Patents

Literature

3942 results about "Isoprene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

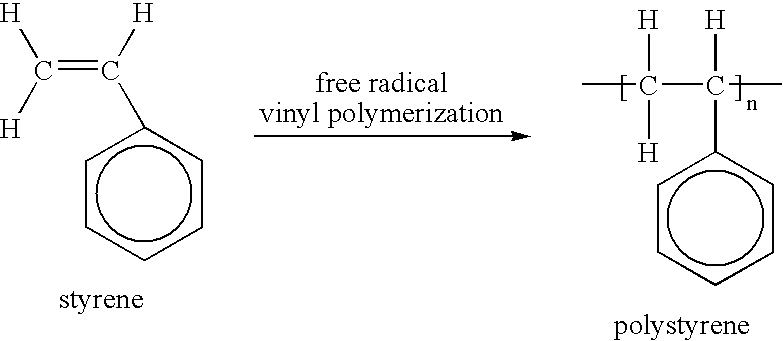

Isoprene, or 2-methyl-1,3-butadiene, is a common organic compound with the formula CH₂=C(CH₃)−CH=CH₂. In its pure form it is a colorless volatile liquid. Isoprene is produced by many plants and animals (including humans) and its polymers are the main component of natural rubber. C. G. Williams named the compound in 1860 after obtaining it from thermal decomposition (pyrolysis) of natural rubber; he correctly deduced the empirical formula C₅H₈.

