Patents

Literature

486 results about "Compression load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Essentially, a compression load cell is a block that is designed to hold a load at one point to measure the compression. While tension load cells measure the pulling force, compression load cells measure a pushing force along a single axis. Generally, a compression load cell is placed beneath the object that needs measuring.

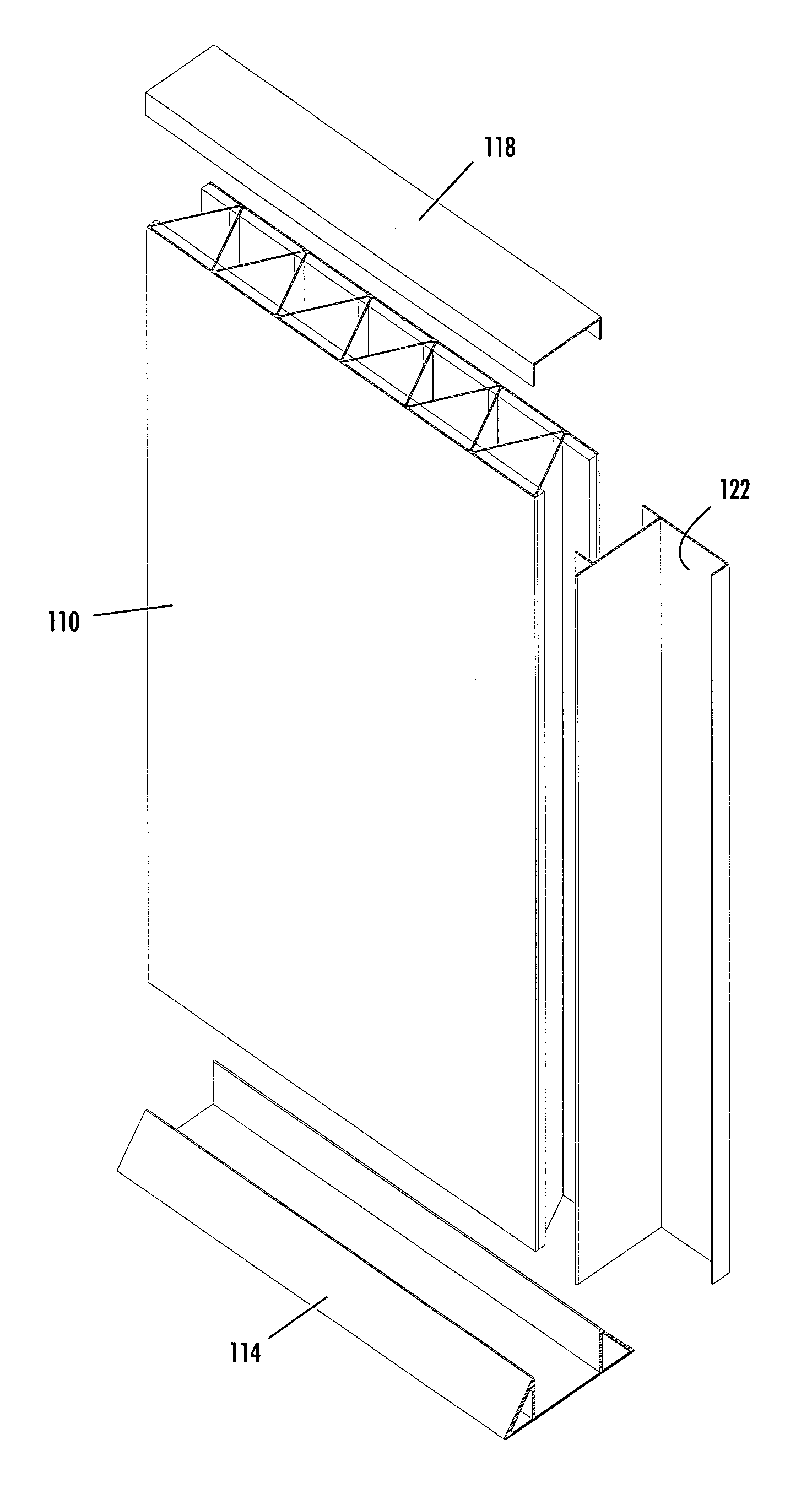

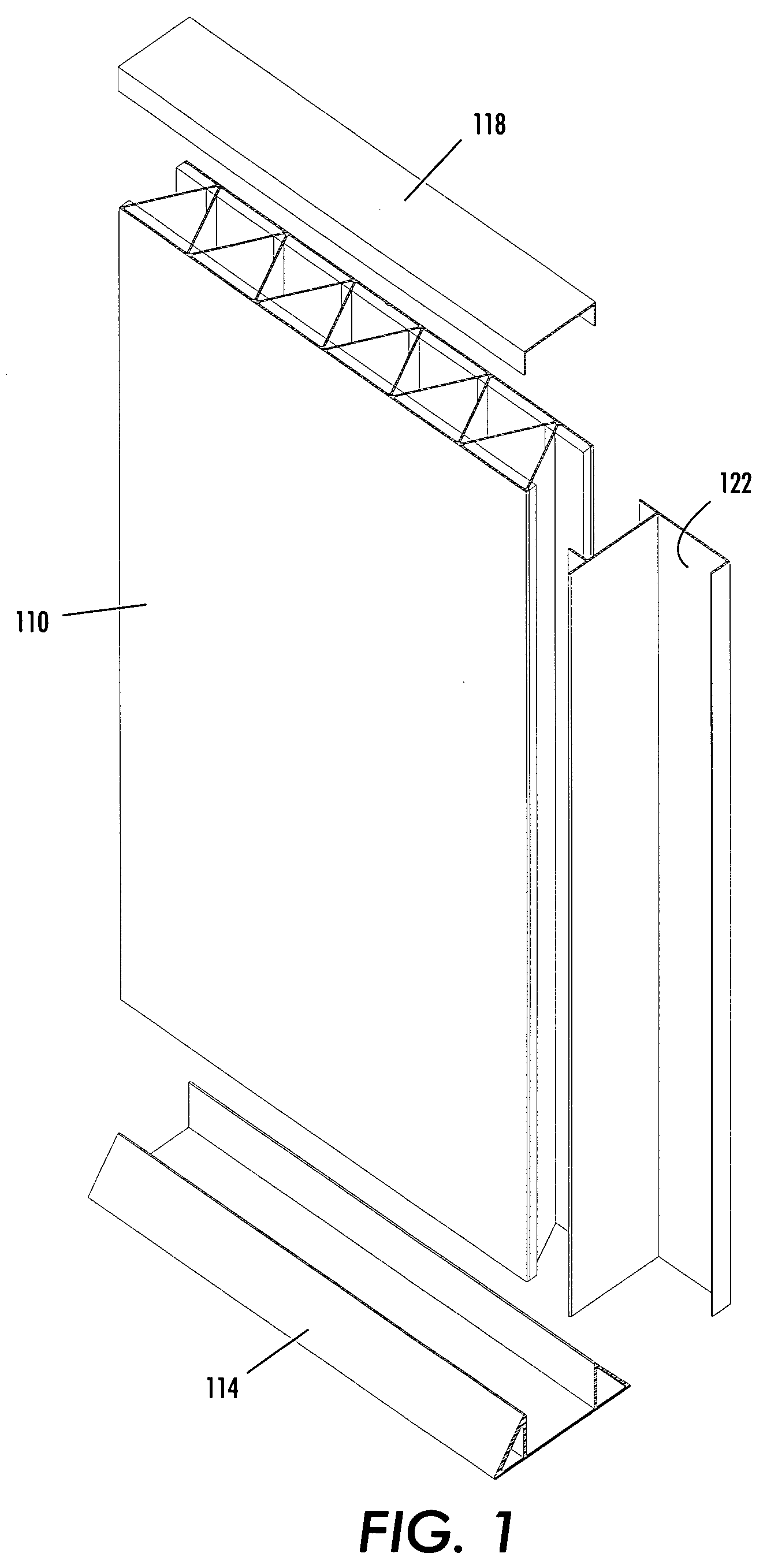

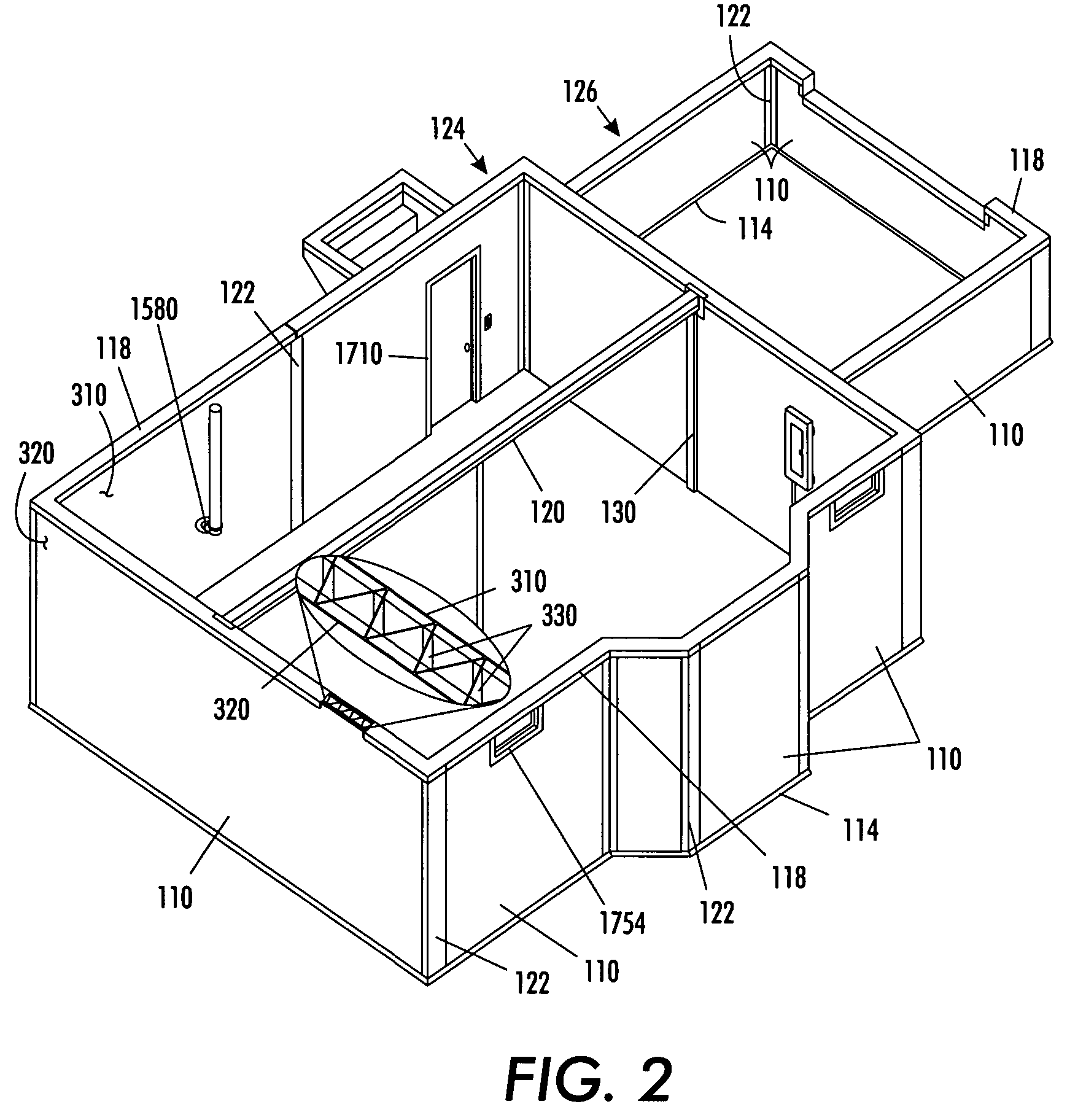

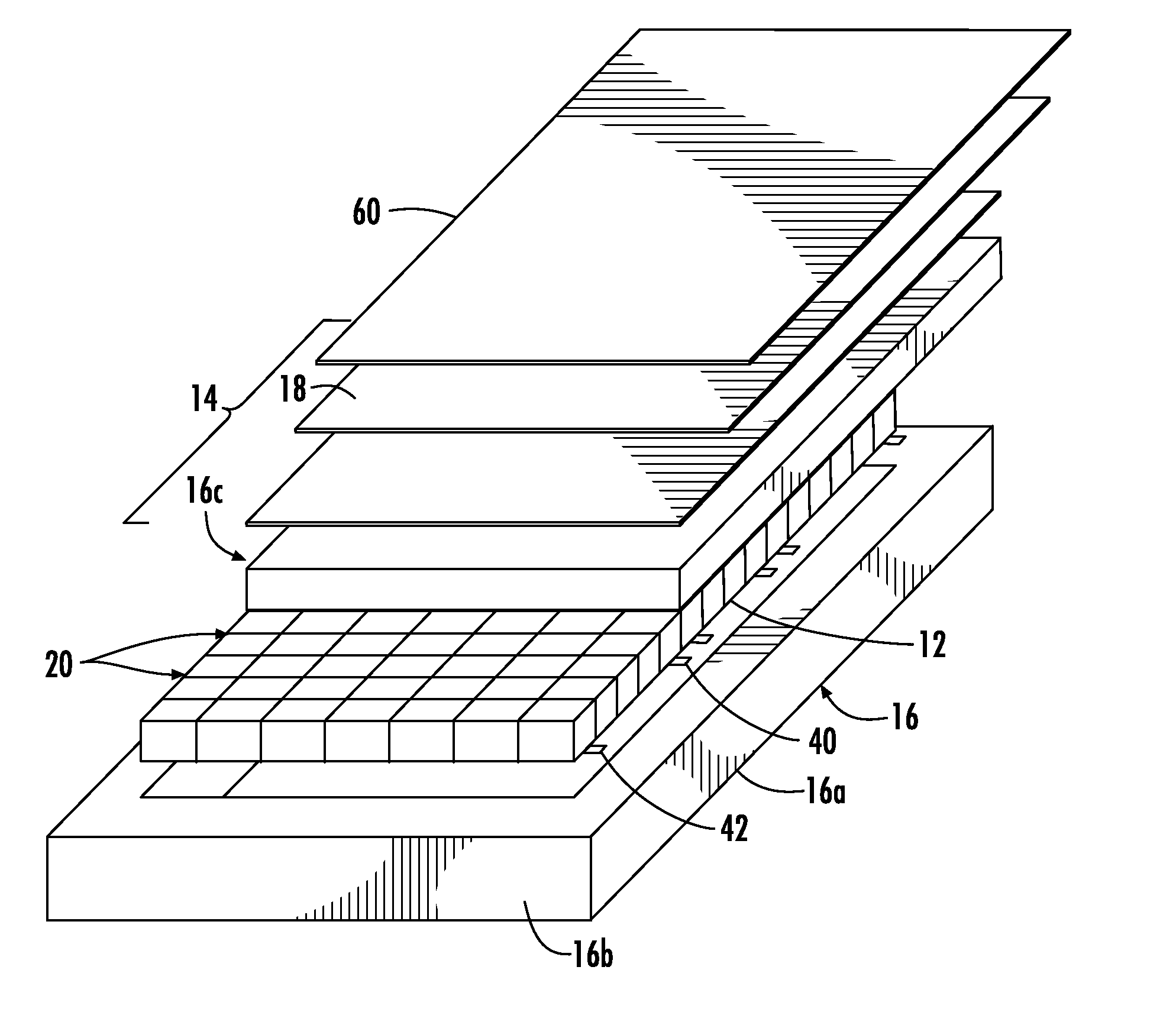

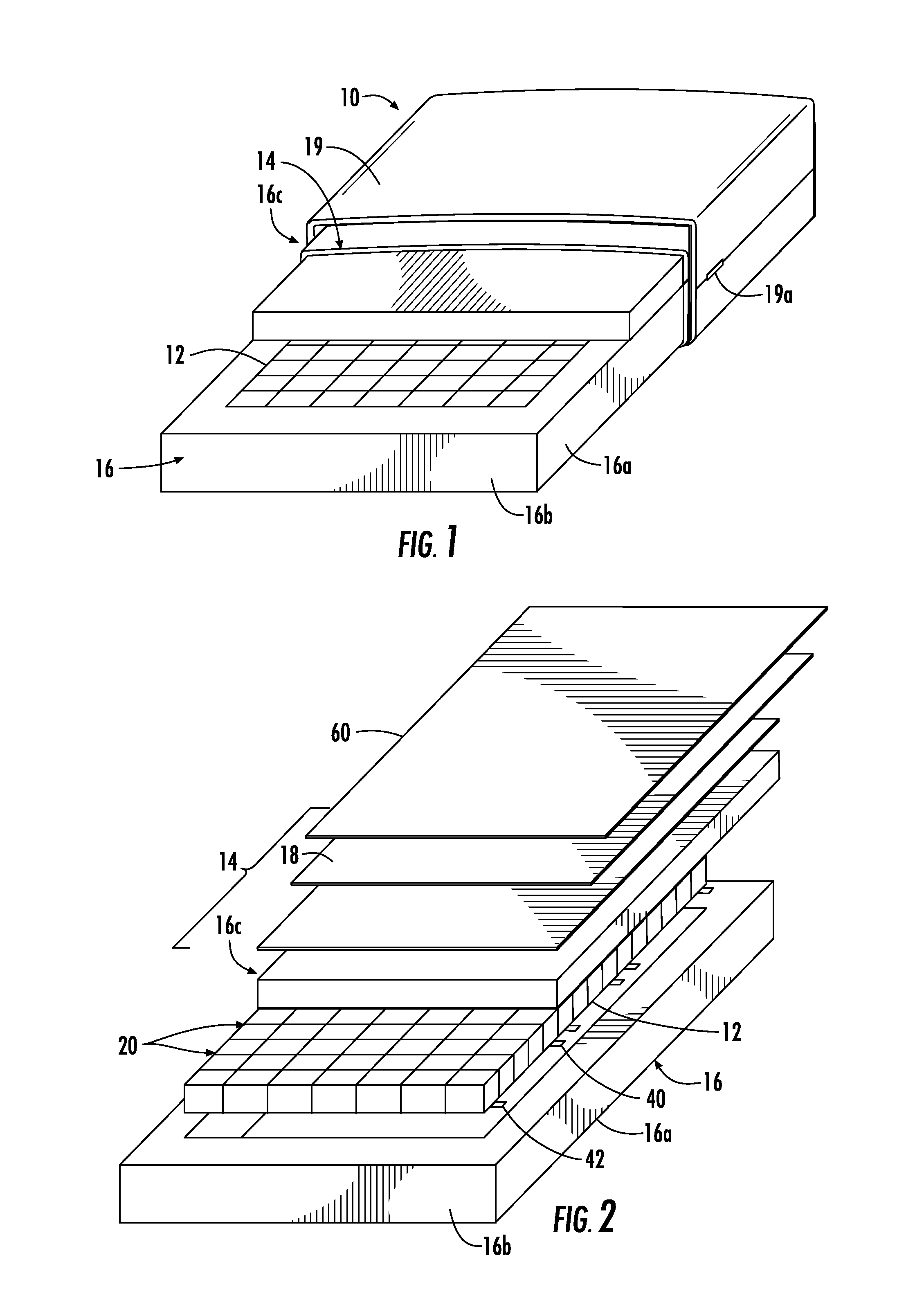

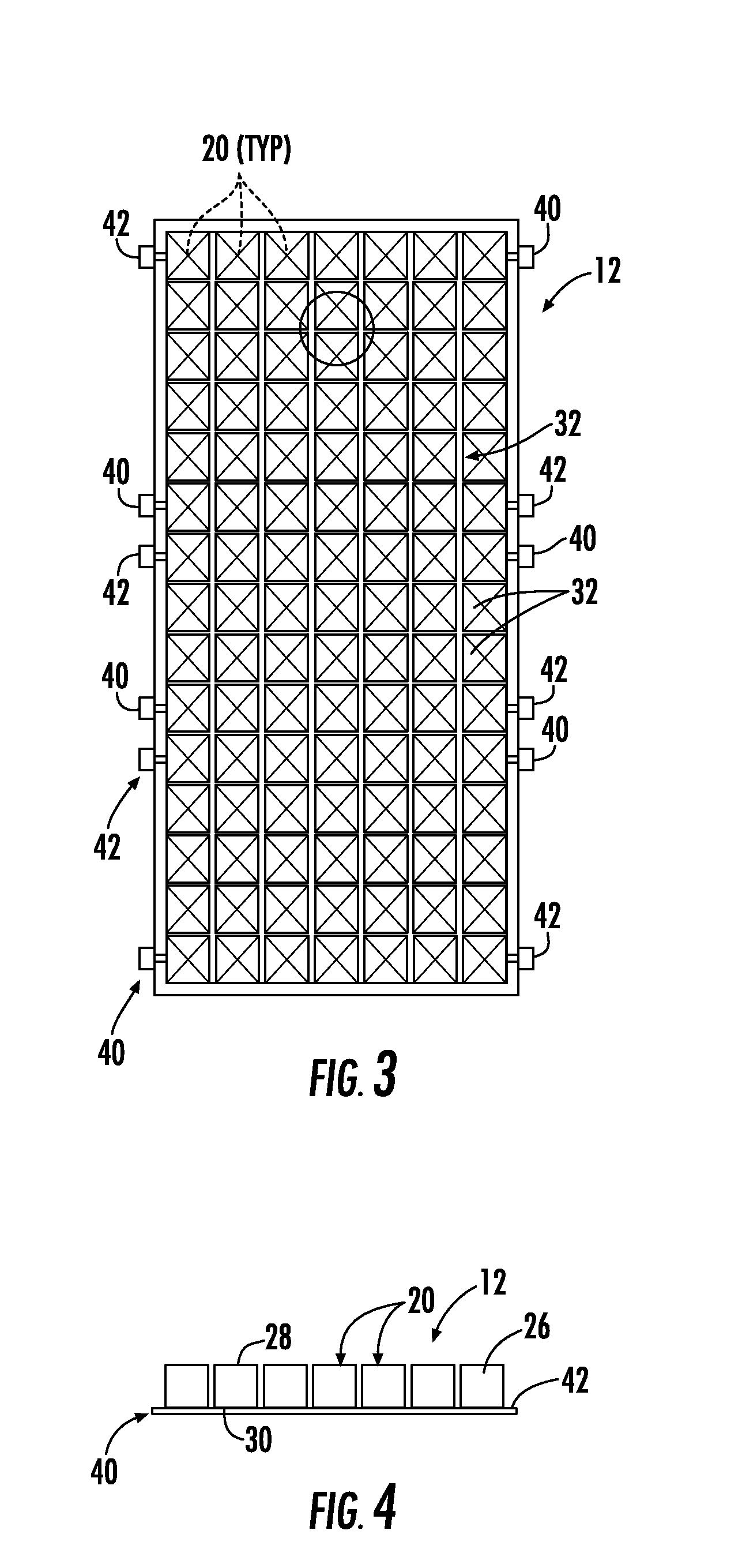

Modular structure for building panels and methods of making and using same

The present invention is a polymeric panel system and method for production and use thereof, enabling the rapid construction of a building foundation wall or other structure and in particular a below-grade foundation. The polymeric foundation system includes polymeric wall panels and other components suitable for withstanding lateral and end compression loads. The walls include two parallel faces separated by a series of webs or ribs, where the webs and faces of the wall panels may be formed of a similar polymer material such as polyvinylchloride (PVC). The wall panels and / or other components may be extruded so as to enable the rapid production of sections of wall panels, where the panels may be cut to length and then affixed to adjacent panels to form a foundation wall. The method of affixing adjacent panels may include welding, gluing or other techniques and may be performed on the job site or in a pre-fabrication facility. Furthermore, the wall panels may be co-extruded with an insulating material inserted in the voids between the parallel faces so as to provide improved thermal performance of the foundation as well.

