Patents

Literature

4039results about How to "High torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

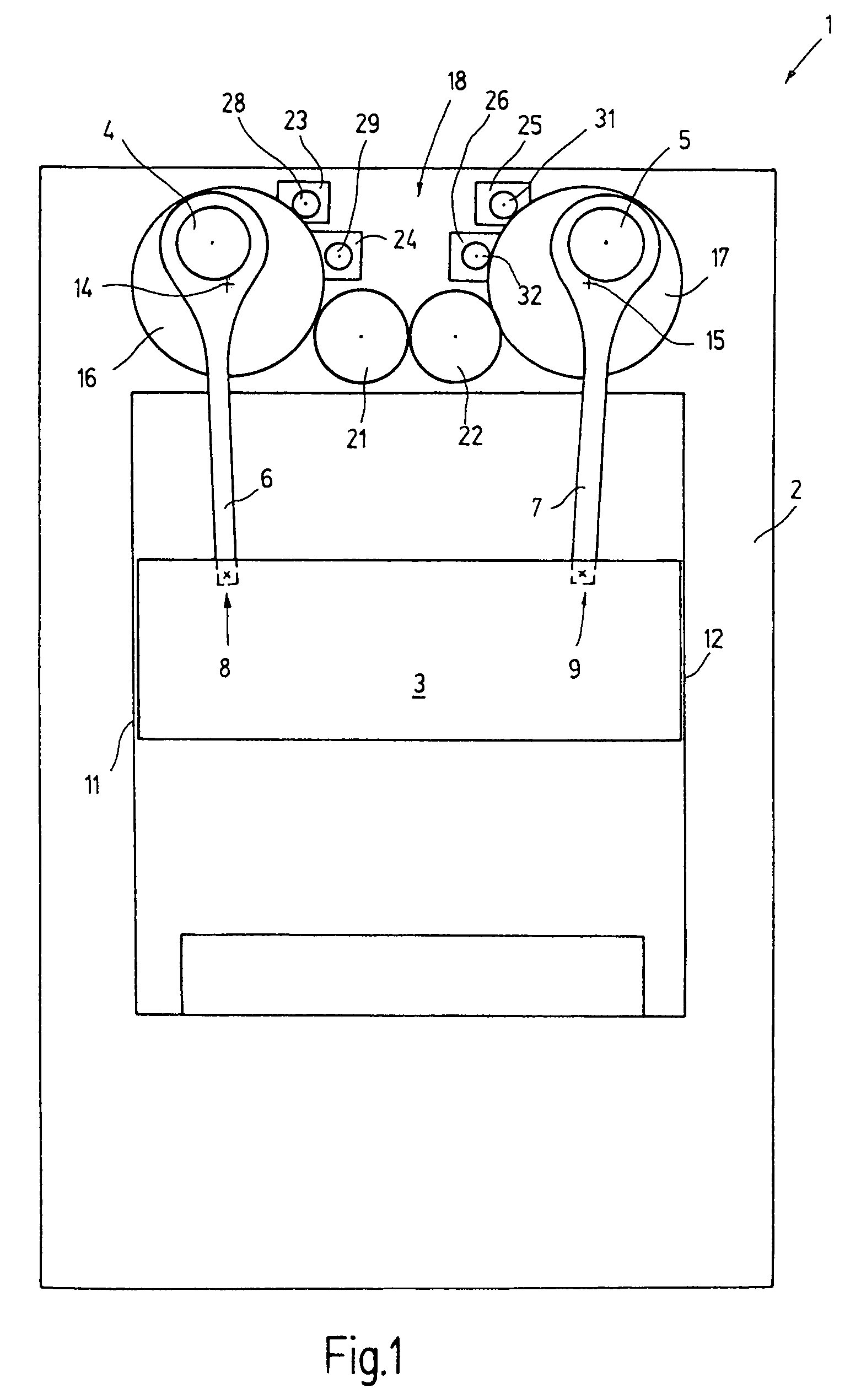

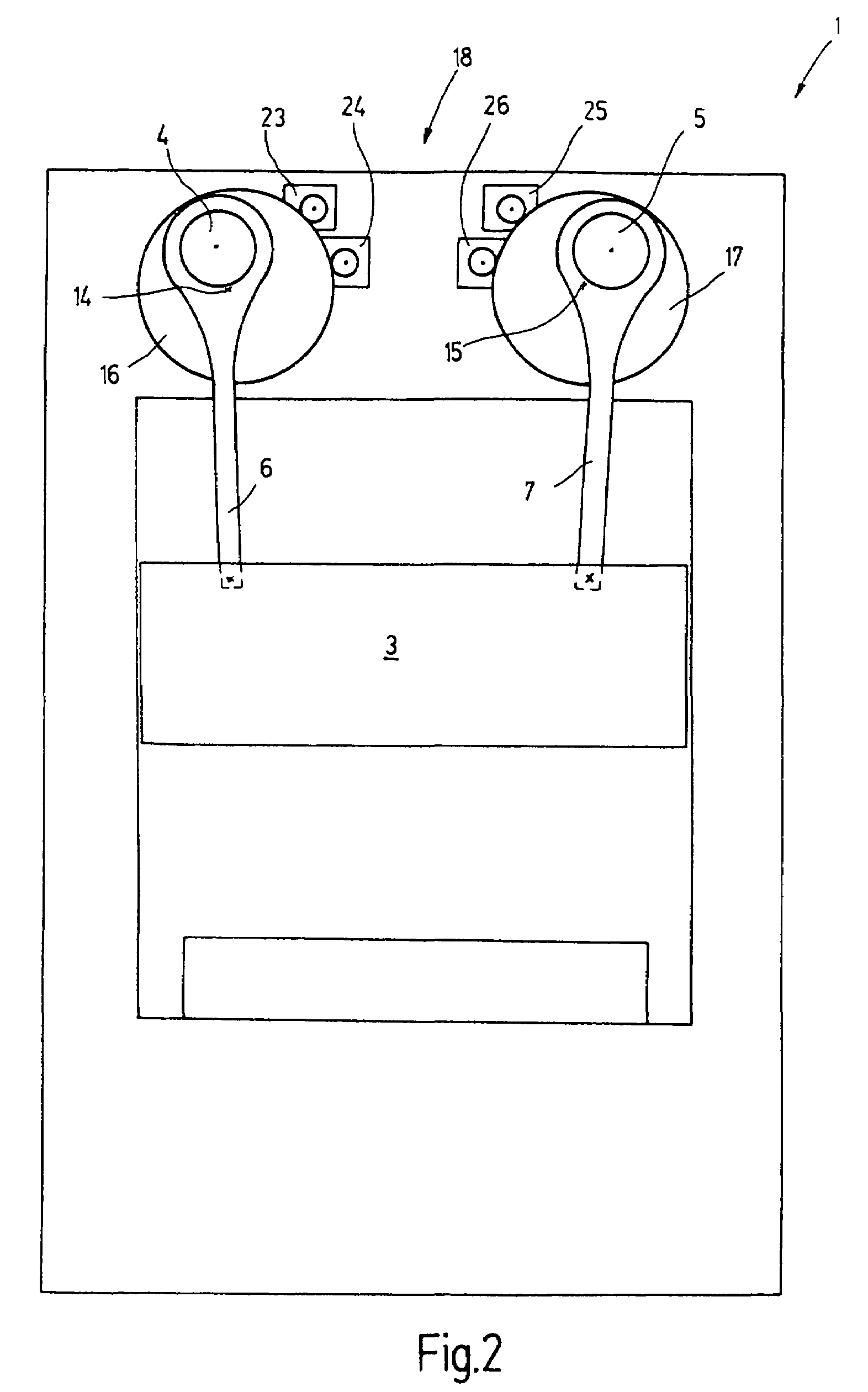

Hybrid-vehicle power train

ActiveUS7246672B2Achieve effectEfficient use ofElectric propulsion mountingElectric machinesClutchHybrid vehicle

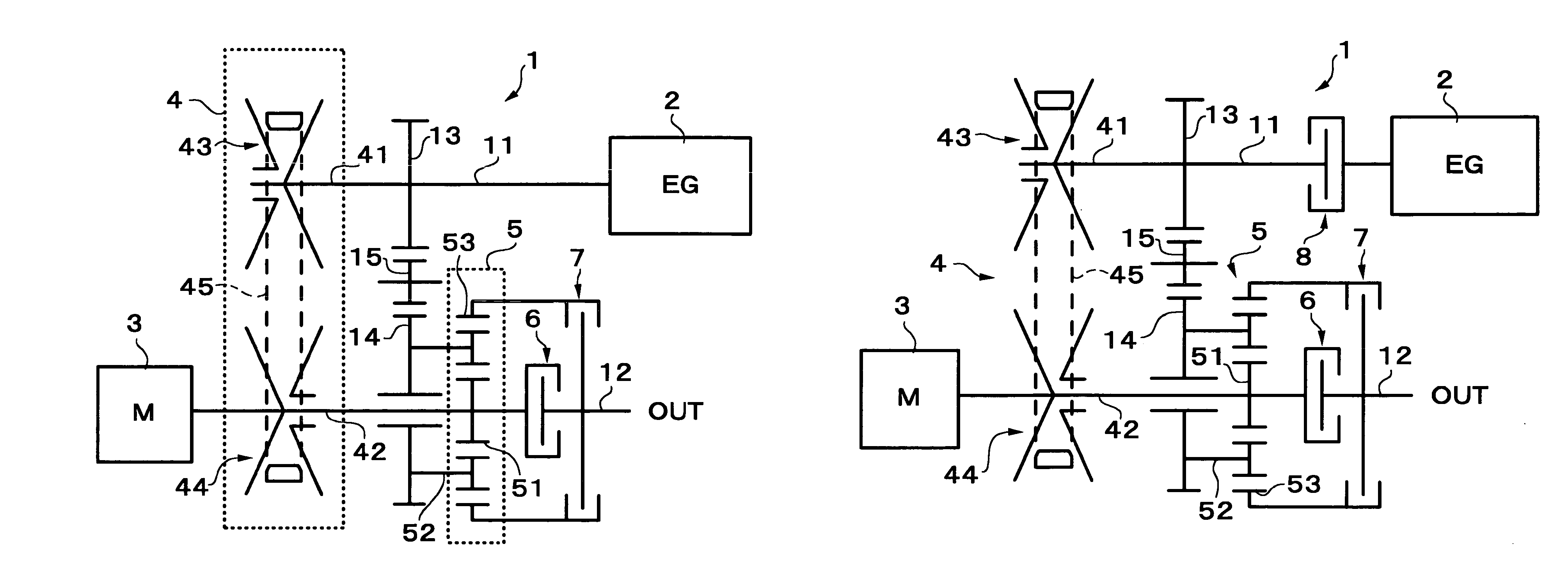

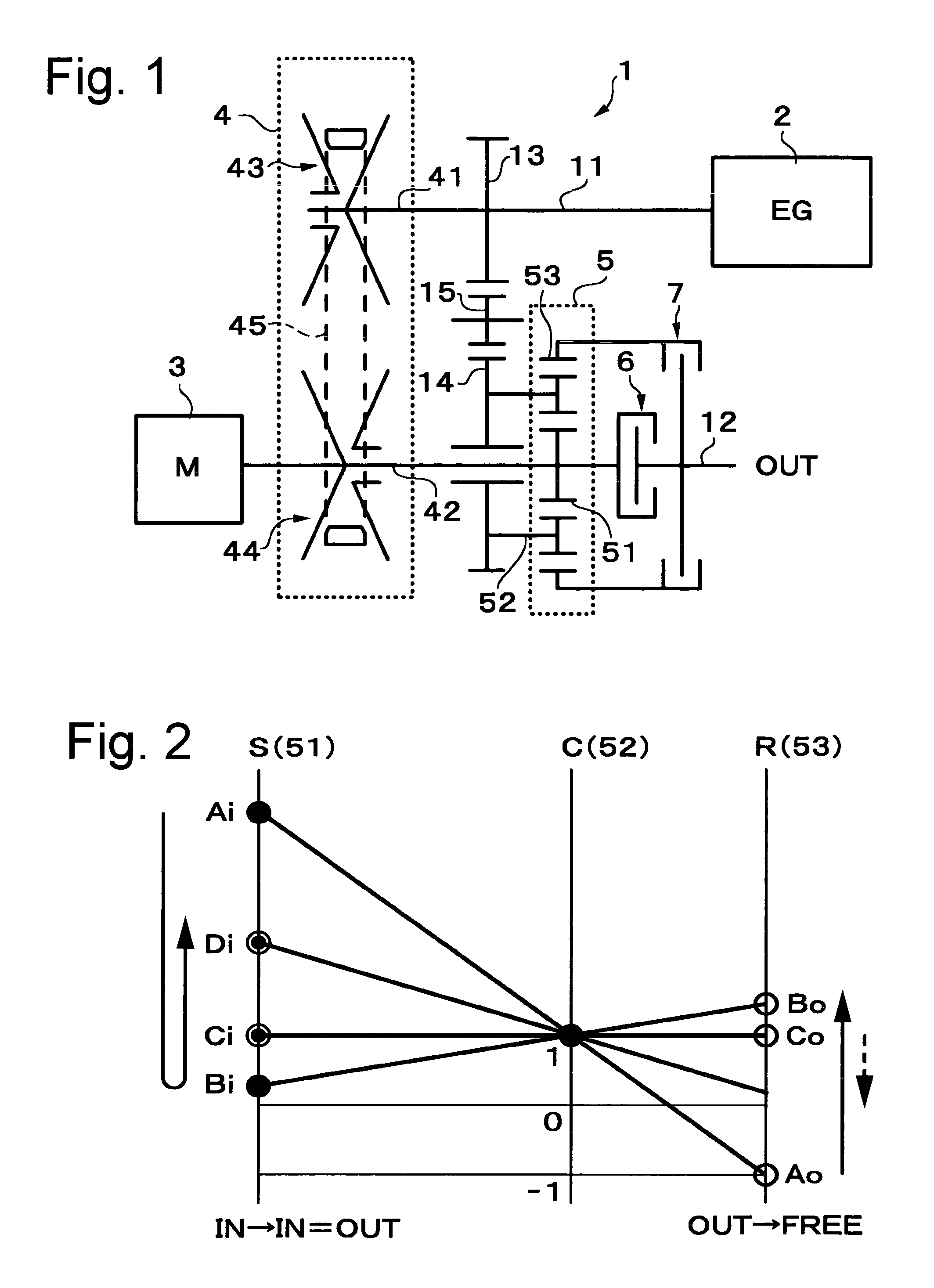

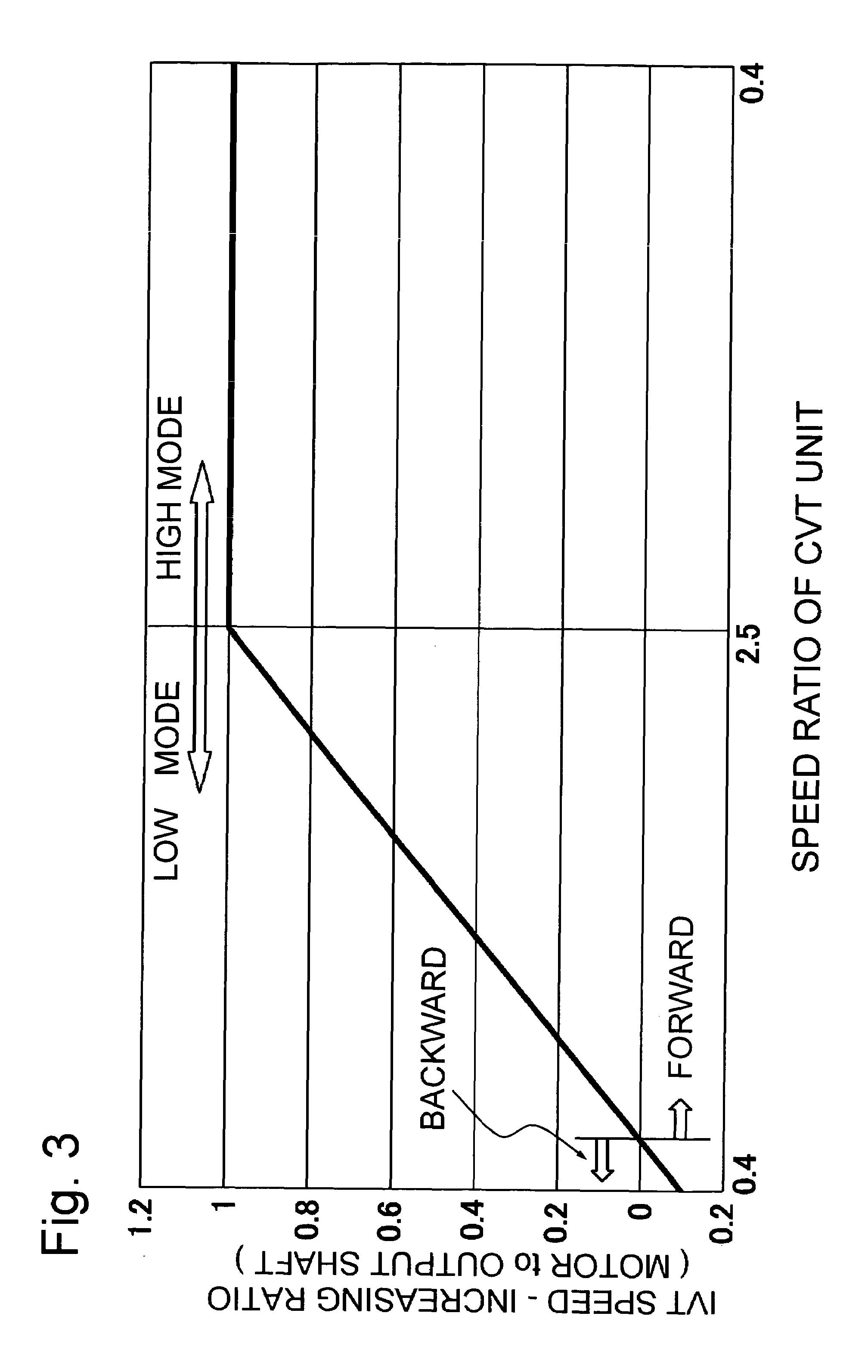

A hybrid-vehicle power train connected to an engine comprises a motor, a CVT unit, a planetary gear unit having at least two input elements, namely, first and second input elements and an output element, a first clutch for engaging / disengaging the first input element with / from a final shaft of the power train, and a second clutch for engaging / disengaging the output element with / from the final shaft of the power train. An input shaft of the CVT unit is connected to the engine and is drivingly connected to the second input element. An output shaft of the CVT unit is connected to the first input element. The motor is connected to the output shaft of the CVT unit. According this configuration, motor torque is amplified and transmitted to the final shaft when the first clutch is engaged, while motor torque is transmit directly to the final shaft when the second clutch is engaged.

Owner:EQUOS RES

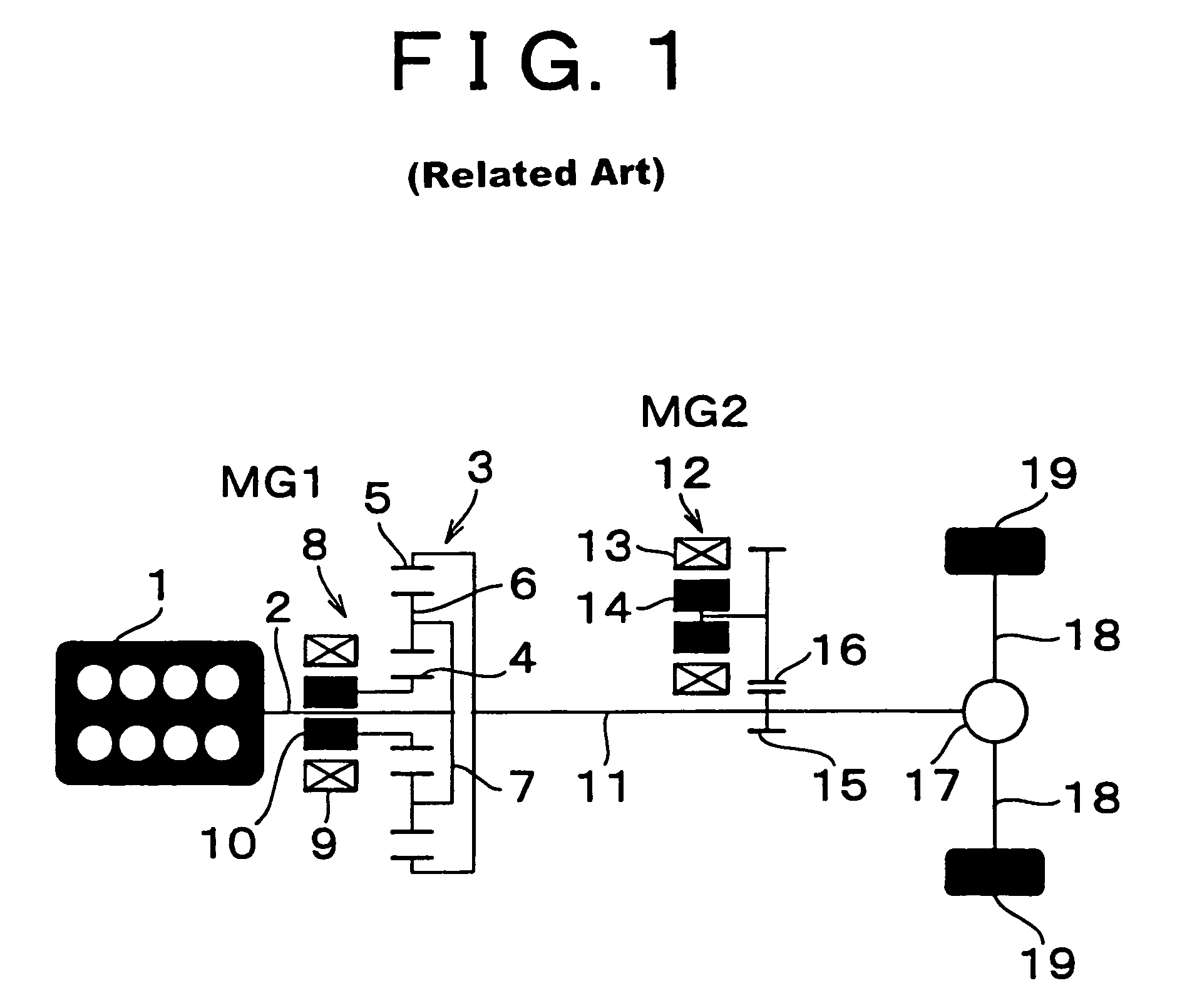

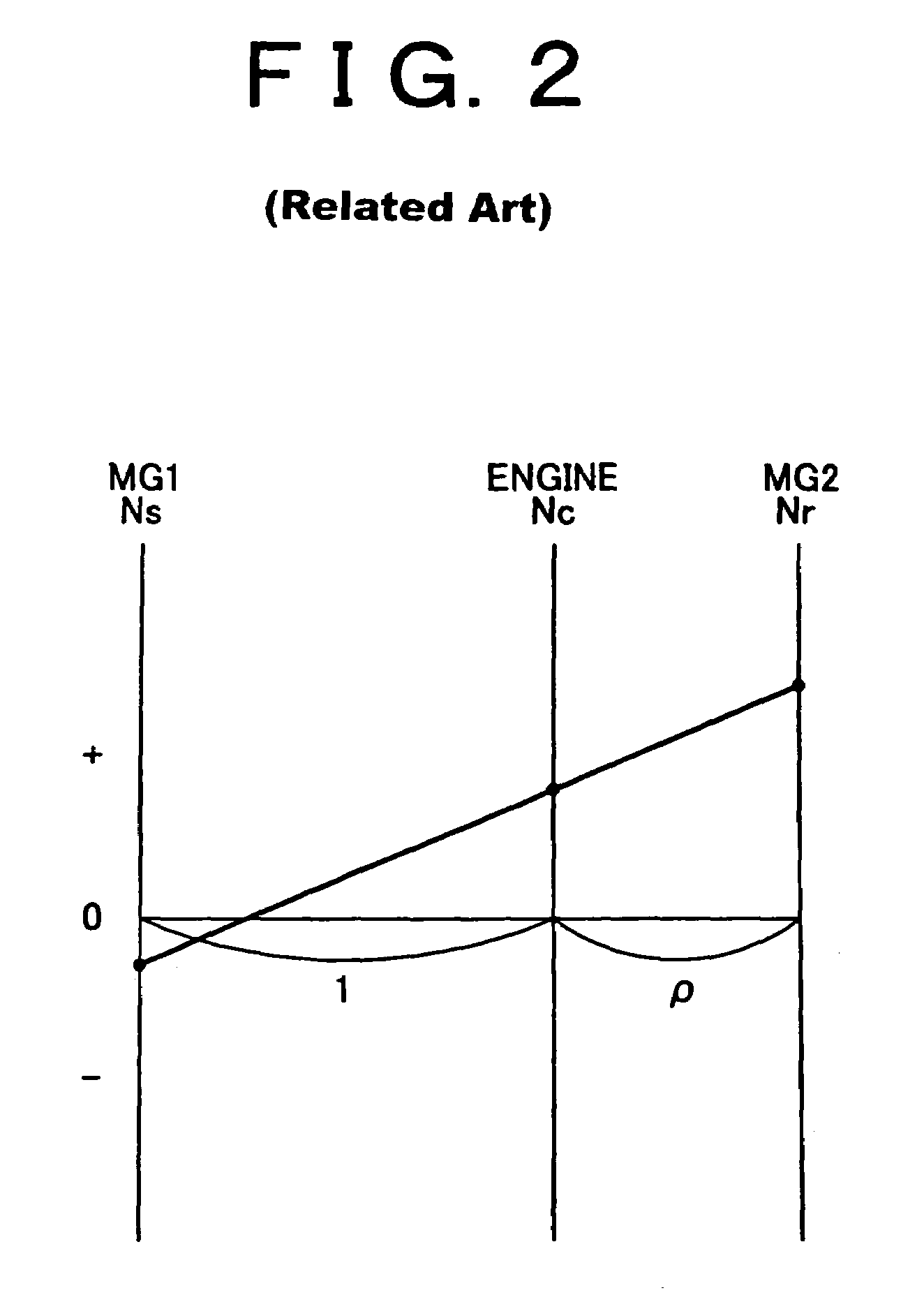

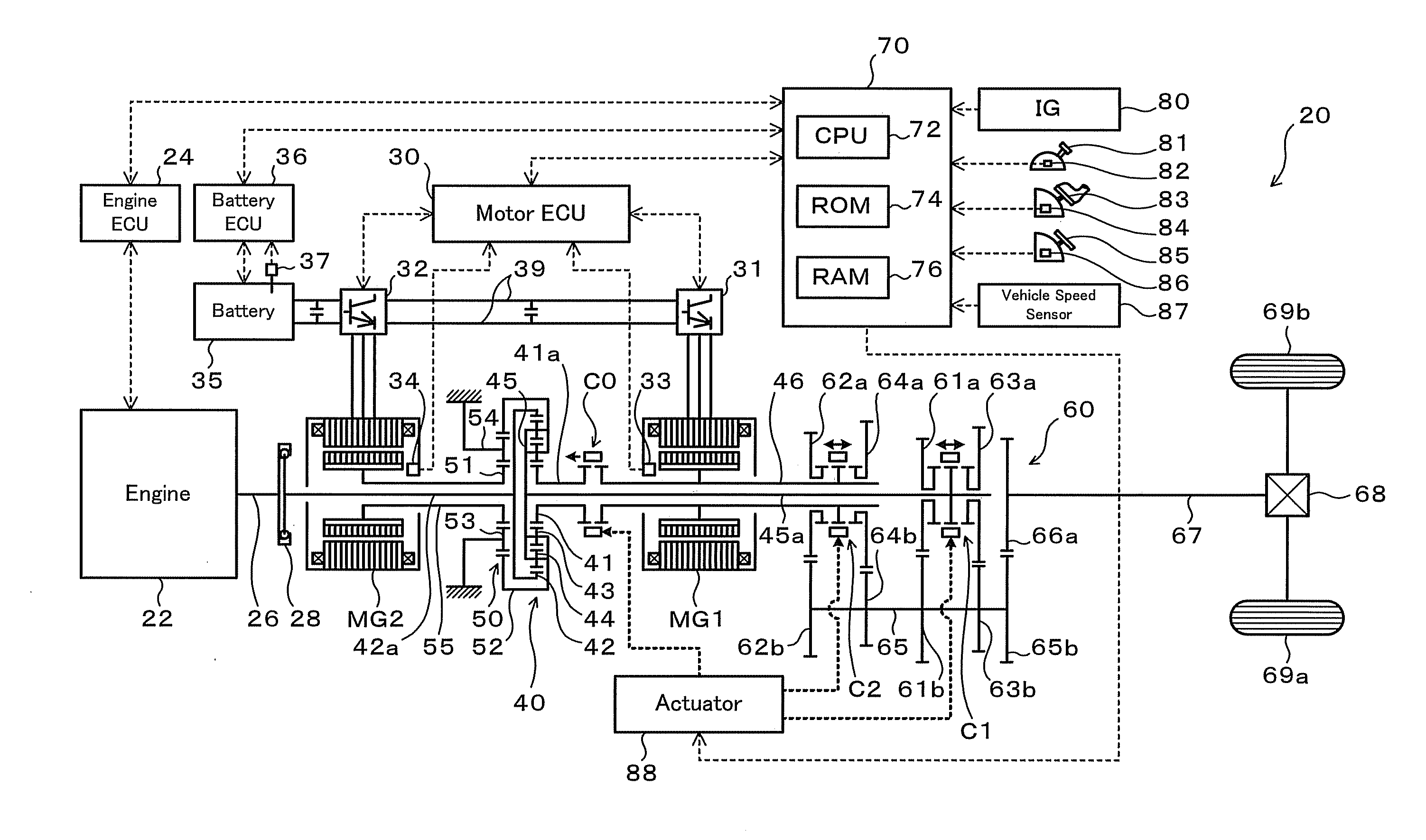

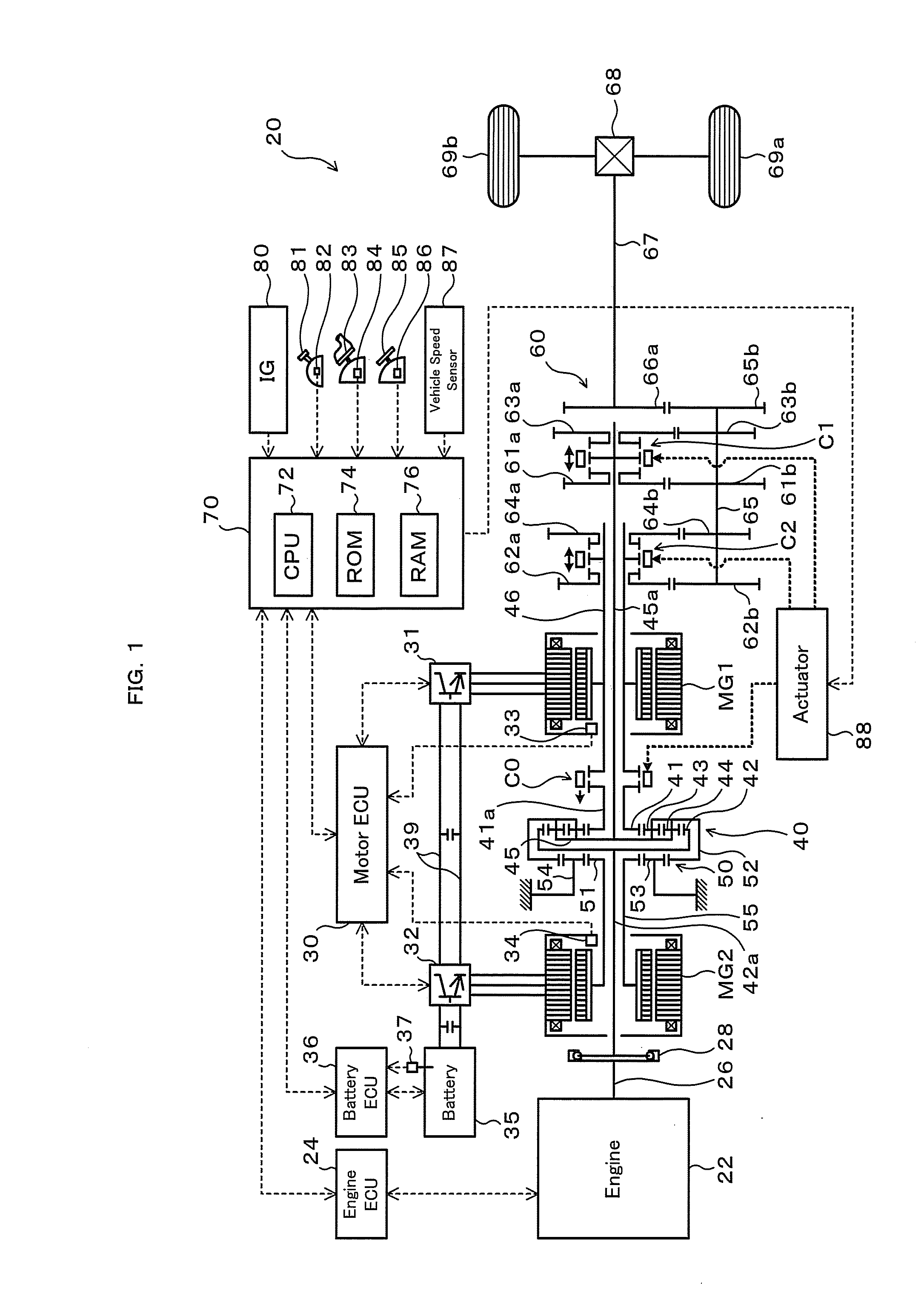

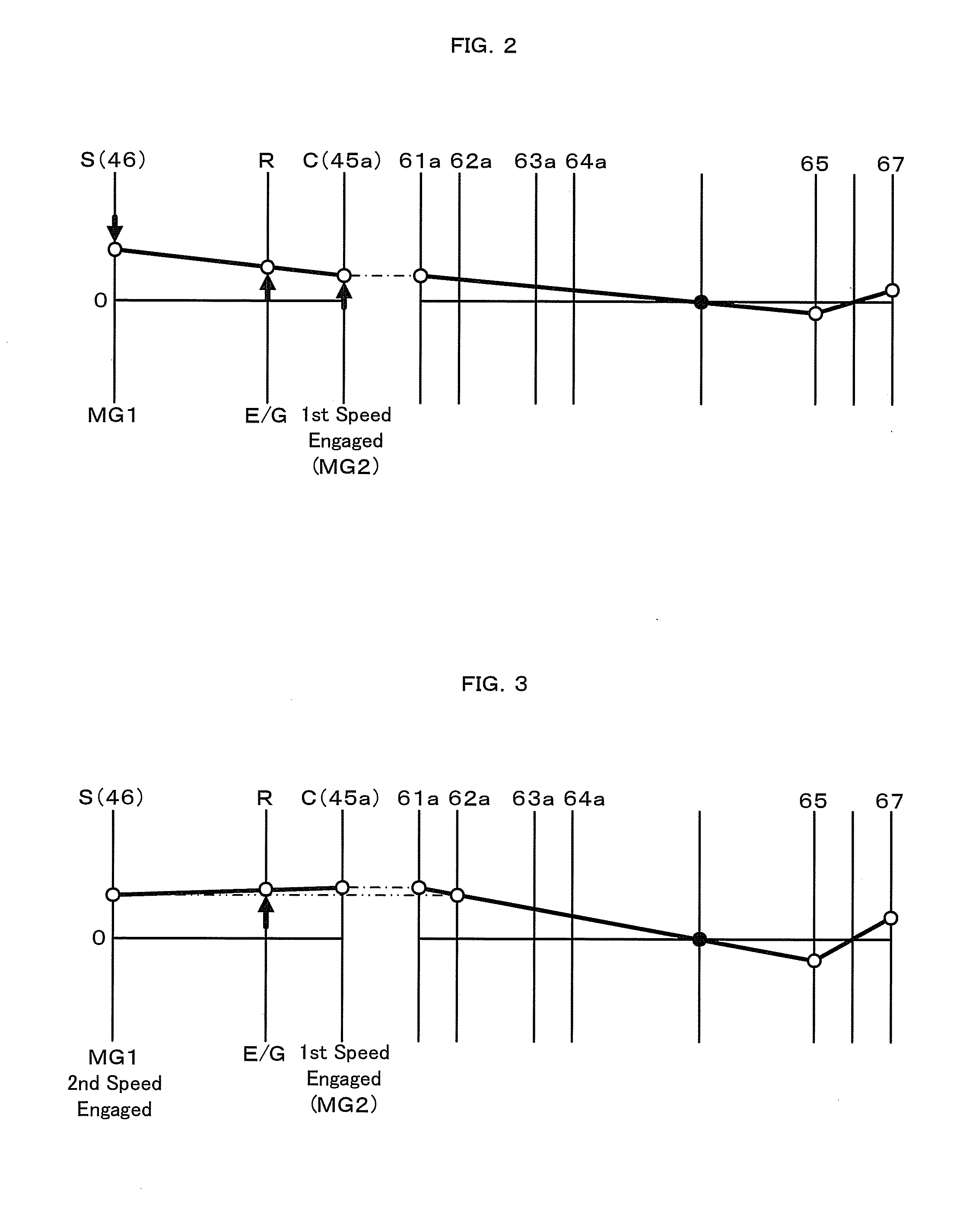

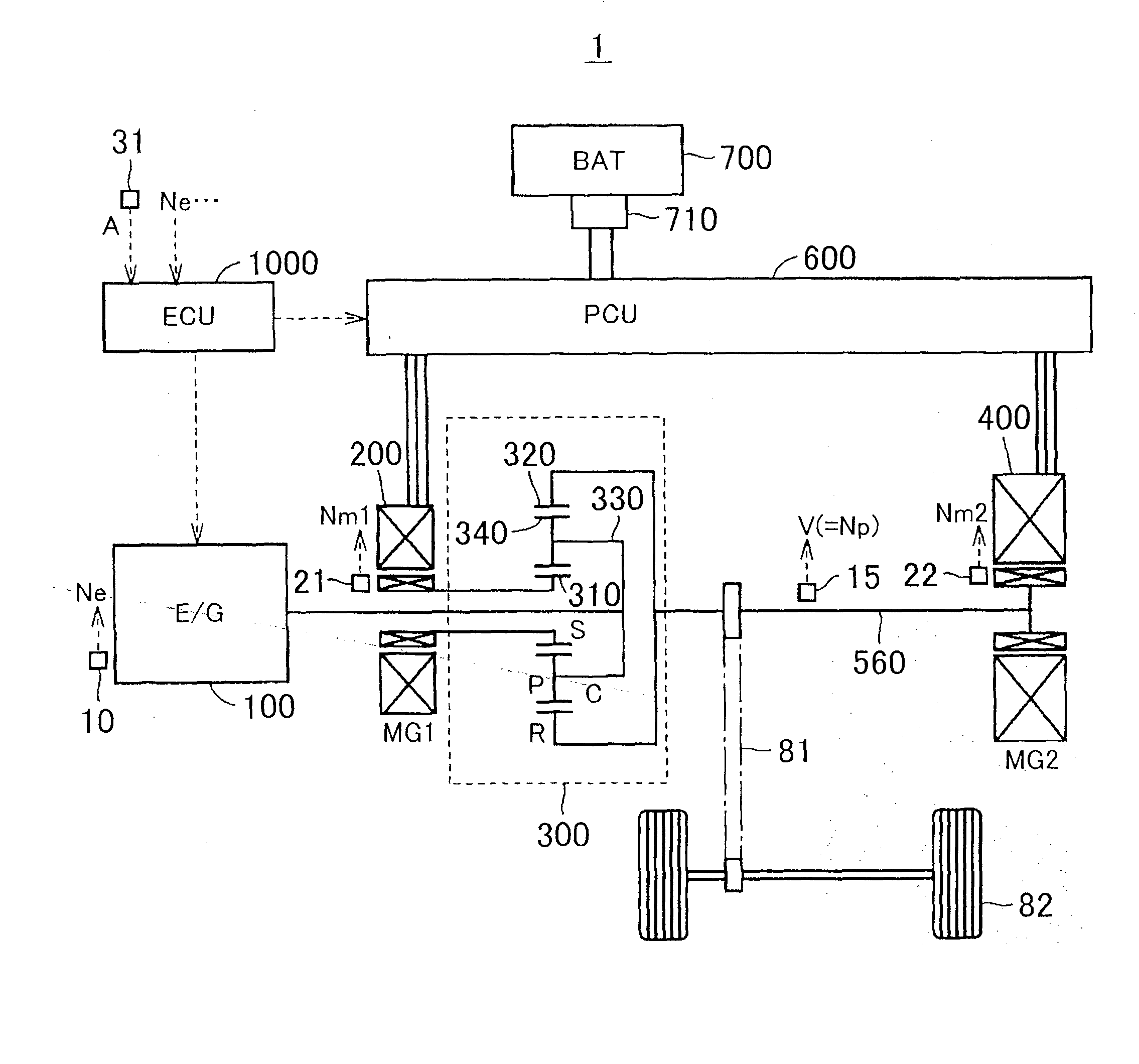

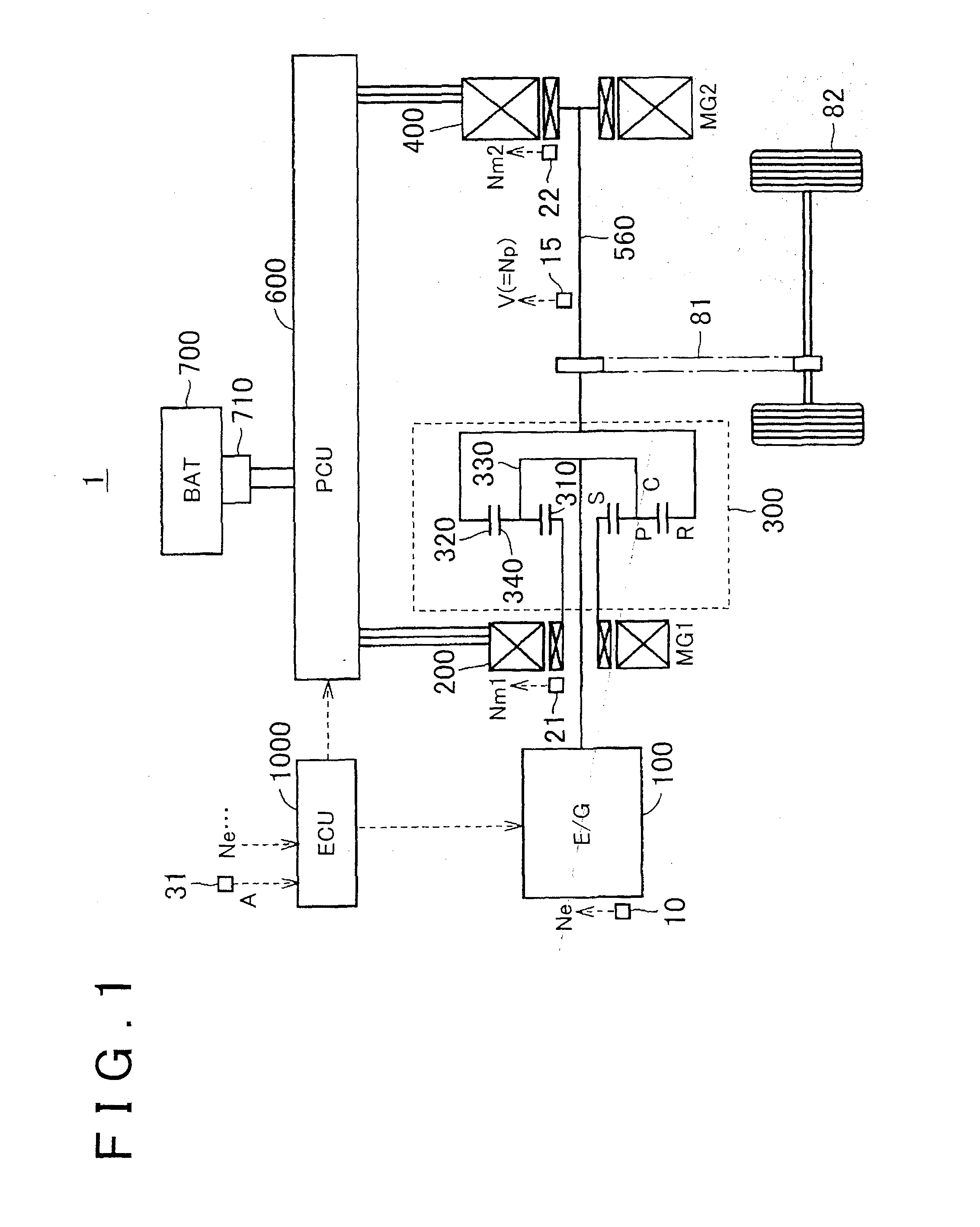

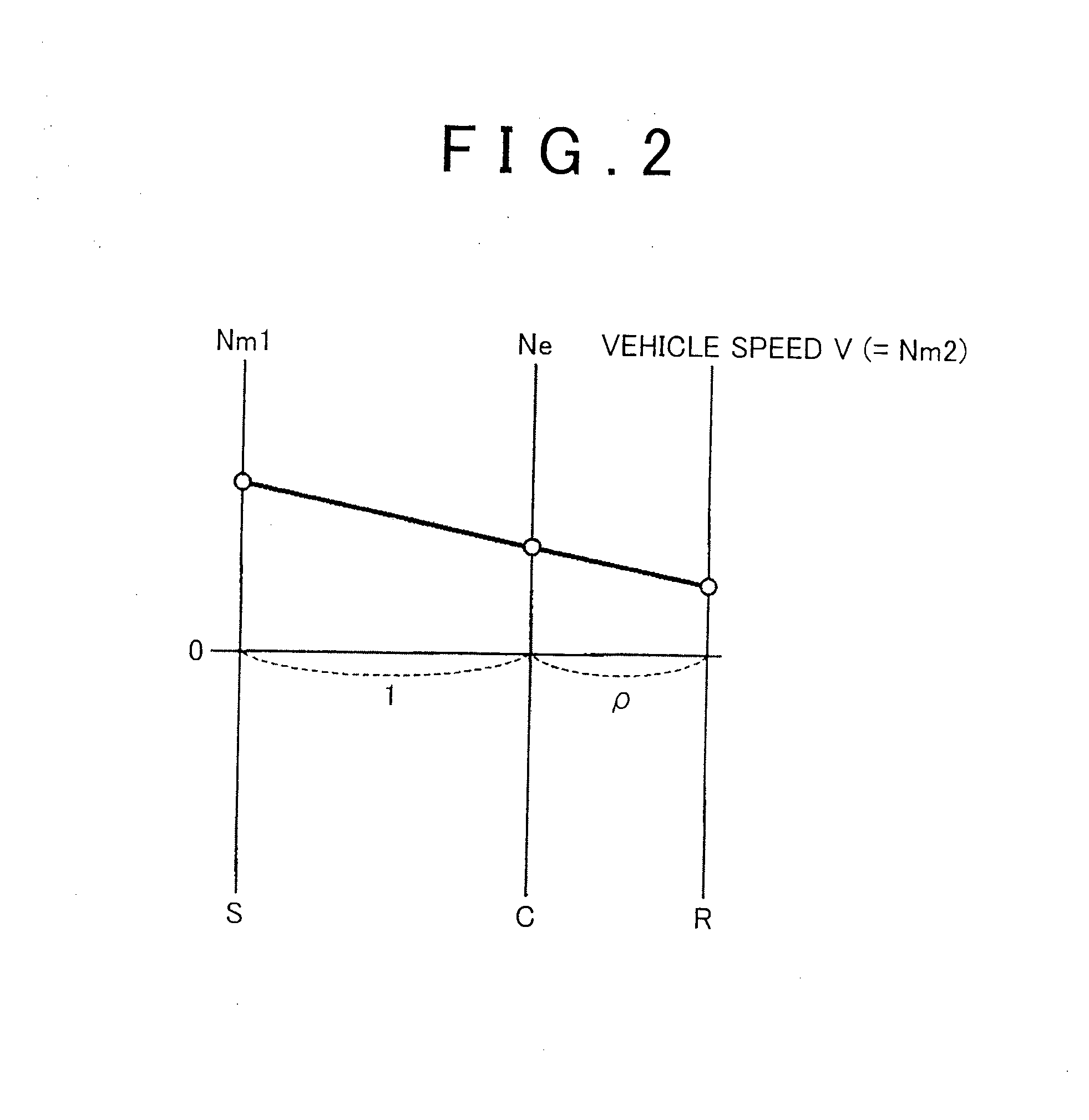

Hybrid-vehicle drive system and operation method with a transmission

InactiveUS7223200B2Increase speedHigh torqueElectric propulsion mountingRailway vehiclesVariatorWheel drive

