Patents

Literature

2882 results about "Coolant flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coolant flow is either laminar or turbulent, or in transition between laminar and turbulent. For laminar flow, heat transfer increases proportional to the cube root of the flow rate.

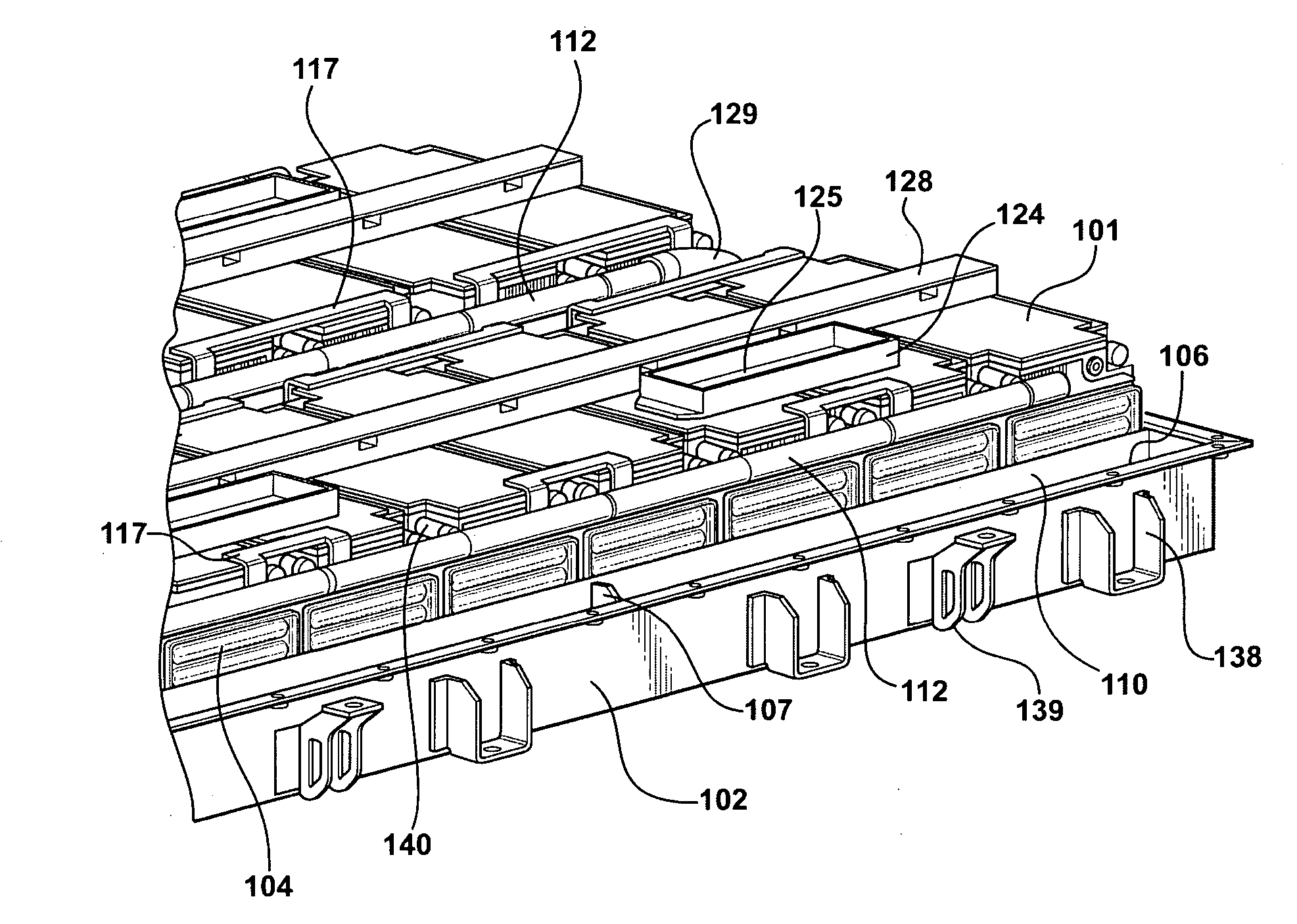

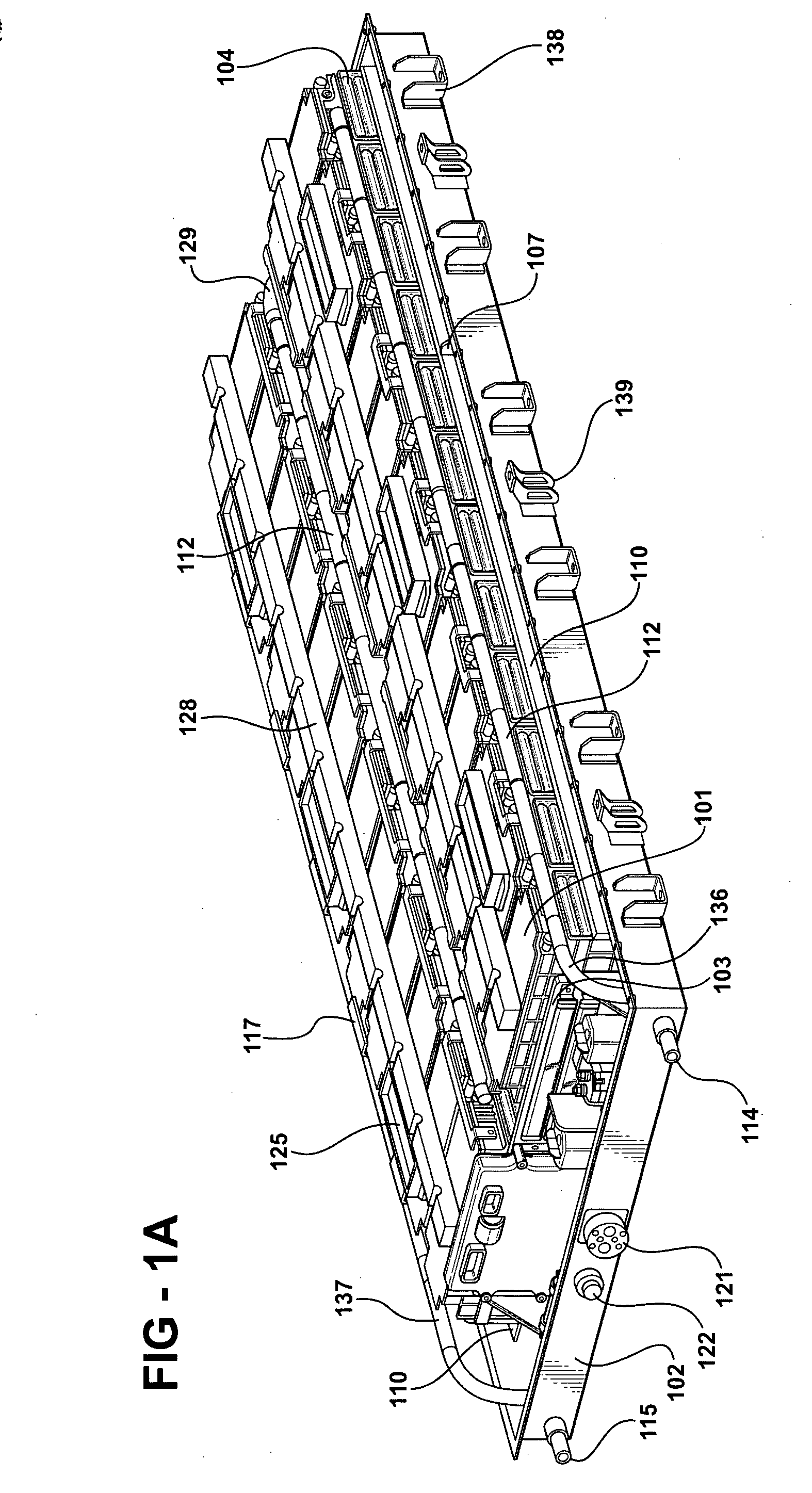

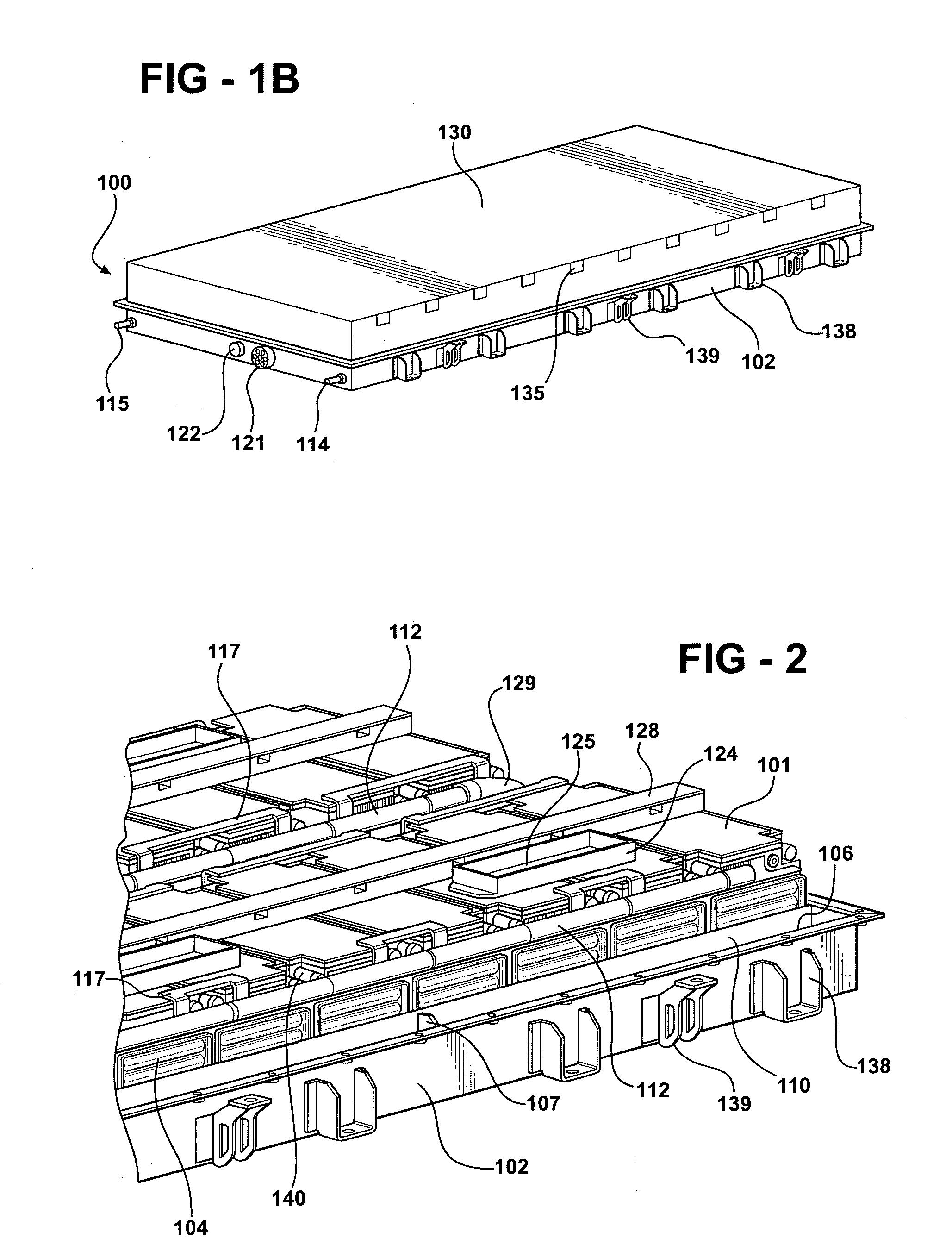

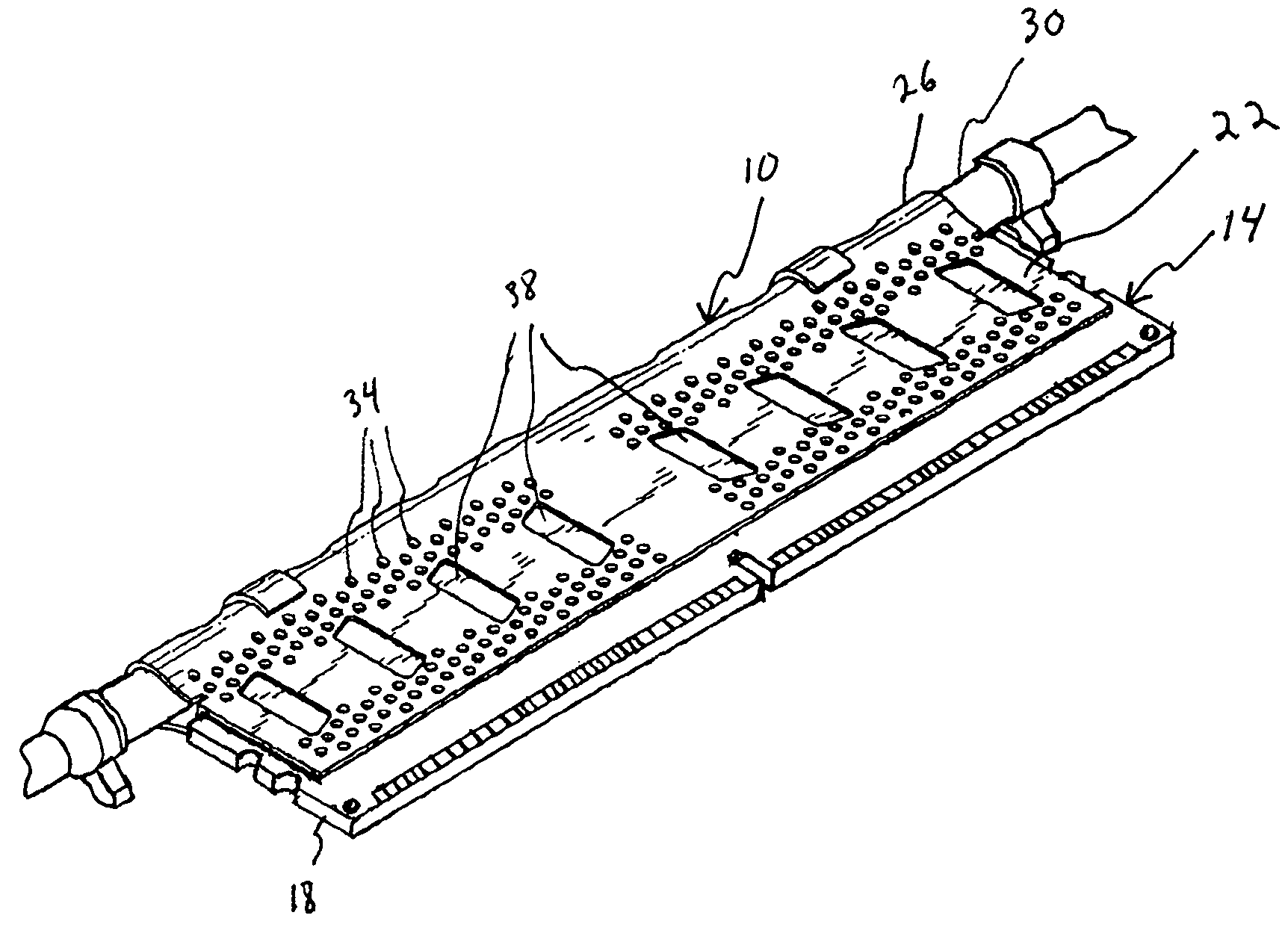

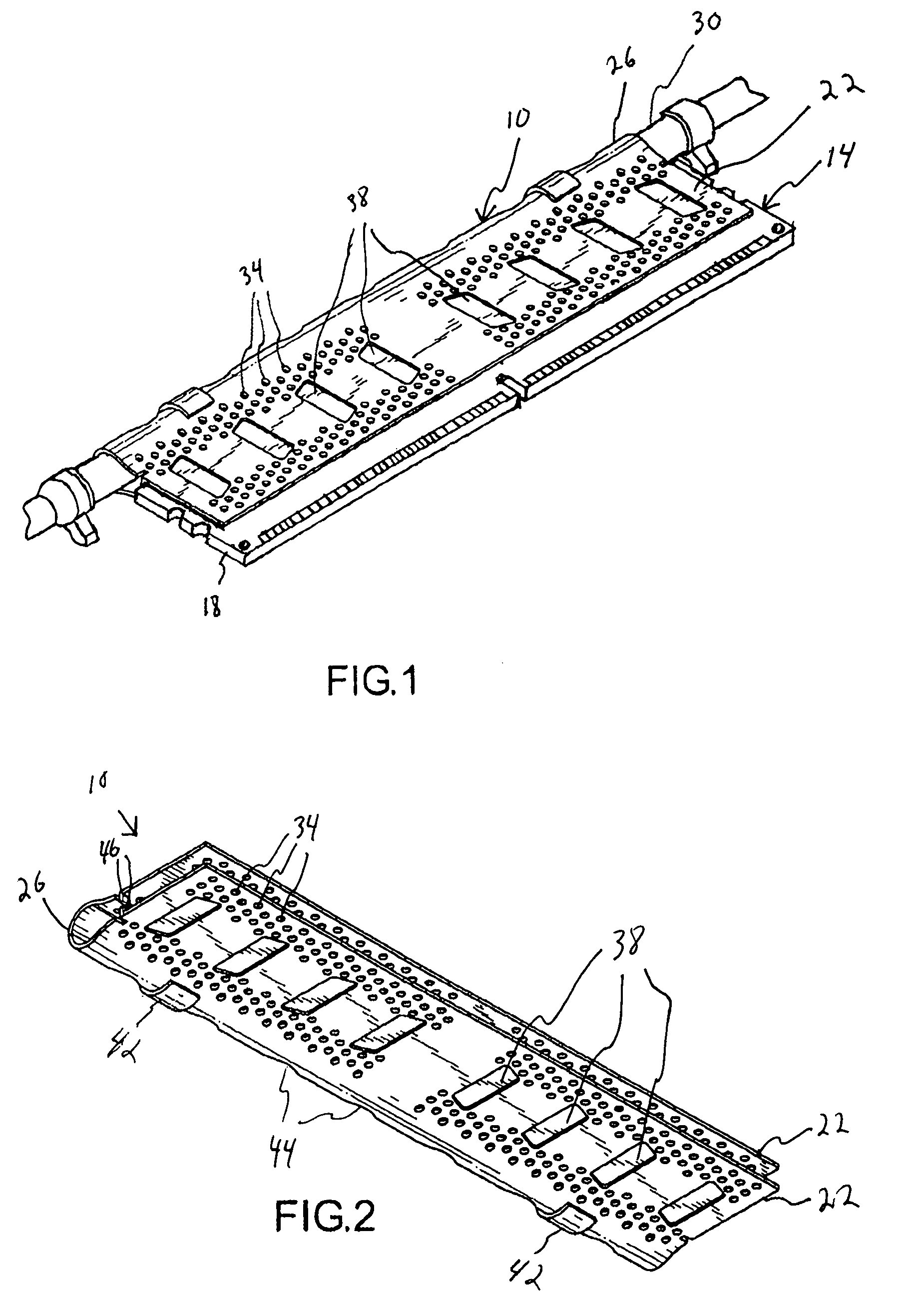

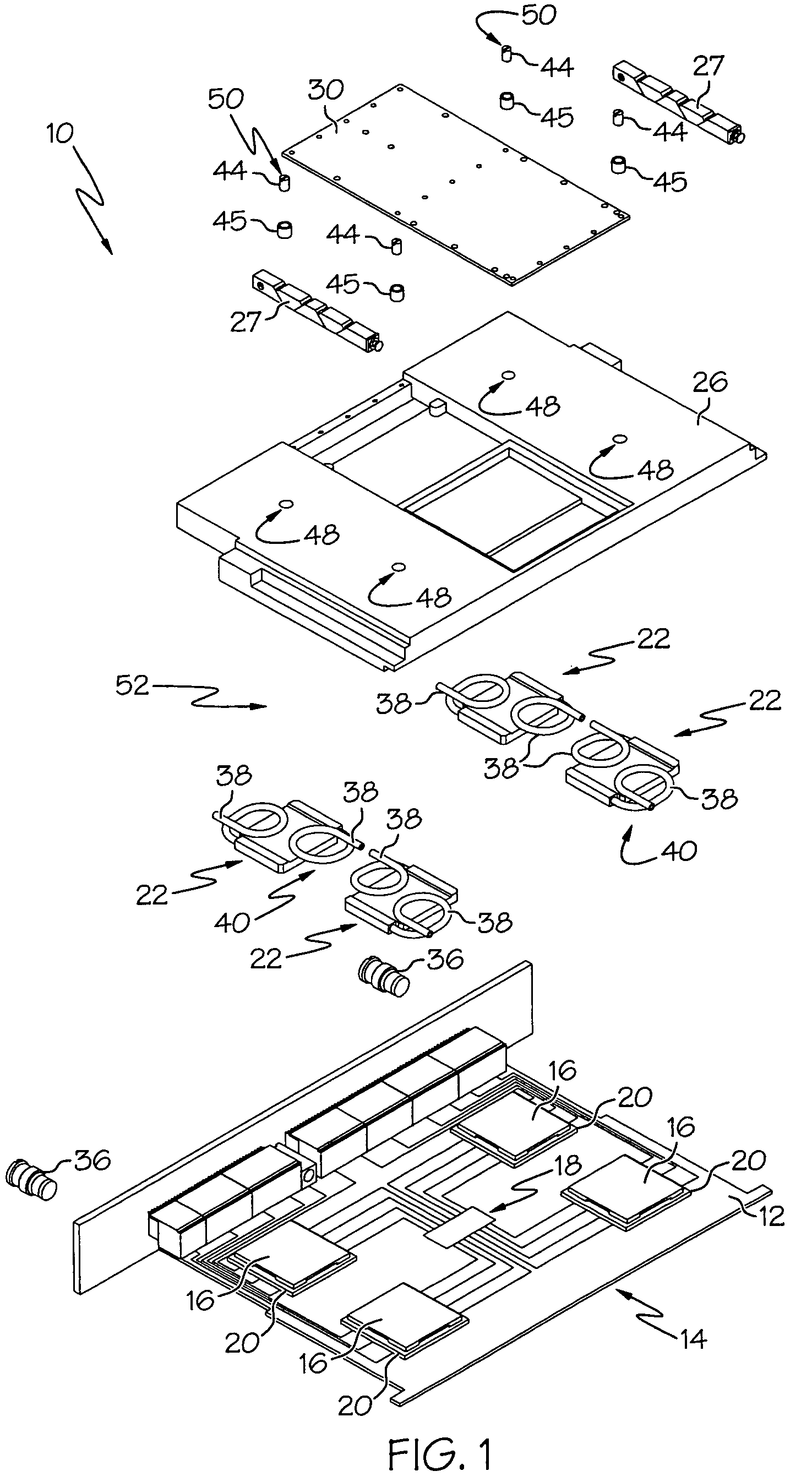

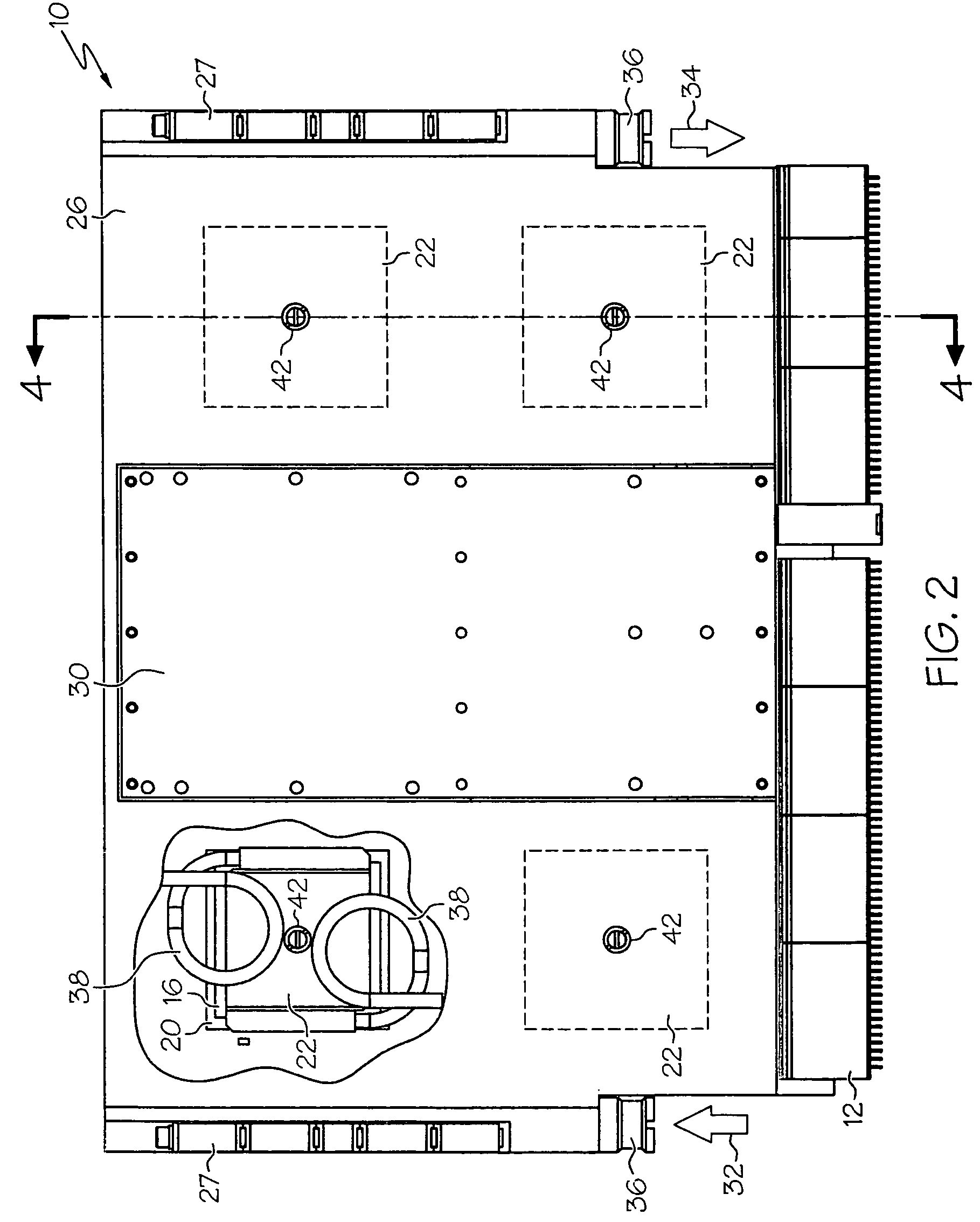

Modular battery system

InactiveUS20070087266A1Primary cell to battery groupingFinal product manufactureCoolant flowMonitoring system

Disclosed herein is a modular battery system having at least one set of battery modules, preferably monoblock modules connected in series. Each of the battery modules may be designed with a first endplate and a second endplate, wherein each battery module is set between the first and second endplates and at least one band member couples the endplates to each other, binding the battery module between the endplates. The endplates are secured between a pair of rails and the system is disposed in a system housing. A cooling manifold provides a system wherein coolant flows into and out of each battery module. The system housing preferably has a coolant inlet and a coolant outlet. The cooling manifold is in flow communication with the coolant inlet and the coolant outlet. A battery monitoring system, which may include a battery control module and at least one remote sensing module, preferably monitors and collects performance and status information, such as voltage and temperature, of the battery modules. An integrated control unit (ICU) may be disposed in the system housing. The ICU supports electronics, some of which are used to collect electrical energy produced by the battery modules and / or monitor the system.

Owner:BATTERY PATENT TRUST

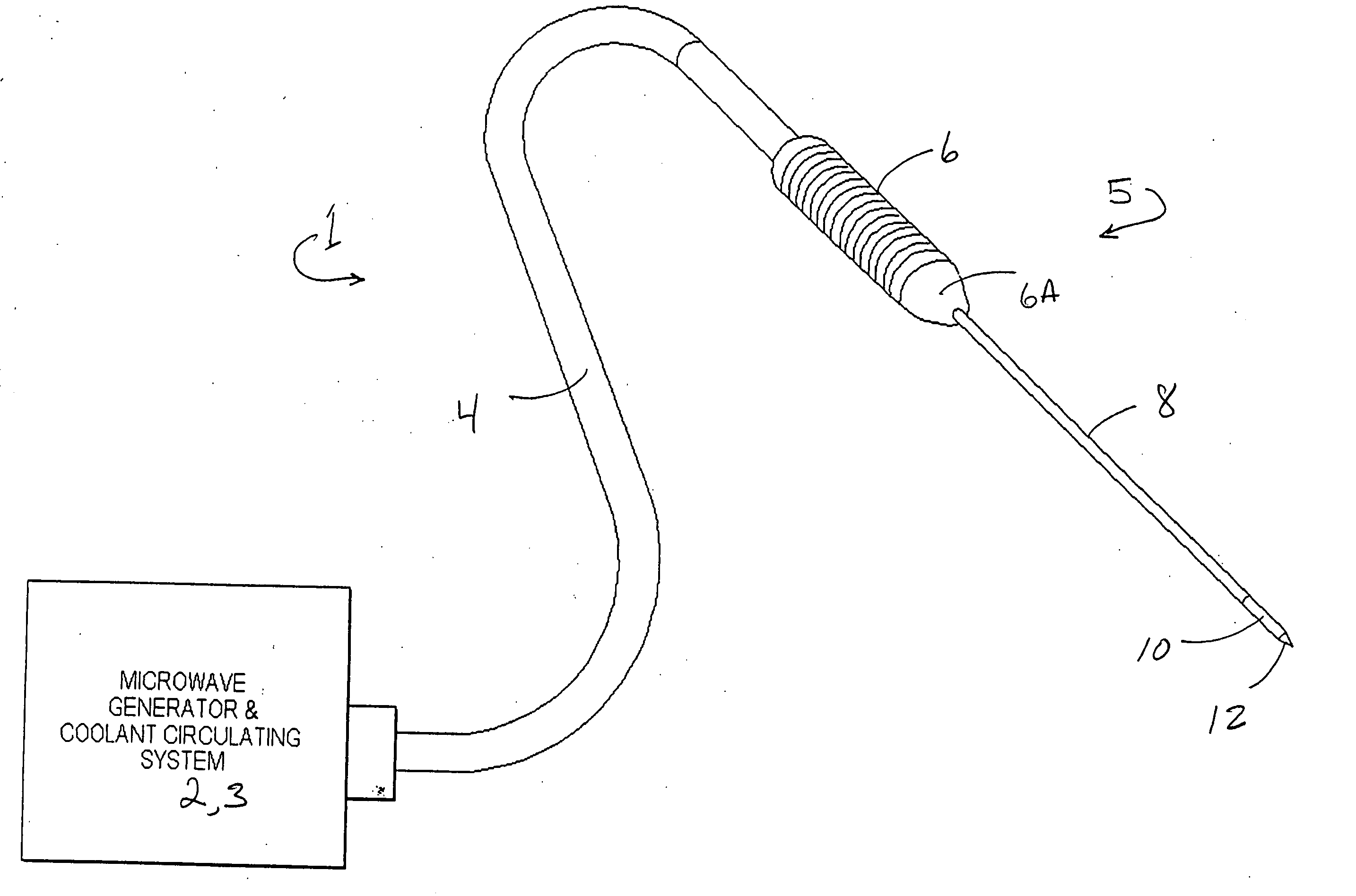

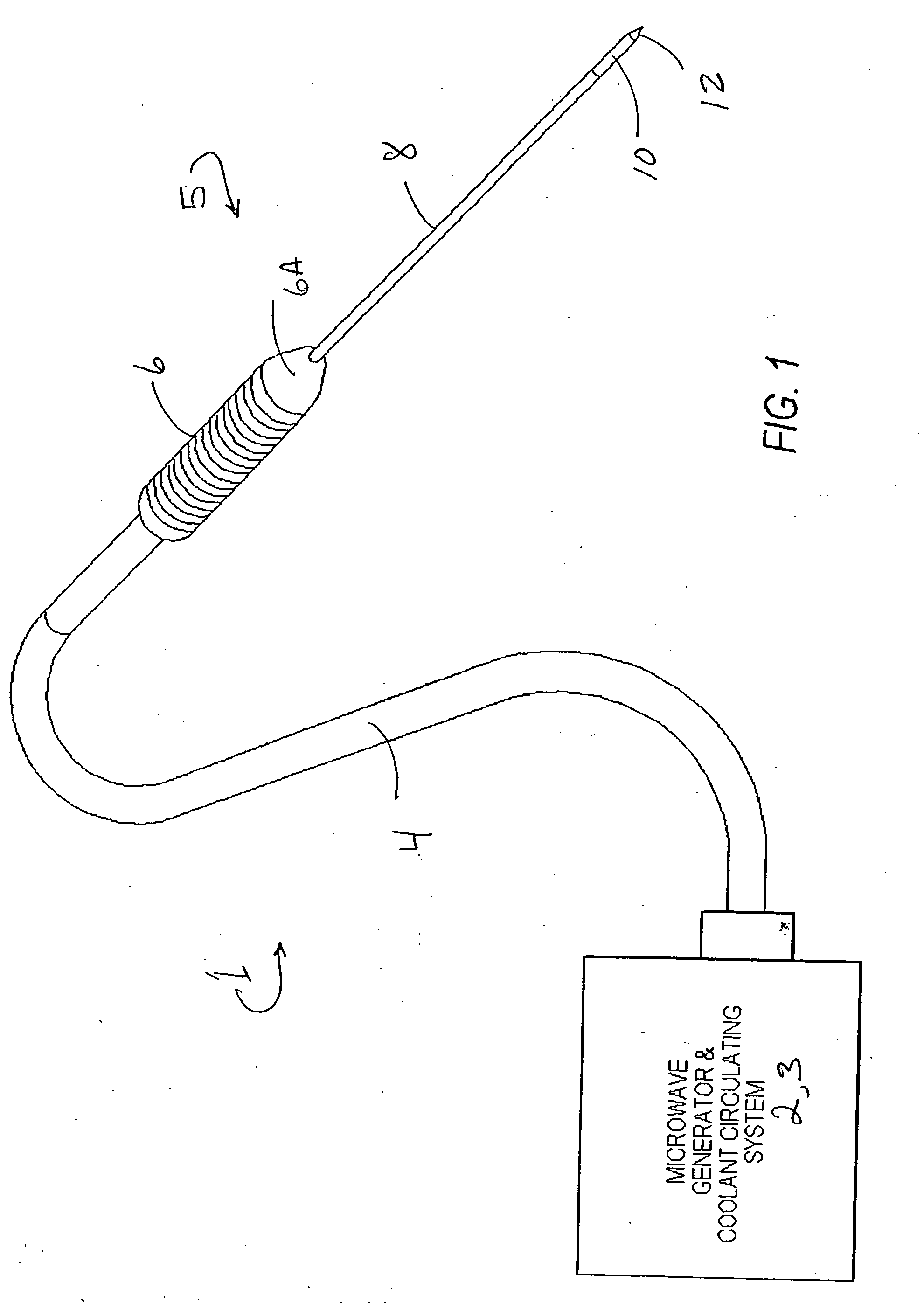

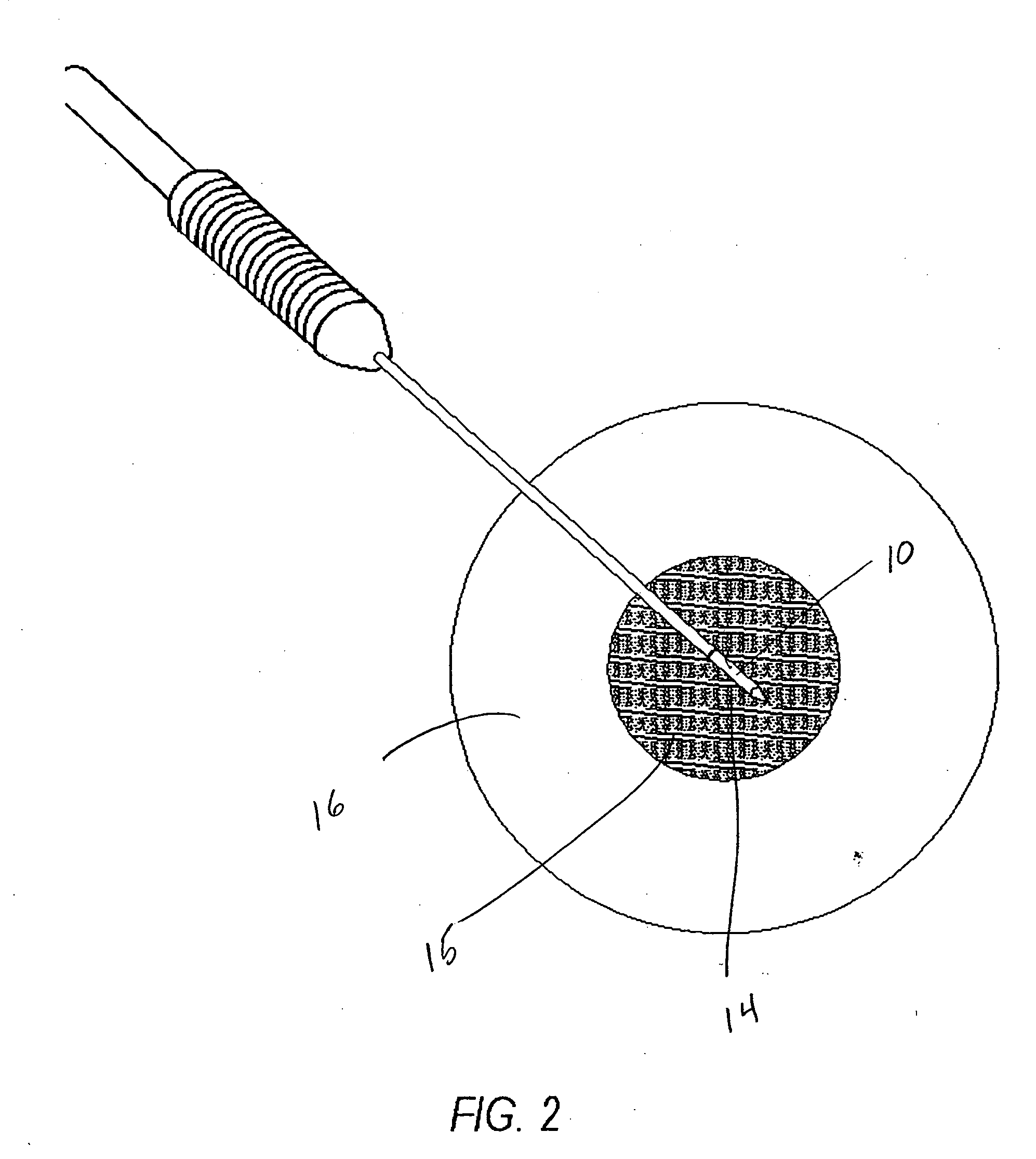

Cell necrosis apparatus with cooled microwave antenna

InactiveUS20050245920A1Minimize potential for bucklingSmall sizeElectrotherapySurgical instruments for heatingElectricityCoolant flow

A cell necrosis apparatus for delivering thermal microwave energy to a specific site in a body, including: a. a microwave generator, b. a coolant delivery system for delivering and circulating a quantity of cooled liquid coolant via inlet and return passageways, c. a probe including a probe handle and a probe body having a proximal portion coupled to the probe handle and a distal portion, d. a microwave antenna in the distal portion of the probe body for applying thermal microwave energy to a specific site in cell necrosis treatment, and e. a microwave transmission line extending from the microwave generator to and through the probe handle and to and through the probe body to the microwave antenna and electrically coupled thereto, where the inlet and return coolant flow passageways extend from the coolant delivery system to and through the probe handle and thence extend coaxially about the microwave transmission line and along the length thereof within the probe body, and extend coaxially about the antenna and long the length thereof within the probe body, and where a first of the inlet and return coolant flow passageways is radially outward of and immediately adjacent the microwave transmission line and the antenna within the probe body and the other of the inlet flow passageways is radially outward of the first flow passageway.