Owner:DOUGLAS ROBERT B

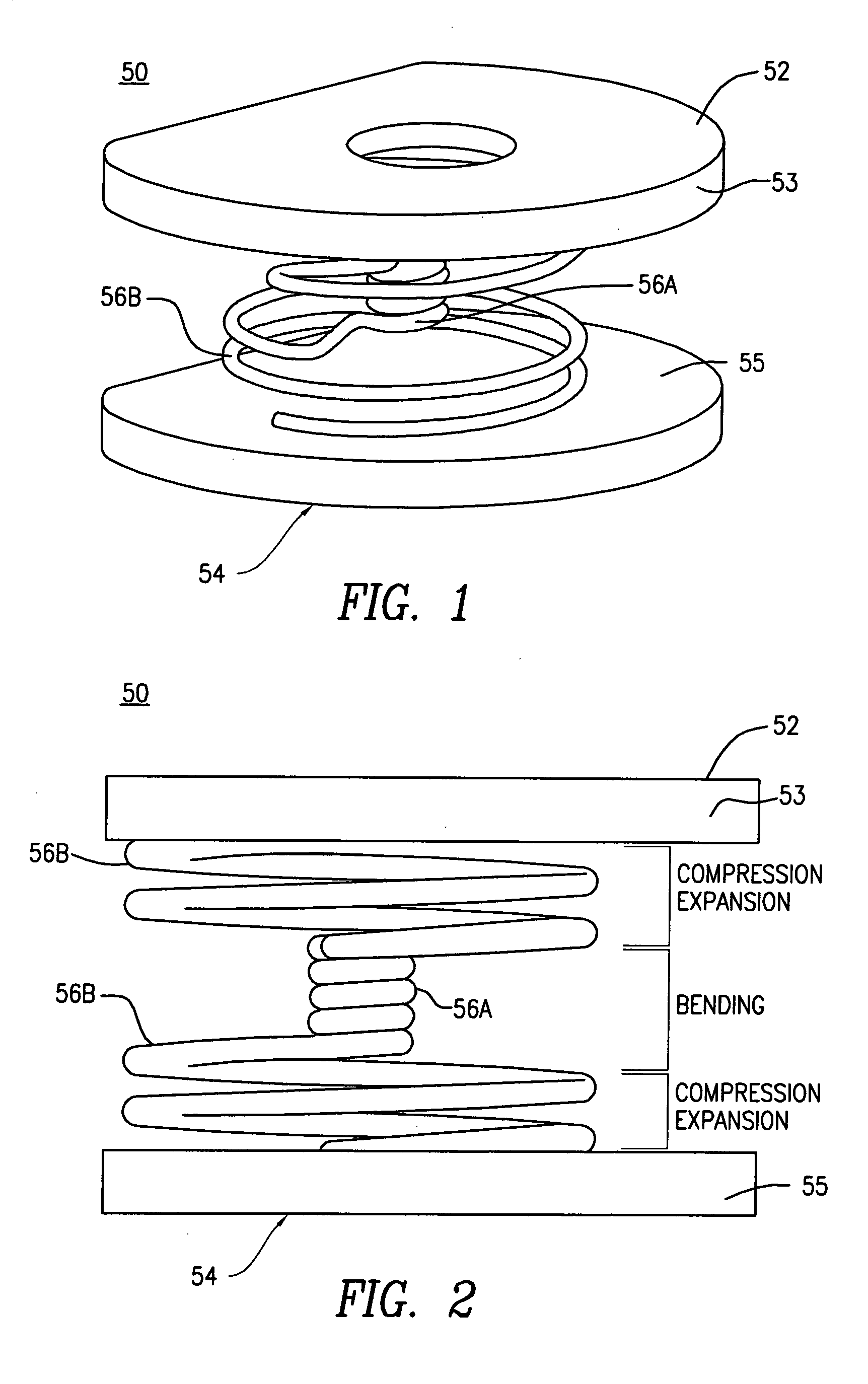

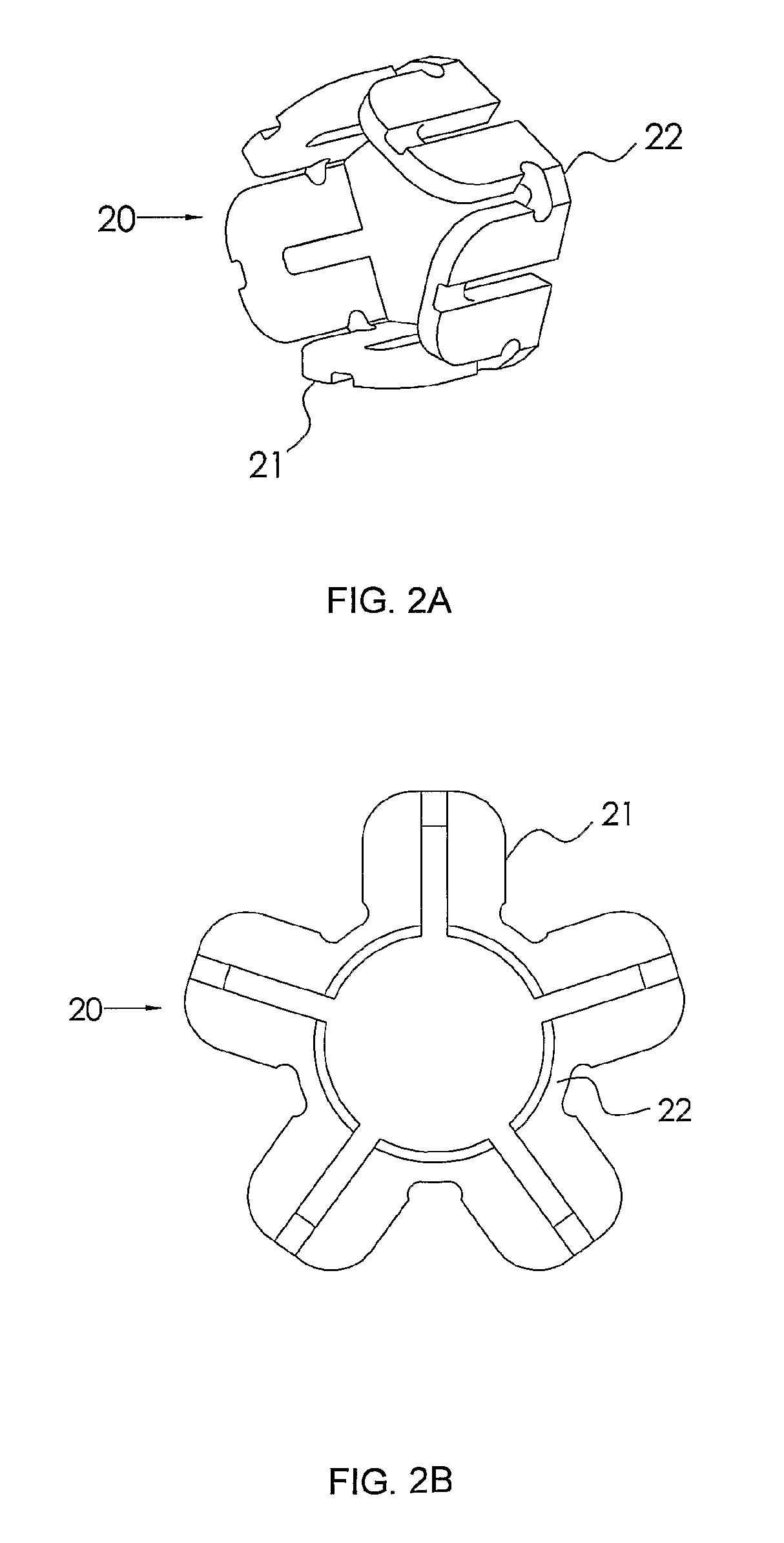

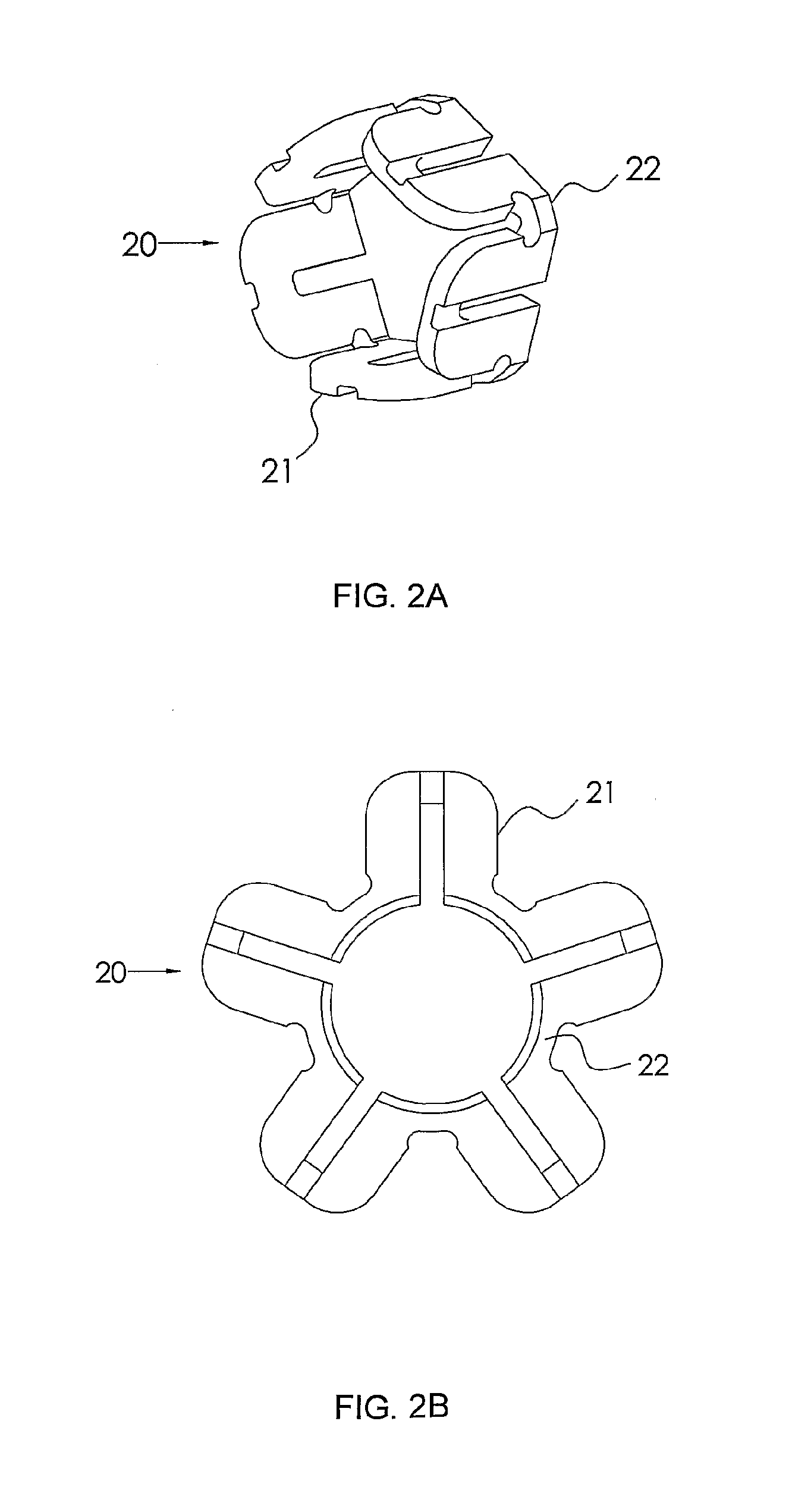

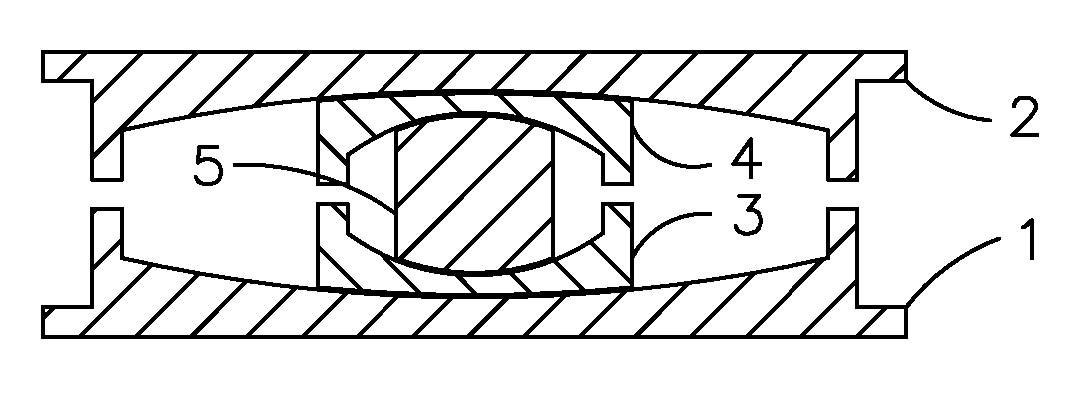

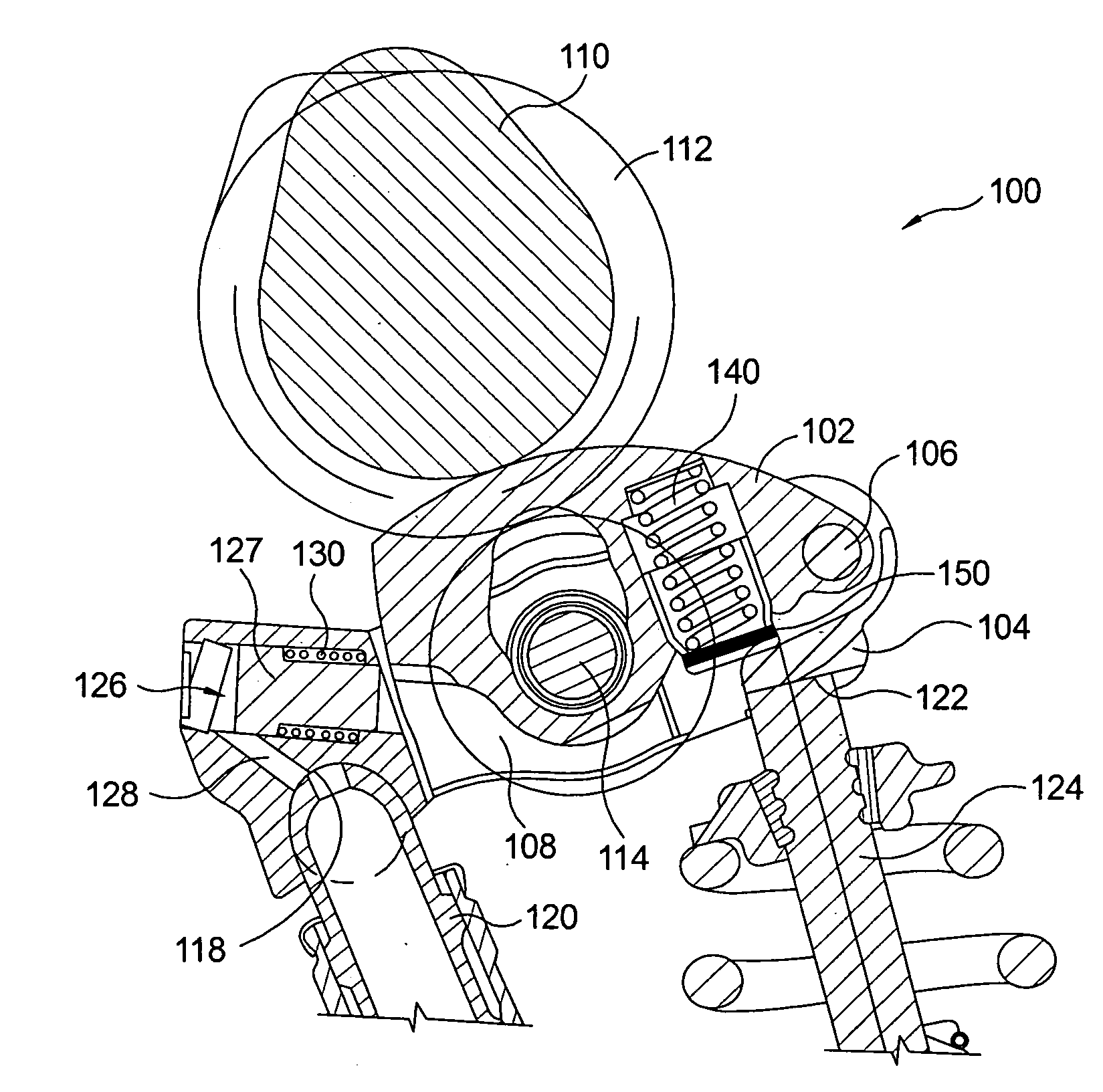

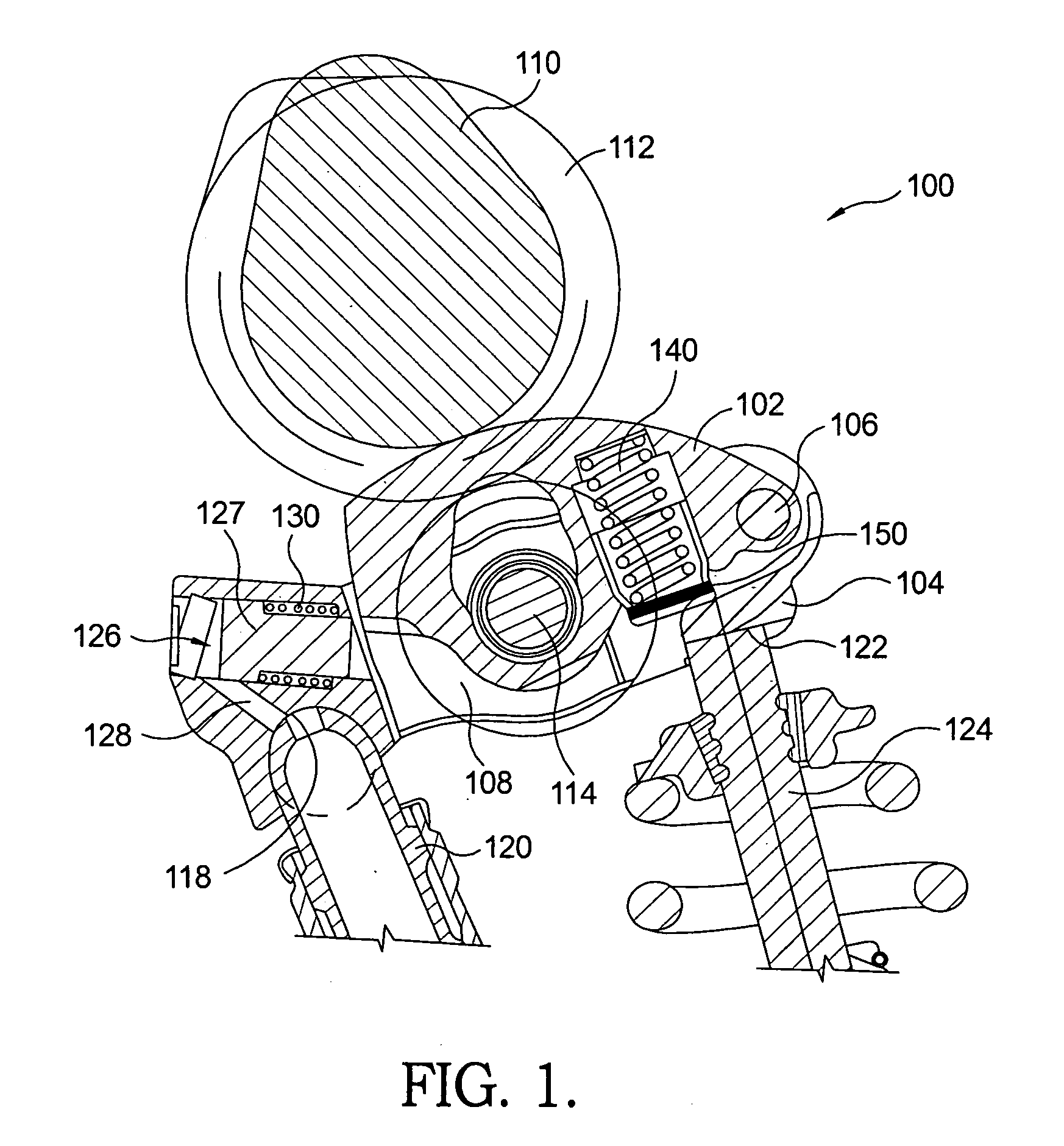

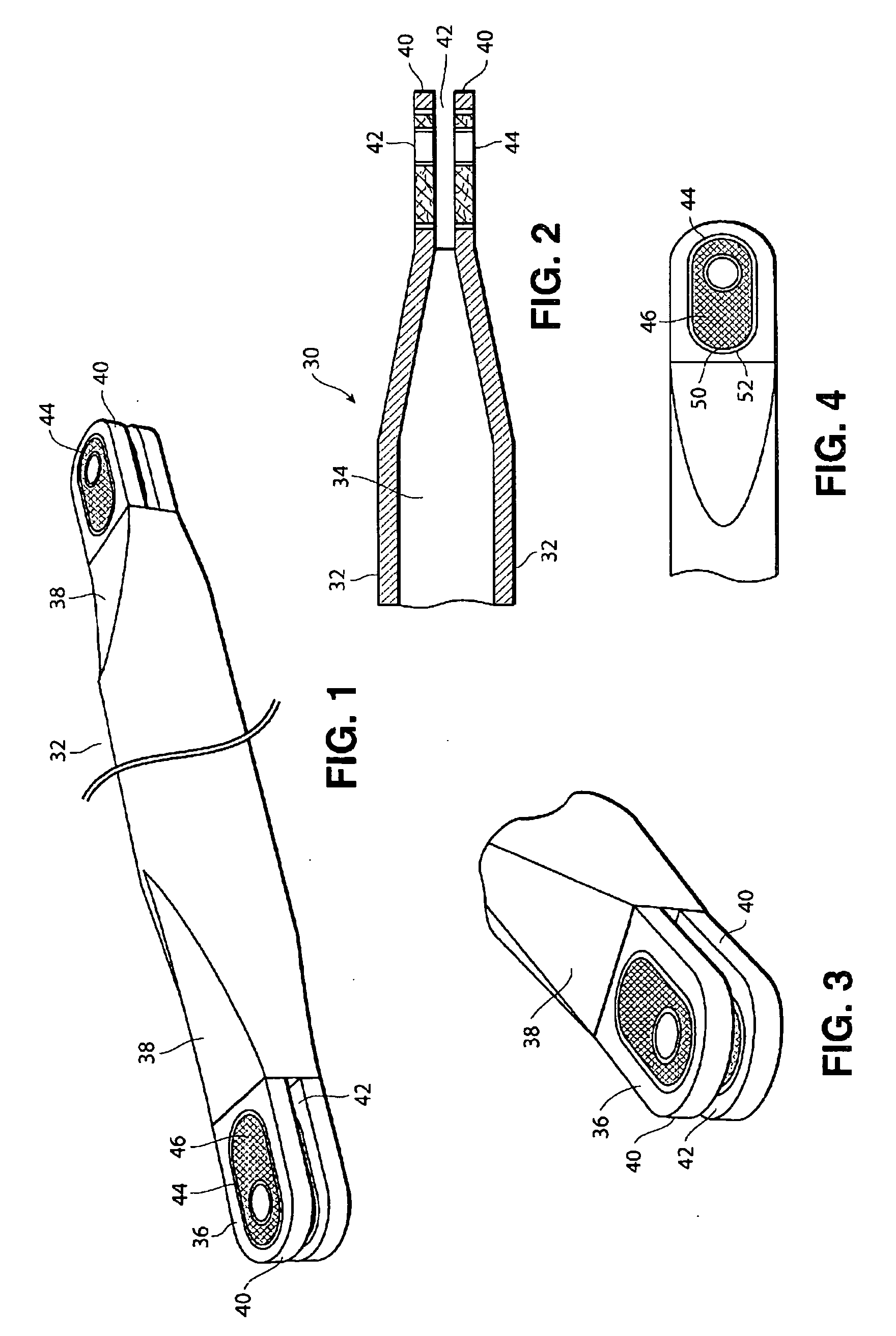

Cervical intervertebral stabilizer

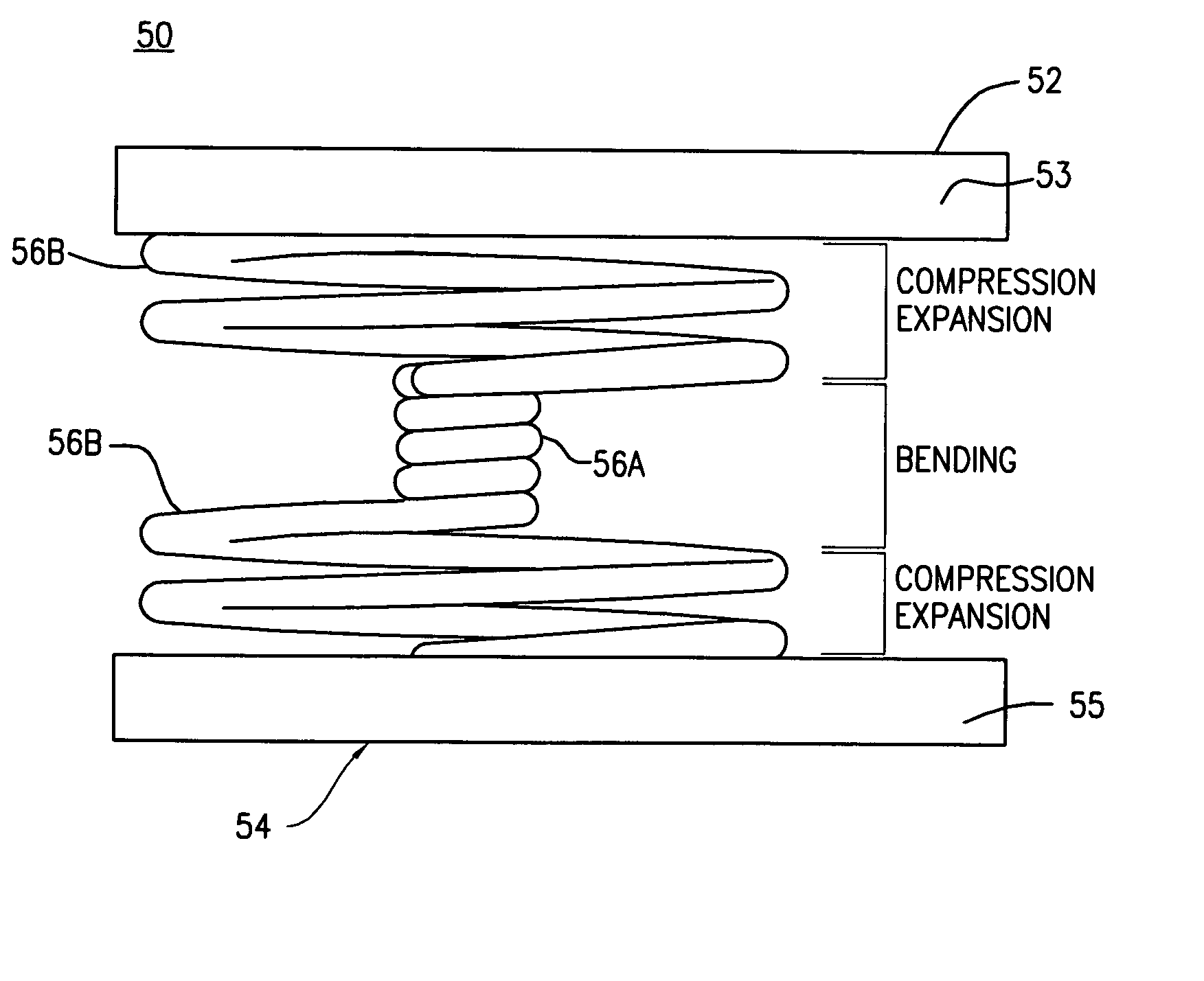

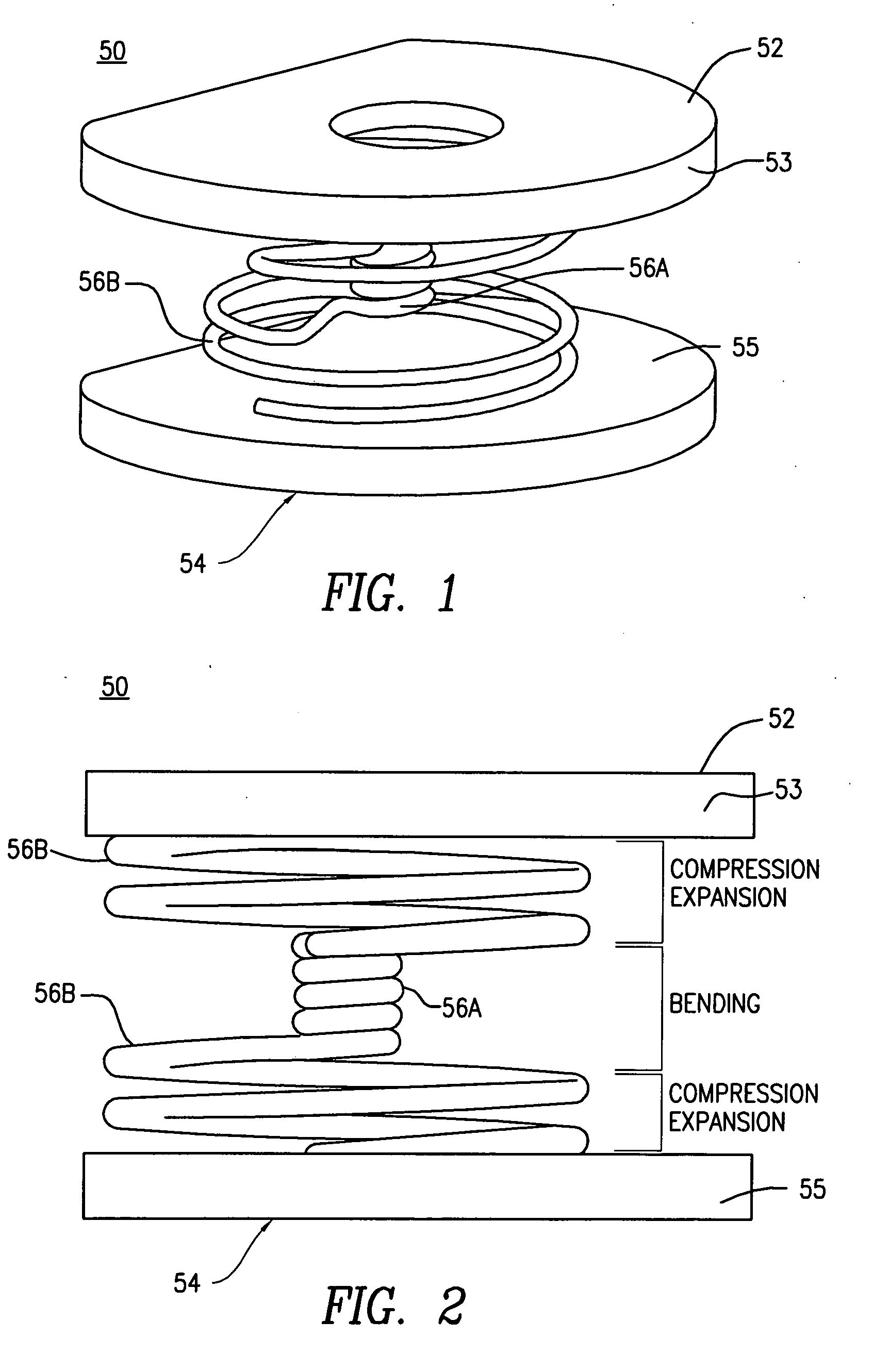

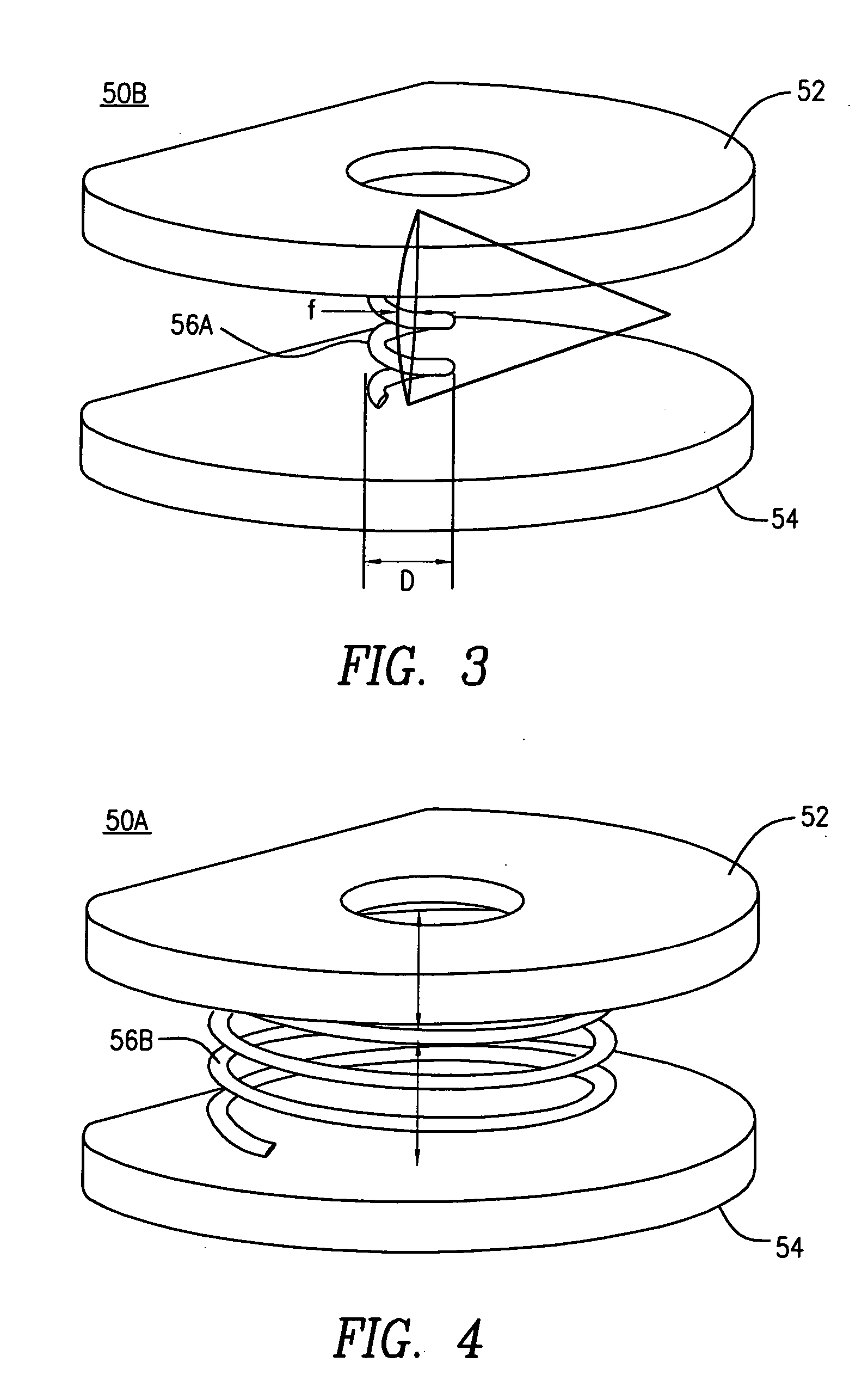

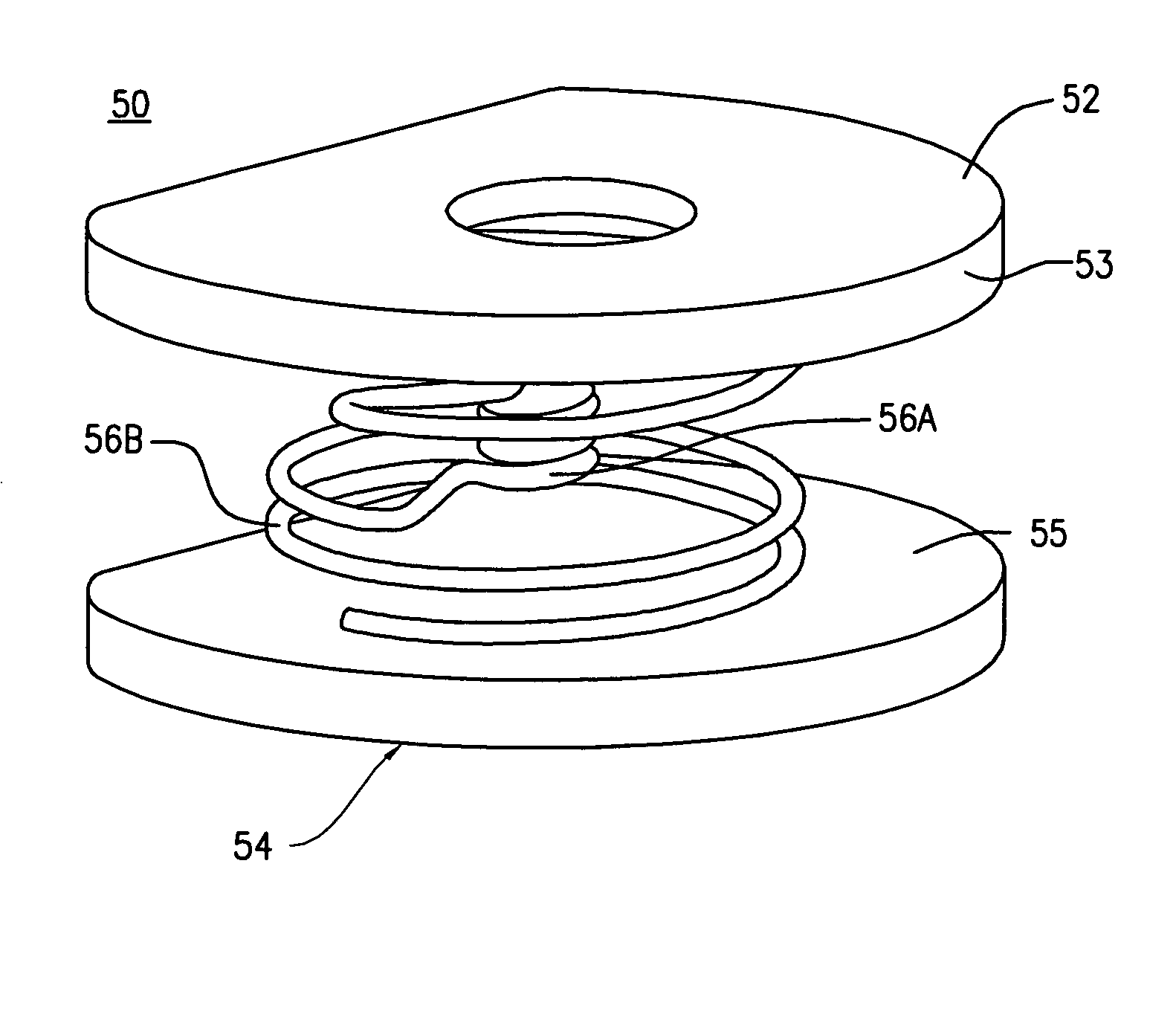

A cervical intervertebral stabilizer for a cervical region of a spine includes: a first surface operable to engage an endplate of a first vertebral bone of a spine; a second surface spaced apart from the first surface and operable to engage an endplate of an adjacent second vertebral bone of the spine; a spring element including at least one of: (i) a helical wound spring; and (ii) a hollow body having at least one slit forming a plurality of annular circumferential helical coils, the spring element being disposed between the first and second surfaces and being operable to provide reactive force in response to compression loads from the first and second vertebral bones, wherein at least some diameters of respective turns of the helical coils differ.

