Patents

Literature

1540results about How to "Improve recovery rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

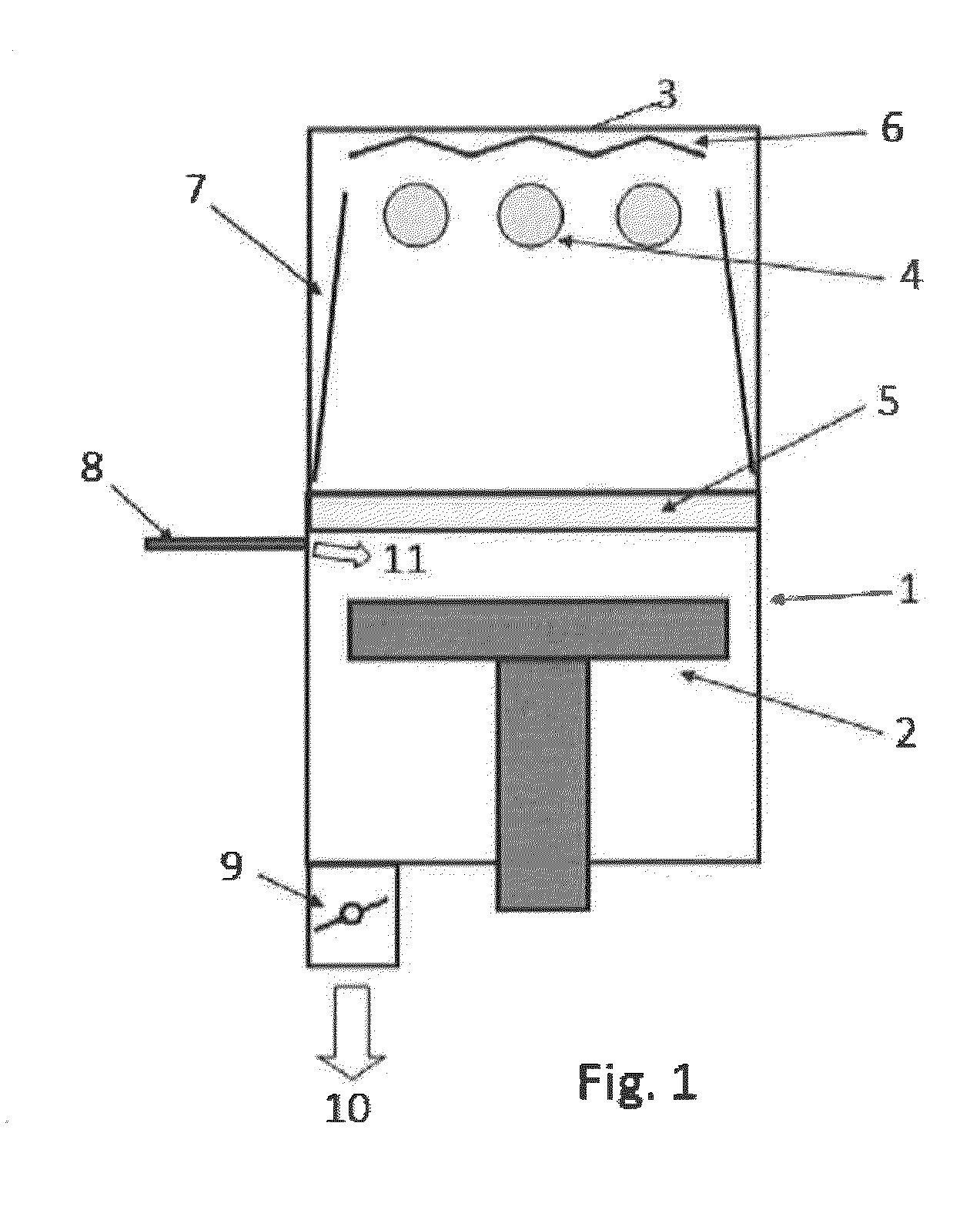

Method for repairing damage of dielectric film by hydrocarbon restoration and hydrocarbon depletion using UV irradiation

A method for repairing process-related damage of a dielectric film formed on a substrate caused by processing the dielectric film includes: irradiating the damaged dielectric film with UV light in an atmosphere of hydrocarbon-containing gas to restore the surface of the dielectric film; and irradiating the surface-restored dielectric film with UV light in an atmosphere of oxygen gas to partially remove the hydrocarbon film.

Owner:ASM IP HLDG BV

Drug for improving prognosis for subarachnoid hemorrhage

InactiveUS20060135607A1Improved prognosisImprove recovery rateBiocideAnimal repellantsEicosapentaenoic acidBULK ACTIVE INGREDIENT

It is intended to provide a drug for improving prognosis for subarachnoid hemorrhage which contains, as the active ingredient, at least one member selected from the group consisting of eicosapentaenoic acid (EPA) and pharmaceutically acceptable salts and esters thereof, and a method of improving prognosis for subarachnoid hemorrhage which comprises orally or gastrically administering the above drug.

Owner:MOCHIDA PHARM CO LTD

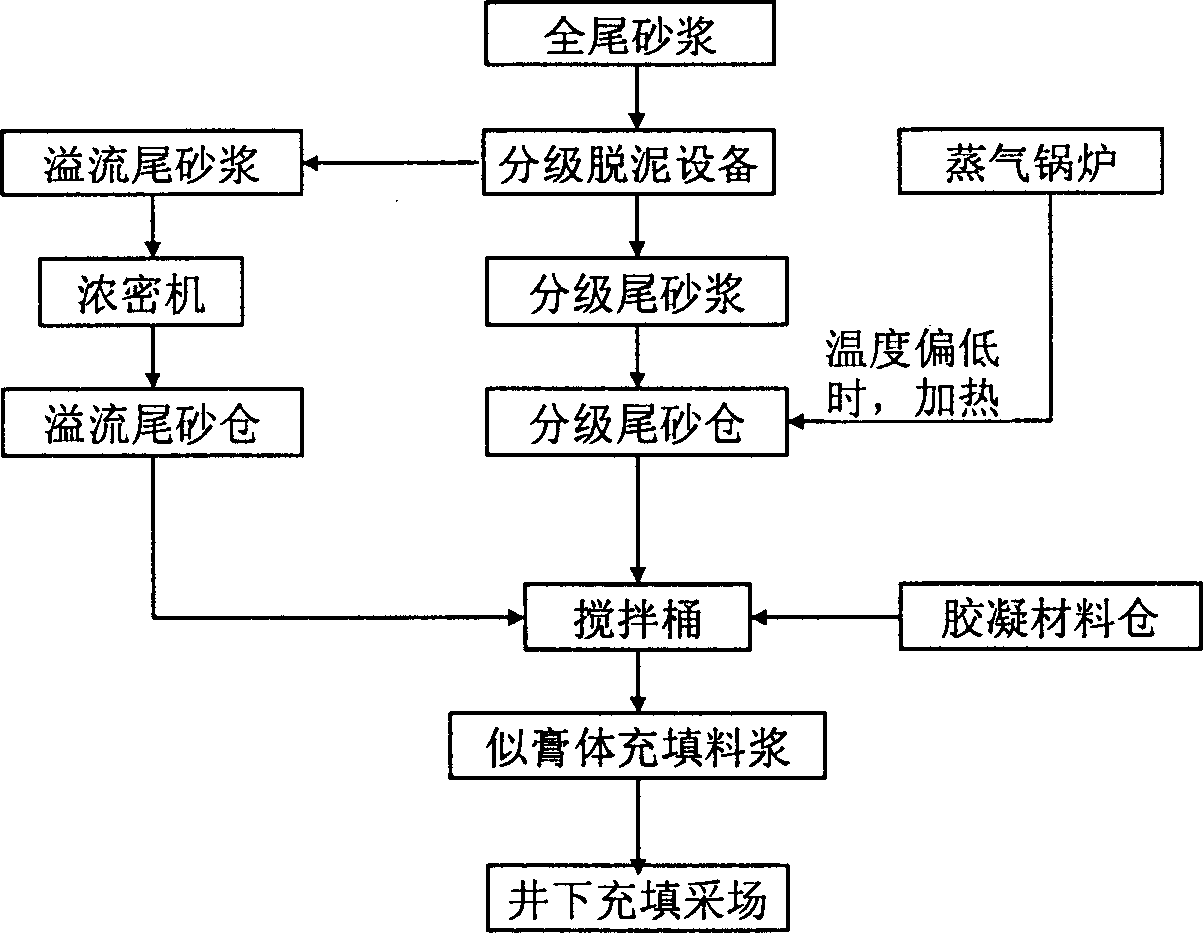

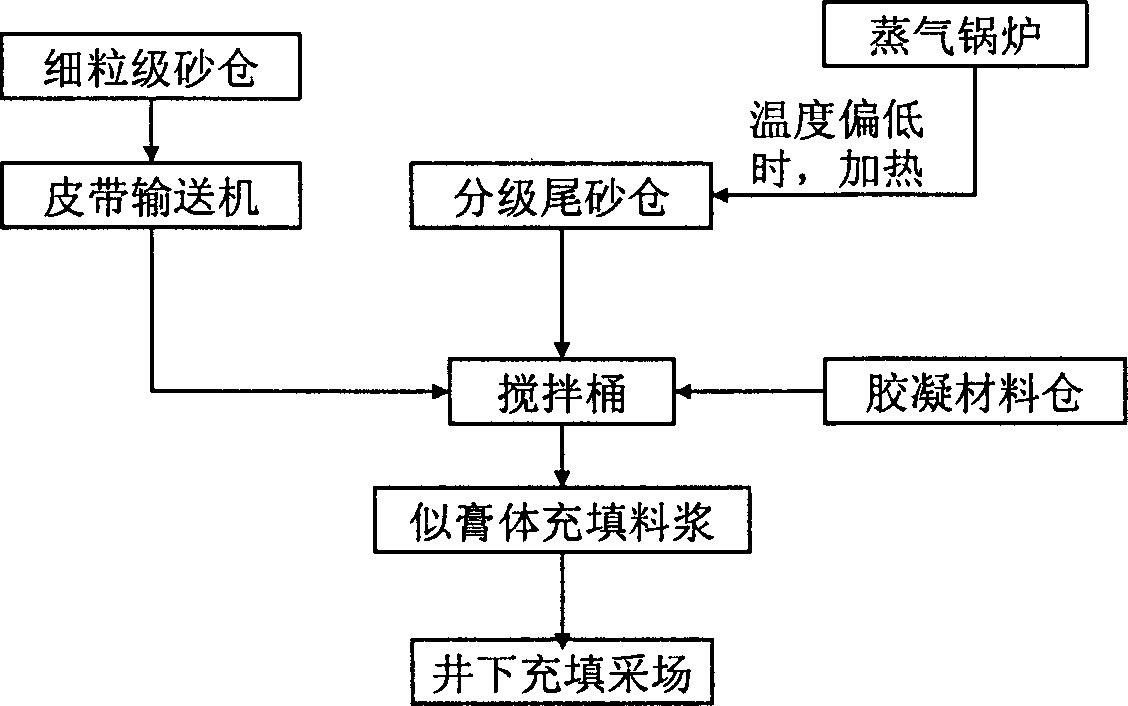

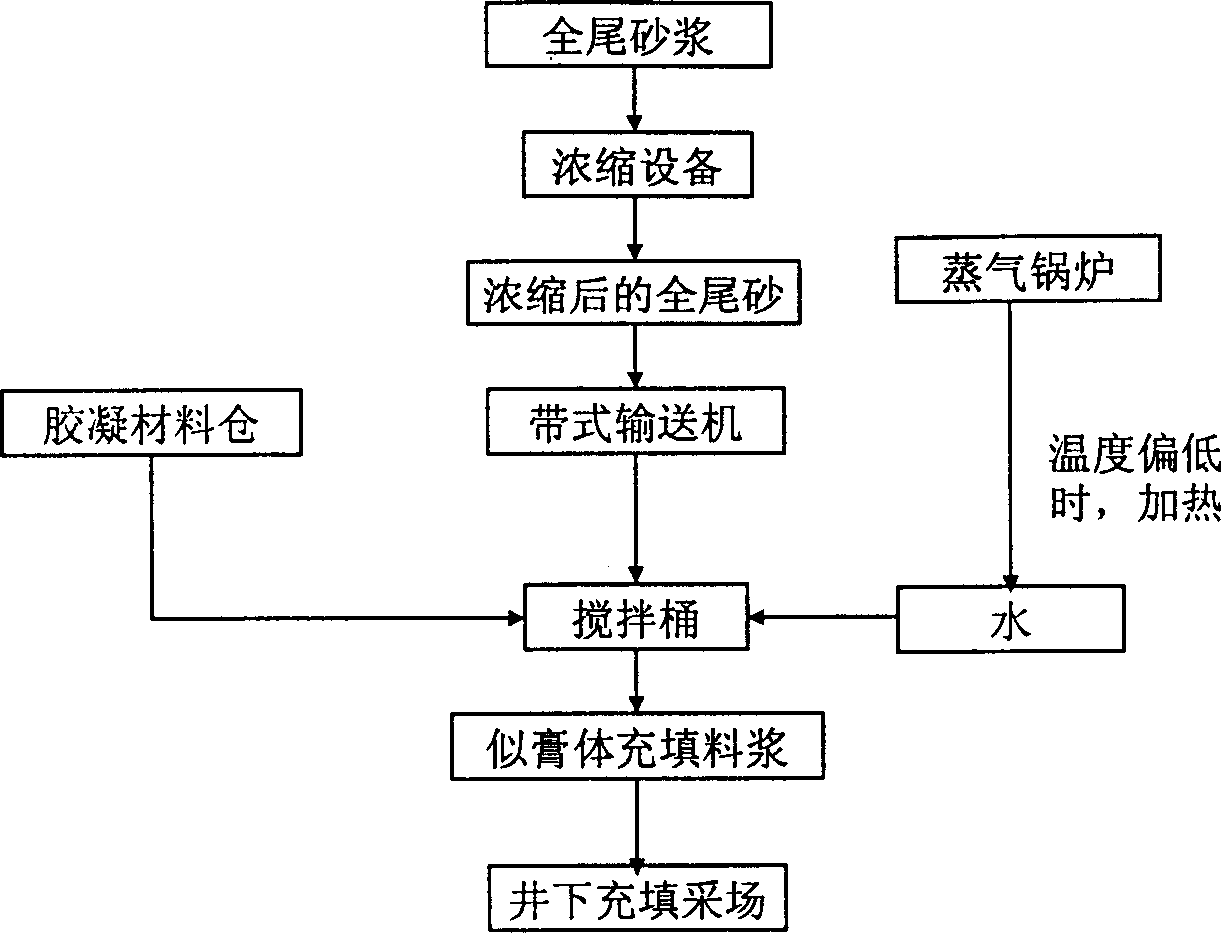

Cementing materials for filling, slurry and preparing and filling processes

InactiveCN1424275AReduce manufacturing costLess investmentSolid waste managementMaterial fill-upSlurrySulfur containing

A gelatining material similar to cream for filling underground working surface is preapred from the Ca-contained non-crystal and microcrystal material, alkali and / or sulfur contained exciting material, active material, aggregate and regulator. A filling slurry is prepared from said gelatining material, filling aggregate, fine particles, regulator and water through heating to at least 18 deg.C and proportional mixing.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