Owner:TELEFLEX LIFE SCI LTD

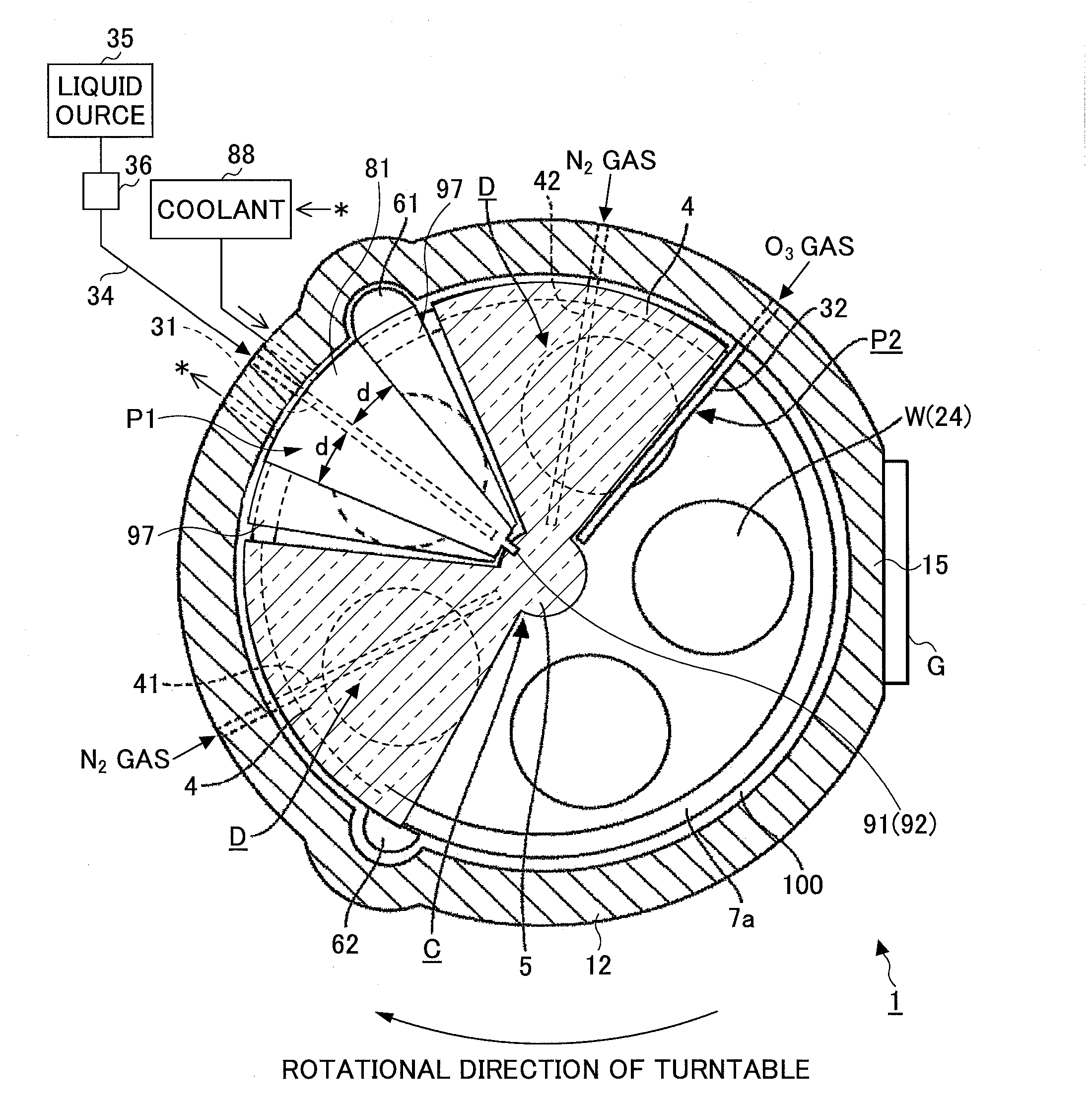

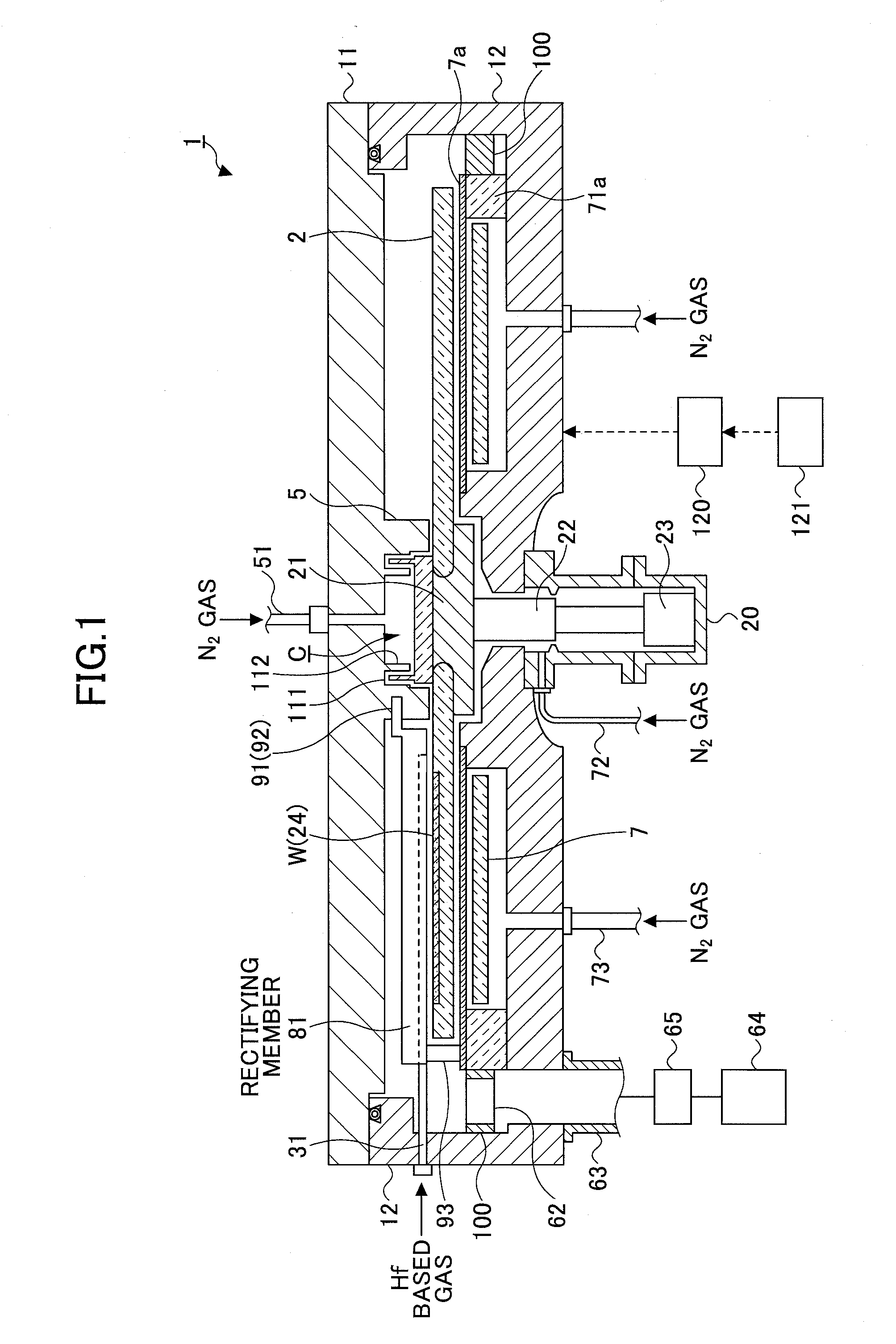

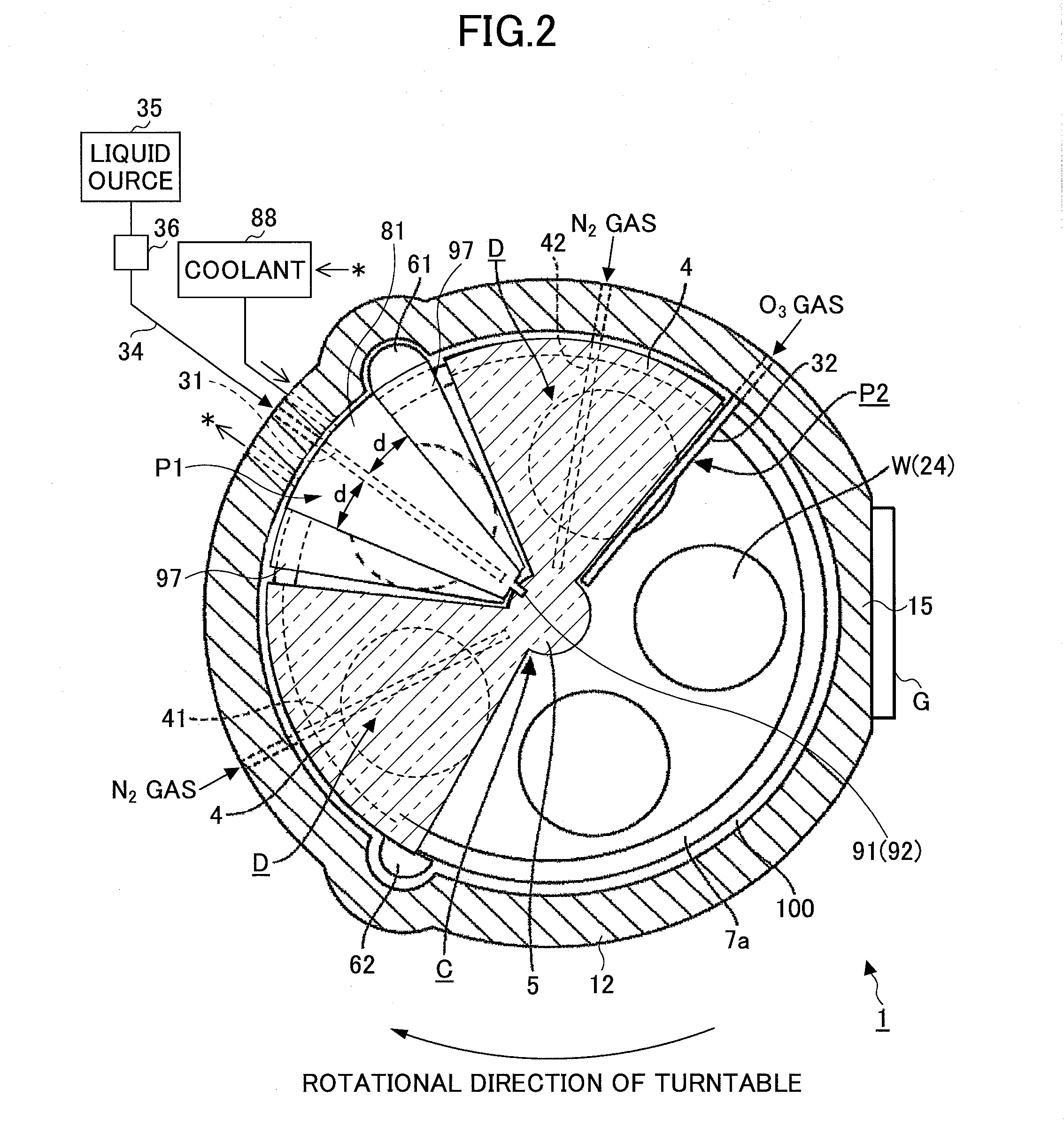

Film deposition apparatus

In discharging a source gas from a first process gas nozzle, rectifying members including a coolant flow passage provided in a concertinaing manner therein are arranged both sides of the first process gas nozzle. Then, a coolant at a temperature higher than a liquefaction temperature of the source gas and lower than a thermal decomposition temperature of the source gas is flown through the coolant flow passage, by which the first process gas nozzle is cooled through the rectifying member.

Owner:TOKYO ELECTRON LTD

Non-linear fin heat sink

InactiveUS20090145581A1Improve power densityDissipating/removing heatSemiconductor/solid-state device detailsSolid-state devicesCoolant flowEngineering

A non-linear fin heat sink is provided for dissipating / removing heat uniformly from a device, where the heat generation is non-uniform over that device, while also providing a small and relatively lightweight heat sink. The heat sink has extended surface protrusions that are optimally shaped in recognition of convective heat transfer, conductive heat transfer, and flow resistance allowing the heat sink to offset the temperature rise of a coolant media and provide enhanced cooling for the coolant temperature, deliver optimized cooling efficiency per the local physical properties of the coolant media, be used with a fluid for effectuating heat transfer; either liquid coolant, gas coolant or a combination thereof. Furthermore the heat sink features turbulence enhancement of the coolant stream by a pin array through which coolant stream passes, such fin array featuring a non-linear shape, spacing, and height pattern to provide optimal cooling while simultaneously reducing volume and flow resistance.

Owner:THERMAL TECH

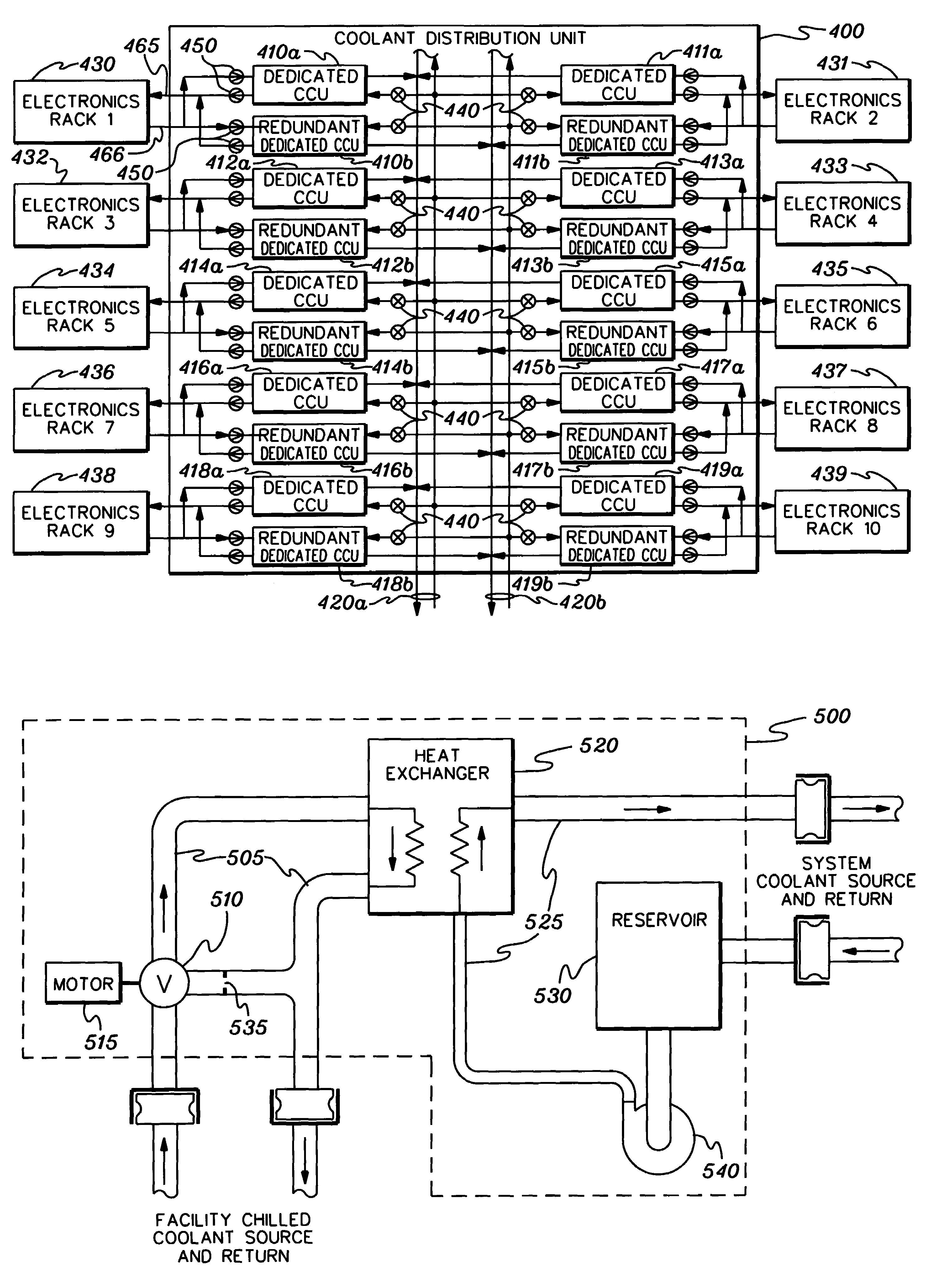

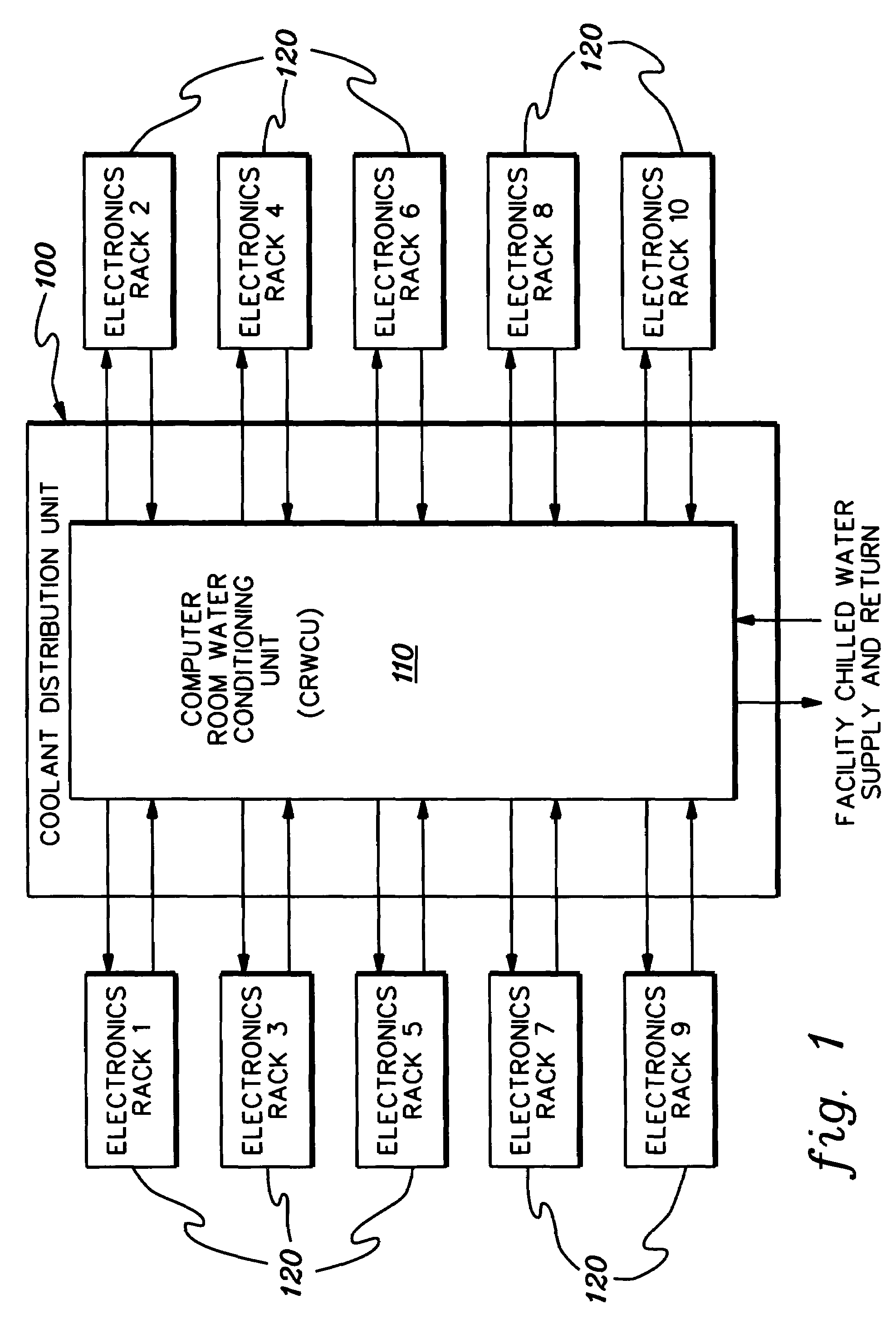

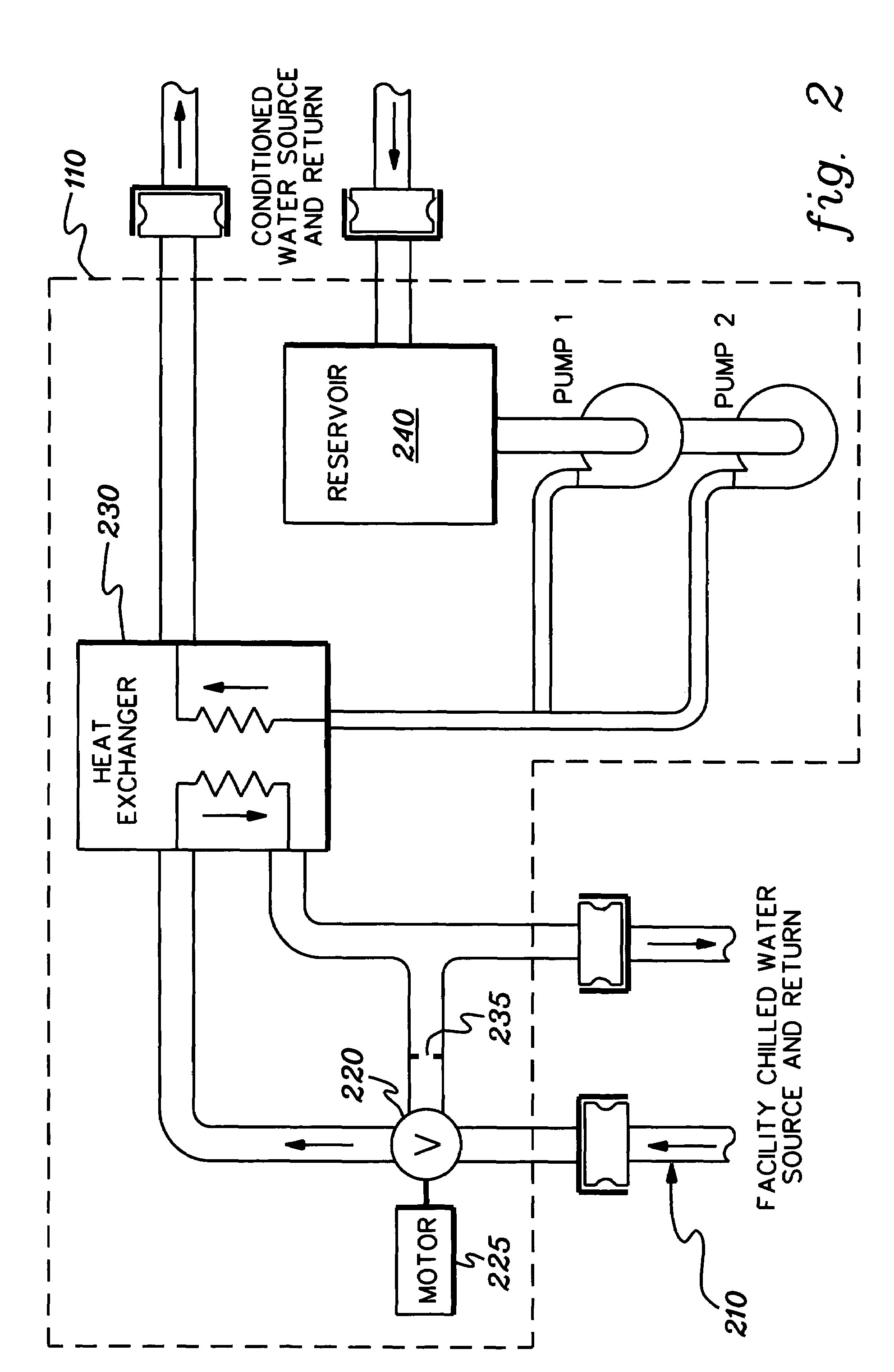

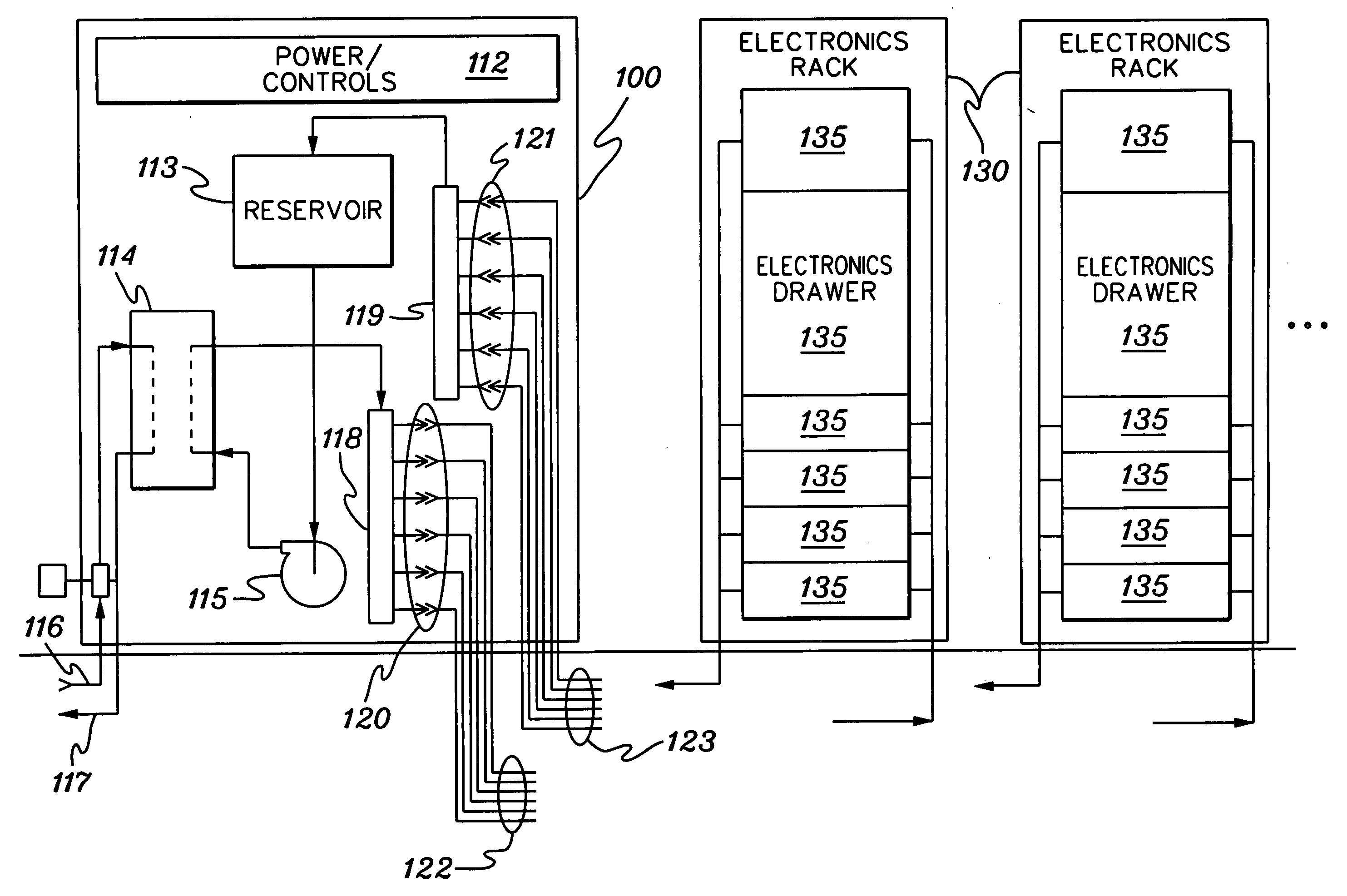

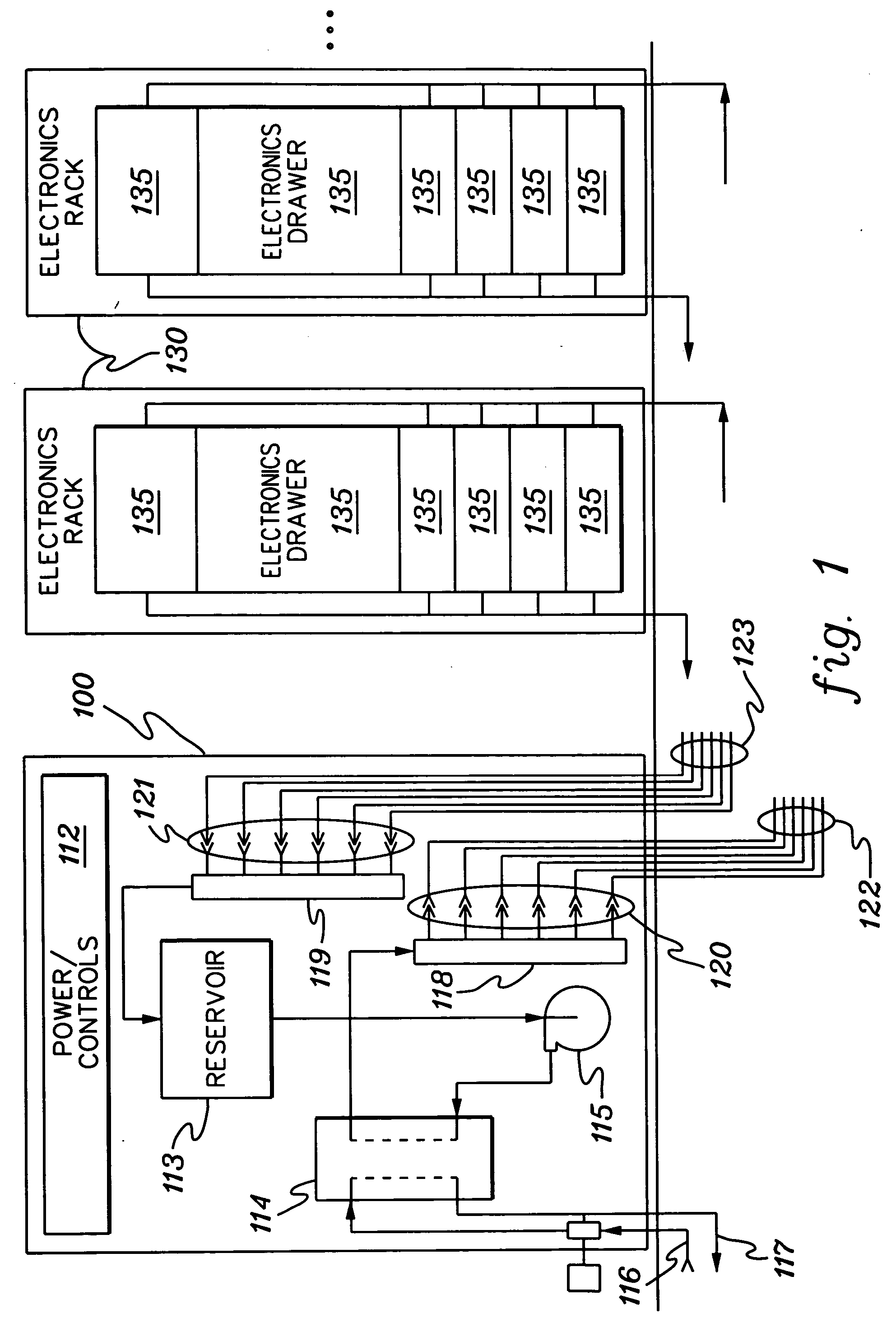

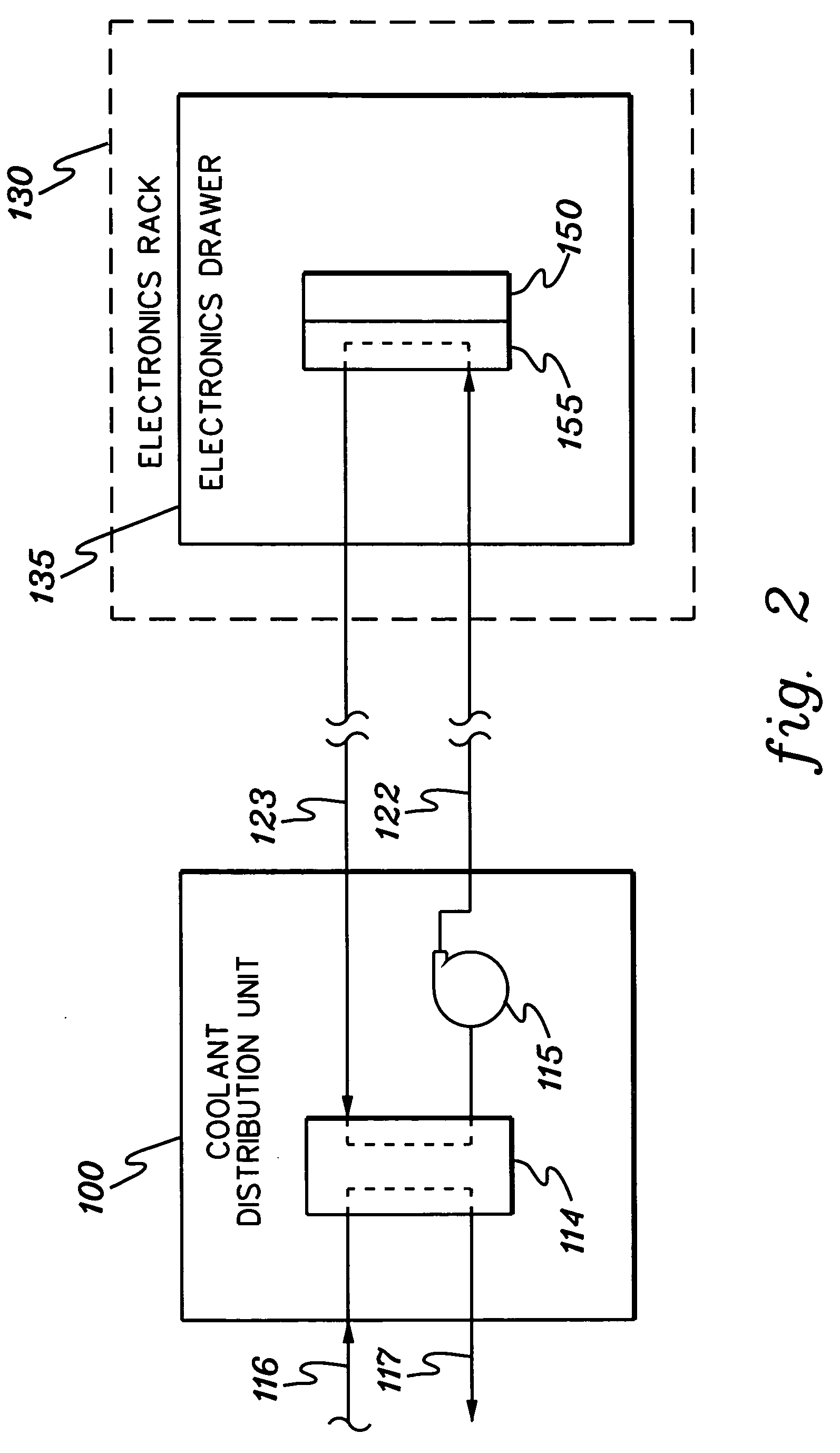

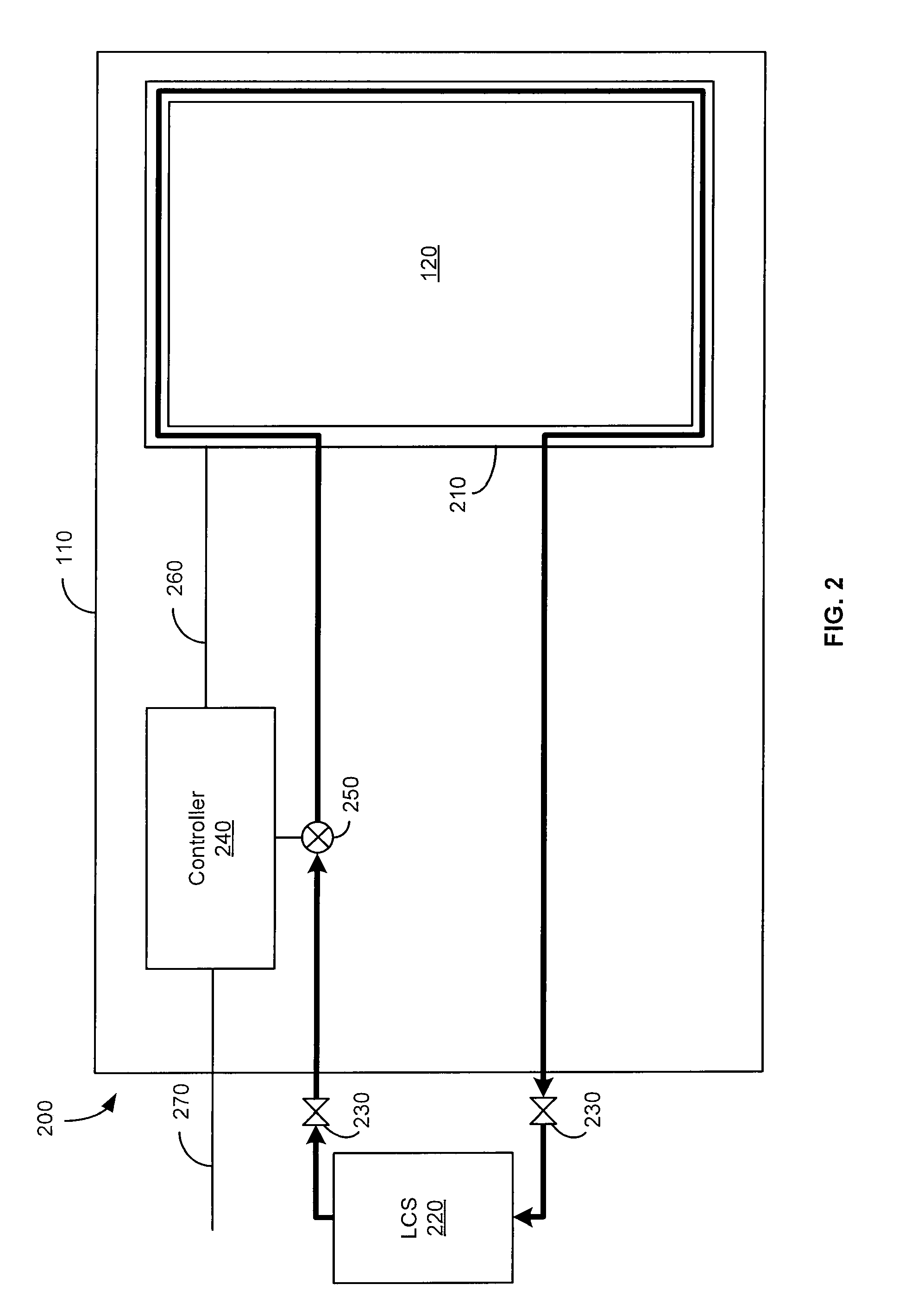

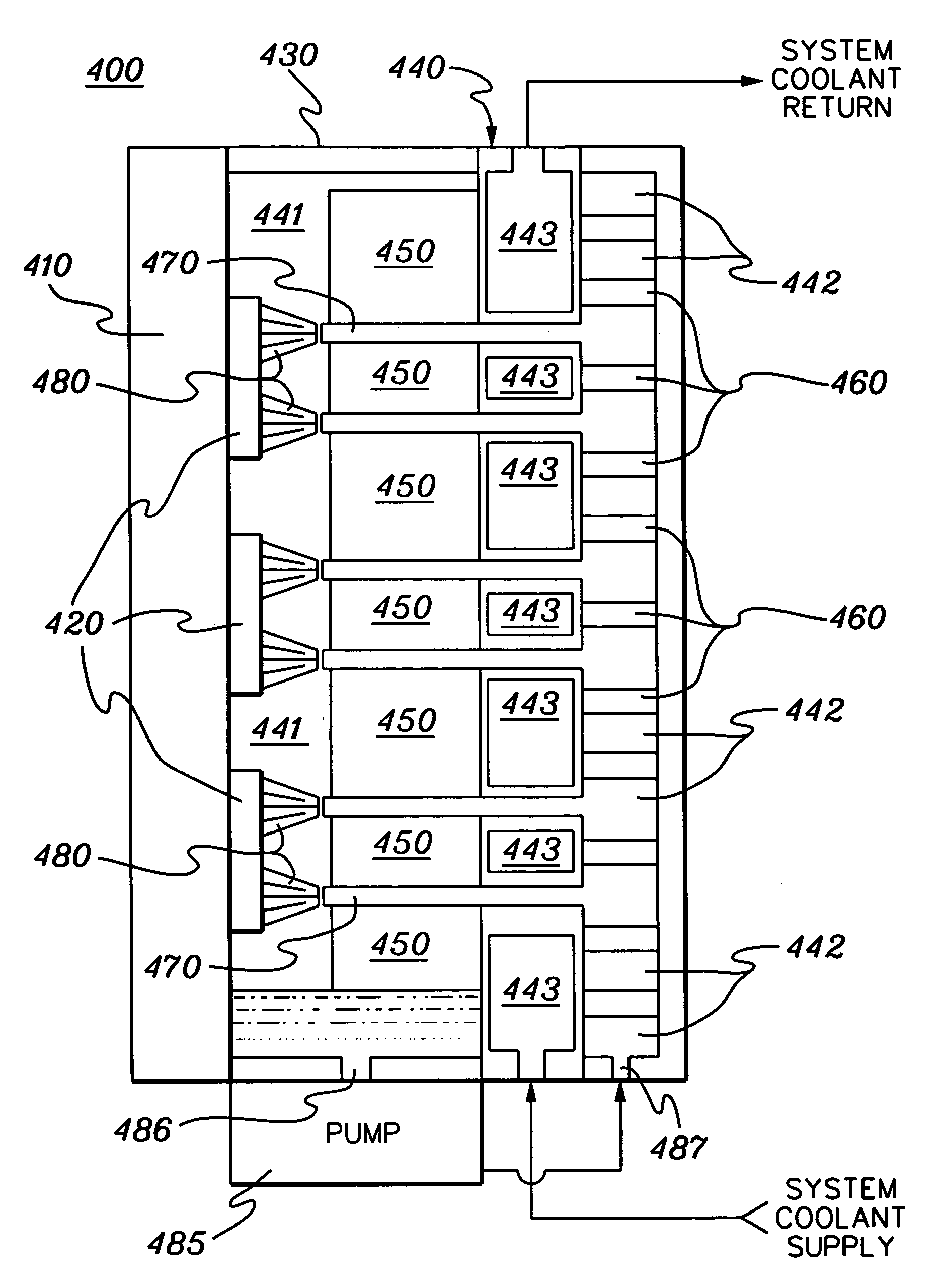

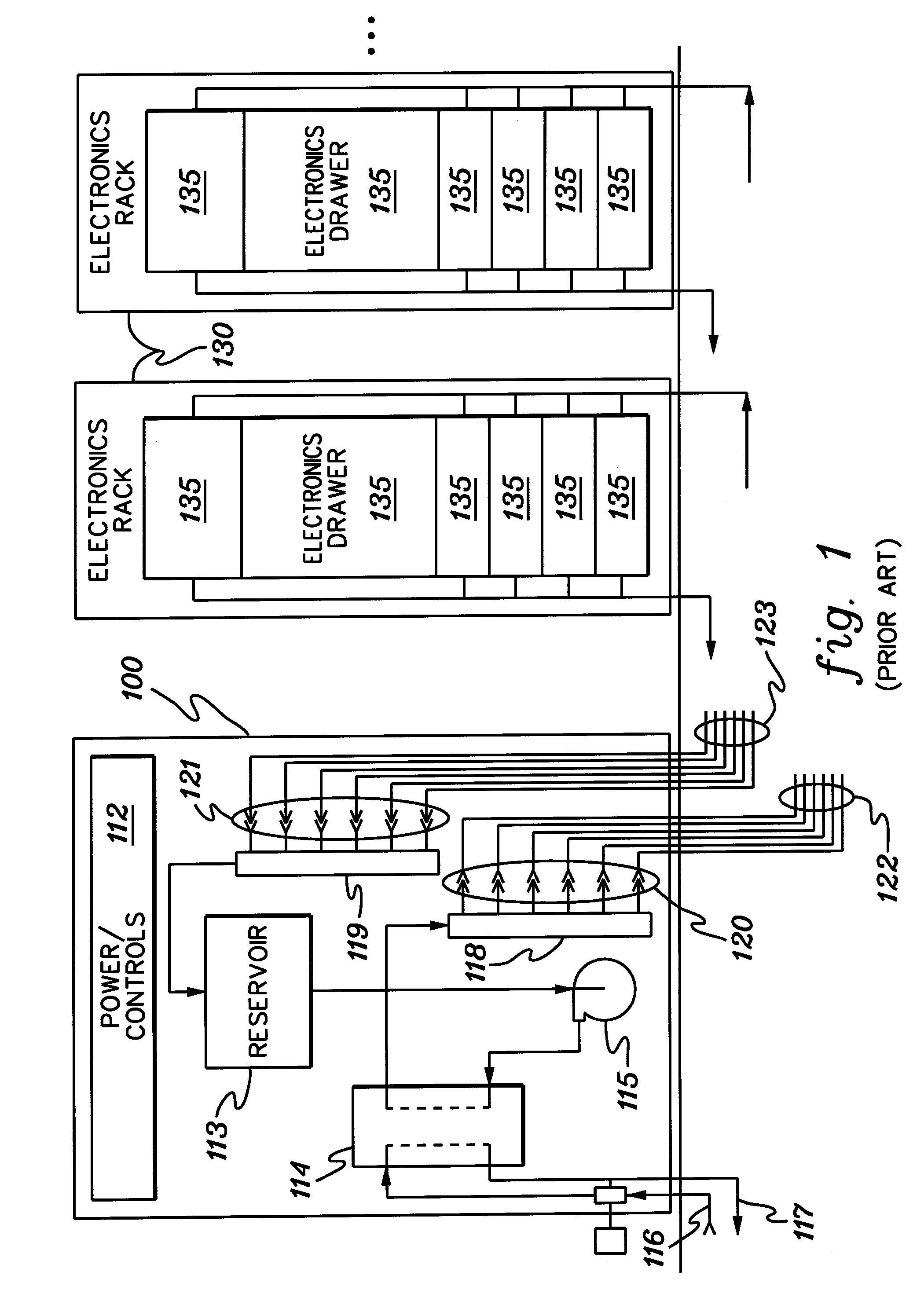

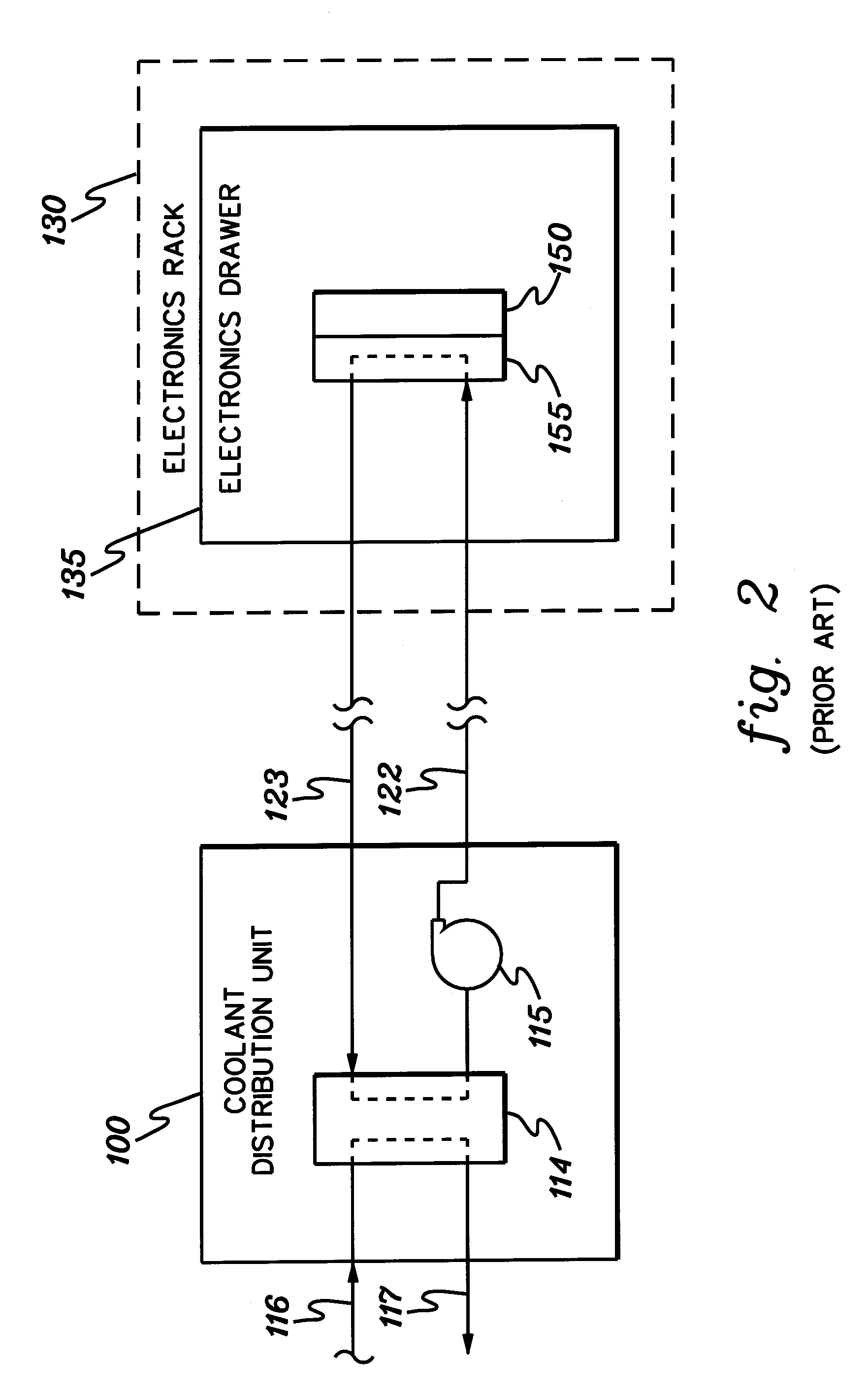

Cooling system and method employing multiple dedicated coolant conditioning units for cooling multiple electronics subsystems

