Patents

Literature

1796results about "Connecting rods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

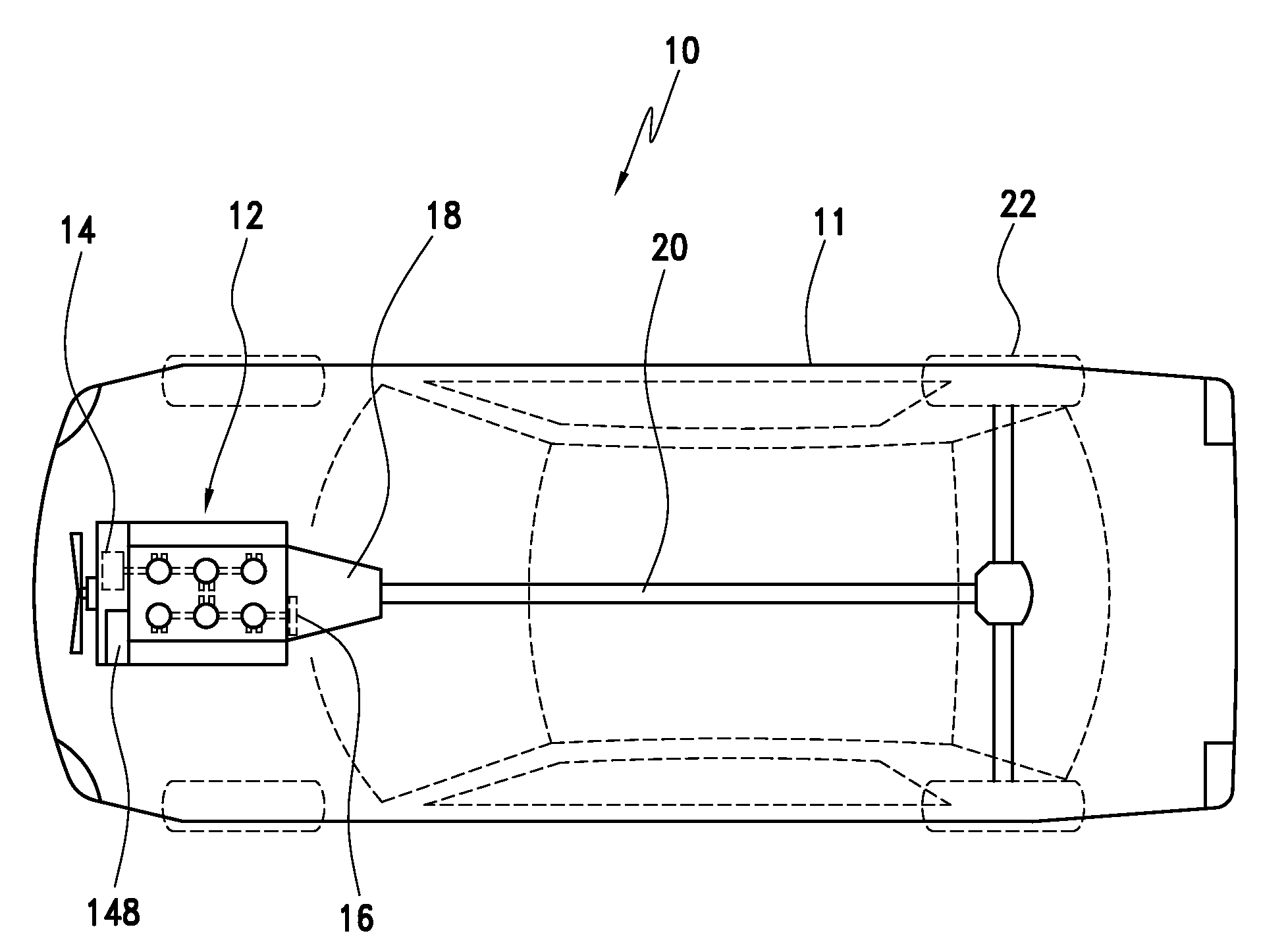

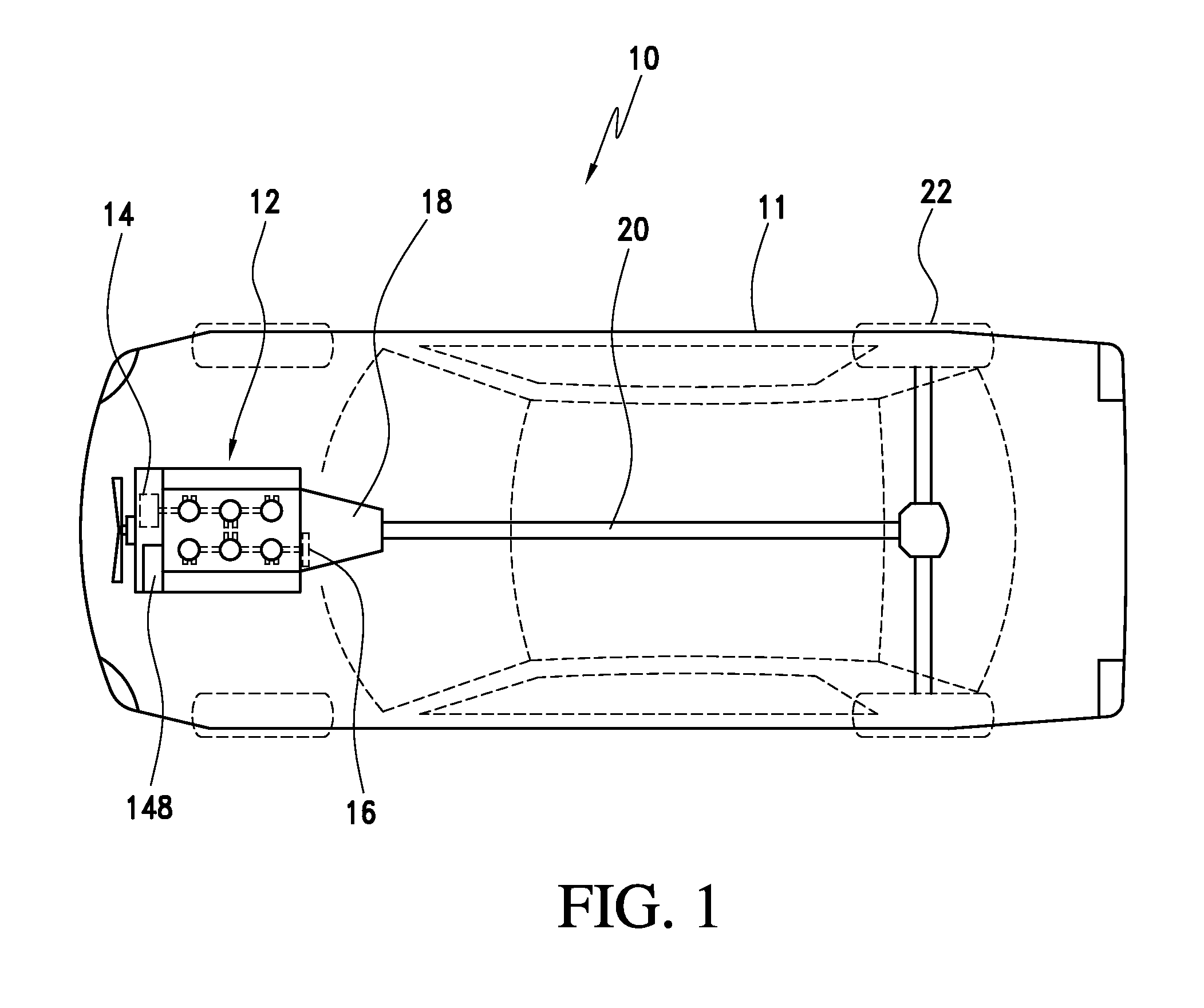

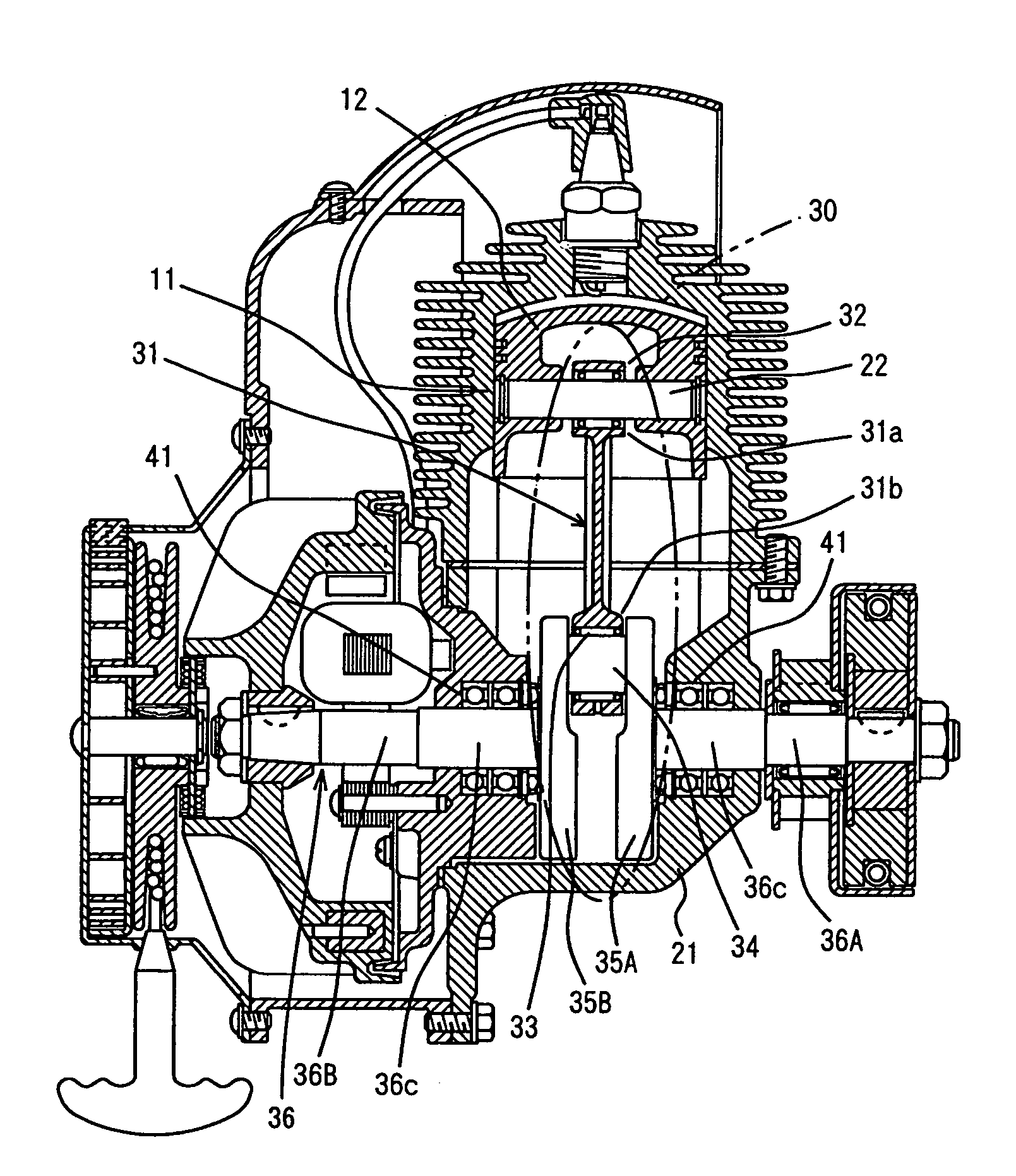

Multi-link variable compression ratio engine

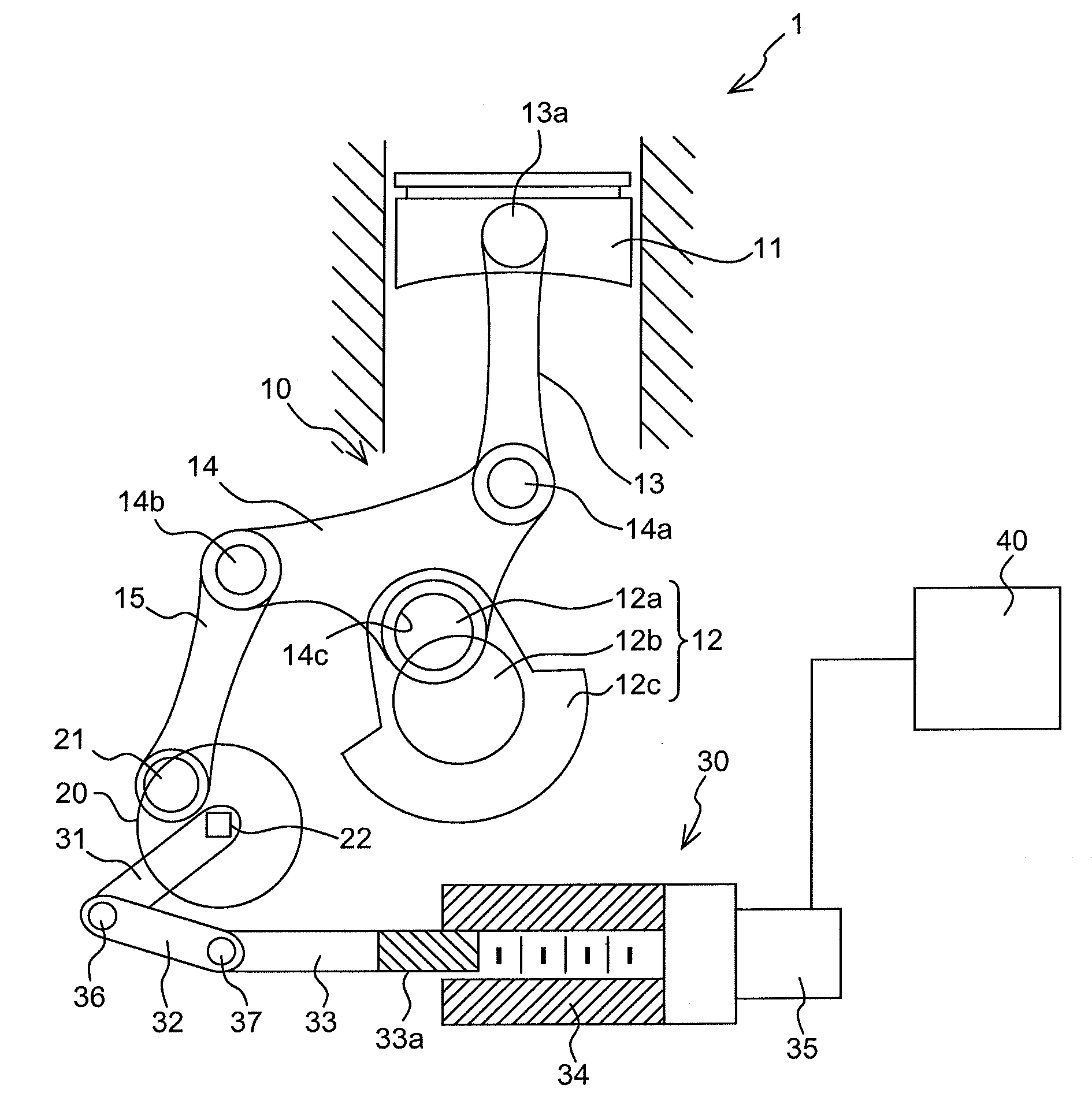

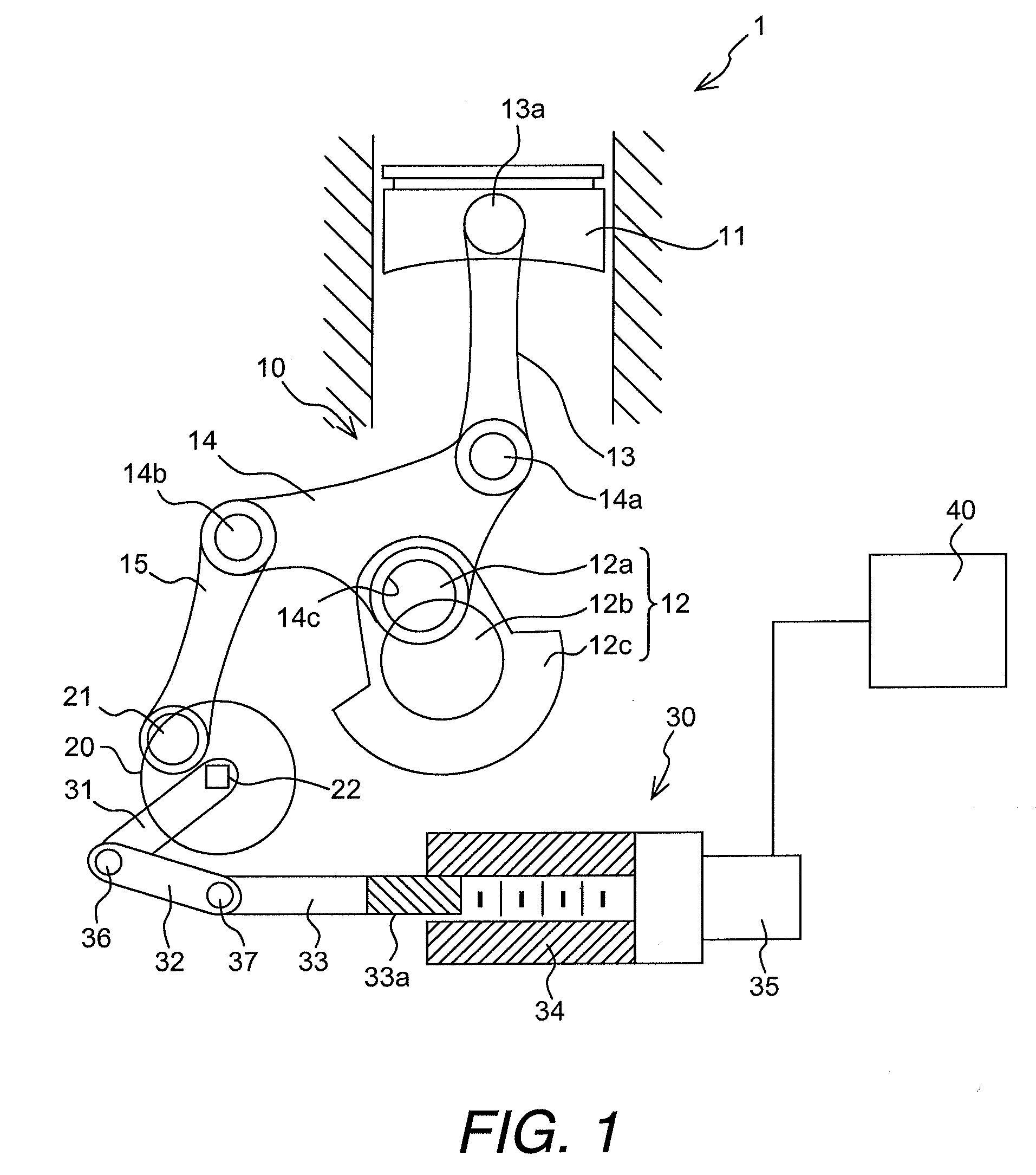

ActiveUS20090107454A1Frequently knockedInhibitionConnecting rodsMachines/enginesTop dead centerReduction ratio

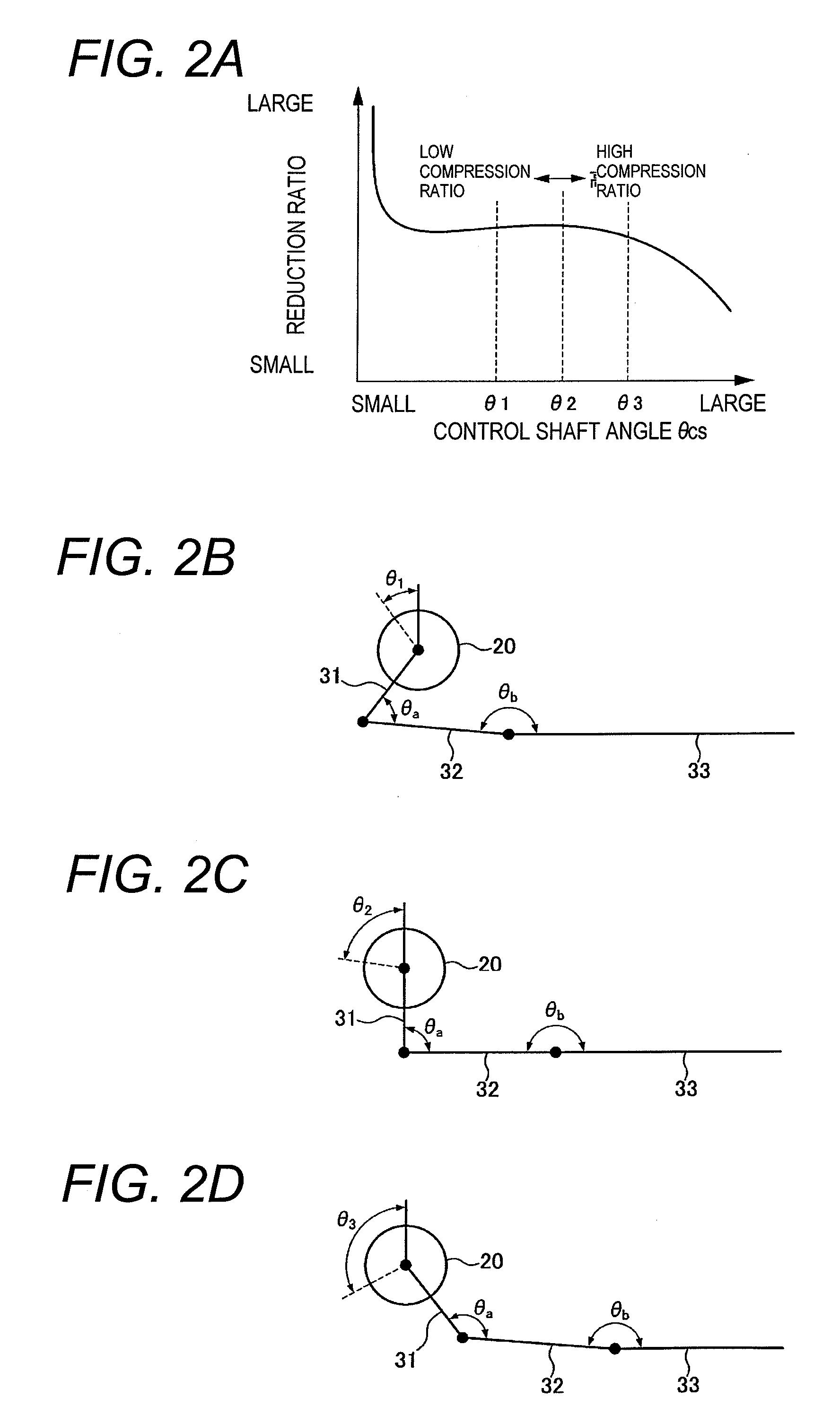

A multi-link variable compression ratio engine is provided with a crankshaft, a piston, a control shaft, a linkage, a motor and a reduction mechanism. The crankshaft moves the piston within an engine cylinder. The control shaft has an eccentric axle eccentric relative to its center-axis. The linkage operatively connects the piston to the crankshaft and the crankshaft to the eccentric axle of the control shaft. The motor rotates the control shaft so a top-dead-center position of the piston changes to vary compression ratios by changing the positions of the eccentric axle and the linkage. The reduction mechanism couples the motor to the control shaft to transmit a reduced rotation of the motor to the control shaft so a reduction ratio of a rotation angle of the motor to a rotation angle of the control shaft is less at high-compression ratios than at intermediate compression ratios.

Owner:NISSAN MOTOR CO LTD

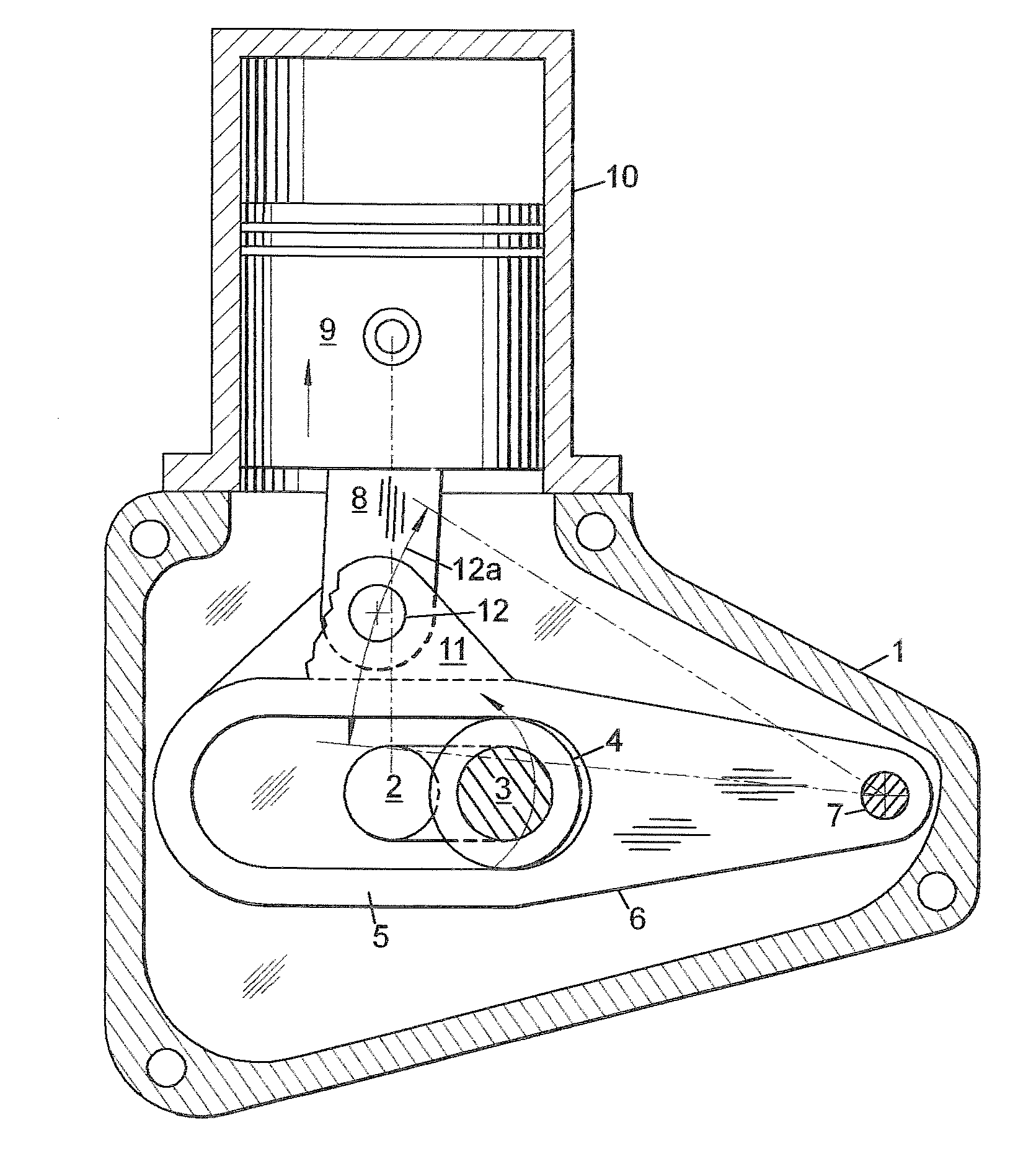

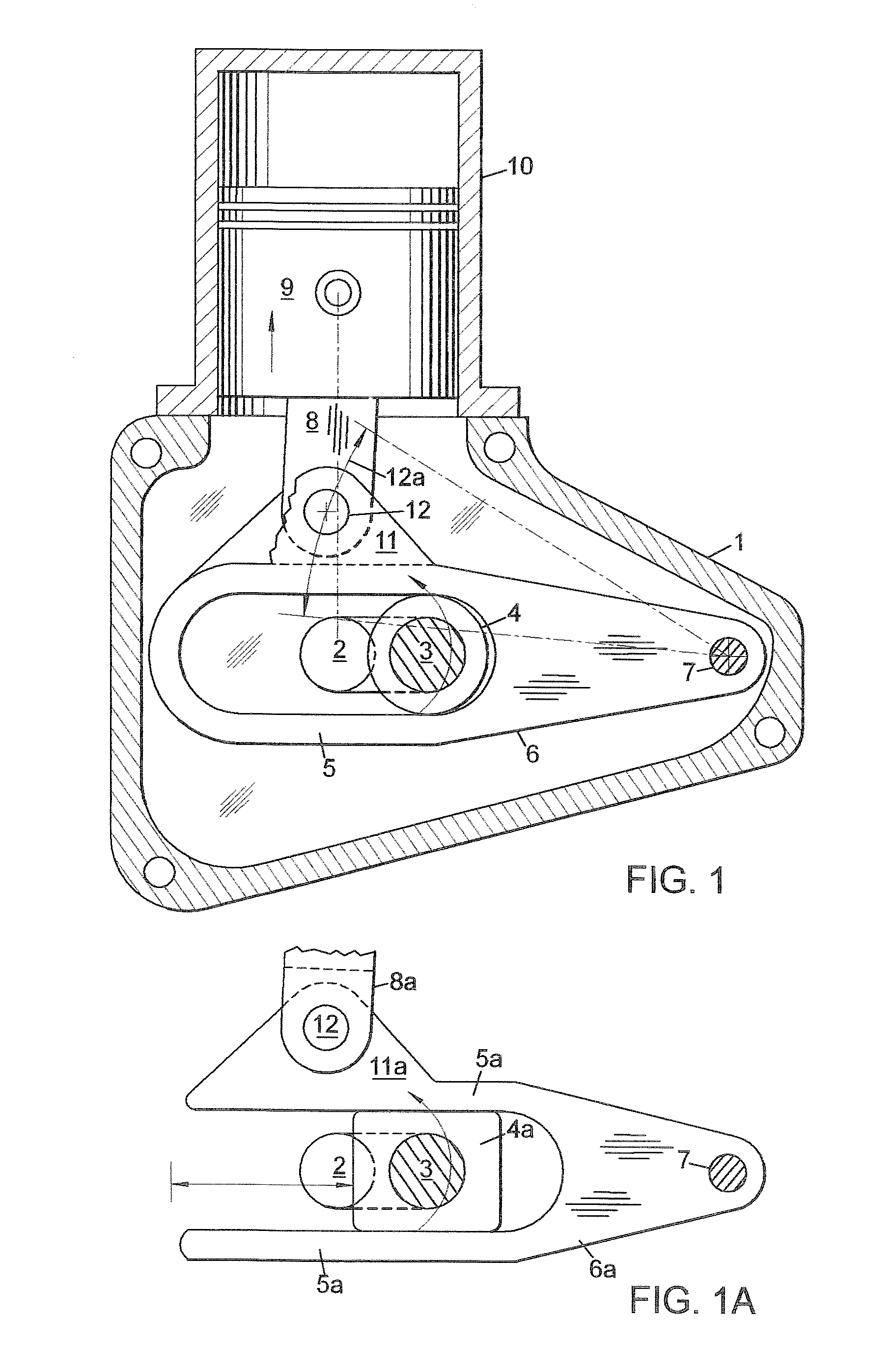

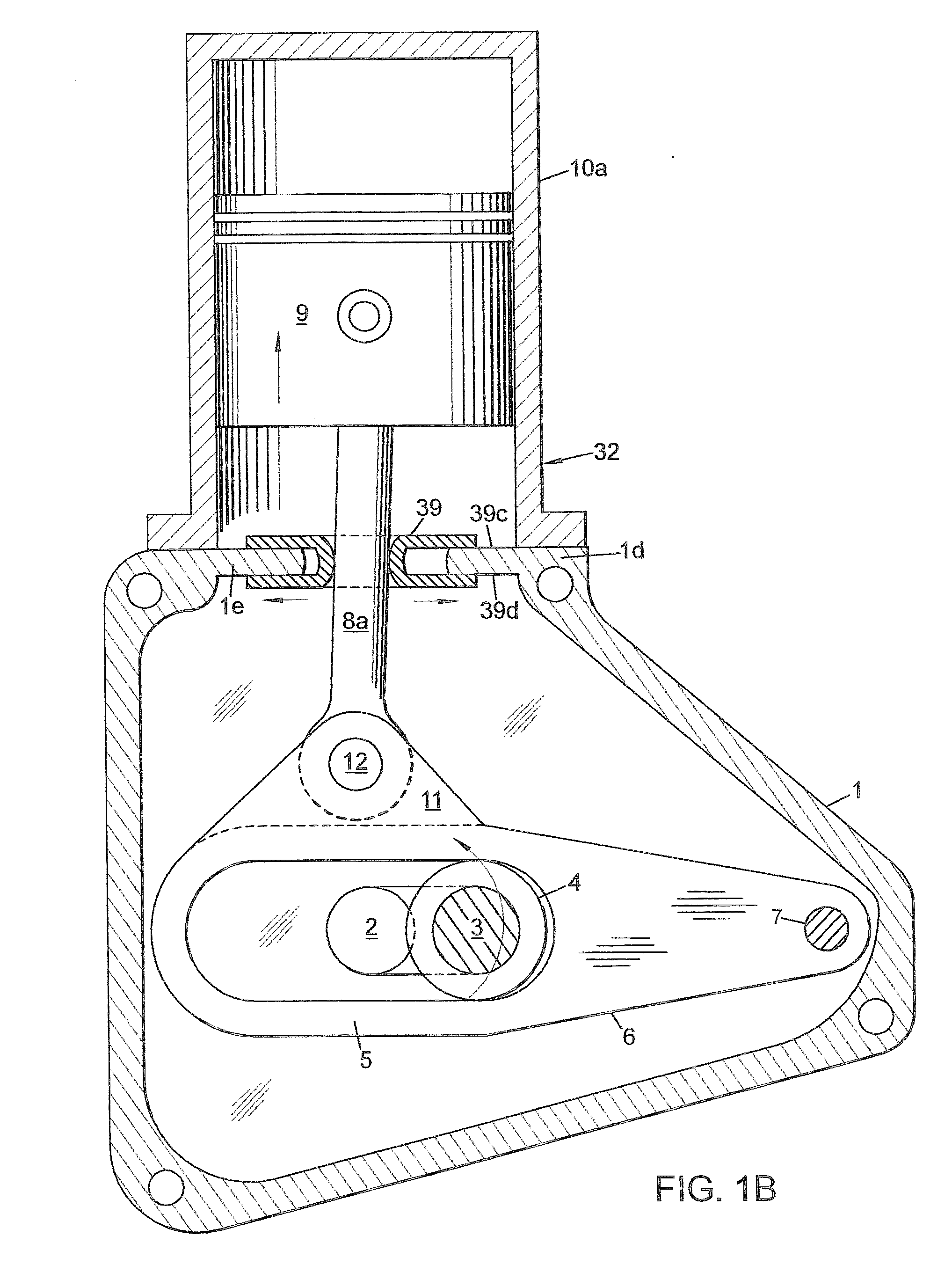

Hydraulic freewheel for an internal combustion engine with variable compression ratio

ActiveUS20150260094A1Little temperature dependenceReduce throttlingRotary bearingsConnecting rodsFlywheelEffective length

A reciprocating-piston internal combustion engine having a hydraulic adjustment mechanism which is assigned to a connecting rod and which comprises at least one eccentric, for adjusting at least one variable compression ratio in at least one cylinder of the reciprocating-piston internal combustion engine by means of a change in an effective length of a connecting rod. Also proposed is a method for changing the effective length of a connecting rod.

Owner:FEV

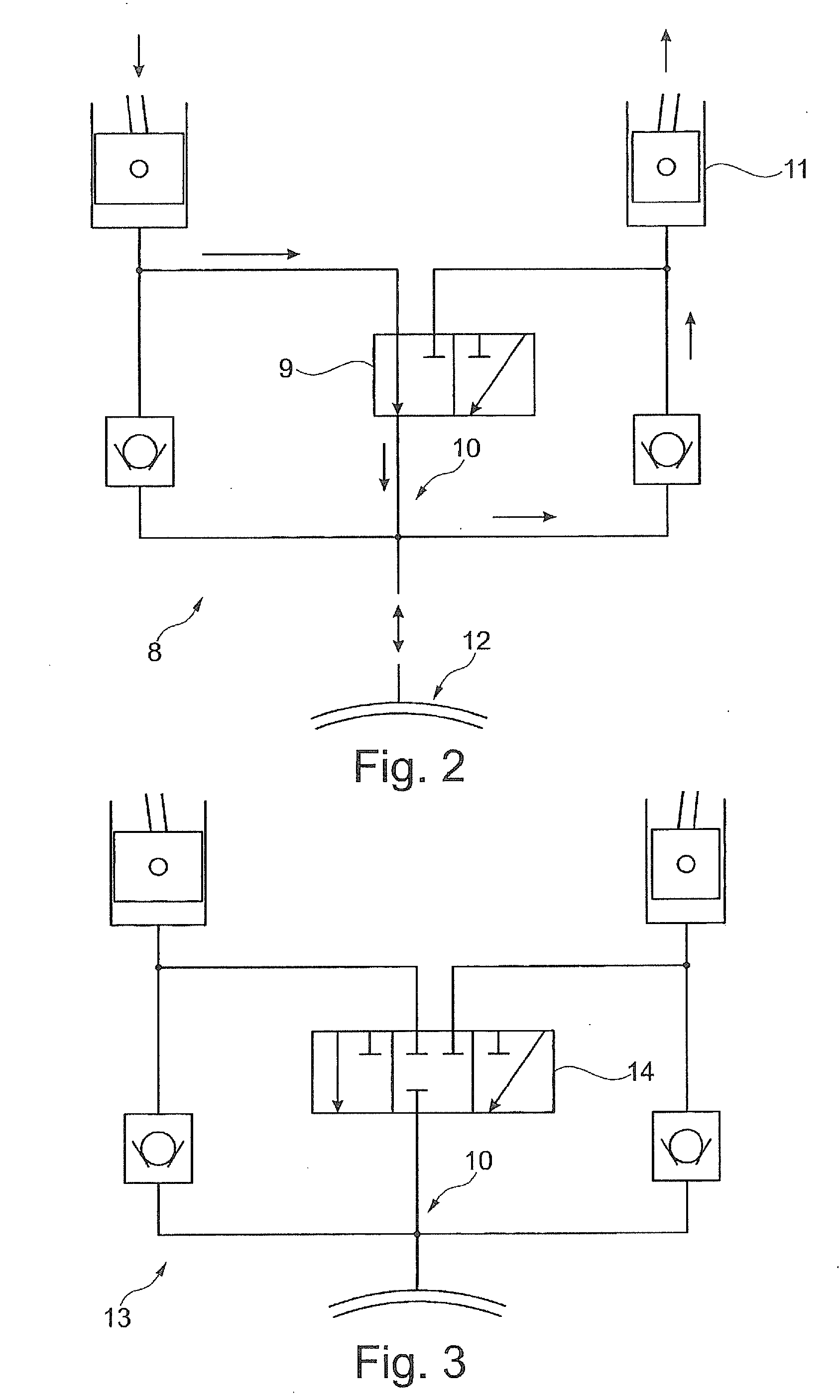

Self-adaption compression ratio variable engine

An engine with variable compression ratios that is simple, reliable and cheap is provided. The compression ratio is at maximum at idling, and is at minimum at the max. valve position, and can be changed automatically and continuously under any valve position, so that the compression ratio of the engine will approach to the max. allowable value for detonation, so the engine is of very high efficiency and substantially complete combustion, very low emission of waste gas, and is a target pursued by the automobile industry at present in the world. The principle of the invention is, a link rod of variable lengths is used, and the length of the link rod is depending upon the pressure of the combustible mixture gas before ignition combustion; when the pressure is approaching and exceeding the detonation pressure, the link rod will shorten automatically, the compression ratio will drop, so that the pressure will not increase any more, and detonation is avoided. The key tech in the invention is that the link rod uses a plunger type hydraulic cylinder, the oil in which is supplied and closed by the neck connected by the link rod on the crankshaft, so that the length of the link rod is variable in the compression period, and not variable during the ignition and work period.