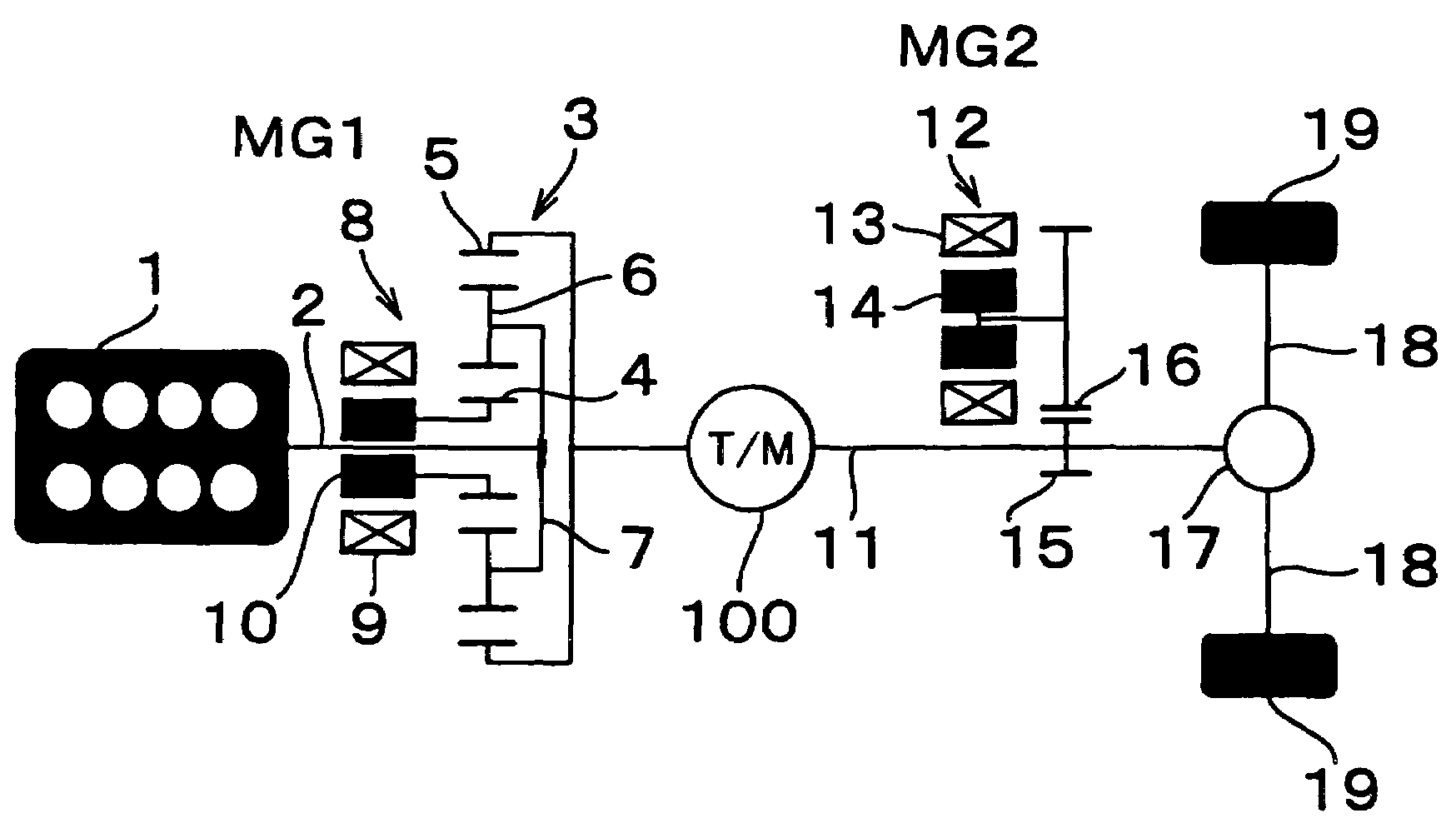

A hybrid-vehicle drive method and system includes an internal combustion engine that includes an output shaft, a first electric motor / generator connected to the output shaft of the internal combustion engine via a power distribution mechanism, a wheel drive shaft connected to the output shaft of the internal combustion engine via the power distribution mechanism, a second electric motor / generator connected to the wheel drive shaft, and a transmission located on at least one of the wheel drive shaft and a connecting portion of the second electric motor / generator with the wheel drive shaft.

Owner:TOYOTA JIDOSHA KK

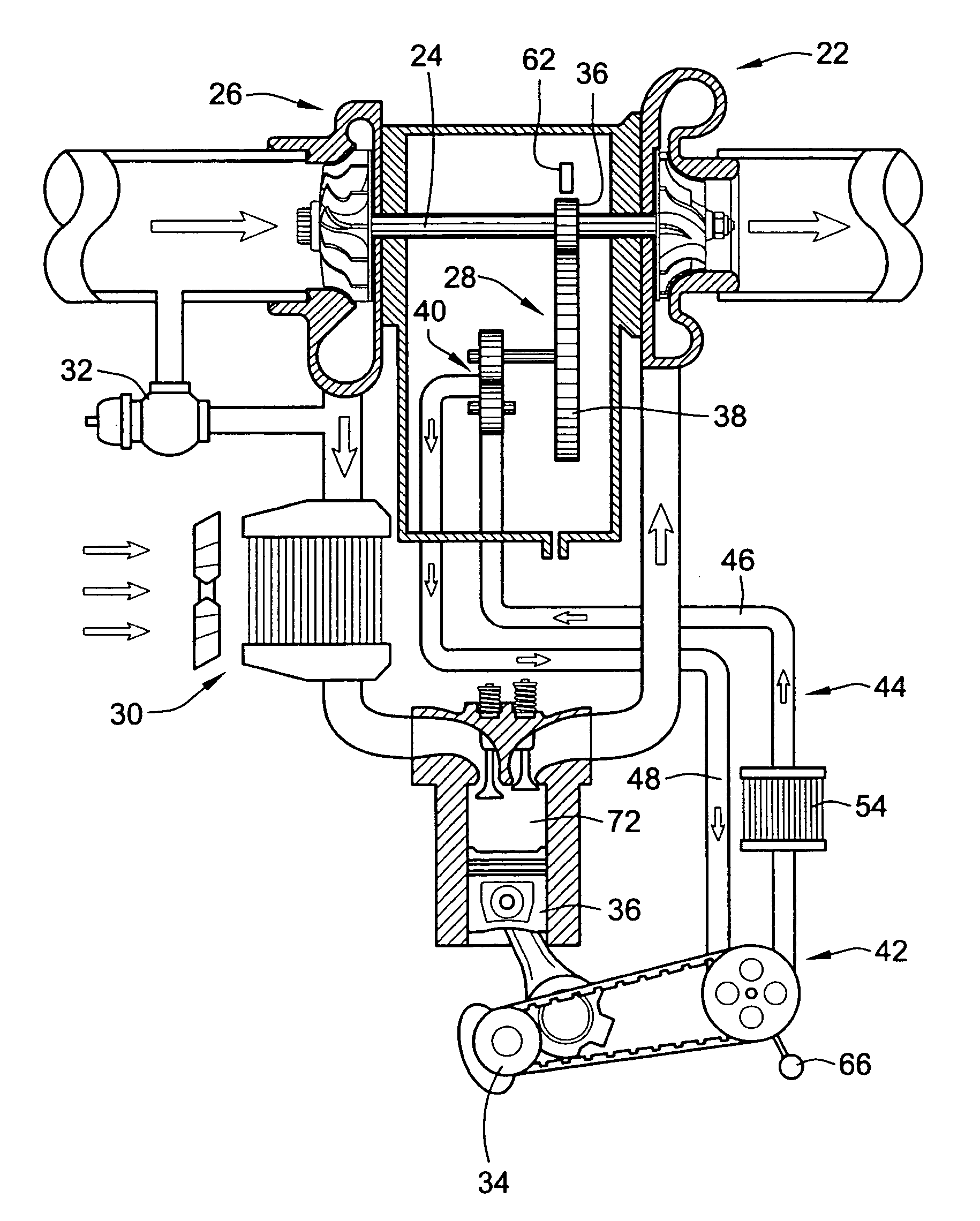

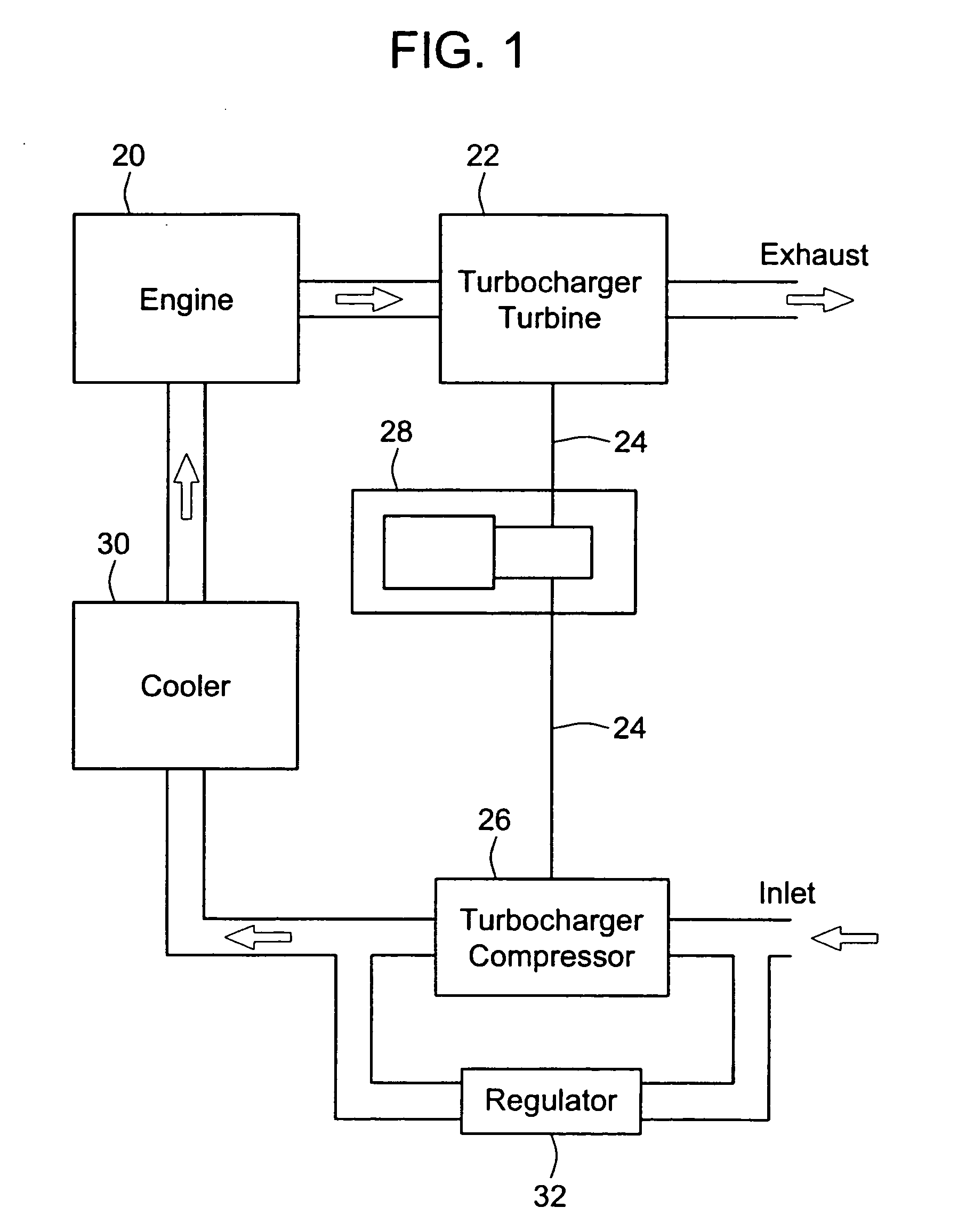

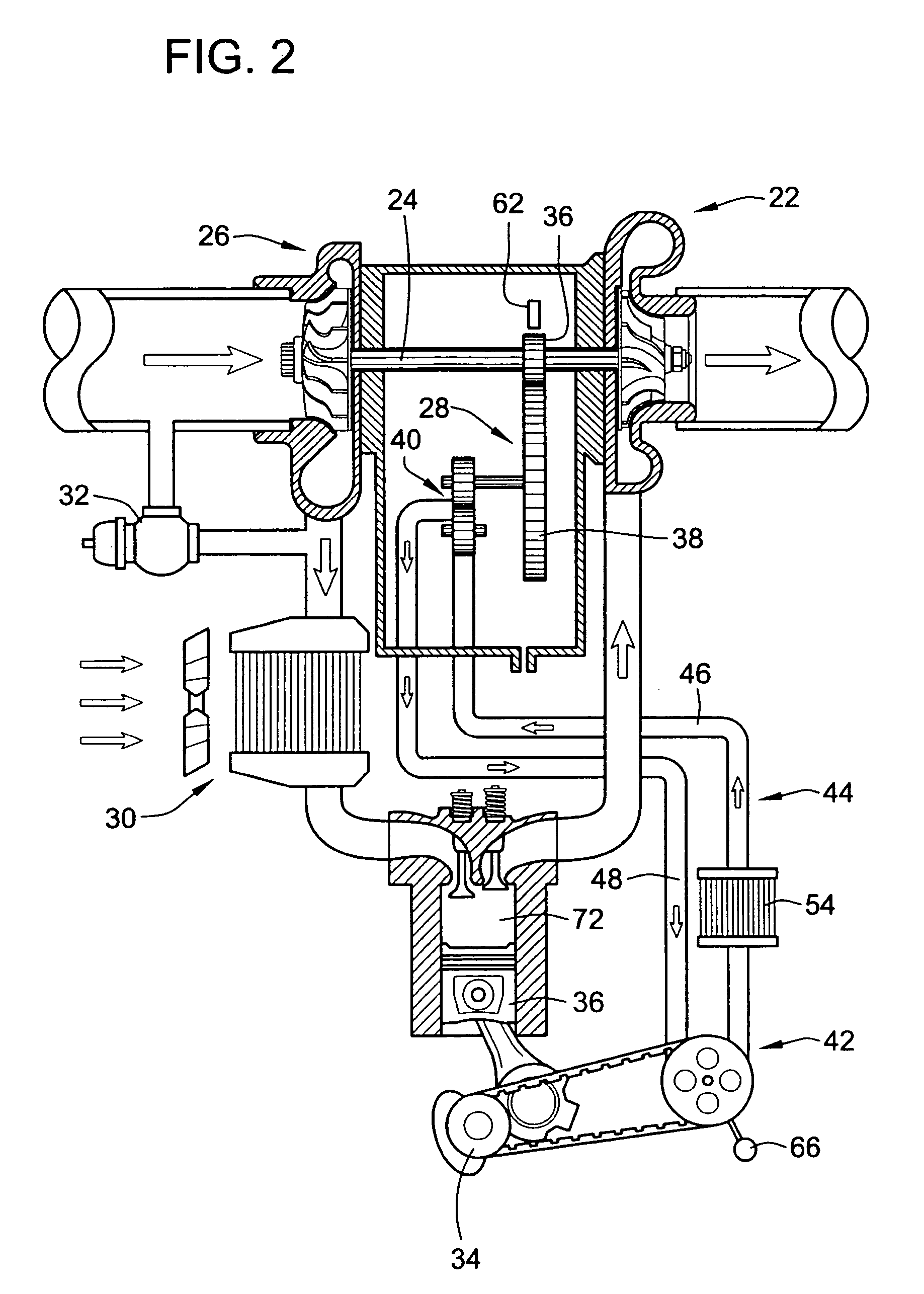

Super-turbocharger

InactiveUS20060032225A1Low speedHigh torqueInternal combustion piston enginesToothed gearingsHigh torqueLow speed

The invention combines the features of a supercharger, a turbocharger and turbo-compounding into one system, utilizing a hydraulic or mechanical continuously variable transmission to drive the turbocharger up to a specific speed or intake manifold pressure and then holding the ideal speed to keep it at the right boost pressure for the engine condition. The benefits of a supercharger, which is primarily good for high torque at low speed, and a turbocharger, which is usually only good for high horsepower at high speeds are merged. Once the exhaust energy begins to provide more work than it takes to drive the intake compressor, the invention recovers that excess energy and uses it to add torque to the crankshaft. As a result, the invention provides the benefits of low speed with high torque and the added value of high speed with higher horsepower or better fuel economy all from one system.

Owner:VANDYNE SUPERTURBO

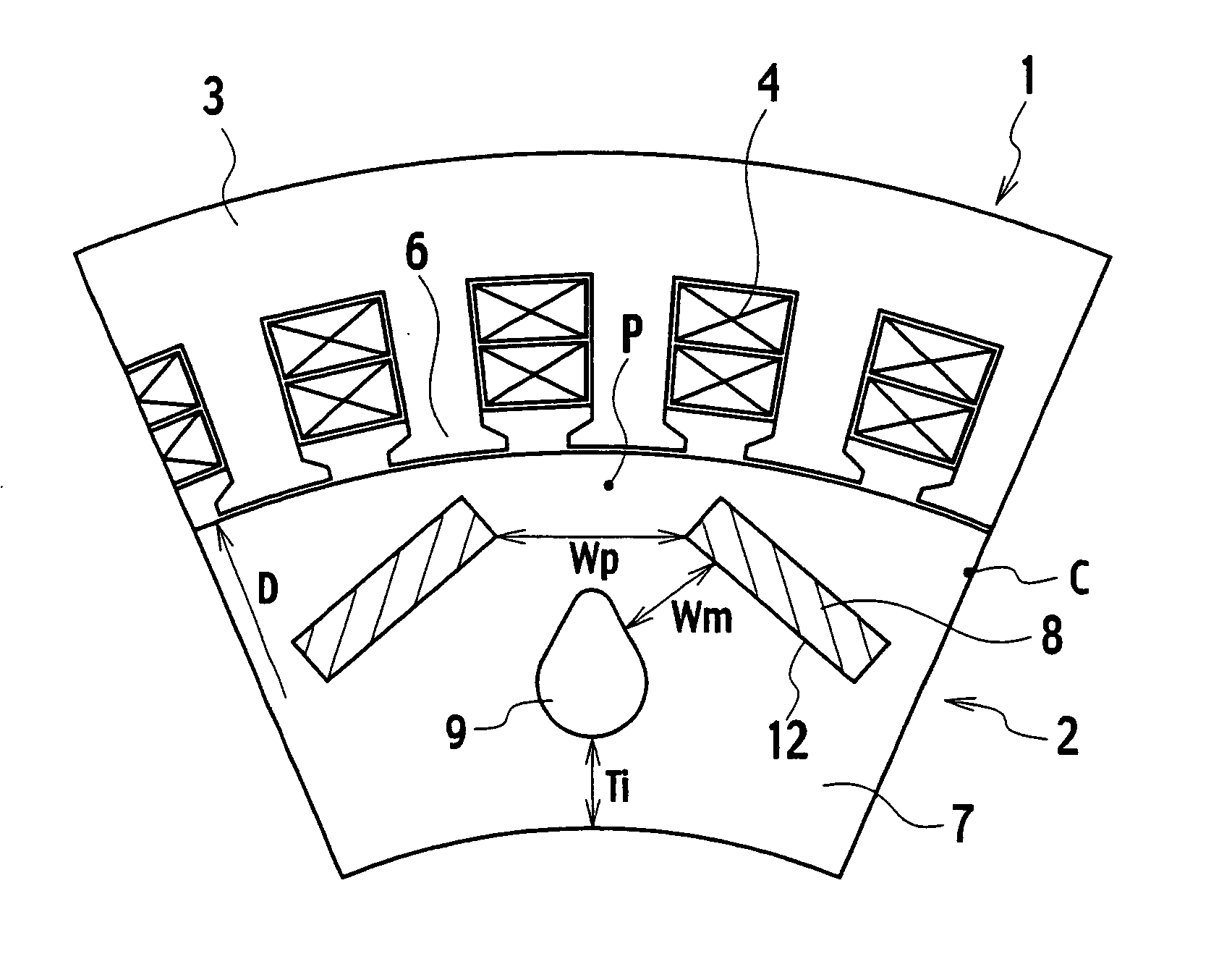

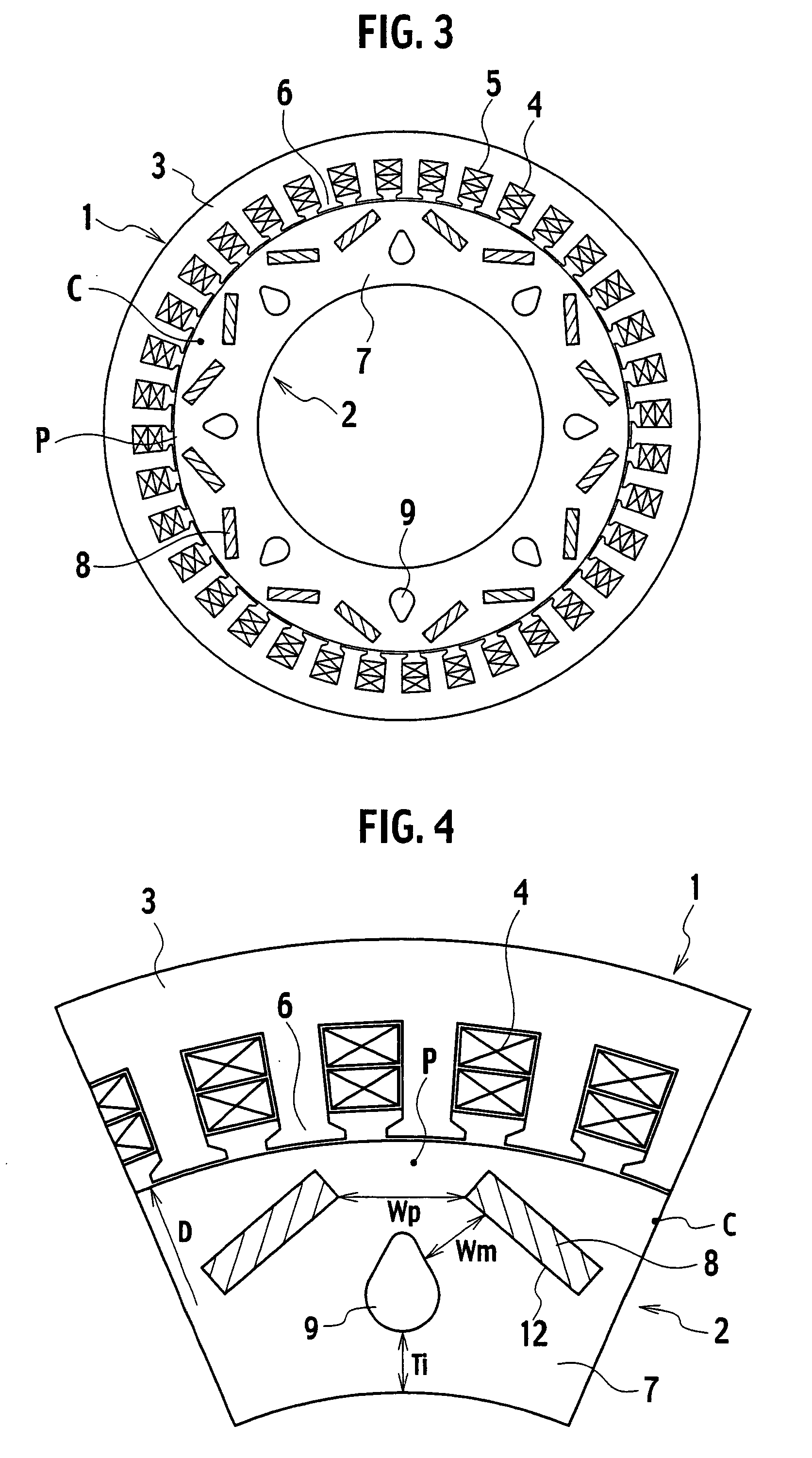

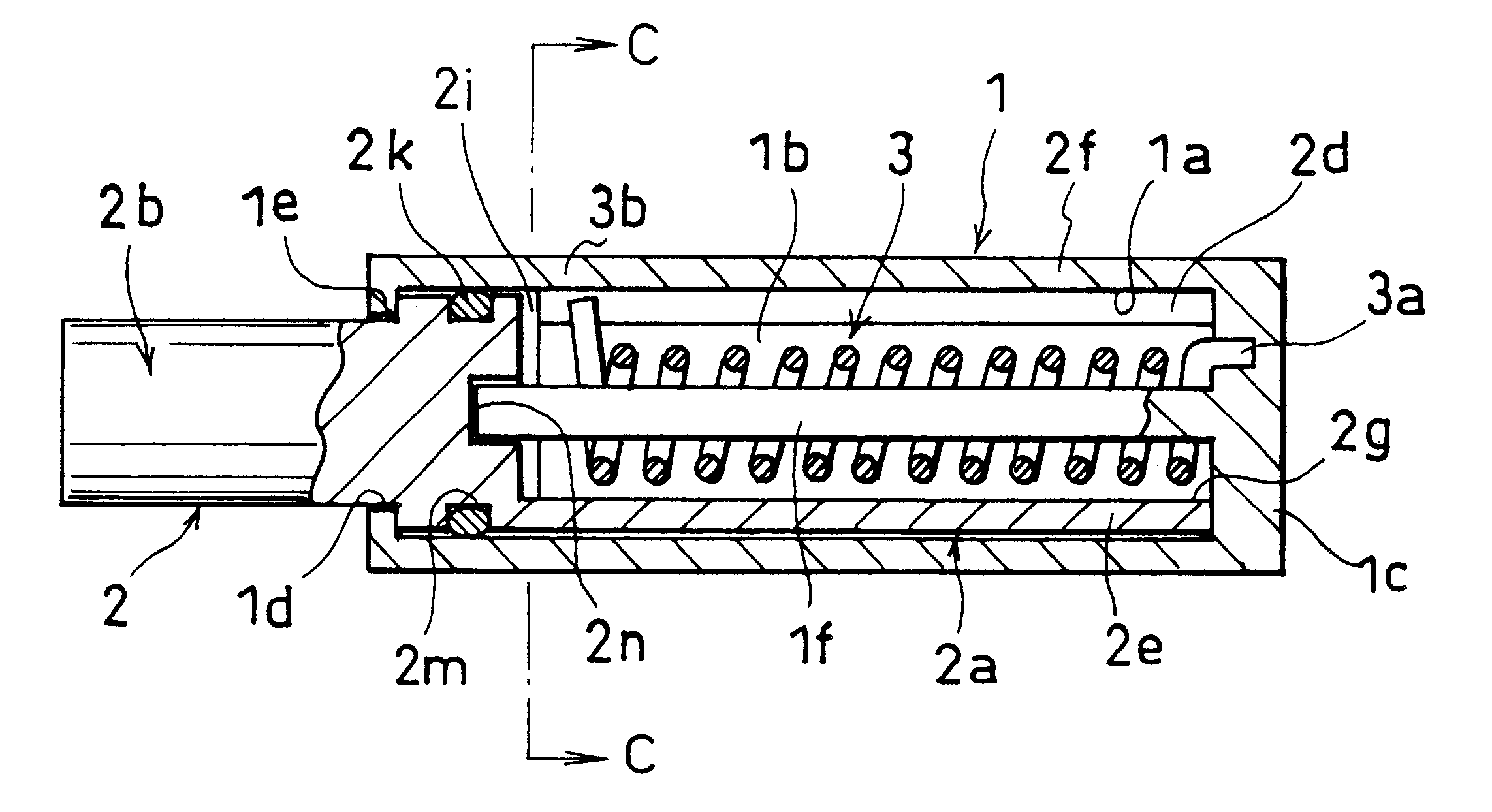

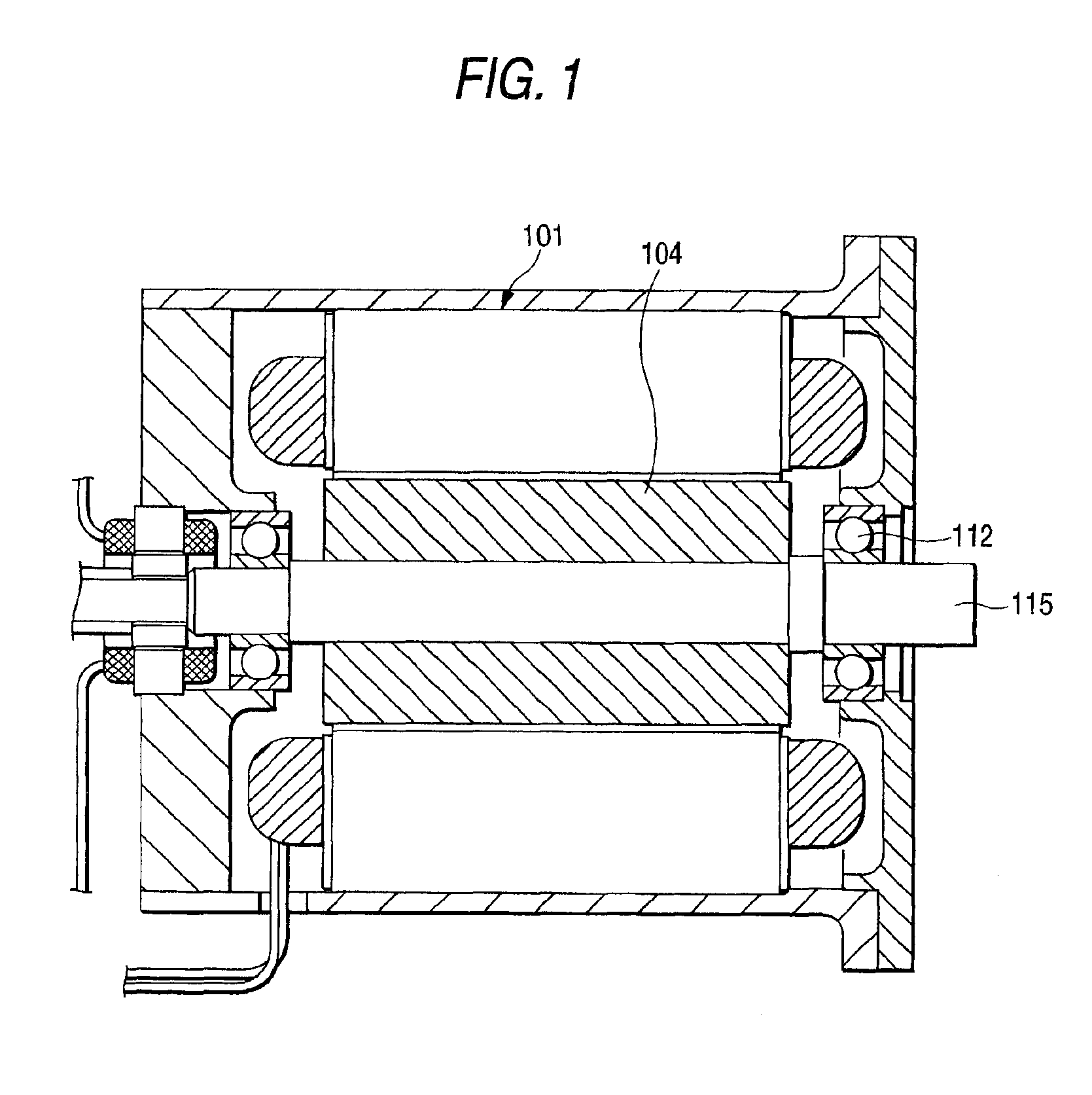

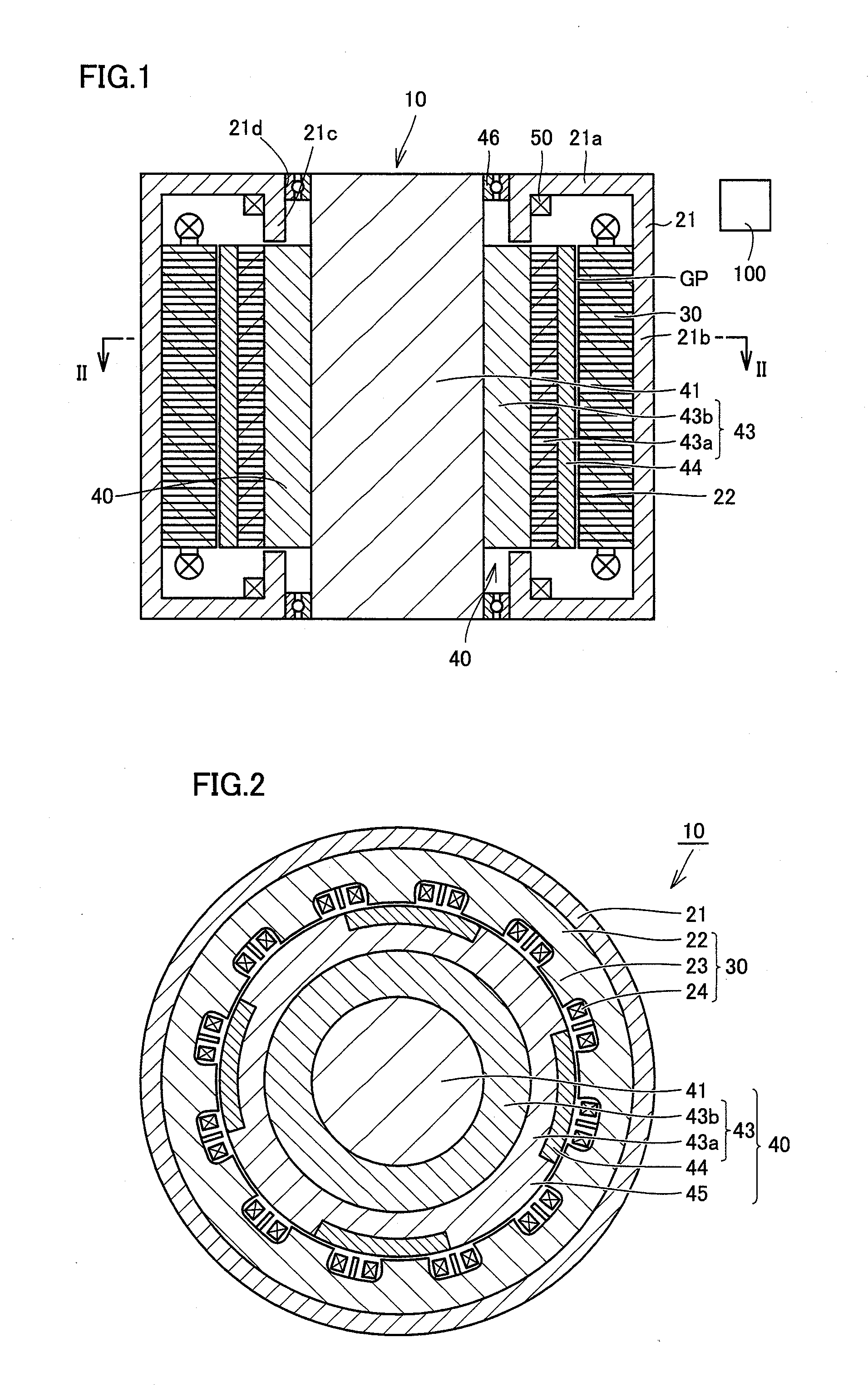

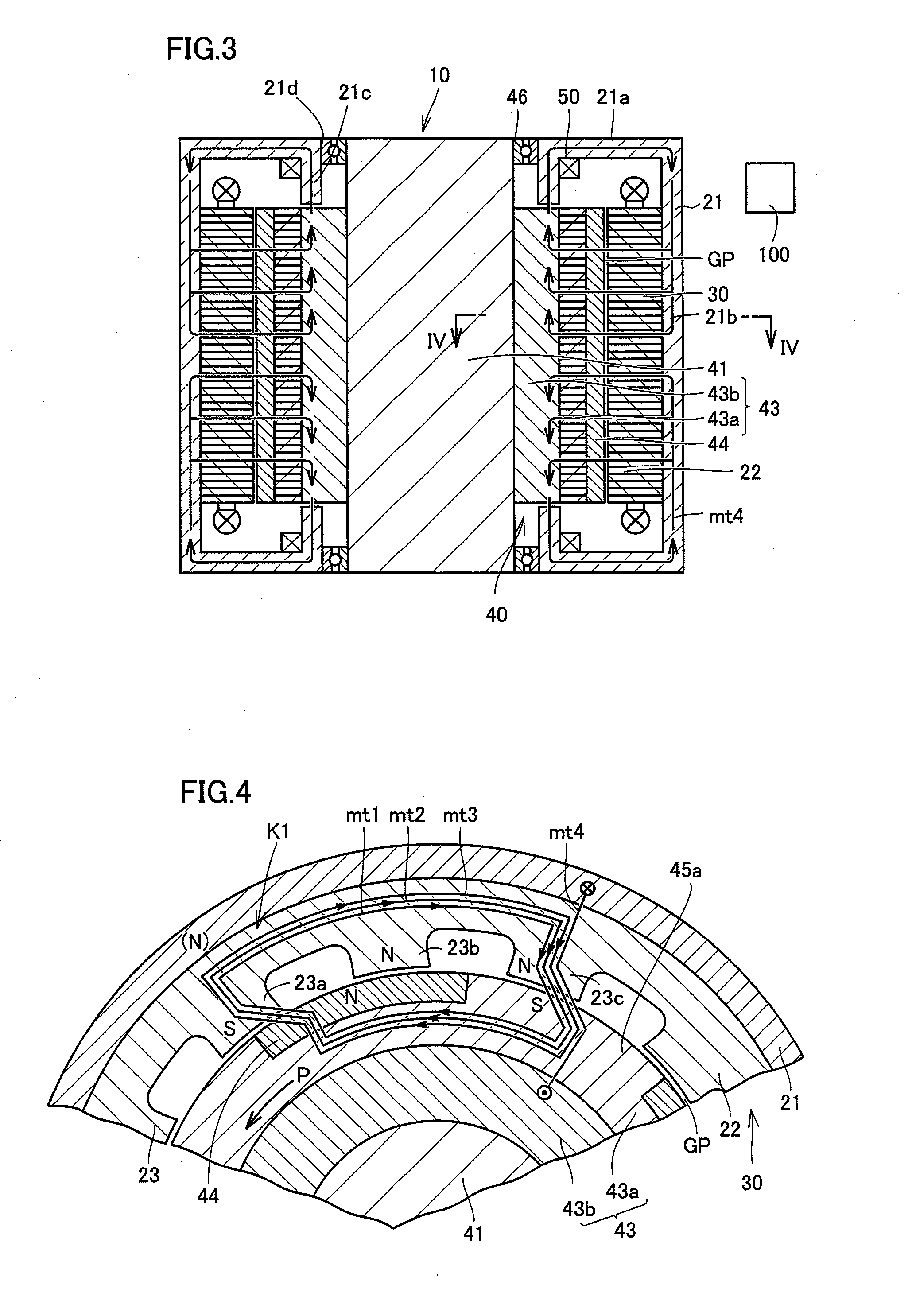

Rotating electrical machine

ActiveUS20070052313A1Improve cooling effectHigh torqueMagnetic circuit rotating partsCooling/ventillation arrangementCoolant flowElectric machine

Included are a ring-shaped stator and a ring-shaped rotor arranged inside the stator; the stator includes a stator core with armature windings; the rotor includes a rotor core in which a plurality of permanent magnets are inserted and cooling holes are formed, a coolant flowing in each of the cooling holes; and each of the cooling holes is formed so as to have a sectional view which is a convex toward the outer periphery thereof.