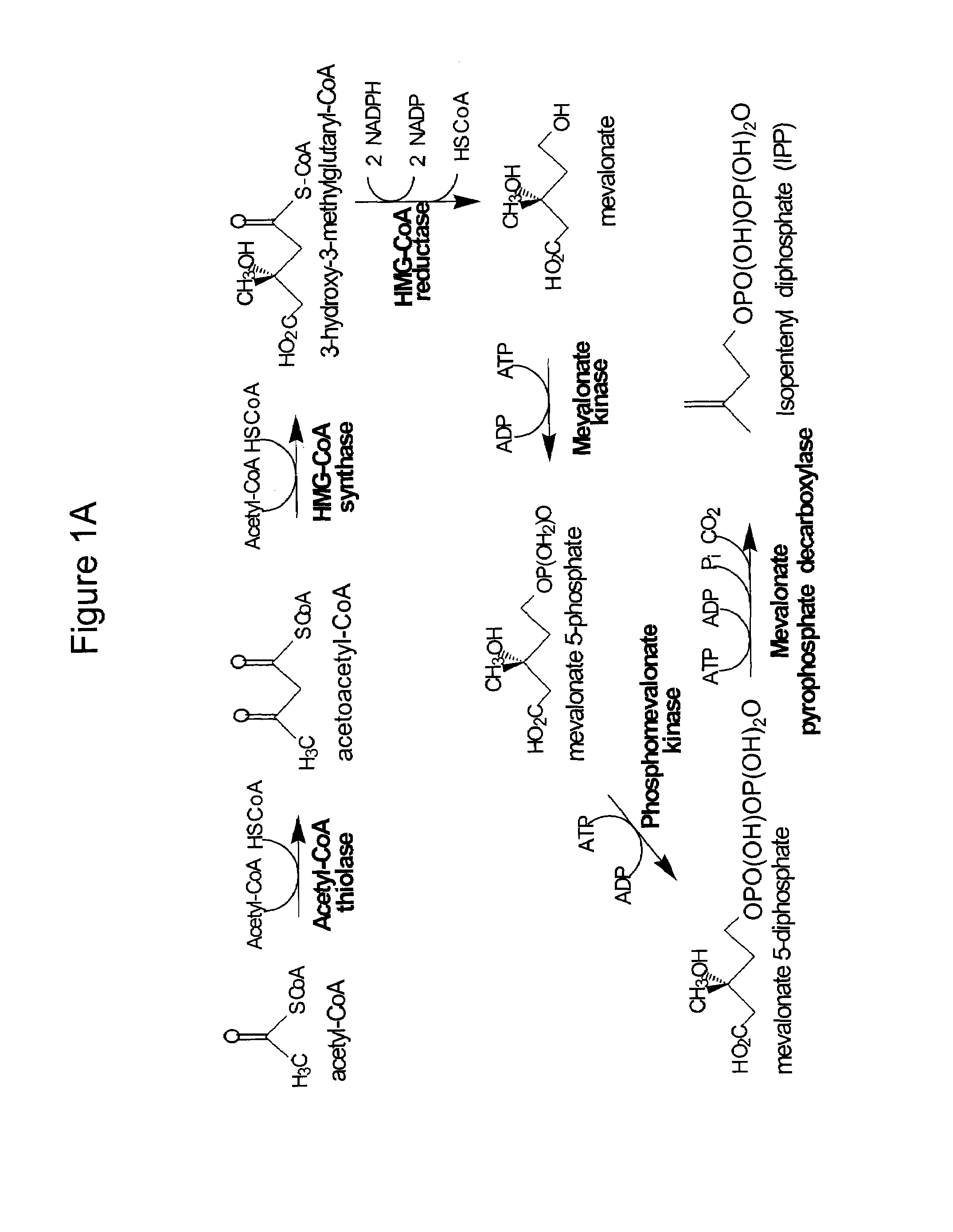

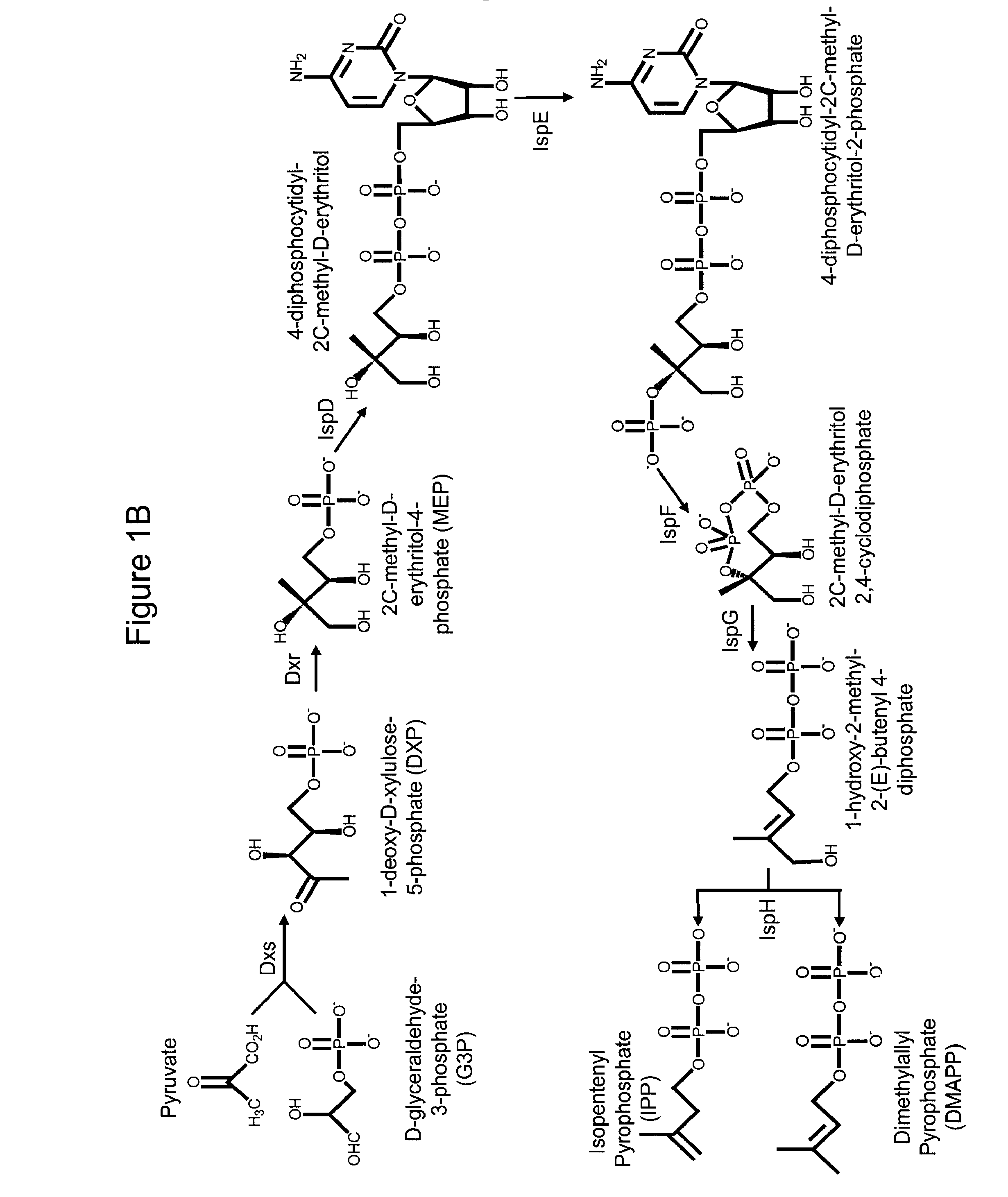

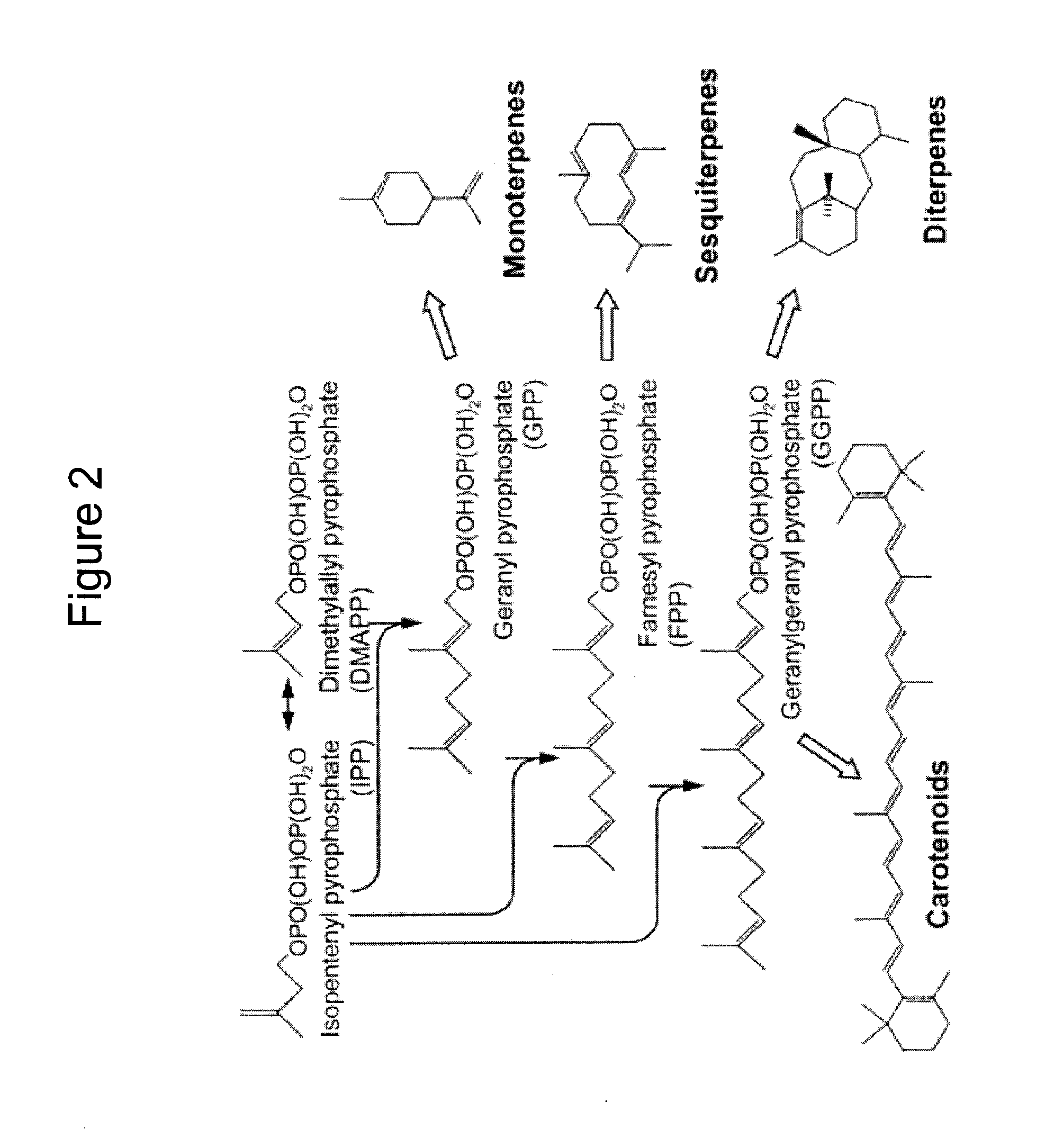

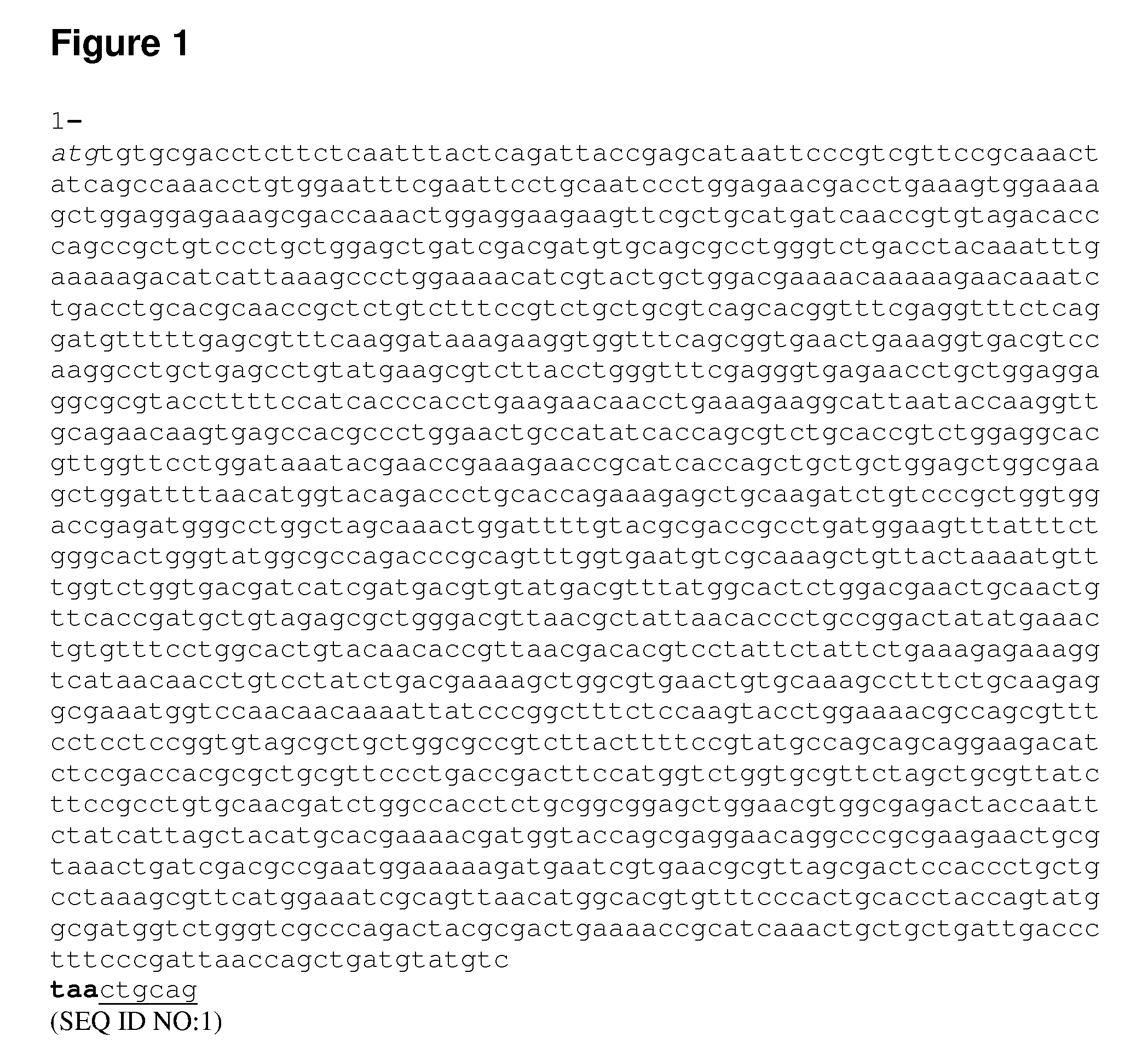

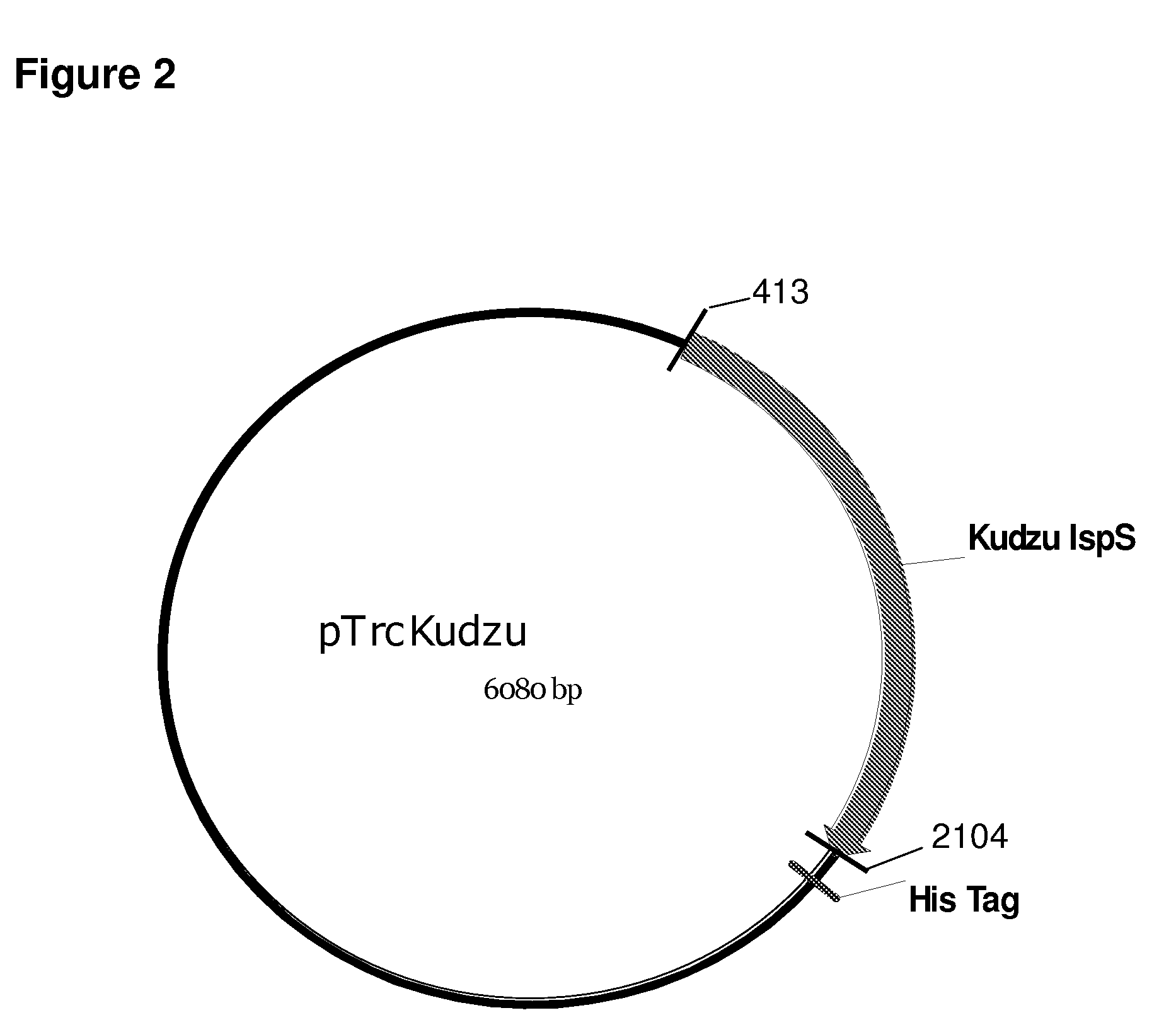

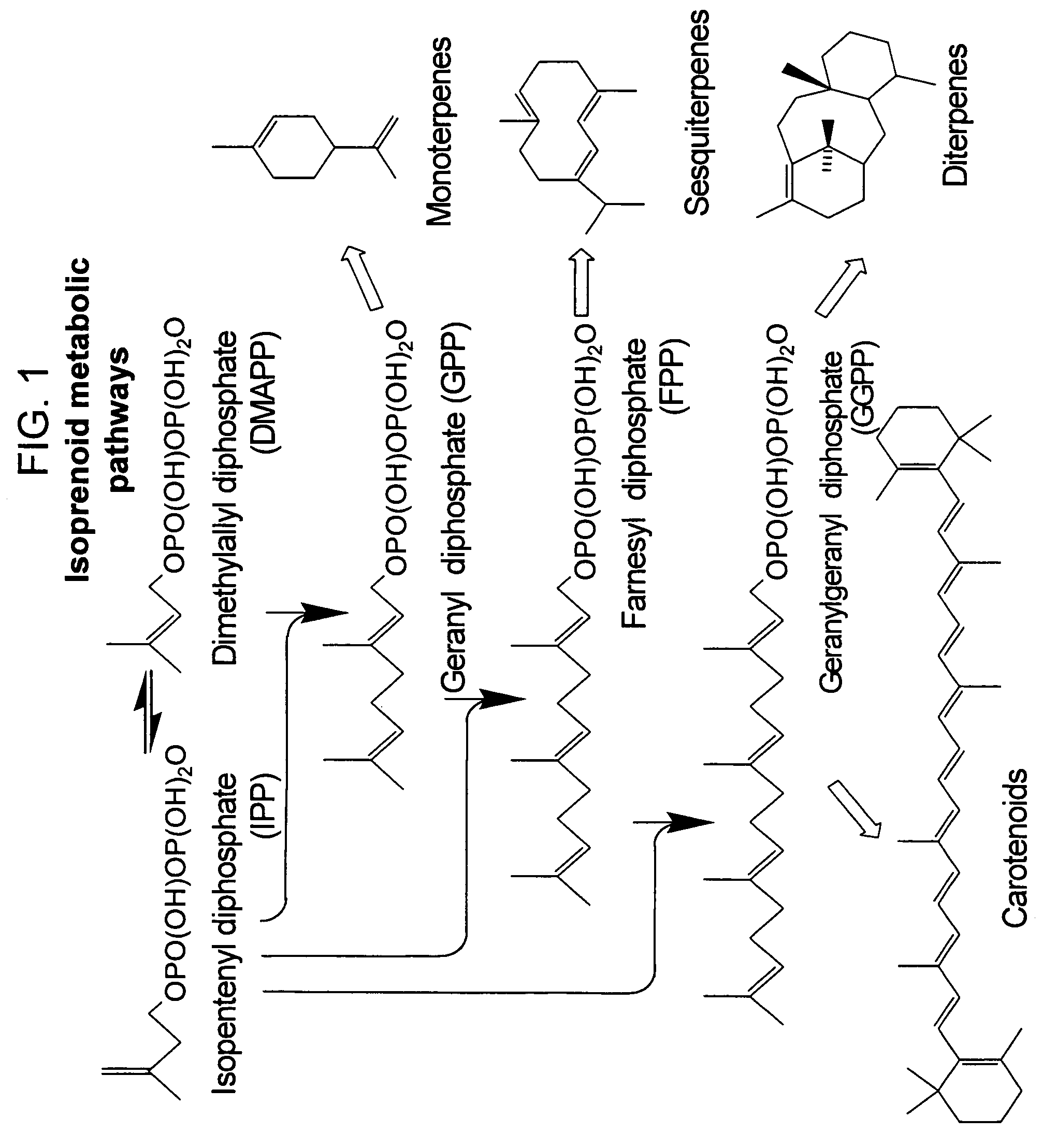

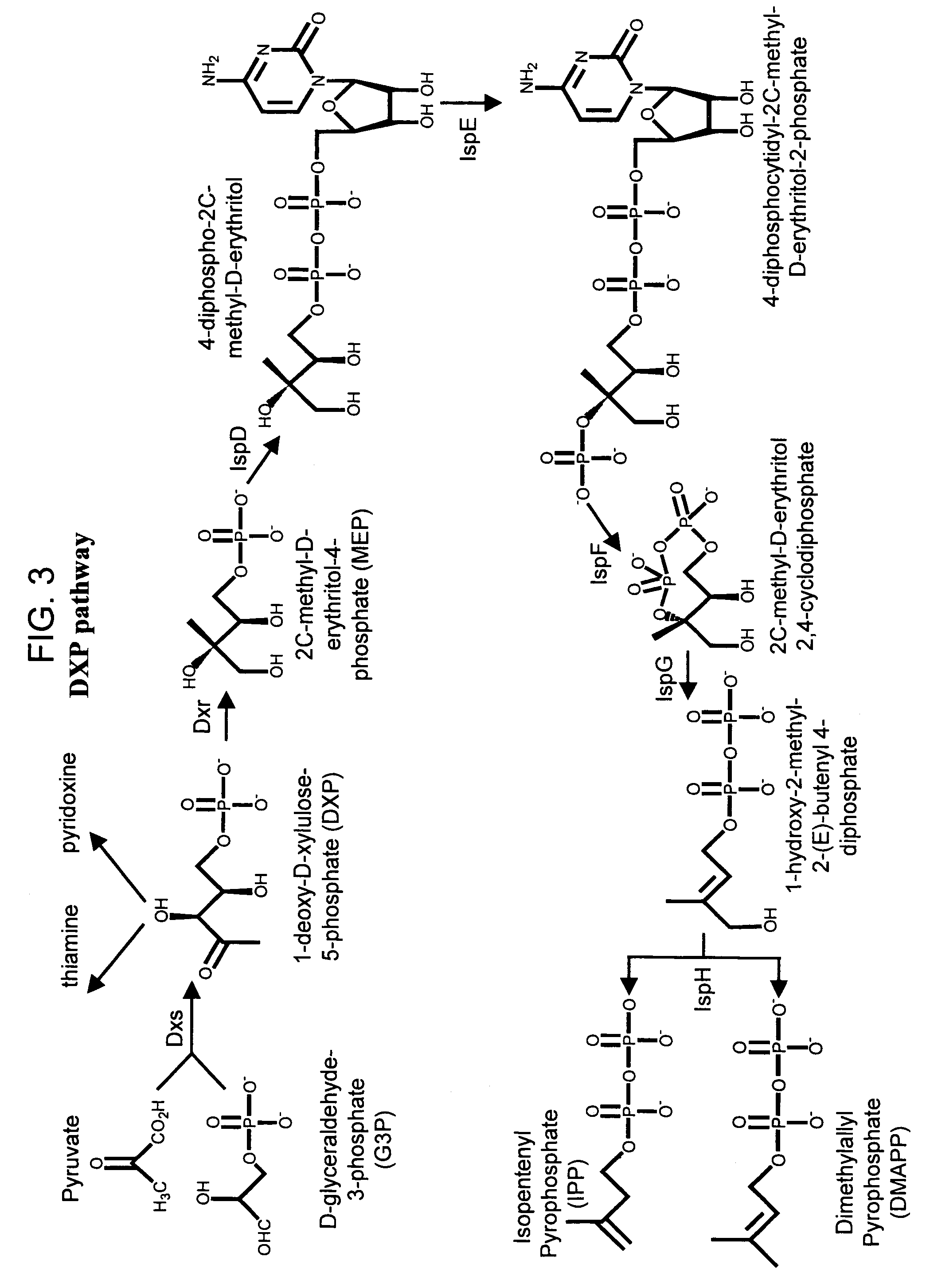

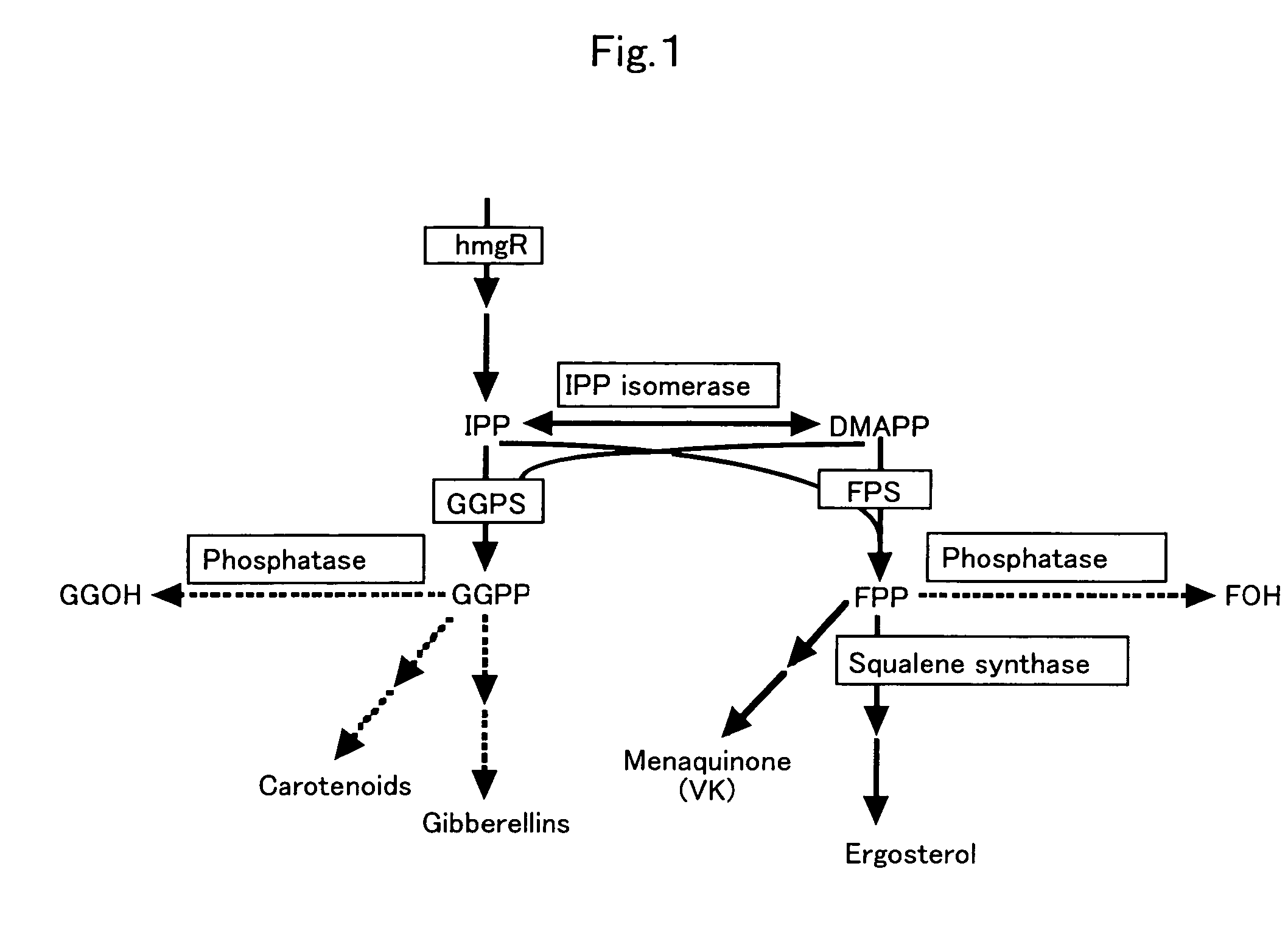

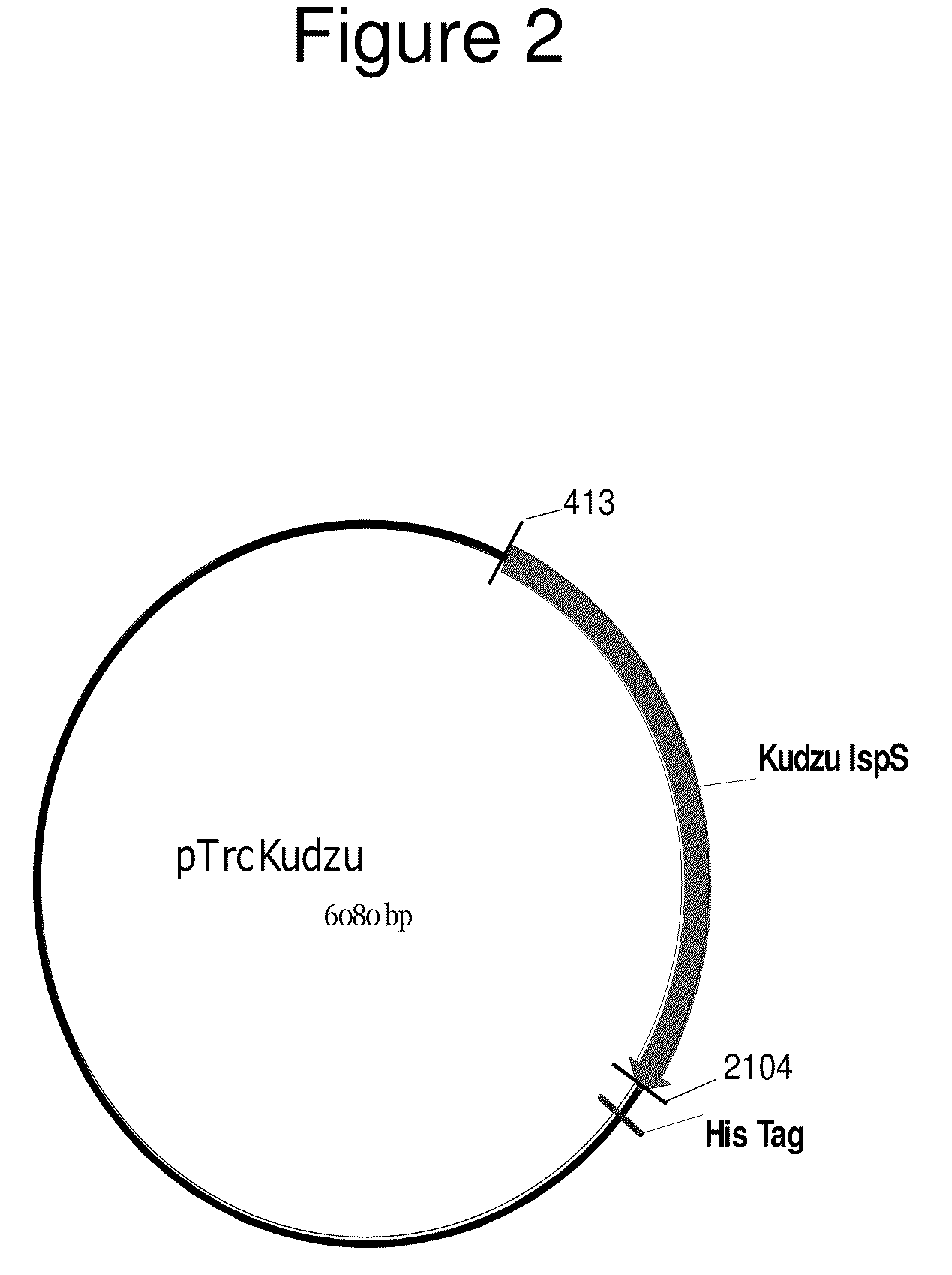

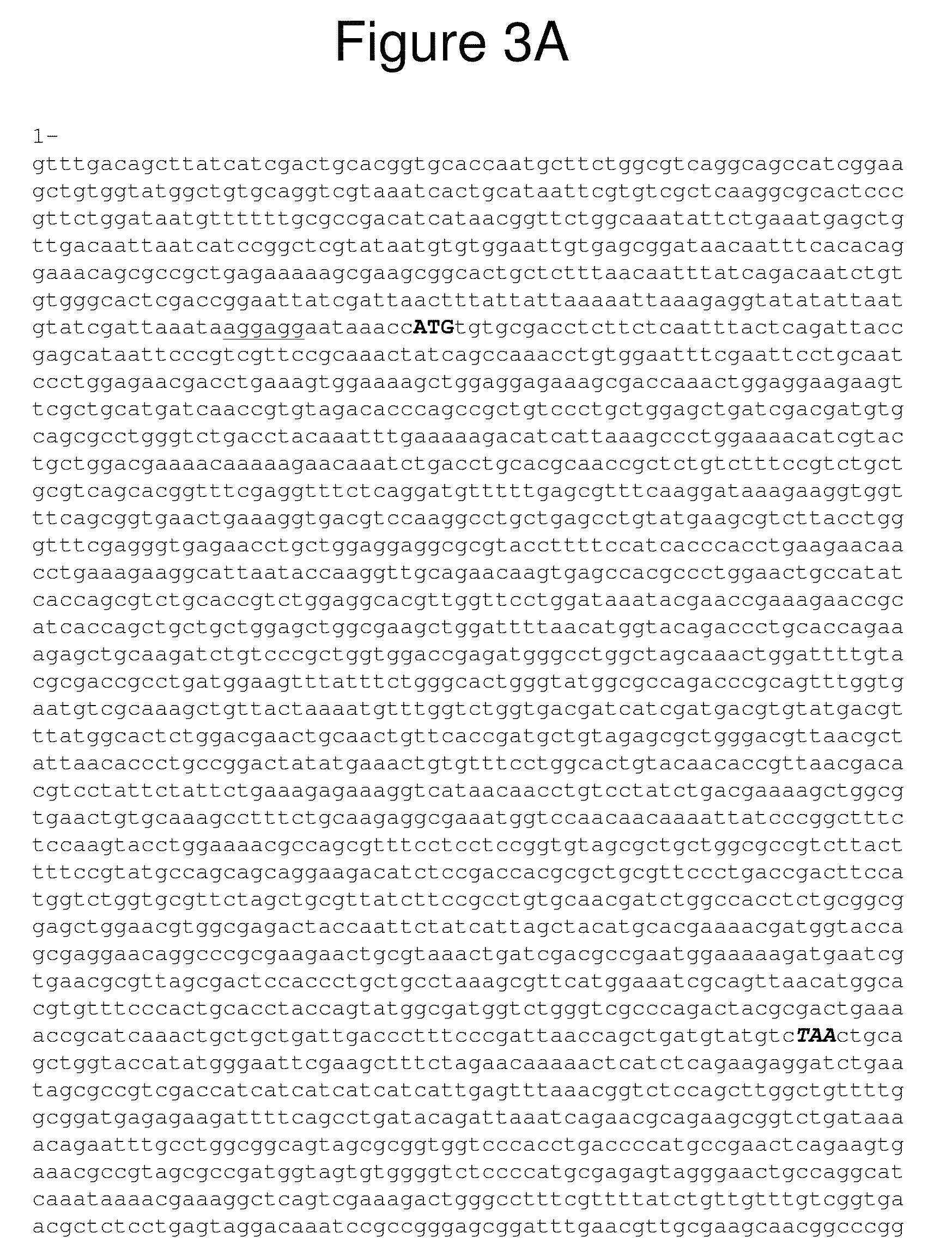

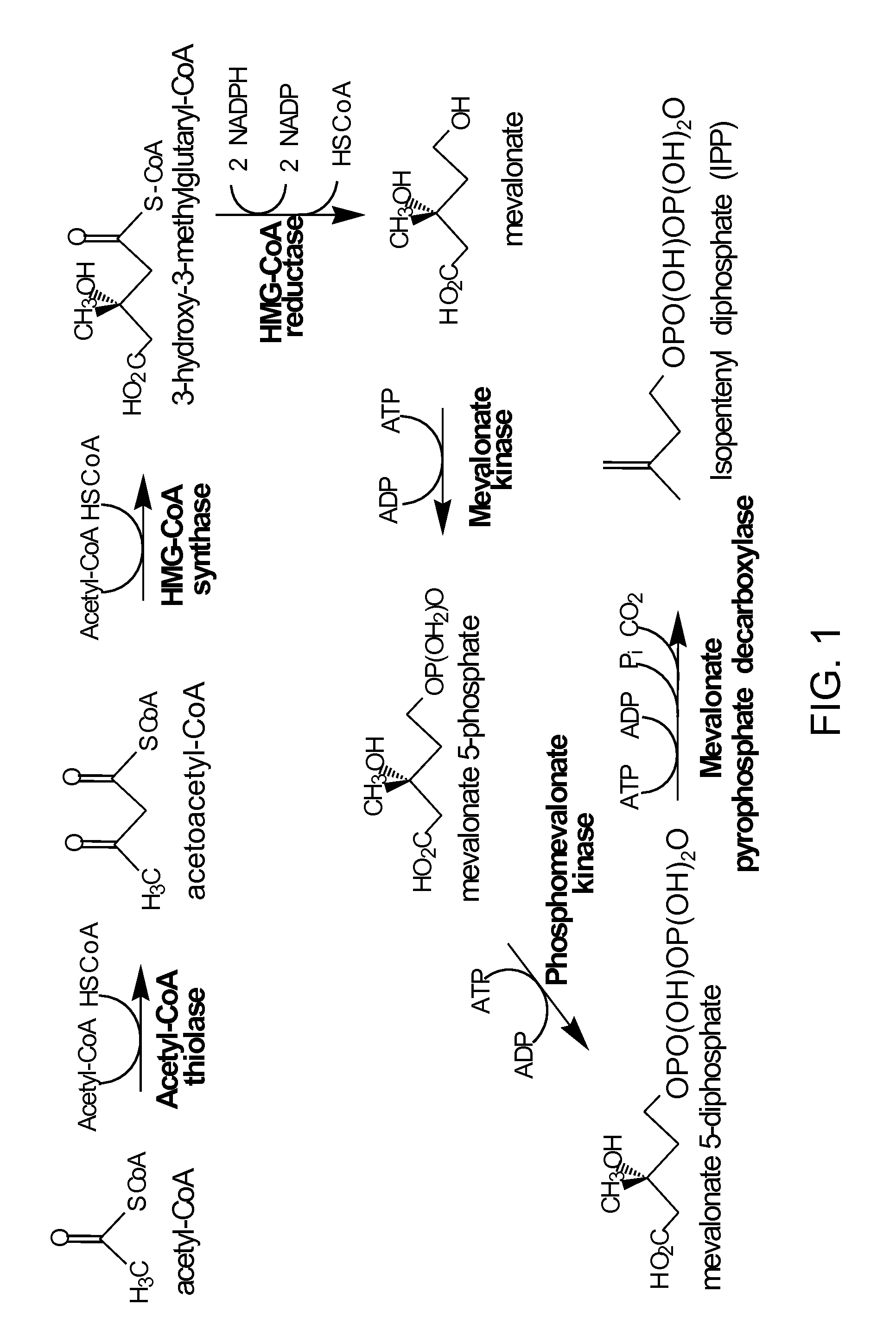

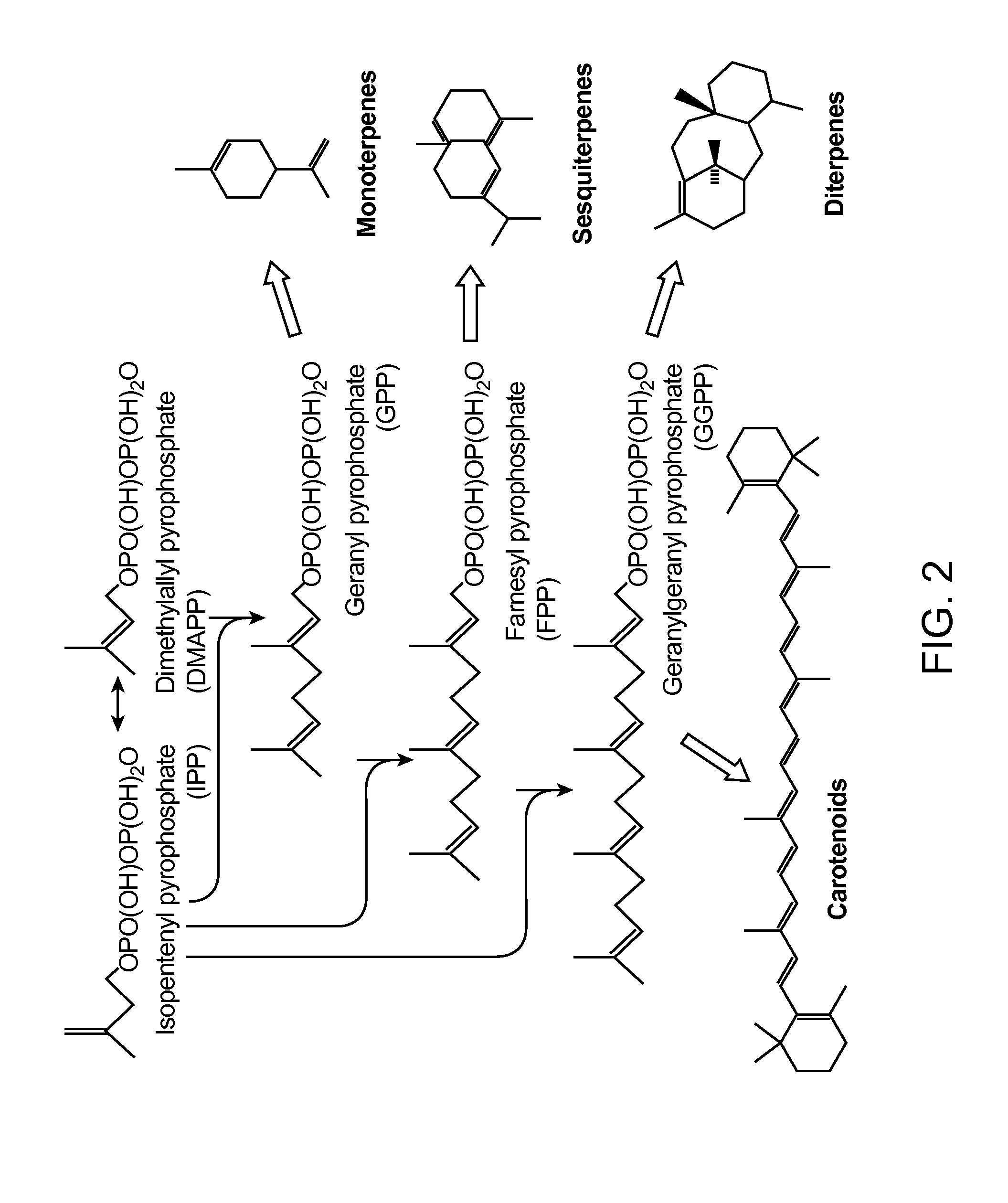

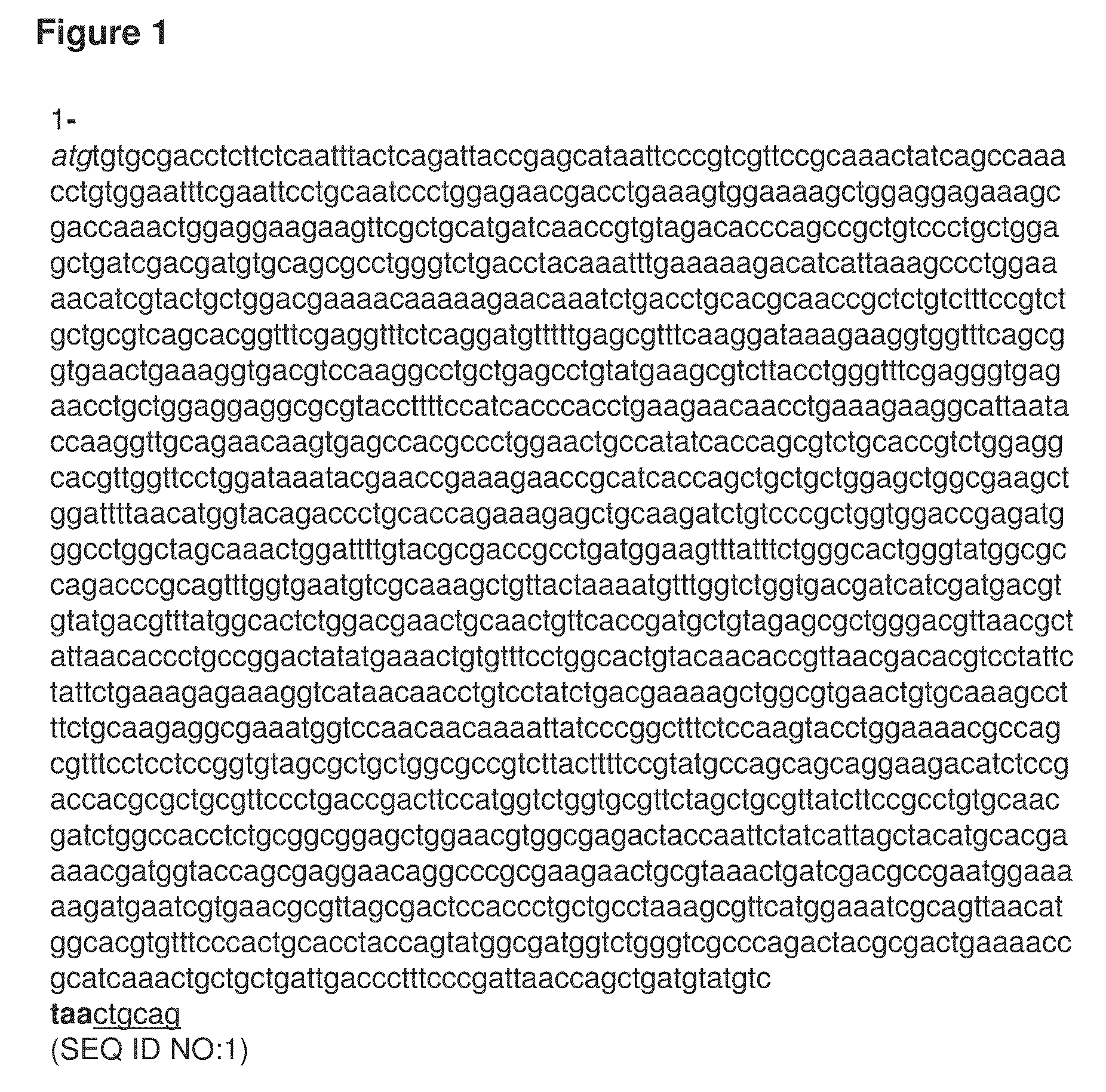

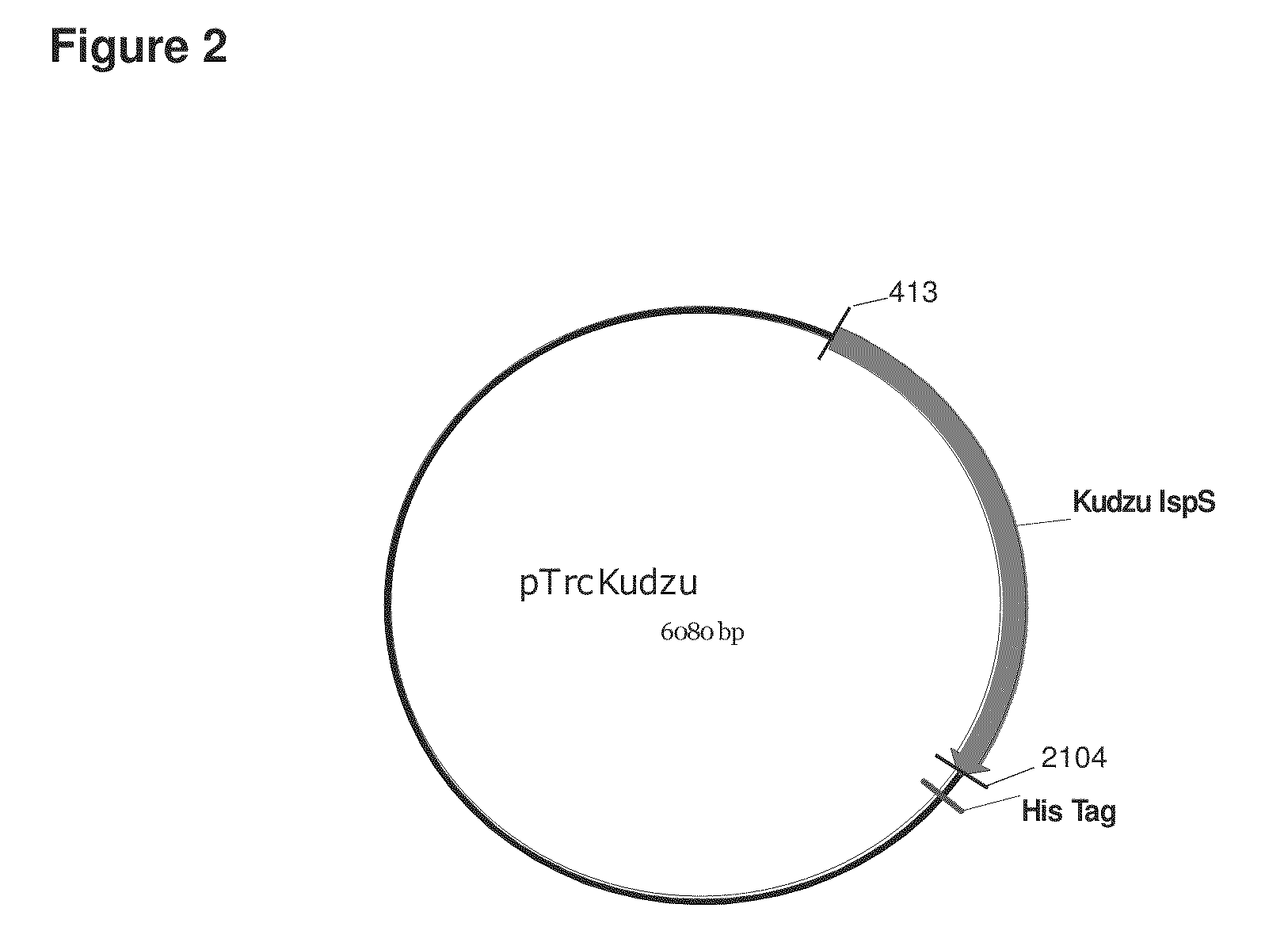

Production of isoprenoids

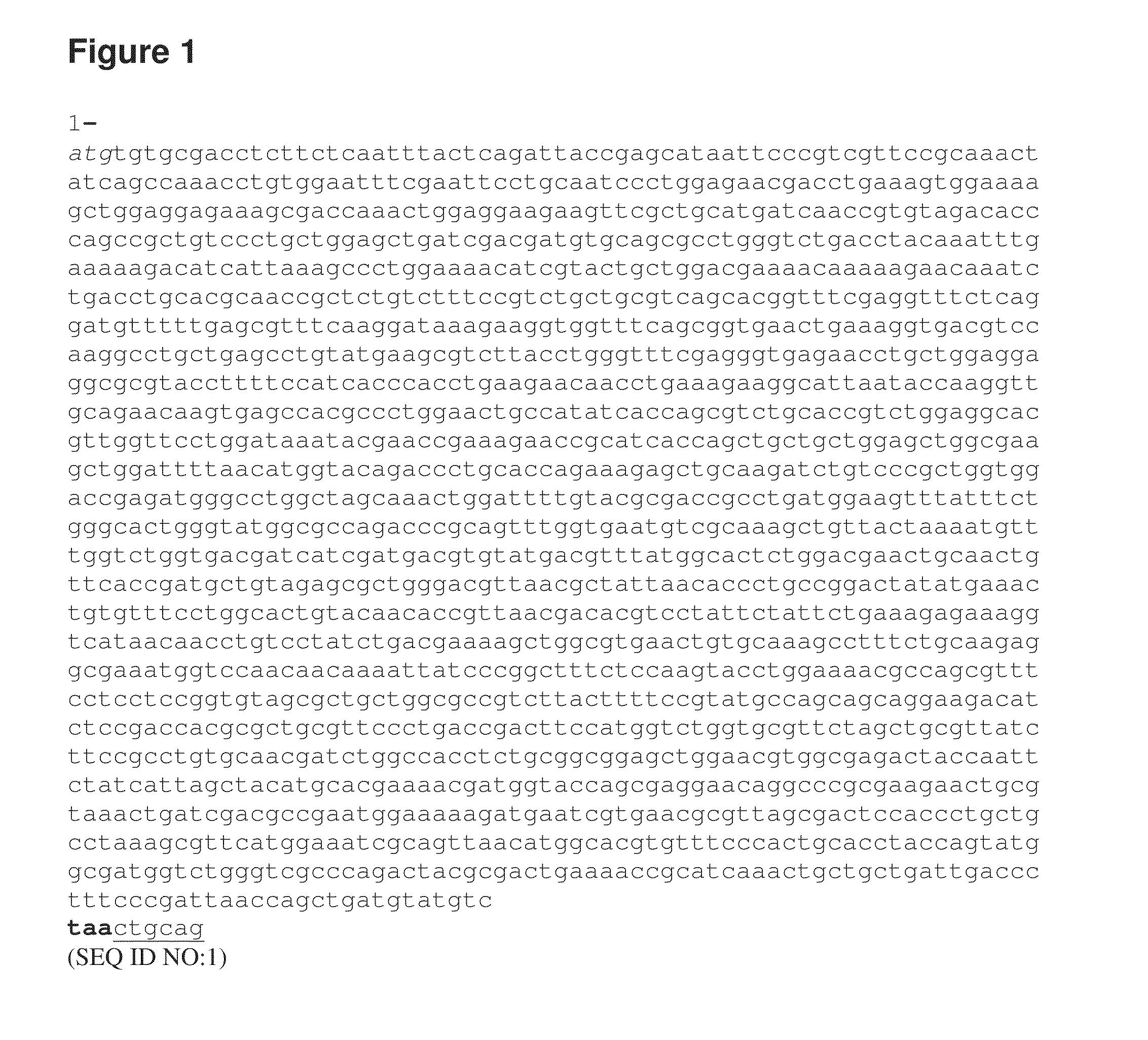

The present invention provides methods for a robust production of isoprenoids via one or more biosynthetic pathways. The invention also provides nucleic acids, enzymes, expression vectors, and genetically modified host cells for carrying out the subject methods. The invention also provides fermentation methods for high productivity of isoprenoids from genetically modified host cells.

Owner:AMYRIS INC

Compositions and methods for producing isoprene free of c5 hydrocarbons under decoupling conditions and/or safe operating ranges

The invention features methods for producing isoprene from cultured cells wherein the cells in the stationary phase. The invention also provides compositions that include these cultured cells and / or increased amount of isoprene. The invention also provides for systems that include a non-flammable concentration of isoprene in the gas phase. Additionally, the invention provides isoprene compositions, such as compositions with increased amount of isoprene or increased purity.

Owner:DANISCO US INC +1

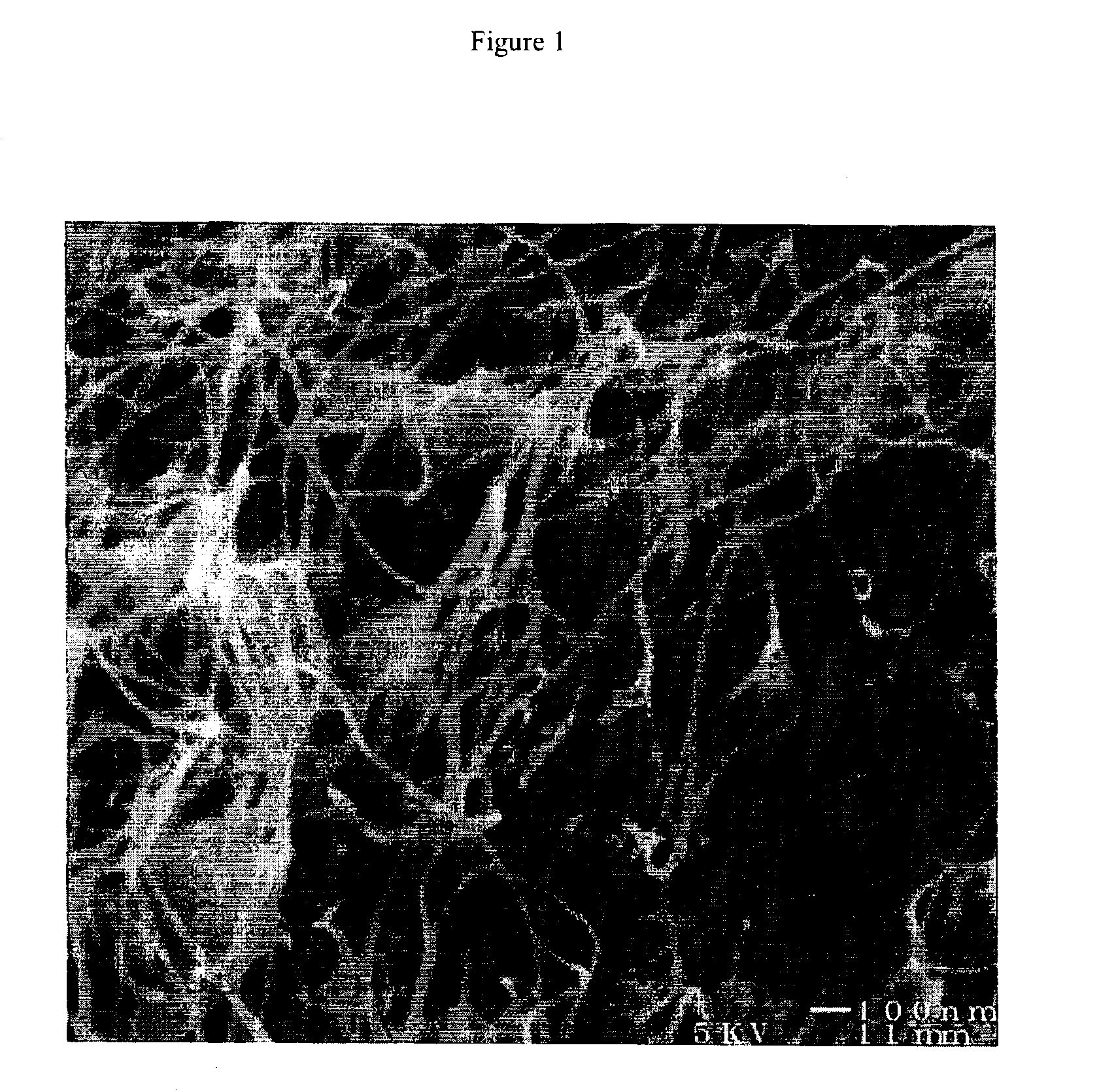

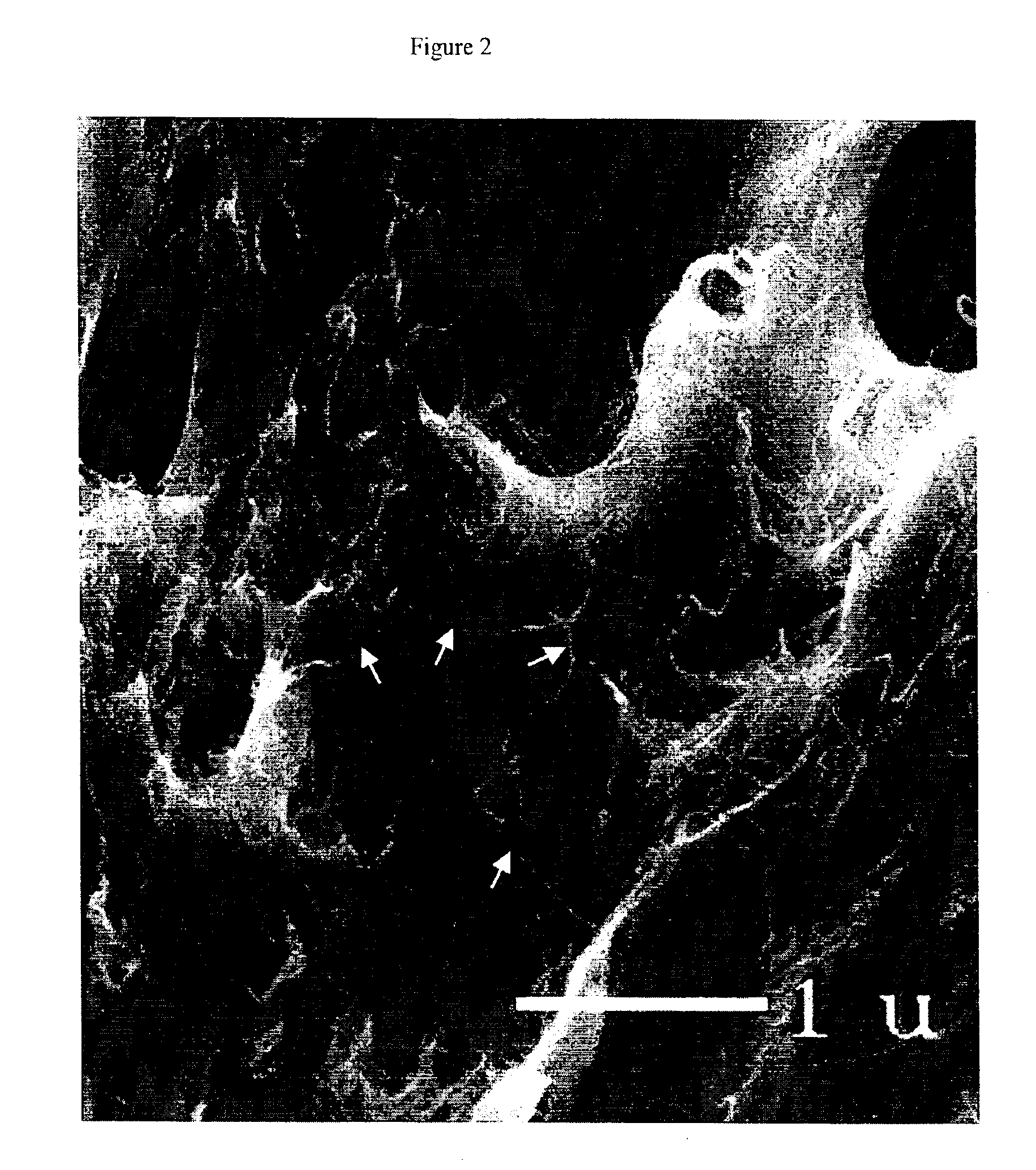

Composite materials comprising polar polymers and single-wall carbon nanotubes

InactiveUS6936653B2Improve conductivityMaterial nanotechnologyIndividual molecule manipulationPolyesterPolymer science

