Patents

Literature

25633 results about "Crankshaft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A crankshaft is a shaft driven by a crank mechanism, consisting of a series of cranks and crankpins to which the connecting rods of an engine are attached. It is a mechanical part able to perform a conversion between reciprocating motion and rotational motion. In a reciprocating engine, it translates reciprocating motion of the piston into rotational motion, whereas in a reciprocating compressor, it converts the rotational motion into reciprocating motion. In order to do the conversion between two motions, the crankshaft has "crank throws" or "crankpins", additional bearing surfaces whose axis is offset from that of the crank, to which the "big ends" of the connecting rods from each cylinder attach.

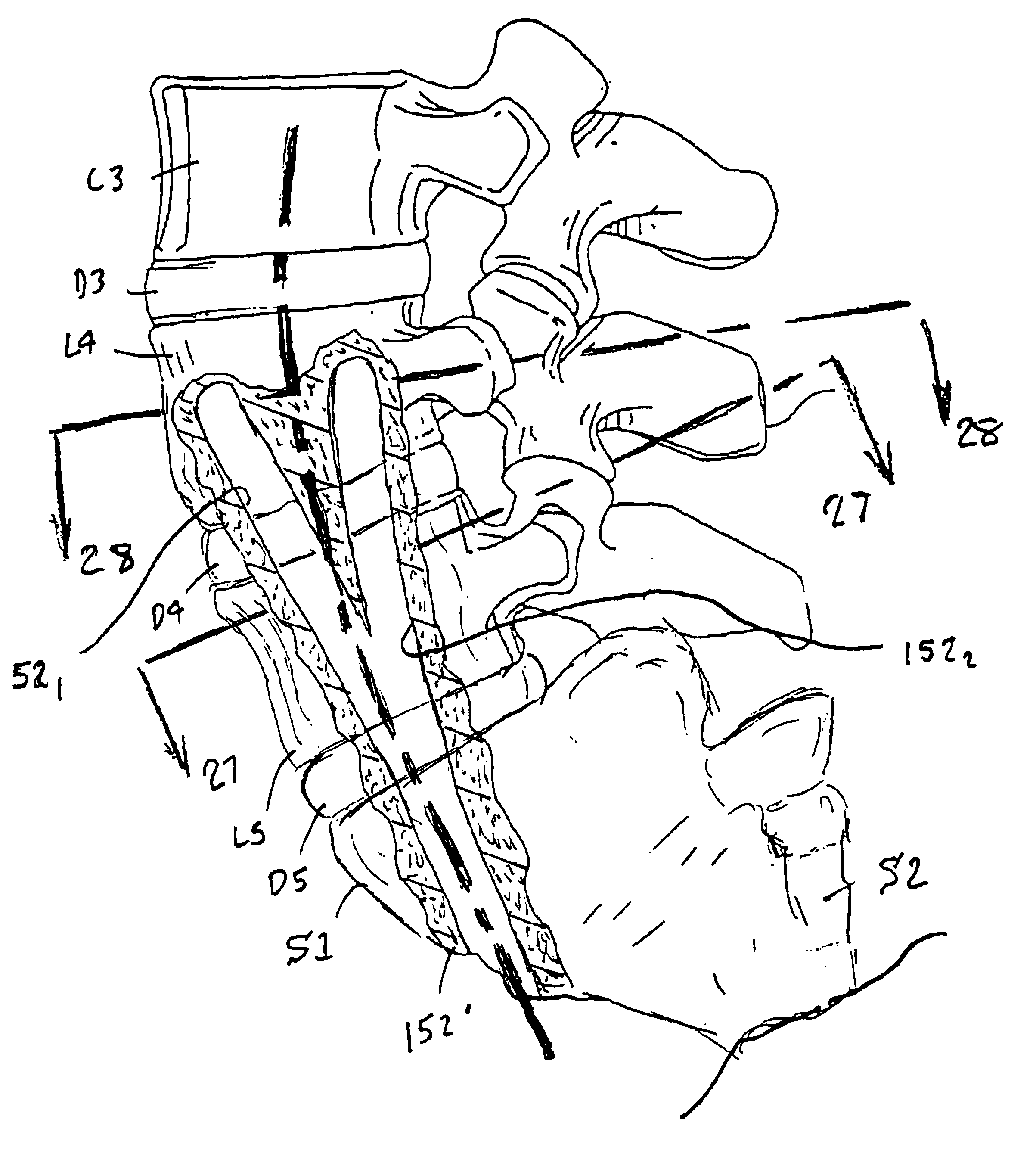

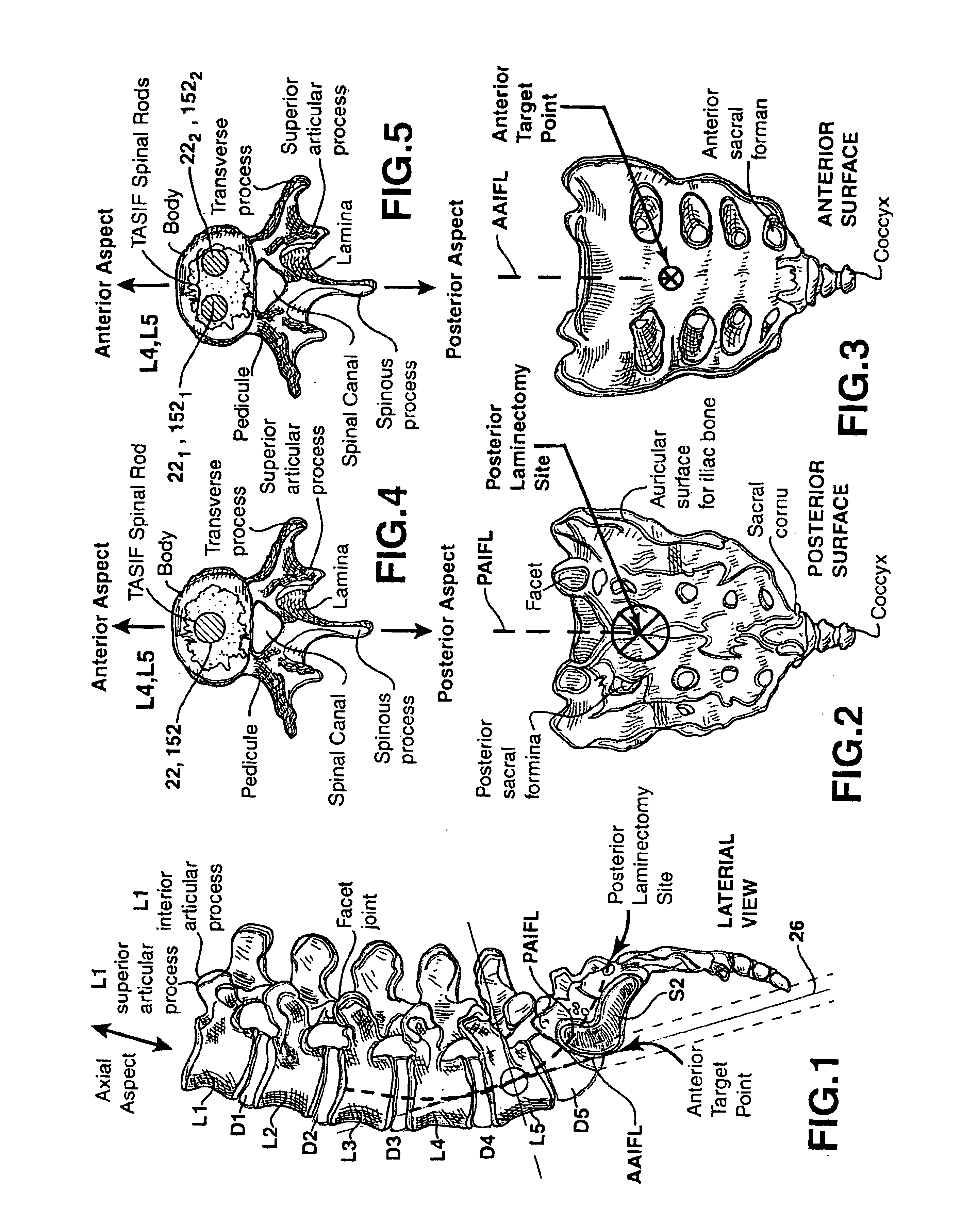

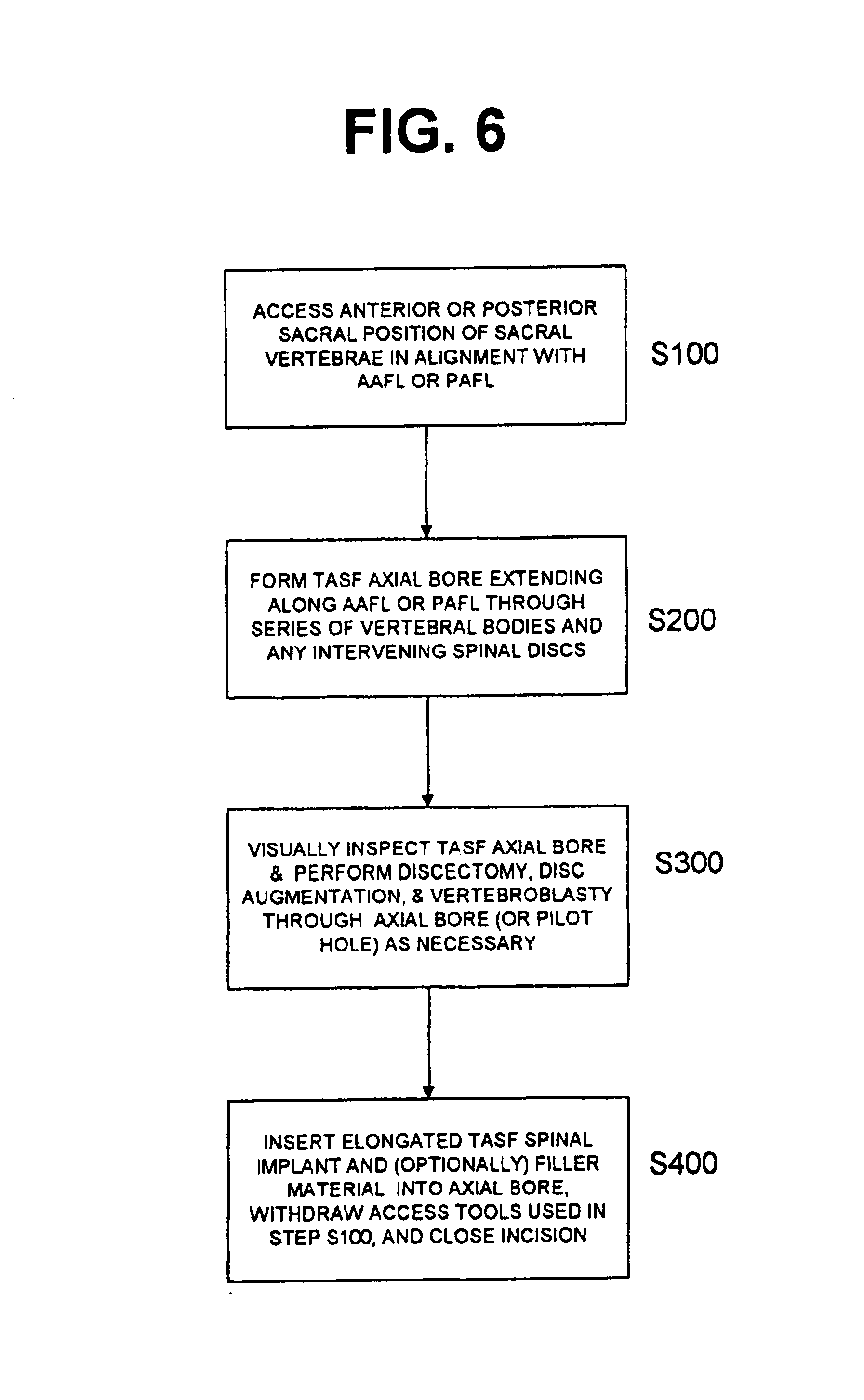

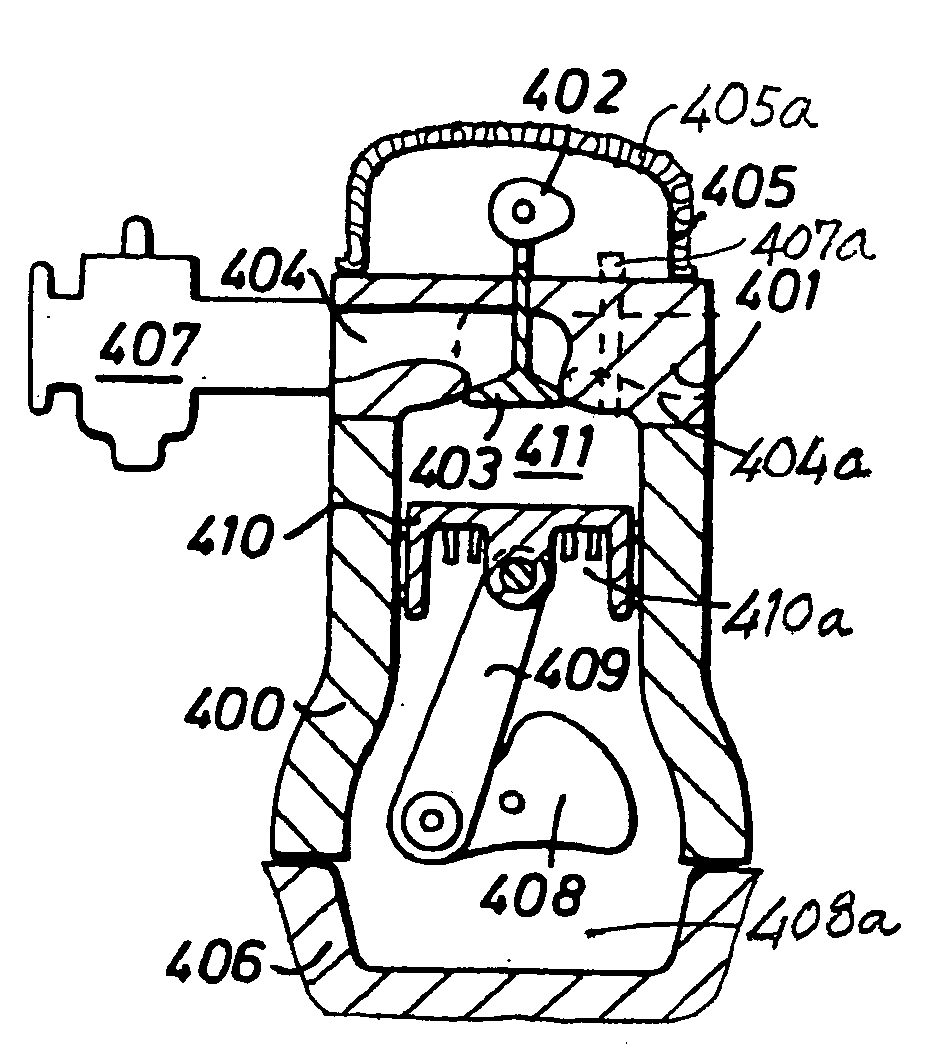

Methods and apparatus for forming curved axial bores through spinal vertebrae

One or more curved axial bore is formed commencing from an anterior or posterior sacral target point and cephalad through vertebral bodies in general alignment with a visualized, trans-sacral axial instrumentation / fusion (TASIF) line in a minimally invasive, low trauma, manner. An anterior axial instrumentation / fusion line (AAIFL) or a posterior axial instrumentation / fusion line (PAIFL) that extends from the anterior or posterior target point, respectively, in the cephalad direction following the spinal curvature through one or more vertebral body is visualized by radiographic or fluoroscopic equipment. Generally curved anterior or posterior TASIF axial bores are formed in axial or parallel or diverging alignment with the visualized AAIFL or PAIFL, respectively. The anterior and posterior TASIF axial bore forming tools can be manipulated from proximal portions thereof to adjust the curvature of the anterior or posterior TASIF axial bores as they are formed in the cephalad direction. The boring angle of the distally disposed boring member or drill bit can be adjusted such that selected sections of the generally curved anterior or posterior TASIF axial bores can be made straight or relatively straight, and other sections thereof can be made curved to optimally traverse vertebral bodies and intervening disc, if present.