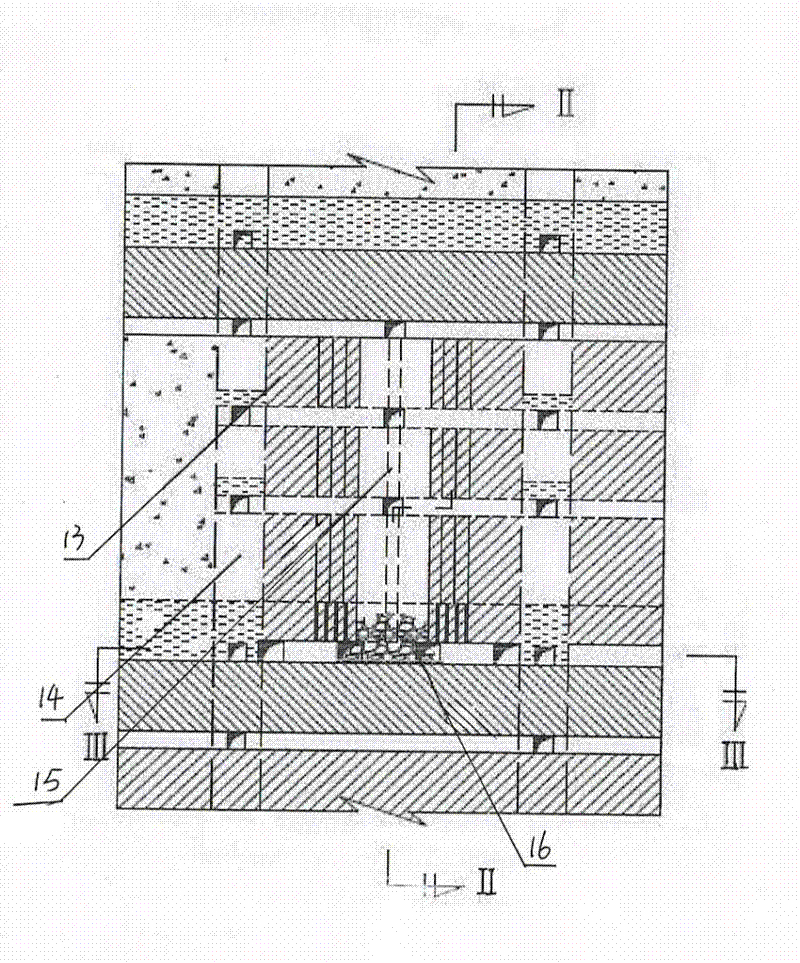

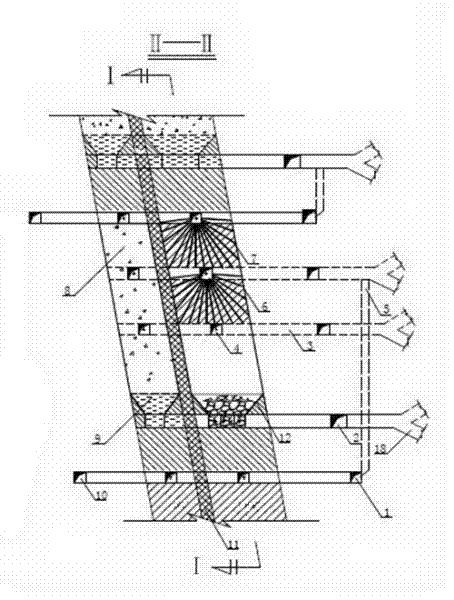

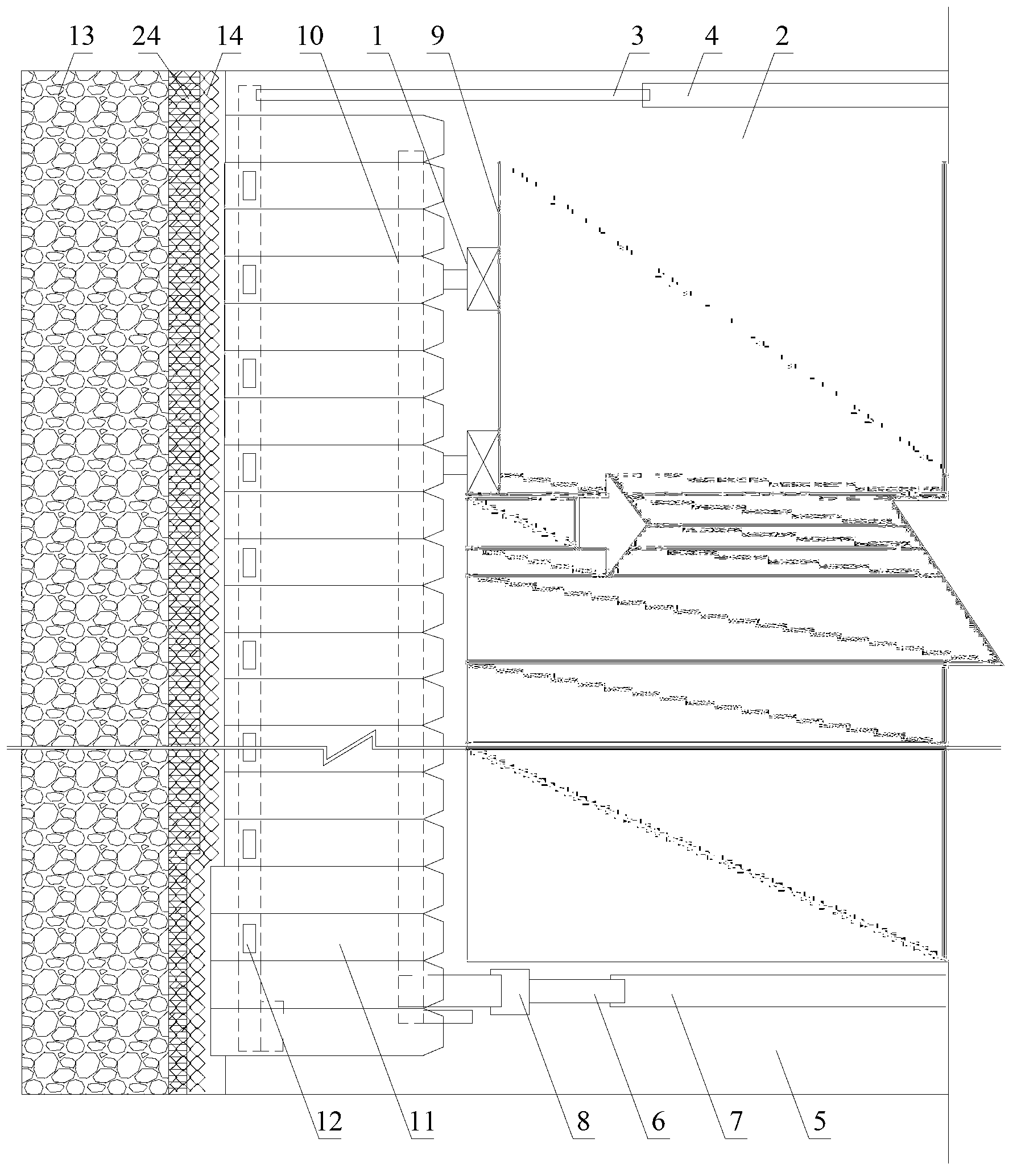

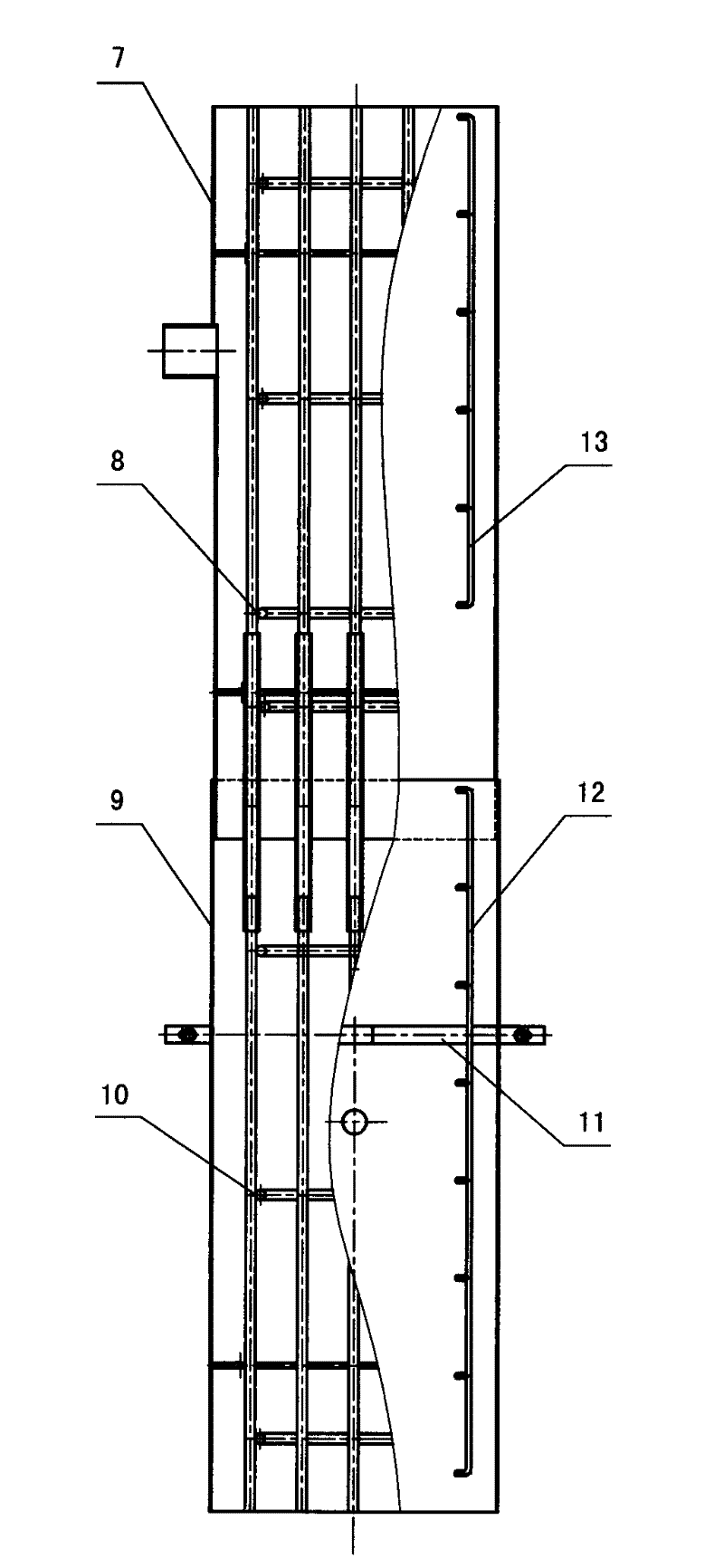

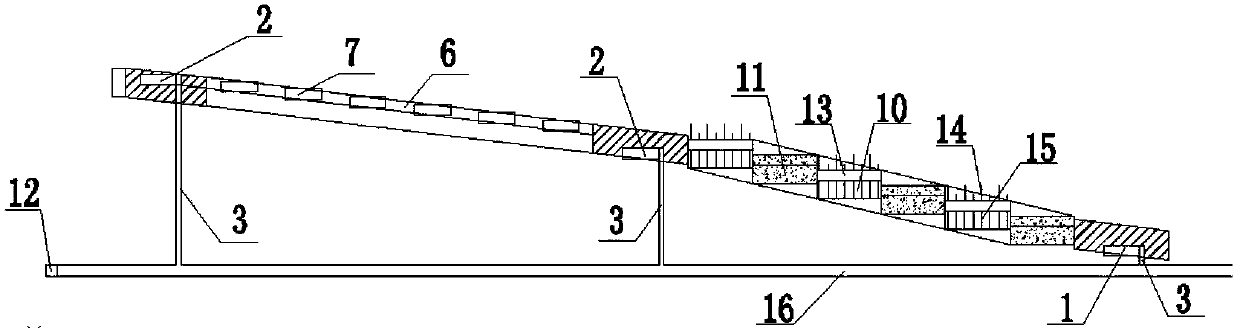

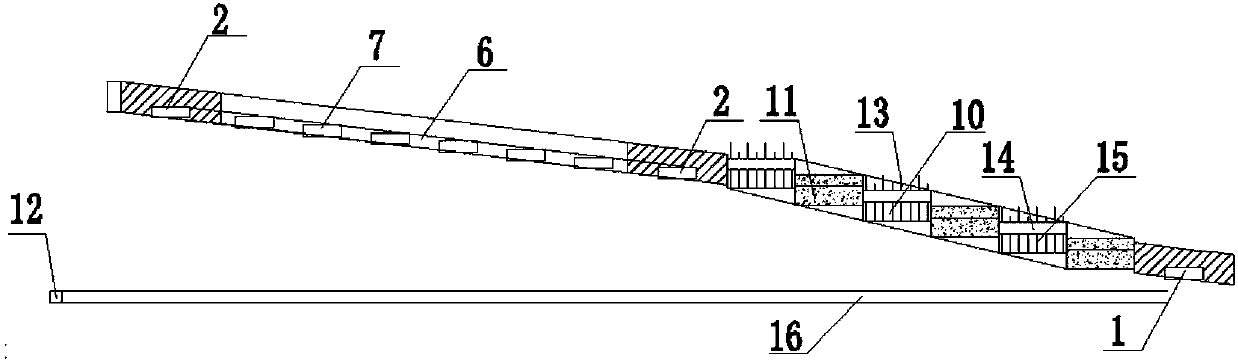

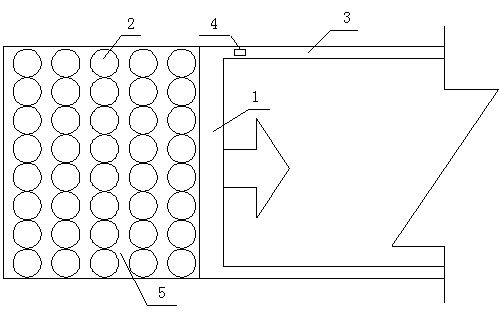

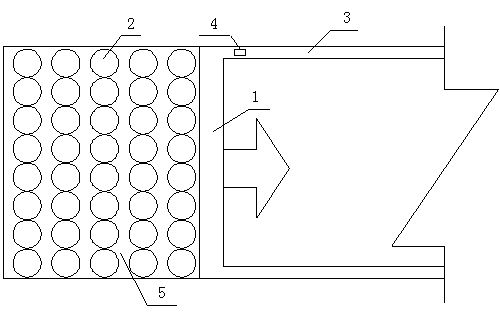

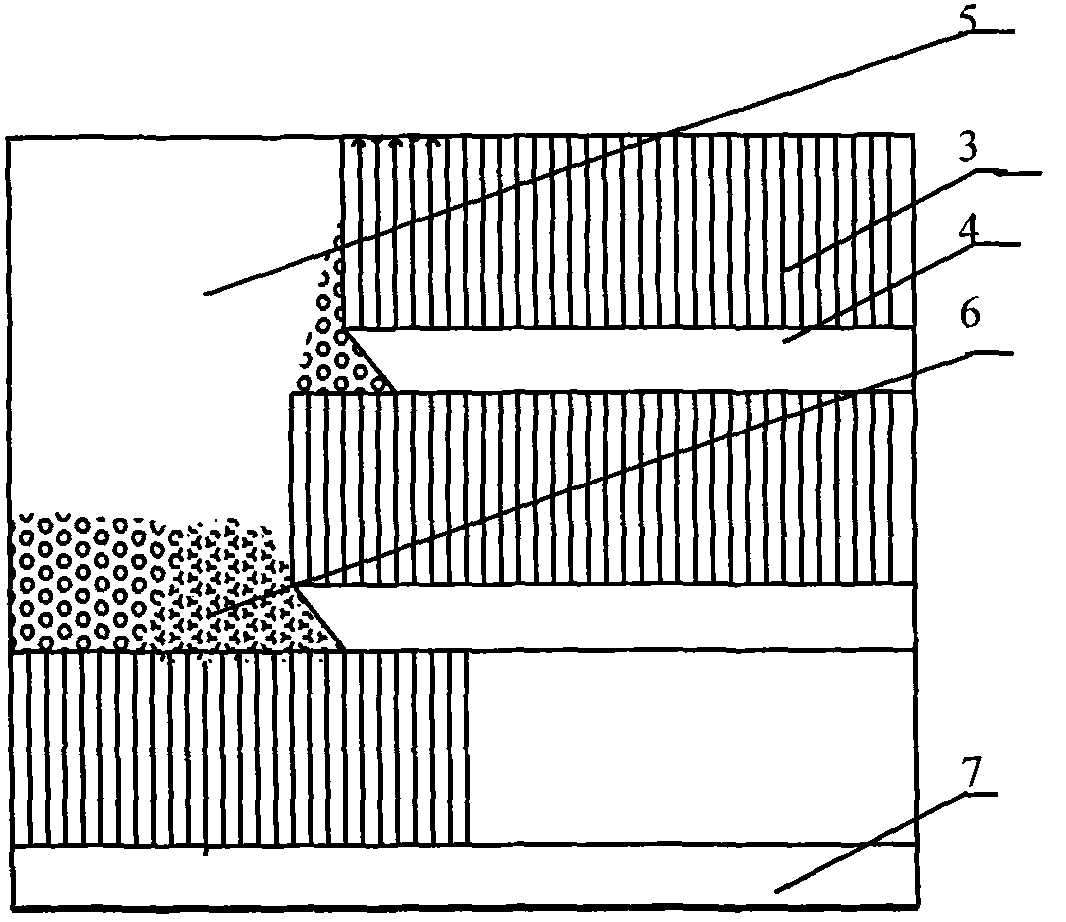

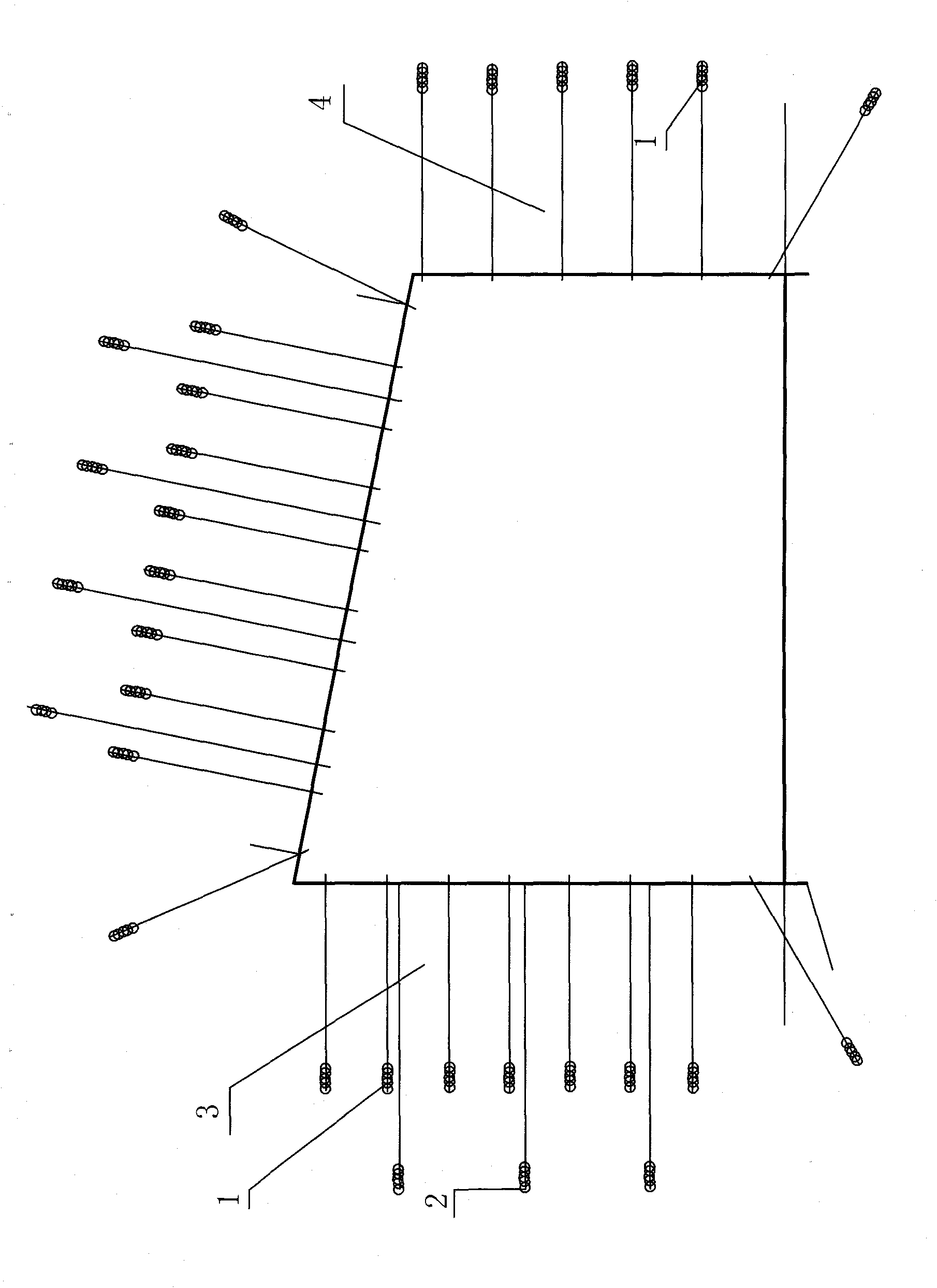

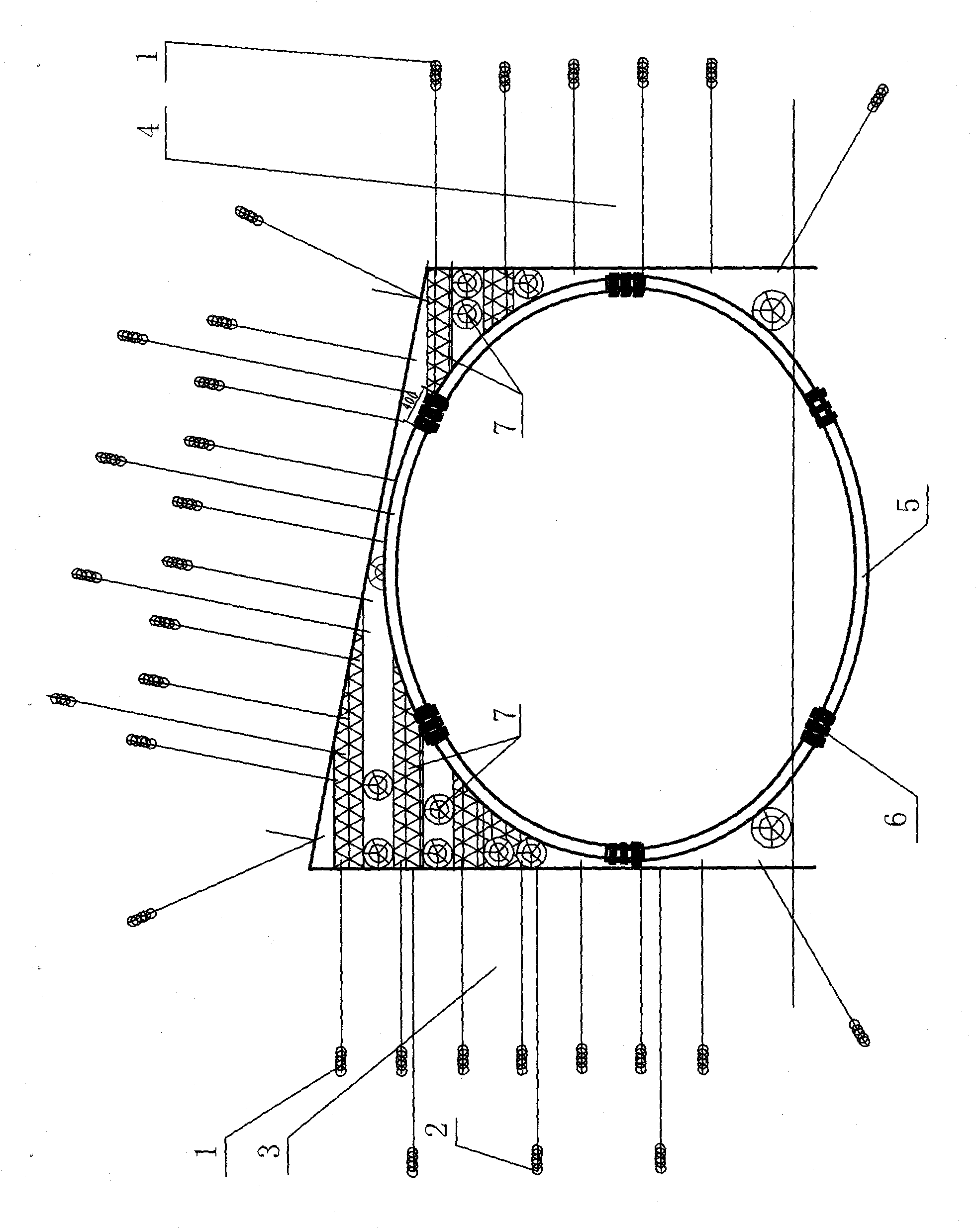

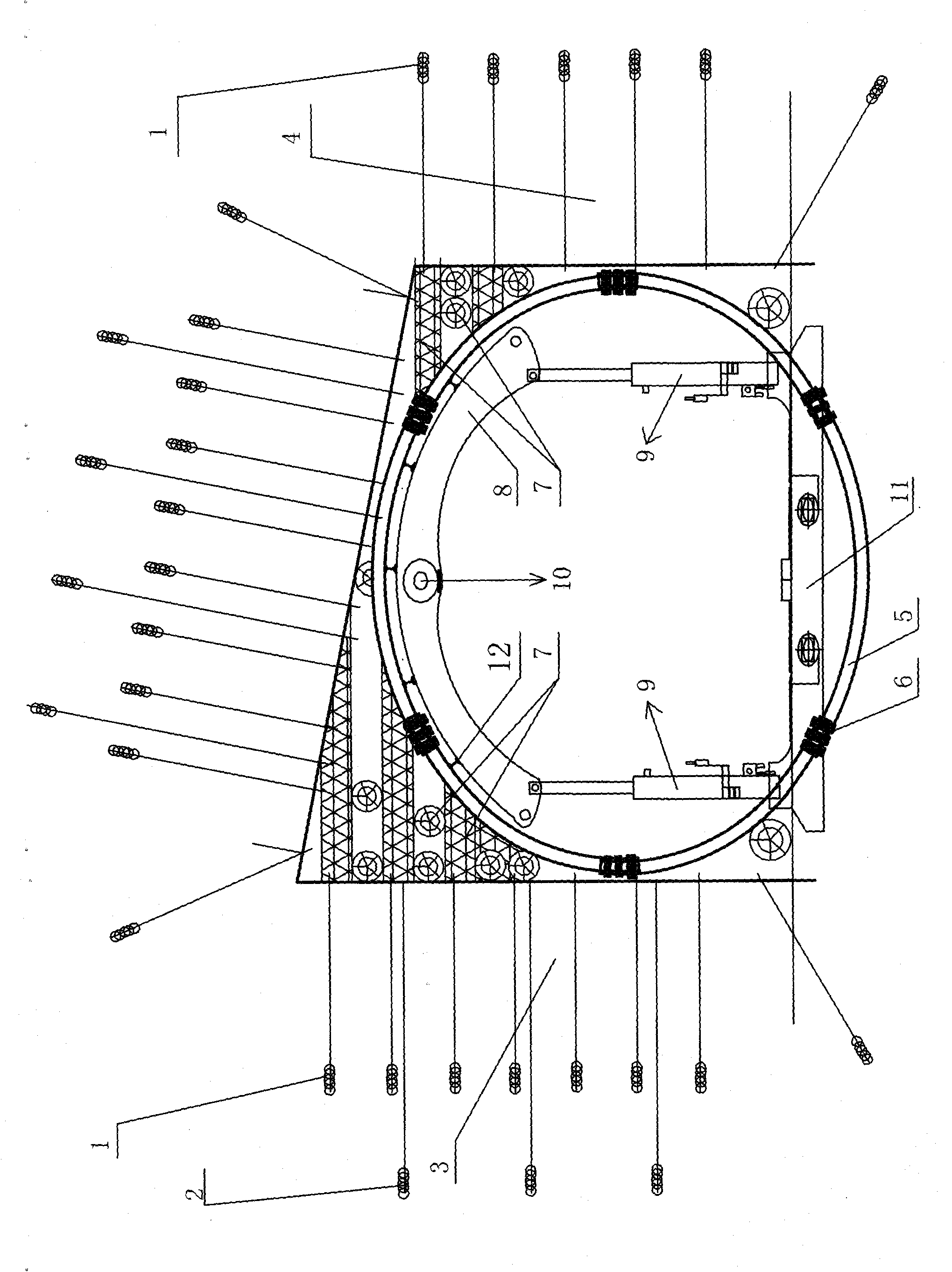

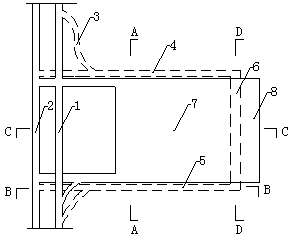

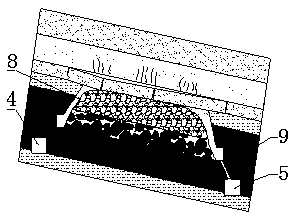

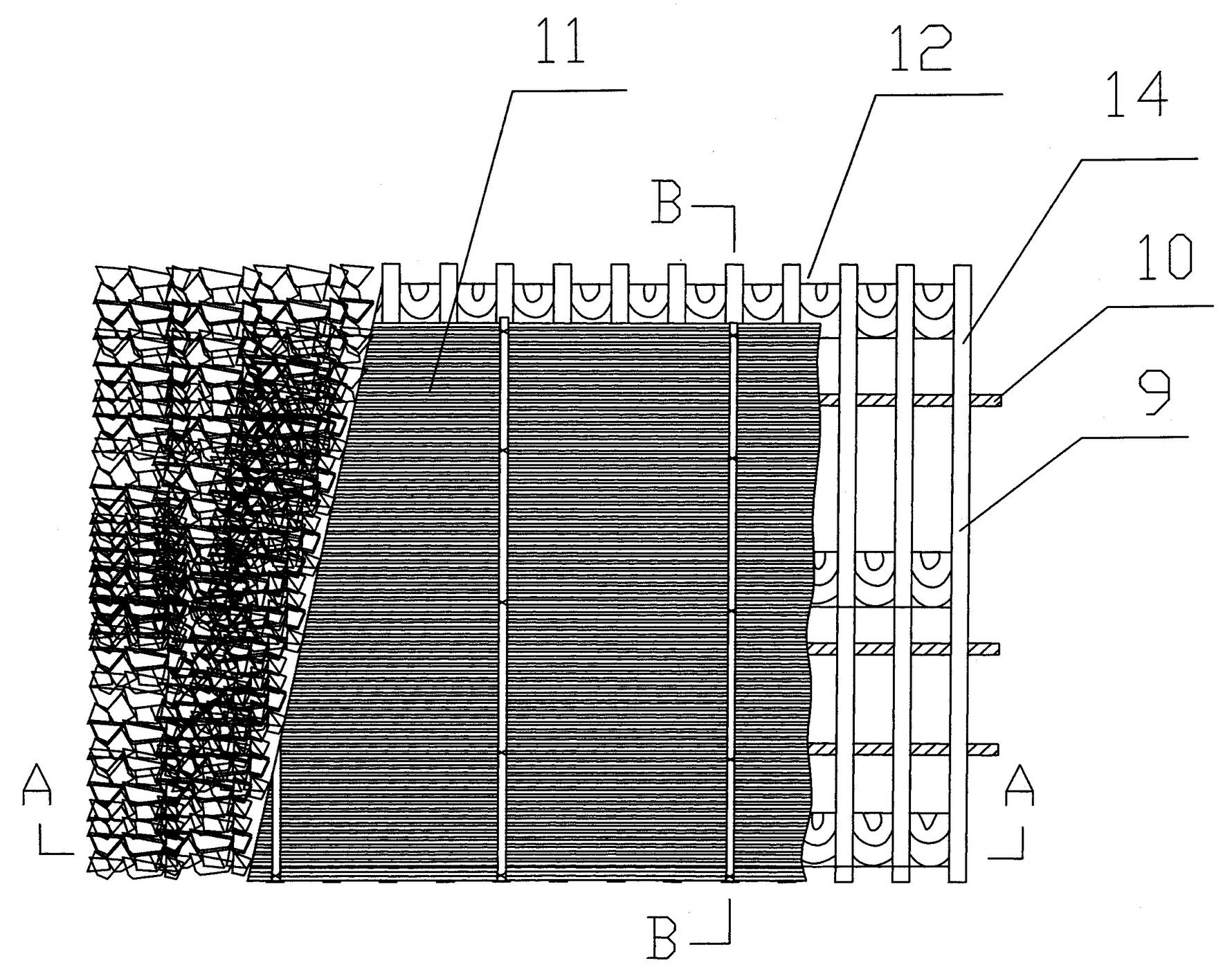

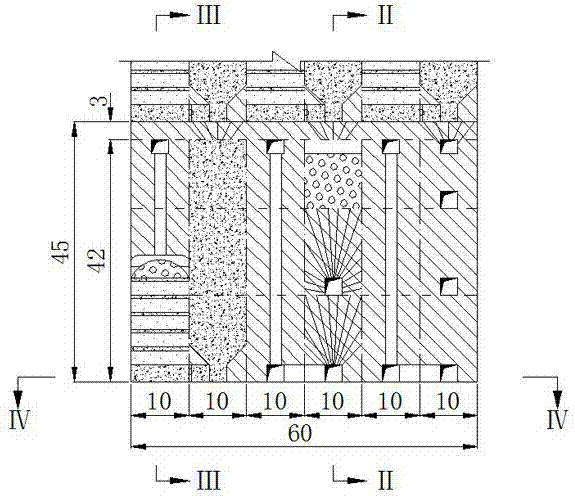

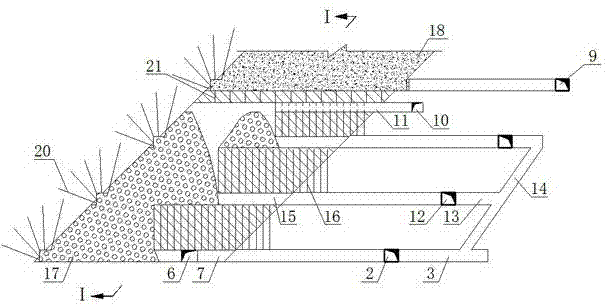

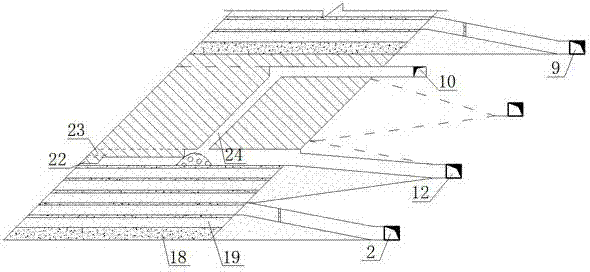

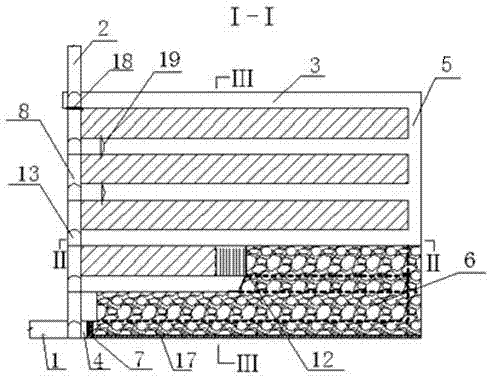

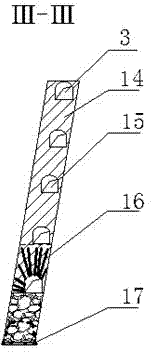

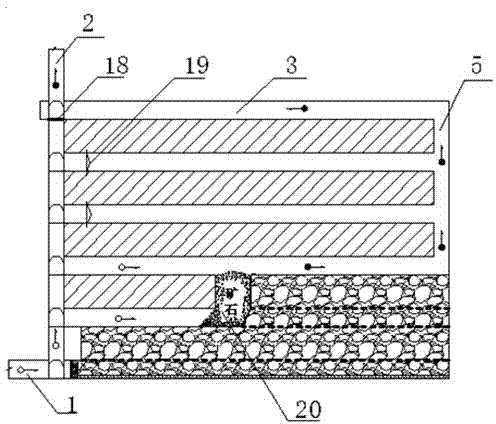

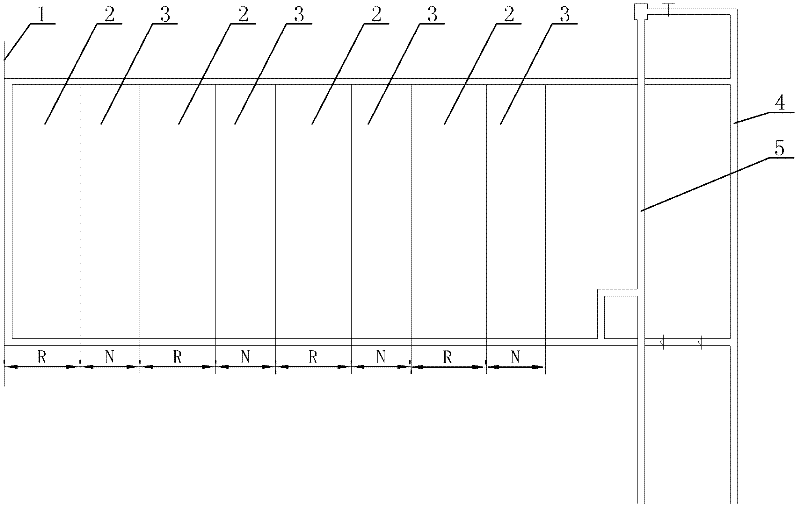

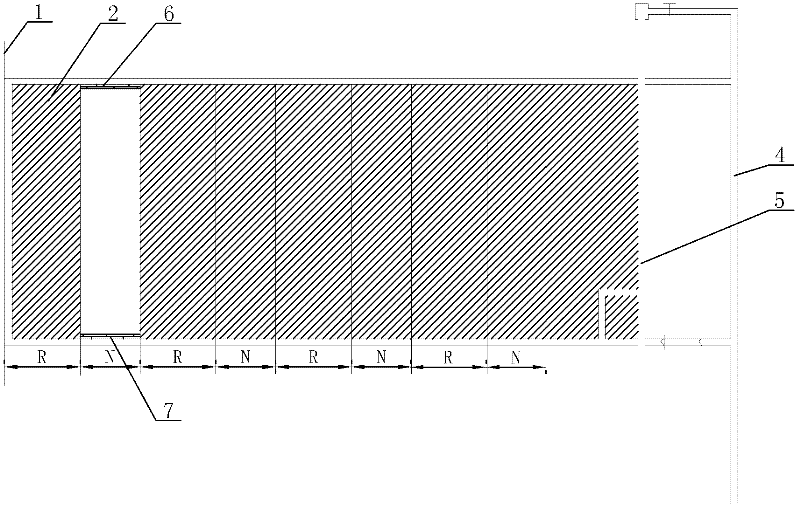

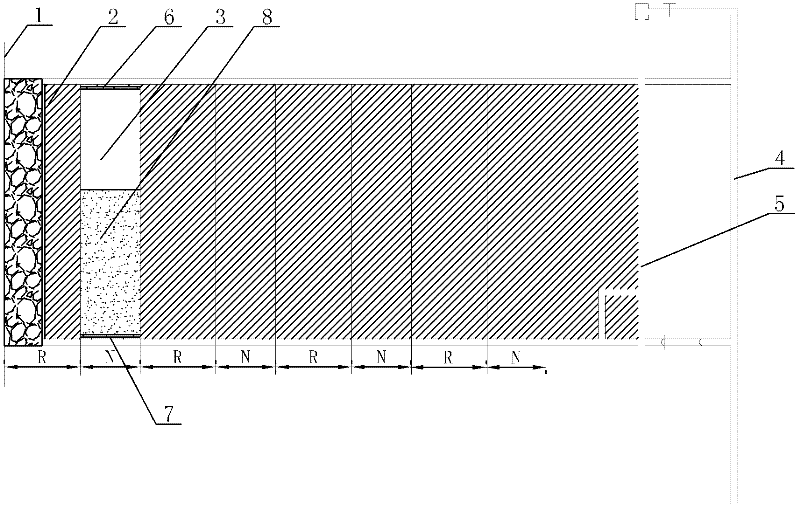

High-sublevel subdivision mining method of moderately thick heavy-pitch waste-rock-containing interlayer phosphate orebody along strike

InactiveCN102418526AAvoid damageIncrease productivityUnderground miningSurface miningMining engineeringSlag

The invention discloses a high-sublevel subdivision mining method of a moderately thick heavy-pitch waste-rock-containing interlayer phosphate orebody along a strike. The high-sublevel subdivision mining method comprises four steps of exploiting, mining preparation, cutting and recovery, wherein a footwall intermediate-section main roadway is respectively arranged on a high sublevel along a top plate and a bottom plate of the orebody, and the intermediate-section main roadways of the top plate and the bottom plate are connected through a communication channel at intervals of 100m, therefore reduced roadway cutting construction, small development rate and simple process are achieved; after overall blasting of a stope is finished, a large amount of concentrated ore drawing is carried out, and the production efficiency is high; tail sand is adhered and filled after space pillars are mined first, then rooms are evacuated, and the rooms are filled with waste rocks or tail sand in a non-adhering way, thus recovery rate is high; and the high-sublevel subdivision mining method has little damage to the environment and capabilities of changing oredressing tail sand and waste rocks generated in open-air production into valuables and reducing geological disaster from happening. Due to the adoption of the high-sublevel subdivision mining method disclosed by the invention, ore recovery rate can be increased, ore dilution rate and emission of mine wastes are reduced, capacity of slag disposal pit is relatively increased, expropriation of land is decreased, and mineral land harmony is promoted.

Owner:WENGFU (GRP) CO LTD

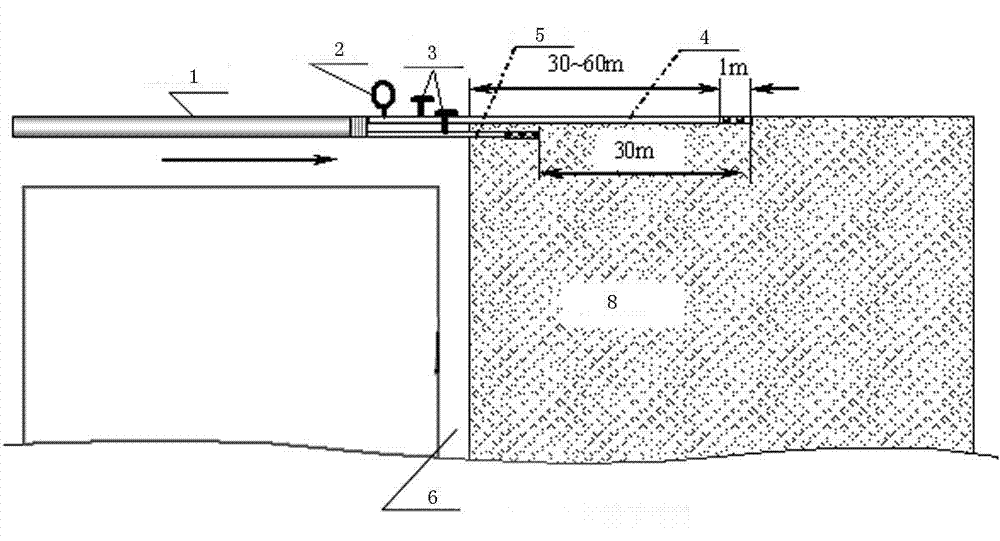

Gob natural fire control method

InactiveCN102828767AThe temperature is not easy to riseImprove fire prevention effectDust removalFire preventionCoalEnvironmental resource management

