Patents

Literature

202 results about "Cut and fill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In earthmoving, cut and fill is the process of constructing a railway, road or canal whereby the amount of material from cuts roughly matches the amount of fill needed to make nearby embankments, so minimizing the amount of construction labor.

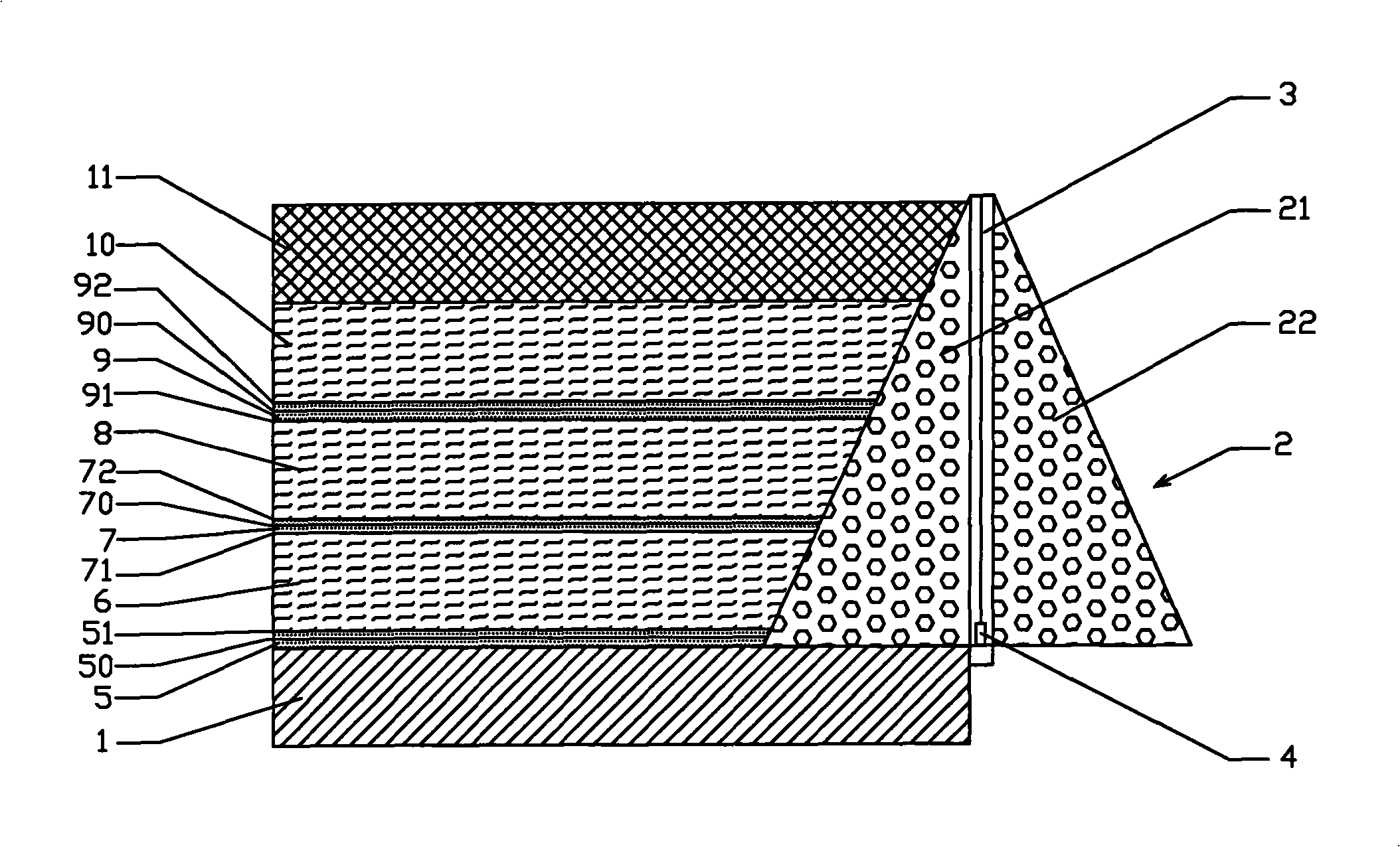

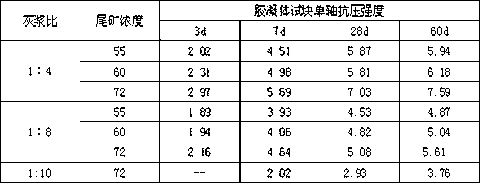

Self-compaction filling paste body and preparation process thereof

The invention discloses a self-compaction filling paste body and a preparation process thereof, relates to a filling material with self-compaction performance for coal mine cut and fill mining and a corresponding proportion stirring process, and belongs to the field of construction materials. The self-compaction filling paste body is characterized by being prepared by uniformly mixing coal gangue, coal ash, cements, high-efficiency water reducing agent and water according to proper proportion, wherein the slurry concentration of the paste body is 75-85 percent; and in terms of mass percentage, the proportion of the coal gangue to the coal ash to the cements to the water reducing agent to the water is 45-55 percent to 15-20 percent to 10-15 percent to 3-5 percent to 15-25 percent. The paste body is high in flowability, stability and filling performance, low in bleeding rate and uniform and consistent in quality, and fully fills every corner of a worked-out section; the bleeding and the segregation of the aggregates are avoided; the convenience in transportation and control is achieved; a pipeline is not blocked during transportation; and original mine wastes are adopted for the paste body for realizing the filling so as to protect the environment.

Owner:TAIYUAN UNIV OF TECH

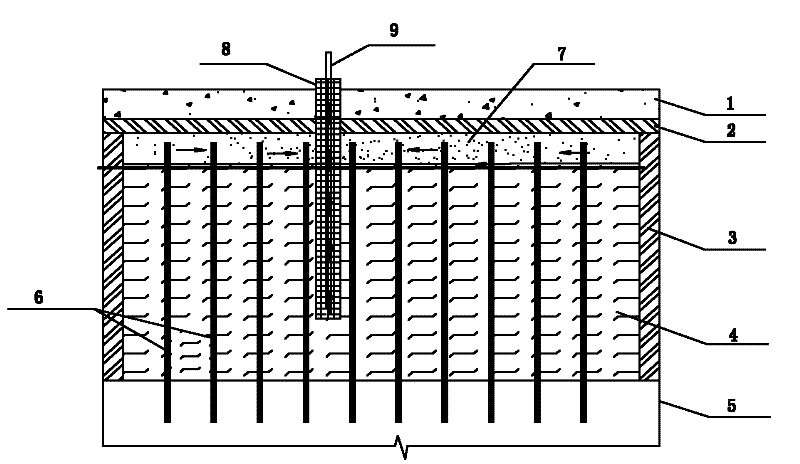

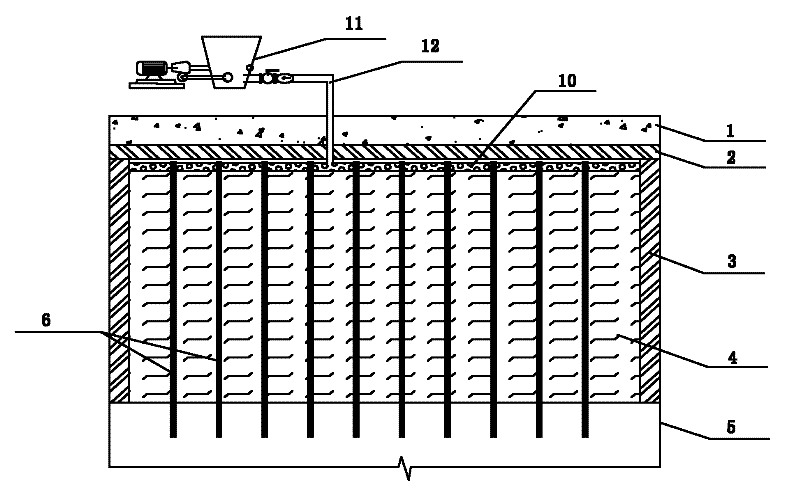

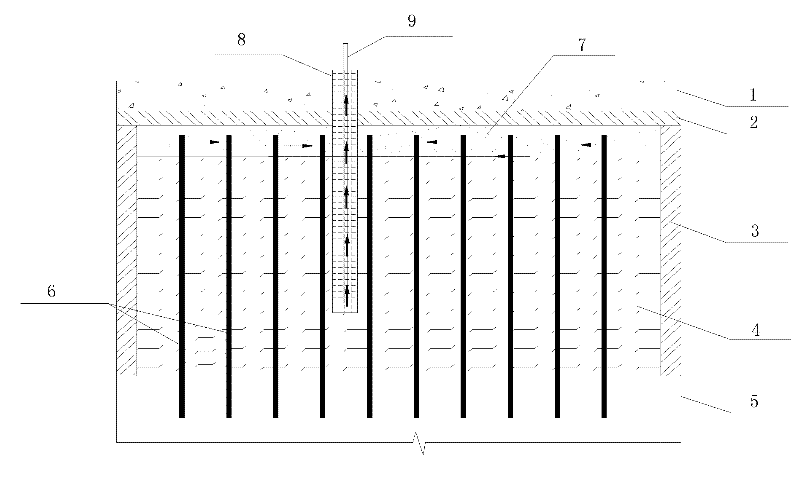

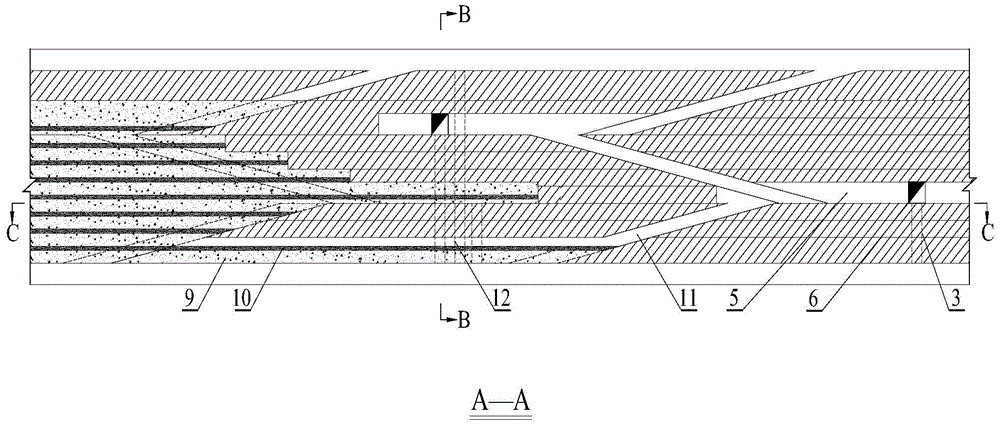

Foundation treatment method for controlling post-construction settlement and deformation of soft soil

InactiveCN102226335AIncrease effective preloadEffective reinforcementSoil preservationEngineeringCut and fill

The invention discloses a foundation treatment method for controlling the post-construction settlement and deformation of soft soil. the method sequentially comprises the following steps: setting a vertical envelope wall around an area to be reinforced; inserting vertical drainage systems and laying horizontal drainage systems in the area to be reinforced; paving sealing materials on the surface of a foundation; backfilling settlement refills or exerting pre-loads on the foundation; carrying out vacuumizing, well-point dewatering or vacuum well-point dewatering on the drainage systems so as to reinforce the foundation; and after the consolidation degree of the foundation reaches 60-90%, carrying out sealing on all the vertical and horizontal drainage systems. The method disclosed by the invention is used for simultaneously carrying out reinforcement and plugging on an untreated soft soil foundation, so that the post-construction settlement can be controlled while the foundation is treated. Duo to the one-time treatment, the treatment time can be saved, and the treatment cost can be reduced, thereby achieving the purpose of effectively reinforcing the foundation and controlling the post-construction settlement.

Owner:CCCC FOURTH HARBOR ENG INST +4

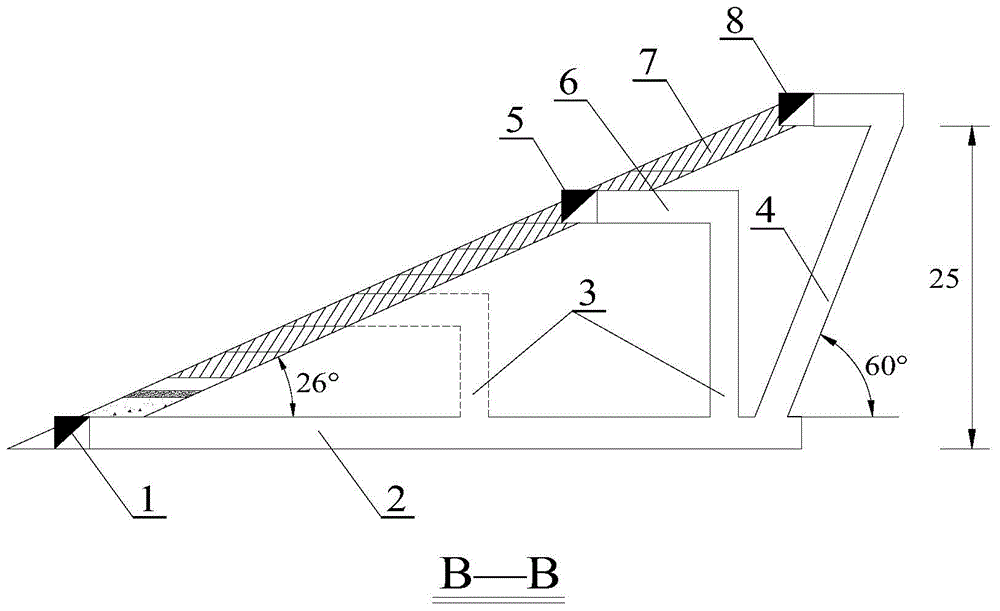

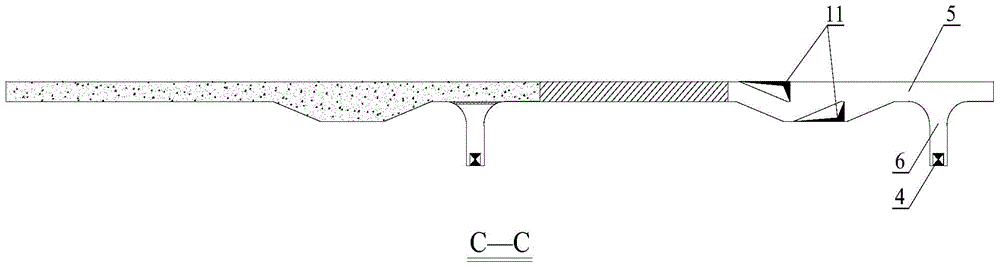

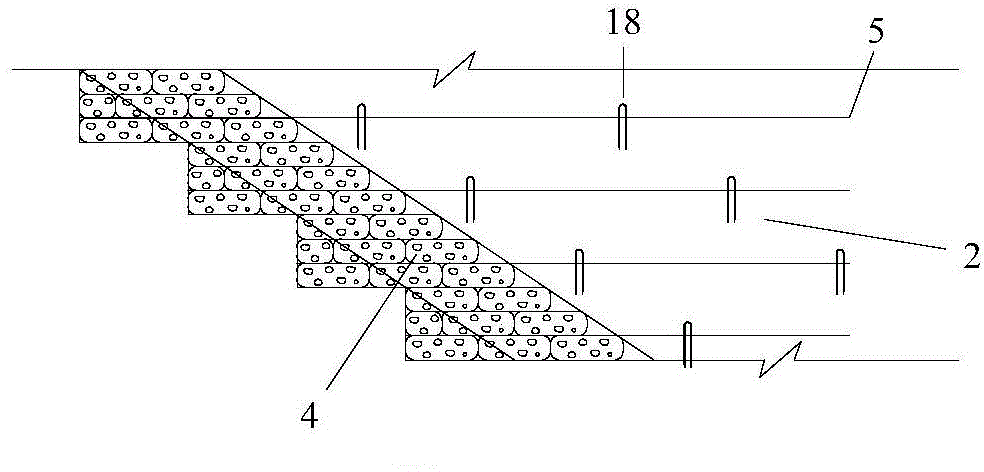

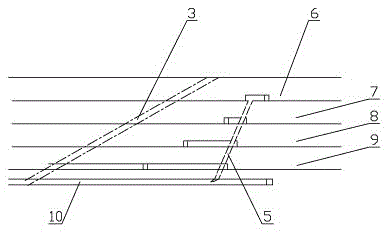

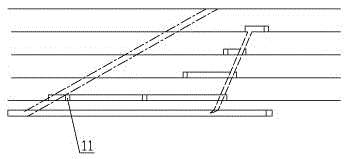

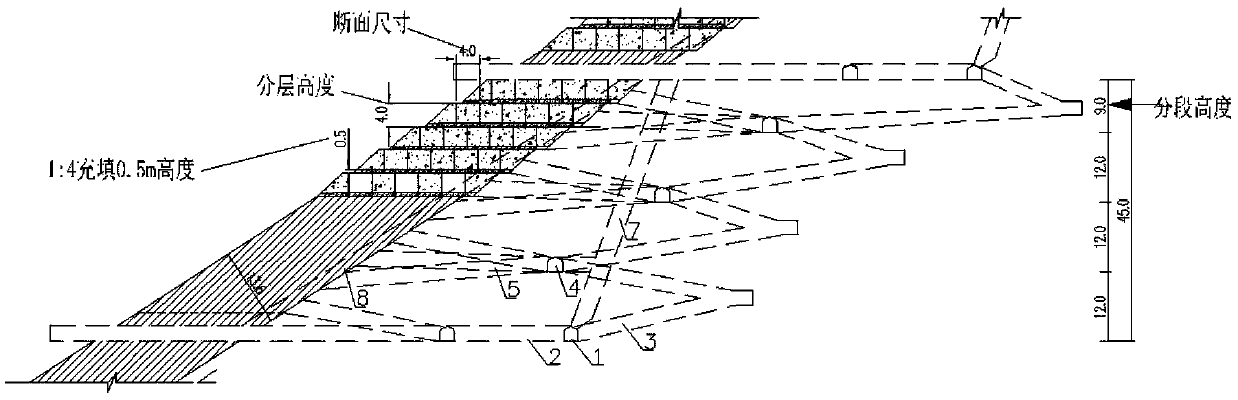

Upward cut-and-fill mining method for in-vein slope ramp of gentle dip thin vein

ActiveCN104060991AEnsure safetyImprove recovery efficiencyUnderground miningSurface miningVeinCut and fill

The invention discloses an upward cut-and-fill mining method for an in-vein slope ramp of a gentle dip thin vein. The method comprises the following steps: stoping layers of an ore body, tunneling a cross gateway from a bottom middle haulage drift to the ore body, tunneling a diagonal slope ramp along the vein to rise for certain height, and tunneling a slice drift, a reversing chamber and a sectional ore removal draw shaft forwards along the vein, wherein the reversing chamber and the sectional ore removal draw shaft are perpendicular to the slice drift; reversely tunneling the diagonal slope ramp along the vein from one side of the slice drift to rise for the certain height, and tunneling the slice drift, the reversing chamber and the sectional ore removal draw shaft along the vein; dividing a stope by using the diagonal slope ramp as the boundary, continuously propelling from one end of the vein to the other end of the vein, reaching all the layers of the ore body by virtue of the diagonal slope ramp which is tunneled in the vein, and sequentially stoping and filling from bottom to top by virtue of each layer stoping unit in the stope. The upward cut-and-fill mining method for the in-vein slope ramp of the gentle dip thin vein is high in mechanization degree, small in out-vein stope preparation engineering amount, low in labor intensity, low in ore dilution loss, safe to operate and high in efficiency.

