Patents

Literature

56 results about "Particle temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

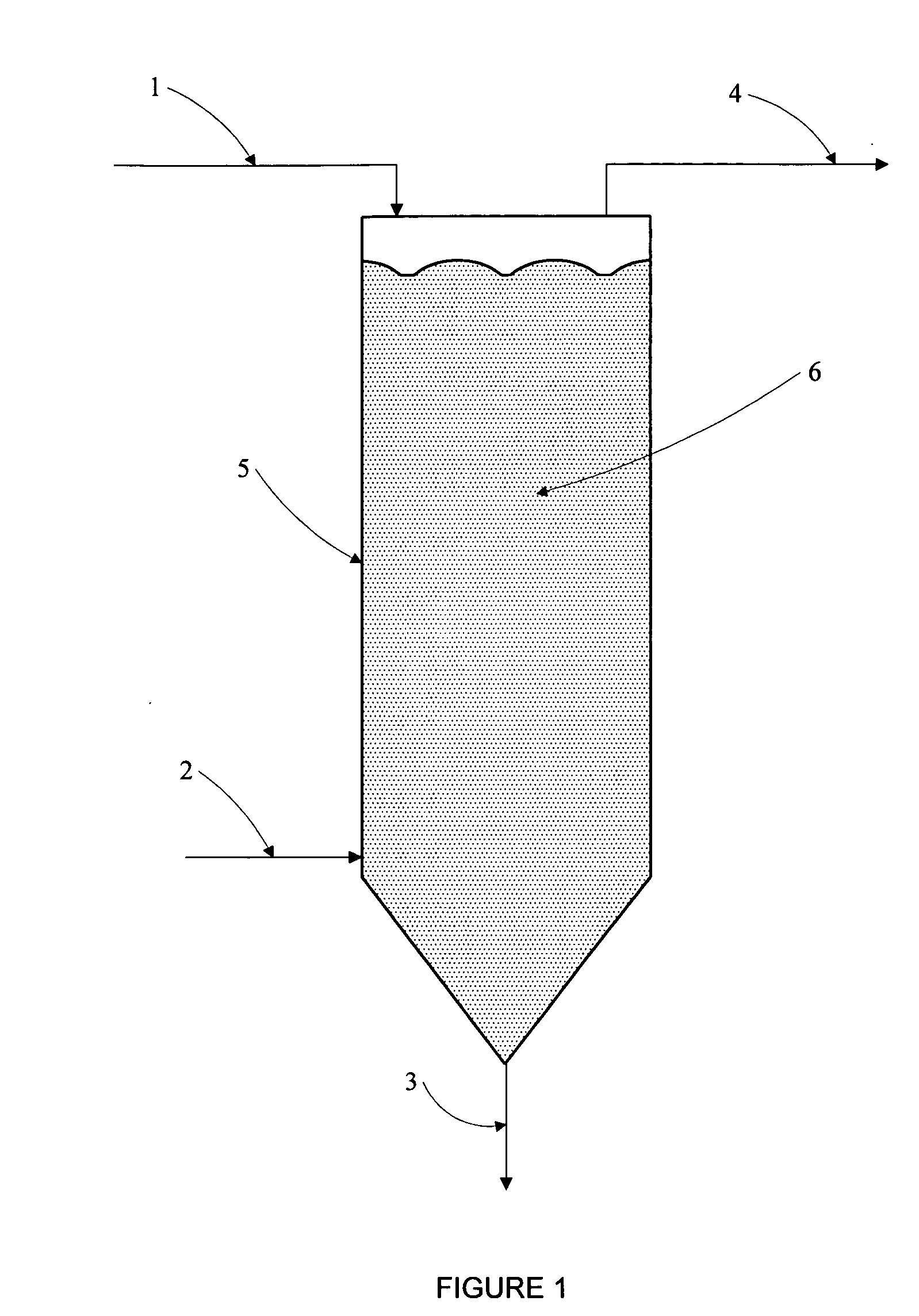

Removal of residual acetaldehyde from polyester polymer particles

In one embodiment, there is provided a process comprising introducing polyester polymer particles containing residual acetaldehyde into a vessel at a temperature within a range of 130° C. to 195° C. to form a bed of particles within the vessel, flowing a gas through at least a portion of the particle bed, and withdrawing finished particles from the vessel having a reduced amount of residual acetaldehyde. In this process, it is not necessary to introduce a hot flow of gas at high flow rates otherwise required to heat up cool particles to a temperature sufficient to strip acetaldehyde. Rather, this process provides a benefit in that, if desired, gas introduced into the vessel at low flow rates and low temperatures can nevertheless effectively strip acetaldehyde in a reasonable time because the hot particles quickly heat a the gas to the particle temperature.

Owner:ALPEK POLYESTER SA DE CV

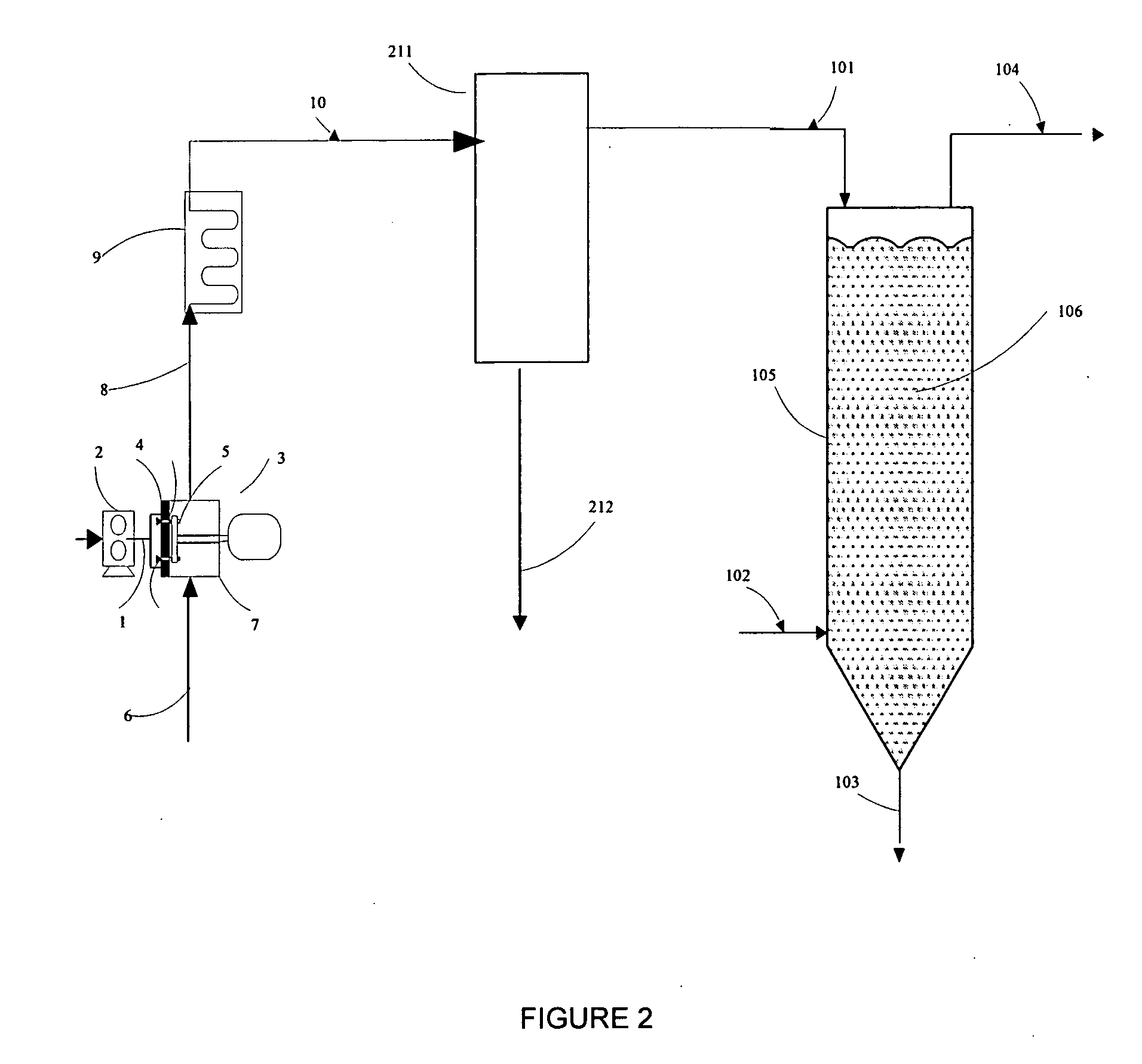

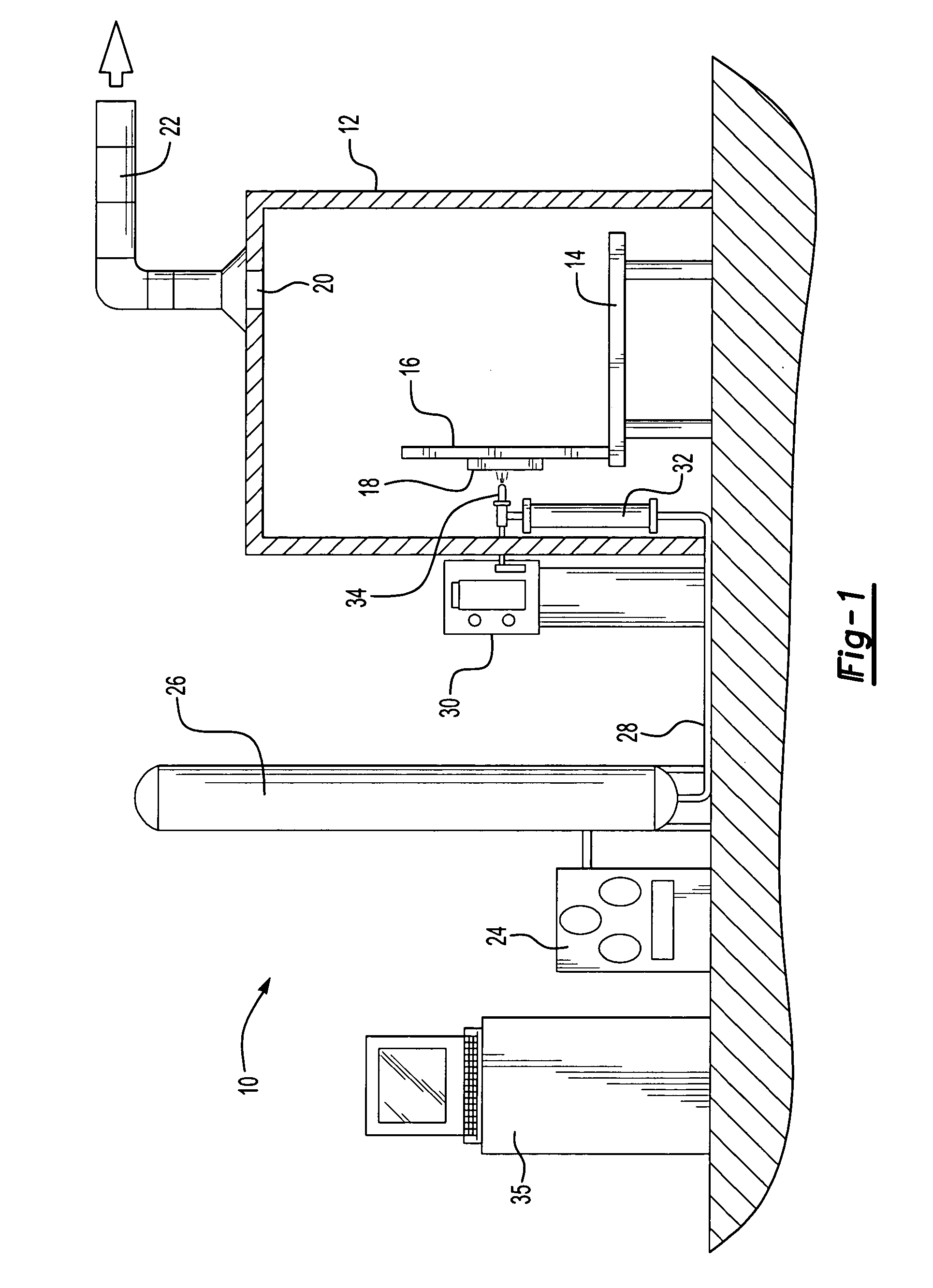

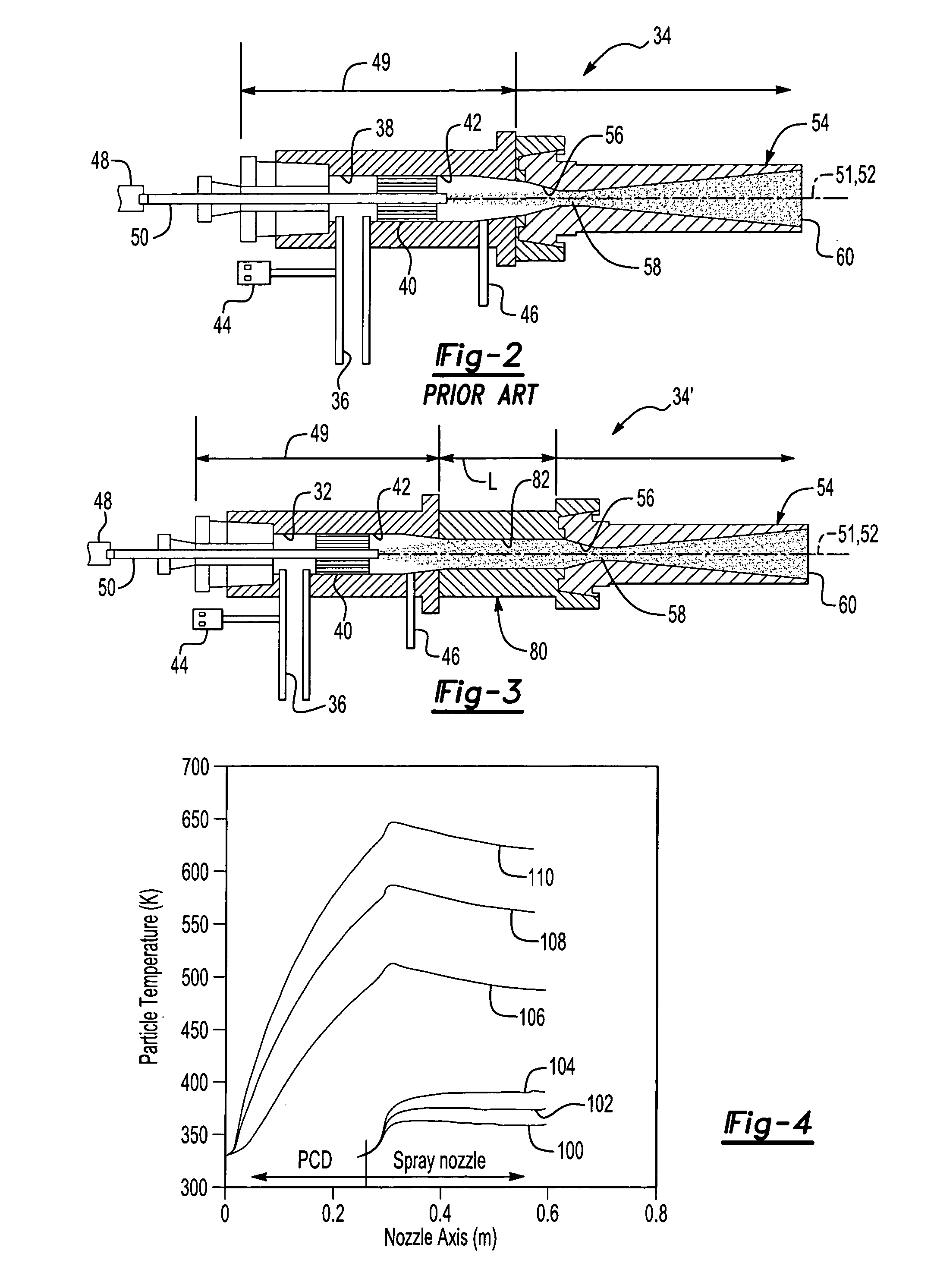

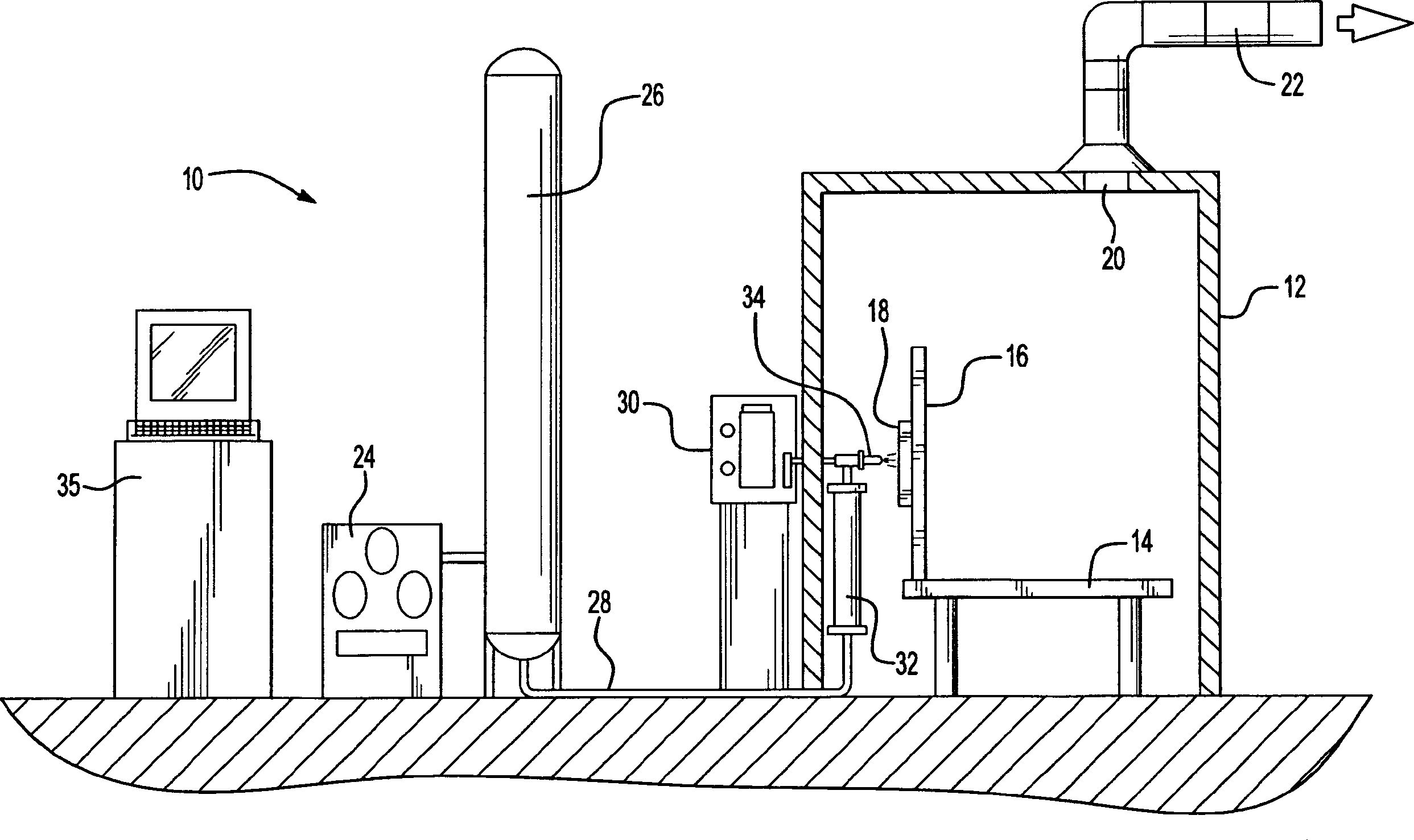

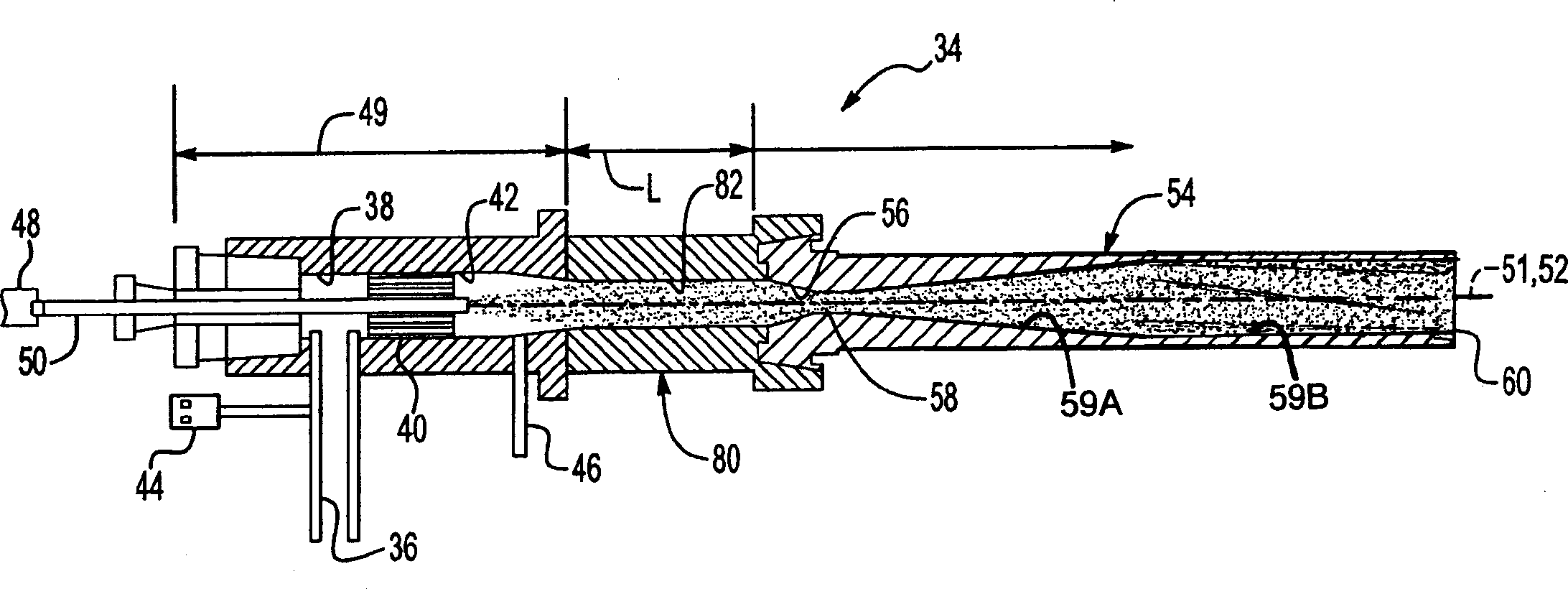

Kinetic spray nozzle system design

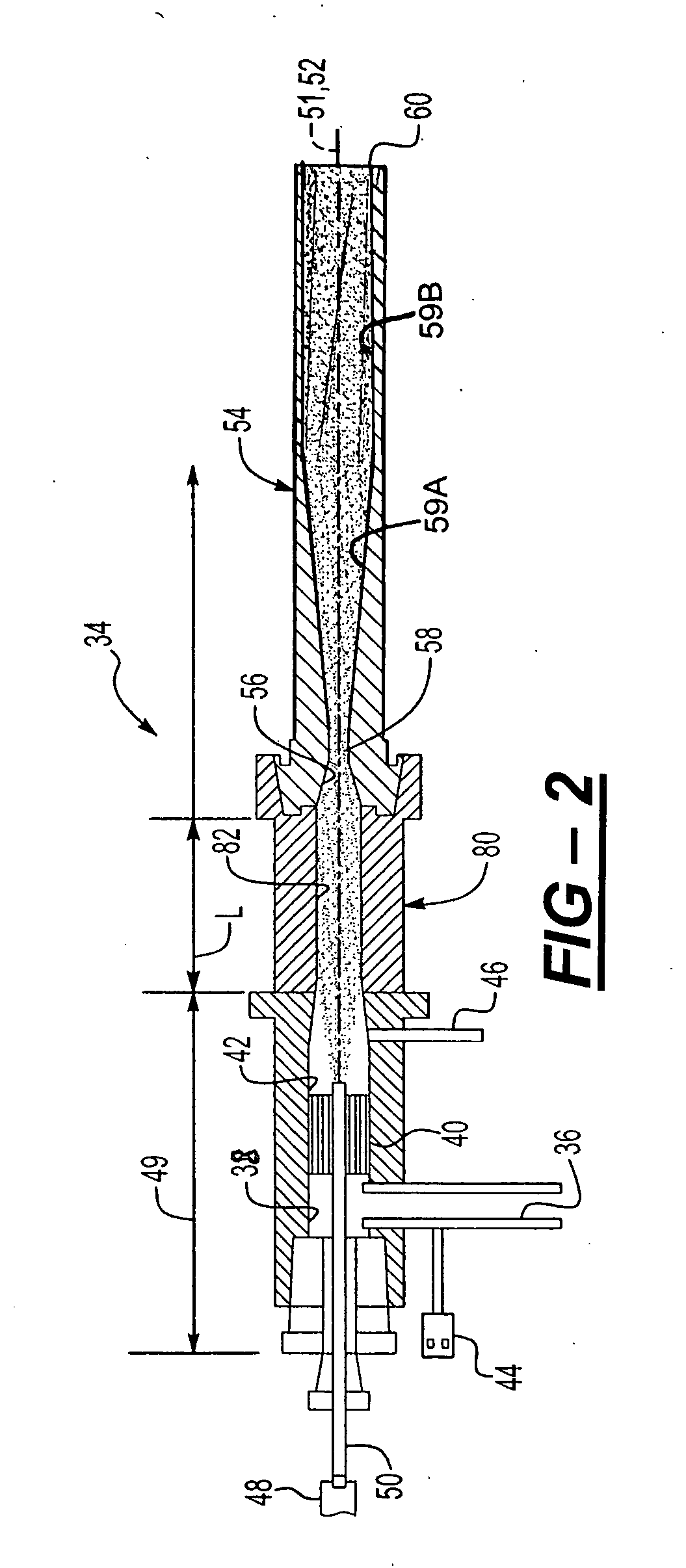

InactiveUS20050214474A1Molten spray coatingLiquid/solution decomposition chemical coatingSystems designSpray nozzle

An improved kinetic spray nozzle system is disclosed in addition to improved methods for injection particle powders into a nozzle. Utilization of the nozzle enables one to dramatically increase the deposition efficiency of a variety of particles using a kinetic process. The improved nozzle includes a powder / gas conditioning chamber that increases the particle residence time within the nozzle enabling one to achieve higher particle temperatures prior to their acceleration in the supersonic portion of the kinetic spray nozzle.

