Patents

Literature

2651 results about "Acetaldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

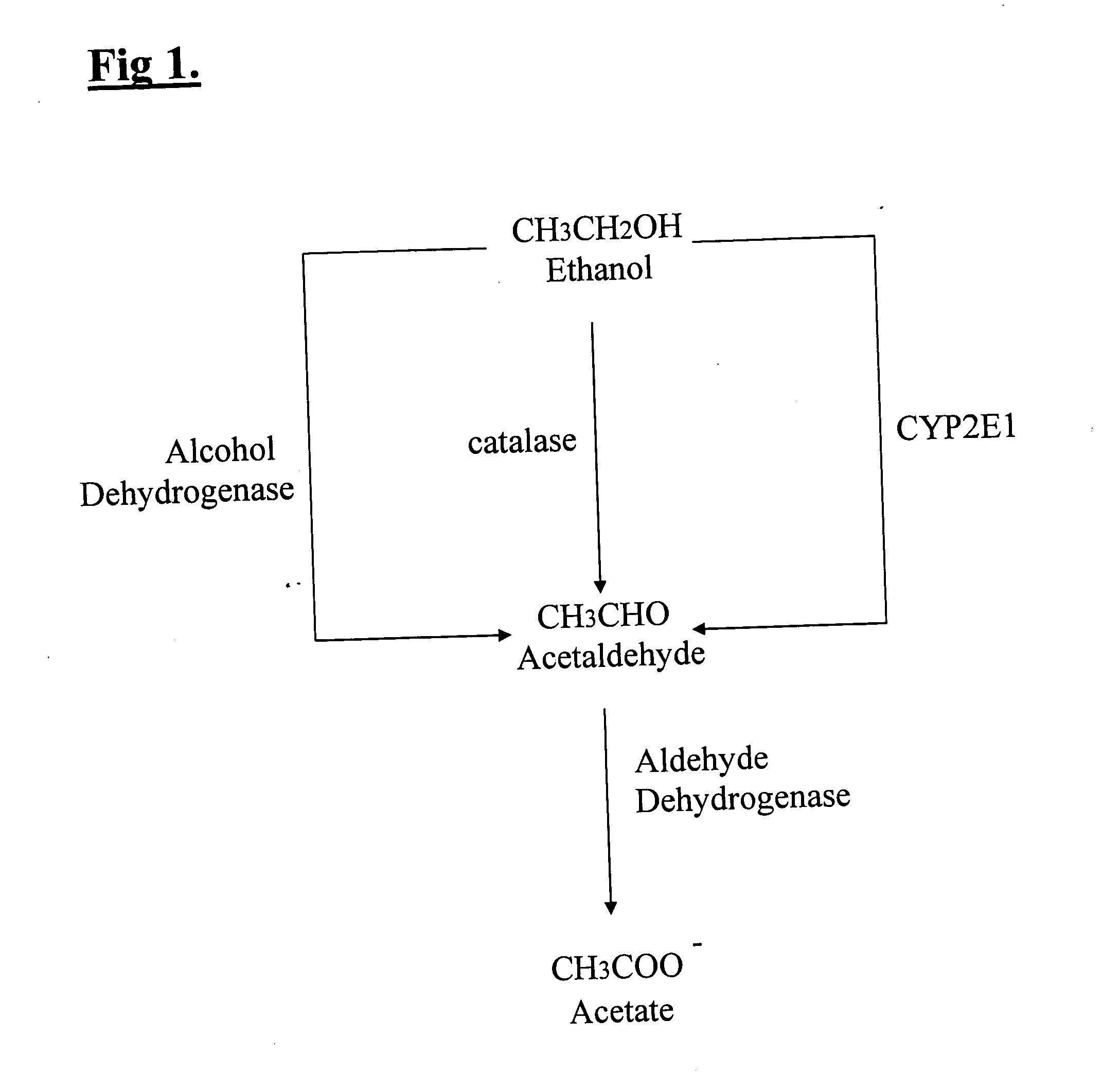

Acetaldehyde (systematic name ethanal) is an organic chemical compound with the formula CH₃CHO, sometimes abbreviated by chemists as MeCHO (Me = methyl). It is one of the most important aldehydes, occurring widely in nature and being produced on a large scale in industry. Acetaldehyde occurs naturally in coffee, bread, and ripe fruit, and is produced by plants. It is also produced by the partial oxidation of ethanol by the liver enzyme alcohol dehydrogenase and is a contributing cause of hangover after alcohol consumption. Pathways of exposure include air, water, land, or groundwater, as well as drink and smoke. Consumption of disulfiram inhibits acetaldehyde dehydrogenase, the enzyme responsible for the metabolism of acetaldehyde, thereby causing it to build up in the body.

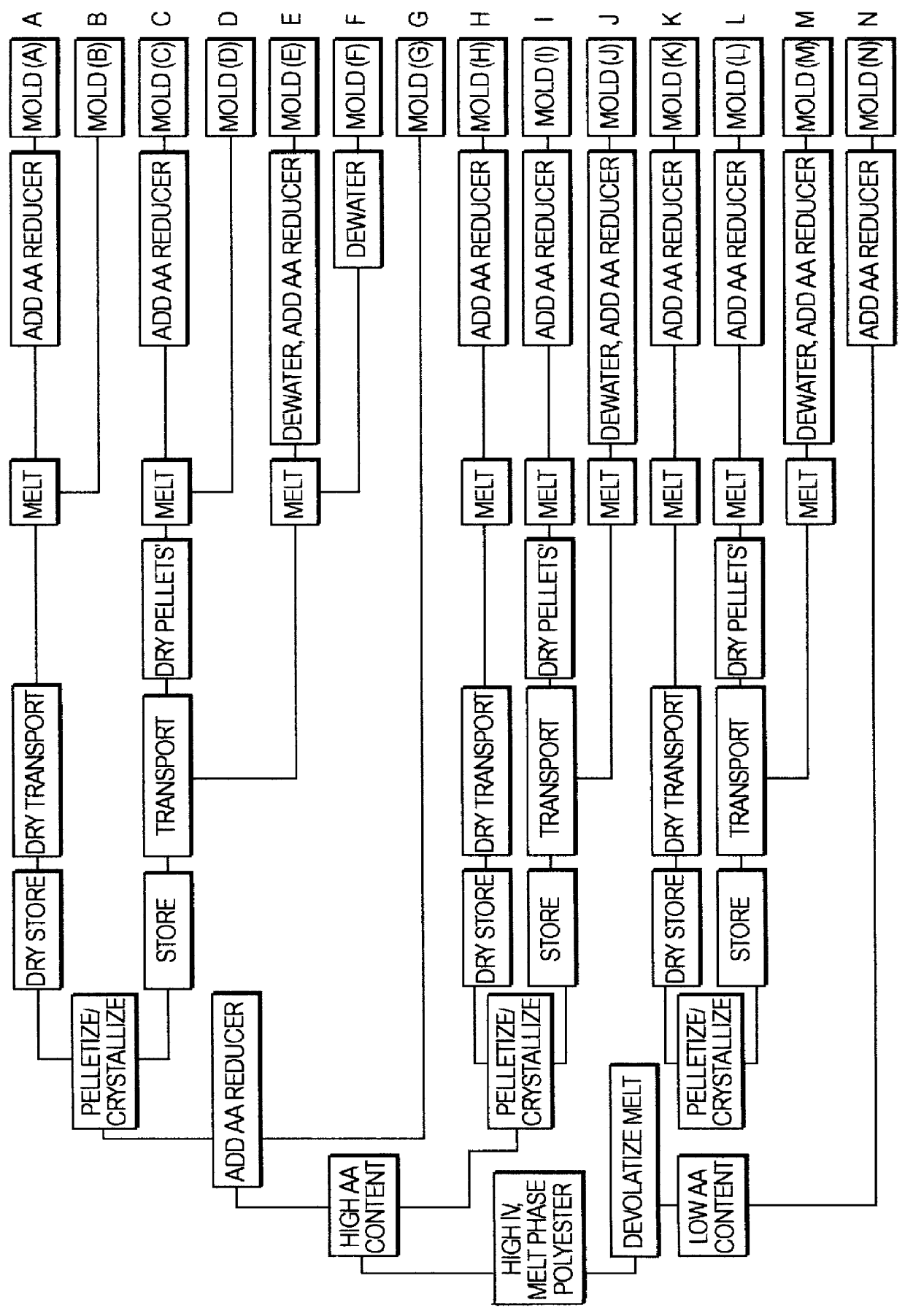

Process for producing pet articles with low acetaldehyde

The present invention discloses a process for producing molded, shaped or extruded articles comprising the steps of: a) melt reacting, in the presence of a catalyst which is substantially free of Co compounds, at least one glycol and at least one dicarboxylic acid to form a polyester having an I.V. of at least about 0.5 dL / g, wherein said at least one glycol is selected from the group consisting of glycols having up to 10 carbon atoms and mixtures thereof and said dicarboxylic is selected from the group consisting of alkyl dicarboxylic acids having 2 to 16 carbon atoms, aryl dicarboxylic acids having 8 to 16 carbon atoms and mixtures thereof; b) adding an acetaldehyde reducing additive to said polyester to form a reduced acetaldehyde polyester; and c) forming said reduced acetaldehyde polyester into articles directly from step b. Thus, the present invention provides a process for directly producing from the melt article having extremely low acetaldehyde content.

Owner:GRUPO PETROTEMEX DE C V

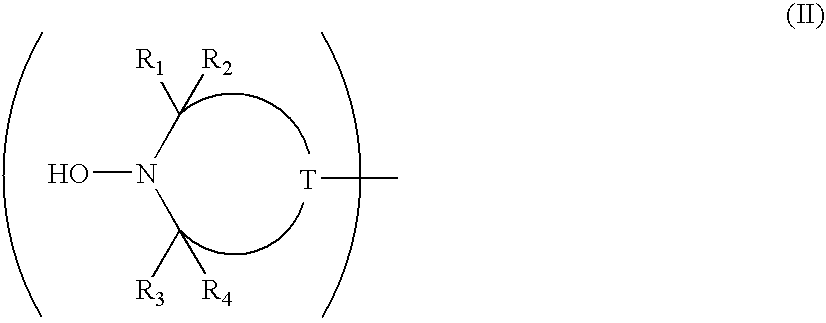

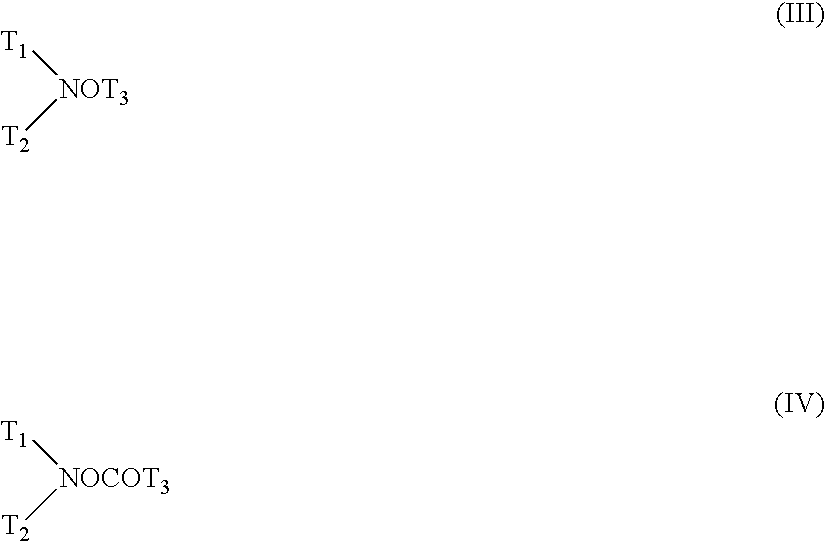

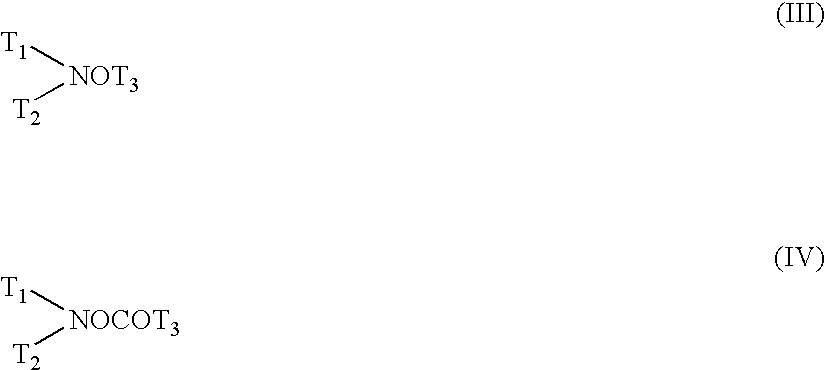

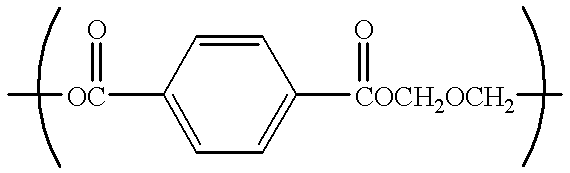

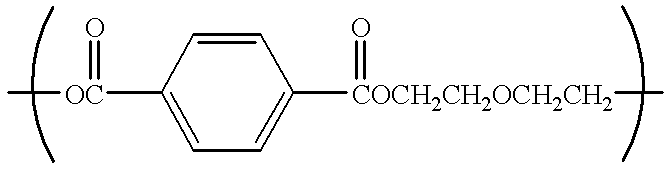

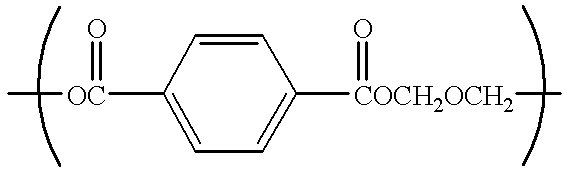

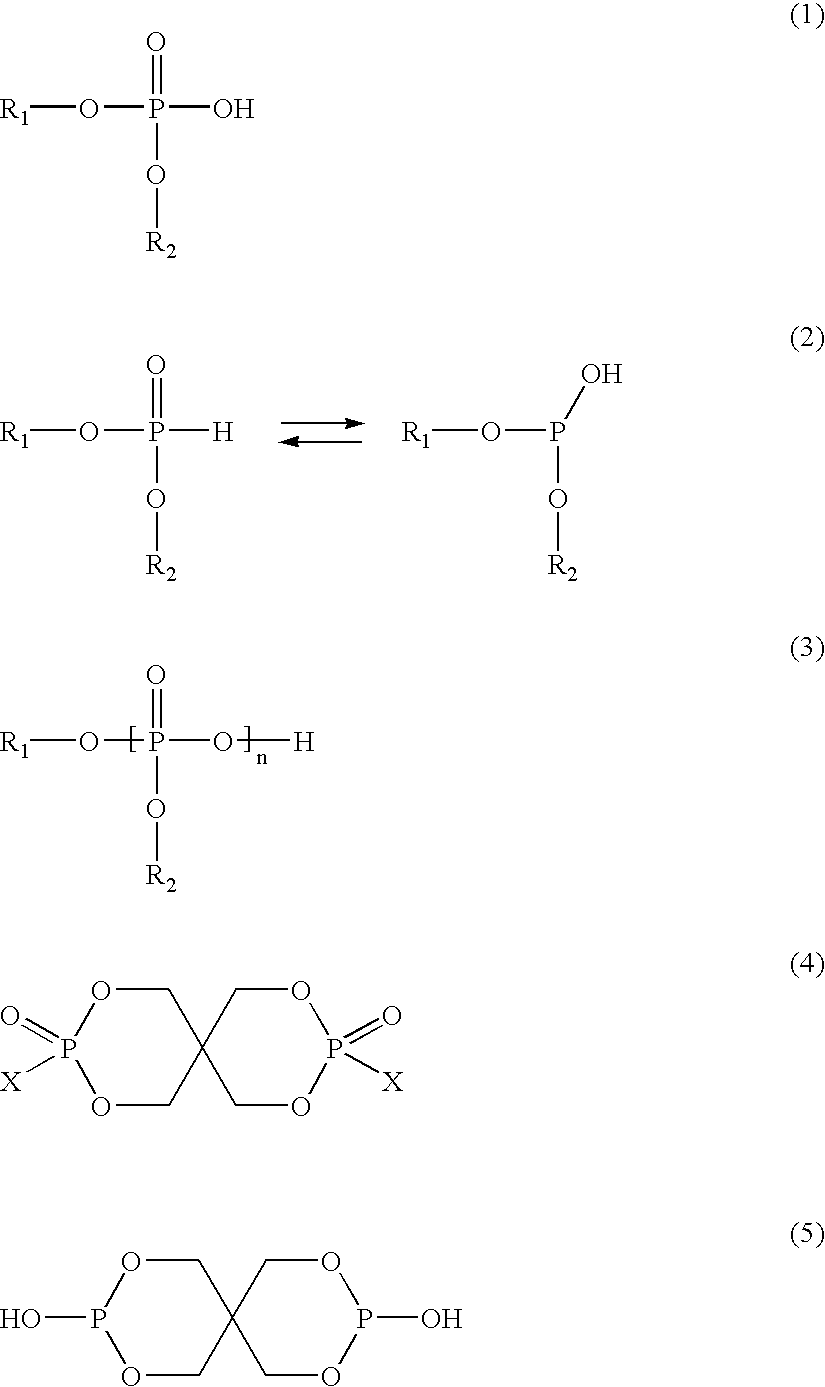

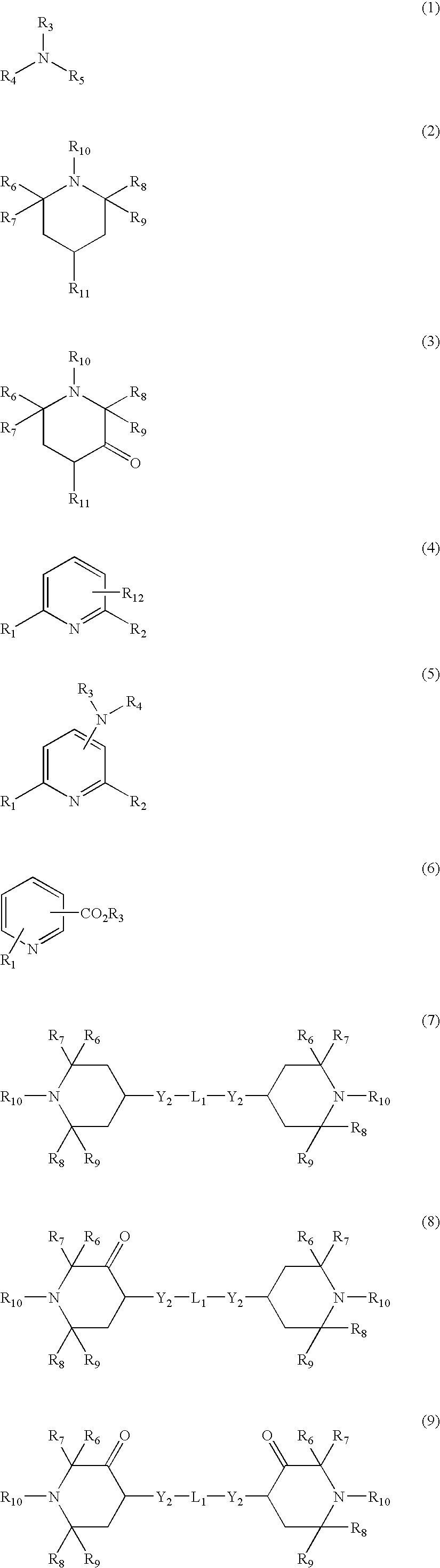

Polyester and polyamide compositions of low residual aldehyde content

A mixture of a polyester, such as poly(ethylene terephthalate) PET, or a polyamide, and a suitable stabilizer selected from the group consisting of hydroxylamine stabilizers, substituted hydroxylamine stabilizers, nitrone stabilizers and amine oxide stabilizers, when extrusion compounded exhibits a lower residual acetaldehyde content than does polyester or polyamide alone when similarly treated. The invention pertains to any polyester or polyamide used in the manufacture of molded articles, fibers or films, for instance bottles or containers which are used to store consumer materials, for example food, beverages and water.

