Patents

Literature

1729results about "Granulation by liquid drop formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

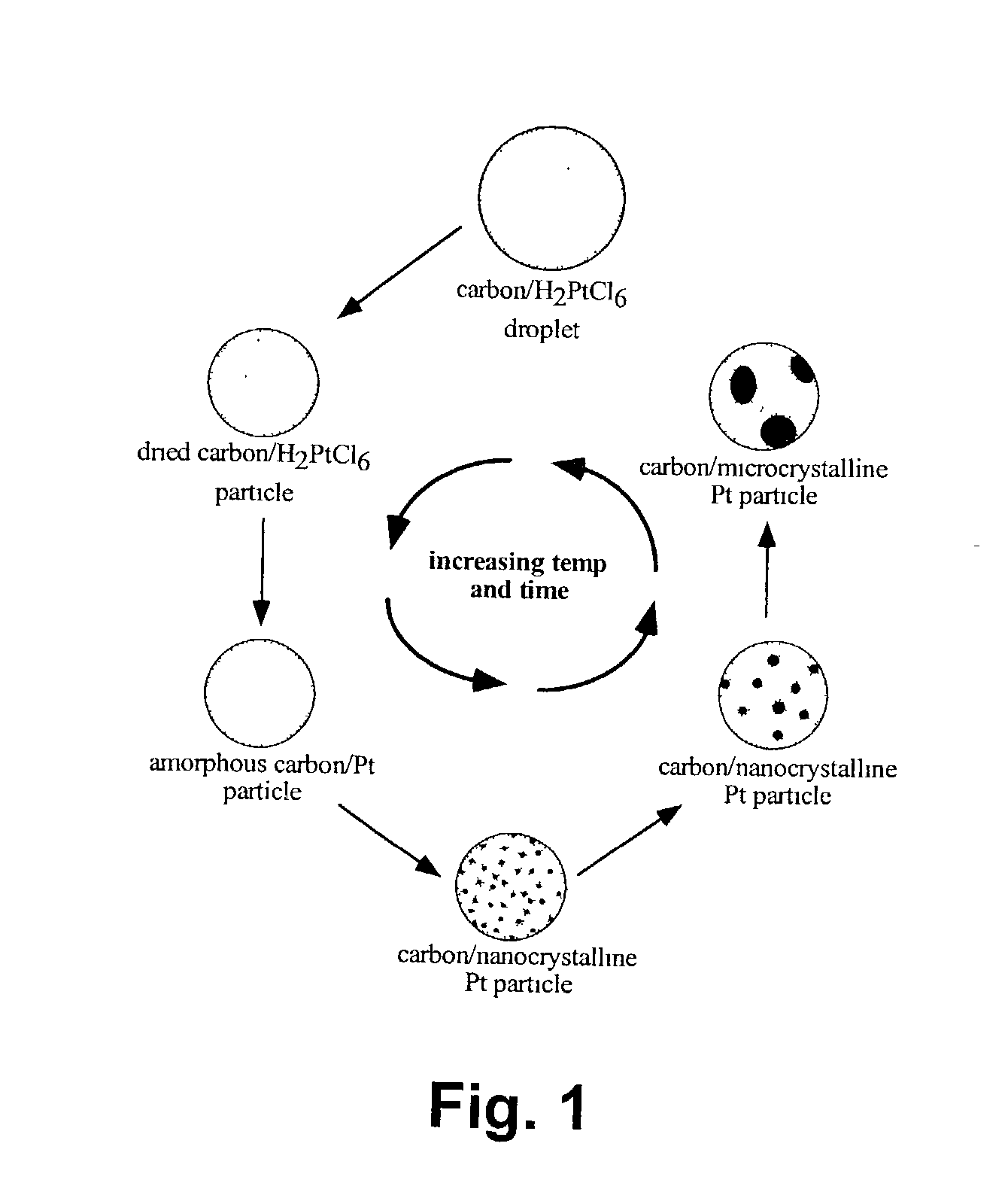

Electrocatalyst powders, methods for producing powders and devices fabricated from same

Electrocatalyst powders and methods for producing electrocatalyst powders, such as carbon composite electrocatalyst powders. The powders have a well-controlled microstructure and morphology. The method includes forming the particles from an aerosol of precursors by heating the aerosol to a relatively low temperature, such as not greater than about 400° C.

Owner:CABOT CORP

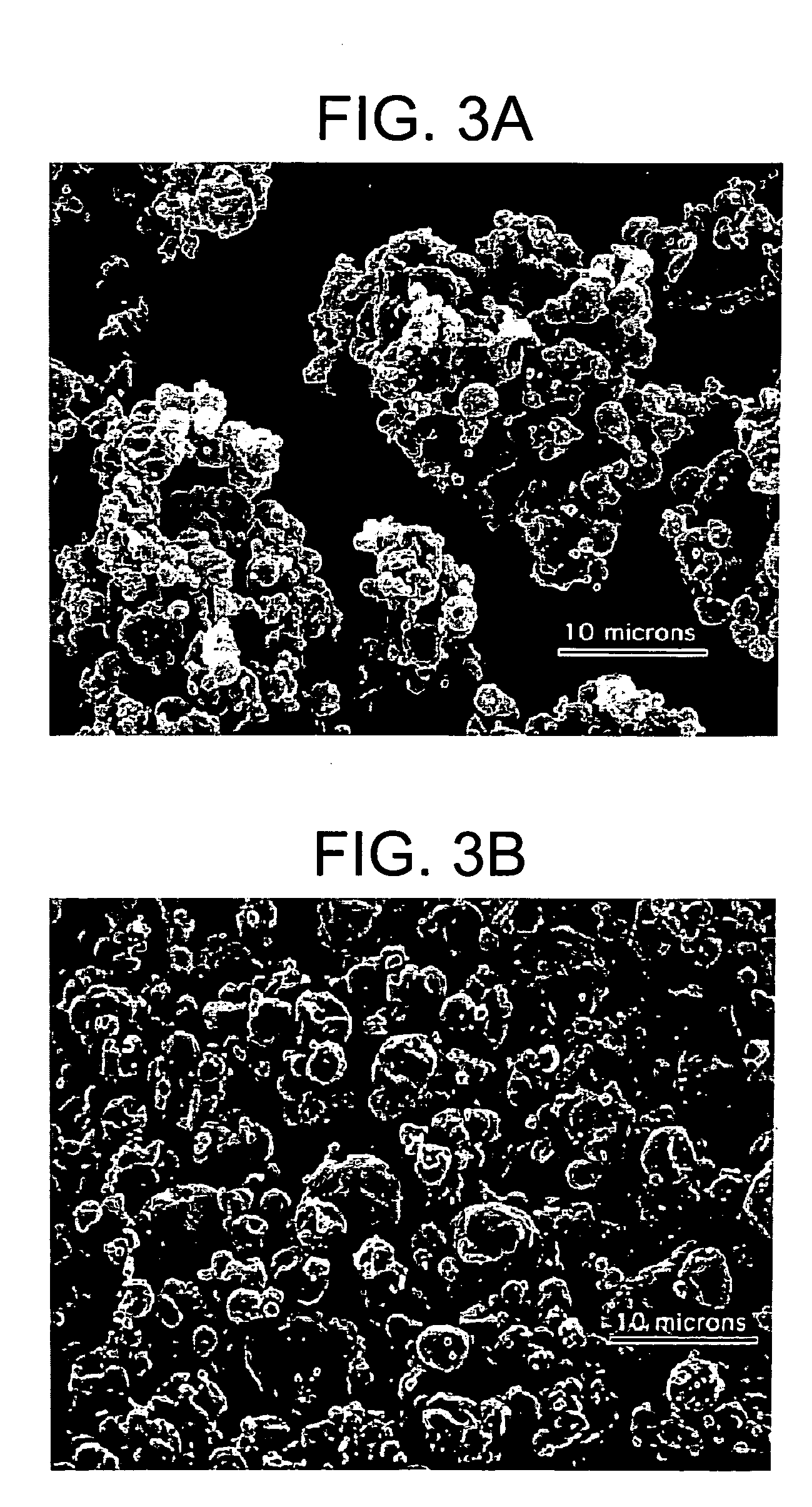

Methods for making pharmaceutical formulations comprising microparticles with improved dispersibility, suspendability or wettability

InactiveUS20050079138A1Good dispersibilityImproved suspendabilityPowder deliveryGranulation by liquid drop formationPowder mixtureMicroparticle

Methods are provided for making a dry powder blend pharmaceutical formulation, comprising the steps of: (a) providing microparticles which comprise a pharmaceutical agent; (b) blending the microparticles with at least one excipient in the form of particles to form a powder blend; and (c) jet milling the powder blend to form a dry powder blend pharmaceutical formulation having improved dispersibility, suspendability, or wettability as compared to the microparticles of step (a) or the powder blend of step (b). The method can further include dispersing the dry powder blend pharmaceutical formulation in a liquid pharmaceutically acceptable vehicle to make an formulation suitable for injection. Alternatively, the method can further include processing the dry powder blend pharmaceutical formulation into a solid oral dosage form. In one embodiment, the microparticles of step (a) are formed by a solvent precipitation or crystallization process.

Owner:ACUSPHERE INC

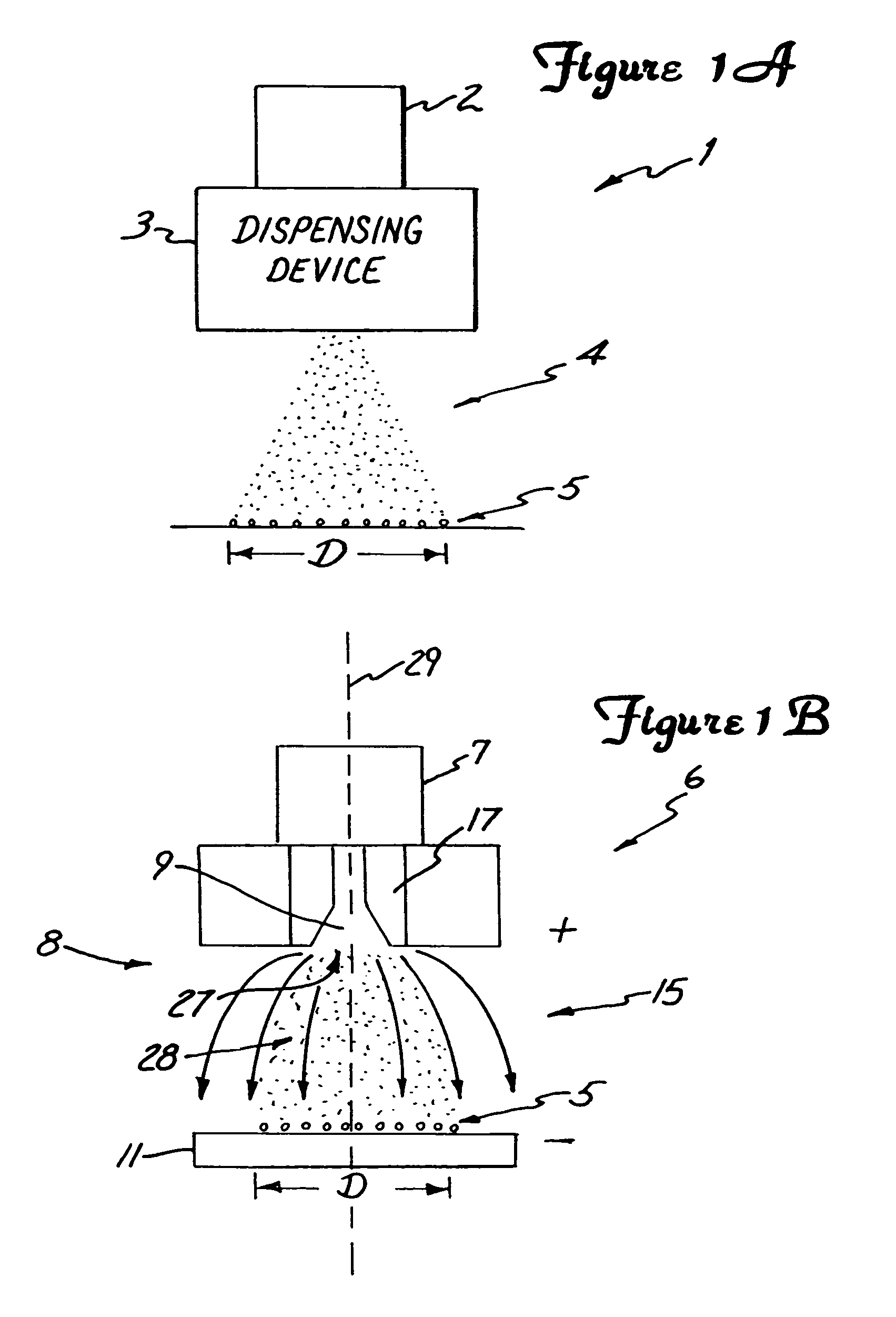

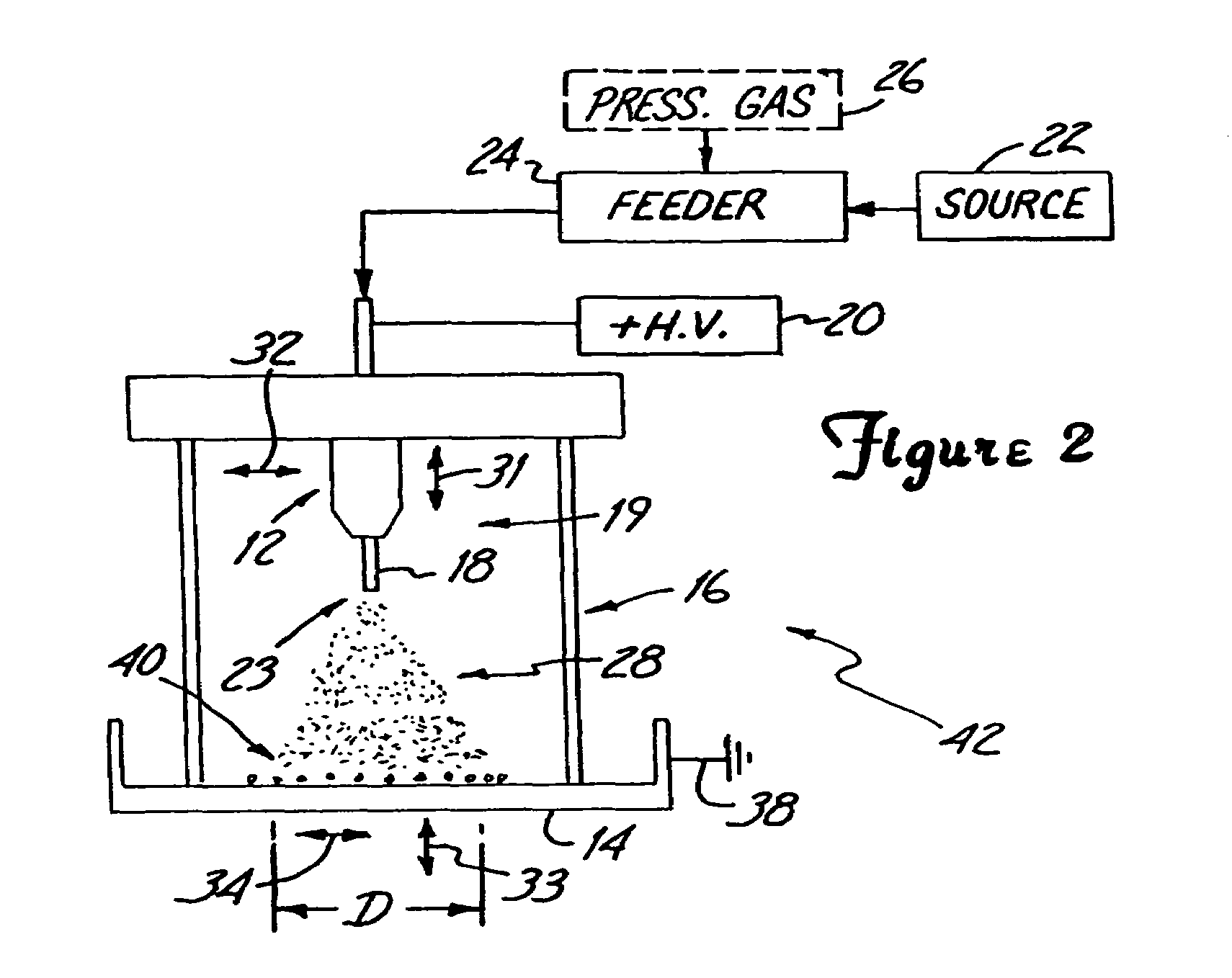

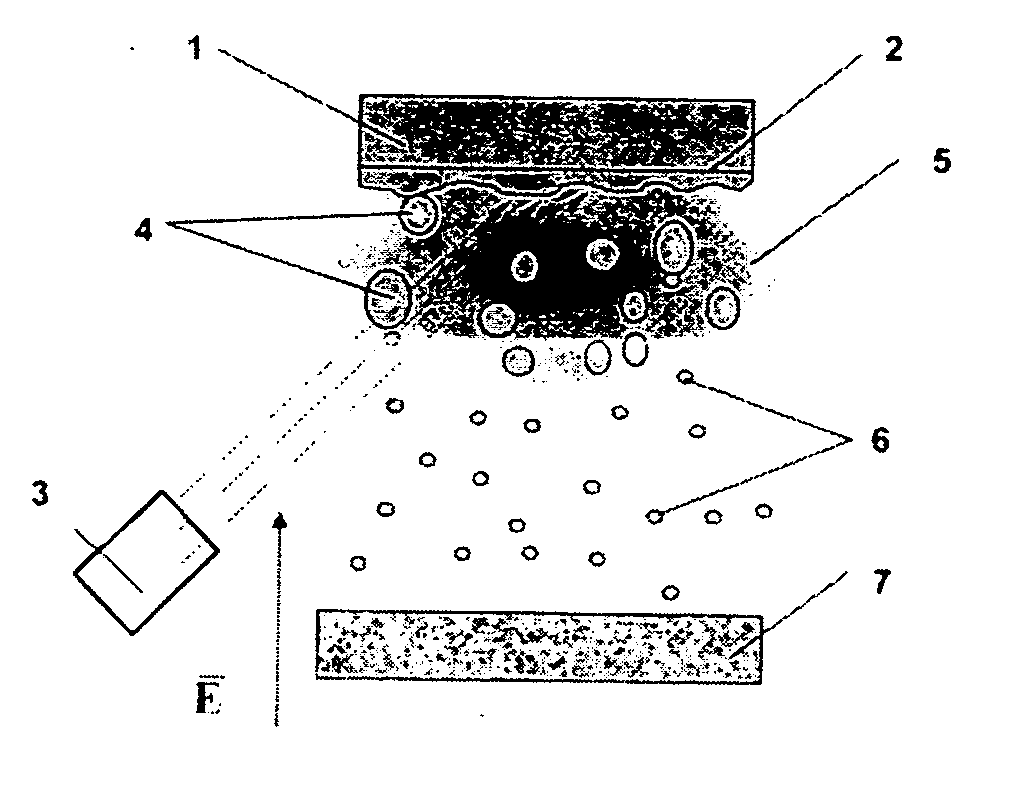

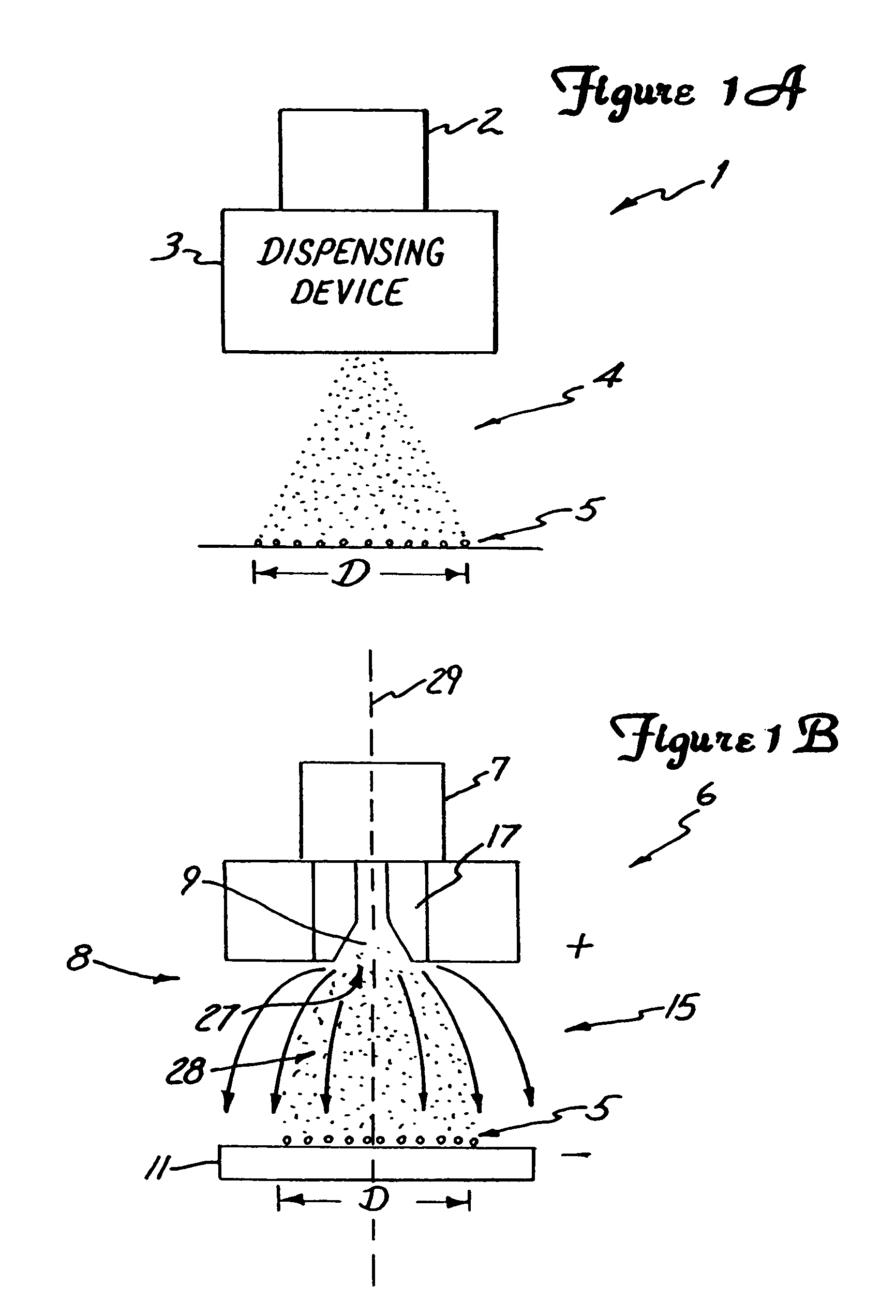

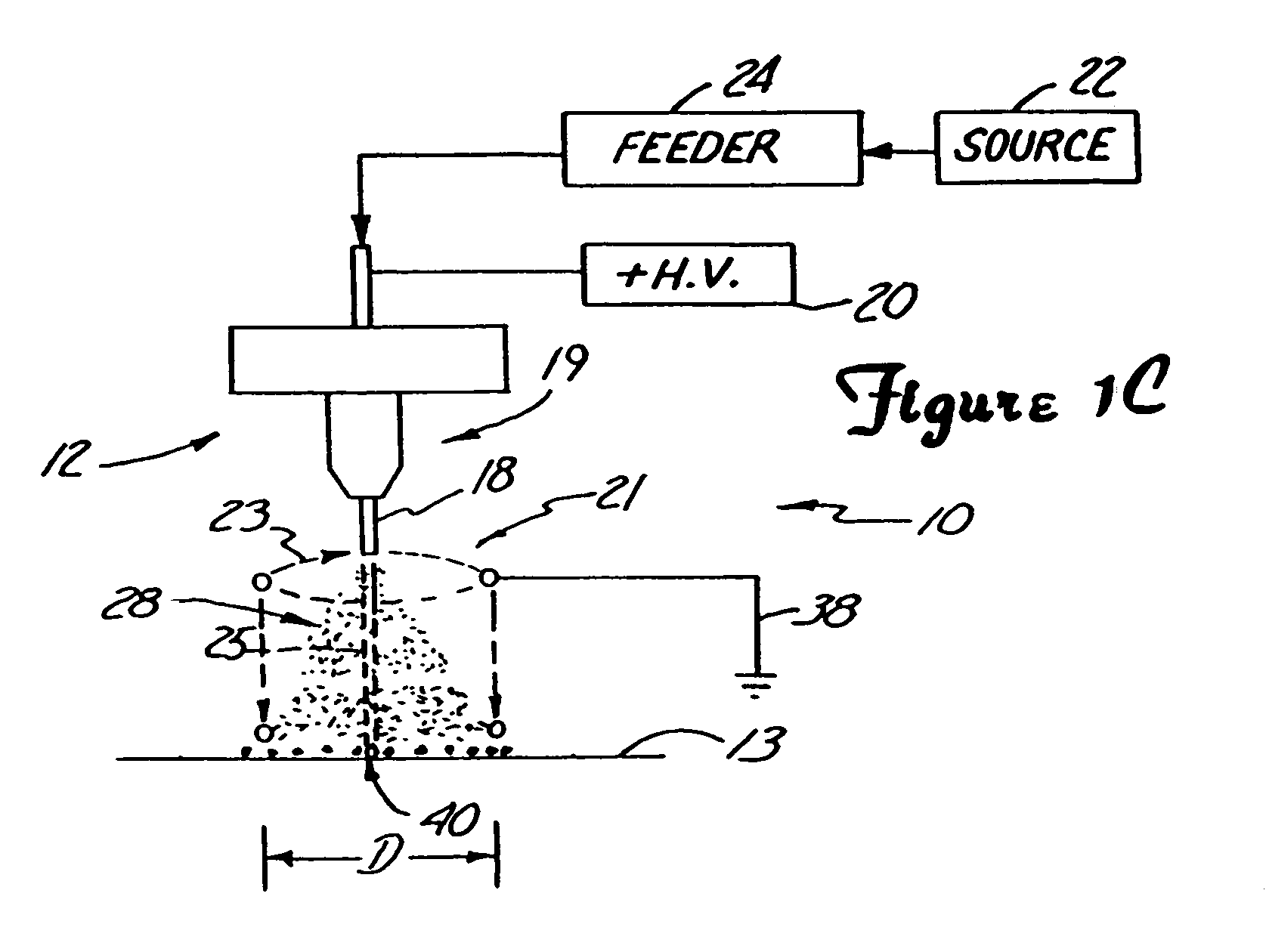

Electrospraying apparatus and method for coating particles

An electrospraying apparatus and / or method is used to coat particles. For example, a flow including at least one liquid suspension may be provided through at least one opening at a spray dispenser end. The flow includes at least particles and a coating material. A spray of microdroplets suspending at least the particles is established forward of the spray dispenser end by creating a nonuniform electrical field between the spray dispenser end and an electrode electrically isolated therefrom. The particles are coated with at least a portion of the coating material as the microdroplet evaporates. For example, the suspension may include biological material particles.

