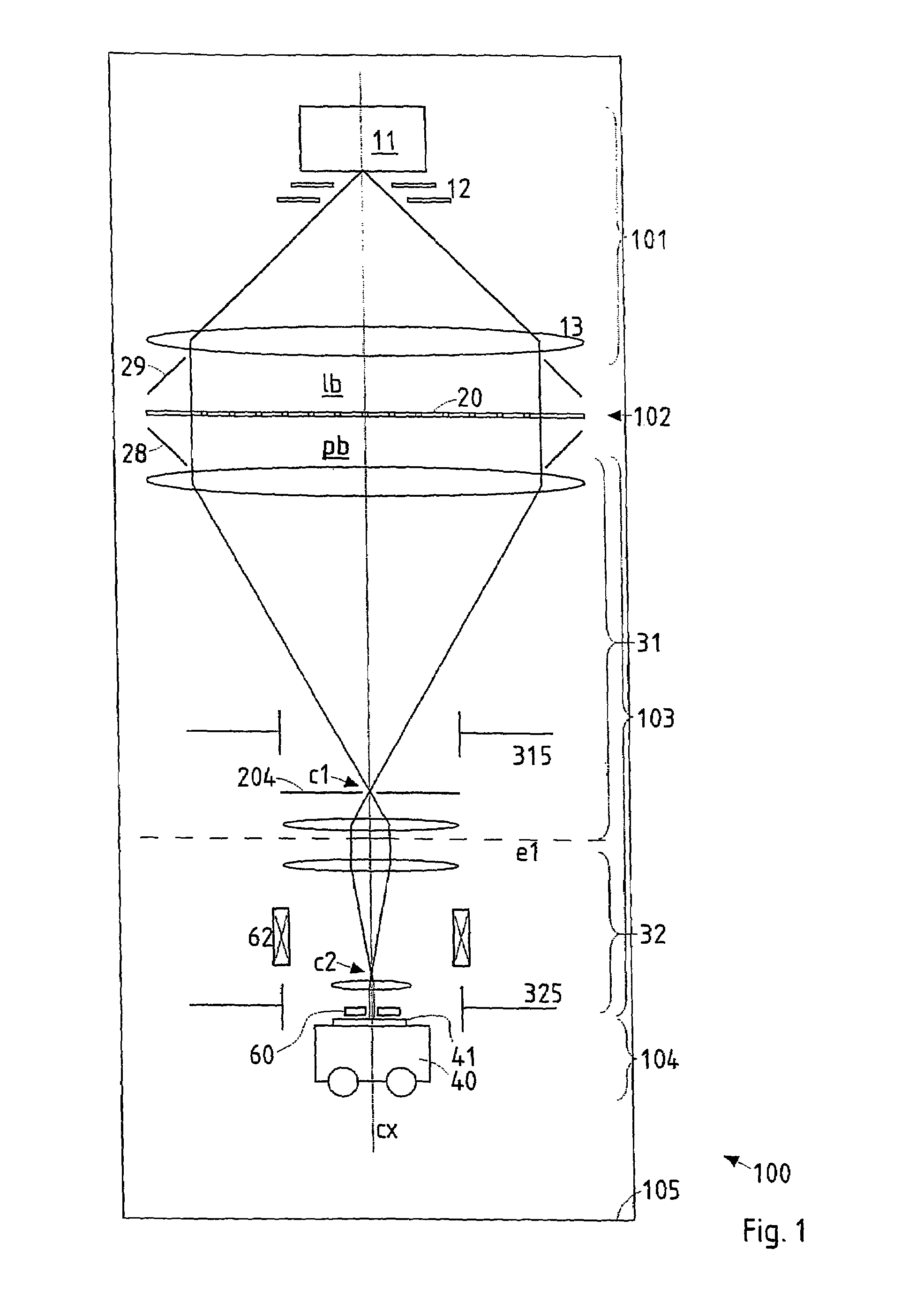

Device for varying the energy of a particle beam extracted from an accelerator

InactiveUS6433336B1Radiation/particle handlingElectrode and associated part arrangementsLower limitParticle accelerator

A device for varying the energy of a particle beam extracted from a fixed-energy particle accelerator includes a block of energy degrading material positioned in the path of the particle beam. The block of energy degrading material is preferably in the form of a ring arranged on a wheel. The ring is of a staircase configuration, having discrete steps defining a thickness between parallel entry and exit faces. According to one aspect of the invention, the block is configured so that the particle beam energy variation reaches a maximum at the edges of each step. This upper limit is also the lower limit of the next step. Thus, continuous energy variation is possible despite the fact that the thickness of the block varies in discrete steps.

Owner:ION BEAM APPL

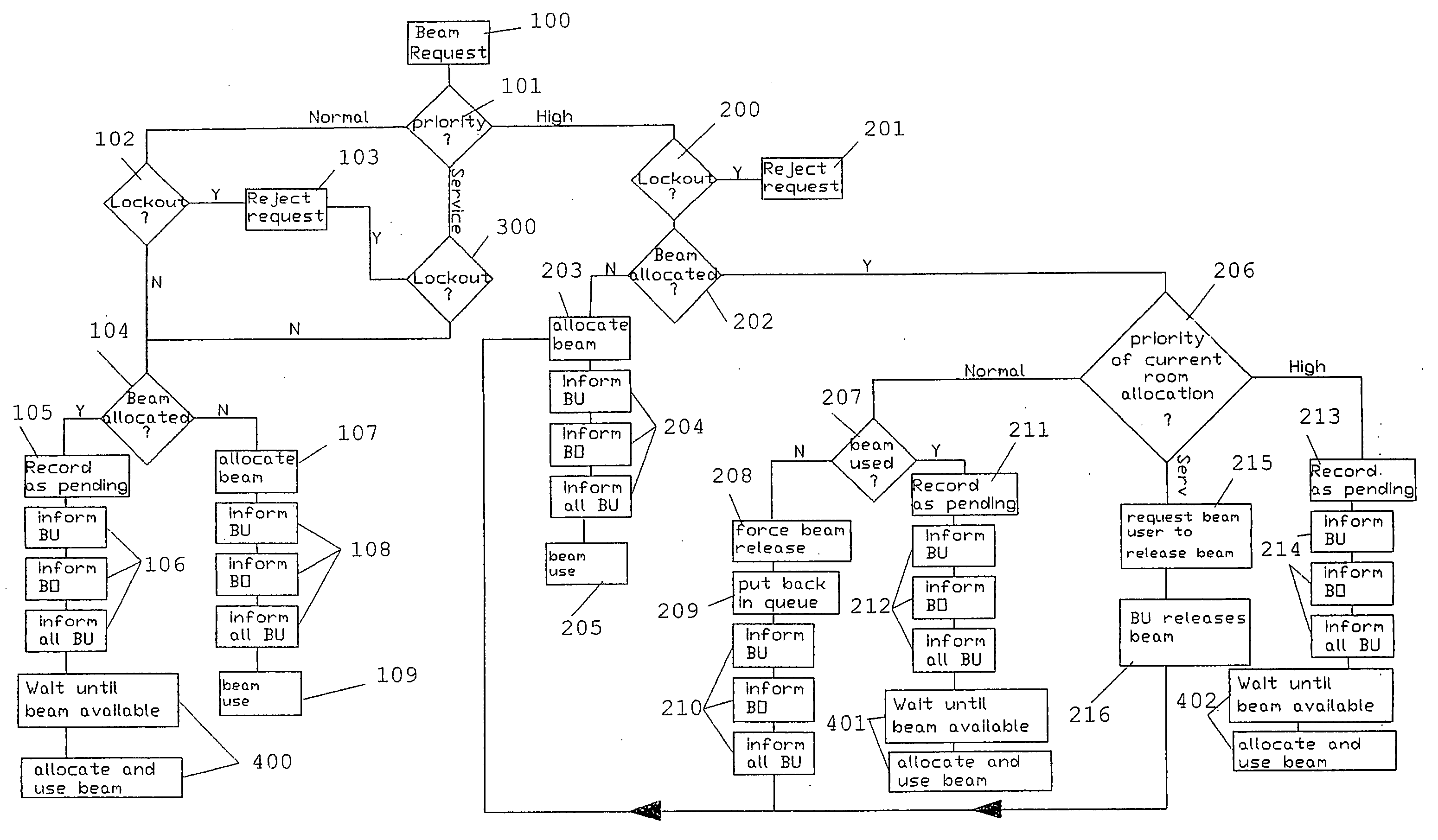

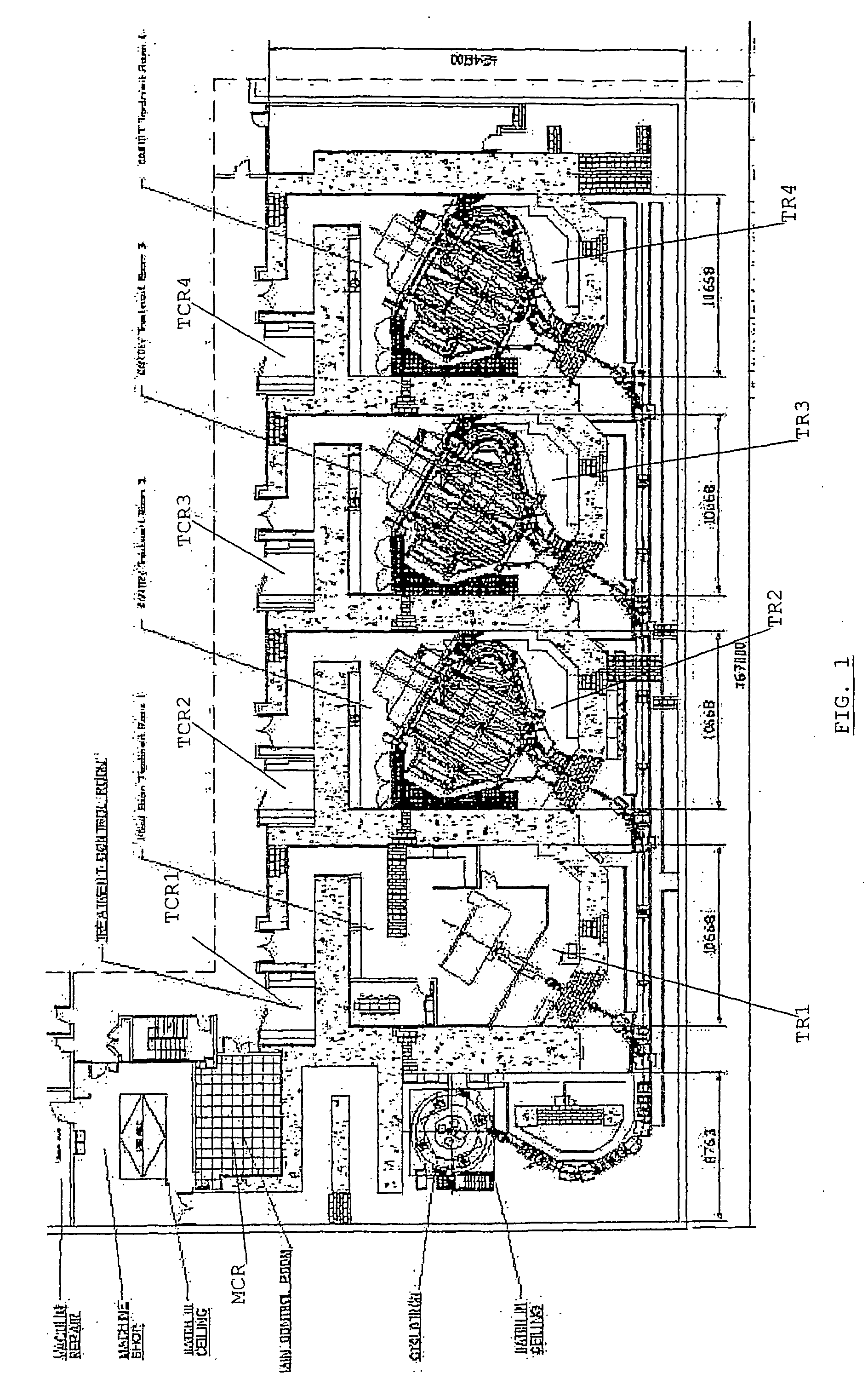

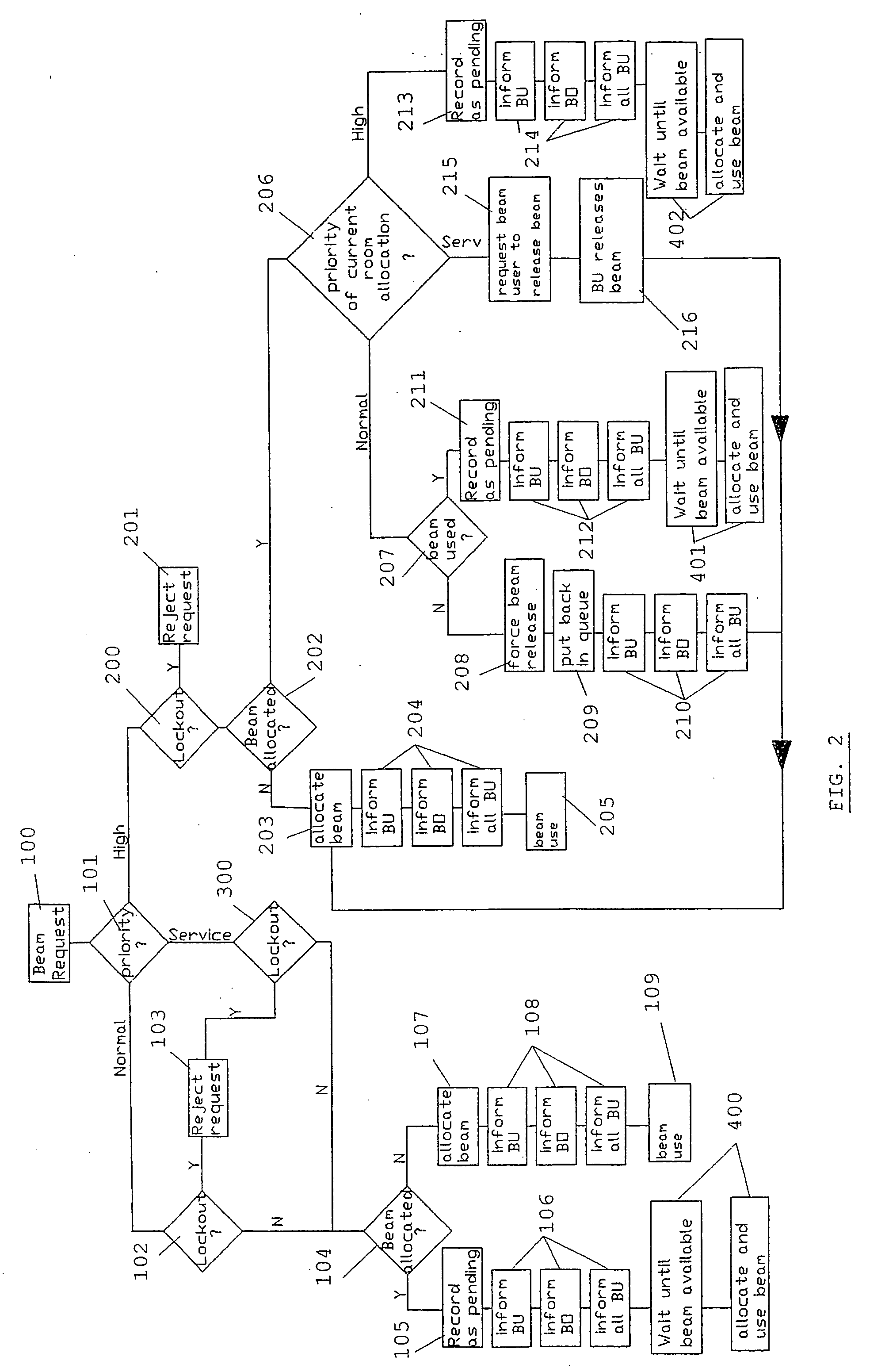

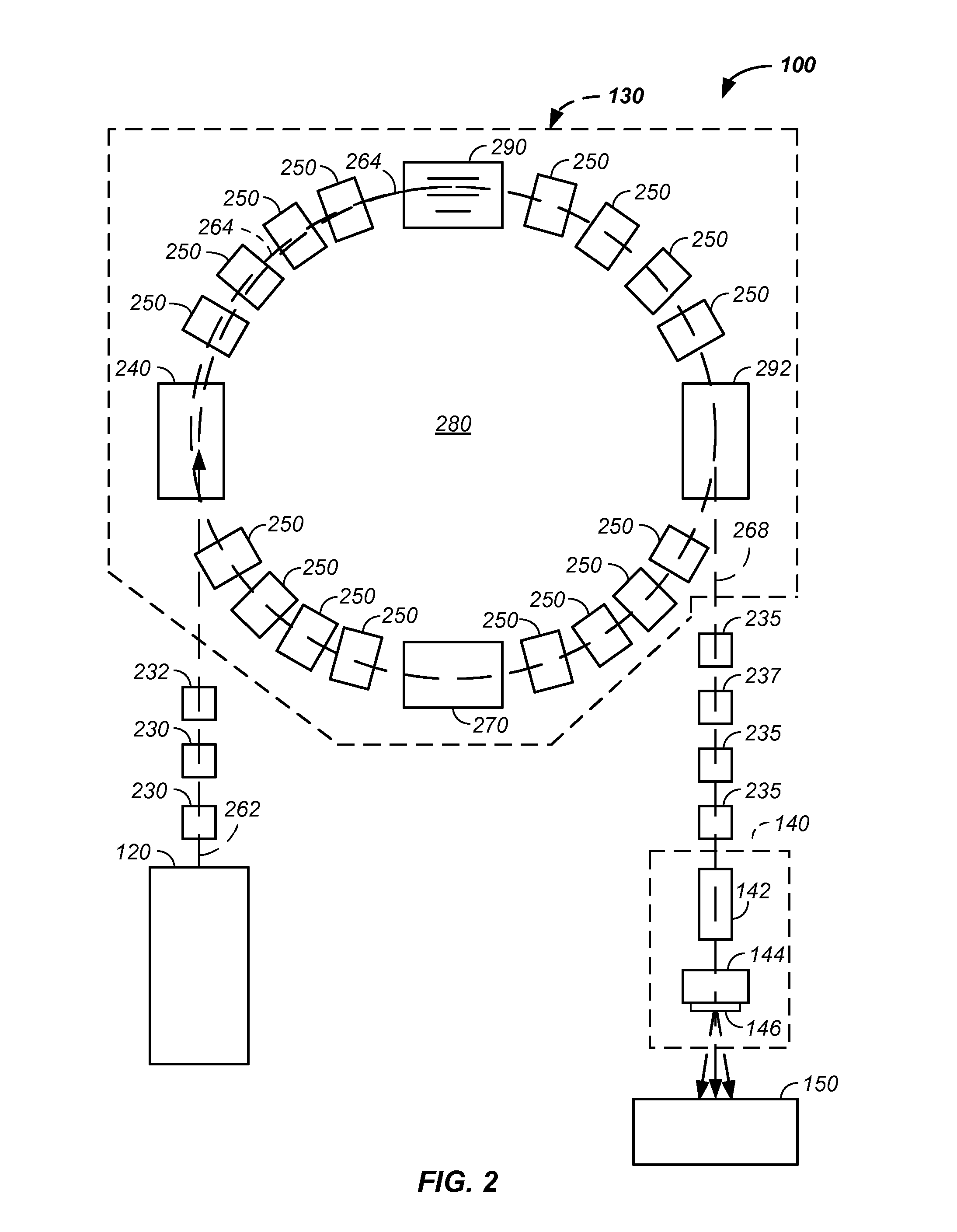

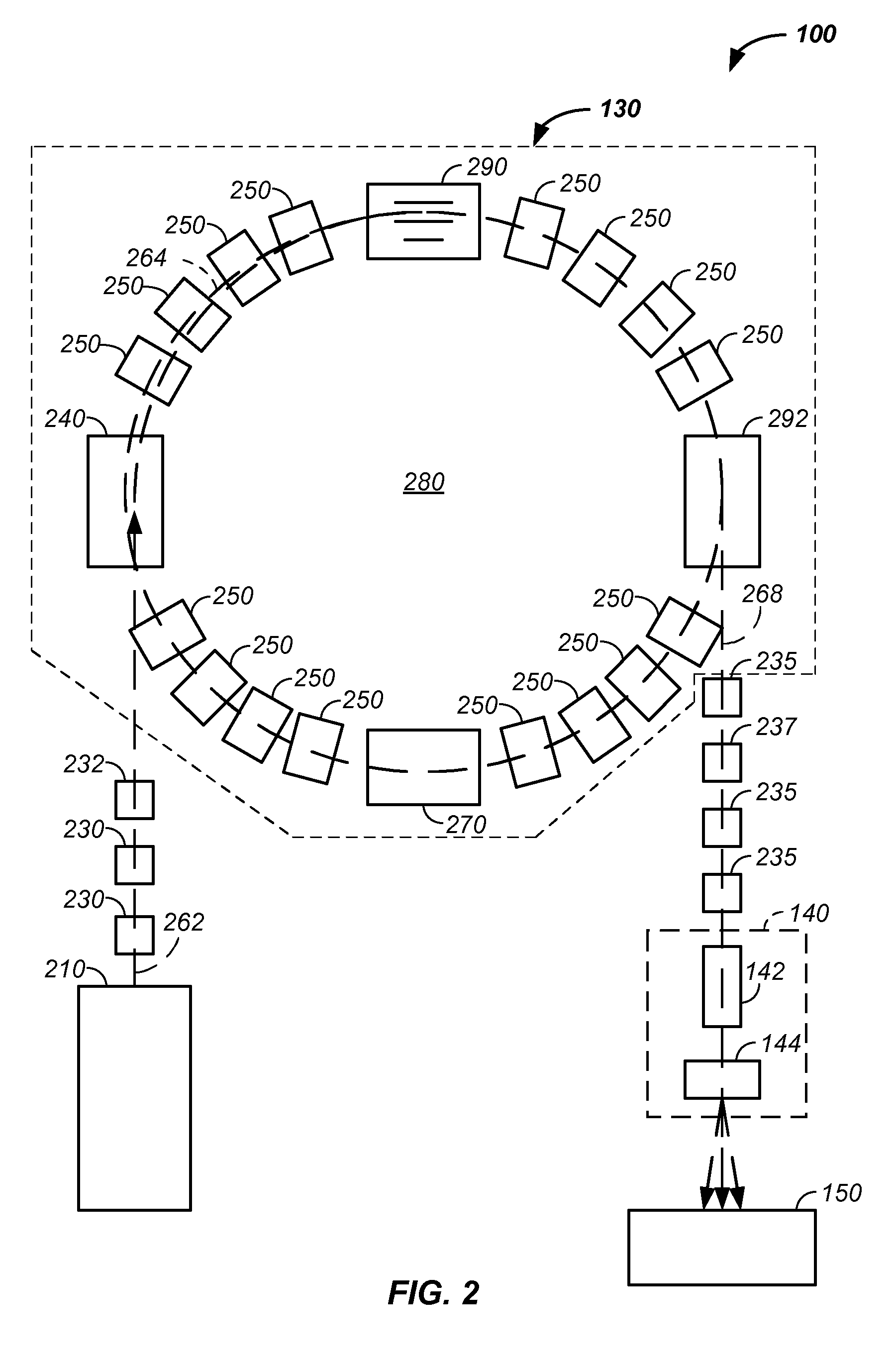

Method and system for automatic beam allocation in a multi-room particle beam treatment facility

InactiveUS20070018121A1Light therapyX-ray/gamma-ray/particle-irradiation therapyParticle beamLight beam

The present invention is related to a method and a system for automatically allocating a particle beam to one of a plurality of treatment rooms. Upon receiving a request from one of the beam users, the system checks whether the beam is available and may automatically allocate the beam to the requesting room. Otherwise, the request may be put on a waiting list of pending requests, in a position which depends on the priority level (and arrival lime) coupled to said request.

