Patents

Literature

532 results about "Residual moisture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Residual moisture is determined by the gravimetric method as follows: Residual moisture is driven from the test product by heating under vacuum. The residual moisture content (as per cent) of the test product is calculated based the product weight loss during the drying cycle.

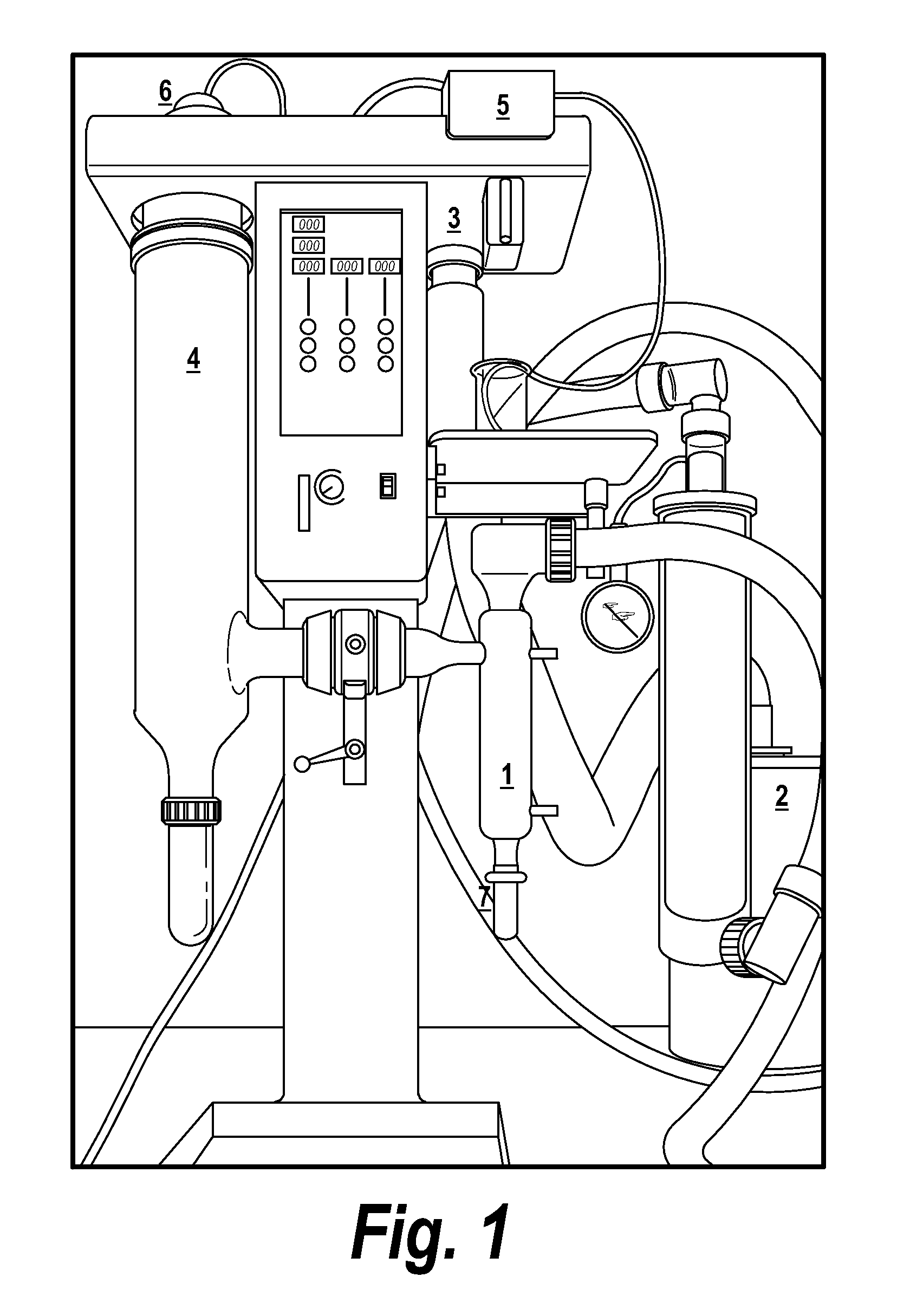

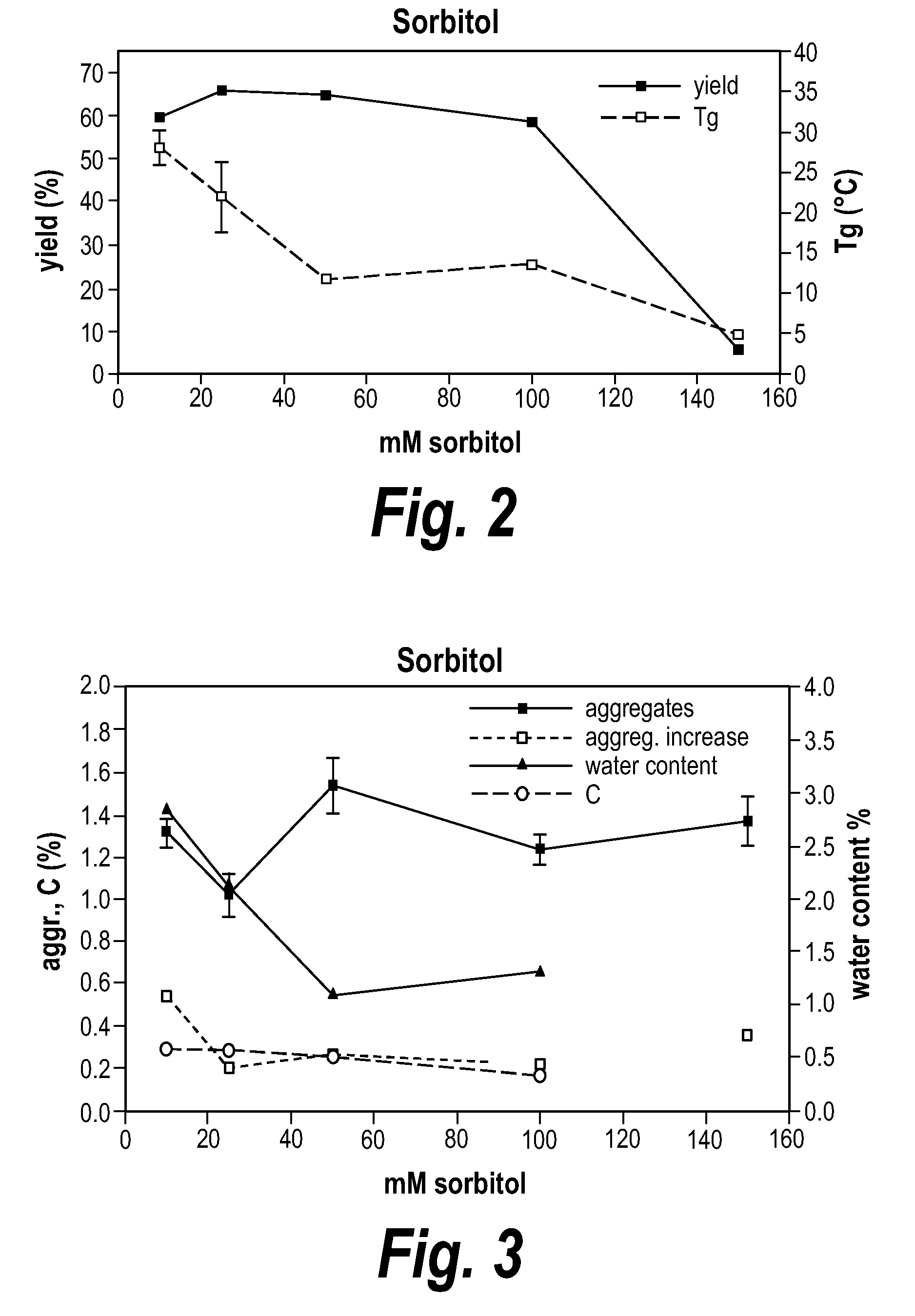

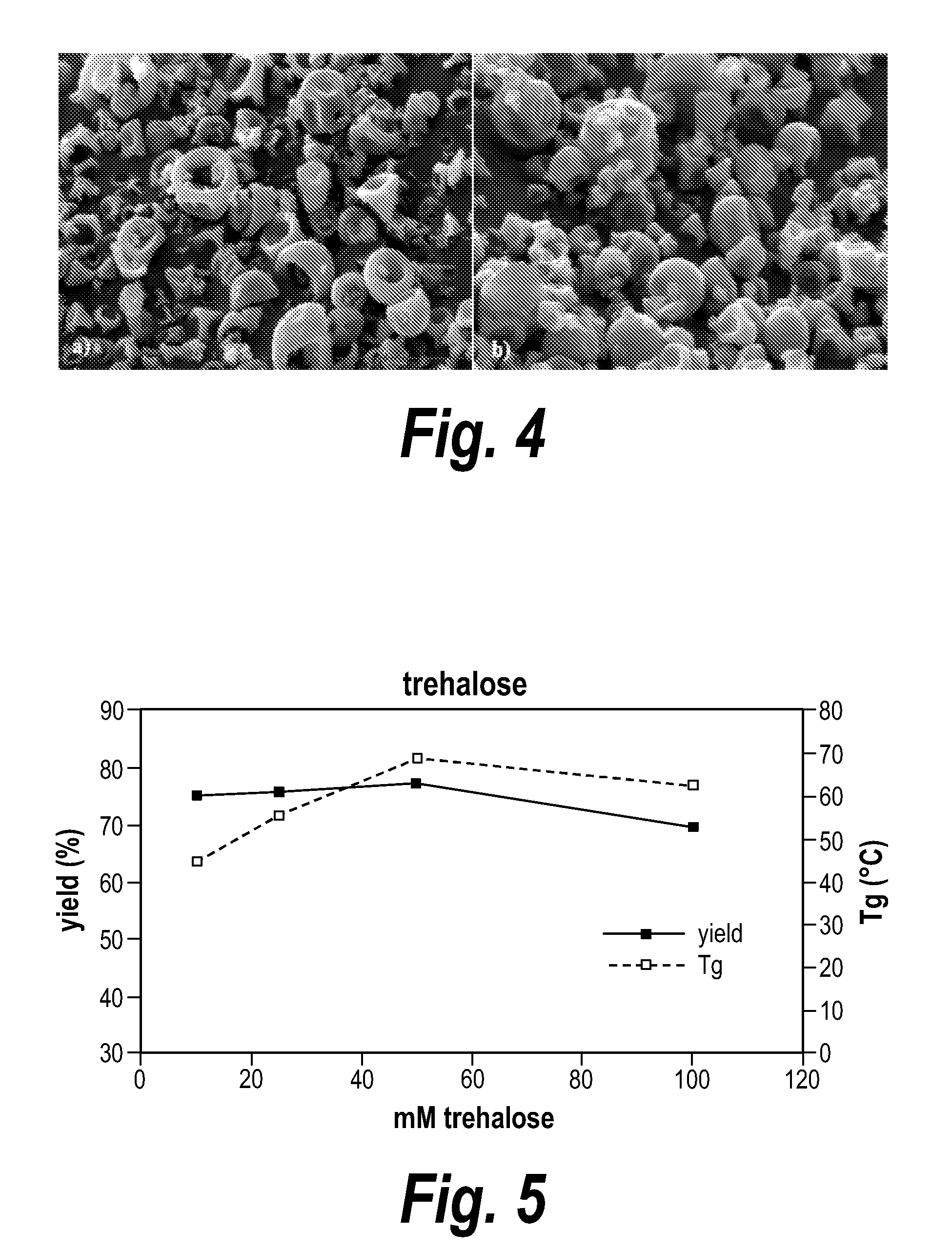

Powdered protein compositions and methods of making same

InactiveUS20090226530A1Easy to moveWide concentration rangeAntibacterial agentsPowder deliveryBiotechnologyProtein composition

Owner:ABBVIE DEUTSHLAND GMBH & CO KG

Stable probiotic microsphere compositions and their methods of preparation

The invention relates to viable and stable probiotic formulations for intestinal targeting made of microspheres comprising each a core of one or more probiotic bacteria, microcrystallline cellulose with a degree of polymerization from 165-365 and mean diameter from 45 to 180 μm, a disintegrant and a stabilizer, the core being coated with a non-enteric coating and further coated with an enteric coating. Each probiotic microsphere has a residual moisture level of less than 5% and a water activity (aw) between 0.1 and 0.5. Such a probiotic microsphere shows no reduction in viable bacteria after one hour in simulated gastric fluid. The present invention also relates to the process of preparing such formulation.

Owner:CANACURE CORP

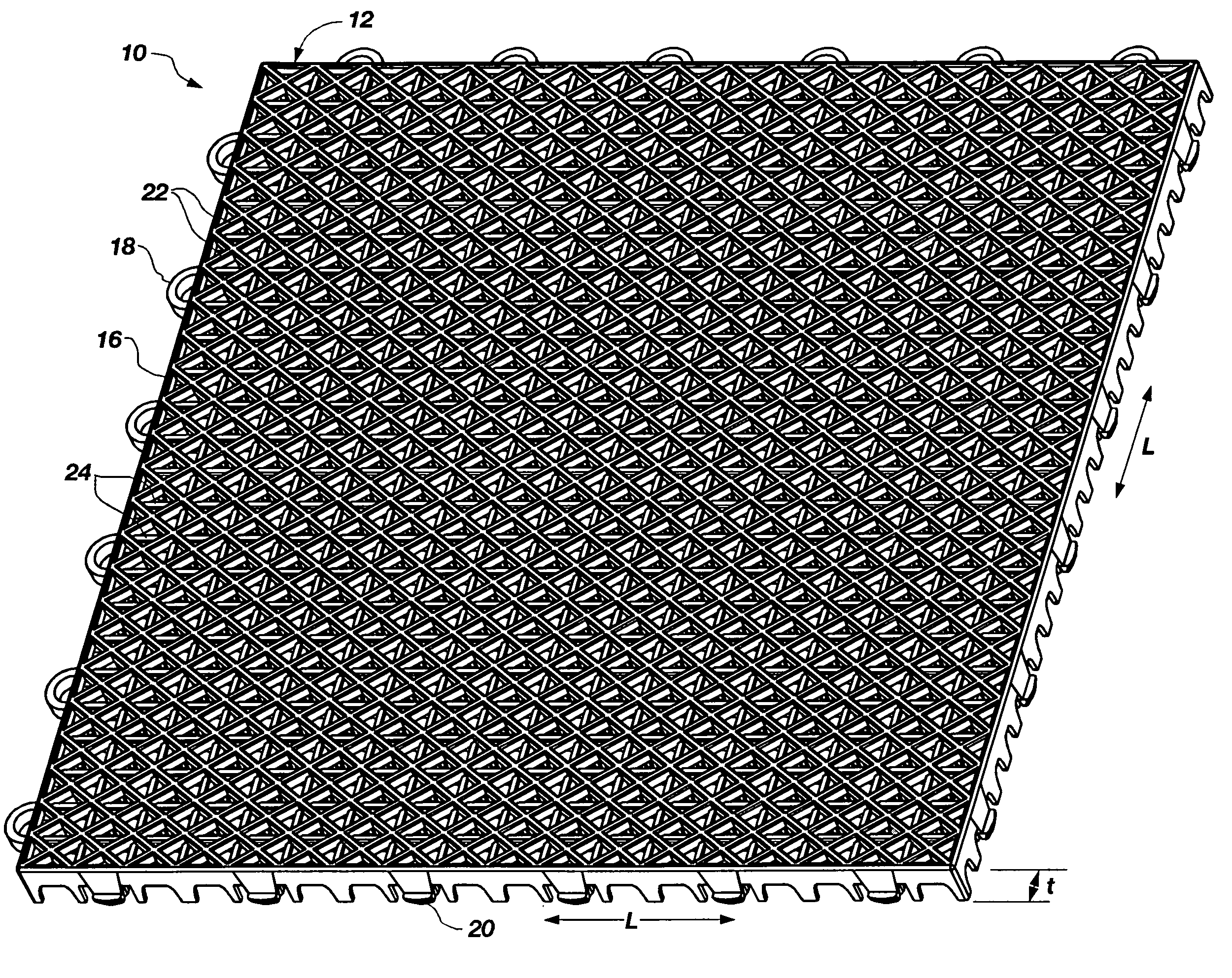

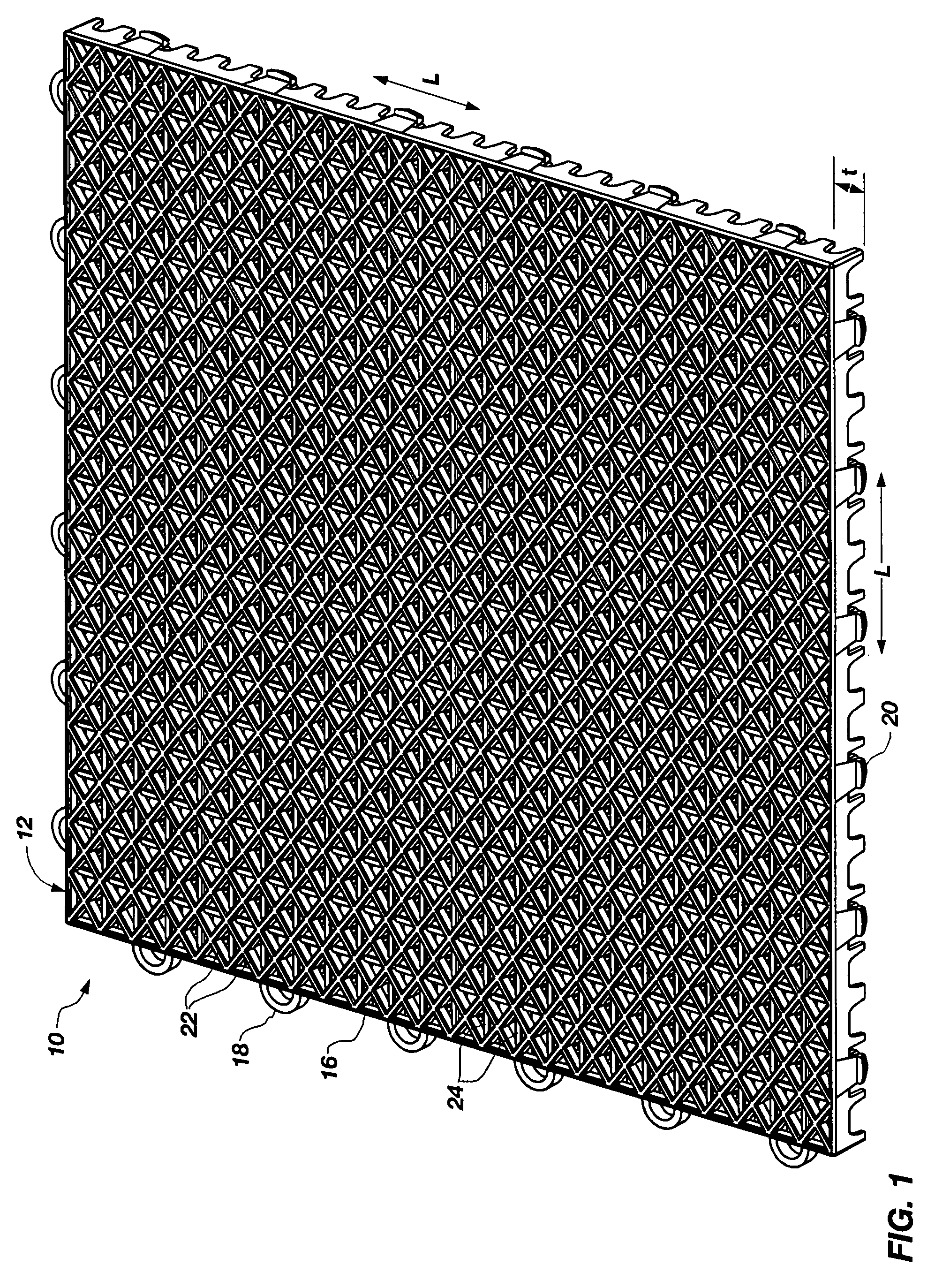

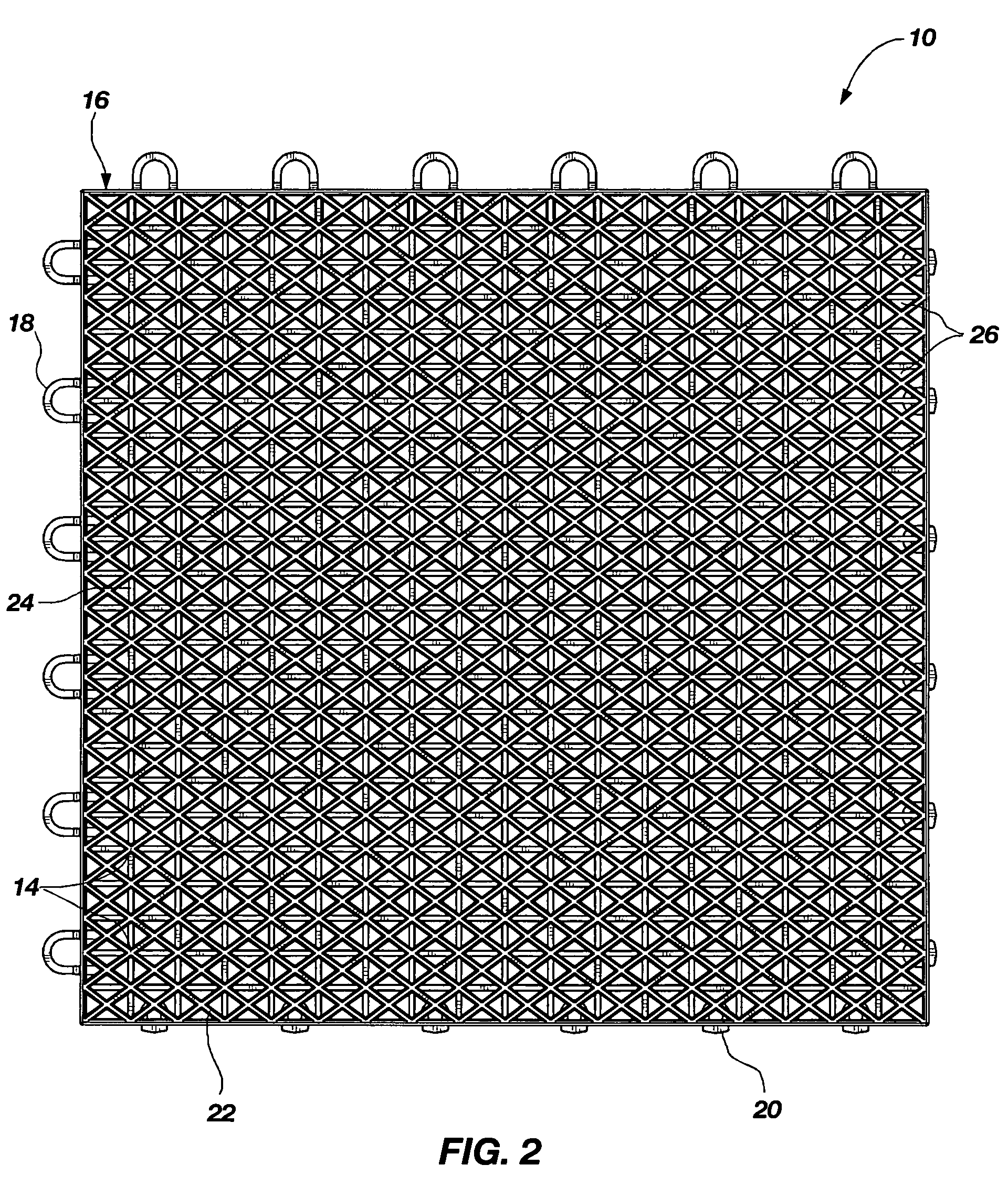

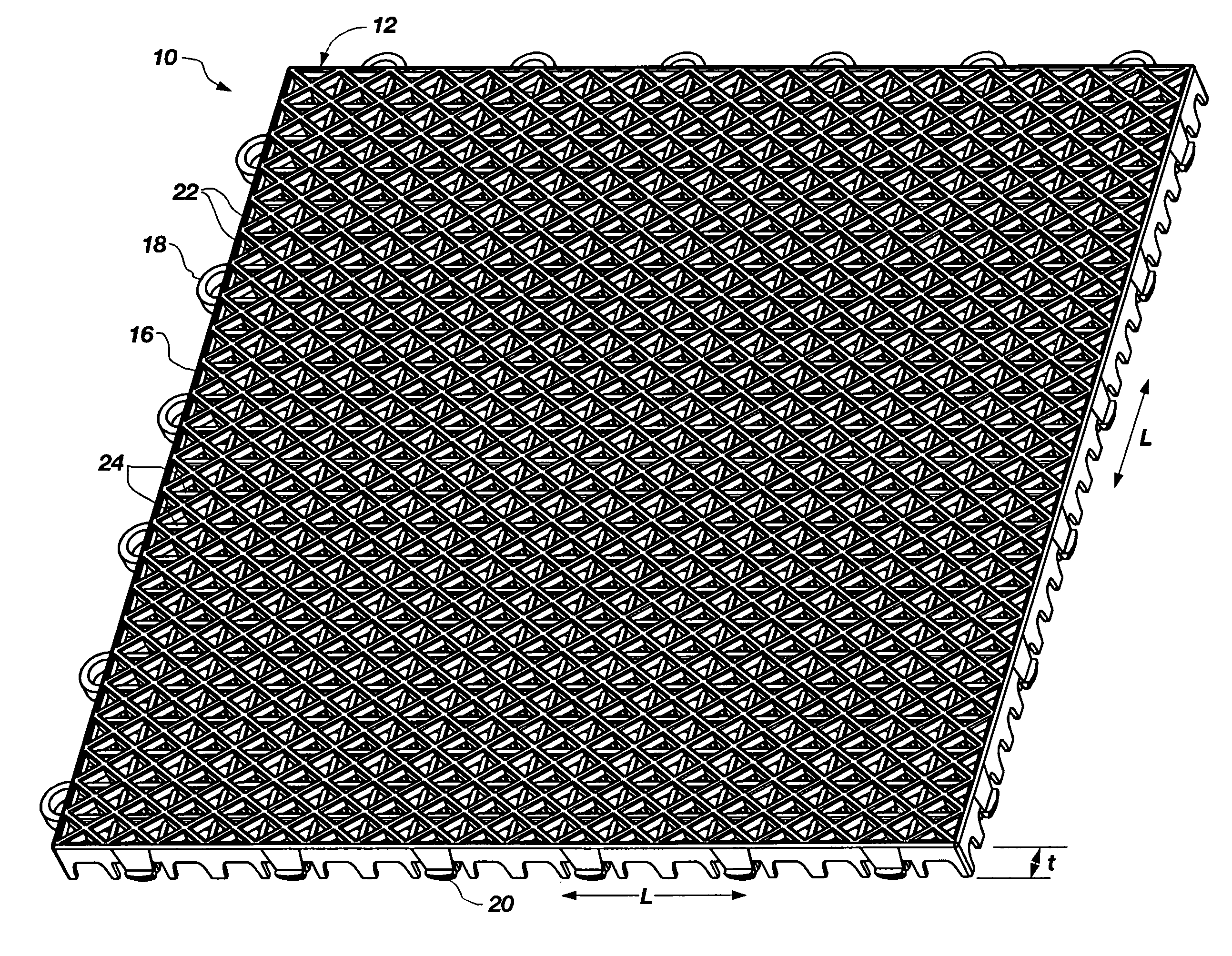

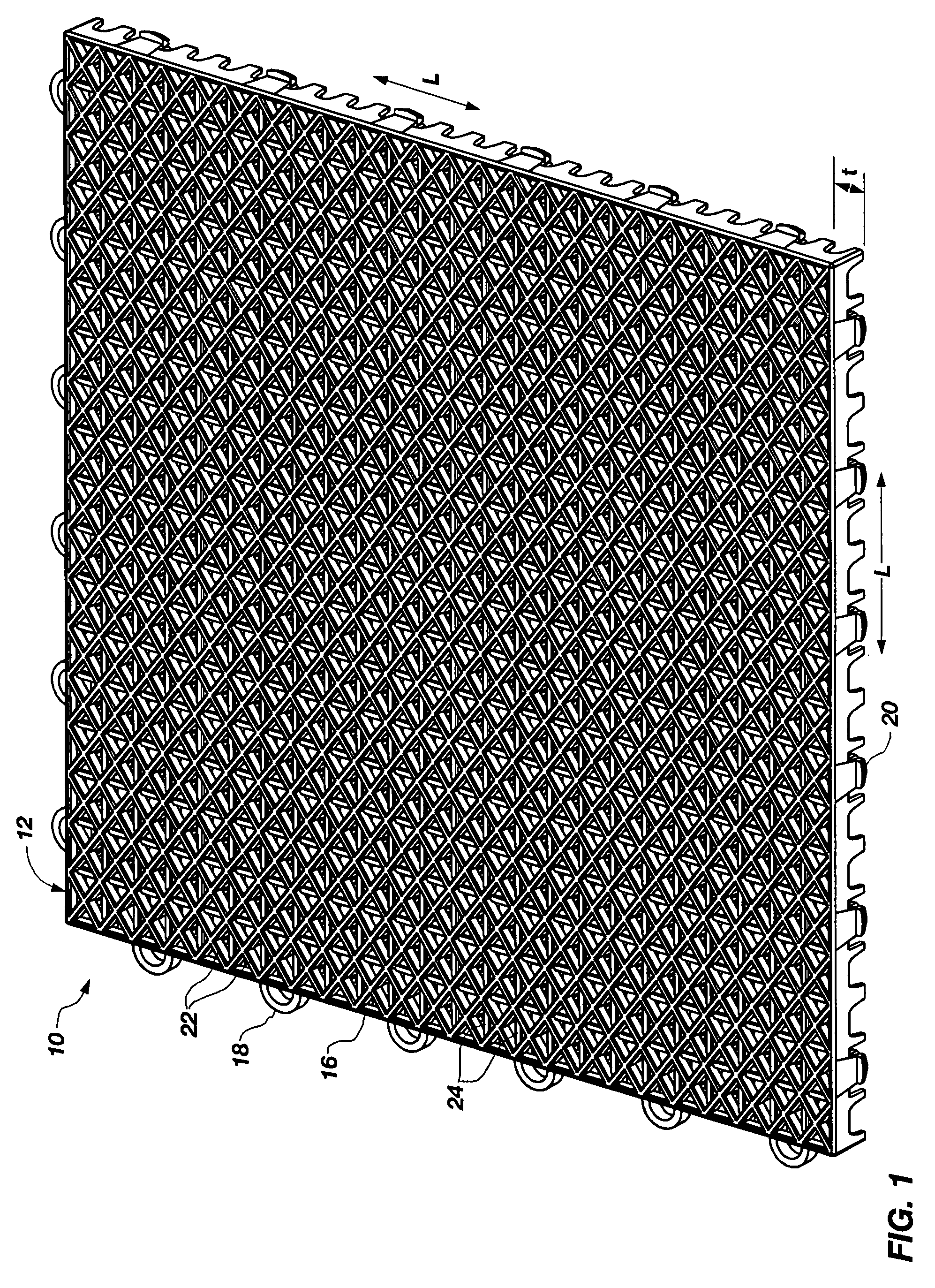

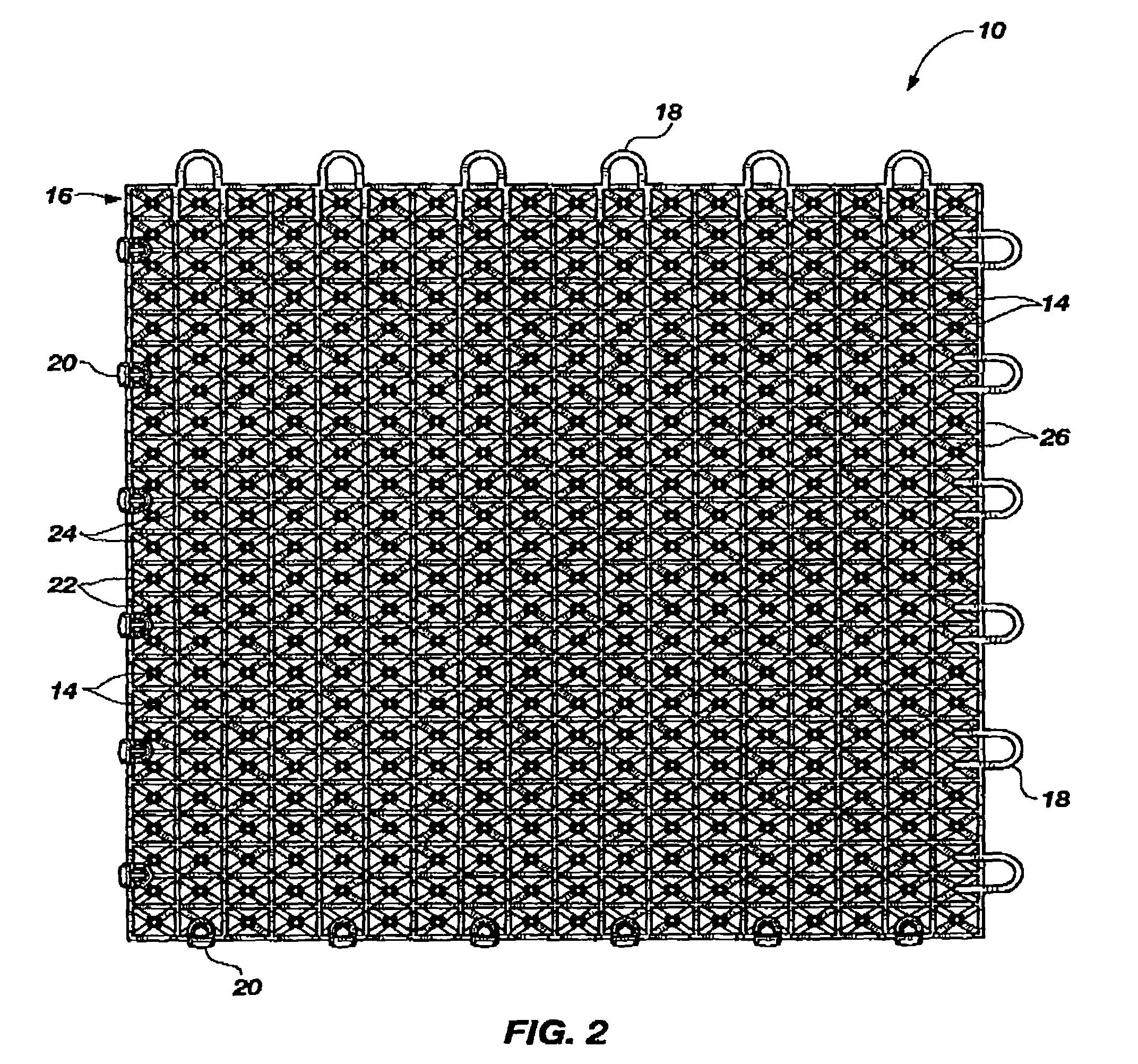

Tile with multiple-level surface

A grid-top floor tile for outdoor use includes a polymer tile having a grid-type top surface with multiple levels, such as a bi-level surface having an upper lattice and a lower lattice oriented generally transverse to the upper lattice. The multiple levels of the surface are preferably integrally formed with one another and provide drainage gaps therethrough. In a bi-level surface configuration, the lower lattice has a top surface below a top surface of the upper lattice, so as to draw residual moisture below the top surface of the upper lattice. The tile further includes a support structure, configured to support the tile on a support surface and provide drainage pathways beneath the top surface. The tile still further comprises various reinforcement members on each of the loop and pin connectors used to interlock the tiles when forming a flooring assembly.