Owner:KK TOSHIBA +1

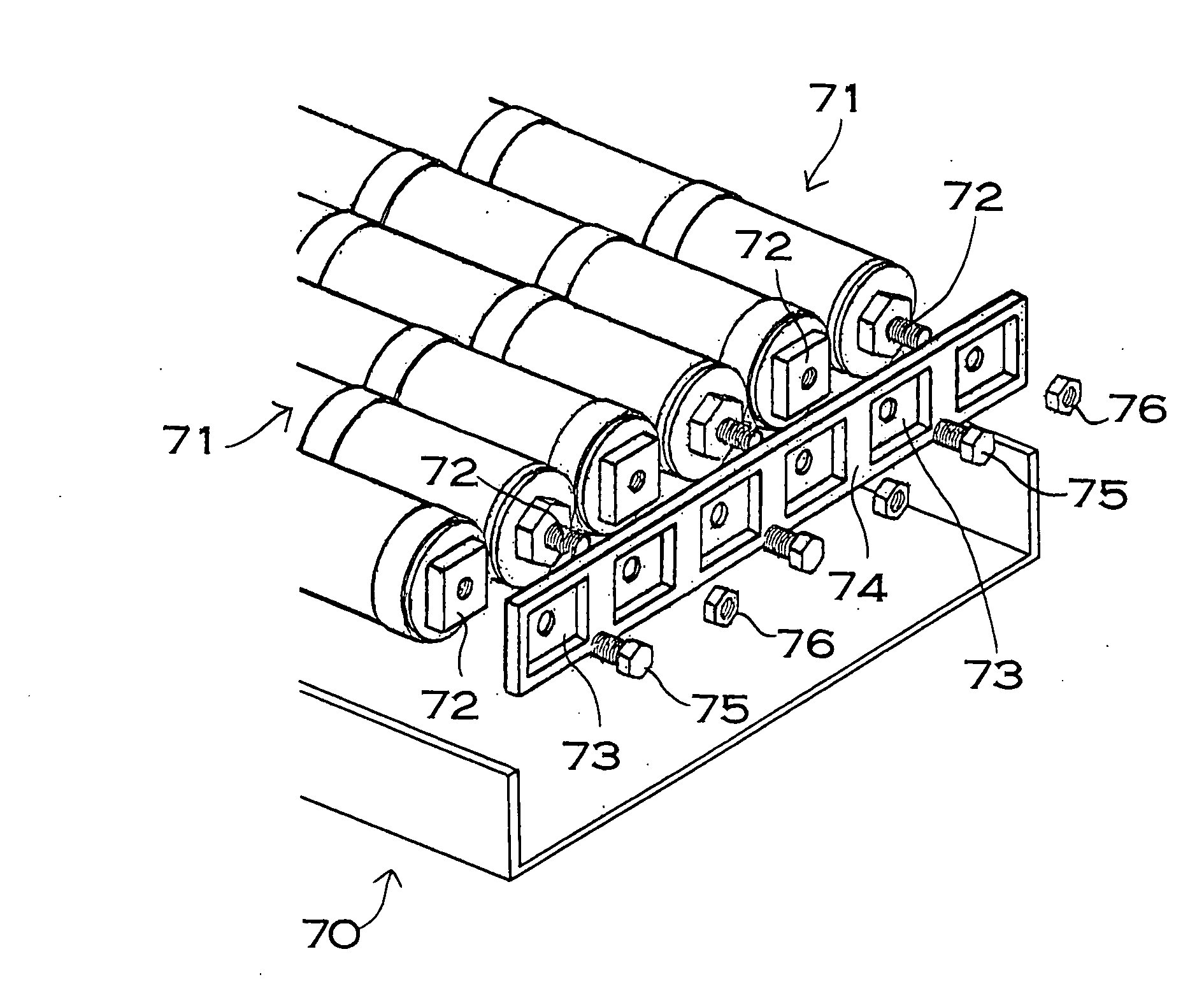

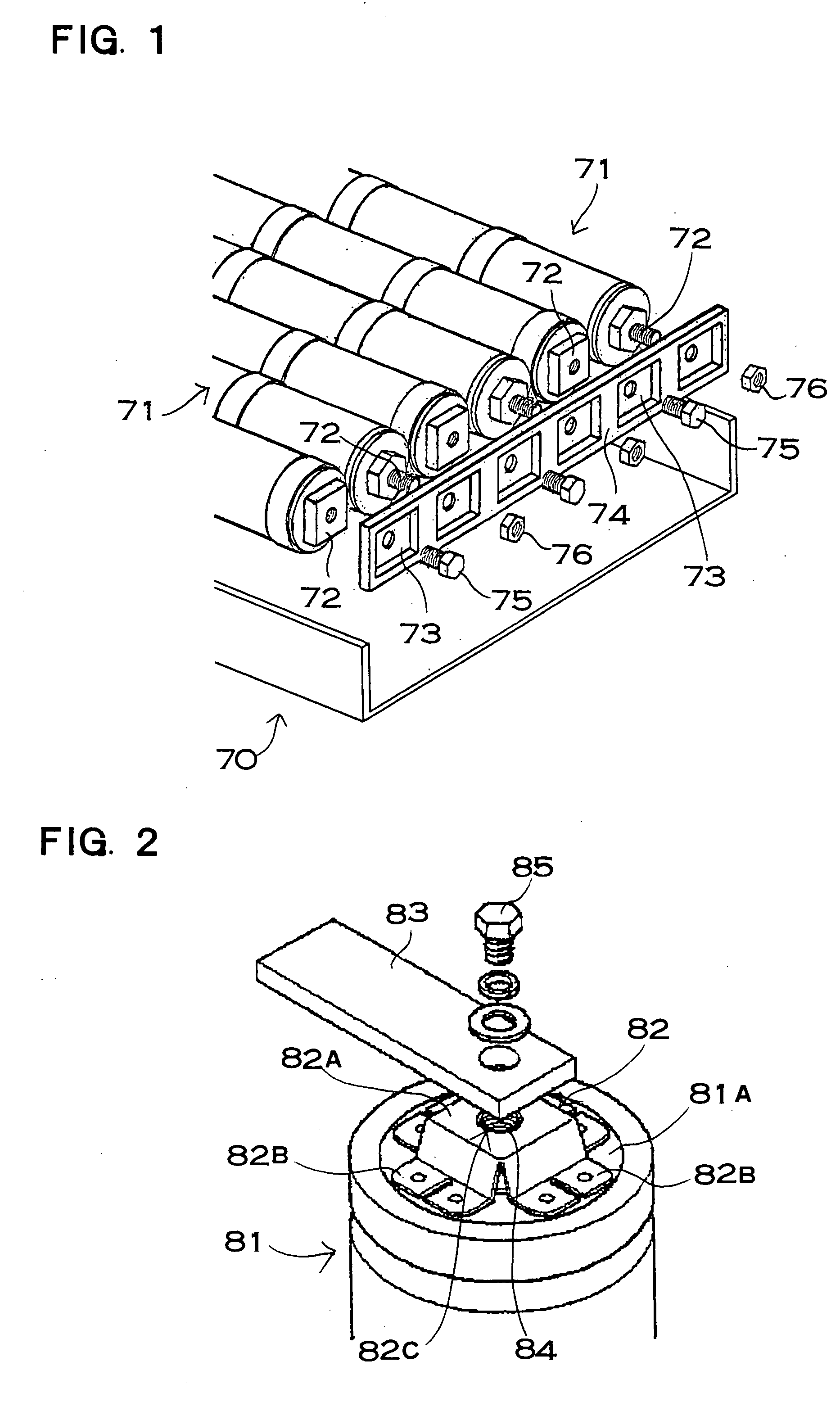

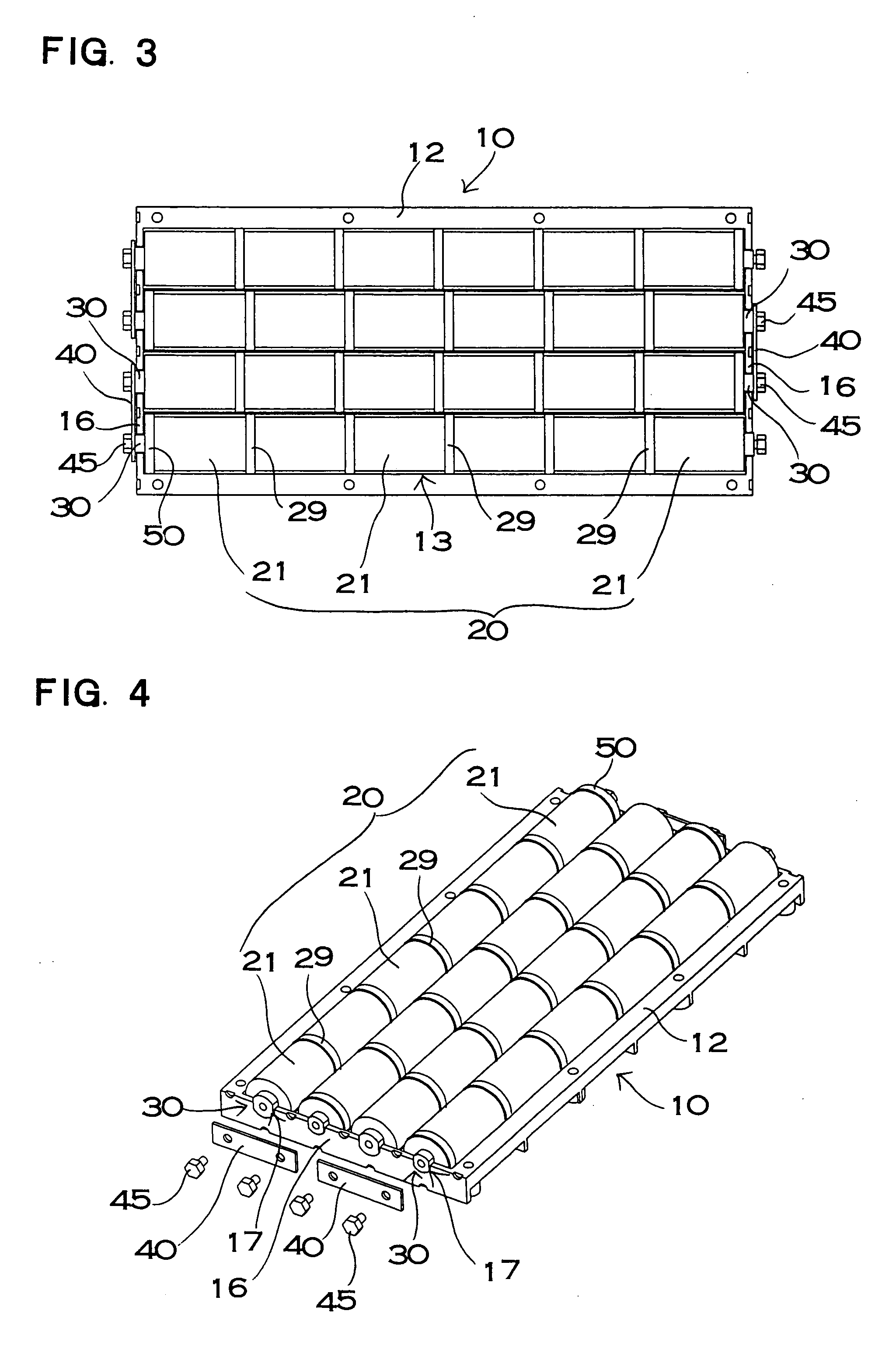

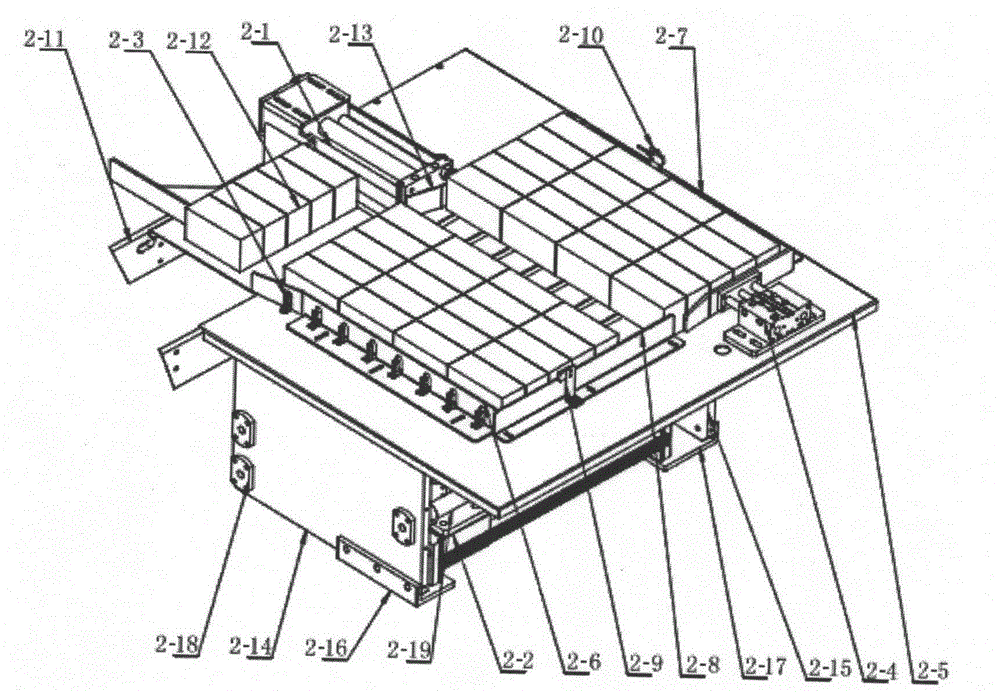

Power device

ActiveUS20060105624A1Inexpensively mass-producedHigh torqueCoupling device connectionsElectrically conductive connectionsEngineeringSurface plate

A power device includes a battery module for fixing a connecting terminal to an end and a bus bar connected to the connecting terminal of the battery module. The connecting terminal includes a fixing plate portion fixed to the end of the cell, an outer cylindrical portion protruded cylindrically from the fixing plate portion, an end face plate portion closing a tip surface of the outer cylindrical portion, and an inner cylindrical portion protruded from the end face plate portion toward the fixing plate portion. The connecting terminal is provided with a female screw on an internal surface of the inner cylindrical portion and a setscrew penetrating through the bus bar is screwed toward the female screw, and the bus bar is fixed to the connecting terminal through the setscrew.

Owner:SANYO ELECTRIC CO LTD

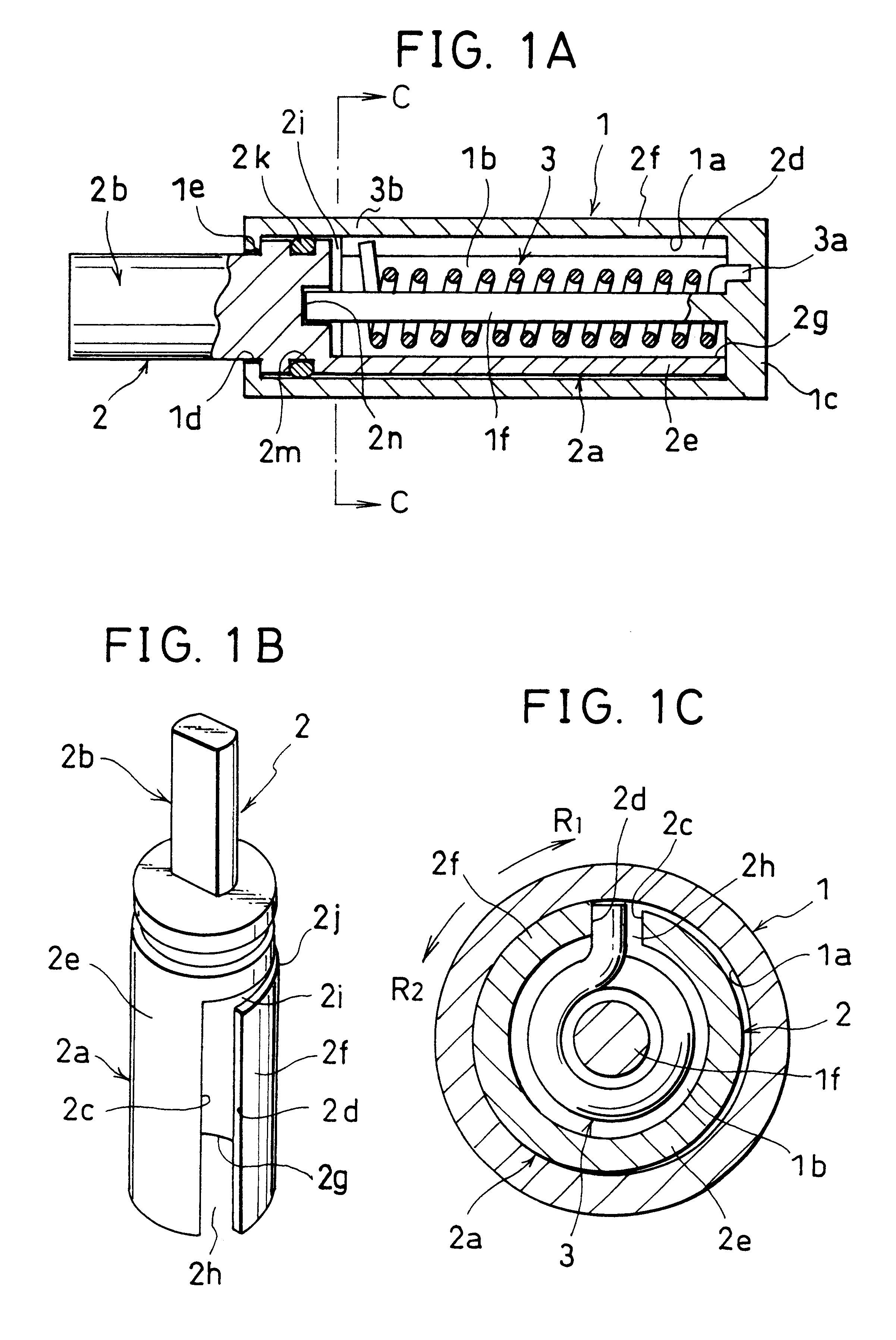

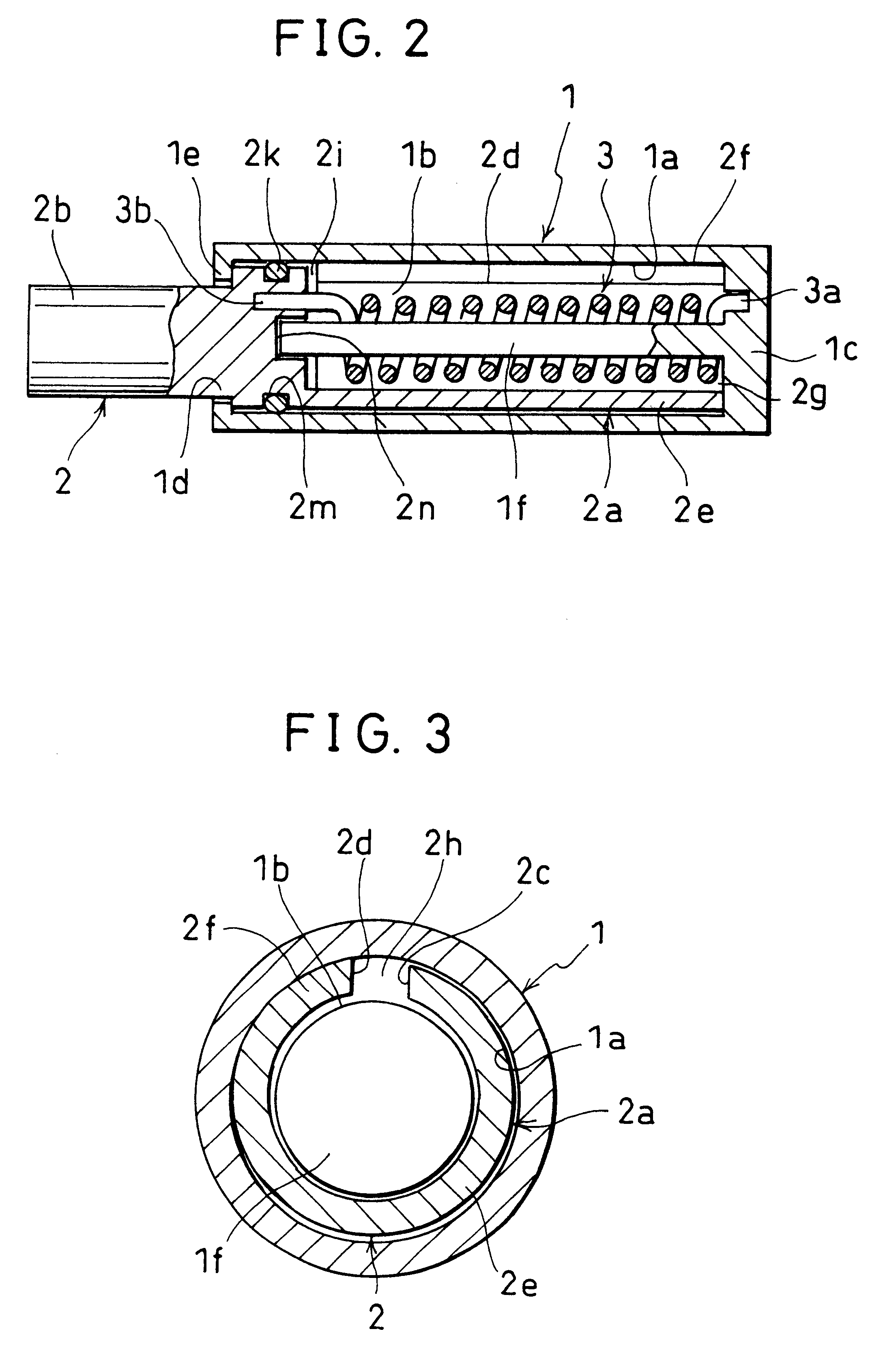

Rotary damper

InactiveUS6336252B1Enhanced level of machining precisionImprove the forceBuilding braking devicesWing fastenersFriction forceBase line

A rotary damper is adapted to exert braking force to an upswung door, a toilet lid or the like when the door is closed and dampen the impact produced by the closing door by a damping force far greater than the one obtained by a conventional rotary damper using viscous shearing resistance. The rotary damper can also make the door open by a force far smaller than a conventional rotary damper. A movable shaft is rotatably housed in a casing and has a cylindrical shaft section including an arcuate non-resilient section extending from a peripheral edge thereof to an axial base line close to the other free peripheral edge thereof and an eccentric resilient section extending from the axial base line to the other free peripheral edge thereof with its eccentricity increasing as a function of the distance from the base line relative to the radius of curvature of the inner peripheral surface so as resiliently abut the inner peripheral surface. The frictional force between the eccentric rest section and the inner peripheral surface increases when the movable shaft is driven to rotate to close the door to which it is fitted but falls remarkably when the movable shaft is driven to rotate in the opposite sense to open the door.

Owner:SUGATSUNE IND CO LTD

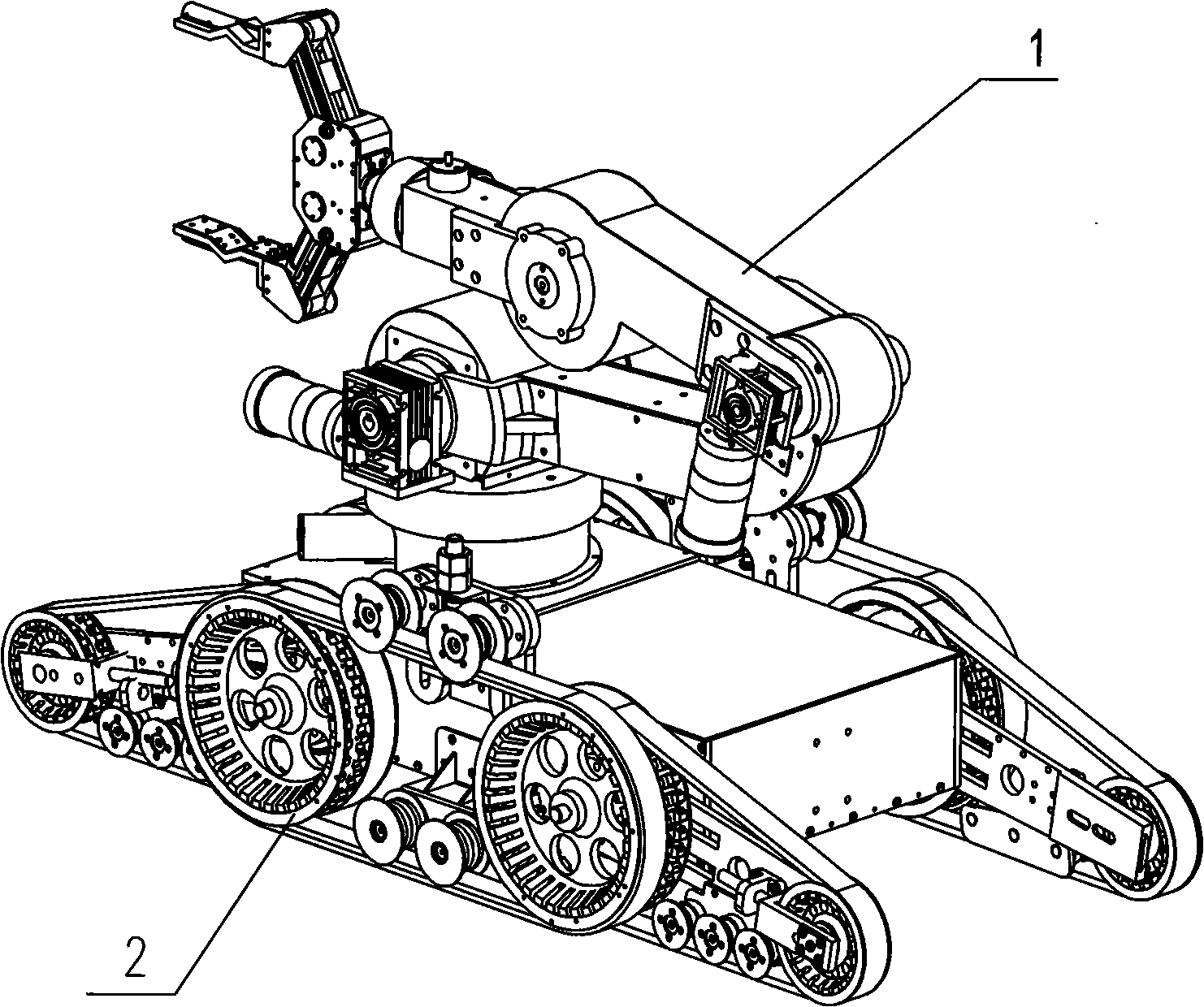

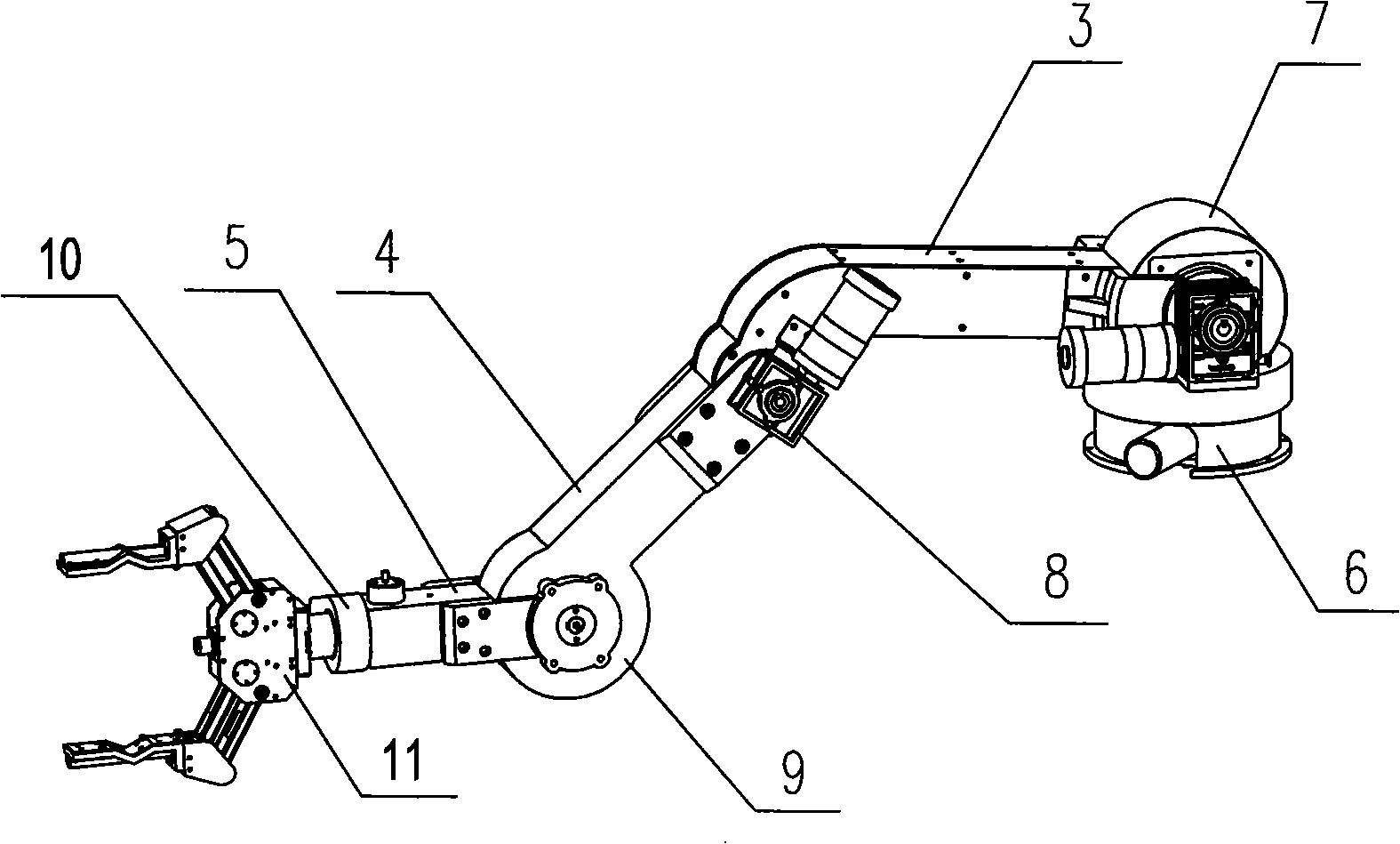

Crawler type multi-arm rod mobile robot

InactiveCN101279618AIncrease flexibilityAdaptableEndless track vehiclesManipulatorWorking environmentHigh intensity

The invention relates to the robot field, which provides a pedrail type movable robot with multiple arm links and consists of an arm working device and a pedrail type walking device. The invention can realize normal movable driving on a plurality of complicated road surfaces and finish a plurality of human hand bionic actions. The robot of the invention can substitute for human to work under a plurality of complicated, dangerous and abominable working environments, and has the advantages of strong adaptability, good flexibility, high intensity, etc.

Owner:北京中泰恒通科技有限公司

Heat assisted magnetic write element

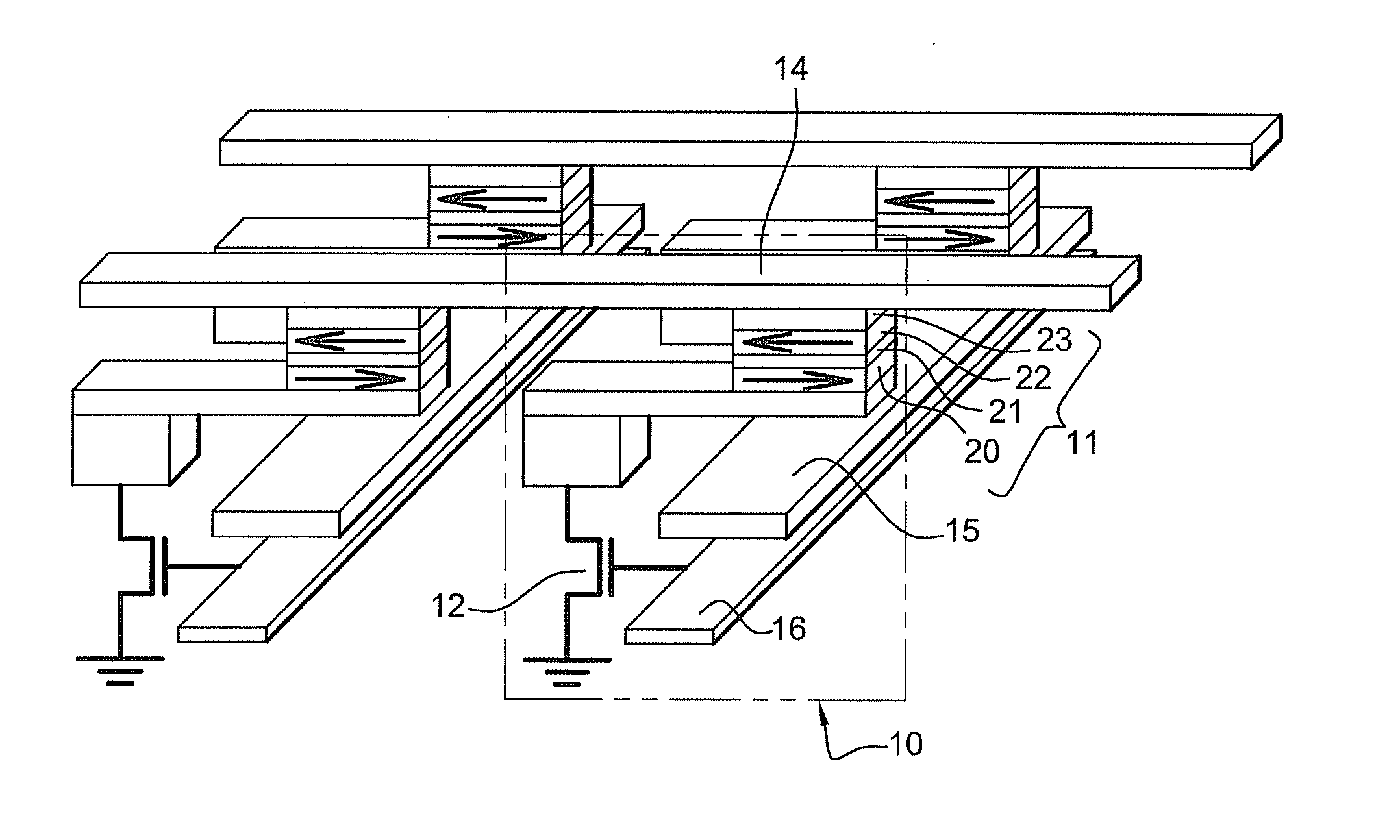

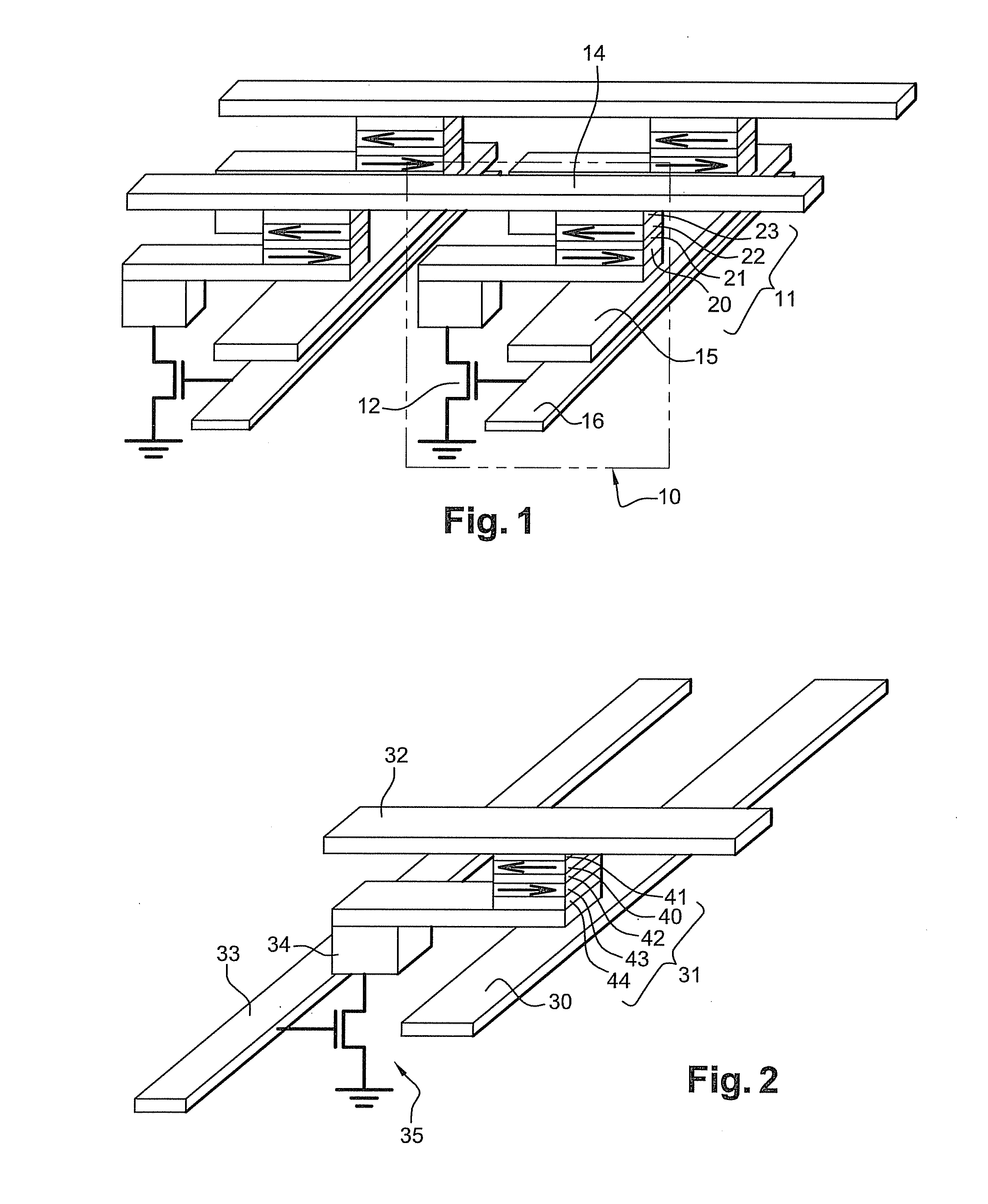

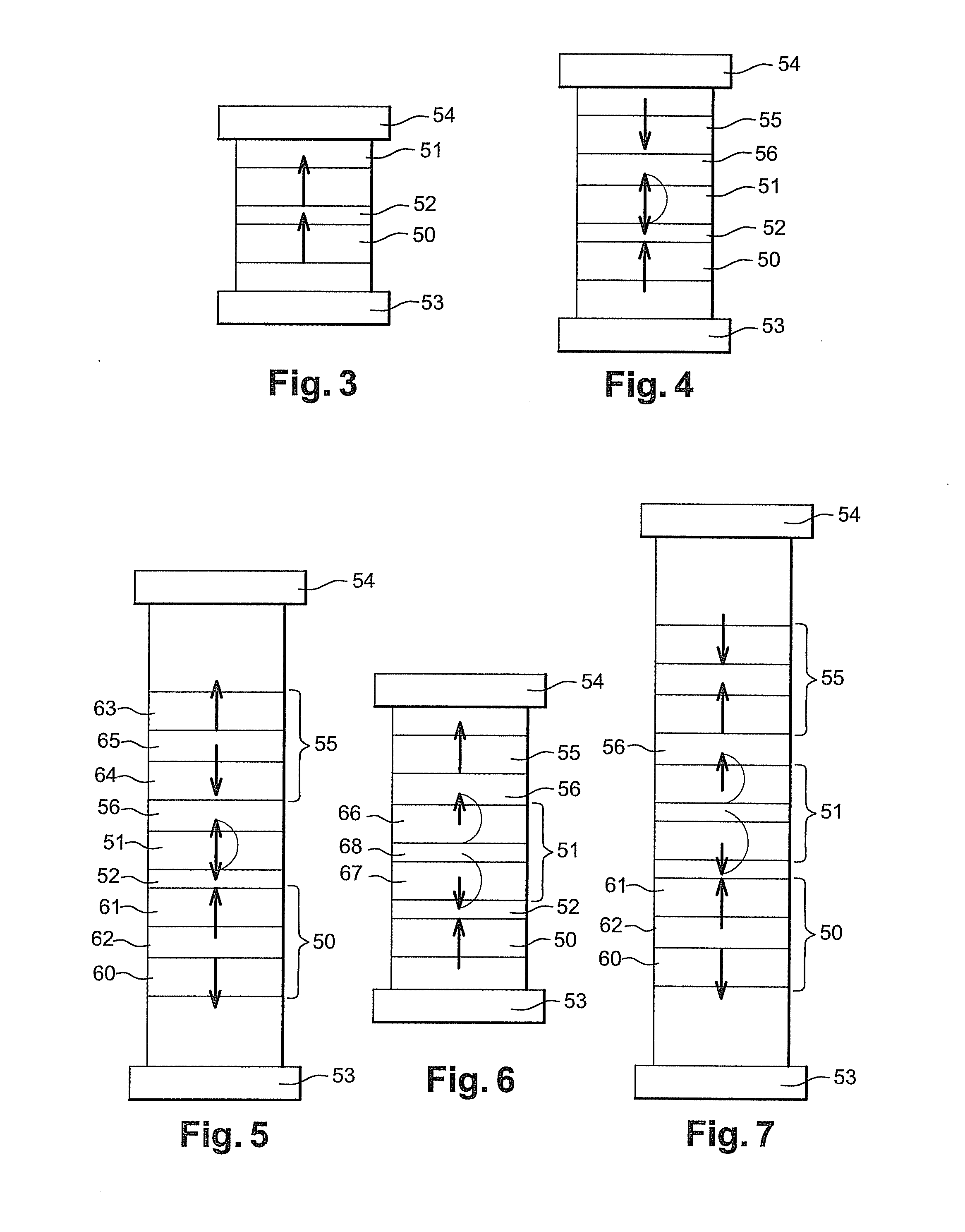

ActiveUS20110044099A1Maximizing the magnetic torqueHigh torqueNanomagnetismMagnetic-field-controlled resistorsStable stateSpin transfer