Owner:MIS IP HLDG LLC

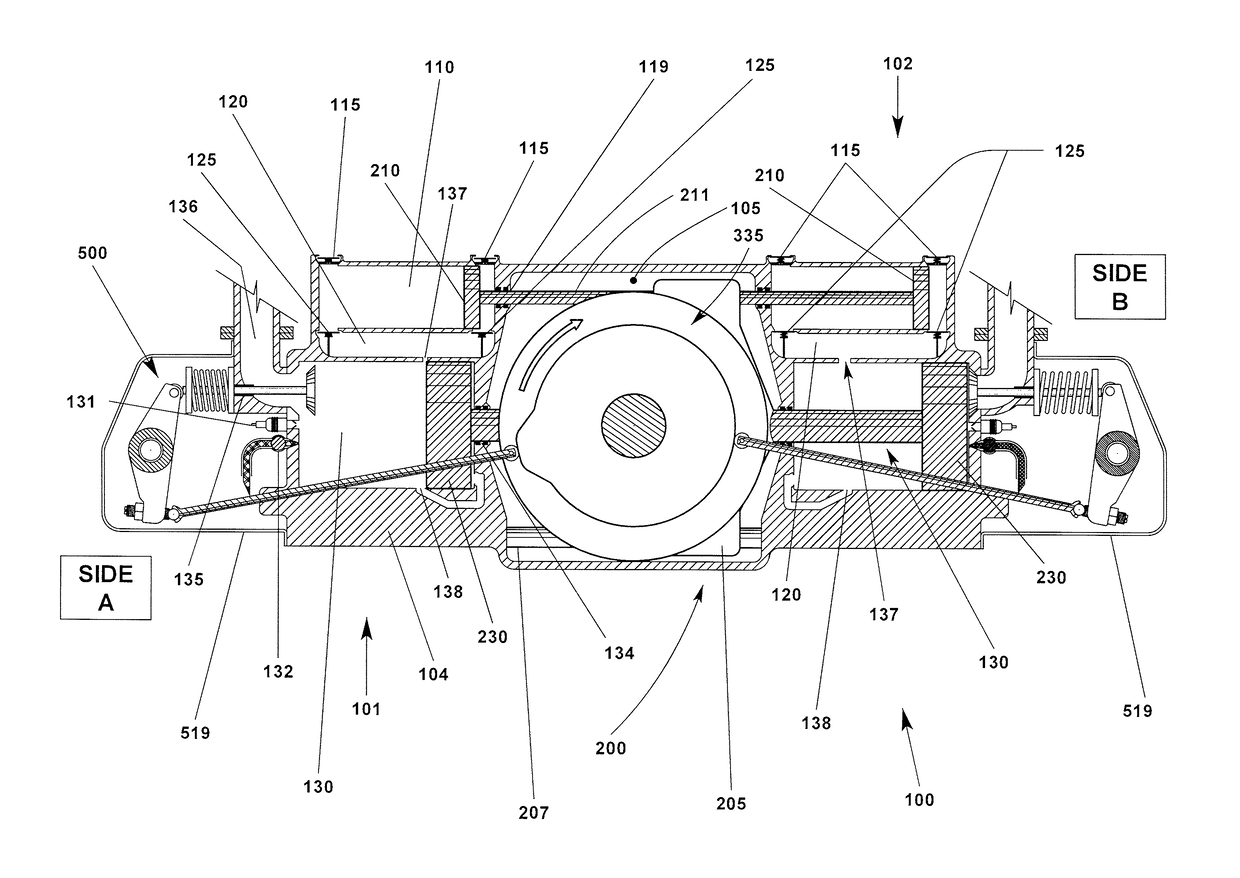

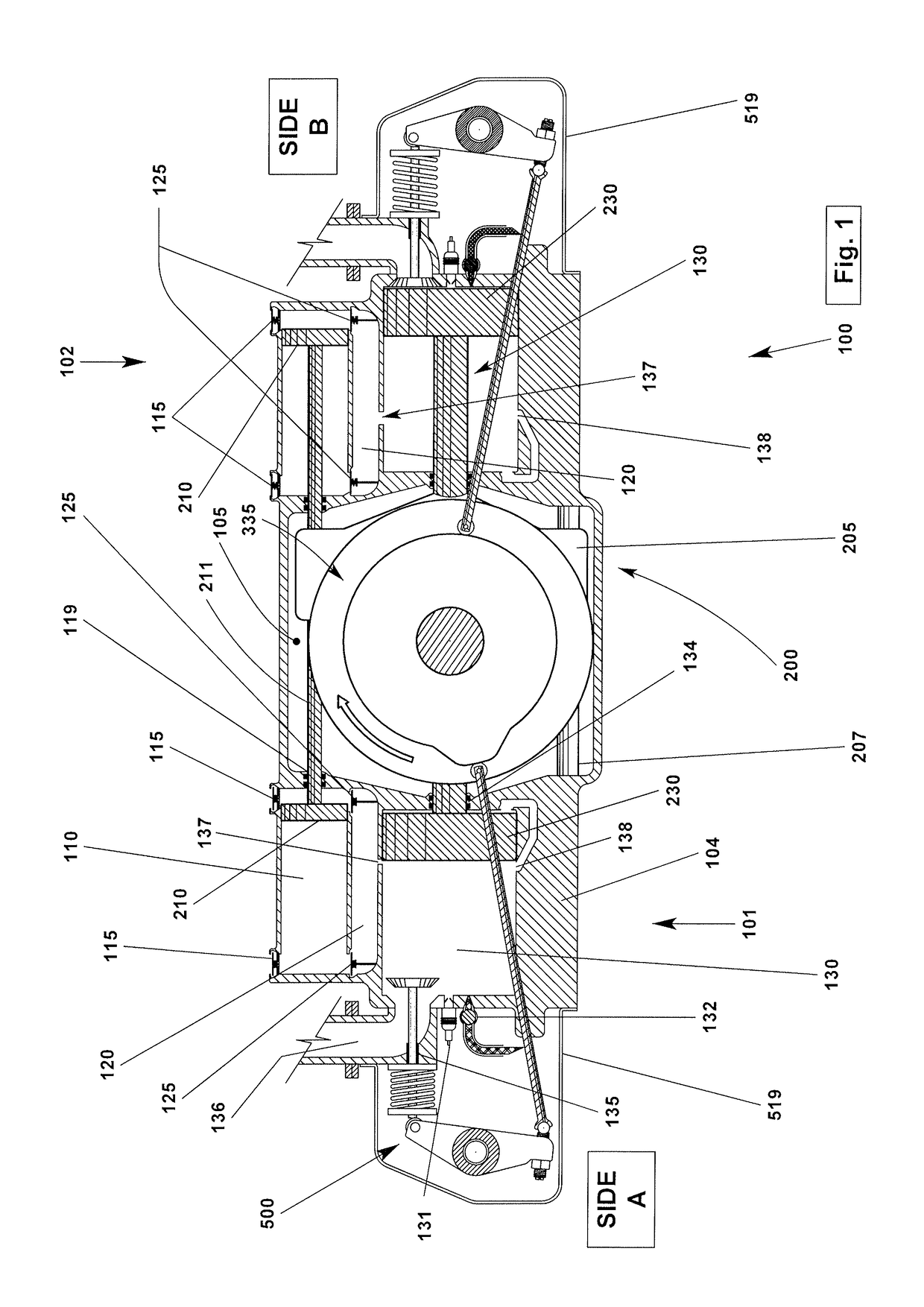

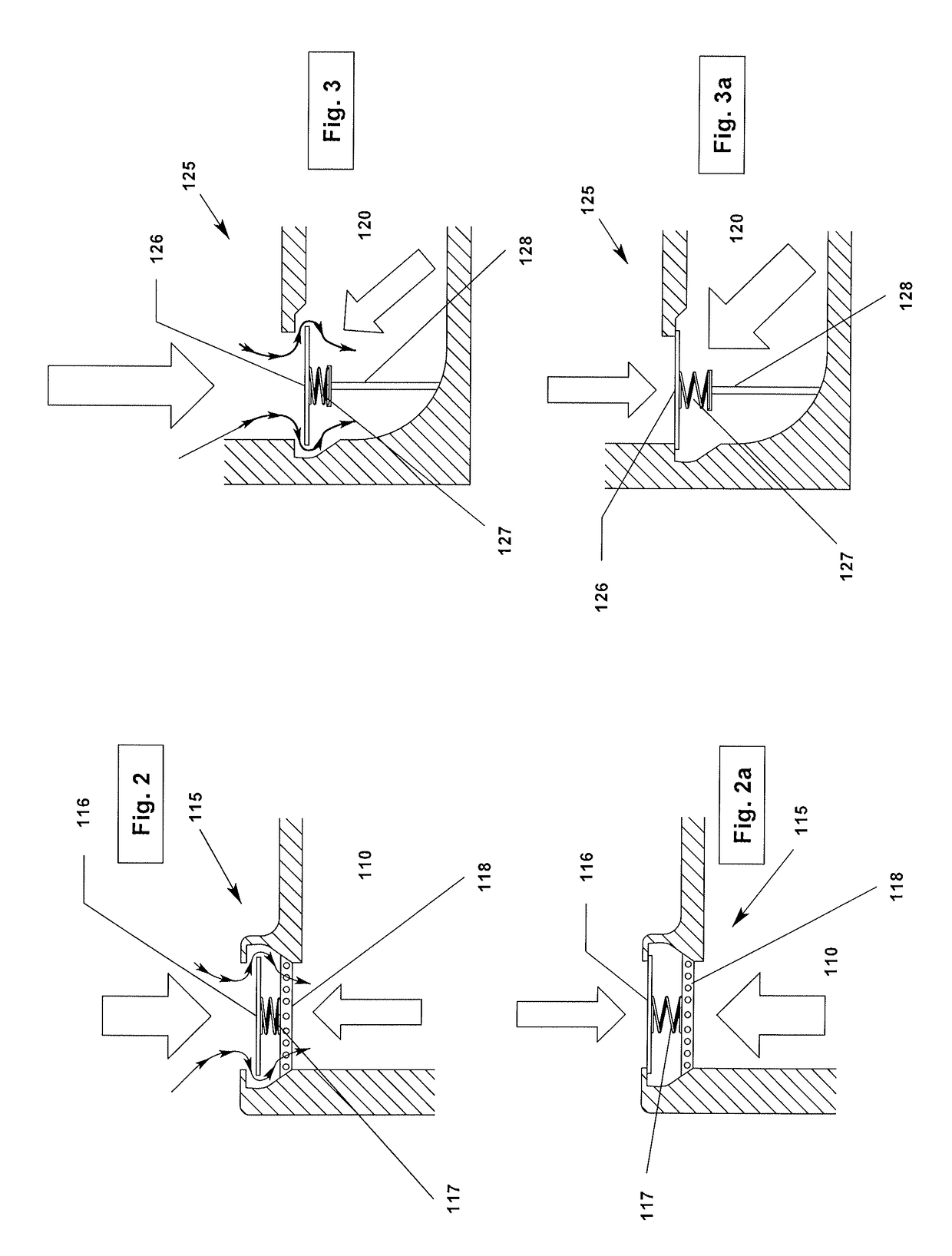

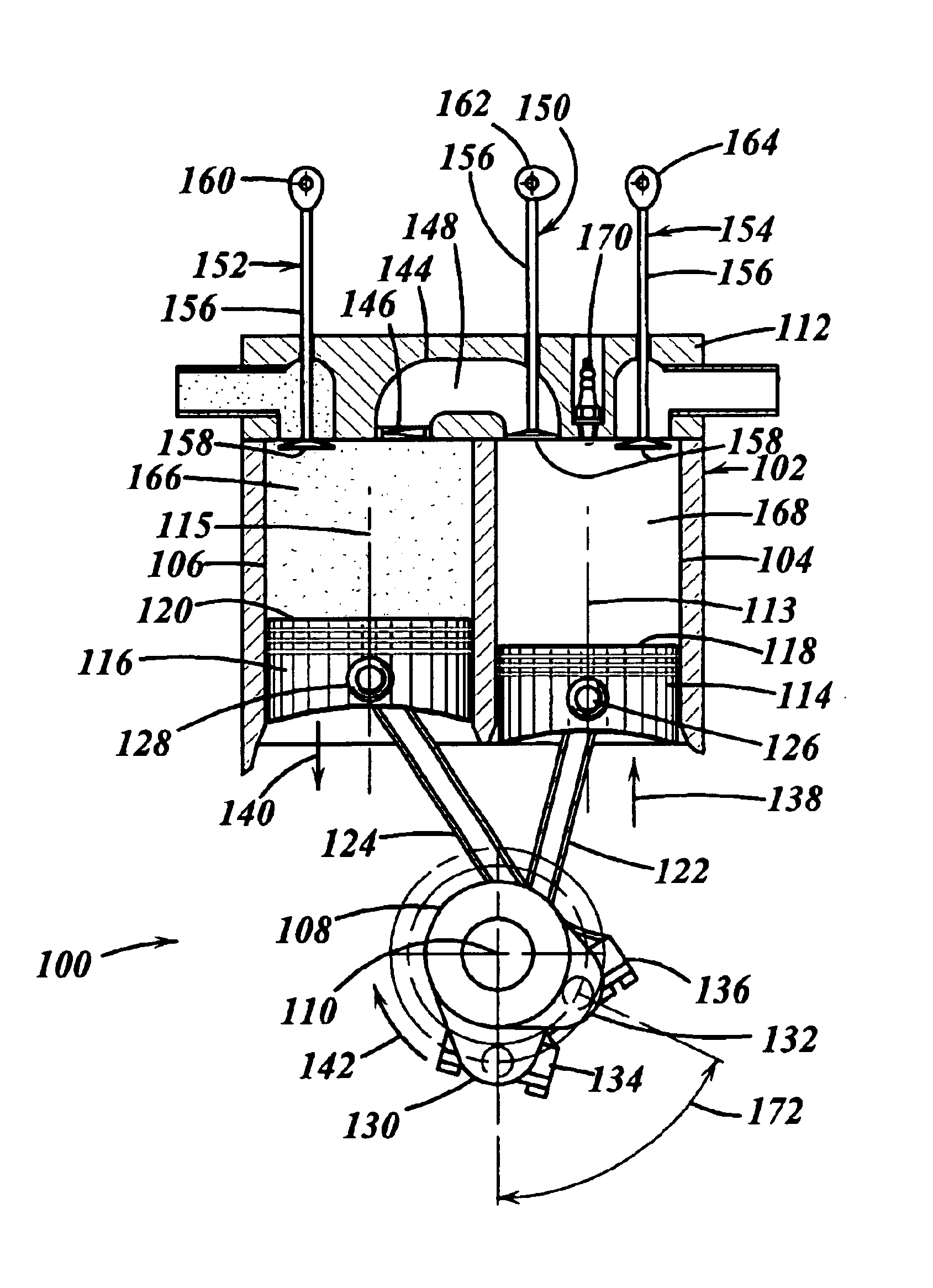

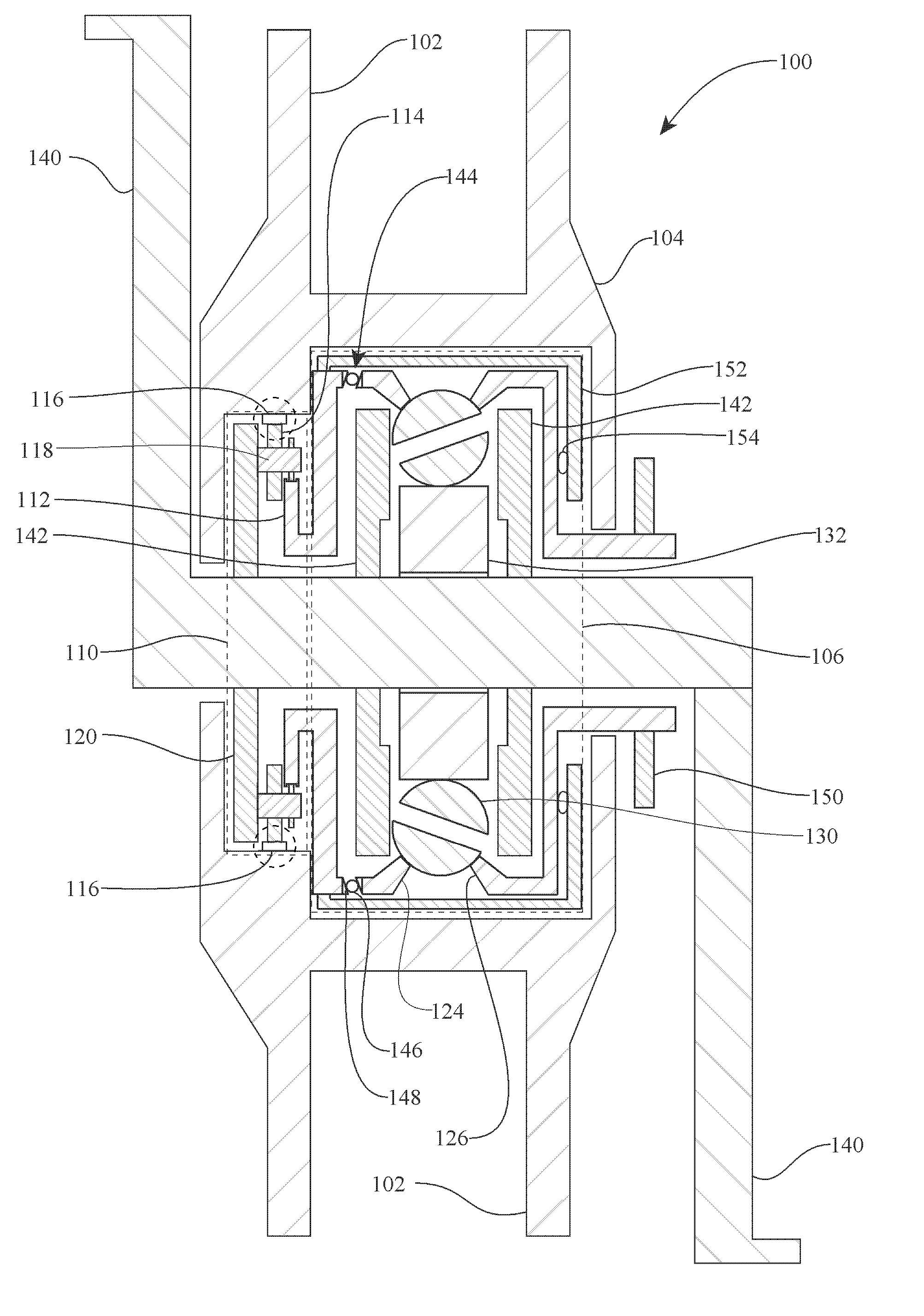

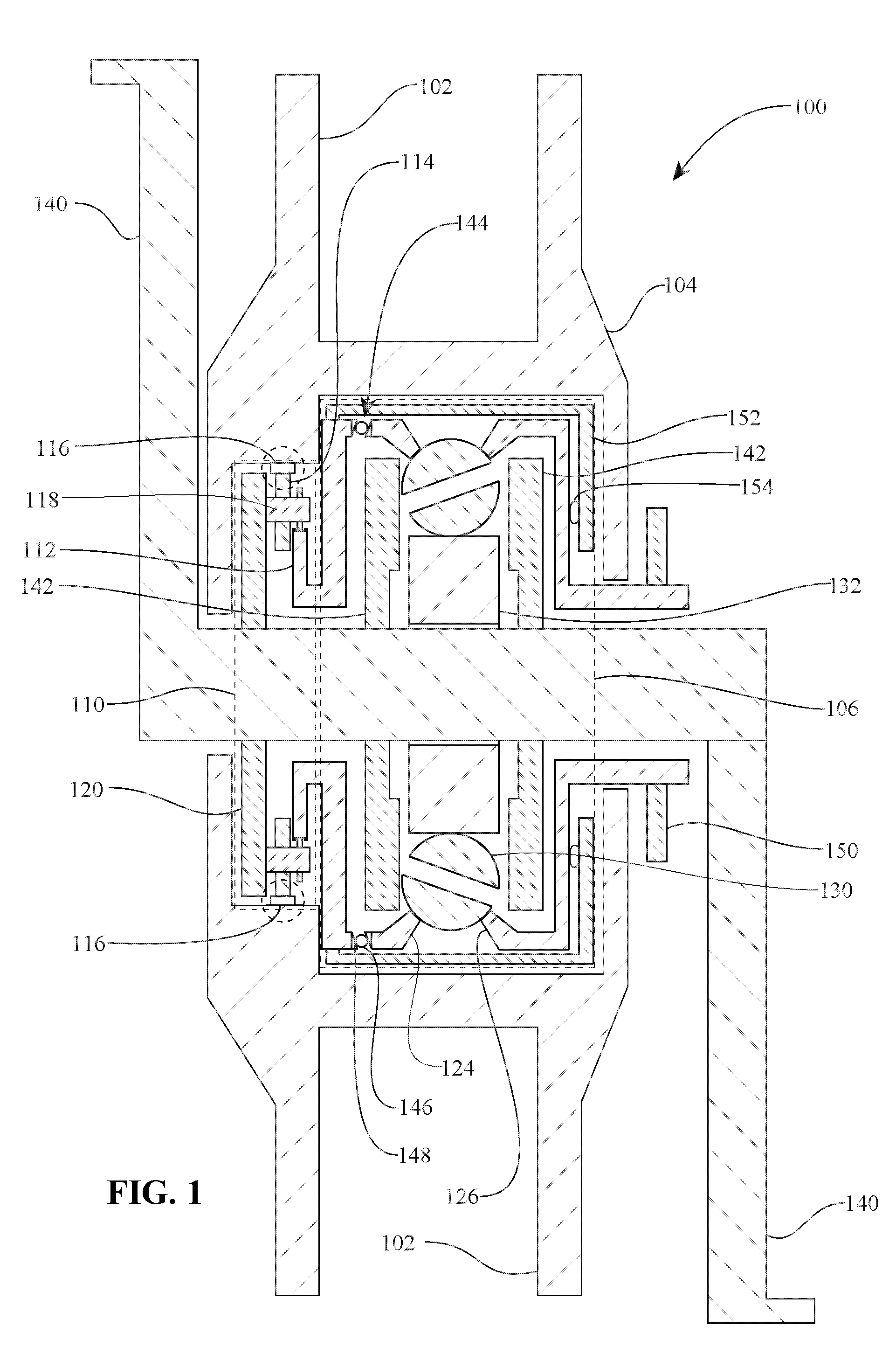

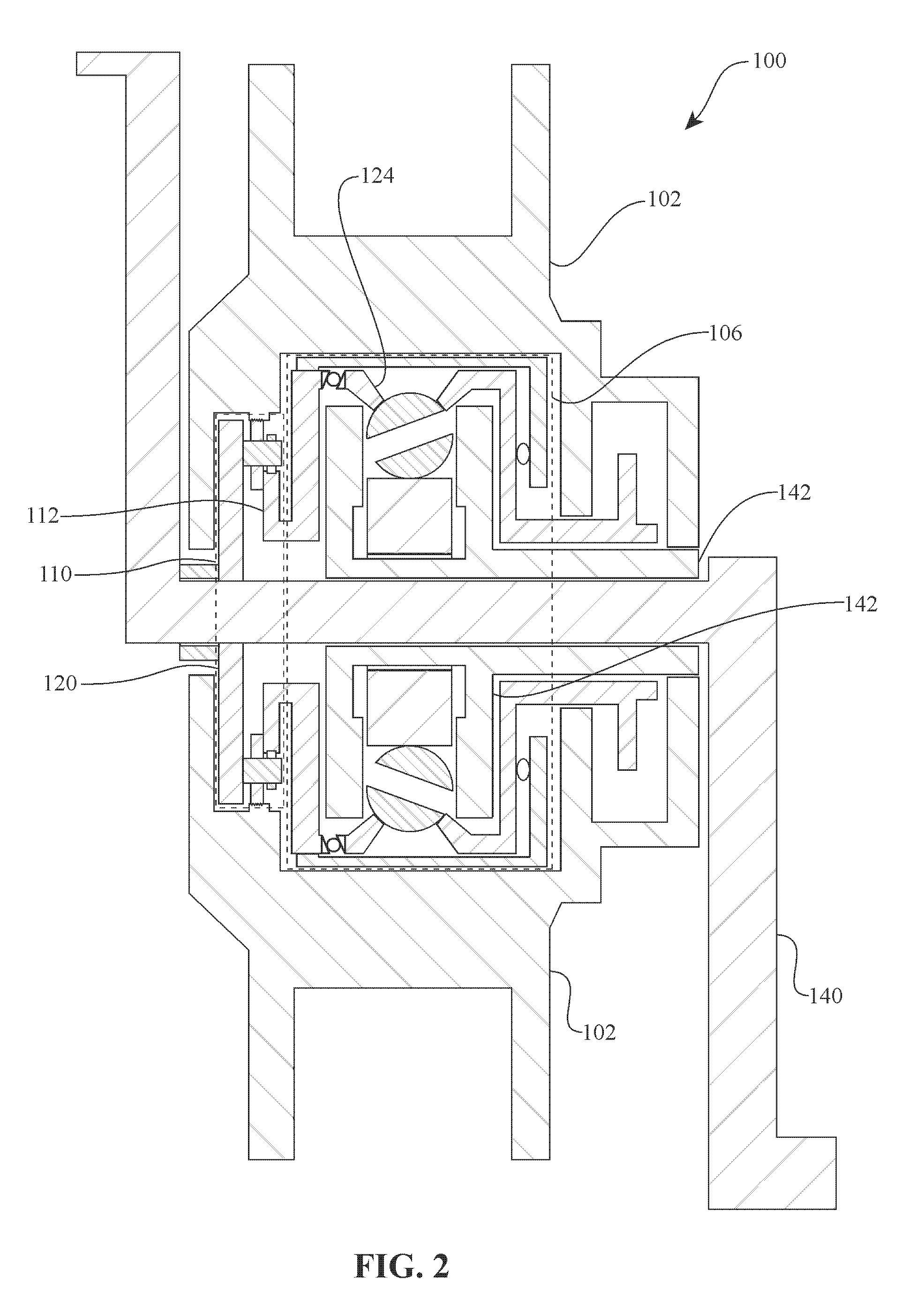

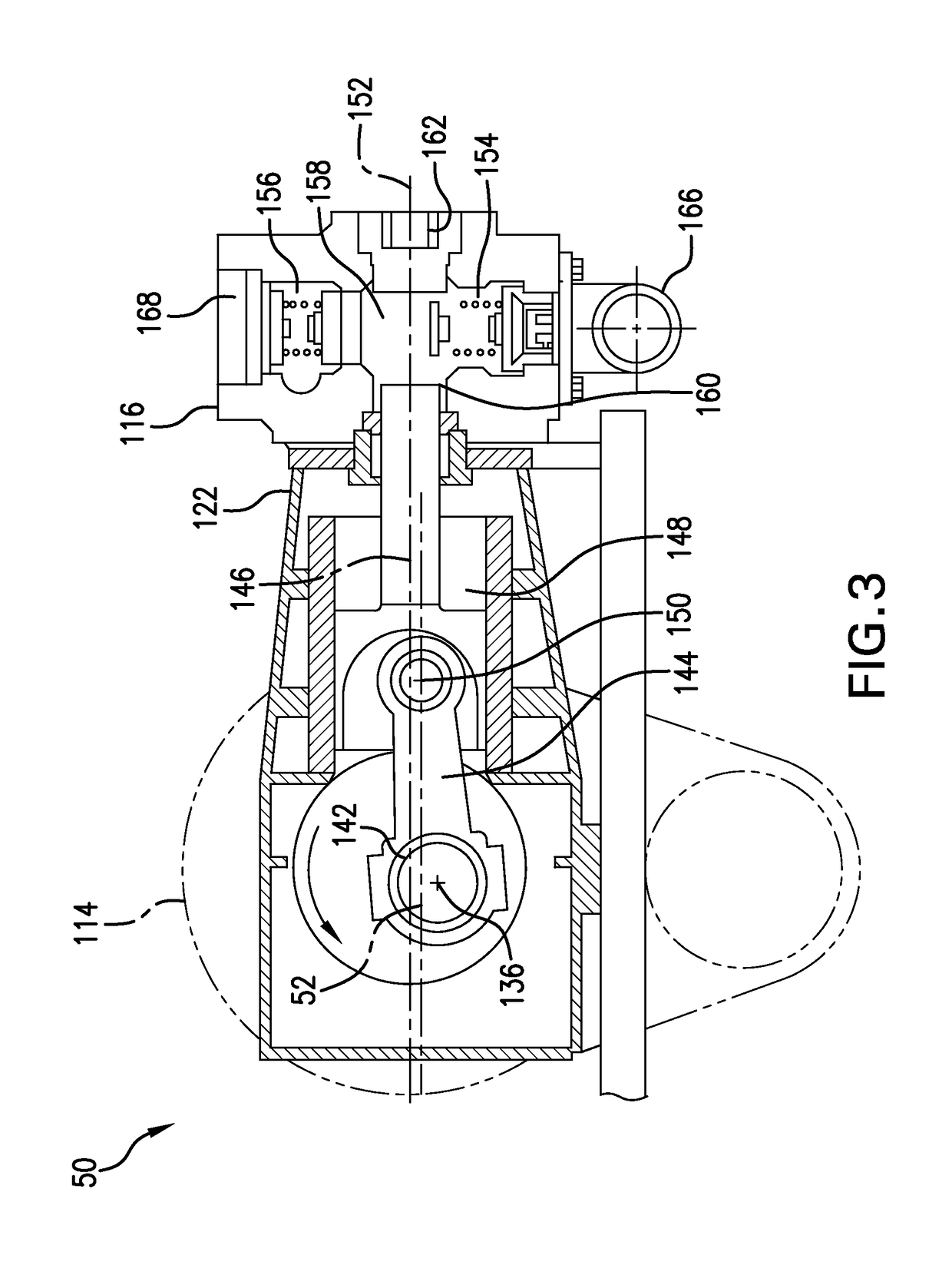

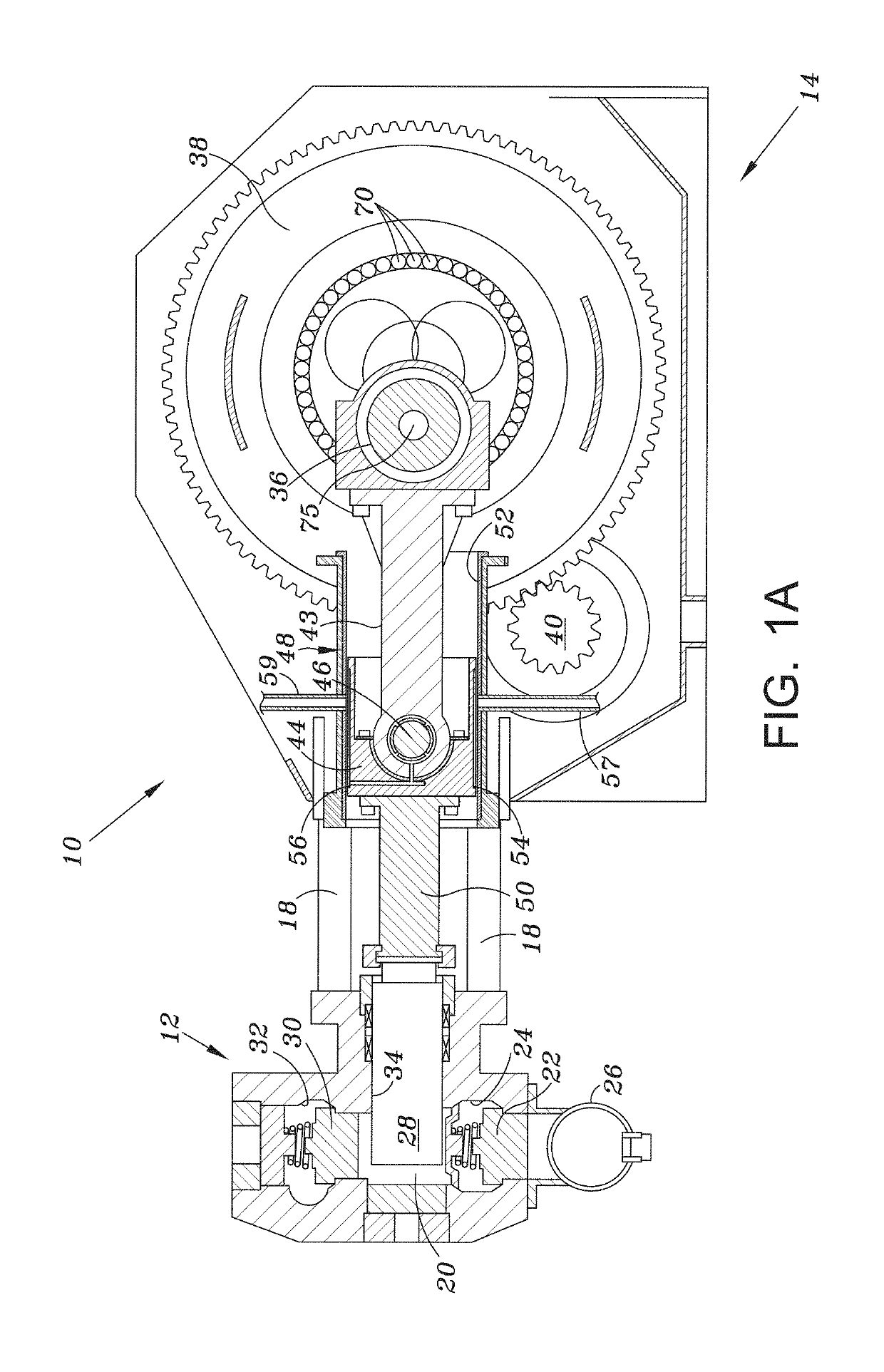

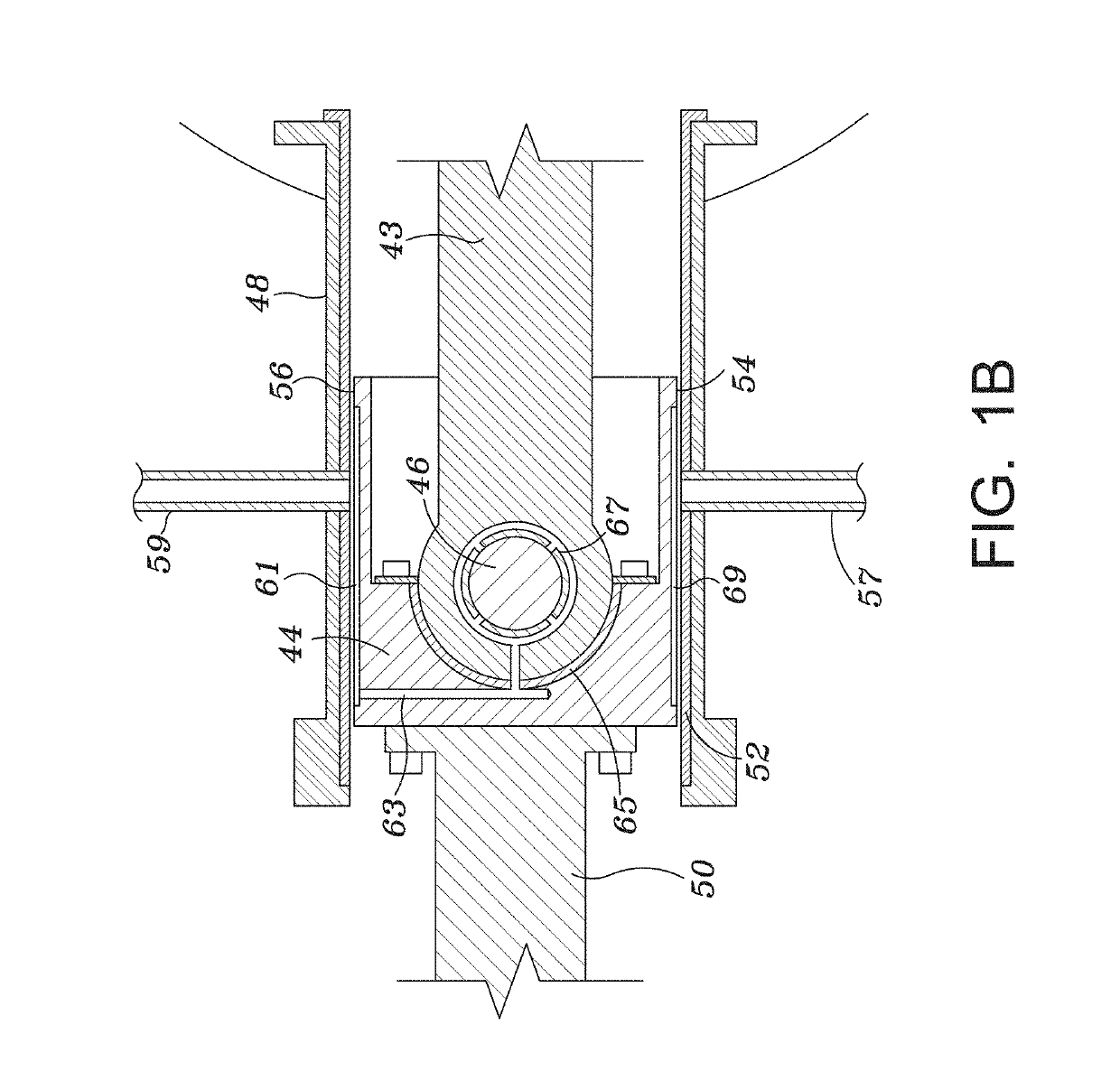

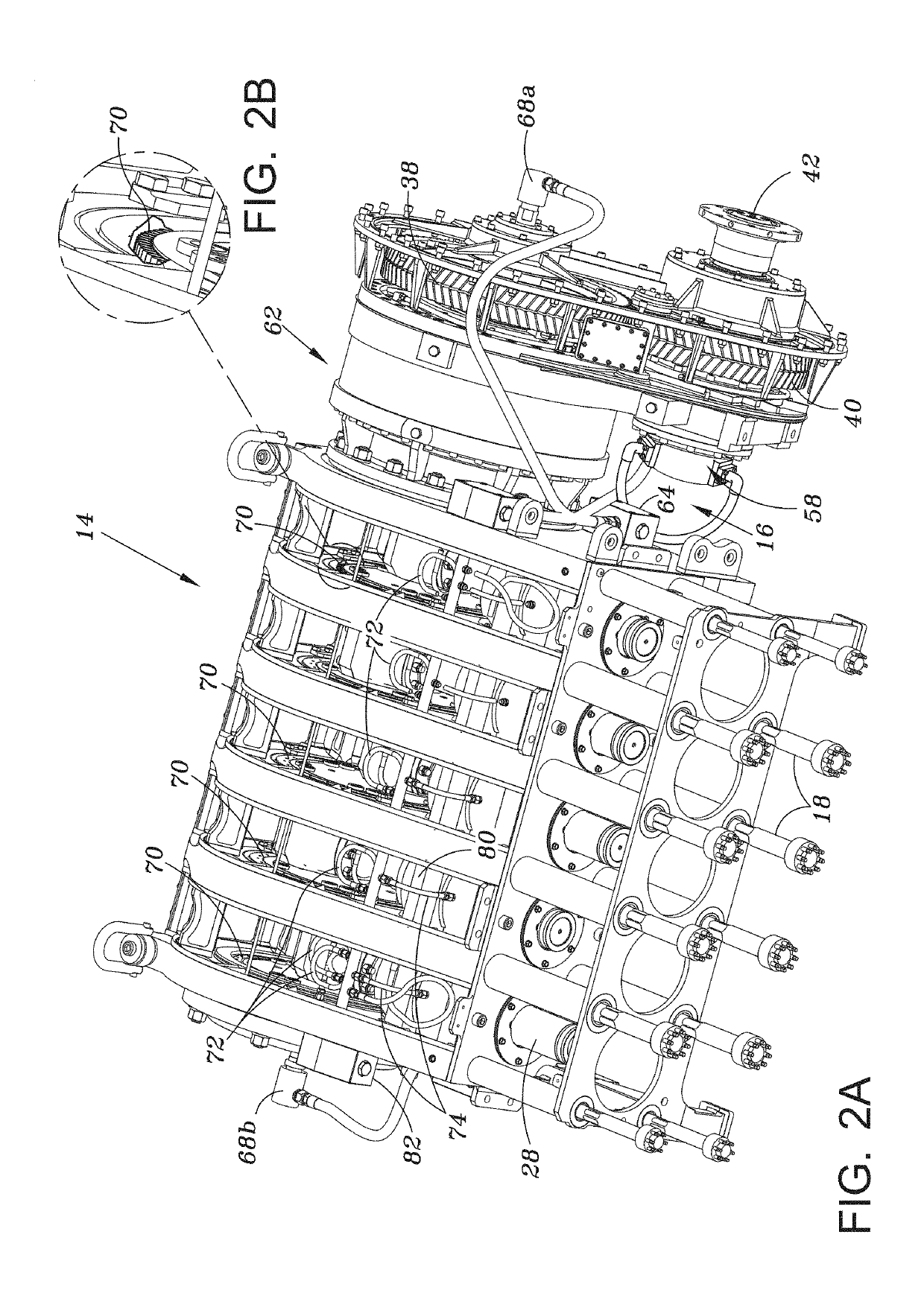

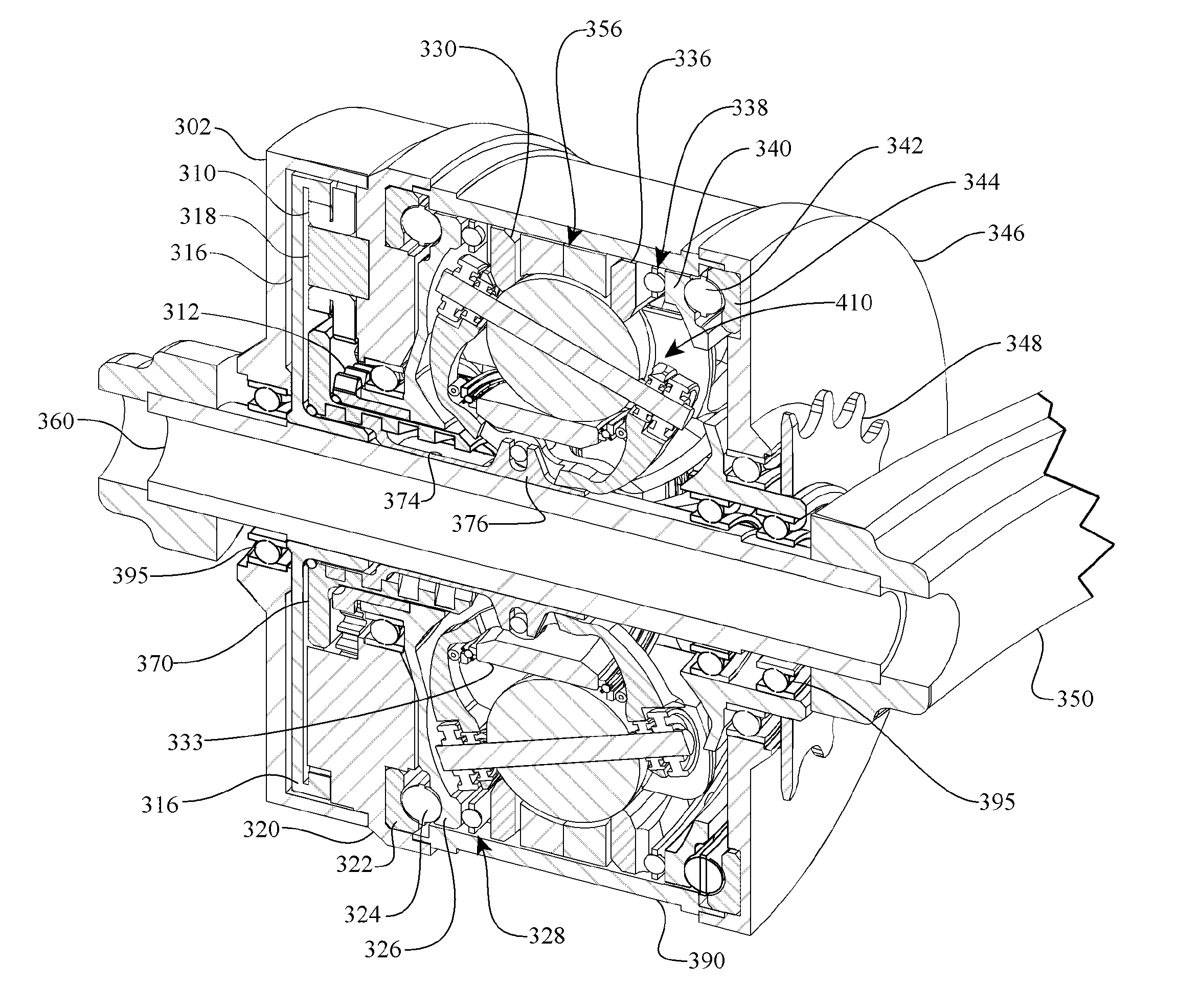

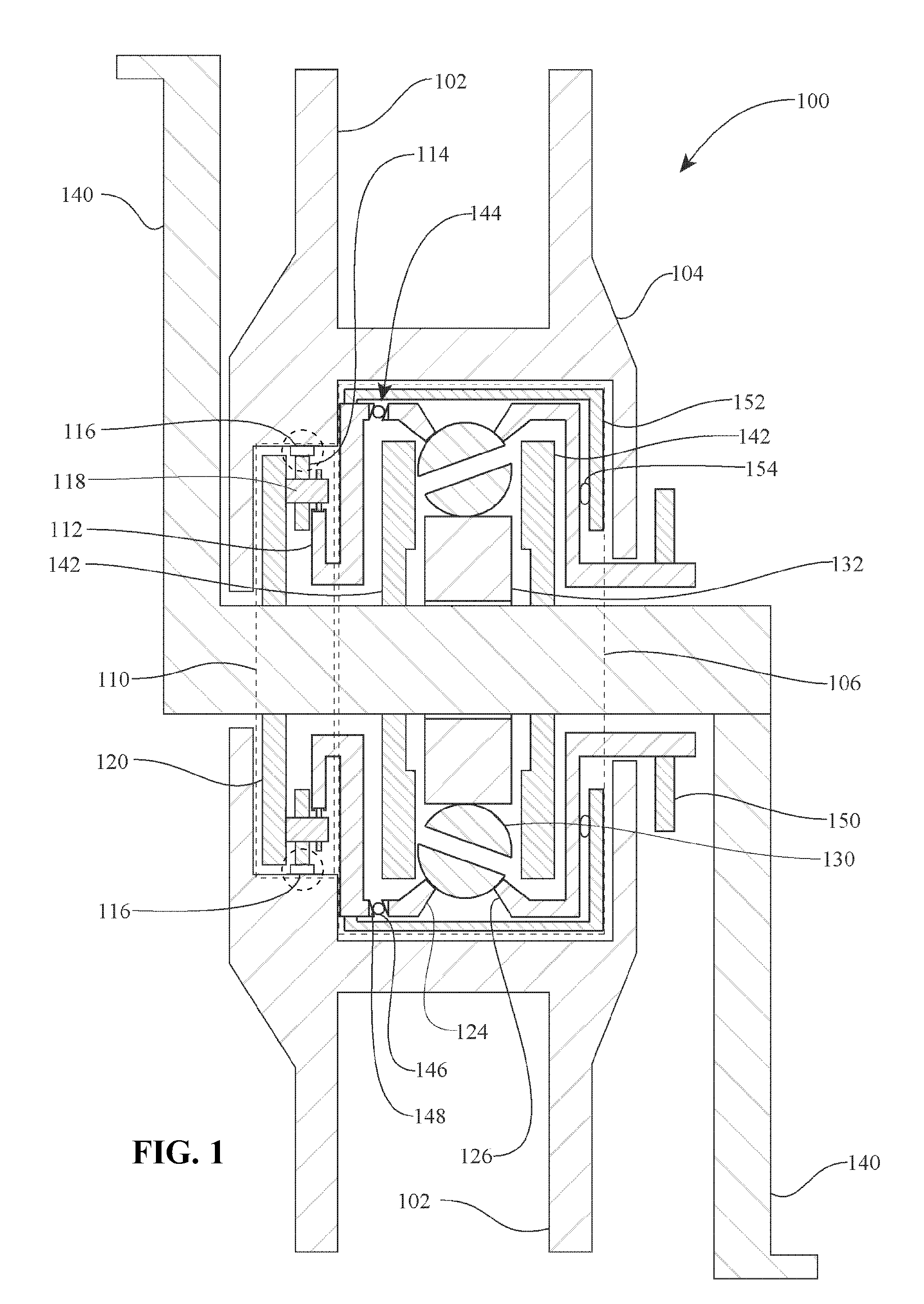

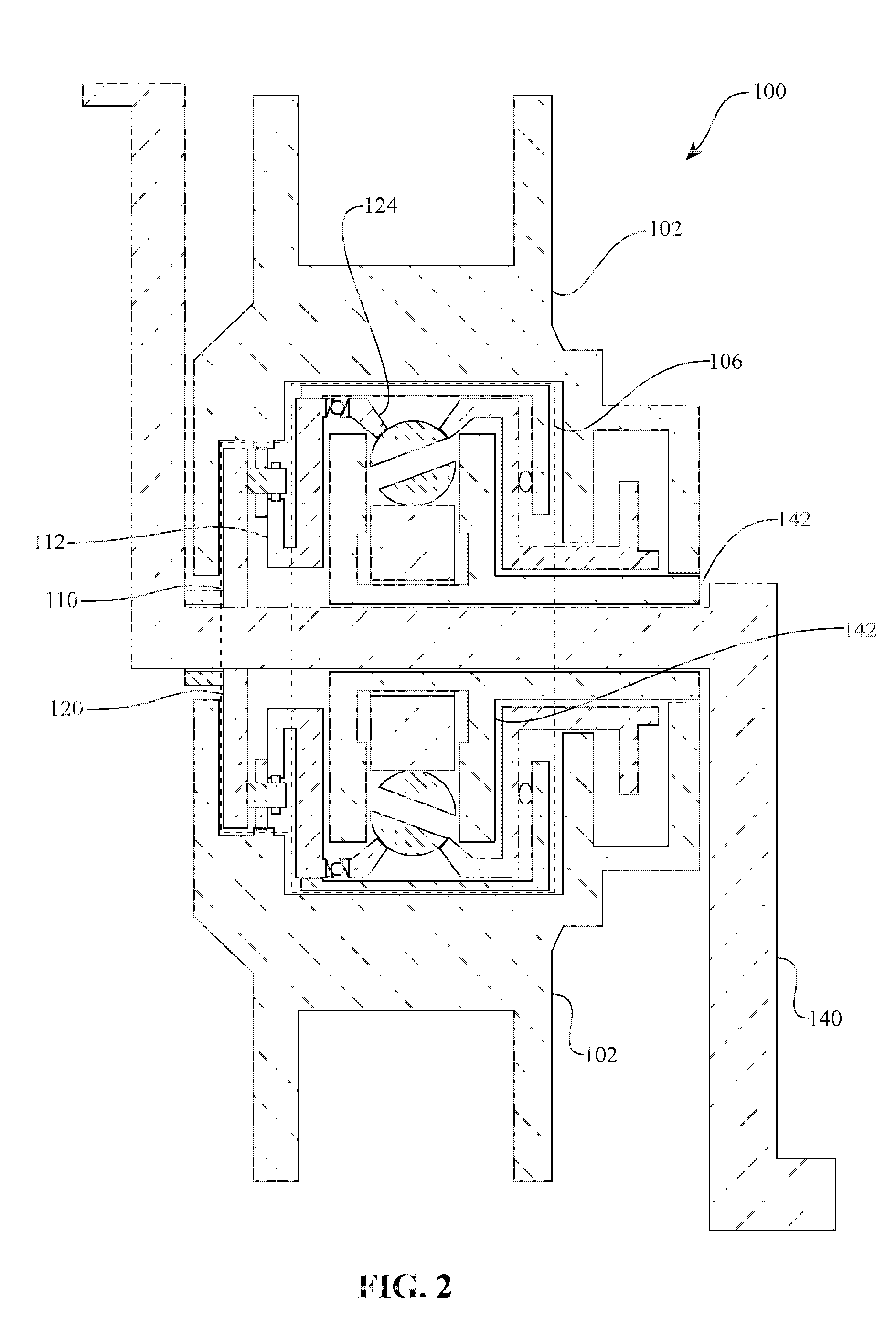

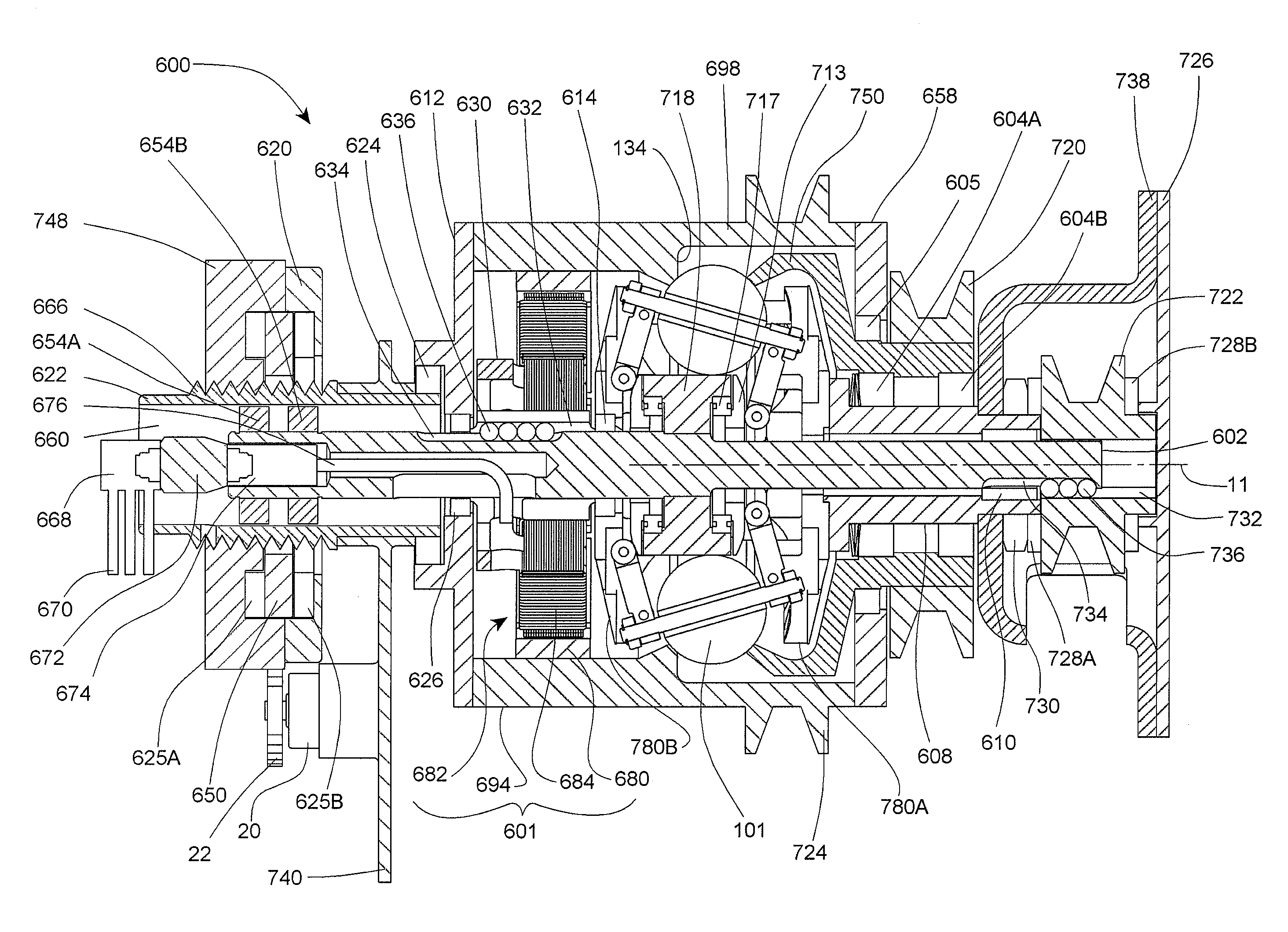

Opposed piston internal combustion engine with inviscid layer sealing

InactiveUS9909492B2Close toleranceAccurate concentricityCombustion enginesReciprocating piston enginesDetonationCombustion

An opposed-piston engine that forms an inviscid layer between pistons and the respective cylinder walls. In an aspect, the opposed-piston engine utilizes a Scotch yoke assembly that includes rigidly connected opposed combustion pistons. In an aspect, the Scotch yoke assembly is configured to transfer power from the combustion pistons to a crankshaft assembly. In an aspect, the crankshaft assembly can be configured to have dual flywheels that are internal to the engine, and can be configured to assist with an exhaust system, a detonation system, and / or a lubrication system.

Owner:PRIME GRP ALLIANCE

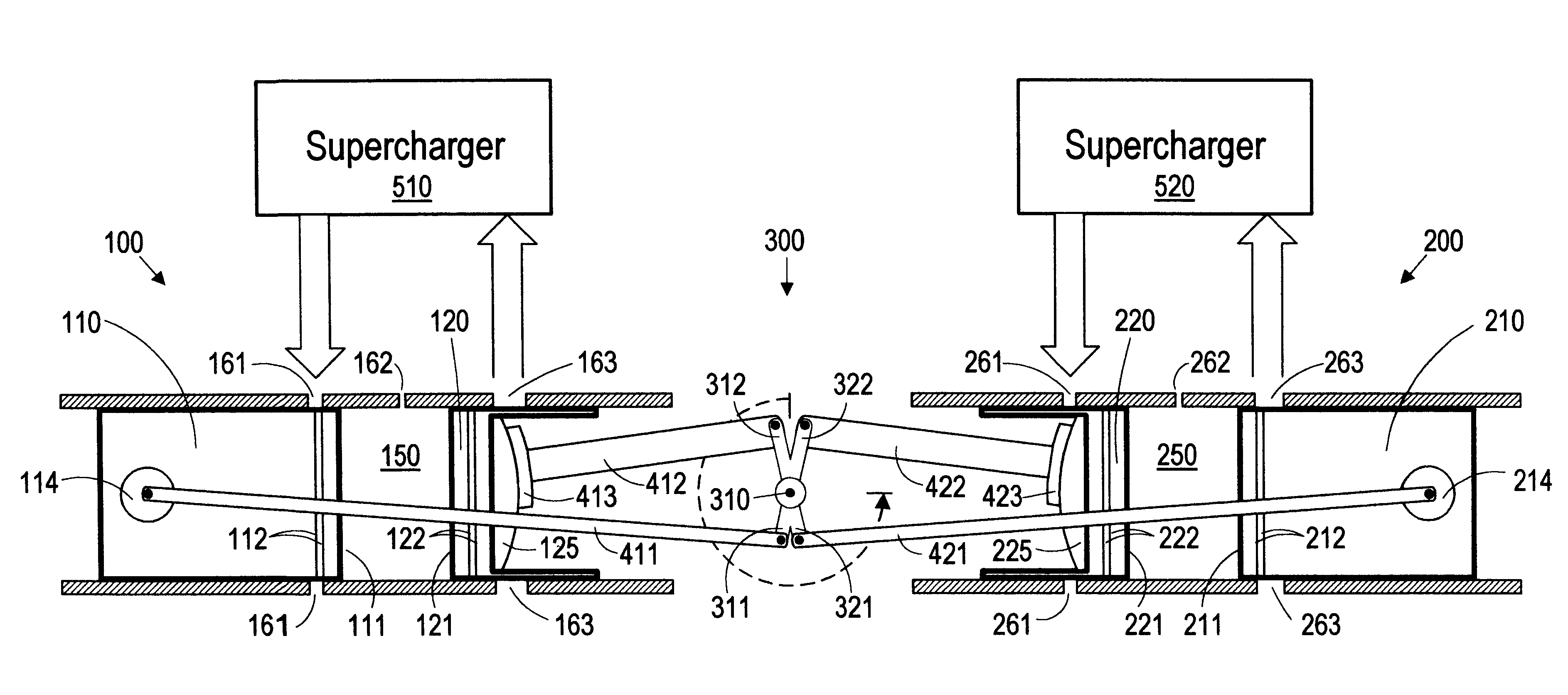

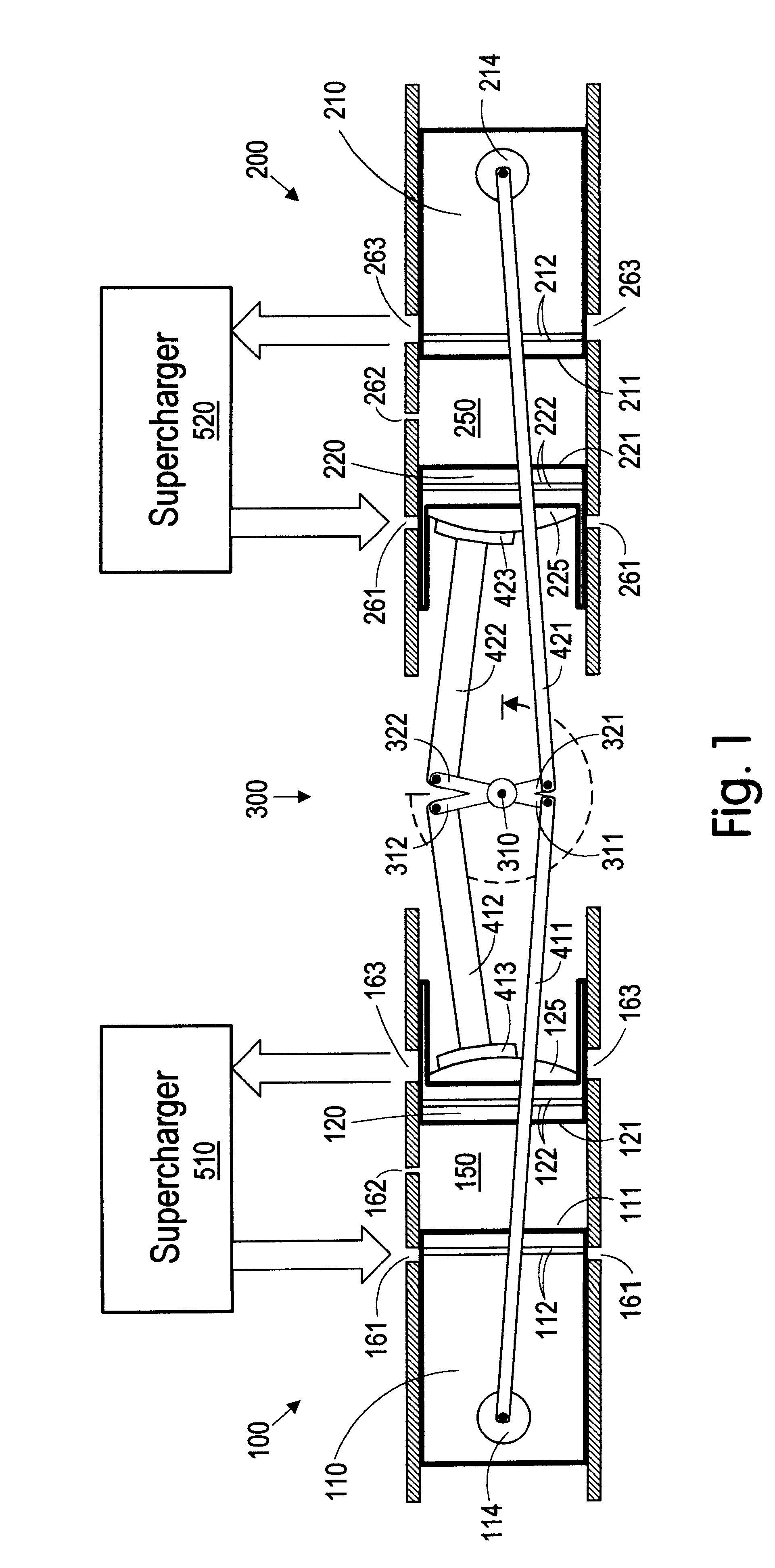

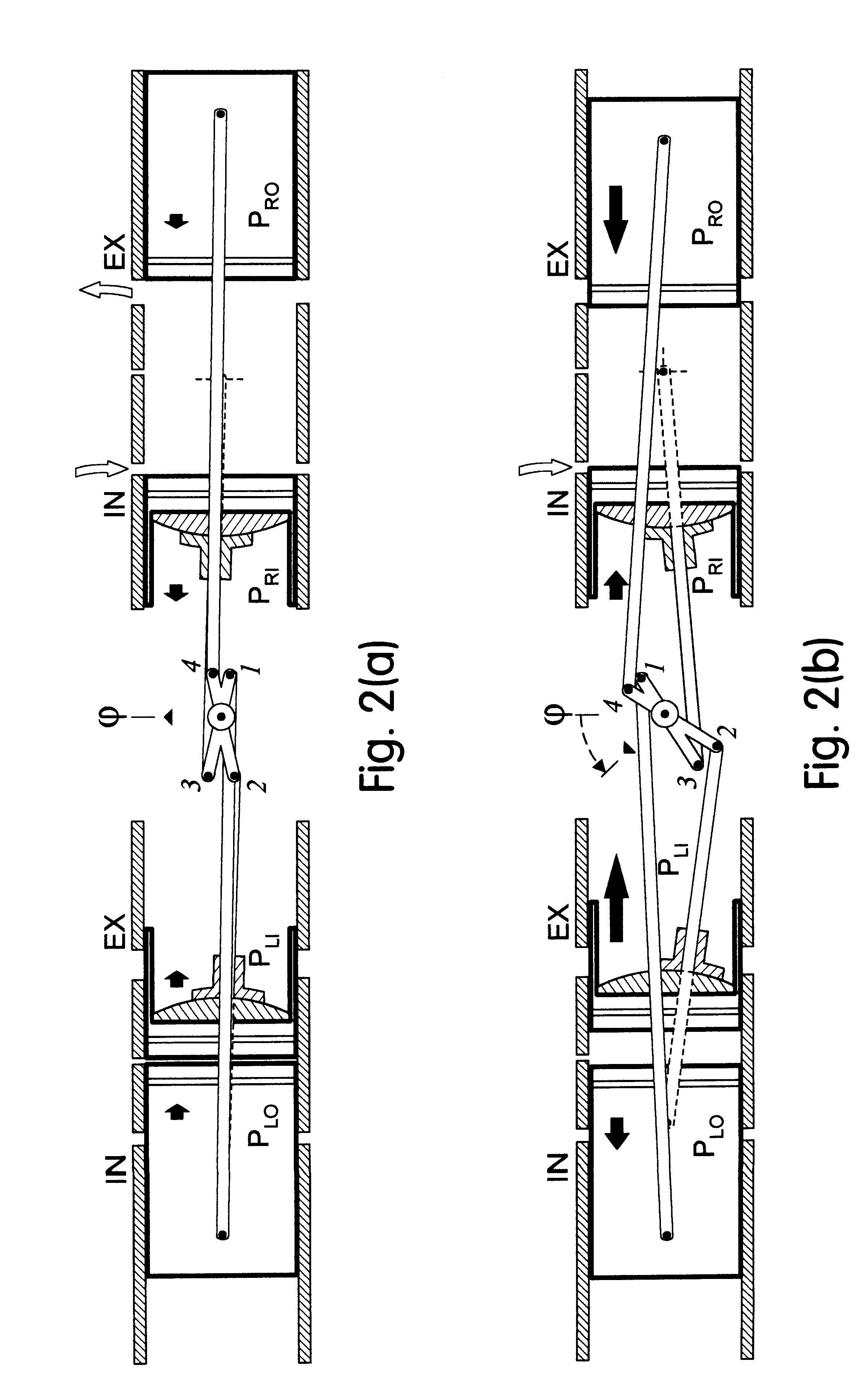

Internal combustion engine with a single crankshaft and having opposed cylinders with opposed pistons

InactiveUS6170443B1MiniaturizationEliminates dynamic imbalanceCombustion enginesReciprocating piston enginesExternal combustion engineEngineering

A two-stroke internal combustion engine is disclosed having opposed cylinders, each cylinder having a pair of opposed pistons, with all the pistons connected to a common central crankshaft. The inboard pistons of each cylinder are connected to the crankshaft with pushrods and the outboard pistons are connected to the crankshaft with pullrods. This configuration results in a compact engine with a very low profile, in which the free mass forces can be essentially totally balanced. The engine configuration also allows for asymmetrical timing of the intake and exhaust ports through independent angular positioning of the eccentrics on the crankshaft, making the engine suitable for supercharging.