Owner:CIBA SPECIALTY CHEM CORP

Polyester and polyamide compositions of low residual aldehyde content

A mixture of a polyester, such as poly(ethylene terephthalate) PET, or a polyamide, and a suitable stabilizer selected from the group consisting of hydroxylamine stabilizers, substituted hydroxylamine stabilizers, nitrone stabilizers and amine oxide stabilizers, when extrusion compounded exhibits a lower residual acetaldehyde content than does polyester or polyamide alone when similarly treated. The invention pertains to any polyester or polyamide used in the manufacture of molded articles, fibers or films, for instance bottles or containers which are used to store consumer materials, for example food, beverages and water.

Owner:CIBA SPECIALTY CHEM CORP

Catalyst for polyester production, process for producing polyester using the catalyst, polyester obtained by the process, and uses of the polyester

InactiveUS6346070B1High catalytic activityLow in acetaldehydeLactams stabilisationDevelopersFiberPolyester

The present invention provides a catalyst for polyester production capable of producing a polyester with high catalytic activity and a process for producing a polyester using the catalyst. The catalyst for polyester production comprises a solid titanium compound which is obtained by dehydro-drying a hydrolyzate obtained by hydrolysis of a titanium halide and which has a molar ratio (OH / Ti) of a hydroxyl group (OH) to titanium (Ti) exceeding 0.09 and less than 4. The present invention also provides a method to obtain a polyester having a small increase of the acetaldehyde content during the molding. This method comprises bringing a polyester, which is obtained by the use of a titanium compound catalyst and in which the reaction has been completed, into contact with a phosphoric ester aqueous solution or the like having a concentration of not less than 10 ppm in terms of phosphorus atom. The present invention further provides a polyester having excellent transparency and tint and molded products of the polyester such as a blow molded article, a film, a sheet and a fiber. The polyester is obtained by polycondensing an aromatic dicarboxylic acid or an ester-forming derivative thereof and an aliphatic diol or an ester-forming derivative thereof in the presence of a catalyst for polyester production which comprises a polycondensation catalyst component comprising a solid titanium compound and a co-catalyst component comprising a magnesium compound. This polyester has a titanium content of 1 to 100 ppm, a magnesium content of 1 to 200 ppm and a weight ratio (Mg / Ti) of magnesium to titanium of not less than 0.01.

Owner:MITSUI CHEM INC

Flavor enhancing methods

InactiveUS6287620B1Improve roundnessEnhances juicy characterMilk preparationDough treatmentKetopinic acidPropanoic acid

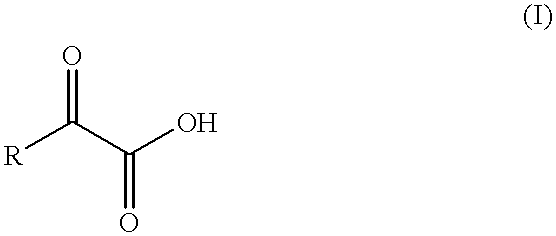

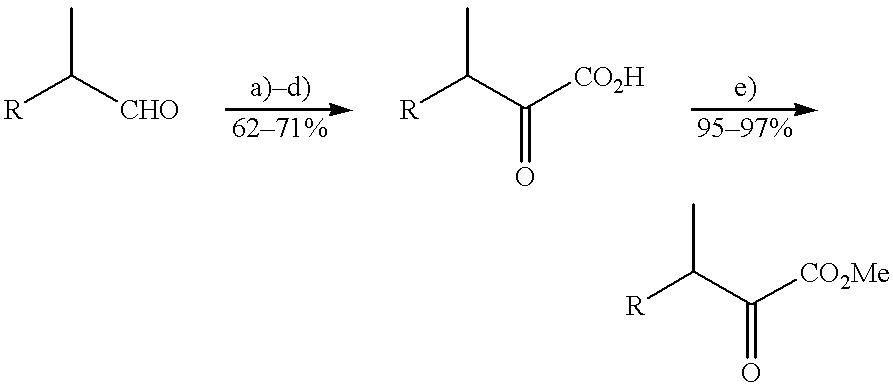

alpha-keto acids and certain precursors and derivatives thereof, particularly those selected from the group which consists of glyoxylic acid, 2-oxo-propanoic acid, 2-oxo-butanoic acid, 3-methyl-2-oxo butanoic acid, 3-methyl-2-oxo pentanoic acid, 4-methyl-2-oxo pentanoic acid, 3-hydroxy-2-oxo-propanoic acid, oxalacetic acid, 2-oxo-glutaric acid, 2-oxo-3-phenyl-propanoic acid, 3-(4-hydroxy-phenyl)-2-oxo-propanoic acid, 2-oxo-1H-indole-3-propanoic acid, 2-oxo-1H-imidazole-4-propanoic acid, 4-methylthio-2-oxo-butanoic acid, 3-mercapto-2-oxo-propanoic acid, 3-hydroxy-2-oxo-butanoic acid, 6-amino-2-oxo-hexanoic acid and 5-guanido-2-oxo-pentanoic acid, and precursors and derivatives thereof that are capable of being formed from or releasing said acids in the use medium, are useful as flavouring ingredients. Such ingredients are useful for preparing flavouring compositions and a wide variety of flavoured foodstuffs to which they impart greater creaminess and bulkiness so that they have heightened effect in the mouth and generally an enhanced mouthfeel. They are also useful for enhancing the sweetness of foods sweetened with natural or artificial sweeteners, and giving it a more natural character.