Owner:ION BEAM APPL

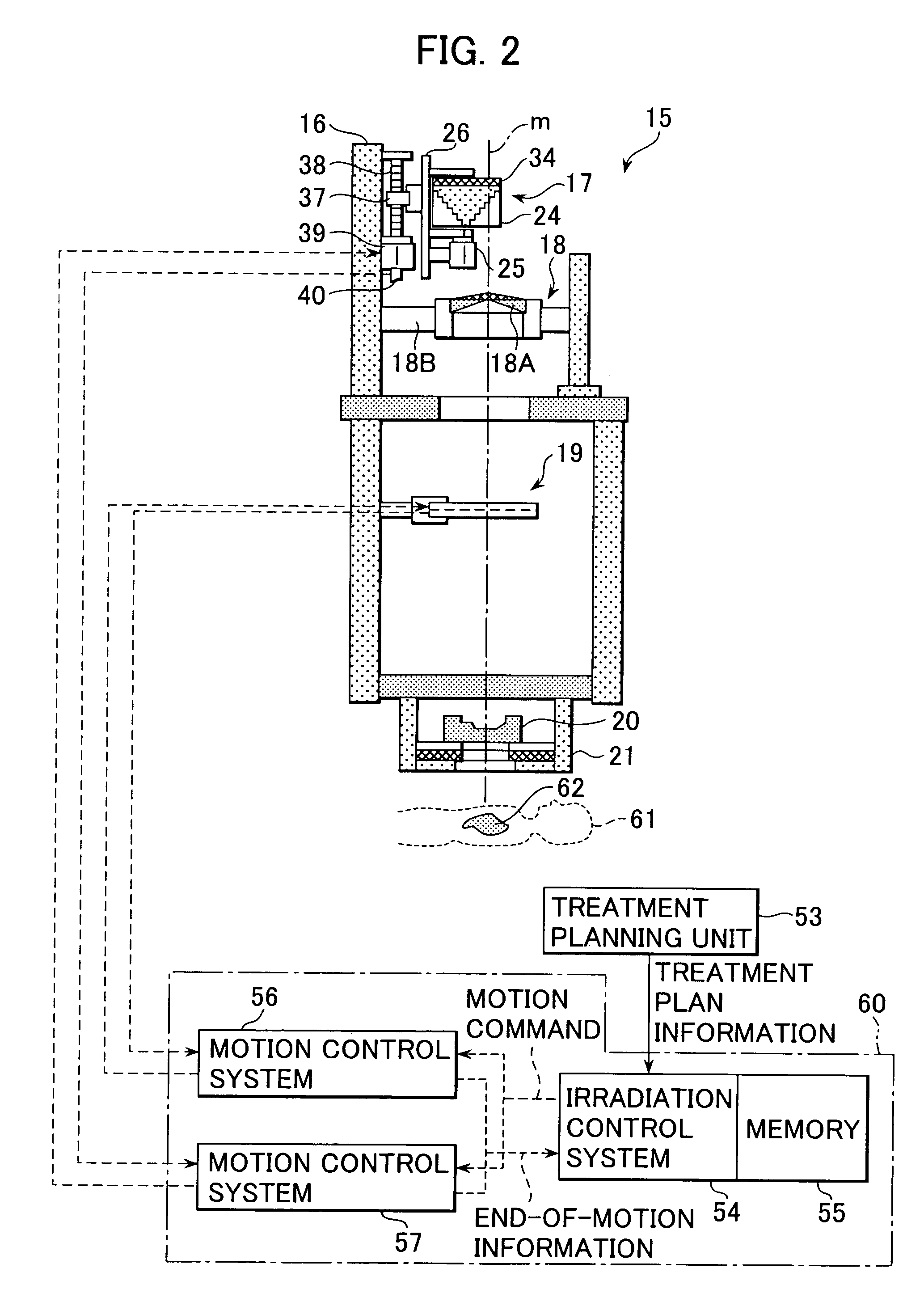

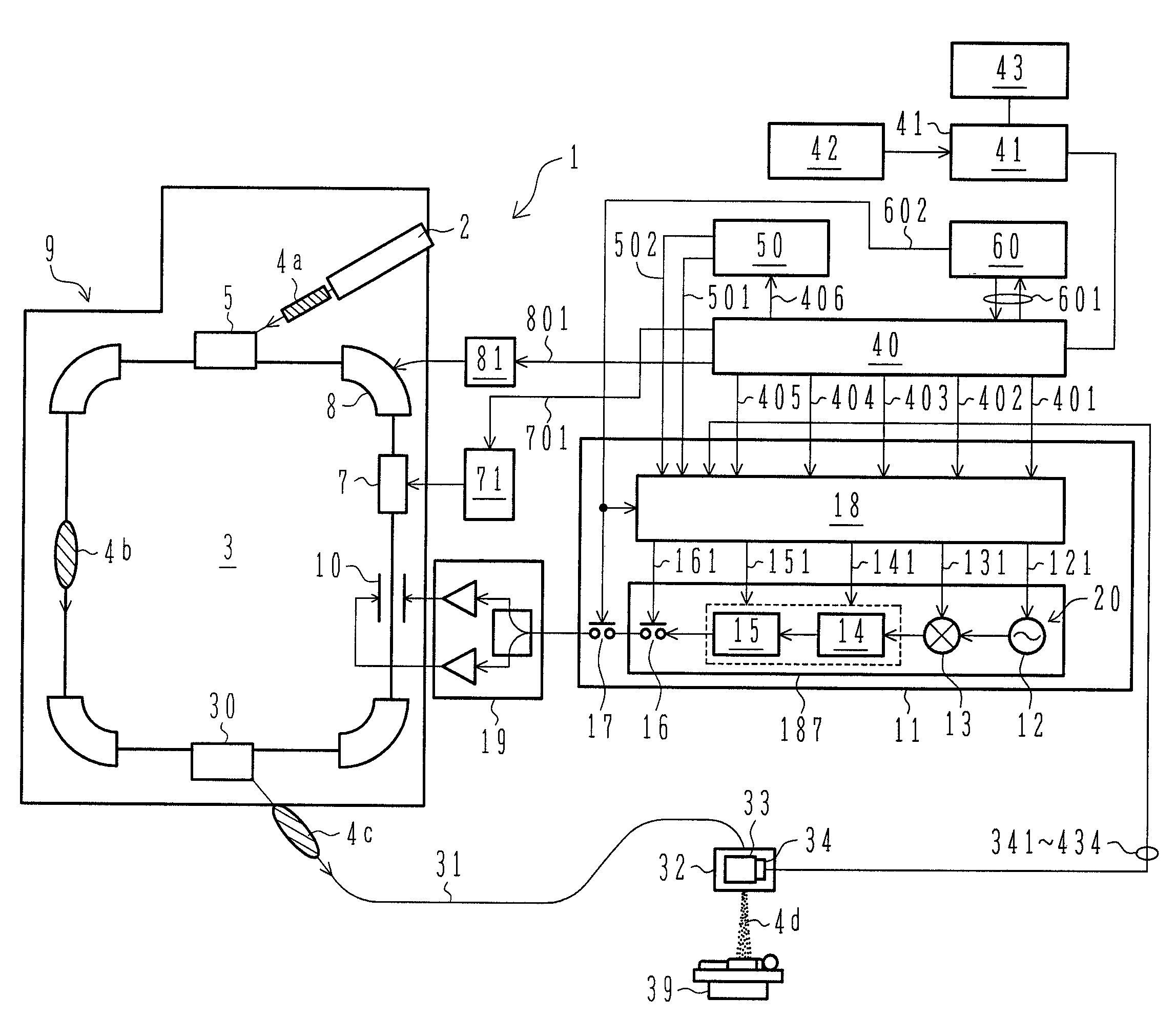

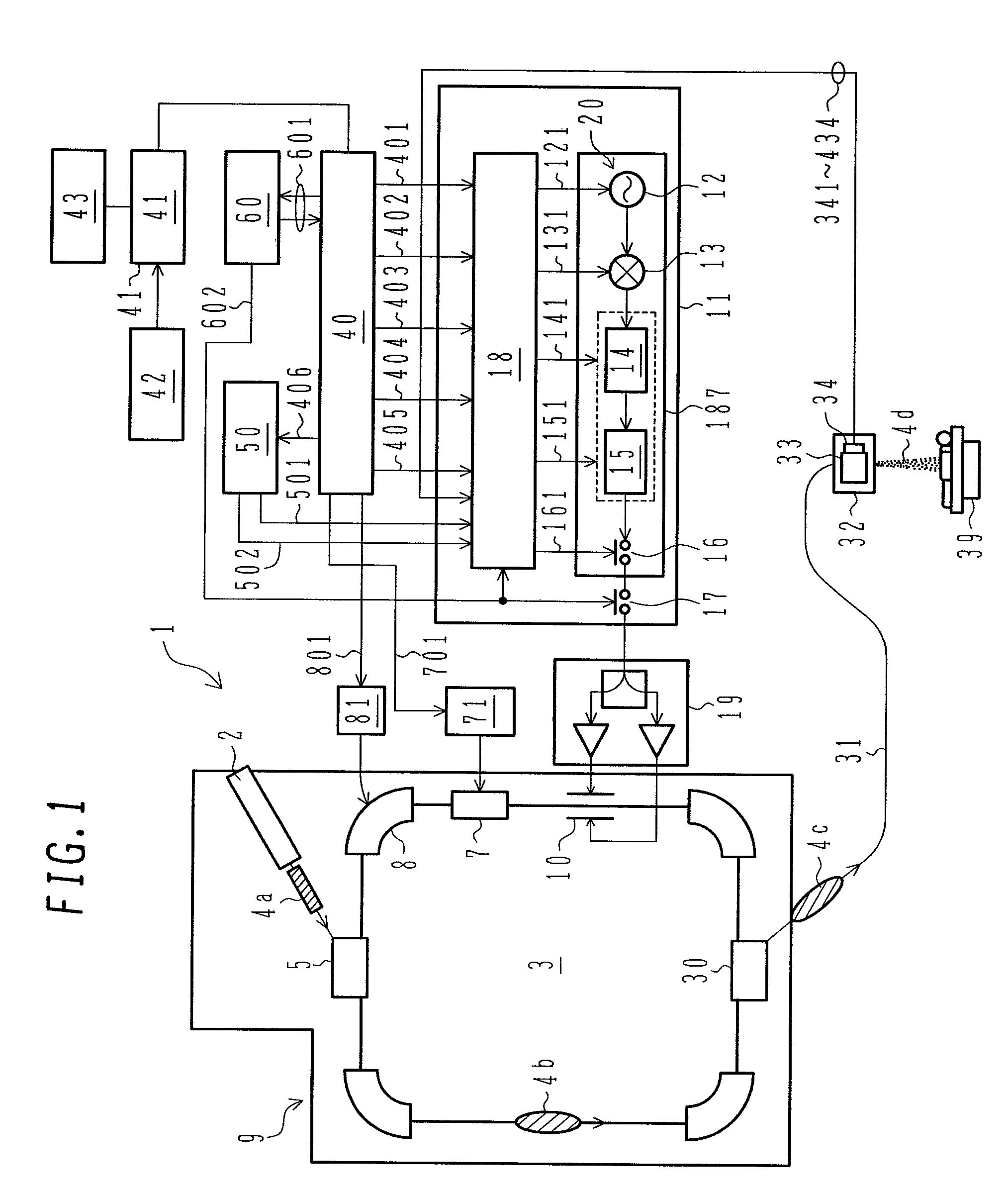

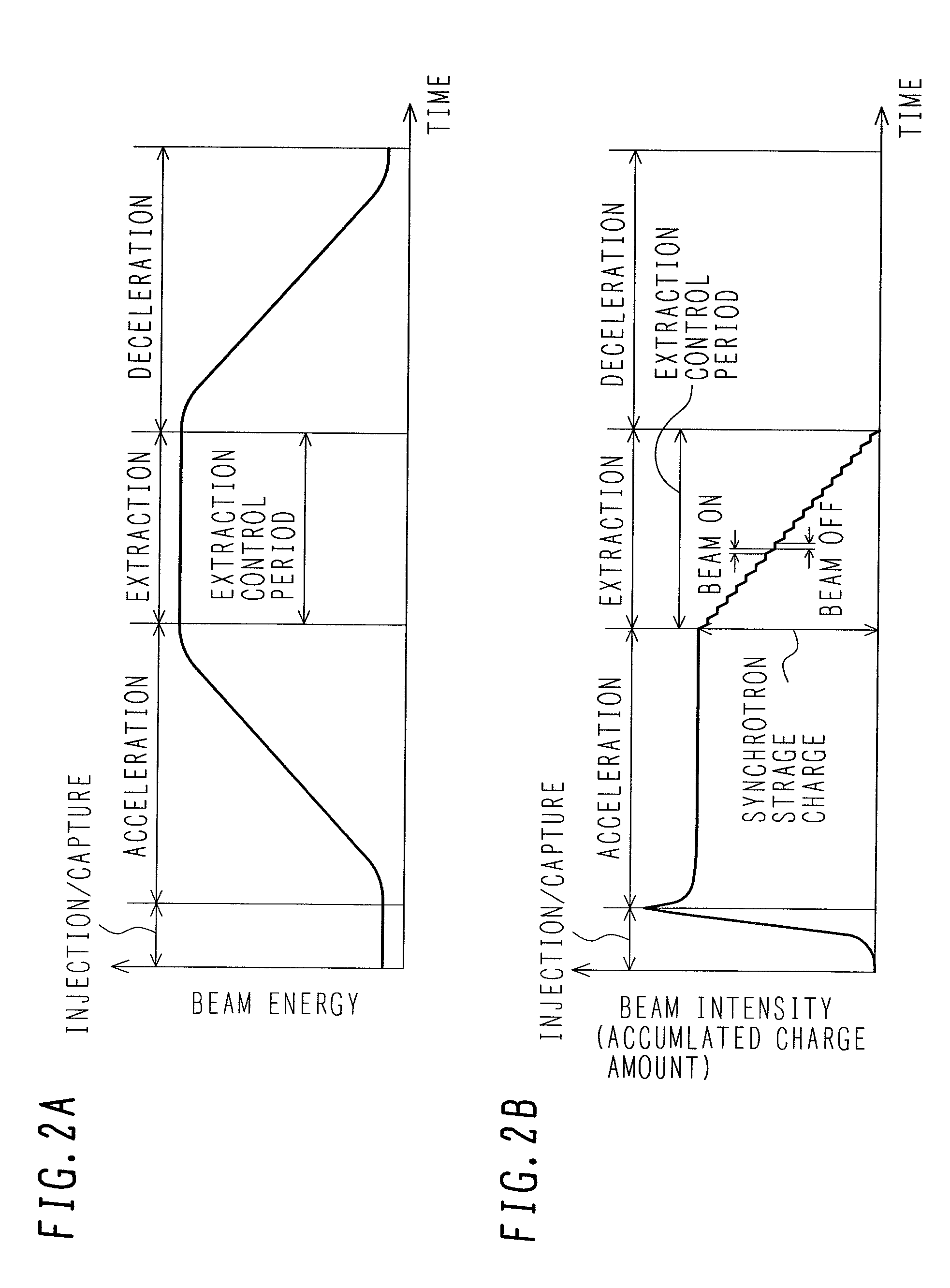

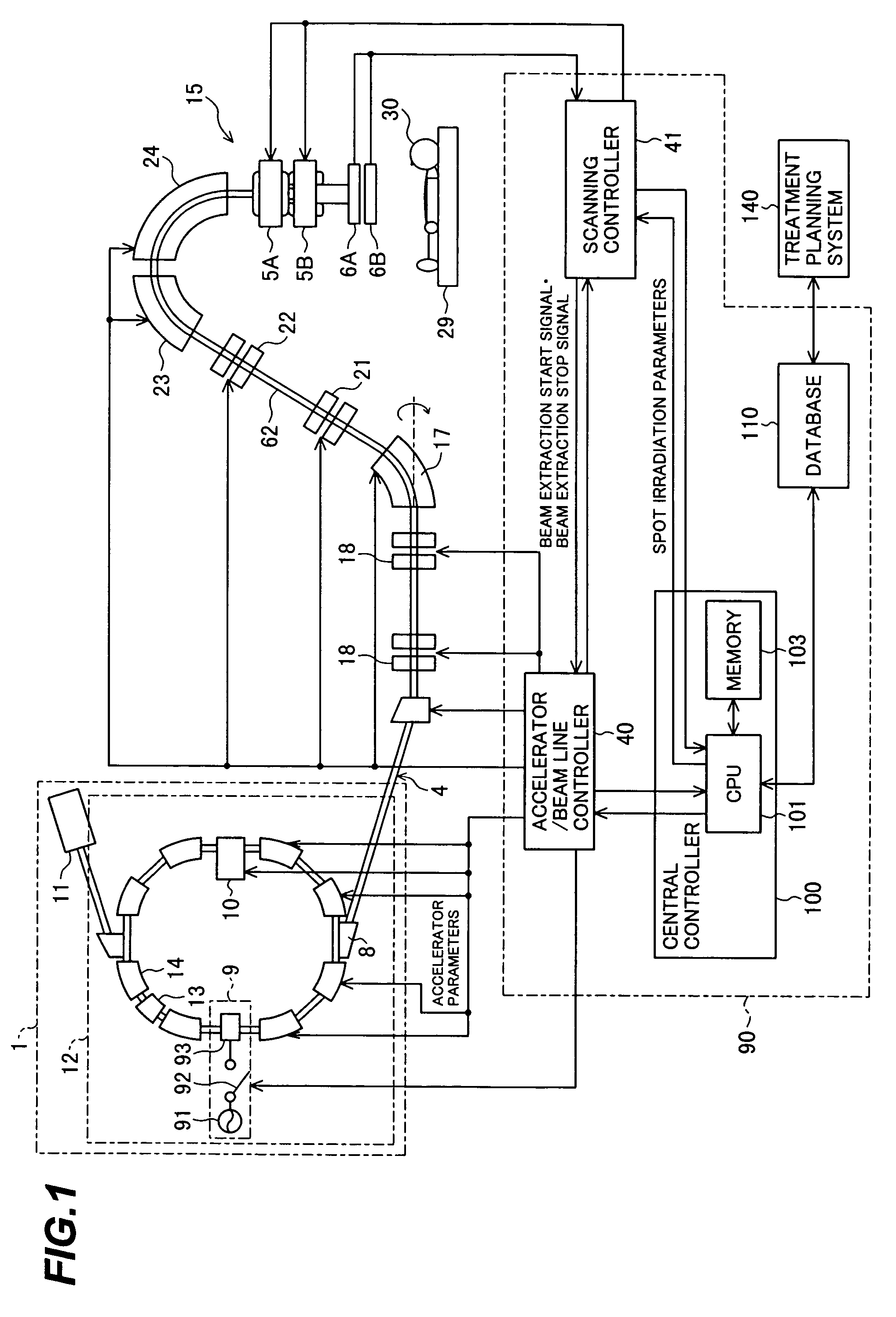

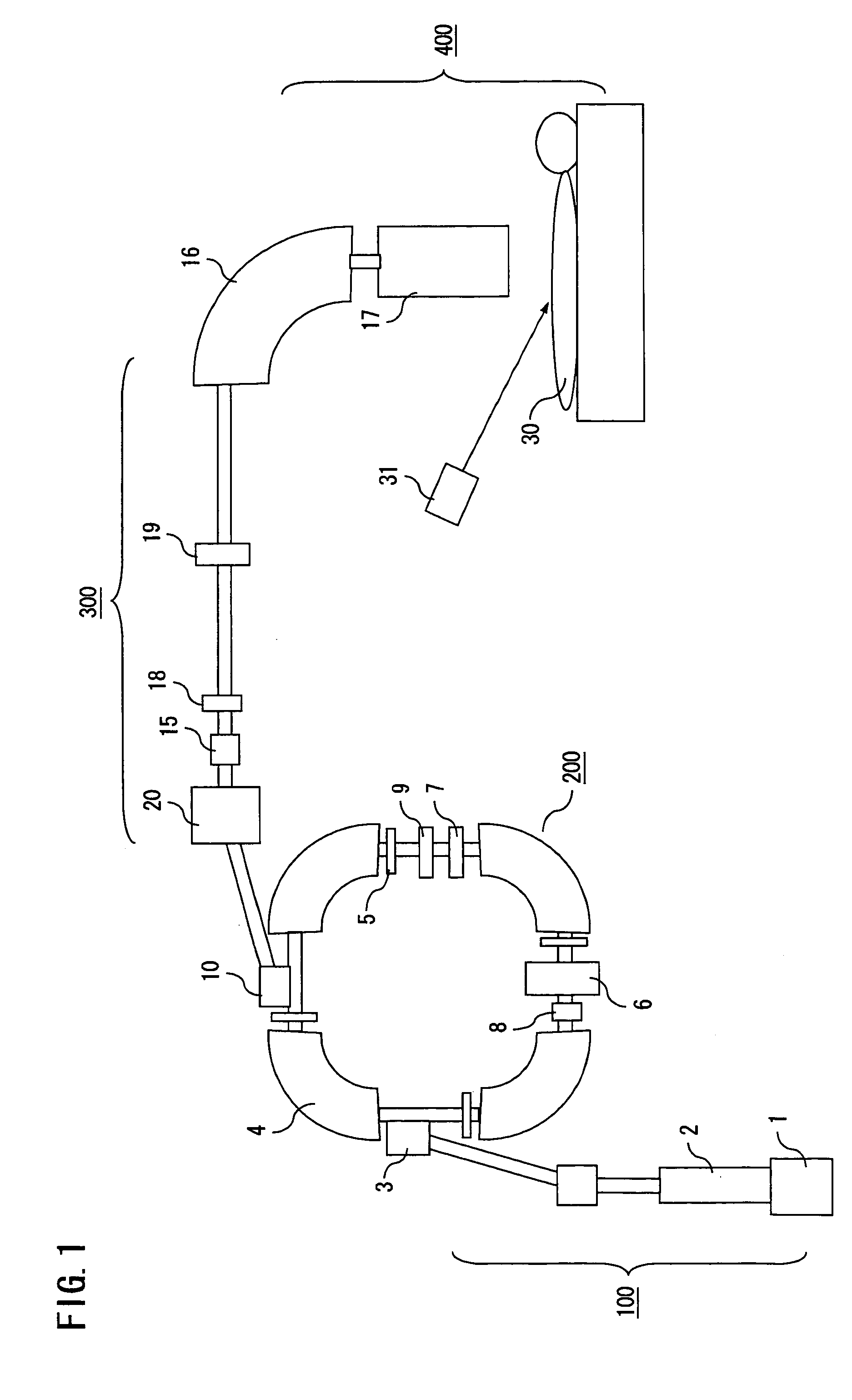

Particle beam irradiation system

ActiveUS7807982B2Simplify device configurationEasy to controlLaser detailsParticle separator tubesIntensity controlSynchrotron

It is an object of the present invention to provide a charged particle beam extraction method and particle beam irradiation system that make it possible to exercise intensity control over an extracted ion beam while a simple device configuration is employed. To accomplish the above object, there is provided a particle beam irradiation system comprising: a synchrotron for accelerating and extracting an charged particle beam; an irradiation apparatus for extracting the charged particle beam that is extracted from the synchrotron; first beam intensity modulation means for controlling the beam intensity of the charged particle beam extracted from the synchrotron during an extraction control period of an operation cycle of the synchrotron; and second beam intensity modulation means for controlling the beam intensity during each of a plurality of irradiation periods contained in the extraction control period of the operation cycle.

Owner:HITACHI LTD

Particle beam irradiation system

ActiveUS7301162B2Minimize exposureUniform dose distributionMaterial analysis using wave/particle radiationRadiation/particle handlingParticle beamLight beam

A particle beam irradiation system capable of ensuring a more uniform dose distribution at an irradiation object even when a certain time is required from output of a beam extraction stop signal to the time when extraction of a charged particle beam from an accelerator is actually stopped. The particle beam irradiation system comprises a synchrotron, an irradiation device including scanning magnets and outputting an ion beam extracted from the synchrotron, and a control unit. The control unit stops the output of the ion beam from the irradiation device in accordance with the beam extraction stop signal, controls the scanning magnets to change an exposure position in a state in which the output of the ion beam is stopped, and after the change of the exposure position, starts the output of the ion beam from the irradiation device again. The control unit further outputs a next beam extraction stop signal when an increment of dose integrated from the time of a preceding beam extraction stop signal as a start point reaches a setting dose stored in advance.

Owner:HITACHI LTD

Particle beam processing system

InactiveUS6838676B1Decreased beam sizeLow costStability-of-path spectrometersMaterial analysis by optical meansParticle beamParticle physics

A method for slowing and controlling a beam of charged particles includes the steps of superimposing at least one magnetic field on a mass and passing the beam through the mass and at least one magnetic field such that the beam and the mass slows but does not stop the particles. An apparatus for slowing and controlling a beam of charged particles includes a bending magnetic field superimposed on a focusing magnetic field within a mass.