Owner:CONNOR SPORT COURT INT

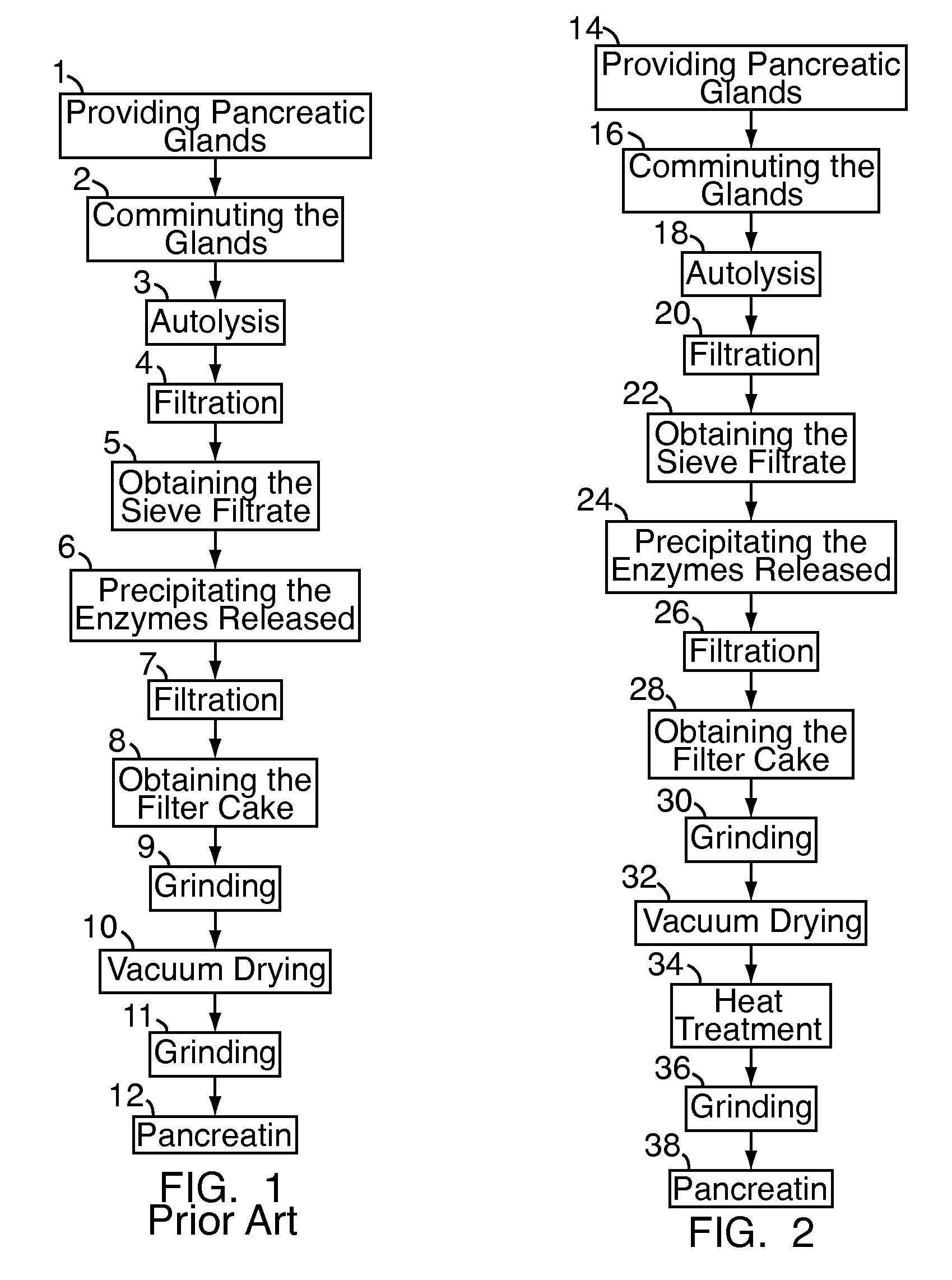

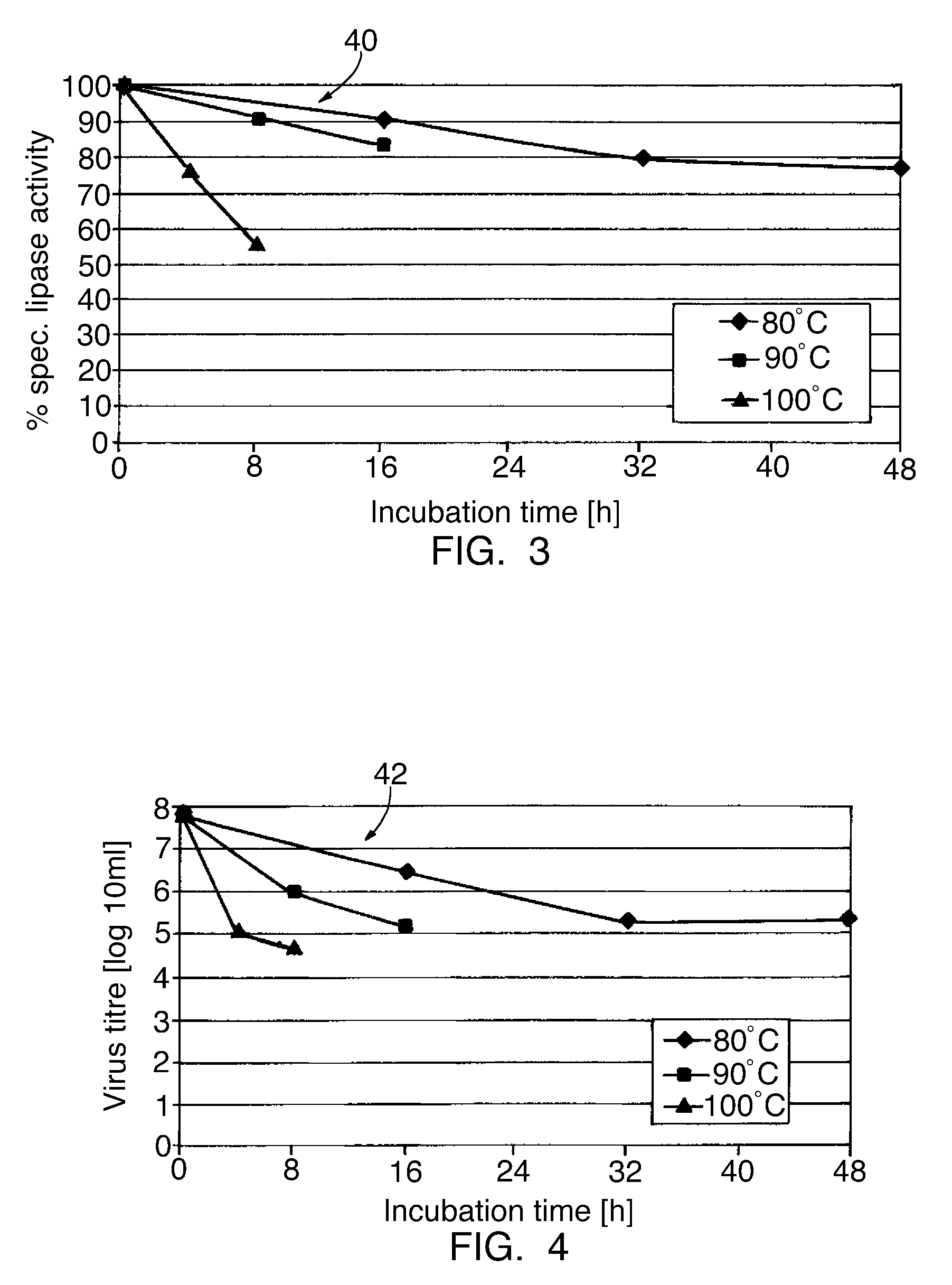

Pancreatin and method for reducing the viral and microbial contamination of pancreatin

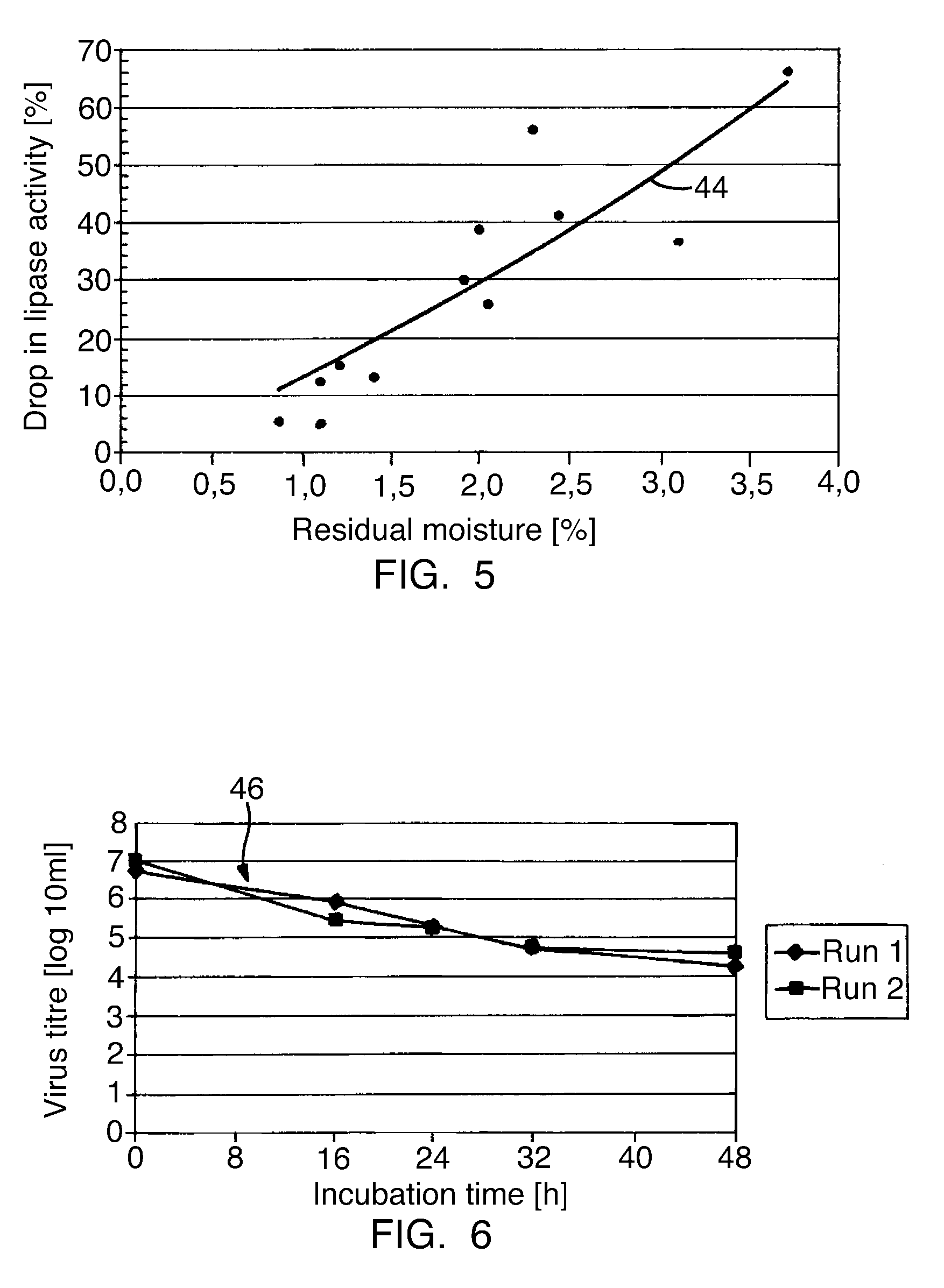

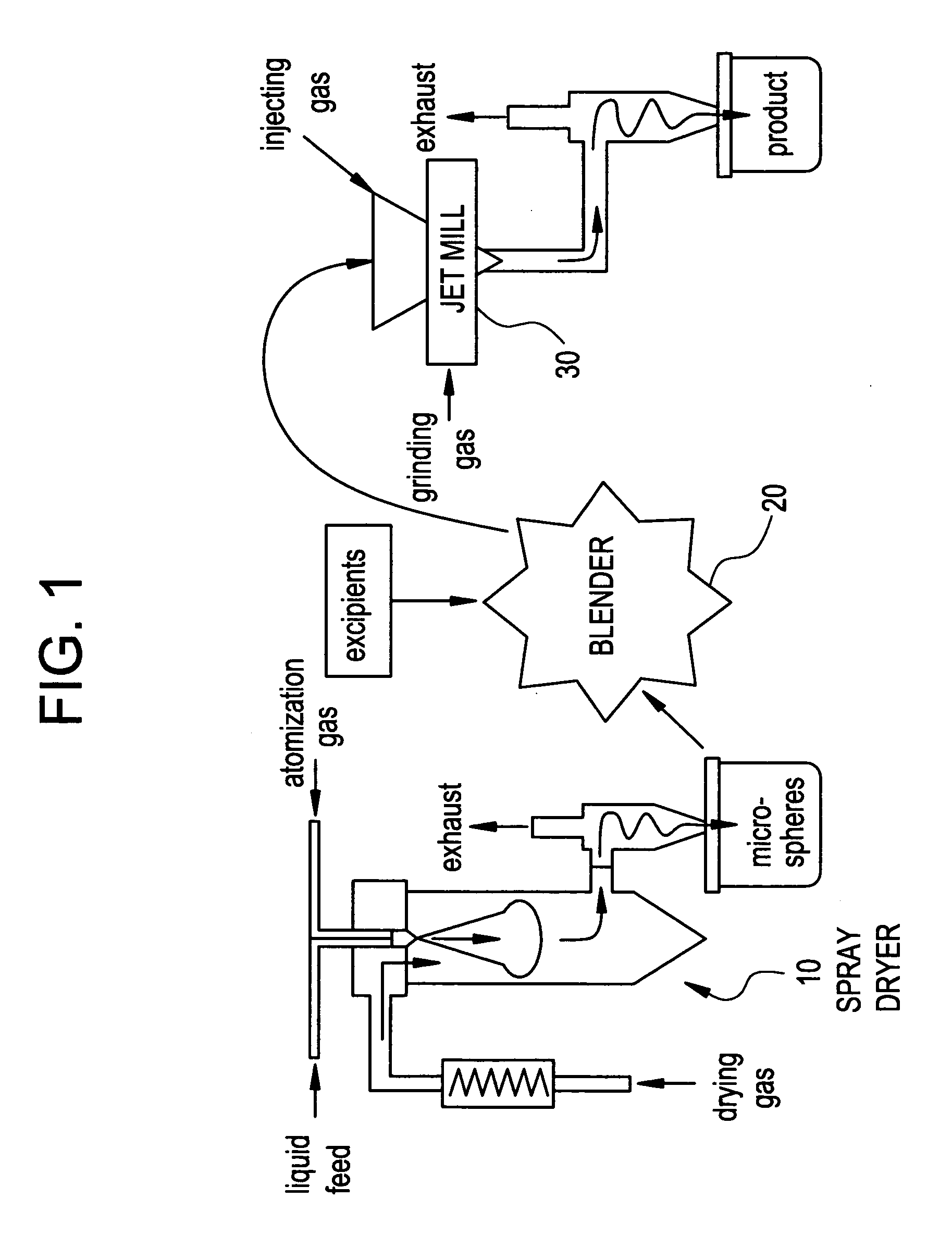

The invention relates to a method for producing pancreatin with reduced viral and microbial contamination, comprising the steps of (a) providing the pancreatin in solid form with a residual moisture of 0.5 weight % or less, down to almost zero, based on the pancreatin provided; (b) subjecting the pancreatin provided in step (a) to a heat treatment at a temperature of 84° C., preferably 80° C. and below; wherein, the biological activity of the pancreatin obtained in step (b) corresponds to at least 50% of the biological activity of the pancreatin provided in step (a); and the viral infectiousness of the pancreatin obtained in step (b) has been reduced by a factor of more than 1 log10 in comparison with the viral infectiousness of the pancreatin provided in step (a), as well as a pancreatin produced according to this method and its use for producing a medicine or a nutritional supplement.

Owner:NORDMARK PHARMA GMBH

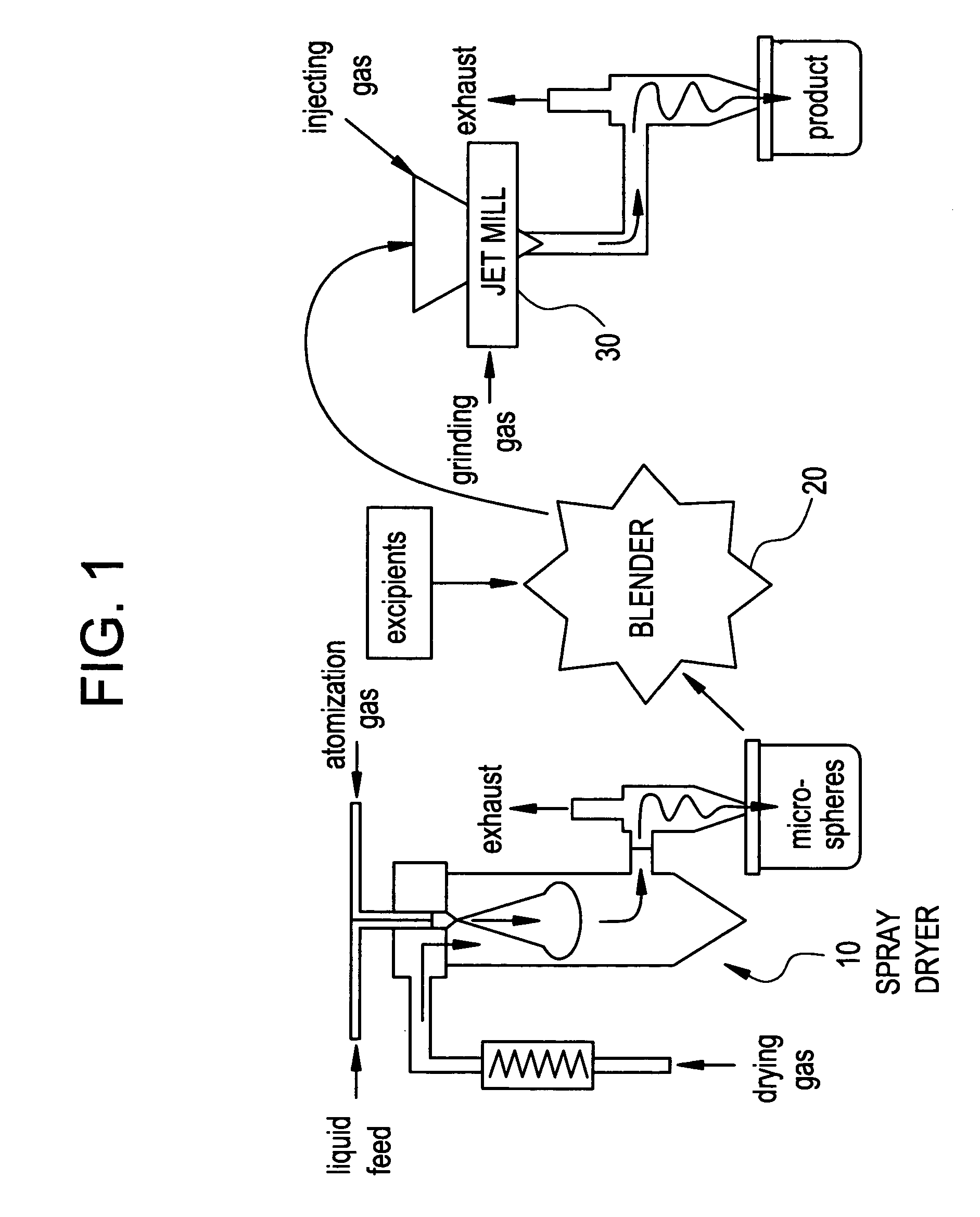

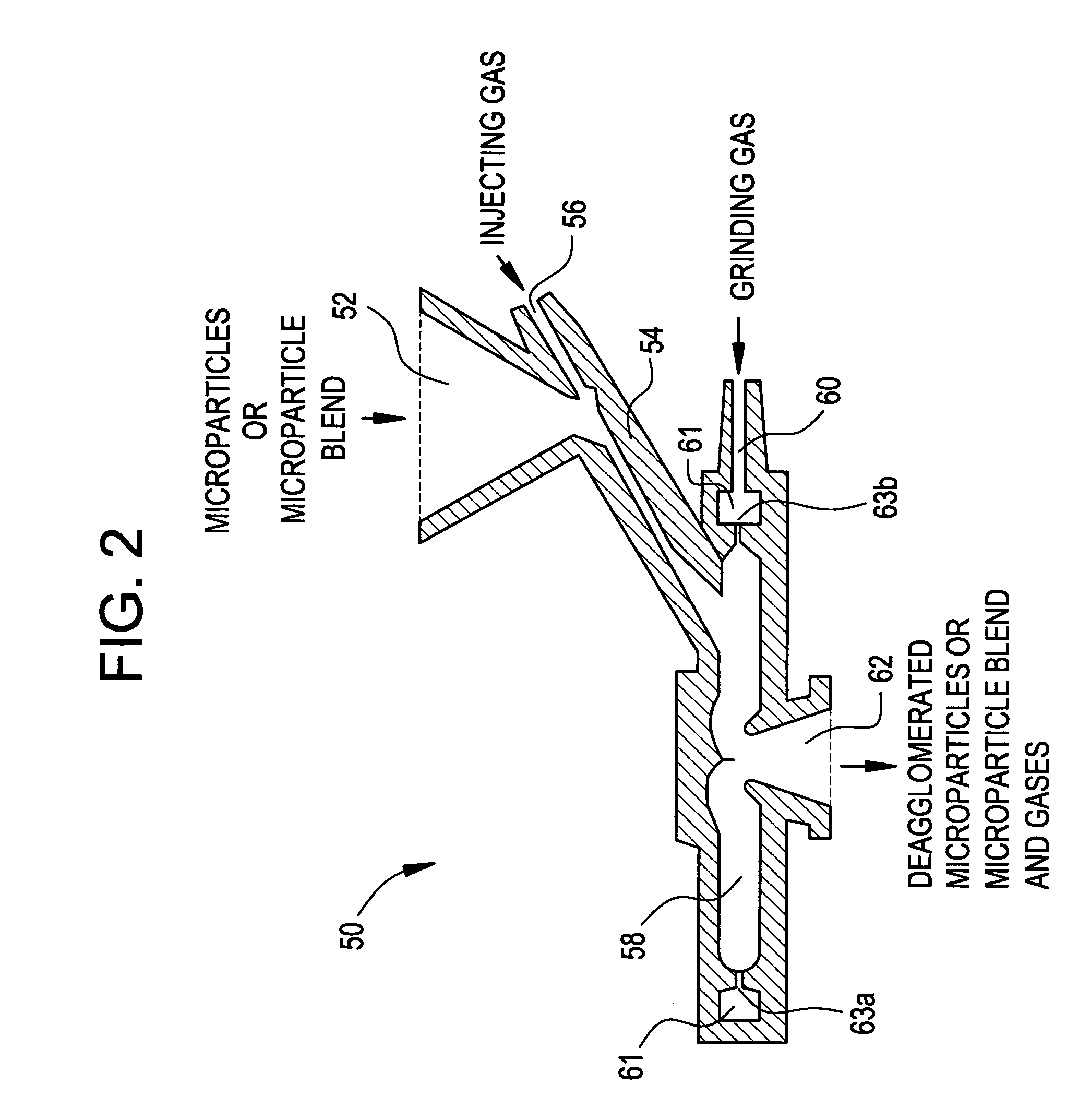

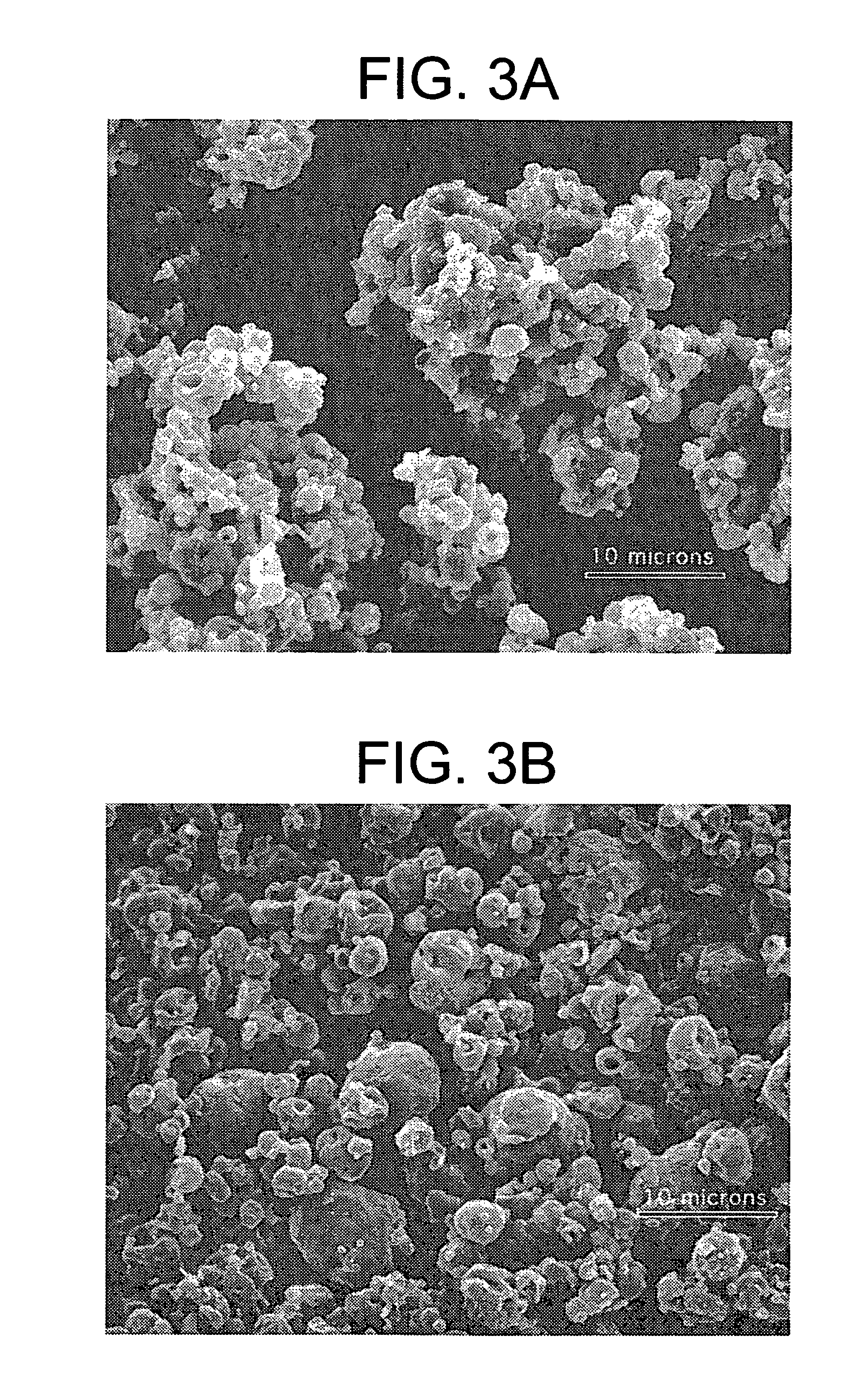

Methods for making pharmaceutical formulations comprising deagglomerated microparticles

InactiveUS20060093678A1High crystallinityReduce contentPowder deliveryGranulation by liquid drop formationMicroparticleVolume average