Owner:DELPHI TECH INC

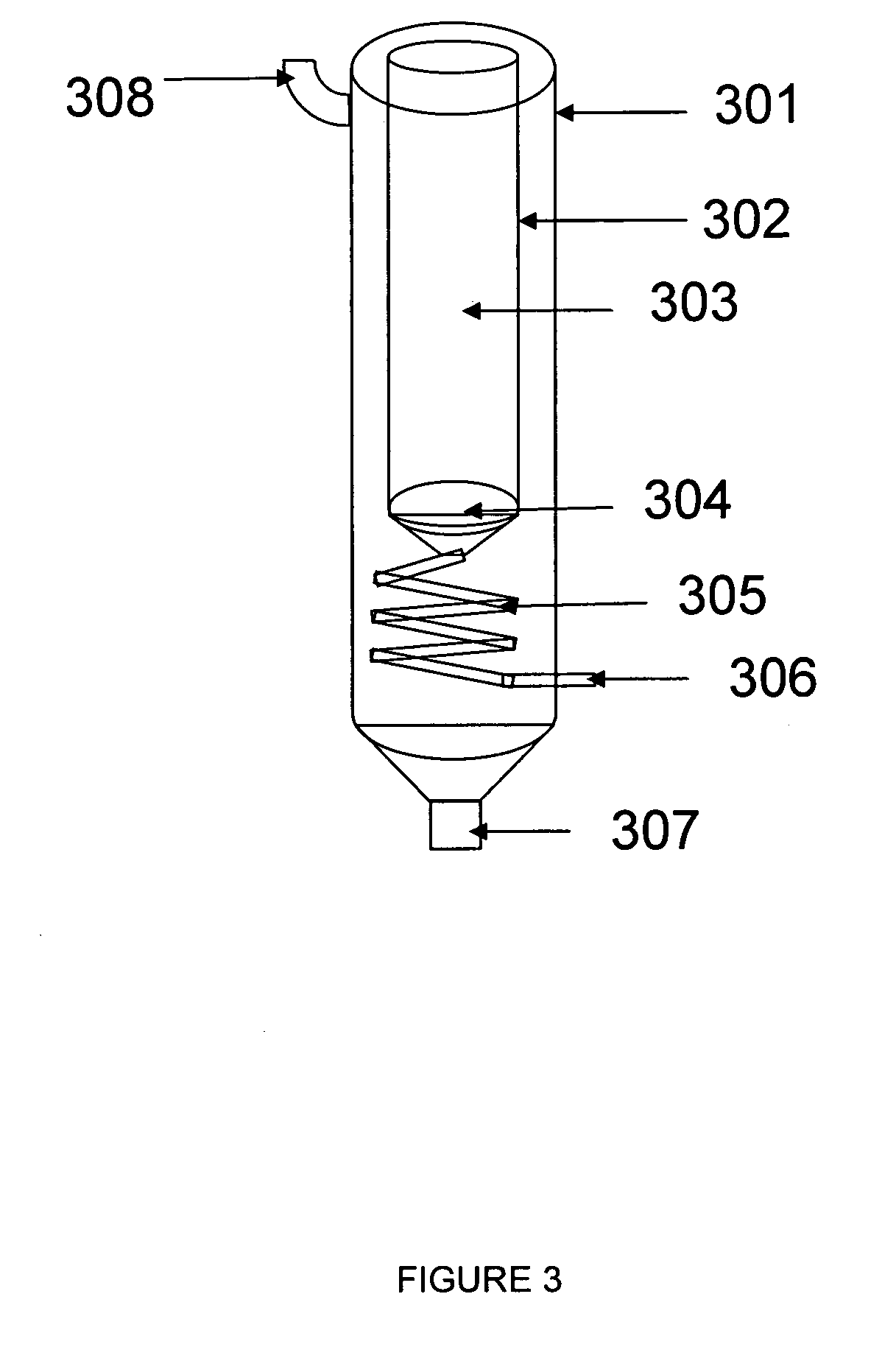

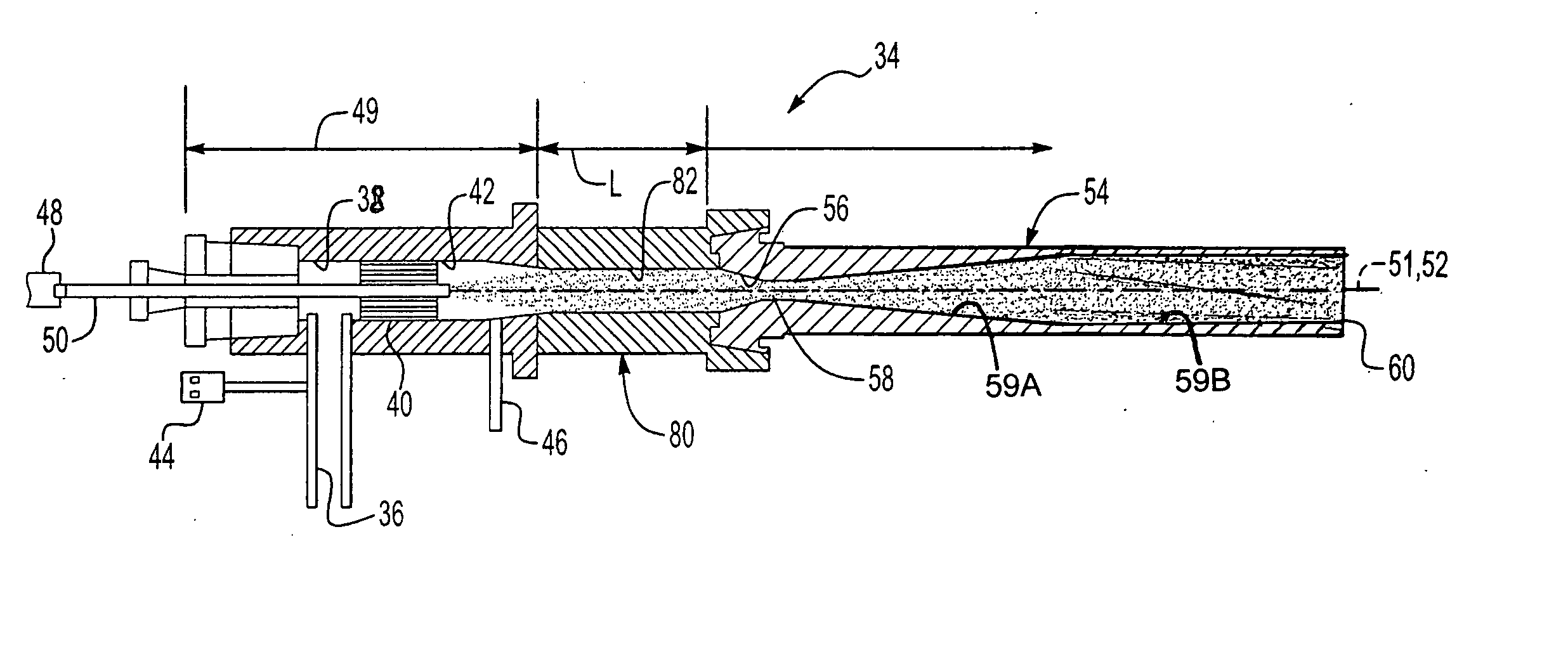

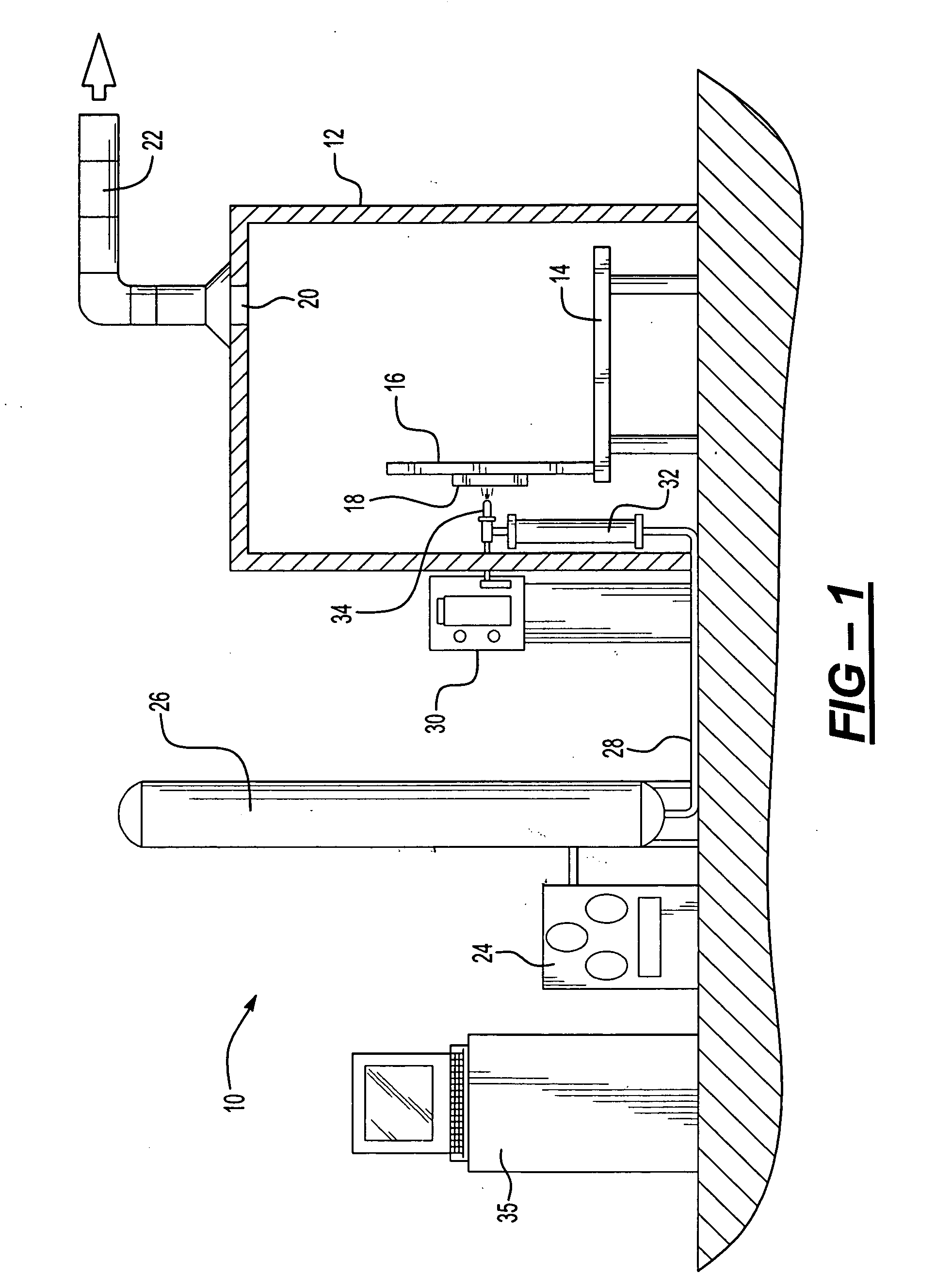

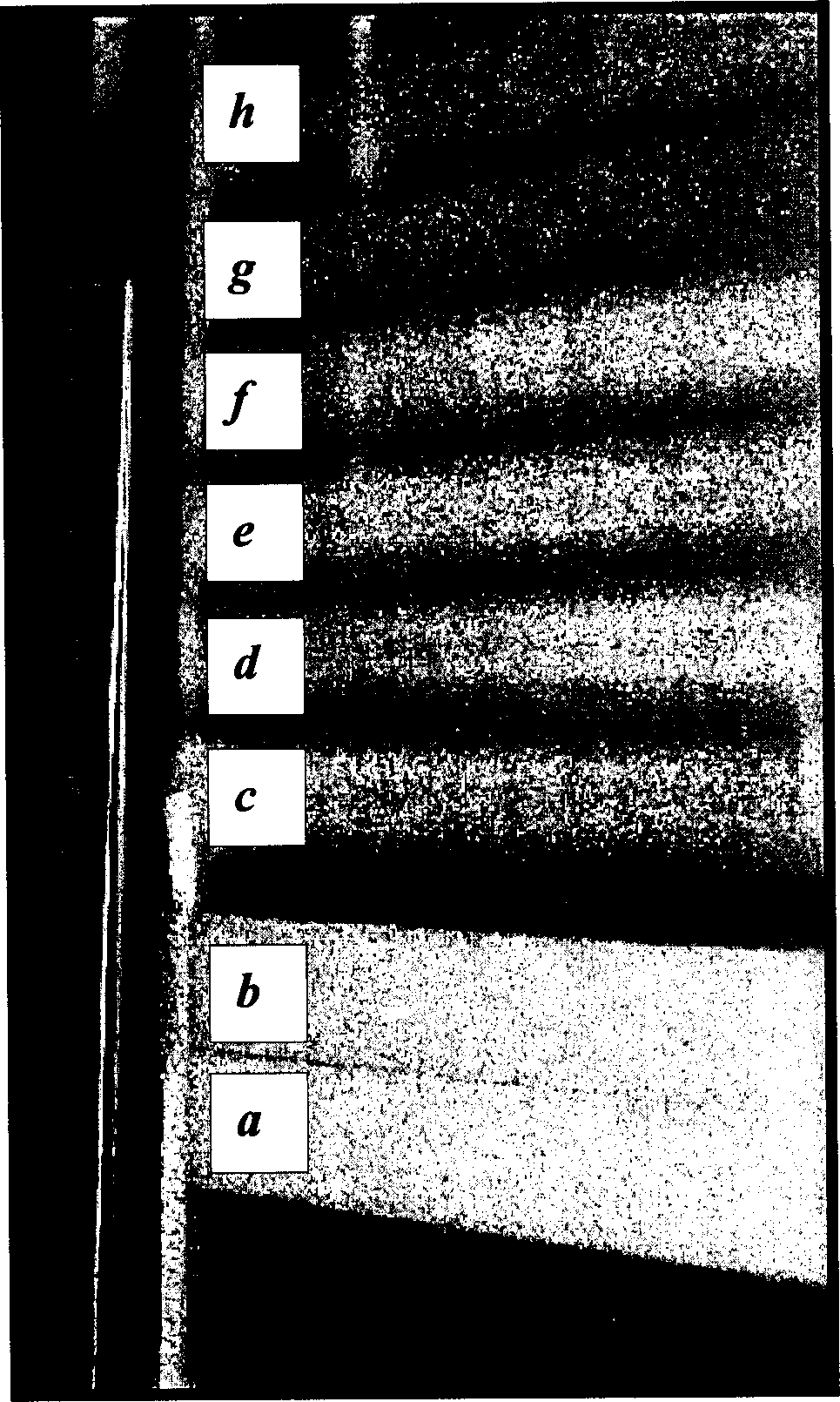

Continuous in-line manufacturing process for high speed coating deposition via a kinetic spray process

InactiveUS20060040048A1Constant cross-sectional areaMolten spray coatingPretreated surfacesSpray coatingEngineering

An improved kinetic spray system and a method for using the same in a high speed manufacturing environment are disclosed. The improved kinetic spray nozzle system comprises: a gas / powder exchange chamber connected to a first end of a powder / gas conditioning chamber having a length along a longitudinal axis of equal to or greater than 20 millimeters; a converging diverging supersonic nozzle, the supersonic nozzle having a converging section separated from a diverging section by a throat, the diverging section comprising a first portion and a second portion, with the first portion having a cross-sectional area that increases along a length of the first portion and with the second portion having a substantially constant cross-sectional area along a length of the second portion; and the converging section connected to a second end of the powder / gas conditioning chamber opposite the first end. The method includes: use of the disclosed nozzle system with the addition of hard particles that permit maximum enhancement of particle temperature while not permitting clogging of the nozzle; use of controlled particle feed rates to match the desired very high traverse speeds; and use of pre-heating of the substrate to clean it an to enhance particle bonding. With the disclosed nozzle system coupled with the disclosed methods one can apply kinetic spray coatings at traverse speeds of over 200 centimeters per second with a deposition efficiency of over 80 percent.