The invention relates to the coal mine safety technology and discloses a gob natural fire control method which has good effect of fire preventing and extinguishing. The gob natural fire control method comprises the following steps: pouring nitrogen, wherein a nitrogen pouring point is 30 to 60 meters from a working face, and the amount of the liquid nitrogen is 2000m3 / h; reducing the air leaking volume of a gob, and reducing the pressure difference of the working face, and controlling the pressure difference of the working face within 120Pa; blocking the leakage within an area in which the tight caving cannot be achieved due to the cantilever beams formed at an air inlet side and an air return side of the gob through a top plates, and timely closing a transverse rail at the gob; accelerating the advance velocity of the working face, wherein the working face is at the speed of 4m / d; increasing the recovery ratio; and controlling the thickness of the residual coal to be below 1.3 meters. According to the gob natural fire control method, a comprehensive working face gob comprehensive fire preventing and extinguishing measure based on 'nitrogen pouring first, leakage blocking, wind resisting, accelerating of advance velocity and recovery rate increasing second' is proposed, and measure implementing parameters are provided; with the adoption of the method, the effect of preventing and extinguishing the fire of the gob can be improved; and the mining on the working face can be ensured to be smoothly carried out.

Owner:DATONG COAL MINE GRP

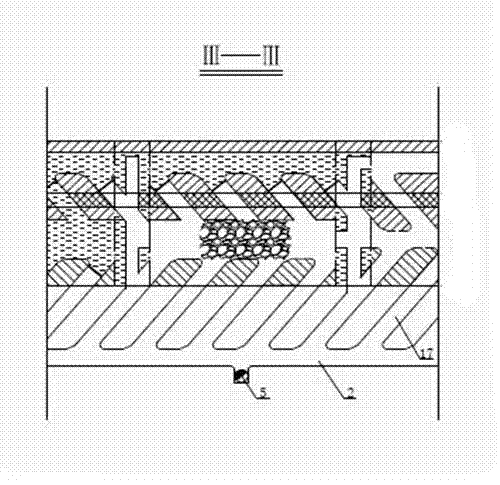

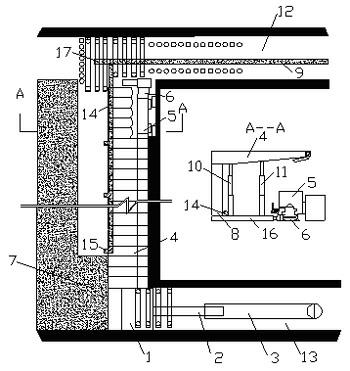

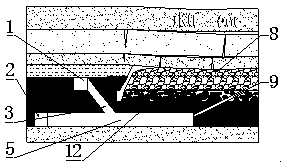

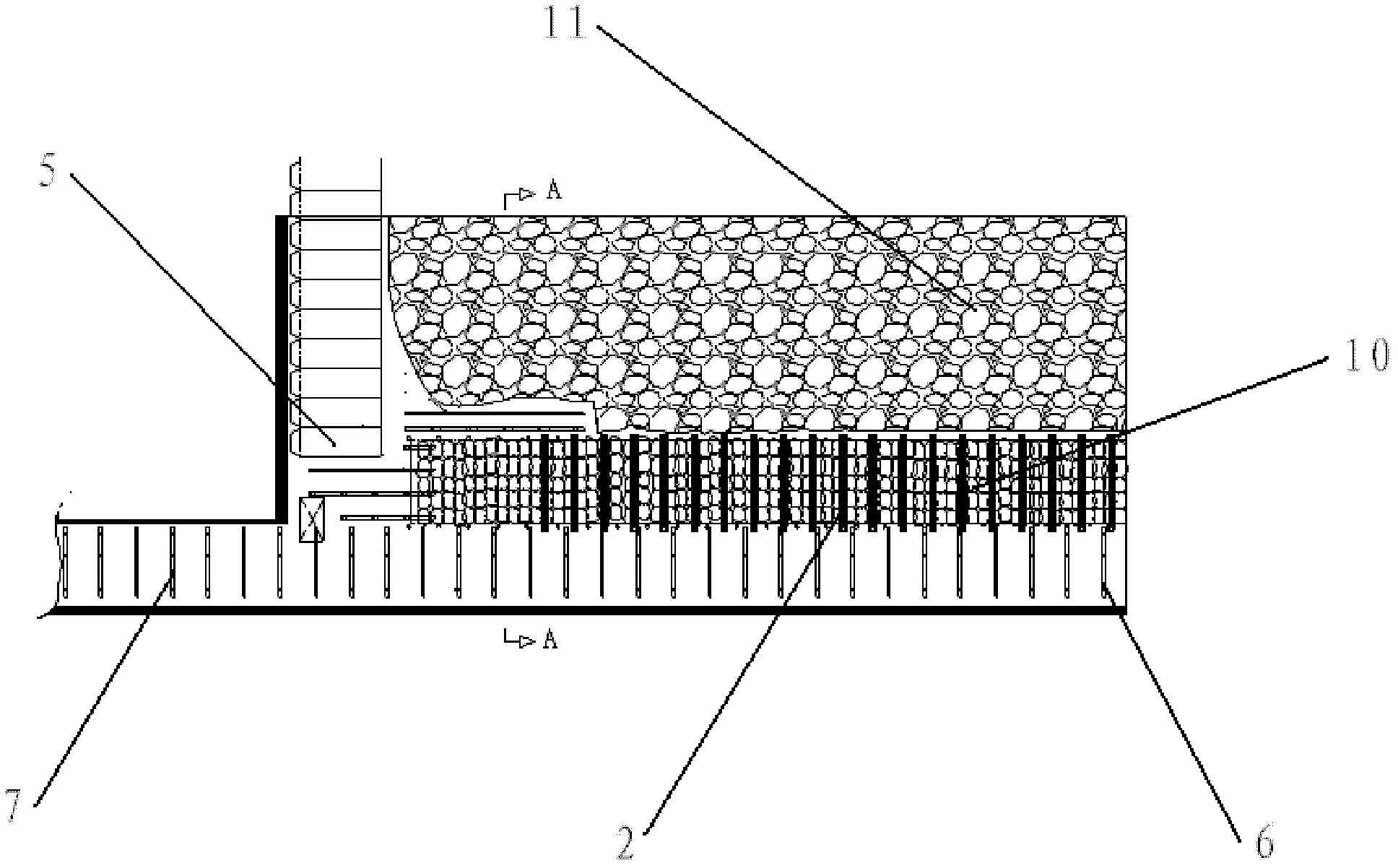

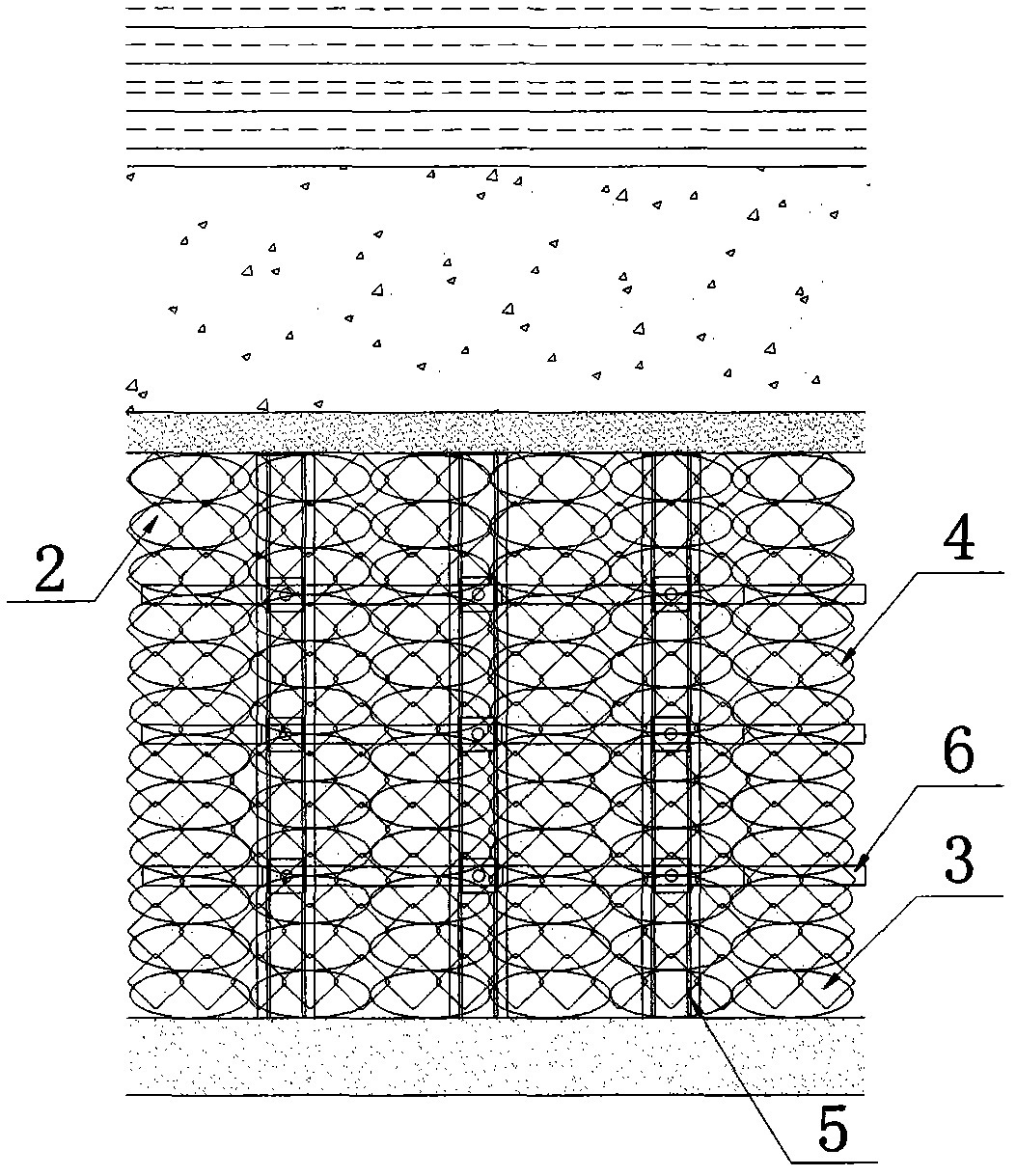

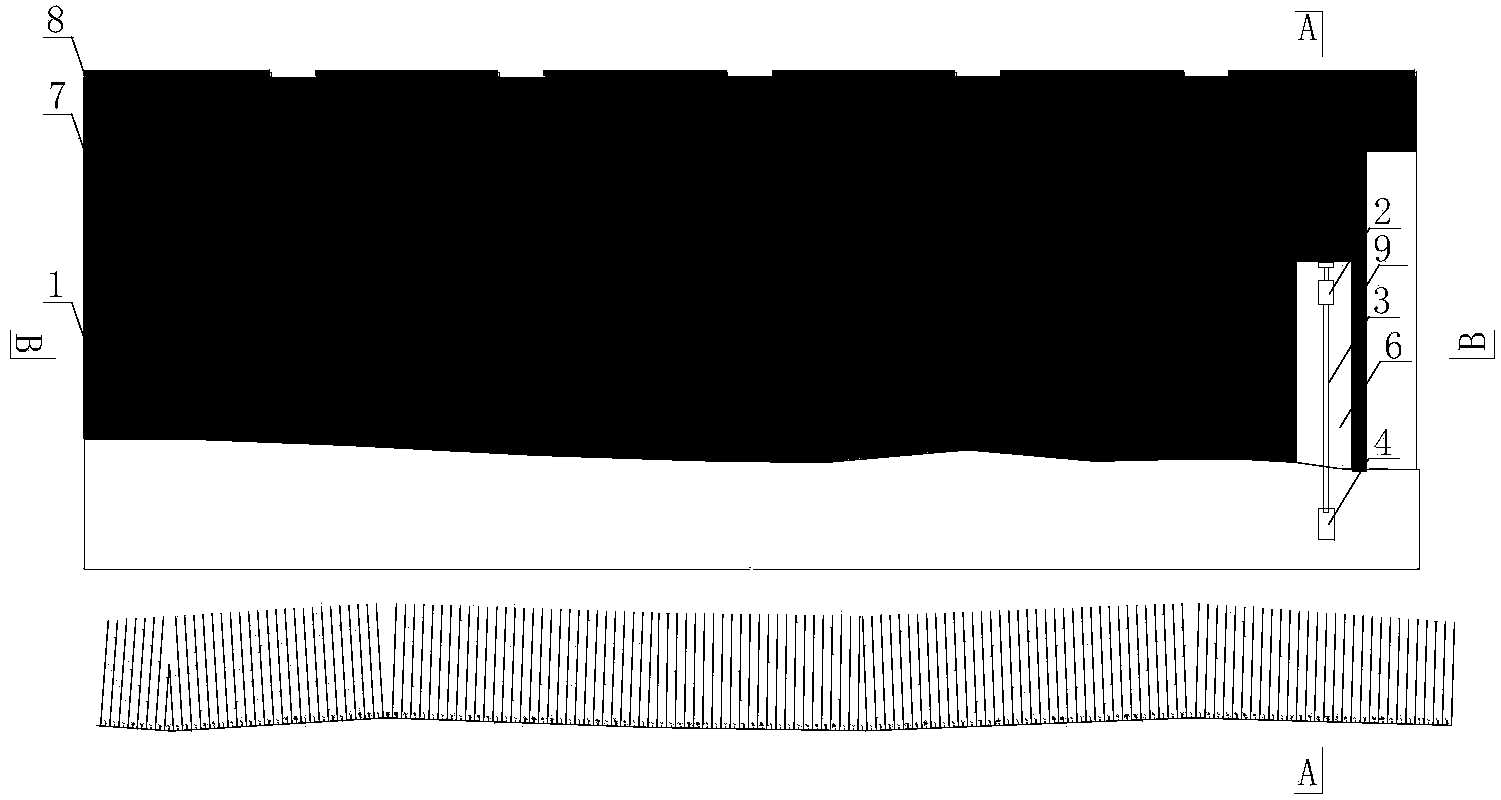

Inclined separated layer solid filling coal mining method for super thick coal seam

ActiveCN103306720ASolve sinkingFree resourcesUnderground miningSurface miningSolid massEarth surface

The invention discloses an inclined separated layer solid filling coal mining method for a super thick coal seam, which is suitable for the exploitation of an 'under three' super thick coal seam. The method comprises the following steps: determining the number of inclined separated layers according to the principle that thickness of each separated layer is 2.5-4.5 m; adopting a exploitation sequence that mining layer by layer, and filling at a next row; arranging tunnels and equipment according to the conventional solid filling coal mining method; carrying out a circulating sequence that coal mining firstly, metal nets and bamboo fences paving secondly, and filling finally to complete the filling exploitation of a first mining surface and a first separated layer; meanwhile, mining according to the same filling coal mining method under the shield of a manual false roof formed by the first separated layer at the corresponding position of a second separated layer 4 months after a working face of the first separated layer finishes mining; circulating in the way that the exploitation of one separated layer is performed under the shield of a manual false roof manufactured by an upper separated layer continuously until the whole super thick coal seam is mined out. Through the adoption of the method, resources of the 'under three' super thick coal seam can be utilized, the rock formation movement and earth surface sinking can be effectively controlled; and the recovery ratio is high, the production efficiency is high, the cost is low, and the method has wide practicability in the field of thick coal seam filling exploitation.