Owner:ADVANCED PROPULSION TECH +1

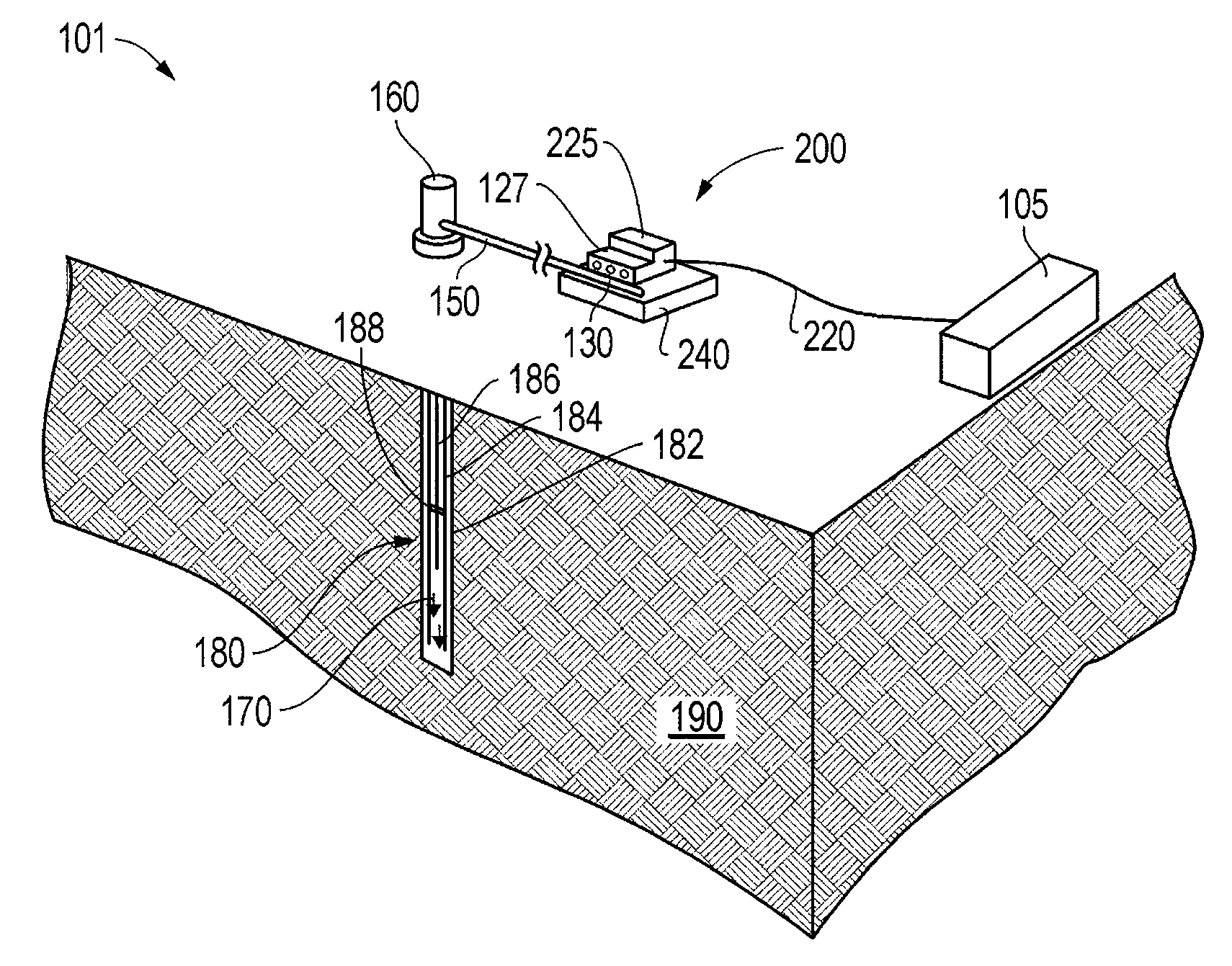

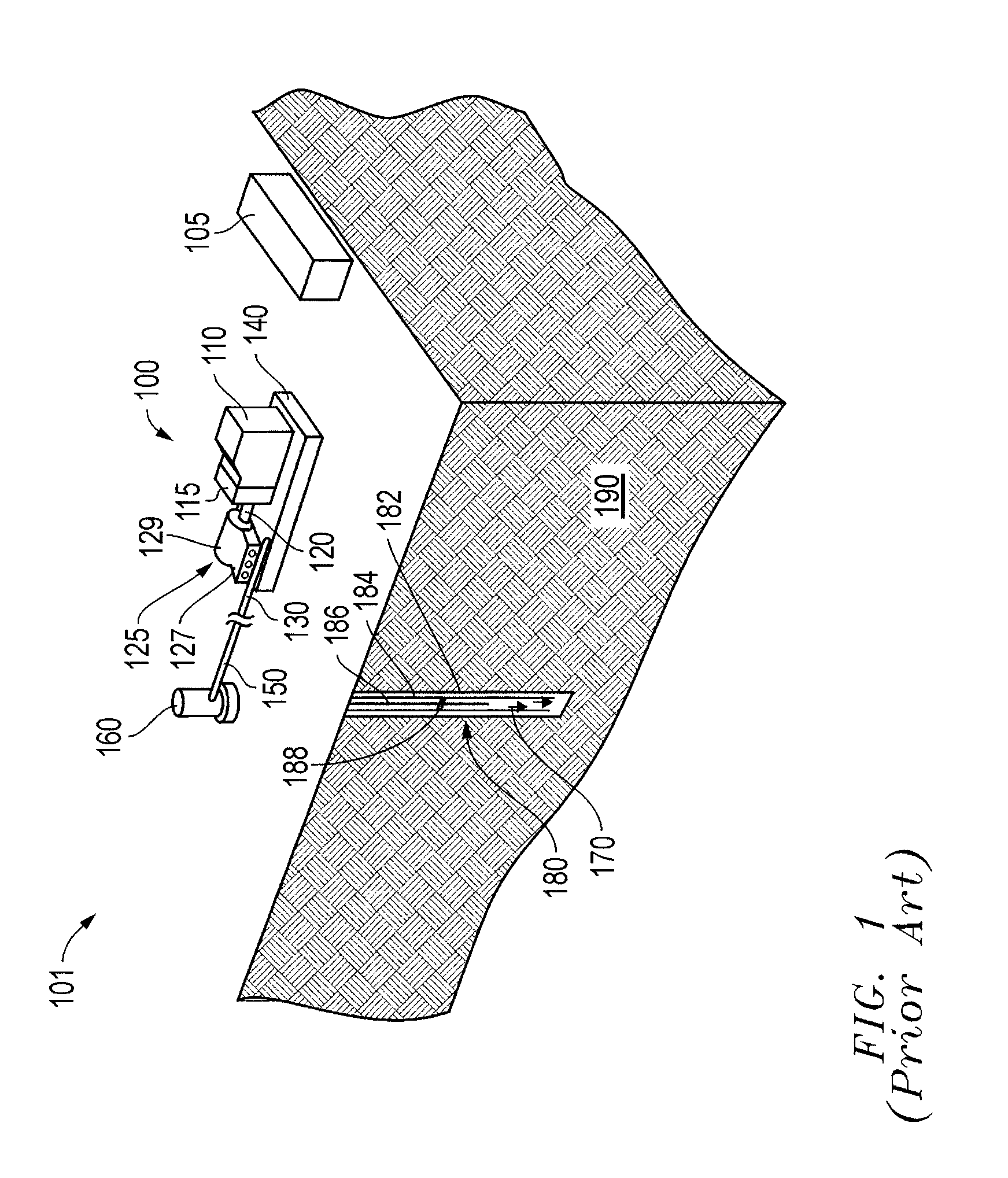

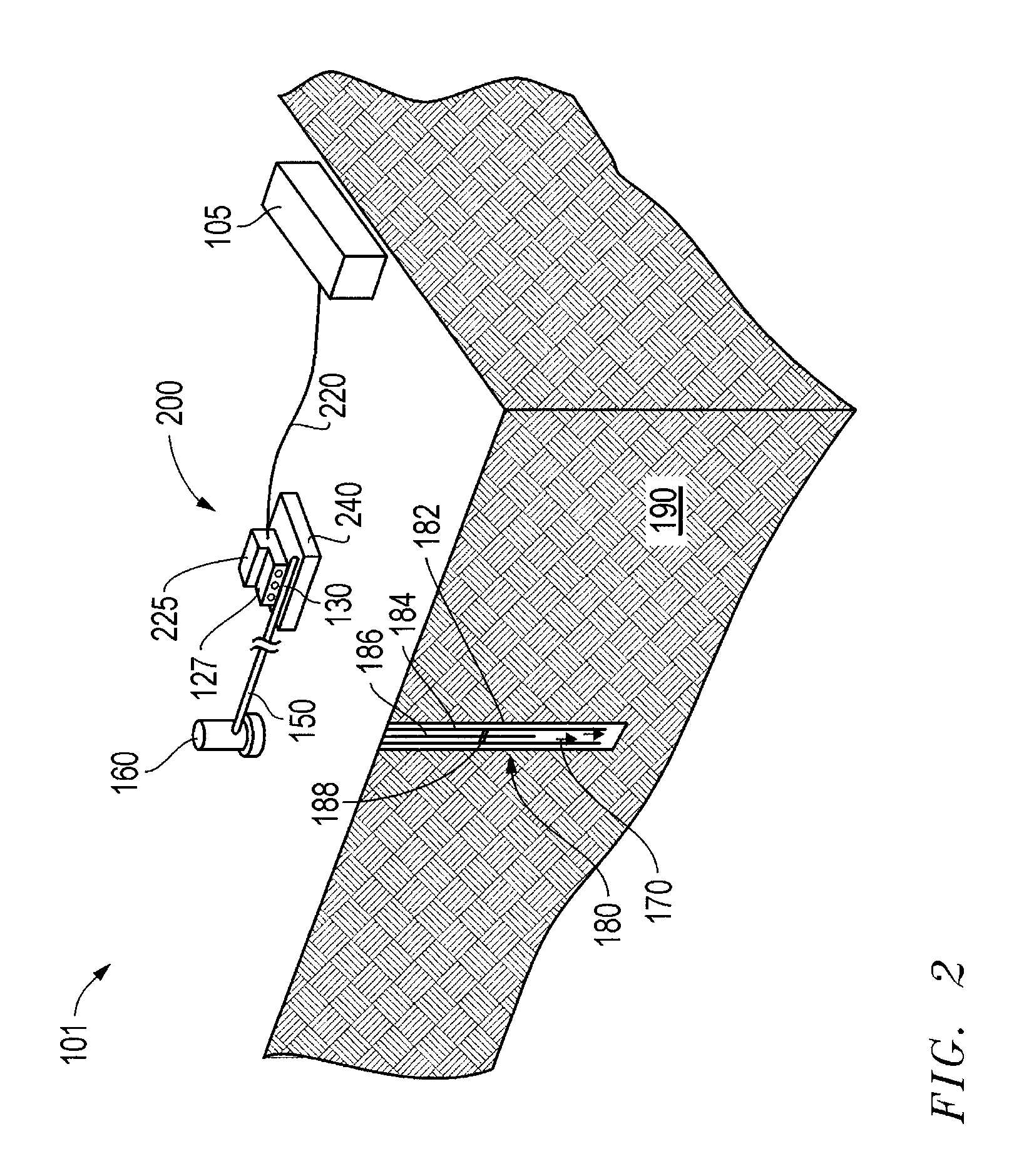

Linear electric motor for an oilfield pump

An oilfield pump employing a linear electric motor. The linear electric motor replaces a conventional crankshaft or hydraulic techniques for driving a plunger of the pump. This may reduce the number of equipment parts and amount of maintenance expenses associated with the operation of oilfield pumps. Furthermore, the use of a linear electric motor may also increase the precision and control over the fluid delivery provided by the pump assembly.

Owner:SCHLUMBERGER TECH CORP

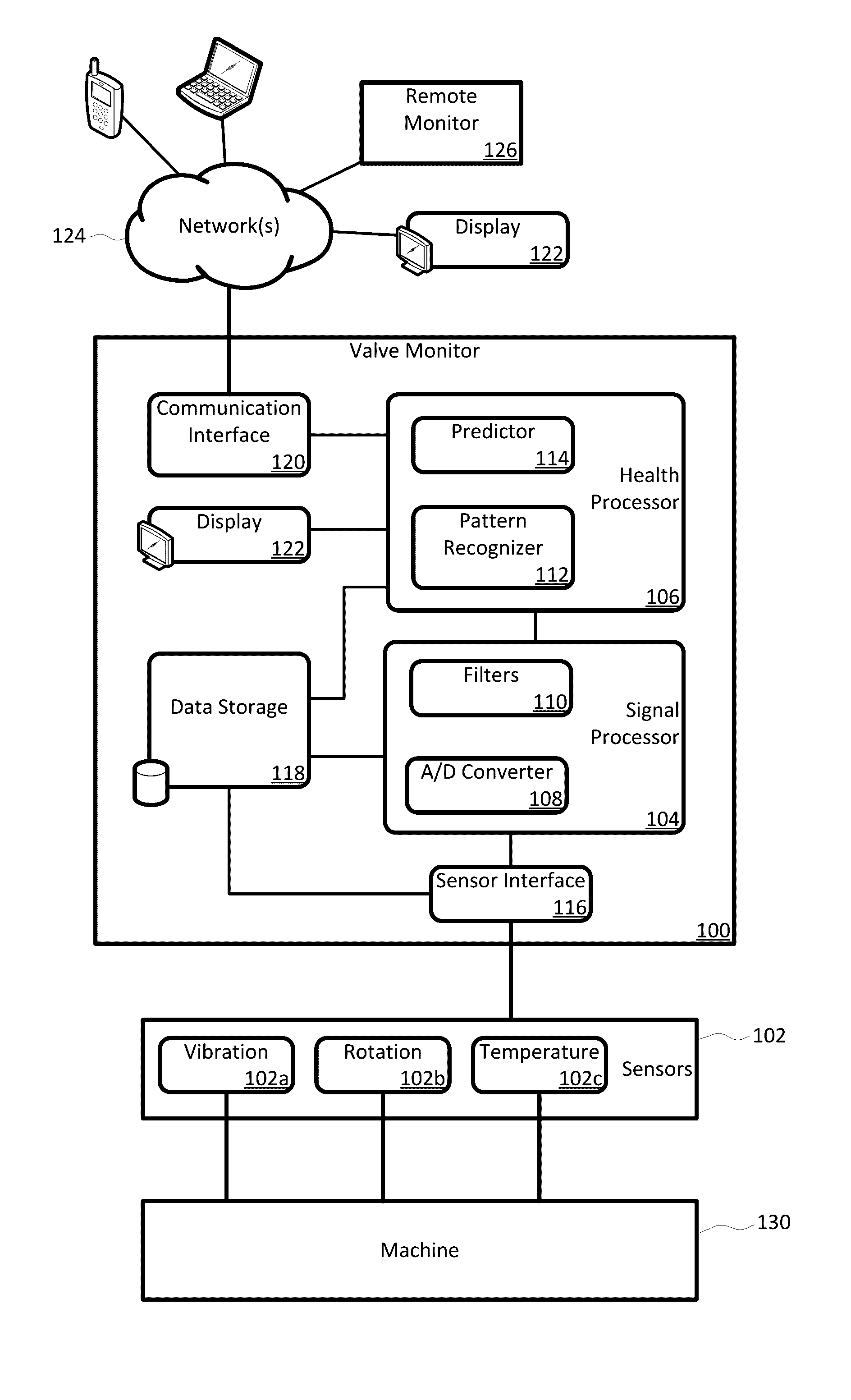

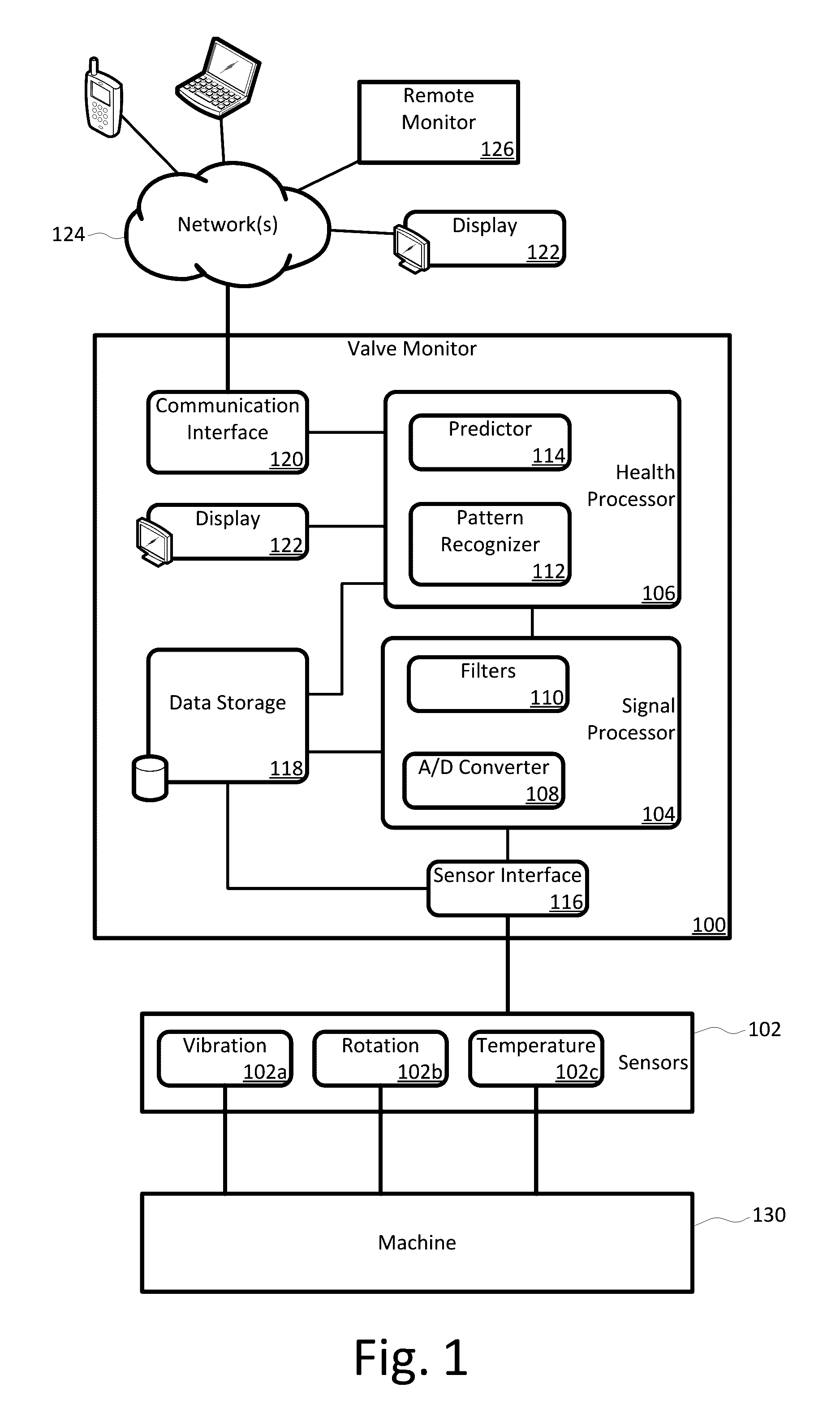

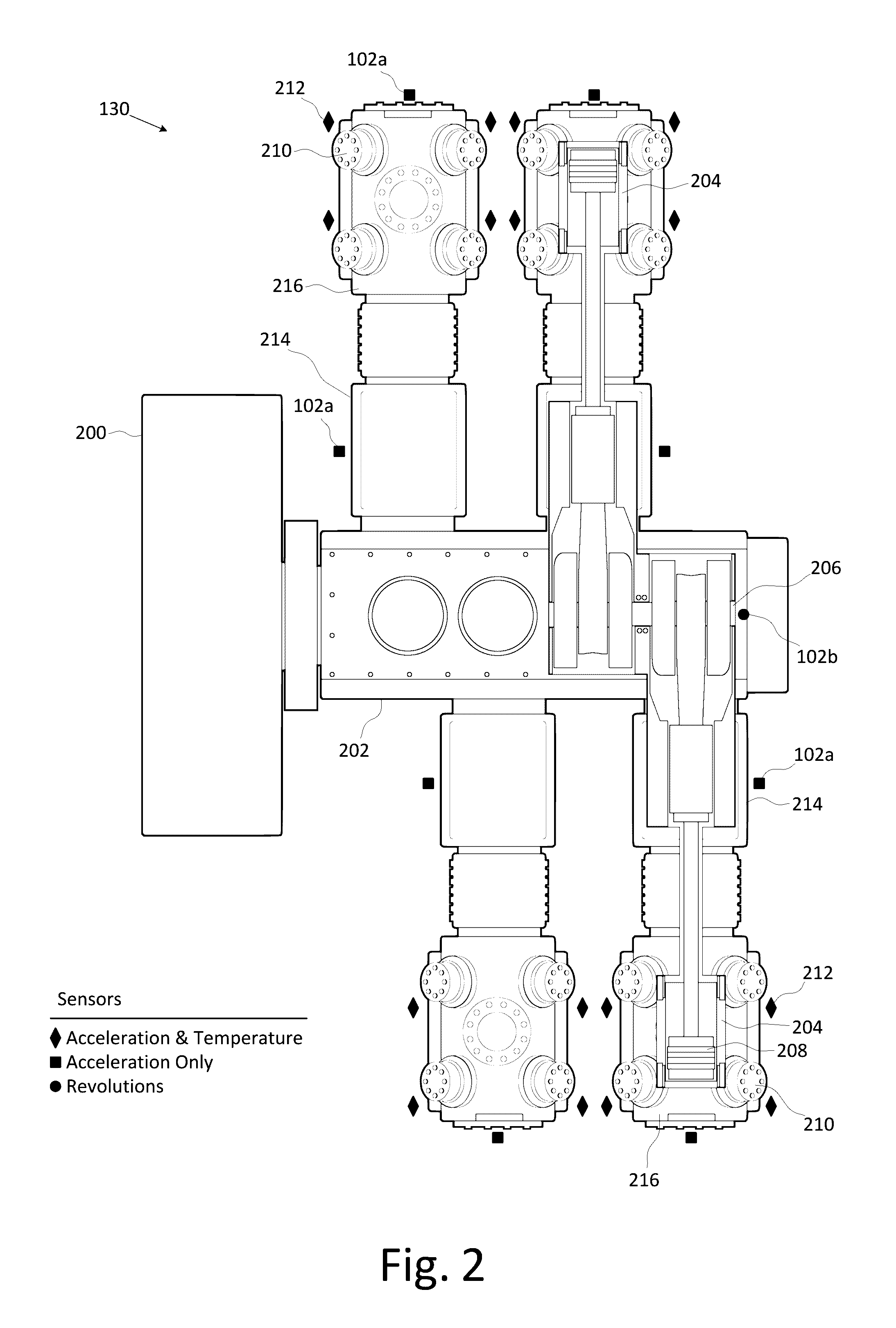

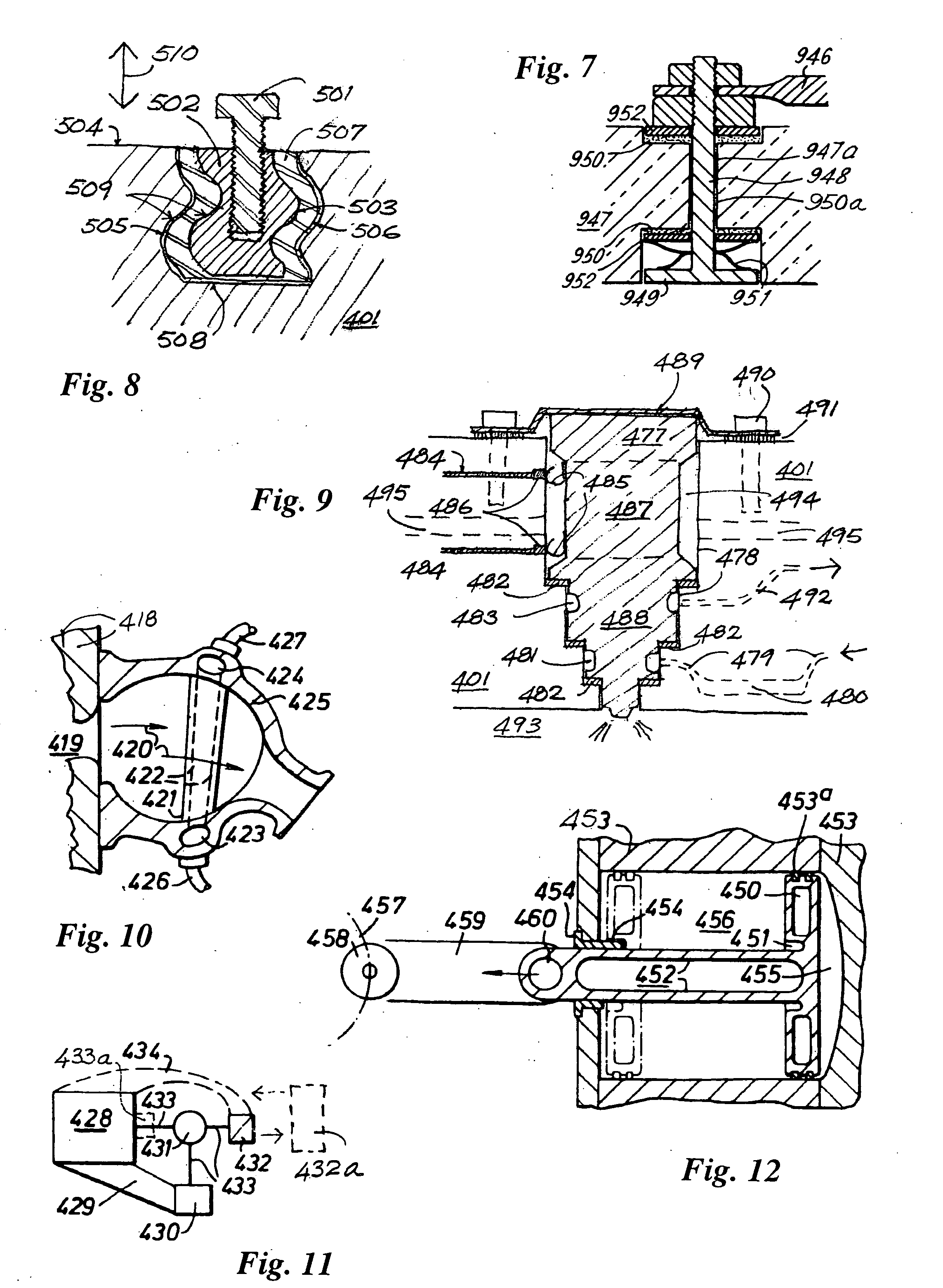

Compressor Valve Health Monitor

ActiveUS20170030349A1Improve analysisImprove notificationsExternal parameterPositive displacement pump componentsSignal-to-noise ratio (imaging)Engineering

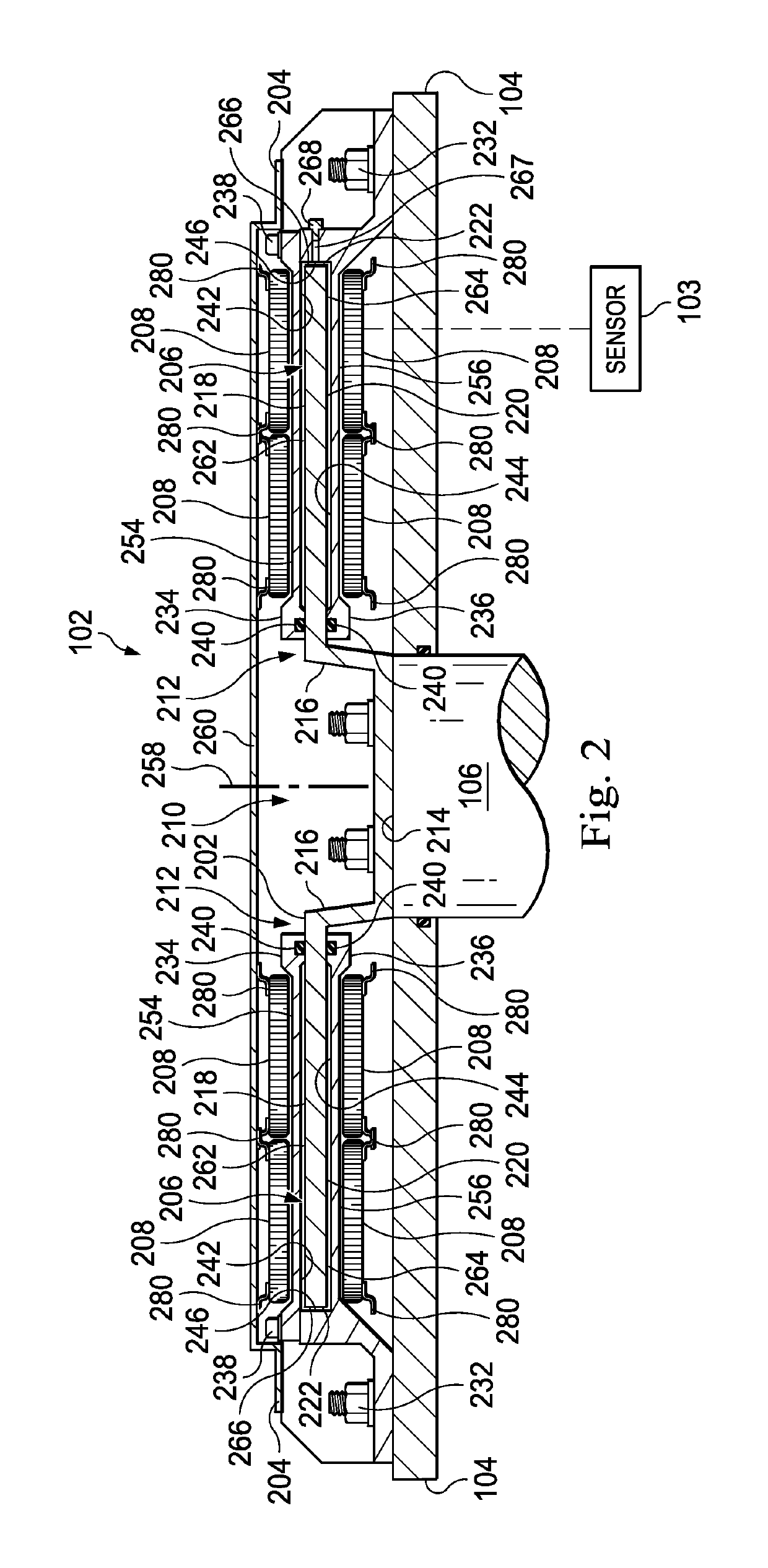

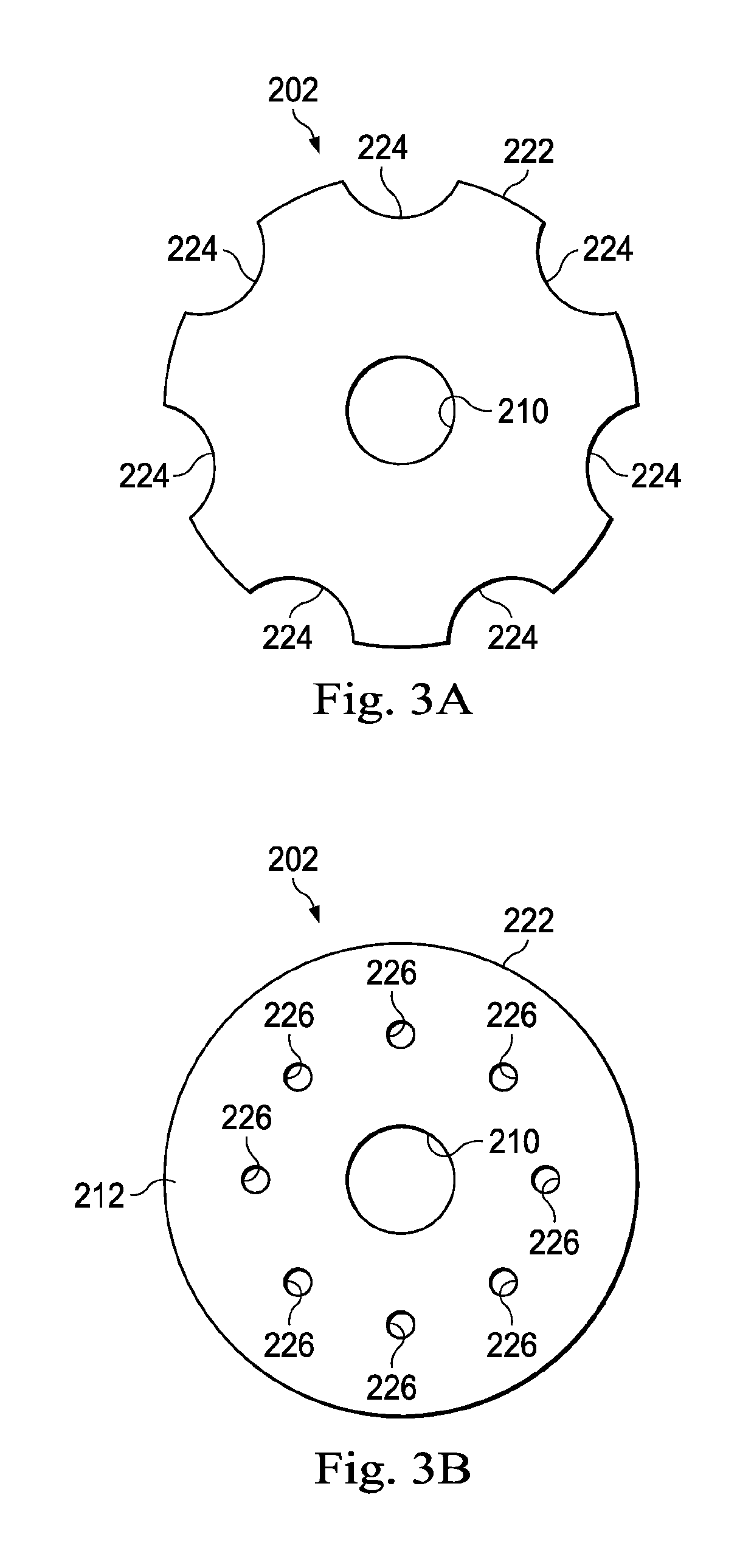

A rotating machine valve health monitor. Aspects of the valve monitor include instrumenting each valve of a reciprocating compressor, or other rotating machine, with a sensor capable of detecting at least vibration and instrumenting the crank shaft with a sensor capable of detecting at least rotation. A controller directly monitors the operation and condition of each valve to precisely identify any individual valve exhibiting leakage issues rather than only identifying the region of the leakage. The valve monitor uses a relatively high frequency stress wave analysis technique to provide a good signal-to-noise ratio to identify impact events indicative of leakage. The valve monitor uses circular waveforms of vibration data for individual valves to identify leakage by pattern recognition or visual identification. The valve monitor provides ongoing data collection to give warning of predicted valve failure and scheduling of preventative maintenance for failing valves.

Owner:COMPUTATIONAL SYST

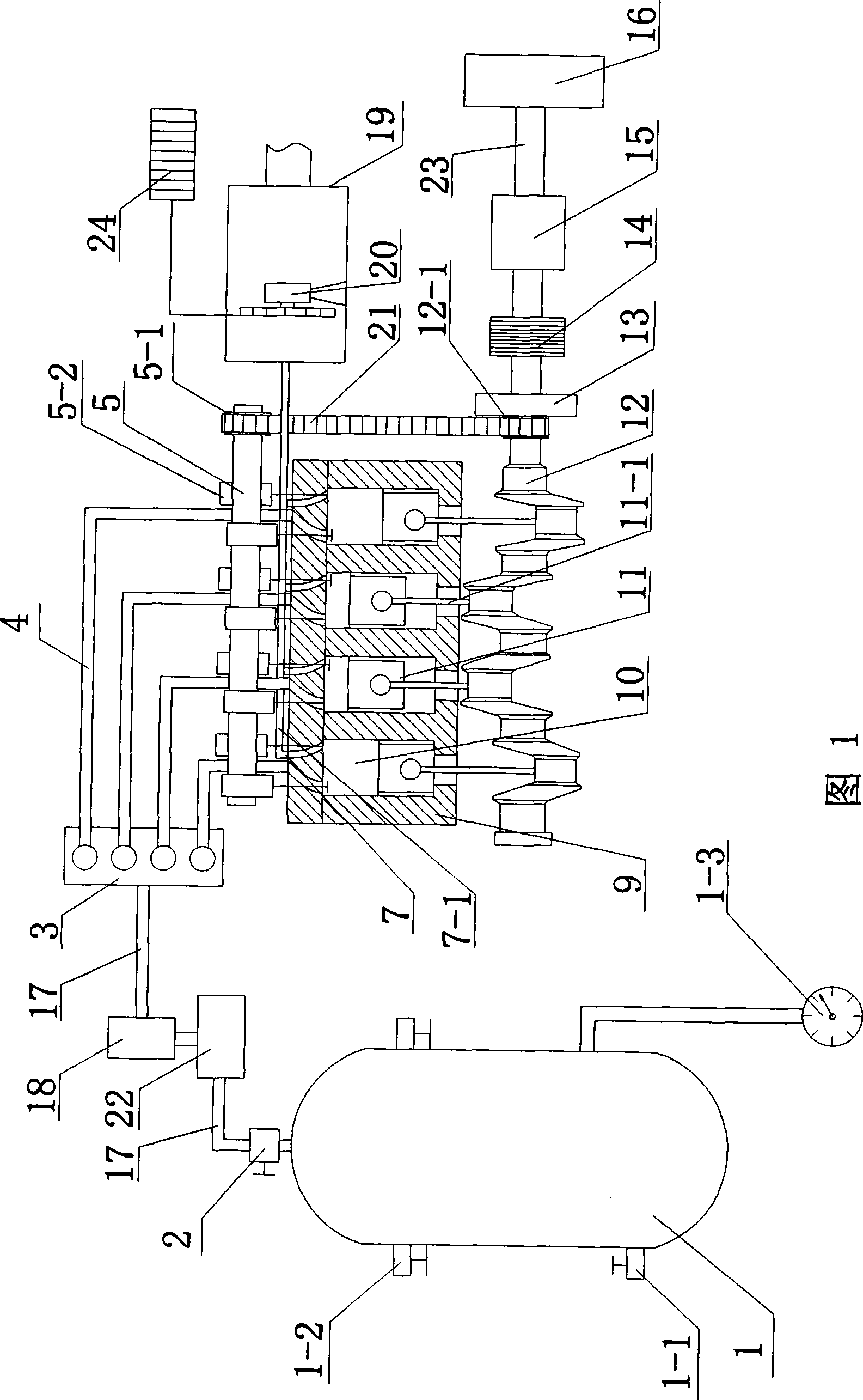

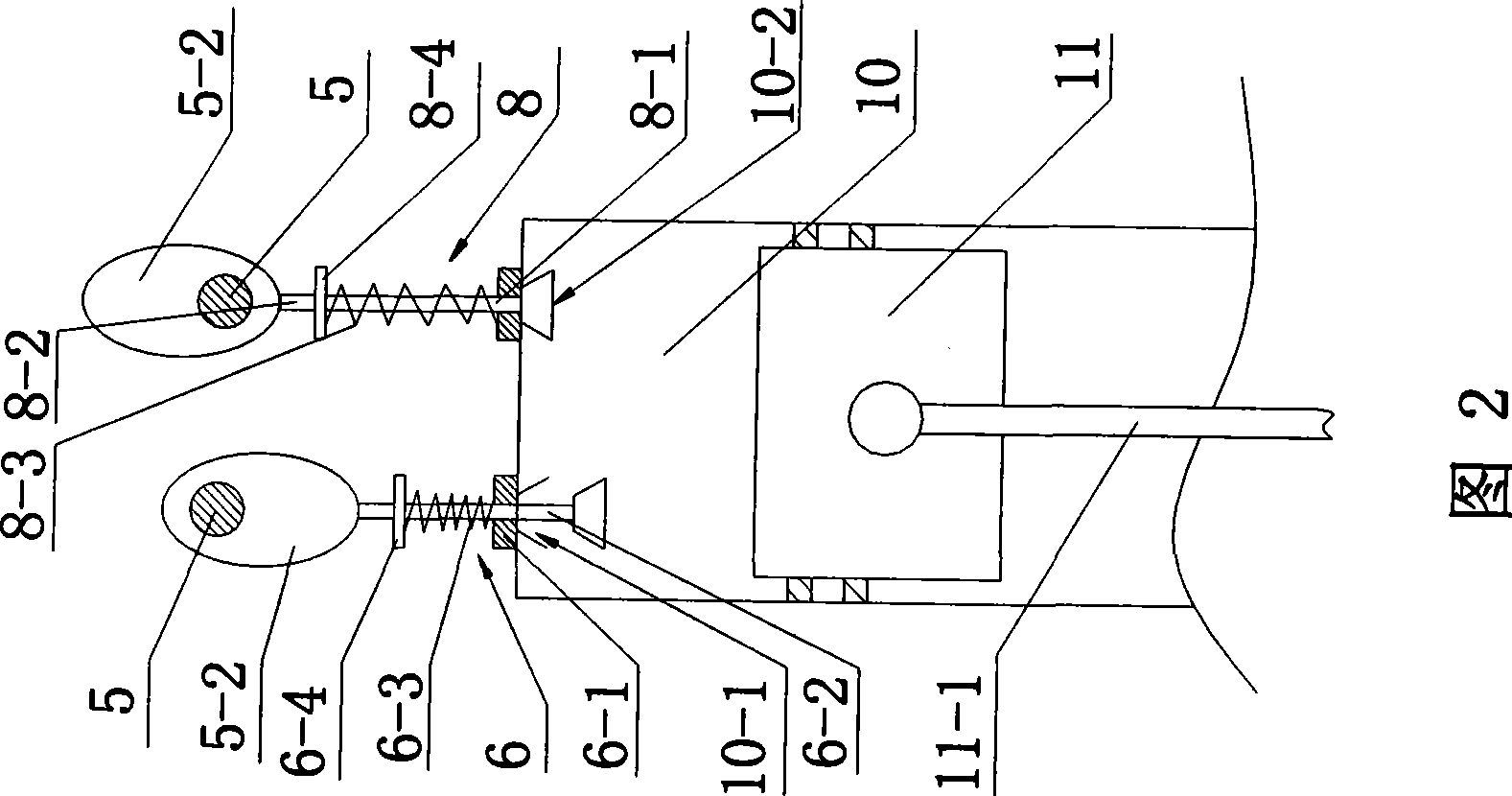

Air power engine assembly

InactiveCN101413403ALow costNo pollutionMechanical power devicesEngines characterised by uniflow principleDistributorPiston

The invention relates to an air-powered engine assembly, which comprises an air tank, an air valve, an air distributor, an intake pipe, camshafts, an intake duct, an exhaust control device, air cylinders, pistons, crankshafts, couplers, clutches, automatic gearboxes and differentials connected with the outside. The assembly is characterized in that the air valve, a constant pressure chamber and a pressure controller are arranged between the air tank and the air distributor; the air distributor is connected with a plurality of air cylinders on an air cylinder gasket; each air cylinder is connected with an exhaust chamber through an exhaust manifold; the exhaust chamber is provided with a turbine generator which is connected with a storage batter; the air cylinders are provided with the camshafts for controlling the air intake and exhaust of the air cylinders; the air cylinders are provided inside with the pistons for driving the crankshafts to rotate; the camshafts and the crankshafts are connected by chains; and the crankshafts are connected with the differentials through the couplers, the clutches and the gearboxes in turn. Therefore, doing work through air compression rather than fuel, the air-powered engine assembly has the advantages of avoiding waste gas discharge and air pollution, along with reliable operation, convenient operation, economical efficiency, practicality and so on. In addition, due to recycle of the waste gas for power generation, the air-powered engine assembly saves energy and reduces costs.