Owner:F W GARTNER THERMAL SPRAYING

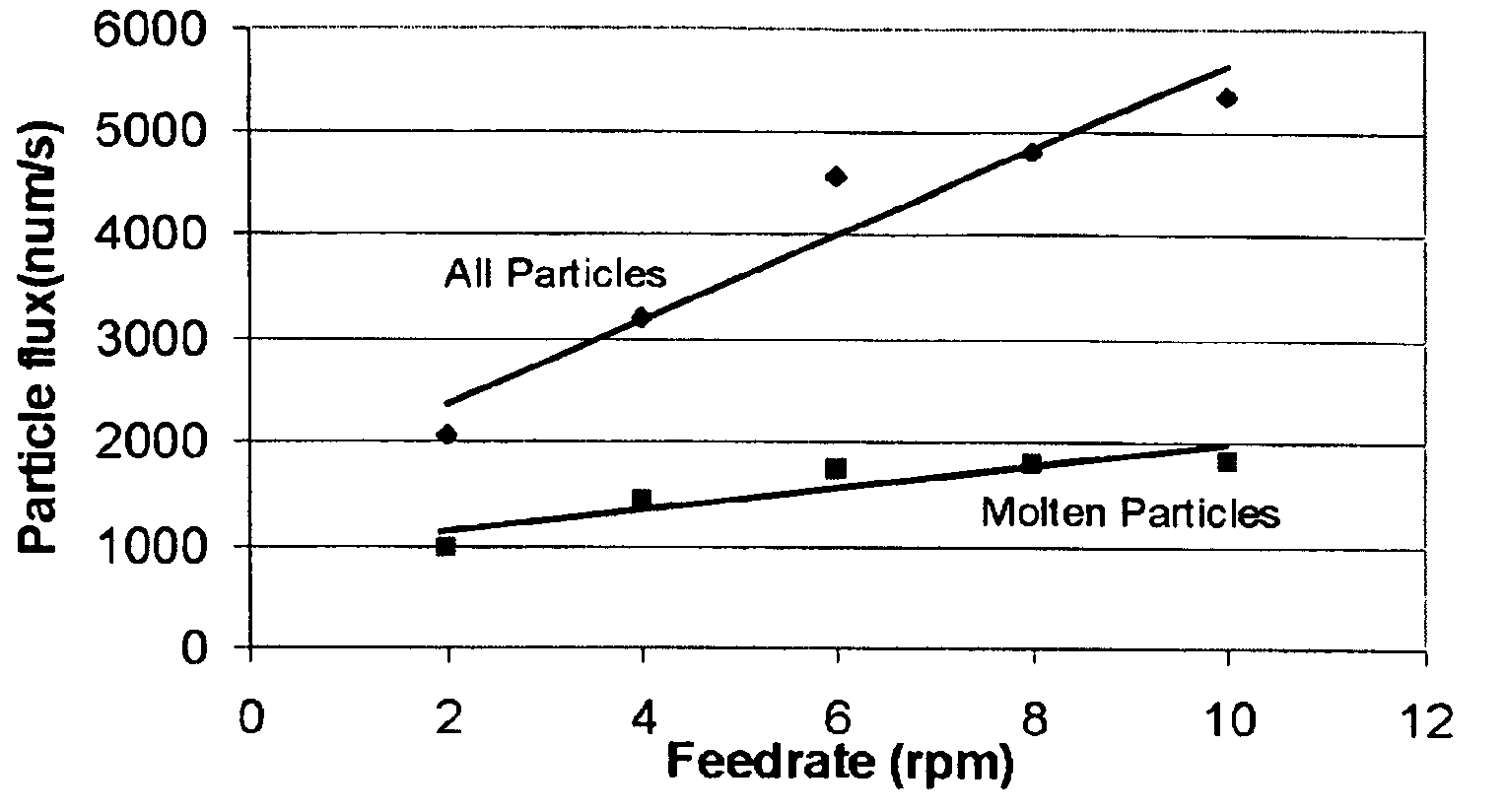

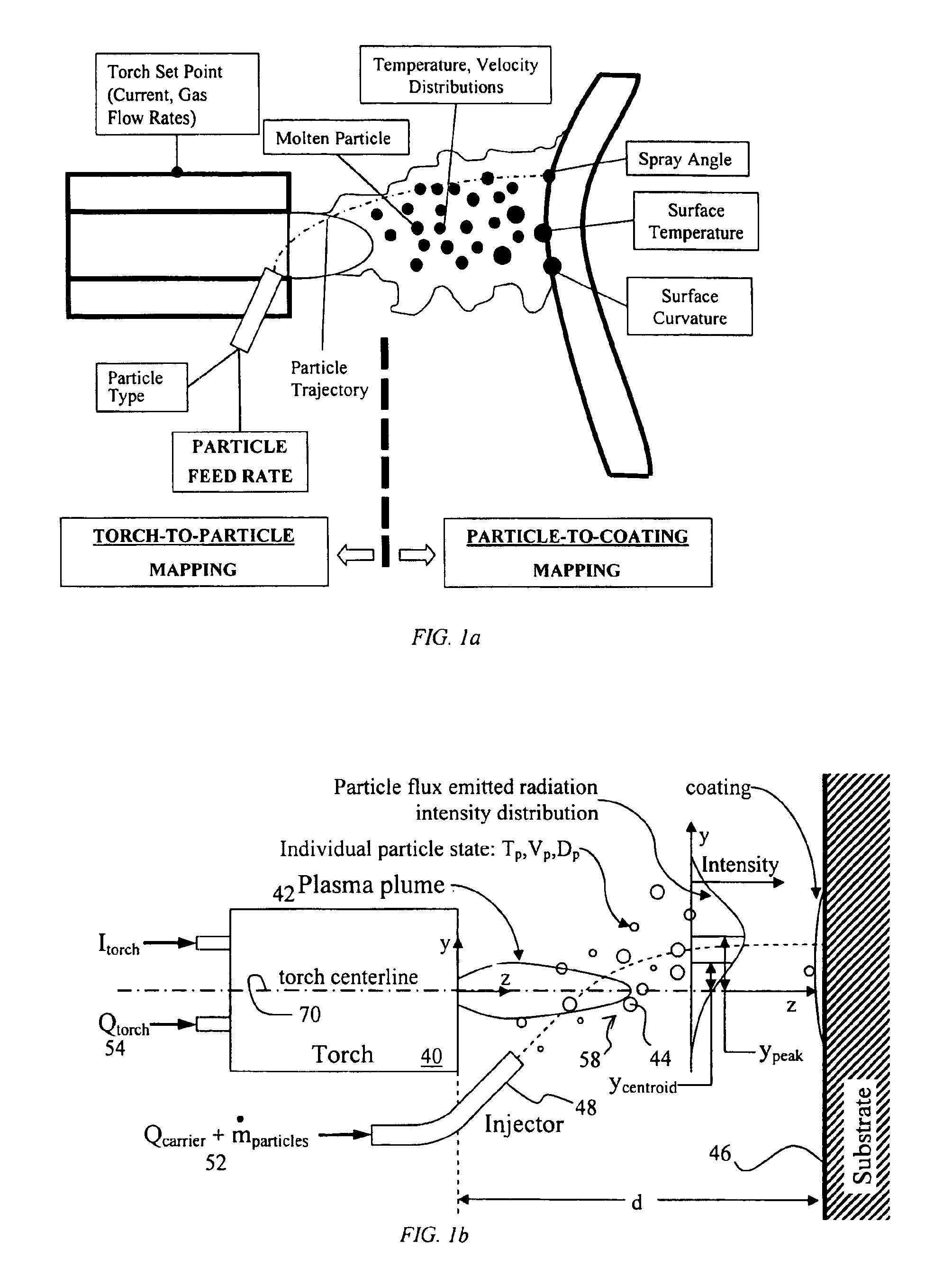

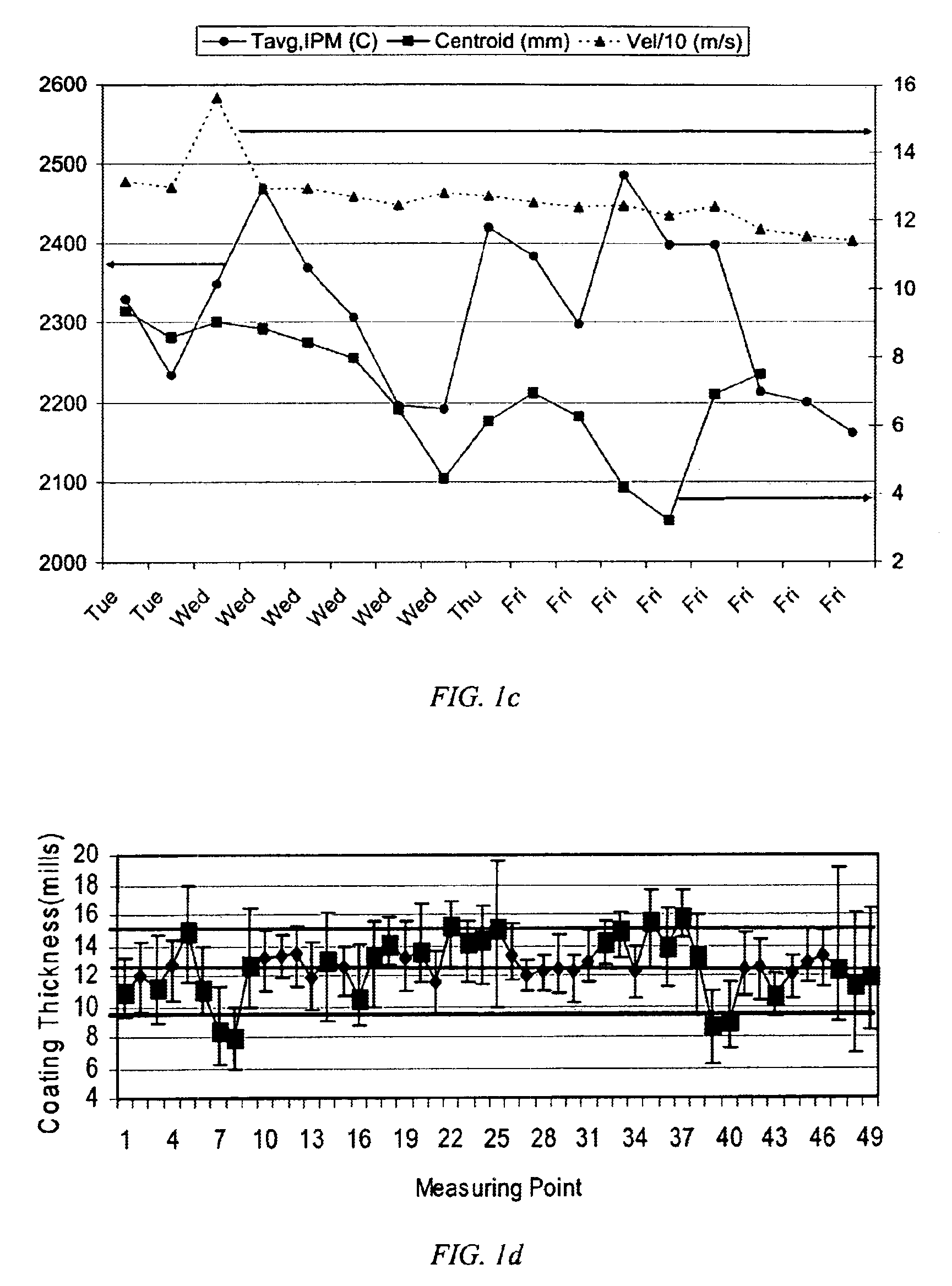

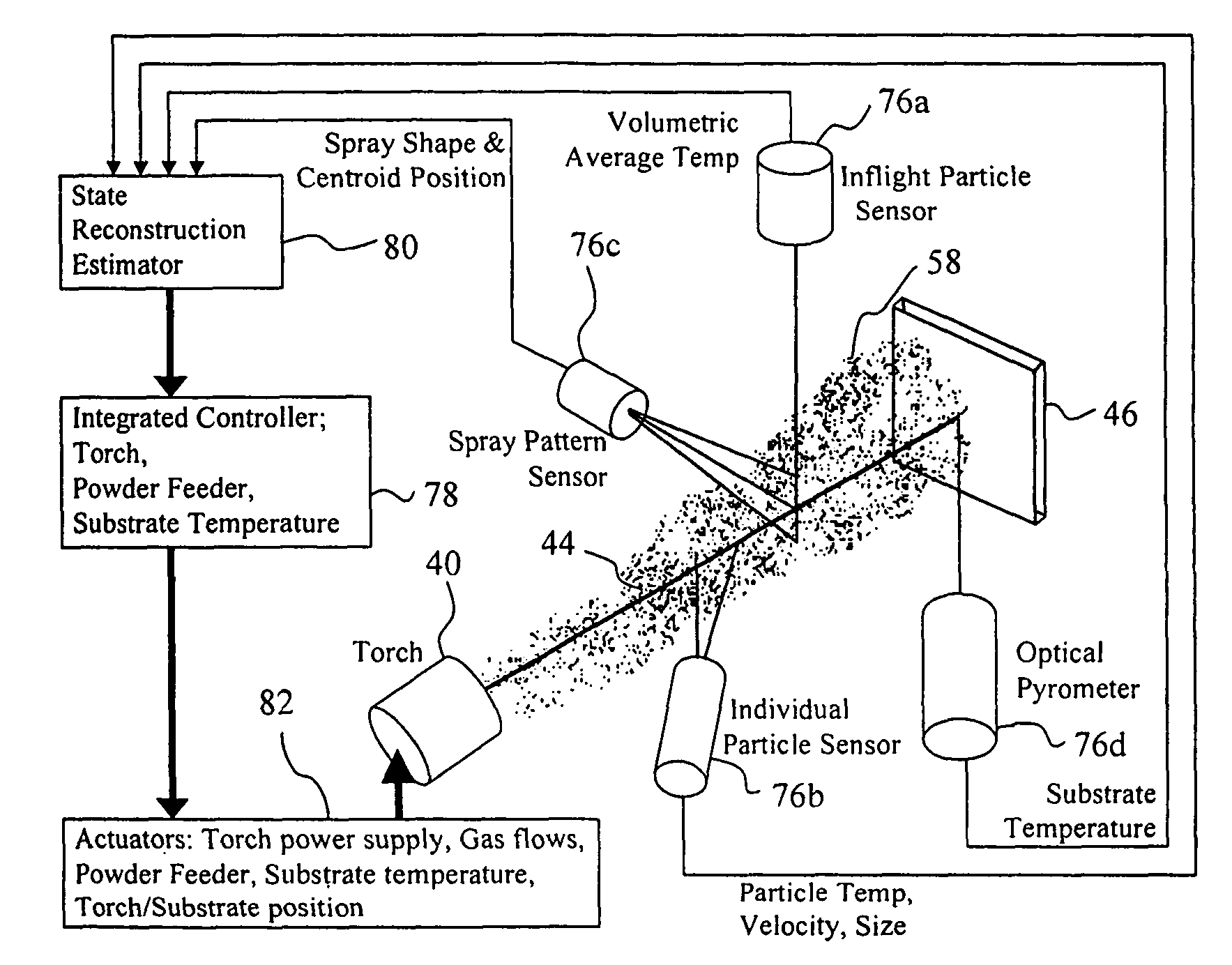

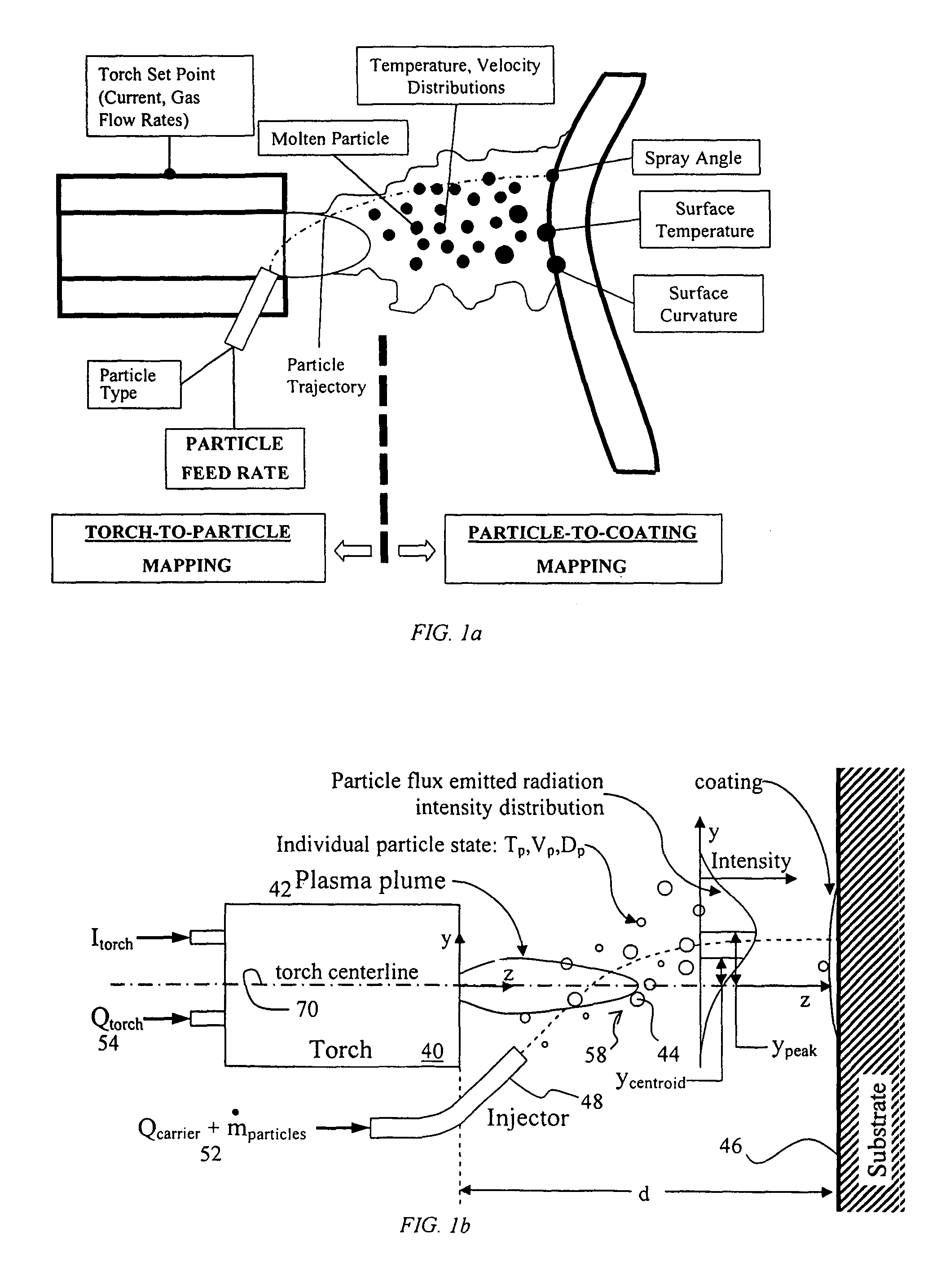

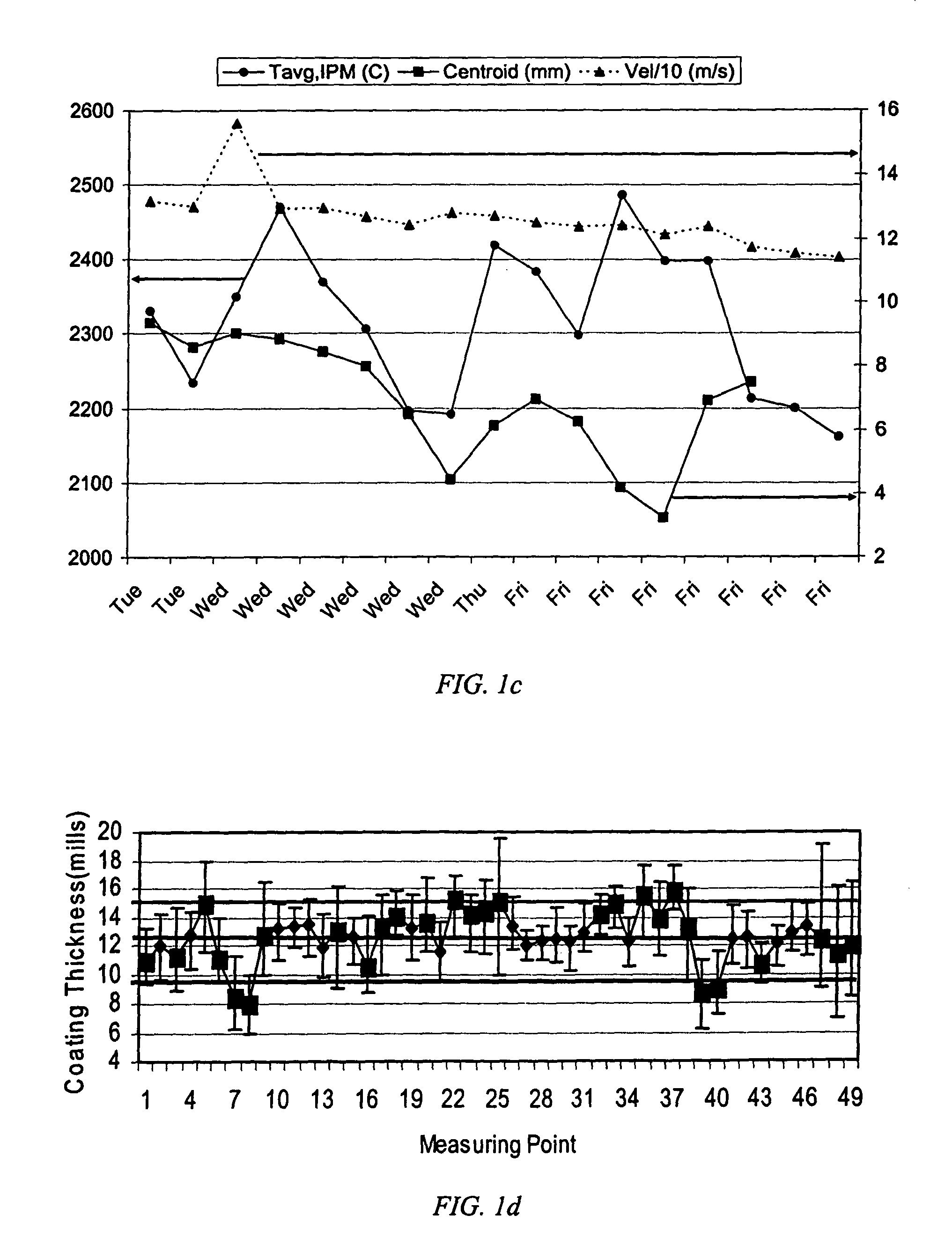

Feedback enhanced plasma spray tool

InactiveUS6967304B2Maintaining control over variableIncrease deposition rateMolten spray coatingSpraying apparatusPorosityMetallurgy

An improved automatic feedback control scheme enhances plasma spraying of powdered material through reduction of process variability and providing better ability to engineer coating structure. The present inventors discovered that controlling centroid position of the spatial distribution along with other output parameters, such as particle temperature, particle velocity, and molten mass flux rate, vastly increases control over the sprayed coating structure, including vertical and horizontal cracks, voids, and porosity. It also allows improved control over graded layers or compositionally varying layers of material, reduces variations, including variation in coating thickness, and allows increasing deposition rate. Various measurement and system control schemes are provided.

Owner:CYBER MATERIALS +1

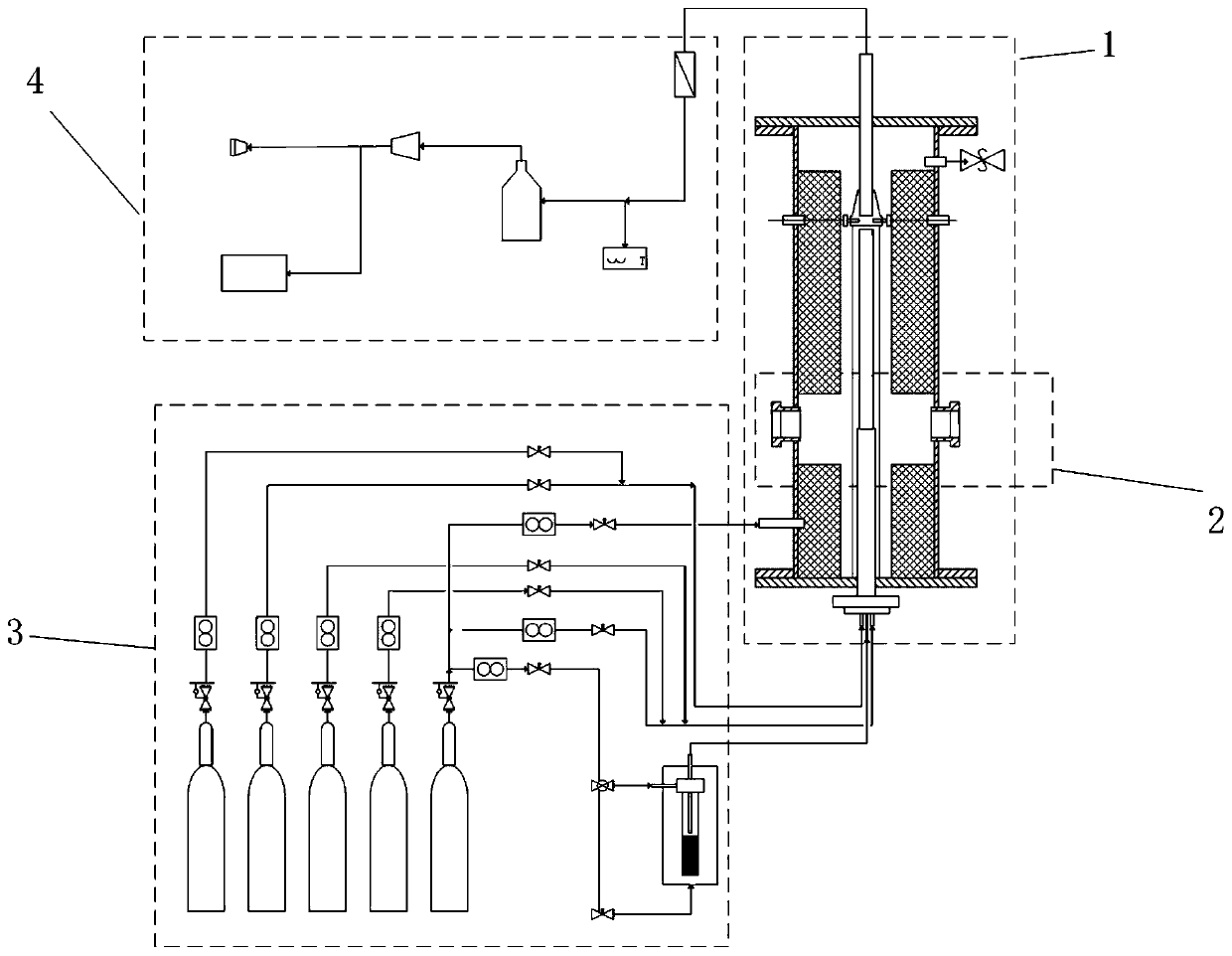

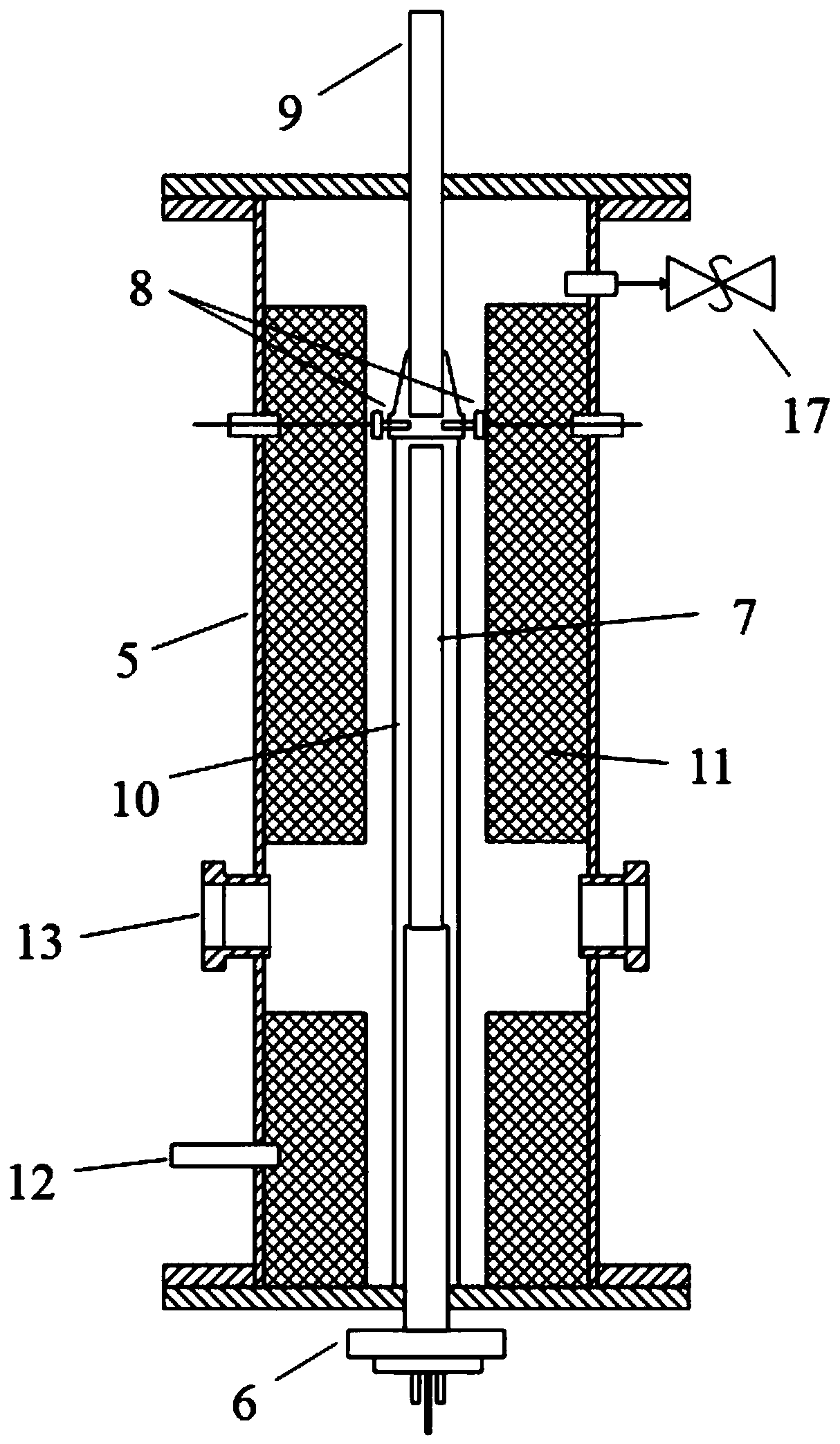

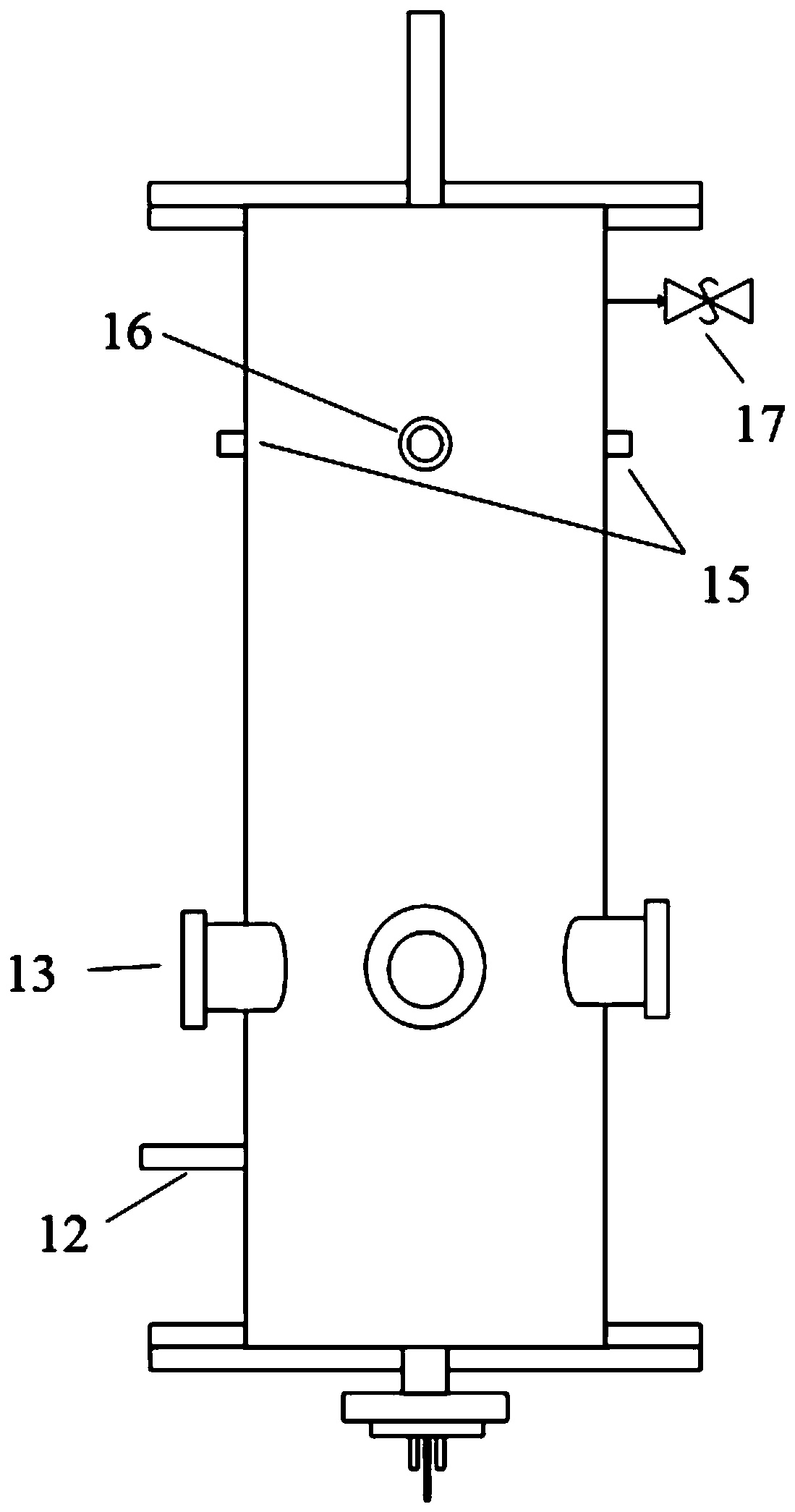

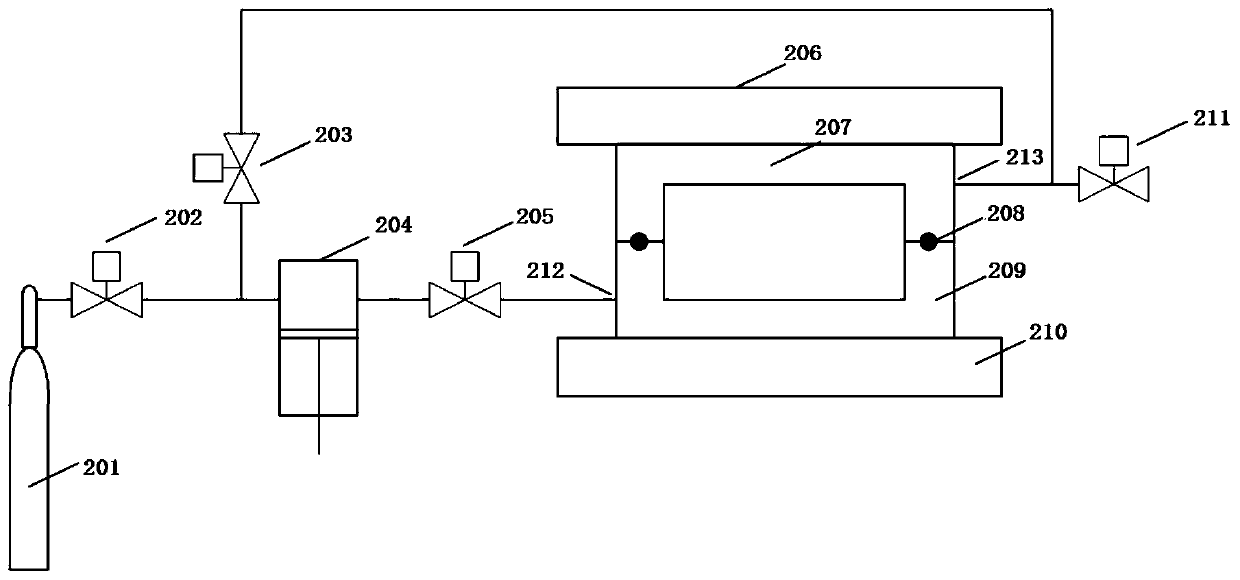

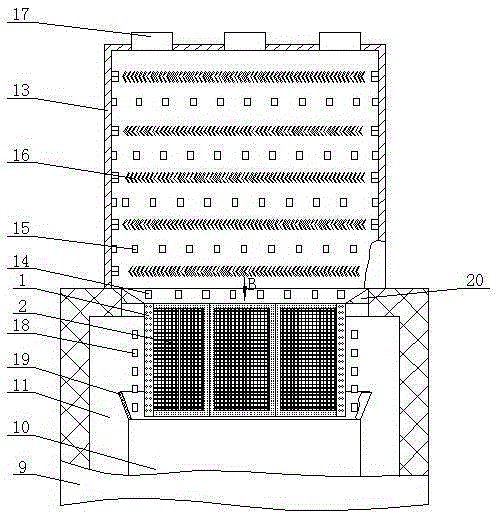

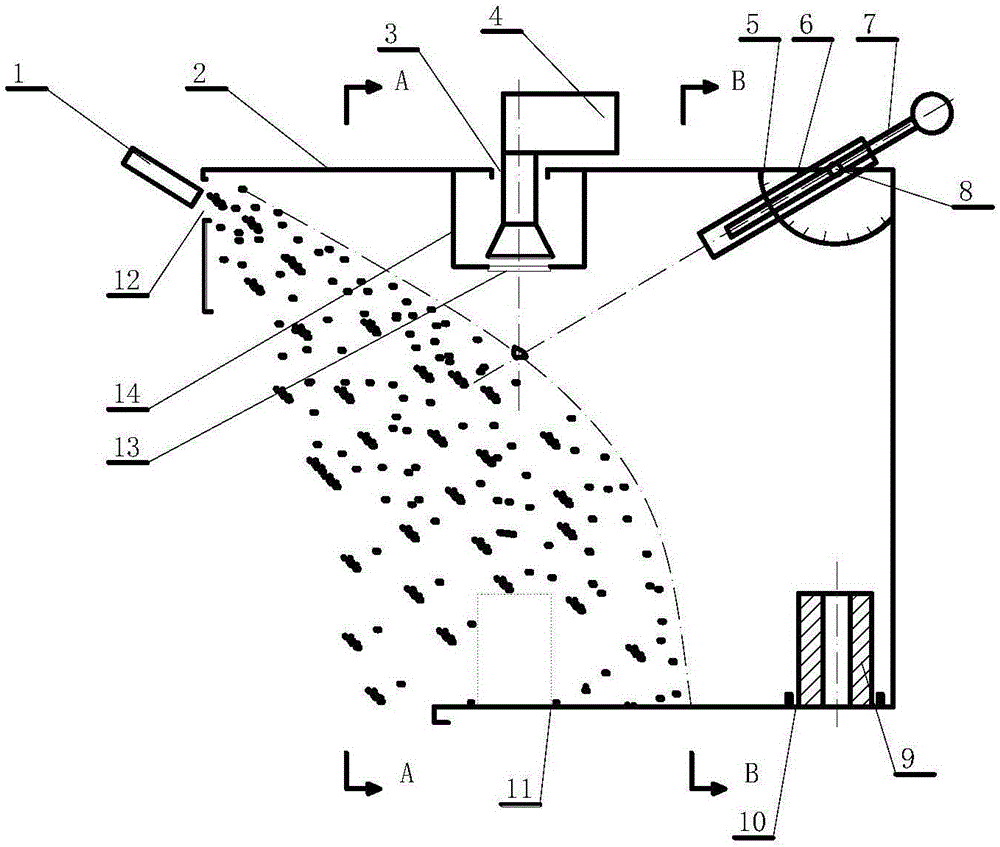

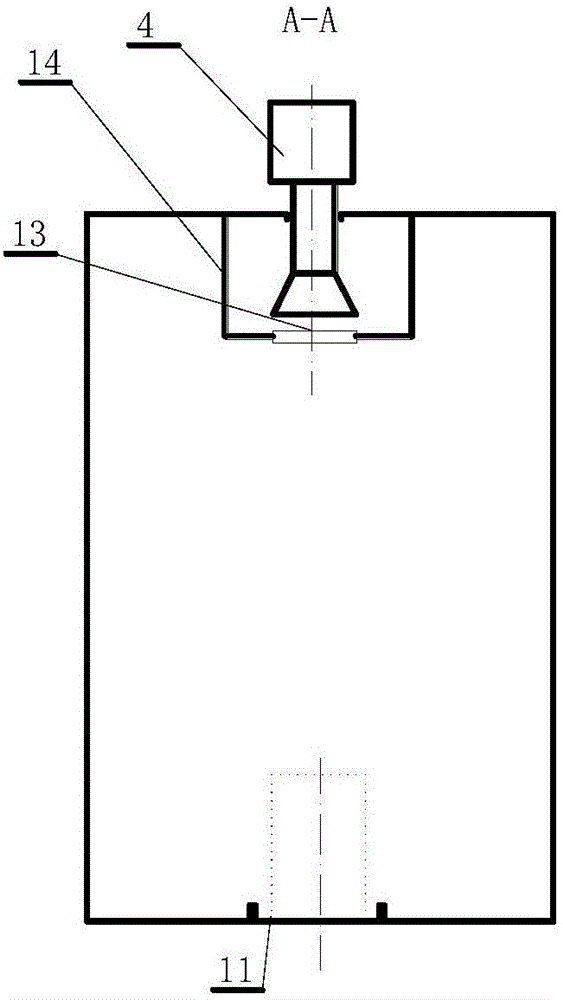

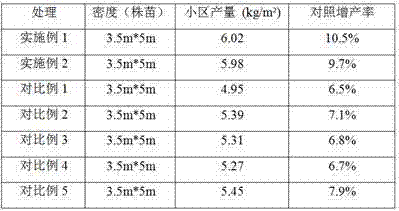

Visual pressurized discrete particle reaction kinetics experiment system

ActiveCN109991228AGood for ignition delay timeGood for ignition temperatureMaterial heat developmentAnalysing gaseous mixturesEngineeringKnowledge Field

The invention discloses a visual pressurized discrete particle reaction kinetics experiment system, and belongs to the field of study on reaction kinetics characteristics of solid fuel particles, suchas fire catching, combustion and gasification. The system is characterized in that an optical view window is formed in a pressure container; a plane flame combustor provided with double-layer squarequartz tubes is used as a heat source; and the visual monitoring on the reaction process of the solid fuel particles in high-temperature and high-pressure environment can be realized. Through the matching of continuous laser and high-speed image pick-up, the mesoscopic morphology and brightness evolution of the particles in the whole process from cold state heating to hot state fire catching luminescence to reaction exhausting can be continuously observed on line; and the characteristic parameters such as the fire catching delay time, the fire catching temperature, the particle temperature change and the particle reaction speed are favorably obtained in the subsequent process through data processing.

