Patents

Literature

756 results about "Volume average" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Average Volume is the total volume for a specified period divided by the number of bars in that same period.

Aqueous dispersion, its production method, and its use

ActiveUS20050100754A1Liquid surface applicatorsSynthetic resin layered productsVolume averageAlpha-olefin

Aqueous dispersions including at least one thermoplastic resin; at least one dispersing agent; and water; wherein the dispersion has a pH of less than 12 are disclosed along with dispersions including at least one thermoplastic resin; at least one dispersing agent; and water wherein the dispersion has a volume average particle size of less than about 5 μm. Some dispersions include less than about 4 percent by weight of the dispersing agent based on the weight of the thermoplastic resin. Other dispersions include at least one propylene-rich alpha-olefin interpolymer; at least one dispersing agent; and water. Methods of making such dispersions are also described.

Owner:DOW GLOBAL TECH LLC

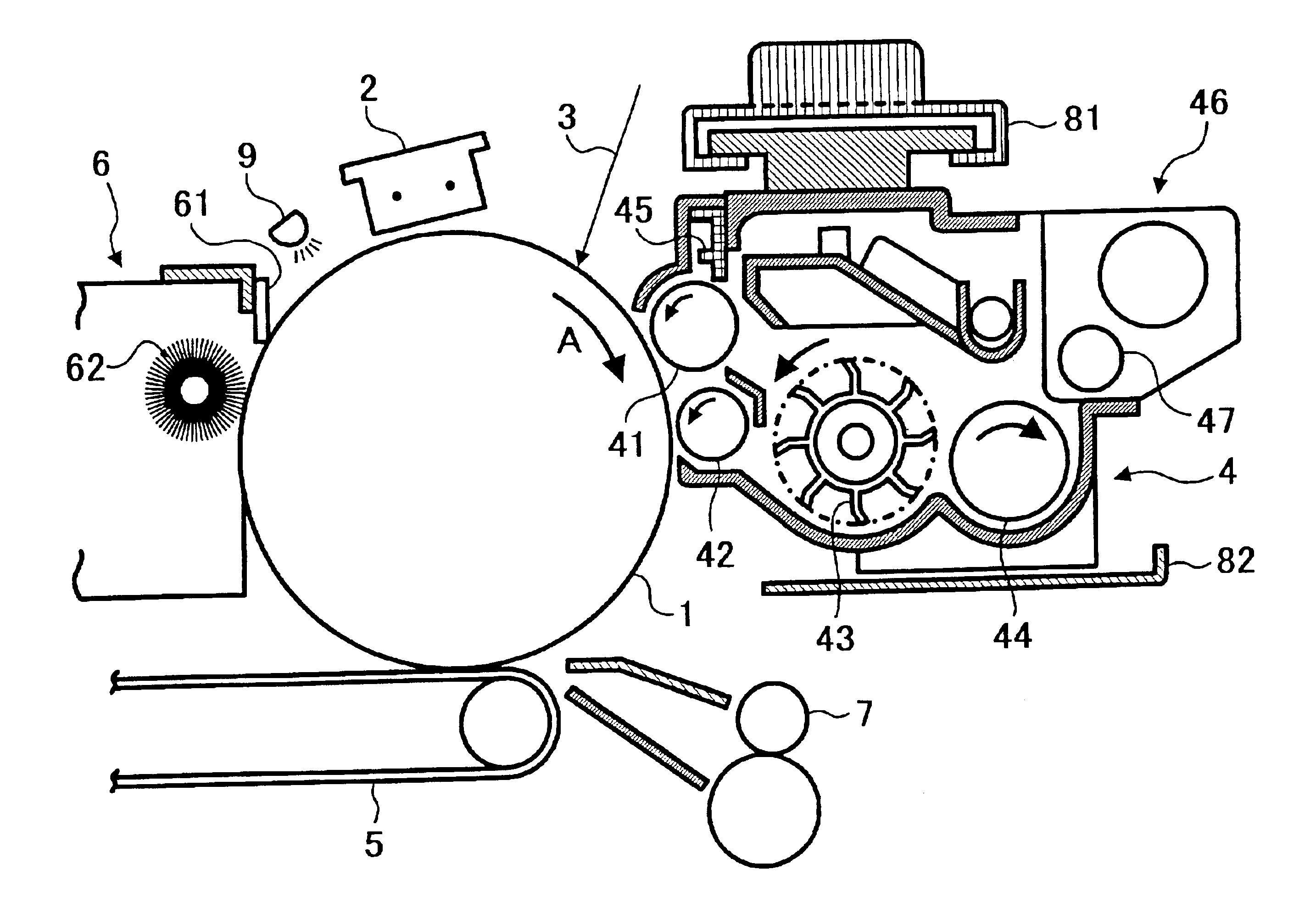

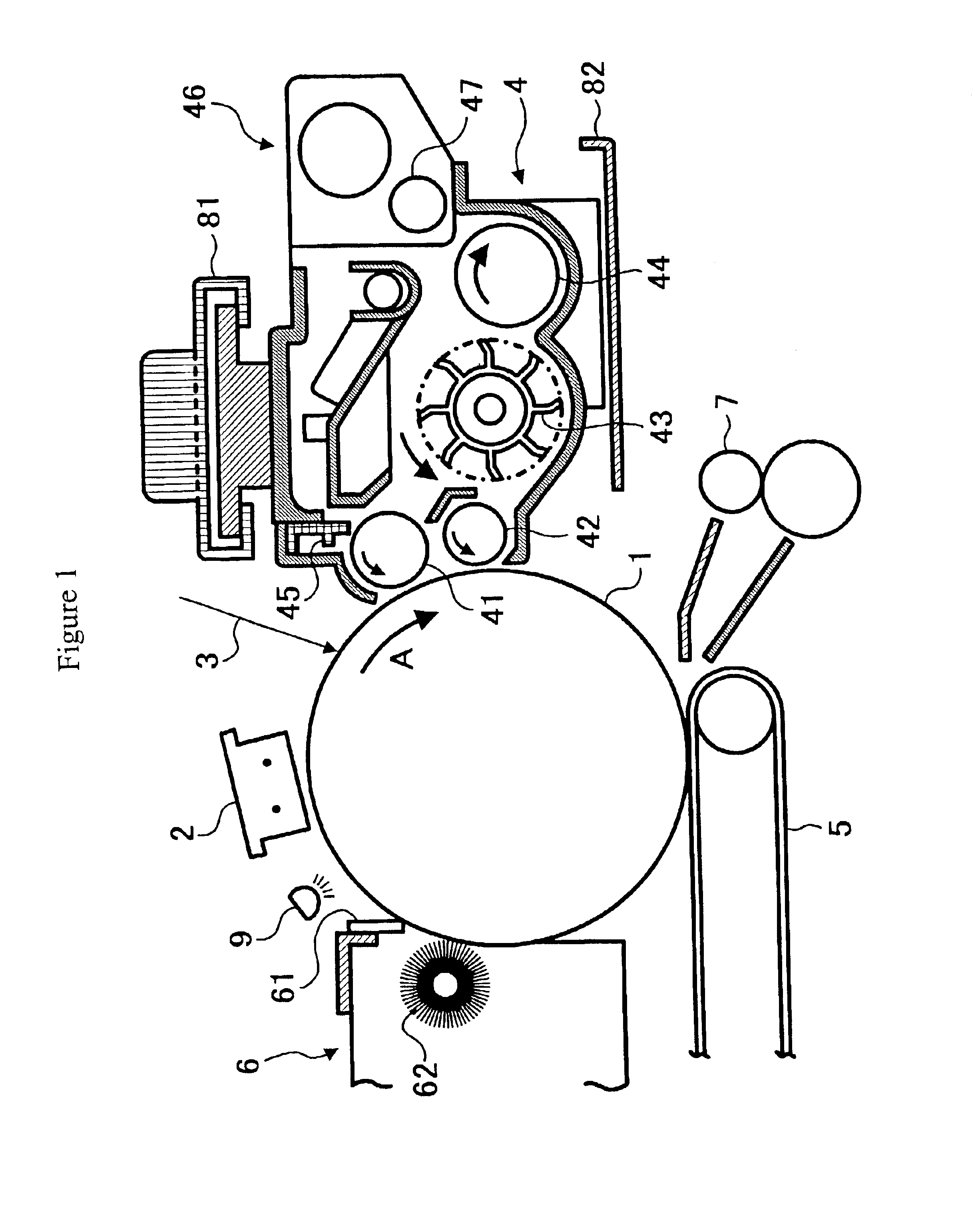

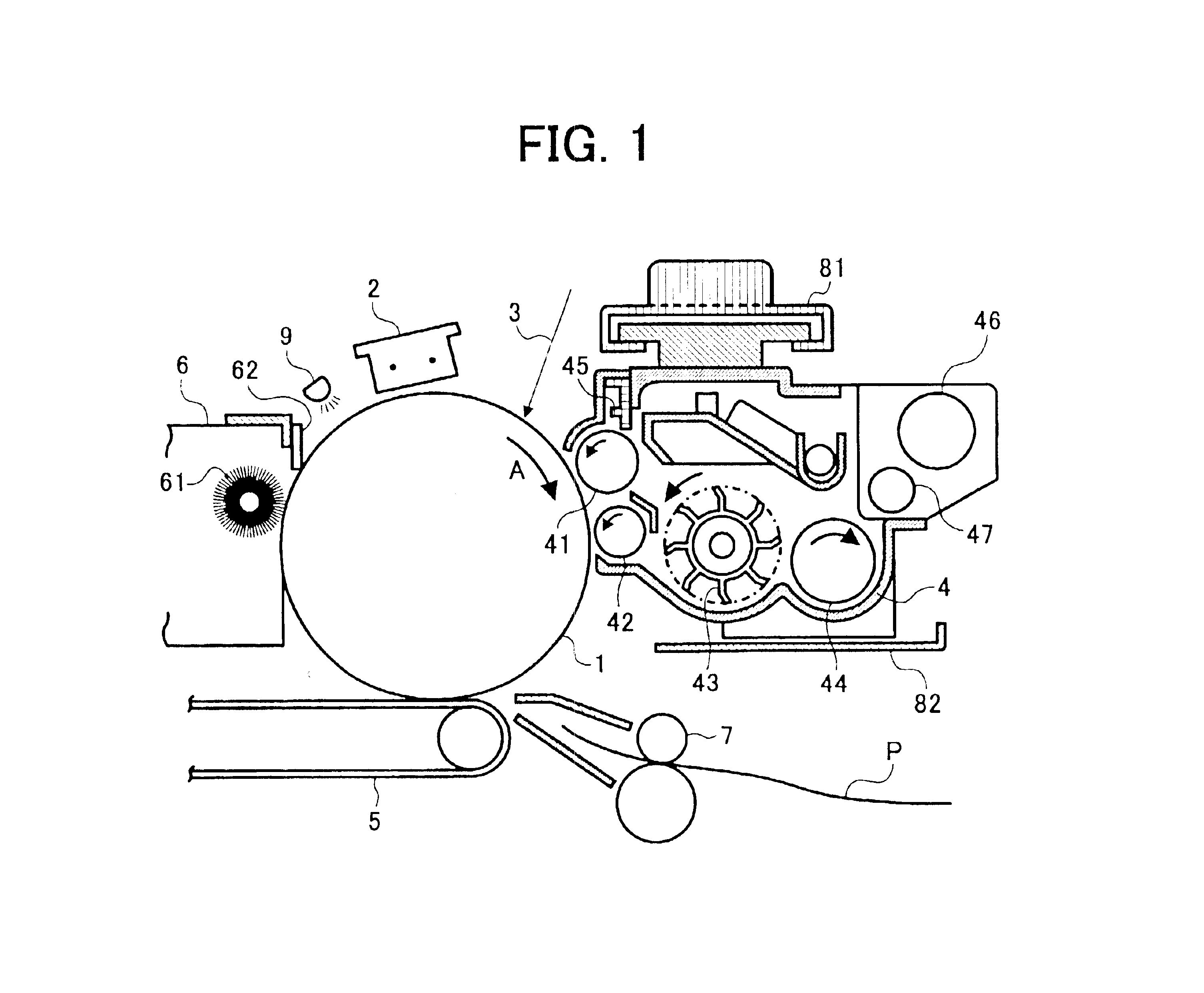

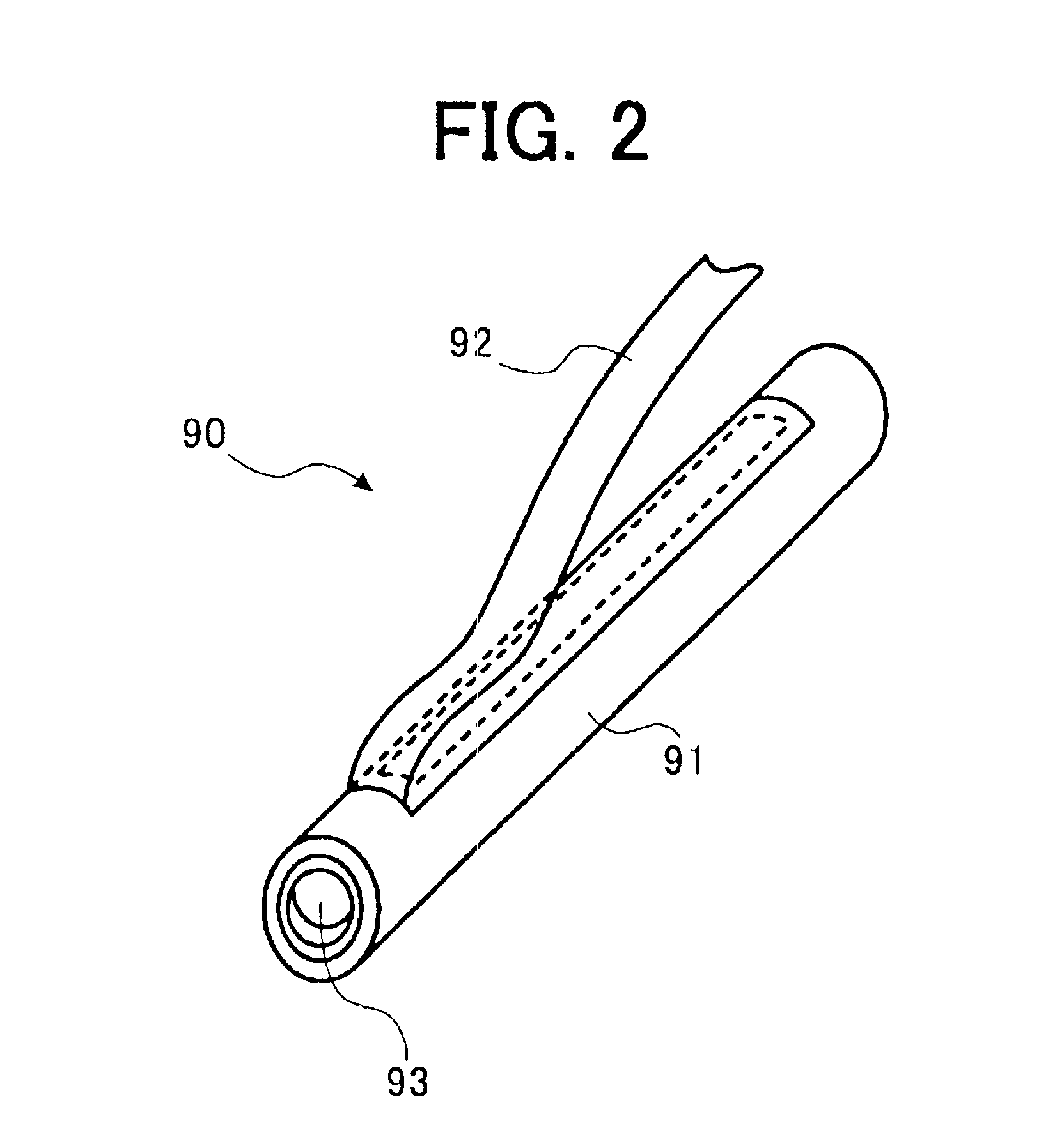

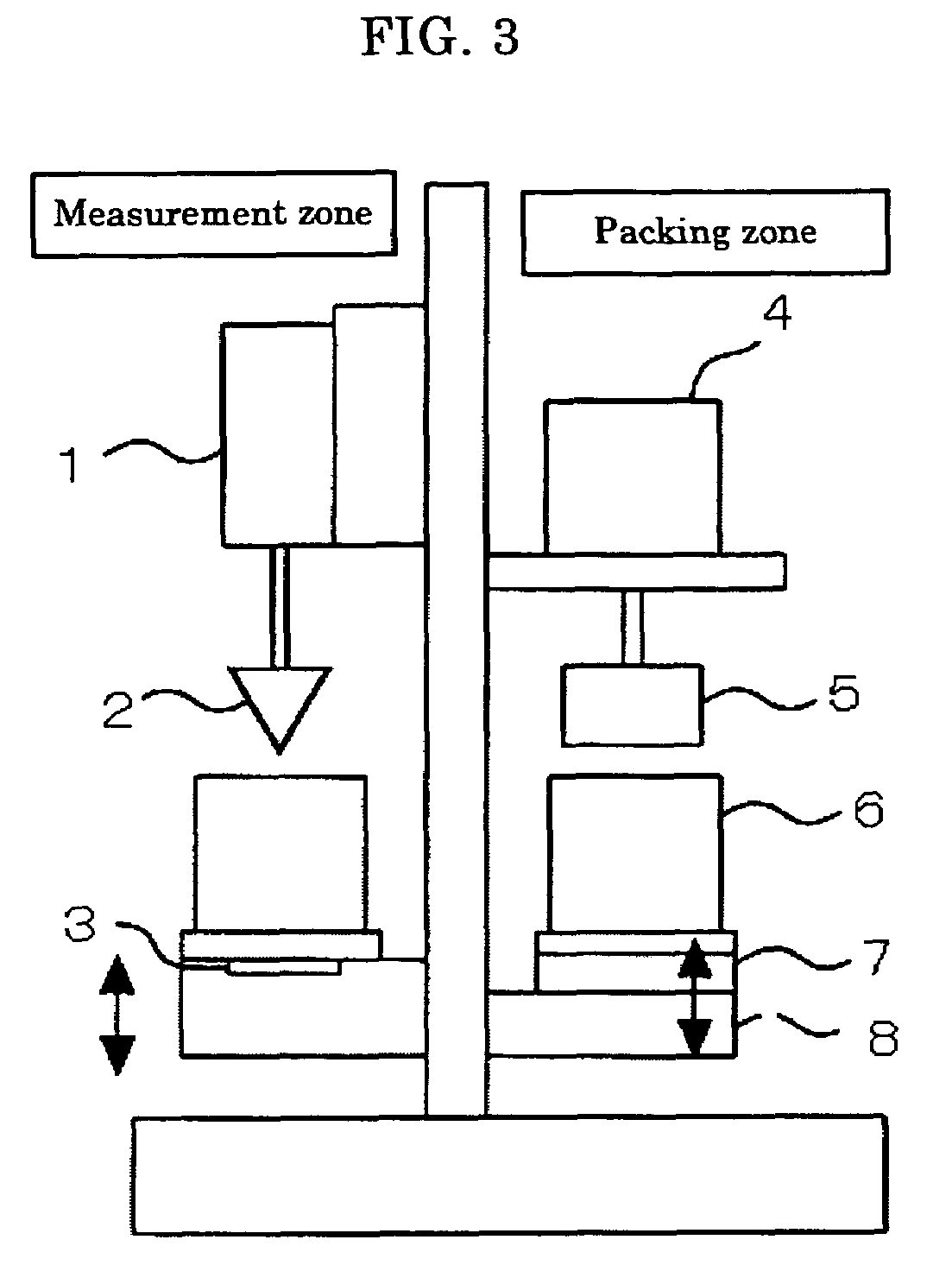

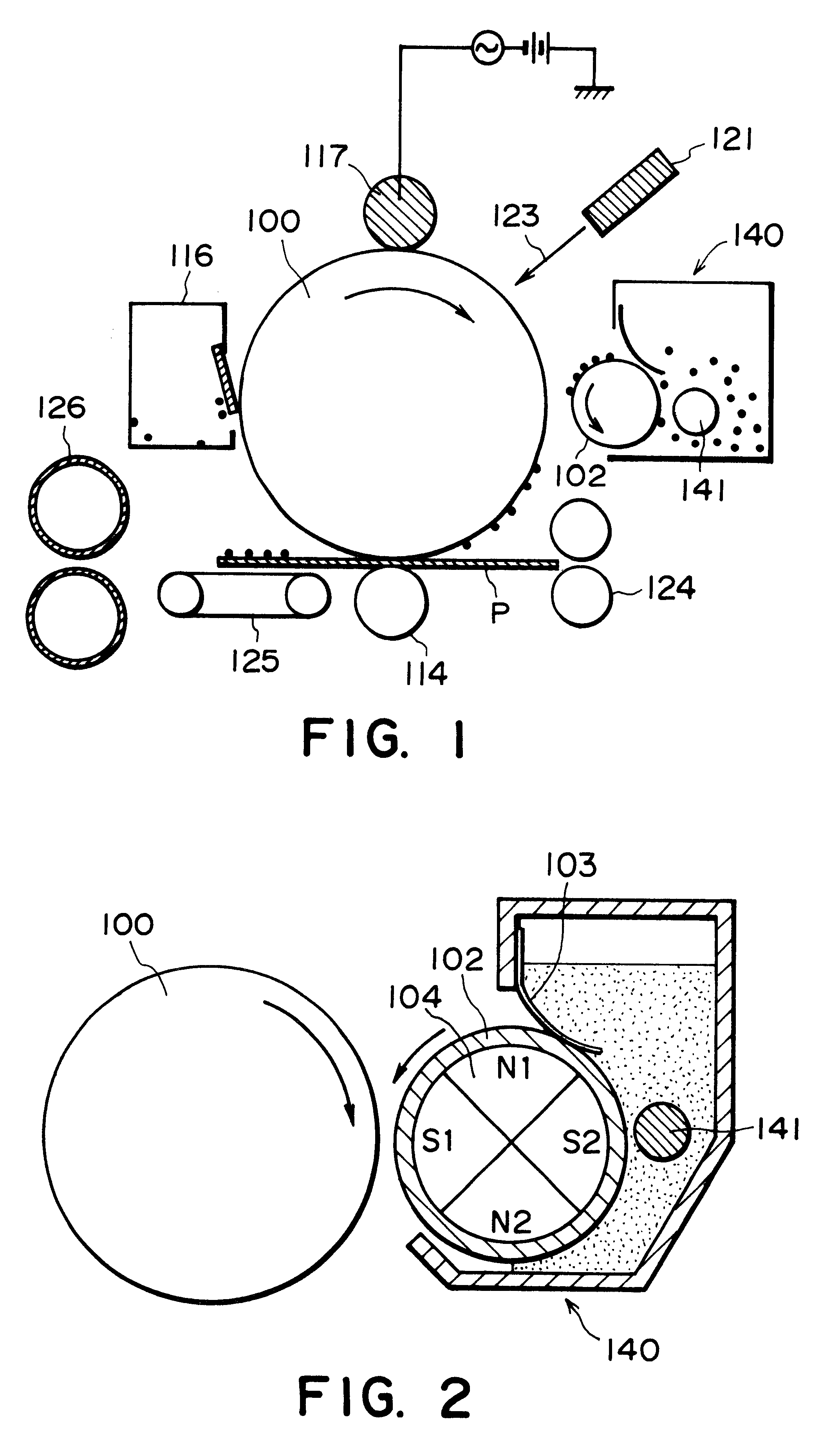

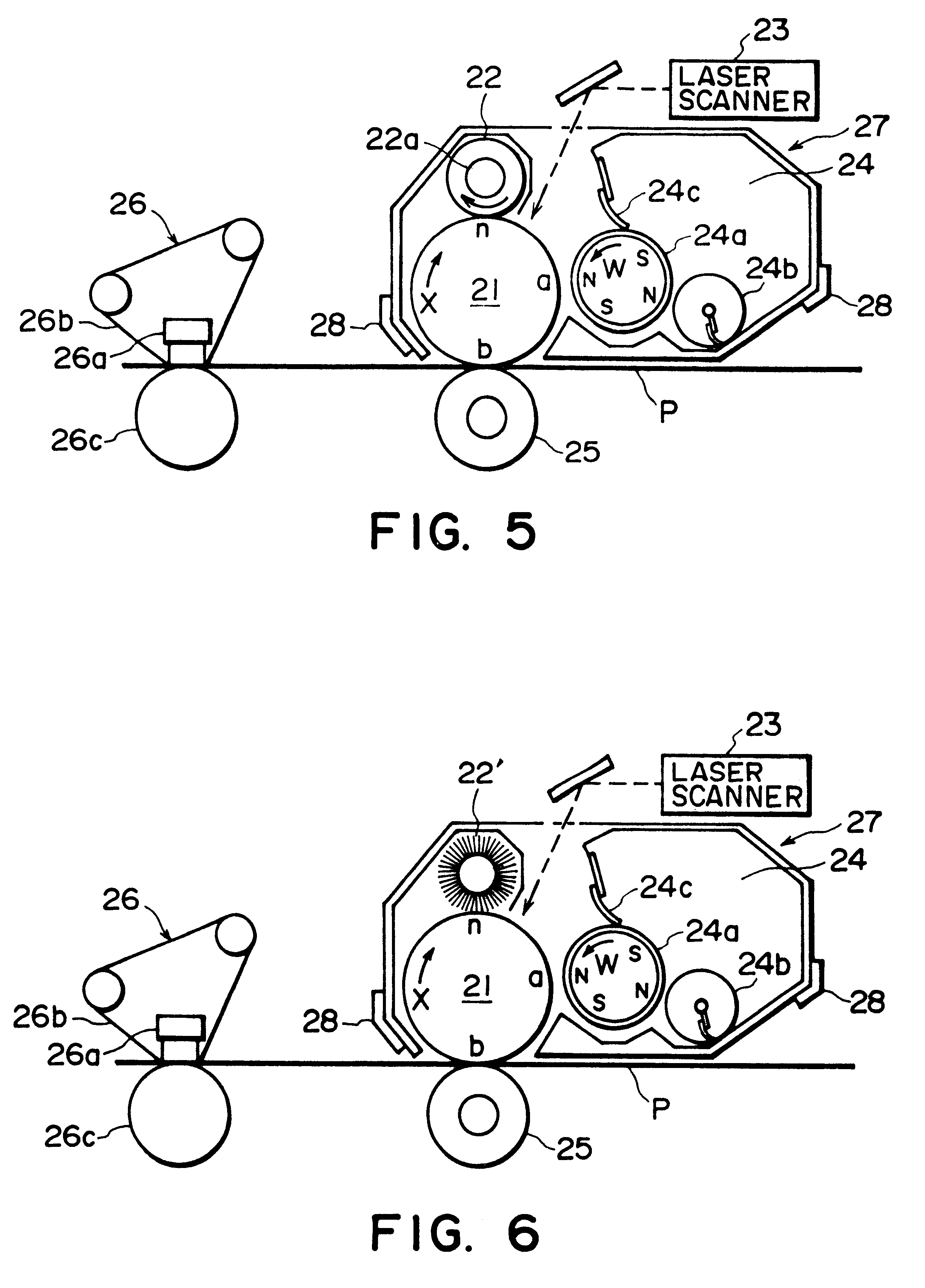

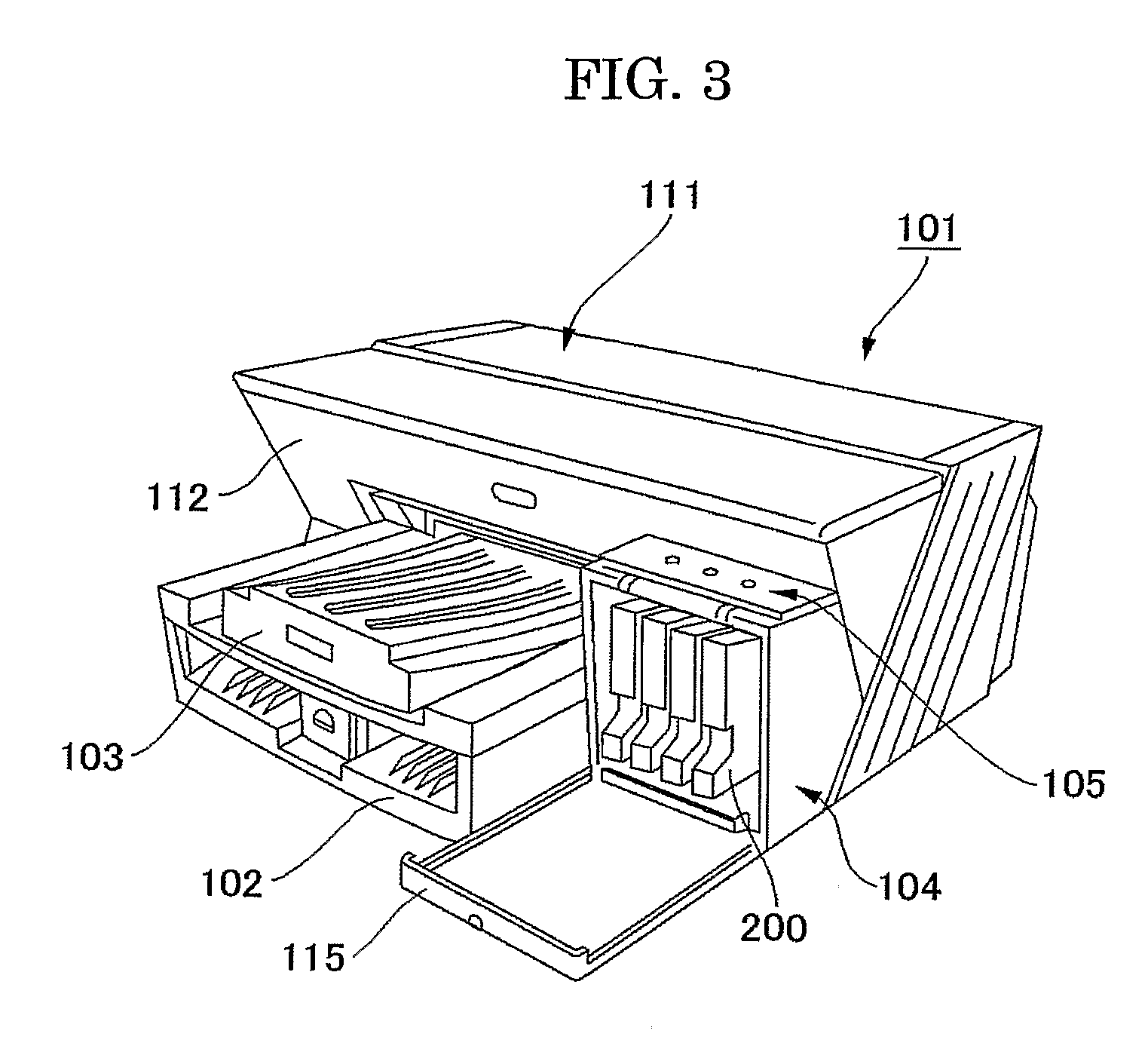

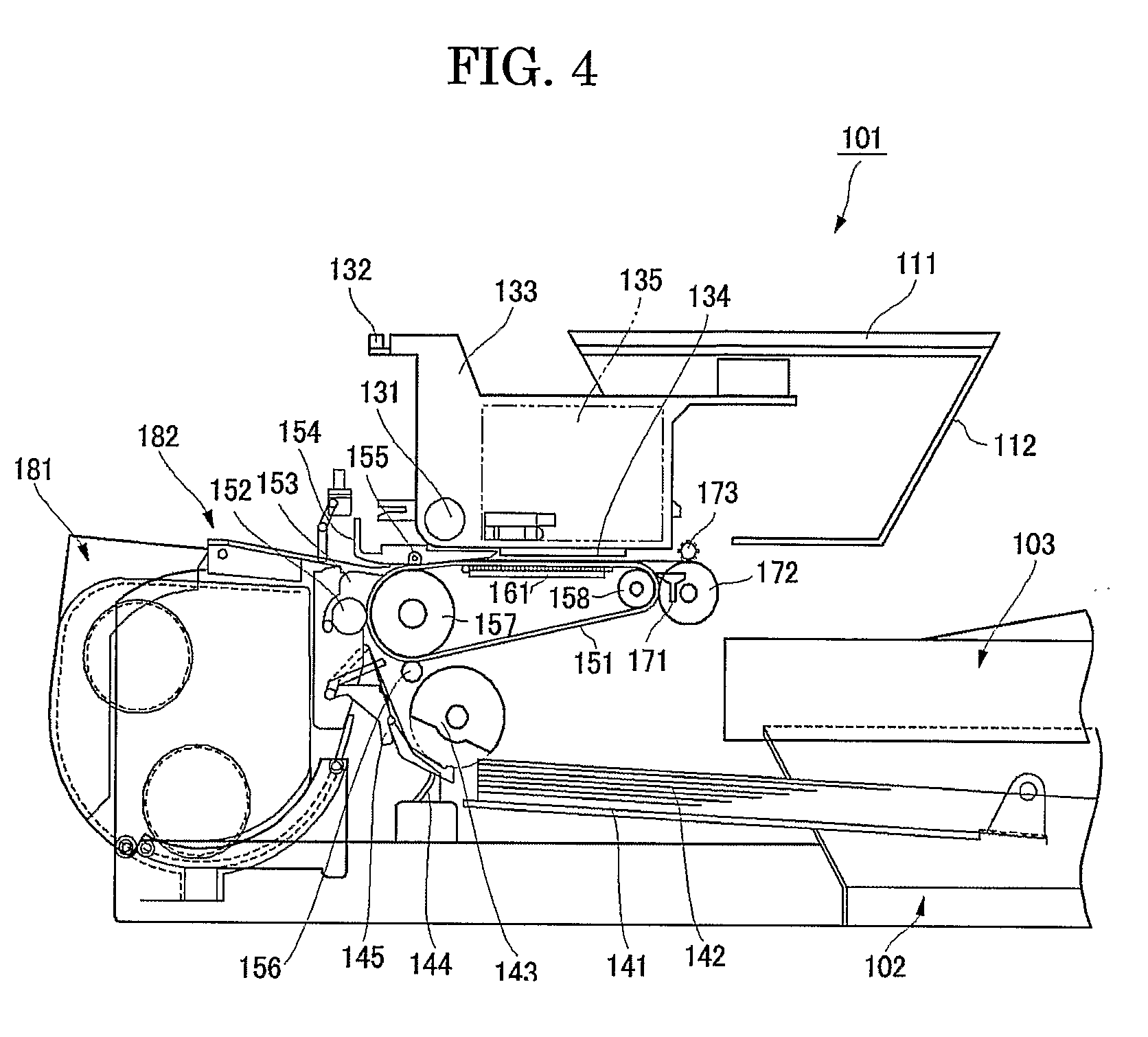

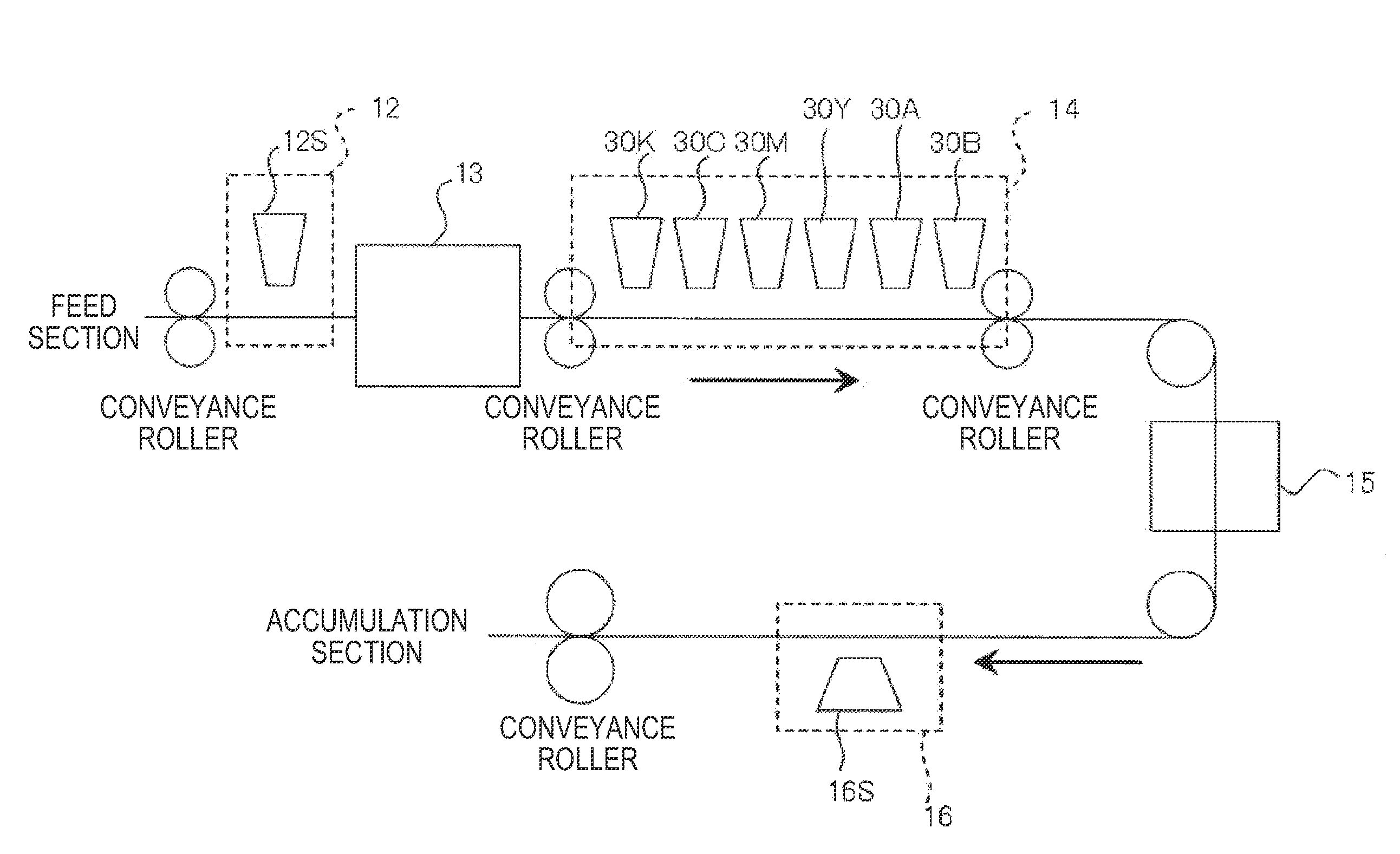

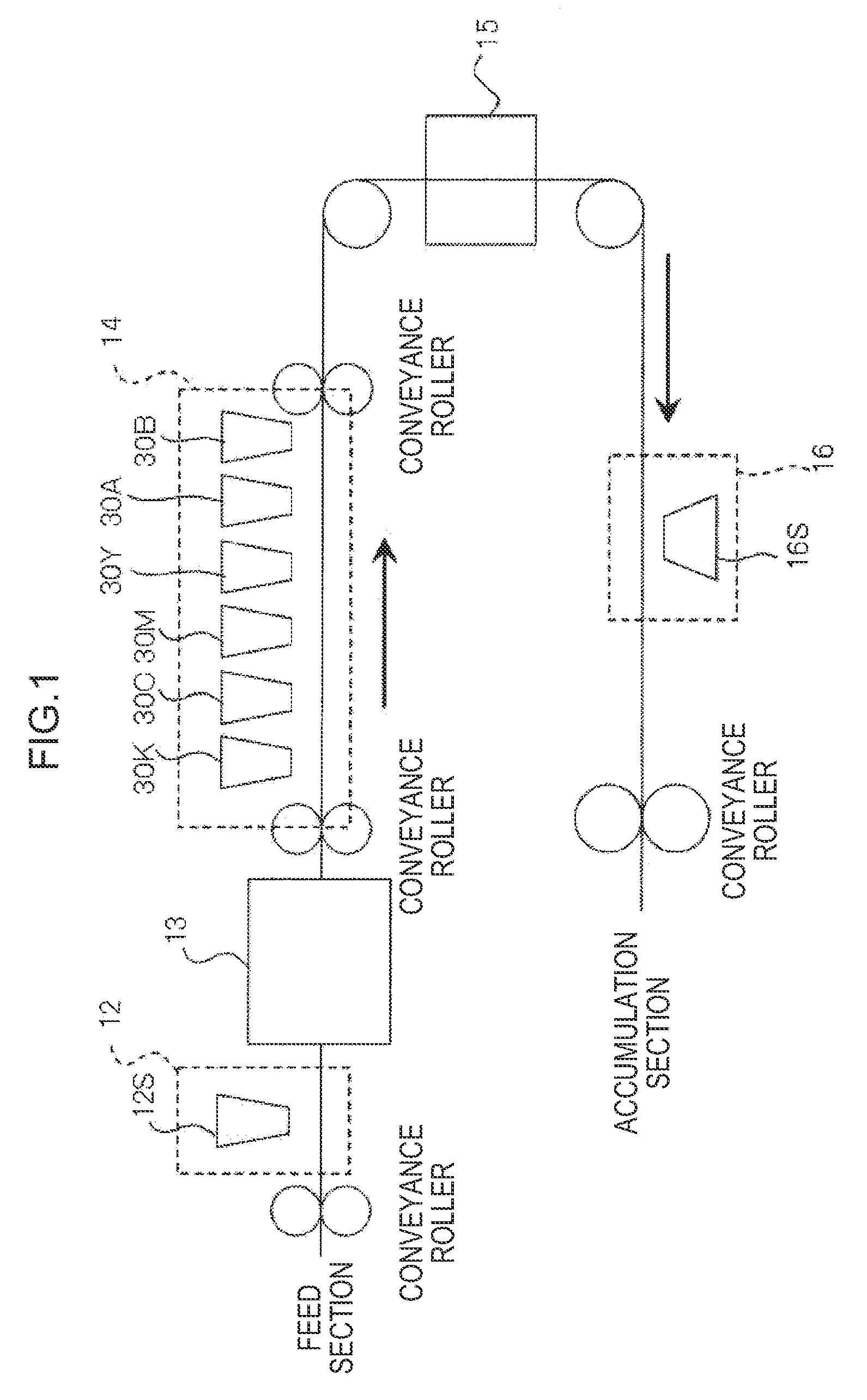

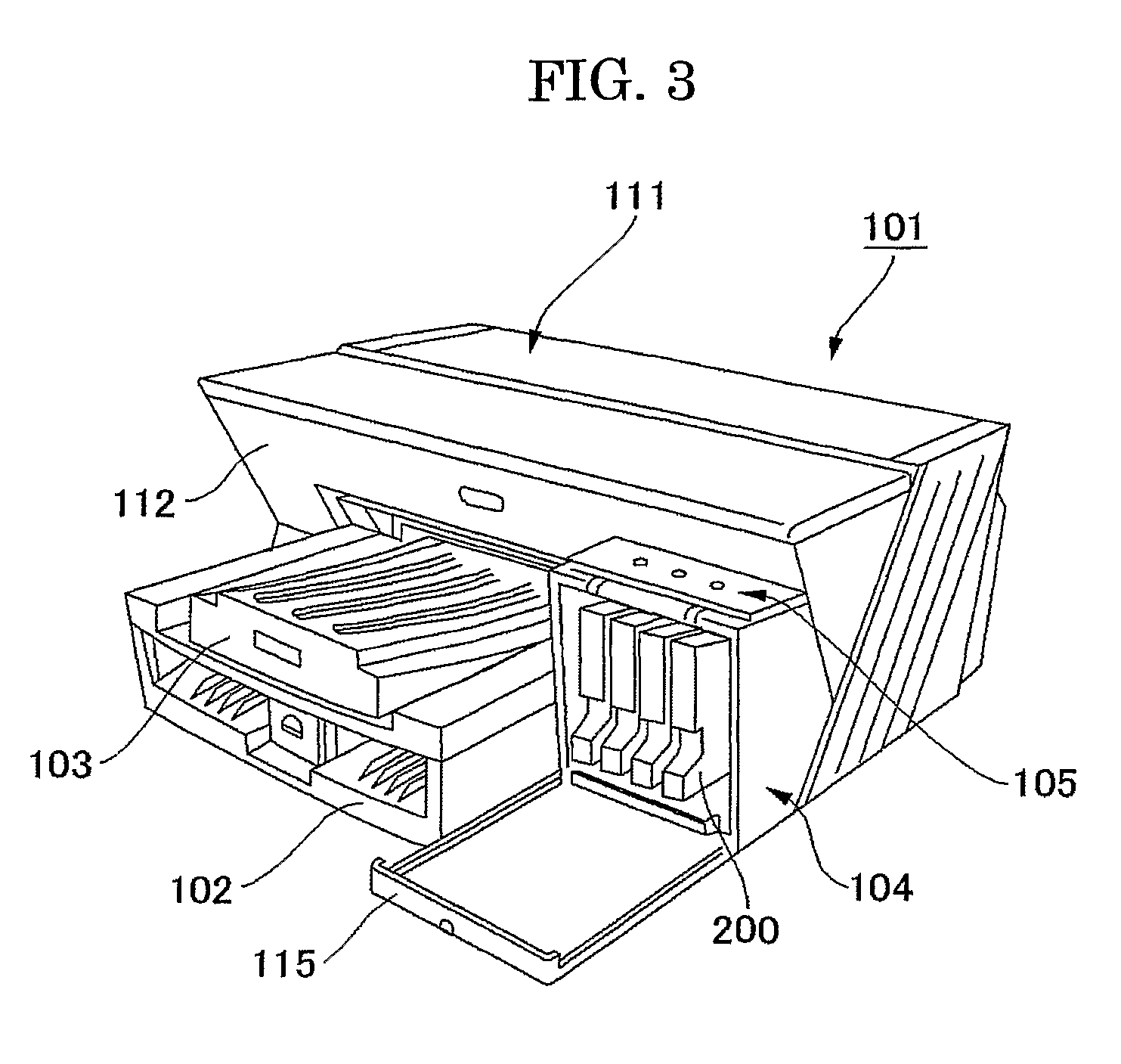

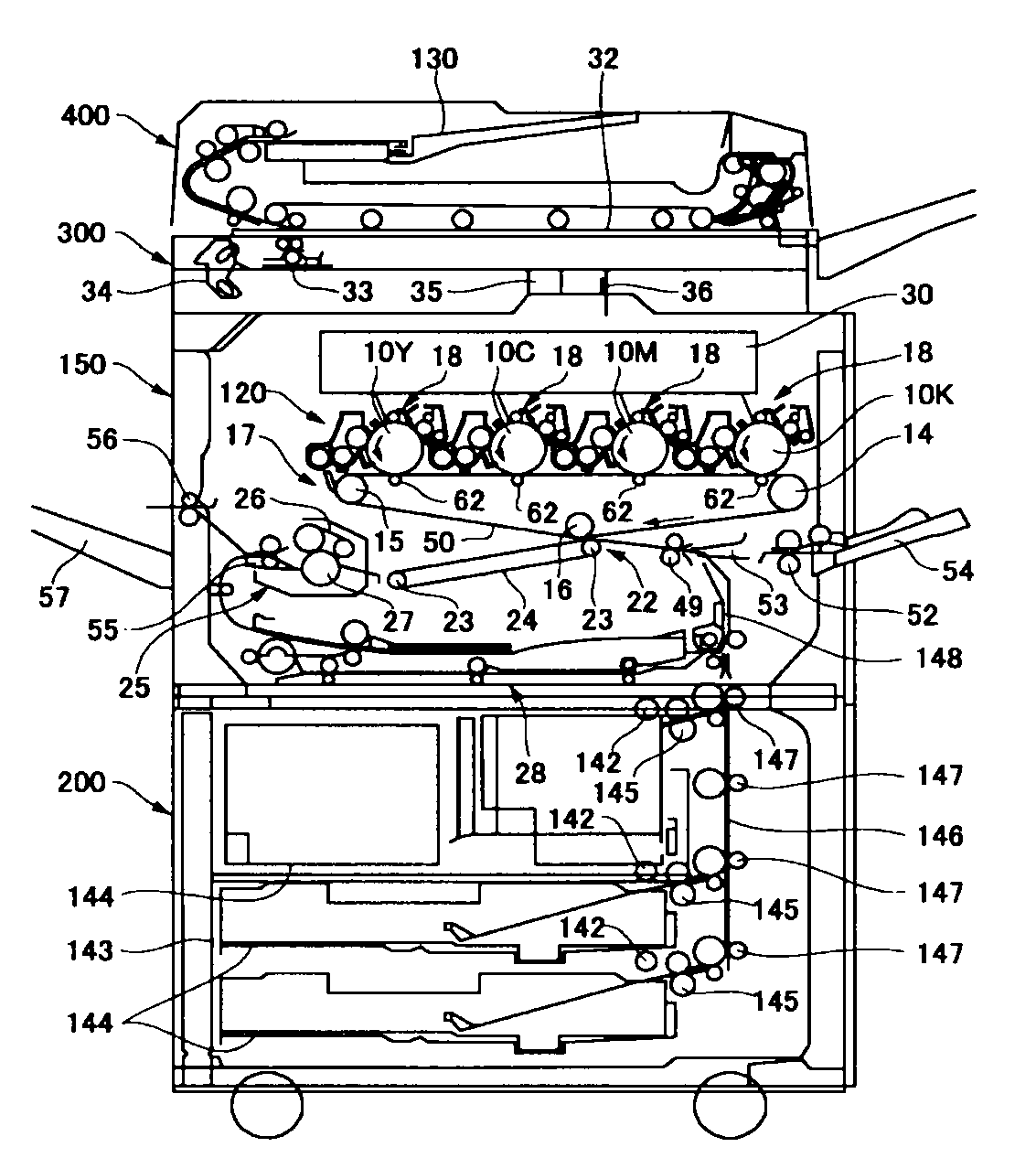

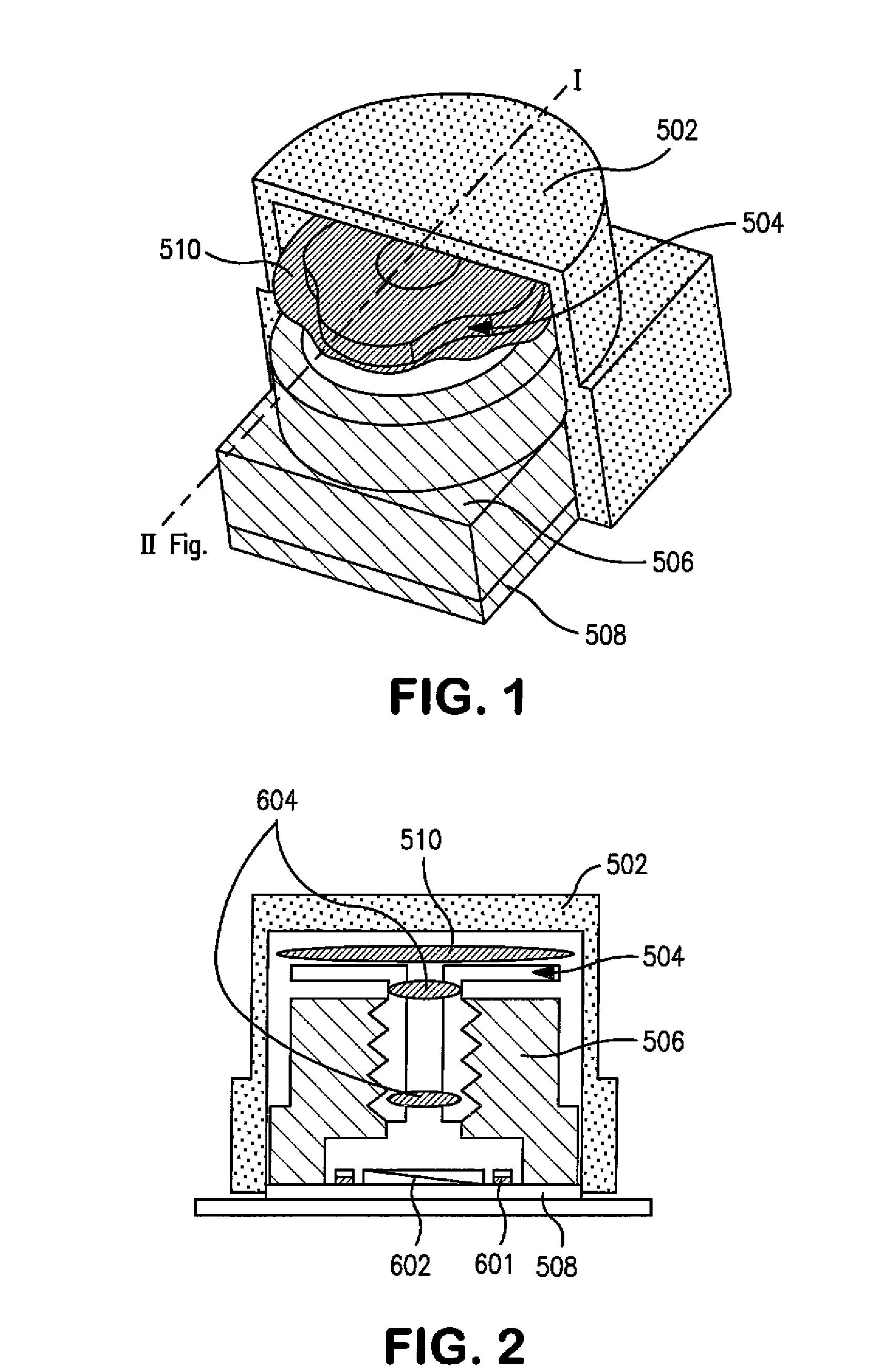

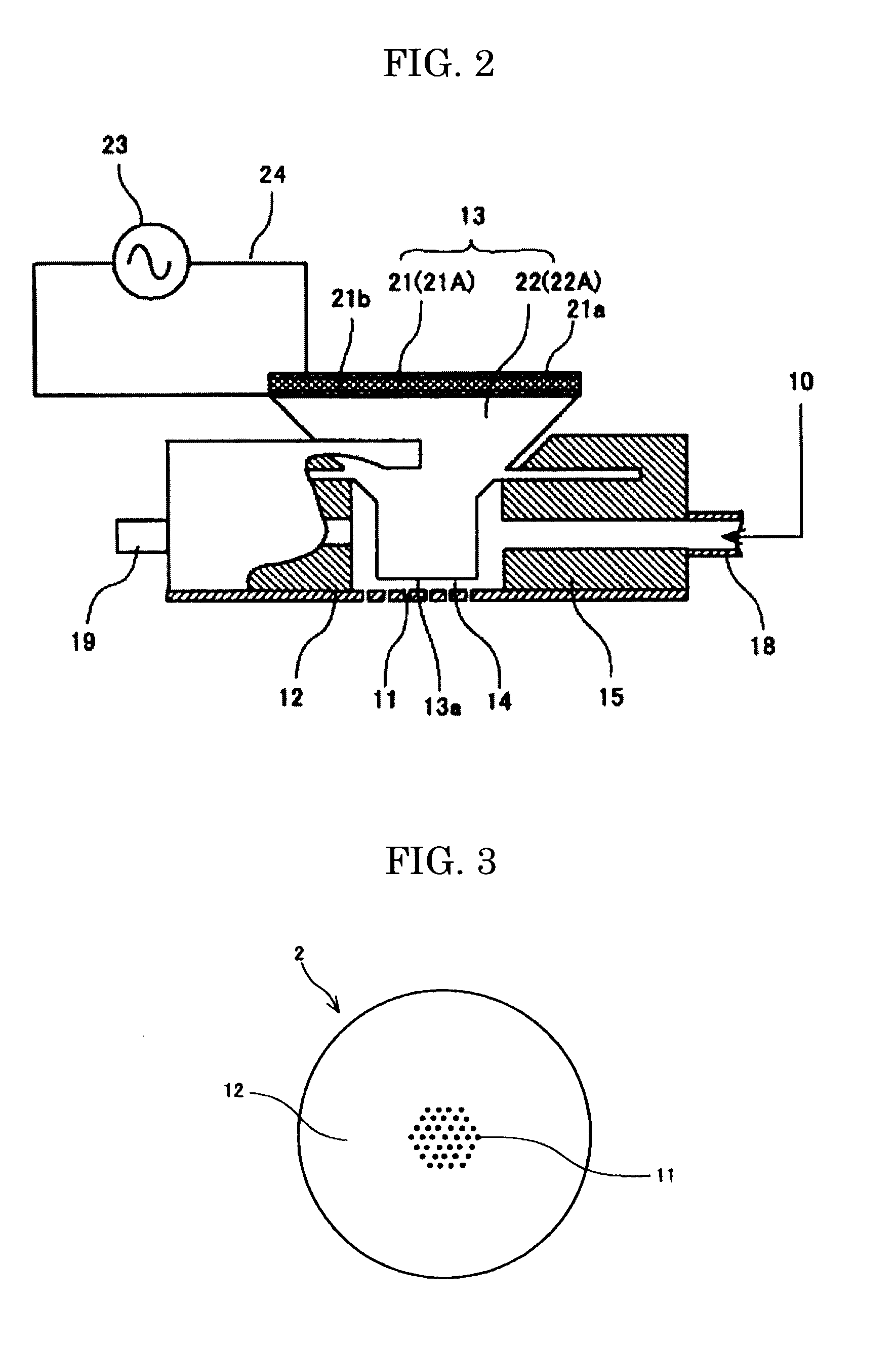

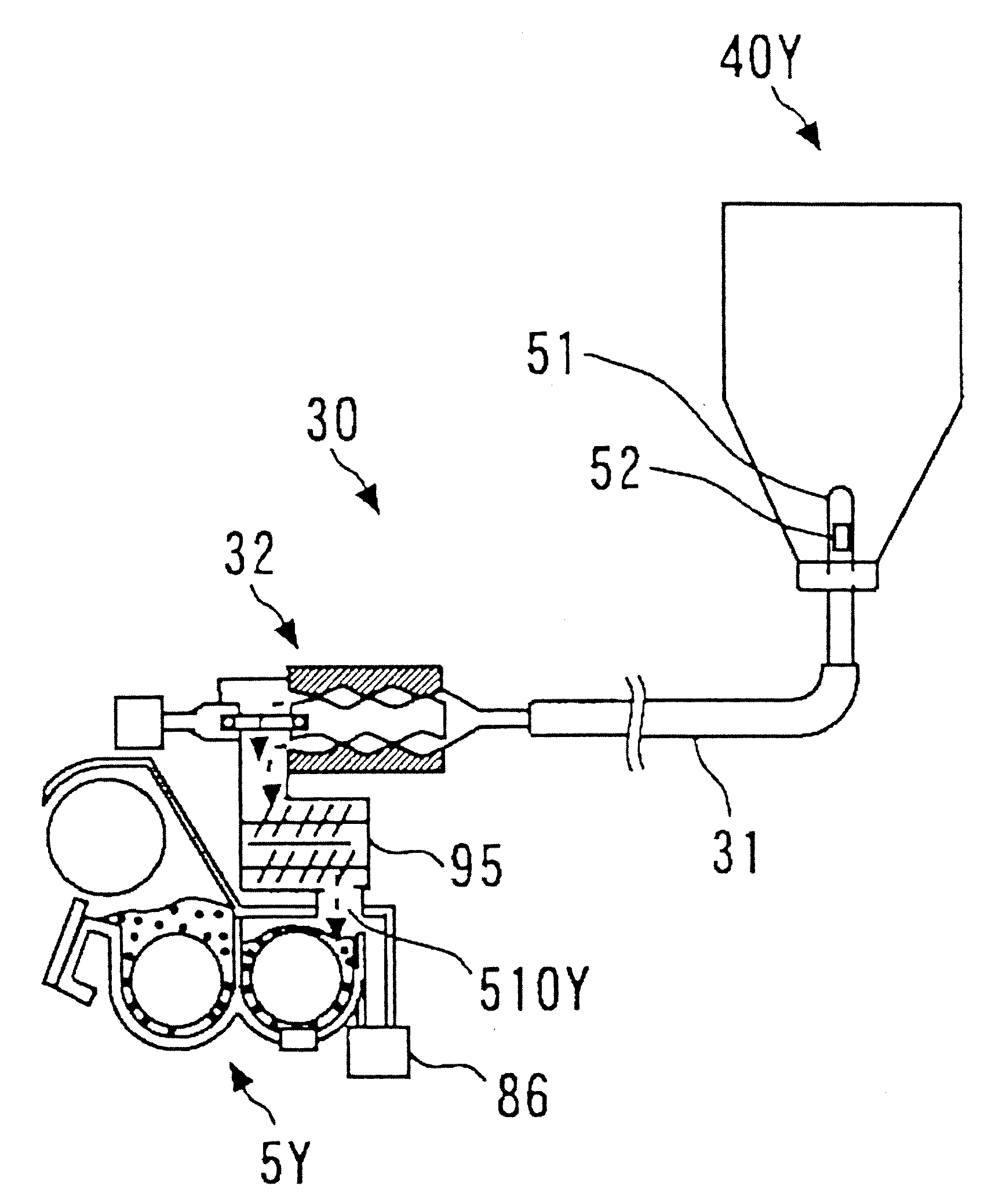

Toner, toner manufacturing method, developer, image forming apparatus, and process cartridge for the image forming apparatus

ActiveUS20060204882A1High quality imagingStable productionElectrographic process apparatusDevelopersPolyesterImage formation