Owner:陈晨

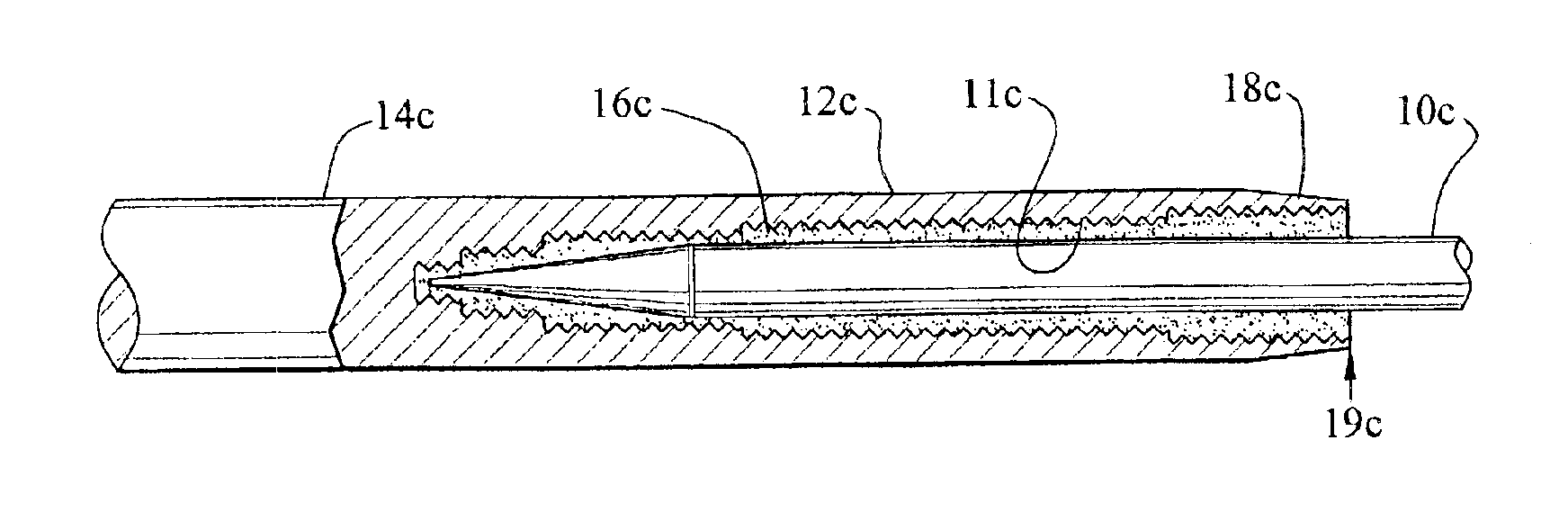

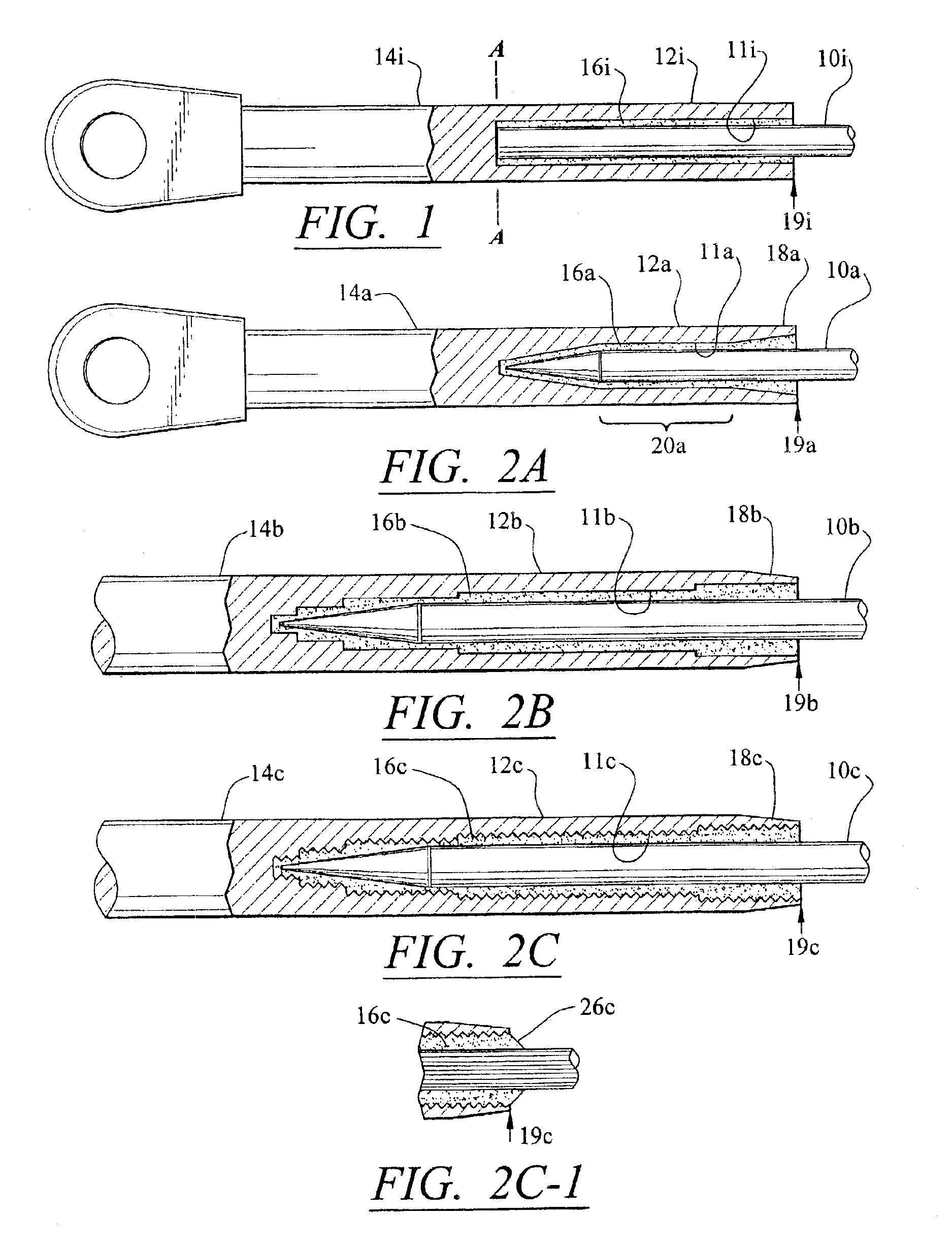

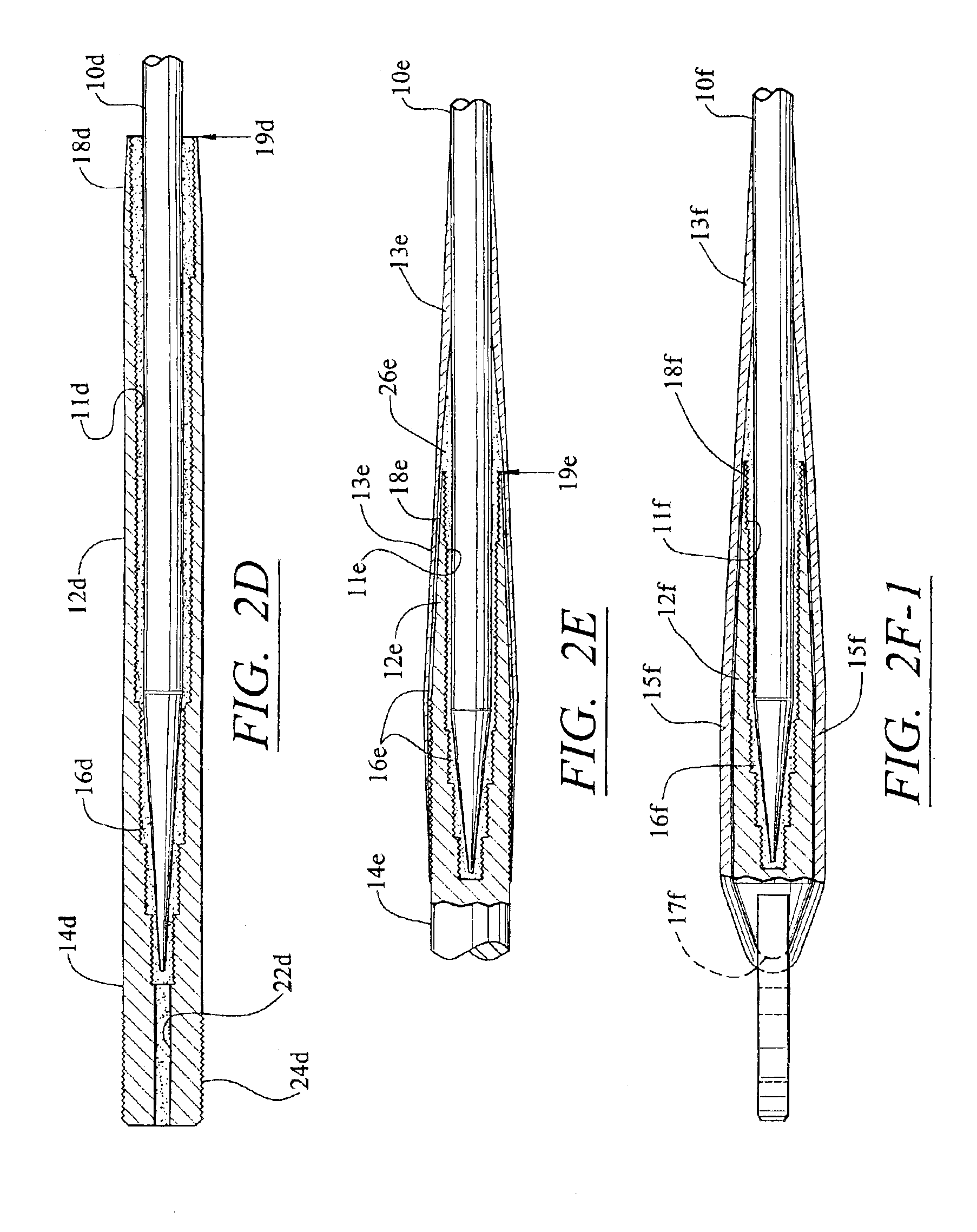

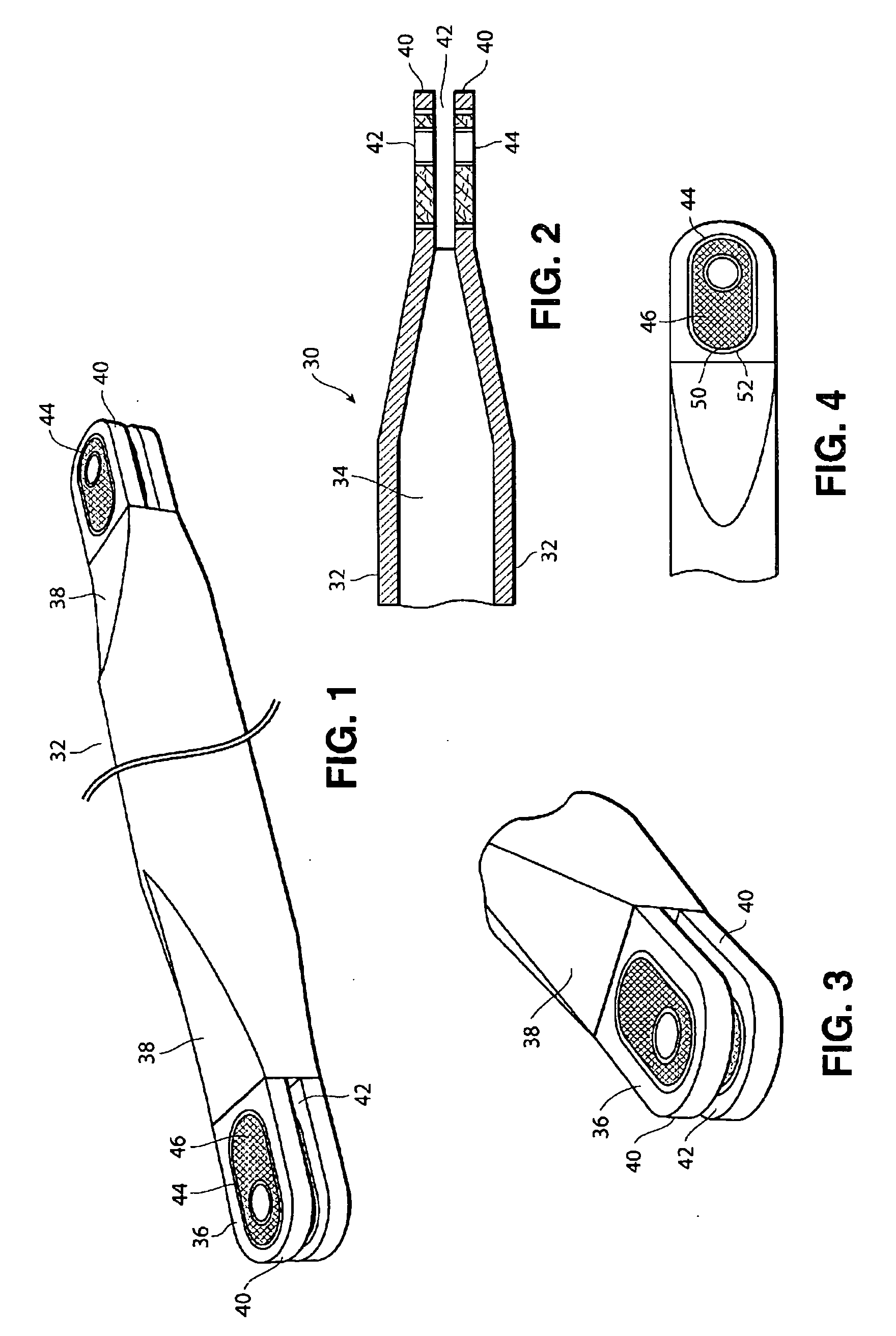

Composite tension rod terminal systems

InactiveUS6886484B2Superior combination of strengthSuperior combination of lightnessConnecting rodsRod connectionsFiberMechanical engineering

A composite tension rod is received in the sleeve portion of a shank that forms part of a terminal fitting, and is spaced from the shank sleeve and connected thereto by a potting resin. The shank sleeve wall tapers out from thin at its distal end to thick at the bury depth of the rod. The rod is tapered outwardly from a point of minimum diameter at its inner end to its full diameter a given distance from the end. The shank sleeve and rod have complementary dual tapering along said length such that as the diameter of the rod along said distance increases, the wall thickness of the shank sleeve decreases. The resin layer and the rod are secured to each other against relative longitudinal movement, as are the resin layer and the shank sleeve.In another aspect of the invention, a tension rod sleeve is fixed to the tension rod and extends over the distal end of the shank sleeve and along all or a majority of the length of the shank sleeve. The rod sleeve is tapered so that its wall thickness decreases to a minimum in the vicinity of the proximal end of the shank sleeve, or the rod sleeve, as it extends along the shank sleeve, is divided, or divides, into two halves or bands which join to form loop extending around a loop-engaging, convex, fiber-turnaround face formed on the terminal fitting. Such face extends transversely from one side to the other of the fitting.

Owner:THOMAS GEORG K

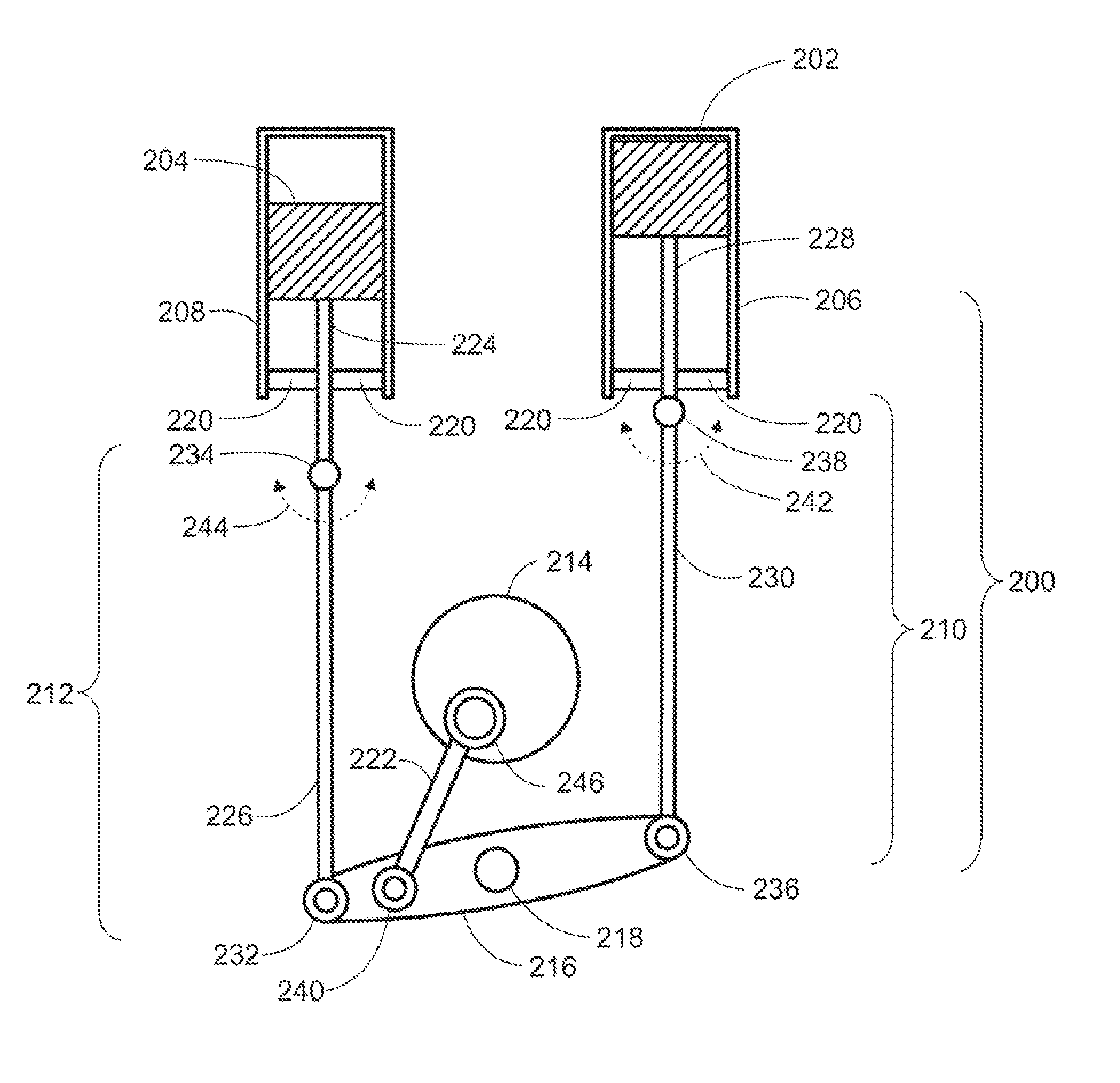

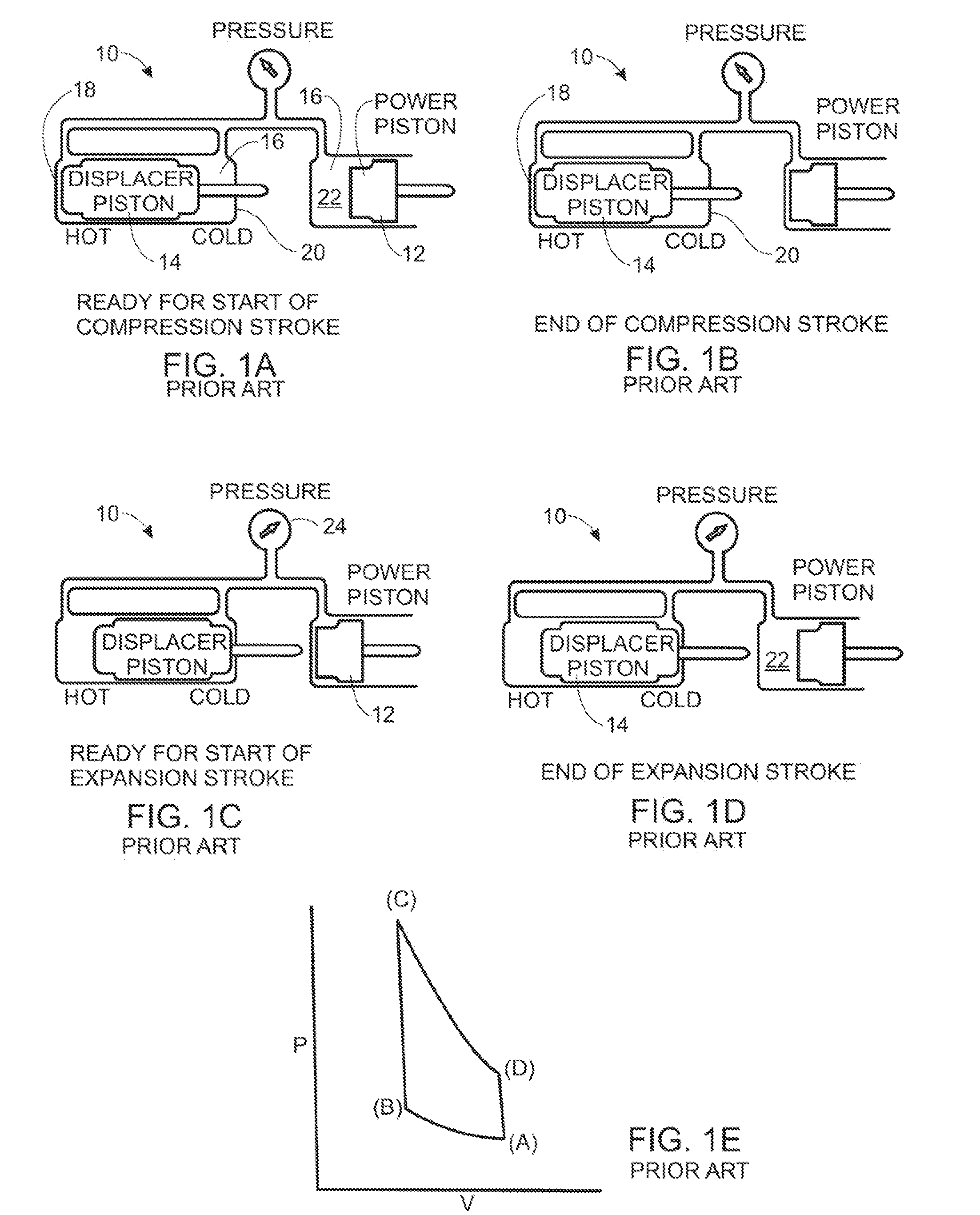

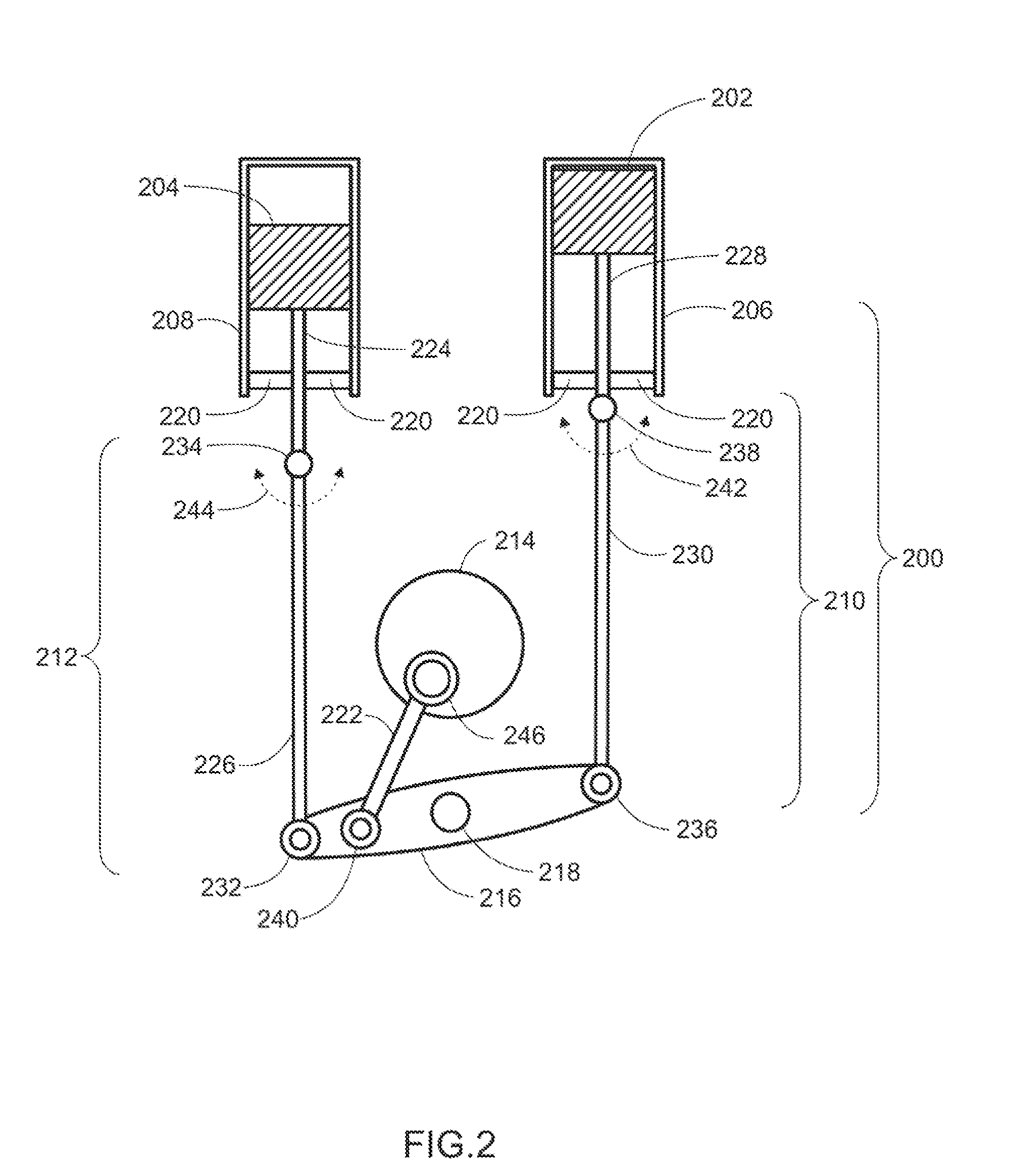

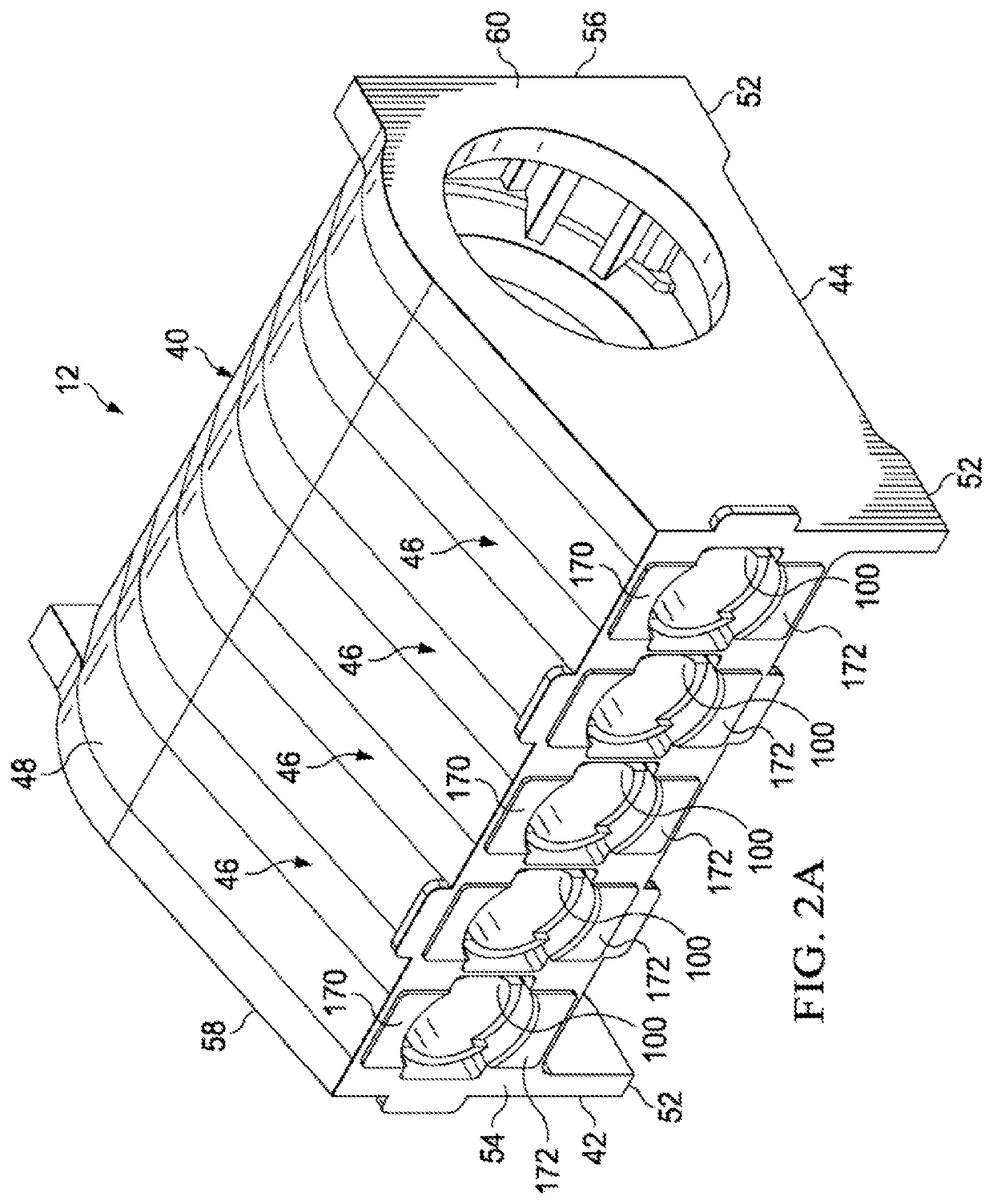

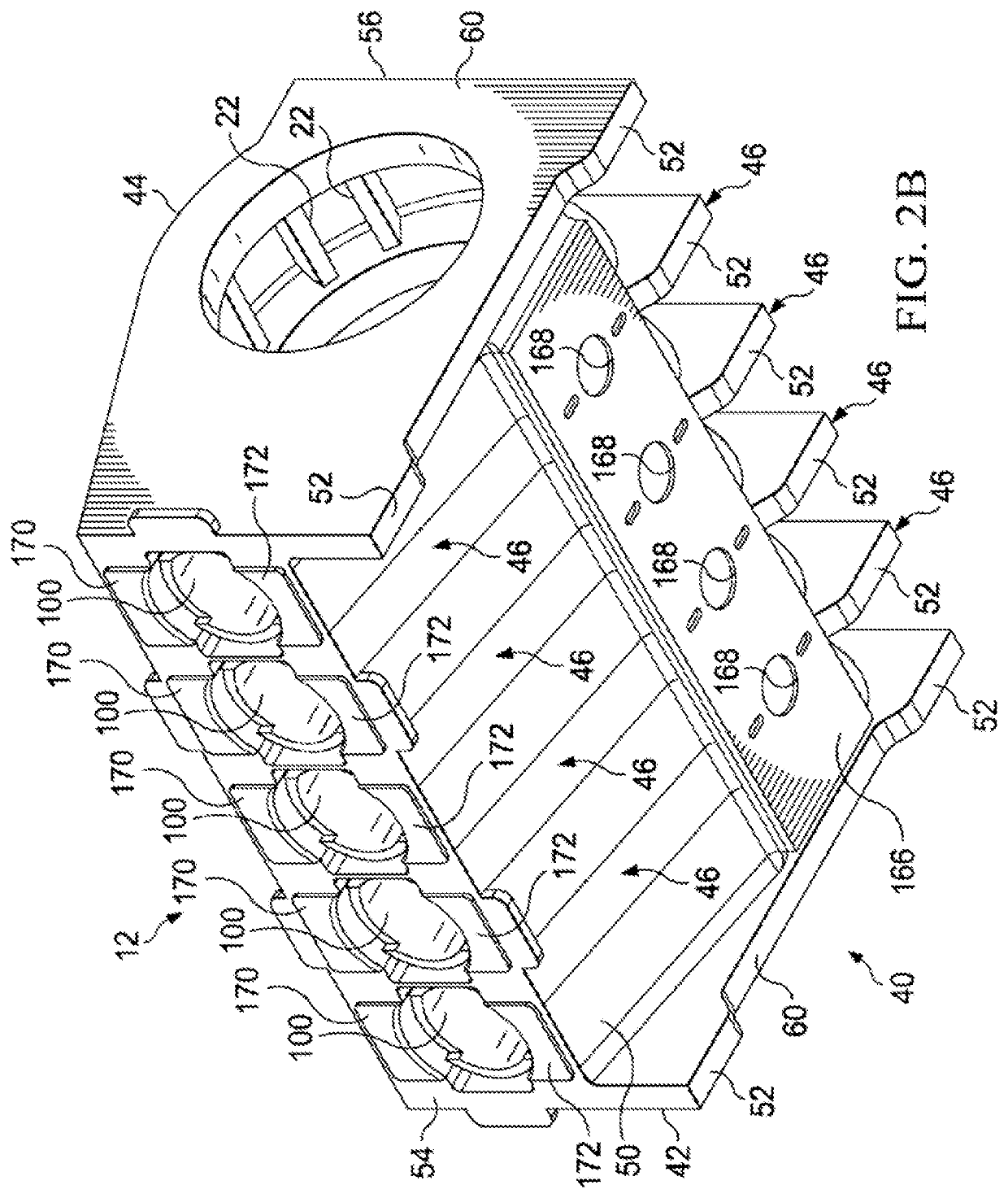

Stirling Cycle Machine

A Stirling cycle machine. The machine includes at least one rocking drive mechanism which includes: a rocking beam having a rocker pivot, at least one cylinder and at least one piston. The piston is housed within a respective cylinder and is capable of substantially linearly reciprocating within the respective cylinder. Also, the drive mechanism includes at least one coupling assembly having a proximal end and a distal end. The proximal end is connected to the piston and the distal end is connected to the rocking beam by an end pivot. The linear motion of the piston is converted to rotary motion of the rocking beam. Also, a crankcase housing the rocking beam and housing a first portion of the coupling assembly is included. A crankshaft coupled to the rocking beam by way of a connecting rod is also included. The rotary motion of the rocking beam is transferred to the crankshaft. The machine also includes a working space housing the at least one cylinder, the at least one piston and a second portion of the coupling assembly. A seal is included for sealing the workspace from the crankcase.

Owner:NEW POWER CONCEPTS

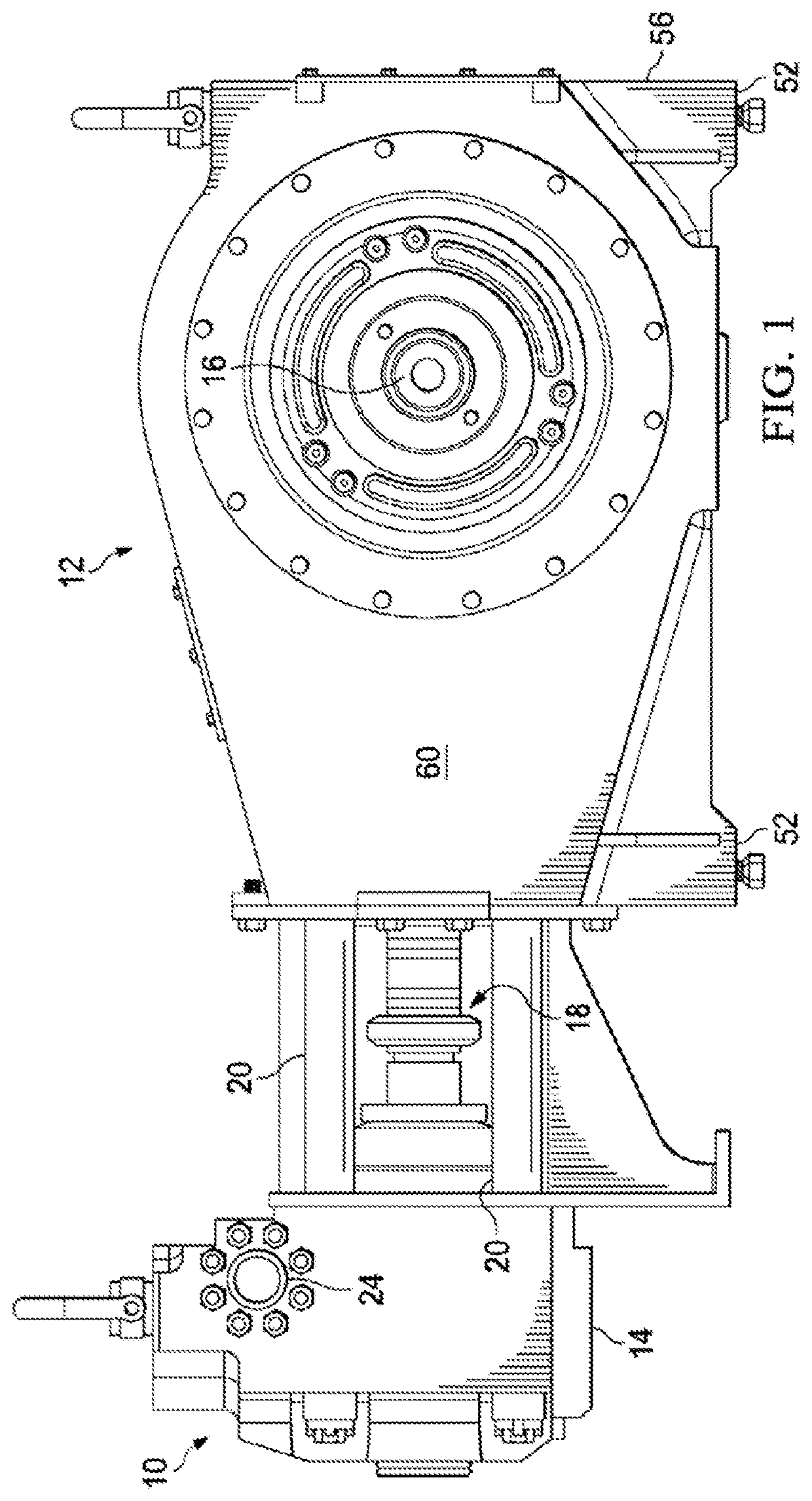

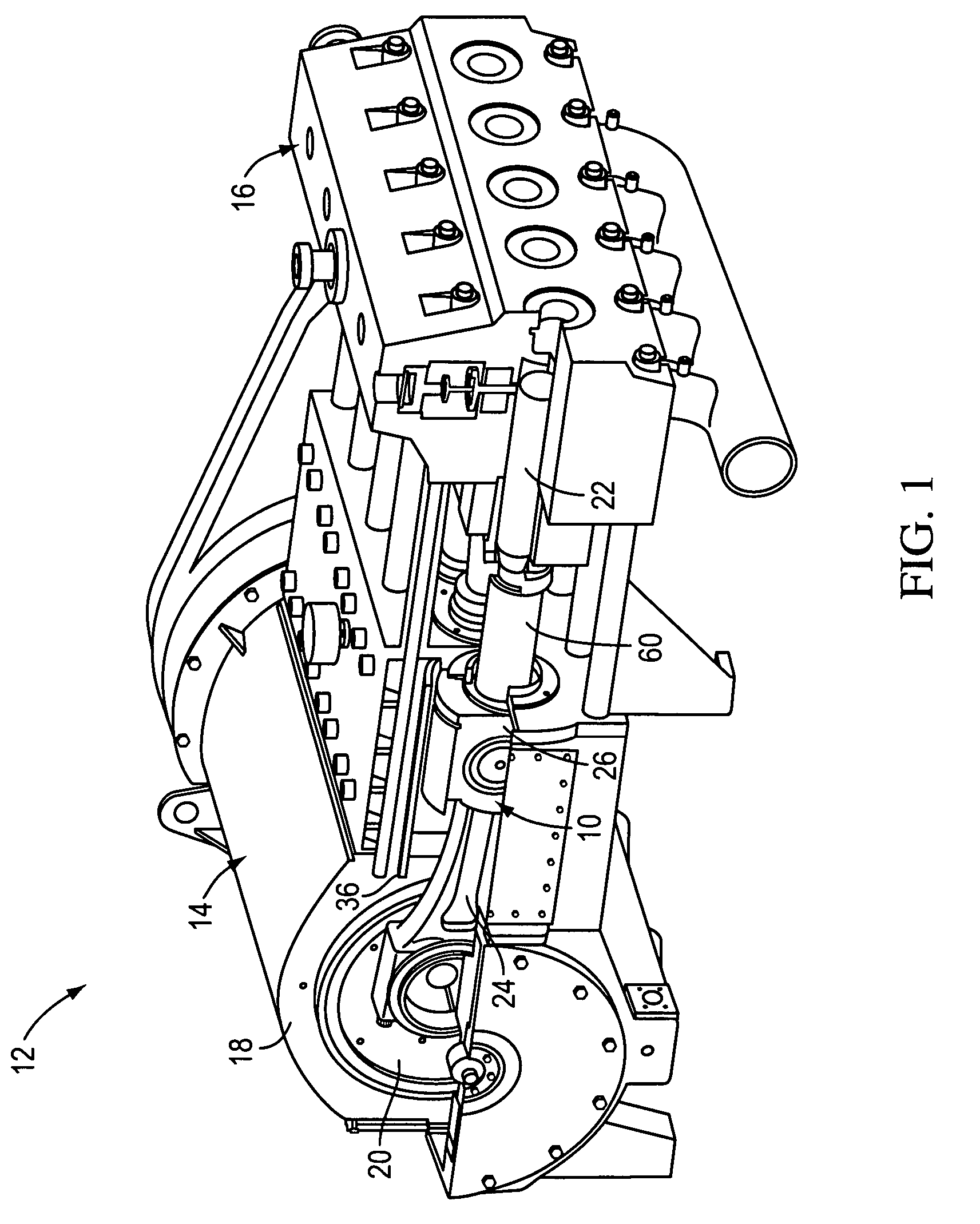

Support for Reciprocating Pump

A gearbox is coupled to a power end housing of a reciprocating pump, where the gearbox includes at least one support member having a first end securely affixed to the gearbox, and the at least one support member having a second end securely affixed to an immobile part of the reciprocating pump for supporting the gearbox and resisting movement of the gearbox relative to the reciprocating pump.