Owner:HUAZHONG UNIV OF SCI & TECH

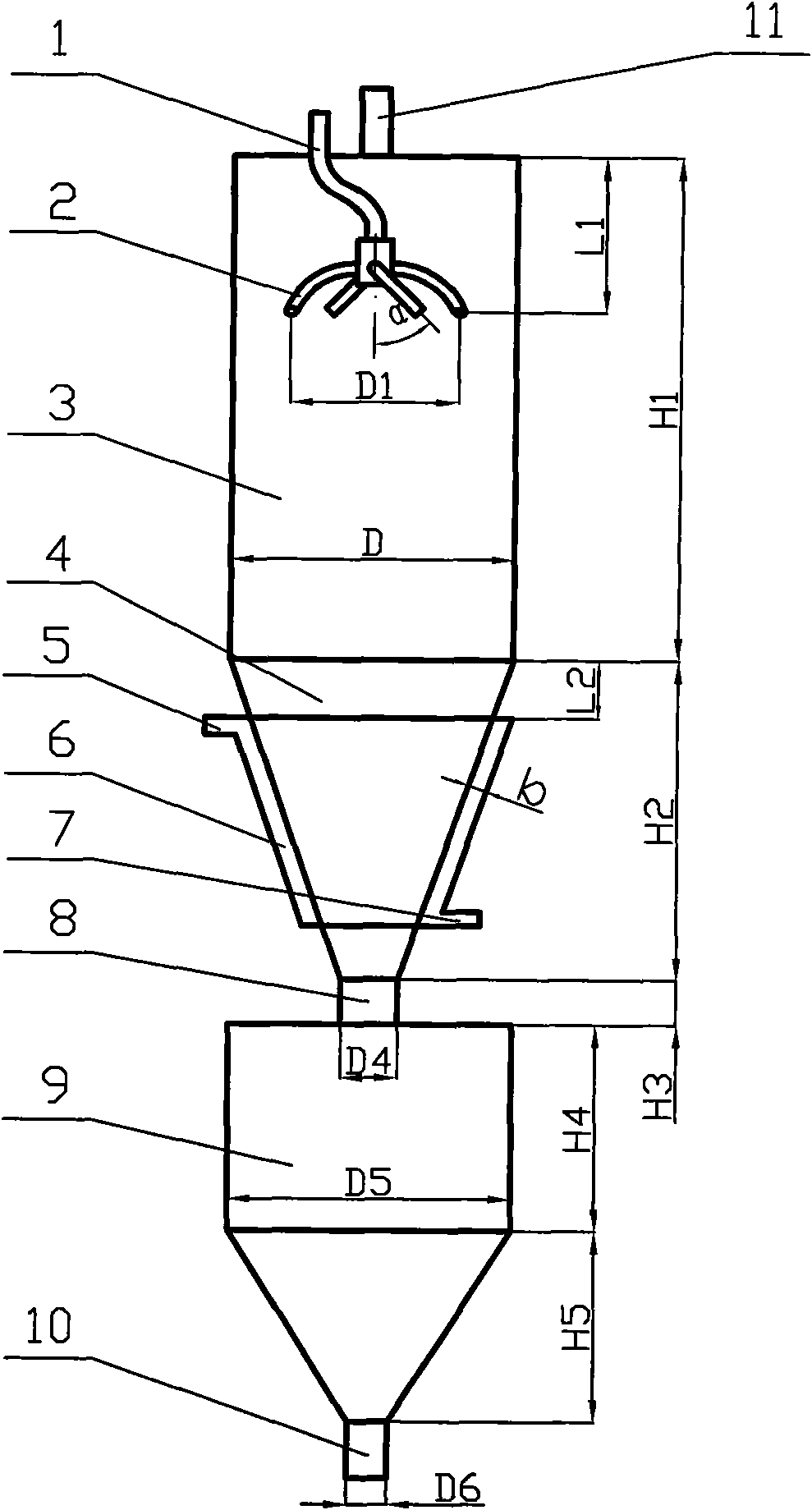

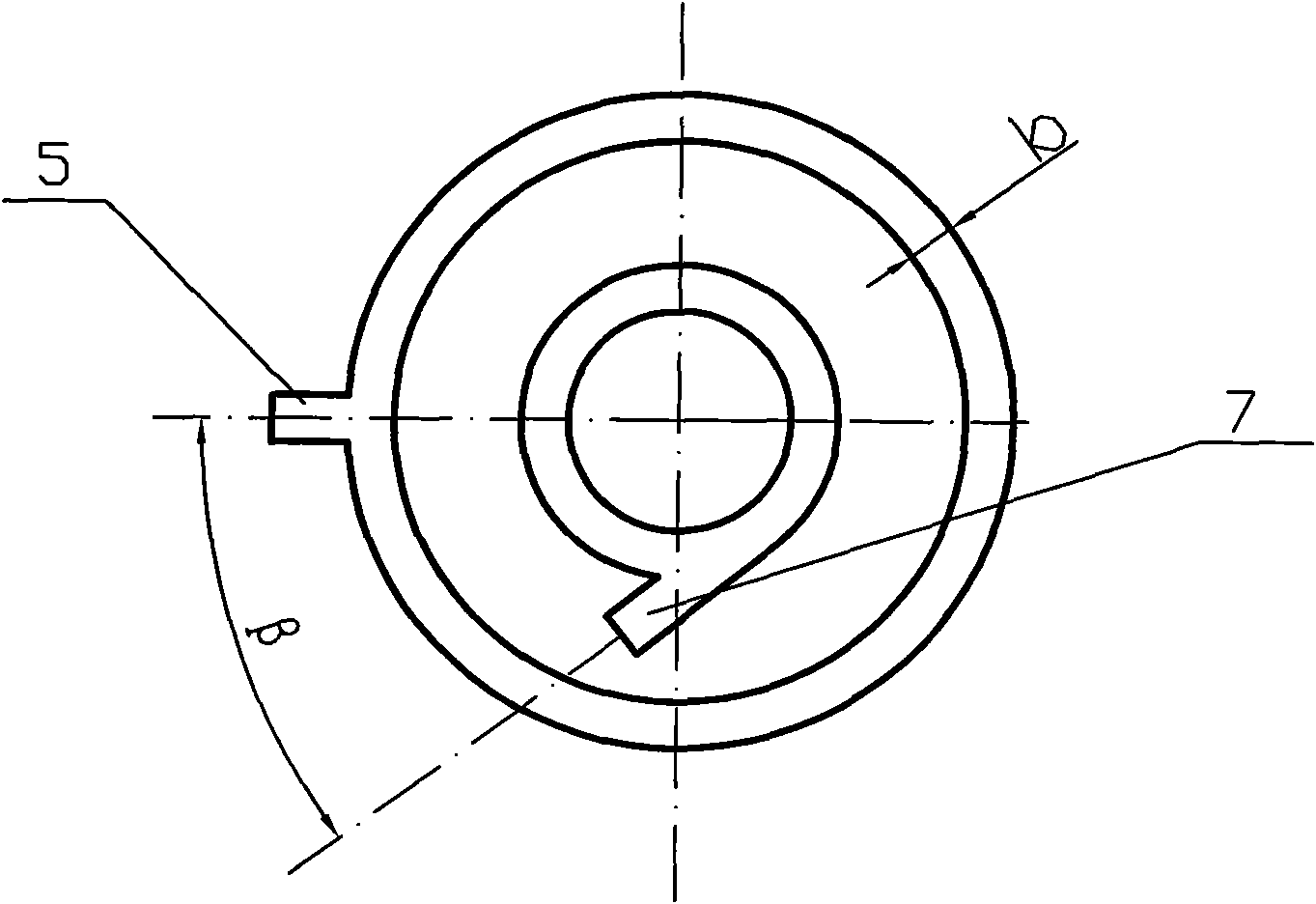

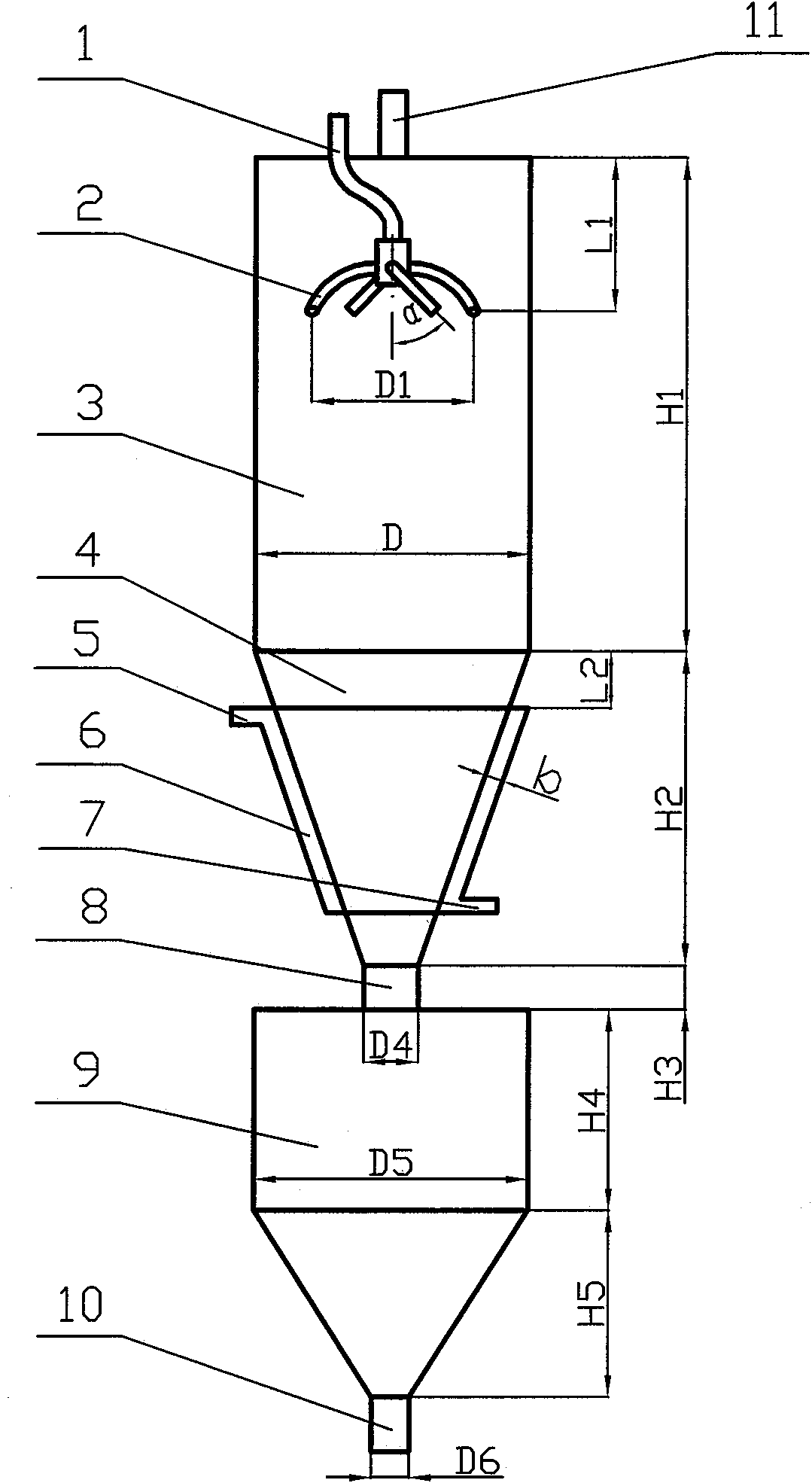

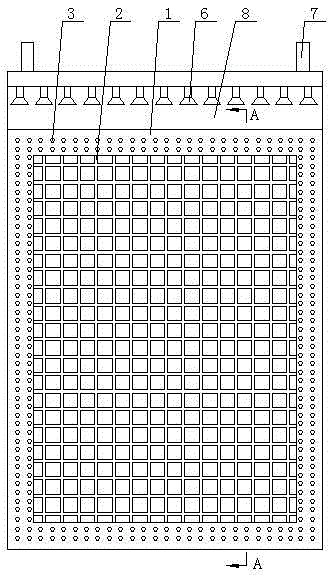

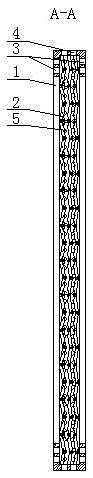

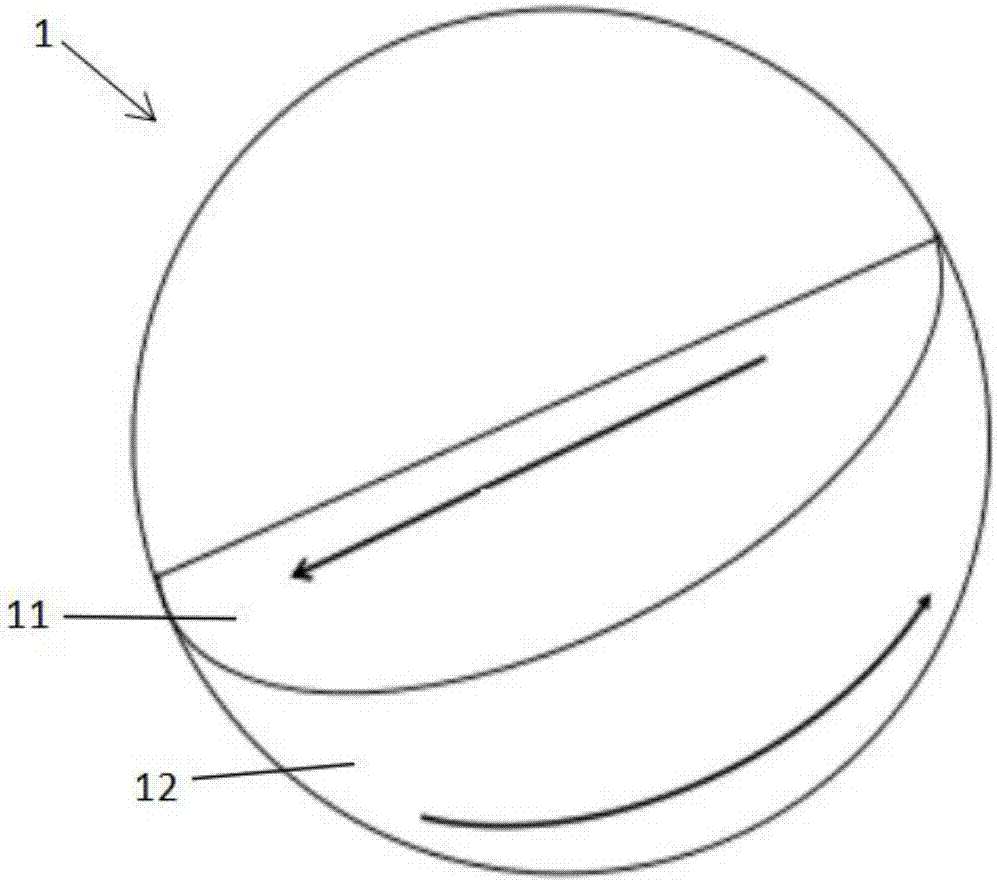

Spraying and granulating separation column with jacket cooling system on taper section

InactiveCN101987286AAchieve coolingNo internal components addedGranulation by liquid drop formationWorking-up pitch/asphalt/bitumen by solidifying/disintegratingSpray nozzleEngineering

The invention relates to a spraying and granulating separation column with a jacket cooling system on a taper section. The main structure of the separation column mainly comprises a granulating column body, a spraying and granulating nozzle system and a lower discharge pot from top to bottom, wherein the granulating column body can be formed by a separation and precipitation section, a taper section and a jacket cooling system; the spraying and granulating nozzle system can be formed by a distributor master pipe and a plurality of distributor branch pipes; the distributor branch pipes are symmetrically distributed, and the jet direction of the outlets of the distributor branch pipes form a certain angle with the vertical direction, which can form a rotating flow field with tangential velocity; the jacket cooling system comprises a tangential cooling water outlet, a radial cooling water inlet and a jacket main body; and cooling water rotates and upwards flows in a jacket, separated particles rotate and downwards flow in the spraying and granulating separation column, and the rotating and flowing directions of the cooling water and the separated particles are opposite to form contranatant heat exchange. In the invention, rotating flow fields of different degrees can be formed in the granulating column through adjusting the angles of the charge distributor and the number of the distributor branch pipes to realize different particle distribution states and improve the gas-solid separation efficiency; and different heat exchange efficiencies can be realized through adjusting the temperature, the pressure and the flow rate of a cooling water inlet and the structural size of a cooling water jack, and then the particle temperature can be reduced to control the temperature of the granulating column.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