Owner:RGT UNIV OF MINNESOTA

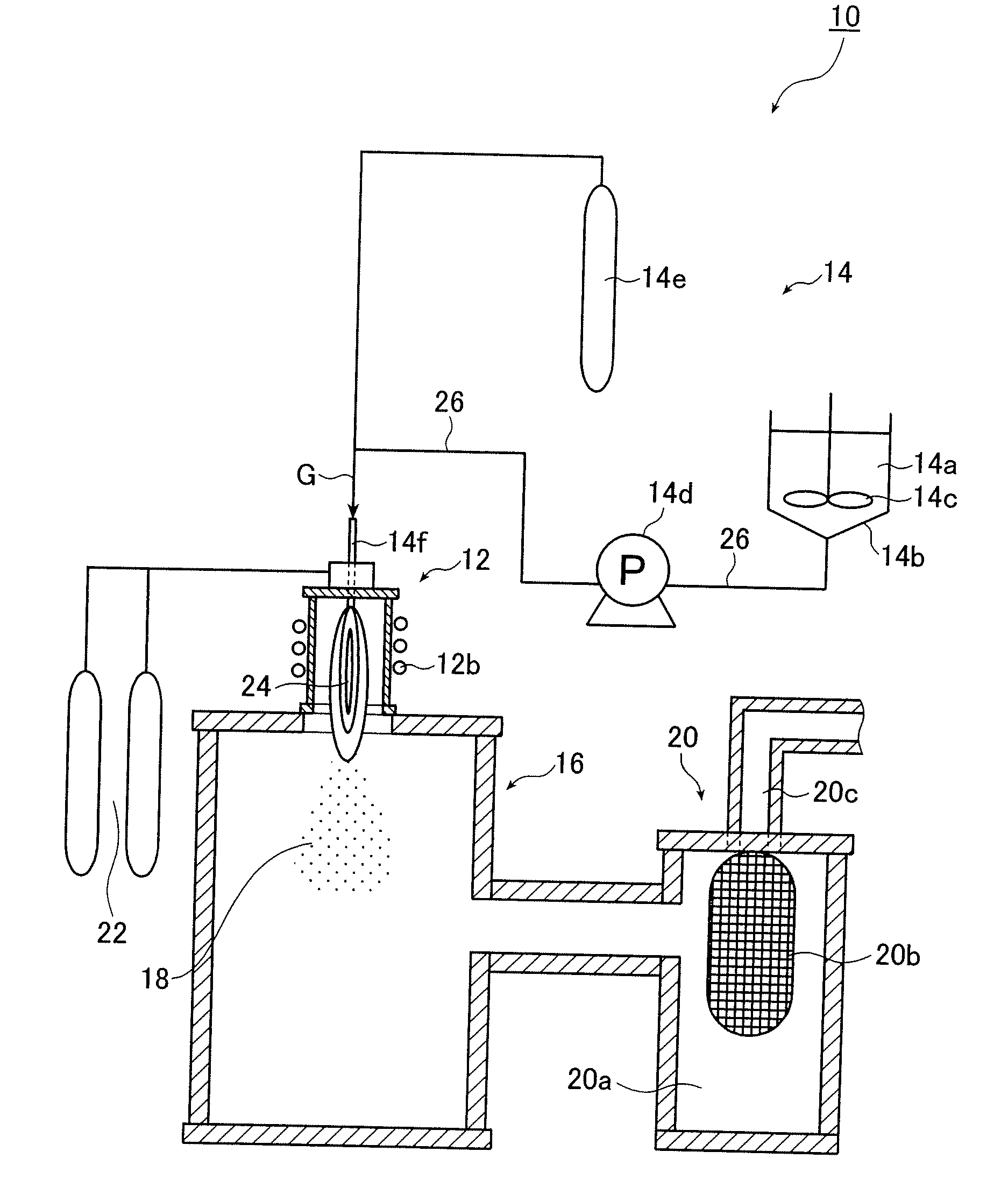

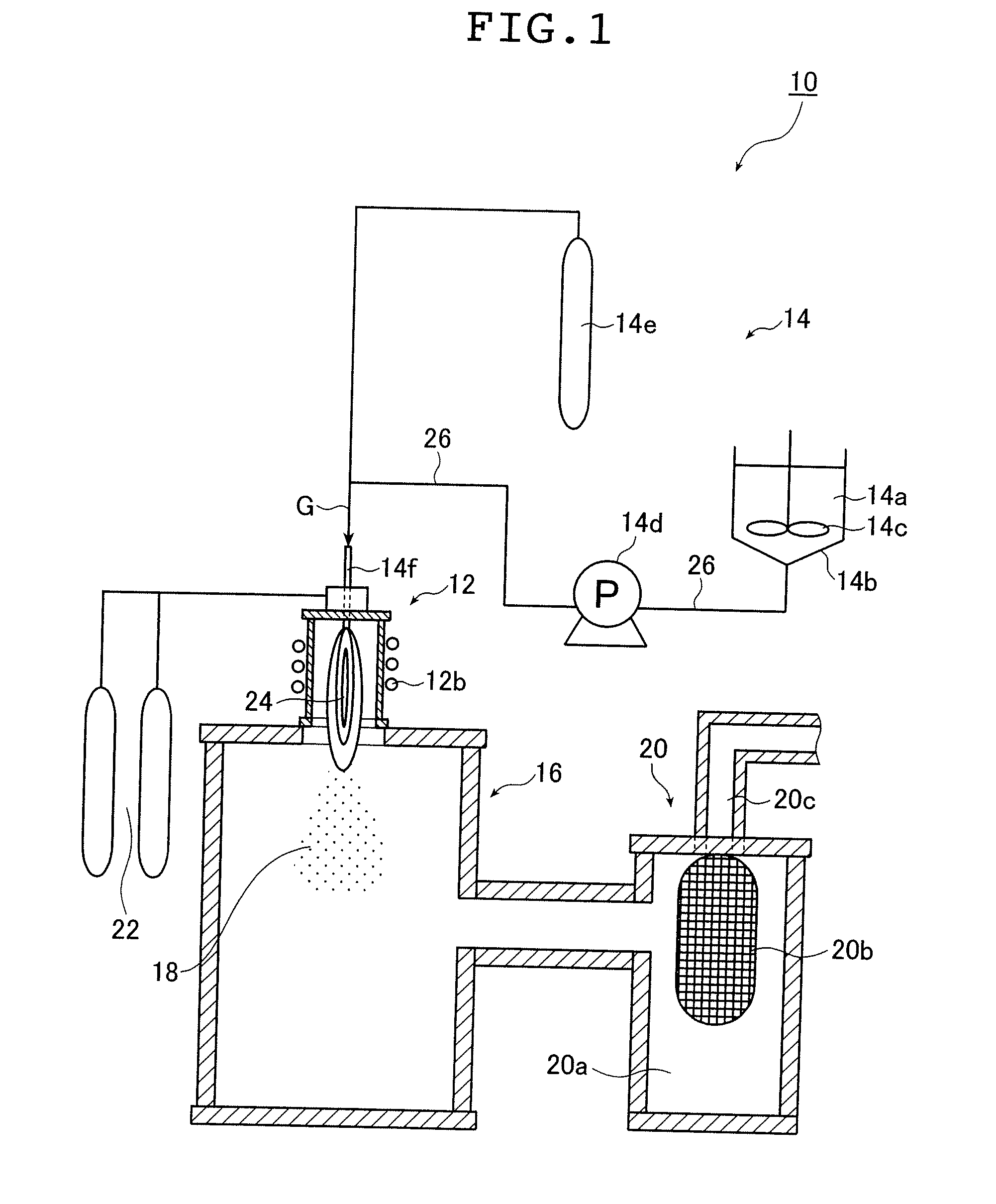

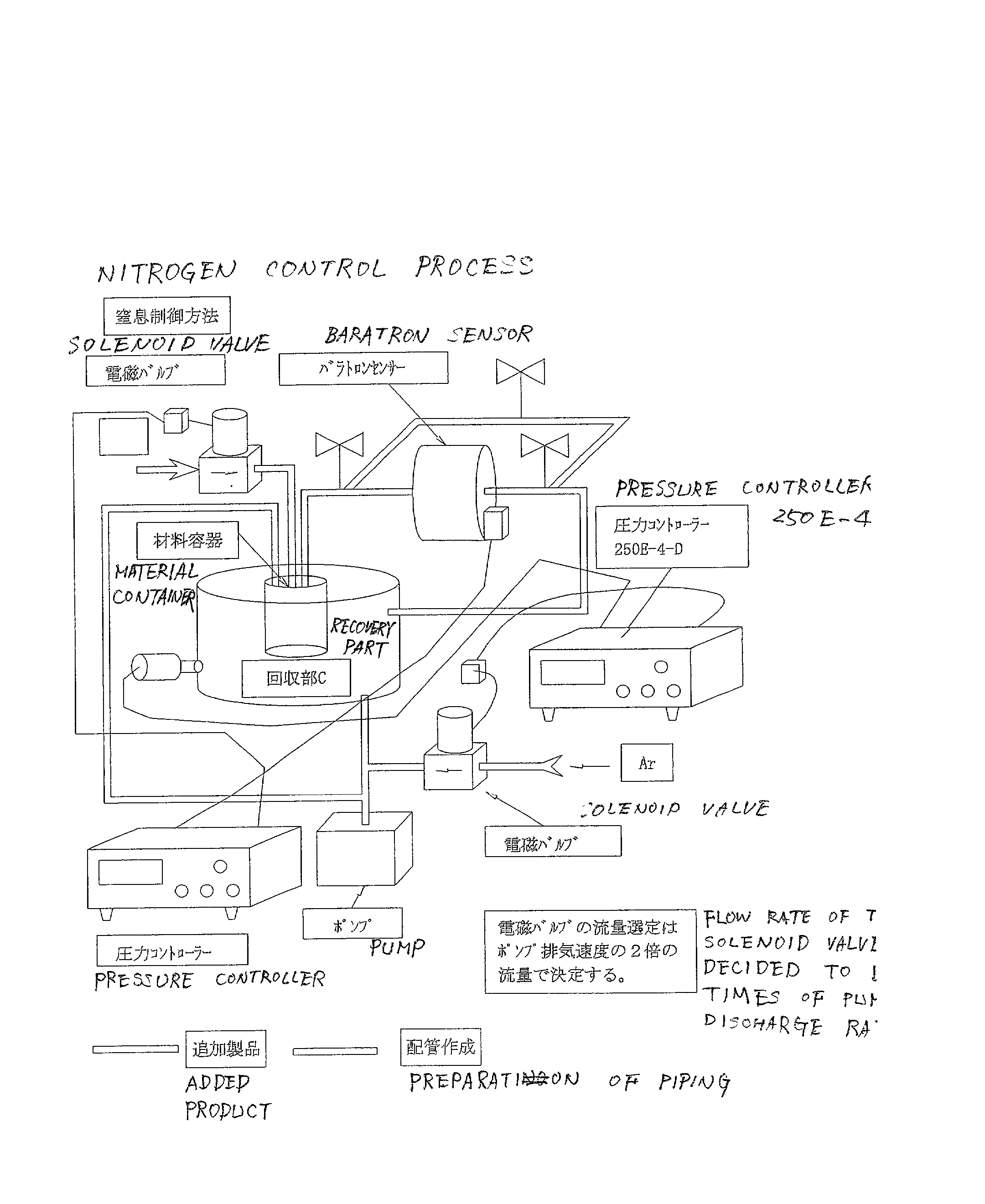

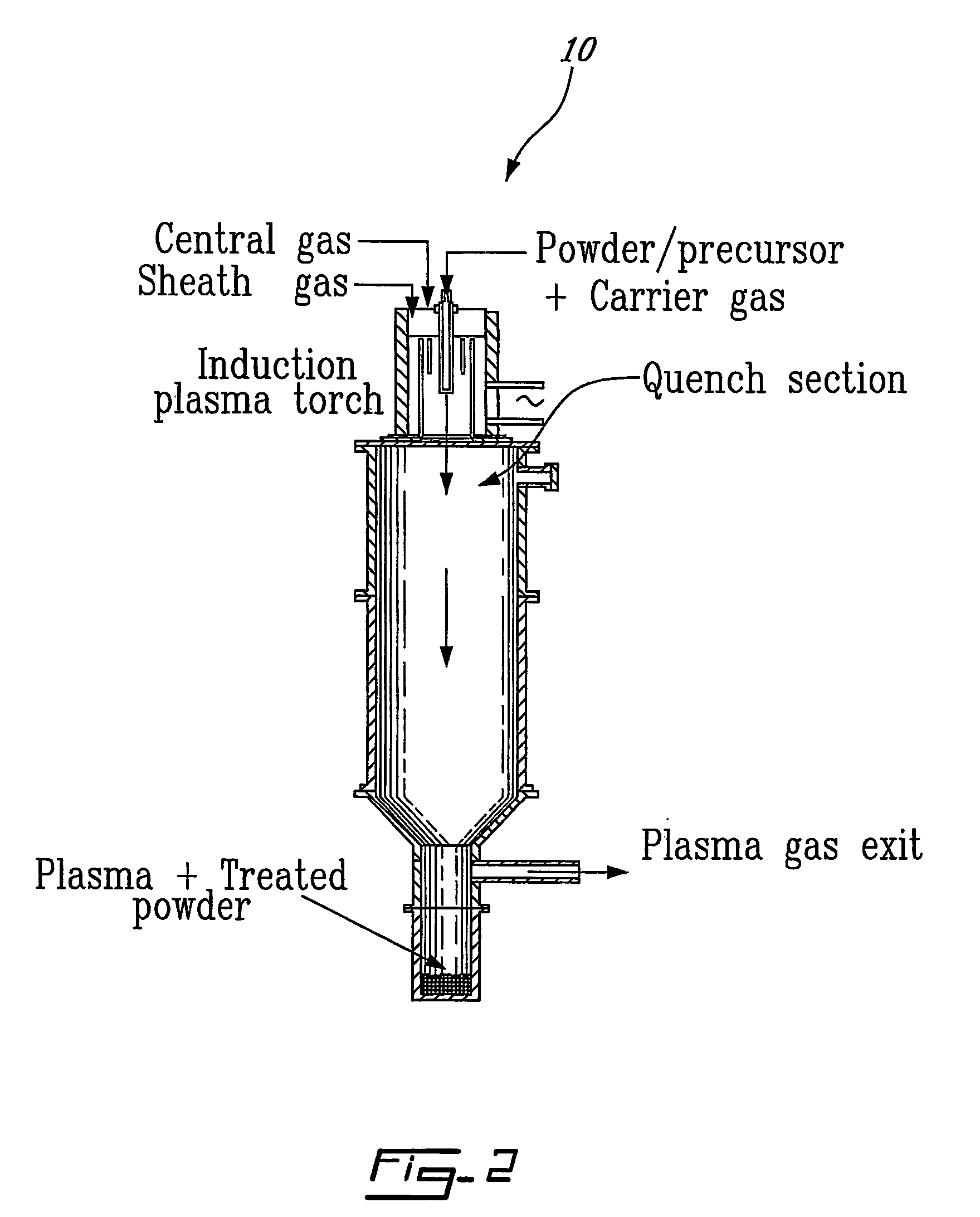

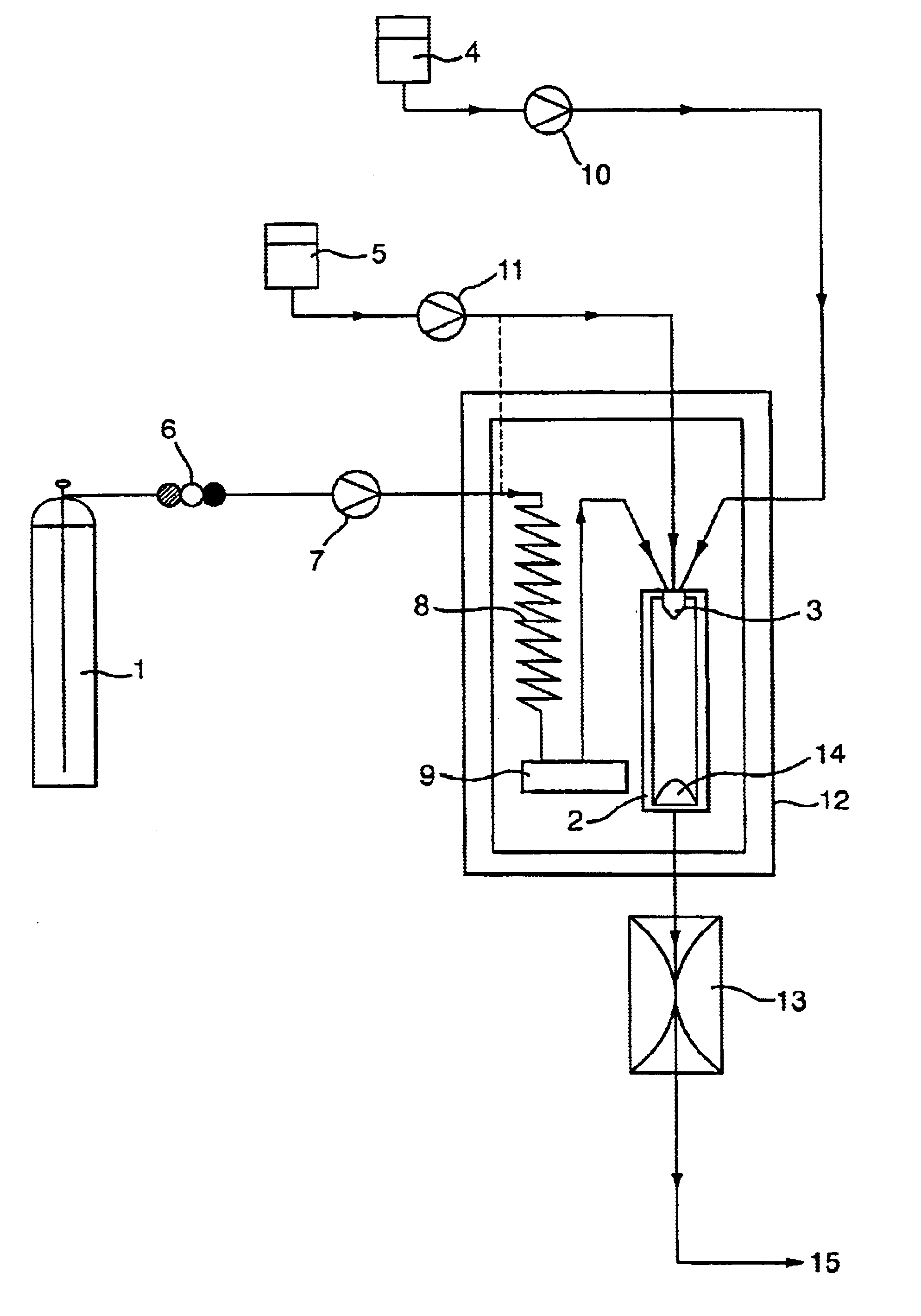

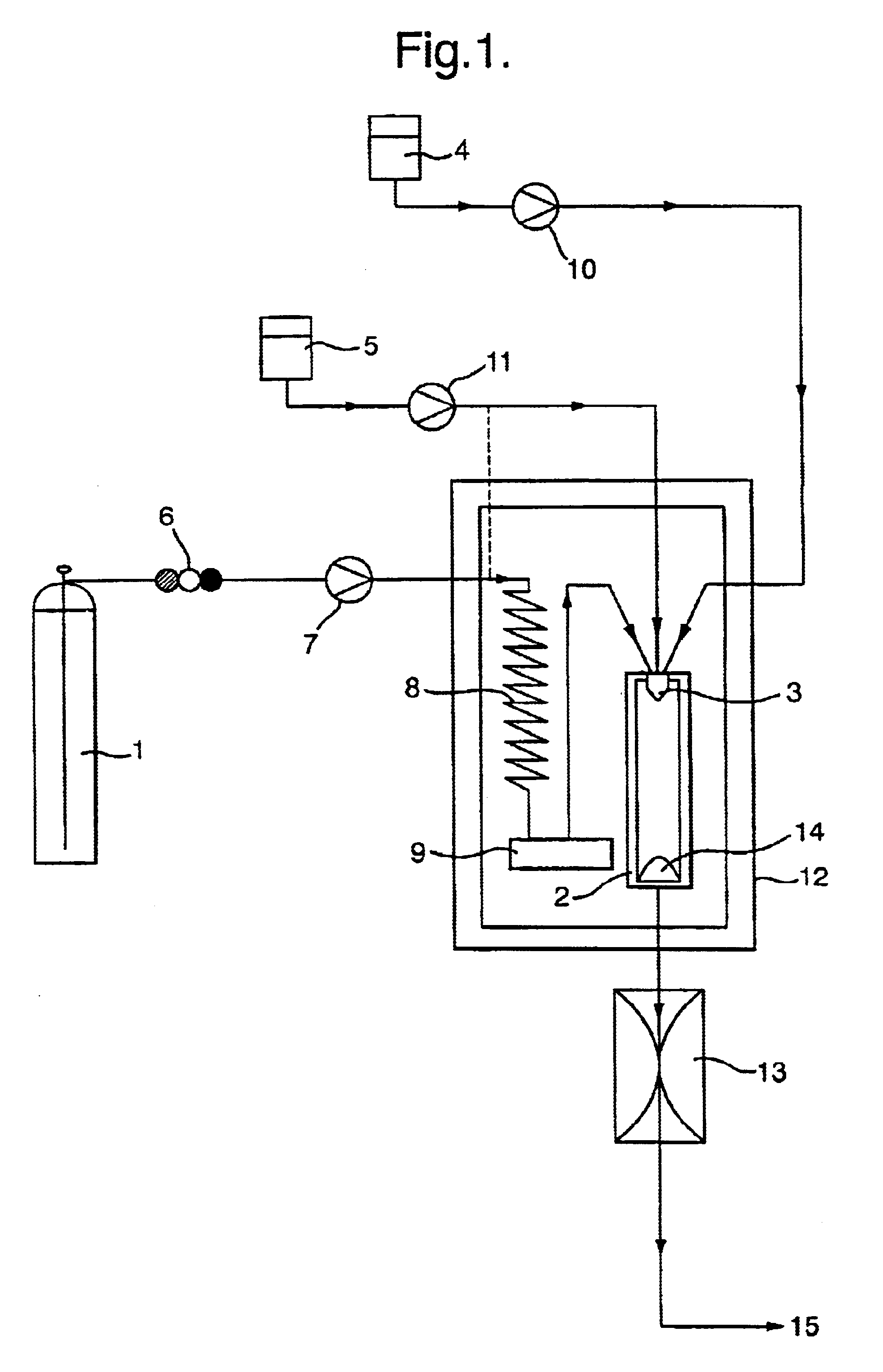

Process and Apparatus for Producing Fine Particles

ActiveUS20080006954A1Improve productivityFunction increaseAlkaline earth titanatesMaterial nanotechnologyGas phaseSlurry

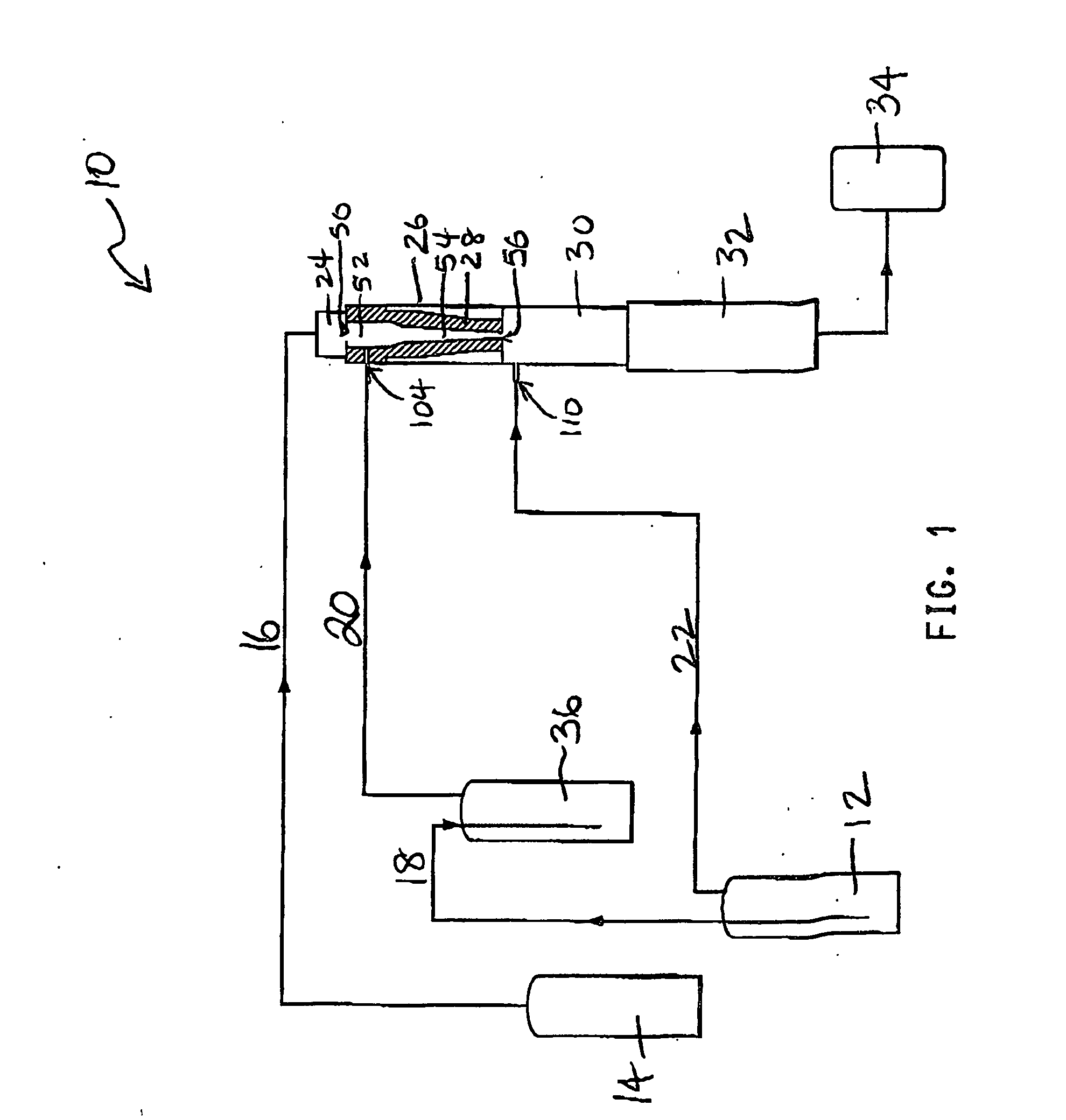

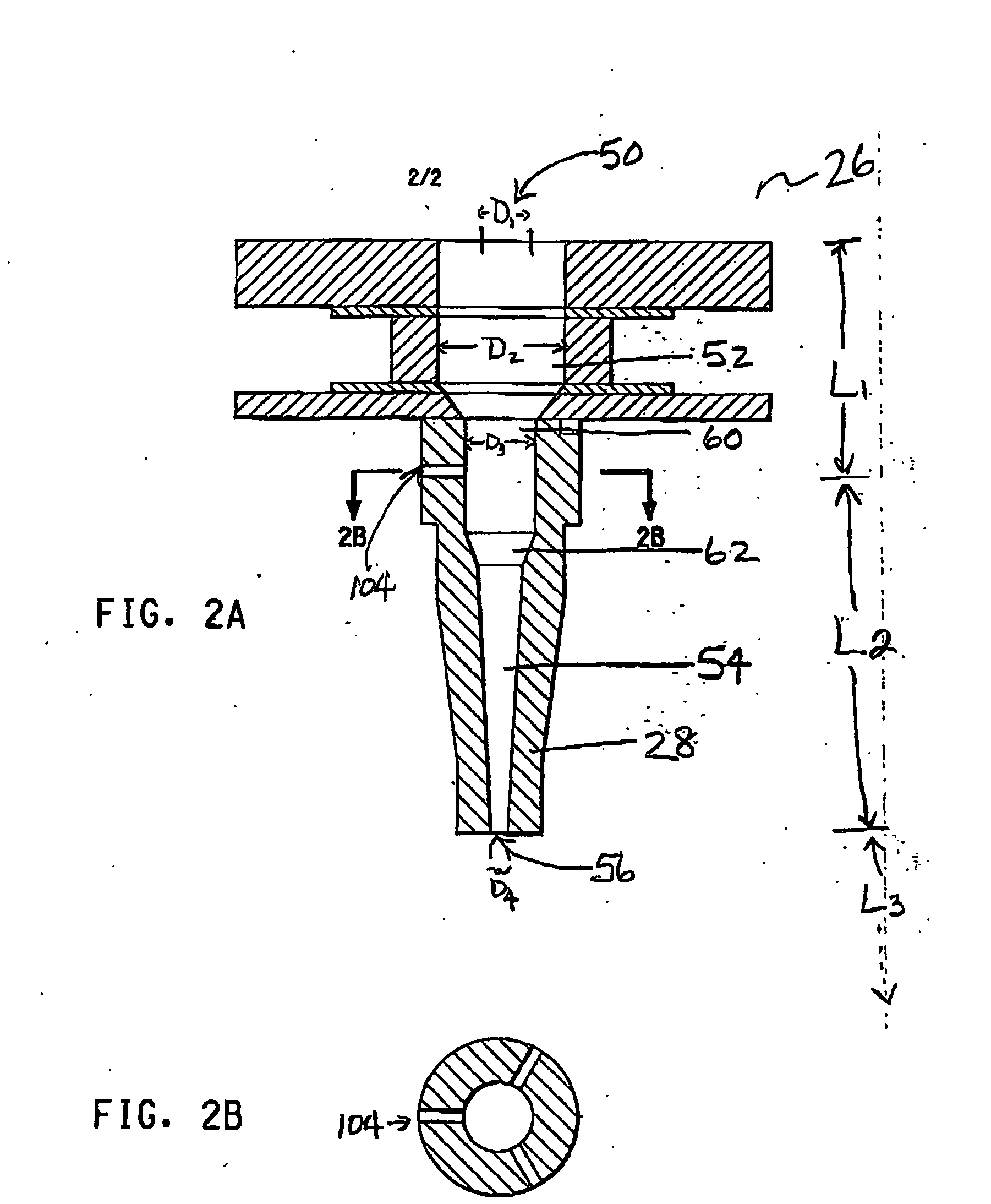

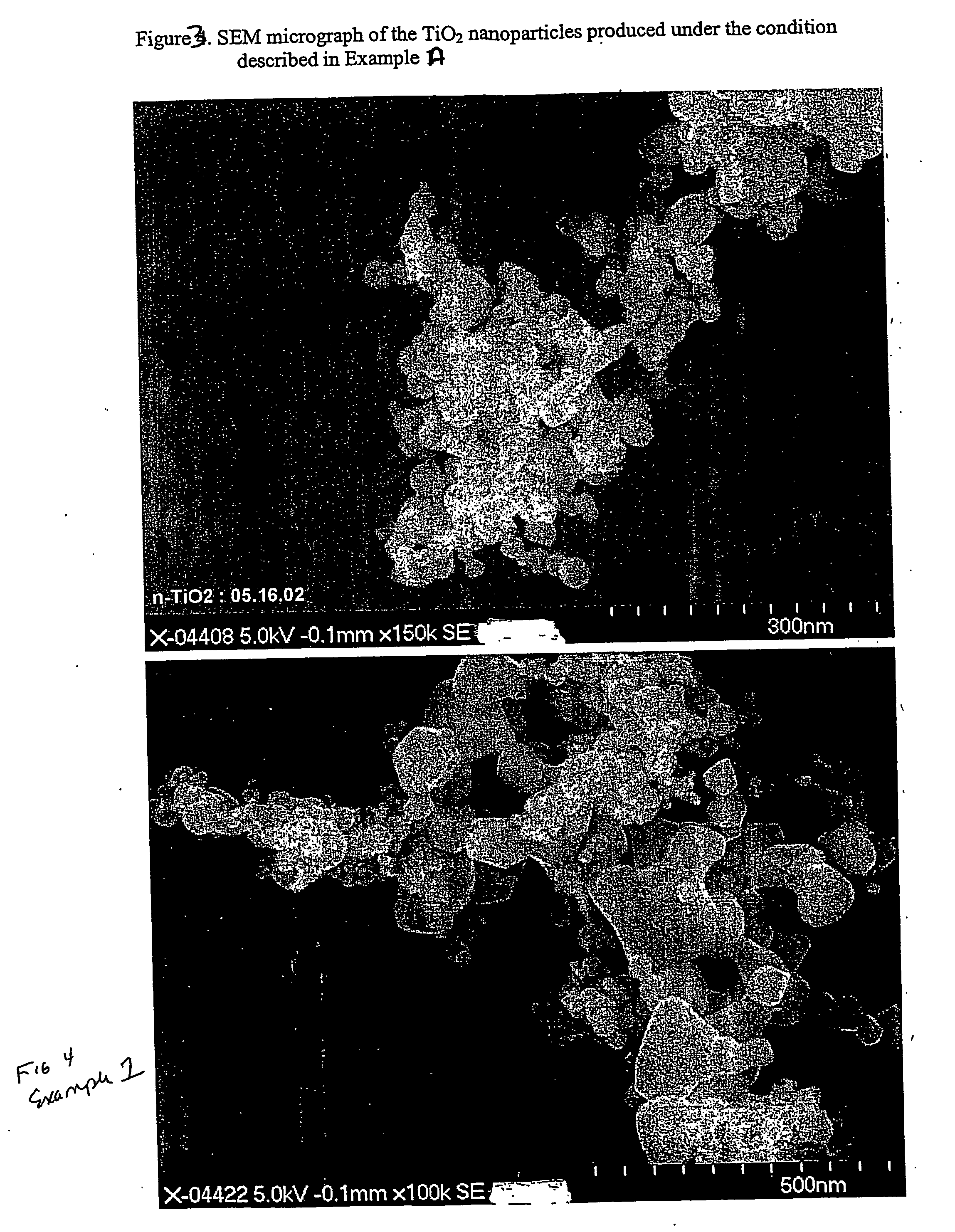

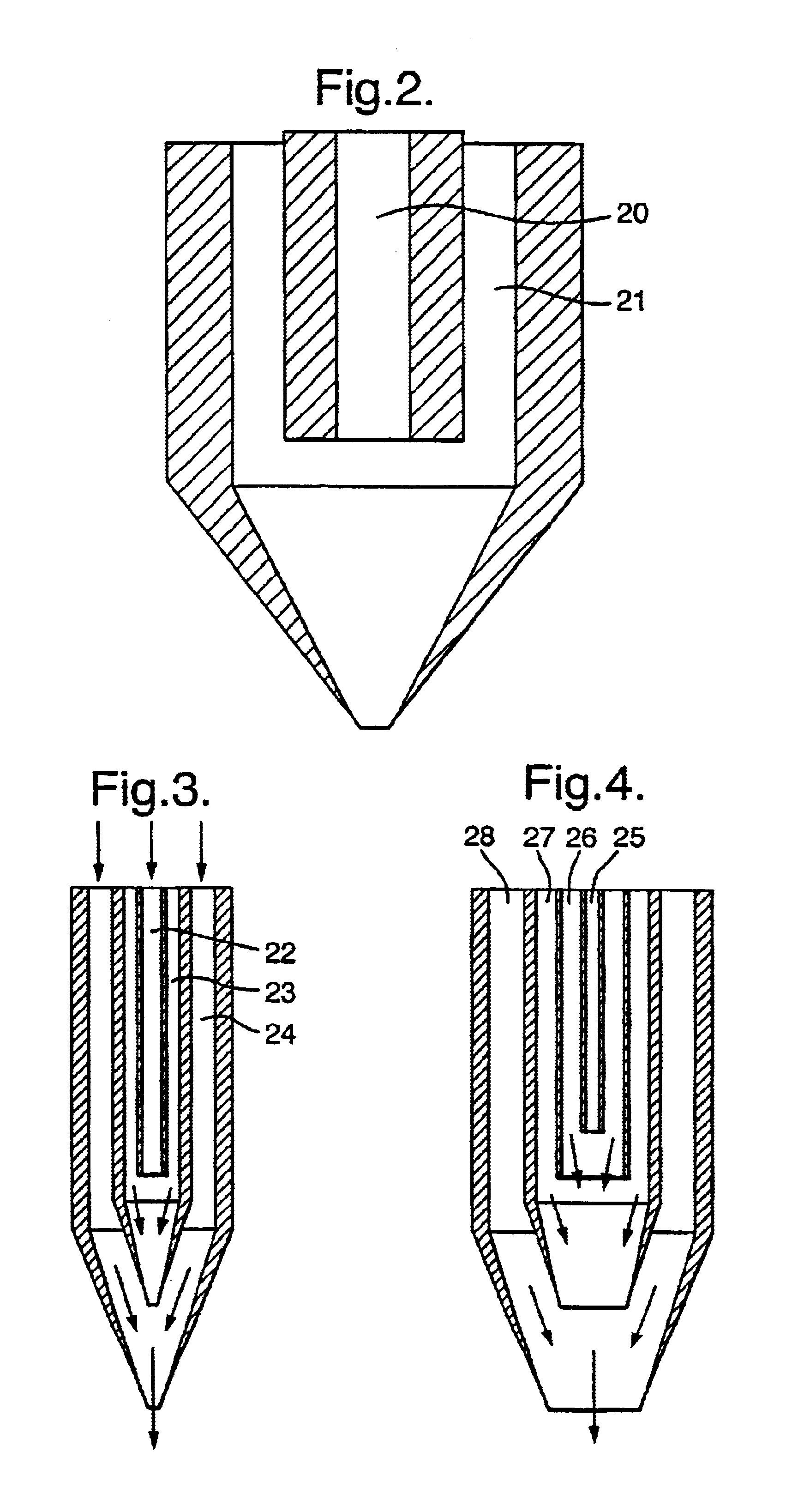

A fine particle producing process introduces a material for producing fine particles into a thermal plasma flame to make a vapor-phase mixture and quenches the vapor-phase mixture to form the fine particles. In the process, the material for producing the fine particles is dispersed or dissolved in a dispersion medium or solvent, preferably containing a combustible material to prepare a dispersion such as a slurry, a colloidal solution or a dissolution solution, the dispersion is made into a form of droplets, or the material for producing the fine particles is dispersed with a carrier gas and a combustible material and the dispersion in a droplet form or the dispersed material is introduced into the thermal plasma flame. In the fine particle producing process and apparatus, a gas of an amount sufficient to quench the vapor-phase mixture is supplied toward a tail of the thermal plasma flame. In the process and apparatus, primary fine particles are introduced into a cyclone to be subjected to cooling and classification and secondary fine particles having a particle size of 100 nm or less which are left upon removal of coarse particles are recovered.

Owner:NISSHIN SEIFUN GRP INC +1

Process for the production of particles or powders

In a novel process for the production of particles or powders, a substance or mixture of substances to be treated is provided in a pressure vessel. A highly compressible fluid is dissolved under pressure in the substance or mixture of substances provided until a solution containing 5% to 90% by weight of said highly compressible fluid has formed. The melting point of said highly compressible fluid is at least around 40 K lower than the melting point of the substance or mixture of substances to be treated. The solution obtained by dissolving said highly compressible fluid in the substance or mixture of substances provided is adjusted to a temperature of up to around 50 K above or below the melting point under atmospheric pressure of the substance or mixture of substances to be treated and is then rapidly decompressed by means of a decompression device in such a way that the temperature falls, downstream of the decompression device, below the solidification point of the substance or mixture of substances to be treated and essentially all of the highly compressible fluid turns gaseous, whereby particles of the substance or mixture of substances provided form. Subsequently, the particles which have formed are removed from the stream of decompressed highly compressible fluid.

Owner:WEIDNER ECKHARD +2

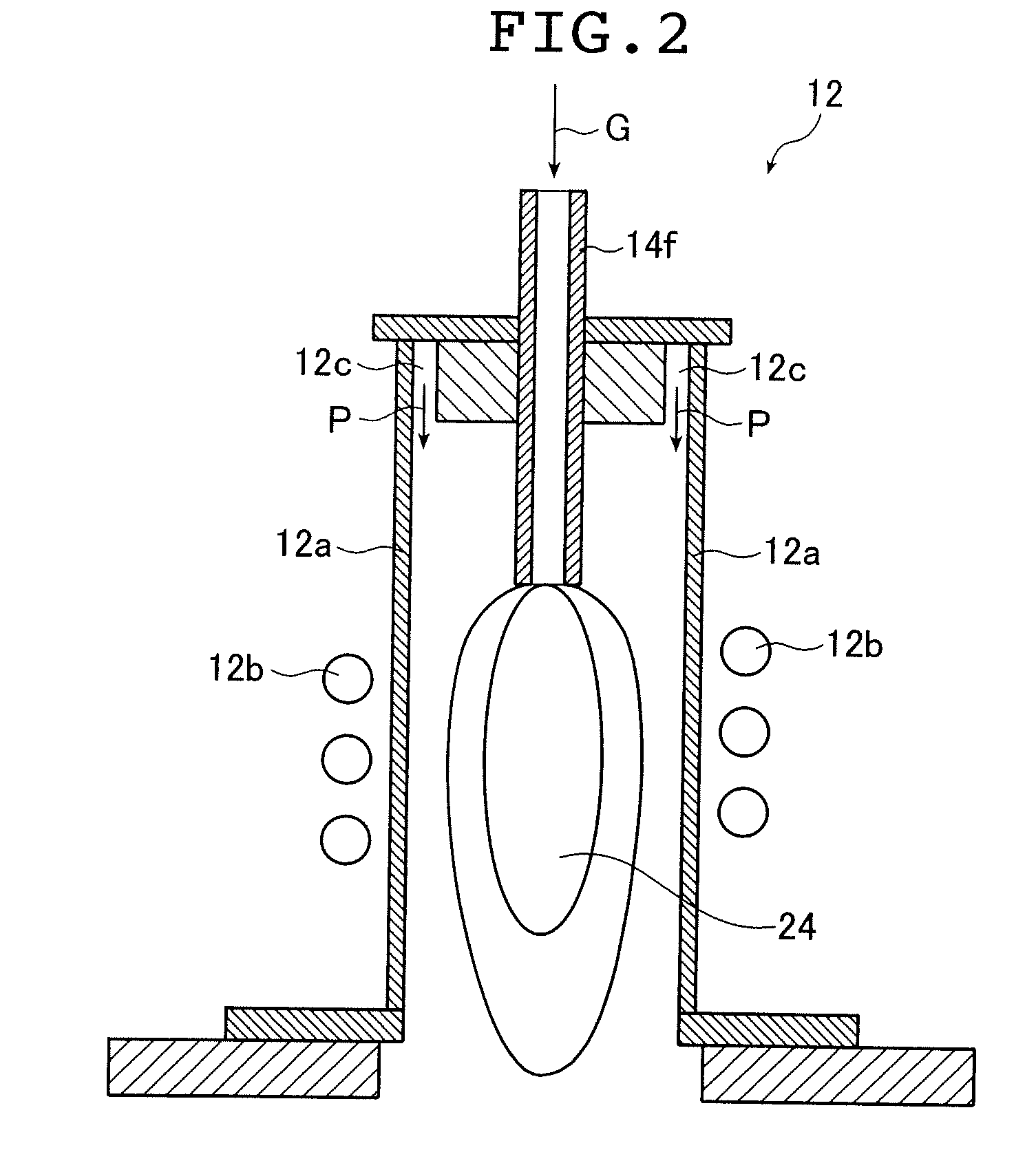

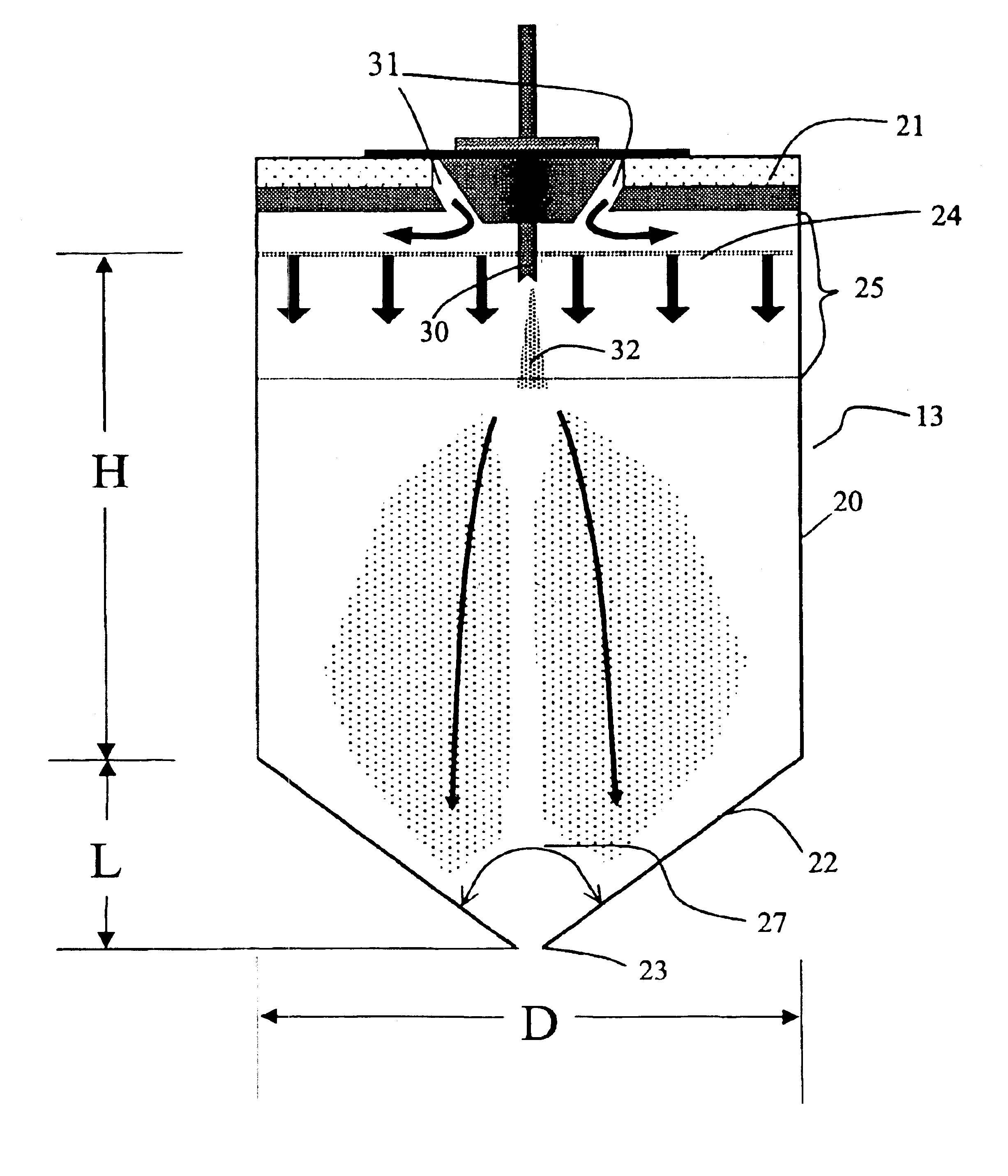

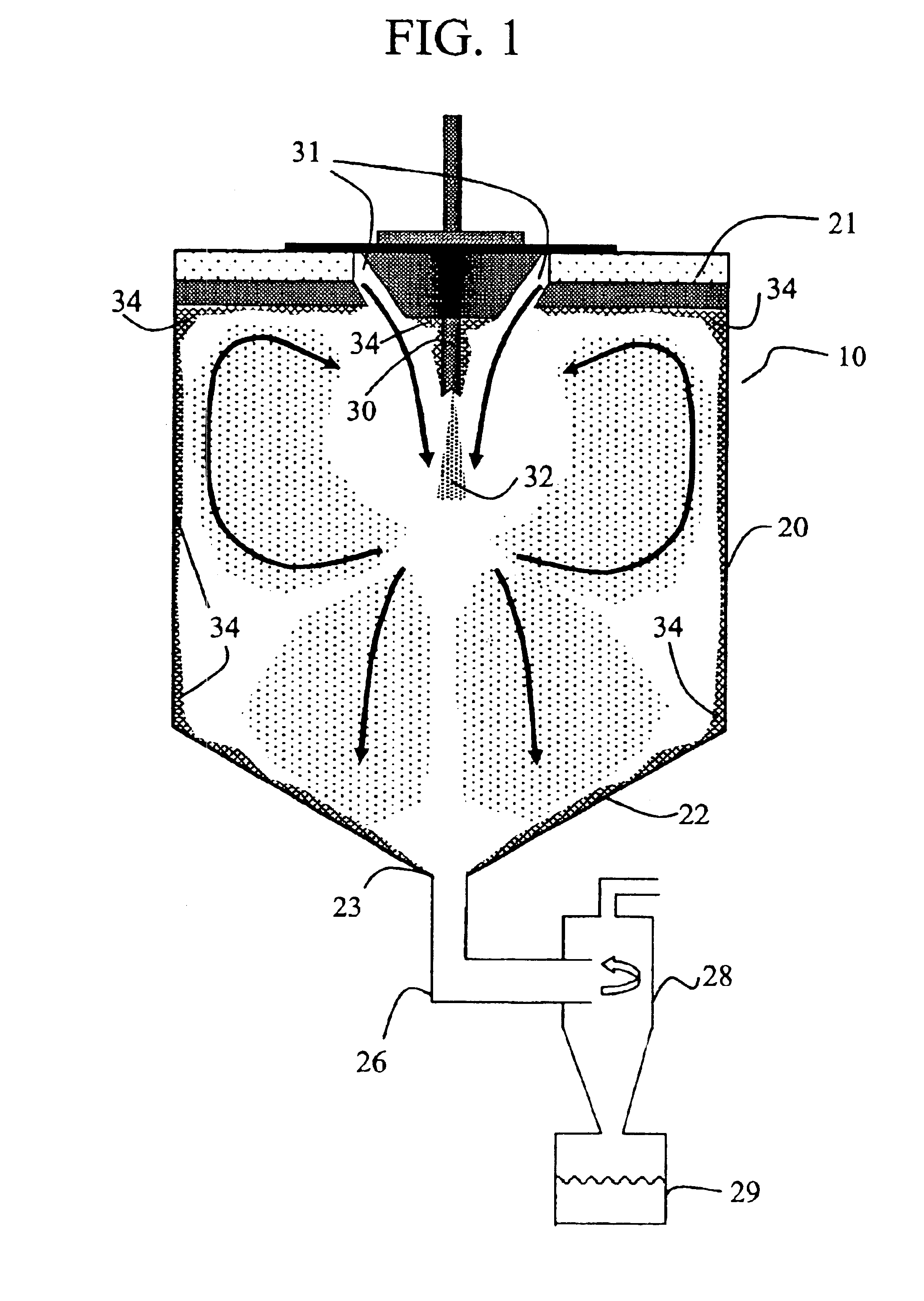

Method of forming nanoparticles and microparticles of controllable size using supercritical fluids with enhanced mass transfer