Owner:FIRMENICH SA

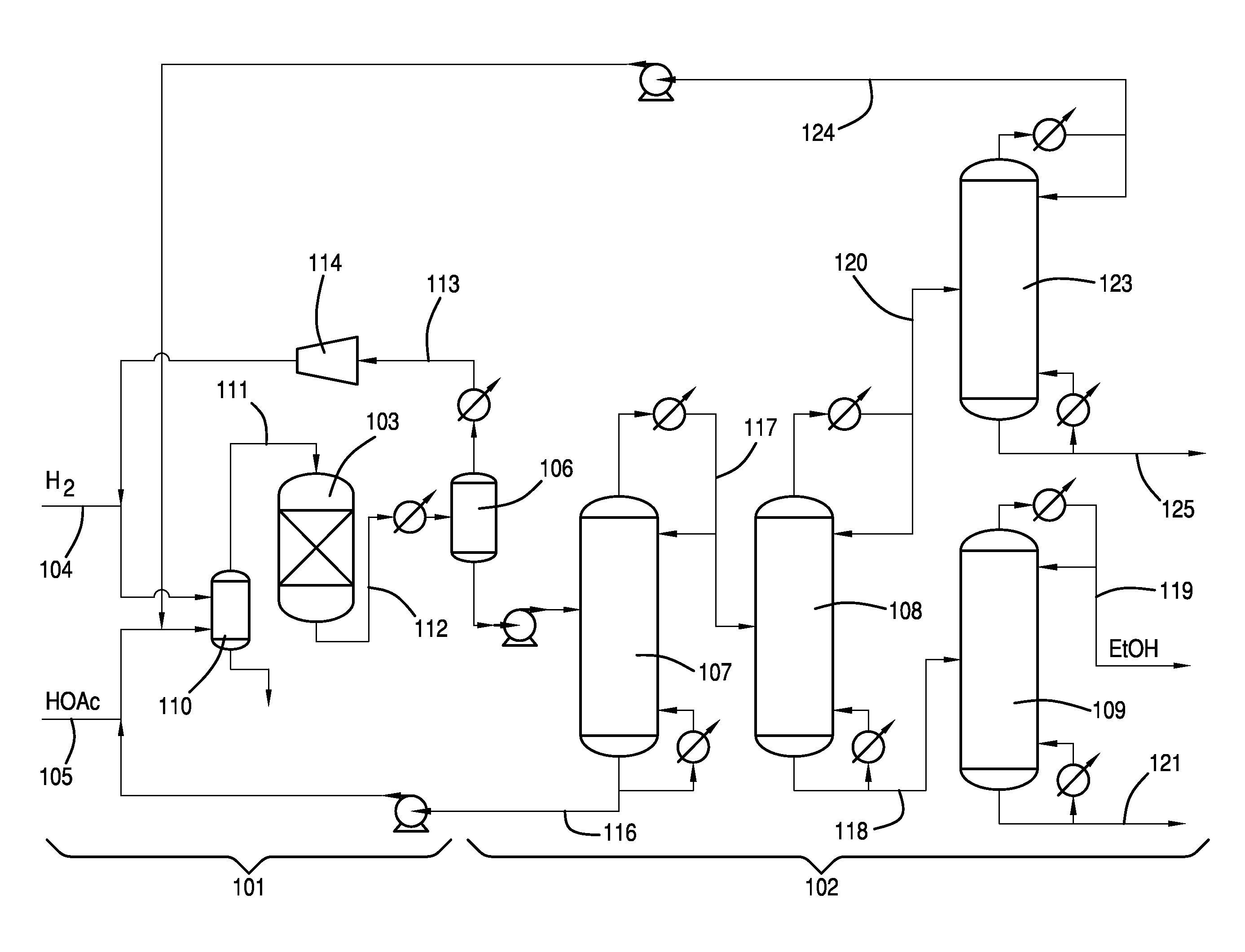

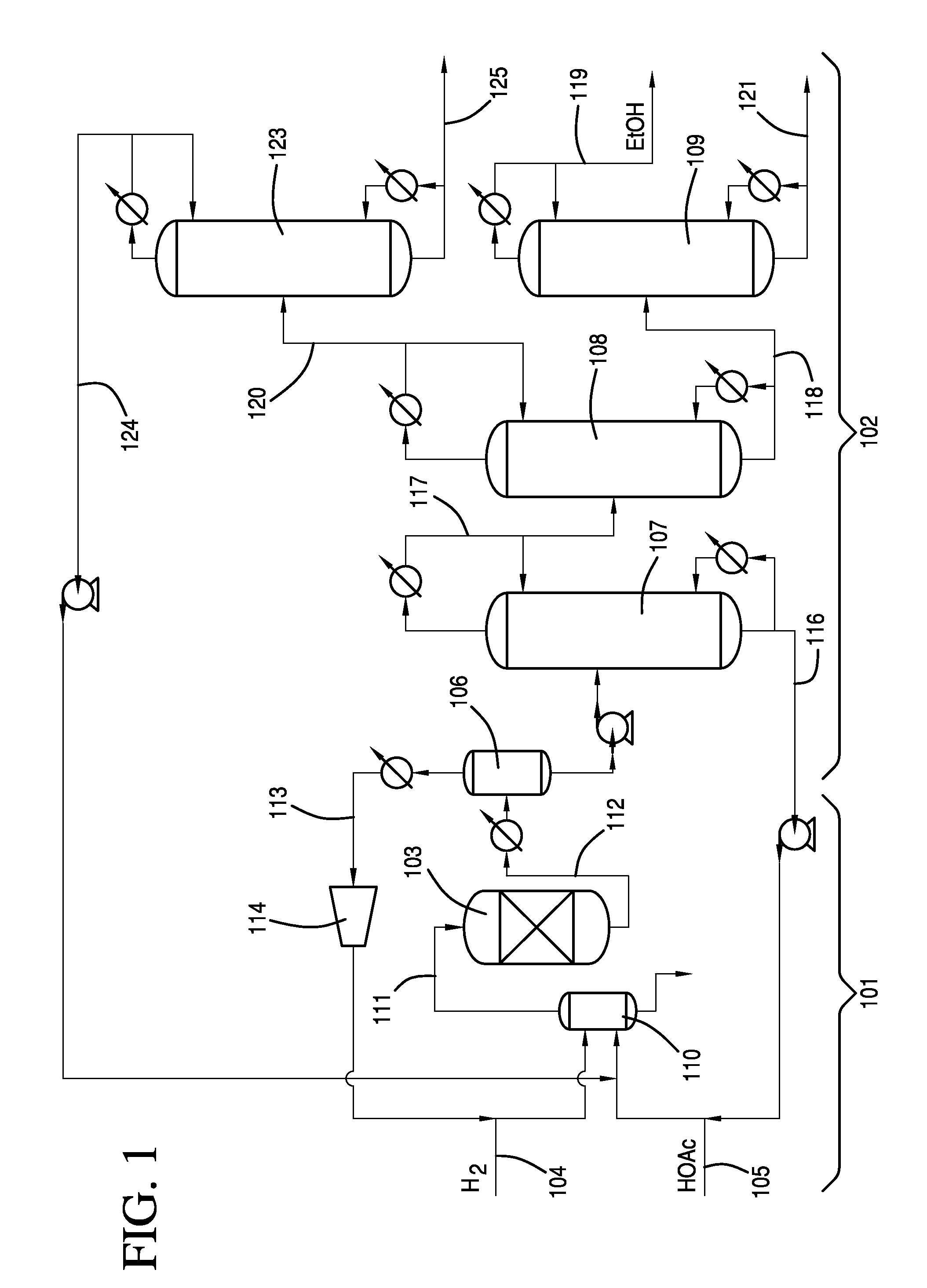

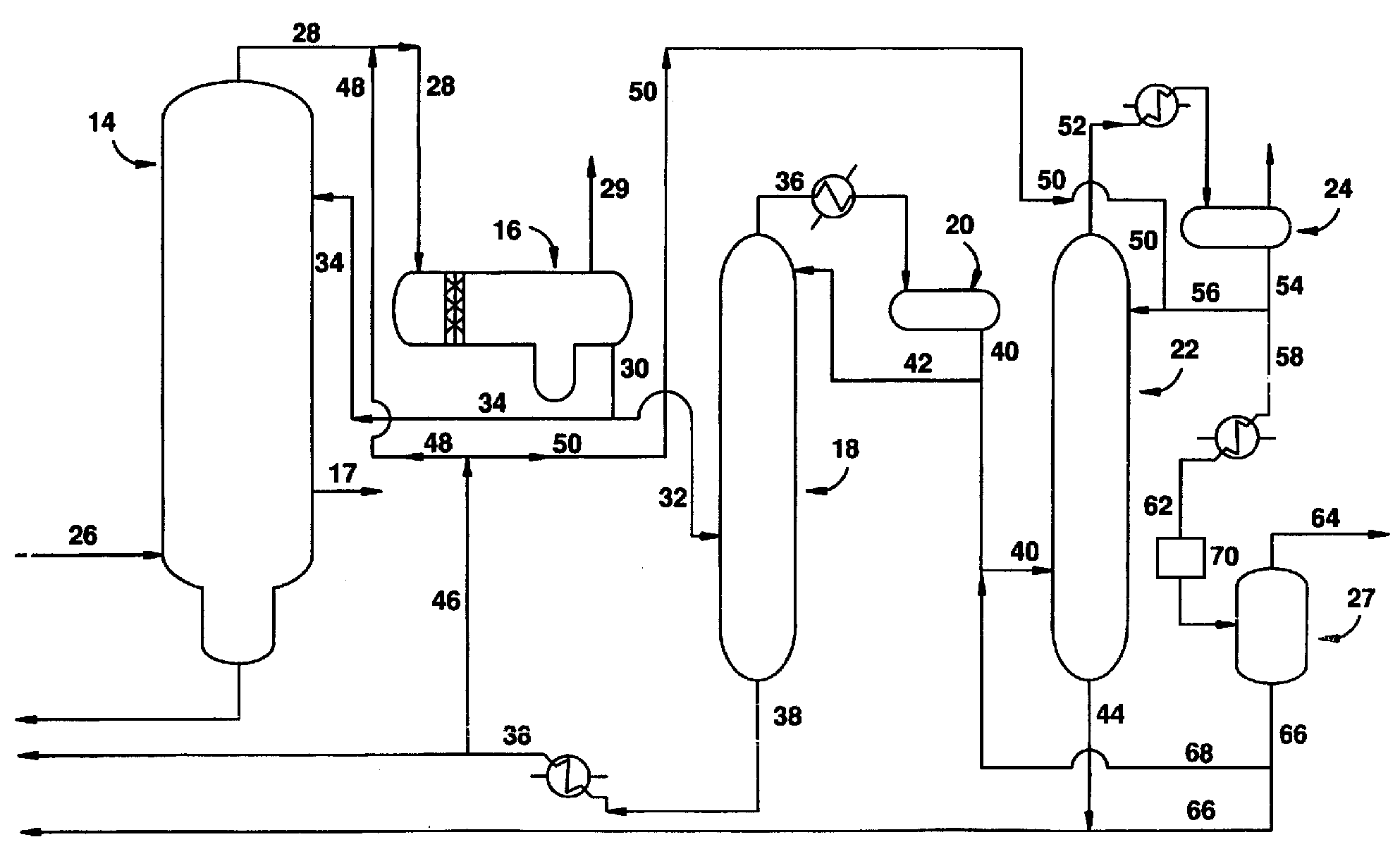

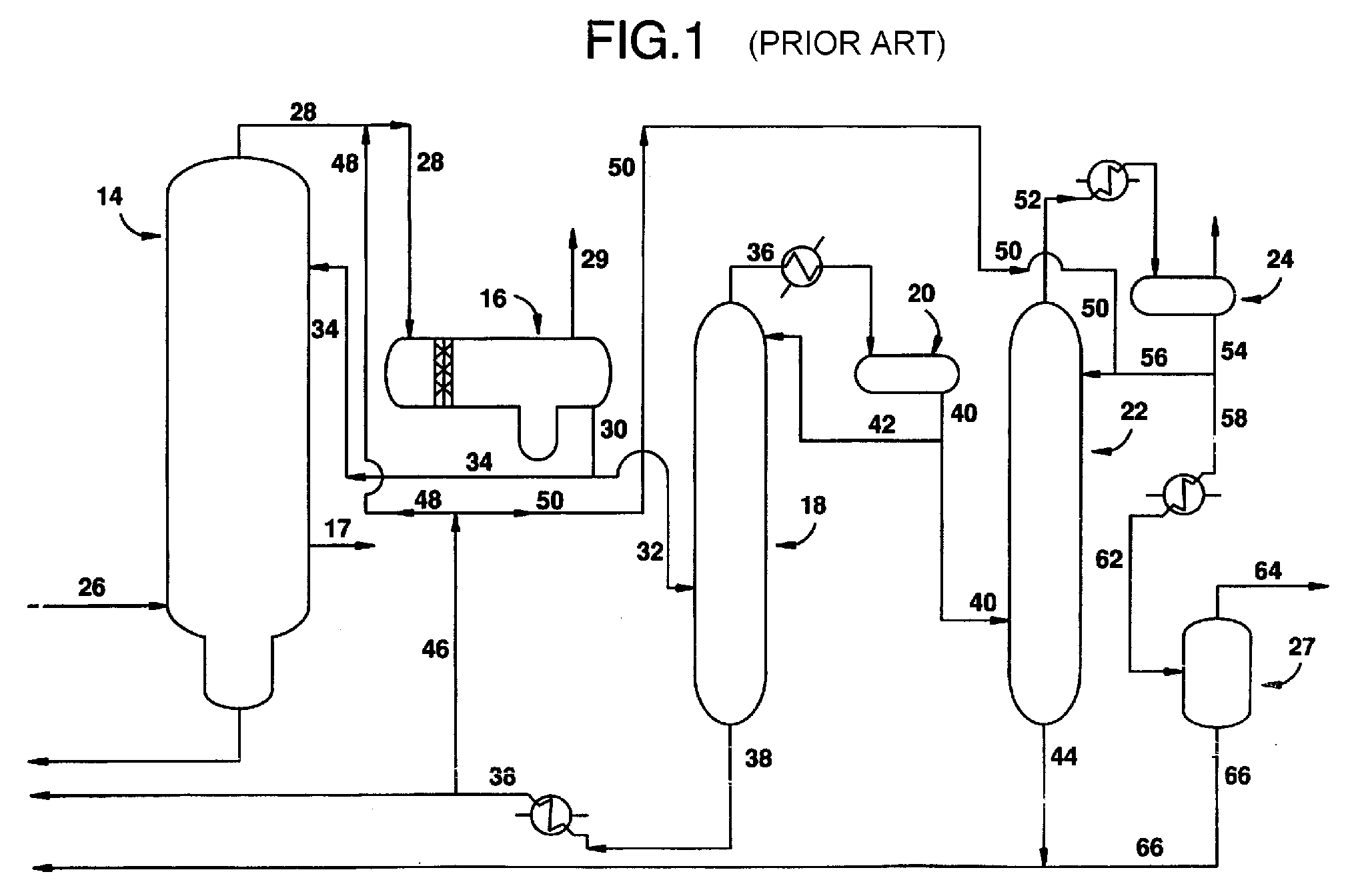

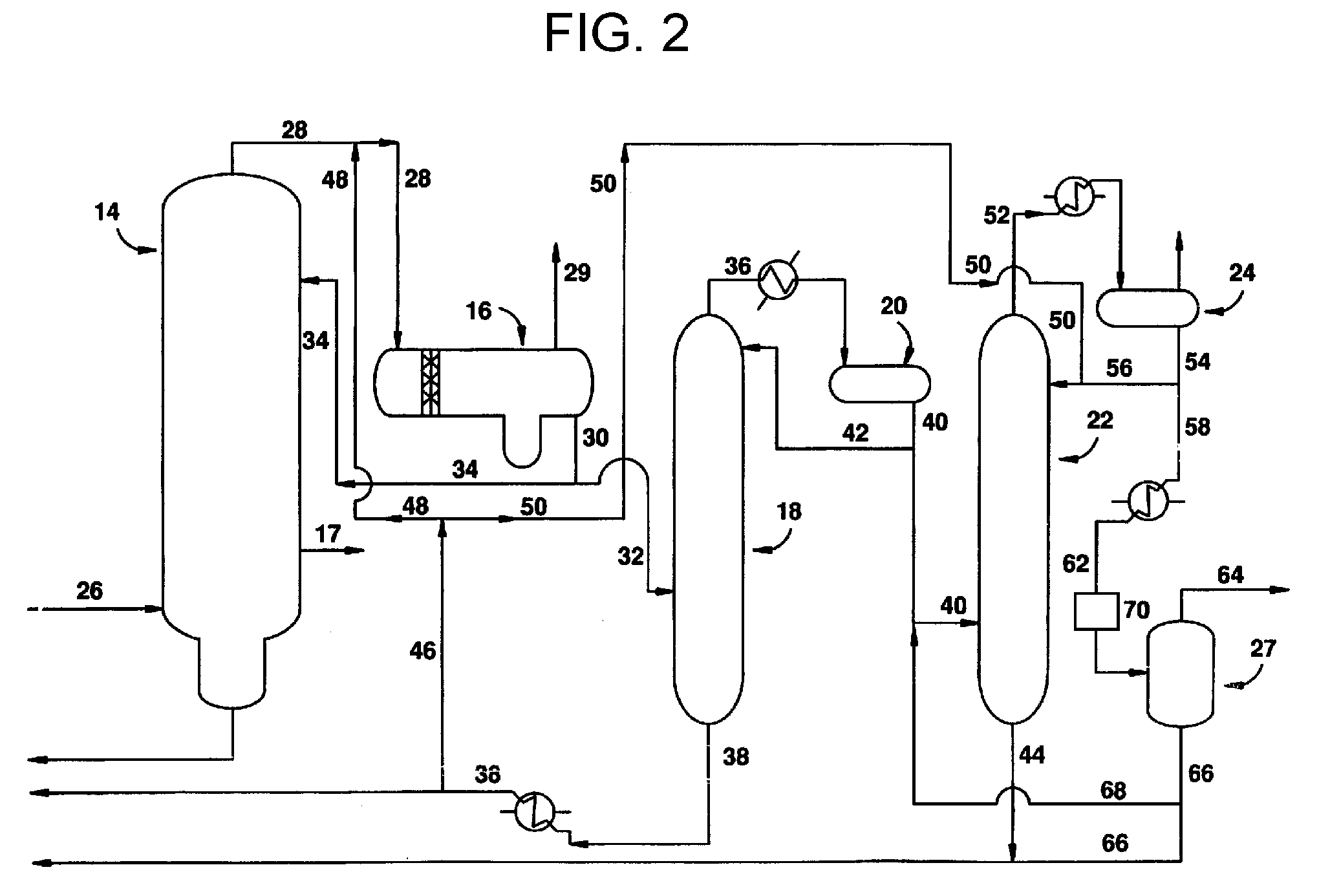

Process for purifying ethanol

InactiveUS20110190548A1Organic compound preparationOxygen compounds preparation by reductionAcetic acidAcetaldehyde

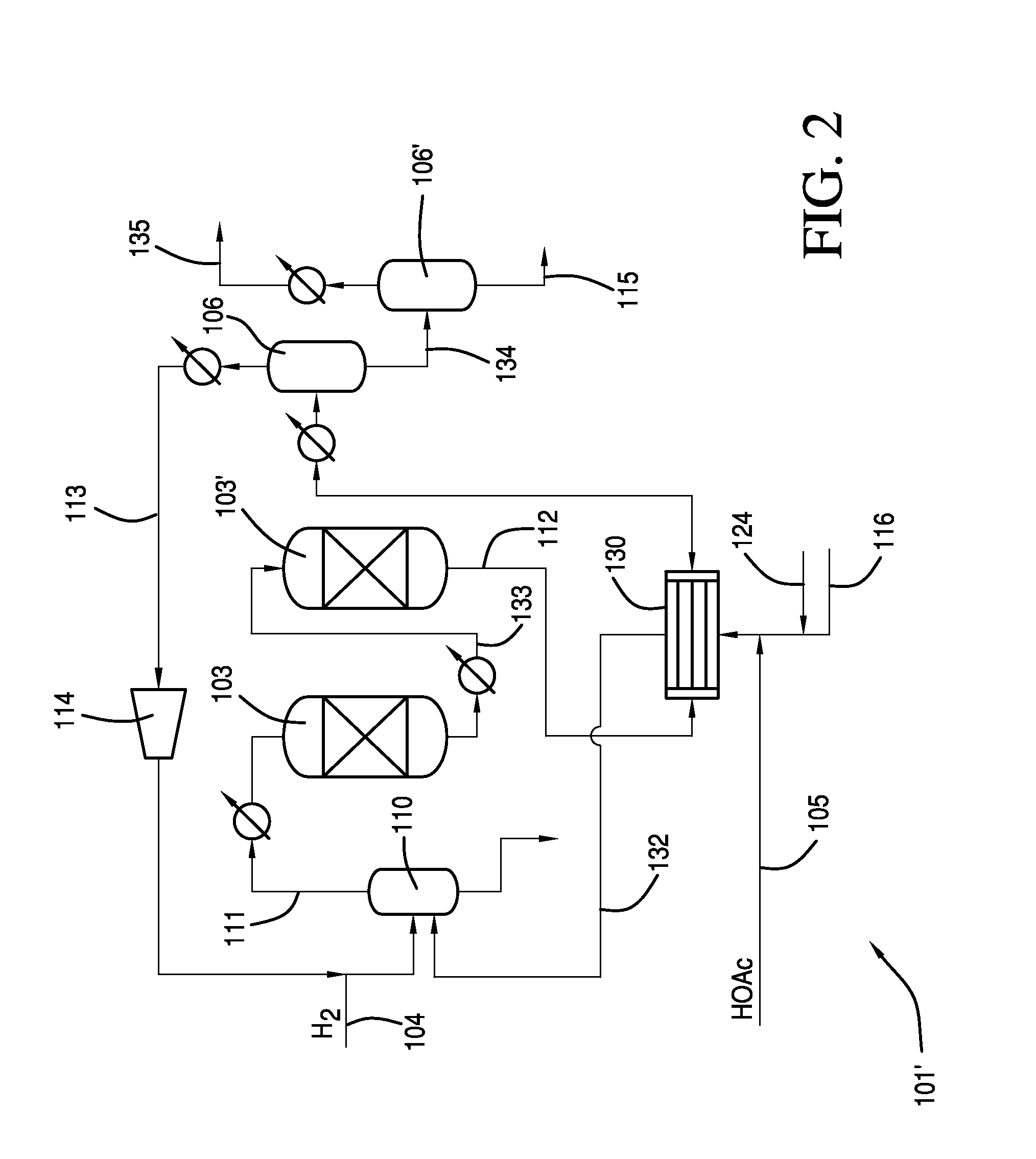

Purifying and / or recovery of ethanol from a crude ethanol product obtained from the hydrogenation of acetic acid. Separation and purification processes of crude ethanol mixture are employed to allow recovery of ethanol and remove impurities. In addition, the process involves returning acetaldehyde separated from the crude ethanol product to the reactor.

Owner:CELANESE INT CORP

Polyester and process for preparing polyester

Owner:MITSUI CHEM INC

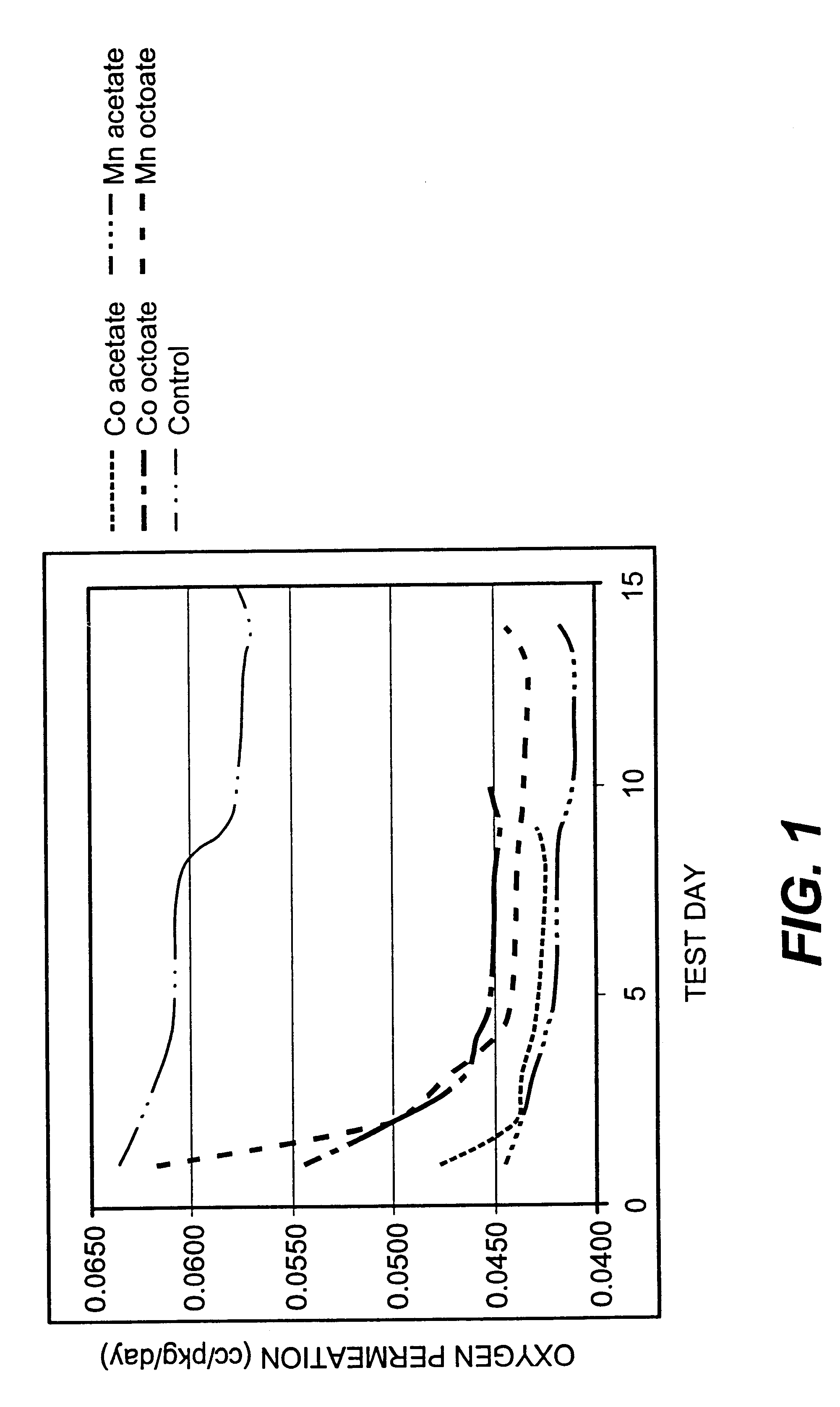

Process for reduction of acetaldehyde and oxygen in beverages contained in polyester-based packaging

InactiveUS6569479B2Reduce and eliminate migrationReduce and eliminate migration of oxygenReady-for-oven doughsFruit and vegetables preservationPolyesterAcetic acid

A process for reducing acetaldehyde concentration in beverages contained in polyester-based packaging, wherein oxygen permeation into the container is reduced or eliminated. The polyester contains an oxidation catalyst active for the oxidation of acetaldehyde to acetic acid. A composition comprising a polyester and said oxidation catalyst. A polyester-based container comprising said oxidation catalyst, and a bottled beverage having a polyester-based container comprising an oxidation catalyst active for the oxidation of acetaldehyde to acetic acid.

Owner:THE COCA COLA CO

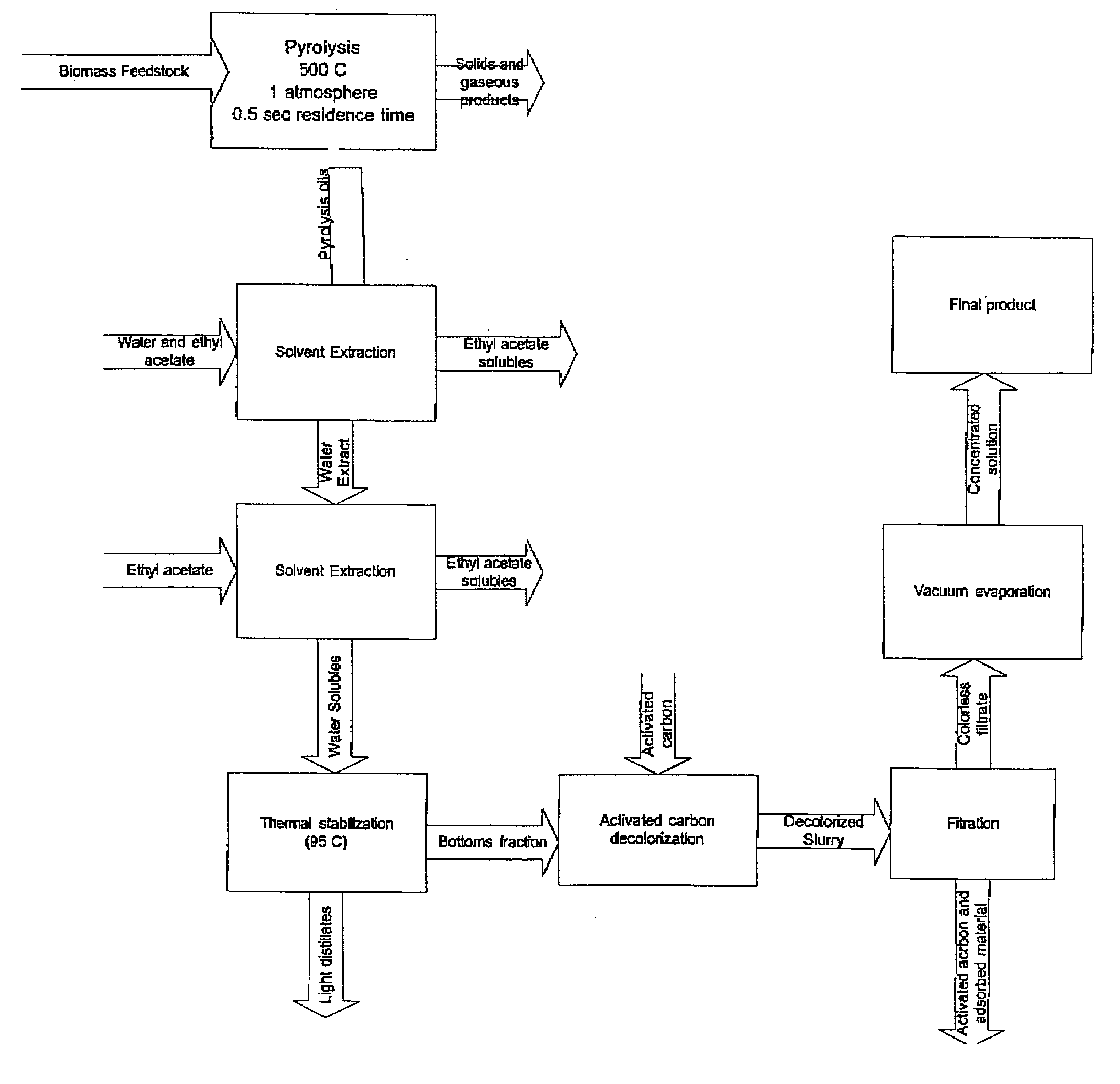

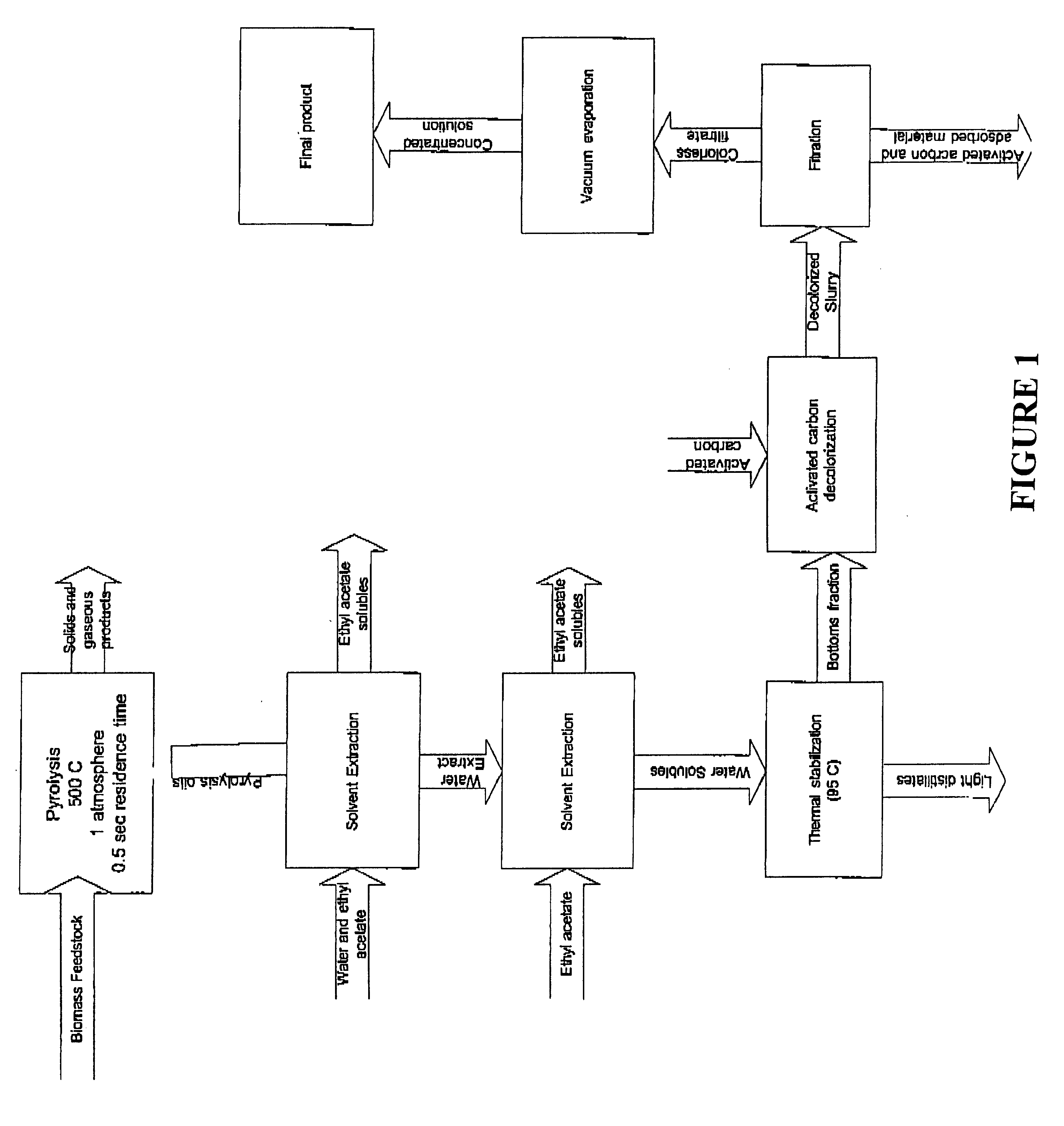

Preparation of brightness stabilization agent for lignin containing pulp from biomass pyrolysis oils