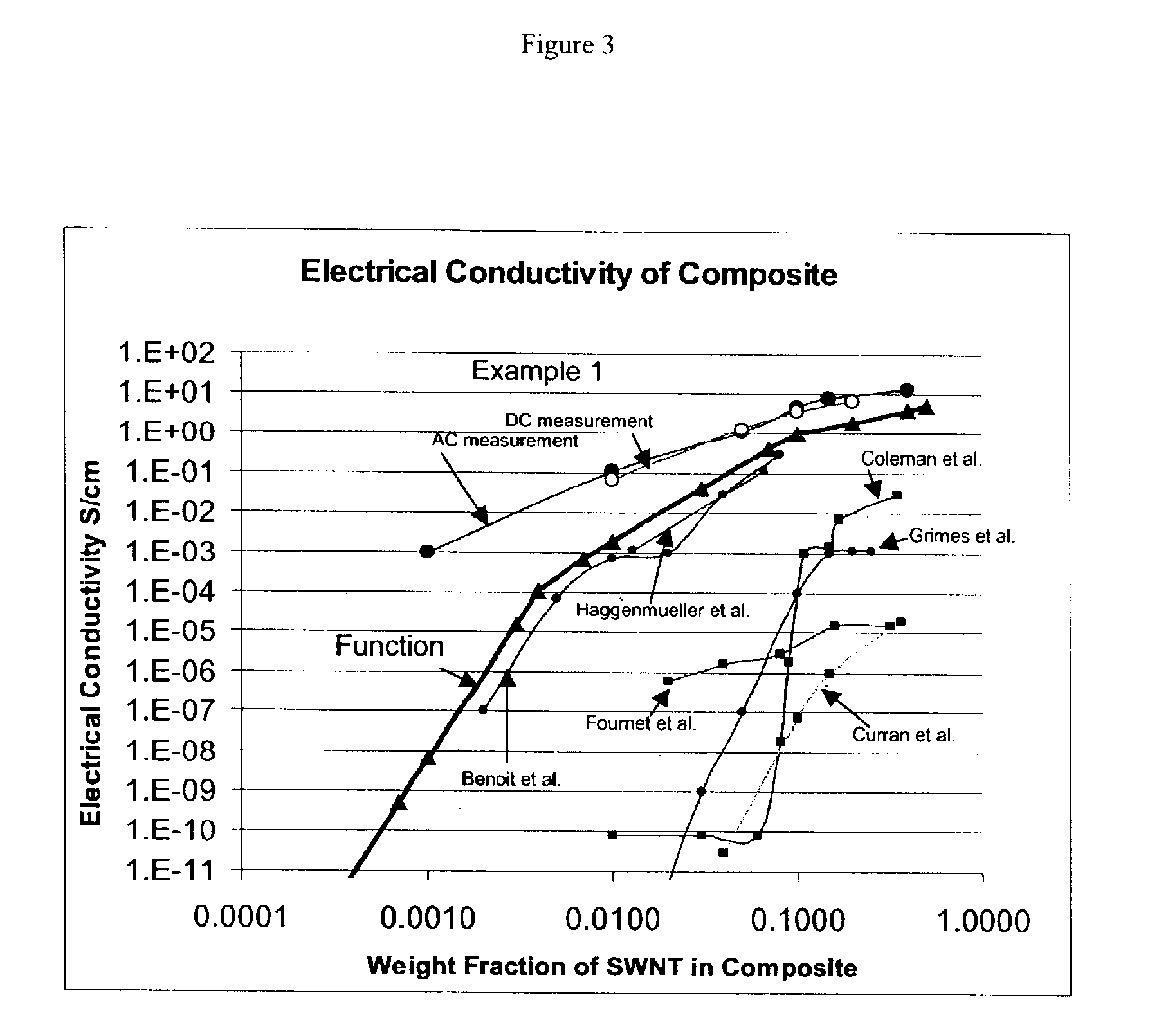

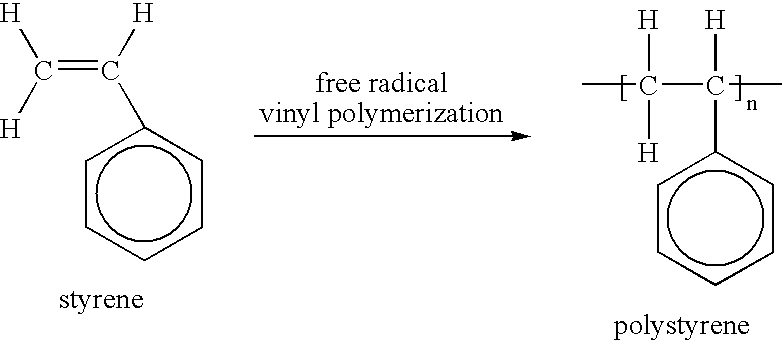

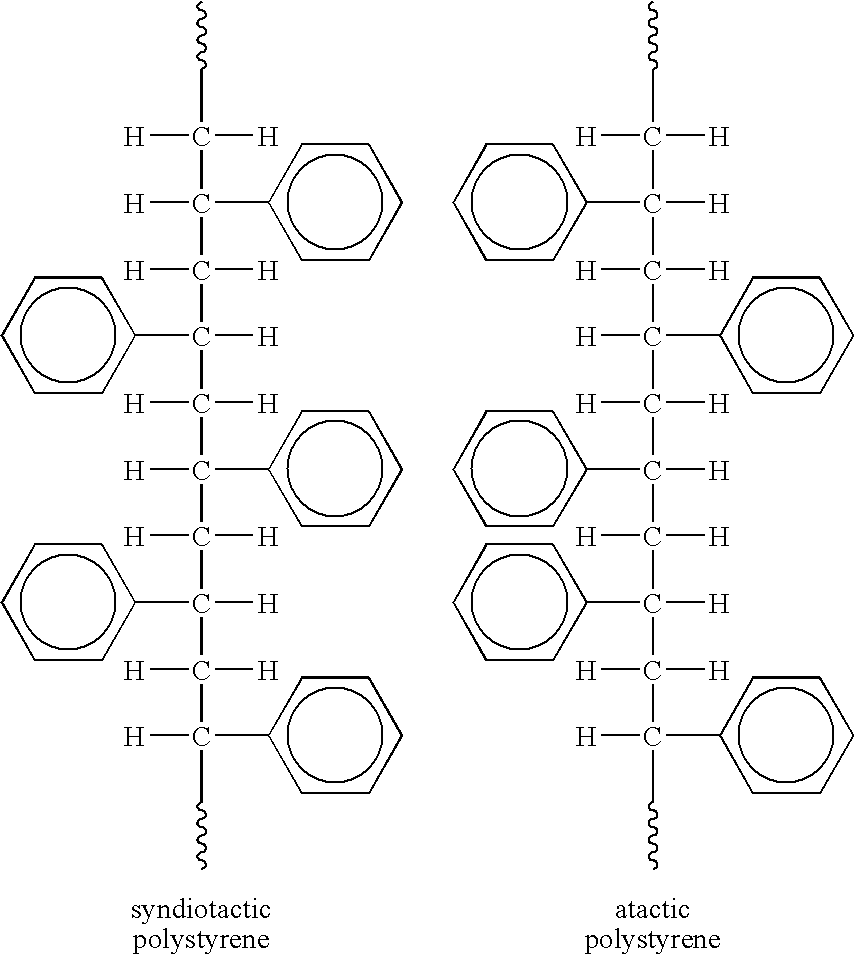

The invention relates to a composite comprising a weight fraction of single-wall carbon nanotubes and at least one polar polymer wherein the composite has an electrical and / or thermal conductivity enhanced over that of the polymer alone. The invention also comprises a method for making this polymer composition. The present application provides composite compositions that, over a wide range of single-wall carbon nanotube loading, have electrical conductivities exceeding those known in the art by more than one order of magnitude. The electrical conductivity enhancement depends on the weight fraction (F) of the single-wall carbon nanotubes in the composite. The electrical conductivity of the composite of this invention is at least 5 Siemens per centimeter (S / cm) at (F) of 0.5 (i.e. where single-wall carbon nanotube loading weight represents half of the total composite weight), at least 1 S / cm at a F of 0.1, at least 1×10−4 S / cm at (F) of 0.004, at least 6×10−9 S / cm at (F) of 0.001 and at least 3×10−16 S / cm (F) plus the intrinsic conductivity of the polymer matrix material at of 0.0001. The thermal conductivity enhancement is in excess of 1 Watt / m-° K. The polar polymer can be polycarbonate, poly(acrylic acid), poly(acrylic acid), poly(methacrylic acid), polyoxide, polysulfide, polysulfone, polyamides, polyester, polyurethane, polyimide, poly(vinyl acetate), poly(vinyl alcohol), poly(vinyl chloride), poly(vinyl pyridine), poly(vinyl pyrrolidone), copolymers thereof and combinations thereof. The composite can further comprise a nonpolar polymer, such as, a polyolefin polymer, polyethylene, polypropylene, polybutene, polyisobutene, polyisoprene, polystyrene, copolymers thereof and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