Owner:SPM OIL & GAS INC

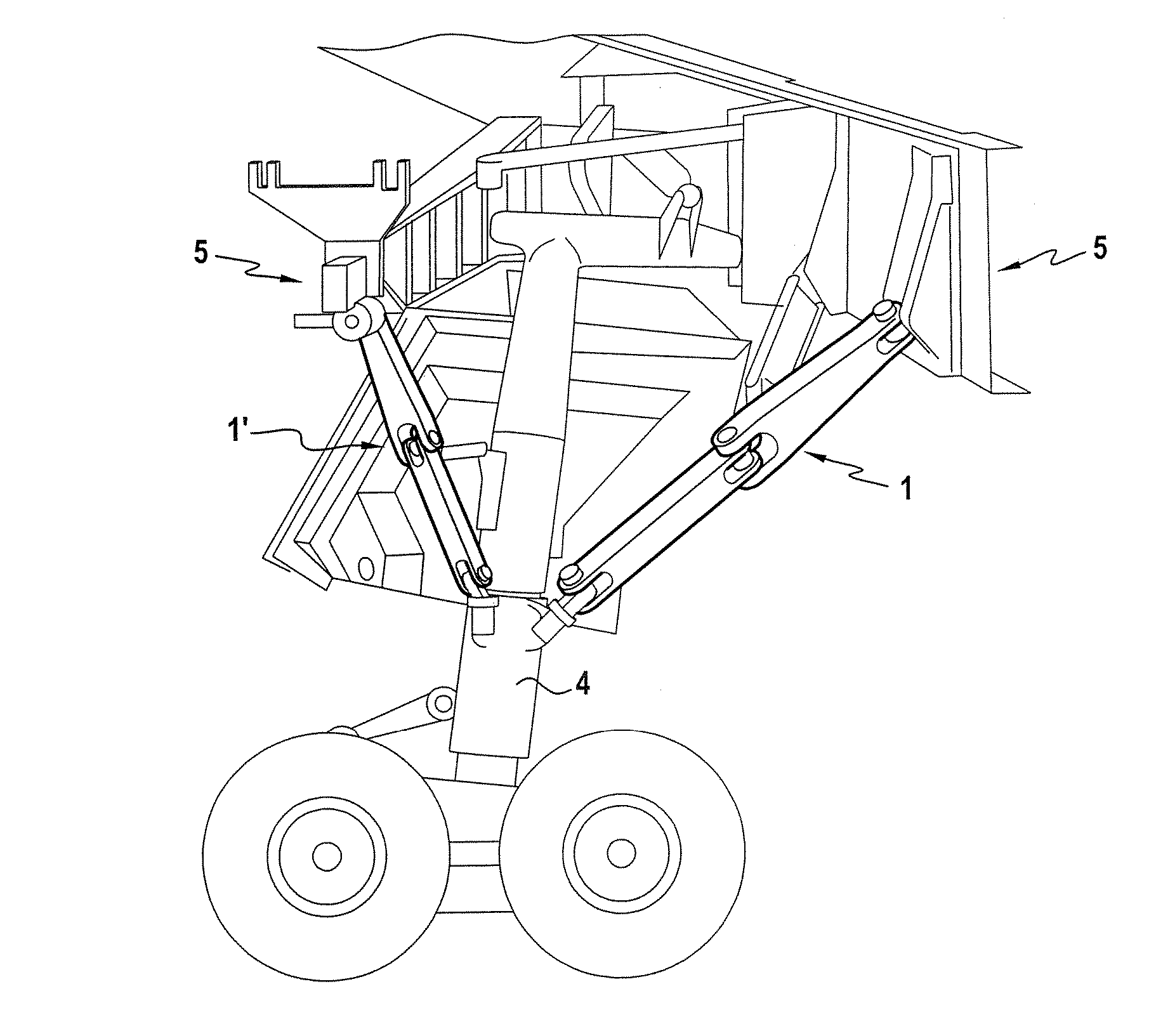

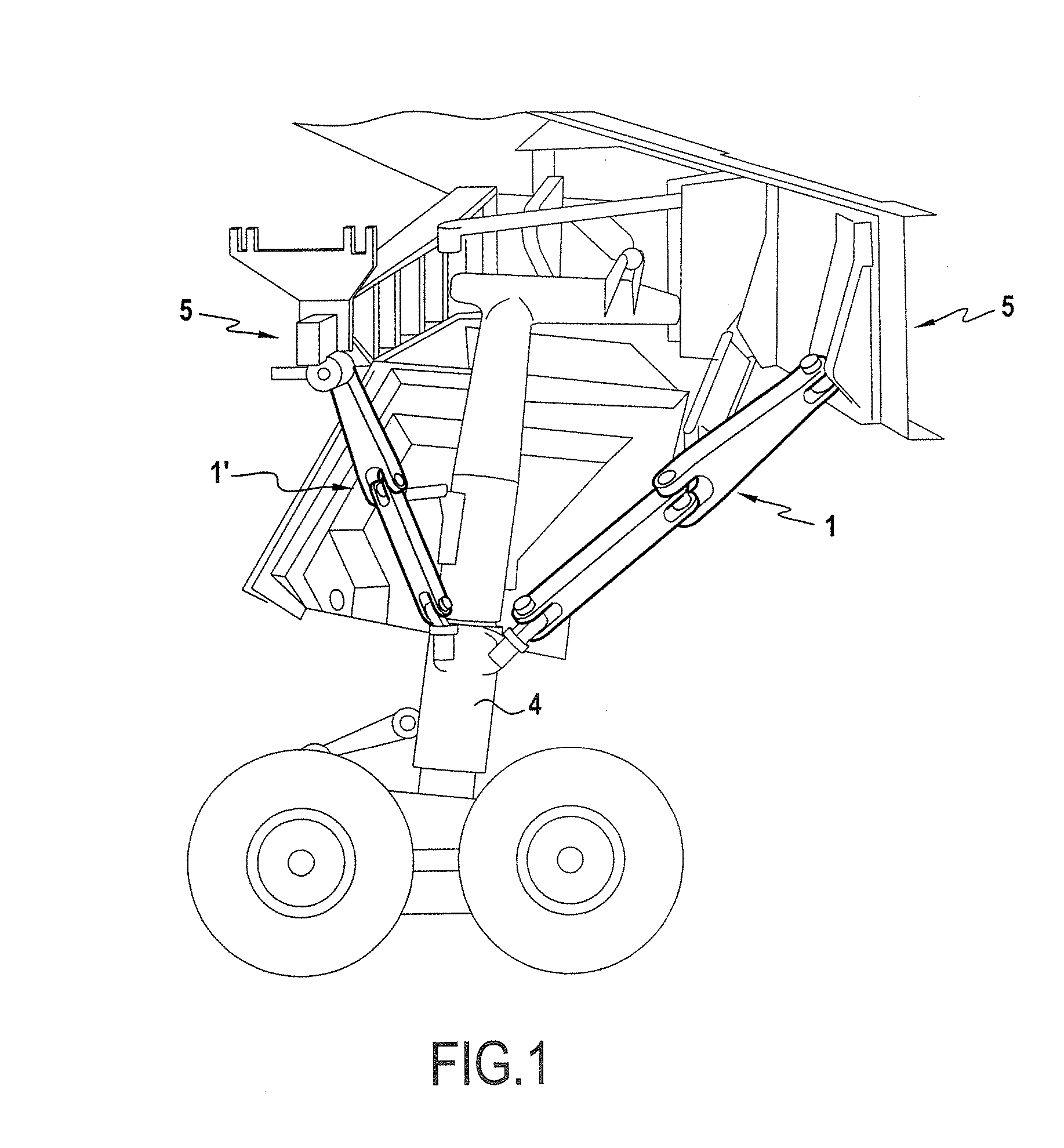

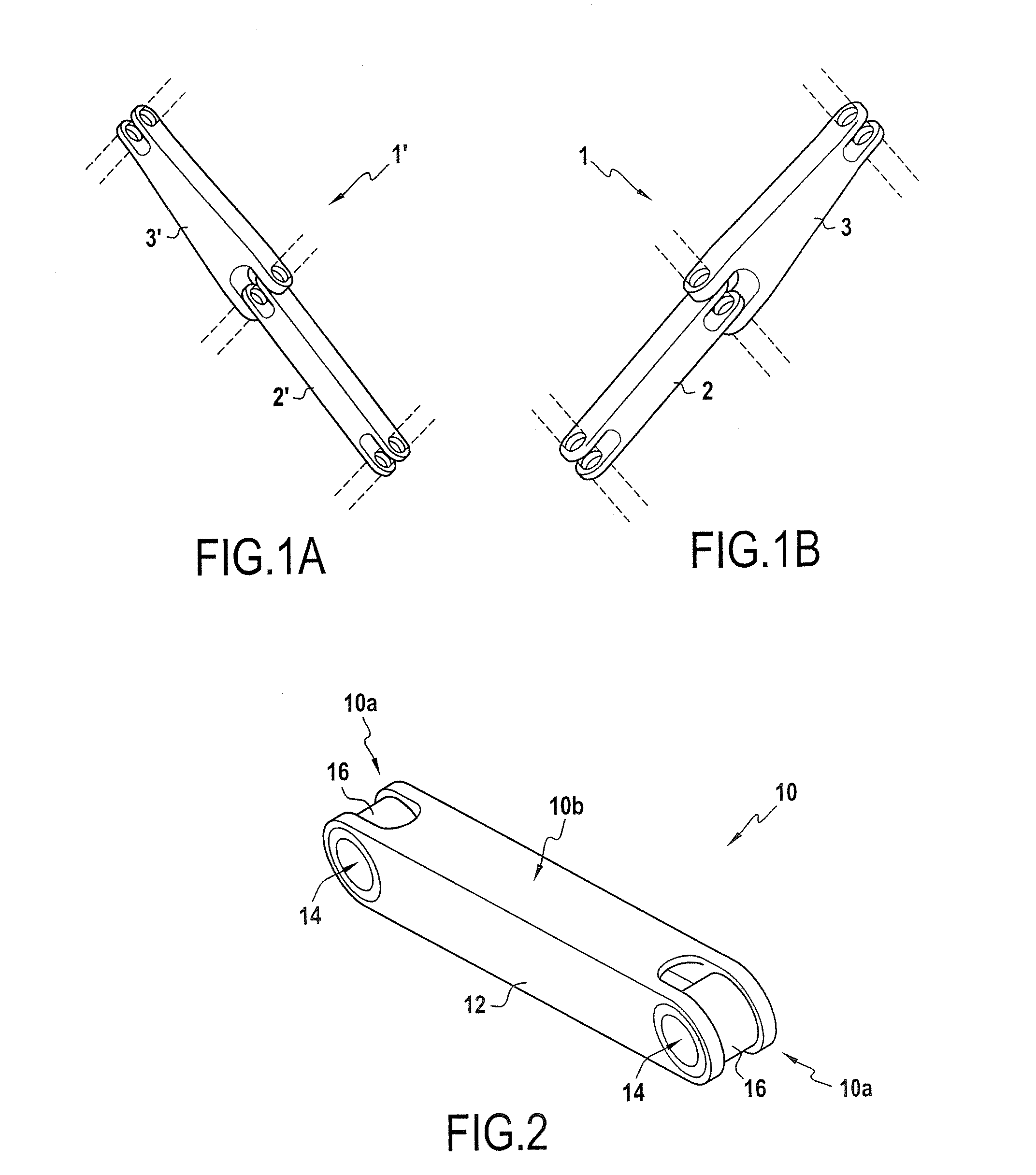

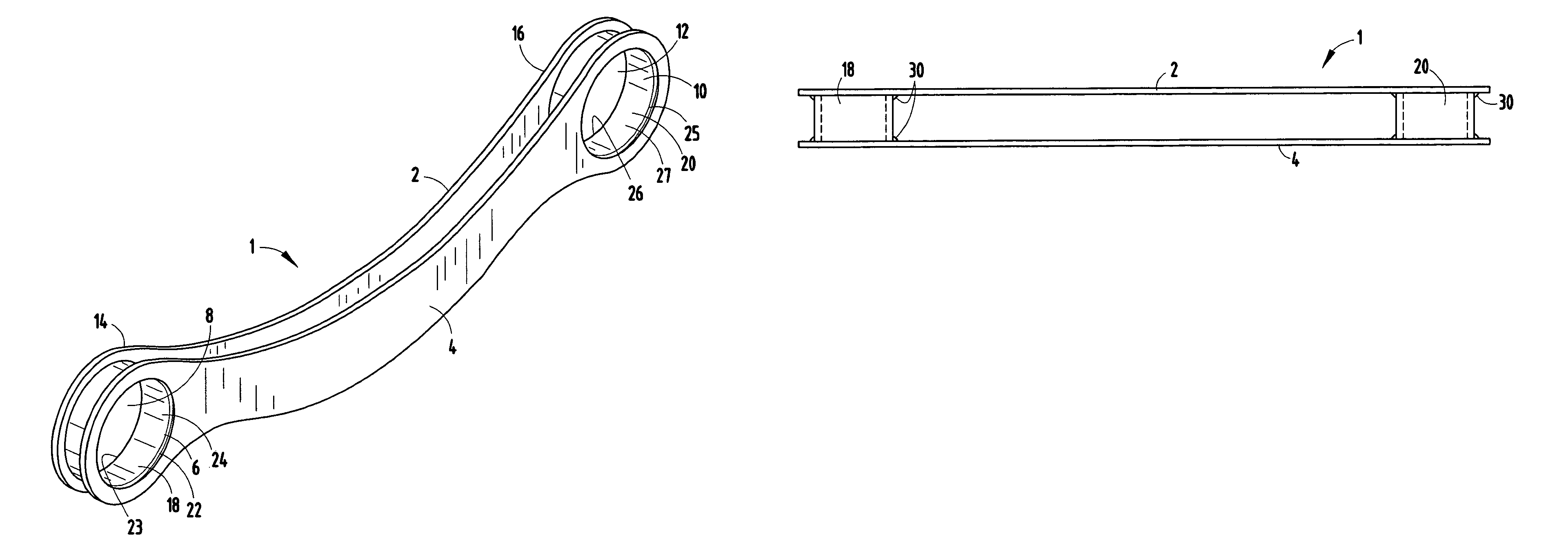

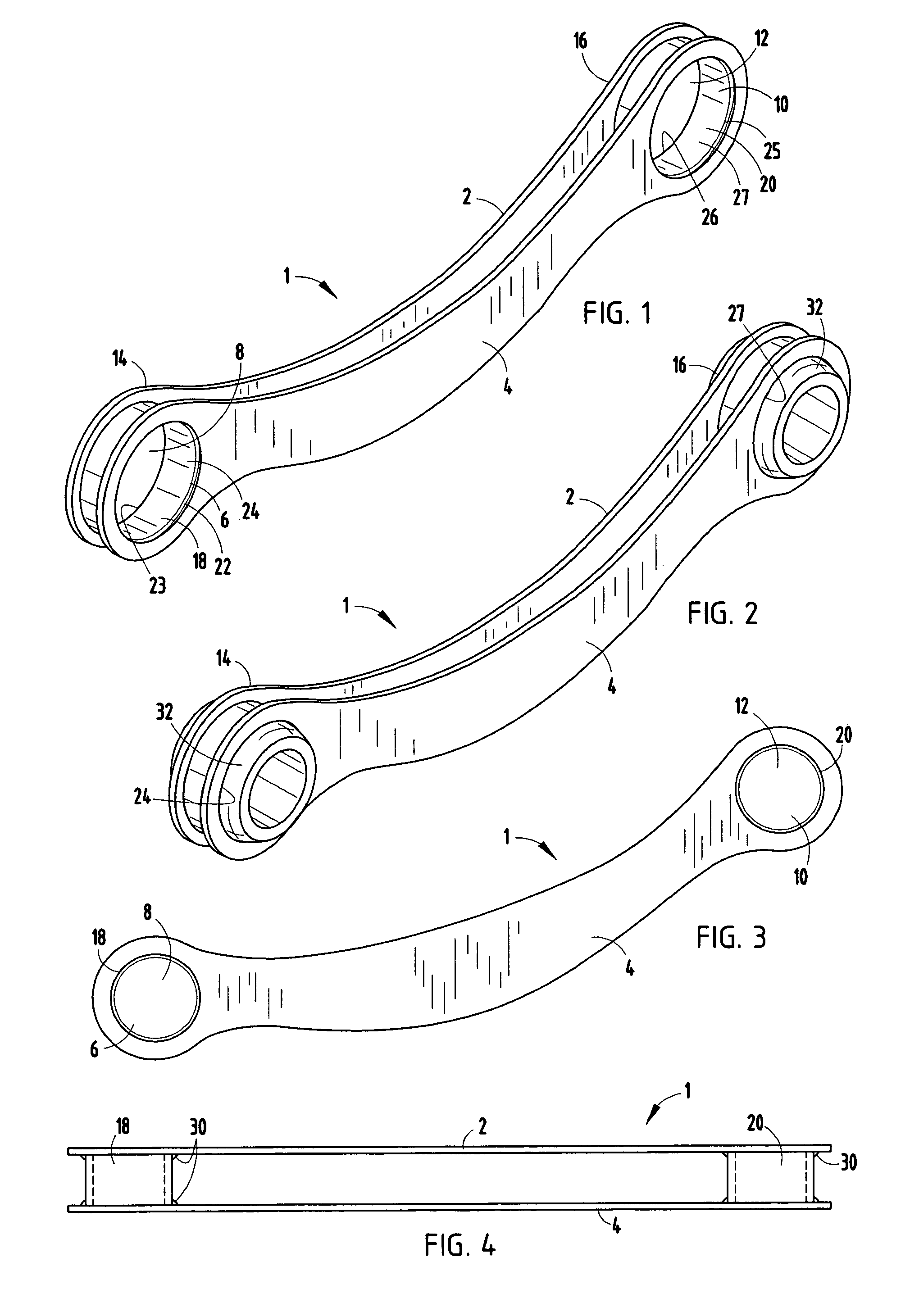

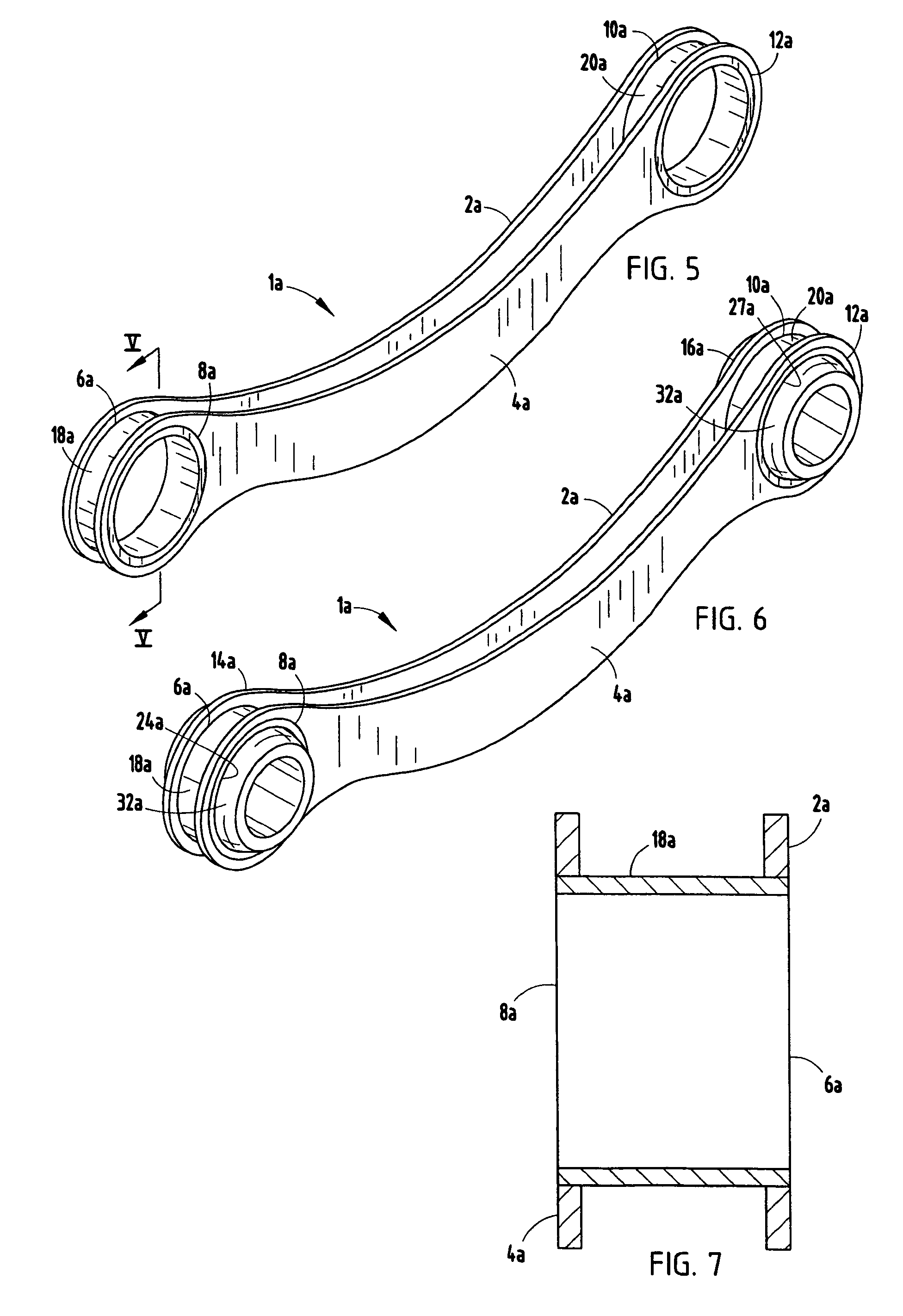

Mechanical part and method of manufacturing such a part

The invention provides a mechanical part for hinging to other mechanical parts at its ends, the mechanical part being made at least in part out of composite material from a central fiber preform and a peripheral fiber preform both of three-dimensional woven fabric, which preforms are assembled together while dry and then impregnated with resin, the peripheral preform surrounding the central preform in such a manner as to leave two empty spaces at the ends of the part and between the two preforms, which spaces are dedicated to hinging to said other parts. Metal inserts can be received in said spaces. The mechanical part can be used as a lever for a landing gear brace.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

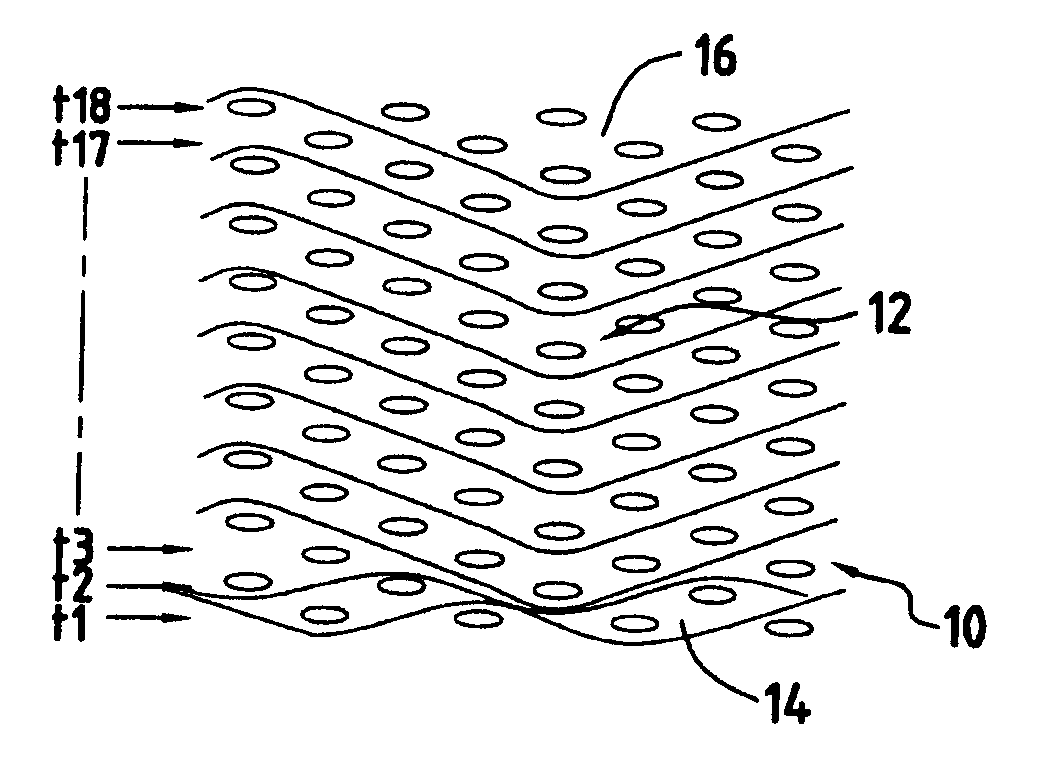

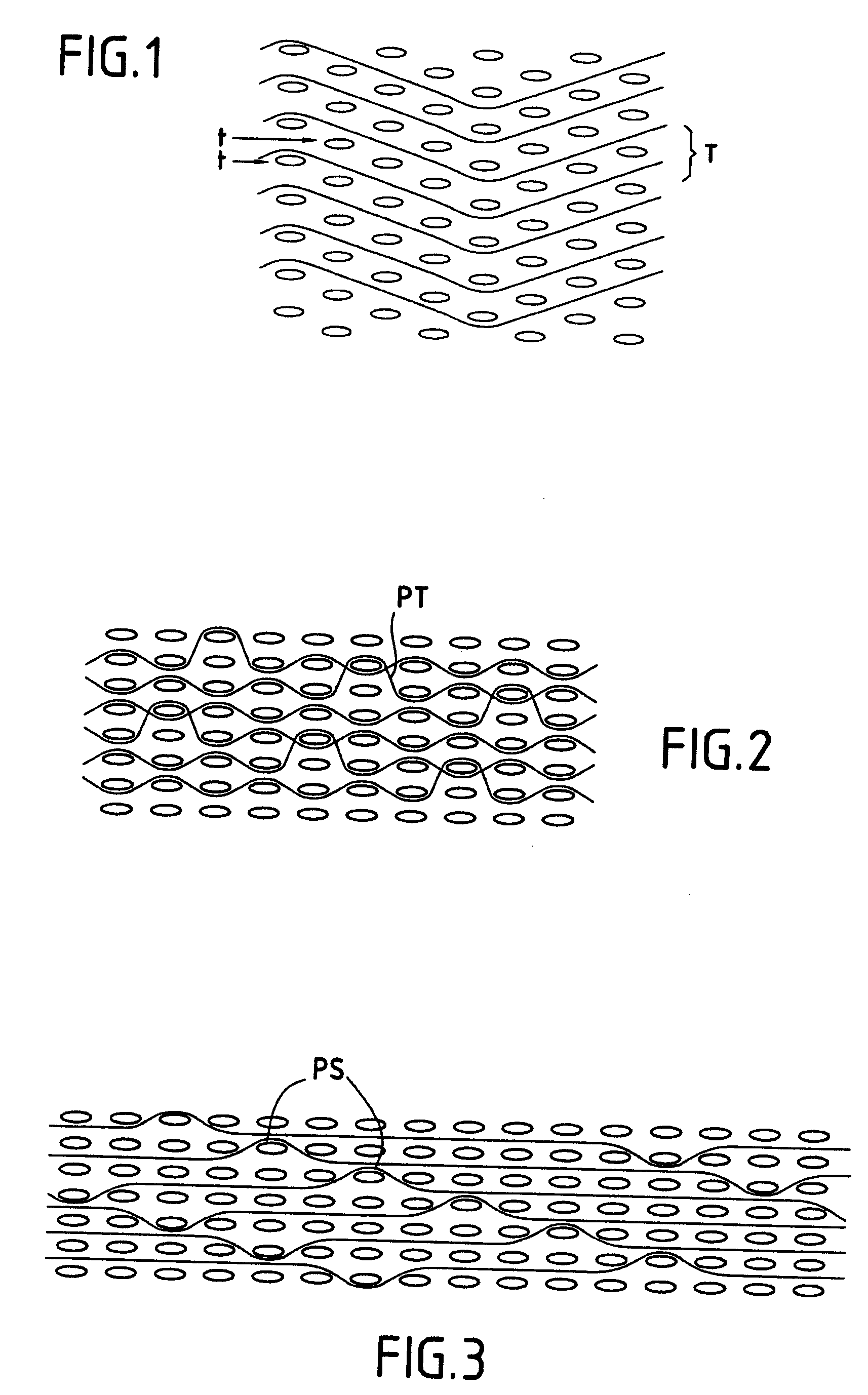

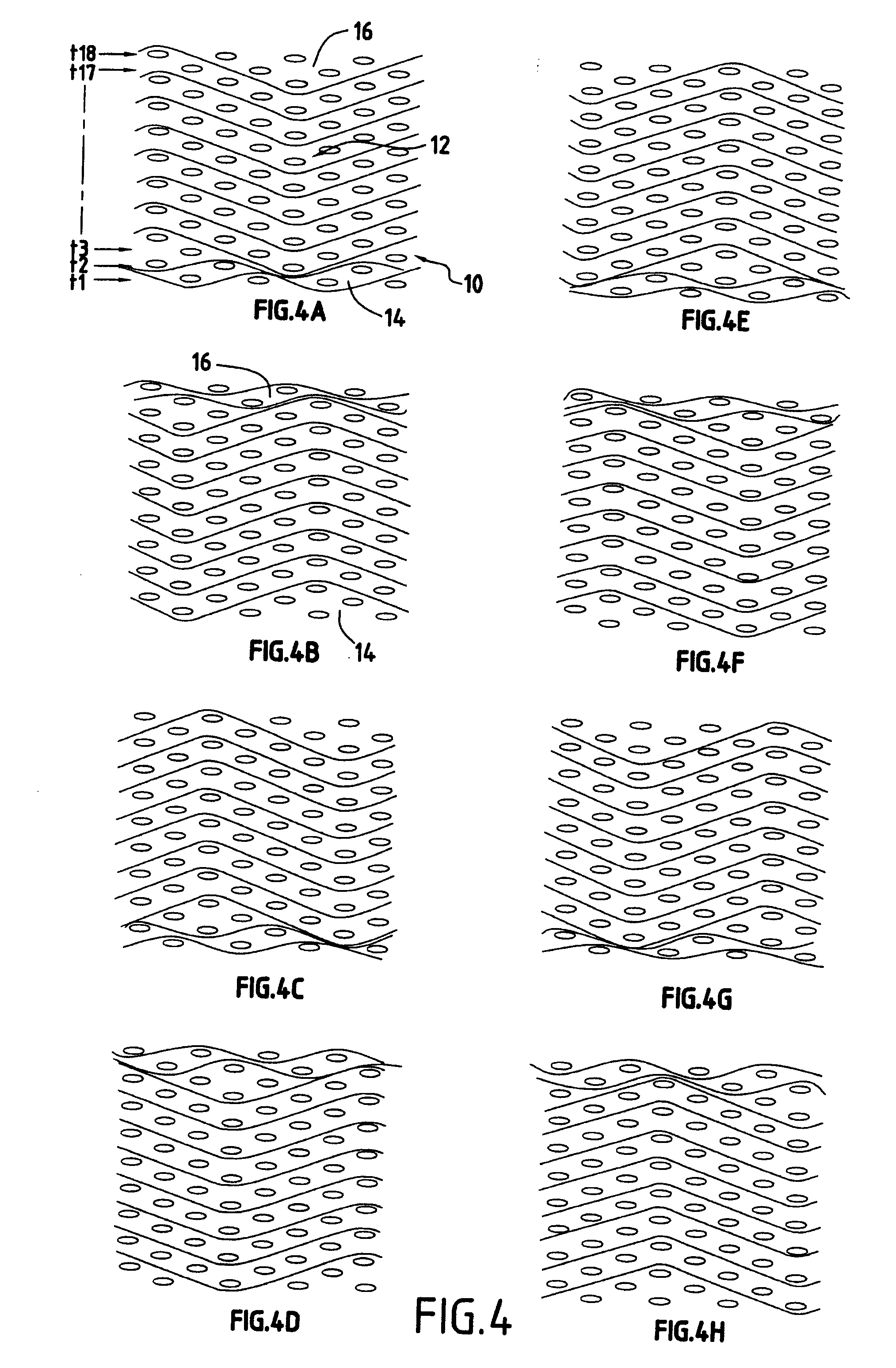

Reinforcing fibrous structure for a composite material and a part containing said structure

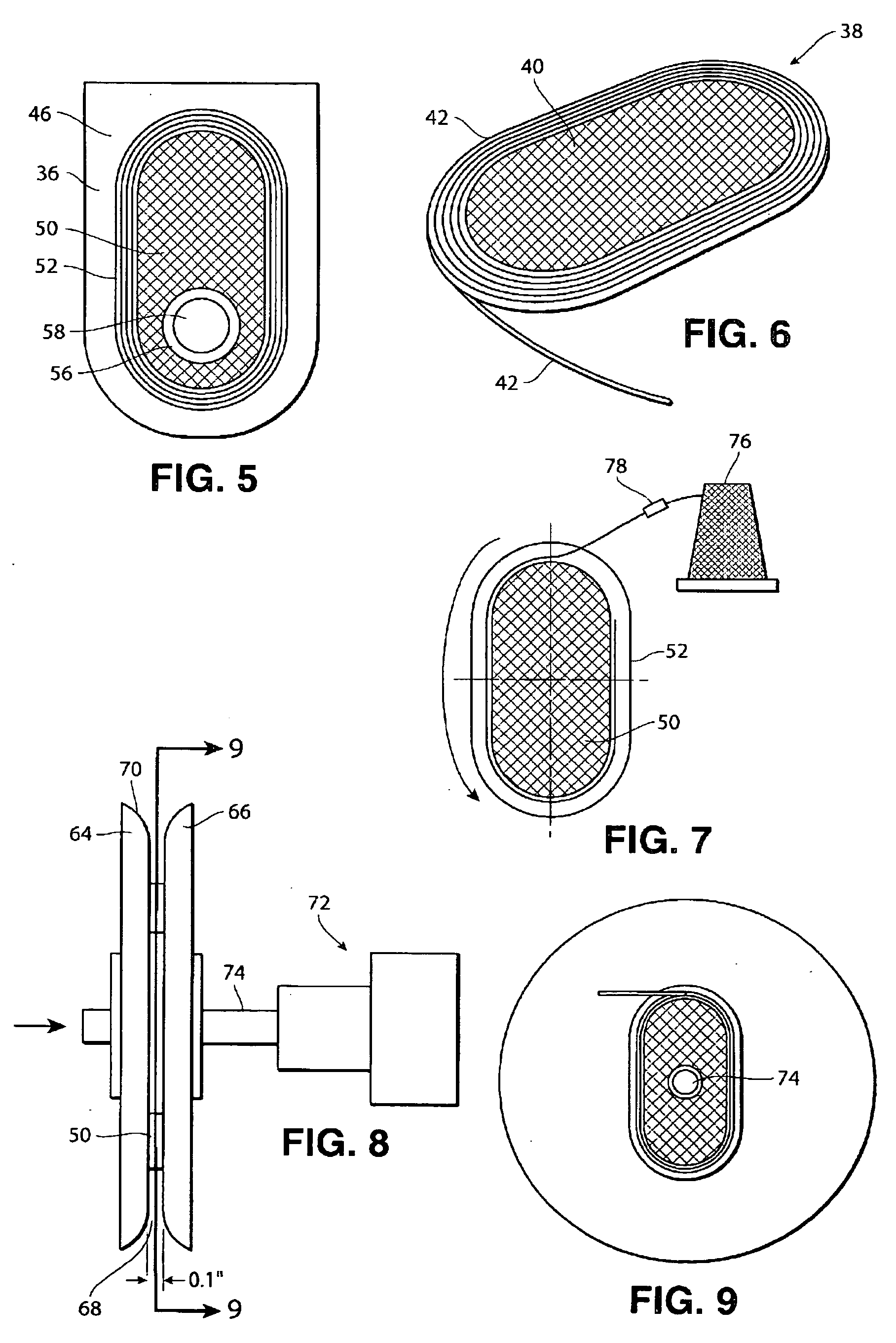

ActiveUS20100144227A1Easy accessReduce irregularitiesConnecting rodsMulti-ply fabricsBiomedical engineeringFiber structure

A woven fibrous structure embodied in one piece, used for producing a composite material part and comprising an internal part or a core (72) and a part adjacent to the external surface thereof or a skin (74, 76), is formed by three-dimensional core weaving with at least one weave selected from interlock and multilayer weaves and by skin weaving with a weave which differs from the core weave and selected from a multilayer weave and a two-dimensional weave. It can be also formed by three-dimensional weaving with at least one core interlock weave (72) and weaving with a fabric-, satin or skin twill-type weave, wherein skin weaving is of a multilayer or two-dimensional type.