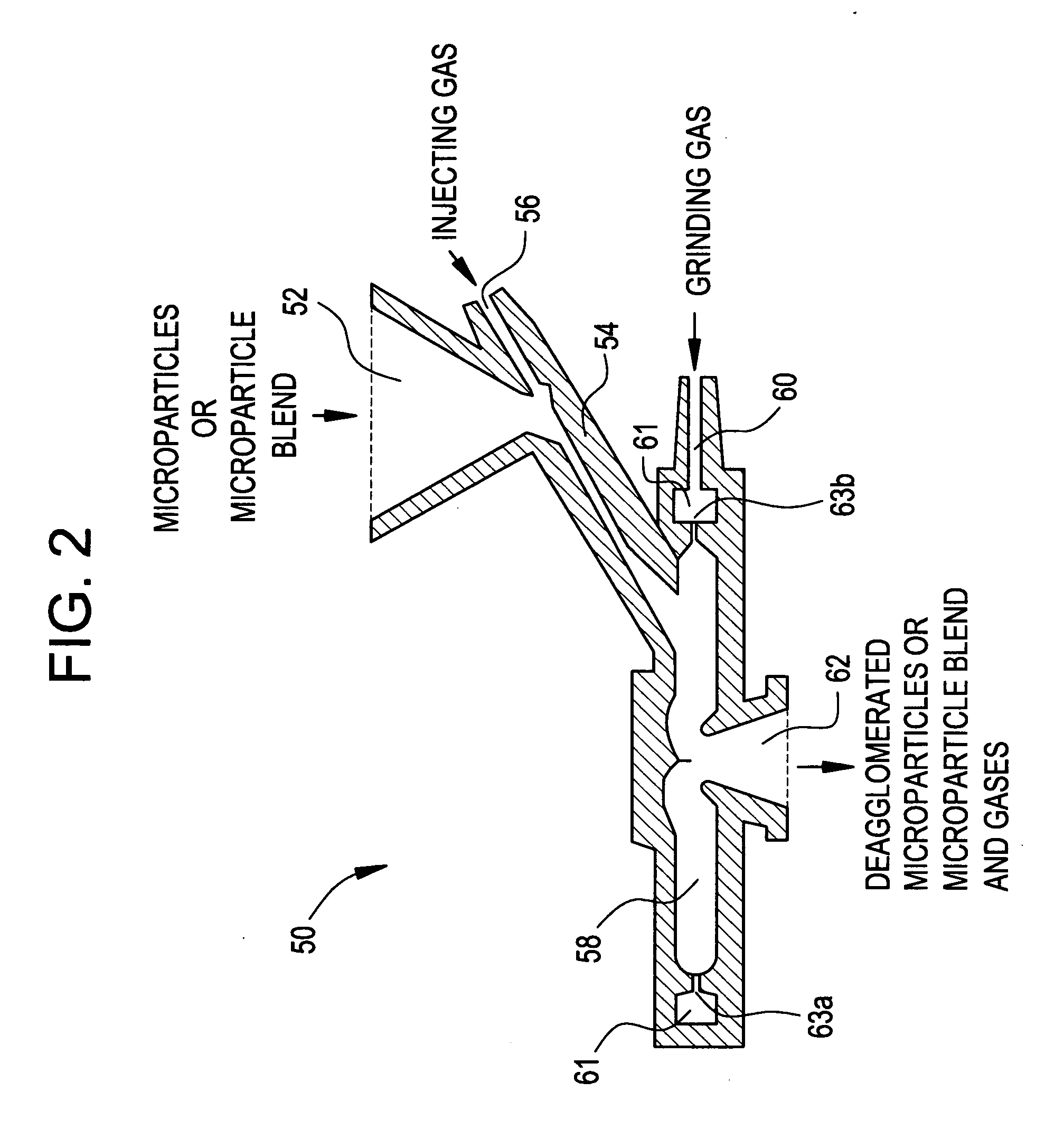

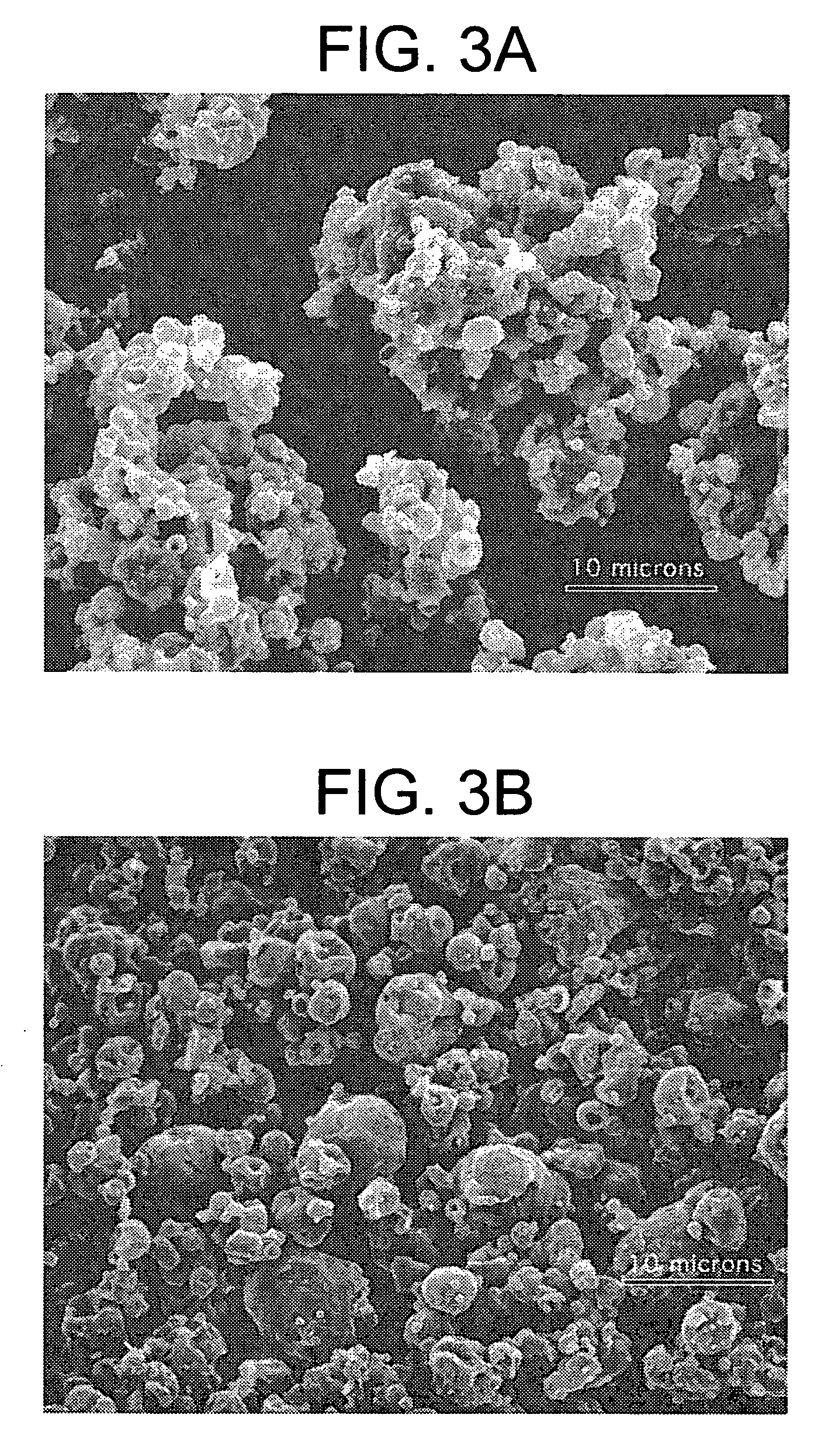

Methods are provided for making a dry powder blend pharmaceutical formulation comprising (i) forming microparticles which comprise a pharmaceutical agent; (ii) providing at least one excipient in the form of particles having a volume average diameter that is greater than the volume average diameter of the microparticles; (iii) blending the microparticles with the excipient to form a powder blend; and (iv) jet milling the powder blend to deagglomerate at least a portion of any of the microparticles which have agglomerated, while substantially maintaining the size and morphology of the individual microparticles. Jet milling advantageously can eliminate the need for more complicated wet deagglomeration processes, can lower residual moisture and solvent levels in the microparticles (which leads to better stability and handling properties for dry powder formulations), and can improve wettability, suspendability, and content uniformity of dry powder blend formulations.

Owner:CHICKERING DONALD E III +6

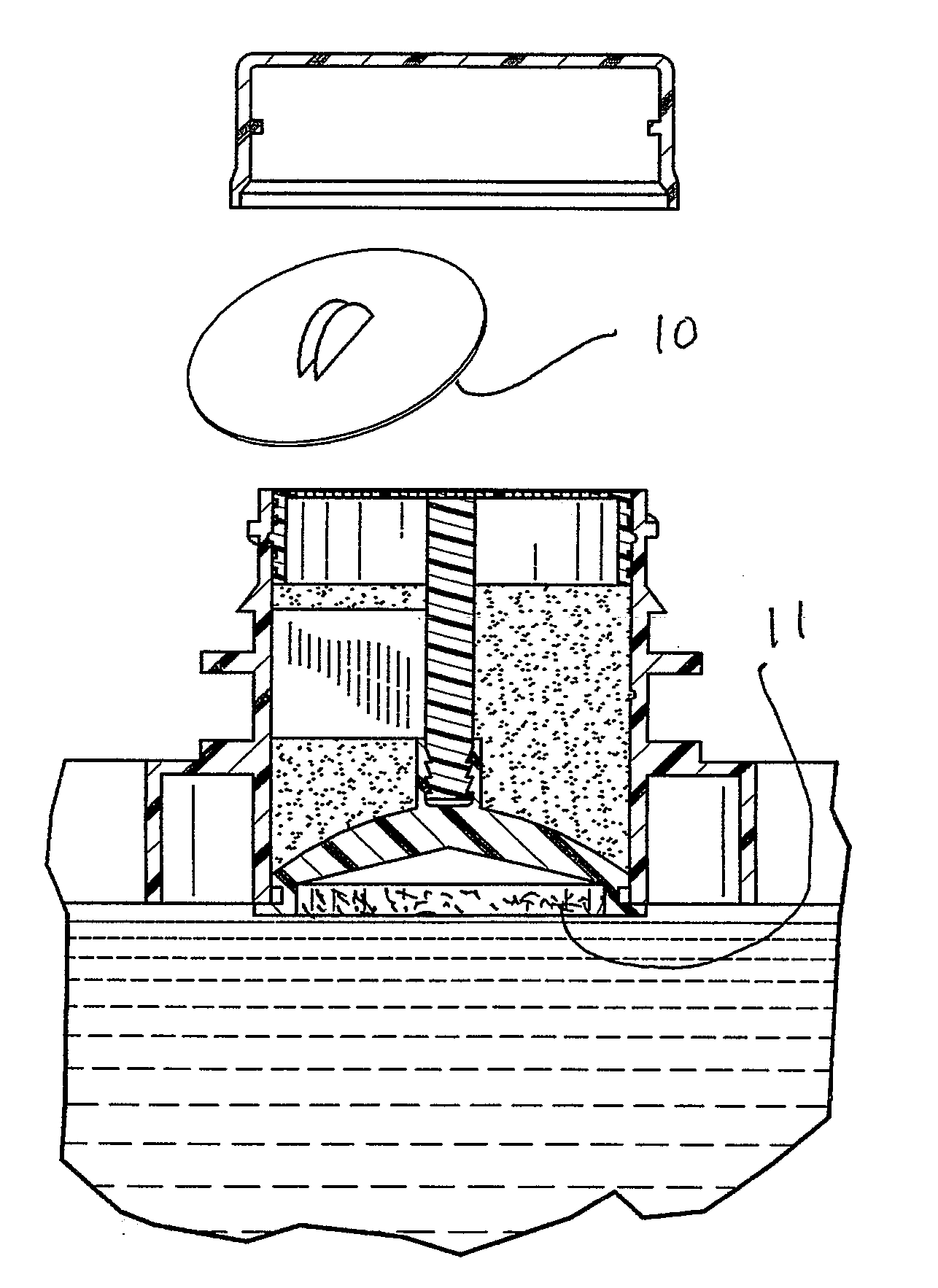

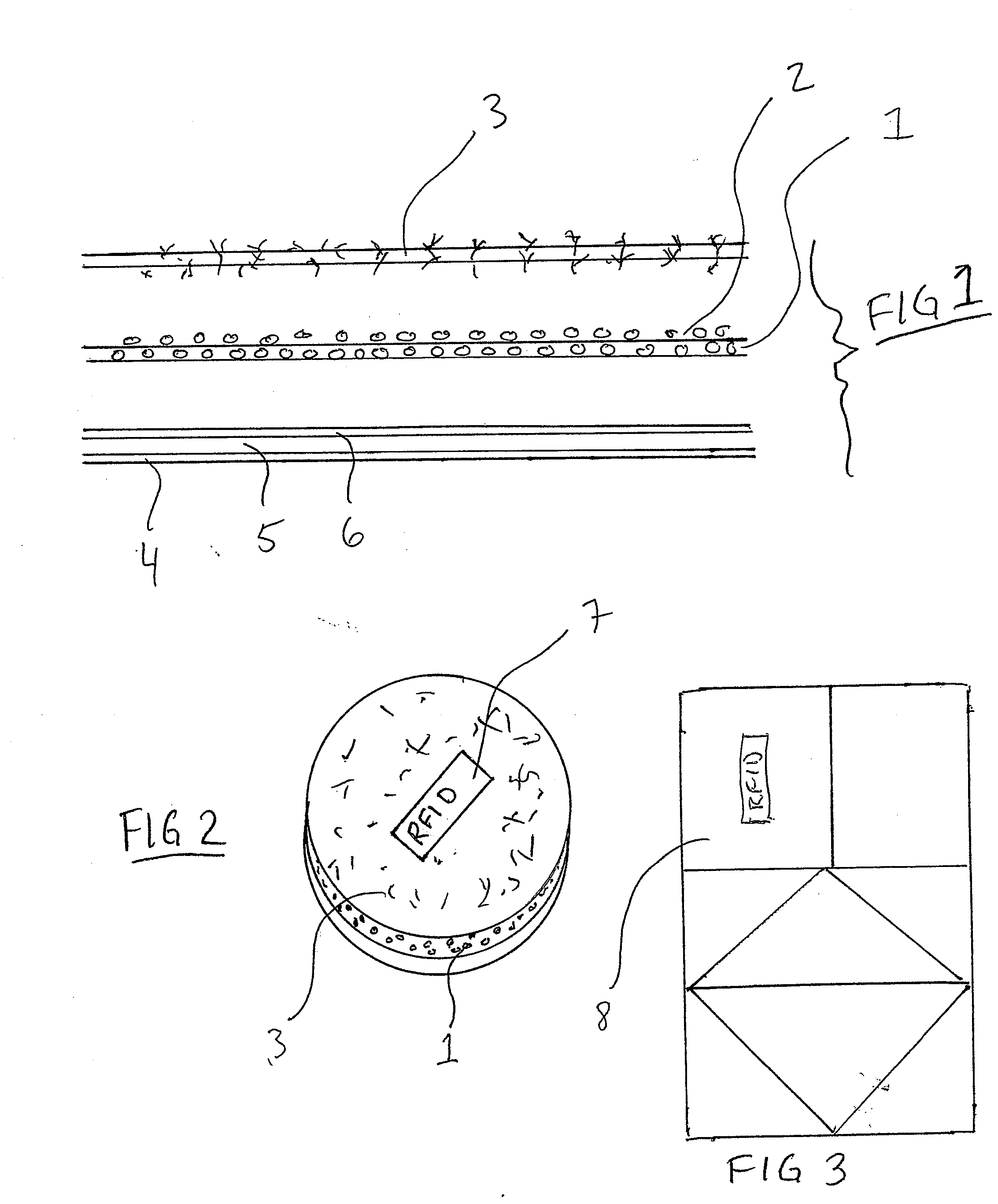

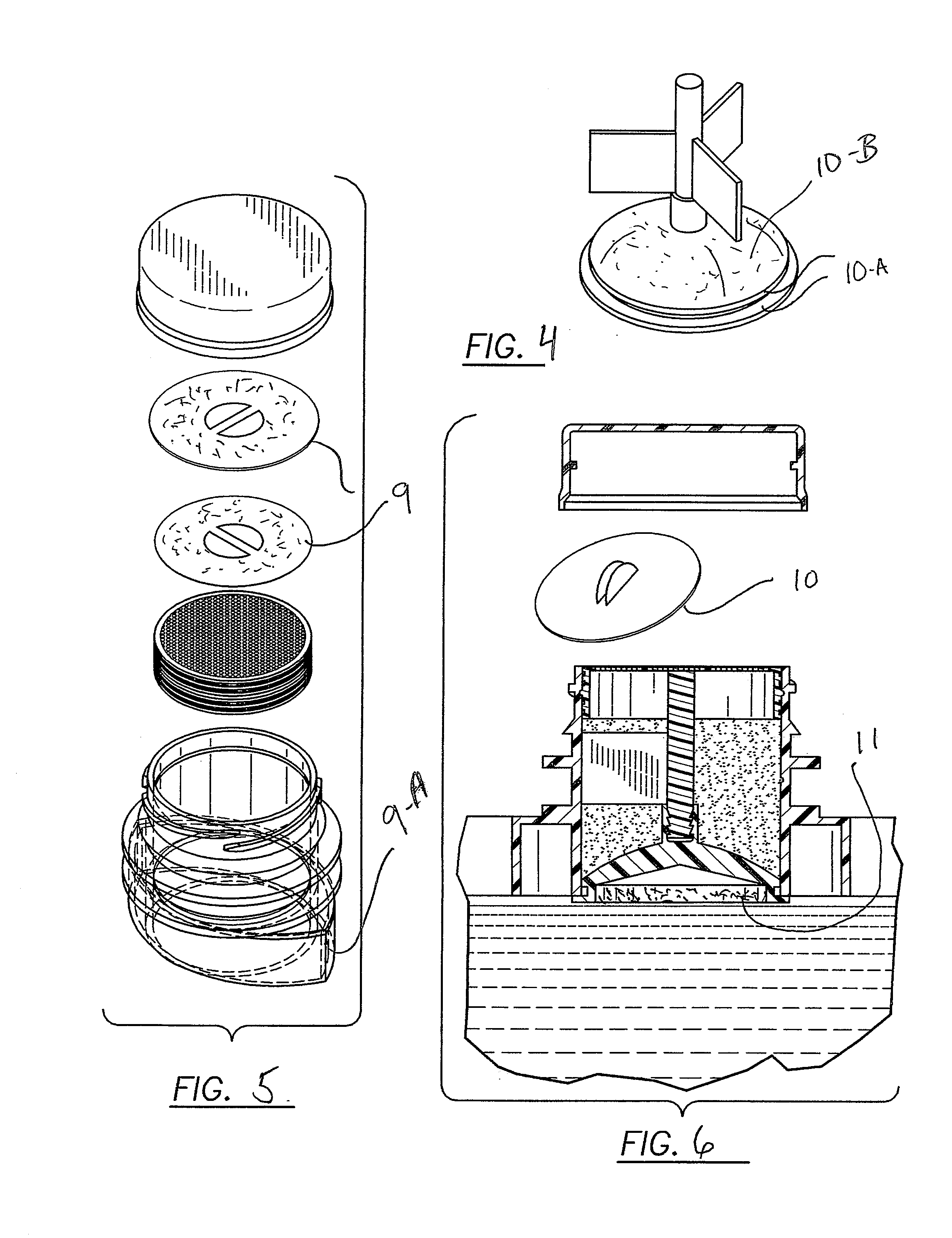

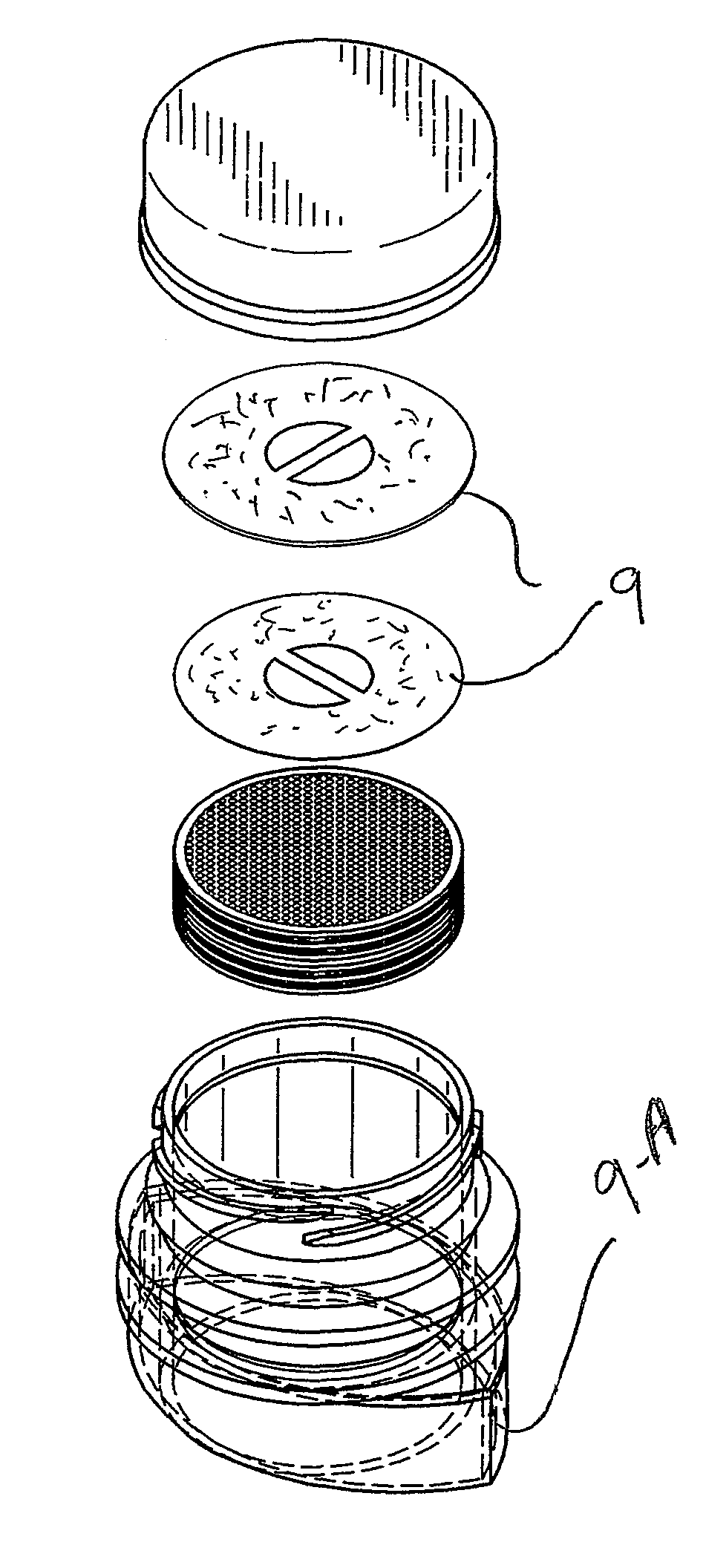

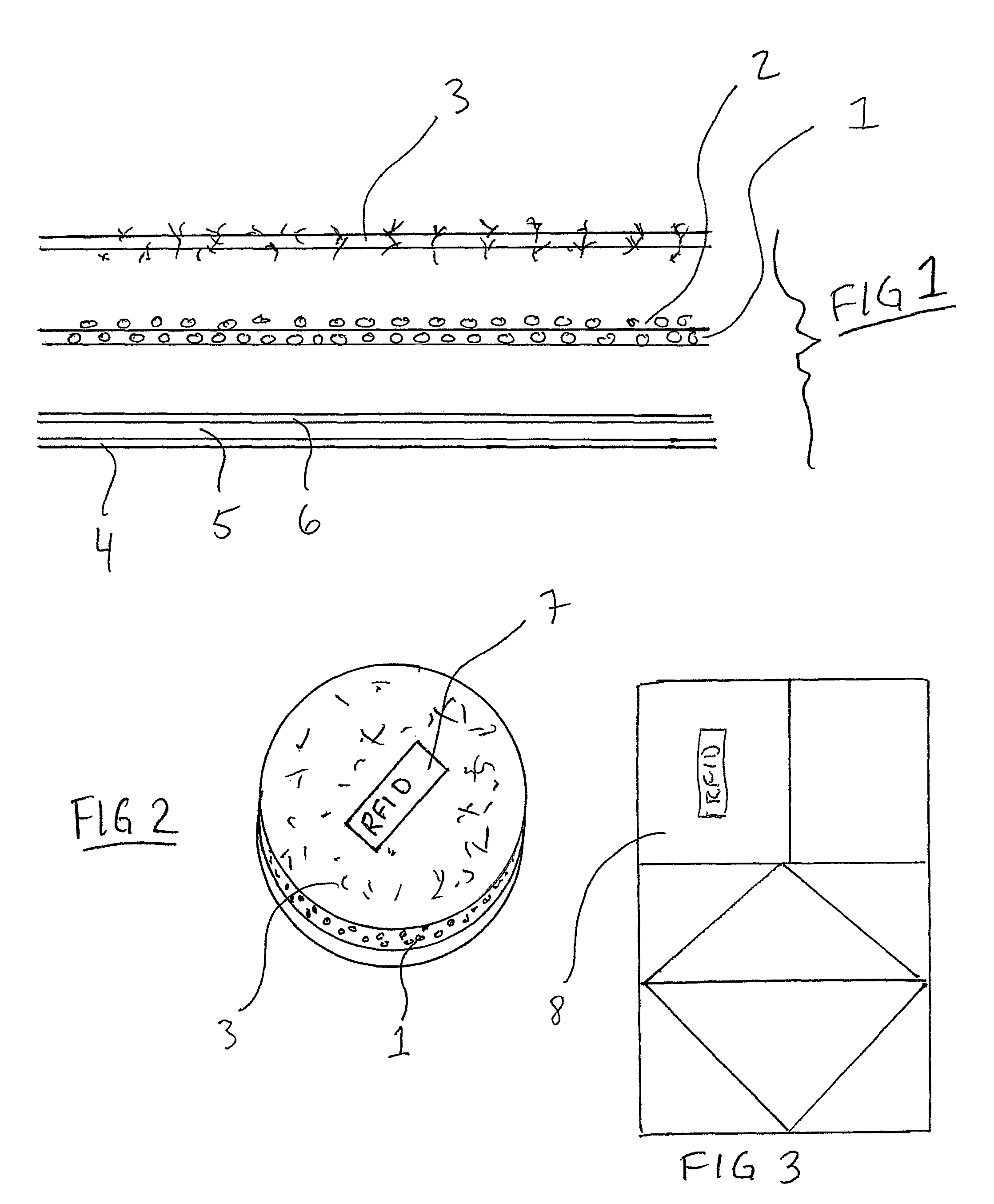

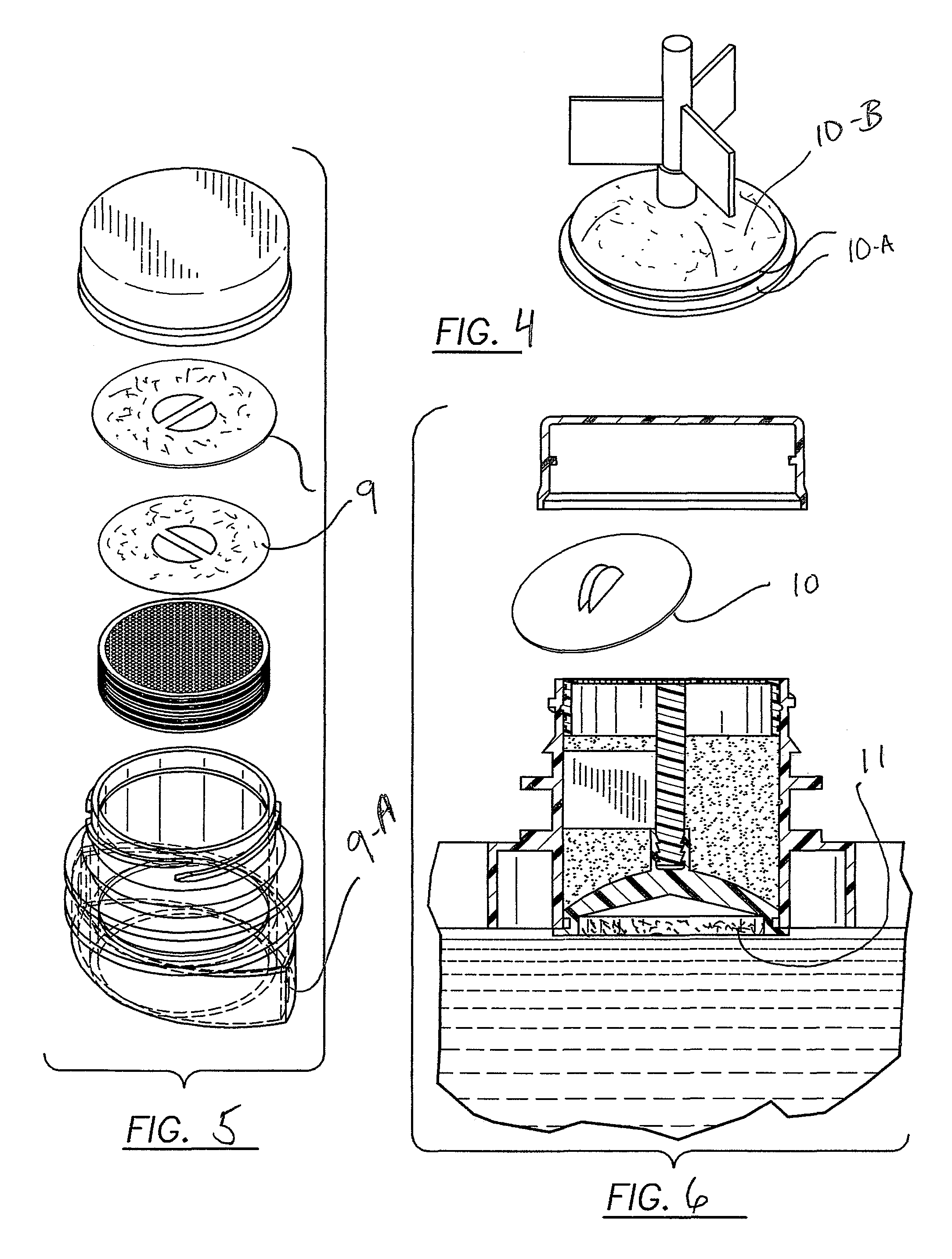

Seal absorbent pad-rfid-bar code-label-container for a dosing cap

A dosing cap for use with or without a separate container for combining two different ingredients at time of use by dispensing ingredient one from the dosing cap into a container with ingredient two. The dosing cap includes a moisture and waterproof seal to prevent the ingredients from receiving any moisture during storage, an absorbent material (desiccant) included with the seal to absorb any residual moisture in the container or that might be received into the container during storage to ensure a moisture free environment for the ingredient and a tracking device such as a radio frequency identifying chip (RFID) that is attached to the dosing cap for product identification and tracking purposes.