Owner:周登荣 +1

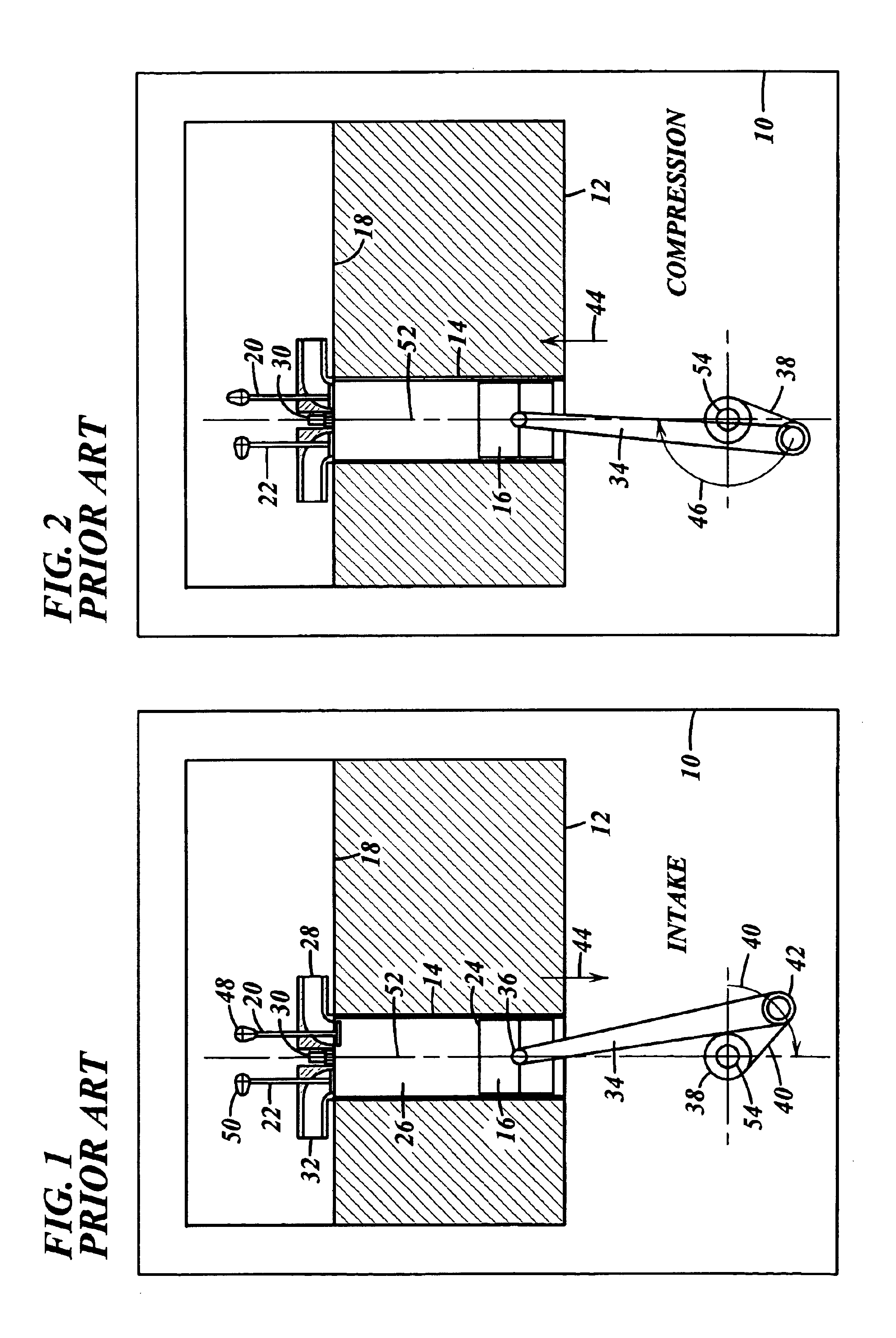

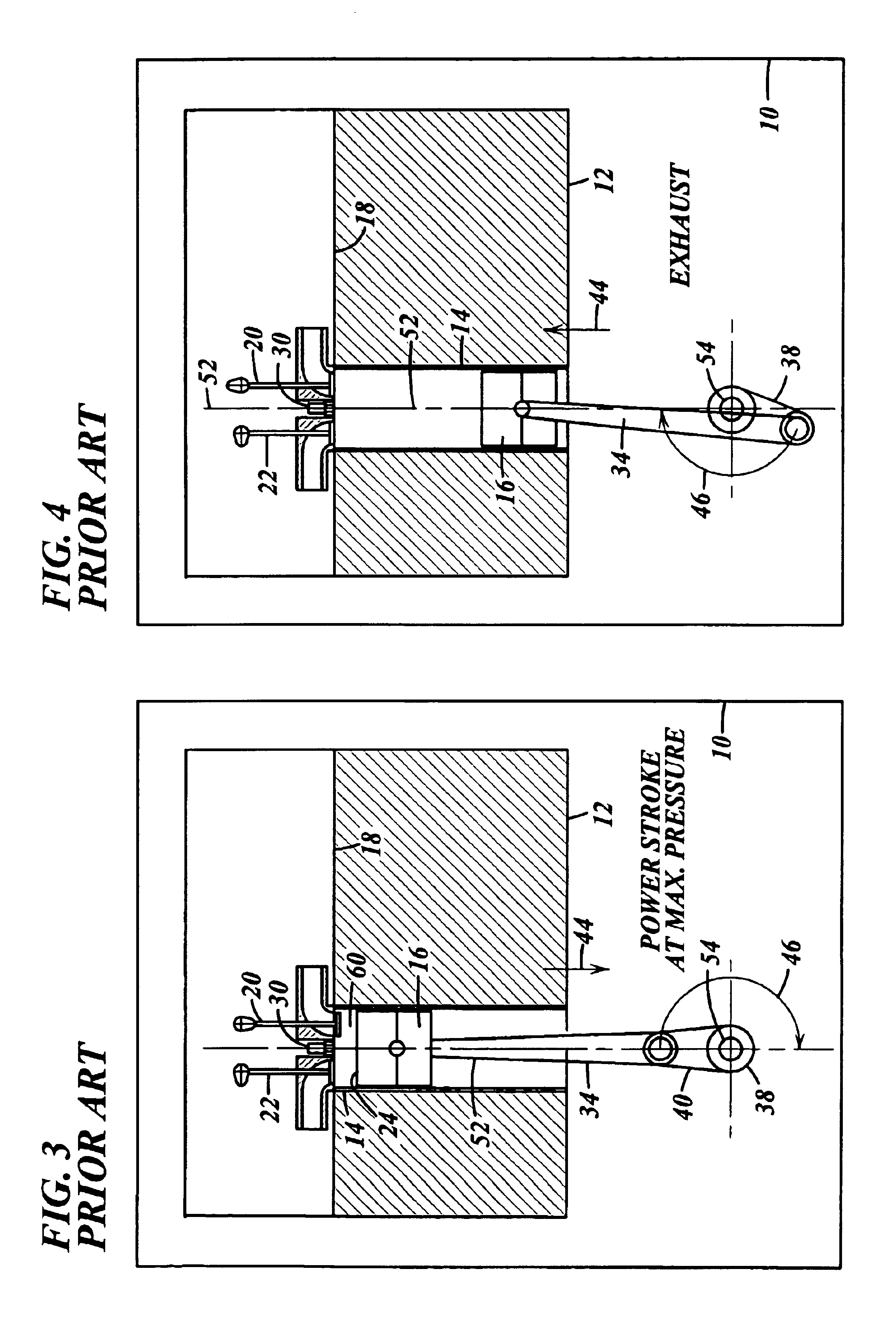

Split-cycle four-stroke engine

InactiveUS6952923B2Improve efficiencyImprove performanceInternal combustion piston enginesGas pressure propulsion mountingReciprocating motionFour-stroke engine

An engine has a crankshaft, rotating about a crankshaft axis of the engine. An expansion piston is slidably received within an expansion cylinder and operatively connected to the crankshaft such that the expansion piston reciprocates through an expansion stroke and an exhaust stroke of a four stroke cycle during a single rotation of the crankshaft. A compression piston is slidably received within a compression cylinder and operatively connected to the crankshaft such that the compression piston reciprocates through an intake stroke and a compression stroke of the same four stroke cycle during the same rotation of the crankshaft. A ratio of cylinder volumes from BDC to TDC for either one of the expansion cylinder and compression cylinder is substantially 20 to 1 or greater.

Owner:SKADERI GRUP LLC

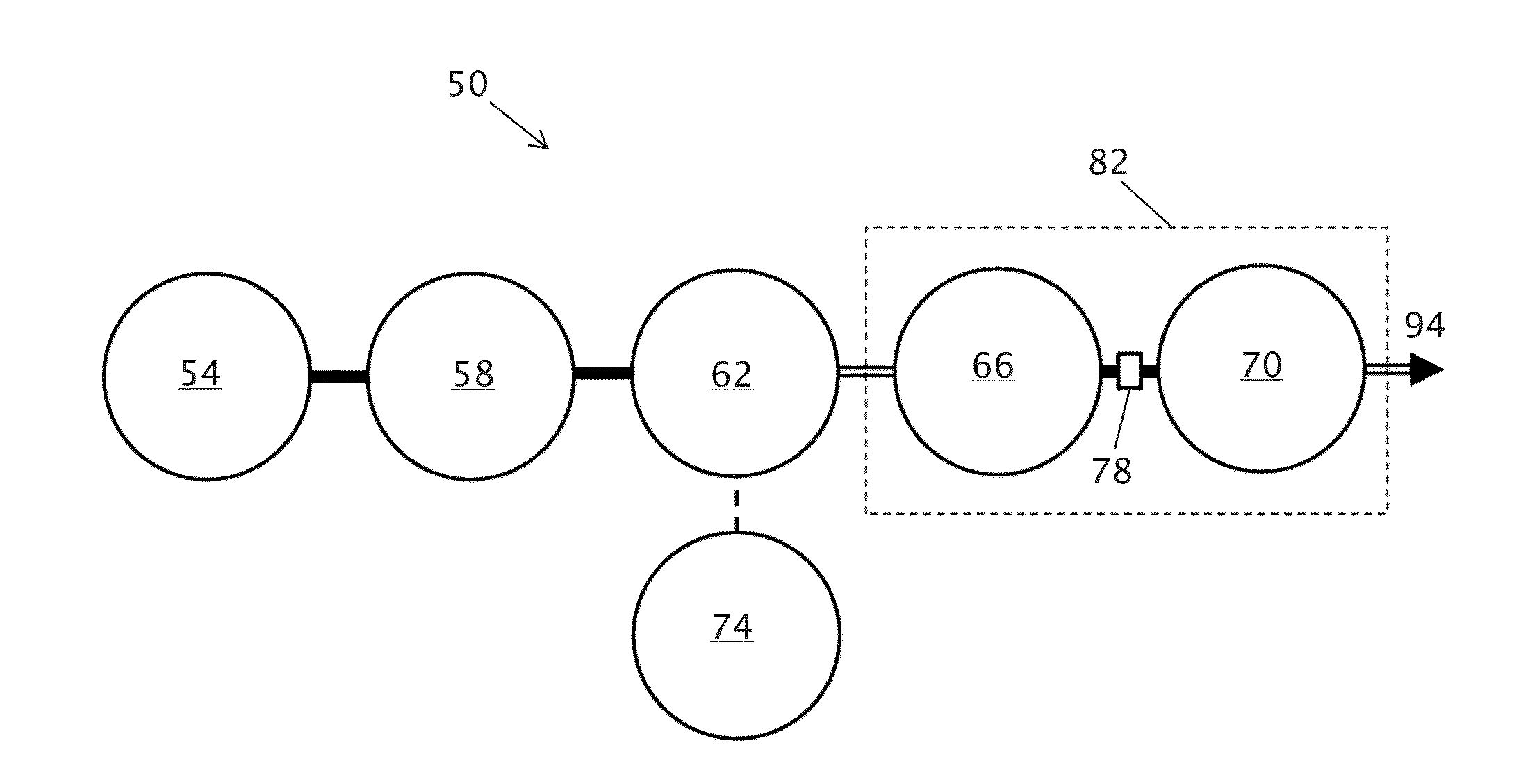

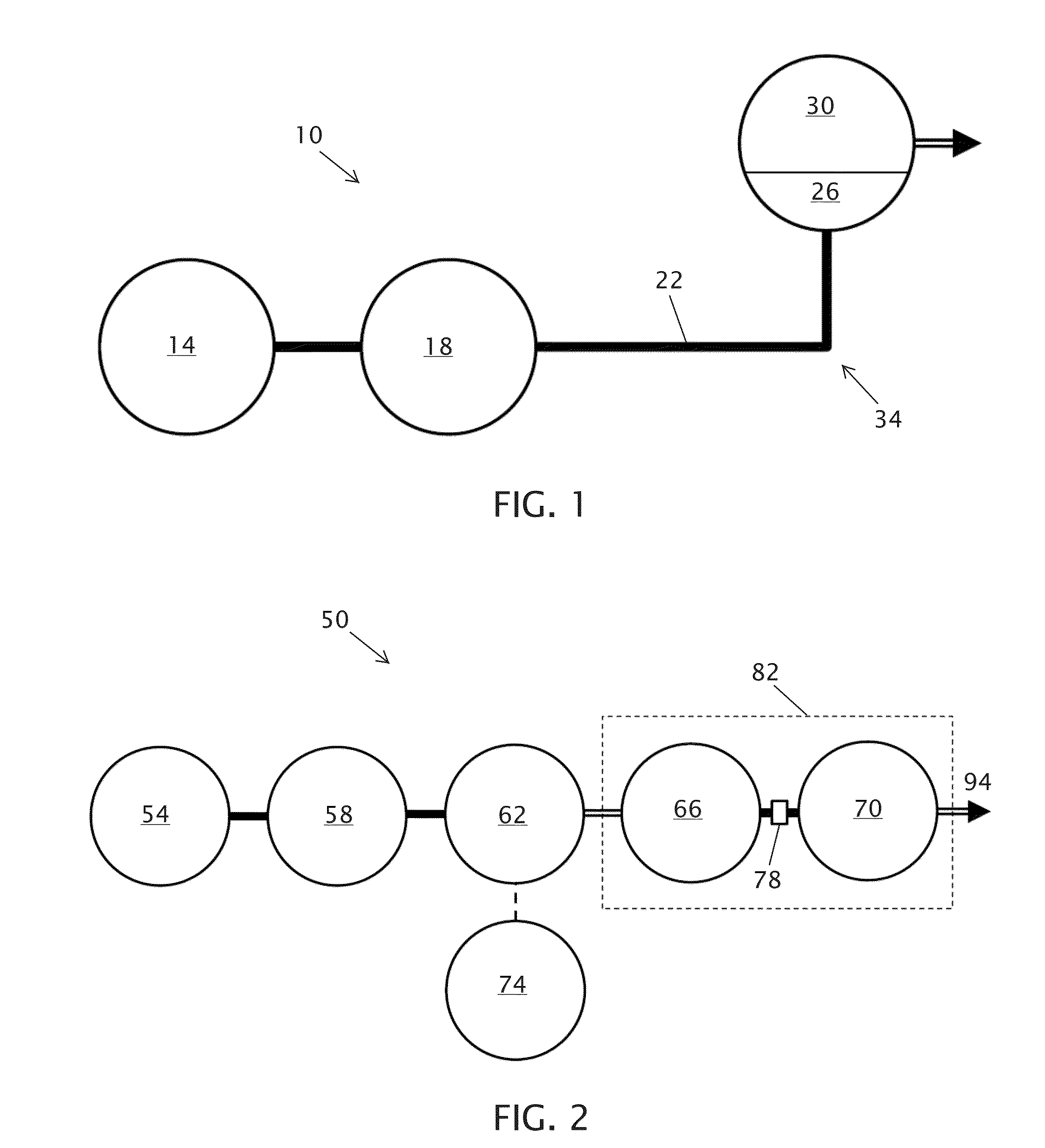

Continuously variable transmission

InactiveUS20070155567A1Easy to adjustImprove translationWheel based transmissionChain/belt transmissionEngineeringMechanical engineering

Traction planets and traction rings can be operationally coupled to a planetary gearset to provide a continuously variable transmission (CVT). The CVT can be used in a bicycle. In one embodiment, the CVT is mounted on the frame of the bicycle at a location forward of the rear wheel hub of the bicycle. In one embodiment, the CVT is mounted on and supported by members of the bicycle frame such that the CVT is coaxial with the crankshaft of the bicycle. The crankshaft is configured to drive elements of the planetary gearset, which are configured to operationally drive the traction rings and the traction planets. Inventive component and subassemblies for such a CVT are disclosed. A shifting mechanism includes a plurality of pivot arms arranged to pivot about the centers of the traction planets as a shift pin hub moves axially.

Owner:FALLBROOK INTPROP COMPANY

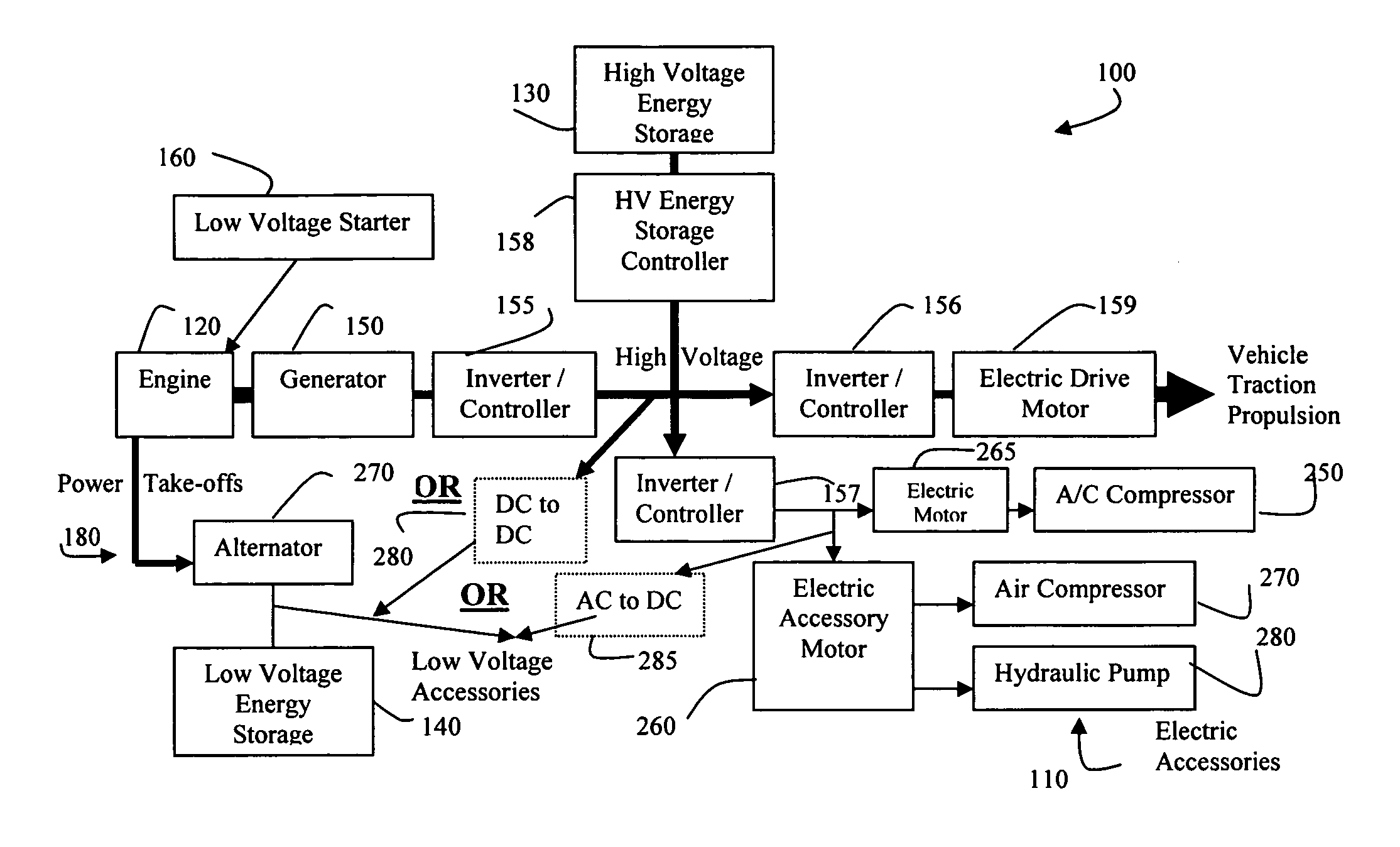

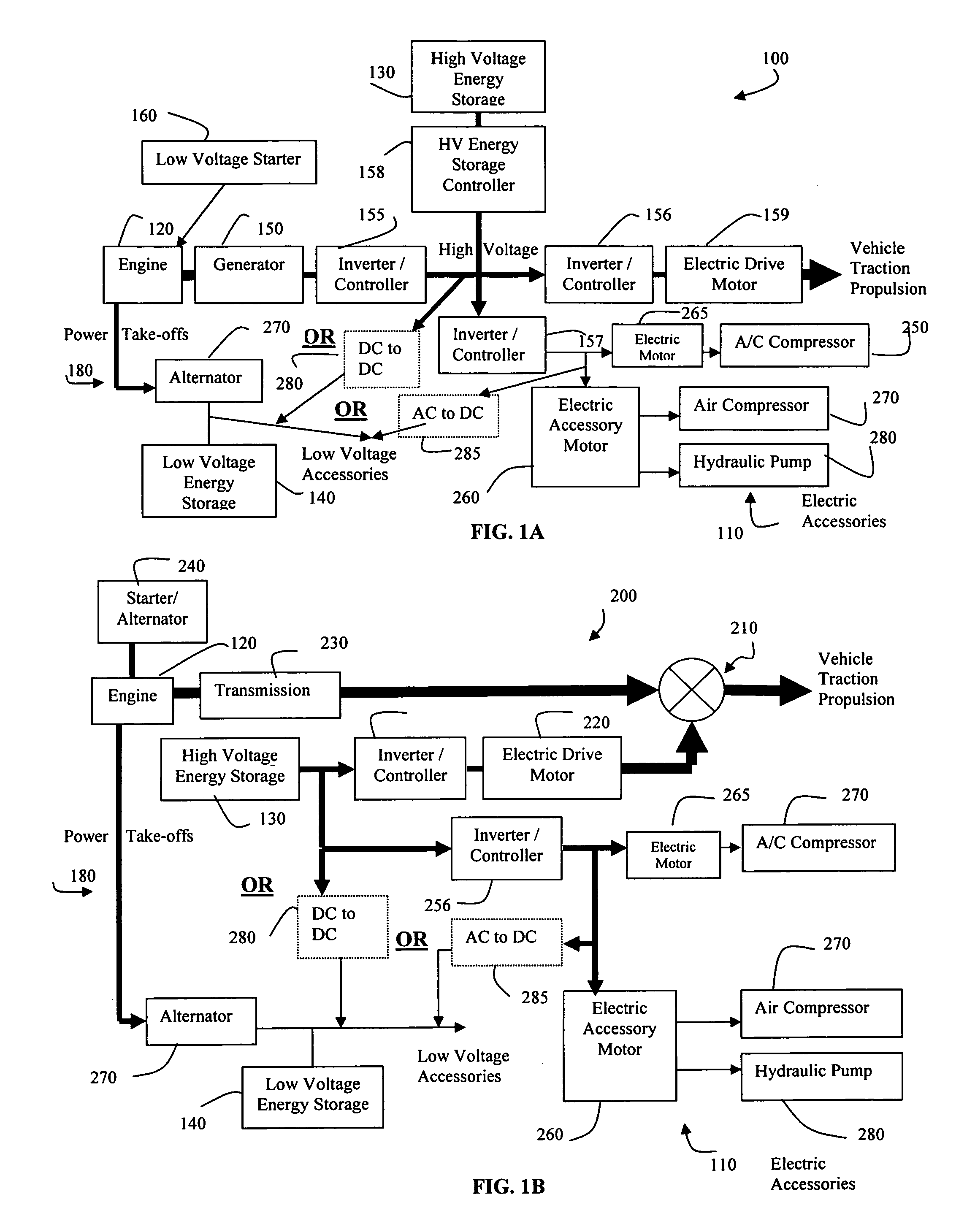

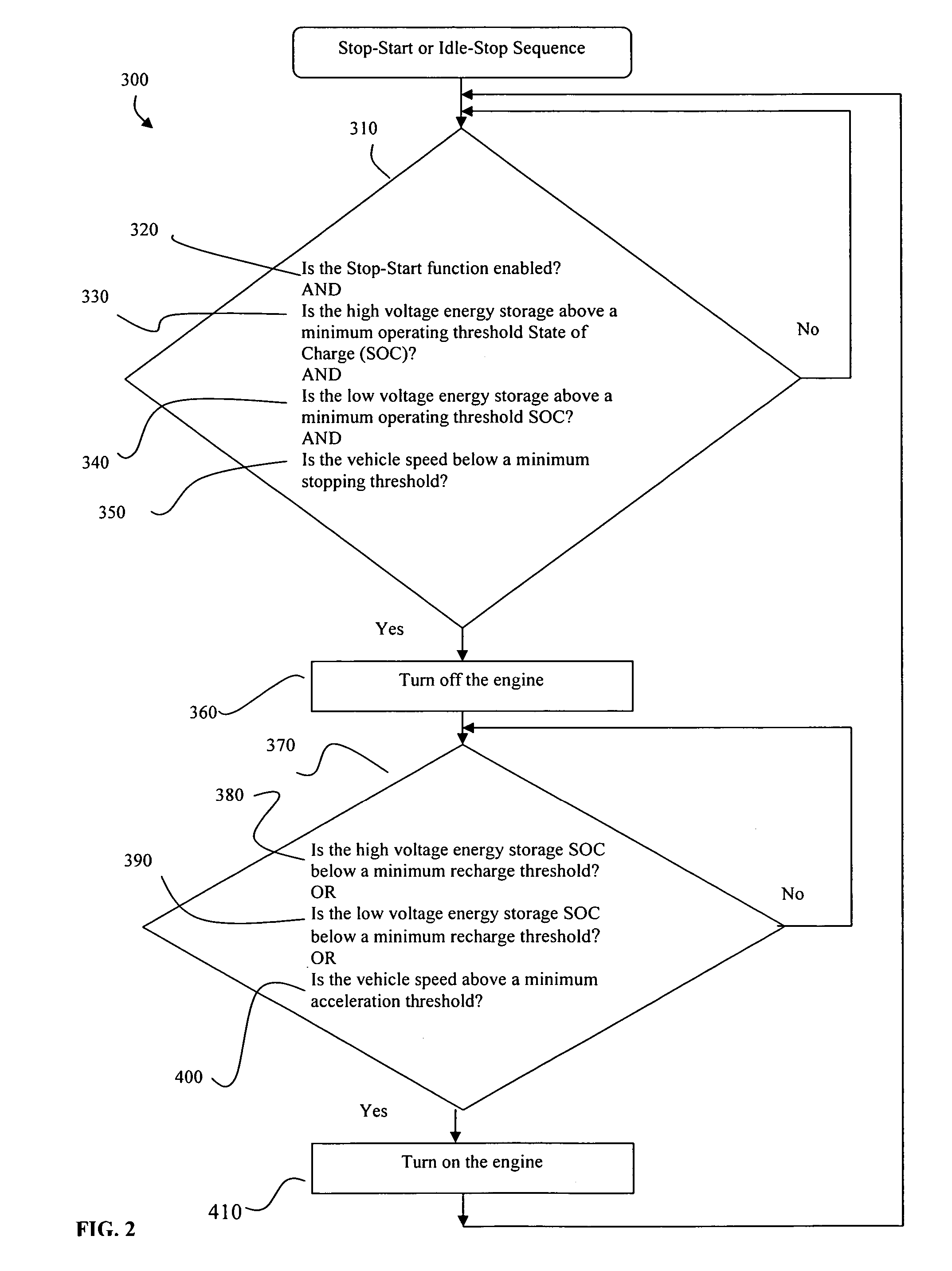

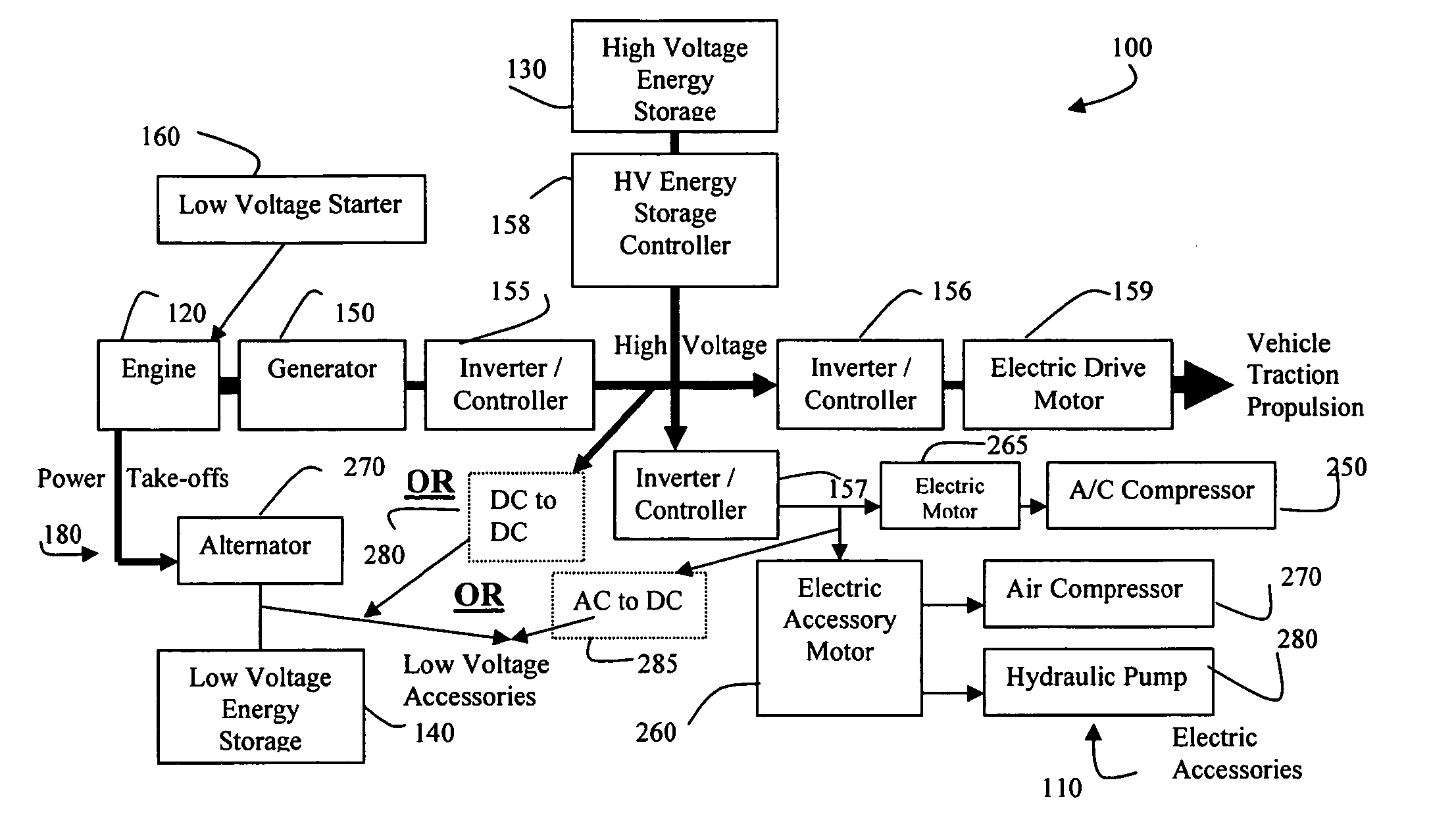

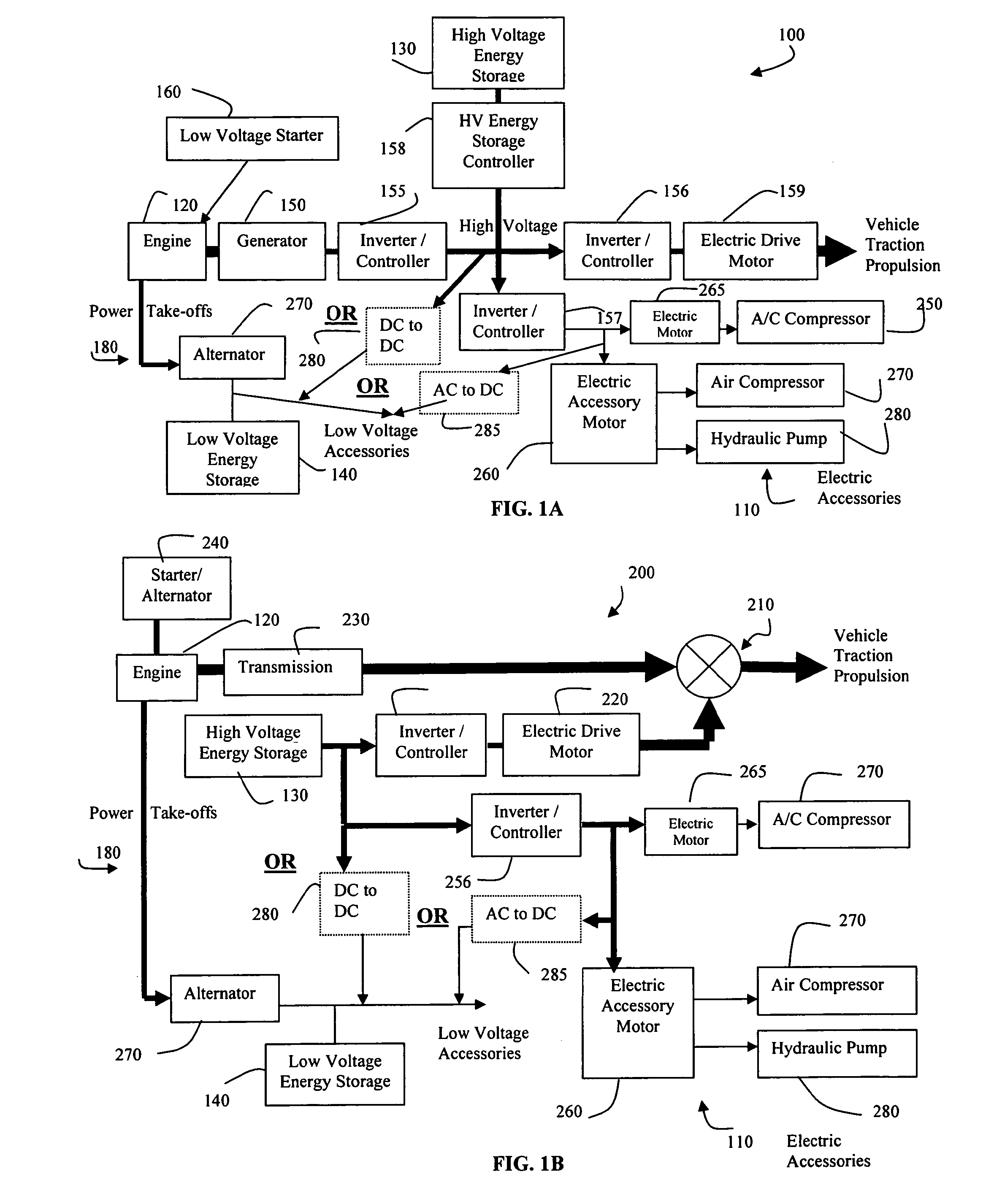

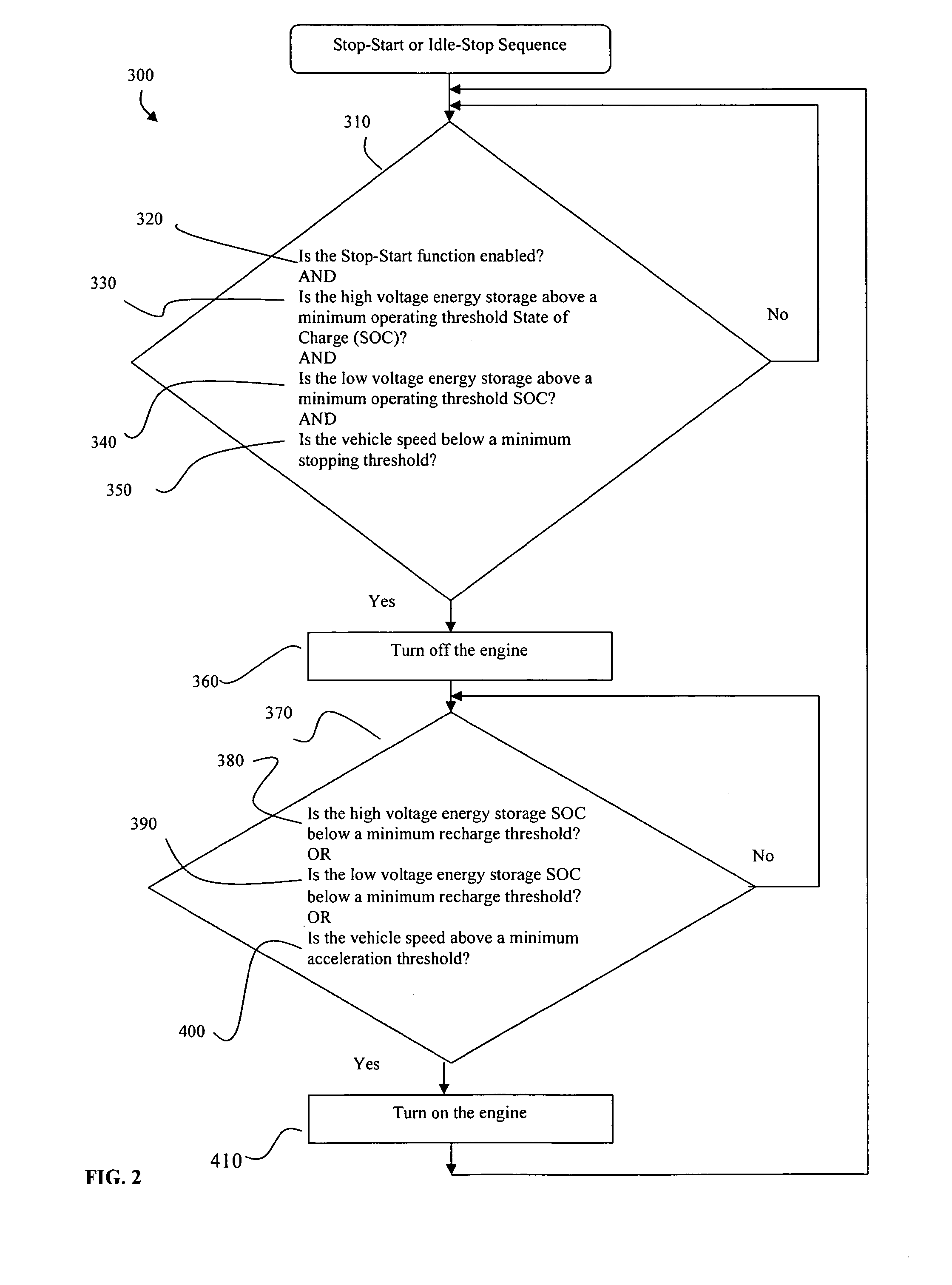

Method of controlling engine stop-start operation for heavy-duty hybrid-electric and hybrid-hydraulic vehicles

InactiveUS20070124037A1Minimizes engine noiseNoise minimizationInternal combustion piston enginesDigital data processing detailsEngineeringInternal combustion engine

A start-stop or idle-stop method for a heavy-duty hybrid vehicle that turns off the fuel supply while maintaining the crankshaft rotation of the internal combustion engine when the vehicle stops or, optionally, when the vehicle travels downhill, travels in a noise sensitive location, travels in an exhaust emissions sensitive location, or operates in an emergency situation. The stop-start or idle-stop method automatically turns on the engine fuel supply to restart combustion when the vehicle starts accelerating, is no longer traveling downhill, is no longer traveling in a noise sensitive or exhaust sensitive location, is no longer in an emergency situation, or has dropped below the minimum energy storage restart level.