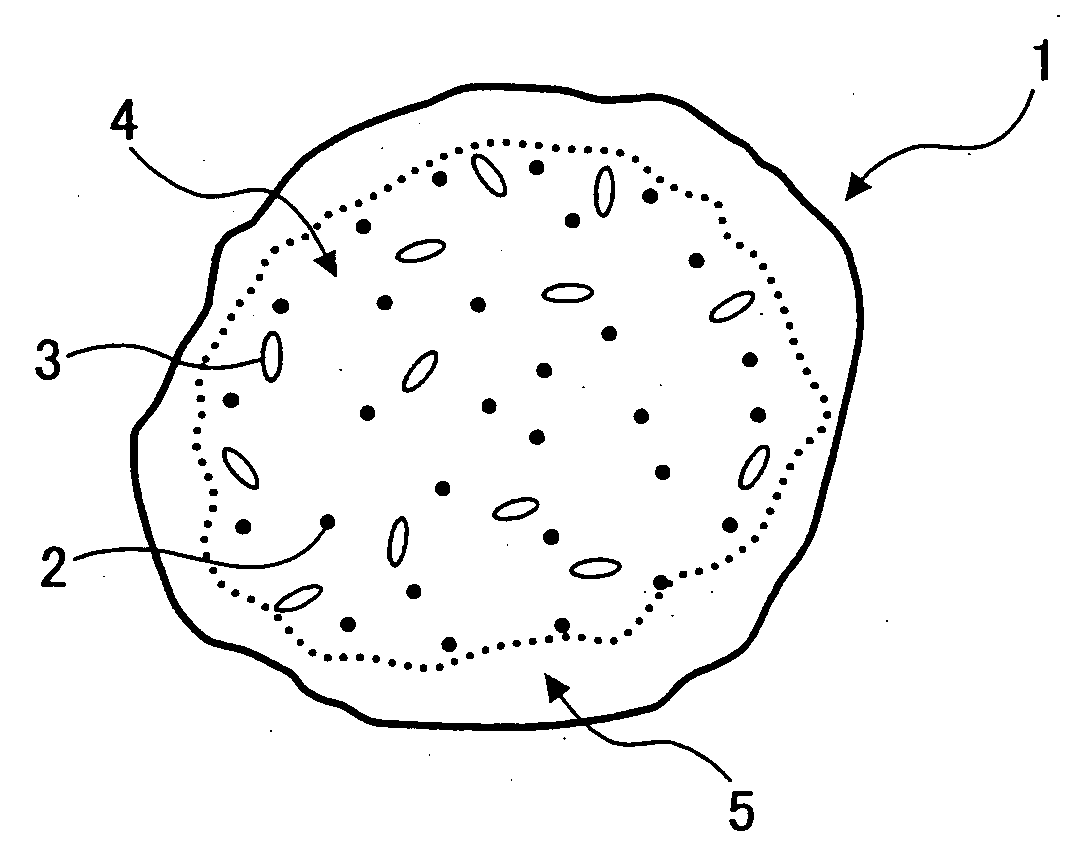

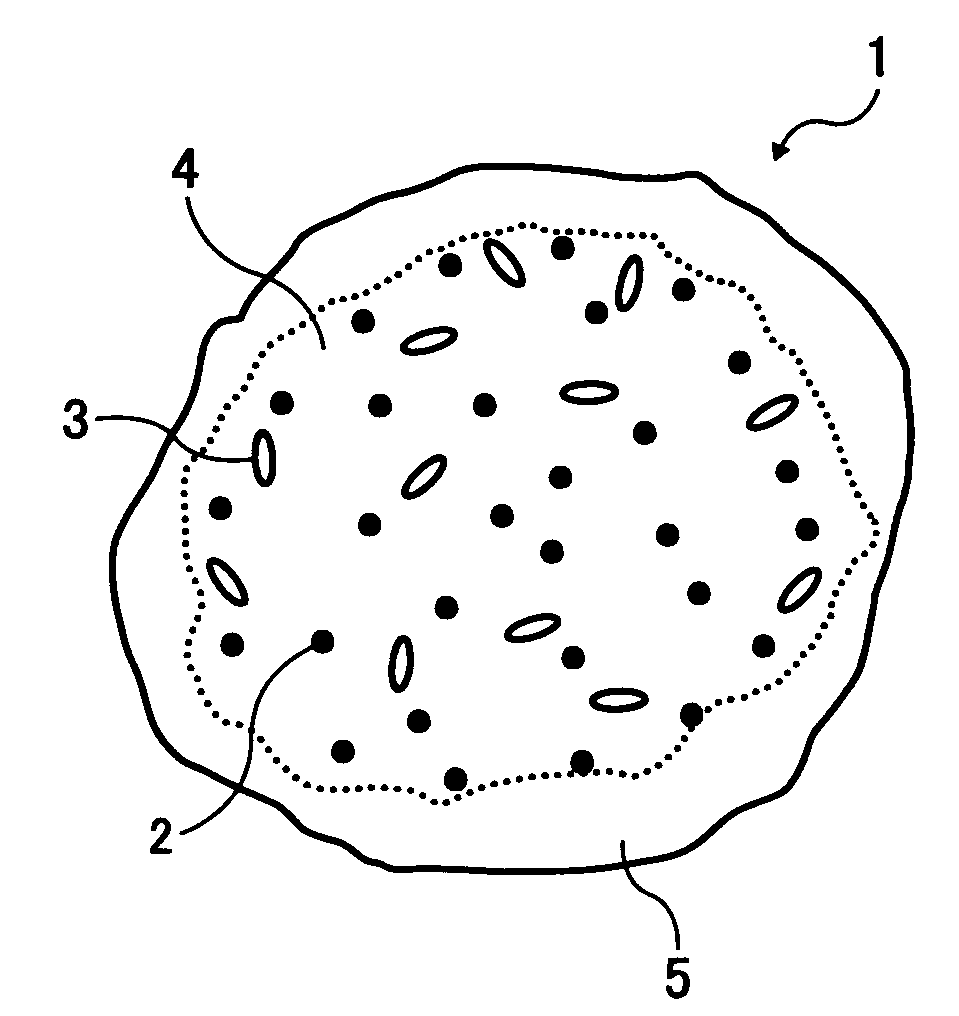

A toner having a core containing a colorant, a release agent and a binder resin (A), and a shell containing a binder resin (B), the shell overlying the core, wherein the binder resin (A) contains a resin having a polyester skeleton, the binder resin (B) contains a vinyl copolymer resin, and a weight ratio of the shell to the core is from 0.05 to 0.5, and wherein the toner has a volume average particle diameter of from 3 to 8 μm; a toner manufacturing method of such the toner can be used in an image forming apparatus and in a process cartridge.

Owner:RICOH KK

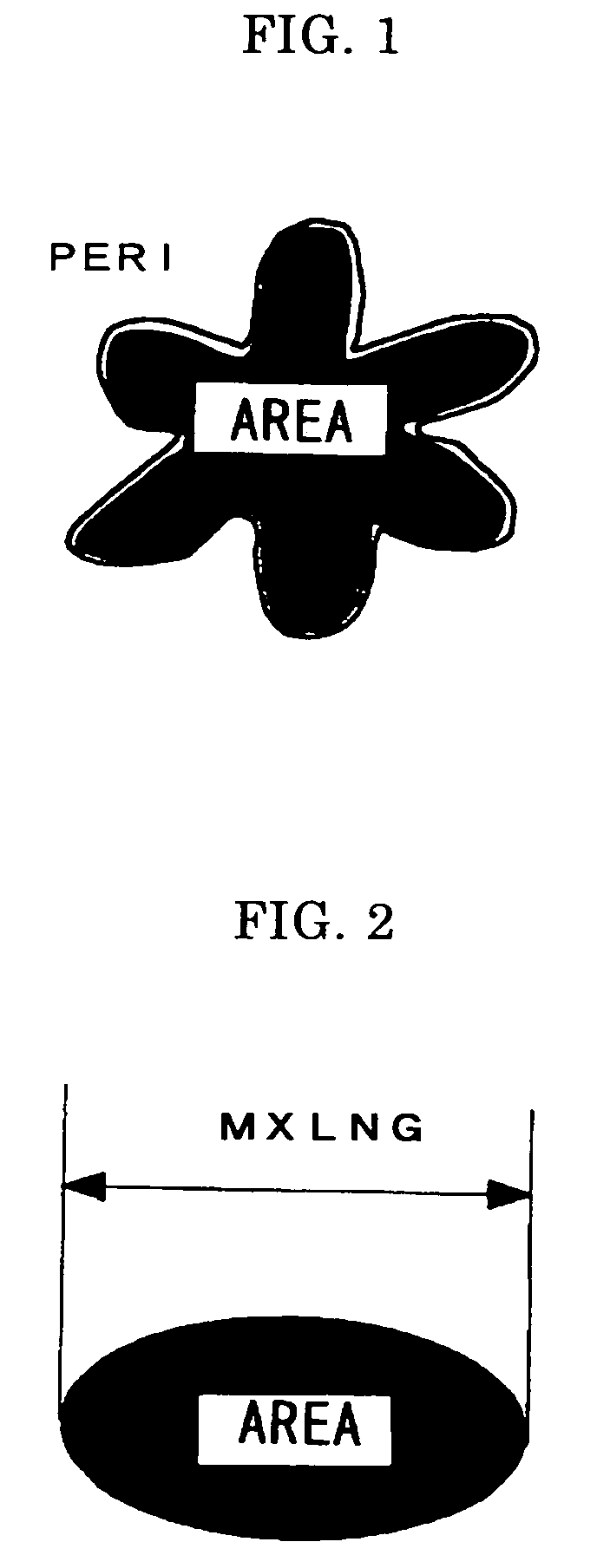

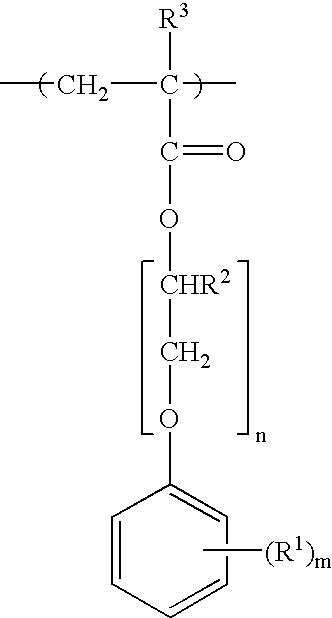

Toner, method of forming the toner, and image forming method and apparatus using the toner

InactiveUS6852462B2Good reproducibilityQuality improvementDevelopersElectrographic processes using charge patternEngineeringVolume average

A toner comprising:a binder resin which is at least a resin selected from the group consisting of modified polyester resins and unmodified polyester resins; anda colorant; the product toner having a volume-average particle diameter (Dv) to a number-average particle diameter (Dn) ratio (Dv / Dn) ranging from 1.00 to 1.30, and the toner having a shape factor SF-1 ranging from 140 to 200.

Owner:RICOH KK

Toner and method of preparing the toner

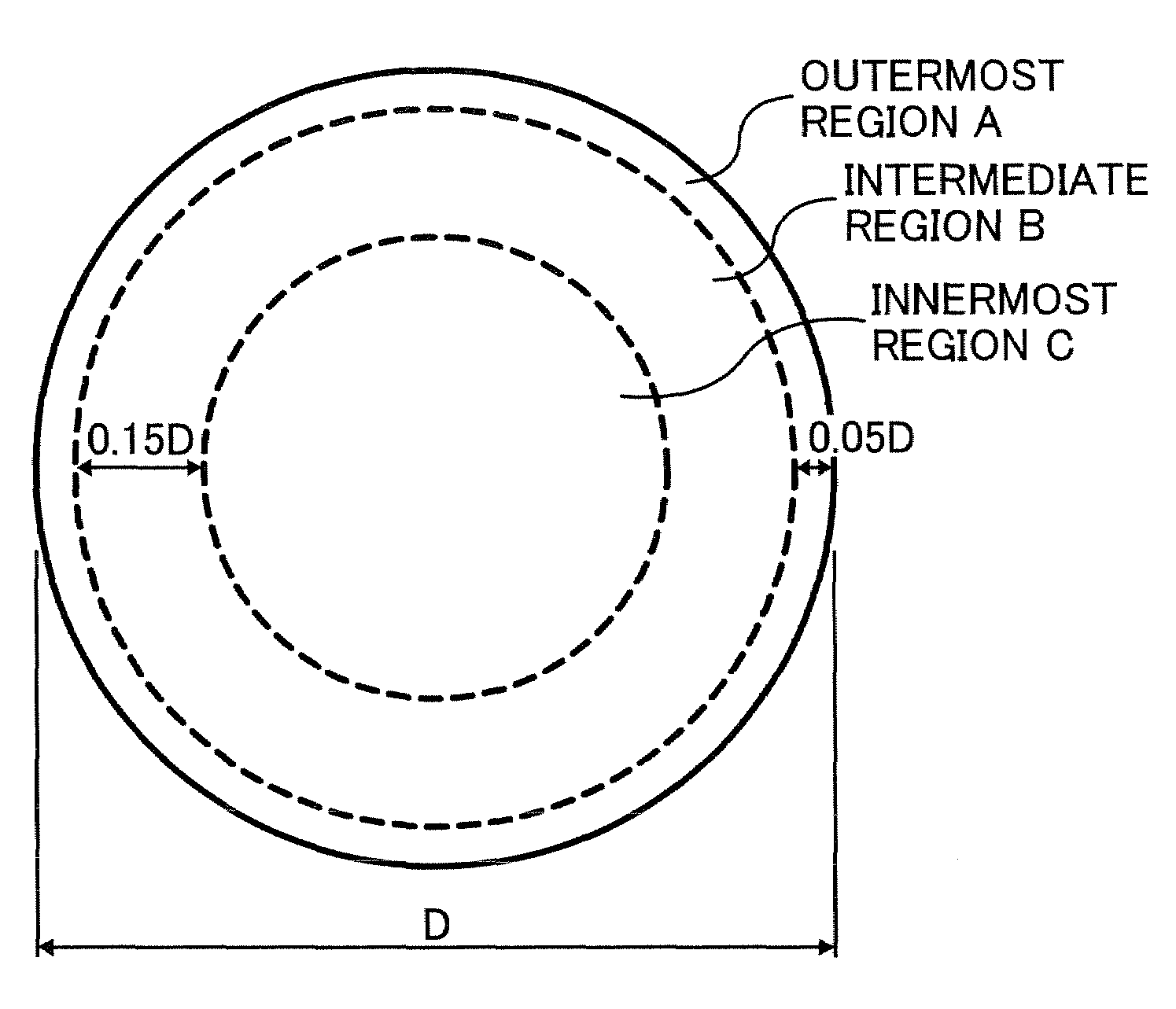

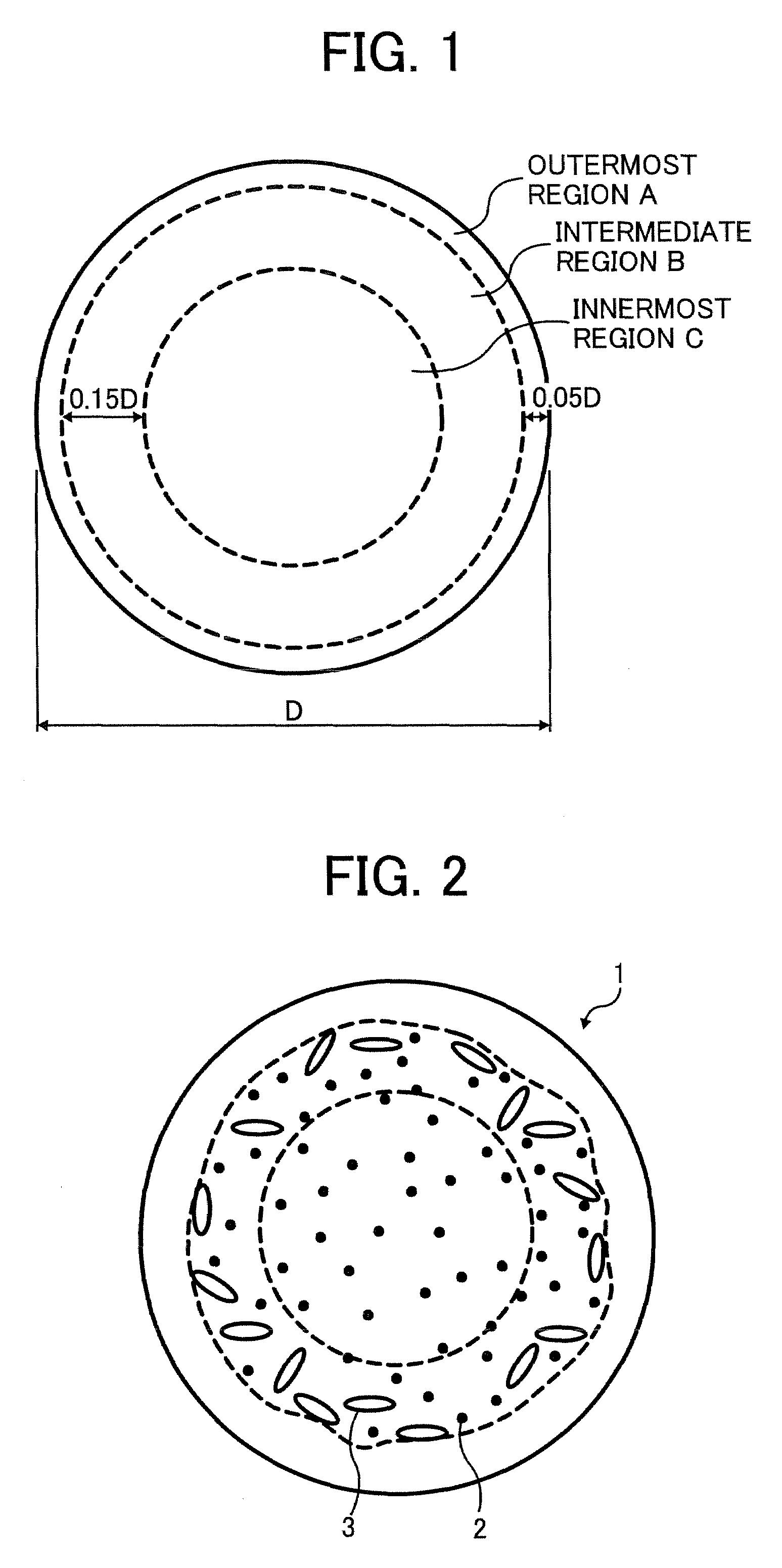

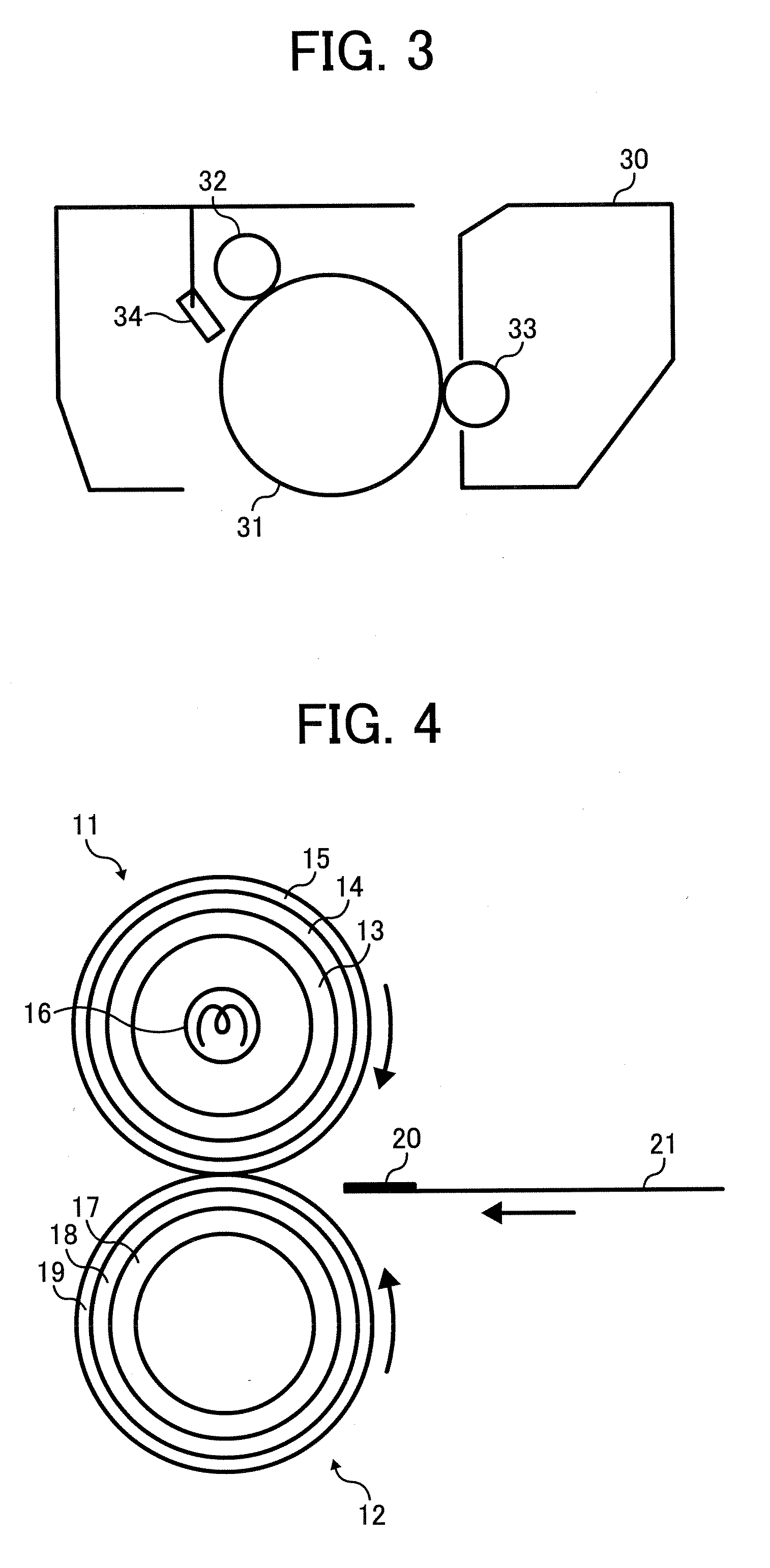

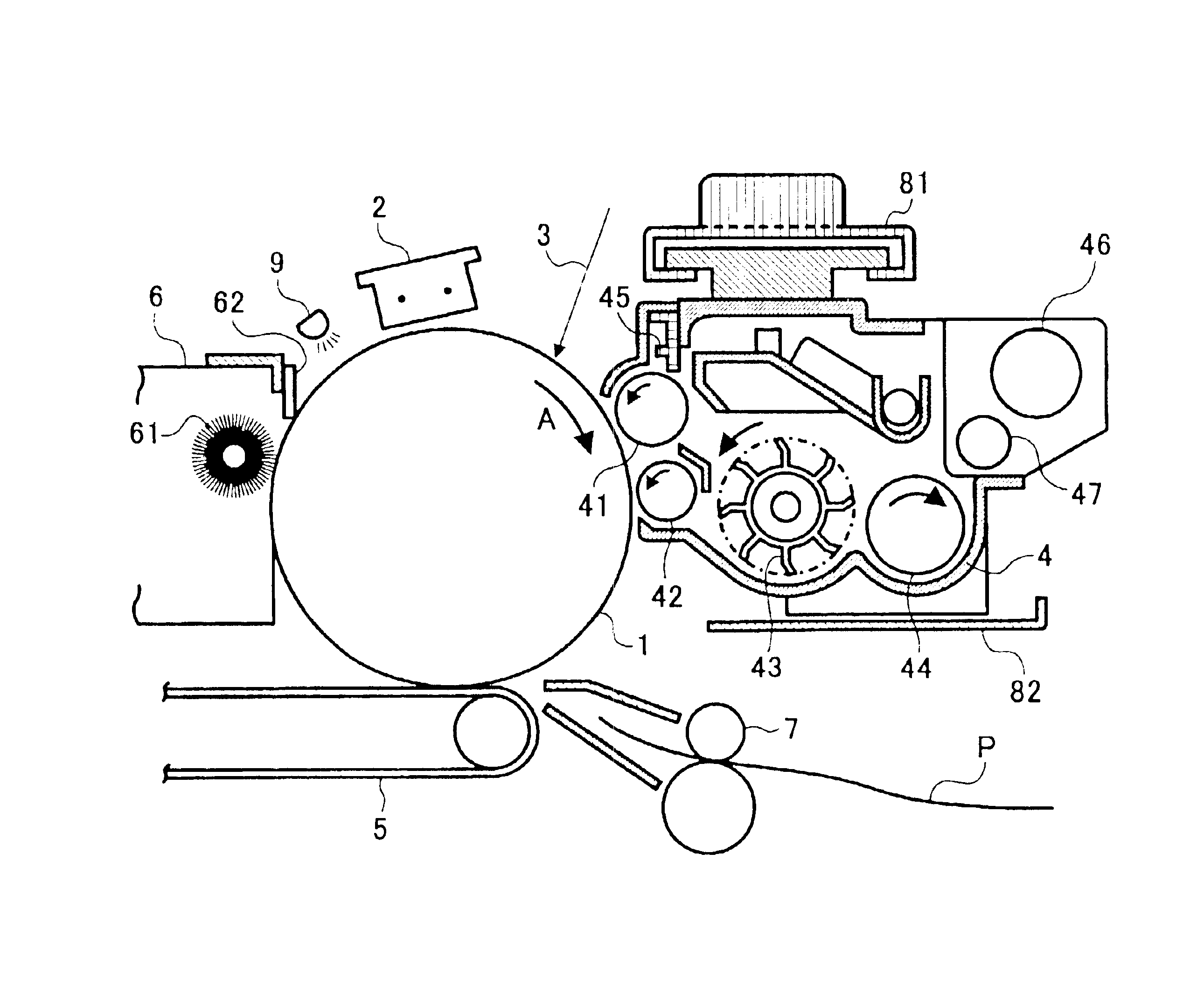

A toner is provided including a binder resin, a colorant, and a release agent, which has a volume average particle diameter (Dv) of from 3 to 9 μm, and wherein the binder resin and the release agent form a sea-island structure in which the island formed of the release agent is dispersed in the sea formed of the binder resin in a cross-sectional image of the toner obtained by a transmission electron microscope (TEM), and the following relationships are satisfied: IB>IA and IB>IC, wherein each of IA, IB, and IC represents an area ratio (%) of the island in an outermost region (A) of the cross-sectional image of the toner, an intermediate region (B) thereof located under the outermost region (A), and an innermost region (C) thereof located under the intermediate region (B); and a method of preparing the toner.

Owner:RICOH KK

Toner for developing electrostatic image, method for manufacturing the toner, developer including the toner, container containing the toner, and developing method using the toner

InactiveUS6849369B2Good reproducibilityLow fixabilityDevelopersElectrographic processes using charge patternVitrificationParticulates

Toner particles including a binder resin; a colorant; and a particulate resin which is present at least on a surface of the toner particles and which has a glass transition temperature of form 50 to 90° C., wherein a ratio (Dv / Dn) of a volume average particle diameter (Dv) of the toner particles to a number average particle diameter (Dn) thereof is from 1.00 to 1.40 and the surface of the toner particles is covered with the particulate resin at a covering ratio of from 1 to 90 %. A method for manufacturing the toner particles is provided. A developer including a toner including the toner particles is provided. A developing method using a toner including the toner particles is provided. A toner container containing the toner particles is provided.

Owner:RICOH KK

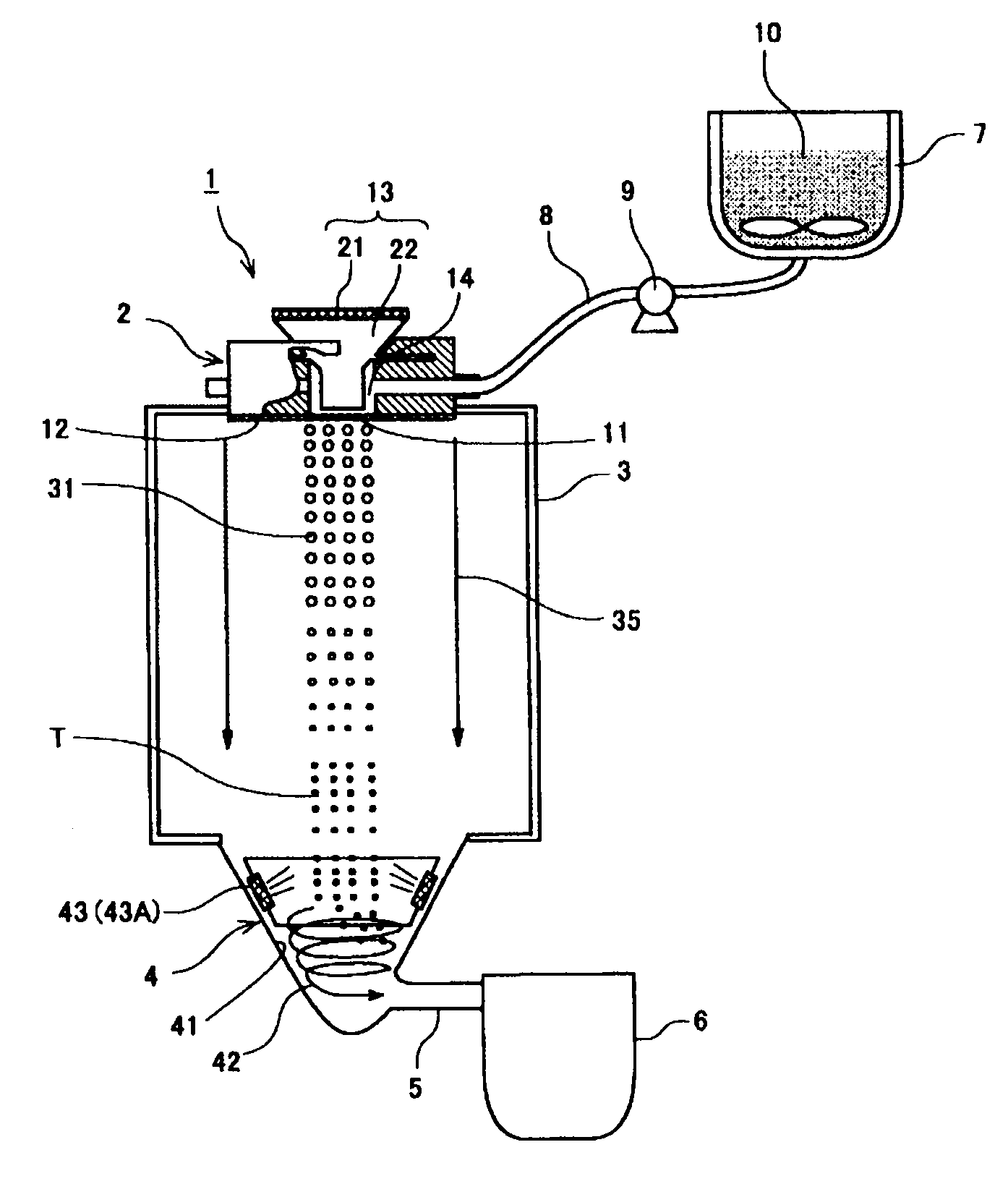

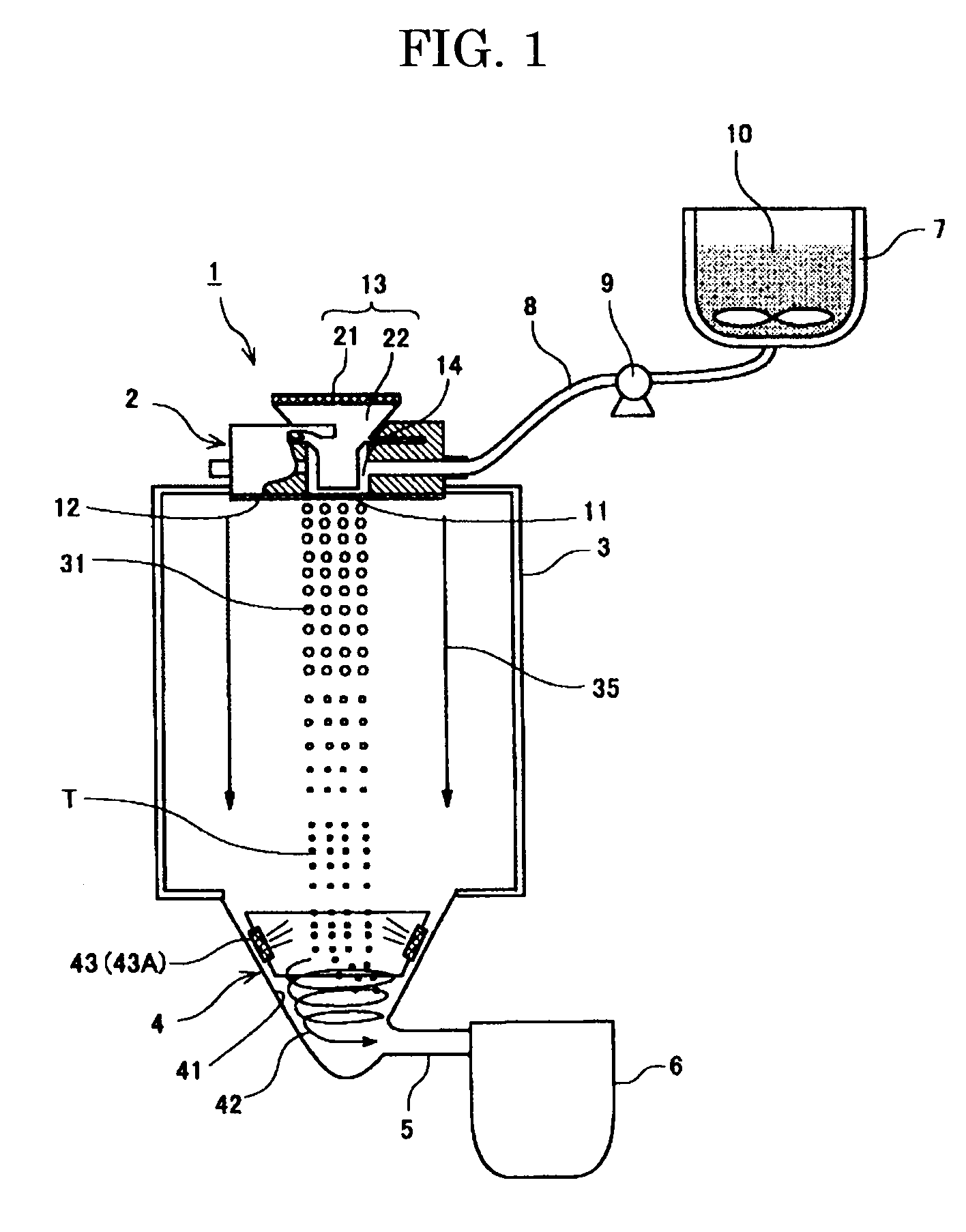

Composition and method for recovering hydrocarbon fluids from a subterranean reservoir

A composition comprising expandable cross linked polymeric microparticles having an unexpanded volume average particle size diameter of from about 0.05 to about 10 microns and a cross linking agent content of from about 9,000 to about 200,000 ppm of labile cross linkers and from 0 to about 300 ppm of non-labile cross linkers. The composition is used for modifying the permeability of subterranean formations and increasing the mobilization and / or recovery rate of hydrocarbon fluids present in the formations.