Owner:GERAKL

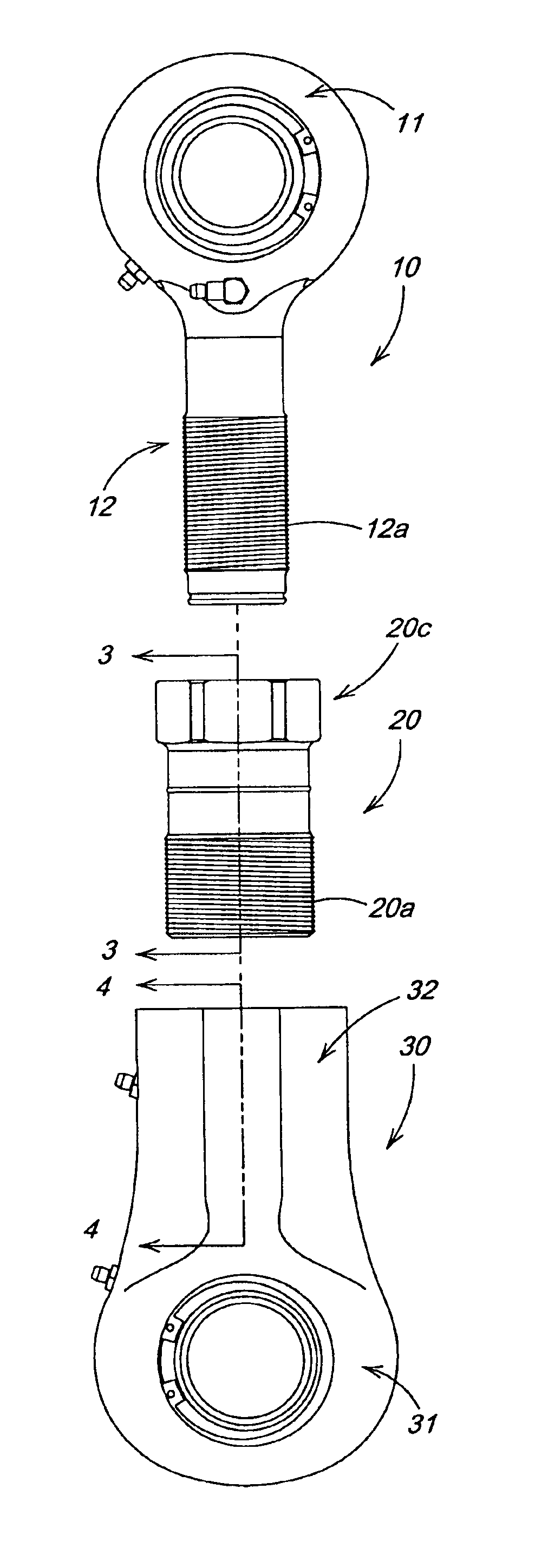

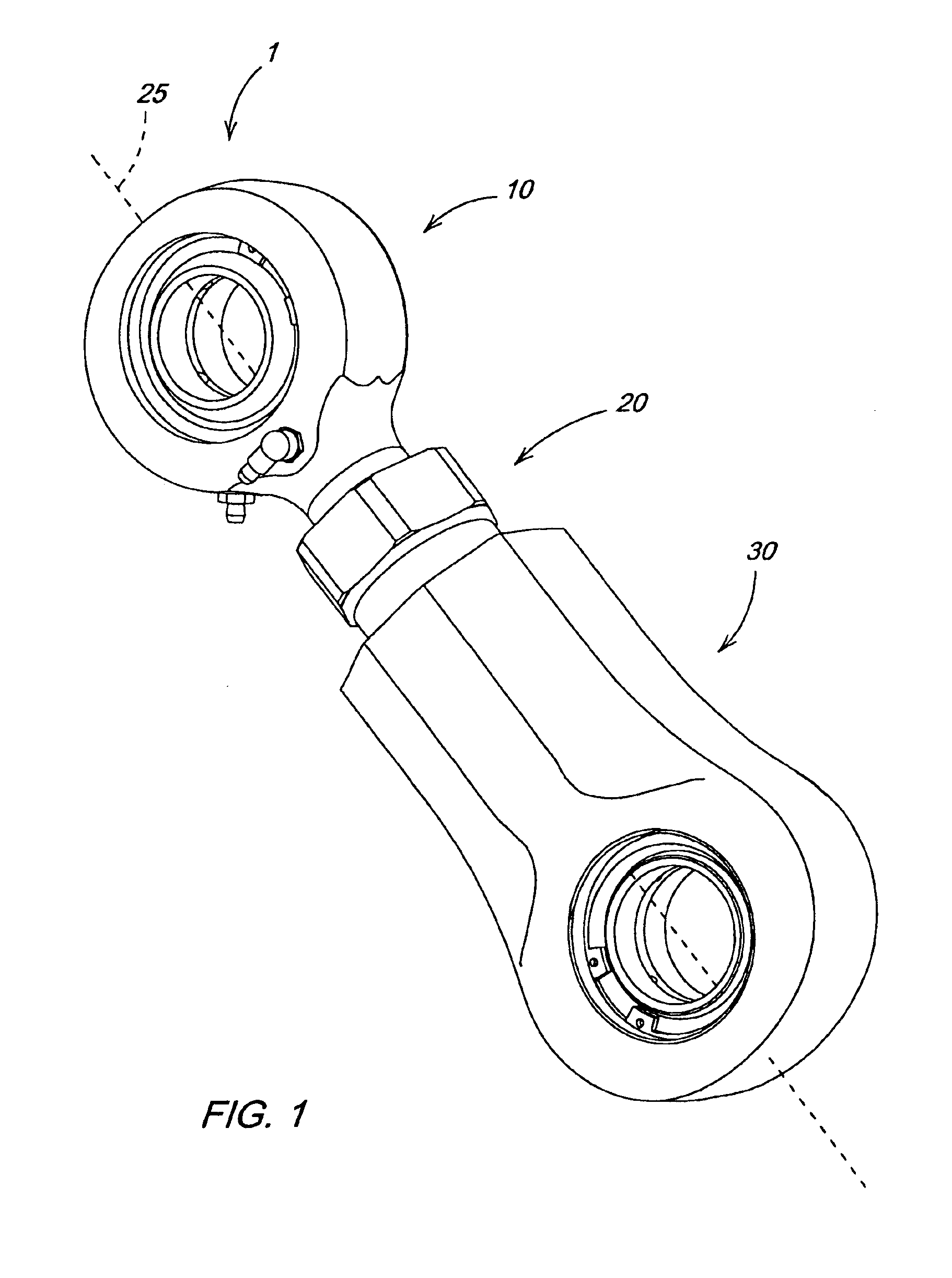

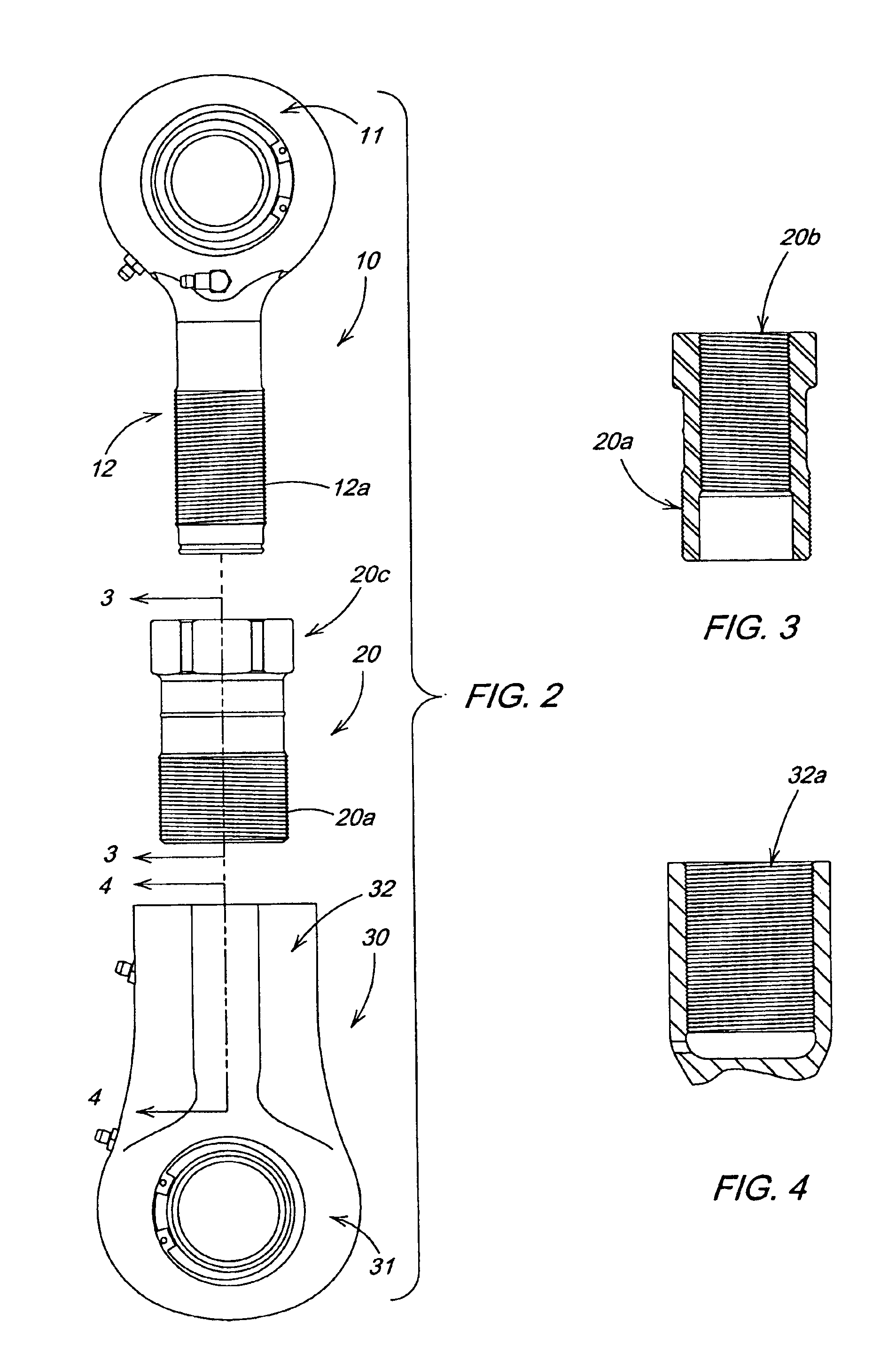

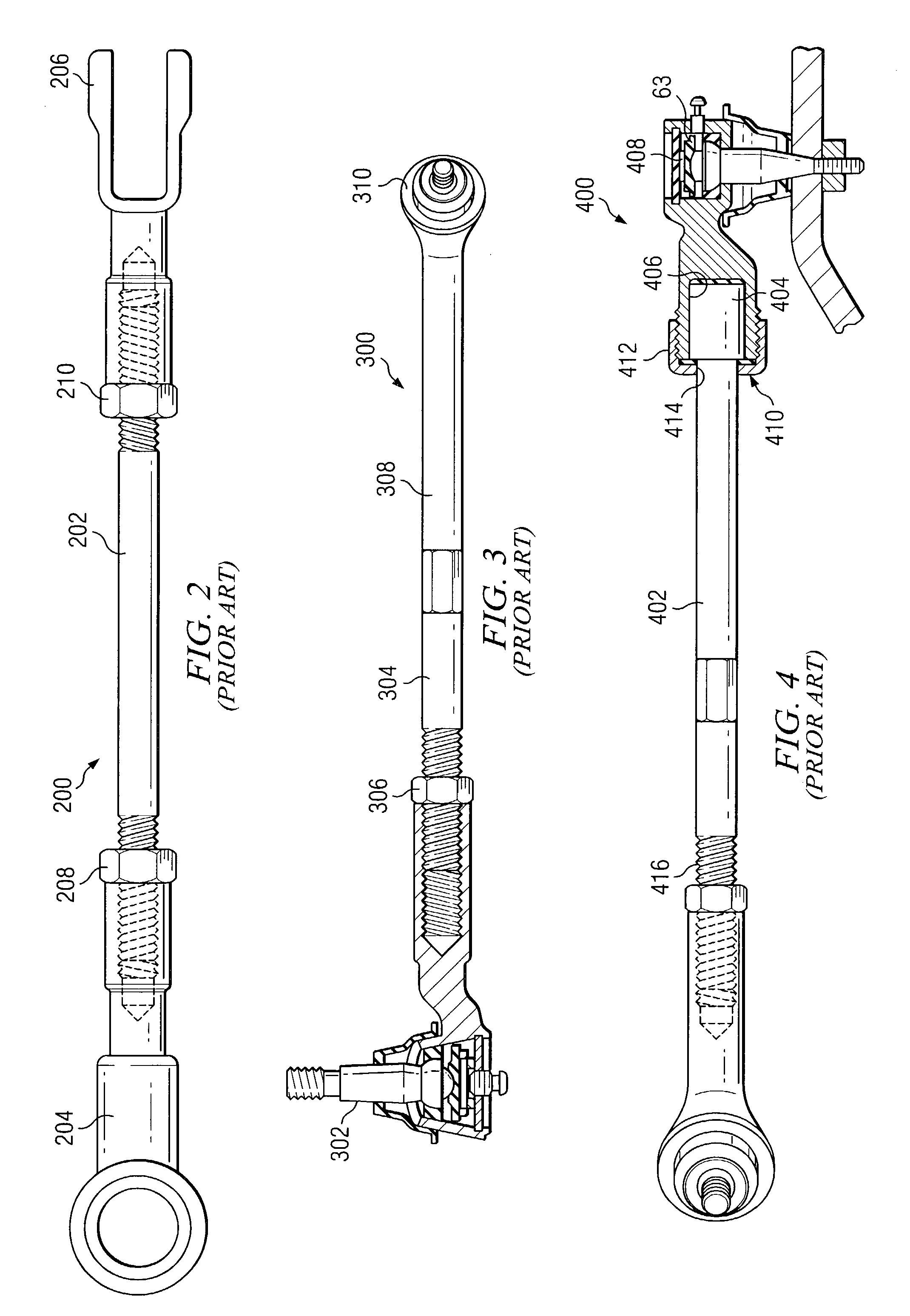

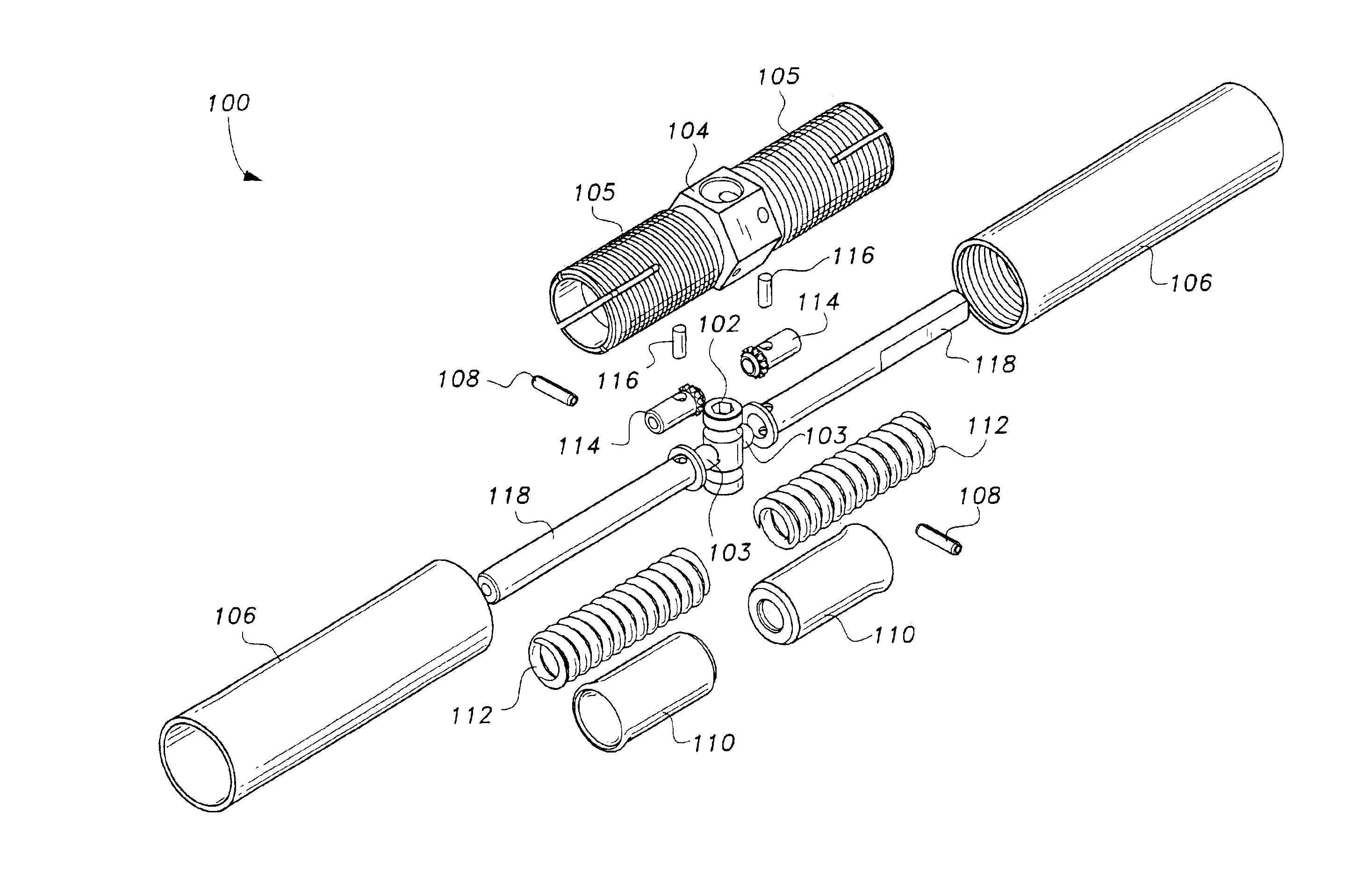

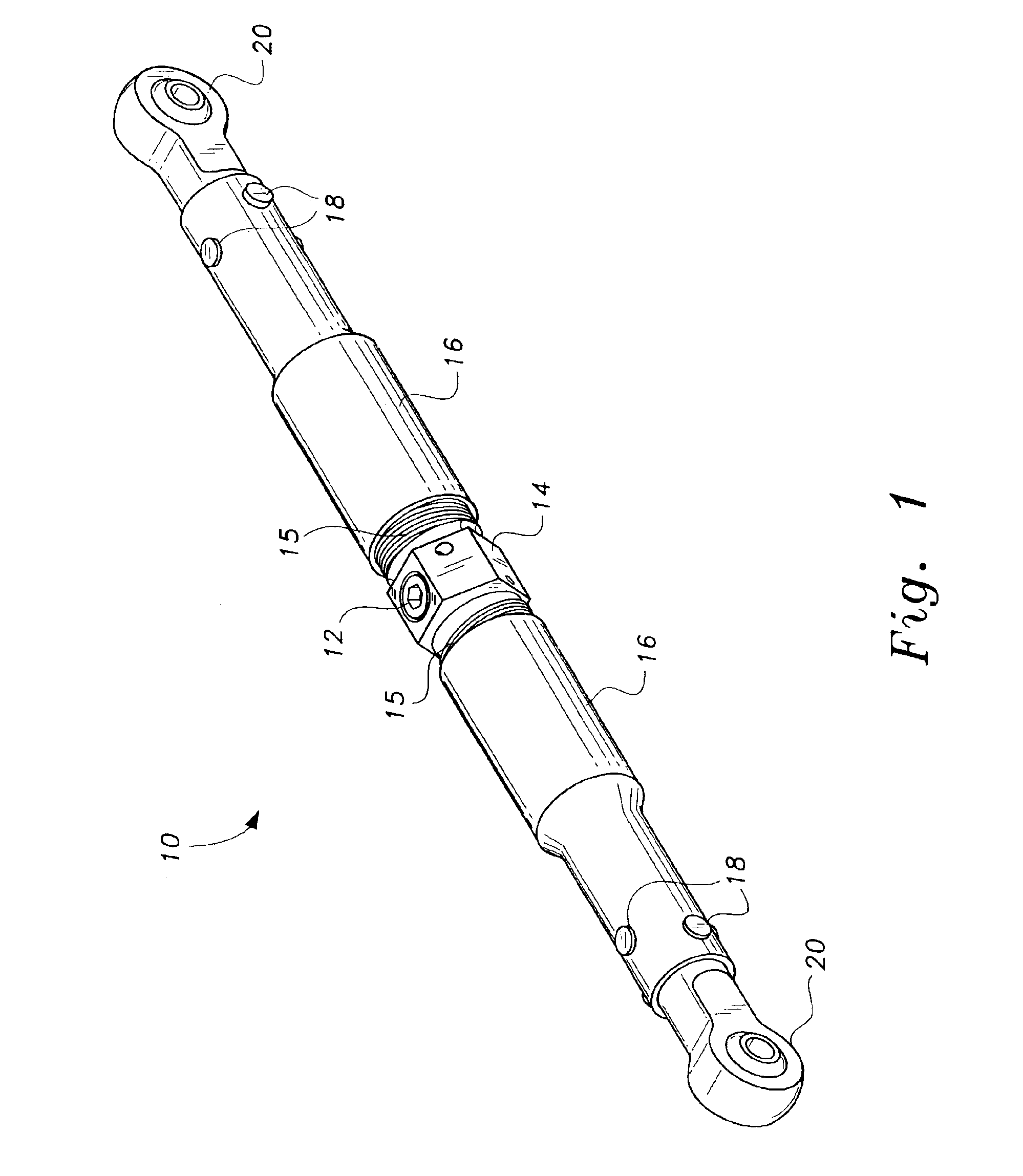

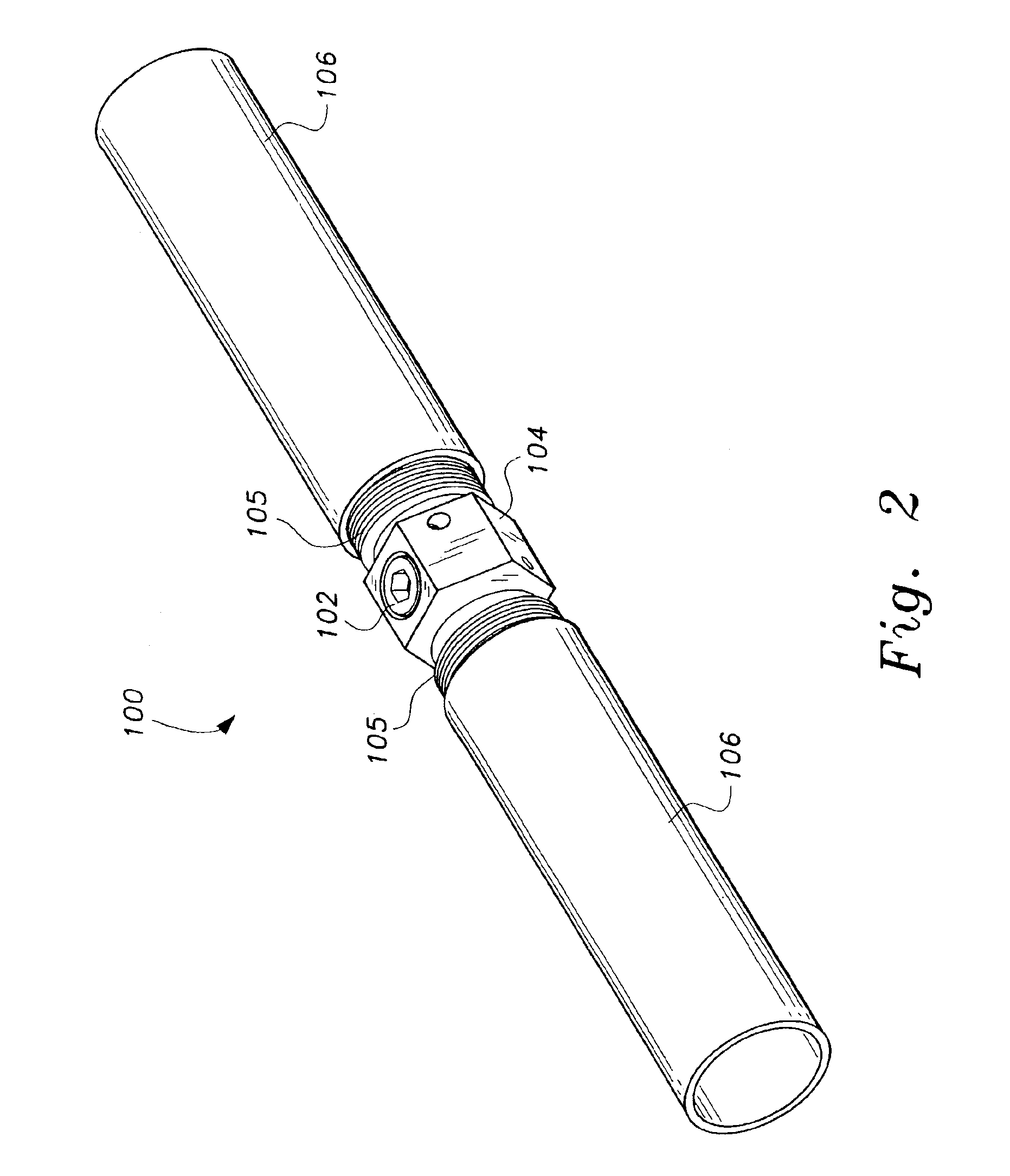

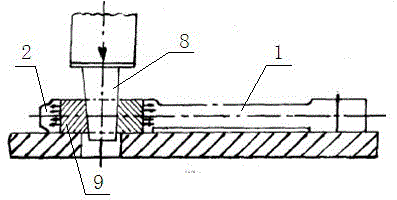

Short telescoping turnbuckle

ActiveUS6902342B1Lower Reliability RequirementsReduced strengthConnecting rodsYielding couplingRotational axisScrew thread

A short and simple telescoping turnbuckle is formed by threadedly engaging three parts including a first end, a second end and a length adjuster. The first end includes a connection portion such as a hook or a ring and a threaded shaft. The second end includes a connection portion and a internally threaded tubular potion. The length adjuster includes a cylinder having internal threads to engage the shaft of the first end and external threads to engage the tubular portion of the second end. The length of the telescoping turnbuckle may be altered by rotating the length adjuster about the rotational axis of the turnbuckle.

Owner:DEERE & CO

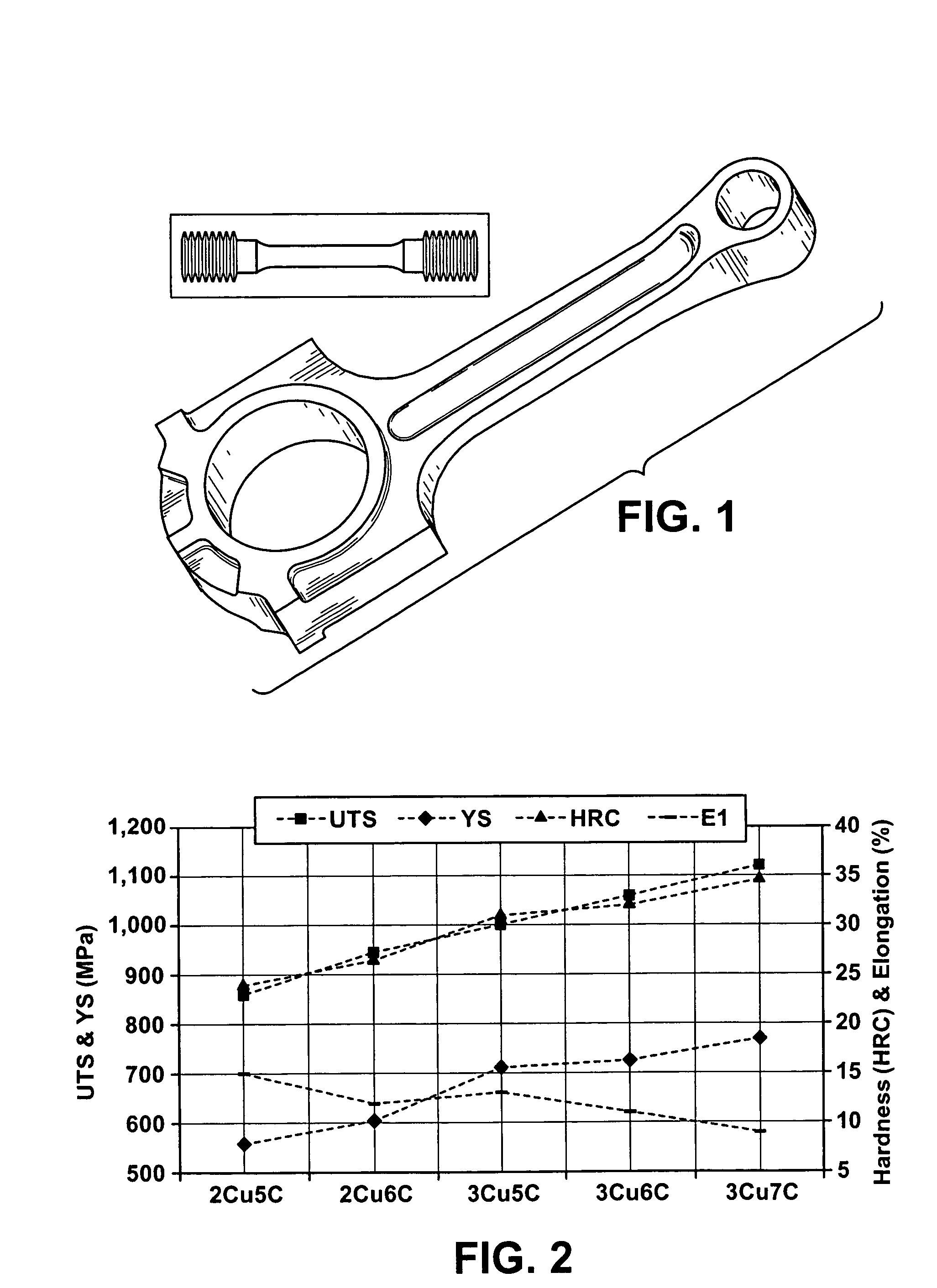

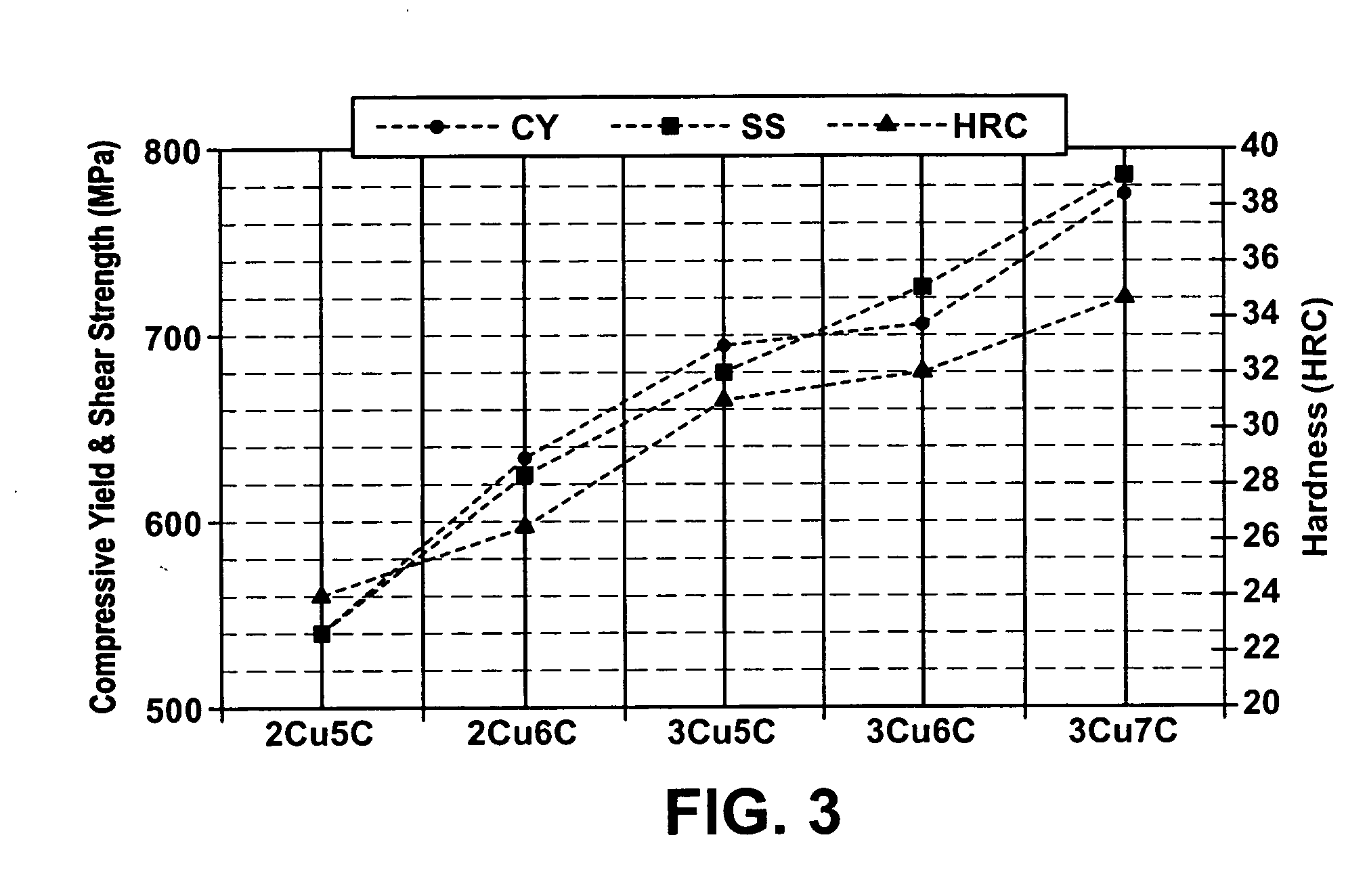

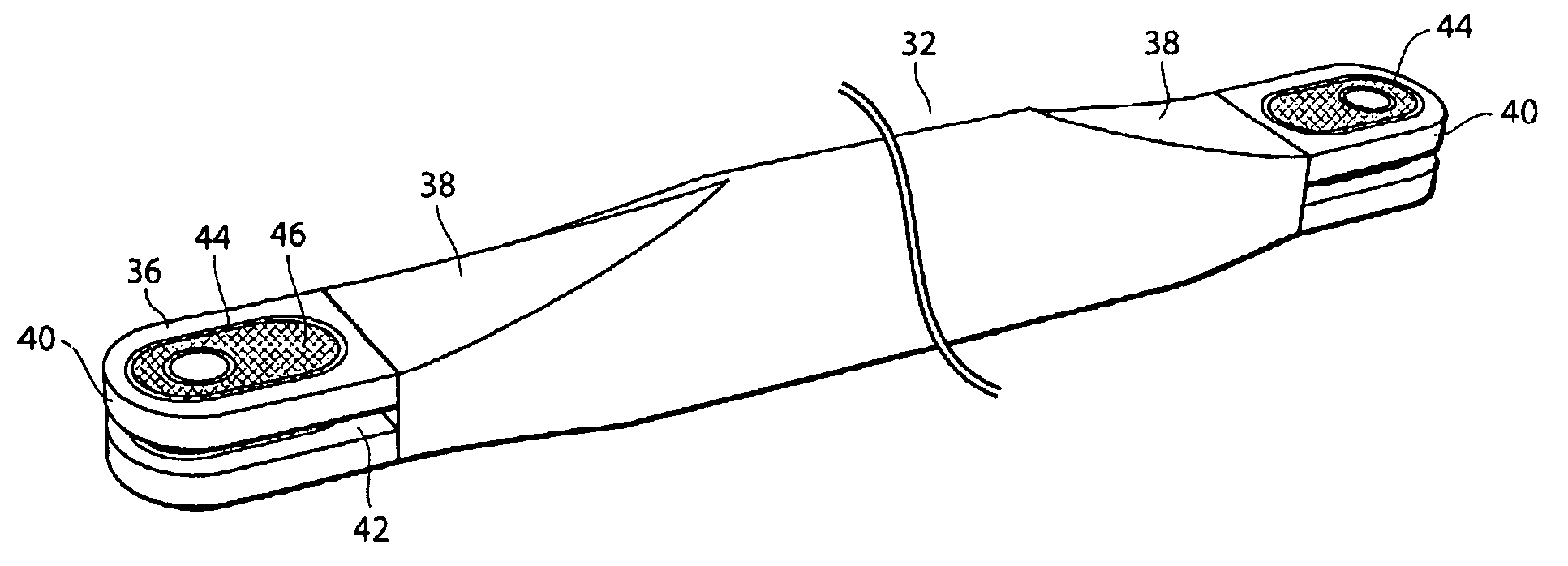

Impact of copper and carbon on mechanical properties of iron-carbon-copper alloys for powder metal forging applications

Owner:METALDYNE LLC

Composite strut and method of making same

InactiveUS20050056117A1Highly effective in reacting both tensionEfficiently transfer both shearConnecting rod bearingsFuselage framesBiomedical engineeringCompression load

Owner:KAISER COMPOSITEK

Cardioid cycle internal combustion engine

InactiveUS6526935B2Improve fuel efficiencyMore outputConnecting rodsMachines/enginesFuel efficiencyTangential force

Owner:SHAW RALPH

Self-Aspirated Reciprocating Internal Combustion Engine

InactiveUS20110146601A1Eliminating shaft counter weightExcessive vibrationConnecting rodsSealing arrangements for enginesSingle plateInternal combustion engine

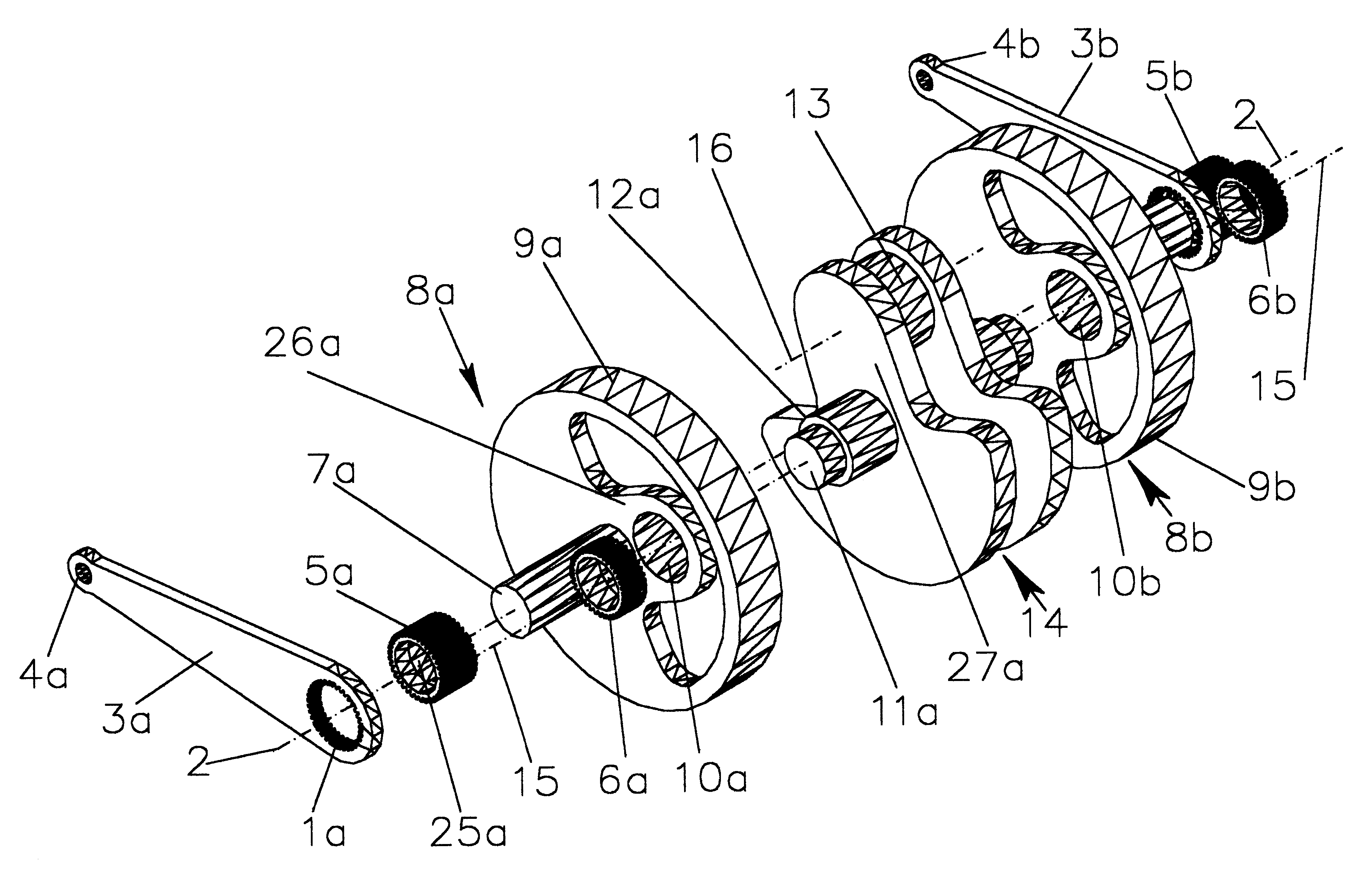

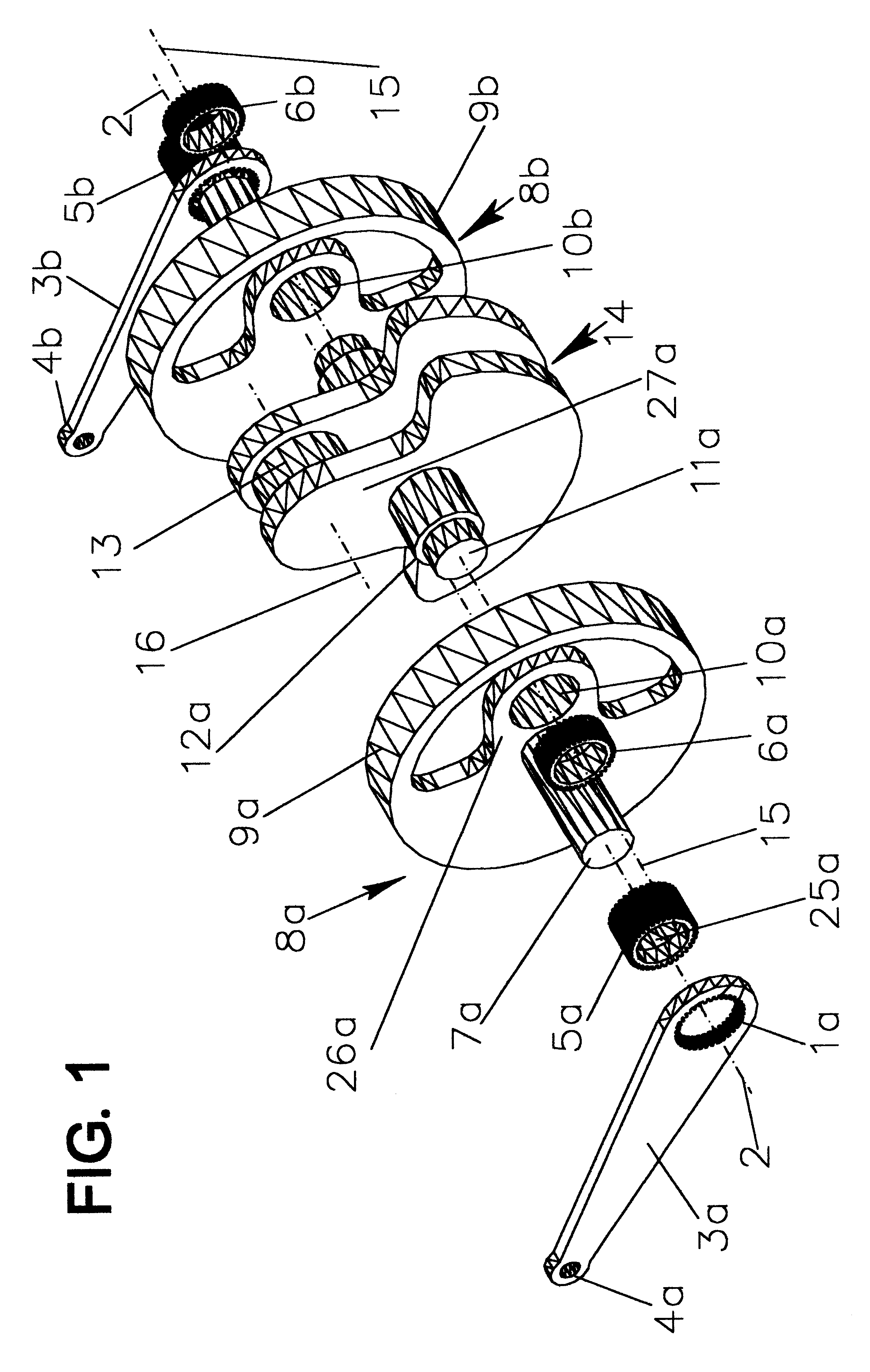

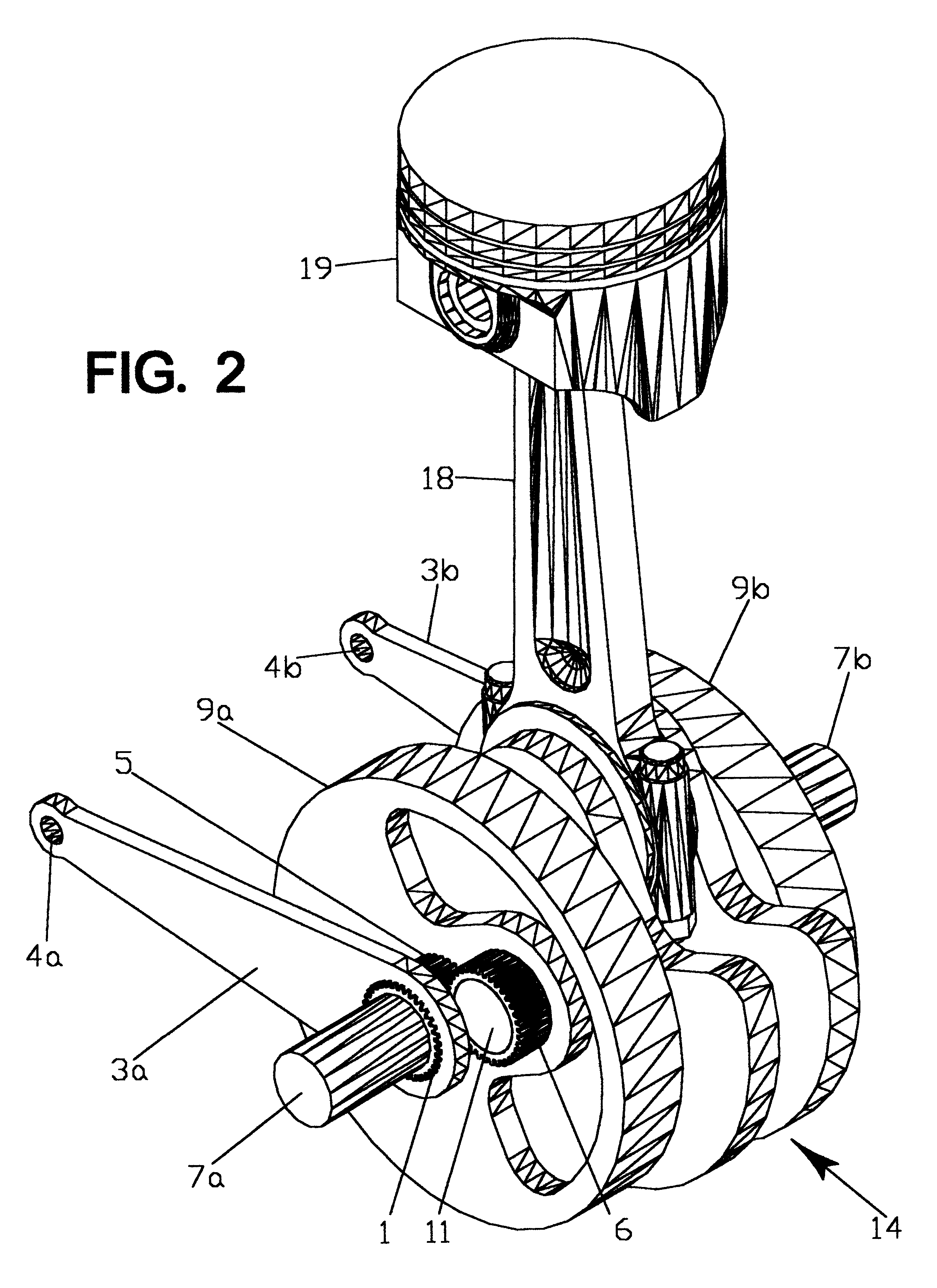

Disclosed are crankshaft, single-plate cam and beam mechanisms that provide significant improvements in performance for 2- & 4-stroke engines, compressors and pumps. These cost effective mechanisms include linkages with the new and improved use of pivoting arms that operate with a variety of cylinder arrangements. One embodiment of the crankshaft mechanism has its crankpin roller positioned within a novel yoke-arm. The cam mechanism uses a pair of centrally positioned parallel links that are connected to roller cam followers and single or diametrically-opposed pistons. A pair of laterally extending follower arms connects to the ends of the links to provide support and alignment for the piston rods. Between the reciprocating links, cam followers and follower arms is a rotating odd-lobe plate cam. A beam mechanism uses opposite-direction extending balancing beams that are connected to links, cam followers and piston rods.