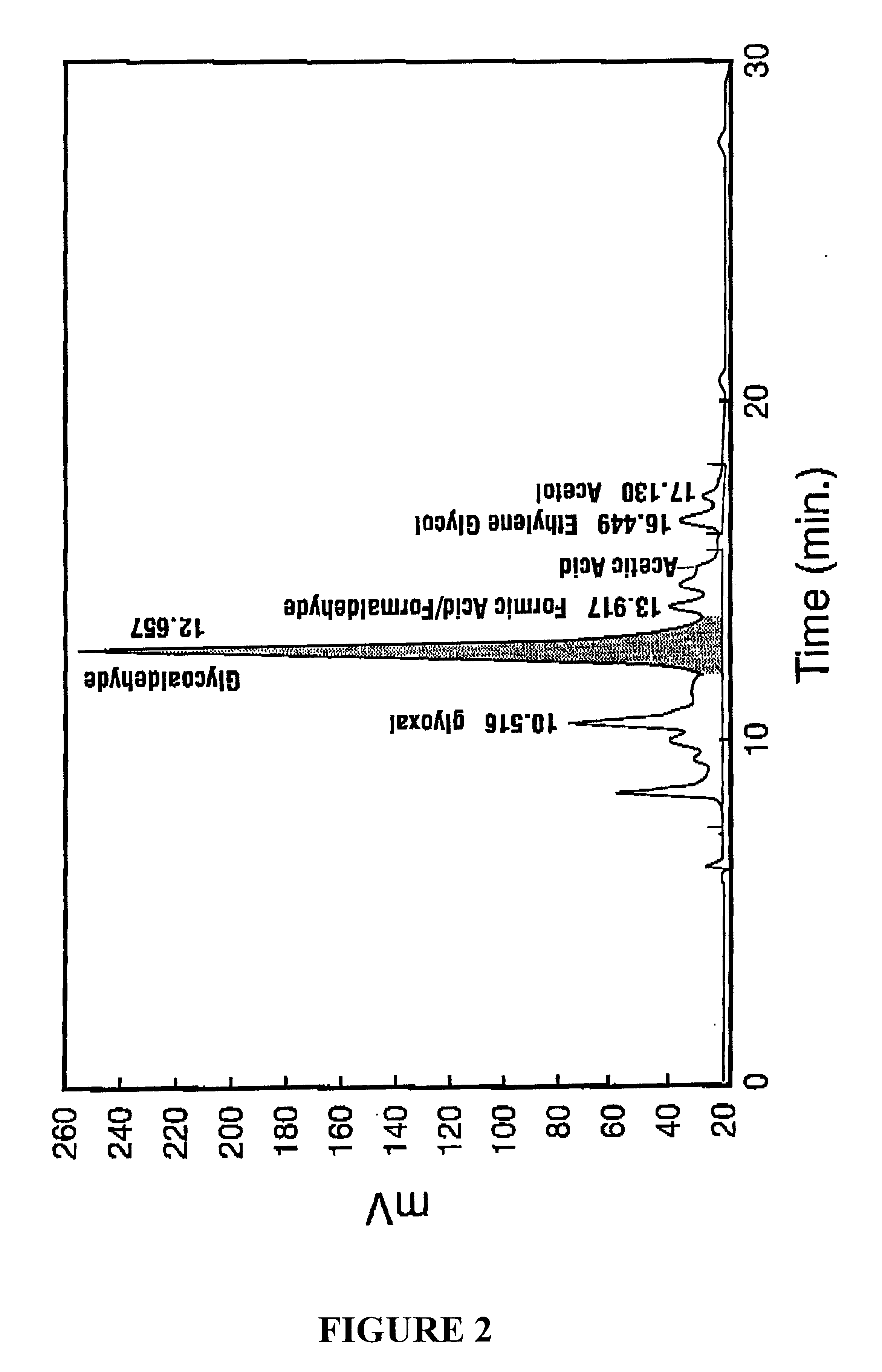

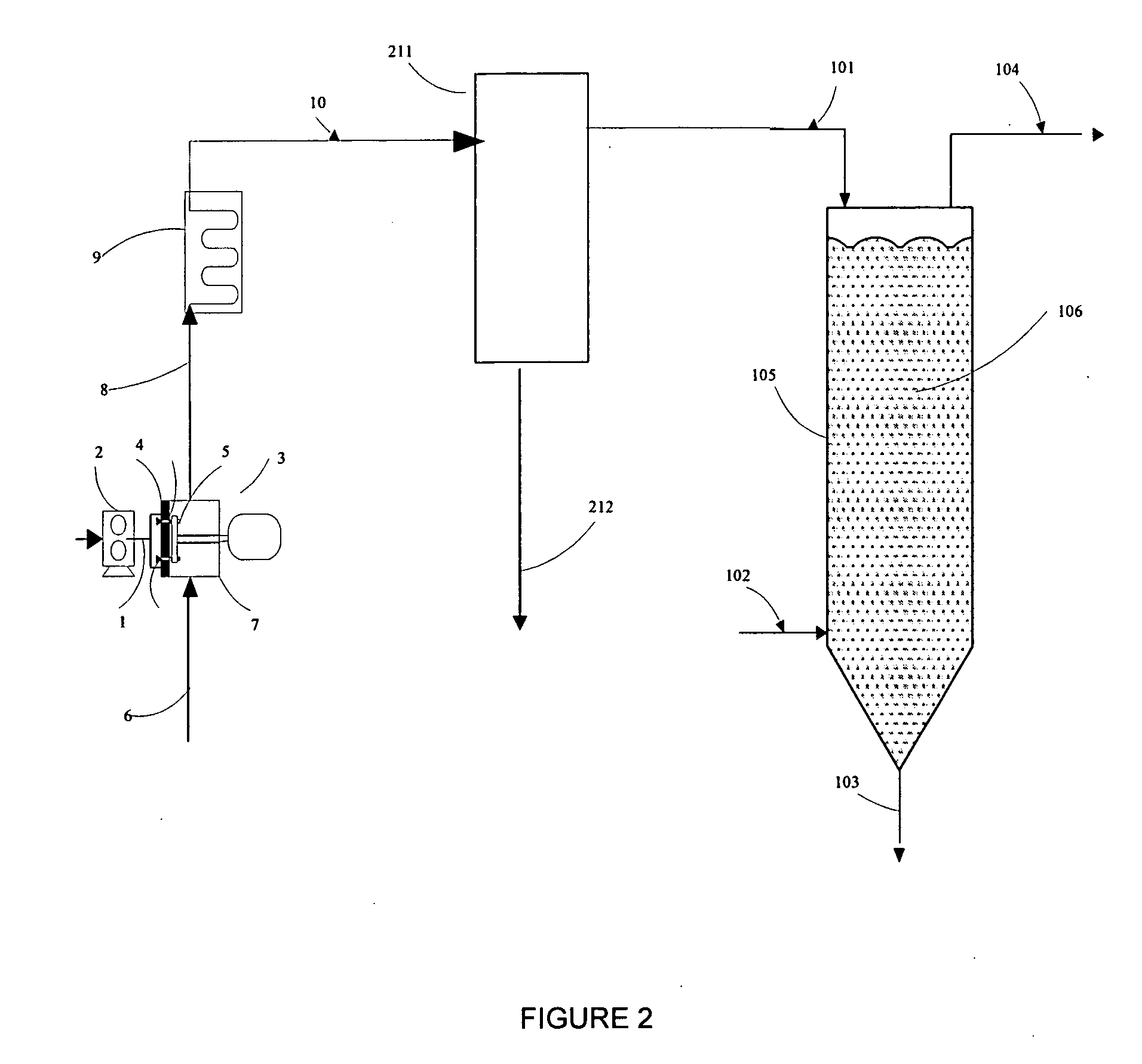

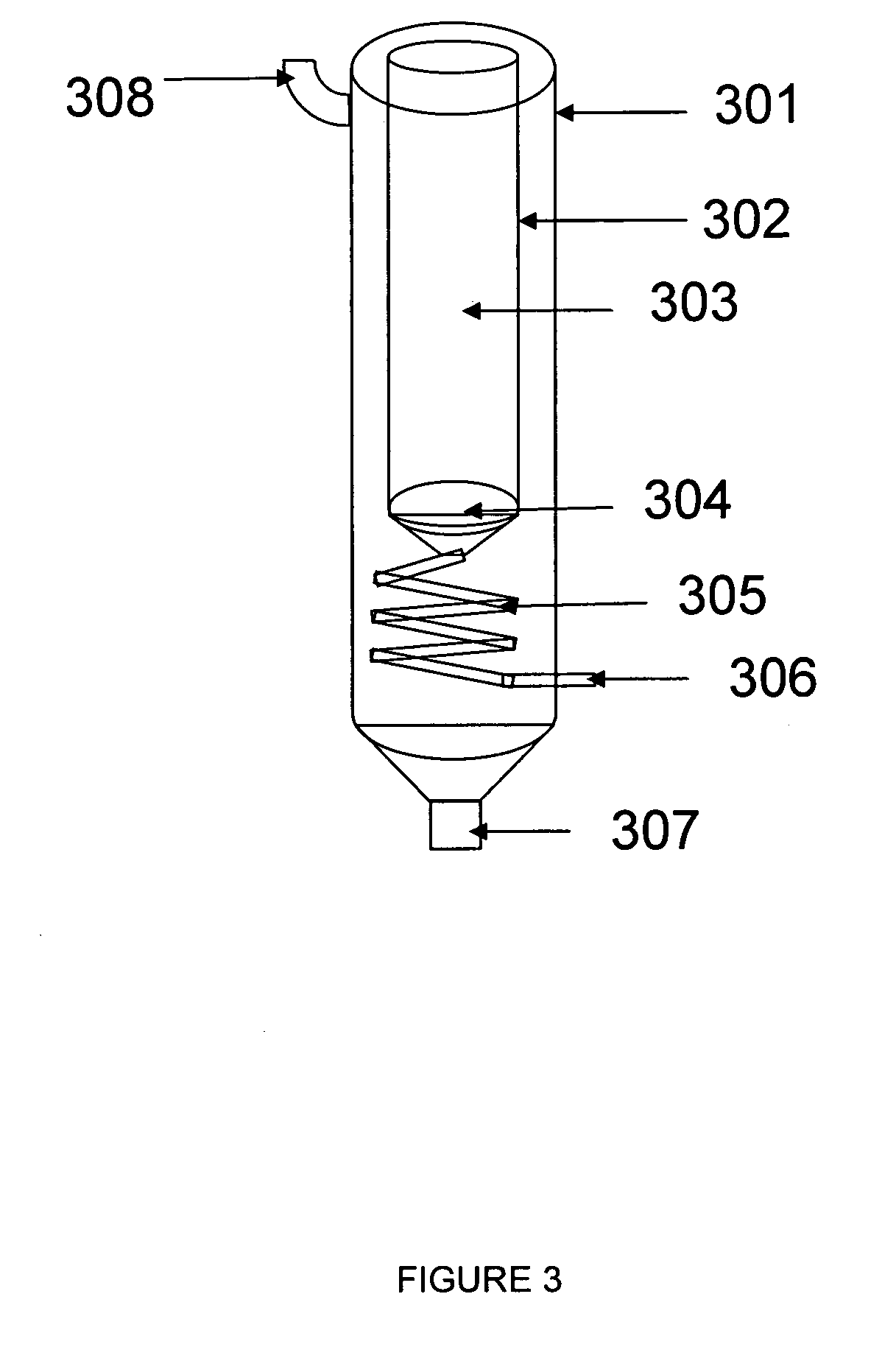

A process for producing a brightness stabilization mixture of water-soluble organic compounds from biomass pyrolysis oils comprising:a) size-reducing biomass material and pyrolyzing the size-reduced biomass material in a fluidized bed reactor;b) separating a char / ash component while maintaining char-pot temperatures to avoid condensation of pyrolysis vapors;c) condensing pyrolysis gases and vapors, and recovering pyrolysis oils by mixing the oils with acetone to obtain an oil-acetone mixture;d) evaporating acetone and recovering pyrolysis oils;e) extracting the pyrolysis oils with water to obtain a water extract;f) slurrying the water extract with carbon while stirring, and filtering the slurry to obtain a colorless filtrate;g) cooling the solution and stabilizing the solution against thermally-induced gelling and solidification by extraction with ethyl acetate to form an aqueous phase lower layer and an organic phase upper layer;h) discarding the upper organic layer and extracting the aqueous layer with ethyl acetate, and discarding the ethyl acetate fraction to obtain a brown-colored solution not susceptible to gelling or solidification upon heating;i) heating the solution to distill off water and other light components and concentrating a bottoms fraction comprising hydroxyacetaldehyde and other non-volatile components having high boiling points; andj) decolorizing the stabilized brown solution with activated carbon to obtain a colorless solution.

Owner:MIDWEST RES INST

Aluminum containing polyester polymers having low acetaldehyde generation rates

ActiveUS20070066791A1Organic-compounds/hydrides/coordination-complexes catalystsCeramic shaping apparatusPolyesterPolymer science

A polyester polymer composition containing polyester polymers such as polymers having repeating ethylene terephthalate units, aluminum atoms in an amount of at least 3 ppm based on the weight of the polymer, the polyester polymers having an It.V. of at least 0.72 dL / g obtained through a melt phase polymerization and a residual acetaldehyde level of 10 ppm or less. Also provided are polyester polymer compositions containing polyester polymers and: (i) aluminum atoms (ii) alkaline earth metal atoms or alkali metal atoms or alkali compound residues, and (iii) a catalyst deactivator such as a phosphorus compound. The phosphorus compound is added to the polyester melt either late in the polycondensation or upon remelting a solid polyester polymer. The polyester polymer exhibits good L* brightness, clarity, and low levels of acetaldehyde generated upon melting.