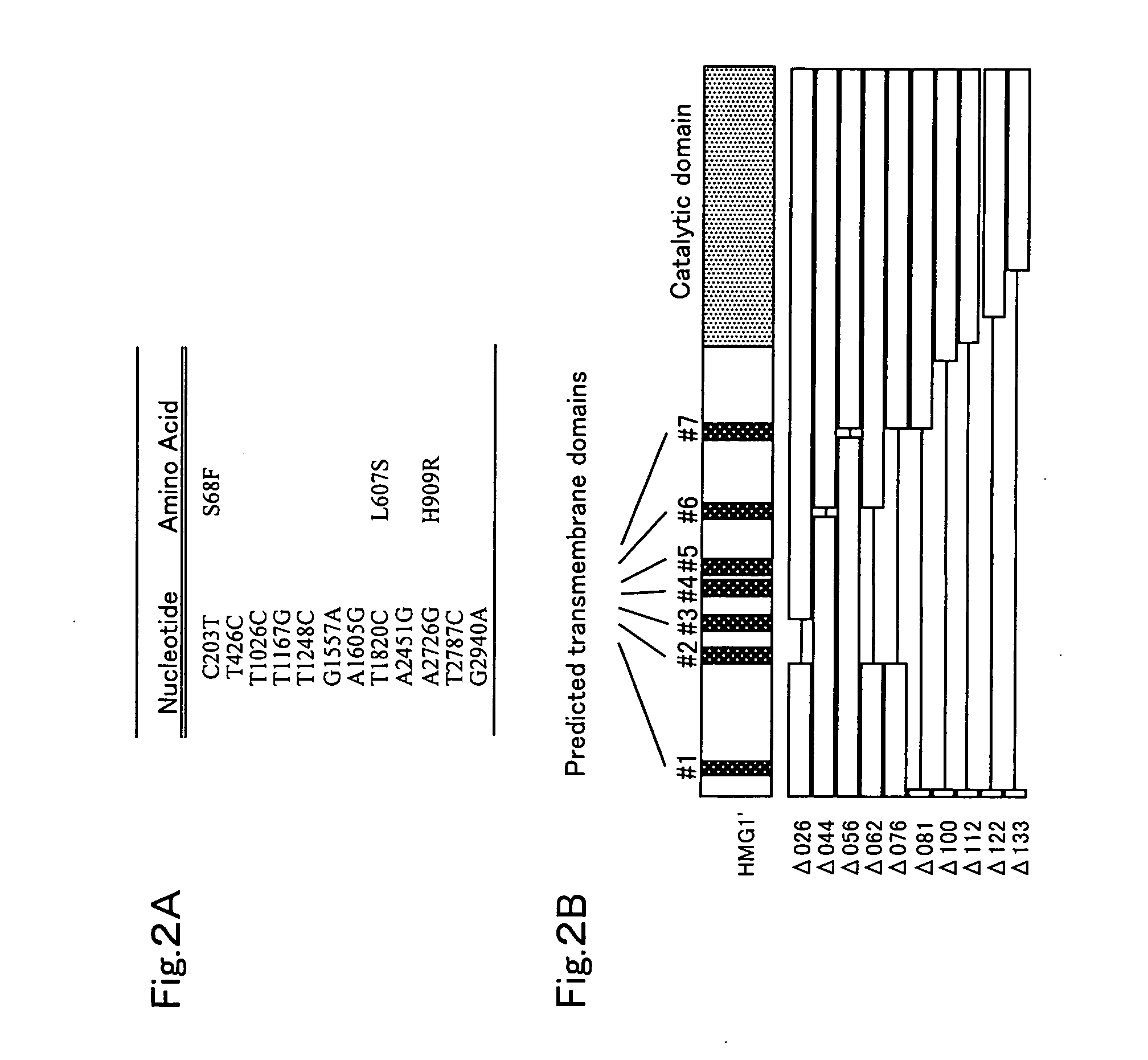

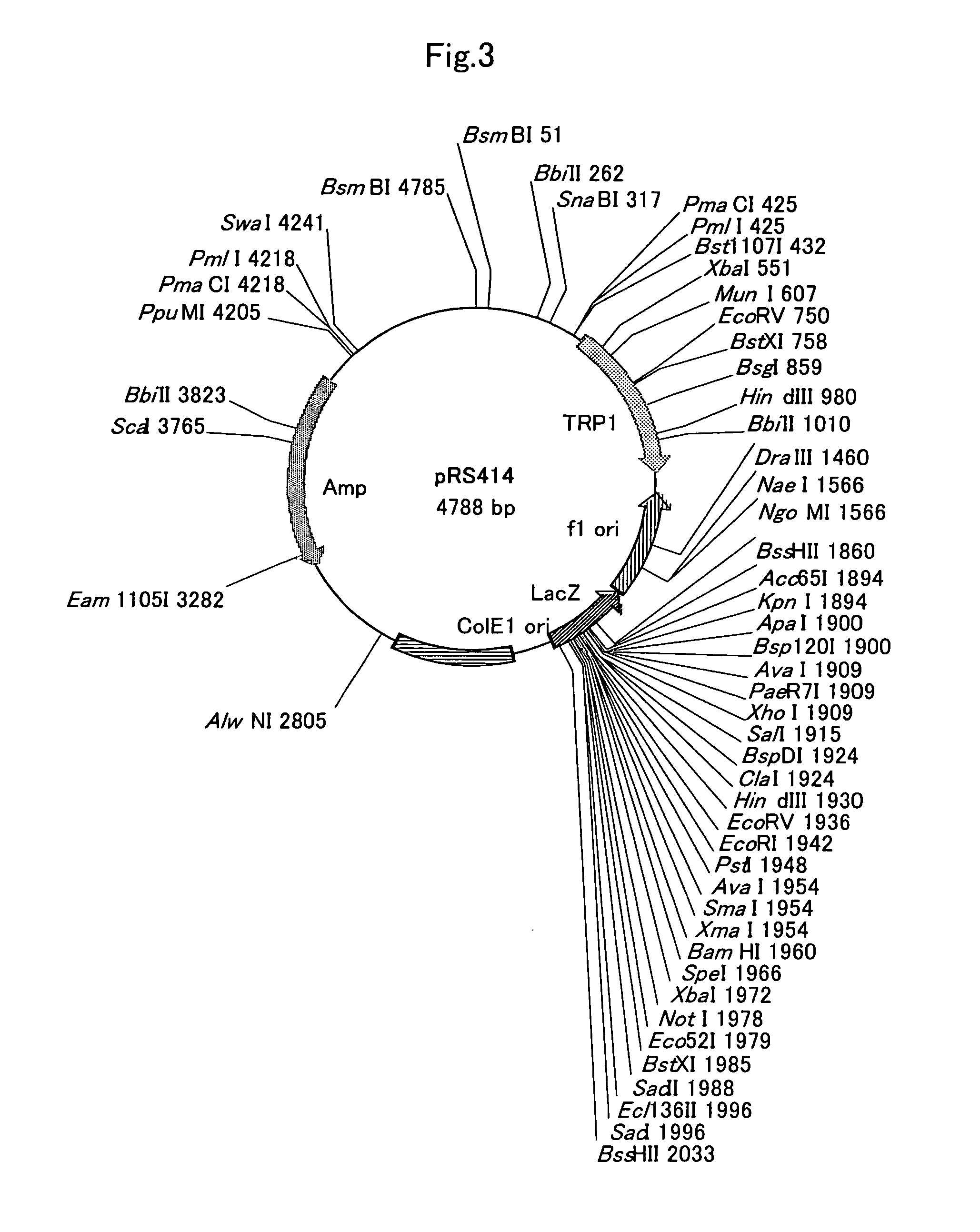

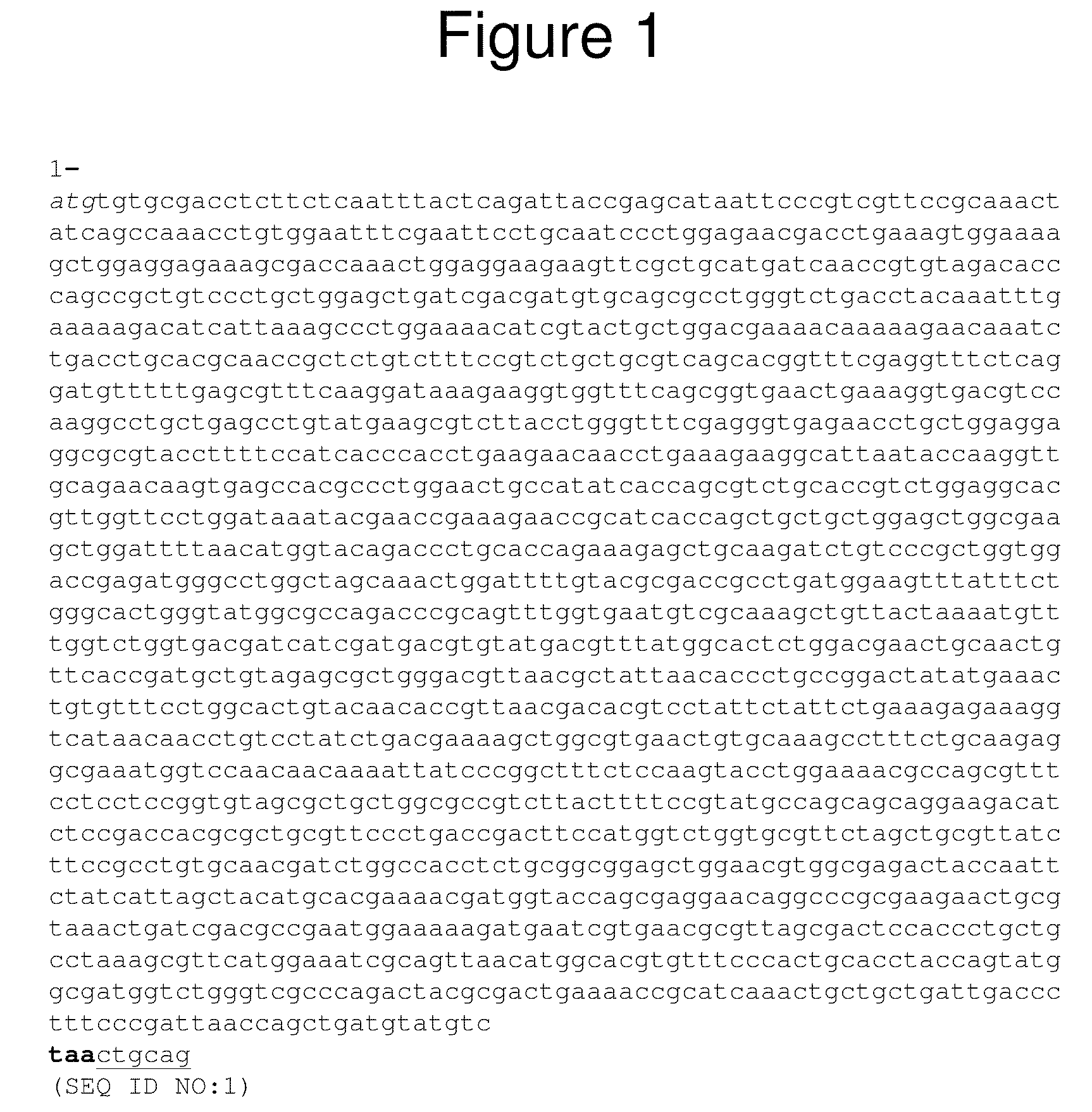

Method for enhancing production of isoprenoid compounds

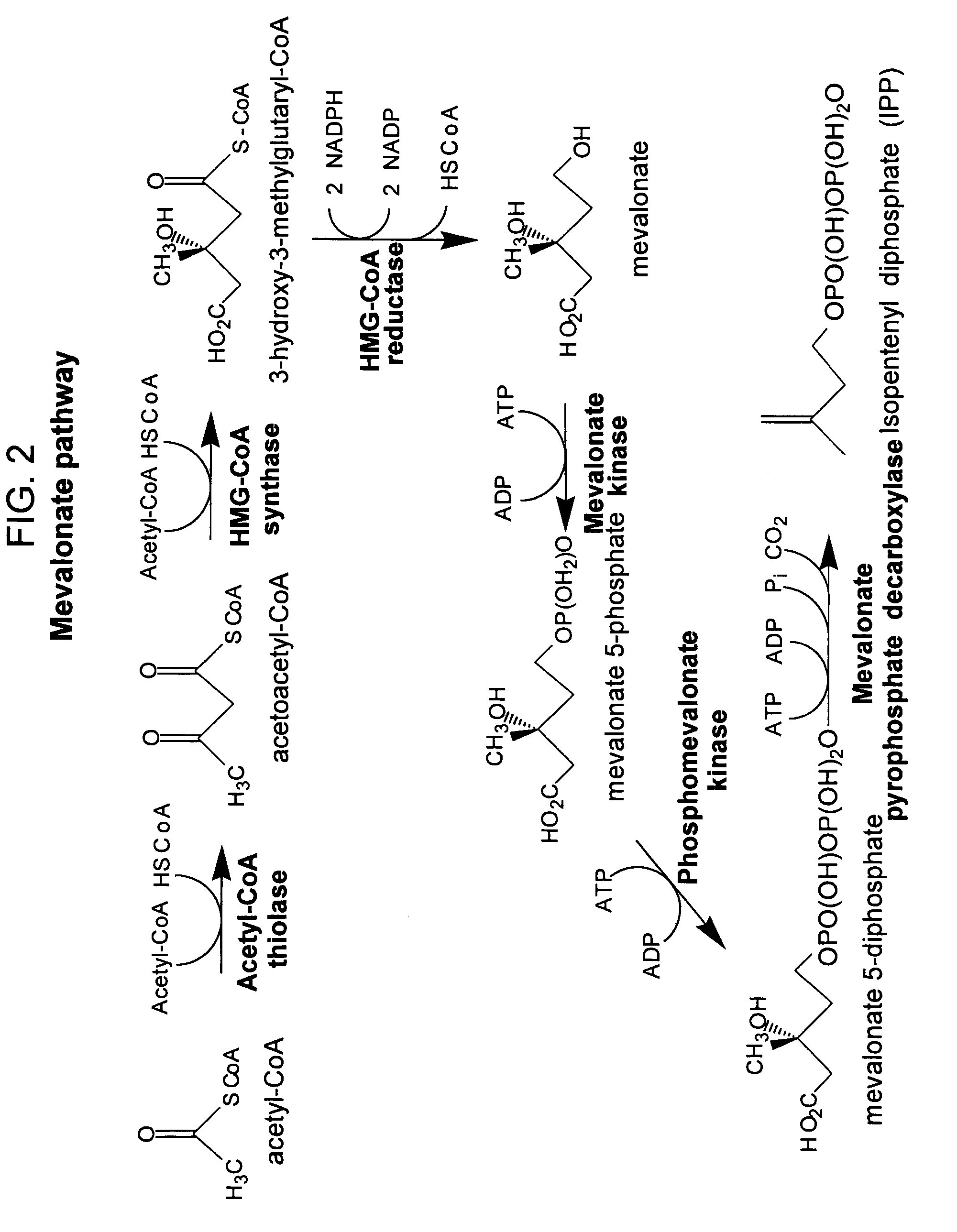

The present invention provides methods of producing an isoprenoid or an isoprenoid precursor in a genetically modified host cell. The methods generally involve modulating the level of hydroxymethylglutaryl-CoA (HMG-CoA) in the cell, such that the level of HMG-CoA is not toxic to the cell and / or does not substantially inhibit cell growth, but is maintained at a level that provides for high-level production of mevalonate, IPP, and other downstream products of an isoprenoid or isoprenoid pathway, e.g., polyprenyl diphosphates and isoprenoid compounds. The present invention further provides genetically modified host cells that are suitable for use in a subject method. The present invention further provides recombinant nucleic acid constructs for use in generating a subject genetically modified host cell, including recombinant nucleic acid constructs comprising nucleotide sequences encoding one or more mevalonate pathway enzymes, and recombinant vectors (e.g., recombinant expression vectors) comprising same. The present invention further provides methods for identifying nucleic acids that encode HMG-CoA reductase (HMGR) variants that provide for relief of HMG-CoA accumulation-induced toxicity. The present invention further provides methods for identifying agents that reduce intracellular accumulation of HMG-CoA.

Owner:RGT UNIV OF CALIFORNIA

Methods of producing prenyl alcohols

InactiveUS20070087425A1Efficient cultivationIncrease productivityPolypeptide with localisation/targeting motifFungiBiotechnologyAlcohol

A method of producing a prenyl alcohol, comprising creating a recombinant by transferring into a host a recombinant DNA for expression or a DNA for genomic integration each comprising a prenyl diphosphate synthase gene or a mutant thereof, culturing the resultant recombinant, and recovering the prenyl alcohol from the resultant culture.