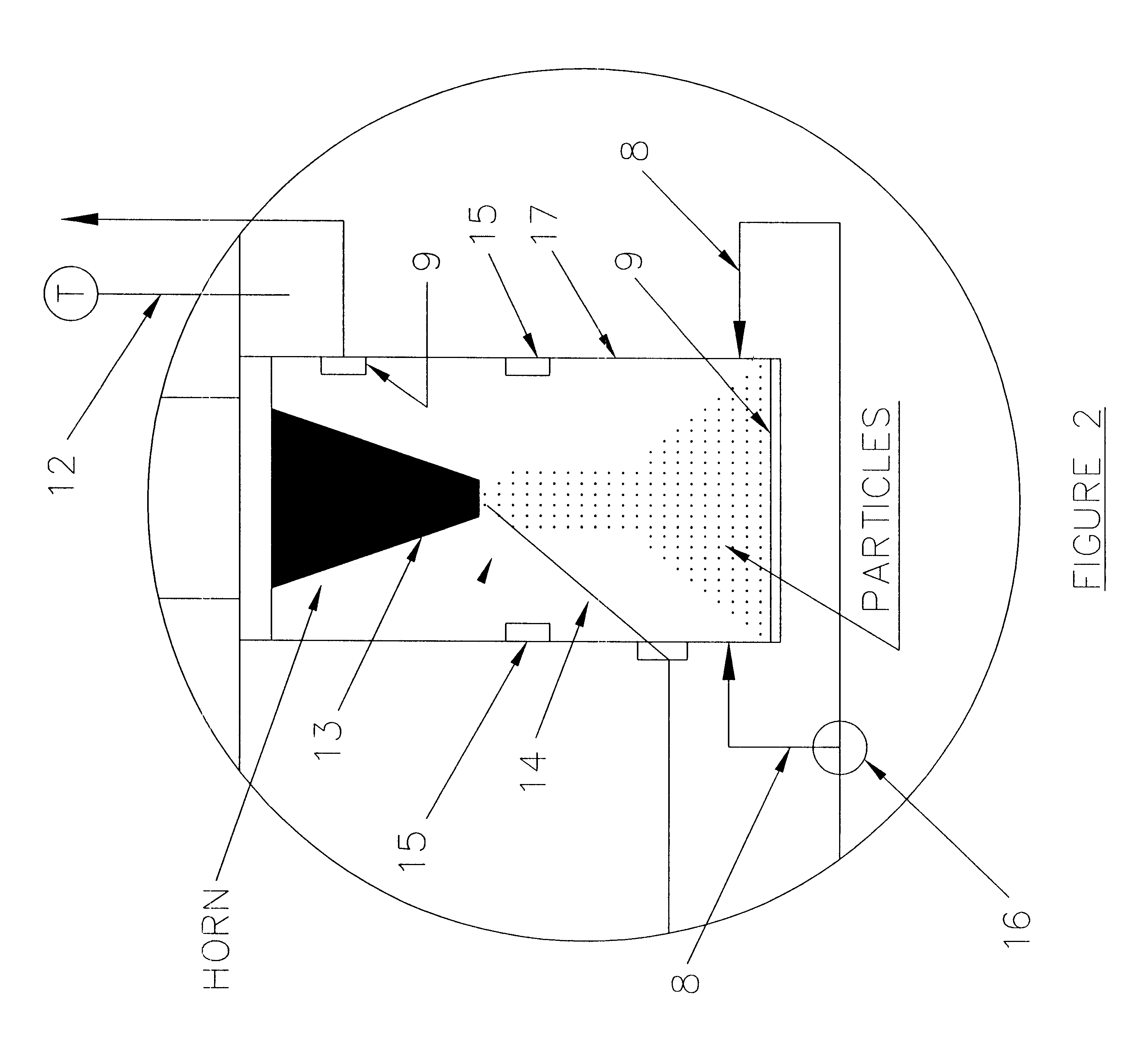

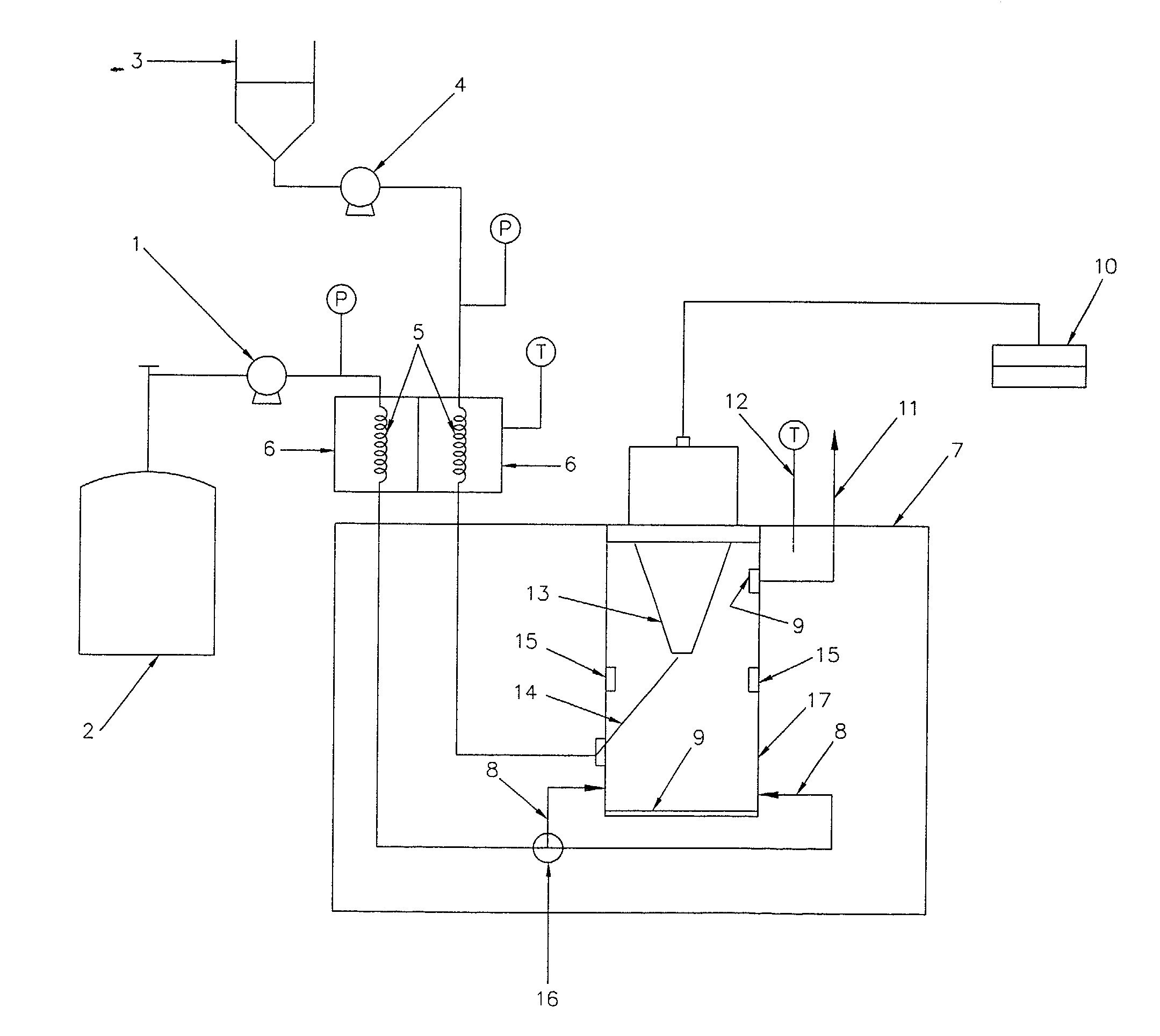

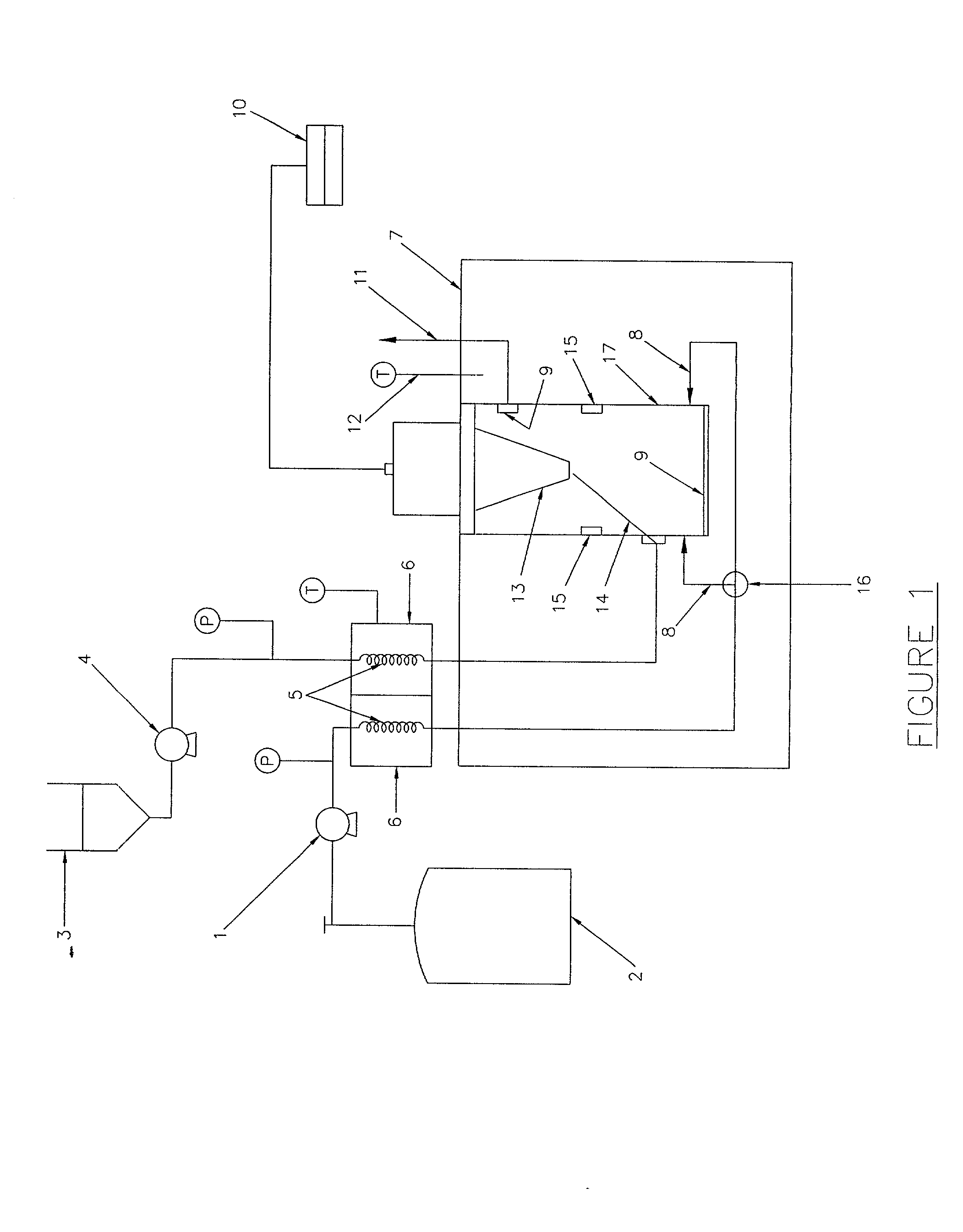

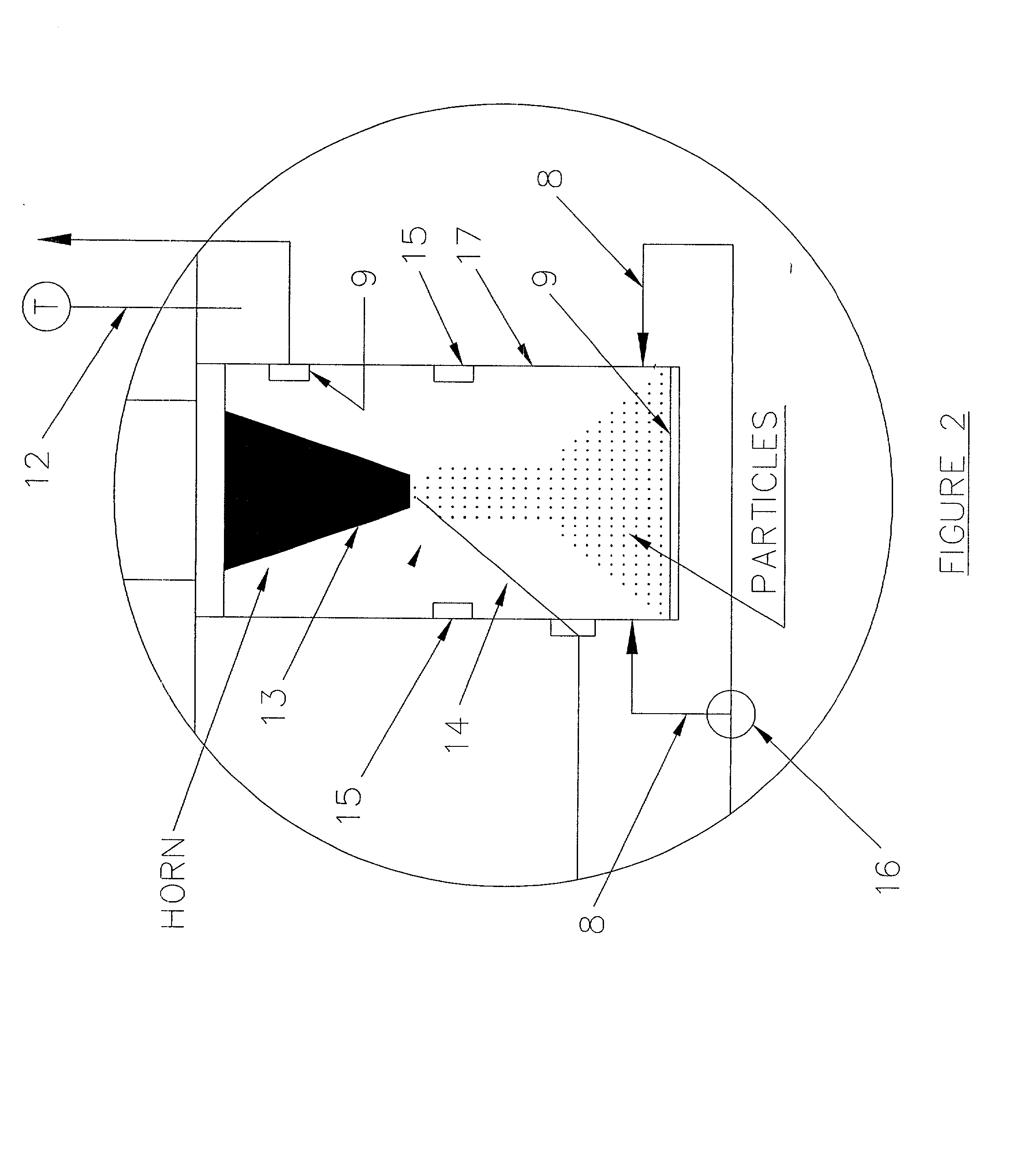

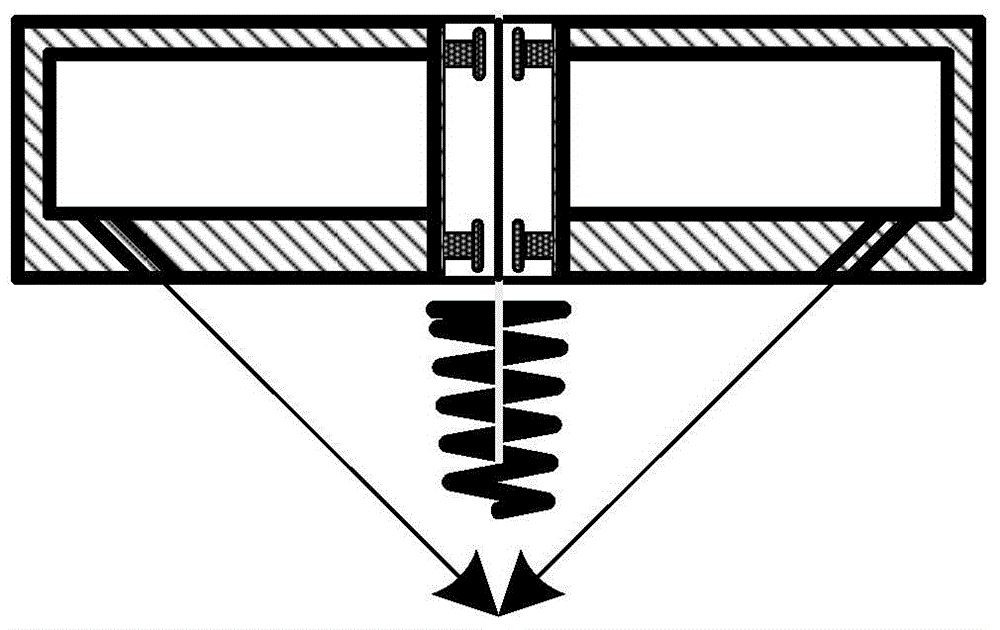

The current invention, Supercritical Antisolvent Precipitation with Enhanced Mass Transfer (SAS-EM) provides a significantly improved method for the production of nano and micro-particles with a narrow size distribution. The processes of the invention utilize the properties of supercritical fluids and also the principles of virbrational atomization to provide an efficient technique for the effective nanonization or micronization of particles. Like the SAS technique, SAS-EM, also uses a supercritical fluid as the antisolvent, but in the present invention the dispersion jet is deflected by a vibrating surface that atomizes the jet into fine droplets. The vibrating surface also generates a vibrational flow field within the supercritical phase that enhances mass transfer through increased mixing. Sizes of the particles obtained by this technique are easily controlled by changing the vibration intensity of the deflecting surface, which in turn is controlled by adjusting the power input to the vibration source. A major advantage of the SAS-EM technique is that it can be successfully used to obtain nanoparticles of materials that usually yield fibers or large crystals in SAS method. Microencapsulation via coprecipitation of two or more materials can also be achieved using the SAS-EM technique.

Owner:UNIV AUBURN

Method of forming nanoparticles and microparticles of controllable size using supercritical fluids and ultrasound

The current invention, Supercritical Antisolvent Precipitation with Enhanced Mass Transfer (SAS-EM) provides a significantly improved method for the production of nano and micro-particles with a narrow size distribution. The processes of the invention utilize the properties of supercritical fluids and also the principles of virbrational atomization to provide an efficient technique for the effective nanonization or micronization of particles. Like the SAS technique, SAS-EM, also uses a supercritical fluid as the antisolvent, but in the present invention the dispersion jet is deflected by a vibrating surface that atomizes the jet into fine droplets. The vibrating surface also generates a vibrational flow field within the supercritical phase that enhances mass transfer through increased mixing. Sizes of the particles obtained by this technique are easily controlled by changing the vibration intensity of the deflecting surface, which in turn is controlled by adjusting the power input to the vibration source. A major advantage of the SAS-EM technique is that it can be successfully used to obtain nanoparticles of materials that usually yield fibers or large crystals in SAS method. Microencapsulation via coprecipitation of two or more materials can also be achieved using the SAS-EM technique.

Owner:UNIV AUBURN

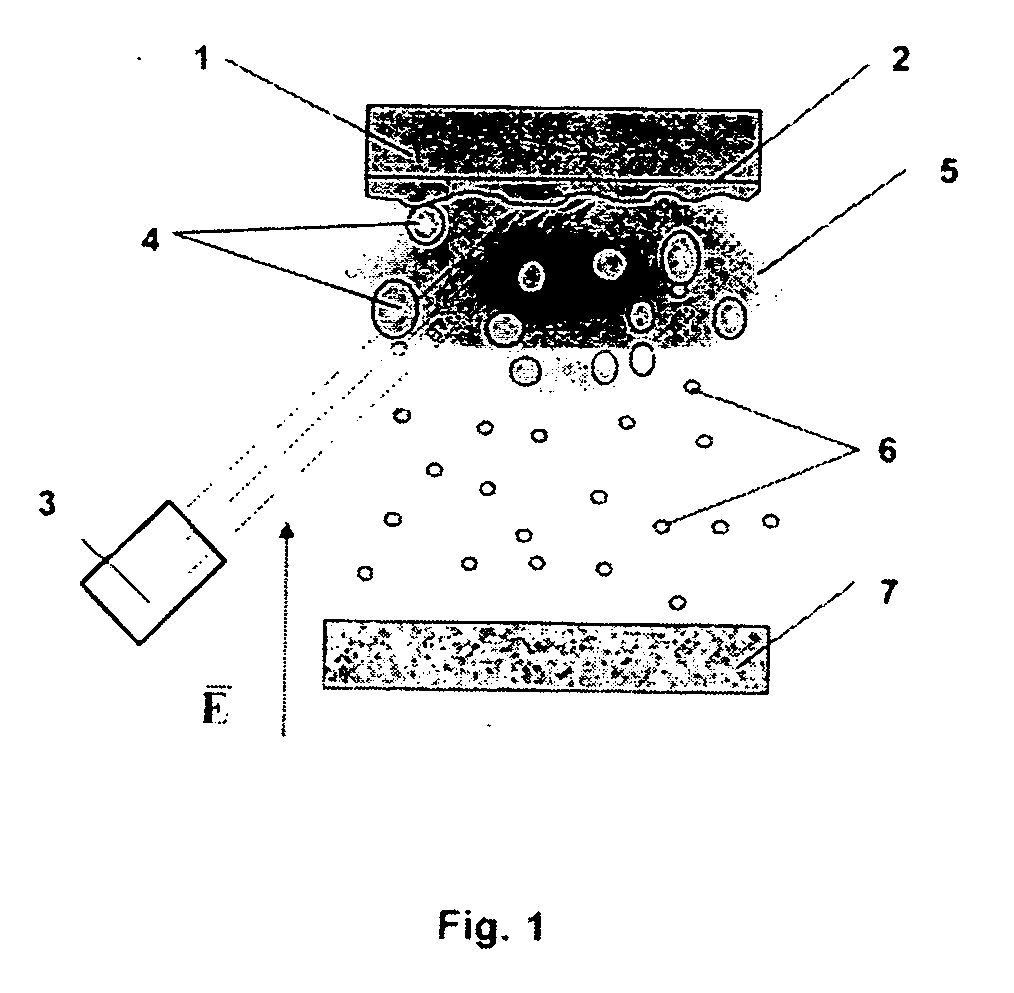

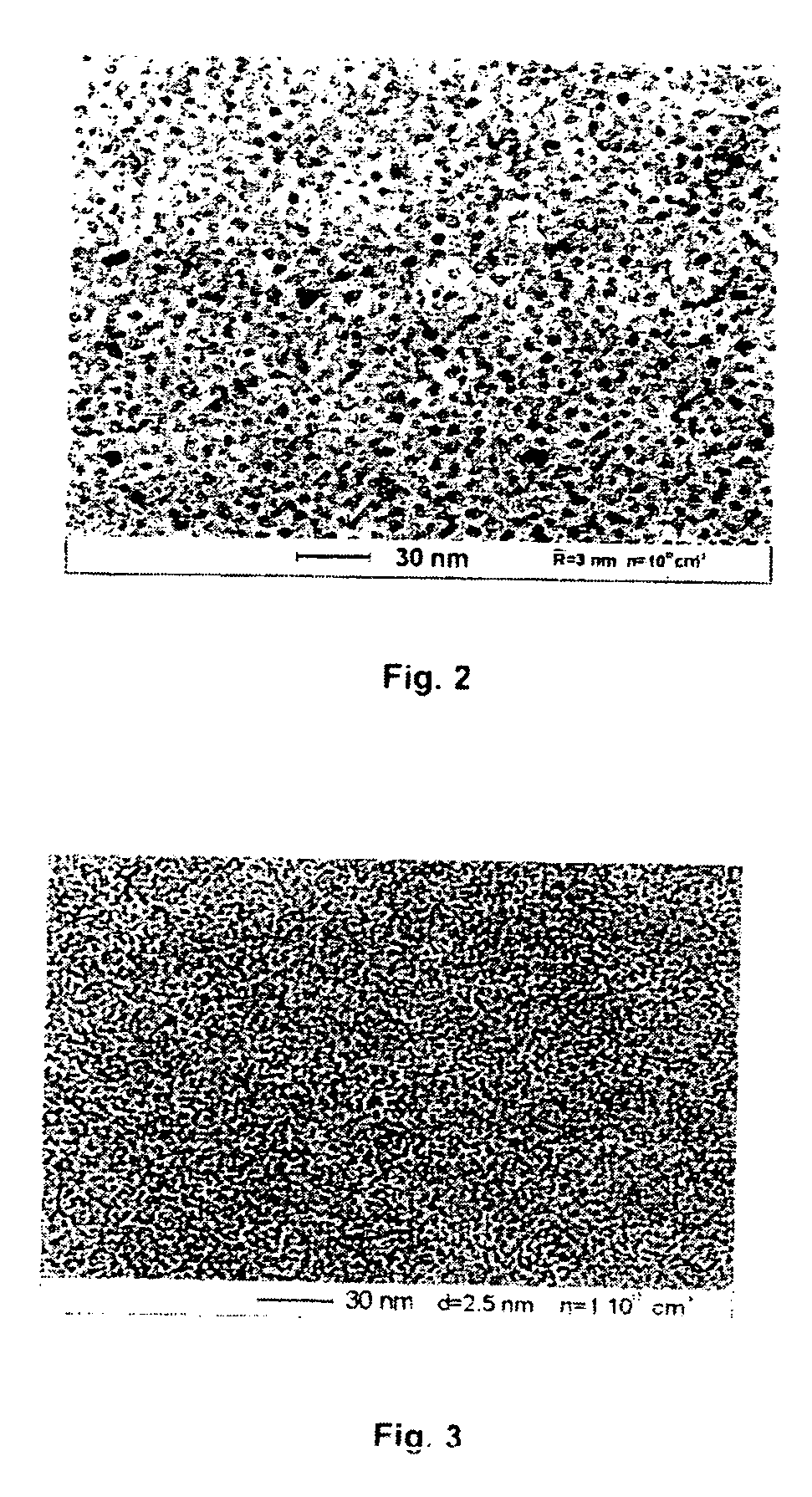

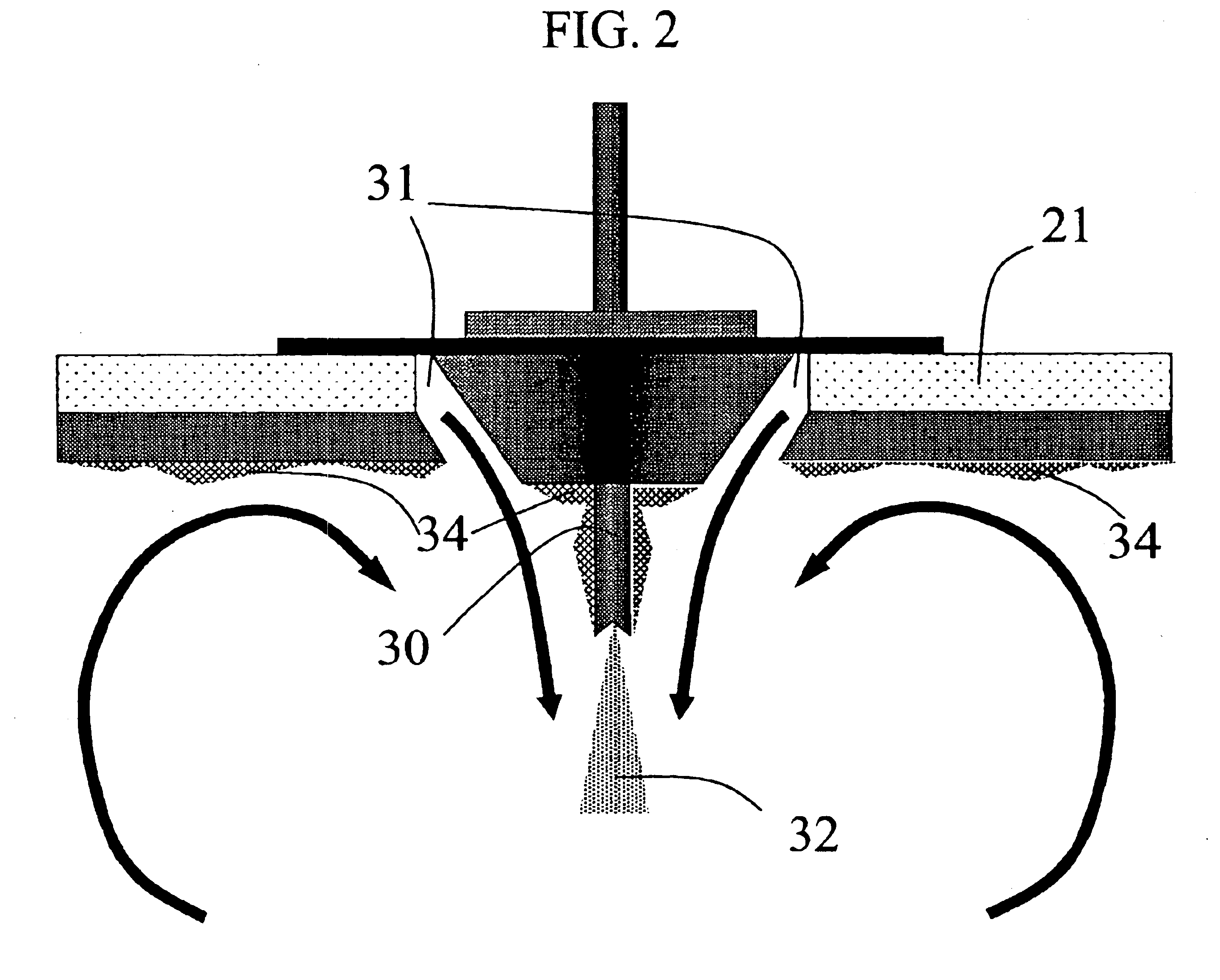

Method of producing nanoparticles using a evaporation-condensation process with a reaction chamber plasma reactor system

InactiveUS20060159596A1Reduce the temperatureMaterial nanotechnologyNanostructure manufactureNanoparticleReaction zone

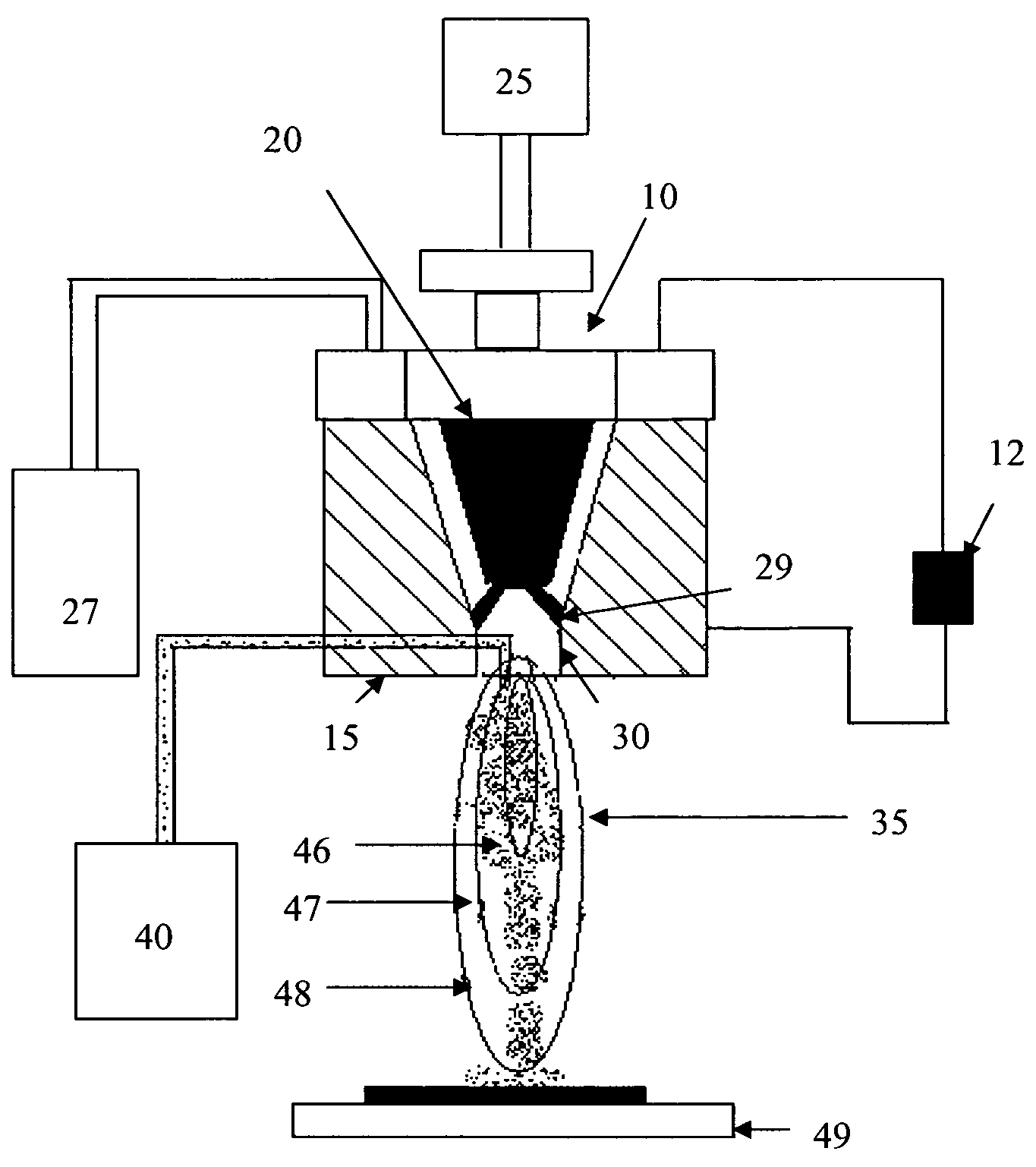

The present invention provides a method and apparatus for the controlled synthesis of nanoparticles using a high temperature process. The reactor chamber includes a high temperature gas heated by means such as a plasma torch, and a reaction chamber. The homogenizer includes a region between the reactant inlets and the plasma (the spacer zone) to ensure that feeds from the reactant inlets are downstream of the recirculation zone induced by the high temperature gas. It also includes a region downstream of the reactant inlets that provides a nearly I dimensional (varying only in the axial direction) flow and concentration profile in the reaction zone to produce nanoparticles with narrow size distribution.