Owner:ALPEK POLYESTER SA DE CV

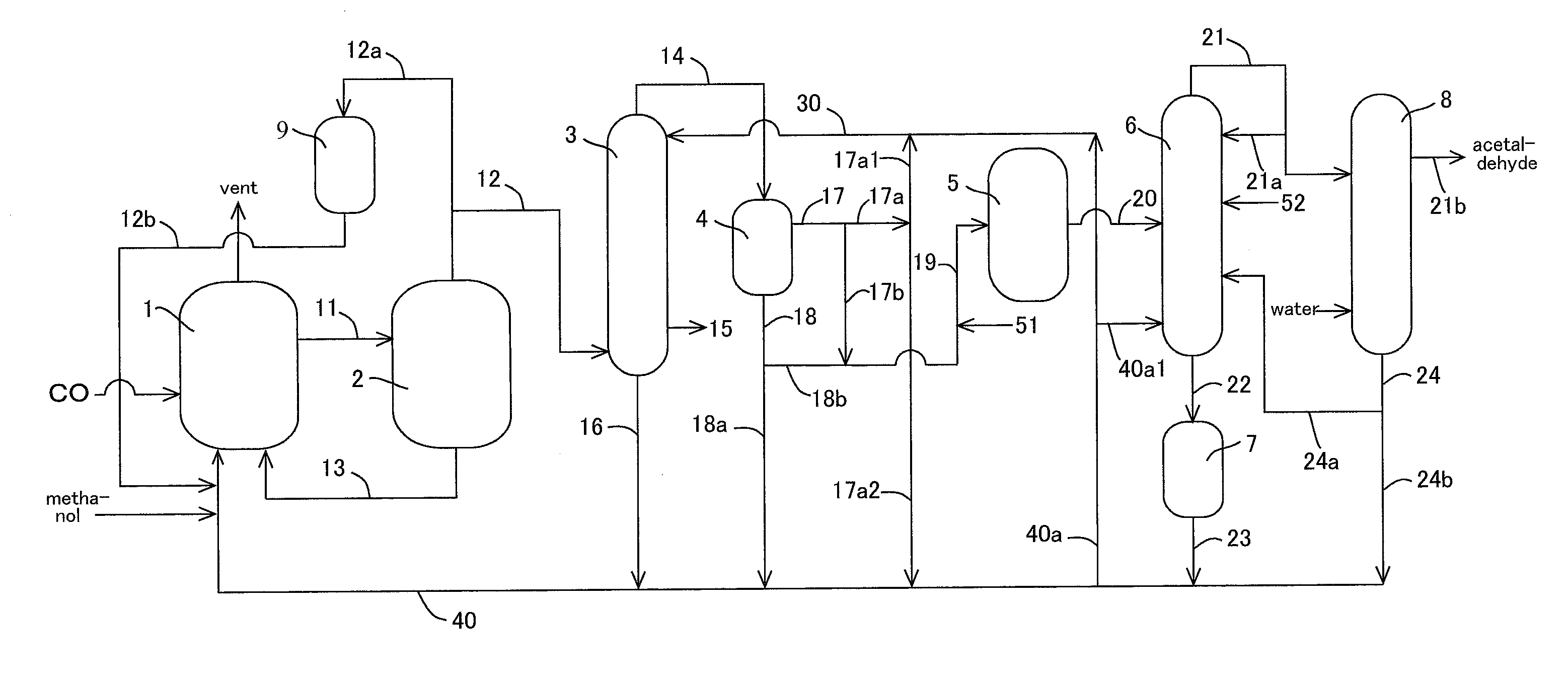

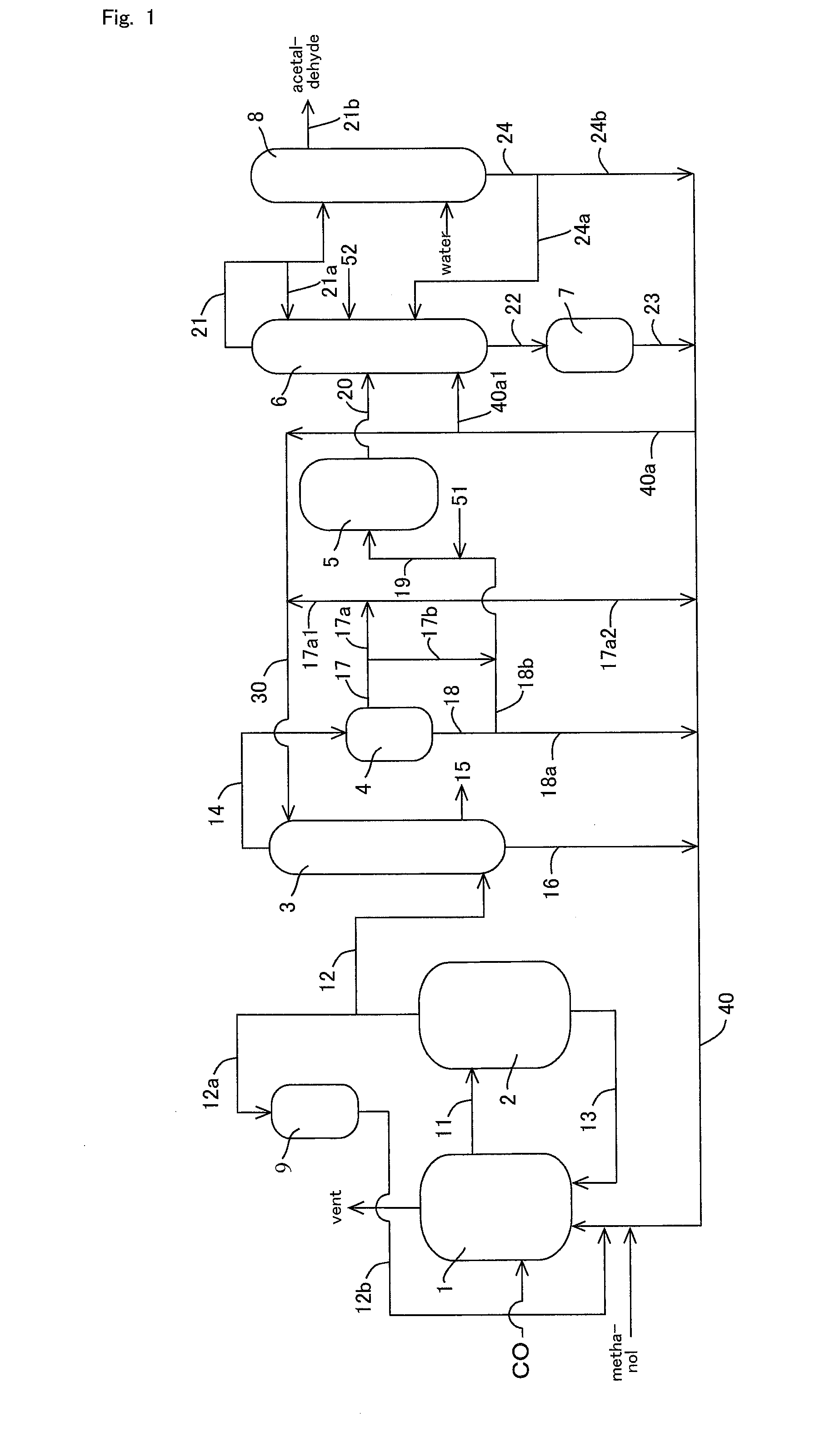

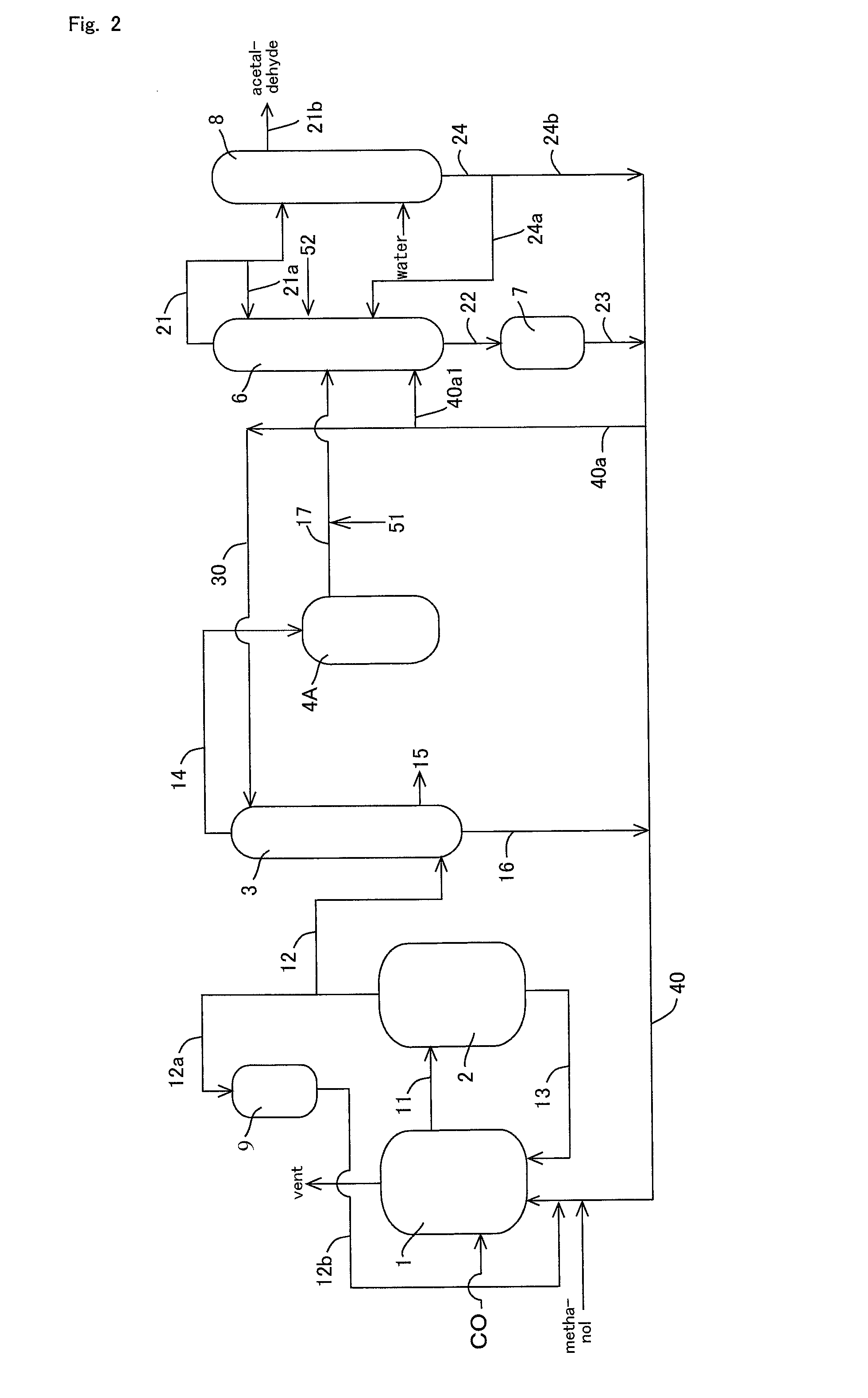

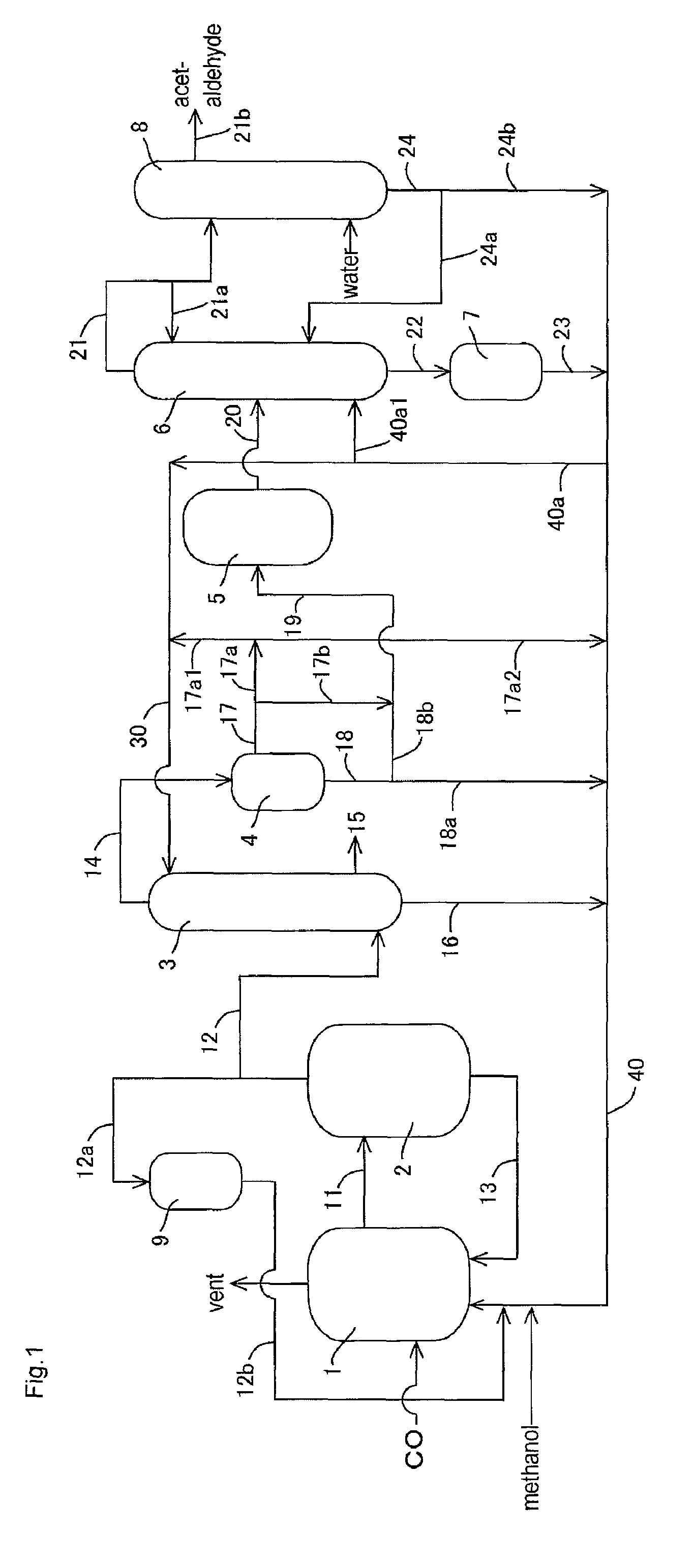

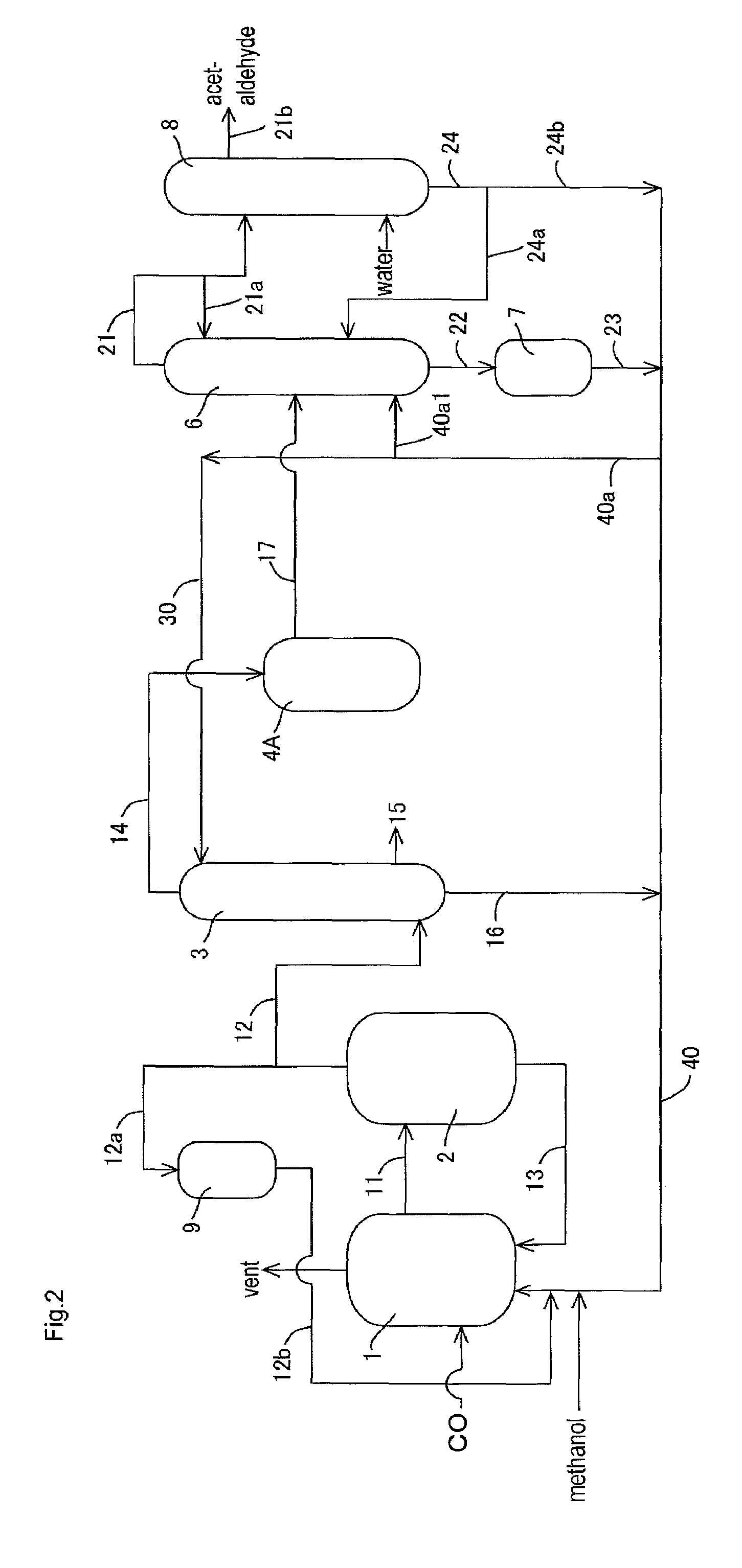

Process for producing acetic acid

ActiveUS20130281735A1Efficient removalImprove corrosion resistanceOrganic compound preparationOrganic chemistry methodsDistillationMethyl acetate

Acetic acid is produced while inhibiting increased concentrations of hydrogen iodide and acetic acid in an acetaldehyde distillation column.A production process of acetic acid comprises a step for allowing methanol to react with carbon monoxide; a step for feeding a flasher with the reaction mixture to separate a volatile component (2A) and a low-volatile component (2B); a step for feeding a distillation column with the volatile component (2A), and separating an overhead (3A) containing methyl iodide, acetic acid, methyl acetate, water, acetaldehyde, and hydrogen iodide, and a stream (3B) containing acetic acid to collect acetic acid; and a separation step for feeding an acetaldehyde distillation column with at least part of the overhead (3A) and separating a liquid object to be treated containing the overhead (3A) into a lower boiling point component (4A) containing acetaldehyde and a higher boiling point component (4B); wherein, in the separation step, the liquid object contains methanol and / or dimethyl ether in a concentration of 0.1 to 50% by weight is subjected to distillation.

Owner:DAICEL CHEM IND LTD

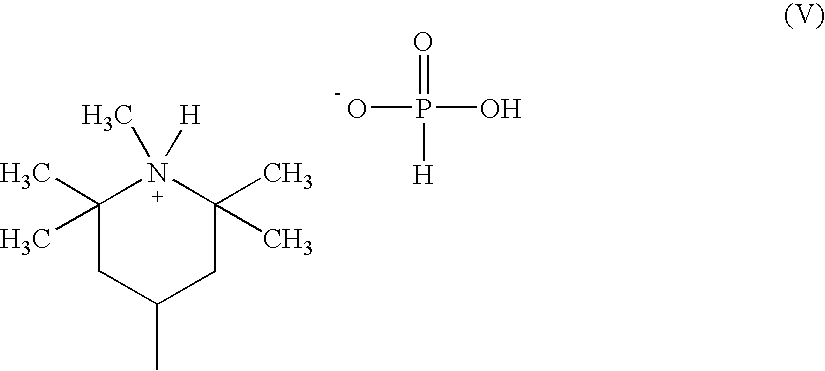

Process for the purification of crude propene oxide

InactiveCN1714087ACarbonyl compound separation/purificationPurification methodsExtractive distillation

The present invention relates to a method for purifying crude propylene oxide containing methanol and acetaldehyde by extractive distillation operated continuously, wherein an extraction solvent capable of reducing the volatility of methanol is used, and the crude propylene oxide is fed into a distillation column above the feed point of the crude propylene oxide A compound containing unsubstituted NH2 groups and capable of reacting with acetaldehyde is added to obtain purified propylene oxide containing less than 100 ppm methanol and less than 100 ppm acetaldehyde. The present invention also relates to a method for catalytic epoxidation of propylene comprising said purification step.

Owner:EVONIK OPERATIONS GMBH +1

Aluminum/alkaline or alkali/titanium containing polyesters having improved reheat, color and clarity

ActiveUS20070066735A1Improving reheat rateIncrease ratingsHydrogenOther chemical processesPolyesterPolymer science

A polyester composition containing: a) aluminum atoms; and b) alkaline earth atoms or alkali metal atoms or alkali compound residues such as lithium atoms; and c) particles comprising titanium, zirconium, vanadium, niobium, hafnium, tantalum, chromium, tungsten, molybdenum, iron, or nickel atoms or combinations thereof, where the particles improve the reheat rate of the polyester composition. The polyester polymer compositions may also contain phosphorus catalyst deactivators / stabilizers. The polyester compositions and the articles made from the compositions such as bottle preforms and stretch blow molded bottles have improved reheat rate while maintaining low haze, high L*, a b* below 3, and have low levels of acetaldehyde. In the process for making the polyester polymer, the polymer melt is polycondensed in the presence of a) and b), with the particles c) added in a melt phase process or added to the polymer in an injection molding machine or extruder. The polyester polymer composition can be made to high IV from the melt phase while avoiding solid state polymerization.

Owner:ALPEK POLYESTER SA DE CV

Manufacturing method of copolyester for low acetaldehyde content of PET bottles

InactiveUS6489434B2Reduce productionLow in acetaldehydeLayered productsBottlesPolyethylene terephthalate glycolBottle

The present invention provides a manufacturing method of copolyester for low acetaldehyde content of PET bottles. The polyethylene terephthalate (PET) polymer is added with an appropriate modifier in order to decrease the production of acetaldehyde caused by pyrolysis side reaction during the blow molding process of PET bottles. The modifier comprises stabilizer and primary antioxidant, wherein the stabilizer is an inorganic phosphorous compound with an addition quantity of 0.003~0.5 weight % based on the weight of the total copolyester copolymer and the primary antioxidant is a hindered phenolic antioxidant containing Ca+2 with an addition quantity of 0.005~5.0 weight % based on the weight of the total copolyester copolymer. The present invention owns an improving effect of decreasing the production of side product-acetaldehyde at least 30% than those without the addition of said modifier.

Owner:NANYA PLASTICS CORP

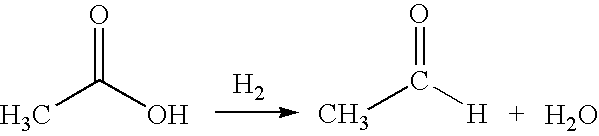

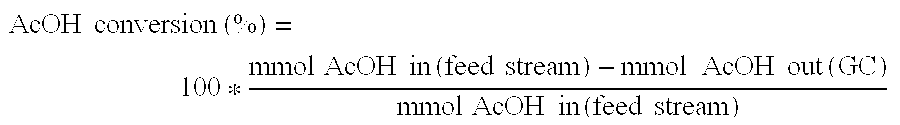

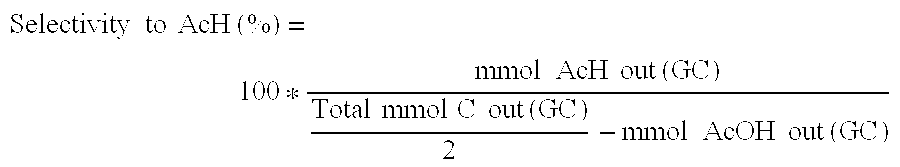

Direct and selective production of acetaldehyde from acetic acid utilizing a supported metal catalyst

InactiveUS20100029993A1High selectivityHigh yieldOrganic compound preparationPreparation by hydrogenolysisAcetic acidPlatinum

A process for the selective production of acetaldehyde by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form acetaldehyde is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over platinum and iron supported on silica selectively produces acetaldehyde in a vapor phase at a temperature of about 300° C.