Owner:GACERS LLC

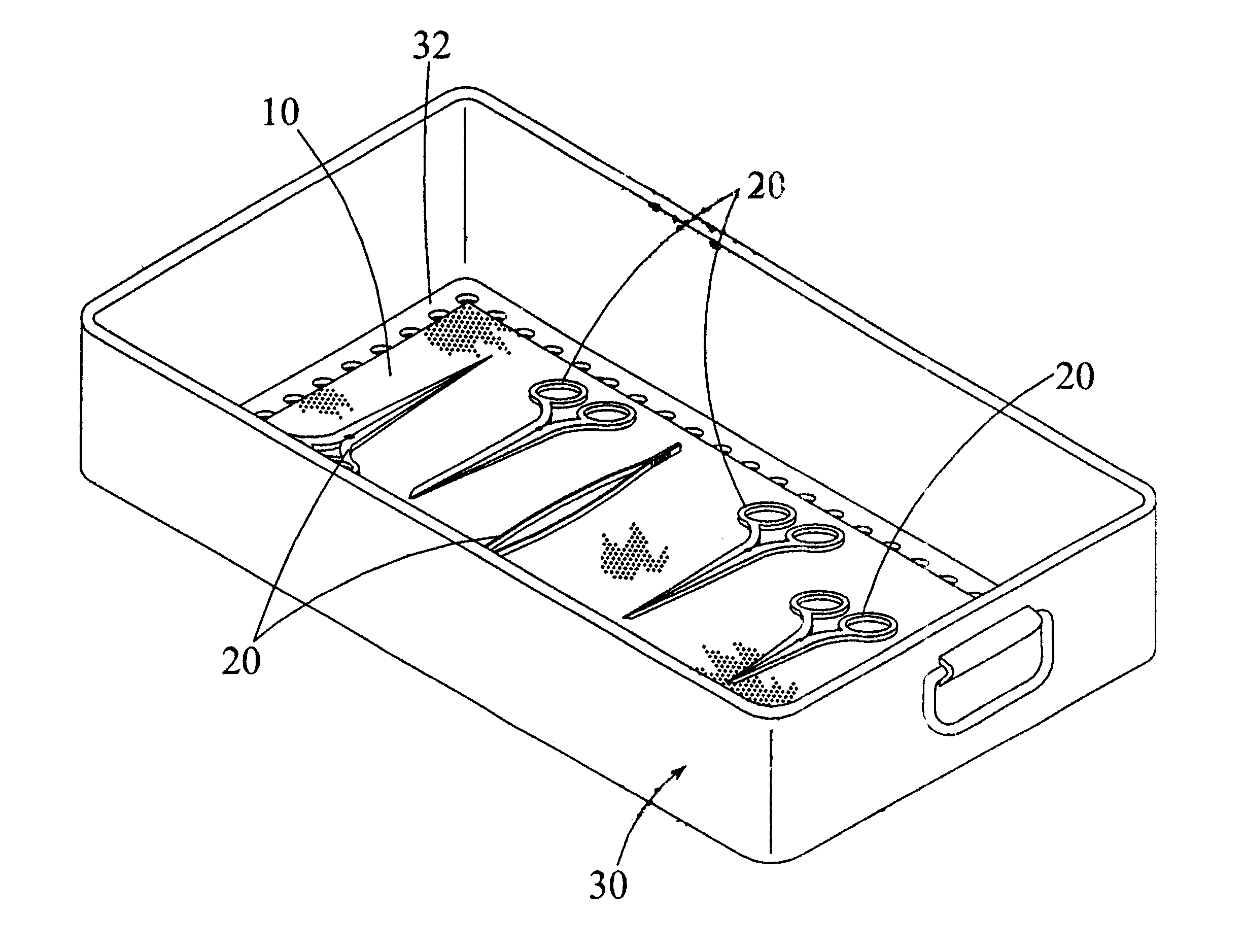

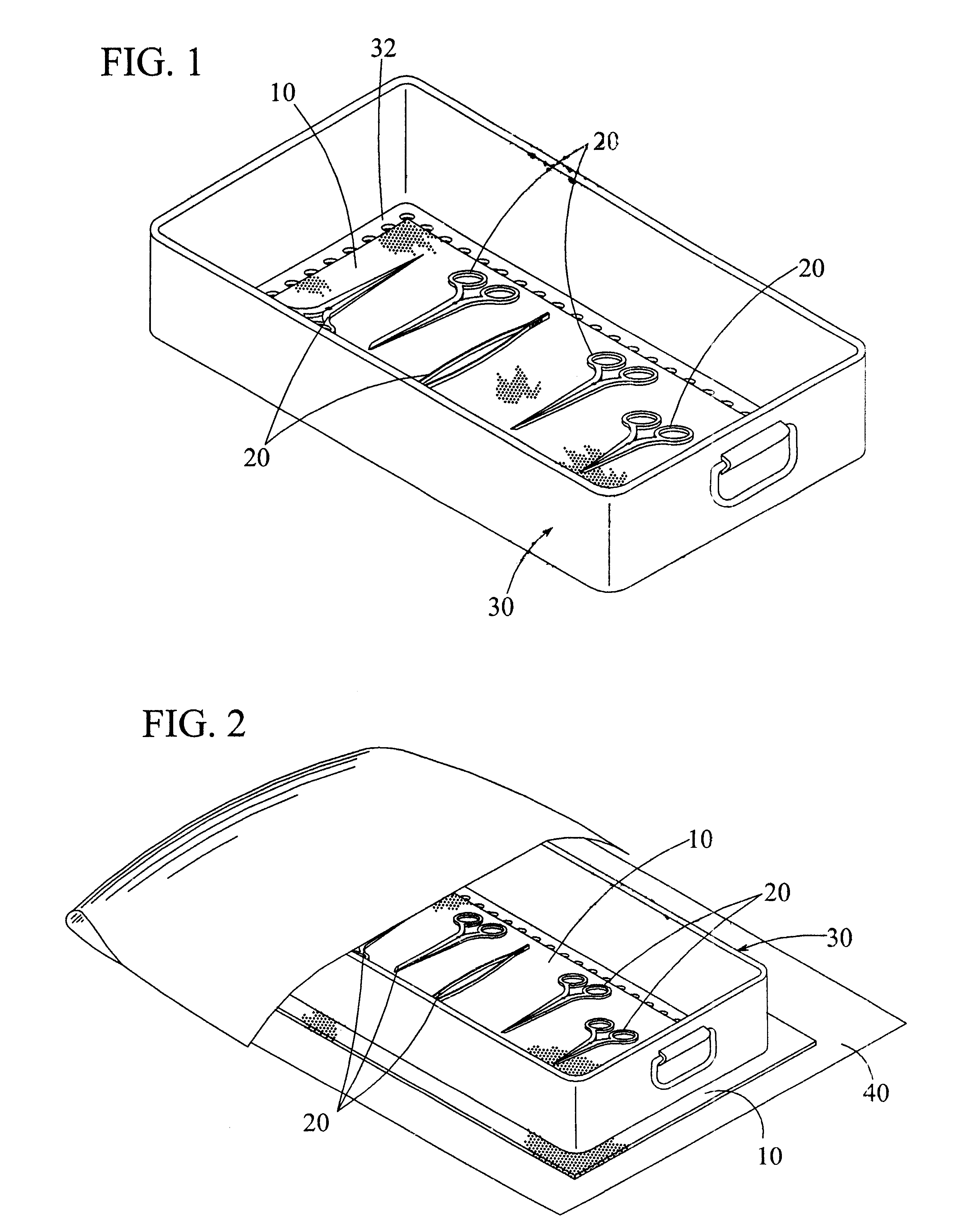

Absorbent instrument trayliner for sterilization process and method of sterilizing surgical instruments

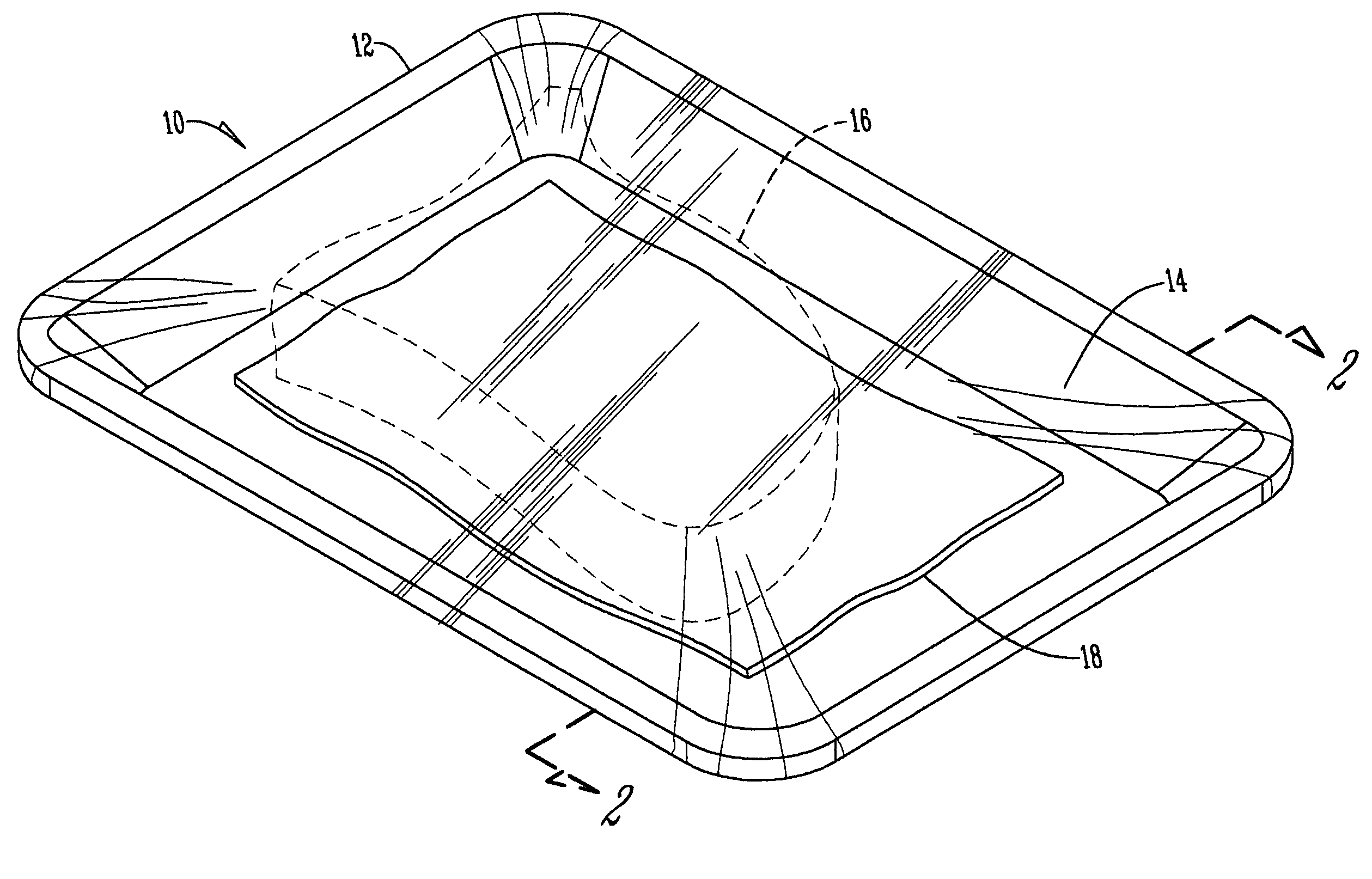

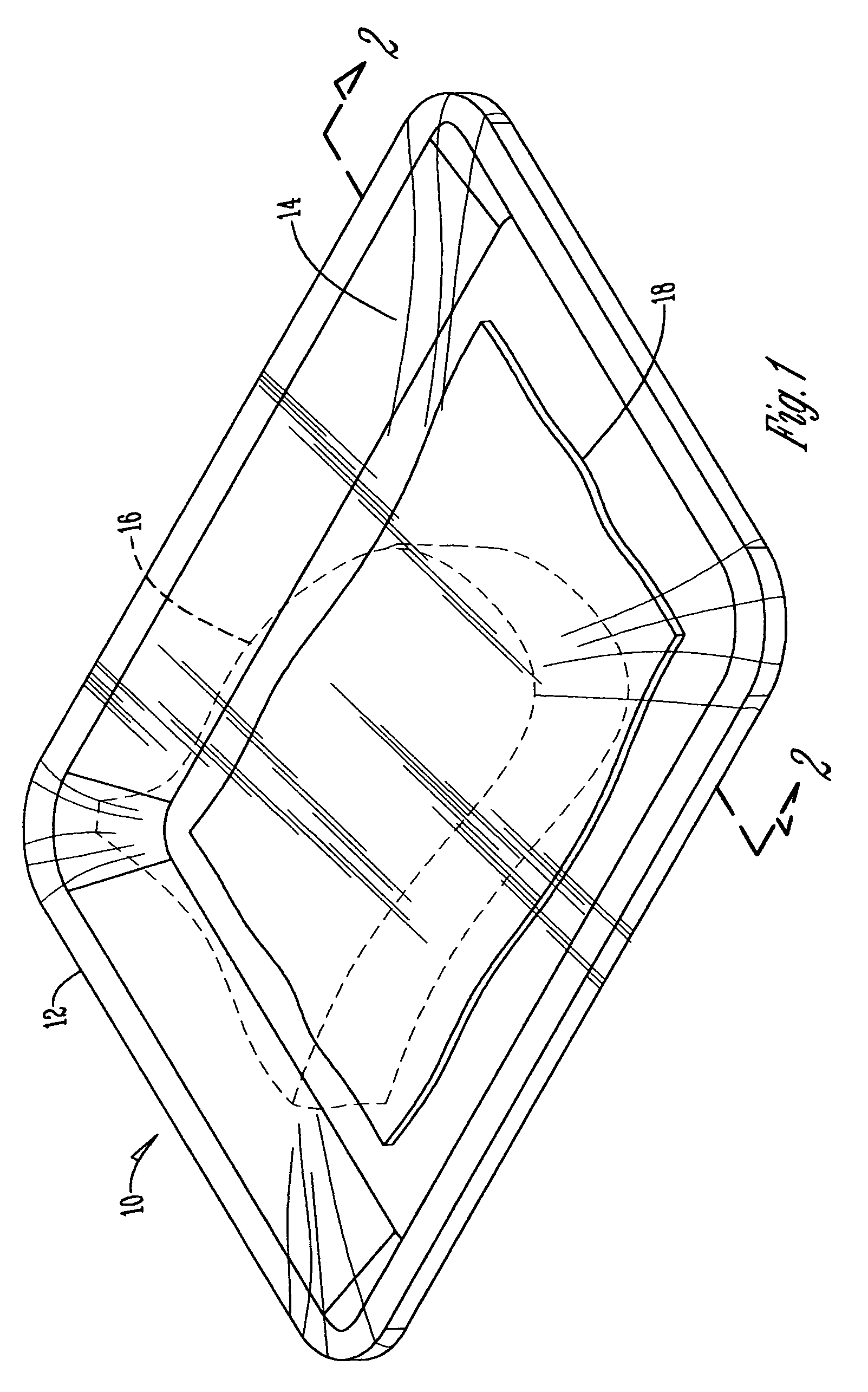

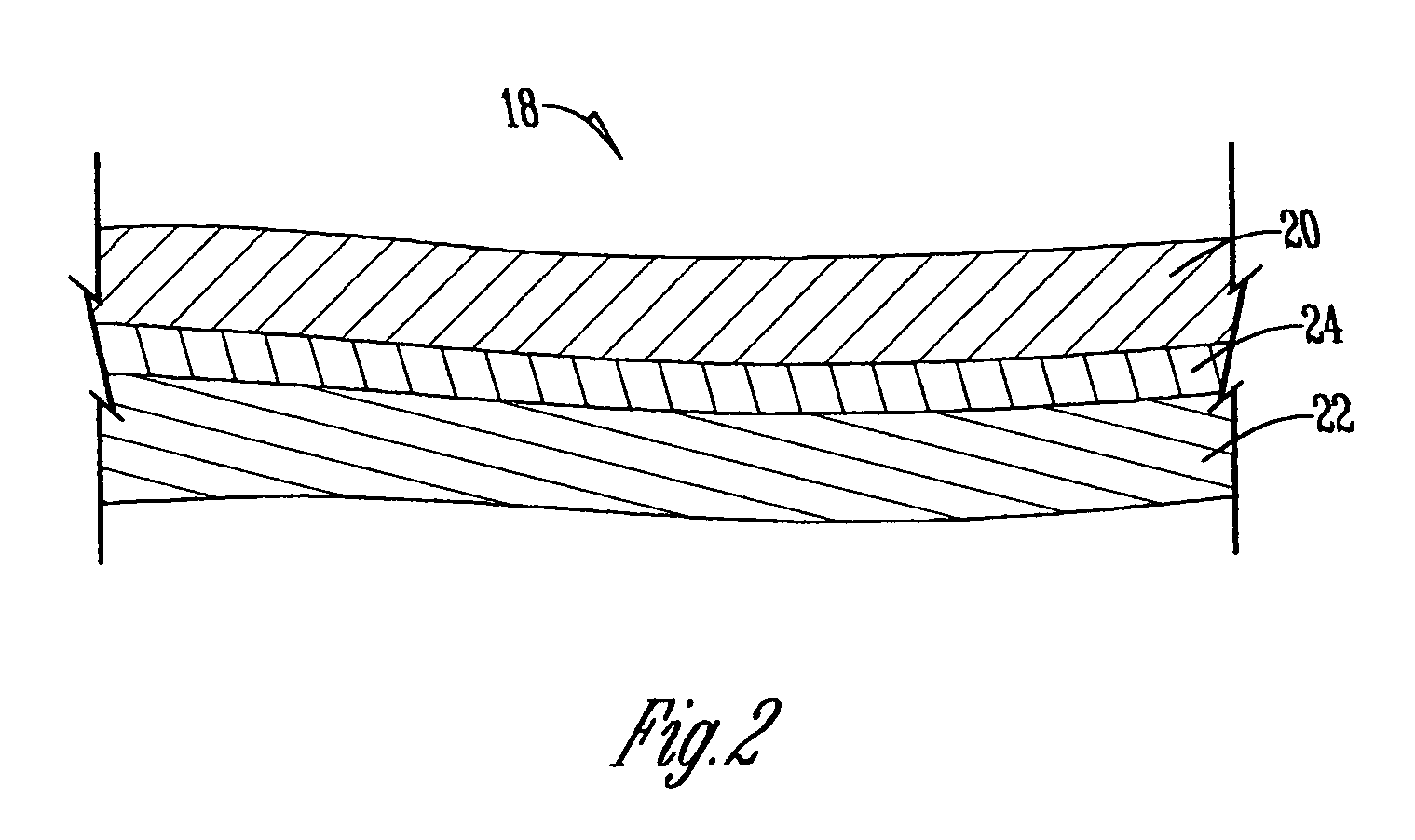

InactiveUS6440375B1Potential damageSterilizationSurgical furnitureDispensing apparatusDry weightEthylene oxide

The present invention is directed to a super-absorbent trayliner for use in a sterilization process and, more particularly, to a super-absorbent trayliner for cushioning surgical instruments and providing an advantageous moisture absorption functionality during and after completion of a sterilization process. The super-absorbent trayliner functions advantageously with steam or ethylene oxide gas as the sterilization agent. The super-absorbent trayliner is fabricated from a material having a desired level of moisture absorption, e.g., on the order of at least about thirty percent (30%) by dry weight, and is preferably fabricated from a hydrophilic polymeric foam material, e.g., a hydrophilic polyurethane foam. The disclosed super-absorbent trayliner may be advantageously utilized in sterilizing surgical instruments such that potential residual moisture is eliminated from the surface of the sterilized surgical instruments.

Owner:GENERAL HOSPITAL SUPPLY CORP

Tile with multiple-level surface

Owner:CONNOR SPORT COURT INT

Seal absorbent pad-RFID-bar code device for a dosing cap

A dosing cap for use with or without a separate container for combining two different ingredients at time of use by dispensing ingredient one from the dosing cap into a container with ingredient two. The dosing cap includes a moisture and waterproof seal to prevent the ingredients from receiving any moisture during storage, an absorbent material (desiccant) included with the seal to absorb any residual moisture in the container or that might be received into the container during storage to ensure a moisture free environment for the ingredient and a tracking device such as a radio frequency identifying chip (RFID) that is attached to the dosing cap for product identification and tracking purposes.

Owner:BLAST MAX

Decomposition maturing agent for fast decomposition-maturing straw

InactiveCN101139561ASimple structureHigh organic contentBio-organic fraction processingFungiBacillus licheniformisDecomposition

The invention discloses a farm fertilizer produced by biologic technology, in particular a decomposing agent for rapidly decomposing straws at low cost, the mixture ratio of which is aerobic bacillus subtilis Cohn 20%, Bacillus licheniformis 10%, aspergillus flavus 20%, chaetomiaceae 20%, absidia corymbifera 20%, and saccharomycetes 10%. The production procedures are: extracting different beneficial decomposed bacteria from organics from different environments, purifying, rejuvenating, breeding and culturing; inoculating the cultured bacterial strains into disinfected solid culture medium; fermenting for 4-5 days under 25-50 DEG C, airing dry so that the residual moisture in the bacterial strains is 25%; mixing, agitating evenly and packing the aired solid bacterial strains into solid decomposing agent. As the invention is made by using a unique optimization and combination of aerobic bacterial group and a high and new technology and production process, the invention is a pure biologic product, is free from smell and harm for making organic fertilizer by effectively decomposing wastes in the countryside, and the fermenting speed is high, the cost is low, and the source of raw material is wide. The invention has improved the soil structure and reduces environmental pollution.

Owner:李海泉

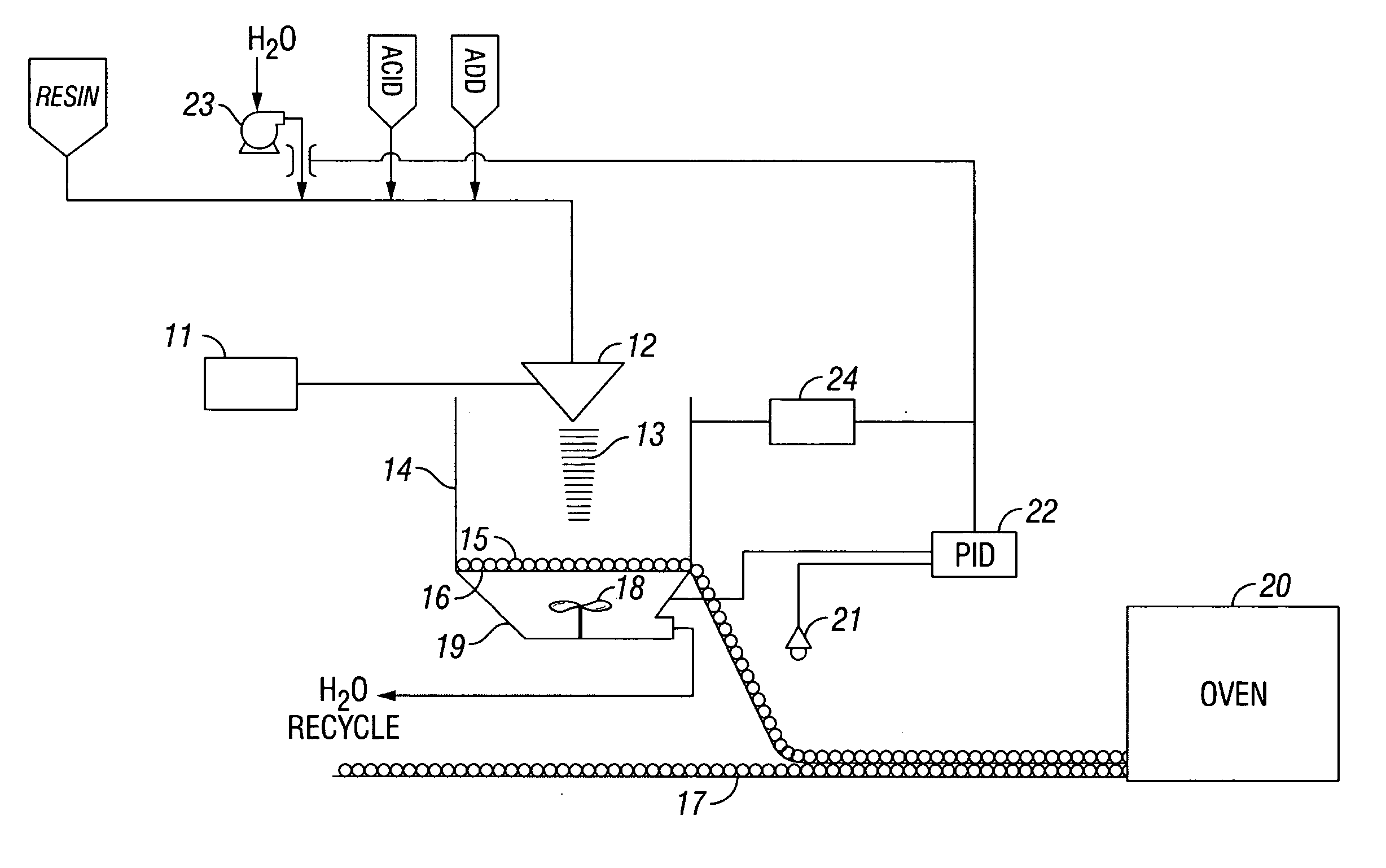

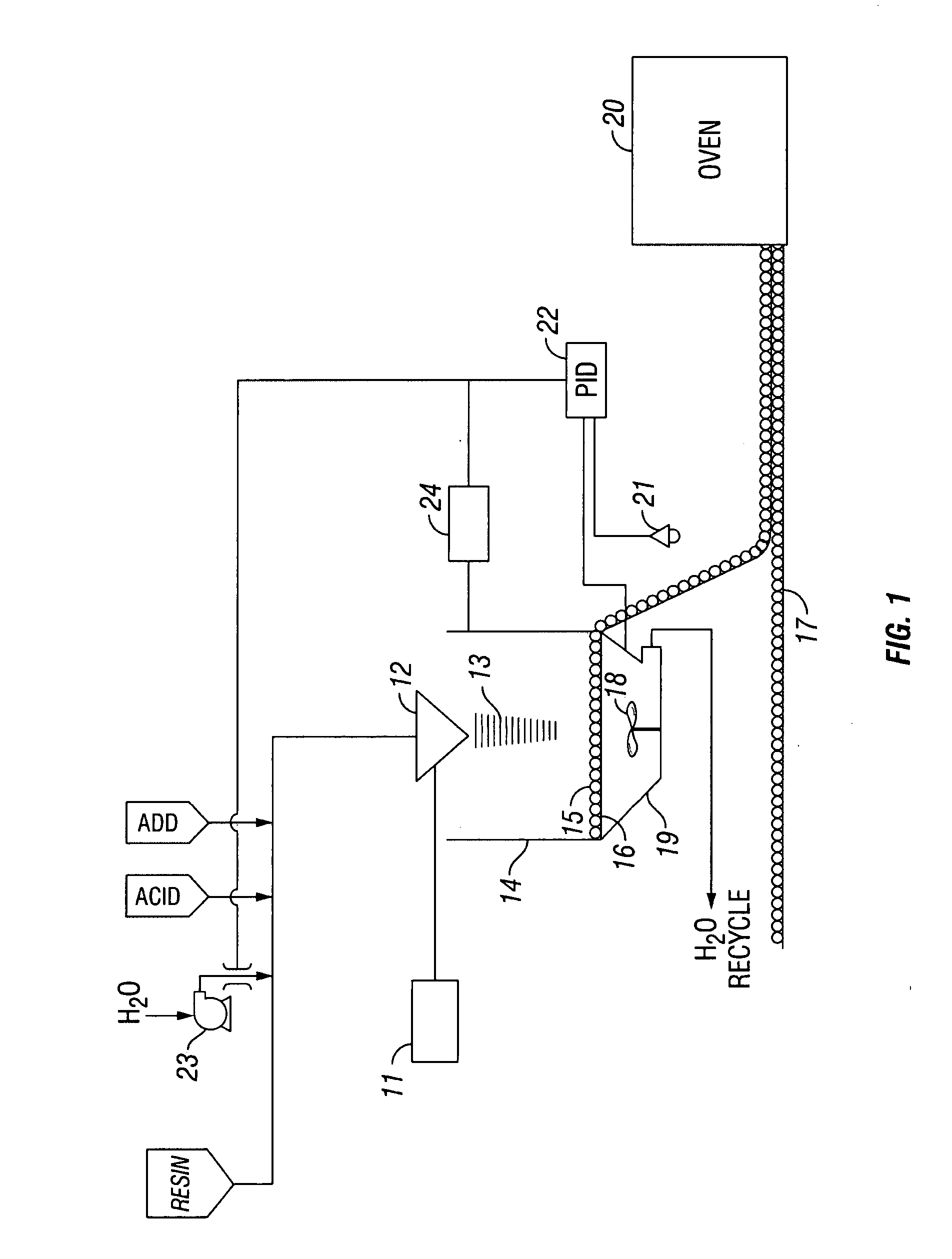

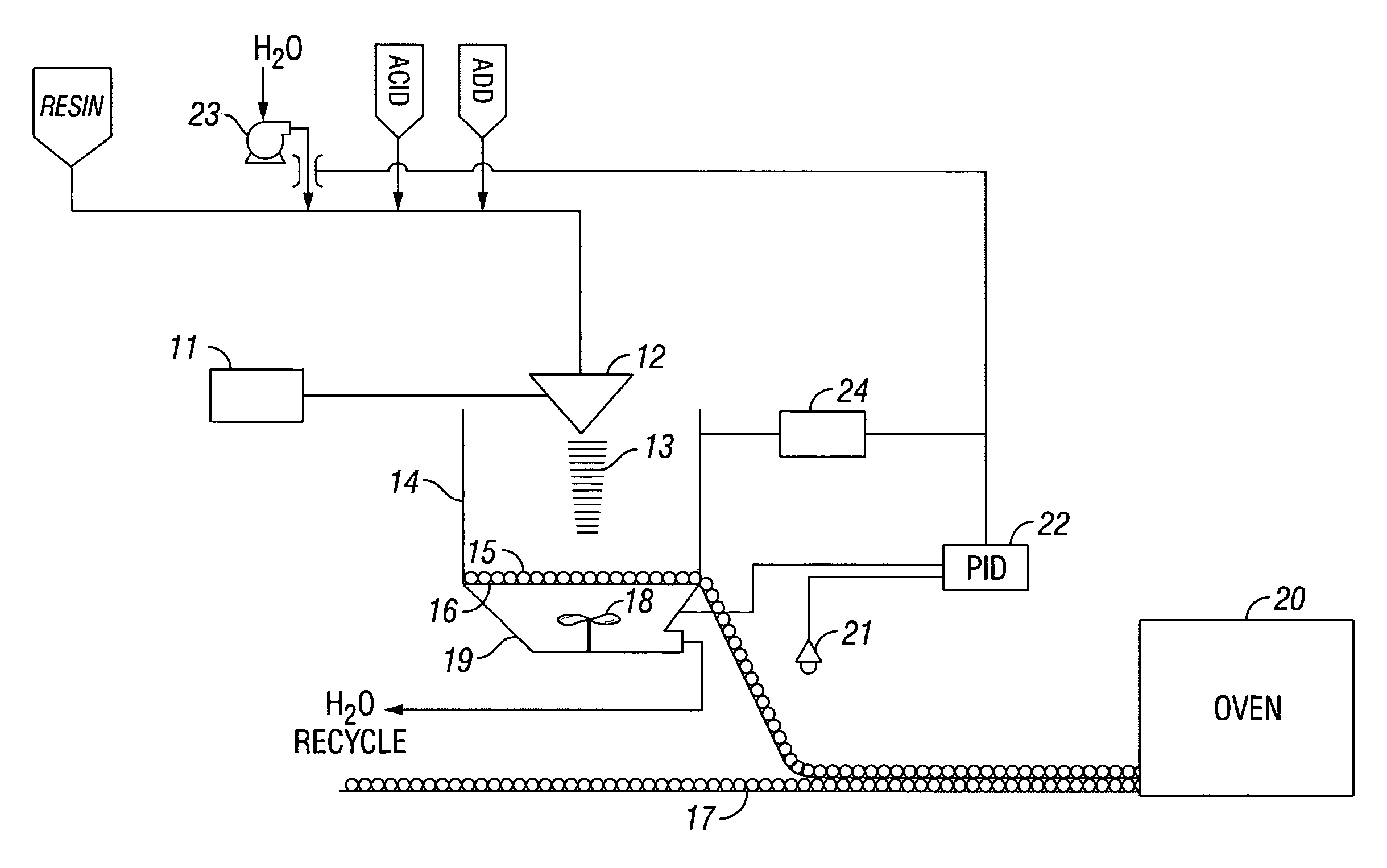

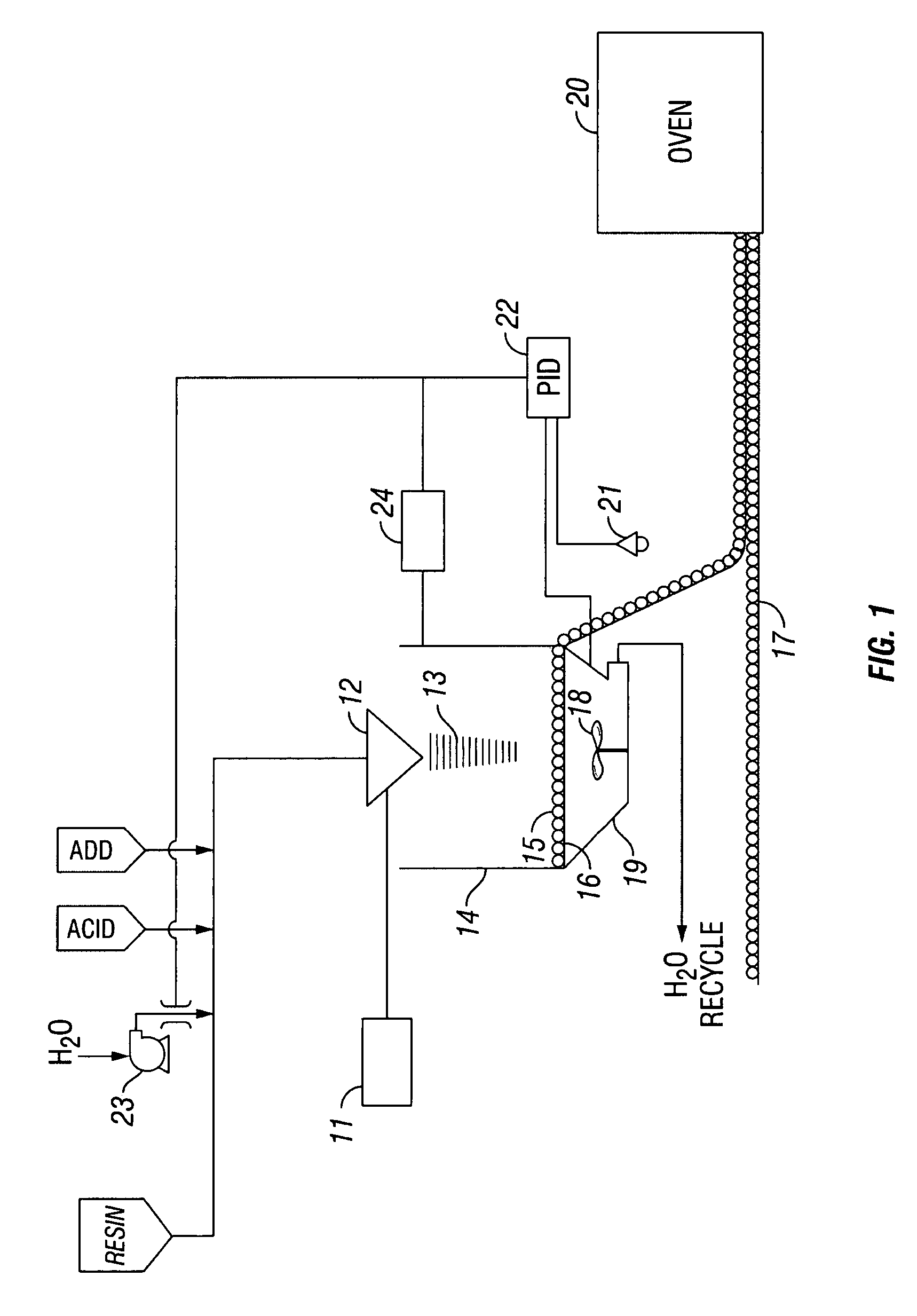

Control of pre-cured product moisture for formaldehyde-free fiberglass products

ActiveUS20060019024A1Reduced residual water contentReduce contentPretreated surfacesChemical vapor deposition coatingGlass fiberMoisture measurement

A system for controlling the residual moisture in pre-cured binder coated glass fibers. The moisture of the binder coated glass fibers is measured after the process water is extracted in a collection box. Based on the level of moisture found in the coated glass fibers, adjustments are made to the process upstream of the moisture measurements. The adjustments include, but are not limited to, adjusting the amount of water used to make the binder composition; adjusting the amount of heat applied to the binder composition as it is applied to the glass fibers and adjusting the vacuum conditions used to extract the process water from the binder coated glass fibers. Control of the residual moisture in the precured binder coated glass fibers helps ensure proper curing of the binder during the subsequent curing step.