Owner:河南发恩德矿业有限公司

Reinforcing method for demixing sole weight, prepressing water discharge concretion combination dynamic consolidation soft ground base

InactiveCN101270571ALess investmentReduce post-construction settlementClimate change adaptationLand reclamationWater dischargeDynamic compaction

A dynamic compaction soft foundation reinforcing method by combing layered dead weight and pre-pressing drain concretion includes: filling a water-isolation cofferdam; a water collecting well is arranged in the middle of the cofferdam; a sand layer of 0.5m to 0.8m is filled by hydraulically filled or manually filled on the original water-drained ground; a horizontal drain pipe is embedded in the sand layer to carry out first earth hydraulic filling; a drain pump is arranged in the water collecting well to continuously drain water; when the thickness of hydraulic filling reaches the designed elevation of the first layer, the hydraulic filling is stopped; when the surface of the hydraulic filling earth forms a hard shell layer with a thickness of 30m to 40m under the actions of vaporizing and dead weight drain, the hydraulic filling to a second layer and a third layer are carried out according to the steps; even a required hydraulic filling height is designed; finally hill-skill soil or mixed backfill soil and sandy soil are back filled on the layers; dynamic compaction is carried out after leveling. The invention has the technical economic indexes of fast speed, saving investment, small settlement after construction and high surface layer bearing capacity, etc., and has remarkable technical advantages on lower ground elevation and the projects of polder reclamation by hydraulically fill the soft soil like silt.

Owner:张伯谦

Binding material for filling fine-grain tailings

The invention discloses a binding material for filling fine-grain tailings. The binding material is prepared by milling and mixing the following components in percentage by mass: 15-40% of belite-sulphate aluminum cement, 2-10% of gypsum, 2-8% of quick lime, 40-70% of superfine-grain slag powder, 2-10% of coal ash, 1-6% of activating agent, 0.1-0.5% of activating accelerant, 0.1-0.5% of coagulant, and 0.1-0.5% of water reducer, wherein the activating agent is Na2SiO3, the activating accelerant is sodium fluosilicate, and the coagulant is any one or a mixture of two or more of LiOH, LiCO3 and LiCl; and the water reducer is a naphthalene water reducer or a polycarboxylic acid water reducer. According to the binding material for filling the fine-grain tailings, the problems that -0.074-mm fine-grain tailings and high-silt-content tailings are difficultly solidified and are low in strength after being solidified, and the strength of a filling body can meet a strength requirement on cut and fill of a mine on the filling body by using the binding material; the liquidity of slurry can be improved, and roof-contacting performance of the filling body can be improved; and the water retention capacity can be improved, and the water seepage of the slurry is reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

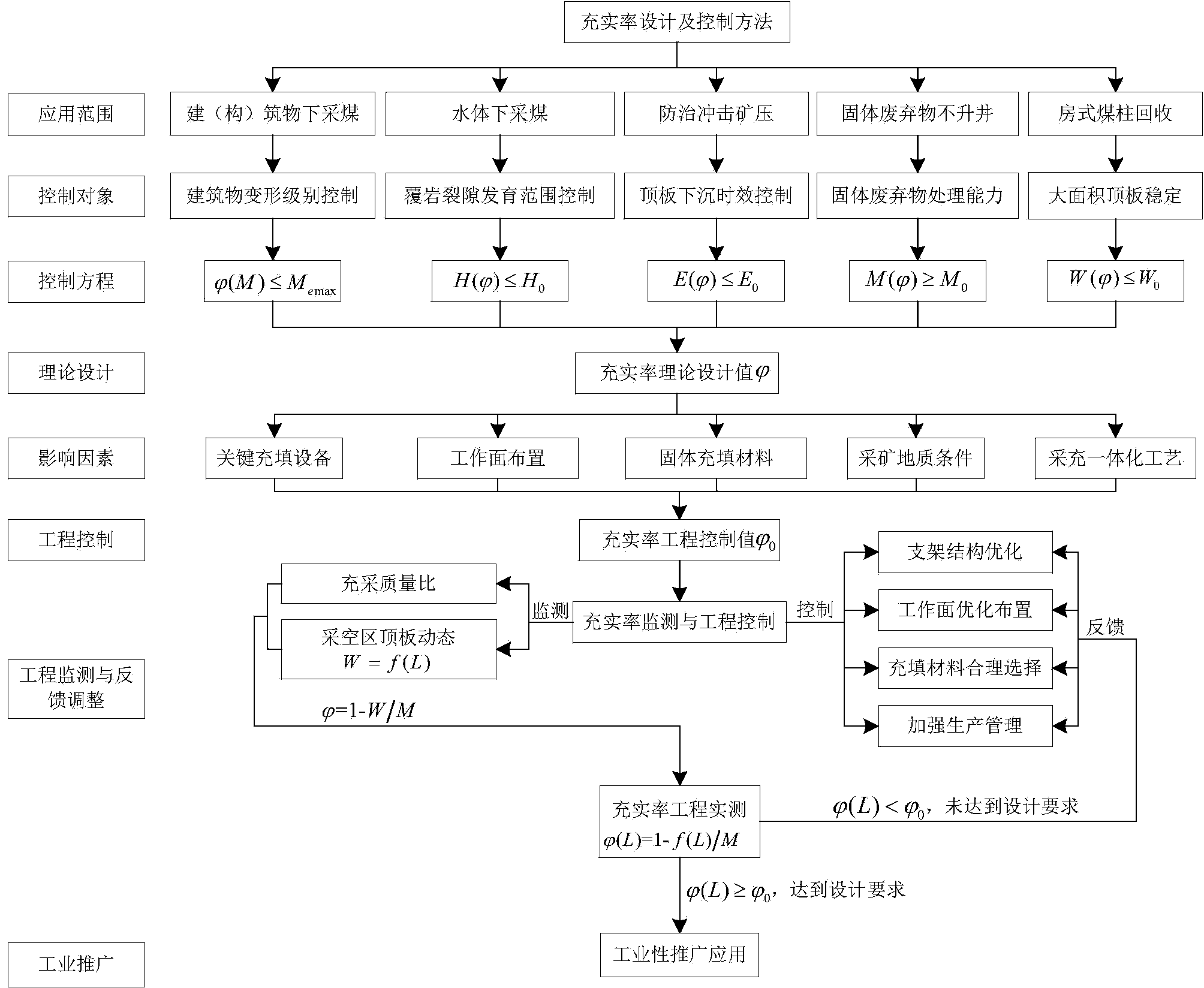

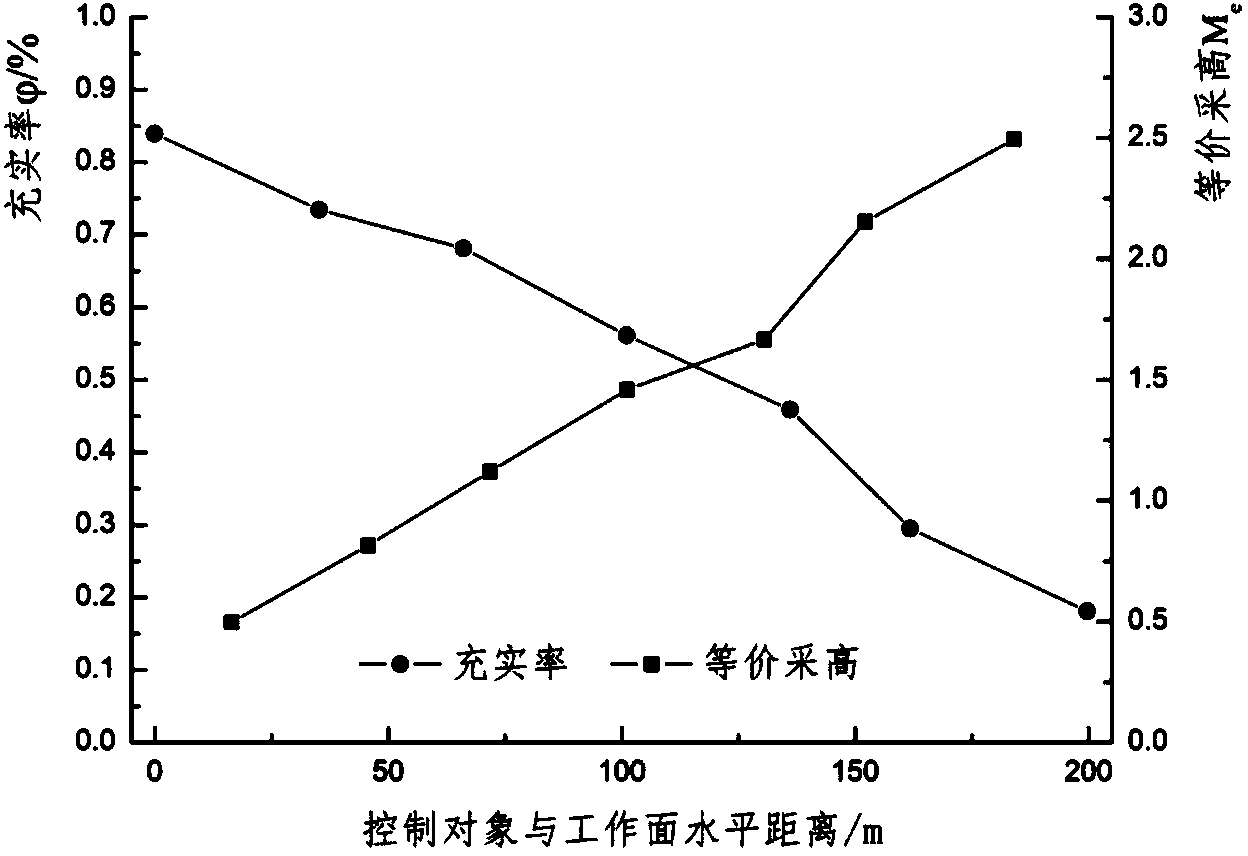

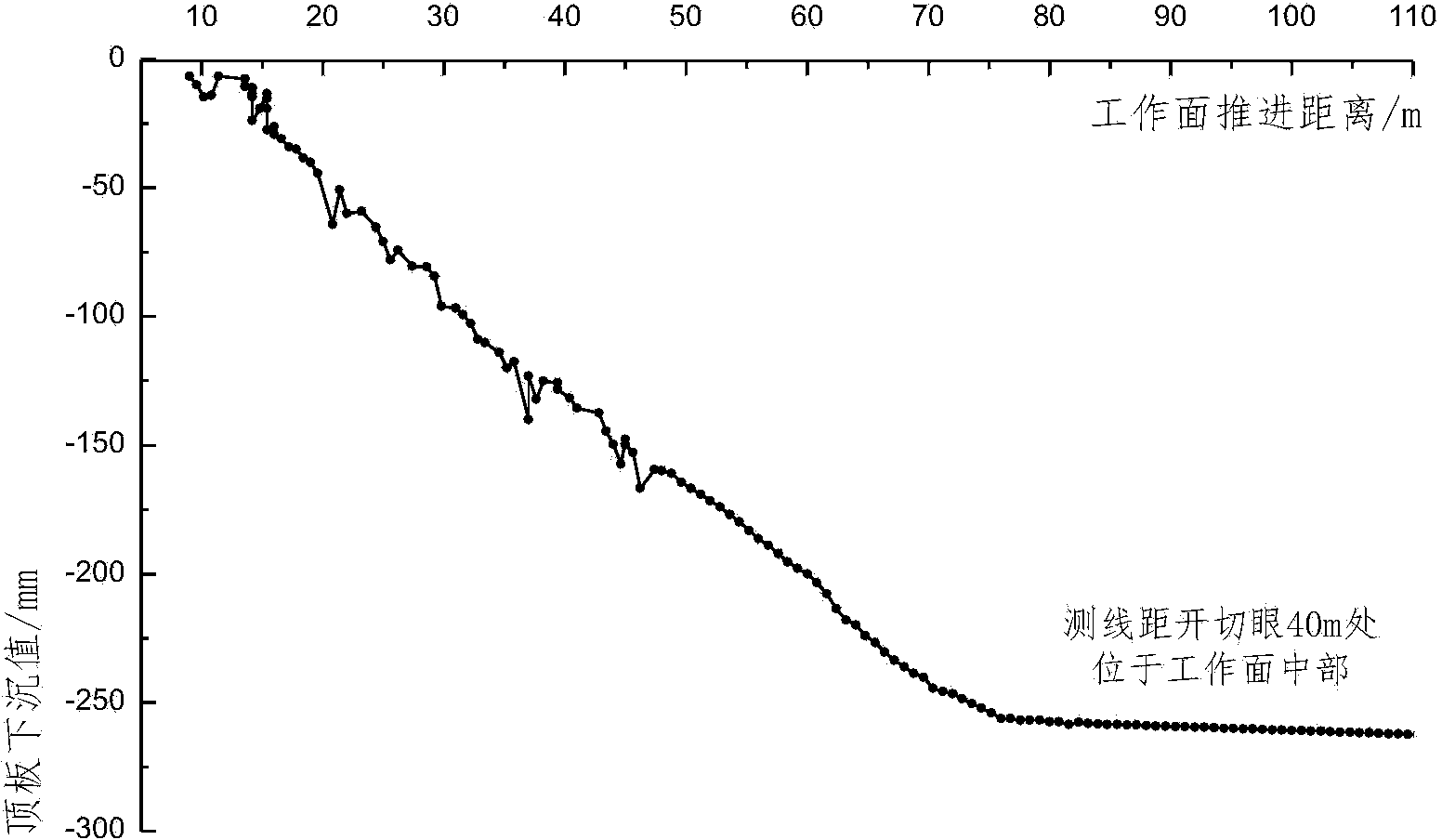

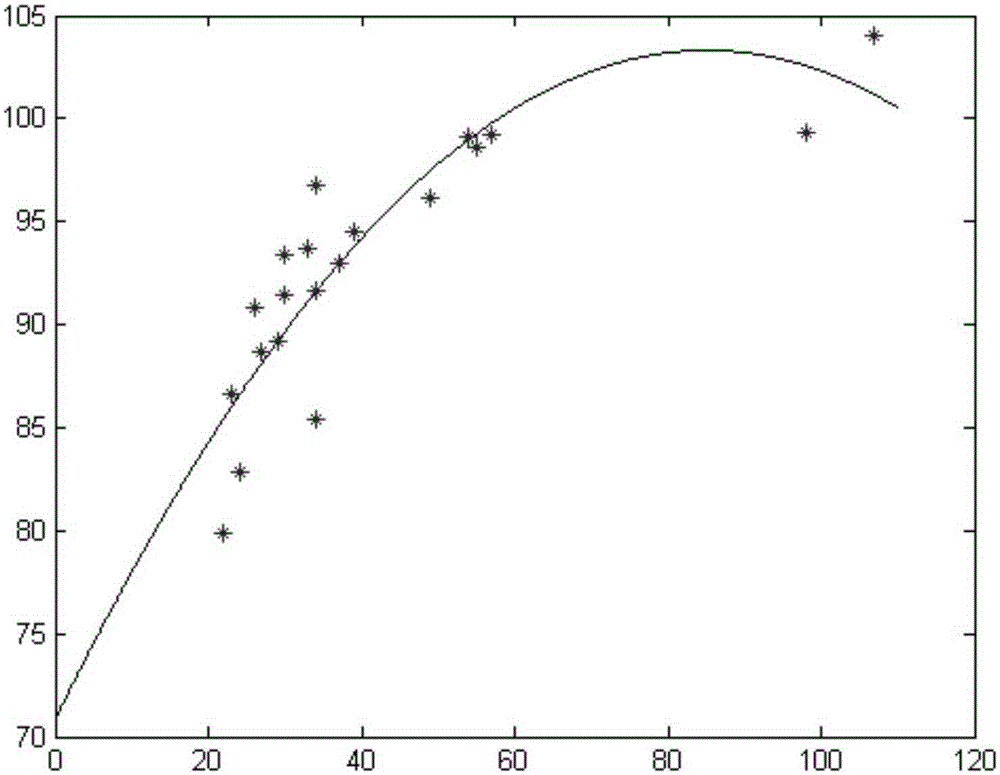

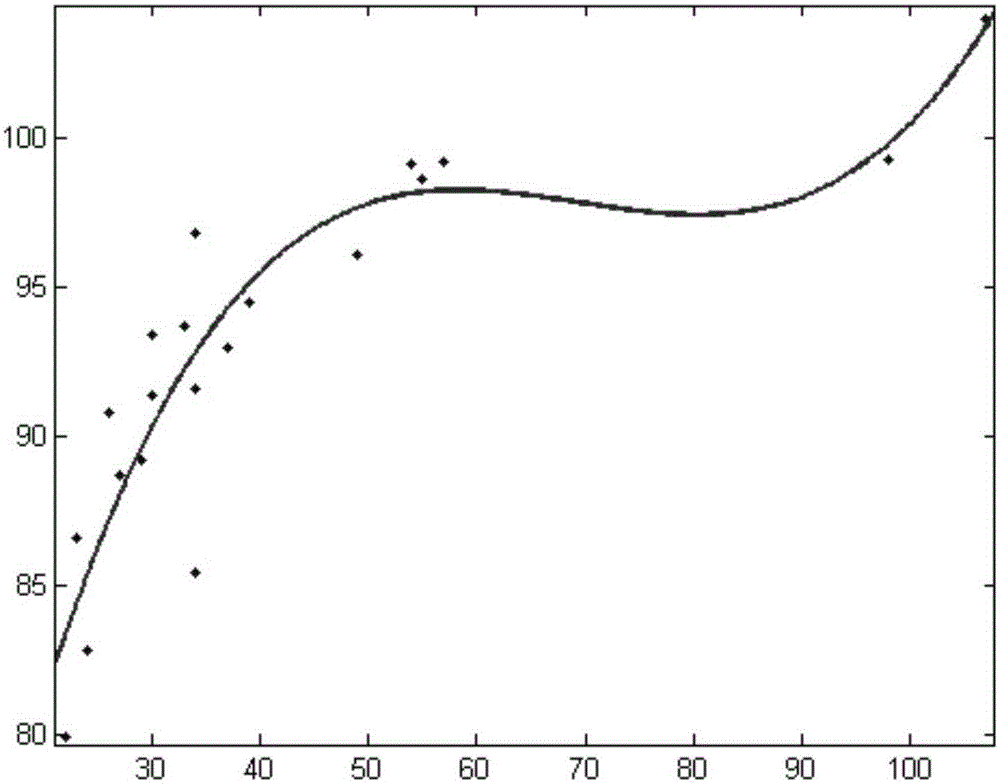

Filling rate design and control method for solid filing in coal mining

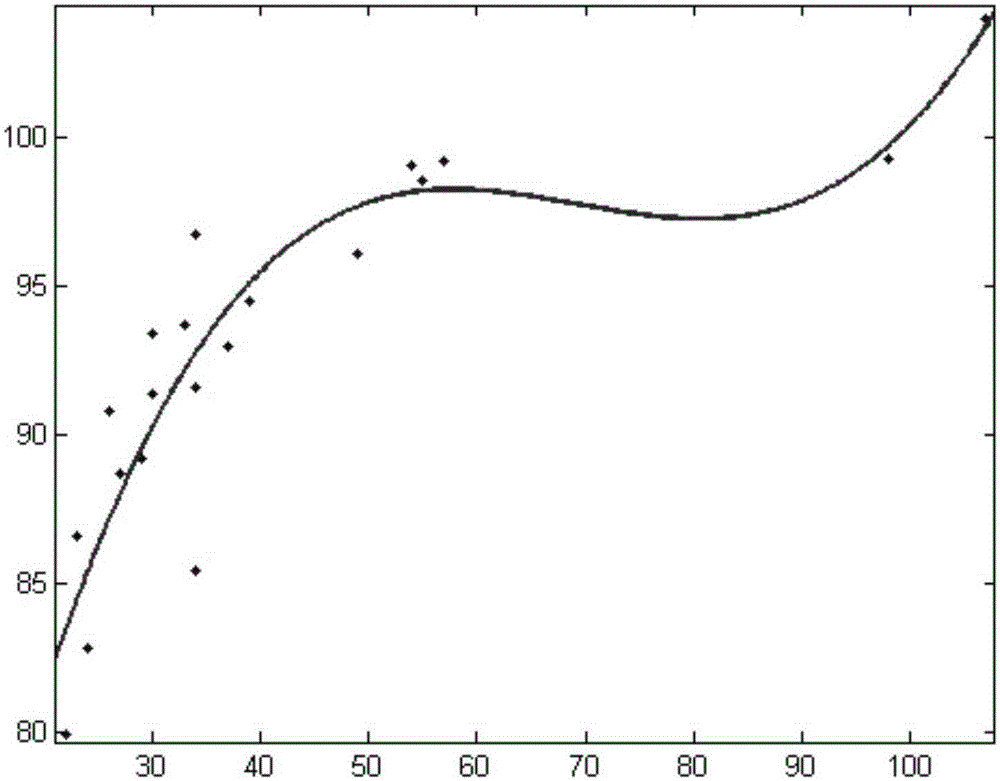

The invention discloses a filling rate design and control method for solid filing in coal mining, and belongs to filling rate design and control methods in cut and fill. The filling rate design and control method includes firstly, acquiring a theoretical design value phi of a solid filling coal mining filling rate according to cut and fill objectives and control objects; comprehensively analyzing influences of main controlling factors including key filling equipment, working face arrangement, solid filling materials, mining geological conditions and cut and fill integrated technologies on the filling rate to design an engineering control value of the filling rate phi0; during engineering practice, mounting a roof dynamic monitoring device in a gob to acquire measured filing rate curves phi(L) of different advancing positions of an on-site working face through actual measurement; comparing the engineering control value phi0, and adjusting the technology and the management method to ensure a measured filling value to meet engineering design requirements and guarantee filling effect. The method provides reference for design and control of the solid filling coal mining filling rate, and provides theoretical support for on-site popularization and application of the solid cut and fill technology.