Owner:CELANESE INT CORP

Polyester polycondensation with catalyst and a catalyst enhancer

InactiveUS20020032300A1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyesterPotassium

The present invention is based upon the discovery that nontitanyl oxalates can enhance the catalytic functionality of titanyl oxalate catalysts. This invention provides a novel catalytic composition containing a titanyl oxalate catalyst and a metallic oxalate catalyst enhancer and optionally containing a metallic cocatalyst such as an antimony based catalyst. A synergistic relationship has been discovered between titanyl oxalate catalyst and the catalyst enhancer. A synergistic relationship has also been discovered between the titanyl oxalate catalyst, catalyst enhancer and a metallic cocatalyst such as antimony oxide or antimony triacetate. Also provided is an improved process of producing polyester by the polycondensation of polyester forming reactants in the presence of a catalytically effective amount of a polycondensation catalyst, wherein the improvement comprises utilizing, as the polycondensation catalyst, the novel catalyst composition containing a titanyl oxalate such as lithium titanyl oxalate and a catalyst enhancer such as a nontitanyl metallic oxalate like lithium oxalate and optionally containing a metallic catalyst such as antimony oxide or antimony triacetate. The improved process produces an improved polyester having lower acetaldehyde numbers and good color. The titanyl oxalate / catalyst enhancer composition can be used as a polycondensation catalyst in combination with other catalysts to achieve synergistic catalytic activity. Preferred is a combination of lithium or potassium titanyl oxalate, Li2 or K2TiO(C2O4)2, lithium or potassium oxalate, Li2 or K2(C2O4)2 with antimony oxide or antimony triacetate or antimony trisglycoxide.

Owner:ARKEMA INC

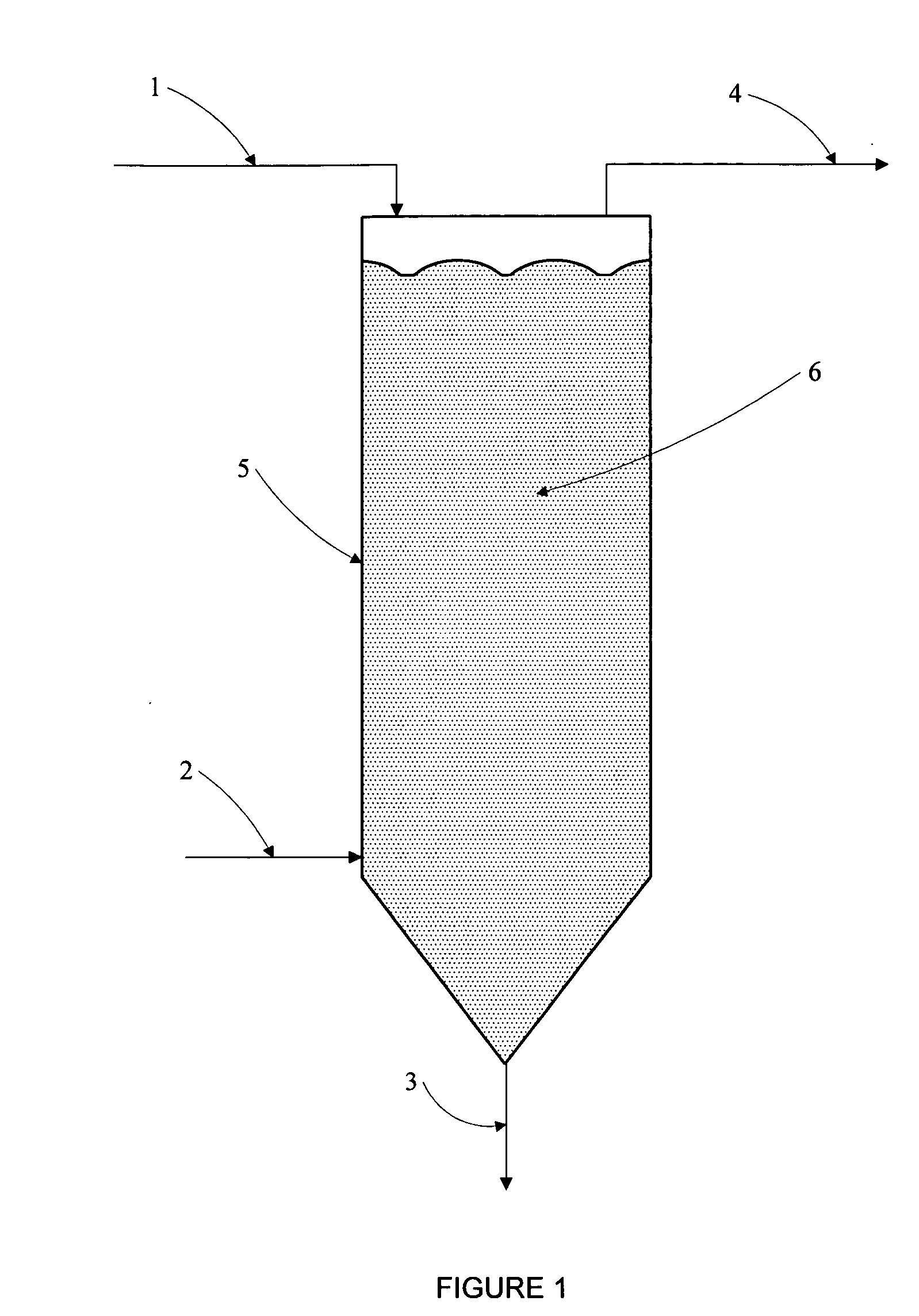

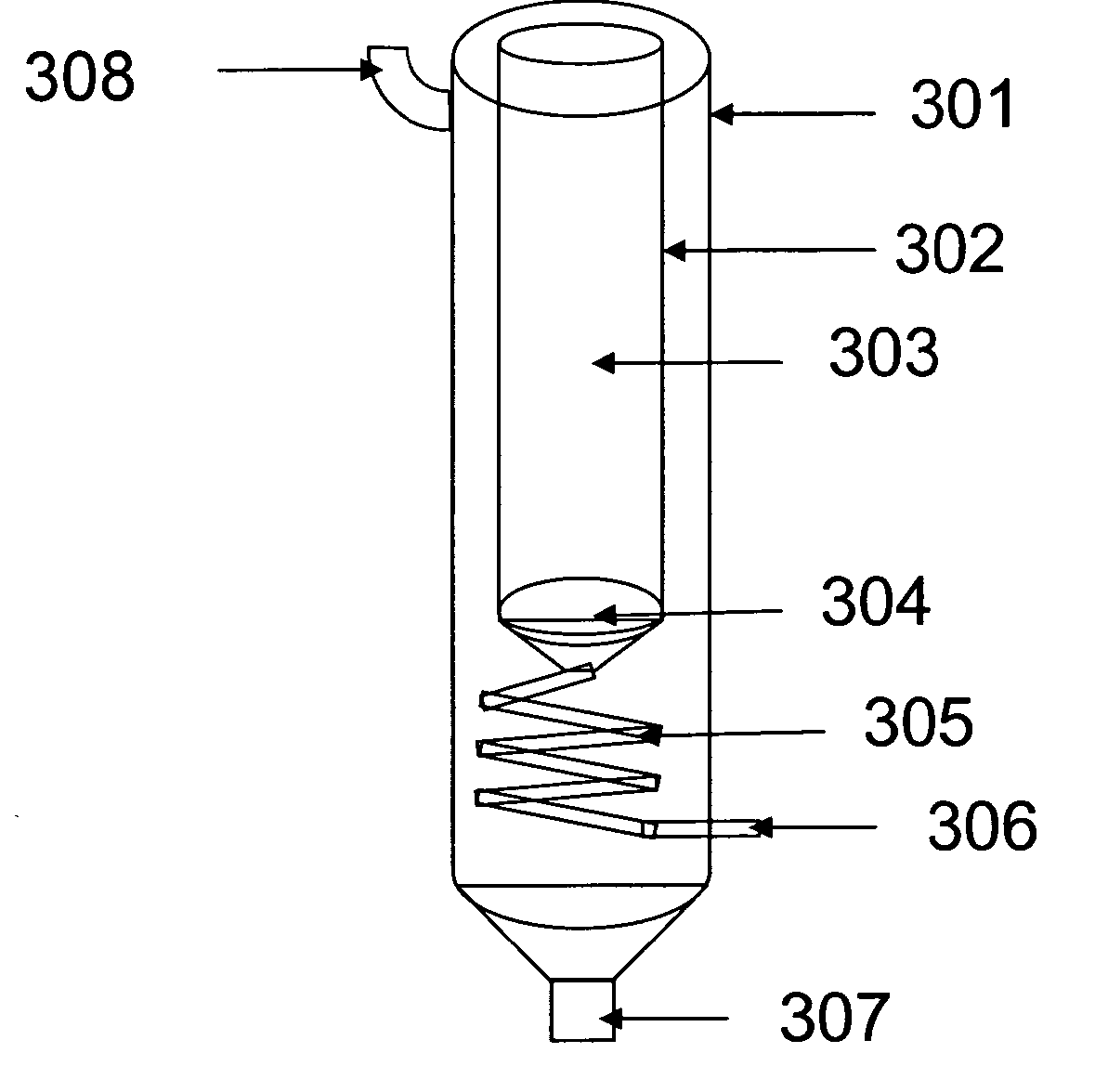

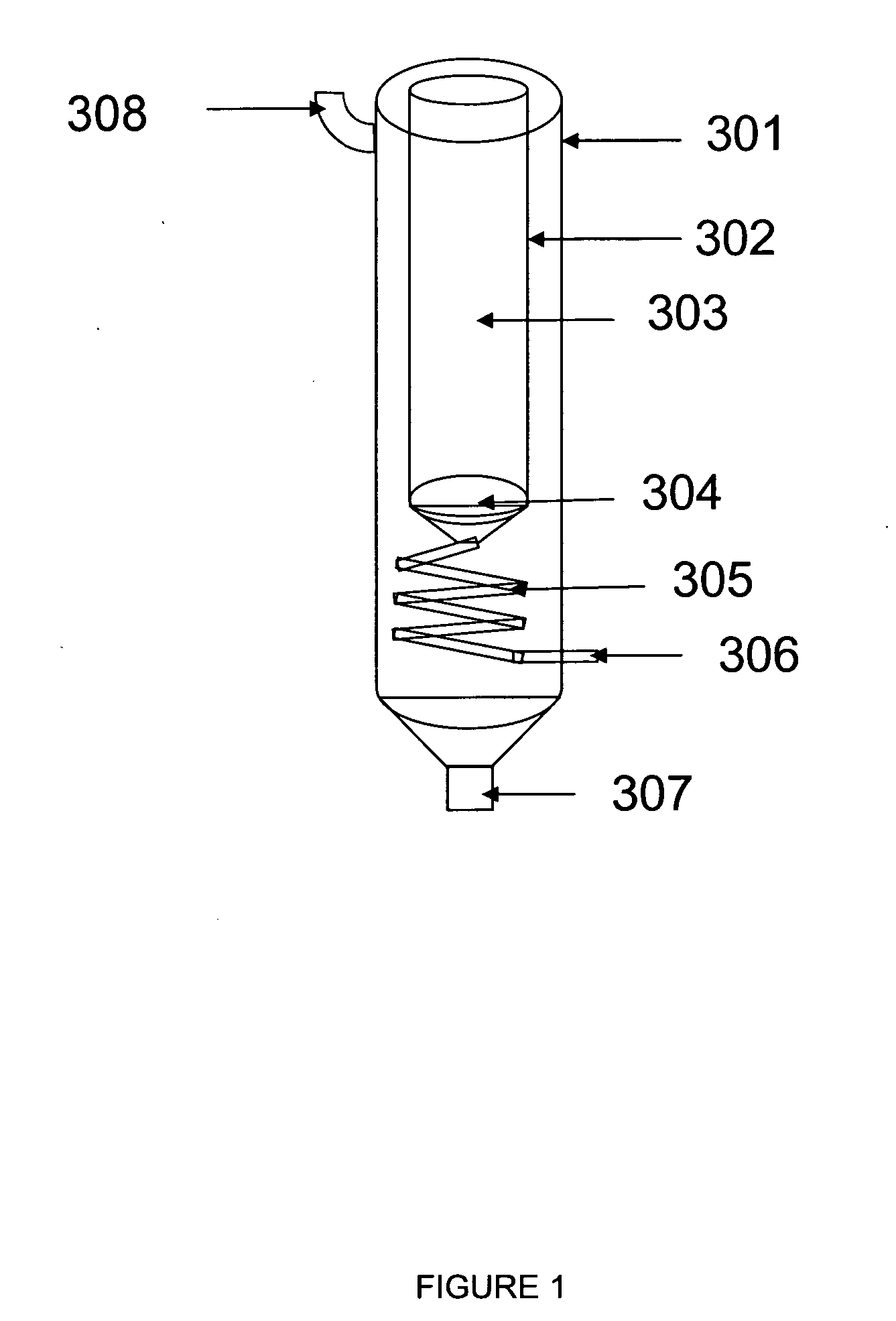

Removal of residual acetaldehyde from polyester polymer particles

In one embodiment, there is provided a process comprising introducing polyester polymer particles containing residual acetaldehyde into a vessel at a temperature within a range of 130° C. to 195° C. to form a bed of particles within the vessel, flowing a gas through at least a portion of the particle bed, and withdrawing finished particles from the vessel having a reduced amount of residual acetaldehyde. In this process, it is not necessary to introduce a hot flow of gas at high flow rates otherwise required to heat up cool particles to a temperature sufficient to strip acetaldehyde. Rather, this process provides a benefit in that, if desired, gas introduced into the vessel at low flow rates and low temperatures can nevertheless effectively strip acetaldehyde in a reasonable time because the hot particles quickly heat a the gas to the particle temperature.

Owner:ALPEK POLYESTER SA DE CV

Process for producing acetic acid

ActiveUS8940932B2Stable productionEfficient removalOrganic compound preparationCarboxylic preparation from carbon monoxide reactionAcetic acidBoiling point

A process for stably producing high purity acetic acid comprising a condensation step for condensing and temporarily holding the lower boiling component in a decanter and discharging from the decanter; and a step for separating the lower boiling component discharged from the decanter into acetaldehyde and a liquid residue and recycling the liquid residue to the reaction system. In the condensation step, the amount of the lower boiling component to be held is controlled based on the fluctuating flow rate of the lower boiling component to be fed to the decanter.

Owner:DAICEL CHEM IND LTD

Manufacturing method of copolyester for low acetaldehyde content of PET bottles

The present invention provides a manufacturing method of copolyester for low acetaldehyde content of PET bottles. The polyethylene terephthalate (PET) polymer is added with an appropriate modifier in order to decrease the production of acetaldehyde caused by pyrolysis side reaction during the blow molding process of PET bottles. The modifier comprises stabilizer and primary antioxidant, wherein the stabilizer is an inorganic phosphorous compound with an addition quantity of 0.003~0.5 weight % based on the weight of the total copolyester copolymer and the primary antioxidant is a hindered phenolic antioxidant containing Ca+2 with an addition quantity of 0.005~5.0 weight % based on the weight of the total copolyester copolymer. The present invention owns an improving effect of decreasing the production of side product-acetaldehyde at least 30% than those without the addition of said modifier.

Owner:NANYA PLASTICS CORP

Polyester polymer particles having a small surface to center molecular weight gradient

There is now provided a polyester polymer particle having an It.V., a surface, and a center, wherein the It.V. at the surface of the particle is less than 0.25 dL / g higher than the It.V. at the center of the particle. The polyester polymer particle is desirably crystalline to prevent the particles from sticking to each other while drying, and desirably contains less than 10 ppm acetaldehyde. A polyester container, preferably a preform or beverage bottle, is made by feeding crystallized polyester particles having an It.V. of at least 0.70 dL / g to an extrusion zone, melting the particles in the extrusion zone to form a molten polyester polymer composition, and forming a sheet or a molded part from extruded molten polyester polymer, wherein at least a portion of the polyester particles have an It.V. at their surface which does not vary from their It.V. at their center by more than 0.25 dL / g, and the particles have not been solid state polymerized. Such polyester compositions have an It.V. suitable for containers, yet lose less It.V. during melt processing than existing polyesters.