Owner:CHINA UNIV OF MINING & TECH

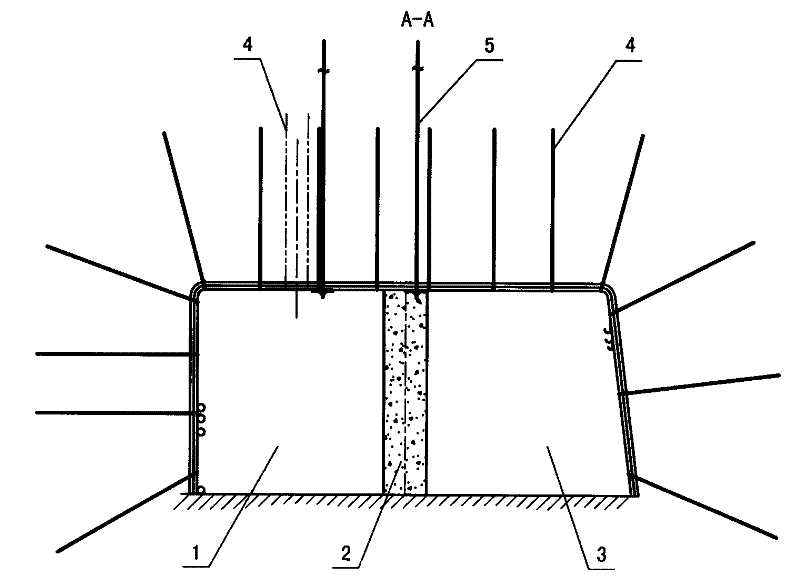

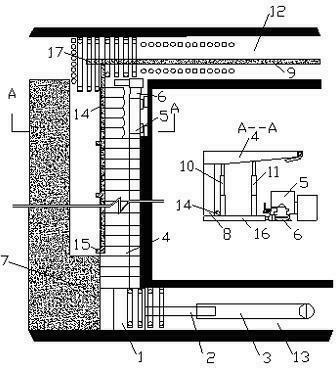

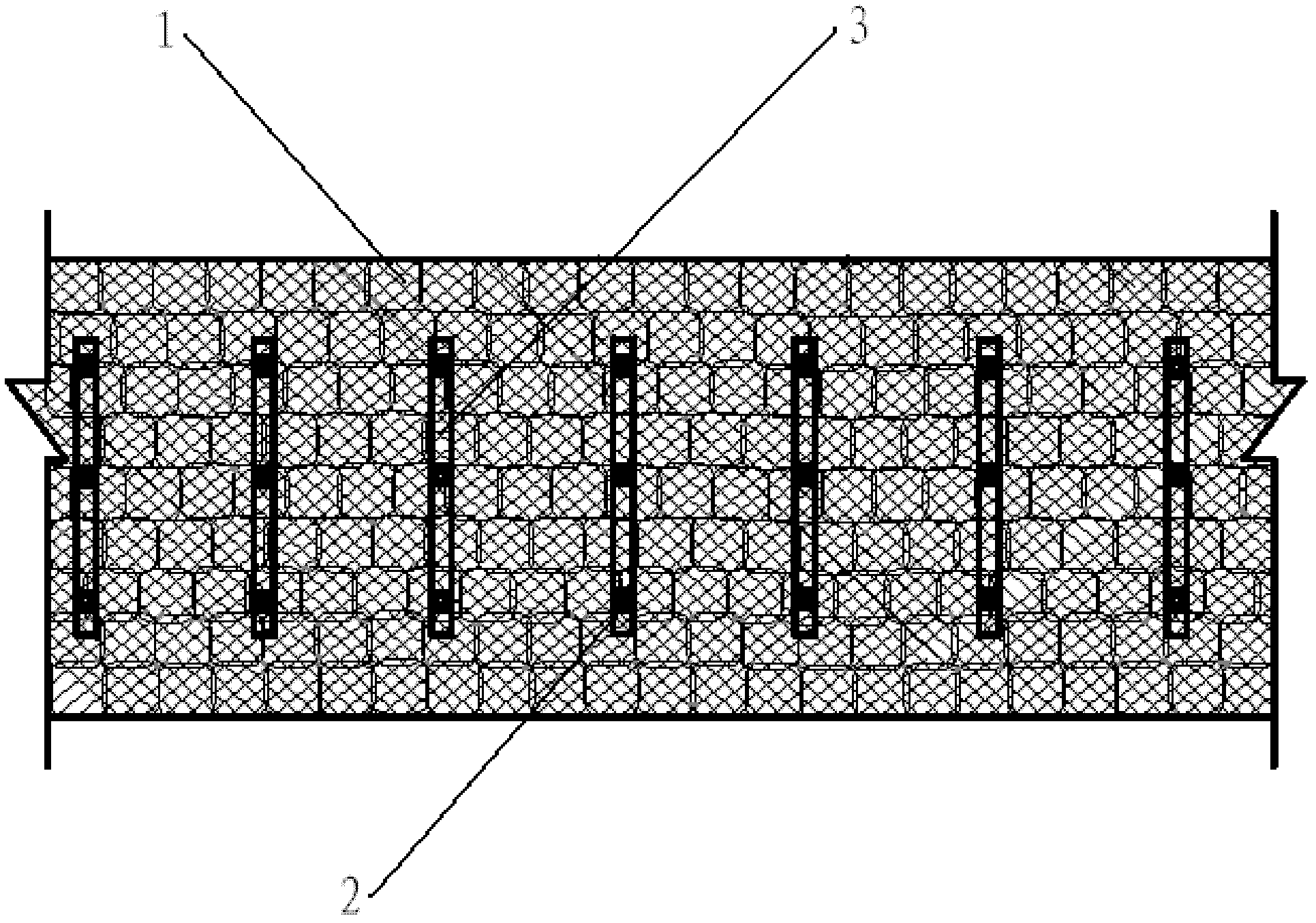

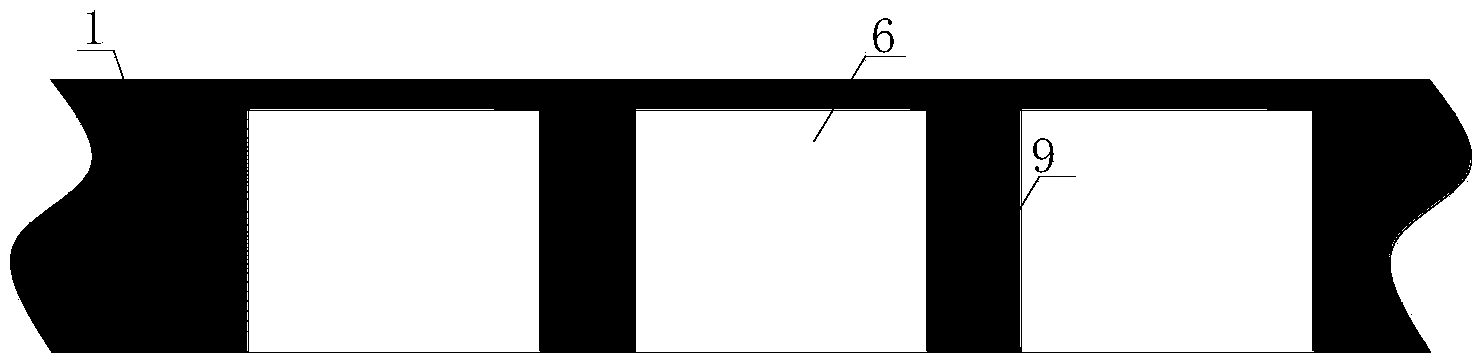

Method for retaining gob-side tunnel

InactiveCN102337904AAchieve miningTake advantage ofMining devicesUnderground chambersEngineeringStructural engineering

The invention discloses a method for retaining a gob-side tunnel, which overall arranges the retaining of the gob-side tunnel in a stope working face gateway tunneling period, and comprises the steps of: combining the stope working face gateway with the gob-side retained tunnel, namely the next section gateway, together to be served as one tunnel for tunneling; and constructing tunnel concrete pier columns between the stope working face gateway and the gob-side retained tunnel, wherein the tunnel concrete pier columns are served as support in the tunnel and also served as one part of the side support for the gob-side retained tunnel; namely comprising the steps of: widening the section of the tunnel by tunneling, reserving the tunnel section according to the shrinkage factor of the god-side retained tunnel suffering from two times of support pressure, and pouring the reinforcing steel bar concrete pier columns in middle of the transverse direction of the tunnel to match with a cable anchor for supporting. The tunnel concrete pier columns are arranged along the whole length of the tunnel at intervals, and used for dividing the tunnel into two parts. Insulating walls are constructed between two adjacent columns after the columns are constructed. When the stope is starting, the support is needed to be temporarily reinforced at two sides of the columns according to requirements along with the advancing of the stope working face. According to the method for retaining a gob-side tunnel, the retaining of the gob-side tunnel and the tunneling of the stope working face gateway are overall arranged, and the tunnel concrete pier column support is arranged; therefore, the side support intensity and support resistance of the retained tunnel are greatly enhanced, the influence of support pressure in two times of mining is effectively controlled. The method for retaining gob-side tunnel is particularly suitable for using in flexible mining faces of bottom plate and / or top plate.

Owner:贾民

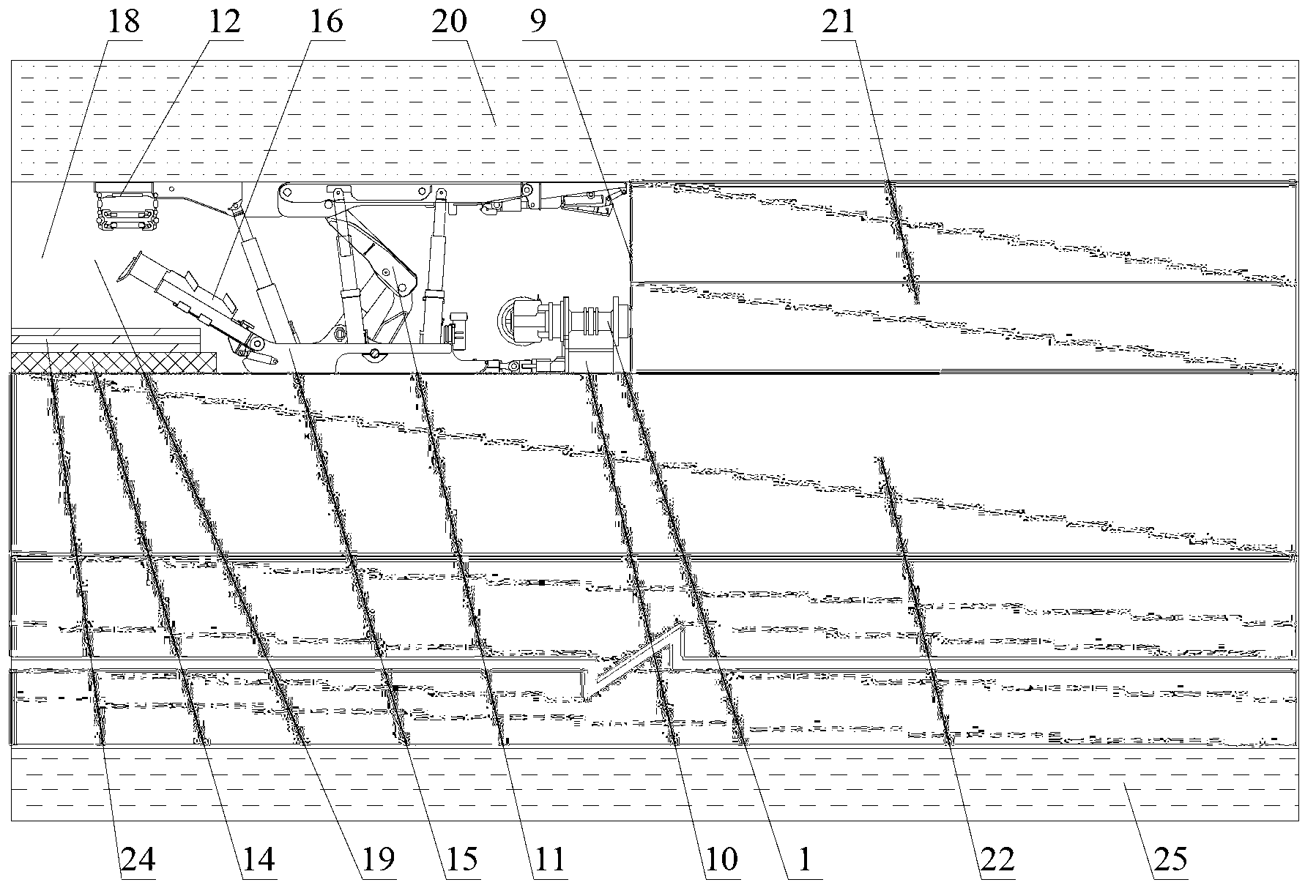

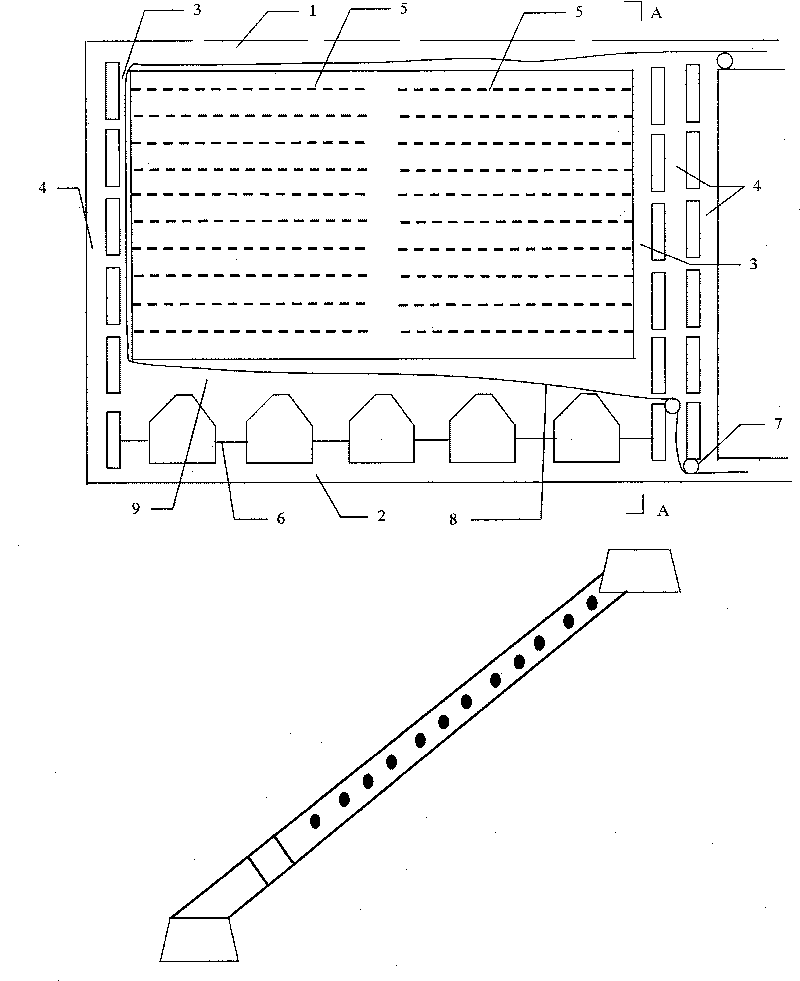

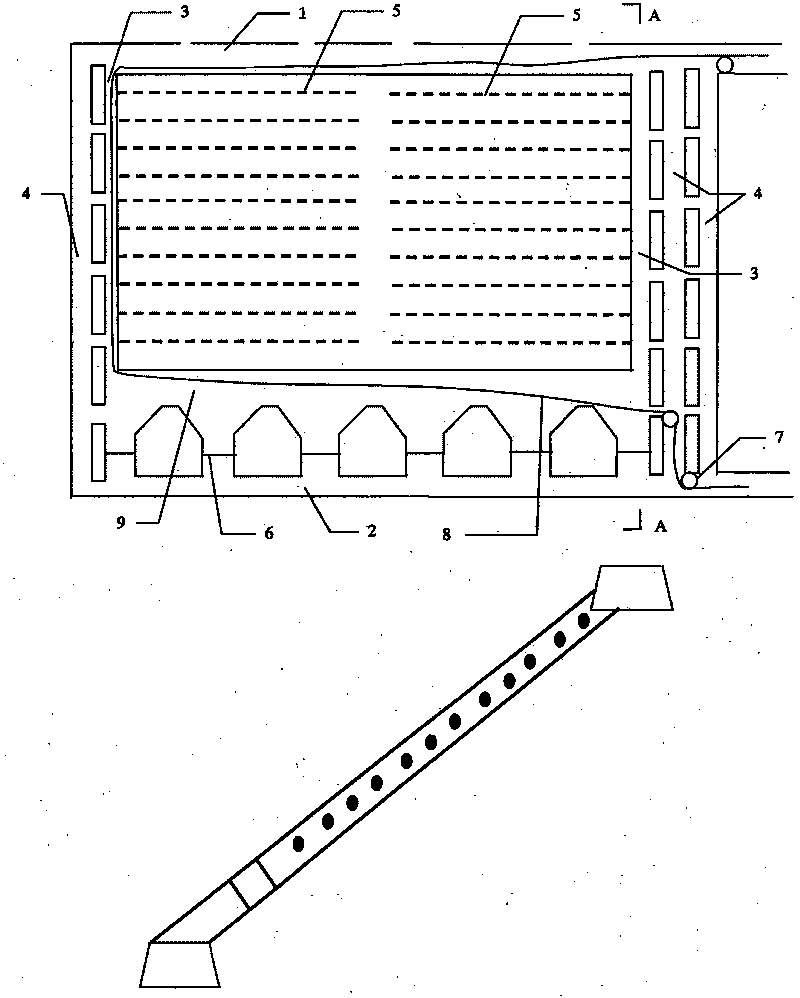

Method for fully mechanized continuously-filling coal mining of steeply pitching coal seam

InactiveCN102493838AIncrease the level of mechanizationReduce labor intensityUnderground miningSurface miningStopped workEngineering

The invention provides a method for fully mechanized continuously-filling coal mining of steeply pitching coal seams, which comprises the following steps: a stoping face is arranged as per the method of long-wall mining along the strike, and fully mechanized mining equipment for the steeply pitching coal seam is adopted; an air cushion and a working face filling pipeline are arranged on a base on the side of a mined out space of rear pillars of a fully mechanized mining support; whenever the working face advances for every 1.4 to 1.8 meters and after the support is moved, the working face filling pipeline is connected with an upper gateway filling main pipeline; the air cushion is filled with air, and auxiliary separation is arranged; paste is conveyed to a filling pipe branch sequentially from low to high so as to ensure filling and compacting, and finally the paste is conveyed to a supplementary filling pipe of the upper gateway; after the paste is coagulated, a portion of air in the air cushion is released, and the working face advances forward continuously; the steps are repeated until the stopping work for the whole working face and the filling work for the mined out space are finished. The method provided by the invention is convenient to operate and simple to carry out, can improve the mechanization level for mining the steeply pitching coal seams under buildings, railways and water bodies, improves the output of the working face, efficiently reduces the roof subsidence and the ground deformation, and realizes coal mining without the pillars and achieves Y type ventilation.

Owner:HUNAN UNIV OF SCI & TECH

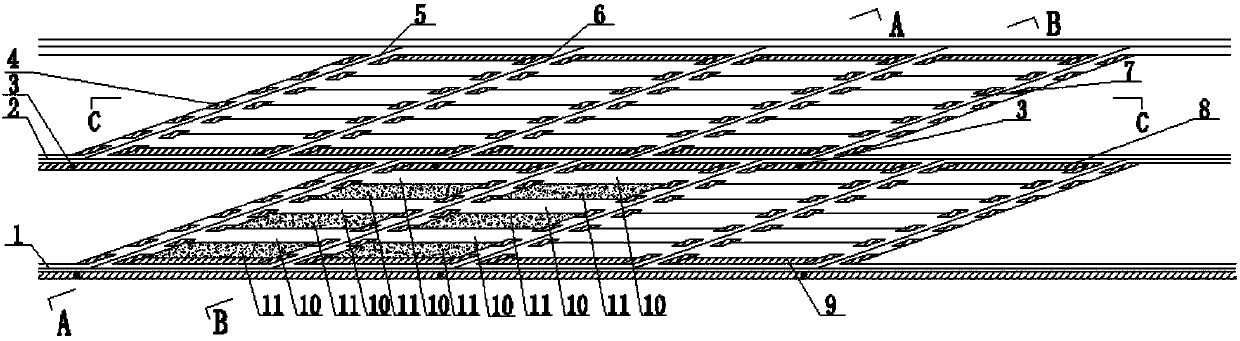

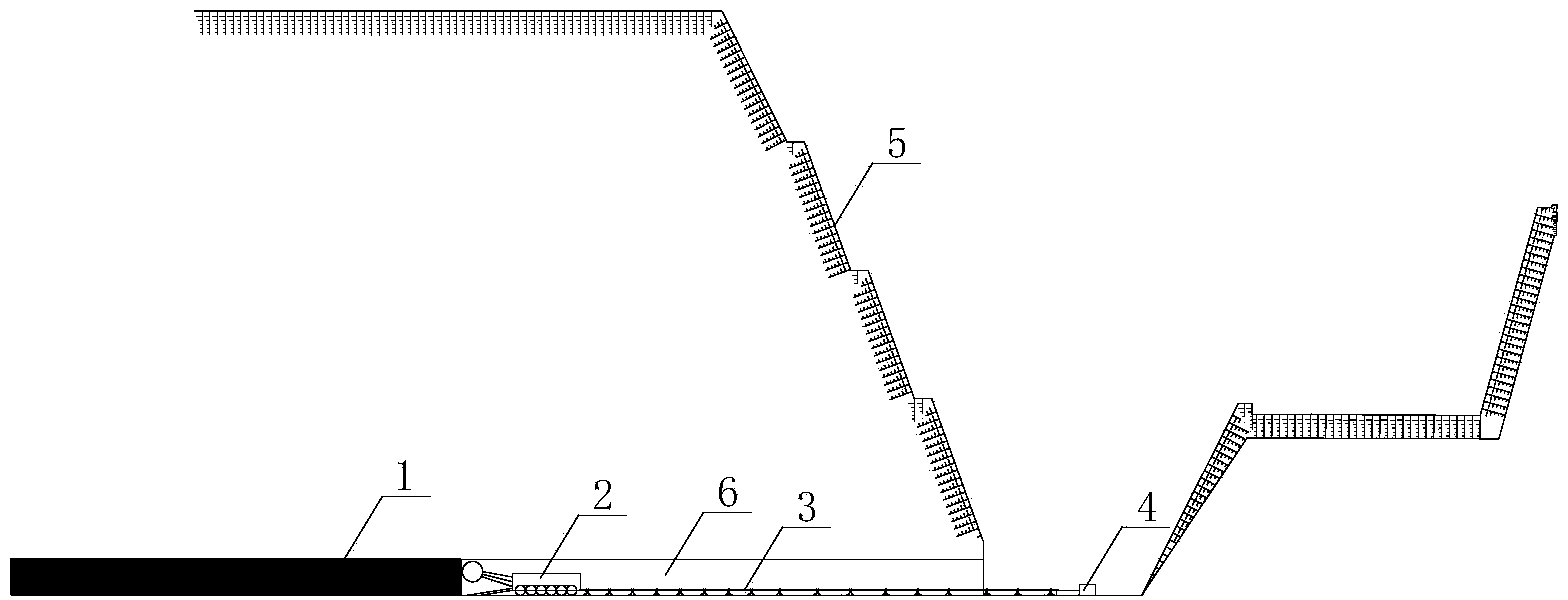

Mechanized mining method for gently-inclined medium-thick ore body

ActiveCN107869349AContinuous and efficient miningIncrease production capacityUnderground miningSurface miningMineralogyLoss rate

The invention provides a mechanized mining method for a gently-inclined medium-thick ore body, and belongs to the technical field of mining. The method comprises the following steps: dividing a gently-inclined medium-thick ore body into a panel area, dividing the ore body in the panel area into strips in a heading direction, driving a pseudo-inclined mining uphill roadway and a return air uphill roadway in the inclining direction of the ore body, driving a stope connecting roadway in a mining uphill direction and a return air uphill direction respectively, reserving a top safety ore pillar anda bottom safety ore pillar at the top and the bottom of each section respectively, and reserving a safety ore pillar between adjacent stopes in the heading direction of the ore body. The strips in the panel area is divided into one-step stopes and two-step stopes, the ore body is stoped at intervals sequentially from bottom to top, the one-step stopes are mined first, and then the two-step stopesare mined. After filling and final setting of all one-step and two-step stopes, uphill safety ore pillars, top safety ore pillars and bottom safety ore pillars are recovered. The method provided by the invention has the advantages of high mechanization degree, large production capacity, small mining and cutting work amount, high ore recovery rate, low lean loss rate and good safety.