Owner:CHINA UNIV OF MINING & TECH

Muck soil composite curing agent

InactiveCN101081981AImprove early strengthStable late strengthBuilding constructionsOrganic fertilisersHigh resistanceSludge

The composite sludge curing agent consists of Portland cement as cementing material; alkaline exciting component selected from lime, water glass and sodium hydroxide; expanding component of gypsum; and surfactant selected from triethanolamine and superplasticizer FDN. It has the advantages of high early strength, stable long-term strength, high water stability, high frost resistance, etc. It may be used in curing waste sludge into stable building material for road bed, composite foundation, etc.

Owner:ZHEJIANG UNIV

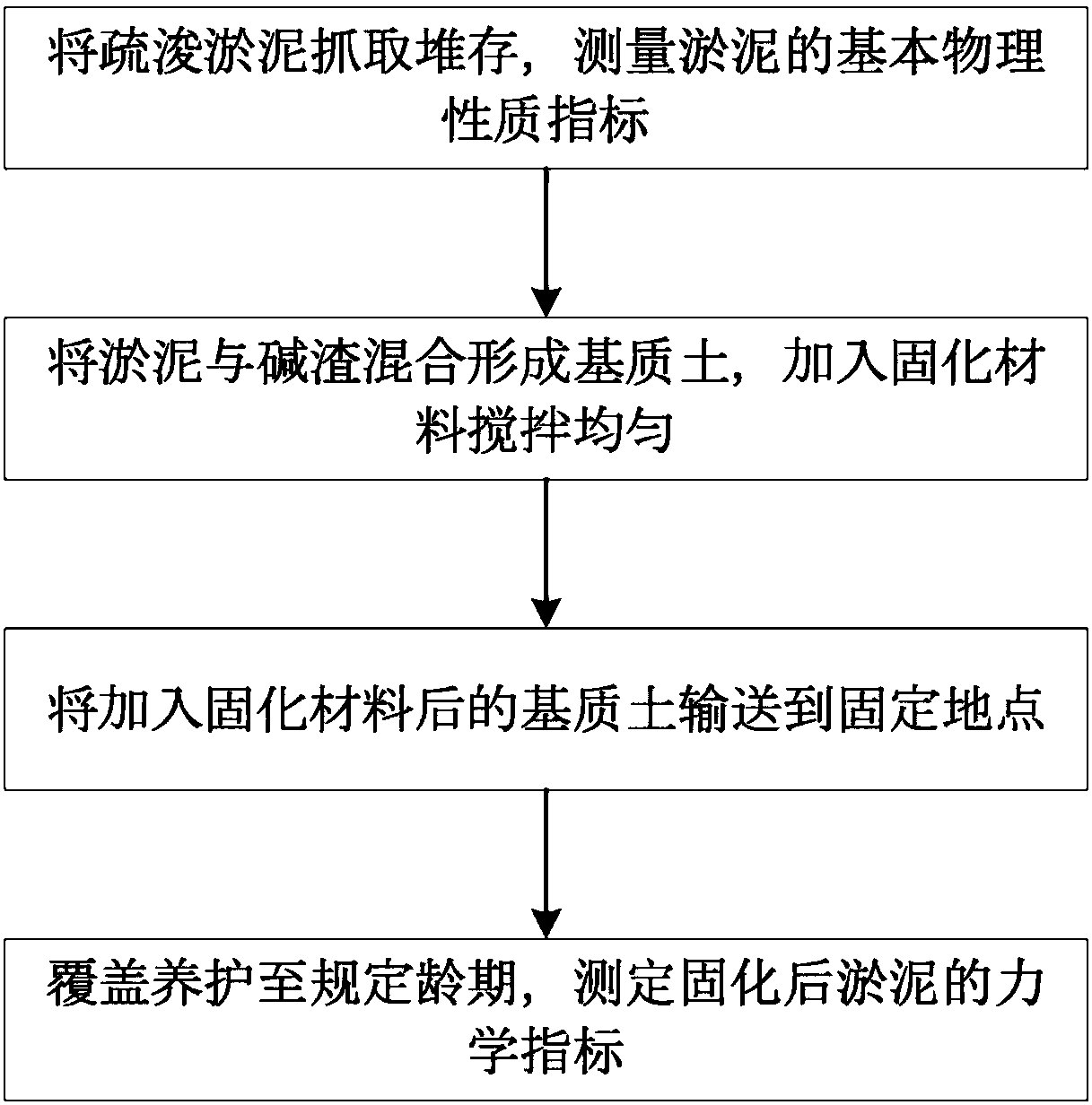

Method for solidifying sludge with high water content

InactiveCN108218317ARealize resource utilizationAchieve sustainable developmentFixation/solidifcation sludge treatmentSludgeMechanical index

The invention discloses a method for solidifying sludge with a high water content. At first, dredged sludge is collected and stored, basic physical indexes of sludge are measured, the sludge and alkali residues are mixed to form matrix soil; a curing material is added and then is evenly mixed and stirred; then the matrix soil containing the curing agent is transported to a fixed location; the matrix soil is covered and cured for a prescribed period; and finally the mechanical indexes of cured sludge are measured. The optimal ratio of alkali residues to dry sludge is 30-50:100. The curing material comprises following components in percentage by the weight of dry mixed soil: 10 to 25% of mineral powder, 0.1 to 0.5% of super absorbent resin, and 2 to 6% of sodium silicate. The cooperative effect between alkali residues and sludge with a high water content is utilized to form matrix soil; super absorbent resin is used to reduce the water content of sludge, the utilization rate of alkali residues is increased, the solidification cost is reduced, and the solidified soil has the advantages of high early strength and low compressibility and meets the engineering requirements of filling soil.

Owner:HUBEI UNIV OF TECH

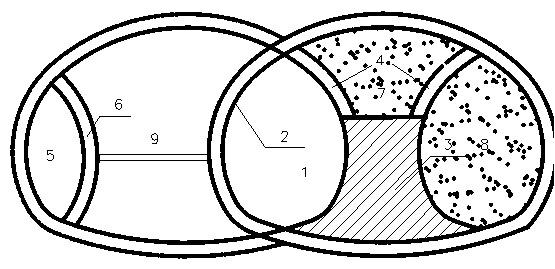

Chamber and overhand cut combined cut-and-filling stoping method in pre-roof-protecting stage

InactiveCN104847352AImprove mining safetyImprove stope production capacityUnderground miningSurface miningEngineeringCut and fill

The invention relates to a chamber and overhand cut combined cut-and-filling stoping method in a pre-roof-protecting stage. The method comprises the following steps: dividing a middle ore body into panels along the trend of the ore body, further dividing the middle section into a plurality of sections in the vertical direction, and mainly adopting a footwall out-out-pulse traceless accurate mining mode; arranging chambers and pillars in the panels at intervals; recovering the chambers first, and adopting a sublevel open stoping method with subsequent backfilling; after recovering the chambers, recovering the pillars and adopting an overhand horizontal cut-and fill method for the pillars, and before recovering the chamber in stages, pre-supporting a long cable in advance for an upper panel in a sublevel upper panel supporting lane; pre-supporting the fore-set by using an anchor rod and a metal net in an air return cross gateway below the fore-set; when the pillars are recovered in layers, stopping mining when the pillar is 3m close to the main crack of the upper panel F1 in horizontal distance and reserving the panel as an upper panel roof-protecting ore of the sub layer, and when the lower layer is recovered, fully recovering the upper panel roof-protecting ore reserved in the previous layer, and meanwhile, reserving the upper panel roof-protecting ore in the lower sub layer; and sequentially circularly recovering and reserving the upper panel roof-protecting ore. By virtue of the method provided by the invention, safe, efficient and low-cost mining can be implemented for thick and large ores which are relatively broken.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

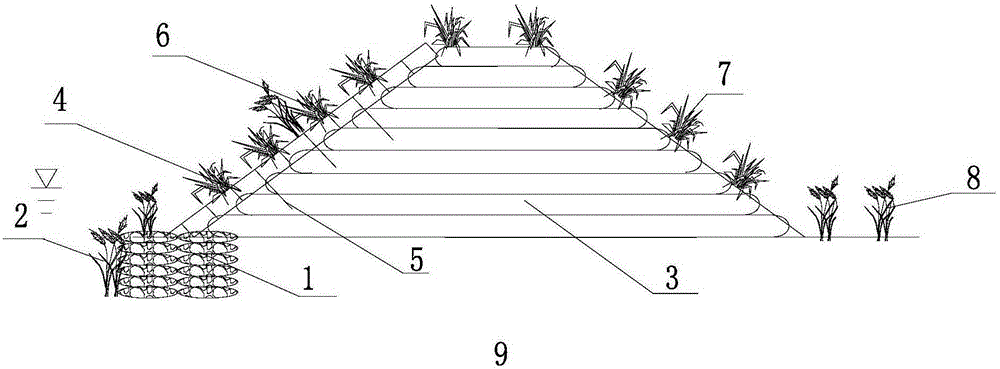

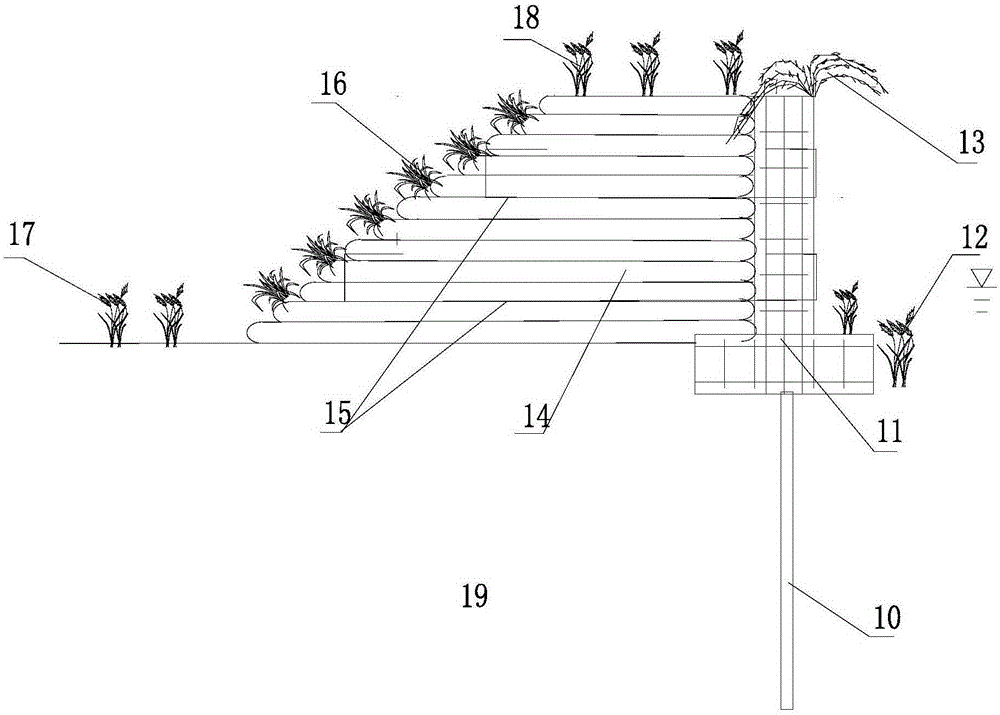

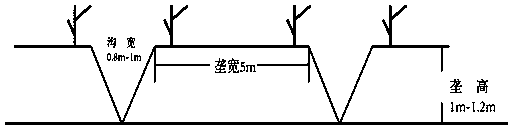

Large filling bag ecological embankment and revetment building method for river lake channel

The invention provides a large filling bag ecological embankment and revetment building method for a river lake channel. The method comprises the steps that (1), on the basis of cleaning and leveling, an embankment structure is filled with cleaned river lake bottom mud layer by layer through the large filling bag technology until the embankment structure reaches up to a designed elevation of the embankment top and the height of 0.5-1 m beyond the designed elevation is reserved through filling construction; (2), the cleaned river lake bottom mud is filled through a land pump, or special complete equipment and corresponding construction technologies are adopted to directly conduct mechanical paving and filling, and then the filled cleaned river lake bottom mud is sewn into bags; and (3), filling soil materials of the large geotextile filling bag embankment structure are taken from local resources, the bottom mud obtained through river lake regulation and channel excavation and cleaning is used as the filling soil materials, the initial water content of the filling soil materials is controlled within the range from 50%-80%, and the large filling bag embankment structure which is layered appropriately is adopted according to the practical situation. According to the method, the design is reasonable, the process is simple, construction is easy, operation is convenient, cost is low, popularization is easy, the ecological functions are good, and the method is applicable to ecological management and ecological channel construction of river lakes in soft soil areas.

Owner:NANJING HYDRAULIC RES INST

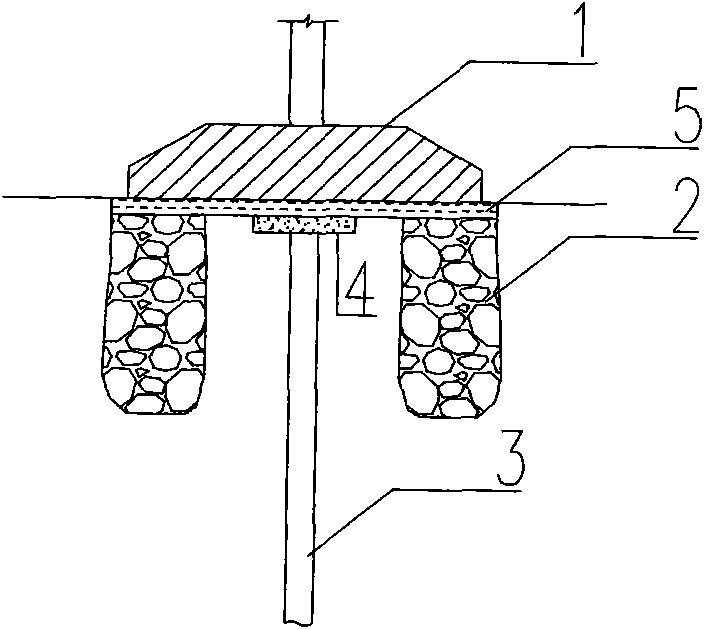

Automatic tamper type waste filling hydraulic support

InactiveCN102135006AGood topping effectSmooth connectionMaterial fill-upMine roof supportsGround subsidenceCut and fill

The invention discloses an automatic tamper type waste filling hydraulic support which comprises a base and a top beam, wherein the base and the top beam are connected by uprights, the front end of the top beam is provided with a forepole, the rear end of the top beam is provided with a scraper conveyor and further connected with an internally-telescopic extrusion scraping plate by a retractable jack which is arranged horizontally; the rear side of the base is provided with the extrusion scraping plate by a first and a second extrusion jacks, and the first extrusion jack is horizontally arranged. The automatic tamper type waste filling hydraulic support solves the problems that conventional cut and fill hydraulic support equipment can not ensure top filling of filler and has poor tamper intensity; in addition, the automatic tamper type waste filling hydraulic support realizes the high-strength supporting for a gob roof by virtue of waste fillers, effectively eliminates the defect of ground subsidence, realizes safe recovery for part of permanent coal pillars, corner coals and coal under buildings on the premise of not destroying factories and relocating villages, and improves the recovery of the coal resources. The invention is also suitable for various solid fillers such as coal ash, river sand, loess and the like.

Owner:HENAN POLYTECHNIC UNIV

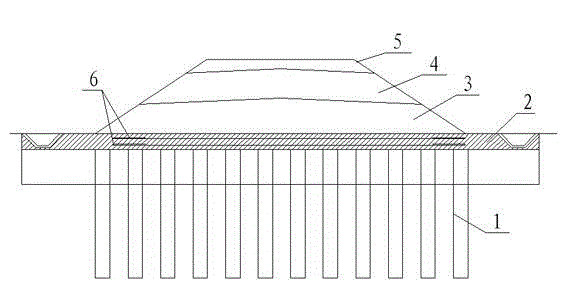

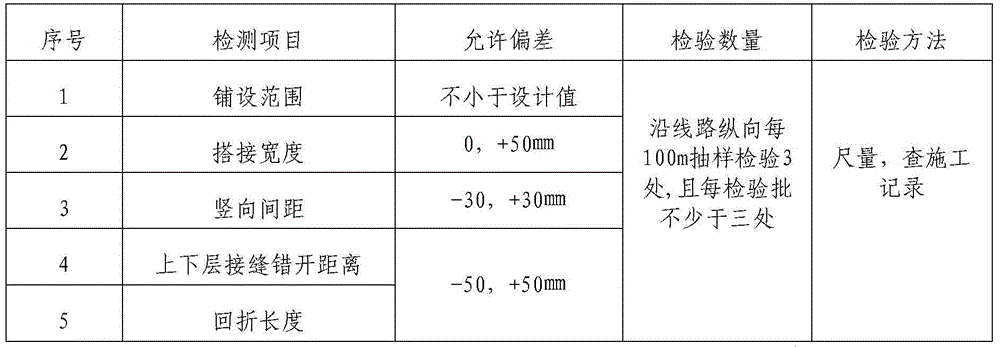

Filling construction method for collapsible loess subgrade

ActiveCN104358188AEnsure the quality of filling constructionEnsure stabilityRailway tracksEngineeringCut and fill

The invention discloses a filling construction method for a collapsible loess subgrade, and belongs to the technical field of construction of railway subgrades. The filling construction method for the collapsible loess subgrade comprises the following steps of 1, finishing foundation treatment on a collapsible loess subgrade foundation by combining CFGs (cement flyash gravel pile) and water soil compaction piles; 2, laying a 1m-thick water soil cushion layer on the top surface of the foundation, wherein two layers of geogrids with tensile strength of not weaker than 120KN / m in the water soil cushion layer; 3, after the filling construction of a part (3) below the foundation, adjusting the width of the subgrade and the slope of side slopes according to needs, removing redundant filled soil, and compacting the side slopes. According to the filling construction method for the collapsible loess subgrade, the technical problem of how to implement reasonable filling construction under a dry condition in a northwest region is mainly solved, and a continuous compaction technology is adopted for a filling construction process for the collapsible loess subgrade as an auxiliary quality control means.