Owner:ALPEK POLYESTER SA DE CV

Methods for producing acetic acid

ActiveUS7683212B2Efficient productionReduce formationHydrogenOrganic compound preparationGas phaseReaction rate

Owner:DAICEL CHEM IND LTD

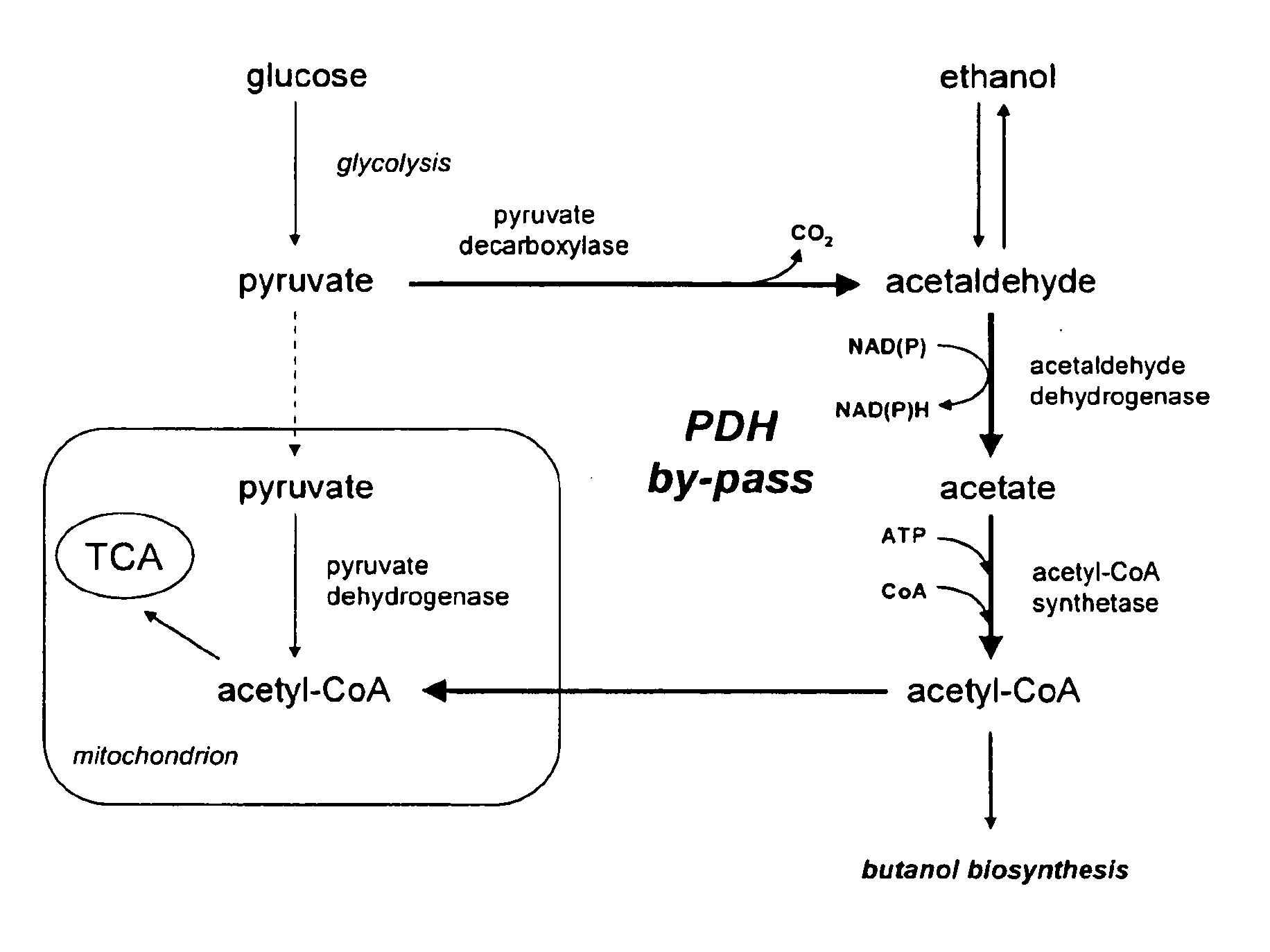

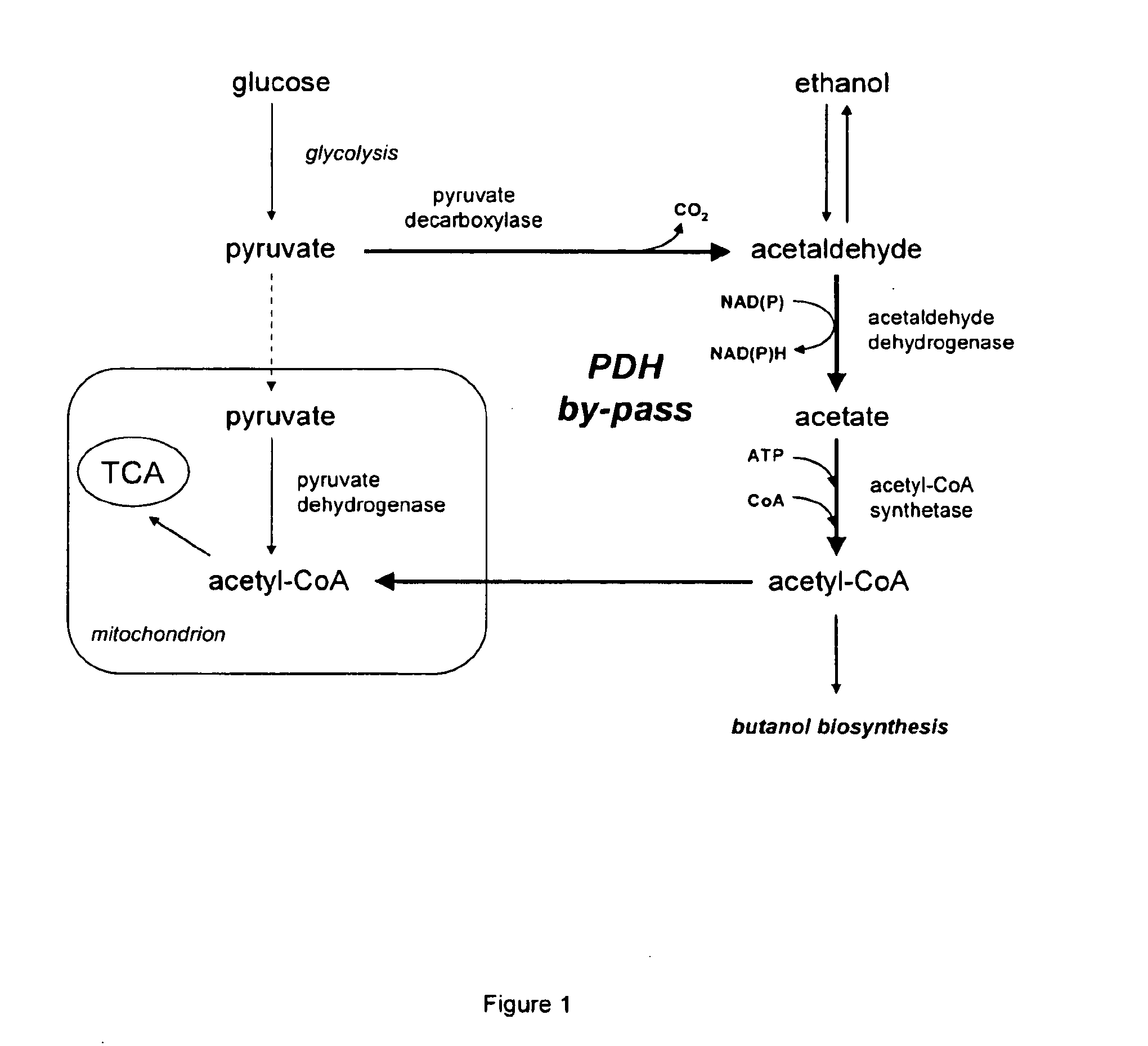

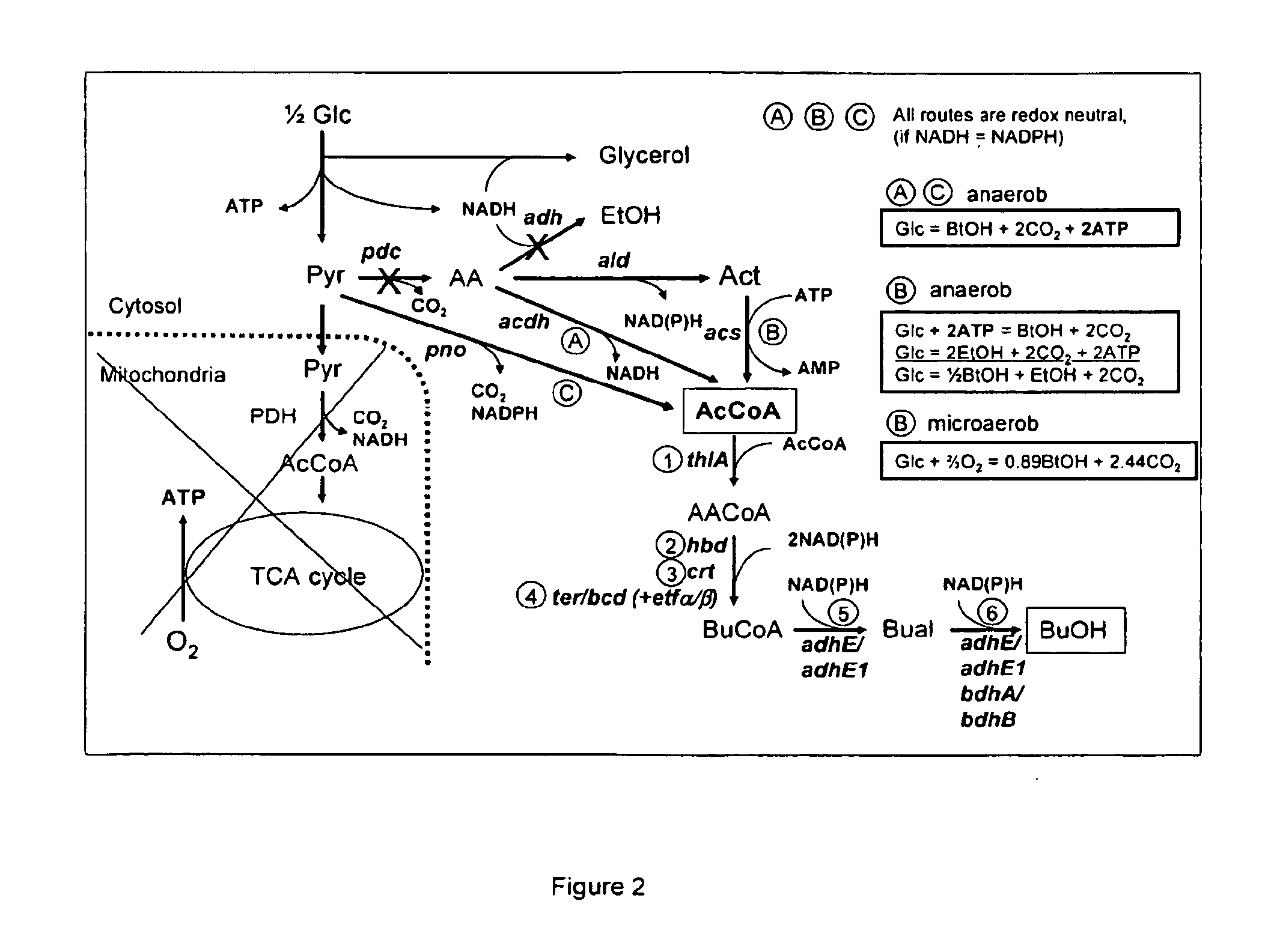

Acetyl-coa producing enzymes in yeast

InactiveUS20100248233A1Increase productionFungiMicrobiological testing/measurementHeterologousAcetyl Coenzyme A Synthetase

The present invention relates to a method of identifying a heterologous polypeptide having enzymatic activity for converting pyruvate, acetaldehyde or acetate into acetyl-CoA in (the cytosol of) a yeast cell comprising: a) providing a mutated yeast cell comprising a deletion of at least one gene of the (PDH) by-pass, selected from the genes encoding the enzymes pyruvate decarboxylase (PDC), acetaldehyde dehydrogenase (ALD), and acetyl-CoA synthetase (ACS); b) transforming said mutated yeast cell with an expression vector comprising a heterologous nucleotide sequence encoding a candidate polypeptide having potential enzymatic activity for converting pyruvate, acetaldehyde or acetate into acetyl-CoA; c) testing said recombinant mutated yeast cell for its ability to grow on minimal medium containing glucose as sole carbon source, and d) identifying said candidate polypeptide as a heterologous polypeptide having enzymatic activity for converting pyruvate, acetaldehyde or acetate into acetyl-CoA in (the cytosol of) said yeast cell when growth of said cell is observed. The invention further relates to a method of producing a fermentation production such as butanol.

Owner:DSM IP ASSETS BV

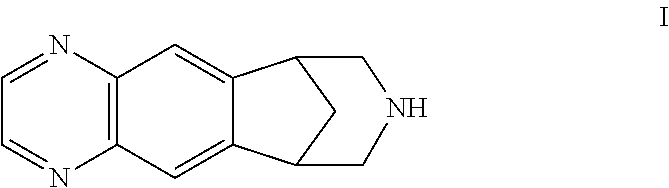

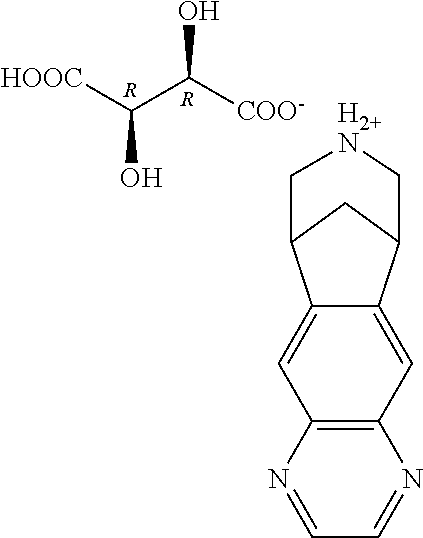

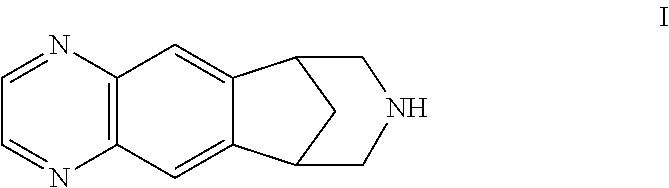

Process for preparing varenicline, varenicline intermediates, pharmaceutically acceptable salts thereof

Provided herein is an improved, convenient, commercially viable and environmentally friendly process for the preparation of varenicline or a pharmaceutically acceptable salt thereof comprising reacting 1-(4,5-diamino-10-aza-tricyclo[6.3.1.02 7]dodeca-2(7),3,5-trien-10-yl)-2,2,2-trifluoro-ethanone with chloroacetaldehyde in the presence of an oxygen source. Provided further herein is an improved and industrially advantageous process for the preparation of 1-(4,5-diamino-10-aza-tricyclo[6.3.1.02 7]dodeca-2(7),3,5-trien-10-yl)-2,2,2-trifluoro-ethanone.

Owner:ACTAVIS GRP PTC EHF

Low melting polyester polymers

ActiveUS20060046004A1Less energyShorten melting timeEnvelopes/bags making machineryLayered productsCarboxylic acidBottle

A bulk of polyester polymer particles comprising polyester polymer comprising greater than 75% virgin polyester polymer, the particles having: A) an It.V. of at least 0.72 dl / g, and B) 10 ppm or less of residual acetaldehyde; and C) at least two melting peaks, wherein one of said at least two melting peaks is a low peak melting point within a range of 140° C. to 220° C. and having a melting endotherm area of at least the absolute value of 1 J / g. The particles may also have a degree of crystallinity within a range of 20% and a maximum degree of crystallinity Tcmax defined by the equation: Tcmax=50%−CA−OH where CA is the total mole % of all carboxylic acid residues other than terephthalic acid residues, based on 100 mole % of carboxylic acid residues, and OH is the total mole % of all hydroxyl functional compound residues other than ethylene glycol residues, based on 100 mole % of hydroxyl functional compounds residues. The preforms and bottles made from these particles can be obtained by melt processing these particles at either lower overall power, faster screw speeds, lower residence time, or lower overall cycle time to thereby reduce the level of residual acetaldehyde generated in the melt.

Owner:ALPEK POLYESTER SA DE CV

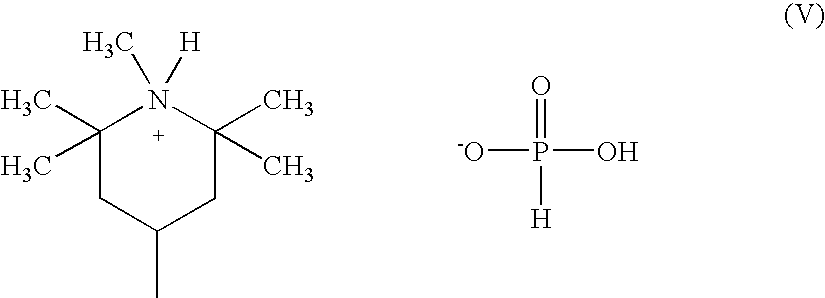

Gas delivery pipeline drag reducer and preparation thereof

The invention relates to a gas conveying pipeline drag reducer used in gas and particularly natural gas conveying pipeline drag reduction and a preparation method thereof, relating to a macromolecular compound composition and the pipeline system technical field. The gas conveying pipeline drag reducer is characterized in that: the drag reducer consists of pyridine, secondary amine, formaldehyde or acetaldehyde, aromatic acid and deionized water; when total weight is counted as 100 percent, the compositions in percentage by weight are: 10 to 20 percent of the pyridine, 20.4 to 28.4 percent of the secondary amine, 7.6 to 8.4 percent of the formaldehyde or the acetaldehyde, 37 to 38.4 percent of the aromatic acid and 13 to 15 percent of the deionized water. The preparation method comprises the following steps that: the pyridine and the secondary amine in proportional quantities are added in a container and are mixed evenly; the formaldehyde or the acetaldehyde in proportional quantity is dripped to carry out reaction; the aromatic acid in proportional quantity is added, and the deionized water in proportional quantity is dripped so as to carry out reaction continuously; and finally, redundant water is removed, and a target product is obtained after purification. The gas conveying pipeline drag reducer has direct source of raw materials; moreover, the preparation method has simple process, convenient operation and moderate reaction conditions, and a product prepared by the method has excellent drag reduction effect.

Owner:PIPECHINA SOUTH CHINA CO

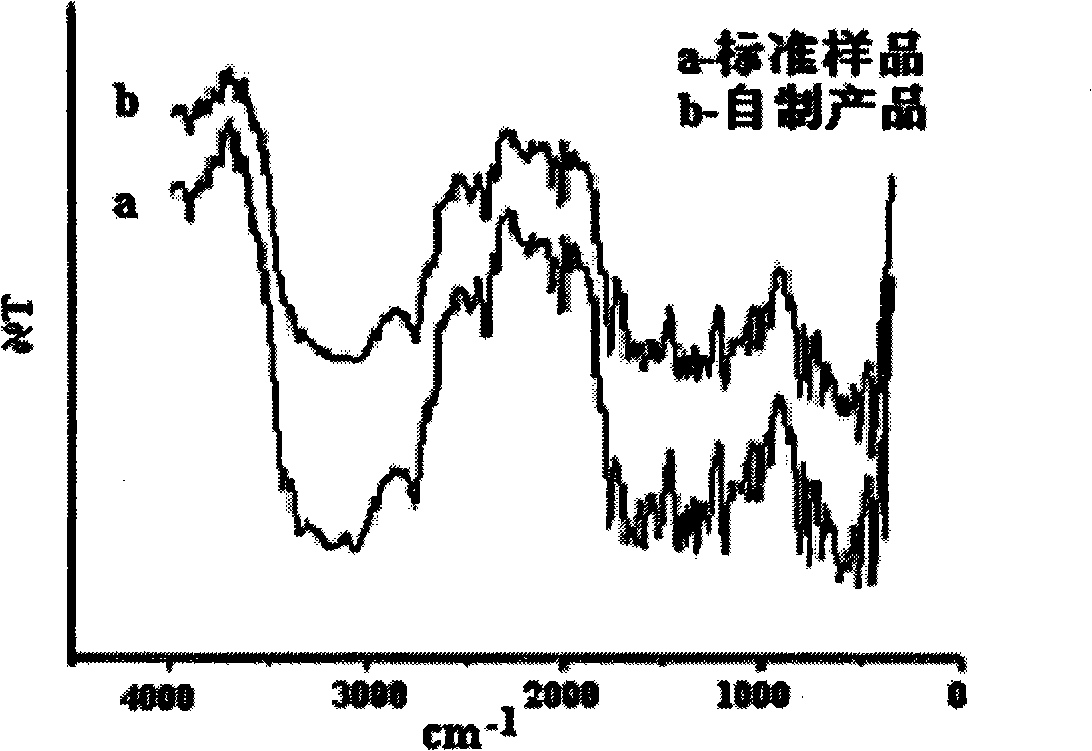

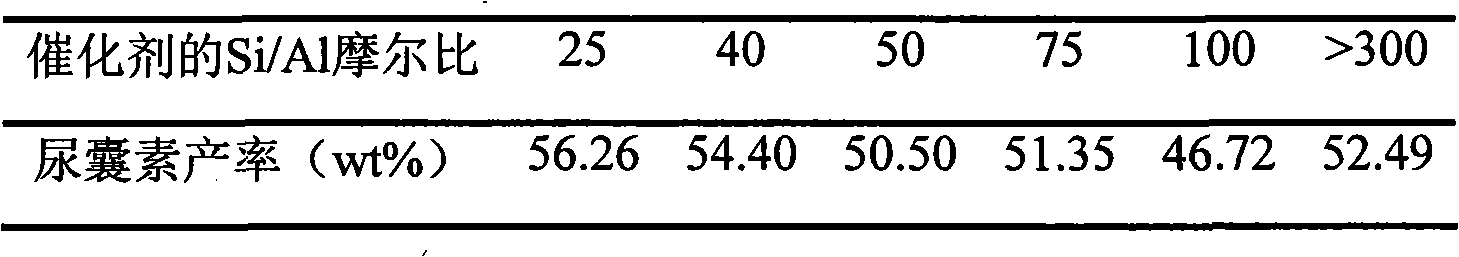

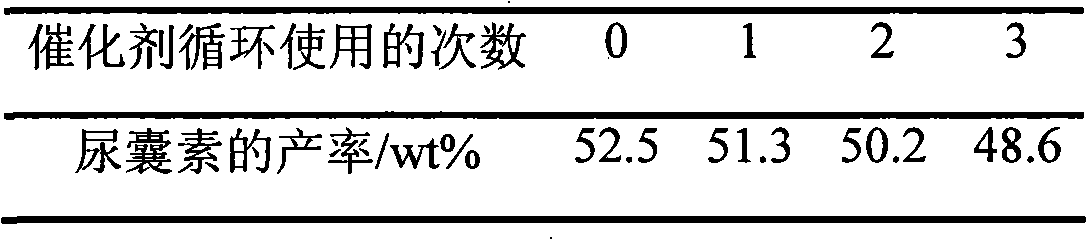

Solid acid catalyst and reaction technique for synthesis of allantoin

InactiveCN101347739AHigh activityImprove stabilityOrganic chemistryMolecular sieve catalystsRare-earth elementSolid acid

The invention relates to a catalyst for synthesis of allantoin by the reaction of glyoxylic acid and urea and a corresponding reaction process. The catalyst is the solid acid catalyst and takes one or the combination of more of oxides and molecular sieves of IVB to VIB elements as a carrier, or a complex which is composed of one or the combination of more of the oxides and the molecular sieves of IVB to VIB elements and one or the combination of more of the oxides of IB, IIB, VIIB, VIIIB and rare earth element as the carrier, and the carrier is carried out the impregnation supporting, the drying and the calcination by using inorganic strong acid or ammonium salt solution thereof for the preparation. The use of the catalyst can synthesize an allantoin product by one-step reaction of the glyoxylic acid and the urea in an atmospheric pressure tank reactor. The catalyst of the invention has the advantages of high activity and stability, recyclable property, no corrosion of the device and environmental pollution, etc. The synthesis reaction process of the allantoin has the advantages of simple process, less using amount of the catalyst, short reaction time and high yield of the allantoin, etc.