Owner:HBAR TECH LC

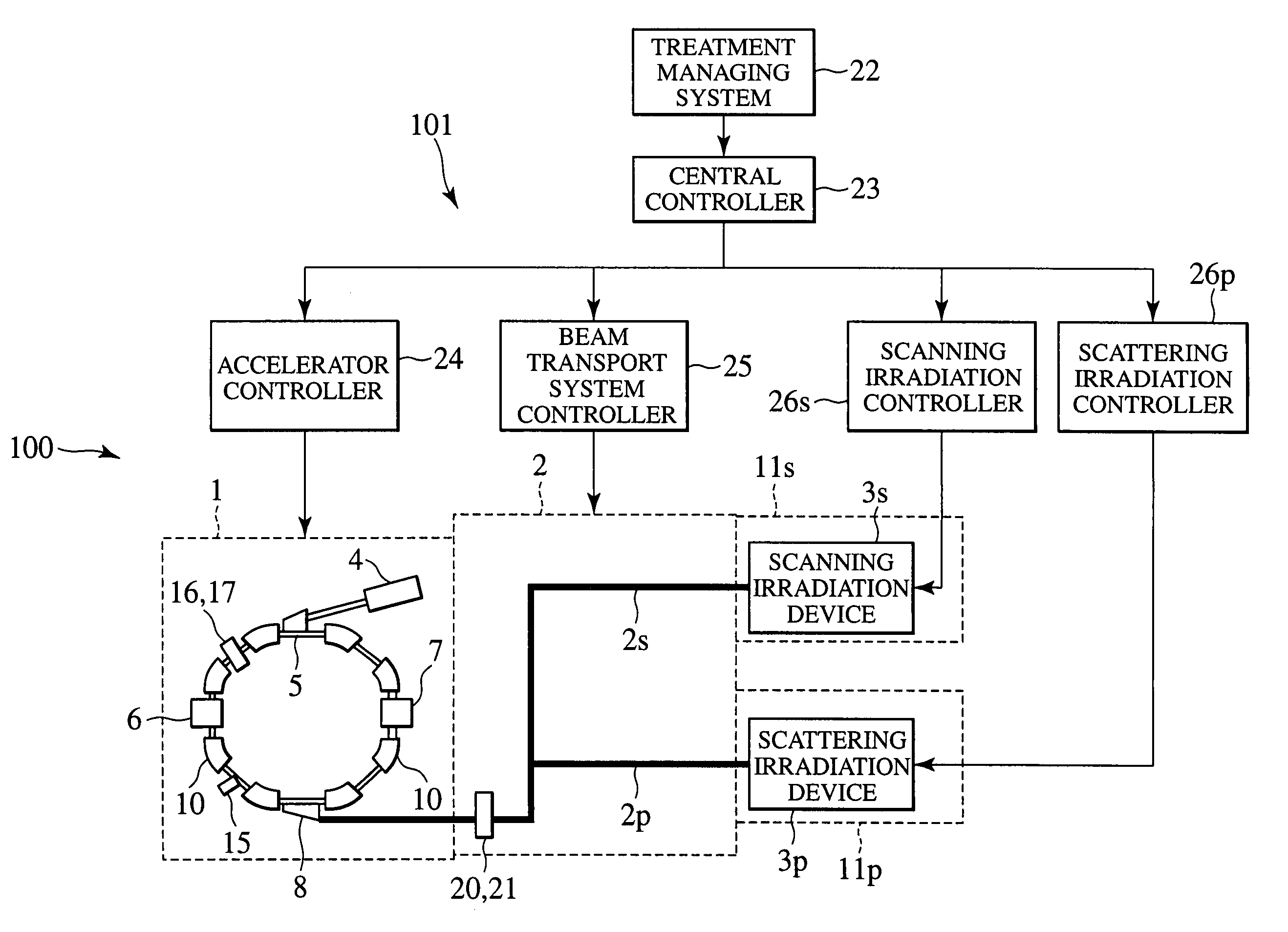

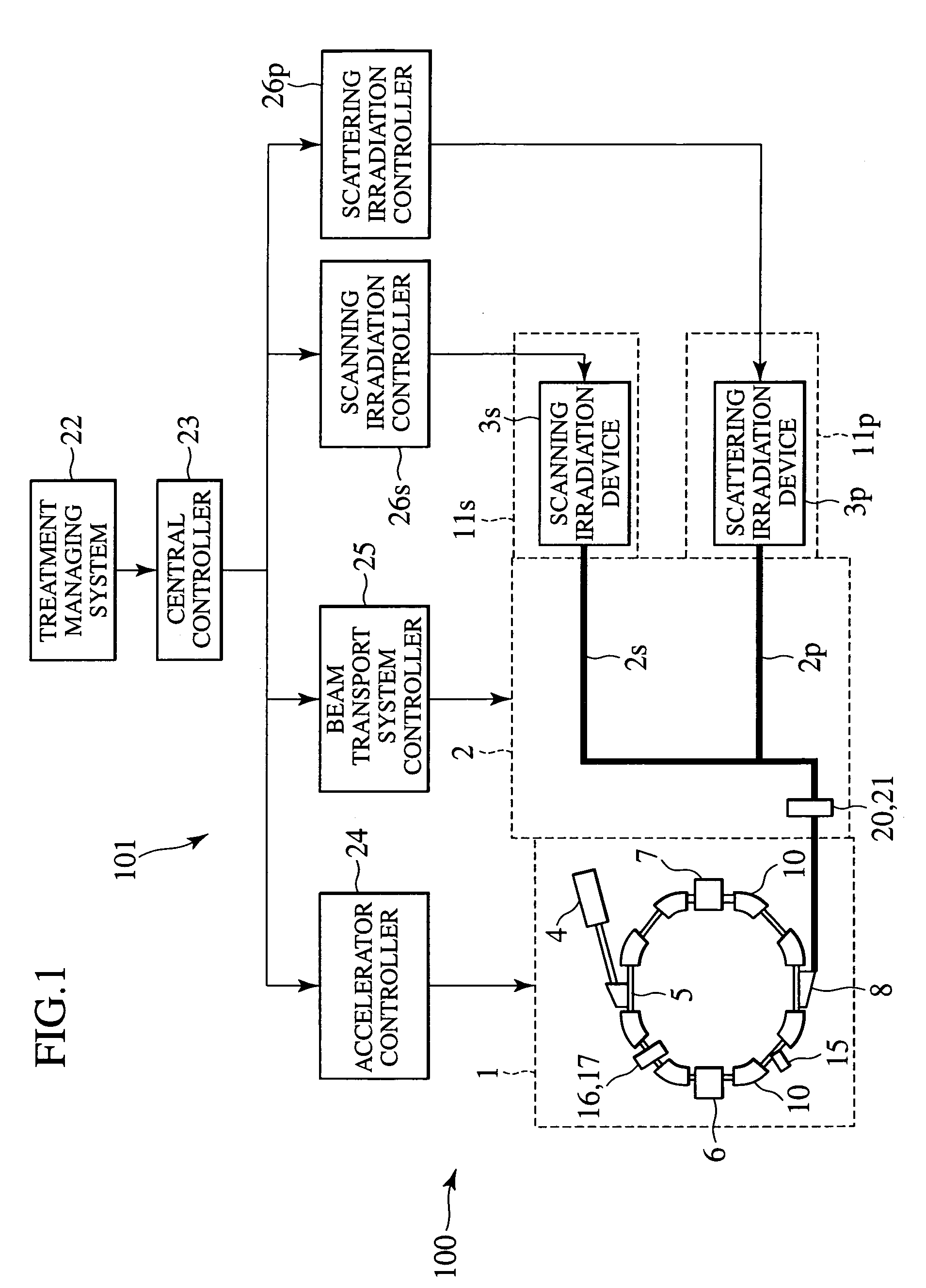

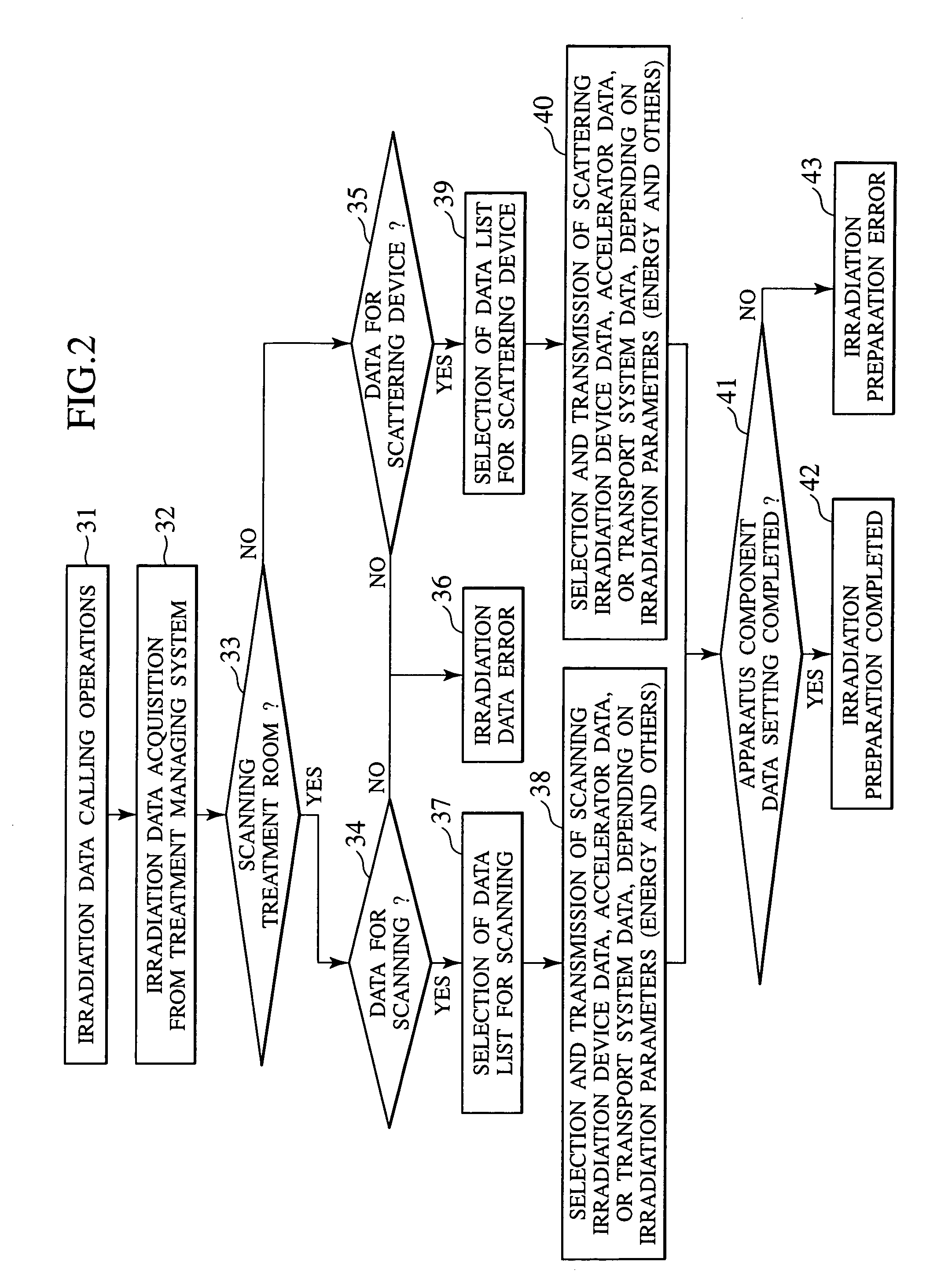

Particle beam irradiation apparatus and particle beam irradiation method

ActiveUS7709818B2Guaranteed accuracyAccurate judgmentThermometer detailsBeam/ray focussing/reflecting arrangementsTransport systemParticle beam

To ensure irradiation accuracy and safety, even when an irradiation device employing a different irradiation method is used, disclosed is herein a charged particle beam irradiation apparatus that irradiates an irradiation target with charged particle beams includes:a charged particle beam generator for generating the charged particle beams; a passive scattering irradiation device and a scanning irradiation device, both for irradiating the irradiation target with the charged particle beams; a beam transport system for transporting the charged particles beam extracted from the charged particle beam generator, to selected one of the two irradiation devices; and a central controller that modifies operating parameters on the charged particle beam generator, according to the irradiation method adopted for the selected irradiation device.

Owner:HITACHI LTD

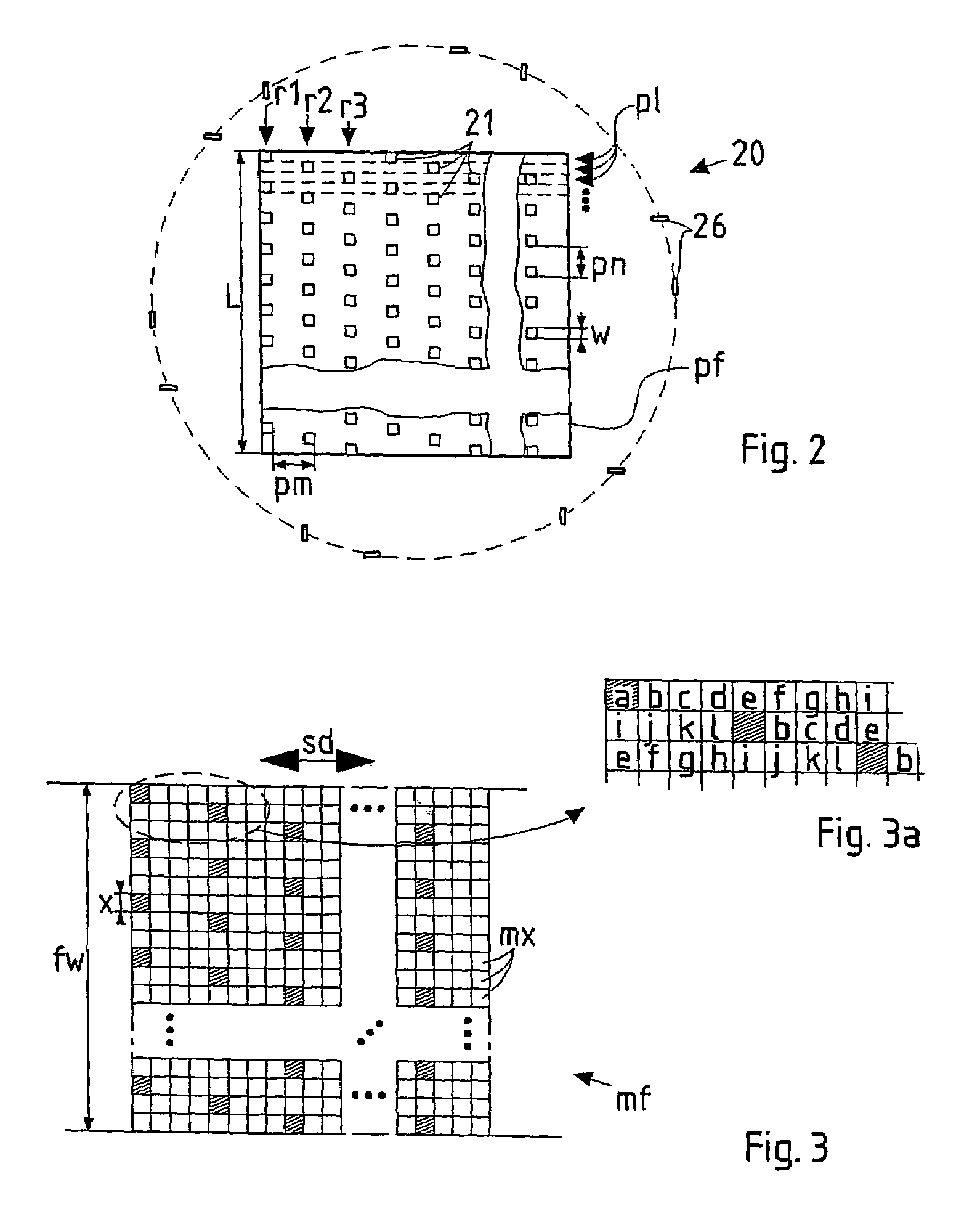

Advanced pattern definition for particle-beam processing

ActiveUS7276714B2High resolutionReduce roughnessElectric discharge tubesNanoinformaticsParticle beamMechanical engineering

In a pattern definition device for use in a particle-beam processing apparatus a plurality of apertures (21) are arranged within a pattern definition field (pf) wherein the positions of the apertures (21) in the pattern definition field (pf) taken with respect to a direction (X, Y) perpendicular, or parallel, to the scanning direction are offset to each other by not only multiple integers of the effective width (w) of an aperture taken along said direction, but also multiple integers of an integer fraction of said effective width. The pattern definition field (pf) may be segmented into several domains (D) composed of a many staggered lines (pl) of apertures; along the direction perpendicular to the scanning direction, the apertures of a domain are offset to each other by multiple integers of the effective width (w), whereas the offsets of apertures of different domains are integer fractions of that width.