This magnetic element for writing by magnetic field or heat assisted spin transfer comprises a stack consisting of:a free magnetic layer, also called storage layer or switchable magnetization layer (51), of which the magnetization direction is switchable between two nonwrite stable states, both directed out-of-plane and substantially perpendicular to the plane of said layer, and of which the magnetization is spontaneously reoriented from substantially perpendicular to the plane to substantially in the plane under the effect of the rise in temperature during the writing;at least one reference magnetic layer (50, 55), called pinned layer, of which the magnetization is oriented substantially perpendicular to the plane of said layer;a nonmagnetic spacer (52) inserted between the two layers;means for making an electric current flow perpendicular to the plane of said layers.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

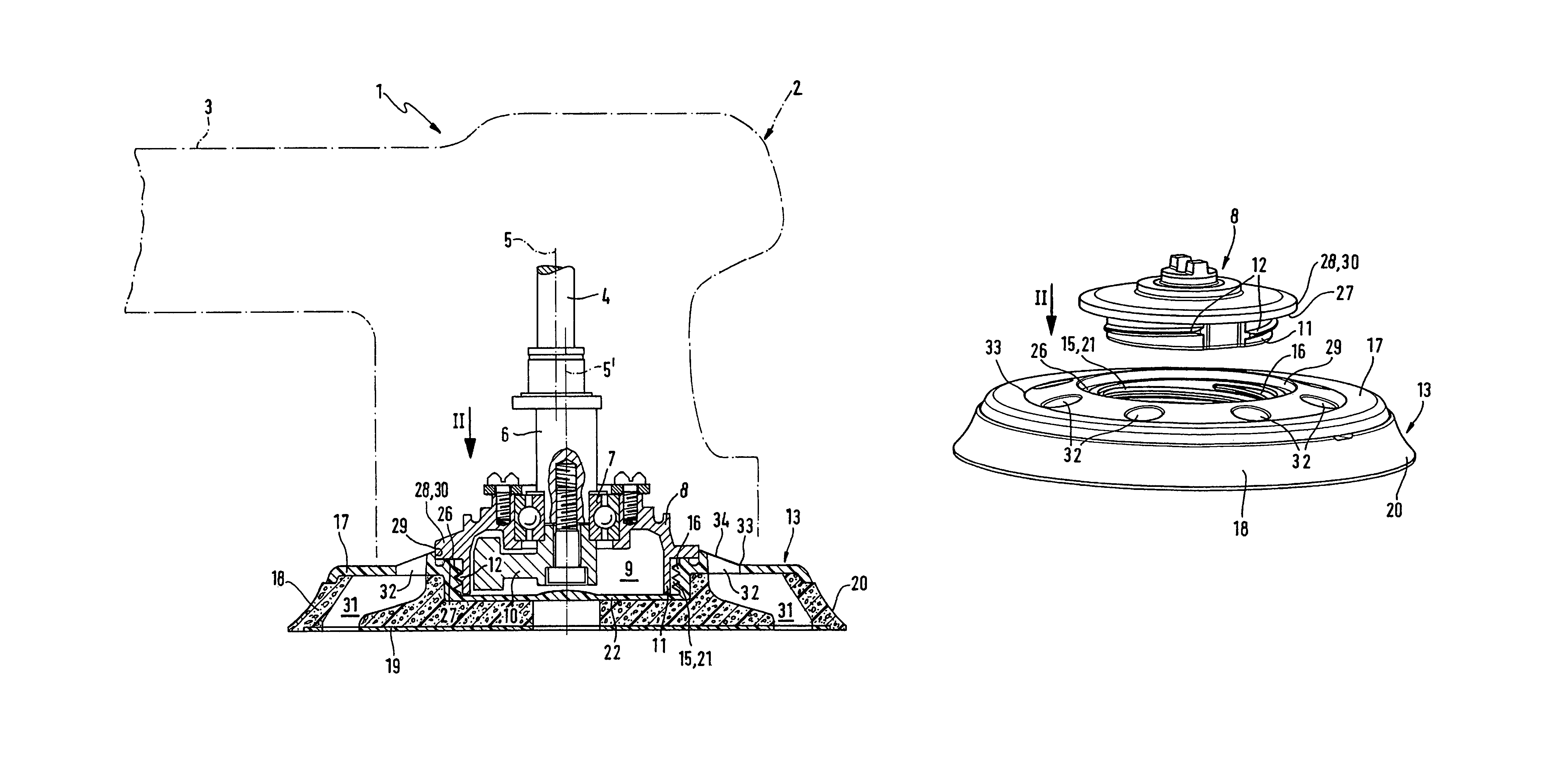

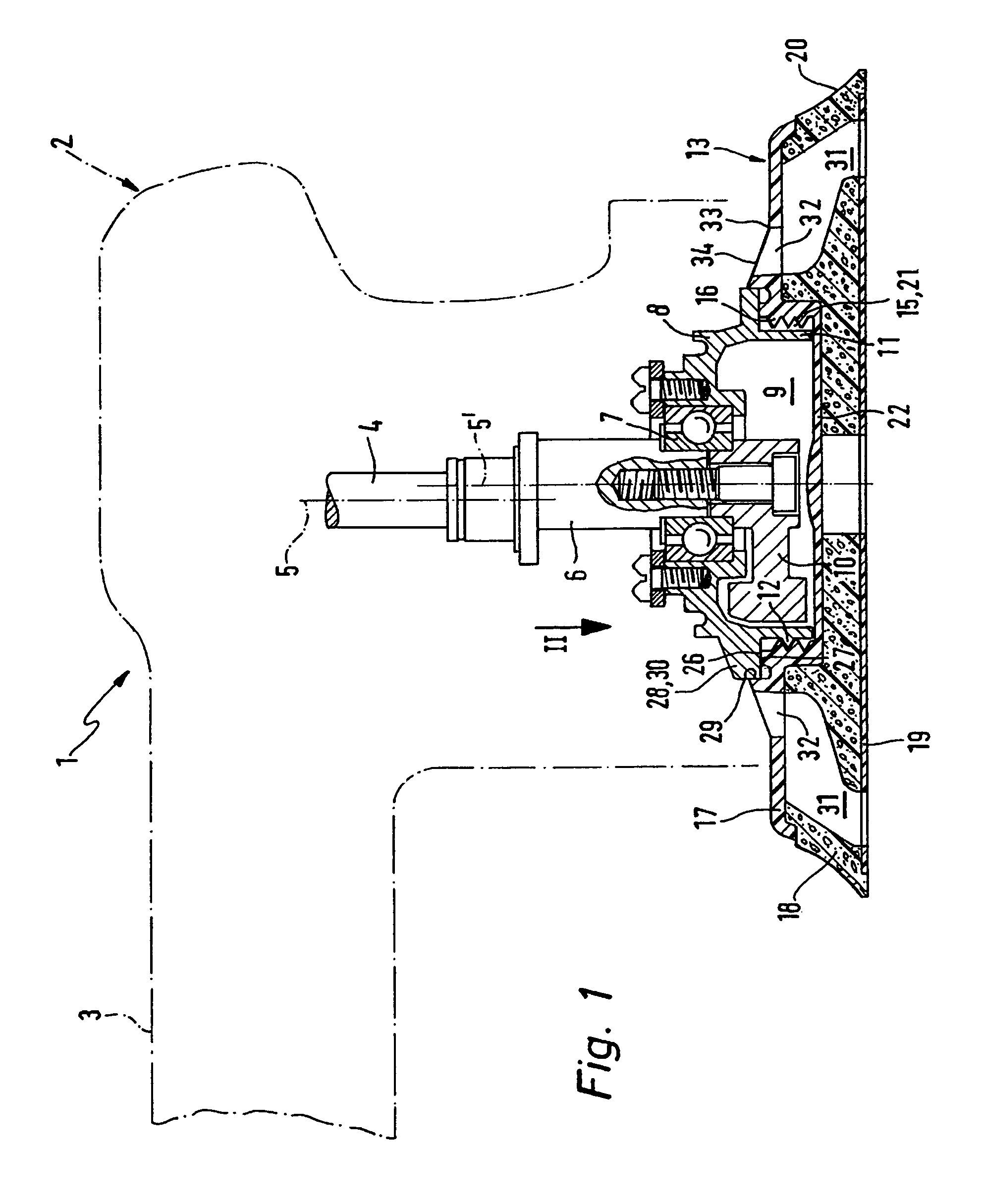

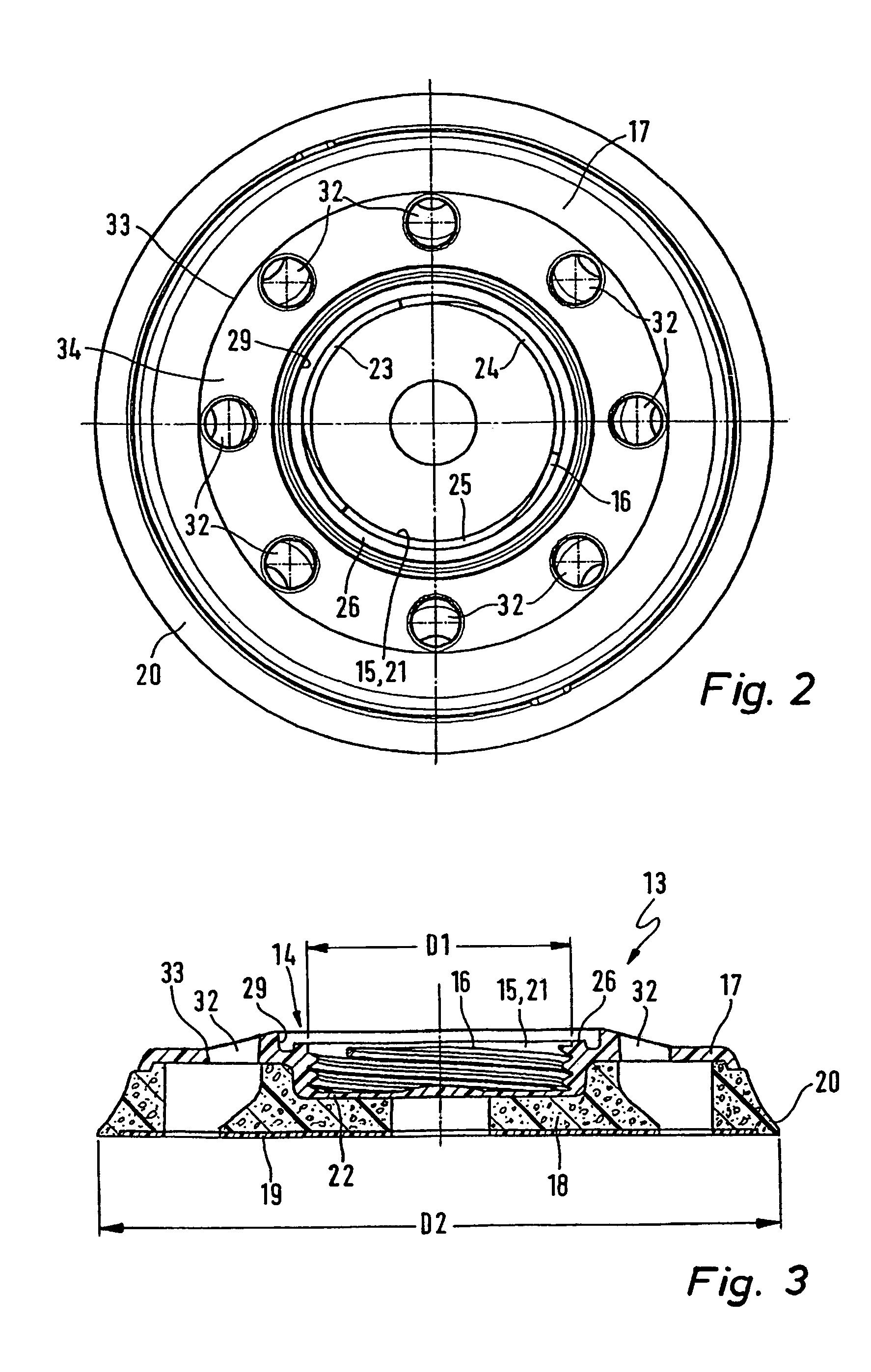

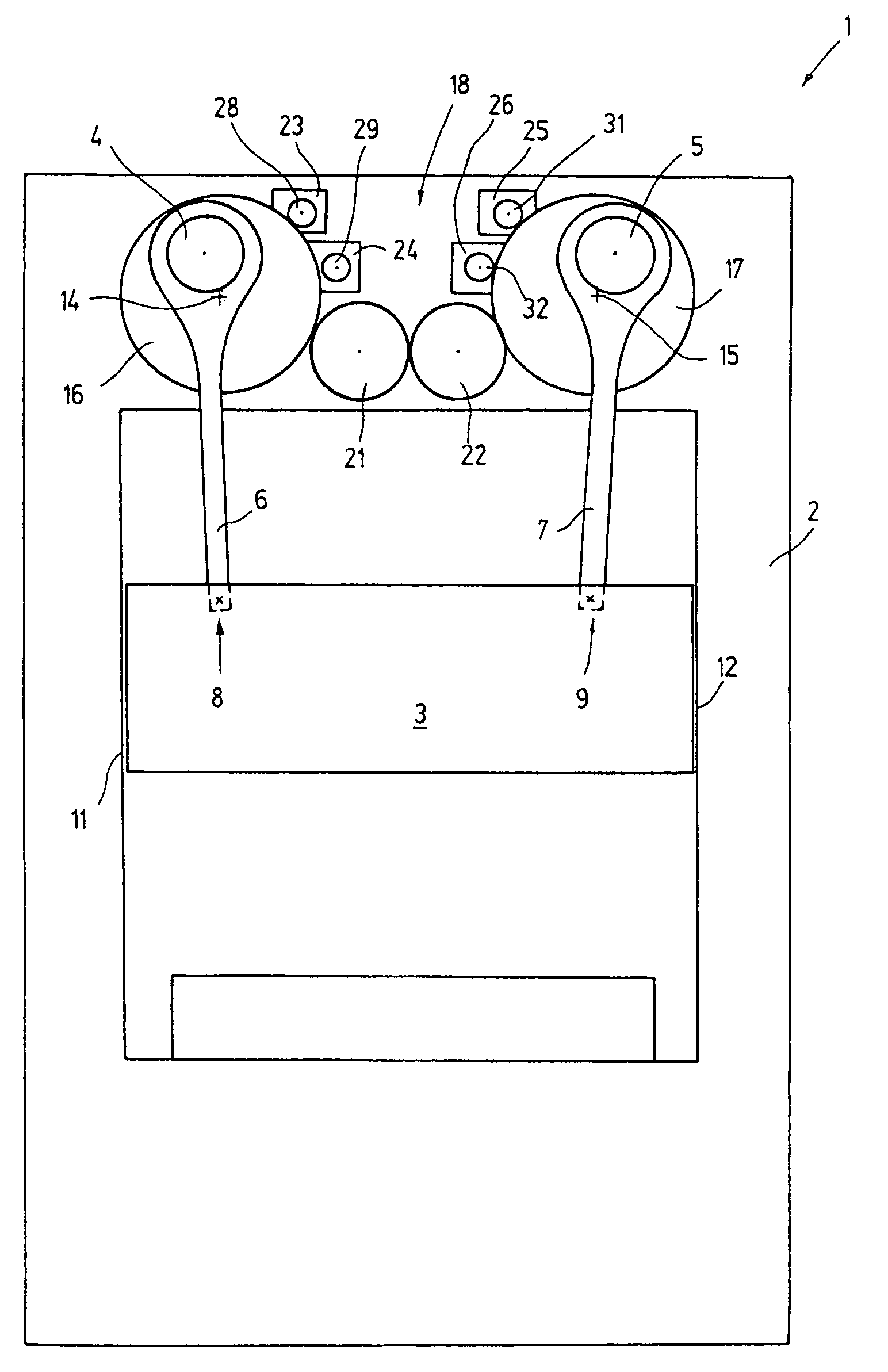

Grinding disk

ActiveUS7029384B2High torqueFine pitchGrinding wheel securing apparatusRevolution surface grinding machinesDiameter ratioEngineering

A grinding disk (13) for manually held, motor-driven grinders (1) has a centrally arranged fastening recess (15) open at the grinding disk upper side with an internal thread arrangement (16), with which the grinding disk (13) can be screwed onto a connecting part (8), which is arranged on the side of the grinder and is driven for the grinding motion during operation, and which connecting part has a thread section (11) with an external thread arrangement (12), which is associated with the internal thread arrangement (16) of the grinding disk (13). The internal thread arrangement (16) is formed by a multiple thread with at least two thread courses, which are arranged angularly offset to one another. The diameter ratio between the diameter of the internal thread arrangement (16) and the outside diameter of the grinding disk (13) is at least approximately 0.25.

Owner:FESTOOL GMBH

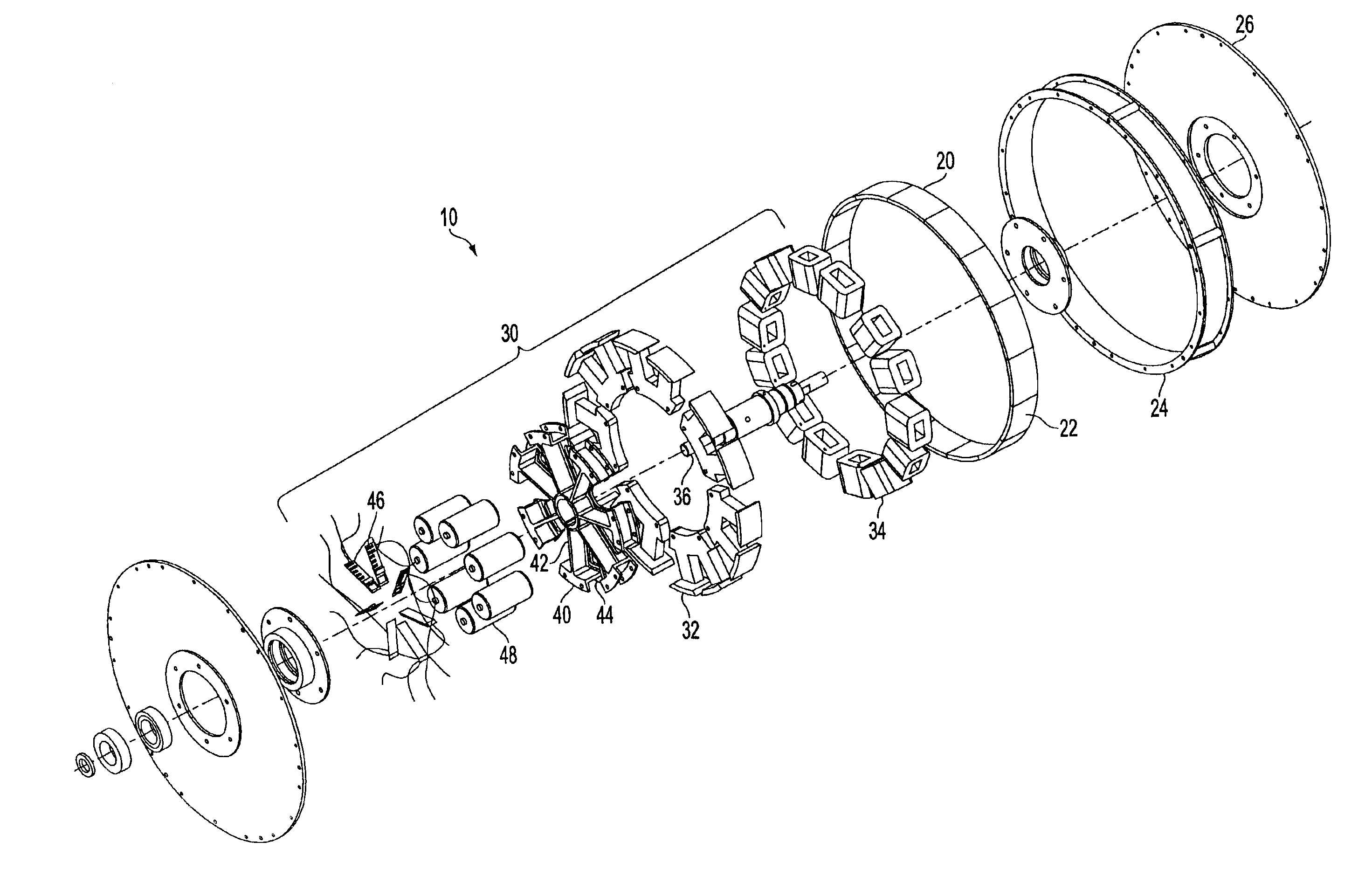

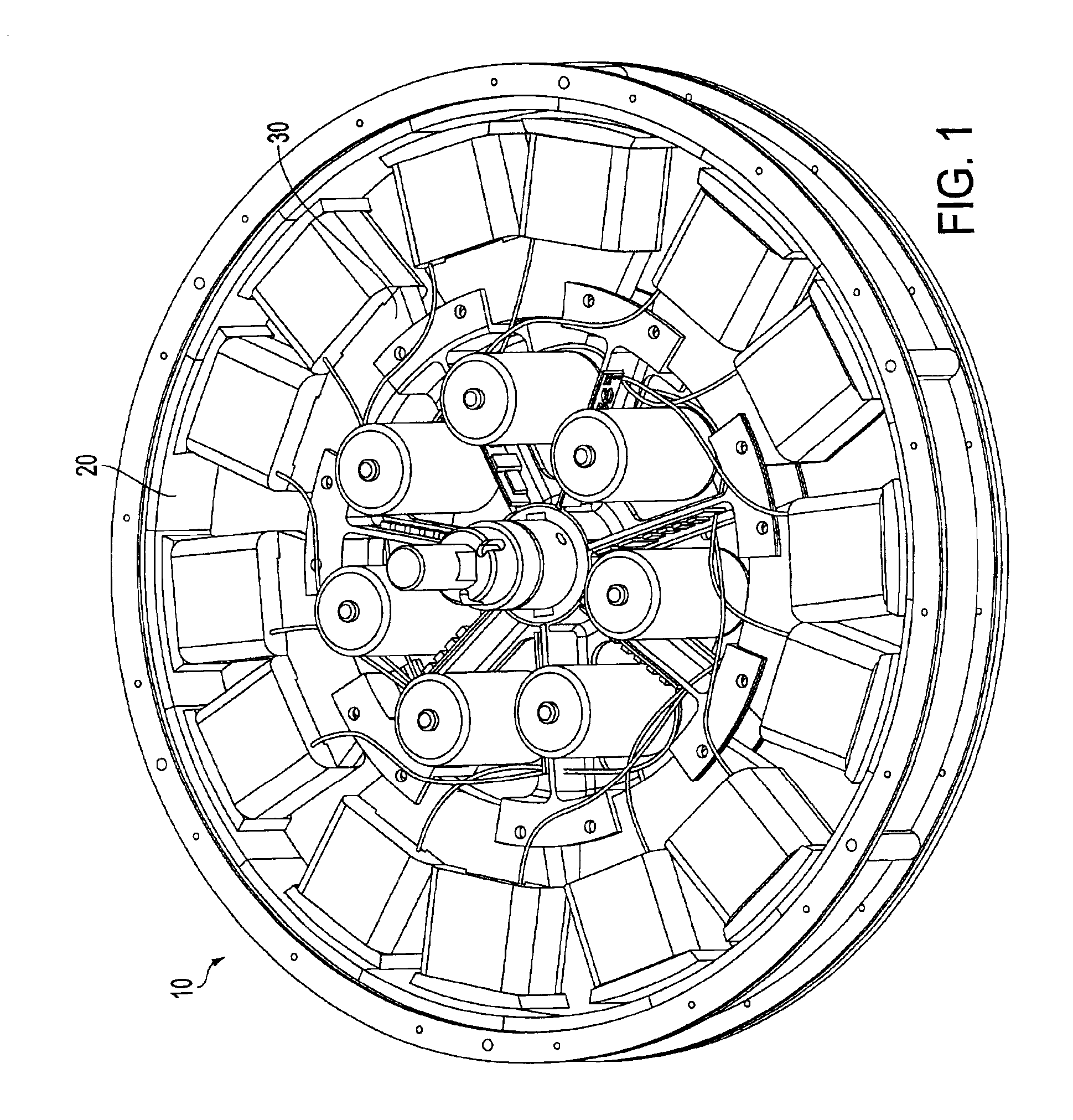

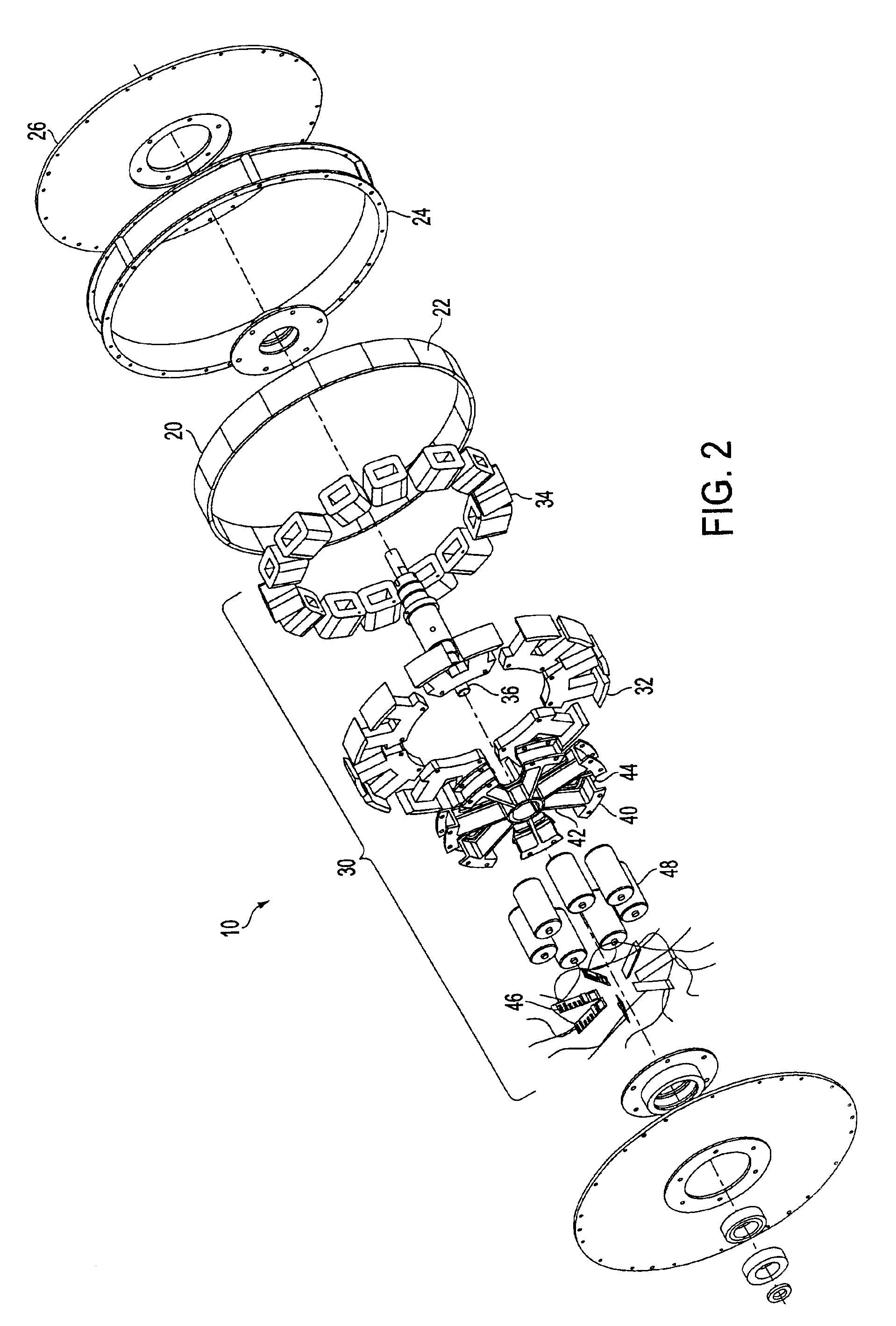

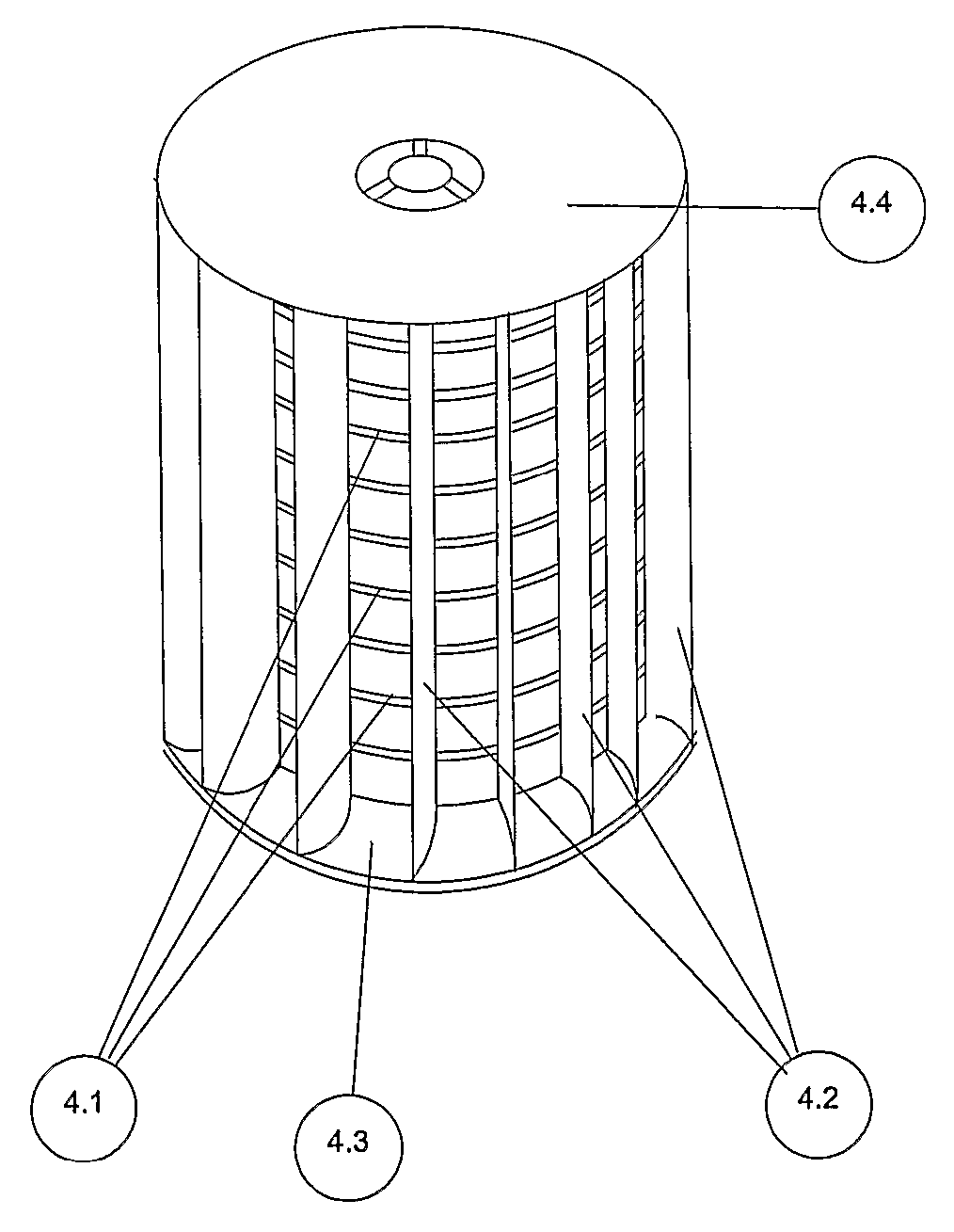

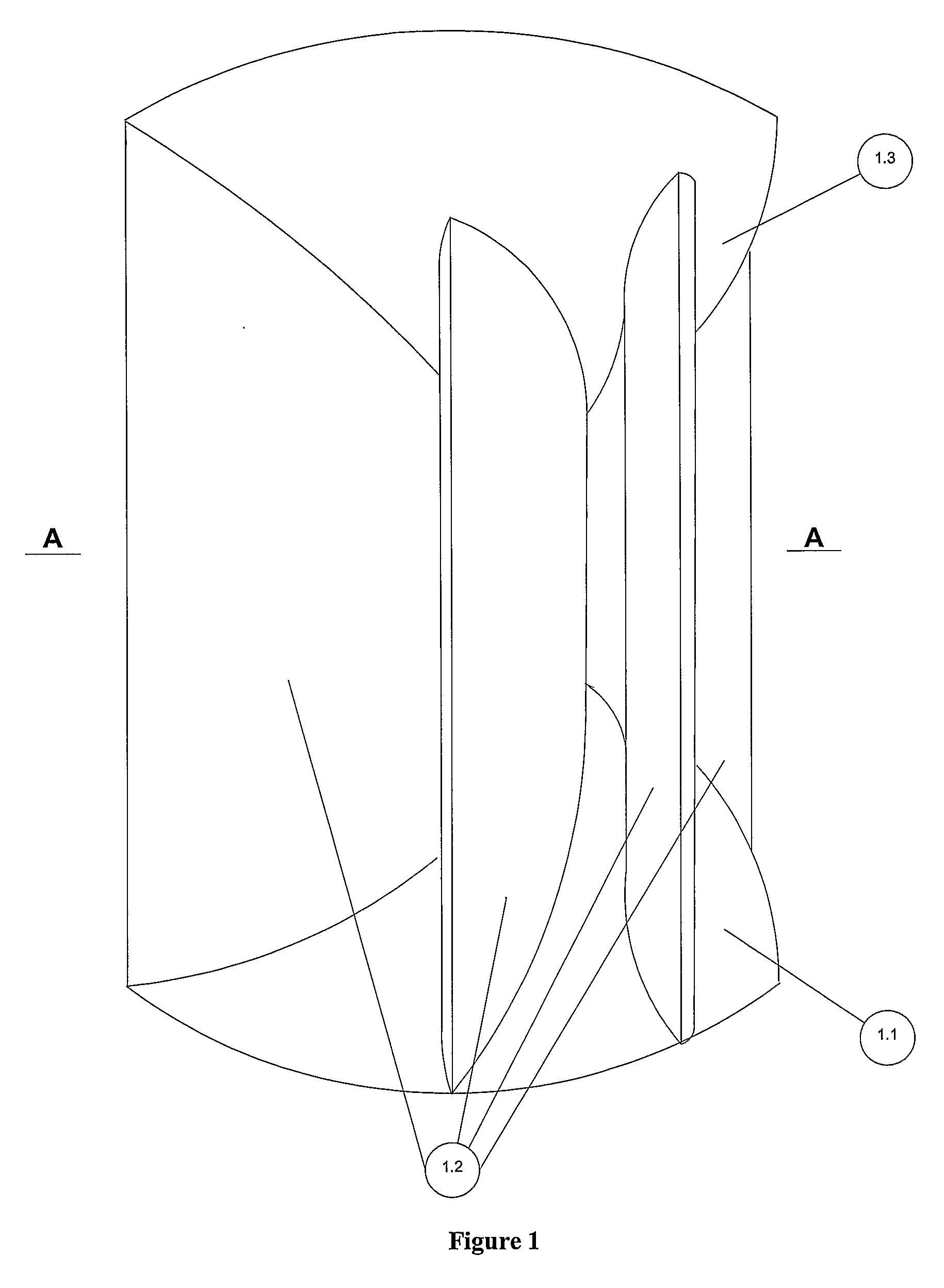

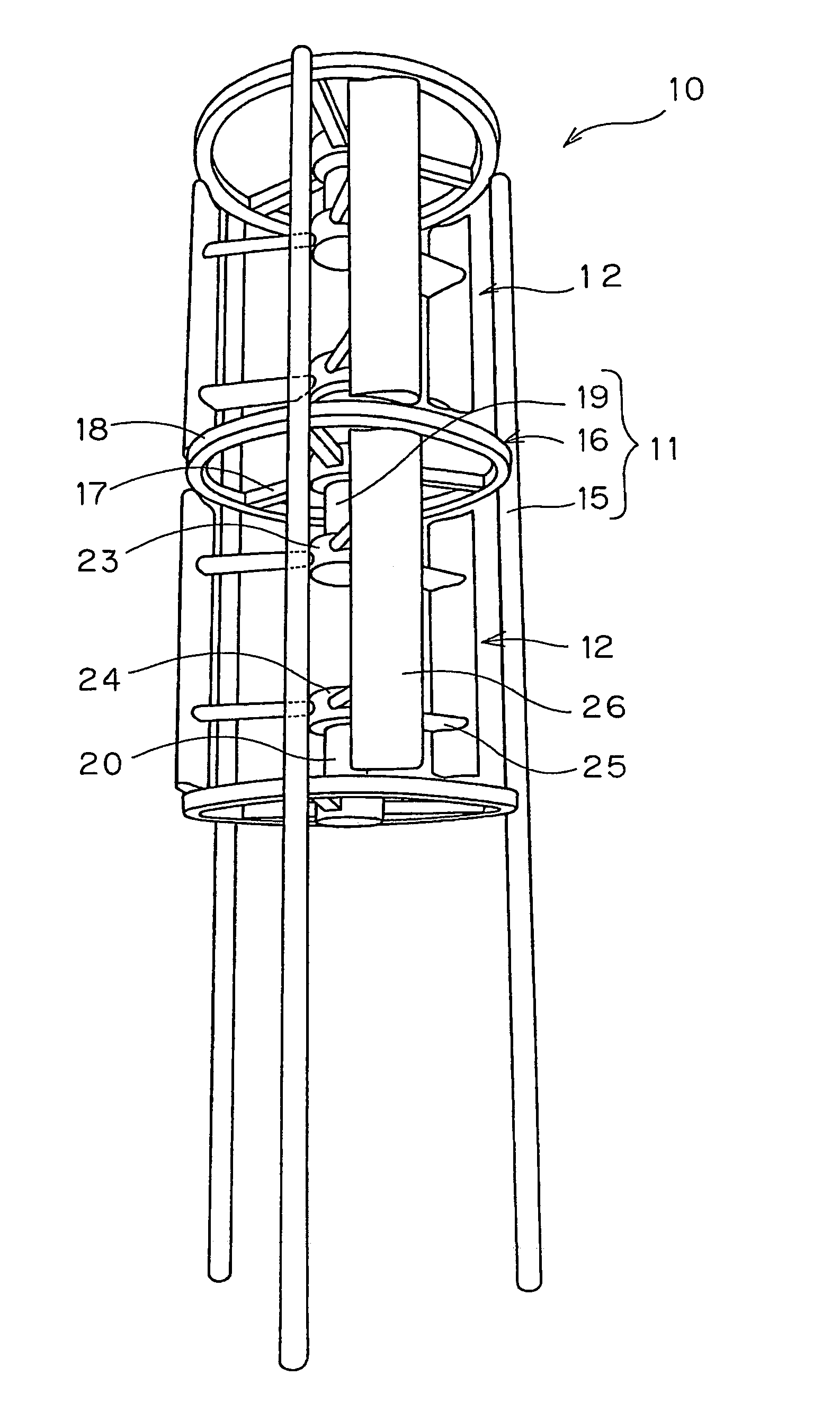

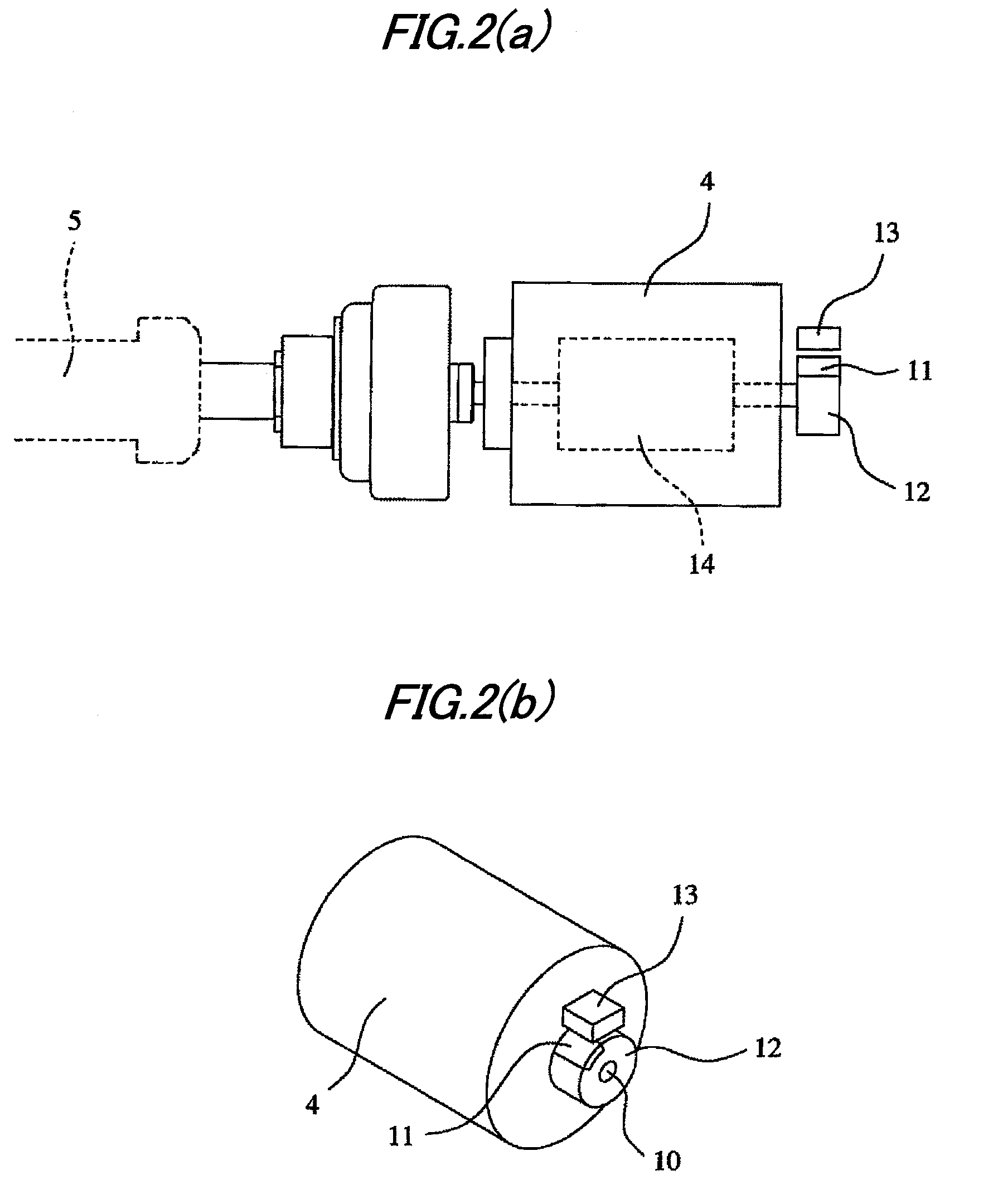

Rotary electric motor having separate control modules for respective stator electromagnets

InactiveUS6927524B2High torqueWide operating rangeAssociation with control/drive circuitsDC motor speed/torque controlElectrical controlDriven element

A rotary brushless electric motor is formed within a cylindrical rotor housing structure that surrounds an annular stator ring. The stator is formed of a plurality of individual power modules and corresponding core segments, each module including electrical control and drive elements supplied by a power source incorporated within the stator. Such parallel architecture provides relatively independently controlled functionality for each module. Each module and stator core segment can be individually installed and removed without disturbing the other units. Should a particular module or stator core segment fail, it can be easily removed for repair or replacement and reinstallation.