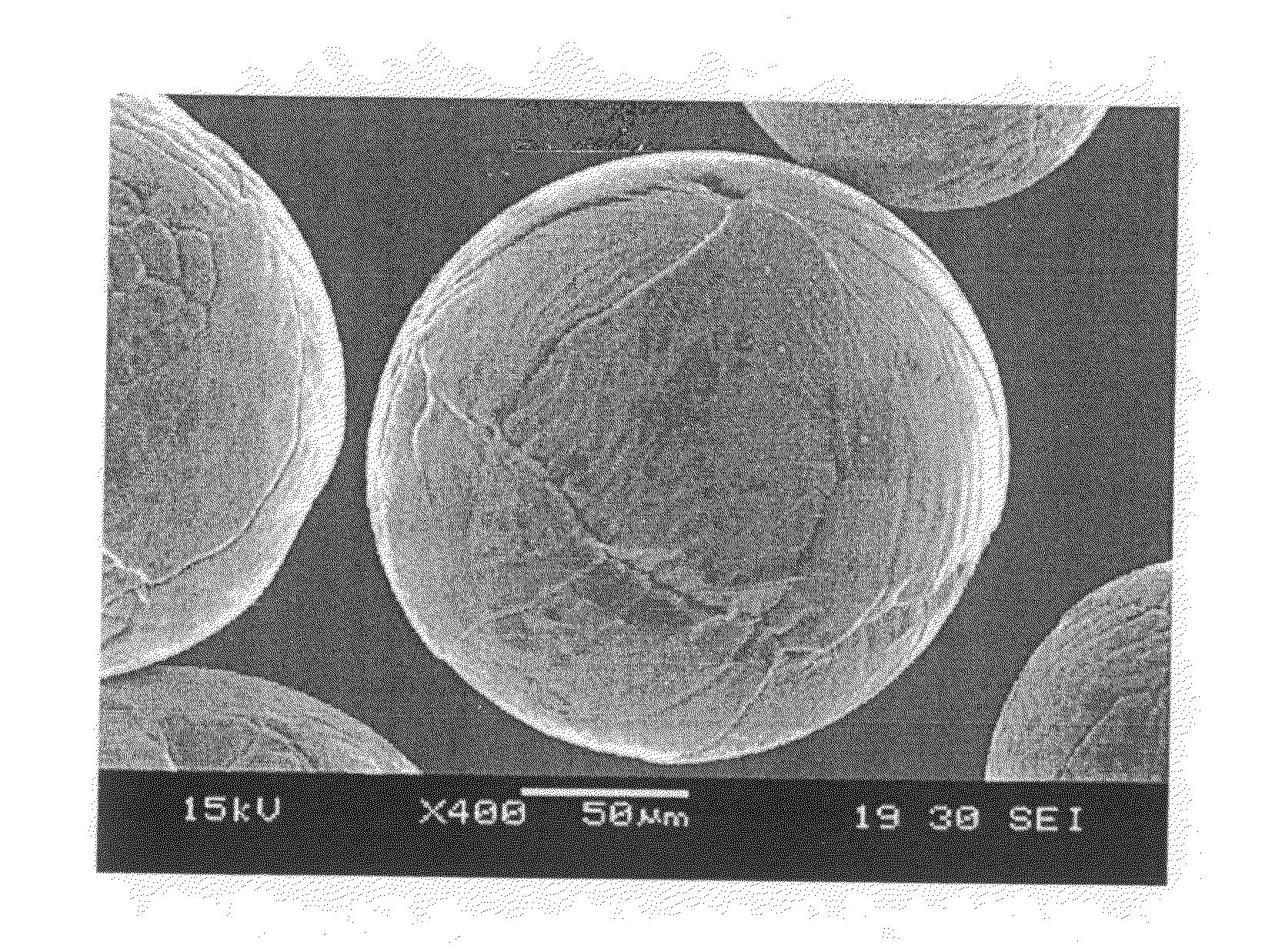

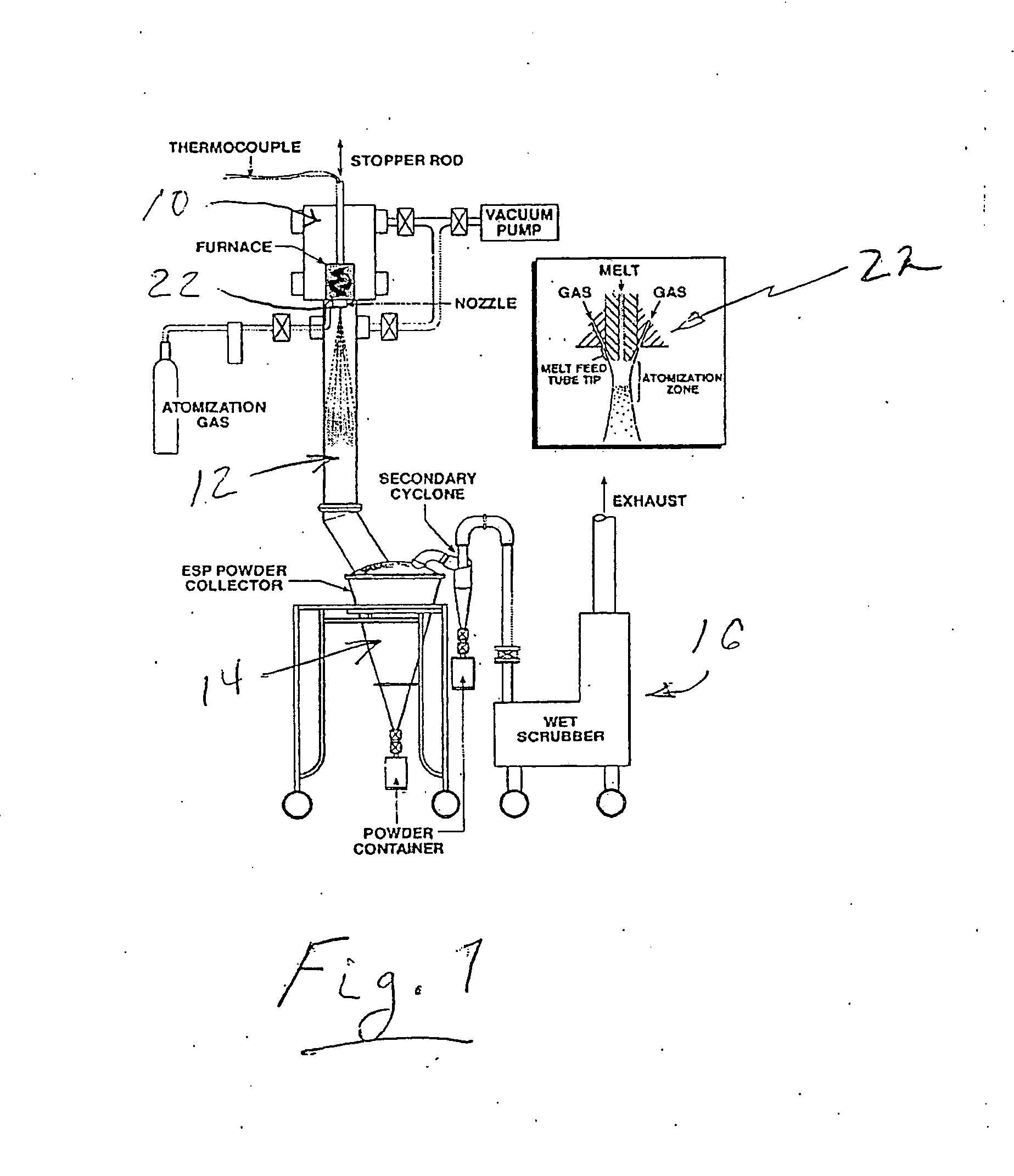

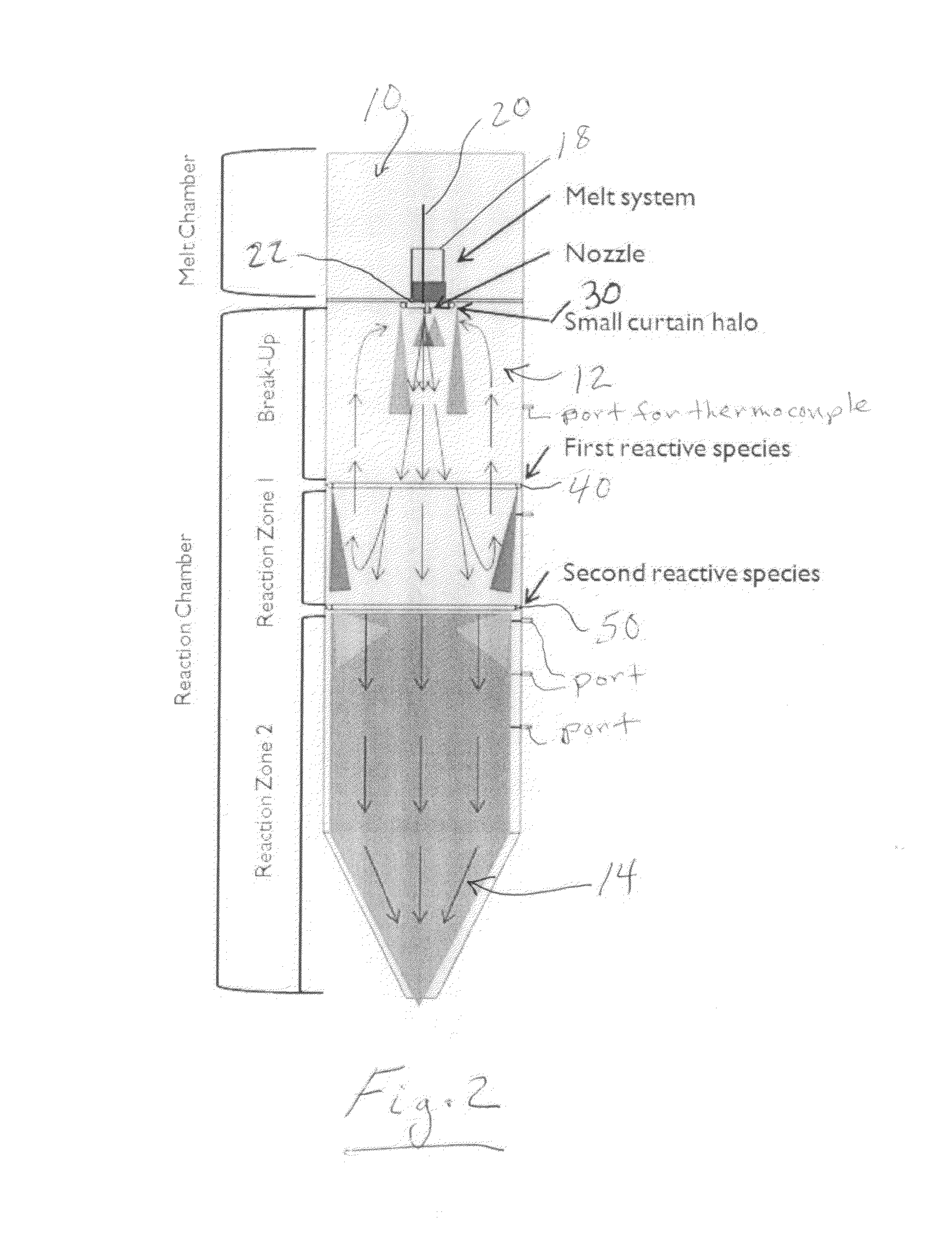

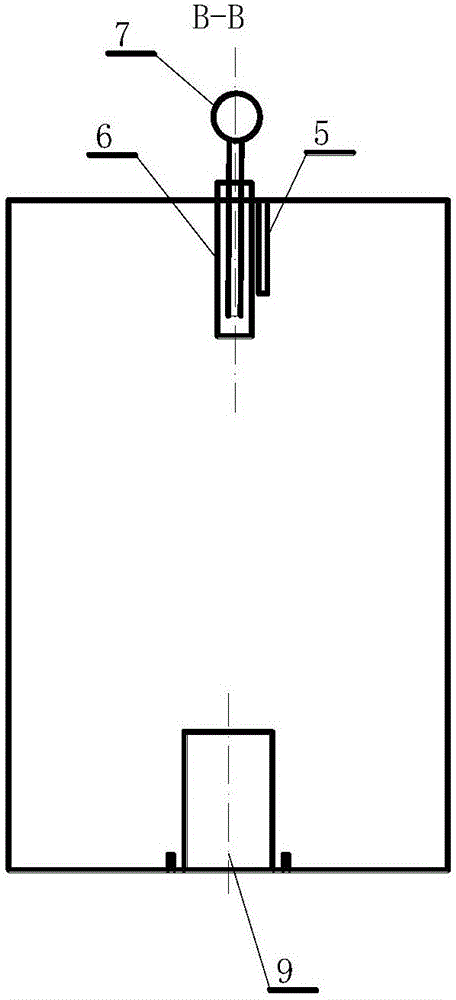

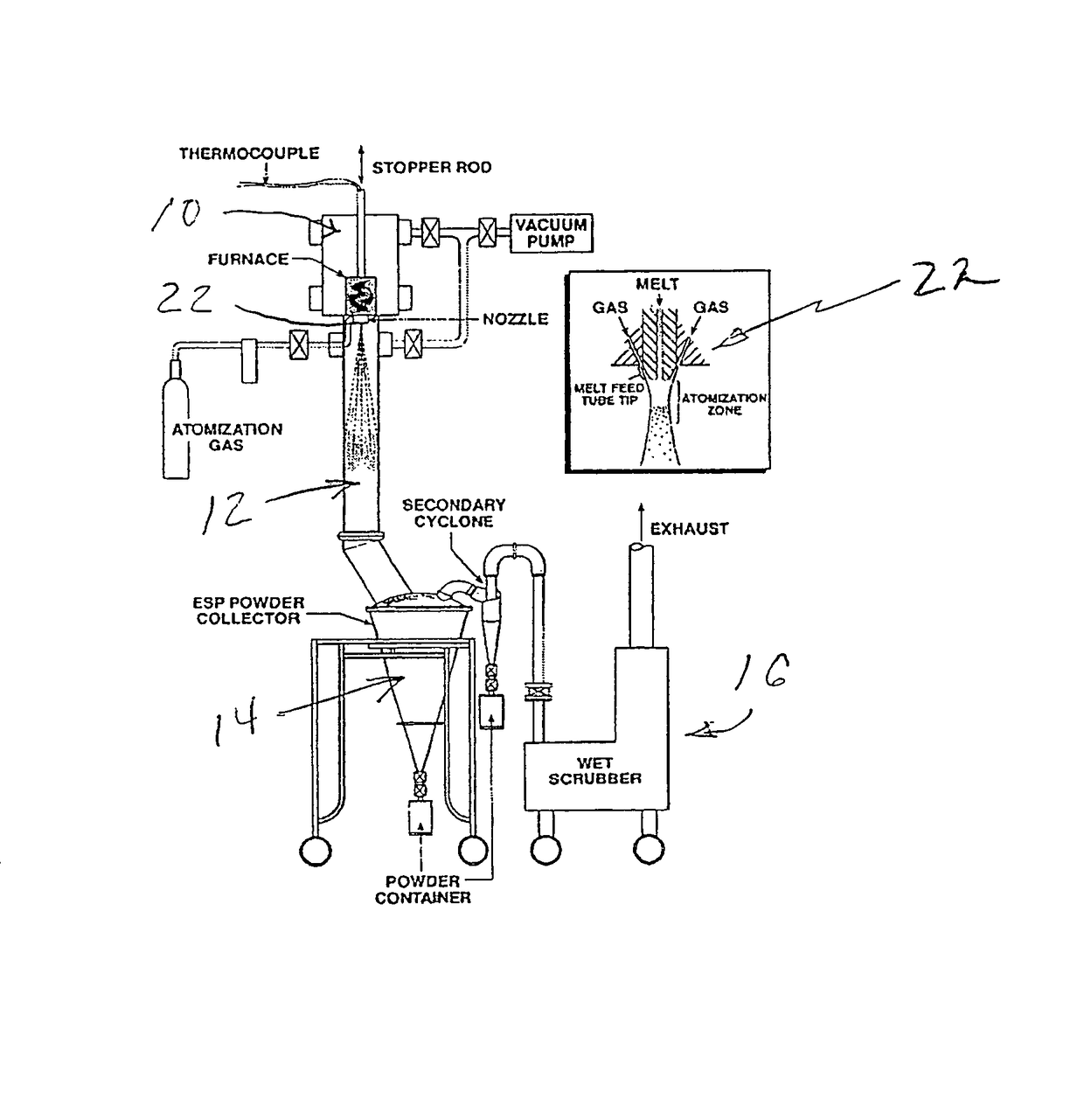

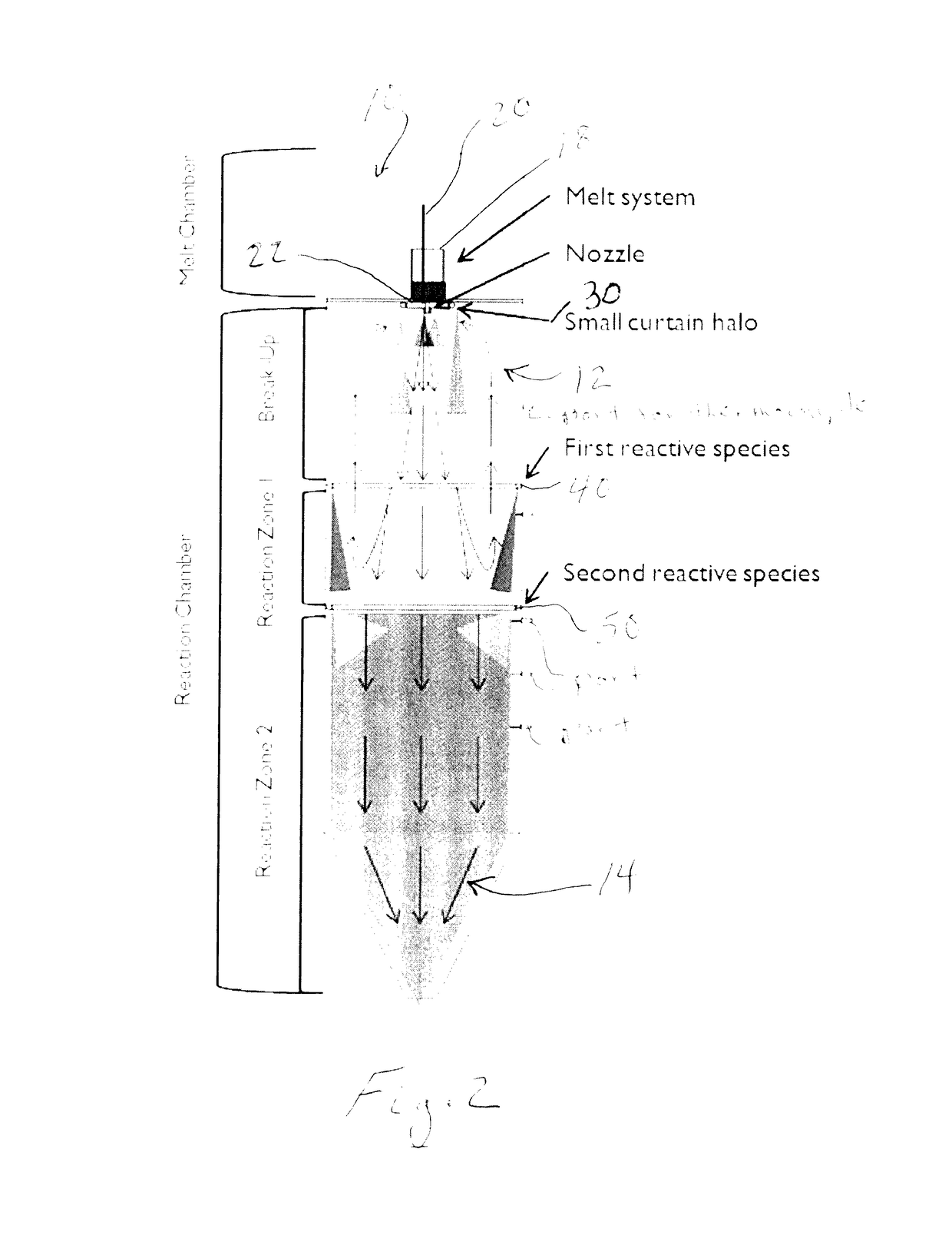

Stability of gas atomized reactive powders through multiple step in-situ passivation

ActiveUS20130306205A1Increases thermal ignition temperatureIncreases ignition spark resistanceTransportation and packagingMetal-working apparatusOxygenReactive agent

A method for gas atomization of oxygen-reactive reactive metals and alloys wherein the atomized particles are exposed as they solidify and cool in a very short time to multiple gaseous reactive agents for the in-situ formation of a protective reaction film on the atomized particles. The present invention is especially useful for making highly pyrophoric reactive metal or alloy atomized powders, such as atomized magnesium and magnesium alloy powders. The gaseous reactive species (agents) are introduced into the atomization spray chamber at locations downstream of a gas atomizing nozzle as determined by the desired powder or particle temperature for the reactions and the desired thickness of the reaction film.

Owner:IOWA STATE UNIV RES FOUND

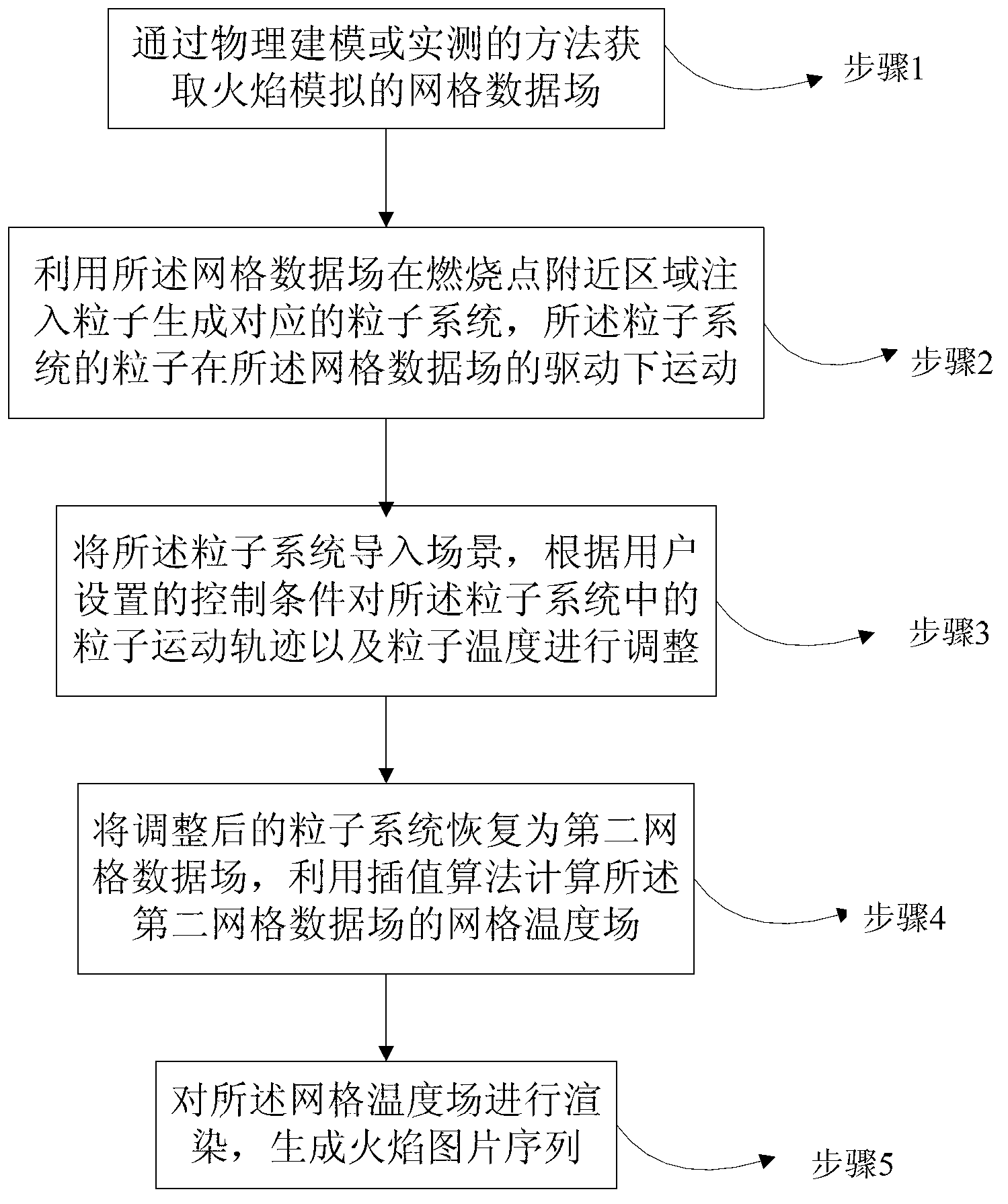

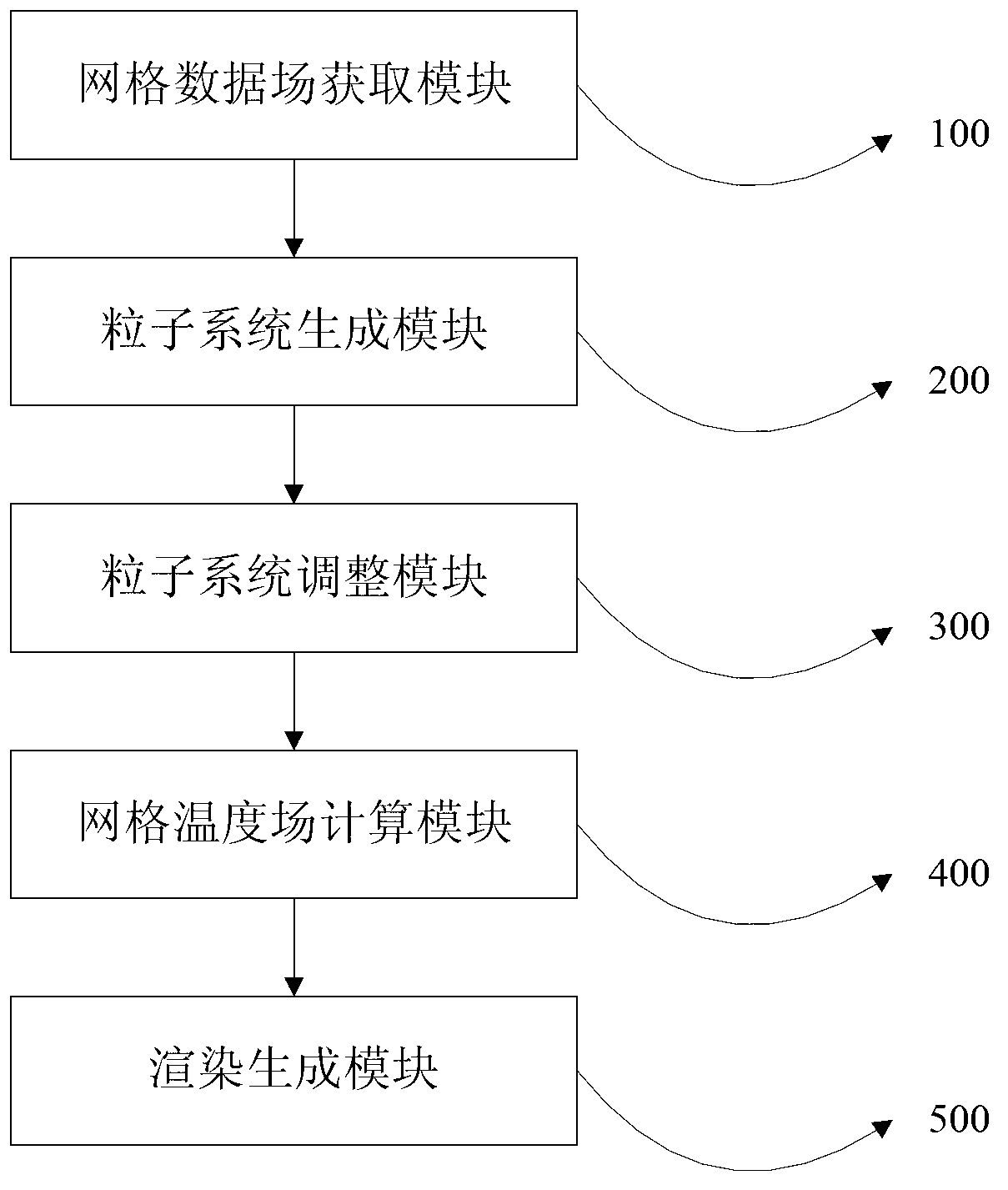

Controllable flame animation generation method and system

The invention discloses a controllable flame animation generation method and a controllable flame animation generation system. The controllable flame animation generation method comprises the steps: 1. obtaining flame-simulated grid data field through a method of using physical modeling or actual measurement; 2. injecting particles at neighboring areas of burning points by utilizing the grid data field to generate a corresponding particle system, wherein the particles of the particle system move under the driving of the grid data field; 3. importing the particle system into a scene, and adjusting the particle movement trail and particle temperature in the particle system according to control conditions set by a user; 4. reverting the adjusted particle system to a second grid data field, and calculating the grid temperature field of the second grid data field by utilizing interpolation algorithm; and 5. rendering the grid temperature field to generate a flame picture sequence. The controllable flame animation generation method and the controllable flame animation generation system are on the basis of physical simulation data, and can generate animation sequence with better realistic quality at faster speed.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