InactiveUS7106590B2Superconductors/hyperconductorsDomestic cooling apparatusCoolant flowNuclear engineering

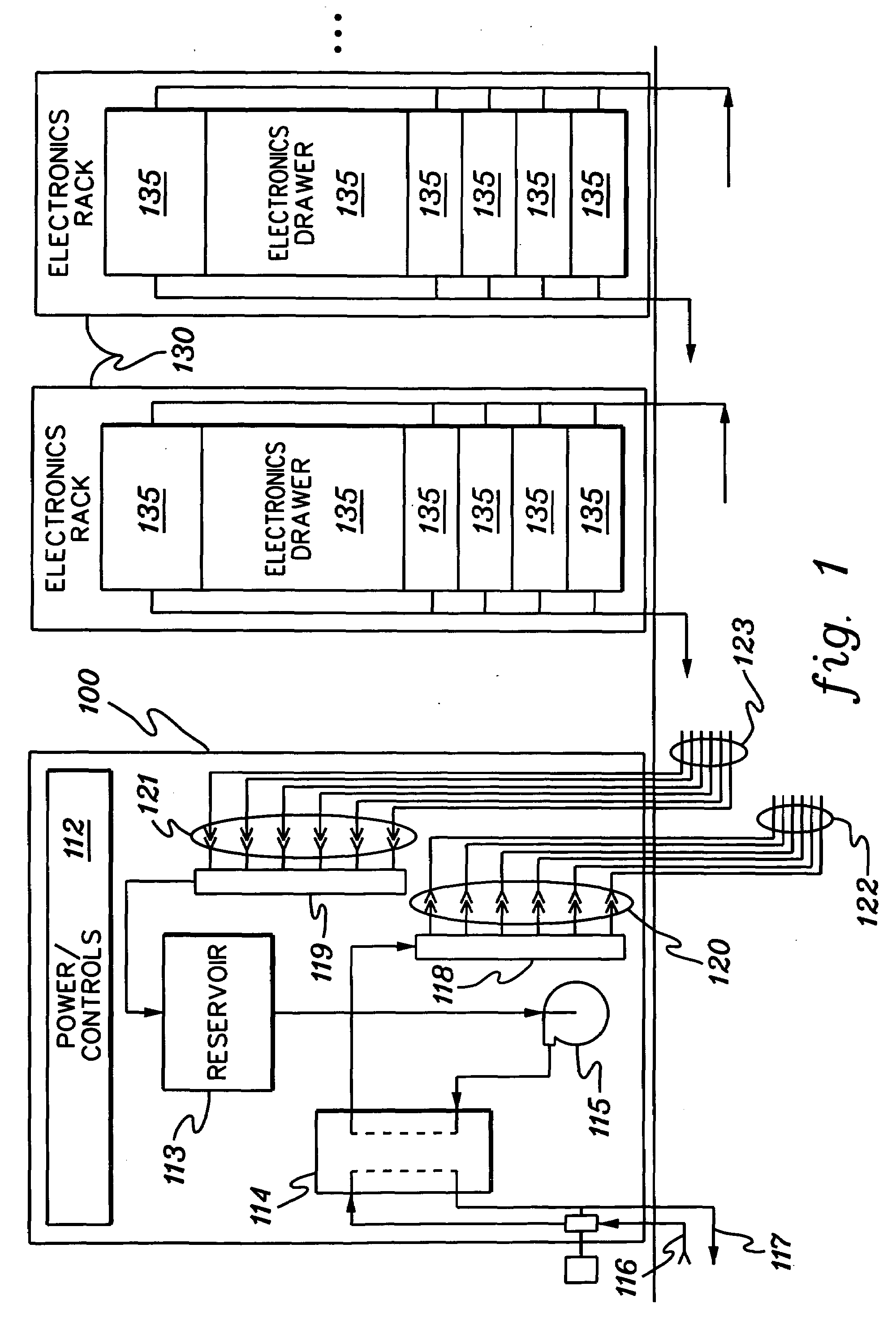

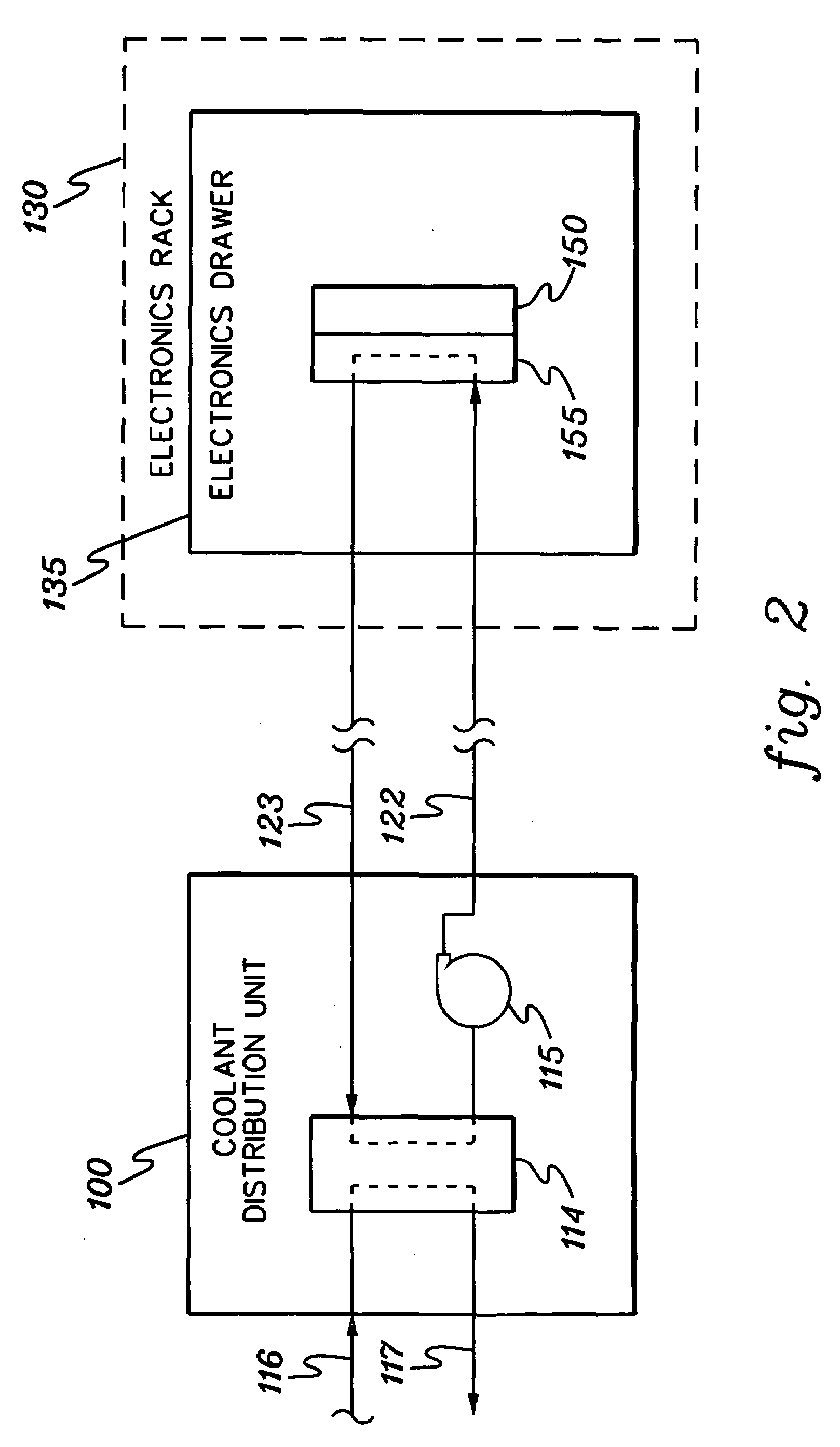

A cooling system is provided employing multiple coolant conditioning units (CCUs). Each CCU, which is coupled to a different, associated electronics rack of multiple electronics racks to be cooled, includes a heat exchanger, a first cooling loop with a control valve, and a second cooling loop. The first cooling loop receives chilled facility coolant from a source and passes at least a portion thereof via the control valve through the heat exchanger. The second cooling loop provides cooled system coolant to the associated electronics rack, and expels heat in the heat exchanger from the electronics rack to the chilled facility coolant in the first cooling loop. The control valve allows regulation of the facility coolant flow through the heat exchanger, thereby allowing independent control of temperature of the system coolant in the second cooling loop. Various CCU and associated component redundancies of the cooling system are also provided.

Owner:INT BUSINESS MASCH CORP

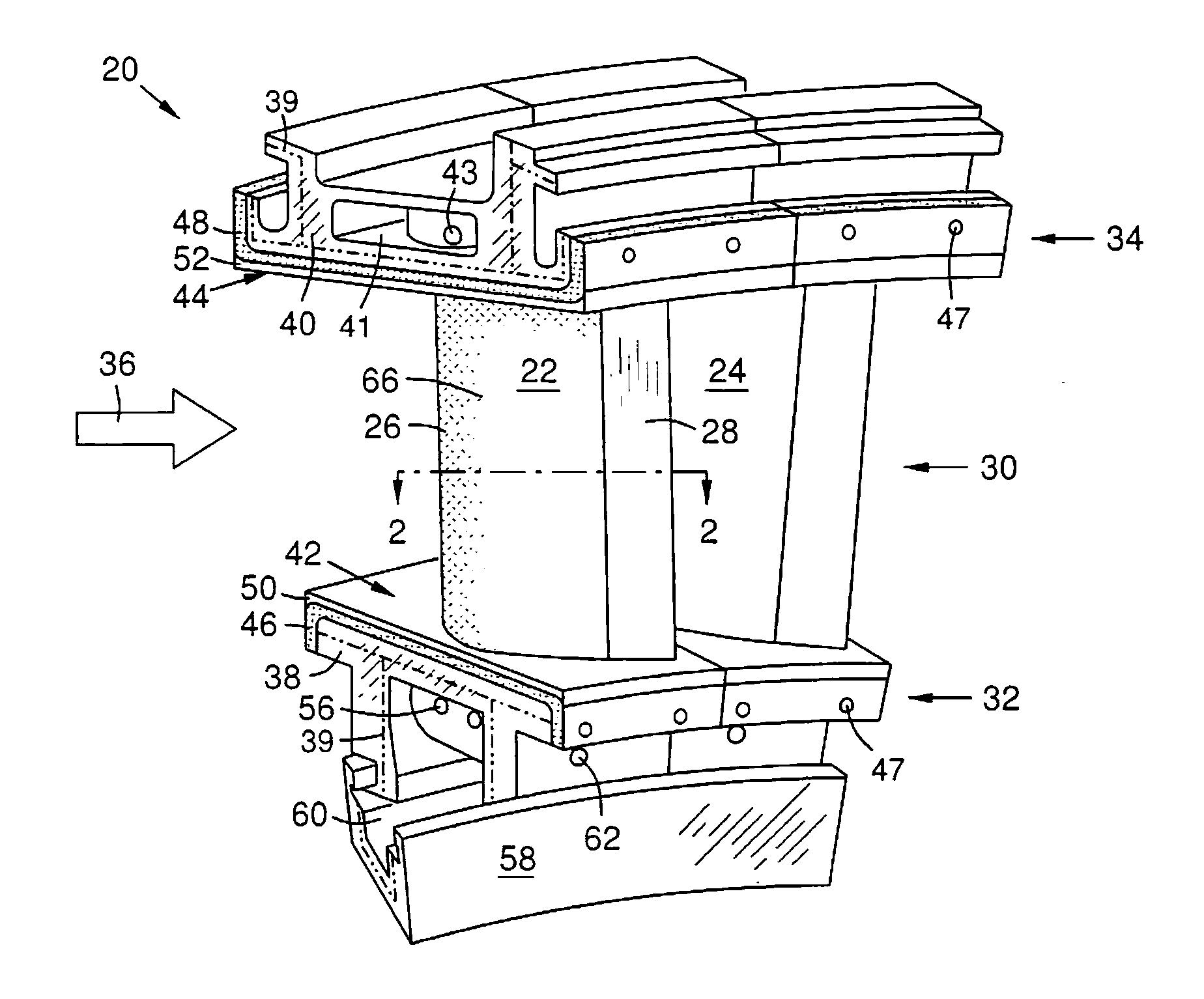

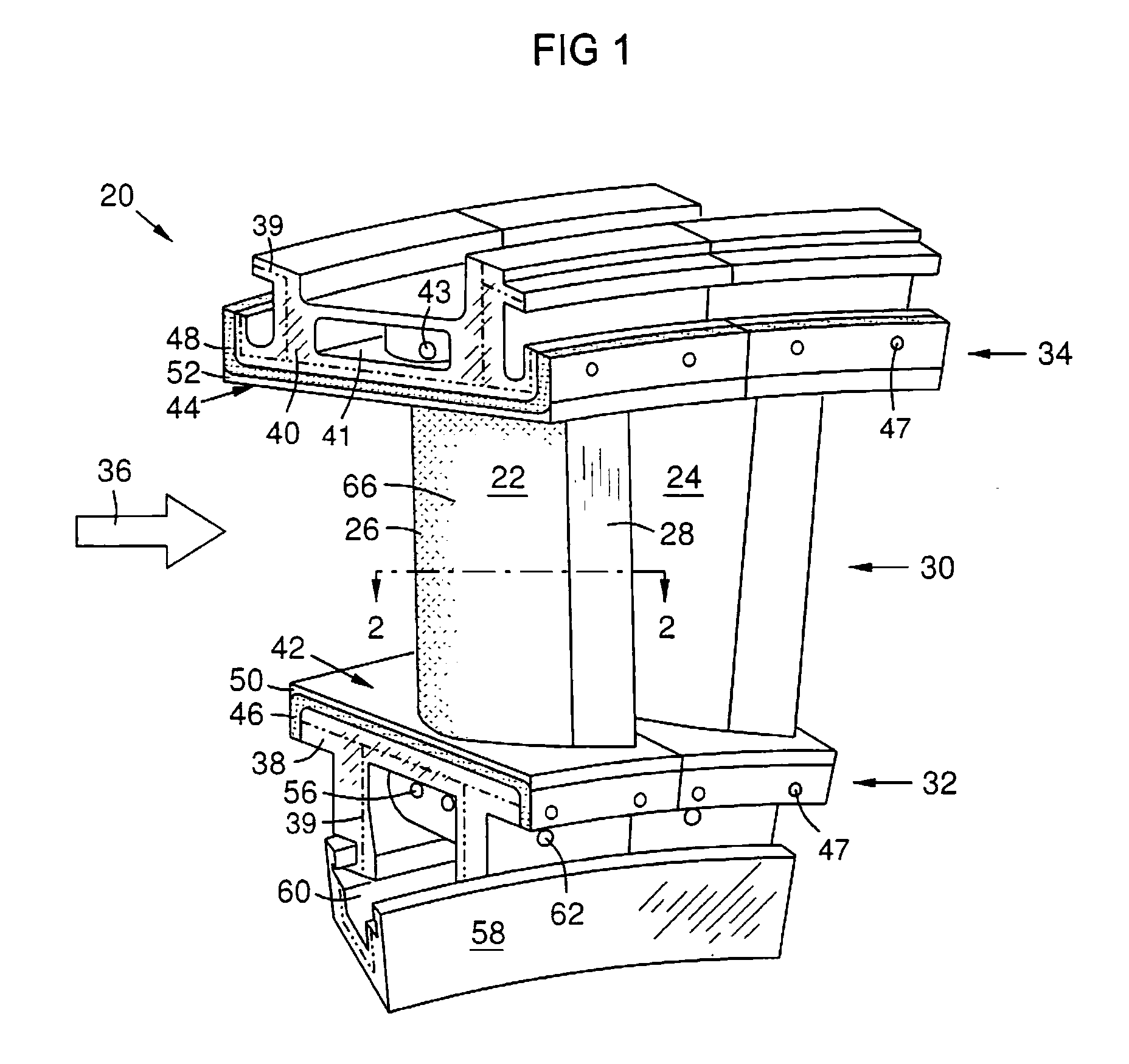

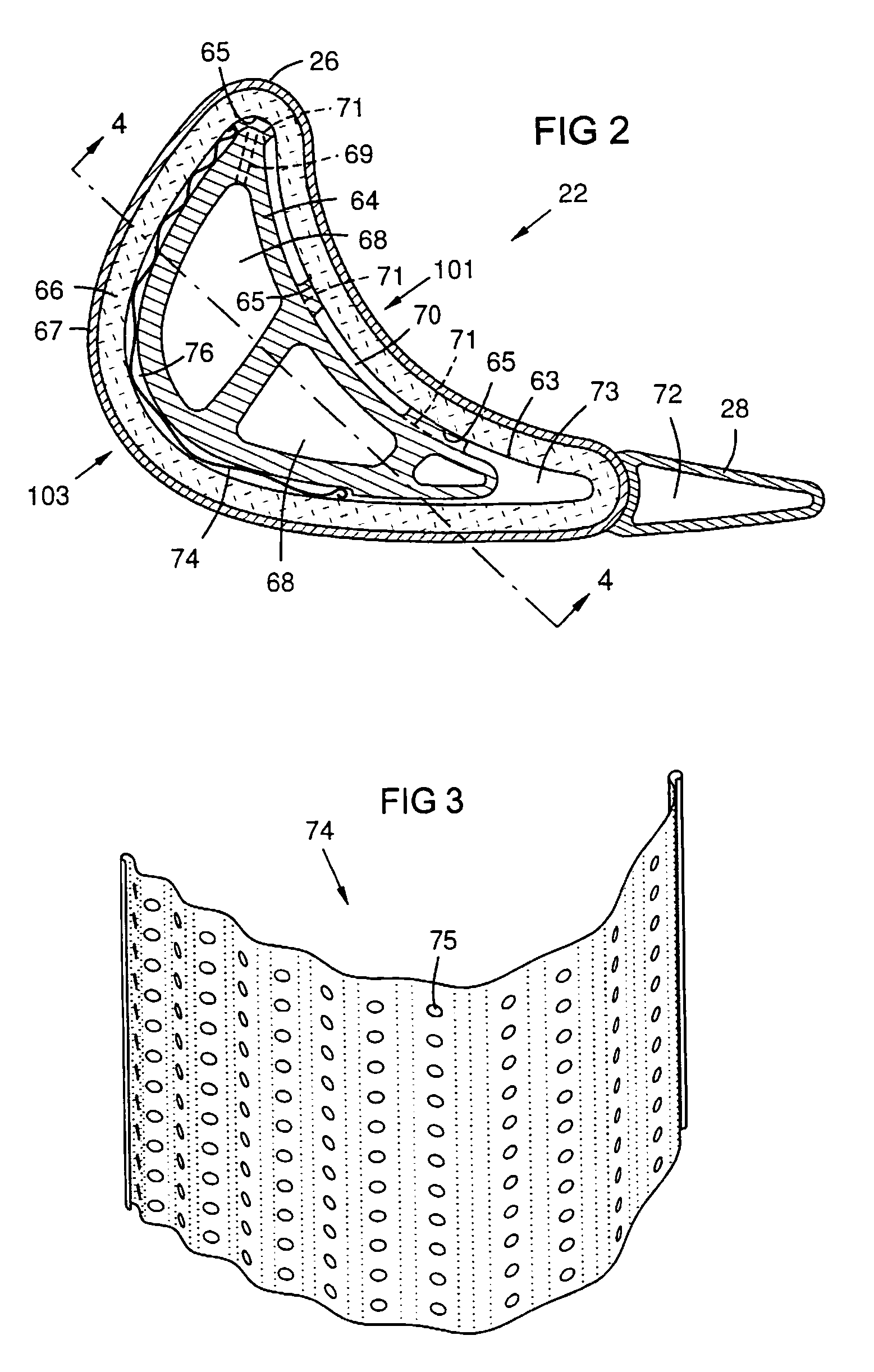

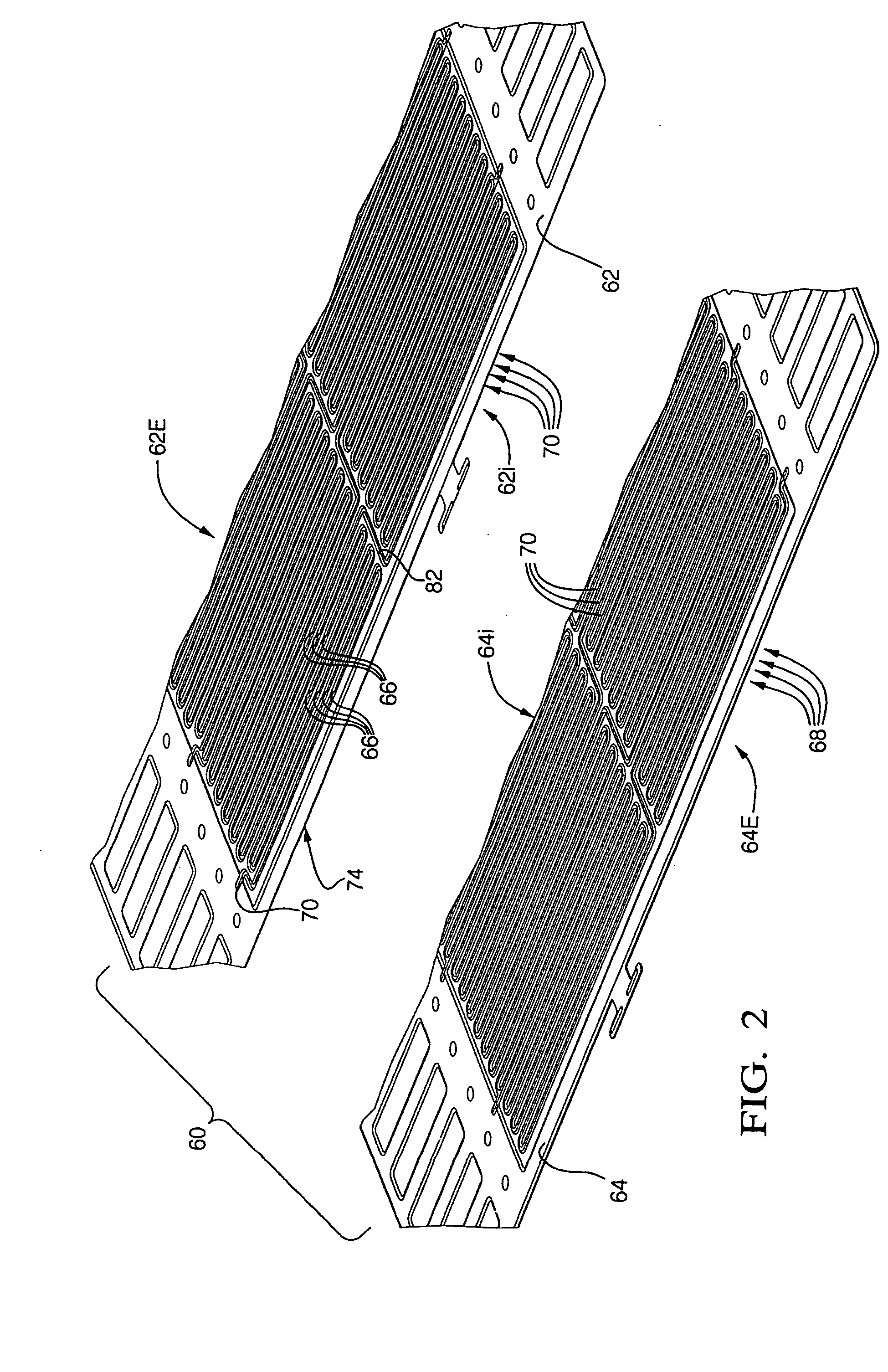

CMC Vane Assembly Apparatus and Method

A metal vane core or strut (64) is formed integrally with an outer backing plate (40). An inner backing plate (38) is formed separately. A spring (74) with holes (75) is installed in a peripheral spring chamber (76) on the strut. Inner and outer CMC shroud covers (46, 48) are formed, cured, then attached to facing surfaces of the inner and outer backing plates (38, 40). A CMC vane airfoil (22) is formed, cured, and slid over the strut (64). The spring (74) urges continuous contact between the strut (64) and airfoil (66), eliminating vibrations while allowing differential expansion. The inner end (88) of the strut is fastened to the inner backing plate (38). A cooling channel (68) in the strut is connected by holes (69) along the leading edge of the strut to peripheral cooling paths (70, 71) around the strut. Coolant flows through and around the strut, including through the spring holes.

Owner:SIEMENS ENERGY INC

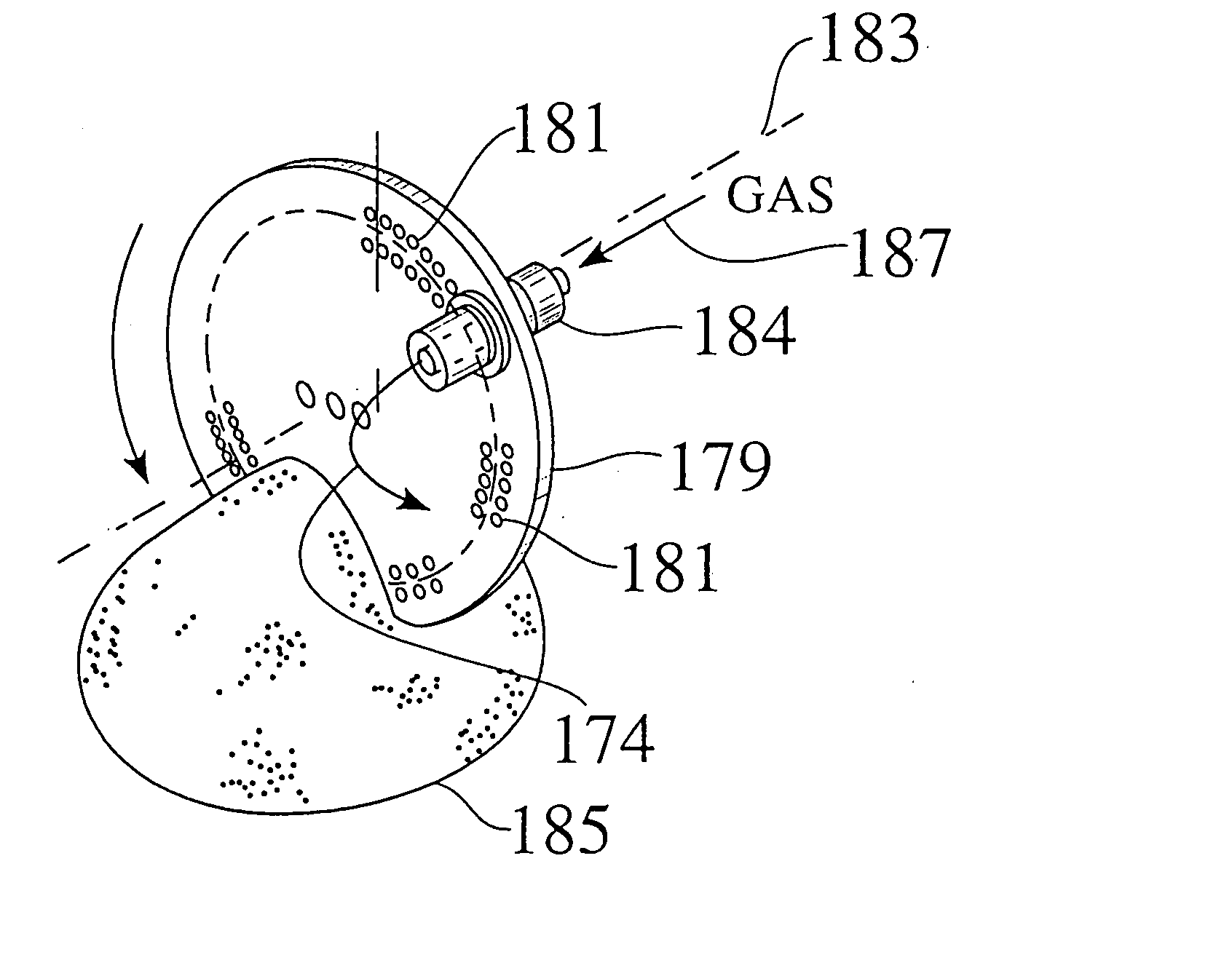

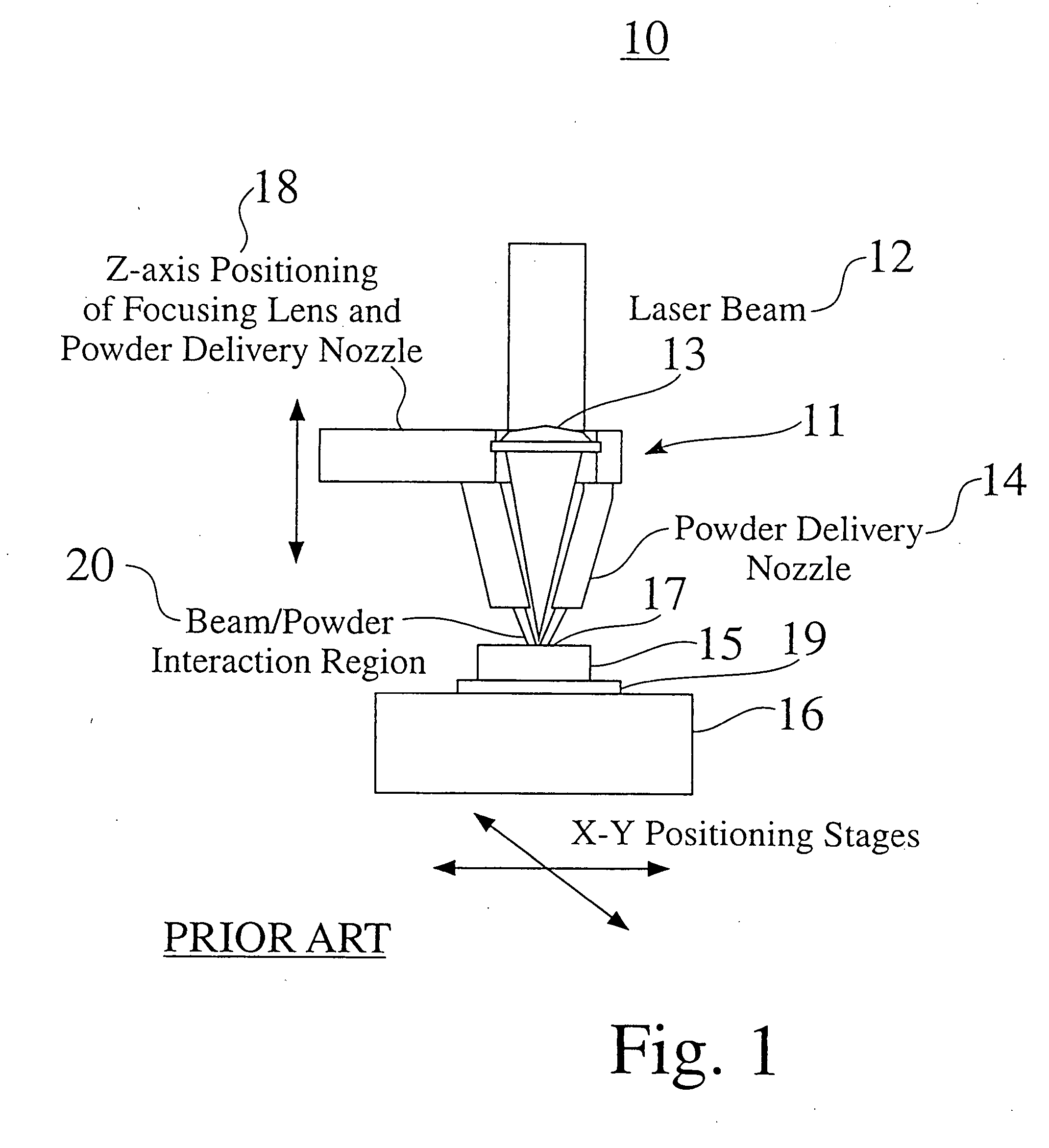

Powder feeder for material deposition systems

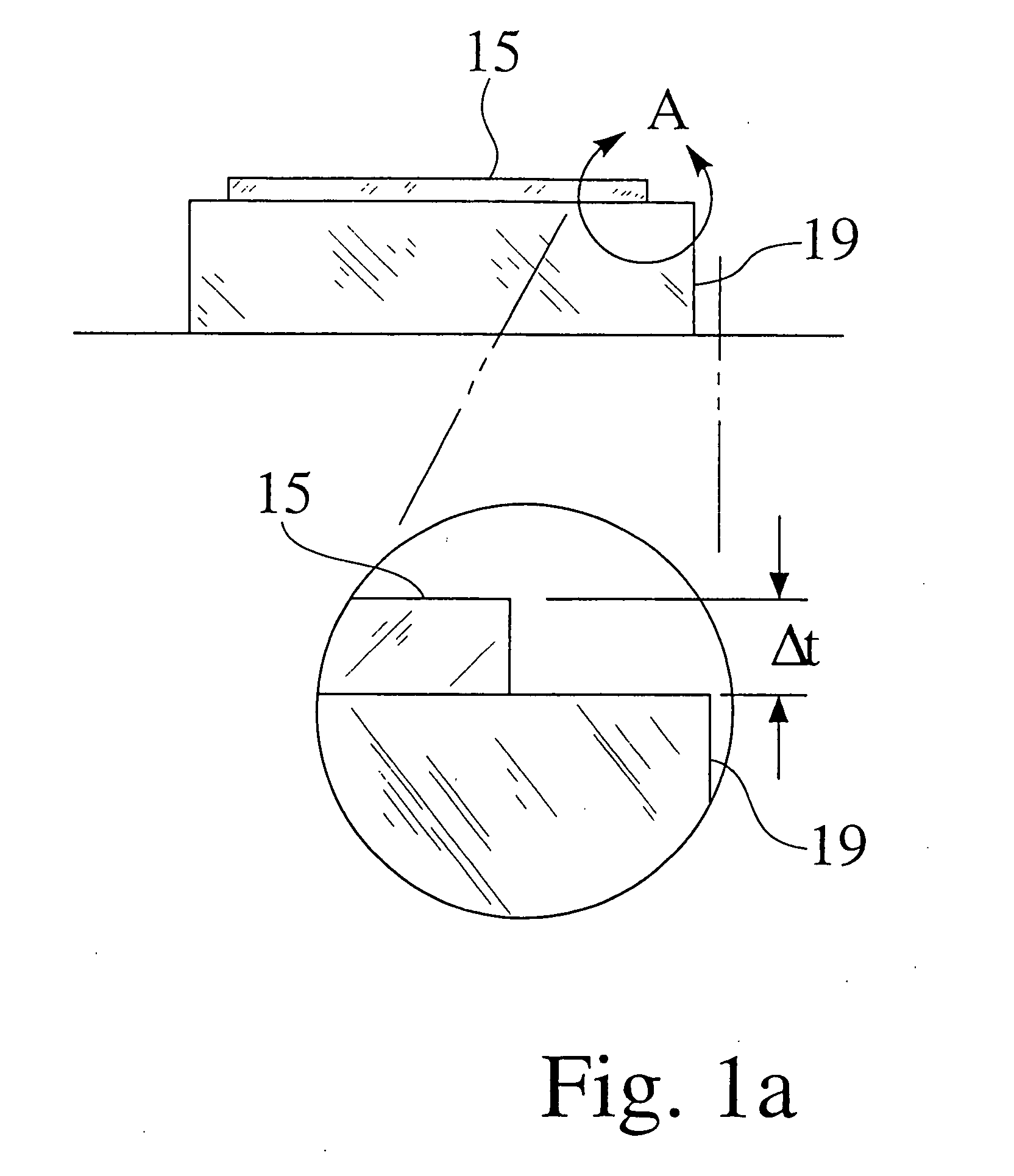

InactiveUS20050133527A1Small sizeEliminate warpingPower operated devices3D object support structuresSolid componentCoolant flow

A method and apparatus for embedding features and controlling material composition in a three-dimensional structure (130) is disclosed. The invention enables the control of material characteristics, within a structure (130) made from a plurality of materials, directly from computer renderings of solid models of the components. The method uses stereolithography and solid model computer file formats to control a multi-axis head (480) in a directed material deposition process (123). Material feedstock (126, 127) is deposited onto a pre-heated substrate (19). Depositions (15) in a layer-by-layer pattern, defined by solid models (141, 146), create a three-dimensional article having complex geometric details. Thermal management of finished solid articles (250-302), not available through conventional processing techniques, is enabled by embedded voids (152) and / or composite materials (126, 127), which include dissimilar metals (210, 216). Finished articles control pressure drop and produce uniform coolant flow and pressure characteristics. High-efficiency heat transfer is engineered within a solid structure by incorporating other solid materials with diverse indexes. Embedding multi-material structures (132, 134) within a normally solid component (141) produces articles with diverse mechanical properties. Laser and powder delivery systems (420, 170) are integrated in a multi-axis deposition head (480) having a focused particle beam (502) to reduce material waste.