Owner:CHAMPIONX USA INC

Composition for recovering hydrocarbon fluids from a subterranean reservoir

A composition comprising expandable cross linked polymeric microparticles having an unexpanded volume average particle size diameter of from about 0.05 to about 10 microns and a cross linking agent content of about 6,000 to less than about 9,000 ppm of labile cross linkers and from 0 to about 300 ppm of non-labile cross linkers, useful for modifying the permeability of subterranean formations and increasing the mobilization and / or recovery rate of hydrocarbon fluids present in the formations.

Owner:CHAMPIONX USA INC

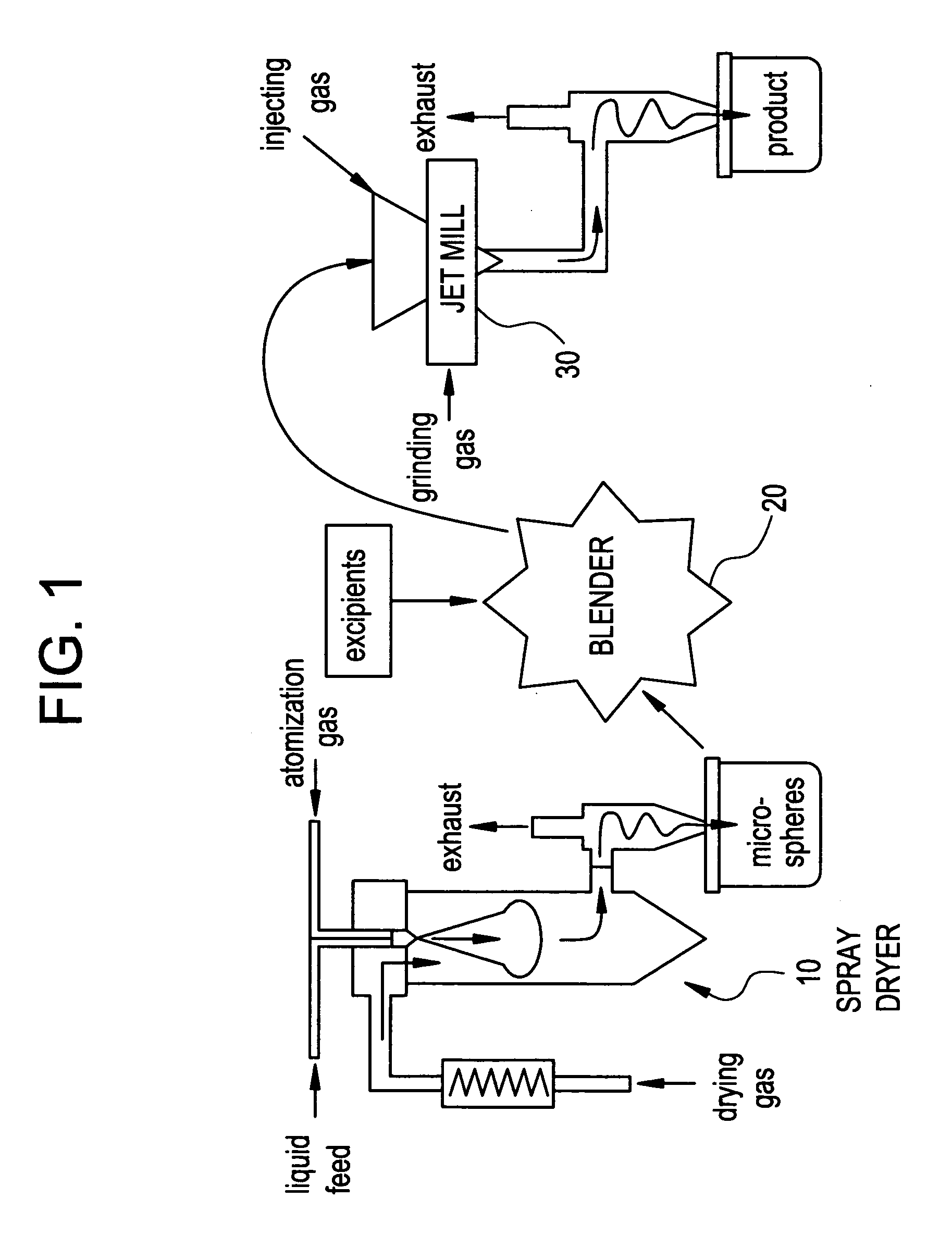

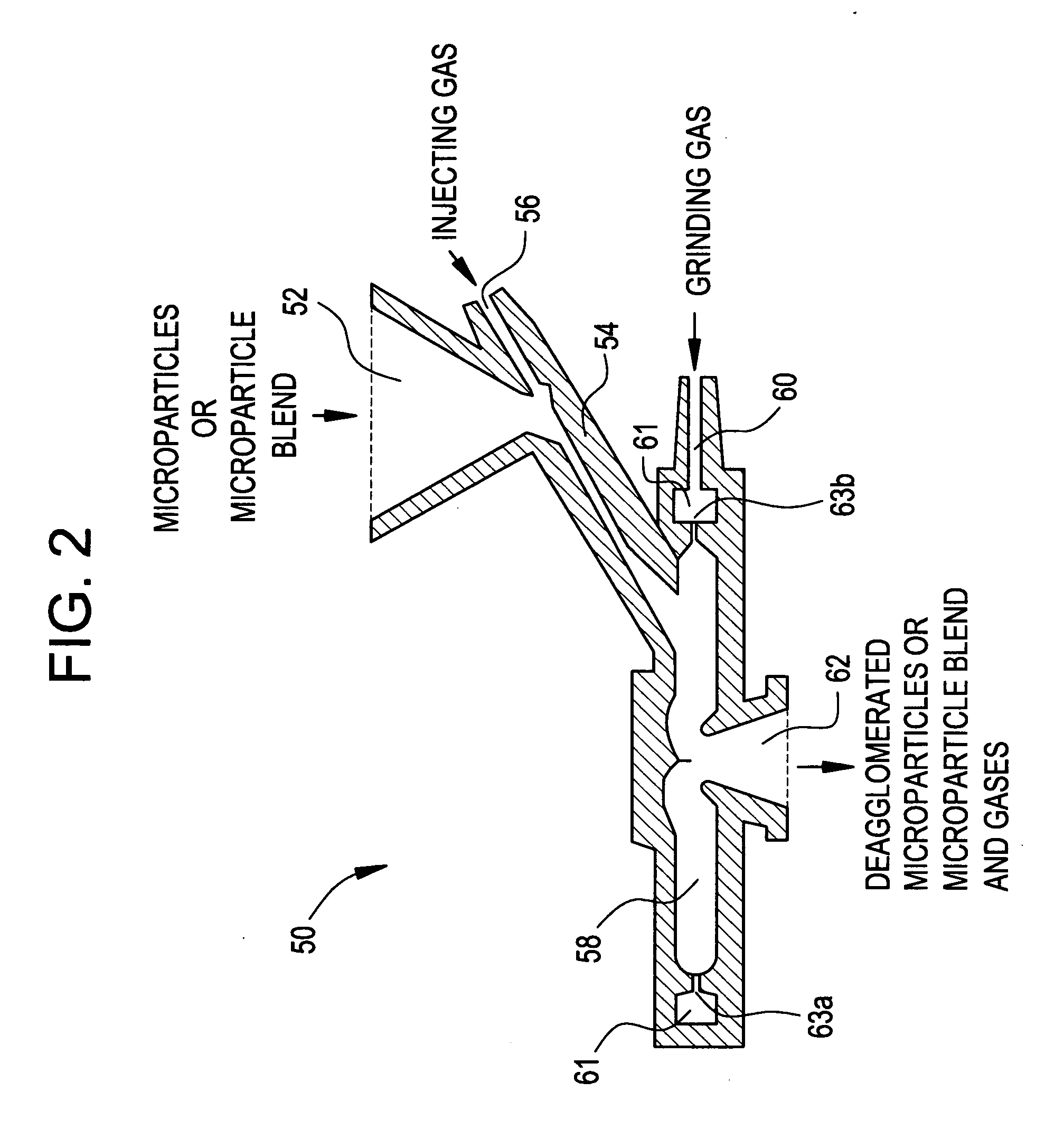

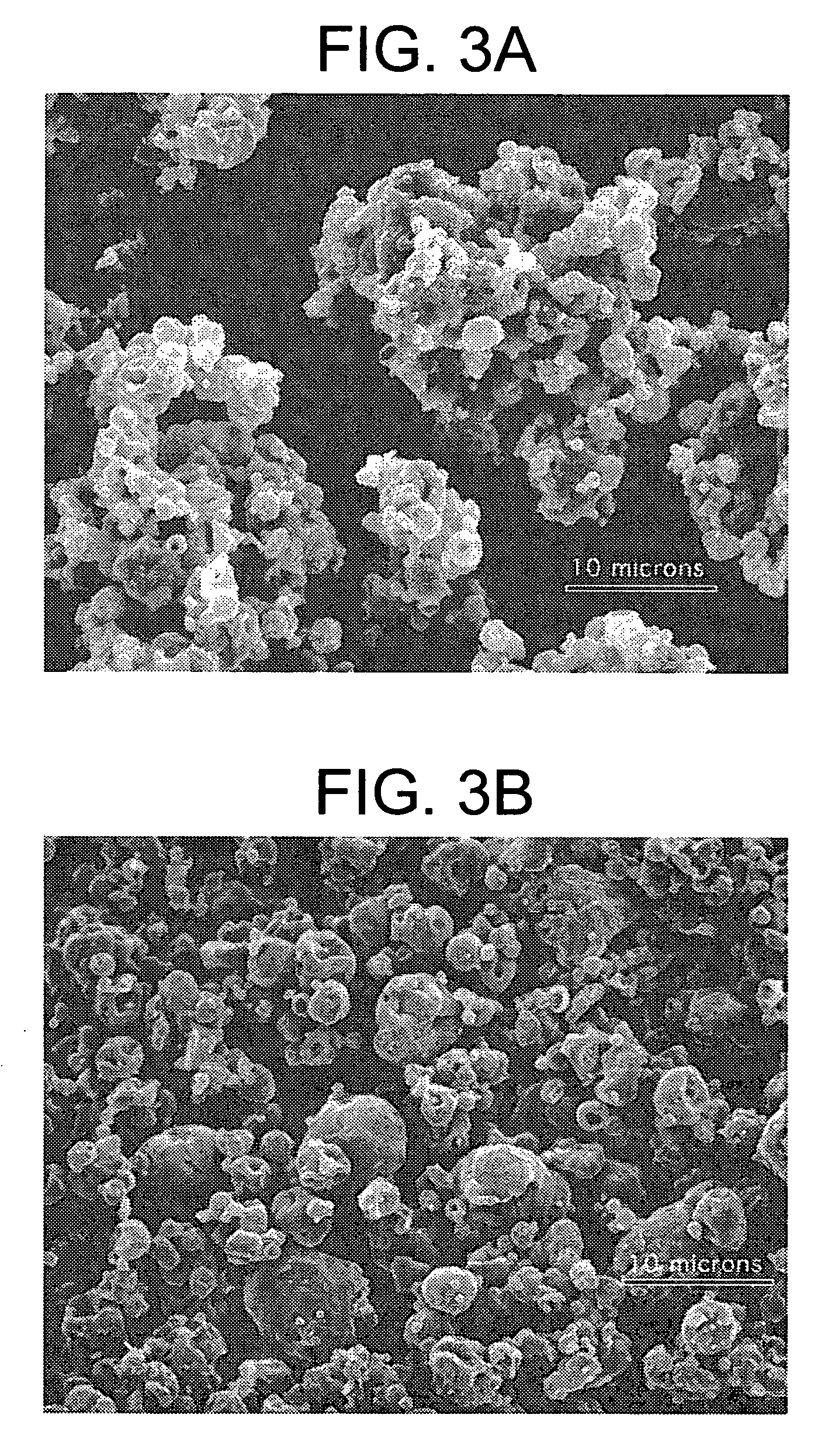

Methods for making pharmaceutical formulations comprising deagglomerated microparticles

InactiveUS20060093678A1High crystallinityReduce contentPowder deliveryGranulation by liquid drop formationMicroparticleVolume average

Methods are provided for making a dry powder blend pharmaceutical formulation comprising (i) forming microparticles which comprise a pharmaceutical agent; (ii) providing at least one excipient in the form of particles having a volume average diameter that is greater than the volume average diameter of the microparticles; (iii) blending the microparticles with the excipient to form a powder blend; and (iv) jet milling the powder blend to deagglomerate at least a portion of any of the microparticles which have agglomerated, while substantially maintaining the size and morphology of the individual microparticles. Jet milling advantageously can eliminate the need for more complicated wet deagglomeration processes, can lower residual moisture and solvent levels in the microparticles (which leads to better stability and handling properties for dry powder formulations), and can improve wettability, suspendability, and content uniformity of dry powder blend formulations.

Owner:CHICKERING DONALD E III +6

Silicone containing powders

A spray-dried, granular powder comprising: (i) from about 50% to about 99% of a water-soluble carrier, (ii) from about 1% to about 50% of a hydrophobic silicone oil dispersed within the carrier, wherein the spray-dried powder has a volume average particle size in the range from about 20 .mu.m to about 500 .mu.m, the powder being prepared by spray-drying an aqueous dispersion of the silicone oil and the water-soluble carrier, characterized in that the silicone oil is present in the dispersion in the form of discrete droplets having a volume average droplet size in the range from about 0.5 .mu.m to about 20 .mu.m and that the ratio of the average spray-dried particle size to the average droplet size is at least about 2.5:1. The powder is dry, free-flowing and processable into a punched tablet or other compressed forms, yet efficiently delivers the silicone oil on subsequent dissolution in water.

Owner:THE PROCTER & GAMBLE COMPANY

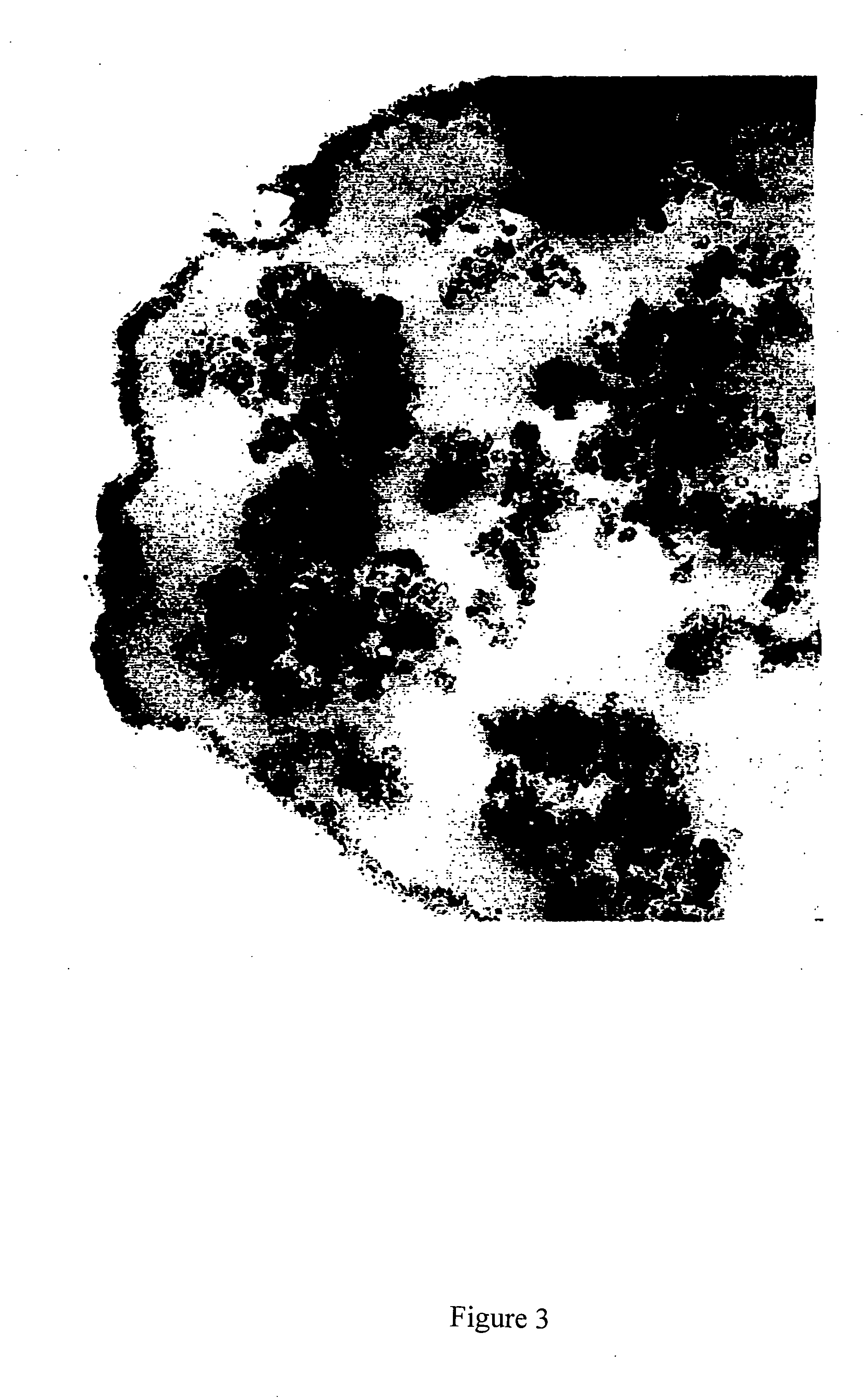

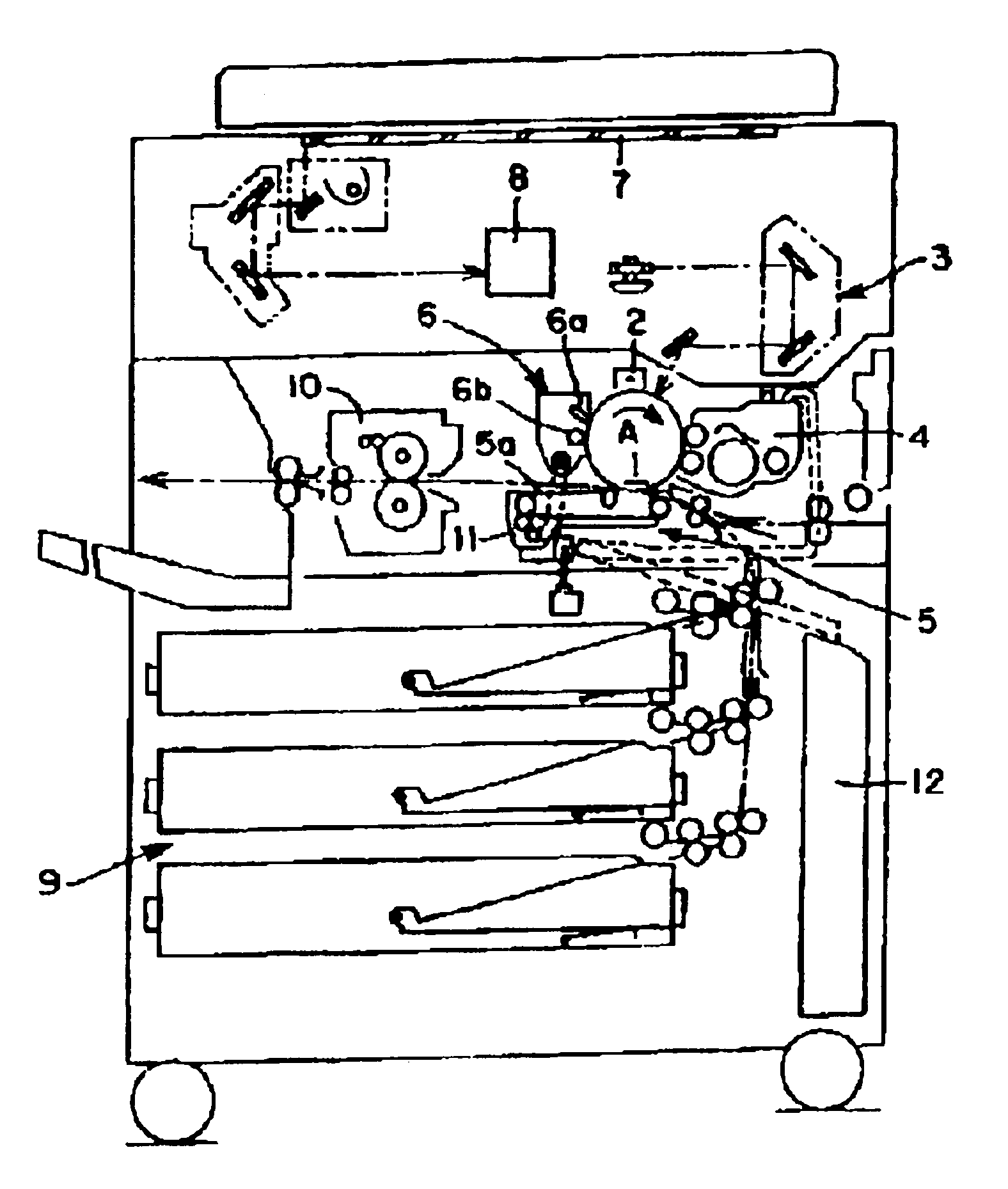

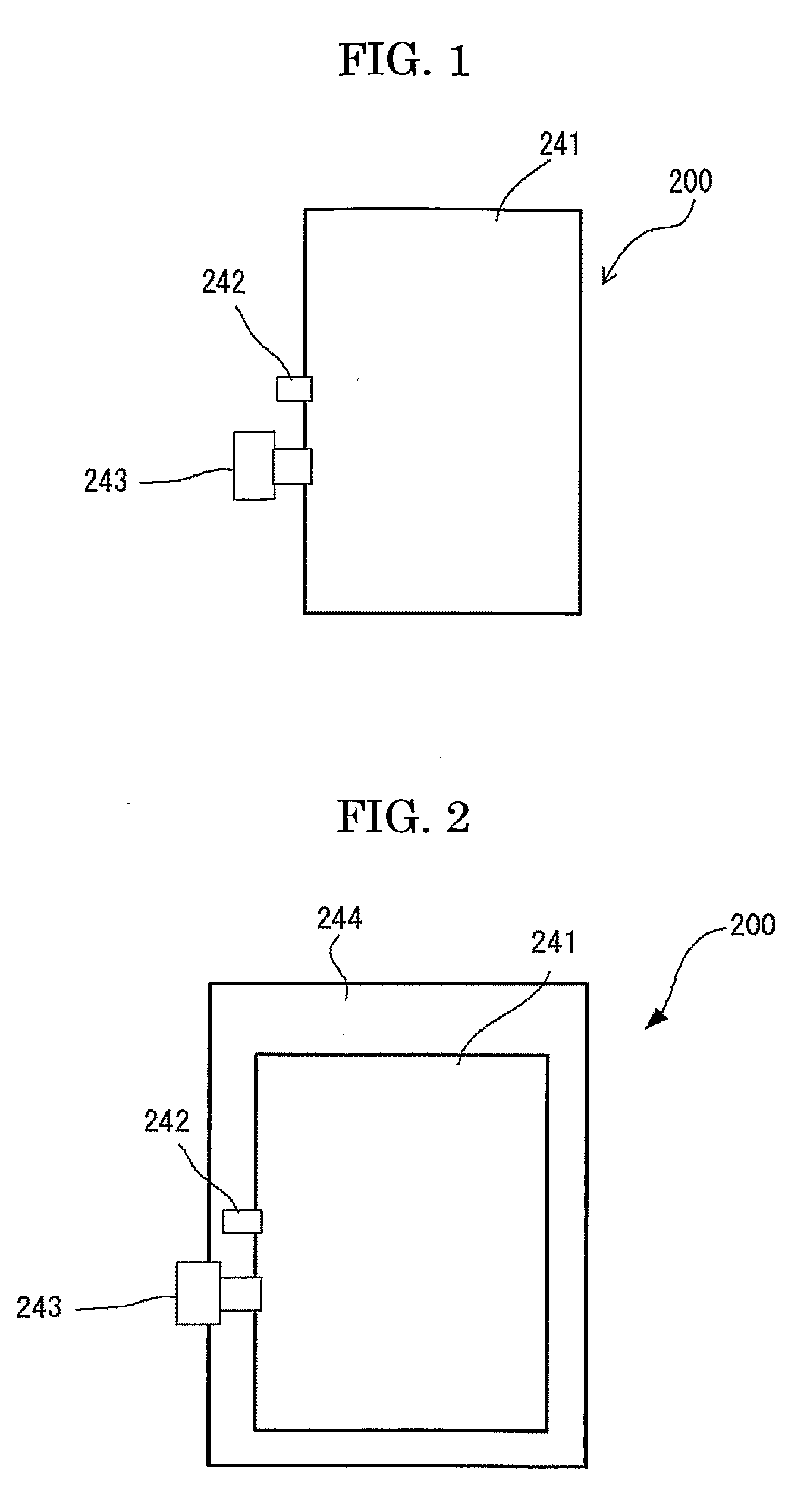

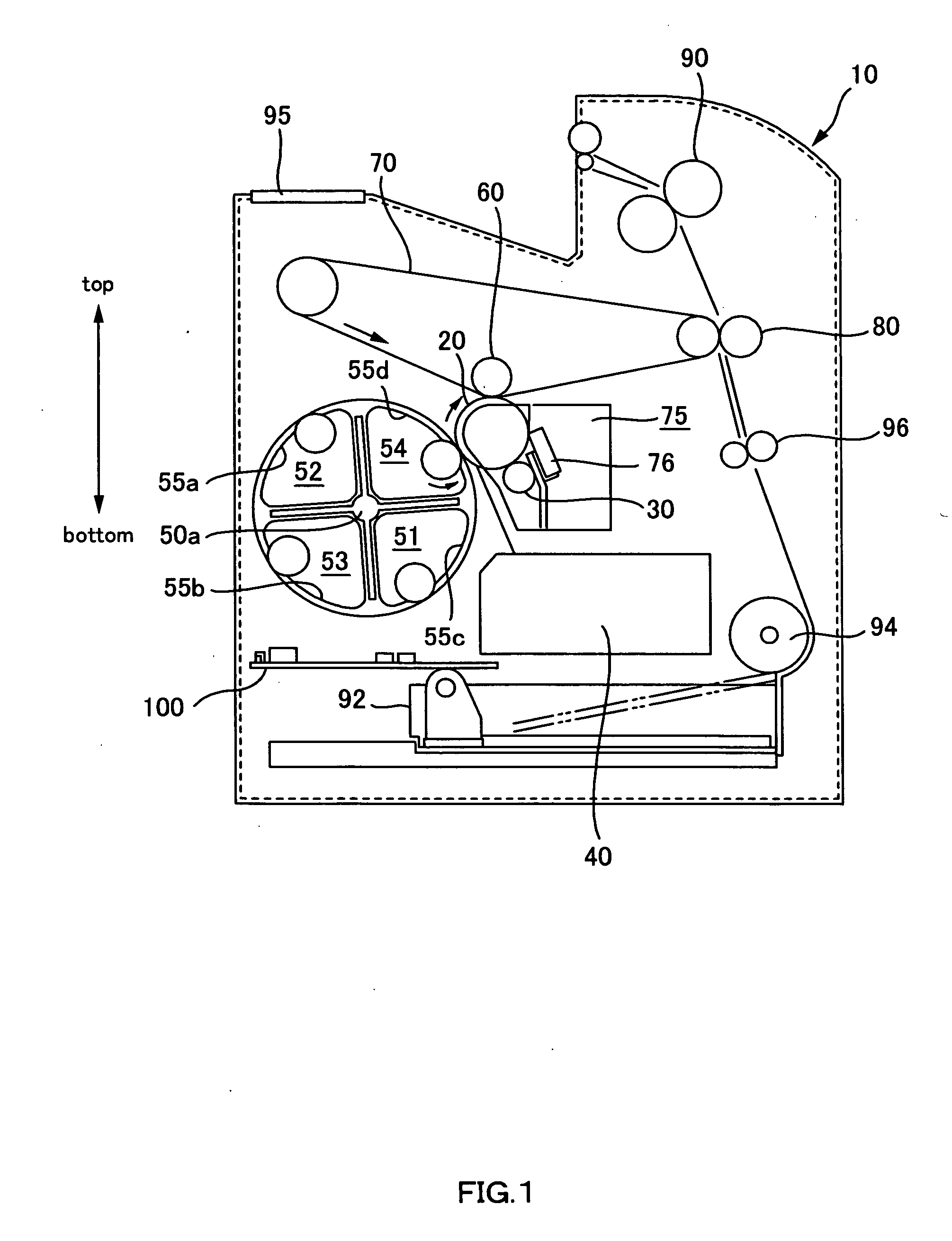

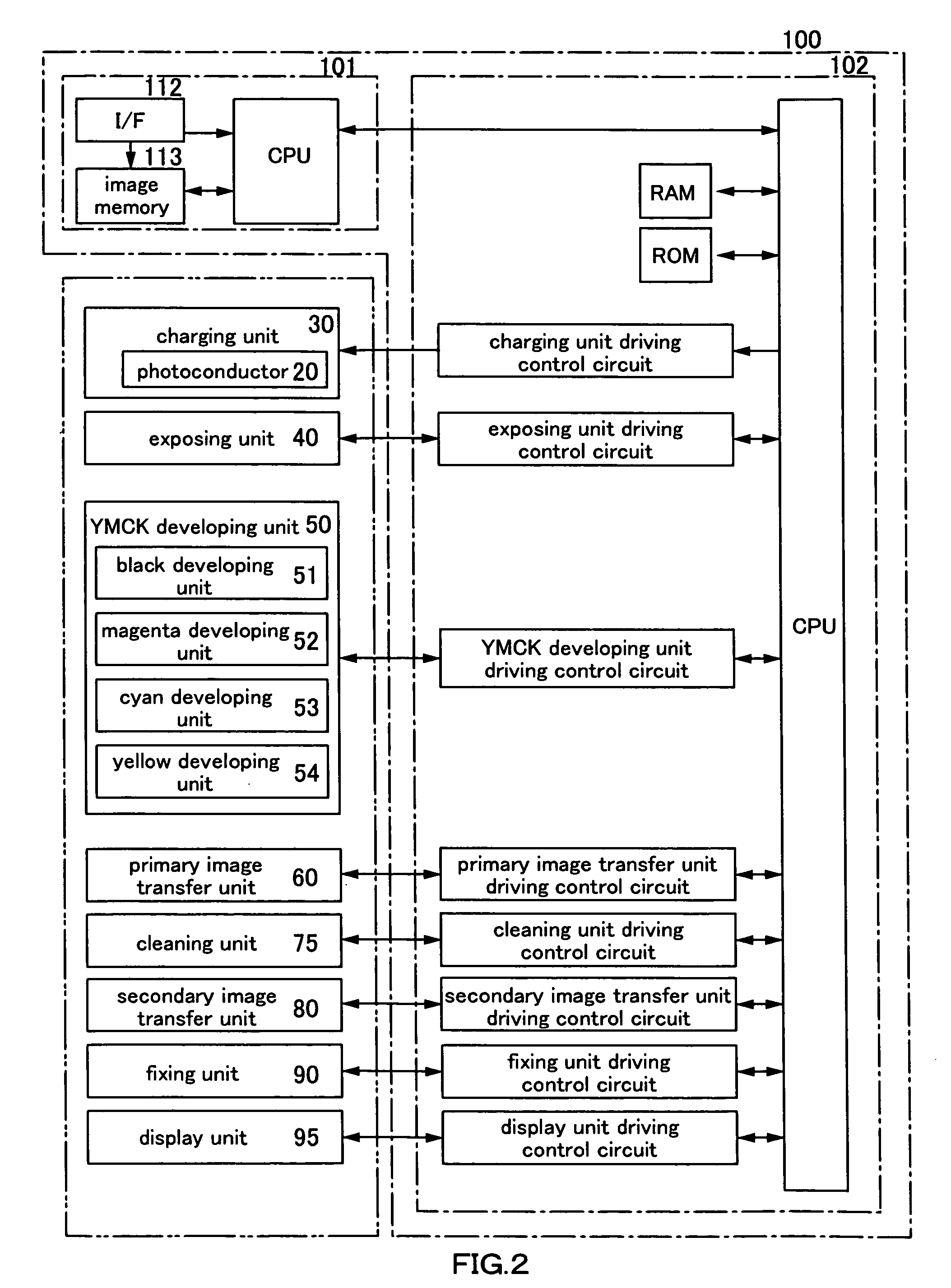

Toner, developer, toner container, process cartridge, image forming apparatus, and image forming method