Owner:CARDO MEDICAL

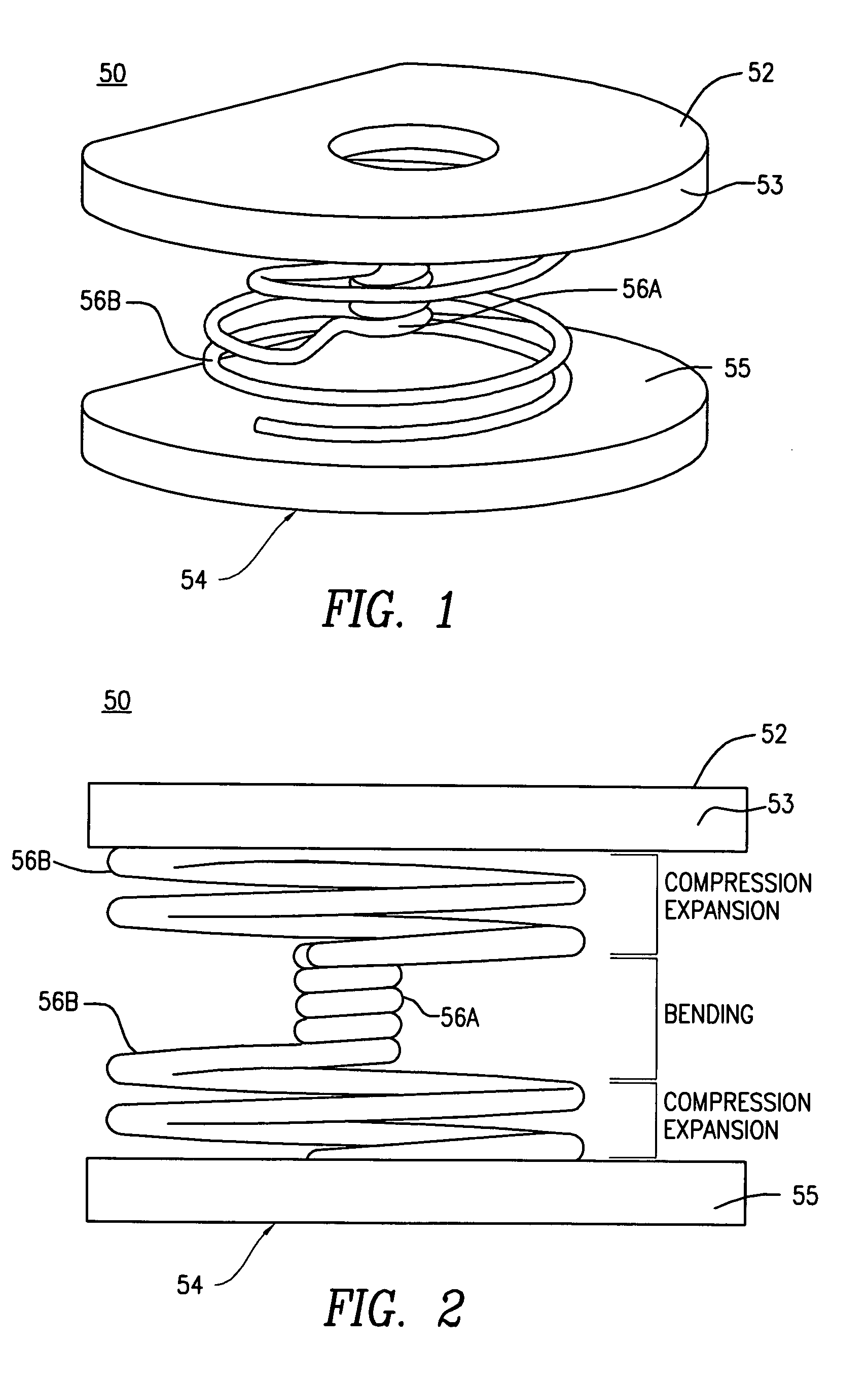

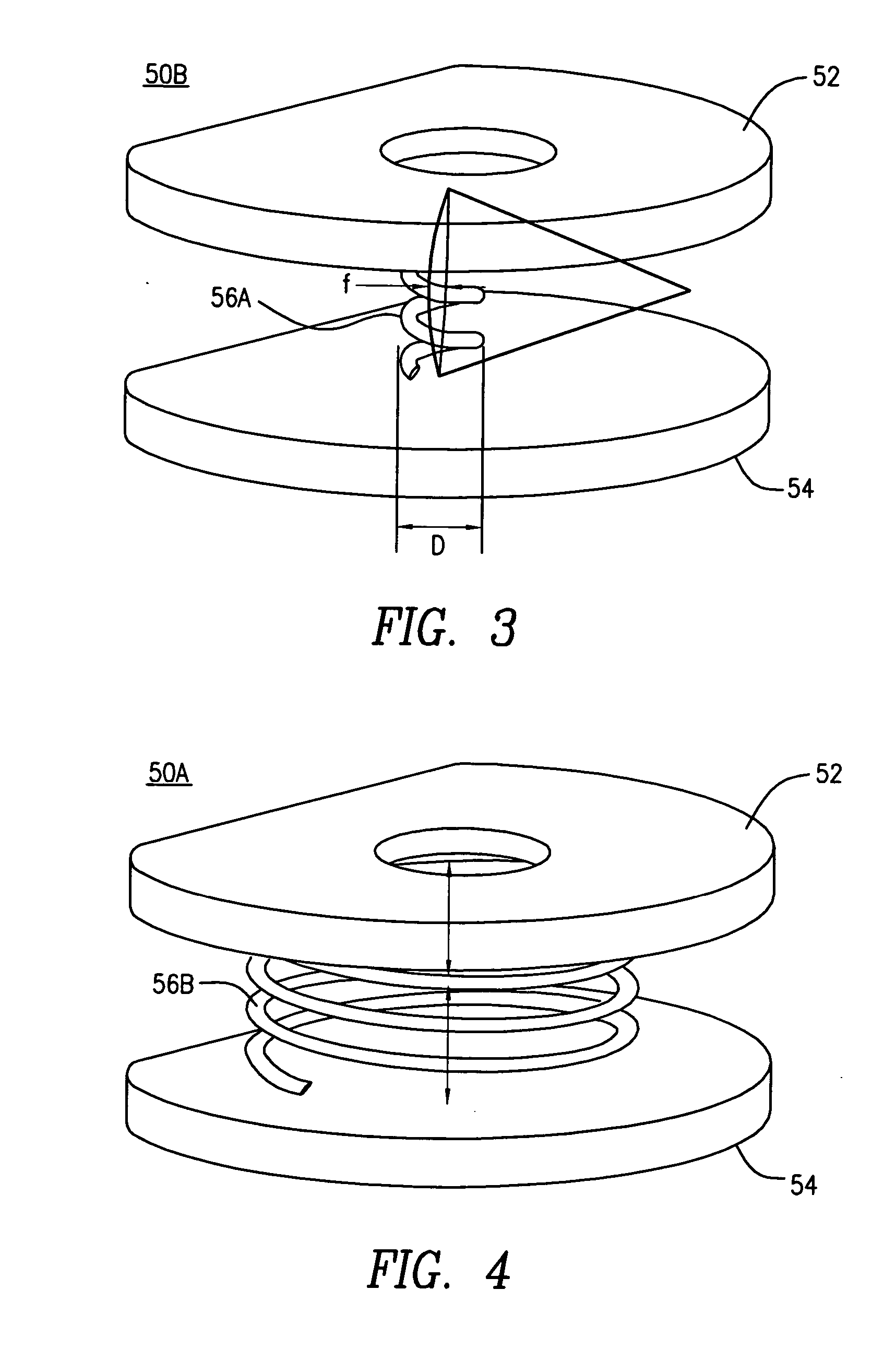

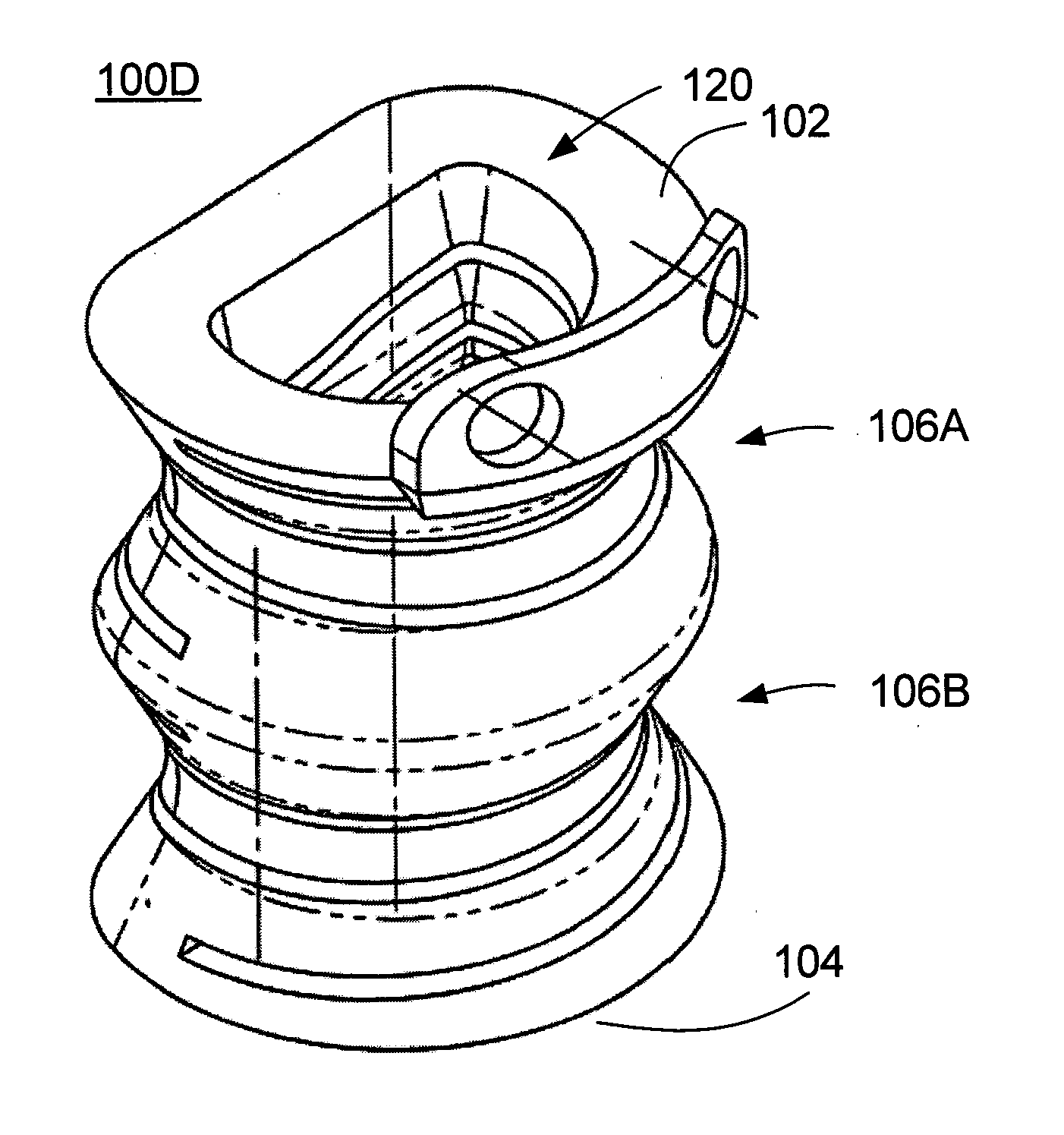

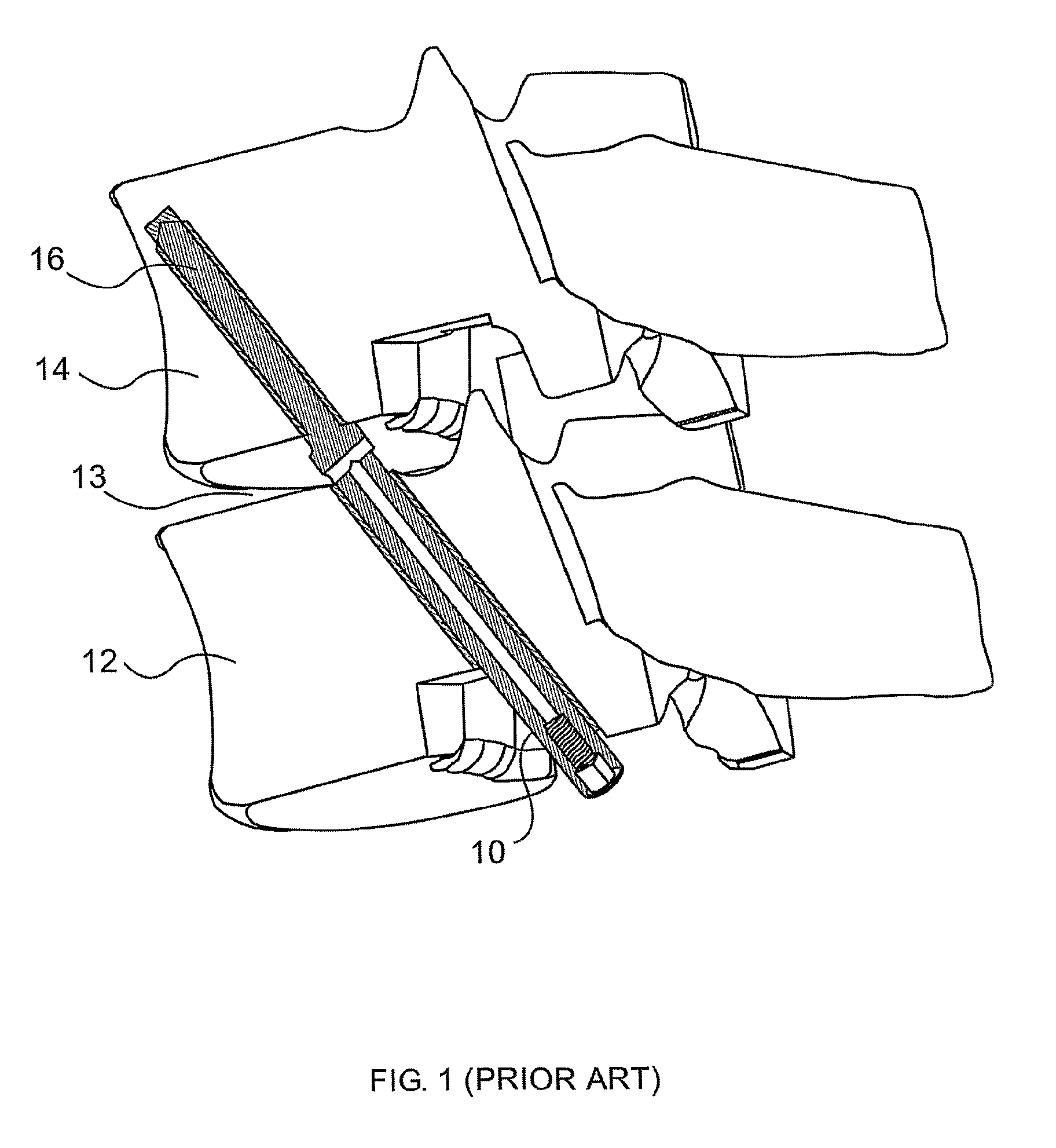

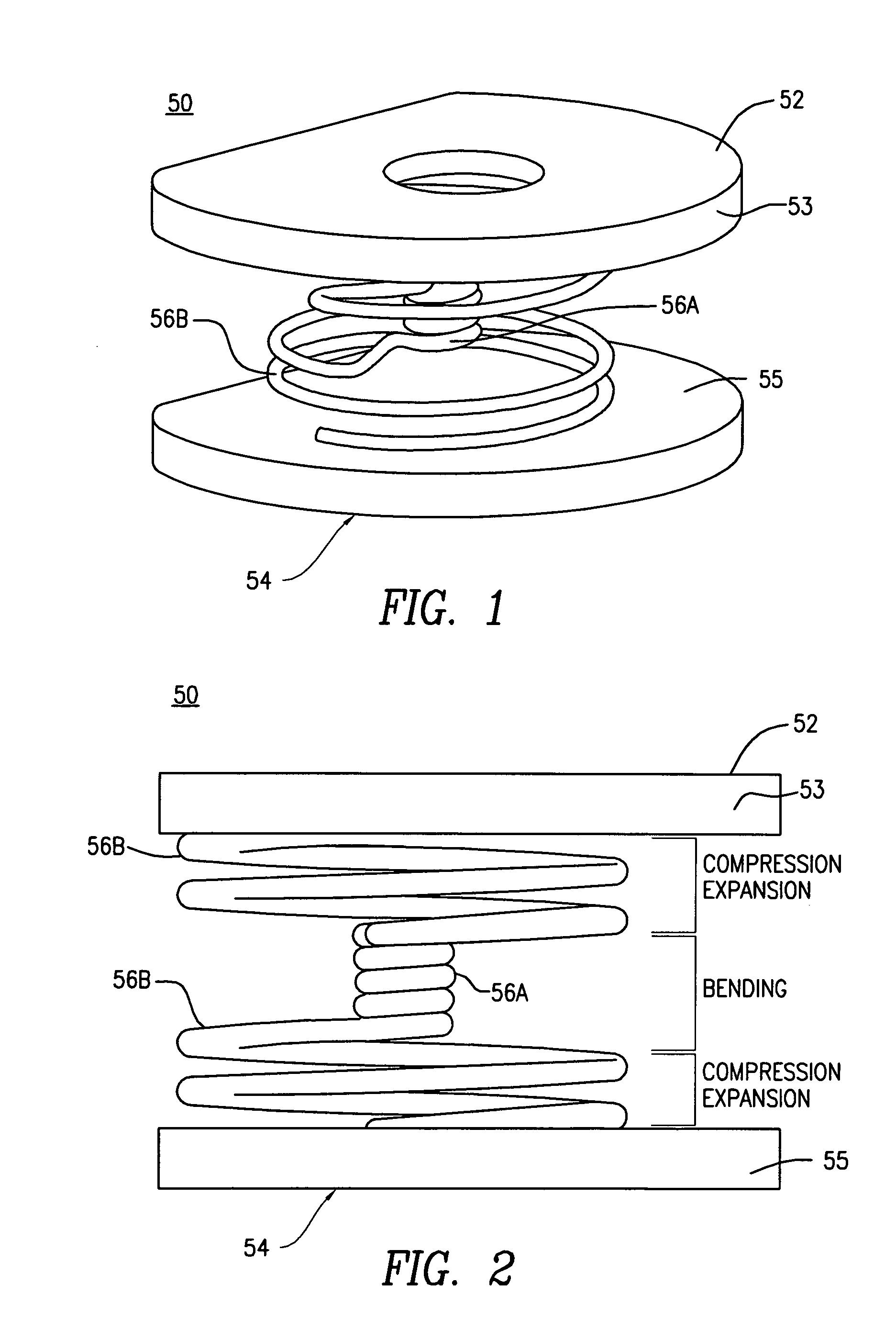

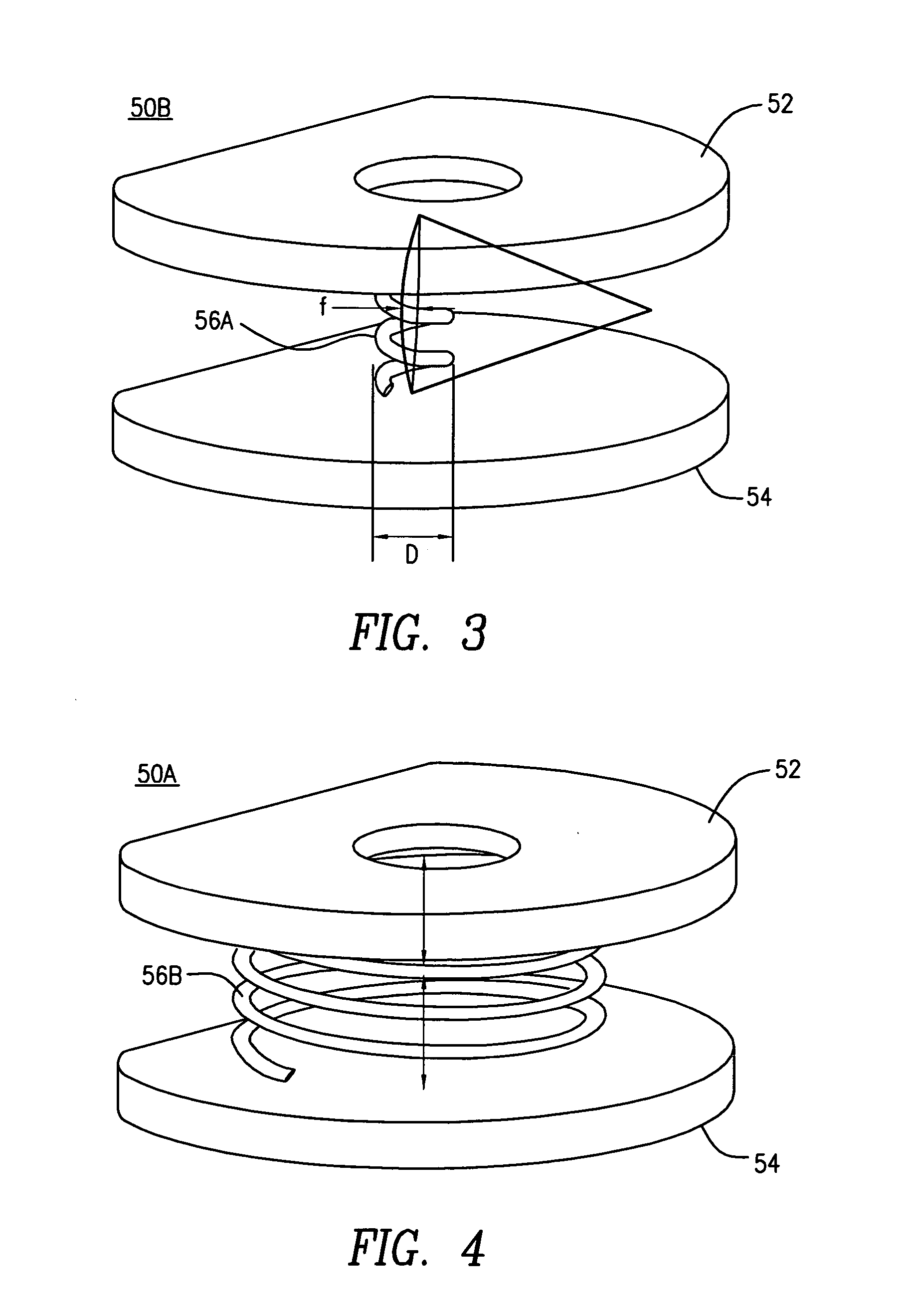

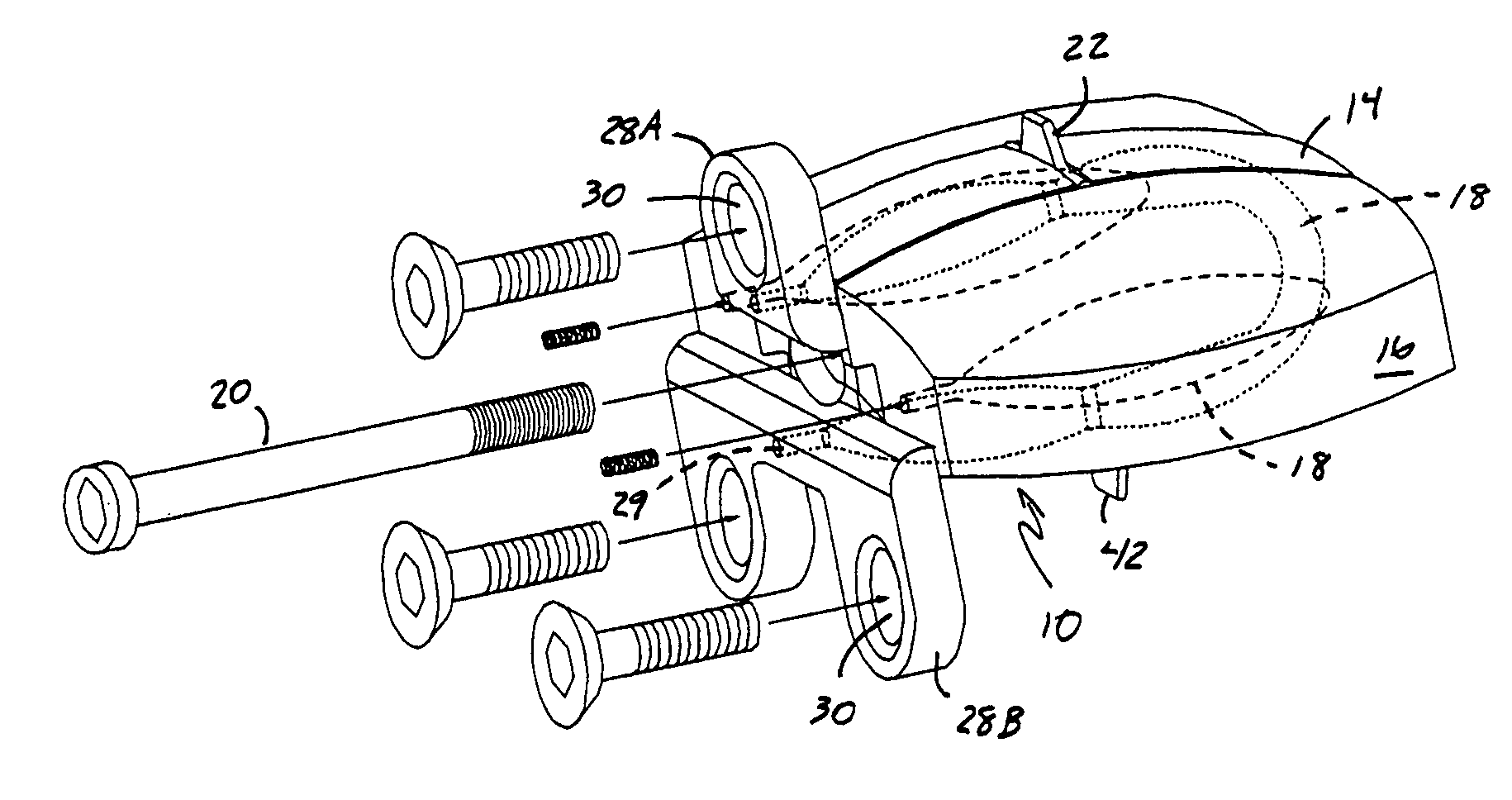

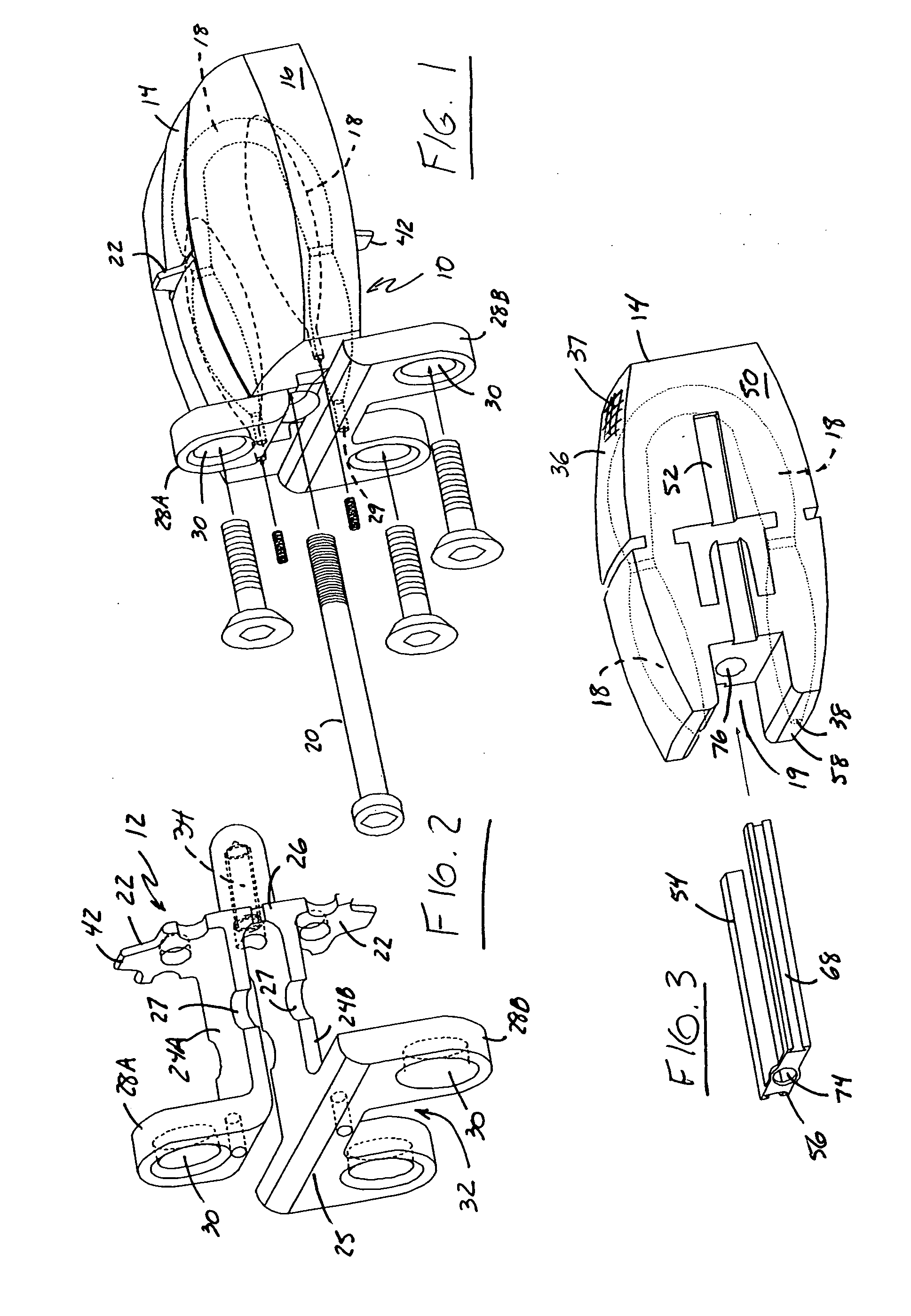

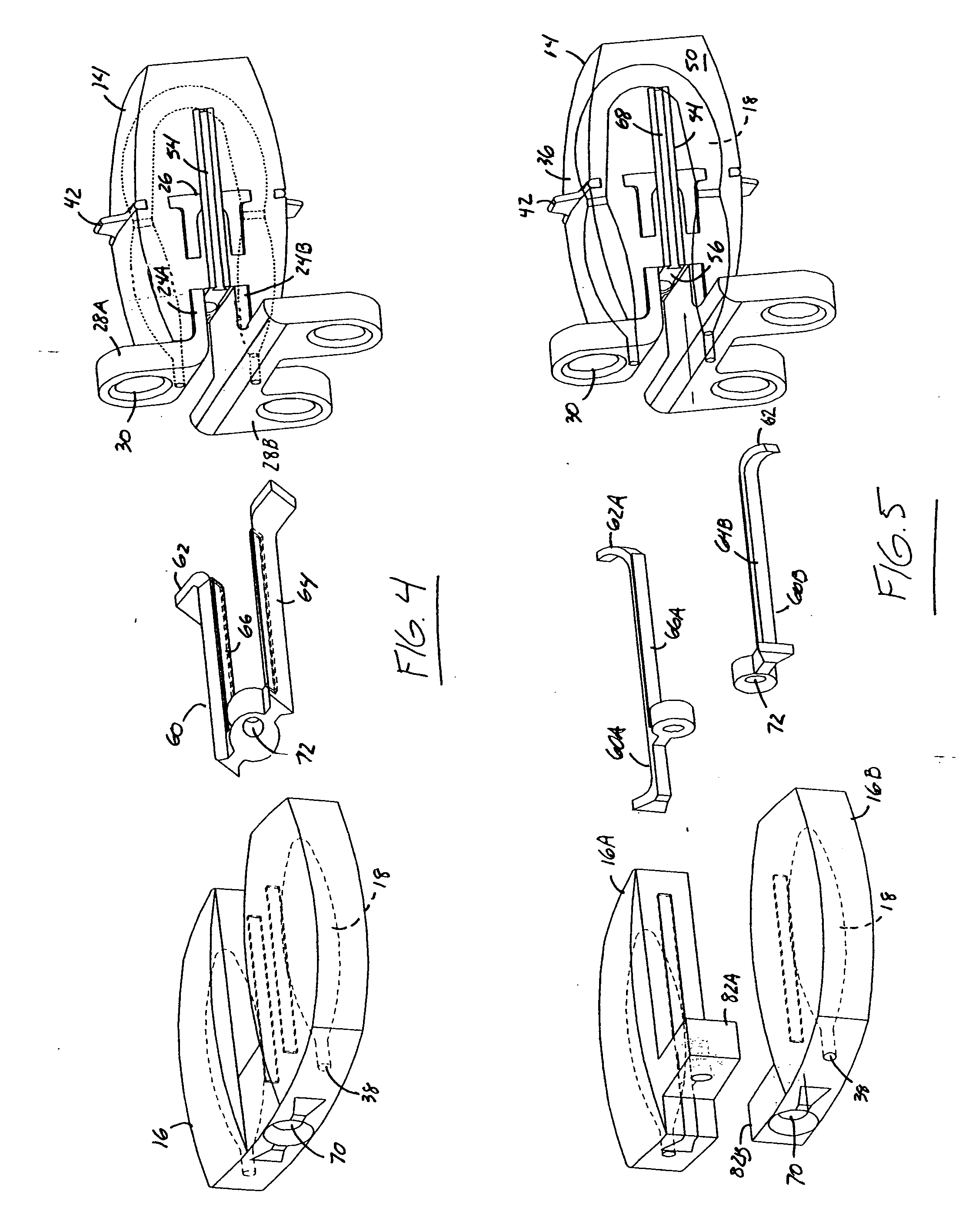

Intervertebral stabilizer, methods of use, and instrumentation therefor

An intervertebral stabilizer includes: a first surface operable to engage an endplate of a first vertebral bone of a spine; a second surface spaced apart from the first surface and operable to engage an endplate of an adjacent second vertebral bone of the spine; a spring element between the first and second surfaces and operable to provide reactive force in response to compression loads from the first and second vertebral bones, wherein a cross-sectional profile taken through the surfaces is hourglass shaped.

Owner:CARDO MEDICAL

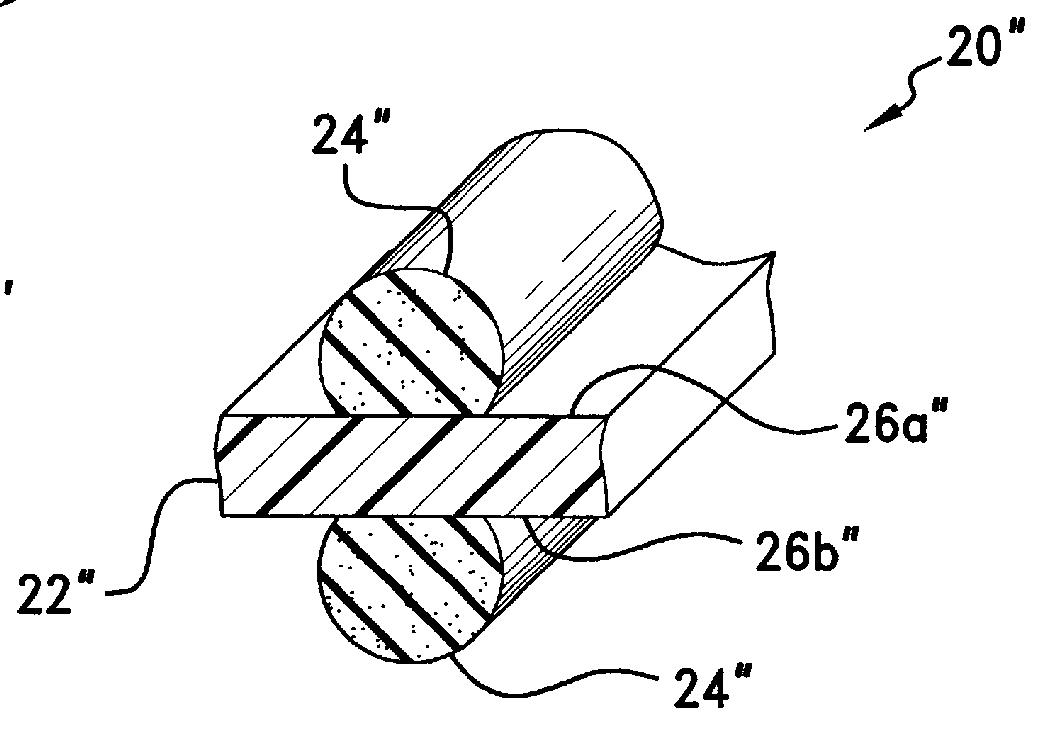

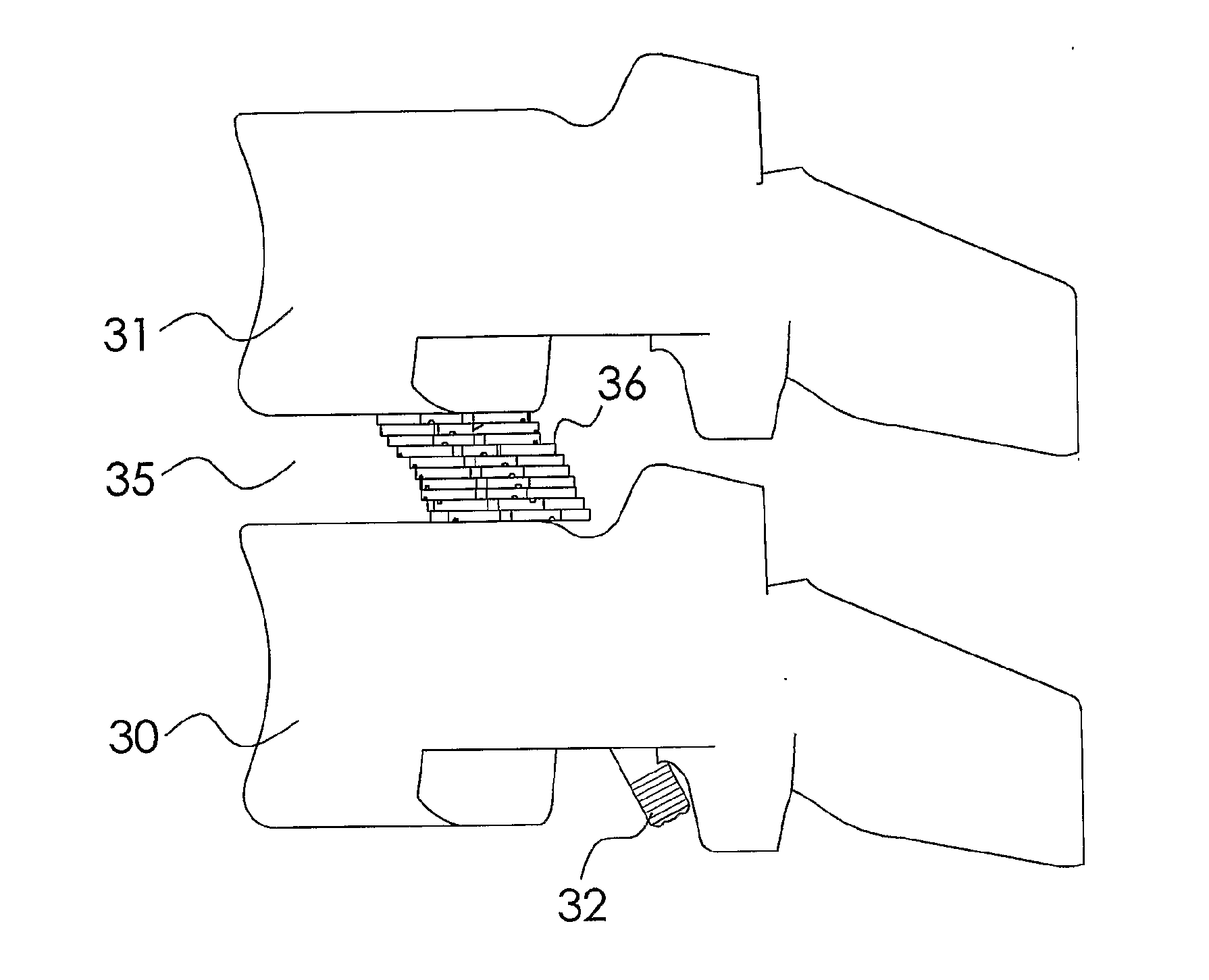

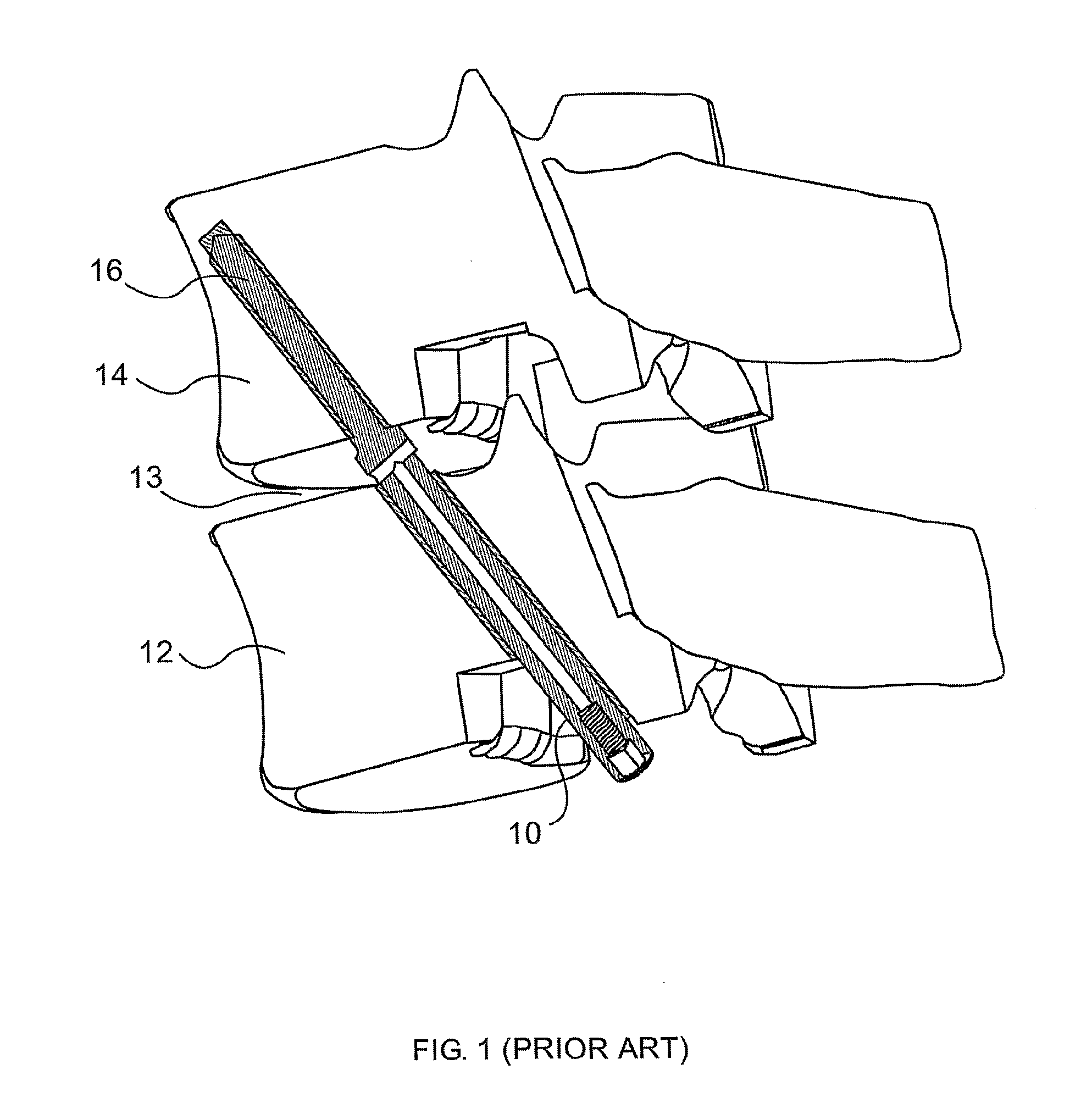

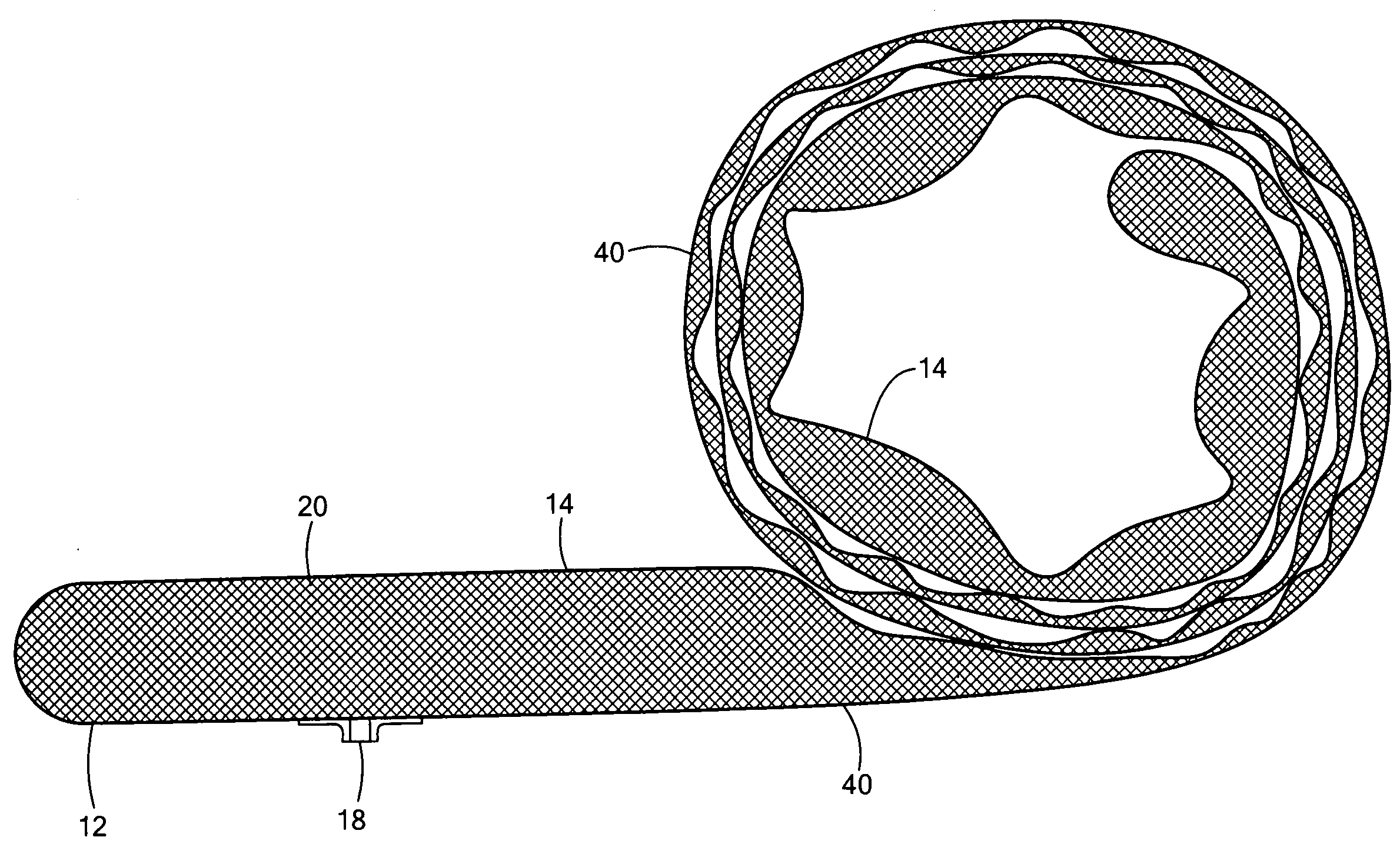

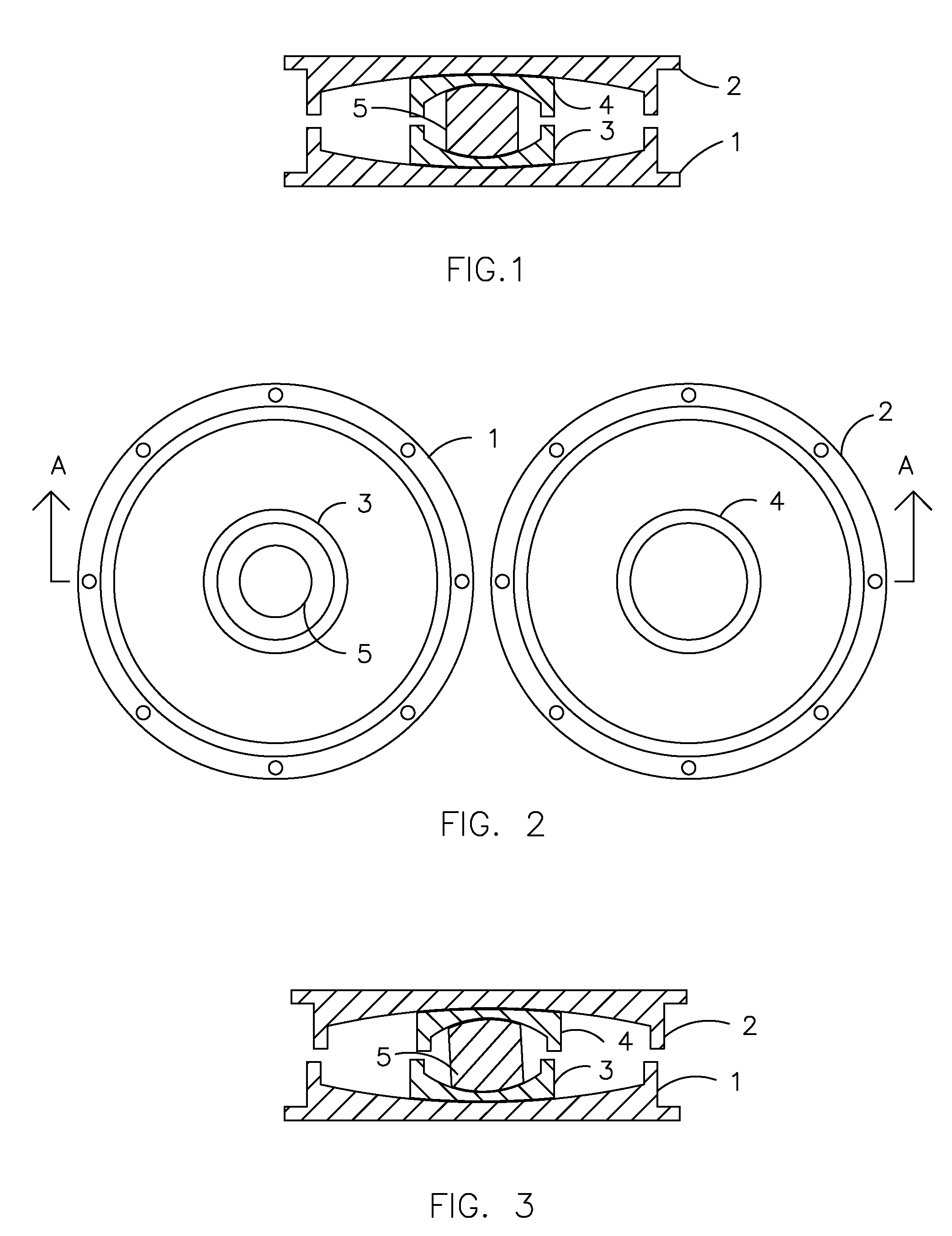

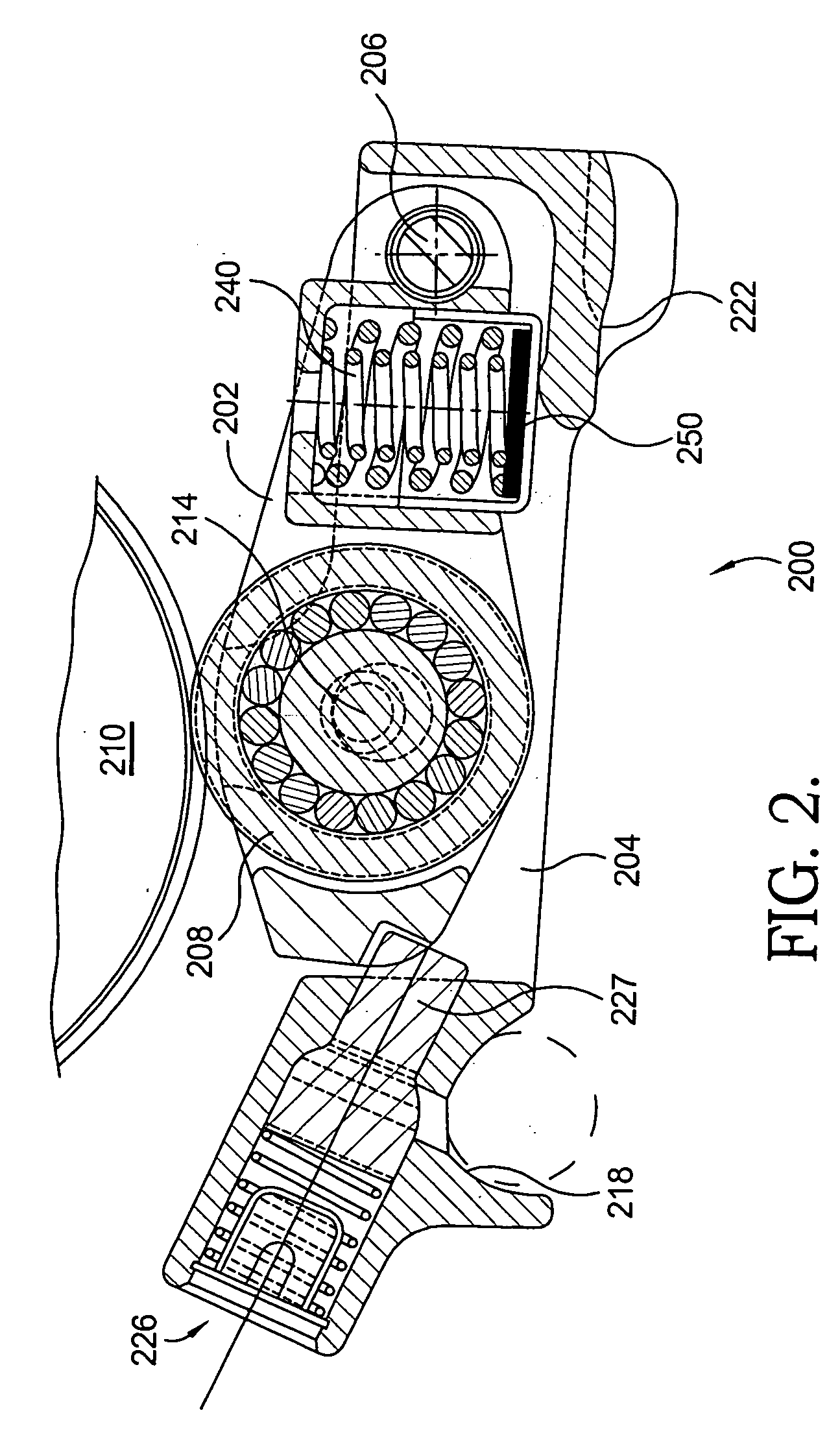

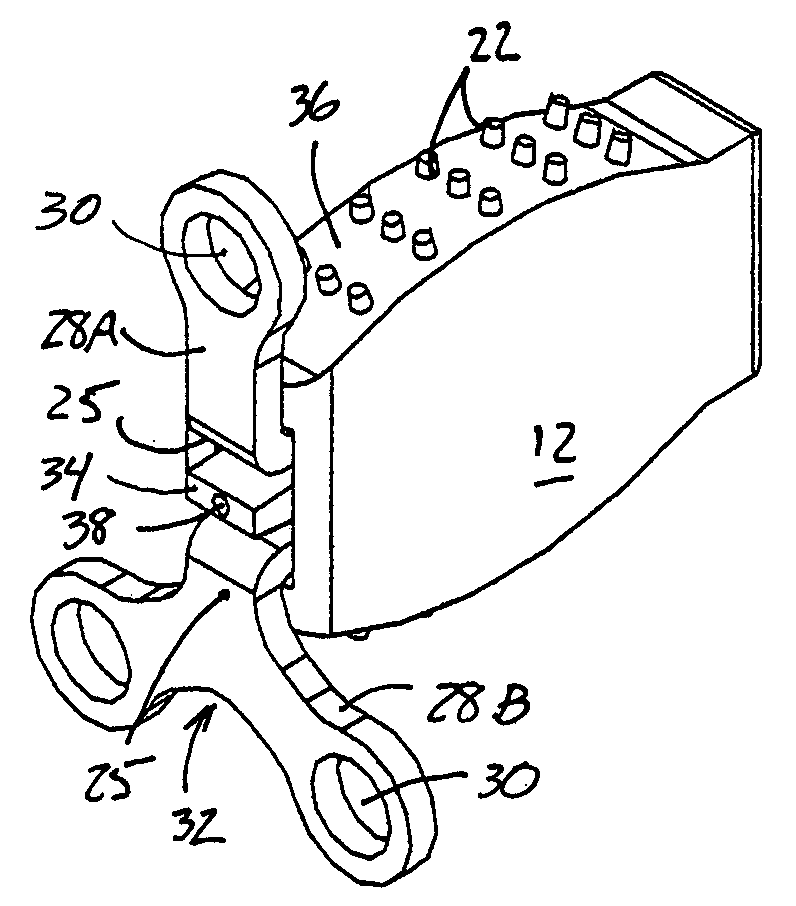

Segmented insert for intervertebral support

ActiveUS8328852B2Reduce loadImprove stabilityInternal osteosythesisJoint implantsIntervertebral spacesEngineering