Owner:EI DU PONT DE NEMOURS & CO

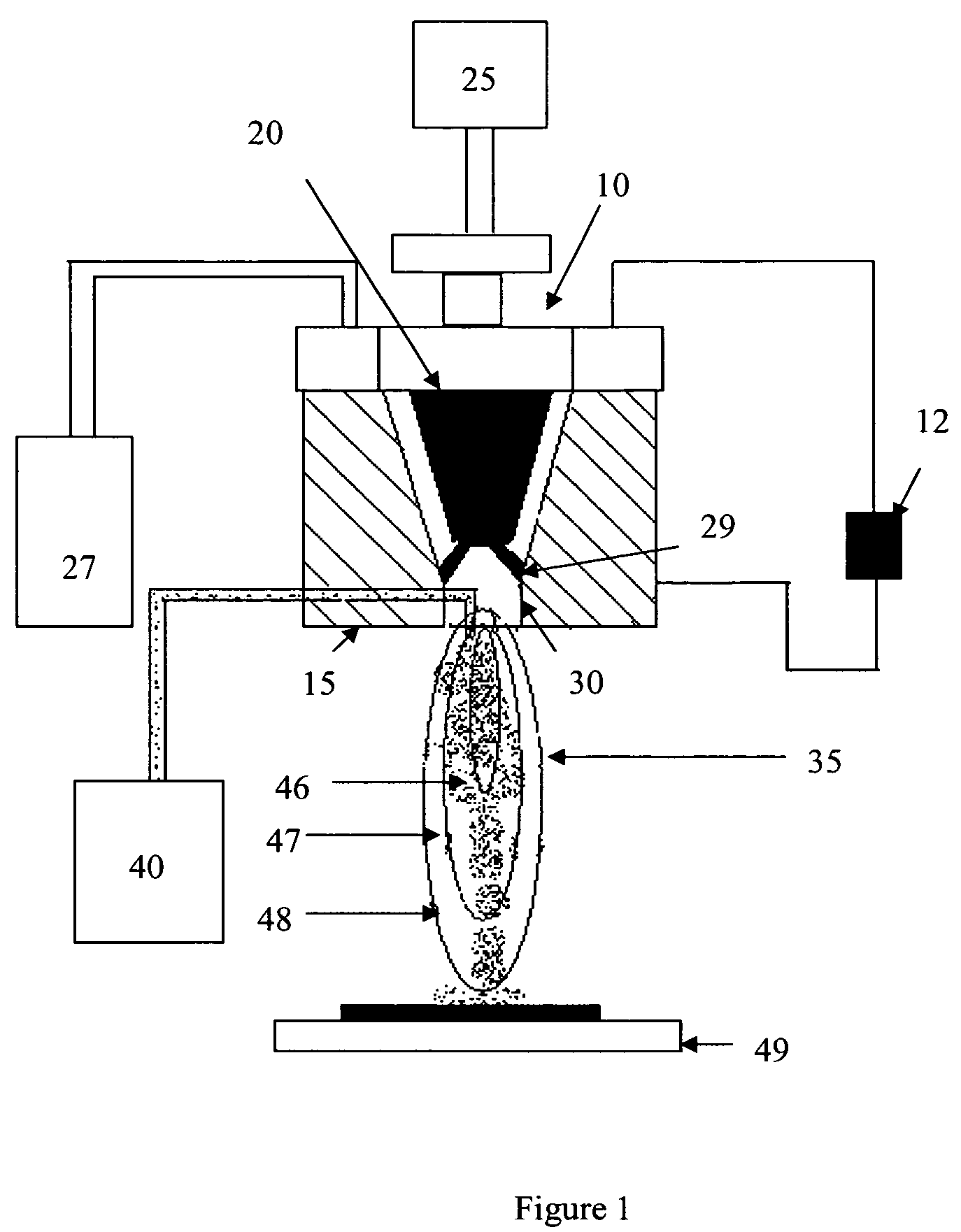

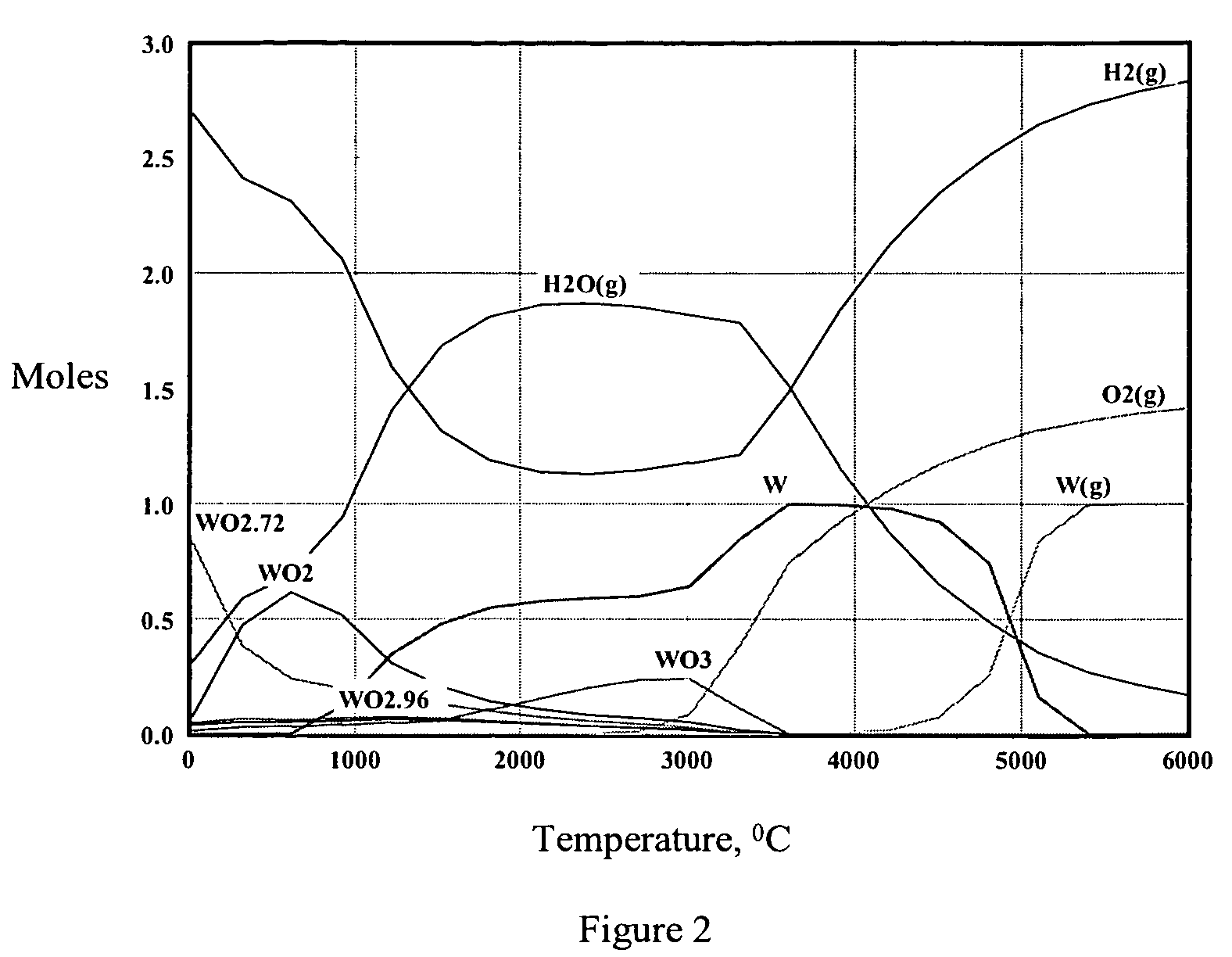

Nano powders, components and coatings by plasma technique

ActiveUS7615097B2Rapid quenching and generationHigh materialLiquid surface applicatorsMolten spray coatingRheniumChemical reaction

Ultra fine and nanometer powders and a method of producing same are provided, preferably refractory metal and ceramic nanopowders. When certain precursors are injected into the plasma flame in a reactor chamber, the materials are heated, melted and vaporized and the chemical reaction is induced in the vapor phase. The vapor phase is quenched rapidly to solid phase to yield the ultra pure, ultra fine and nano product. With this technique, powders have been made 20 nanometers in size in a system capable of a bulk production rate of more than 10 lbs / hr. The process is particularly applicable to tungsten, molybdenum, rhenium, tungsten carbide, molybdenum carbide and other related materials.

Owner:PLASMA PROCESSES

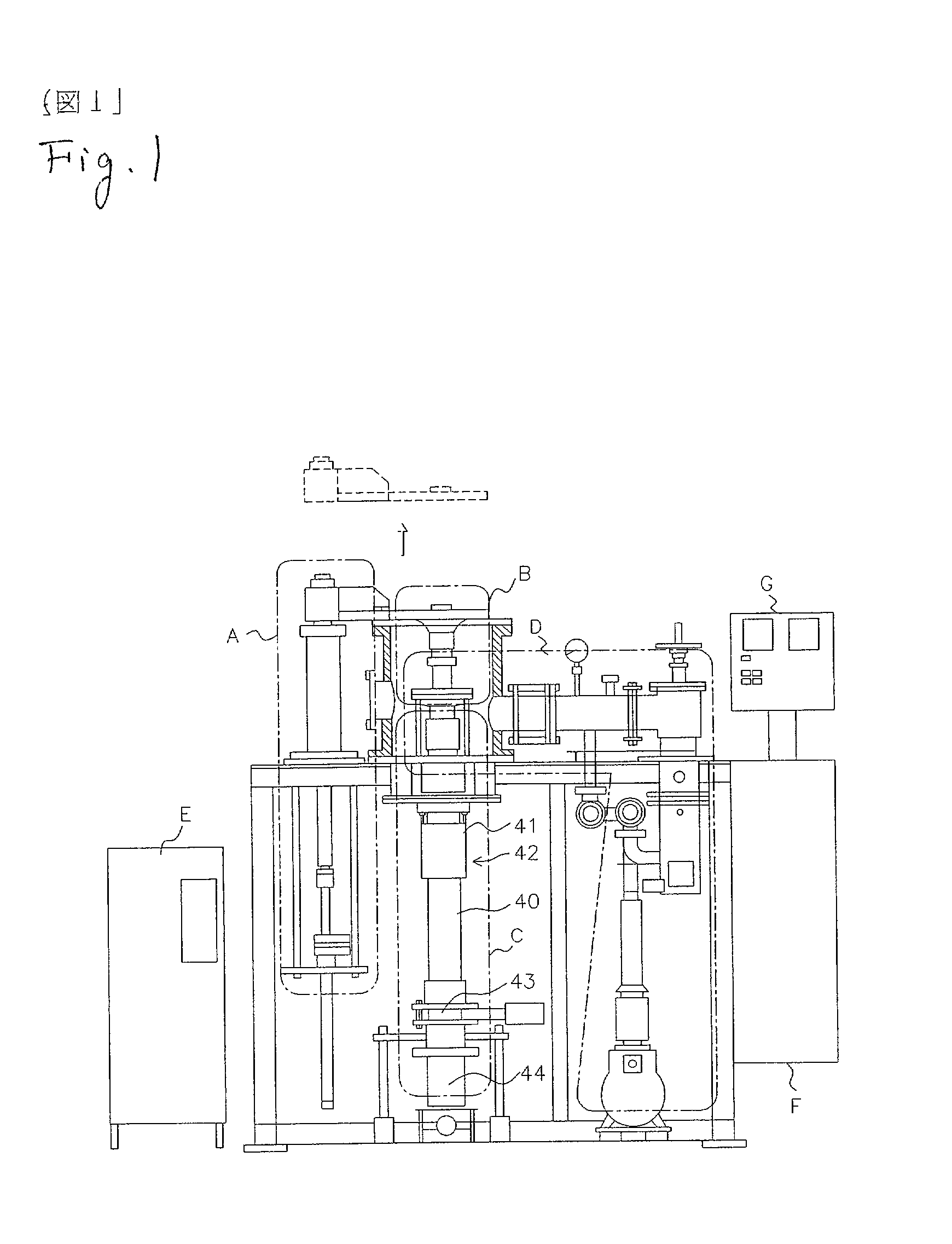

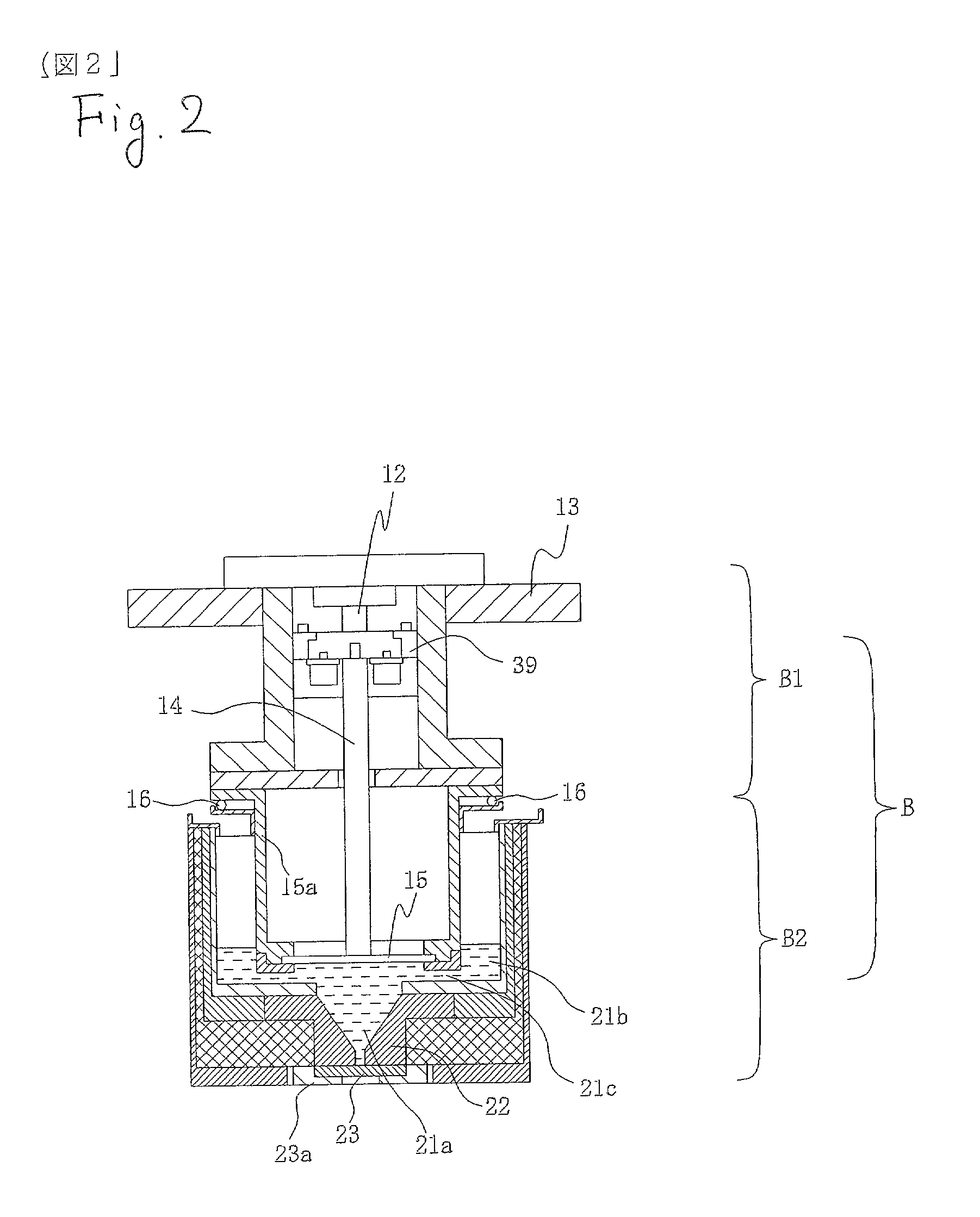

Production apparatus of monodisperse particle and production process of monodisperse particle and monodisperse particle produced by the process

InactiveUS20020089100A1Highly multi-purpose monodisperse particle industrially and cheaplyEasy to controlTransportation and packagingMetal-working apparatusMetallurgySlurry

It is the object to provide a production process of monodisperse particle in which monodisperse particle with uniform particle size (particle diameter) can be stably mass-produced, and monodisperse particle produced by this process, and its production apparatus. The supply pipe diameter deltaf is set to be greater than the orifice diameter deltao and the internal and external pressure of the slurry retention part b is controlled, and this allows to facilitate supply of the slurry through the supply pipe (21c), and continuously and efficiently supply the slurry, and then to produce monodisperse particle with uniform particle size (particle diameter).

Owner:KAWASAKI CORP KK

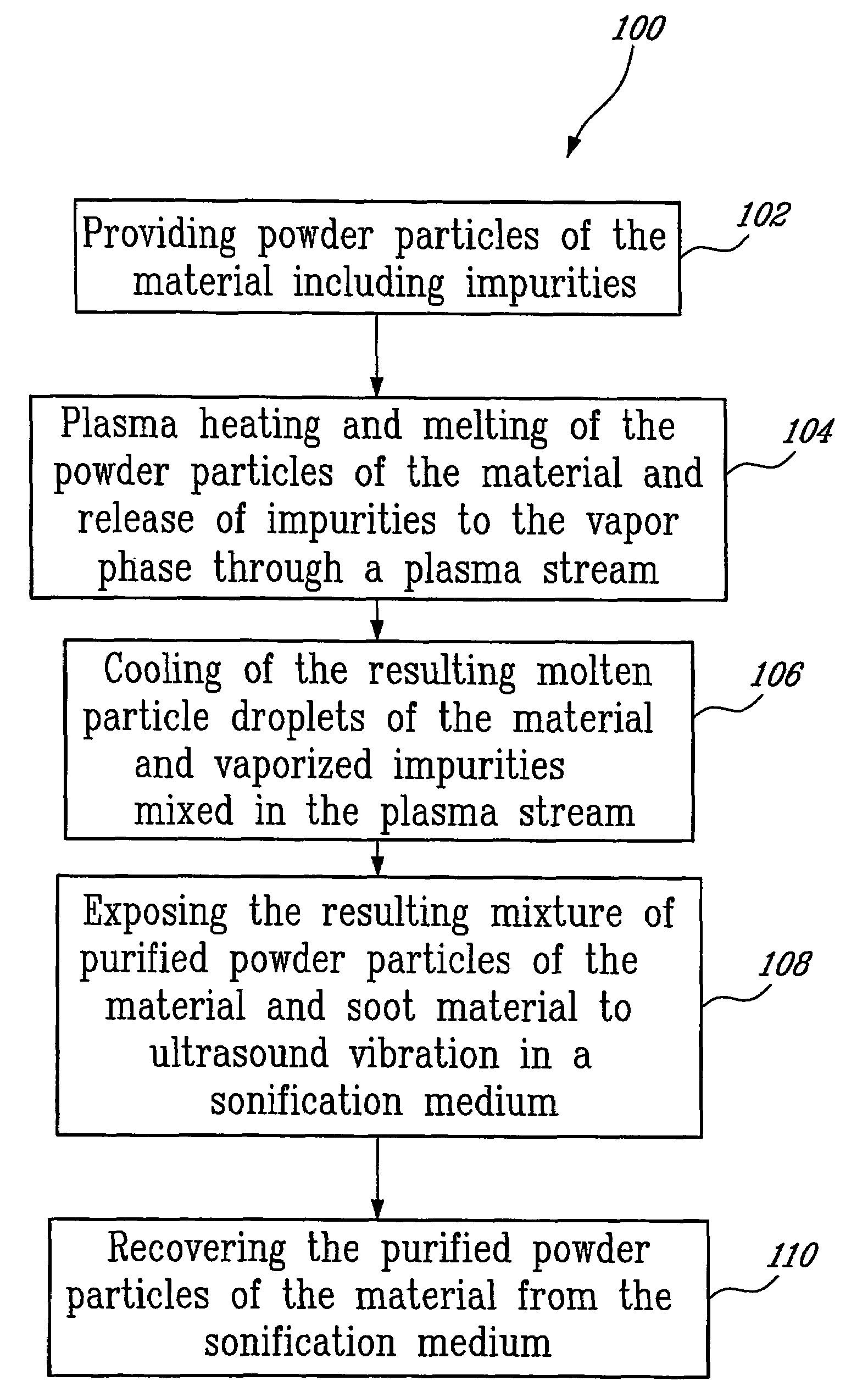

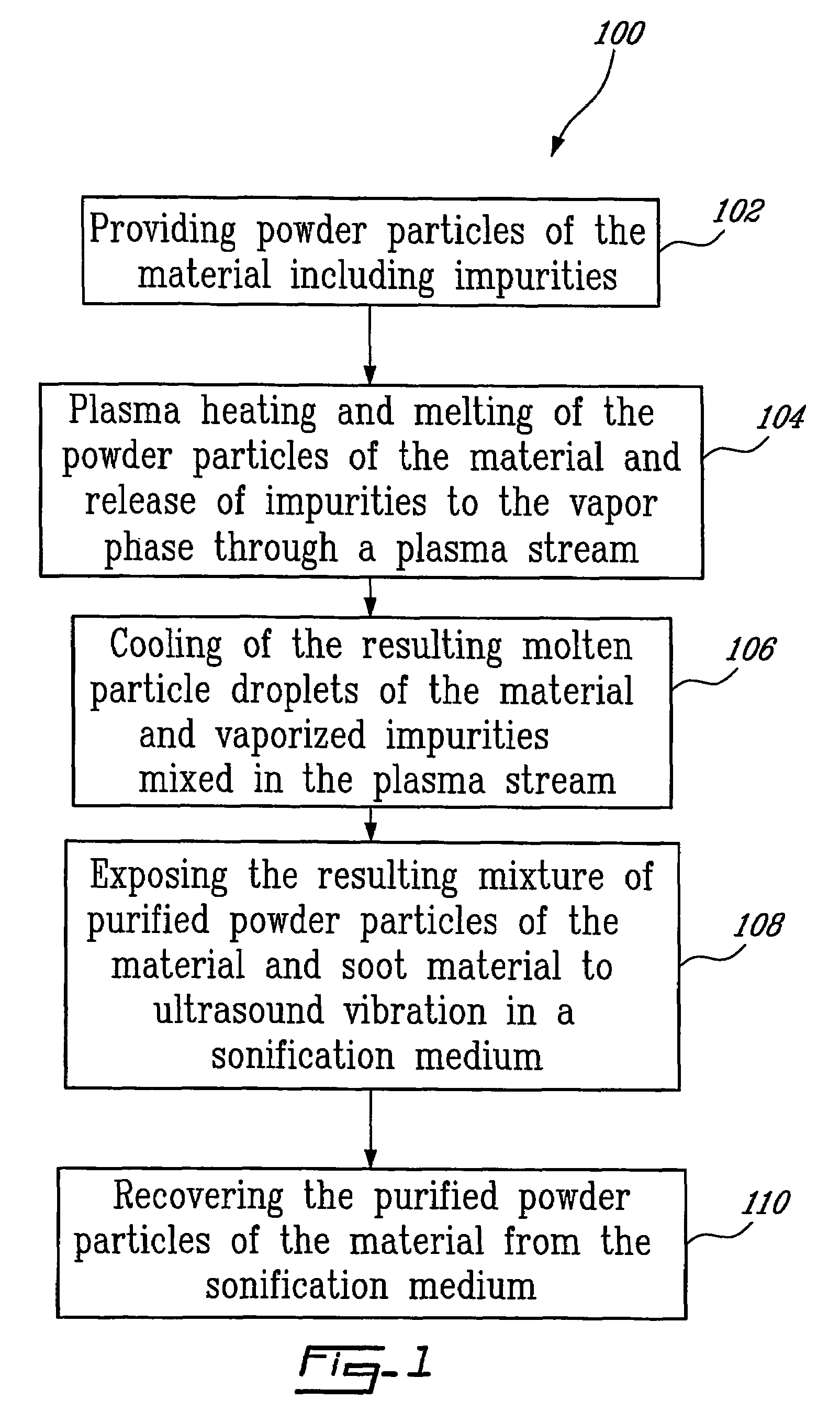

Process for the synthesis, separation and purification of powder materials

ActiveUS7572315B2Speed up the processTransportation and packagingMetal-working apparatusPurification methodsVaporization

Owner:TEKNA PLASMA SYST INC

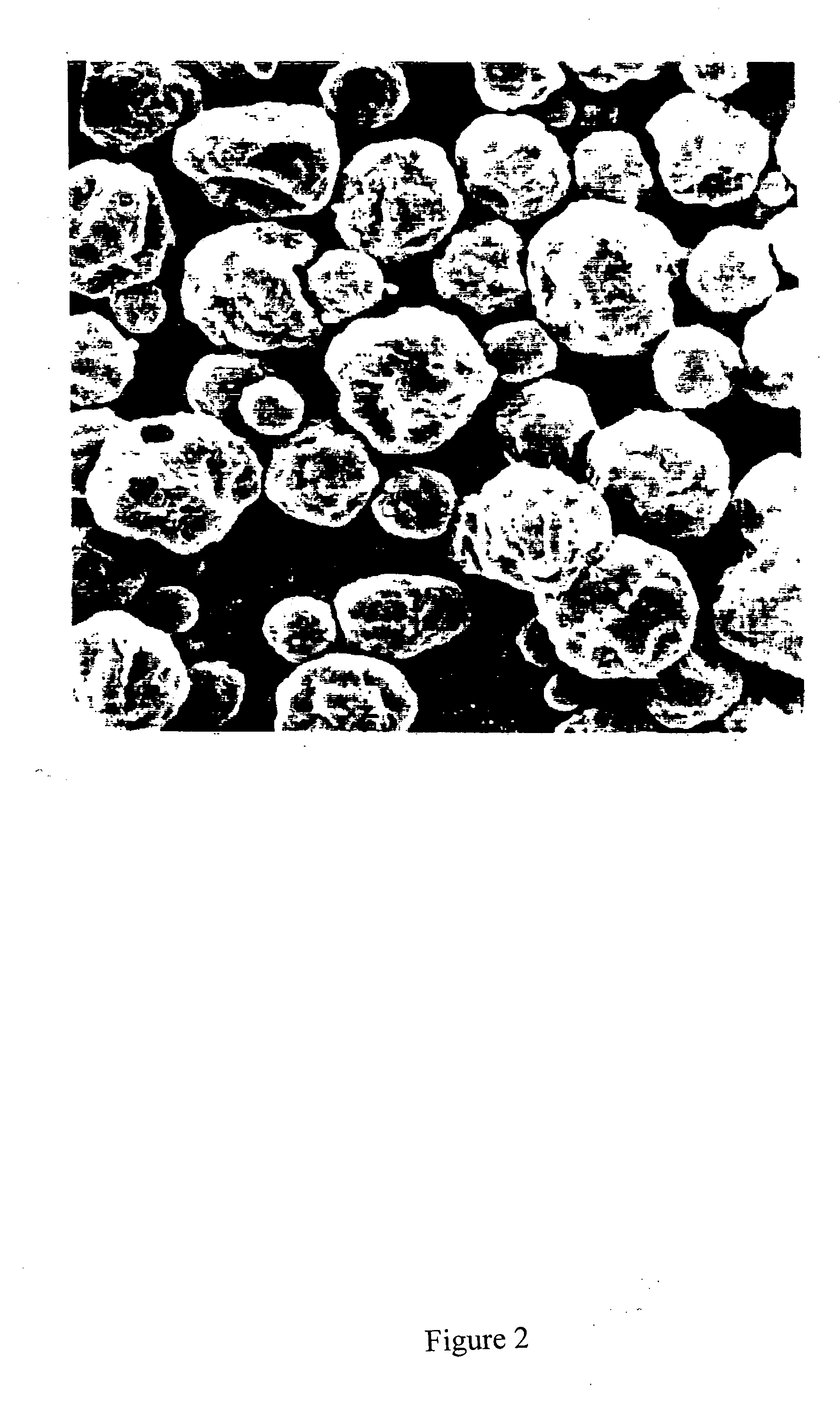

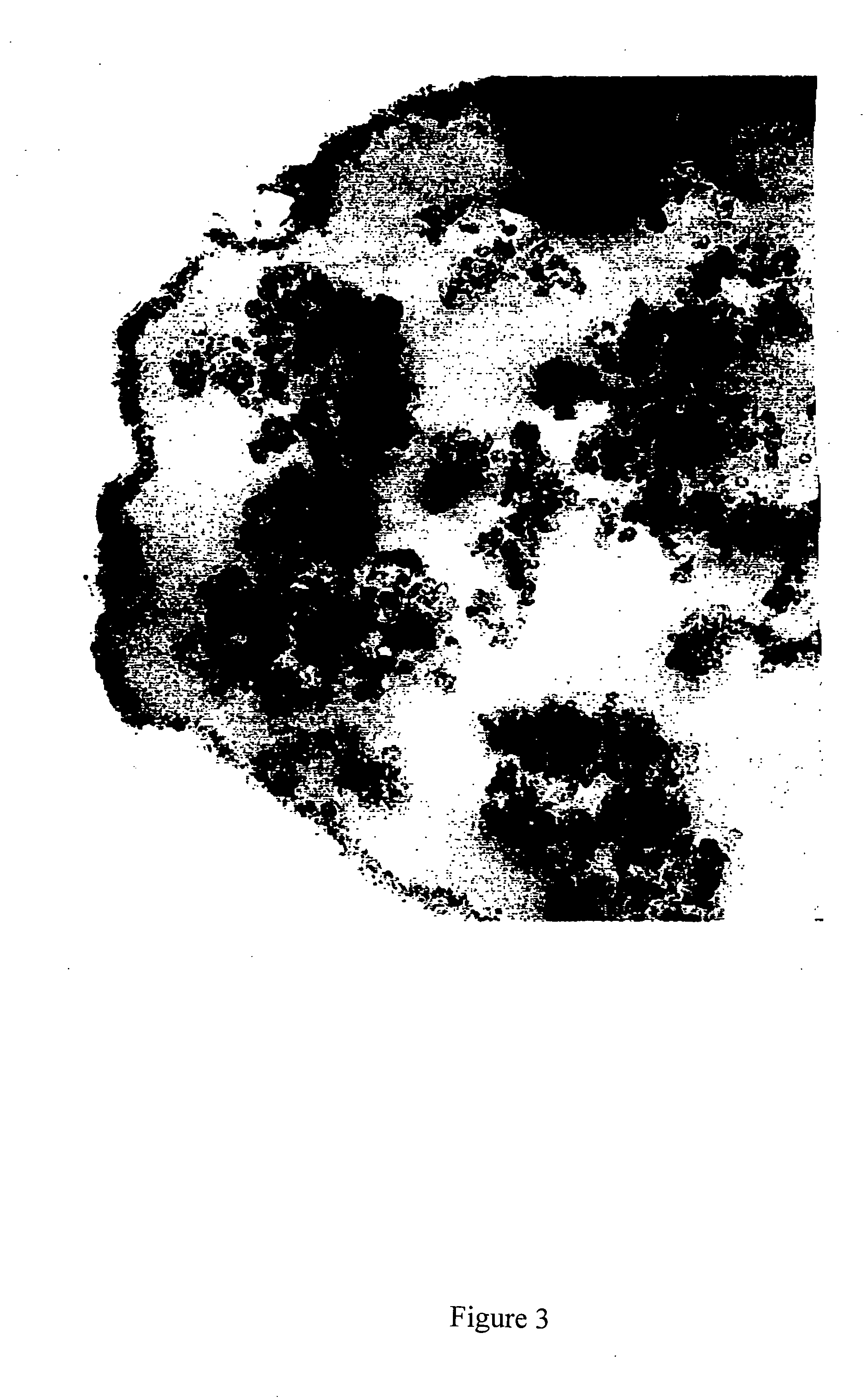

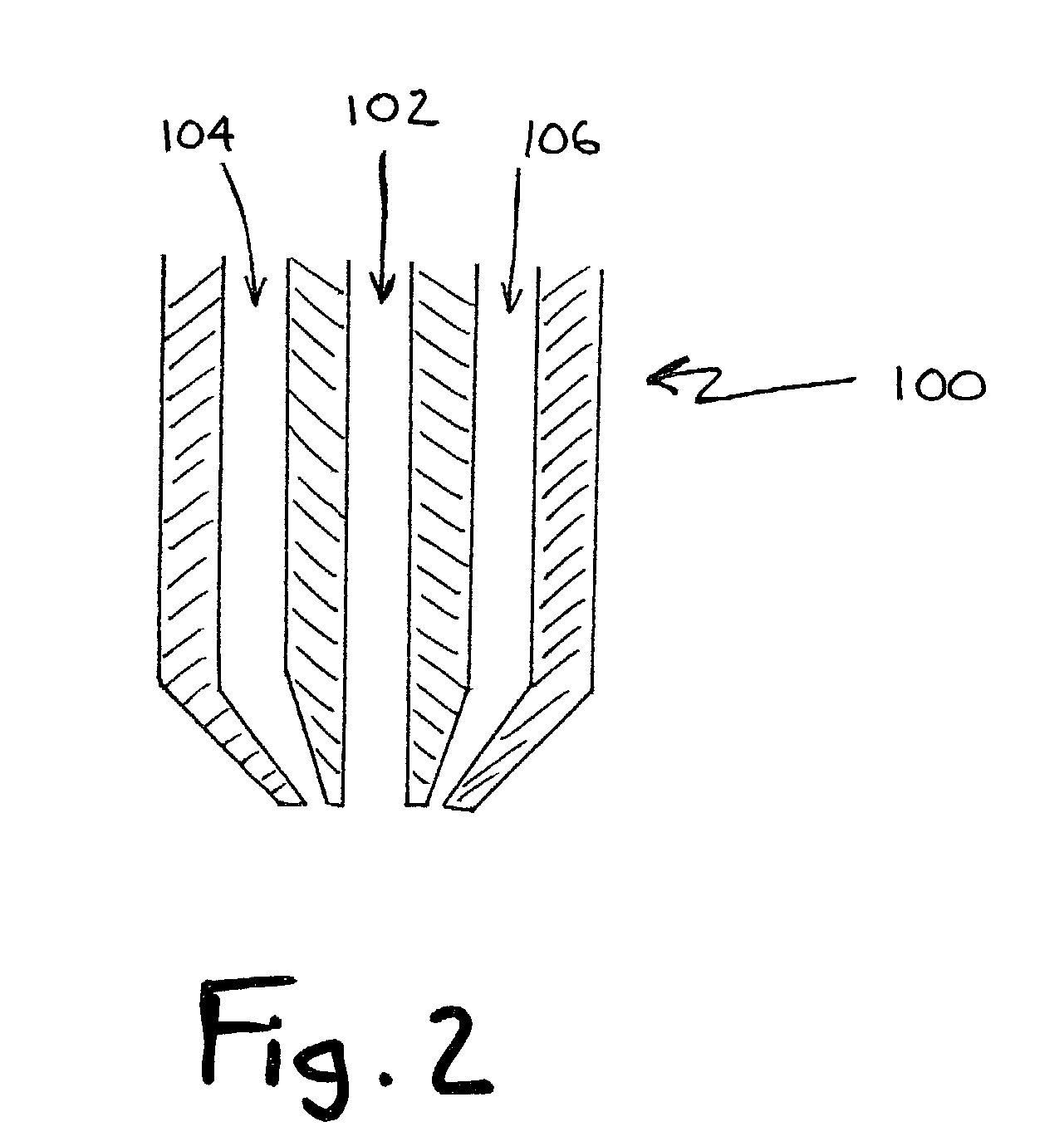

Coated nickel-containing powders, methods and apparatus for producing such powders and devices fabricated from same