Owner:FISHER PATRICK T

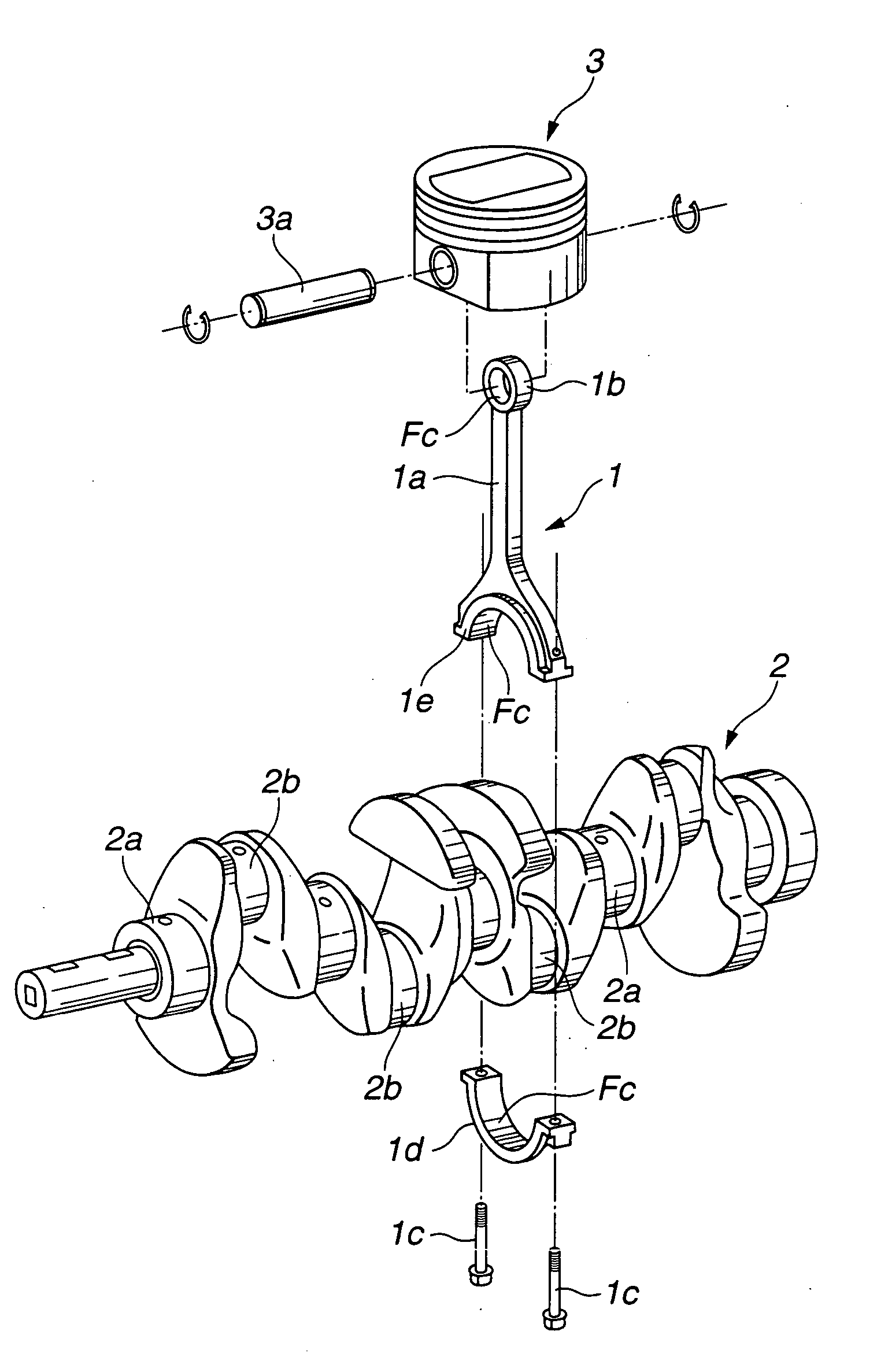

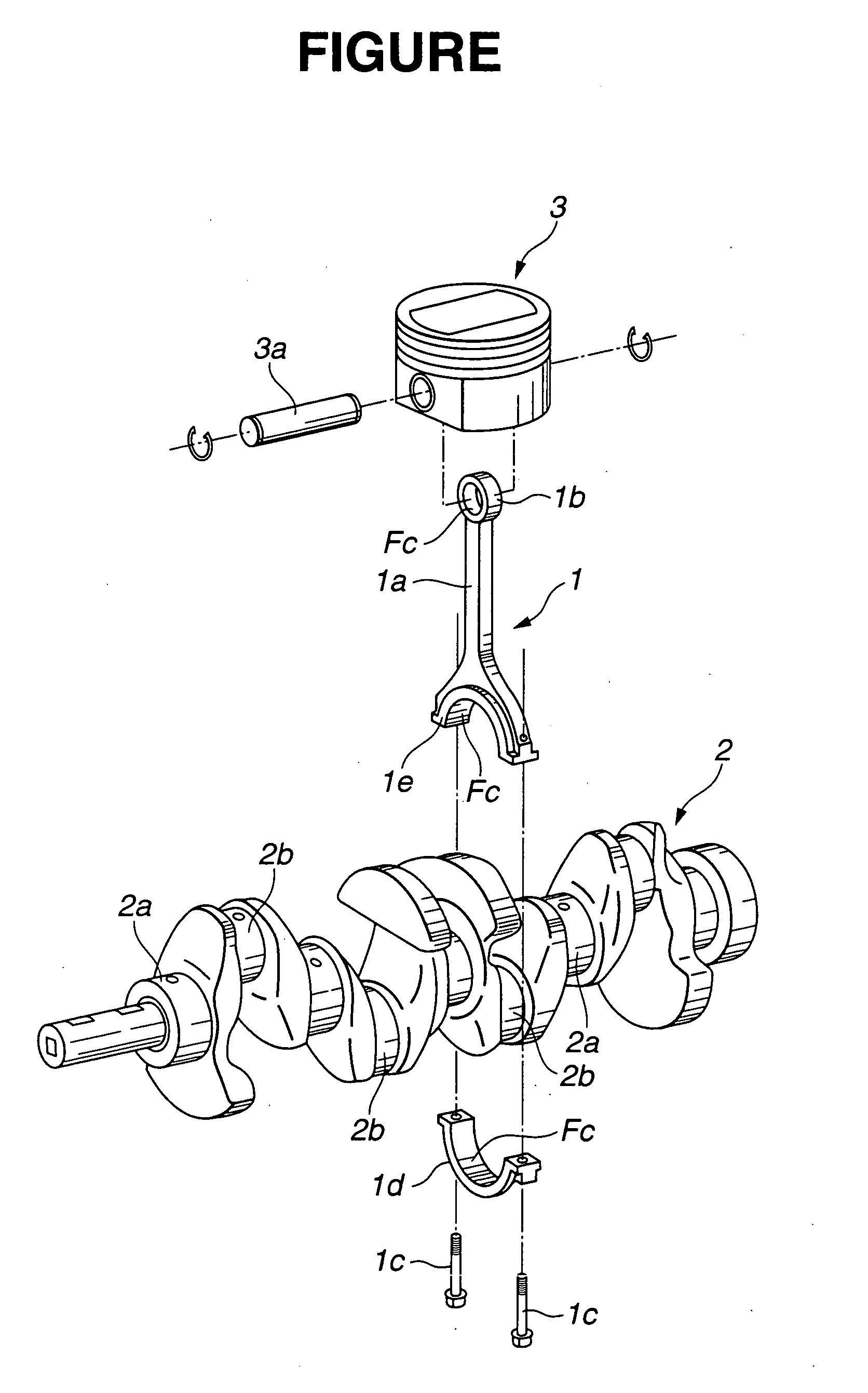

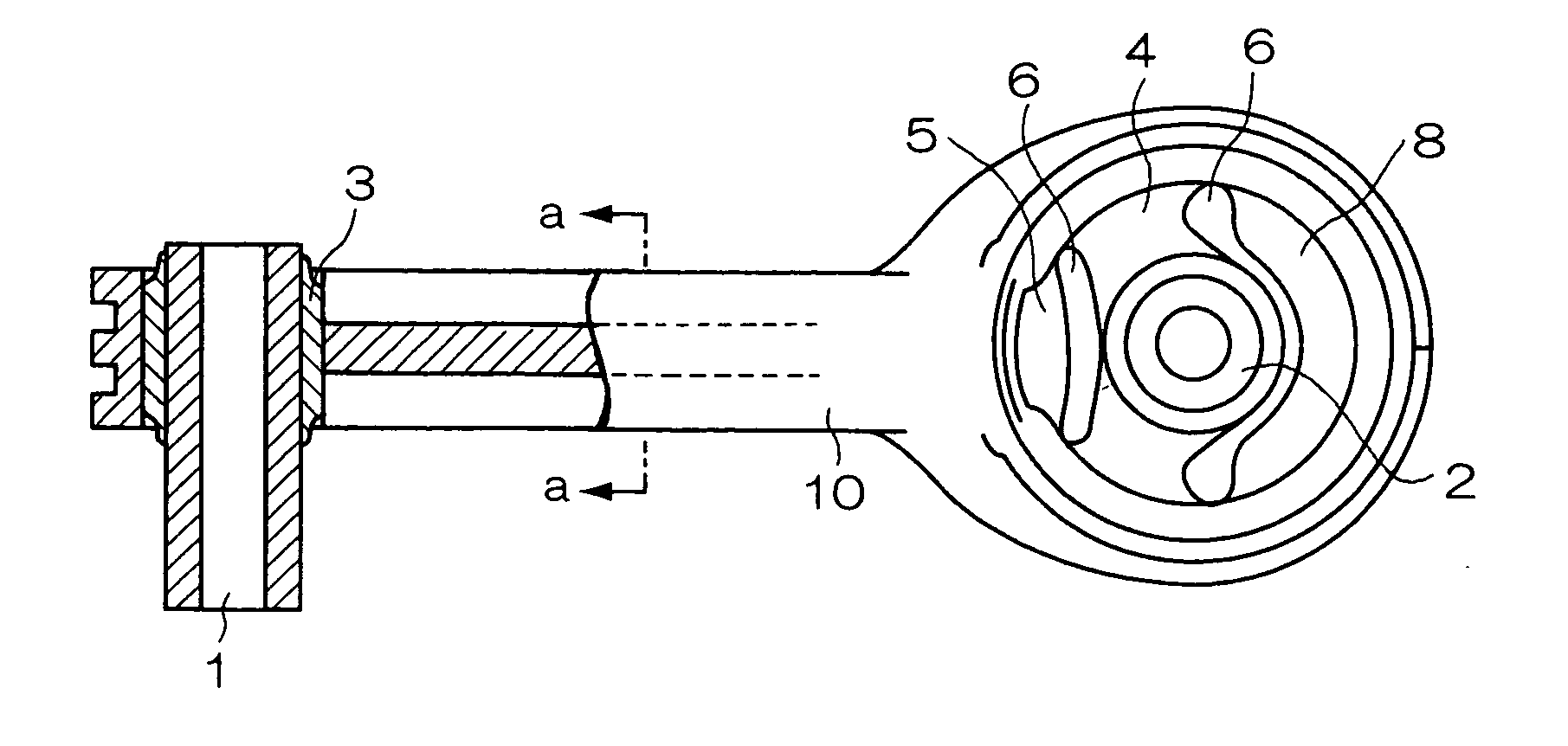

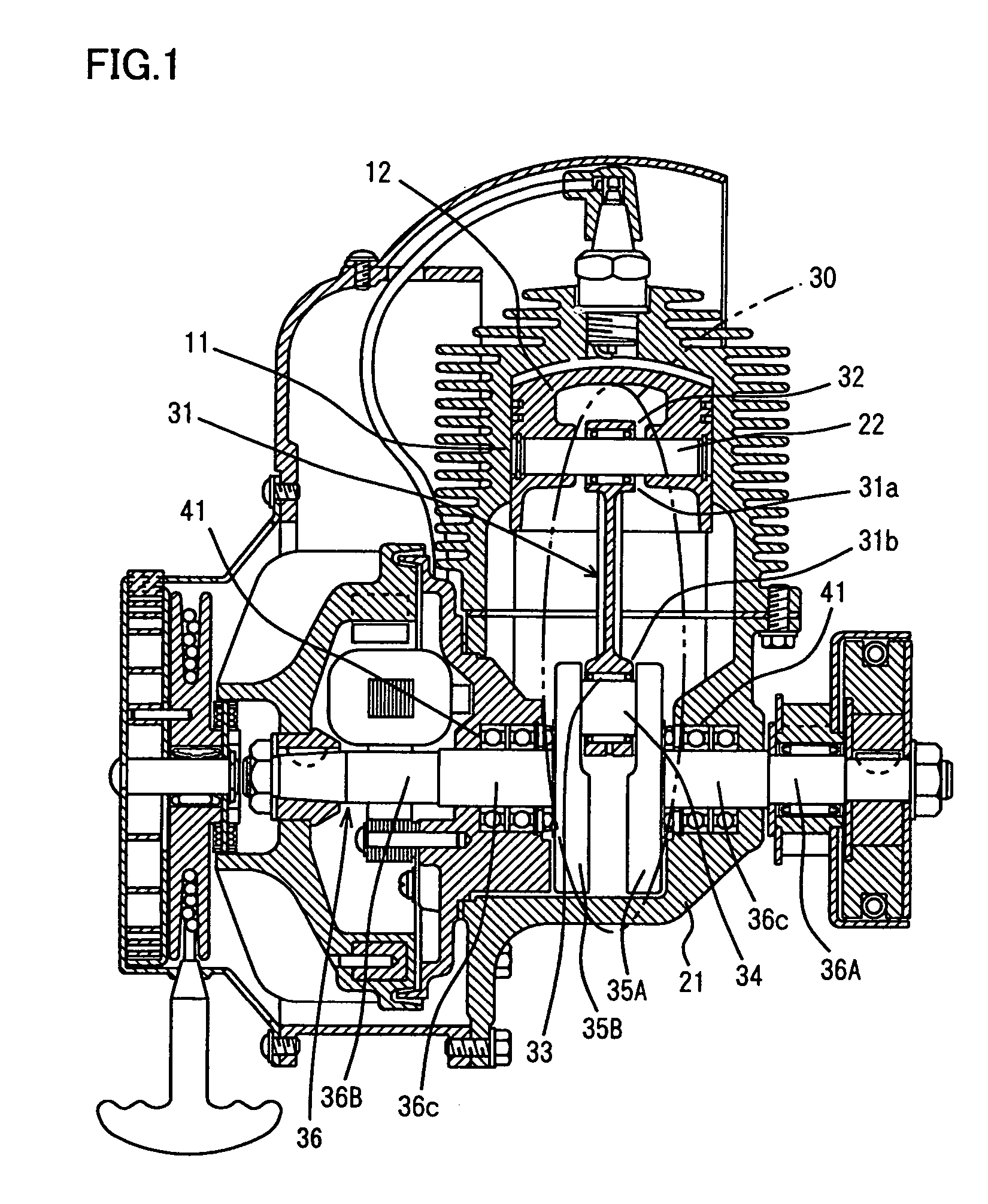

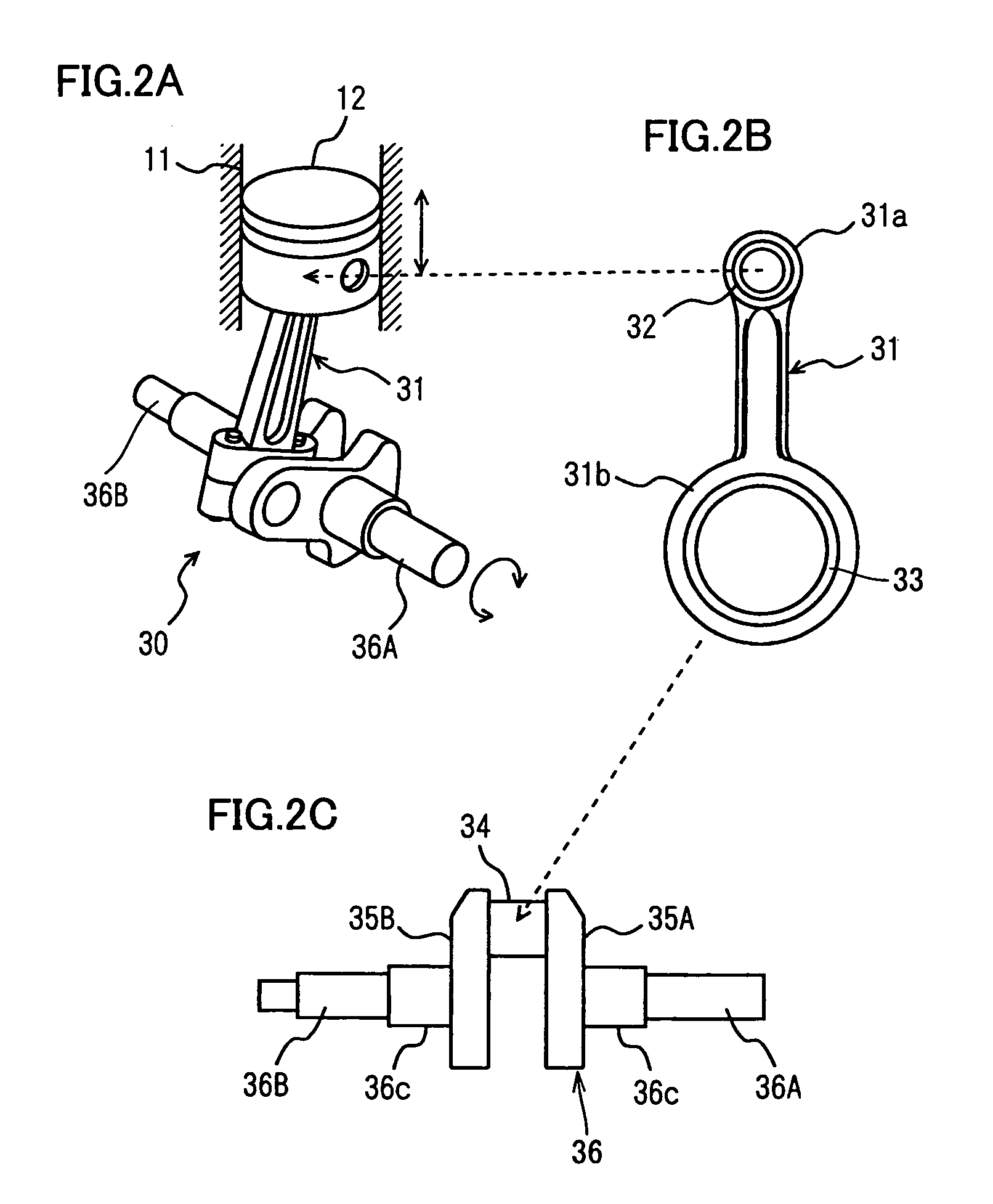

Structure for connecting piston to crankshaft

InactiveUS20050061291A1Reduce sliding frictionImprove engine performanceCrankshaftsConnecting rodsCarbon coatingHydrogen content

There is provided a structure for connecting a piston to a crankshaft in an internal combustion engine, including a piston pin fitted into the piston, a crankpin integral with the crankshaft and a connecting rod having a piston pin bearing portion slidably engaged with an outer cylindrical portion of the piston pin and a crankpin bearing portion slidably engaged with an outer cylindrical portion of the crankpin. At least one of the piston pin bearing portion of the connecting rod and the outer cylindrical portion of the piston pin and at least one of the crankpin bearing portion of the connecting rod and the outer cylindrical portion of the crankpin have hard carbon coatings formed thereon with a hydrogen content of 20 atomic % or less.

Owner:NISSAN MOTOR CO LTD

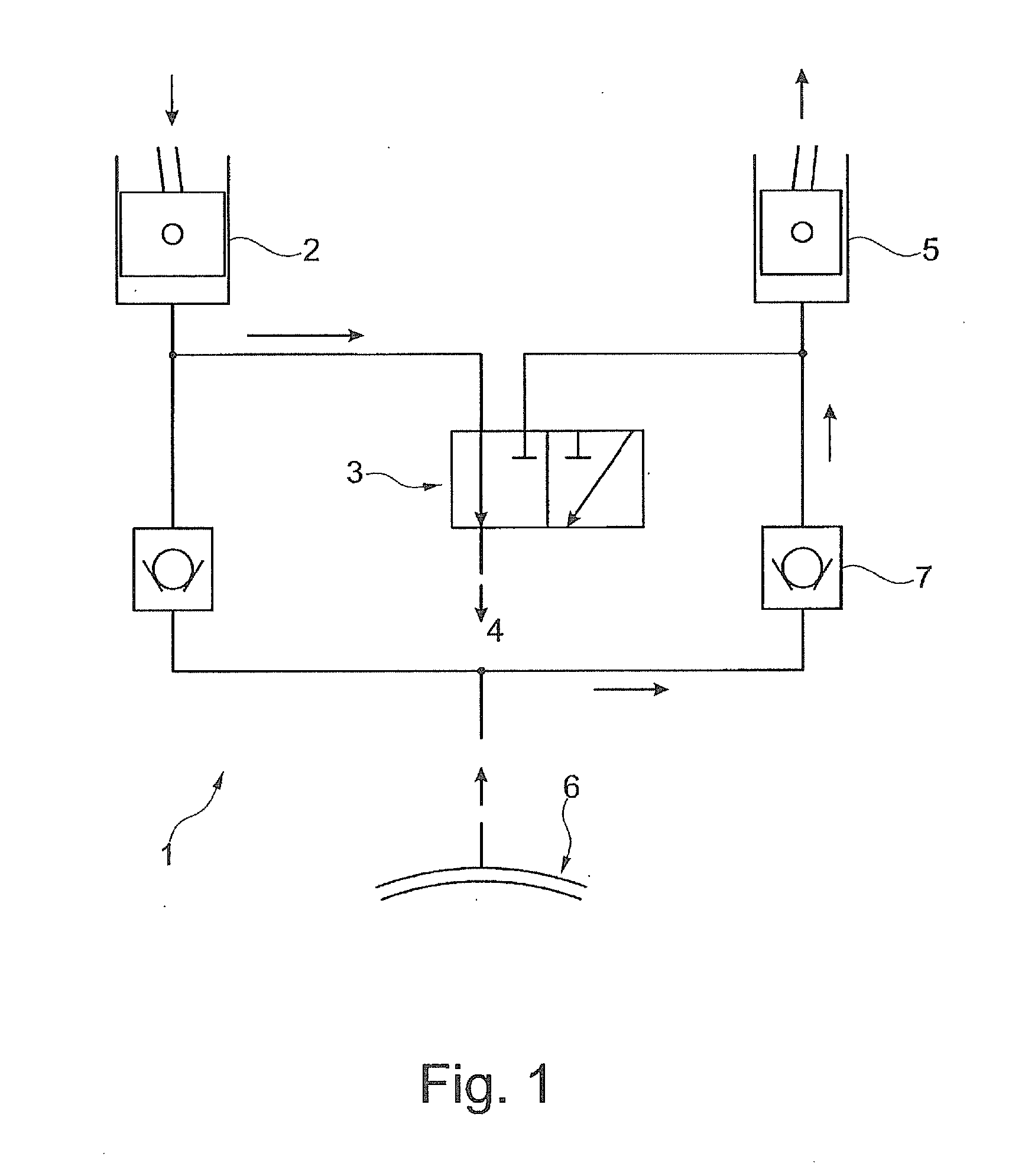

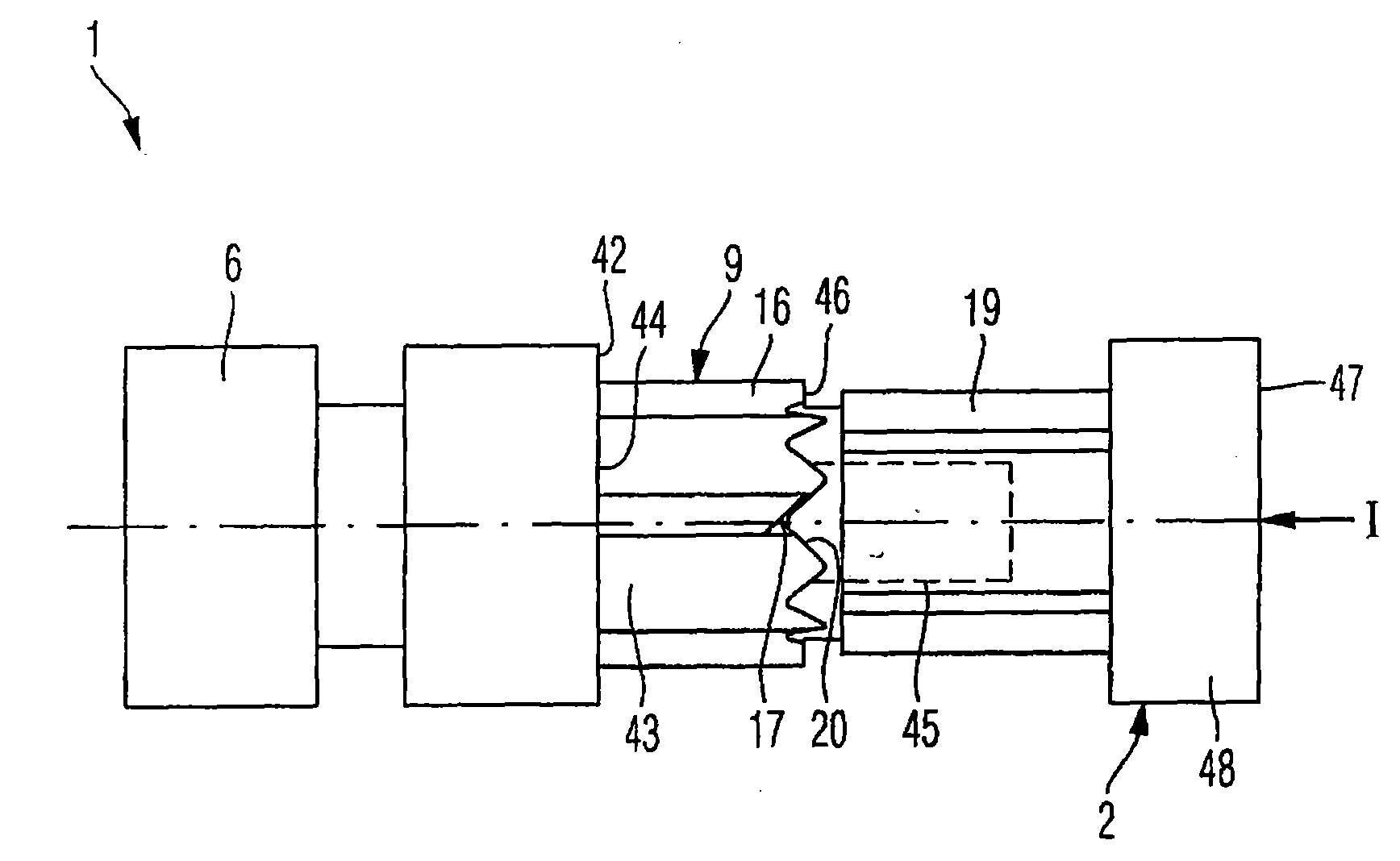

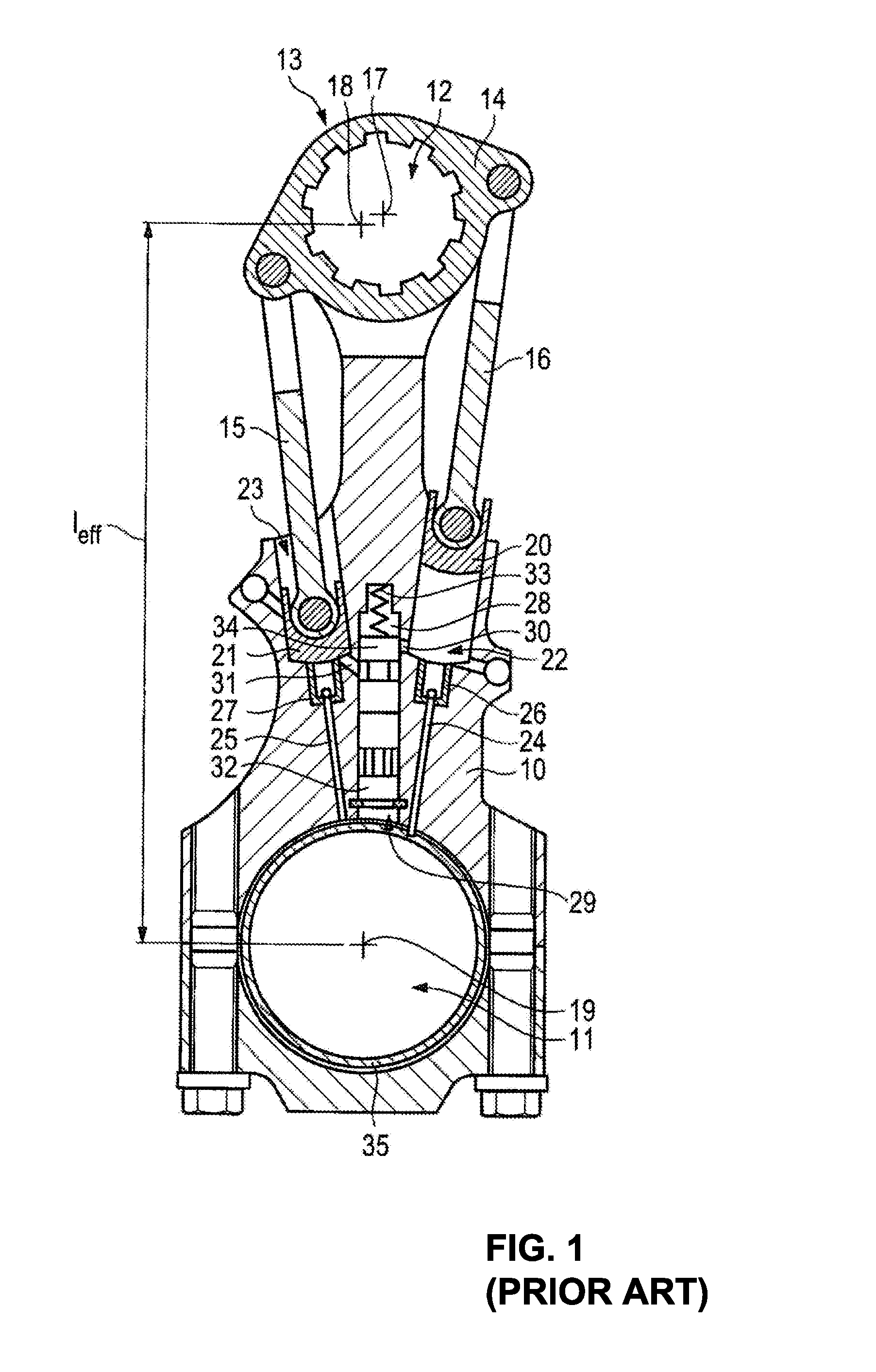

Reversing valve and combustion engine with the reversing valve

InactiveCN102213332AEasy to switchEasy to manufactureRotary bearingsConnecting rodsCombustionEffective length

The invention relates to a reversing valve (1), particularly a reversing valve (1) with a ballpoint pen mechanism (2) for controlling hydraulic fluid flow. The ballpoint pen mechanism can be alternately latched in a first or a second positions and is coupled with the reversing valve (1) by applying a control pulse (I) on the actuation means (3) of the ballpoint pen mechanism (2), so that the first or the second position is respectively correspondent to the first or the second switch positions of the control piston (6) of the reversing valve (1). The invention further relates to a combustion engine having an adjustable compression ratio, which comprises the above reversing valve (1) and a connection rod arrangement (3). The connection rod arrangement (3) has an eccentric device (36) capable of being adjusted in a hydraulic mode, which is arranged inside a connection rod bearing hole (34) and / or a crane bearing hole (35) for adjusting the effective length of the connection rod (leff). The adjusting stroke of the eccentric device (36) can be controlled by the reversing valve (1).

Owner:DR ING H C F PORSCHE AG

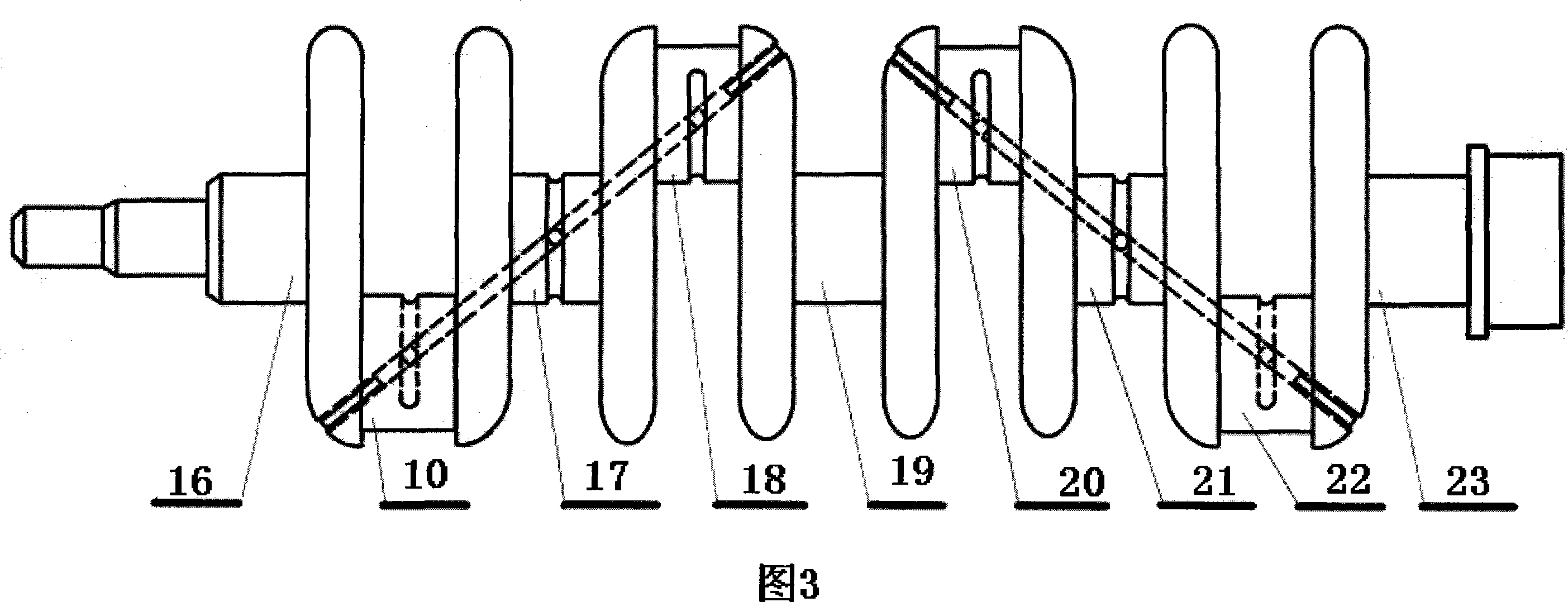

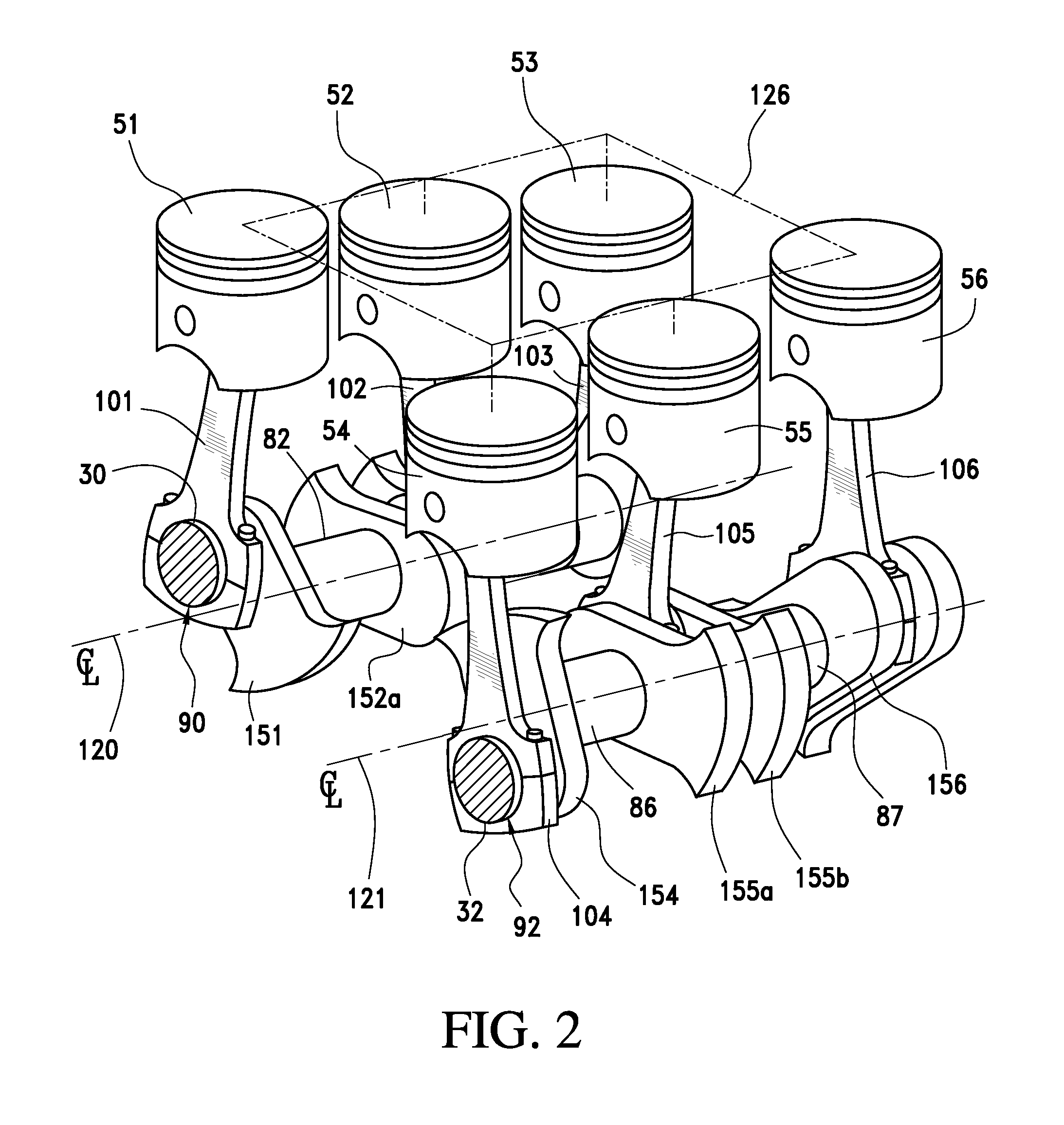

Dual crankshaft engine with counter rotating inertial masses

InactiveUS20090107426A1Improve balanceConnecting rodsElectric propulsion mountingInternal combustion engineCylinder block

A dual crankshaft internal combustion engine is symmetrically constructed to form a perfectly balanced engine assembly. A first crankshaft, having a first end, a second end, and being formed of a shape and with a torsional flexibility, is housed within a cylinder block and connected to a first series of cooperating pistons and cylinders. A second crankshaft, having a first end and a second end, is formed of substantially the same shape as the first crankshaft and has substantially the same torsional flexibility as the first crankshaft. The second crankshaft is also housed within the cylinder block and connected to a second series of cooperating pistons and cylinders, while being positioned parallel to the first crankshaft, with the first end of the first crankshaft being positioned adjacent to the second end of the second crankshaft.