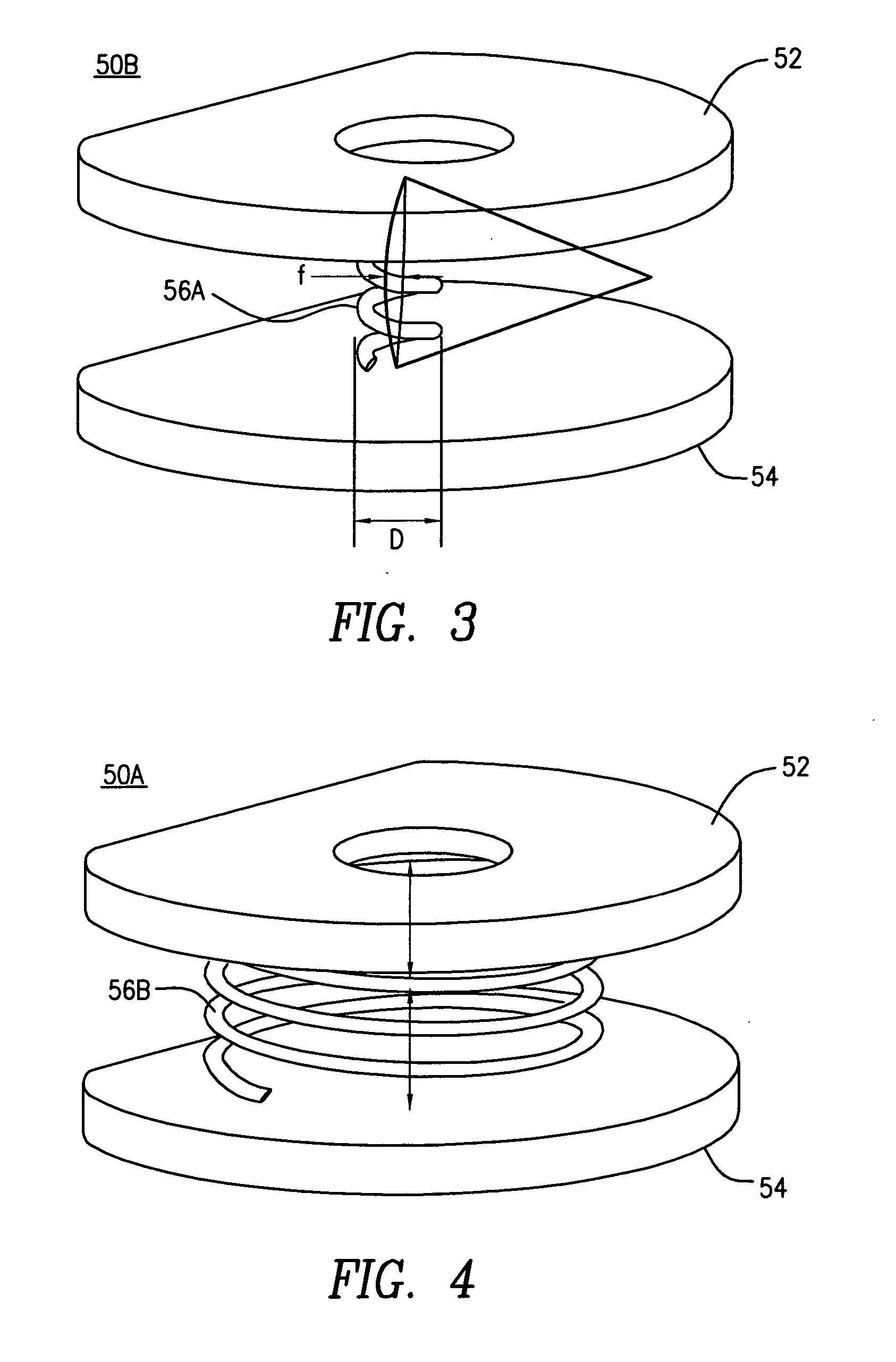

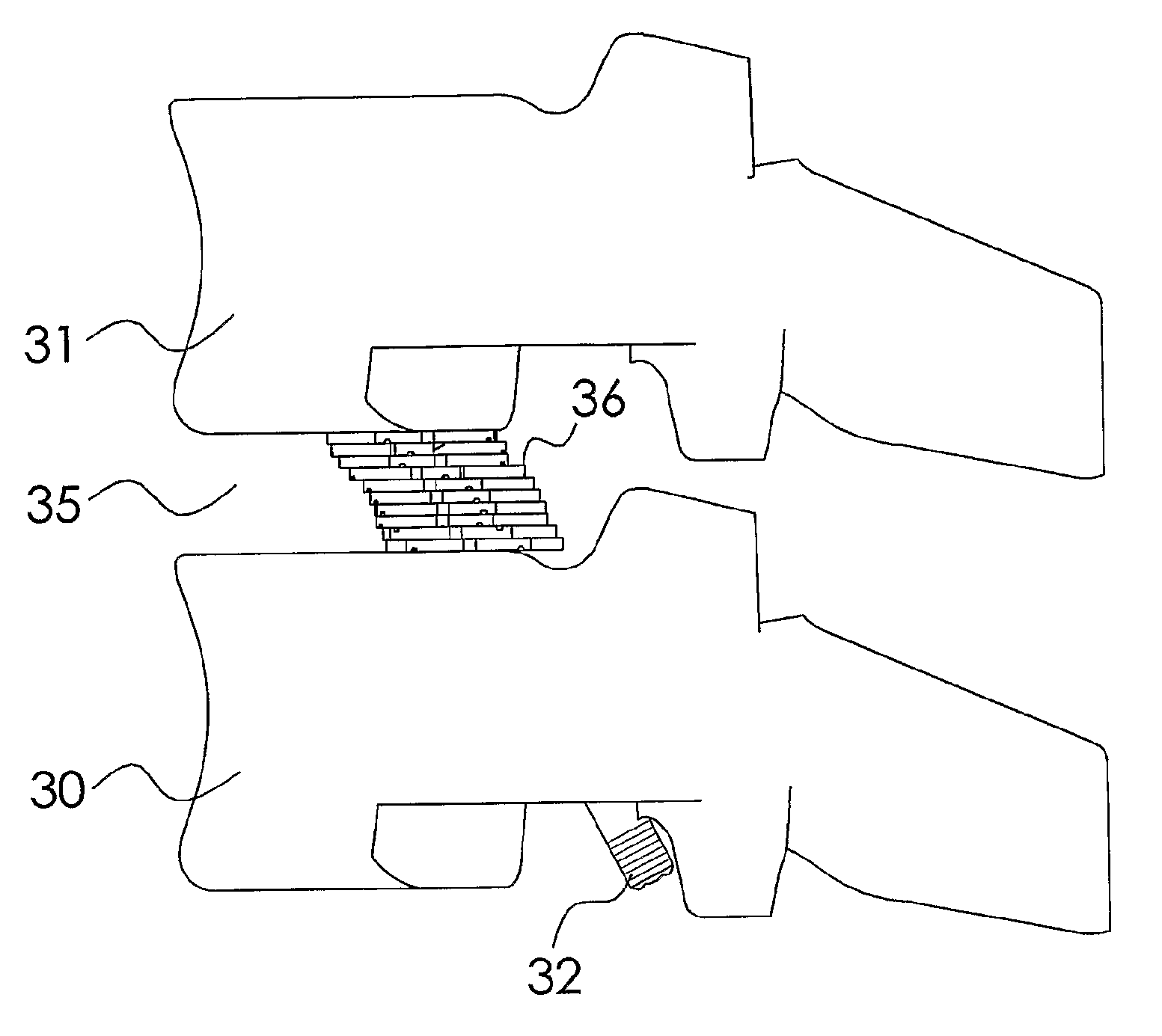

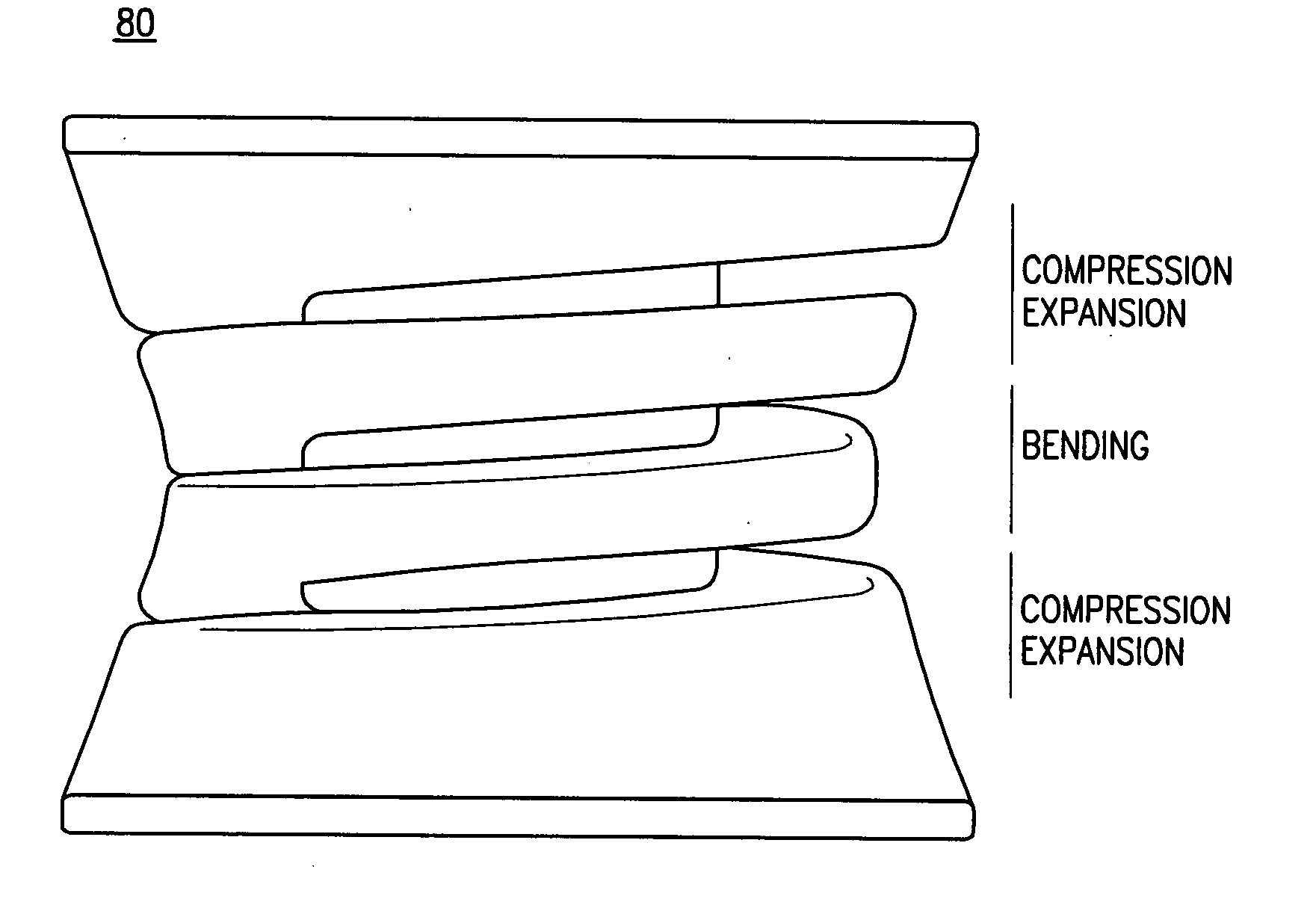

A spinal intervertebral support implant, for fusion or for dynamic stabilization purposes. A rod, preferably in the form of a screw, is inserted obliquely from the pedicle of an inferior vertebra into the body of a neighboring superior vertebra, through the disc space. The rod can be anchored into the body of the superior vertebra by means of a force fit or a screw thread. A pile of elements is disposed on the rod in the disc space like a pile of washers, so that the compression load between vertebrae is carried partly by these elements. These elements can be inserted through the bore through which the rod was inserted in a tightly folded configuration, and deployed into their washer-like form only when in position in the intervertebral space, such that there is no need for any additional incisions.

Owner:MAZOR ROBOTICS

Intervertebral stabilizer

An intervertebral stabilizer includes: a first surface operable to engage an endplate of a first vertebral bone of a spine; a second surface spaced apart from the first surface and operable to engage an endplate of an adjacent second vertebral bone of the spine; a spring element between the first and second surfaces and operable to provide reactive force in response to compression loads from the first and second vertebral bones, wherein a cross-sectional profile taken through the surfaces is hourglass shaped.

Owner:CARDO MEDICAL

Anterior lumbar intervertebral stabilizer

A lumbar intervertebral stabilizer for a lumbar region of a spine includes: a first surface operable to engage an endplate of a first vertebral bone of a spine; a second surface spaced apart from the first surface and operable to engage an endplate of an adjacent second vertebral bone of the spine; a spring element including at least one of: (i) a helical wound spring; and (ii) a hollow body having at least one slit forming a plurality of annular circumferential helical coils, the spring element being disposed between the first and second surfaces and being operable to provide reactive force in response to compression loads from the first and second vertebral bones, wherein at least some diameters of respective turns of the helical coils differ.

Owner:CARDO MEDICAL

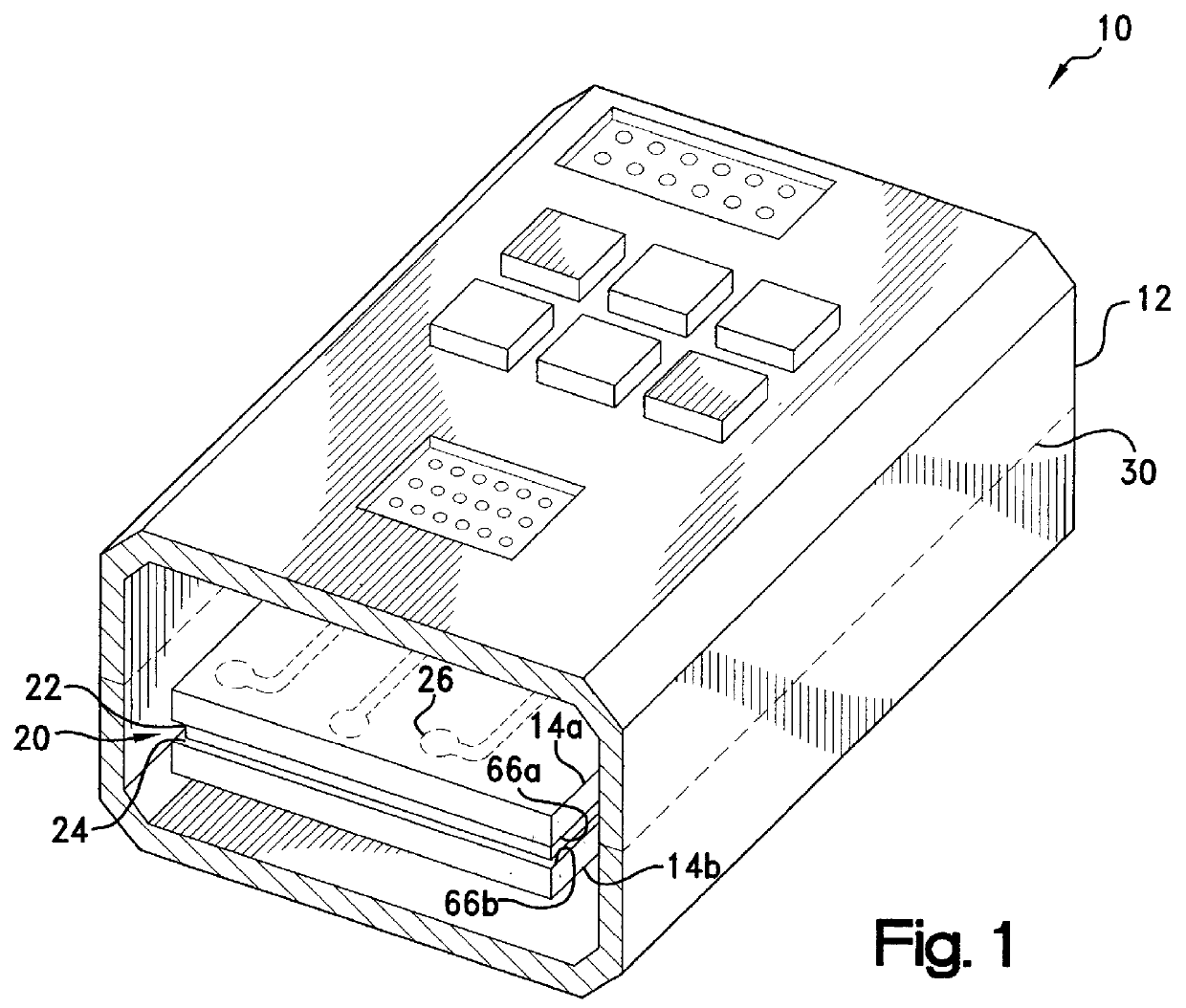

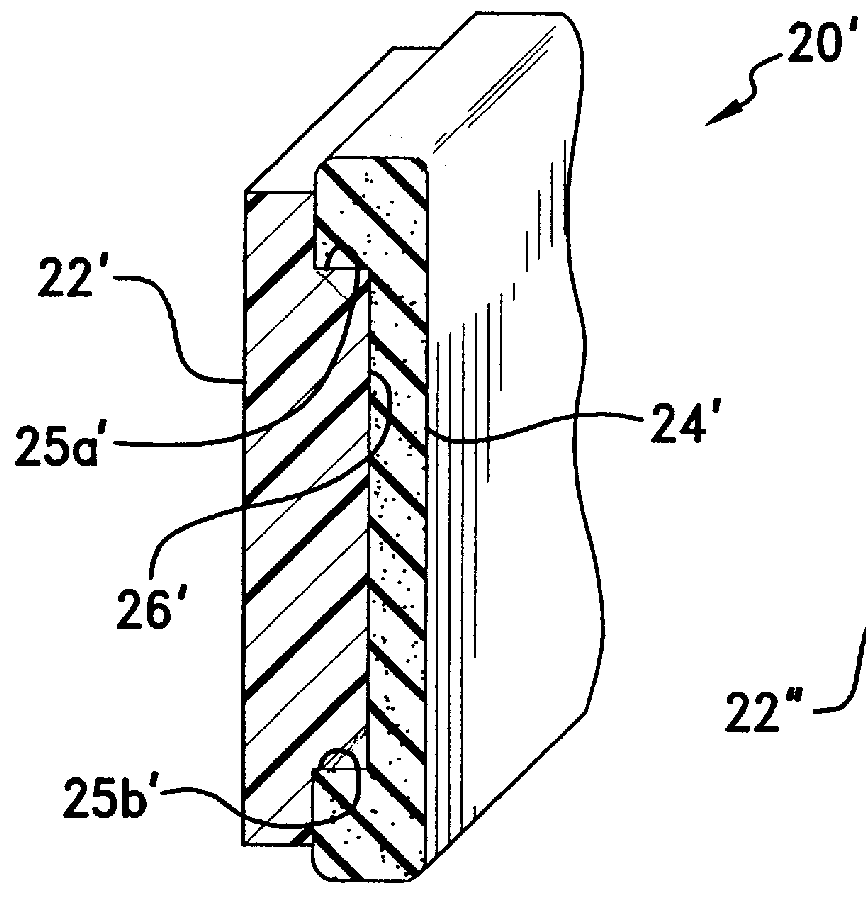

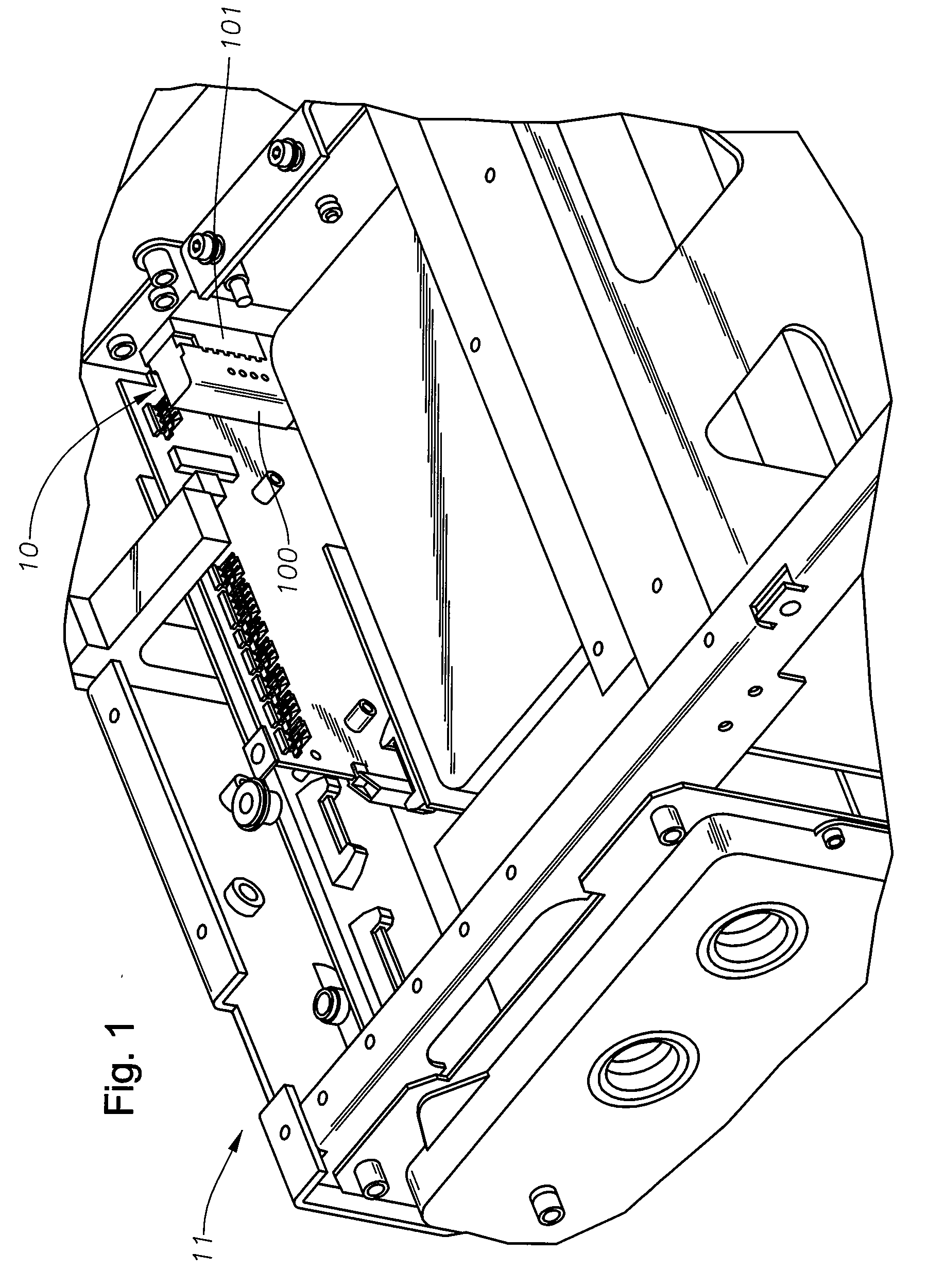

Low closure force EMI shielding spacer gasket

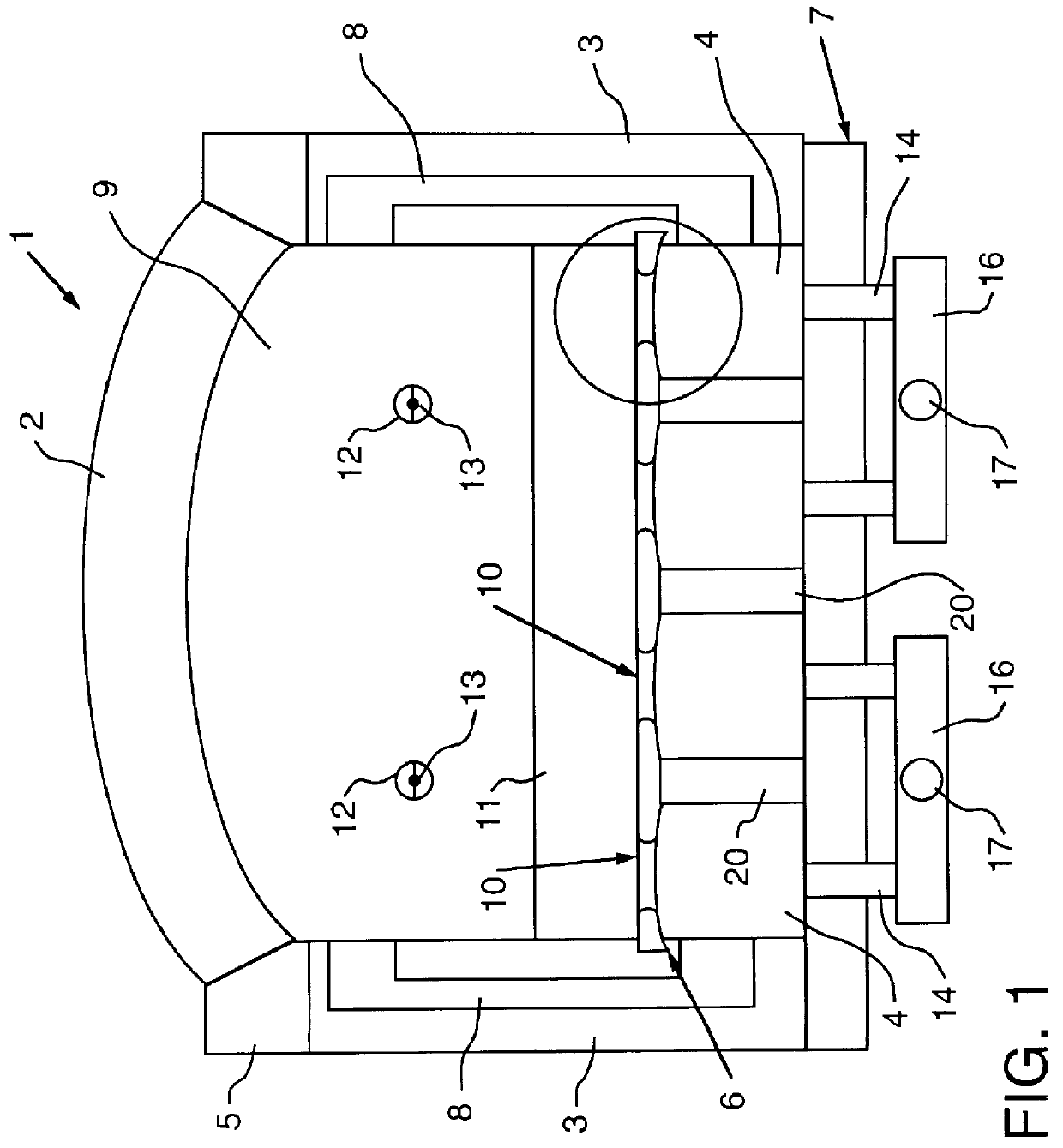

InactiveUS6121545AEnhance the imageEnsure electrical continuityEngine sealsScreening gaskets/sealsEdge surfaceBending moment

An EMI shielding spacer gasket assembly for interposition under a predetermined compressive load within an electronics enclosure between a first surface and an oppositely-disposed second surface of the enclosure. The assembly includes a frame member and an electrically conductive, elastomeric member extending along at least a portion of the perimeter of the frame member as retained on a corresponding peripheral edge surface thereof. The elastomeric member has an outboard side which is compressible axially under the compressive load for providing an electrically conductive pathway between the surfaces of the enclosure. In an uncompressed orientation, the outboard side of the elastomeric member exhibits elongate upper and lower bearing portions which are disposed at a spaced-apart radial distance from the frame member to define a corresponding bending moment arm. Each of the bearing portions is angularly deflectable relative to the moment arm to effect the compression of the elastomeric member under a relatively low compressive load.

Owner:PARKER INTANGIBLES LLC

Segmented insert for intervertebral support

ActiveUS20110054538A1Lateral dimension be relatively largeReduce loadInternal osteosythesisJoint implantsIntervertebral spacesEngineering

A spinal intervertebral support implant, for fusion or for dynamic stabilization purposes. A rod, preferably in the form of a screw, is inserted obliquely from the pedicle of an inferior vertebra into the body of a neighboring superior vertebra, through the disc space. The rod can be anchored into the body of the superior vertebra by means of a force fit or a screw thread. A pile of elements is disposed on the rod in the disc space like a pile of washers, so that the compression load between vertebrae is carried partly by these elements. These elements can be inserted through the bore through which the rod was inserted in a tightly folded configuration, and deployed into their washer-like form only when in position in the intervertebral space, such that there is no need for any additional incisions.

Owner:MAZOR ROBOTICS

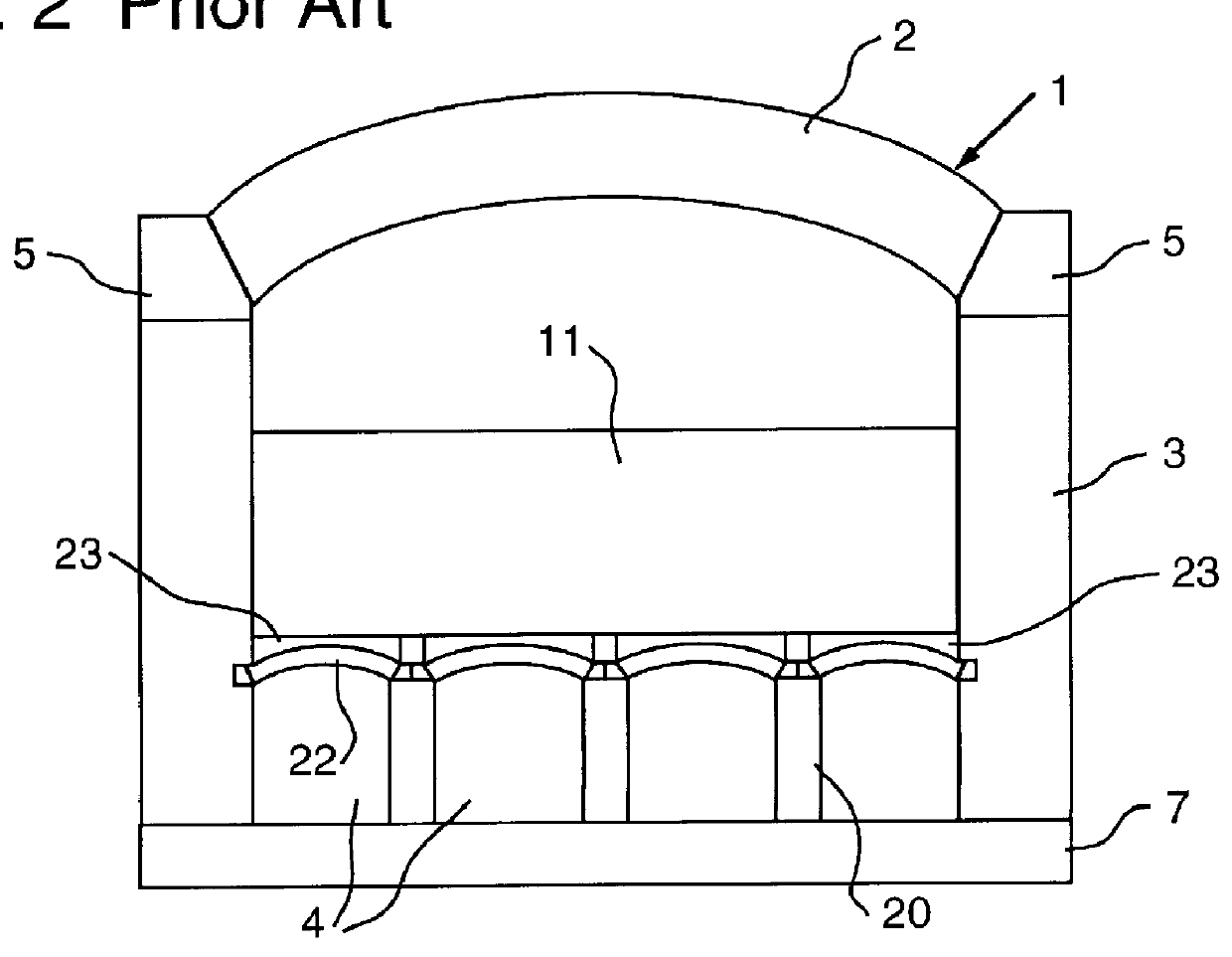

Interlocking floor brick for non-recovery coke oven

An improved non-recovery coke oven floor constructed of a single layer of refractory bricks including, for each oven sole flue, a pair of trunnion bricks and a center bridge brick spanning the width of the flue, having lower brick surfaces in the form of an arch, and joined end-to-end by a tapered tongue-and-groove joint disposed approximately perpendicular to the direction of a compression load transmitted by the center bridge brick to the trunnion bricks.