Owner:MATRA MFG & SERVICES

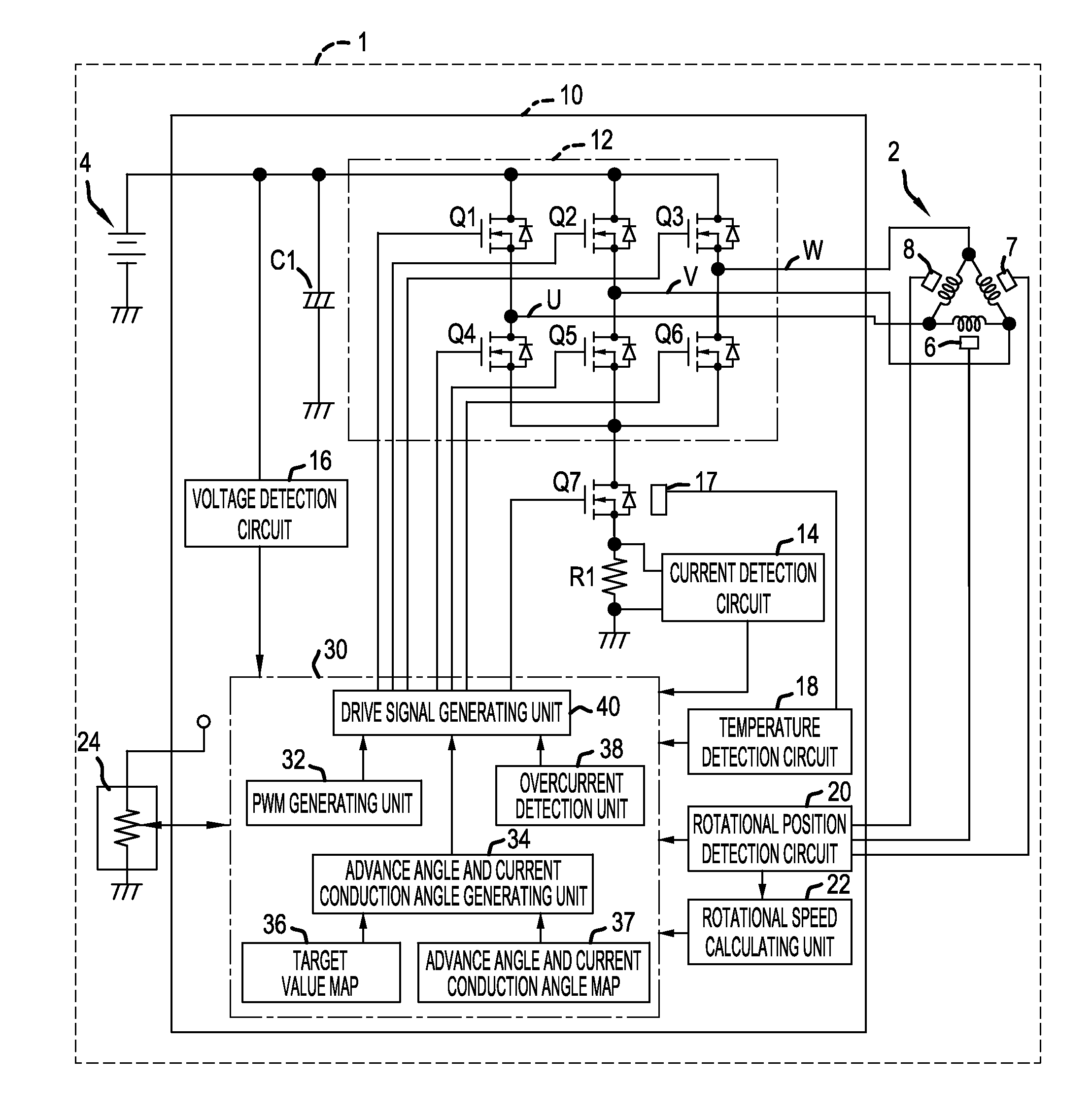

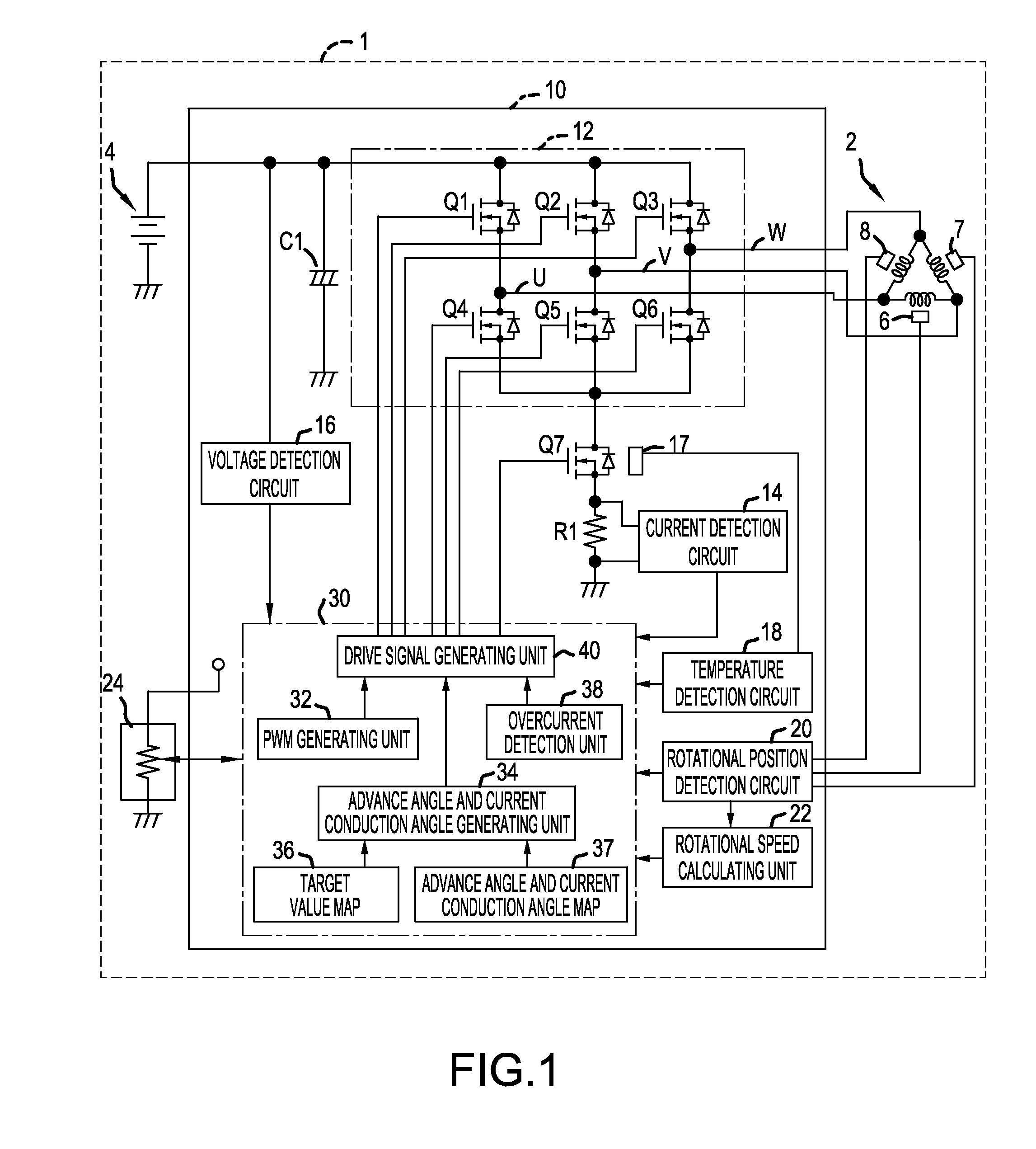

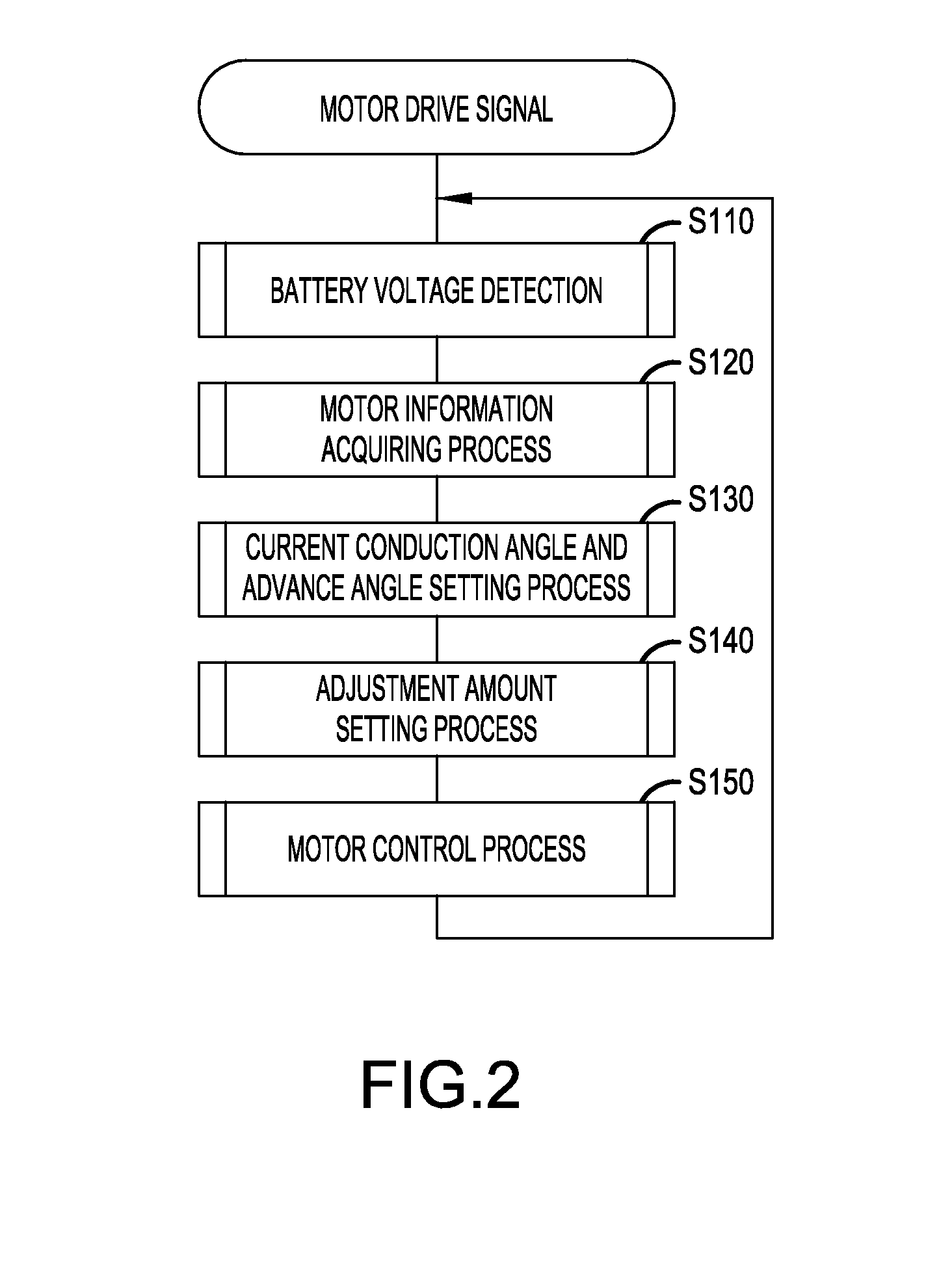

Power tool having a brushless motor and a control unit for controlling the brushless motor

ActiveUS20140210379A1Reducing and preventing variationReduce speedSingle motor speed/torque controlDynamo-electric converter controlBrushless motorsLocation detection

A power tool according to one aspect of one embodiment described in the disclosure includes a brushless motor, a battery voltage detection unit configured to detect a voltage of a battery that provides energy for driving the brushless motor, a rotational position detection unit configured to detect a rotational position of the brushless motor, and a control unit configured to control a drive output supplied to the brushless motor based at least in part on a signal from the rotational position detection unit. The control unit controls a current conduction angle and / or an advance angle supplied to the brushless motor so that, during control of the drive output to the brushless motor, a rotational speed or a conducting current of the brushless motor approaches or reaches a target value, the target value being based at least in part on a battery voltage detected by the battery voltage detection unit.

Owner:MAKITA CORP

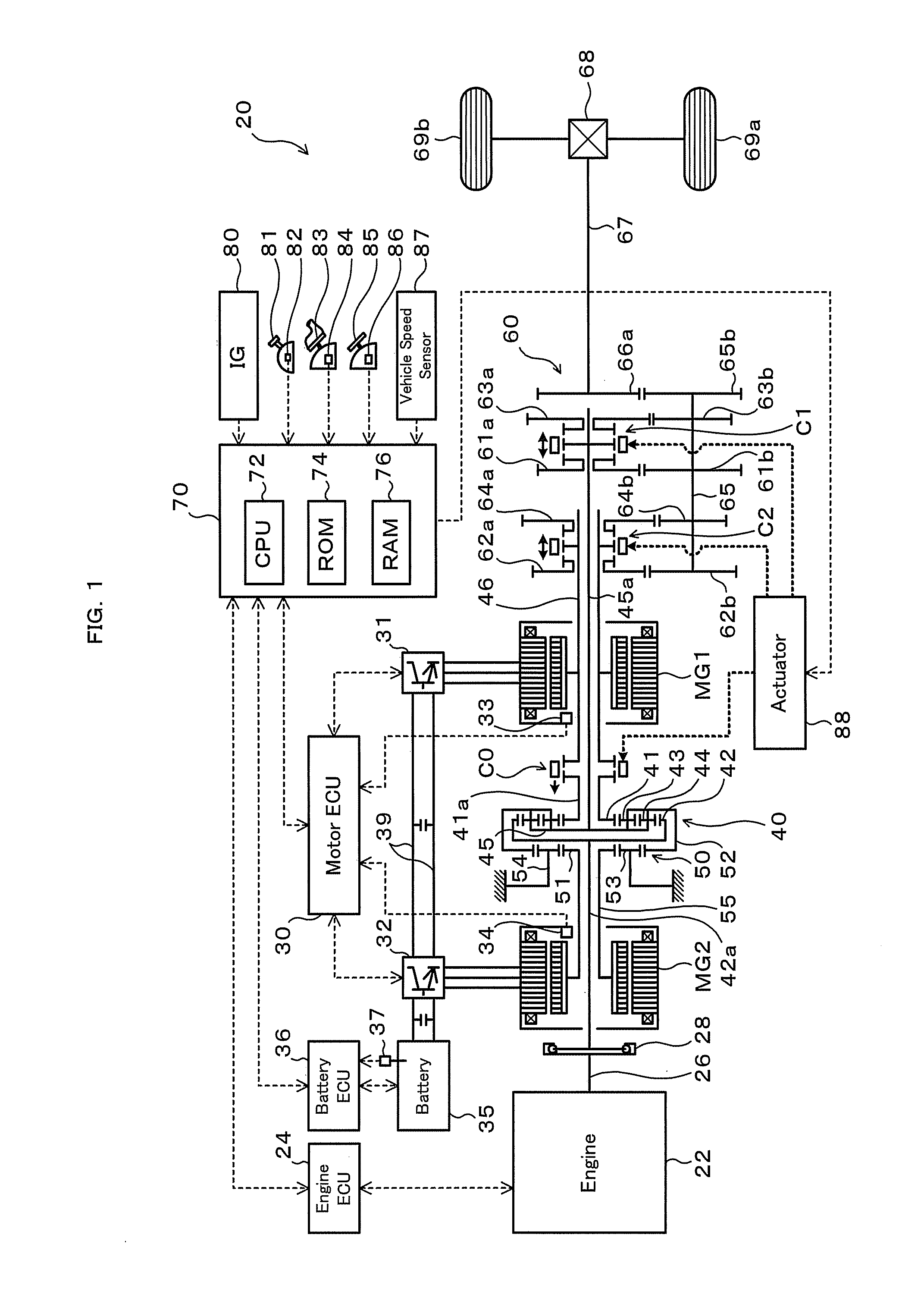

Power output apparatus, vehicle equipped with power output apparatus, and control method of power output apparatus

InactiveUS20100051361A1High torqueAvoid overall overheatingHybrid vehiclesSpeed controllerMotor driveHybrid vehicle

In a 2-motor drive mode with connection of both motors with a driveshaft by means of a transmission, a hybrid vehicle sets torque commands of the motors to substantially equalize an output torque of the second motor with an output torque of the first motor and to ensure output of a torque equivalent to a preset torque demand to the driveshaft. This arrangement ensures continuous output of a relatively large torque.

Owner:TOYOTA JIDOSHA KK

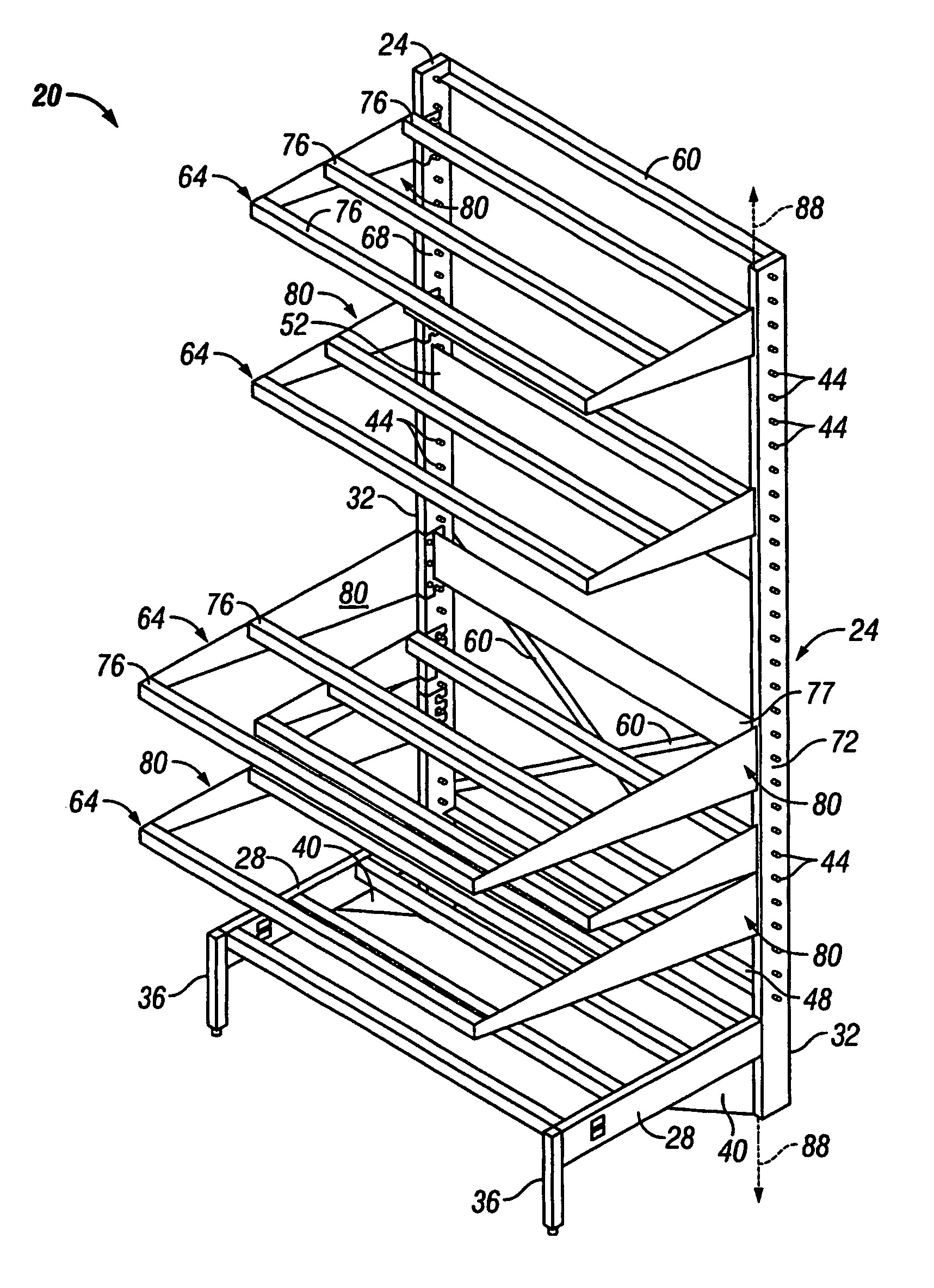

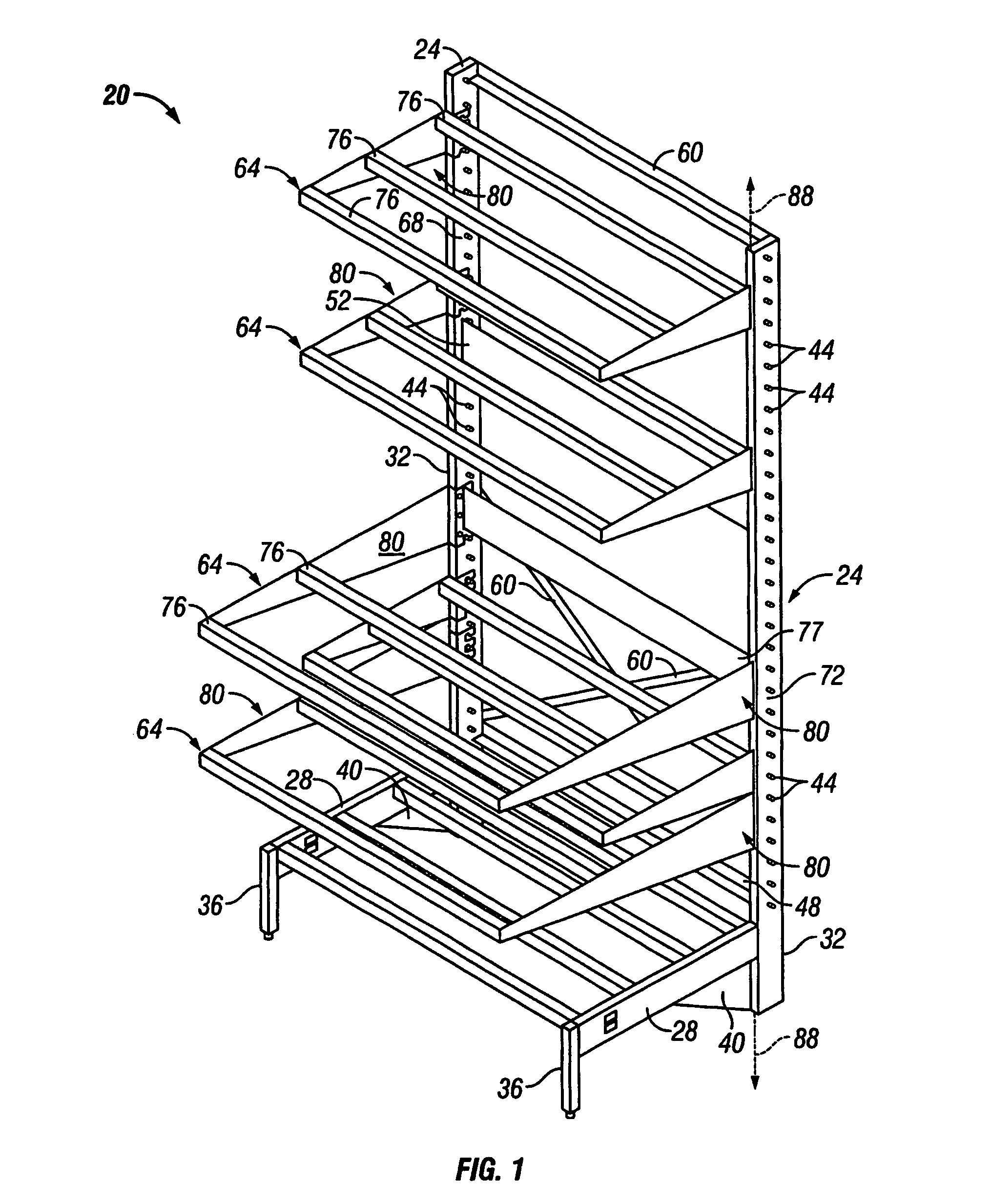

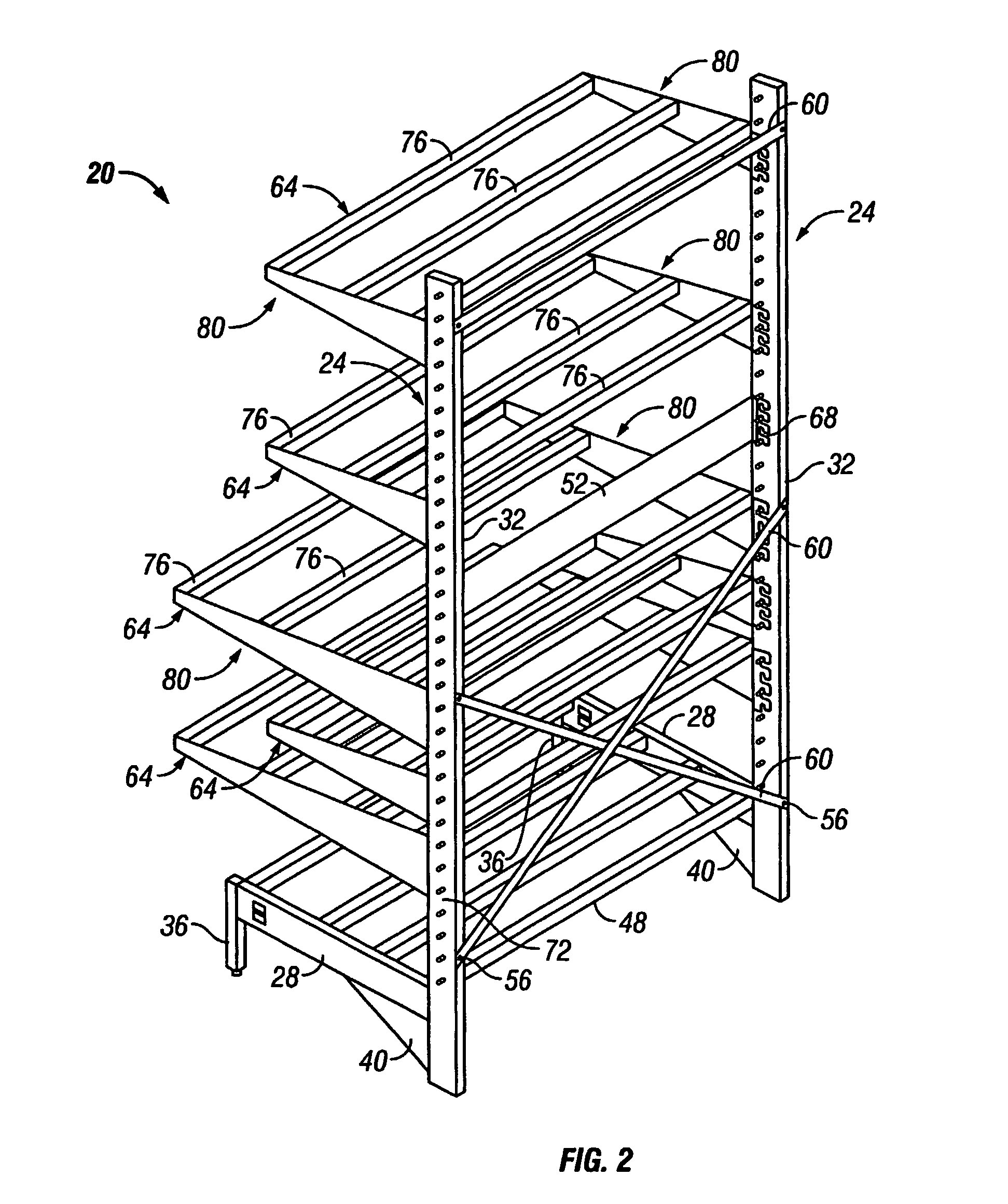

Modular cantilevered shelving assembly and method

InactiveUS7494019B2Easy to cleanEasy and fast assemblyFurniture partsFolding cabinetsModularityMechanical engineering

Some embodiments of the present invention disclose a shelving system having one or more support posts with a plurality of shelf connectors connected to the side of the support post. The connectors can be rigidly secured to the posts and / or can extend through the post and have a portion protruding from both lateral sides of the post. One or more shelves can attach to one or more of the shelf connectors at a variety of heights and extend in a variety of directions with respect tot the support post. These shelves can have a plurality of fingers for connection with laterally-extending support pins mounted to the support posts. Some embodiments also employ shelf brackets having bearing surfaces to distribute load from the shelves tot the vertical support posts.

Owner:SPG INT

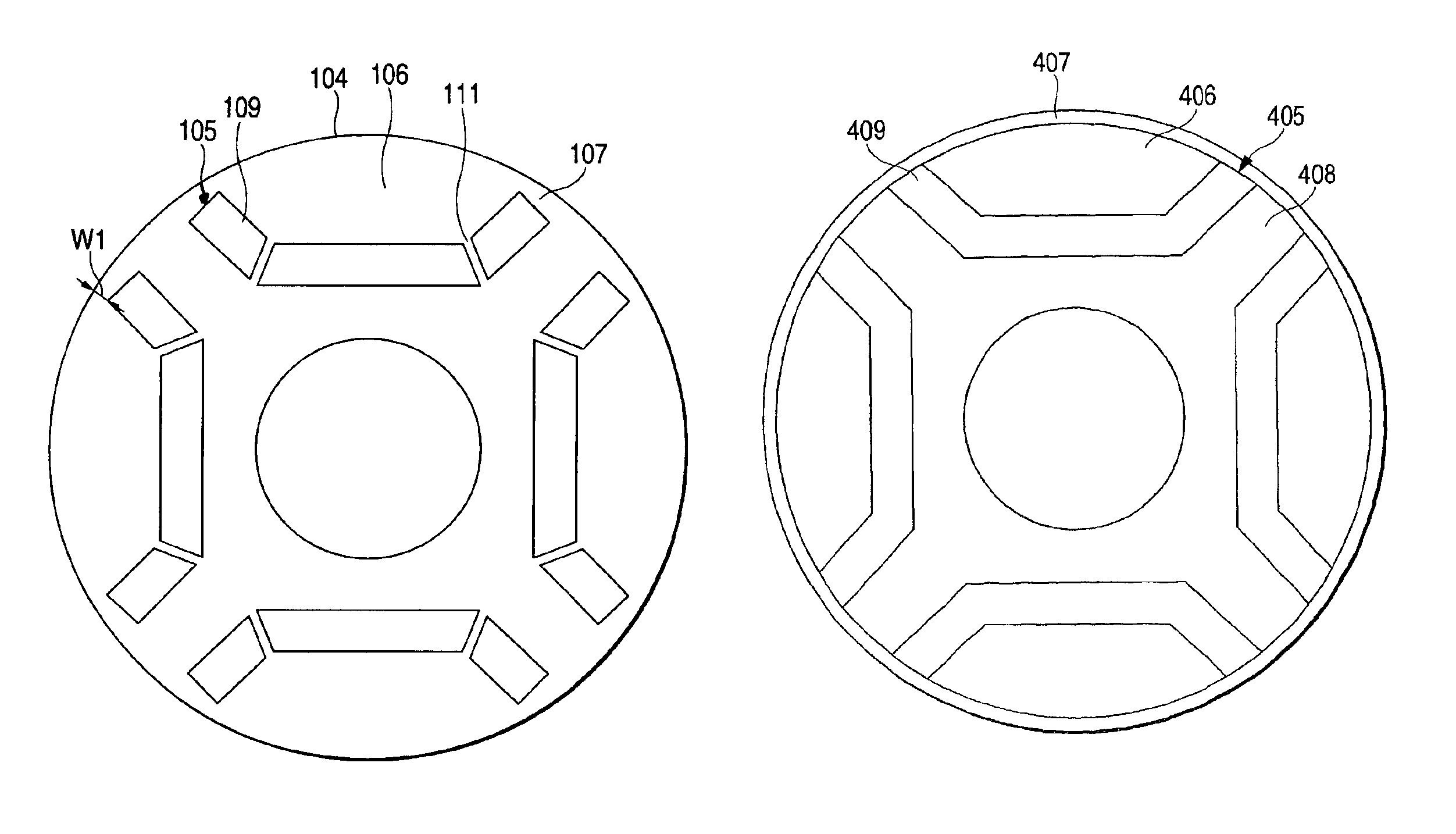

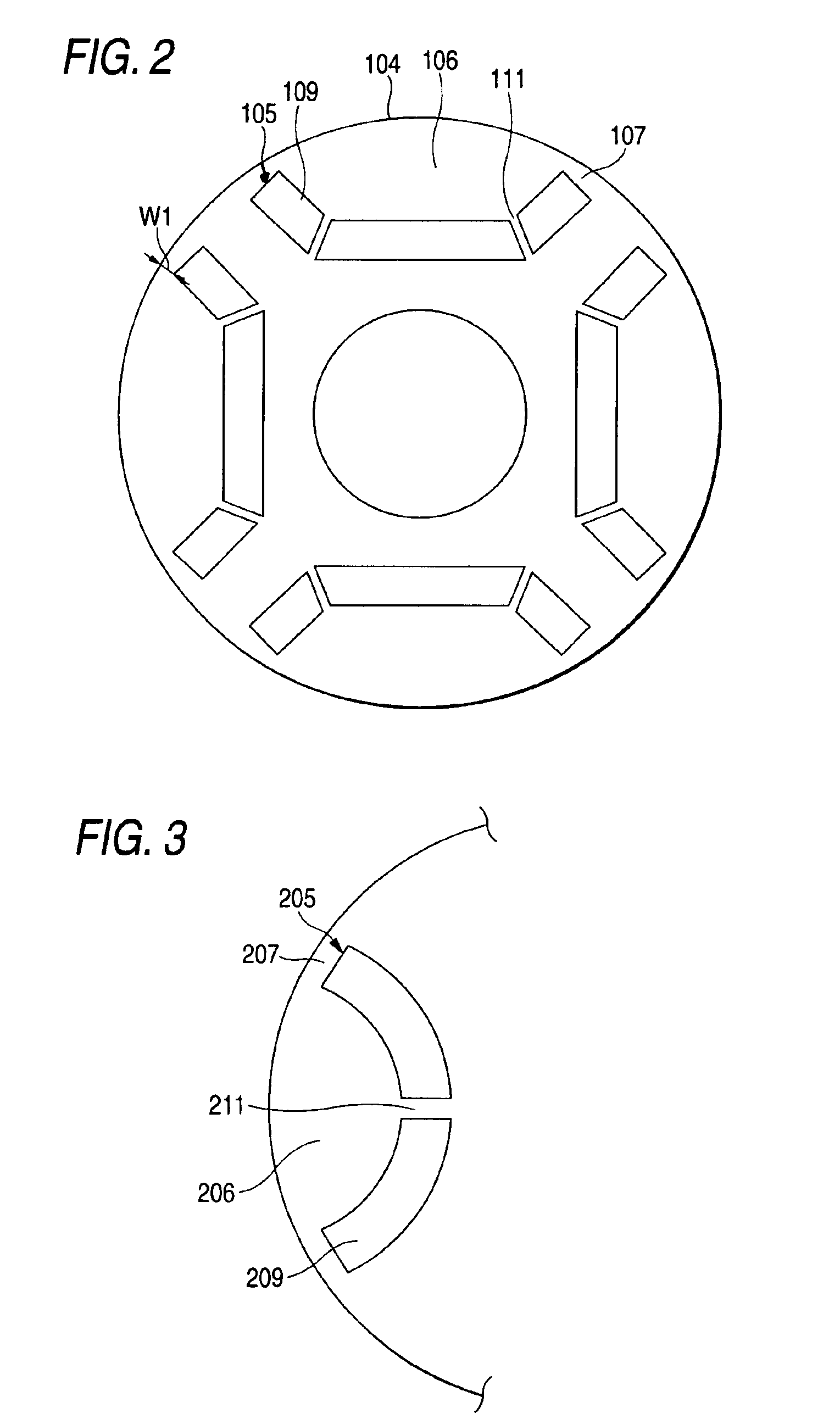

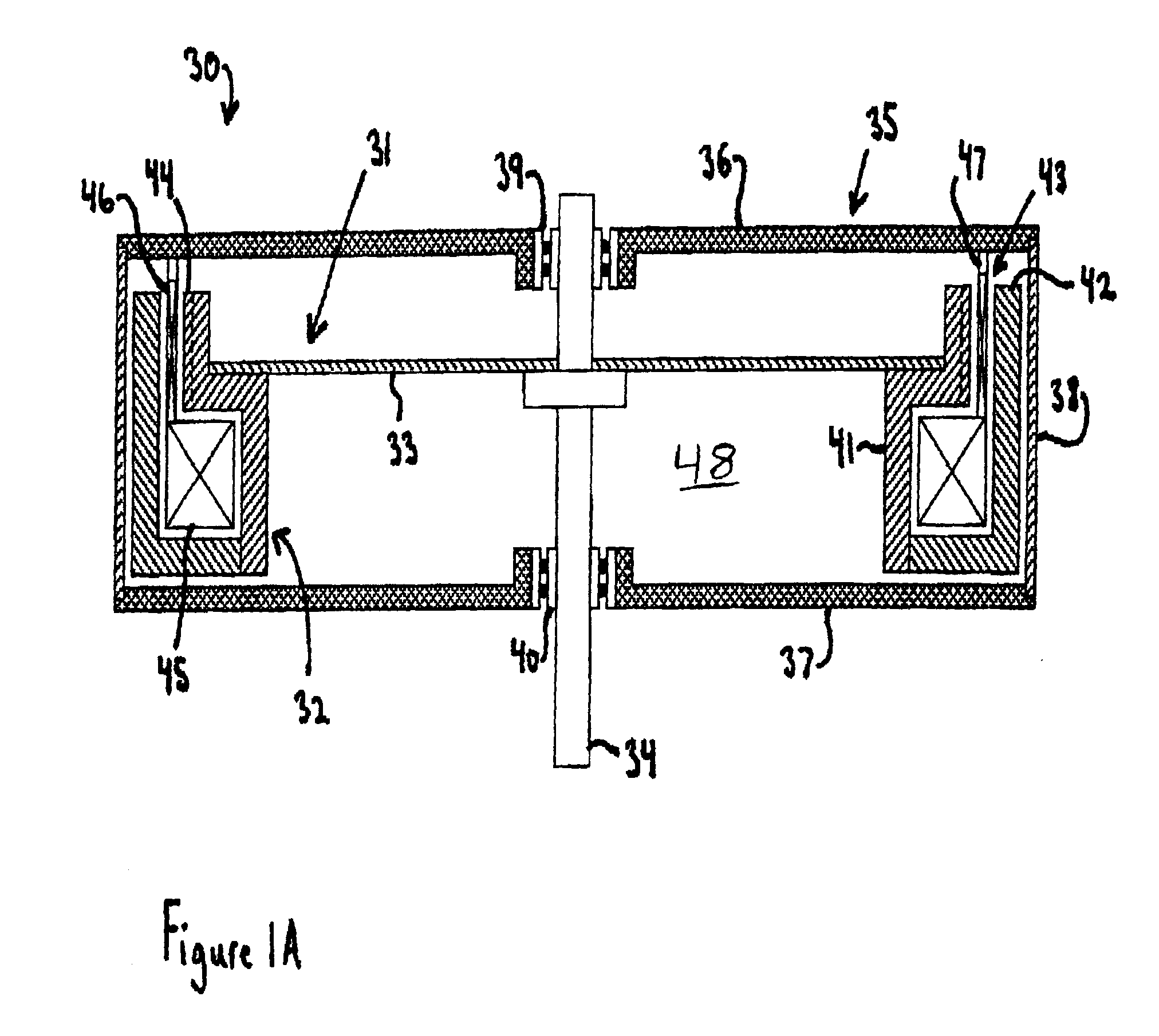

Permanent magnet motor

InactiveUS6906444B2Reduce leakage fluxReduce the applied forceMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPermanent magnet motorLettering

Each permanent magnet formed in an open-letter shape is divided into a plurality of parts, the divided magnets are respectively fitted in open letter-shaped inserting portions, and ribs are respectively provided in dividing portions of the permanent magnets. Accordingly, it is possible to prevent the breakage of pole connecting portions at an outermost periphery of the rotor as adjacent inner peripheral-side permanent magnets directly come into contact with and push the outer peripheral-side permanent magnets. Alternatively, an annular nonmagnetic material is provided on an outer peripheral portion of the rotor so as to cover the open letter-shaped permanent magnets and magnetic material portions inside the open-letter portions, whereby the rotor core is made resistant against breakage, and the flux leakage is minimized.