Owner:TOYOTA JIDOSHA KK

Increased isoprene production using the archaeal lower mevalonate pathway

Owner:THE GOODYEAR TIRE & RUBBER CO

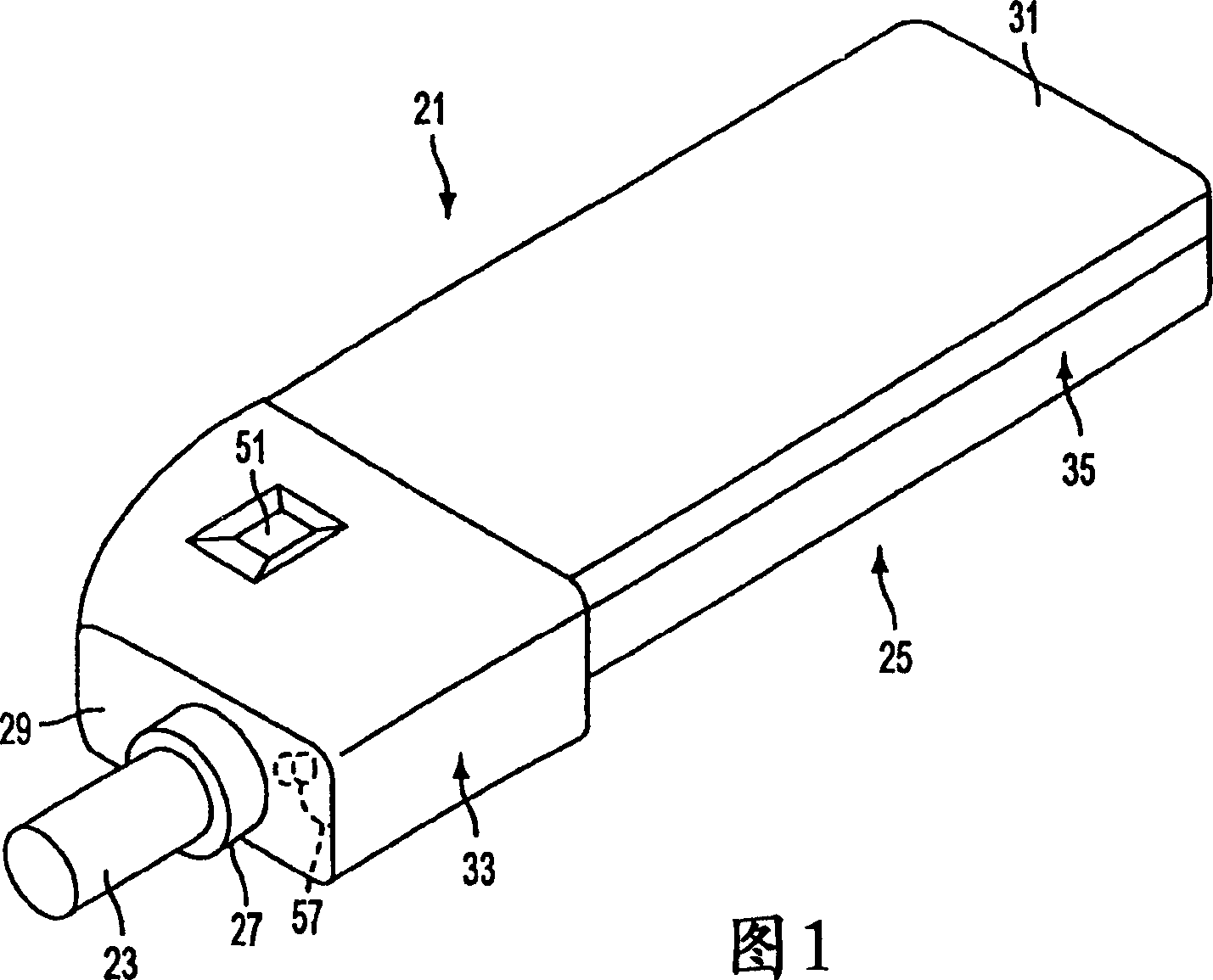

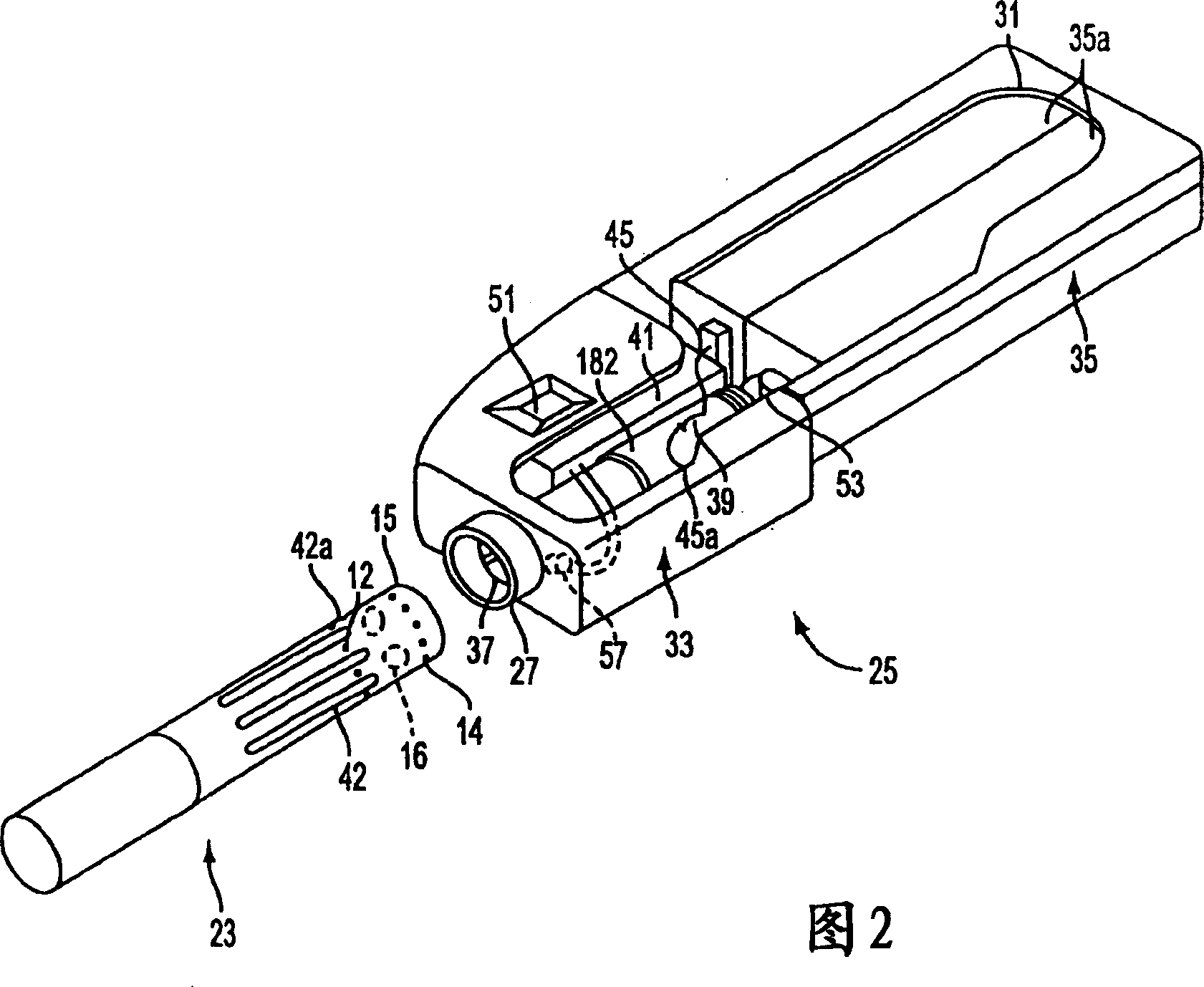

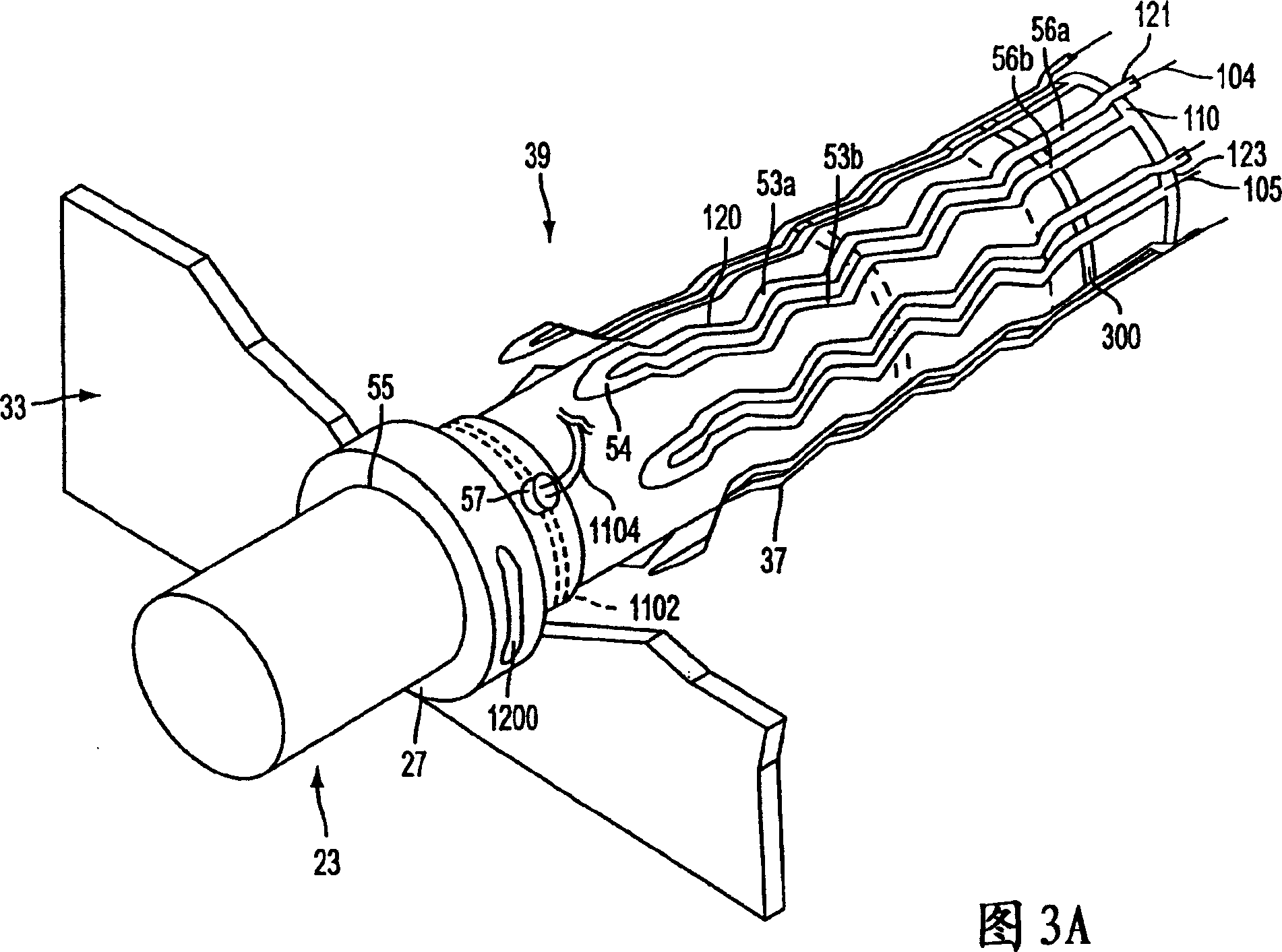

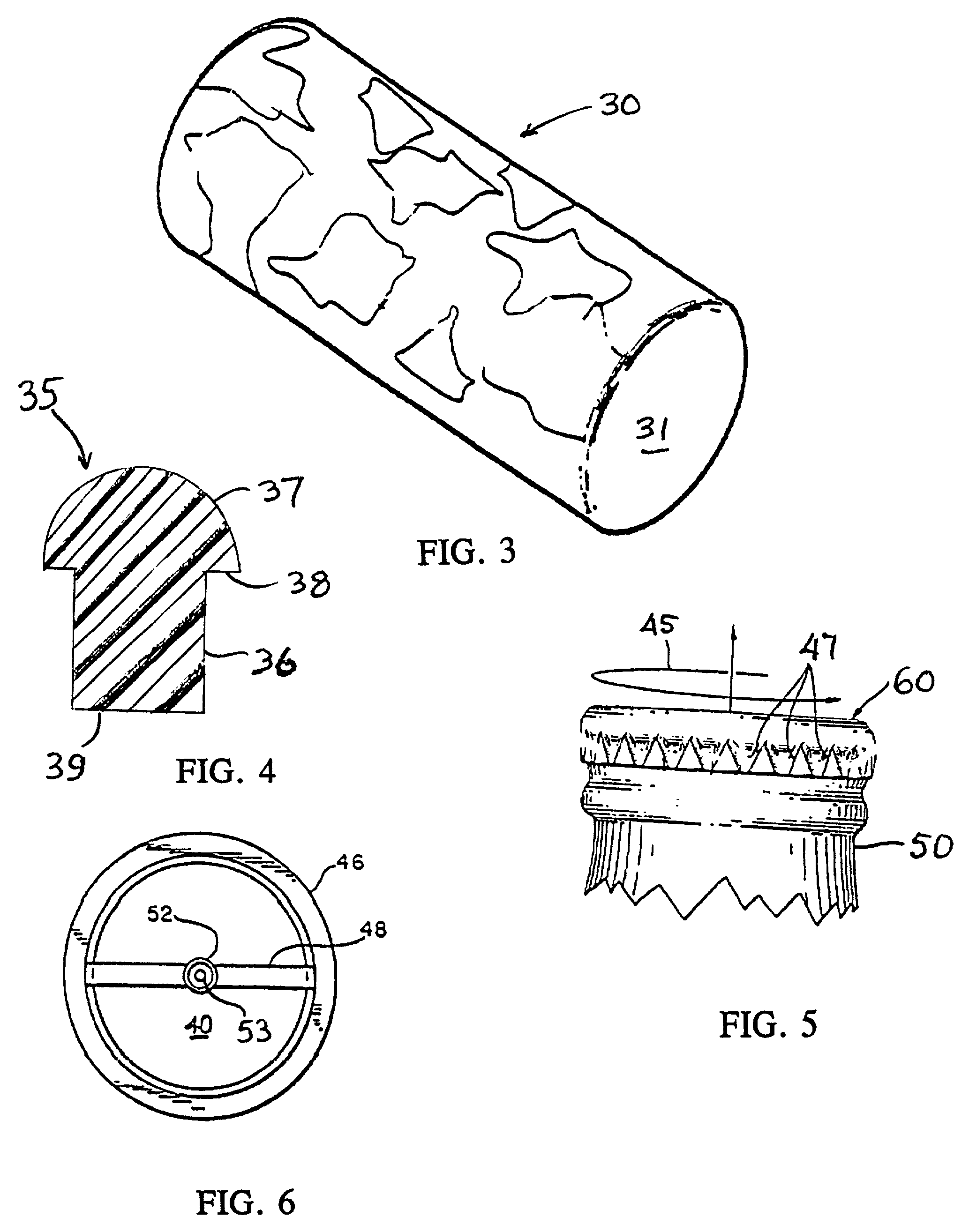

Electrical smoking system and method

InactiveCN1633247AReduce gaseous componentsIncandescent ignitionCigar manufactureIntegratorAcrylonitrile

An electric smoking system includes a cigarette including a cylindrical tobacco web partially filled with tobacco material to define a filled tobacco rod portion and an unfilled tobacco rod portion, and an electric lighter. The wrapper includes a filler of ammonium-containing compounds effective to reduce the gaseous constituents of the smoke produced during smoking. The system includes a pilot burner including at least one heating vane and a controller adapted to control heating of the heating vane. The lighter is configured to at least partially contain the cigarette such that the heater blade heats the heating region of the cigarette. Manipulating the controller to limit the heating of the heater blades to a predetermined temperature range which allows the delivery of the smoke generated when the portion of the tobacco rod is heated while at least reducing the amount of smoke present in the smoke as compared to smoking a cigarette having only calcium carbonate as filler. A gaseous component. The gaseous components that can be reduced include carbon monoxide, 1,3 butadiene, isoprene, acrolein, acrylonitrile, hydrogen cyanide, 0-toluidine, 2-naphthylamine, nitrogen oxide, benzene, NNN, Phenol, catechol, benzanthracene and benzopyrene.

Owner:PHILIP MORRIS PROD SA

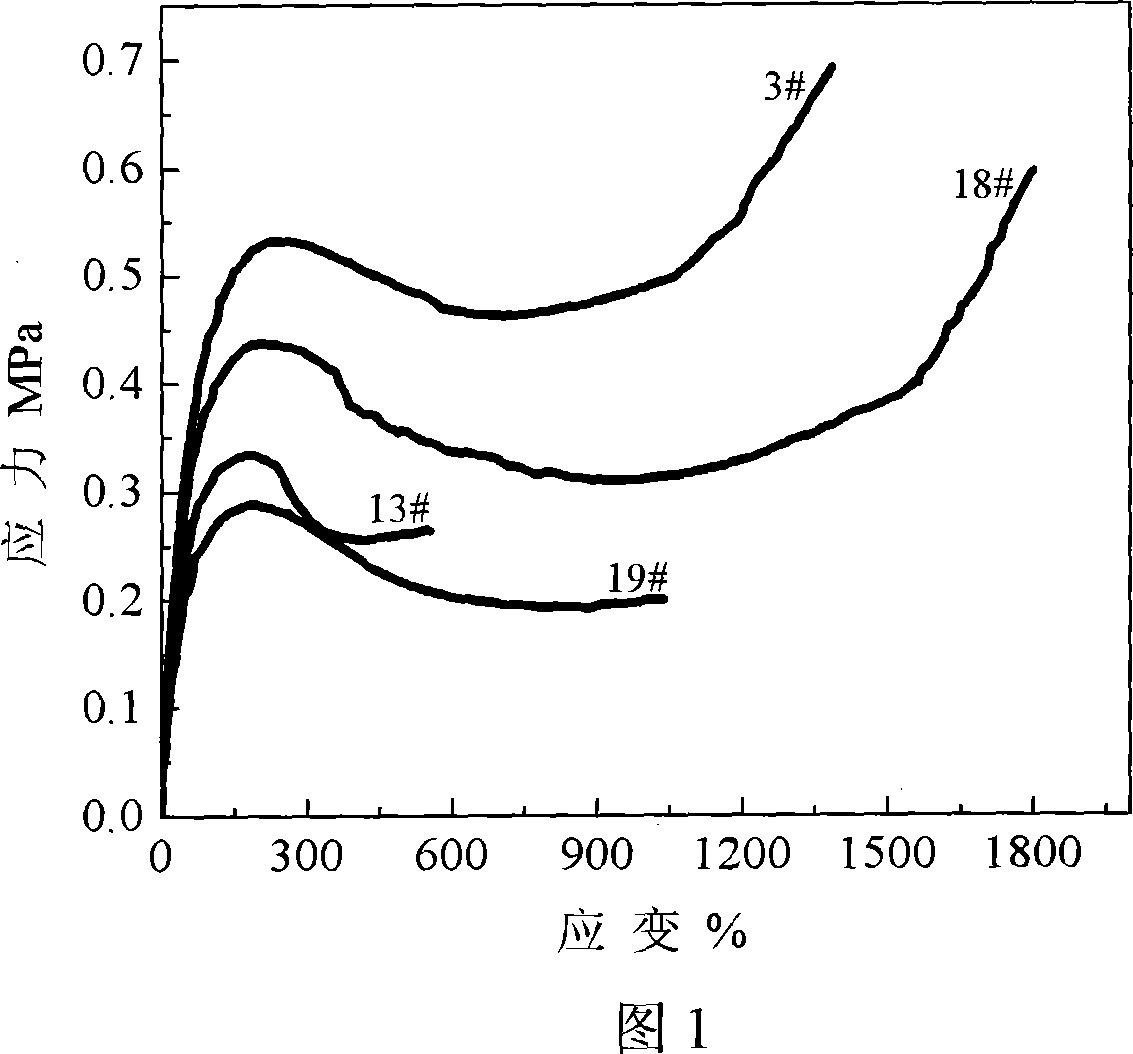

Rare earth catalyst for preparing polyisoprene and preparation method and method for preparing polyisoprene

This invention belongs to rare earth catalyzer for preparing polyisoprene, and its preparation method. This catalyzer is composed by carboxylic acid neodymium, aluminium alkyl, chloride, conjugated diolefine. Mixture ratio of aluminium alkyl, chloride, conjugated diolefine,and carboxylic acid neodymium is 5 - 30:1.0 -4.0:5 - 20:1. This invention could obtain homogeneous phase and stable rare earth catalyzer. This catalyzer possess higher catalytic activity, trigger off isoprene polymerization at higher polymerization temperature, obtain polyisoprene that has high content of syn- 1, 4 structure( not less than 96 percent) and narrow molecular weight distribution ( less than 3.0), and possess tensile crystallinity trait.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Organic-inorganic hybrids surface adhesion promoter

An organic-inorganic hybrid surface adhesion promoter having the general formula, A-B, wherein A is hydrolyzed and polycondensed from a trioxysilane R-Si(OR')3 or its mixture with one or two more silanes, where R' is methyl, ethyl or propyl, and where R is an organic group of methacrylate, epoxy, amine, isolyante, hydroxide or non-halogens or halogens containing alkyl, alkenyl, aryl, alkylary or arylalky, and wherein B is hydrolyzed and polycondensed from an alkoxy silane, chloride silane, or alkoxy or chloride metal compound, whereby B reacts with a substrate to form a uniting group which is selected from the group consisting of Si-O-Si, M-O-M, M-O-S and Si-O-M, M being a metal atom.

Owner:ZENASTRA PHOTONICS INC

Lipo-Conjugation of Peptides

InactiveUS20090054623A1Improving pharmacological parameterProlong half-life in vivoPeptide/protein ingredientsPeptide preparation methodsIsopreneGlycosyl

The present invention provides peptide conjugates that are formed between a modified lipid and a glycosyl residue and / or an amino acid residue on a peptide. The modified lipid includes a modifying group and a lipid linking group. Exemplary lipid linking groups include myristoyl, palmitoyl, and isoprenyl moieties.

Owner:NOVO NORDISK AS

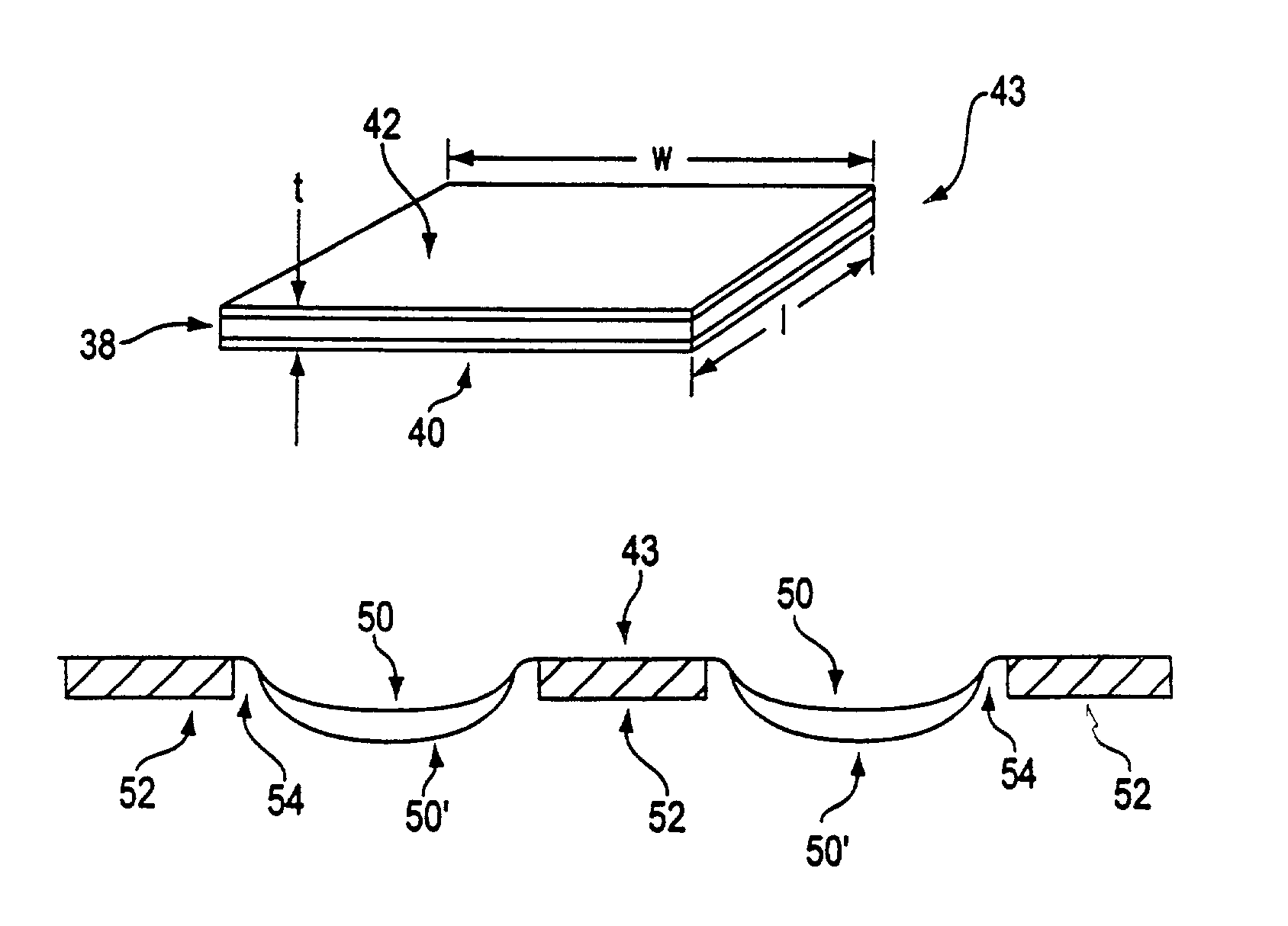

Elastomeric dielectric polymer film sonic actuator

InactiveUS7062055B2Optimize power outputLow working voltagePiezoelectric/electrostrictive gramophone pickupsStirling type enginesDielectricConductive polymer

A sonic actuator including a multi-layer membrane having a non-metallic elastomeric dielectric polymer layer with a first surface and a second surface, a first compliant electrode layer contacting the first surface of the polymer layer, and a second compliant electrode layer contacting the second surface of the polymer layer. The actuator further includes a support structure in contact with the sonic actuator film. Preferably, the non-metallic dielectric polymer is selected from the group consisting essentially of silicone, fluorosilicone, fluoroelastomer, natural rubber, polybutadiene, nitrile rubber, isoprene, and ethylene propylene diene. Also preferably, the compliant electrode layer is made from the group consisting essentially of graphite, carbon, and conductive polymers. The support structure can take the form of grid having a number of circular apertures. When a voltage is applied to the electrodes, portions of the film held at the aperture of the support structure can bulge due to the electrostriction phenomenon. The resultant “bubbles” can be modulated to generate sonic vibrations, or can be used to create a variable surface for airflow control.

Owner:SRI INTERNATIONAL

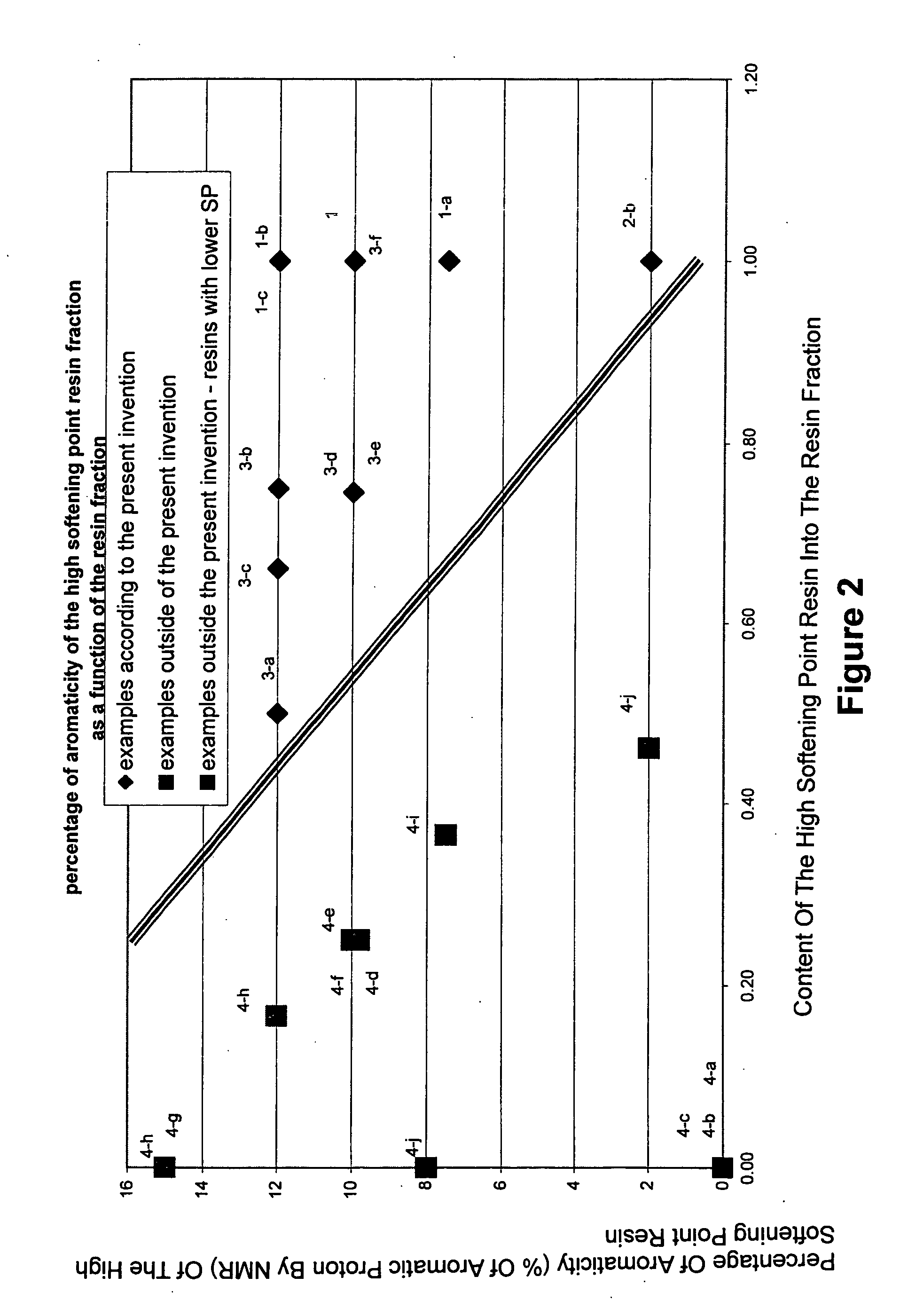

Low application temperature hot melt adhesive

InactiveUS20070088116A1High bond strength levelSame level of performanceAbsorbent padsAdhesivesElastomerCardboard

A hot melt adhesive composition, comprising a blend of components including about 10% to about 40% by weight of an elastomeric block copolymer, preferably styrene-isoprene-styrene (SIS) or styrene-butadiene-styrene (SBS), about 15% to about 70% by weight of a first midblock tackifying resin having a softening point of at least about 110° C. and having an aromatic content of at least about 1.5% by weight; about 0 to 55% of second midblock tackifying resin, about 5% to about 35% by weight of a plasticizer; and about 0% to about 20% by weight of an end block resin having a softening point lower than 125° C.; wherein the components total 100% by weight of the composition, the viscosity of the composition is equal to or less than about 20,000 mPa.s at 120° C., and is applied at a temperature lower that 150° C. and initial bond retention of the composition on elastic strands is at least about 60%. Also, the elastic modulus G′ of the composition is higher than about 5000 Pa, the vicous modules G″ is higher than about 50 Pa, and the tan delta value is between about 0.5 and about 60. Laminates, especially those used in disposable soft goods, and methods of making such laminates are also described. The adhesive composition and / or laminate may be used in making a variety of end products such as a disposable diaper, a sanitary napkin, a bed pad, a bandage, a surgical drape, a tape, a label, a plastic sheet, a nonwoven sheet, a paper sheet, a cardboard, a book, a filter, or a package.

Owner:BOSTIK INC

Hot melt pressure sensitive adhesives based on blends of styrene/butadiene copolymers

Hot melt pressure sensitive adhesives useful in a wide range of end-use applications may be formulated without the use of isoprene-containing polymers using combinations of different styrene / butadiene copolymers including at least one S-B-S triblock copolymer.