Owner:PENNSYLVANIA COKE TECH

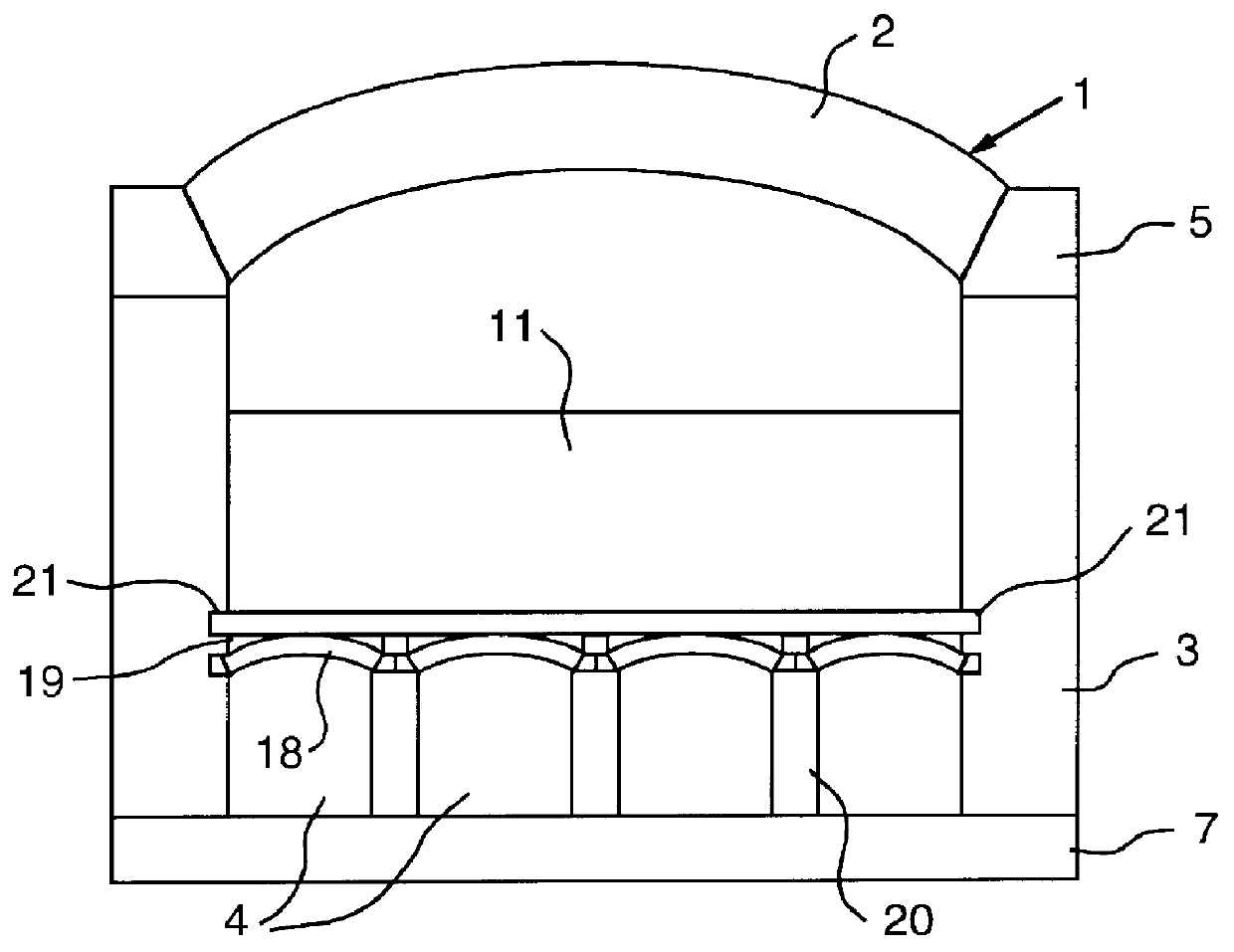

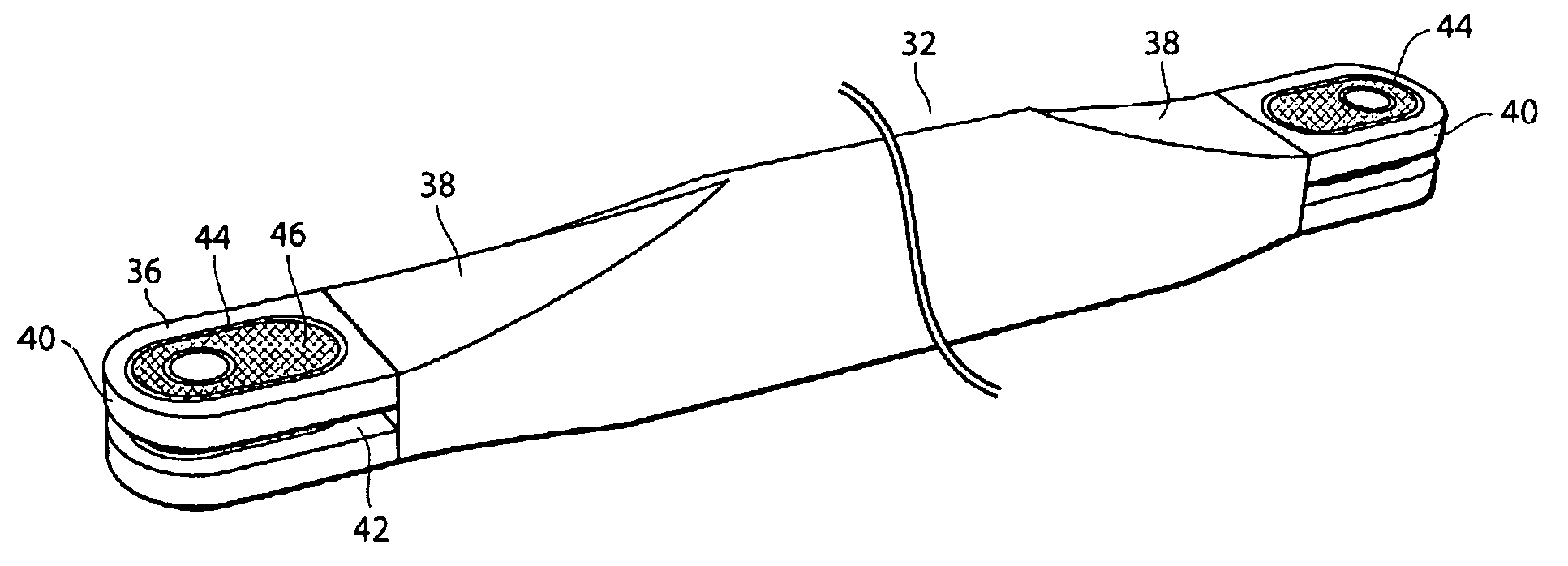

Roll-up inflatable beam structure

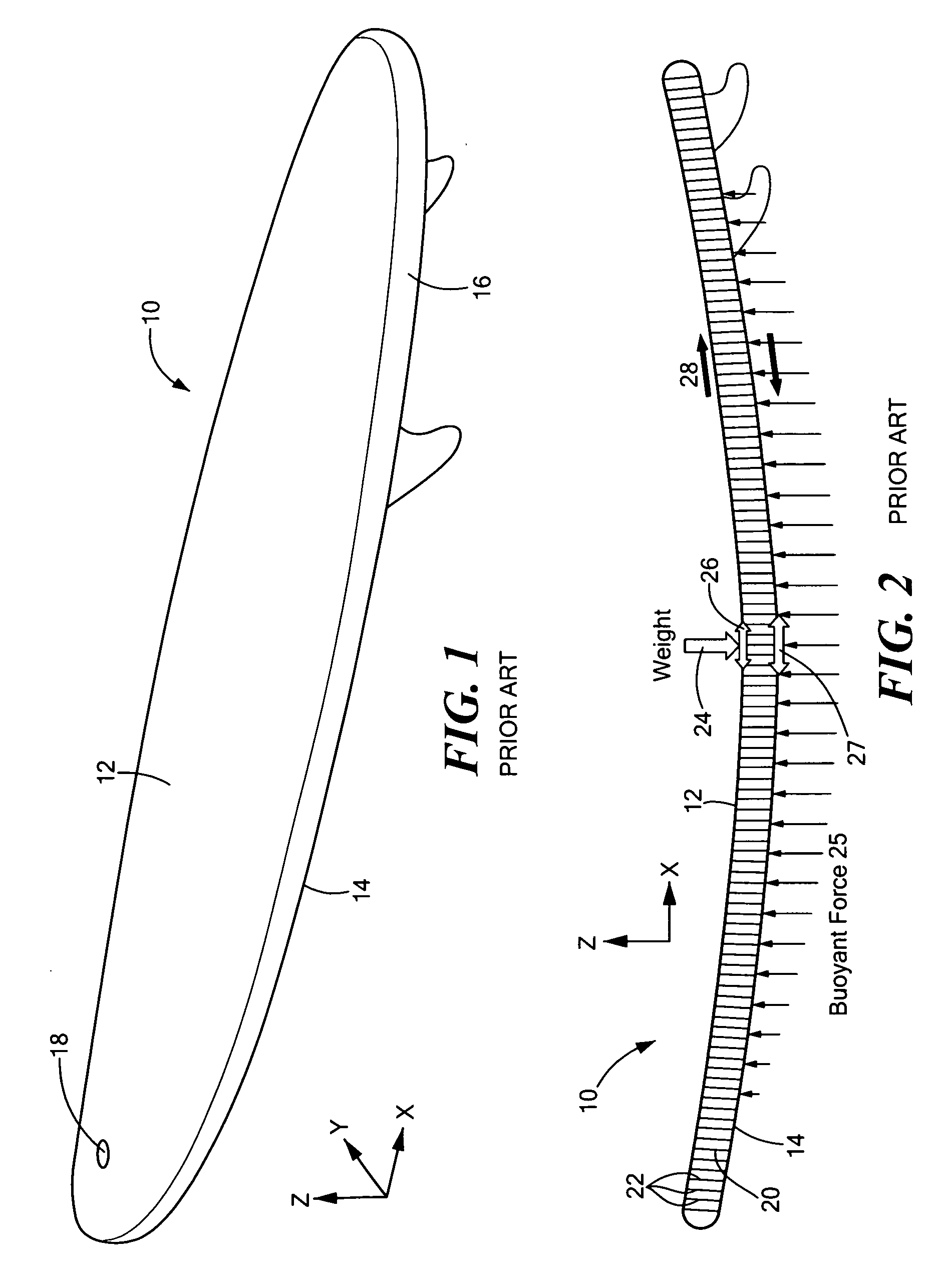

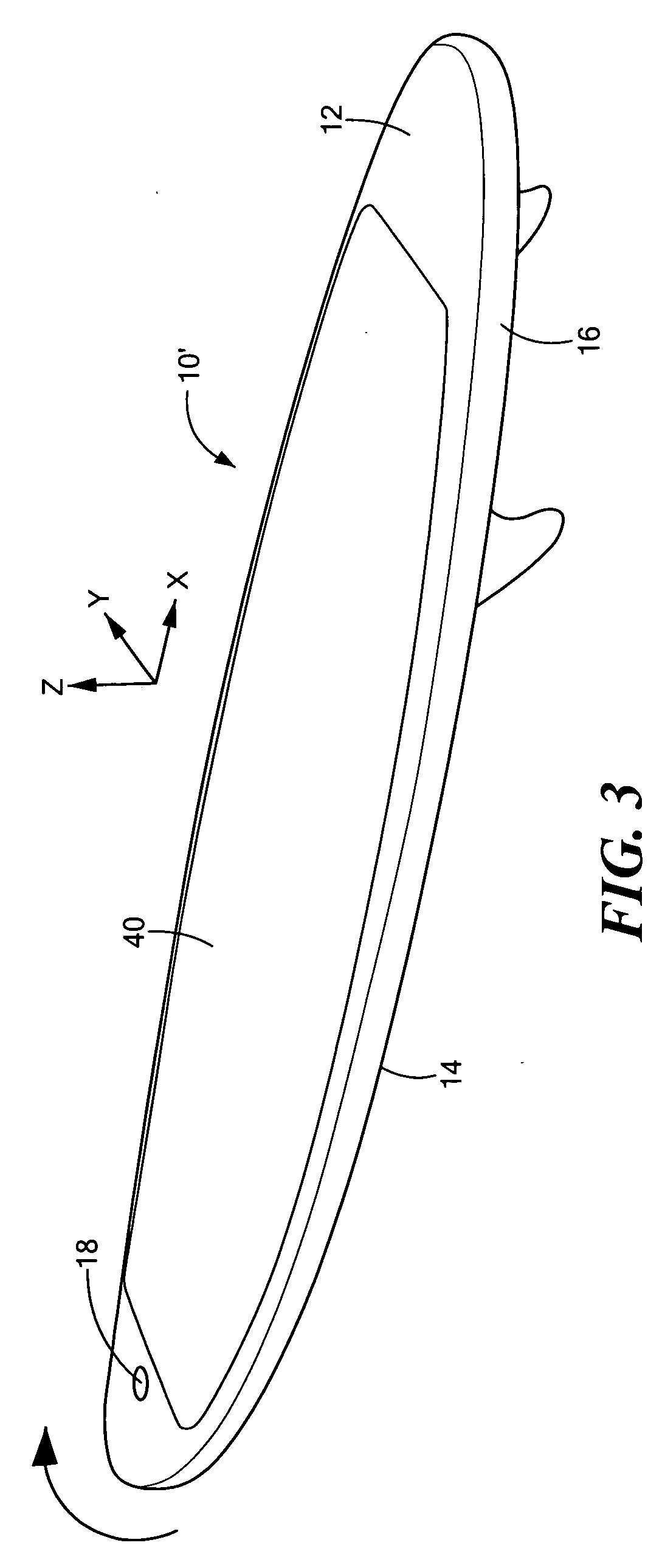

InactiveUS20090049757A1Strong and stable structureGood withstands buckling loadWaterborne vesselsWater sport boardsNuclear engineeringGas pressure

A sandwich beam including in one example first and second spaced walls, a core configured to maintain a predetermined spacing between the walls when the core is filled with pressurized gas and to resist shear when the beam is loaded in bending and a port for filling the core with gas biasing both walls in tension. The tension tends to increase in the second wall and decrease and cause a compression load in the first wall in response to a sufficiently large applied bending load. A compression element is fixed only with respect to the first wall and is configured (a) to support the compression load so that the beam is stronger at a given gas pressure and (b) to flex sufficiently to allow the beam to be rolled up when the gas is emptied from the core via the port.

Owner:FOSTER-MILLER

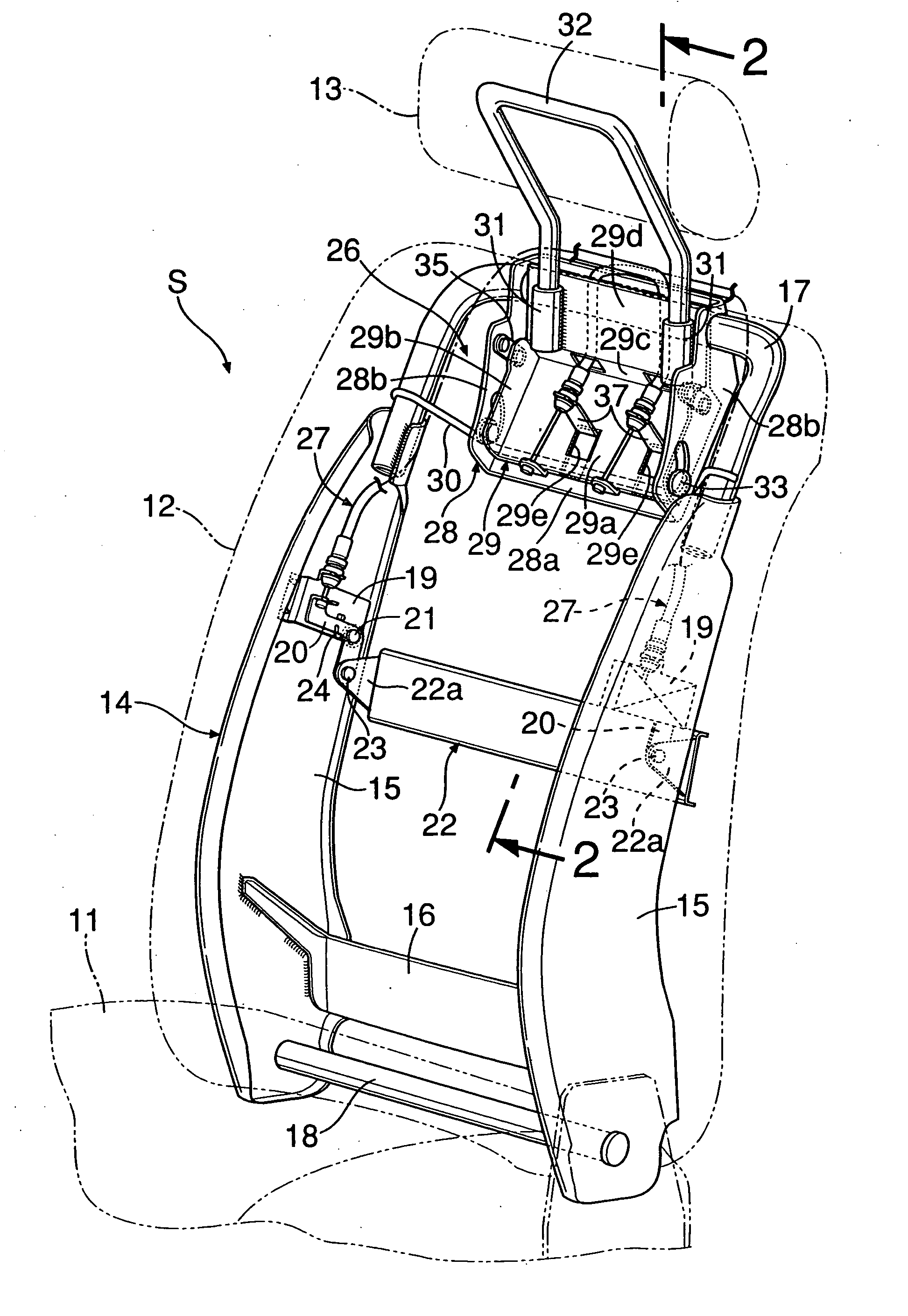

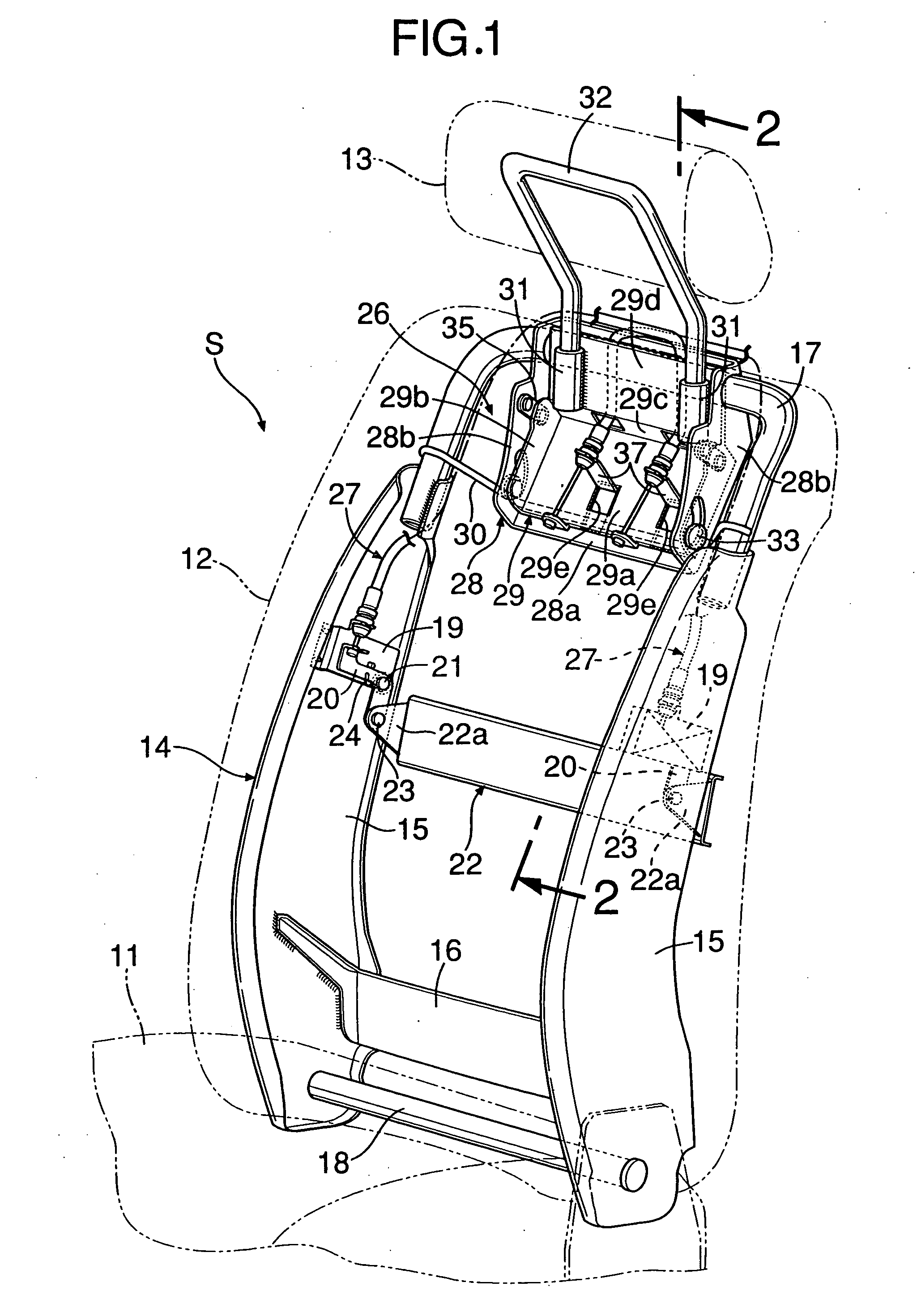

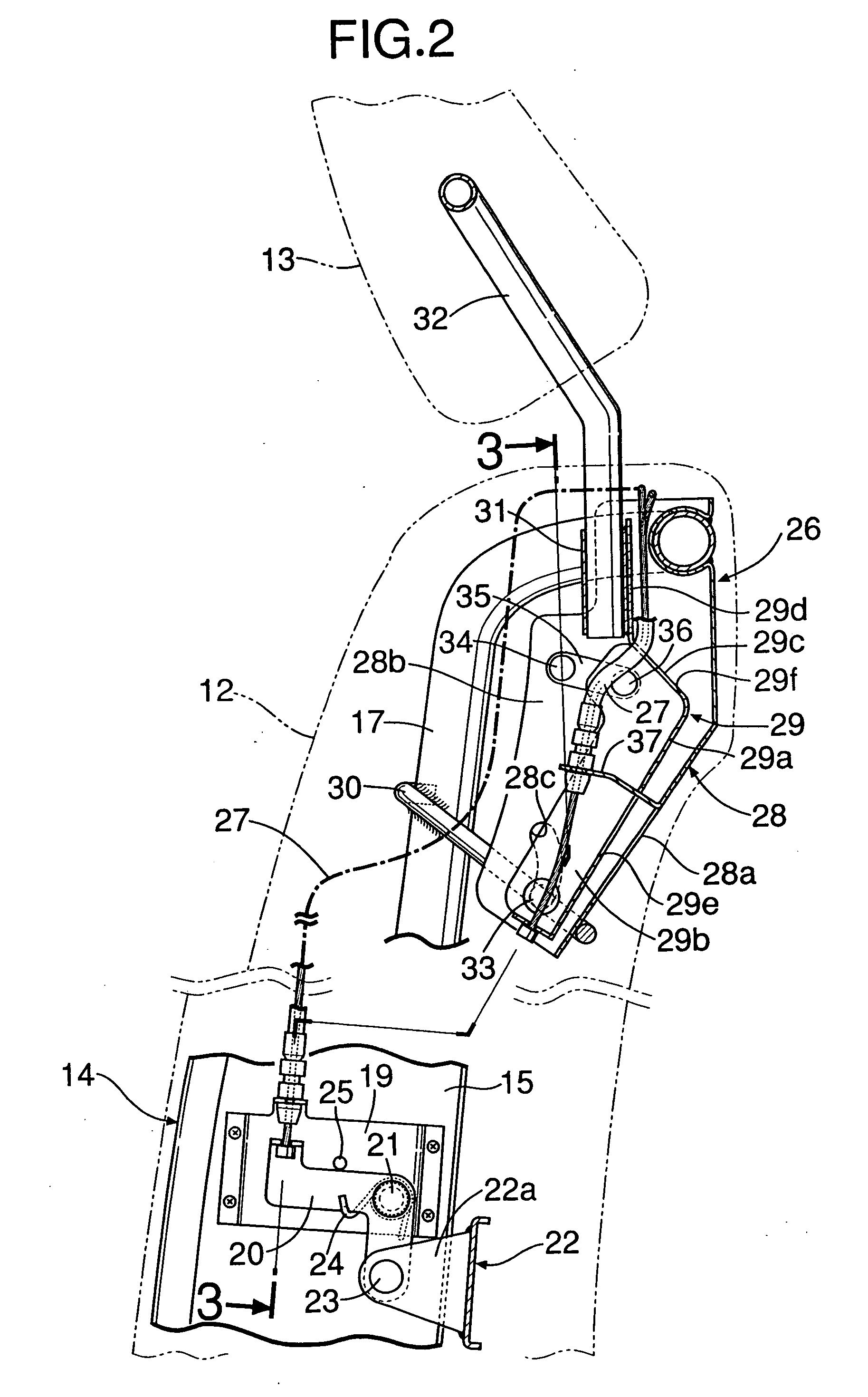

Head rest device

InactiveUS20060006709A1Reduce rigidityReliable holdBack restsPedestrian/occupant safety arrangementRear-end collisionBowden cable

When a pressure receiving plate provided at a seat back moves to a rear side of a vehicle body when a vehicle is collided from behind, a Bowden cable transmits movement of the pressure receiving plate to a headrest ascending mechanism as a tensile load, thereby quickly ascending a headrest to reliably hold a head of an occupant. The Bowden cable transmits only the tensile load, and hence the Bowden cable is not buckled. Reduction in weight is made possible as compared with the case using a rod for transmitting a compression load. Since the Bowden cable is light, it is not required to unreasonably place the pressure receiving plate at a position near the headrest ascending mechanism for reduction in weight, and hence the pressure receiving plate can be placed at the optimal position where a sufficient driving force is obtained at the time of collision. Thus, a headrest is ascended with favorable responsiveness upon a rear-end collision of a vehicle while using a thin transmission member with low rigidity.

Owner:HONDA MOTOR CO LTD

Sliding Pendulum Seismic Isolation System

ActiveUS20060174555A1Increase effective frictionReduce earthquake forceStands/trestlesKitchen equipmentCost effectivenessSeismic gap

An inventive method is presented for a sliding pendulum seismic isolation system that reduces seismic forces on the supported structure and reduces the costs of the isolation bearings, seismic gaps, and supported structural frame. The inventive method is to configure the isolation system to achieve increased effective friction with increased displacement amplitudes, and to employ specific bearing configurations that suit the different types and magnitudes of loads present at particular structure support locations. Three bearing configurations are presented which are comprised of multiple sliders that slide along different concave spherical surfaces, each constituting an independent sliding pendulum mechanism having a specified pendulum length and friction. Two bearing configurations are presented which are comprised of multiple sliders that slide along different concave or convex cylindrical surfaces, one configured to carry both compression and tension loads, and one configured to be cost-effective for carrying light compression loads and accommodating large displacements.

Owner:EARTHQUAKE PROTECTION SYST

Diagnostics for two-mode variable valve activation devices

ActiveUS20090228167A1Vehicle testingInternal-combustion engine testingElectricityRadio frequency signal

A method for detecting a low-lift or zero-lift failure mode in a variable valve activation system of an internal combustion engine includes the steps of positioning a piezo-electric element that acts as a radio frequency transmitter relative to a lost motion spring of a two-mode variable valve activation lost motion device, subjecting the piezo-electric element to a compression load when a load from displacement of a lobe of a camshaft acts on the lost motion spring, broadcasting a radio frequency signal each time the piezo-electric element is subjected to the compression load, and evaluating the presence or absence of the broadcasted radio frequency signal in relation to an expected presence or absence of the radio frequency signal. The direct measurement of the mode of each two-mode device is both more reliable and more efficient in the use of engine controller resources compared to currently existing diagnostic methods.

Owner:DELPHI TECH IP LTD

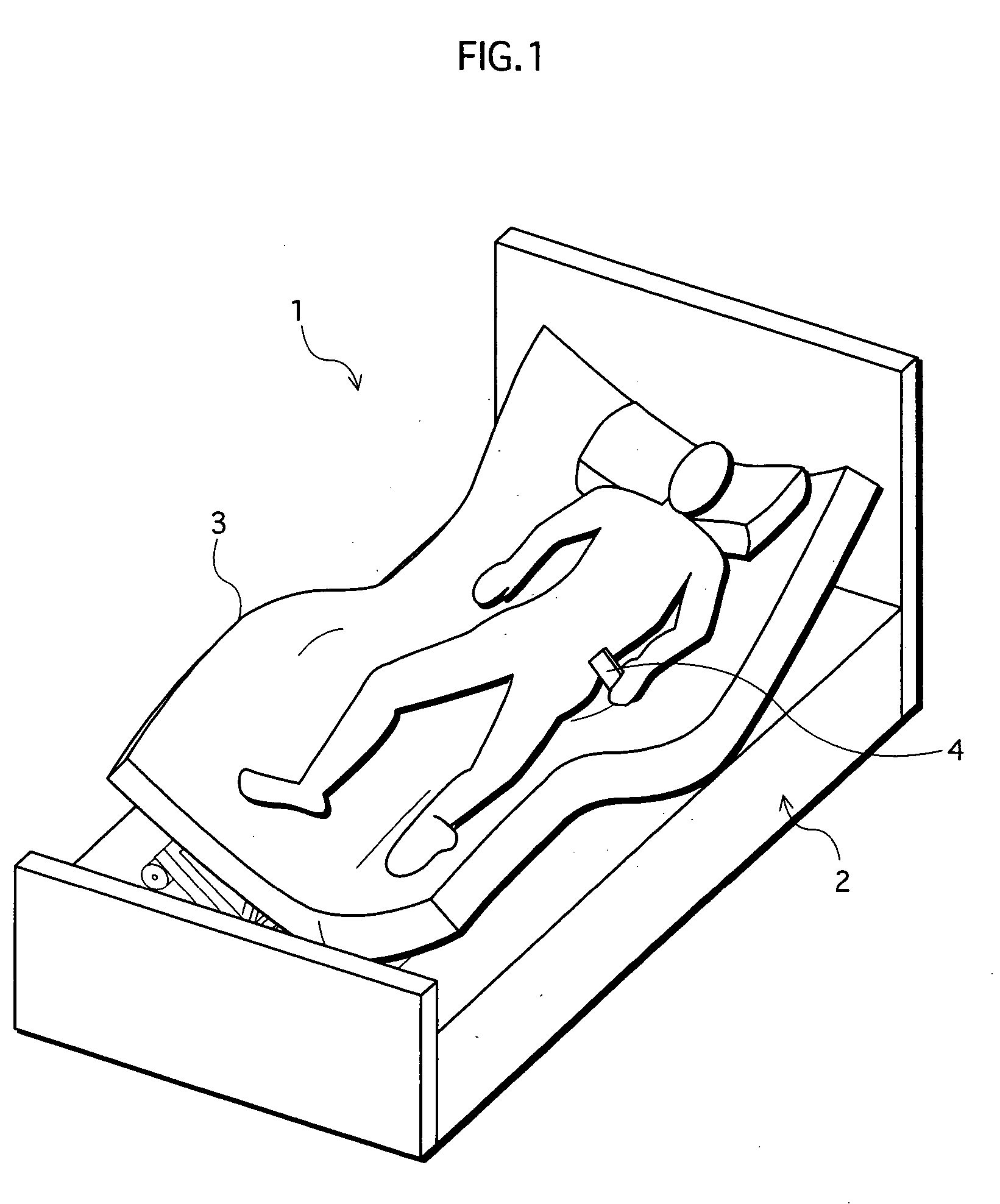

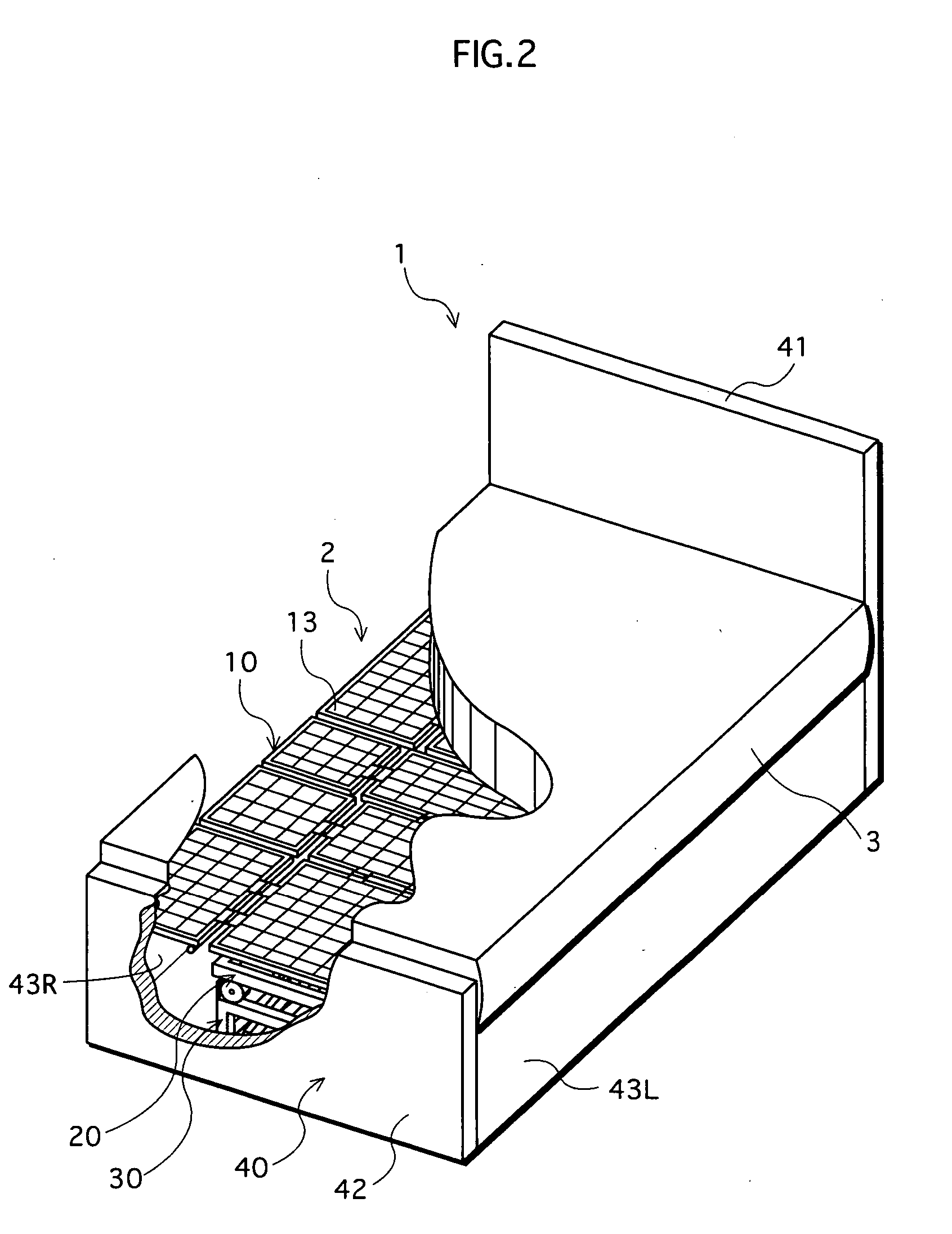

Movable bed

InactiveUS20050166323A1Not to subject to unnecessary stressAvoid intermittent operationSofasBedsEngineeringGravity center

An adjustable bed including a laterally tiltable platform, a tilt mechanism that tilts the platform laterally, and a load-applying unit that applies, in a state in which the platform is tilted within a predetermined angle range during operation of the tilt mechanism, a load to the platform in a direction that suppresses an expansion of the tilt angle, so as to prevent one of a compression load and a tension load exerted on the tilt mechanism by the platform from reversing to the other load type. The adjustable bed may be structured so that the predetermined angle range includes a tilt angle at which a gravitational center of the platform during the tilt operation traverses a vertical line containing a rotational center of the platform with the load-applying unit in a non-operational state.

Owner:SANYO ELECTRIC CO LTD

Method of construction for density screening outer transport walls

InactiveUS6033564AThin and inexpensiveReduced toleranceRotary centrifugesCeramic shaping apparatusBursting strengthDynamic balance

A method for combining three different means of constructing the concentric layers of the outer collecting wall for industrial size centrifuges, whereby treating the inward-facing elements of easily cast or stamped materials using processes such as Physical Vapor Deposition, Chemical Vapor Deposition or metal plating, transforms them into an innermost member with superior hardness and durability, and whereby said wear surface member or deposited layer is physically supported by a middle composite layer made up of one or more investment castings designed to optimally transfer centrifugally-induced compression loads from the innermost wear surface toward the outer surface of the composite wall, such castings being of ceramic, metals or other materials, and whereby the outer surface of said composite wall is comprised of a filament-wound hoop strength reinforcement layer, using aramid, graphic, carbon or such fibers mixed and embedded in resin, such that all highly desirable characteristics for a centrifuge outer, heavies-collecting wall are provided, including interior hardness and wear abrasion, incompressibility and intrinsic dynamic balance, and substantially higher hoop or bursting strength, than can be attained through any metal-crafted centrifuge outer wall, and, model for model, for substantially lower design and fabrication costs.

Owner:BERKELEY F FULLER

Patient support

ActiveUS20100146709A1Improve immersionIncreased contact surface areaUpholstery manufactureStuffed mattressesElastomerEngineering

A patient support includes a layer of fluid pressurized bladders, the bladders each having a chamber and an upwardly facing surface for facing and supporting a patient, and a cover over the layer of fluid pressurized bladders. Respective bladders in at least a group of the bladders each have a resilient body in its respective chamber to reform the shape of the respective bladder when a compression load on the respective bladder is removed wherein the pressure in the respective bladders is generally maintained without a powered supply of air. The cover has an upwardly facing patient surface and a bladder layer facing surface, with the patient surface for forming a patient support surface on the support, and the bladder layer facing surface for lying on the upwardly facing surfaces of the bladders.