Owner:FORD GLOBAL TECH LLC

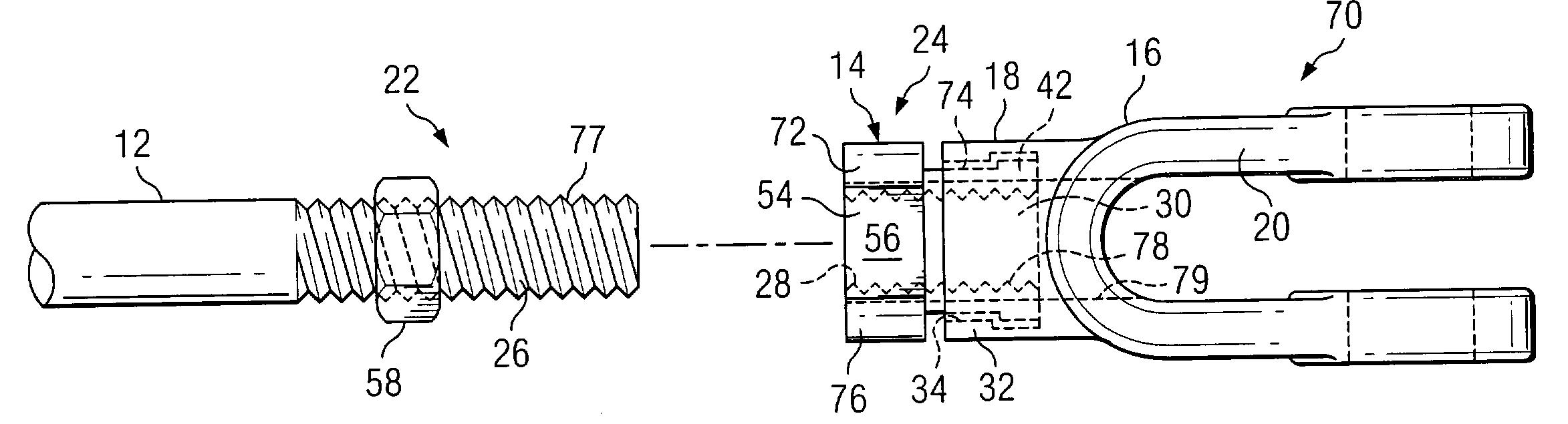

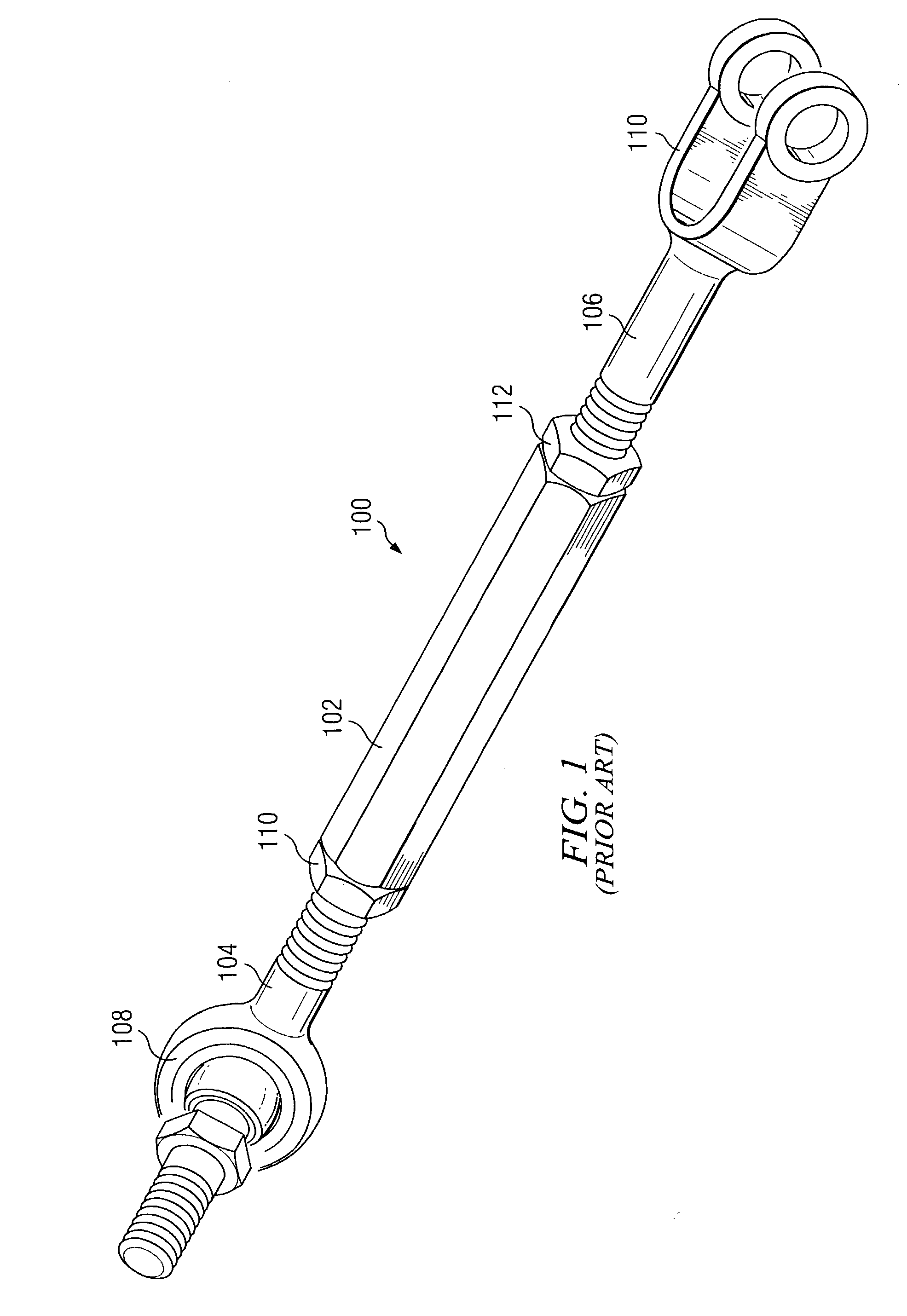

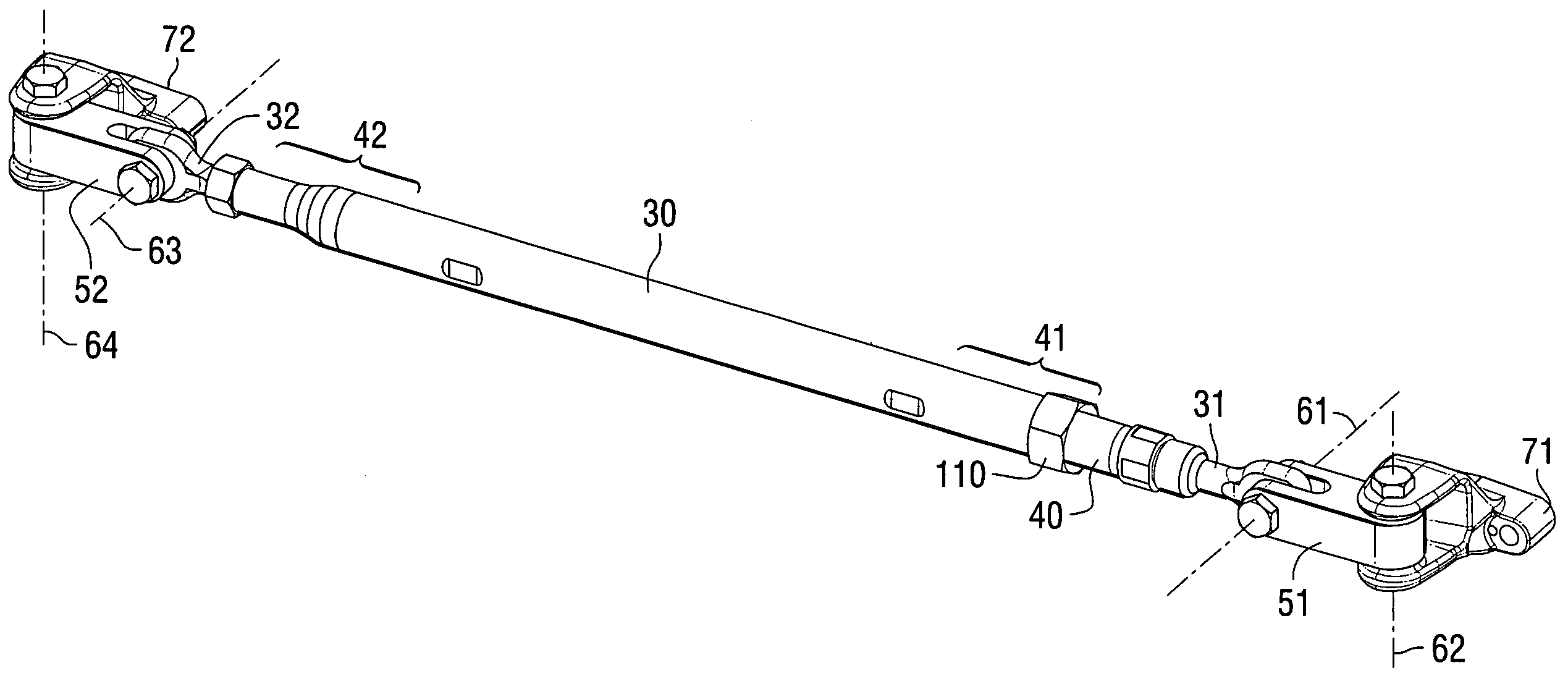

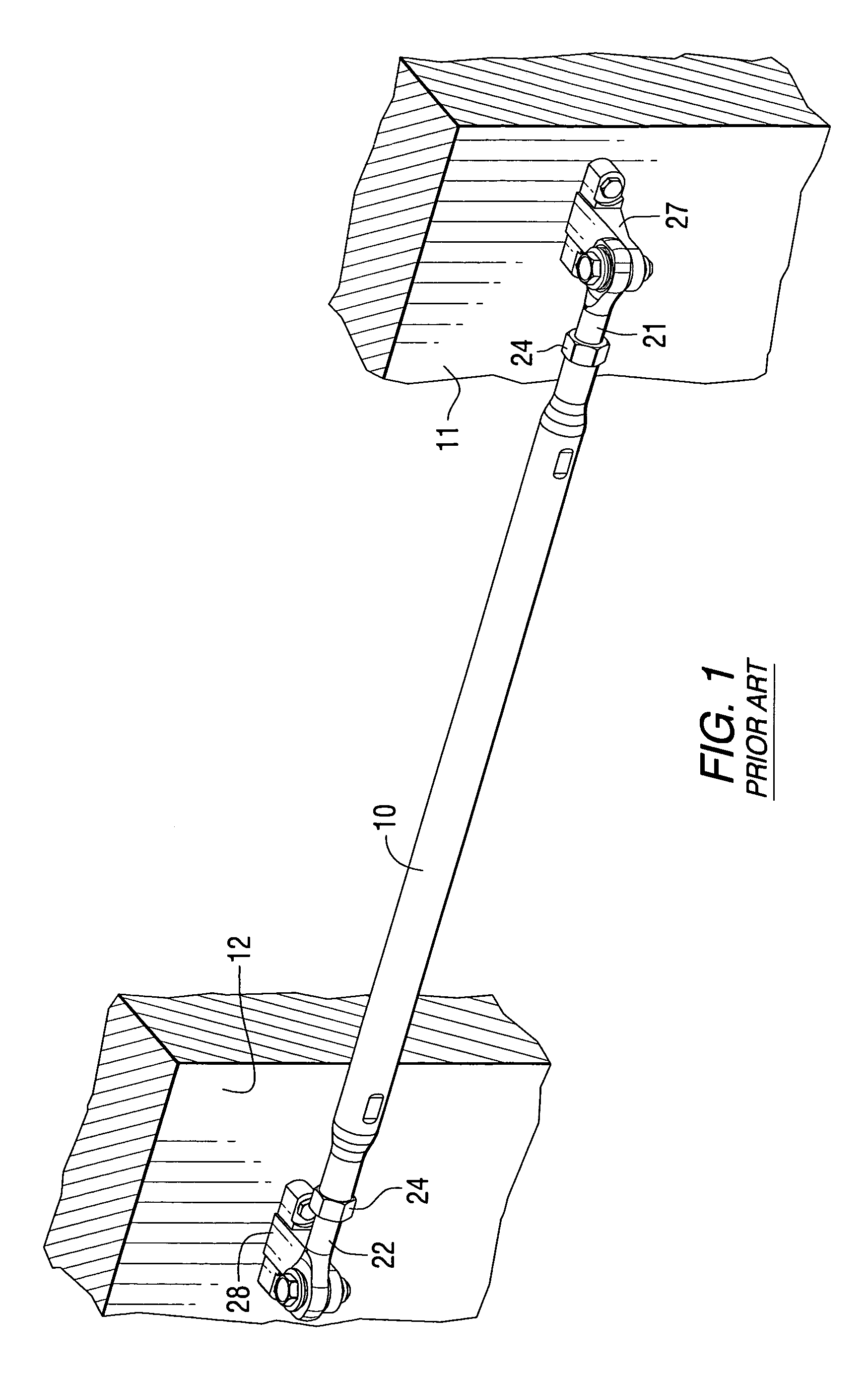

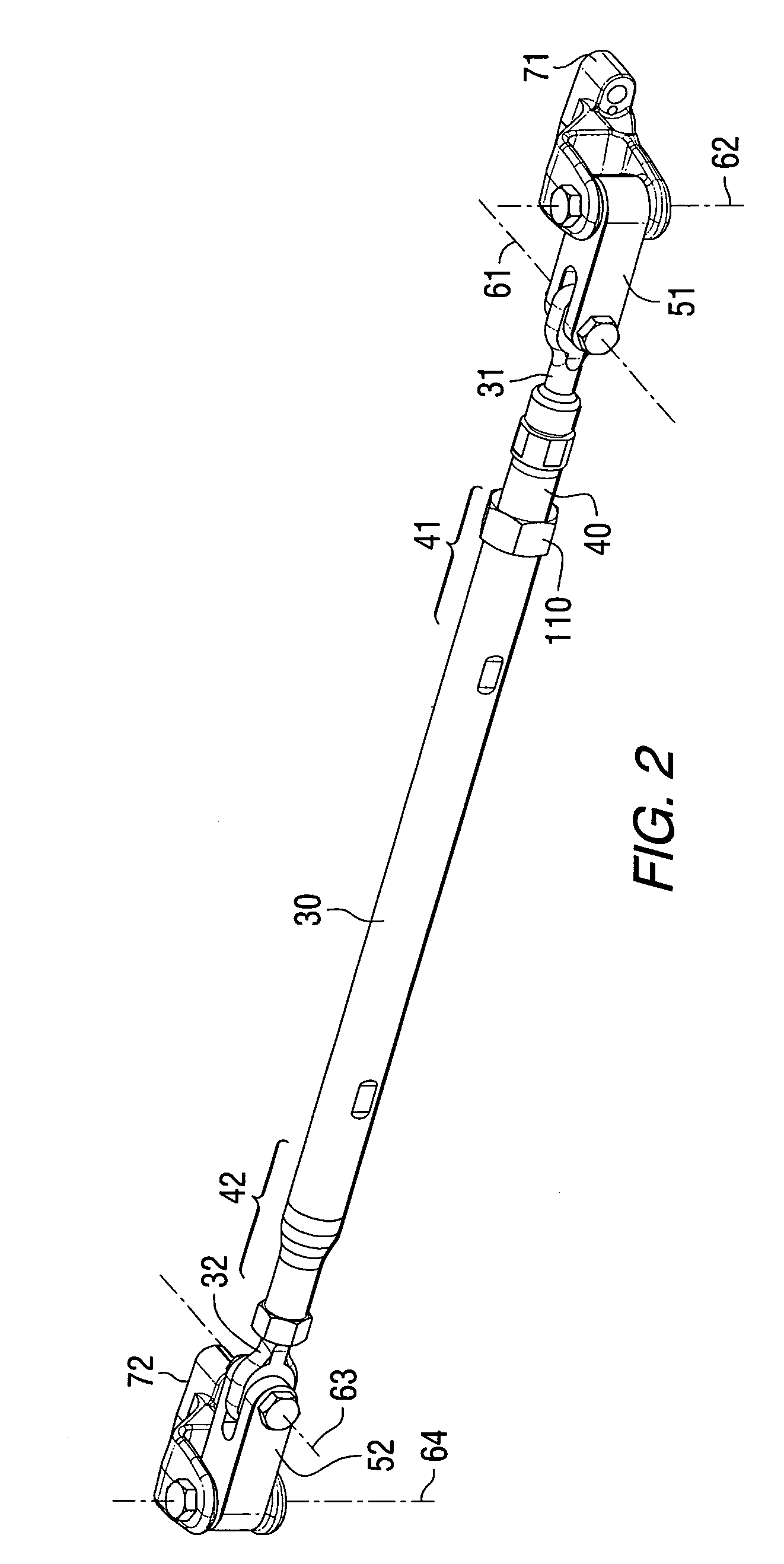

Turnbuckle linkage assembly

InactiveUS6902341B1Significant translationControlling membersConnecting rodsInterference fitEngineering

A turnbuckle linkage assembly is provided for transmitting a force between first and second locations in a machine. The assembly includes a first link for connecting to the first location such as a rod, tube or cable, a second link for connecting to the second location, and a turnbuckle. A first, threaded connection connects the turnbuckle to the first link, and a second connection connects the turnbuckle to the second link. The second connection and the second link are arranged along an axis, and an interference fit at the second connection is formed by the turnbuckle and the second link permitting the turnbuckle to rotate relative to the second link but axially affixing the turnbuckle to the second link.

Owner:MIDWEST CONTROL PROD

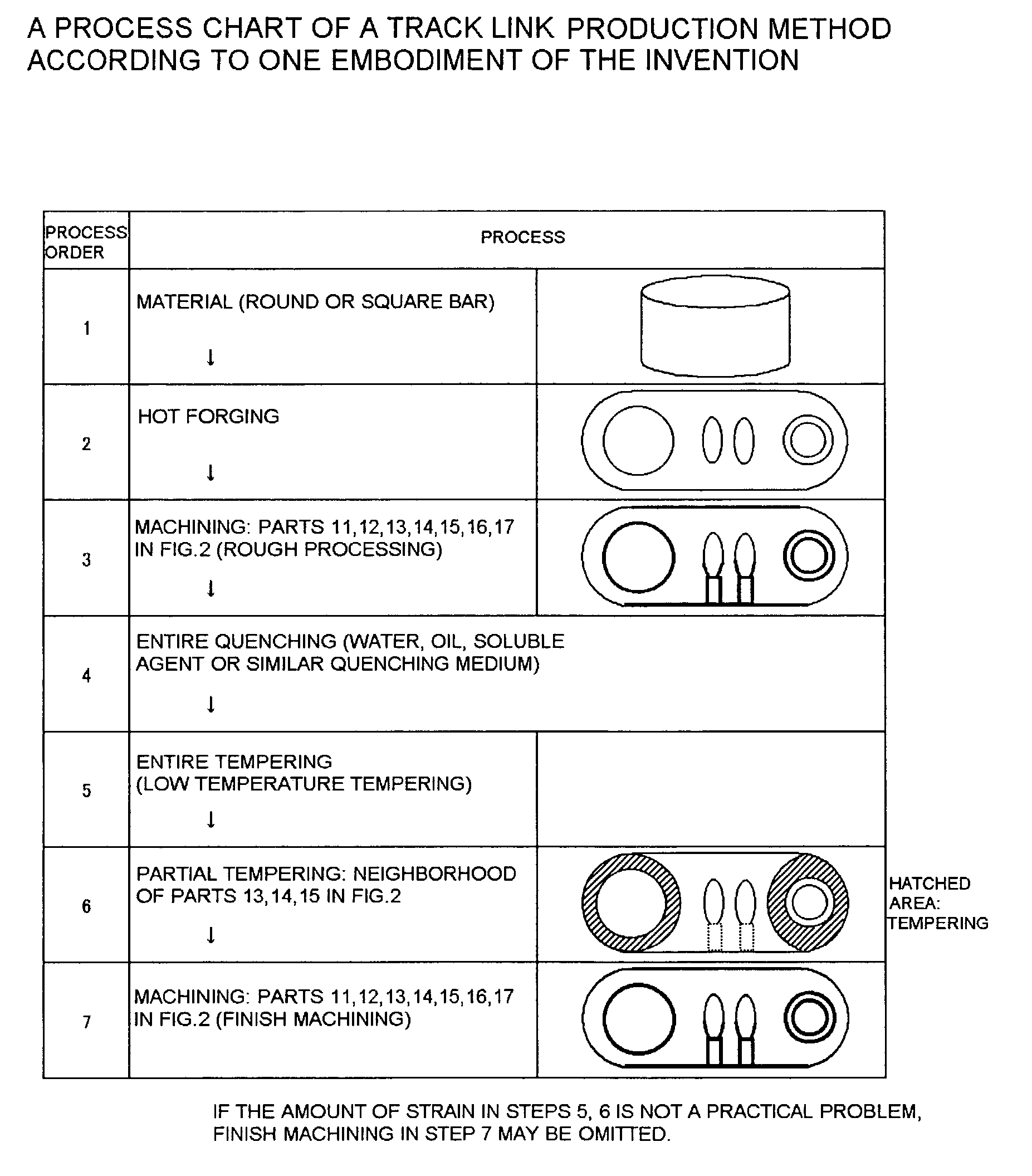

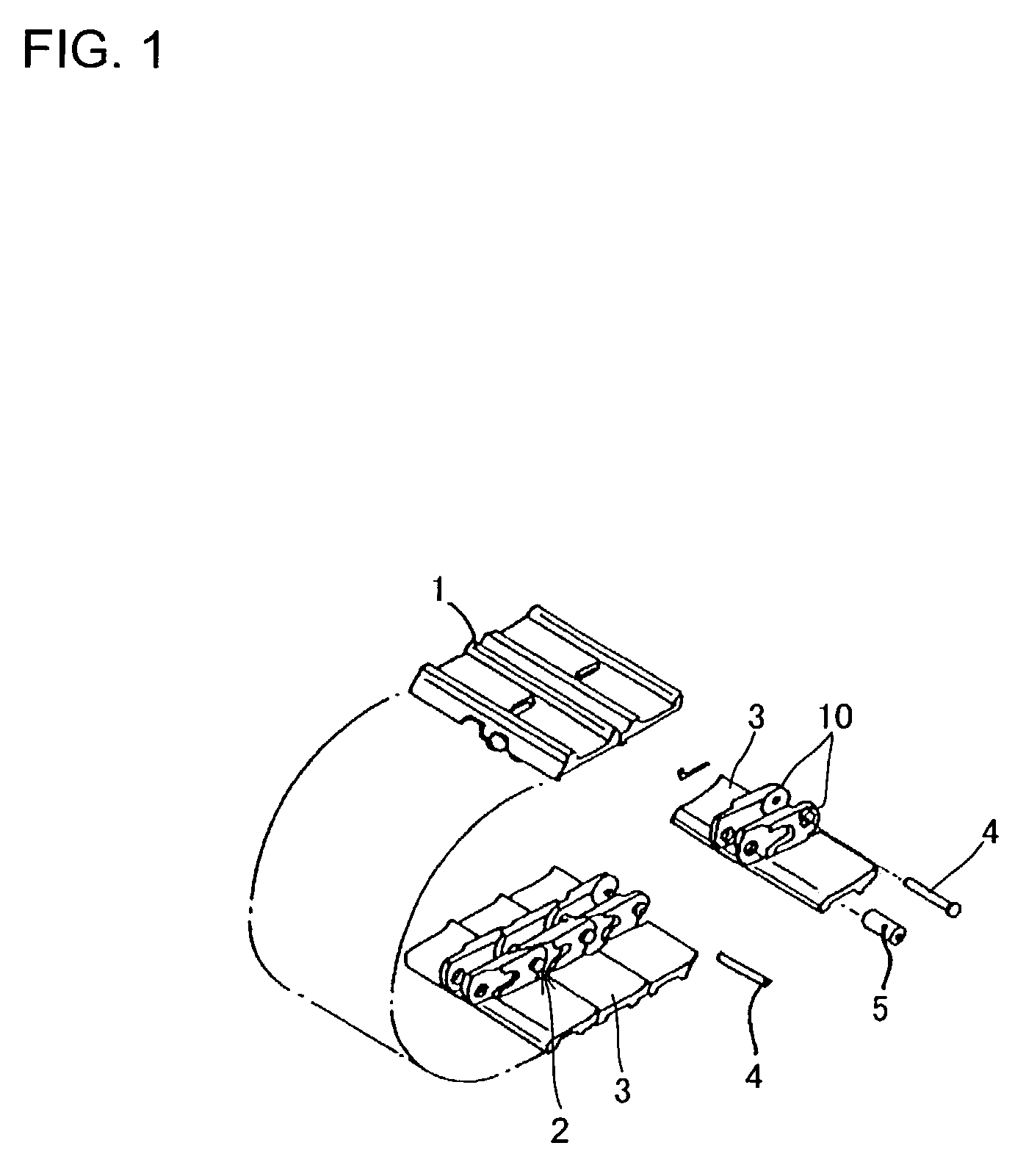

Track link production method and track link produced by the same

InactiveUS7040080B2Delayed failureIncrease pressureConnecting rodsMetal-working apparatusHigh dimensionalMachining process

There are proposed a track link production method capable of providing markedly improved wear life with good cost performance and a track link produced by this method. To this end, the track link production method includes a heat treatment process (Steps 4, 5) of applying quenching and low temperature tempering treatment to a whole link material after hot forging (Step 2), and is designed such that desired machining is applied to the link material (Step 3) before the heat treatment process (Steps 4, 5) and such that after the heat treatment process (Steps 4, 5), tempering (Step 6) and finish machining (Step 7) are sequentially applied to some of the parts which have undergone the machining process, the some parts including at least parts where high dimensional accuracy is required.

Owner:KOMATSU LTD

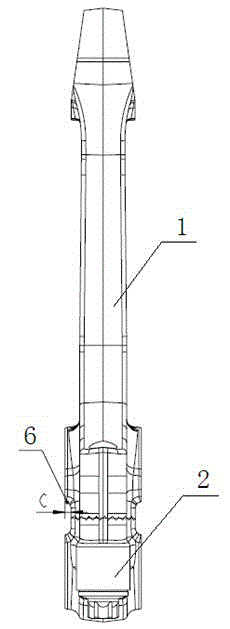

Pump crosshead and connecting rod assembly

ActiveUS7610847B2Increase surface areaBearing stressConnecting rodsPositive displacement pump componentsEngineeringMechanical engineering

A crosshead and connecting rod assembly for a pump comprises a connecting rod which includes a first end that is rotatably connected to the crankshaft of the pump, a second end that comprises a generally cylindrical configuration, and a shaft that extends between the first and second ends. The second end comprises at least one annular shoulder adjacent to the shaft, and the crosshead and connecting rod assembly further comprises a crosshead which includes a body that comprises a generally semi-cylindrical socket within which the second end is rotatably received and at least one trunnion that comprises a generally semi-cylindrical recess which aligns with the socket and within which the shoulder is rotatably received when the trunnion is connected to the body.

Owner:FMC TECH INC

Self-locking linear adjustment mechanism

Owner:TYLOSKY GORDON

Tubular Composite Strut Having Internal Stiffening and Method for Making the Same

ActiveUS20130112309A1Optimize of structural strength-to-ratioReduce thicknessConnecting rodsWeight reductionBiomedical engineering