Owner:HUNAN UNIV

Composition for stimulation of specific metallo-enzymes

A stable composition preferably a refreshing drink for accelerating degradation of alcohol and acetaldehyde in the body, comprises synergistic combination of caffeine, herbs and fructose. Preferably, the composition comprises, Caffeine, Guaranà caffeine, Yerba Matè, Eleutherococcus senticous, Panax ginseng, ginger, Glycyrrhiza glabra (Liquorice Root), fructose and additional ingredients (sugars, flavourings, colourings, vitamins, stabilisers, whole fruit powder and the like), and optionally ginkgo biloba.

Owner:ZOBRIUS PHARMA AS

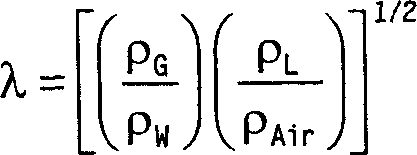

Control method for process of removing permanganate reducing compounds from methanol carbonylation process

ActiveUS20050197513A1Organic compound preparationCarbonyl compound preparationAcetic acidDistillation

Disclosed is a method of controlling a separation process for removing moving permanganate reducing compounds from a process stream in the methanol carbonylation process for making acetic acid, where the method includes the steps of measuring the density of a stream containing acetaldehyde and methyl iodide, optionally calculating the relative concentrations of acetaldehyde and methyl iodide in the stream, and adjusting distillation or extraction process parameters based on the measured density or one or more relative concentrations calculated therefrom.

Owner:CELANESE INT CORP

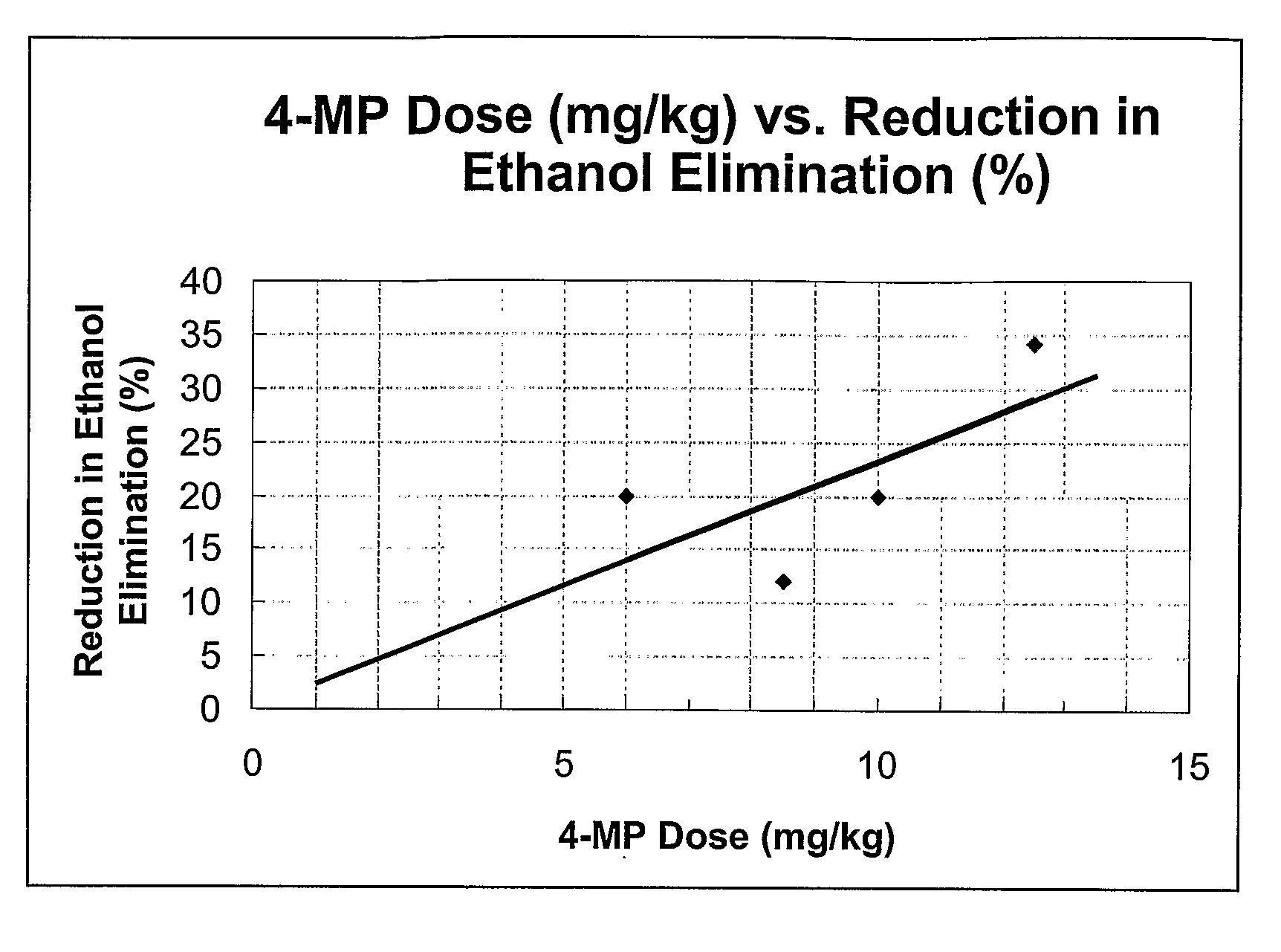

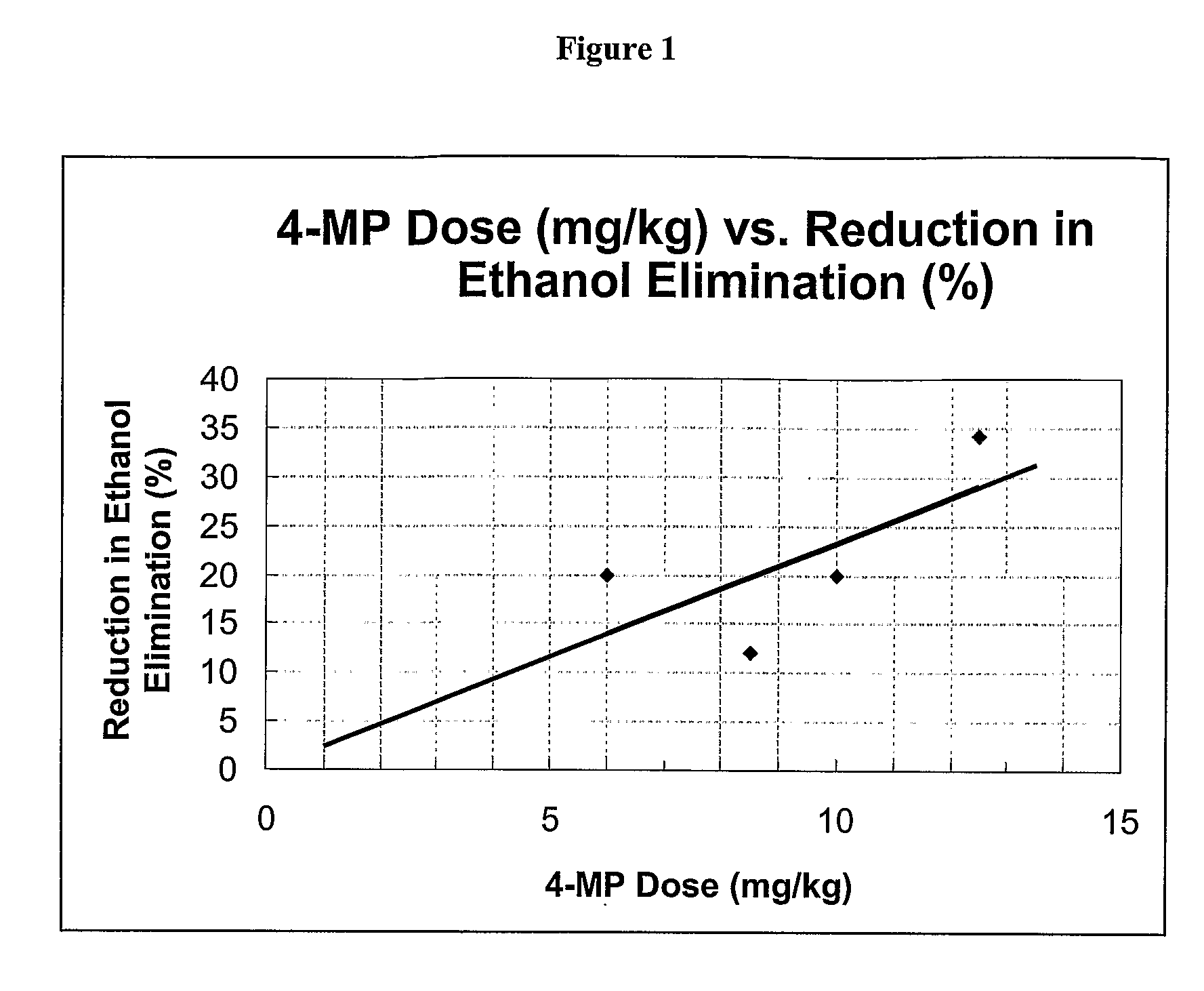

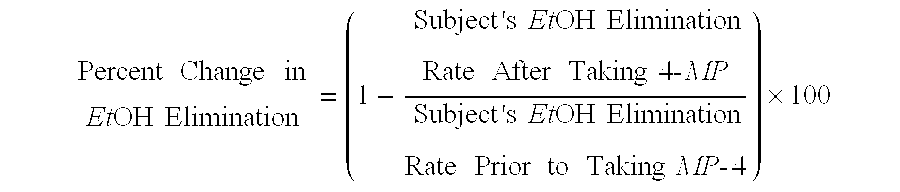

4-Methylpyrazole Formulations for Inhibiting Ethanol Intolerance

InactiveUS20080021083A1Avoid symptomsReducing ALDH activityOrganic active ingredientsBiocideMedicineAcetaldehyde

Methods, articles of manufacture and compositions are provided useful for the prevention or amelioration of a symptom of acetaldehyde accumulation or ethanol intolerance in a subject with reduced or absent reduced or absent aldehyde dehydrogenase subtype 2 (ALDH2) activity wherein about 1 mg / kg to about 4 mg / kg 4-methylpyrazole, or an equivalent mass of a 4-MP salt, are to be orally administered to the subject.

Owner:RAPTOR PHARMA

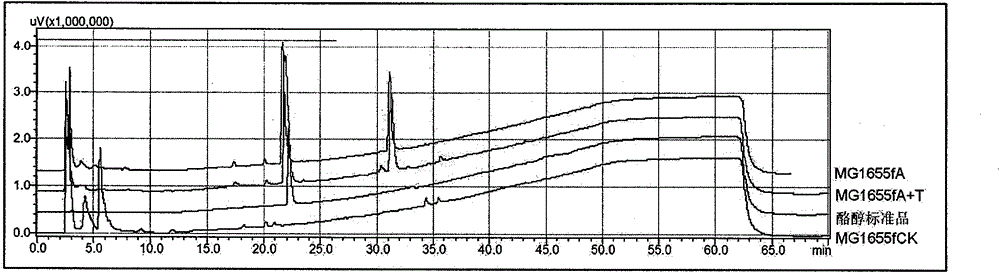

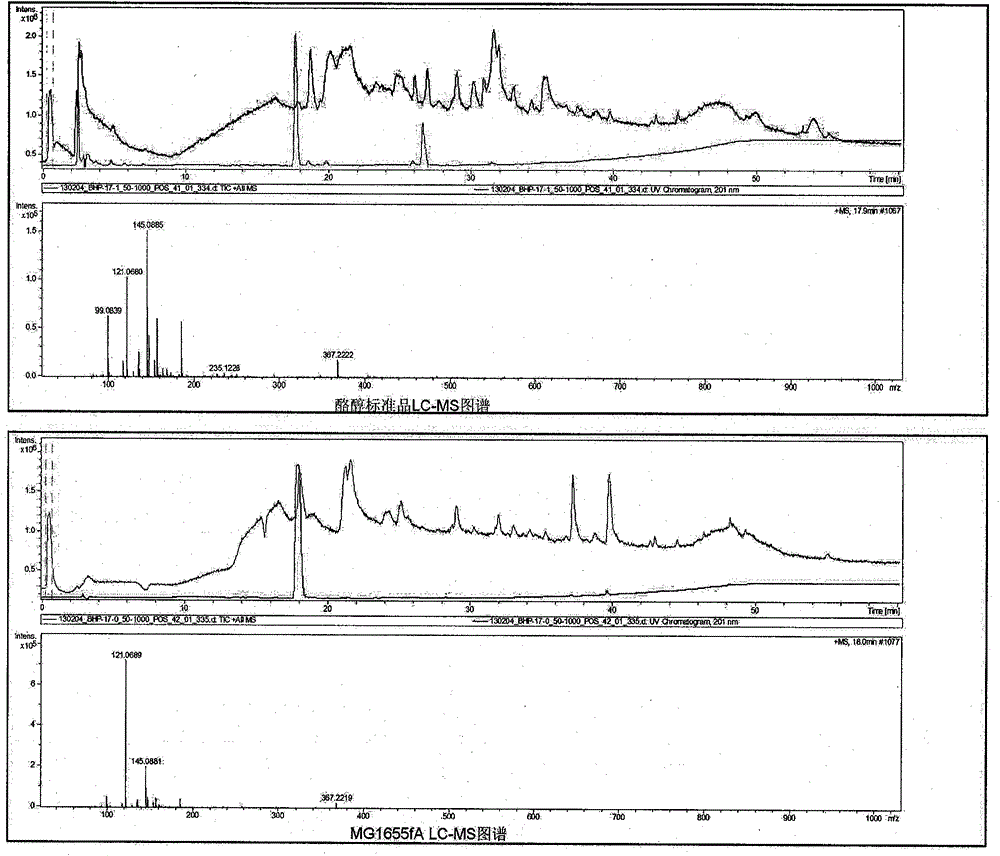

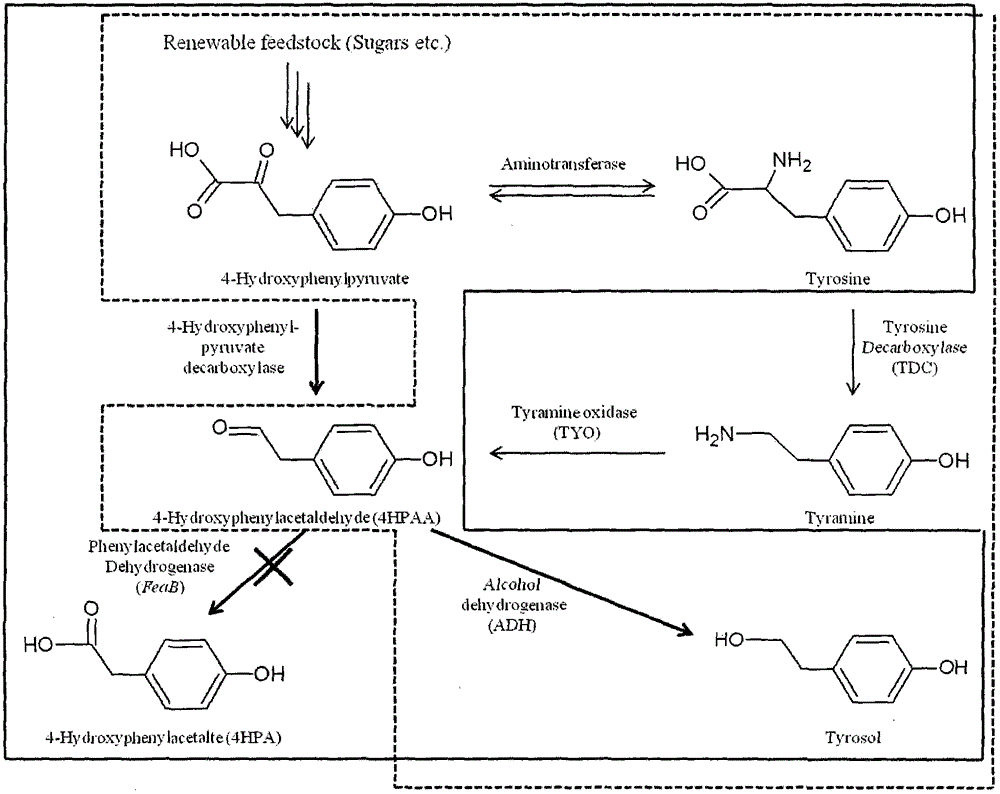

Method for biosynthesis of tyrosol in Escherichia coli and application of tyrosol

ActiveCN104099379ABacteriaMicroorganism based processesEscherichia coliPhenylacetaldehyde dehydrogenase

The invention relates to a method for biosynthesis of tyrosol in Escherichia coli and application of tyrosol, which belongs to the field of bioengineering technology. According to the method for biosynthesis of tyrosol in Escherichia coli, tyrosine or glucose is used as a substrate, (4-hydroxyphenyl)pyruvic acid is produced under the catalysis of ammonialyase coded by Escherichia coli; (4-hydroxyphenyl)acetaldehyde is produced under the action of the microzyme 4-hydroxyphenylpyruvate decarboxylase; (4-hydroxyphenyl)acetaldehyde is catalyzed by alcohol dehydrogenase so as to produce tyrosol; and a phenylacetaldehyde dehydrogenase gene of Escherichia coli is knocked out at the same time so as to block the transformation channel for (4-hydroxyphenyl)acetaldehyde into (4-hydroxyphenyl)acetic acid and promote accumulation of (4-hydroxyphenyl)acetaldehyde and transformation of (4-hydroxyphenyl)acetaldehyde into tyrosol. The invention provides a novel production approach for tyrosol; and the method lays a foundation for large-scale industrial production of tyrosol and has important economic values and social benefits.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com