Owner:JOHNS MANVILLE CORP

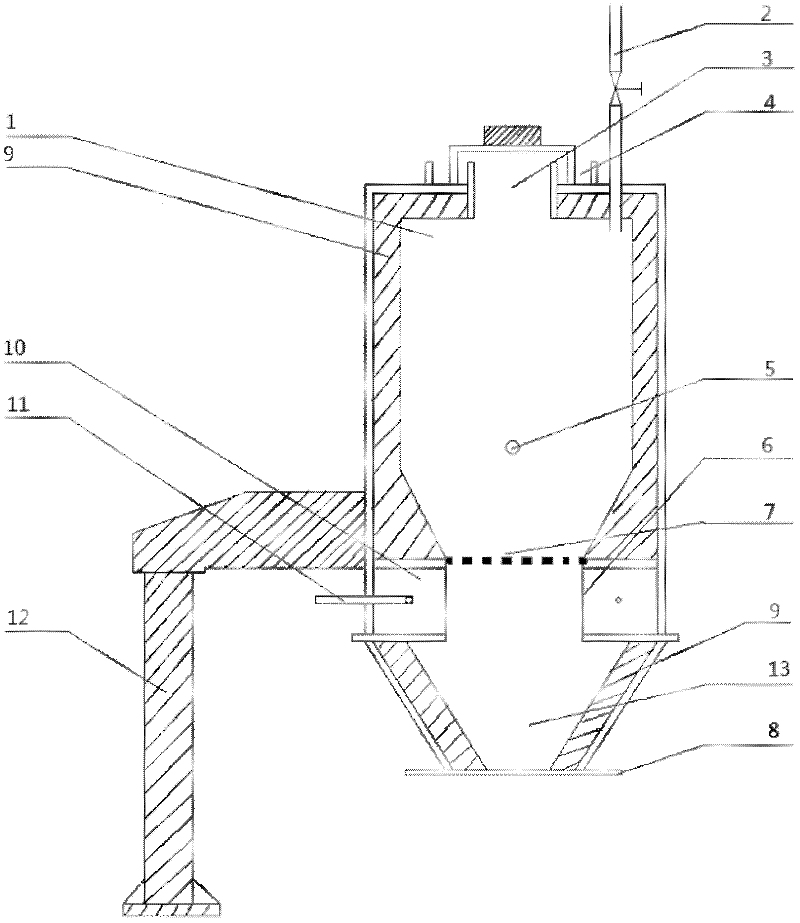

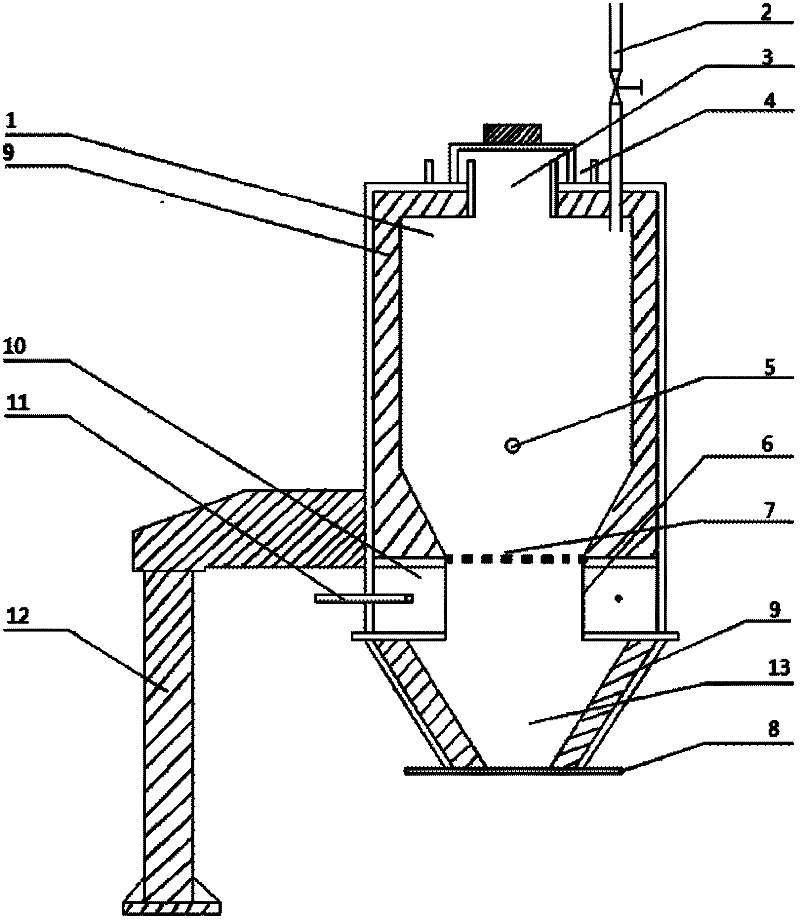

Method of preparing biomass charcoal with biomass material and carbonization furnace

InactiveCN102533292ACompact structureSmooth dischargeBiofuelsSpecial form destructive distillationCarbonizationEngineering

The invention relates to a method of preparing biomass charcoals with natural materials, which comprises the following steps: collecting and putting the natural materials into a carbonization furnace after drying and removing impurities, covering the sealing cap, opening the airflow adjusting valve, and heating to remove residual moisture; continuously heating for pre-carbonization; after adjusting the temperature in the furnace to the carbonization temperature, closing the airflow adjusting valve, carrying out therrmolysis and carbonization in the airproof and oxygen-deficient environment, cooling the furnace to the temperature of 60 DEG C, and discharging the biomass charcoals from the discharging port. High temperature insulation materials are coated on the inner wall of the carbonization furnace body, and an oven, an electric heating zone and a funnel-shaped discharging zone are sequentially arranged on the furnace body from top to bottom, wherein the lower part of the oven is of a funnel shape, the center of the electric heating zone is provided with a material discharging straight channel, the lower edge of the funnel-shaped structure is communicated with the upper edge of the material discharging straight channel, a movable mesh grate is arranged at the junction, a circular electric heating tube is wound around the discharging channel; a sealing cap is arranged on the feeding port, and a sealing baffle is arranged on the discharging port of the funnel-shaped discharging zone.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

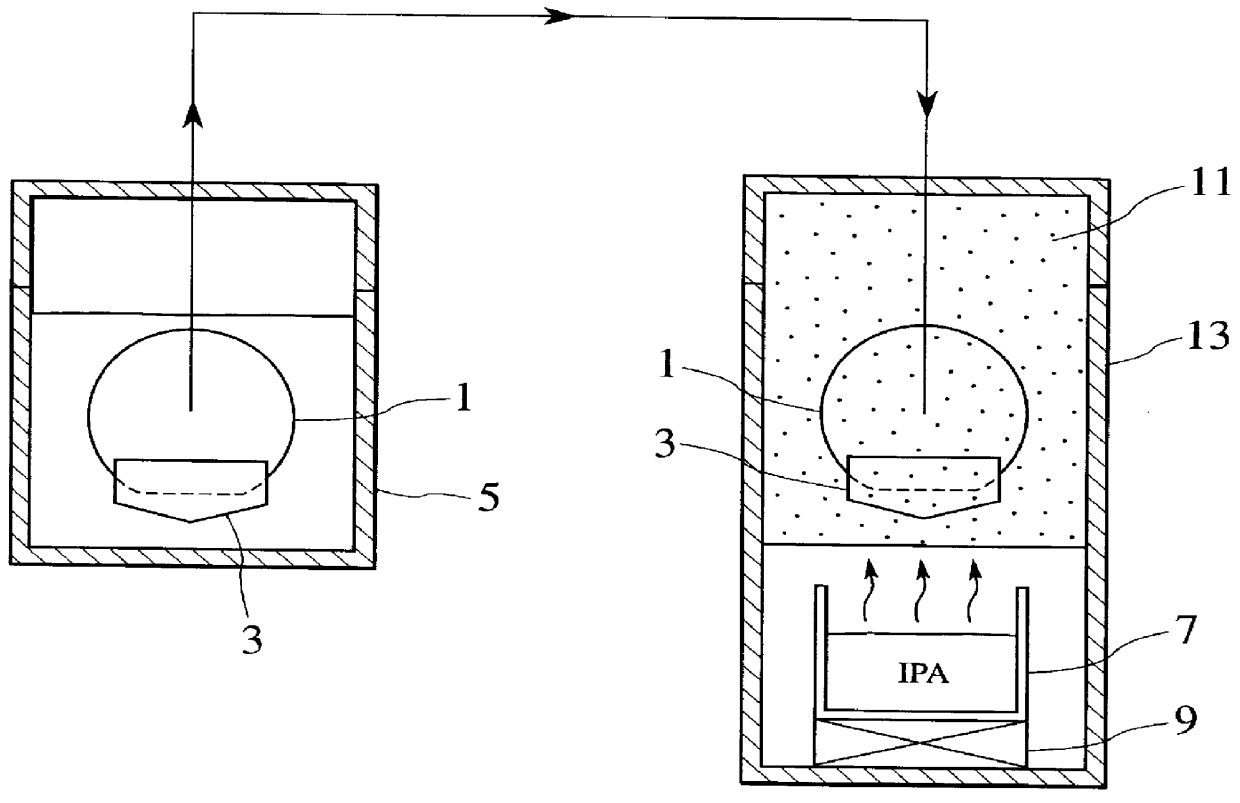

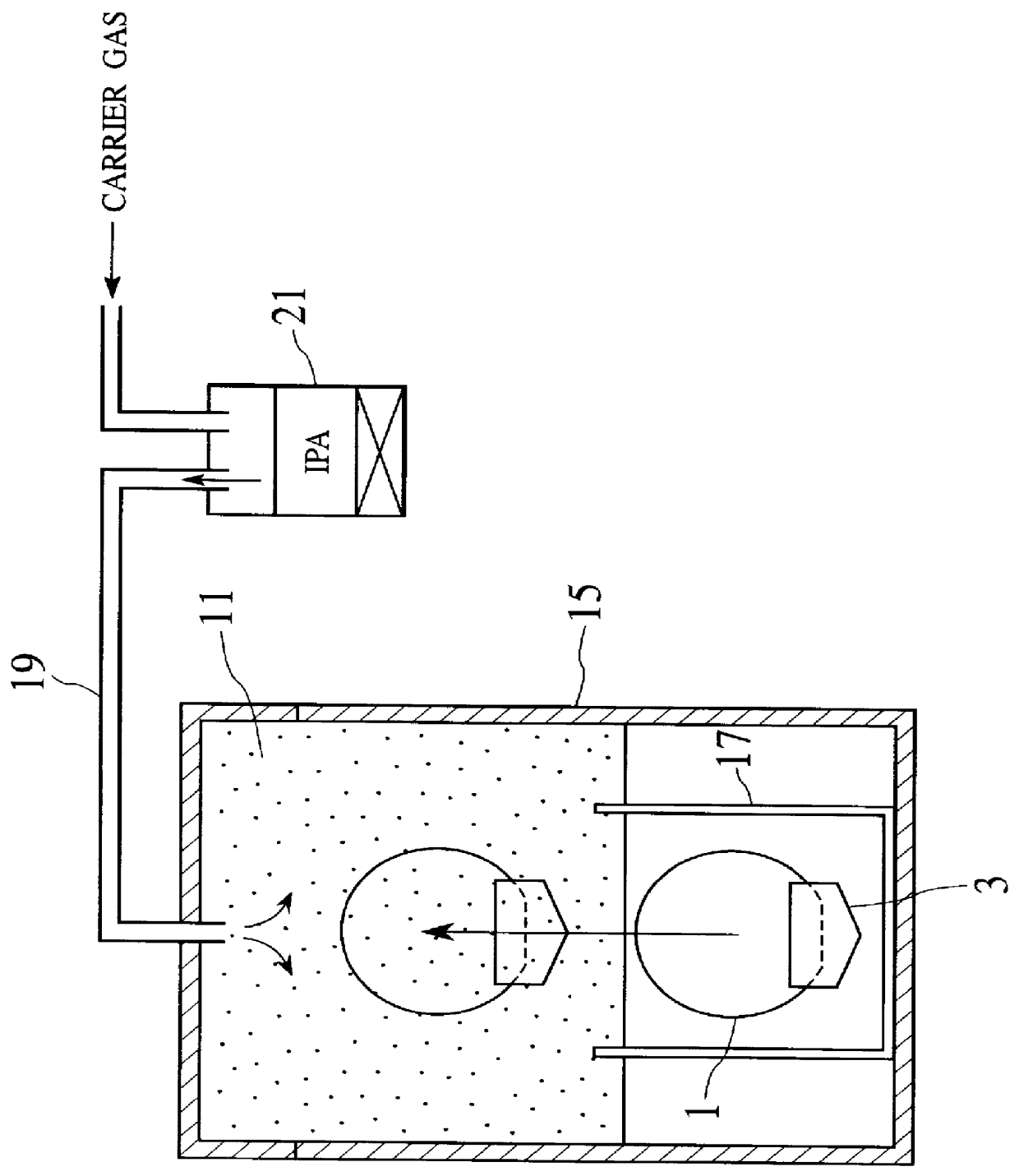

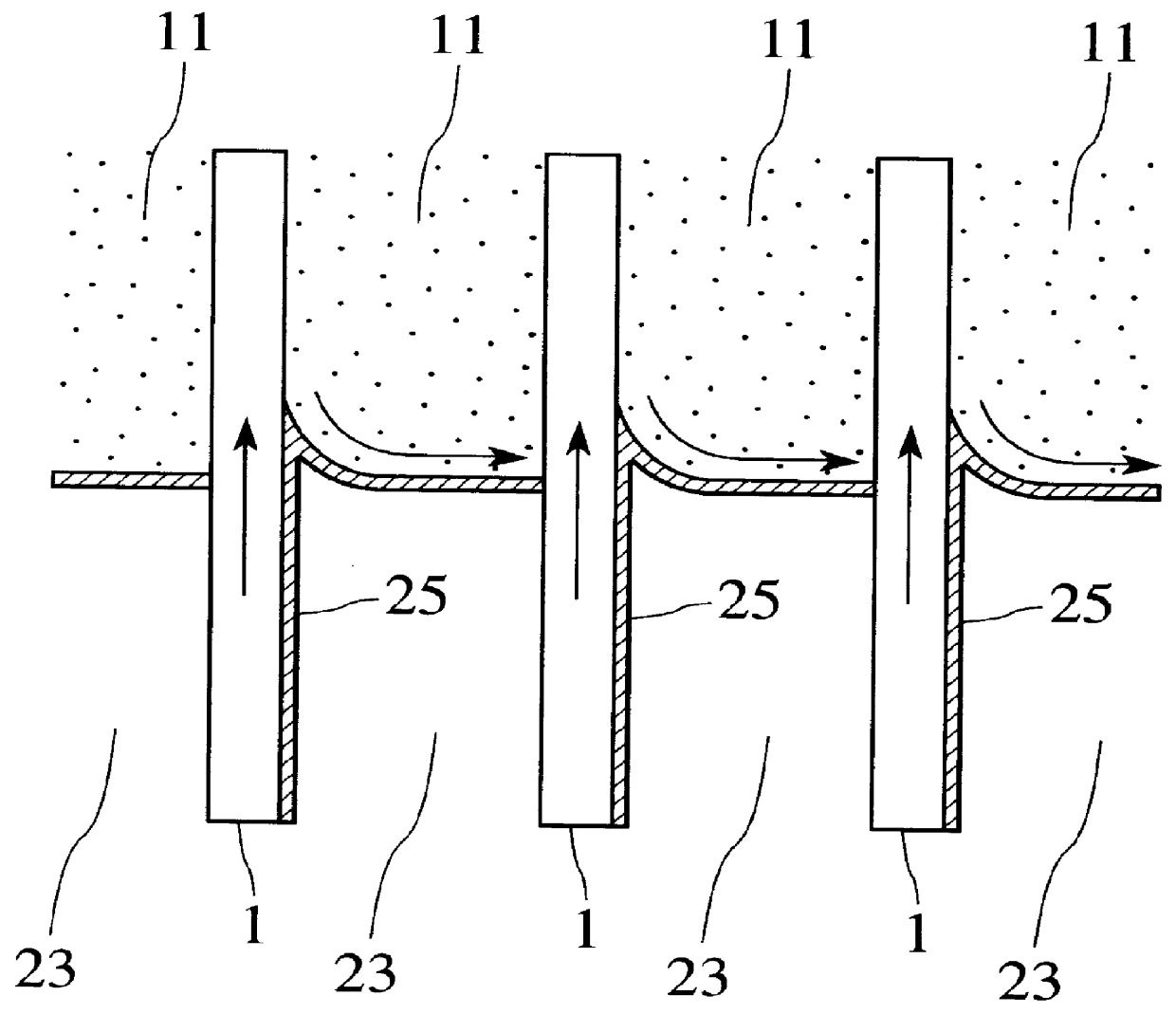

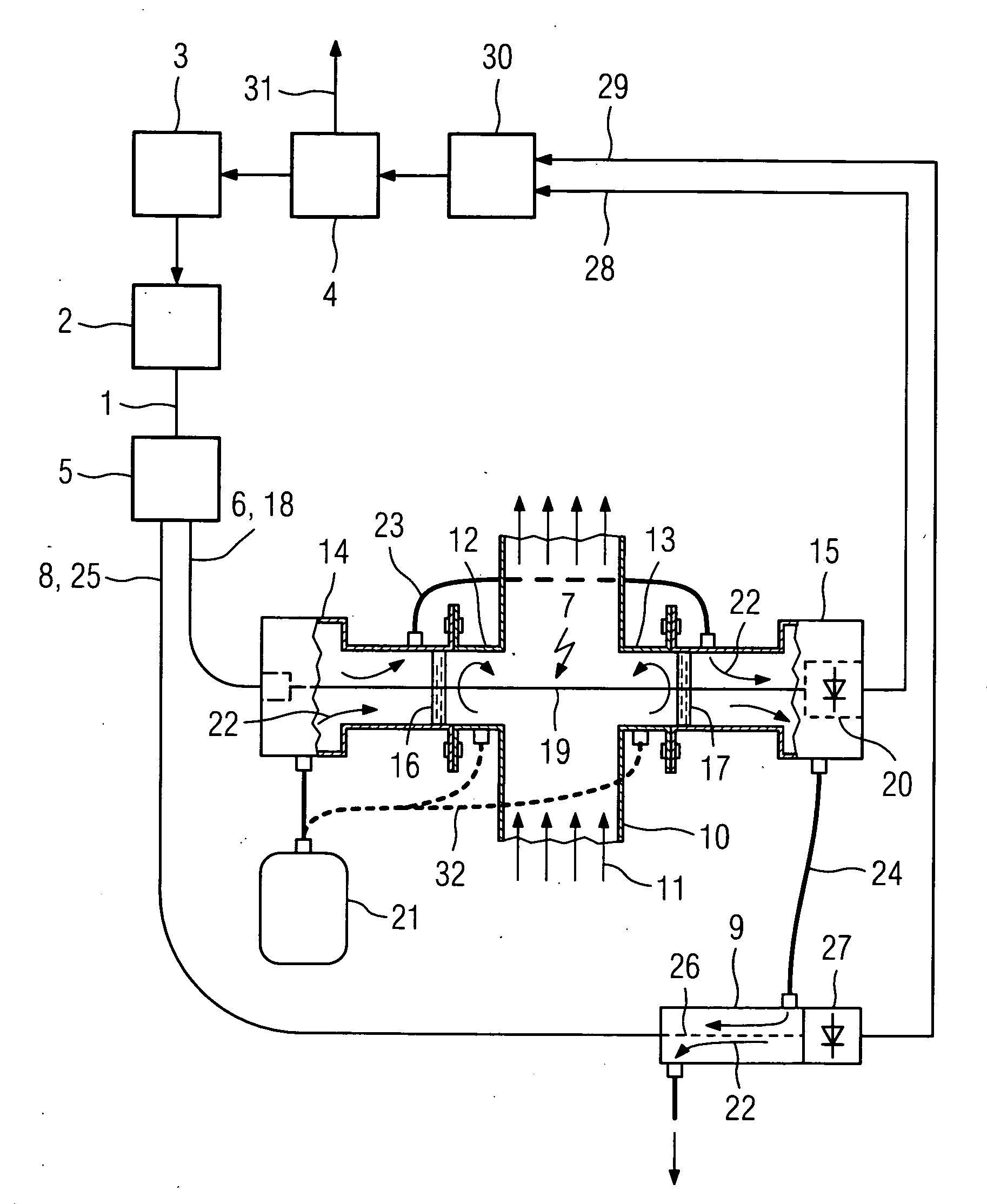

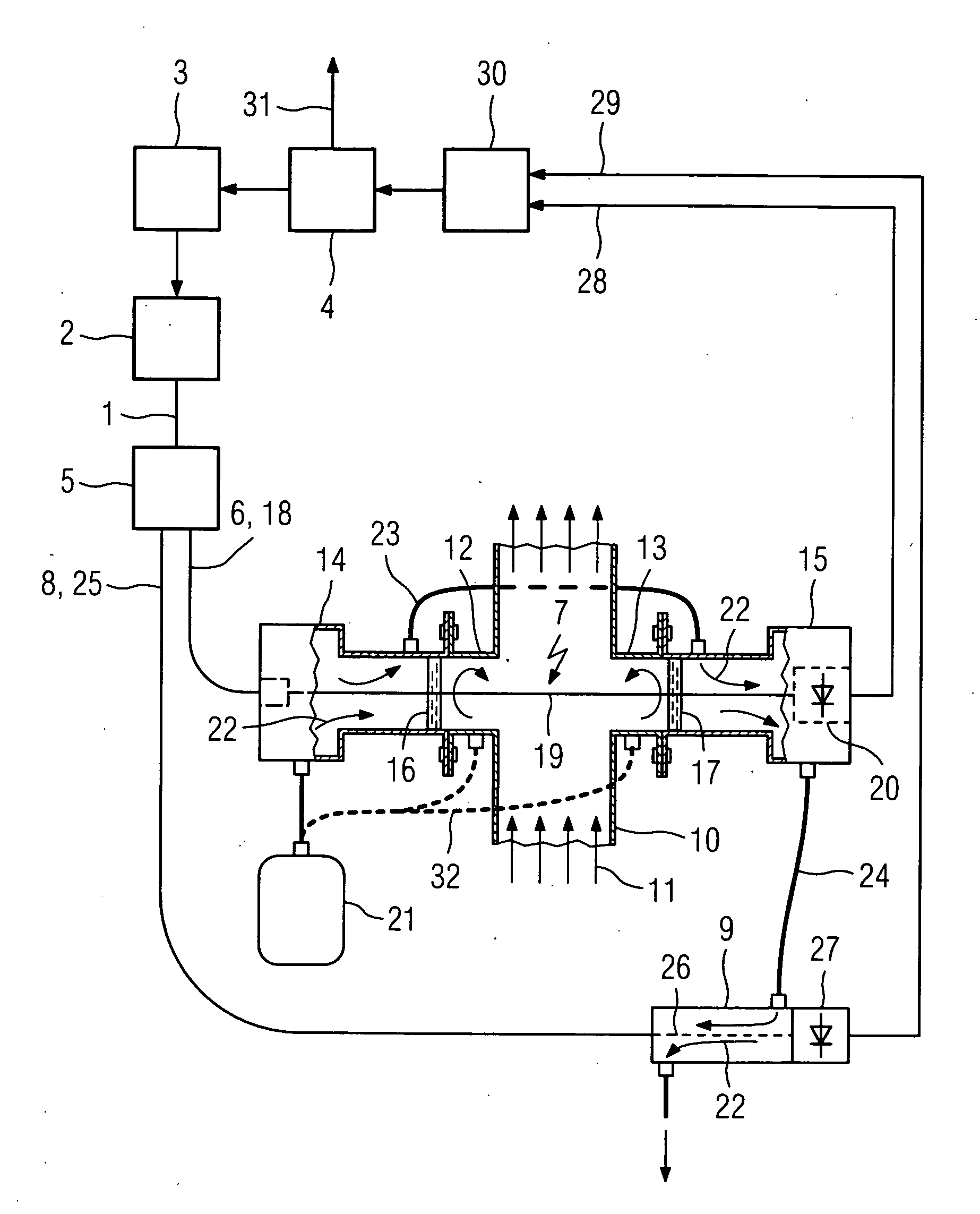

Substrate cleaning/drying equipment and substrate cleaning/drying method

InactiveUS6152153AHollow article cleaningSemiconductor/solid-state device manufacturingEngineeringUltrapure water

There is provided a substrate cleaning / drying equipment for removing residual moisture from a substrate by exposing the substrate to an IPA steam after the substrate has been cleaned by a ultra pure water. The substrate cleaning / drying equipment comprises a cleaning / drying chamber for cleaning / drying the substrate, a cleaning tub which is provided below the cleaning / drying chamber and to which at least a ultra pure water is supplied, an IPA steam supplying pipe for supplying the IPA steam to an upper area of the cleaning / drying chamber such that the upper area of the cleaning / drying chamber is filled with the IPA steam, a steam supplying pipe for supplying a steam between the ultra pure water in the cleaning tub and the IPA steam, and a carrying unit for carrying the substrate, which has been cleaned by the ultra pure water, from the ultra pure water into the IPA steam via the steam. The ultra pure water, the steam, the IPA steam may be supplied onto the substrate by using injection nozzles respectively in order of the ultra pure water, the steam, the IPA steam.