Owner:UNIV OF SCI & TECH BEIJING +1

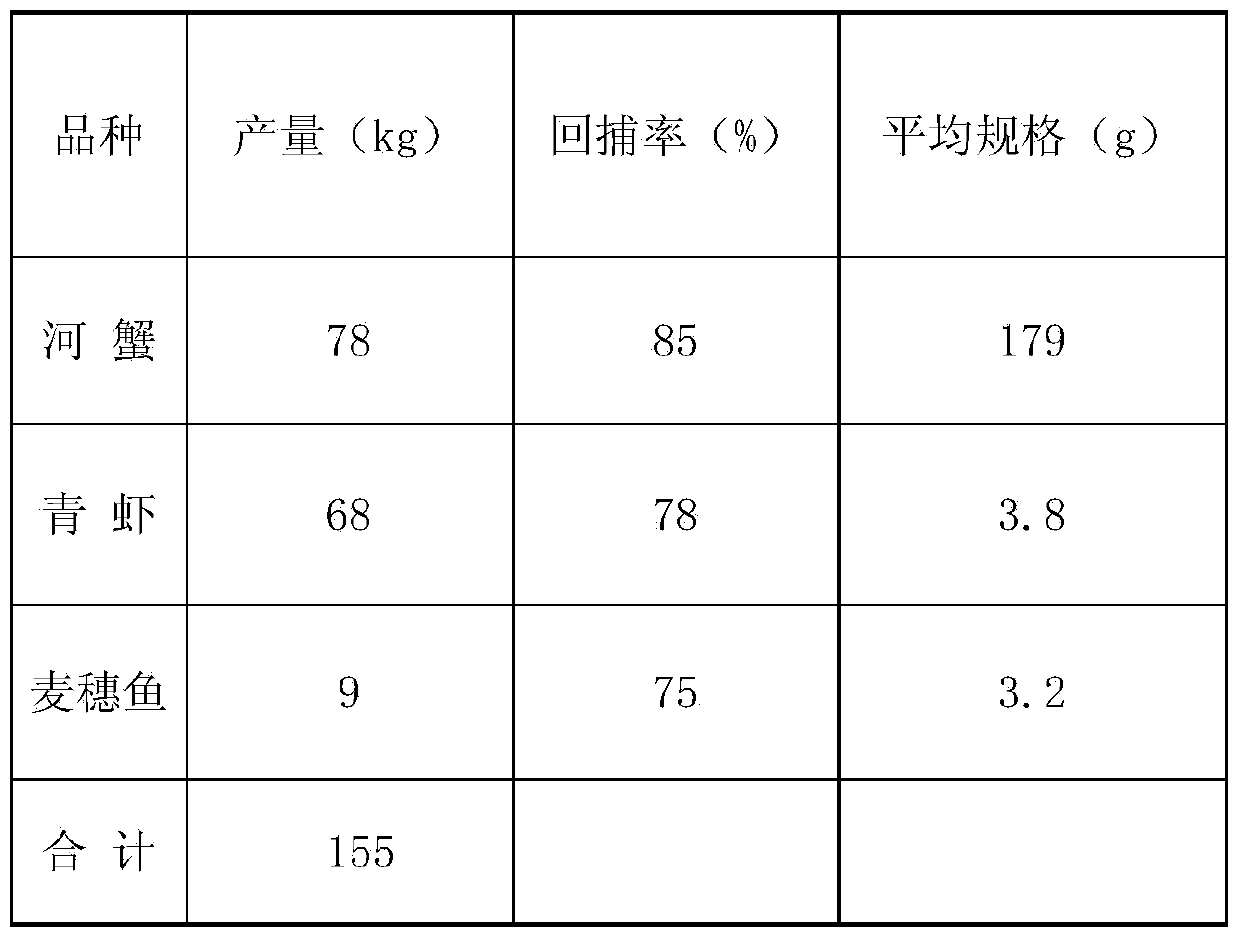

Ecological breeding method for efficient polyculture of river crabs, freshwater shrimps and pseudorasbora parva

ActiveCN103718993AStrong foraging abilityIncrease shrimp productionBiocideClimate change adaptationFertilizerMugil

The invention discloses an ecological breeding method for efficient polyculture of river crabs, freshwater shrimps and pseudorasbora parva. The method comprises preparing conditions of a pond, constructing escape-preventing facilities, airing and sterilizing the bottom of the pond, applying fertilizer to the pond, planting water plants, putting in snails, putting in fingerlings, regulating and controlling water quality, throwing in feed and the like. According to the ecological breeding method, the situation that siniperca chuatsi feed on freshwater shrimps in the breeding mode of shrimps, crabs and siniperca chuatsi in the past is avoided, so that the output of the freshwater shrimps is increased greatly, and the recapture rate of the freshwater shrimps is high; the pseudorasbora parva play a role as a scavenger by feeding on residual feed, so that water quality pollution is reduced greatly, water quality is improved, and the growth of river crabs, freshwater shrimps and pseudorasbora parva is boosted. According to the ecological breeding method, the output and quality of river crabs, freshwater shrimps and pseudorasbora parva are improved remarkably, death rate is lowered, feed waste is reduced, breeding cost is lowered, breeding benefit is improved, income of fishermen is increased, and efficiency improvement of the fishery industry is realized.

Owner:NANJING SHUAIFENG FEED

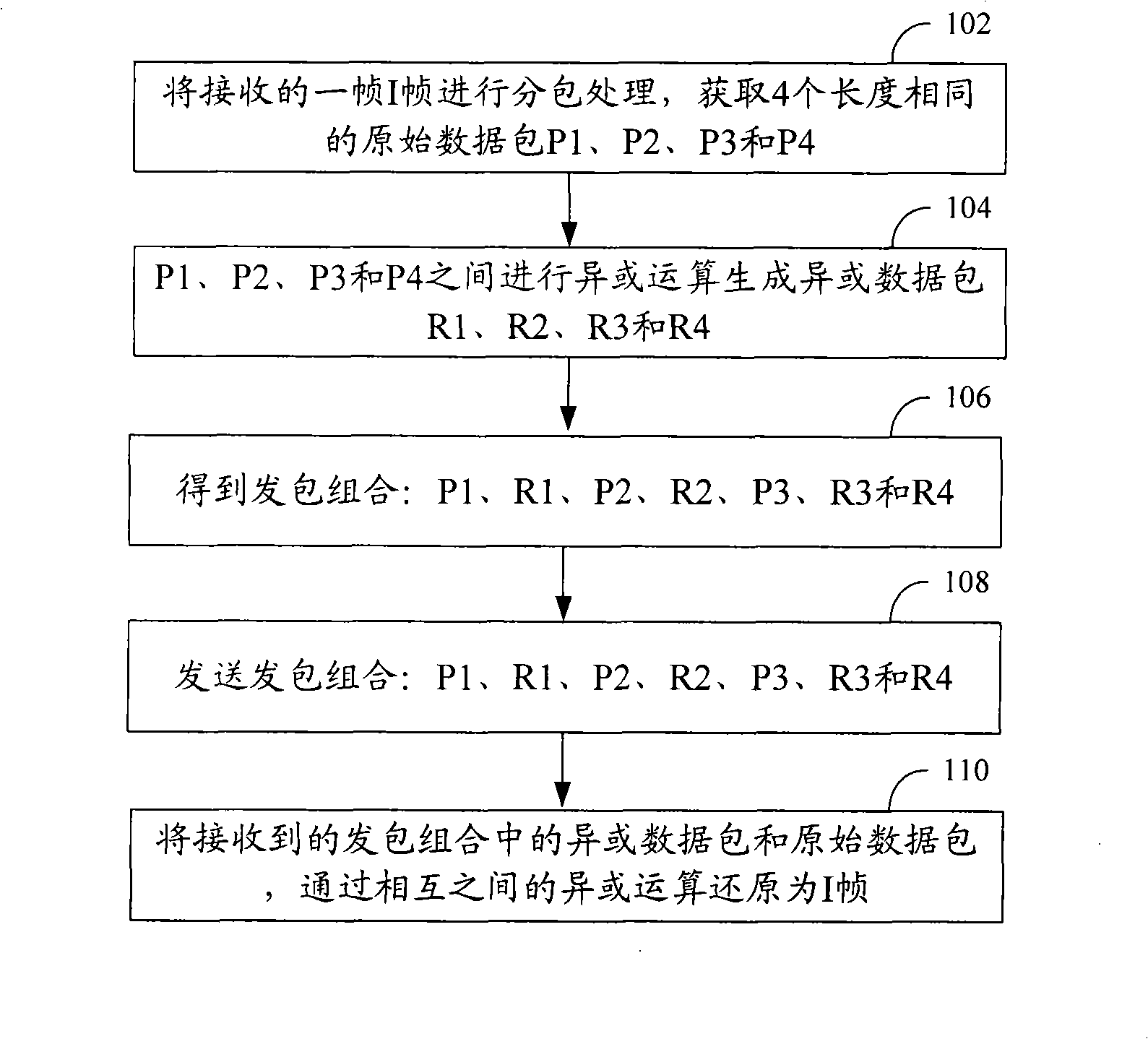

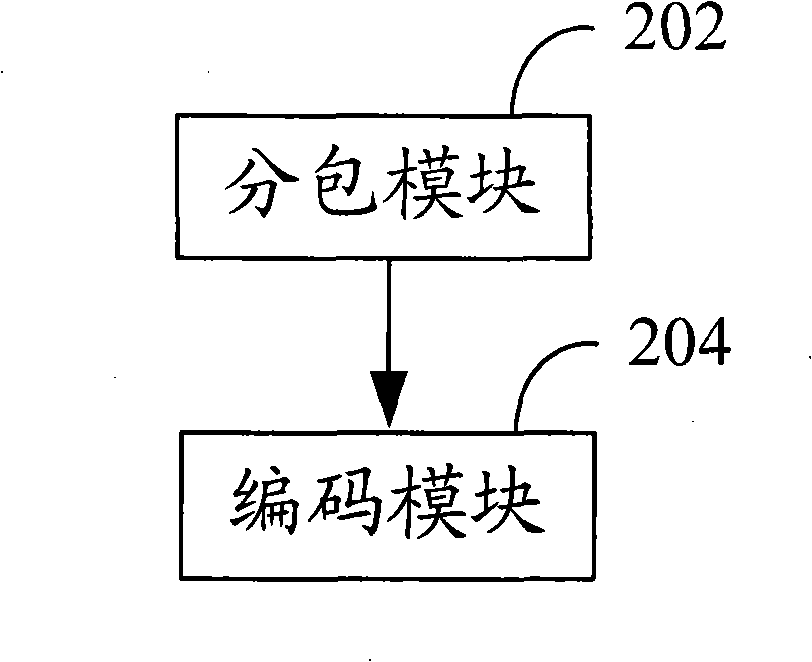

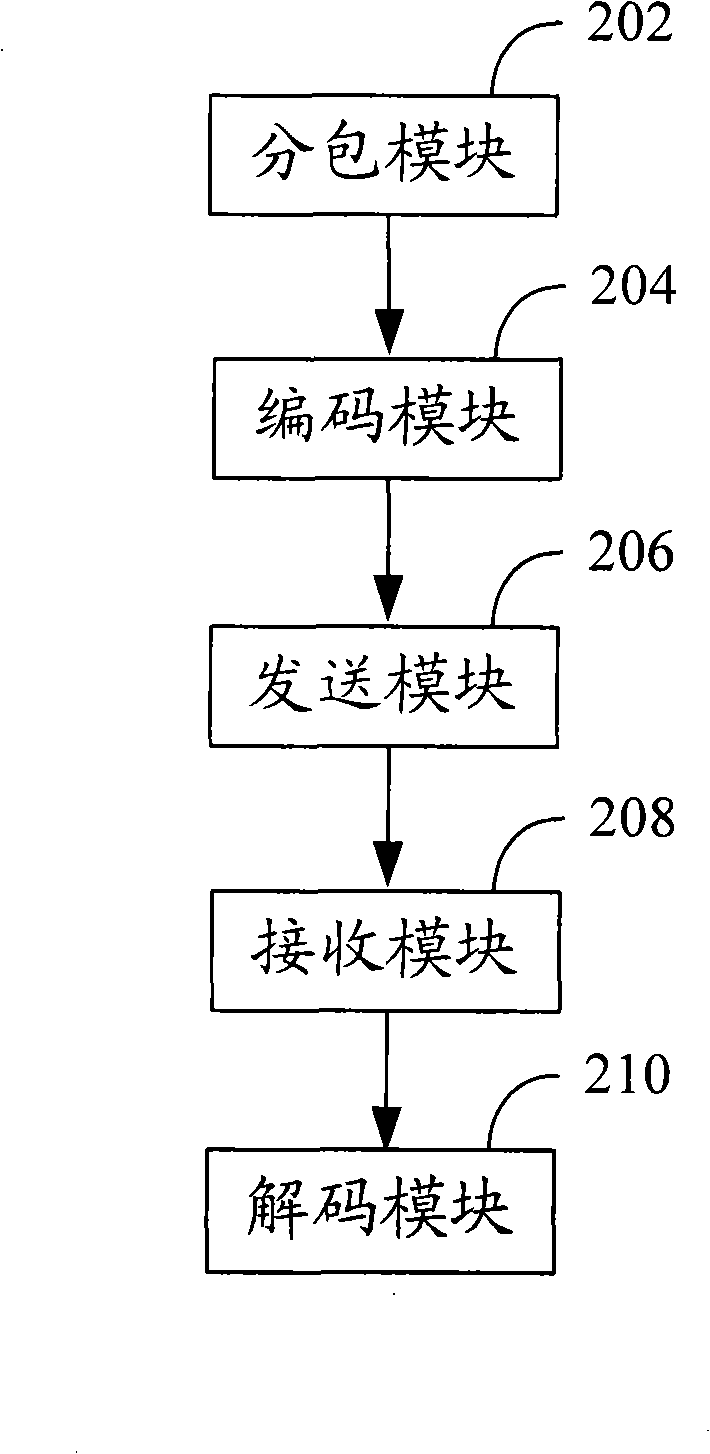

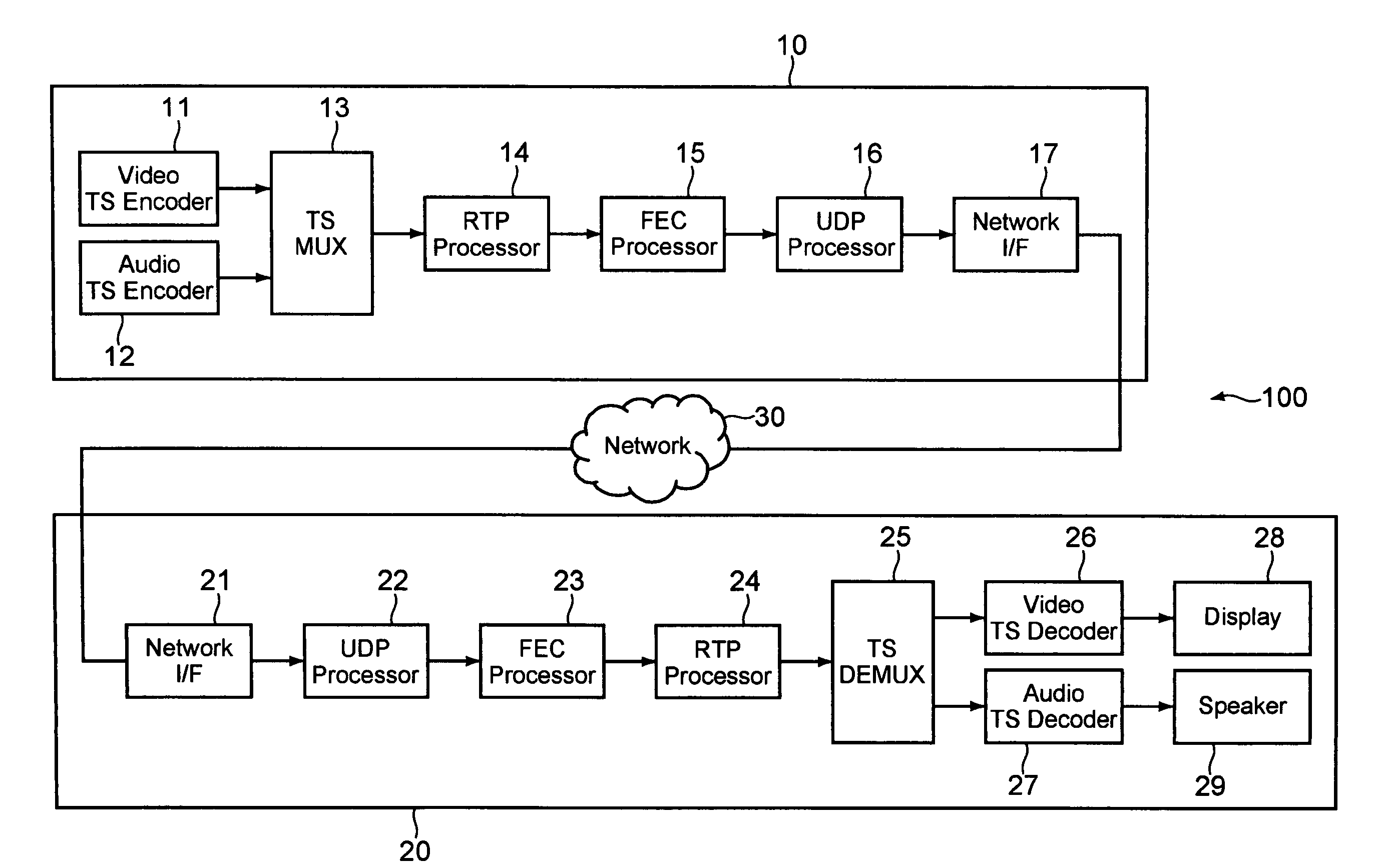

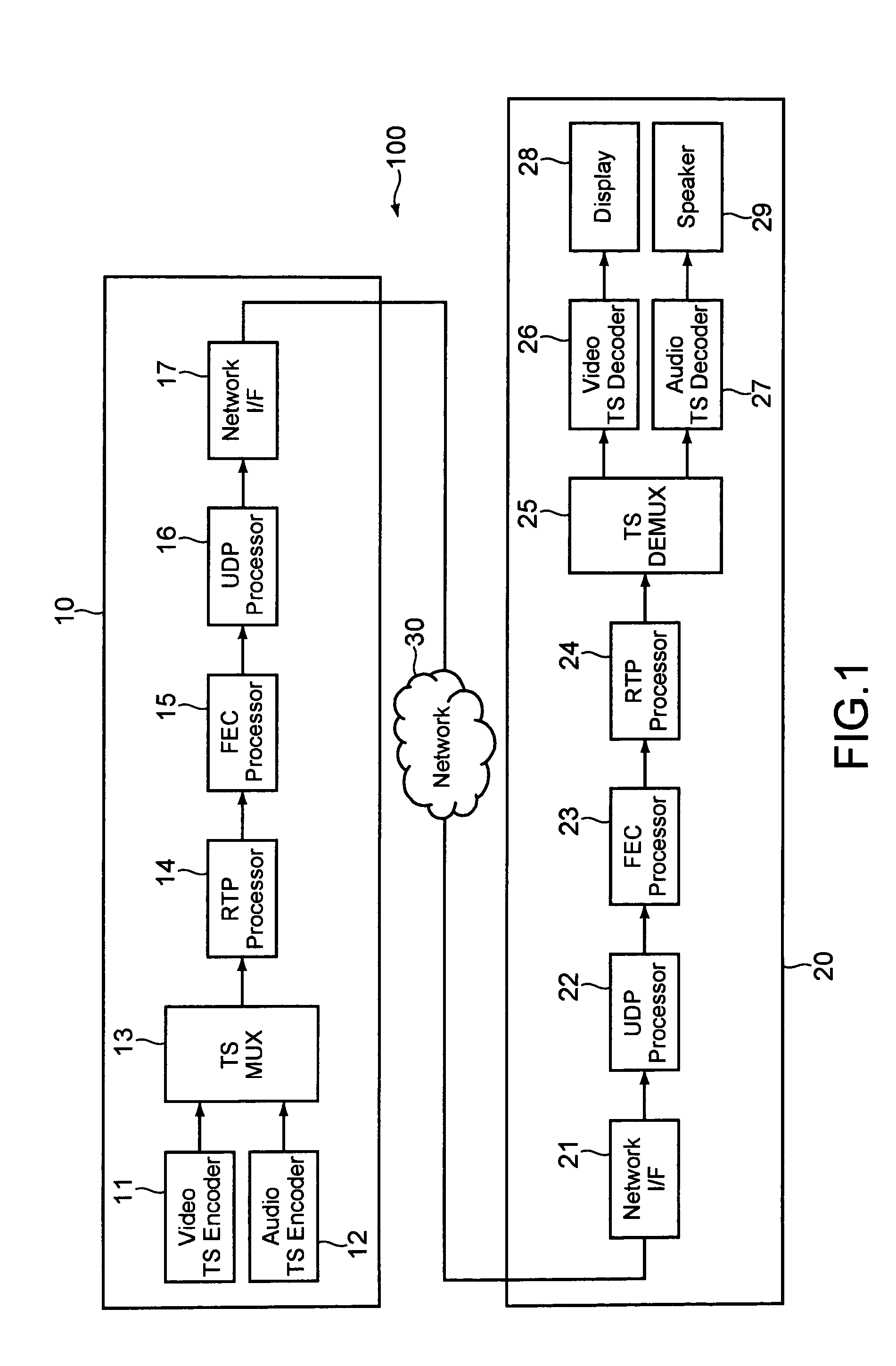

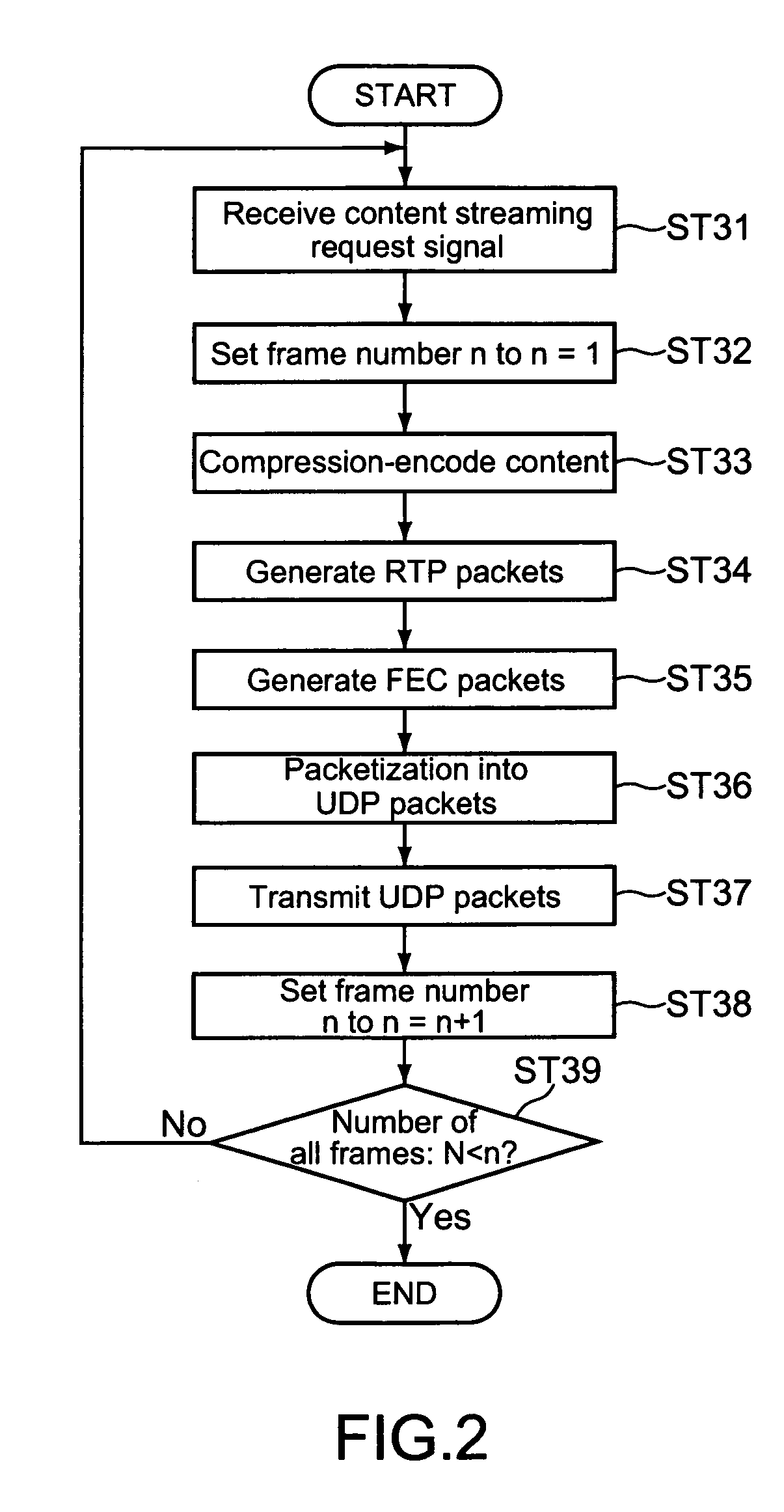

Method, apparatus and system for data packet redundant encoding and decoding

ActiveCN101359981AImprove recovery rateError preventionData switching networksOriginal dataNetwork packet

The invention discloses a method, a device and a system of data packet redundancy encoding and decoding. In order to solve the problem that the loss of two data packets probably leads to low probability of data reconstruction, the method comprises: initial data is divided into a plurality of equilong initial data packets; XOR operation is performed to the initial data packets and the initial data to produce XOR data packets, the number of XOR to any initial data packet is not less than two; the initial data packets and the XOR data packets are coded, and then a sending packet combination of the initial data packets and XOR data packets is obtained; wherein, in the condition of redundancy being equal, the probability that the sending packet combination carries out mutual XOR with the rest data packets to recover all initial data packet is the biggest after any two data packets are lost; just because the number of the initial data packet XOR is not less than two, the probability of recovery at a receiving terminal is improved when any two data packets are lost.