Owner:CHINA RAILWAY NO 8 ENG GRP CO LTD

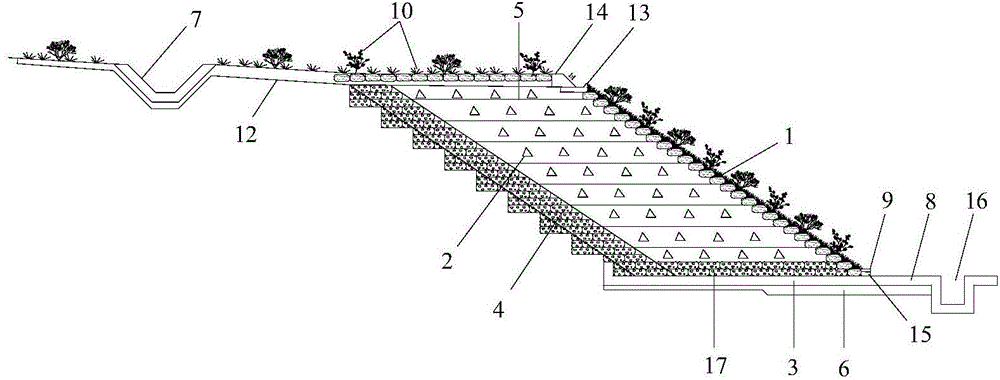

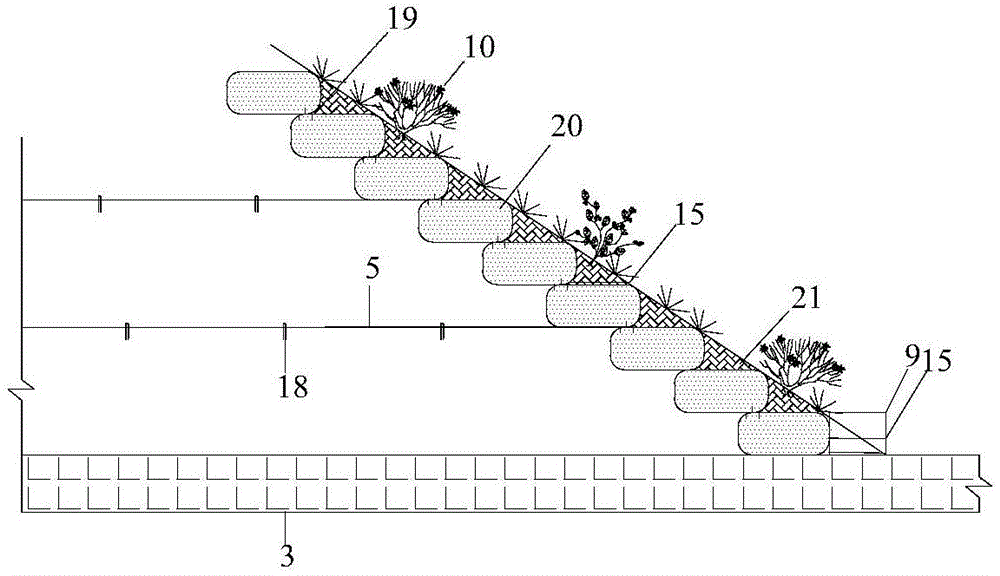

Flexible expansion reduced ecological slope protection construction

InactiveCN104532857ASolve technical problemsSave engineering investmentExcavationsGasketsCut and fillEngineering

Flexible expansion reduced ecological slope protection construction effectively solves the technical problem of expansion soil or expansion rock in road cut slope protection, ensures that the road slope protective structure has the good short-term and long-term protective effect, and is beneficial to reducing the project investment of slope protection. The flexible expansion reduced ecological slope protection construction comprises an ecological slope protection face, a filling or refilling soil layer, foundations, a drainage system and a waterproof system. The filling or refilling soil layer is formed to be a flexible reinforced body by layered filling and layered compacting non-expansion soil or weak-middle-expansion soil and a geogrid paved in the expansion soil in layers. The ecological slope protection face is formed by ecology bags which are paved on the top surface and outside face of the filling or refilling soil layer. Slope covering soil is paved outside the ecological slope protection face. Green plants are planted on the slope covering soil.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

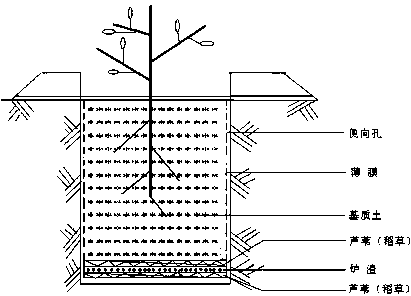

Method of landscaping planting of coastal dredger fill saline and alkaline land

The invention discloses a method of landscaping planting of a coastal dredger fill saline and alkaline land. The method comprises the following steps of 1, carrying out fine soil preparation on the coastal dredger fill saline and alkaline land, ditching, ridging, discharging salt and discharging alkali; 2, utilizing a cave-shaped lining membrane basement tree planting technology on a ridge; 3, managing, wherein the cave-shaped lining membrane basement tree planting technology comprises the steps of (1) digging a forest planting hole according to the size of seedlings; (2) laying plastic films which can be provided with round cracks on the bottom and the lateral surfaces in the hole; (3) arranging an isolating course of 30 cm in the forest planting hole; (4) planting seedlings by adopting a planting method of burying for three times, stamping twice and lifting once; (5) adopting matrix soil suitable for seedling growth as planting soil, and applying 4 kg of biological efficient organic fertilizer to every square meter of matrix soil; (6) covering the earth surface with a layer of film with holes so as to storage water and preserve soil moisture, and ridging and compacting on the film; (7) ridging at the periphery of the forest planting hole to form a round sill. By adopting the method, the survival rate of landscaping planting of the coastal dredger fill saline and alkaline land is effectively improved, and is up to more than 90%. The method has the advantages of simplicity in operation, low cost and easiness in popularization.

Owner:HIGH TECH RES INST NANJING UNIV LIANYUNGANG

Efficient mechanical mining method for gently-inclined thin ore bodies

ActiveCN105649631AReduce layered mining and filling workloadReduce work intensityUnderground miningSurface miningEngineeringCut and fill

The invention discloses an efficient mechanical mining method for gently-inclined thin ore bodies. The method includes steps: step one, tunneling a drilling roadway of a first layer of a first section; step two, cutting waste rock of a foot wall; step three, forming side collapse vertical grooves; step four, constructing fan-patterned blast holes; step five, laterally blasting to form a footwall compensation space; step six, blasting in upper fan-patterned blast holes for stoping; step seven, constructing a connection roadway of a second layer of the first connection; step eight, tunneling the drilling roadway while cutting the waste rock according to procedures of the step one and the step two; step nine, repeating the step one to the step eight, and continuing stoping of a next section until stoping of four sections is finished. By the efficient mechanical mining method, defects of a breast stoping method and an upward horizontal cut-and-fill stoping method are overcome, and reduction of labor cost, relief of work intensity and the like can be realized by efficient mechanical operations. Furthermore, the efficient mechanical mining method is especially applicable to mining of gently-inclined thin ore bodies with high values or rare precious metals.

Owner:DAYE NONFERROUS METALS

Road foundation compactness detection method

Owner:CHANGAN UNIV

Tunnel excavation method for extending existing single-hole tunnel into double-arch tunnel

InactiveCN102121385AReduce distractionsShorten the construction periodUnderground chambersTunnel liningFracture zoneCut and fill

The invention belongs to the field of tunnel engineering, and particularly relates to a tunnel excavation method for extending the existing single-hole tunnel into a double-arch tunnel. The method comprises the following steps of: constructing mid-boards on a plurality of cross sections in the existing tunnel; after the mid-boards are constructed, filling a cavity on one side of the existing tunnel; excavating a side wall guide hole of a newly-constructed tunnel on the other side of the existing tunnel; excavating a middle soil body; after the second lining of the side tunnel is constructed, excavating a cavity on the other side; excavating a guide hole on the other side while excavating filling in the existing tunnel; after excavation, removing a lining and constructing the second lining; and excavating two caverns at a certain interval, wherein the interval is determined according to the diameter of a single hole of the double-arch tunnel. A newly-constructed cavern is excavated by excavating the side wall guide hole, constructing a temporary support, excavating the middle soil body, removing the temporary support and constructing the second lining of the tunnel in turn. Before the newly-constructed cavern is excavated, the other side of the existing tunnel opposite to the cavern to be excavated is filled, and a filled part is removed during excavation of the side cavern. Due to the consideration of the disturbance of excavation on enclosing rock, the excavation time and the space effect and under the assistance of a pre-supporting measure, the excavation method is suitable for extending tunnels under poor geological conditions such as soft soil layers, fracture zones and the like. The excavation method has the advantages of easiness and convenience in implementing and small quantity of procedures, the disturbance of enclosing rock can be reduced, and the construction period is reduced.