Owner:HENKEL CORP

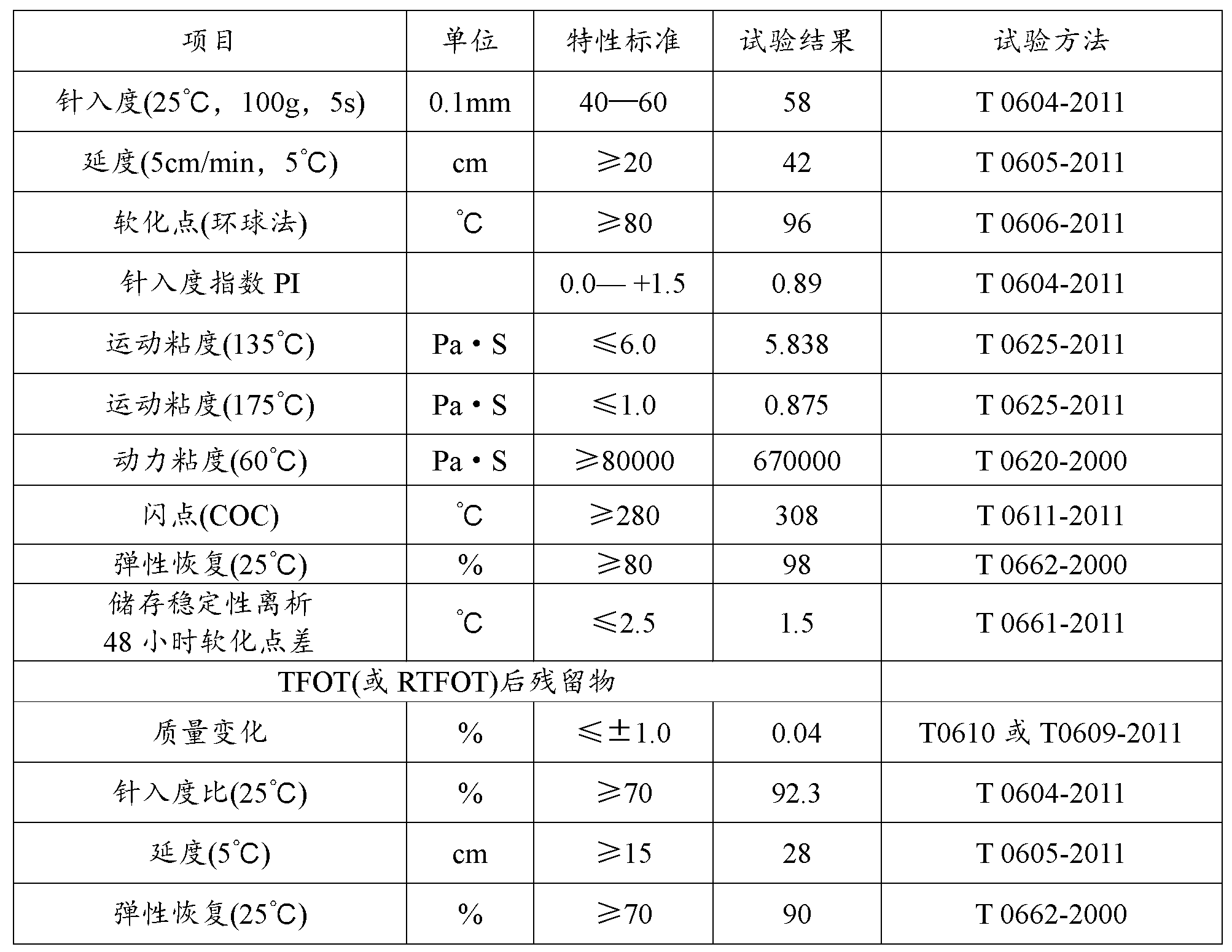

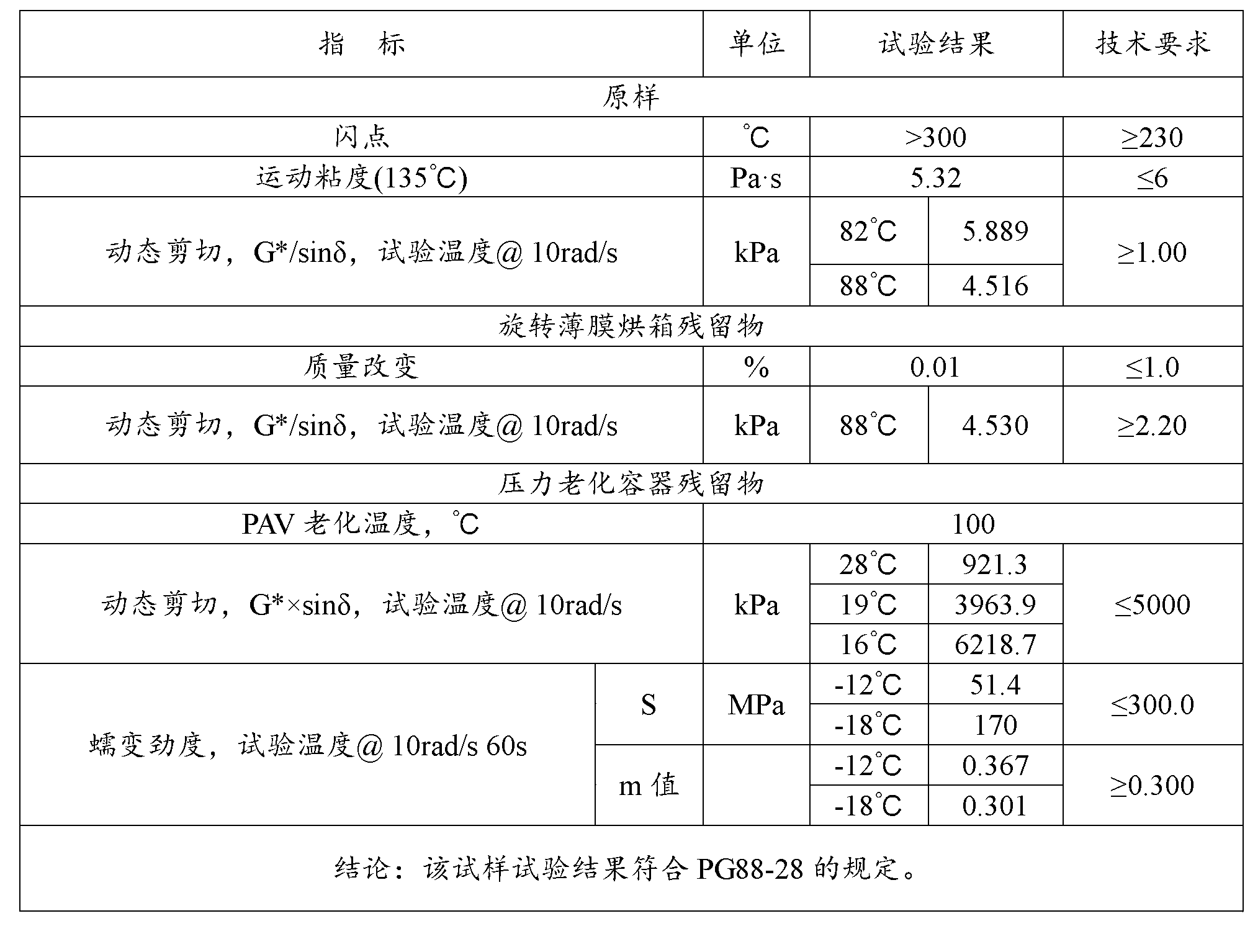

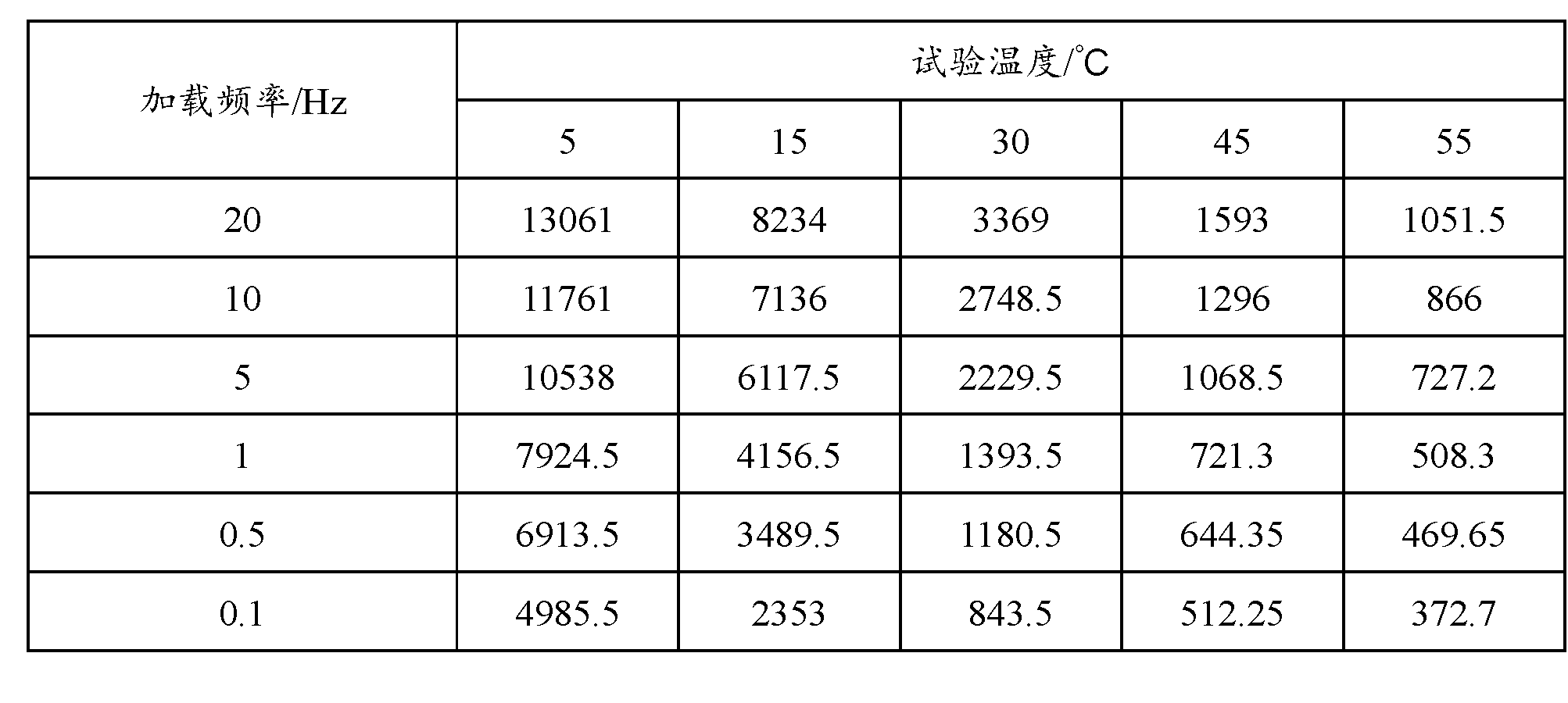

Asphalt modifier, modified asphalt and asphalt mixture

ActiveCN102838874AExcellent Adhesive PropertiesImprove low temperature 60°C viscosityIn situ pavingsBuilding insulationsRoad engineeringBridge deck

The invention belongs to the field of road engineering, and particularly relates to a hyperviscous and high-elastic asphalt modifier applicable to steel bridge deck pavement. The asphalt modifier comprises the following raw materials in parts by weight: 3-10 parts of junked tire rubber powder, 3-10 parts of polyethylene wastes, 3-8 parts of styrene-butadiene-styrene block copolymer, 1-5 parts of styrene-isoprene-styrene block copolymer, 1-5 parts of terpene resin, 5-10 parts of solvent naphtha, and 0.3-0.7 part of alcohol ether carboxylate adhesion agent. In addition, a modified asphalt and amodified asphalt mixture are prepared on the basis of the modifier, the 60 DEG C dynamic viscosity of the modified asphalt prepared by applying the modifier can reach more than 300000Pa.s, and the performance grading reaches PG 88-28; and the asphalt mixture has favorable water stability, higher dynamic modulus, higher track dynamic stability and low temperature failure strain, and can resist complicated mechanics and temperature environment of a steel bridge deck.

Owner:山东高速交通建设集团股份有限公司

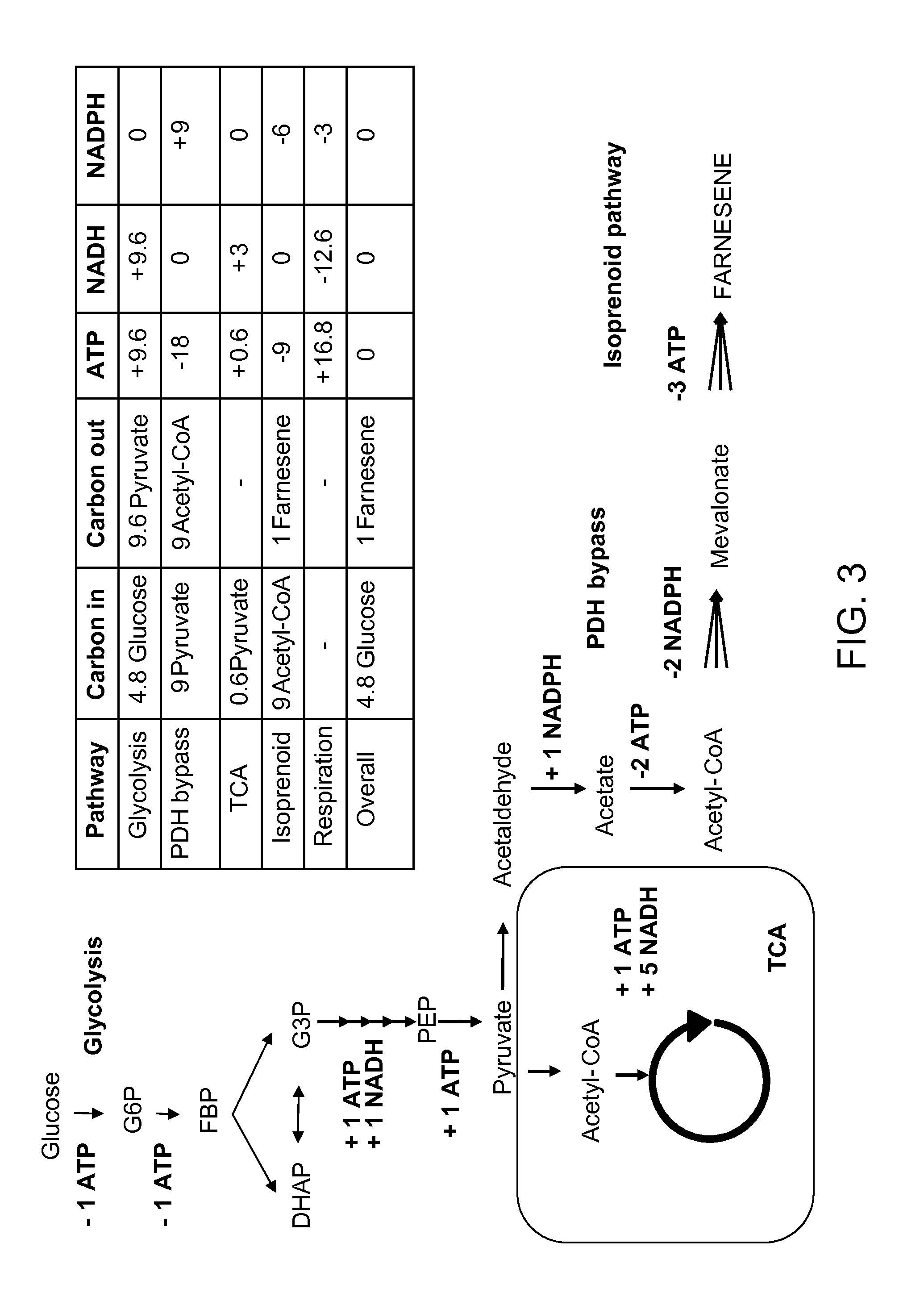

Production of acetyl-coenzyme a derived isoprenoids

ActiveUS8415136B1Avoid high forceThermodynamically favorableFungiTransferasesHeterologousHMG-CoA reductase

Provided herein are compositions and methods for the heterologous production of acetyl-CoA-derived isoprenoids in a host cell. In some embodiments, the host cell is genetically modified to comprise a heterologous nucleotide sequence encoding an acetaldehyde dehydrogenase, acetylating (ADA, E.C. 1.2.1.10) and an MEV pathway comprising an NADH-using HMG-CoA reductase. In some embodiments, the host cell is genetically modified to comprise a heterologous nucleotide sequence encoding an ADA and an MEV pathway comprising an acetoacetyl-CoA synthase. In some embodiments, the genetically modified host cell further comprises one or more heterologous nucleotide sequences encoding a phosphoketolase and a phosphotransacetylase. In some embodiments, the genetically modified host cell further comprises a functional disruption of the native PDH-bypass. The compositions and methods described herein provide an energy-efficient yet redox balanced route for the heterologous production of acetyl-CoA-derived isoprenoids.

Owner:AMYRIS INC

Thermoplastic elastomer composition

InactiveUS20050288393A1Low costGood oil resistanceFilm/foil adhesivesCoatingsThermoplastic elastomerPolystyrene

A thermoplastic elastomer composition comprised of (a) a thermoplastic resin selected from the group consisting of polyphenylene ether, polypropylene, polyethylene, and polystyrene, (b) a block copolymer selected from the group consisting of styrene-ethylene butylene-styrene, styrene-ethylene propylene-styrene, hydrogenated polybutadiene, hydrogenated polyisoprene, hydrogenated styrene-isoprene random copolymer, styrene-ethylene propylene block copolymer, styrene-ethylene ethylene propylene-styrene and hydrogenated styrene-butadiene random copolymers, (c) a core-shell polymer comprised of a polymeric core and a polymeric shell with the proviso that the polymeric core and / or the polymeric shell may be crosslinked, and (d) an oil.

Owner:THE GOODYEAR TIRE & RUBBER CO

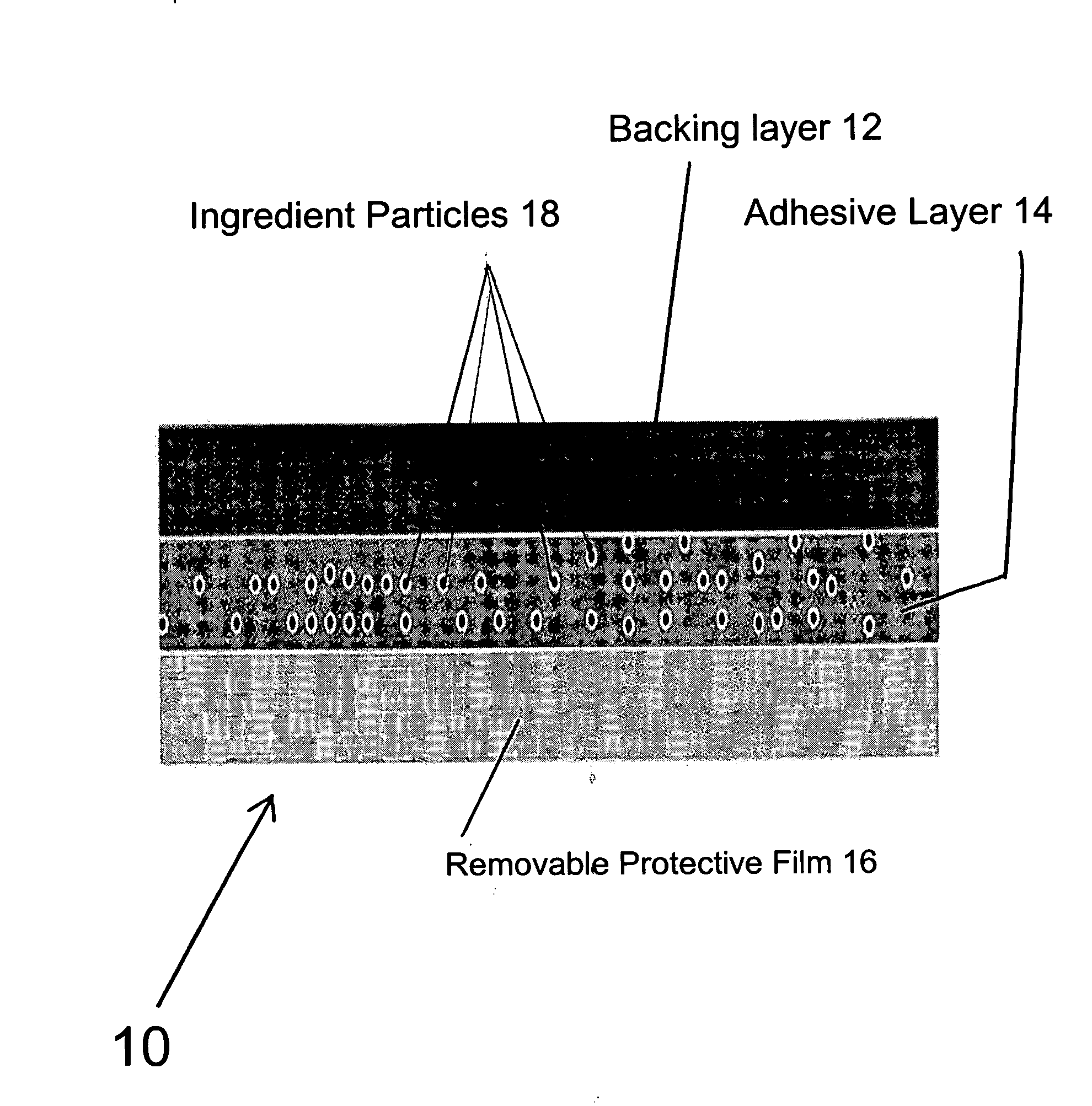

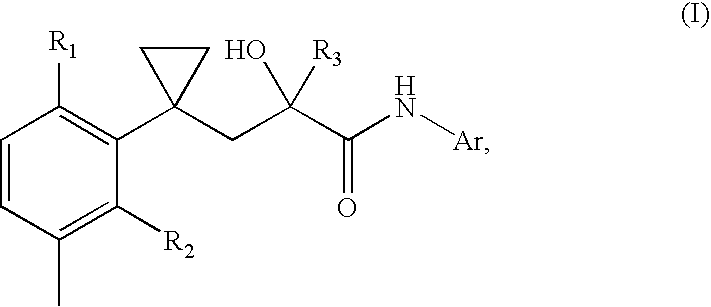

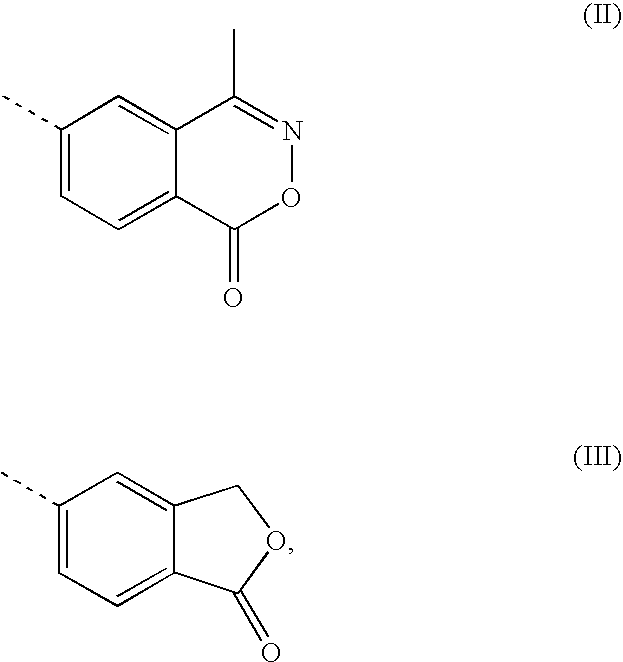

Transdermal pharmaceutical preparation with a progesterone A-specific ligand (PRASL) as active ingredient

InactiveUS20060134188A1Avoid reactionReduce riskBiocideOrganic active ingredientsTransdermal patchAdditive ingredient

A transdermal patch for hormone therapy and fertility control has a backing layer, an effective-ingredient-containing adhesive layer adhering to the backing layer and a removable protective film. The adhesive layer includes a progestagenic effective ingredient and an estrogen in an adhesive matrix based on a silicone polymer, a polyisobutylene polymer (PIB), a polyacrylate polymer or a styrene block copolymer with butadiene or isoprene (SBS or SIS). The transdermal patch contains from 0.1 to 10%, based on a total weight of the adhesive matrix, of a progestagenic effective ingredient of formula I: wherein R1 and R2 each represent, independently of each other, H or F; R3 represents CH3 or CF3 and Ar is a group of formula II or III: or a pharmaceutically suitable derivative thereof.