Owner:IMS NANOFABTION

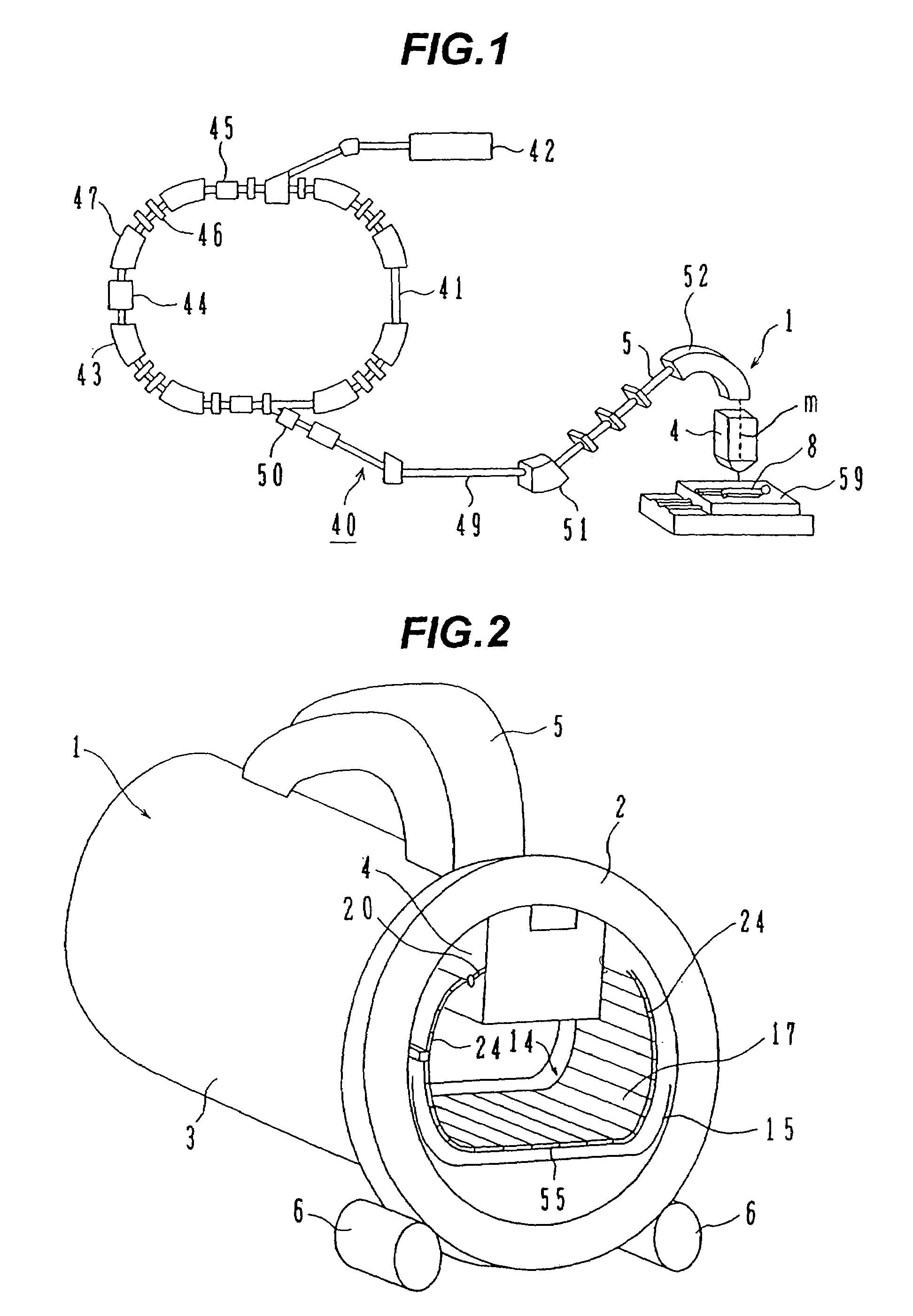

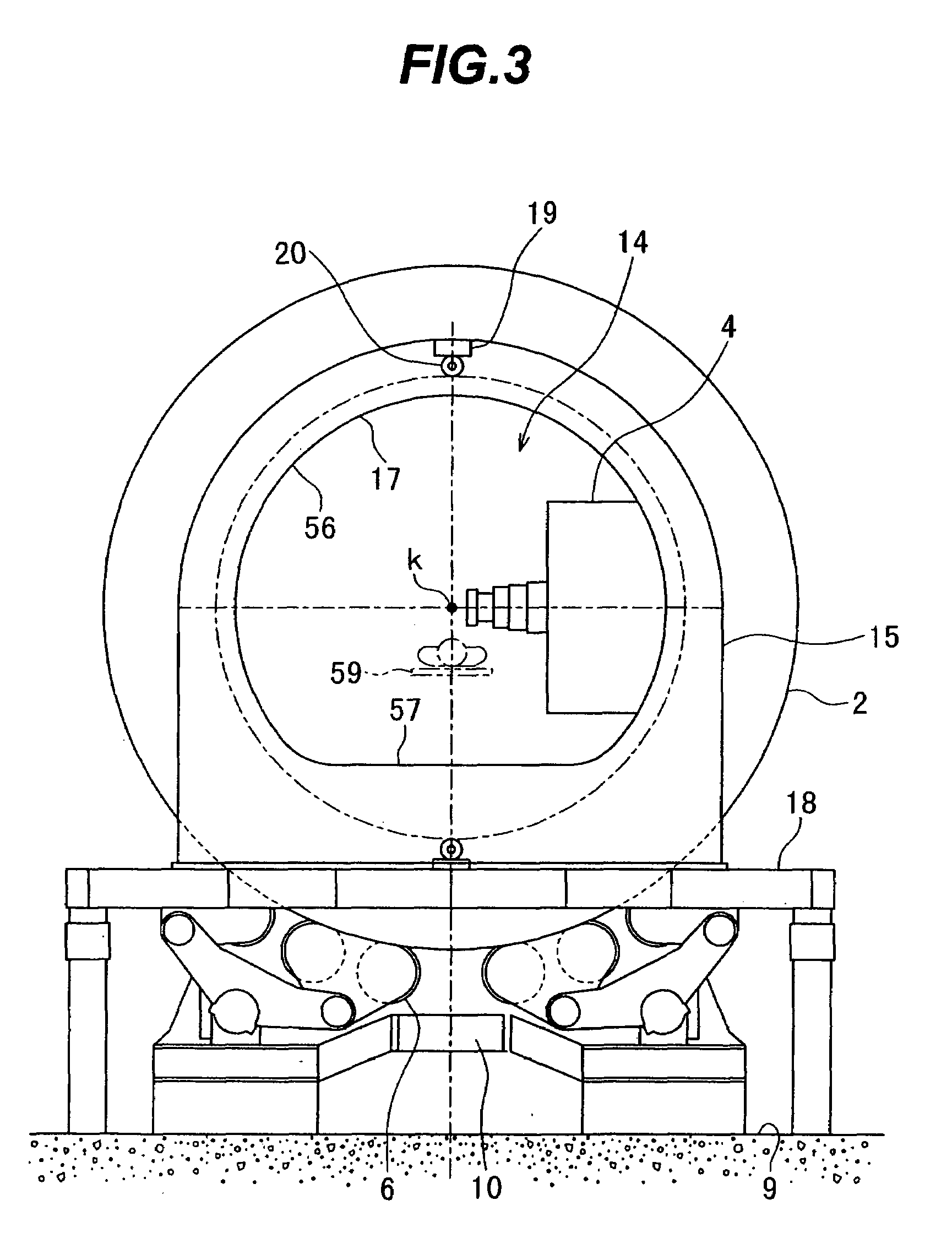

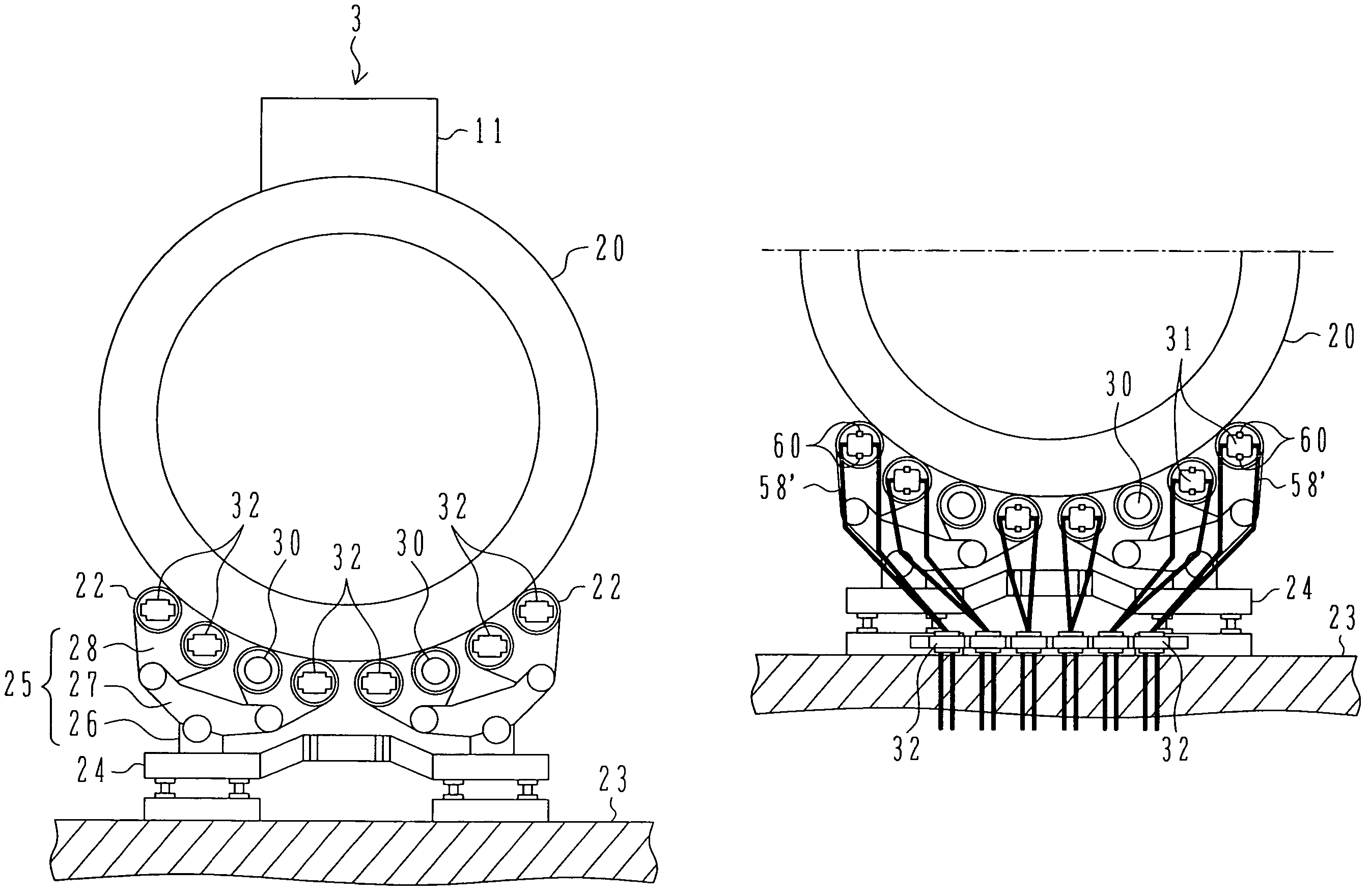

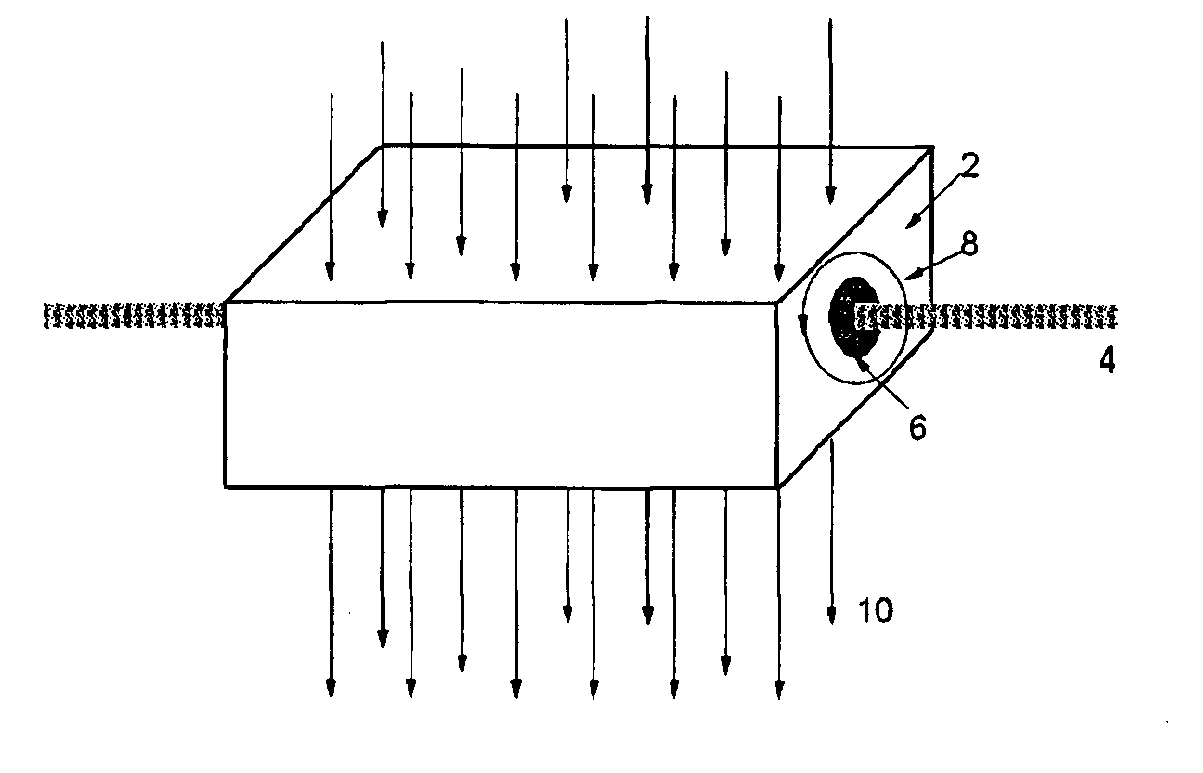

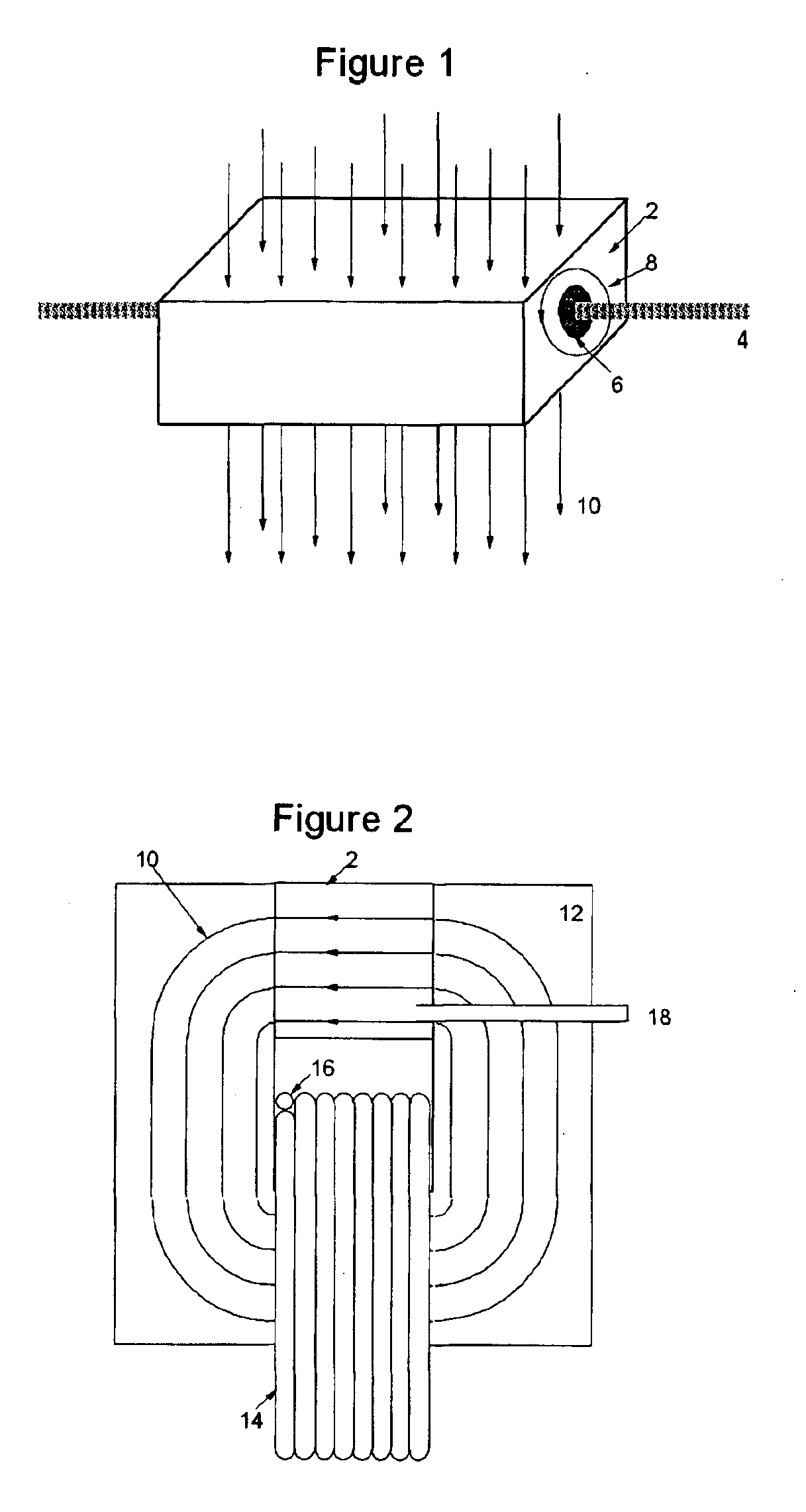

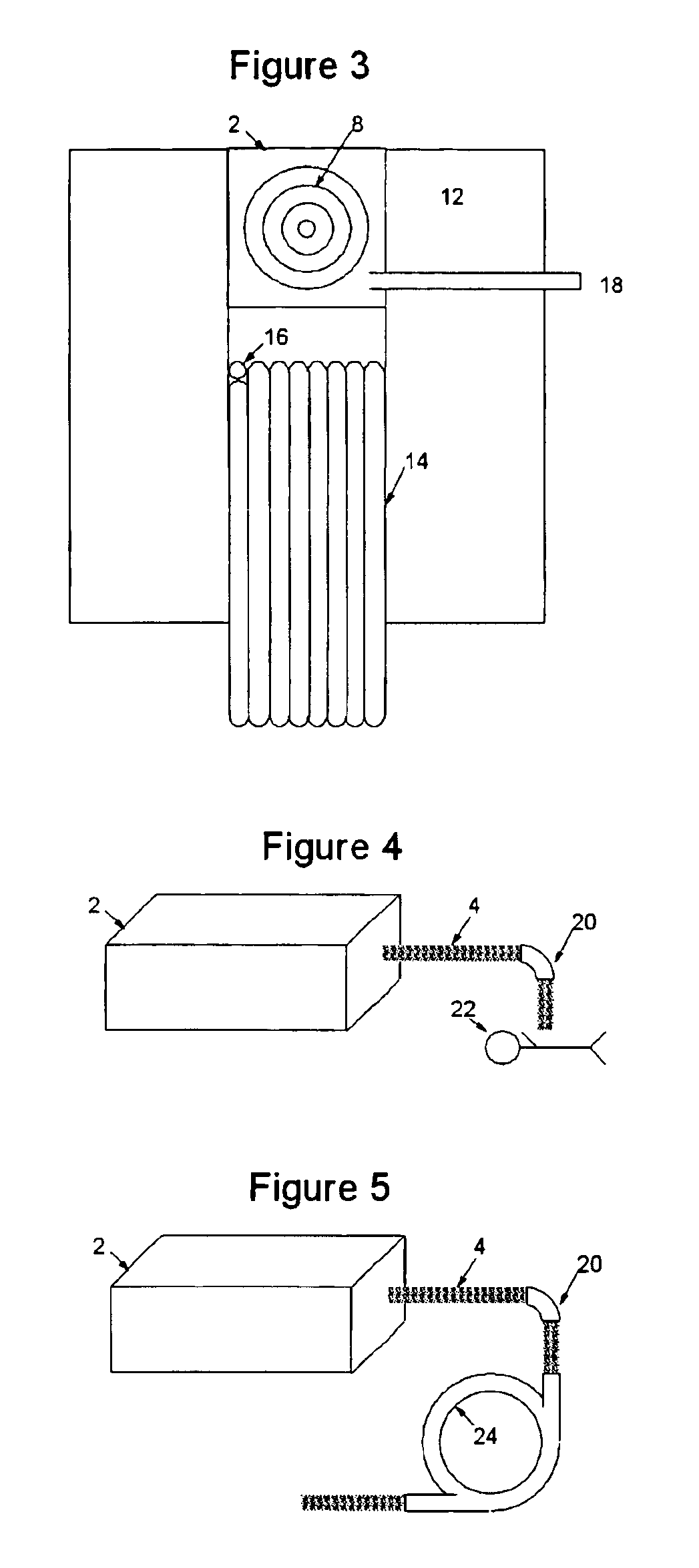

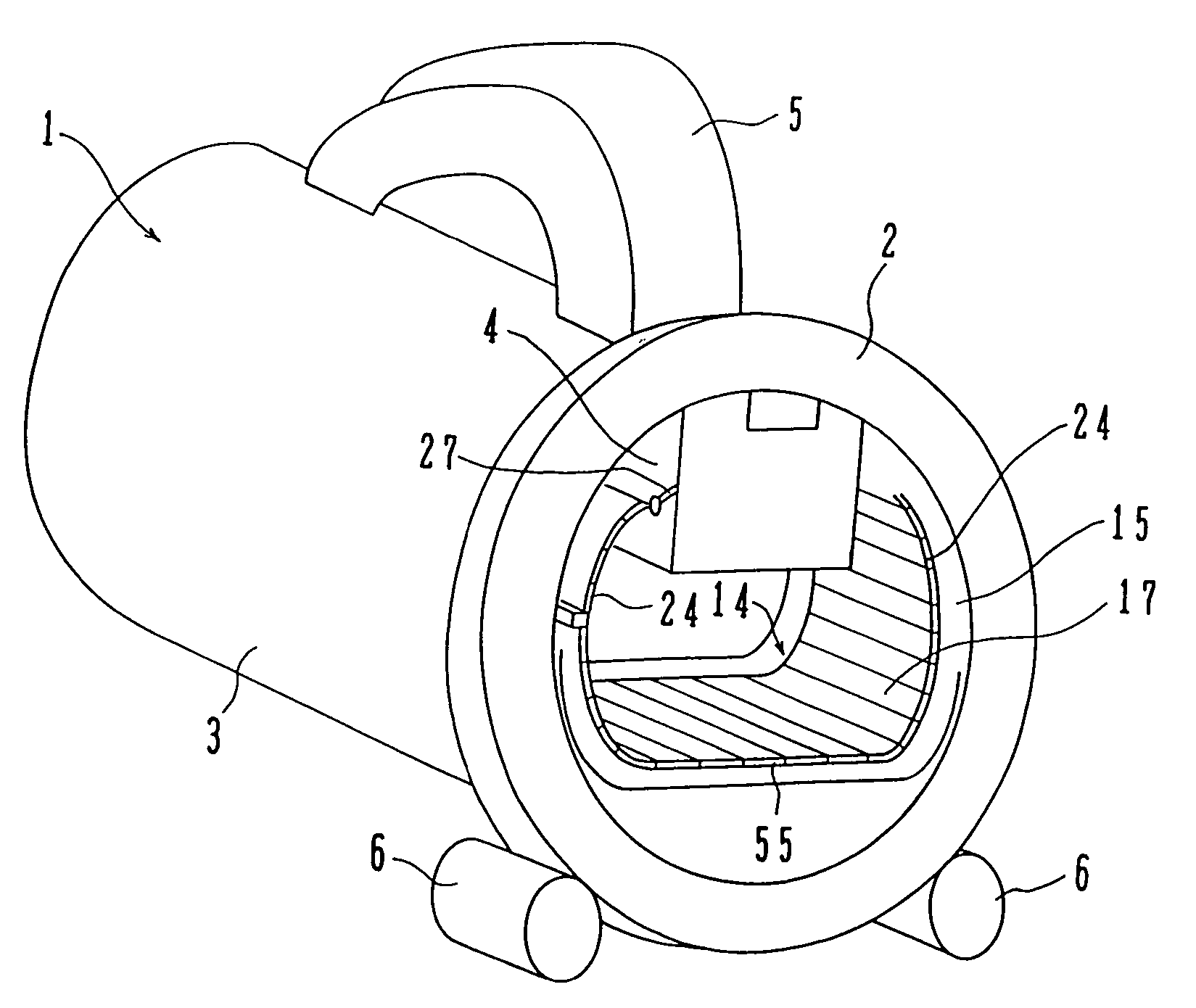

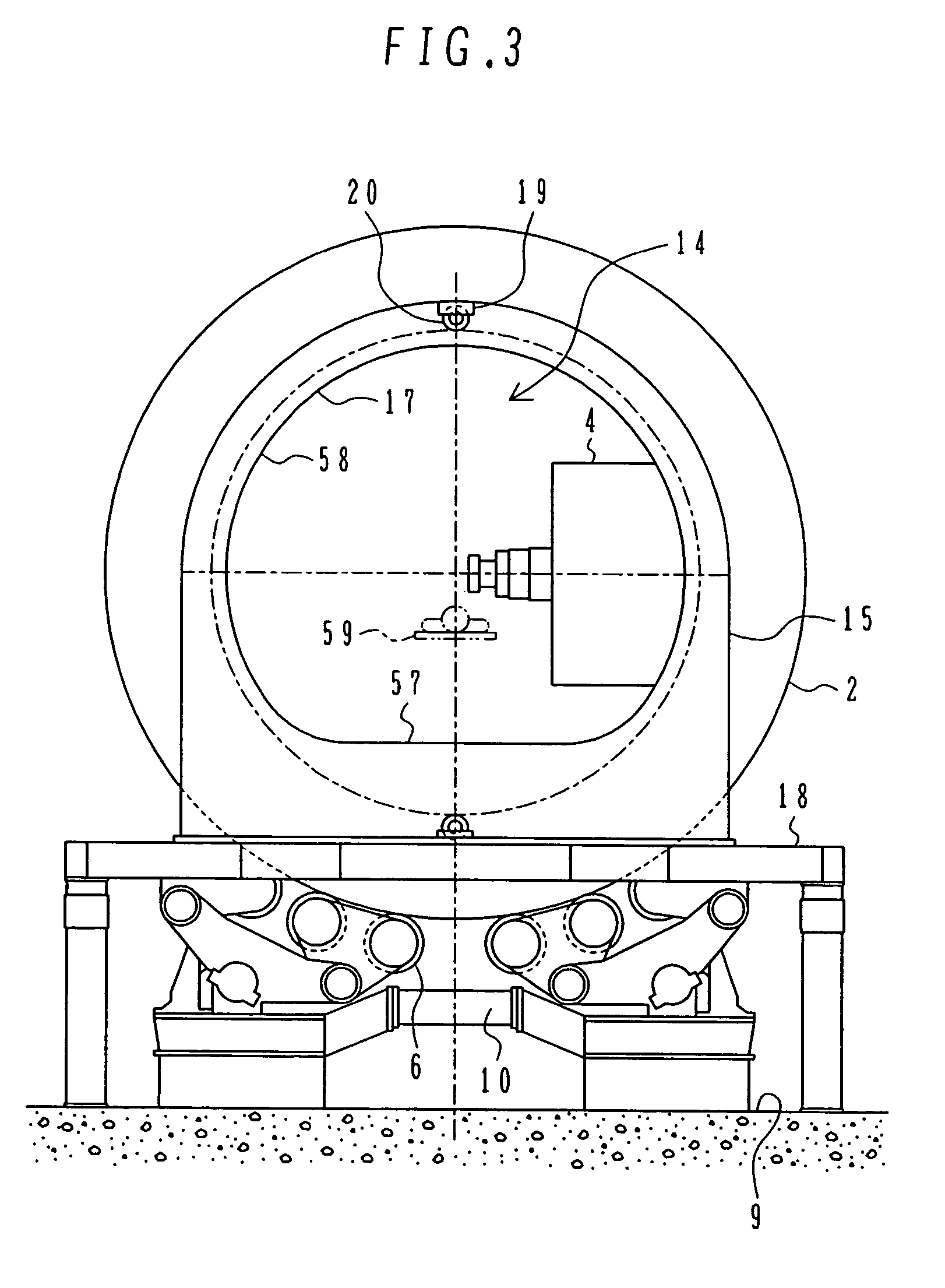

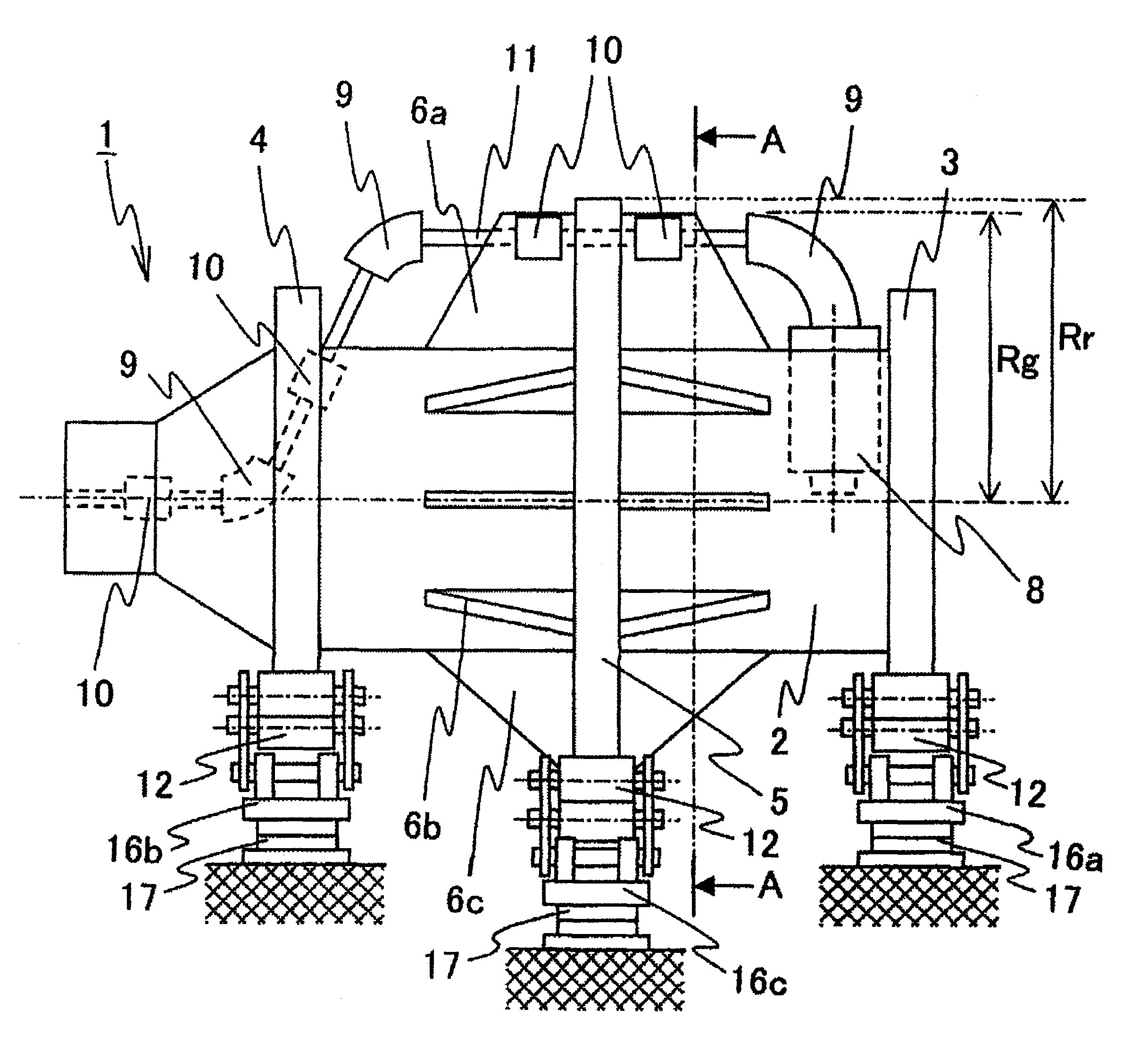

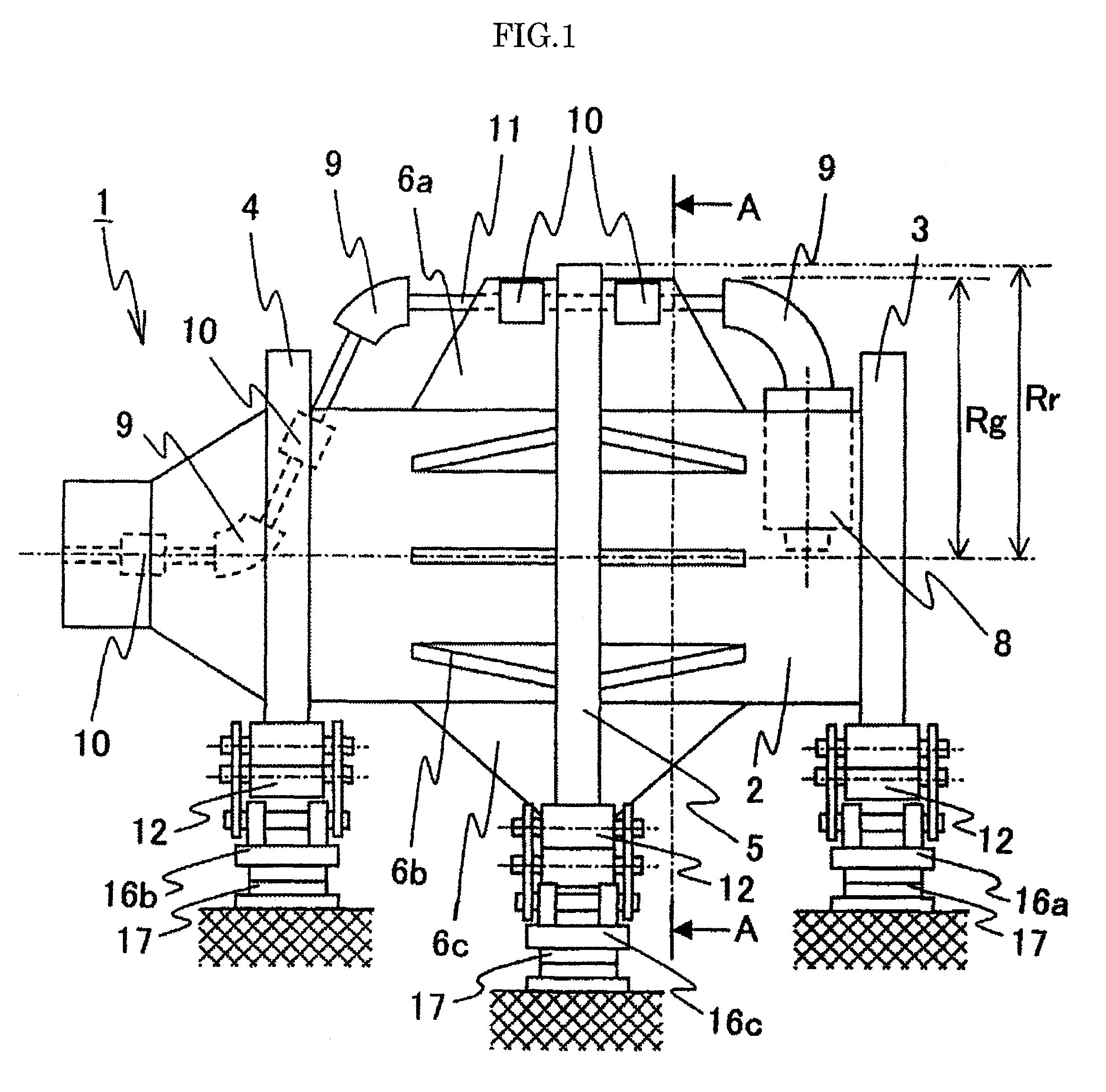

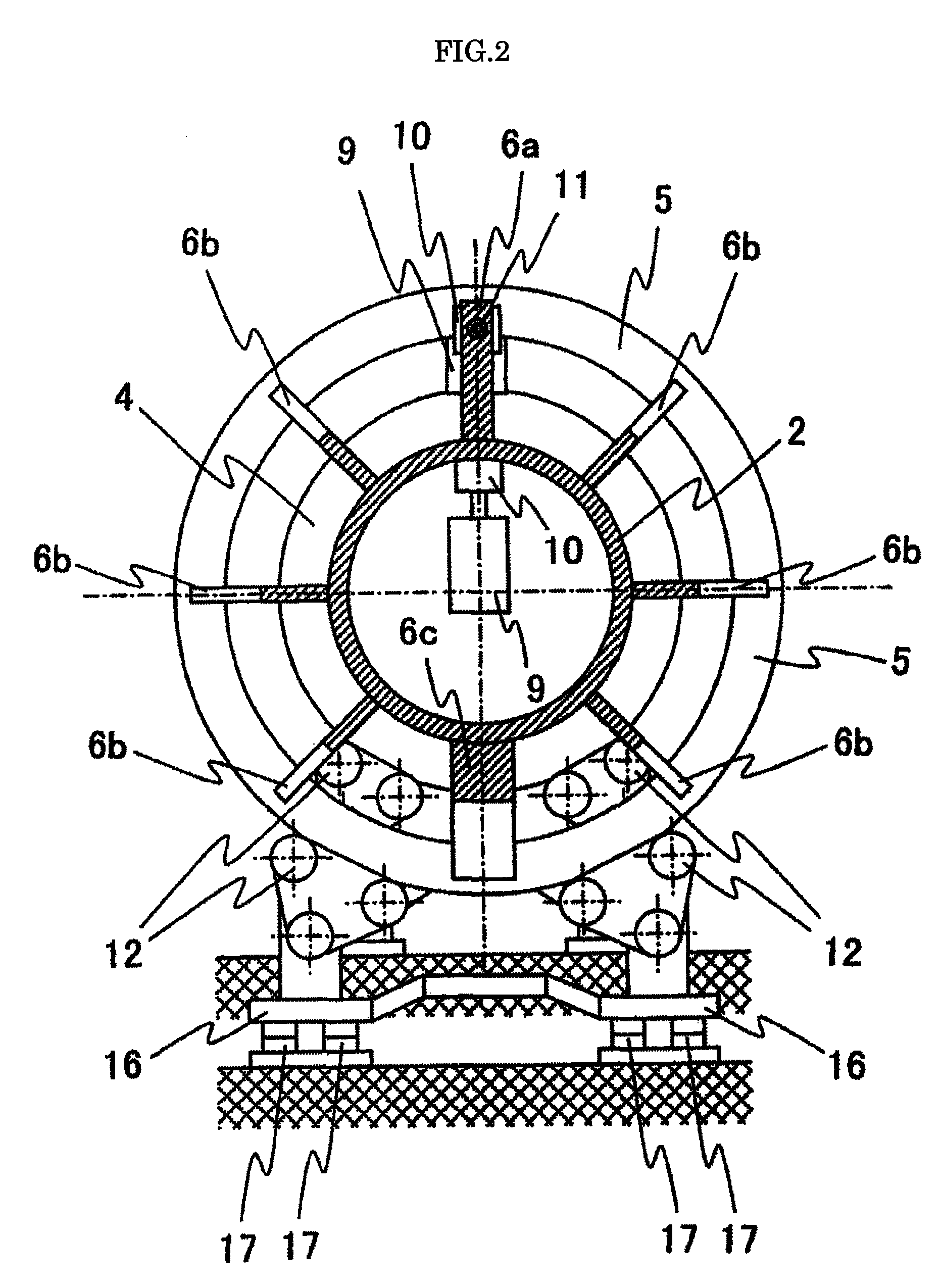

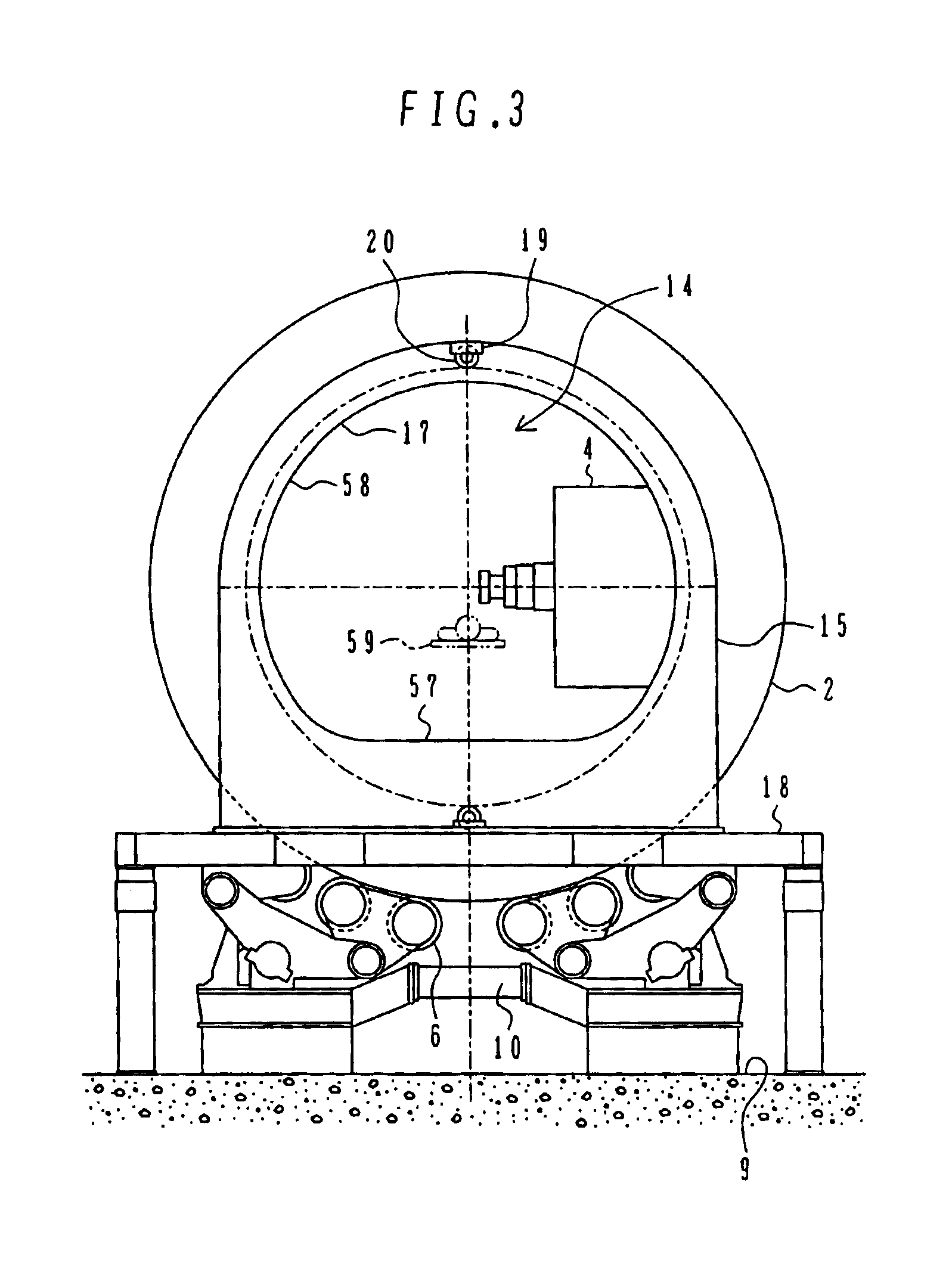

Medical particle irradiation apparatus

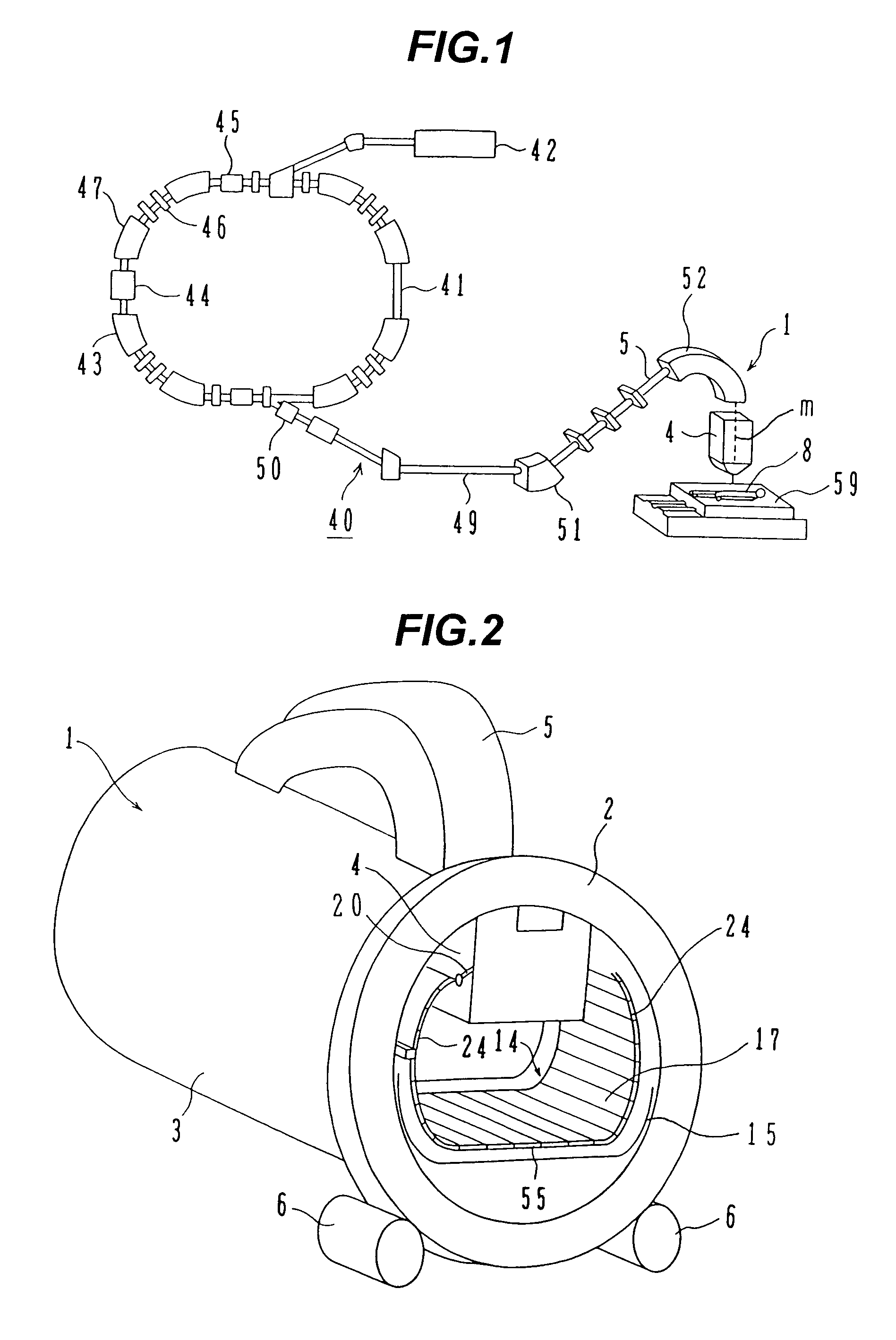

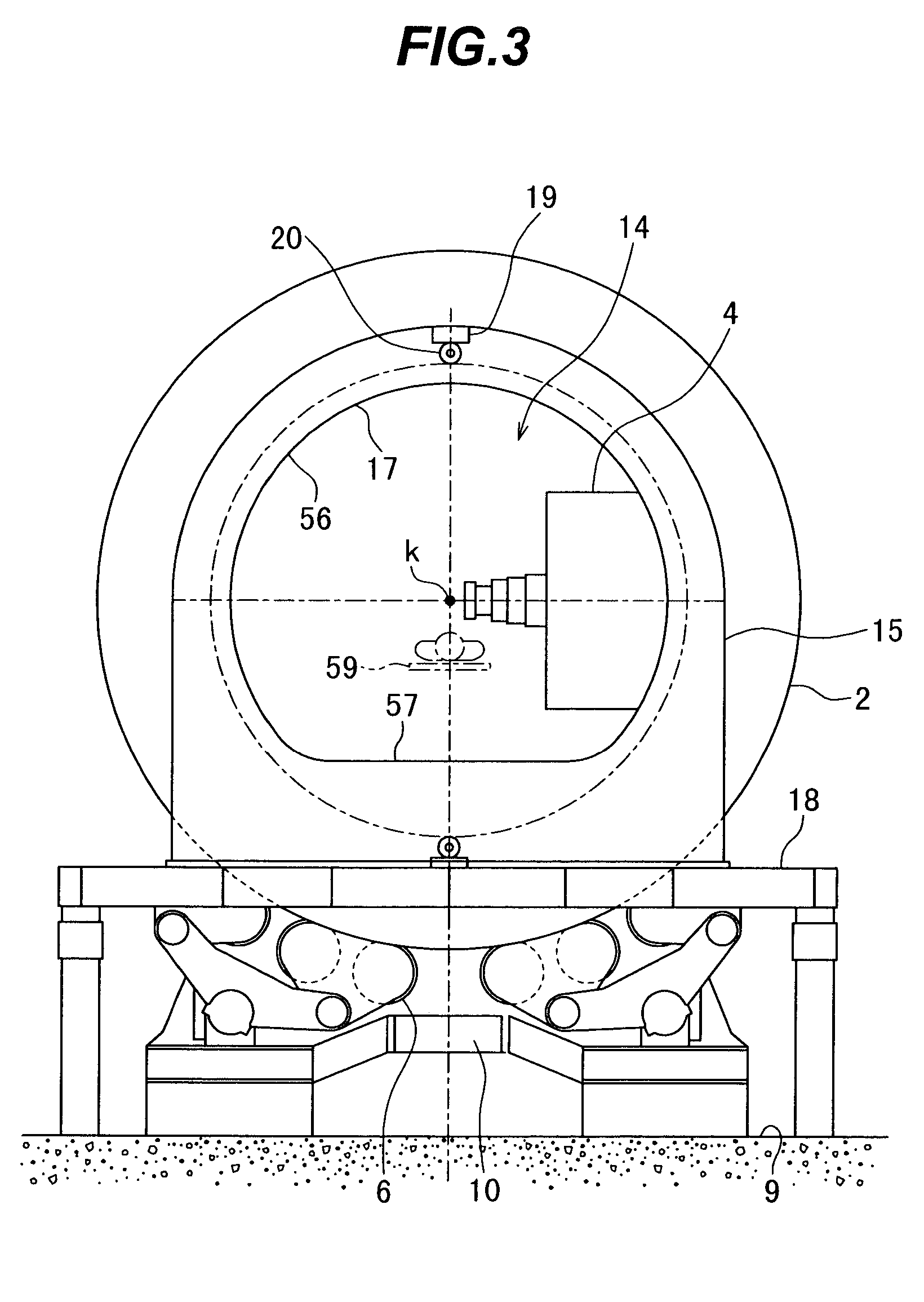

InactiveUS7030396B2Simple structurePrevent rotationThermometer detailsBeam/ray focussing/reflecting arrangementsMoving floorParticle beam

Disclosed is a medical particle irradiation apparatus comprising a rotating gantry 1 including an irradiation unit 4 emitting particle beams; an annular frame 16 located within and supported by the rotating gantry 1 such that it can rotate relative to the rotating gantry 1; an annular frame 15 fixedly located opposite the annular frame 16; an anti-corotation mechanism 34 being in contact with both the annular frames 16 and 15 to prevent the annular frame 16 from rotating together with the rotating gantry 1 during rotation of the rotating gantry 1; and a flexible moving floor 17 interposed between the annular frames 15 and 16, the flexible moving floor 17 being engaged with the annular frames 15 and 16 in such a manner as to move freely such that its bottom is substantially level and that it moves as the rotating gantry rotates.

Owner:HITACHI LTD +1

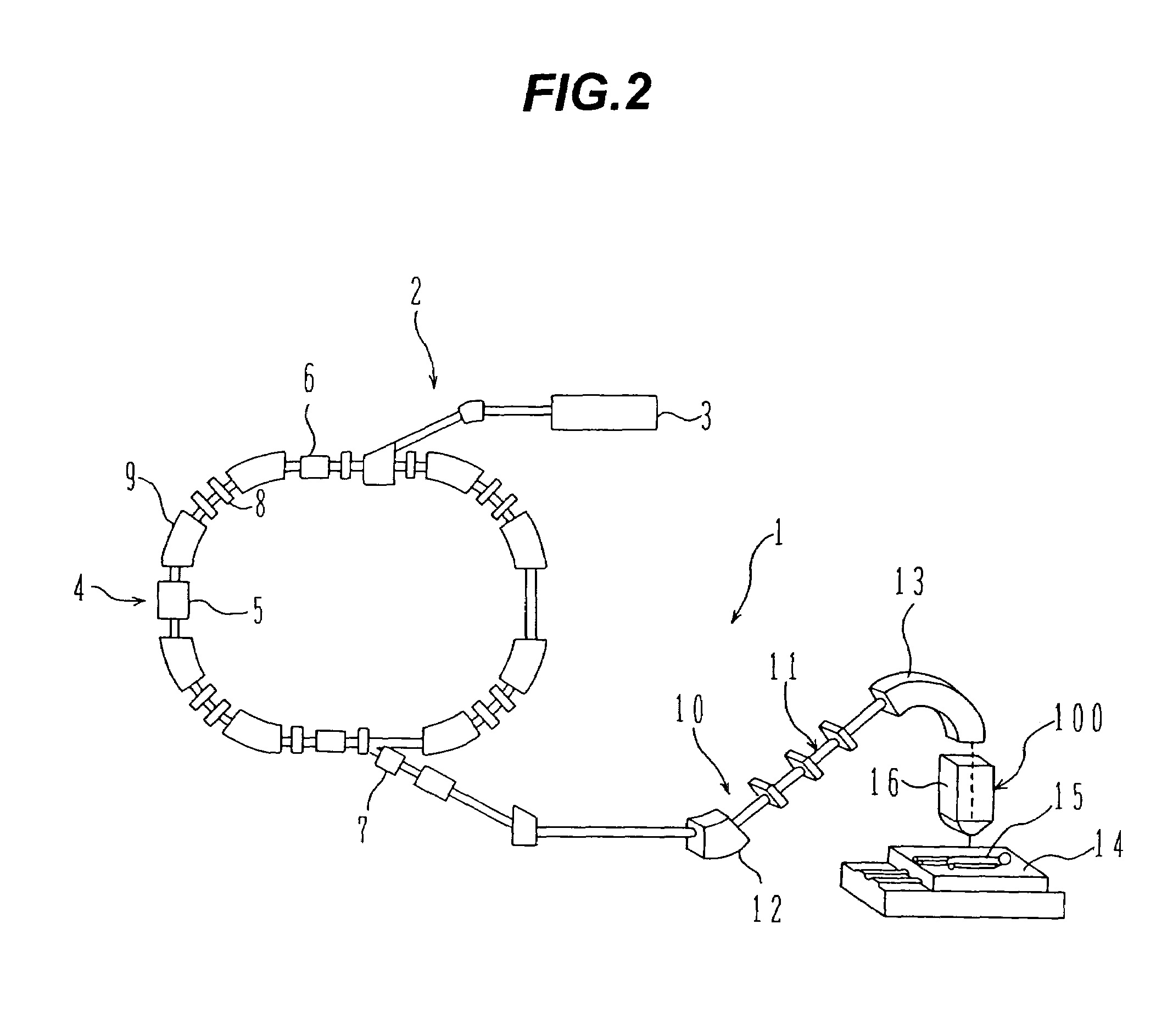

Charged-particle beam accelerator, particle beam radiation therapy system using the charged-particle beam accelerator, and method of operating the particle beam radiation therapy system

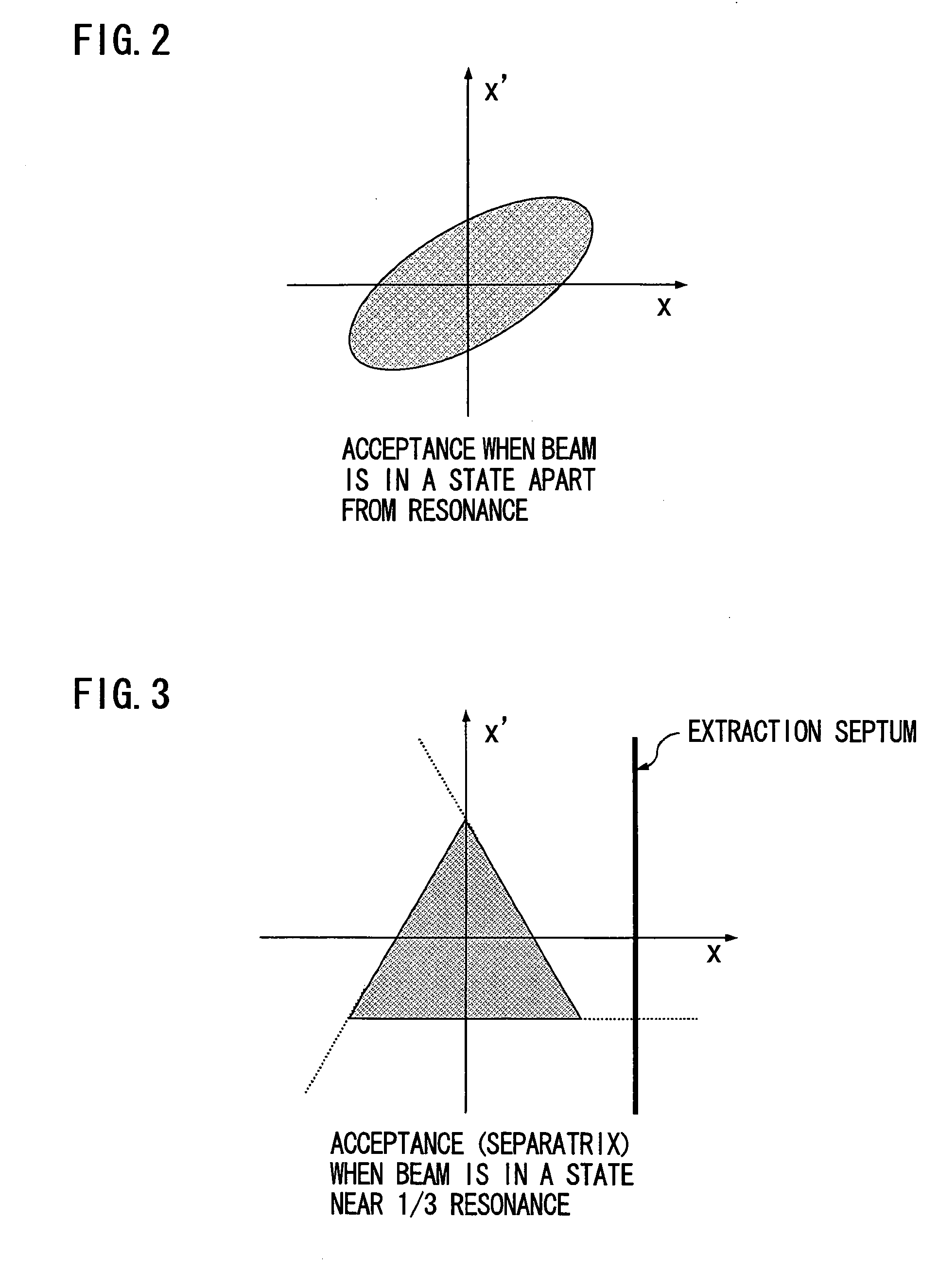

ActiveUS7122978B2Easy to identifyMagnetic induction acceleratorsMagnetic resonance acceleratorsParticle acceleratorResonance

A charged-particle beam accelerator includes an RF-KO unit for increasing the amplitude of betatron oscillation of a charged-particle beam within a stable region of resonance and an extraction quadrupole electromagnet unit for varying the stable region of resonance. The RF-KO unit is operated within a frequency range in which the circulating beam does not go beyond a boundary of the stable region of resonance, and the extraction quadrupole electromagnet unit is operated with appropriate timing as required for beam extraction so that the charged-particle beam is extracted with desired timing.

Owner:MITSUBISHI ELECTRIC CORP

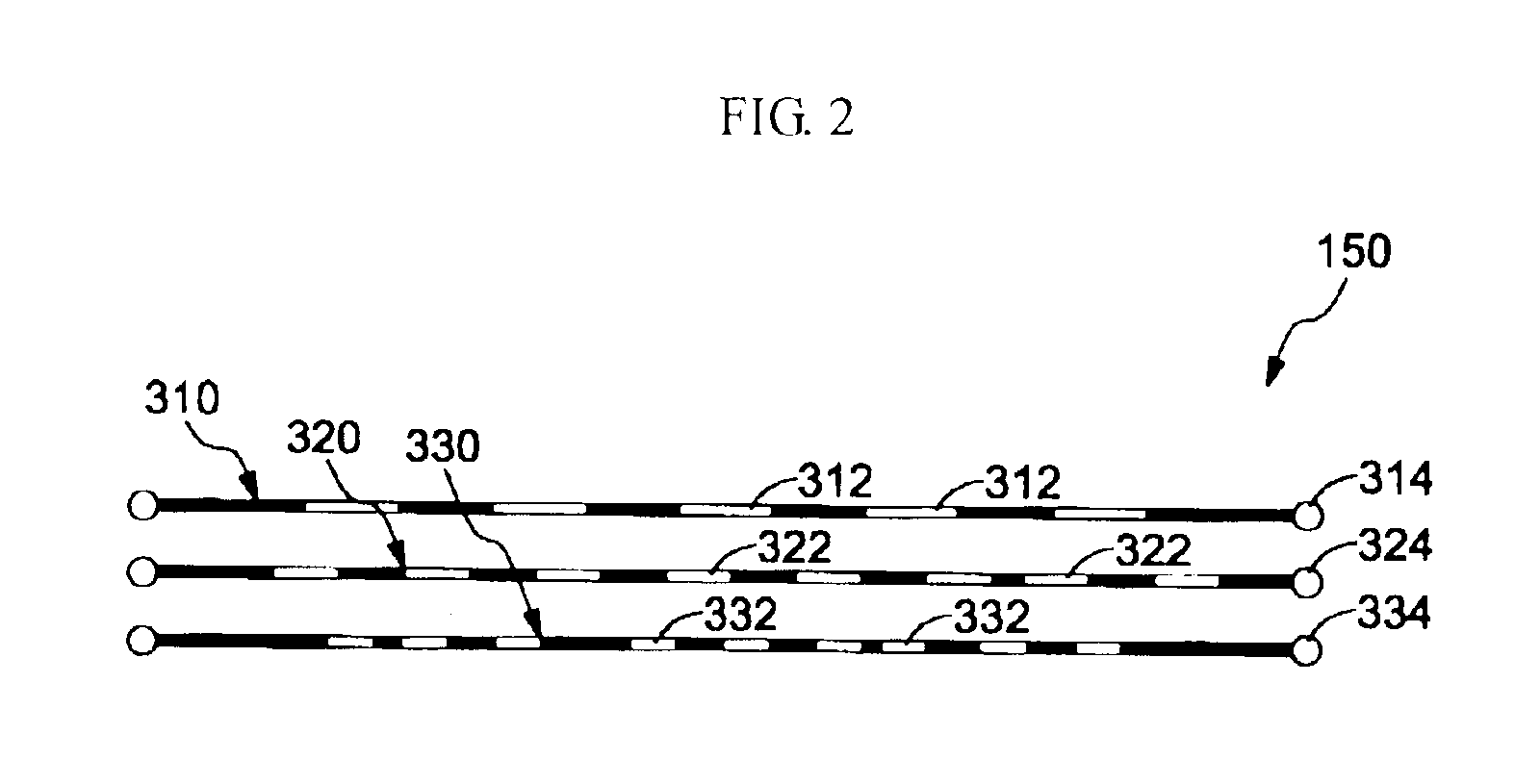

Organo luminescent semiconductor nanocrystal probes for biological applications and process for making and using such probes

A semiconductor nanocrystal compound is described capable of linking to an affinity molecule. The compound comprises (1) a semiconductor nanocrystal capable of emitting electromagnetic radiation and / or absorbing energy, and / or scattering or diffracting electromagnetic radiation—when excited by an electromagnetic radiation source or a particle beam; and (2) at least one linking agent, having a first portion linked to the semiconductor nanocrystal and a second portion capable of linking to an affinity molecule. The compound is linked to an affinity molecule to form a semiconductor nanocrystal probe capable of bonding with a detectable substance. Subsequent exposure to excitation energy will excite the semiconductor nanocrystal in the probe causing the emission of electromagnetic radiation. Further described are processes for respectively: making the luminescent semiconductor nanocrystal compound; making the semiconductor nanocrystal probe; and using the probe to determine the presence of a detectable substance in a material.