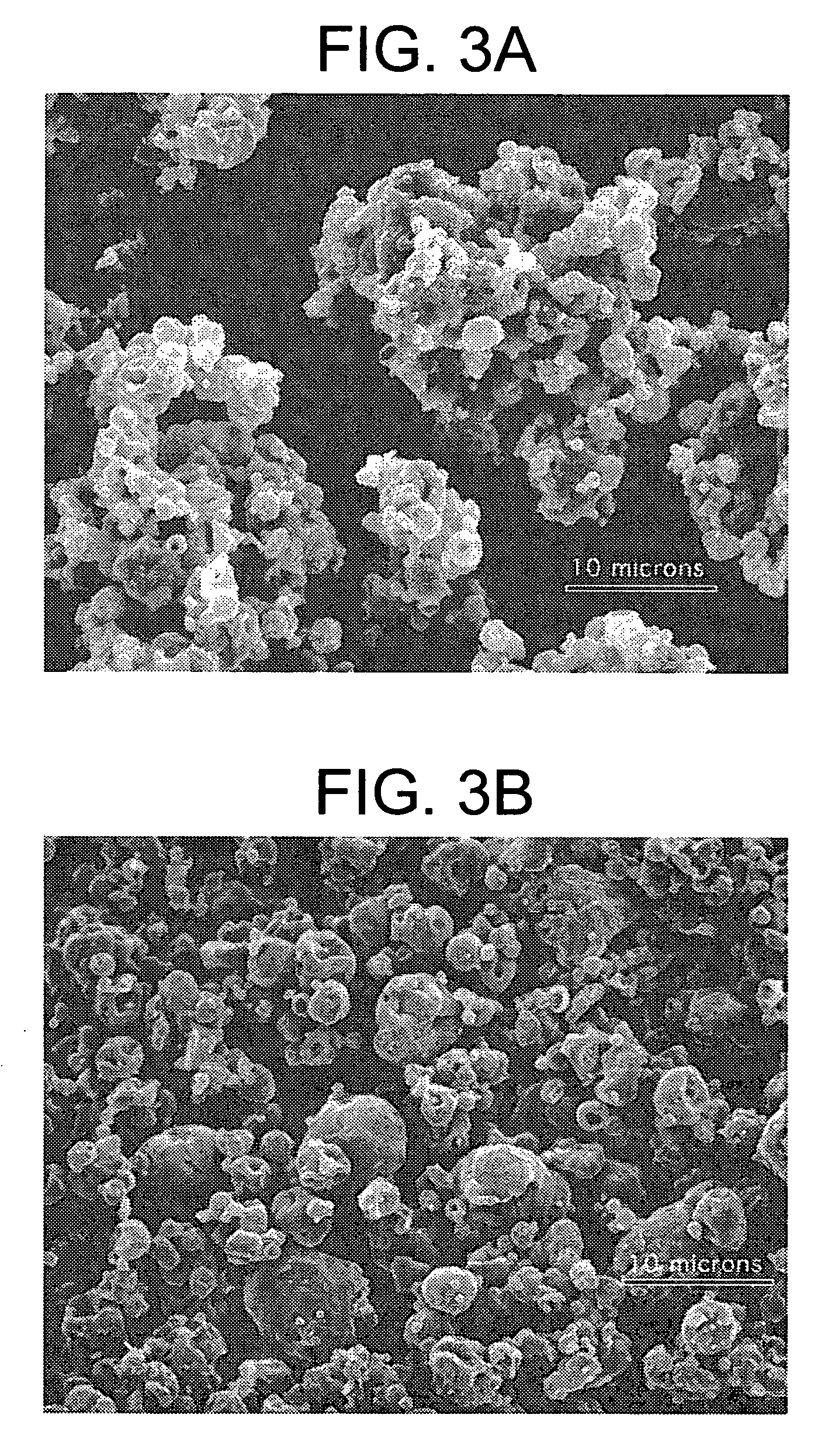

InactiveUS20050097988A1High rateIncrease loadMaterial granulation and coatingGranule coatingSpherical morphologySmall particle

Nickel powder batches including coated nickel-containing particles and methods for producing the same. The coated nickel-containing particles having have a small particle size, narrow size distribution and a spherical morphology. The present invention is also directed to devices incorporating the coated nickel-containing particles.