Owner:OPTOMEC DESIGN CO

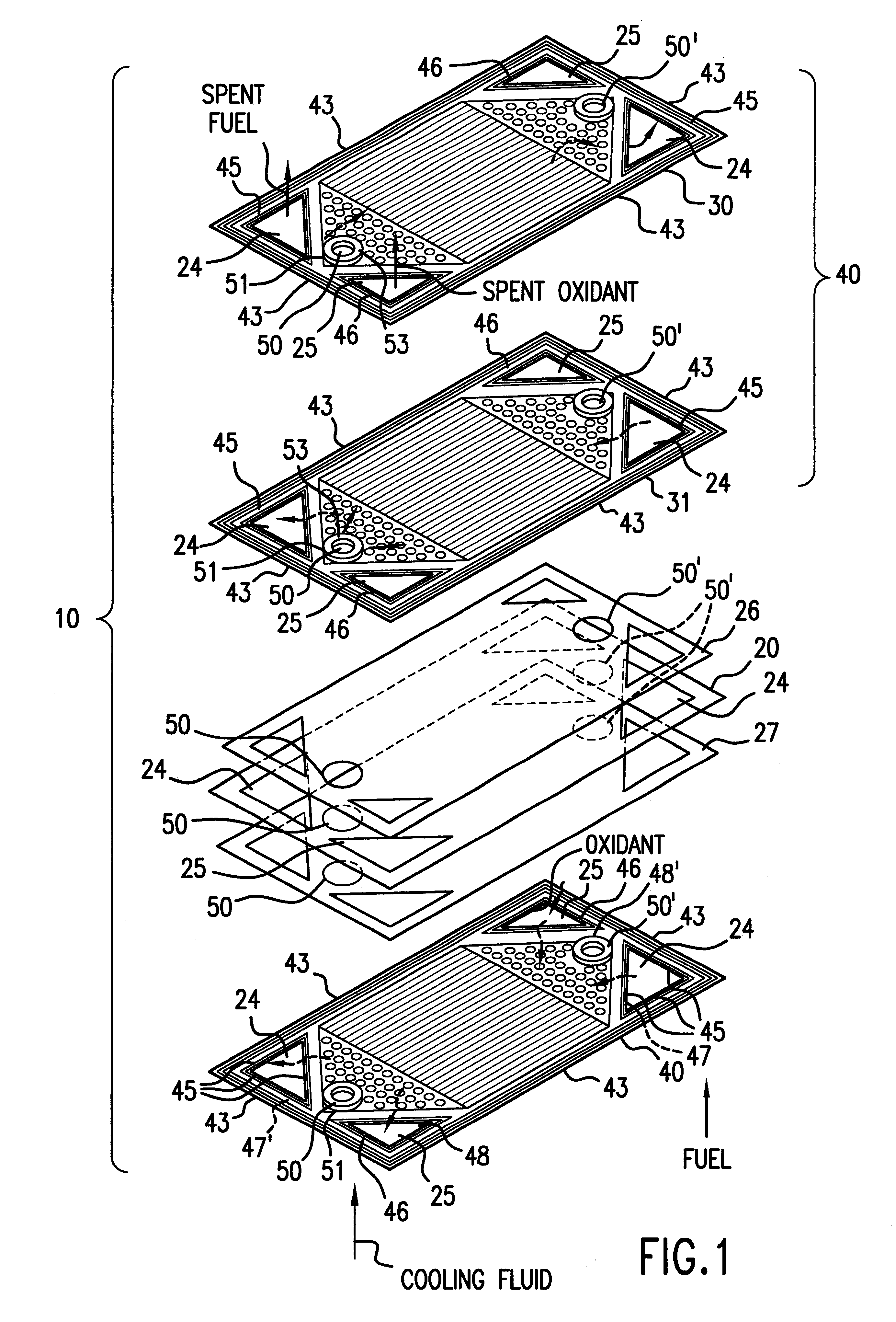

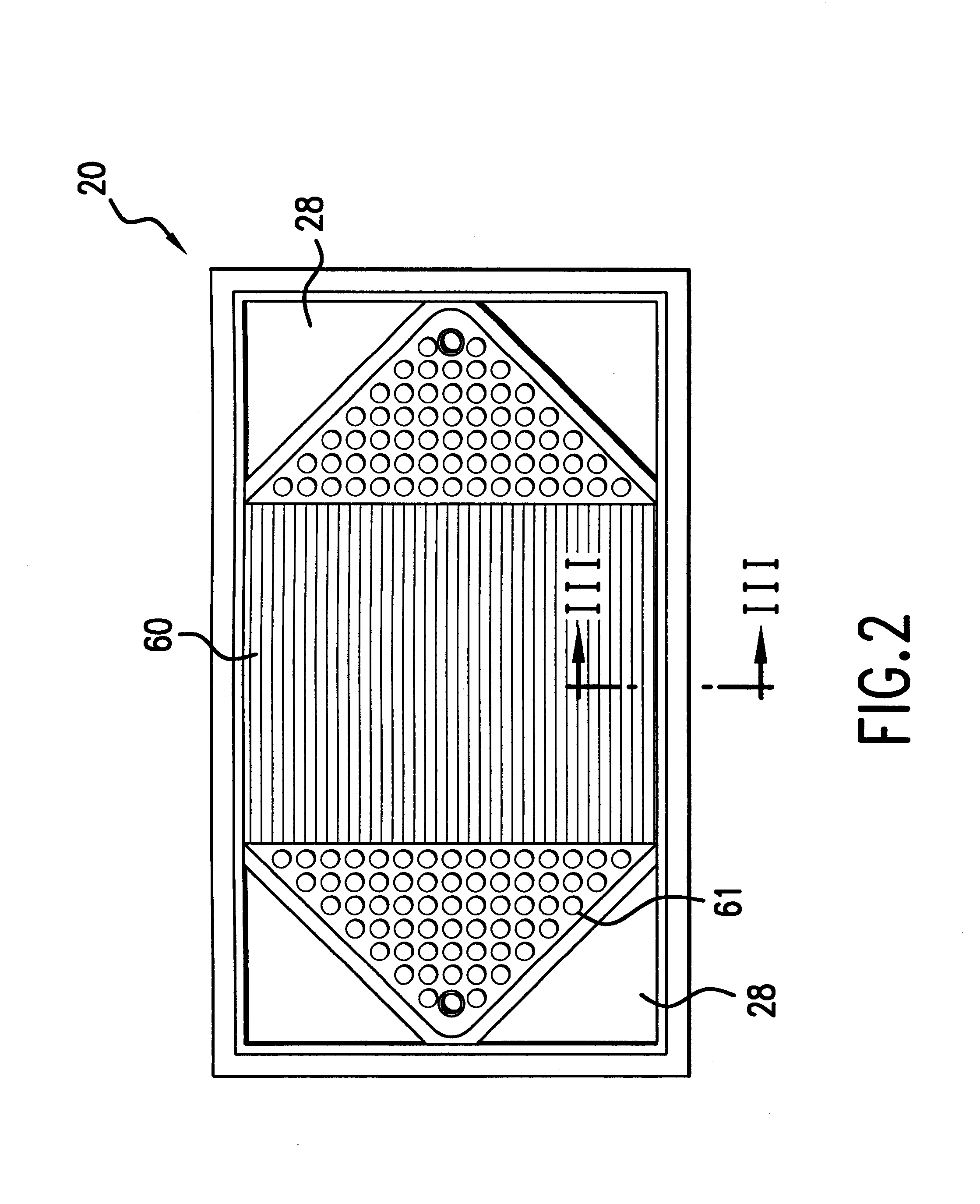

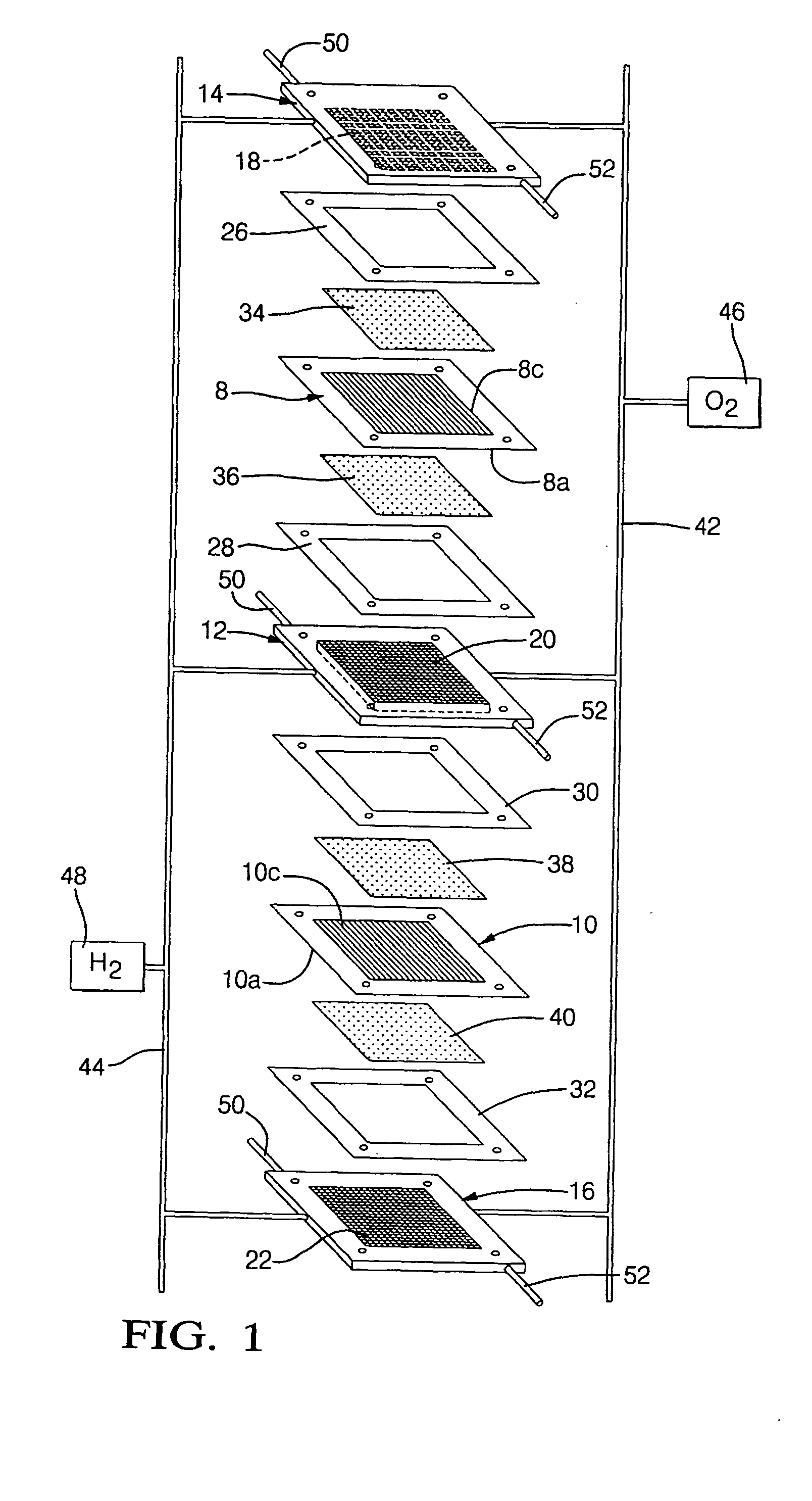

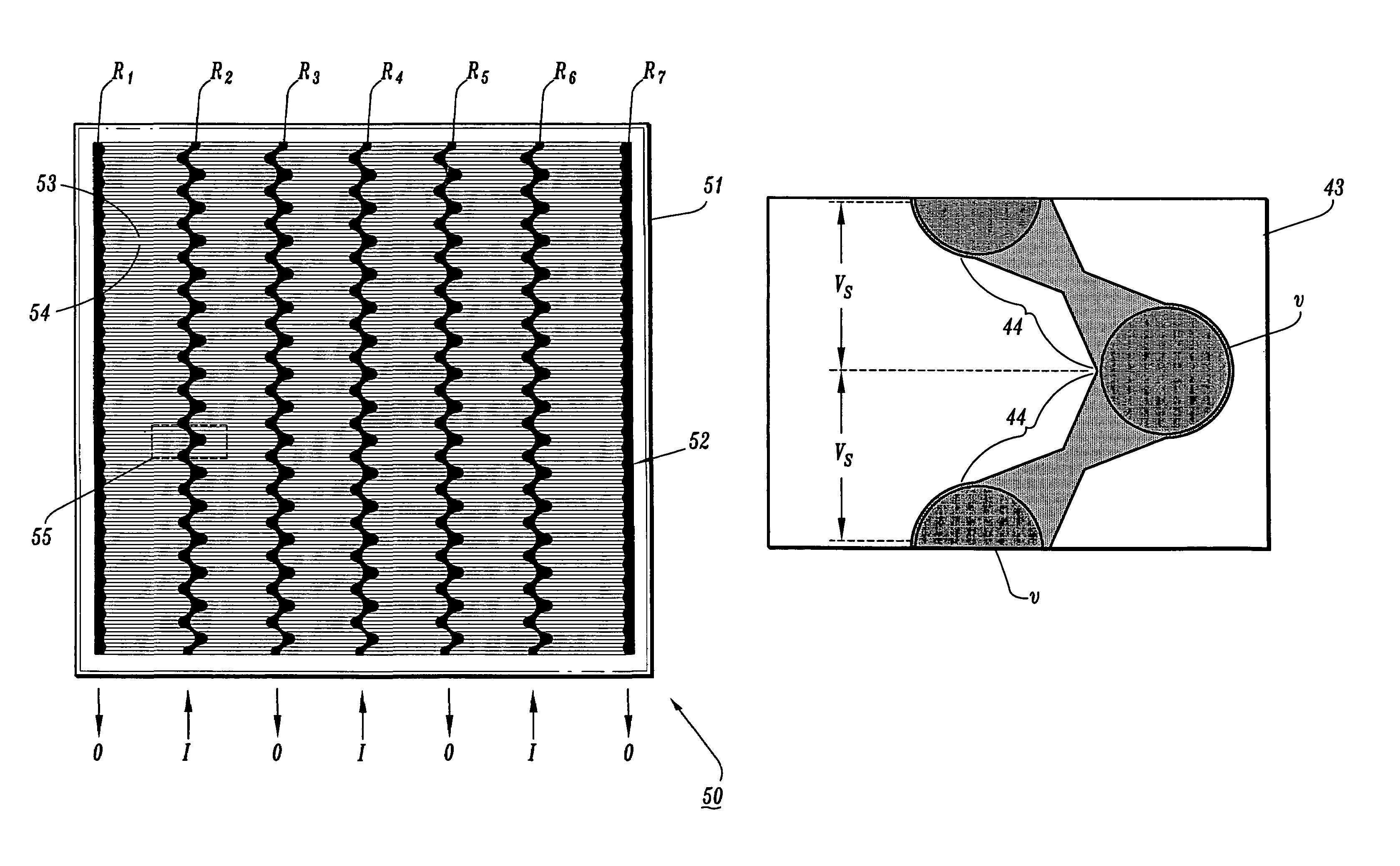

Sheet metal bipolar plate design for polymer electrolyte membrane fuel cells

InactiveUS6261710B1Compact designIncrease the number ofSolid electrolytesFuel cells groupingPolymer electrolytesFuel cells

A separator plate for a polymer electrolyte membrane fuel cell stack constructed of at least two coextensive sheet metal elements shaped to promote the distribution of reactant gases to the electrodes of the fuel cell units of the fuel cell stack. The coextensive sheet metal elements are nestled together and form a coolant flow space therebetween.

Owner:INST OF GAS TECH

Cooling apparatus and method for an electronics module employing an integrated heat exchange assembly

A cooling apparatus for an electronics assembly having a substrate and one or more electronics devices includes an enclosure sealably engaging the substrate to form a cavity, with the electronics devices and a heat exchange assembly being disposed within the cavity. The heat exchange assembly defines a primary coolant flow path and a separate, secondary coolant flow path. The primary coolant flow path includes first and second chambers in fluid communication, and the secondary flow path includes a third chamber disposed between the first and second chambers. The heat exchange assembly provides a first thermal conduction path between primary coolant in the first chamber and secondary coolant in the third chamber, and a second thermal conduction path between primary coolant in the second chamber and secondary coolant in the third chamber. The heat exchange assembly further includes coolant nozzles to direct primary coolant towards the electronics devices.

Owner:IBM CORP

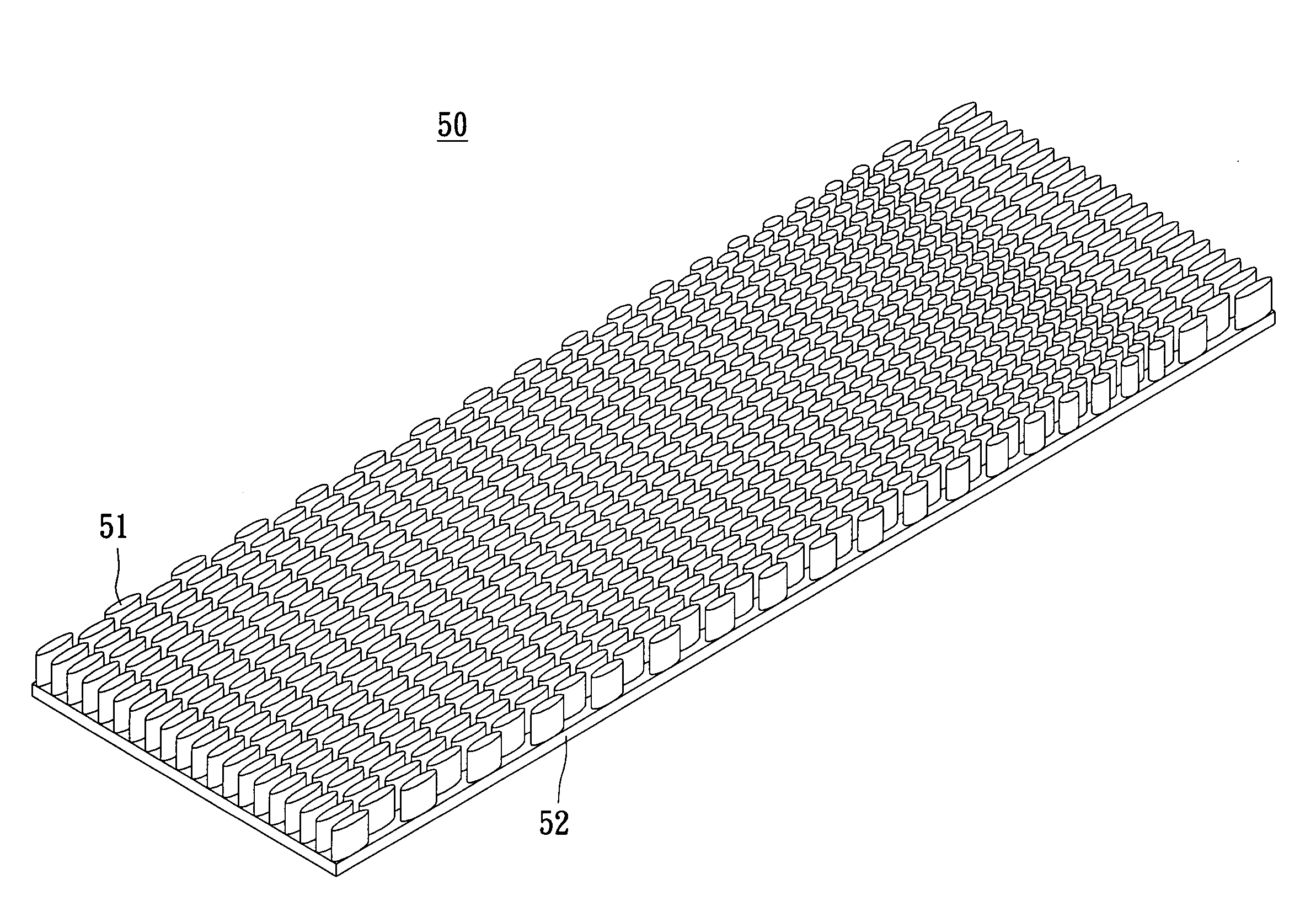

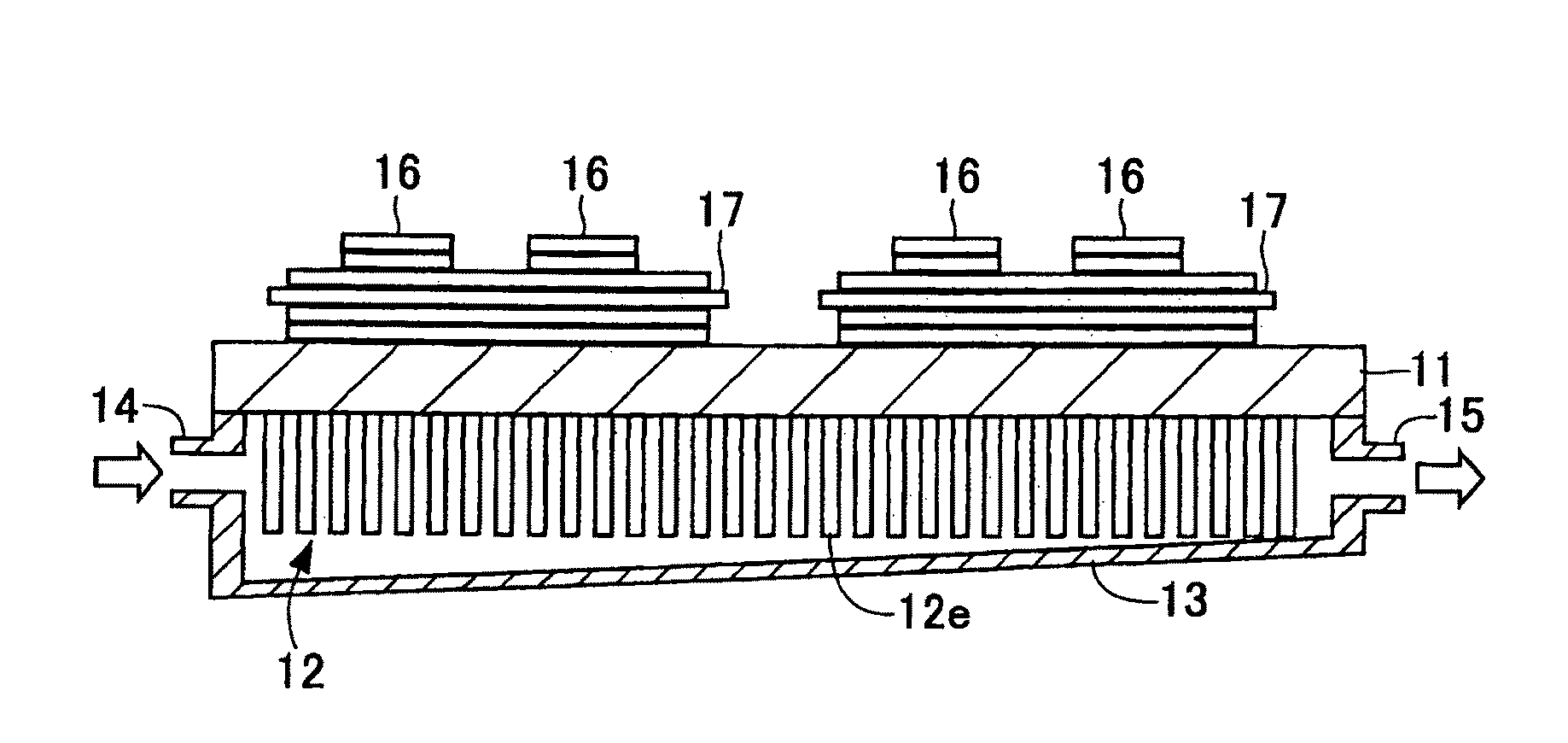

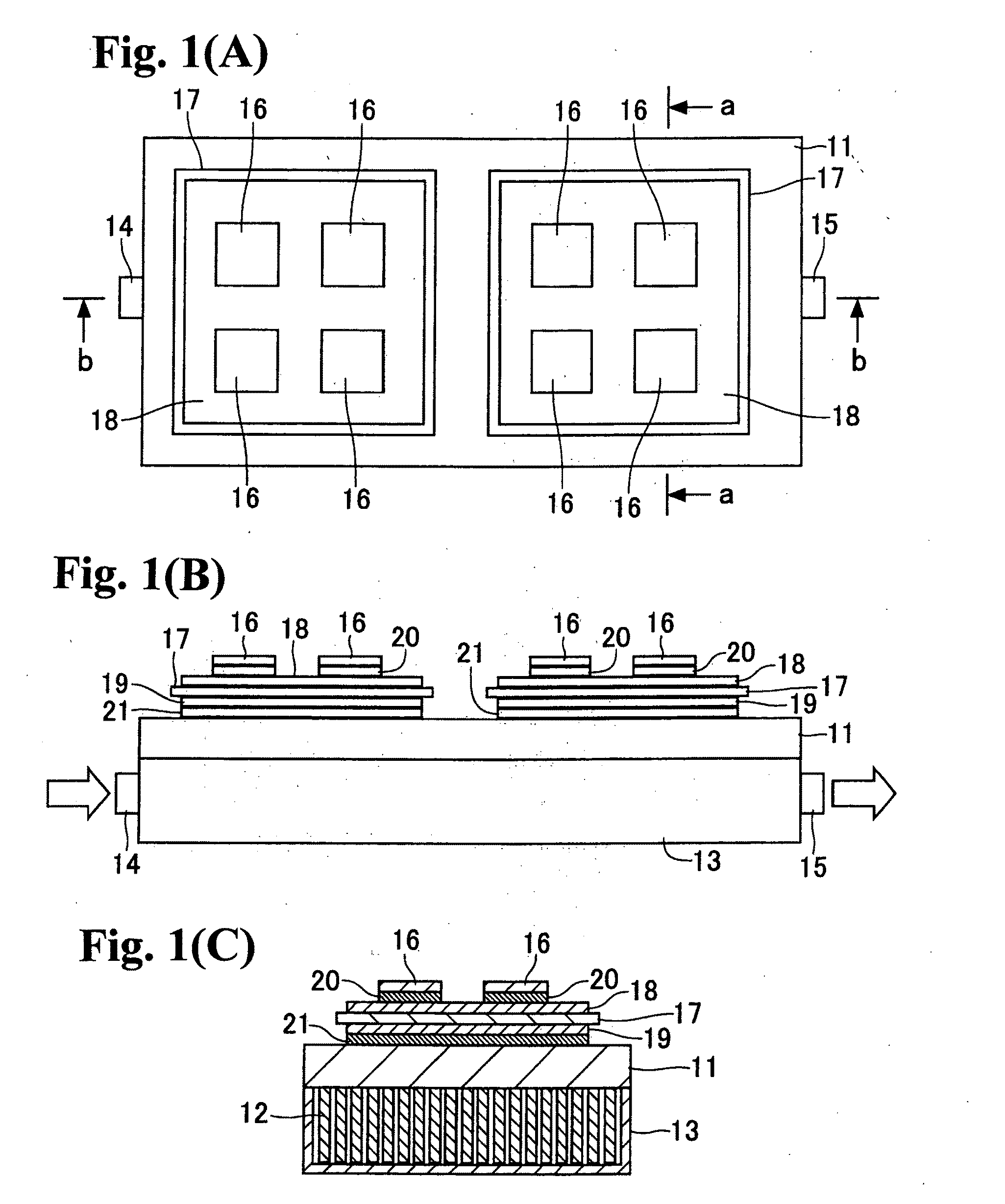

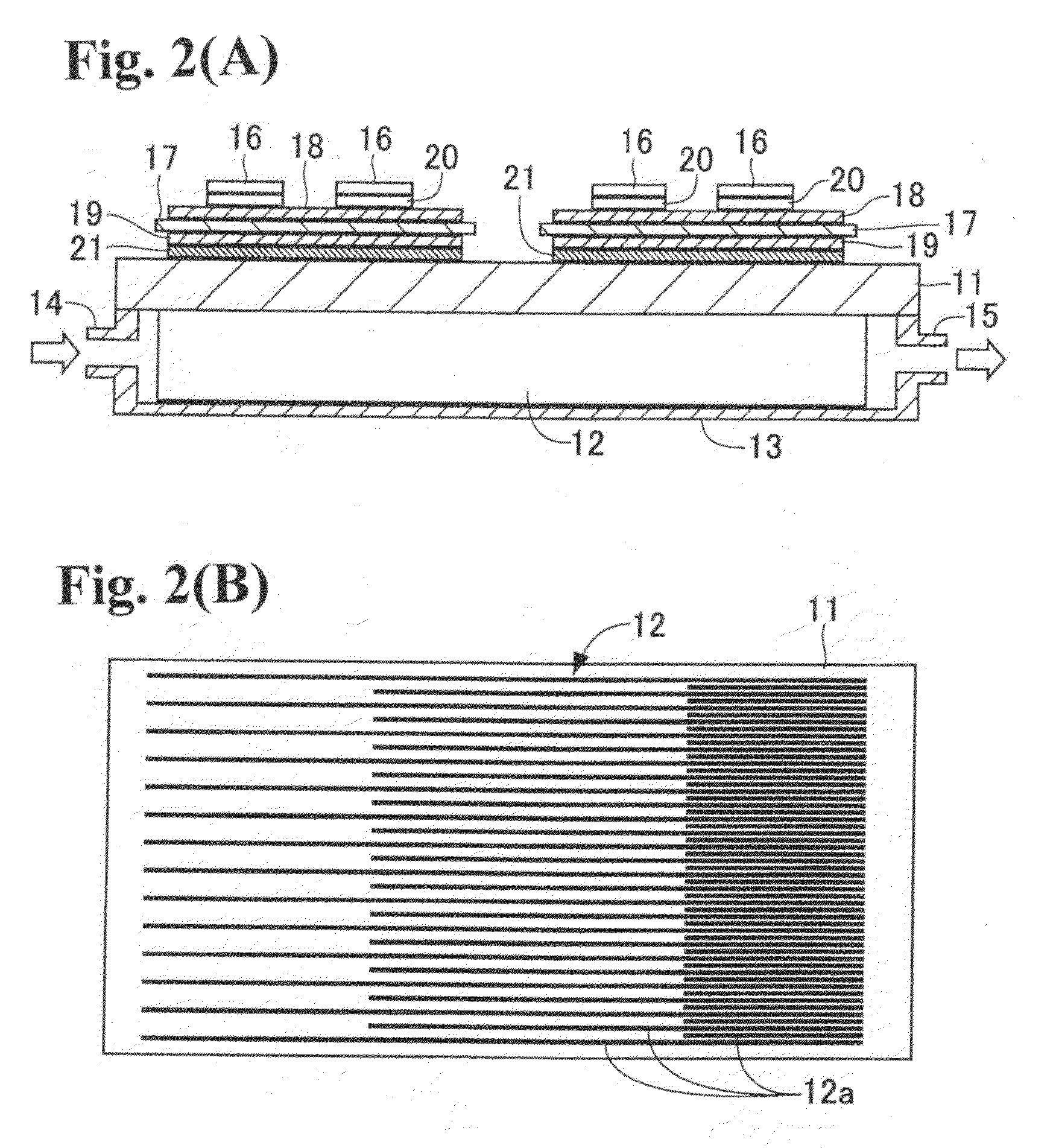

Cooling apparatus for semiconductor chips

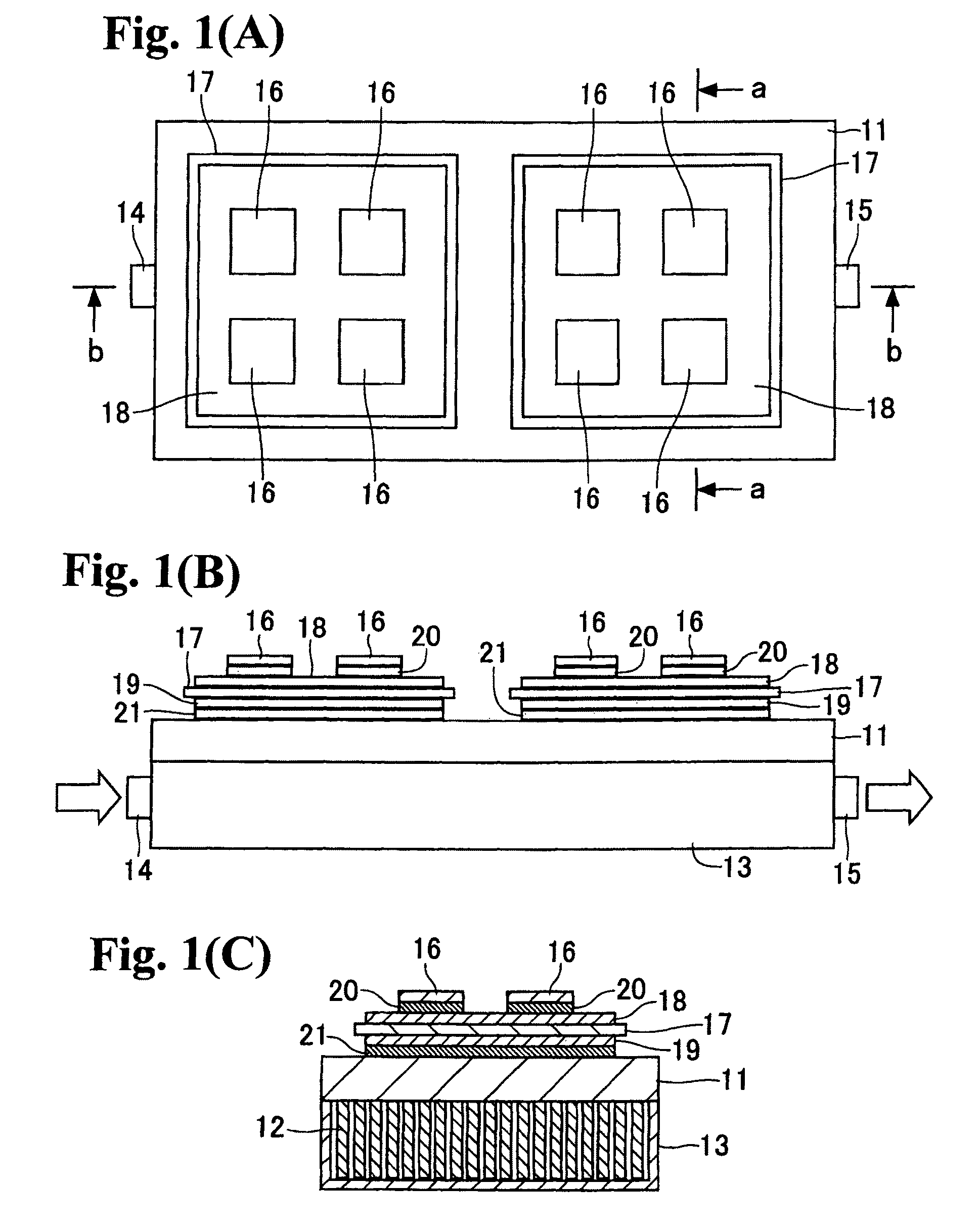

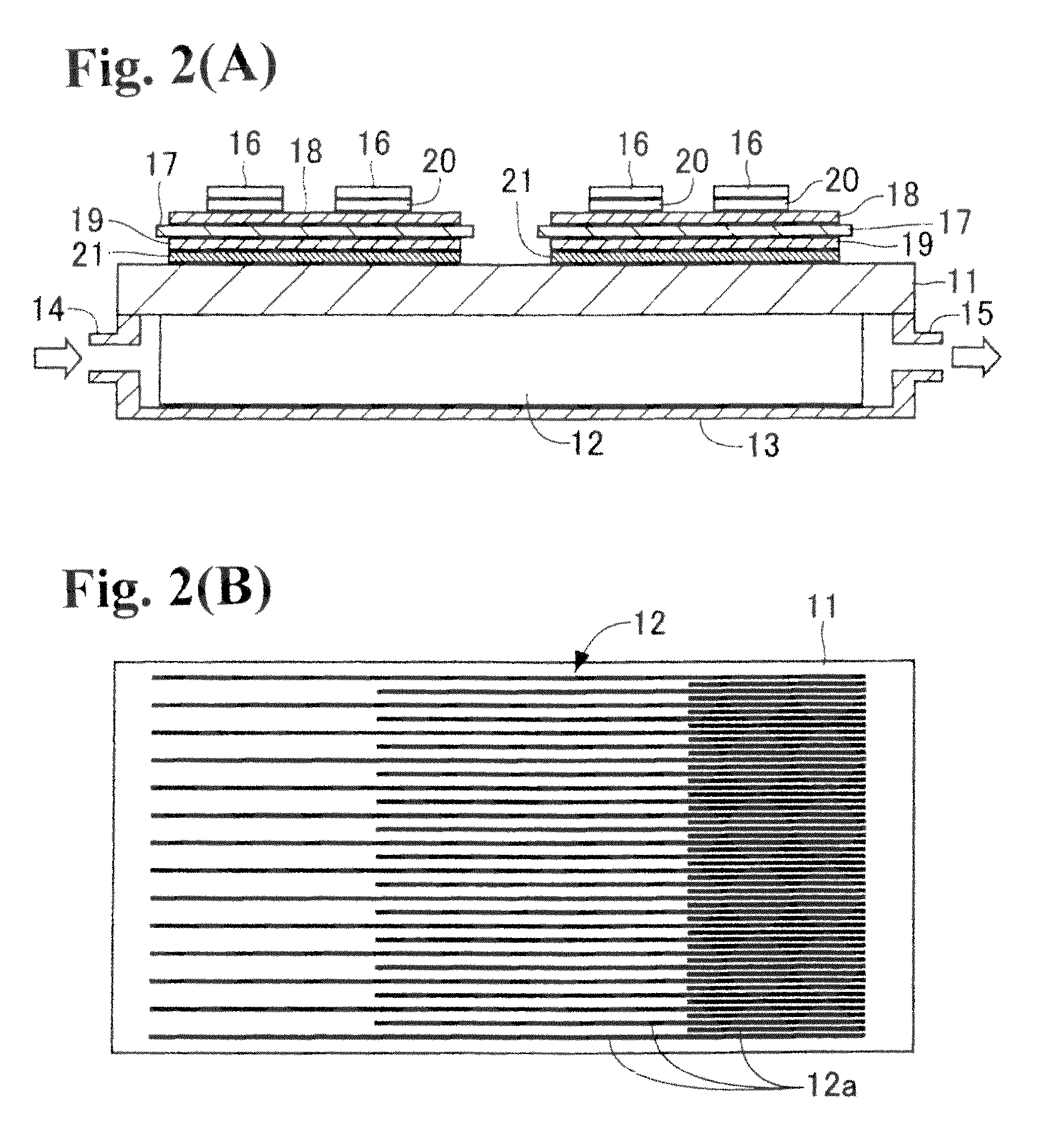

ActiveUS8081465B2Improve flowLarge outputSemiconductor/solid-state device detailsSolid-state devicesCoolant flowSemiconductor chip

A cooling apparatus for semiconductor chips includes radiation fins formed on the opposite surface of metal base opposite to the surface of metal base, to which an insulator base board mounting semiconductor chips thereon, is disposed. The radiation fins, such as sheet-shaped fins having different lengths are arranged such that the surface area density of the fins becomes higher in the coolant flow direction, whereby the surface area density is the total surface area of radiation fins on a unit surface area of the metal base. As a result, the temperatures of semiconductor chips arranged along the coolant flow direction are closer to each other.

Owner:FUJI ELECTRIC CO LTD

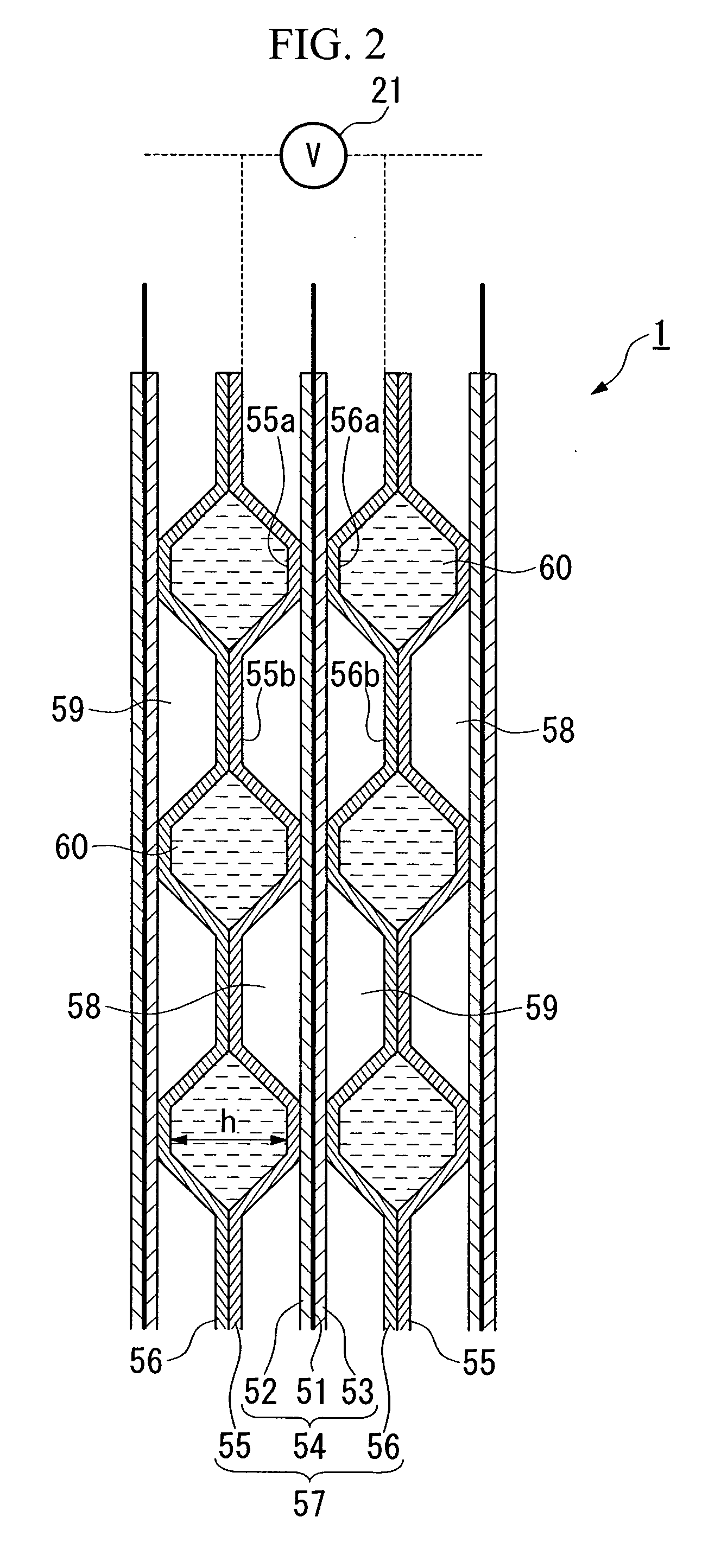

Nested bipolar plate for fuel cell and method

Between adjacent MEA's is a bipolar plate assembly having a first sub-plate with a flow channel which is open to the anode side of the one of the MEA's. A second sub-plate has a flow channel which is open to the cathode side of the adjacent MEA. The sub-plates are nested together to form a coolant flow channel between the sub-plates. The coolant flow path has a height dimension wherein the distance between the adjacent MEA's is substantially unaffected by the height dimension of the coolant flow path. A method of manufacturing a bi-polar plate assembly includes forming a closed coolant flow channel between the sub-plates by nesting the sub-plates together. A method of operating a fuel cell includes passing the coolant through a flow path having a height dimension which is substantially aligned with the height dimension of the hydrogen flow path, the oxygen flow path, or both.

Owner:GM GLOBAL TECH OPERATIONS LLC

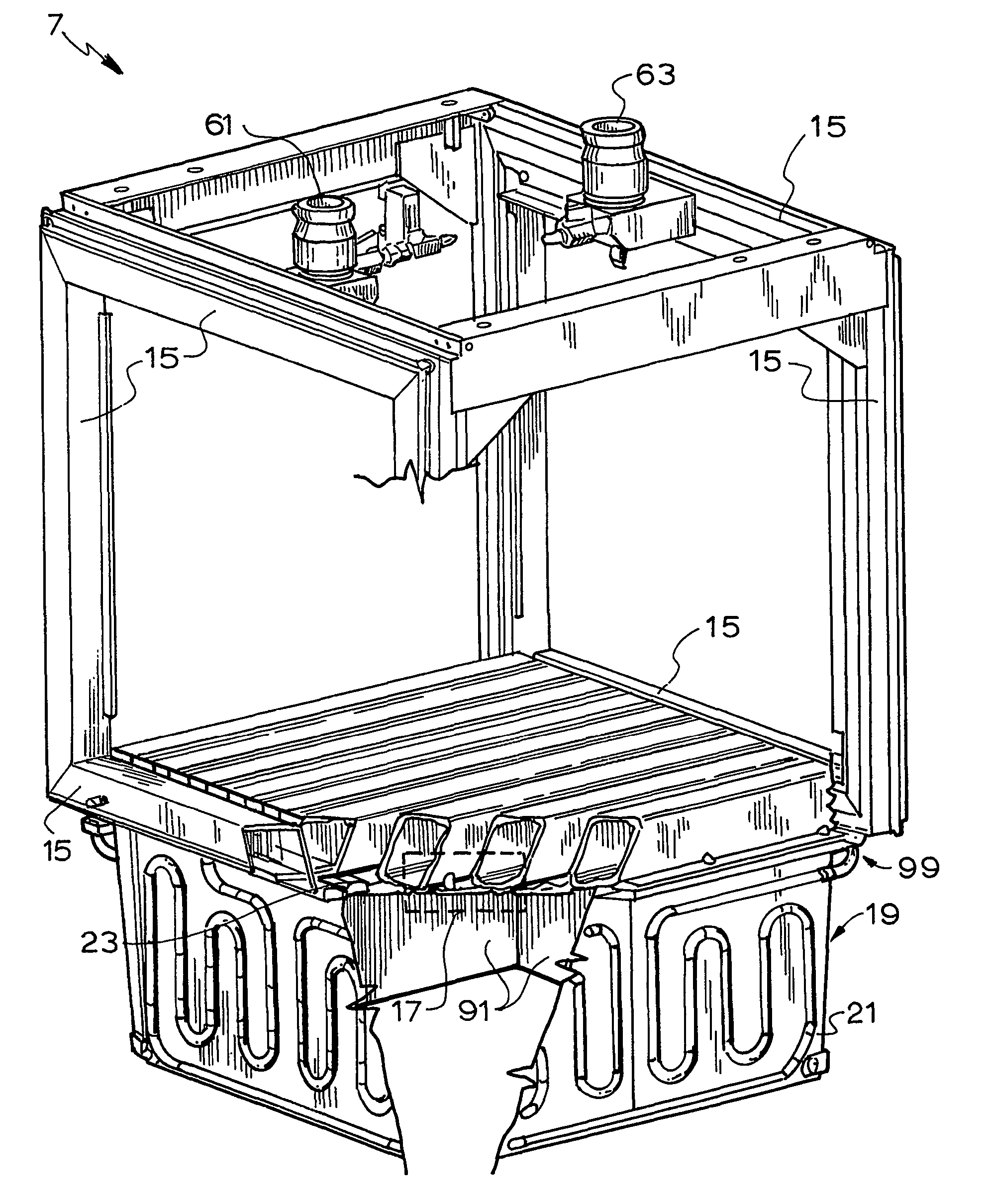

Refrigeration systems and methods for connection with a vehicle's liquid cooling system

An exemplary refrigeration system for cooling food or beverages may use a liquid cooling system of a vehicle. The refrigeration system may include a compartment in which the food or beverages may be placed and removed, a chilled liquid coolant system having a connection through which liquid coolant is received from the liquid cooling system of the vehicle, and a heat exchanger operationally coupled with the chilled liquid coolant system and the compartment to transfer heat from the compartment into the liquid coolant. The refrigeration system may also include a second chilled coolant system through which a second coolant flows and a second heat exchanger operationally coupled with the second chilled coolant system and the compartment to transfer heat from the compartment. The chilled liquid coolant system and the second chilled coolant system may operate together as a cascade cooling system.

Owner:BE AEROSPACE INCORPORATED

Cooling apparatus and method for an electronics module employing an integrated heat exchange assembly

A cooling apparatus for an electronics assembly having a substrate and one or more electronics devices includes an enclosure sealably engaging the substrate to form a cavity, with the electronics devices and a heat exchange assembly being disposed within the cavity. The heat exchange assembly defines a primary coolant flow path and a separate, secondary coolant flow path. The primary coolant flow path includes first and second chambers in fluid communication, and the secondary flow path includes a third chamber disposed between the first and second chambers. The heat exchange assembly provides a first thermal conduction path between primary coolant in the first chamber and secondary coolant in the third chamber, and a second thermal conduction path between primary coolant in the second chamber and secondary coolant in the third chamber. The heat exchange assembly further includes coolant nozzles to direct primary coolant towards the electronics devices.