Owner:TONGJI UNIV

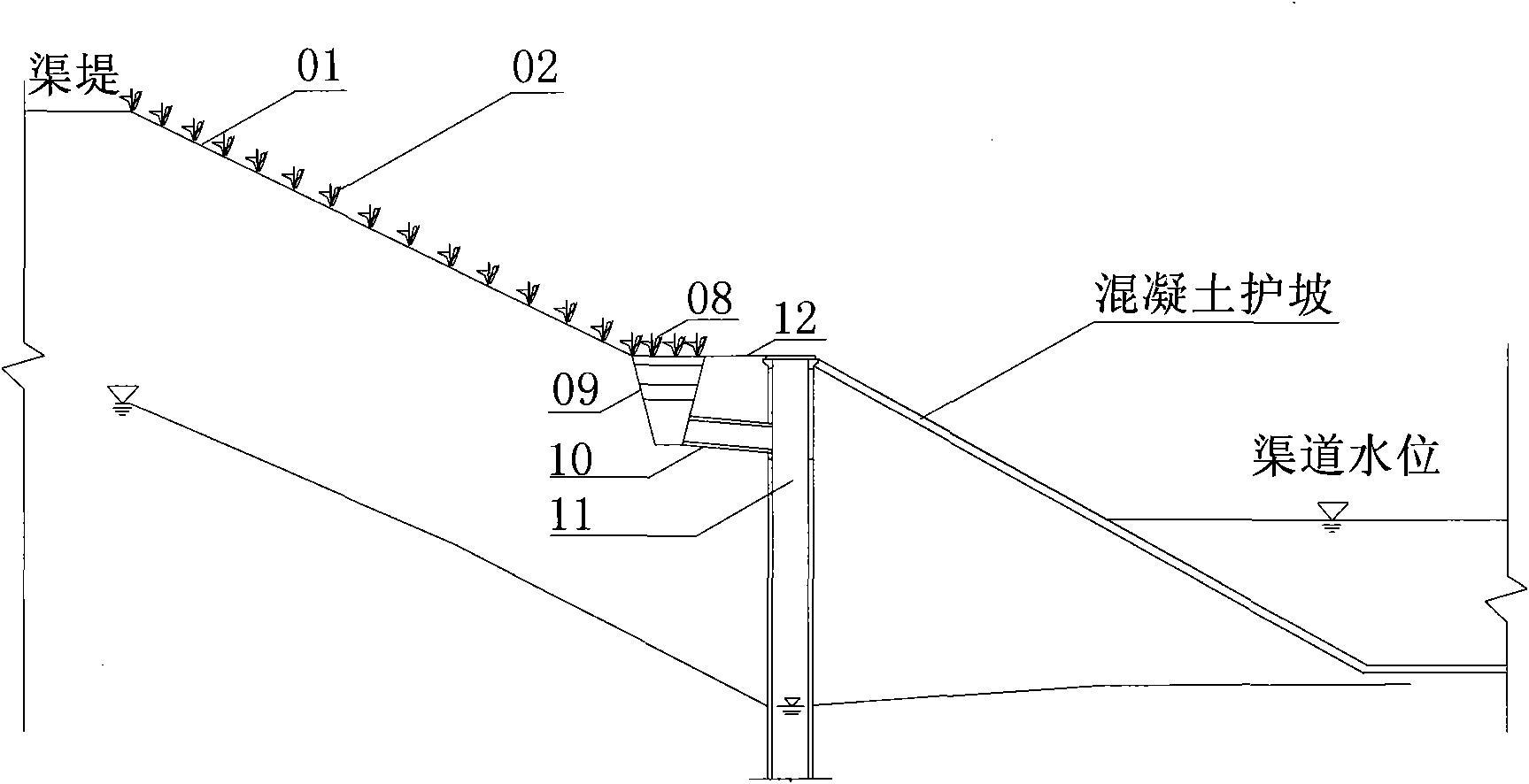

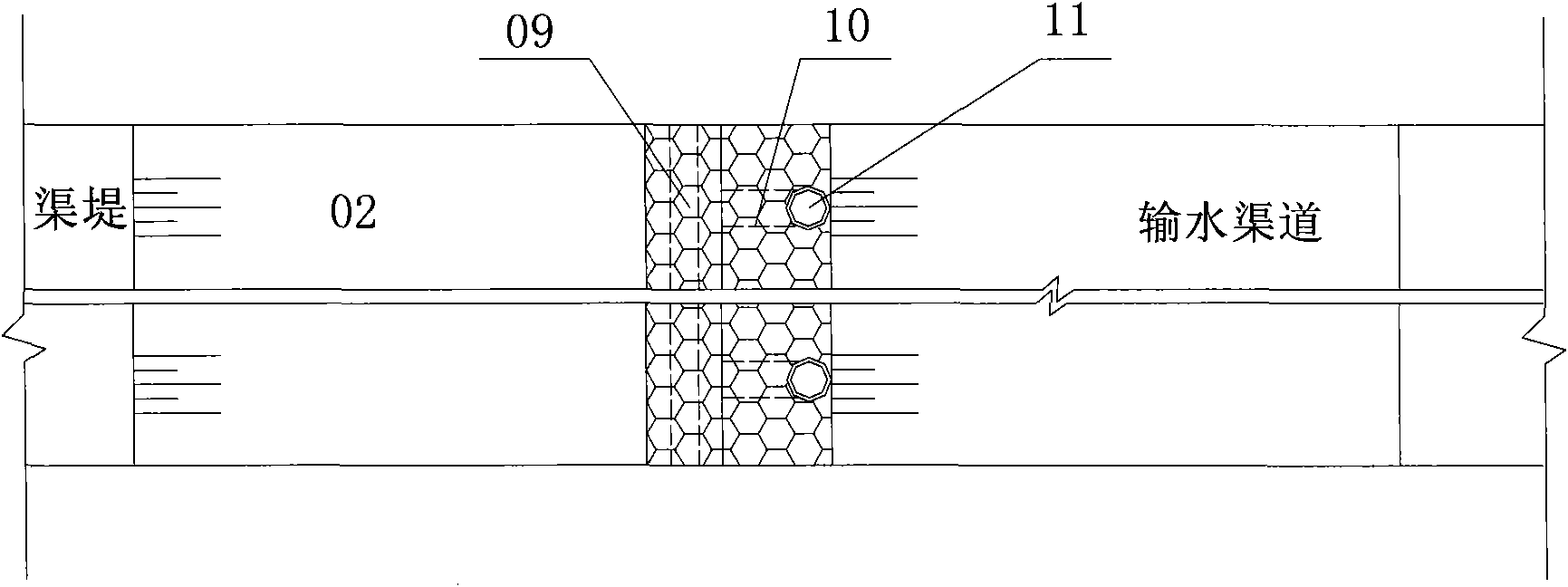

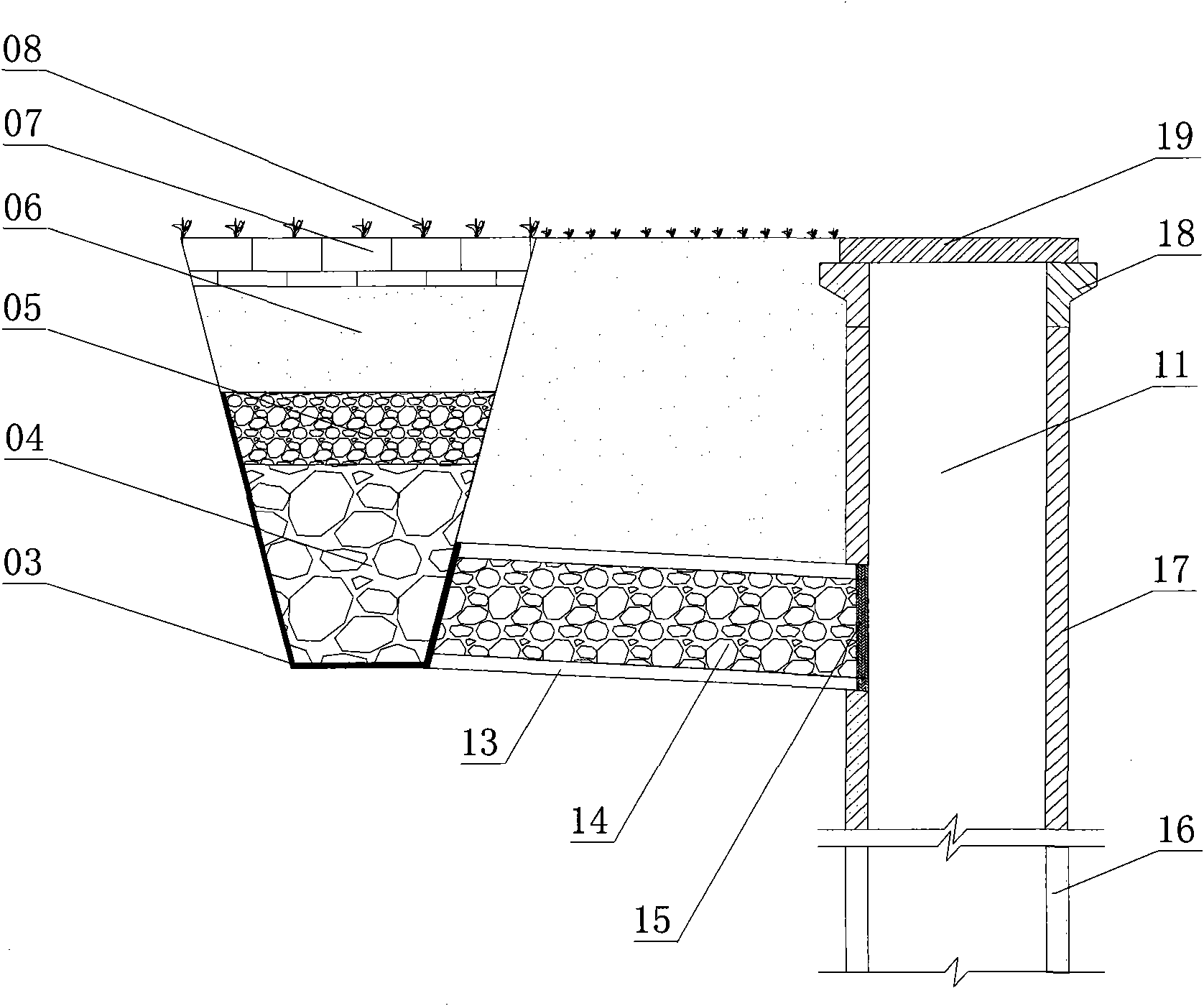

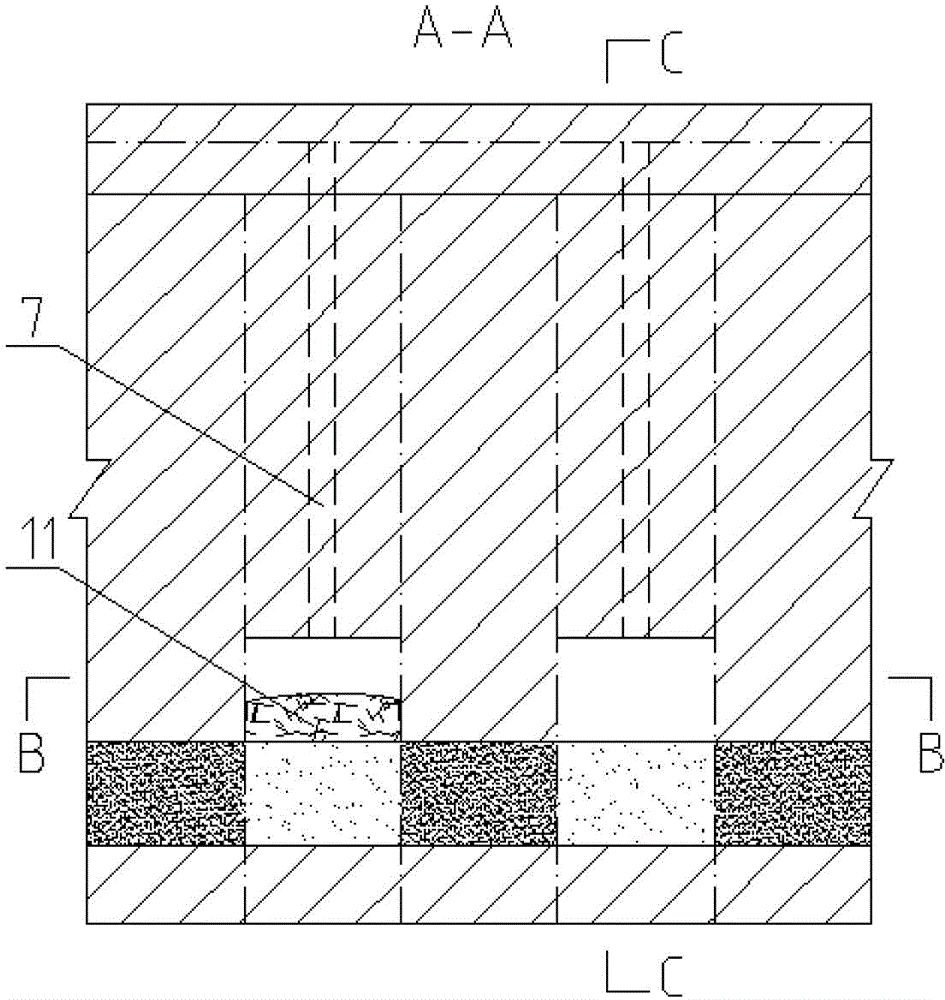

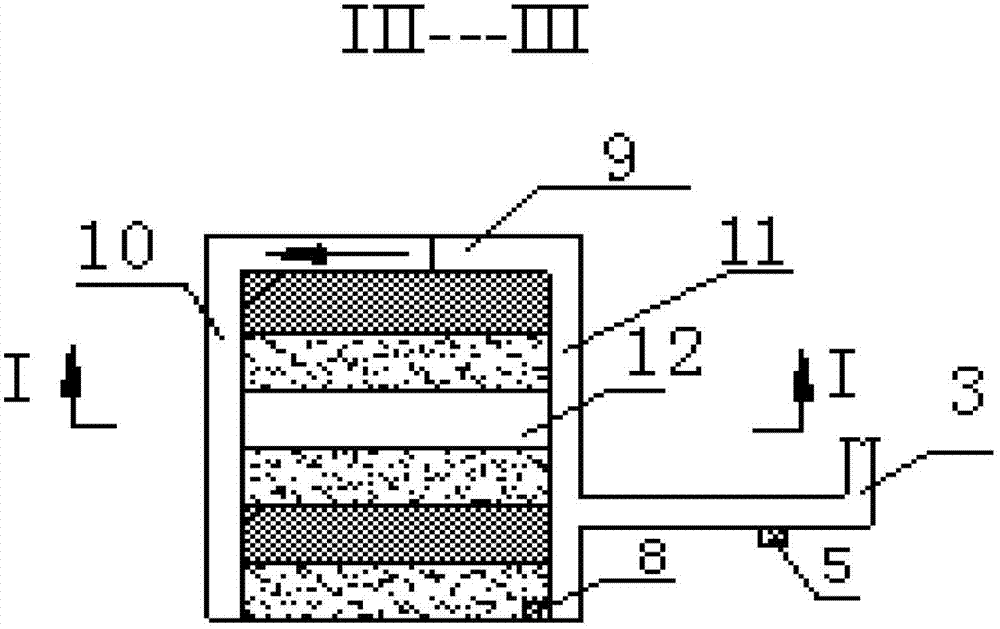

Seepage-intercepting and pollutant-removing system of large channel non-water passing slope

InactiveCN101560757AEffective interceptionSlow down runoff movementIrrigation ditchesExcavationsShortest distanceWater flow

The invention relates to a seepage-intercepting and pollutant-removing system of a large channel non-water passing slope, and the system mainly comprises four parts: a greensward slope protection belt, an ecological seepage-intercepting ditch, a drainage subsurface pipe and a water collecting well. The greensward slope protection belt is a concrete grid turf slope or the combination slope protection of grass and shrubs; the ecological seepage-intercepting ditch is arranged at a berm which is near to the slope toe part of an inner slope of the channel non-water passing cross section and shaped like an inverted trapezoid which is wide at the top and narrow at the bottom, the ditch is under cut and fill method by sands and stones with different particle sizes, plants are plated at the upper part, thereby being capable of effectively intercepting radial flow, depositing silty sands and granular pollutants during the rapid infiltration process of water flow in a short distance and ingesting, absorbing or converting soluble pollutants; and the water flow after the purification is collected in the water collecting well along the drainage undersurface pipe. The invention constructs the seepage-intercepting and pollutant-removing system which integrates flow interception, seepage interception, flow guide, flow collection and water quality purification and has the advantages of less project investment, simple structure, no additon of occupied area and the like, thereby being an ecological protection new technology of the large channel slopes which takes actions that suit local circumstances being economic and practical and having important promotional value.

Owner:HOHAI UNIV

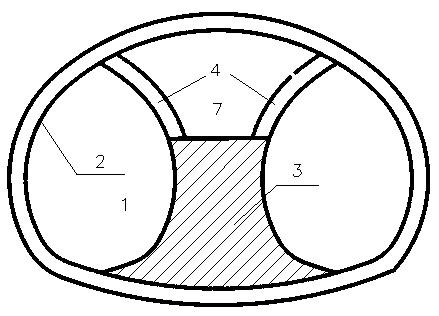

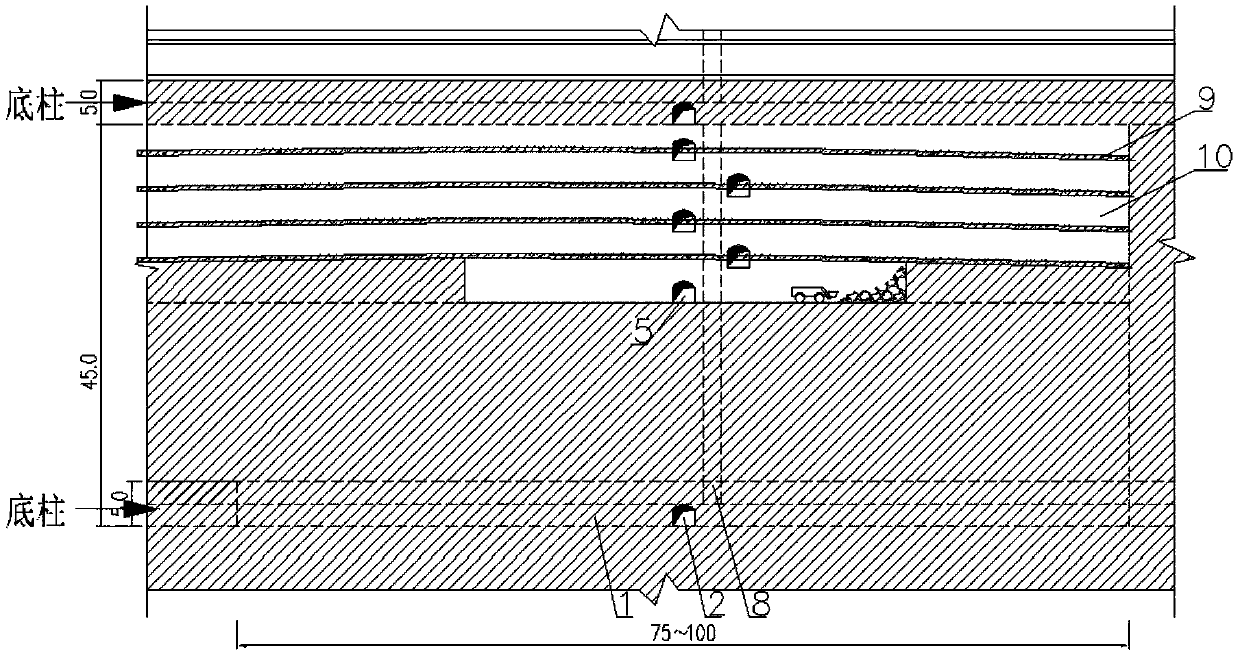

Two-step upward high-layering bagging cut-and-filling stoping method

InactiveCN104373125AReduce construction costsReduce complexityUnderground miningSurface miningSlurryCut and fill

The invention relates to a two-step upward high-layering bagging cut-and-filling stoping method. A fragmented haulage way is constructed from a slope opening; a stope connection way is drilled from the fragmented haulage way to an ore body footwall; an intra-vein haulage way is constructed in a vein of the ore body footwall for communicating ore chambers with jamb stopes; after the stoping of the ore chamber stopes is finished, a bagging tailing stop wall is built in an outlet position for stope filling; when the stop wall is built, the intra-vein haulage way of the footwall is remained as a stoping channel of the jamb stopes; after the stoping of the jamb stopes is finished, multiple jamb stopes are taken as one district; filling stop walls are built at the two ends of the intra-vein haulage way of the footwall and in an outlet of the stope connection way; and the multiple jamb stopes are filled once through the mobility of filling slurry. The method is low in stope preparation work amount, is low in production cost of the filling stop walls, can realize synchronous filling of the multiple two-step stopes, and reduces the complexity of the filling process.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

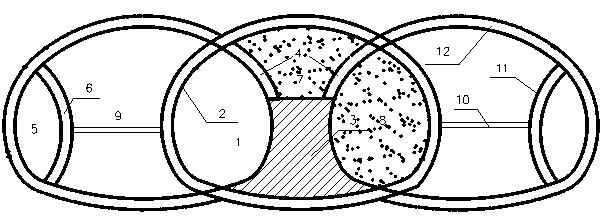

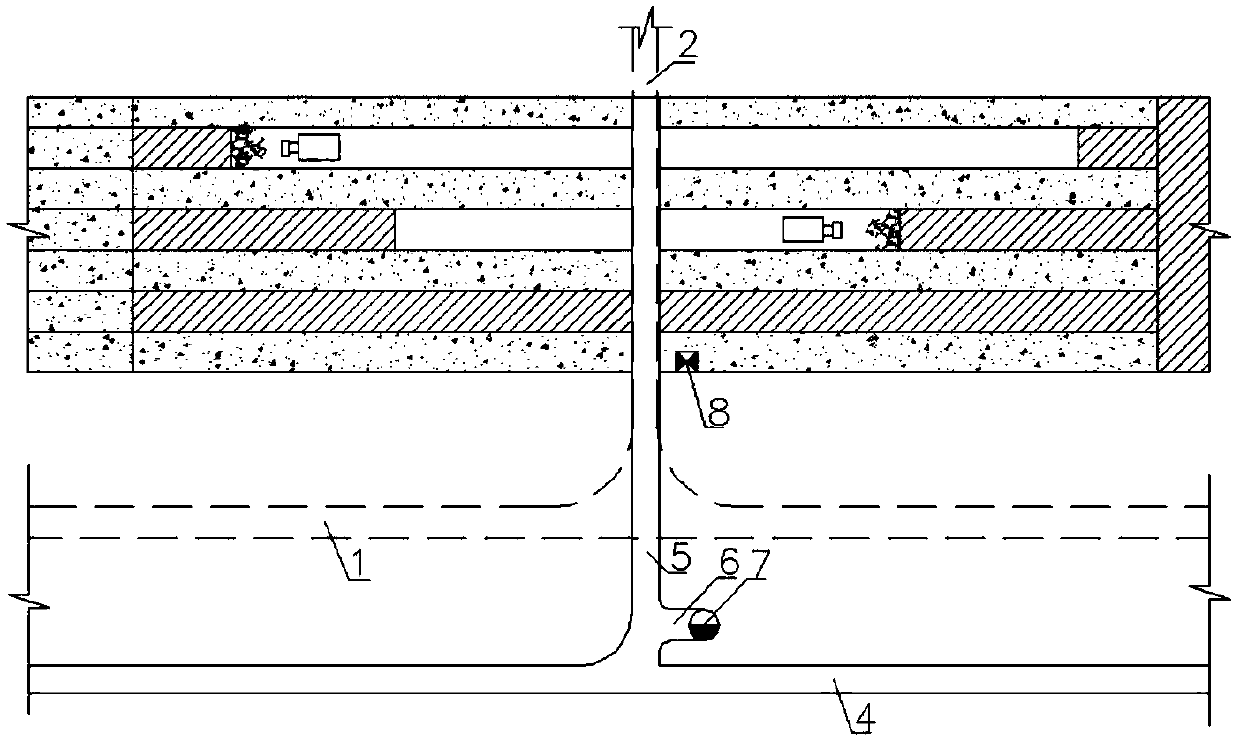

Precontrol top upward access cut-and-filling stopping method

ActiveCN103206215AImprove securityHigh recovery rateUnderground miningSurface miningControl layerCut and fill

The invention discloses a precontrol top upward access cut-and-filling stopping method. The method comprises the following steps of: stopping an upper slice (namely roof control layer) by an access mining method, stopping a lower slice (namely stopping layer) after a top plate is reinforced by measures, filling after two slices are stopped, and rising to two upper slices after the upper and lower layers of access are stopped and filled. According to the method, the single-slice stopping of an ordinary upward access filling method is changed into double-slice stopping, so that the access support work amount and support cost (requiring only support upper slice) are reduced, and the access filling time is lowered, and the operation cycling progress is accelerated; and besides, the upper slice stopped provides a compensating space for lower slice stopping, so that the stopping efficiency of the lower slice is improved, the access mining production efficiency and the production capacity are greatly improved, and the production cost is obviously reduced.

Owner:湖北楚磷矿业股份有限公司

Collaborative mining method and system for ore deposit and terrestrial heat

ActiveCN107023294AThe method steps are novelTaking into account the cooling of high temperature stopeOther heat production devicesUnderground miningResource recoveryGround system

The invention discloses a collaborative mining method and system for ore deposit and terrestrial heat. The collaborative mining method comprises the steps that firstly, ore block accurate mining and cutting are conducted according to the cut and fill mining technology; secondly, construction of a mine terrestrial heat mining ground system is conducted on the ground; thirdly, first-layer back production is conducted, and construction of a mine terrestrial heat mining underground system is conducted below the ground; fourthly, first-layer filling is conducted, and a heat collecting filling body is formed; and fifthly, from the part above the first layer, mining, back production and filling of various layers are sequentially conducted from bottom to top till the operation is conducted upwards to a stage transporting roadway. The collaborative mining system comprises the mine terrestrial heat mining ground system and the mine terrestrial heat mining underground system. The mine terrestrial heat mining underground system comprises a vertical well vertical pipe, a roadway transverse pipe, a top well vertical pipe and the heat collecting filling body, wherein the vertical well vertical pipe, the roadway transverse pipe and the top well vertical pipe are laid during back production of the layers, and the heat collecting filling body is formed during layer filling. Design is novel and reasonable, resource recovery and terrestrial heat development are conducted, meanwhile, high-temperature stope cooling is combined, practicability is high, and the application and popularization value is high.