Owner:CABOT CORP

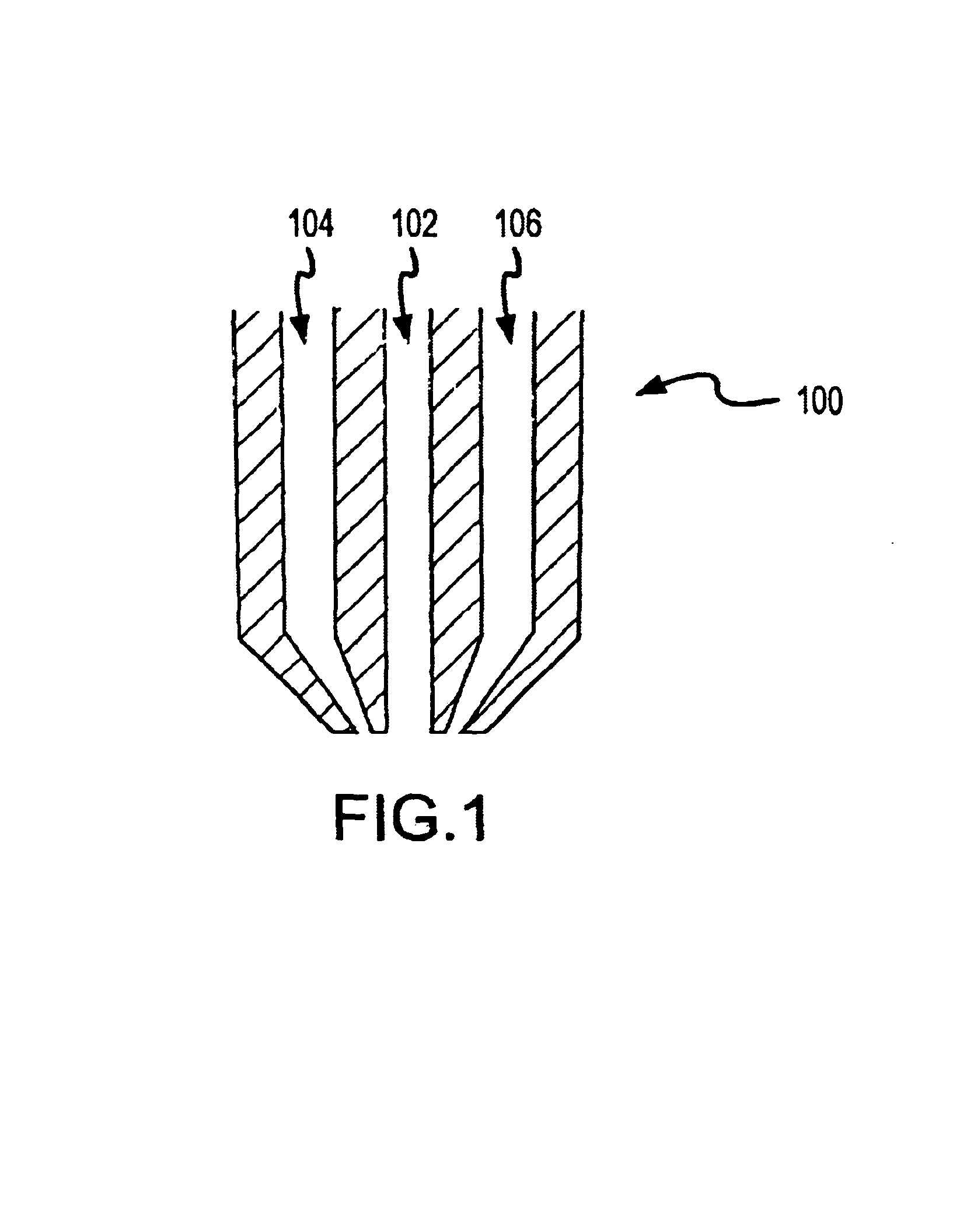

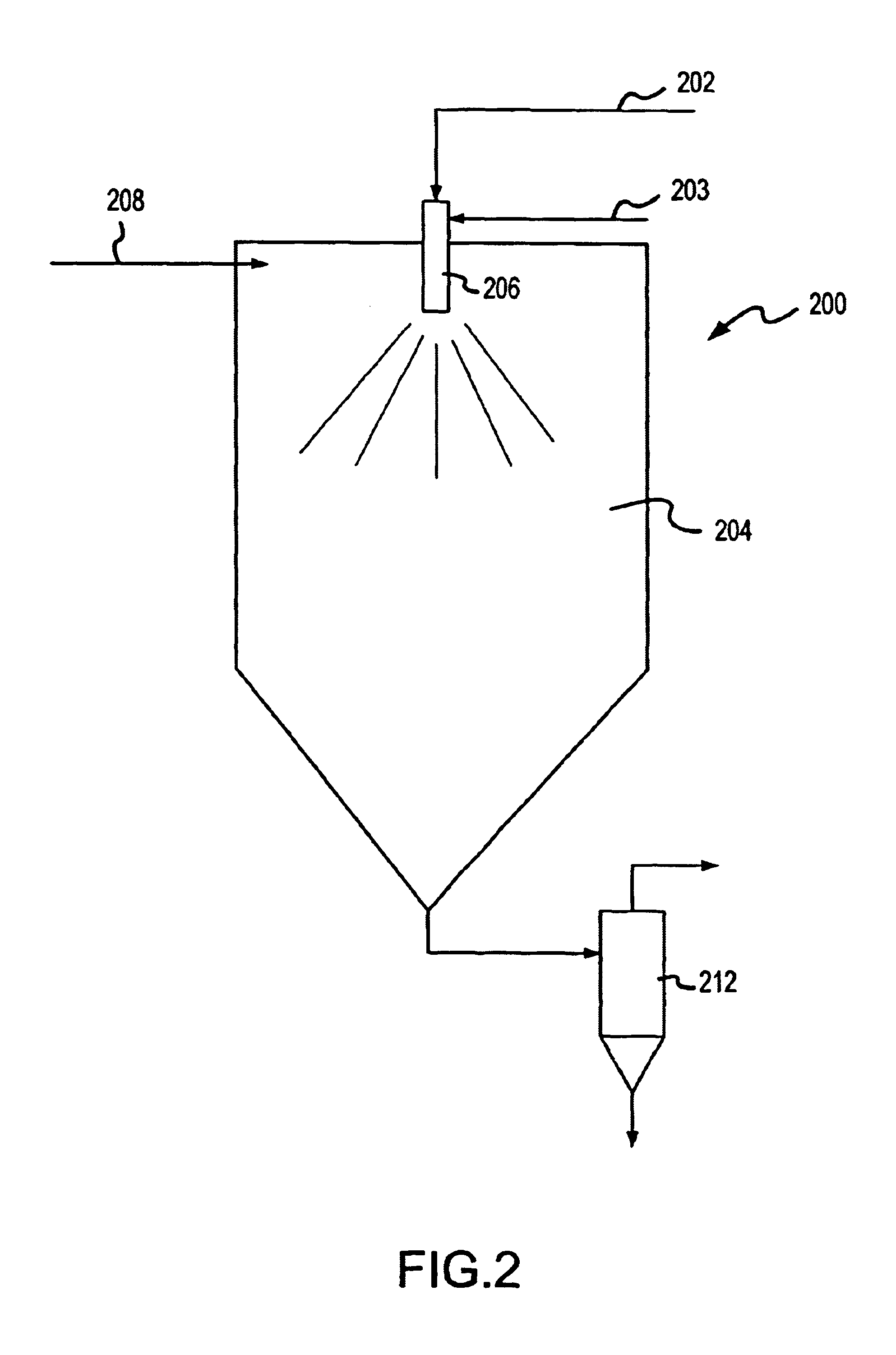

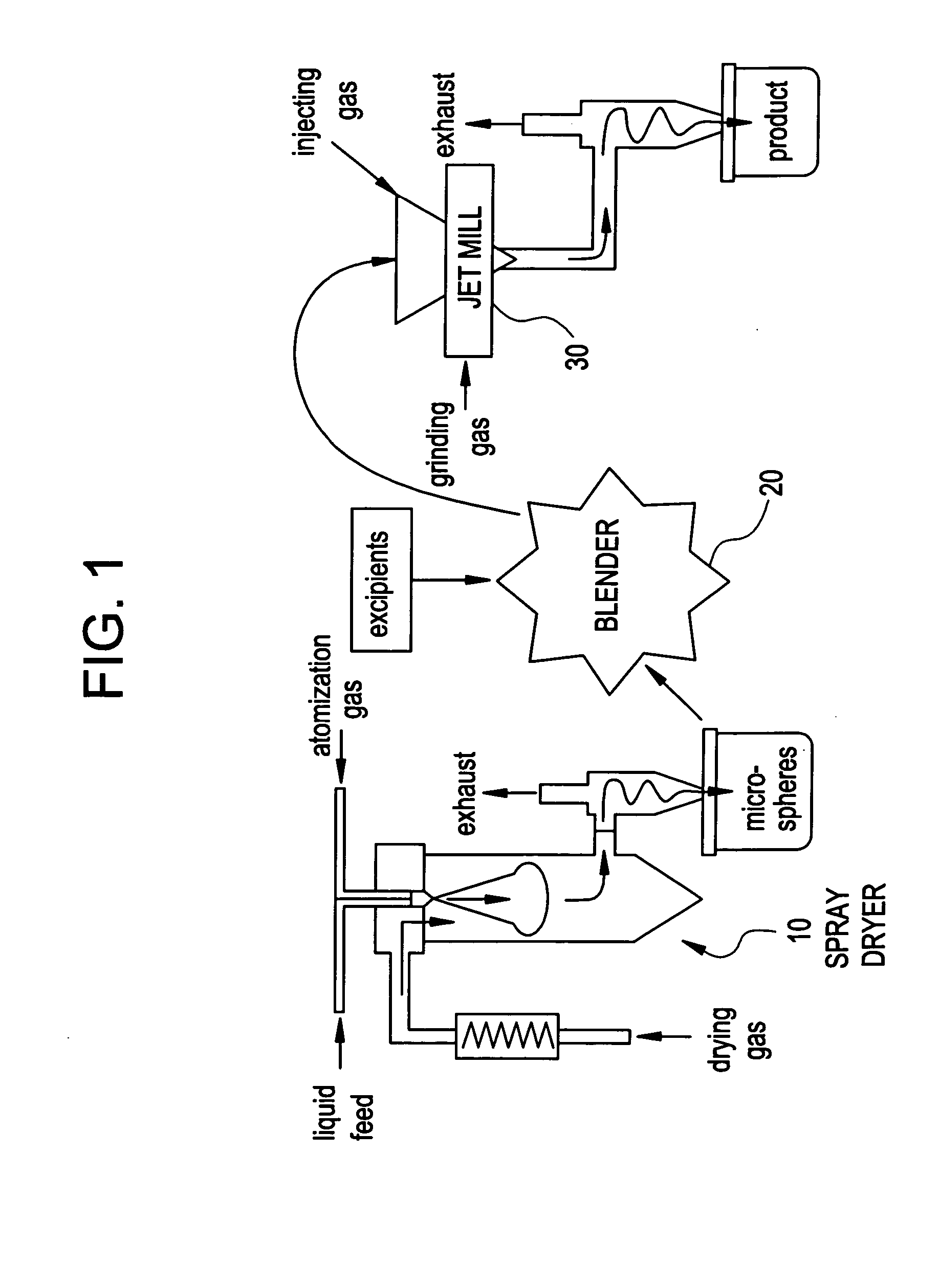

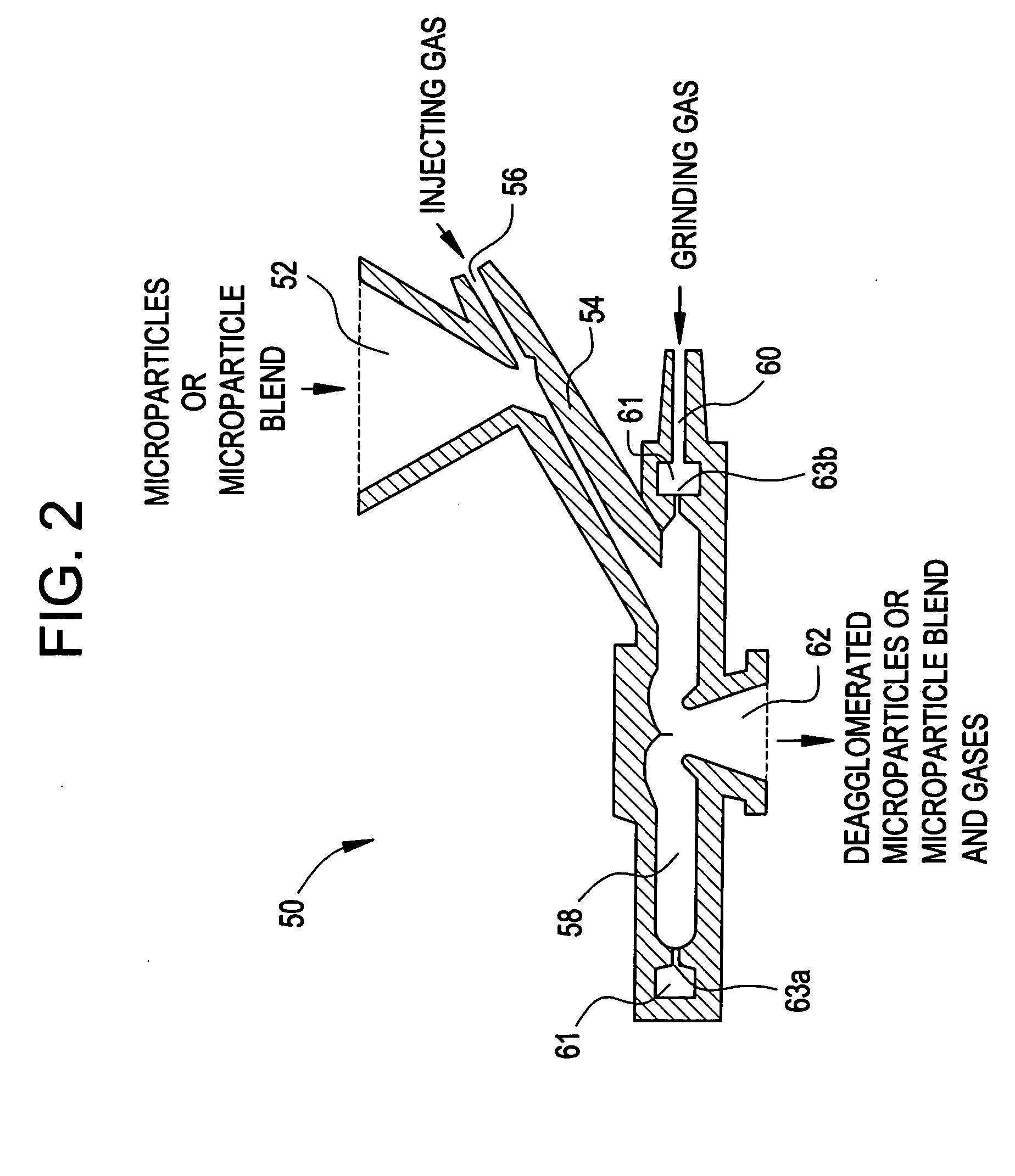

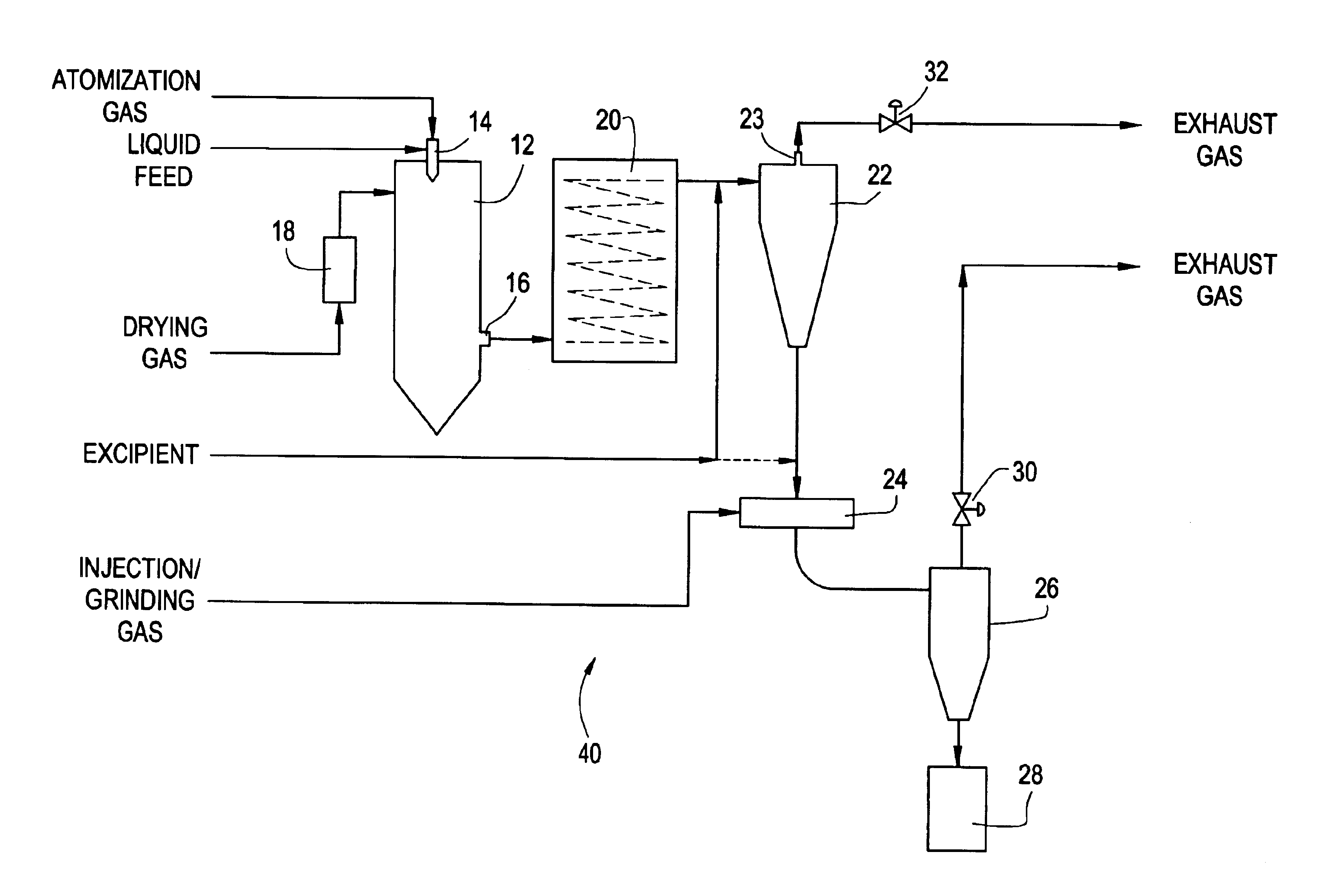

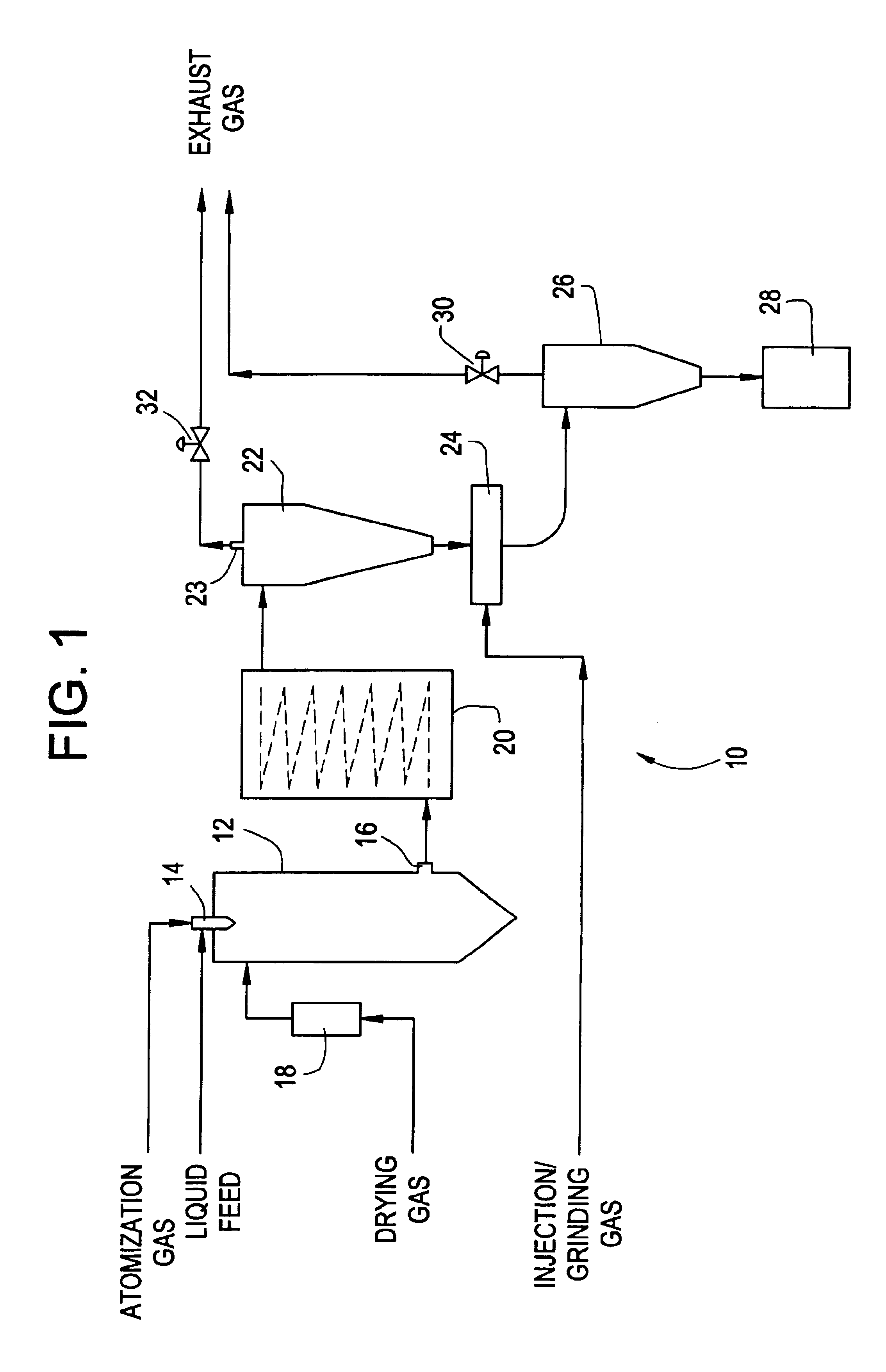

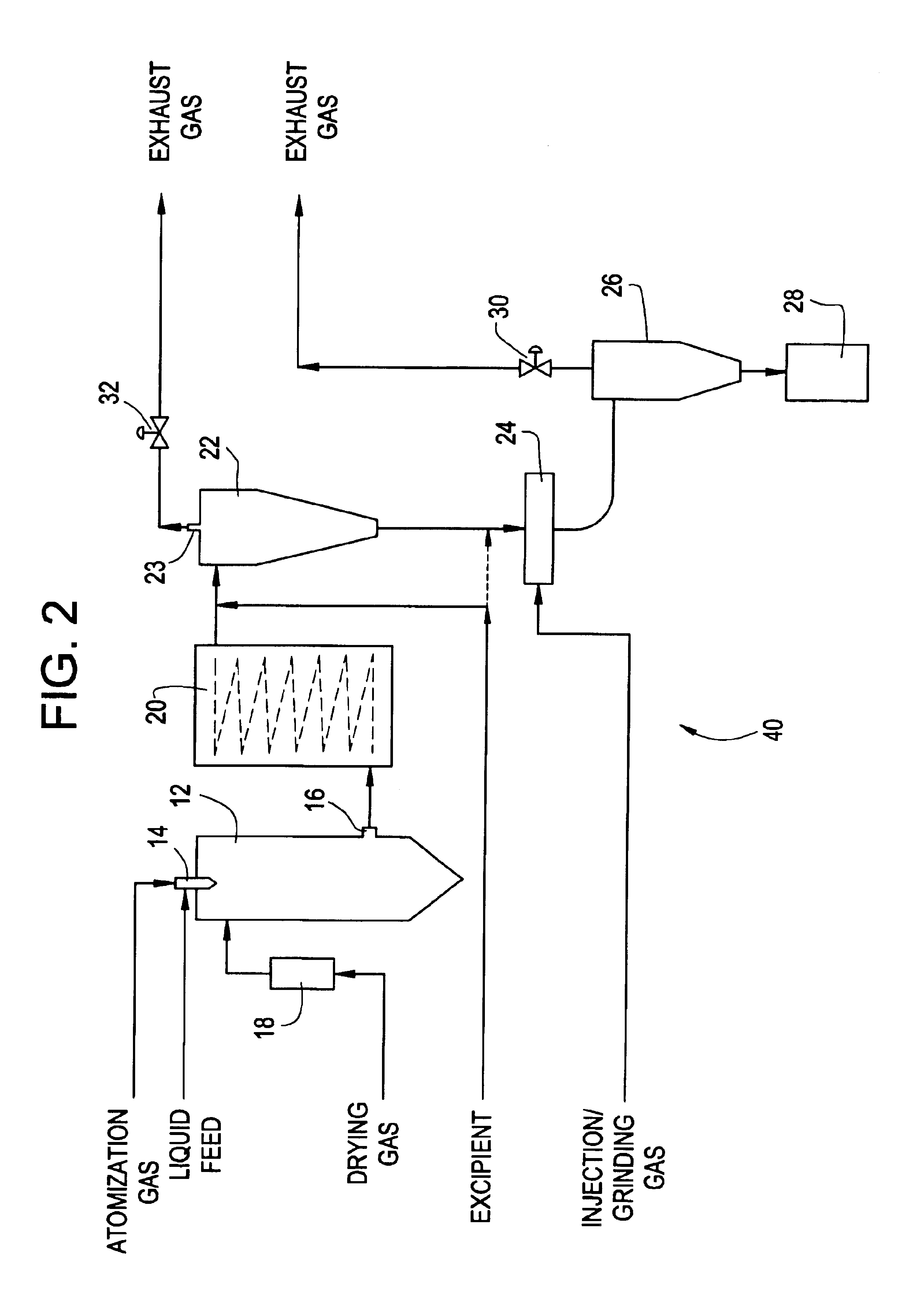

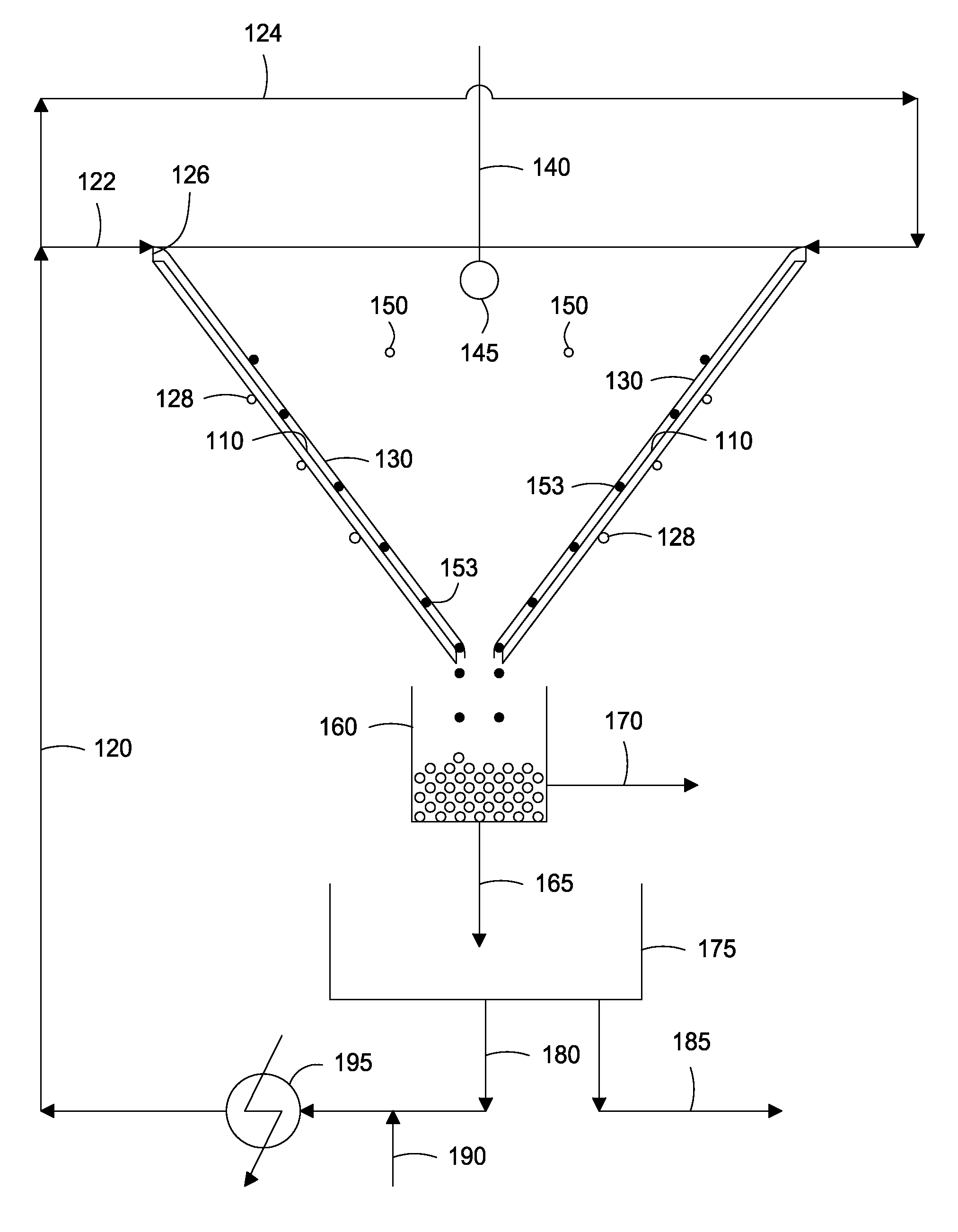

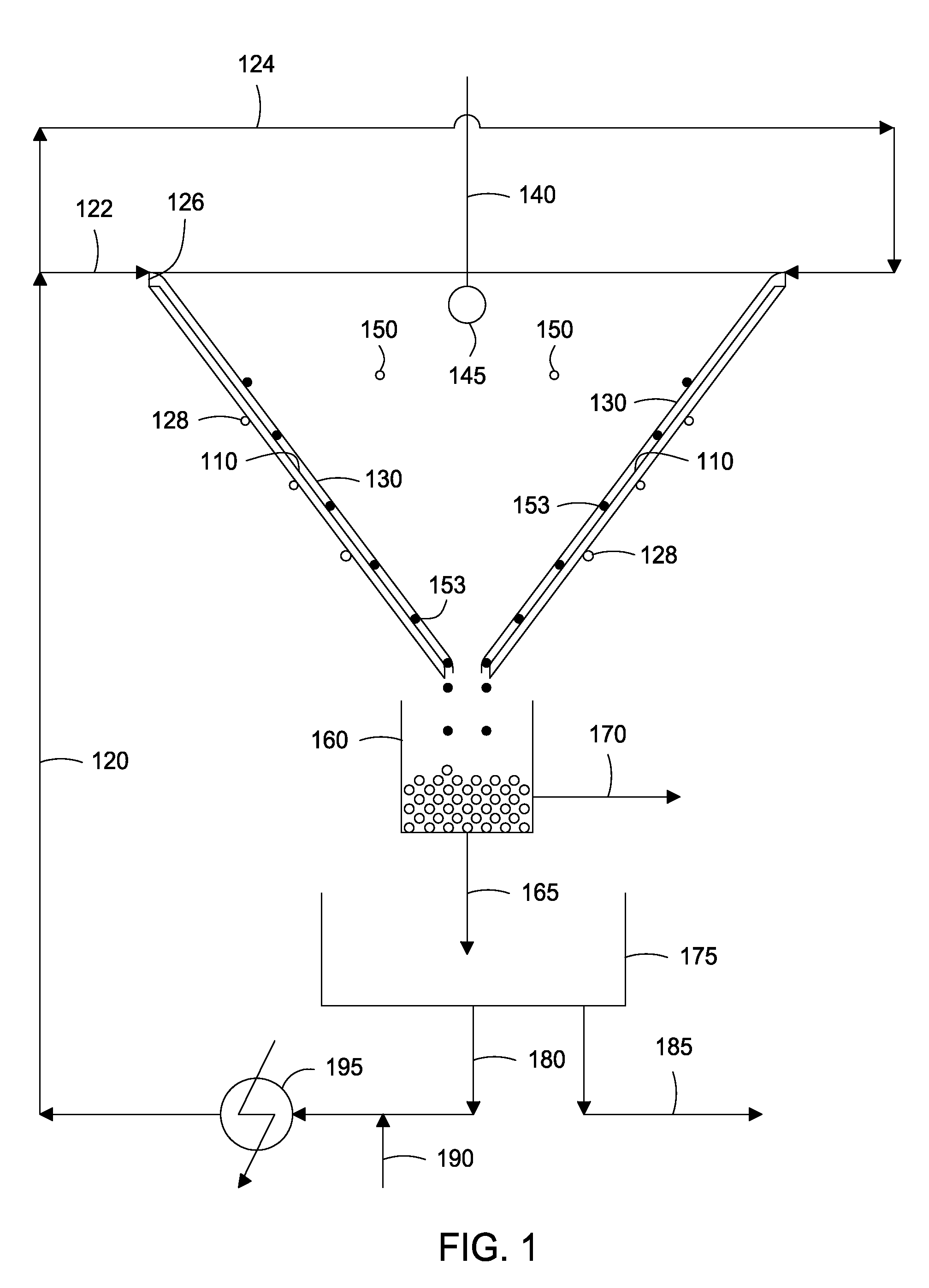

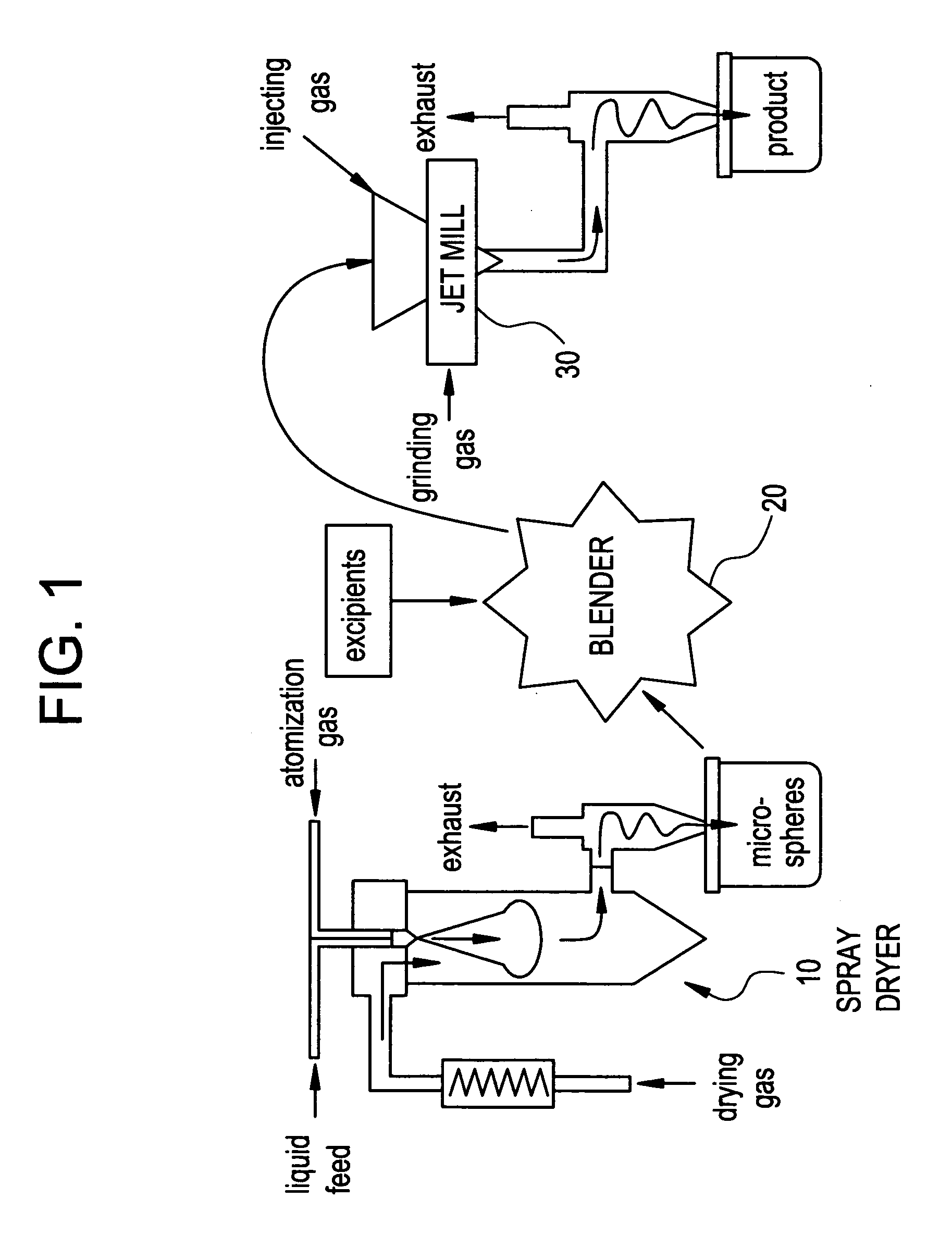

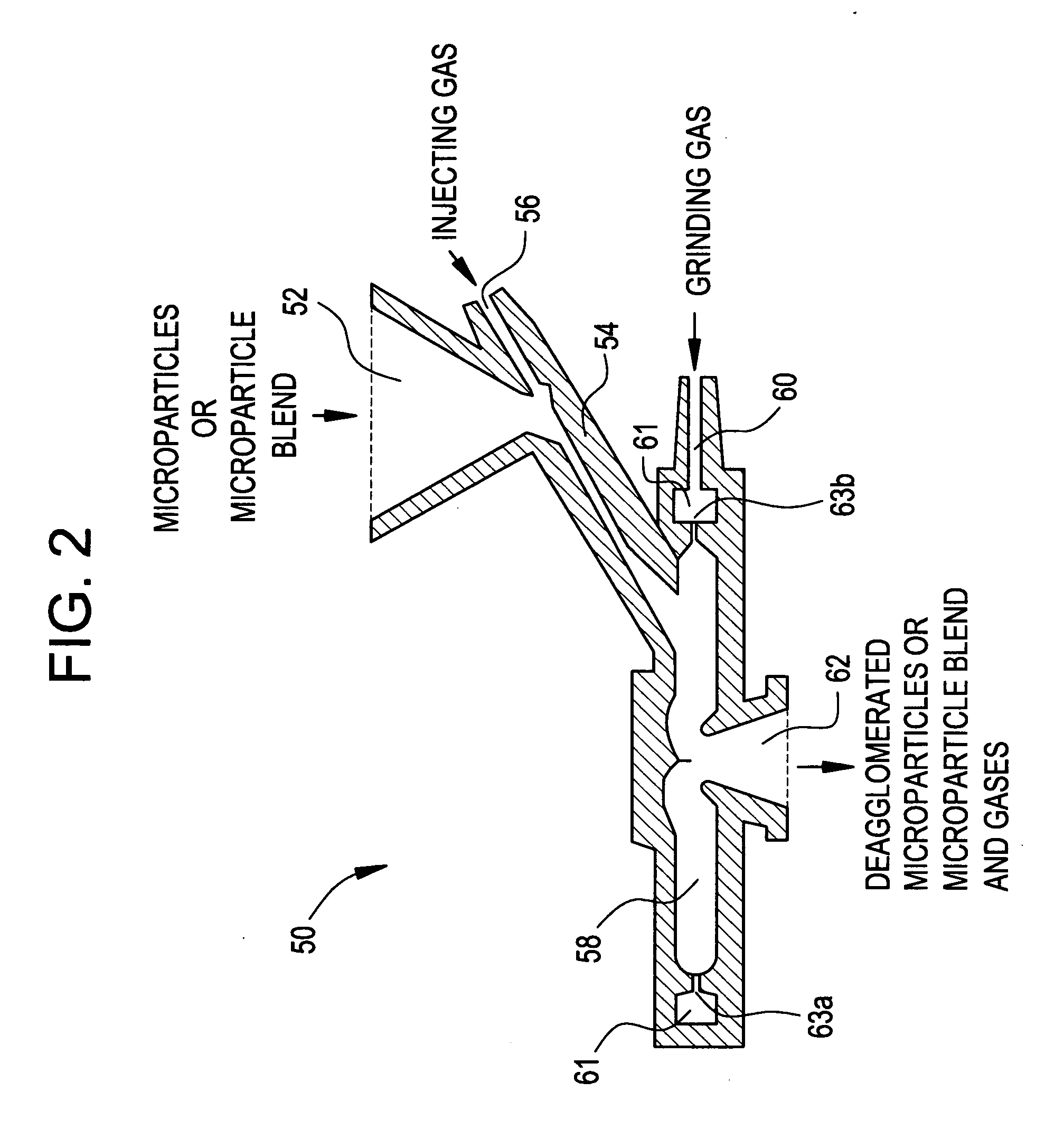

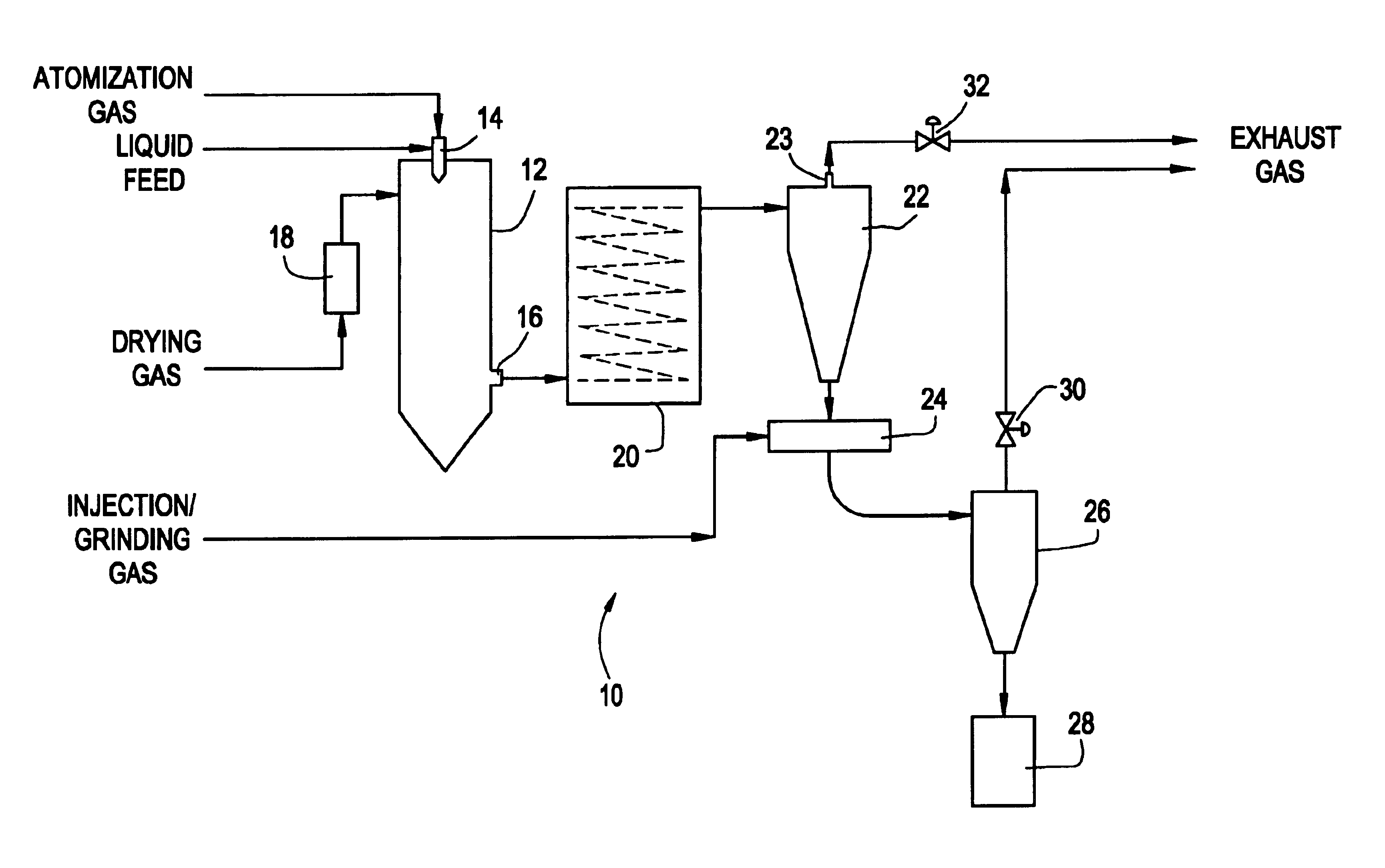

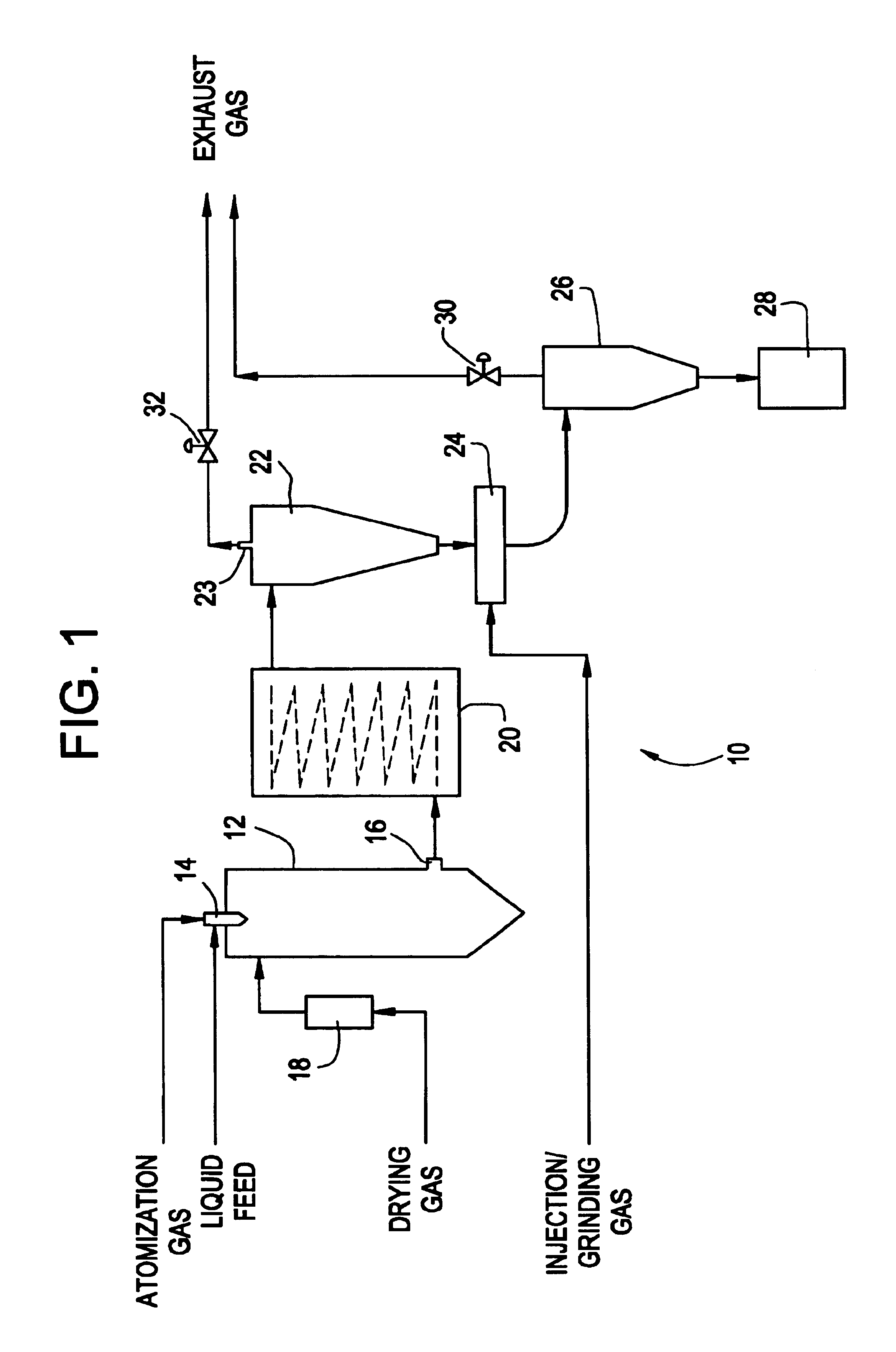

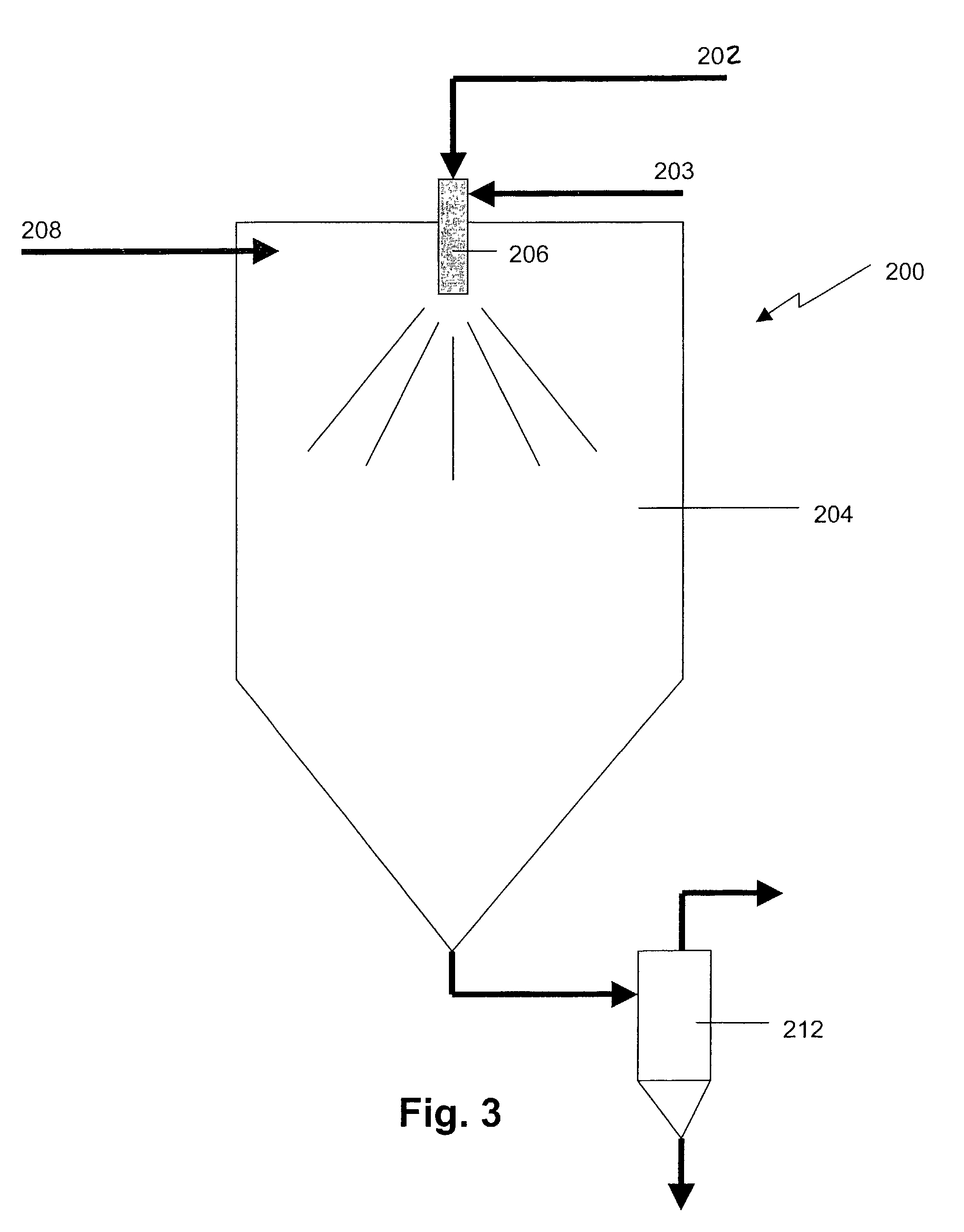

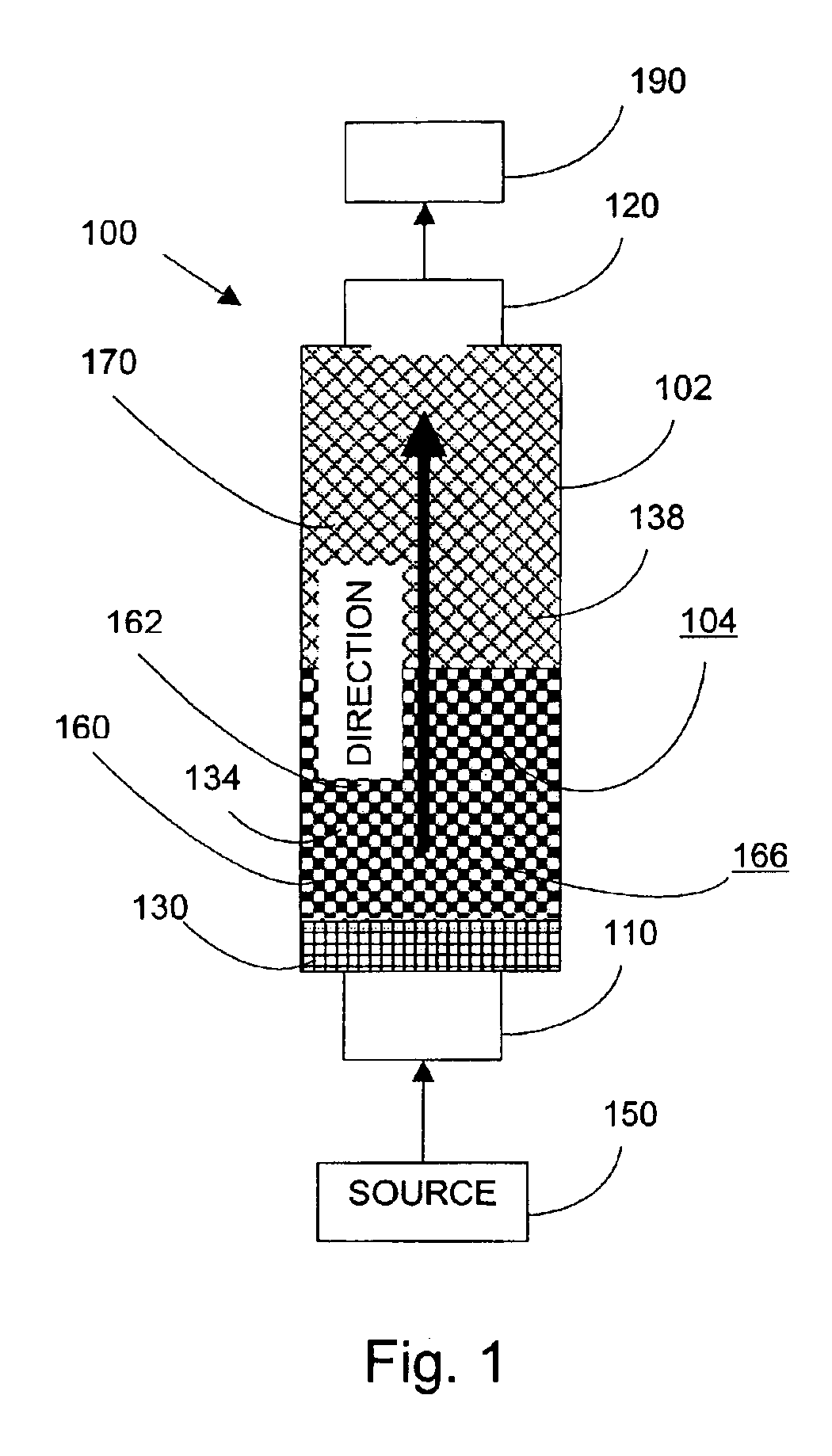

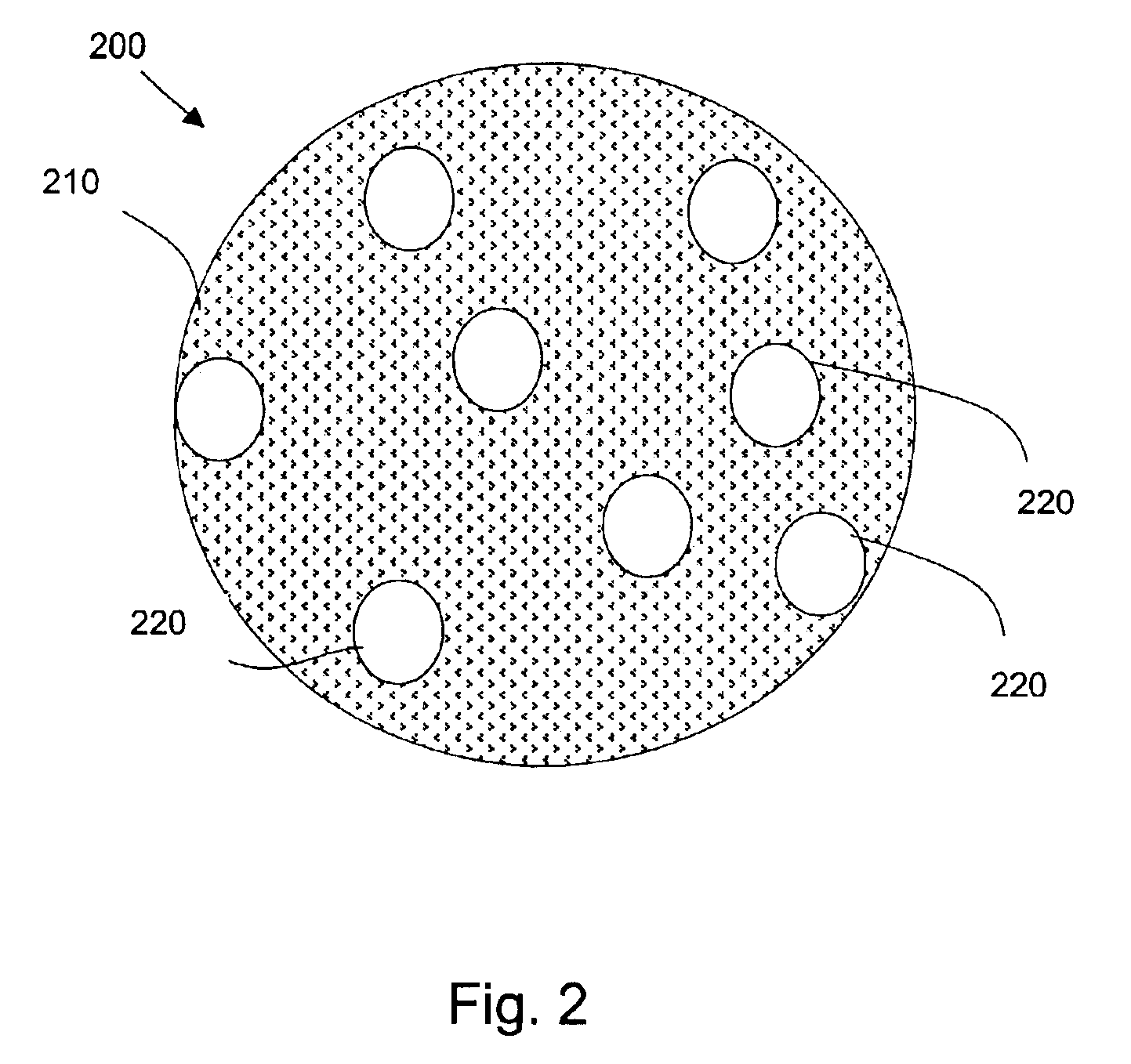

Methods and apparatus for making particles using spray dryer and in-line jet mill

InactiveUS6918991B2Reduce processing timeDrying solid materials with heatGranulation by liquid drop formationPolymer scienceEmulsion

Methods and apparatus are provided for making particles comprising: (a) spraying an emulsion, solution, or suspension, which comprises a solvent and a bulk material (e.g., a pharmaceutical agent), through an atomizer and into a primary drying chamber, having a drying gas flowing therethrough, to form droplets comprising the solvent and bulk material dispersed in the drying gas; (b) evaporating, in the primary drying chamber, at least a portion of the solvent into the drying gas to solidify the droplets and form particles dispersed in drying gas; and (c) flowing the particles and at least a portion of the drying gas through a jet mill to deagglomerate or grind the particles. By coupling spray drying with “in-line” jet milling, a single step process is created from two separate unit operations, and an additional collection step is advantageously eliminated. The one-step, in-line process has further advantages in time and cost of processing.

