Patents

Literature

2374 results about "Cofferdam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cofferdam (also called a coffer) is an enclosure built within, or in pairs across, a body of water to allow the enclosed area to be pumped out. This pumping creates a dry work environment so that the work can be carried out safely. Enclosed coffers are commonly used for construction or repair of permanent dams, oil platforms, bridge piers, etc ., built within or over water.

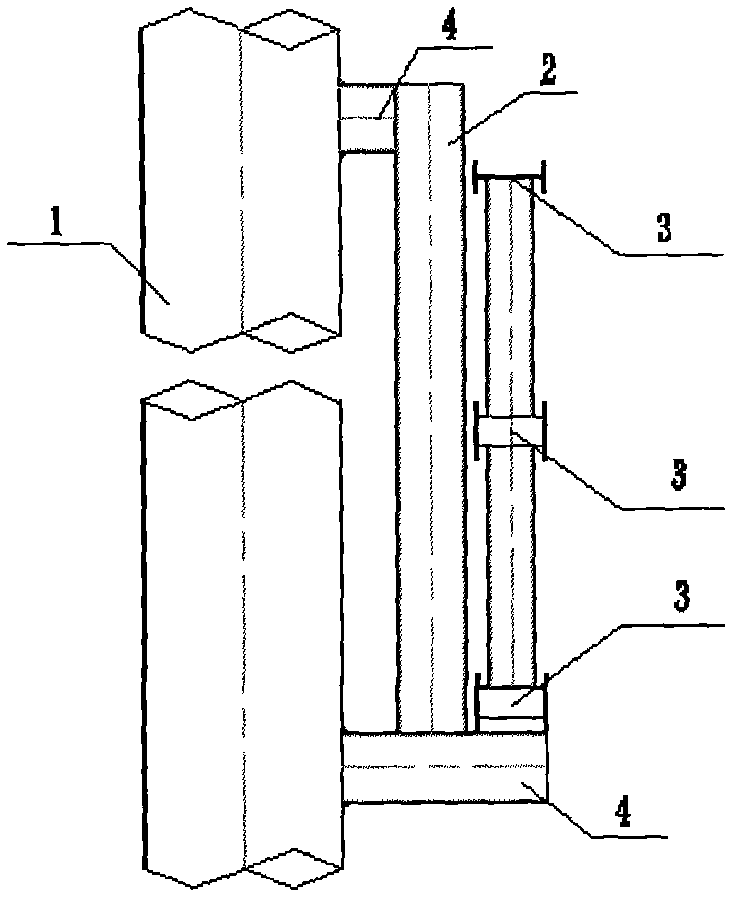

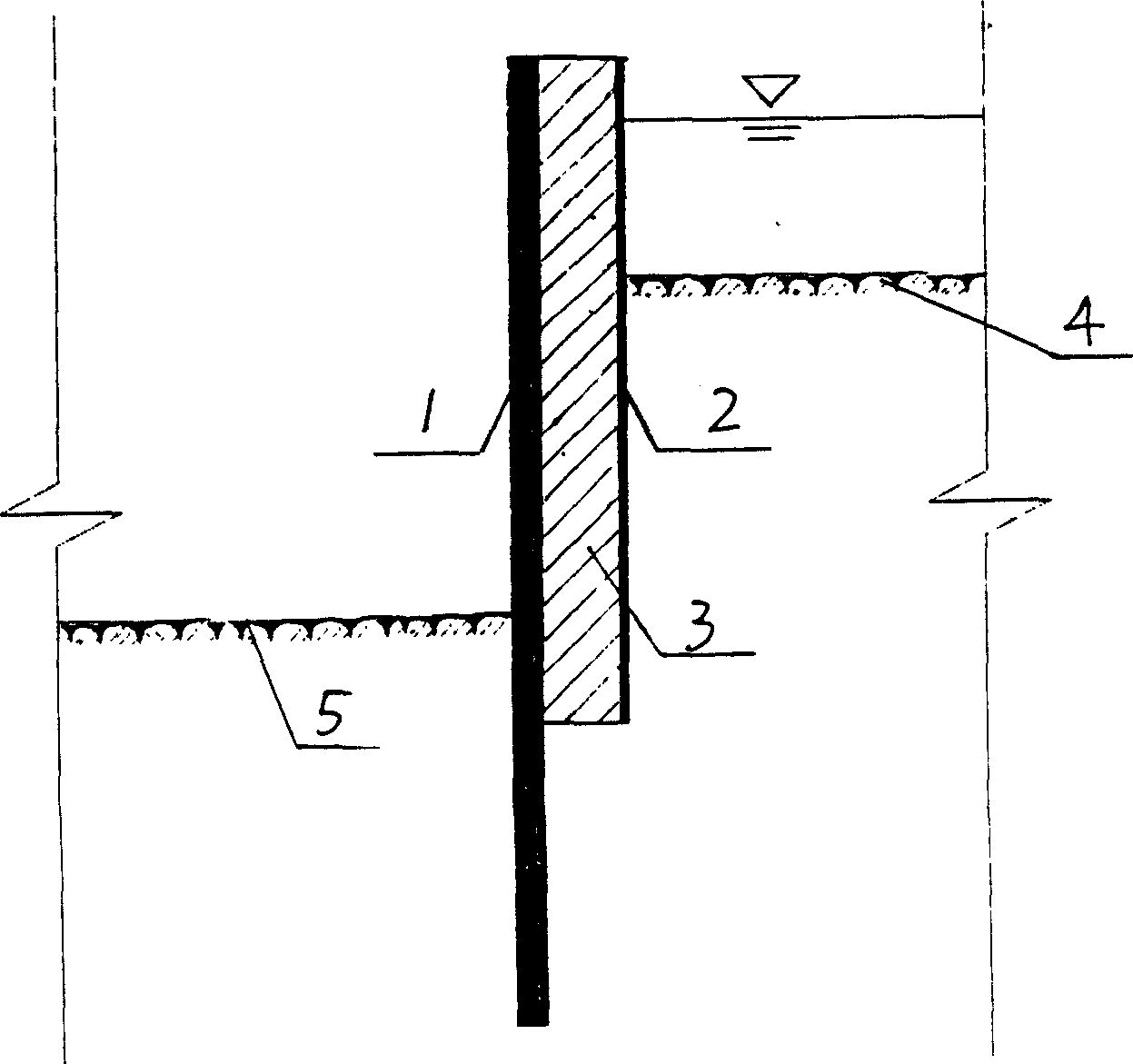

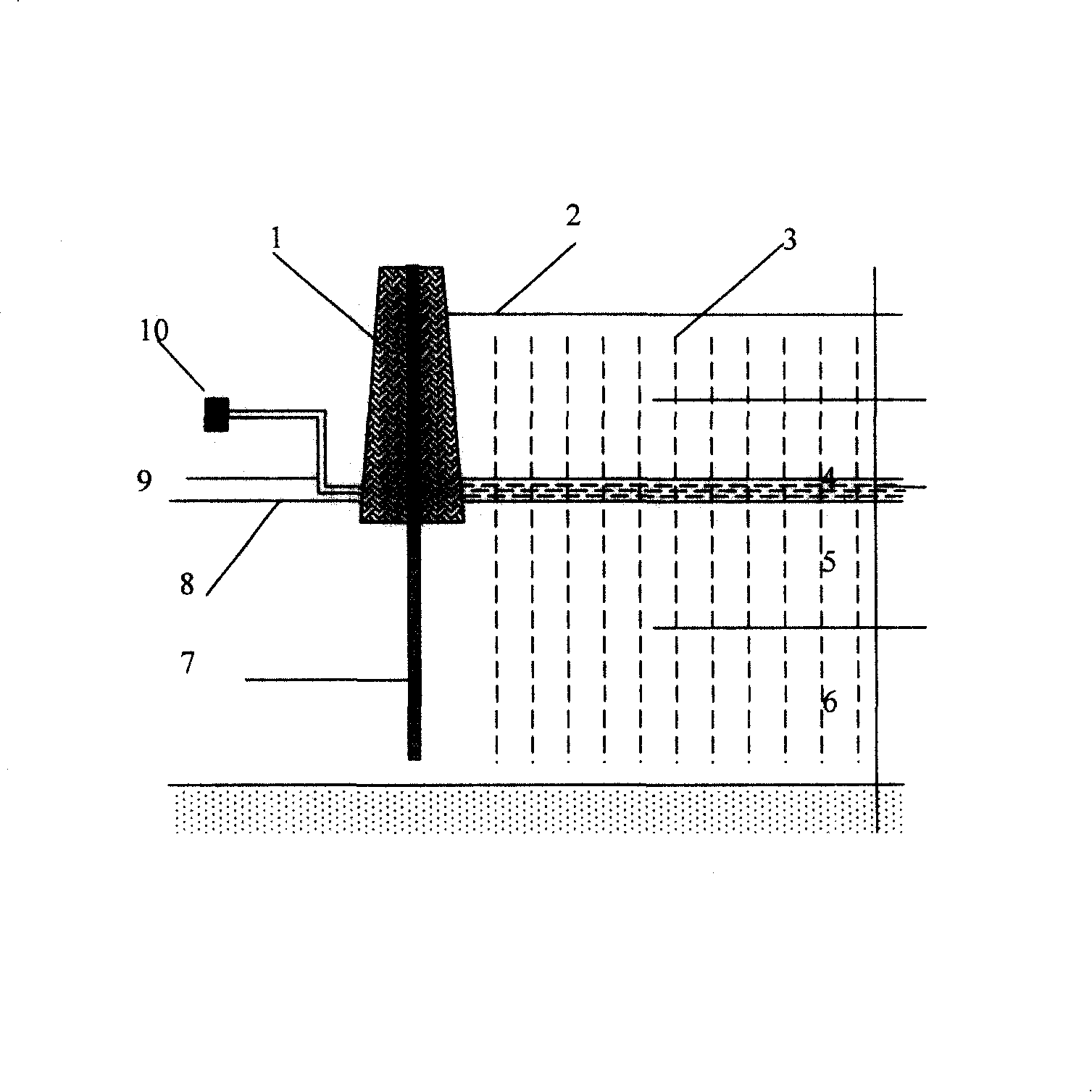

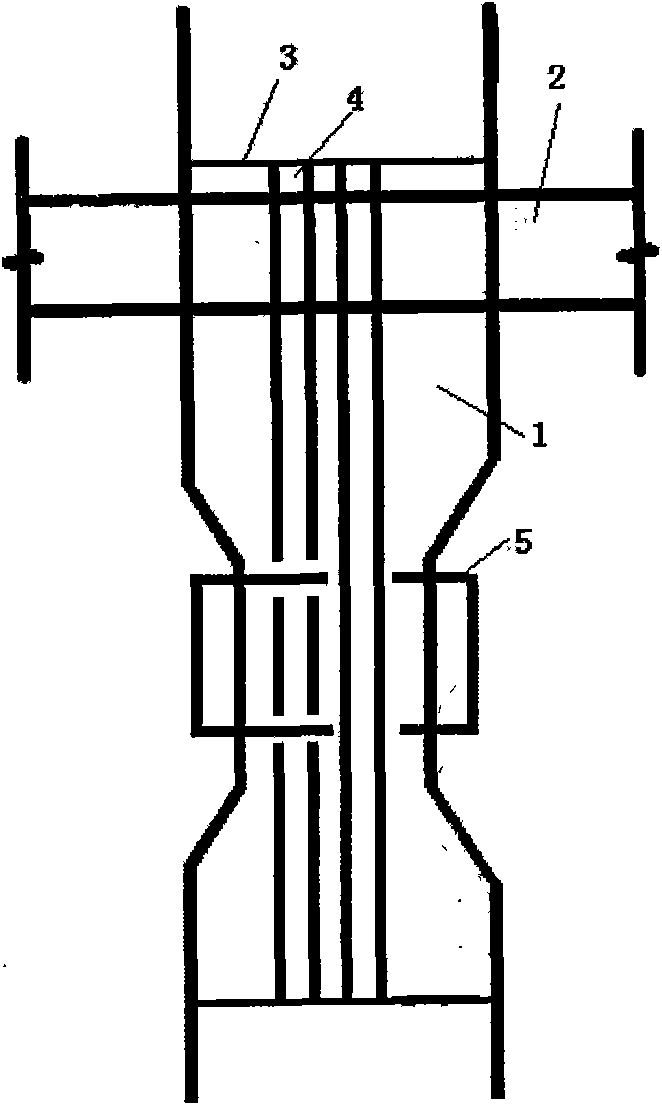

Combined cofferdam of steel slab pile and steel pipe pile an method for manufacturing the same