Owner:TENCENT TECH (SHENZHEN) CO LTD

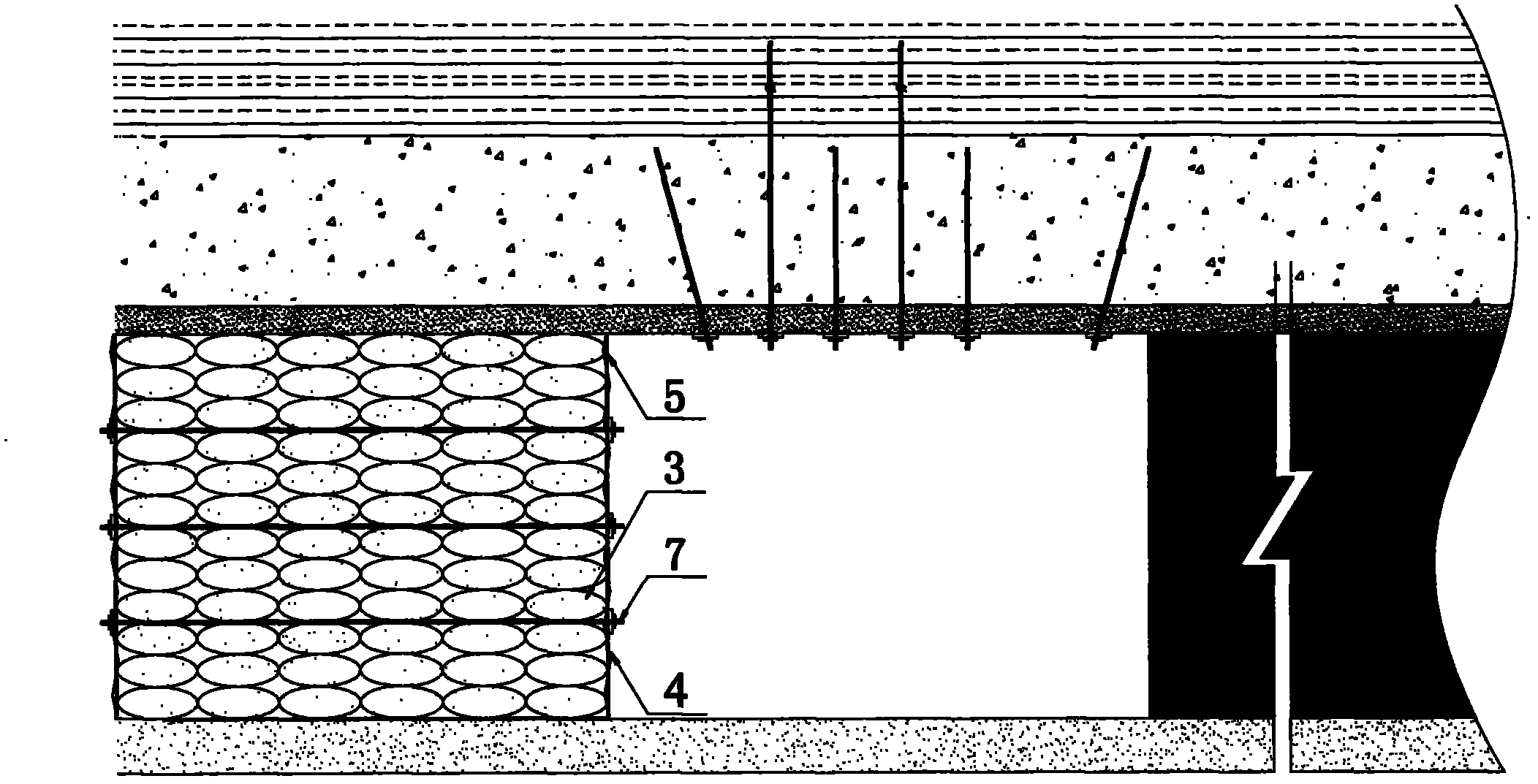

Filling and mining method of coal gases

InactiveCN102155225ALow costWide variety of sourcesUnderground miningSurface miningMining engineeringHigh pressure

The invention relates to a filling and mining method of coal gases, comprising the following steps: arranging a gas pressurization room on the ground and then arranging an underground gas booster pump connected with a ground high-pressure gas storage tank pipeline in a mining region haulage way in front of an underground coal mining working face; distributing a row of cylindrical rubber airbags in a gob behind the coal mining working face when the coal mining working face is advanced for 5-8 m from the open-off cut; filling gas into the cylindrical rubber airbags till the top is tight; sealing the openings of the cylindrical rubber airbags to finish filling gas into one cylindrical rubber airbag; continuously distributing a row of cylindrical rubber airbags behind the row of gas-filling cylindrical rubber airbags when the coal mining working face is advanced for each step along with the continuous advance of the coal mining working face and charging gas in rows till finishing the gas filling and supporting in the whole gob. In the invention, the filling method is simple, the gas filling speed is high, the cost is low and the filling capacity is great, and the method is convenient for onsite underground operation.

Owner:CHINA UNIV OF MINING & TECH

Transmitting apparatus, receiving apparatus, error correcting system, transmitting method, and error correcting method

InactiveUS20090016228A1Improve recovery rateError preventionFrequency-division multiplex detailsComputer hardwareDiagonal

A transmitting apparatus includes a generating unit and a transmitting unit. The generating unit generates first error correction packets by performing predetermined operation processing on a plurality of data packets arranged in a plurality of rows and columns respectively in each of the rows and columns and generating at least one second error correction packet by performing the predetermined operation processing on the data packets existing in a diagonal direction crossing the plurality of rows and columns. The transmitting unit transmits the plurality of data packets and the generated first and second error correction packets.

Owner:SONY CORP

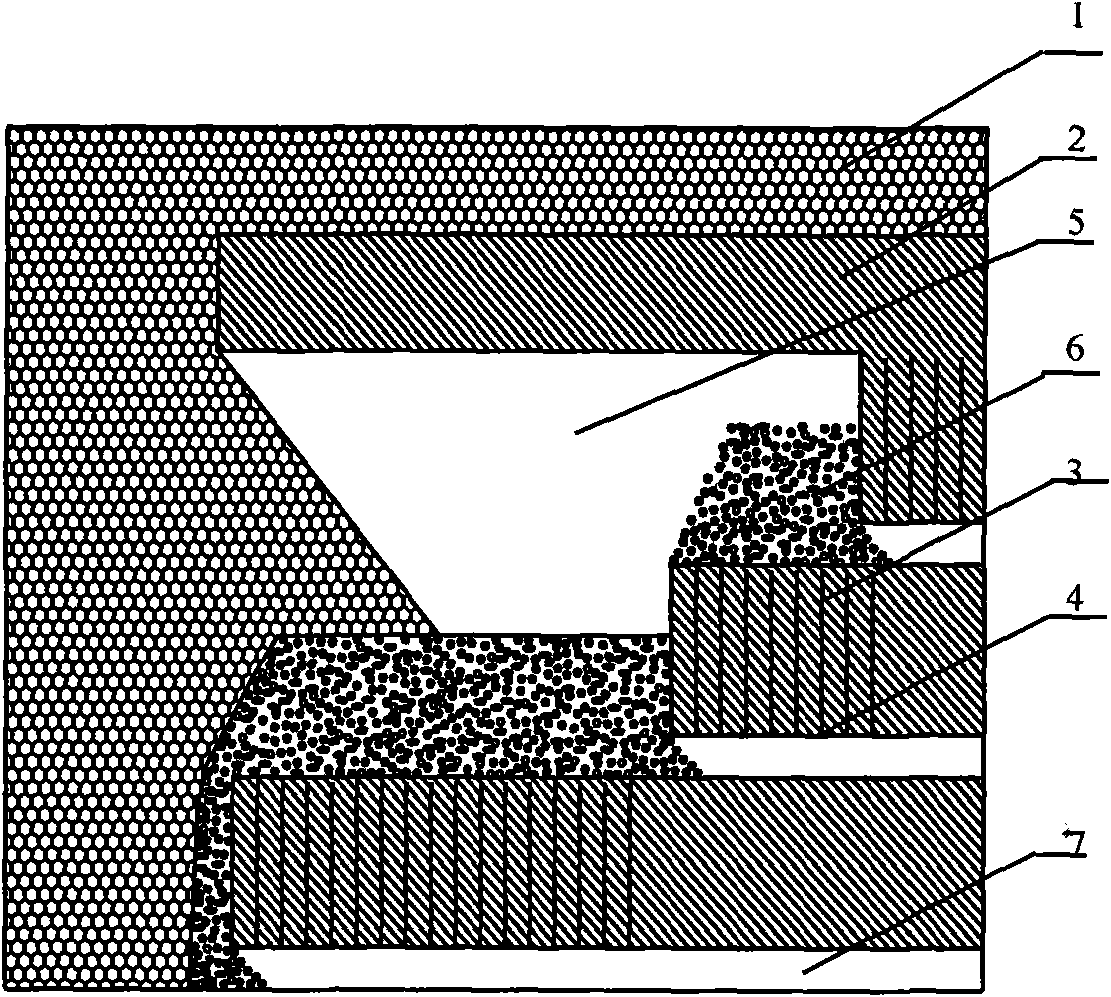

Open stope-caving combined mining method

The invention relates to the field of underground mine mining process, especially to an open stope-caving combined mining method suitable for mining minerals of which the orebody inclination angle is between 60 DEG and 90 DEG and the thickness is less than 10m. The method is characterized in that each mining ore block consists of a support pillar, an open-stope caving sublevel and a roadway thereof, a caving recovery sublevel and a roadway thereof, an ore chute and the like, wherein the open-stope caving sublevel is arranged along the strike direction of the orebody. The mining scheme has the advantages of simple process, safe production, low cost, high production efficiency, low loss and dilution and the like and is easy to manage. The ore recovery ratio of ore blocks is increased to 75% from about 50%; the ore dilution rate is controlled below 15%; and the mining production capacity is improved from the current 200 tons per day to 350 tons per day. With the gradually reduced thick and large orebodies which are easy to exploit, the requirement on efficiently mining thin ore bodies is more and more urgent, and therefore the method of the invention has very strong competitive power in the mining technical field at home and abroad and has broad application prospect.

Owner:ANSTEEL GRP MINING CO LTD

Method for mining coal of steeply inclined thin seam

InactiveCN101737047ALow costEasy dischargeUnderground miningBlastingMining engineeringEconomic benefits

The invention provides a method for mining coal of a steeply inclined thin seam on the basis of learning from a long-hole blasting coal mining method and a wire saw coal mining method, which is a long-hole blasting and wire saw coal mining method and relates to underground coal mining. The method comprises the following steps: long boreholes are arranged in a direction which is parallel to the cross pitch of the coal seam for coal blasting; after finishing blasting a work surface, making the coal slip out from a section coal bin and loading the coal for outward transport through a haulage drift; and when blasting to the vicinity of a tailgate through the long boreholes, stopping the blasting and utilizing a wire saw to mine remaining coal. The method has the advantages of no work surface support, rational tunnel arrangement, simple ventilation management, the capacity of realizing unmanned work surface mining, low cost, strong security, high coal mining rate, low worker labor intensity, good social and economic benefits and the like.

Owner:孙广义 +2

Cuprous modified metal organic skeleton adsorbent, preparation method and application

InactiveCN103752276AEfficient removalImprove recovery rateOther chemical processesHydrocarbon oils refiningSorbentGasoline

The invention discloses cuprous modified metal organic skeleton absorbent, a preparation method and application, belonging to the technical field of fuel oil processing. The absorbent can effectively adsorb sulfide in gasoline. The cuprous modified metal organic skeleton absorbent adopts a metal organic skeleton as a carrier, a cupric precursor is reduced by adopting a reducing agent through a vapor induction reduction method to prepare the metal organic skeleton adsorbent which is loaded with monovalent copper, and the cuprous content is 0.1 to 1mmol / g.

Owner:NANJING UNIV OF TECH

Impact-resistant combined anti-pressure supporting system

InactiveCN102182482AImprove efficiencyReduce maintenanceProps/chocksAnchoring boltsSupporting systemSocial benefits

The invention discloses an impact-resistant combined anti-pressure supporting system which is characterized by comprises a three-grade supporting system; and the impact-resistant combined anti-pressure supporting system has the advantages that: (1) by an optimized three-grade supporting manner, the maintenance amount of engineering roadways is reduced, the coal mining rate and the recovery ratio of a working face are increased, the safety coefficient is enlarged, and the comprehensive benefits of a mine are increased; (2) by applying a combined supporting system technology, the deformation of the roadway is effectively controlled when the working face is influenced by the ground pressure; and when the rock burst generates during production, the system plays a role of impact-resisting, realizes shrinkage and buffering changes and protects the safety of equipments and operators; and (3) according to the supporting system during recovery, dynamic alternatively circulative operation is realized, thus the purposes of resisting impaction, removing pressure and solving danger are realized, the construction process is simplified, various costs are saved, the quality is easy to control, the economic benefit is remarkable, the social benefit is also gained at the same time, and the competition among enterprises is improved.

Owner:义马煤业集团股份有限公司跃进煤矿

Method for re-mining residual floor coal in fully-mechanized top coal caving face

ActiveCN103742149APrevent oxidative spontaneous combustionRemoving threats to safe recoveryUnderground miningSurface miningEconomic benefitsProcess engineering

The invention relates to a method for re-mining residual floor coal in a fully-mechanized top coal caving face. The method is used for re-mining residual floor coal with complete coal seam at the bottom and fragmentized coal bodies at the upper part and having accumulated water, CO, CO2, gas and other harmful gases in the fragmentized coal bodies and an upper goaf; the method comprises the steps of proving reserves, accumulated water amount and accumulated gas amount, draining, filling nitrogen gas and fire retardants, tunneling an upper gateway and a lower gateway of a re-mining working face in a width equivalent to a distance away width of one-two roadways from re-mining residual floor coal bottom plate, reasonably setting zone protective coal pillars, cutting holes, reinforcing a top plate and controlling the coal seam, and then performing re-mining the residual floor coal in the fully-mechanized top coal caving face, wherein the ratio of the thickness of the cut coal and the sum of the thicknesses of the controlled coal seam and the fragmentized coal body at the upper part is controlled to be 1:3. The method for re-mining the residual floor coal liberates dead reserves, fully excavates and unleashes resources potential, improves the economic benefit, relieves the enterprise pressure and prolongs the life of mines.

Owner:TAIYUAN UNIV OF TECH

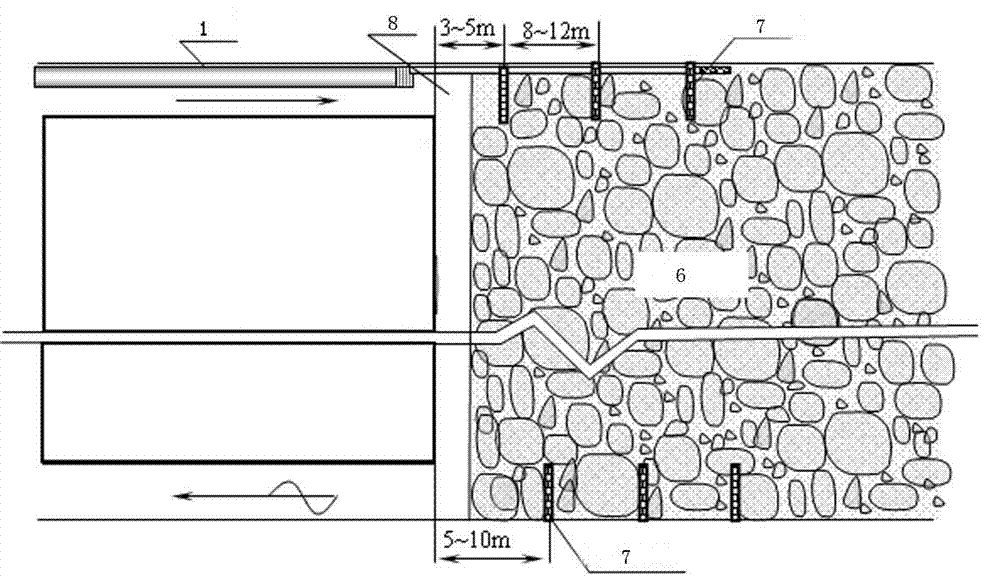

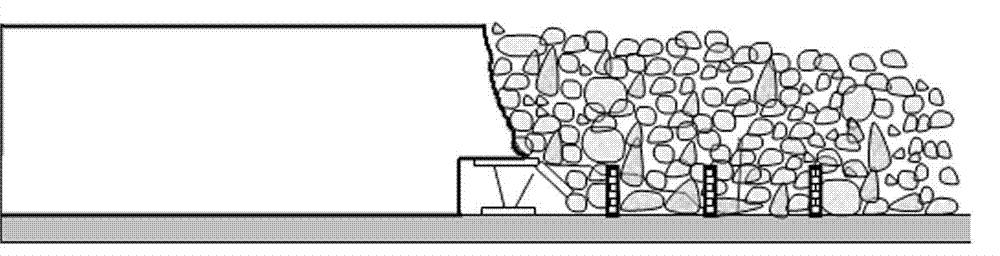

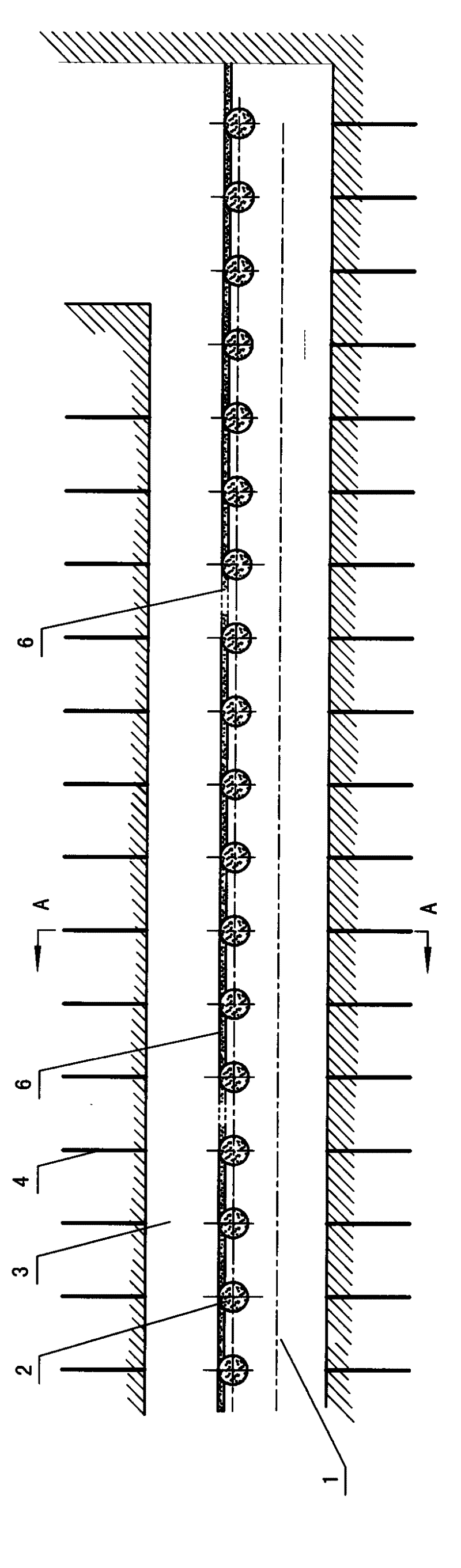

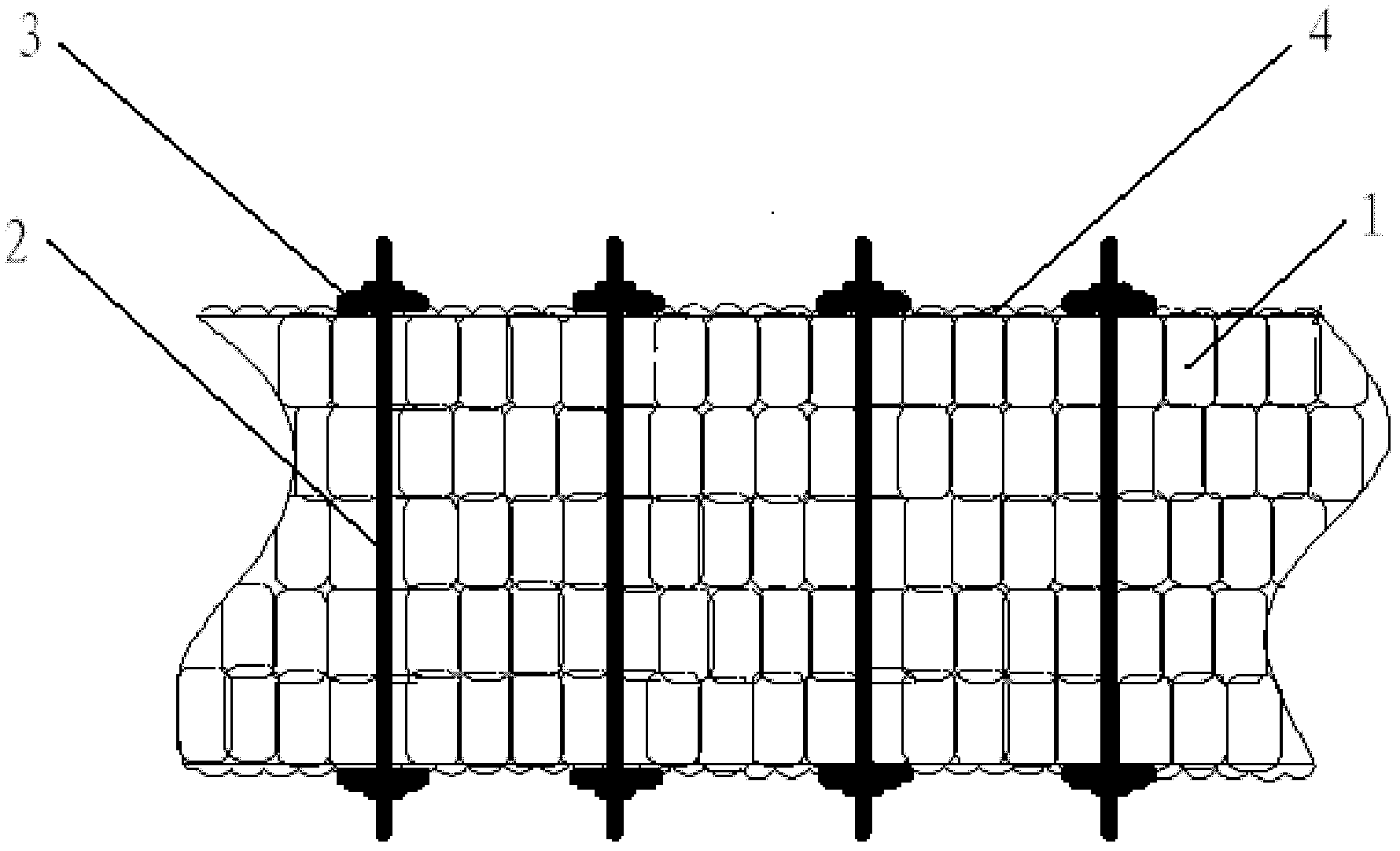

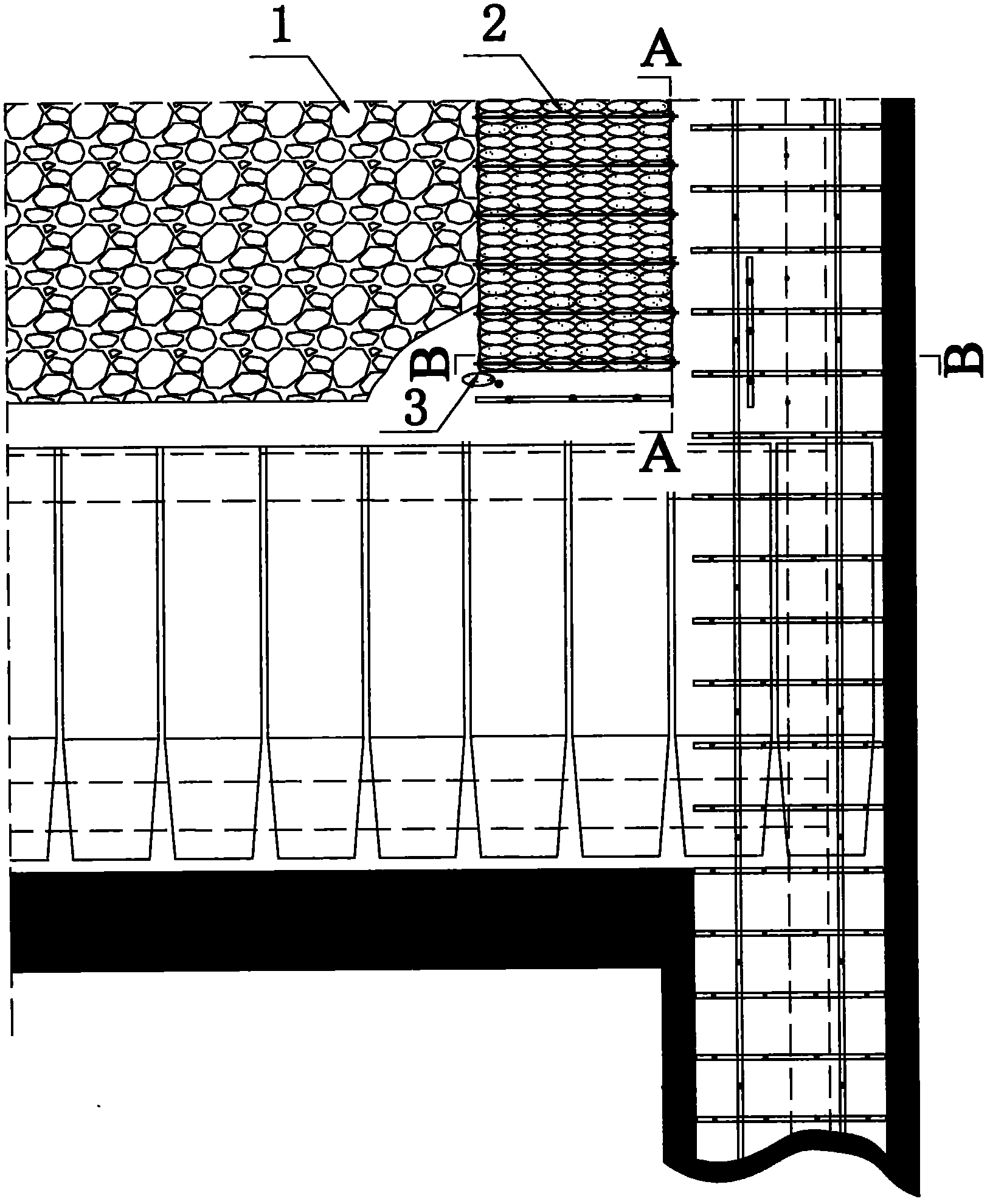

Gob-side entry retaining method for anchor bolt network gangue bag wall body for coal mining without pillars