Owner:INT BUSINESS MASCH CORP

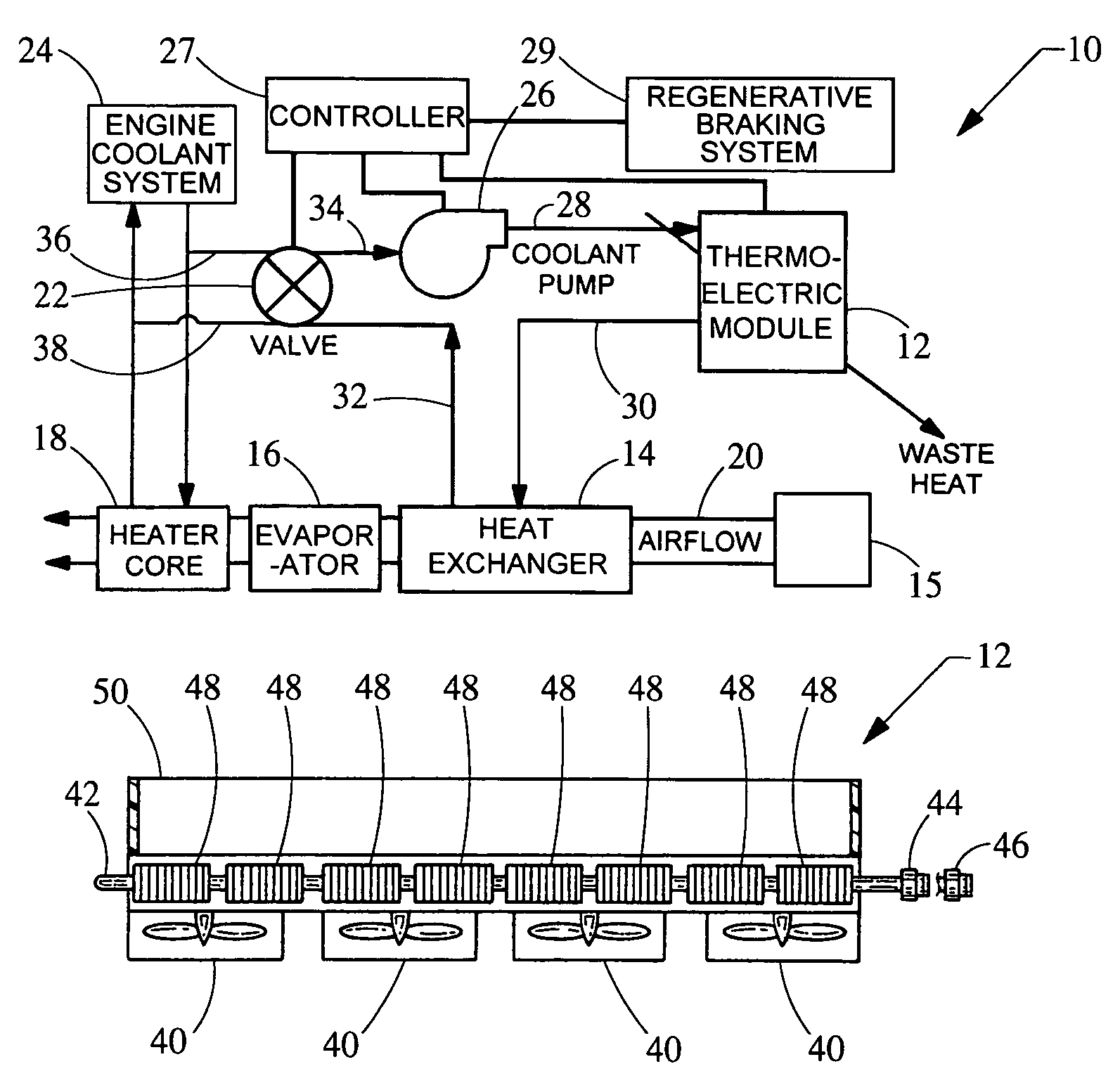

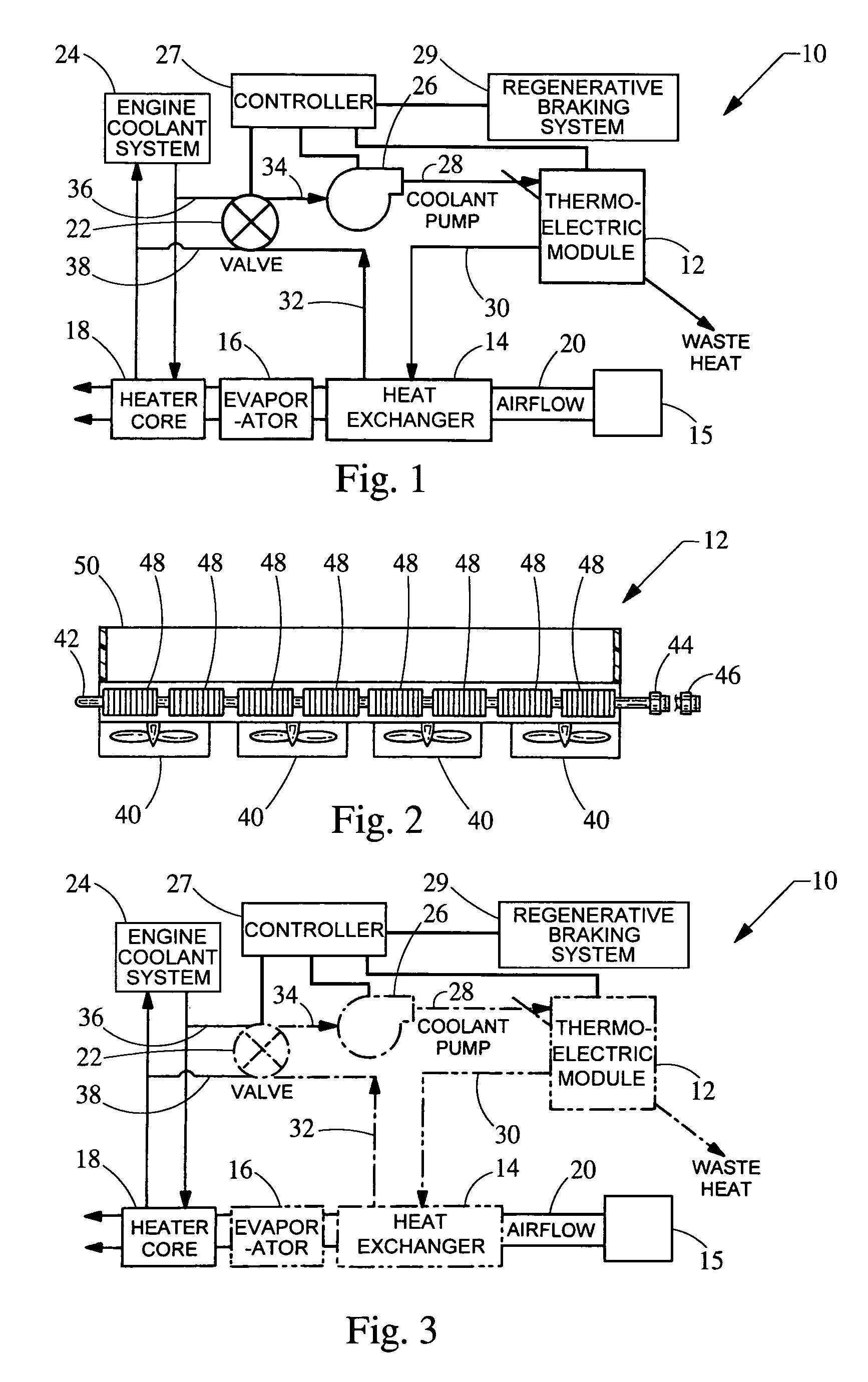

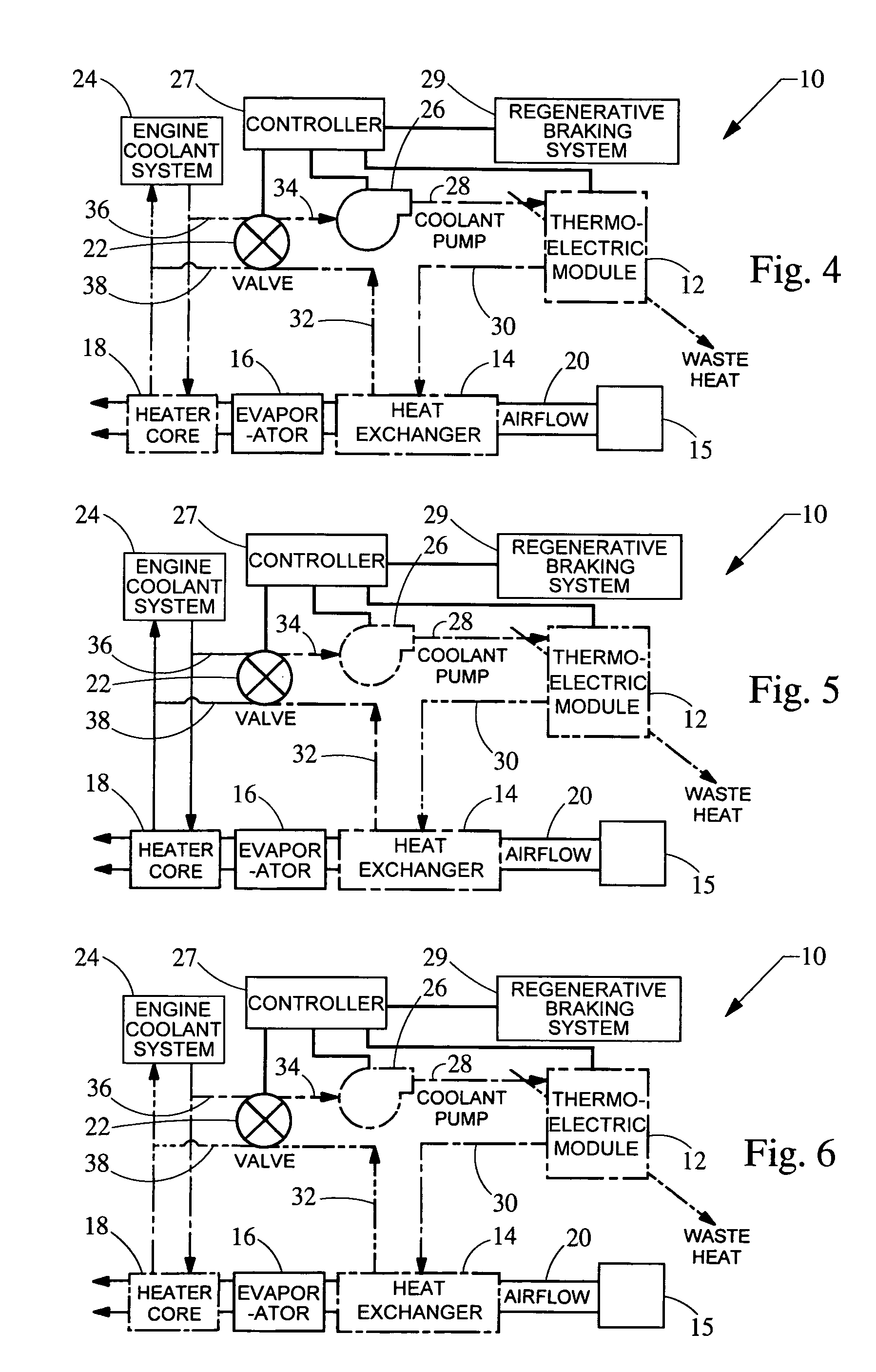

Climate control system for hybrid vehicles using thermoelectric devices

ActiveUS7380586B2Climate controlAir-treating devicesRailway heating/coolingThermal energyControl system

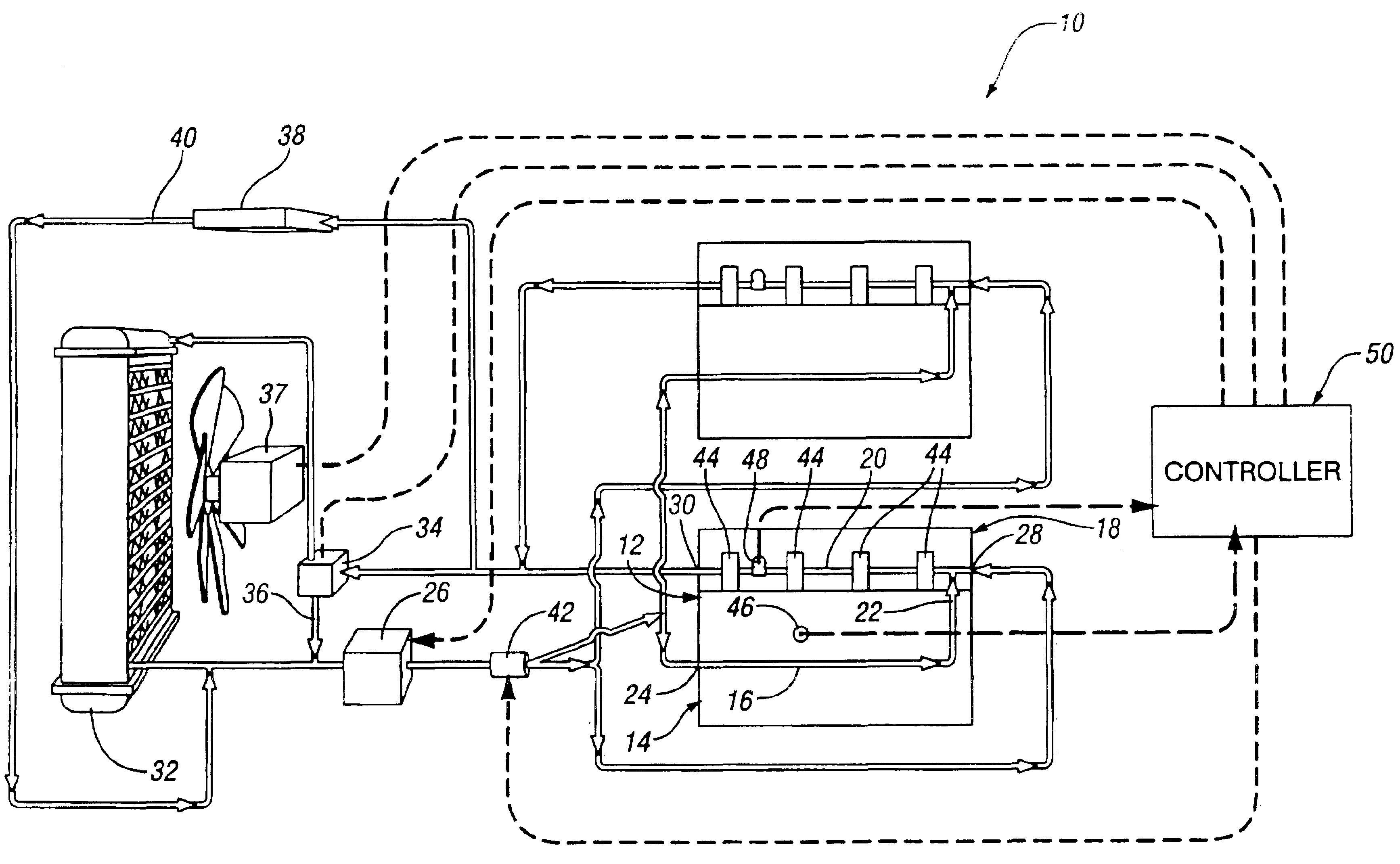

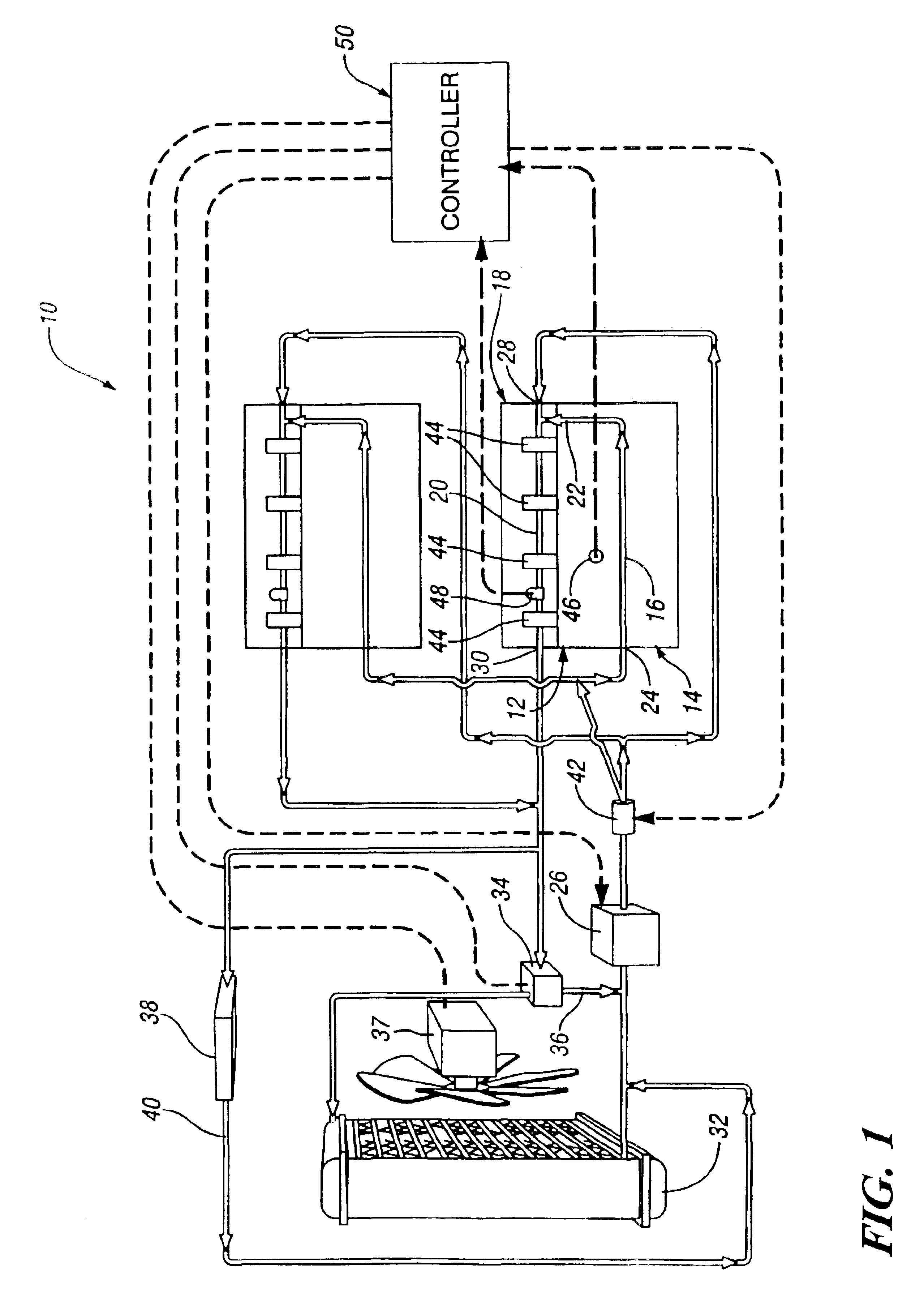

The present invention provides a system for controlling the climate of a hybrid vehicle. The system includes a thermoelectric module, a heat exchanger, a pump, and a valve. The thermoelectric module includes thermoelectric elements powered by electric energy. The thermoelectric elements emit or absorb heat energy based on the polarity of the electrical energy provided. A tube containing coolant runs proximate the thermoelectric elements. To aid in the transfer of heat energy, a blower is provided to generate an air flow across the thermoelectric elements and the tube. The coolant is provided from the thermoelectric module to a heat exchanger that heats or cools the air flow provided to the cabin of the vehicle. The pump and valve are in fluid communication with the heat exchanger and thermoelectric module. The pump pressurizes the coolant flow through the tube and coolant lines. In a cooling mode, the valve is configured to selectively bypass the engine coolant system of the vehicle.

Owner:GENTHERM INC

Memory heat sink

InactiveUS7151668B1Increase surface areaIncrease coolant flowSemiconductor/solid-state device detailsSolid-state devicesCoolant flowEngineering

An apparatus is provided for dissipating heat from a semiconductor device that meets dimensional requirements for the semiconductor device and provides enhanced cooling for the semiconductor device. The apparatus provides a relatively large surface area for transferring heat away from a semiconductor device, and provides for enhanced coolant flow through or around the apparatus. The apparatus includes a channel that may accommodate a heat pipe to further enhance transfer of heat away from the semiconductor device.

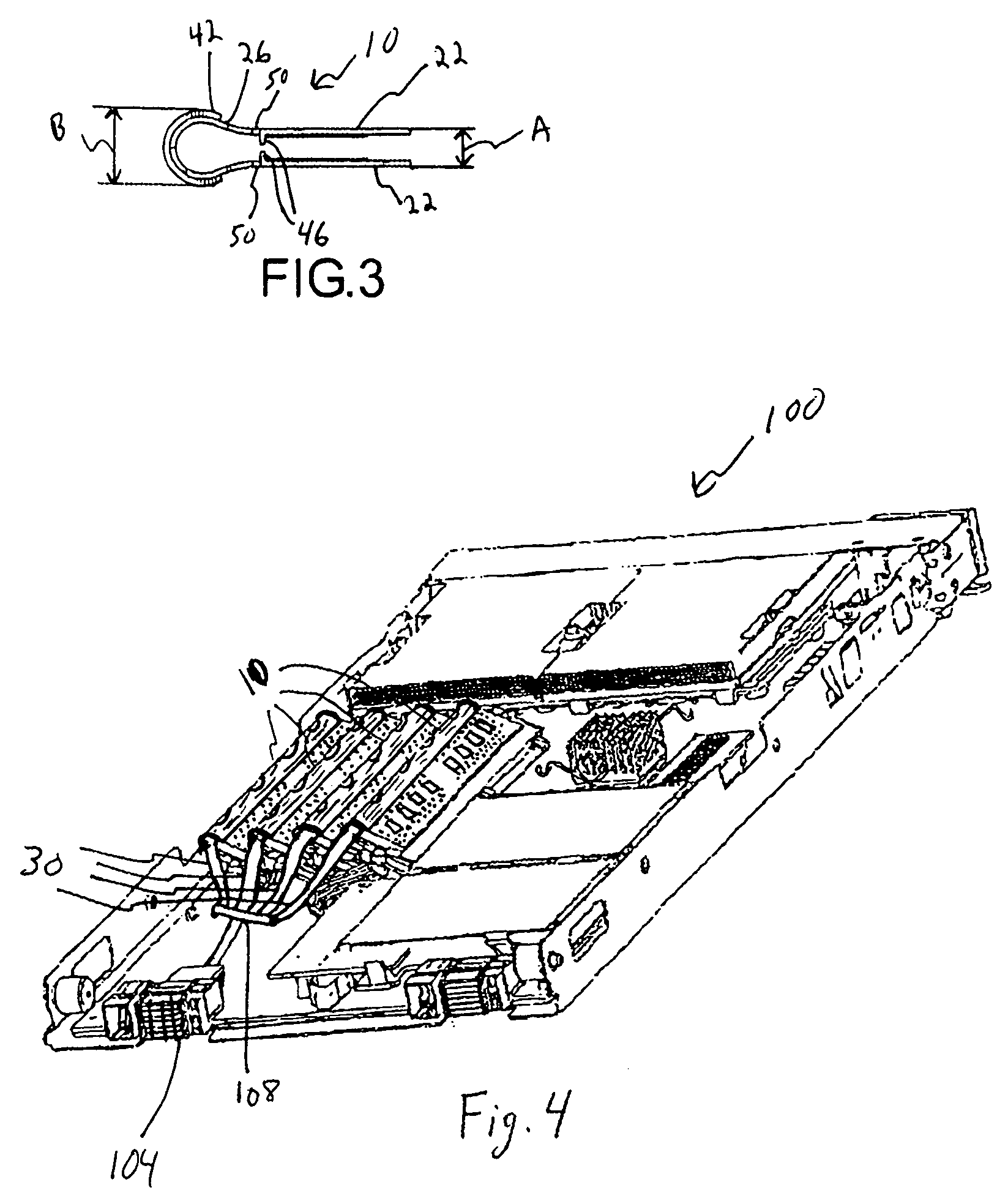

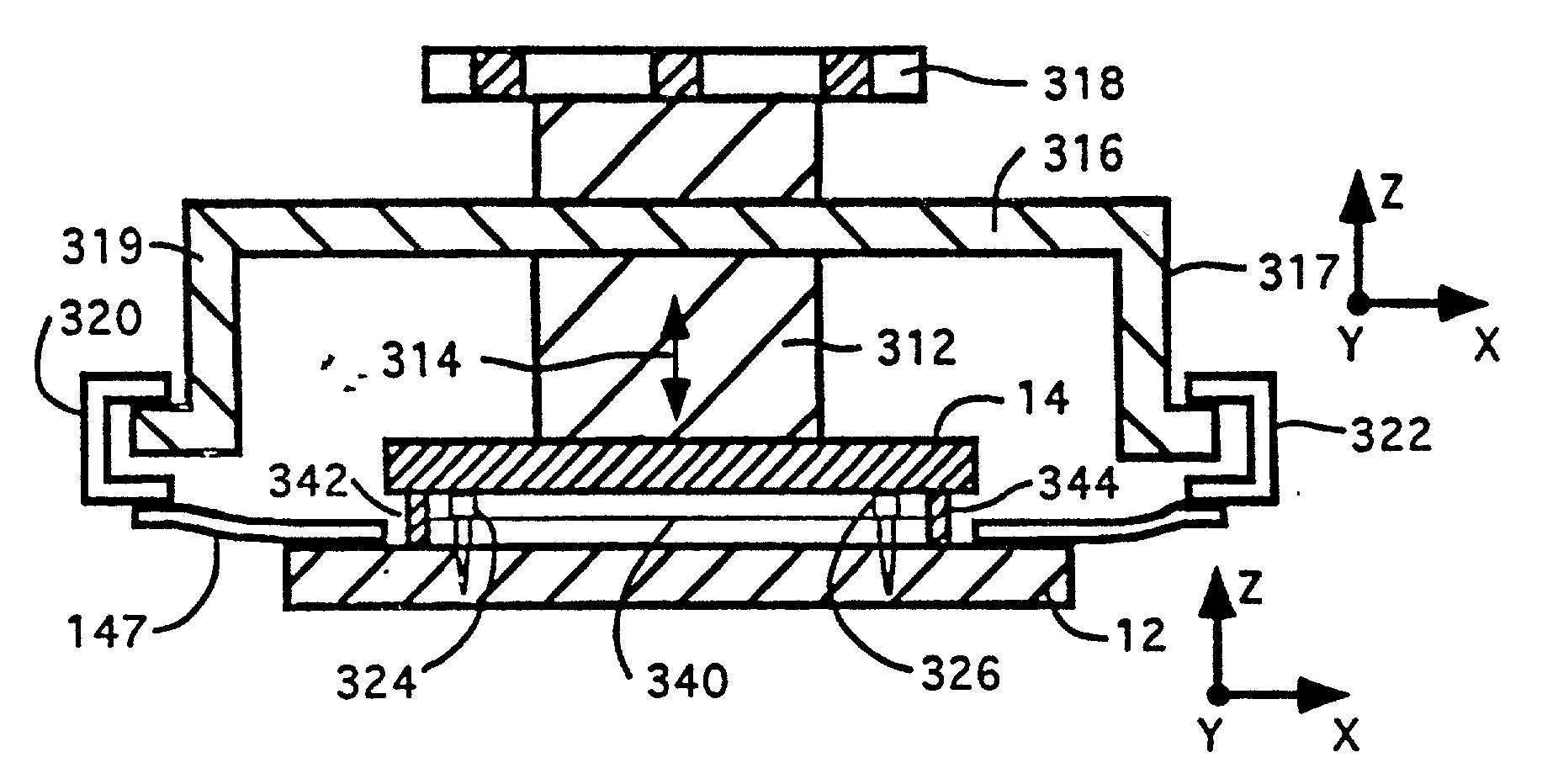

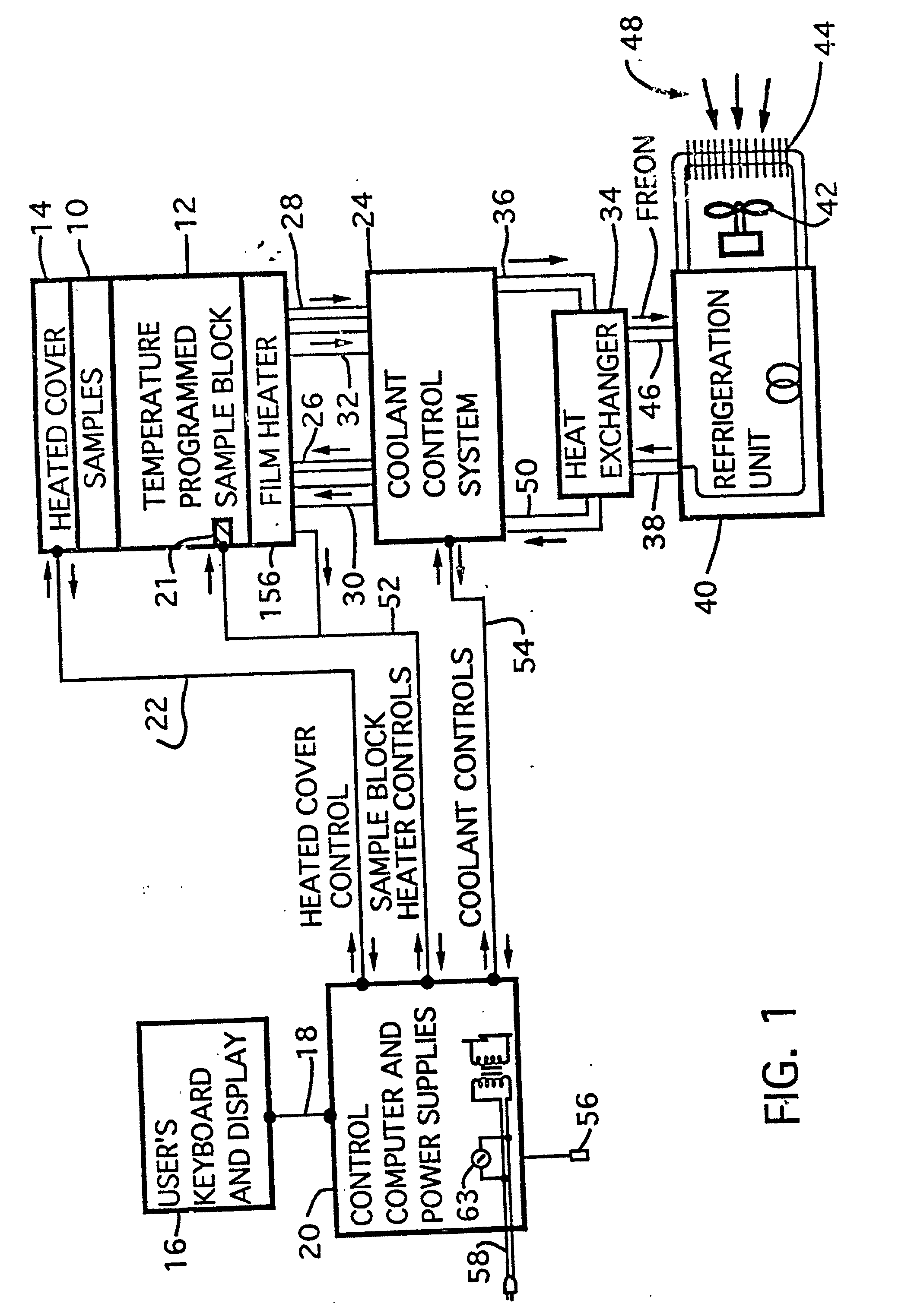

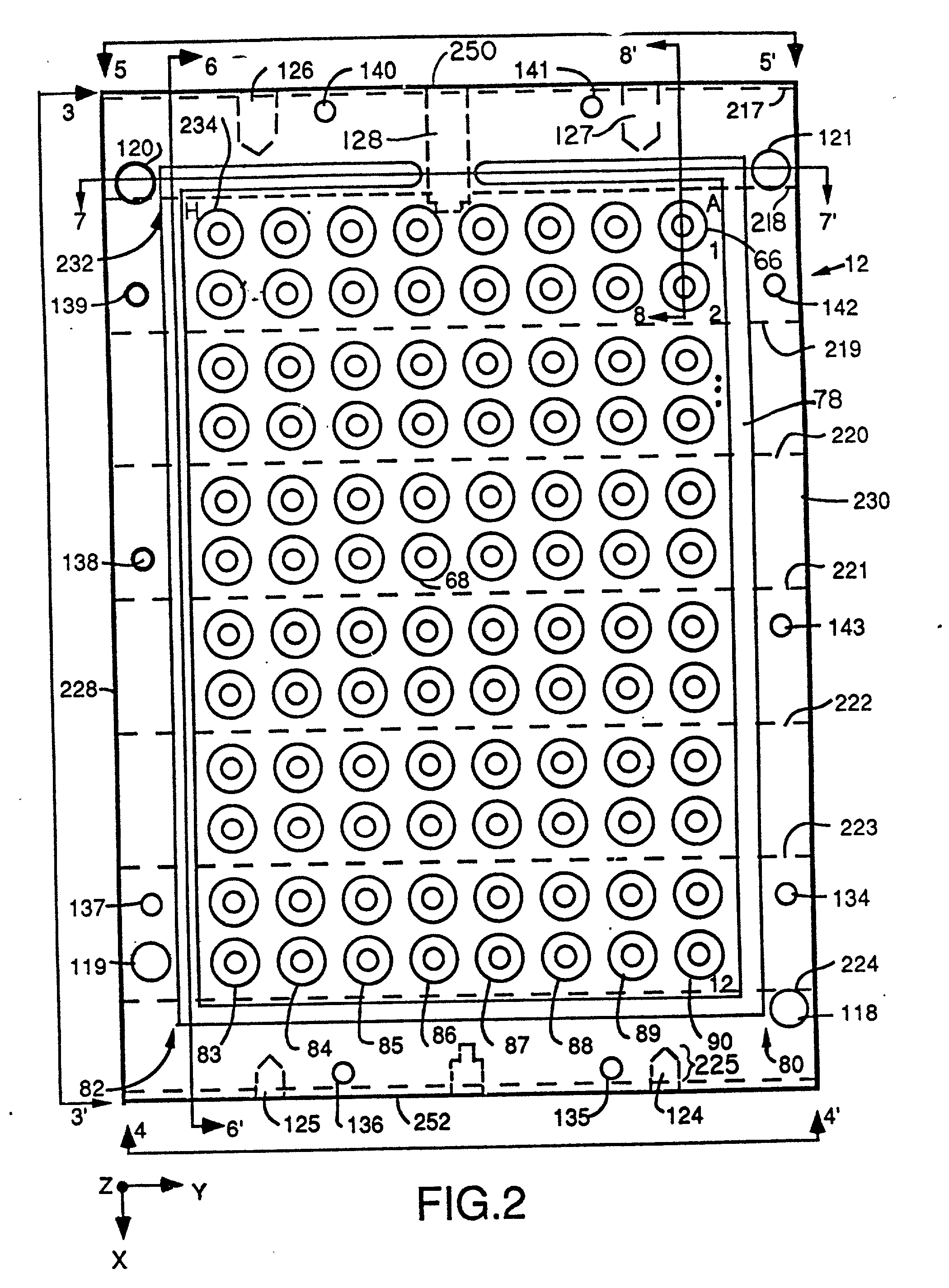

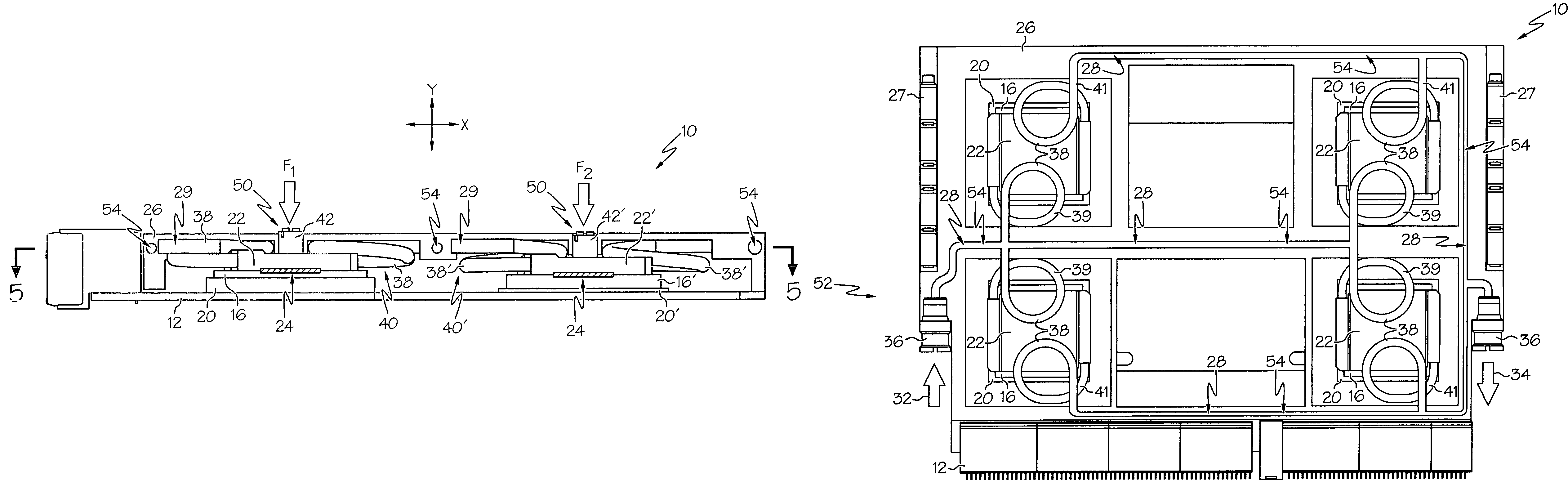

Thermal cycler for automatic performance of the polymerase chain reaction with close temperature control

InactiveUS20020072112A1Shorten cycle timeLow cost of reagentsBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlSolenoid valve

An instrument for performing highly accurate PCR employing a sample block in microtiter tray format. The sample block has local balance and local symmetry. A three zone film heater controlled by a computer and ramp cooling solenoid valves also controlled by the computer for gating coolant flow through the block controls the block temperature. Constant bias cooling is used for small changes. Sample temperature is calculated instead of measured. A platen deforms plastic caps to apply a minimum acceptable threshold force for seating the tubes and thermally isolates them. A cover isolates the block. The control software includes diagnostics. An install program tests and characterizes the instrument. A new user interface is used. Disposable, multipiece plastic microtiter trays to give individual freedom to sample tubes are taught.