Owner:RGT UNIV OF CALIFORNIA

Particle beam irradiation equipment and particle beam irradiation method

ActiveUS7449701B2Improve dose uniformityLong rangeRadiation/particle handlingElectrode and associated part arrangementsField sizeParticle beam

Particle beam irradiation equipment and a method of adjusting irradiation nozzle, which can ensure a long range and high dose uniformity at any field size are provided. The particle beam irradiation equipment comprises charged particle beam generation equipment and an irradiation nozzle for irradiating a charged particle beam extracted from the charged particle beam generation equipment to an irradiation target. The irradiation nozzle comprises a first scatterer device including a first scatterer for spreading out the charged particle beam into a Gaussian-like distribution, and multiple stages of second scatterer devices including second scatterers for producing a uniform intensity distribution of the charged particle beam having been spread out into a Gaussian-like distribution by the first scatterer. For forming irradiation fields having sizes different from each other, the second scatterer devices are disposed downstream of the first scatterer device in the direction of travel of the charged particle beam at the spacing depending on the difference in the field size.

Owner:HITACHI LTD

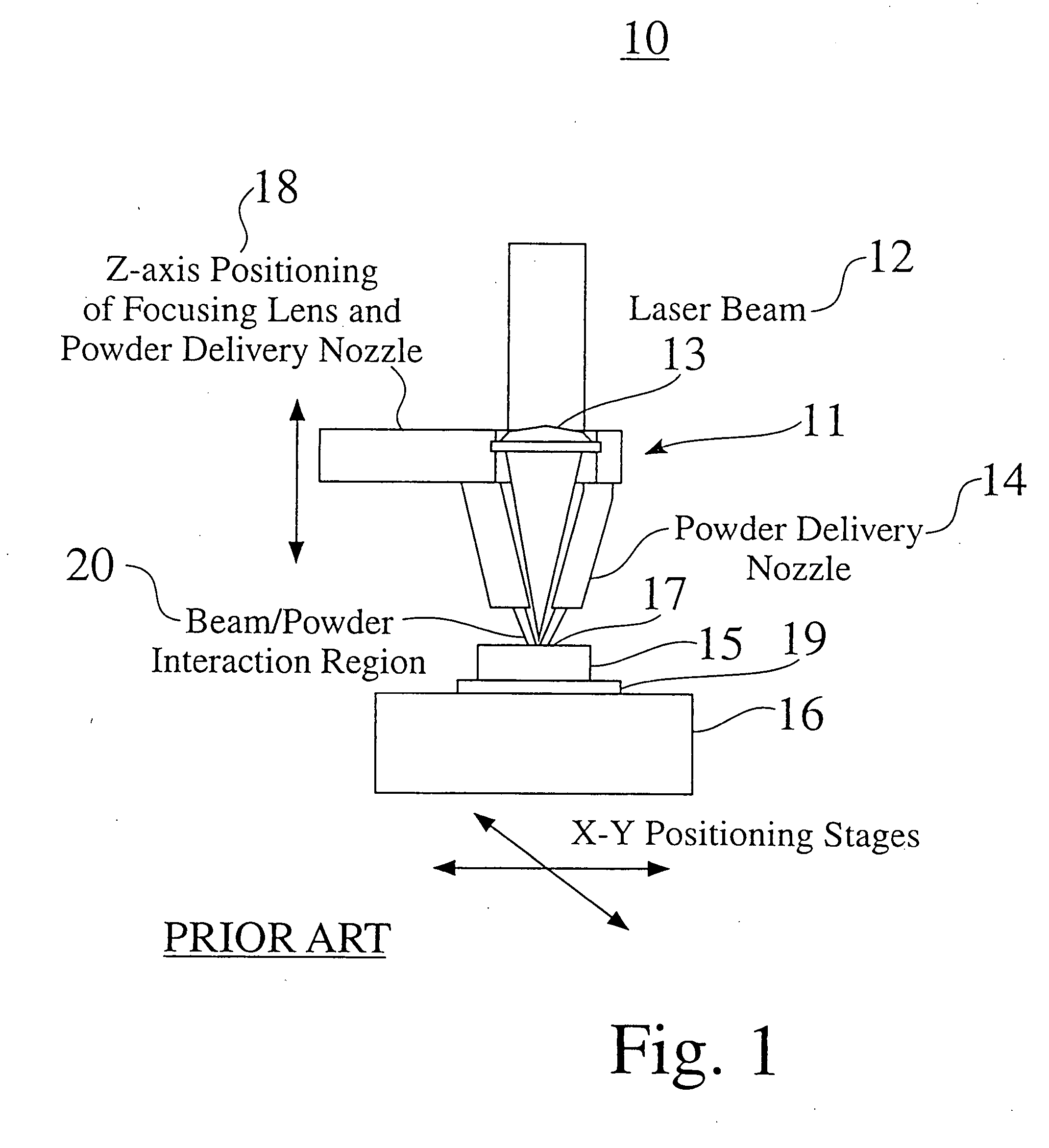

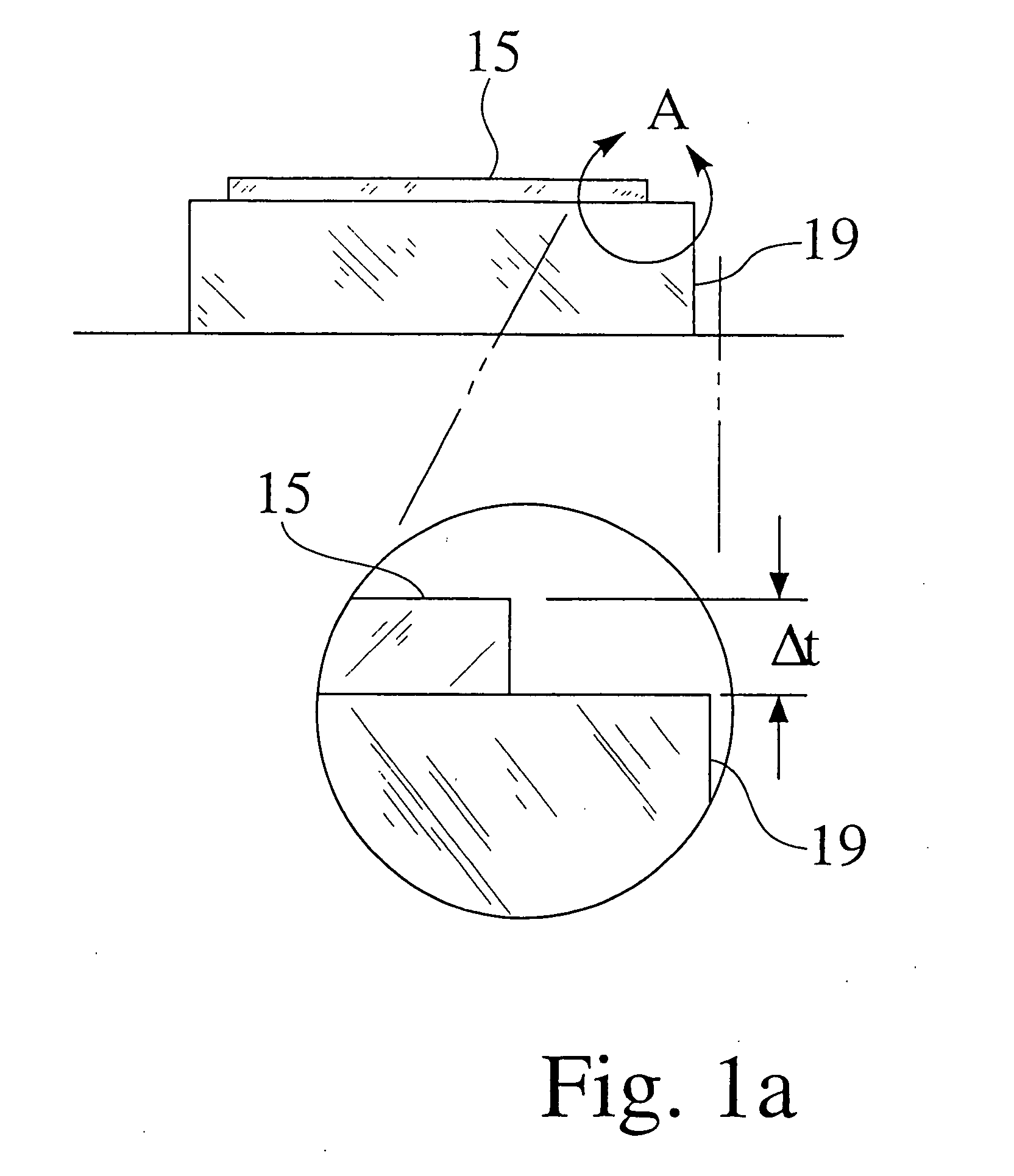

Powder feeder for material deposition systems

InactiveUS20050133527A1Small sizeEliminate warpingPower operated devices3D object support structuresSolid componentCoolant flow

A method and apparatus for embedding features and controlling material composition in a three-dimensional structure (130) is disclosed. The invention enables the control of material characteristics, within a structure (130) made from a plurality of materials, directly from computer renderings of solid models of the components. The method uses stereolithography and solid model computer file formats to control a multi-axis head (480) in a directed material deposition process (123). Material feedstock (126, 127) is deposited onto a pre-heated substrate (19). Depositions (15) in a layer-by-layer pattern, defined by solid models (141, 146), create a three-dimensional article having complex geometric details. Thermal management of finished solid articles (250-302), not available through conventional processing techniques, is enabled by embedded voids (152) and / or composite materials (126, 127), which include dissimilar metals (210, 216). Finished articles control pressure drop and produce uniform coolant flow and pressure characteristics. High-efficiency heat transfer is engineered within a solid structure by incorporating other solid materials with diverse indexes. Embedding multi-material structures (132, 134) within a normally solid component (141) produces articles with diverse mechanical properties. Laser and powder delivery systems (420, 170) are integrated in a multi-axis deposition head (480) having a focused particle beam (502) to reduce material waste.