Owner:XIAN UNIV OF SCI & TECH

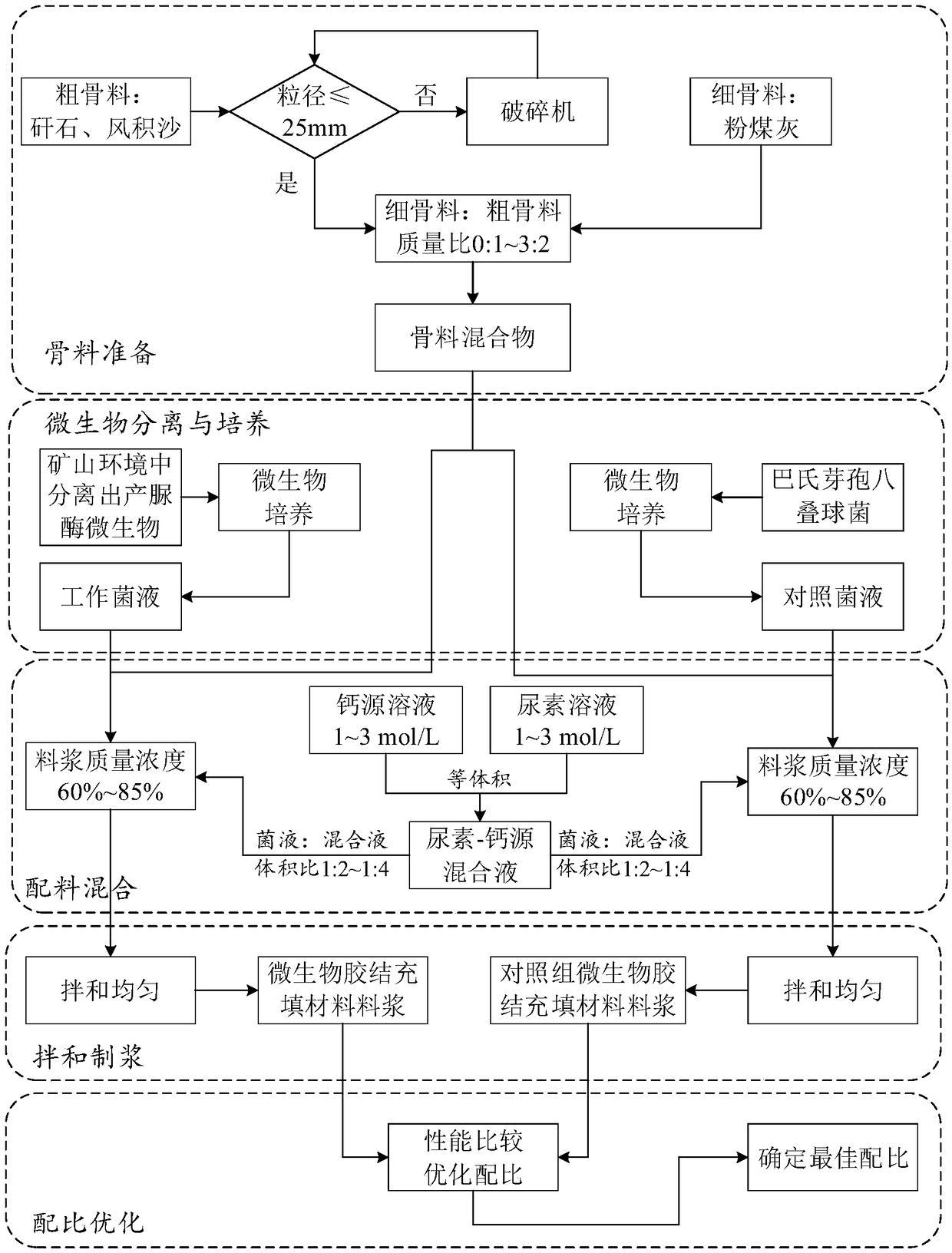

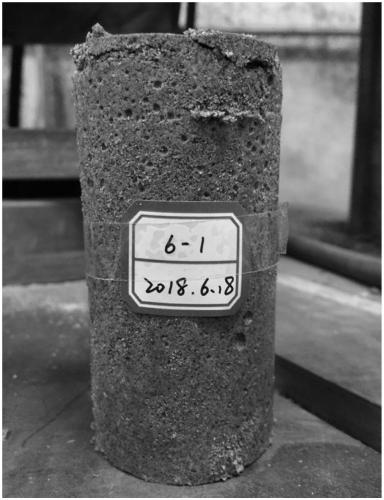

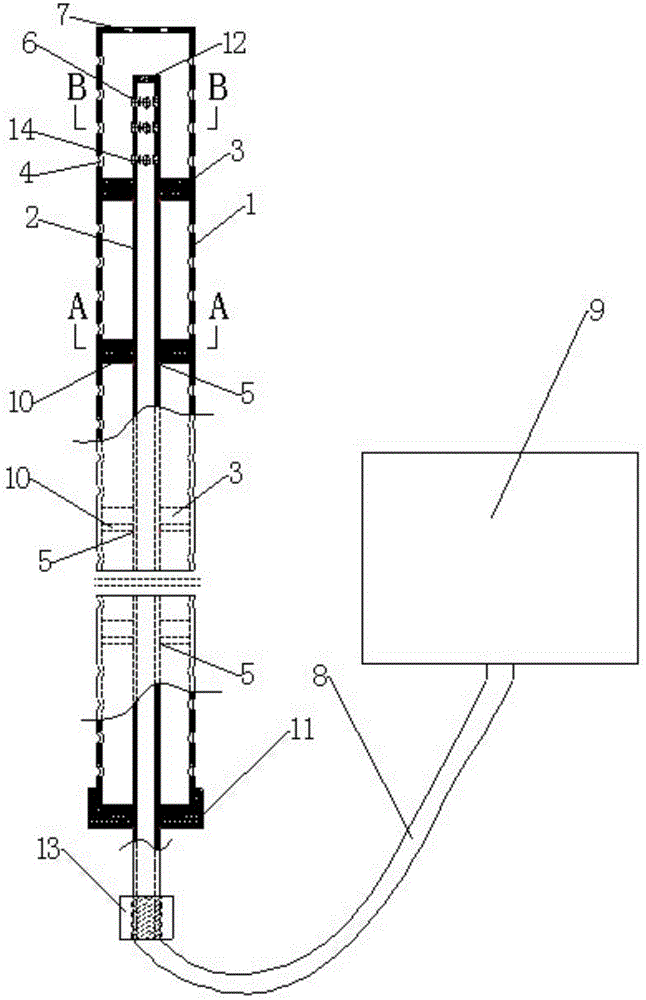

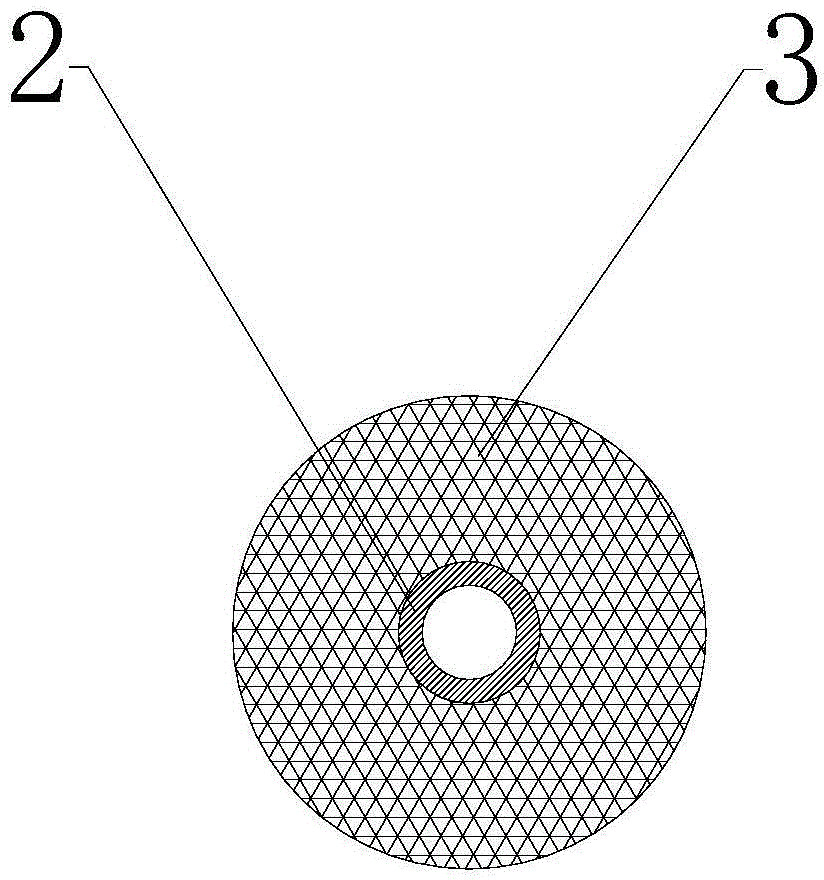

Coal mine microbial cemented filling material and preparation method thereof

The invention discloses a coal mine microbial cemented filling material and a preparation method thereof. The material is prepared from raw materials of aggregate and a microorganism, wherein the microorganism is a urease-producing microorganism. Urea hydrolysis reaction of the urease-producing microorganism is adopted to induce calcium carbonate deposition to form gel, the gel completely replacesa cement base in a traditional cemented filling material to serve as a cementing material for coal mine cemented filling, and a microbial liquid solution and a urea and calcium source solution are adopted to blend the aggregate to a required concentration and prepare the coal mine microbial cemented filling material. The applied microorganism in the coal mine microbial cemented filling material replaces a cement-based cementing material, reduces the negative impact on the environment caused by the use of a large amount of cement, reduces the cost of the cemented filling material, and ensuresthat the performance of a filling body meets the technical requirements of coal mine cut and fill mining. The coal mine microbial cemented filling material is a novel cemented filling material with environmental friendliness, low energy consumption and low emission, and has wide applicable fields and promotion value.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

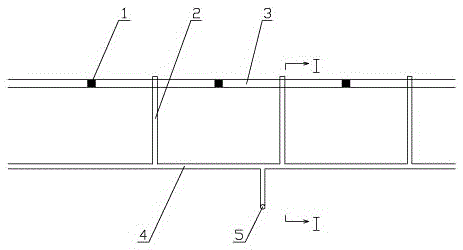

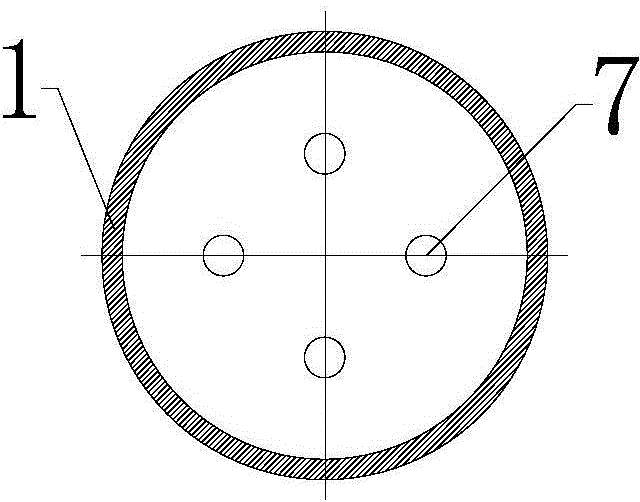

Grouting pipe for miscellaneous fill stratum and construction method

InactiveCN104975594AEffective reinforcementEasy to processSoil preservationArchitectural engineeringSlurry

Disclosed are a grouting pipe for a miscellaneous fill stratum and a construction method. The grouting pipe is mainly composed of an external grouting pipe body, an internal grouting pipe body, a slurry stop plug, a segment spacer ring and a sealing plug, wherein one end of the external grouting pipe body and the surface of the pipe body are provided with grouting holes; the internal grouting pipe body is fixed to the segment spacer ring through the slurry stop plug; a grouting hole is formed in the top end of the internal grouting pipe body, and grouting holes are evenly distributed around one end of the pipe body; the bottom end of the internal grouting pipe body is connected with a grouting machine through a mortar conveying pipe; the segment spacer ring is fixed to the inner wall of the external grouting pipe body. The grouting pipe has the characteristics of low pressure, high frequency, segmentation and quick grouting, thereby accurately controlling the grouting pressure and grouting parameters for the complex situations of miscellaneous fill stratums containing large gravel or building rubbish; a grouting curtain within a certain range is formed in the stratum, greening vegetation over the stratum is not affected, and the purpose of effectively reinforcing the miscellaneous fill stratum is achieved. The grouting pipe is convenient to use, conducts grouting quickly and can be widely applied to miscellaneous fill stratums needing reinforcing.

Owner:CHINA UNIV OF MINING & TECH

Downward drift cut-and-fill mining false roof construction method

InactiveCN109595016AHigh strengthImprove stabilityUnderground chambersMaterial fill-upCarrying capacityCut and fill

The invention provides a downward drift cut-and-fill mining false roof construction method. The method comprises the following steps: ore body components: ore bodies and a drift are arranged in the moving direction; stope preparation and ore body cutting; stoping; false roof construction: after stoping of a stope, residual ore is laid at bottom of the drift immediately, steel bars are laid on theresidual ore to form a steel bar net, steel bars are reserved on the steel bar net, bent, filled with a filling material and connected with a roof, after the reserved steel bars are strengthened afterfilling, lower edges are bent into hooks, and steel bars are connected with reserved steel bars bent into hooks on the upper layer during next layered net laying. The method is mainly applied to orebodies with instable or very stable rock, and the defects that roofs are constructed to be horizontal or in a large-angle inverted V shape, have poorer carrying capacity and shorter roof control timein downward drift cut-and-fill mining in the prior art are overcome.