Owner:KK TOSHIBA

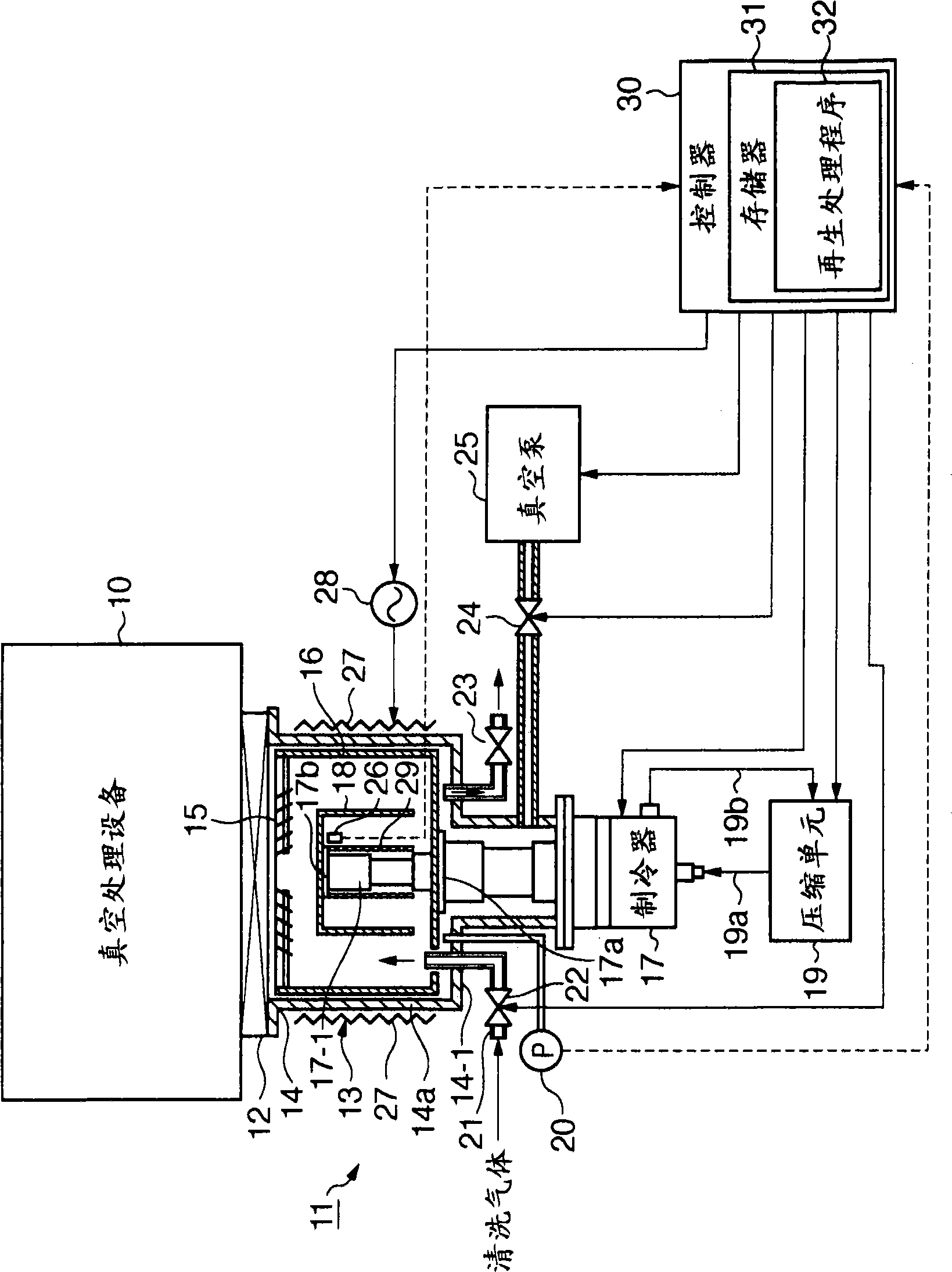

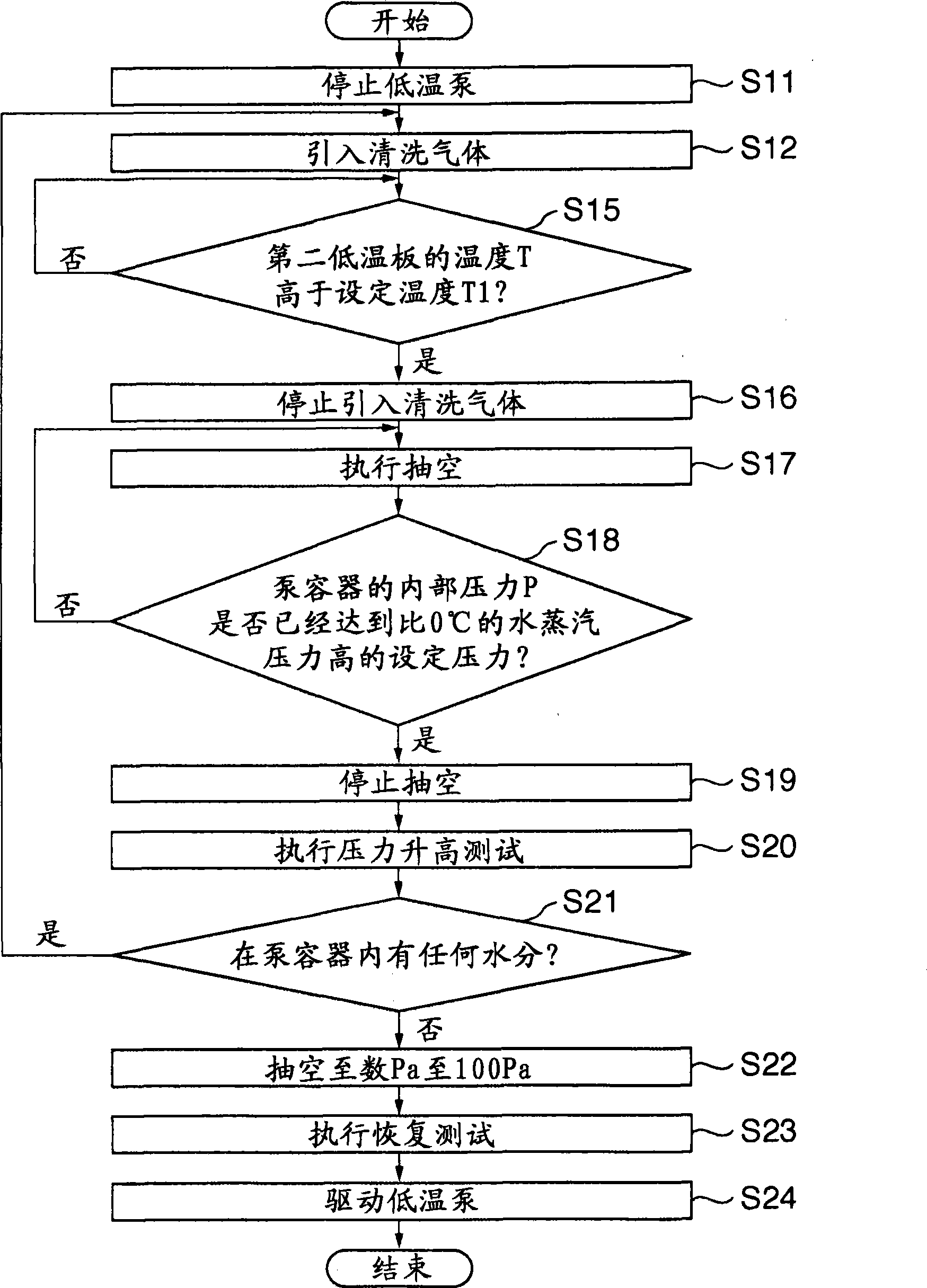

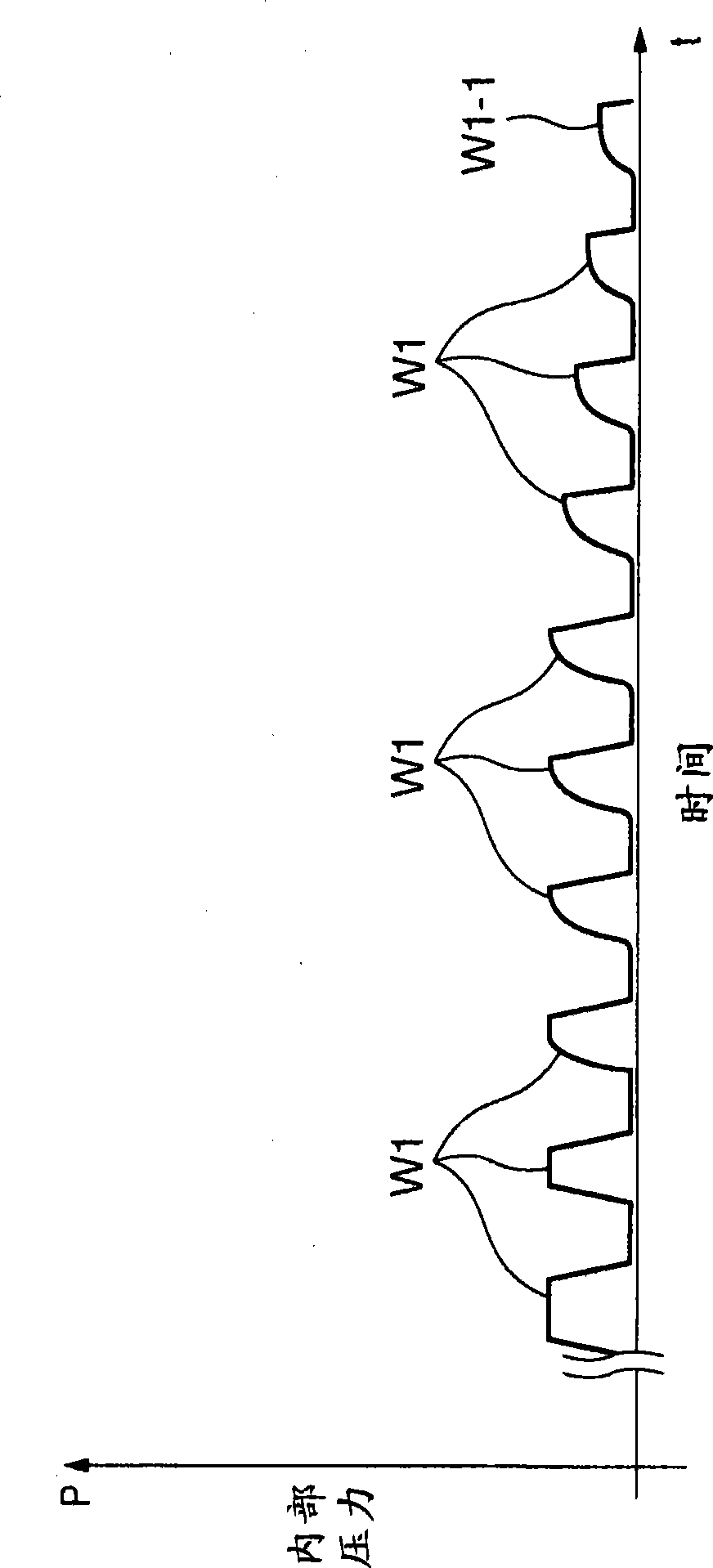

Cryopump, cryopump unit, vacuum processing apparatus including cryopump unit, and cryopump regeneration method

InactiveCN101469689AAccurate observationShort regeneration timePumpsPositive-displacement liquid enginesInternal pressurePressure rise

Owner:CANON ANELVA CORP

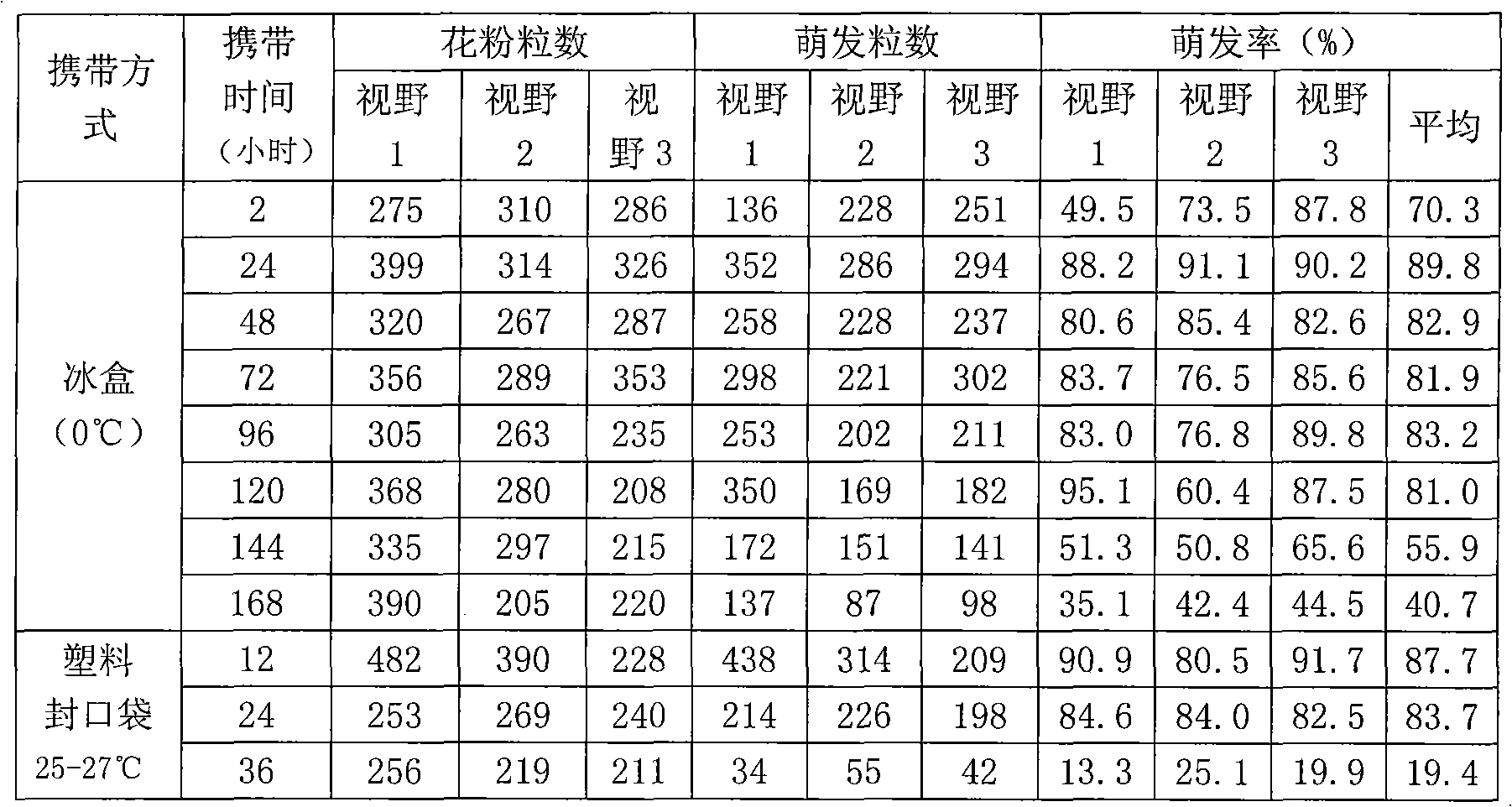

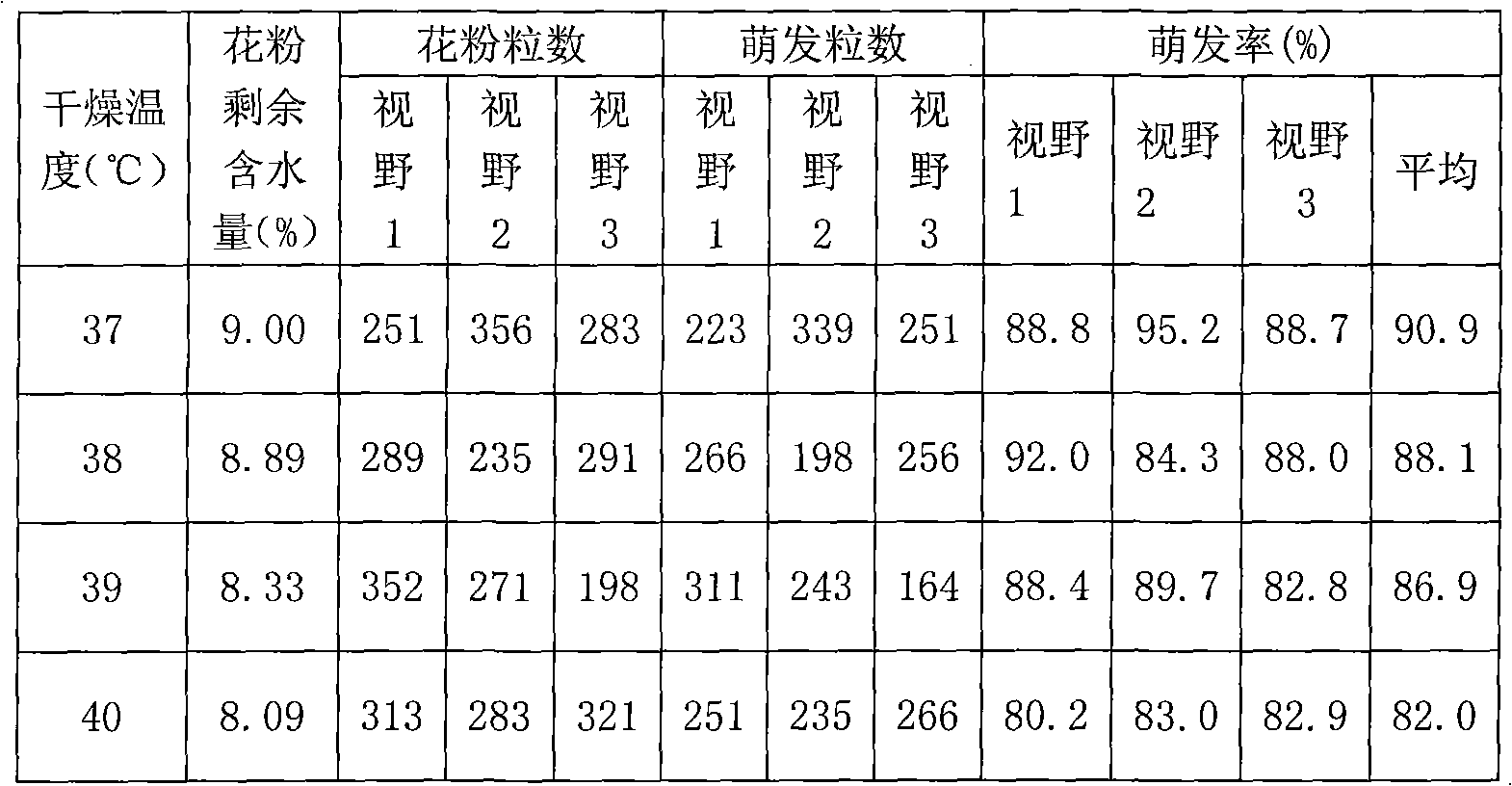

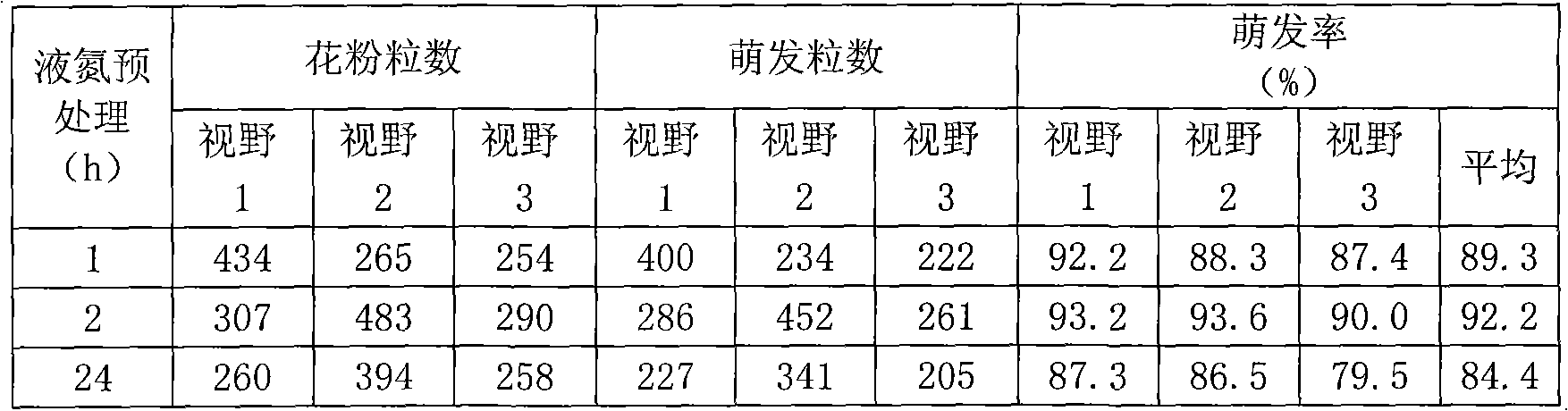

Ultra-low temperature preservation method for oil palm pollen

InactiveCN101926323AImprove germination rateAchieve long-term preservationDead plant preservationUltra Low Temperature FreezerPollen

The invention relates to an ultra-low temperature preservation method for oil palm pollen, which comprises the following steps of: drying the collected fresh oil palm pollen after impurity removal to control the residual moisture content of the oil palm pollen to between 8 and 9 percent; filling the dried oil palm pollen into a freezing pipe, directly putting the freezing pipe into liquid nitrogen to perform pre-freezing treatment, then transferring the freezing pipe to an ultra-low temperature refrigerator for preservation, and flushing the ultra-low temperature preserved oil palm pollen by using normal-temperature tap water during de-freezing. The method has simple process and low cost, effectively realizes long-term preservation of the oil palm pollen by preserving the oil palm pollen at the ultra-low temperature on the premise of controlling the residual moisture content of the pollen, and has the advantages of low preservation cost, long storage time, high pollen germination rateand the like.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

Methods for making pharmaceutical formulations comprising deagglomerated microparticles

InactiveUS20060093677A1High crystallinityReduce contentPowder deliveryGranulation by liquid drop formationMicroparticleVolume average

Methods are provided for making a dry powder blend pharmaceutical formulation comprising (i) forming microparticles which comprise a pharmaceutical agent; (ii) providing at least one excipient in the form of particles having a volume average diameter that is greater than the volume average diameter of the microparticles; (iii) blending the microparticles with the excipient to form a powder blend; and (iv) jet milling the powder blend to deagglomerate at least a portion of any of the microparticles which have agglomerated, while substantially maintaining the size and morphology of the individual microparticles. Jet milling advantageously can eliminate the need for more complicated wet deagglomeration processes, can lower residual moisture and solvent levels in the microparticles (which leads to better stability and handling properties for dry powder formulations), and can improve wettability, suspendability, and content uniformity of dry powder blend formulations.