Owner:TEIJIN SEIKI CO LTD

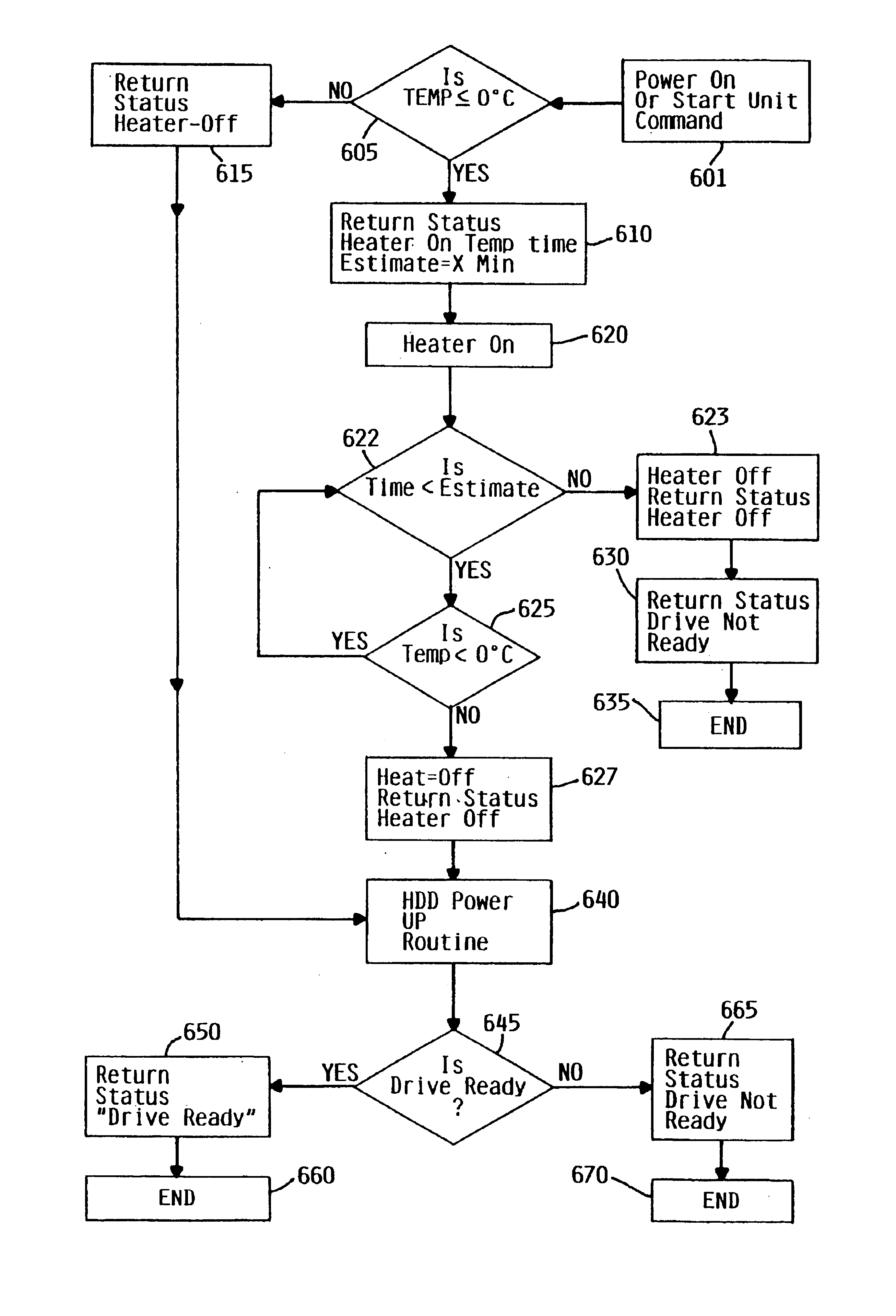

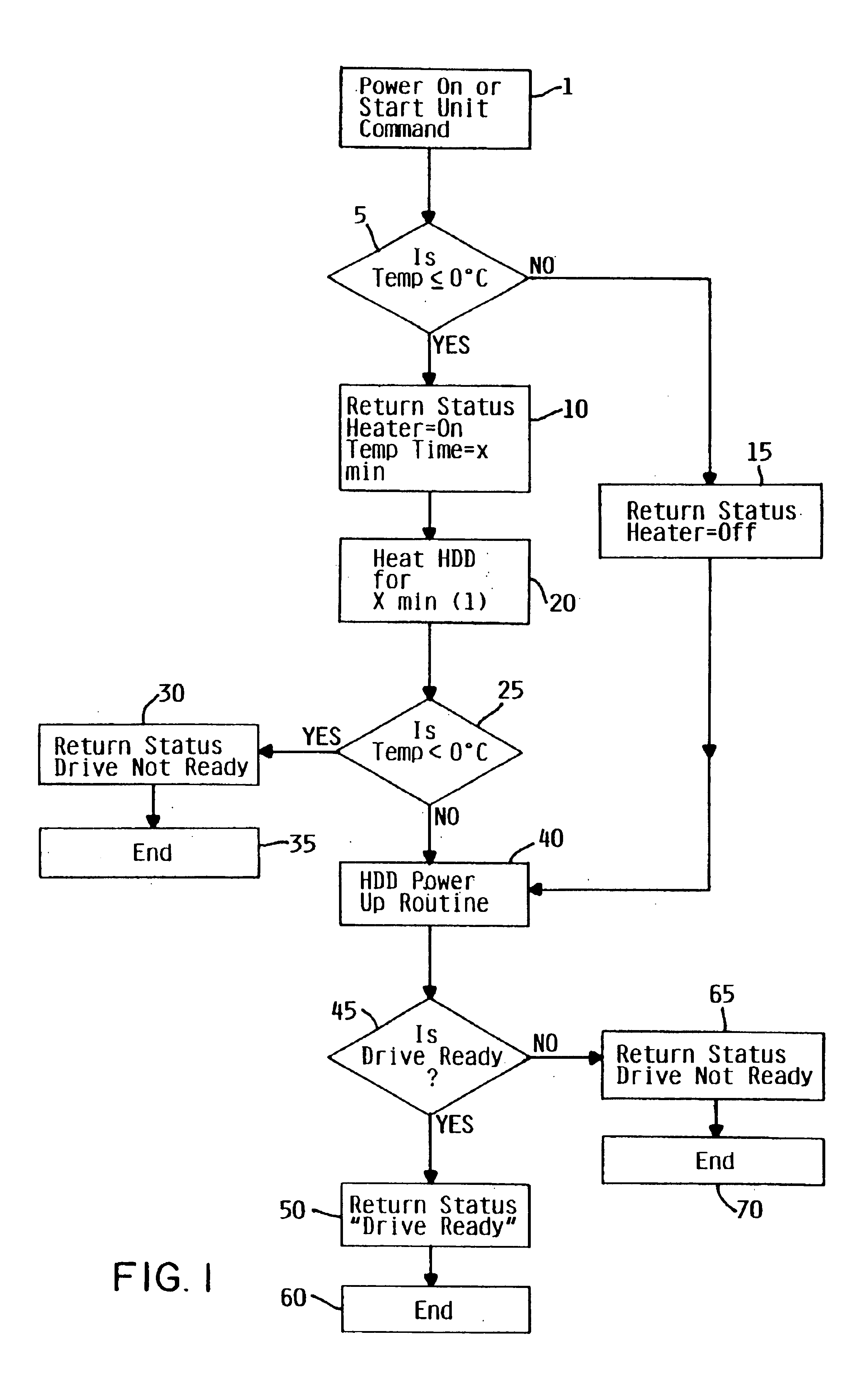

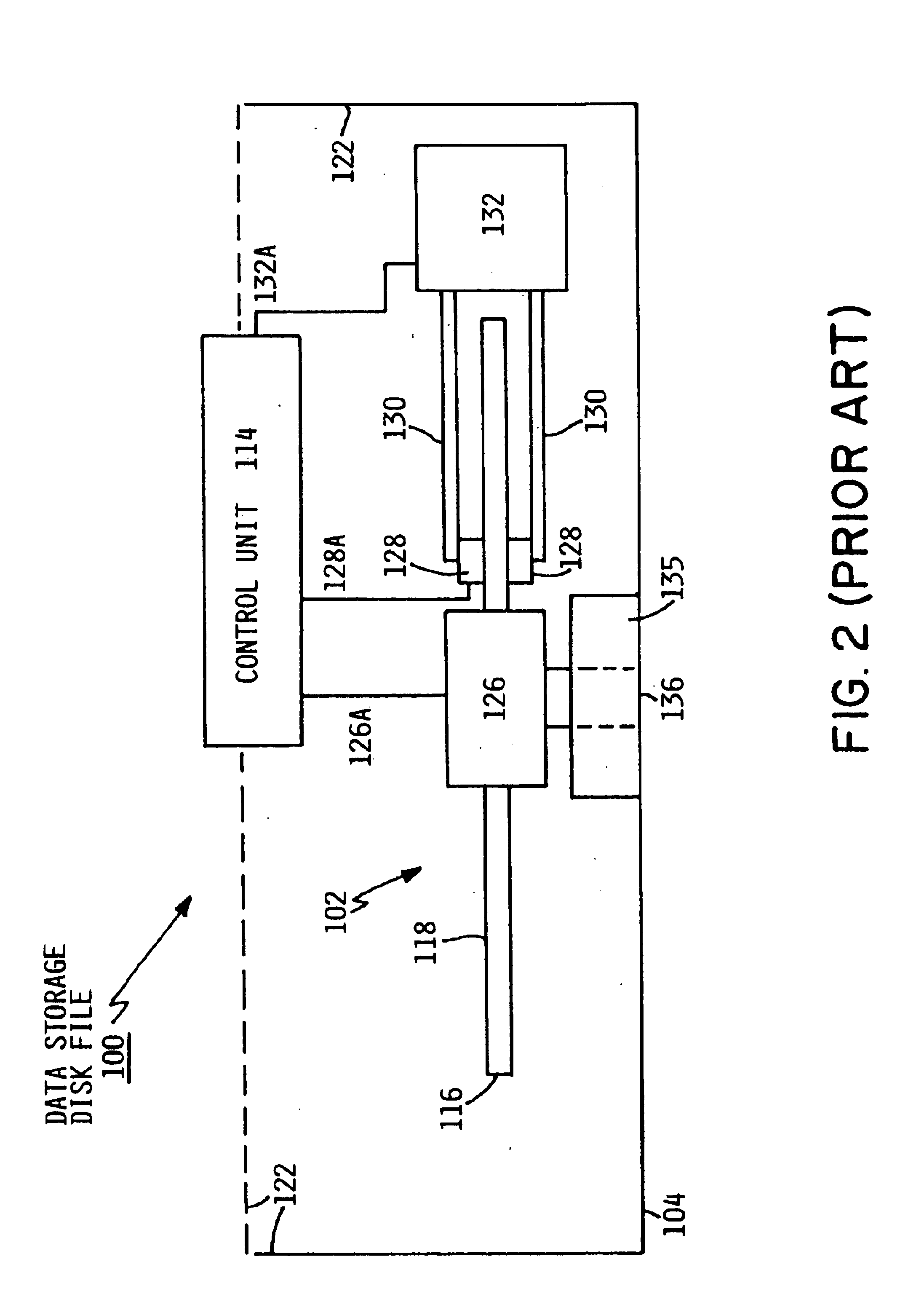

Method and apparatus for enabling cold temperature performance of a disk

InactiveUS6735035B1High torqueHigh viscosityCommutation monitoringApparatus for flat record carriersDirect-access storage deviceEngineering

In cold weather, the higher torque required for normal spinning operation of a spindle motor assembly in a direct access storage device due to the increased viscosity of the grease, is overcome by localizing the heating to the spindle motor assembly to reduce the viscosity of the grease, and then let a disk driven self heat during and after spin-up of the spindle motor assembly.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

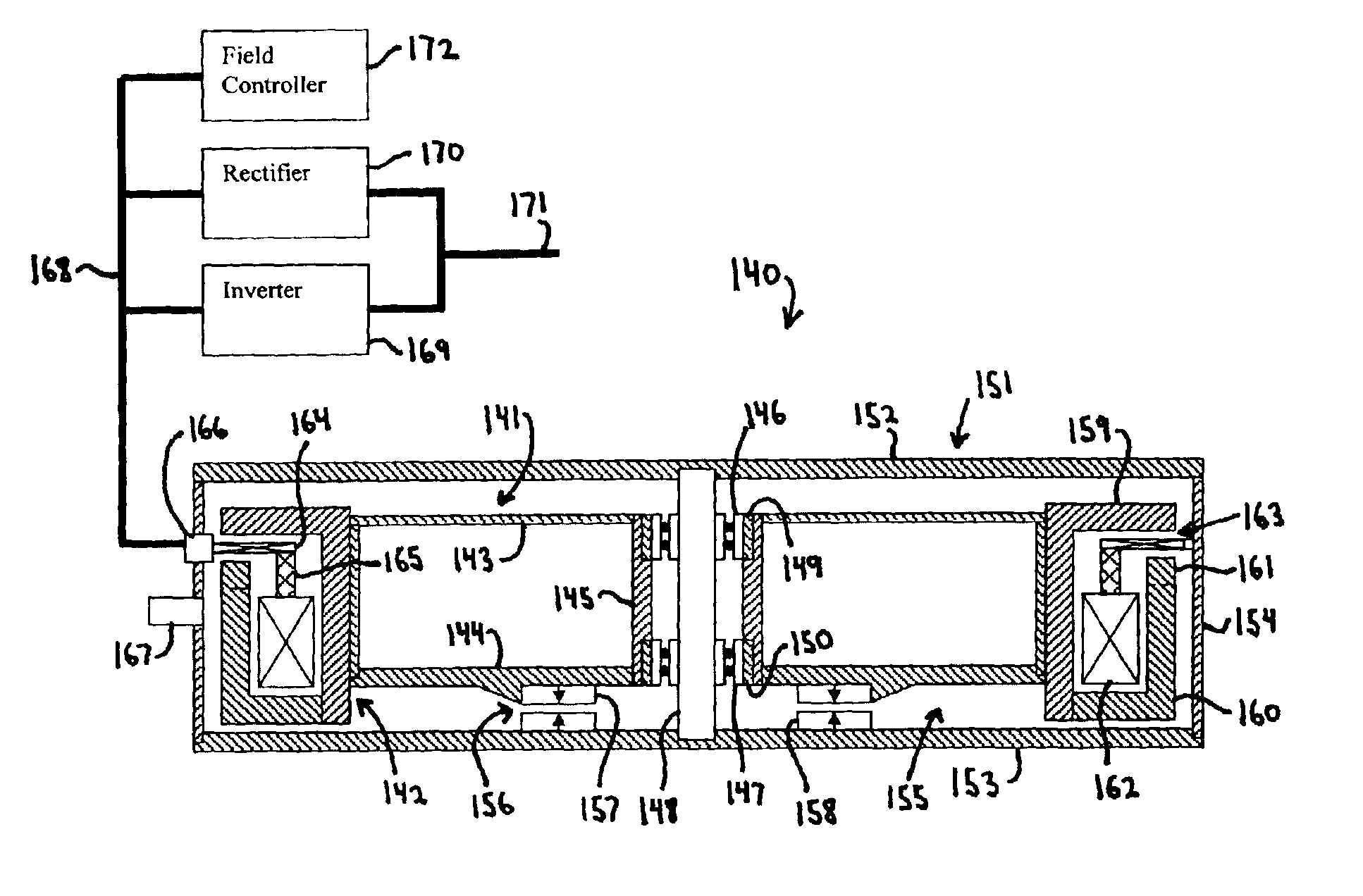

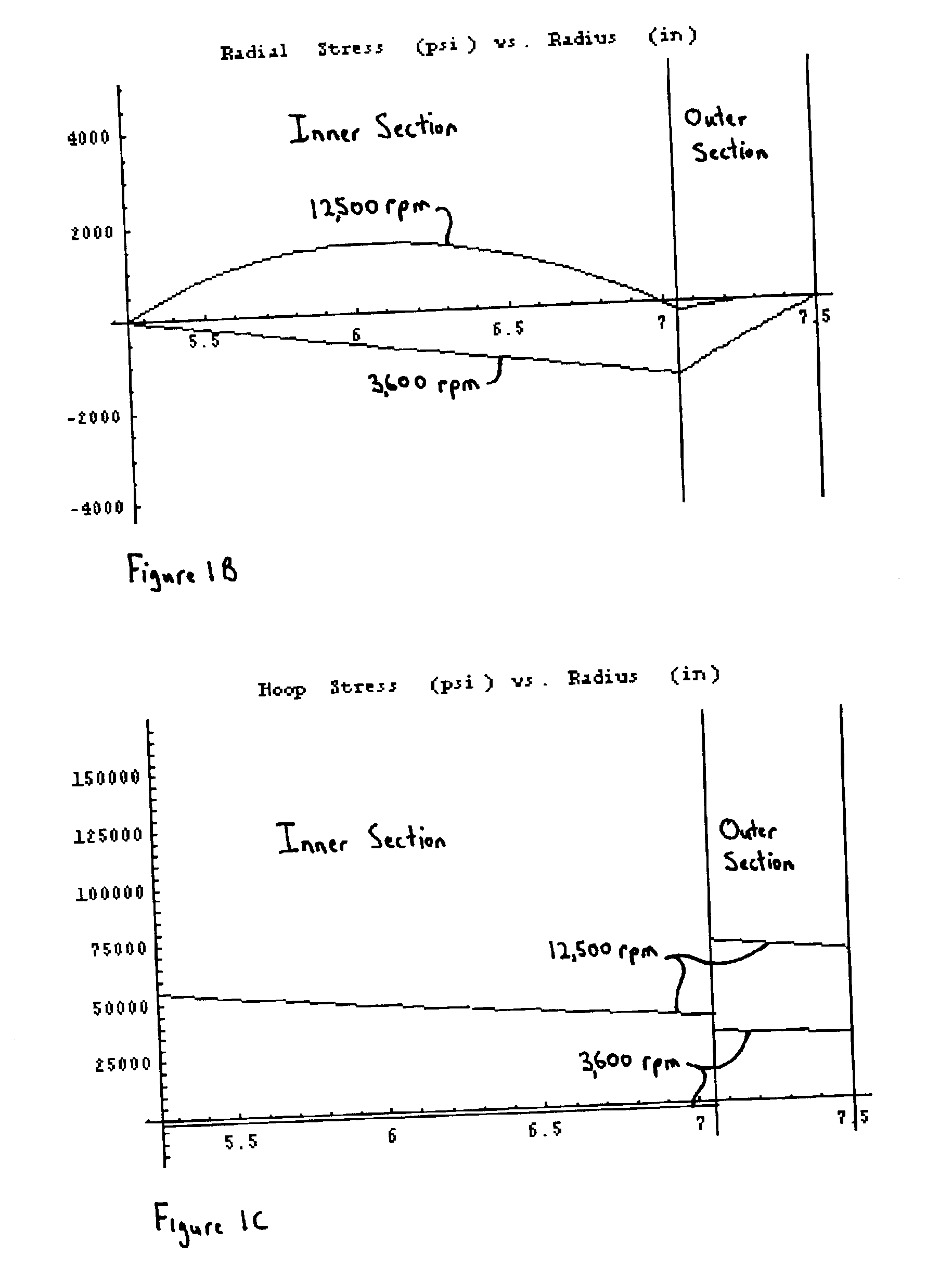

Light-weight high-power electrical machine

InactiveUS6891302B1High energyMotor/generator magnetic lossHybrid vehiclesWindingsAlternatorElectrical polarity

A brushless electrical machine, usable as a motor, generator, or alternator, has a rotor that is comprised of a rim portion and a substantially open center portion. The rim portion has a partially hollow core in which a stationary field coil is supported. Current to the field coil generates magnetic flux that circulates in a poloidal flux path in the rim, crossing a single magnetic air gap formed by the rim. Protrusions in the rim located around the circumference form poles all having the same polarity. As the rotor rotates, the flux exiting the poles passes through multiple stationary armature windings around the circumference that are located in the single air gap. An AC voltage is induced in the armature windings from rotation.

Owner:REVOLUTION ELECTRIC MOTOR

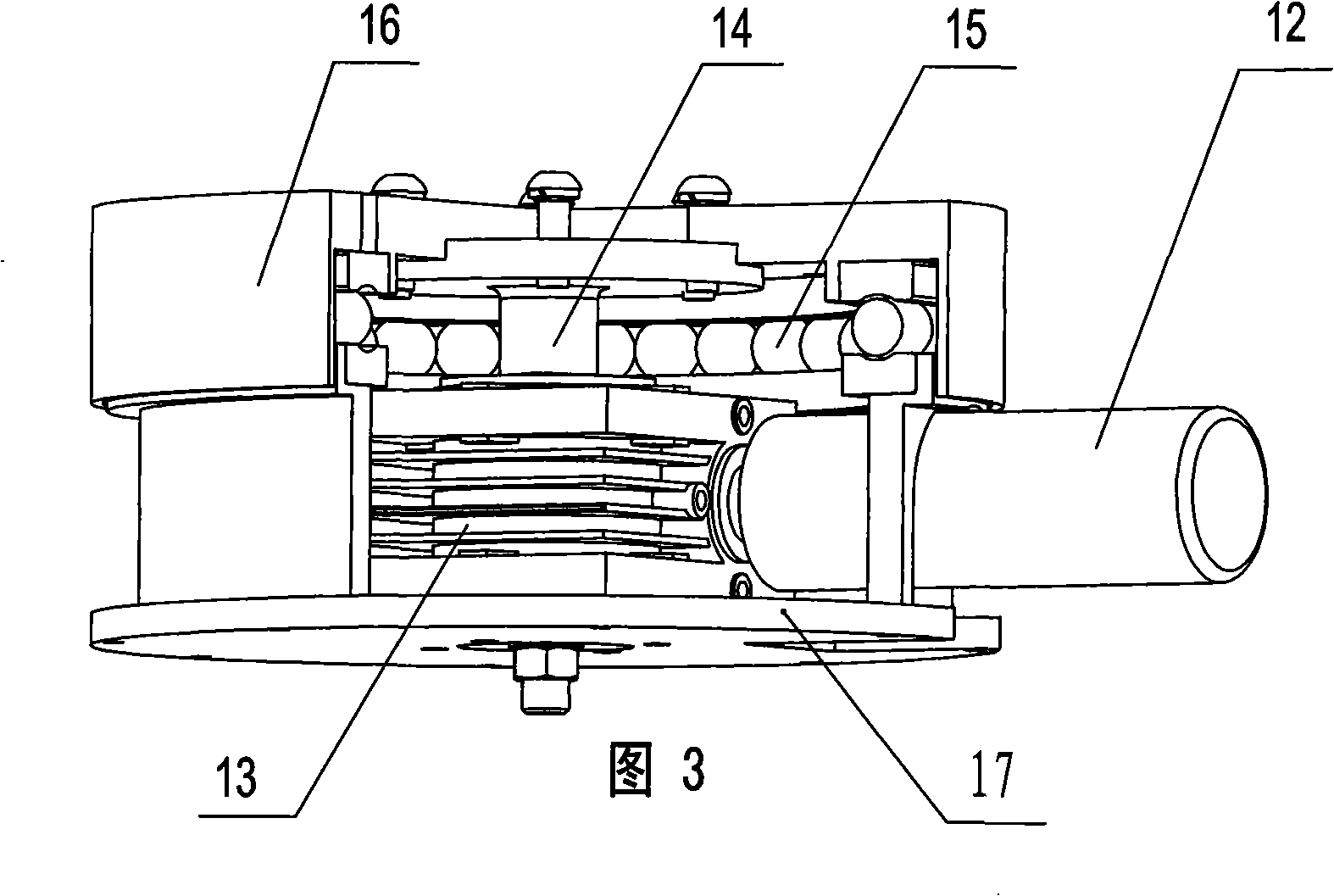

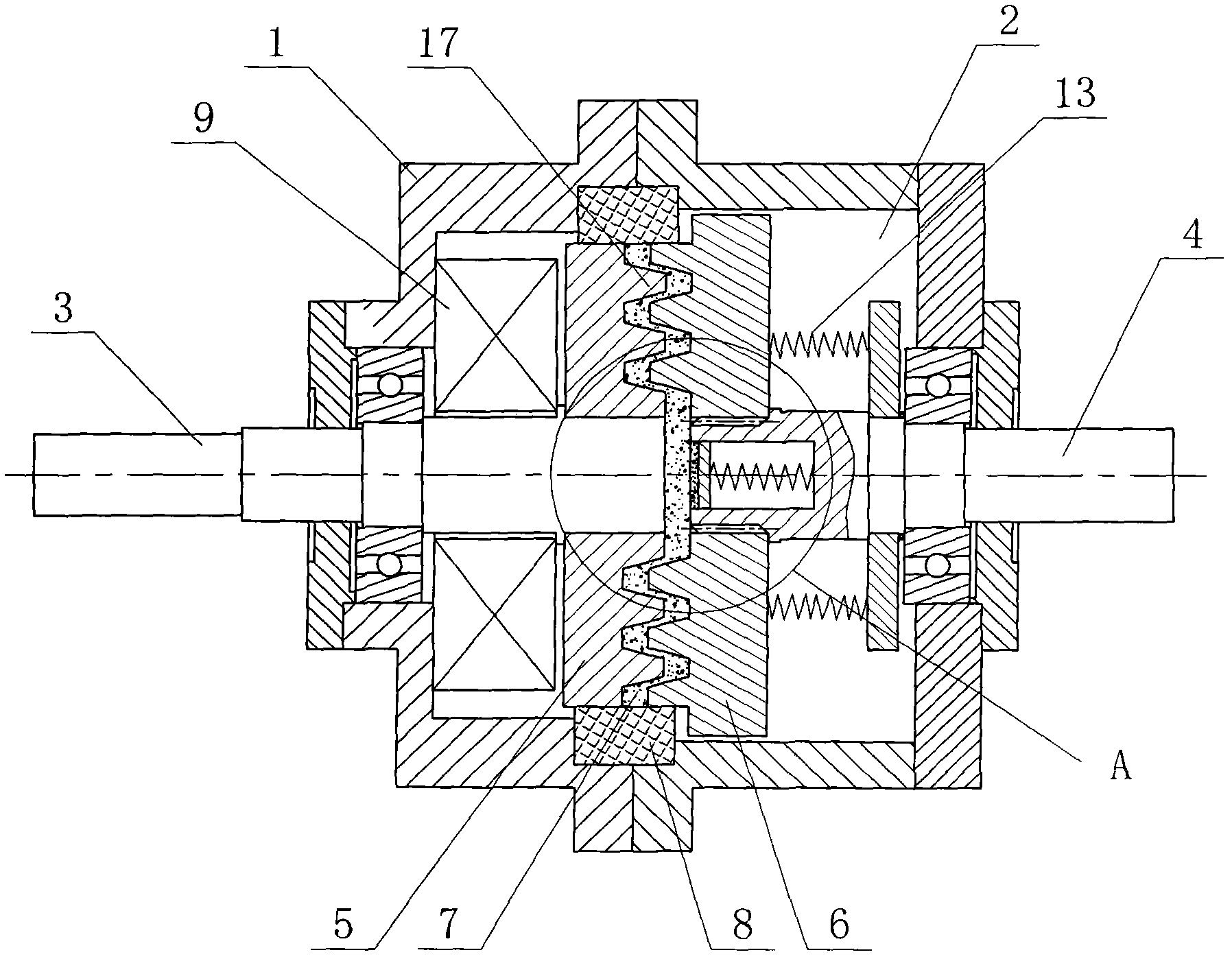

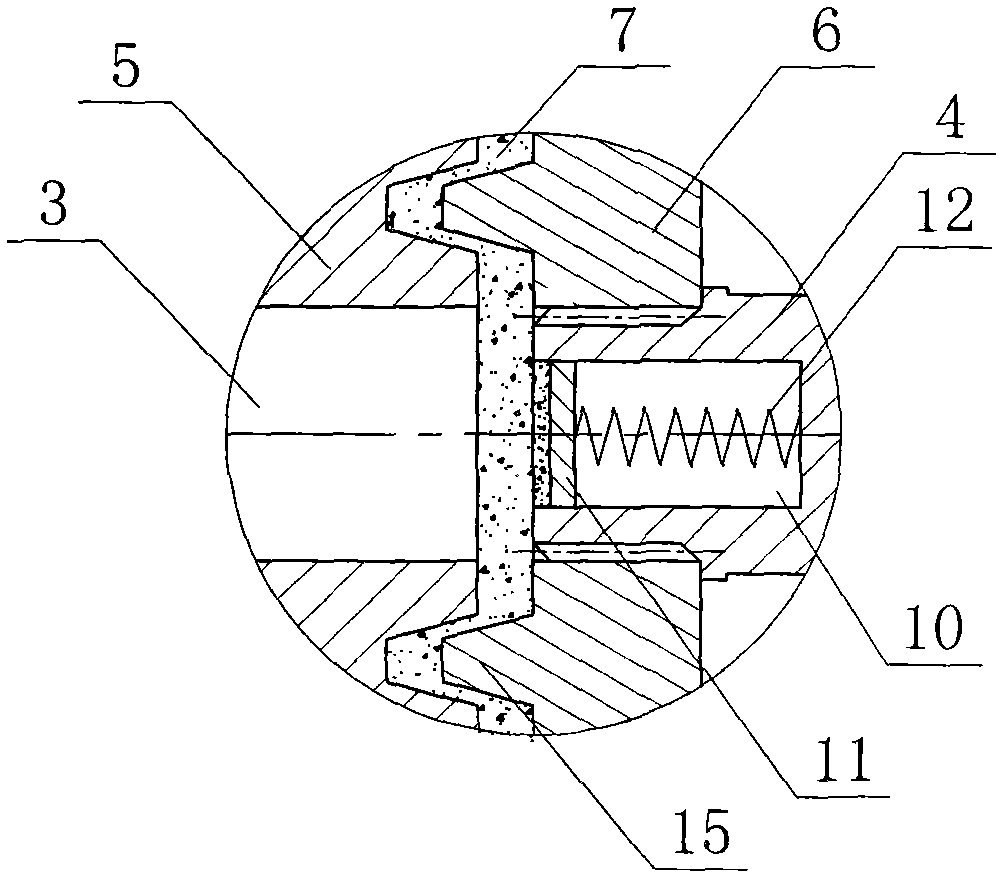

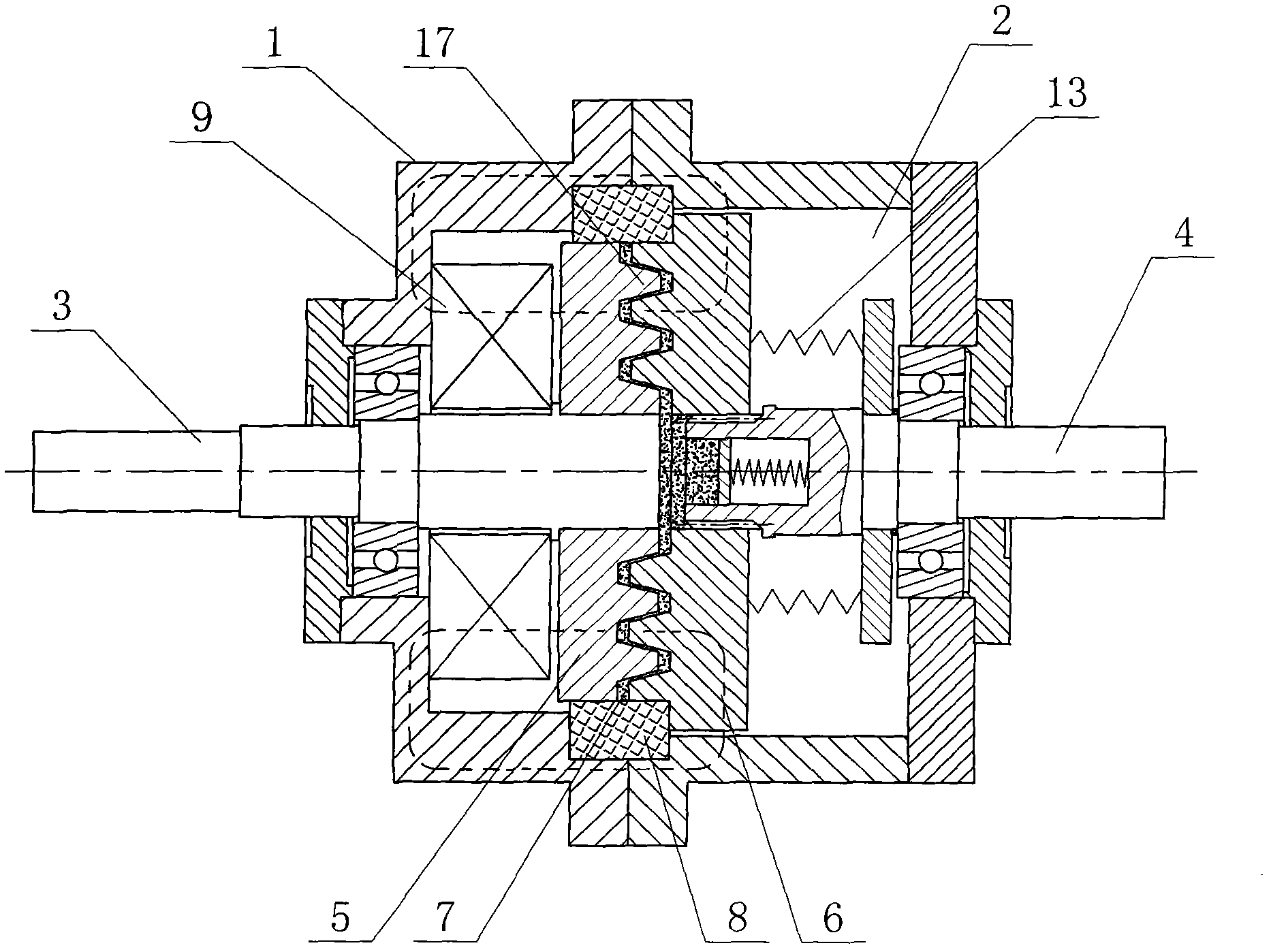

Conical extrusion-shearing type magnetorheological clutch

The invention discloses a conical extrusion-shearing type magnetorheological clutch. An iron core input disc is fixed at a front end of an input shaft and an armature output disc sliding axially is arranged at a front end of an output shaft, or the armature output disc sliding axially is arranged at the front end of the input shaft and the iron core output disc is fixed at the front end of the output shaft; a containing cavity is formed between the iron core input disc and the armature output disc; magnetorheological fluid is filled in the containing cavity; a sealing ring for sealing the magnetorheological fluid in the containing cavity is arranged on the periphery of the containing cavity; a coil for driving the armature output disc to move axially to the iron core input disc is further arranged in a working cavity; and an adjusting device for adjusting the volume of the containing cavity is further arranged between the iron core input disc and the armature output disc. The conical extrusion-shearing type magnetorheological clutch has the advantages that: when the clutch is in the working state, through attraction to the armature output disc by a magnetic field generated by the coil, the volume of the containing cavity is reduced, and meanwhile, an extrusion and shearing force is generated against the magnetorheological fluid, so as to transfer a greater torque; in addition, the conical extrusion-shearing type magnetorheological clutch is small in volume, reliable in performance, compact in structure, and good in effect.

Owner:ZHEJIANG NORMAL UNIVERSITY

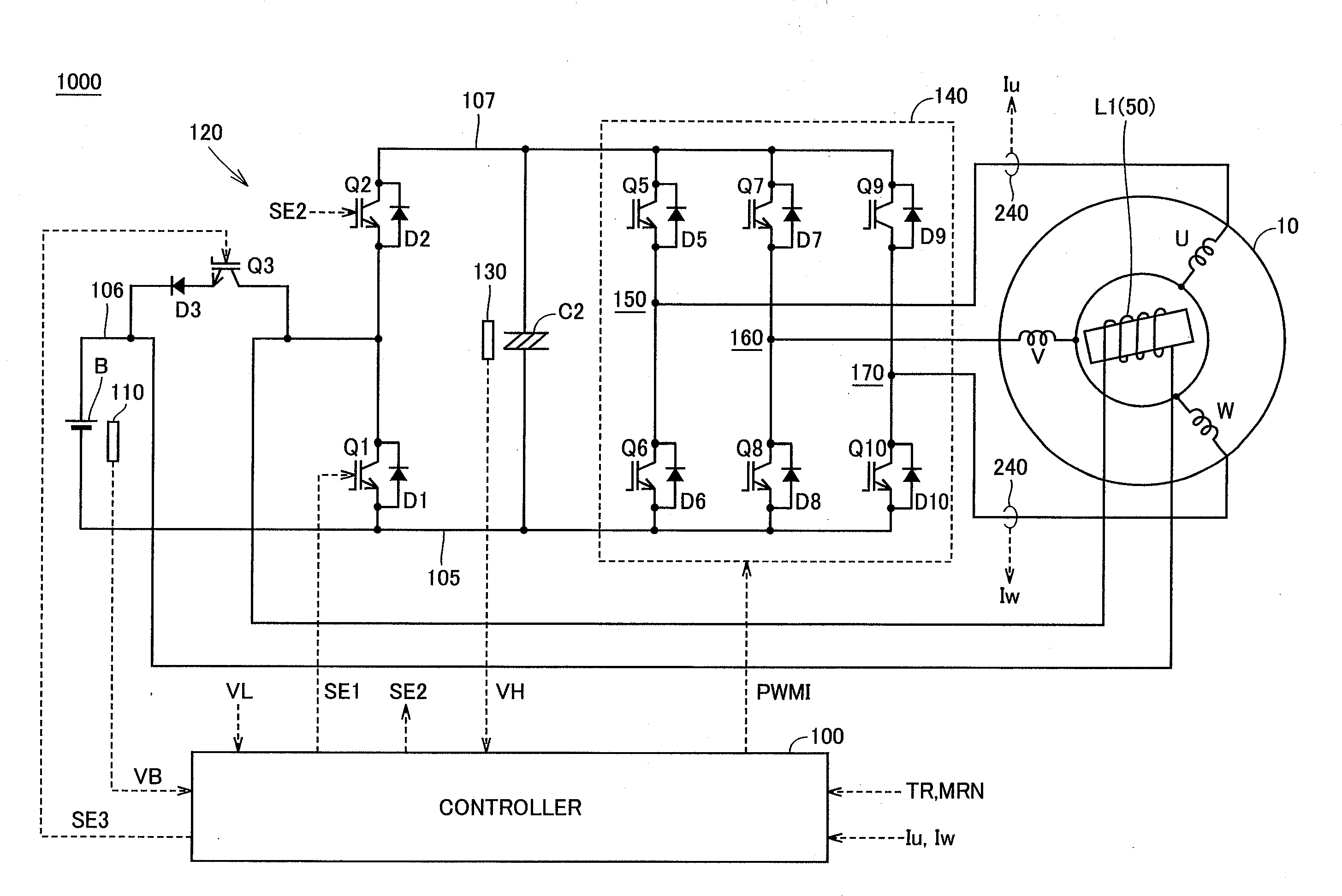

Drive device of electric motor

InactiveUS20100071971A1Reduce Flux LeakageSmall sizeSynchronous motors startersWindingsExcitation currentEngineering

An electric motor (10) has a field pole formed by a field current passing through a field winding (50). A voltage booting converter (120) converts output voltage of a battery (B) and outputs the voltage between a power source line (107) and a grounding line (105). Field winding (50) is electrically connected onto an electric current channel between battery (B) and power source line (107) and formed so that voltage switched by a switching element (Q1) is applied to both ends. A controller (100) controls the field current so as to adjust density of magnetic flux between a rotor and a stator by performing switching control on switching element (Q1) and a switching element (Q3) connected in parallel to field winding (50) and converts the output voltage of battery (B) into voltage in accordance with a voltage command value.