Owner:CENT SOUTH UNIV

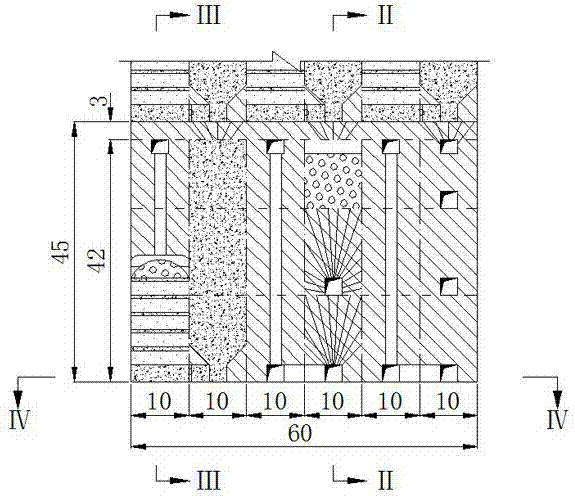

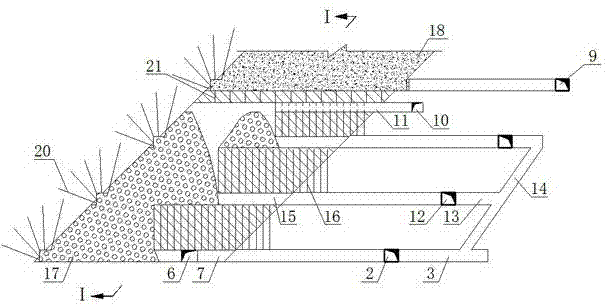

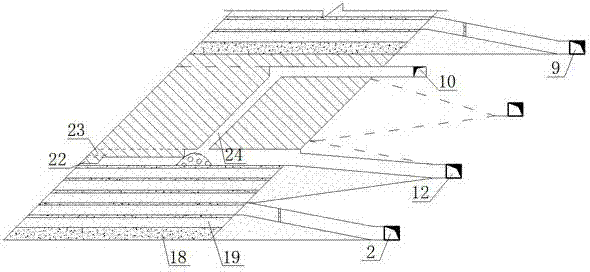

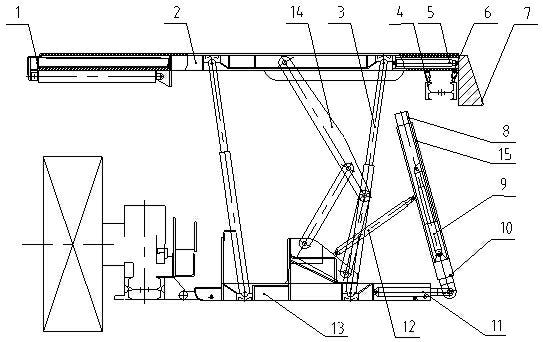

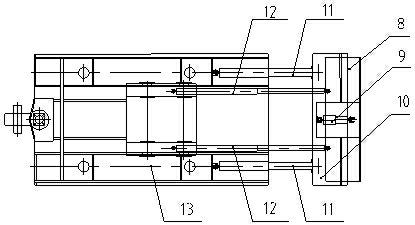

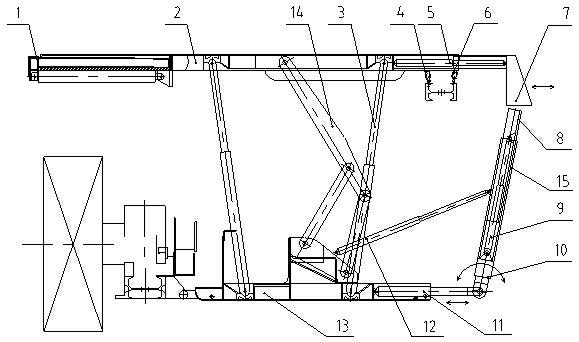

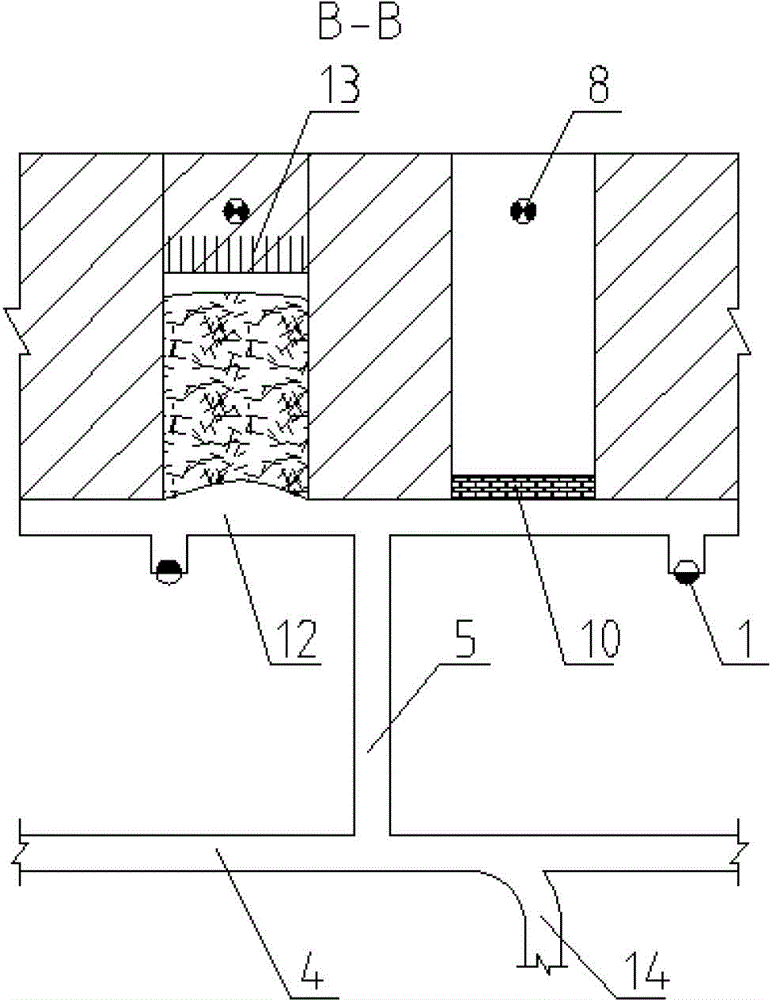

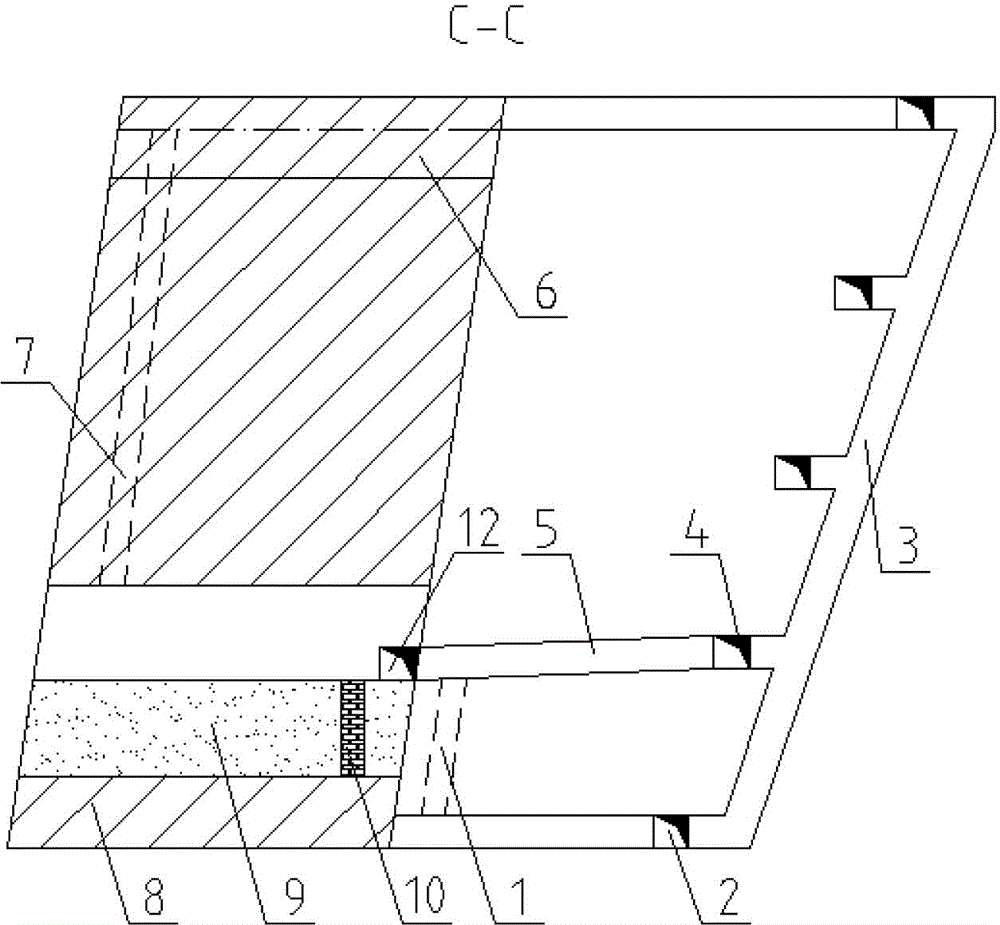

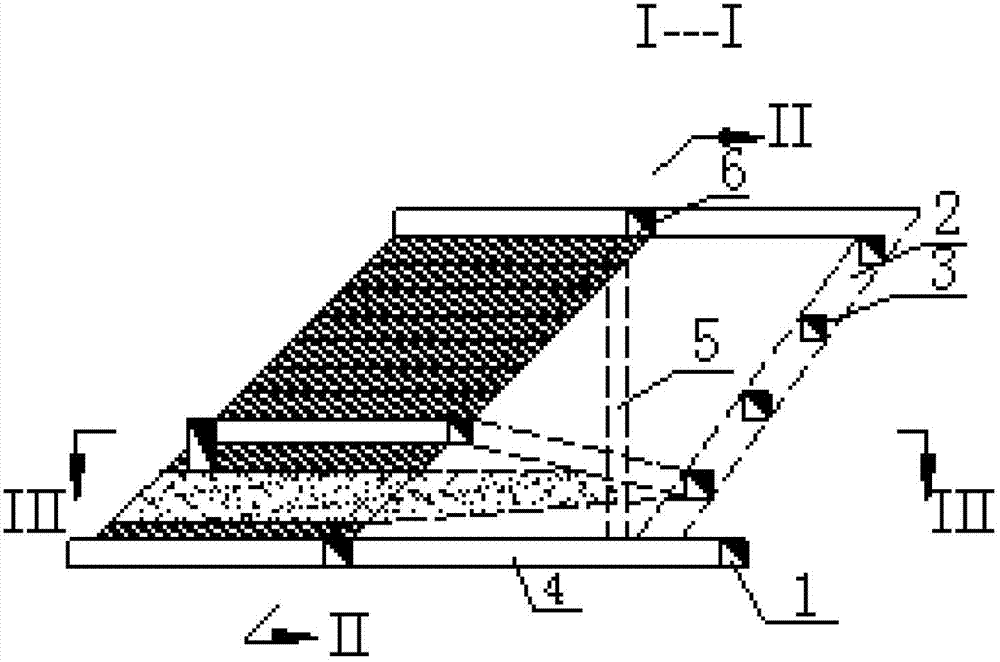

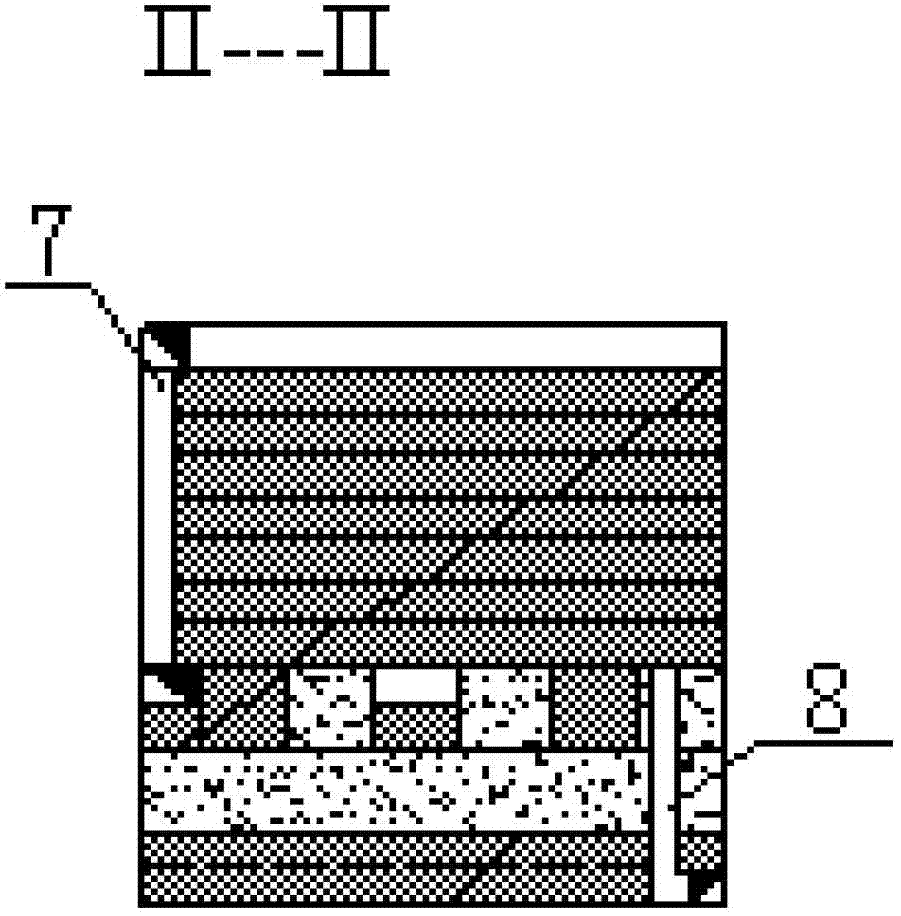

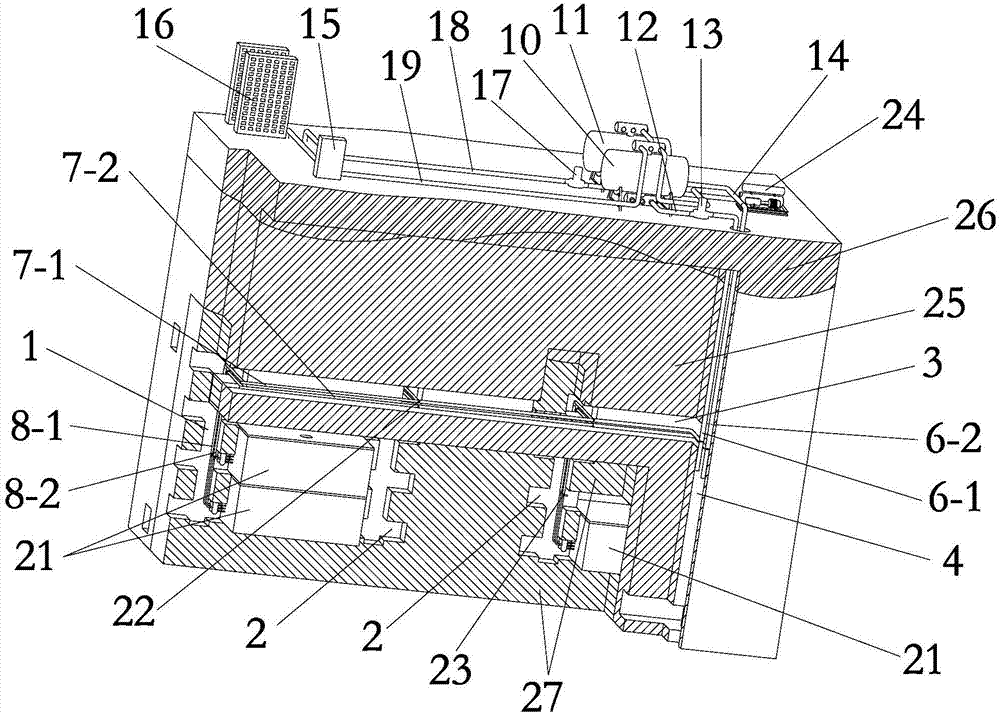

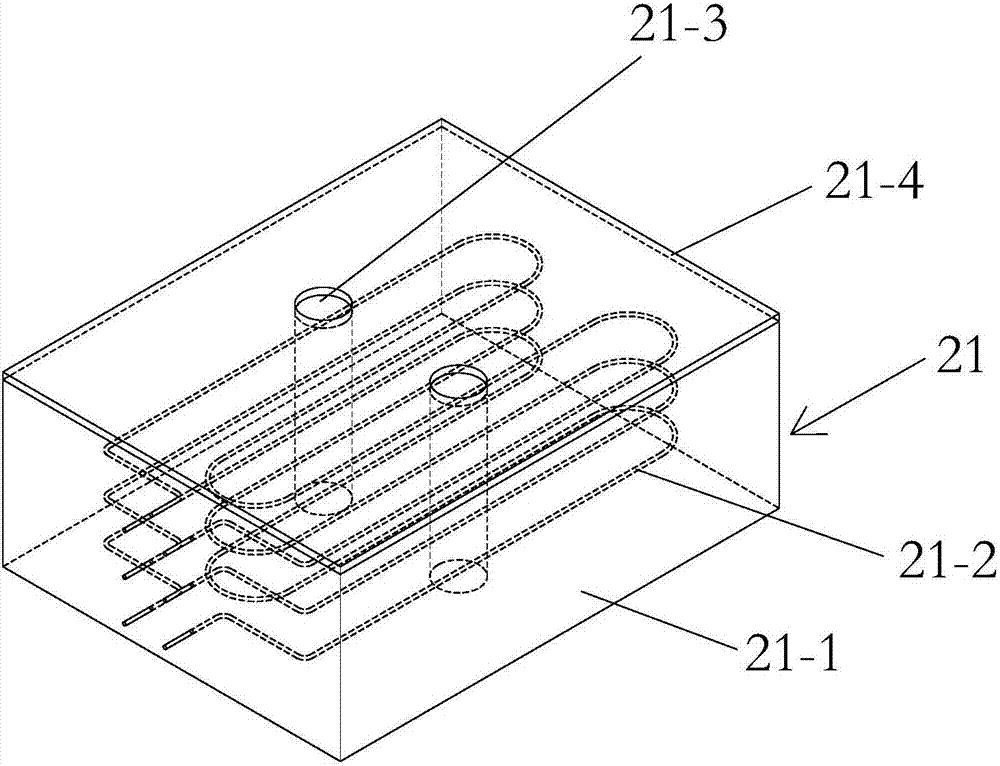

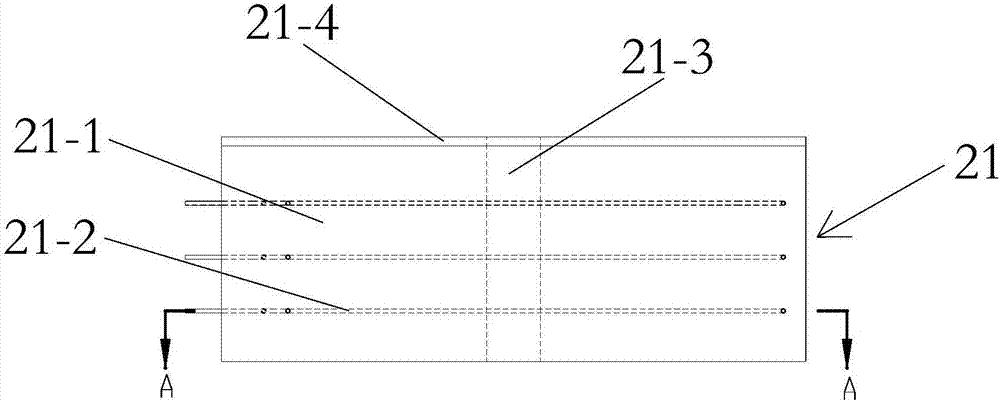

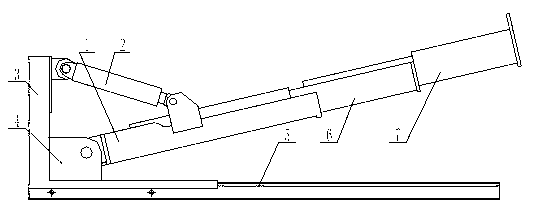

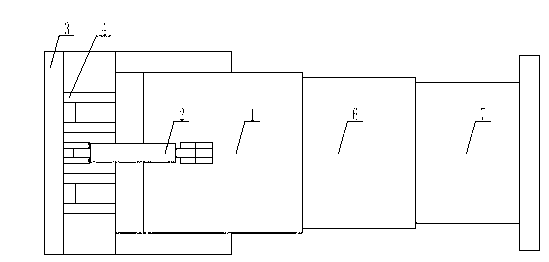

Simulation experiment platform of compacting system of solid-filling coal mining solid material

InactiveCN103018105AOptimizing the filling processSignificant engineering effectMaterial strength using tensile/compressive forcesFilling materialsCut and fill

The invention relates to a simulation experiment platform of a compacting system of a solid-filling coal mining solid material, which mainly consists of a power supply system, a compacting system, a loading system, a data collecting and processing system, a base and a box frame. The systems are sequentially matched to realize simulation of cut and fill field, filling and compacting process of the solid material in solid cut and fill technology can be realized in a laboratory, and associated parameters are obtained through the data collecting and processing system. The compacting system of the platform can realize the compacting force of 2MPa, the loading system can realize the loading pressure of 10MPa maximally. The loading pressure can be continuously constant or alternately loads. The experiment device can measure the stress-strain characteristics of same filling material under different loading pressures, the stress-strain characteristics of different filling materials under same loading pressure, and the creep property of a special filling material under continuous constant pressure in real time. The platform is simple in structure and easy to operate, and is an important platform for mechanical property of an evolutive theoretic research of the solid filling material under a special loaded condition in the solid filling coal mining technology.

Owner:CHINA UNIV OF MINING & TECH

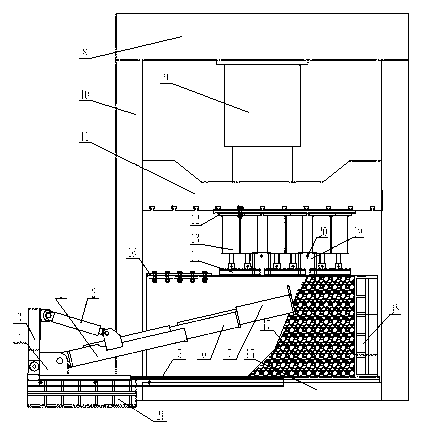

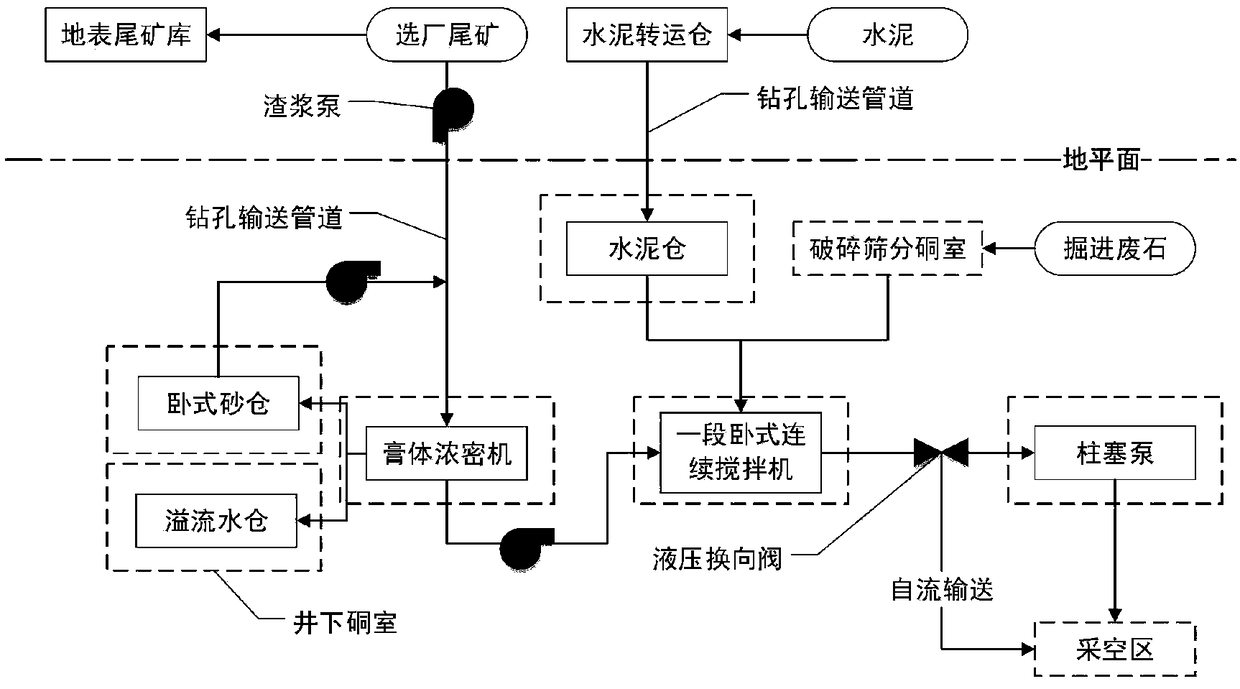

Underground all tailings-waste gypsum filling system and filling method

ActiveCN108915765ASave investment in infrastructure constructionSolve consolidationMaterial fill-upUnderground tunnelCut and fill

The invention belongs to the field of metal ore all tailings gypsum filling, and particularly relates to an underground all tailings-waste gypsum filling system and filling method. The filling systemand filling method are suitable for underground construction of an all tailings gypsum filling station and cut-and-filling stoping method mine applications with underground tunneling dead rock in pits. The underground all tailings-waste gypsum filling system utilizes the existing underground chamber or roadway engineering and achieves the effect the underground dead rock can no longer be requiredto be lifted to the surface for storage or treatment. At the same time, the beneficiation all tailings are made into the gypsum for bashing, the stock of all tailings in a surface tailings pond is reduced, investment and operating costs are greatly saved, and the mining operation safety conditions are improved.