Owner:SHEPPARD MULLIN RICHTER & HAMPTON

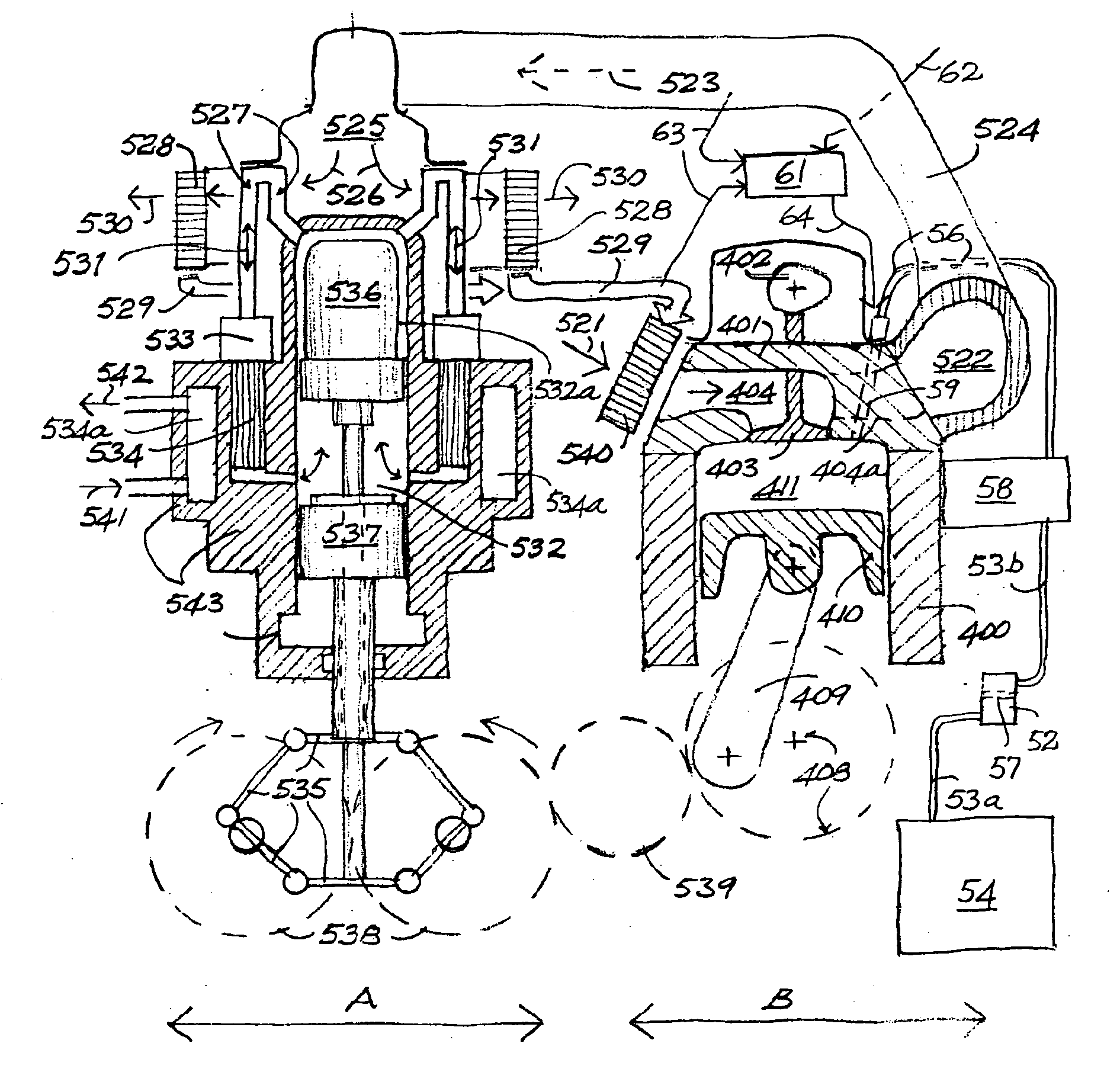

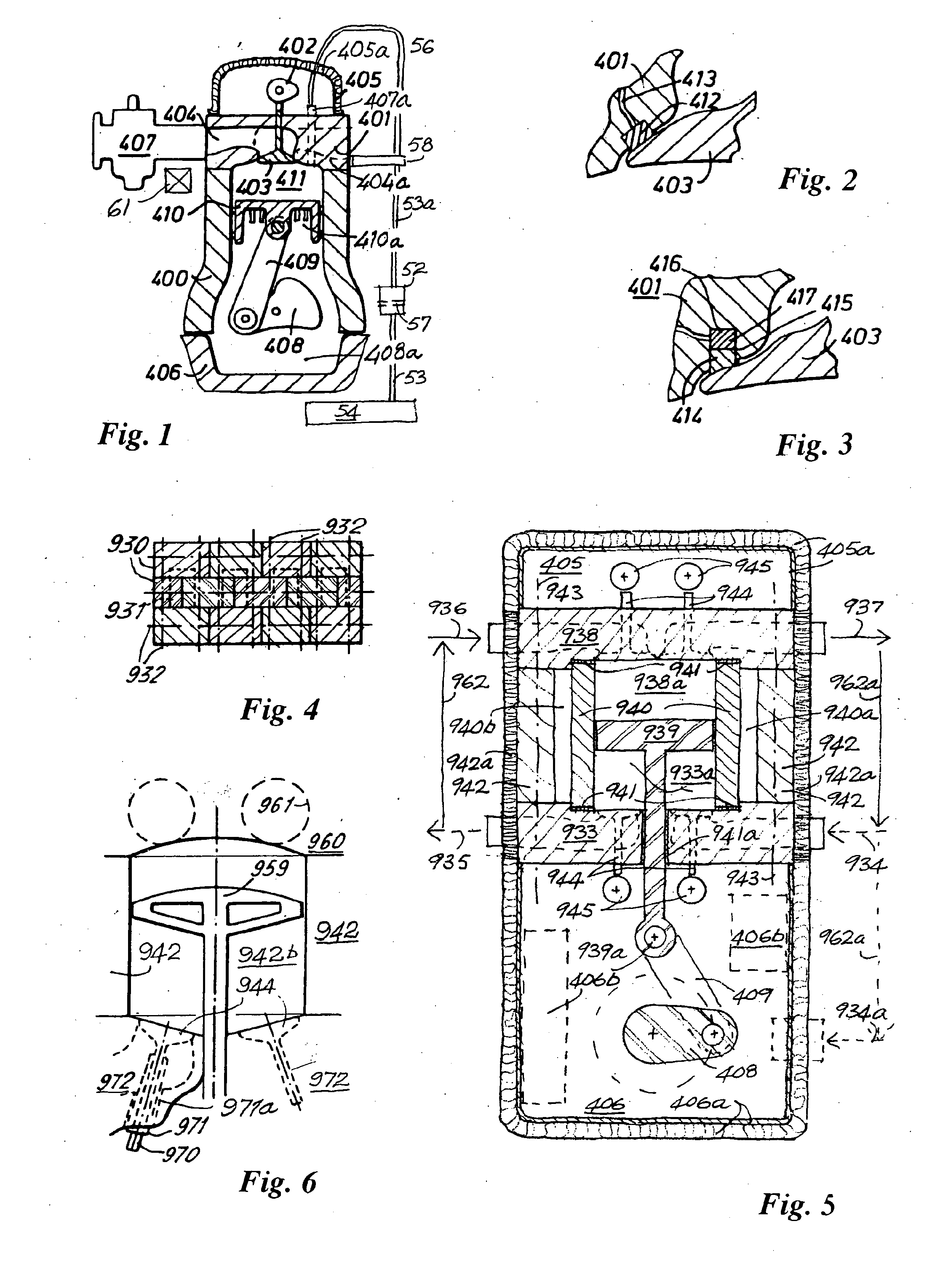

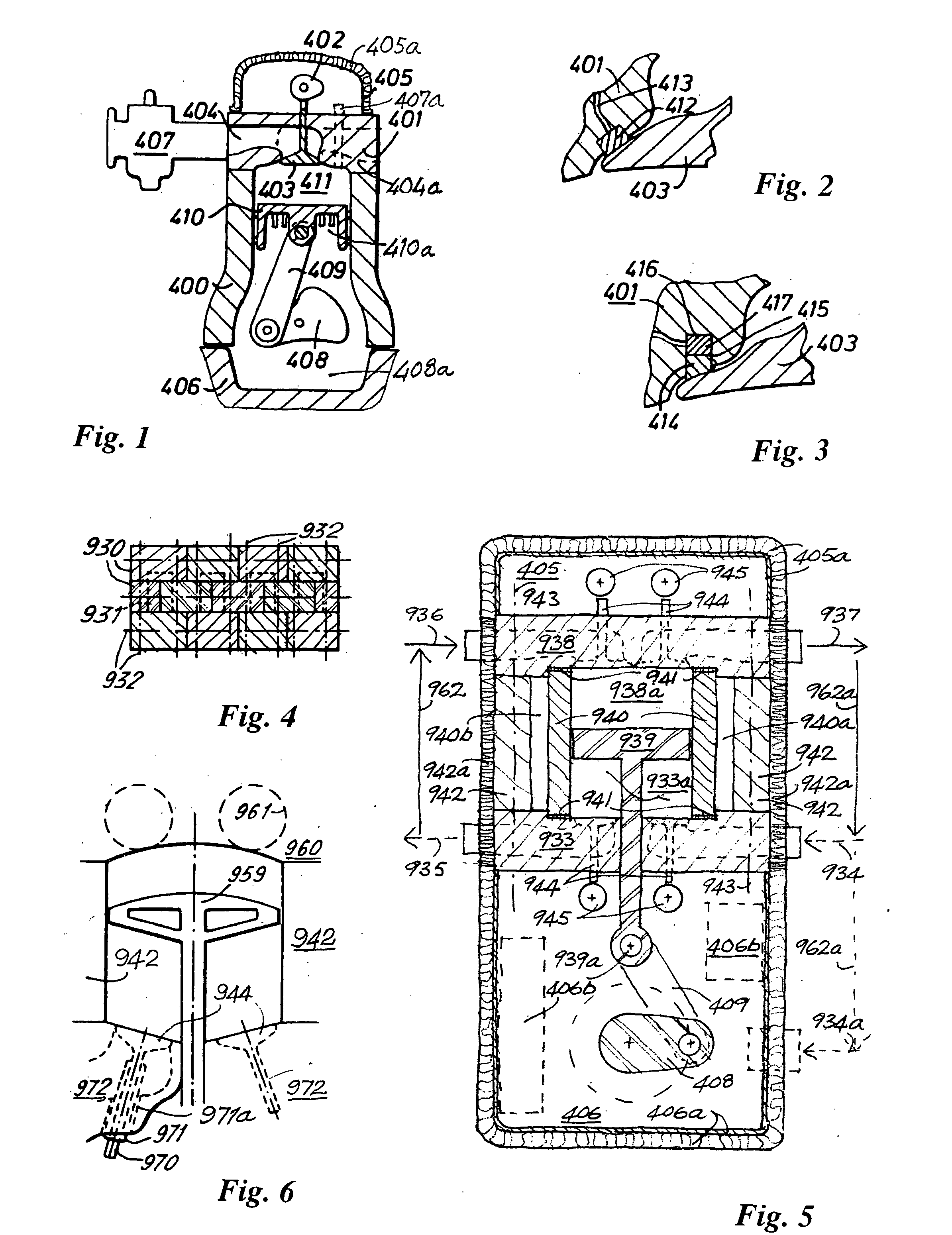

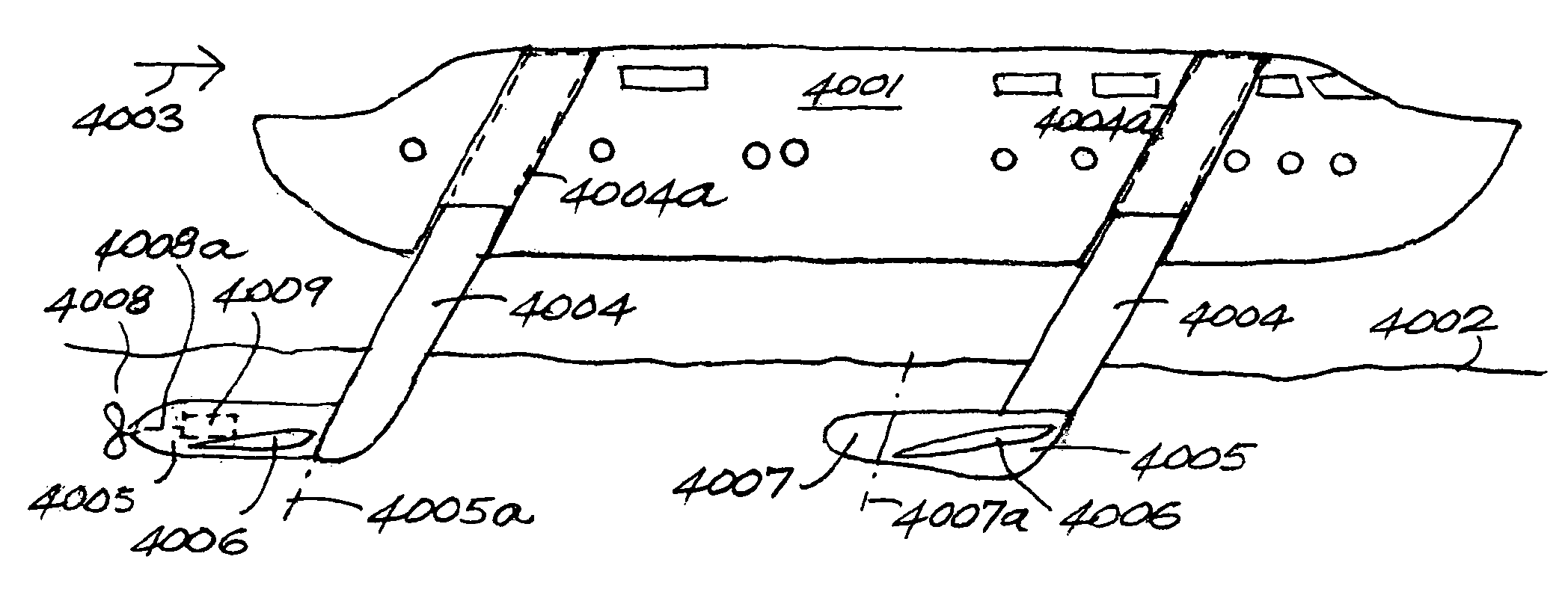

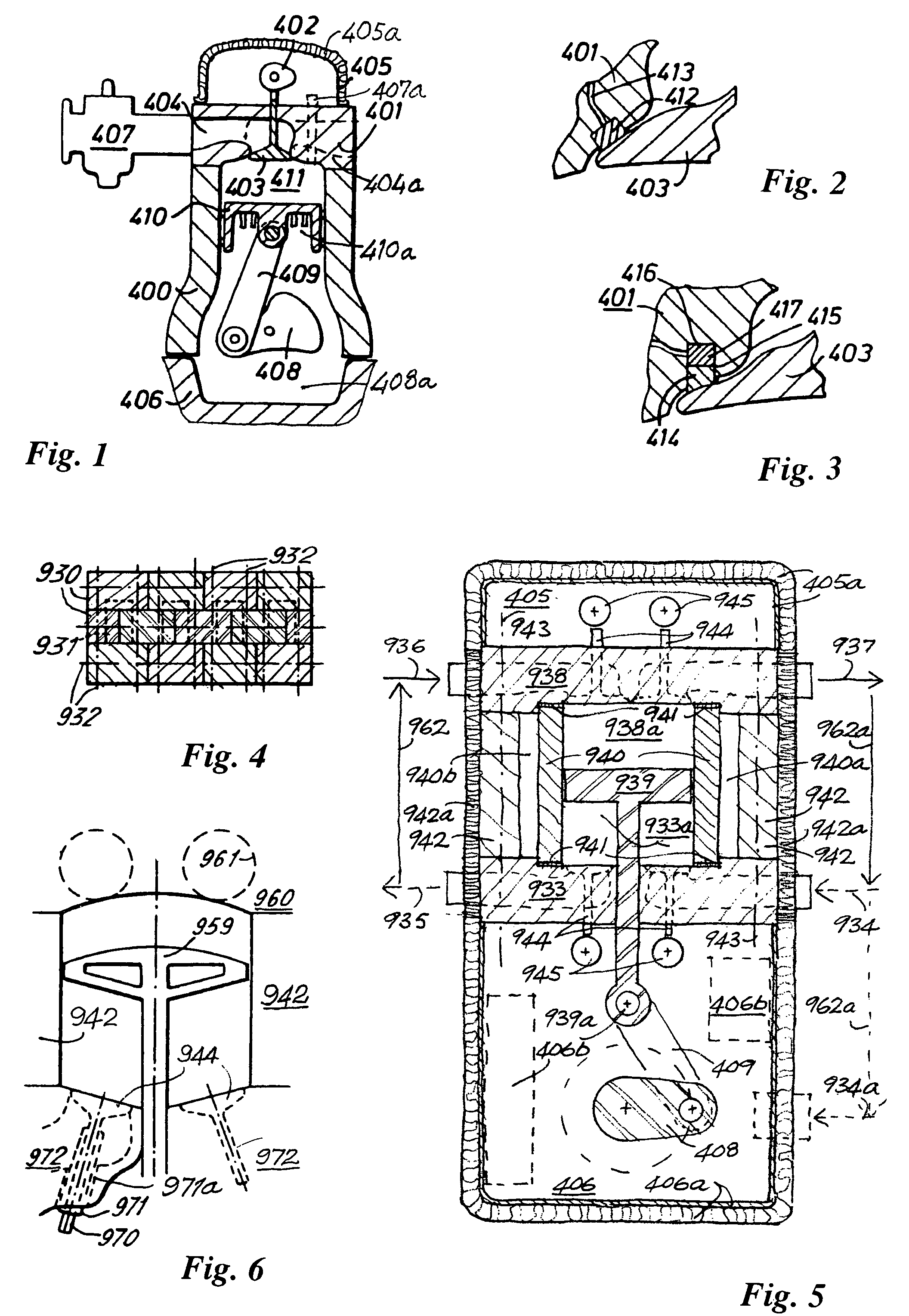

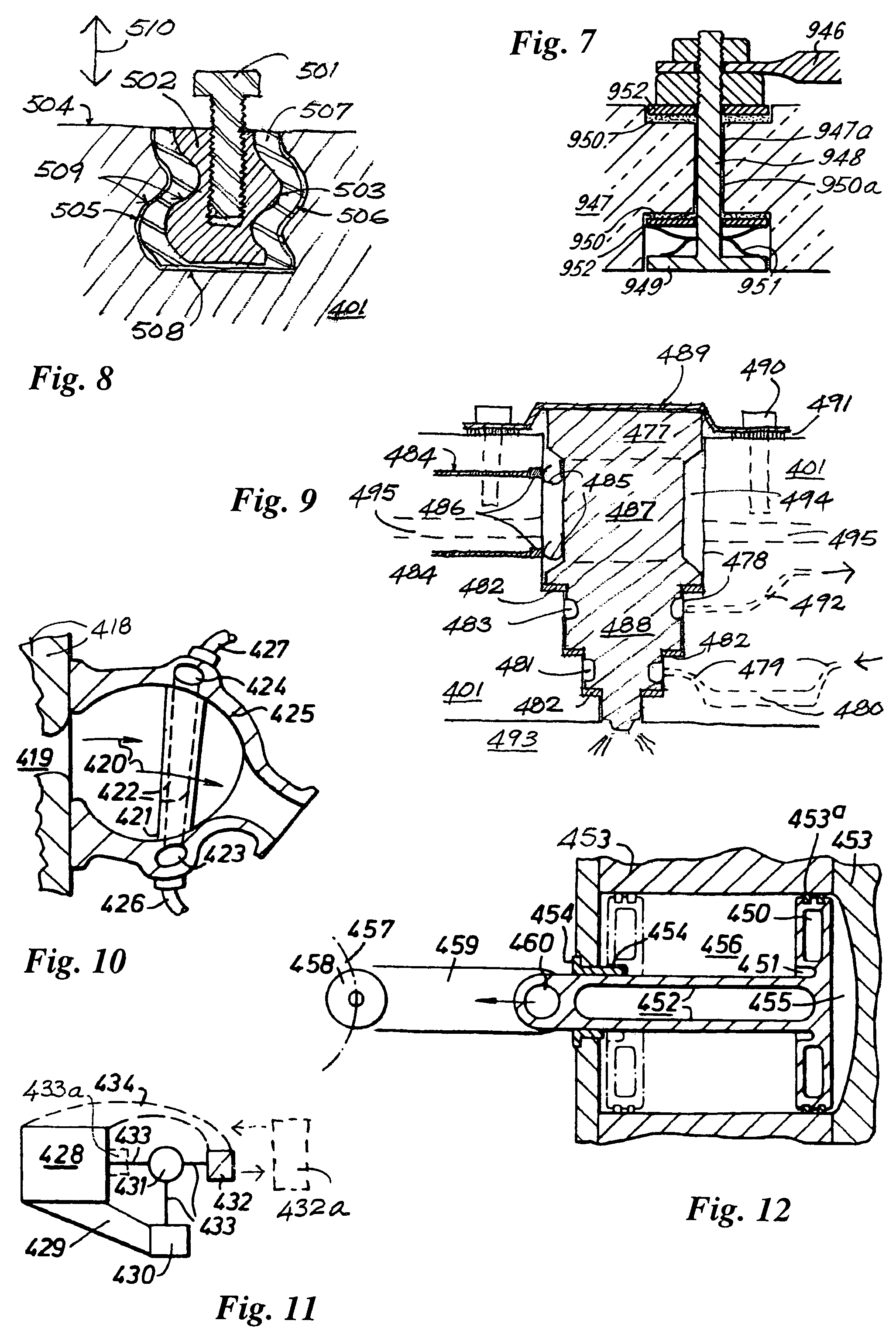

Reciprocating machine & other devices

InactiveUS20120227389A1Improve power densityImprove efficiencyLiquid coolingCasingsCombustionReciprocating motion

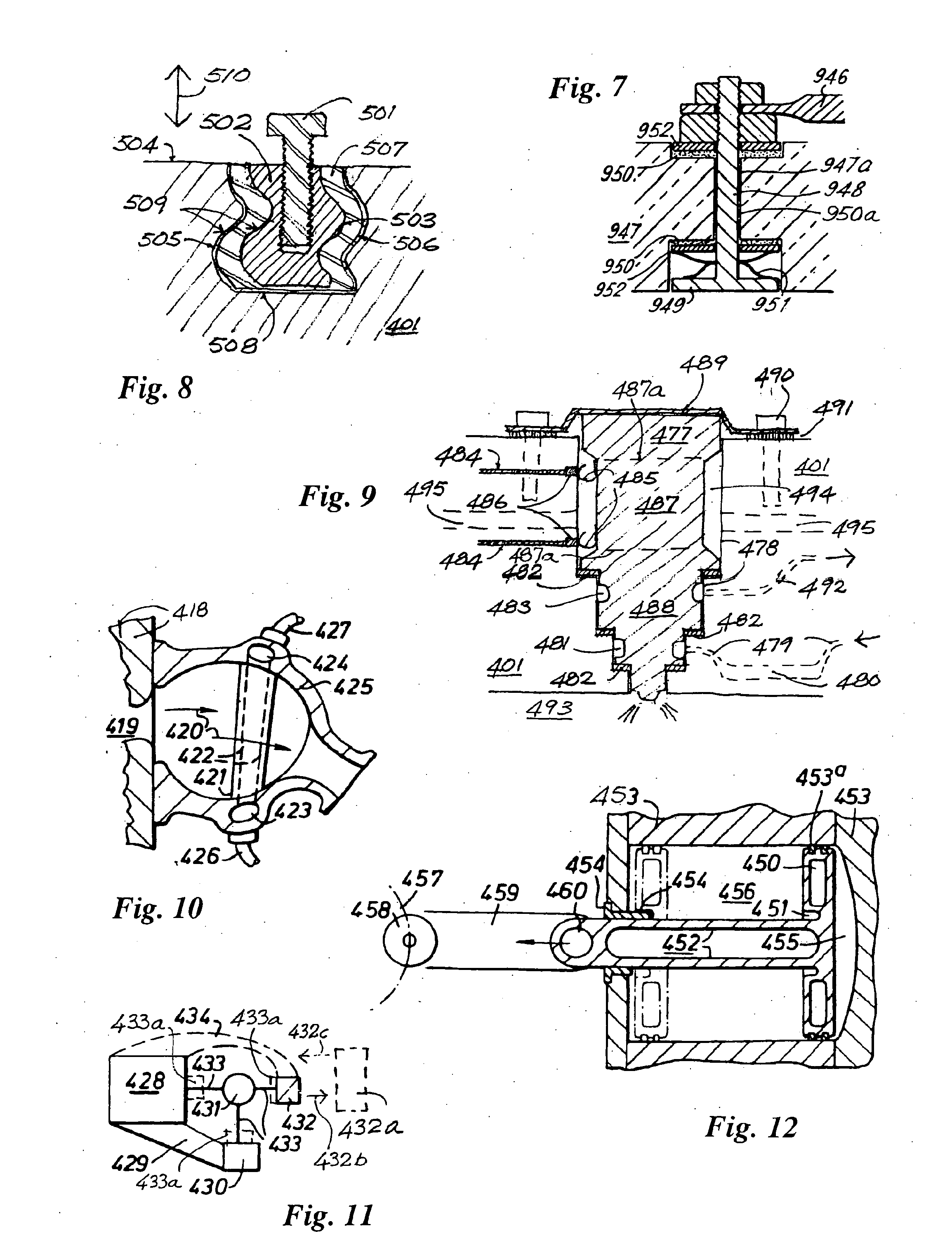

The disclosure relates to reciprocating fluid working devices including internal combustion engines, compressors and pumps. A number of arrangements for pistons and cylinders of unconventional configuration are described, mostly intended for use in IC engines operating without cooling. Included are toroidal combustion or working chambers, some with fluid flow through the core of the toroid, a single piston reciprocating between a pair of working chambers, tensile valve actuation, tensile links between piston and crankshaft, energy absorbing piston-crank links, crankshafts supported on gas bearings, cylinders rotating in housings, injectors having components which reciprocate or rotate during fuel delivery. In some embodiments pistons mare rotate while reciprocating. High temperature exhaust emissions systems are described, including those containing filamentary material, as are procedures for reducing emissions during cold start by means of valves at reaction volume exit. Also disclosed are improved vehicles, aircraft, marine craft, transmissions and exhaust emission systems suited to the engines of the invention.

Owner:HINDERKS MITJA VICTOR

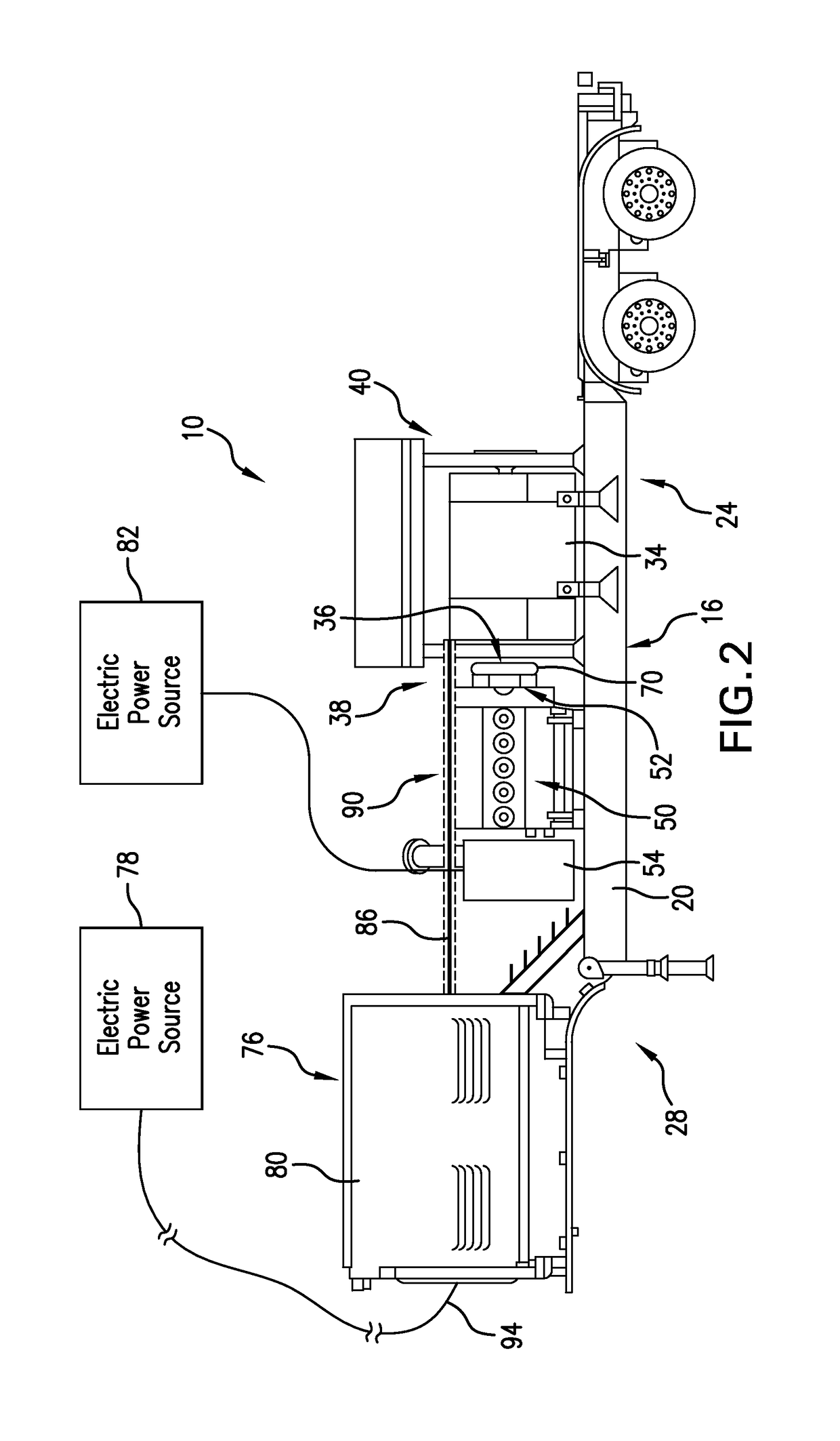

Well Service Pump System

A well service pump system supplies high pressure working fluid to a well. The pump system is a linear design which incorporates a diesel engine, a hydraulic drive gear box, open loop hydraulic Pumps, hydraulic ram cylinders, controls for the hydraulic system hydraulic cylinders, working fluid end cylinders and a coupling to connect the hydraulic cylinders and the working fluid ends. The engine powers the hydraulic system which, in turn, provides hydraulic fluid to operate the hydraulic ram cylinders. Each of the polished rods of the hydraulic ram cylinders is connected axially to a plunger rod end of a working fluid end cylinder. There is no crankshaft or automatic transmission required. The linear design allows for a longer plunger stroke length while still allowing highway transport on a truck or skid.

Owner:AMERIFORGE GRP

Reciprocating devices

ActiveUS20080141921A1Improve power densityImprove efficiencyHybrid vehiclesInternal combustion piston enginesExternal combustion engineEnergy absorption

The disclosure relates to fluid working devices including reciprocating internal combustion engines, compressors and pumps. A number of arrangements for pistons and cylinders of unconventional configuration are described, mostly intended for use in reciprocating internal combustion IC engines operating without cooling. Included are toroidal combustion or working chambers, some with fluid flow through the core of the toroid, pistons reciprocating between pairs of working chambers, tensile valve actuation, tensile links between piston and crankshaft, energy absorbing piston-crank links, crankshafts supported on gas bearings, cylinders rotating in housings, injectors having components reciprocate or rotate during fuel delivery. In some embodiments pistons mare rotate while reciprocating. High temperature exhaust emissions systems are described, including those containing filamentary material, as are procedures for reducing emissions during cold start by means of valves at reaction volume exit. Compound engines having the new engines as a reciprocating stage are described. Improved vehicles, aircraft, marine craft and transmissions adapted to receive or be linked to the improved IV engines are also disclosed.

Owner:HINDERKS MITJA VICTOR

Pump drivetrain damper system and control systems and methods for same

ActiveUS10316832B2Reduce vibrationLiquid resistance brakesPositive displacement pump componentsControl signalDrivetrain

Owner:SPM OIL & GAS INC

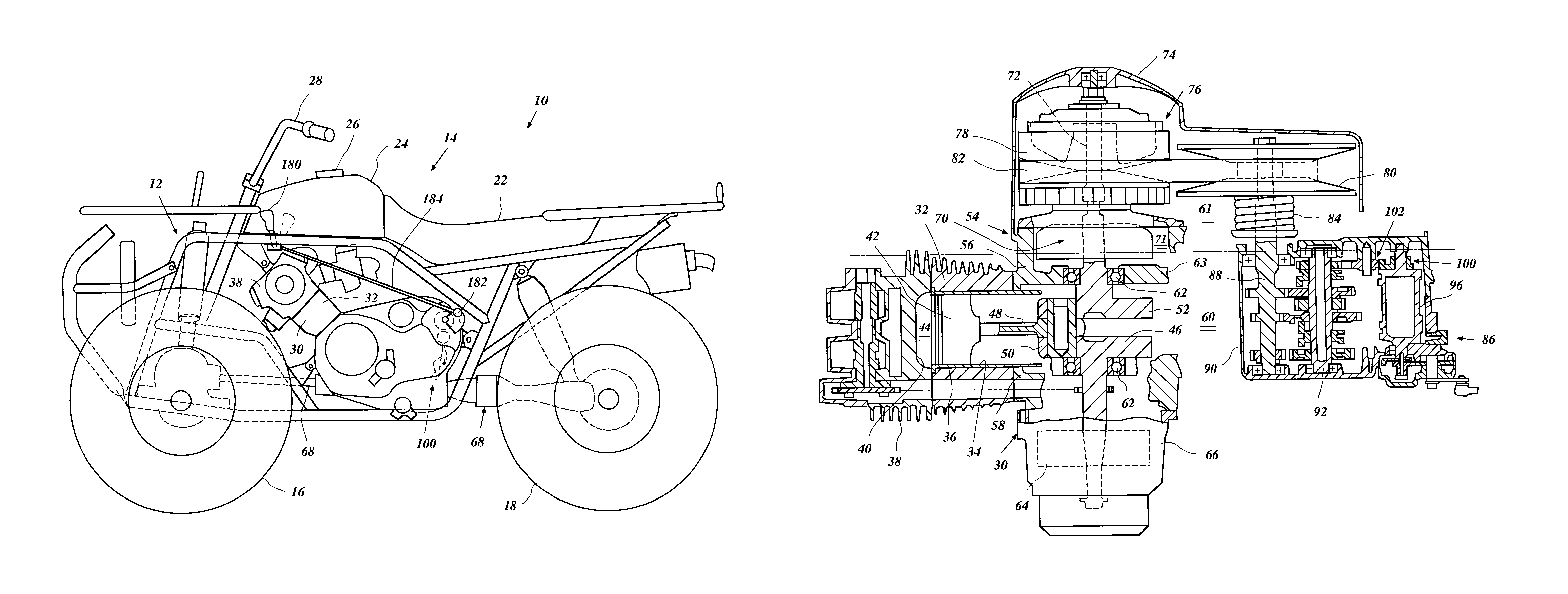

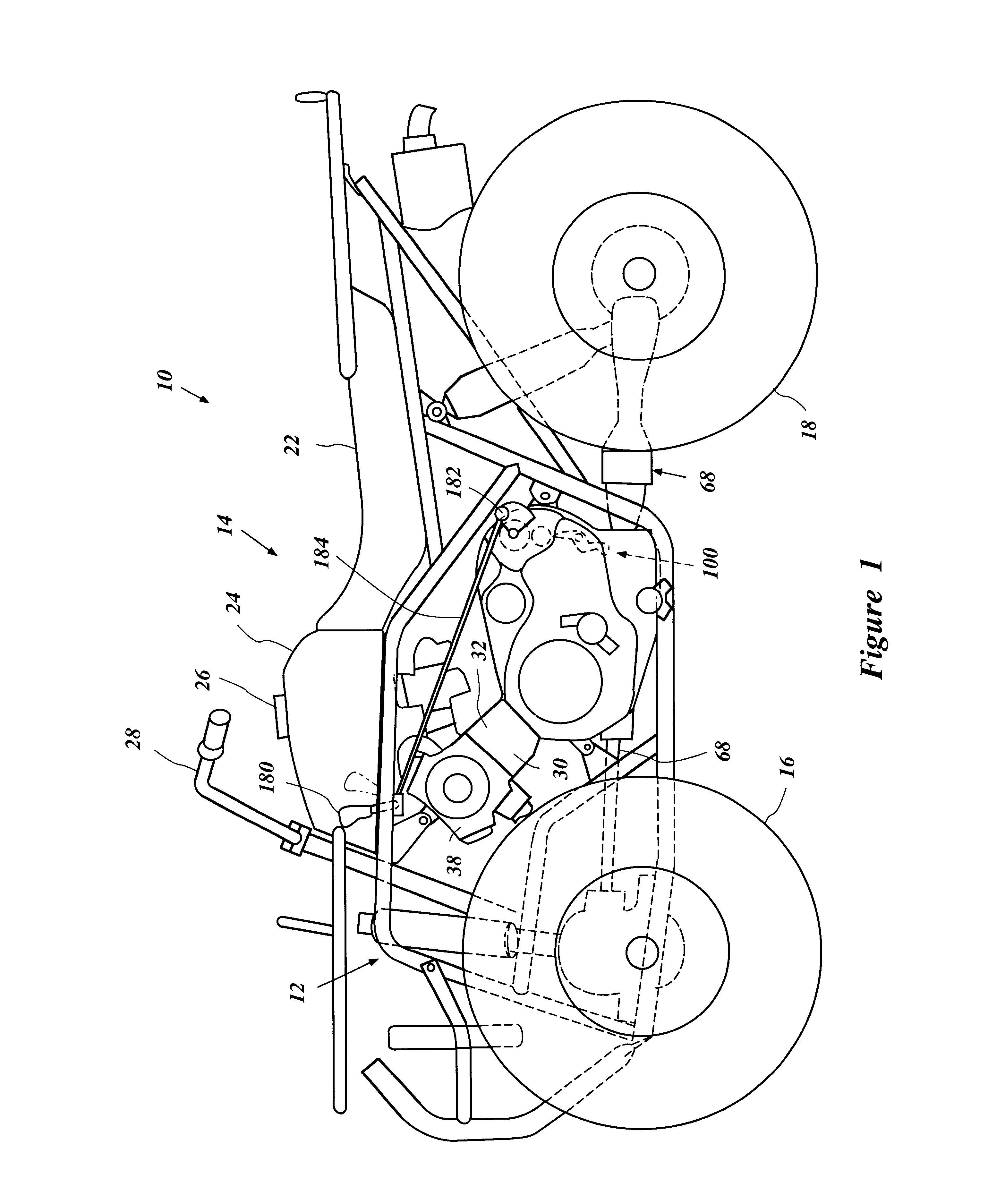

Transmission lock for all-terrain vehicle

InactiveUS6725962B1Braking element arrangementsElectric propulsion mountingCentrifugal clutchCrankshaft

All all-terrain vehicle has a shiftable transmission that is coupled to a variable speed V-belt transmission. The variable speed V-belt transmission is joined to a crankshaft through a centrifugal clutching arrangement. The shiftable transmission enables an operator to go between low, high, neutral, reverse, and park. In the park position, the transmission is locked from substantial rotation such that the engaged wheels of the all-terrain vehicle are also locked from substantial rotation, whether or not the engine speed is sufficient to allow the centrifugal clutch to be engaged with the variable speed transmission.