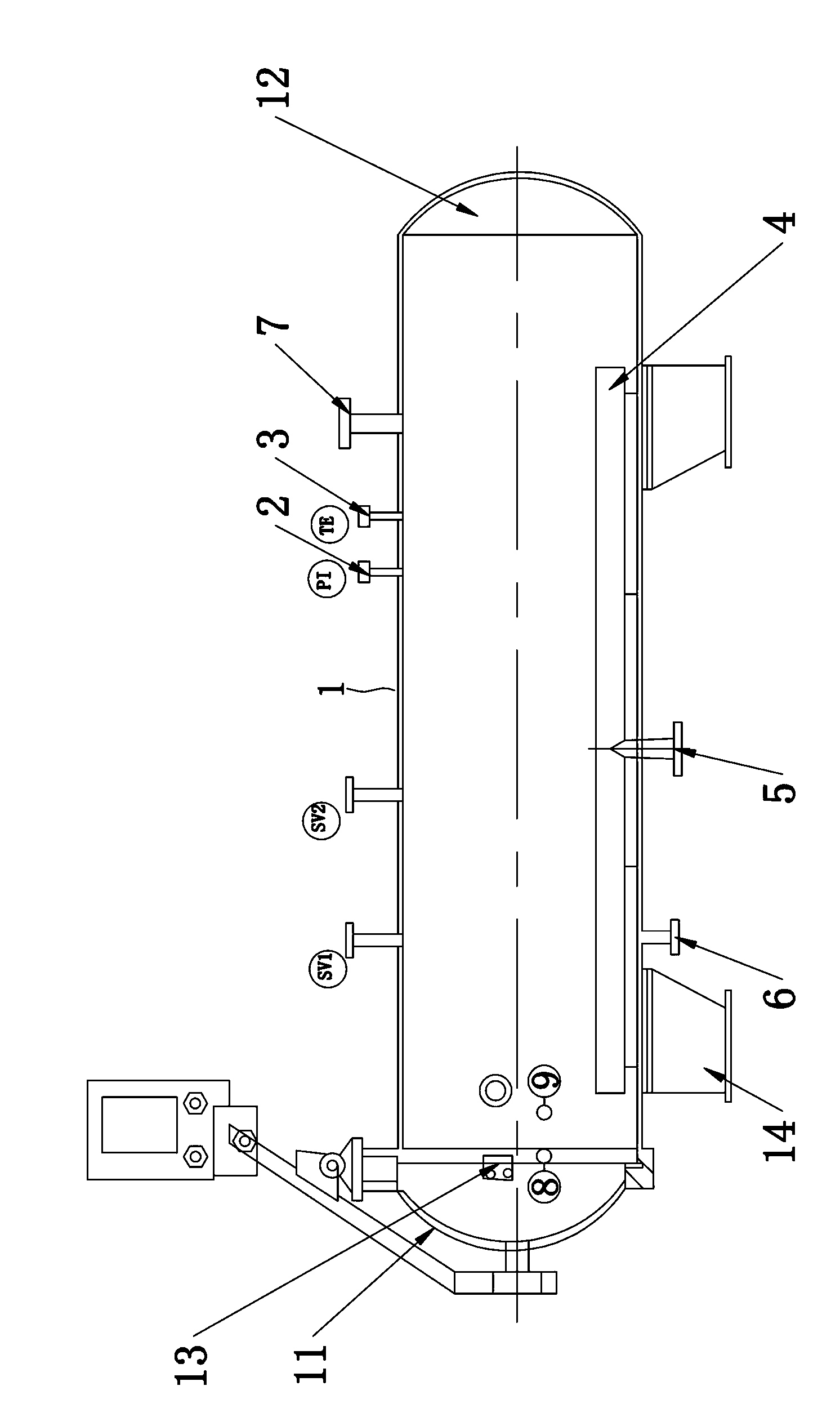

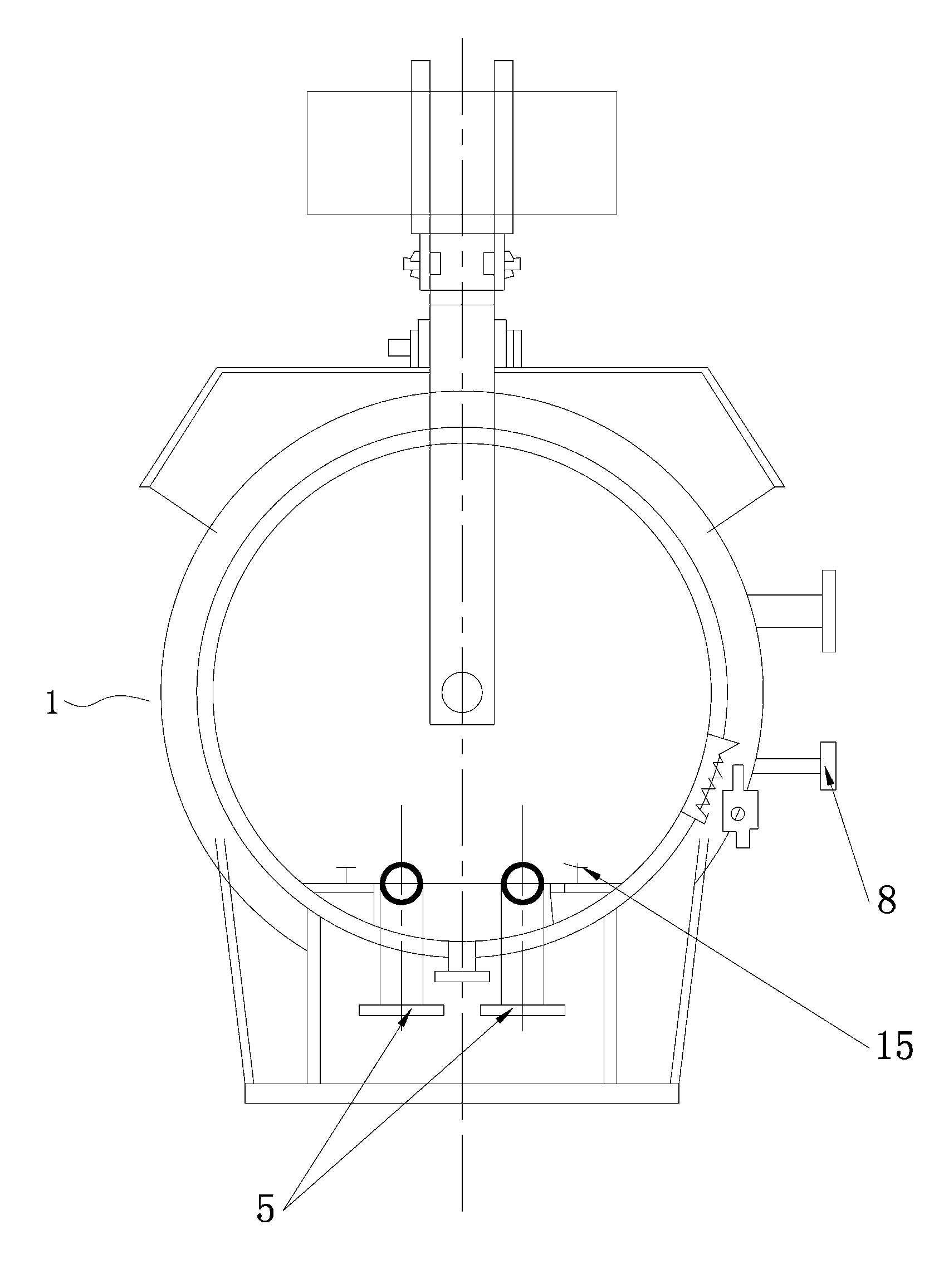

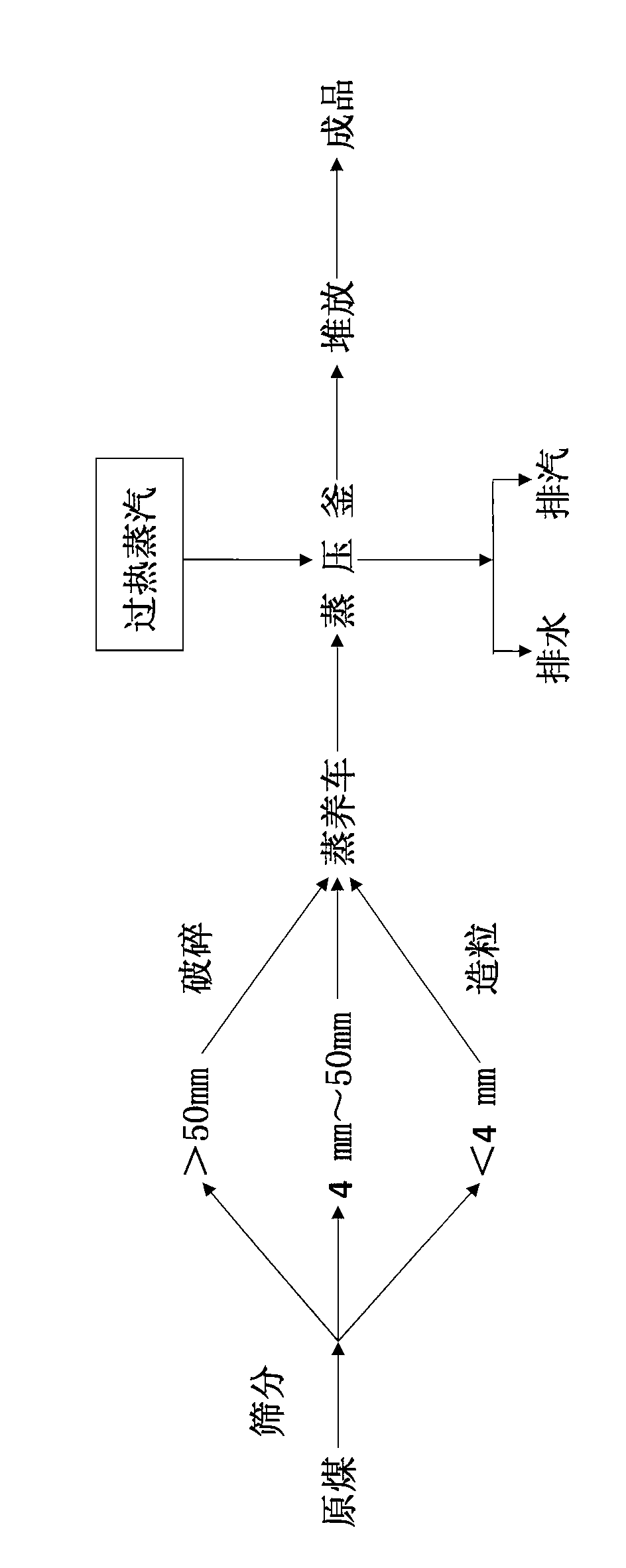

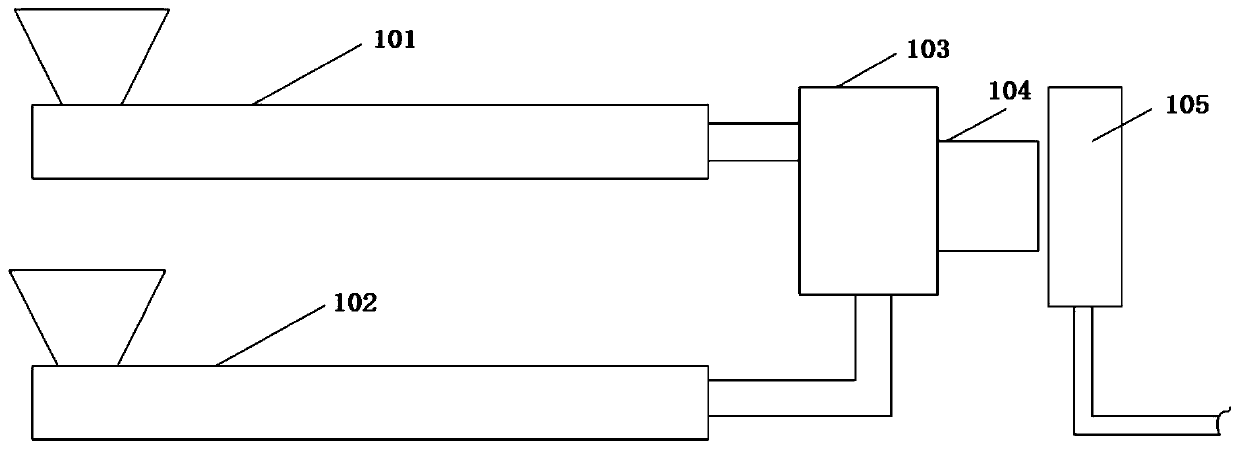

Method and equipment for drying lignite particles and pulverized coal granules

The invention discloses a method and equipment for drying lignite particles and pulverized coal granules. The method comprises the steps of: screening and crushing lignite raw materials with the grain size over 50mm into granules with the grain sizes of 4mm-50mm, and lignite raw materials with the grain size less than 4mm into granules with the grain size of 4mm-12mm, and feeding the particles into a pressure container to be sealed; filling low-pressure high-temperature superheated steam into the pressure container to exchange heat with the lignite particles, stopping supplying the superheated steam when the lignite particle temperature reaches 130 DEG C-290 DEG C or the inside pressure of the pressure container is higher than 1.5 megapascals, and starting stabilizing the pressure; and taking the modified lignite which is heated by superheated steam out after stabilizing the pressure for 10 minutes, and stacking and cooling under natural conditions. The superheated steam is taken as a heating medium, so that the lignite particles are modified to have the characteristics tending to bituminous coal. The pressure container effectively ensure that the lignite particles are dried at the optimum temperature and pressure and timely discharges waste gases and condensed water, so that the water content of the dried lignite particles is obviously reduced, very small back absorption is generated, spontaneous igniting and weathering are not generated, and the unit heating value is greatly increased.

Owner:蔡京鹏

Integrated foaming molding process for polymer particles

The invention discloses an integrated foaming molding process for polymer particles. The method comprises the following steps of (1) preparing polymer particles with high-melting-point macromolecule resin coated by low-melting-point macromolecule resin; and (2) carrying out one-step foaming molding on the polymer particles to obtain a foamed product. The polymer particles with the high-melting-point macromolecule resin coated by the low-melting-point macromolecule resin and of a core-shell structure is prepared, in the foaming process, the foaming temperature is below the melting point of thecore resin, so that the core of the particles can form foaming beads, the foaming temperature is higher than the melting point of the shell resin, the surface is in a molten state, and when the particles are expanded and mutually extruded, the shell resin in the molten state enables the particles to be welded together; meanwhile, the particles are in a fluidized state in the foaming process, the temperatures of all the particles are consistent, the particles are ensured not to be bonded in advance, the internal welding is uniform and consistent when expansion occurs, and filling defects are avoided.

Owner:SHINCELL NEW MATERIAL CO LTD

Feedback enhanced plasma spray tool

An improved automatic feedback control scheme enhances plasma spraying of powdered material through reduction of process variability and providing better ability to engineer coating structure. The present inventors discovered that controlling centroid position of the spatial distribution along with other output parameters, such as particle temperature, particle velocity, and molten mass flux rate, vastly increases control over the sprayed coating structure, including vertical and horizontal cracks, voids, and porosity. It also allows improved control over graded layers or compositionally varying layers of material, reduces variations, including variation in coating thickness, and allows increasing deposition rate. Various measurement and system control schemes are provided.

Owner:CYBER MATERIALS

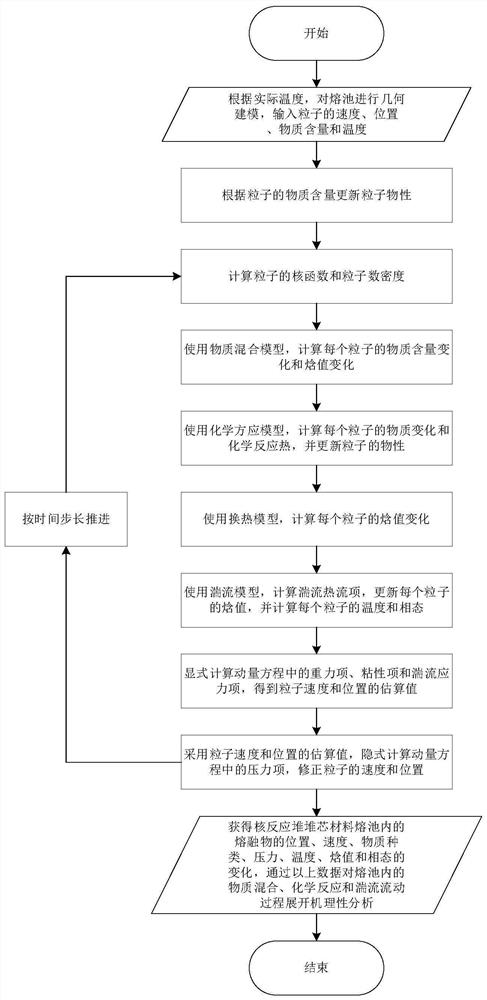

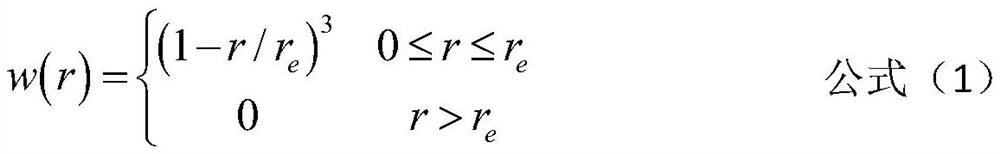

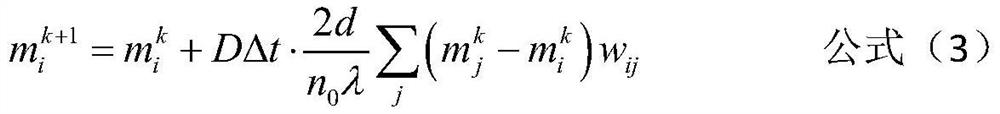

Nuclear reactor core material molten pool evolution characteristic analysis method based on particle method

ActiveCN112102894APrevent penetrationAccurate restoration of structural propertiesChemical processes analysis/designDesign optimisation/simulationNuclear reactor coreChemical reaction

The invention discloses a nuclear reactor core material molten pool evolution characteristic analysis method based on a particle method. The method mainly comprises the following steps: 1, modeling ageometric model; 2, initializing physical properties; 3, calculating a kernel function and particle number density between particles; 4, calculating a substance mixing process, and updating the content, enthalpy value and physical property of the particulate matters; 5, calculating a chemical reaction process, and updating the content and enthalpy value of the particulate matters; 6, calculating aheat transfer process, and updating a particle enthalpy value; 7, calculating the particle temperature and the phase state according to the enthalpy value; 8, explicitly calculating a viscosity itemand a gravity item; 9, explicitly calculating a turbulence stress term, estimating particle speed and position, calculating a turbulence heat flow term, and updating a particle enthalpy value; 10, carrying out implicit iterative computation on the particle pressure; 11, correcting the speed and position of the particles according to the pressure value; and 12, outputting a calculation result. According to the method, all phenomena in a nuclear reactor core material molten pool are considered; and based on a particle method, substance changes, phase state changes and flow characteristics in a molten pool can be accurately captured.

Owner:XI AN JIAOTONG UNIV

Built-in water curtain wall in dust collection apparatus

InactiveCN105413356APromote absorptionExtended stayUsing liquid separation agentRetention timeEngineering

The invention provides a built-in water curtain wall in a dust collection apparatus. The built-in water curtain wall includes a rectangular metal frame. A waved metal screen is installed in the metal frame. The waved metal screen includes 7-16 layers in a laminated manner to a certain thickness. A plurality of water inlet pores are formed in each of an upper frame, a lower frame, a left frame and a right frame and a upper end surface, a lower end surface, a left end surface and a right end surface of the metal frame. The water inlet pores are uniformly distributed. The water curtain wall is installed in a dust collection apparatus, wherein dust, when enters the collection apparatus, is fully contacted with a water film formed on the water curtain wall, thereby delaying the retention time of an adsorption solution in the dust gas and further achieving the object of absorbing the dust through the adsorption solution. The built-in water curtain wall greatly improves the adsorption effect of the adsorption solution on the dust. The structure also reduces air resistance in the dust collection apparatus and greatly reduces particle temperature in a granulation column, thereby further saving energy.

Owner:DEZHOU BEST CHEM TECH CO LTD

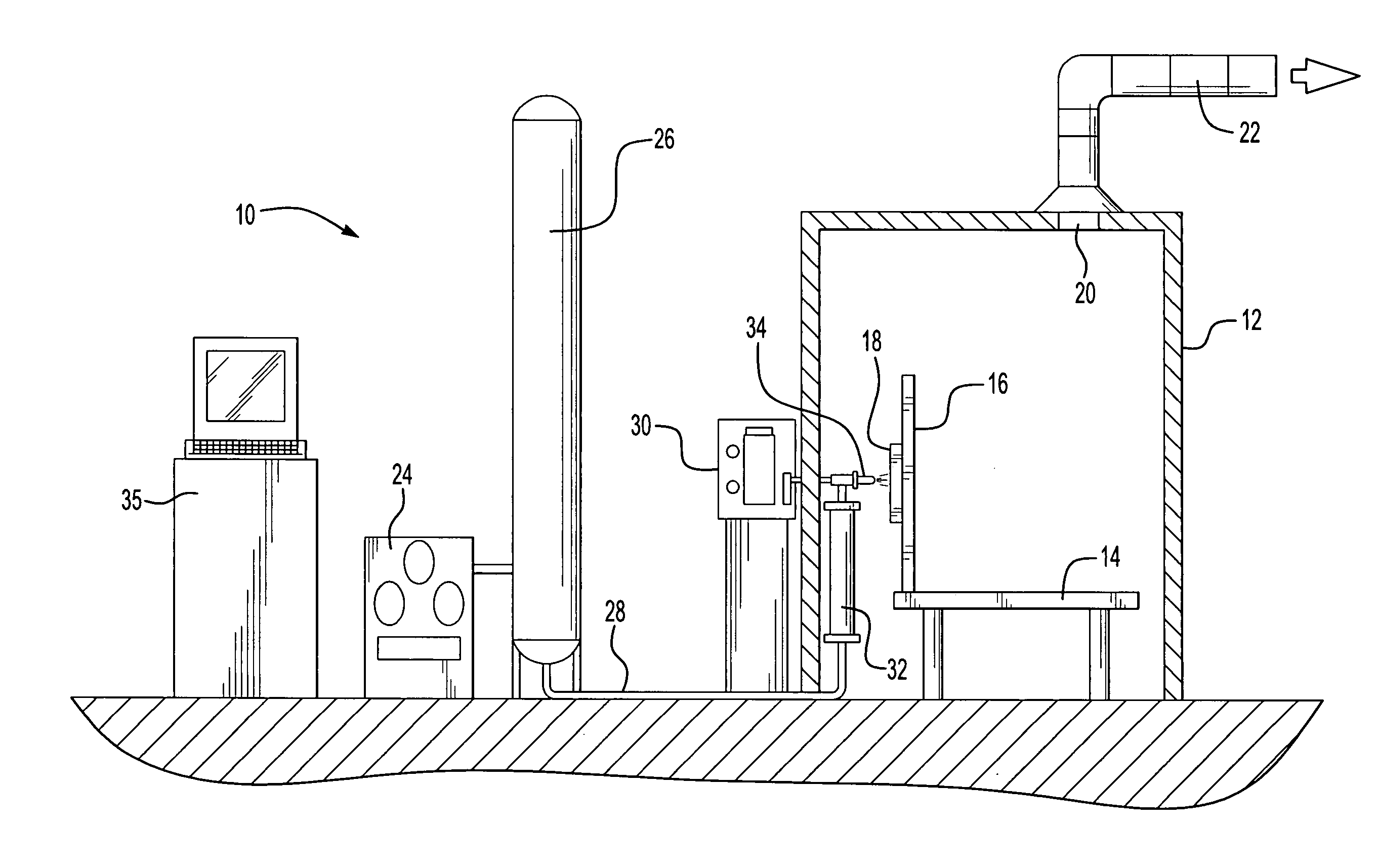

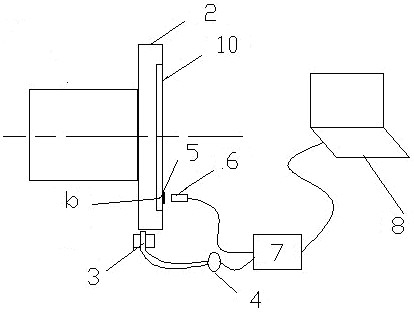

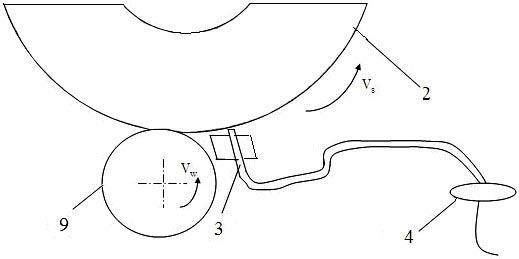

Temperature measuring device for abrasive particles of surfaces of grinding wheels

InactiveCN102528664AOptimum grinding parametersImprove grinding efficiencyGrinding feed controlMeasurement deviceWear particle

The invention relates to a temperature measuring device for abrasive particles of surfaces of grinding wheels, which comprises an infrared optical fiber sensor, a signal processing device, a reflector, a non-contact type photoelectric sensor, a data acquisition card and a computer. The reflector of a photoelectric sensor is adhered on the outer end surface of a flange of a grinding wheel, the non-contact type photoelectric sensor is arranged corresponding to the reflector and connected with the data acquisition card, the infrared optical fiber sensor is mounted in a grinding contact area close to the grinding wheel and a workpiece, and connected with the data acquisition card by the signal processing device, and the data acquisition card is connected with the computer. The temperature measuring device can measure the temperature of the abrasive particles on the surface of the grinding wheels in different types and distribution of the abrasive particles. By means of comparing grinding wheel abrasive particle experimental measurement results and maximum abrasive particle temperatures under conditions with different grinding parameters, best grinding technological parameters can be obtained by means of optimization, and the temperature measuring device plays an important role in improving grinding efficiency and grinding quality.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

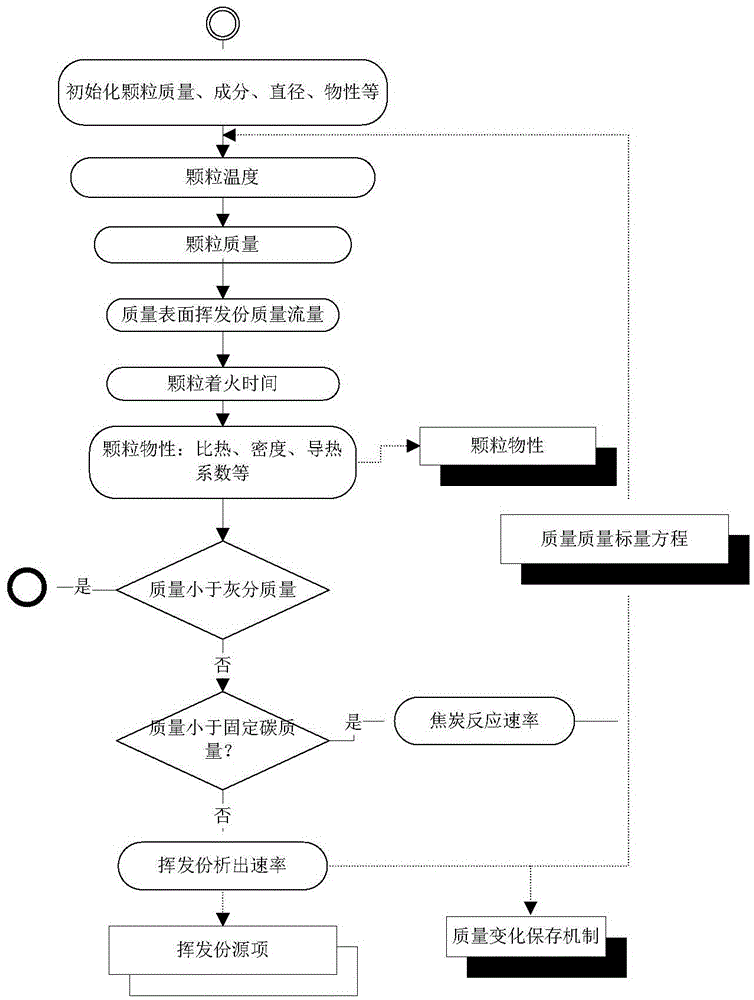

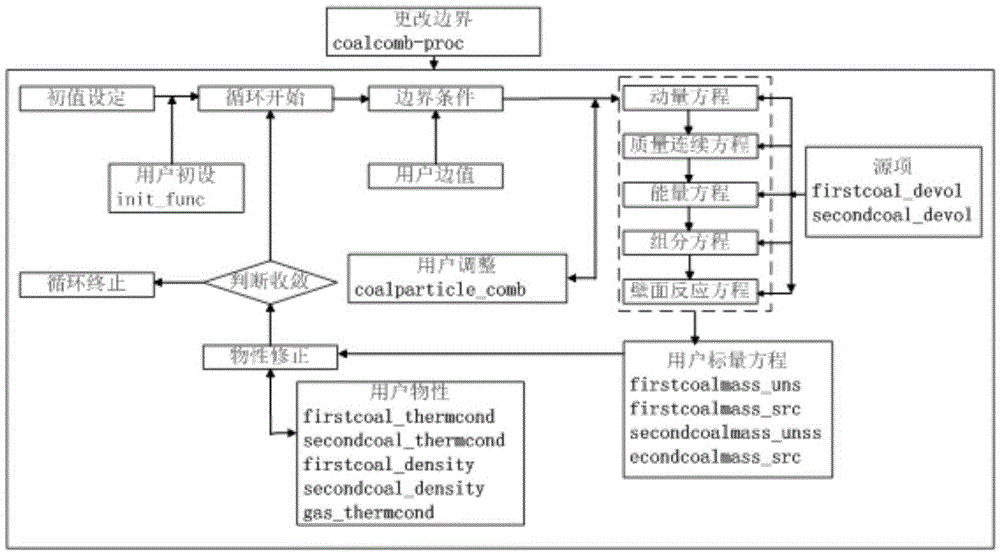

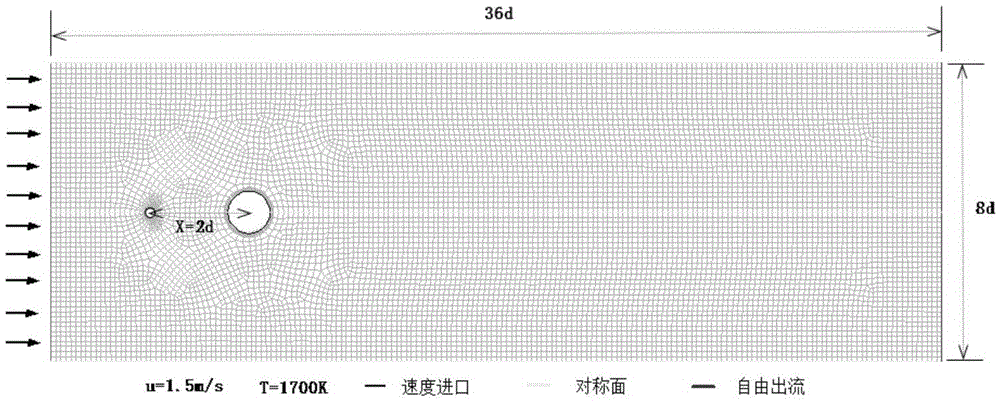

Numerical simulation method for interaction of coal powder particles in burning

ActiveCN105590005ARealize Holographic SimulationConvenient and efficient holographic simulationSpecial data processing applicationsPrillHybrid programming

The invention discloses a numerical simulation method for interaction of coal powder particles in burning, belonging to the technical field of computer numerical simulation. According to the characteristics of burning of the coal powder particles, the method is characterized in that on the basis of calculation of an existing mathematical model of fluid mechanics software FLUENT, FLUENT UDF and FLUENT Scheme are used for hybrid programming, and user-customized models, namely, a coal powder particles interaction model (a particle construction form, a particle mass change model, a particle size dynamic change model and a volatile element precipitation model) and a mass change storage mechanism, are coupled, so that numerical simulation of interaction of the coal powder particles in burning is realized. Experiments show that change rules of coal powder particle temperature and so on obtained through the numerical simulation method are generally consistent with experiment data. Through adoption of the method, a real, objective interaction mechanism of coal powder particles in burning is disclosed conveniently and efficiently, thereby providing powerful theoretical basis and technological support for improvement and optimization design of the coal powder burning technology.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