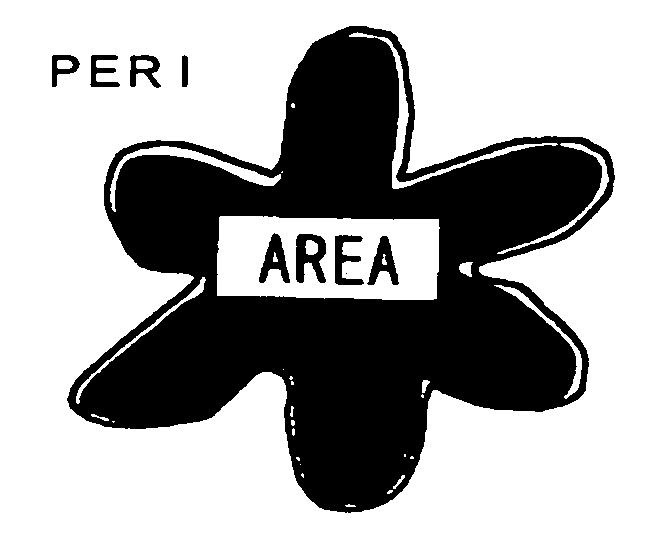

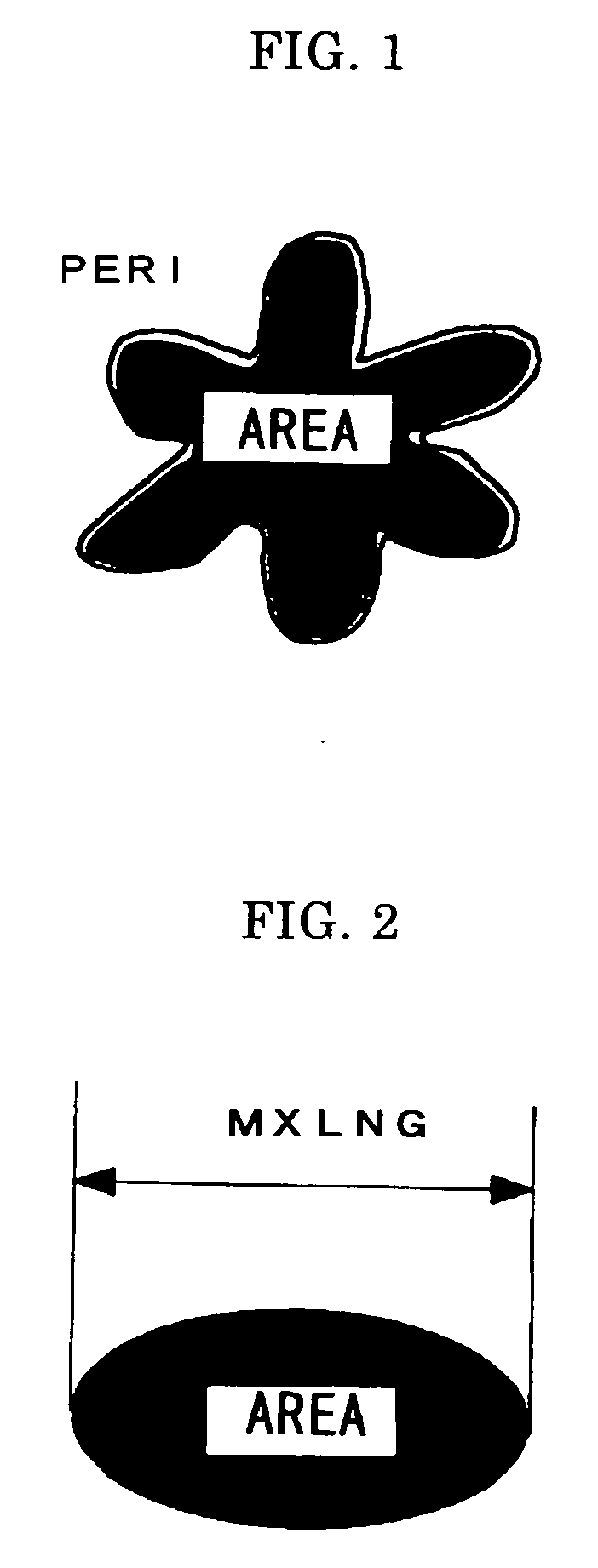

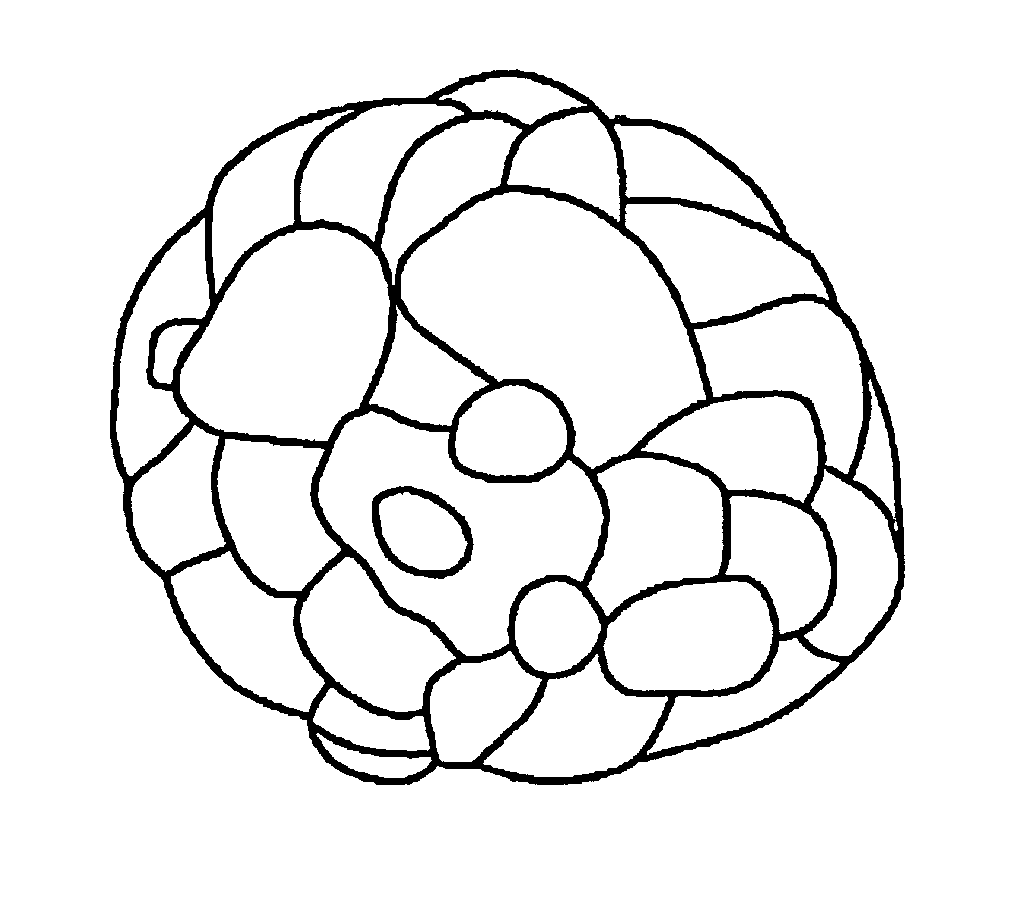

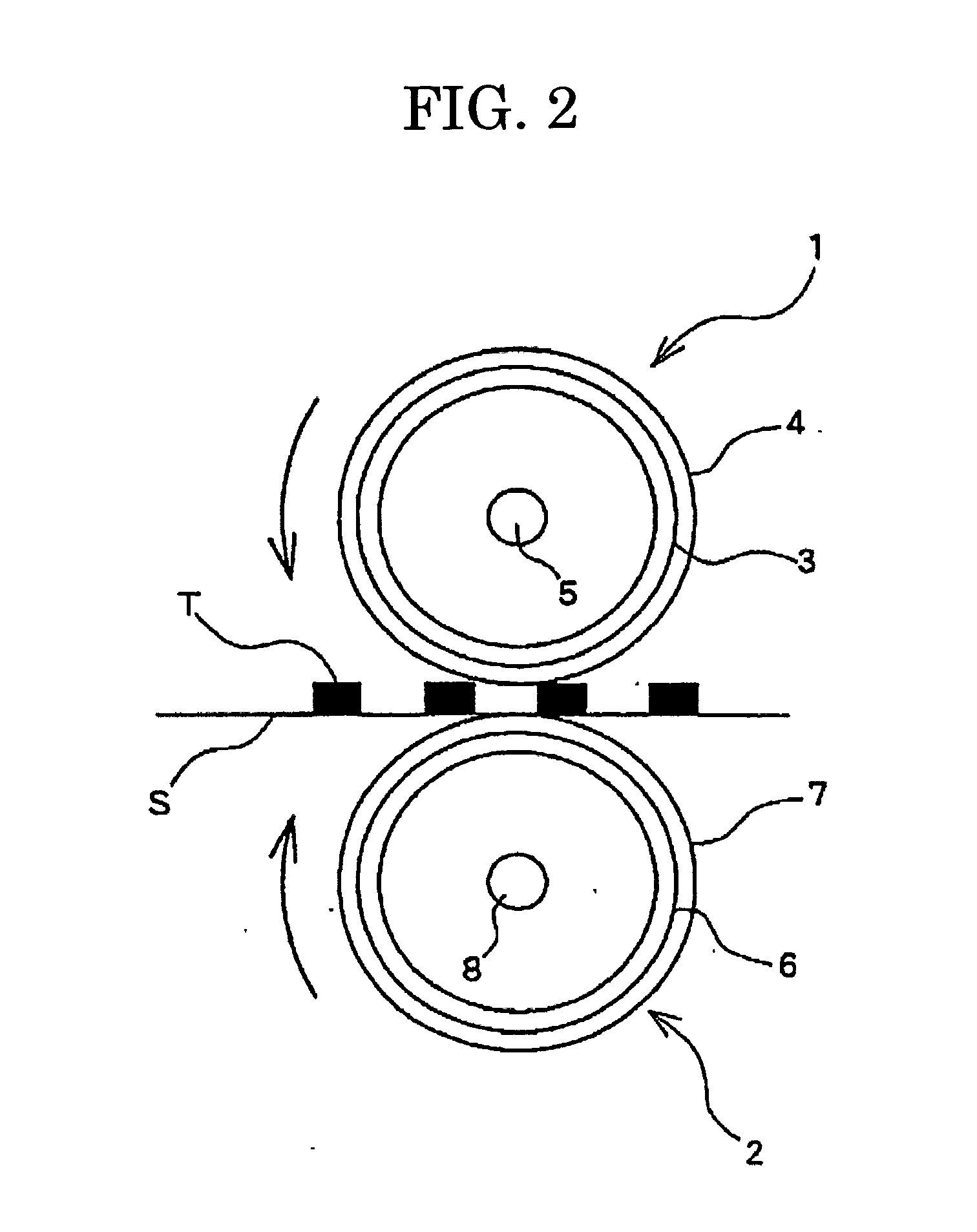

ActiveUS7318989B2Reduce thicknessDevelopersElectrographic processes using charge patternImage formationSpherical shaped

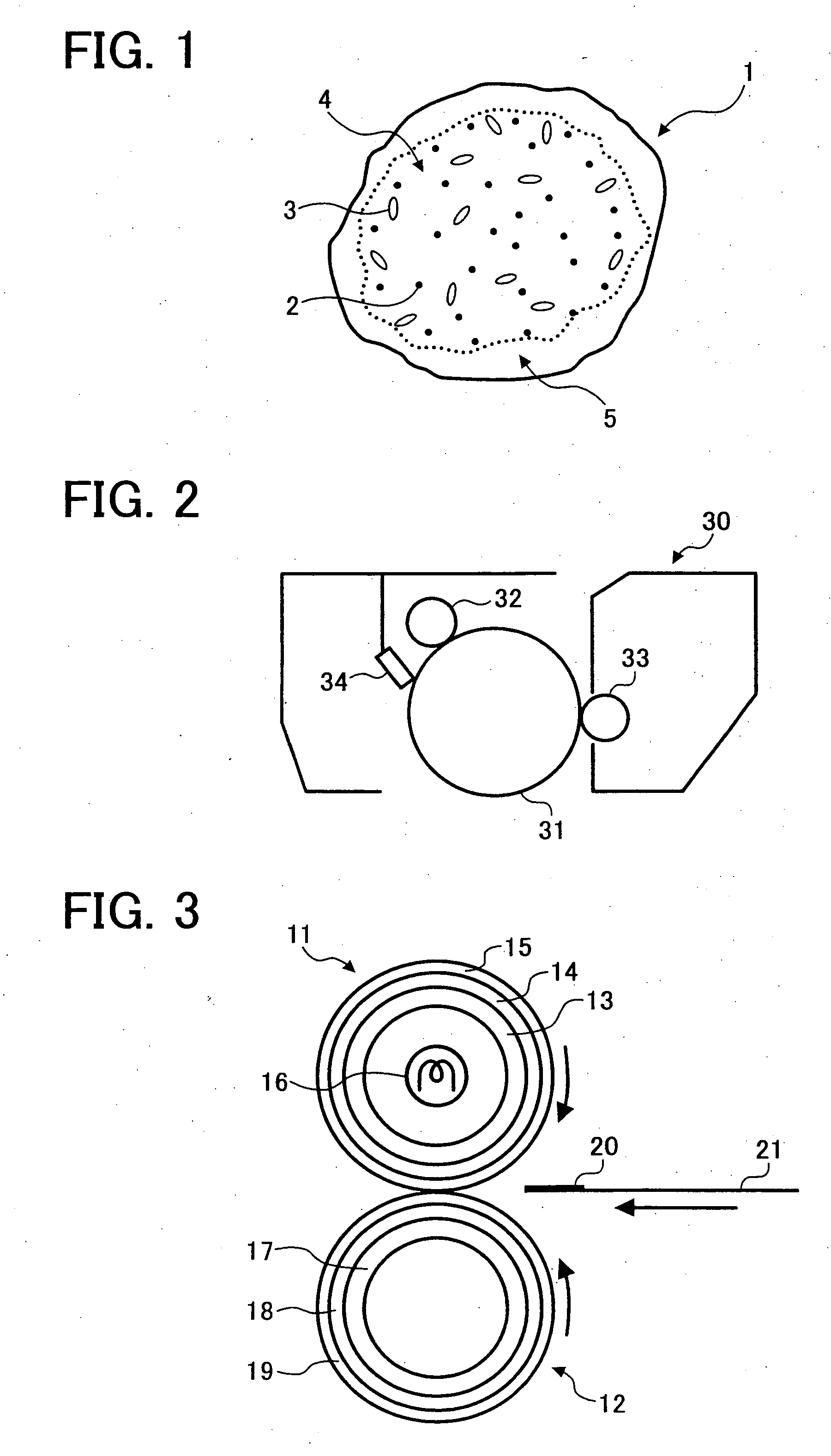

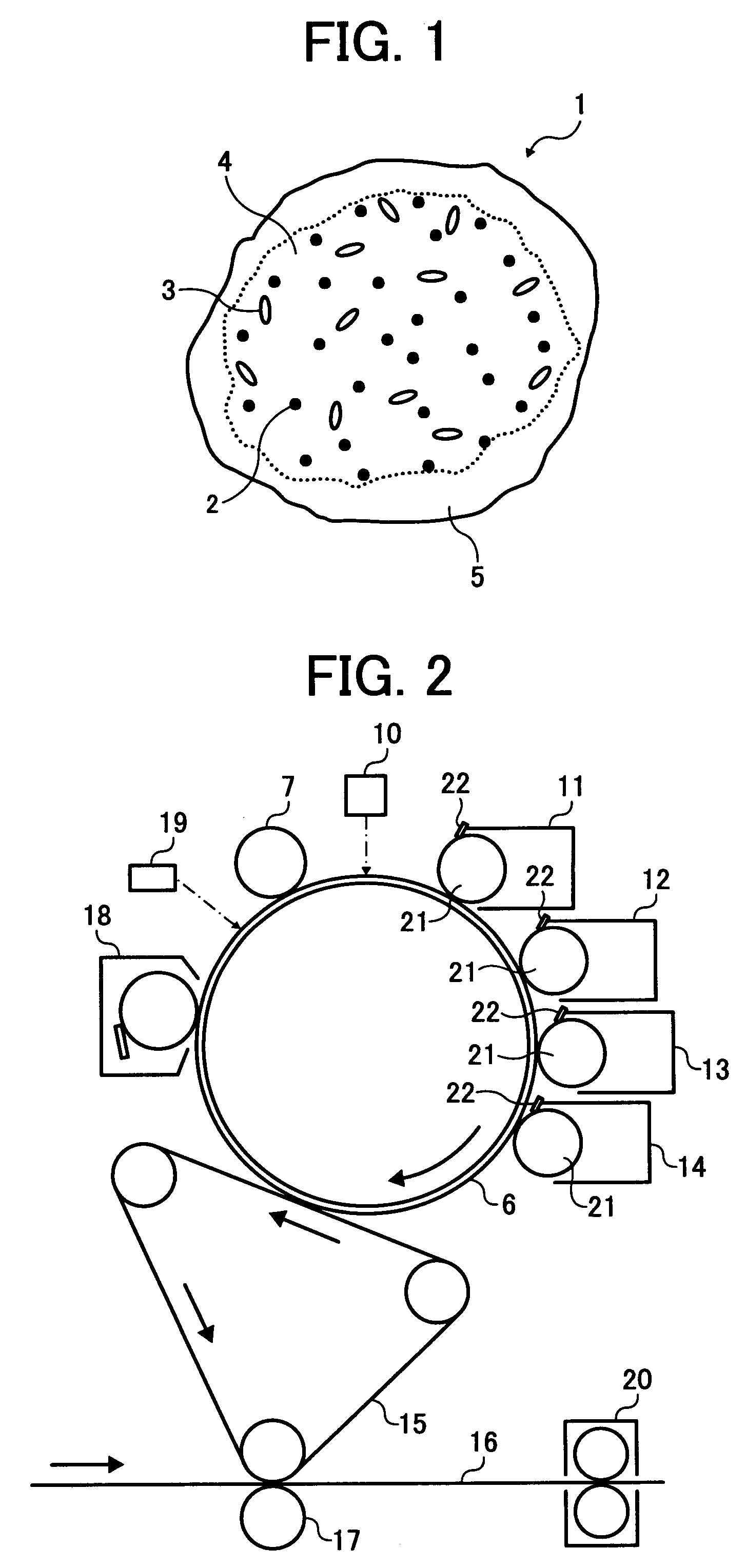

To provide a toner that can provide long-term removability and high-definition images with reduced image layer thickness and densely-packed toner particles, a developer capable of forming high-quality images using the toner, a toner container for containing the toner, a process cartridge using the toner, an image forming apparatus using the toner, and an image forming method using the toner. The toner of the present invention is a toner having a substantially spherical shape with irregularities on its surface and containing at least a binder resin and a colorant, wherein a surface factor SF-1 that represents the sphericity of toner particles is 105 to 180, a surface factor SF-2 that represents the degree of surface irregularities of the toner particles is correlated with the volume-average diameter of the toner particles, and the toner particles have an inorganic oxide particle-containing layer within 1 μm from their surfaces.

Owner:RICOH KK

Resin particle and process of producing the same

ActiveUS20060165989A1Improve wear resistanceExcellent in anti-hot offset propertyPretreated surfacesGranulation by liquid drop formationVolume averageWear resistance

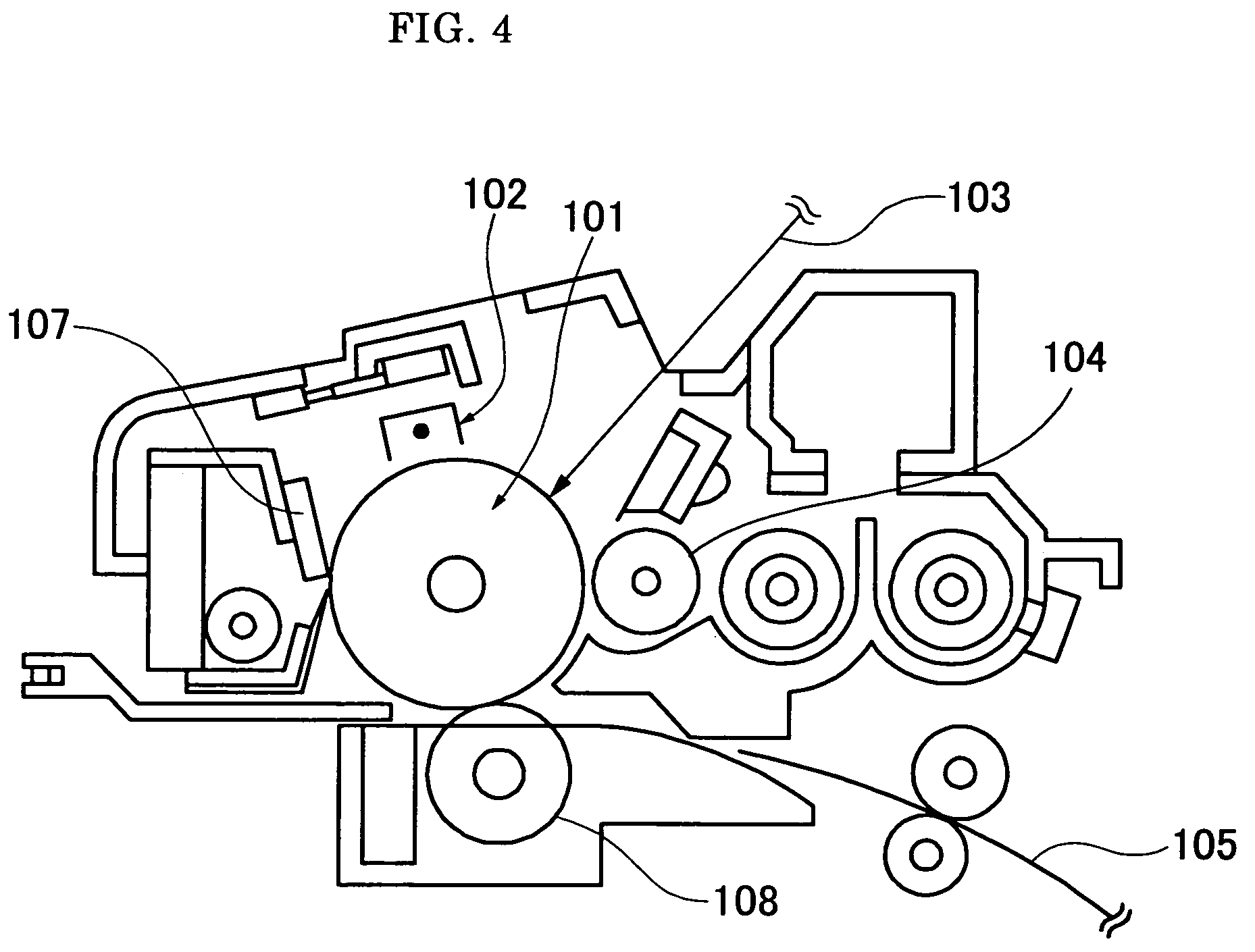

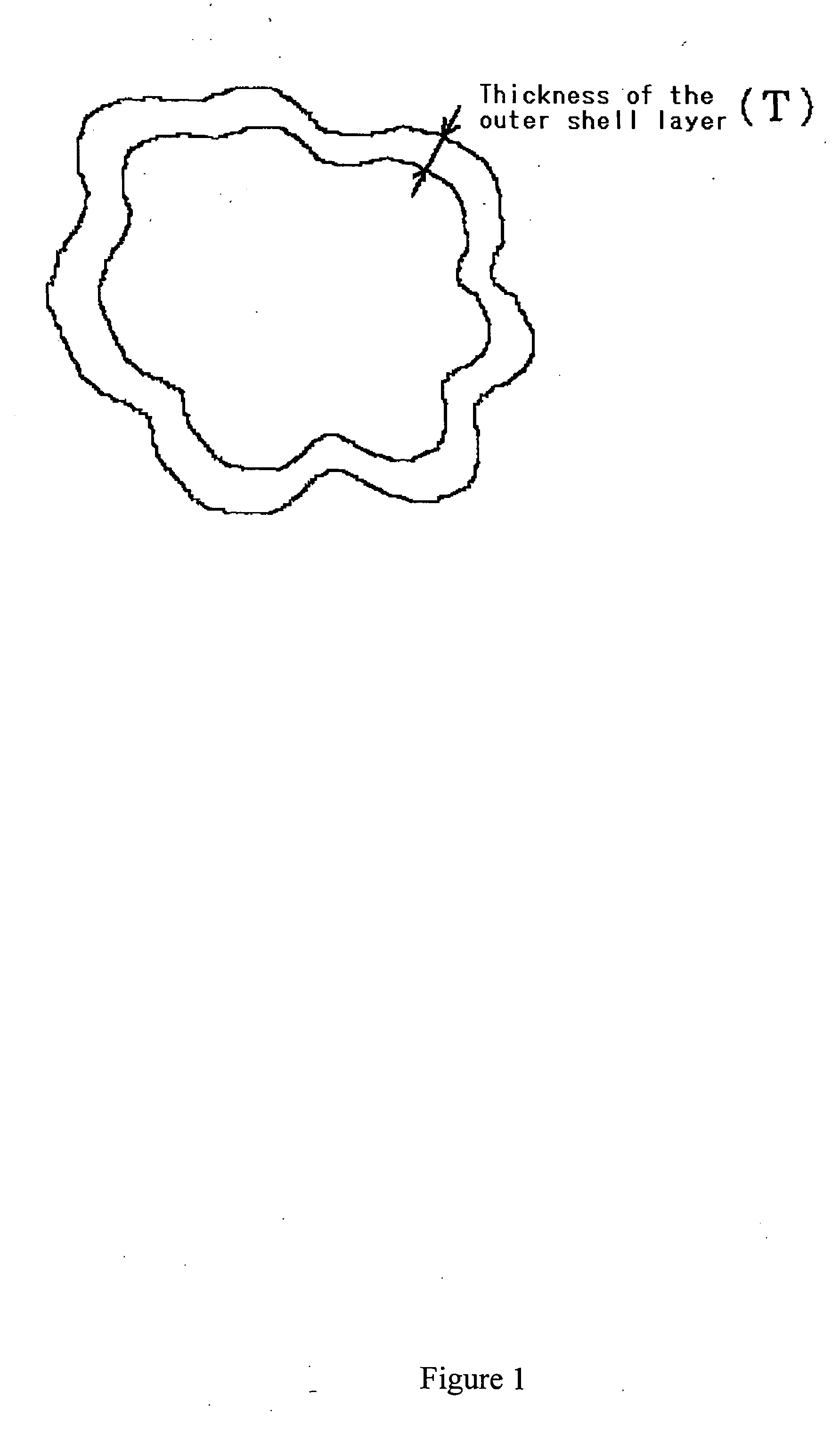

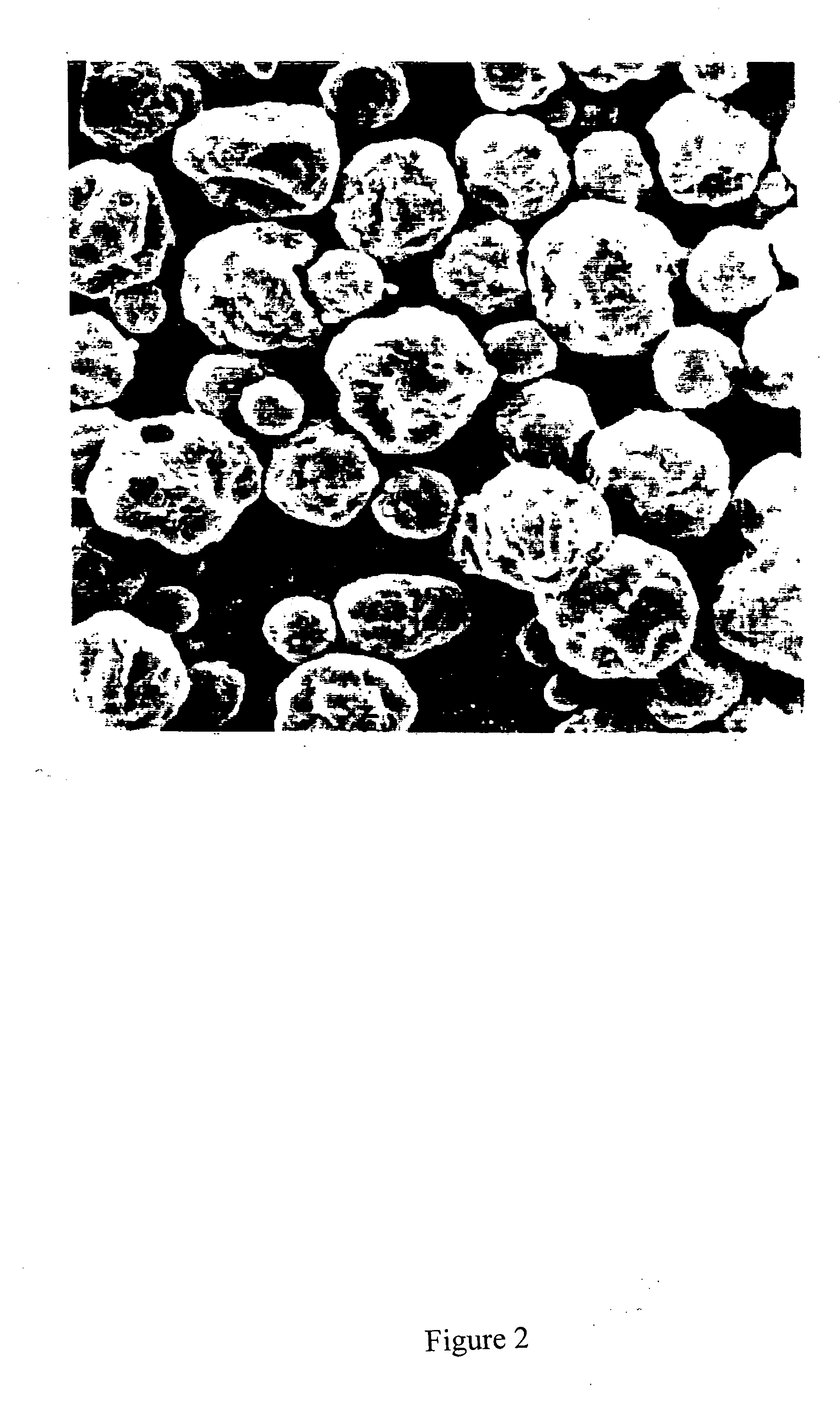

Provided is a resin particle comprising a resin (a) and a filler (b) contained in the particle; the particle has a volume average particle diameter of from 0.1 to 300 μm and a shape factor of from 110 to 300; the particle has an outer shell layer (S) comprising at least a portion of the filler (b); the layer (S) is at least 0.01 μm thick and has a thickness that is ½ or less of the maximum inscribed circle radius of the particle cross section. When used as a toner resin, it is excellent in blade cleaning properties and wide in the fixation temperature range; when employed as a paint additive or a cosmetics additive, it is excellent in masking properties; when used as paper coating additive, it is excellent in ink retention; when utilized as an abrasive, it is excellent in abrasion.