Owner:YAMAHA MOTOR CO LTD

Method of Controlling Engine Stop-Start Operation for Heavy-Duty Hybrid-Electric Vehicles

InactiveUS20100145562A1Noise minimizationHybrid vehiclesInternal combustion piston enginesElectric vehicleInternal combustion engine

A start-stop or idle-stop method for a heavy-duty hybrid vehicle that turns off the fuel supply while maintaining the crankshaft rotation of the internal combustion engine when the vehicle stops or, optionally, when the vehicle travels downhill, travels in a noise sensitive location, travels in an exhaust emissions sensitive location, or operates in an emergency situation. The stop-start or idle-stop method automatically turns on the engine fuel supply to restart combustion when the vehicle starts accelerating, is no longer traveling downhill, is no longer traveling in a noise sensitive or exhaust sensitive location, is no longer in an emergency situation, or has dropped below the minimum energy storage restart level. The stop-start or idle-stop may be inhibited upon certain override conditions.

Owner:SHEPPARD MULLIN RICHTER & HAMPTON

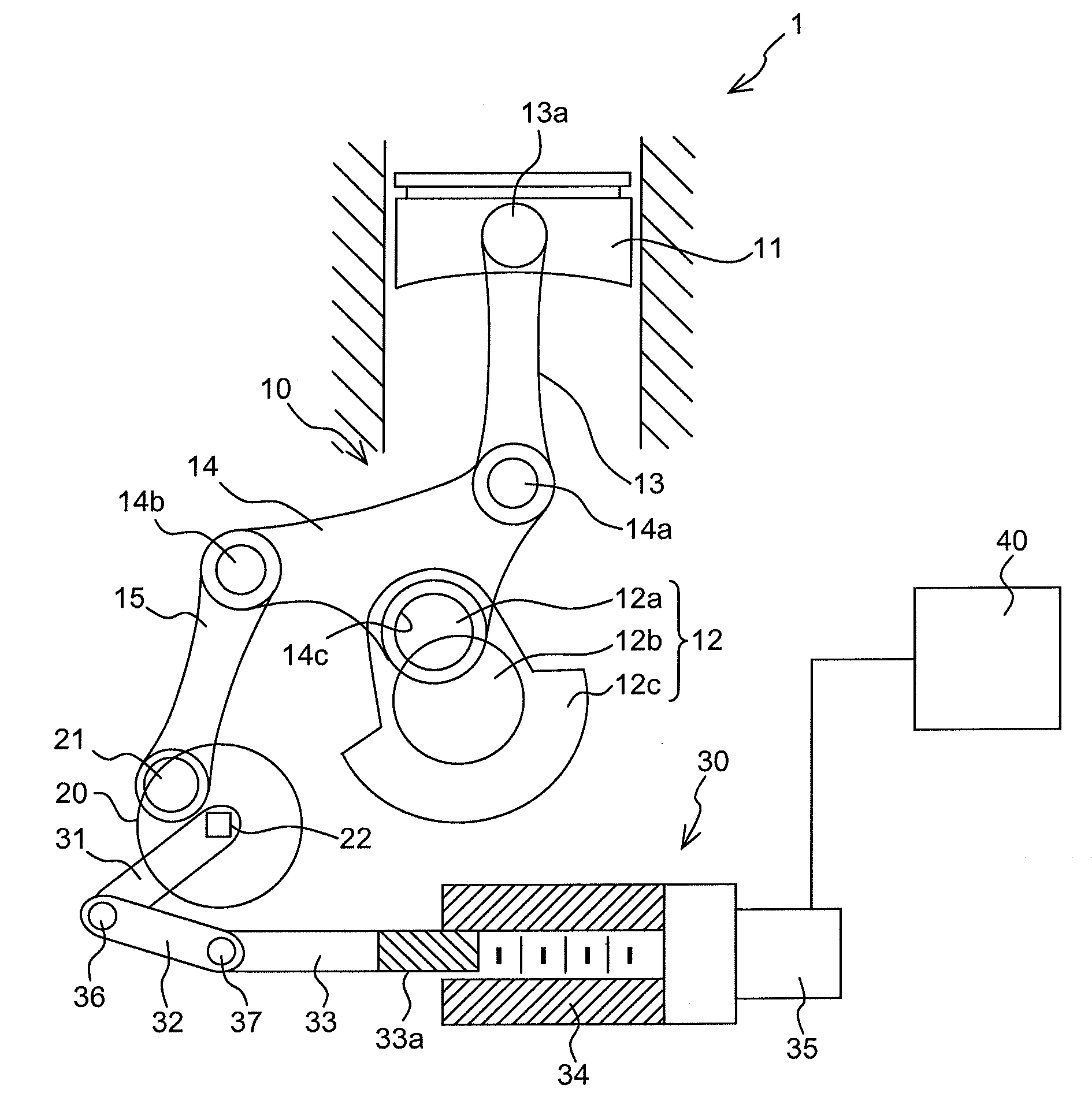

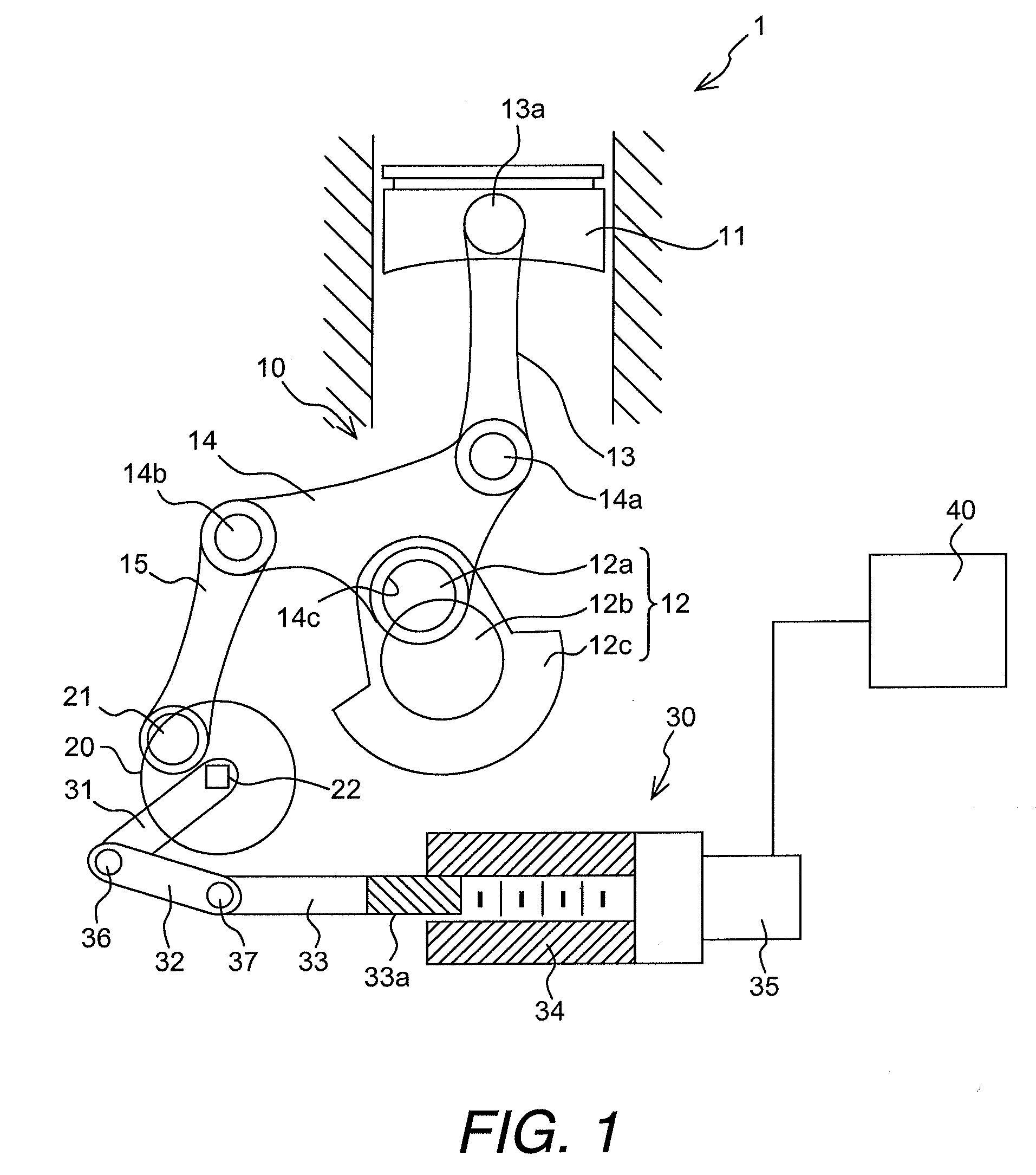

Multi-link variable compression ratio engine

ActiveUS20090107454A1Frequently knockedInhibitionConnecting rodsMachines/enginesTop dead centerReduction ratio

A multi-link variable compression ratio engine is provided with a crankshaft, a piston, a control shaft, a linkage, a motor and a reduction mechanism. The crankshaft moves the piston within an engine cylinder. The control shaft has an eccentric axle eccentric relative to its center-axis. The linkage operatively connects the piston to the crankshaft and the crankshaft to the eccentric axle of the control shaft. The motor rotates the control shaft so a top-dead-center position of the piston changes to vary compression ratios by changing the positions of the eccentric axle and the linkage. The reduction mechanism couples the motor to the control shaft to transmit a reduced rotation of the motor to the control shaft so a reduction ratio of a rotation angle of the motor to a rotation angle of the control shaft is less at high-compression ratios than at intermediate compression ratios.

Owner:NISSAN MOTOR CO LTD

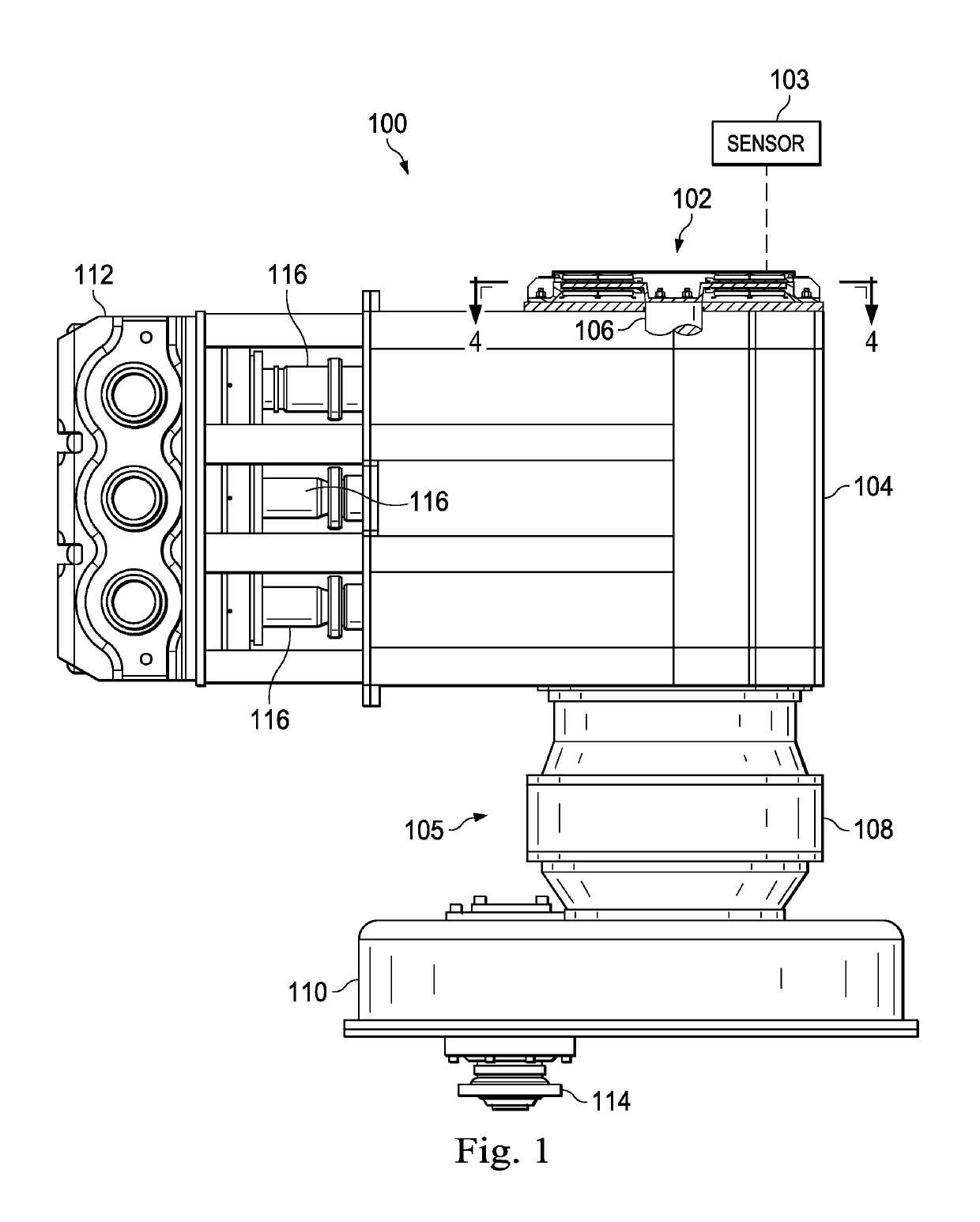

Pump system and method of starting pump

A pump system positionable at a surface of a well site for downhole operations includes a pump assembly having a pump and a starting assist. The pump includes a crankshaft and is operable by a first motor. The starting assist includes a second motor and a gear system.

Owner:BJ ENERGY SOLUTIONS LLC +1

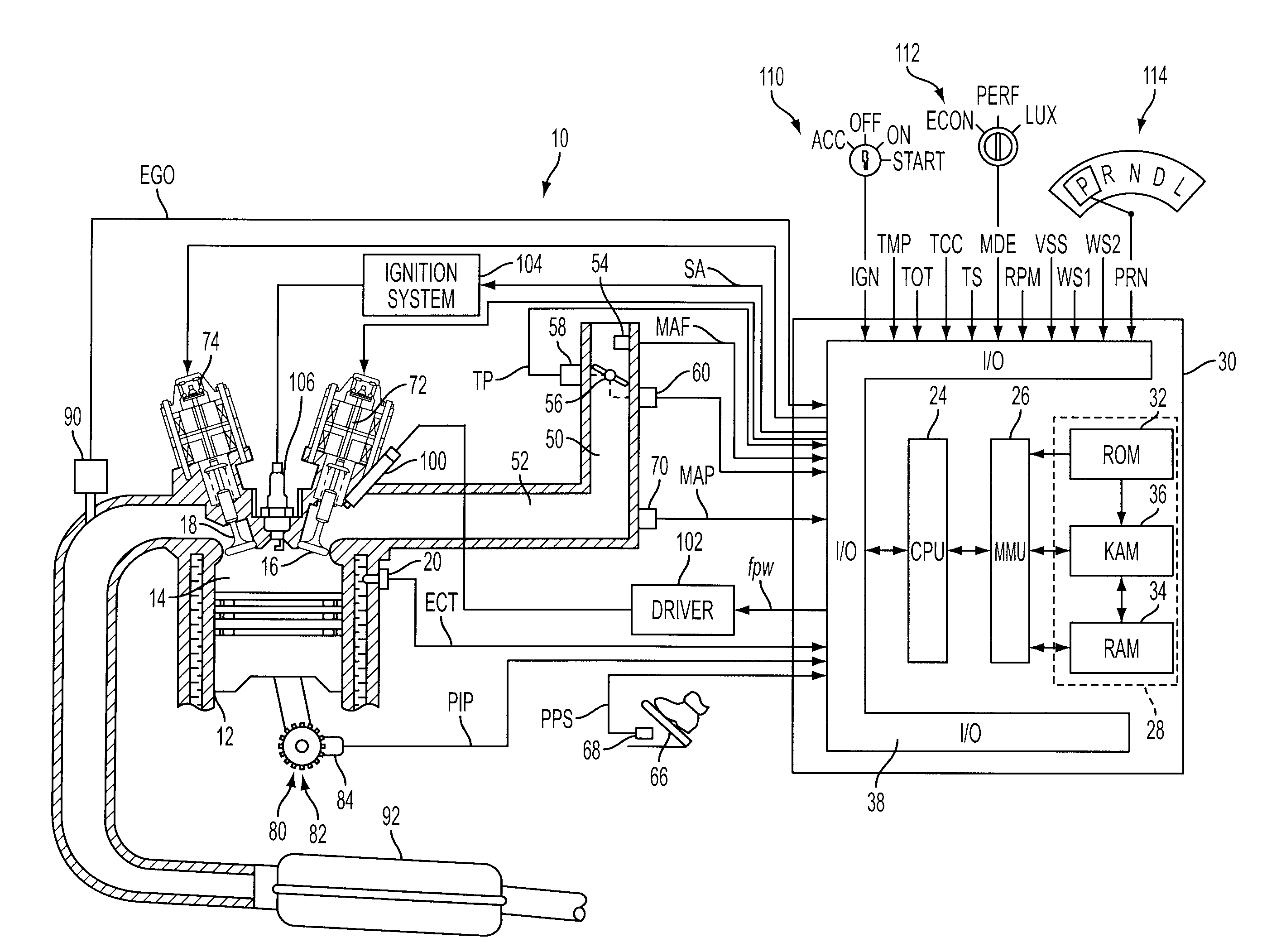

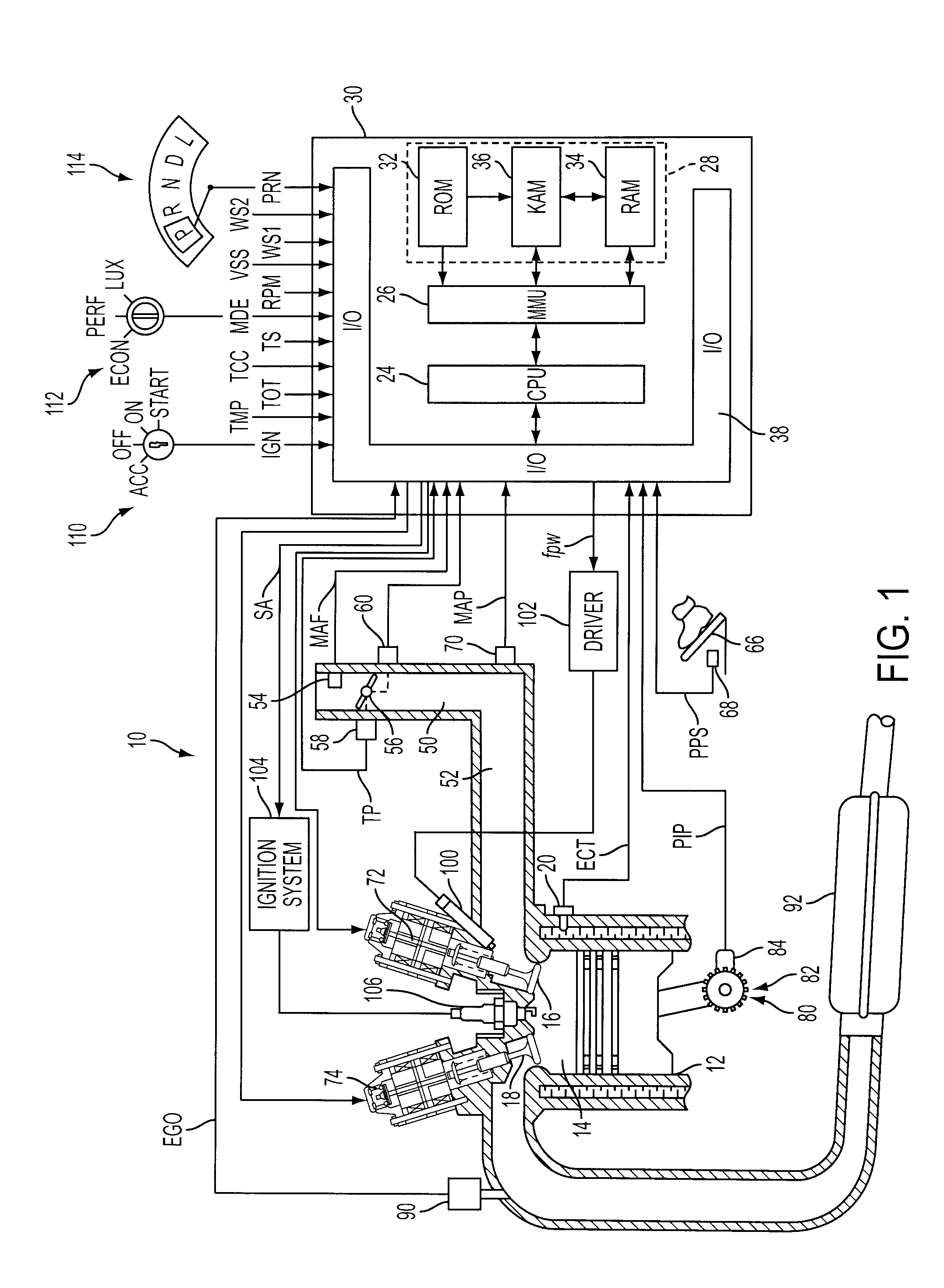

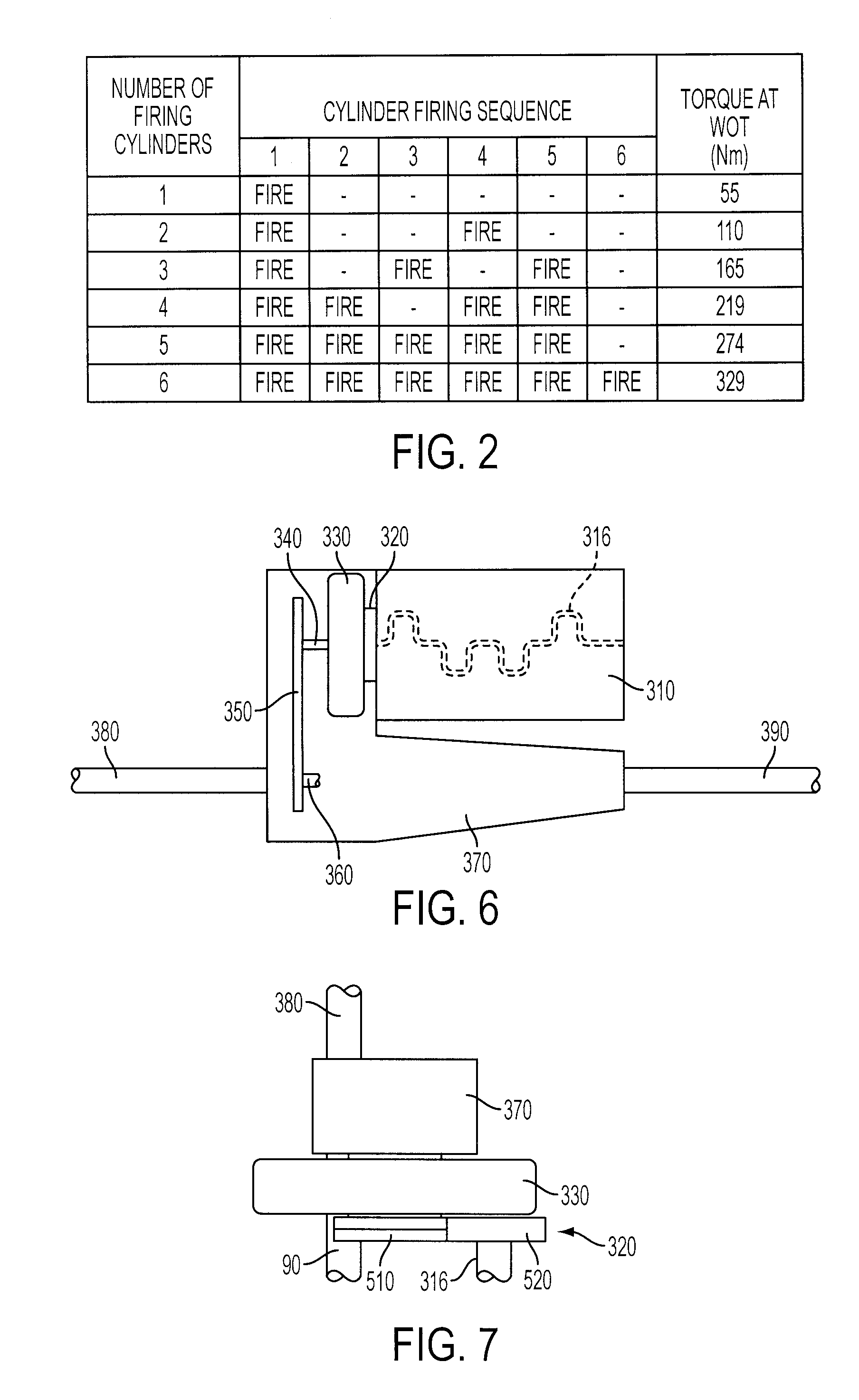

Variable Displacement Engine Operation With NVH Management

InactiveUS20080154468A1Reduce and eliminate torque reactionNo backlashAnalogue computers for vehiclesDigital data processing detailsClose couplingDrivetrain

A system and method for controlling an internal combustion engine operable with a first cylinder firing frequency and a second cylinder firing frequency to reduce or eliminate transmission of torsional vibrations associated with the second cylinder firing frequency to reduce or eliminate constraints on reduced displacement mode operation using a closely coupled drive train component rotating in an opposite direction relative to rotating components of the engine. A close coupling device allows the inertia of the counter-rotating elements to reduce or eliminate the torque reaction of the drivetrain associated with acceleration and deceleration of the engine crankshaft in response to the second cylinder firing frequency in the reduced displacement mode.

Owner:FORD GLOBAL TECH LLC

Reciprocating pump with dual circuit power end lubrication system

ActiveUS20190277279A1Positive displacement pump componentsRotary/oscillating piston combinationsHigh pressureLubrication

A dual circuit lubrication system for a power end of a reciprocating pump that includes a lubrication pump that supplies lubrication fluid to a high pressure lubrication circuit and a low pressure lubrication circuit. The high pressure lubrication circuit is fluidly coupled to a crankshaft to supply lubrication fluid to journal surfaces associated with the crankshaft at a first lubrication fluid pressure. The crankshaft drives a crosshead coupled to a plunger to displace fluid from a fluid end of the reciprocating pump. The low pressure lubrication circuit is fluidly coupled to supply the lubrication fluid to a plurality of roller bearing surfaces associated with the crankshaft at a second lubrication fluid pressure. The first lubrication fluid pressure is greater than the second lubrication fluid pressure.