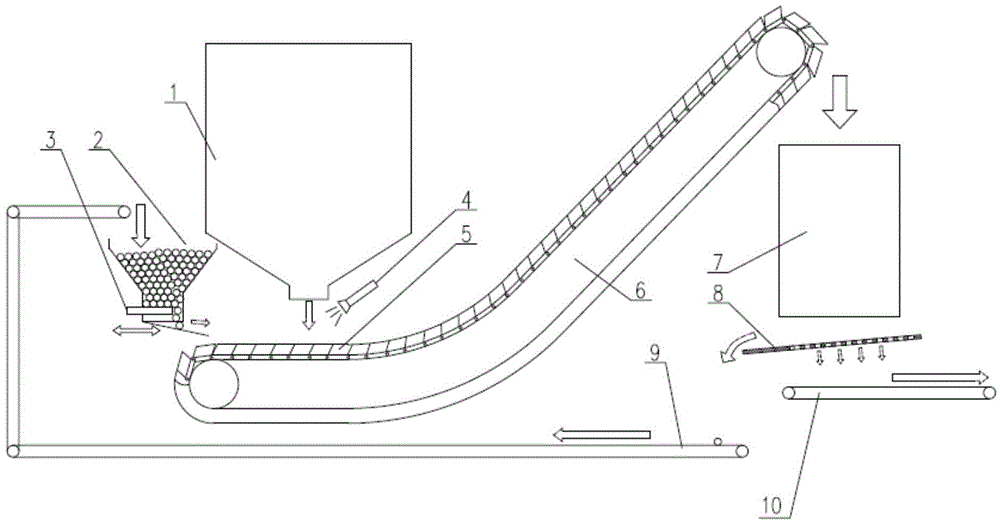

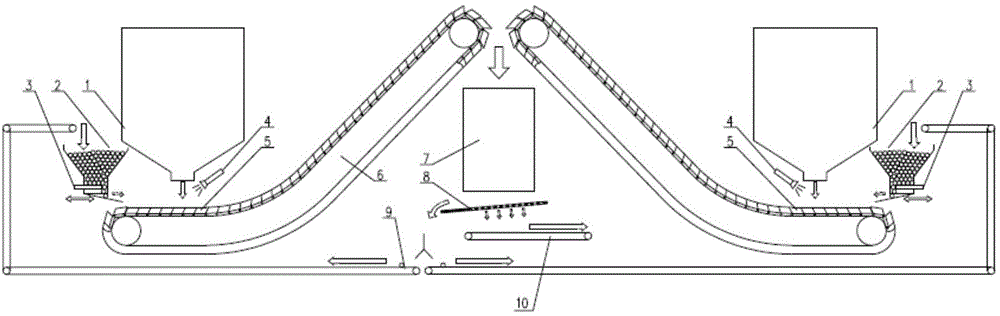

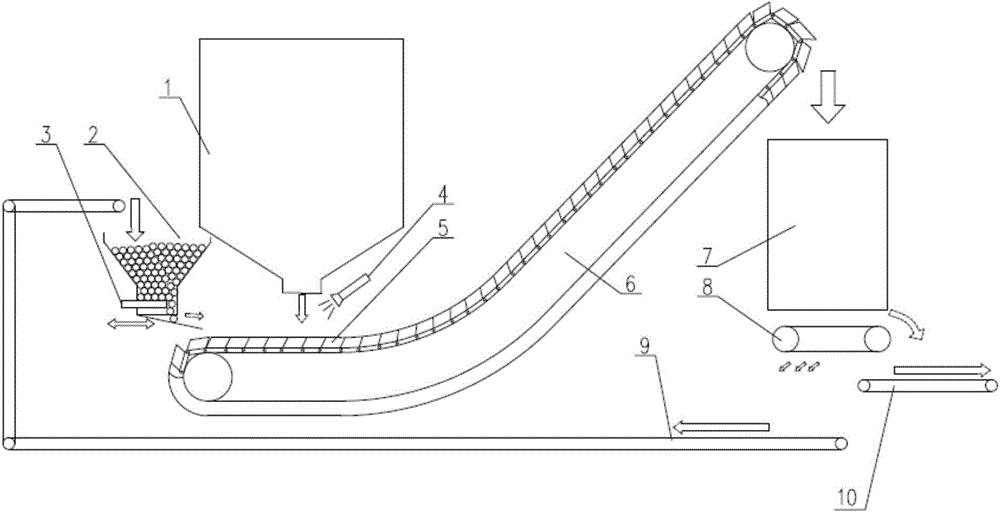

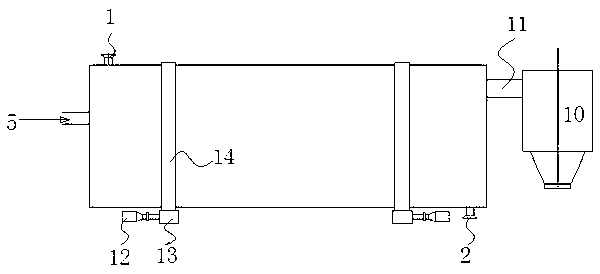

Molten slag dry granulation and waste heat recovery system

InactiveCN104404178AAvoid remeltingReduce the temperatureRecycling and recovery technologiesWaste heat treatmentWaste heat recovery unitChain conveyor

The invention relates to a molten slag dry granulation and waste heat recovery system, and belongs to the technical field of metallurgy energy saving. The system comprises a molten slag dry granulation unit 1 and a waste heat recovery unit 7, wherein the molten slag dry granulation unit 1 is connected with the waste heat recovery unit 7 through a bucket chain conveyor 6; a cold material bin 2 is arranged above the head part of the bucket chain conveyor 6 and can unload a cold material into the conveyor; a flow adjustment device 3 is arranged at the bottom of the cold material cabin 2, and the flow of the cold material is adjusted by the flow adjustment device 3, so that the flow of the cold material is controllable. According to the system, the cold material and granulated slag particles are mutually mixed; the temperature of the slag particles is reduced; the re-melting of the slag particles is avoided; the requirement for the high temperature resistance of conveying machinery is reduced; the slag particles are transported by using the bucket chain conveyor; the molten slag dry granulation unit and the waste heat recovery unit are arranged conveniently and flexibly according to actual situations; a slag particle temperature control method is provided, so that the temperature of the materials at the inlet of the waste heat recovery unit basically keeps stable.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD

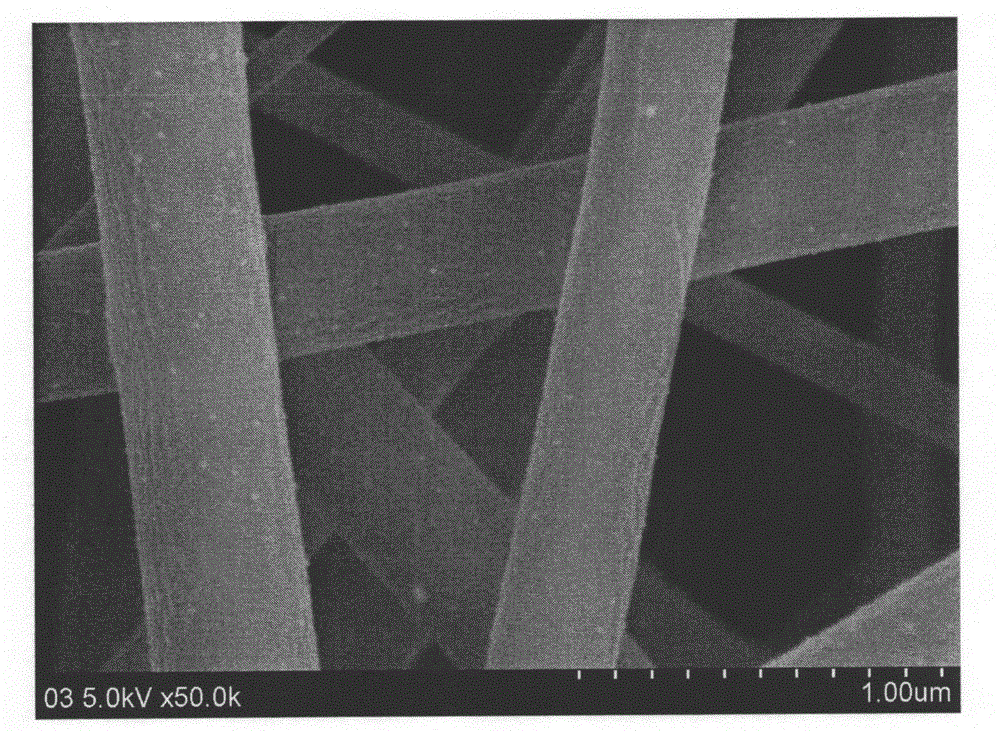

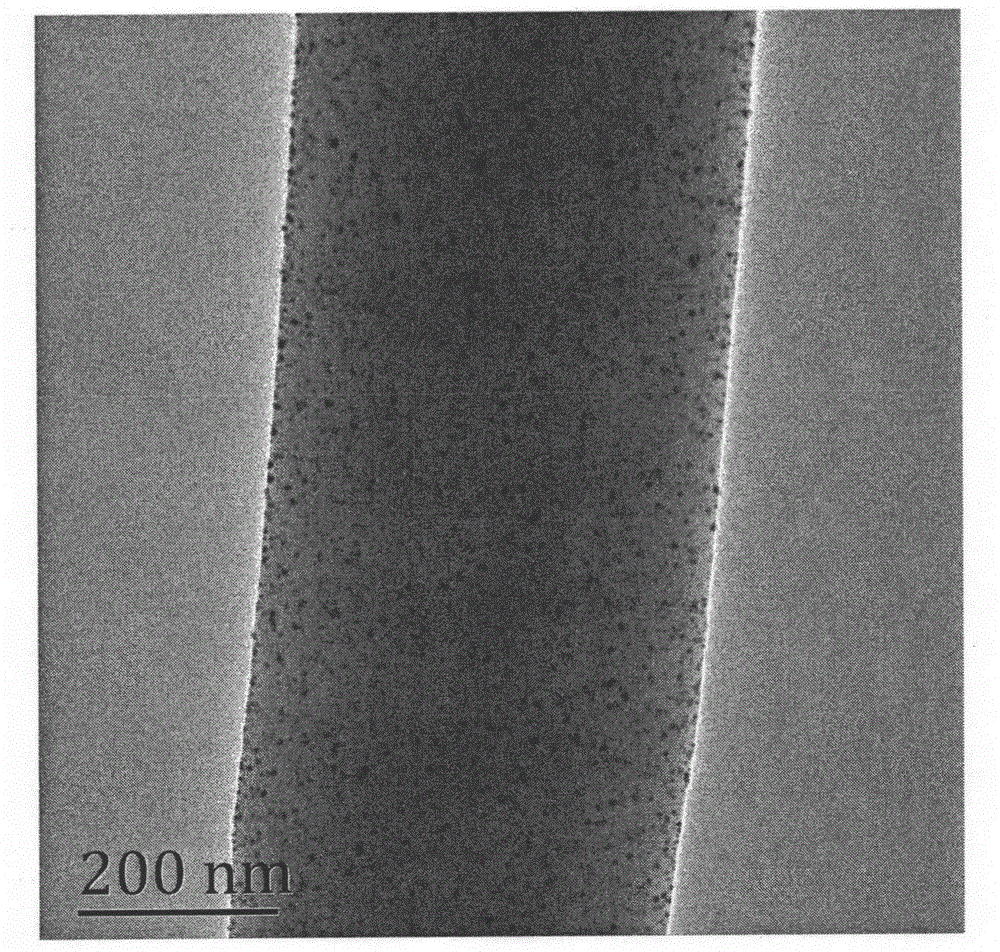

Preparation method for silver-loaded nano particle temperature stimuli responsiveness hybrid nanofiber membrane

InactiveCN104928851ASimple processMass-producedHeating/cooling textile fabricsNon-woven fabricsPolymer dissolutionFunctional monomer

The invention discloses a preparation method for a silver-loaded nano particle temperature stimuli responsiveness hybrid nanofiber membrane. The method comprises the steps that temperature stimuli responsiveness monomers and functional monomers with heat reactivity groups are copolymerized to form a polymer with the temperature stimuli responsiveness by adopting a free radical polymerization method; the polymer is dissolved in deionized water at room temperature, proper silver nitrate is added into the deionized water with the polymer, the mixture is mixed evenly, and the silver ions in the mixture are reduced to silver nanoparticles through ultraviolet light irradiation; electrostatic spinning is conducted on a polymer aqueous solution with the silver nanoparticles, and the silver-loaded nano particle temperature stimuli responsiveness hybrid nanofiber membrane is obtained. According to the preparation method for the silver-loaded nano particle temperature stimuli responsiveness hybrid nanofiber membrane, the hybrid nanofiber membrane is prepared by adopting an electrostatic spinning method, in the preparation process, water is adopted to serve as the solution, mild conditions are achieved, and harmful and poisonous products are not produced; the silver-loaded nano particle temperature stimuli responsiveness hybrid nanofiber membrane can be stored in the water stably, dissociation does not occur, the temperature stimuli responsiveness is achieved, and the silver-loaded nano particle temperature stimuli responsiveness hybrid nanofiber membrane can be used for catalytic reaction or a substrate with the surface-enhanced Raman spectrum or antiseptic dressing.

Owner:DONGHUA UNIV

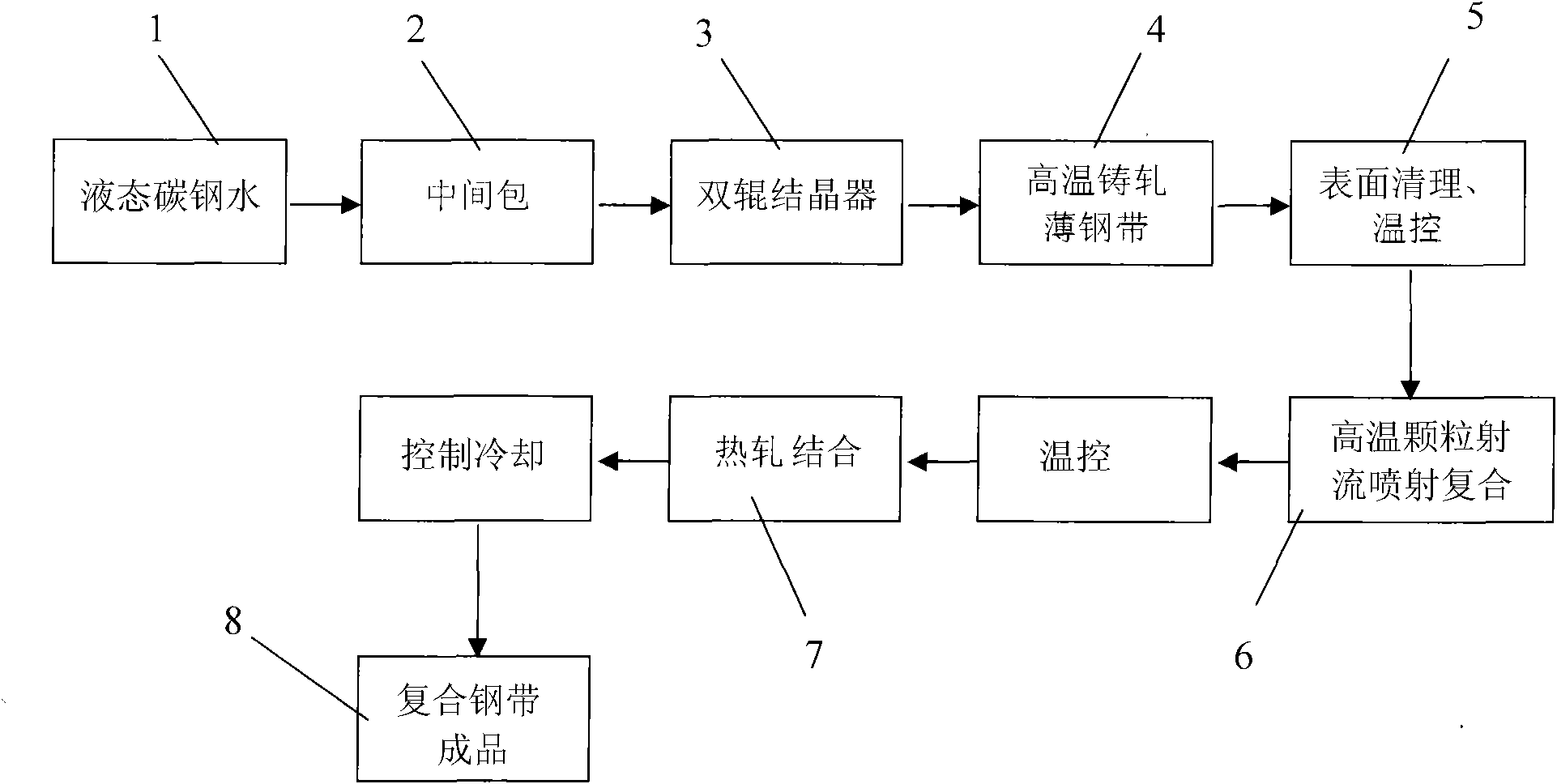

Method for producing composite steel plate by strip continuous casting and tandem rolling

ActiveCN101683656AGood deformabilityEffective bondingTemperature control deviceWork treatment devicesSurface layerLiquid carbon

The invention discloses a method for producing composite steel plate by strip continuous casting and tandem rolling. Liquid carbon molten steel forms a thin steel band by twin-roll strip continuous casting; after the thin steel band leaves a casting roll contact point, high-temperature stainless steel particles are jetted on the surface of the thin steel band, the stainless steel particles are spliced to form a stainless steel surface layer, and particle temperature is 550-650 DEG C; hot rolling is performed to form a composite steel plate with the carbon steel being in the core and stainlesssteel being on the surface. The composite steel plate of the invention has the characteristics of favourable surface corrosion resistance, high core strength, favourable comprehensive performance andthe like.

Owner:BAOSHAN IRON & STEEL CO LTD

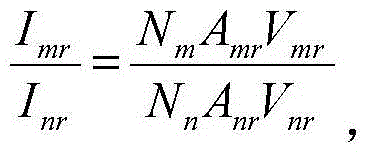

Analyzing method of gas discharge experiment under unconventional condition

InactiveCN104360253ARealize visualizationUnderstand clearlyTesting dielectric strengthHigh energyMechanical equilibrium

The invention discloses an analyzing method of gas discharge experiment under an unconventional condition, belonging to the technical field of high-voltage and high-energy physical gas discharge. The analyzing method is used for solving the problem that information expressed by an air-gap discharge signal cannot be analyzed as the experimental means of the gas discharge process under the unconventional condition are laggard, and the discharge process state cannot be accurately obtained. The analyzing method comprises the following steps: firstly, obtaining spectral line intensity Inm when particles jump towards low energy level Em from high energy level En; obtaining a relative intensity ratio of two spectral lines, under the public low energy level, of the particles; establishing boltzmann distribution equation, and calculating according to the particle density ratio on the two energy levels Em and En of the same particles when the particles achieve thermodynamic equilibrium or local thermodynamic equilibrium to obtain a particle temperature T; and obtaining the particle density distribution by determining the spectral characteristic of a gas medium in a sealed discharge chamber according to the particle temperature T. The analyzing method disclosed by the invention is used for analyzing the gas discharge process.

Owner:HARBIN UNIV OF SCI & TECH

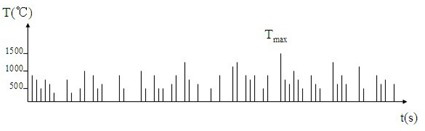

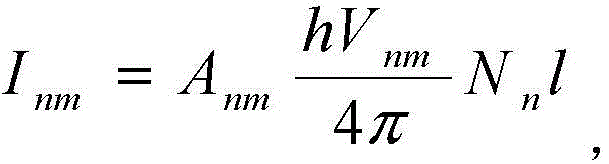

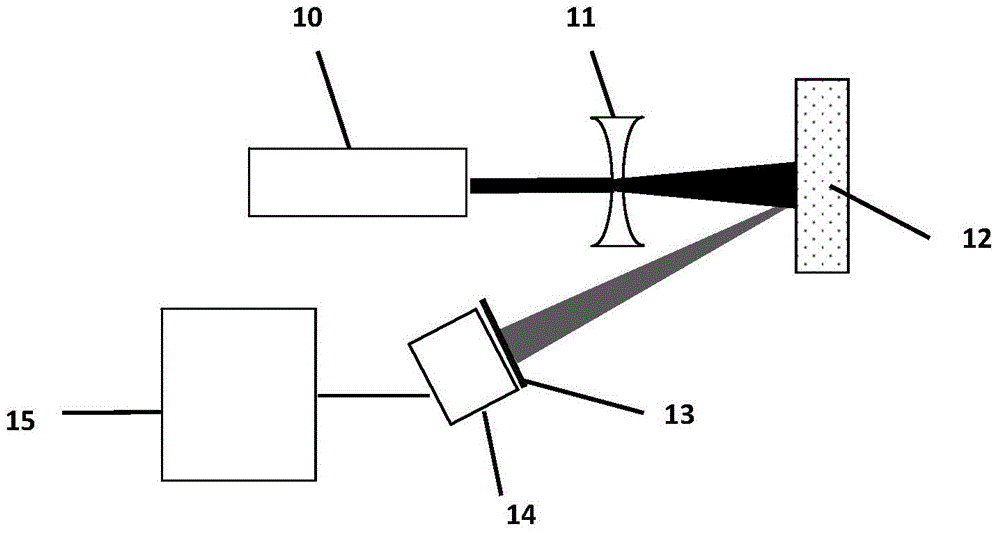

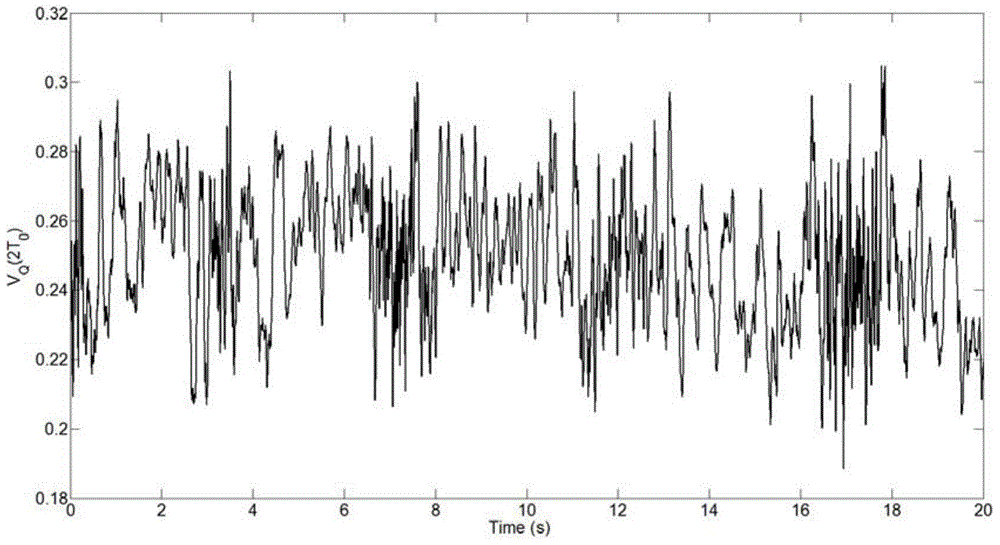

Particle temperature delta v measuring method

InactiveCN103604514AMeet the needs of particle temperature measurementMeet the needs of temperature measurementThermometers using mean/integrated valuesMaterial analysisDelta-vImage resolution

The invention provides a particle temperature delta v measuring method used for measuring temperature of particles in a fluidized bed. The measuring method is characterized in that laser acts as a light source which is diffused via a concave lens and then irradiated on the particles in the fluidized bed. Dynamically fluctuated speckles are generated in a far field, and the speckles are continuously imaged by an imaging device with a unit exposure time T0 so that a series of speckle images with T0 as exposure time are obtained. The speckle images are inputted to a computer, and the speckle images with unit exposure time T0 are converted into pixel grey values with unit exposure time T0 by the computer. The pixel grey values with unit exposure time T0 are calculated so that a curve indicating that temperature delta v of the particles changes with time is obtained. According to the particle temperature delta v measuring method, a space-time resolution can reach a microsecond level and a nanometer level.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Continuous in-line manufacturing process for high speed coating deposition via kinetic spray process

InactiveCN1781610AIncrease the cross-sectional areaConstant cross-sectional areaPretreated surfacesLiquid spraying apparatusUltrasonic nozzleEngineering

An improved power injection system and its method of use in a high speed manufacturing environment. The powered nozzle system comprises: a gas / powder exchange chamber connected to a first end of a regulating chamber having a length along a longitudinal axis equal to or greater than 20 mm; a convergent ultrasonic nozzle having a converging portion separated from a diverging portion by a throat, the diverging portion comprising a first portion of increasing cross-sectional area along its length and a second portion of substantially constant cross-sectional area along its length; and a converging portion connected to a second end of the adjustment cavity opposite said first end. The method includes: using a nozzle system with the addition of hard particles that allow for maximum particle temperature without clogging the nozzle; using controlled particle feed rates to accommodate very high traverse speeds; and preheating the substrate for cleaning substrate thereby enhancing particle binding properties. In conjunction with the disclosed nozzle systems and methods, kinetic spraying can be performed at traverse speeds in excess of 200 cm / s and deposition efficiencies in excess of 80%.

Owner:DELPHI TECH INC

Diamond abrasive particle wear prediction method based on finite element dynamic scribing simulation

ActiveCN110263476AThe result is easy to convergeDesign optimisation/simulationSpecial data processing applicationsMaterials scienceModelling software

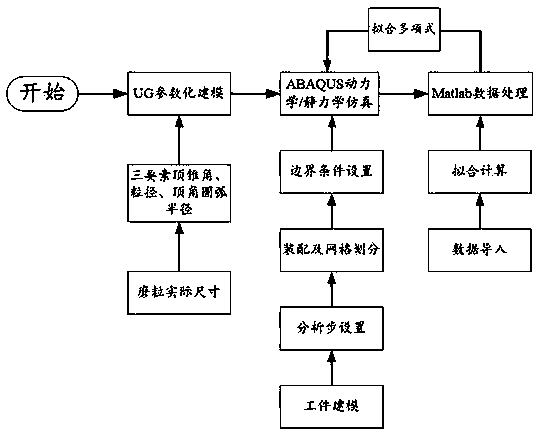

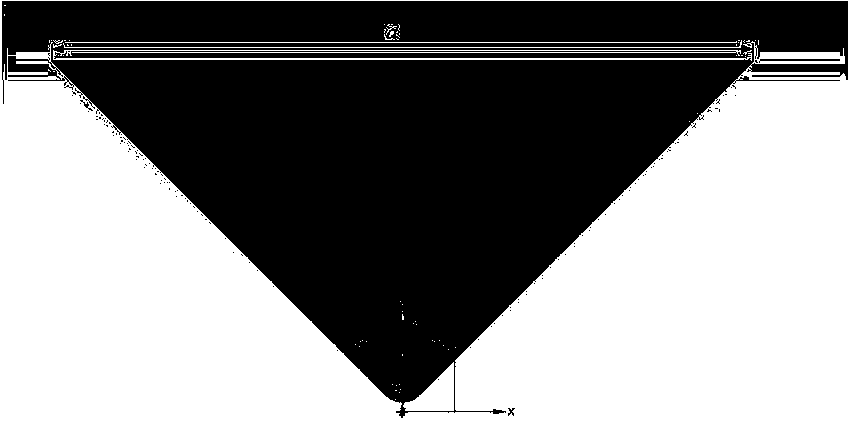

The invention provides a diamond abrasive particle abrasion prediction method based on finite element dynamic scribing simulation. According to the method, stress data and temperature data obtained in the abrasive particle dynamic scribing process are fitted and loaded to abrasive particles for calculation and prediction of abrasive particle abrasion. The method comprises the steps that the geometric size of abrasive particles is defined according to actual machining conditions, and modeling software is used for conducting parametric modeling; a workpiece model is established in finite element simulation software, and workpiece and abrasive particle material attribute endowing, assembling work, analysis step setting, grid division, contact setting and the like are sequentially completed; single diamond abrasive particle scribing simulation is finished, and stress data, abrasive particle temperature distribution data and the like are obtained in the scribing process through post-processing; mathematical software is used to fit scribing time-stress data and scribe time-temperature data into a polynomial; and the obtained stress and temperature data are loaded on the abrasive particles in the form of an equation to predict the wear area and the wear amount of the abrasive particles. Combined dynamic simulation of single abrasive particle scribing and abrasion evolution and abrasion loss prediction of the diamond abrasive particle scribing process are carried out by combining modeling software, a finite element simulation analysis technology and mathematical software.