Owner:THE BOEING CO

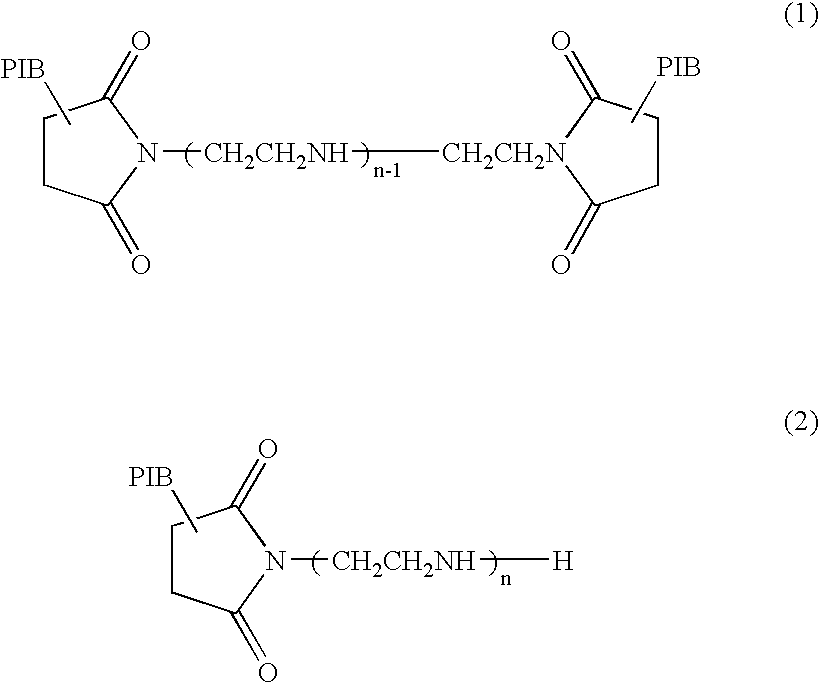

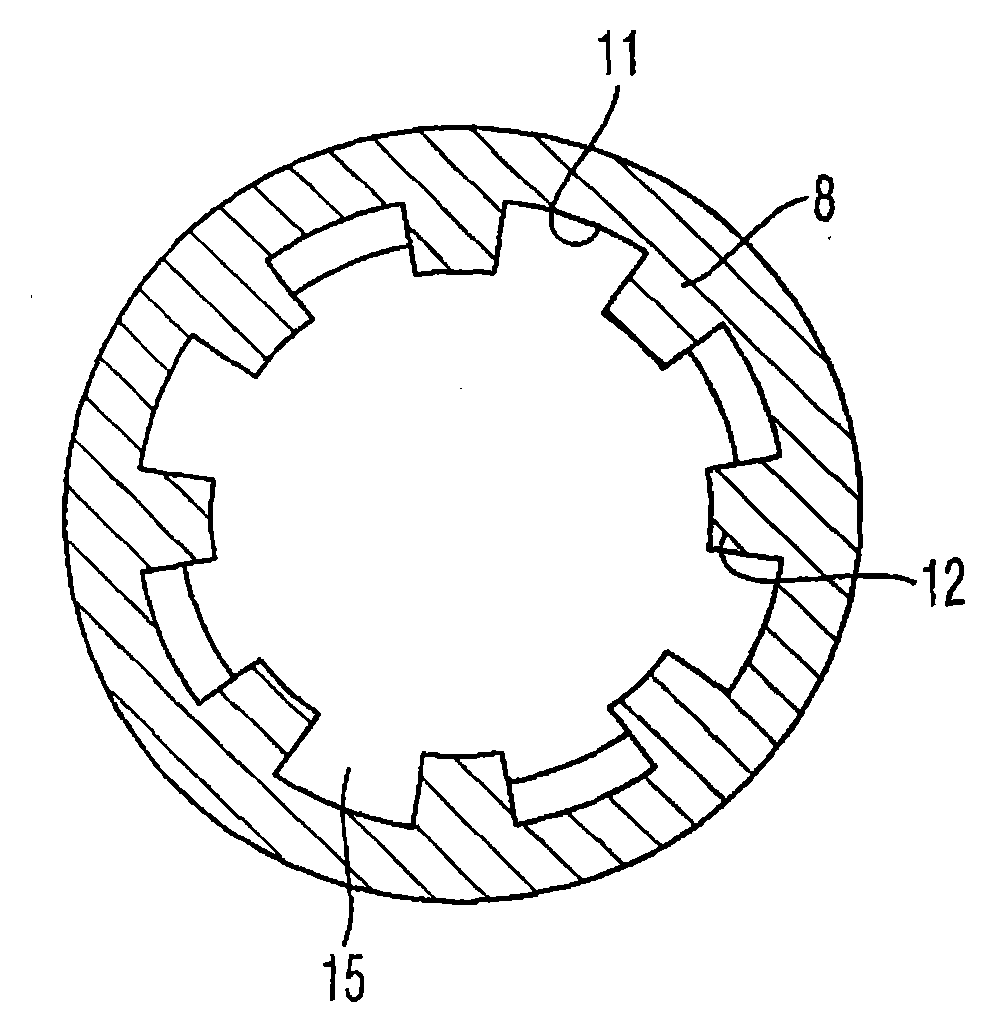

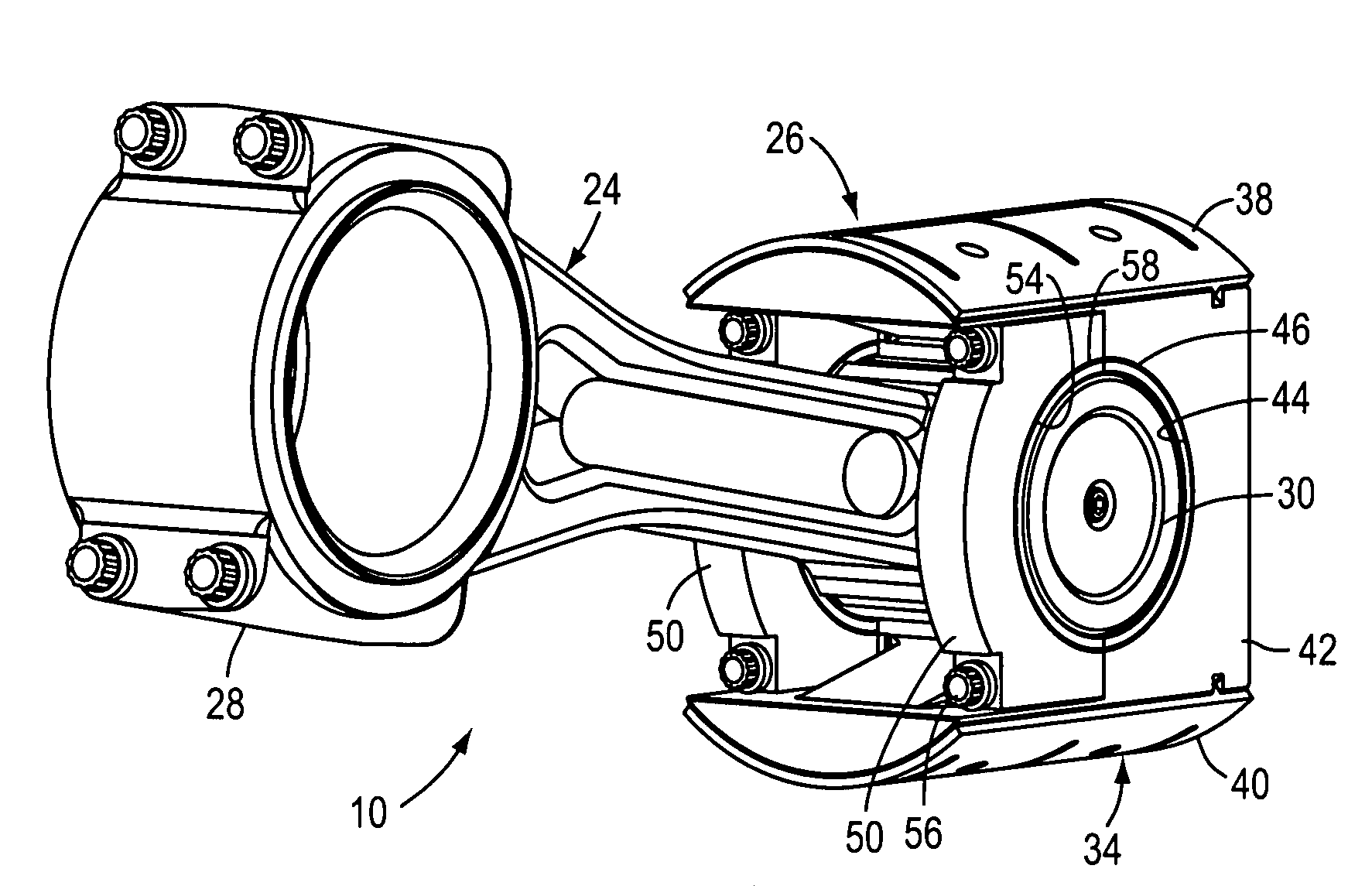

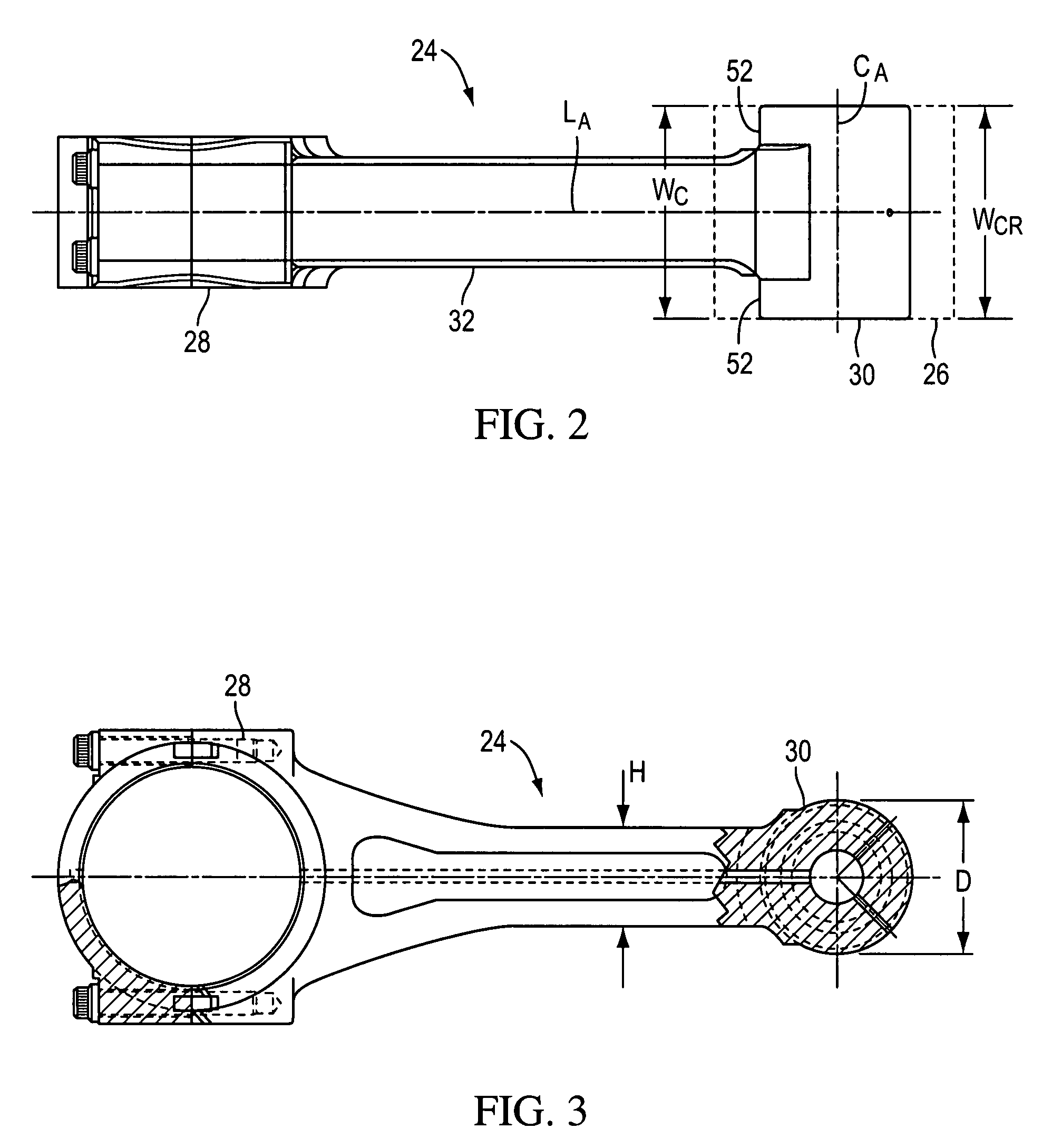

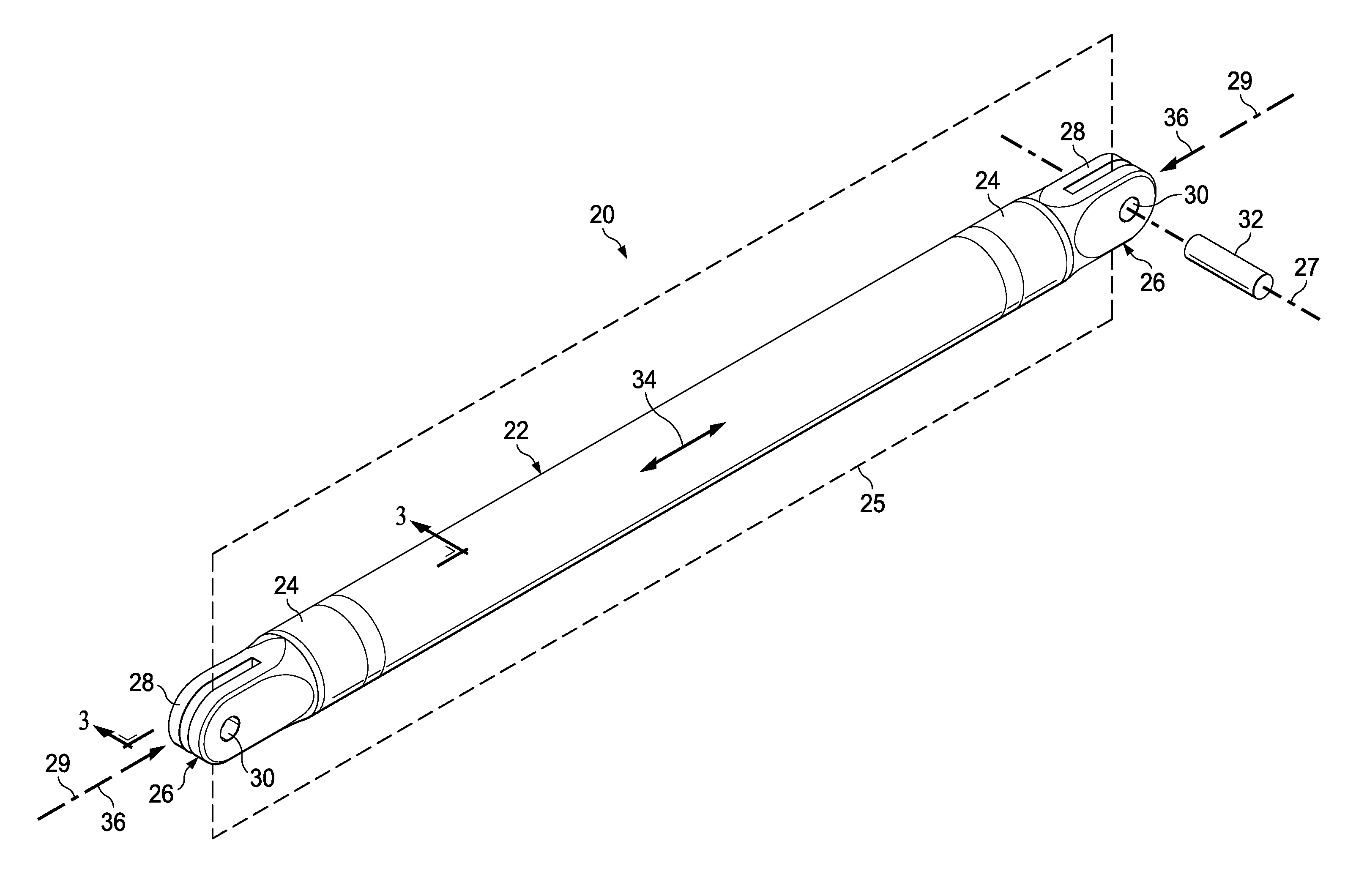

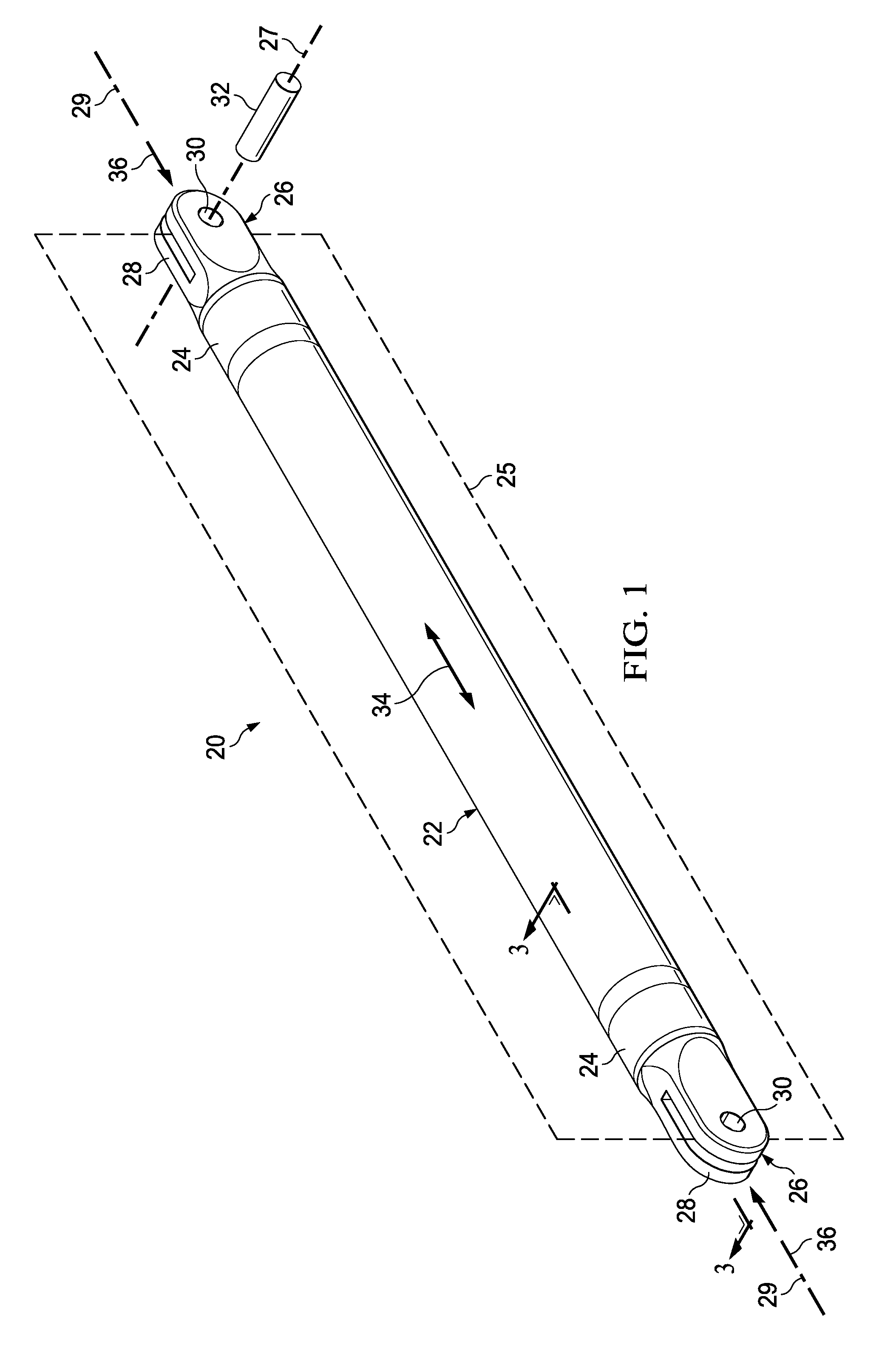

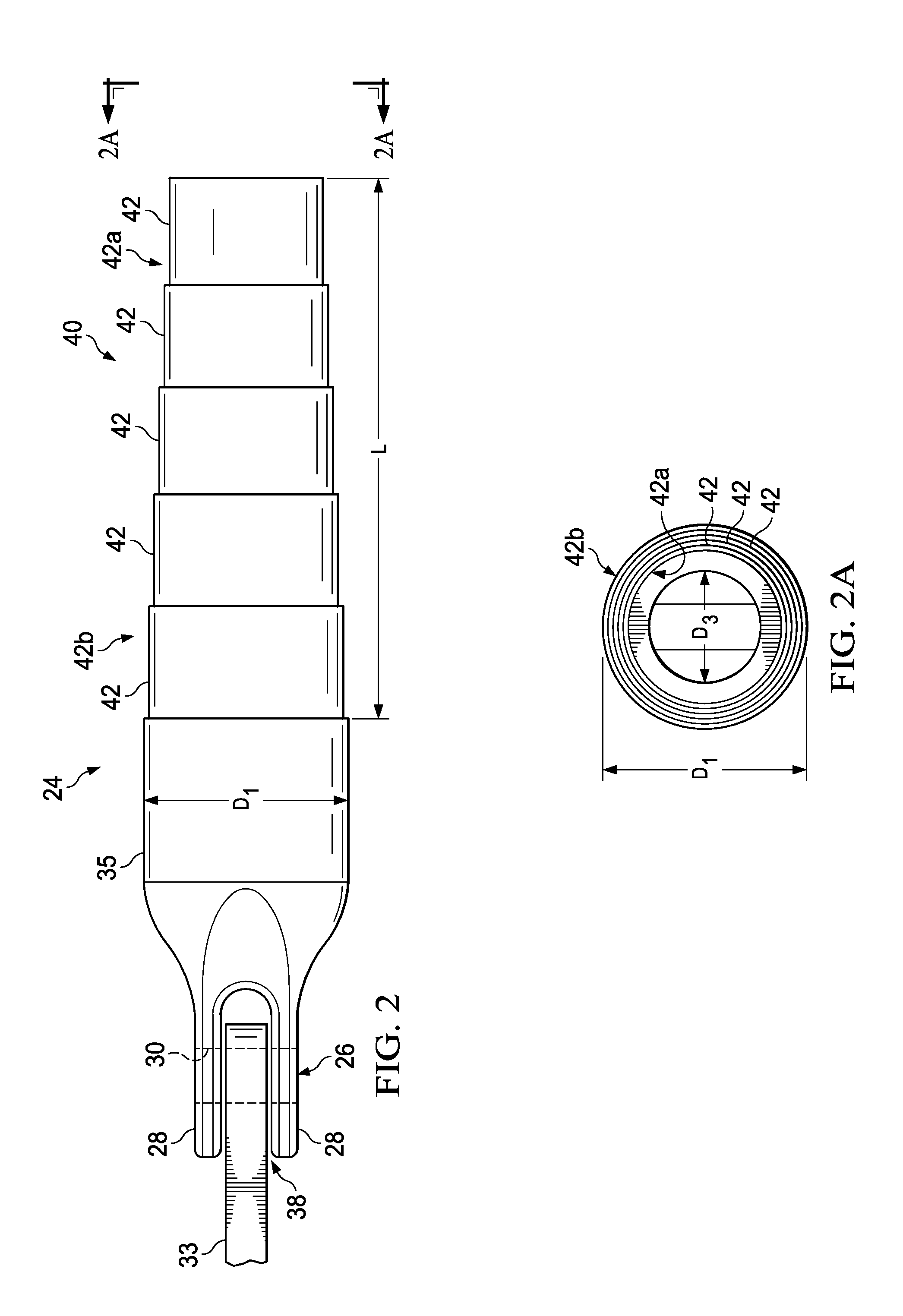

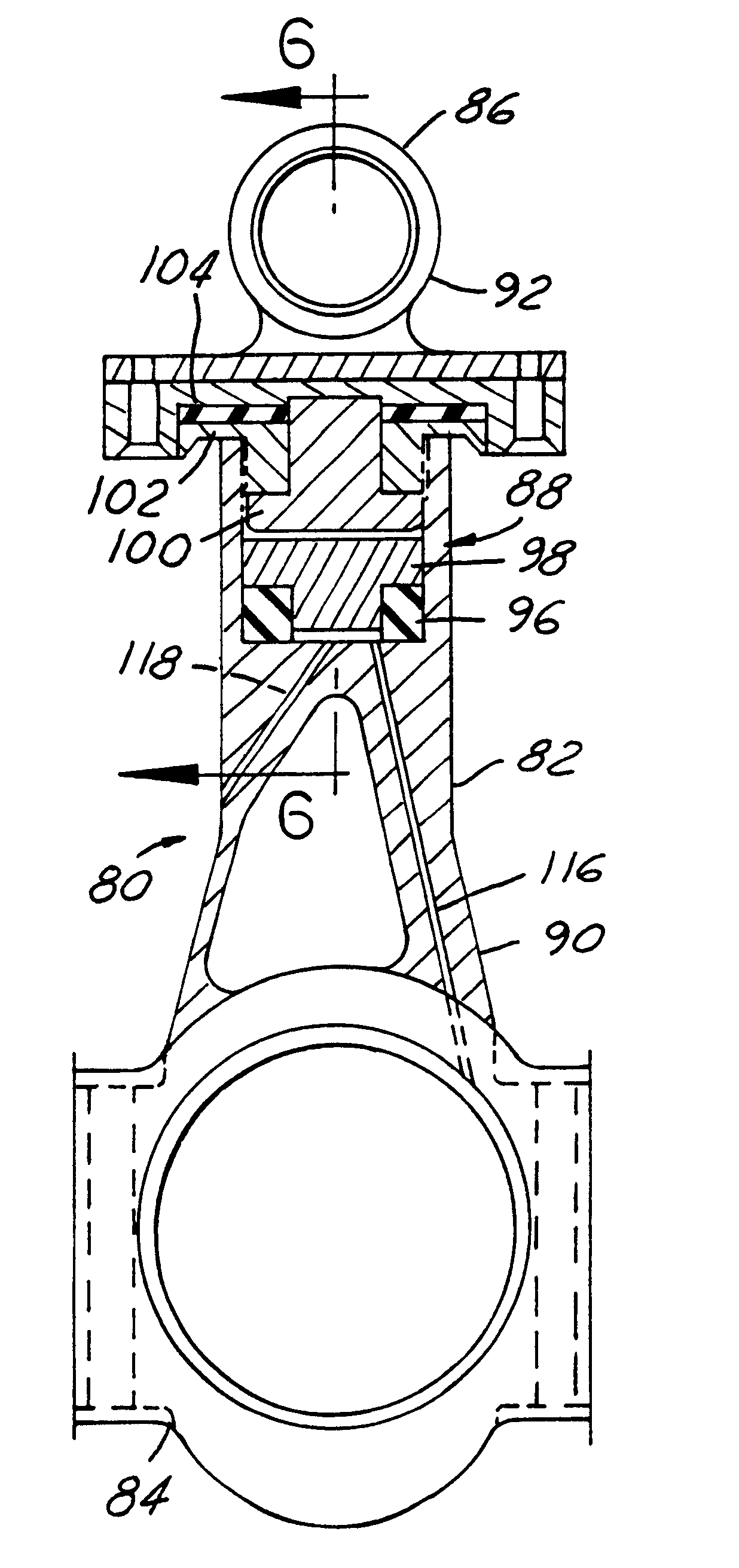

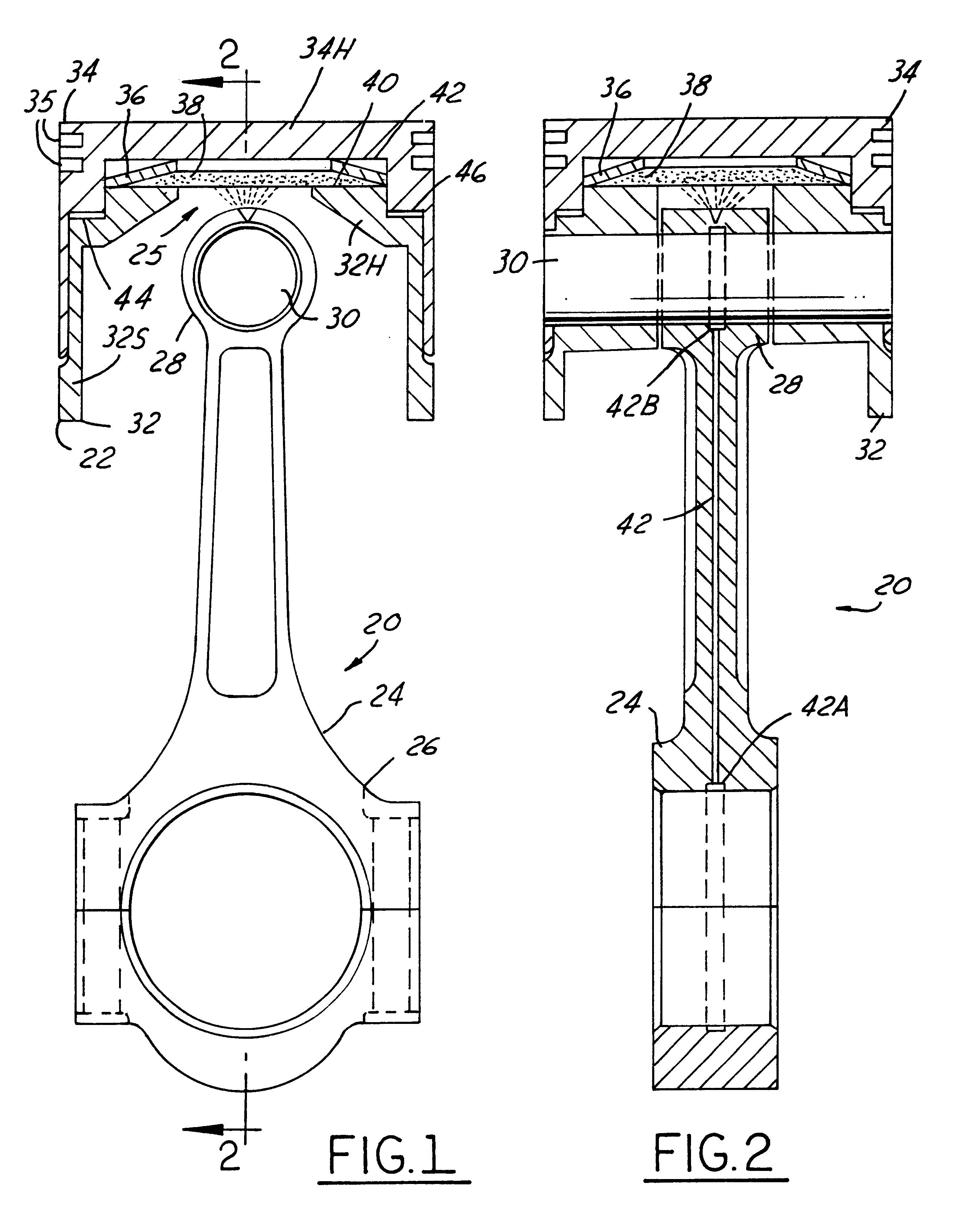

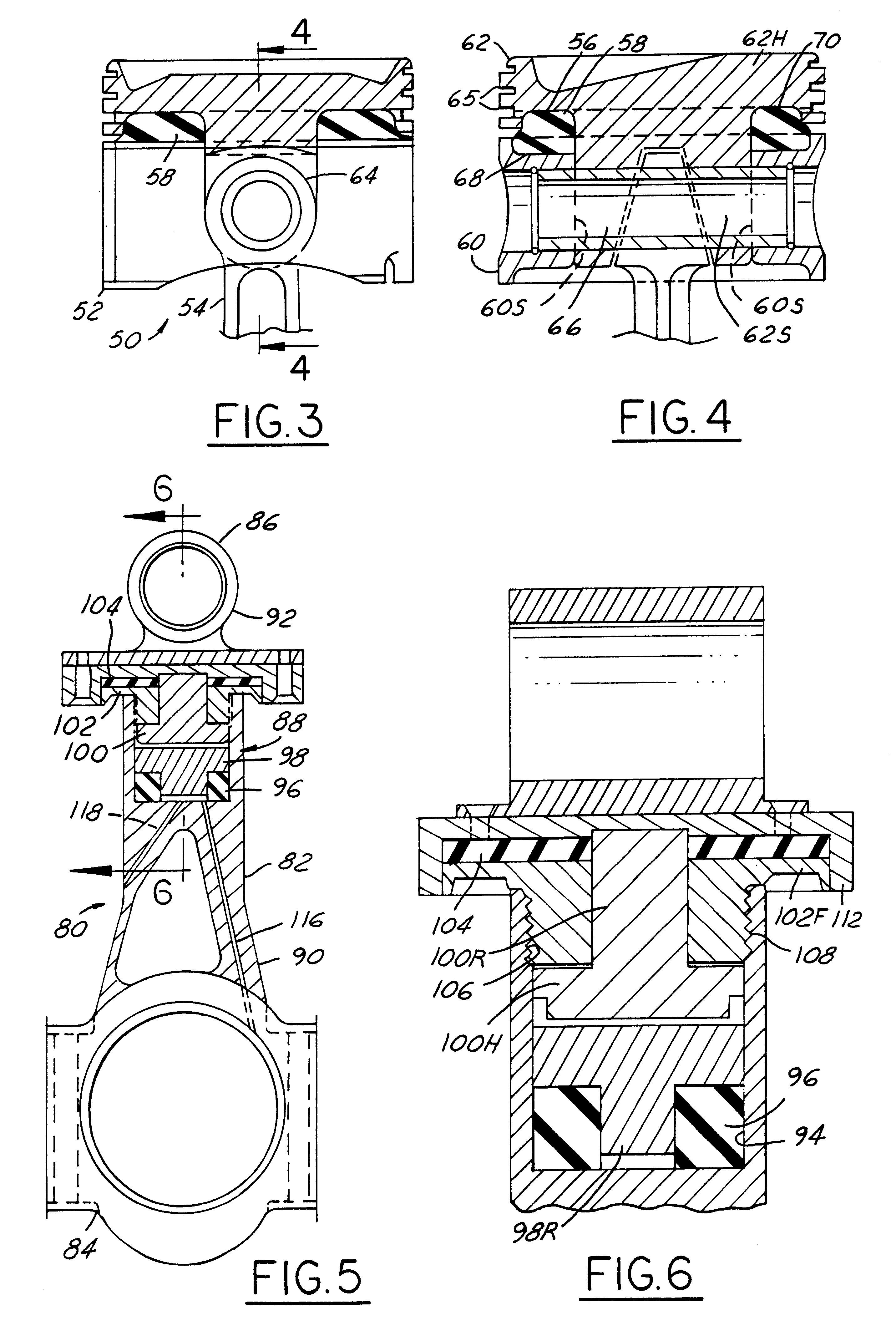

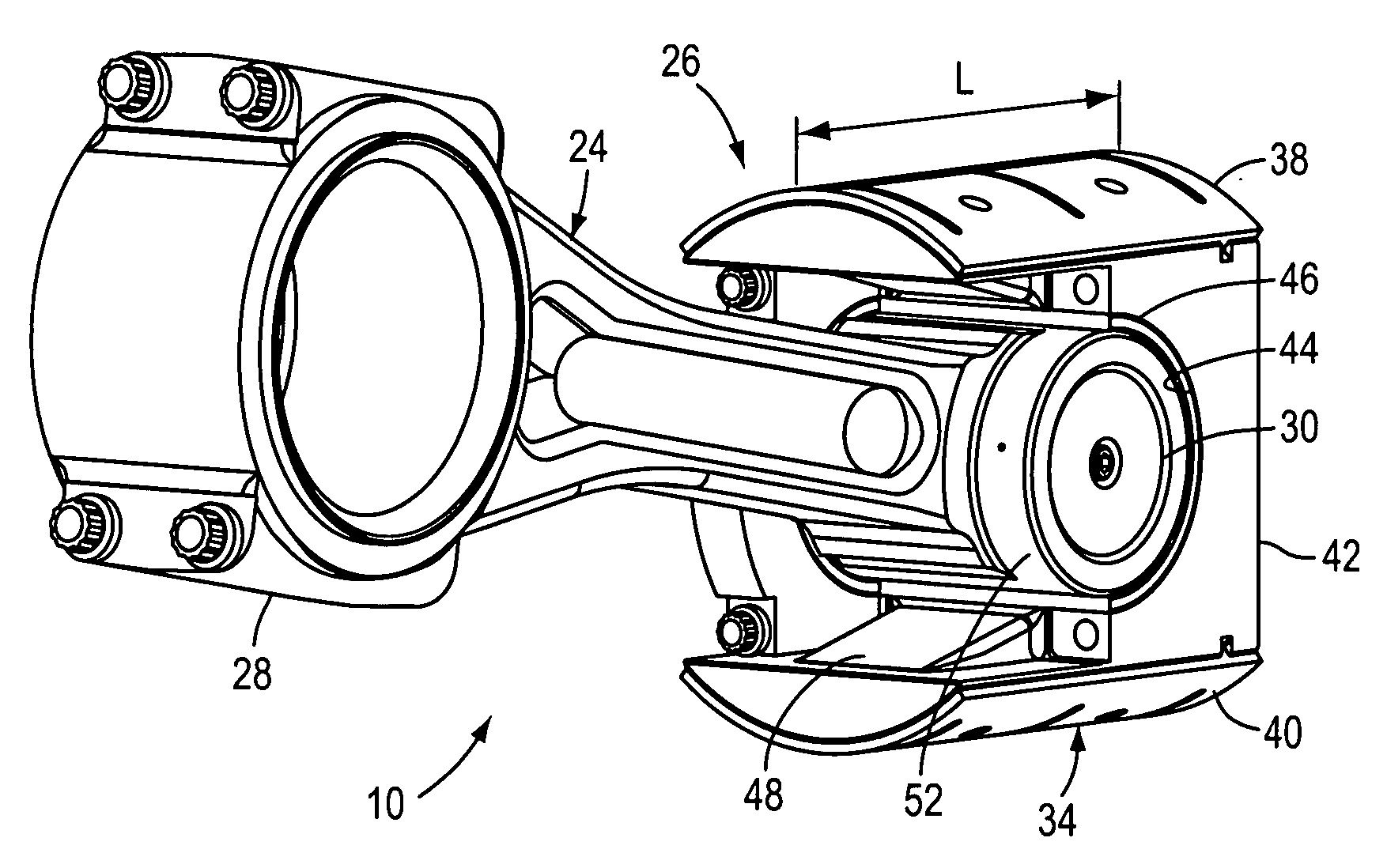

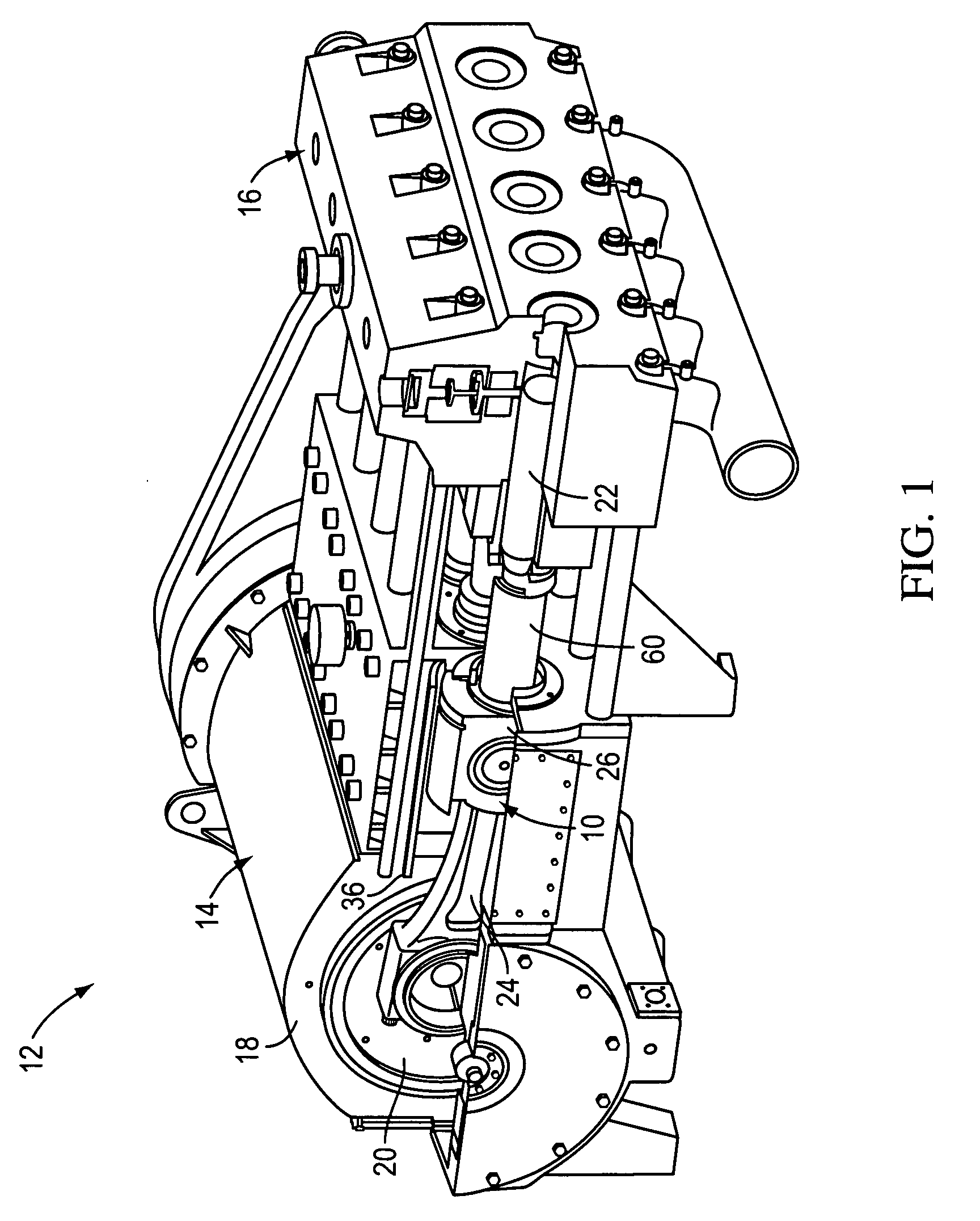

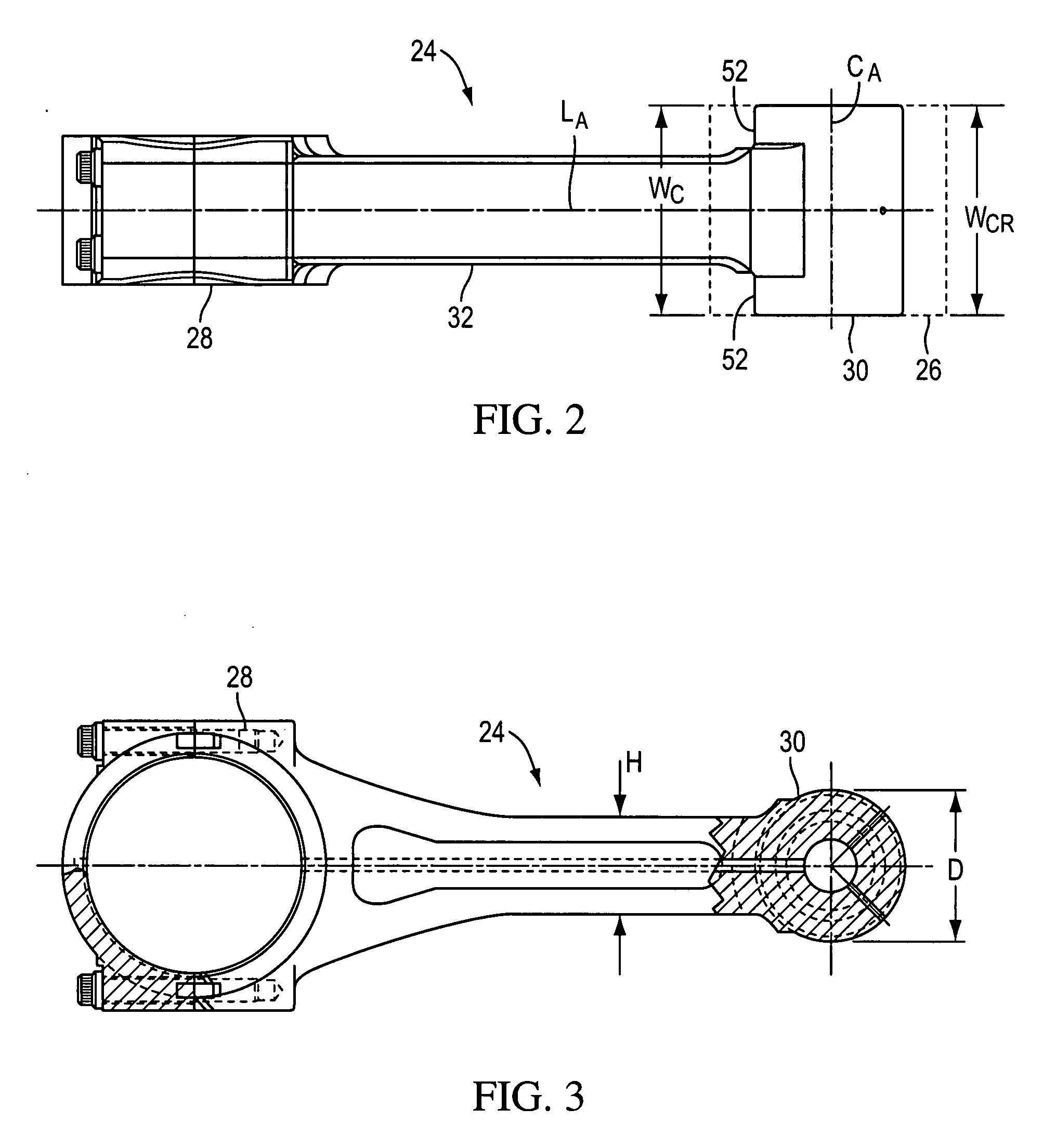

Variable compression ratio pistons and connecting rods

Various embodiments (20; 50; 50; 120) of variable length piston and connecting rod assemblies for imparting a variable compression ratio to an internal combustion engine. The embodiments incorporate novel arrangements of relatively movable parts (32, 34; 60, 62; 84, 86; 124, 126) related by various elastomeric elements (38; 58; 96, 104; 136) and oil passages (42; 116, 118; 140, 142) to change compression ratios.

Owner:FORD GLOBAL TECH LLC

Pump crosshead and connecting rod assembly

ActiveUS20080006148A1Increase surface areaBearing stressConnecting rodsPositive displacement pump componentsEngineeringMechanical engineering

A crosshead and connecting rod assembly for a pump comprises a connecting rod which includes a first end that is rotatably connected to the crankshaft of the pump, a second end that comprises a generally cylindrical configuration, and a shaft that extends between the first and second ends. The second end comprises at least one annular shoulder adjacent to the shaft, and the crosshead and connecting rod assembly further comprises a crosshead which includes a body that comprises a generally semi-cylindrical socket within which the second end is rotatably received and at least one trunnion that comprises a generally semi-cylindrical recess which aligns with the socket and within which the shoulder is rotatably received when the trunnion is connected to the body.