Owner:SCHERING AG

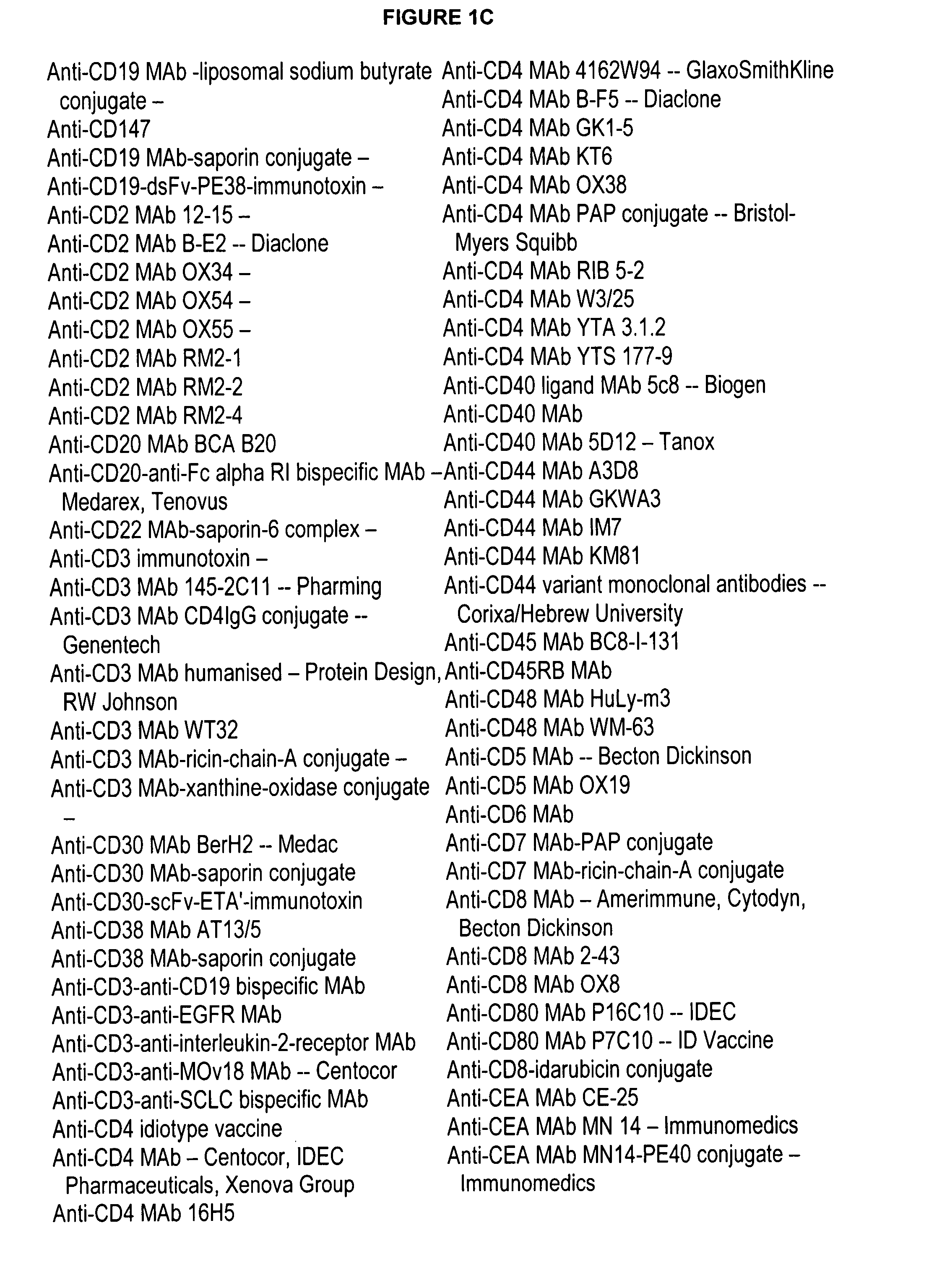

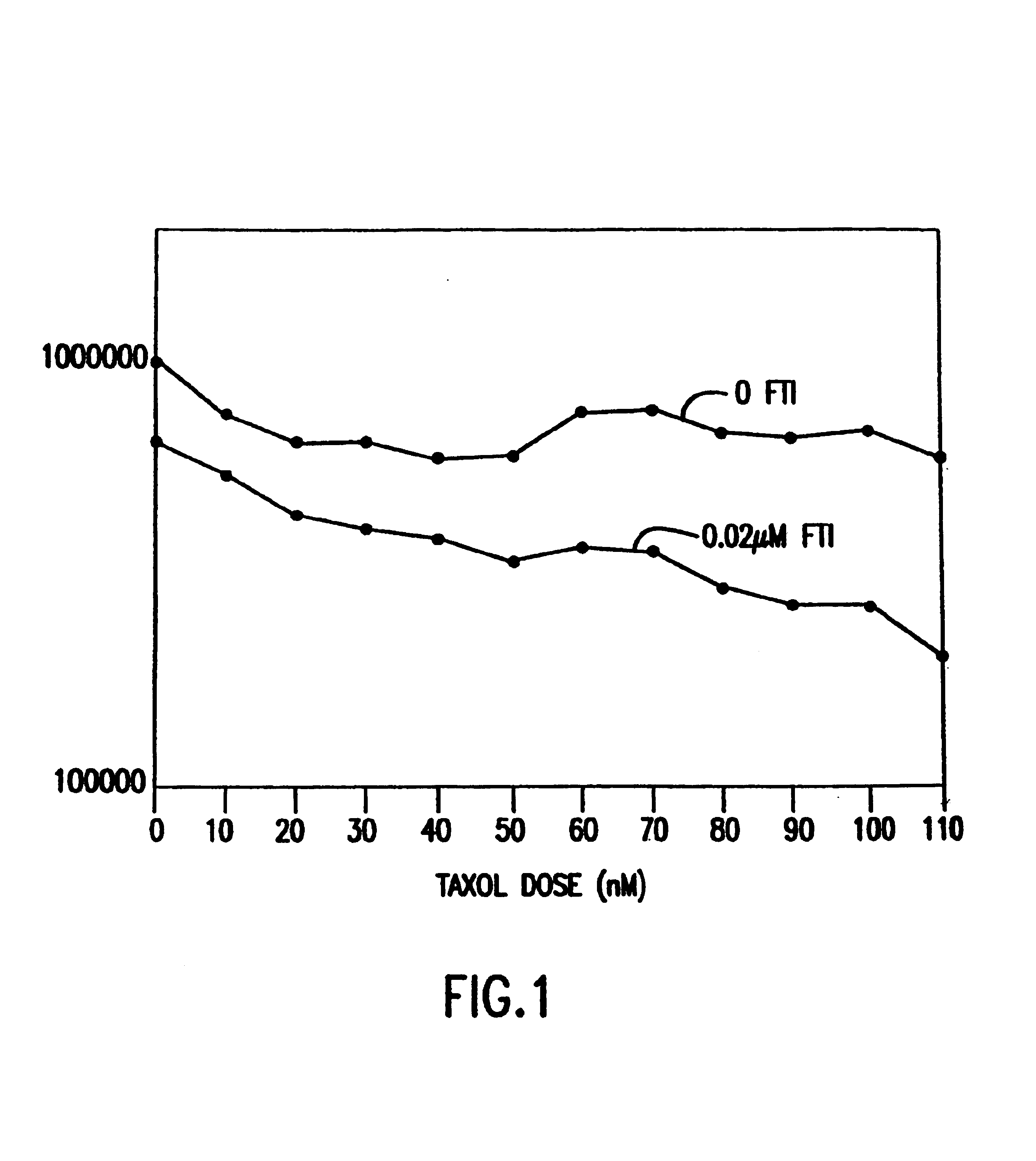

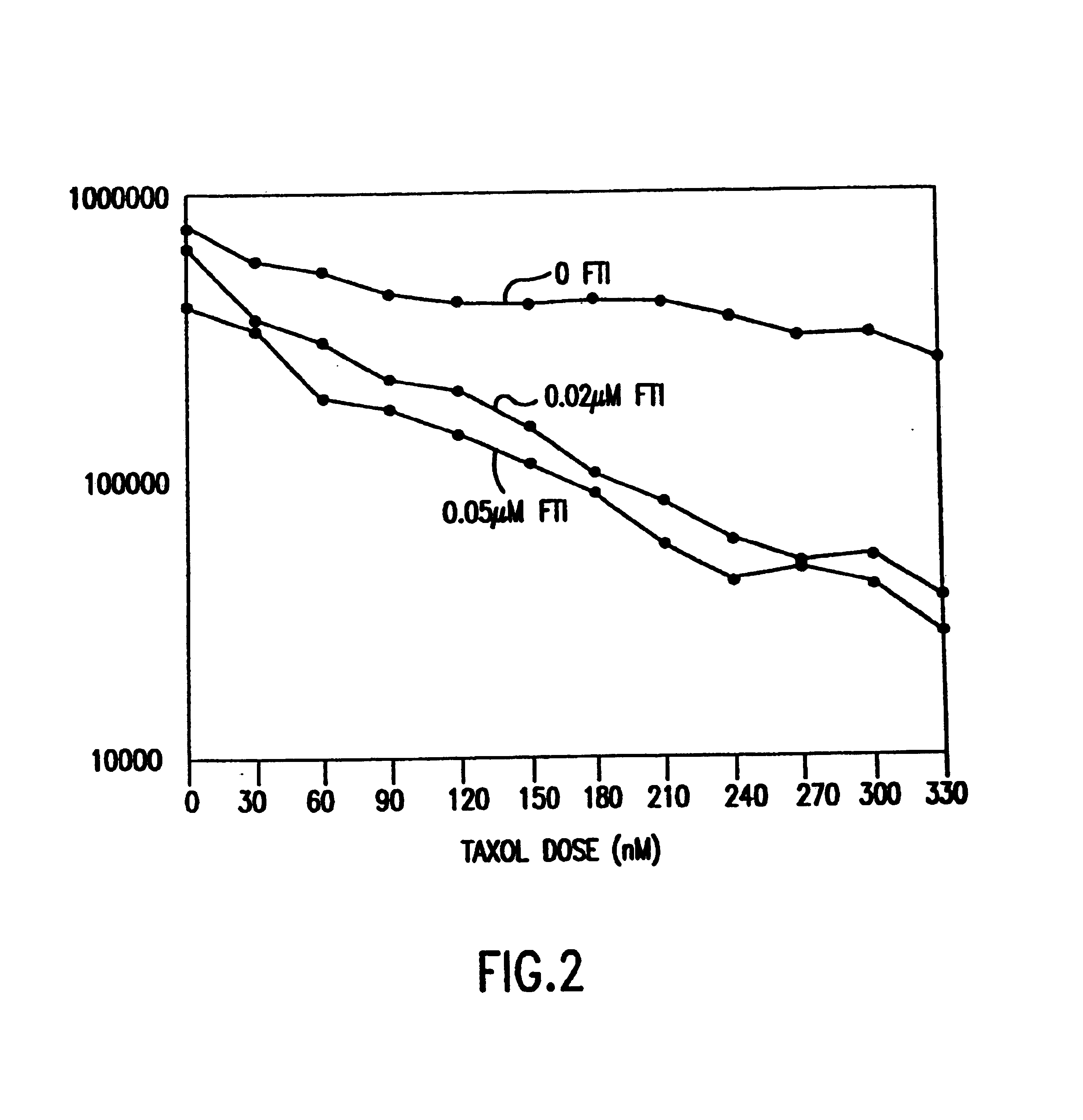

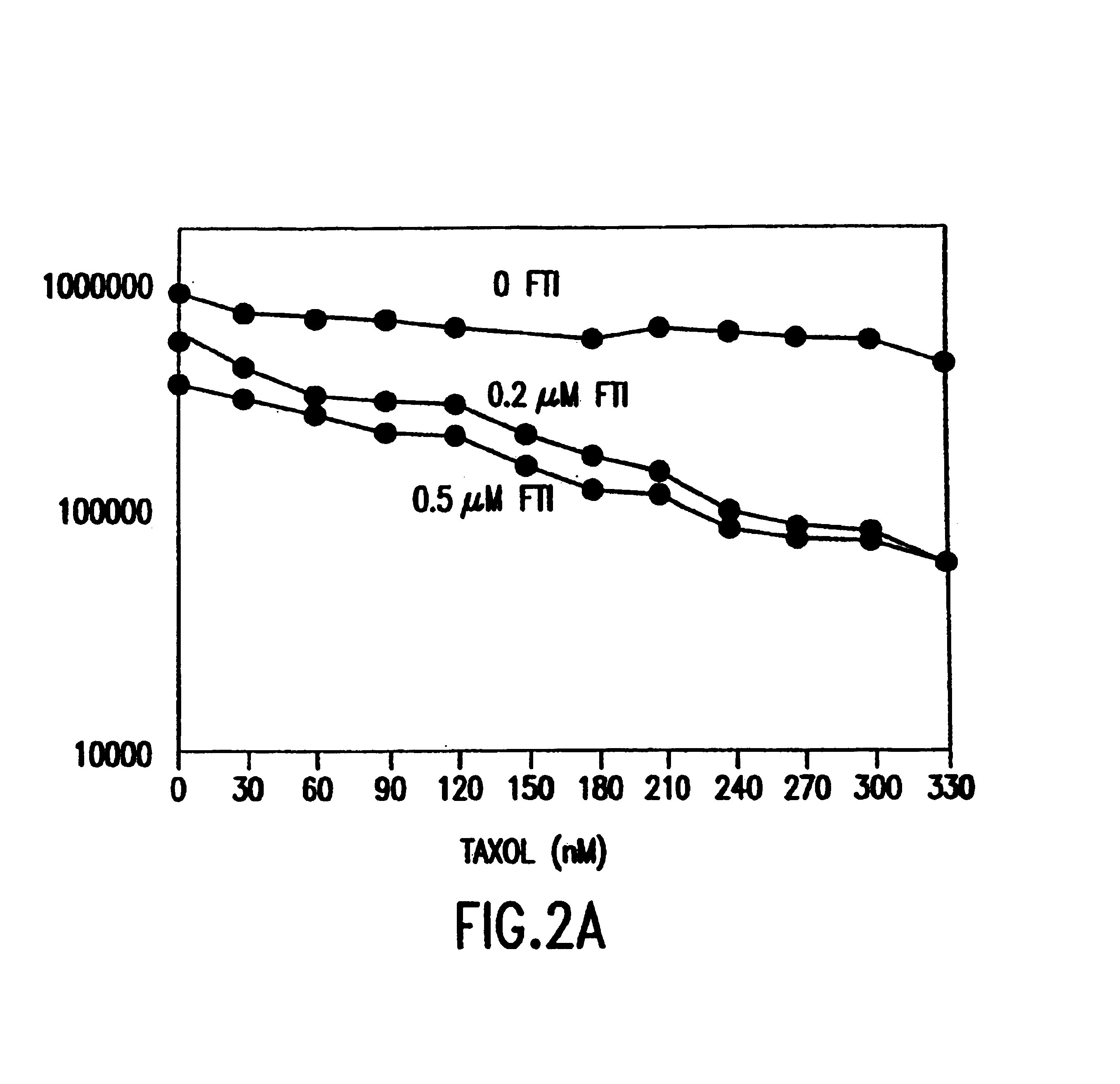

Method of treating cancer

The present invention relates to methods of treating cancer using a combination of a compound which is an antineoplastic agent and a compound which is a inhibitor of prenyl-protein transferase, which methods comprise administering to said mammal, either sequentially in any order or simultaneously, amounts of at lest two therapeutic agents selected from a group consisting of a compound which is an antineoplastic agent and a compound which is an inhibitor or prenyl-protein transferase. The invention also relates to methods of preparing such compositions.

Owner:SLOAN KETTERING INST FOR CANCER RES

Essentially gas-impermeable thermoplastic elastomer

A thermoplastic elastomer (“TPE”) which is oxygen-permeable is provided with excellent barrier properties against oxygen by melt-blending with a liquid polyisobutene oil plasticizer in an amount insufficient to render the plasticized elastomer tacky. If made tacky, enough detackifier is used to allow the product to be formed into a removable seal. The TPE may be a conventional thermoplastic vulcanizate or a block copolymer of a vinylaromatic compound, typically styrene, and a conjugated diene, typically butadiene or isoprene, or mixtures thereof; the block may be a diblock, triblock or higher block, but the preferred polyblock copolymer is a triblock with styrene end-blocks and a butadiene / isoprene mid-block. Preferably the diene mid-block is hydrogenated to provide a poly(lower)monoolefin mid-block. When the TPE is a TPV, some or all of the mineral oil used to make the TPV processable may also be substituted with the polyisobutene plasticizer. The elastomeric product is particularly useful for sealing elements for containers in which foods, beverages and medical products must be preserved for a long period.

Owner:AVIENT CORP

Anti-inflammatory analgesic adhesive patch for external use

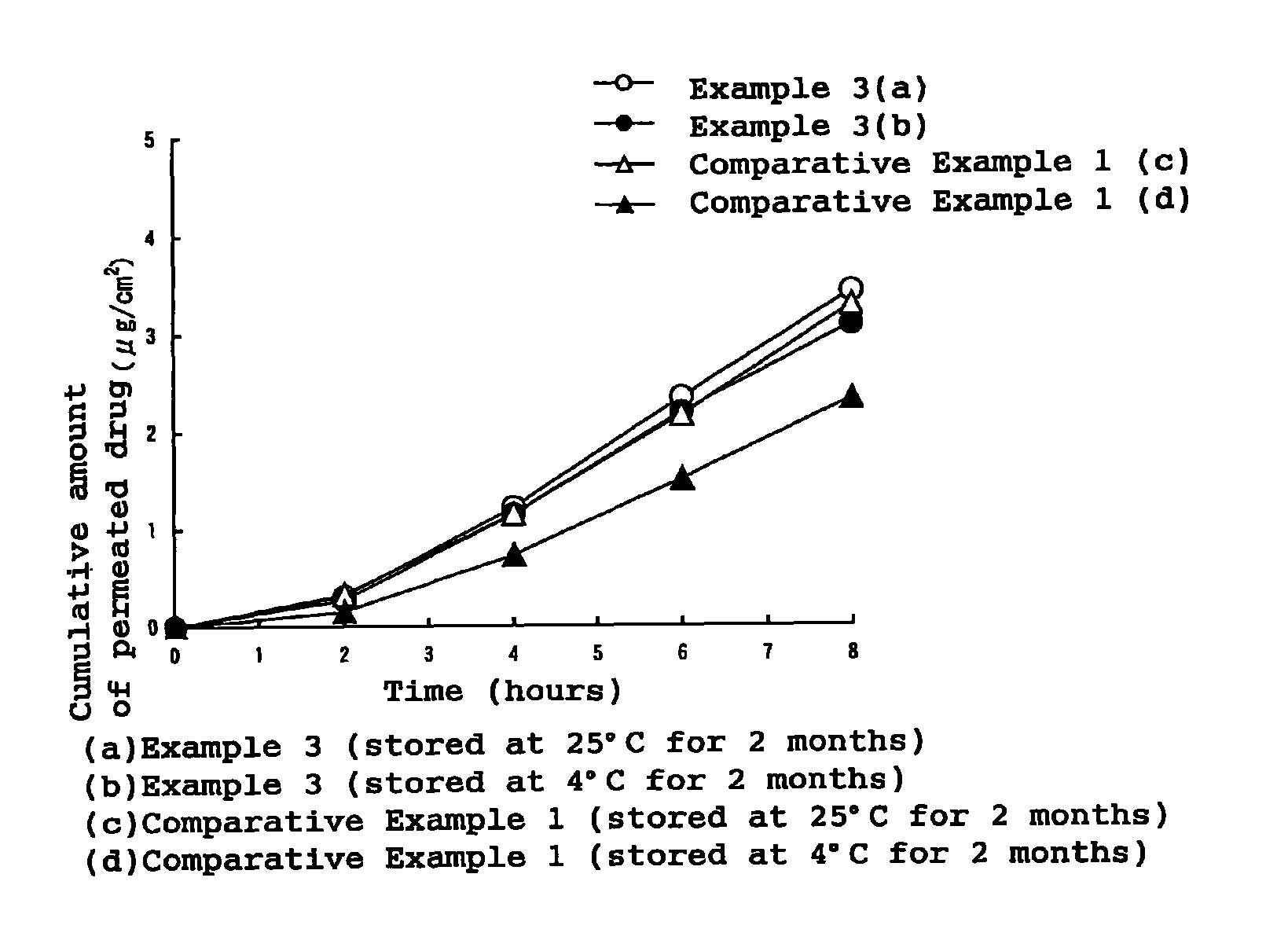

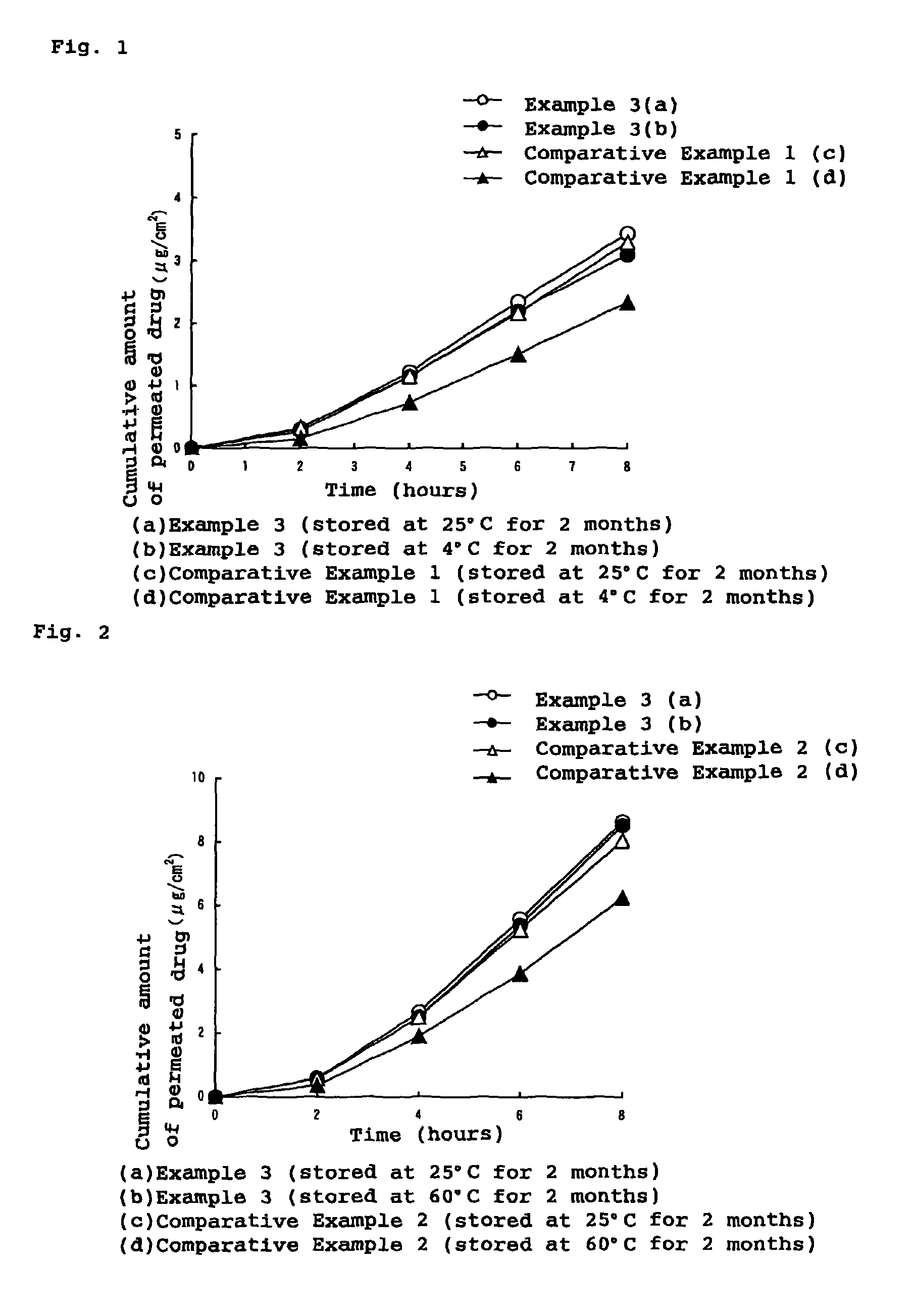

ActiveUS20120283671A1Promote absorptionLess irritatingAntipyreticAnalgesicsAdditive ingredientTackifier

An external patch containing diclofenac hydroxyethylpyrrolidine prepared by laminating an adhesive layer on a backing, wherein said adhesive layer is characterized by comprising 5-50% by weight of styrene•isoprene•styrene block copolymer, 20-50% by weight of a tackifier resin, 5-70% by weight of a softening agent, and 0.5-20% by weight of one or more solubilizers selected from N-methyl-2-pyrrolidone, propylene glycol and dimethyl sulfoxide as essential ingredients, and 0.5-20% by weight of diclofenac hydroxyethylpyrrolidine as an active ingredient. The patch has excellent transdermal absorption, less skin-irritation and excellent stability of the drug.

Owner:TEIKOKU SEIYAKU KK TEIKOKU SEIYAKU CO LTD +1

Conversion of prenyl derivatives to isoprene

InactiveUS20100113846A1HydrolasesHydrocarbon from oxygen organic compoundsPetrochemicalCultured cell

The present invention provides methods for producing derivatives from cultured cells. In addition, the present invention provides methods for conversion of prenyl deerivatives, obtained from biological or petrochemical sources, to isoprene by employing chemical or biological catalysts. The present invention also provides compositions that include the cultured cells or isoprene or prenyl derivatives produced there from.

Owner:THE GOODYEAR TIRE & RUBBER CO

Tie-layer adhesive compositions for styrene polymers and articles

Tie-layer adhesives for styrene polymer resins are provided. The adhesive compositions suitable for use in multi-layer film and sheet constructions are blends comprising ethylene-butene-1 LLDPE resins, styrene-isoprene-styrene triblock copolymers, graft-modified polyethylene and, optionally, ethylene-propylene elastomers.