Owner:ACUSPHERE INC

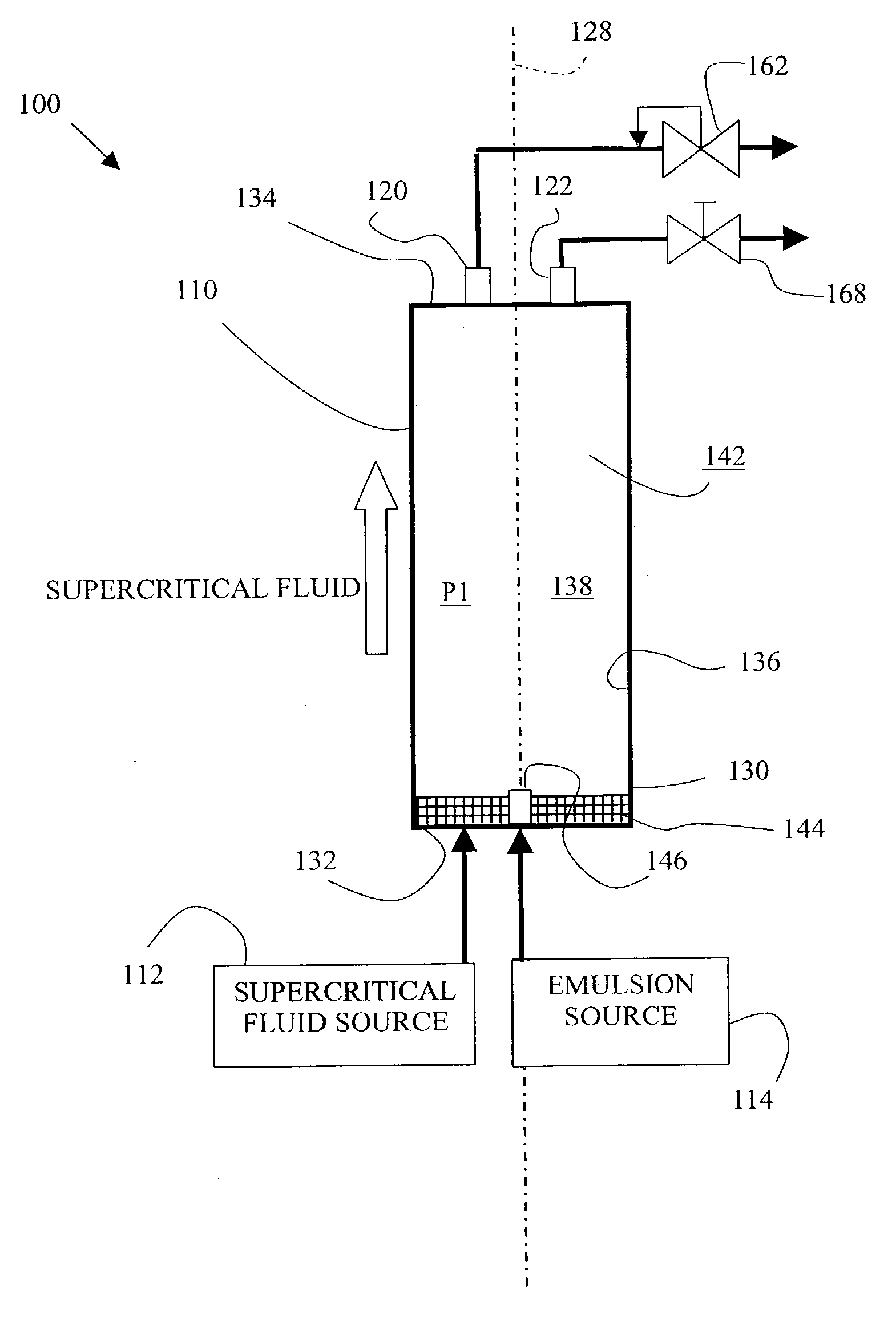

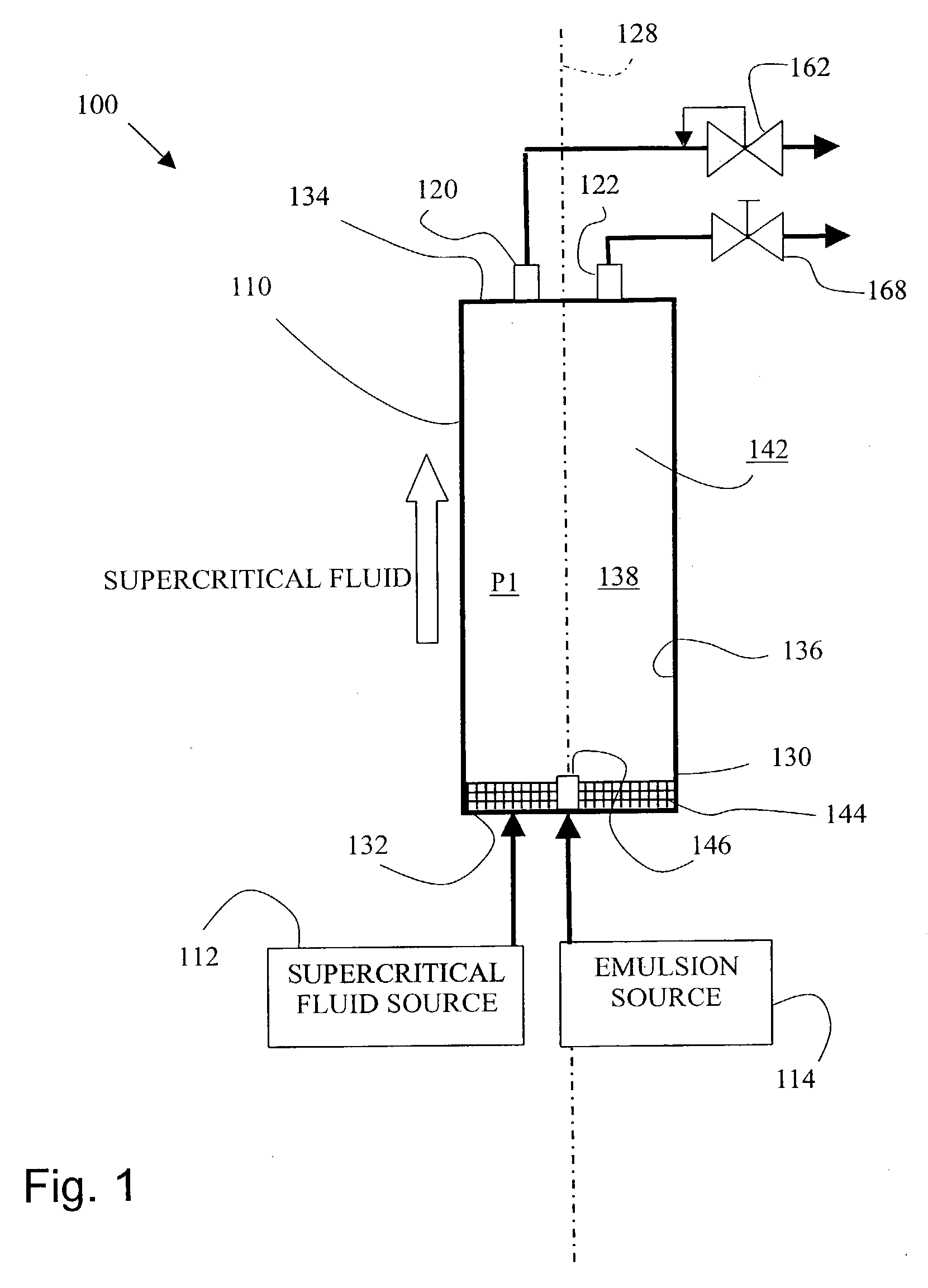

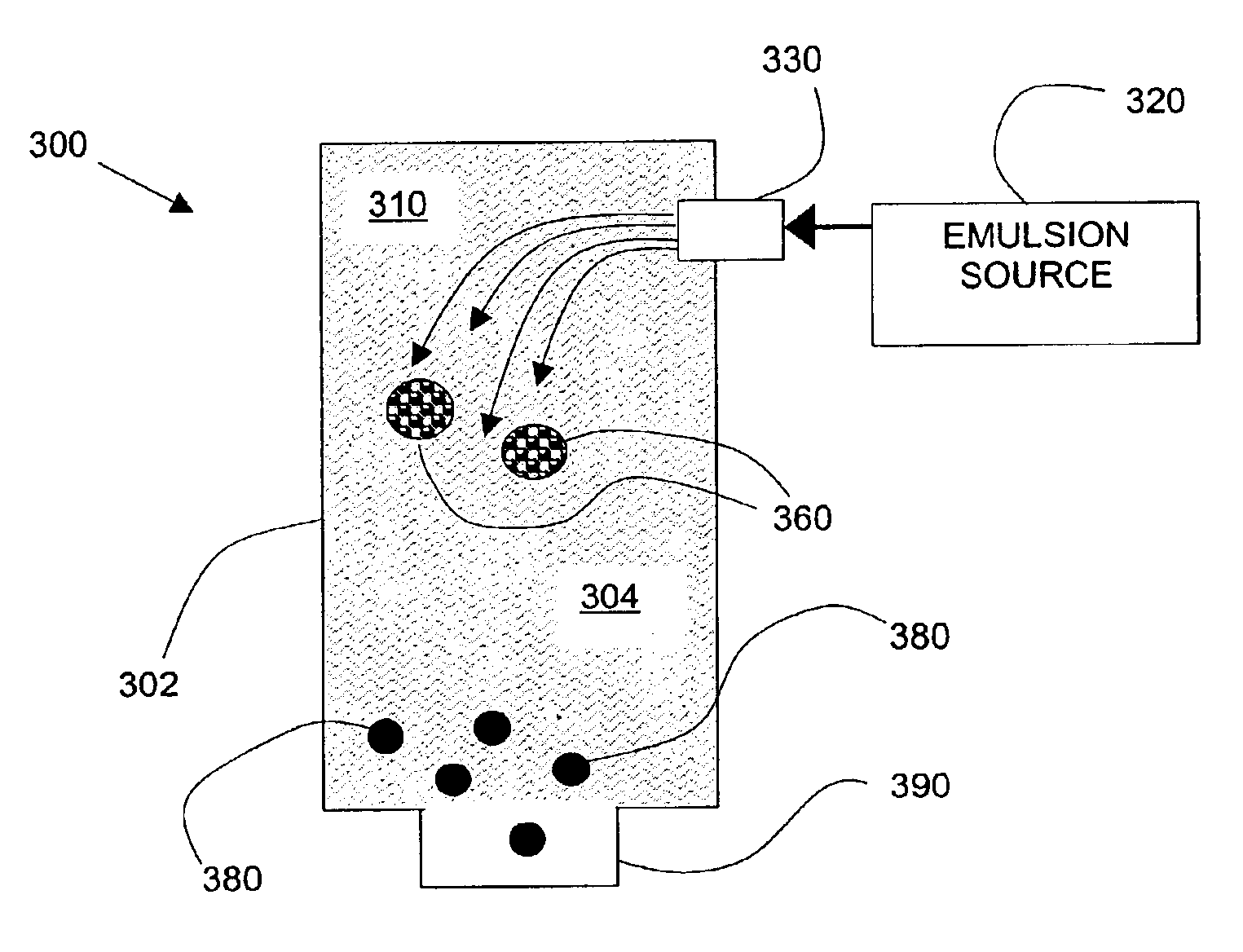

Particles from supercritical fluid extraction of emulsion

A method of producing microparticles and nanoparticles of a solute via the extraction of solvent, having the solute dissolved therein, from an emulsion using a supercritical fluid. The solute to be precipitated is dissolved in the solvent to form a solution, and the solution is dispersed in an immiscible or partially miscible liquid to form an emulsion. The particles are produced via the extraction of the solvent from the emulsion using the supercritical fluid. The process can produce an aqueous suspension of particles that are substantially insoluble in water, and the solvents used in the process to form the emulsion initially can be recovered and recycled.

Owner:FERRO CORP

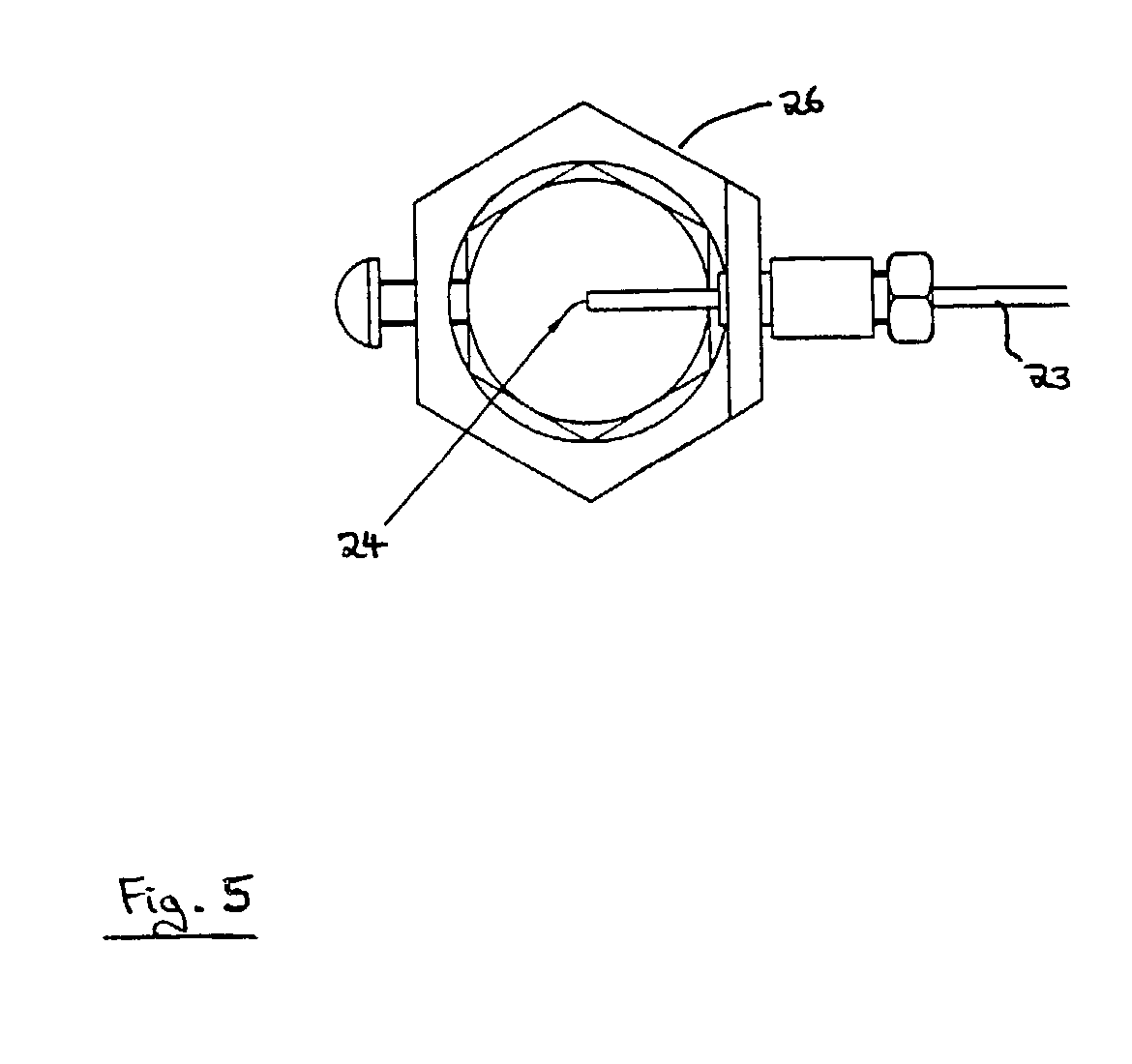

Method of particle formation

InactiveUS6860907B1Characteristic is differentPressurized chemical processPeptide/protein ingredientsSolventMechanical engineering

The invention provides a method for forming particles of a target substance, comprising (a) co-introducing into a particle formation vessel, under controlled temperature and pressure, a supercritical or near-critical anti-solvent fluid; a “target solution or suspension” of the target in a first vehicle; and a second vehicle which is soluble in the anti-solvent fluid; and (b) using the anti-solvent to disperse the target solution / suspension and the second vehicle, and to extract the vehicles, substantially simultaneously and substantially immediately on introduction of the fluids into the particle formation vessel, wherein the second vehicle is immiscible with the first, and wherein contact between the target solution / suspension and the second vehicle occurs a sufficiently short period of time before their dispersion by the anti-solvent, and with sufficient physical mixing, as to allow only insignificant, if any, phase separation to occur between the two vehicles between their contact with one another and their dispersion

Owner:INHALE THERAPEUTIC SYST INC

Hot asphalt cooling and pelletization process

ActiveUS7968020B2Granulation by liquid drop formationAuxillary shaping apparatusProcess systemsAsphalt

Owner:KELLOGG BROWN & ROOT LLC

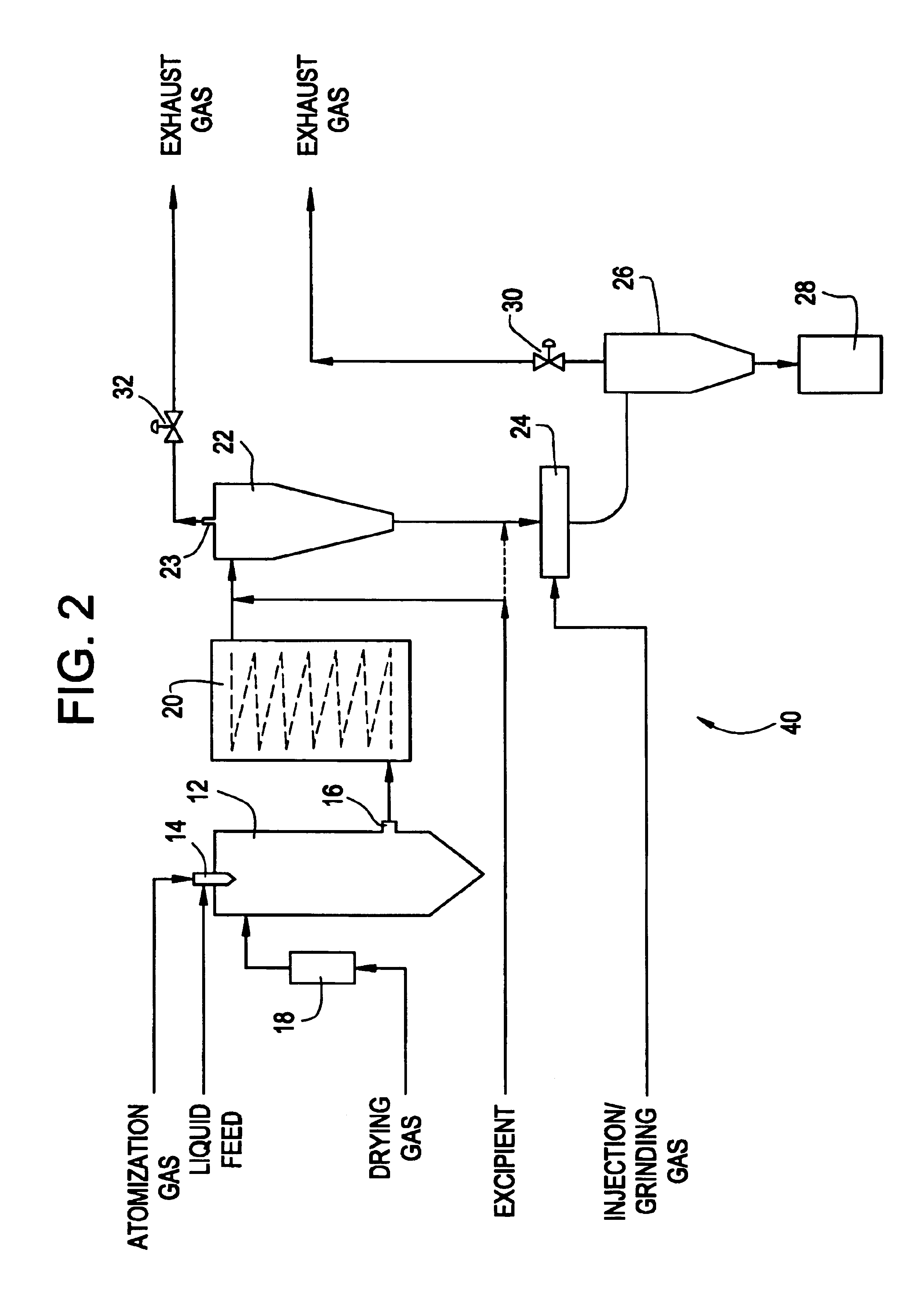

Methods for making pharmaceutical formulations comprising deagglomerated microparticles

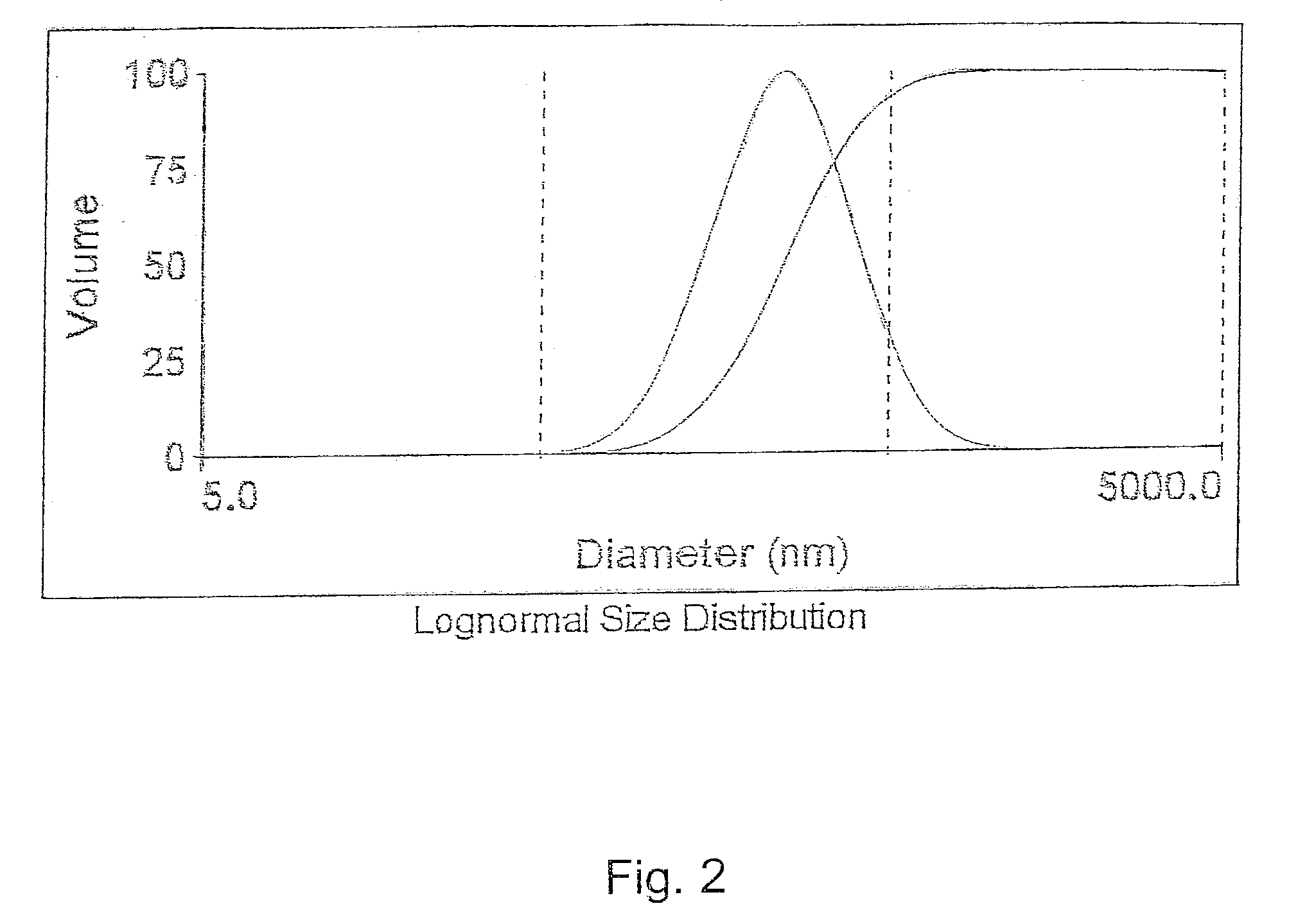

InactiveUS20060093678A1High crystallinityReduce contentPowder deliveryGranulation by liquid drop formationMicroparticleVolume average

Methods are provided for making a dry powder blend pharmaceutical formulation comprising (i) forming microparticles which comprise a pharmaceutical agent; (ii) providing at least one excipient in the form of particles having a volume average diameter that is greater than the volume average diameter of the microparticles; (iii) blending the microparticles with the excipient to form a powder blend; and (iv) jet milling the powder blend to deagglomerate at least a portion of any of the microparticles which have agglomerated, while substantially maintaining the size and morphology of the individual microparticles. Jet milling advantageously can eliminate the need for more complicated wet deagglomeration processes, can lower residual moisture and solvent levels in the microparticles (which leads to better stability and handling properties for dry powder formulations), and can improve wettability, suspendability, and content uniformity of dry powder blend formulations.

Owner:CHICKERING DONALD E III +6

Method for obtaining nanoparticles

ActiveUS20060222780A1High densityImprove conversion efficiencyMaterial nanotechnologyMolten spray coatingNanoparticleNanometre

The method is intended for obtaining nanosize amorphous particles, which find use in various fields of science and technology; in particular, metallic nanostructures can be regarded as a promising material for creating new sensors and electronic and optoelectronic devices and for developing new types of highly selective solid catalysts. The method for obtaining nanoparticles includes the following stages: dispersion of a molten material; supply of the resulting liquid drops of this material into a plasma with parameters satisfying the aforementioned relationships, which is formed in an inert gas at a pressure of 10−4-10−1 Pa; cooling of liquid nanoparticles formed in the said plasma to their hardening; and deposition of the resulting solid nanoparticles onto a support.

Owner:GUREVICH +2

Methods and apparatus for making particles using spray dryer and in-line jet mill

InactiveUS6921458B2Reduce processing timeDrying solid materials with heatGranulation by liquid drop formationPolymer scienceEmulsion

Methods and apparatus are provided for making particles comprising: (a) spraying an emulsion, solution, or suspension, which comprises a solvent and a bulk material (e.g., a pharmaceutical agent), through an atomizer and into a primary drying chamber, having a drying gas flowing therethrough, to form droplets comprising the solvent and bulk material dispersed in the drying gas; (b) evaporating, in the primary drying chamber, at least a portion of the solvent into the drying gas to solidify the droplets and form particles dispersed in drying gas; and (c) flowing the particles and at least a portion of the drying gas through a jet mill to deagglomerate or grind the particles. By coupling spray drying with “in-line” jet milling, a single step process is created from two separate unit operations, and an additional collection step is advantageously eliminated. The one-step, in-line process has further advantages in time and cost of processing.

Owner:ACUSPHERE INC

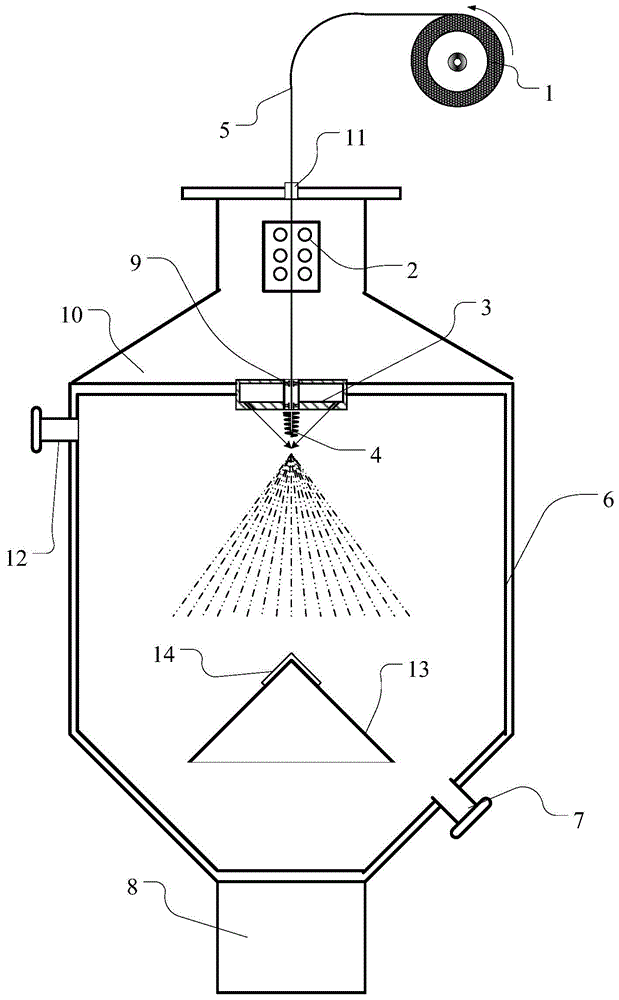

Device and method for preparing spherical titanium powder and titanium alloy powder through gas atomization

ActiveCN104475744AAvoid pollutionHigh sphericityGranulation by liquid drop formationHigh frequency powerTitanium alloy

The invention relates to a device and method for preparing spherical titanium powder and titanium alloy powder through gas atomization, which belongs to the field of powder metallurgy industry. The device comprises a vacuum chamber, a continuous feeder for titanium or titanium alloy wires / rods is arranged outside the vacuum chamber, a dynamic sealing device is arranged at the top of the vacuum chamber, a metal straightening device is arranged inside the vacuum chamber, an atomizing chamber is arranged below the vacuum chamber, a gas atomization nozzle is installed between the atomizing chamber and the vacuum chamber, the center hole of the nozzle is internally provided with a wire / rod guiding device, a high-frequency smelting coil is installed below the nozzle, wherein the dynamic sealing device, the straightening device, the guiding device and the high-frequency smelting coil are installed on the same axis; a heat dissipation cover is installed inside the atomizing chamber, a protective cover is arranged at the top of the heat dissipation cover, and the centers of the heat dissipation cover and protective cover and the center of the high-frequency smelting coil are on the same axis; a powder collecting pot is arranged below the atomizing chamber. By means of controlling the diameters of the wires, the atomizing gas pressure and the power of a high-frequency power supply, titanium and titanium alloy powder with different particle sizes and particle size distributions can be obtained.

Owner:有研增材技术有限公司

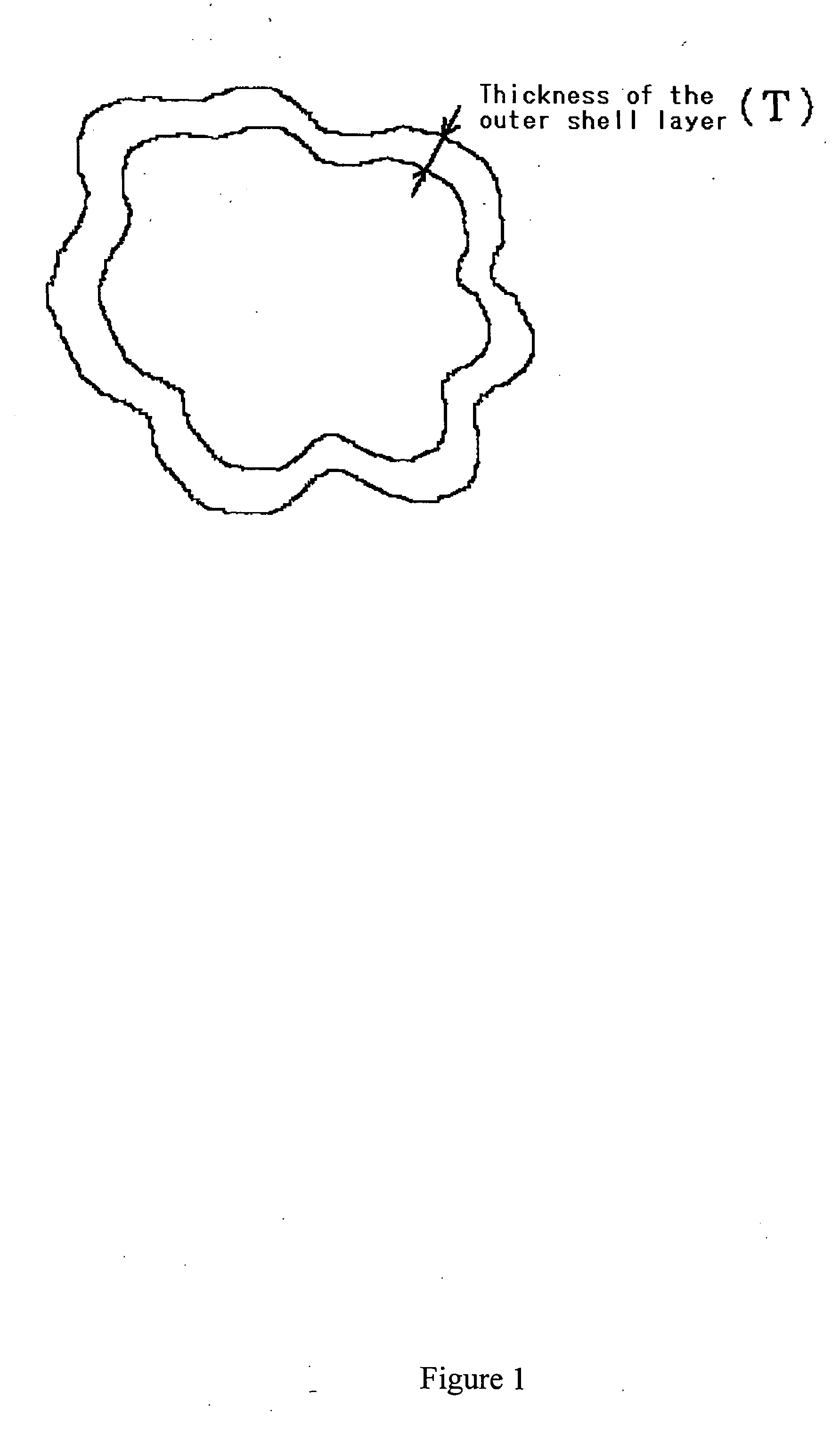

Resin particle and process of producing the same

ActiveUS20060165989A1Improve wear resistanceExcellent in anti-hot offset propertyPretreated surfacesGranulation by liquid drop formationVolume averageWear resistance

Provided is a resin particle comprising a resin (a) and a filler (b) contained in the particle; the particle has a volume average particle diameter of from 0.1 to 300 μm and a shape factor of from 110 to 300; the particle has an outer shell layer (S) comprising at least a portion of the filler (b); the layer (S) is at least 0.01 μm thick and has a thickness that is ½ or less of the maximum inscribed circle radius of the particle cross section. When used as a toner resin, it is excellent in blade cleaning properties and wide in the fixation temperature range; when employed as a paint additive or a cosmetics additive, it is excellent in masking properties; when used as paper coating additive, it is excellent in ink retention; when utilized as an abrasive, it is excellent in abrasion.

Owner:RICOH KK +1

Particle formation

InactiveUS20030109421A1Risk minimizationPeptide/protein ingredientsGranulation by liquid drop formationAnti solventEngineering

Method for preparing a target substance in particulate form, comprising introducing into a particle formation vessel, through separate first and second fluid inlets respectively, (a) a "target solution / suspension" of the substance in a fluid vehicle and (b) a compressed fluid anti-solvent, and allowing the anti-solvent to extract the vehicle so as to form particles of the substance, wherein the anti-solvent fluid has a sonic, near-sonic or supersonic velocity as it enters the vessel, and wherein the anti-solvent and the target solution / suspension enter the vessel at different locations and meet downstream (in the direction of anti-solvent flow) of the second fluid inlet. Also provided is apparatus for use in such a method.

Owner:NEKTAR THERAPEUTICS INC

Membrane electrode assemblies for use in fuel cells

InactiveUS20030064265A1High purityImprove electrocatalytic activityGranule coatingCell electrodesCarbon compositesFuel cells

Owner:CABOT CORP

Electrospraying method with conductivity control

An electrospraying apparatus and / or method is used to coat particles. For example, a flow including at least one liquid suspension may be provided through at least one opening at a spray dispenser end. The flow includes at least particles and a coating material. A spray of microdroplets suspending at least the particles is established forward of the spray dispenser end by creating a nonuniform electrical field between the spray dispenser end and an electrode electrically isolated therefrom. The particles are coated with at least a portion of the coating material as the microdroplet evaporates. For example, the suspension may include biological material particles.

Owner:RGT UNIV OF MINNESOTA

Composite particles and method for preparing

A method for producing composite particles using a supercritical fluid extraction technique on an emulsion. First and second materials (for example; a polymer and a biologically active material) are dissolved or suspended in a preferably solvent to form a solution or dispersion. The solution or dispersion is emulsified in a polar solvent to form an oil-in-water or water-in-oil-in-water emulsion. The emulsion is contacted with a supercritical fluid to extract the solvent. Removal of the solvent by the supercritical fluid from the emulsion supersaturates at least the first material in the solution causing the first material to precipitate out of the solution as composite particles that include both the first and second materials.