Owner:STRYKER CORP

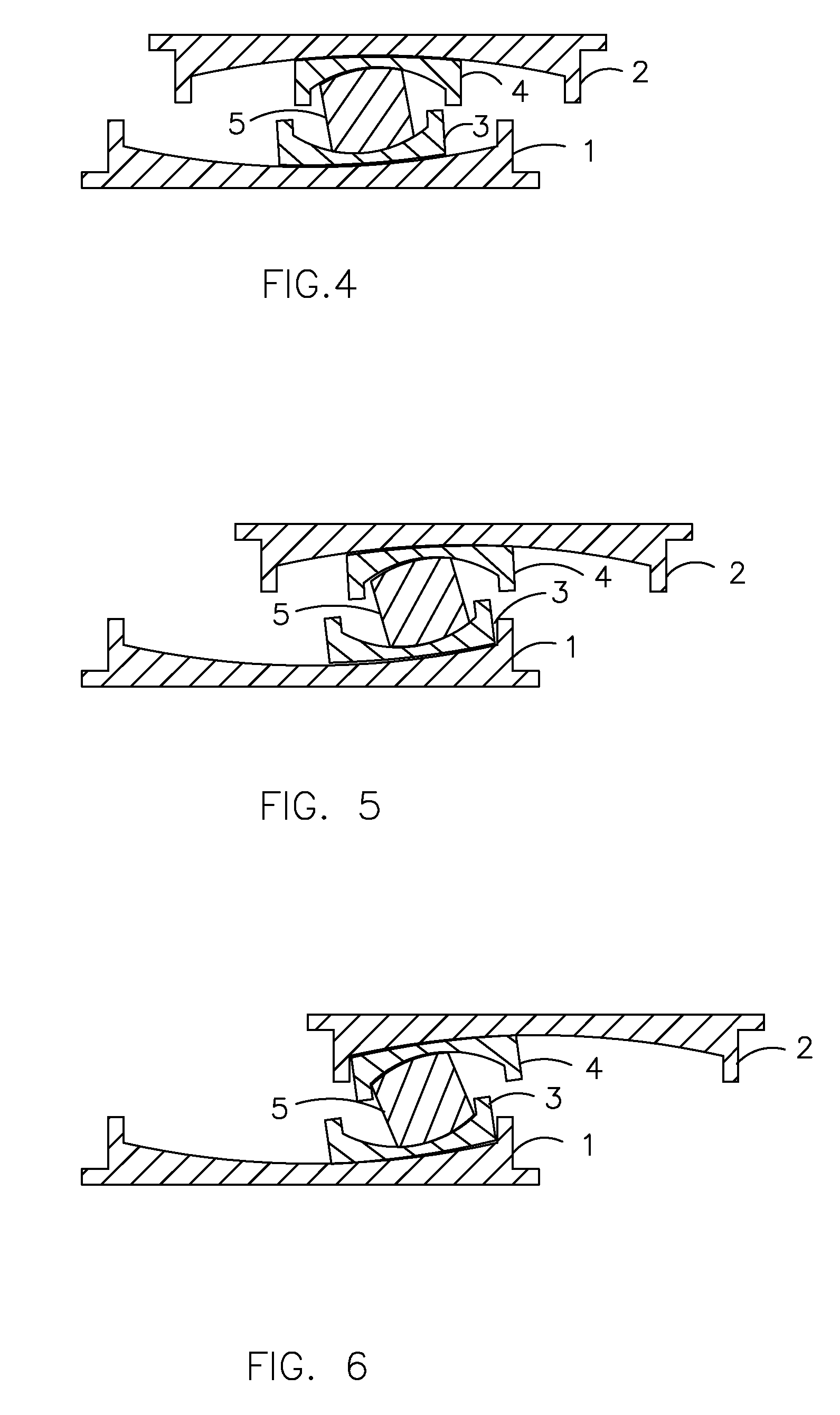

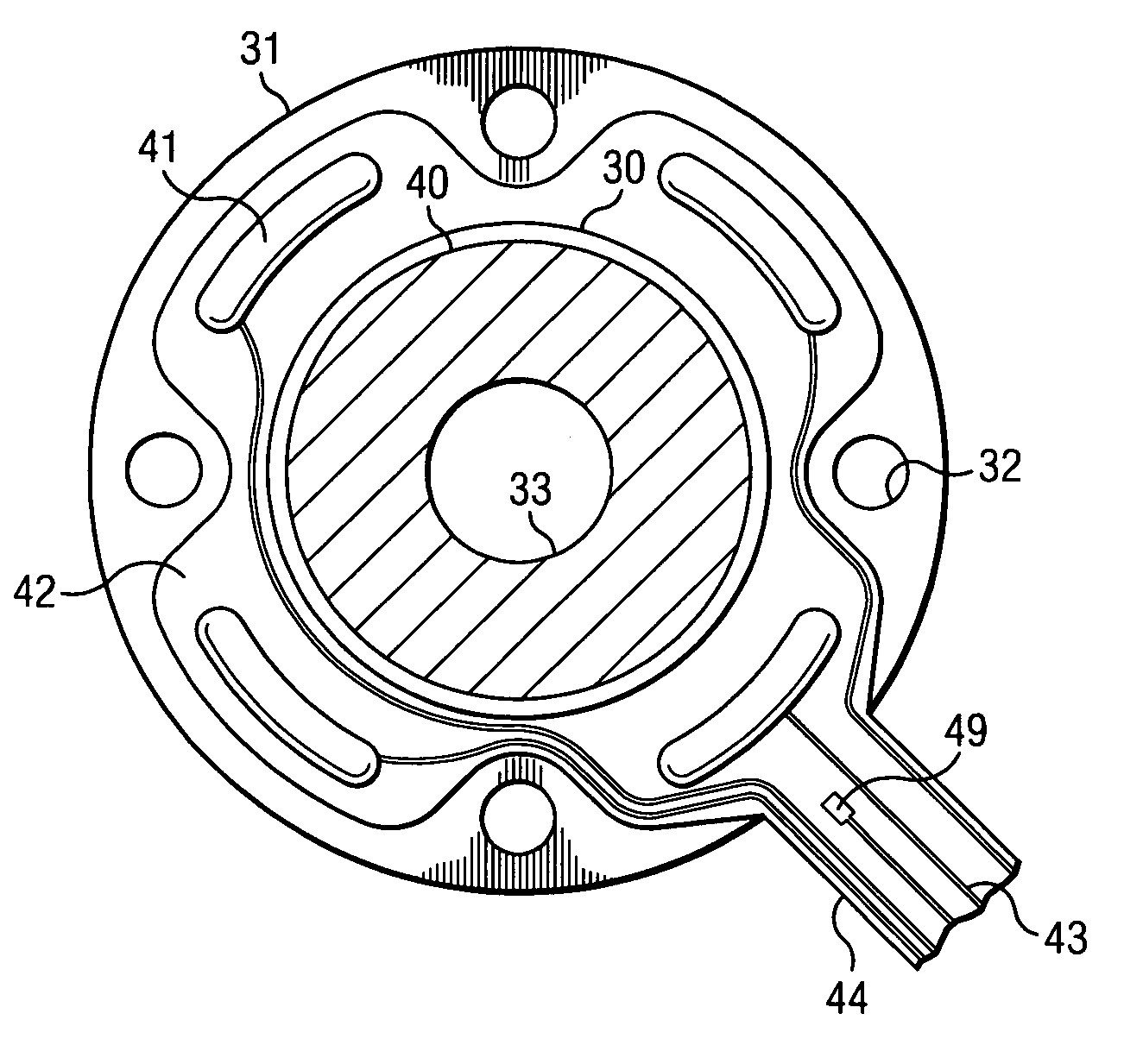

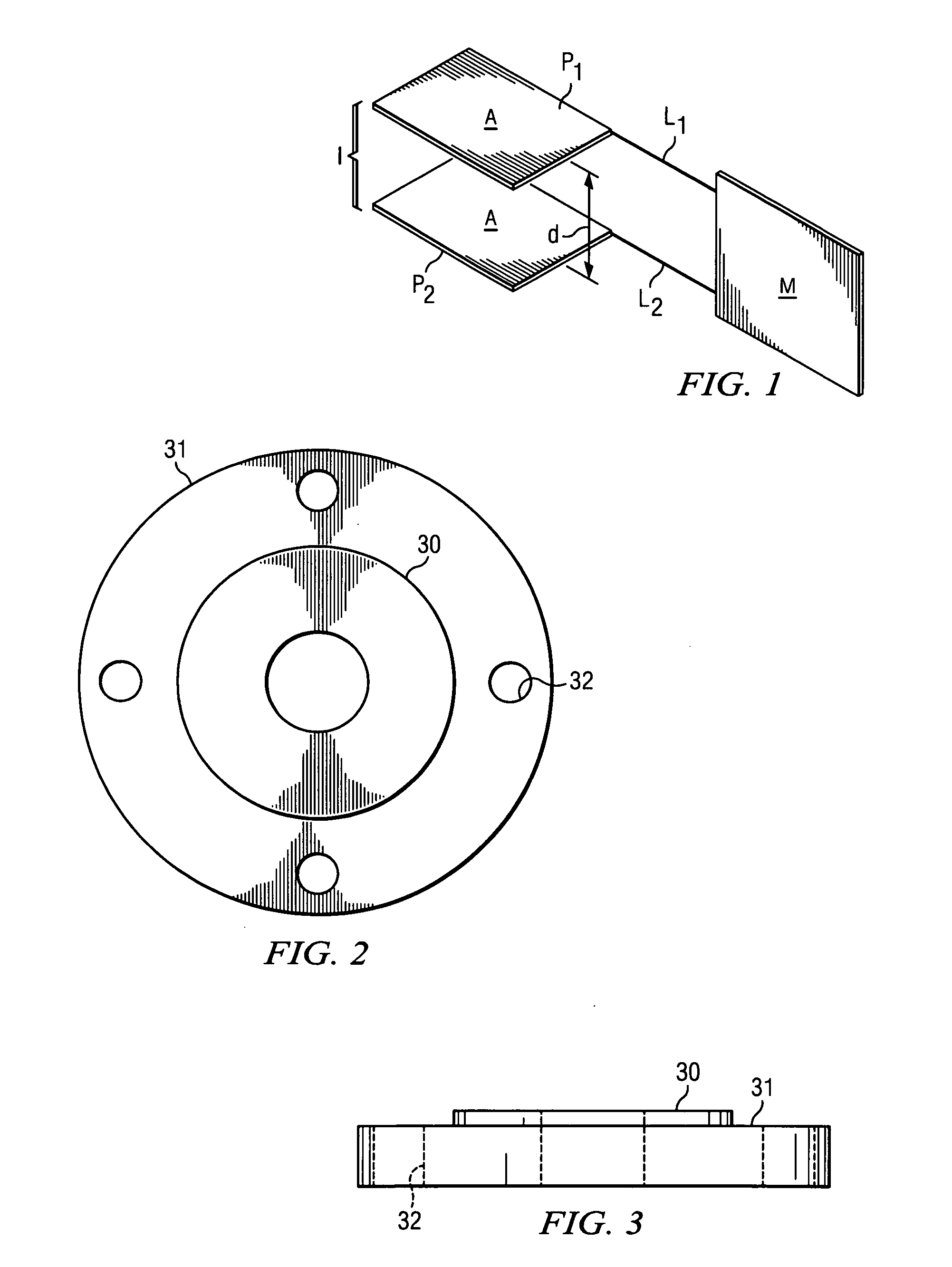

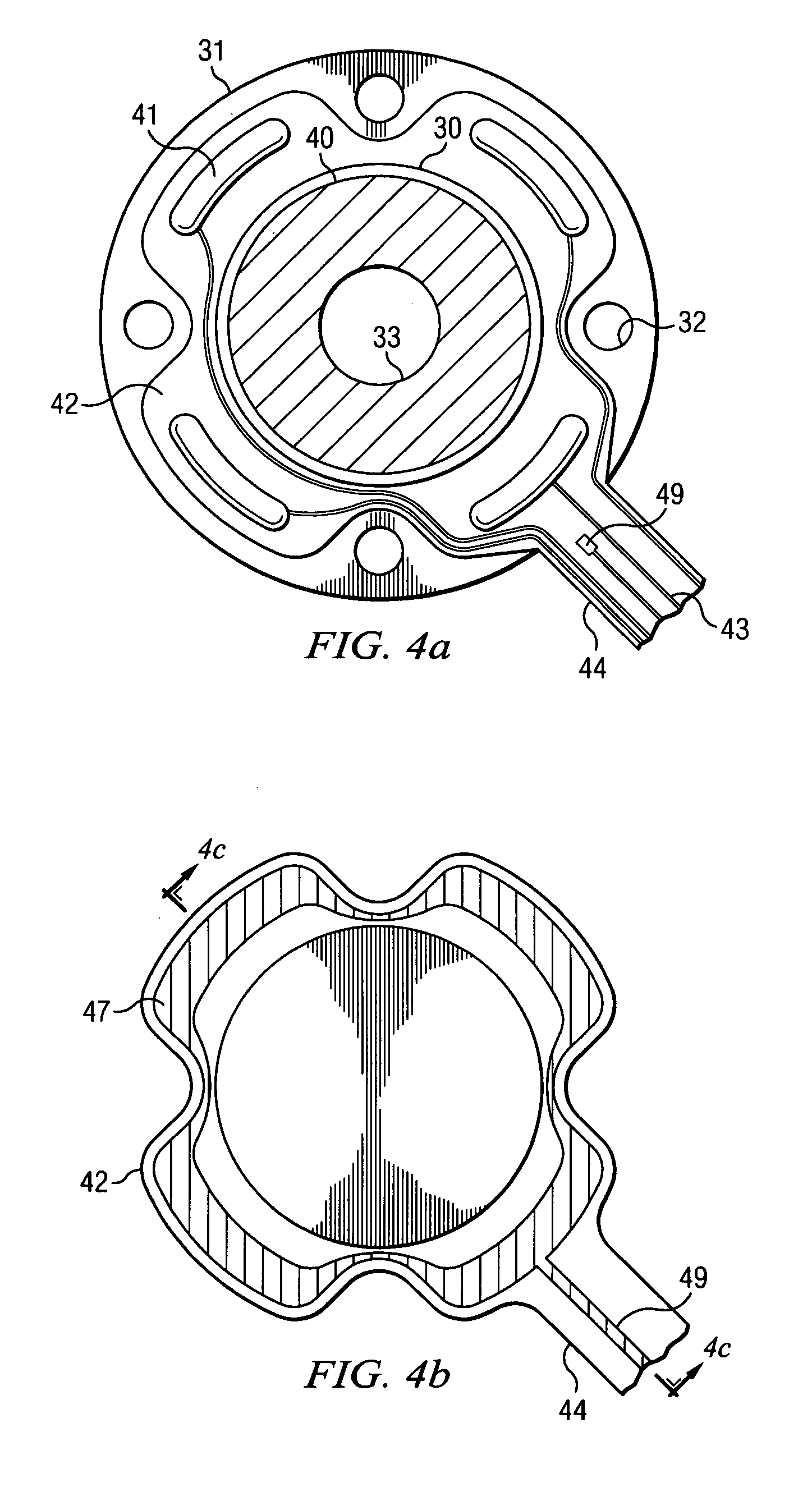

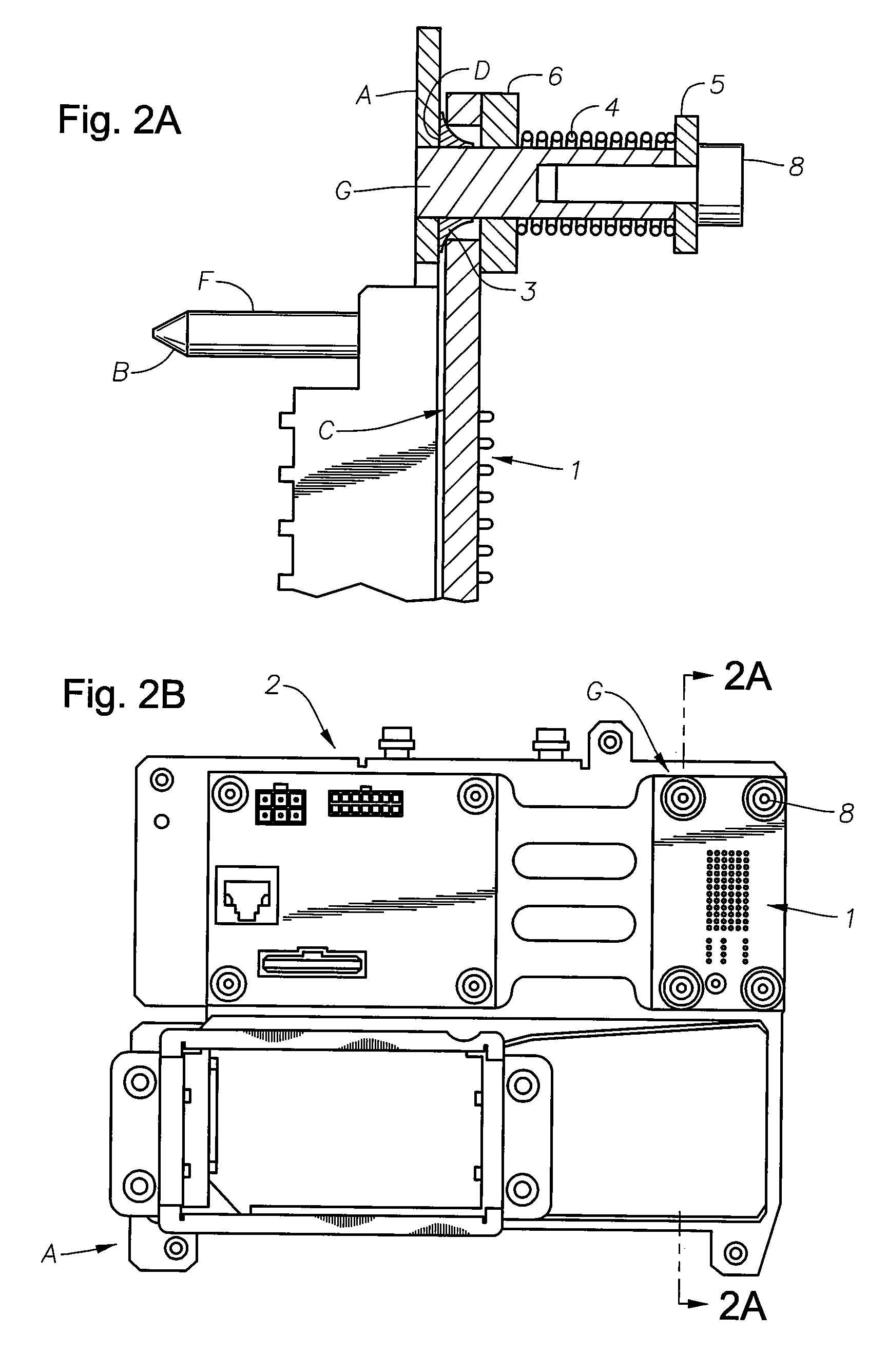

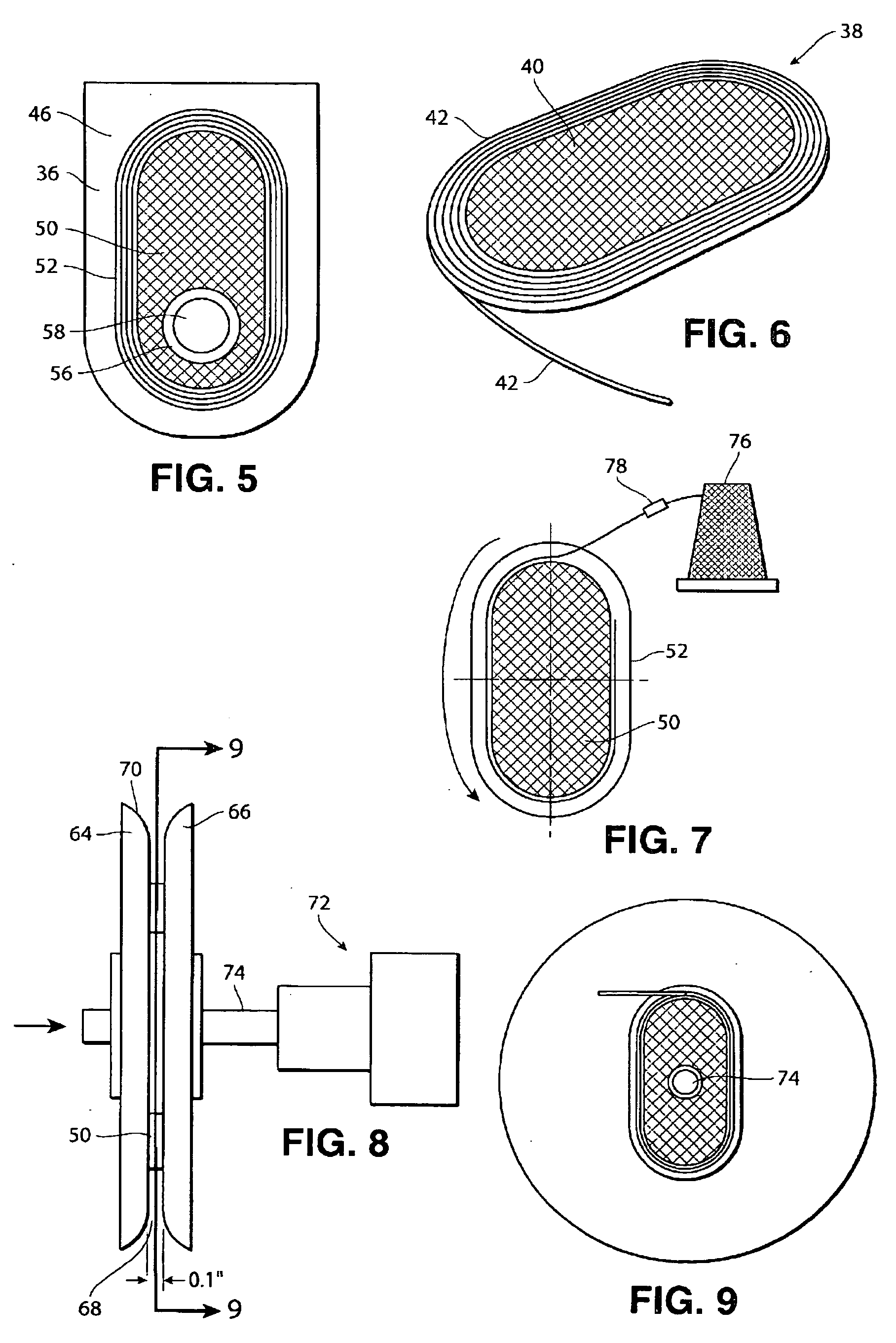

Compressive load sensor by capacitive measurement

InactiveUS20070193361A1Effectively measure parameterMaintain measurement accuracyForce measurementMachine sealing rings testingContinuous measurementElectricity

A thin, flat capacitive load sensor, such as of layered sandwich construction, having a variety of shapes, so as to provide a seal between two or more opposing surfaces. The load sensor includes a thin first and second insulating outer layer between which an inner layer is secured. The inner layer can be formed of dielectric material of a known dielectric constant, with at least one thin electrical conductor to accommodate load sensing disposed against a first face, and another thin electrical conductor to accommodate load sensing disposed against a second face. Electrical conductors connect the thin conductive areas on the first and second faces to the distal end of a tab extending beyond the load or connection measurement area. The distal end of the tab accommodates a connection with electrical measurement apparatus. As the inner layer is compressed, the spacing between the electrically conductive areas on the opposing faces is decreased such that compressive forces can be measured as a function of the changes in capacitance of the sensor. In this manner, proper compression can be achieved by monitoring capacitance during installation. Follow-up sampling or continuous measurement of sensor compression provides early detection prior to failure to allow corrective action.

Owner:DAVIE COFFEY TECH L L C

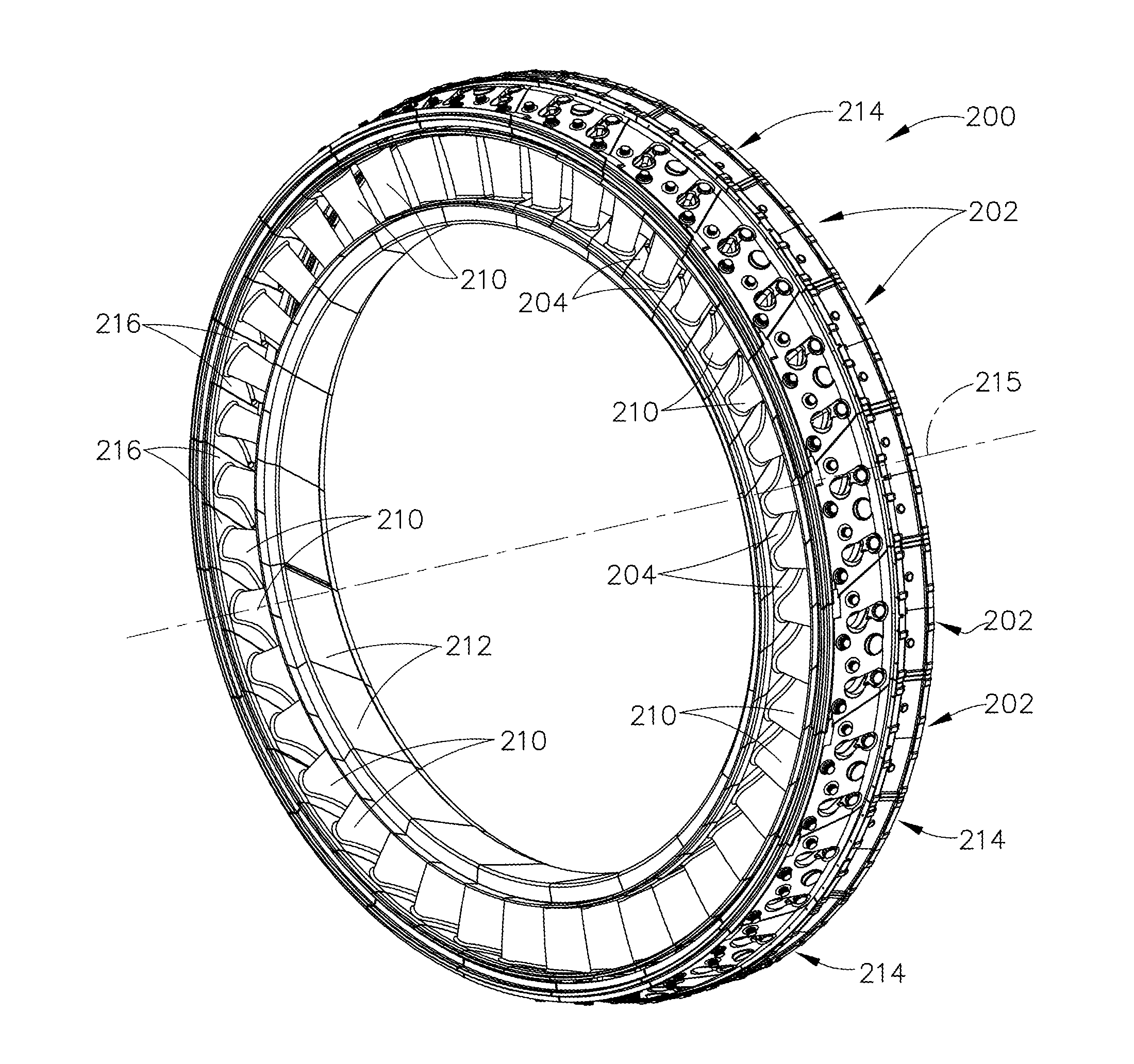

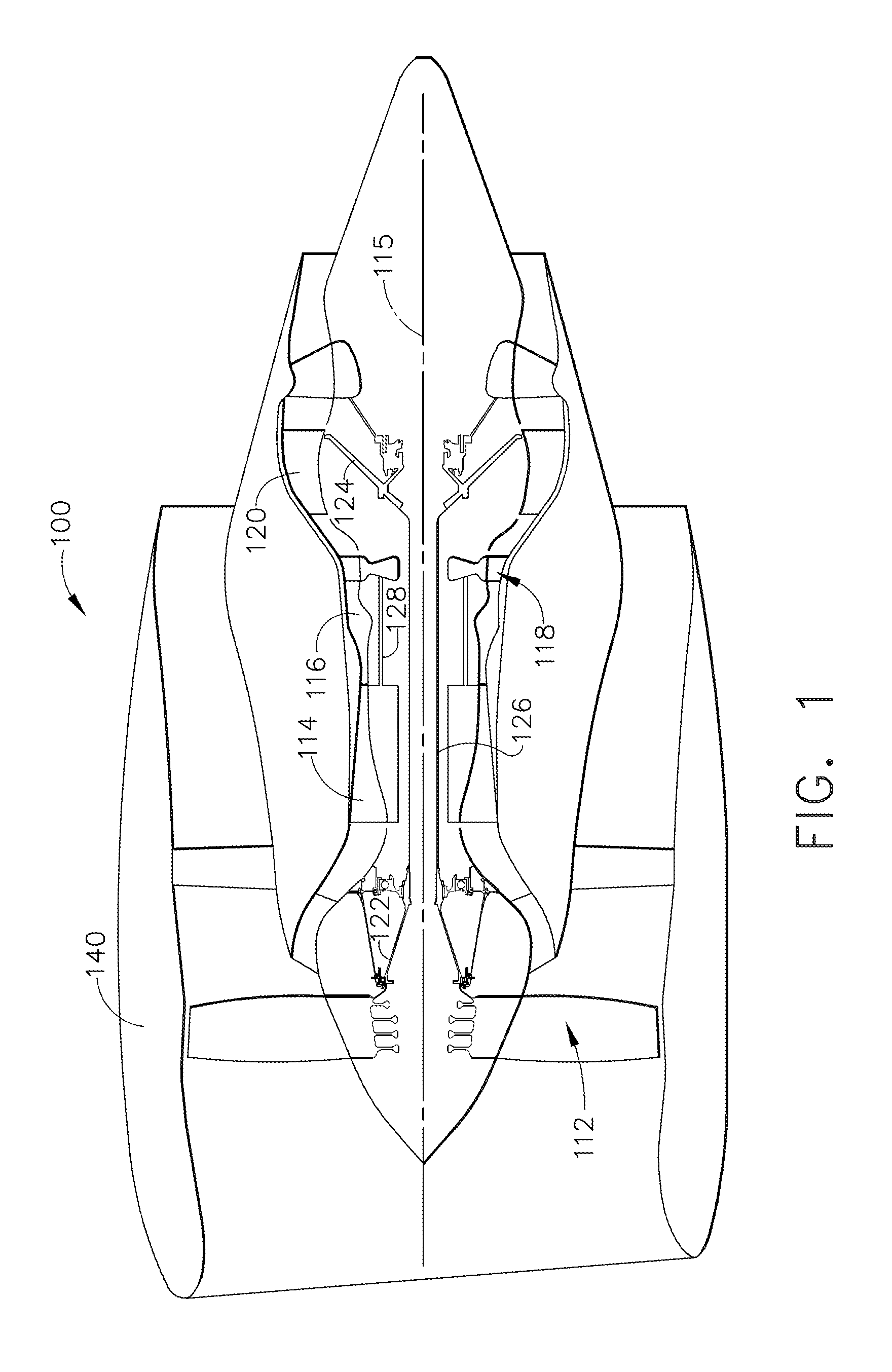

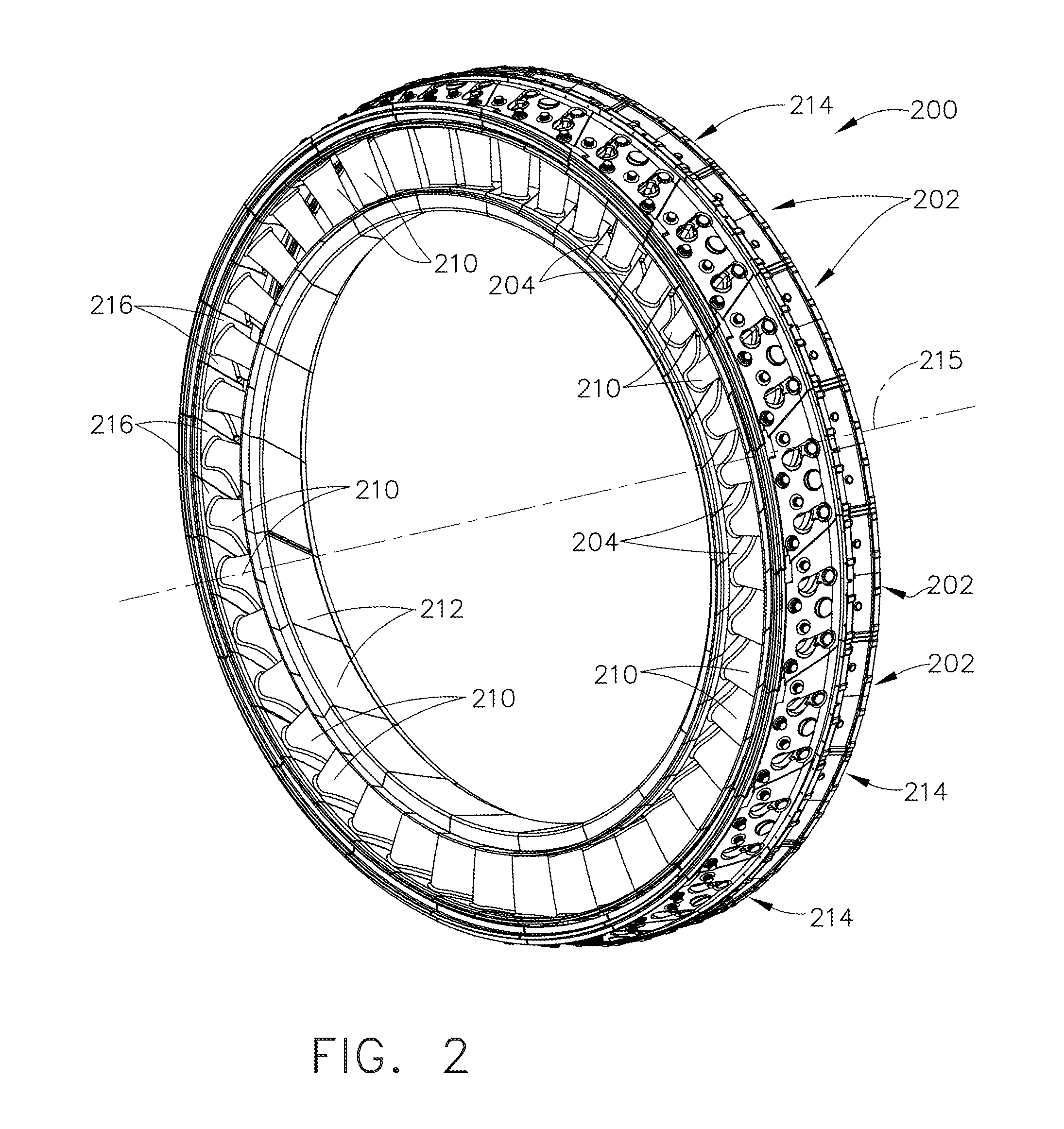

Method and system for interfacing a ceramic matrix composite component to a metallic component

An airfoil assembly for a gas turbine engine and a method of transferring load from the ceramic matrix composite (CMC) airfoil assembly to a metallic vane assembly support member are provided. The airfoil assembly includes a forward end and an aft end with respect to an axial direction of the gas turbine engine. The airfoil assembly further includes a radially outer end component including a radially outwardly-facing end surface having a non-compression load-bearing feature extending radially outwardly from the outwardly-facing end surface and formed integrally with the outer end component, the feature configured to mate with a complementary feature formed in a radially inner surface of a first airfoil assembly support structure, the feature selectively positioned orthogonally to a force imparted into the airfoil assembly. The airfoil assembly also includes a radially inner end component, and a hollow airfoil body extending therebetween, the airfoil body configured to receive a strut couplable at a first end to the first airfoil assembly support structure.