Owner:EQUSR CHEM LP

Halogen-free flame-retardant thermal-shrinkage sleeve materials and sleeve prepared thereby

ActiveCN1629216AWon't happenRaw materials are readily availableTubular articlesLow-density polyethyleneLinear low-density polyethylene

The invention provides a bittern-free flame-proof thermal contraction sleeve which comprises (by weight ratio), (1) 100 parts of one or more selected from ethane-vinyl acetate copolymer (EVA), ethene-ethyl acrylate copolymer (EEA), low density polyethylene (LDPE), linear low density polyethylene (LLDPE), (2) 5-50 parts of one or more selected from ethylene-propylene terpolymerisate rubber (EPDM), ethylene propylene rubber (EPM), dimethyl silicone rubber (MQ), methylvinyl silicone rubber (VMQ), methylsilicone rubber with phenyl and vinyl Group (PVMQ), thermoplastic elastomer styrene - butadiene - styrene blocked copolymer (SBS), styrene-isoprene blocked copolymer (SIS), (3) 50-100 parts of bittern-free flame retardant, and (4) 0.5-6 parts of coupling agent.

Owner:深圳市沃尔热缩有限公司

Pneumatic tire having built-in sealant layer and preparation thereof

This invention relates to a pneumatic tire having a built-in sealant layer and its preparation. The sealant layer precursor is a layer of a butyl rubber based composition which contains an organoperoxide. The butyl rubber of said precursor is a copolymer of isobutylene and isoprene containing from about 0.5 to about 5, alternately less than 1, mole percent isoprene. The precursor composition contains carbon black and / or coal dust and may contain a dispersion of liquid conjugated diene polymer (e.g. liquid cis 1,4-polyisoprene polymer), short fibers and / or hollow glass microspheres. A layer of the sealant precursor is built into the tire between a sulfur vulcanized halobutyl rubber innerliner and conjugated diene-based rubber of the tire carcass. The butyl rubber of the sealant precursor is partially depolymerized by the organoperoxide during the elevated temperature vulcanization of the tire to form the built-in sealant layer. In one aspect of the invention, said uncured butyl rubber sealant precursor layer composition has a storage modulus G′ (80° C.) in a range of about 100 to about 400 kPa and said partially depolymerized butyl rubber sealant layer composition has a storage modulus G′ (80° C.) in range of about 5 to about 50 kPa.

Owner:THE GOODYEAR TIRE & RUBBER CO

Halogenated polymers with new sequence distributions

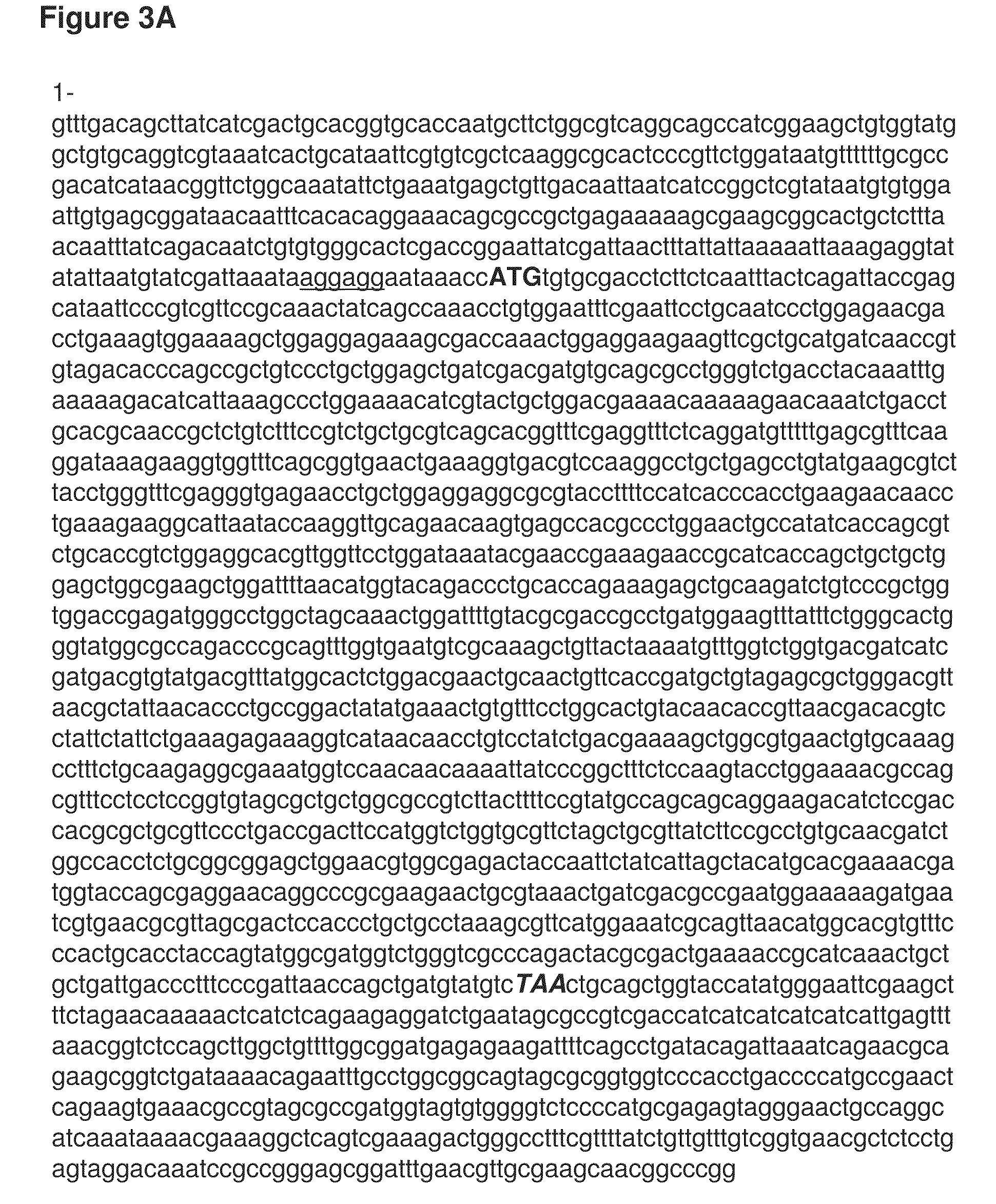

The invention relates to new polymerization processes including diluents including hydrofluorocarbons and their use to produce novel halogenated polymers with new sequence distributions. In particular, the invention relates to halogenated copolymers of an isoolefin, preferably isobutylene, and a multiolefin, preferably a conjugated diene, more preferably isoprene, with new sequence distributions.

Owner:EXXONMOBIL CHEM PAT INC

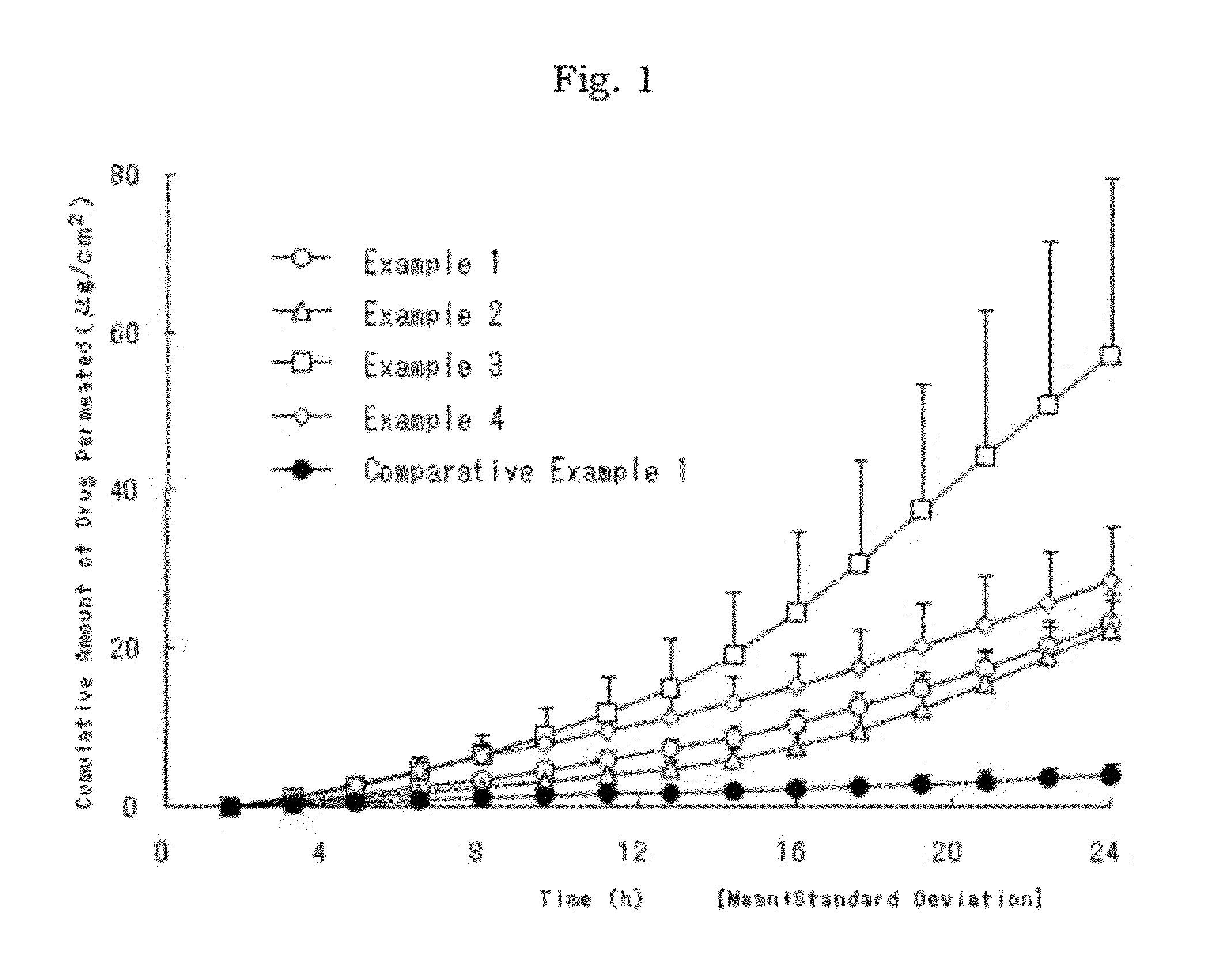

External patch containing estrogen and/or progestogen

InactiveUS8486442B2Stable drug releaseLess irritatingBiocideOrganic active ingredientsIrritationProlonged release

An external patch capable of stable prolonged release and transdermal absorption of active ingredient hormones (estrogens and / or progestogens) contained in a pressure sensitive adhesive layer, which external patch ensures low irritation on the skin. In particular, an external patch comprising a support and, superimposed thereon, a pressure sensitive adhesive layer, characterized in that the pressure sensitive adhesive layer comprises, as indispensable components, 5 to 50 wt. % of styrene / isoprene / styrene block copolymer, 20 to 70 wt. % of tackifier resin, 10 to 60 wt. % of softener and 1 to 20 wt. % of polyvinylpyrrolidone and contains, as an active ingredient, estrogen and / or progestogen.

Owner:TEIKOKU SEIYAKU KK TEIKOKU SEIYAKU CO LTD +1

Sorbefacients and preparations for percutaneous absorption containing the same

InactiveUS7153522B1Softness is littleSoftnessPowder deliveryOrganic active ingredientsMentholLuteal hormone

Percutaneous sorbefacients comprising hexylene glycol and 1-menthol, more particularly, percutaneous sorbefacients for female hormones or derivatives thereof; and preparations for percutaneous absorption which comprise a styrene / isoprene / styrene block copolymer and / or polyisobutylene, a softener and a tackifier as the base components, hormones, in particular, follicle hormone and / or luteal hormone as the drug component and hexylene glycol and 1-menthol as a sorbefacient.

Owner:HISAMITSU PHARM CO INC

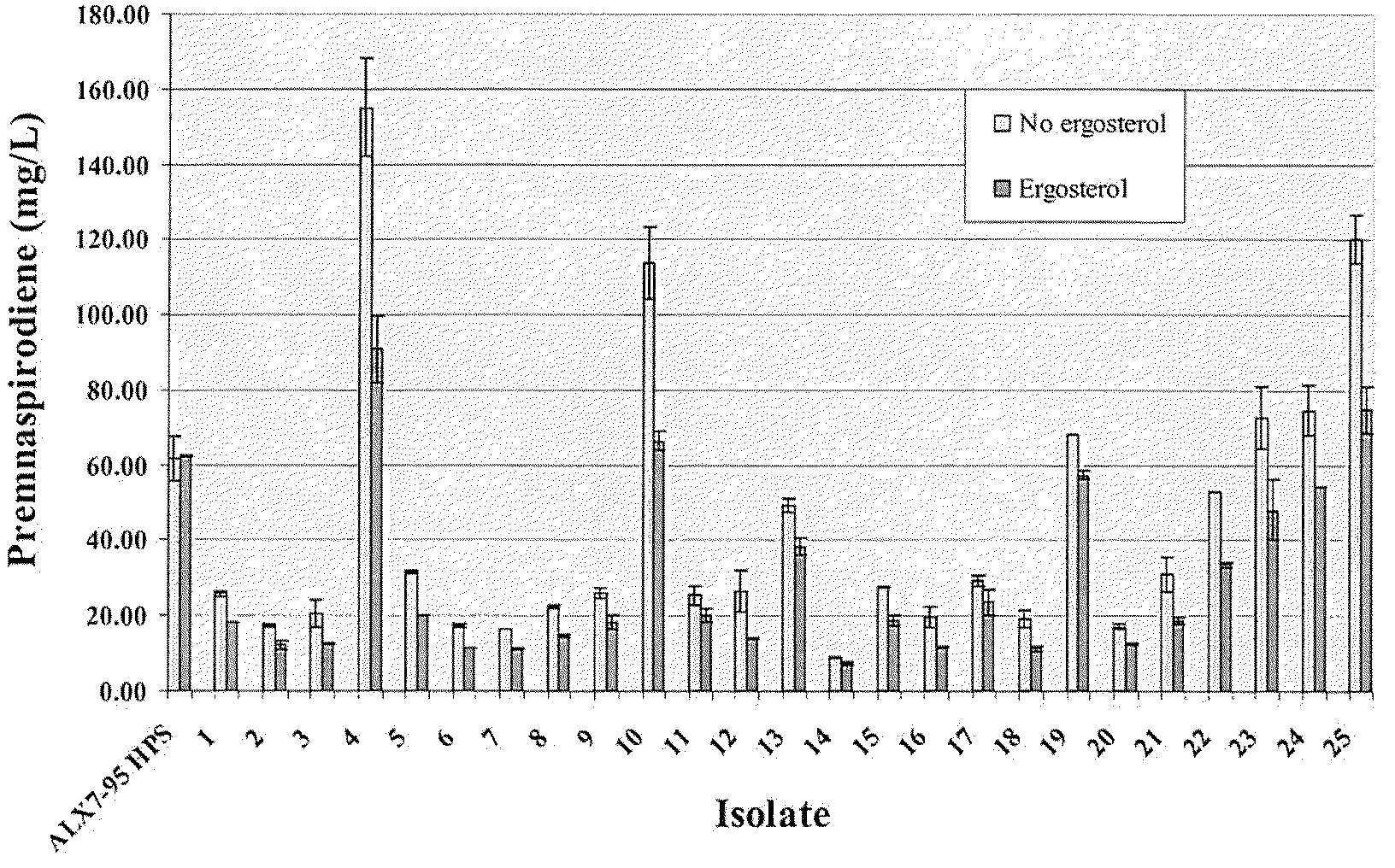

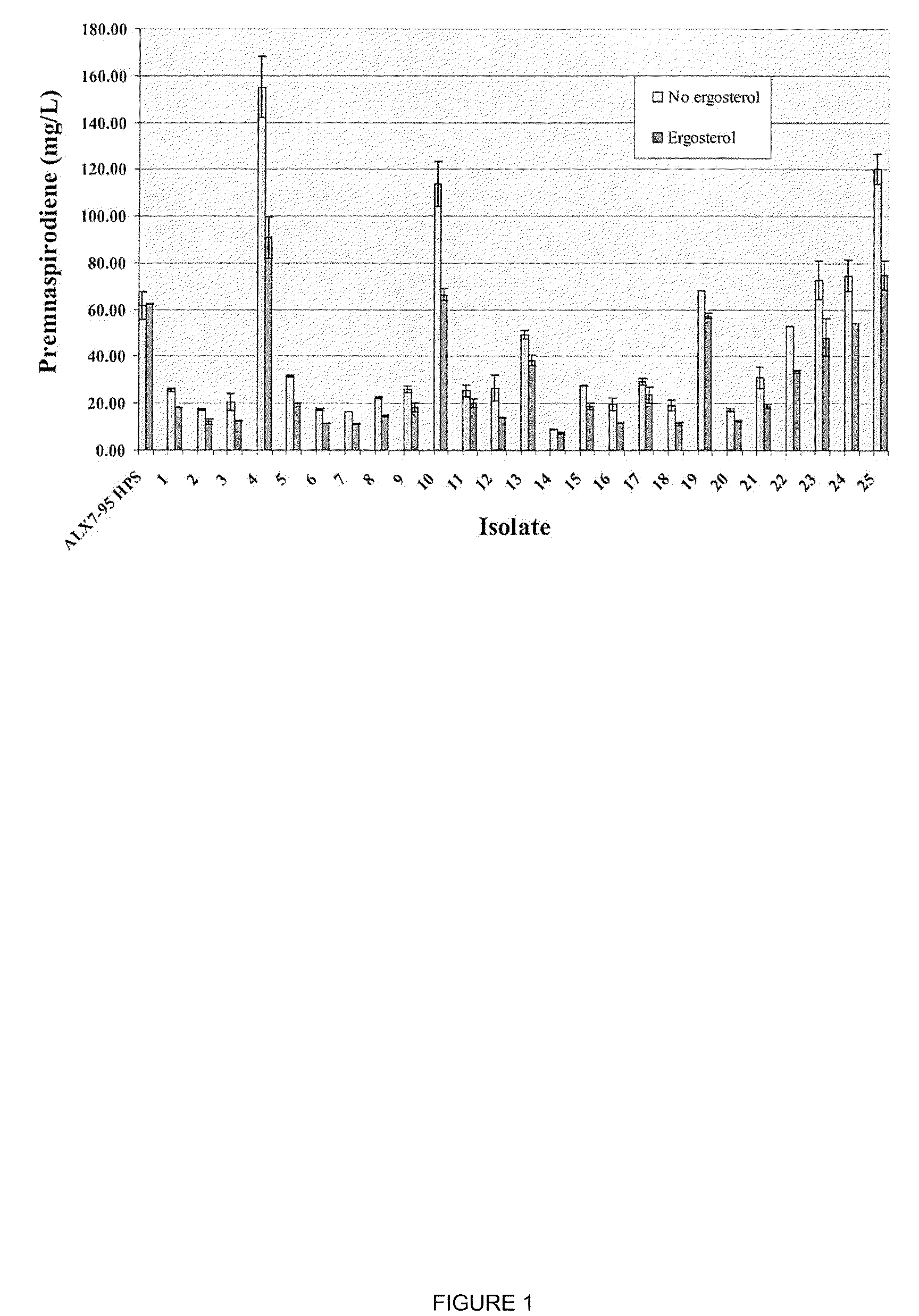

Method for production of isoprenoids

The present invention is directed to variant squalene synthase enzymes, including Saccharomyces cerevisiae squalene synthase enzymes, and to nucleic acid molecules encoding these variant enzymes. These variant enzymes produce squalene at a lower rate than the wild-type enzyme, allowing more farnesyl pyrophosphate to be utilized for production of isoprenoid compounds, while still producing sufficient squalene to allow the S. cerevisiae cells to grow without the requirement for supplementation by sterols such as ergosterol. These variant enzymes, therefore, are highly suitable for the efficient production of isoprenoids.

Owner:EVOLVA INC

Thermoplastic elastomer composition

InactiveUS7244783B2Low costReduce hardnessFilm/foil adhesivesCoatingsThermoplastic elastomerPolystyrene

A thermoplastic elastomer composition comprised of (a) a thermoplastic resin selected from the group consisting of polyphenylene ether, polypropylene, polyethylene, and polystyrene, (b) a block copolymer selected from the group consisting of styrene-ethylene butylene-styrene, styrene-ethylene propylene-styrene, hydrogenated polybutadiene, hydrogenated polyisoprene, hydrogenated styrene-isoprene random copolymer, styrene-ethylene propylene block copolymer, styrene-ethylene ethylene propylene-styrene and hydrogenated styrene-butadiene random copolymers, (c) a core-shell polymer comprised of a polymeric core and a polymeric shell with the proviso that the polymeric core and / or the polymeric shell may be crosslinked, and (d) an oil.

Owner:THE GOODYEAR TIRE & RUBBER CO

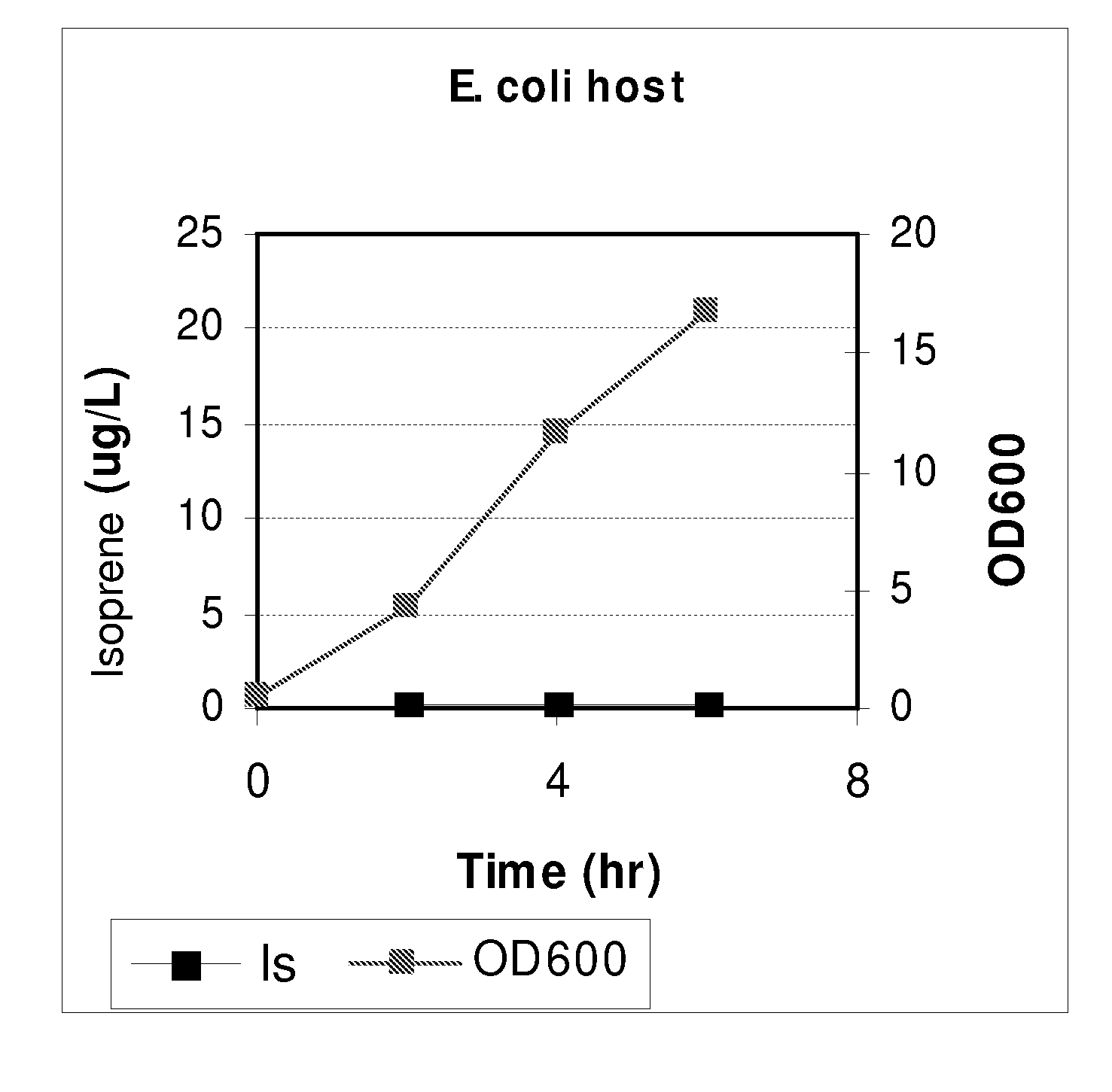

Reduction of carbon dioxide emission during isoprene production by fermentation

The present invention provides methods for increasing the amount of isoprene produced by cultured cells with only a minimal increase in carbon dioxide emitted, thereby resulting in process having a greater yield of isoprene relative to carbon dioxide. In addition, the present invention provides compositions that include the cultured cells or isoprene produced there from.

Owner:THE GOODYEAR TIRE & RUBBER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com