InactiveCN102661169AHigh strengthIncrease stiffnessMaterial fill-upAnchoring boltsGranularityMining engineering

The invention discloses a gob-side entry retaining method for an anchor bolt network gangue bag wall body for coal mining without pillars. The gob-side entry retaining method comprises the following steps of: A, crushing solid wastes obtained by separating tunneling gangue and / or coal gangue until the granularity is small than 0.1m and bagging by adopting plastic woven bags to obtain gangue bags; B, conveying the gangue bags obtained in the step A to the position of a working surface, which is used for building an entry, through an underground conveying system and fixing the gangue bags for building a roadside gangue bag wall body to form a gob-side entry; C, arranging the gangue bag wall body into a plurality of steps with different heights; and D, building the gangue bag wall body to the designed position and height and then mounting anchor bolts and paving a metal net, and simultaneously, paving a vertical protection steel belt, carrying out two-way anchoring or single-side pretightening in a large-pallet lane and keeping a gangue bag filling body in the gangue bag wall body in a three-dimensional stress state to achieve the functions of increasing the side pressure of the gangue bag filling body and improving the strength and the rigidity of the filling body.

Owner:SHANDONG UNIV OF SCI & TECH

A method of retaining entry along the goaf with solid filling coal mining and building gangue walls

InactiveCN102278140AAvoid lostImprove recovery rateMaterial fill-upAnchoring boltsSolid massMining engineering

The invention relates to a method of solid filling coal mining and building gangue walls along the goaf, which is to build a gangue wall on the side of the filling body in the goaf of the coal mining face, and pack the coal mine gangue into the gangue wall with woven bags or snakeskin bags. If it is full and built into a wall, the coal mine gangue can be directly filled with the gangue filling the coal mining face. Then, the gangue wall needs to be pre-prepared with single-layer metal mesh, "W"-shaped steel belt, ladder beam and double-ended threaded anchor rod. Tight support. As the working face continues to advance, this method can leave a complete gangue wall for the mining of the next working face. The roadway retaining method is simple and practical, has high support strength and low cost.

Owner:XUZHOU ZHONGKUANG BACKFILLING&MINING TECH CO LTD

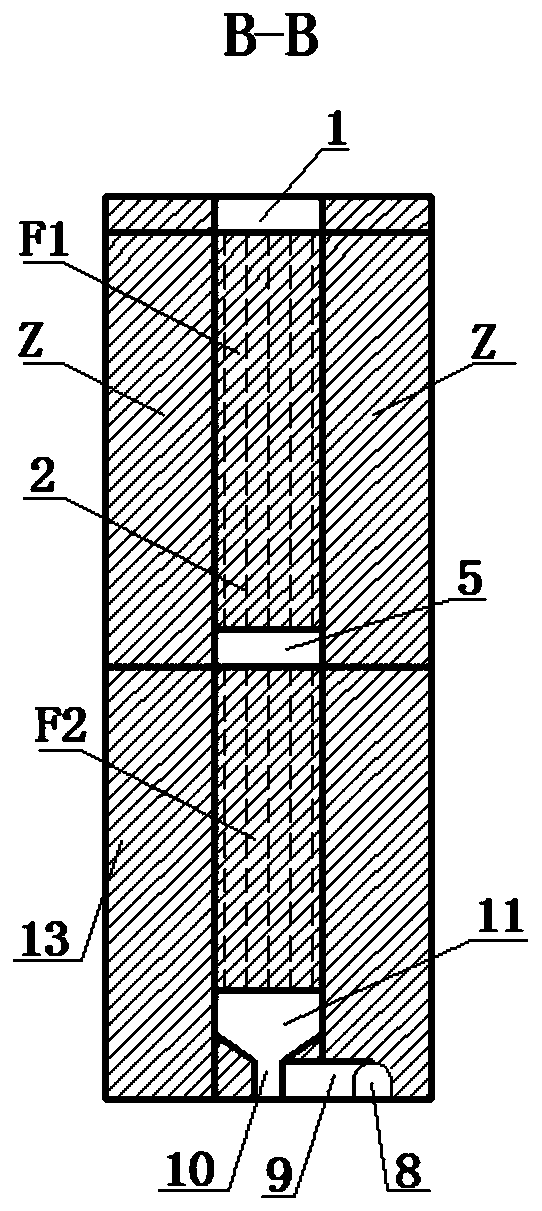

End slope coal bed remote control excavating mining method

InactiveCN104074521AImprove the recovery rate of coal resourcesSimple production processUnderground miningSlitting machinesMining engineeringMan machine

The invention provides an end slope coal bed remote control excavating mining method, which belongs to an end slope residue coal resource extraction method and is used for open pit coal mine end slope and hillside outcrop and shallow surface coal bed mining. A coal mining system adopts a remote control excavating machine system, which comprises an excavating machine and a remote operating and control room, wherein operating and control equipment consists of three parts including a mining flameproof excavating machine electric control box, an excavating machine electric control box and an operating table; the operation function of long-distance wired control is realized; the man-machine separation is realized; and during the coal mining, people operate in a safe operation room. The main mining flow process comprises the steps of cleaning preparation, initial stage mining roadway pit selection, excavating and coal cutting by the excavating machine, coal loading by the excavating machine, belt extending, outward coal conveying by a belt, pile pouring by a loading machine, laneway exiting after coal excavating to a preset position, equipment withdrawing, overhauling, and preparation again for next roadway pit extraction. The end slope coal bed remote control excavating mining method has the characteristics that the coal resource extraction rate improved; the production process is simple, safe and efficient; and the production cost is low, and the like. The safe and efficient mining of open pit coal mine end slope remained coal resources is favorably realized.

Owner:CHINA UNIV OF MINING & TECH

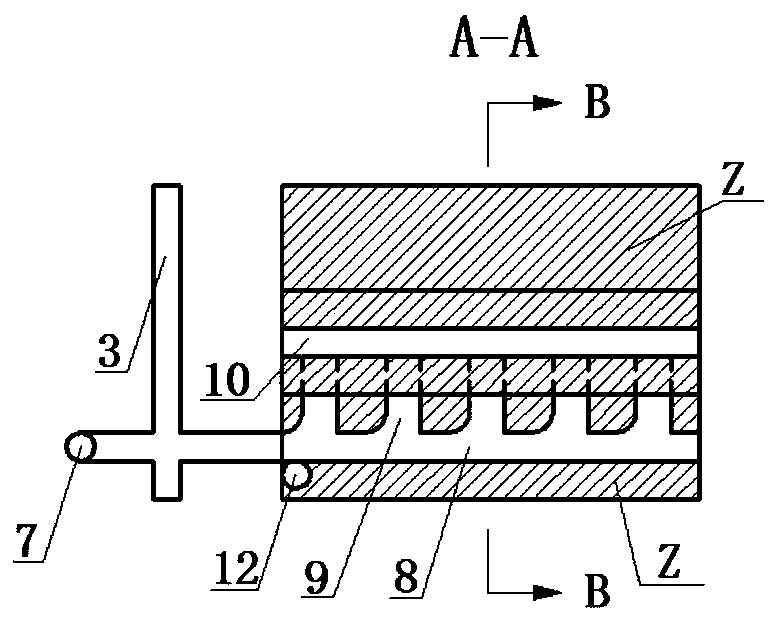

Staged rock drilling and staged mining and subsequent filling mining method

ActiveCN110644997AImprove recovery rateImprove filling efficiencyUnderground miningSurface miningMining engineeringRock cutting

The invention discloses a staged rock drilling and staged mining and subsequent filling mining method. A last-stage ore room and a next-stage ore room share a bottom ore drawing structure of the next-stage ore room, and no top pillar or bottom pillar needs to be arranged between the last-stage ore room and the next-stage ore room; vertical deep holes are drilled in parallel in a rock drilling chamber of the last-stage ore room and a rock drilling chamber of the next-stage ore room; firstly the next-stage ore room is caved row by row, caved ore is shoveled and loaded in a loading roadway, thendischarged into an extra-vein ore pass or an intra-vein ore pass through a loading connecting roadway, a part of ore is reserved as a buffer cushion layer for caving the last-stage ore room; after caved ore of the last-stage ore room and the next-stage ore rooms is completely discharged, a sealing retaining wall is adopted to seal a rock drilling connecting roadway and an ore drawing connecting roadway, a goaf is filled, and the same method is adopted to carry out two-step ore pillar mining after the filling body reaches the specified maintenance strength. Continuous large-scale mining is realized, the workload of pre-mining cutting is reduced, the ore recovery rate and the production efficiency of a stope are improved, and the mining production cost is reduced.

Owner:安徽金安矿业有限公司 +1

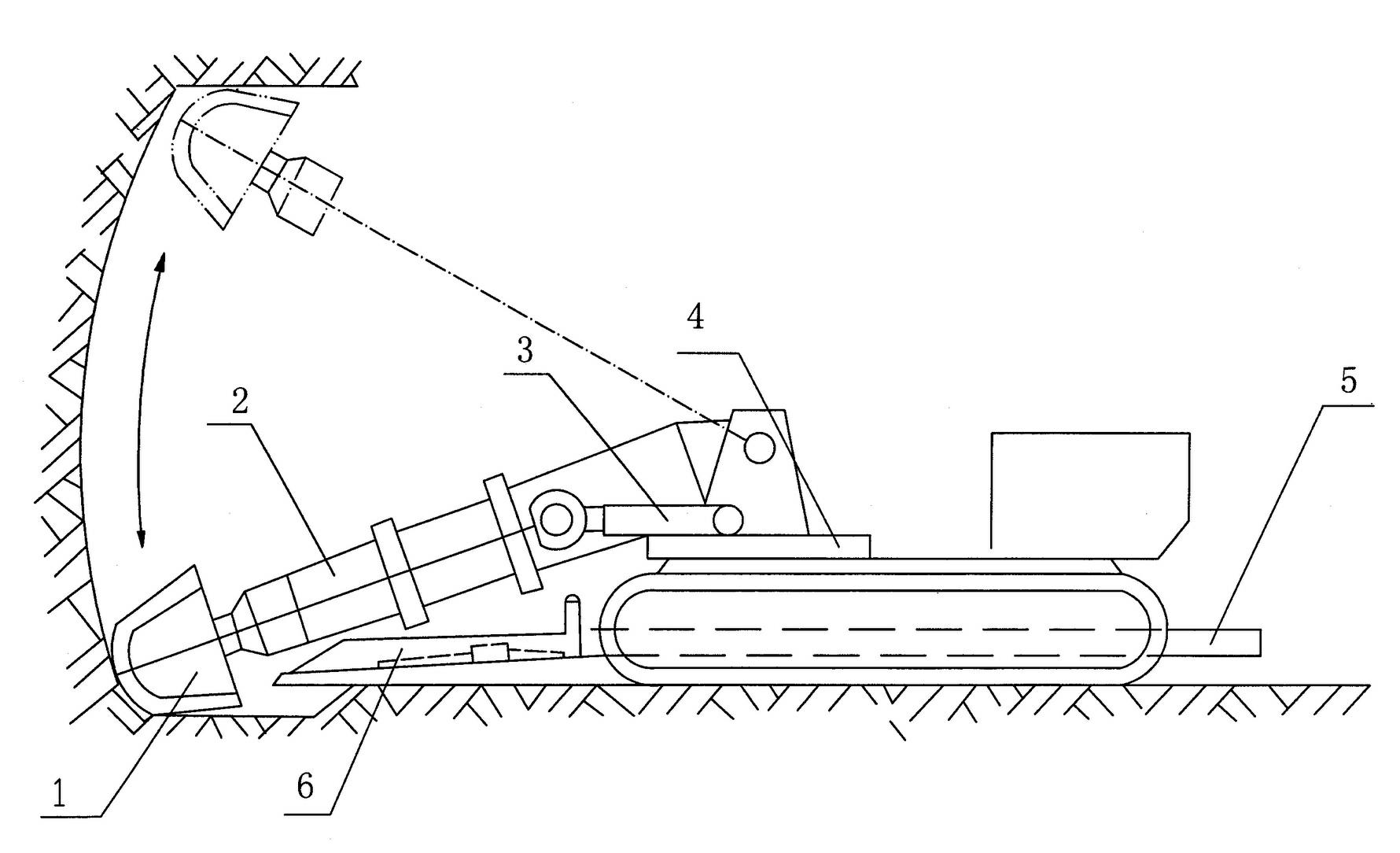

Method for mechanically mining coal by using steep seam pseudo inclination bracing type retractable flexible shield support

InactiveCN102562066ARealize mechanized miningStrong thicknessUnderground miningSlitting machinesHigh probabilityWorking environment

The invention discloses a method for mechanically mining coal by using a steep seam pseudo inclination bracing type retractable flexible shield support. By the method, a steep seam coal mining machine and a bracing type retractable flexible shield support are provided. The method comprises the following steps of: 1, mining, namely mining by arranging the coal mining machine on a pseudo inclination working surface; 2, loading and transporting the coal, namely raking a falling coal body to a conveying mechanism and conveying the falling coal body to the rear part of the coal mining machine by using left and right gathering arms of the coal mining machine, sliding the falling coal body to a coal sliding hole truck loading point through a sliding chute, loading and transporting; 3, supporting an operating area, namely arranging the bracing type retractable flexible shield support in the operating area; 4, ventilating the working surface; 5, atomizing for dust removal; 6, exploiting upper triangle coal; and 7, recycling lower triangle coal, namely dredging a finishing cut, lowering the shield support to a horizontal position gradually, disassembling and decomposing the coal mining machine, transporting to the next stoping working surface and completely recycling the shield support when the working surface is propelled to a place neara district rise hole. By the method, the problems of low recovery ratio, low mechanization degree, low single yield of the working surface, severe working environment, high probability of malignant accidents and the like in domestic and oversea steep seams can be radically solved.

Owner:袁野 +2

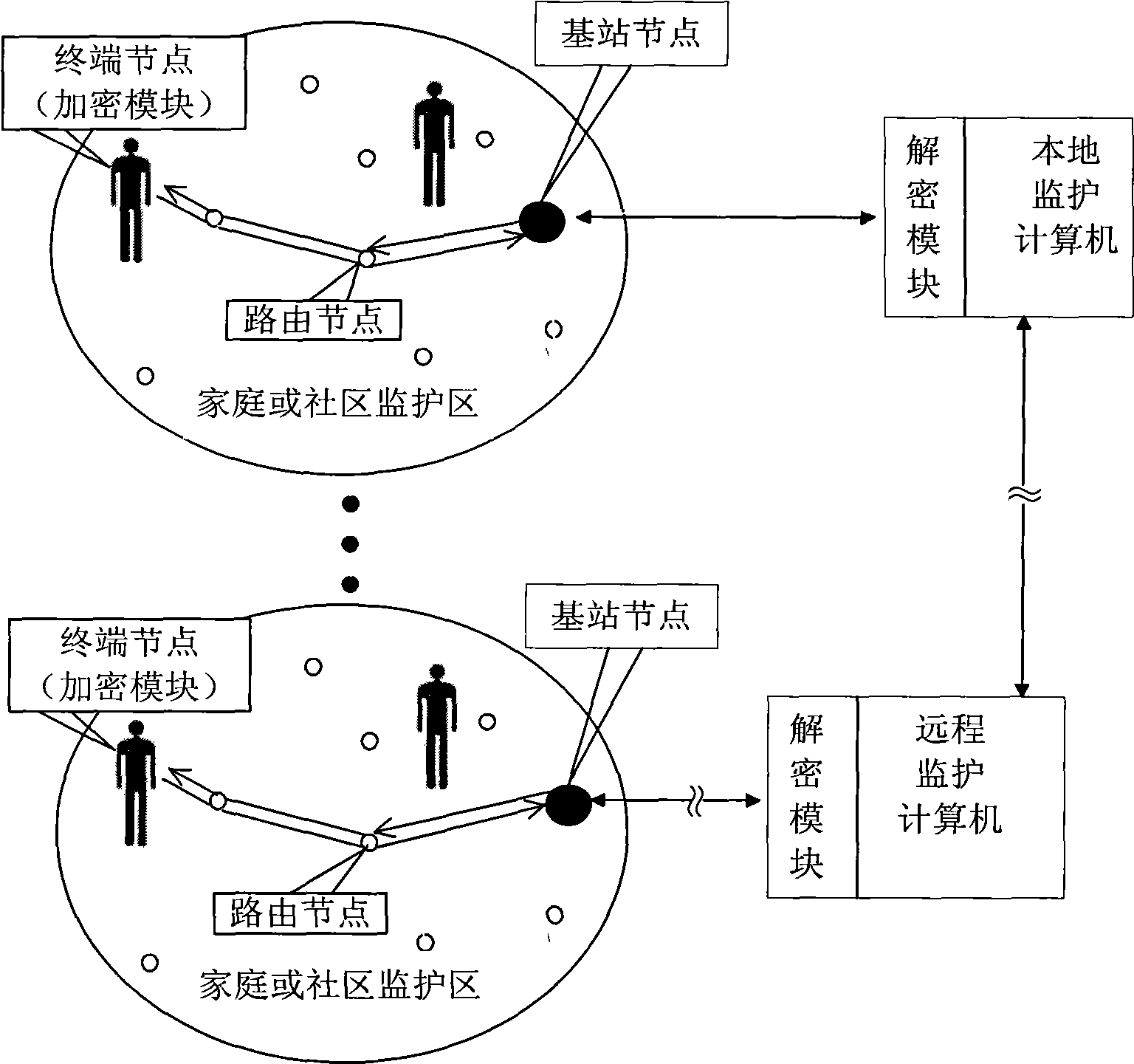

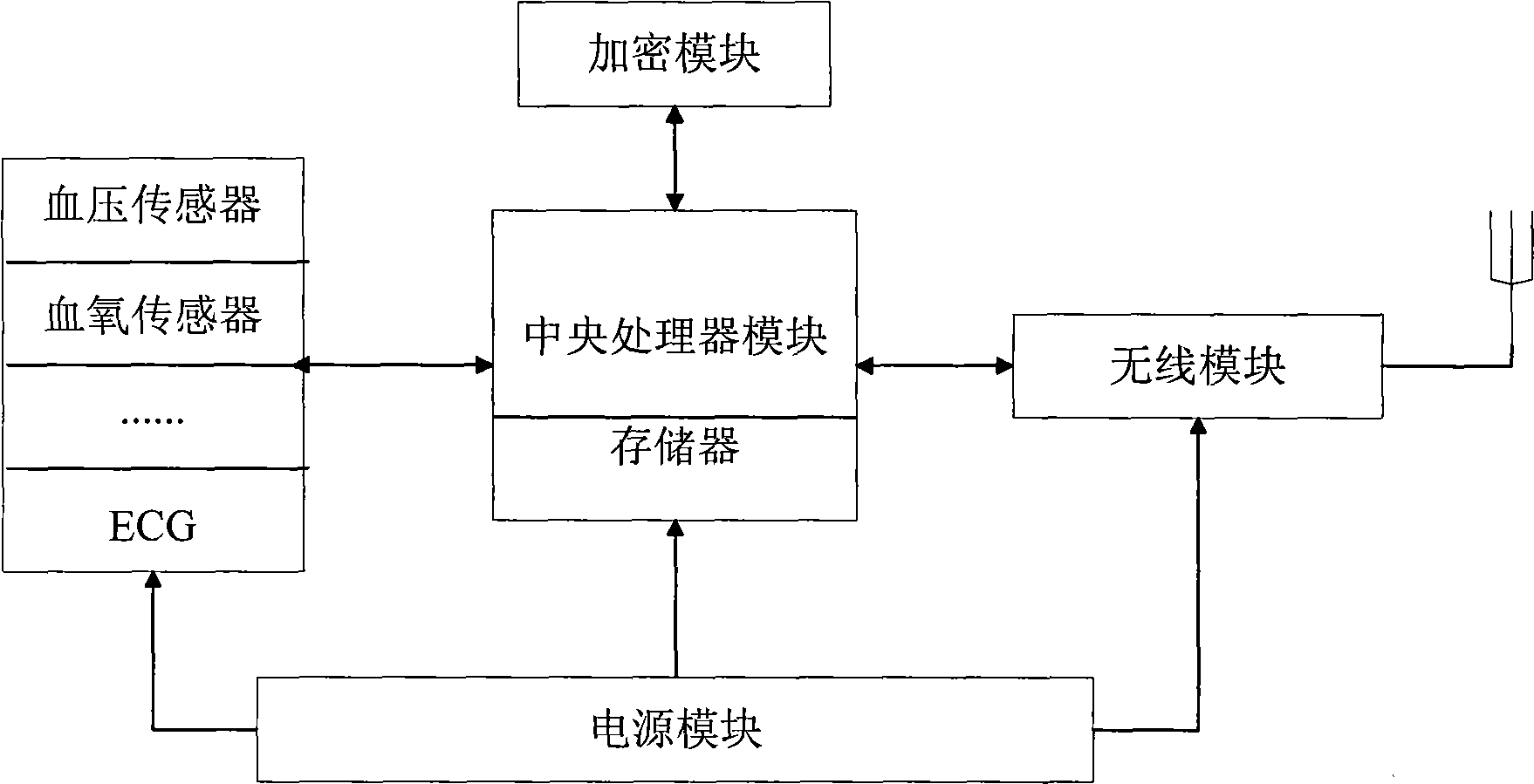

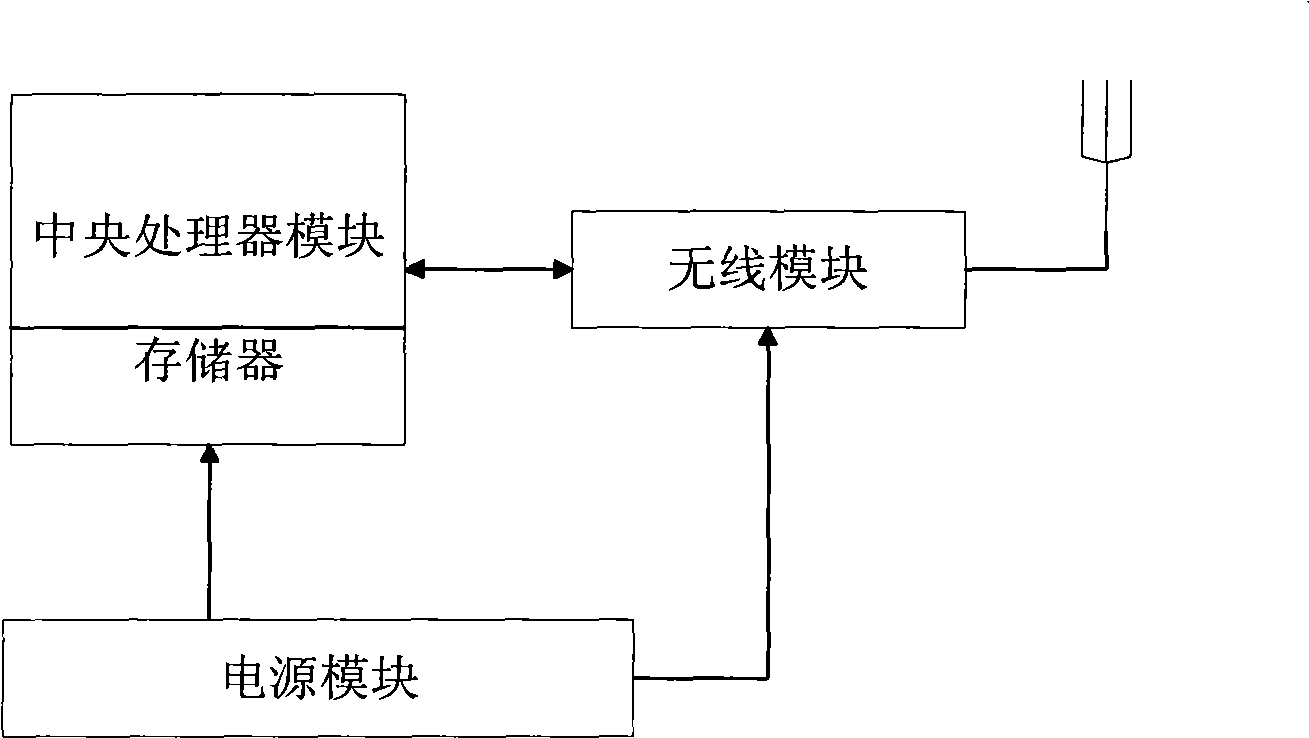

Wireless real-time community medical care monitoring system with security mechanism and wireless real-time community medical care monitoring method