Owner:GENERAL ELECTRIC CO

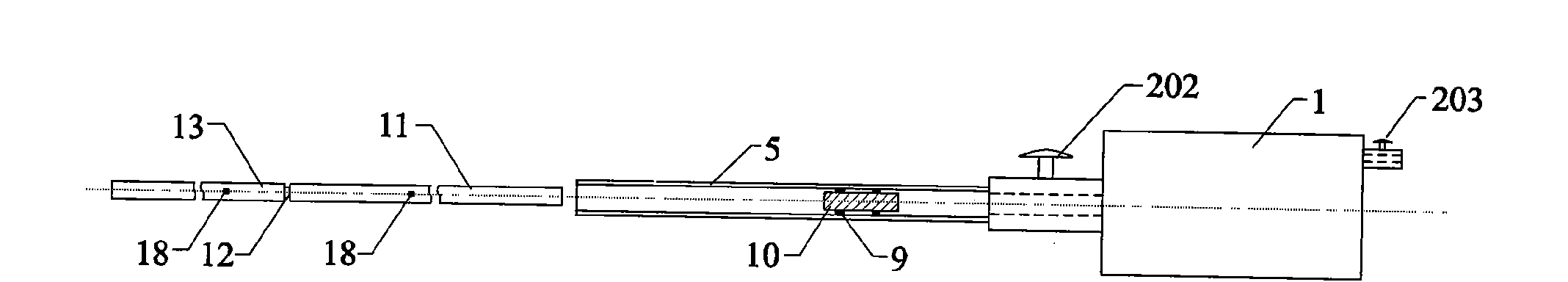

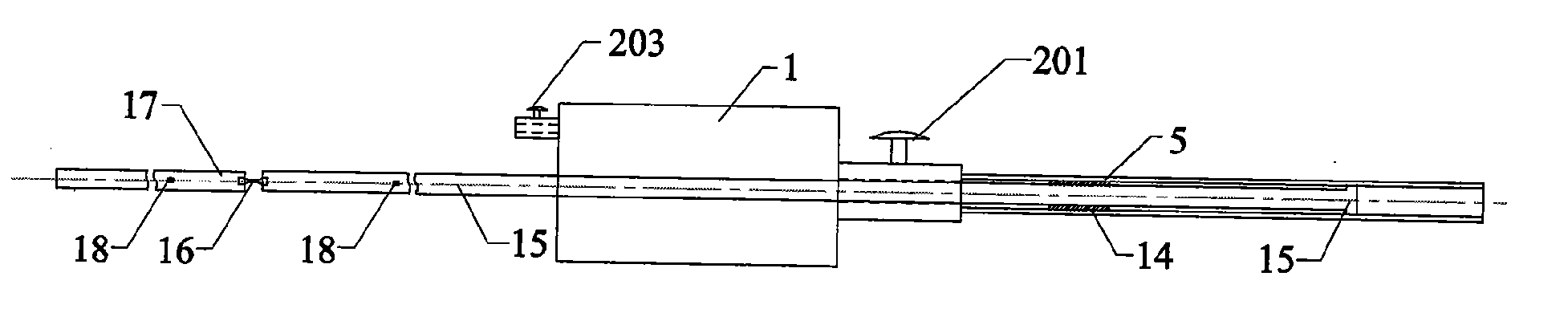

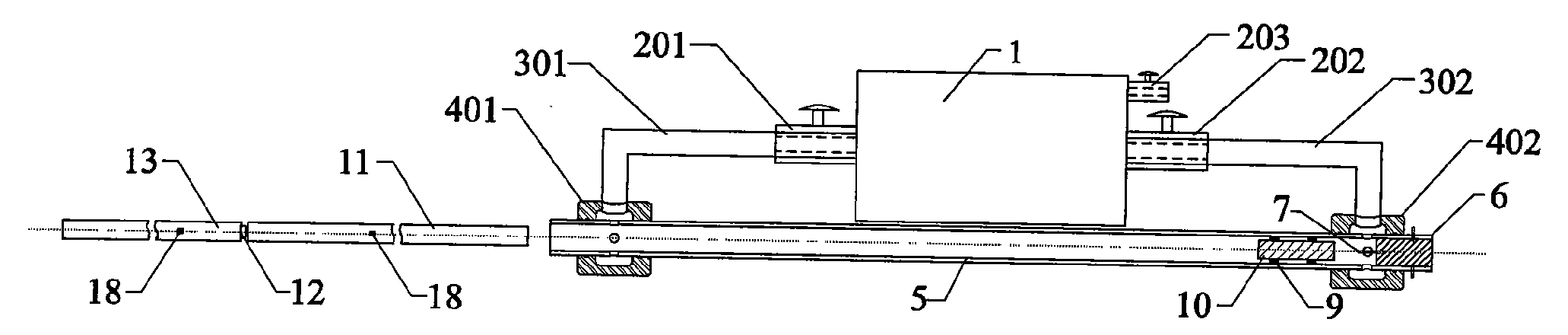

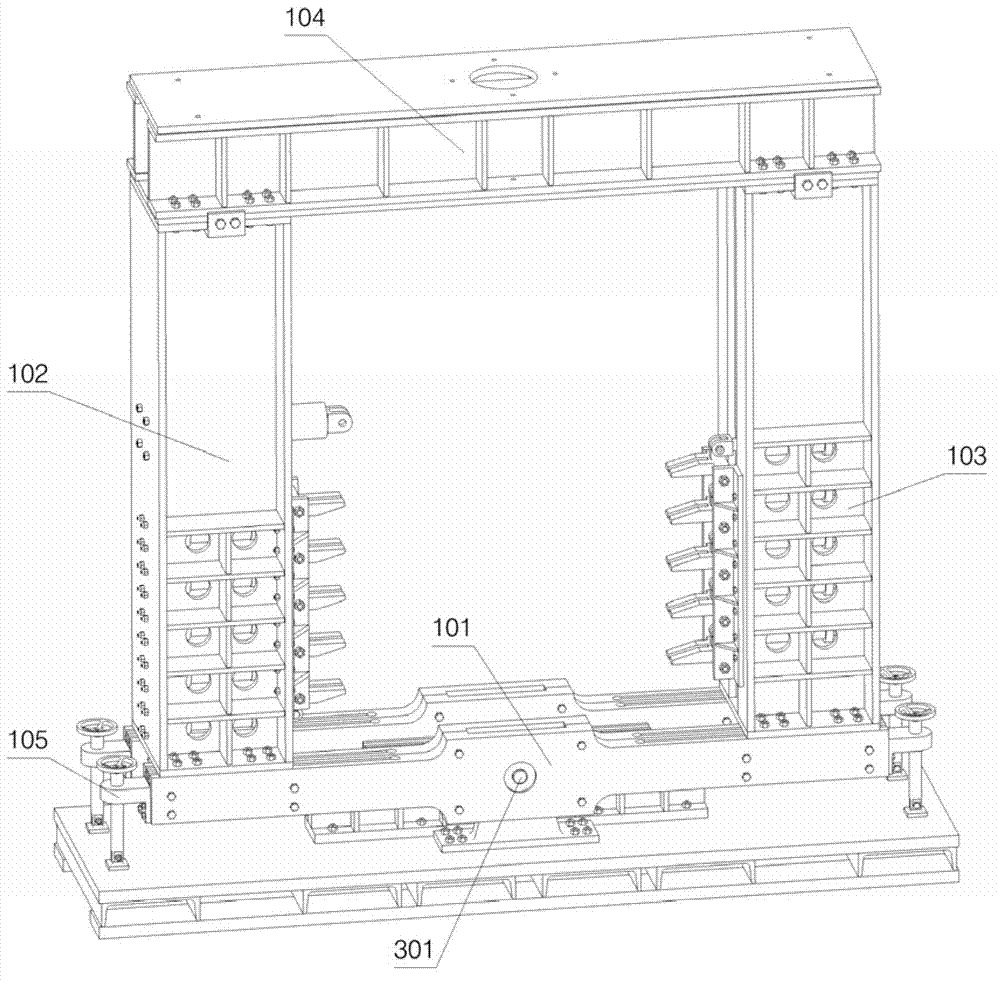

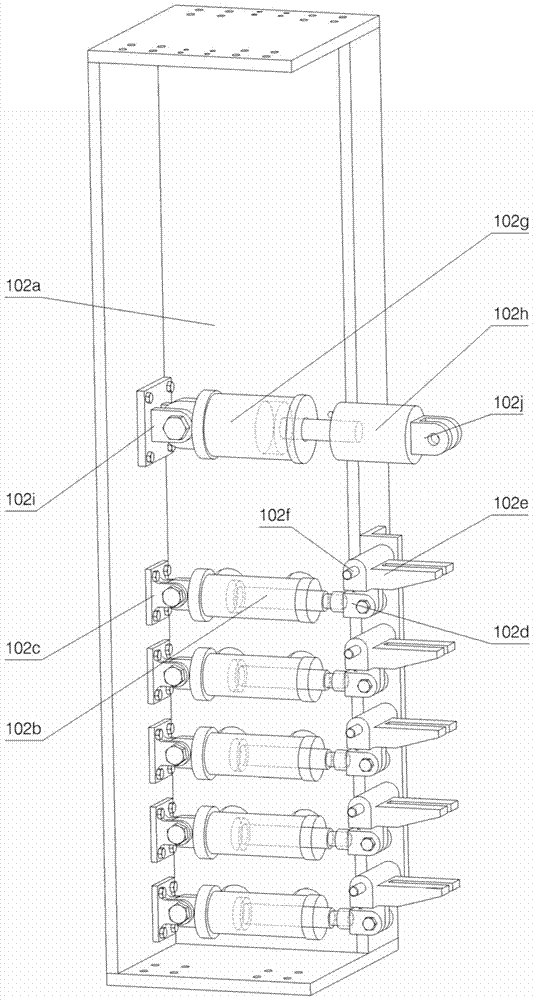

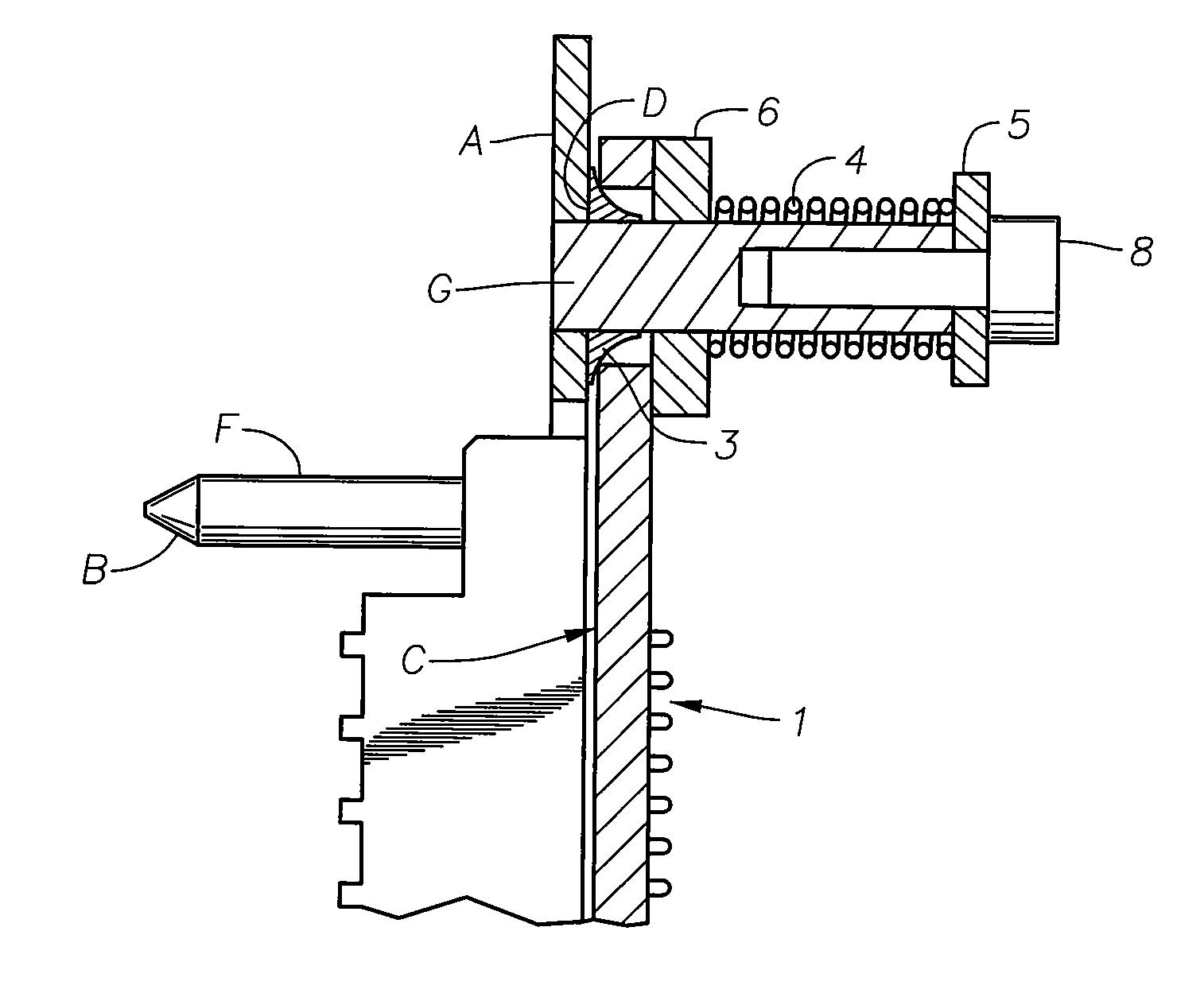

General Hopkinson bar device for compression load and stretching load

InactiveCN101666724AAchieve integrationEasy to convertMaterial strength using repeated/pulsating forcesEngineeringControl valves

The invention discloses a general Hopkinson bar device for compression load and stretching load, which aims to integrate compression load and stretching load into an experiment system. The invention has the technical scheme that the general Hopkinson bar device comprises a bidirectional gas emitting thrower and a bar system. The bidirectional gas emitting thrower accelerates a bullet leftwards orrightwards based on experiment requirements and comprises a high pressure gas container, a thrower pipe, a gas inlet control valve, a first gas outlet control valve, a second gas outlet control valve,a first connection pipe, a second connection pipe, a first gas conversion joint, a second gas conversion joint, a columniform or cylindrical bullet, a columniform or cylindrical top plug corresponding to the columniform or cylindrical bullet, and a top needle. The bar system comprises a compression incident bar, a compression transmission bar, a stretching incident bar, a stretching transmissionbar and strain foils. The general Hopkinson bar device overcomes difficulties in respectively creating two sets of independent equipment for a Hopkinson compression bar and a Hopkinson stretching bar,realizes the integration of the Hopkinson compression bar and the Hopkinson stretching bar and can be converted conveniently between the two load modes.

Owner:NAT UNIV OF DEFENSE TECH

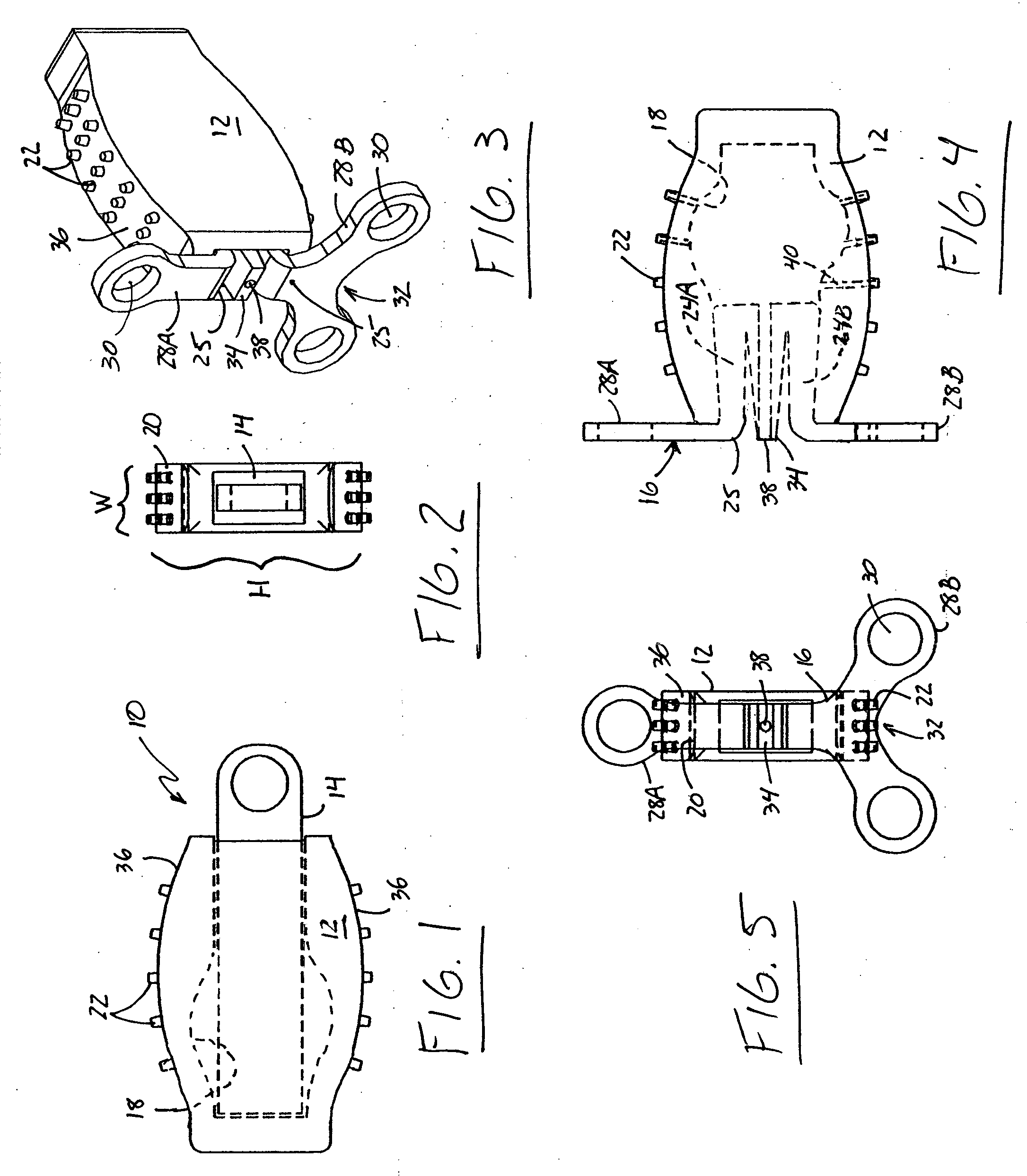

Intervertebral disc implant

An intervertebral disc implant having a body with a greater height than width comprised of a resilient material and an elongate cavity for receiving a key to maintain the spacing between the vertebrae adjacent an intervertebral disc when implanted into the space from which a portion of the disc is removed. To distribute and cushion against compression loads, and to mimic the normal kinematics of the intact, healthy intervertebral disc, the key is removed after the body is implanted into the disc space and a frame that both provides resistance to compression and tension loads and translates the axis of rotation of the spinal column anteriorally and posteriorally as the patient bends and rotates is inserted into the cavity in the implant body. The frame does not extend all the way into the cavity in the body and the portion of the cavity into which the frame does not extend is filled with a hydrogel.

Owner:PERUMALA CORP

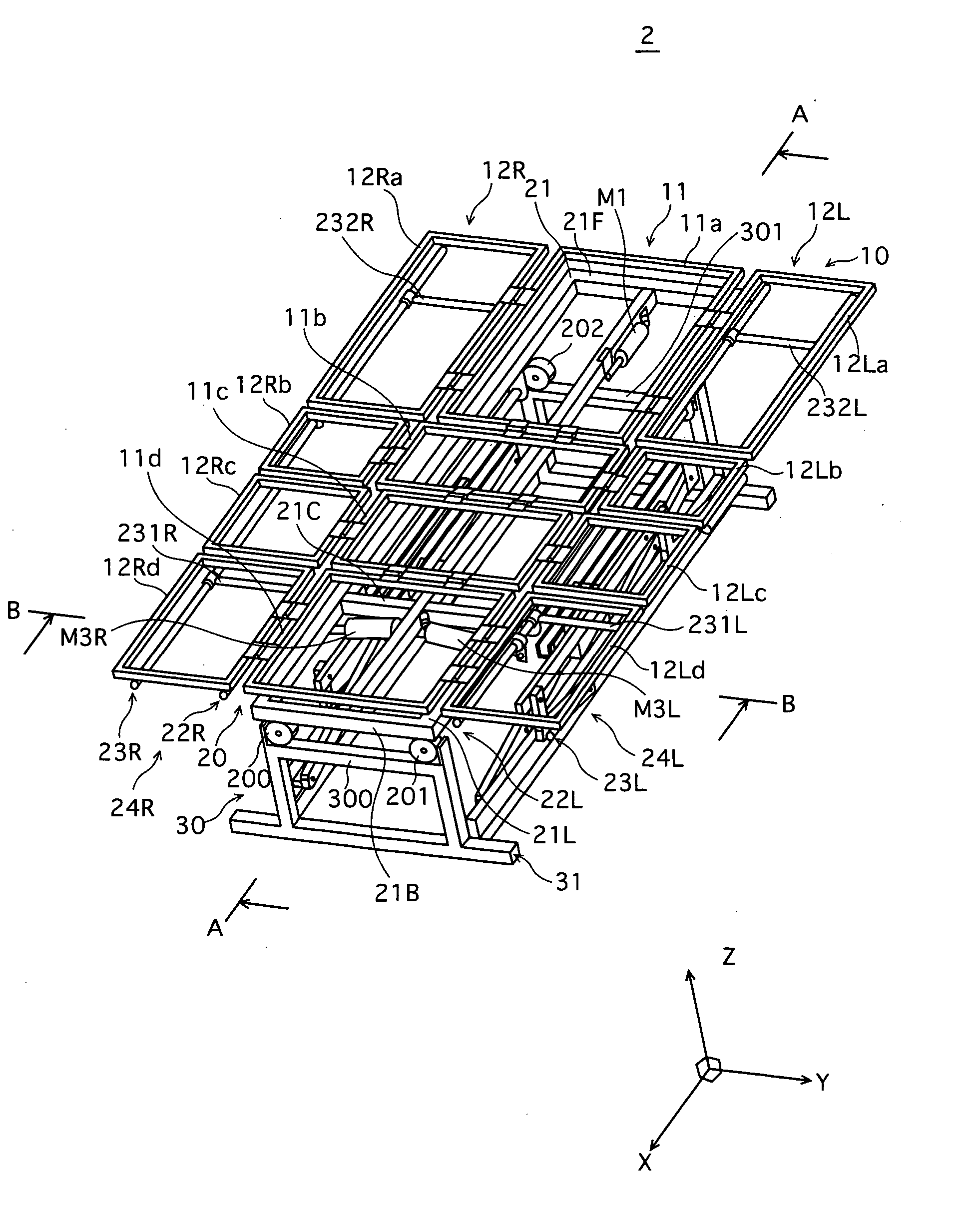

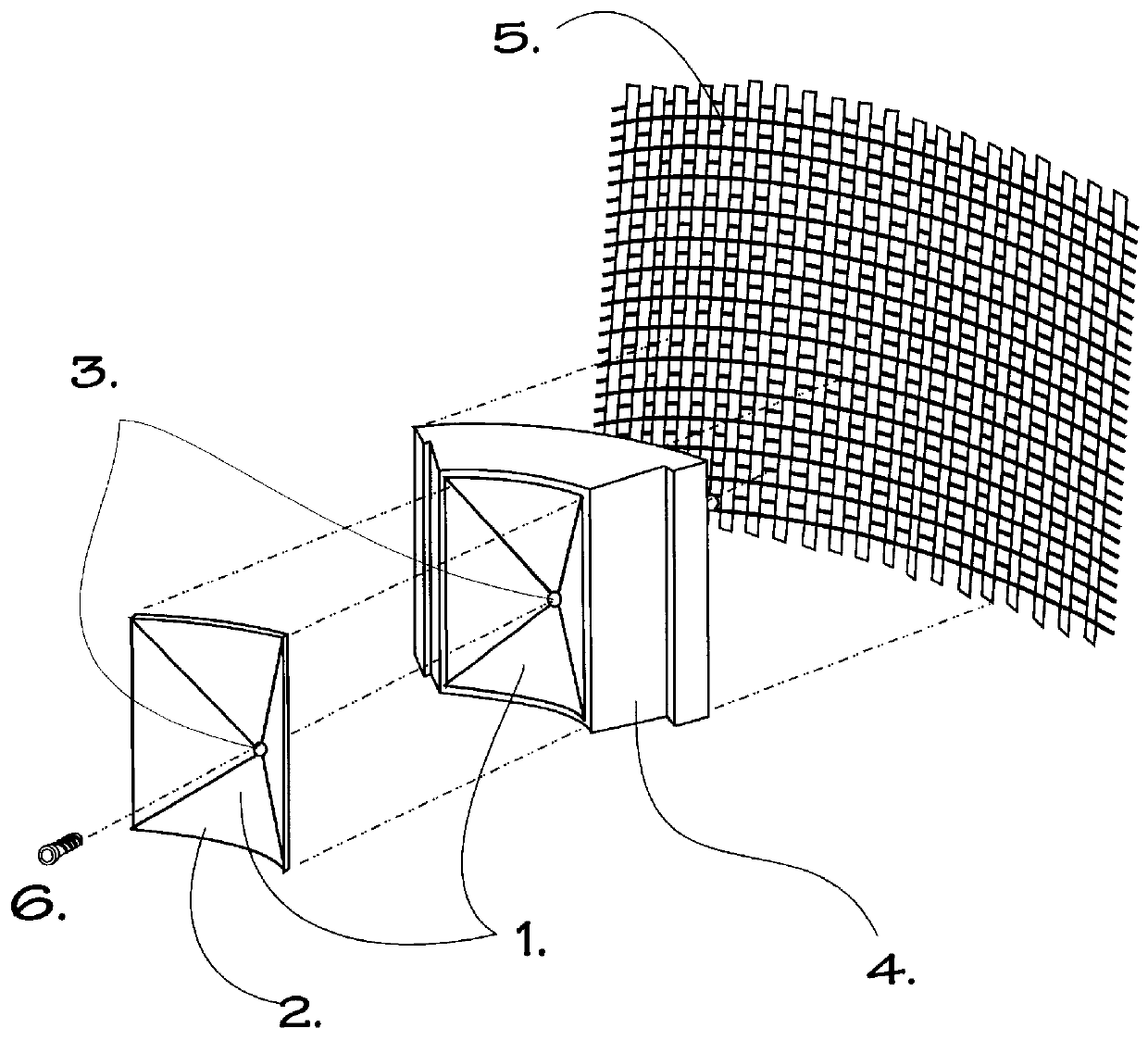

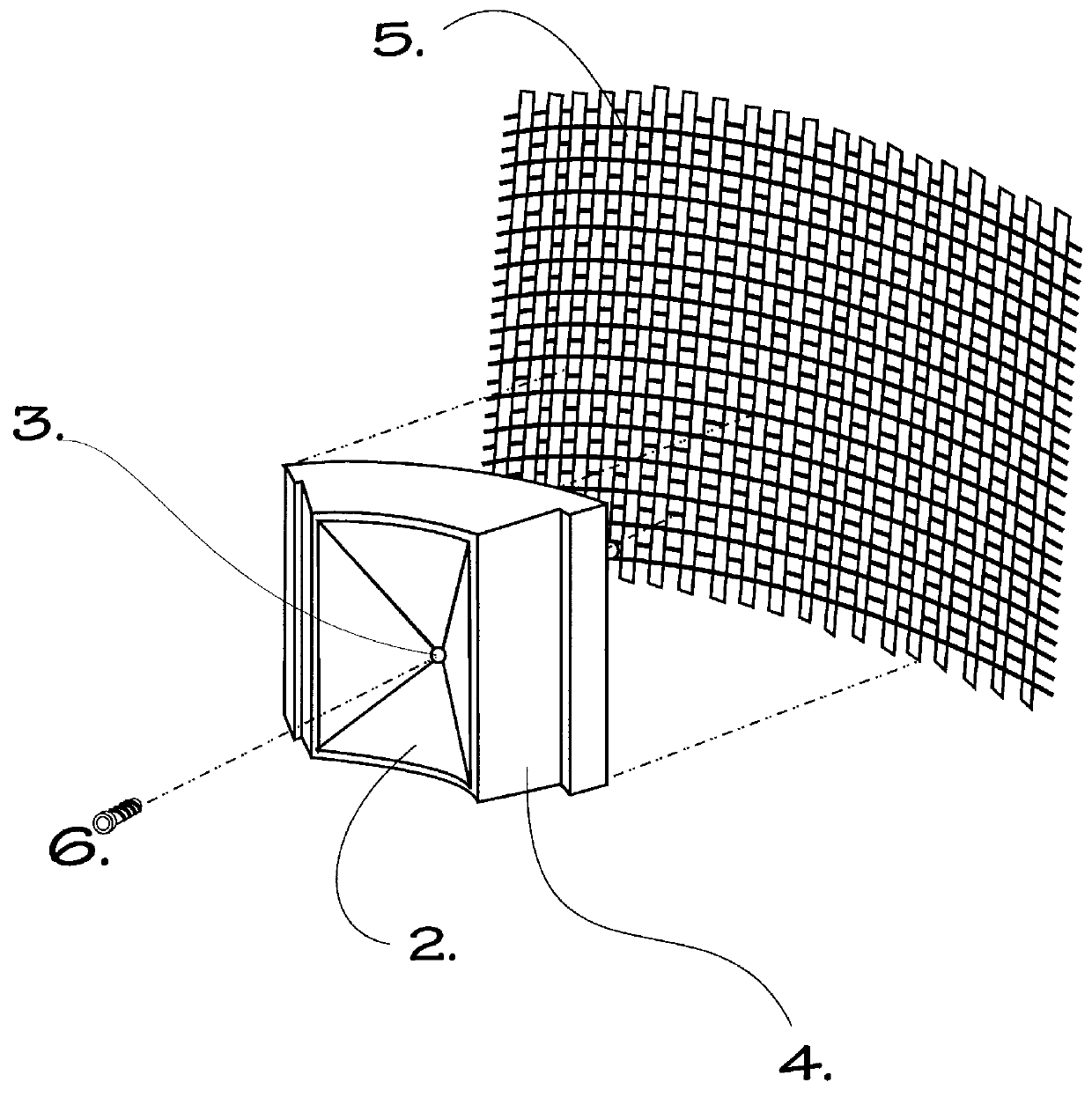

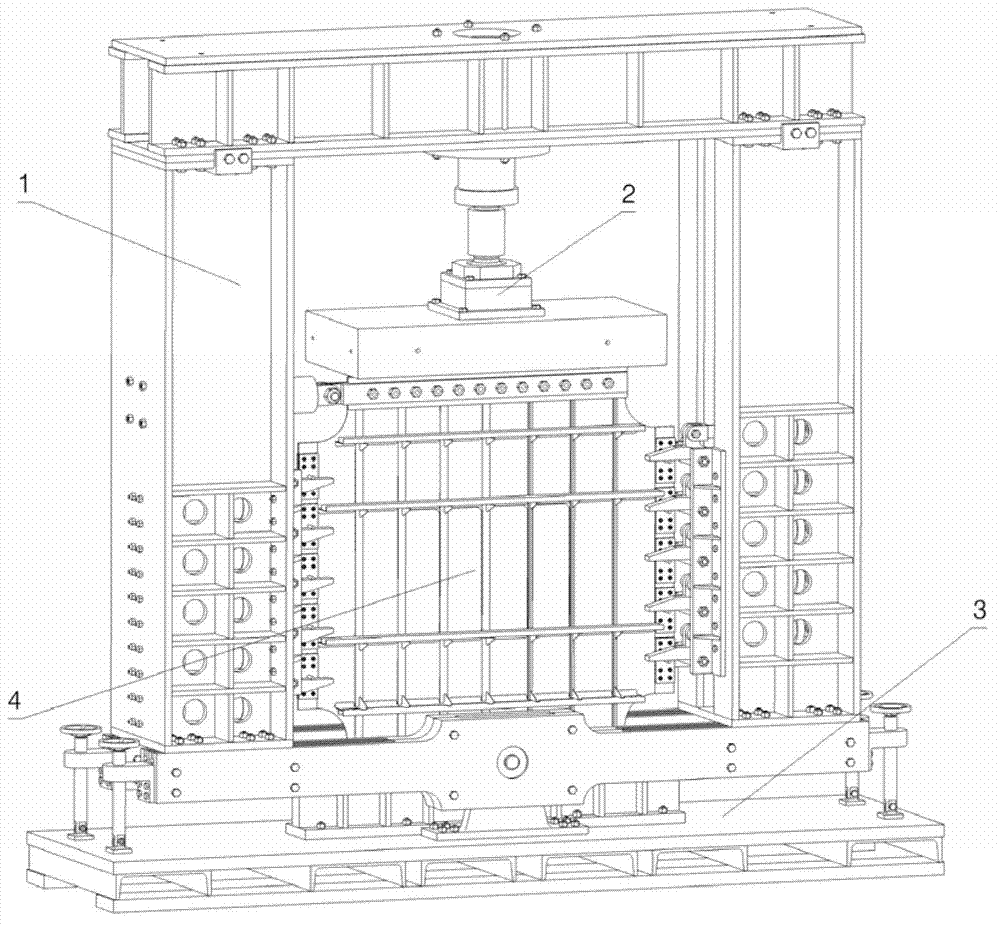

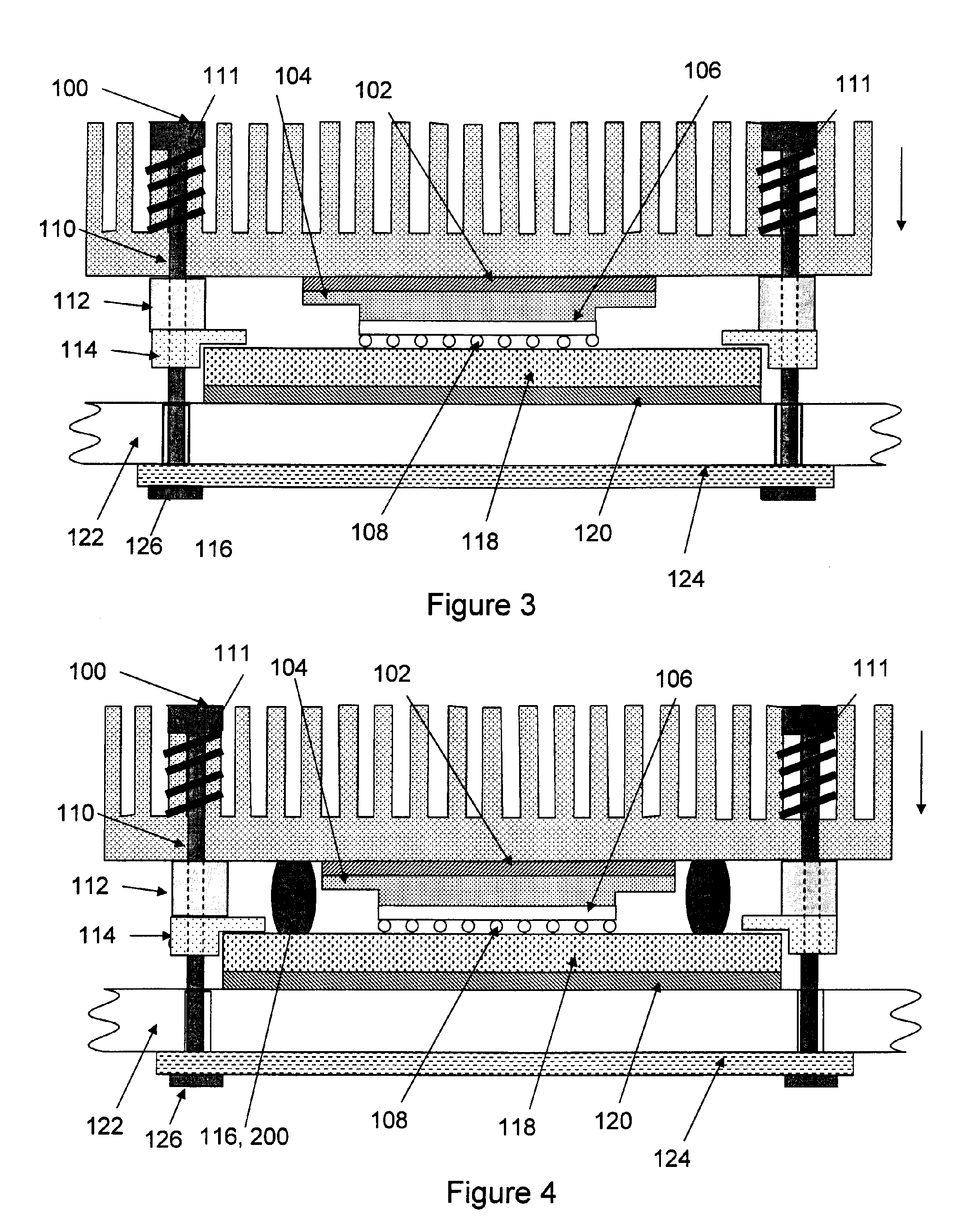

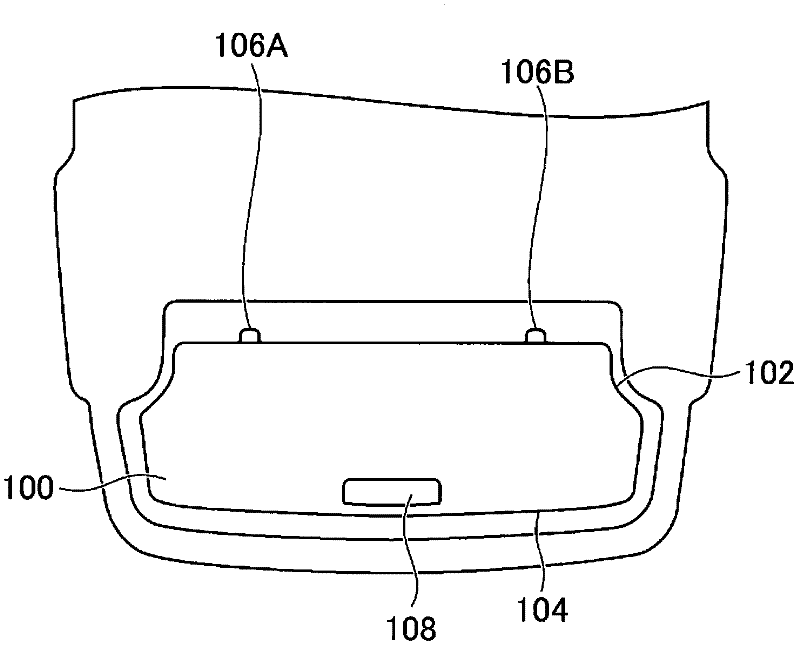

Test device capable of evenly applying axial compression load and shearing load

ActiveCN103033418AApply evenlyDoes not affect applied effectsMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesAviationAxial compression

The invention belongs to the technical field of strength tests in aviation, and particularly relates to a test device capable of evenly applying an axial compression load and a shearing load. The test device comprises a shearing load applying component 1, an axial compression load applying component 2, a lower platform component 3 and a rib-adding flat plate component 4. According to the technology for independently loading the compression load and the shearing load, adopted by the device, the device not only is suitable for the flat plate, but also is suitable for a rib-adding flat plate. Furthermore, the test debugging of the single axial compression load and the single shearing load under the condition that the rib-adding flat plate is invariable in an installing posture can be realized, so that the reference can be provided for the analysis of the stress state of a lower wall plate under the joint action of the compression load and the shearing load. The device applies shearing force by the self-balance principle of a whole frame and a 'load balancer', so that the shearing force can be evenly applied, the axial rigidity of the rib-adding flat plate can not be enhanced due to an adopted segmental shearing reinforcement block, a compression load applying effect can not be influenced, and a 'side frame effect' can be avoided.

Owner:CHINA AIRPLANT STRENGTH RES INST

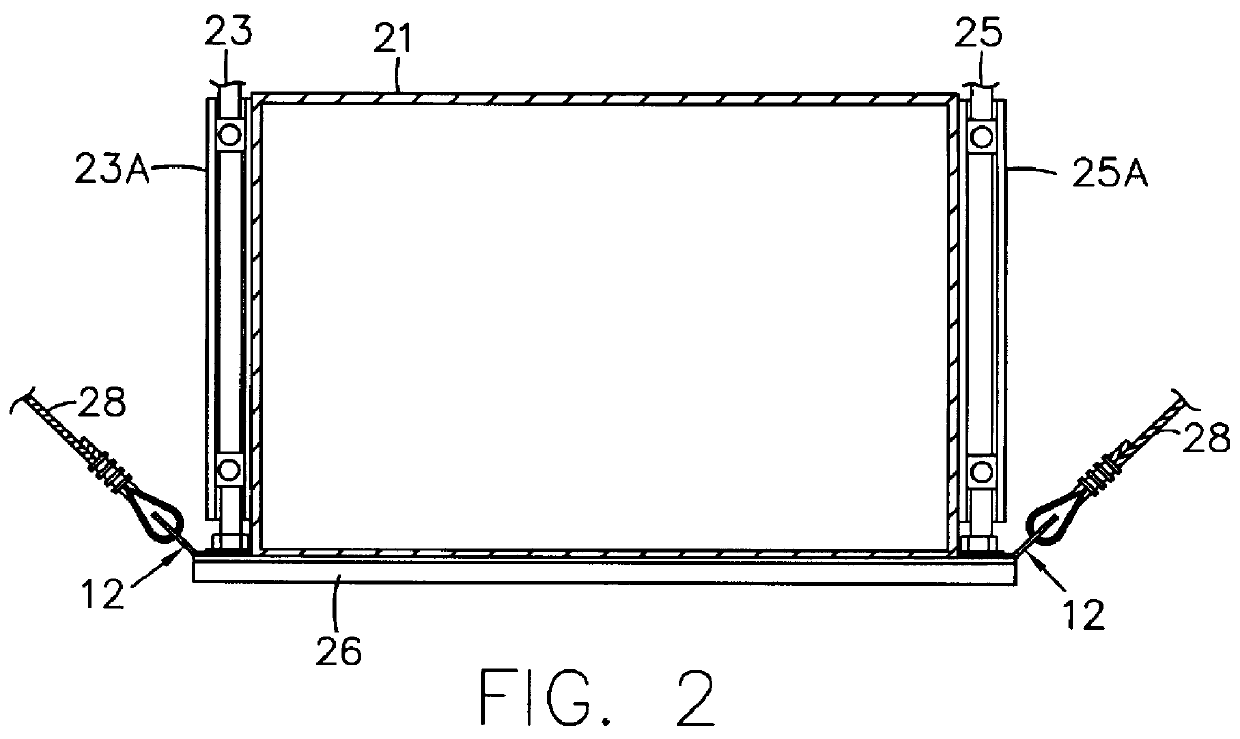

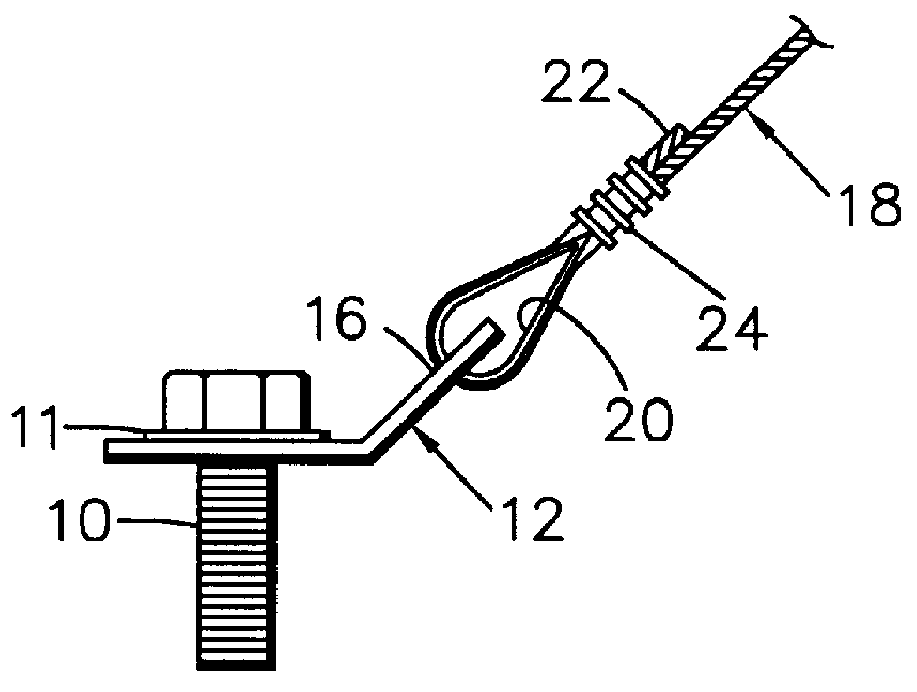

Universal restraint clip fitting

A universal one piece restraint bracket particularly suited for use with wire rope or cable for transverse, longitudinal and combined transverse and longitudinal seismic bracing systems for supporting an object. The bracket is generally L shaped to define a flattened apertured central portion with two wing portions generally at right angles to each other, apertured at their free ends and joined to the flattened central portion, each wing being elevated or upwardly bent away from the plane of the central portion. Aircraft type cables or wire rope connect the bracket to an adjacent support structure with the central portion of the bracket being secured to an object to be supported, whereby the bracing system acts in tension only so as to dampen earthquake loads and forces and thus is not subject to compression loads. A single bracket accommodates a wide variety of seismic bracing, and the bracket is configured for stacking with another bracket where necessary.