Owner:SPM OIL & GAS INC

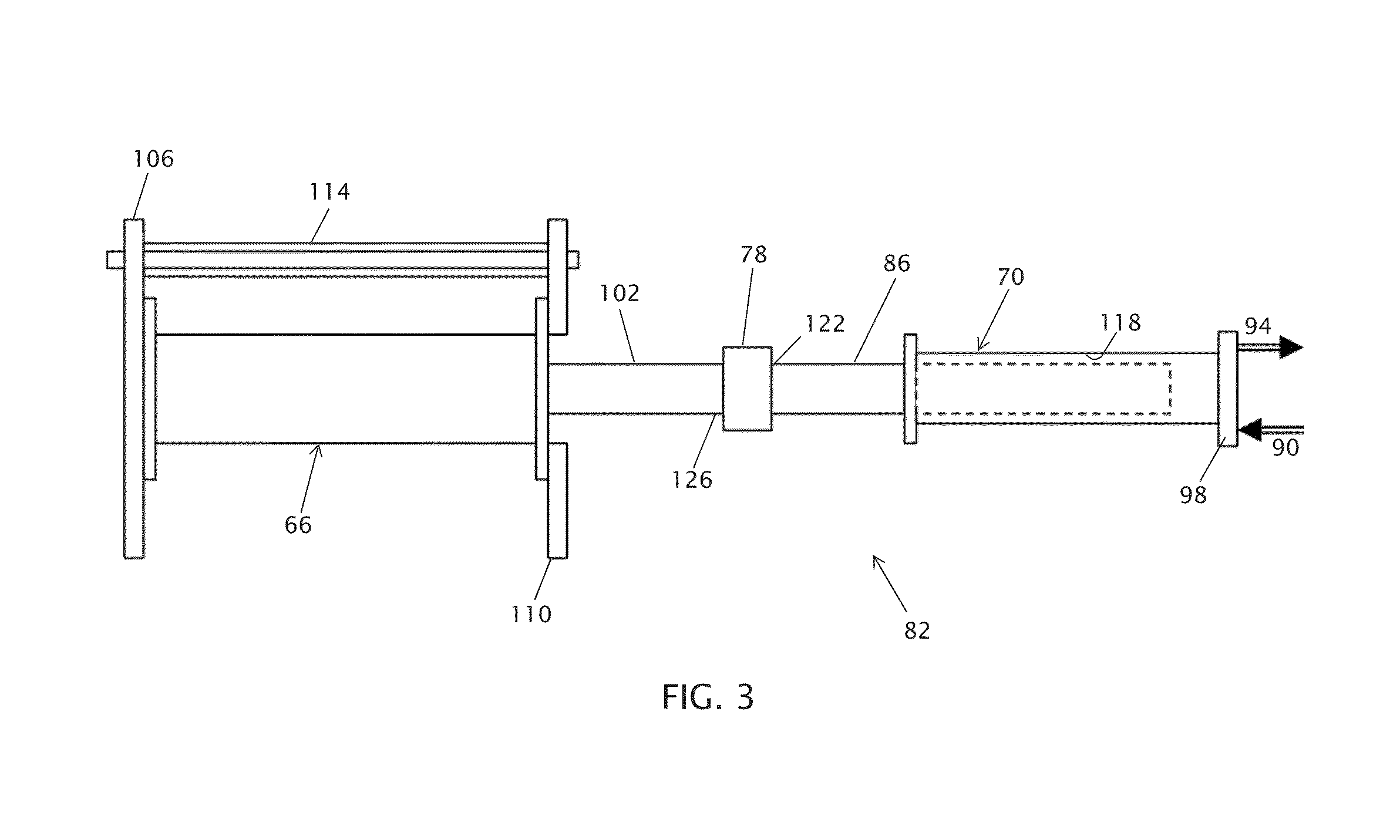

Continuously variable transmission

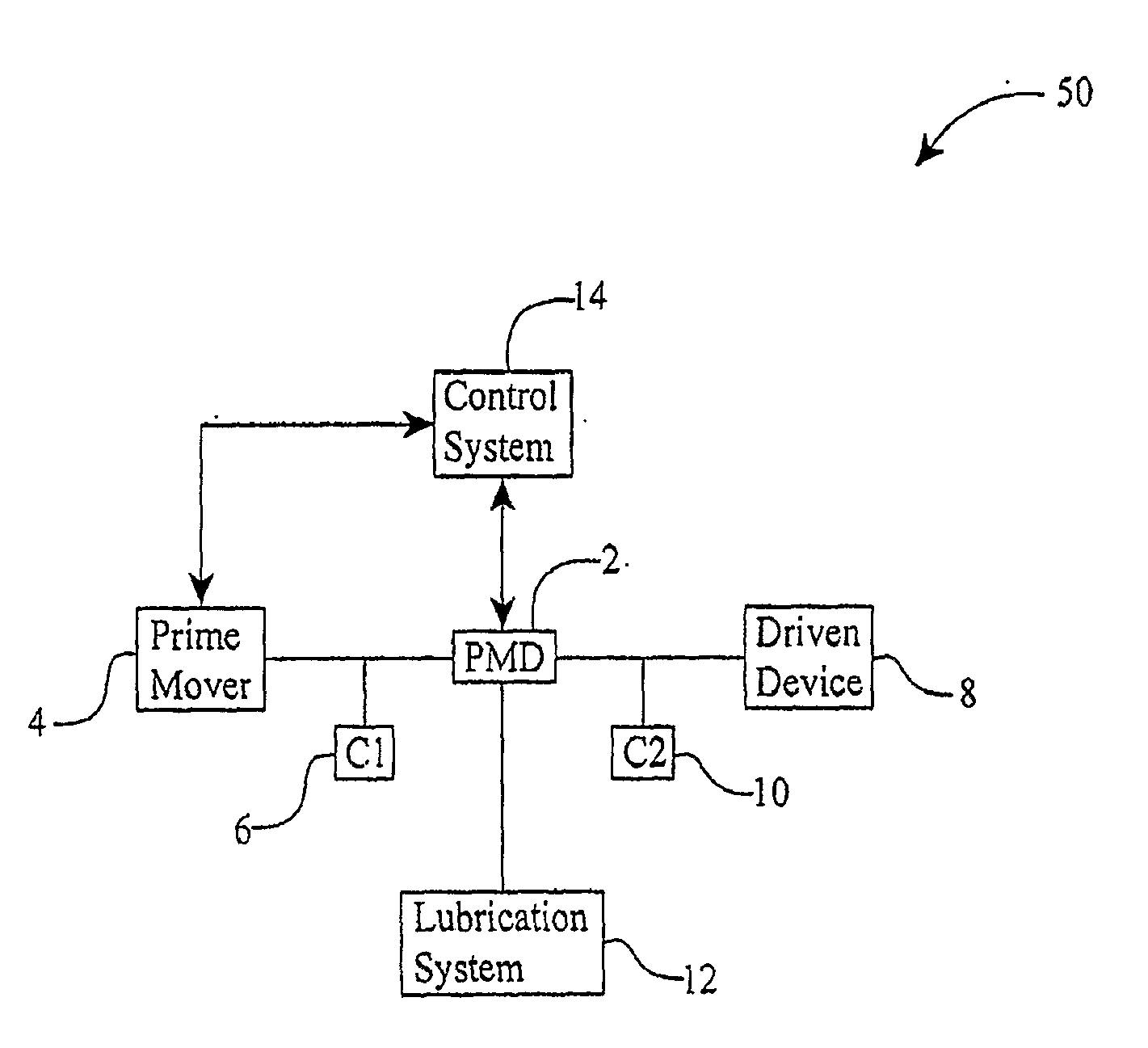

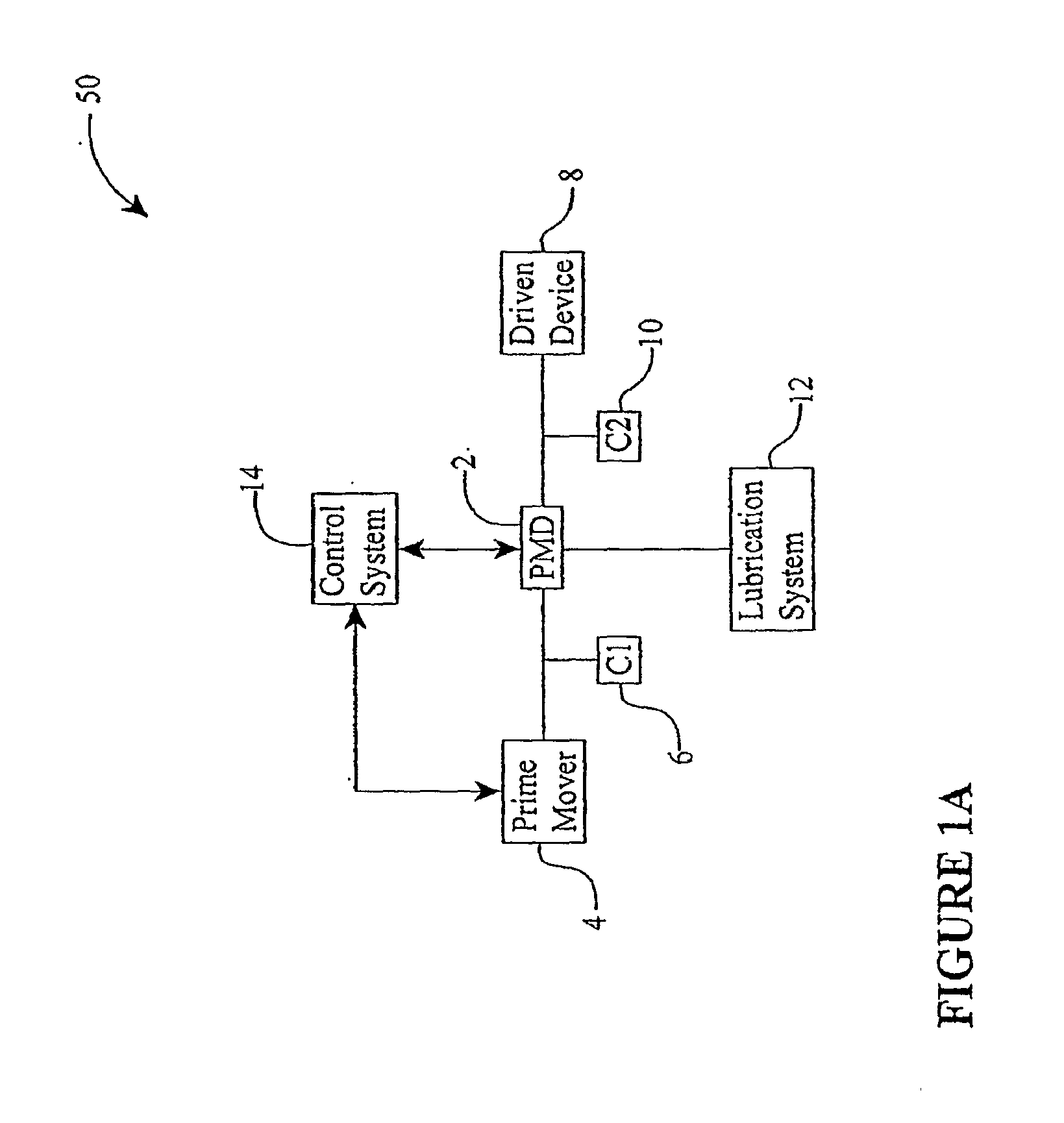

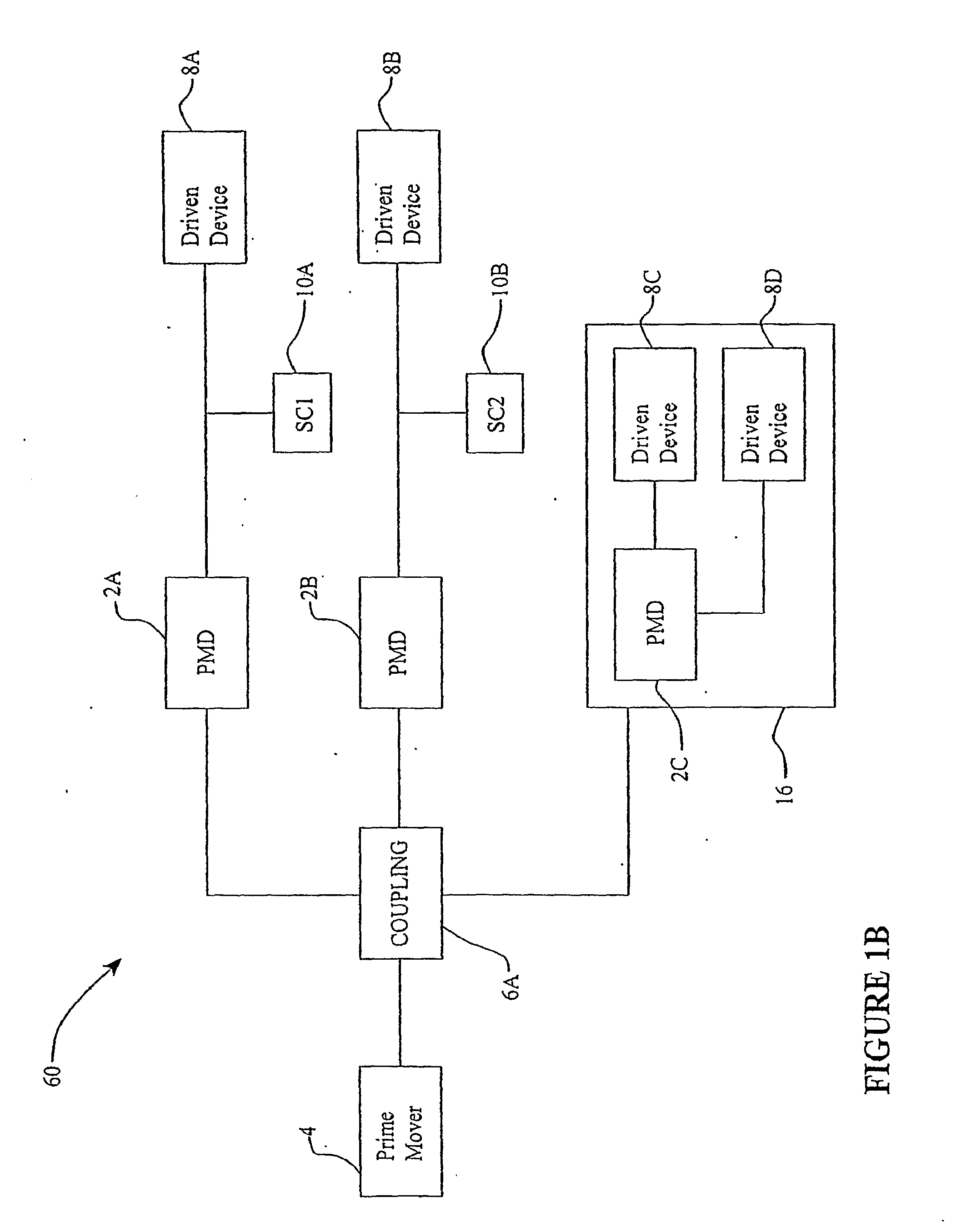

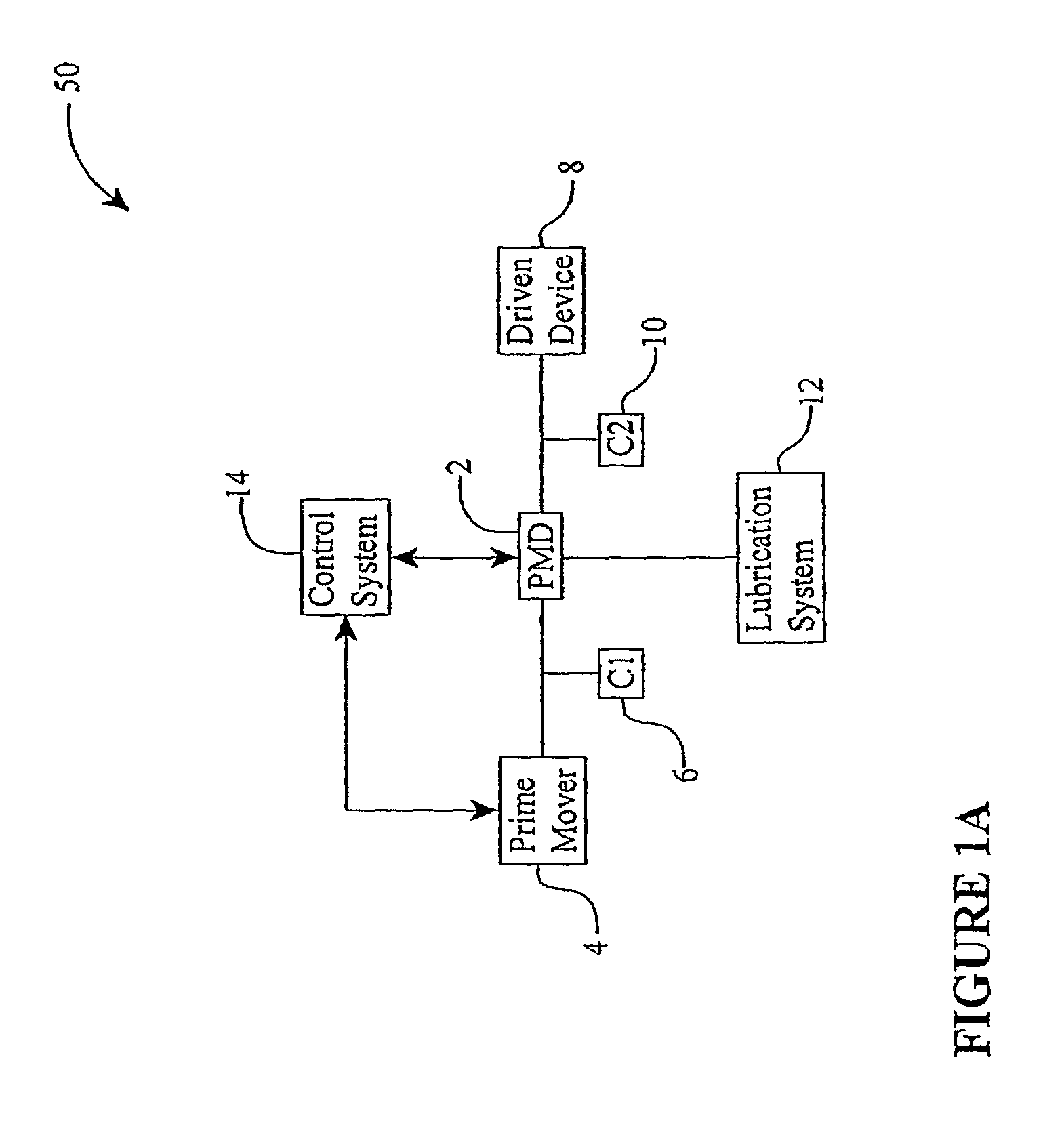

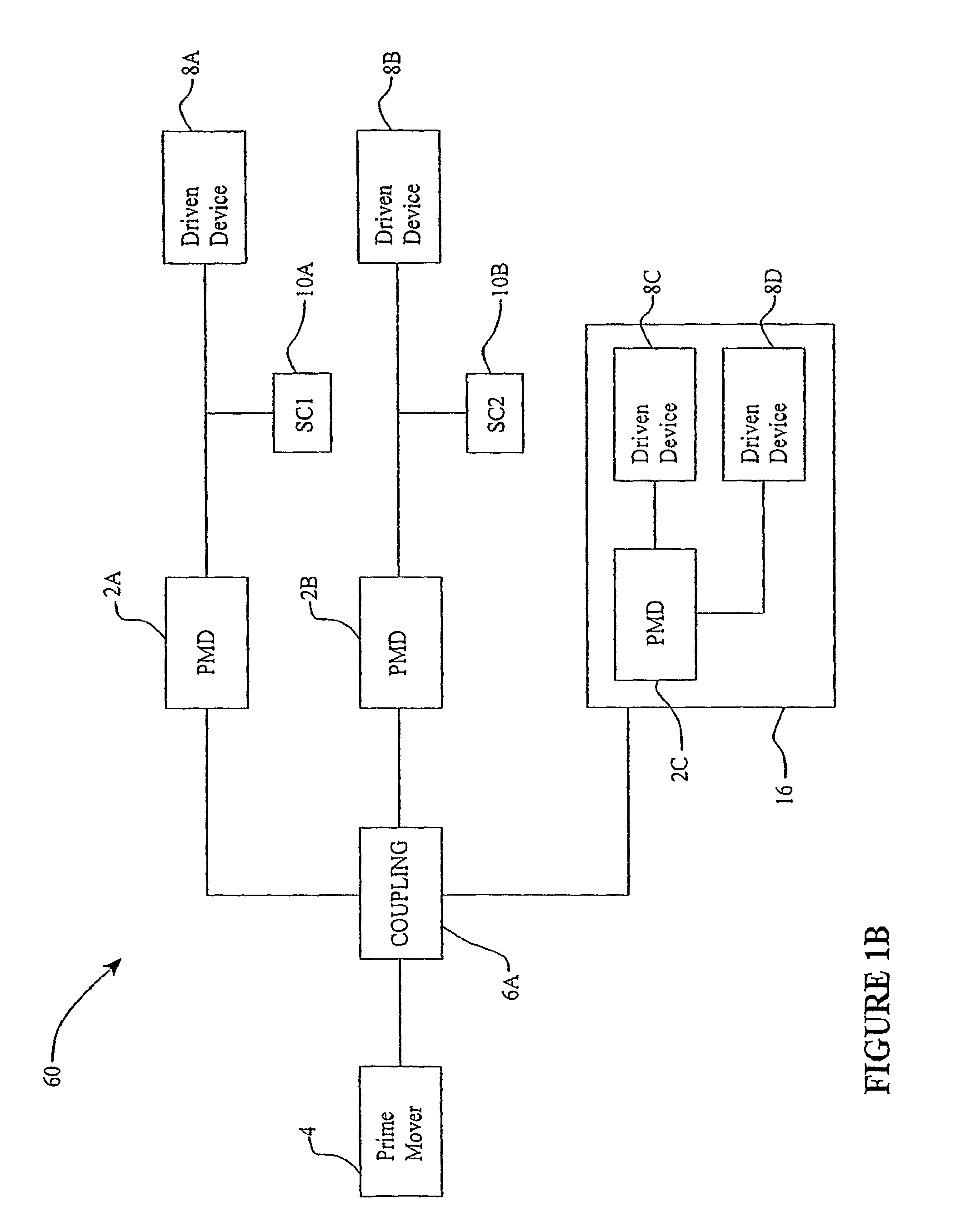

Embodiments are directed to a front end accessory drive (FEAD), subassemblies, and components therefor. Embodiments disclosed cover power modulating devices (PMD) which can be used in a FEAD. In one embodiment, a continuously variable transmission (CVT) is coupled directly to a crankshaft of a prime mover, and the CVT is used to regulate the speed and / or torque delivered to an accessory. A compound drive device includes a motor / generator subassembly cooperating with a CVT subassembly to provide a motor functionality with torque multiplication or division, or alternatively, a generator functionality with torque multiplication or division. In some embodiments, a FEAD includes a PMD having a sun shaft configured to couple to a sun of the PMD and to an electric motor component, such as an electrical armature or an electrical field. In one embodiment, the electrical armature the electrical field are placed concentrically and coaxially and configured to rotate relative to one another in opposite directions.

Owner:FALLBROOK INTPROP COMPANY

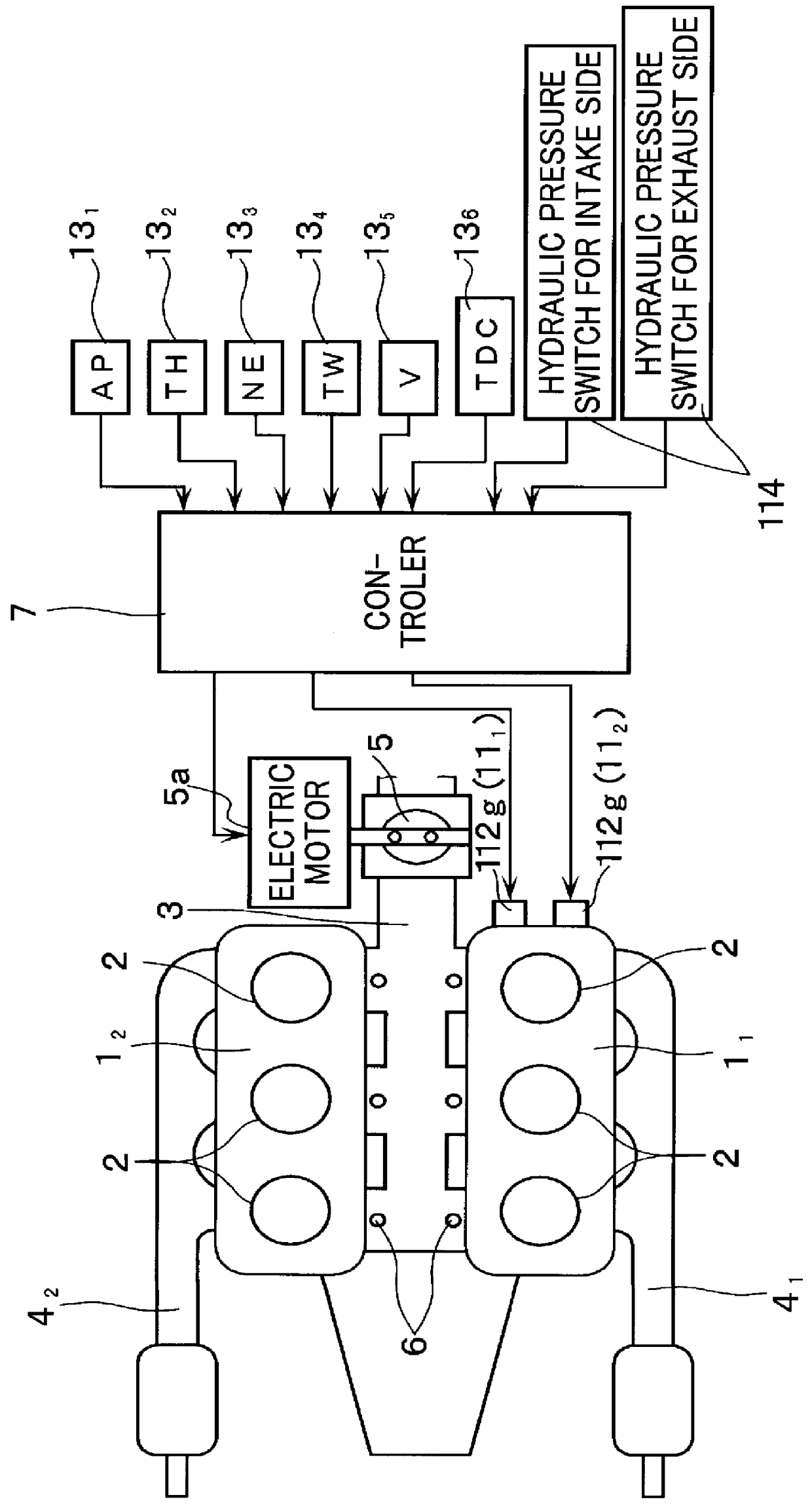

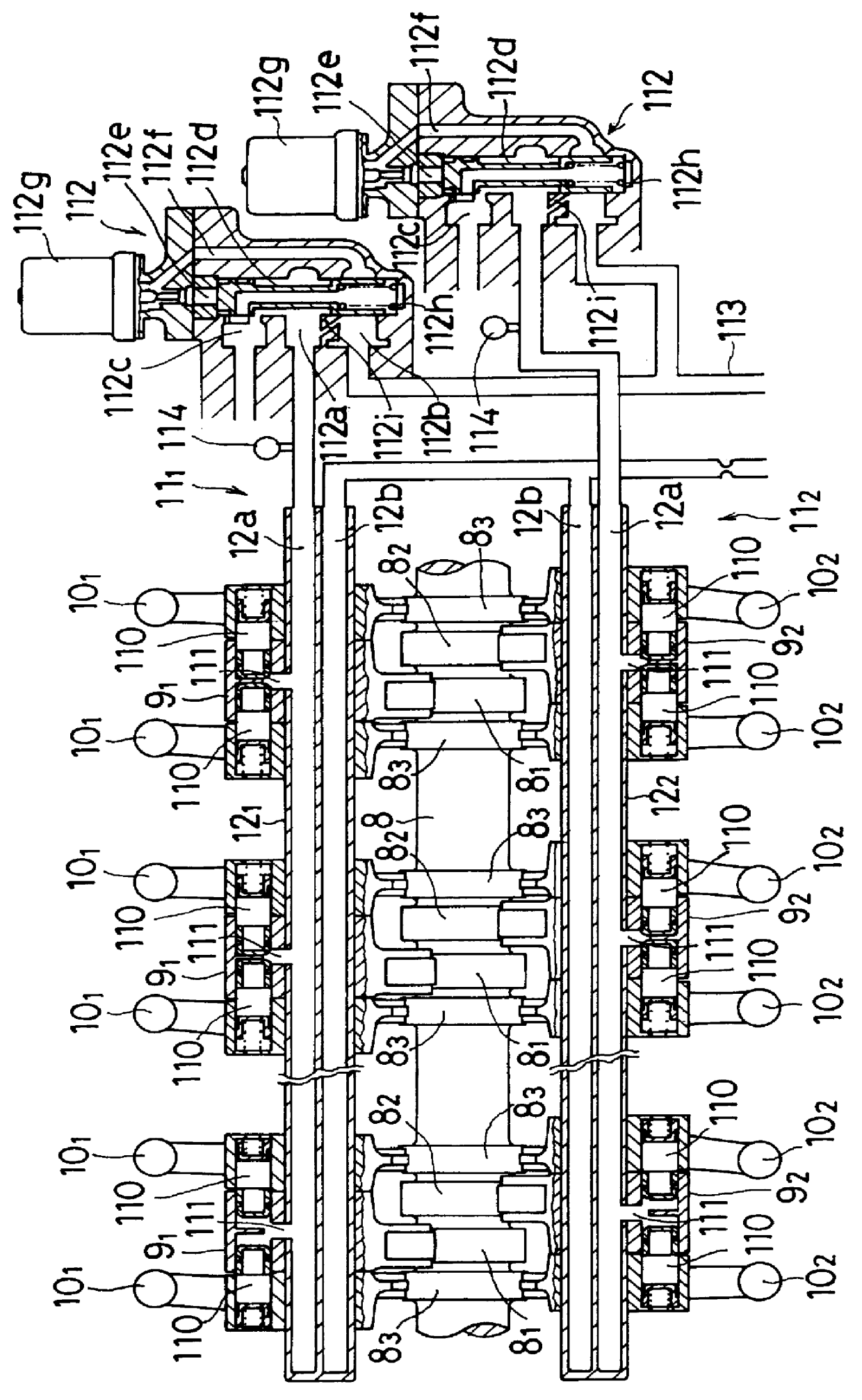

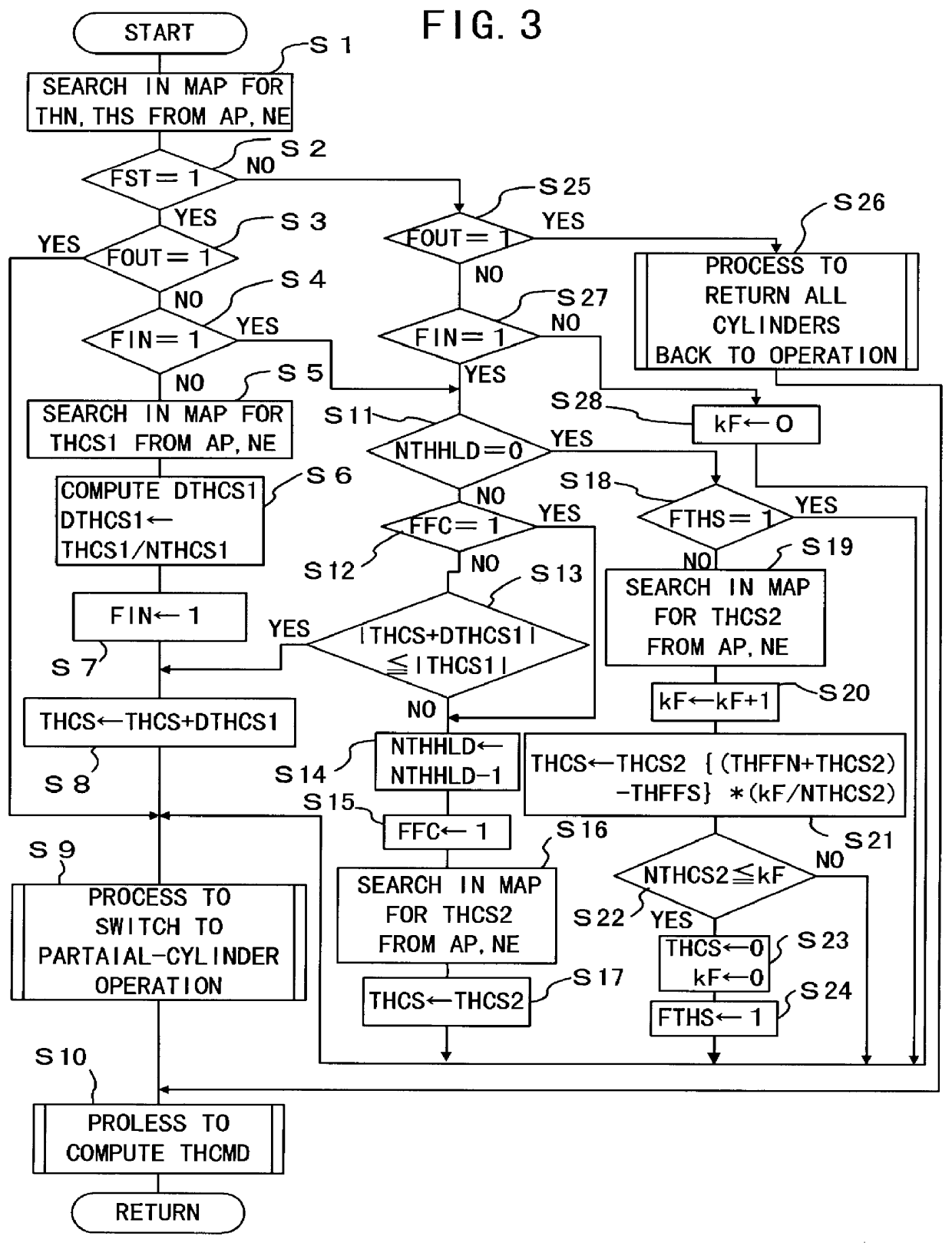

Apparatus for controlling multi-cylinder internal combustion engine with partial cylinder switching-off mechanism

In an apparatus for controlling a multi-cylinder internal combustion engine with partial cylinder switch-off mechanism which is switchable between an all-cylinder operation mode in which all cylinders are operated and a partial-cylinder operation mode in which operation of partial cylinders is suspended, the operation of intake valves and exhaust valves is suspended or resumed in a predetermined order with respect to all of the suspended cylinders irrespective of a rotational frequency of the engine. There are provided a solenoid valve on an intake side and a solenoid valve on an exhaust side for switching input hydraulic pressures for hydraulically operated switching devices respectively on the intake side and on the exhaust side between the driving state and the drive-free state. At the time of switching the operation, one of the solenoid valves on the intake side and the exhaust side is driven in advance. The subsequent number of rotations of a crankshaft is counted. When the number of this counting has reached a predetermined value, the solenoid valve on the other side is driven.