Owner:RICOH KK +1

Toner for developing electrostatic image, and developer, toner container, image forming apparatus and process cartridge using the toner

A toner including a core including at least a colorant, a release agent and a first binder resin; and a shell located overlying the core and including at least a second binder resin, wherein the first binder resin includes a polyester resin including a unit obtained from a diol selected from the group consisting of aliphatic diols and alicyclic diols, and the second binder resin includes a vinyl copolymer, and wherein a weight ratio (S / C) of the shell (S) to the core (C) is from 0.05 to 0.5 and the toner has a volume average particle diameter of from 3 to 8 μm.

Owner:RICOH KK

Compositions and methods for diverting injected fluids to achieve improved hydrocarbon fluid recovery

ActiveUS20090260819A1Increasing mobilizationImprove recovery rateFluid removalFlushingCross-linkMicroparticle

The present disclosure is directed to compositions and methods that may be used for enhanced oil recovery, for modifying the permeability of subterranean formations and for increasing the mobilization and / or recovery rate of hydrocarbon fluids present in the formations. The compositions may include, for example, expandable cross linked polymeric microparticles having an unexpanded volume average particle size diameter of from about 0.05 to about 5,000 microns and a cross linking agent content of from about 100 to about 200,000 ppm of hydrolytically labile silyl ester or silyl ether crosslinkers and from 0 to about 300 ppm of non-labile crosslinkers.

Owner:CHAMPIONX USA INC +1

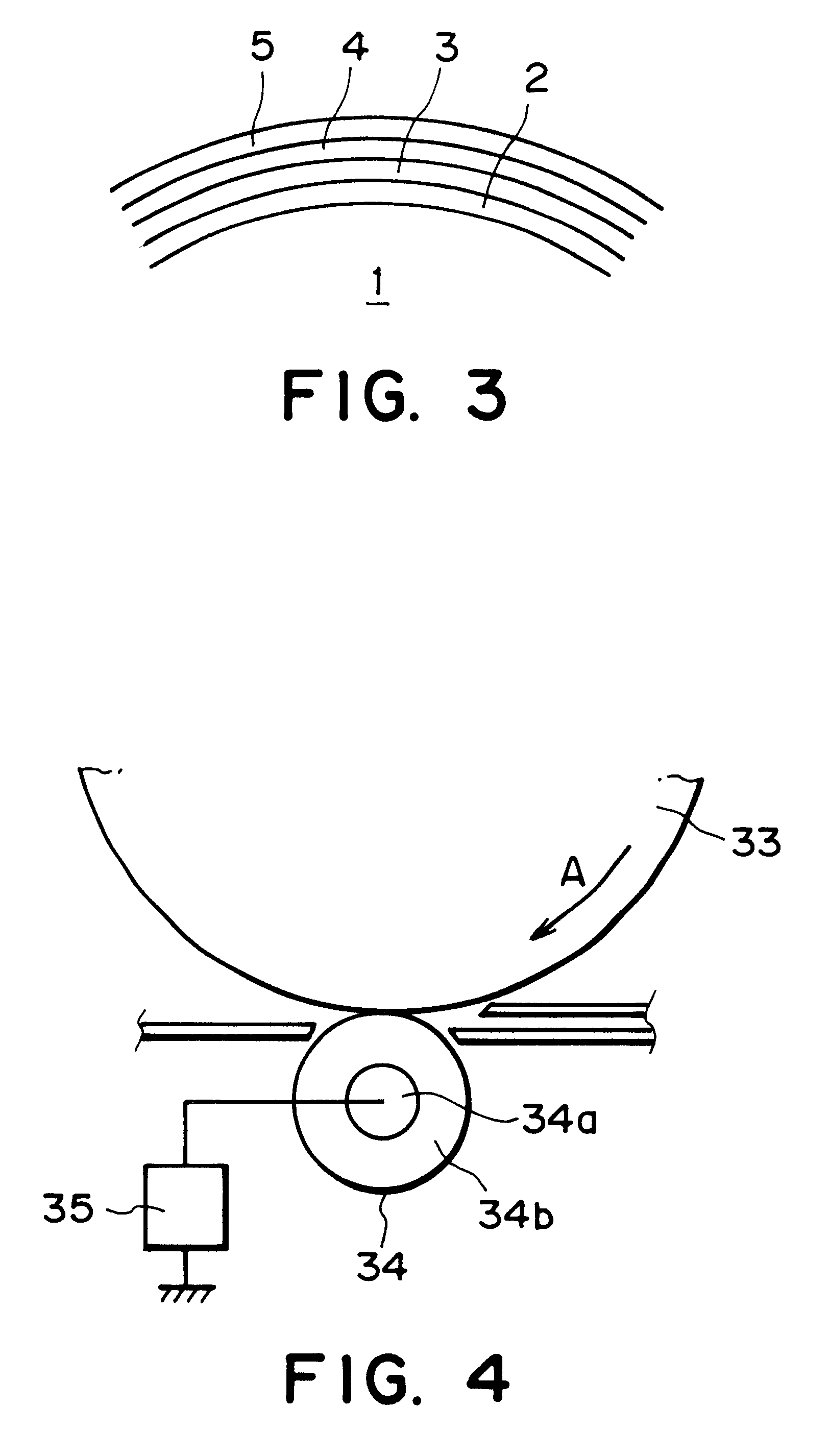

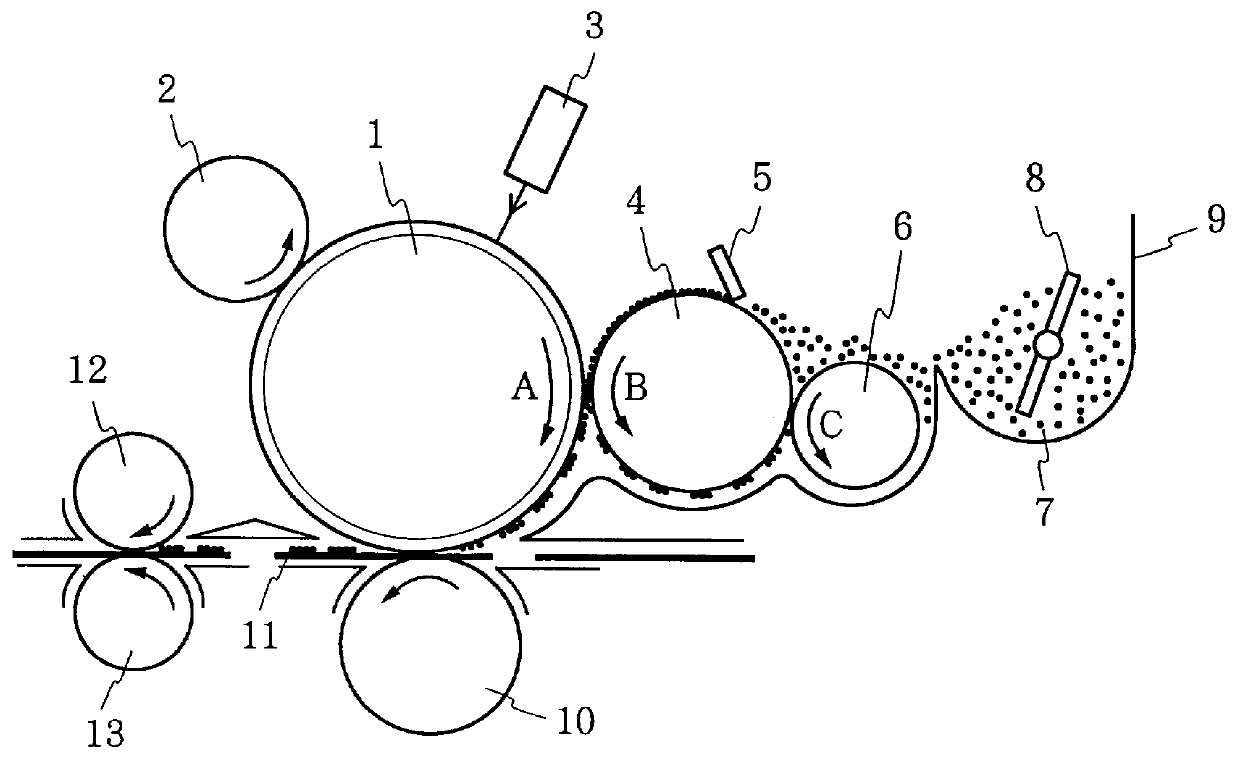

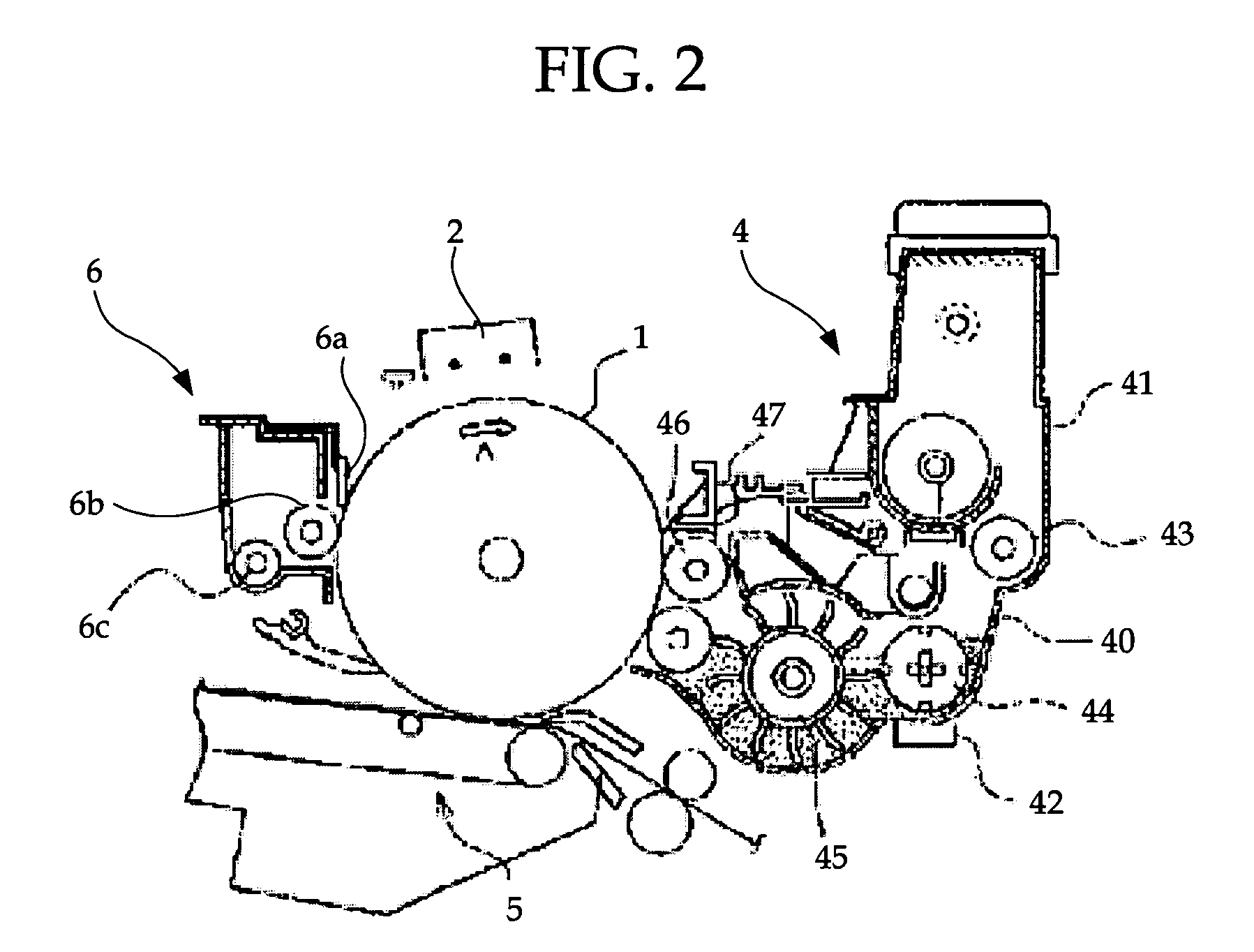

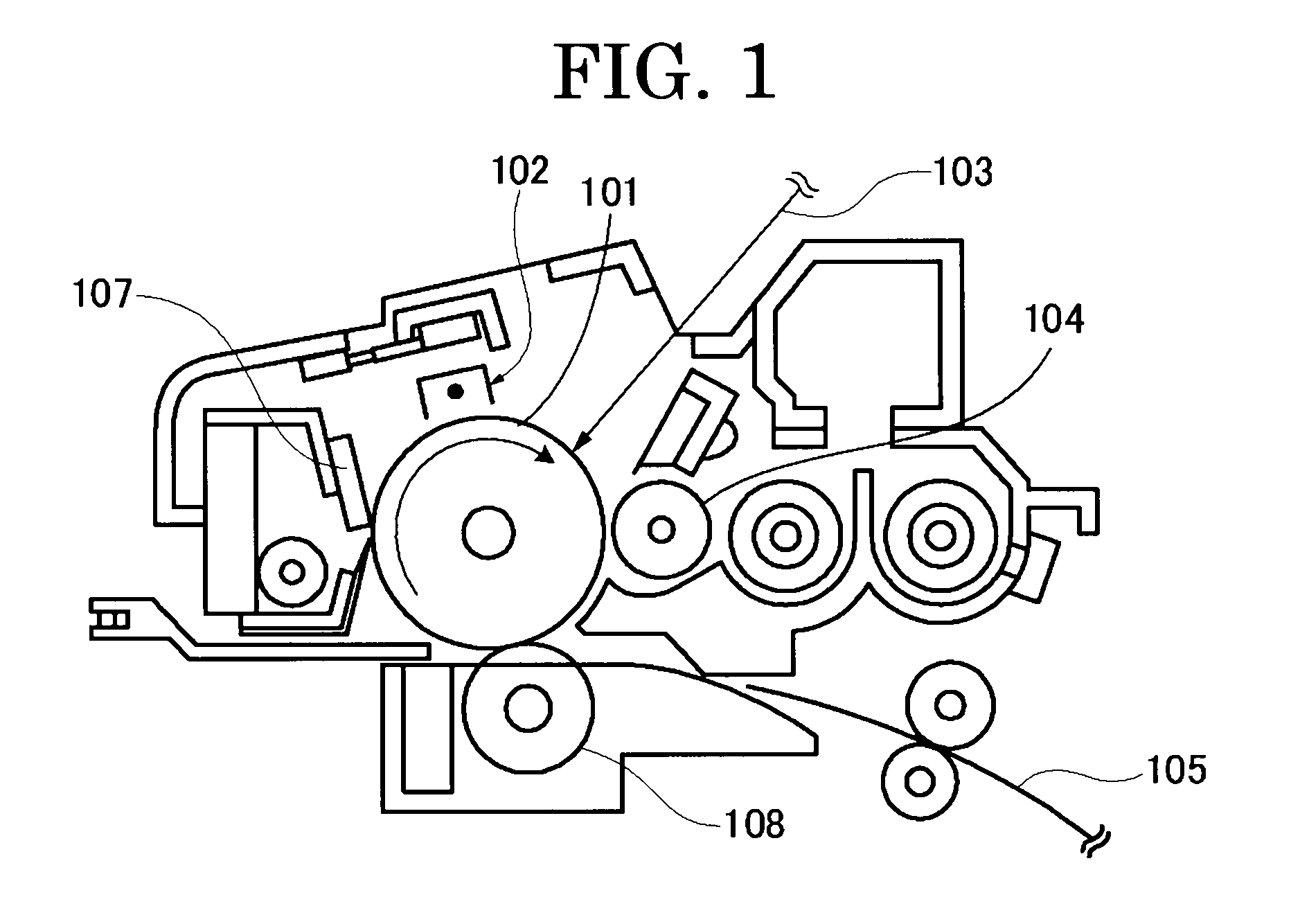

Magnetic toner, process for production thereof, and image forming method, apparatus and process cartridge using the toner

InactiveUS6465144B2Reduce wastePerformance and recoveryDevelopersElectrographic process apparatusMagnetizationX-ray

A magnetic toner includes: magnetic toner particles each comprising at least a binder resin and magnetic toner, and inorganic fine powder. The magnetic toner has an average circularity of at least 0.970, and a magnetization of 10-50 Am2 / kg at a magnetic field of 79.6 kA / m. The magnetic powder comprises at least magnetic iron oxide. The magnetic toner particles retain carbon in an amount of A and iron in an amount of B at surfaces thereof as measured by X-ray photoelectron spectroscopy, satisfying: B / A<0.001. The binder resin comprises a resin formed by polymerization of a monomer comprising at least styrene monomer. The magnetic toner has a residual styrene monomer content of less than 300 ppm, and contains at least 50% by number of toner particles satisfying a relationship of: D / C<=0.02, wherein C represents a volume-average particle size of the magnetic toner, and D represents a minimum distance between the surface of a magnetic toner particle and magnetic powder particles contained in the magnetic toner particle. Owing to the above features, the magnetic toner can exhibit good electrohotographic performances, including excellent chargeability and little transfer-residual toner, even in a cleanerless-mode image forming system.

Owner:CANON KK

Process for producing polymerized toner

Disclosed herein are a polymerized toner of core-shell structure, comprising core particles composed of colored polymer particles having a volume average particle diameter (dv) of 0.5-20 mu m and a ratio (dv / dp) of the volume average particle diameter (dv) to a number average particle diameter (dp) of at most 1.7, and shell which is formed of a polymer layer having an average film thickness of 0.001-0.1 mu m and covers each of the core particles, and a production process thereof.

Owner:ZEON CORP

Toner and image forming apparatus using the toner

A toner is used in an image forming process employing a toner recycling system and contains at least a modified polyester resin, a coloring agent, and a releasing agent. The toner has a volume-average particle diameter Dv, a number-average particle diameter Dn and a shape factor SF-1, wherein Dv is in a range from 4.0 μm to 6.0 μm, the ratio Dv / Dn of Dv to Dn is in a range from 1.00 to 1.30, and the shape factor SF-1 is in a range from 140 to 200.

Owner:RICOH KK

Inkjet recording ink and recording media set, inkjet recording method, recorded matter and recording apparatus

ActiveUS20090258196A1Superior glossinessHigh image densityMaterial nanotechnologyDecorative surface effectsOrganic solventContact time

There is provided an inkjet recording ink and recording media set, which contains: an inkjet recording ink; and a recording medium, wherein the inkjet recording ink comprises at least: water; a water-soluble organic solvent; and a colorant containing carbon black, and having a volume average particle diameter of 40 nm to 100 nm, wherein the recording medium contains: a substrate; and a coating layer on at least one side of the substrate, and wherein an amount of pure water transferred to the recording medium, as measured with a dynamic scanning absorptometer at 23 C and 50% RH, at a contact time of 100 ms is 2 ml / m2 to 35 ml / m2 while an amount of pure water transferred to the recording medium at a contact time of 400 ms is 3 ml / m2 to 40 ml / m2.

Owner:RICOH KK

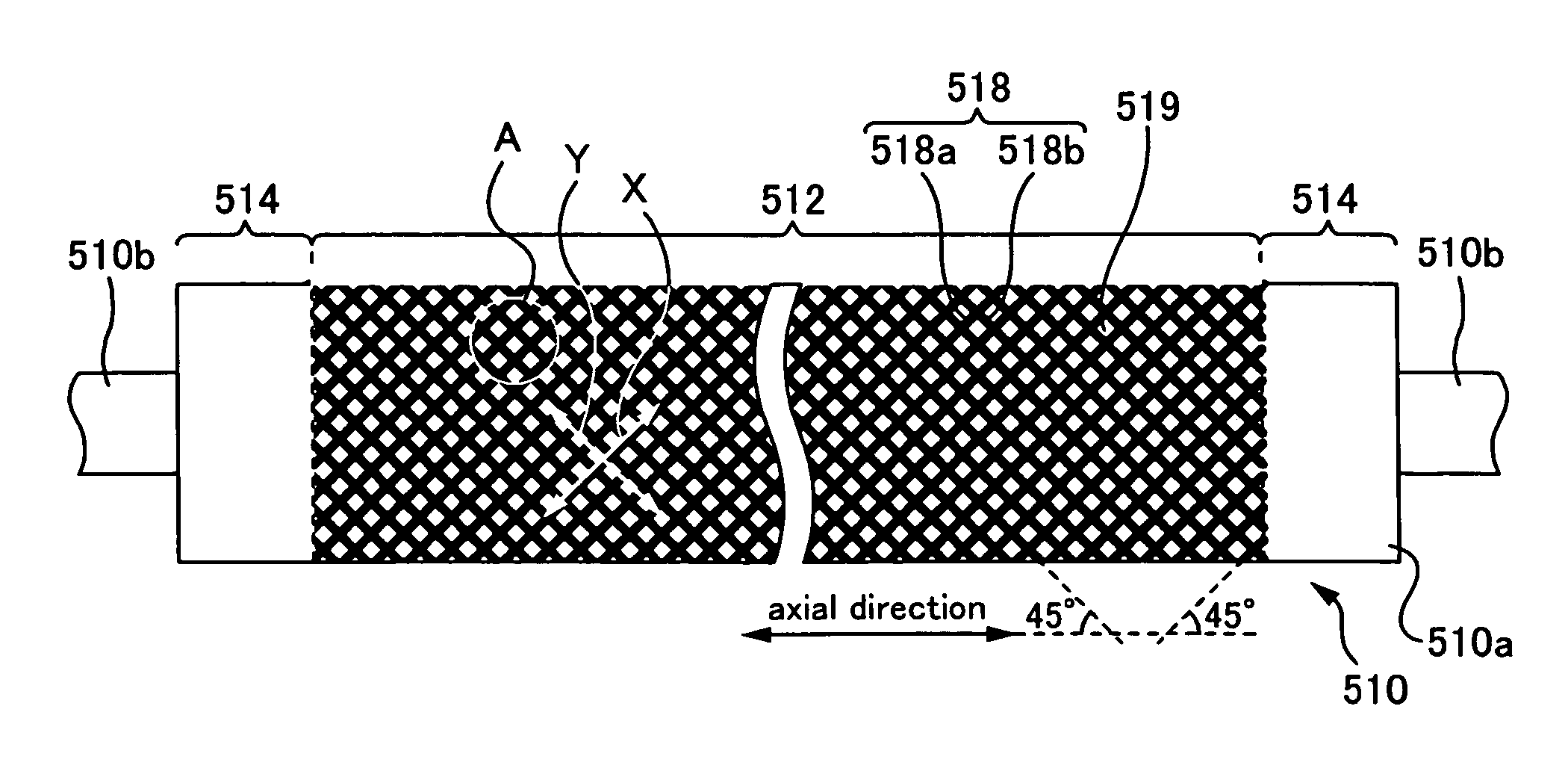

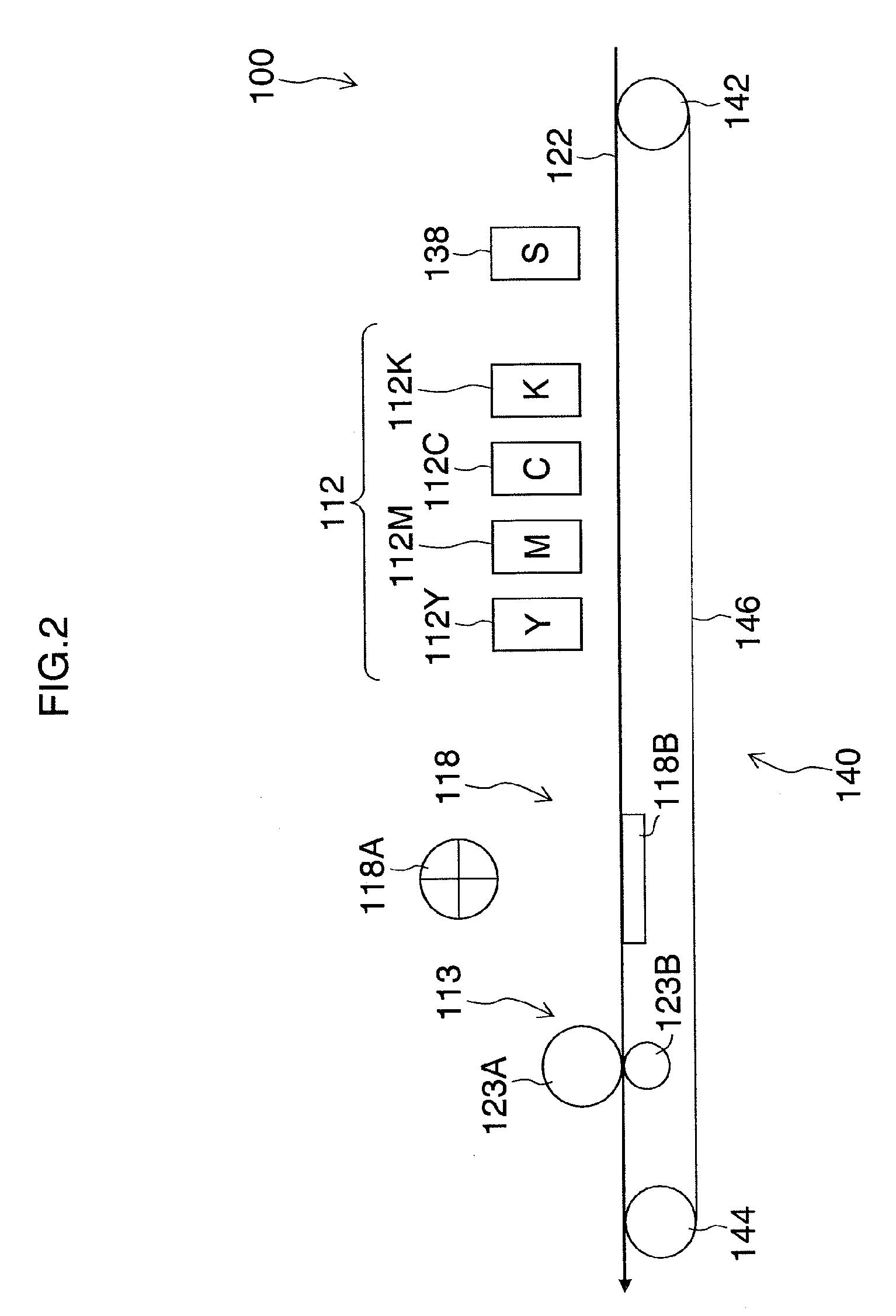

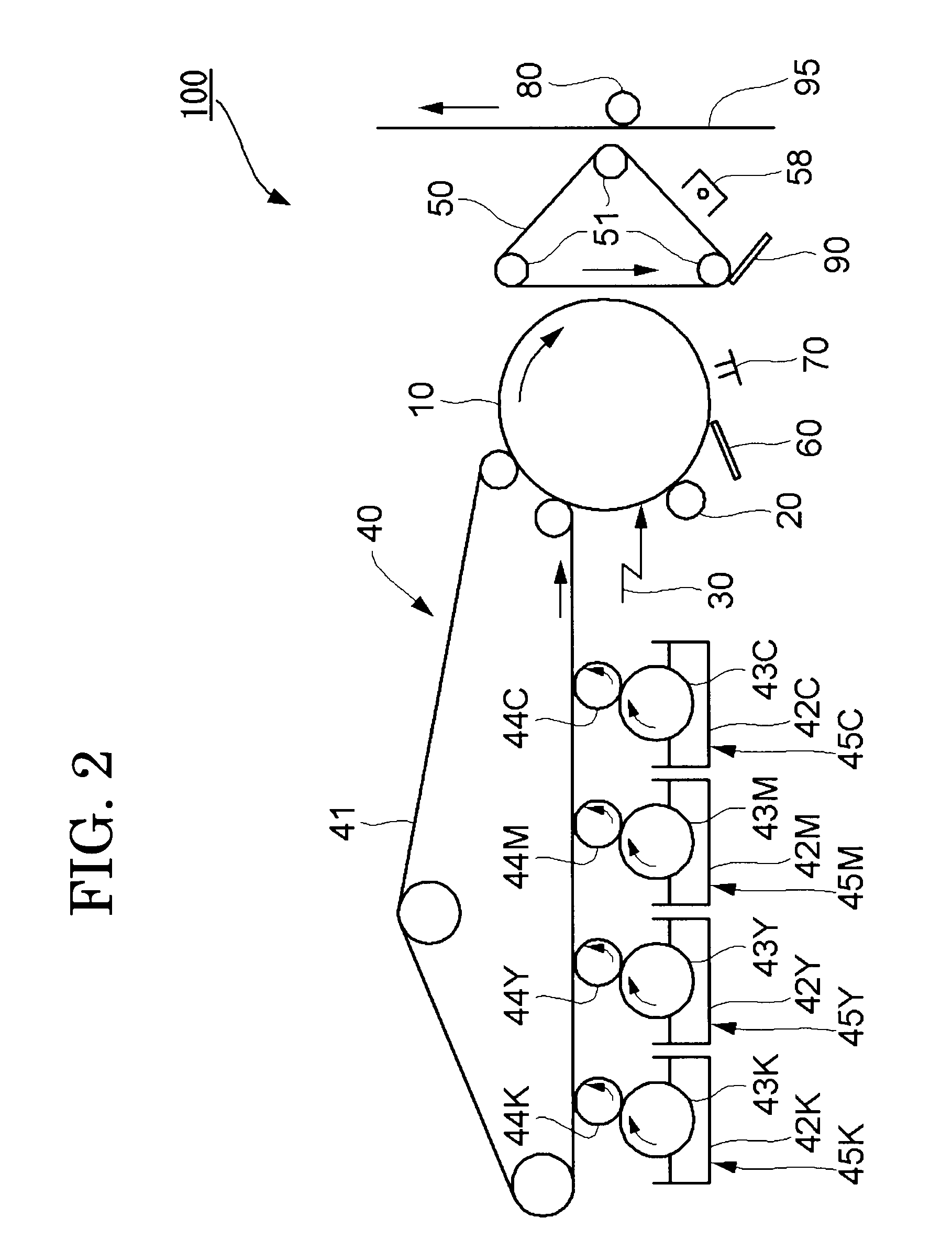

Toner-Particle Bearing Roller, Developing Device, And Image Forming Apparatus

ActiveUS20070110481A1Suppression of deformationElectrographic process apparatusLatent imageImage formation

A developing device includes a toner particle-bearing roller that bears toner particles on its surface and develops a latent image borne by an image-bearing member with those toner particles, the toner particle-bearing roller has a projection portion disposed on its surface, the projection portion having a top surface having a flat portion, and a width of the top surface being equal to or more than a volume average particle diameter of the toner particles.