Owner:NAGOYA INSTITUTE OF TECHNOLOGY +1

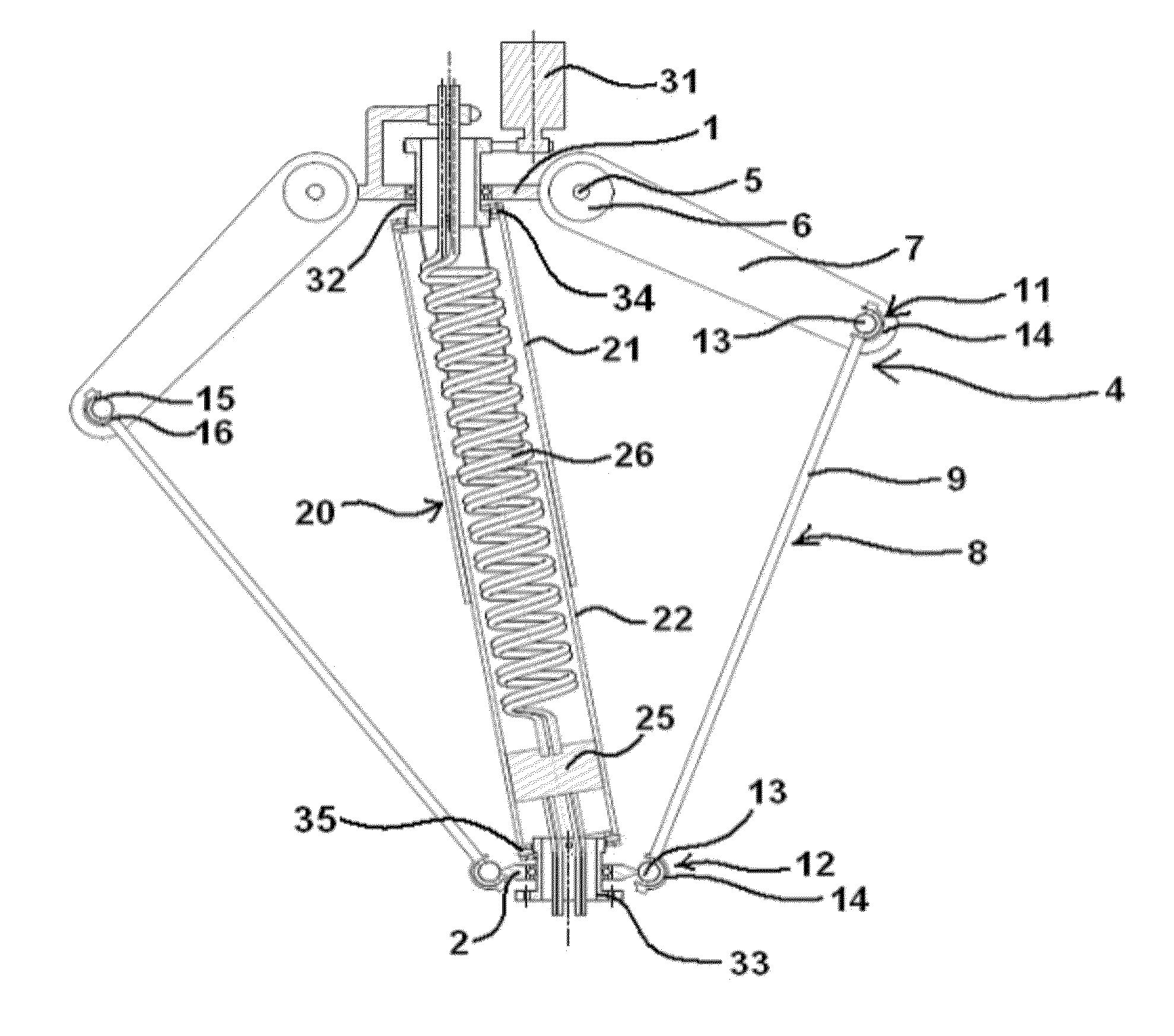

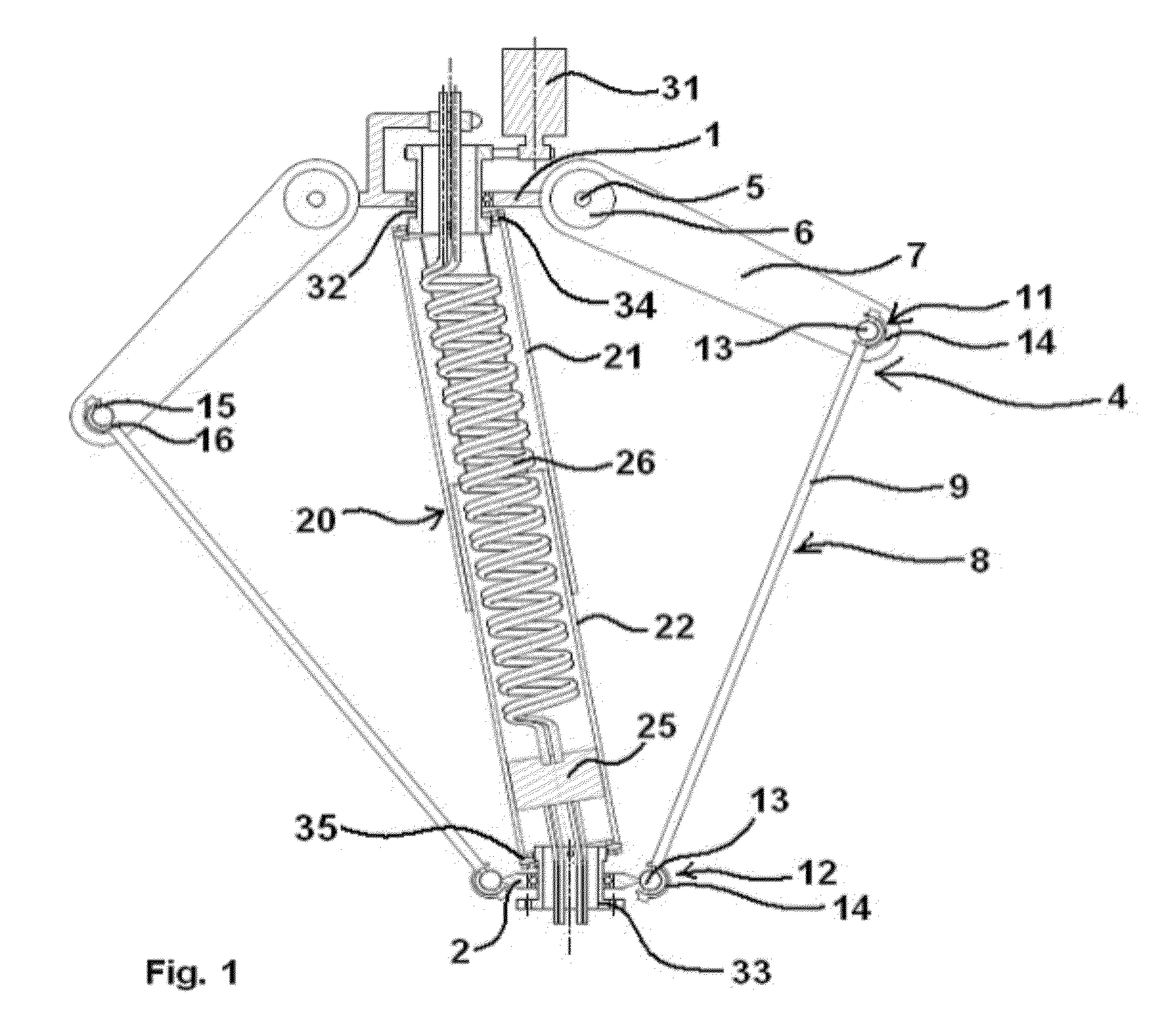

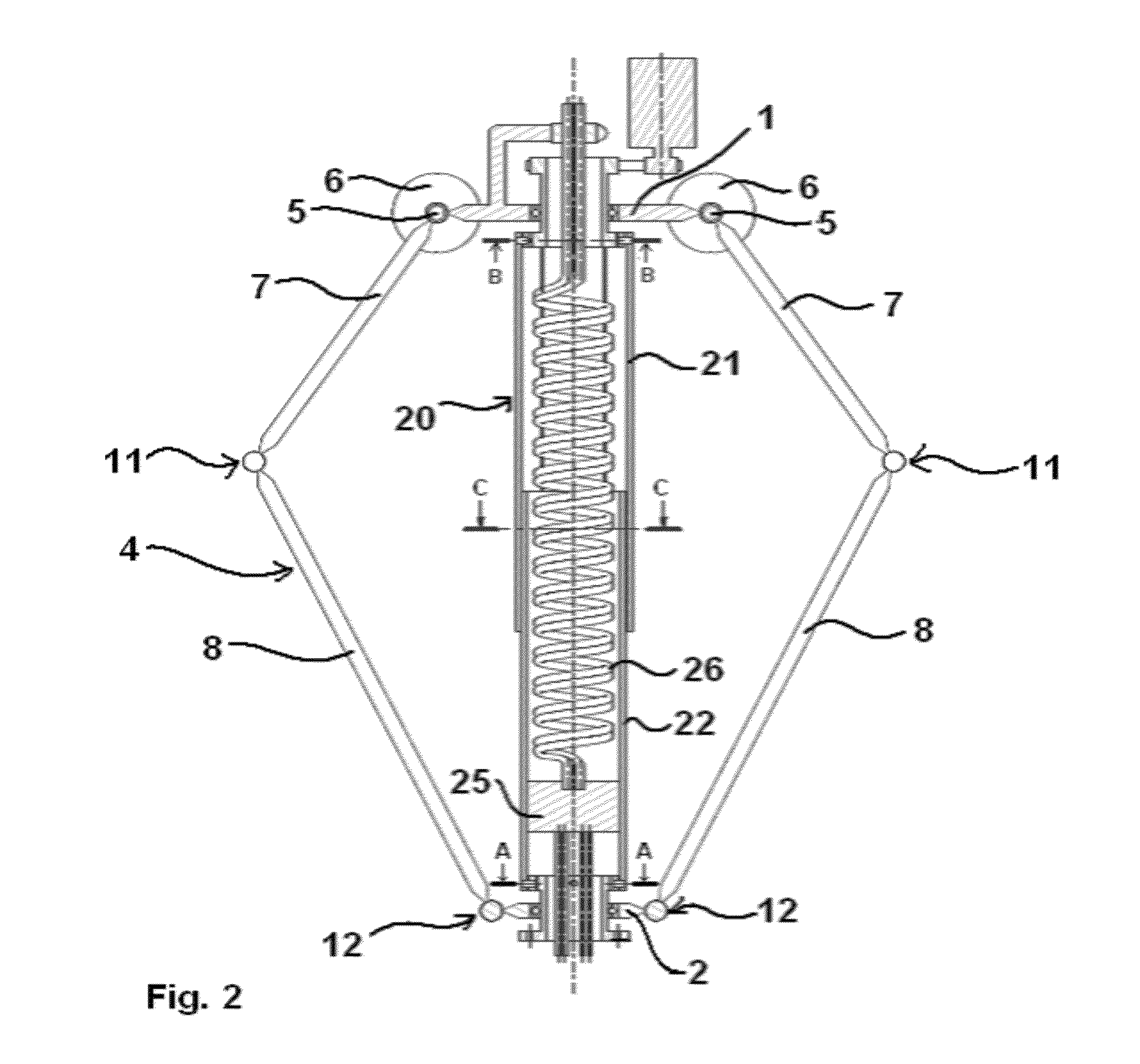

Parallel Robot

ActiveUS20120118097A1Reliable cleaningAvoid damageProgramme-controlled manipulatorMechanical apparatusParallel kinematicsDegrees of freedom

The invention relates to an industrial robot having parallel kinematics, the industrial robot, comprising a robot base (1, 38), a carrier element (2, 42) for accommodating a gripper or a tool, several movable, elongated actuating units (4,36), which are connected at one end thereof to drive units (6, 39) arranged on the robot base (1, 38), and the other end of which is movably connected to the carrier element (2, 42), an elongated hollow body (20, 43, 54), which has a continuous cavity and which is flexibly connected to the robot base (1, 38), a joint (35, 49, 65), which has a continuous cavity and which has several degrees of freedom, by means of which joint the elongated hollow body (20, 43, 54) is movably connected to the carrier element (2, 42), and at least one supply line (26, 51, 64) for a gripper arranged on the carrier element (2, 42) or a tool arranged on the carrier element (2, 42), the supply line being guided through the cavity of the elongated hollow body (20, 43, 54) and the cavity of the hollow joint (35, 49, 65) from the robot base to the carrier element (2, 42).

Owner:MAJATRONIC

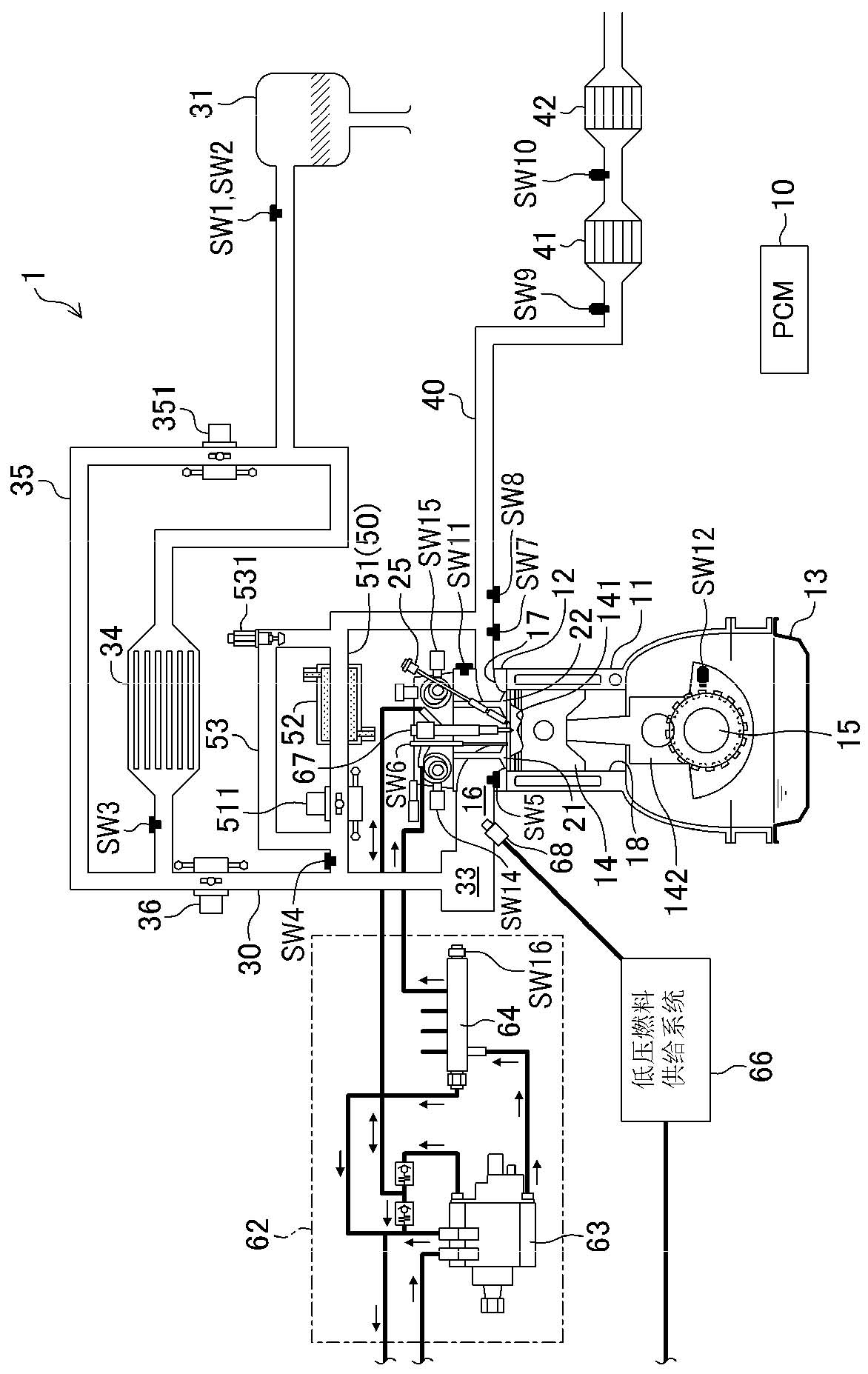

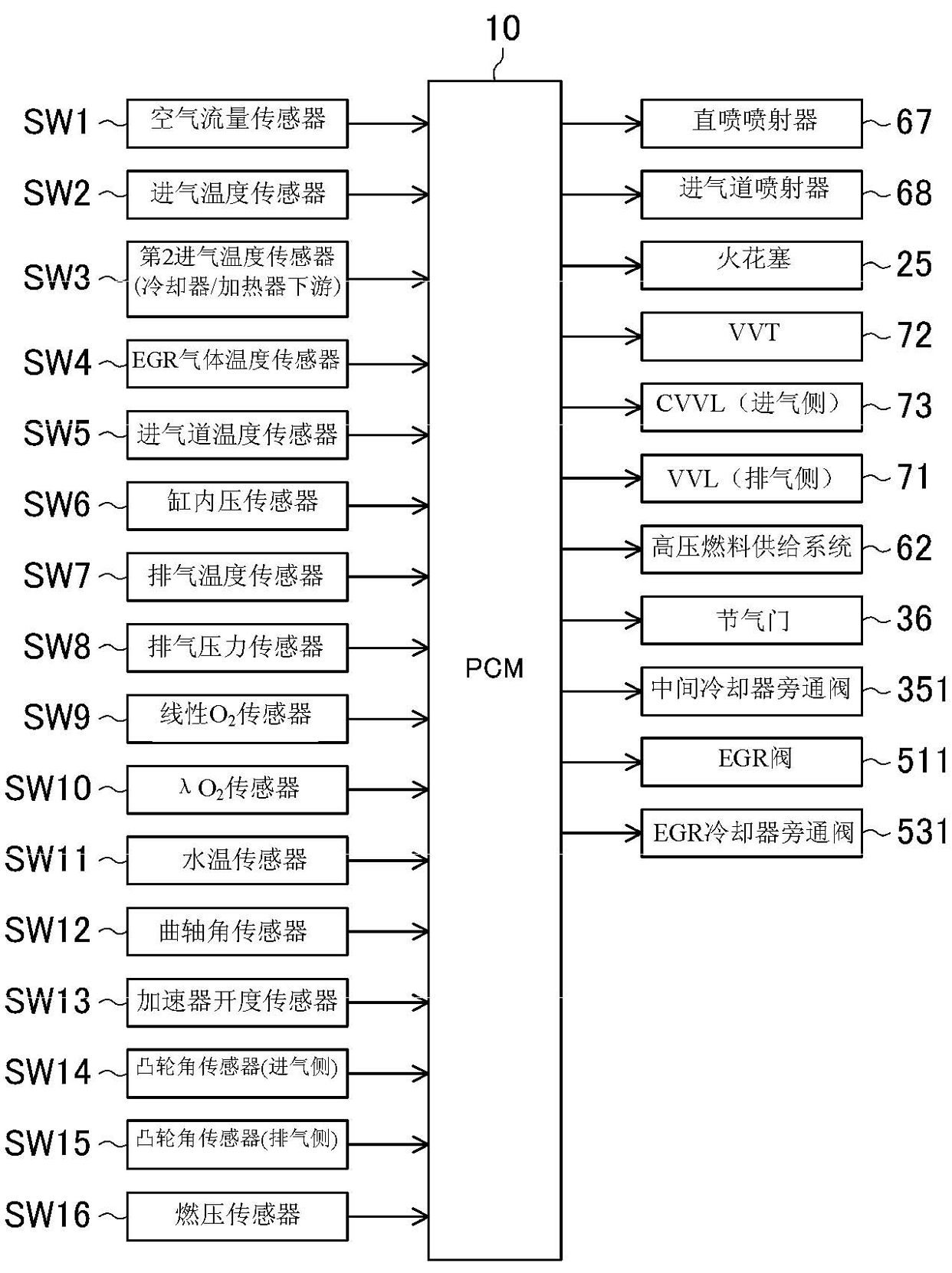

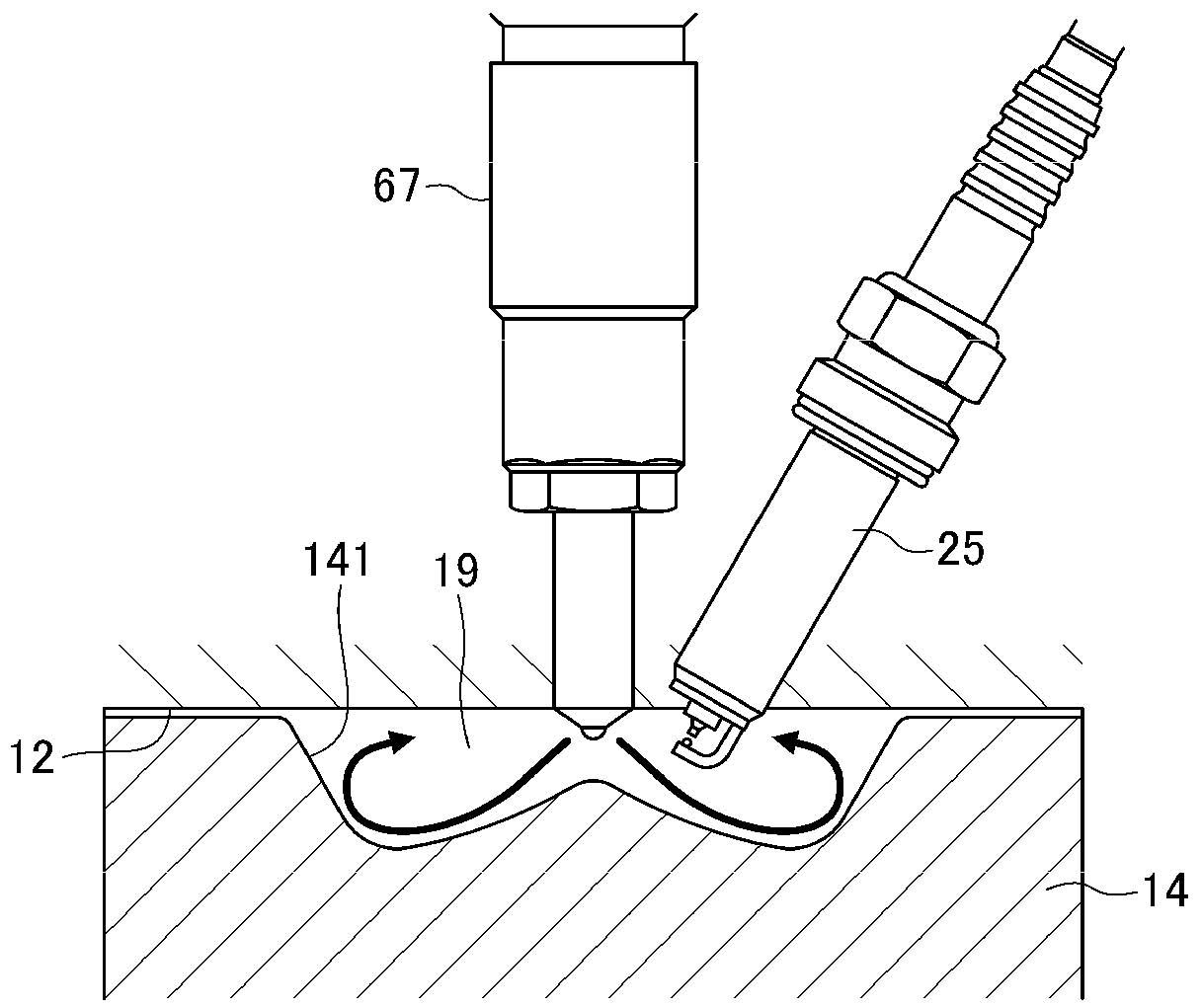

Control device of spark-ignition gasoline engine

InactiveCN102650239ALarge injection volumeShorten the formation periodElectrical controlInternal combustion piston enginesInjectorFuel supply

The disclosure provides a control device of a spark-ignition gasoline engine. According to the invention, in a spark-ignition gasoline engine (1) with a higher high compression ratio, abnormal burning in a high load area can be avoided. When an operating state of an engine body is within a low engine speed range, a controller (PCM 10) operates a fuel pressure variable mechanism (a high pressure fuel supply system 62) so that a fuel pressure is higher within a high engine load range compared to a low engine load range, the controller operates, within the high engine load range, a fuel injection mechanism to perform at least a fuel injection into the cylinder by a cylinder internal injection valve (a straight spray injector 67) at a timing during a retard period from a late stage of a compression stroke to an early stage of an expansion stroke, and the controller (10) operates, within the high engine load range, an ignition plug to ignite at a timing during the retard period and after the fuel injection.

Owner:MAZDA MOTOR CORP

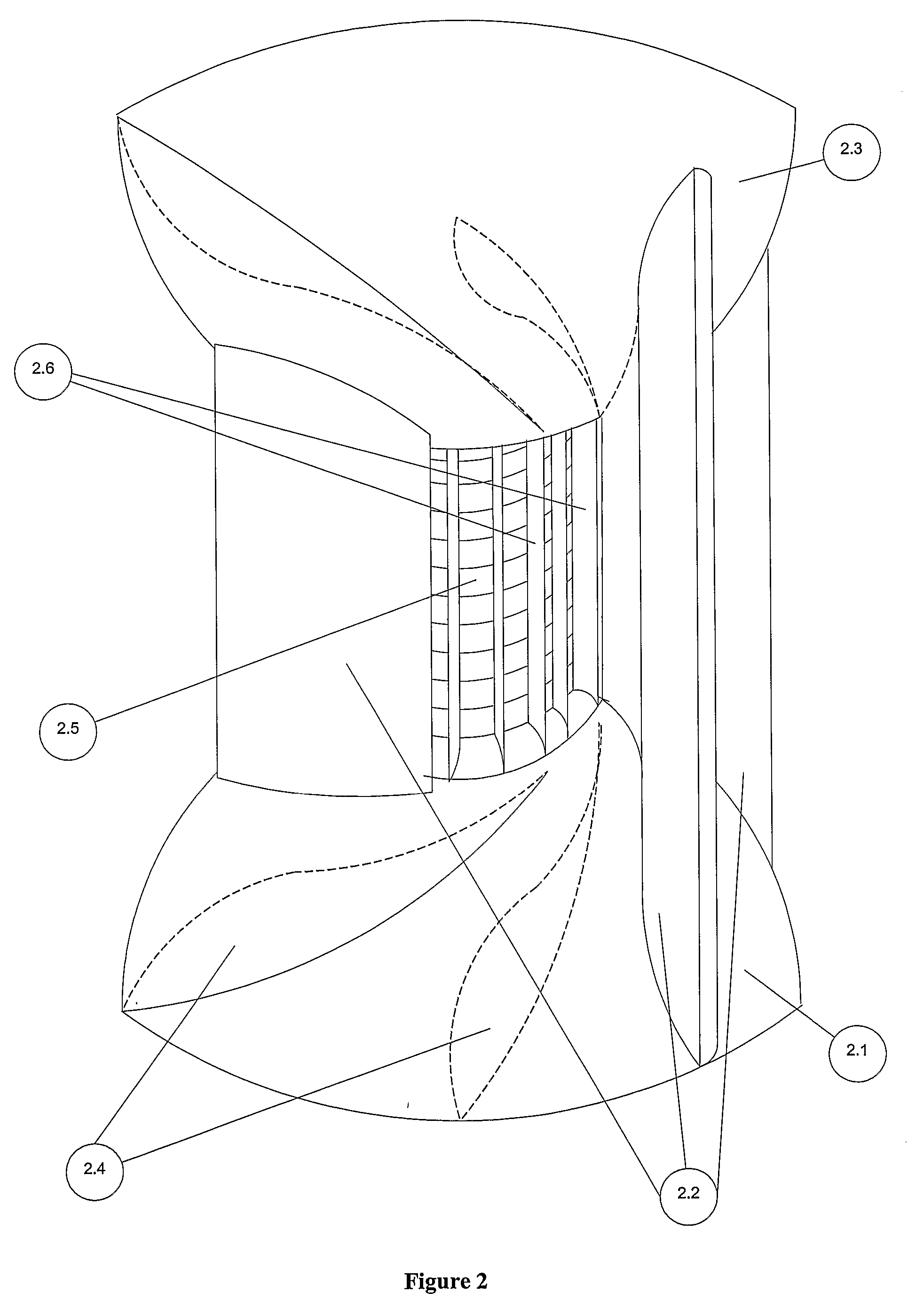

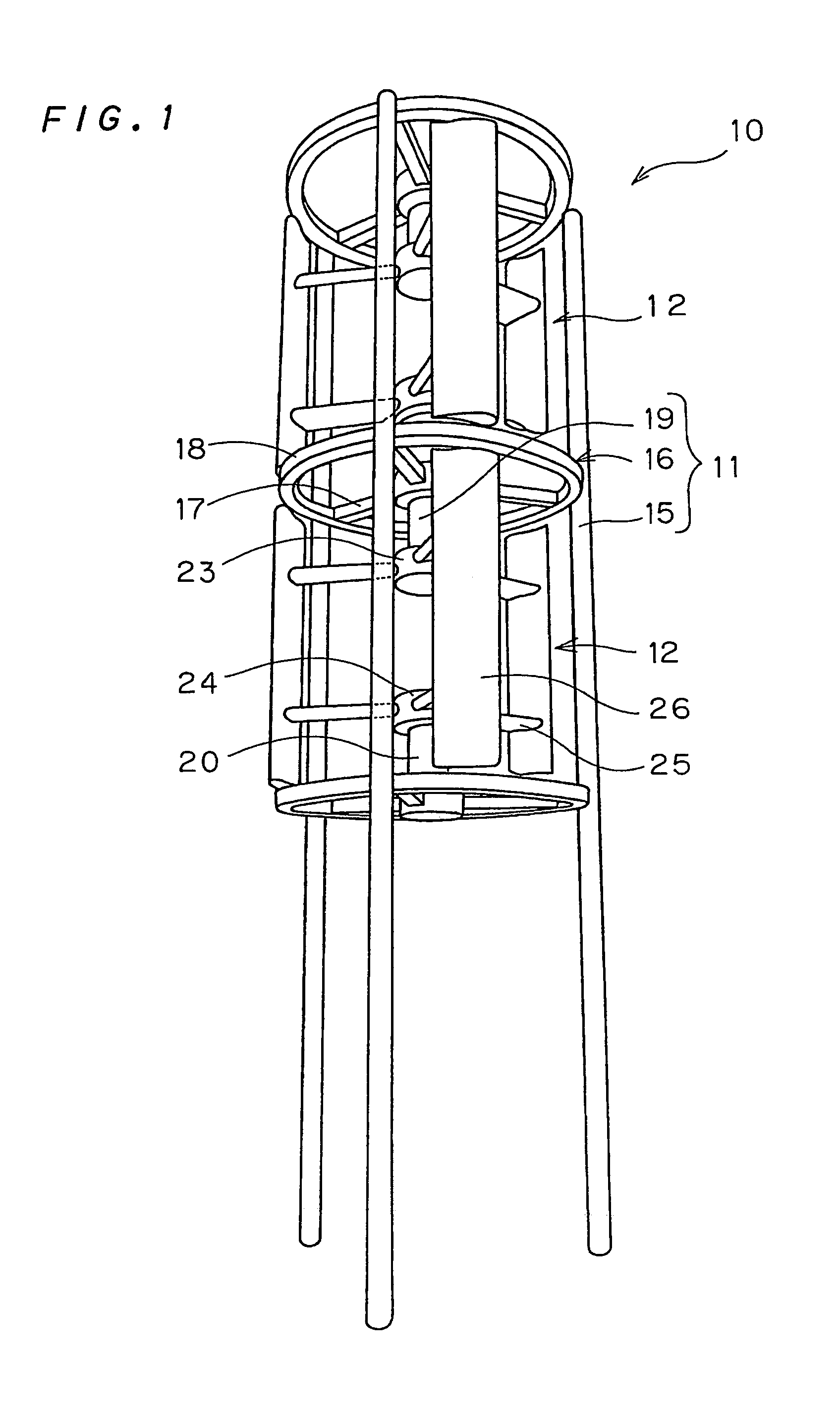

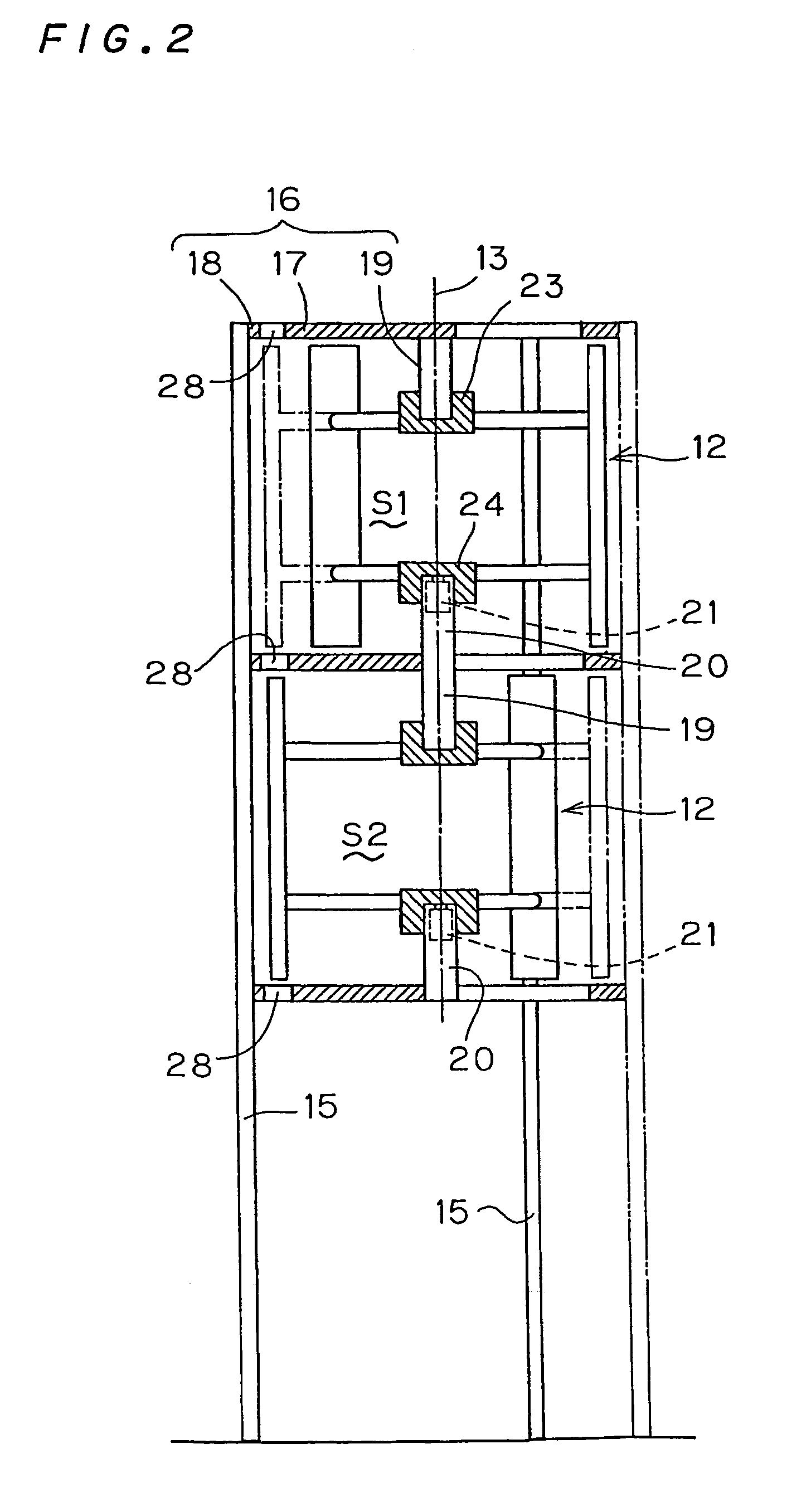

Boundary Layer Wind Turbine

InactiveUS20070296219A1Reliable and effective meanIncrease speedPropellersWind motor controlTurbineWind force

A wind turbine including a stator assembly having a plurality of stator blades for tangentially redirecting wind into a rotor assembly having a plurality of vertical rotor blades disposed circumferentially on a plurality of disks stacked one on top of each other. Each disk defines at least one opening thereon for redirecting the wind axially through each of the disks.

Owner:NICA HORIA

Rotor supporting structure of windmill for power generation

Owner:KINPARA SHIRO

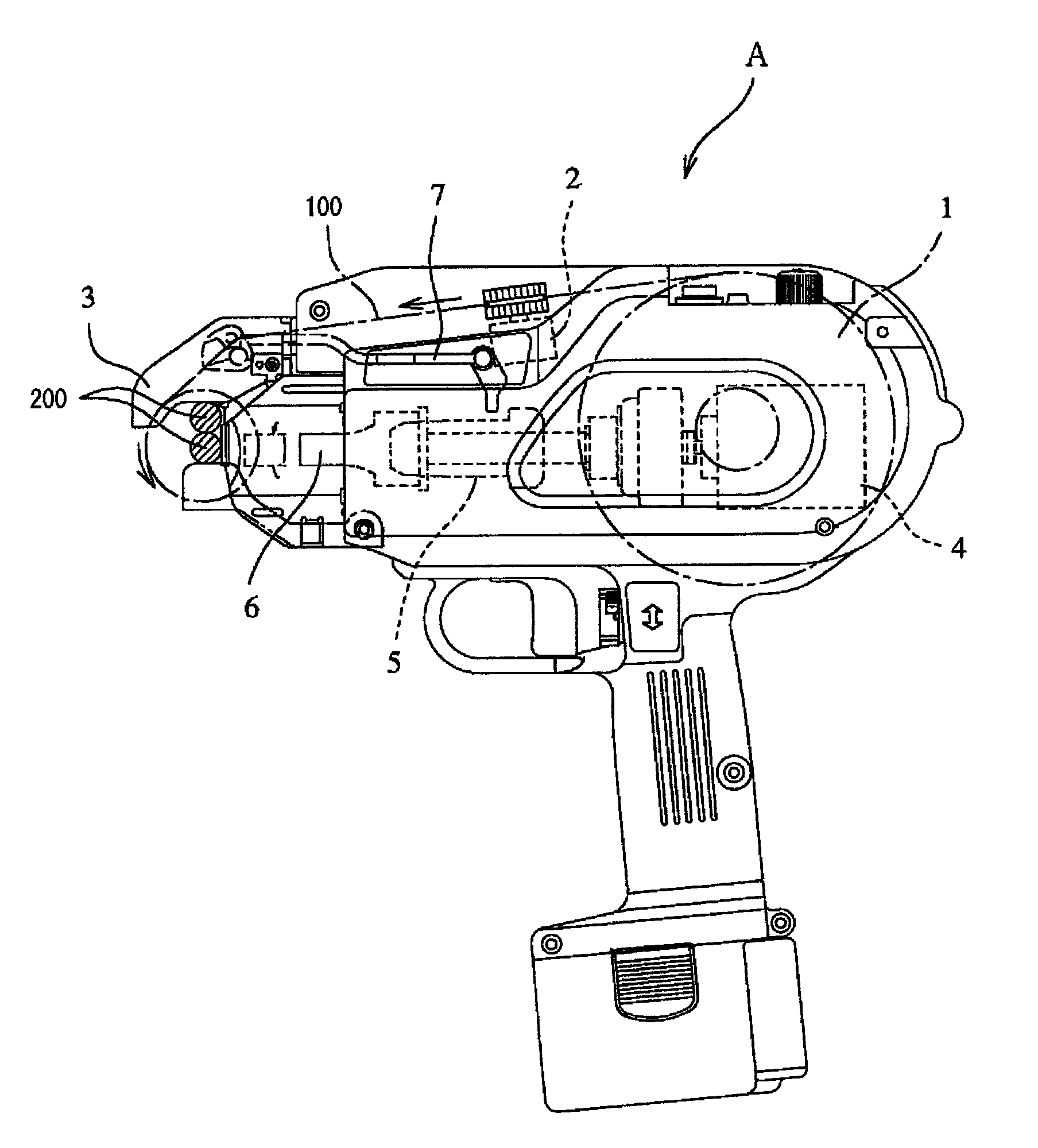

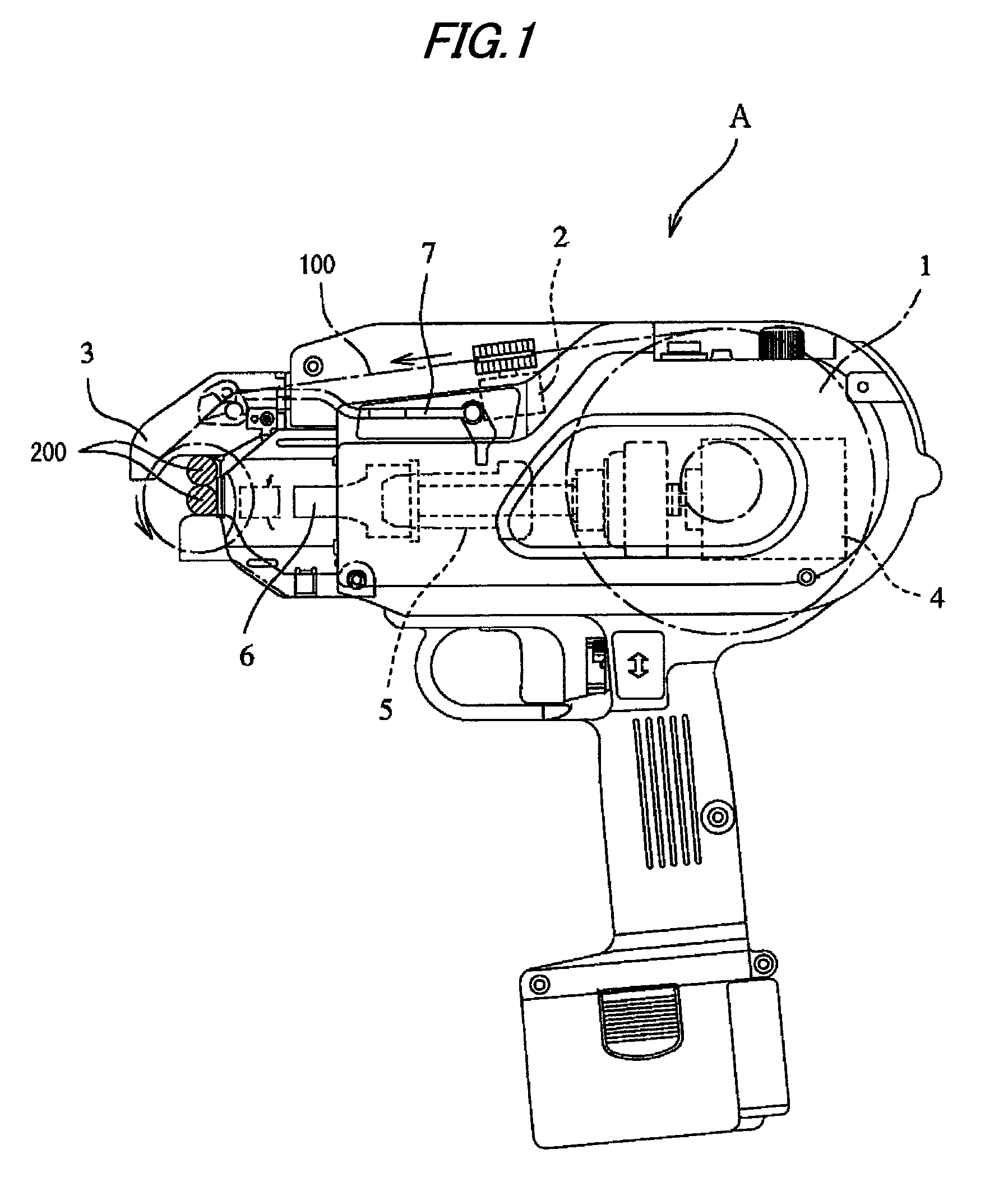

Electric power tool

ActiveUS8198839B2Free from loadReduce in quantitySynchronous motors startersDC motor speed/torque controlBrushless motorsElectric power system

An electric power tool “A” operates a working part 5 by repeating rotation of a motor 4 in a normal direction and in a reverse direction one or more times. The motor 4 includes a brushless motor. Sensors H for detecting a position of a rotor 15 are provided on the motor 4 so as to be advanced by an electrical angle of 30°±θ° from an intermediate position between respective stator teeth 16 in a direction of the normal rotation of the rotor 15. A control part 20 for controlling the rotation of the motor 4 controls a driving signal of the motor 4 based on the results of detection by the sensors H. Moreover, the control part 20 selects a detection signal of the sensors H so that relation between the rotor 15 and the detection signal of the sensors H is equivalent in either of the normal rotation and the reverse rotation of the rotor 15.