Owner:HONDA MOTOR CO LTD

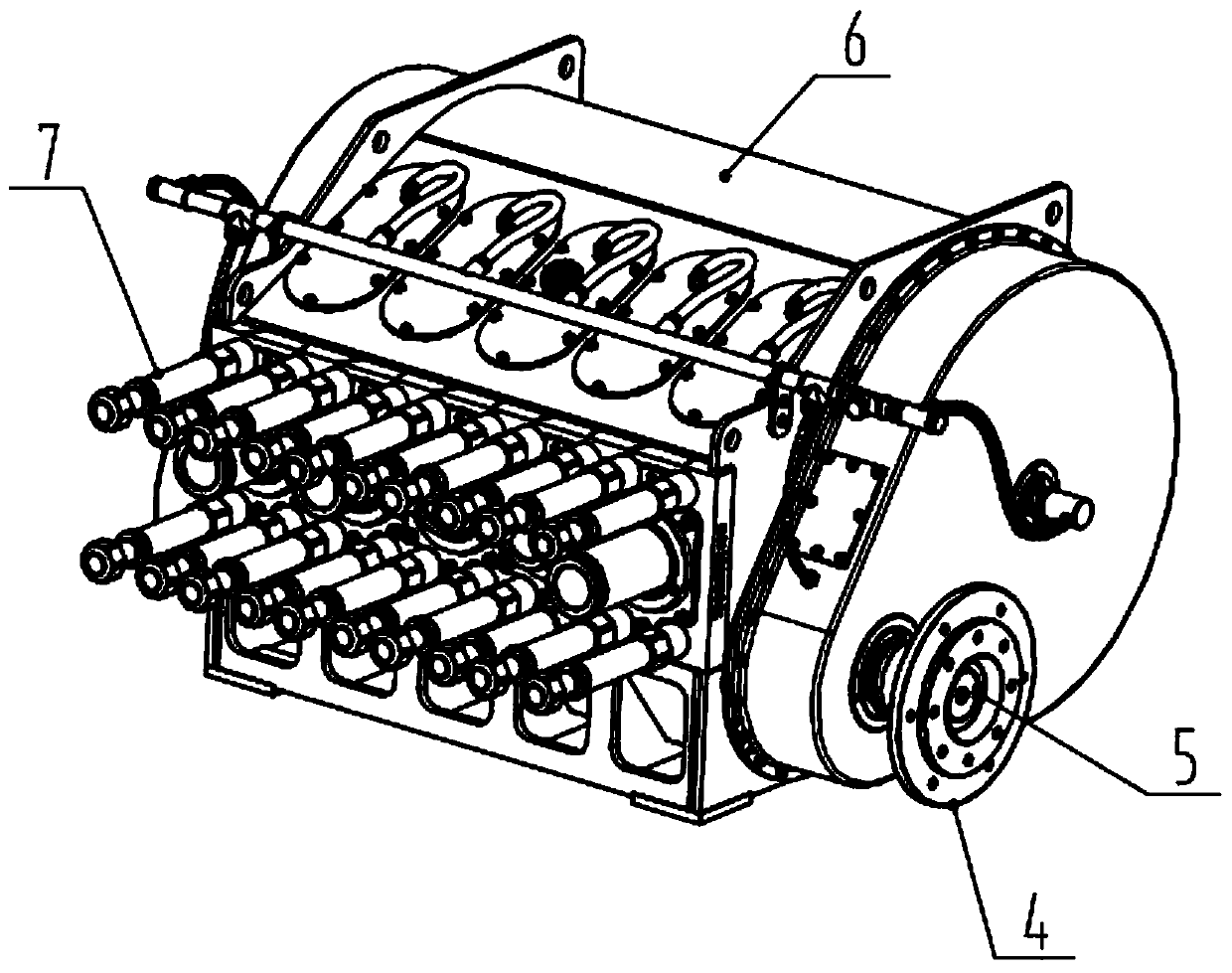

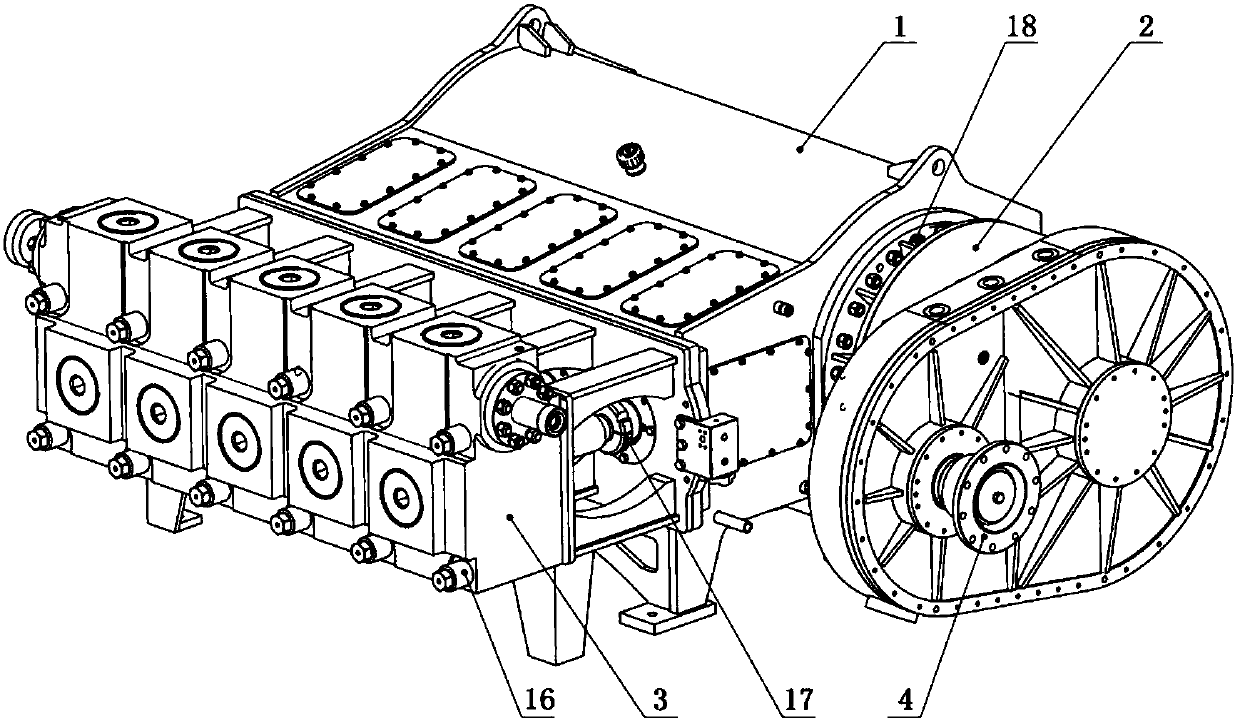

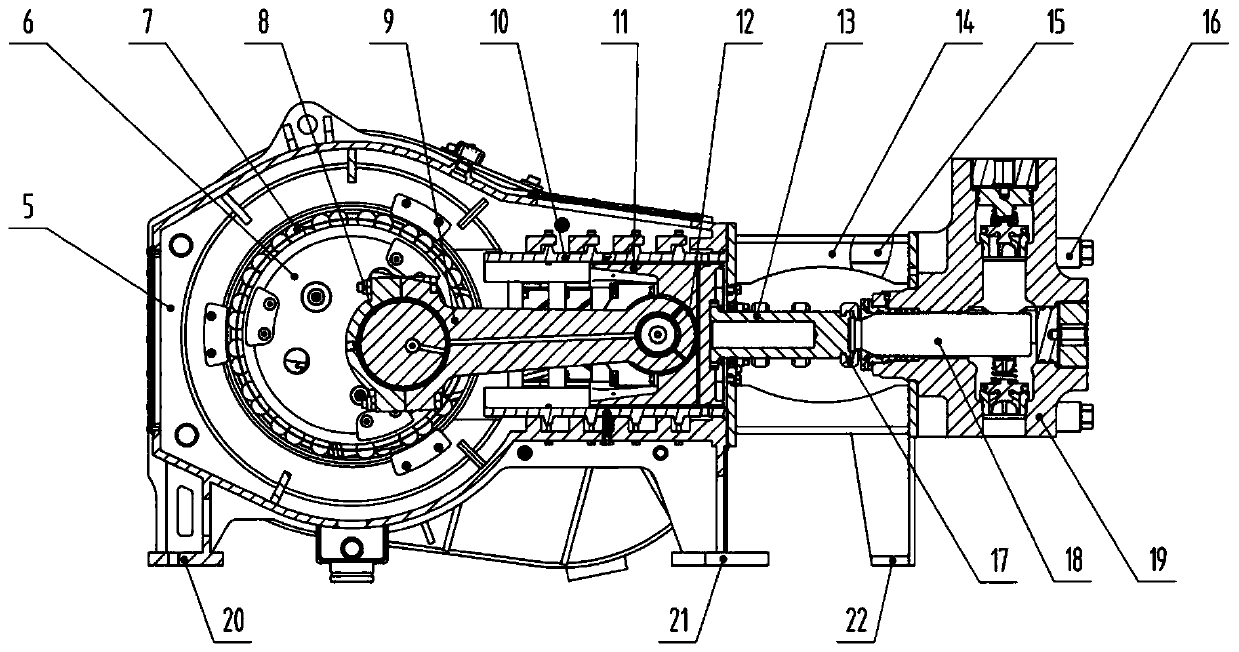

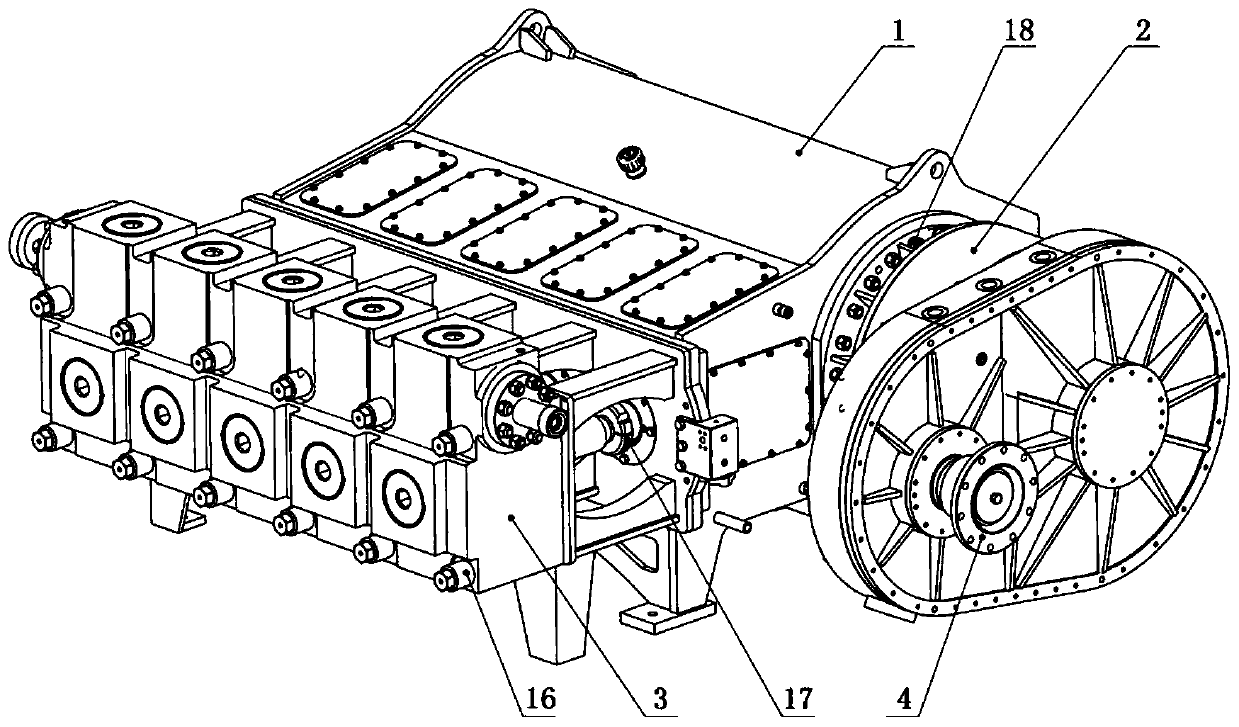

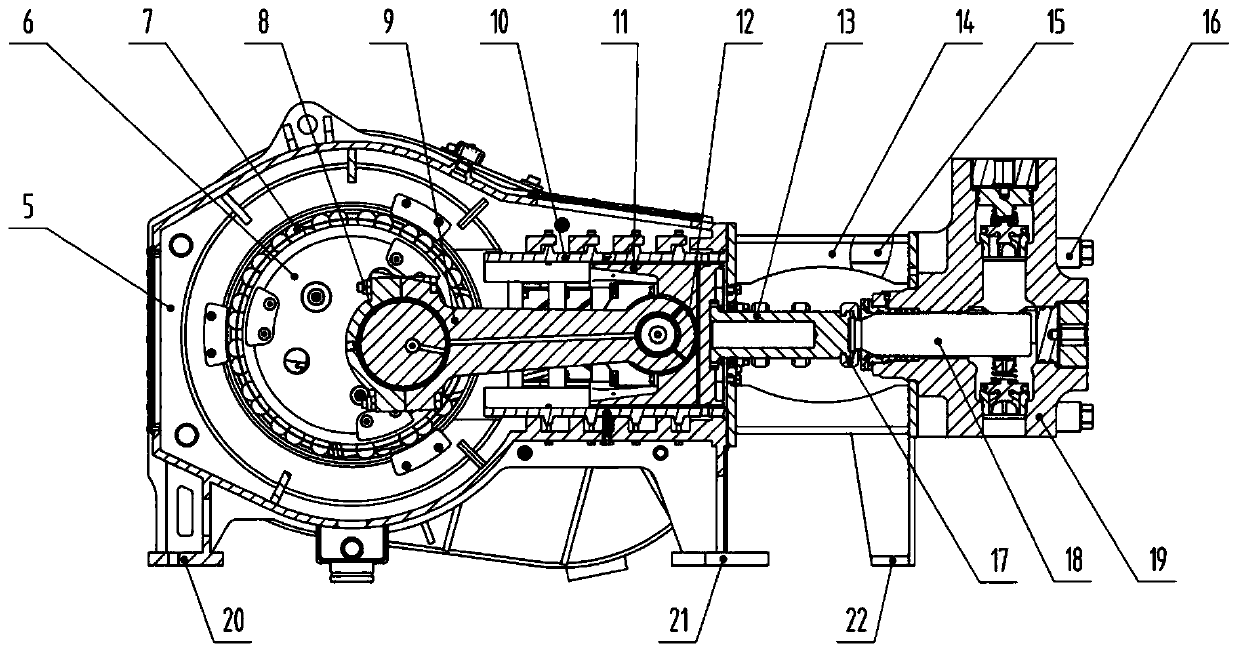

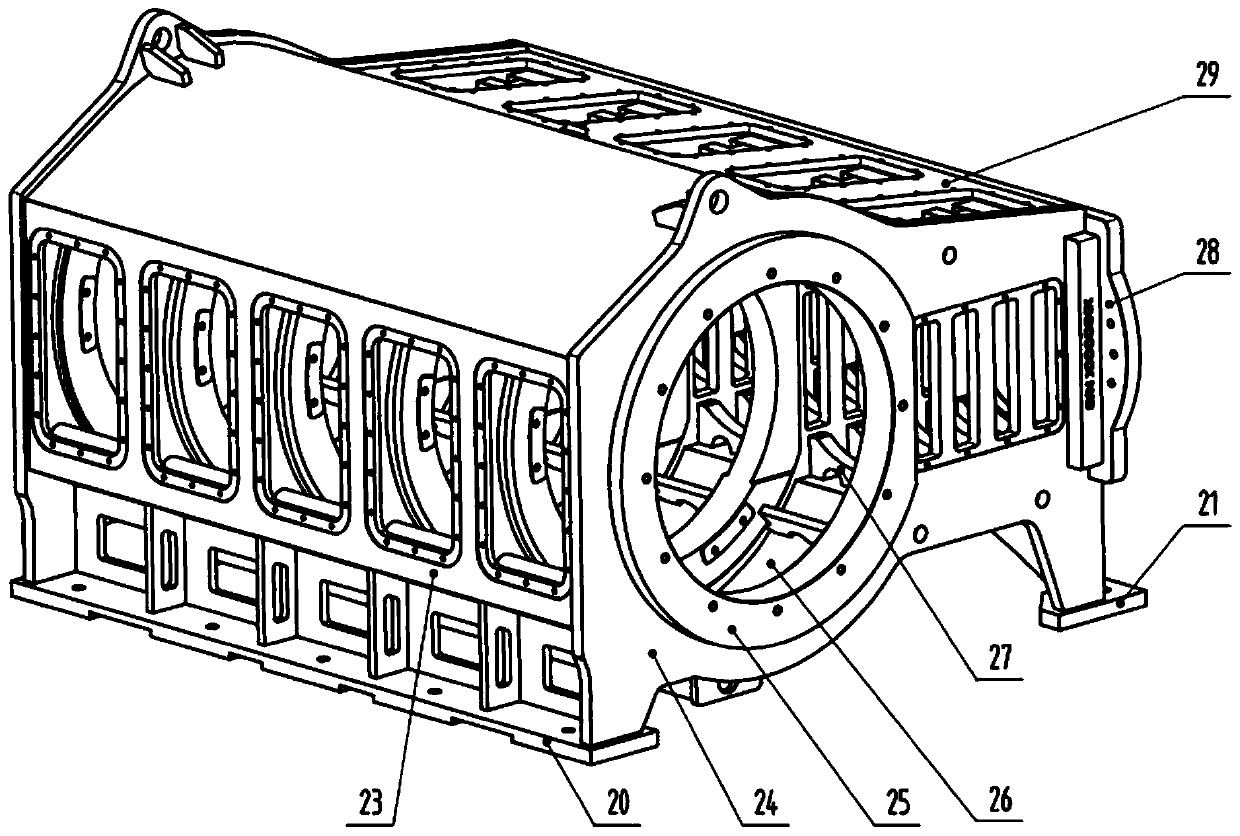

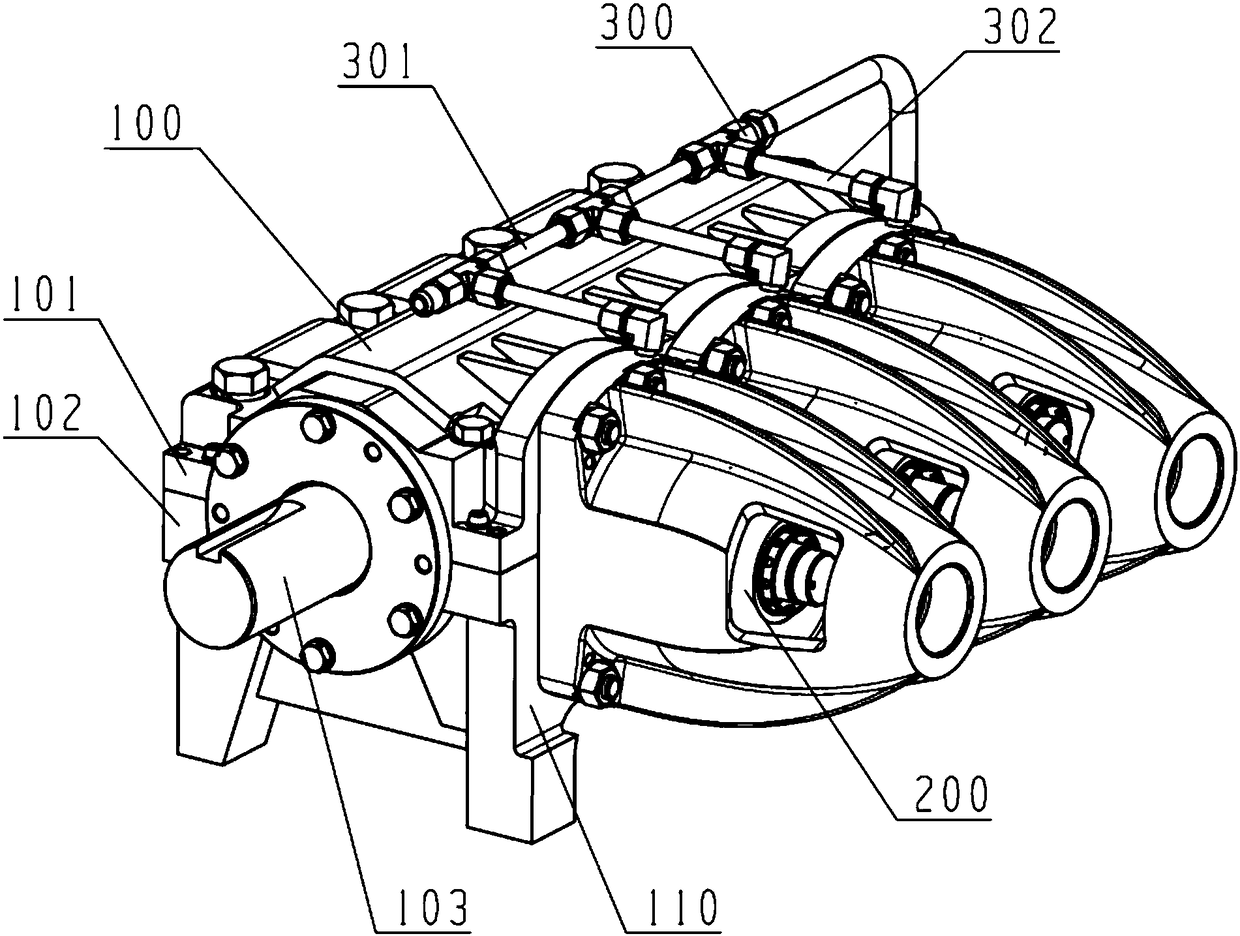

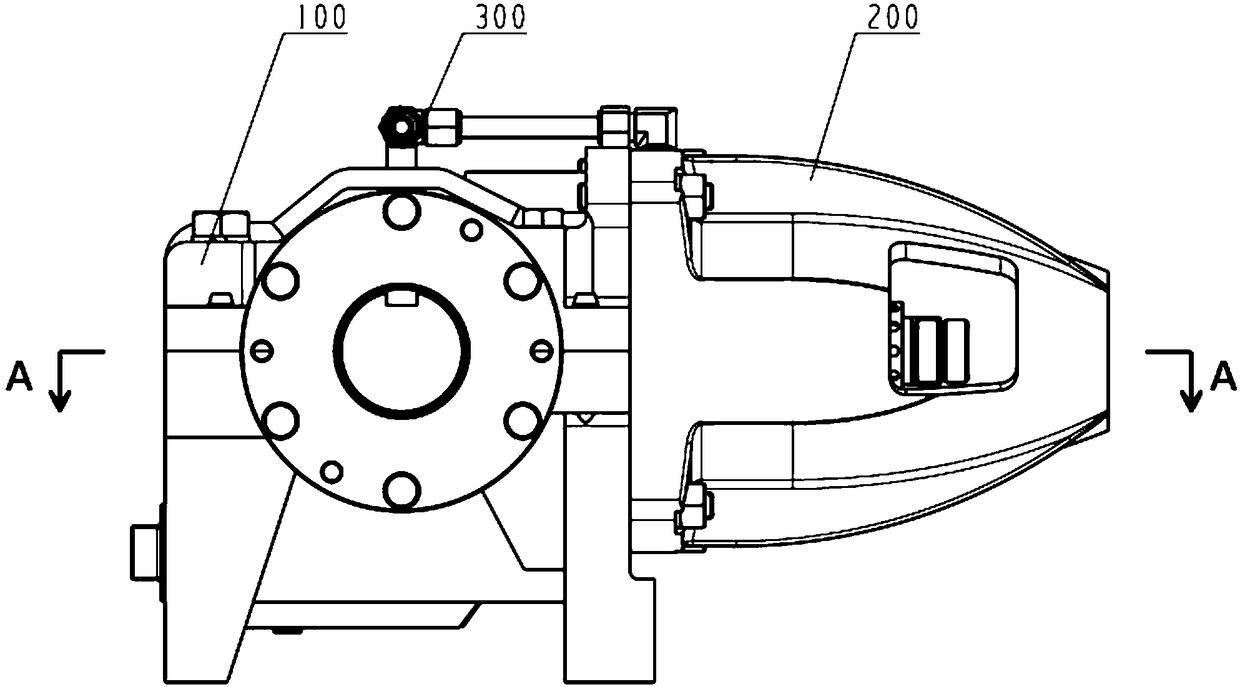

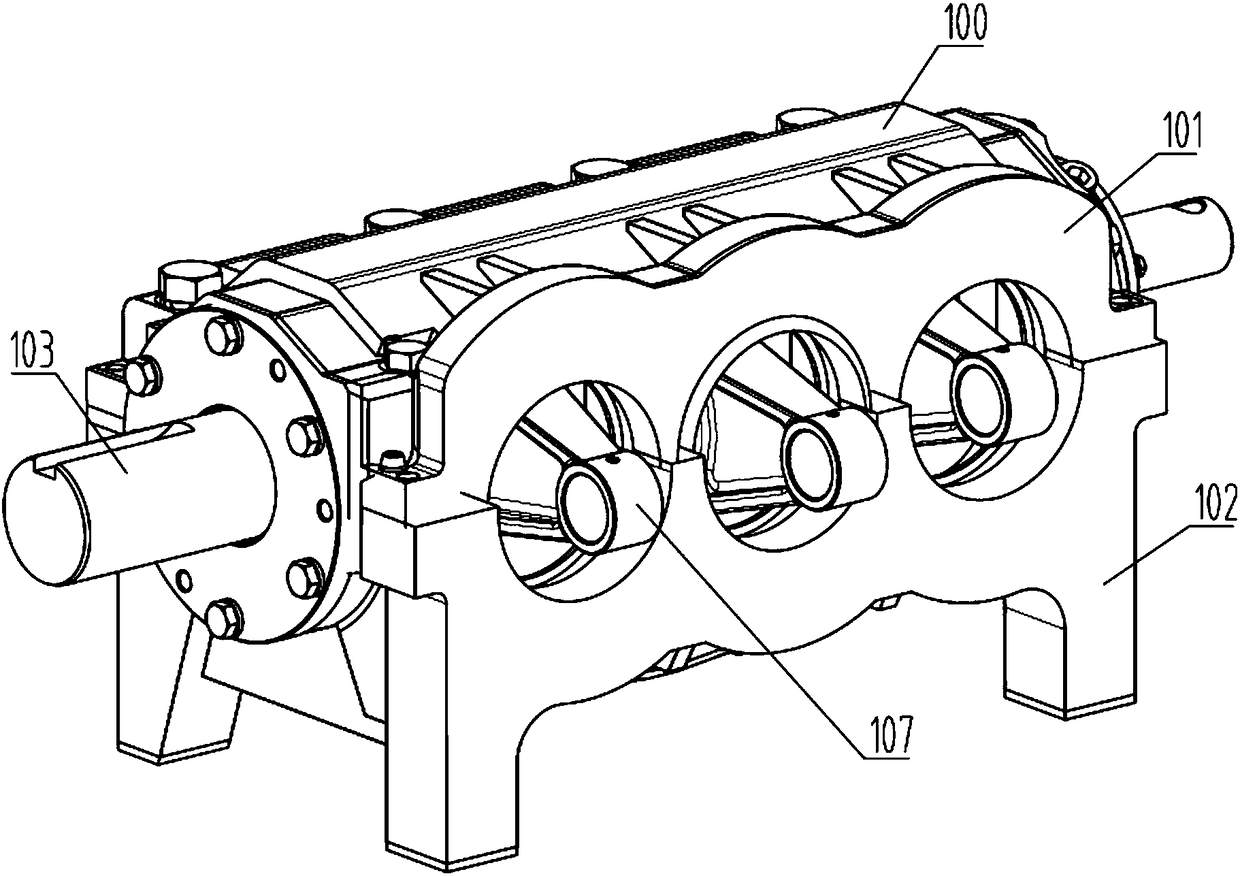

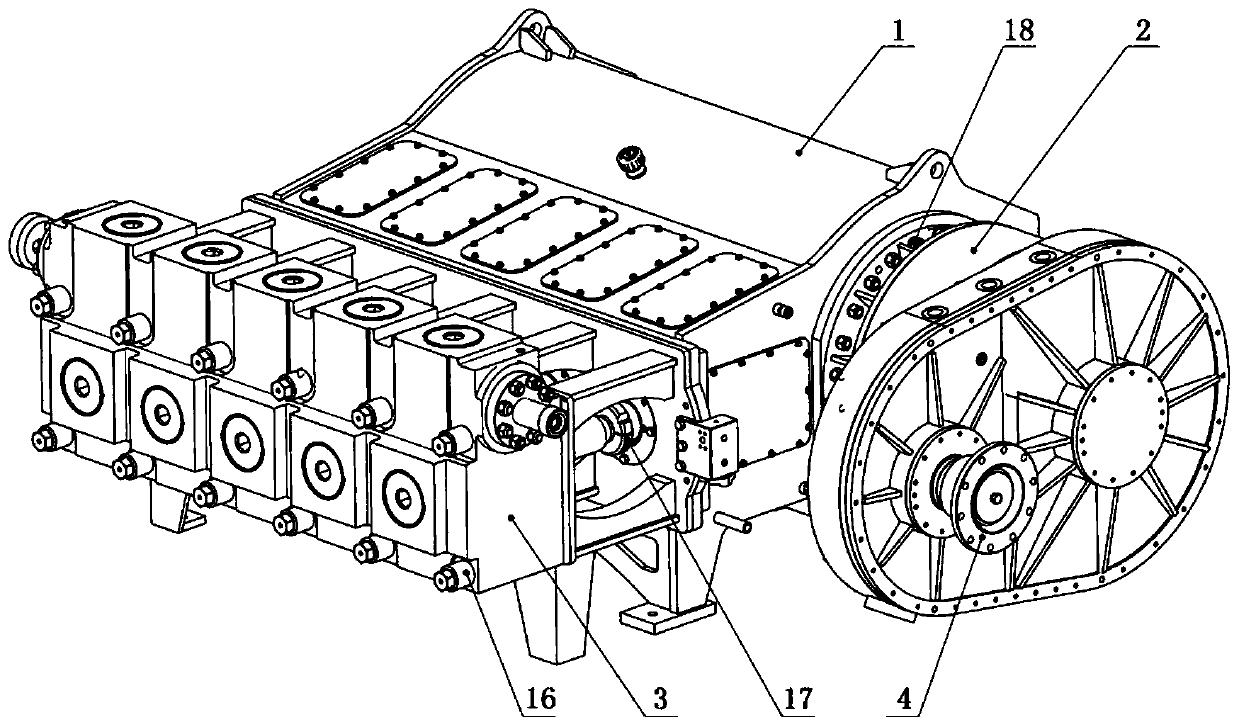

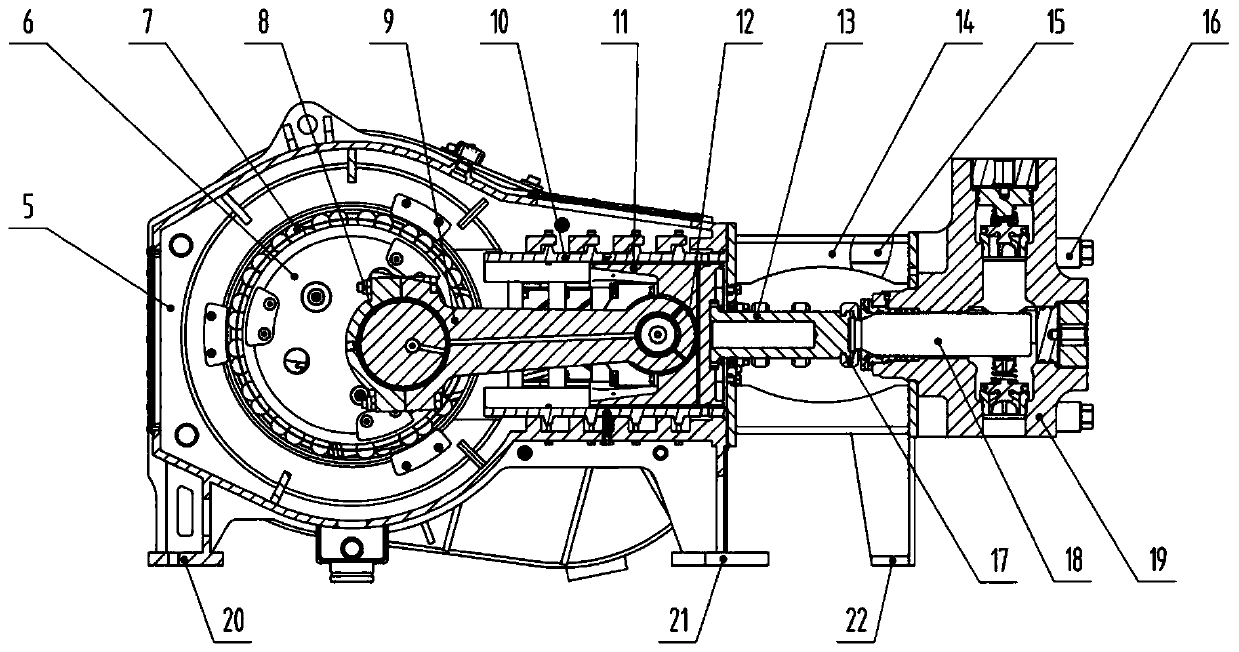

Light five-cylinder plunger pump

PendingCN111441925AIncreased stroke distanceIncrease rated input powerCrankshaftsPositive displacement pump componentsCrankGear wheel

The invention discloses a light five-cylinder plunger pump. The light five-cylinder plunger pump comprises a power end assembly and a hydraulic end assembly, wherein the power end assembly is connected with the hydraulic end assembly; the cylinder spacing of the light five-cylinder plunger pump is 9in; the power end assembly comprises a crank shaft, the crank shaft comprises six crank necks and five crank throws, the crank necks and the crank throws are fixedly connected, the distance between rotating centers of the crank necks and the crank throws is 101.6 mm, and the stroke distance of the light five-cylinder plunger pump is 203.2 mm. According to the light five-cylinder plunger pump, power is increased by increasing stroke, reducing transmission ratio and improving bearing capacity, andmeanwhile, dead weight is reduced by reducing the cylinder spacing, the tooth number of a big gear and the tooth thickness of the big gear and a pinion. The light five-cylinder plunger pump meets conditions of working in the area with severe well cementing operation conditions in aspects of weight and power simultaneously, and working efficiency is increased.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

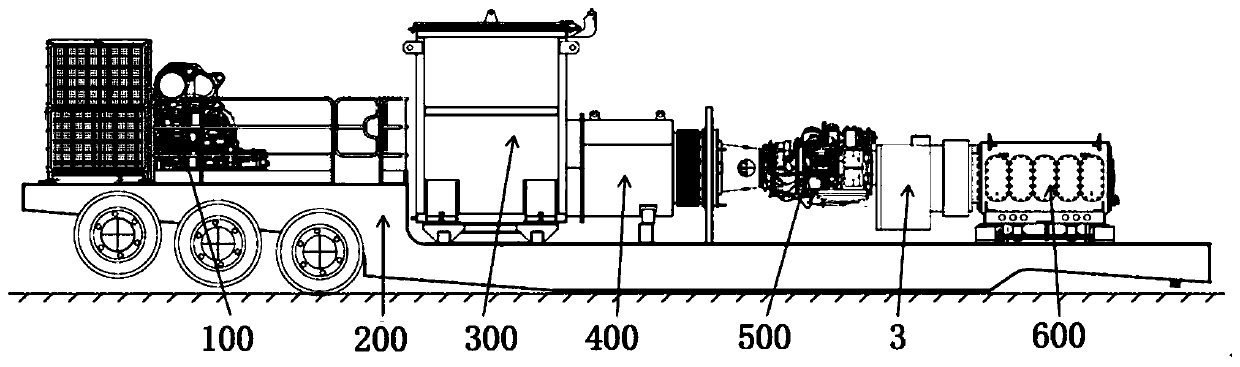

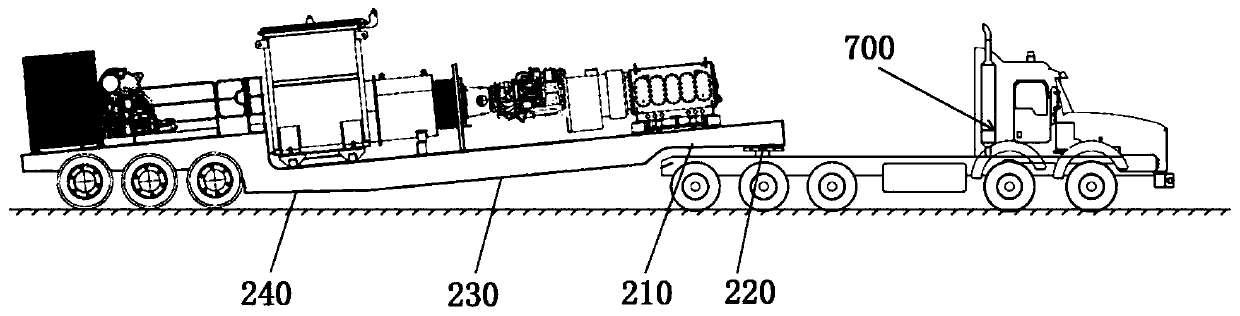

Semitrailer-mounted turbine fracturing equipment

PendingCN110485984AReduce weightLower center of gravityPositive displacement pump componentsFlexible member pumpsOperational costsGravity center

The invention discloses semitrailer-mounted turbine fracturing equipment. Straight-line connection and special chassis design of the whole equipment can double reduce center of gravity of the equipment, stability and safety are better ensured, the structure is simpler, the investment cost and the operation cost are lowered, risks of the whole breakdown of fracturing sites are reduced, transmissionis better, and the semitrailer-mounted turbine fracturing equipment is suitable for continuous operation working conditions with long time and large load. By improving a plunger pump, optimization ofrotating center distances of a crank throw and a crankshaft makes rated power input of the crank throw and the crankshaft increase to 5000-7000 hp, optimization of the transmission ratio of an integrated reduction gearbox on the plunger pump makes the maximum input speed of the integrated reduction gearbox reach 16000 rpm, and ultra-high speed enables reduction gearboxes to be directly connectedwith a turbine engine so as to the solve the problems that turbine fracturing equipment slows down depending on the two reduction gearboxes, and weight of the whole semitrailer is reduced, and boundary dimension of the semitrailer-mounted turbine fracturing equipment is reduced.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

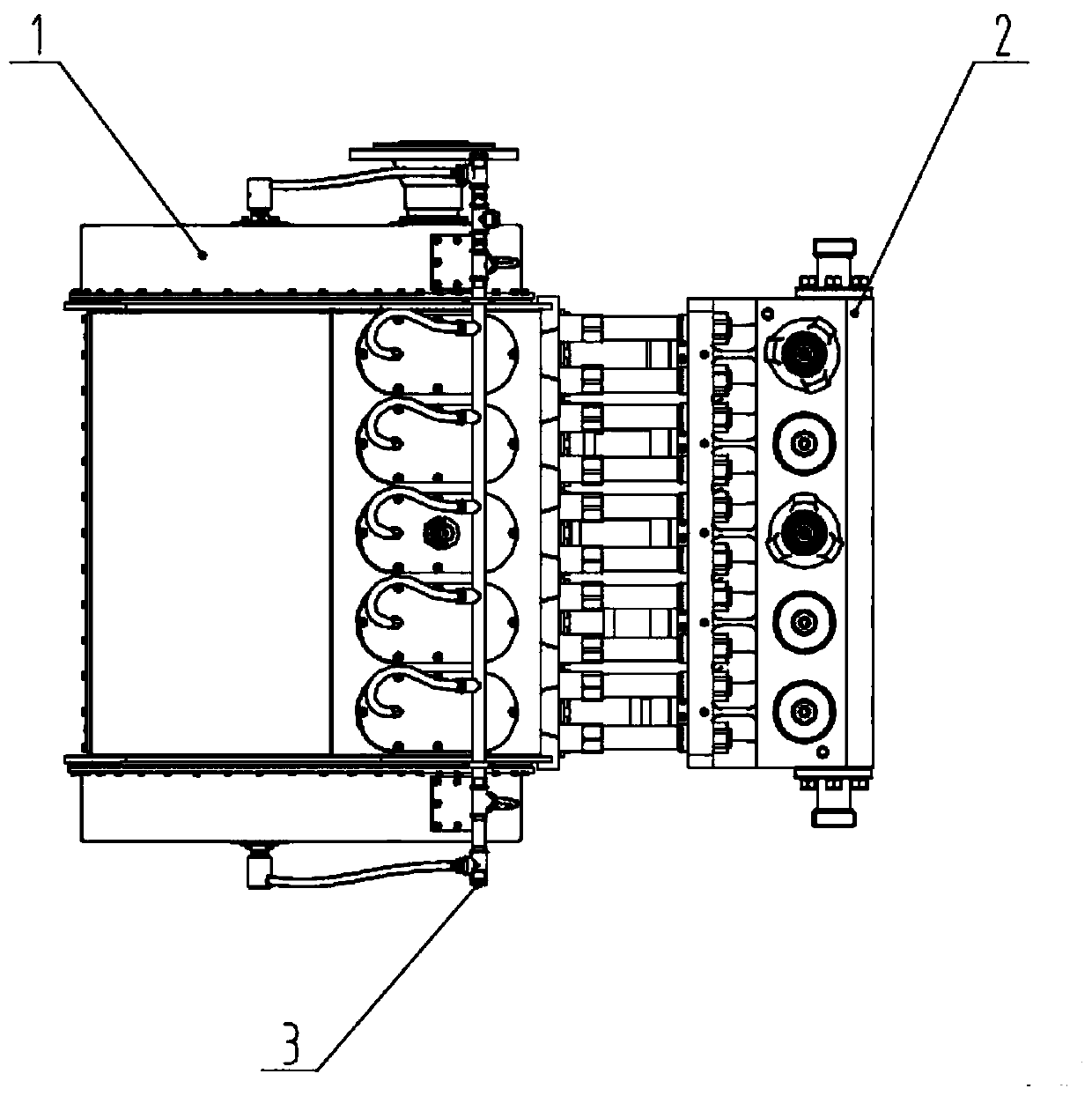

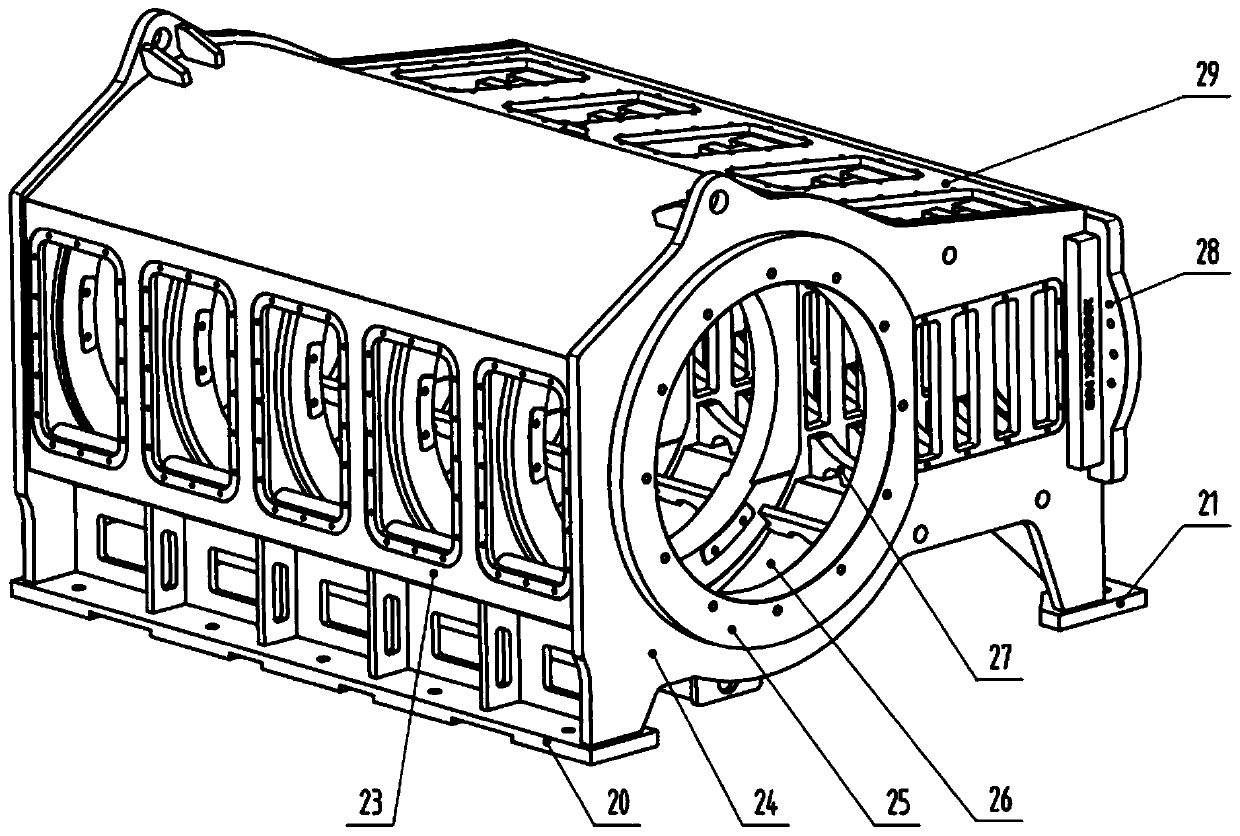

High-power five-cylinder plunger pump

PendingCN110617187AIncrease the carrying areaOptimize layoutPositive displacement pump componentsFluid removalEngineeringMechanical engineering

The invention discloses a high-power five-cylinder plunger pump. The plunger pump comprises a power end assembly, a hydraulic end assembly and a reduction gearbox assembly, wherein the power end assembly comprises a crankshaft box body, a crosshead box body and a spacer frame; the crankshaft box body, the crosshead box body and the spacer frame are sequentially connected; the hydraulic end assembly is fixed on the spacer frame; the reduction gearbox assembly is fixed on the crankshaft box body; and the cylinder spacing of the five-cylinder plunger pump is 13-14 inches, so that a guarantee is provided for the output of high power of the five-cylinder plunger pump. According to the high-power five-cylinder plunger pump, the problems that the area of a shale gas fracturing well site is narrowand the number of required fracturing equipment is relatively large are effectively solved, thus reducing the use of equipment, and facilitating the arrangement of the well site.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Continuously variable transmission

InactiveUS7914029B2Easy to adjustFacilitating axial translationWheel based transmissionChain/belt transmissionEngineeringDriven element

Traction planets and traction rings can be operationally coupled to a planetary gearset to provide a continuously variable transmission (CVT). The CVT can be used in a bicycle. In one embodiment, the CVT is mounted on the frame of the bicycle at a location forward of the rear wheel hub of the bicycle. In one embodiment, the CVT is mounted on and supported by members of the bicycle frame such that the CVT is coaxial with the crankshaft of the bicycle. The crankshaft is configured to drive elements of the planetary gearset, which are configured to operationally drive the traction rings and the traction planets. Inventive component and subassemblies for such a CVT are disclosed. A shifting mechanism includes a plurality of pivot arms arranged to pivot about the centers of the traction planets as a shift pin hub moves axially.

Owner:FALLBROOK INTPROP COMPANY

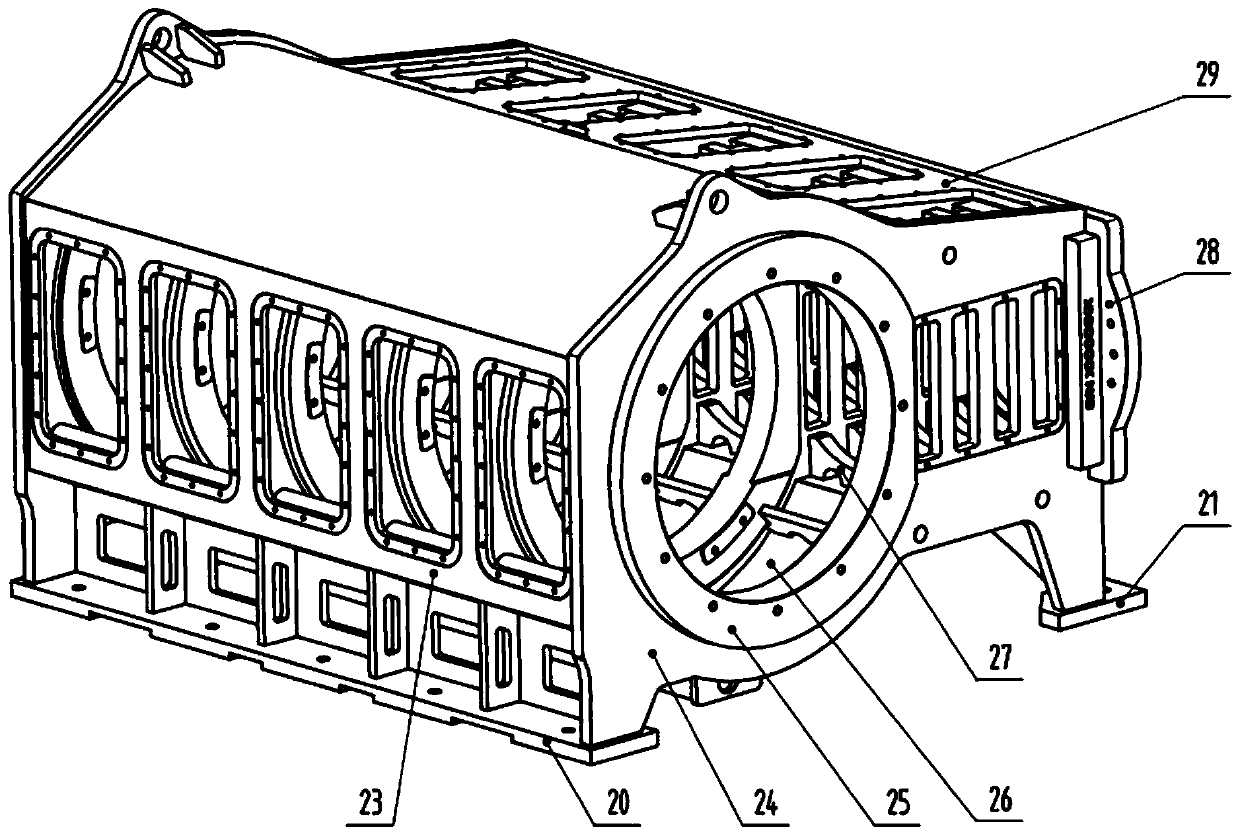

Five-cylinder plunger pump with integral power end structure

PendingCN110617318AExtended service lifeLow strokeCrankshaftsConnecting rod bearingsCrankcaseHigh load

The invention discloses a five-cylinder plunger pump with an integral power end structure. According to the five-cylinder plunger pump, an integral welding structure is adopted for a crankshaft box body and a crosshead box body in a five-cylinder plunger pump power end assembly, so that the structural strength of the power end assembly is higher, the supporting stability is better, and the whole pump vibration can be reduced; the cylinder spacing is 13-14 inches, the bearing area of connecting rods, crossheads and bearing bushes is increased, a guarantee is provided for the output of the high-power of the five-cylinder plunger pump, the high-power five-cylinder plunger pump can effectively solve the problem that the shale gas fracturing well site area is narrow and the required fracturingequipment is relatively large, the use of equipment can be reduced, and the wellsite arrangement is facilitated; the 11-inches long-stroke design can better realize large-displacement operation requirements and improve the operation efficiency; and according to the multi-point supporting design of crankcase bodies, crosshead box bodies and the hydraulic end assembly, the supporting strength of thefive-cylinder plunger pump can be improved, the vibration is reduced, the high-load operation is better guaranteed, and the operation is more stable.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Marine hulls and drives

InactiveUS7984684B2Improve power densityNo coolingHybrid vehiclesInternal combustion piston enginesTravel modeCombustion

Owner:HINDERKS MITJA VICTOR

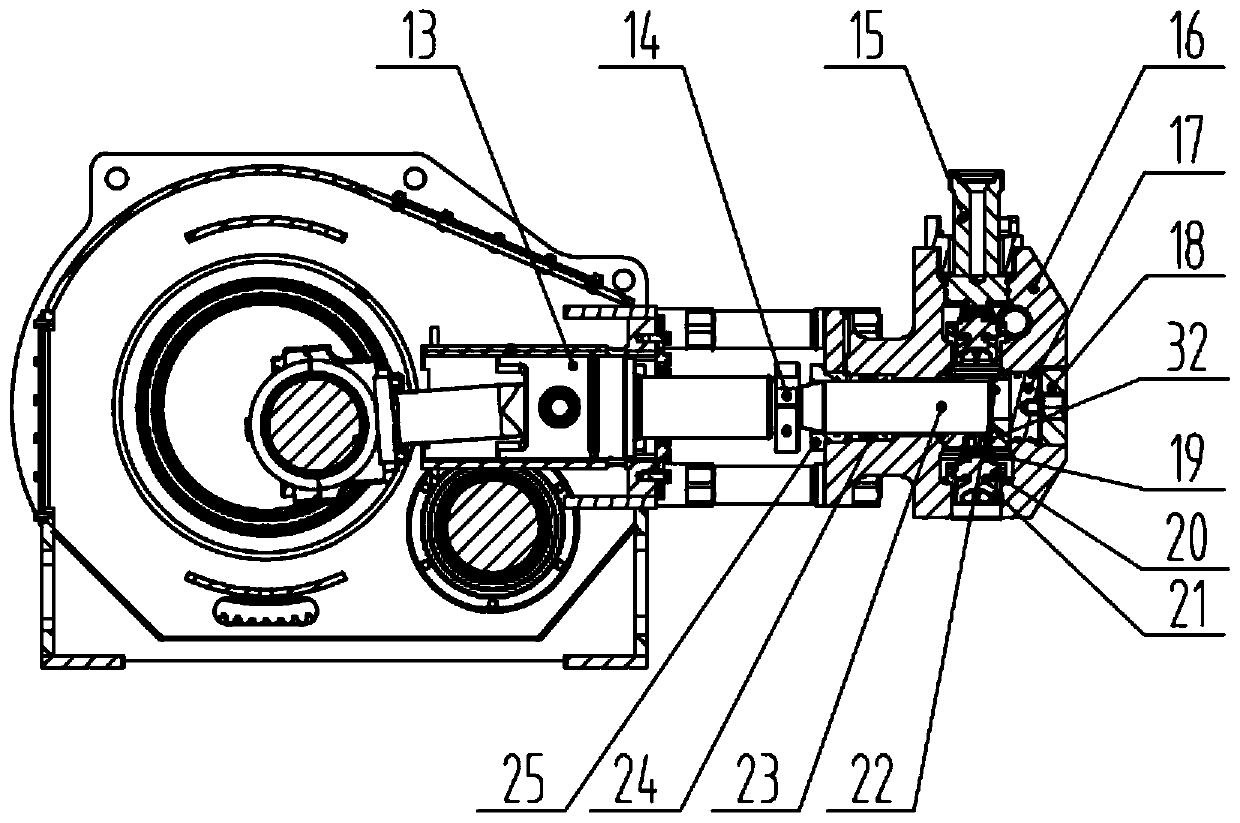

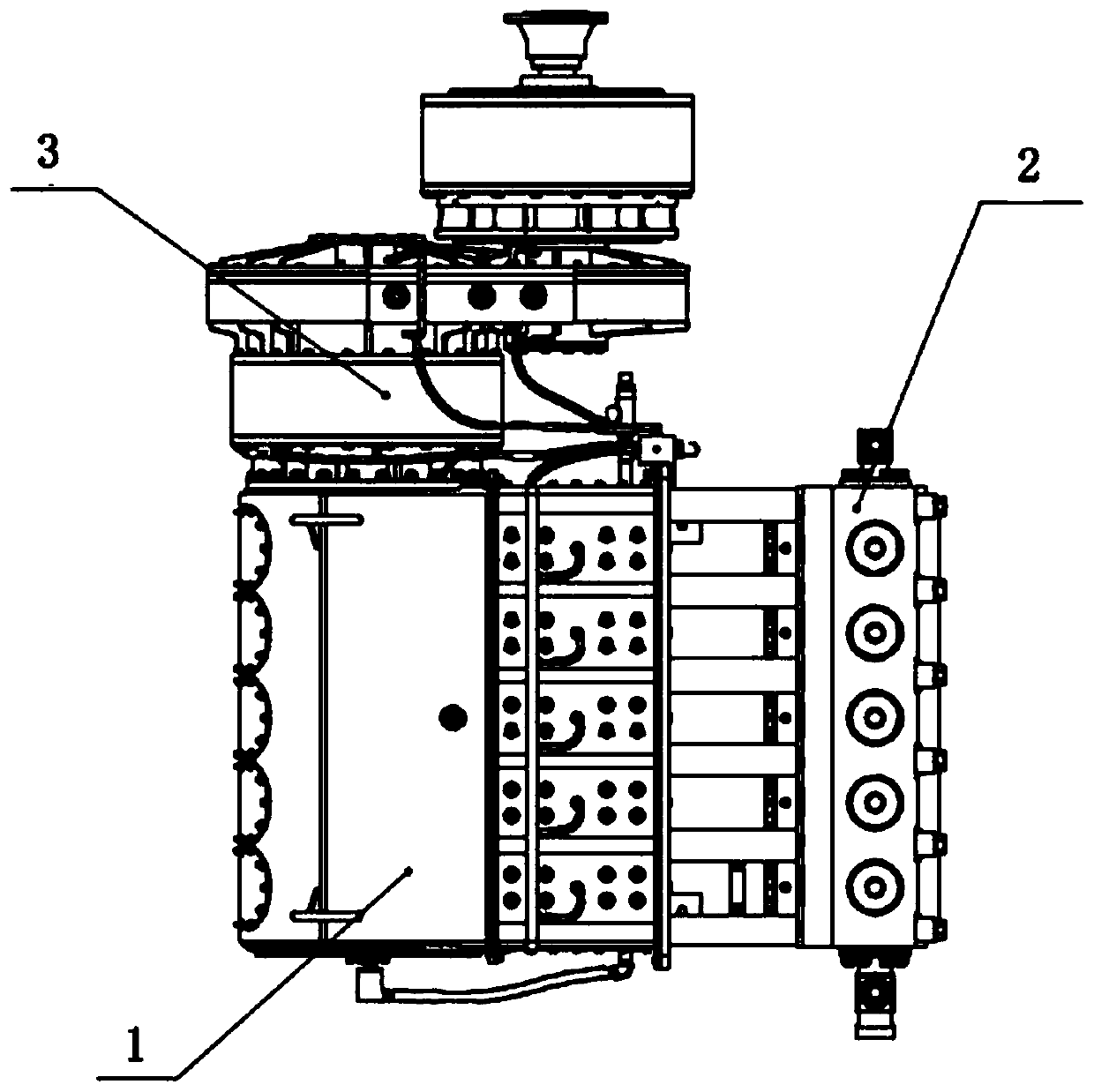

Liquid nitrogen pump power end assembly

PendingCN108547766ACompact structureEasy to processPositive displacement pump componentsPumpsTransmitted powerJackscrew

The invention provides a liquid nitrogen pump power end assembly. The liquid nitrogen pump power end assembly comprises a crankshaft box assembly. The crankshaft box assembly is correspondingly connected with crosshead shell assemblies. Lubricating systems are correspondingly arranged between the crankshaft box assembly and the crosshead shell assemblies. The liquid nitrogen pump power end assembly adopts split type module combination of the crankshaft box assembly and the crosshead shell assemblies to be assembled, a crankshaft box is designed into a welding type, crosshead shells are designed into a casting type, compared with inblock casting or overall welding, the structure is simple and compact, existing machining manners are considered, machining, manufacturing, assembling, repairingand maintaining are facilitated, crossheads are provided with threads for connection and can be connected with fluid ends with different specifications on the market to play a role in transmitting power, a crankshaft adopts a split type structure that a straight shaft and multiple eccentric wheels are connected through flat keys, the crankshaft overall machining difficulty is lowered, crosshead hinge pins are provided with jackscrew holes, by means of jackscrew fixing, axial floating of hinge pins can be eliminated, the lubricating system can protect movement members, and the service life ofeach movement member is prolonged.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Continuously variable transmission

Embodiments are directed to a front end accessory drive (FEAD), subassemblies, and components therefor. Embodiments disclosed cover power modulating devices (PMD) which can be used in a FEAD. In one embodiment, a continuously variable transmission (CVT) is coupled directly to a crankshaft of a prime mover, and the CVT is used to regulate the speed and / or torque delivered to an accessory. A compound drive device includes a motor / generator subassembly cooperating with a CVT subassembly to provide a motor functionality with torque multiplication or division, or alternatively, a generator functionality with torque multiplication or division. In some embodiments, a FEAD includes a PMD having a sun shaft configured to couple to a sun of the PMD and to an electric motor component, such as an electrical armature or an electrical field. In one embodiment, the electrical armature the electrical field are placed concentrically and coaxially and configured to rotate relative to one another in opposite directions.

Owner:FALLBROOK INTPROP COMPANY

Multi-point-support five-cylinder plunger pump

PendingCN110617188AImprove structural strengthImprove support strengthPositive displacement pump componentsPiston pumpsSoftware engineeringHigh load

The invention discloses a multi-point-support five-cylinder plunger pump. The multi-point-support five-cylinder plunger pump comprises a power end assembly, a hydraulic end assembly and a speed reduction box assembly, wherein the power end assembly comprises a crankshaft box body, a crosshead box body and a space rack, and the crankshaft box body, the crosshead box body and the space rack are connected in sequence; the hydraulic end assembly is fixed on the space rack, the speed reduction box assembly is fixed to the crankshaft box body, the bottom of the crankshaft box body is provided with acrankshaft supporting body, and the crankshaft supporting body is used for supporting the crankshaft supporting box body; the bottom of the crosshead box body is provided with a crosshead supportingbody, the crosshead supporting body is used for supporting the crosshead box body, the bottom of the space rack is provided with a hydraulic supporting body, and the hydraulic supporting body is usedfor supporting the hydraulic end assembly. The multi-point-support five-cylinder plunger pump has the advantages that through the multi-point-support design on the crankshaft box body, the crosshead box body and the hydraulic end assembly, the support strength of the plunger pump can be improved, vibration is reduced, high-load work is better guaranteed, and the plunger pump runs more stably.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com