Owner:APPL BIOSYSTEMS INC

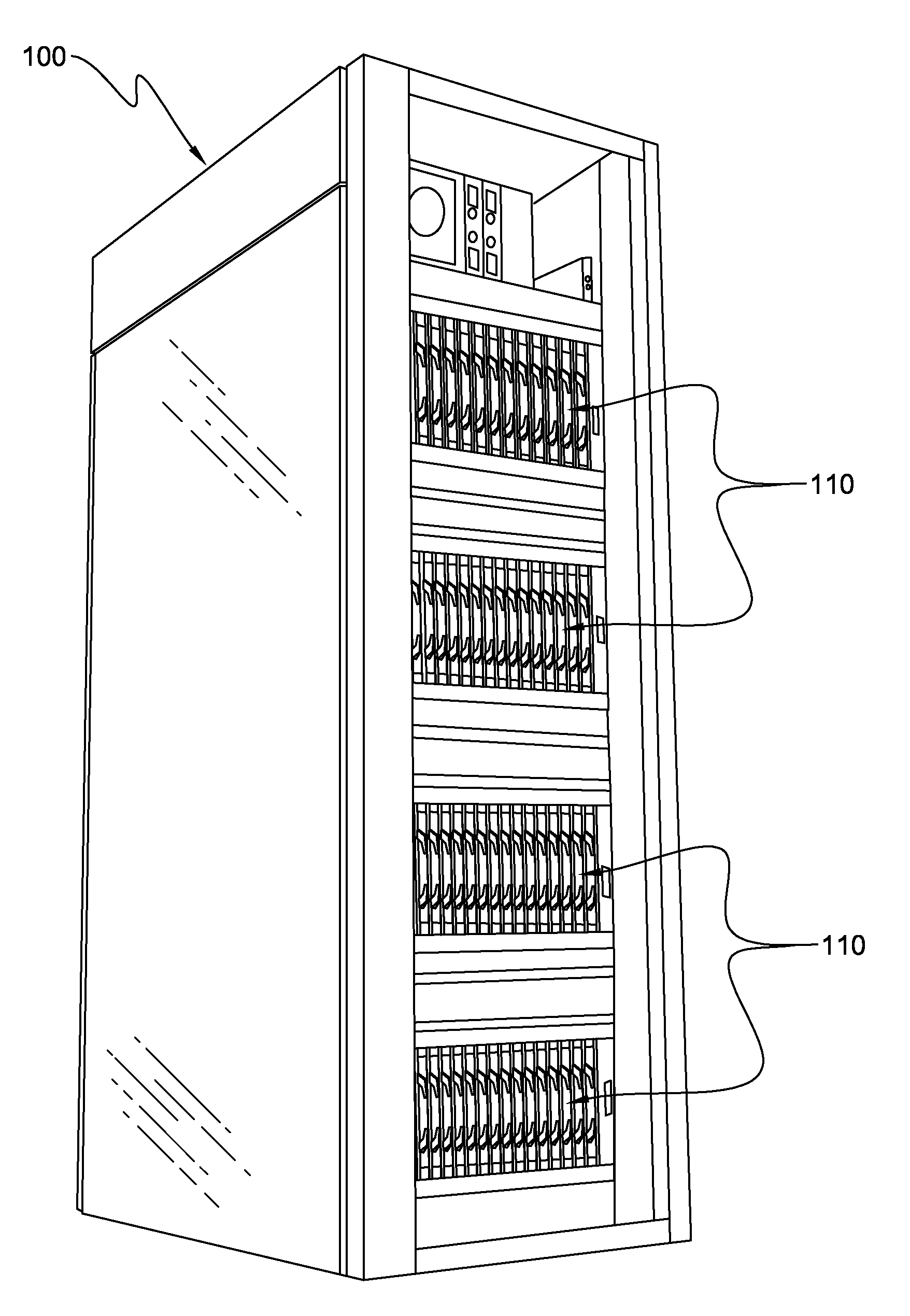

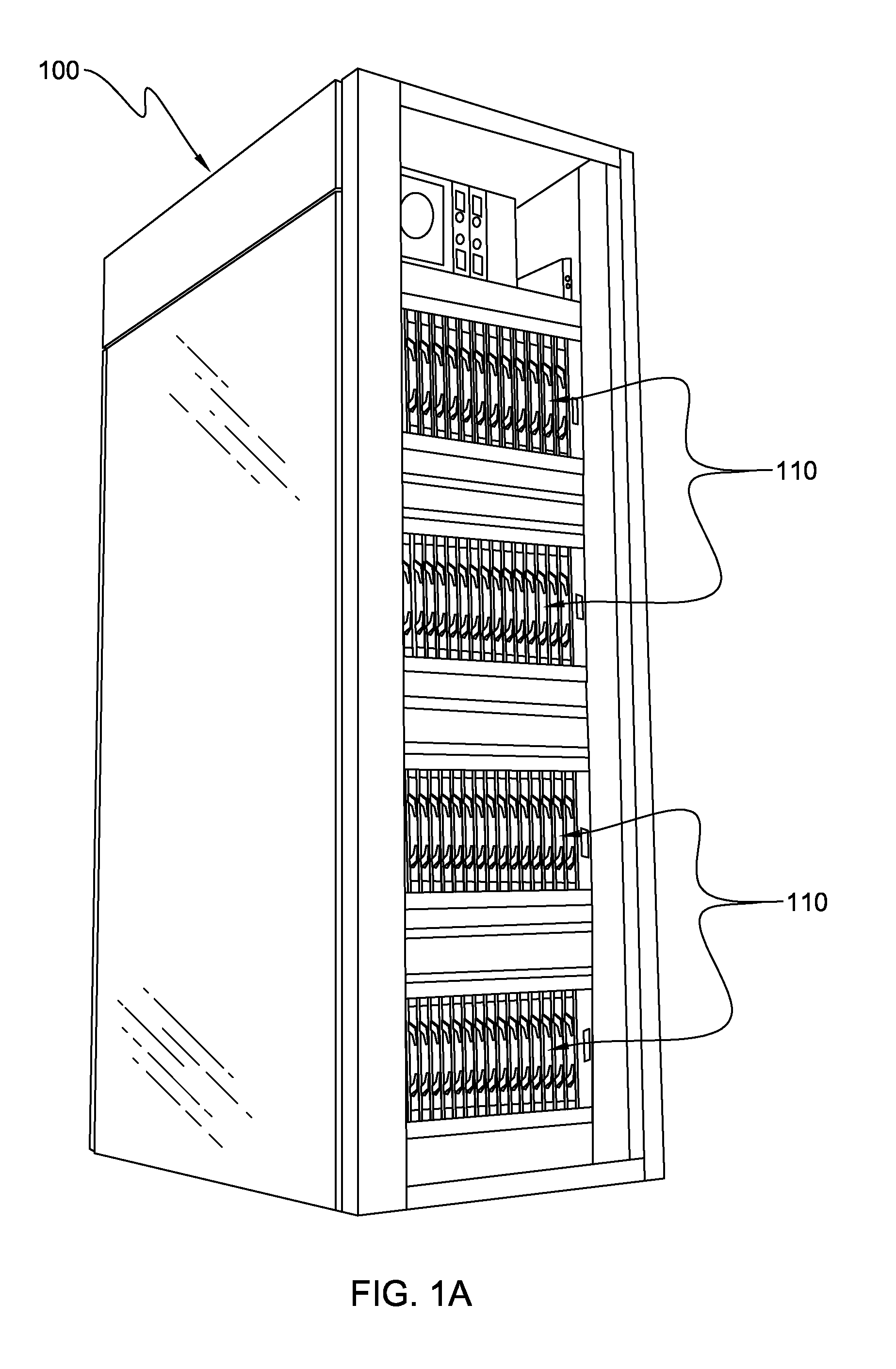

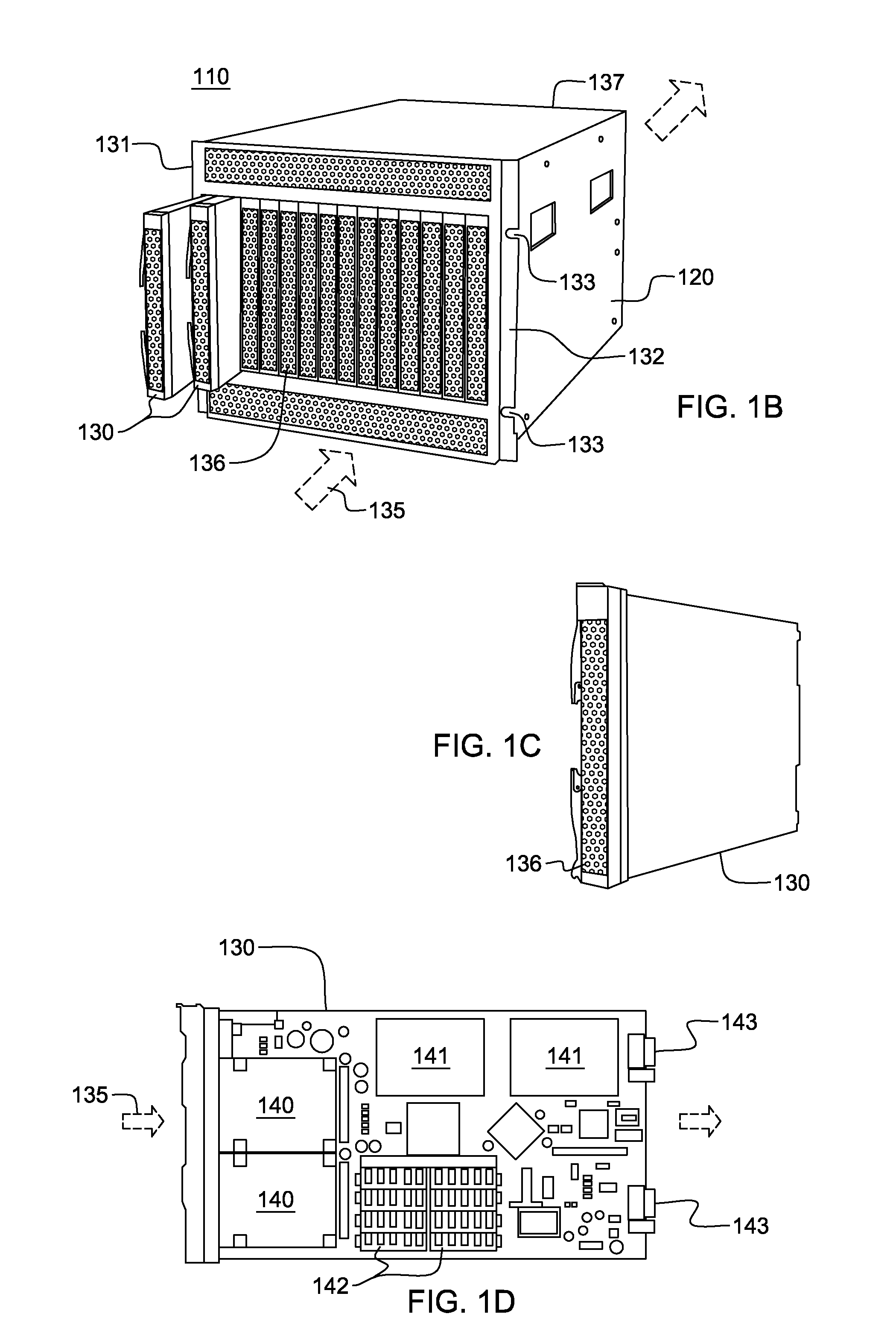

Liquid cooling apparatus and method for cooling blades of an electronic system chassis

InactiveUS20100101765A1Improve heat transfer performanceImprove cooling effectDigital data processing detailsSemiconductor/solid-state device detailsElectronic systemsCoolant flow

Apparatus and method are provided for facilitating liquid cooling of a plurality of blades of an electronic system chassis. The apparatus includes a chassis-level manifold assembly with a first coolant path and a plurality of second coolant paths. The first coolant path is isolated from the plurality of second coolant paths by a heat exchanger. The heat exchanger facilitates transfer of heat from coolant within the second coolant paths to coolant within the first coolant path. Each second coolant path is isolated from the other second coolant paths, and coolant passing therethrough facilitates cooling of a respective blade. When operational, each second coolant path forms a portion of a respective closed loop coolant path extending between the manifold assembly and the electronic system chassis, and in one embodiment, each blade is an immersion-blade, with multiple components thereof immersion-cooled by coolant flowing through the respective second coolant path.

Owner:BRAINSCOPE SPV LLC +1

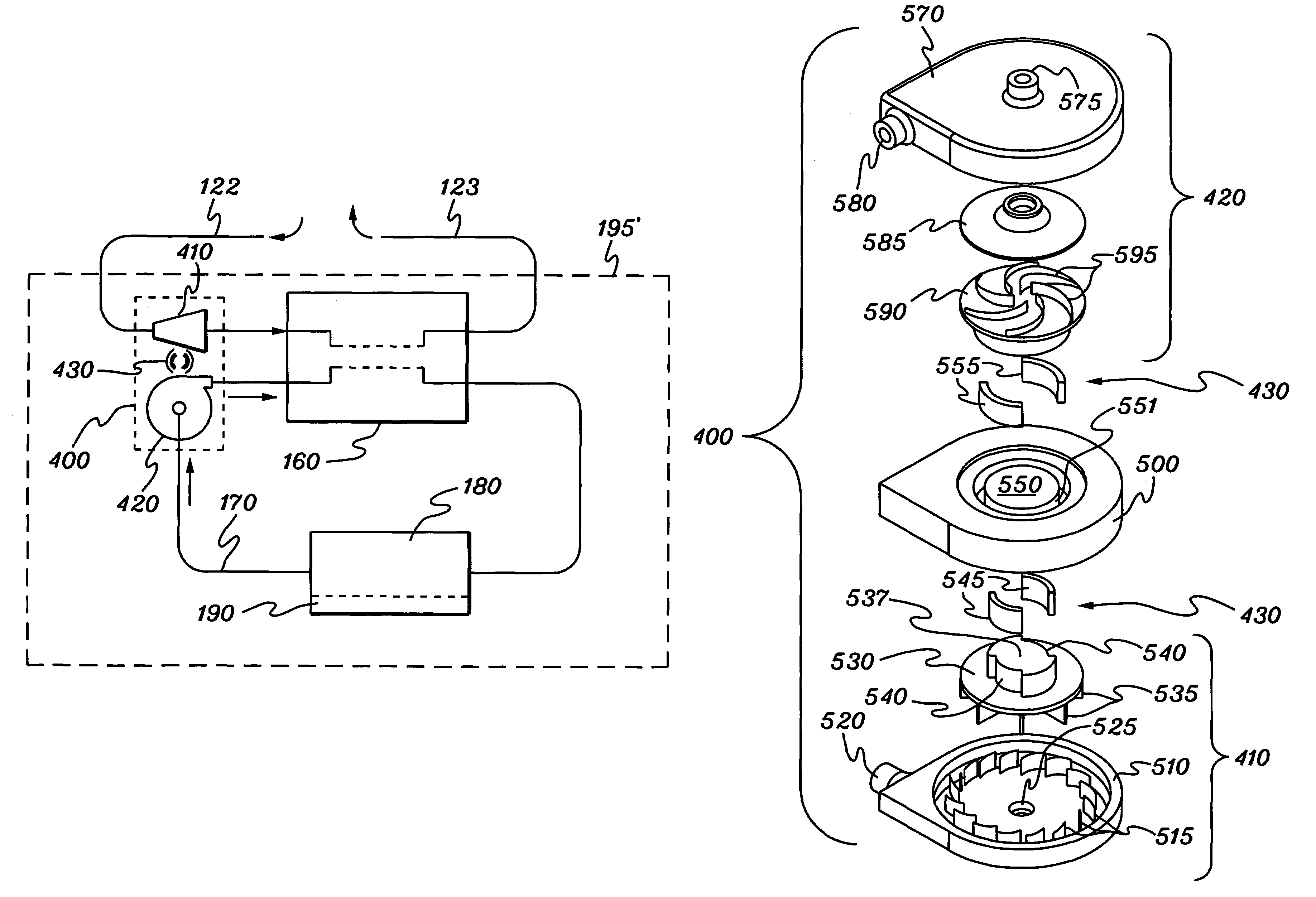

Cooling apparatus for an electronics subsystem employing a coolant flow drive apparatus between coolant flow paths

A coolant flow drive apparatus is provided for facilitating removal of heat from a cooling structure coupled to a heat generating electronics component. The coolant flow drive apparatus includes a turbine in fluid communication with a primary coolant flowing within a primary coolant flow loop, and a pump in fluid communication with a secondary coolant within a secondary coolant flow path. The secondary fluid flow path is separate from the primary coolant flow path. The flow drive apparatus further includes a magnetic coupling between the turbine and the pump, wherein the turbine drives the pump through the magnetic coupling to pump secondary coolant through the secondary coolant flow path.

Owner:LENOVO GLOBAL TECH INT LTD

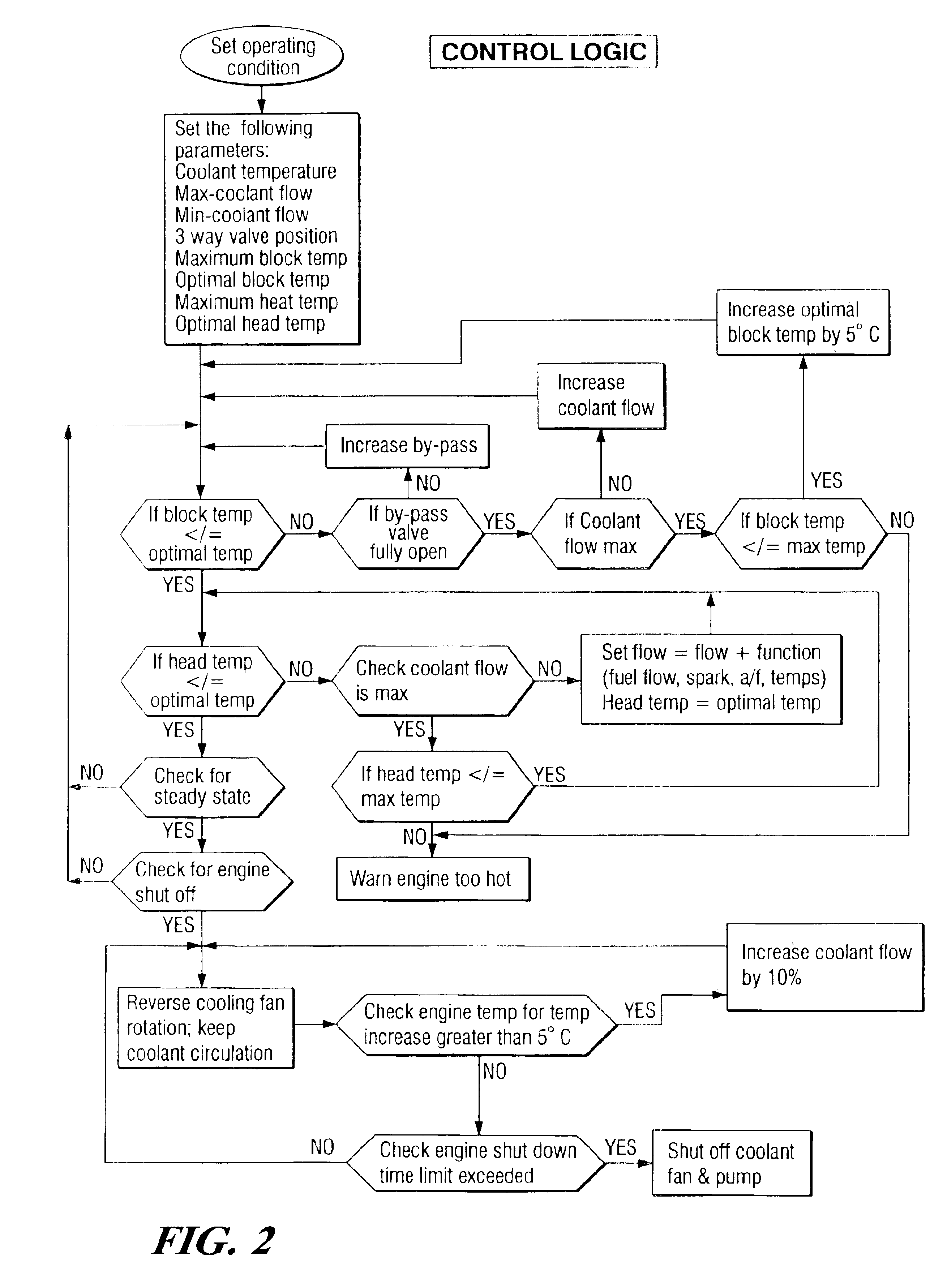

Engine cooling system

InactiveUS6955141B2Minimizes parasitic lossIncrease and decrease flow of coolantLiquid coolingCoolant flow controlCoolant flowCylinder head

A cooling system has a diverter valve to selectively control the flow of coolant through an internal combustion engine having a cylinder block with a cooling jacket and a cylinder head mounted on the block with a cooling jacket. A controller, responsive to the temperature of the block and the head, controls the diverter valve and a water pump to provide adequate coolant flow through the head and the block as needed to maintain optimal operating temperatures. After the engine is shut off, the controller continues to operate the water pump and a cooling fan to continue to cool the engine for a period of time.

Owner:GM GLOBAL TECH OPERATIONS LLC

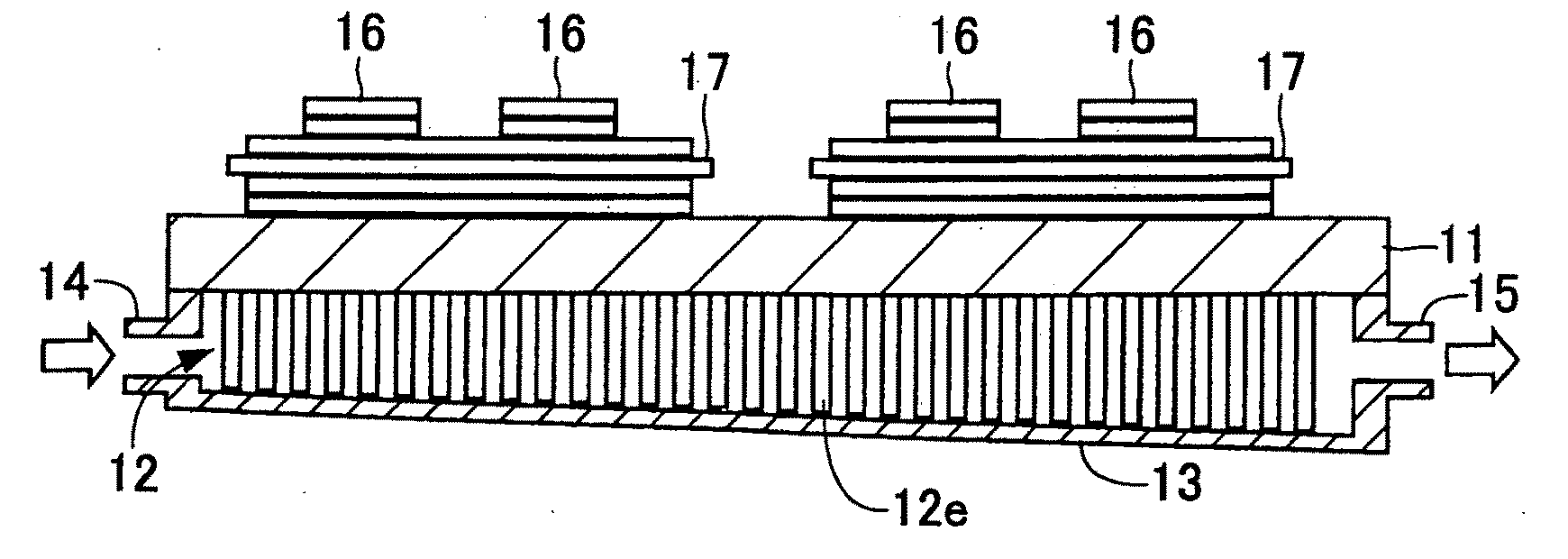

Cooling apparatus for semiconductor chips

ActiveUS20100172091A1Large chip outputManufacturing costSemiconductor/solid-state device detailsSolid-state devicesCoolant flowSemiconductor chip

A cooling apparatus for semiconductor chips includes radiation fins formed on the opposite surface of metal base opposite to the surface of metal base, to which an insulator base board mounting semiconductor chips thereon, is disposed. The radiation fins, such as sheet-shaped fins having different lengths are arranged such that the surface area density of the fins becomes higher in the coolant flow direction, whereby the surface area density is the total surface area of radiation fins on a unit surface area of the metal base. As a result, the temperatures of semiconductor chips arranged along the coolant flow direction are closer to each other.

Owner:FUJI ELECTRIC CO LTD

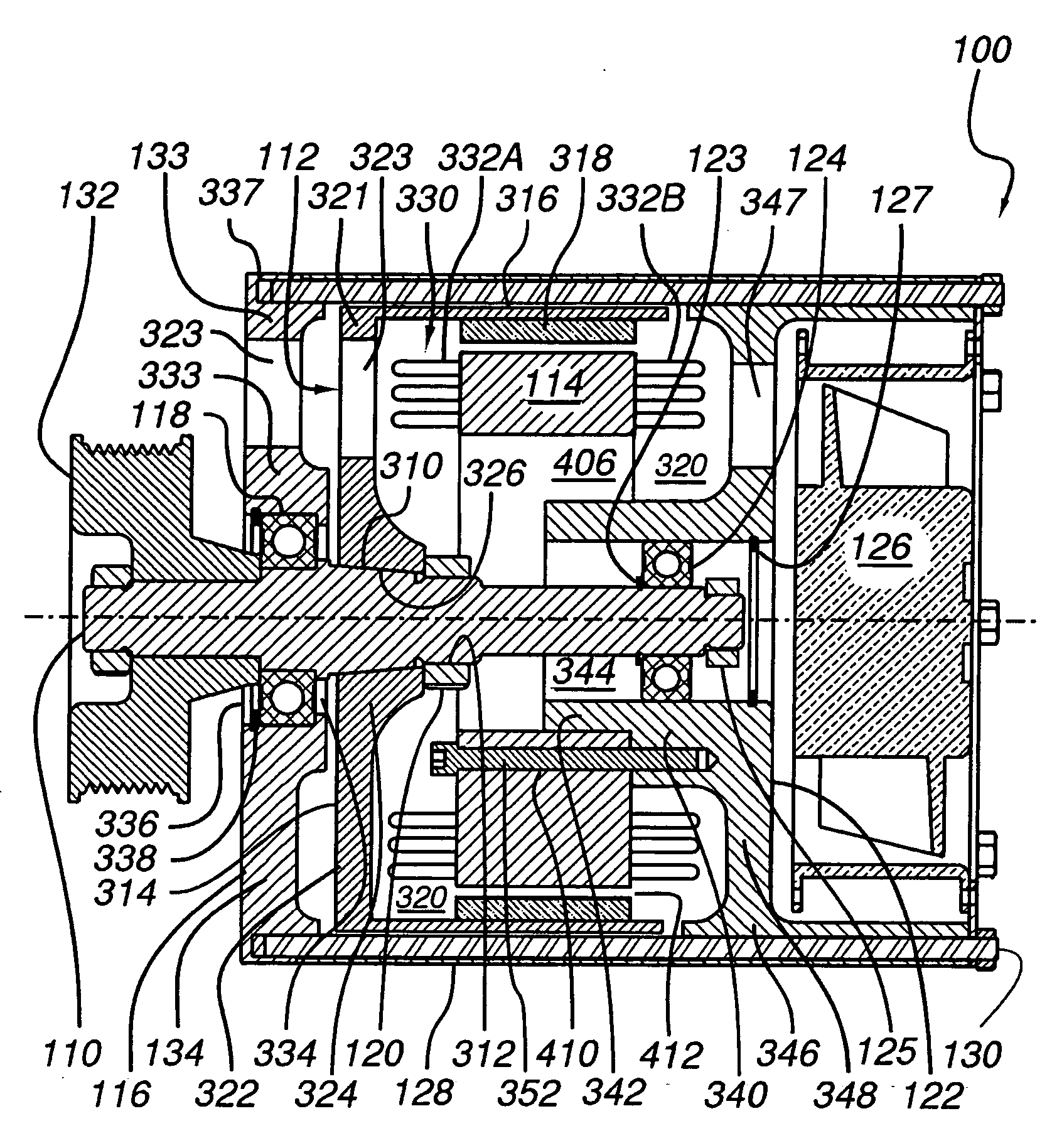

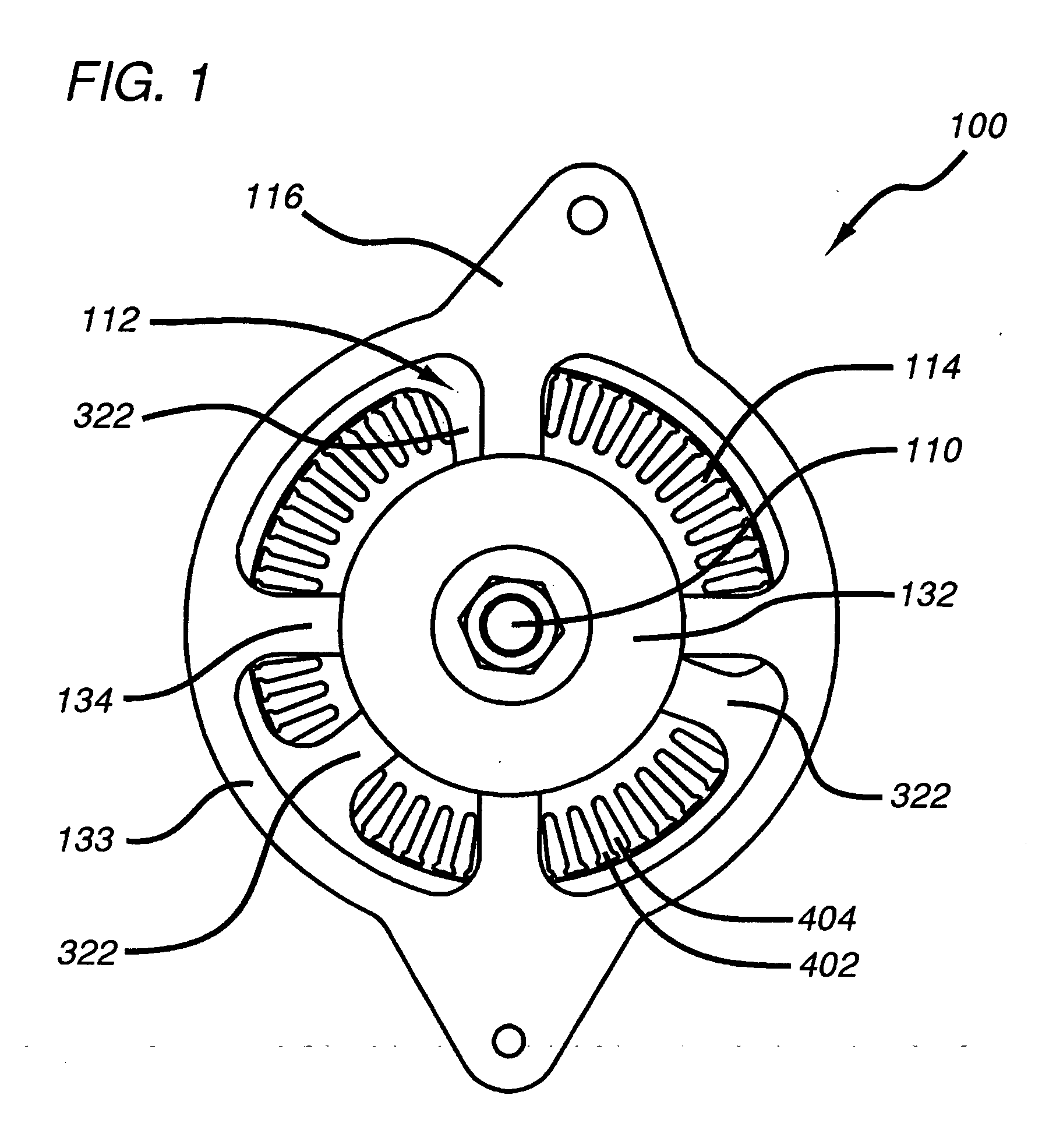

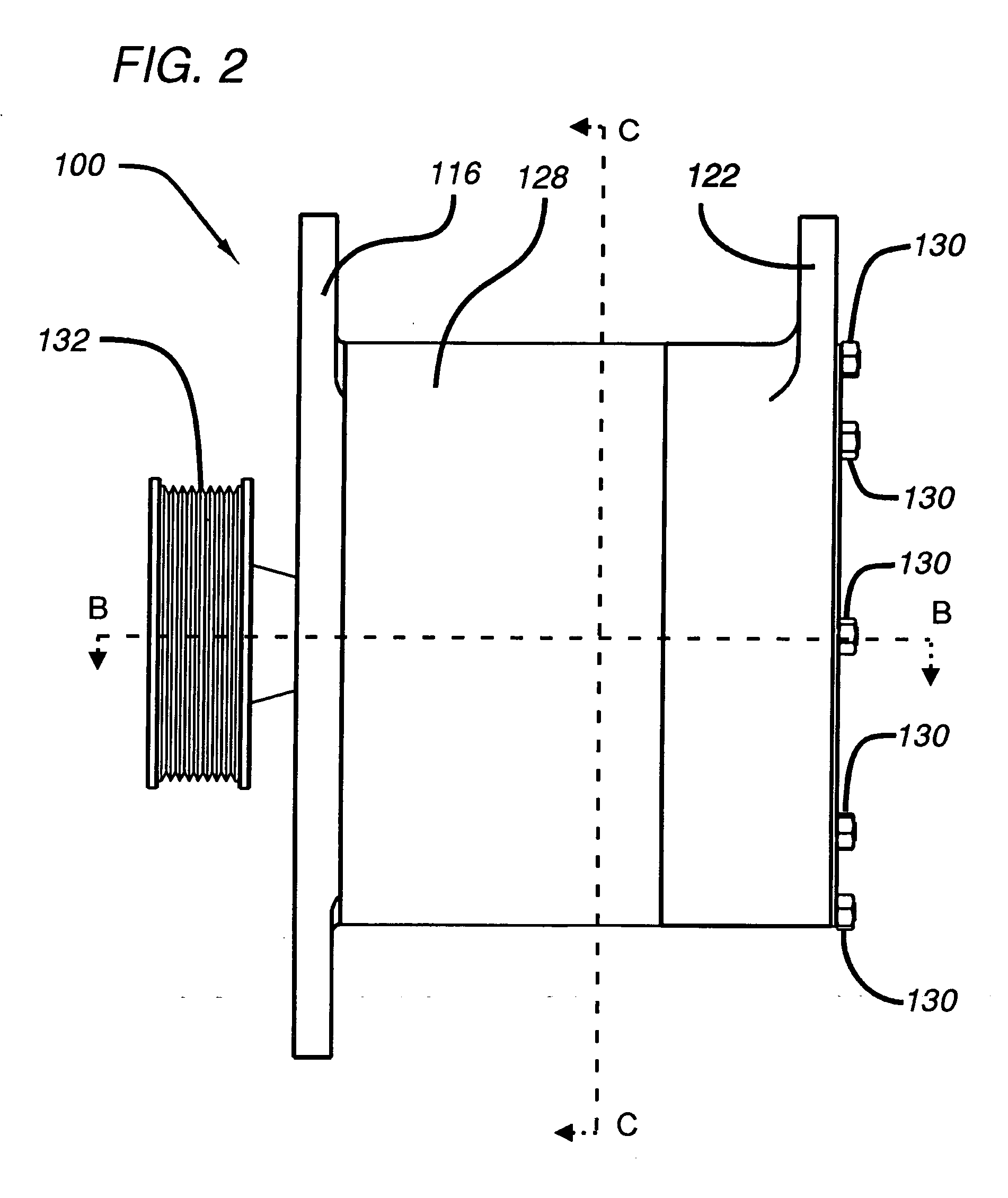

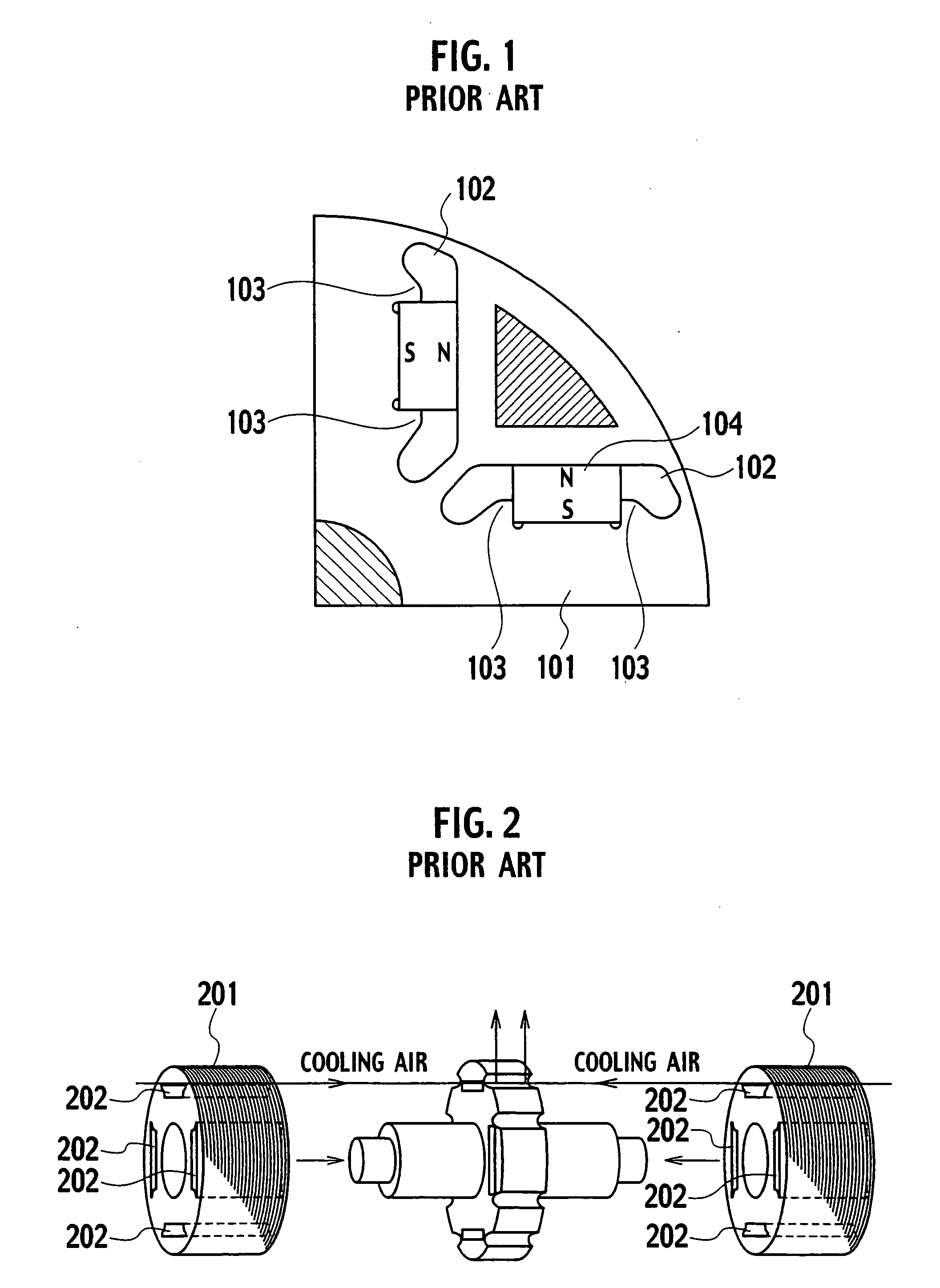

Compact high power alternator

InactiveUS20050035673A1Increase surface areaImprove cooling effectMagnetic circuit rotating partsMagnetic circuit stationary partsAlternatorRotor magnets

An apparatus for converting between mechanical and electrical energy, particularly suited for use as a compact high power alternator for automotive use and “remove and replace” retrofitting of existing vehicles. The apparatus comprises a rotor with permanent magnets, a stator with a winding, and a cooling system. Mechanisms to prevent the rotor magnets from clashing with the stator by minimizing rotor displacement, and absorbing unacceptable rotor displacement are disclosed. The cooling system directs coolant flow into thermal contact with at least one of the winding and magnets, and includes at least one passageway through the stator core. Various open and closed cooling systems are described. Cooling is facilitated by, for example, loosely wrapping the winding end turns, use of an asynchronous airflow source, and / or directing coolant through conduits extending through the stator into thermal contact with the windings.

Owner:MAGNETIC APPL

Adjustable height liquid cooler in liquid flow through plate

An arrangement having a cooling function is provided, comprising a circuit board, a plurality of heat generating devices attached to the circuit board, a cooling device thermally connected to one of the plurality of electronic devices, and a coolant plate. An example of the arrangement can include a source of pressurized coolant fluid connected to the coolant plate and adapted to cause the coolant fluid to be transferred between the coolant plate and the cooling device. In addition or alternatively, the arrangement can include a plurality of flexible conduits and an adjustment device adapted to selectively adjust he height of the cooling device. In addition or alternatively, a cooling apparatus within a cooling arrangement can comprise a cooling device, a coolant plate, and a coolant pathway including a first passage formed in the coolant plate and a second passage formed in the cooling device.

Owner:CURTISS WRIGHT CONTROLS

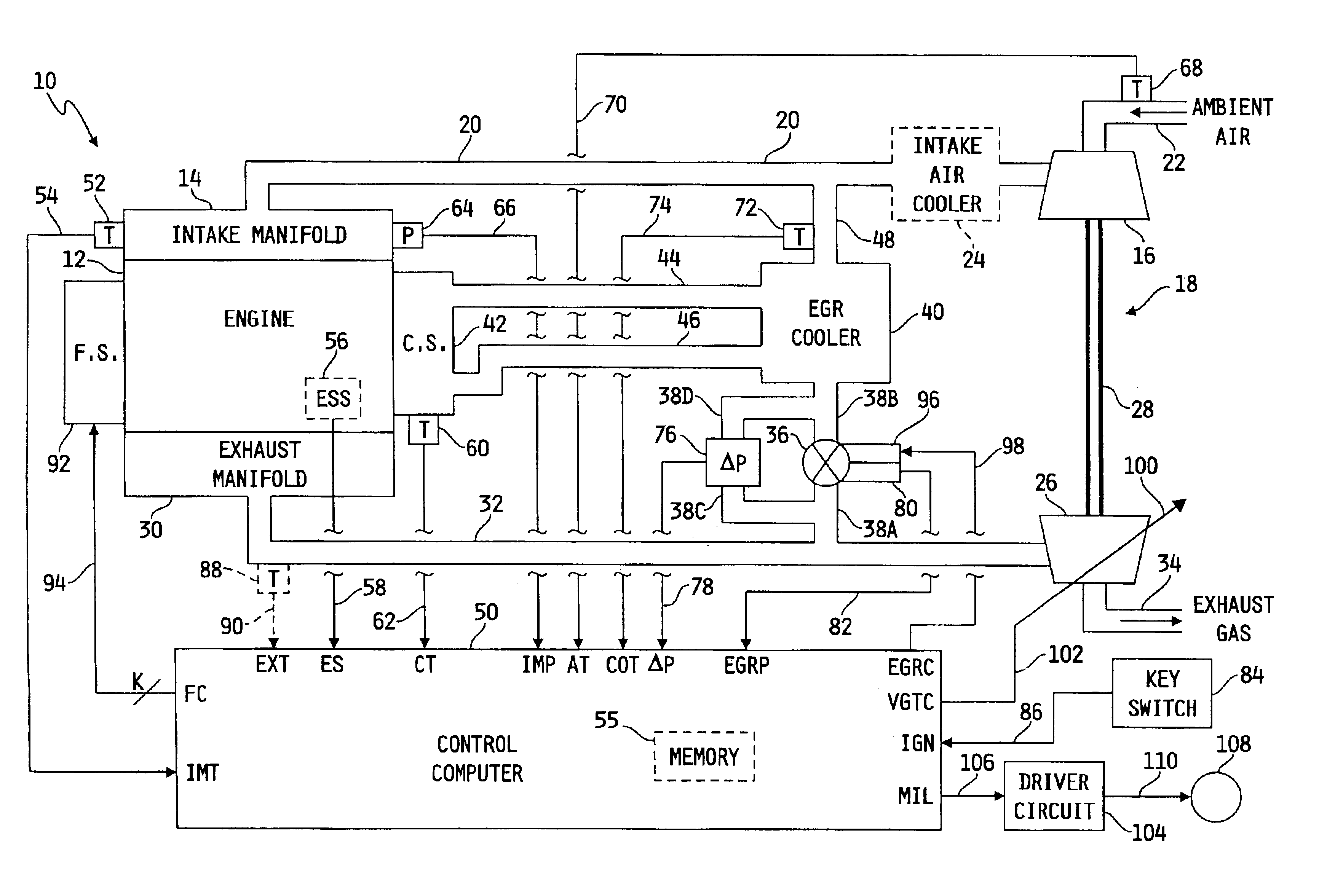

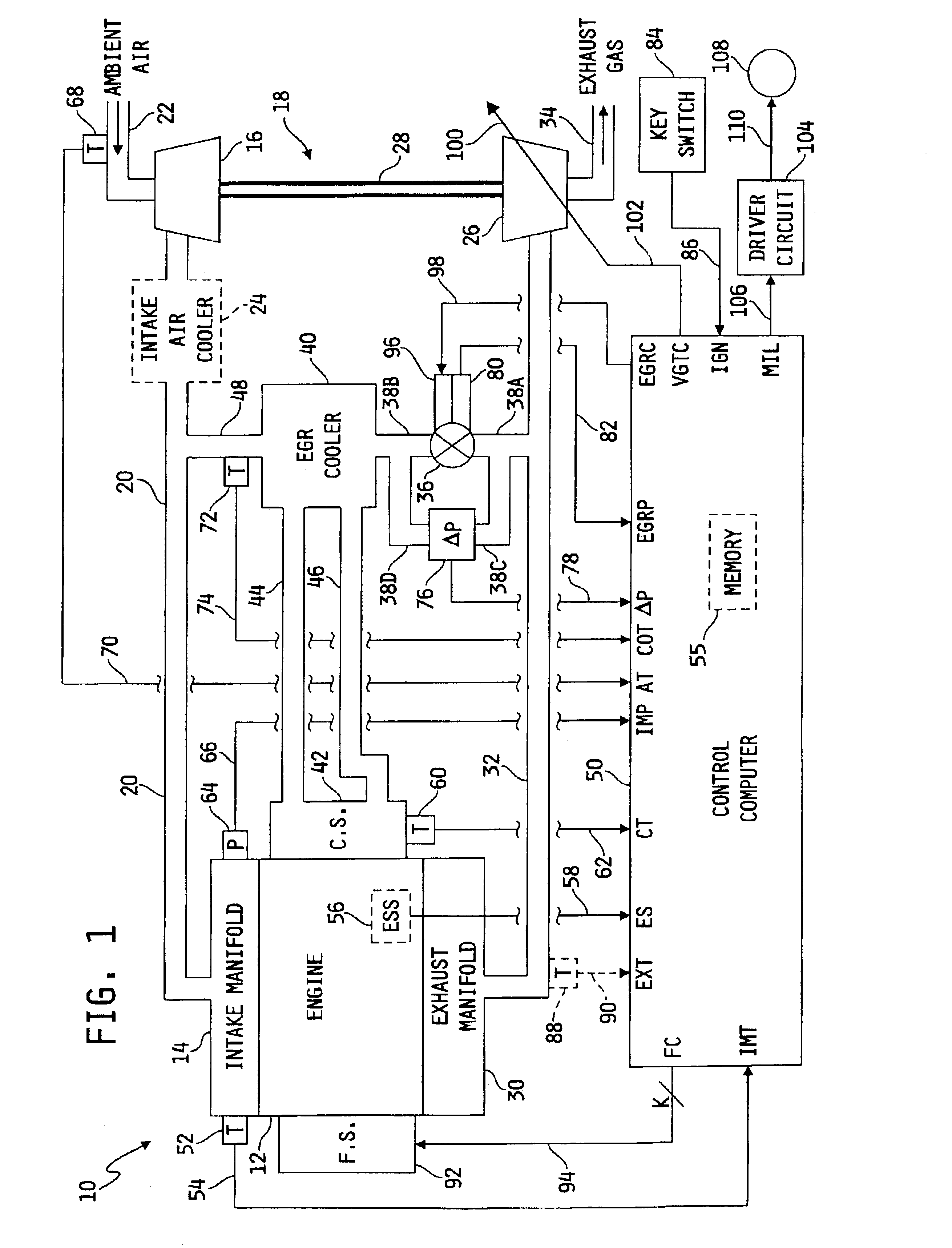

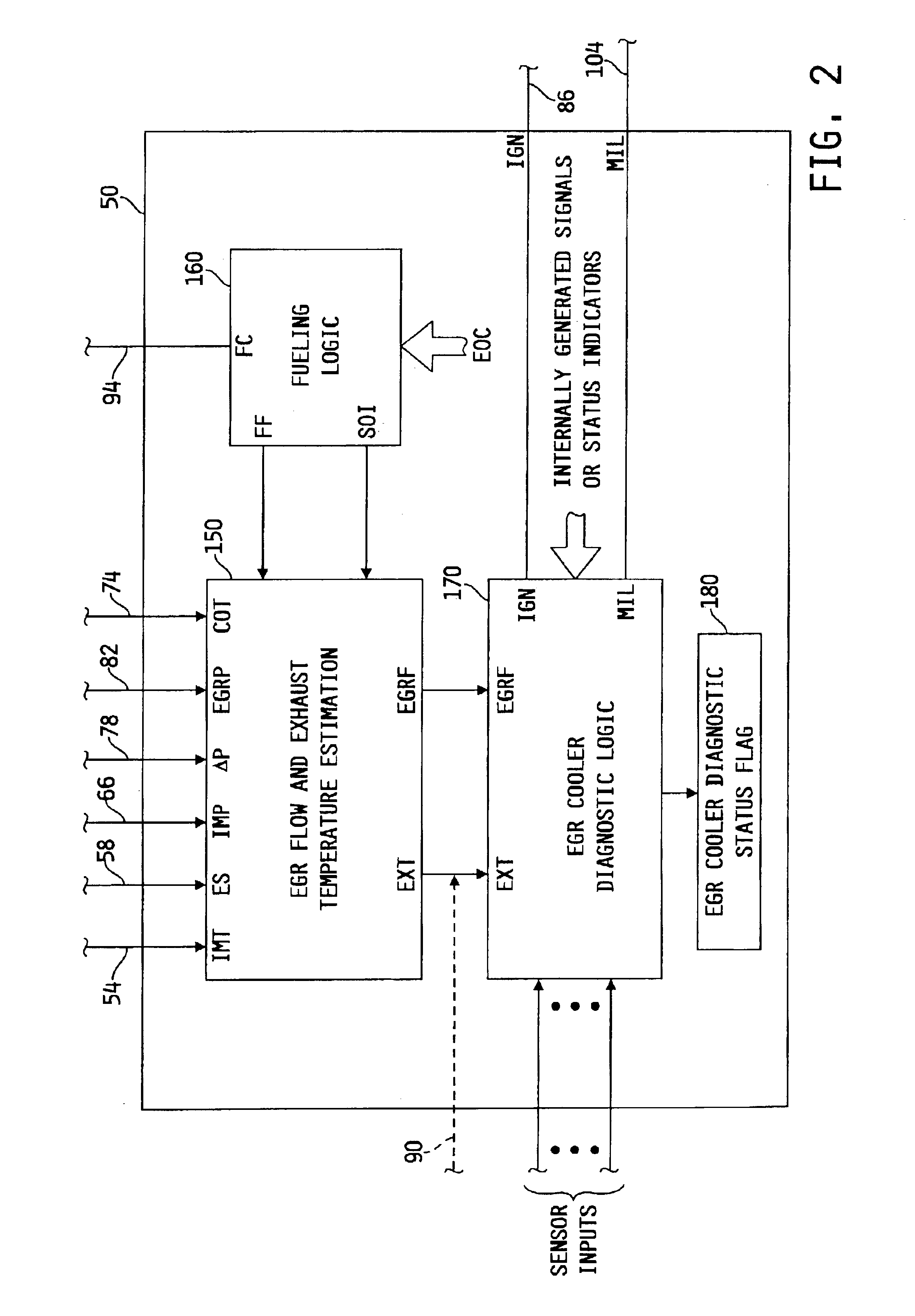

System for diagnosing operation of an EGR cooler

InactiveUS6848434B2Internal combustion piston enginesNon-fuel substance addition to fuelCoolant flowEngineering

A system is disclosed for diagnosing operation of an EGR cooler disposed in-line with an EGR conduit fluidly coupled between an intake manifold and an exhaust manifold of the engine such that exhaust gas flowing through the EGR conduit also flows through the EGR cooler. The EGR cooler is coupled to an engine cooling system such that coolant fluid circulating through the engine also circulates through the EGR cooler. Means are provided for determining a temperature of exhaust gas produced by the engine, a temperature of exhaust gas exiting the EGR cooler, a temperature of the coolant fluid and a flow rate of exhaust gas through the EGR conduit. A control computer is configured to diagnose operation the EGR cooler as a function of the temperature of exhaust gas produced by the engine, the EGR cooler outlet temperature, the engine coolant temperature and the EGR flow rate.