Owner:OPTOMEC DESIGN CO

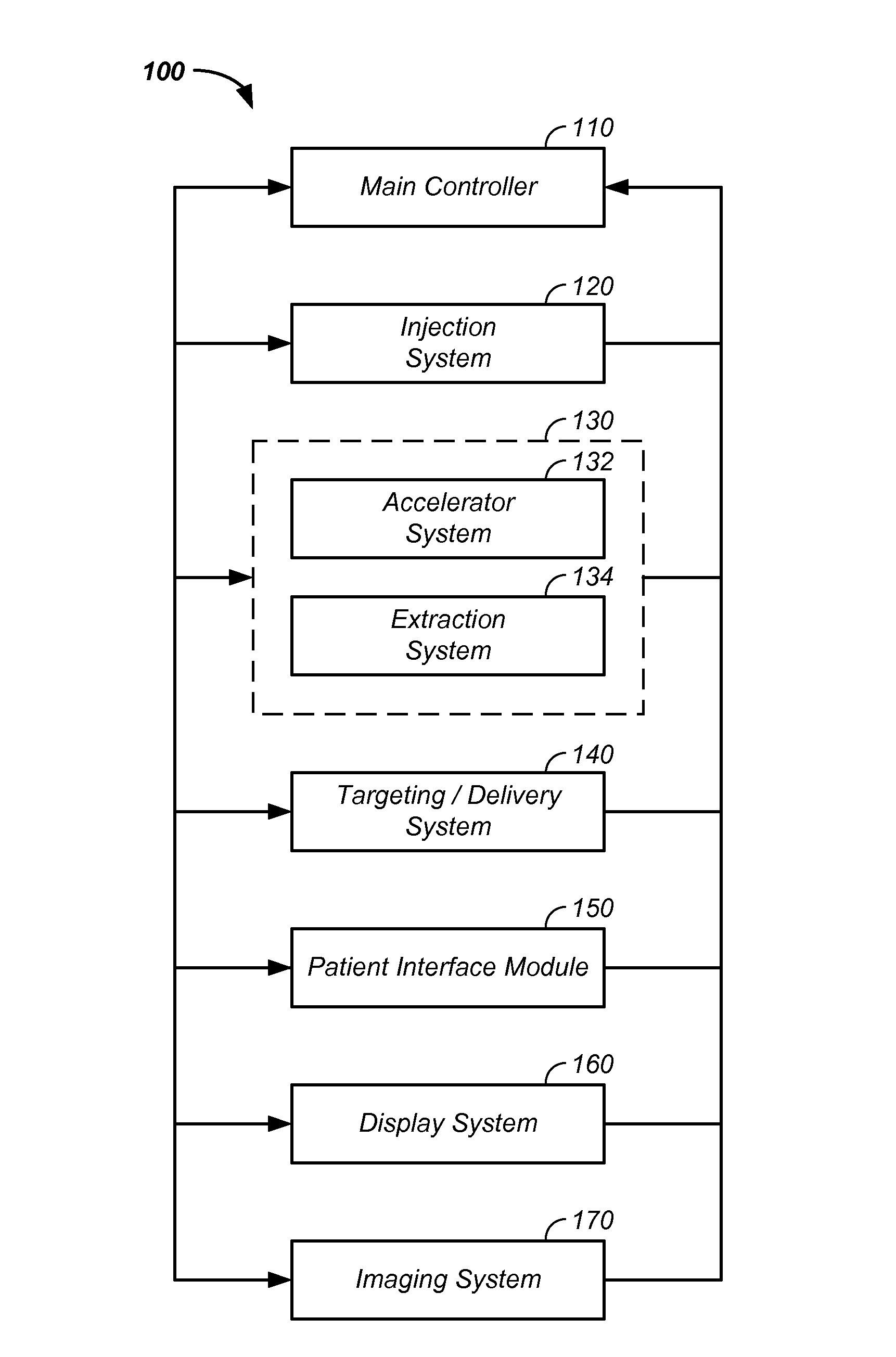

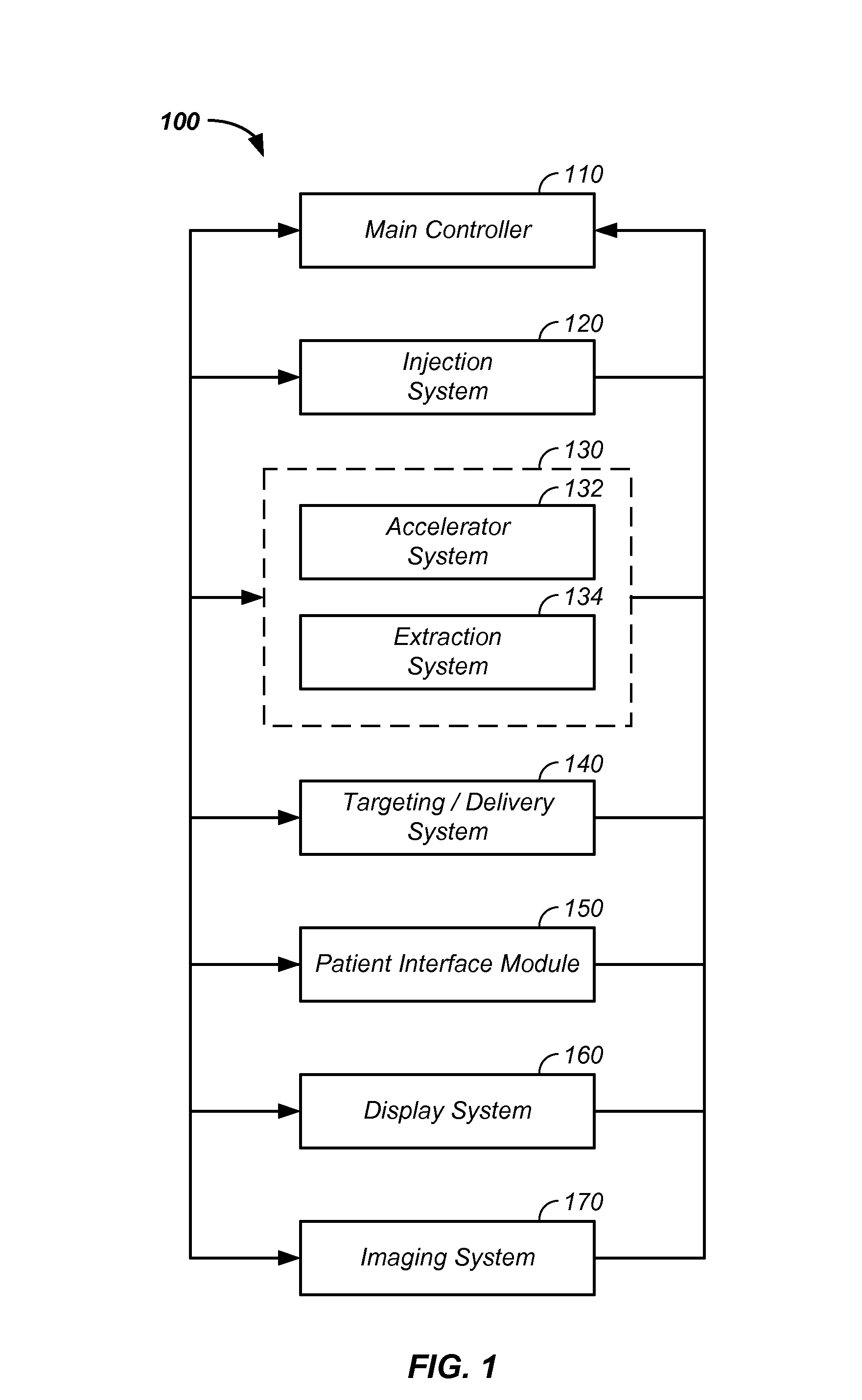

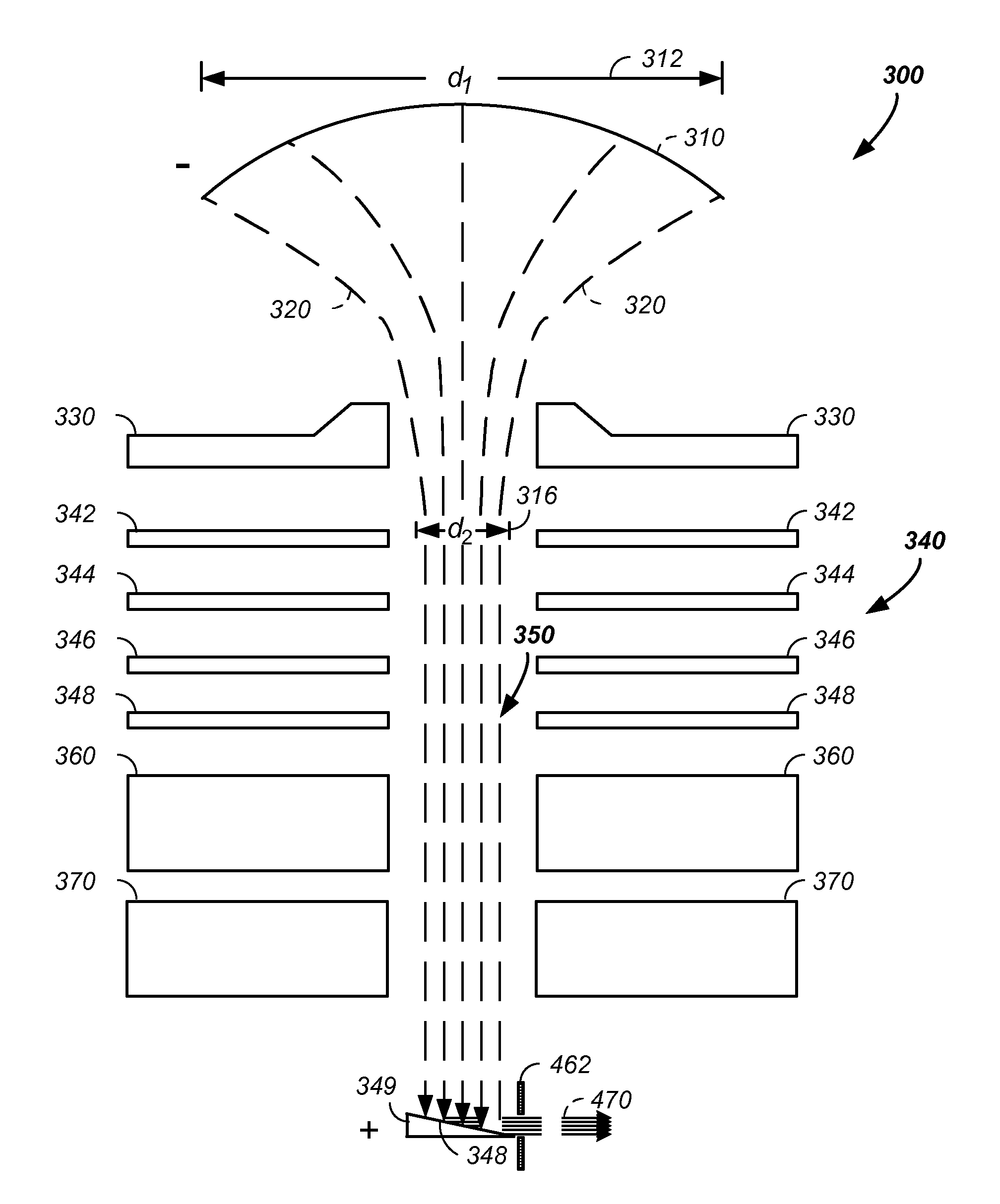

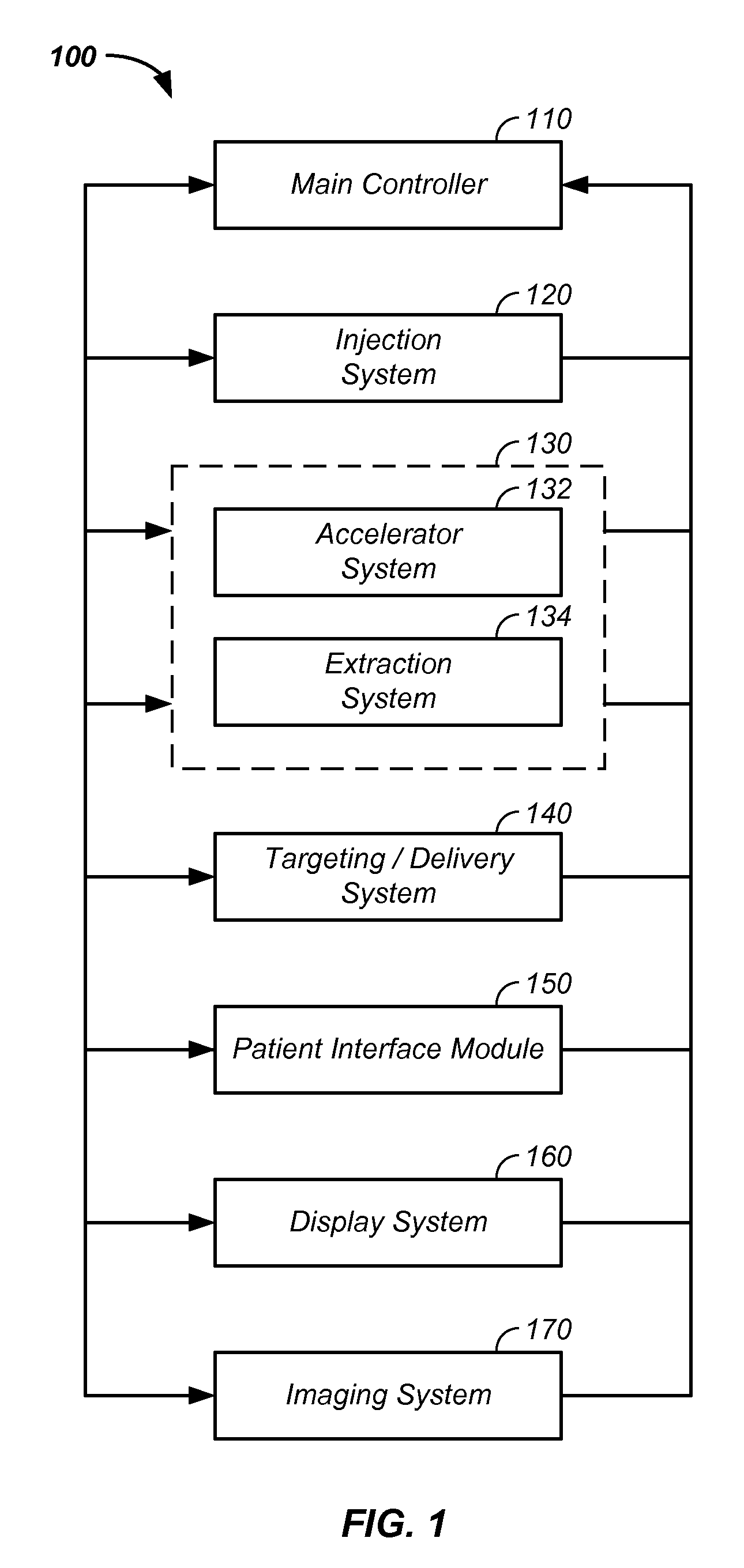

Synchronized x-ray / breathing method and apparatus used in conjunction with a charged particle cancer therapy system

ActiveUS20100128846A1Cathode ray concentrating/focusing/directingMagnetic resonance acceleratorsX-raySynchrotron

The invention comprises an X-ray system that is orientated to provide X-ray images of a patient in the same orientation as viewed by a proton therapy beam, is synchronized with patient respiration, is operable on a patient positioned for proton therapy, and does not interfere with a proton beam treatment path. Preferably, the synchronized system is used in conjunction with a negative ion beam source, synchrotron, and / or targeting method apparatus to provide an X-ray timed with patient respiration and performed immediately prior to and / or concurrently with particle beam therapy irradiation to ensure targeted and controlled delivery of energy relative to a patient position resulting in efficient, precise, and / or accurate noninvasive, in-vivo treatment of a solid cancerous tumor with minimization of damage to surrounding healthy tissue in a patient using the proton beam position verification system.

Owner:BALAKIN ANDREY VLADIMIROVICH +1

Rotating irradiation therapy apparatus

InactiveUS7961844B2Chemical conversion by chemical reactionX-ray/gamma-ray/particle-irradiation therapyParticle beamBody support device

A rotating irradiation therapy apparatus used for particle beam therapy includes a rotating gantry equipped with a charged particle beam irradiation device beam transport devices for guiding a charged particle beam to the irradiation device and a roller in contact with a ring member included in the rotating gantry and supporting the gantry. A front ring is disposed in contact with the roller of a rotating body support device at one end in the axial direction of the rotating gantry, and a rear ring is disposed in contact with the roller at the other end in the axial direction of the rotating gantry. At least one intermediate ring is disposed in a position different in the axial direction of the gantry between the front and rear rings and in contact with the roller.