Owner:SEIKO EPSON CORP

Chemically prepared toner and process therefor

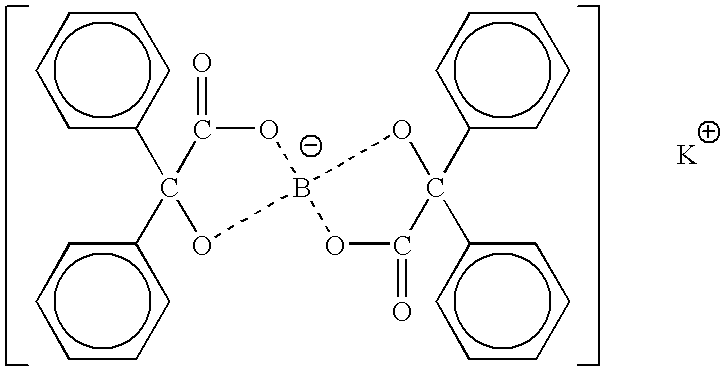

InactiveUS6991884B2Simplifying toner production processShorten reaction timeDuplicating/marking methodsInksCharge controlVolume average

A chemically prepared toner for electrophotographic printers and method therefor using a unique polymeric dispersant. The chemically prepared toner includes agglomerated polymeric dispersant stabilized pigment particles, a fuser release agent, a charge control agent dispersion, and a self-stabilized essentially surfactant free latex binder. The polymeric dispersant includes at least three segments, a hydrophilic polymeric segment, a hydrophobic polymeric segment, and a protective colloid or reactive surfactant segment. The weight average molecular weight range of the dispersant ranges from about 5,000 to about 30,000, and a hydrophobicity ranging from about 10 to about 90 percent by weight. The chemically prepared toner includes agglomerated toner particles have a unimodal particles size distribution with a number average particle size (N) ranging from about 5.0 to about 8.5 microns and a volume average particle size (V) ranging from about 5.0 to about 8.5 microns.

Owner:LEXMARK INT INC +1

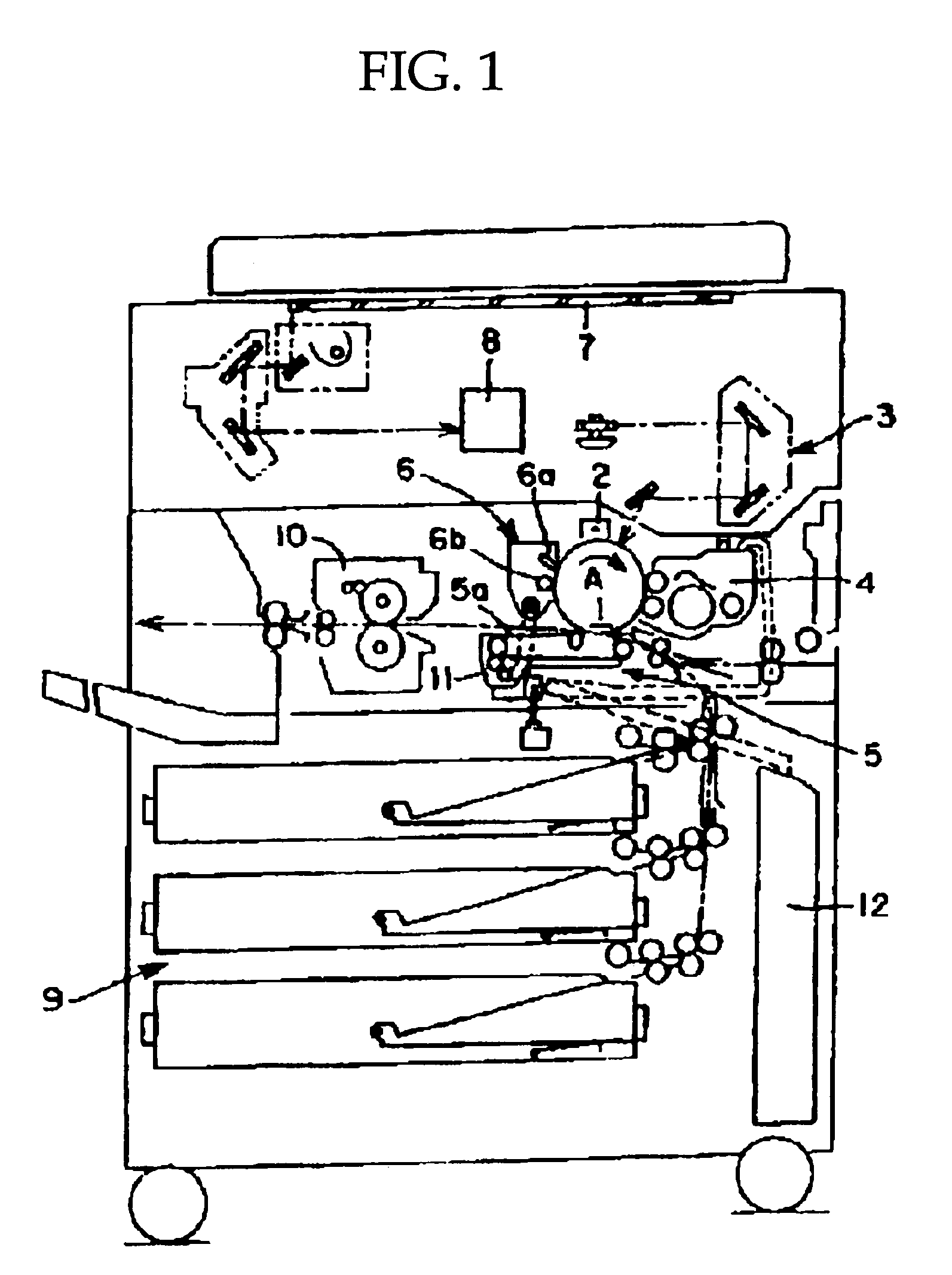

Toner, developer, toner container, process cartridge, image forming apparatus, and image forming method

ActiveUS20070031748A1Reduced image layer thicknessStable formationDevelopersElectrographic processes using charge patternImage formationEngineering

To provide a toner that can provide long-term removability and high-definition images with reduced image layer thickness and densely-packed toner particles, a developer capable of forming high-quality images using the toner, a toner container for containing the toner, a process cartridge using the toner, an image forming apparatus using the toner, and an image forming method using the toner. The toner of the present invention is a toner having a substantially spherical shape with irregularities on its surface and containing at least a binder resin and a colorant, wherein a surface factor SF-1 that represents the sphericity of toner particles is 105 to 180, a surface factor SF-2 that represents the degree of surface irregularities of the toner particles is correlated with the volume-average diameter of the toner particles, and the toner particles have an inorganic oxide particle-containing layer within 1 μm from their surfaces.

Owner:RICOH KK

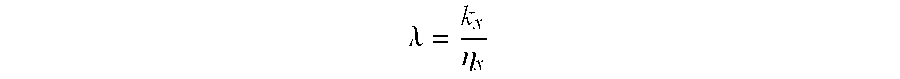

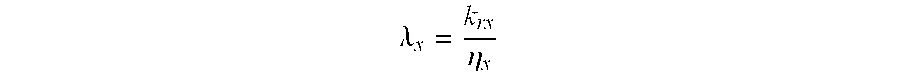

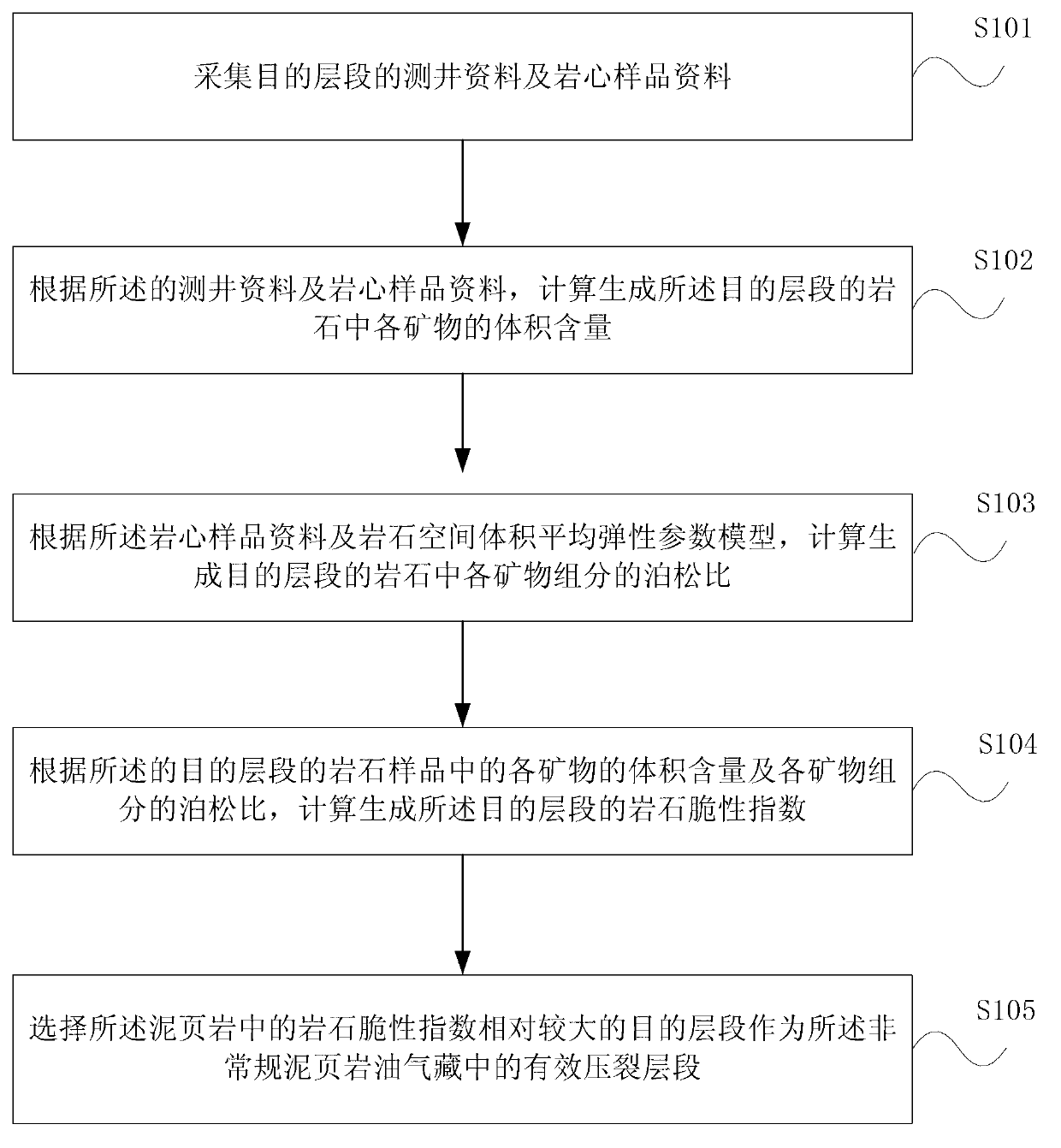

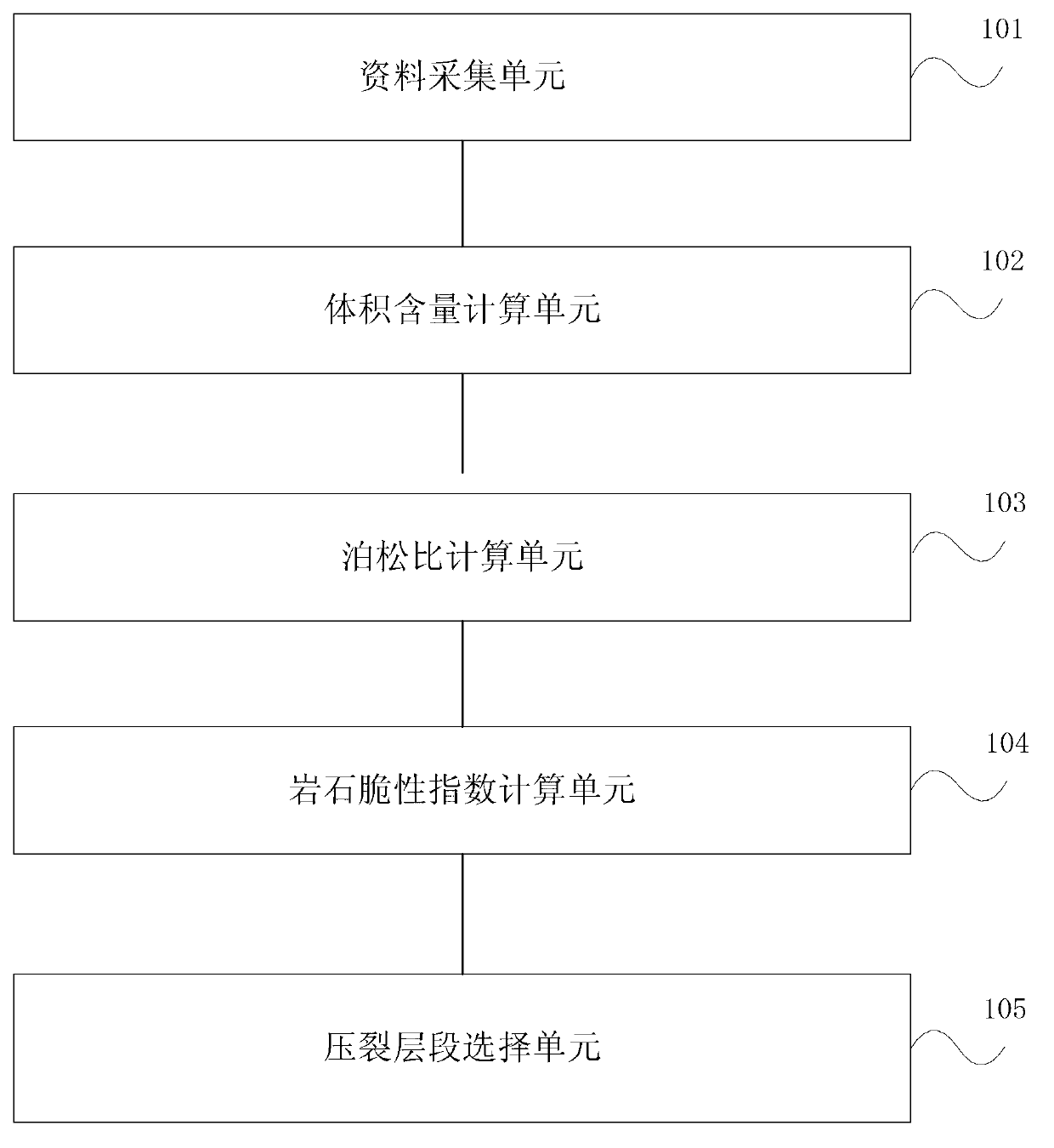

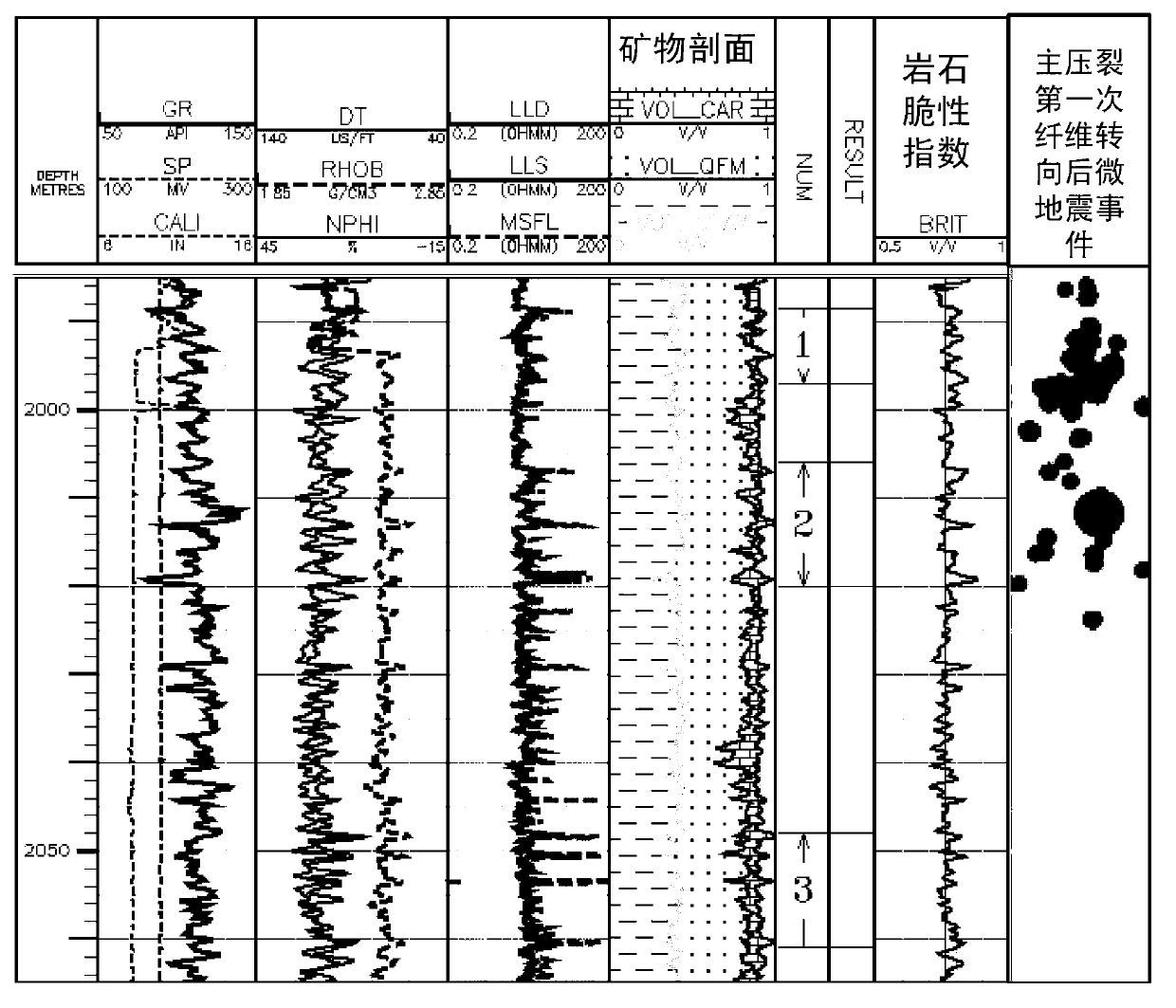

Detection method and device for effective fractured intervals in unconventional shale oil and gas reservoir

The invention discloses a detection method and a device for effective fractured intervals in an unconventional shale oil and gas reservoir. The method includes: collecting logging information and core sample information of intervals of interest; calculating volume contents of all minerals in rock generating the intervals of interest according to the collecting logging information and the core sample information; calculating the poisson ratio of all mineral constituents in the rock generating the intervals of interest according to the core sample information and rock space volume average elastic parameter models; calculating the fragility index of the rock generating the intervals of interest according to the volume contents of all the minerals and the poisson ratio of all the mineral constituents in the rock generating the intervals of interest; and selecting the intervals of interest with the high rock fragility index in the shale as the effective fractured intervals in the unconventional shale oil and gas reservoir. By means of the detection method and the device for the effective fractured intervals in the unconventional shale oil and gas reservoir, the actual production requirement for selecting the effective fractured intervals in exploration and development of the unconventional shale oil and gas reservoir can be met.

Owner:PETROCHINA CO LTD

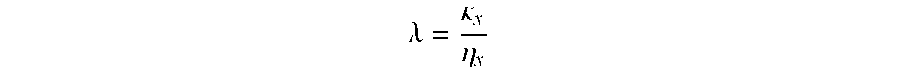

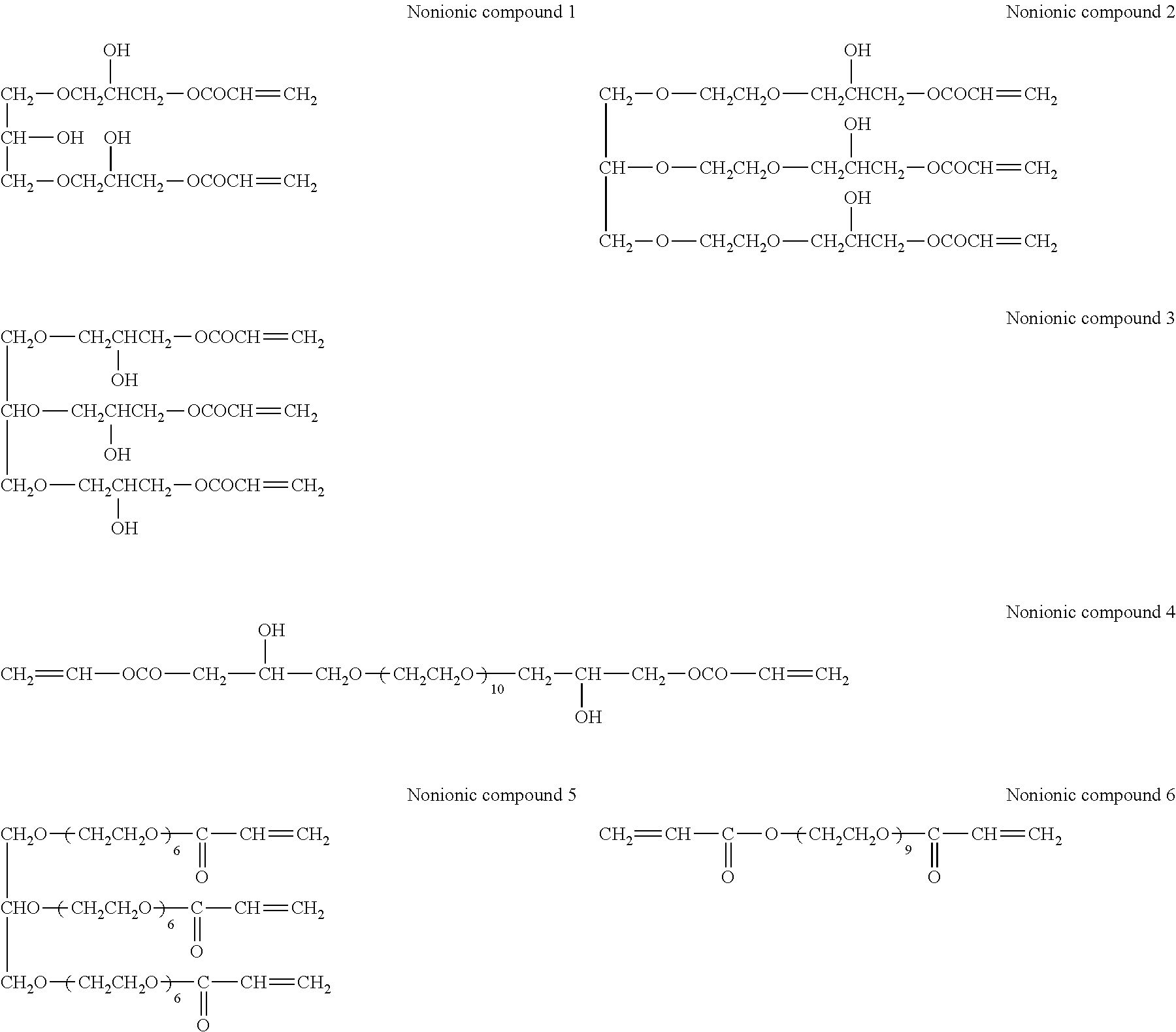

Image forming method

ActiveUS20110211012A1Image strength in terms of adhesiveness and the like is decreasedMeasurement apparatus componentsDuplicating/marking methodsImage formationVolume average

An image forming method includes: applying an ink composition including a pigment having a volume average particle diameter of 70 nm to 130 nm, a polymerizable compound, and water, onto a recording medium using an inkjet under a condition that a maximum application amount of the ink composition is 15 ml / m2 or less; applying, onto the recording medium, a treatment liquid including an aggregating agent that is capable of aggregating components in the ink composition; removing at least a part of the water contained in the ink composition that has been applied onto the recording medium, under a drying condition such that 60% by mass to 80% by mass of the water contained in the ink composition applied at the maximum application amount is removed, thereby performing drying; and irradiating, with an active energy ray, the ink composition from which water has been removed, thereby performing polymerization.

Owner:FUJIFILM CORP

Inkjet recording ink and recording media set, inkjet recording method, recorded matter and recording apparatus

ActiveUS8304043B2High densitySuperior glossinessMaterial nanotechnologyDecorative surface effectsOrganic solventContact time

There is provided an inkjet recording ink and recording media set, which contains: an inkjet recording ink; and a recording medium, wherein the inkjet recording ink comprises at least: water; a water-soluble organic solvent; and a colorant containing carbon black, and having a volume average particle diameter of 40 nm to 100 nm, wherein the recording medium contains: a substrate; and a coating layer on at least one side of the substrate, and wherein an amount of pure water transferred to the recording medium, as measured with a dynamic scanning absorptometer at 23 C and 50% RH, at a contact time of 100 ms is 2 ml / m2 to 35 ml / m2 while an amount of pure water transferred to the recording medium at a contact time of 400 ms is 3 ml / m2 to 40 ml / m2.

Owner:RICOH KK

Inkjet recording method

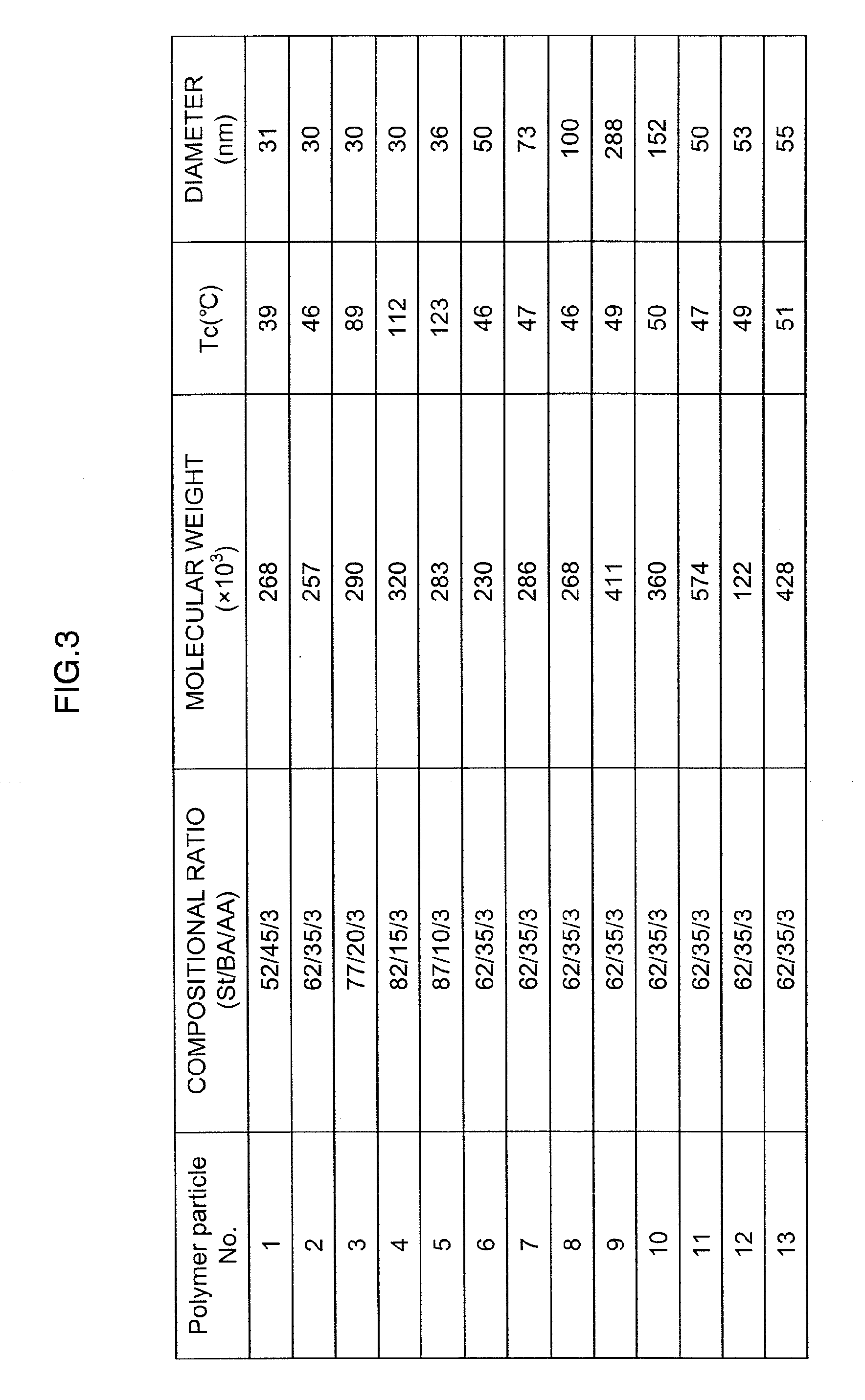

InactiveUS20090087565A1High densityStrong image structureDuplicating/marking methodsInksOrganic solventVolume average

An inkjet recording method includes the steps of: depositing droplets of an ink composition which contains at least water, organic solvent, coloring material particles and polymer micro-particles, one of the coloring material particles and the polymer micro-particles having a volume-average diameter that is 1.3 or more times larger than that of the other of the coloring material particles and the polymer-micro particles, the polymer micro-particles having a softening point (Tc) of 45° C. through 120° C. and a viscoelastic character that satisfies conditions of:logG′1-logG′2≧2 andlogG′2≦5,where G′1 is a storage elastic modulus of the polymer micro-particles at a temperature of T1 (° C.) that is lower than the softening point of the polymer micro-particles by 20° C., and G′2 is a storage elastic modulus of the polymer micro-particles at a temperature of T2 (° C.) that is higher than the softening point of the polymer micro-particles by 20° C.; removing a solvent component in the deposited droplets of the ink composition so that an ink image derived from the deposited droplets of the ink composition is left; and heating the ink image at a temperature not lower than the softening point (Tc) of the polymer micro-particles.