Owner:MAX CO LTD

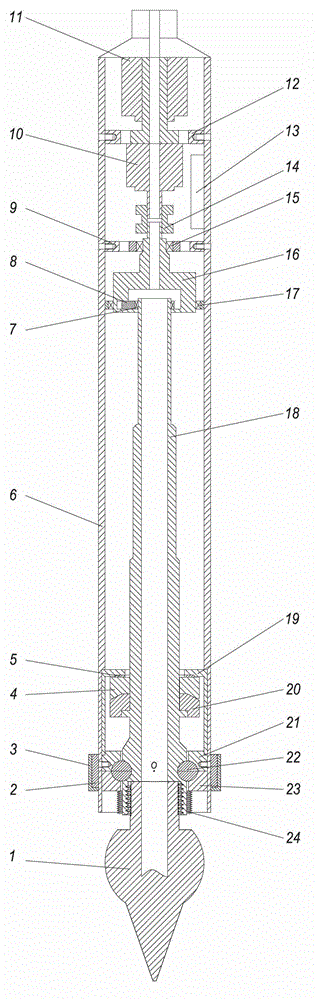

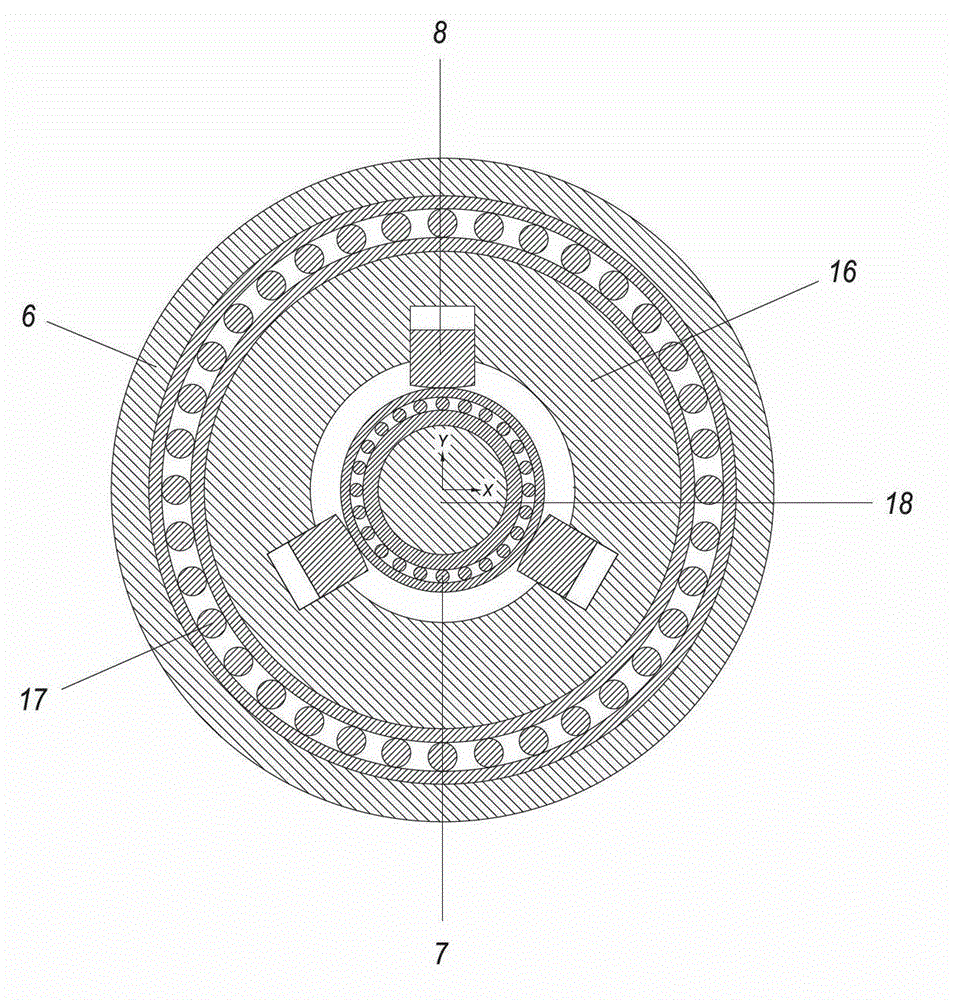

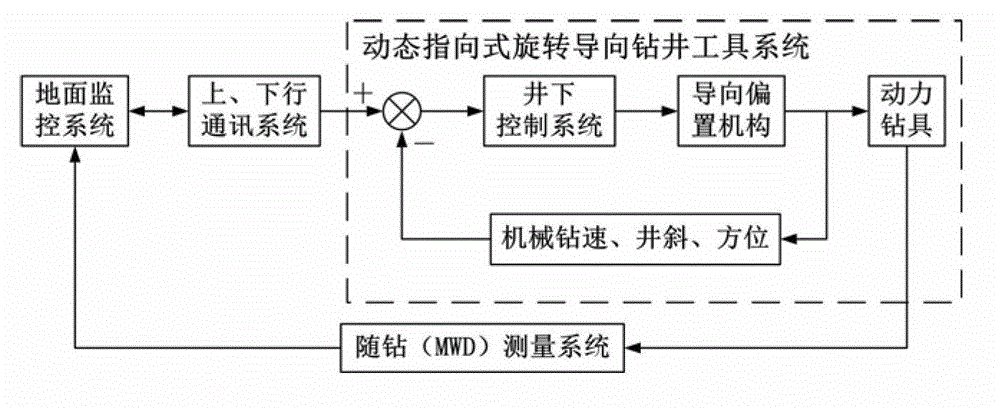

Dynamic point-the-bit rotary steering drilling tool

InactiveCN102913131AFulfill control requirementsEliminate the effects ofDirectional drillingBorehole drivesMonitoring systemTransfer mechanism

The invention relates to a dynamic point-the-bit rotary steering drilling tool. The dynamic point-the-bit rotary steering drilling tool comprises a rotary outer cylinder, a stable platform, a steering offset mechanism, a bit pressure transfer mechanism, a torque transfer mechanism, an upper support plate, a lower support plate, a drill shaft, a drill bit, a sealed corrugated pipe, a drill shaft connecting bearing and a conductive slip ring, and is characterized in that the rotary outer cylinder is used for directly applying bit pressure and torque on the drill bit and driving the drill shaft and the drill bit to rotate jointly, information of hole deviation angle and azimuth angle to be controlled can be calculated by a calculating unit according to a preset borehole trajectory parameter or a remote control command of a ground monitoring system, and precision control of bend angle, in particular to the hole deviation angle and the azimuth angle of the offset mechanism can be realized by adopting a geostationary control method of the stable platform and combining with working principles of a hydraulic drive piston and the steering offset mechanism.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

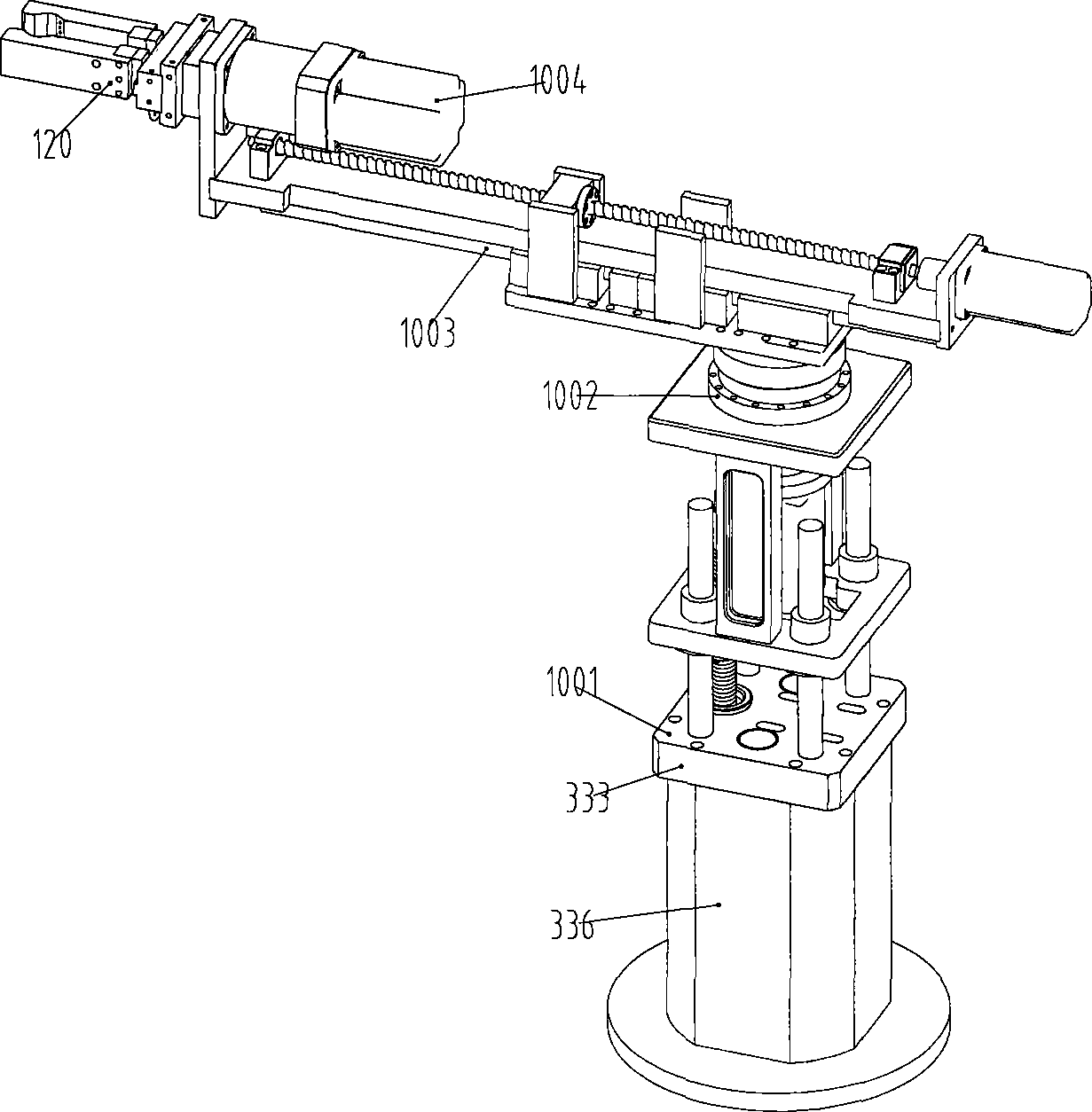

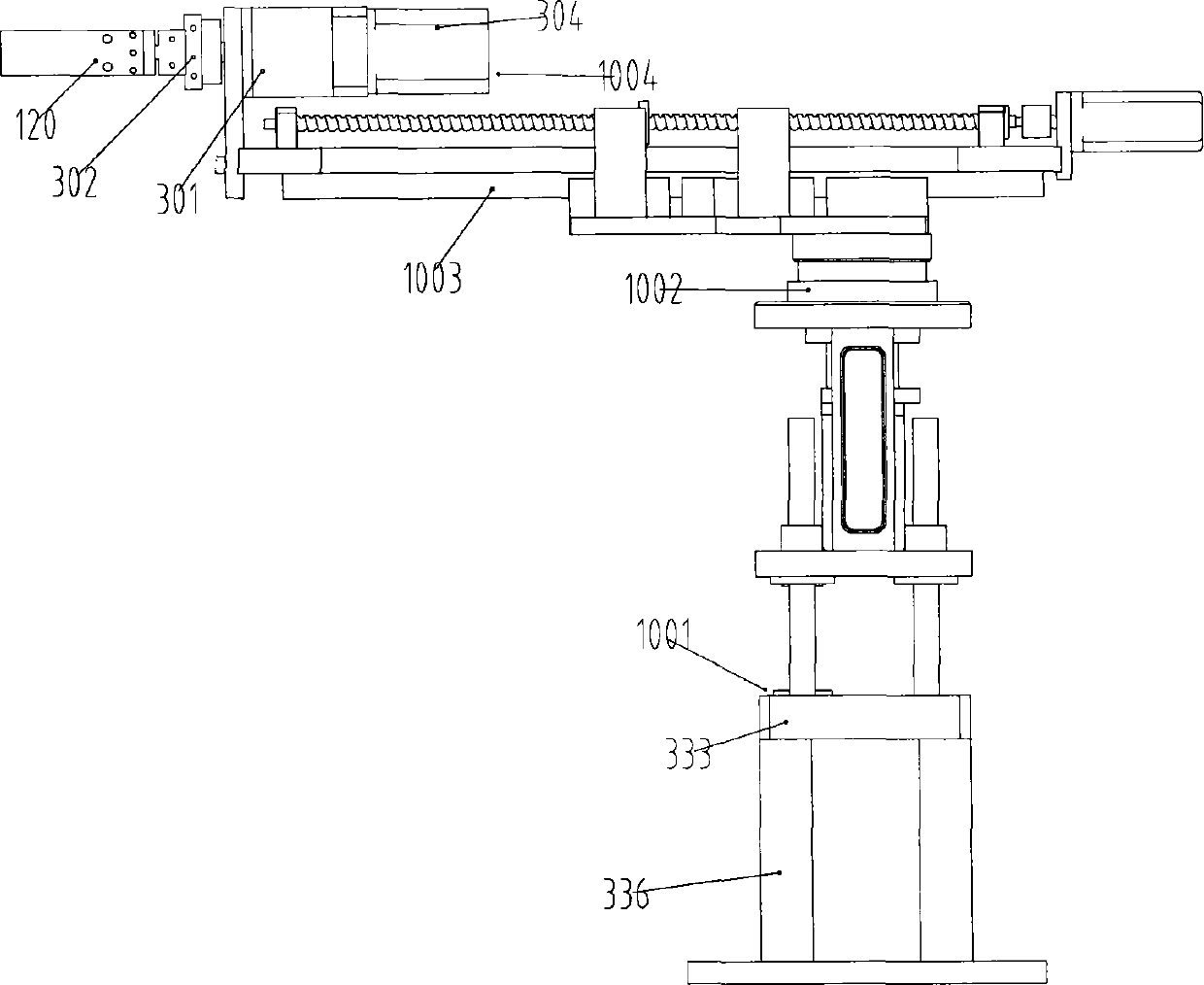

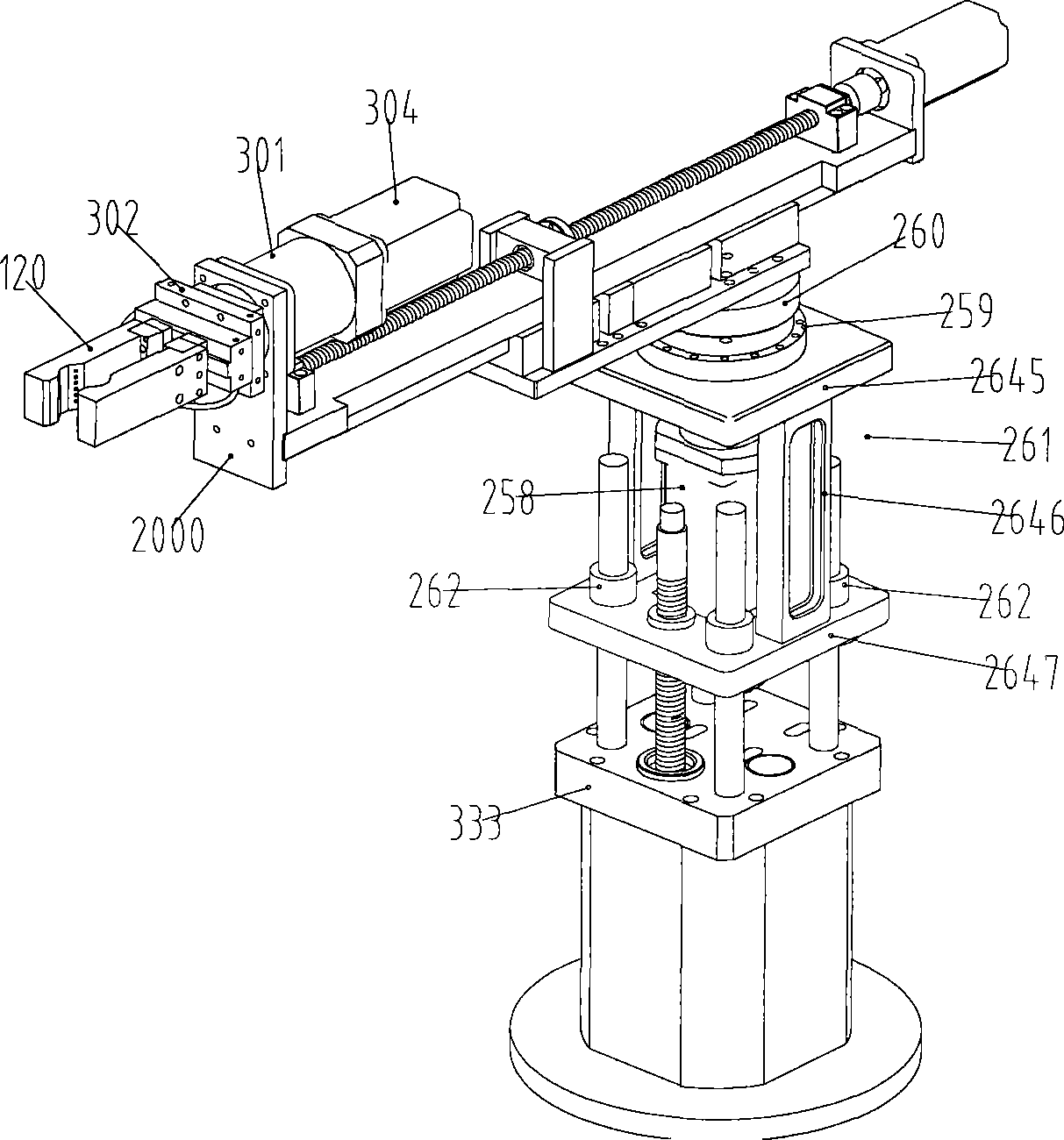

Four-degree-of-freedom servo manipulator

InactiveCN103802095AReduce volumeControl DimensionsProgramme-controlled manipulatorDegrees of freedomEngineering

The invention relates to industrial automation equipment, in particular to an automated manipulator. A four-degree-of-freedom servo manipulator comprises a lifting arm, a rotary arm, a telescopic boom, a torsional arm, a base and a gripper, wherein the lifting arm is fixedly connected to the base, and fixed on the ground; the gripper is fixedly connected to the output end of the torsional arm; the fixing plate of the telescopic boom is fixedly connected to a rotary cover plate; one end of the telescopic boom is fixedly connected to a vertical flange plate, and the torsional arm is fixedly connected to the vertical flange plate. The four-degree-of-freedom servo manipulator provided by the invention is applicable to machine manufacturing processes and achieves material transportation and transmission, the frictional resistance is small, the running is stable, the accuracy is high, the service life is long, the four-degree-of-freedom servo manipulator provided by the invention can be used for picking up workpieces, through the compact structure distribution of the four-degree-of-freedom servo manipulator, the external dimension can be effectively controlled, and a maximal running space can be obtained.

Owner:东莞智得电子制品有限公司

Mechanical press

InactiveUS7102316B2Inertia moment can be increasedSlow downAgriculture tools and machinesComputer controlMechanical pressServomotor

In a press having a plunger supported so as to be movable linearly back and forth by drive means which include at least one servomotor in combination with a rotatably supported inertia structure connected for rotation with the servomotor, the inertia structure has an inertia moment which is small enough to permit reversal of the servomotor within a stroke length of the plunger so that the stroke of the plunger is adjustable under the control of a control device connected to the servomotor for controlling its operation.

Owner:SCHULER PRESSEN GMBH & CO KG

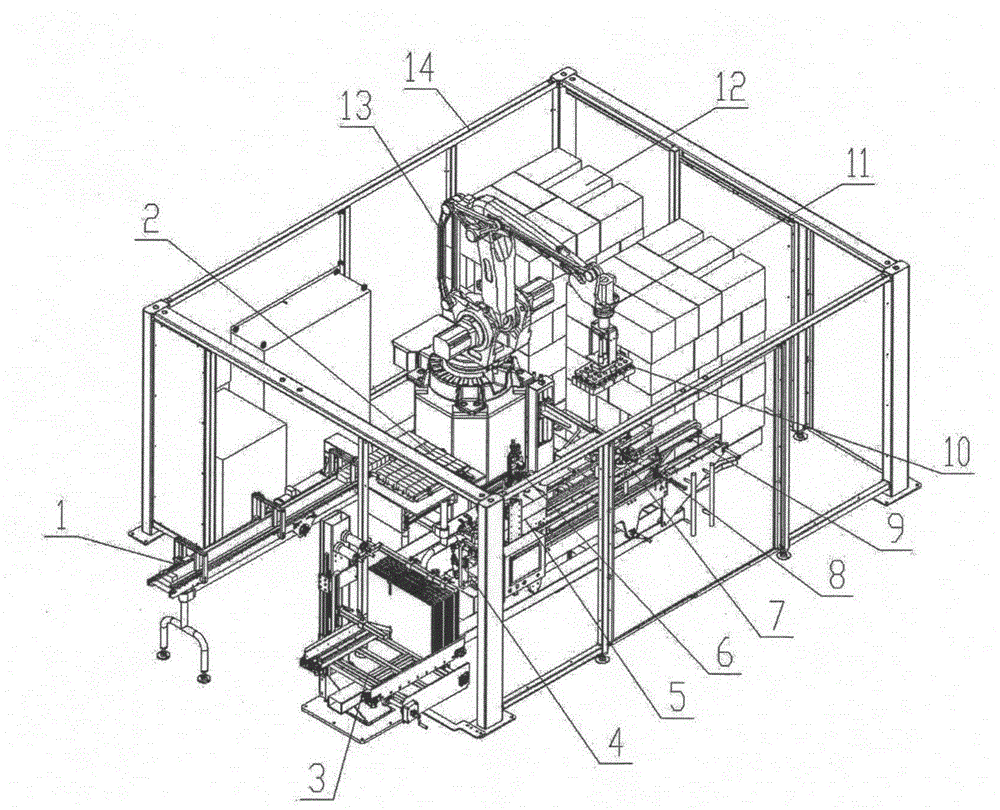

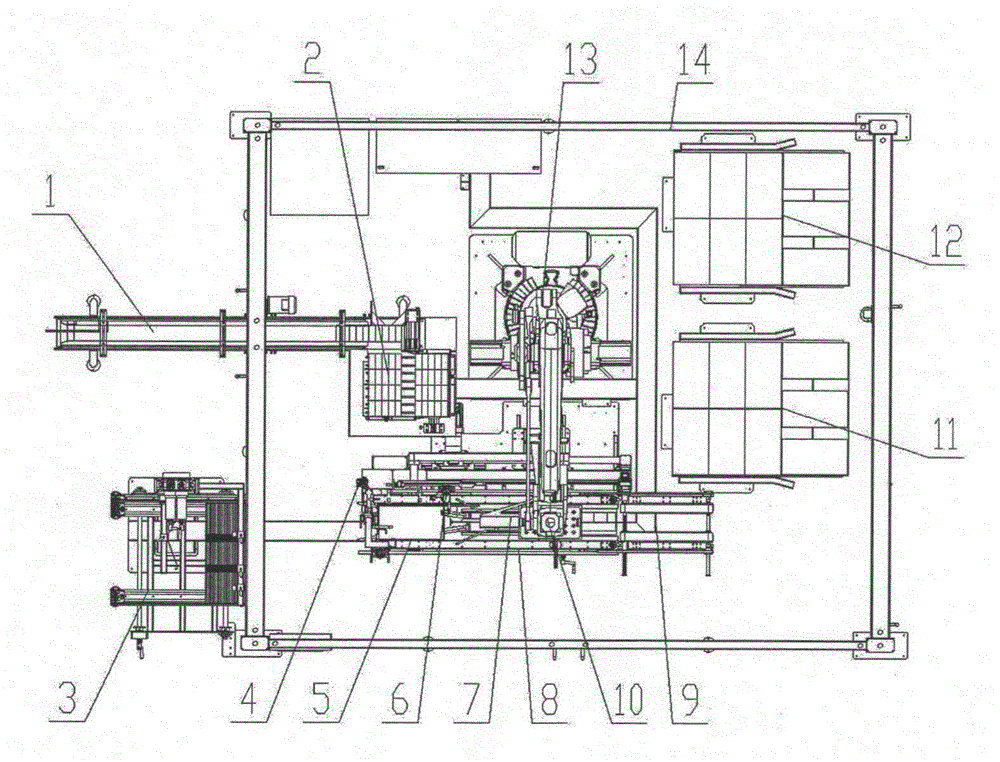

Carton filling and stacking all-in-one machine

ActiveCN104859894AReduce the difficulty of operationSmall footprintPackaging machinesCartonEngineering

The invention discloses a carton filling and stacking all-in-one machine. The carton filling and stacking all-in-one machine is characterized by comprising a carton conveying line and a storage device, wherein the head portion of the carton conveying line is connected with one side of a carton alignment device; the storage device is connected with one side of a carton filling station through an unpacking forming mechanism; the other side of the carton filling station is connected with one side of a carton strutting device; the other side of the carton alignment device is provided with a robot body; the robot body is provided with a carton filling and stacking grasp structure; a carton clamping and conveying device is arranged on the other side of the carton strutting device and connected with a carton sealing device; a carton labeling station is arranged on one side of the carton sealing device; a first tray and a second tray are arranged on one side of the carton labeling station. The functions of existing single machines are completely integrated on one machine, stations are linked tightly, the structure is compact, and operation is easy. The carton filling and stacking all-in-one machine is suitable for various specifications, stable in performance, high in efficiency and capable of greatly reducing labor cost.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

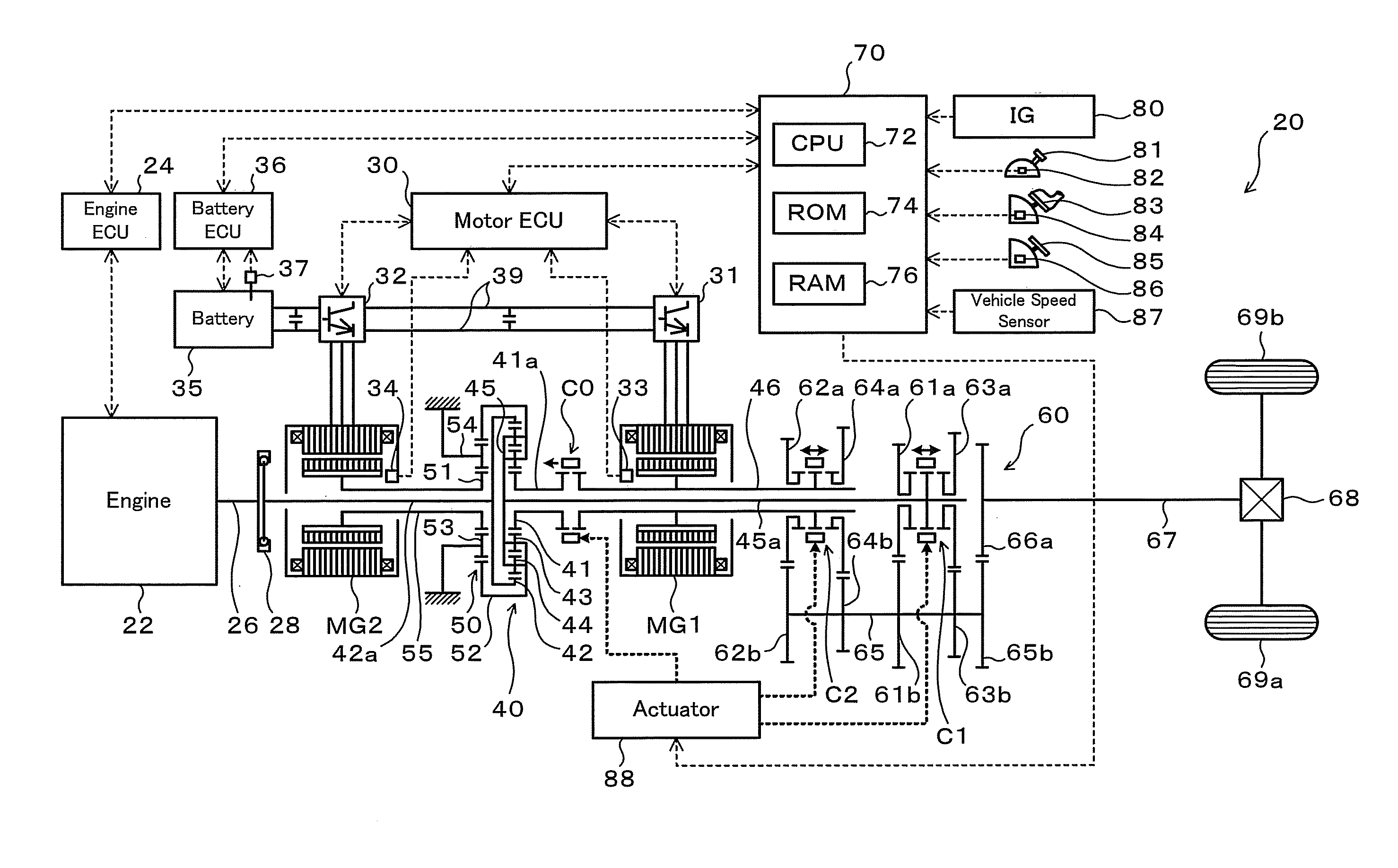

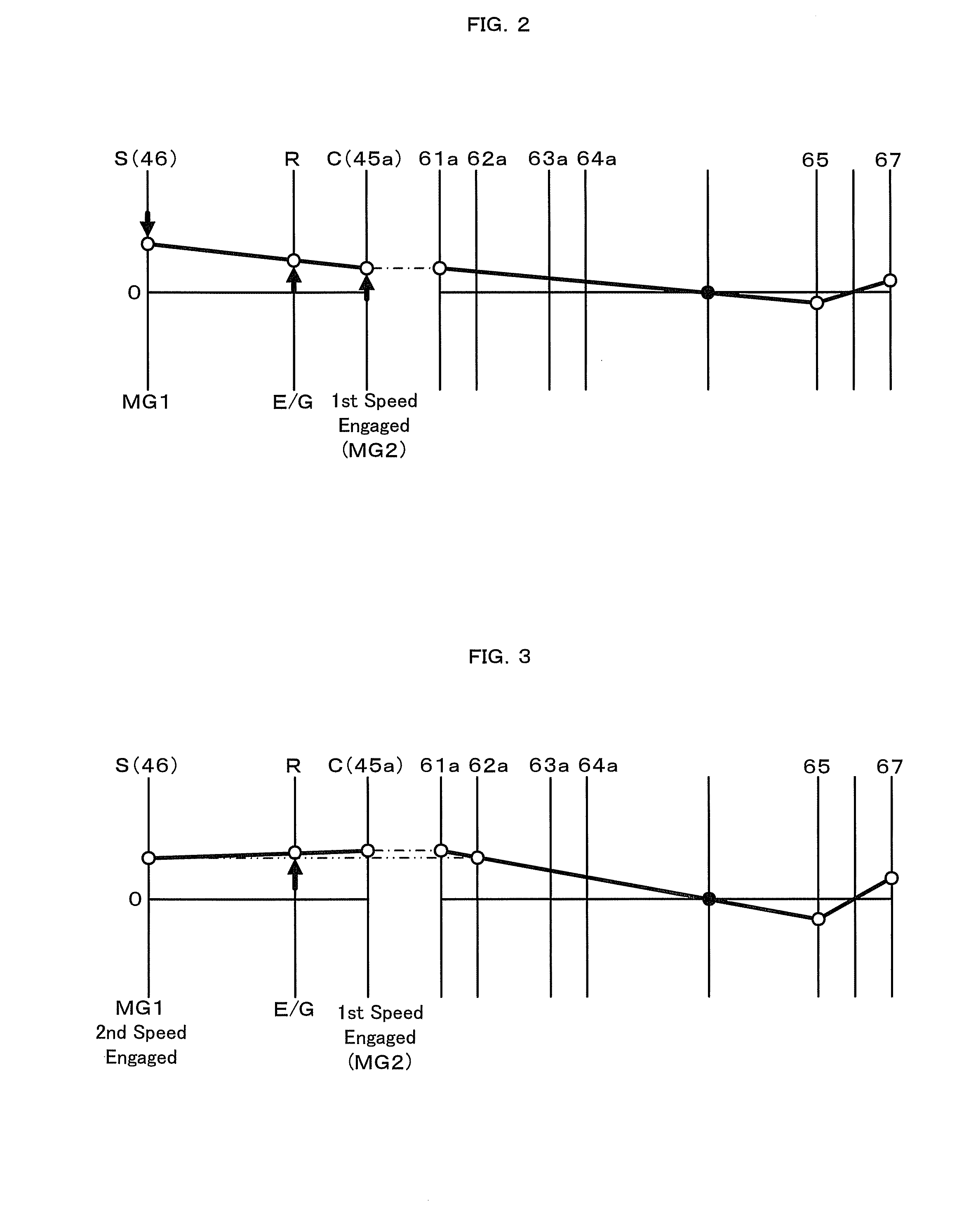

Power output apparatus, vehicle equipped with power output apparatus, and control method of power output apparatus

InactiveUS20100000814A1Large torquePrevent excessive heatingHybrid vehiclesEngine controllersVariatorMotor drive

In a 2-motor drive mode with connection of both motors to a driveshaft by means of a transmission, a hybrid vehicle sets torque commands of the motors to make a work performed by the second motor substantially equal to a work performed by the first motor and to ensure output of a torque equivalent to a preset torque demand to the driveshaft. This arrangement connects both motors to the driveshaft by means of the speed change-transmission assembly and ensures continuous output of a relatively large torque.

Owner:TOYOTA JIDOSHA KK

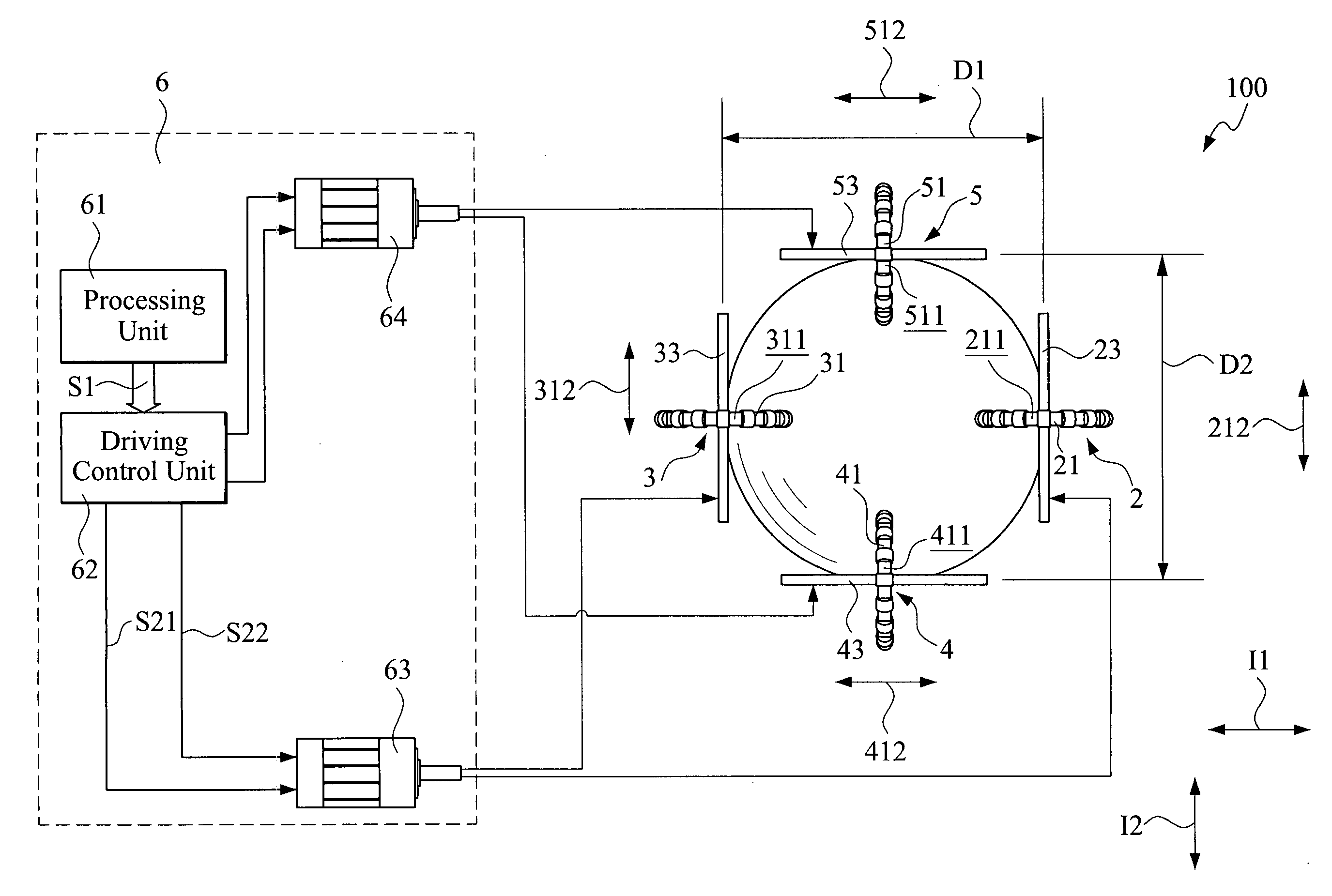

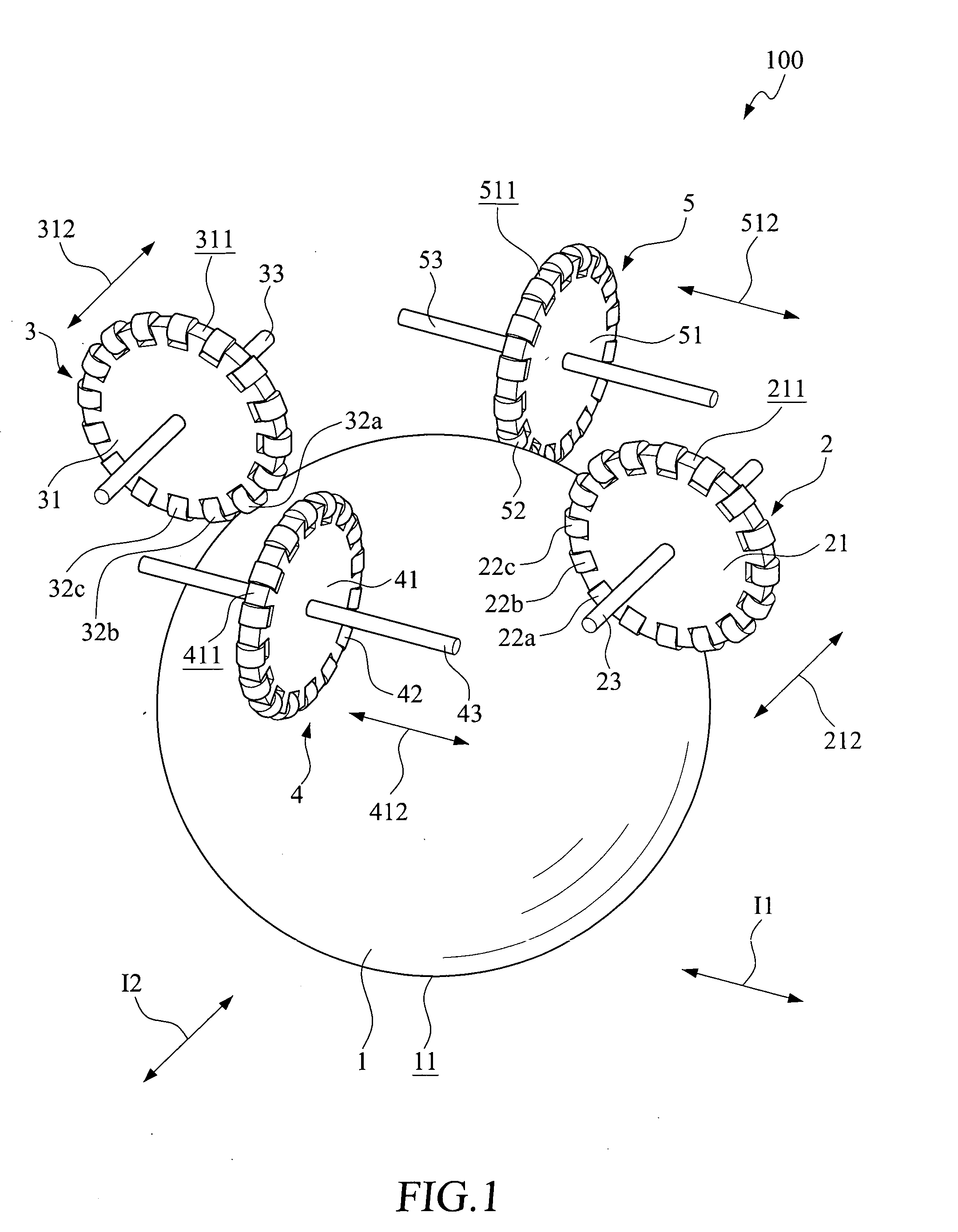

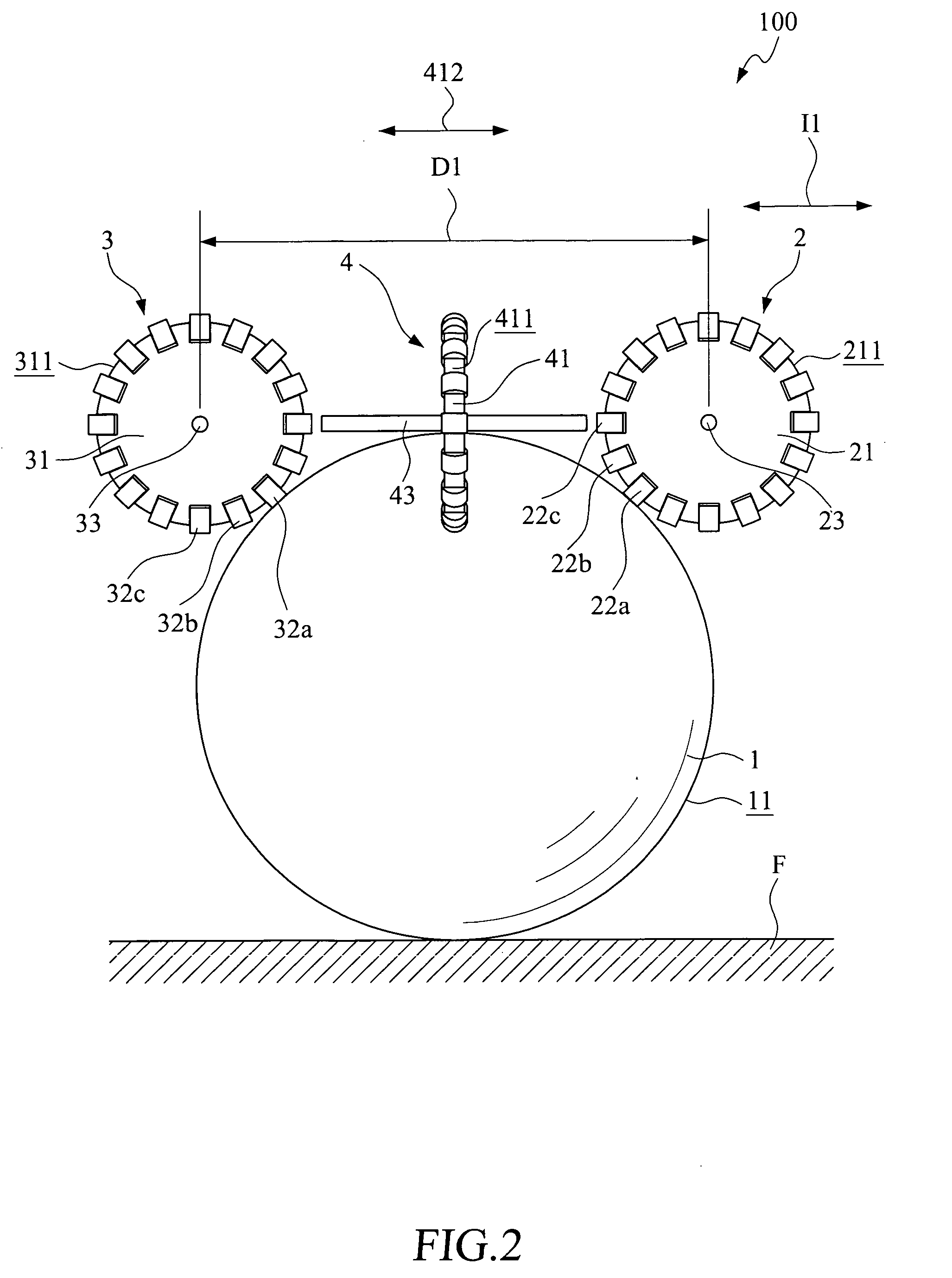

Omni-wheel based drive mechanism

InactiveUS20100243342A1Easy to driveImprove efficiencyEndless track vehiclesWheelsEngineeringMechanical engineering

Owner:CHUNG HUA UNIVERSITY

Vehicle and vehicle control method

ActiveUS20140288756A1Suppress instabilityHigh torqueHybrid vehiclesSpeed controllerElectricityHybrid vehicle

In a hybrid vehicle including an engine, a motor, a generator, and a battery that is electrically connected to the motor and the generator, an ECU performs “battery-less travel control” enabling the vehicle to travel when a fault occurs in the battery by disconnecting the battery from an electrical system including the motor and the generator and driving the motor using power that is generated by the generator using the power of the engine. When the battery-less travel control is underway and a vehicle speed V exceeds a vehicle speed limit Vsh, the ECU implements a vehicle speed limitation. As a result, a control mode of the motor is less likely to shift to a rectangular control mode during the battery-less travel control.

Owner:TOYOTA JIDOSHA KK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com