Owner:UNIV OF SCI & TECH BEIJING

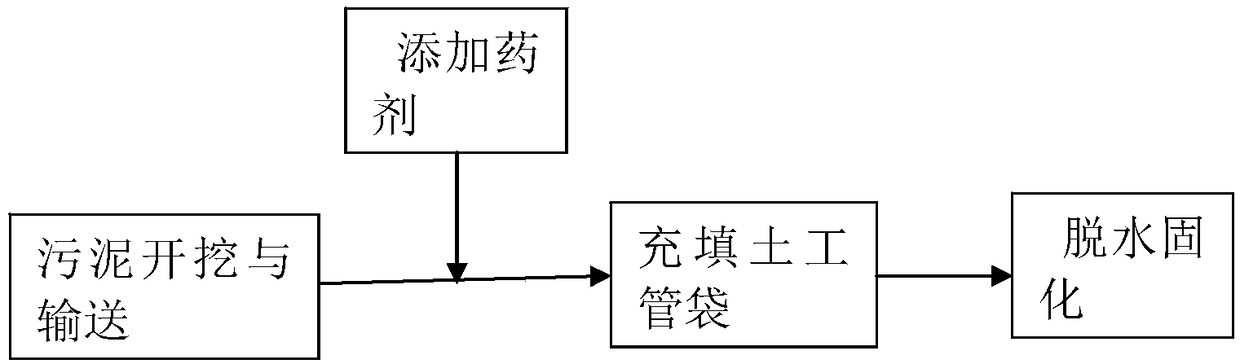

Construction method for dredging ditch sediment based on hydraulic punching and filling geotechnical pipe bag

InactiveCN108978577AContinuityClosedSludge treatment by de-watering/drying/thickeningClimate change adaptationSurface cleaningCut and fill

The invention relates to a construction method for dredging ditch sediments based on a hydraulic punching and filling geotechnical pipe bag and belongs to the technical field of dredging constructionof sediments in stinky water body ditches. The construction method for dredging the ditch sediments based on the hydraulic punching and filling geotechnical pipe bag includes the following steps of temporary storage yard construction, surface cleaning, sectional construction of cofferdam, construction drainage, assembly of a mud conveying pipeline, hydraulic punching and dredging of the sediments,adding medicament, geotechnical pipe bag filling, sludge dewatering and solidification and transportation or reuse of solidified soil. For the construction method, earth excavation is completed withthe help of hydraulic cutting; soil is then filled by a mud pump through the mud conveying pipeline to a large geotechnical pipe bag; in the dredging pipes, dredging mud and the medicament are fully stirred to produce a flocculation group to be precipitated in a geotechnical pipe belt, and then dehydration and solidification treatment of the sediments is achieved. The construction method for dredging the ditch sediments based on the hydraulic punching and filling geotechnical pipe bag has the advantages of continuity, integrated operation of dredging, conveying and filling, low cost, high construction efficiency, sealing property, no secondary pollution during transportation, good environmental protection performance, high construction precision, good effect, convenient operation and savedworking space.

Owner:CCCC TIANJIN DREDGING HARBOR CONSTR ENG

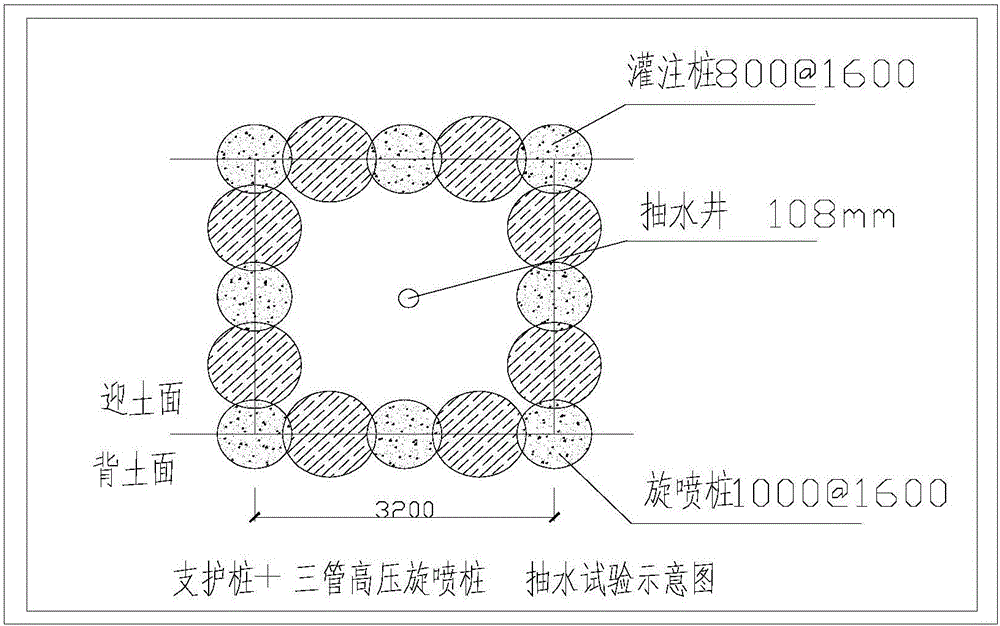

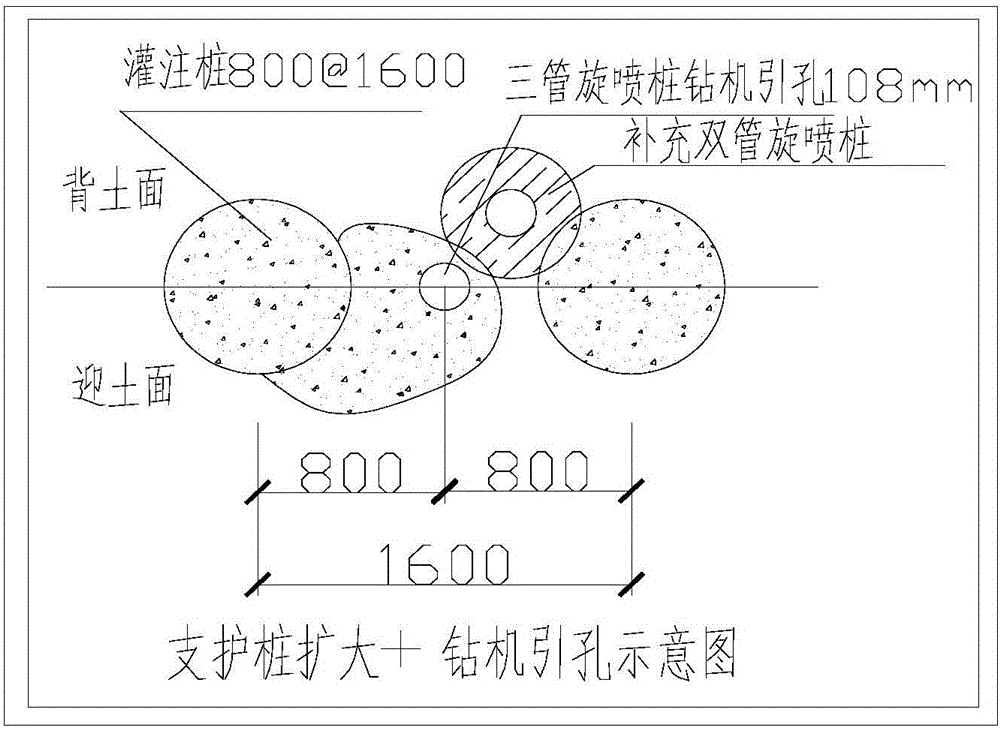

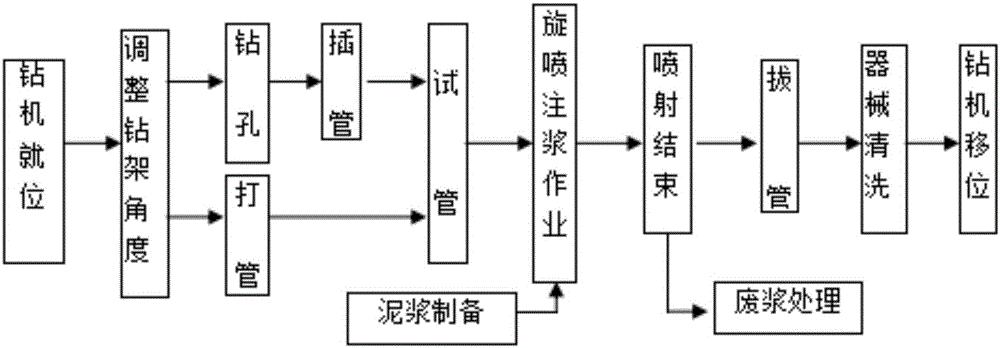

Construction method for deep foundation pit with support piles and three-pipe high-pressure jet grouting piles

InactiveCN106759297AGuaranteed stabilityControlled descentExcavationsBulkheads/pilesSlurryCut and fill

The invention discloses a construction method for a deep foundation pit with support piles and three-pipe high-pressure jet grouting piles. According to the construction method, operation is conducted according to the design requirements, and after a cast-in-place pile is completed, a placing measurement hole position is determined; drilling is conducted through a drill machine, a high-pressure jet grouting pile machine is put in place and aligned with the hole position, slurrying is conducted through a stirring cylinder backstage, slurry supplied by a grouting pump, compressed air supplied by an air compressor and water supplied by a high-pressure pump are tried to be sprayed under the design parameters, debugging is conducted to the normal state, water supplied by the high-pressure pump is reduced to 2.0-3.0 MPa, pipes are sunken to the designed depth, and spraying and grouting are conducted; and after spraying construction is completed, machines and tools are transferred to the next hole position till all hole positions are completed. By the adoption of the construction method, decent and supply of underground water are controlled effectively, meanwhile the reinforcement and advance support functions on miscellaneous fill, silt, silty-fine sand and medium-coarse sand containing gravel are achieved, the stability of the edge walls of the foundation fit and the normal use and safety of surrounding buildings (structures) are guaranteed, the whole support stability is guaranteed, the cost investment is reduced, the benefits are increased, and the construction cost is reasonably distributed.

Owner:中煤江南建设发展集团有限公司

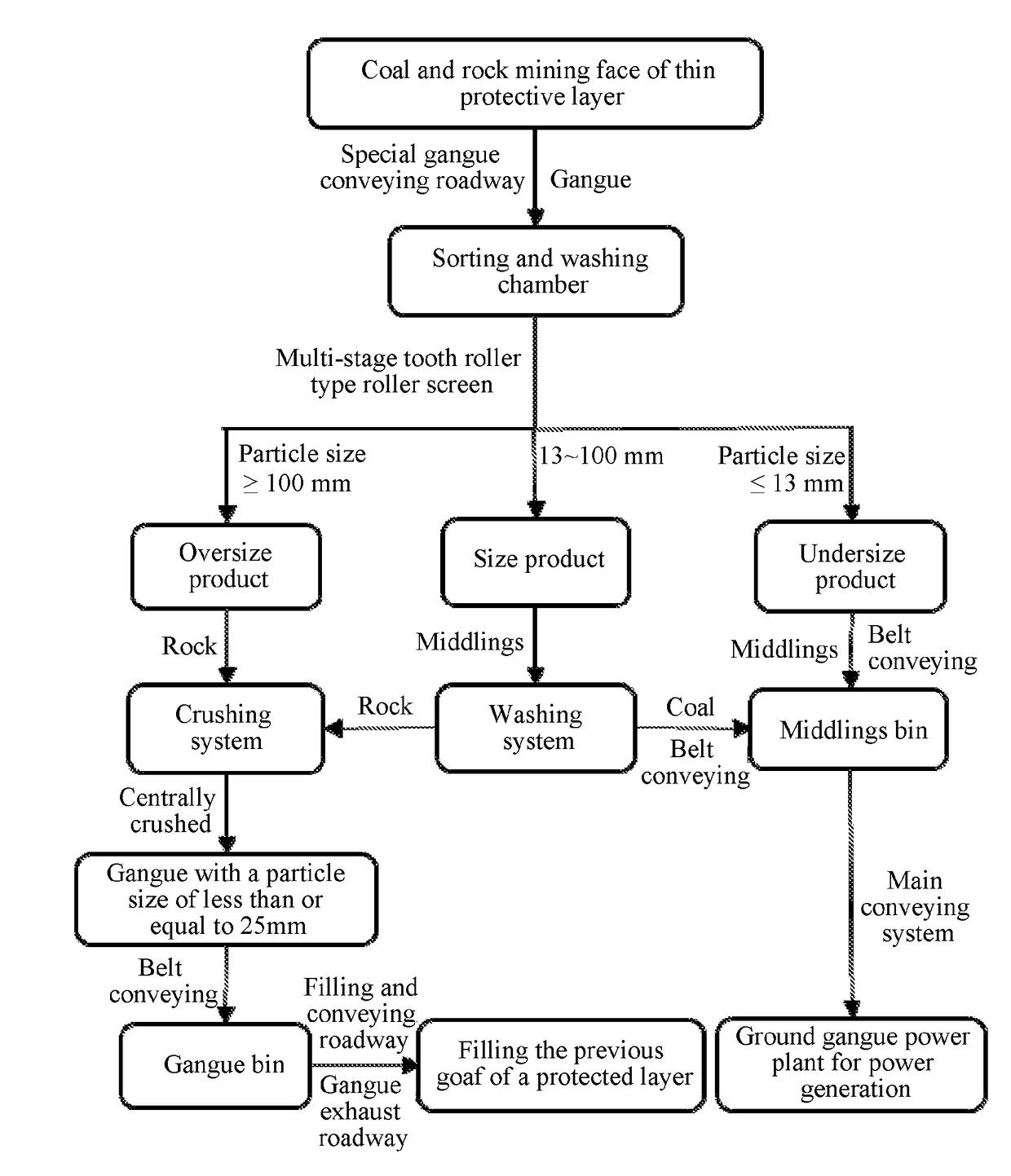

METHOD OF SORTING AND UTILIZING COAL AND ROCK FOR COAL AND ROCK Combined MINING FACE

ActiveUS20180229245A1Low costQuality improvementMining devicesUnderground miningGround subsidenceSocial benefits

The present invention relates to a method for sorting and utilizing coal and rock for a coal and rock combined mining face, and is especially applicable to the sorting and utilization of coal and rock mined from a coal and rock combined mining face when an extremely thin coal seam is used as a protective layer in combined mining of multiple coal seams. Underground gangue transport, storage and filling systems are directly established underground to convey a large amount of coal and gangue mined from the coal and rock mining face to an underground sorting and washing chamber for efficient separation of the coal and the gangue, sorted gangue is crushed and then filled in a mined-out area of a protected layer, thus realizing the environment-friendly cut and fill mining of the protective layer while the gangue is not lifted, and effectively preventing the ground subsidence caused by combined mining of multiple coal seams; sorted middlings are conveyed to a gangue power plant on the ground for power generation through a main conveying system, so that the pressure on mine coal quality is alleviated when benefits are created in the power plant, and thus the average ash content of commercial coal is reduced, and the selling price is increased. The method provided by the invention realizes the efficient utilization of coal and rock while realizing the efficient separation of coal and gangue, and has remarkable economic and social benefits and excellent promotional value.

Owner:CHINA UNIV OF MINING & TECH

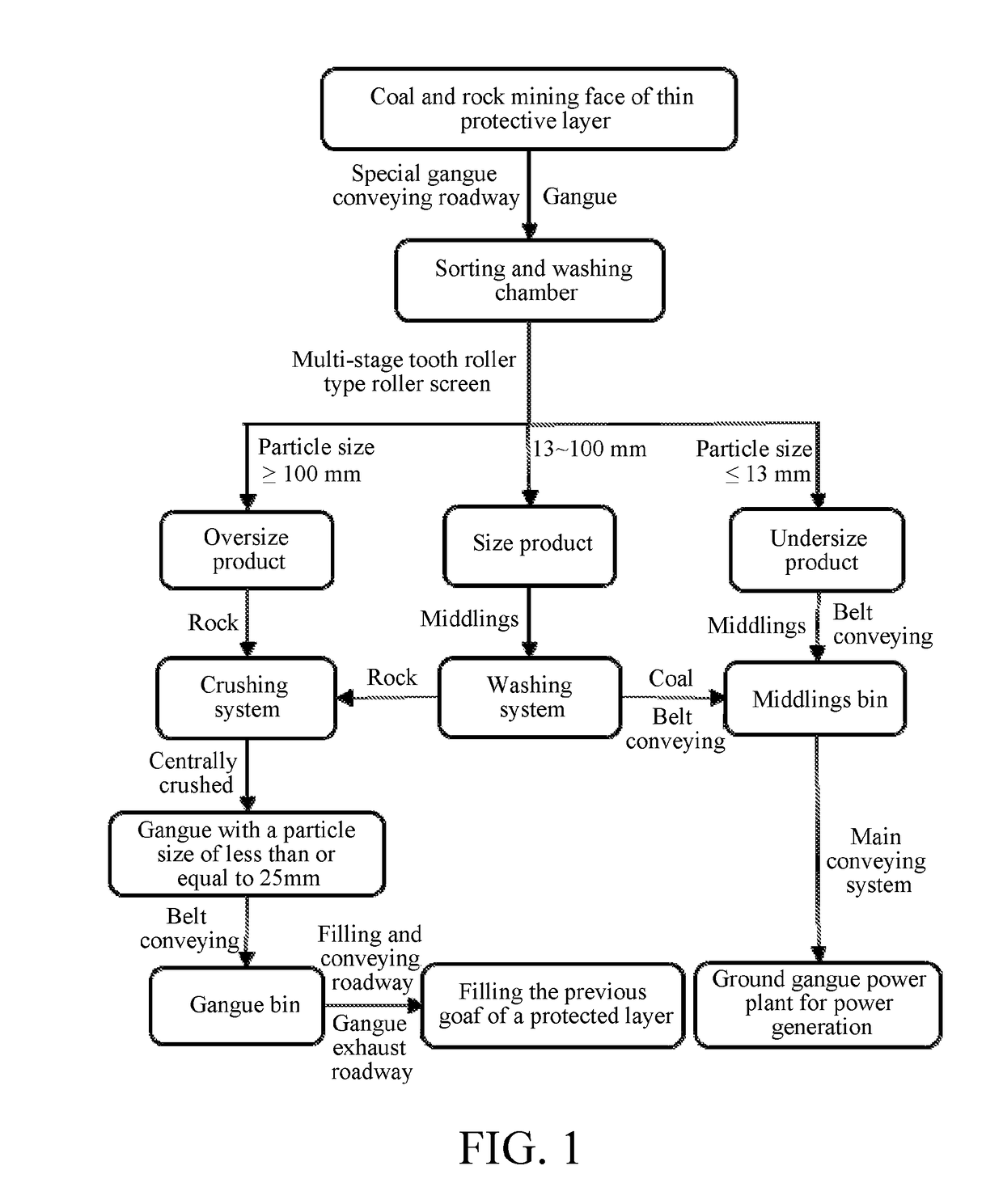

Method for processing long-pile short-pier composite foundation

InactiveCN101591903ALow costSpeed up the construction periodBulkheads/pilesSoil preservationCut and fillEngineering

The invention relates to a method for processing a long-pile short-pier composite foundation, which sets pier-changing and inter-pier pitching piles in the foundation to satisfy the foundation bearing capacity and deformation requirements, performs pier setting mainly through a forced ramming or forced ramming displacement method, and sets sedimentation control piles between the piers. The principle of displacing pier distribution points comprises the following steps: symmetrically setting one or more displacement points for changing the piers in the length direction of an independent foundation, and setting the sedimentation control piles between the displacement points as the inter-pier pitching piles; evenly setting a plurality of displacement points for changing the piers in the length direction of a strip foundation, and arranging the sedimentation control piles between the displacement points according to the designed separation distance; and on the basis of a large size, calculating the required displacement ratio of rectangular or quincuncial distribution points for the displacing pier distribution points according to the bearing capacity, calculating the required pile number for the sedimentation control piles according to sedimentation, and arranging the piles according to rectangular or quincuncial shapes between the displacing piles. The method has the advantages of manufacturing cost saving, mature construction experience, simple process and remarkable effect, and economically and effectively solves the problems that the bearing capacity of deep made ground or a soft soil foundation is insufficient and the foundation deformation is large and uneven.

Owner:上海现代建筑设计(集团)有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com