Owner:HITACHI LTD

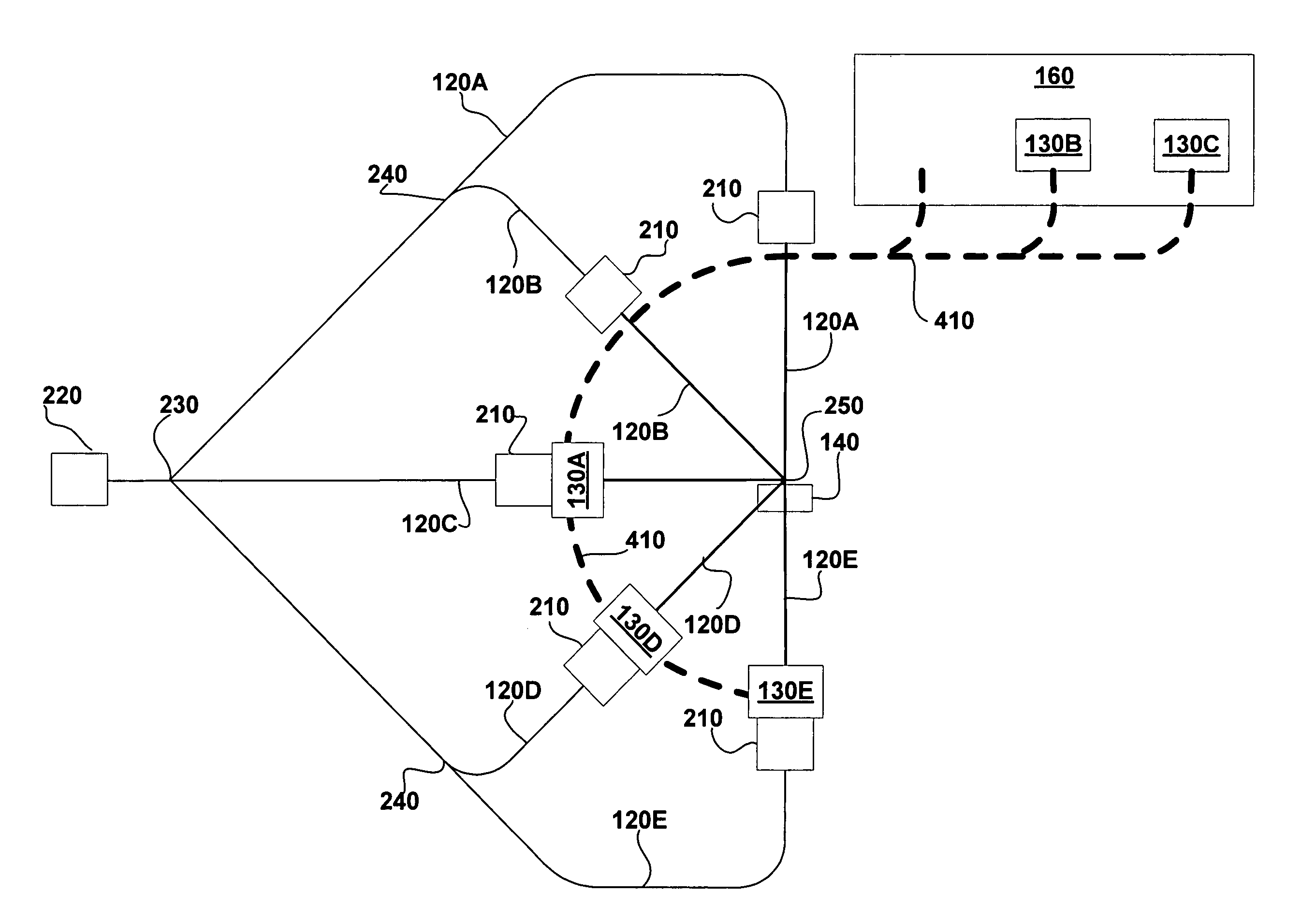

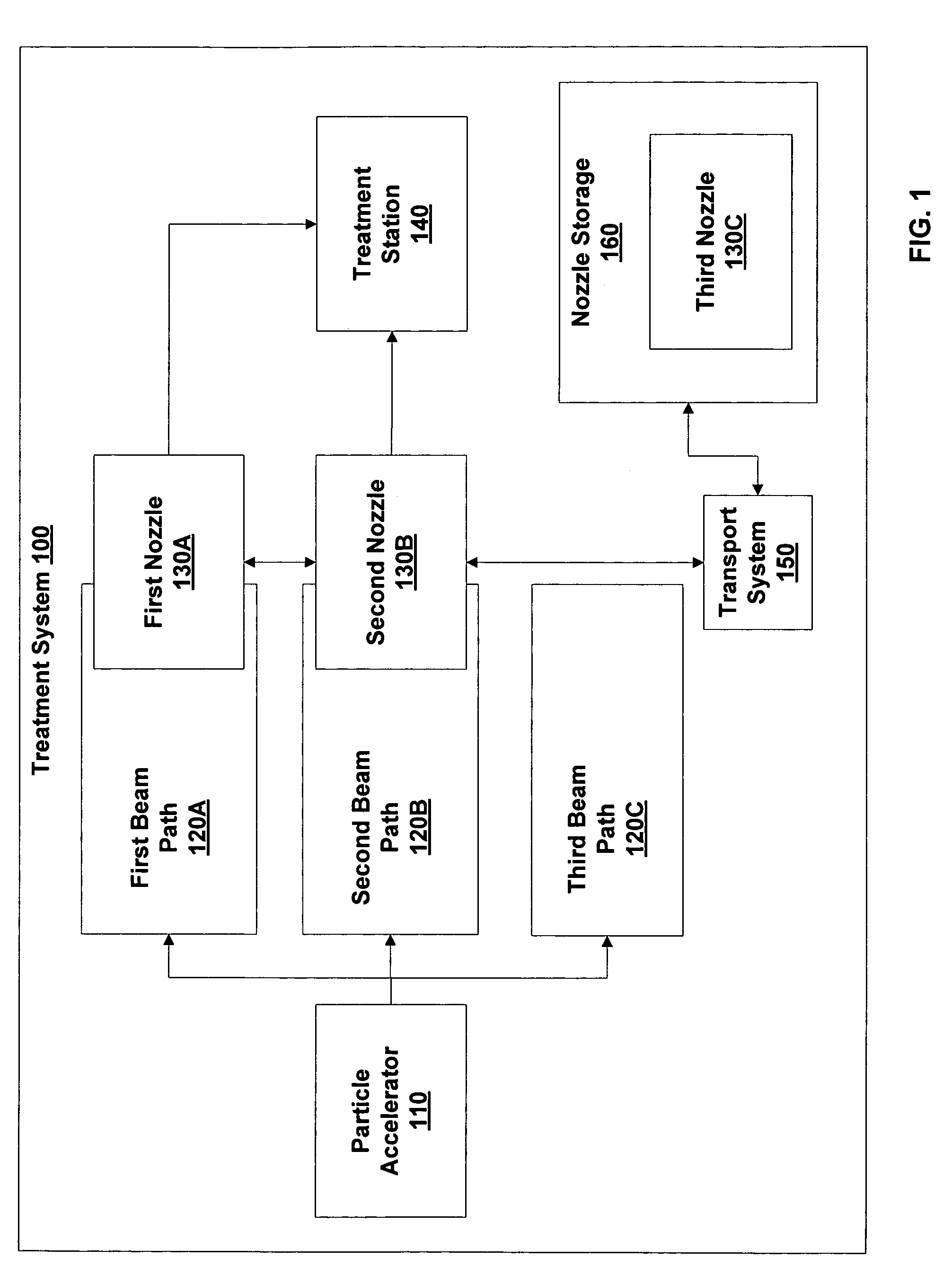

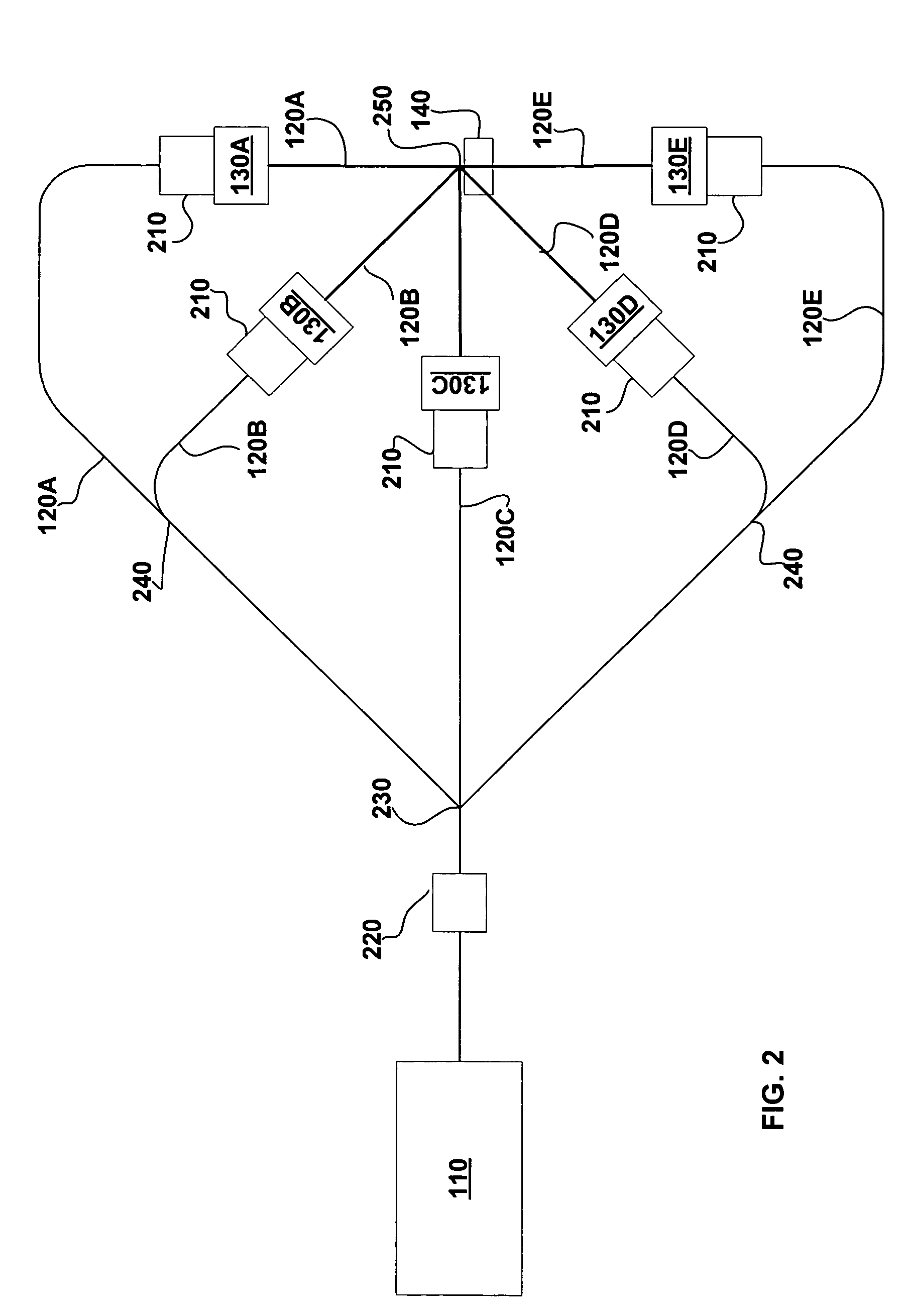

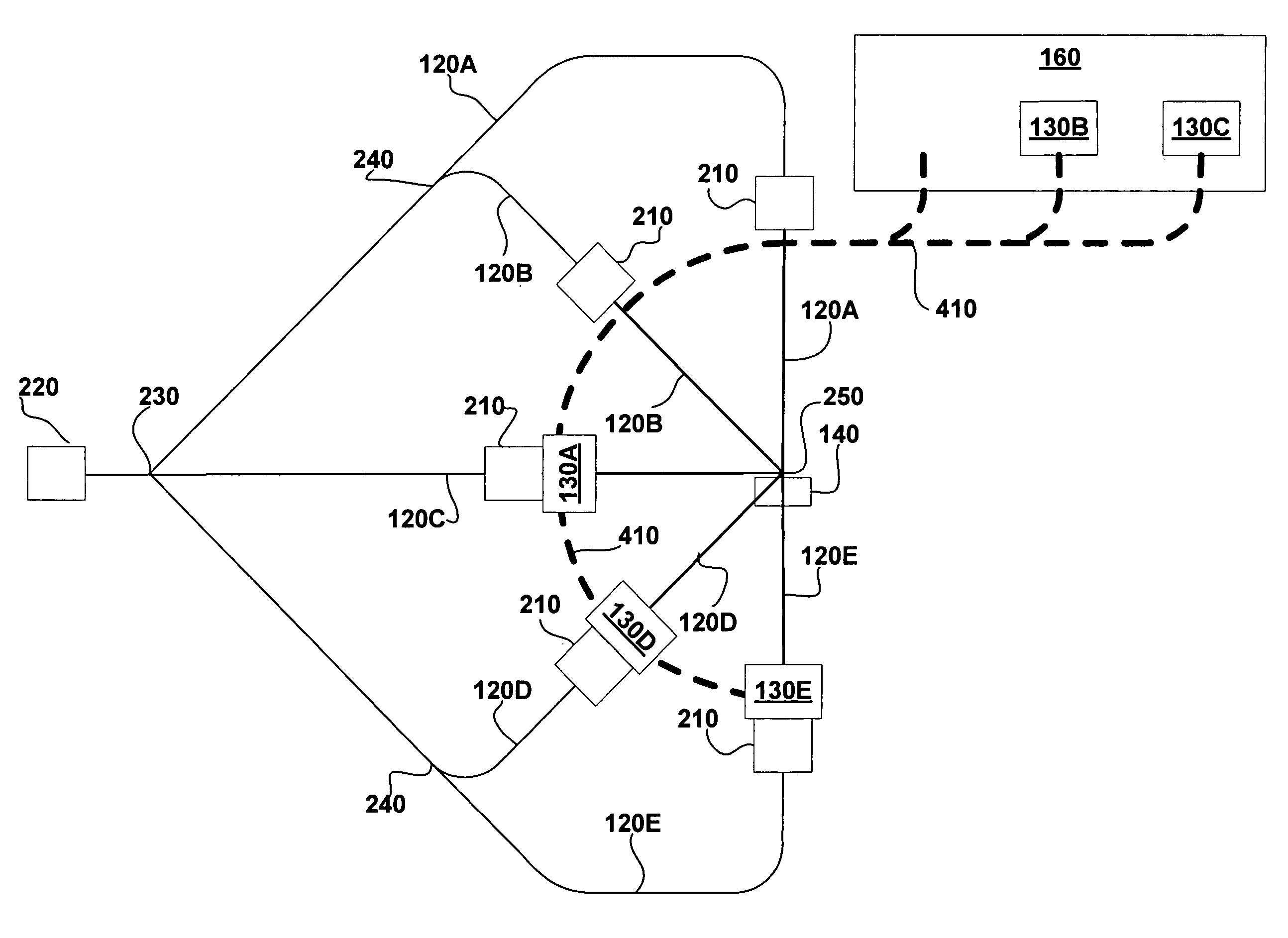

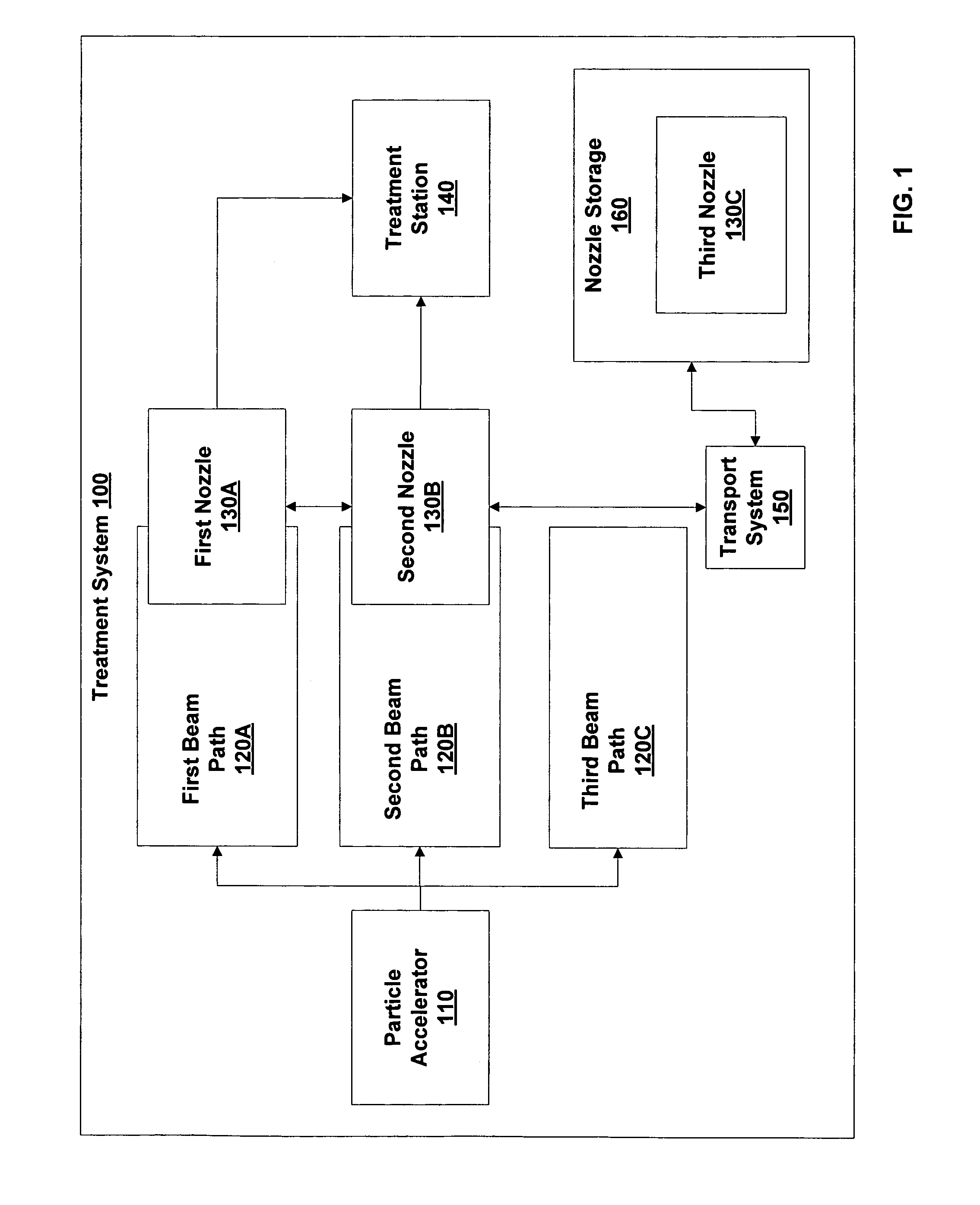

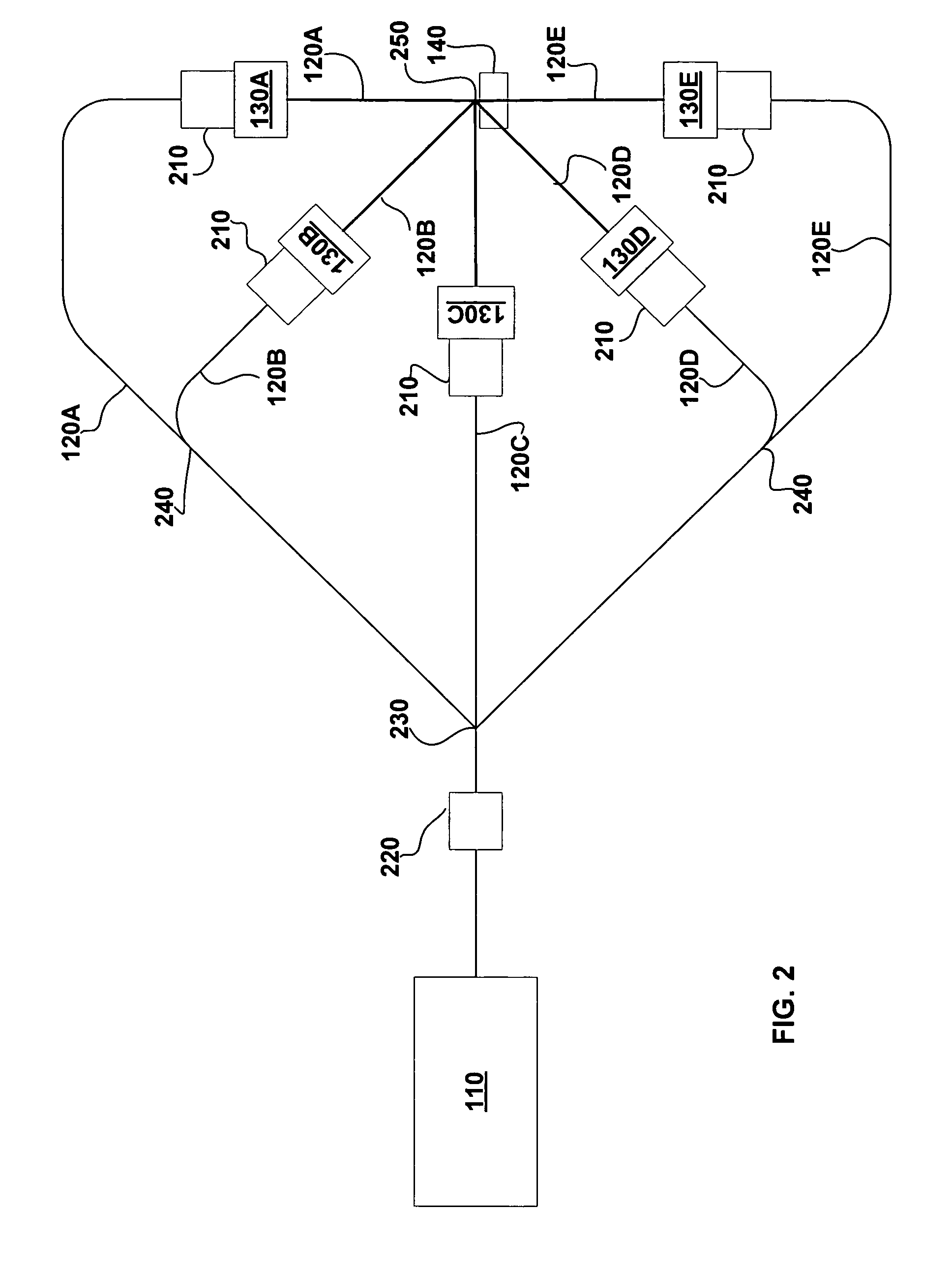

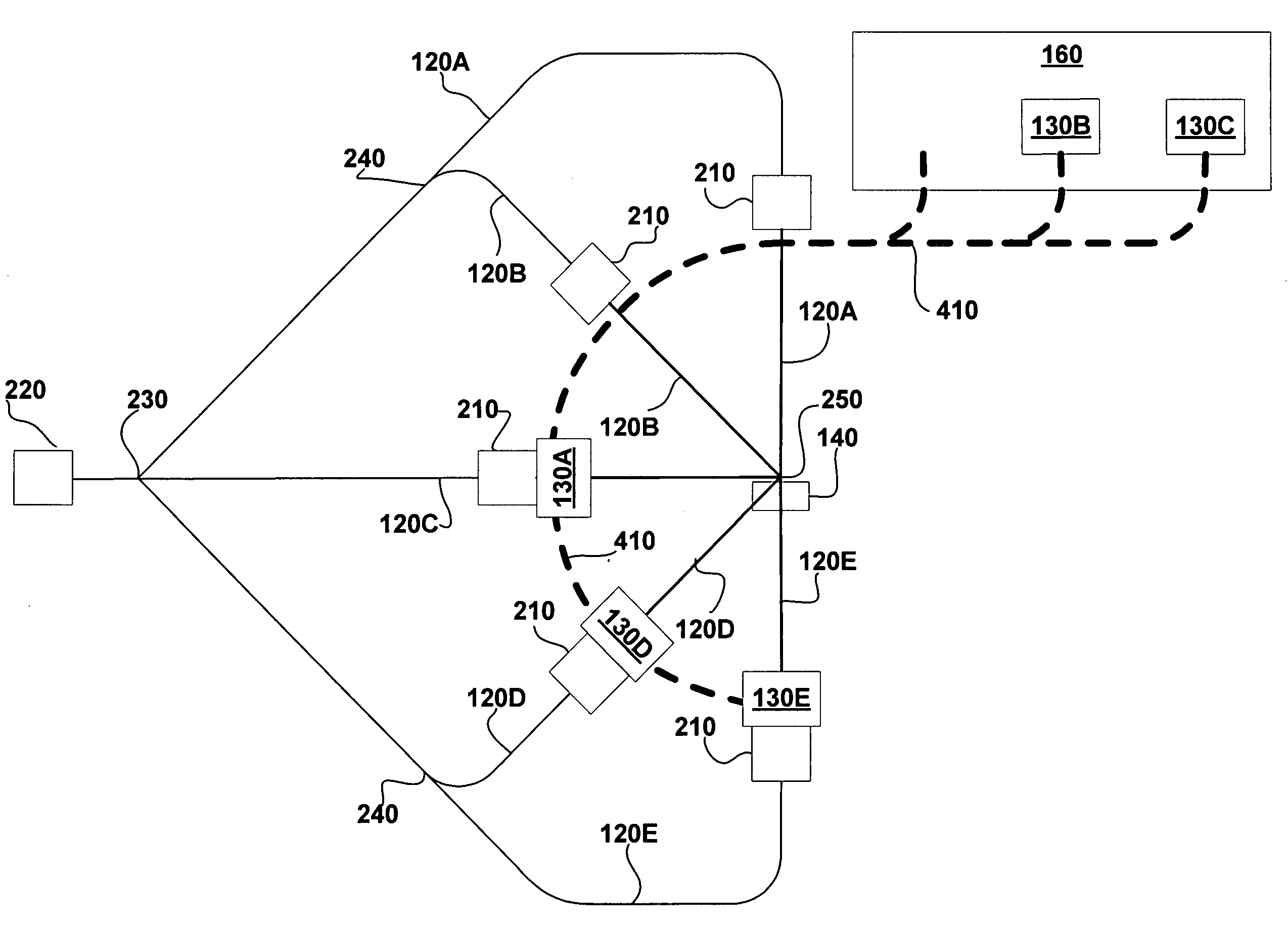

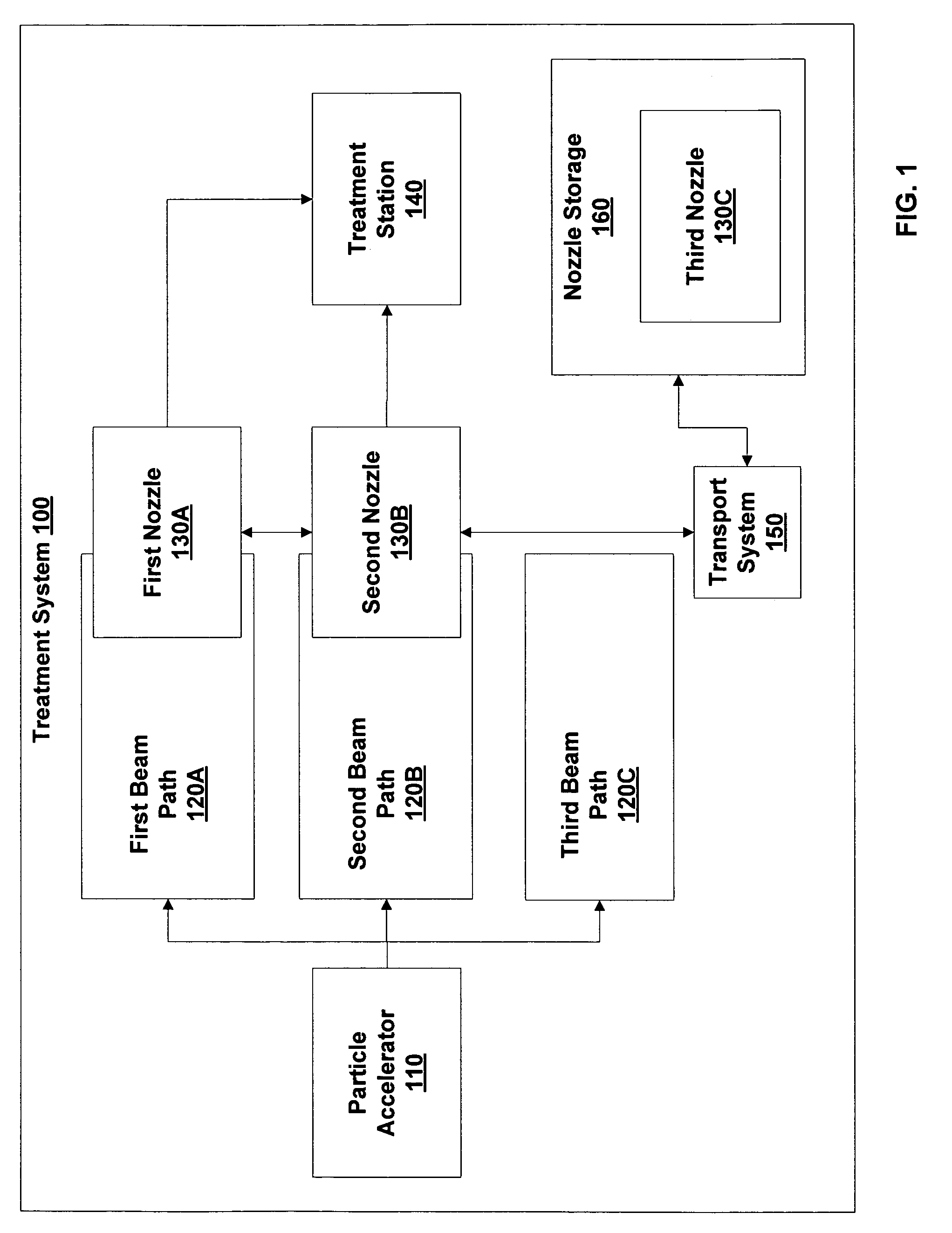

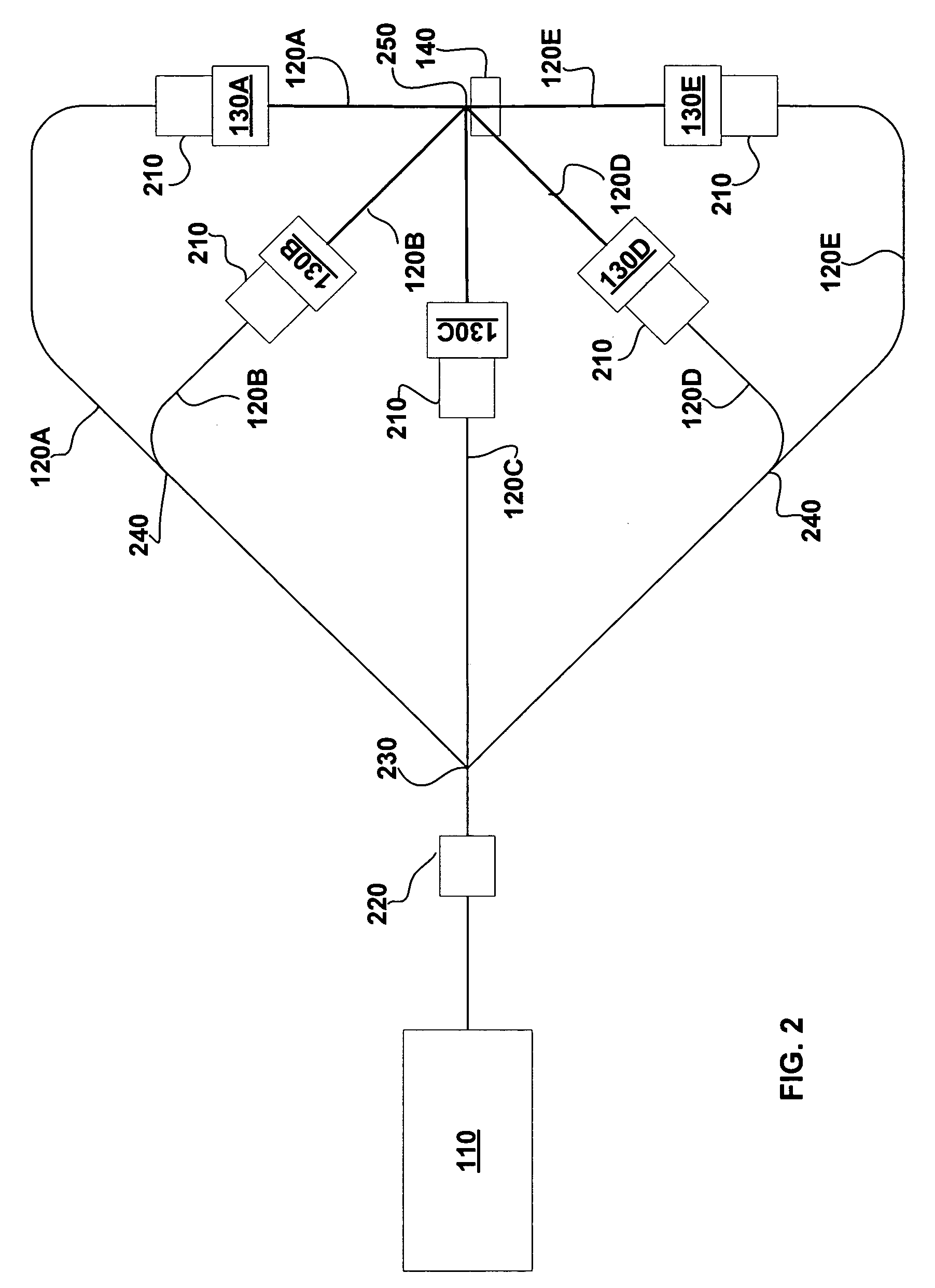

Particle beam nozzle transport system

InactiveUS7402822B2AcceleratorsChemical conversion by chemical reactionTransport systemParticle beam

An improved particle beam treatment system optionally includes exchangeable particle beam nozzles. These particle beam nozzles may be automatically moved from a storage location to a particle beam path or between particle beam paths for use in medical applications. Movement may be achieved using a conveyance, gantry, rail system, or the like. The improved particle beam treatment system optionally also includes more than two alternative particle beam paths. These alternative particle beam paths may be directed to a patient from a variety of different angles and in different planes.