Owner:DUGGAN WERNER INC

Total artificial intervertebral disc

An artificial intervertebral disc that uses two orthogonally-oriented cushions, one with a greater height than width and the other with a greater width than height, comprised of a resilient material and affixed to each other in a manner to resist relative movement therebetween, to maintain the spacing between the vertebrae adjacent an intervertebral disc, to distribute and cushion against compression loads, and to mimic the normal kinematics of the intact, healthy intervertebral disc. One of the two cushions at least partially surrounds a frame that both provides resistance to compression and tension loads and translates the axis of rotation of the spinal column anteriorally and posteriorally as the patient bends and rotates.

Owner:PERUMALA CORP

Floating self-centering connector

InactiveUS20090068870A1Ensure electrical connectionComponent may become misalignedIncorrect coupling preventionCoupling light guidesEngineeringElectrical and Electronics engineering

A self-centering connection is provided. This self-centering connection includes a first substrate, a first connector assembly, a first number of alignment guides, a second substrate, a second connector assembly, a second number of alignment guides, and a number of free-floating compression fastener systems. The first connecting assembly is mounted on the first substrate. The first alignment guides are amounted on both the first and second substrate. The second connector assembly is mounted on the second substrate. The free-floating compression fastener system mechanically couples the first substrate to the second substrate wherein tolerances of the free-floating compression fastener system allow the first substrate to float relative to the second substrate in an XY in a first plane. The compression load of the compression fastener system allows the first substrate to float in a Z axis relative to the second substrate.

Owner:MEZHINSKY VICTOR B

Composite strut and method of making same

InactiveUS20050056117A1Highly effective in reacting both tensionEfficiently transfer both shearConnecting rod bearingsFuselage framesBiomedical engineeringCompression load

Owner:KAISER COMPOSITEK

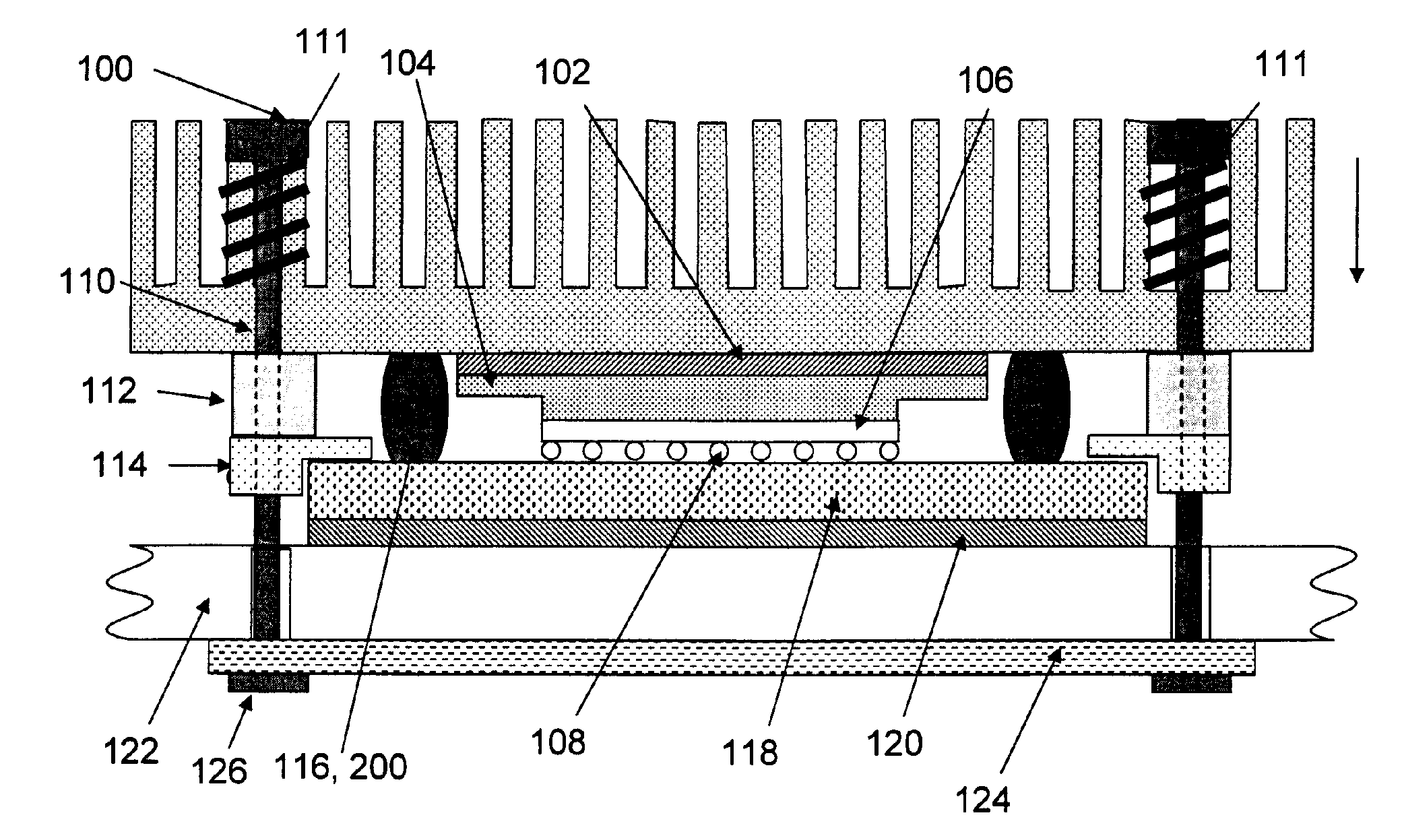

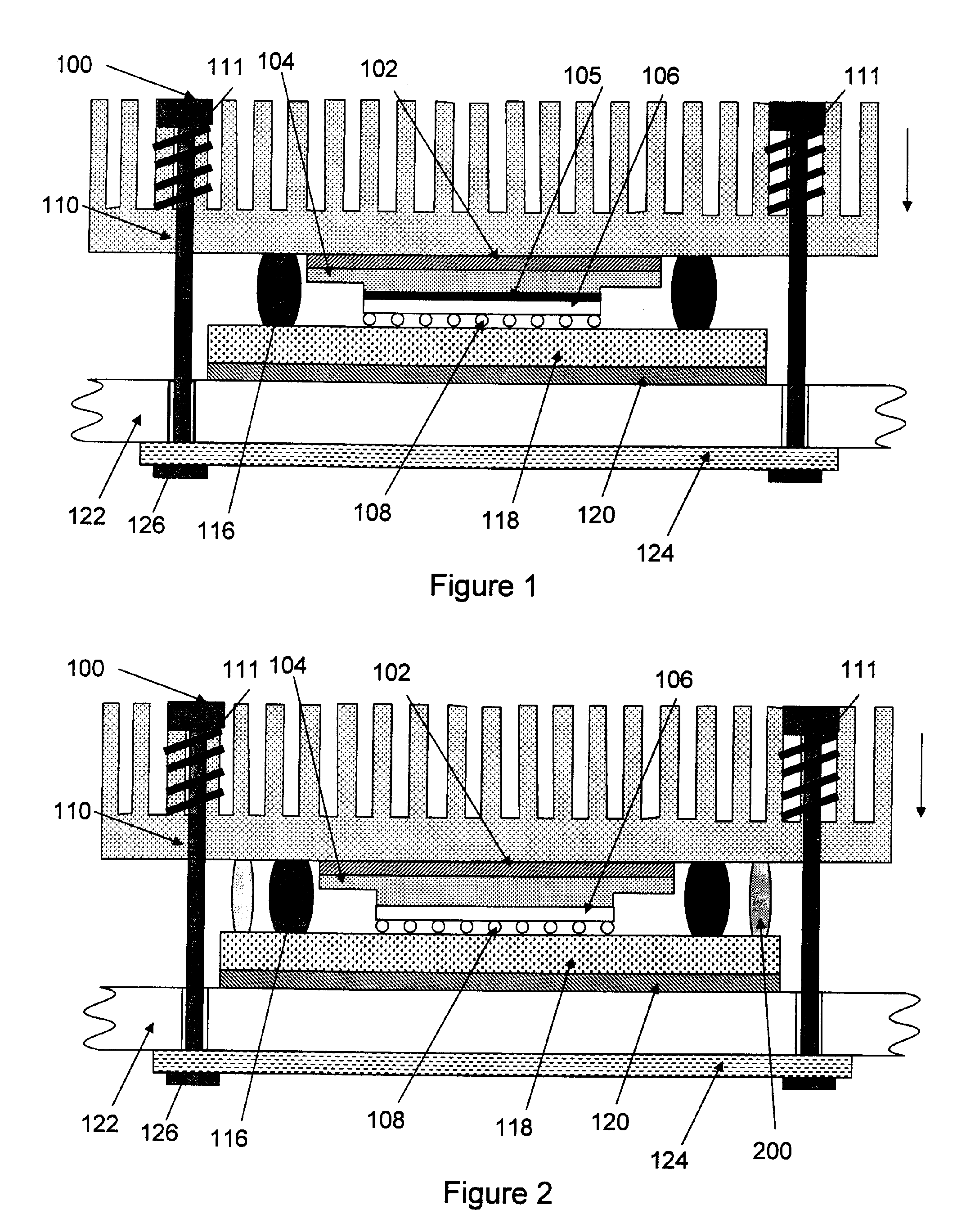

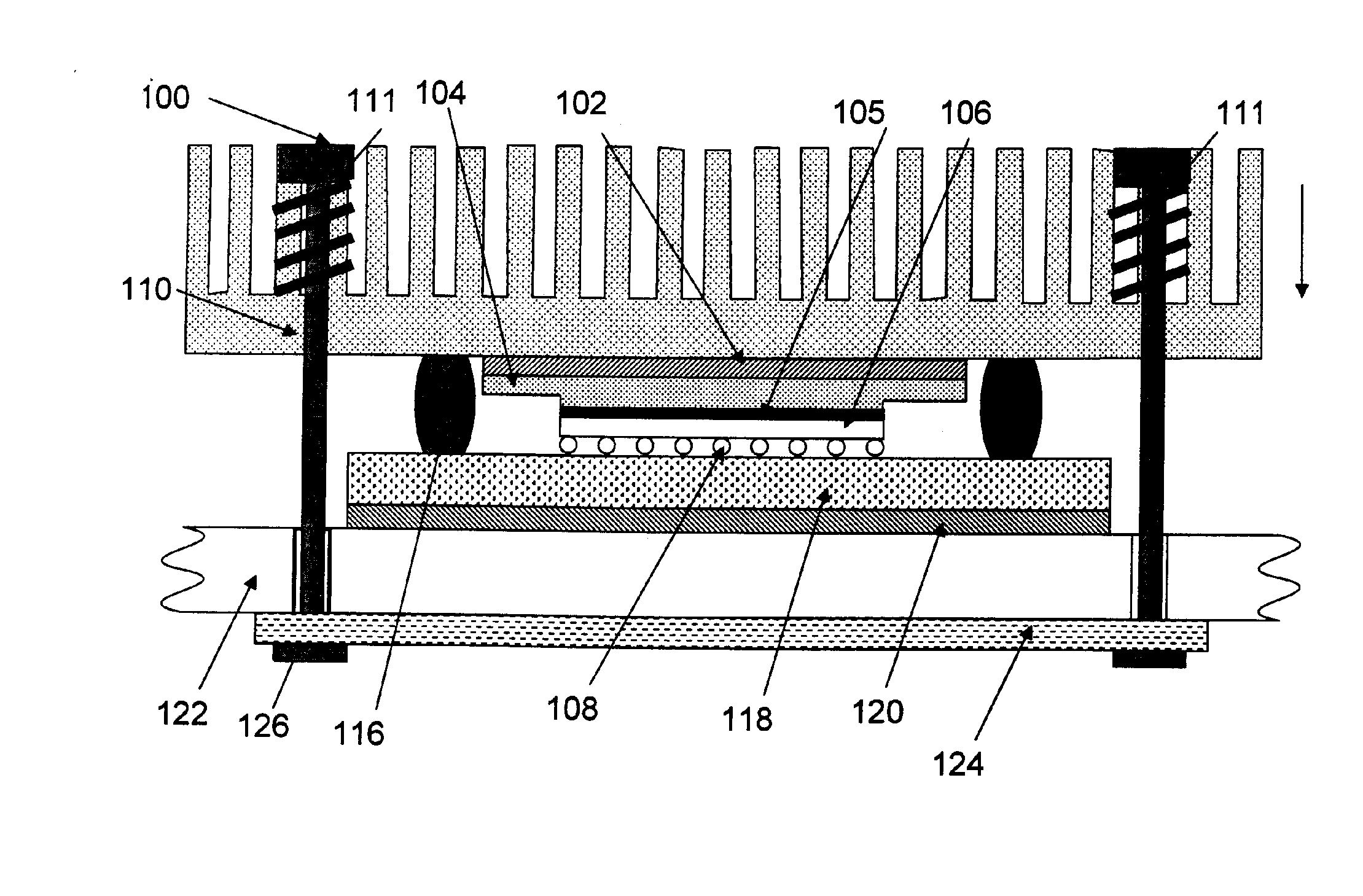

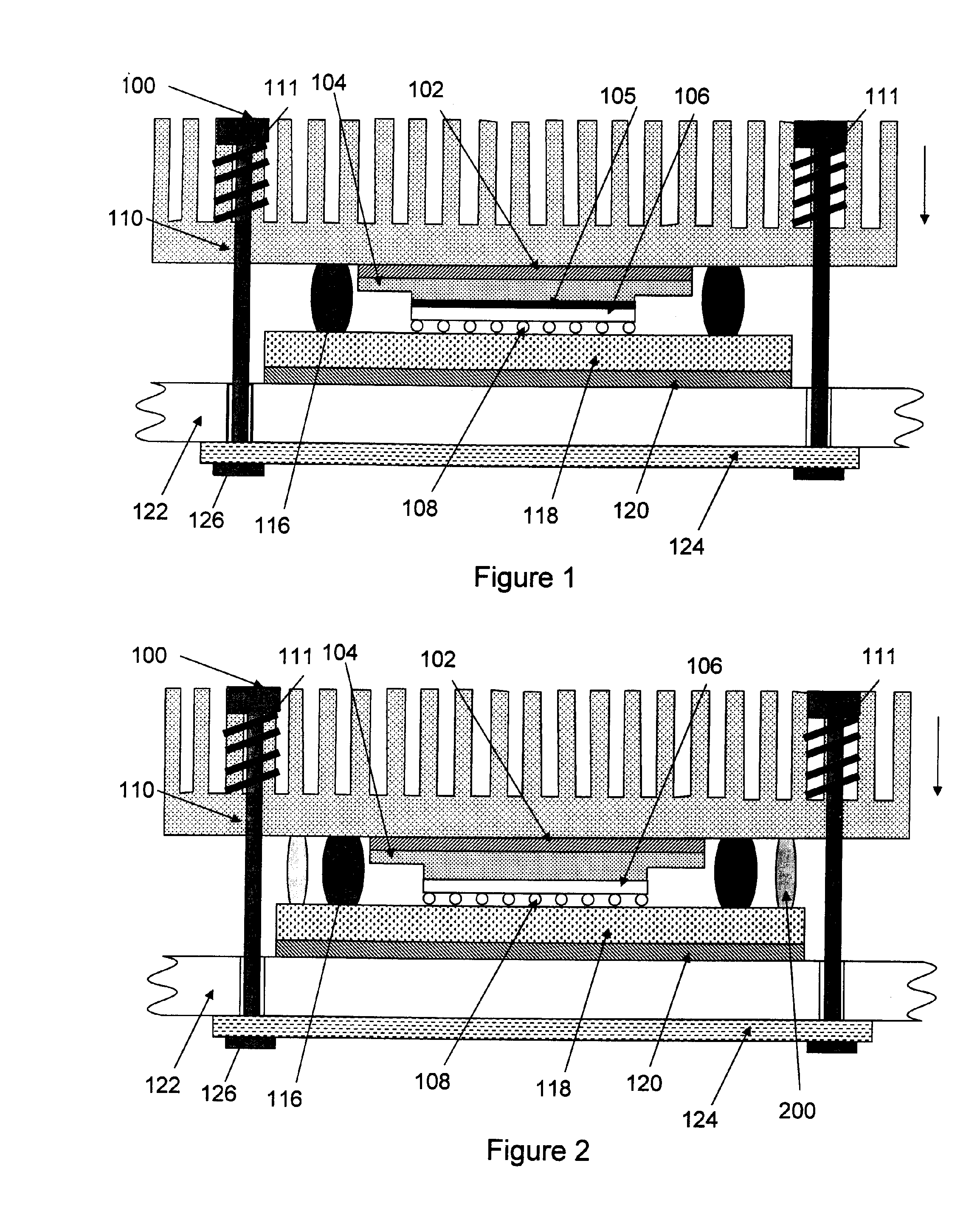

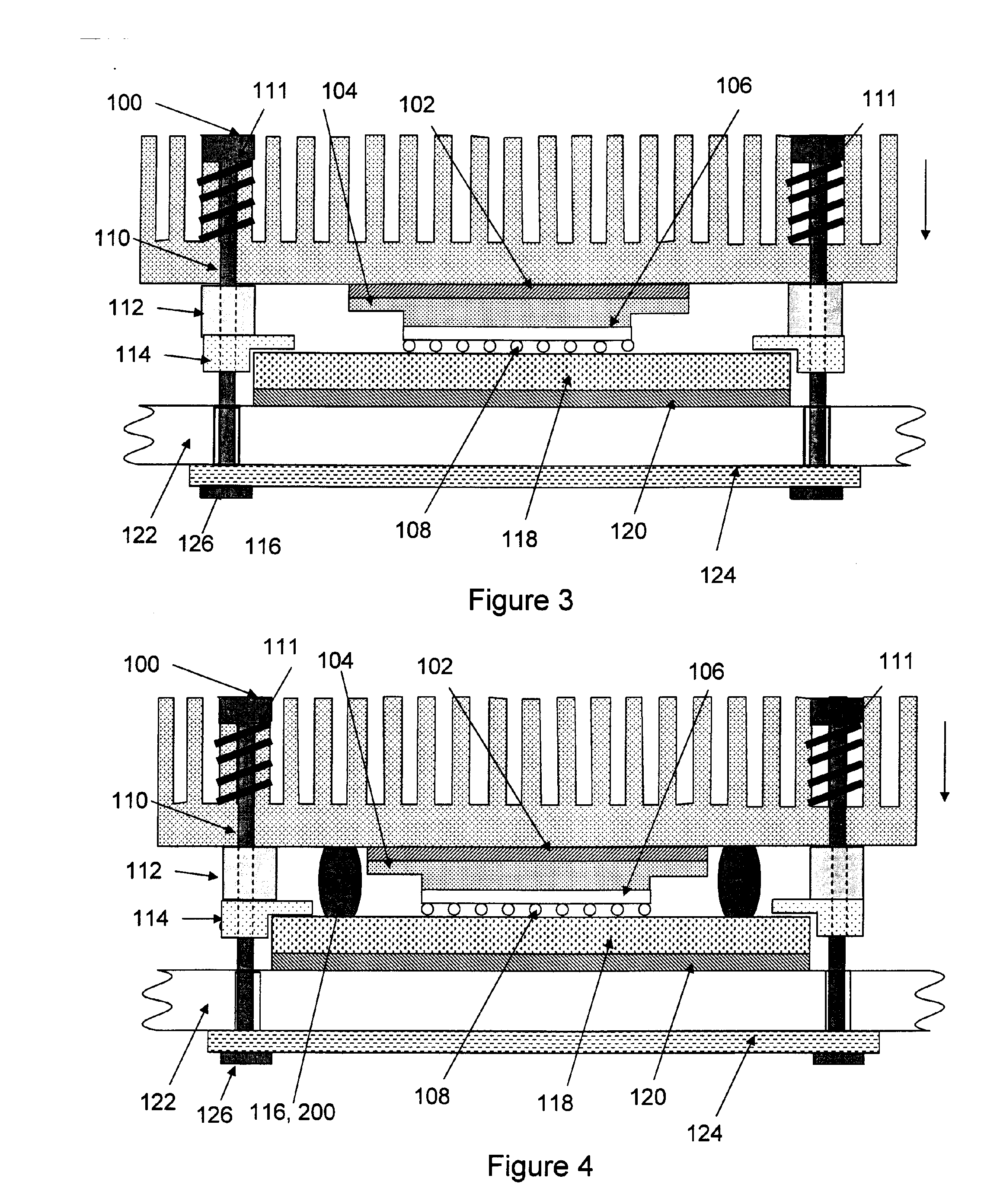

Method and structure to provide balanced mechanical loading of devices in compressively loaded environments

InactiveUS7518235B2Semiconductor/solid-state device detailsSolid-state devicesEngineeringChip carrier

Owner:GLOBALFOUNDRIES INC

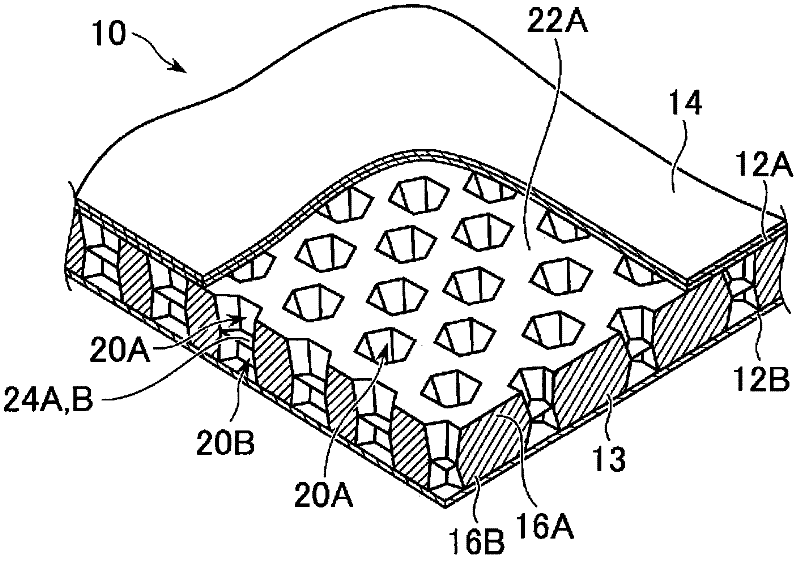

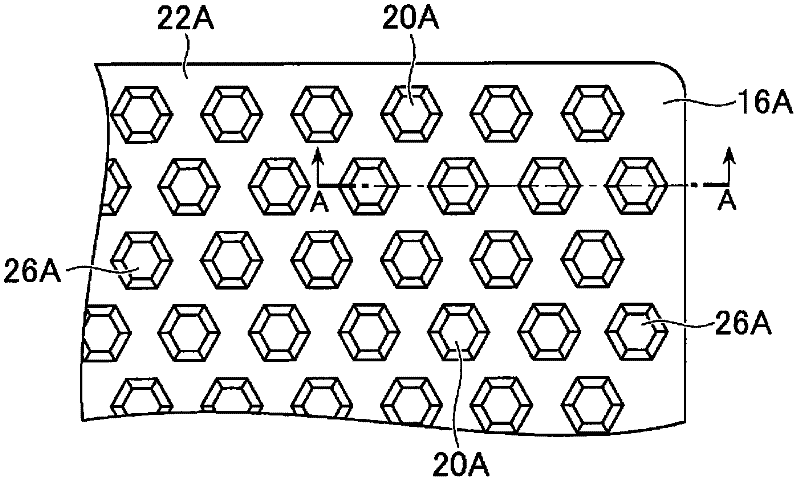

Sandwich panel, method of forming core material for sandwich panel, and method of forming sandwich panel

ActiveCN102202881ALamination ancillary operationsSynthetic resin layered productsEngineeringPolyresin

Owner:KYORAKU CO LTD

Microcellular foams of thermoplastic vulcanizates

The invention described relates to formed profiles comprising microcellular TPE foam compositions, and articles therefrom, wherein the TPE are thermoplastic vulcanizates. The foamed thermoplastic elastomer profile comprises a foamable thermoplastic elastomer composition having a) a cross-linkable hydrocarbon rubber in the presence of b) a thermoplastic polyolefin resin having a Tm greater than 120° C. wherein said composition further comprising: a) 25 to 30 wt % of a partially or fully vulcanized reaction product of said cross-linkable hydrocarbon rubber with a cross-linking agent, said reaction product being present as a dispersed phase; b) 7 to 12 wt % of said thermoplastic resin as a continuous phase; c) 8-22 wt % of an elastomeric thermoplastic modifier comprising 1) 3-7 wt. % copolymers of propylene with one or more of ethylene and C4-C10 alpha-olefins, said copolymers having a Tm greater than 20° C. and less than 120° C., and, 2) 5-15 wt. % hydrogenated, triblock styrenic copolymers from styrene and isoprene; and, optionally, d) 3-12 wt. % solid filler; and / or e) 35-45 wt. % of non-aromatic hydrocarbon oil; wherein said wt. % amounts are based upon the total weight of the composition, and where the composition has been prepared by a process comprising dynamically vulcanizing said composition. The foamed thermoplastic elastomer profiles having smooth surfaces, improved low water absorption, improved compression set and compression load deflection.

Owner:CELANESE INT CORP

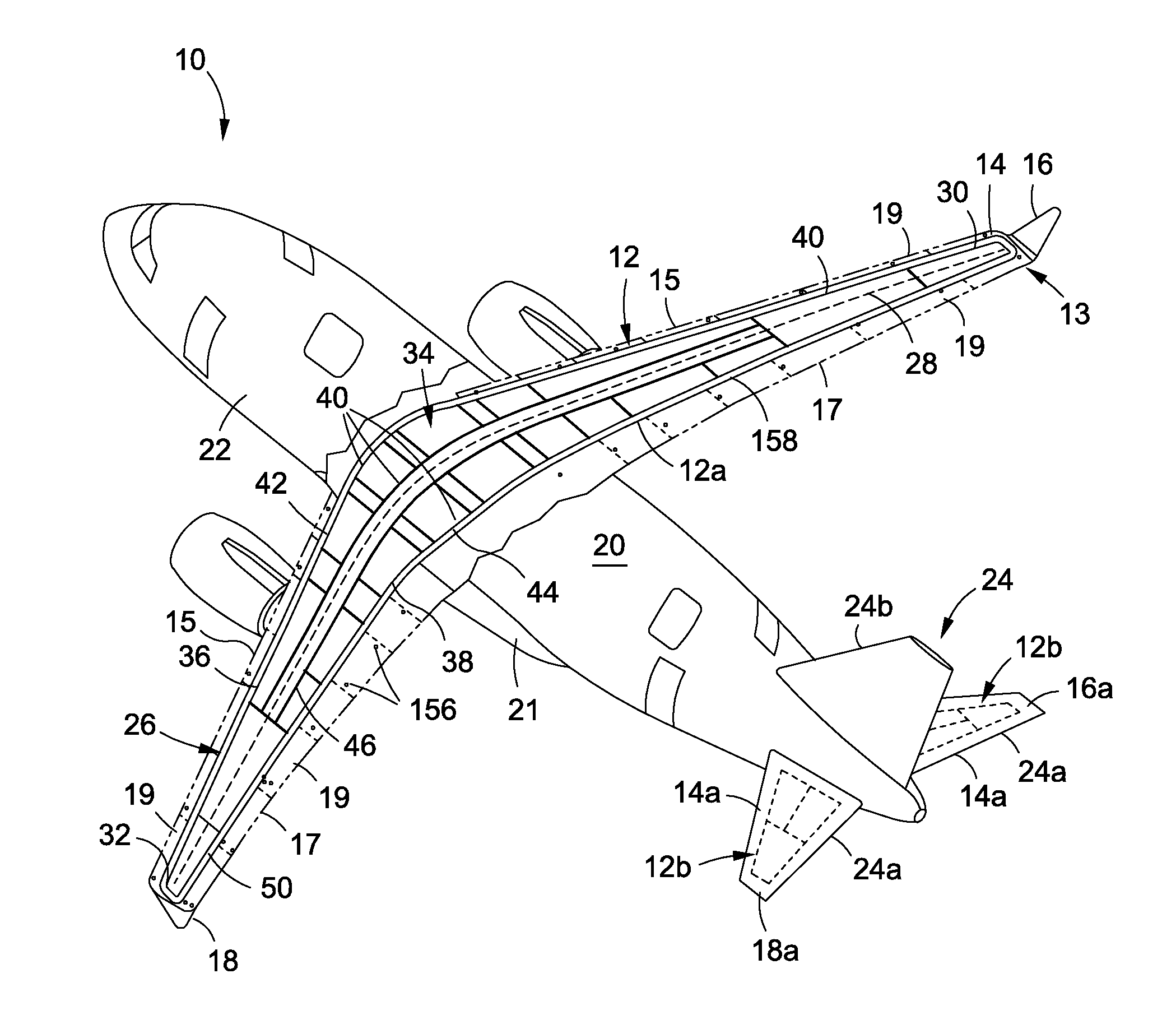

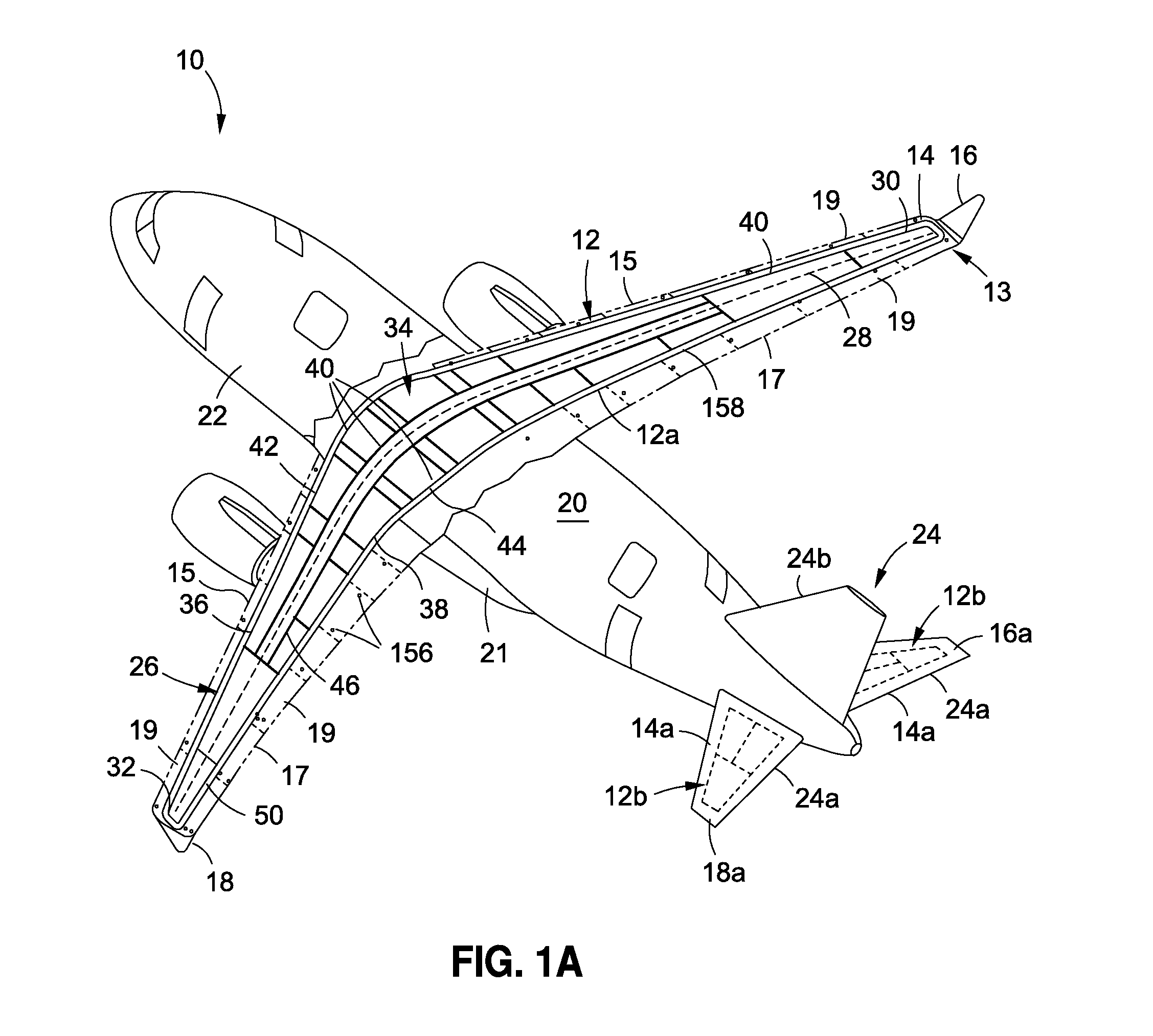

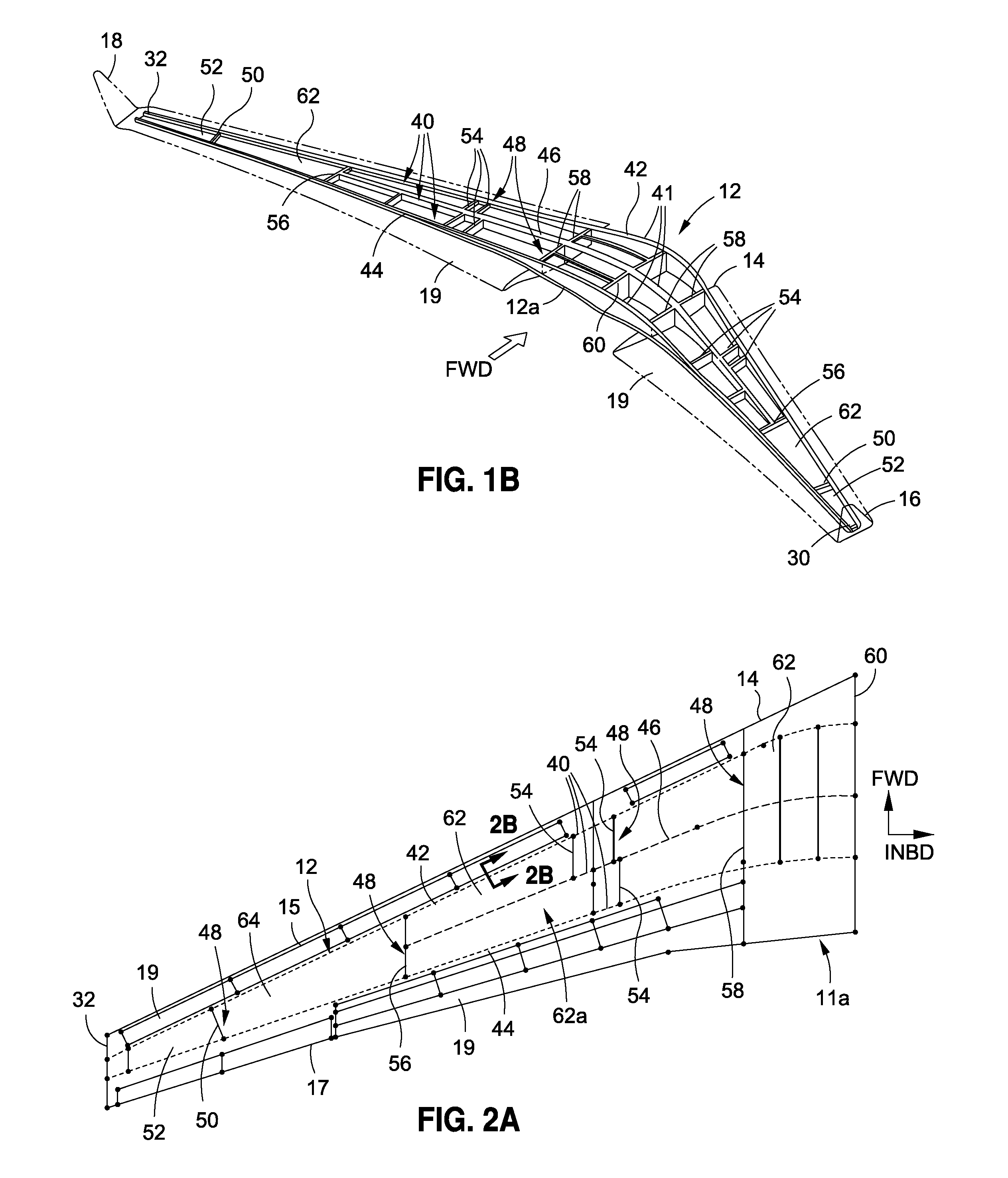

Box Structures for Carrying Loads and Methods of Making the Same

Owner:THE BOEING CO

Method and structure to provide balanced mechanical loading of devices in compressively loaded environments

InactiveUS20060202325A1Semiconductor/solid-state device detailsSolid-state devicesChip carrierIntegrated circuit

An integrated circuit chip mounting structure includes a chip carrier electrically connected to a circuit board with an integrated circuit chip mounted on the chip carrier. In addition, a thermally conductive device is thermally connected to the chip and a set of compressible support members are provided to transmit a portion of an applied compressive load from the thermally conductive device to the chip and chip carrier.

Owner:GLOBALFOUNDRIES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com