ActiveCN101521880ARealize supervisionImprove recovery rateNetwork topologiesTransmissionNetwork formationNetwork interface

The invention discloses a wireless real-time community medical care monitoring system with a security mechanism and a wireless real-time community medical care monitoring method. The wireless real-time community medical care monitoring system mainly comprises a wireless sensor network and a monitoring computer, wherein the wireless sensor network comprises a terminal node, a route node and a base station node; and the base station node is connected with the monitoring computer by a serial port or network port. The invention has three network formation methods according to different demands. The invention better solves the problem that the elderly and the chronic patient can transmit human physiology parameters to a medical monitoring center in real time; meanwhile, the strengthened security function overcomes the detect that the prior wireless sensor network medical monitoring system can not effectively protect the data, the invention protects the important physiology data during the transmission by adopting an efficient elliptical curve cryptographic algorithm and improves the system safety.

Owner:台州颐健科技有限公司

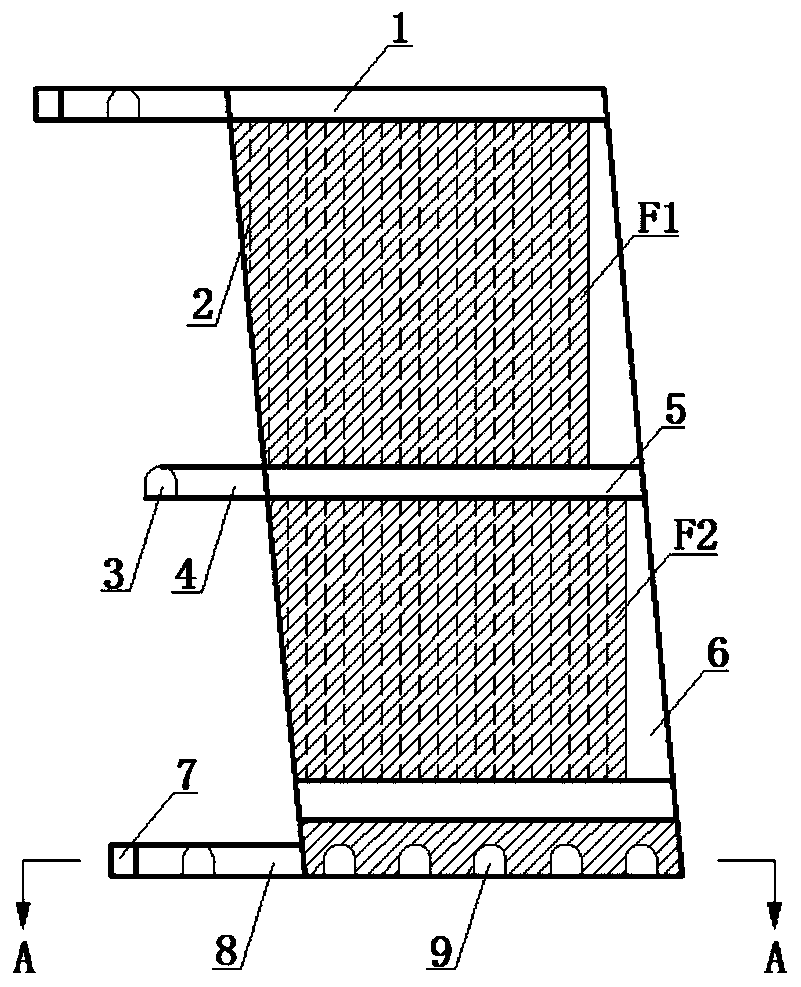

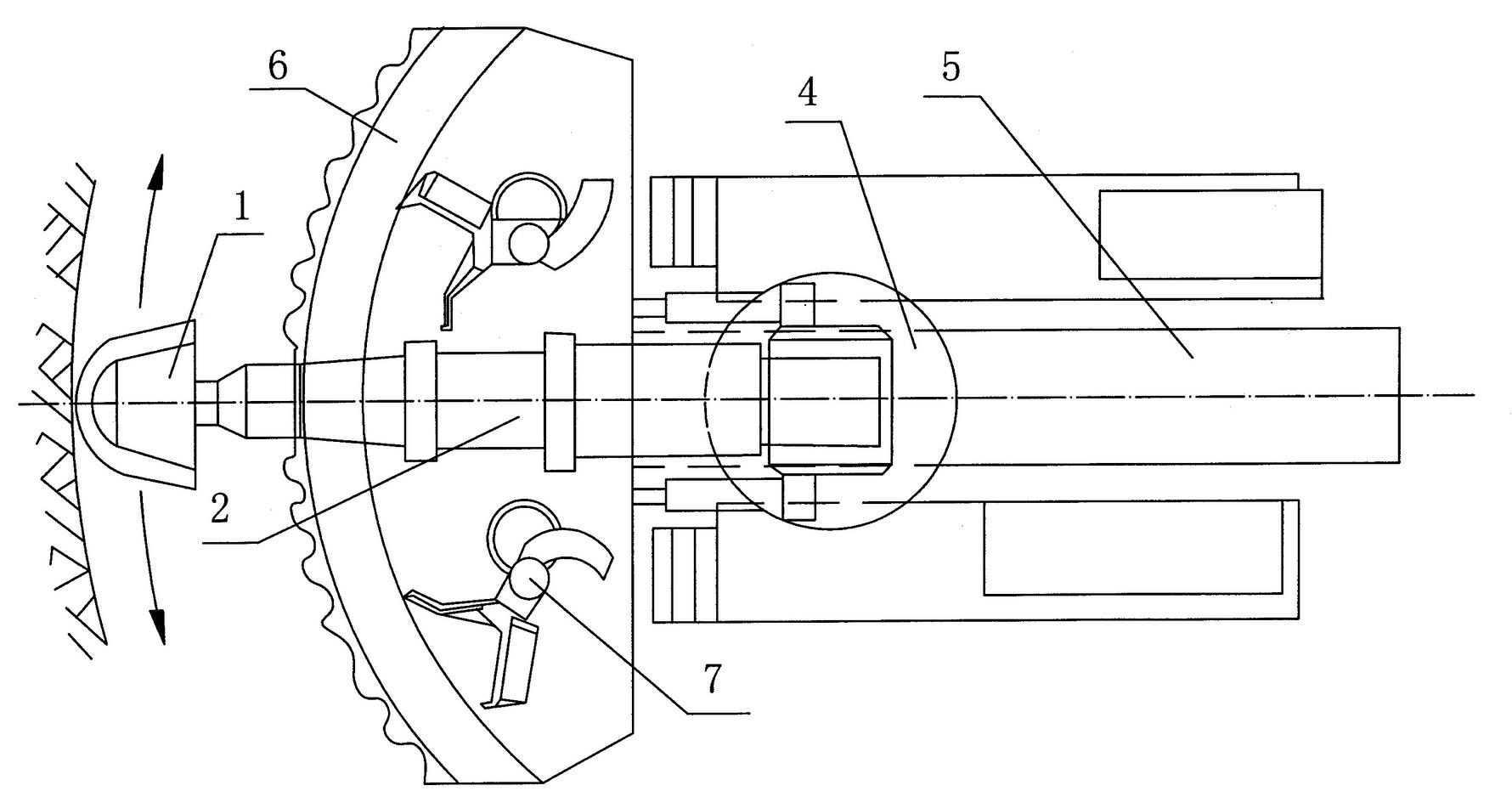

Chamber and overhand cut combined cut-and-filling stoping method in pre-roof-protecting stage

InactiveCN104847352AImprove mining safetyImprove stope production capacityUnderground miningSurface miningEngineeringCut and fill

The invention relates to a chamber and overhand cut combined cut-and-filling stoping method in a pre-roof-protecting stage. The method comprises the following steps: dividing a middle ore body into panels along the trend of the ore body, further dividing the middle section into a plurality of sections in the vertical direction, and mainly adopting a footwall out-out-pulse traceless accurate mining mode; arranging chambers and pillars in the panels at intervals; recovering the chambers first, and adopting a sublevel open stoping method with subsequent backfilling; after recovering the chambers, recovering the pillars and adopting an overhand horizontal cut-and fill method for the pillars, and before recovering the chamber in stages, pre-supporting a long cable in advance for an upper panel in a sublevel upper panel supporting lane; pre-supporting the fore-set by using an anchor rod and a metal net in an air return cross gateway below the fore-set; when the pillars are recovered in layers, stopping mining when the pillar is 3m close to the main crack of the upper panel F1 in horizontal distance and reserving the panel as an upper panel roof-protecting ore of the sub layer, and when the lower layer is recovered, fully recovering the upper panel roof-protecting ore reserved in the previous layer, and meanwhile, reserving the upper panel roof-protecting ore in the lower sub layer; and sequentially circularly recovering and reserving the upper panel roof-protecting ore. By virtue of the method provided by the invention, safe, efficient and low-cost mining can be implemented for thick and large ores which are relatively broken.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

Mesenchymal stem cell frozen stock solution and preparation method thereof

ActiveCN102511471ADoes not affect propertiesProliferation does not changeDead animal preservationMesenchymal stem cellTrehalose

The invention discloses a mesenchymal stem cell frozen stock solution which does not contain animal proteins and DMSO (dimethyl sulfoxide). The frozen stock solution comprises trehaloses, a carbohydrate and electrolyte injection, ATP (adenosine triphosphate) and human serum albumins. The frozen stock solution has the advantages of high recovery rate (90%), no influence on characteristics of stem cells, unchanged cell proliferation, unchanged cell differentiation, easy use, good stability and the like. The invention also discloses a preparation method of the frozen stock solution.

Owner:CHENGDU QINGKE BIOTECH

Medicine for treating coronary heart disease and cerebral thrombus and its preparing method

InactiveCN1985965ABroad-spectrum treatmentHigh cure ratePowder deliveryAnthropod material medical ingredientsCoronary artery diseaseCholesterol

The medicine for treating coronary heart disease and cerebral thrombus is prepared with motherwort, gingko leaf, astragalus root ginseng, red sage and other over 20 kinds of Chinese medicinal materials in certain weight proportion. It is prepared into medicine powder, capsule, bolus or tablet. It has functions of reducing blood fat, lowering blood viscosity, reducing cholesterol and promoting blood circulation to disperse blood clots, and possesses high curative rate.

Owner:李锡尧

Mining method of thin minor ore body

ActiveCN104847356AAvoid lostImprove recovery rateUnderground miningSurface miningMining engineeringCircular economy

The invention discloses a mining method of a thin minor ore body, which comprises the steps of ore recovery and goaf filling, which are alternatively circularly performed from bottom to top in a horizontal layering manner, propelling is performed along with a work surface, lime, loess, dead rock and the like are adopted and mixed layer by layer to fill a goaf, a filling body supports hanging wall and heading wall surrounding rocks, and serves as a work platform of upper layering recovery and ore removal, the ore is conveyed to an ore chute with a mechanical method, spallation ore removal of each recovery spallation step length and the filling procedure of the goaf are performed alternatively, when the uppermost horizontal layer of a chamber is recovered, mechanical and manual fill tightening are performed. The method solves the problem of discharge of tunneled dead rocks, effectively processes the goaf, prevents surface subsidence, accords with requirements of circular economic development and green ore construction. Compared with a shallow hole shrinkage method, the mining method has the advantages of improving ore recovery rate, reducing ore dilution rate and improving ore removal grade and ore removal efficiency through production practice.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

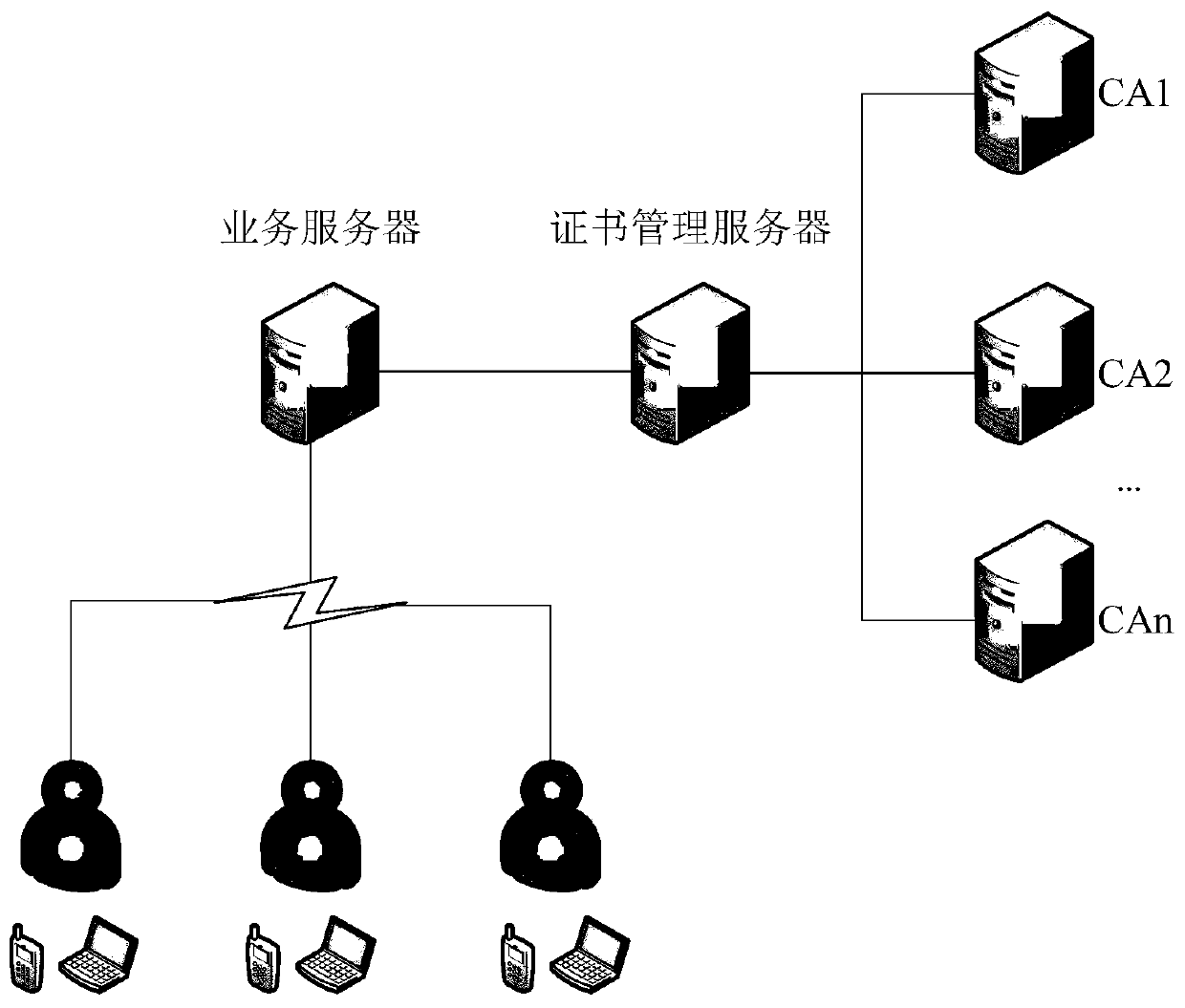

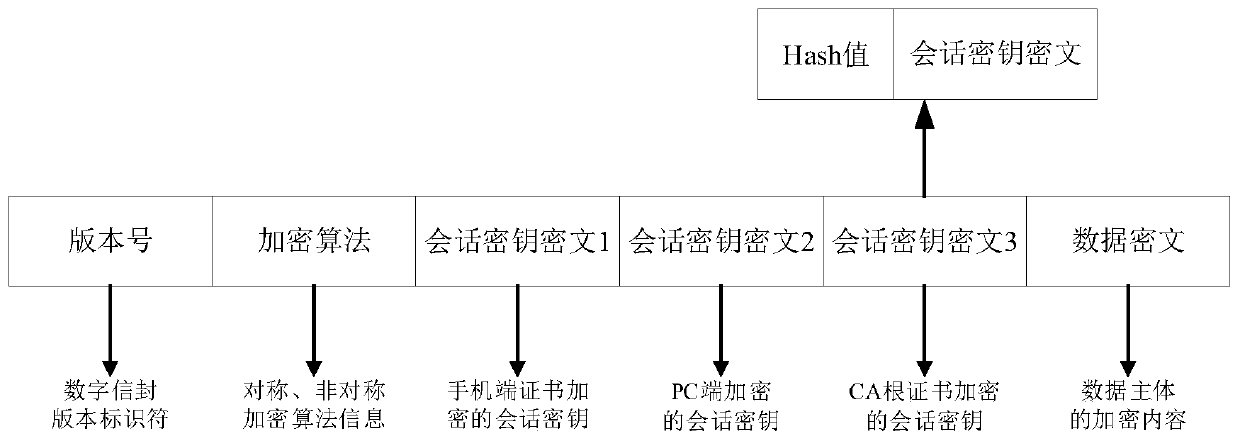

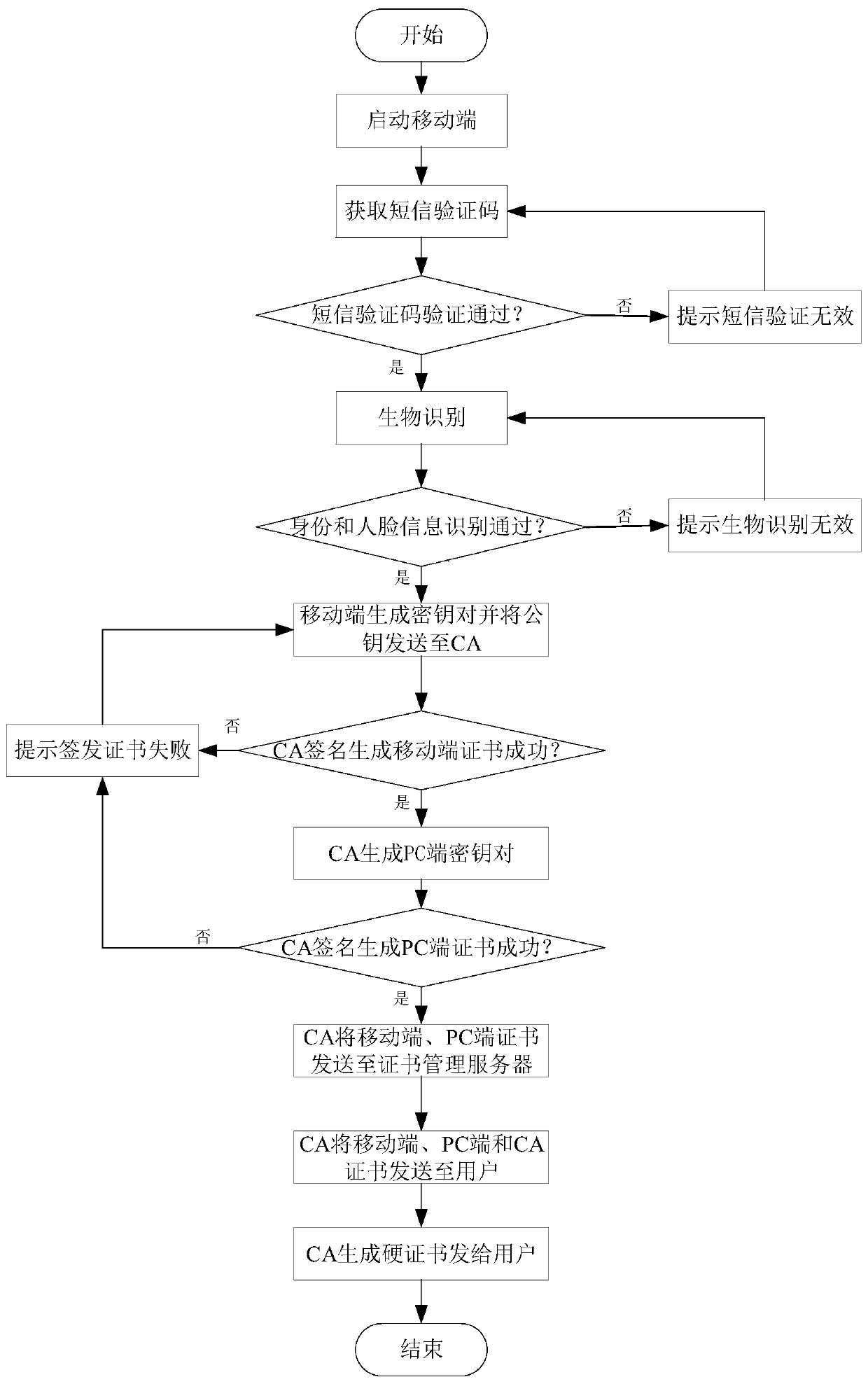

Data encryption, decryption and recovery method based on multiple certificates of digital envelope

ActiveCN109962784AEnsure safetyEasy to manageUser identity/authority verificationMobile endEncryption

The invention discloses a data encryption and decryption method based on multiple digital envelope certificates, which comprises the following steps: in the process of applying for a soft certificate,locally generating a key pair of a user mobile terminal, and sending a public key to a CA server for signing to generate a digital certificate; compared with a manner that a key pair is generated bymeans of a CA server and then is transmitted to a user through a network, the private key does not need to be transmitted through a network; the security of the user private key is ensured; a plurality of certificates of one user are adopted; the certificate is managed in a certificate management server; certificate management server, all digital certificates are stored in a user account in a centralized manner; the certificate management server is simple in structure, convenient to manage, high in efficiency and capable of obtaining all digital certificates of a user at a time according to the account number of the user due to the fact that multiple CAs need to be inquired from the CA for multiple times in the prior art, operation is complex and efficiency is not high due to the fact thatmultiple CAs possibly exist at the same time, and system communication and processing burden is reduced.

Owner:陕西数图行信息科技有限公司

Stripped fluid expansion filling mining method for below middle thick coal seam

InactiveCN102392644AImprove recovery rateUnderground miningSurface miningEnvironmental geologyCoal mining

Owner:ZIBO WANGZHUANG COAL MINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com