Owner:CHICKERING DONALD E III +6

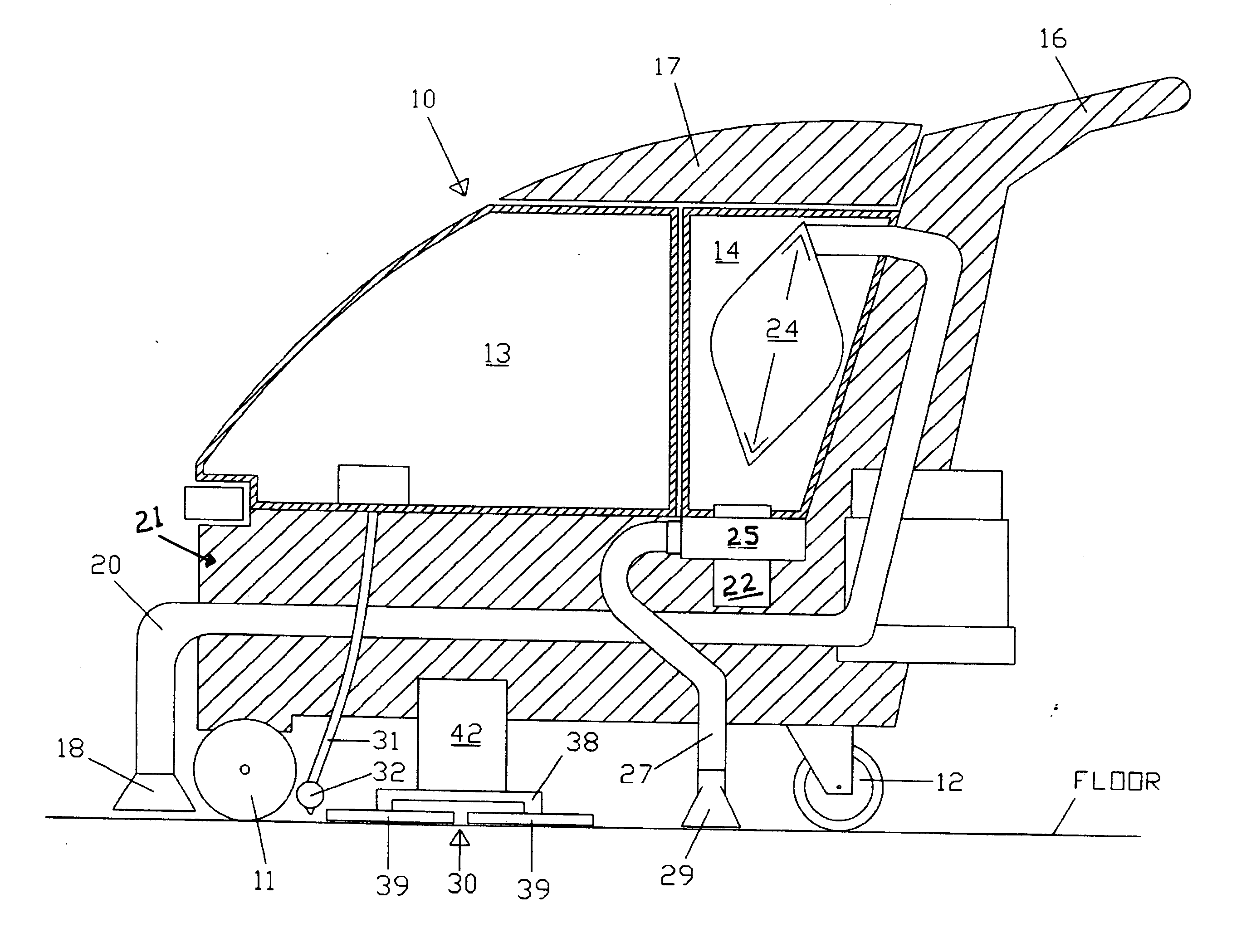

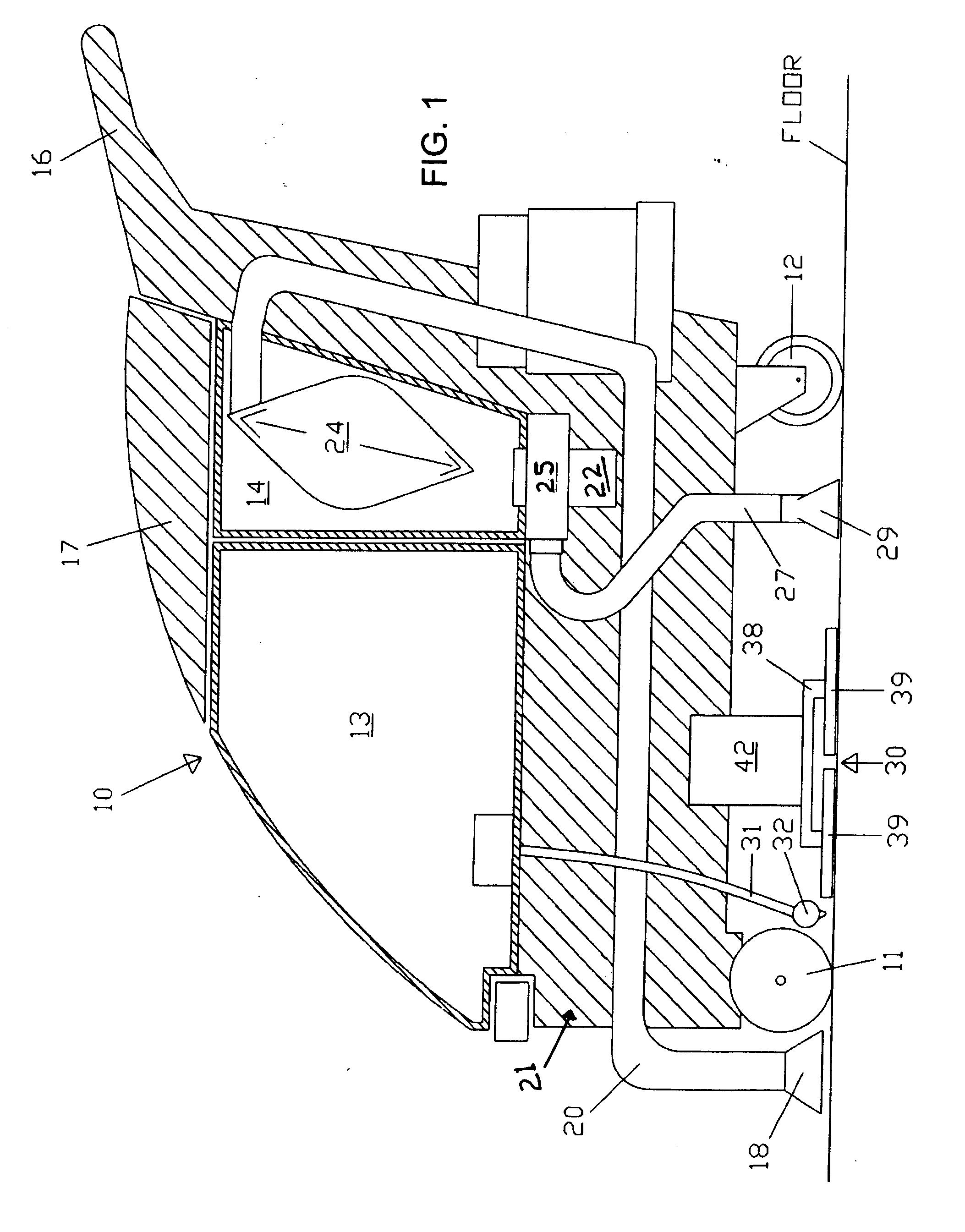

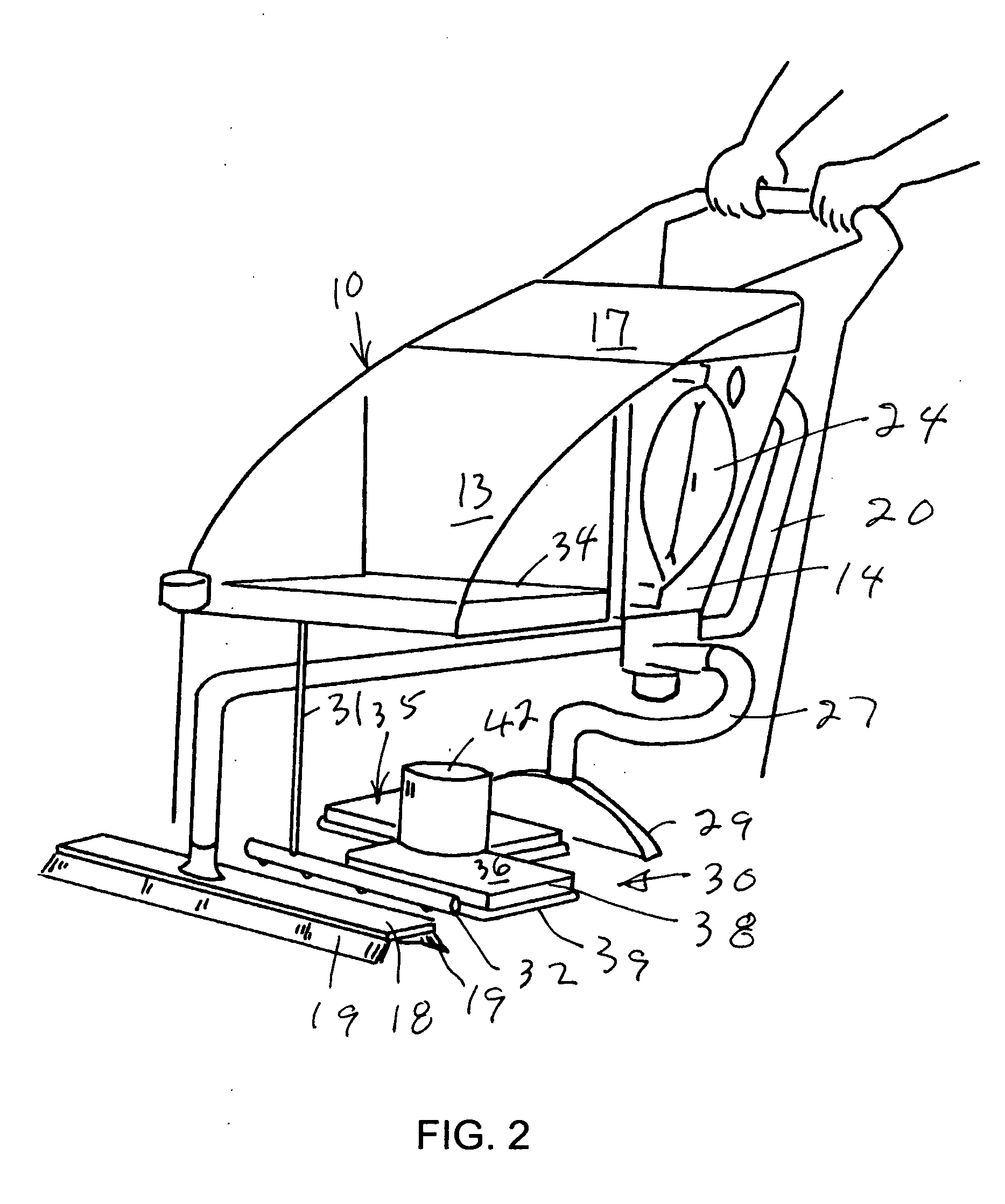

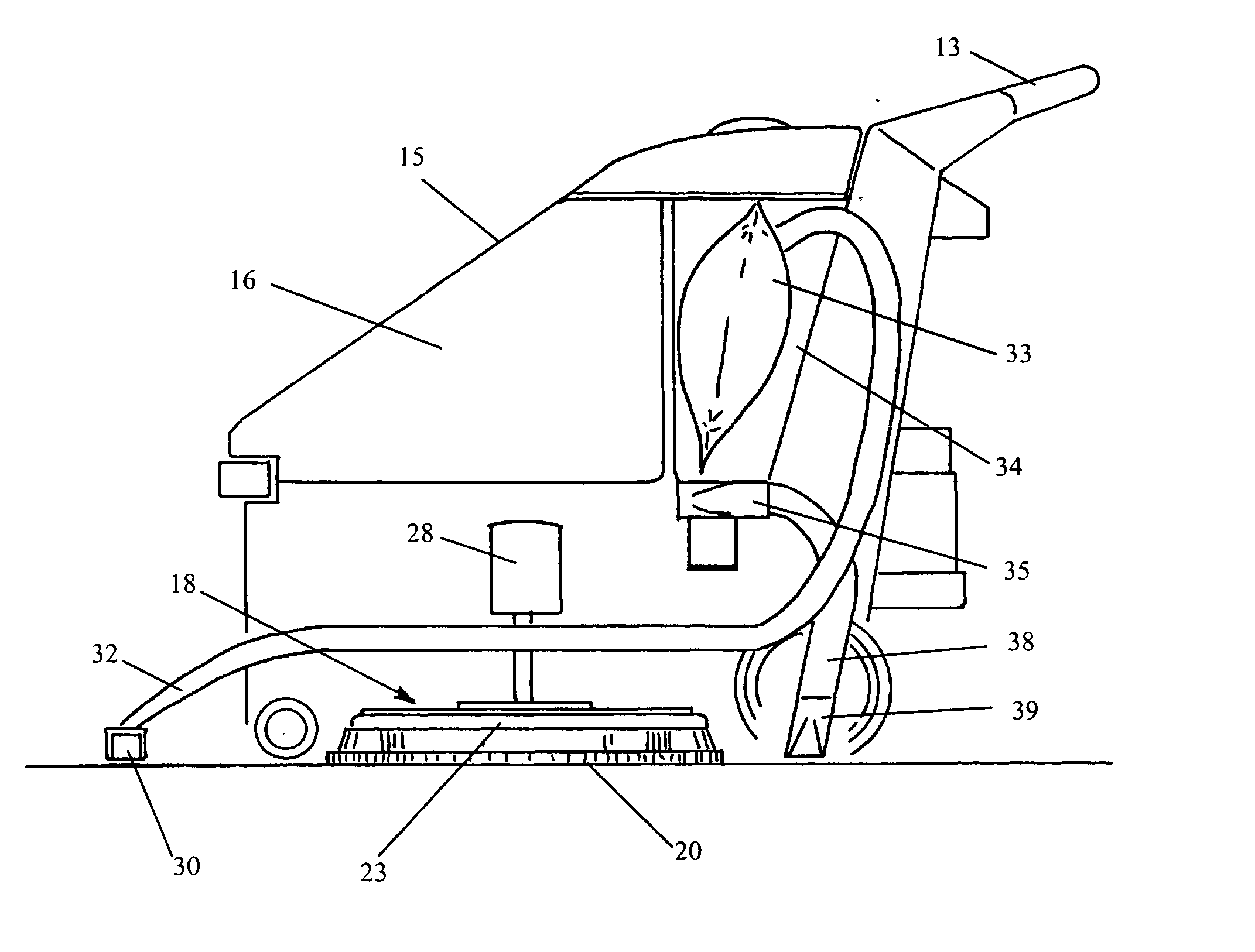

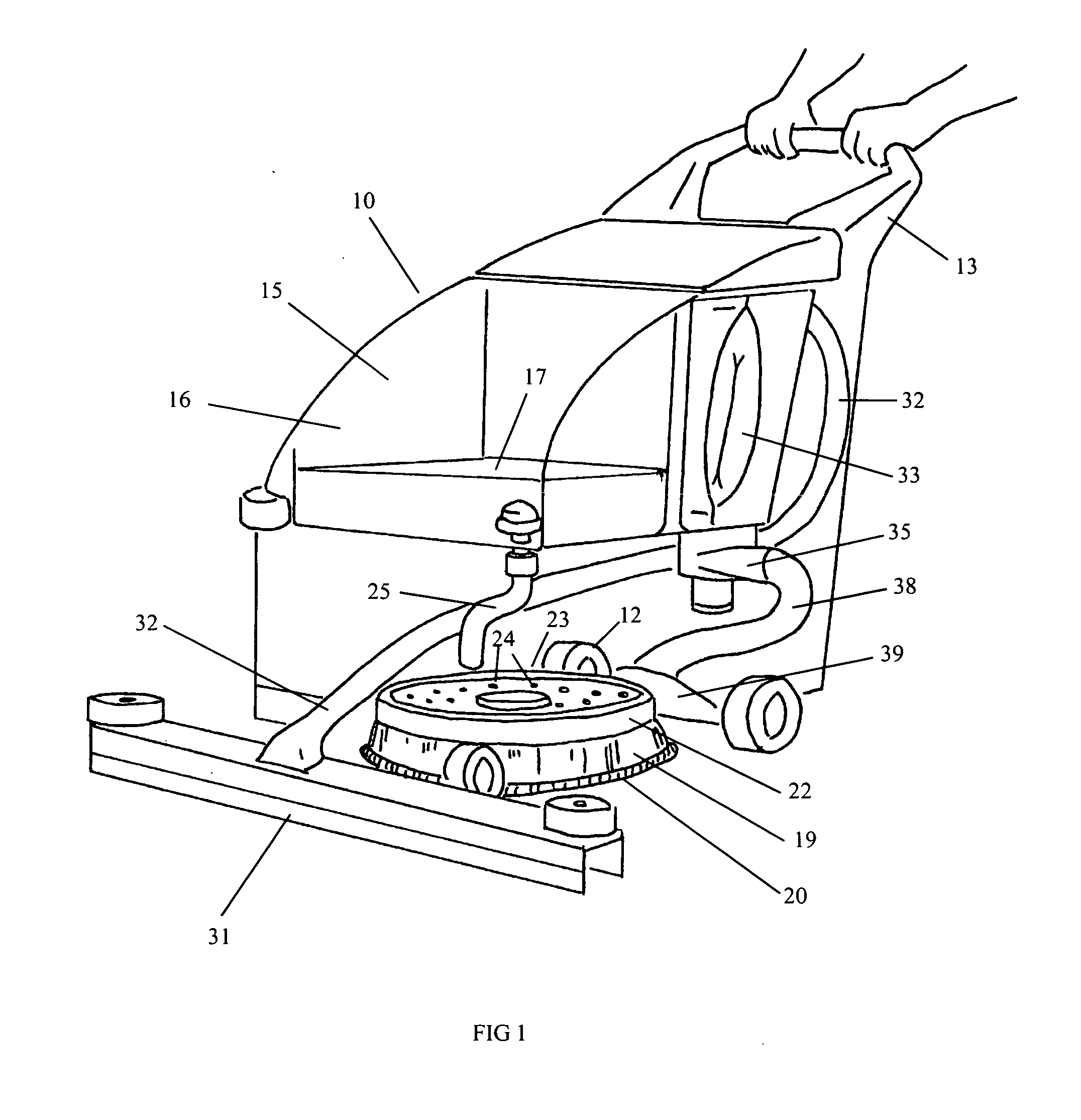

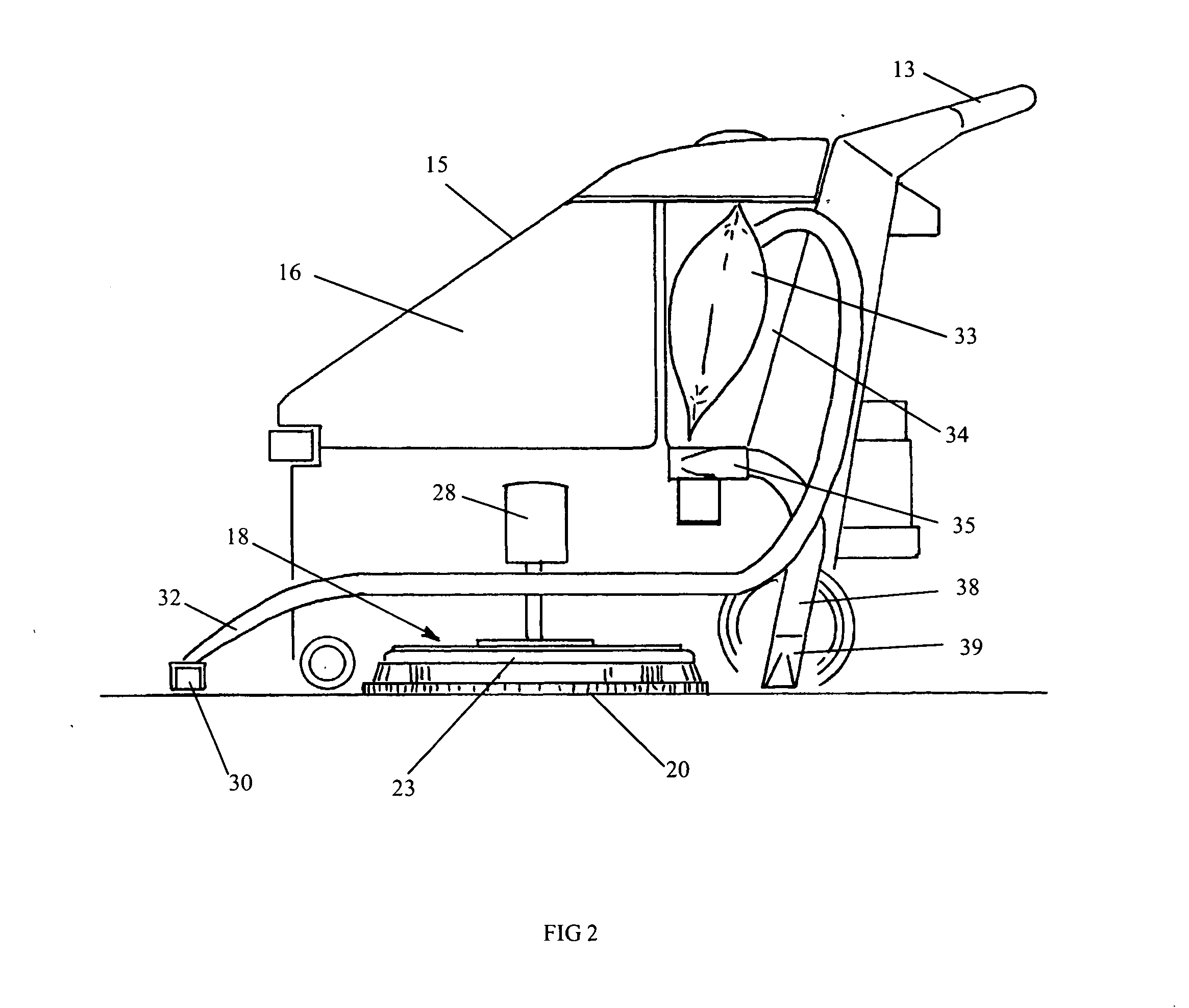

Floor cleaning machine using microfiber pad

InactiveUS20060048331A1Small sizeBroaden the field of applicationCleaning filter meansSuction filtersMotor driveEngineering

A cleaning machine for floors and carpets includes a vacuum pick-up in front of the machine for suctioning loose material and debris off the floor. A microfiber cleaning assembly is mounted beneath the machine for cleaning the floor following the vacuum pick-up. The microfiber cleaning element may be motor driven. A source of solution delivers a controlled amount of solution or water to moisten the microfiber cloth. A vacuum motor provides suction to the forward vacuum pick-up, routes the suctioned air through a filter, and the filtered air is then delivered to an air diffuser to dry any residual moisture behind the microfiber cleaning assembly. The microfiber cleaning assembly may have two offset pads driven by a reciprocating or oscillating drive, or one or two cylindrical rollers for receiving and securing the microfiber fabric in the form of a sleeve.

Owner:MINUTEMAN INT

Method and apparatus for trace gas detection

ActiveUS20060192967A1Improve accuracyEffective compensationInvestigating moving fluids/granular solidsTransmissivity measurementsPorosityWater vapor

Owner:SIEMENS AG

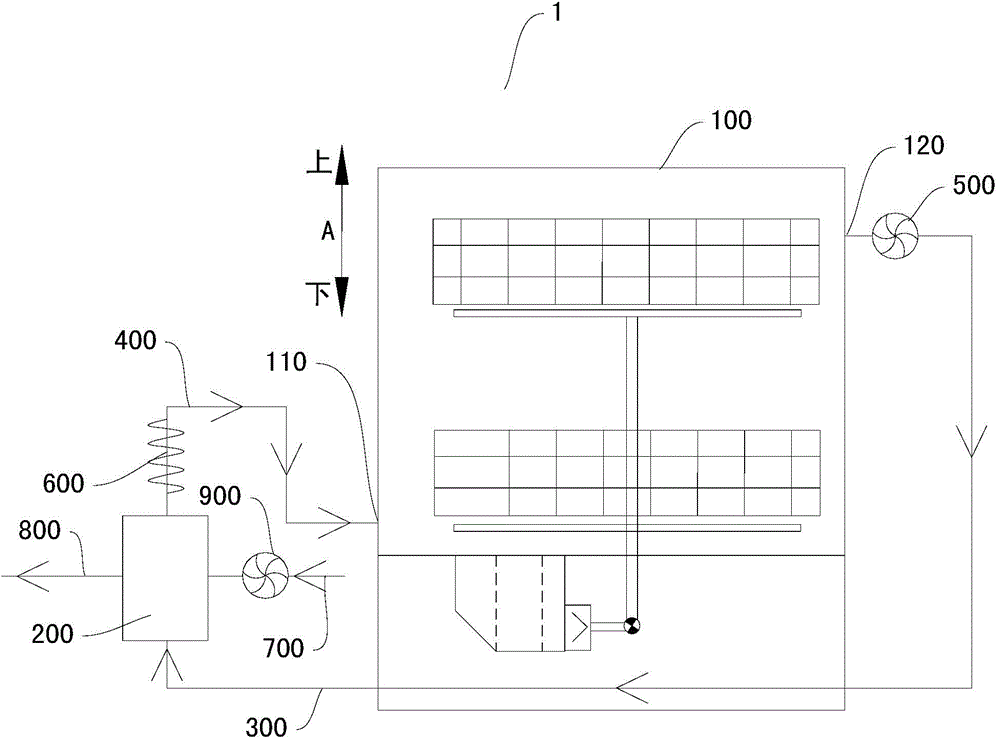

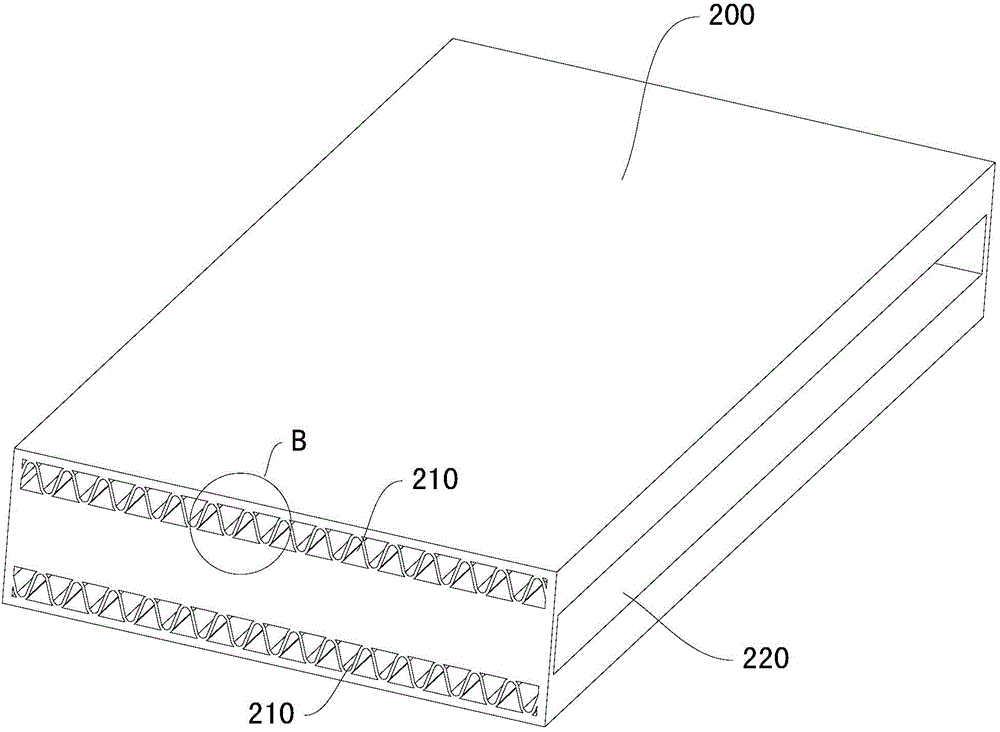

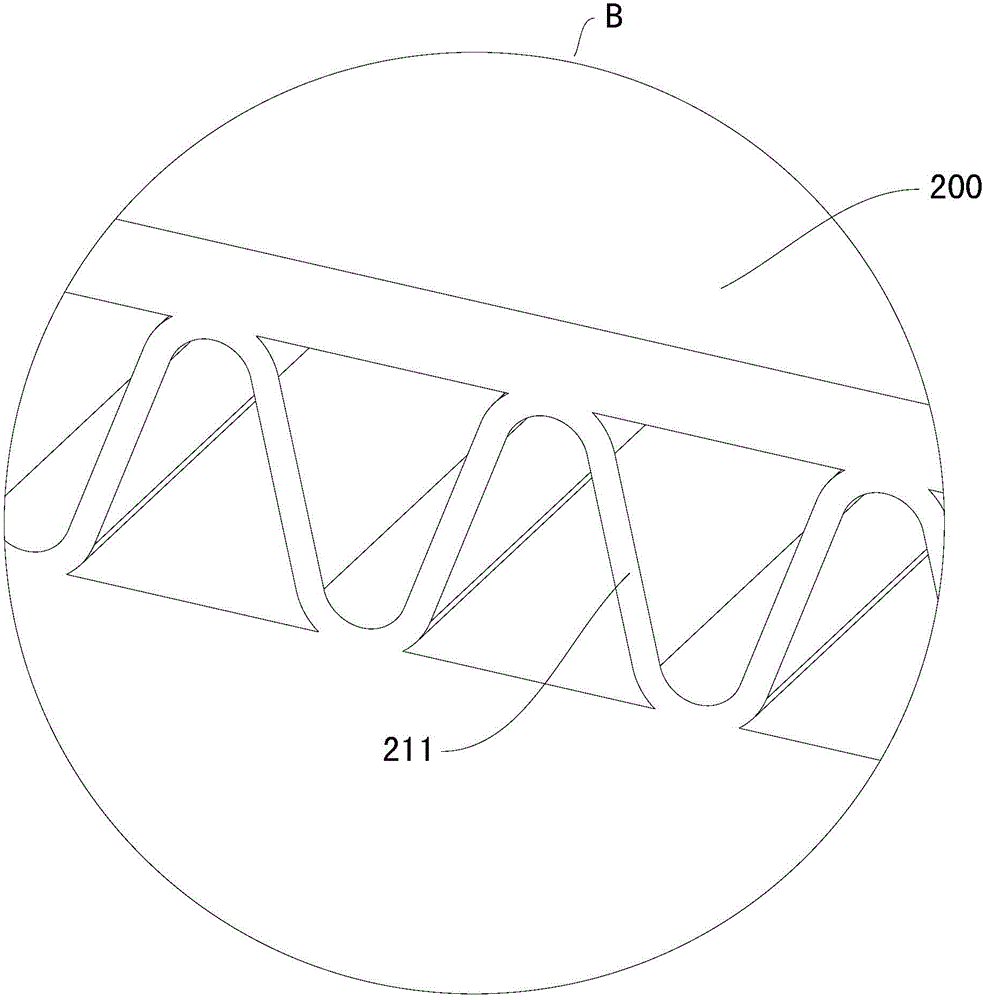

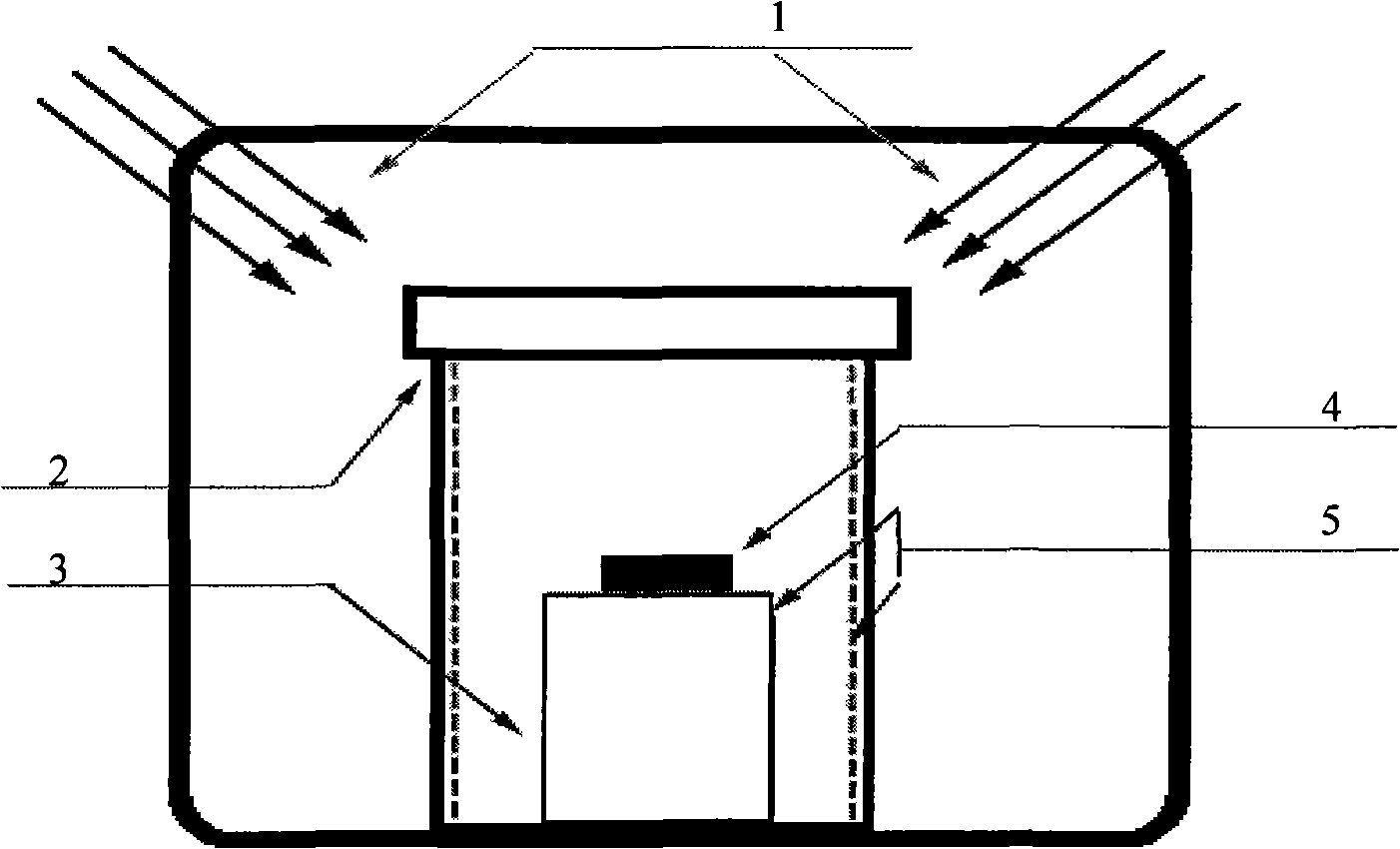

Dish-washing machine and drying system of same

InactiveCN104605804AAvoid residual moistureKeep dryTableware washing/rinsing machine detailsHome appliance efficiency improvementCold airEngineering

The invention discloses a dish-washing machine and a drying system of the same. The dish-washing machine comprises a liner, a heat exchanger, a hot-air guide unit and a heating unit. The liner is provided with an air inlet and an air outlet therein; the heat exchanger is internally provided with a hot air channel and a cold air channel, and one end of the hot air channel is communicated with the air outlet through a damp and hot air duct while the other end is communicated with the air inlet through a dry and hot air duct; the hot-air guide unit is arranged on the damp and hot air duct; the heating unit is arranged on the dry and hot air duct. The dish-washing machine has the advantages that residual moisture on tableware and bowl baskets can be prevented, and the dish-washing machine is good in drying effect, high in drying efficiency and the like.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD

Method of one-step synthesis of hexagonal barium ferrite nanometer crystal by microwave-assistant sol-gel spontaneous combustion

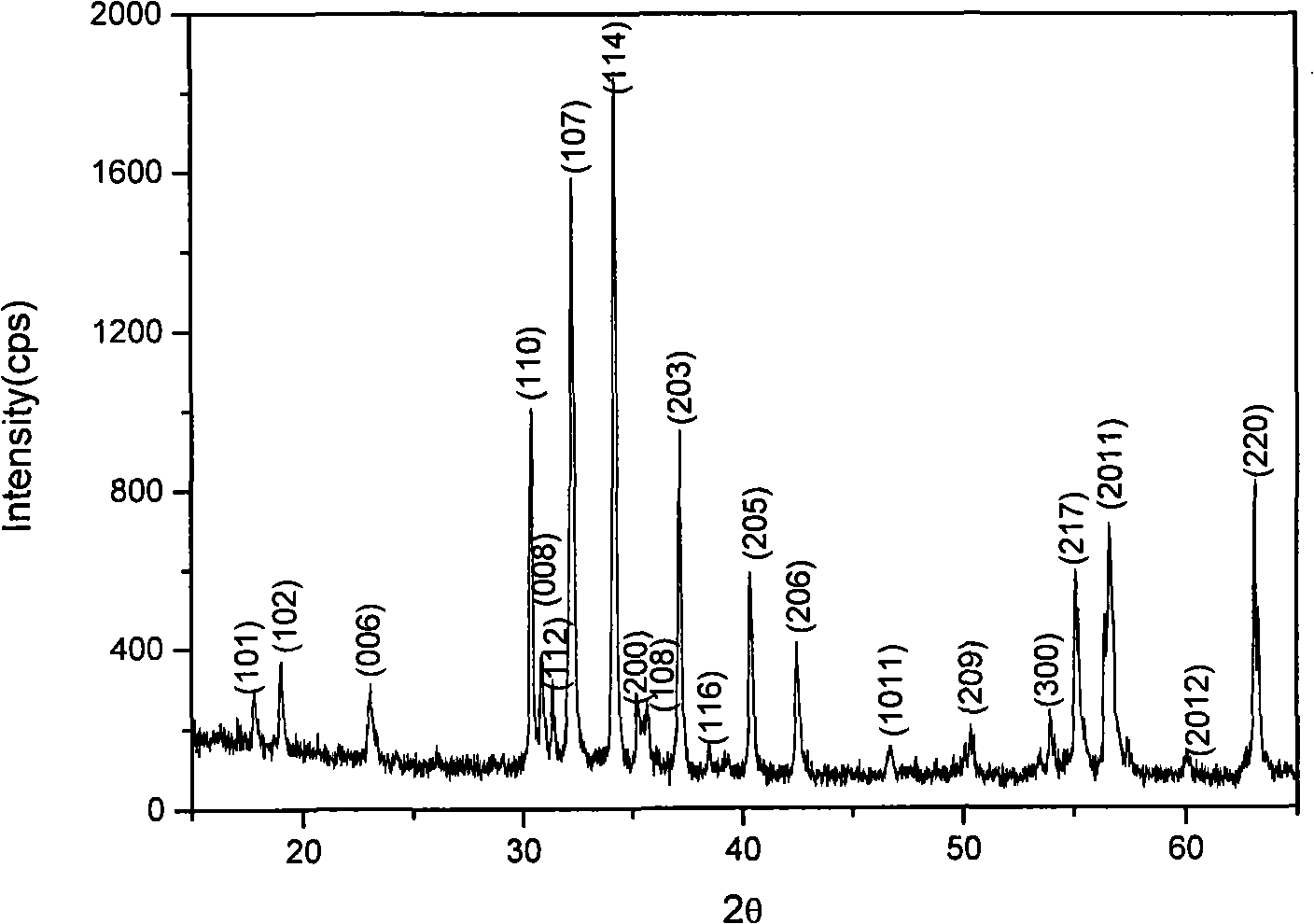

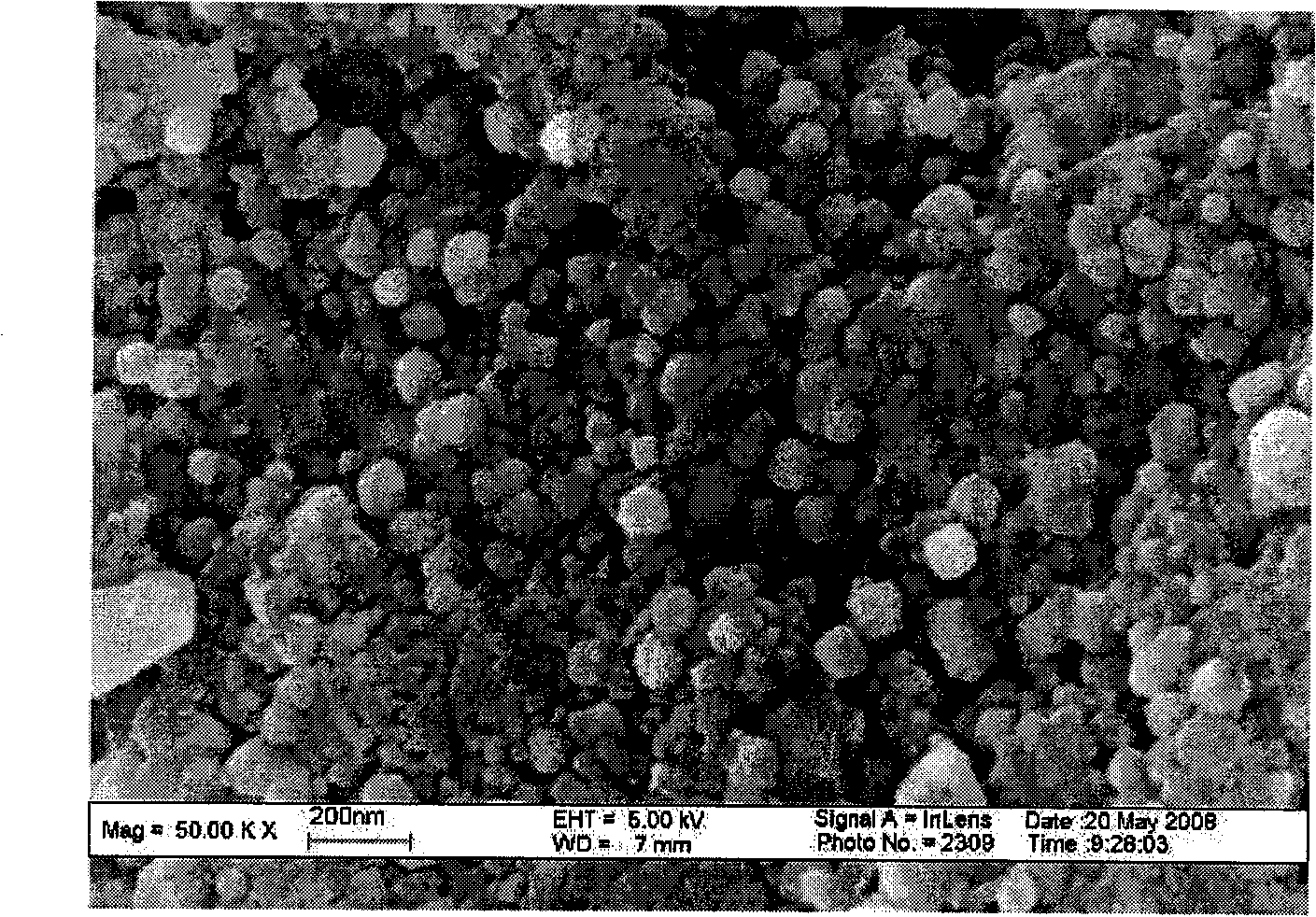

InactiveCN101559982AUniform particle sizeImprove distribution uniformityIron compoundsQuick FreezeSingle crystal

The invention provides a preparation method of one-step synthesis of hexagonal barium ferrite (BaFe12O19) nanometer crystal by microwave-assistant sol-gel spontaneous combustion process. The technical scheme comprises the following steps: 1) nitrate Ba(NO3)2 and Fe(NO3)3 are taken as the raw materials; water solution with certain concentration is prepared according to barium ferrite chemometry; citric acid, ethylene diamine tetraacetic acid, urea, glucose and glycol and other organic reagents or compound thereof are taken as complexing agent of metal ion and hydrocarbon fuel required by sol-gel spontaneous combustion; ammonium nitrate and ammonium hydroxide are in addition added to adjust content of systematic oxidizer and PH value; even sol is formed by complexation. 2) xerogel which with desirable residual moisture content is prepared by using liquid nitrogen quick-freezing sol and vacuum condensation drying process. 3) the xerogel is compressed to form a block which is put into a quartz reaction chamber with microwave absorptive character; the xerogel is induced for spontaneous combustion in a microwave field, single-phase barium ferrite nanometer crystal is synthesized in one step which is precise in components and even in granule size; the invention can be used to prepare quasi-single crystal texture millimeter wave gyromagnetic ferrite.