Owner:CHONGQING UNIV OF TECH

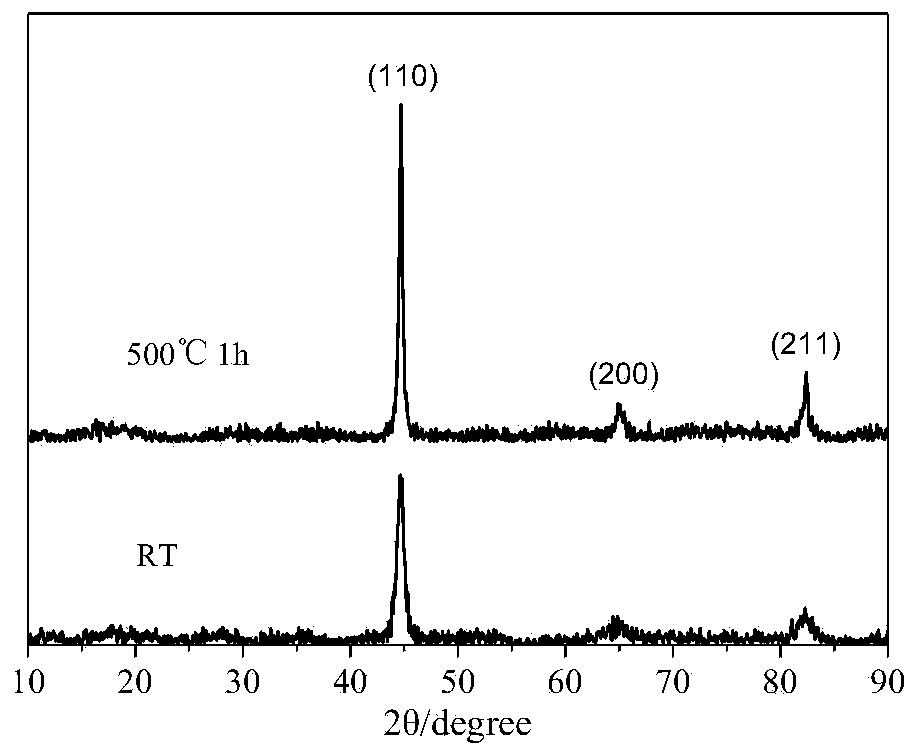

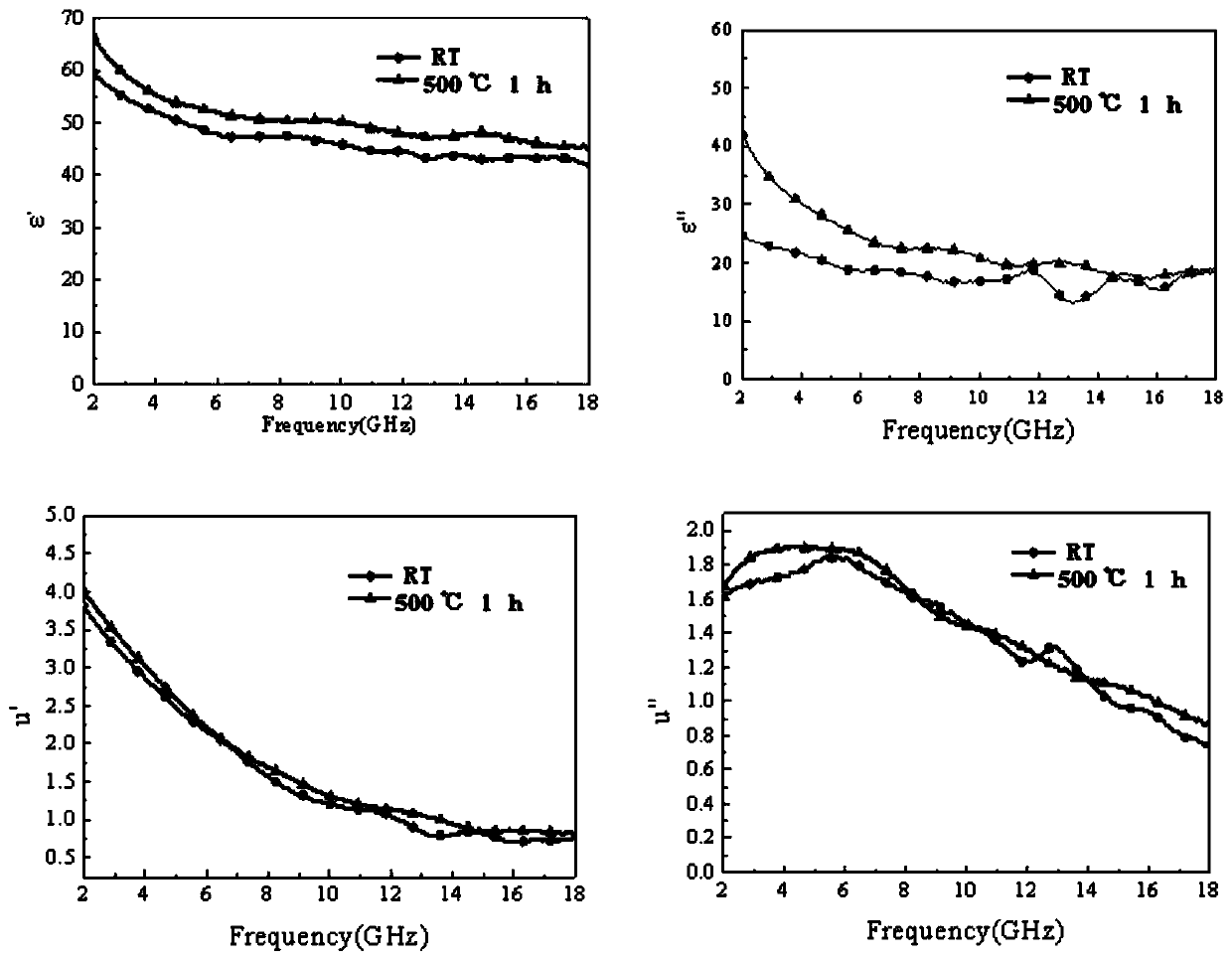

Fe-based composite particle temperature-resisting absorbent and preparing method thereof

InactiveCN110405195AGrain size stabilityElectromagnetic performance does not change significantlyMagnetic/electric field screeningTransportation and packagingIron powderHigh energy

The invention discloses a Fe-based composite particle temperature-resisting absorbent. The raw material of the Fe-based composite particle temperature-resisting absorbent comprises carbonyl iron powder and Si powder, and Fe-based composite particles are formed by carbonyl iron powder and Si powder through a high-energy ball milling manner, the grain structure of the Fe-based composite particles isthe alpha-Fe phase, and the grain size is in the range of 10 to 11 nm. Si elements are evenly distributed in a base body of the carbonyl iron powder, after one-hour heat treatment of 500 DEG C, the grain size and electromagnetic parameters of the composite particles are basically kept unchangeable, and the good temperature resistance is achieved. The method is simple in preparing process, the problem that grains of the magnetic temperature-resisting absorbent grow is solved, and the method has the important significance in development of the temperature-resisting wave-absorbing material.

Owner:AEROSPACE SCI & IND WUHAN MAGNETISM ELECTRON

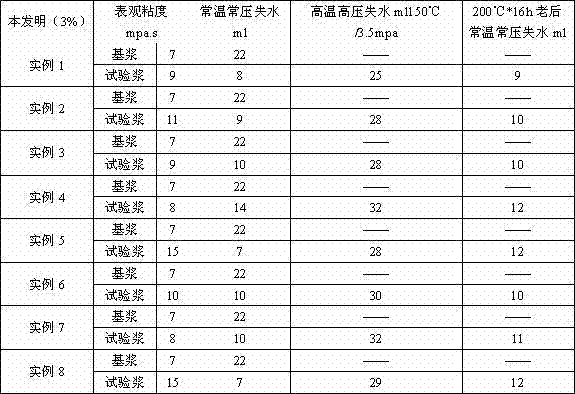

Efficient temperature resistance fluid loss agent for drilling fluid and preparation method thereof

The invention discloses efficient temperature resistance fluid loss agent for drilling fluid and a preparation method thereof. The preparation method comprises the steps that firstly 200 to 230 parts of water are added into a reaction kettle to be heated to 50 to 60 DEG C; 15 to 18 parts of sodium hydroxide is added into the reaction kettle while being stirred; 25 to 40 parts of hydrolyzed polyacrylonitrile is added into the reaction kettle; finally 45 to 70 parts of decomposed coal is added into the reaction kettle; the mixture is heated to 80 to 85 DEG C; reaction is performed for 3 to 4 hours; obtained liquid is fed into drying equipment through a feeding pump; and then black brown spherical fine particle temperature resistance fluid loss agent is obtained. The efficient temperature resistance fluid loss agent is high in dissolving speed, can effectively reduce the loss amount during the drilling process, is in favor of protecting reservoir beds, has good temperature resistance, can be resistant to 200 DEG C, has a certain lubricating property, reduces the friction drag, improves the drilling speed, is simple in production technology, is not required to be cooled, and greatly reduces the labor intensity and the equipment use level, thereby reducing the production cost of enterprises and improving the economic benefit.

Owner:河南海洋化工科技股份有限公司

Device and method for monitoring high-temperature particle temperature field in flight

ActiveCN107525590AImprove accuracySensing radiation from moving bodiesRadiation thermographyContinuous measurementVertical plane

A device for monitoring a high-temperature particle temperature field in flight comprises a particle spray gun, a semi-closed cover housing, an image camera, an optical pyrometer and a black-body furnace. The top end of the semi-closed cover housing is provided with a particle introducing hole, an image photographing hole, a dial, a pin and a temperature measuring guide pipe. The dial is a sector-shaped dial. The dial is a vertical plane and is fixed at top end of the semi-closed cover housing. The pin fixes the temperature measuring guide pipe on the top end of the semi-closed cover housing, and makes the temperature measuring guide pipe rotate around the pin in the vertical plane. The optical pyrometer is inserted into the temperature measuring guide pipe. The bottom of the semi-closed cover housing is provided with a first black-body furnace hearth and a second black-body furnace hearth. Black-body furnaces are respectively placed in the first black-body furnace hearth and the second black-body furnace hearth. The optical pyrometer is calibrated and furthermore a gray scale fitting curve between the temperature and the image which is photographed by the image camera is established. Then high-temperature particles are sprayed. The gray scale is calculated by means of the image which is photographed by the image camera. The temperature of the high-temperature particles is obtained through the fitting curve. The device has advantages of noncontact type, continuous measurement, etc.

Owner:TSINGHUA UNIV

Stability of gas atomized reactive powders through multiple step in-situ passivation

ActiveUS9650309B2Increases thermal ignition temperature and spark ignition resistanceReduce riskTransportation and packagingMetal-working apparatusOxygenReactive agent

A method for gas atomization of oxygen-reactive reactive metals and alloys wherein the atomized particles are exposed as they solidify and cool in a very short time to multiple gaseous reactive agents for the in-situ formation of a protective reaction film on the atomized particles. The present invention is especially useful for making highly pyrophoric reactive metal or alloy atomized powders, such as atomized magnesium and magnesium alloy powders. The gaseous reactive species (agents) are introduced into the atomization spray chamber at locations downstream of a gas atomizing nozzle as determined by the desired powder or particle temperature for the reactions and the desired thickness of the reaction film.

Owner:IOWA STATE UNIV RES FOUND

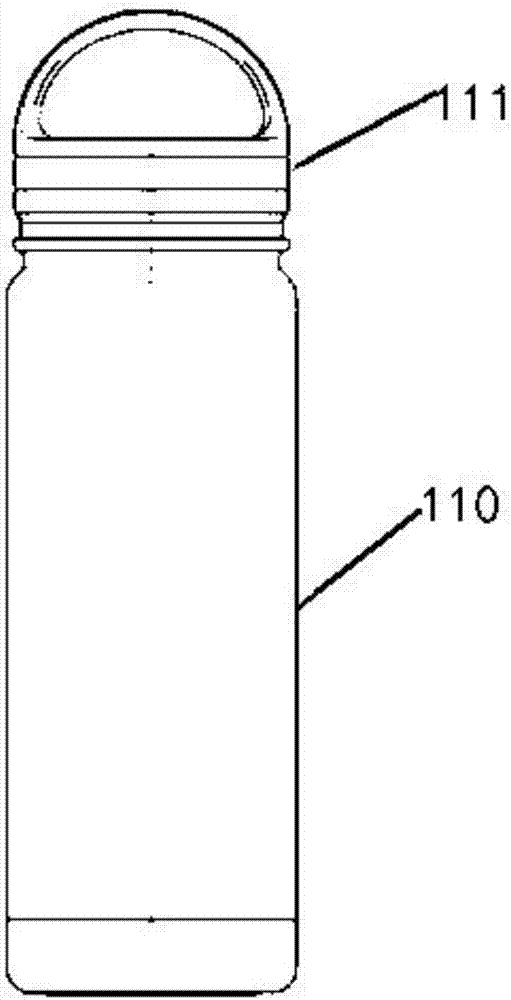

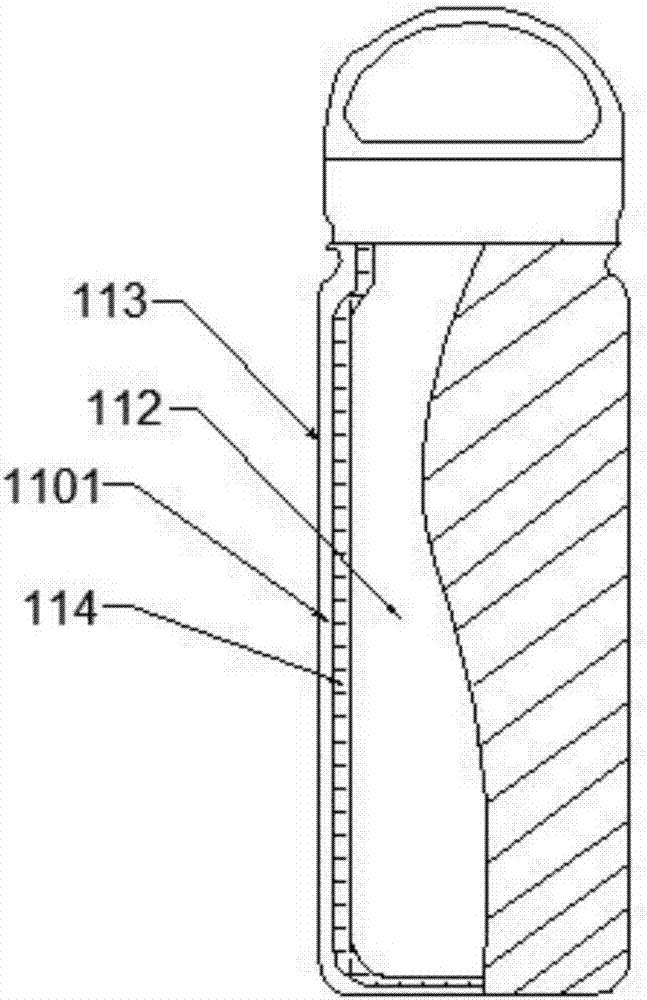

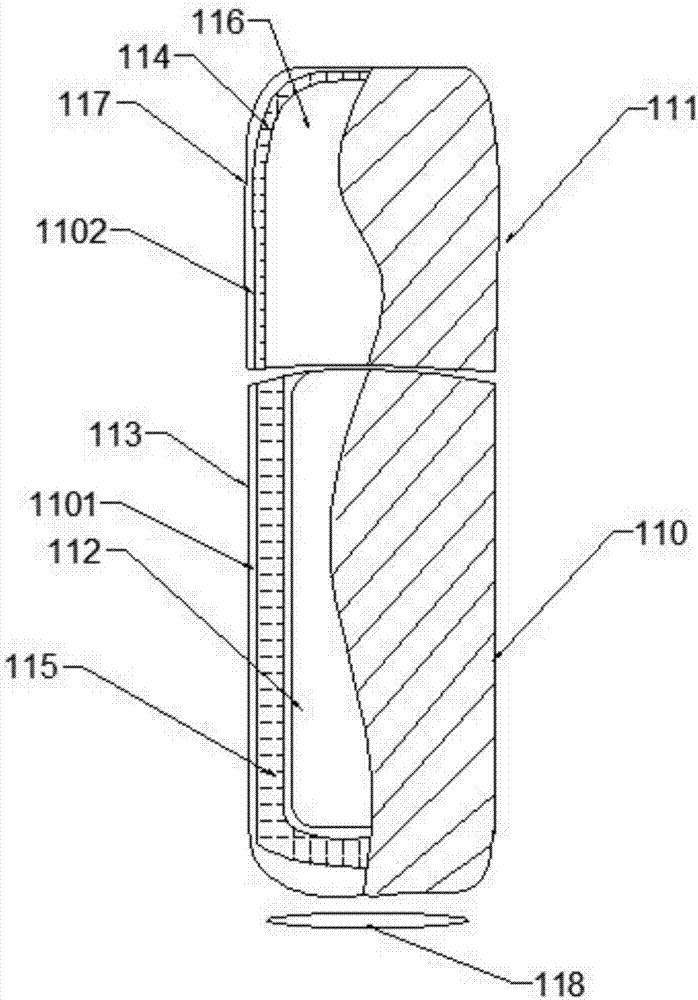

Double-temperature cup

InactiveCN107232921AMeet different drinking water needsSimple processTravelling sacksDrinking vesselsTemperature controlLiquid temperature

The invention provides a double-temperature cup. The double-temperature cup comprises a cup body and a cup lid, and is characterized in that the cup body has three layers, comprises an inner container, a first vacuum layer and a housing in sequence and is arranged at the bottom of the cup lid, and the cup lid of the double-temperature cup is filled with a phase-change composite material to form a sealed temperature control layer; the phase-change composite material is a powder temperature control material or a liquid temperature control material or a particle temperature-variable material or a blocky temperature control material. In the double-temperature cup, by making the cup lid of the double-temperature cup filled with the phase-change composite material, the phase-change composite material is added in a sandwich layer of the double-temperature cup, the heat-absorbing or heat-emitting performance of the phase-change composite material is utilized, different temperature states of water are achieved, relative temperature control is conducted to maintain a constant temperature, and different water-drinking requirements are met. The double-temperature cup is simple in technology and remarkable in temperature control effect, saves energy and protects the environment; meanwhile, the double-temperature cup has the effects of heat preservation and temperature reduction, and can meet requirements for drinking hot water, warm water and cold water in some sense.

Owner:北京宇宙沙盘太空科技有限公司

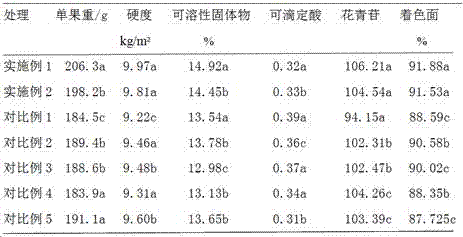

Synergistic lignin apple special-purpose fertilizer and preparation method thereof

InactiveCN106916016AConsistent nutrient requirements during growthControl contentCalcareous fertilisersAlkali orthophosphate fertiliserMathematical modelPhosphate

The invention discloses synergistic lignin apple special-purpose fertilizer and a preparation method thereof and belongs to the technical field of agricultural fertilizer. The synergistic lignin apple special-purpose fertilizer is composed of 200 to 600 parts of urea, 60 to 300 parts of monoammonium phosphate, 300 to 800 parts of potassium sulfate, 3 to 30 parts of lignin, 3 to 30 parts of ferrous sulfate heptahydrate, 3 to 25 parts of zinc sulfate monohydrate, 0.2 to 15 parts of boric acid and 0.2 to 15 parts of EDTA chelated calcium. The formula of the synergistic lignin apple special-purpose fertilizer is reasonably designed according to the law of apple growth. The synergistic lignin apple special-purpose fertilizer contains nitrogen, phosphorus and potassium and the trace elements needed for the growth period of the apples. Under action of lignin, fertilizer nutrient release satisfies nutrient demands in the apple growth period. The preparation method utilizes high tower spraying granulation, builds a mathematical model through a tower inner pressure field, a temperature field and particle temperature change and movement locus, realizes a metering precision and effectively controls content of lignin fertilizer biuret.

Owner:STANLEY AGRI GRP CO LTD

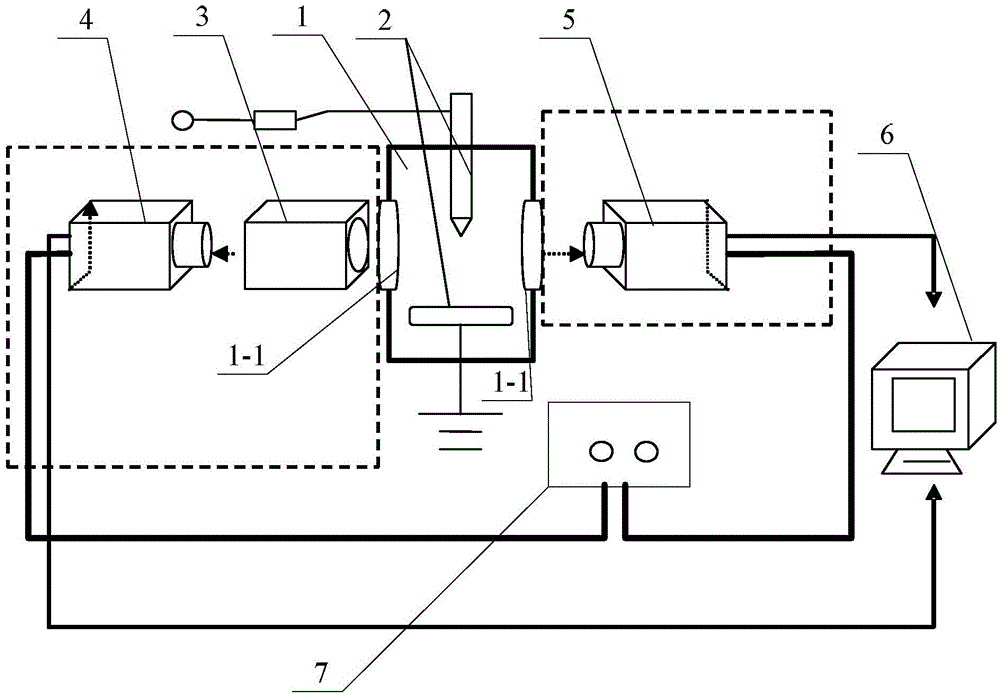

Particle temperature and particle motion synchronous measuring apparatus and method

ActiveCN107271352AHigh resolutionFast measurementIndividual particle analysisParticle flowLaser transmitter

The invention provides a particle temperature and particle motion synchronous measuring apparatus, which is used for measuring a particle temperature of a particle flow in different areas, and obtaining a particle motion condition of different areas. The particle temperature and particle motion synchronous measuring apparatus is characterized by comprising a sample pool which is used for storing particles and driving the particles to roll; a first laser transmitter which is used for emitting first laser; a first concave lens which is used for diffusing first laser and projecting the first laser onto a surface layer of the particle to form first signal light; a first band-pass optical filter which is used for allowing the light of a particular waveband in the first signal light to pass; a first signal acquisition component which is used for acquiring the first signal light to obtain a first speckle image; a second laser transmitter; a second concave lens; a second band-pass optical filter; a second signal acquisition component which is used for acquiring a second speckle image; and a computer which is used for storing, converting and calculating the first speckle image and the second speckle image to obtain a curve graph of the particle temperature and curve graph of the particle motion over time in different areas.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

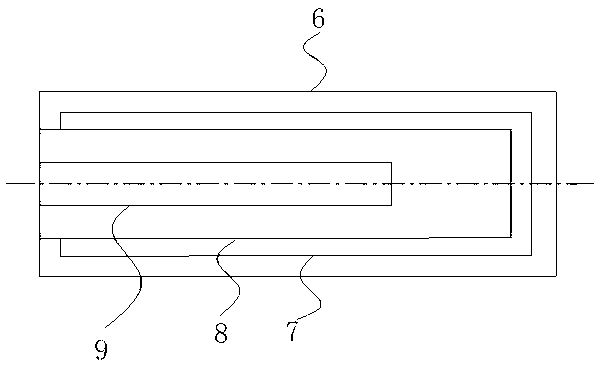

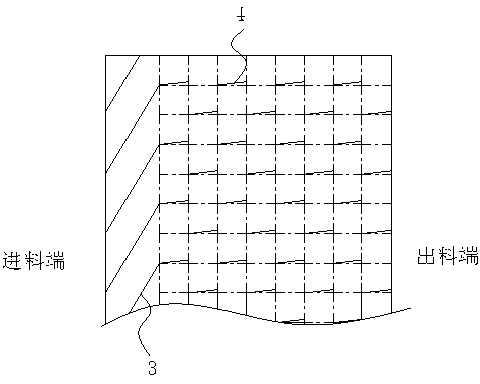

Beta-semi-hydrated gypsum powder calcination preparation technique and calcination apparatus

The invention relates to a beta-semi-hydrated gypsum powder calcination preparation technique and apparatus. The technique comprises the following steps: pulverizing a raw material into 100-140-mesh powder particles; and delivering the powder particles into a rotary kiln through a feed port of the calcination apparatus, calcining, and continuously outputting from a discharge port of the calcination apparatus after sequentially passing through at least two concentric rotating drums, wherein the kiln hood temperature is 450-550 DEG C, the kiln end temperature is 155-190 DEG C, and the powder particle temperature is 150-185 DEG C. The apparatus comprises at least two concentric rotating drums with the same capacity which are sheathed together; and a material delivery part comprises a feed port positioned at one end of the concentric rotating drums, a discharge port arranged at the same or different end of the feed port, and an auxiliary material delivery structure, wherein the auxiliary material delivery structure comprises a helical blade and / or lifting board positioned on the inner wall of the concentric rotating drums. The technique and apparatus have the advantages of massive energy saving and consumption reduction.

Owner:平邑龙源石膏建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com