Owner:FUJIFILM CORP

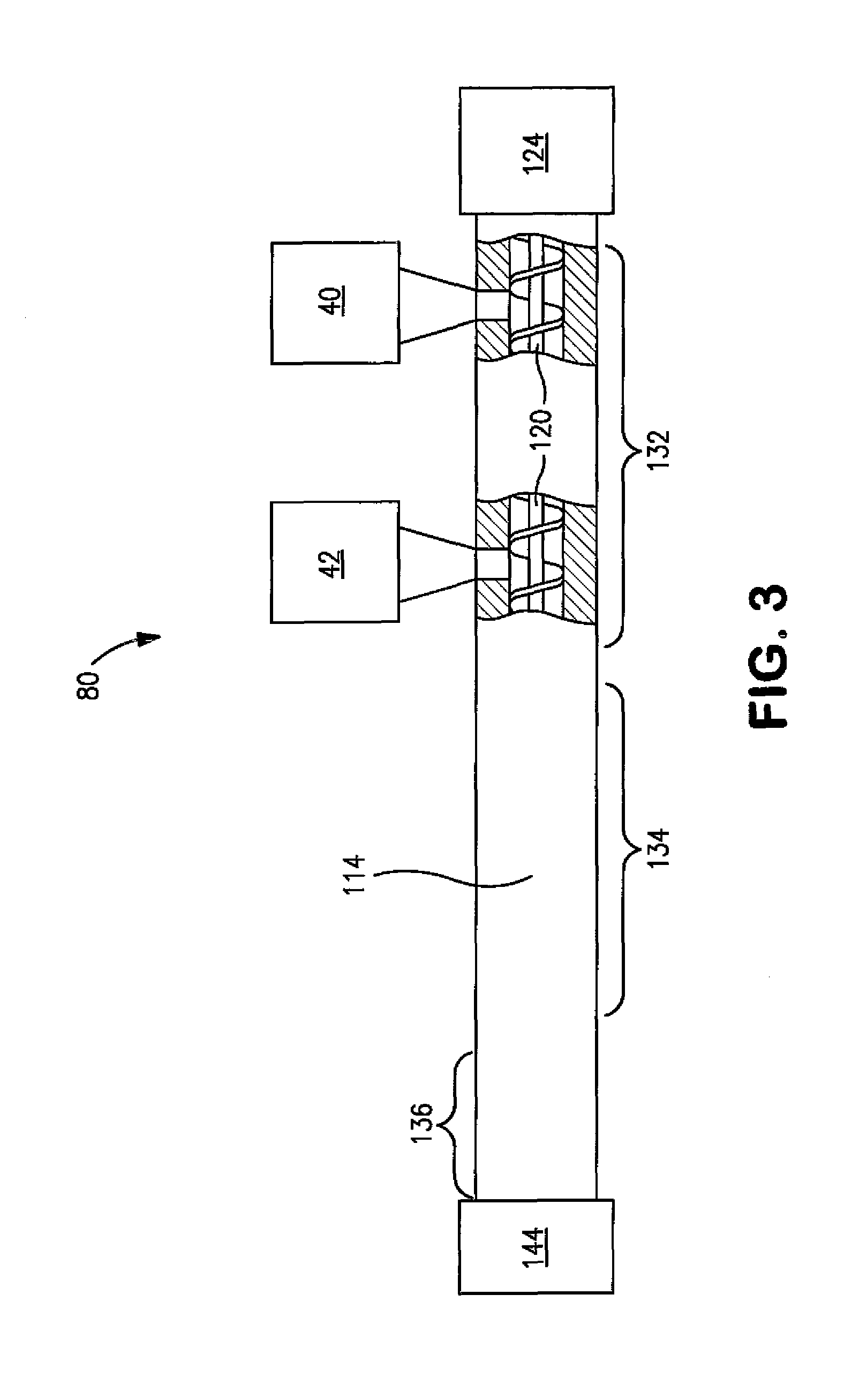

Separator for non-aqueous secondary battery and non-aqueous secondary battery

ActiveUS20140248525A1Improve adhesionEasy to operateCell seperators/membranes/diaphragms/spacersLi-accumulatorsPorous substratePorous layer

A separator for a non-aqueous secondary battery includes a porous substrate and an adhesive porous layer provided on one or both sides of the porous substrate, the adhesive porous layer including a polyvinylidene-fluoride resin and a filler whose difference between a particle diameter at 90% cumulative volume and a particle diameter at 10% cumulative volume is 2 μm or less, and the adhesive porous layer satisfying Inequality (1): 0.5≦a / r≦3.0, wherein, in Inequality (1), “a” represents an average thickness (μm) of the adhesive porous layer on one of the sides of the porous substrate; and “r” represents a volume average particle diameter (μm) of the filler contained in the adhesive porous layer.

Owner:TEIJIN LTD

Toner for developing electrostatic image

InactiveUS20050164114A1High abundanceDevelopersElectrographic process apparatusSurface conditionsEngineering

A toner for developing an electrostatic image which has a small particle size essential for attaining a high-quality image, and can output a high-quality image excellent in frictional charging property and free from scumming. The toner for developing an electrostatic image has the volume average particle diameter of 2.0 μm to 7.1 μm and the surface condition of the toner is in scab form.

Owner:RICOH KK

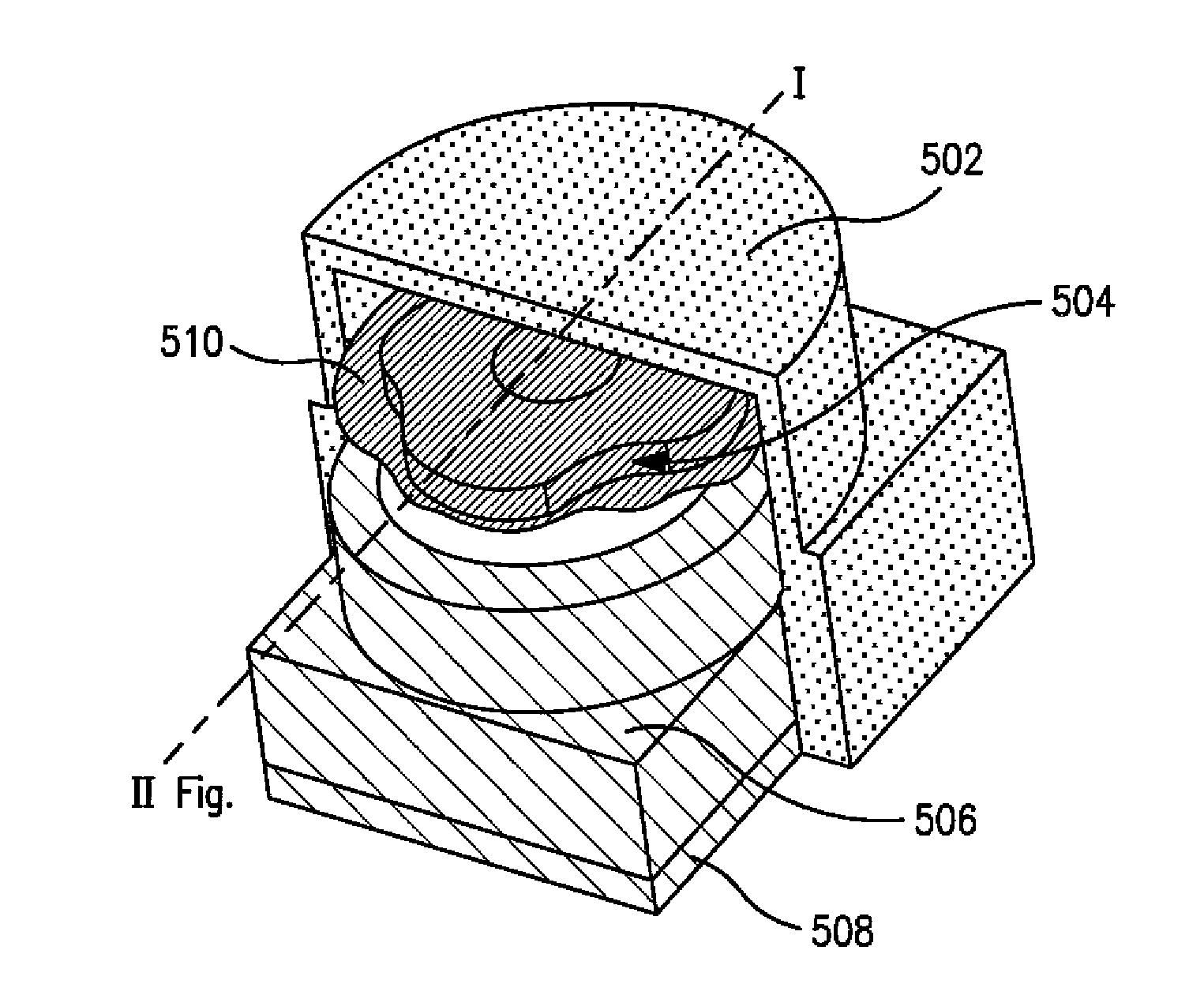

Fine organic silicone particle for latent electrostatic image developing toners, external additive for toners, toner for developing latent electrostatic image, and two-component developer

InactiveUS20080226998A1Improve adhesionSolve the real problemDevelopersElectrographic processes using charge patternCross-linkVolume average

The present invention provides an organic silicone fine particle for latent electrostatic image developing toners, wherein the organic silicone fine particle has a volume average particle diameter of 0.05 μm to 6.0 μm which is obtained by measurement based on Coulter principle, and has a hemispherical polysiloxane cross-linked structure.By mixing an appropriate amount of an organic silicone resin particle formed in a deformed shape (a hemispherical shape) in a toner or developer, the present invention prevents movement of the organic silicone resin particle from surface functional sites, the movement caused by a phenomenon such as detachment thereof from a toner surface or rolling movement on the toner surface, by the effect of its shape, and makes it possible to effectively achieve the expected function.

Owner:RICOH KK

Compact camera module

Owner:TICONA LLC

Electrophotographic toner and method for producing the electrophotographic toner

InactiveUS20080292985A1Improve productivityQuality improvementDevelopersOrganic solventAdditive ingredient

Provided are an electrophotographic toner and a method for producing the electrophotographic toner that satisfy high image quality, cleaning stability, and high productivity.The electrophotographic toner is produced by spray-drying a toner ingredient-containing liquid, wherein the toner ingredient-containing liquid dissolves or disperses at least a resin, a low molecular mass organic material, and a colorant in an organic solvent, the resin is soluble in the organic solvent, the low molecular mass organic material is a crystalline compound or a composition of crystalline compounds that is soluble in the organic solvent, the toner ingredient-containing liquid contains substantially no particles having a particle diameter of 500 nm or more, the crystalline compound or the composition of crystalline compounds crystallizes upon spray-drying to deform toner particles into a circularity of 0.93 or higher to 0.98 or less, and volume average particle diameter of the toner particles is 3.0 μm or higher to less than 7.0 μm.

Owner:RICOH KK

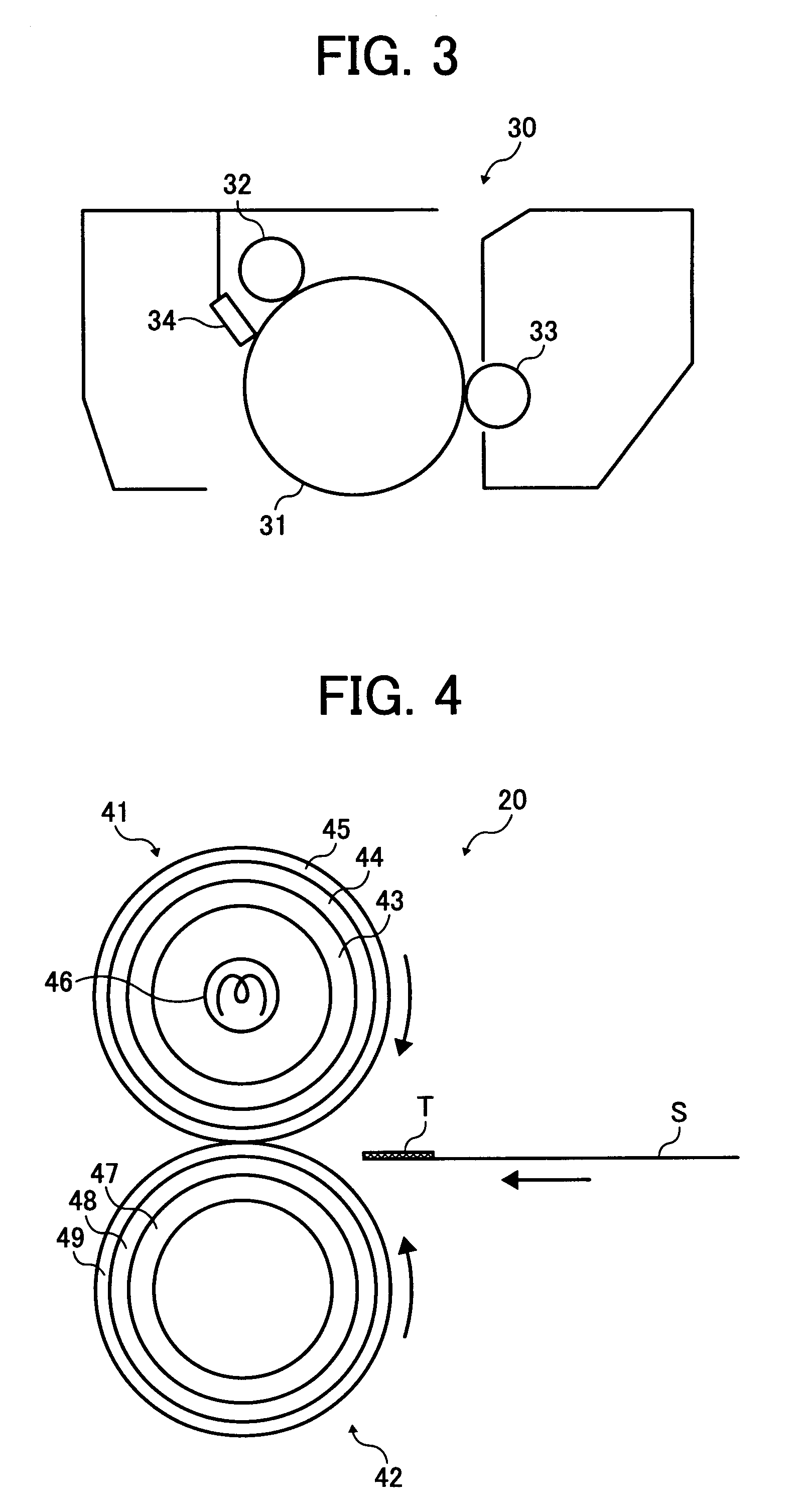

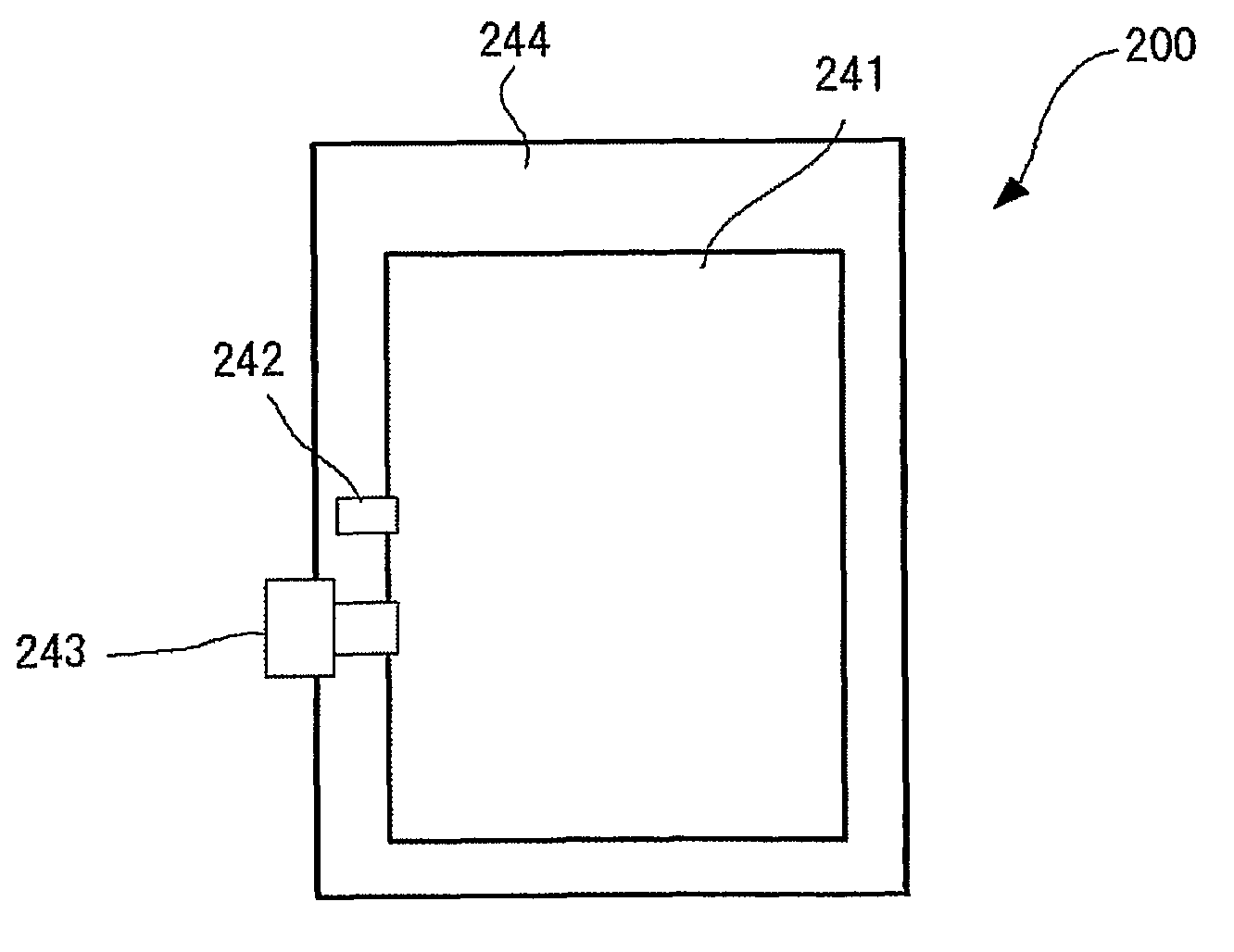

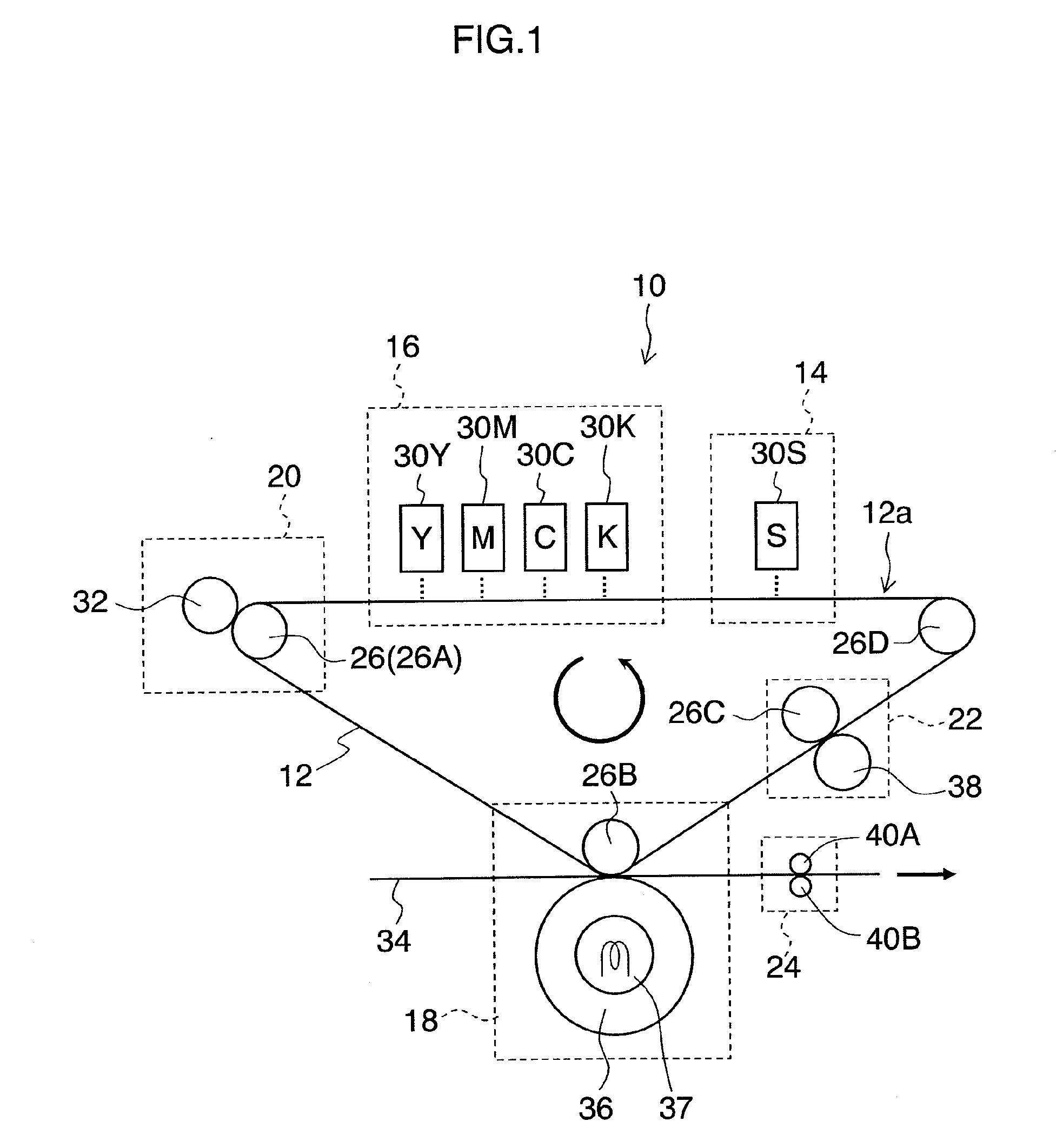

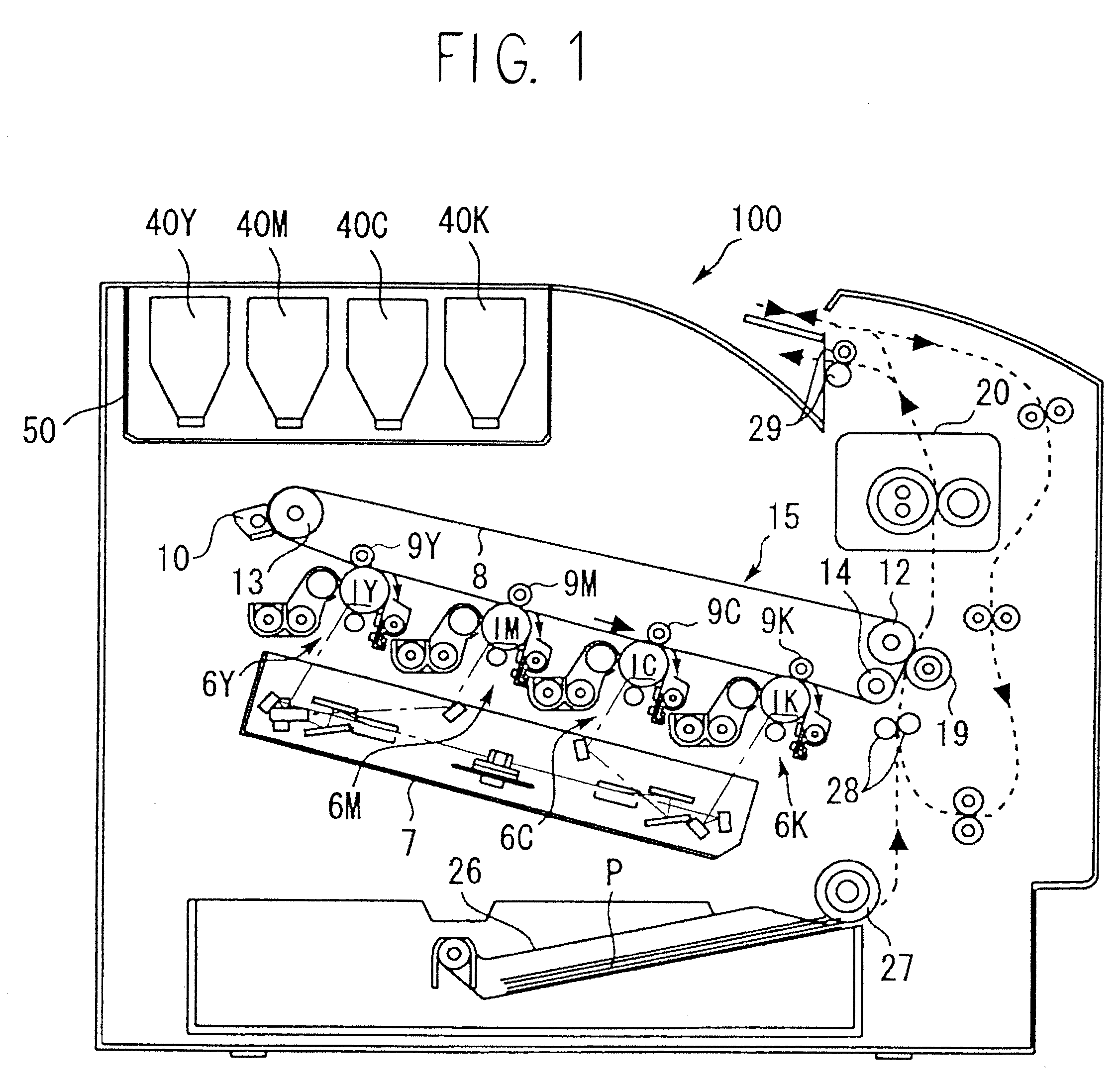

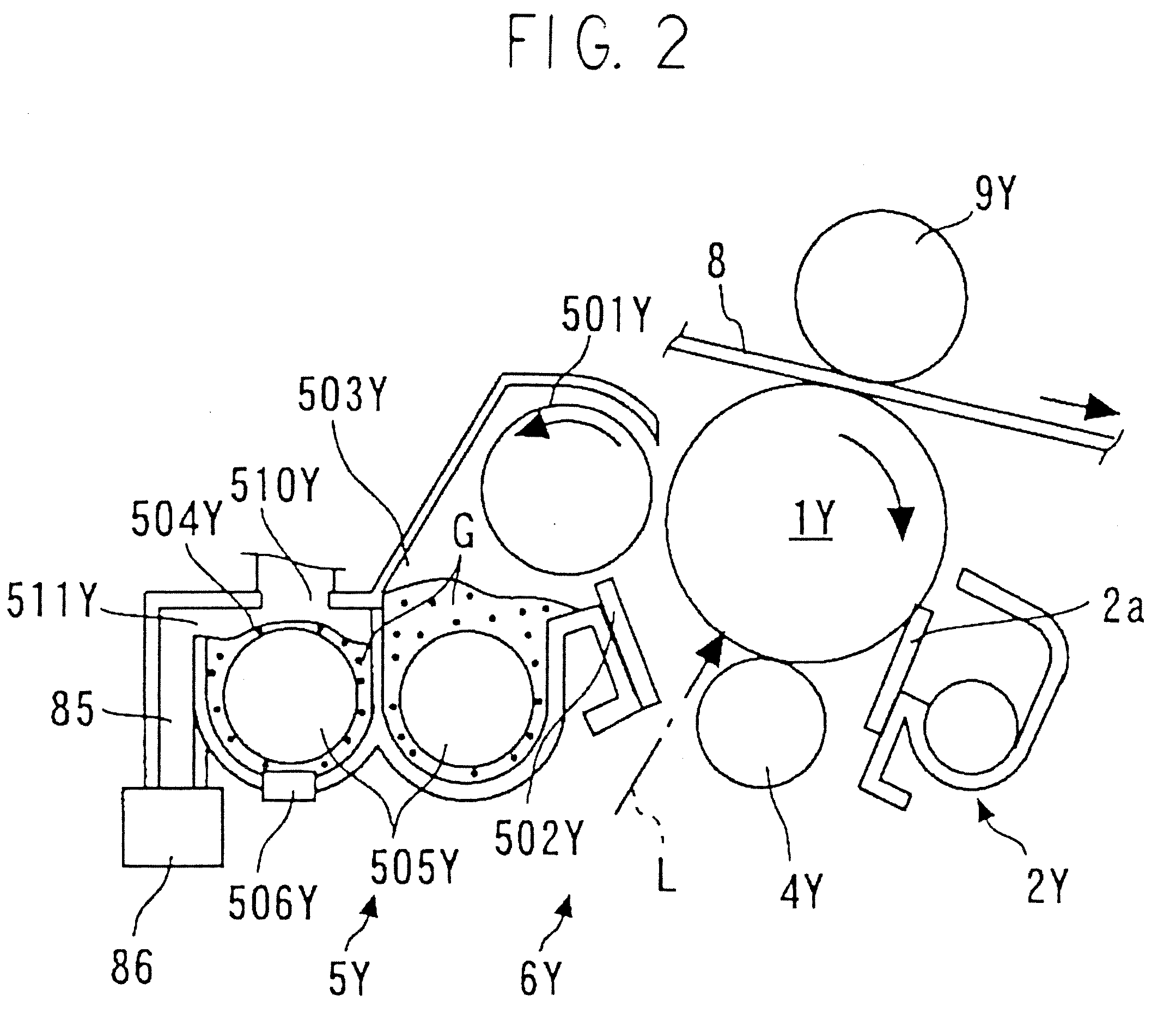

Developer supply device and image forming apparatus comprising same

InactiveUS20070280742A1Stable toner concentrationIncrease freedomElectrographic process apparatusDevelopersCharge carrierImage formation

The invention provides a developer supply device, a developer container, a developer and an image forming apparatus such that the developer is discharged stably from the developer container with a stable toner concentration in the developer, without damaging the developer, and in a relatively simple and small-size device having a relatively high degree of freedom as regards layout. The developer supply device comprises a partially or wholly deformable developer container and a pump for suctioning the developer held in the developer container, together with a gas, and for discharging the developer towards a developing unit. The toner comprises an additive formed so as to have a volume average particle size of 50 to 500 nm. The carrier is formed so as to have a weight average particle size of 20 to 60 μm. The developer is formed so that the carrier concentration thereof is 1 to 30 wt %.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com