Owner:FMC TECH INC

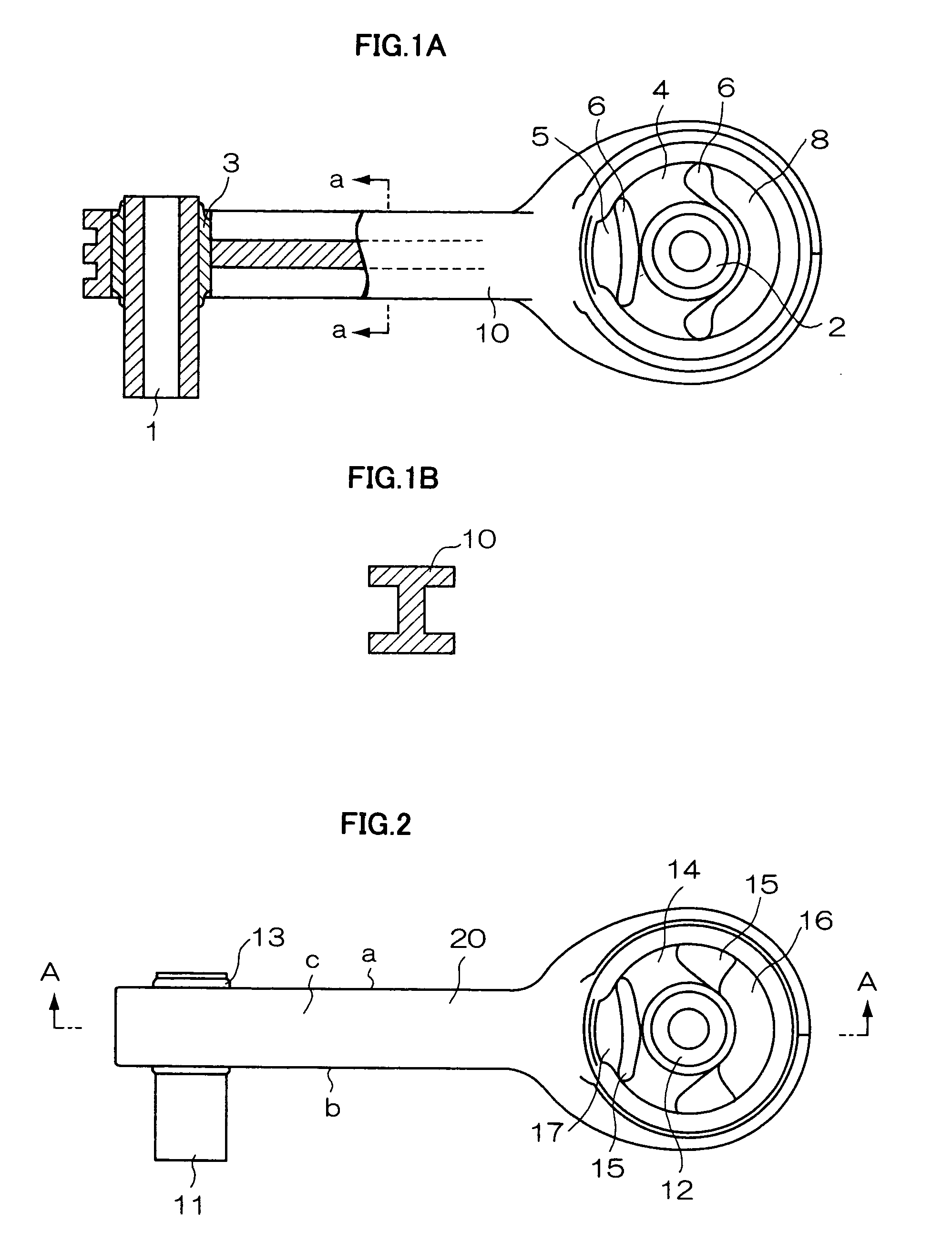

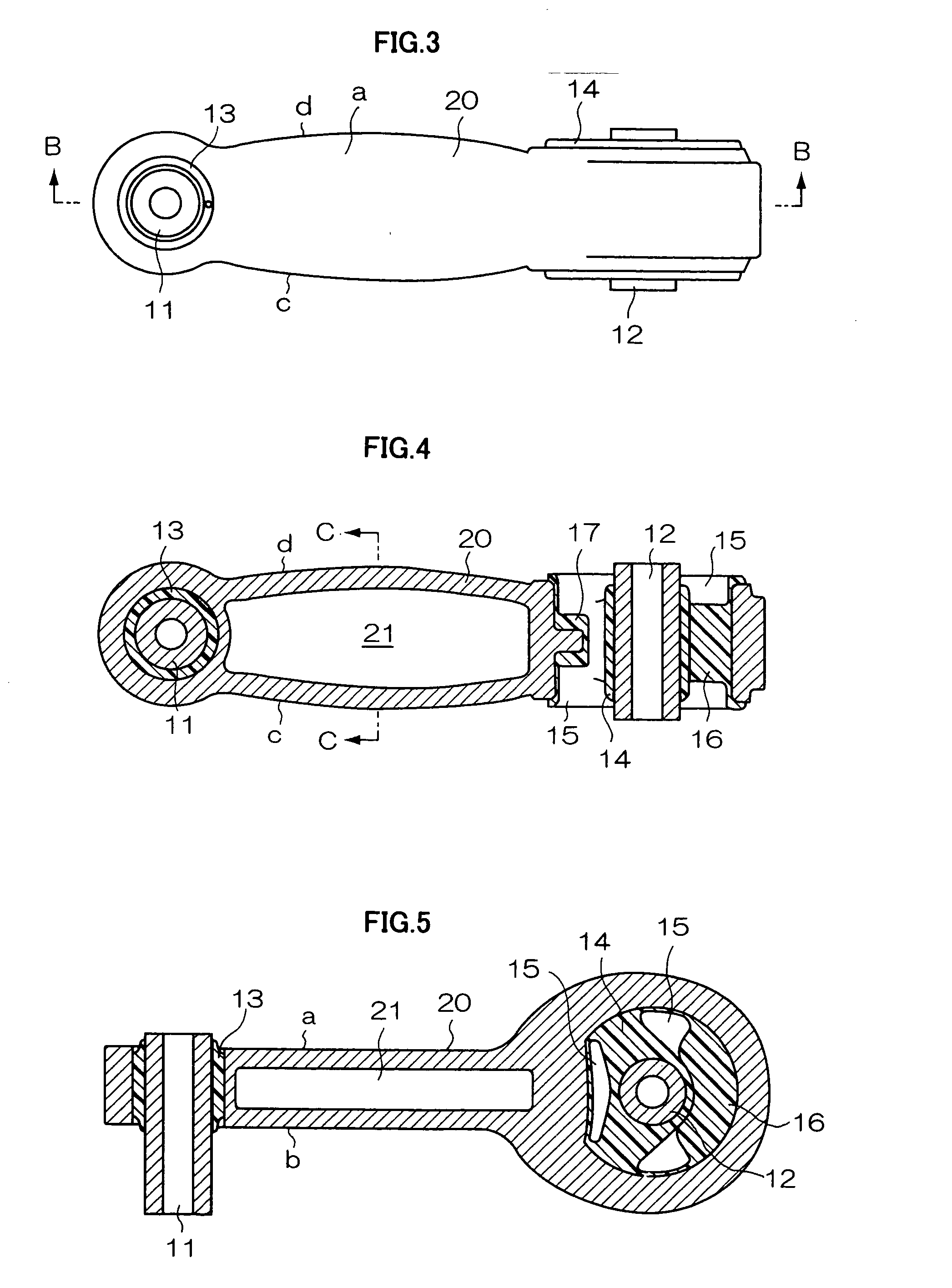

Torque Rod Structure

InactiveUS20070272051A1Increase stiffnessConnecting rod bearingsConnecting rodsEngineeringCompressive strength

Owner:HONDA MOTOR CO LTD

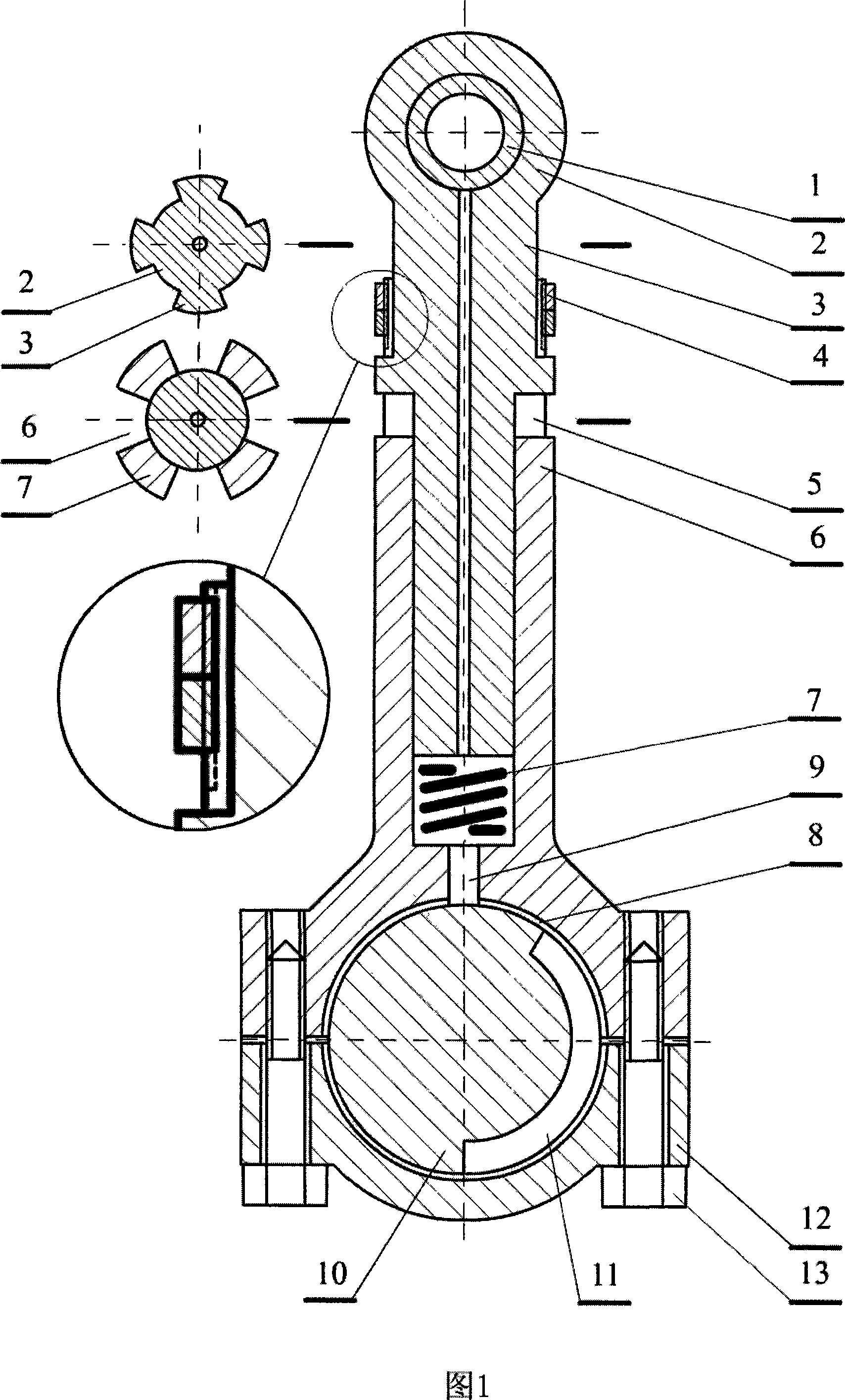

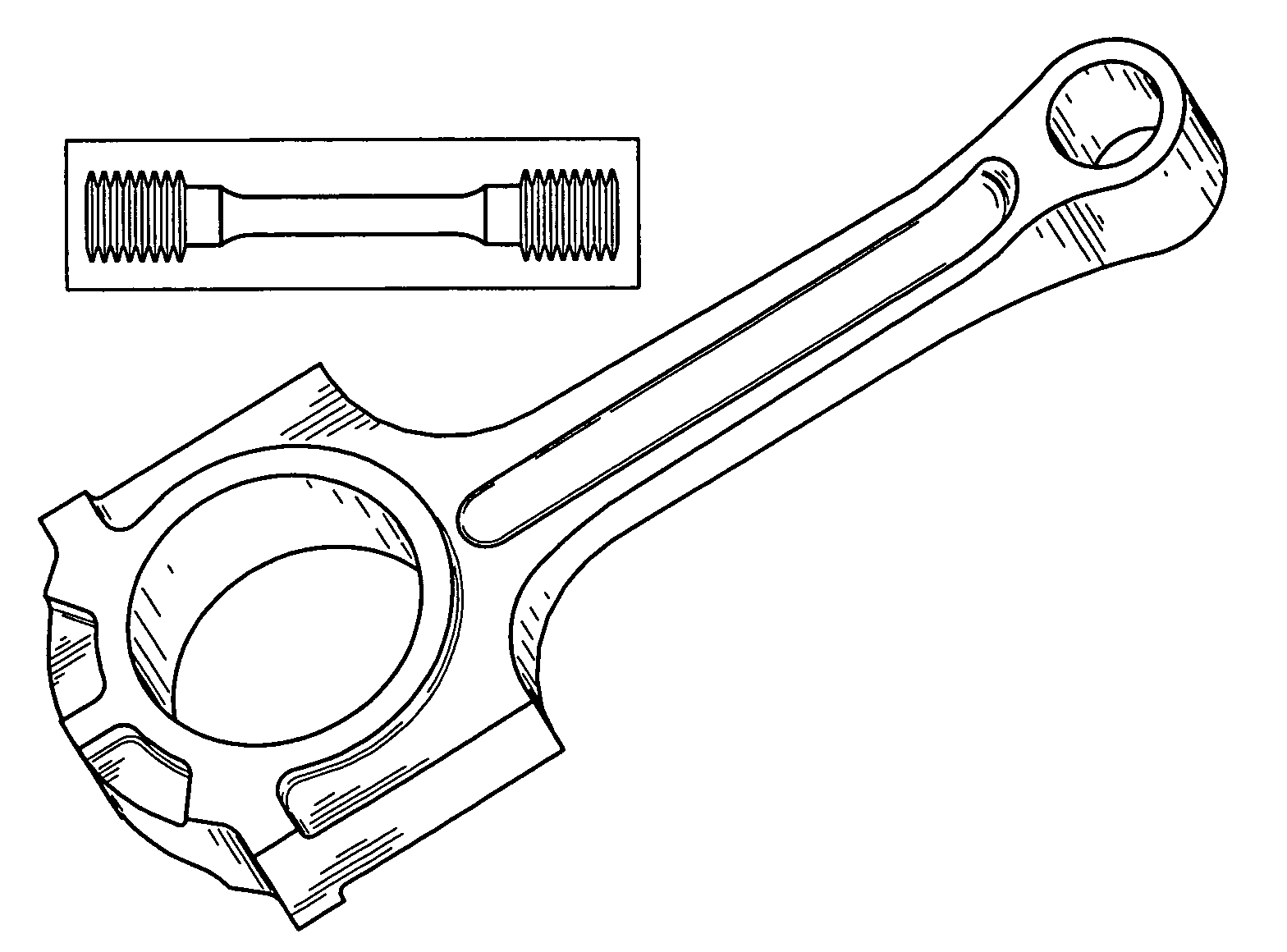

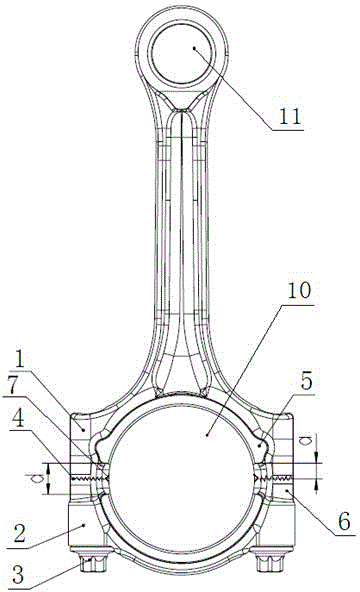

Engine cracking connecting rod and machining method thereof

The invention discloses an engine cracking connecting rod and a machining method of the engine cracking connecting rod. The engine cracking connecting rod comprises a connecting rod body and a connecting rod cover, wherein the connecting rod body is connected with the connecting rod cover in a cracking position of a connecting rod big head through a connecting bolt, U-shaped grooves which are symmetrical relative to a cracking surface are formed in the cracking position of the connecting rod big head, V-shaped splitting grooves are formed in the inner edge, corresponding to the cracking position, of a big head hole of the connecting rod big head, and the V-shaped splitting grooves are symmetrical relative to the cracking surface. The machining method comprises the steps that a forged connecting rod blank with the two symmetrical U-shaped grooves is machined in a rough mode; the connecting rod is cracked into the connecting rod body and the connecting cover; the cracked connecting rod is machined in a fine mode, and a cracking connecting rod finished product is formed. The engine cracking connecting rod and the machining method of the engine cracking connecting rod can lower the cracking difficulty, guarantee the cracking effect, reduce production work procedures, improve reset accuracy after cracking, and guarantee the overall performance of the connecting rod.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

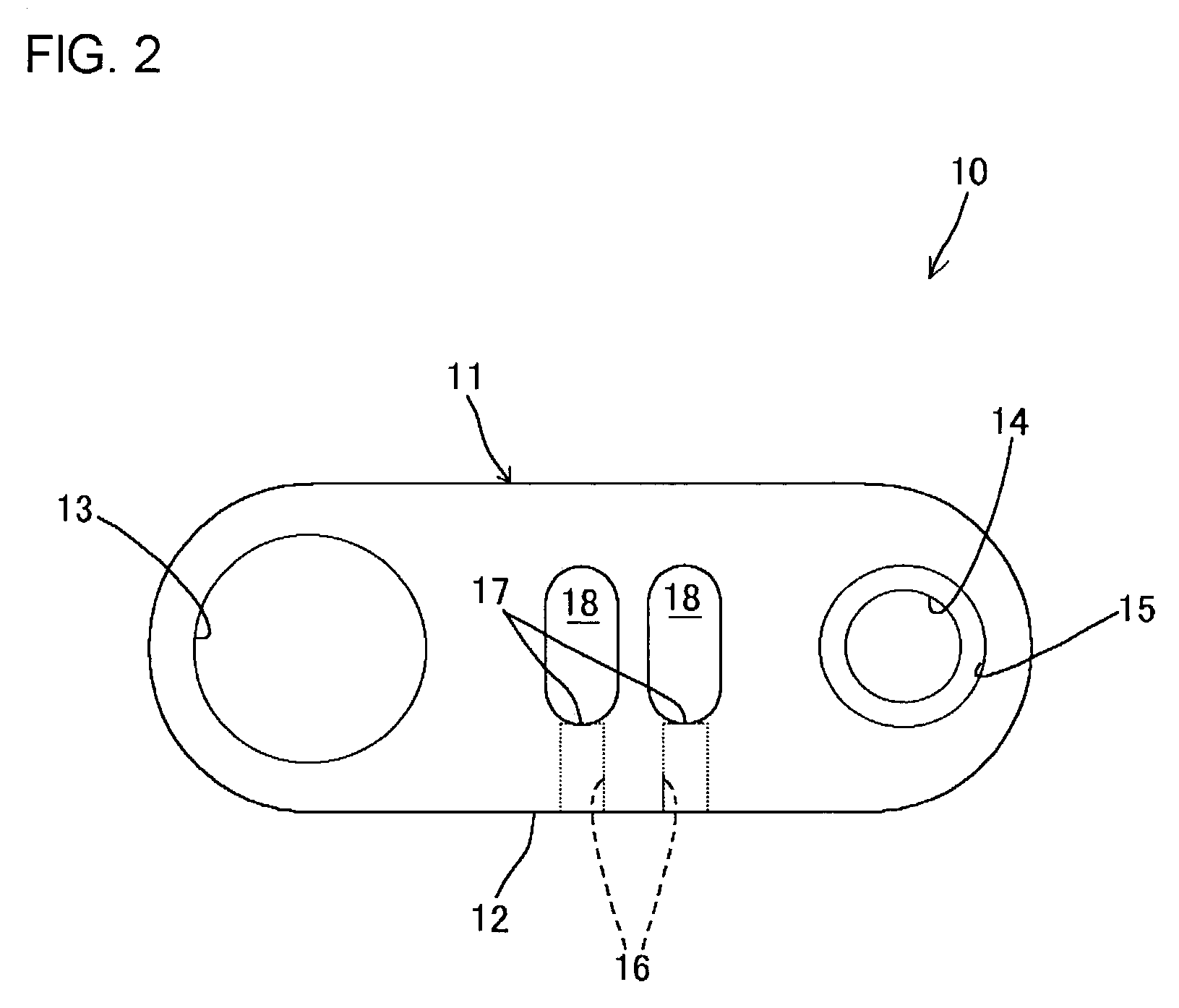

Support structure in crank mechanism and component constituting crank mechanism

InactiveUS7147382B2High strengthSuppressing an increase in rate of secular dimensional changeCrankshaftsConnecting rodsAustenite grainReciprocating motion

A component of a crank mechanism is incorporated in the crank mechanism that converts reciprocating motion of a piston to rotary motion by means of a crank pin, a crank arm and a crank shaft via a connecting bar, and has a hydrogen content of no more than 0.5 ppm, austenite crystal grains of a grain size number exceeding 10, or a fracture stress value of no less than 2650 MPa. Thus, a support structure in and a component of a crank mechanism ensuring a long fatigue life, high anti-crack strength, and a reduced rate of secular dimensional change to improve dimensional stability, can be obtained.

Owner:NTN CORP

Connection system for two or more marine propulsion devices

A tie bar arrangement uses a rod end cartridge assembly that provides relative rotatability between an associated rod end and a coupler tube. The provision of a connecting link and steering arm adapter associated with the rod end cartridge assembly also provides relative rotation about first and second axes which allow sufficient flexibility to avoid placing the tie bar arrangement under excessive stress when one marine propulsion device is tilted relative to another marine propulsion device.

Owner:BRUNSWICK CORPORATION

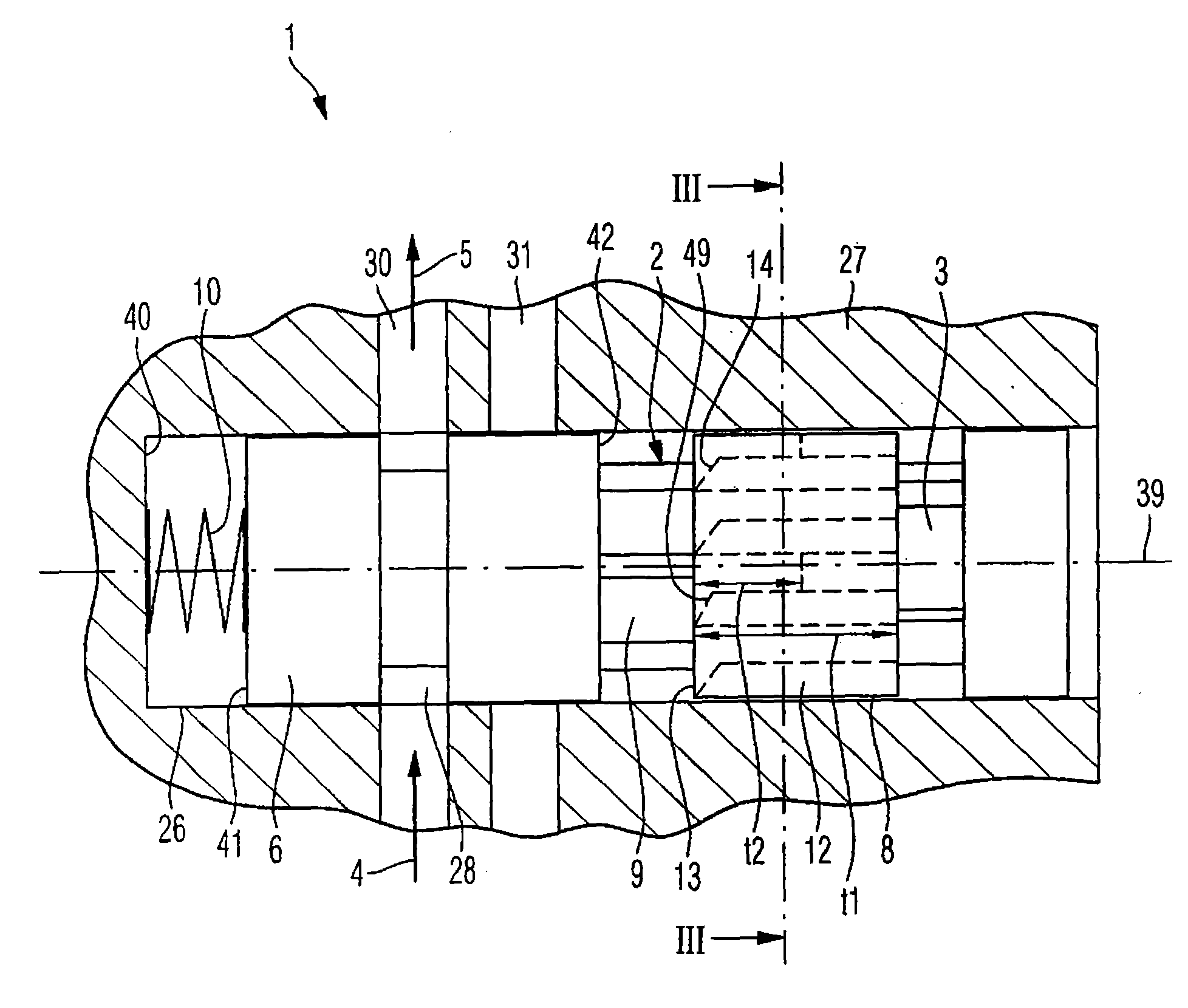

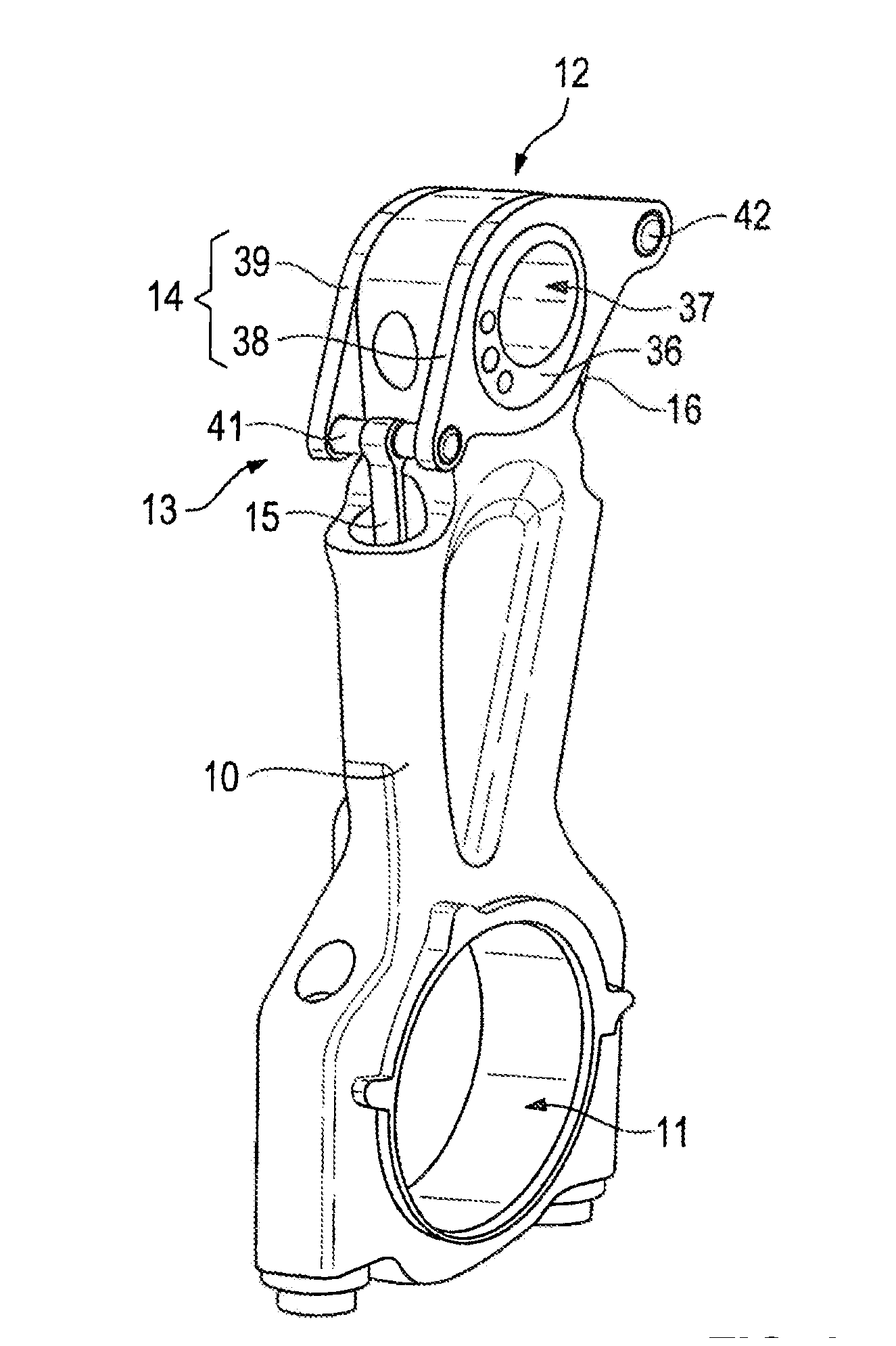

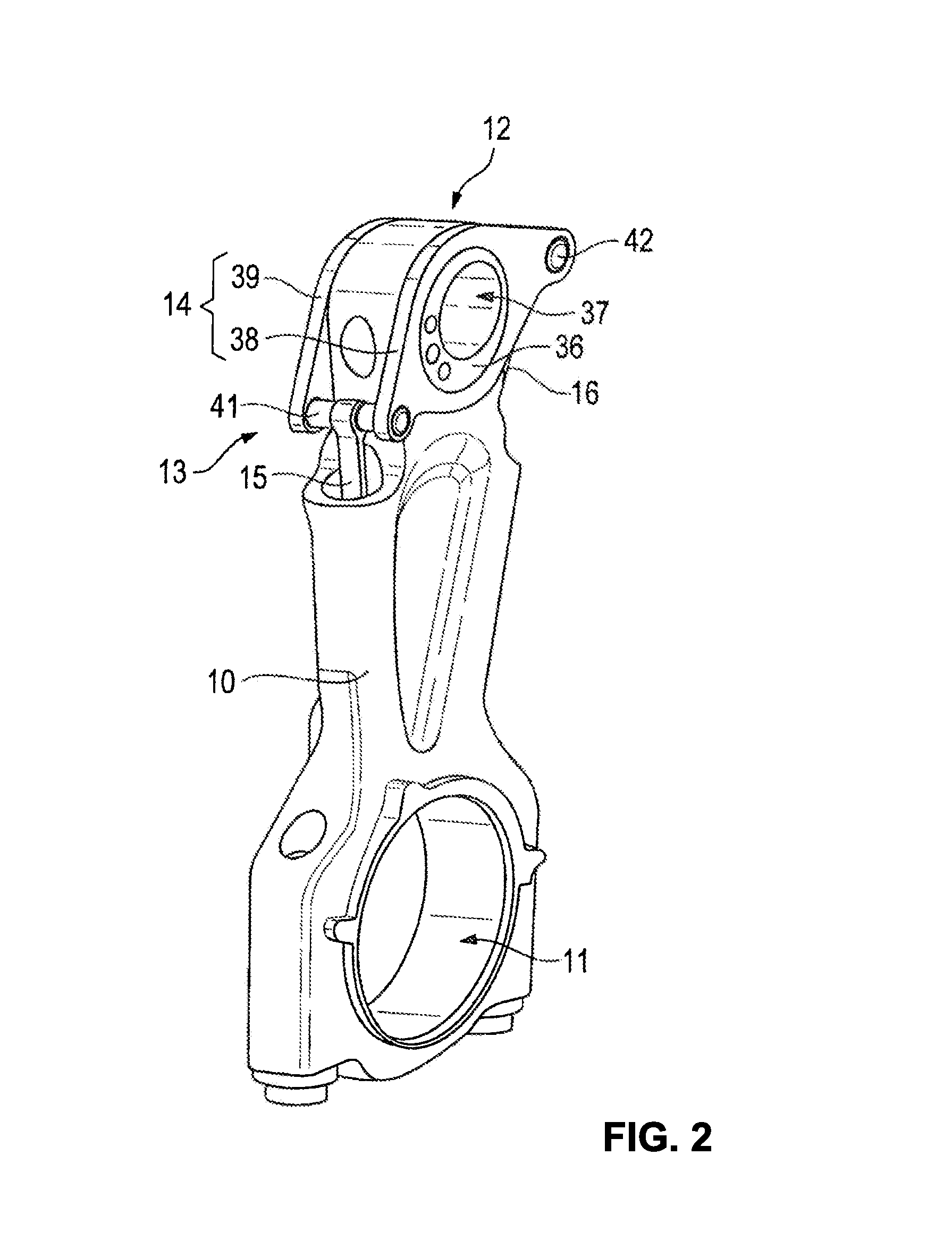

Internal combustion engine and connecting rod

ActiveUS20150059683A1Reduce productionReduce assembly complexityRotary bearingsConnecting rod bearingsExternal combustion engineEngineering

An internal combustion engine with adjustable compression ratio with a connecting rod bearing eye for connecting to a piston of the at least one cylinder and an eccentrical element adjustment device for adjusting an effective connecting rod length, and wherein the eccentrical element adjustment device includes an eccentrical element cooperating with an eccentrical element lever and eccentrical element rods engaging the eccentrical element lever, wherein the eccentrical element rods are loaded with a hydraulic pressure that is provided in hydraulic cavities interacting with the eccentrical element rods, wherein the eccentrical element lever includes at least one eccentrical element lever segment, wherein the at least one eccentrical element lever segment is positioned in axial direction of the eccentrical element in front and / or behind the connecting rod bearing eye, and wherein the at least one eccentrical element lever segment is fixated at the eccentrical element.

Owner:HILITE GERMANY +1

Vehicle suspension control arm and method

InactiveUS7506444B2High strengthLow costControlling membersConnecting rodsControl armMechanical engineering

A control arm for vehicle suspension systems has first and second rigid arm plates having first and second apertures extend laterally through opposing faces of the body adjacent opposite ends thereof. The arm plates are disposed in a mutually parallel, laterally spaced apart and aligned relationship. The first apertures are generally concentric and the second apertures are generally concentric. First and second spacers each have a rigid body with opposite ends and a central bushing aperture extending therebetween. The spacers are disposed between the arm plates adjacent opposite ends thereof. The central bushing aperture of the spacers is positioned generally concentrically with the apertures. Also included is a related method for making vehicle suspension links from ultra high strength steel.

Owner:BENTELER AUTOMOTIVE CORP

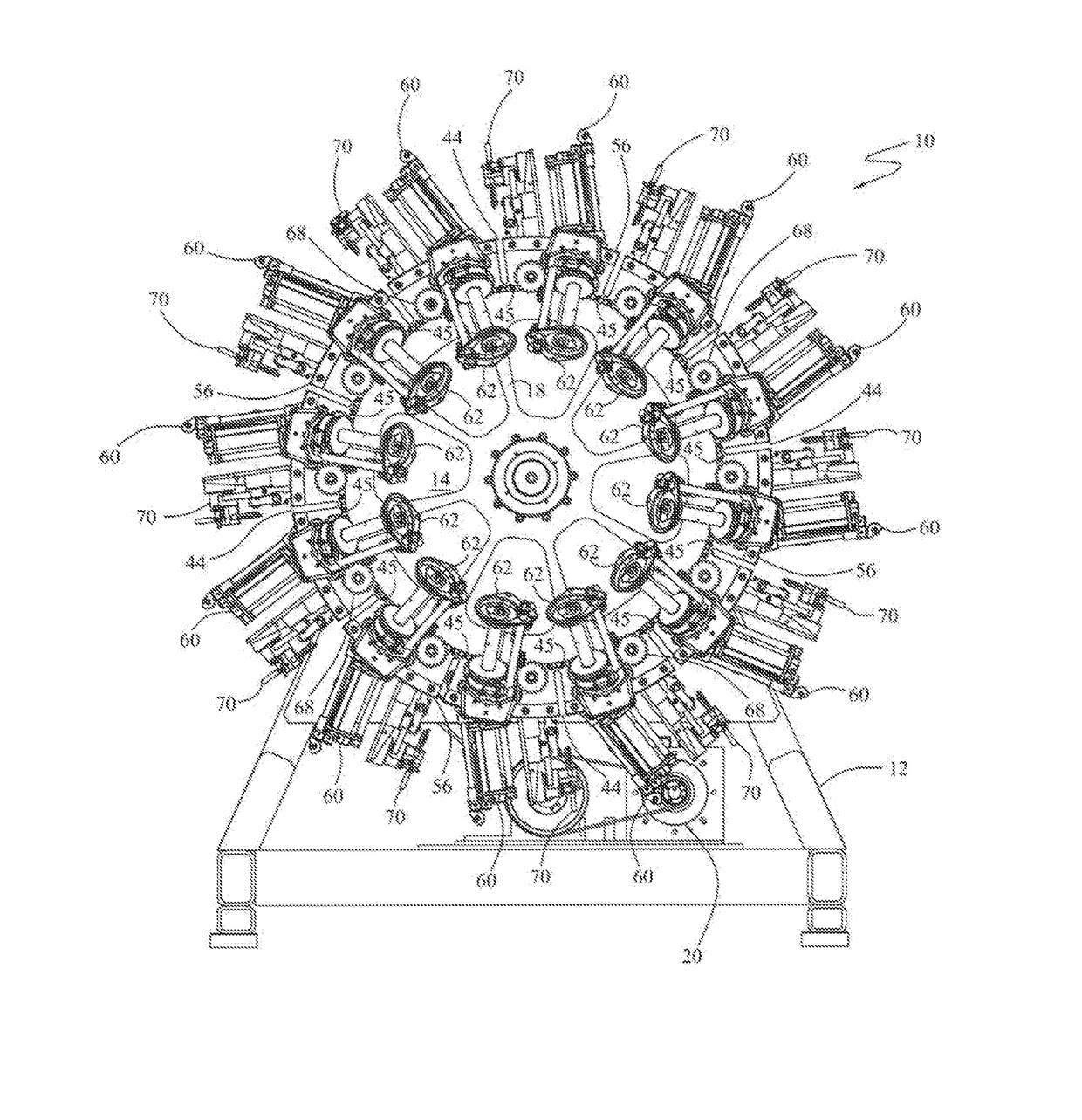

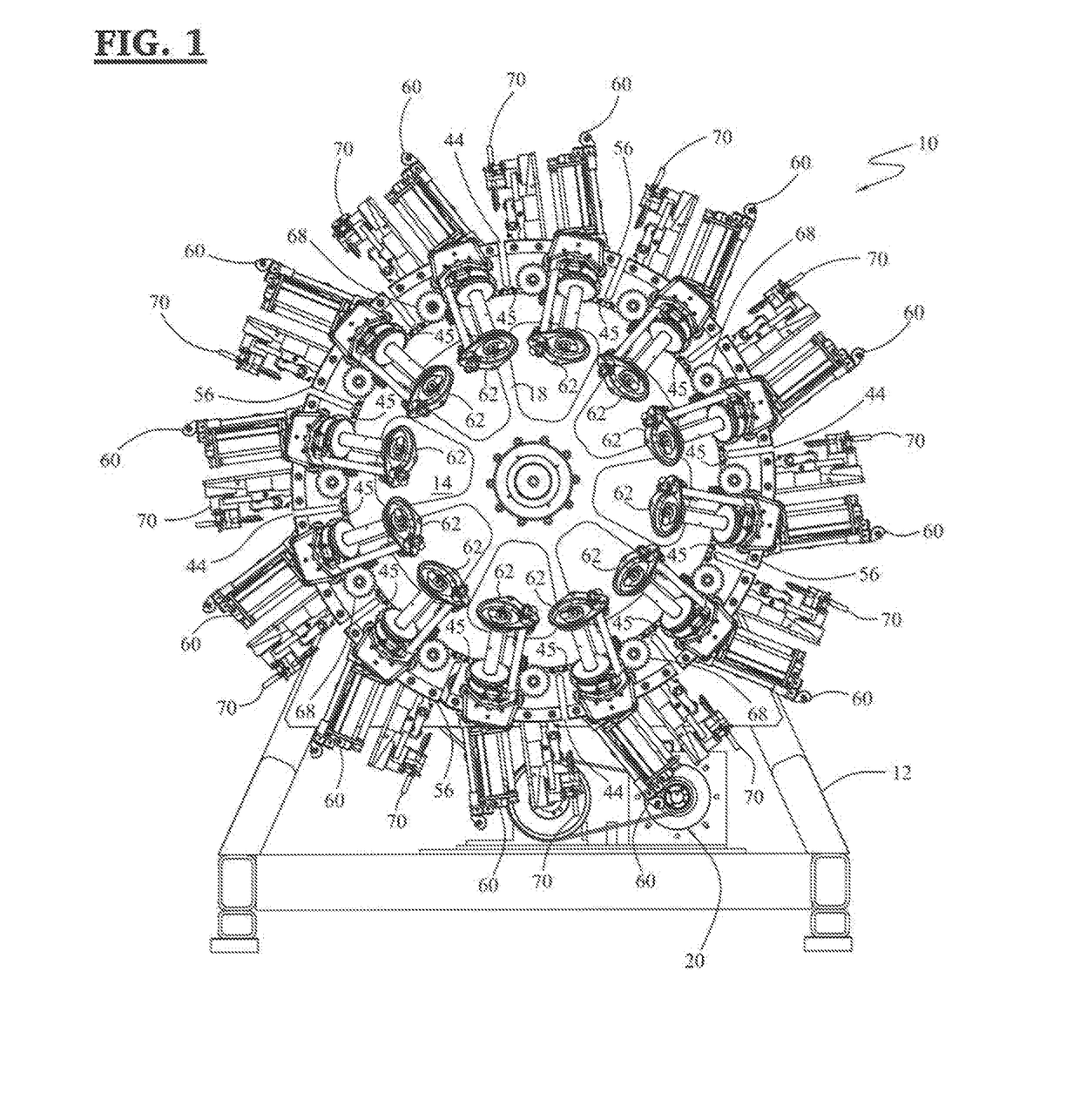

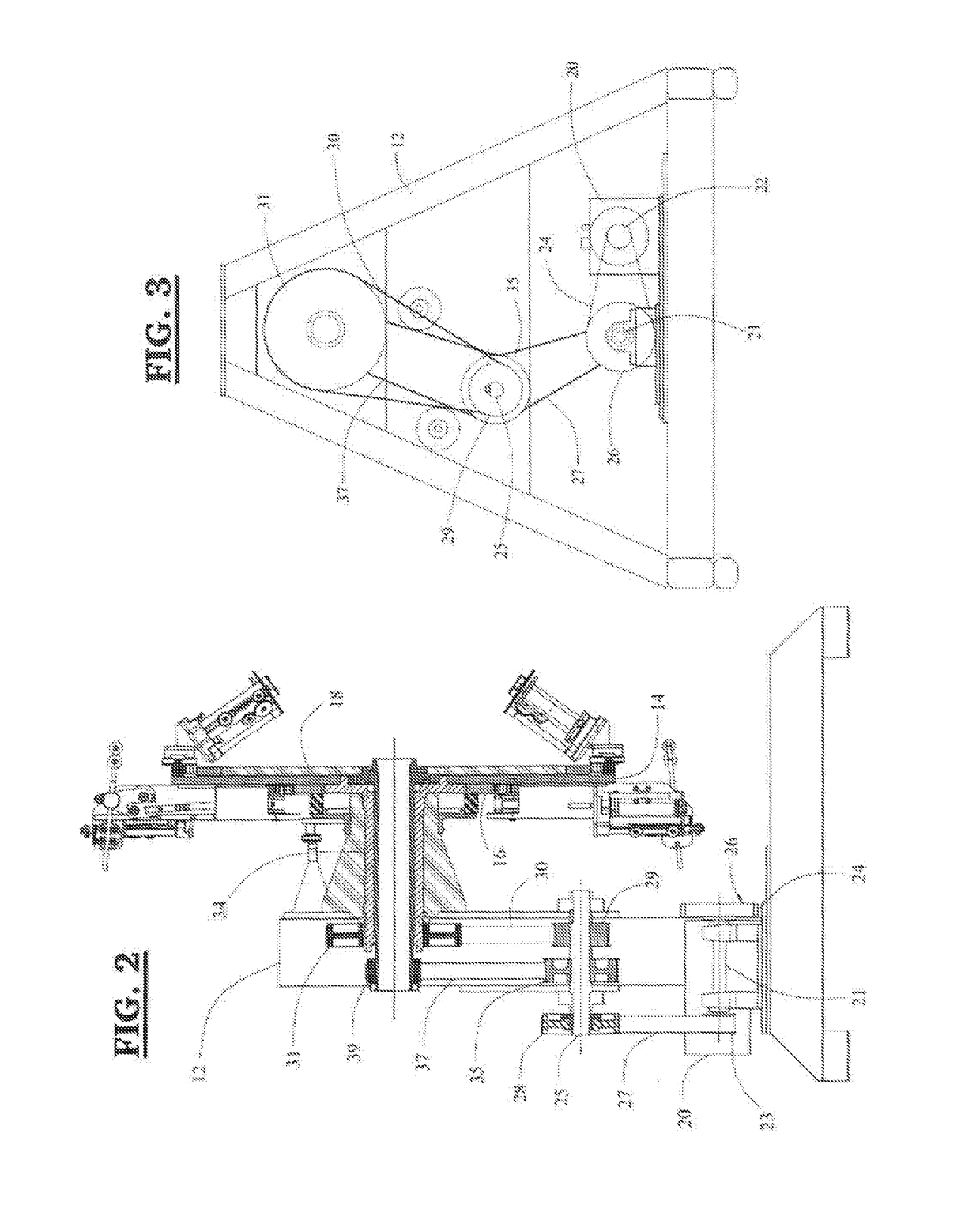

Rotary braiding machine

ActiveUS20170233908A1Faster and efficient braidingOptimization mechanismConnecting rodsBraidActuatorControl theory

In one aspect, various embodiments of the present invention are directed to a rotary braiding machine capable of braiding wire around a cable, hose, mandrel, or other similar item, having an improved actuator arm mechanism that is simpler than those found in conventionally available rotary braiding systems and includes a mechanism for fine-tuning of the dwell timing of the transfer arms. In another aspect, one or more embodiment of the present invention is directed to a method for controlling the dwell timing of a transfer arm in a rotary braiding machine by adjusting the length of the actuator arm mechanism.

Owner:KARG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com