Owner:NANJING UNIV OF TECH

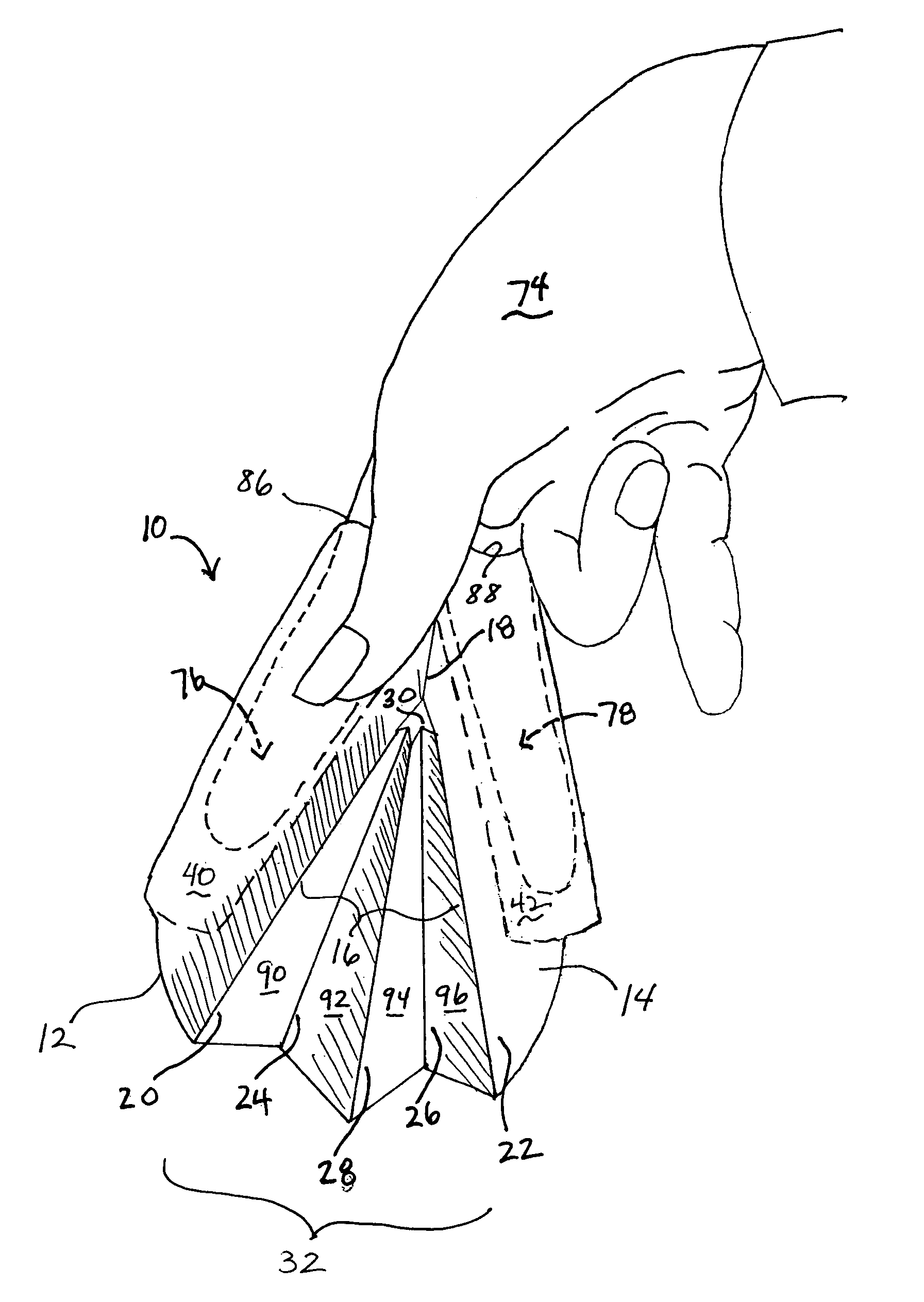

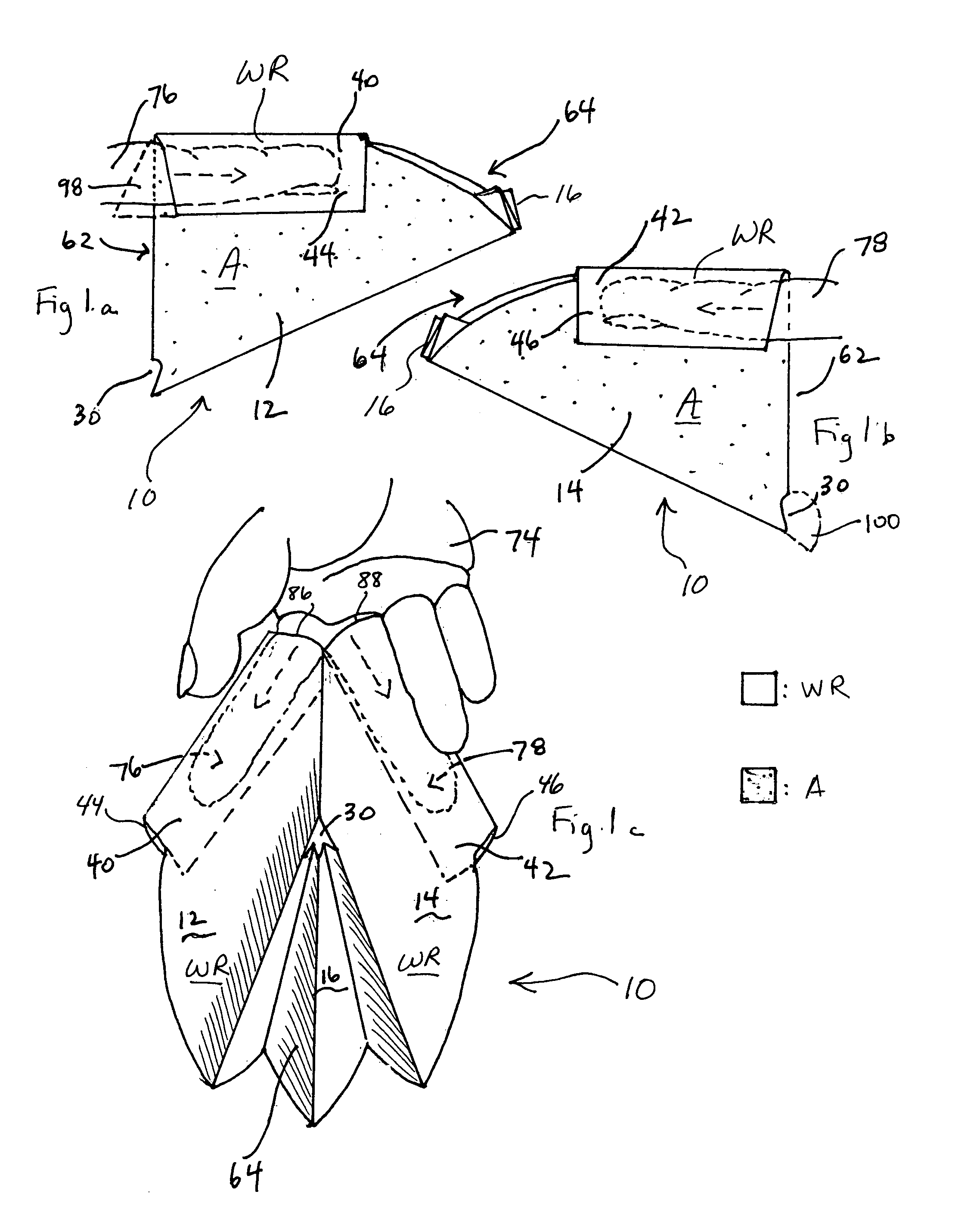

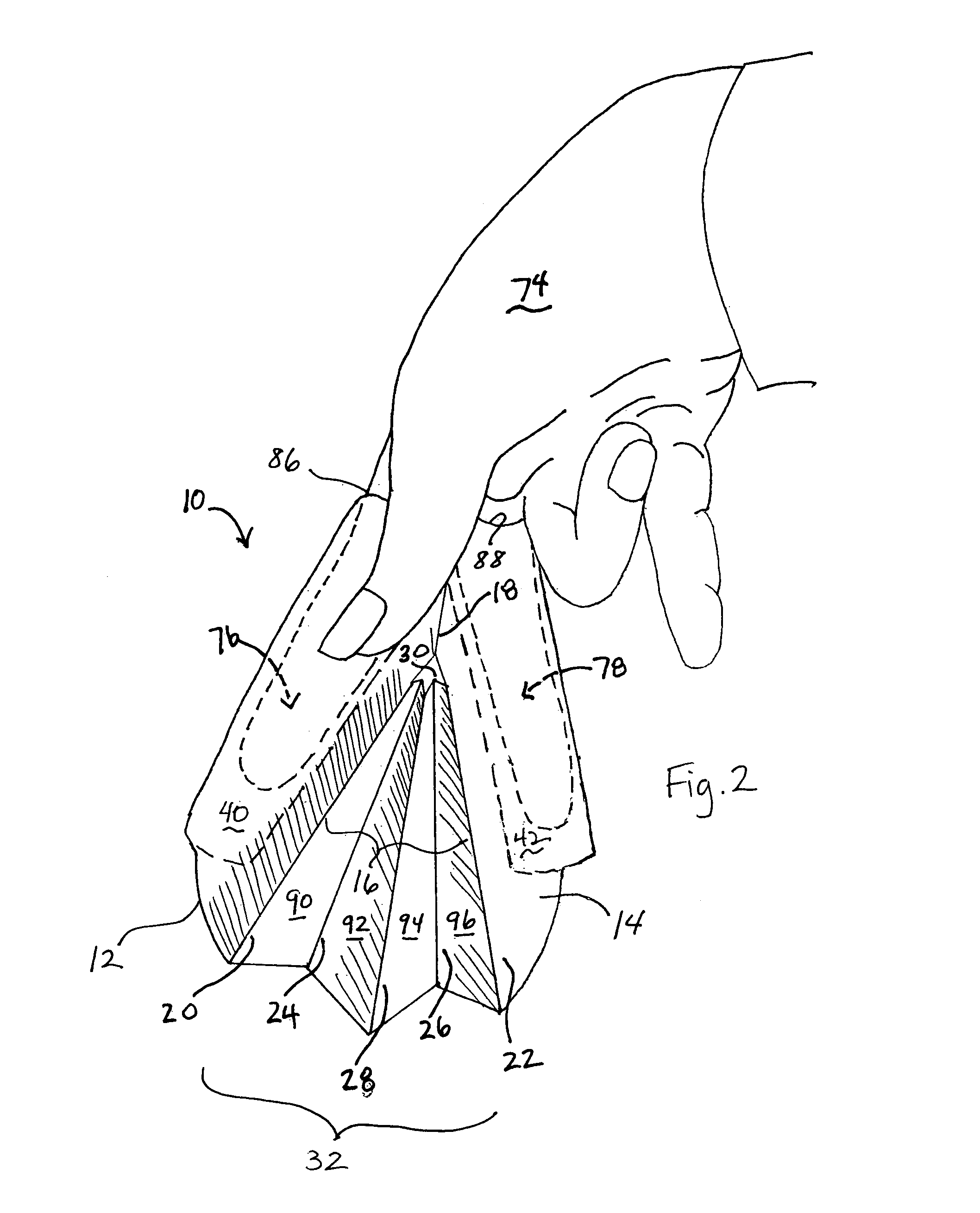

Female urination aid device

ActiveUS7131149B2Easy to carryEasy to storeBathroom accessoriesBodily discharge devicesVulvaEngineering

Owner:LANGFORD MARLYNN J

Floor cleaning machine using micro-fiber pad

A floor cleaning machine includes a vacuum pick-up in front of the machine for suctioning loose material and debris off the floor. A micro fiber pad assembly is mounted beneath the machine for cleaning the floor following the vacuum pick-up. The micro fiber pad may be motor driven. A source of solution delivers a controlled amount of solution or water to moisten the micro fiber pad. A vacuum motor provides suction to the forward vacuum pick-up, routes the suctioned air through filter, and the filtered air is then delivered to an air diffuser at the rear of the machine to dry any residual moisture behind the micro fiber pad.

Owner:MINUTEMAN INT

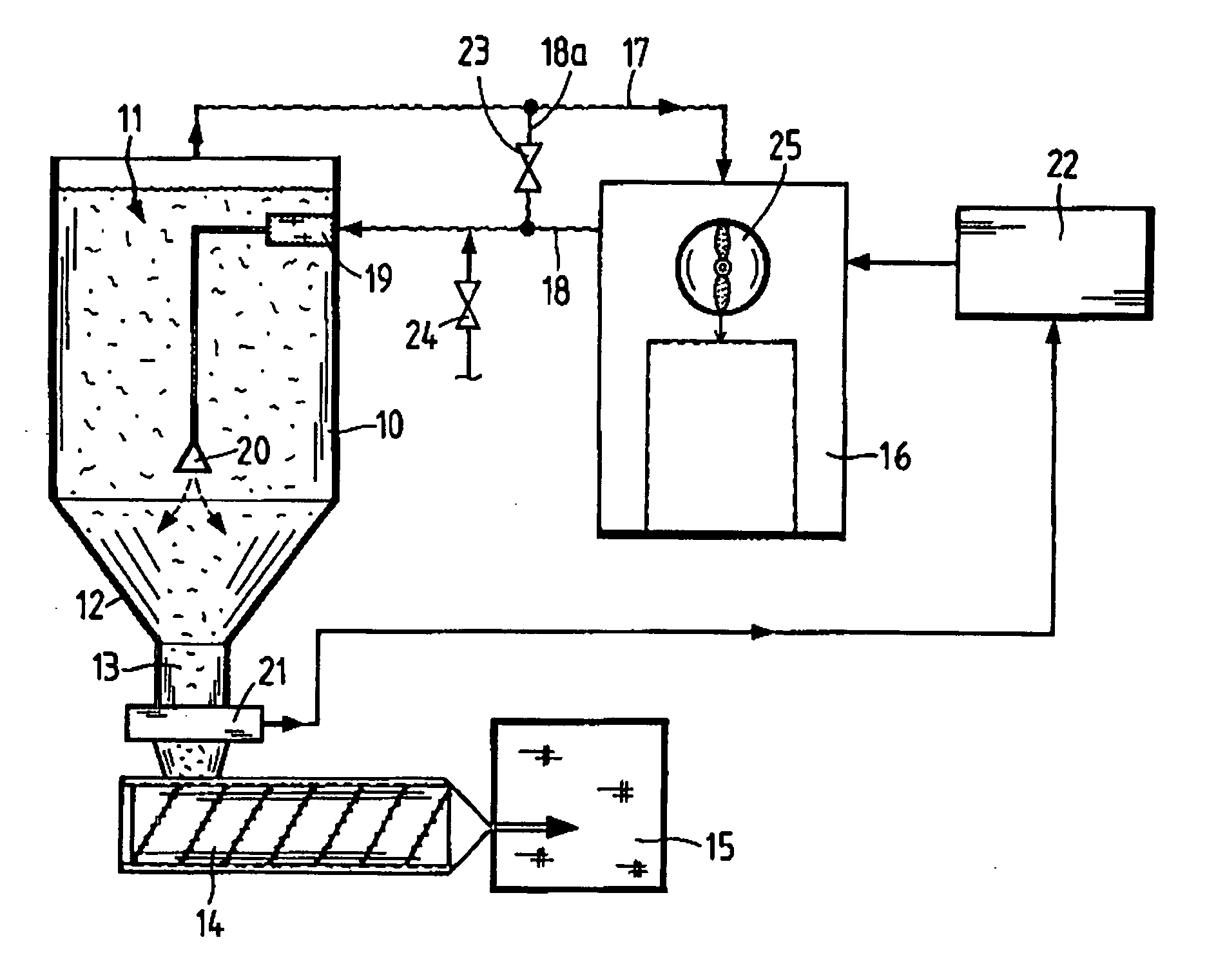

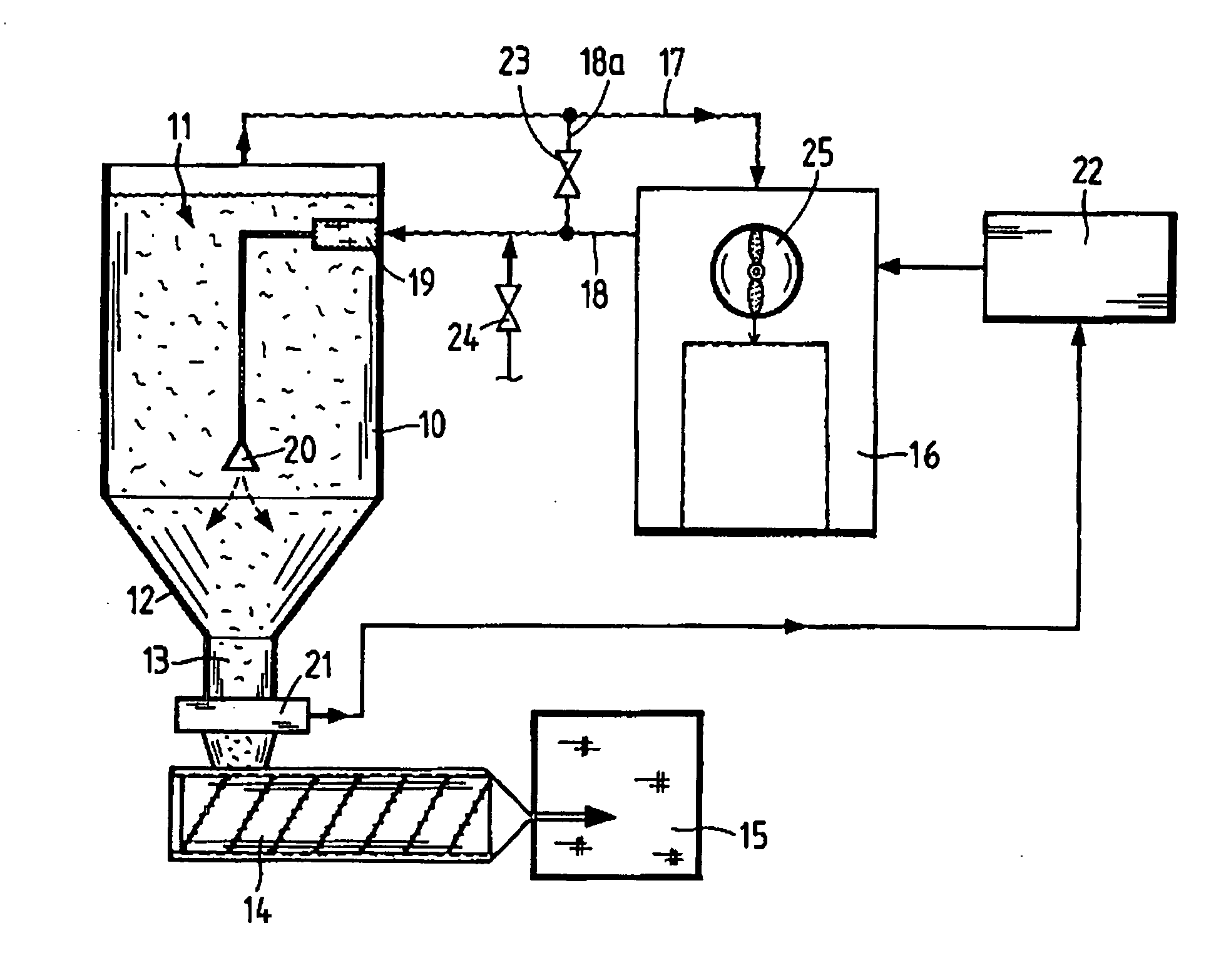

Method for drying synthetic resin pellets

InactiveUS20070277392A1Drying solid materials with heatShaft furnacePolyethylene terephthalateVolumetric Mass Density

A method for drying semi-crystalline synthetic resin pellets, particularly polyethylene terephthalate (PET) pellets, according to which a heating gas is supplied to a drying vessel; synthetic resin pellets are passed countercurrently through the vessel, and the synthetic resin pellets are heated to drying temperature. Depending on pellet parameters measured at the outlet of the vessel, such as temperature, residual moisture content and / or density of the material, the temperature, quantity and / or moisture content of the heating gas supplied to the vessel are regulated.

Owner:MANN & HUMMEL PROTEC GMBH

Control of pre-cured product moisture for formaldehyde-free fiberglass products

ActiveUS7435444B2Reduce contentPretreated surfacesChemical vapor deposition coatingGlass fiberWater use

A system for controlling the residual moisture in pre-cured binder coated glass fibers. The moisture of the binder coated glass fibers is measured after the process water is extracted in a collection box. Based on the level of moisture found in the coated glass fibers, adjustments are made to the process upstream of the moisture measurements. The adjustments include, but are not limited to, adjusting the amount of water used to make the binder composition; adjusting the amount of heat applied to the binder composition as it is applied to the glass fibers and adjusting the vacuum conditions used to extract the process water from the binder coated glass fibers. Control of the residual moisture in the precured binder coated glass fibers helps ensure proper curing of the binder during the subsequent curing step.

Owner:JOHNS MANVILLE CORP

CO2 generating absorbent pads

ActiveUS7189666B2Improve the environmentReady-for-oven doughsMilk preservationEngineeringAbsorbent Pads

A method and means for enhancing the inner environment of a package containing perishable merchandise include taking a closable package containing perishable merchandise and placing in the package a multi-layered sheet including a plurality of layers comprised of moisture absorbing materials to absorb any residual moisture emanating from the perishable merchandise. The multi-layered sheet includes a quantity of CO2 generating material incorporated therein. The CO2 generating material is exposable to humidity and any residual moisture within the package and any moisture absorbing material to allow the CO2 generating material to emit an atmosphere of CO2 within the package from exposure to moisture within the air in the package, and to absorb any residual moisture in the package.

Owner:LONGER SHELF LIFE LLC

Preservation method of Cordyceps sinensis

ActiveCN105199956APreserve active nutrientsMeet the three invariant standardsMicroorganism based processesMicroorganism preservationMaterials preparationAdditive ingredient

The invention provides a preservation method of Cordyceps sinensis. The preservation method needs to be carried out in an operating space of 0-16 DEG C and comprises the following operating steps: (1) material preparation; (2)shape-preserving; (3) cleaning and sterilization; (4) residual moisture treatment; (5) preservation of nutritional moisture; (6) air-drying and dehumidification; (7) sealing and freeze preservation; and (8) storing. Active nutritional ingredients of Cordyceps sinensis are fully preserved; the purpose of directly eating the product is achieved by the step of cleaning and sterilization; and by freezing storage, fresh Cordyceps sinensis can be eaten all year round. Thus, the three unchanged standards of unchanged nutrition, unchanged shape and unchanged mouthfeel of Cordyceps sinensis are achieved.

Owner:青海宗草堂生态科技有限公司

Linear easy-to-tear polyamide film and preparation method thereof

ActiveCN105778488AExcellent linear tear performanceGood linear tear performanceFlat articlesWarm waterPolyamide

The invention discloses a linear easy-to-tear polyamide film which comprises the following components in parts by mass: 39-81 parts of PA6, 8-30 parts of MXD6, 5-10 parts of softening agent, 3-20 parts of PA6 / MXD6 regrind and 1-3 parts of MXD6-g-MAH. The invention also discloses a preparation method of the linear easy-to-tear polyamide film, and the preparation method comprises the following steps: (I) weighing the components of the mass parts and mixing uniformly, melting in an extruder, and casting the melt to a sharp cooling roll quench-cooling cast piece with surface temperature of 20-30 DEG C; (II) conveying the cast piece into a warm-water tank adjusted to 40-65 DEG C and performing humidity adjustment treatment for 1-2min; and blow-drying residual moisture on the surface of the humidity-adjusted cast piece by an air knife; (III) conveying the cast piece with a blow-dried surface into a stretching furnace, and performing synchronous biaxial stretching at a temperature of 170-195 DEG C; and (IV) performing heat setting treatment at a temperature of 200-215 DEG C to continuously prepare linear easy-to-tear polyamide films with thickness of 10-30mu m. The polyamide film prepared in the invention has an excellent linear tearing property.

Owner:厦门长塑实业有限公司

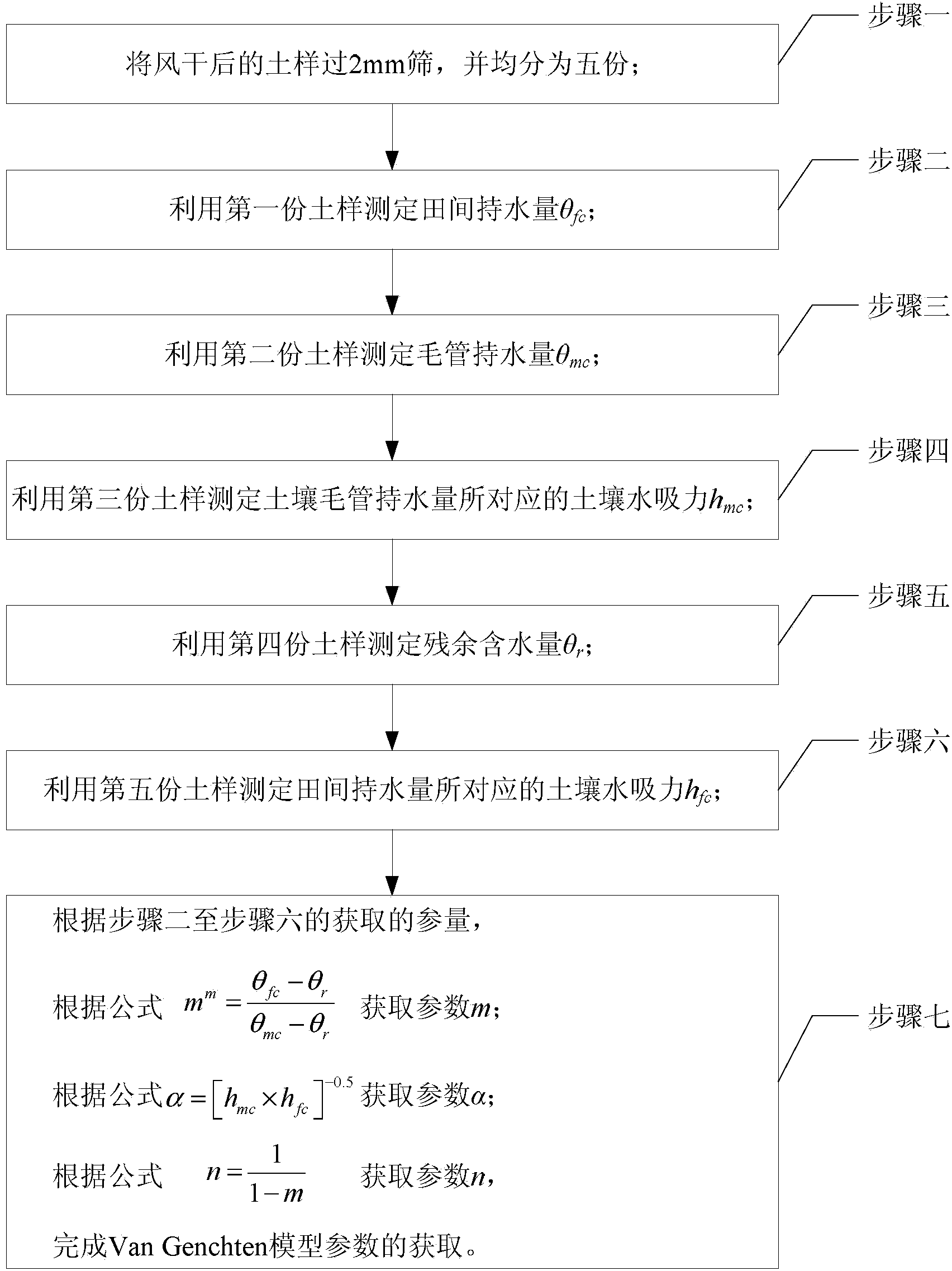

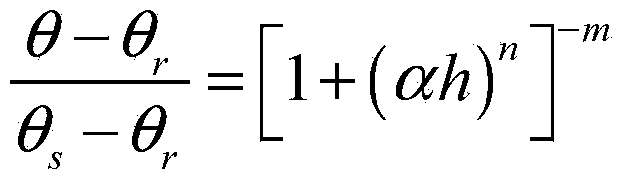

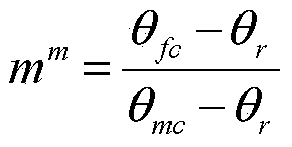

Method for obtaining Van Genchten model parameters of soil moisture characteristic curve

InactiveCN104182647AShorten experiment timeEarth material testingSpecial data processing applicationsSoil scienceMeasuring instrument

The invention relates to model parameter solution methods, particularly to a method for obtaining Van Genchten model parameters of a soil moisture characteristic curve. The method aims at solving the problems that measuring instruments are expensive and the measurement period is long when a soil moisture characteristic curve Van Genchten equation is obtained by an actual measurement method. The method comprises the following steps of sieving a dried soil sample through a 2mm sieve and dividing the dried soil sample into five equal parts; measuring the field moisture capacity theta fc, the capillary moisture capacity theta mc, the soil moisture suction hmc which is corresponding to the soil capillary moisture capacity, the residual moisture content theta r and the soil moisture suction hfc which is corresponding to the field moisture capacity through the five equal parts respectively; obtaining the parameter m according to the formula; obtaining the parameter alpha according to the formula; obtaining the parameter n according to the formula to achieve the obtaining of the Van Genchten model parameters.

Owner:TARIM UNIV

Hot melt type phenolic resin modified by using enzymatic hydrolysis lignin or derivatives thereof, and preparation thereof

The invention provides enzymatic lignin or a derivative for the enzymatic lignin, namely modified hot-melt phenol-formaldehyde resin and a preparation method thereof, wherein the enzymatic lignin or the derivative for the enzymatic lignin, phenols, aldehydes and catalysts are taken as raw materials. The preparation method comprises the following steps: the enzymatic lignin or the derivative for the enzymatic lignin is mixed with the phenols according to the proportion; the mixture is heated and dissolved, added with the aldehydes and the catalysts, and subjected to heating and refluxing for a period of time; and residual water in the system is distilled, and the enzymatic lignin or the derivative for the enzymatic lignin, namely the modified hot-melt phenol-formaldehyde resin is obtained. The preparation method fully utilizes reproducible biological resources, overcomes the defects caused by extracting lignosulphonate from paper-making 'black liquor' in the prior art, can replace partial raw materials of the petrochemical industry, reduce the cost of preparing the phenol-formaldehyde resin by adopting phenyl hydroxide, select proper types of enzymatic lignin additives according to the modification requirements of different types of hot-melt phenol-formaldehyde resin, and improve the performance of the enzymatic lignin or the derivative for the enzymatic lignin, namely the modified hot-melt phenol-formaldehyde resin, has simple technology, is easy to implement, reduces the production cost, and improves the competitive power of products.

Owner:FUZHOU UNIV

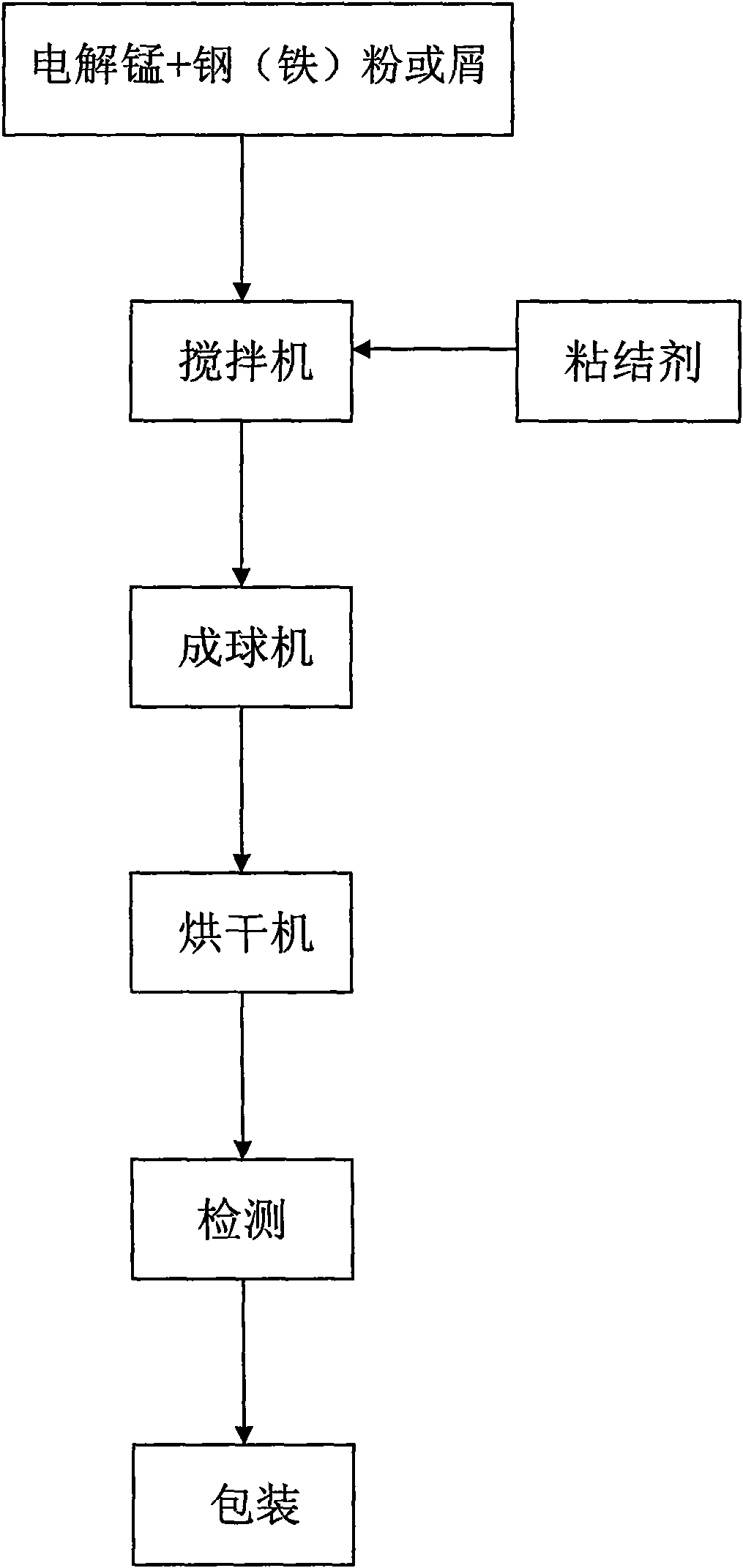

Method for producing manganese alloy

The invention relates to a method for producing a manganese alloy, which belongs to the technical field of ferroalloy production. The process comprises the following steps: adopting powdered or granular electrolytic manganese and pure iron powder or pure scrap iron as raw materials, wherein the electrolytic manganese accounts for 60 to 100 weight percent and the balance is Fe; adding a bonding agent of which the weight is 0.5 to 10 percent of that of the raw materials; sufficiently stirring the raw materials and the bonding agent evenly by a stirring machine; pressing the materials into balls by a ball press of which the pressure is not less than 20 T; drying the manganese alloy balls obtained by pressing for 15 to 25 minutes at a temperature of between 80 and 250 DEG C to obtain manganese alloy ball agglomerations of which the residual moisture is not more than 3 percent; and detecting the components and the strength of the ball agglomerations, and packaging the ball agglomerations for storage according to requirements. The method has the advantages of directly obtaining the manganese alloy with bright and clean surface, high strength and appropriate components.

Owner:CHINA IRON & STEEL RES INST GRP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com