Owner:VARIAN MEDICAL SYSTEMS

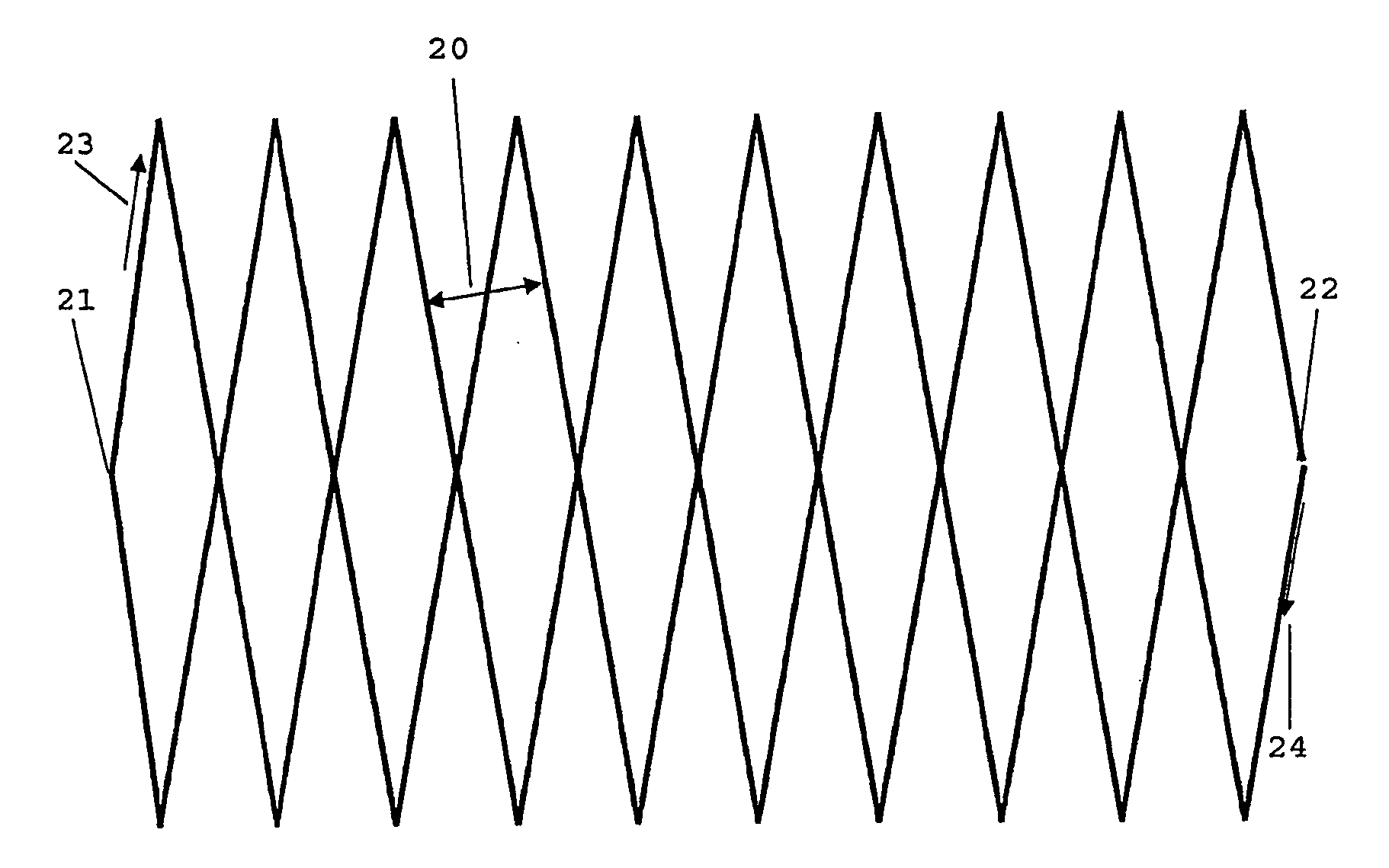

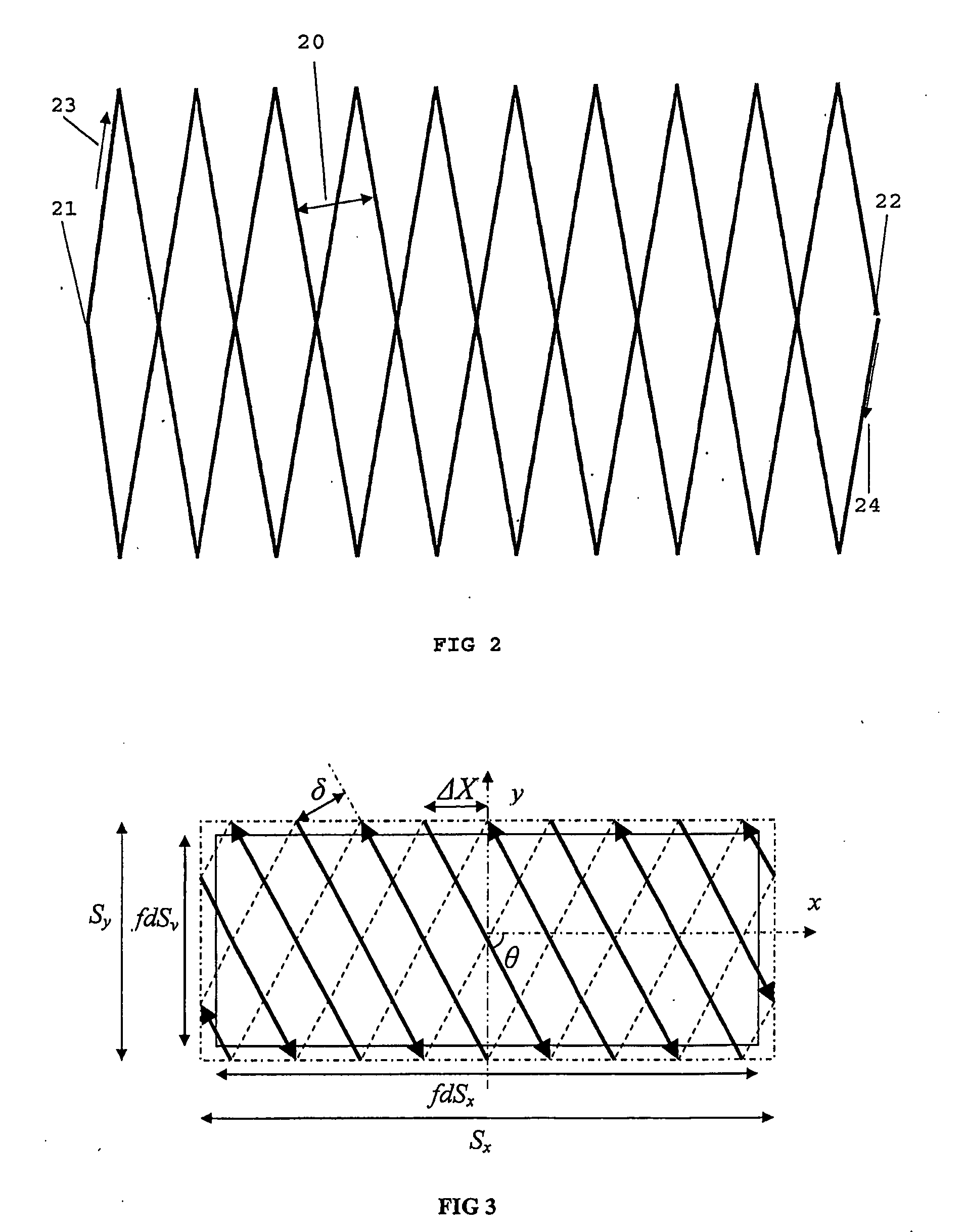

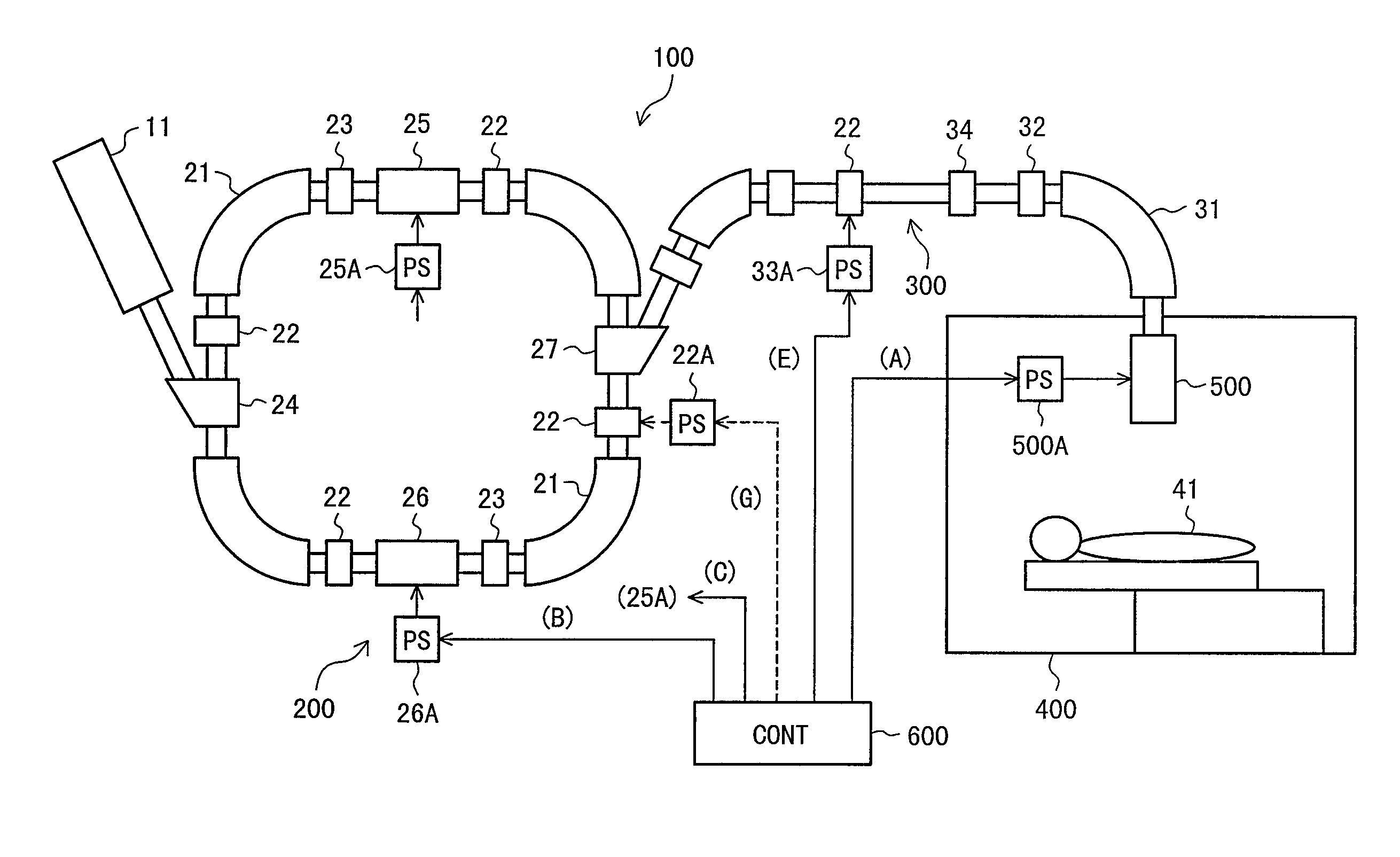

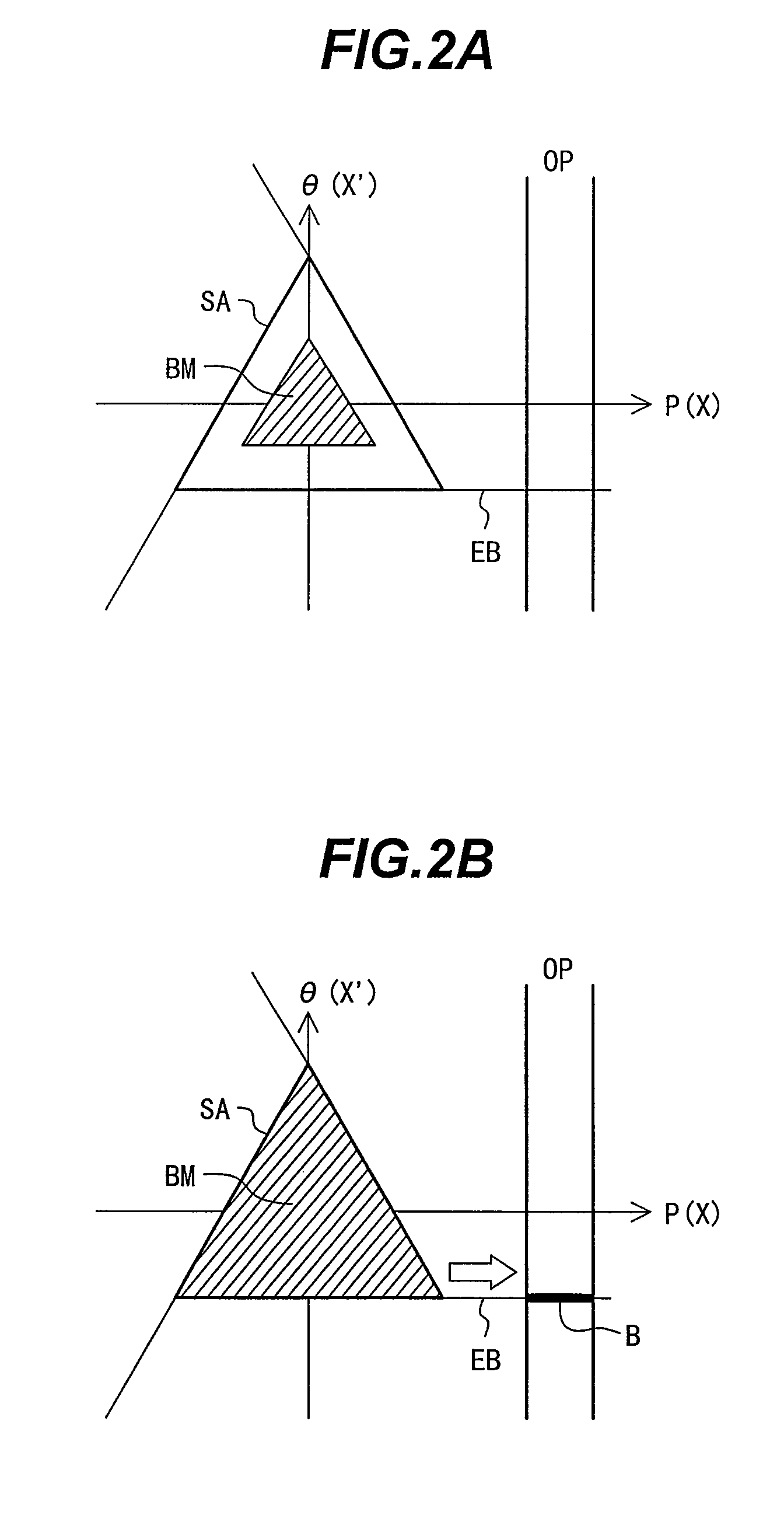

Method And Software For Irradiating A Target Volume With A Particle Beam And Device Implementing Same

The present invention is related to a method for treating or irradiating a target volume with a particle beam produced by an accelerator, comprising the steps of: deflecting said particle beam with the help of scanning means in two orthogonal (X, Y) directions, thereby constituting an irradiation plane perpendicular to the direction (Z) of the beam, defining in the irradiation plane a scanning field which circumscribes the area of intersection of target volume and irradiation plane and scanning said scanning field by drawing scan lines which form a scan pattern comprising interleaved frames of triangle waves. The scan pattern is preferably continuous and represents contiguous rhombi figures. The invention is equally related to a device and a software program or sequencer implementing the method.

Owner:ION BEAM APPL

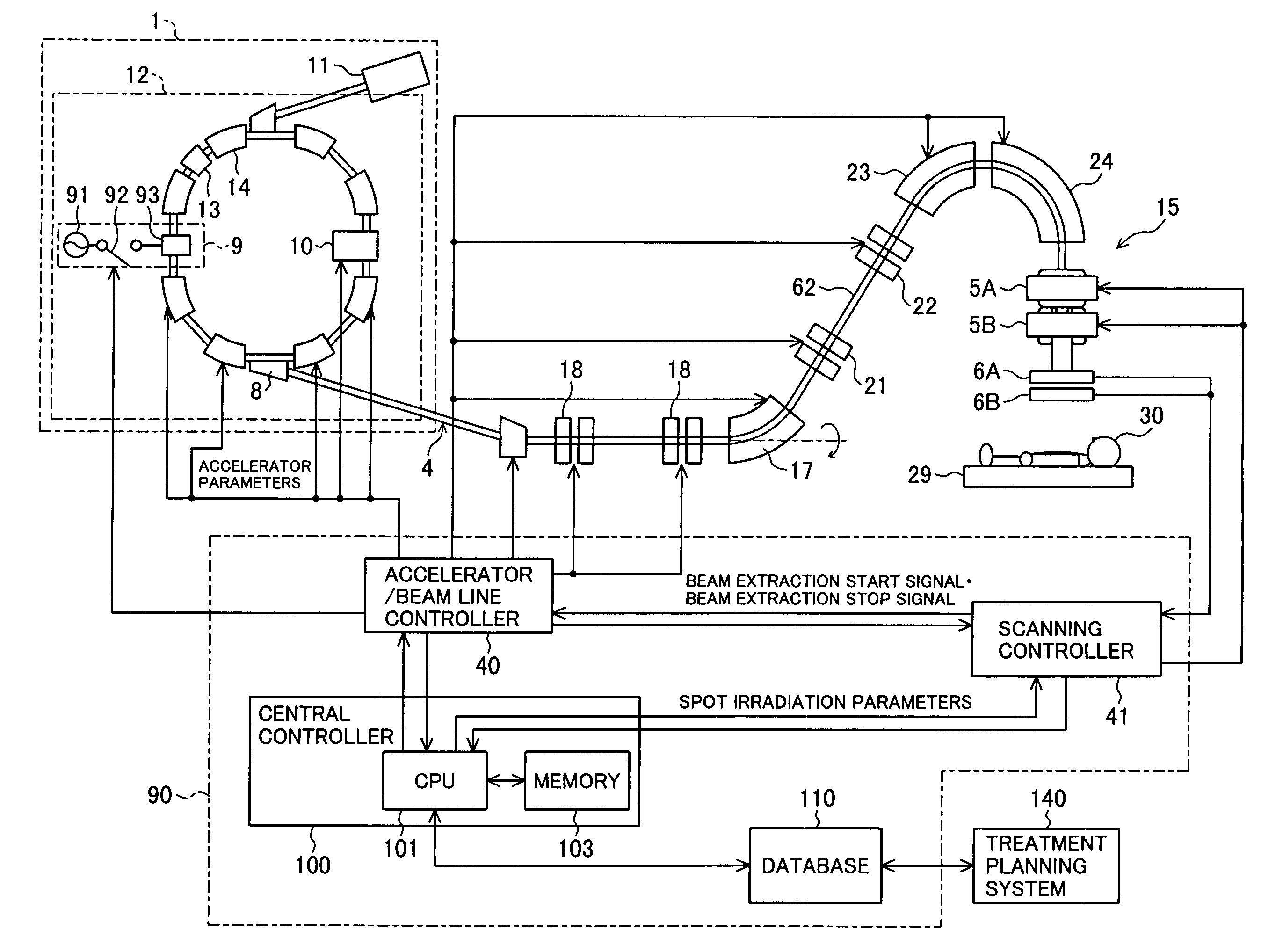

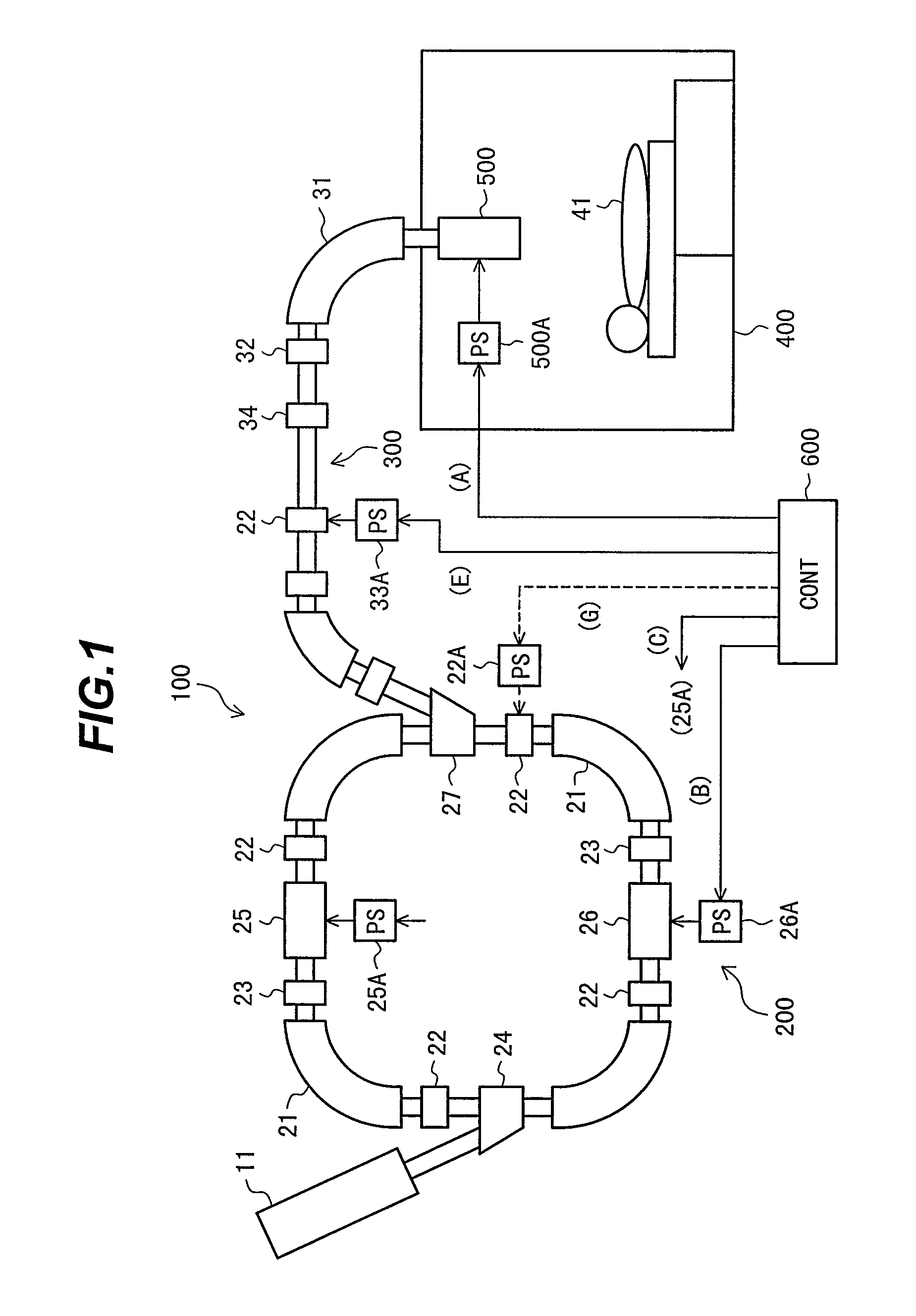

Particle beam therapy system

ActiveUS7772577B2Quality improvementLow costElectrode and associated part arrangementsMaterial analysis by optical meansTransport systemSynchrotron

A particle beam therapy system using a spot scanning method includes a synchrotron, a beam transport system, an irradiation system, and a controller. A controller is configured to turn on a radio frequency electromagnetic field to be applied to an extraction system when a charged particle beam is to be supplied to the irradiation system, and turn off the radio frequency electromagnetic field to be applied to the extraction system when the supply of the charged particle beam to the irradiation system is to be blocked by means of an electromagnet provided in the beam transport system or in the synchrotron. The controller is also adapted to turn off a radio frequency acceleration voltage to be applied to an acceleration cavity in synchronization with the turning-off of the radio frequency electromagnetic field to be applied to the extraction device.

Owner:HITACHI LTD

Particle beam nozzle

An improved particle beam treatment system optionally includes exchangeable particle beam nozzles. These particle beam nozzles may be automatically moved from a storage location to a particle beam path or between particle beam paths for use in medical applications. Movement may be achieved using a conveyance, gantry, rail system, or the like. The improved particle beam treatment system optionally also includes more than two alternative particle beam paths. These alternative particle beam paths may be directed to a patient from a variety of different angles and in different planes.

Owner:VARIAN MEDICAL SYSTEMS

Particle beam system including exchangeable particle beam nozzle

An improved particle beam treatment system optionally includes exchangeable particle beam nozzles. These particle beam nozzles may be automatically moved from a storage location to a particle beam path or between particle beam paths for use in medical applications. Movement may be achieved using a conveyance, gantry, rail system, or the like. The improved particle beam treatment system optionally also includes more than two alternative particle beam paths. These alternative particle beam paths may be directed to a patient from a variety of different angles and in different planes.

Owner:VARIAN MEDICAL SYSTEMS

Medical particle irradiation apparatus

InactiveUS6903356B2Simple structurePrevent rotationThermometer detailsBeam/ray focussing/reflecting arrangementsMoving floorParticle beam

Disclosed is a medical particle irradiation apparatus comprising a rotating gantry 1 including an irradiation unit 4 emitting particle beams; an annular frame 16 located within and supported by the rotating gantry 1 such that it can rotate relative to the rotating gantry 1; an annular frame 15 fixedly located opposite the annular frame 16; an anti-corotation mechanism 34 being in contact with both the annular frames 16 and 15 to prevent the annular frame 16 from rotating together with the rotating gantry 1 during rotation of the rotating gantry 1; and a flexible moving floor 17 interposed between the annular frames 15 and 16, the flexible moving floor 17 being engaged with the annular frames 15 and 16 in such a manner as to move freely such that its bottom is substantially level and that it moves as the rotating gantry rotates.

Owner:HITACHI LTD +1

Elongated lifetime x-ray method and apparatus used in conjunction with a charged particle cancer therapy system

ActiveUS20100008469A1Beam/ray focussing/reflecting arrangementsX-ray tube electrodesX-rayX ray image

The system uses an X-ray imaging system having an elongated lifetime. Further, the system uses an X-ray beam that lies in substantially the same path as a charged particle beam path of a particle beam cancer therapy system. The system creates an electron beam that strikes an X-ray generation source located proximate to the charged particle beam path. By generating the X-rays near the charged particle beam path, an X-ray path running collinear, in parallel with, and / or substantially in contact with the charged particle beam path is created. The system then collects X-ray images of localized body tissue region about a cancerous tumor. Since, the X-ray path is essentially the charged particle beam path, the generated image is usable for precisely target the tumor with a charged particle beam.

Owner:BALAKIN ANDREY VLADIMIROVICH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com