Owner:CUMMINS INC

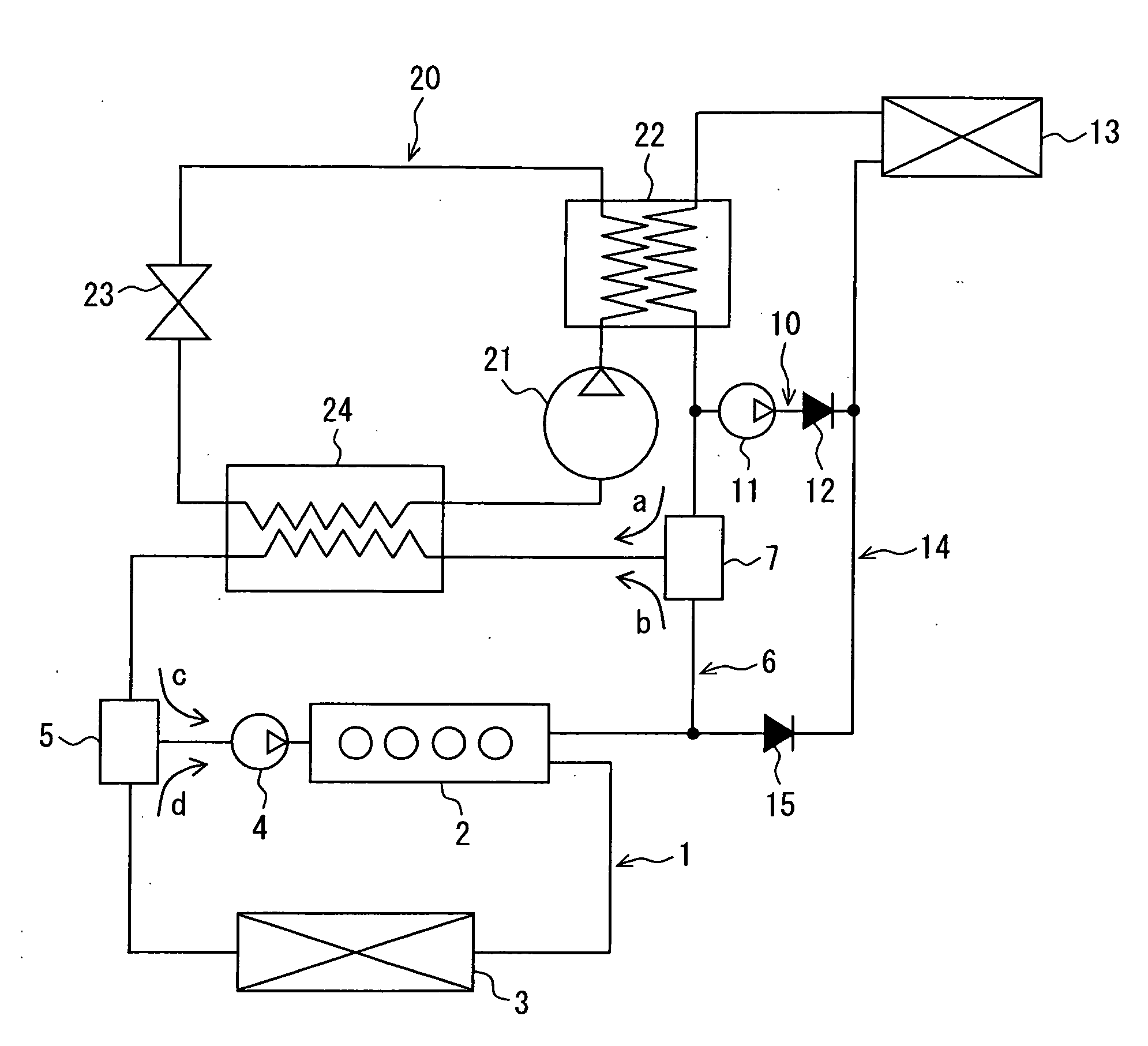

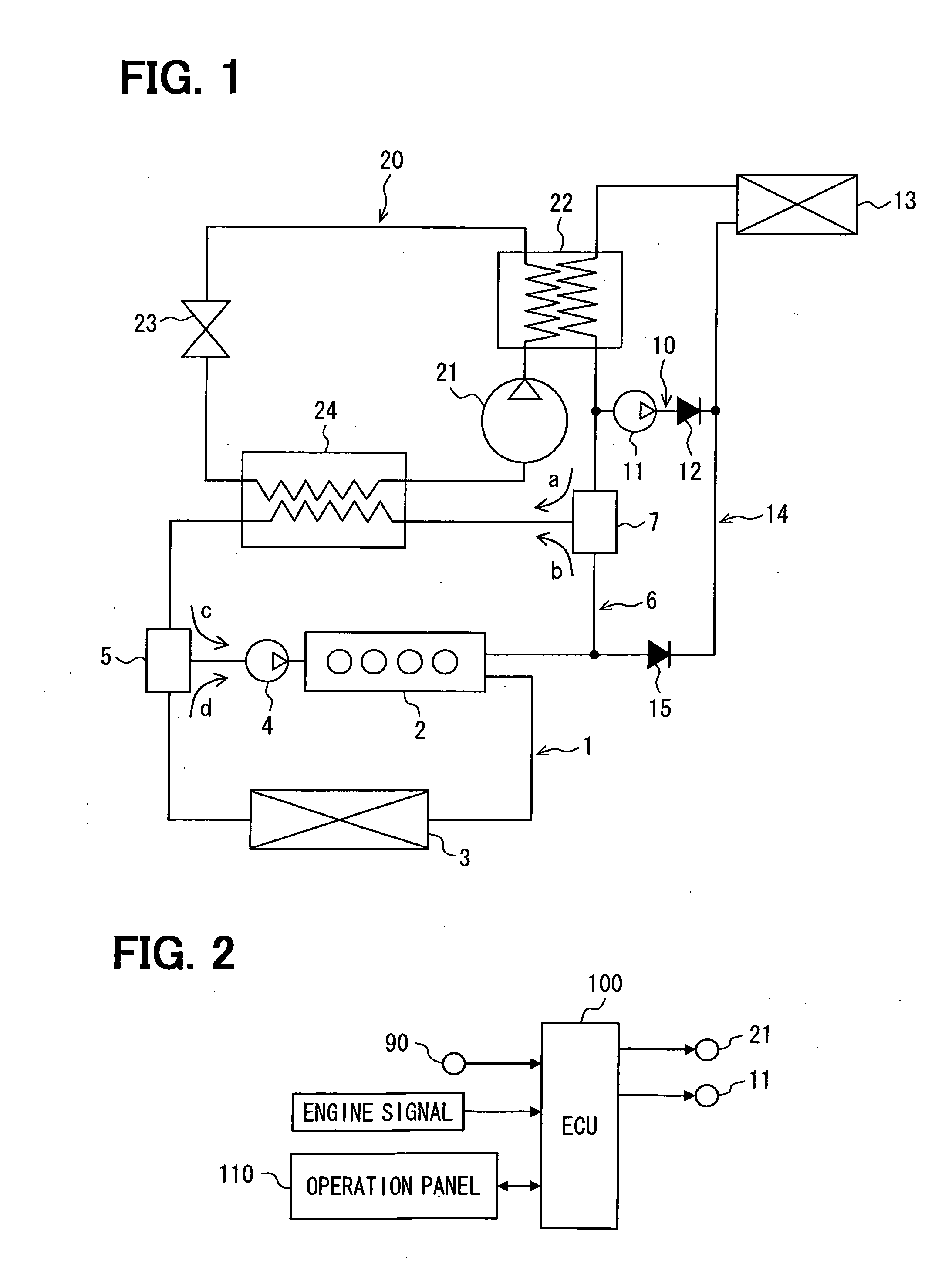

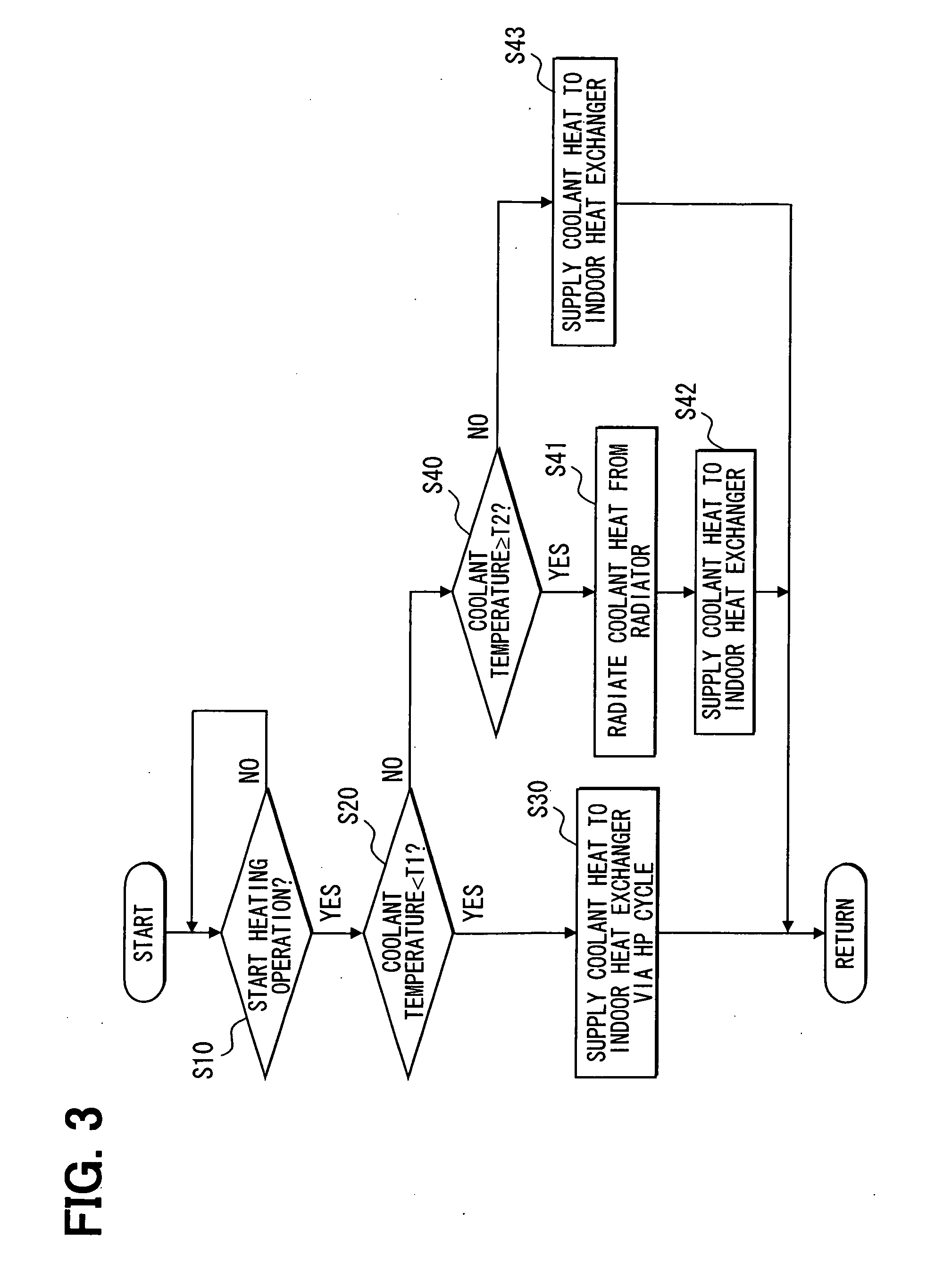

Air conditioner for vehicle

InactiveUS20100281901A1Solve insufficient heating capacityReduce energy lossAir-treating devicesRailway heating/coolingCoolant flowEngineering

In an air conditioner for a vehicle, in a heating operation for heating a vehicle compartment, when heating capacity is obtained by flowing a coolant through an inside of an indoor heat exchanger, the coolant flows directly in the inside of the indoor heat exchanger to heat air to be supplied to the vehicle compartment. In contrast, when the heating capacity is not obtained by flowing the coolant through the inside of the indoor heat exchanger, the coolant flows through a first water-refrigerant heat exchanger and a refrigerant in a heat pump cycle circulates so that heat of the coolant is absorbed by the refrigerant in the first water-refrigerant heat exchanger, and the air is heated in the indoor heat exchanger by using heat of the refrigerant that has absorbed the heat of the coolant.

Owner:DENSO CORP +1

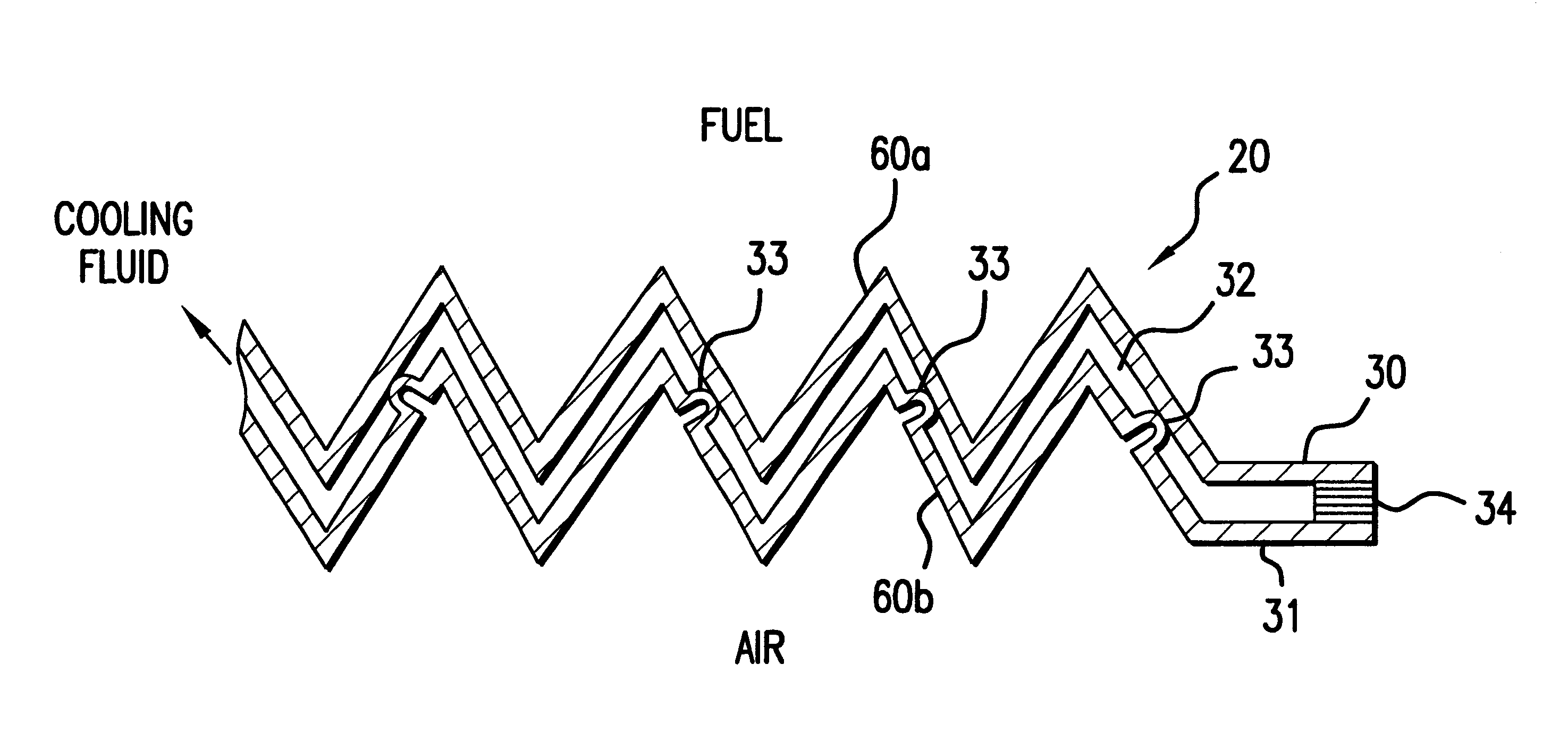

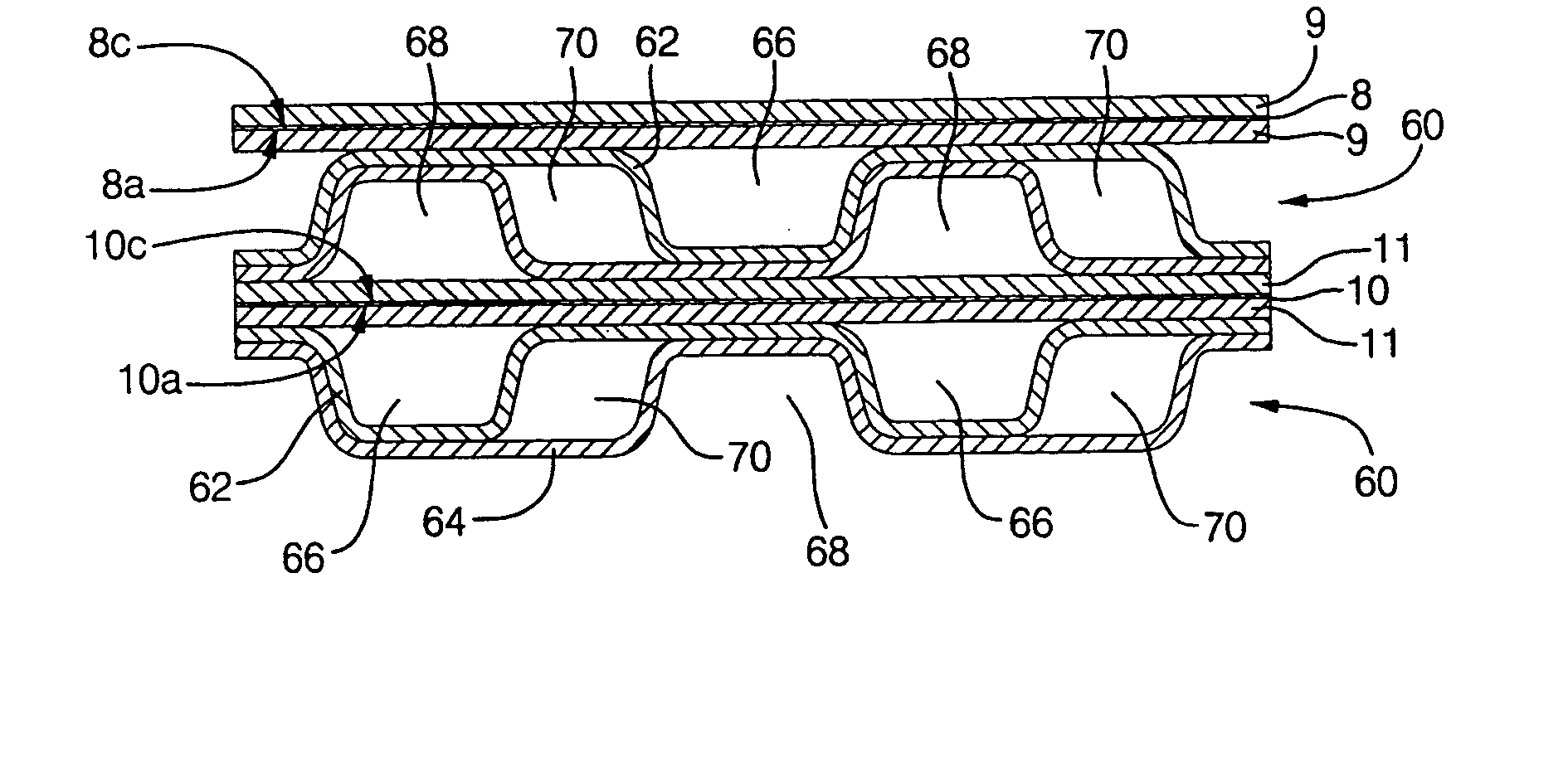

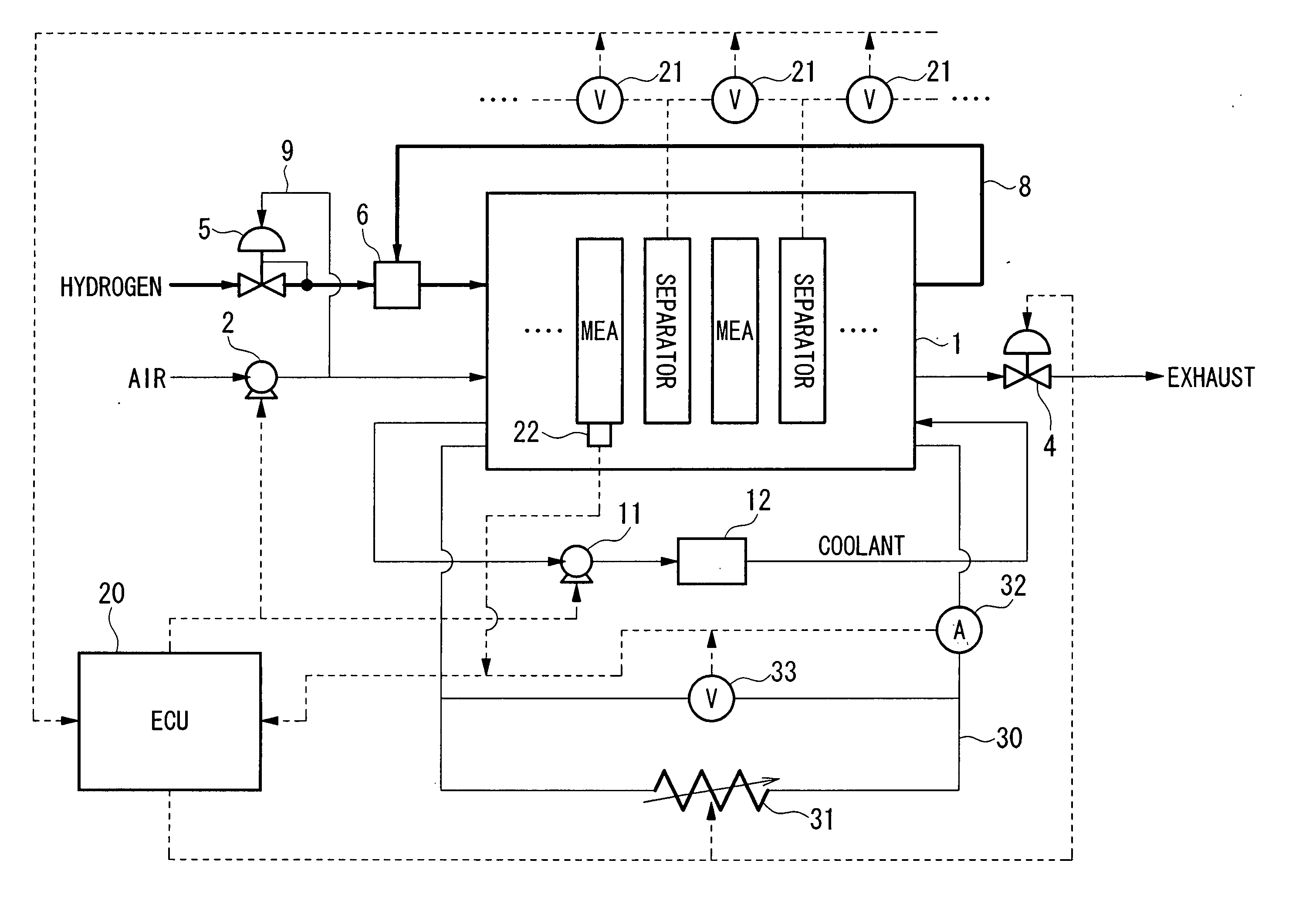

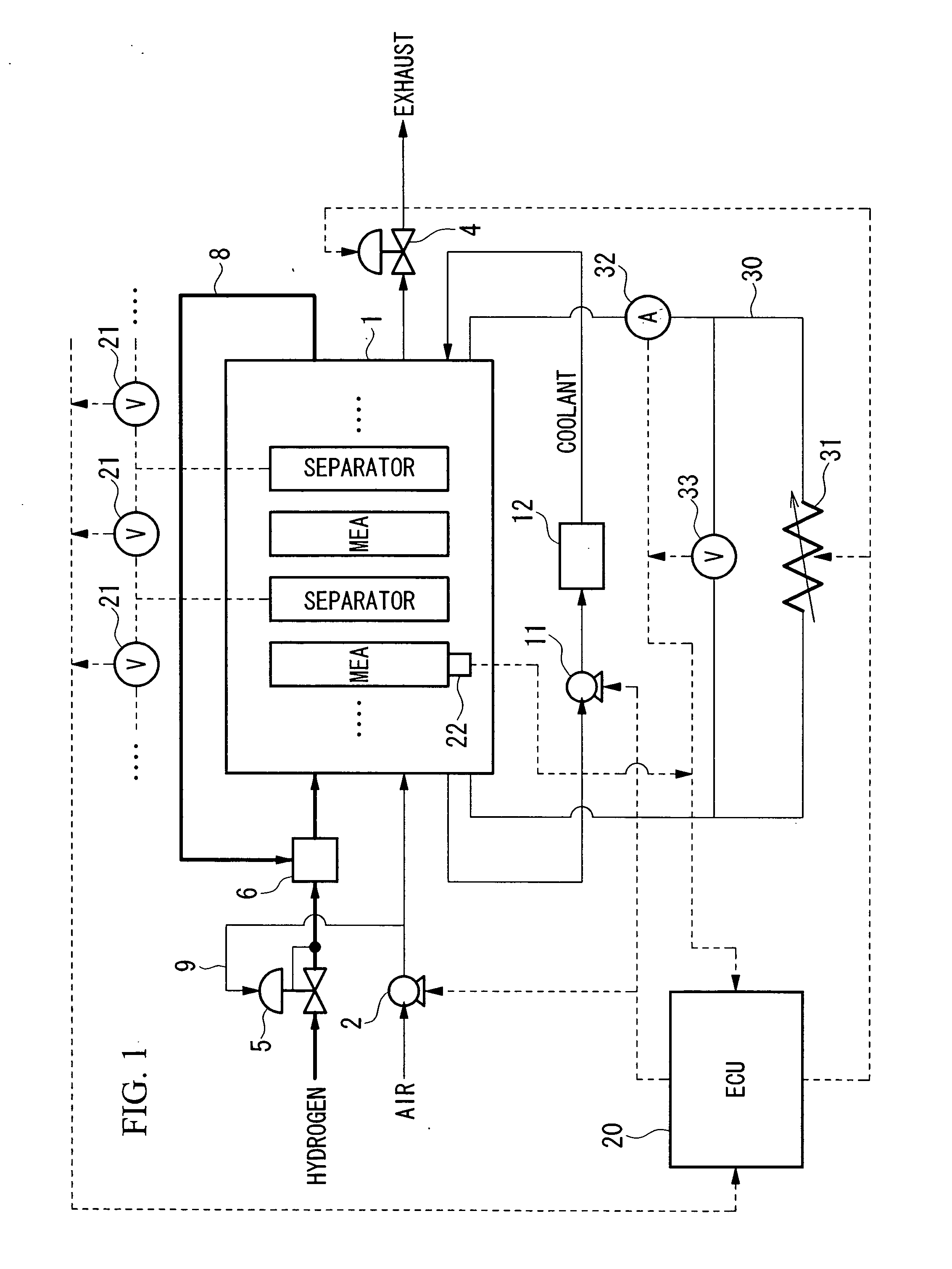

Method and system for starting up fuel cell stack at subzero temperatures, and method of designing fuel cell stack

InactiveUS20050053810A1Shorten warm-up timeSmall heat capacityFuel cells groupingFuel cell auxillariesPolymer electrolytesFuel cells

A method of starting up at a subzero temperature a solid polymer electrolyte fuel cell stack that is formed by stacking a plurality of layers of separators and membrane electrode assemblies having a solid polymer electrolyte membrane and electrodes. The method includes a step of using a solid polymer electrolyte fuel cell stack in which the separators are made from metal and have a cross-sectional waveform structure, and a space that is formed between at least a portion of the separators and separators that are placed adjacent to this portion of the separators is used as a coolant flow passage.

Owner:HONDA MOTOR CO LTD

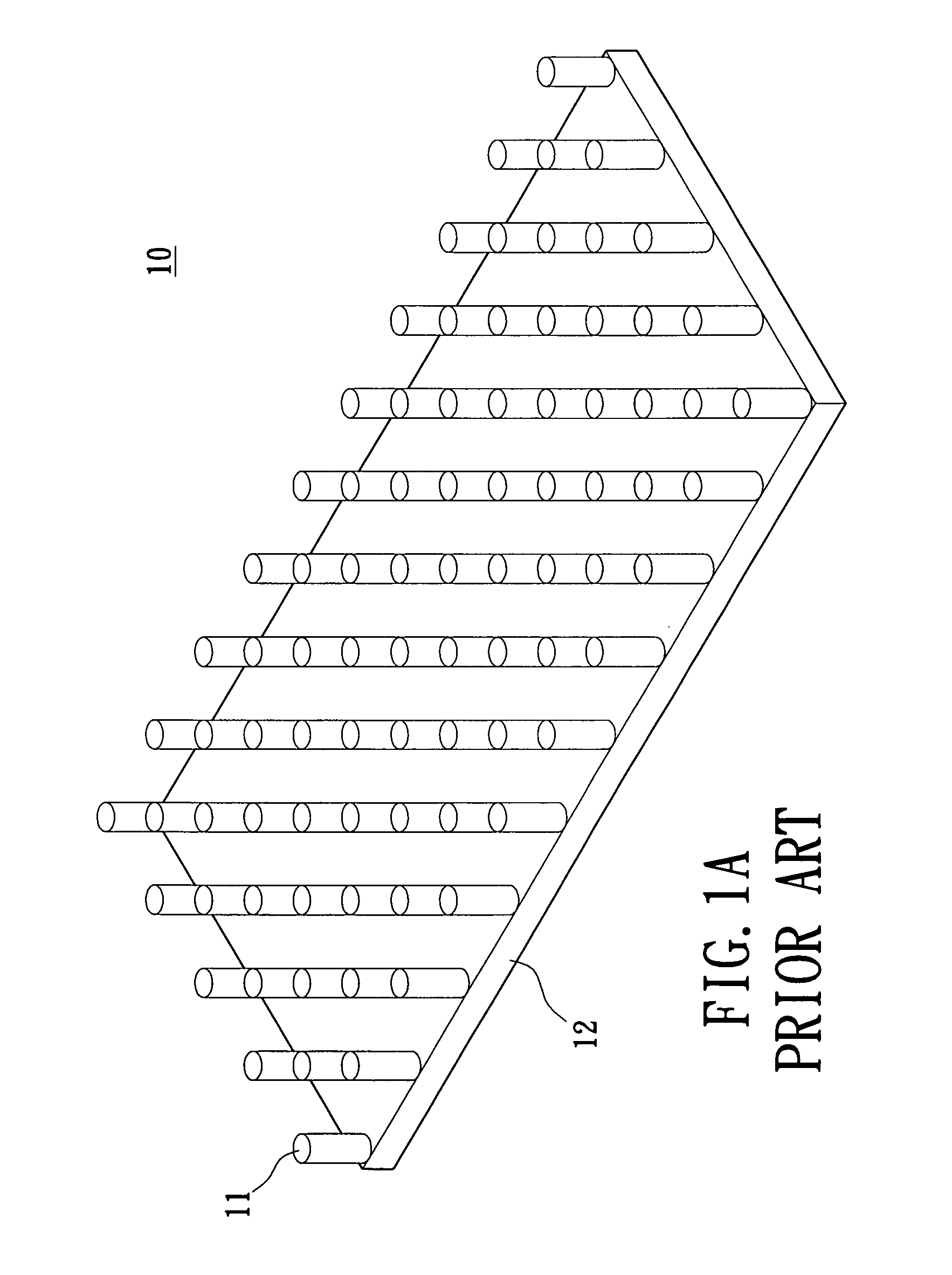

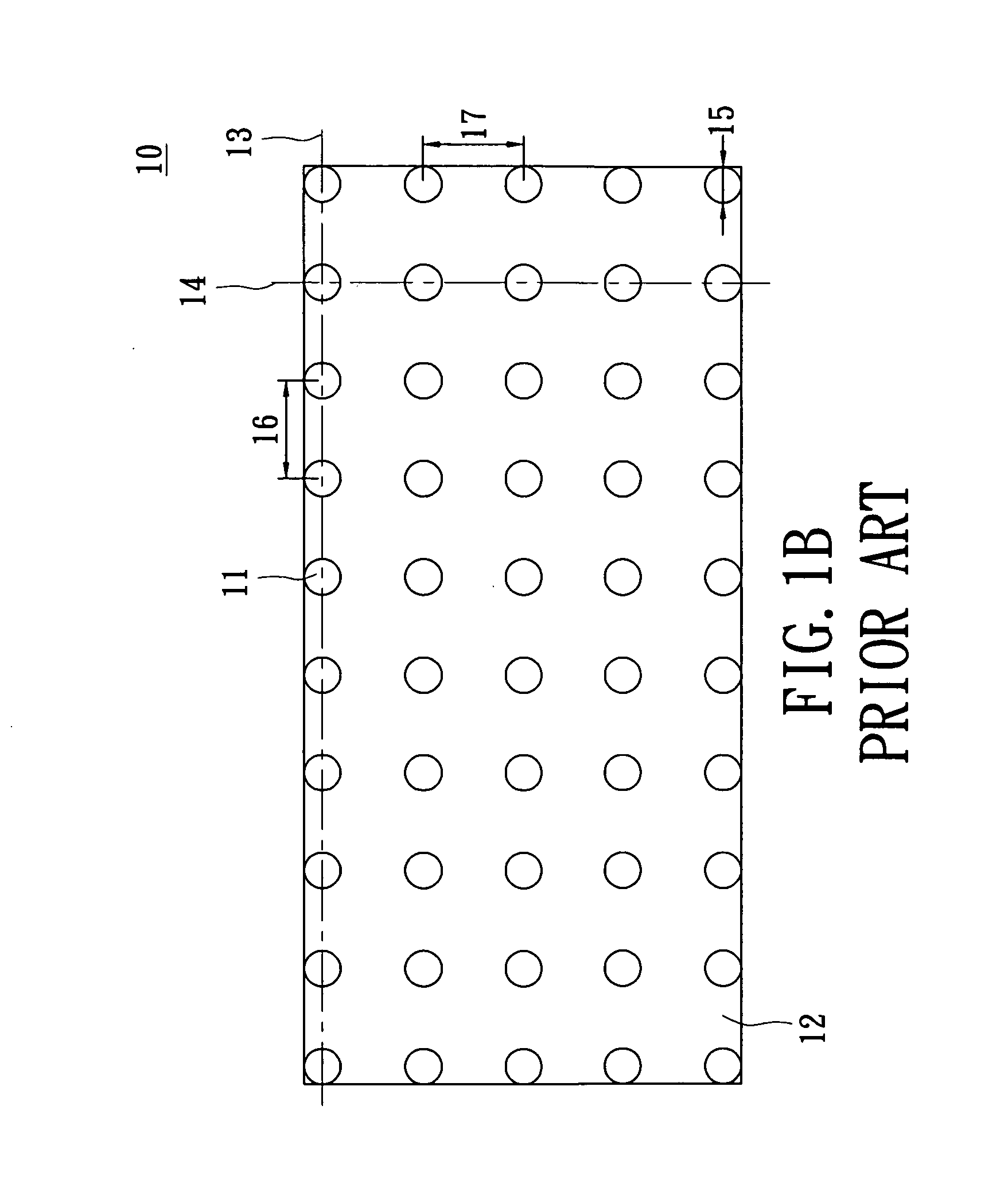

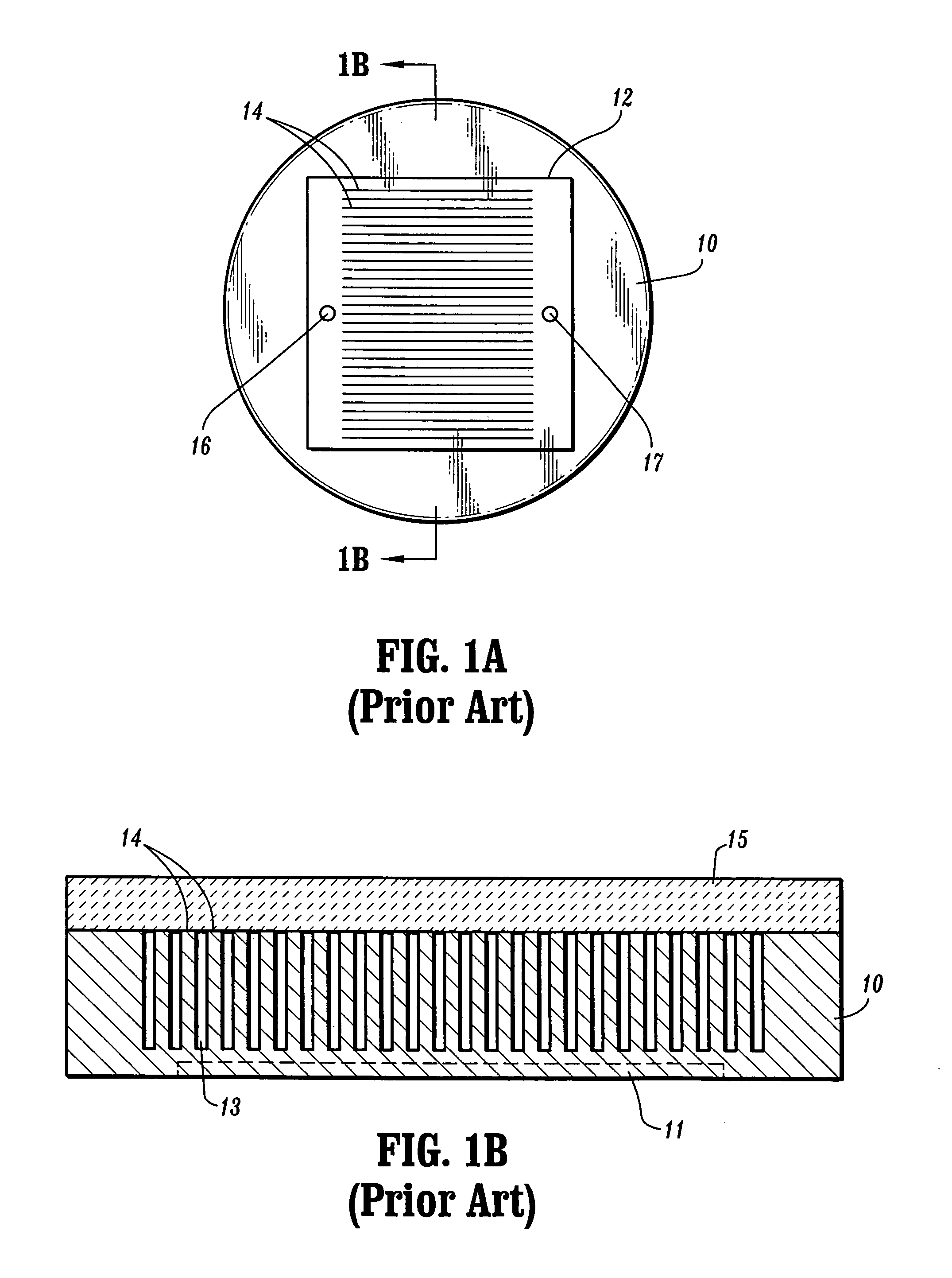

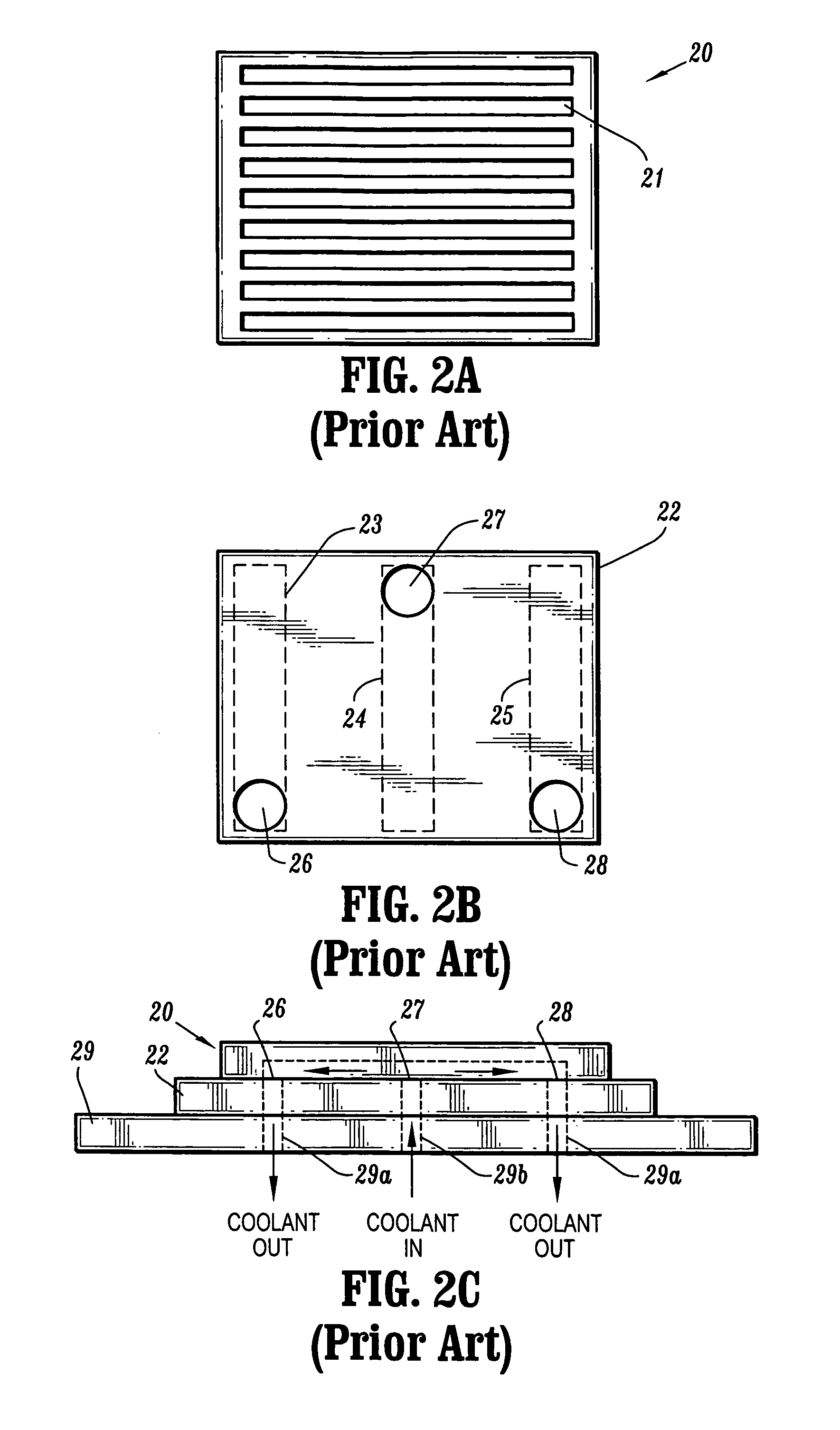

Apparatus and methods for microchannel cooling of semiconductor integrated circuit packages