Owner:FERRO CORP

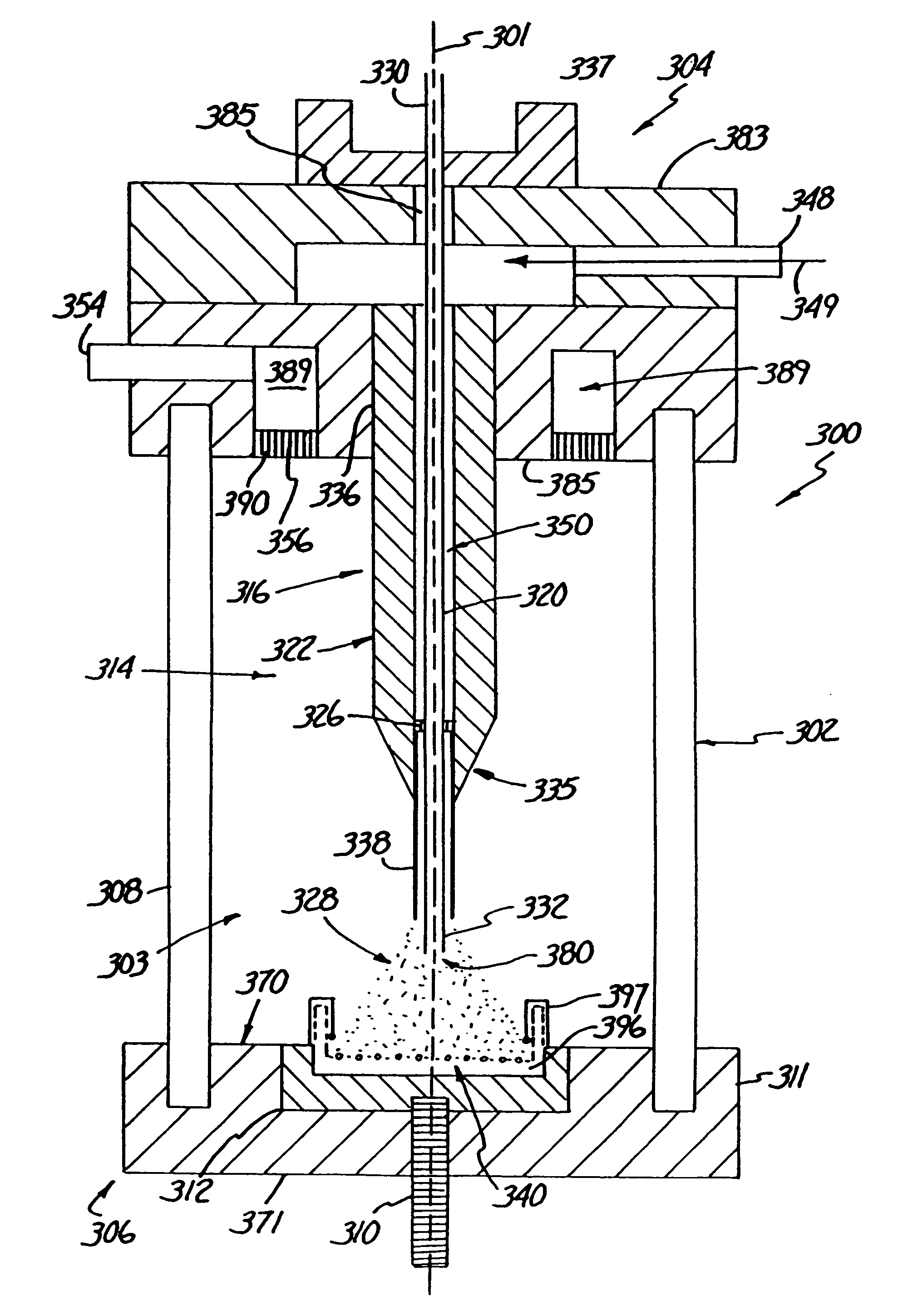

Method for precipitation of small medicament particles into use containers

ActiveUS7744923B2Preventing overflow of liquidPowder deliveryGranulation by liquid drop formationHigh energyProcess engineering

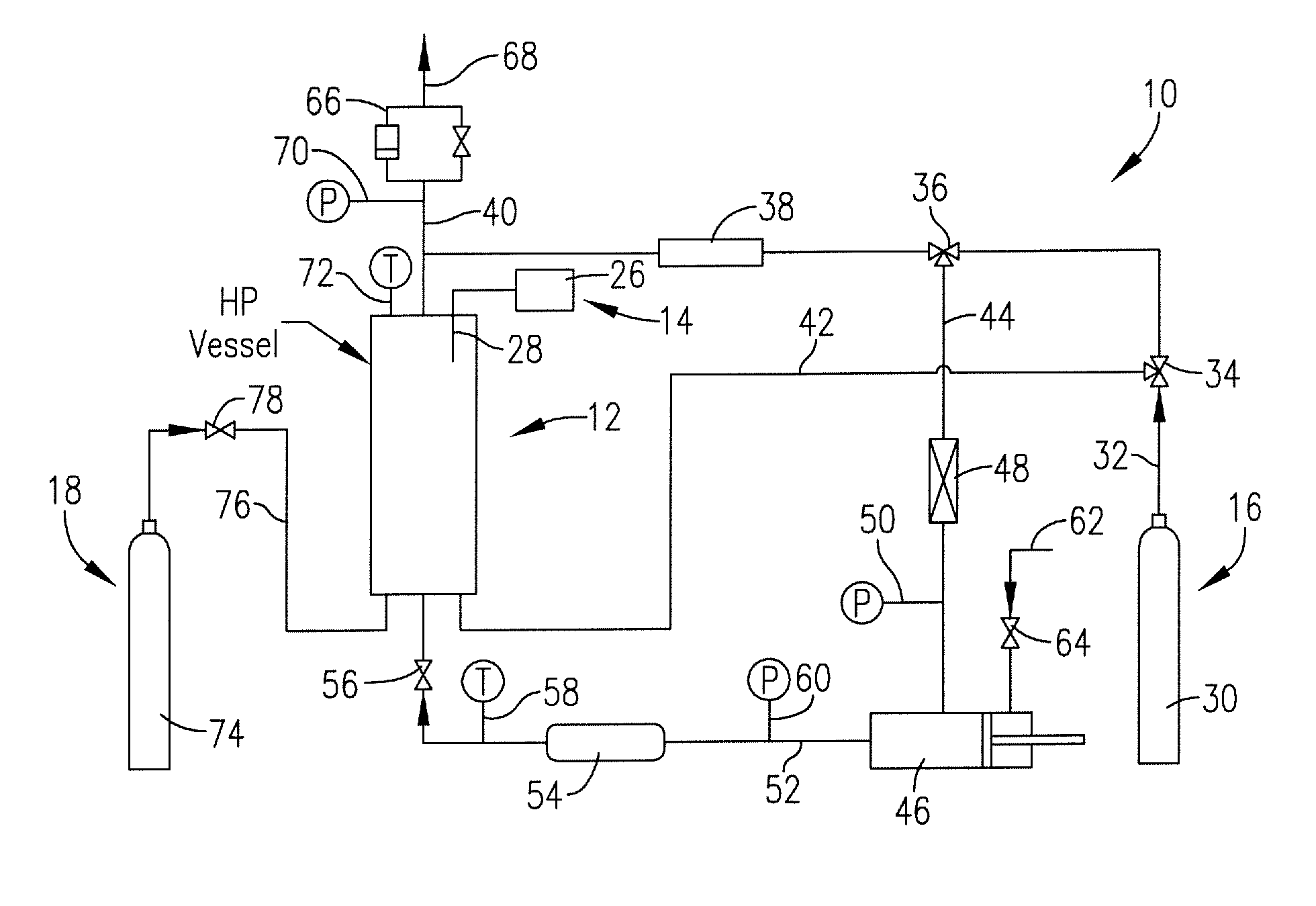

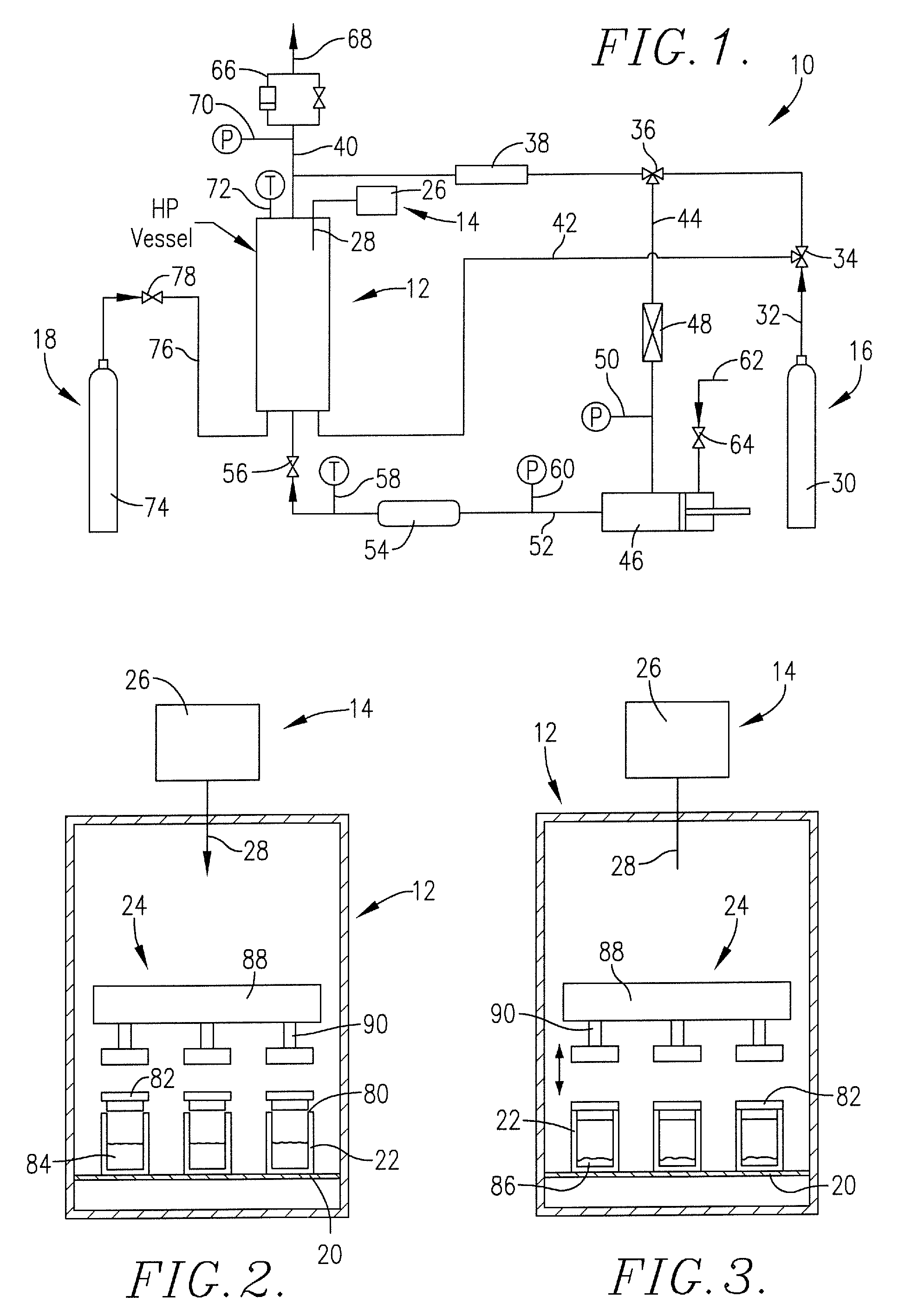

Commercially feasible methods for lyophobic precipitation of liquid-dispersed or dissolved material (e.g., medicaments) are provided wherein a plurality of individual, open containers (22) each containing a quantity (84) of a solution or dispersion are treated within a common pressurizable chamber (12). In this process, desired near-supercritical or supercritical temperature and pressure conditions are established for a selected antisolvent gas such as carbon dioxide, and an ultrasonic device (14) is actuated to generate high energy ultrasonic waves in the chamber (12). This leads to intense mixing of the antisolvent with the liquid solution or dispersion within the containers (22), with consequent solvent removal and material precipitation.

Owner:CRITITECH INC

Method for making homogeneous spray-dried solid amorphous drug dispersions utilizing modified spray-drying apparatus

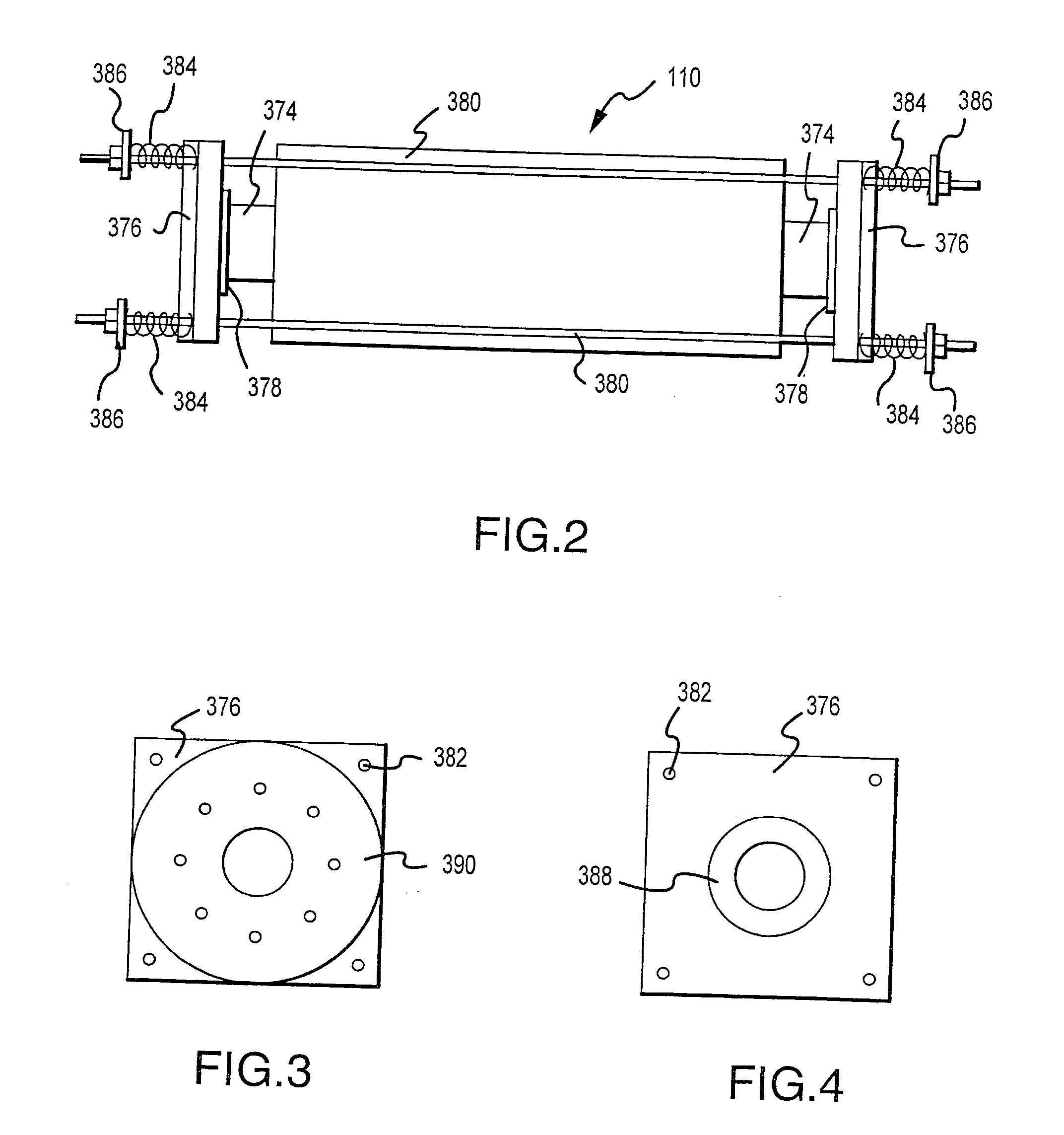

InactiveUS6973741B2Facilitates organized plug flowPowder deliveryDrying solid materials with heatSpray nozzleDrying time

Conventional spray-drying methods are improved by incorporation of a pressure nozzle and a diffuser plate to improve the flow of drying gas and a drying chamber extension to increase drying time, such improvements leading to the formation of homogeneous solid dispersions of drugs in concentration-enhancing polymers.

Owner:LONZA BEND INC

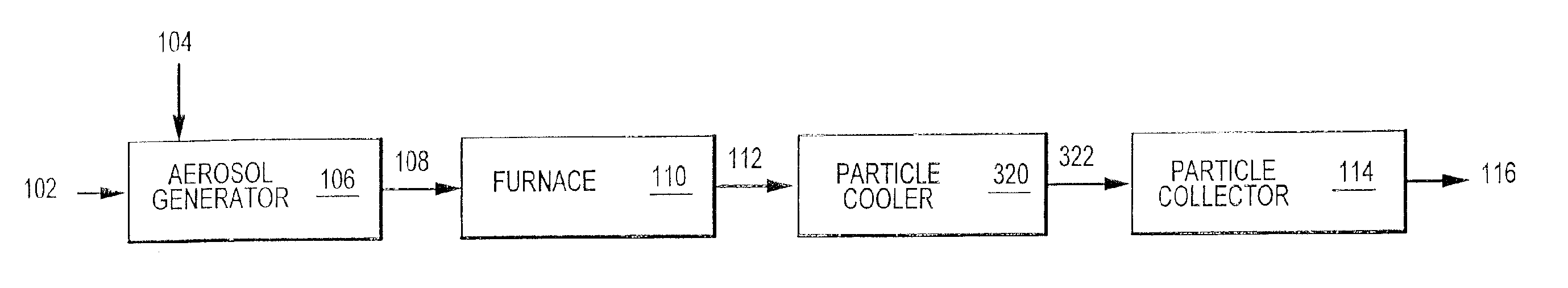

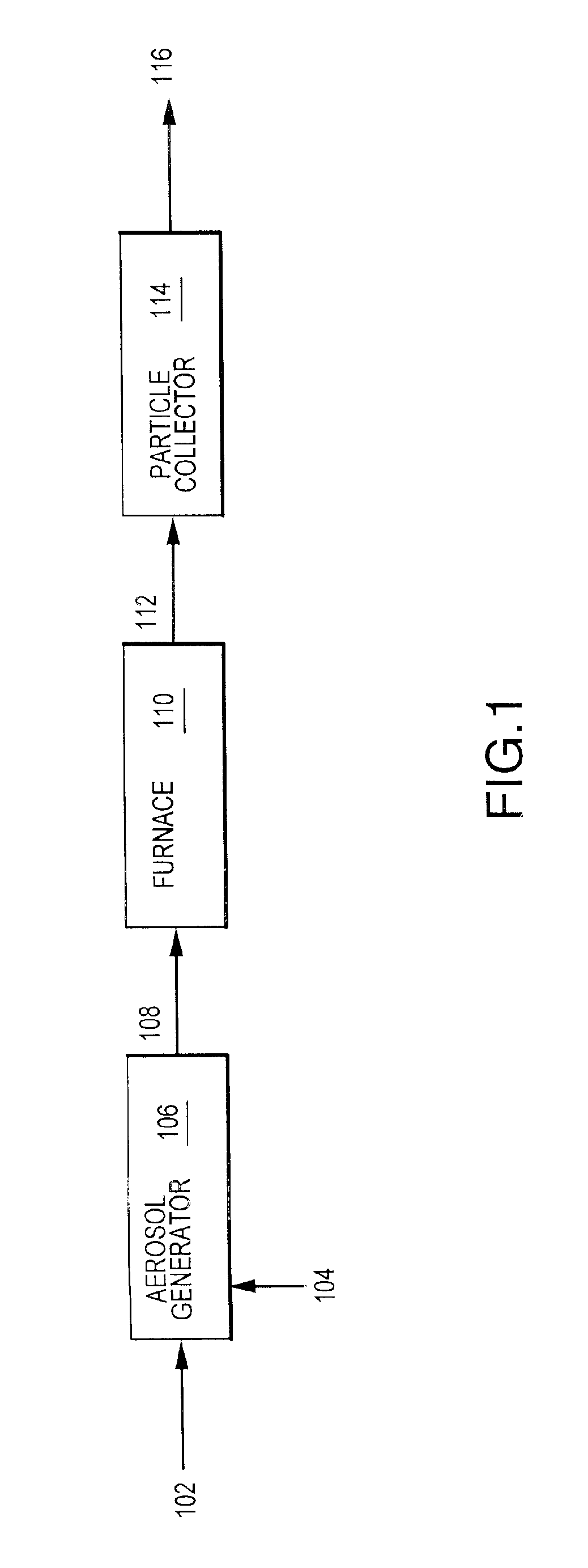

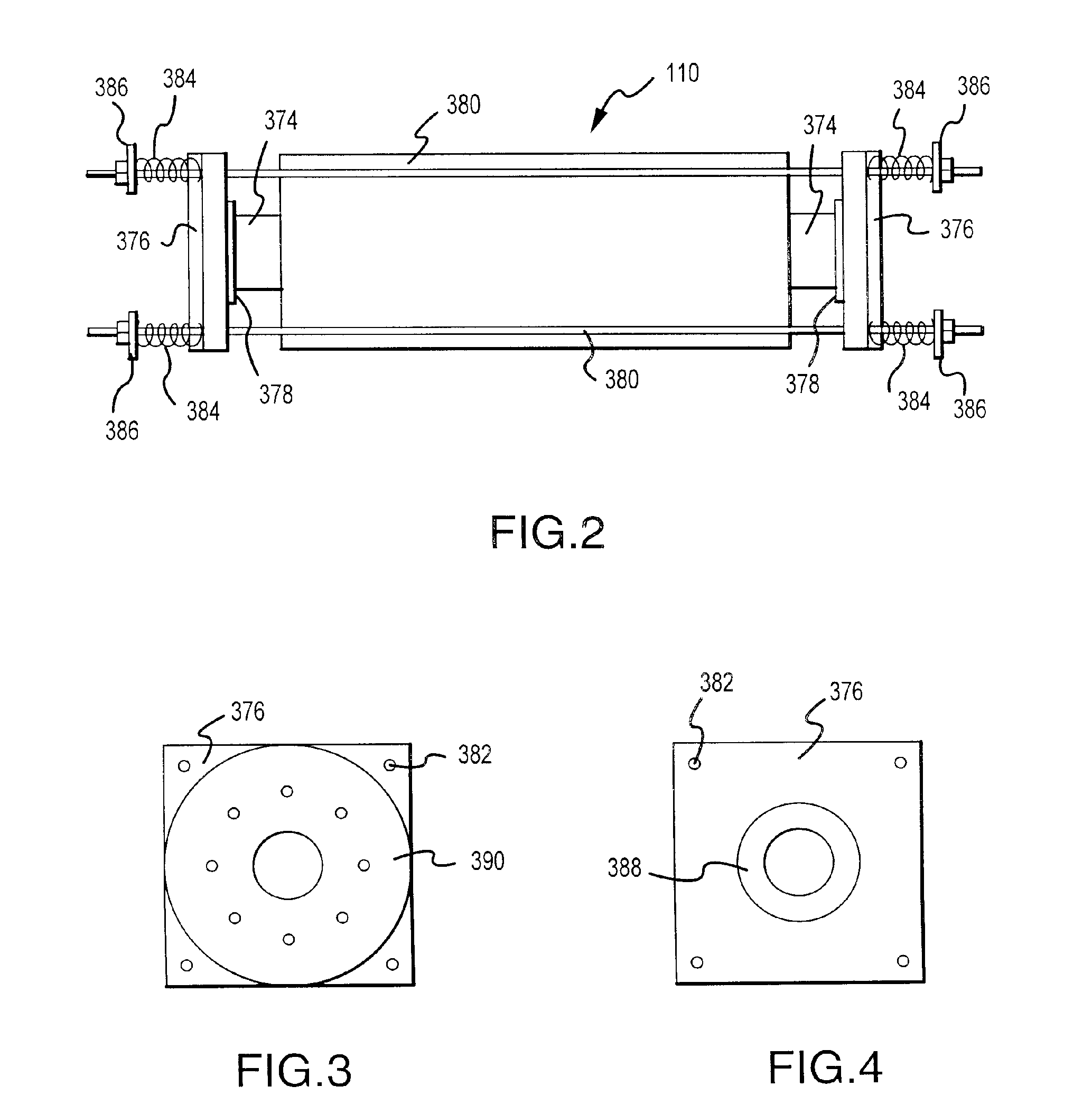

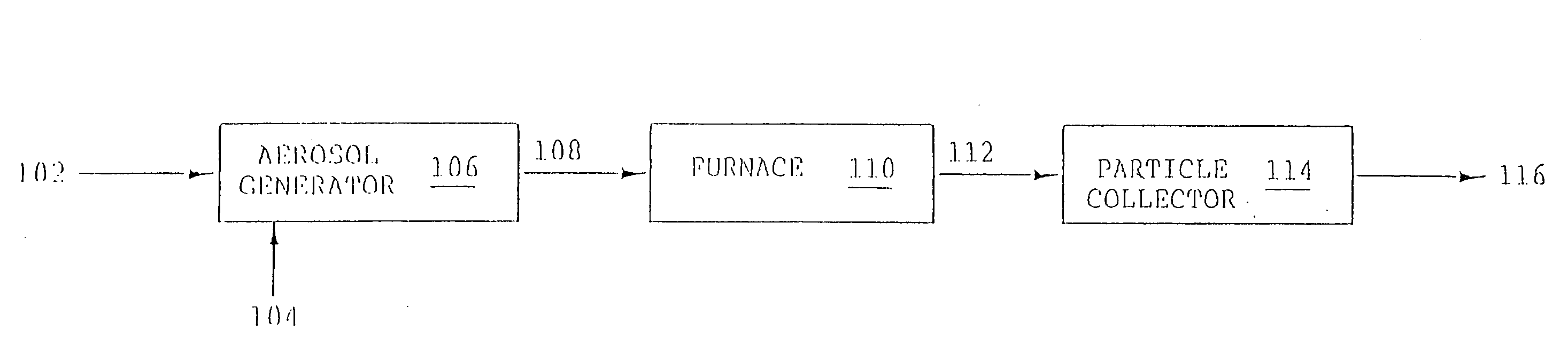

Aerosol method and apparatus, particulate products, and electronic devices made therefrom

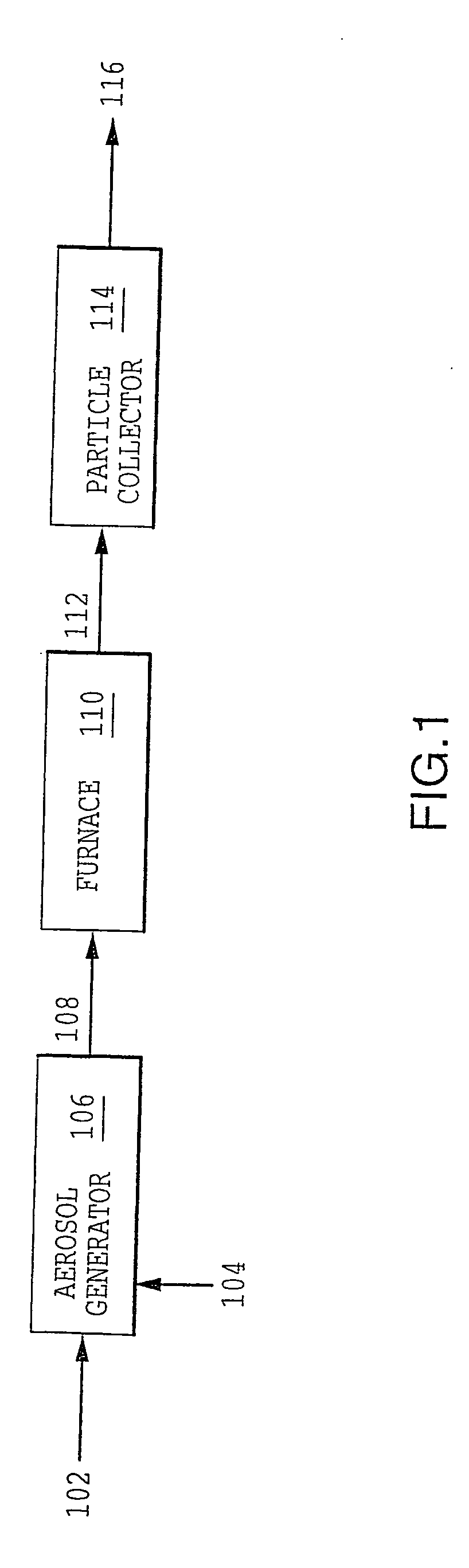

Metal-carbon composite powders and methods for producing metal-carbon composite powders. The powders have a well-controlled microstructure and morphology and preferably have a small average particle size. The method includes forming the particles from an aerosol of powder precursors. The invention also includes novel devices and products formed from the composite powders.

Owner:CABOT CORP

Method for the production of particles

InactiveUS7404828B1Powder deliveryOrganic compounds purification/separation/stabilisationPlastic materialsHigh pressure

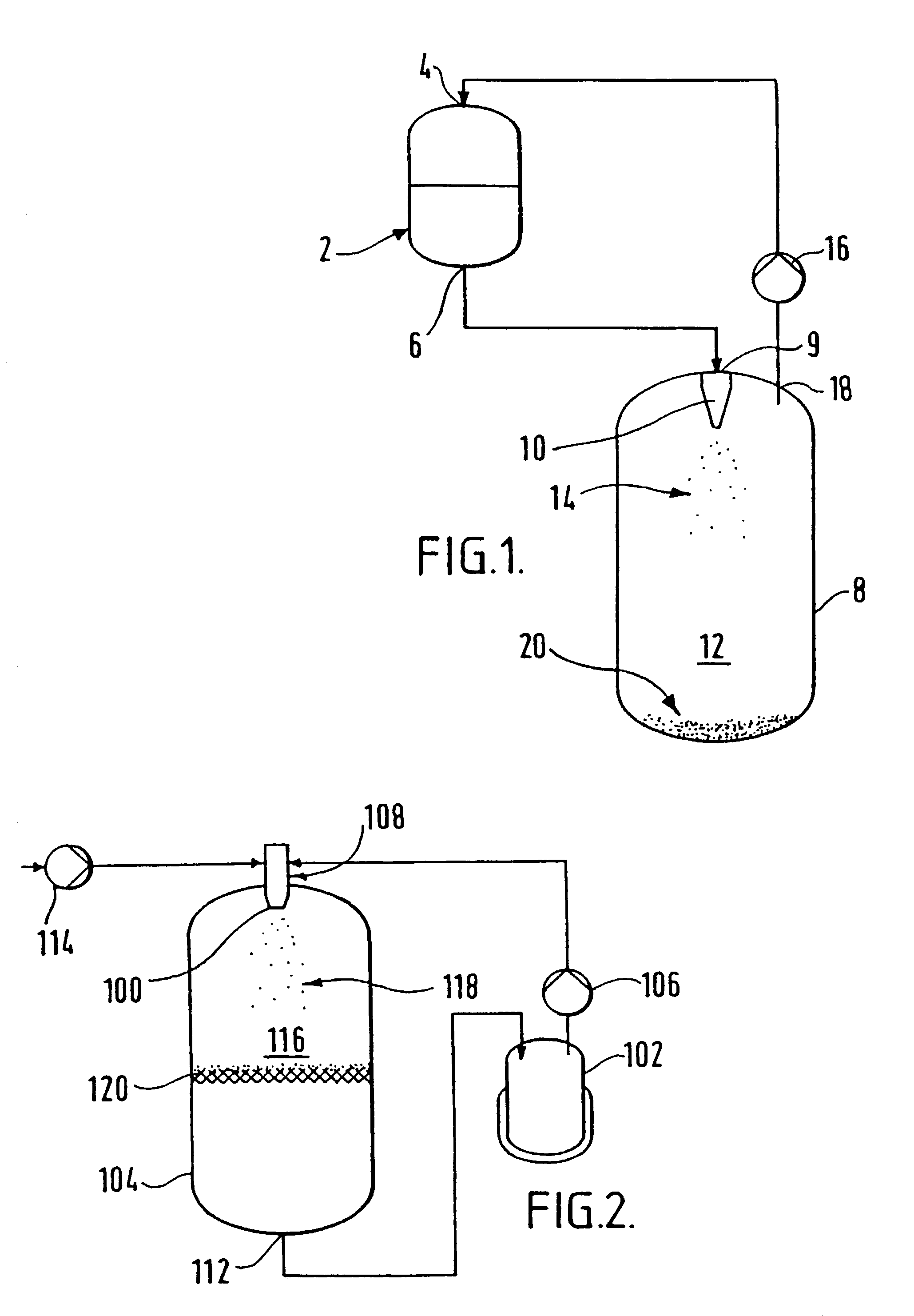

A method of preparing particles of a substance, for example selected from a flavor, fragrance, pigment, dye, biologically active compound or a plastics material, comprises contacting the substance of a formulation (which may include the substance in conjunction with a second solvent) with a first solvent which comprises a C1-C4 hydrofluorocarbon, especially tetrafluoroethane, and subjecting the resultant mixture to a separation process, for example, by allowing the mixture to be sprayed as a mist (14) from a high pressure environment in a first vessel (2) to a low pressure environment in a second vessel (8), thereby to cause separation of a least some of the substance from the first solvent and the formation of fine particles (20) of the substance.

Owner:GLAXO GROUP LTD

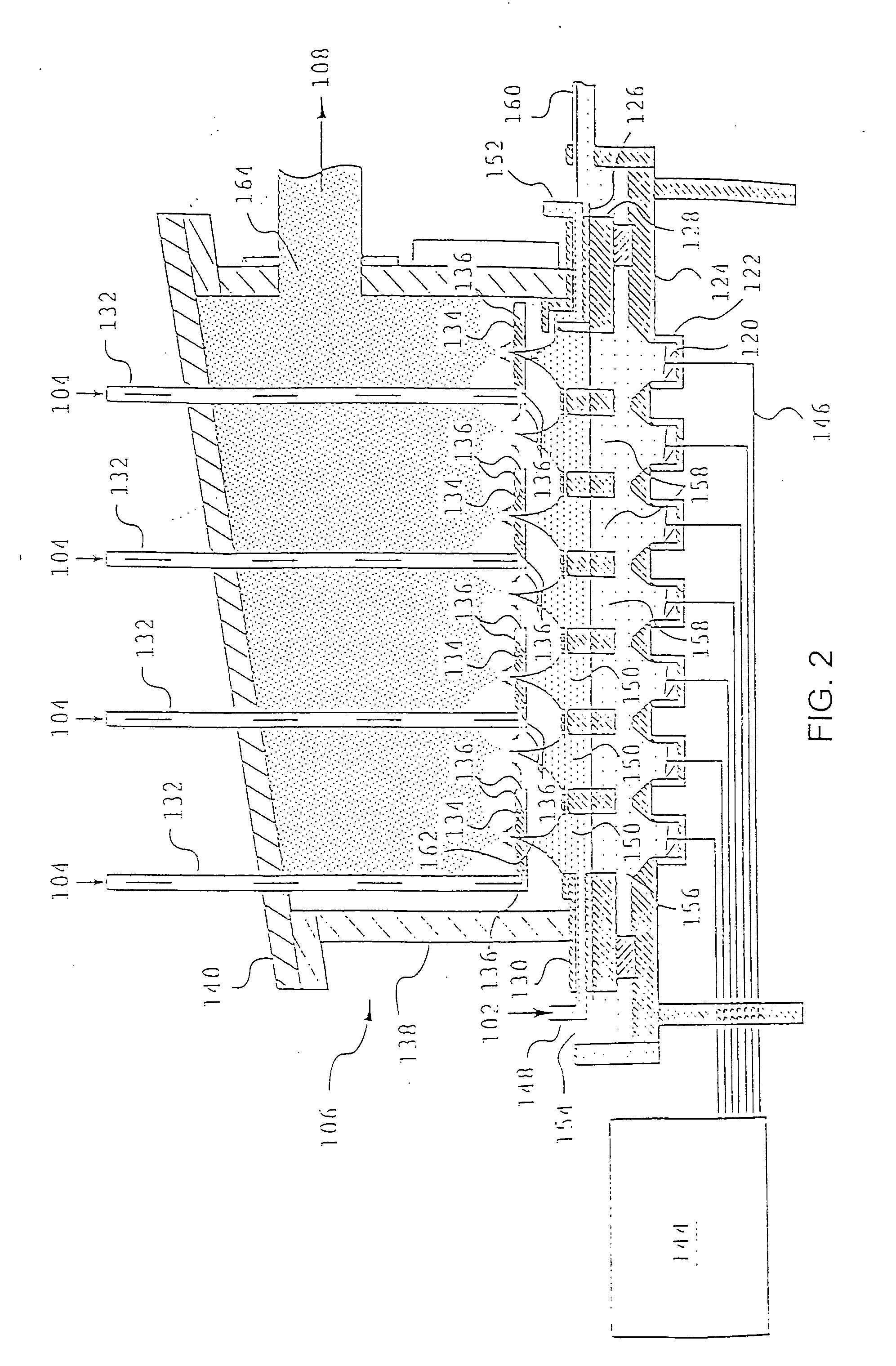

Coated silver-containing particles, method and apparatus of manufacture, and silver-containing devices made therefrom

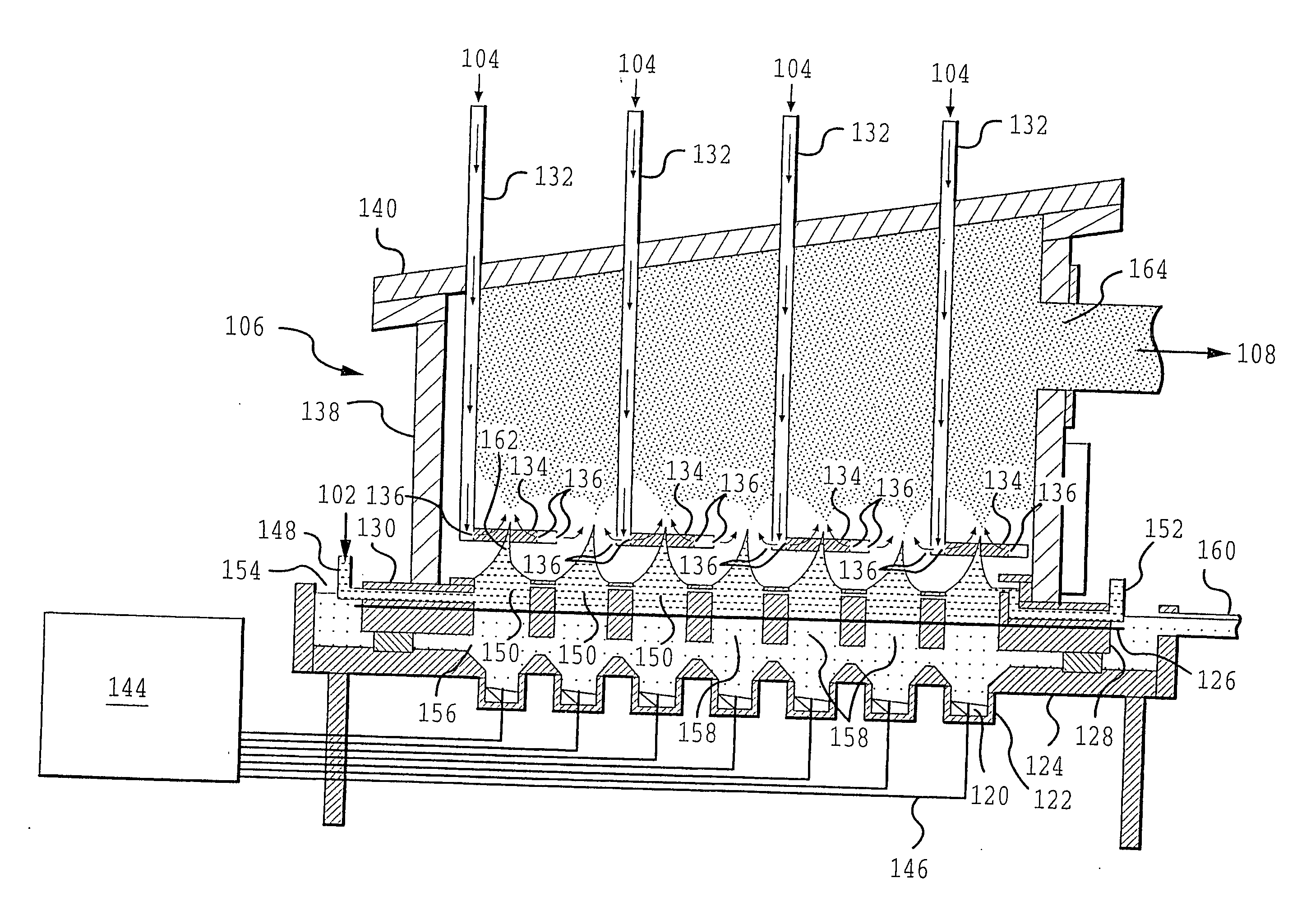

InactiveUS20050061107A1Increase loadMaterial granulation and coatingGranule coatingPolymer scienceDroplet size

Provided are silver-containing powders and a method and apparatus for manufacturing the silver-containing particles of high quality, of a small size and narrow size distribution. An aerosol is generated from liquid feed and sent to a furnace, where liquid in droplets in the aerosol is vaporized to permit formation of the desired particles, which are then collected in a particle collector. The aerosol generation involves preparation of a high quality aerosol, with a narrow droplet size distribution, with close control over droplet size and with a high droplet loading suitable for commercial applications.

Owner:CABOT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com