InactiveUS7190580B2Uniform flow and distributionEfficient and low operating pressure microchannel coolingSemiconductor/solid-state device detailsSolid-state devicesCoolant flowEngineering

Owner:INT BUSINESS MASCH CORP

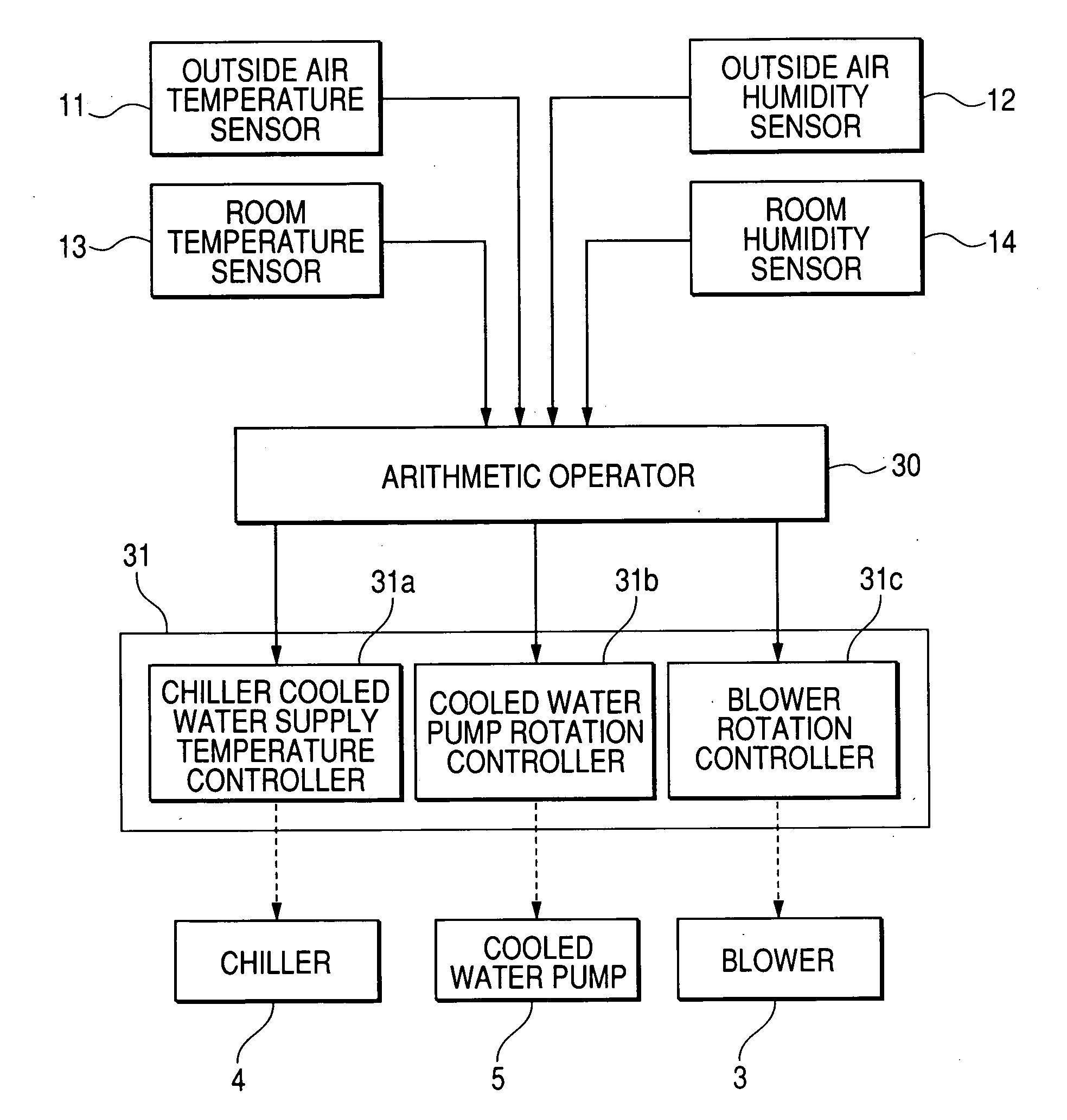

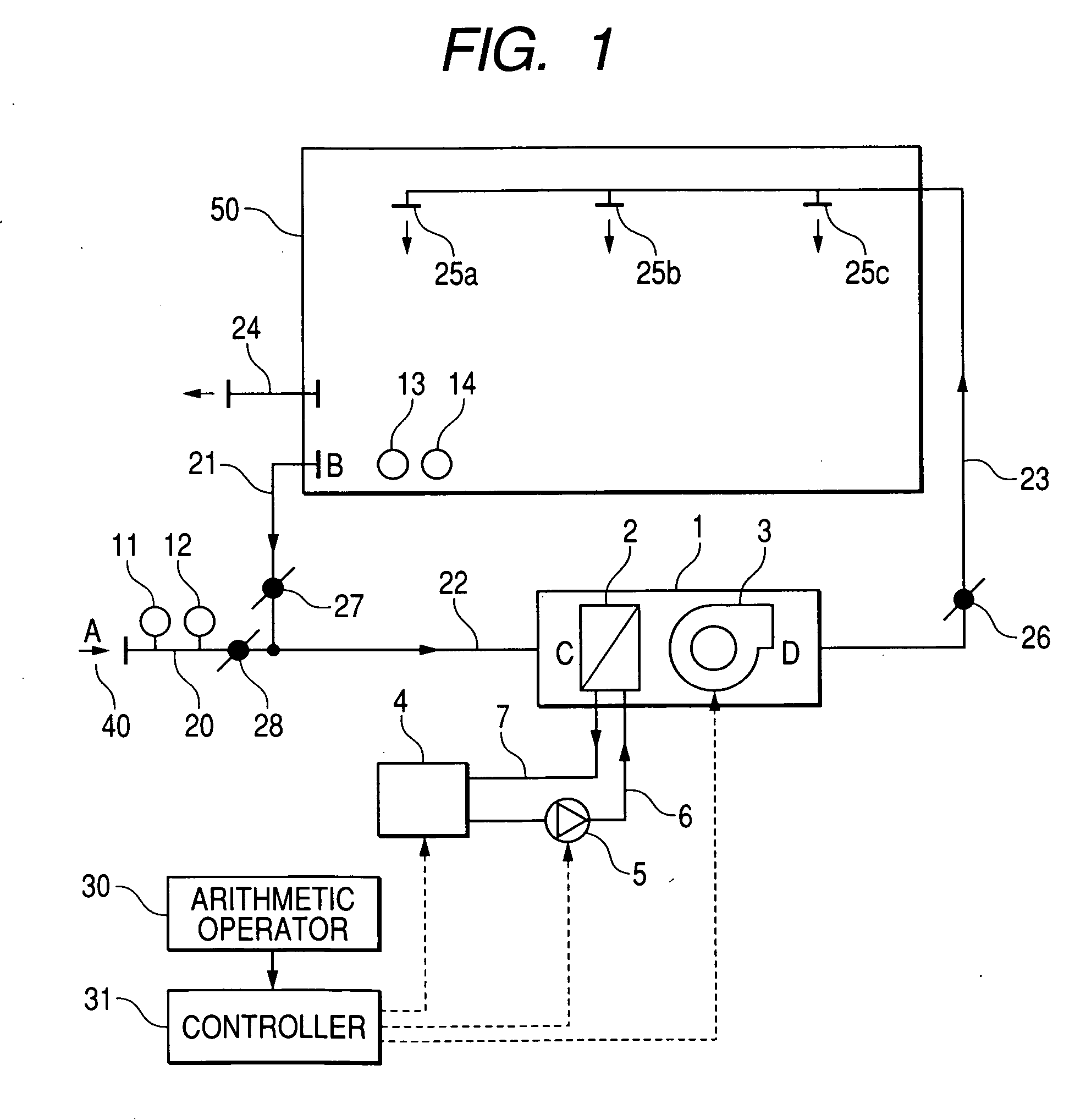

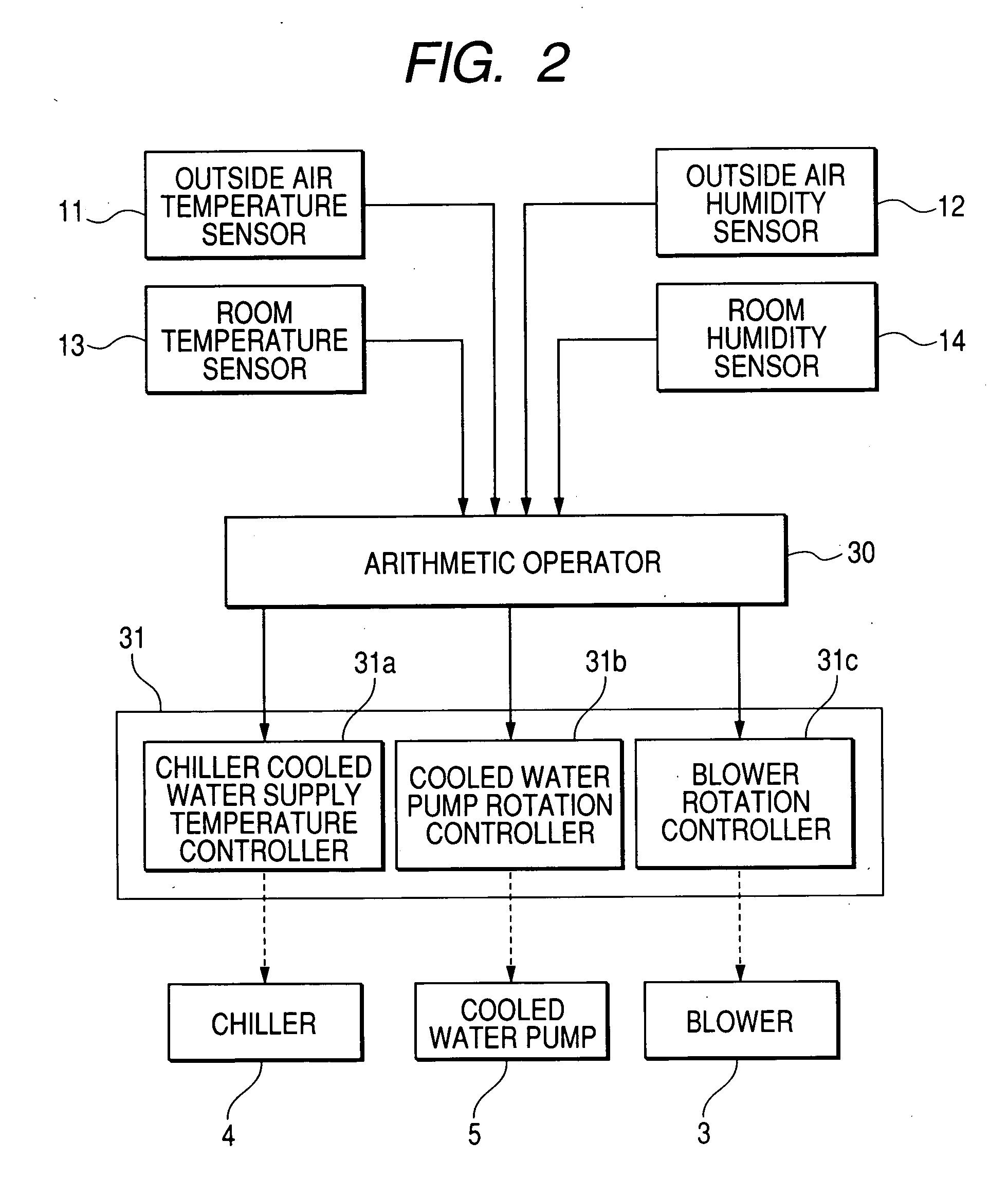

Air conditioning apparatus

InactiveUS20070107450A1Increase in chiller load can be preventedQuantity minimizationMechanical apparatusSpace heating and ventilation safety systemsAir volumeCoolant flow

An air conditioning apparatus comprises an air-conditioning unit including at least a cooling coil as a heat exchanger, a blower, a chiller, and a coolant pump for conducting air-conditioning, wherein the coolant pump pumps the coolant cooled by the chiller to the cooling coil, the cooling coil cools the air through heat exchange of the coolant and the air, the blower supplies the cooled air into a room. Coolant temperature of the chiller, the coolant flow rate of the coolant pump, and the air flow rate of the blower are calculated in accordance with the set points of the indoor temperature and the indoor humidity, and the chiller, coolant pump, and blower are controlled on the basis of the arithmetic calculation results. Thereby, the indoor temperature and indoor humidity are independently controlled in the central air-conditioning system.

Owner:HITACHI LTD

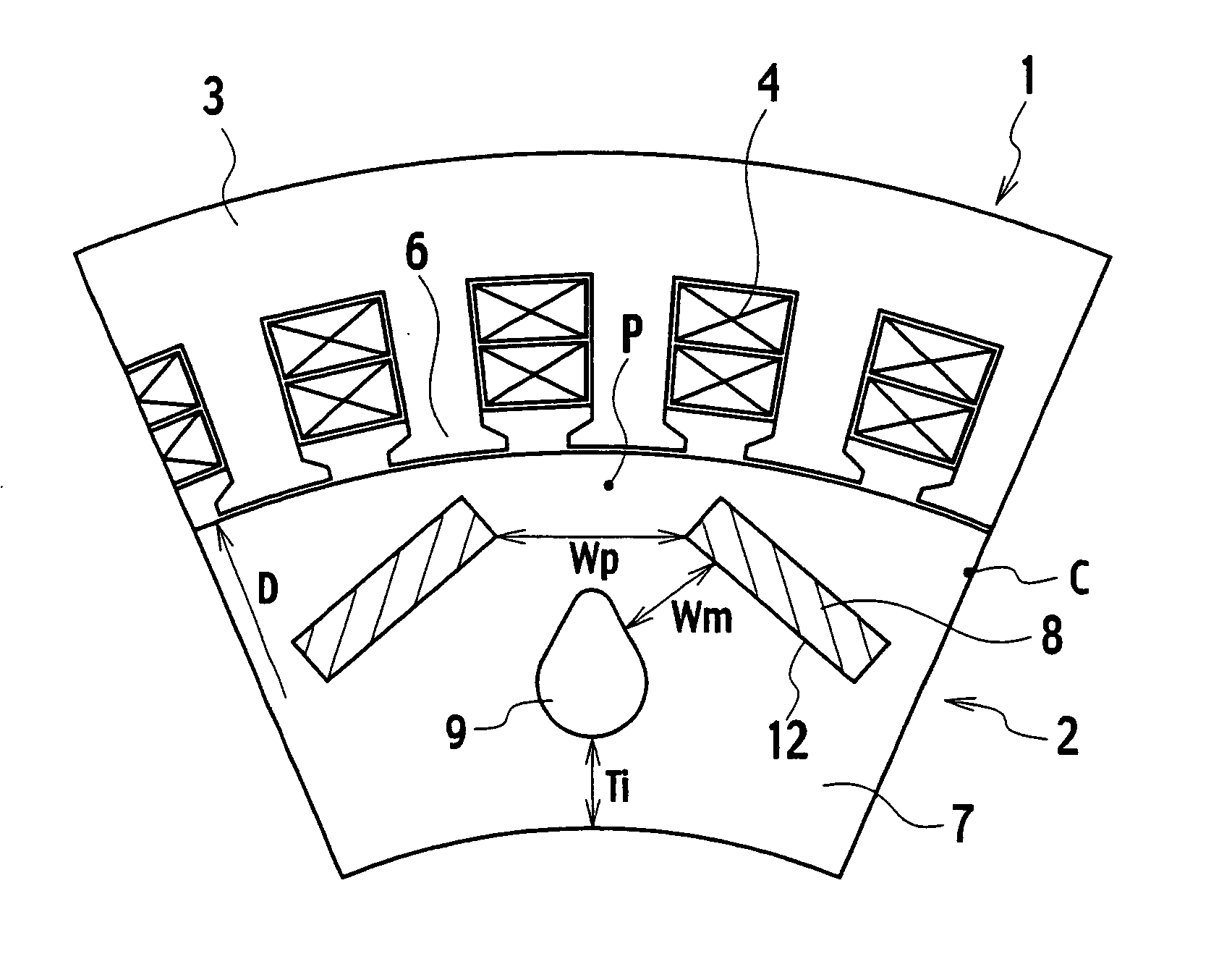

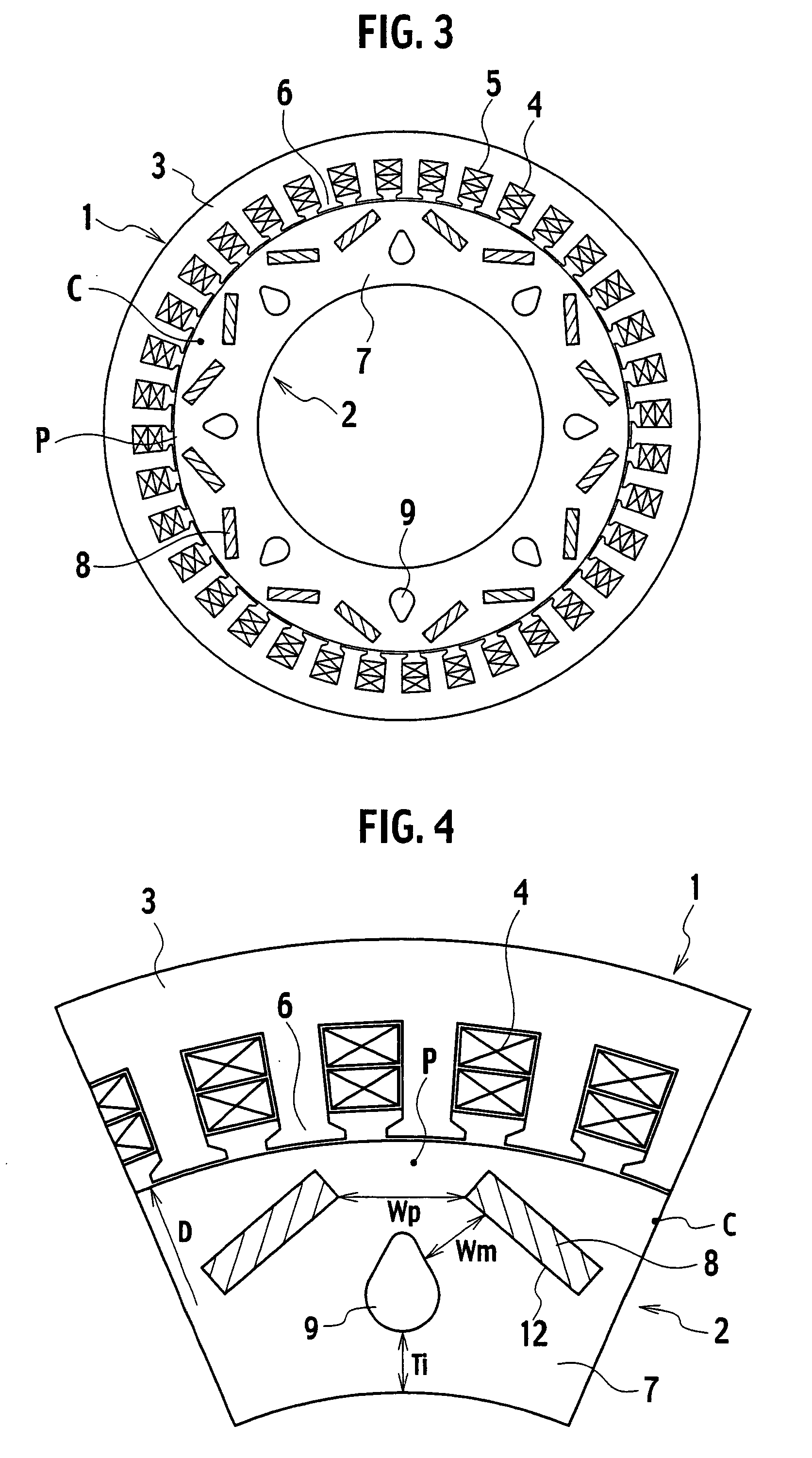

Rotating electrical machine

ActiveUS20070052313A1Improve cooling effectHigh torqueMagnetic circuit rotating partsCooling/ventillation arrangementCoolant flowElectric machine

Included are a ring-shaped stator and a ring-shaped rotor arranged inside the stator; the stator includes a stator core with armature windings; the rotor includes a rotor core in which a plurality of permanent magnets are inserted and cooling holes are formed, a coolant flowing in each of the cooling holes; and each of the cooling holes is formed so as to have a sectional view which is a convex toward the outer periphery thereof.

Owner:KK TOSHIBA +1

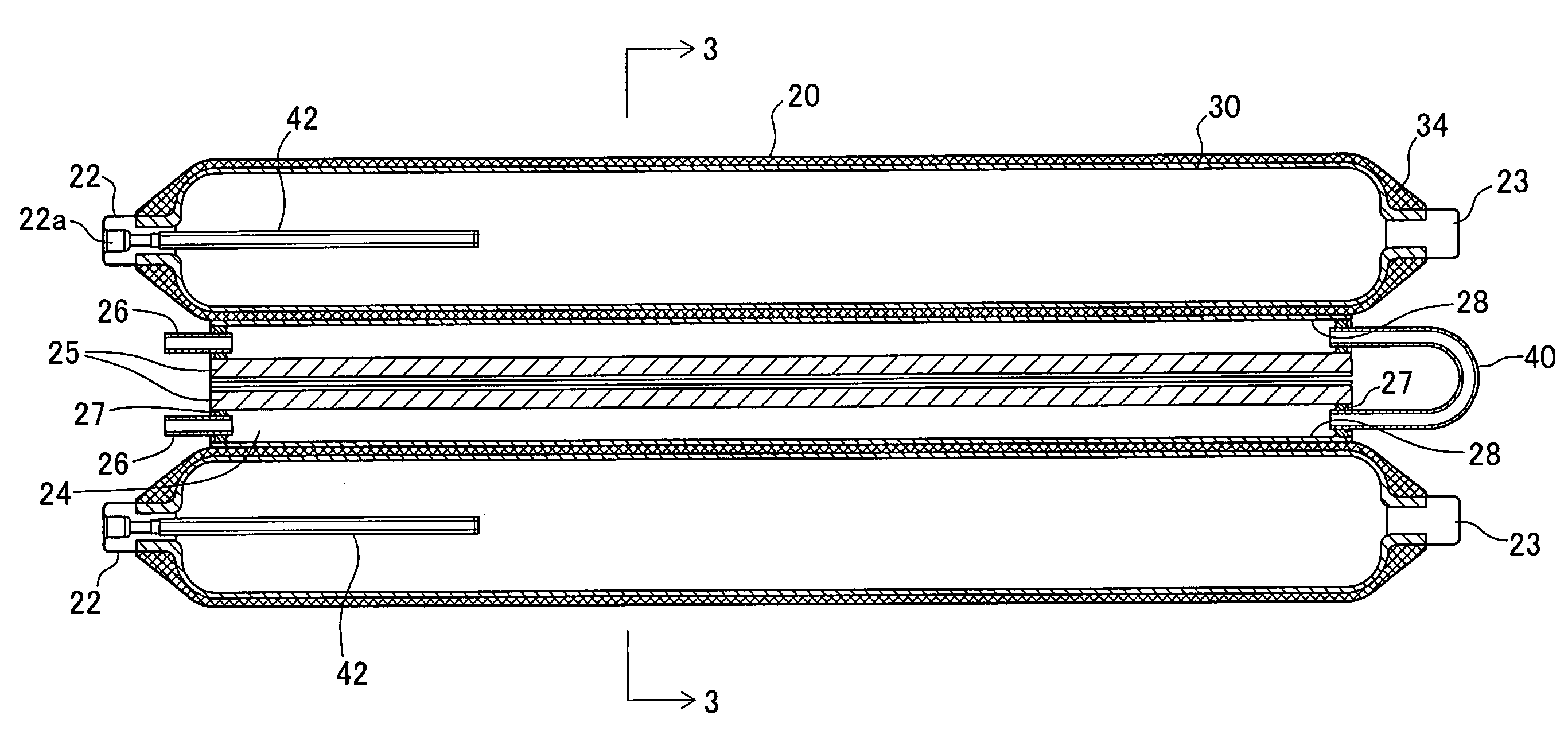

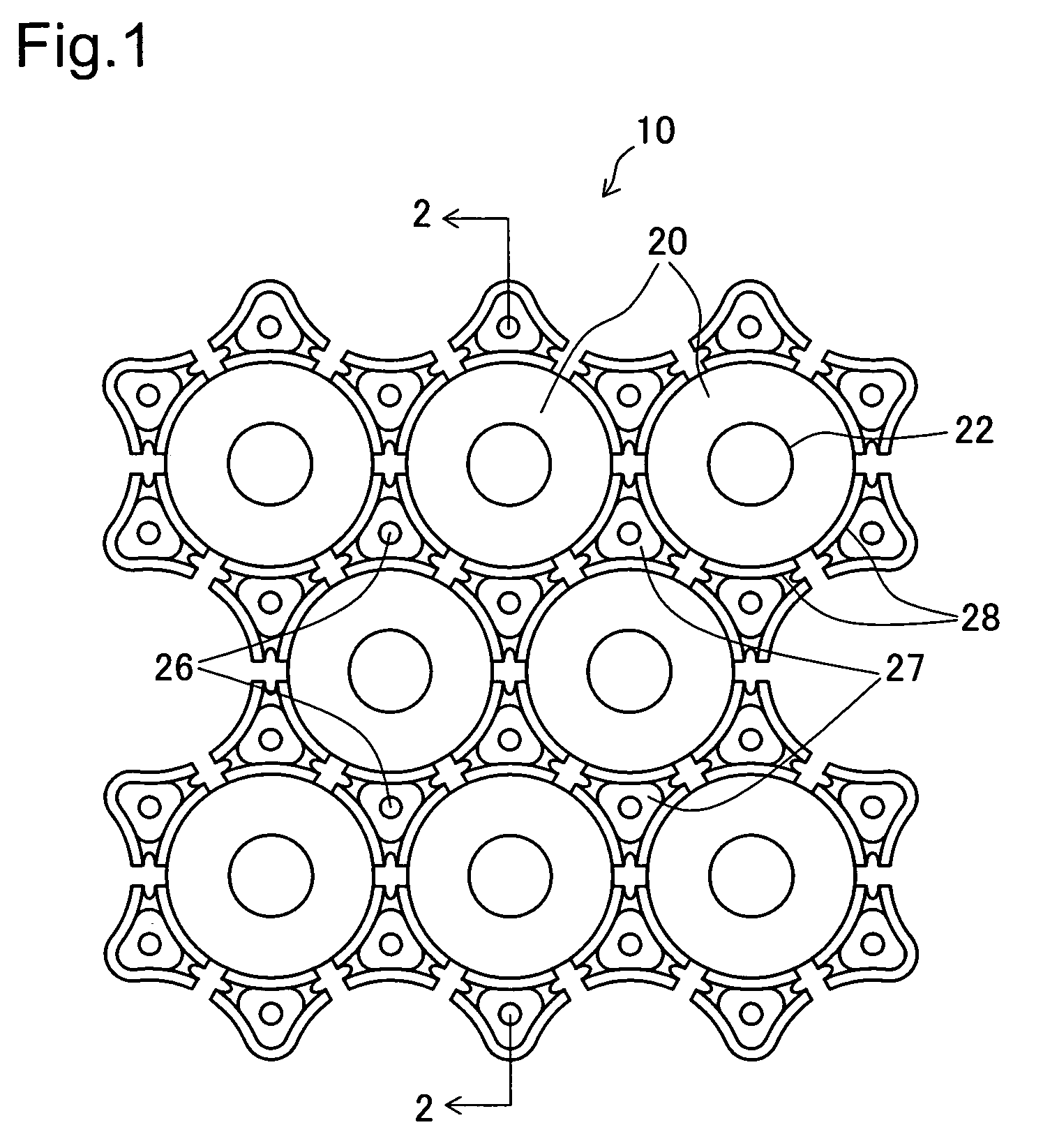

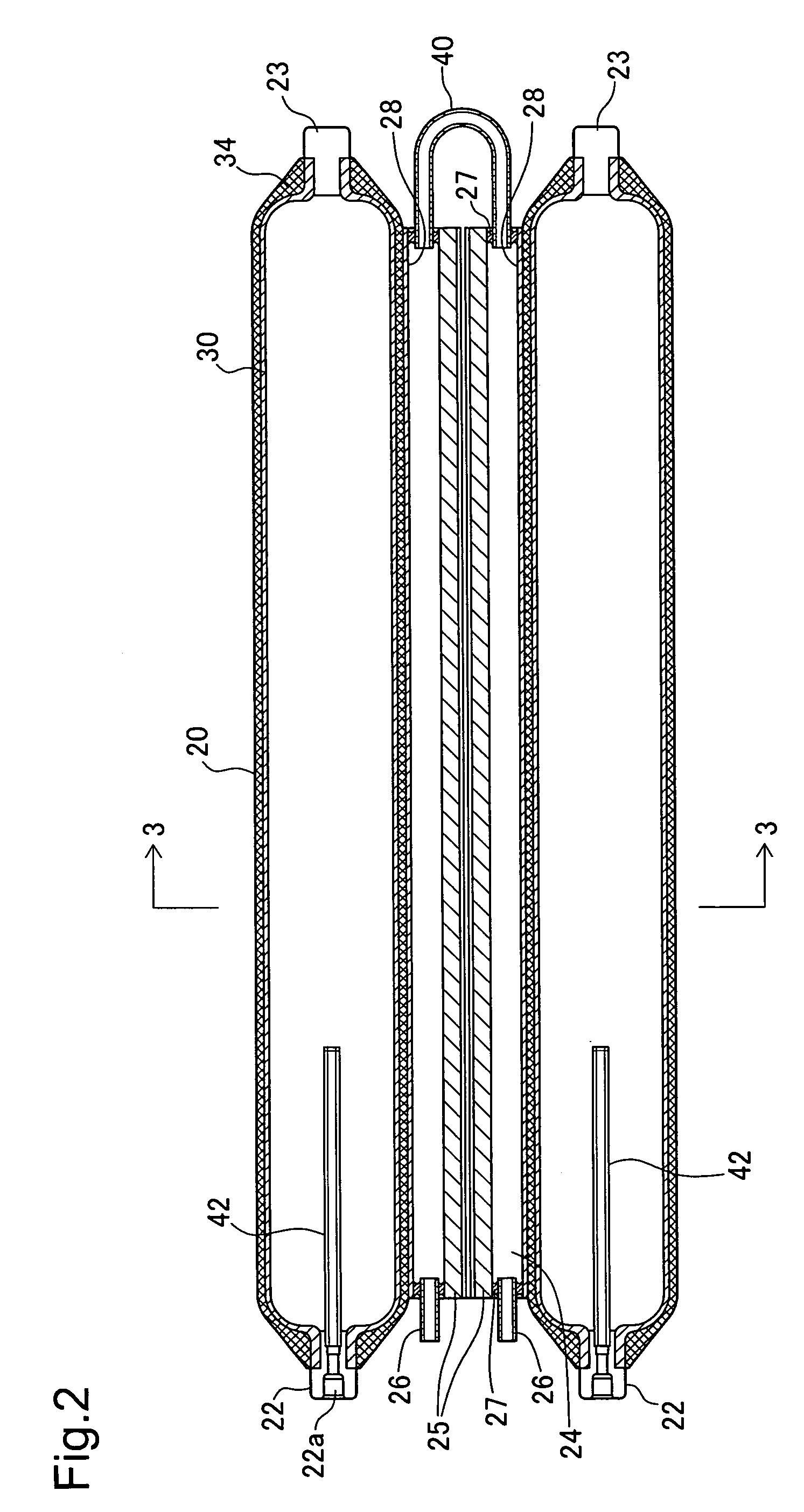

Gas storage apparatus

InactiveUS7112239B2Improve heat transfer efficiencyVessel mounting detailsReversible hydrogen uptakeCoolant flowProduct gas

A hydrogen storage apparatus that includes multiple gas storage tanks that each house a storing / adsorbing material and through the interior of which a fluid travels is provided. The gas storage apparatus 10 includes roughly cylindrical gas storage tanks 20 that house hydrogen-storing alloy. The multiple gas storage tanks 20 are disposed longitudinally parallel to each other in an ordered fashion such that roughly triangular prism-shaped empty spaces are formed between multiple adjacent hydrogen storage tanks 20. Coolant paths through which coolant flows are formed in these roughly triangular prism-shaped empty spaces. These coolant paths are thermally connected to the hydrogen-storing alloy in the gas storage tanks 20 via constituent members of the gas storage tanks 20 and via heat transfer plates 28 disposed on the gas storage tanks 20.

Owner:TOYOTA JIDOSHA KK +1

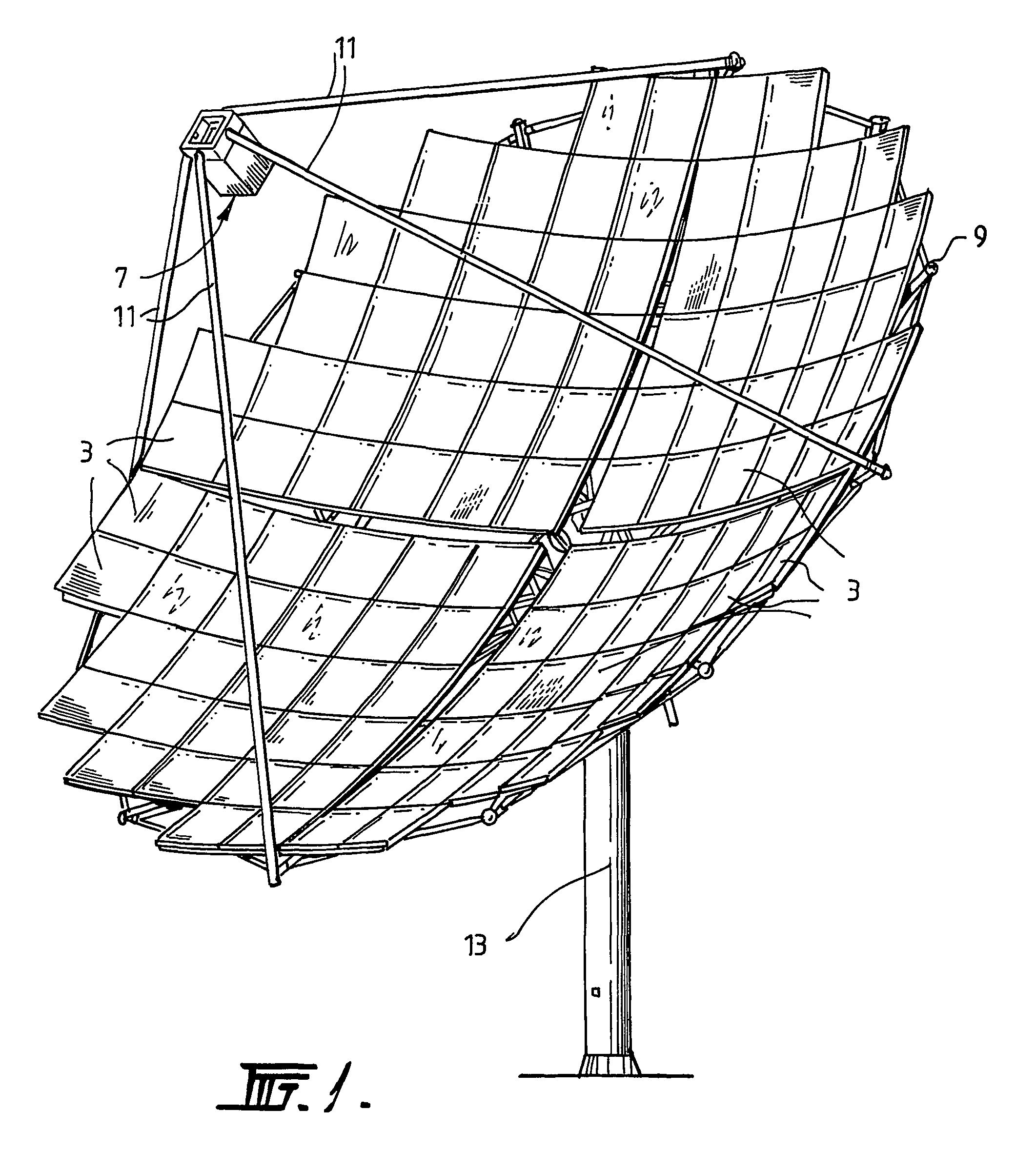

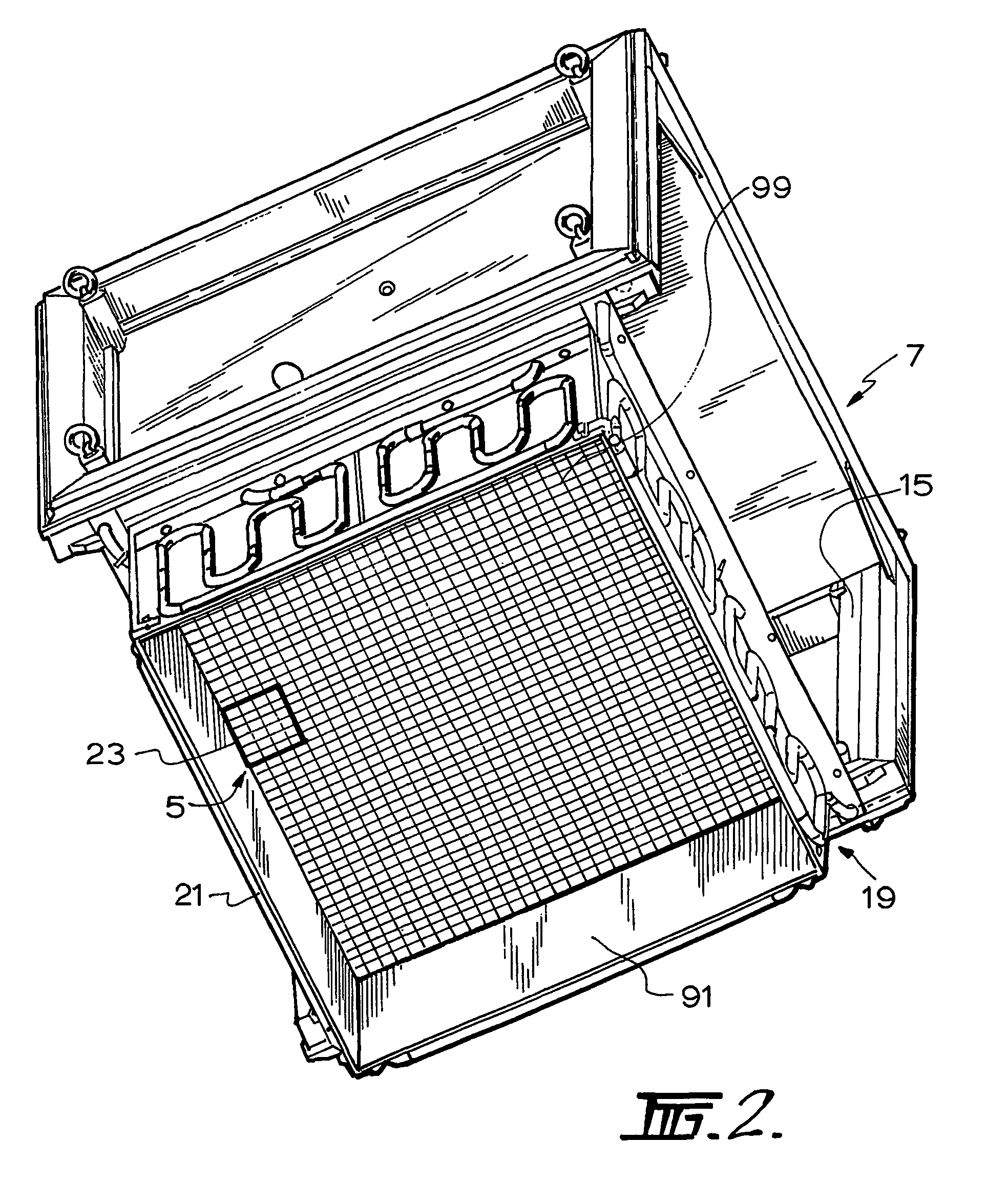

Cooling circuit for receiver of solar radiation

InactiveUS7076965B2Increasing available contact surface areaImprove heat transfer performancePhotovoltaic supportsSolar heating energyElectrical batteryCoolant flow

A receiver for a system for generating electrical power from solar radiation is disclosed. The systems includes the receiver and a means (3) for concentrating solar radiation onto the receiver. The receiver includes a plurality of photovoltaic cell modules. Each module includes a plurality of photovoltaic cells (5), and includes an electrical connection that forms part of the receiver electrical circuit. The receiver includes a coolant circuit for cooling the photovoltaic cells with a coolant. The coolant circuit includes a coolant flow path in each module that is in thermal contact with the photovoltaic cells so that in use coolant flowing through the flow path extracts heat from the photovoltaic cells and thereby cools the cells.

Owner:SOLAR SYST PTY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com