The invention discloses a steel plate-tube post combined cofferdam and relative method, which is characterized in that: at least one steel plate post is arranged between two steel tube posts; and nearby steel plate and tube posts are connected by grooves; the depths of steel tube and plate posts are the same. The invention can combine the properties of steel plate and tube posts, to solve the waterproof problem. It can reduce the material consumption and the working time, with better economic benefits.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

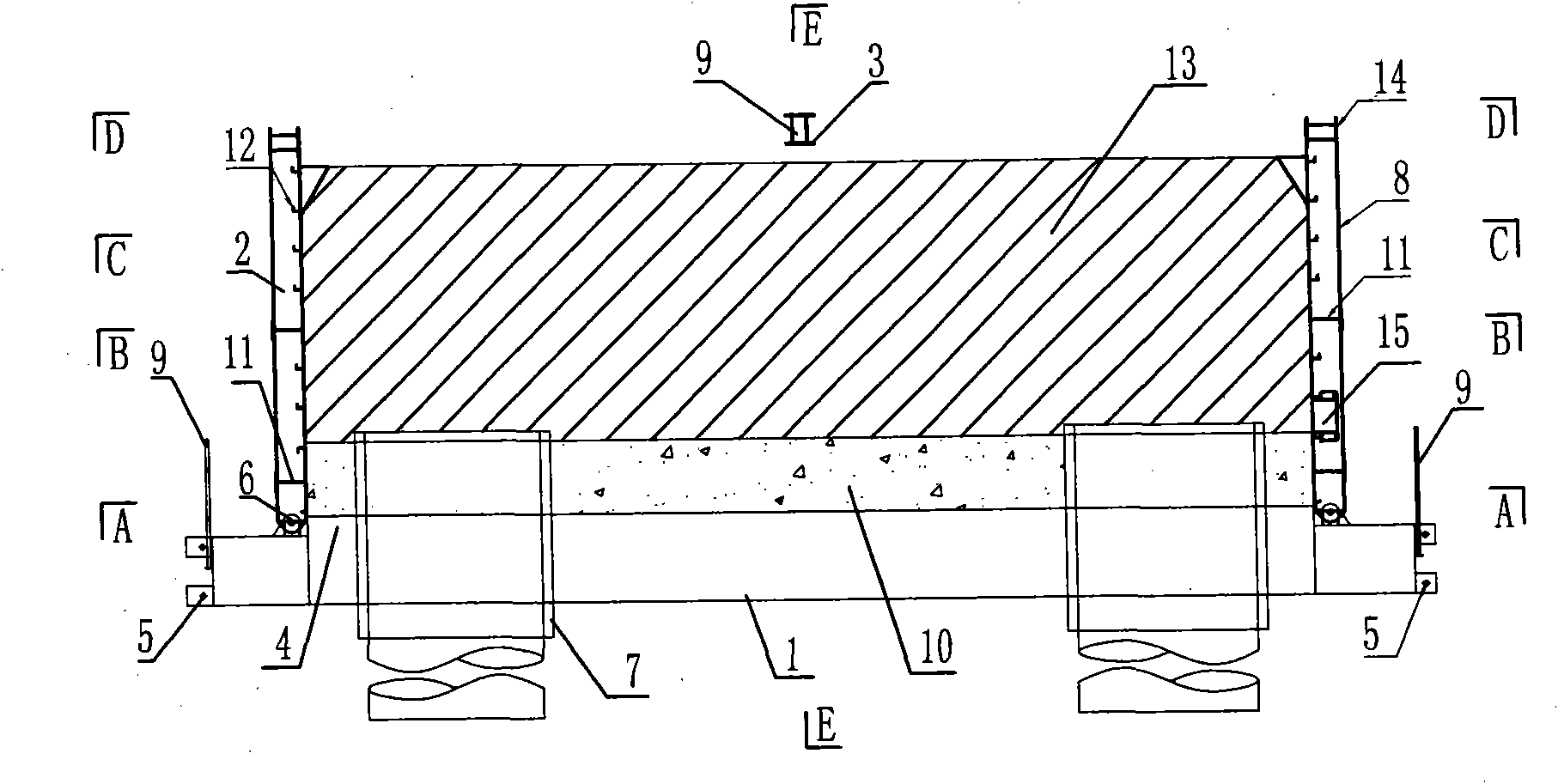

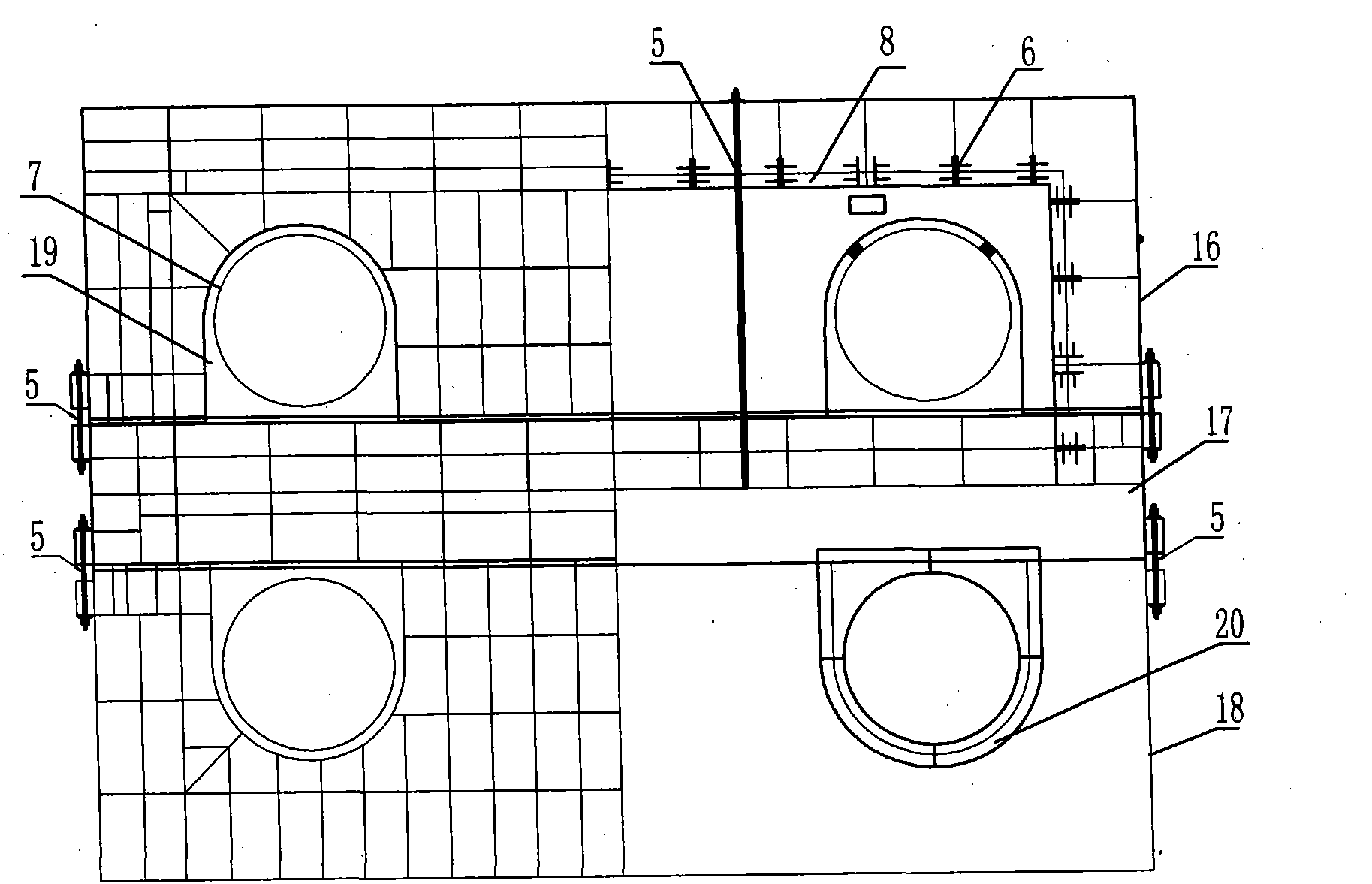

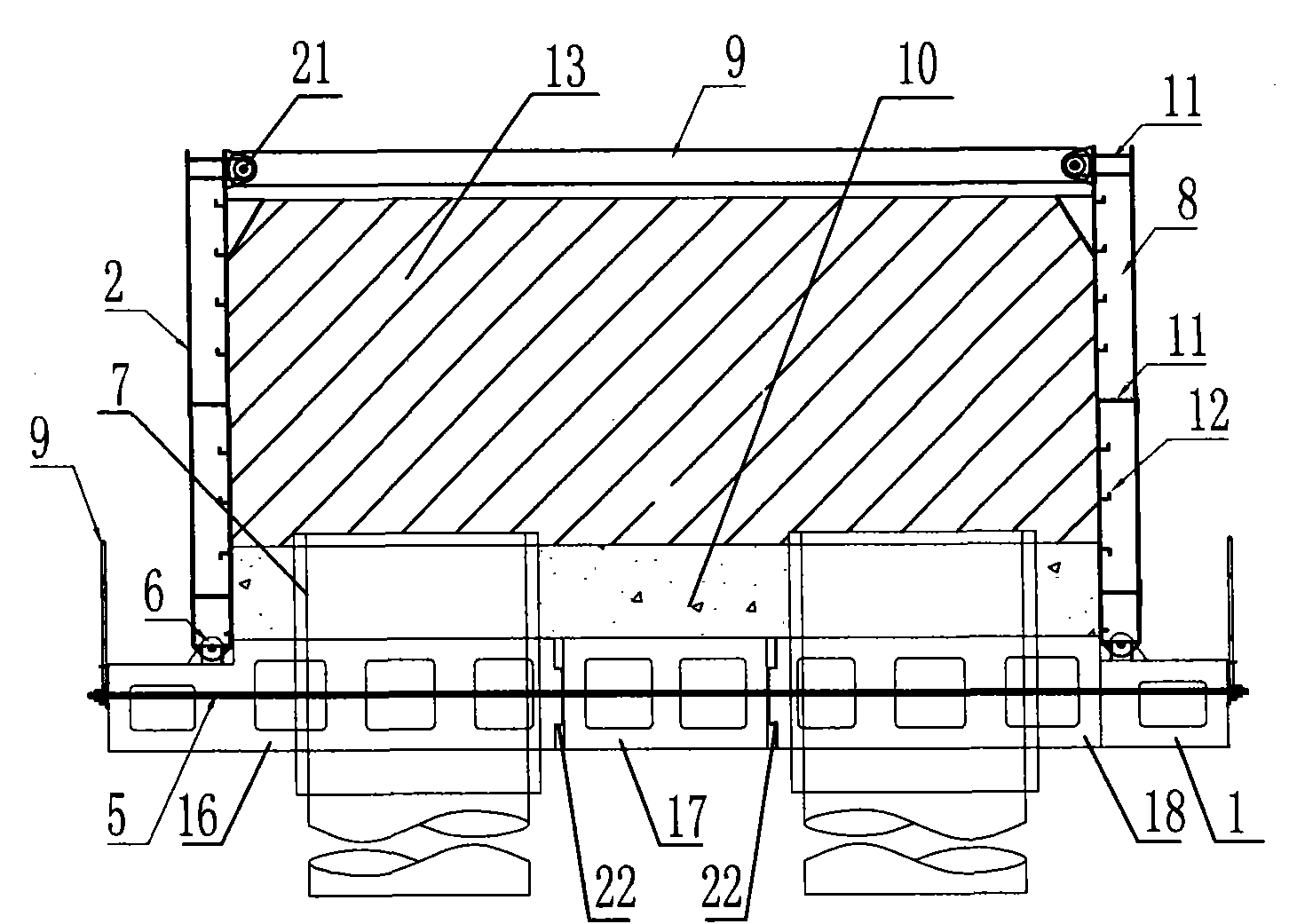

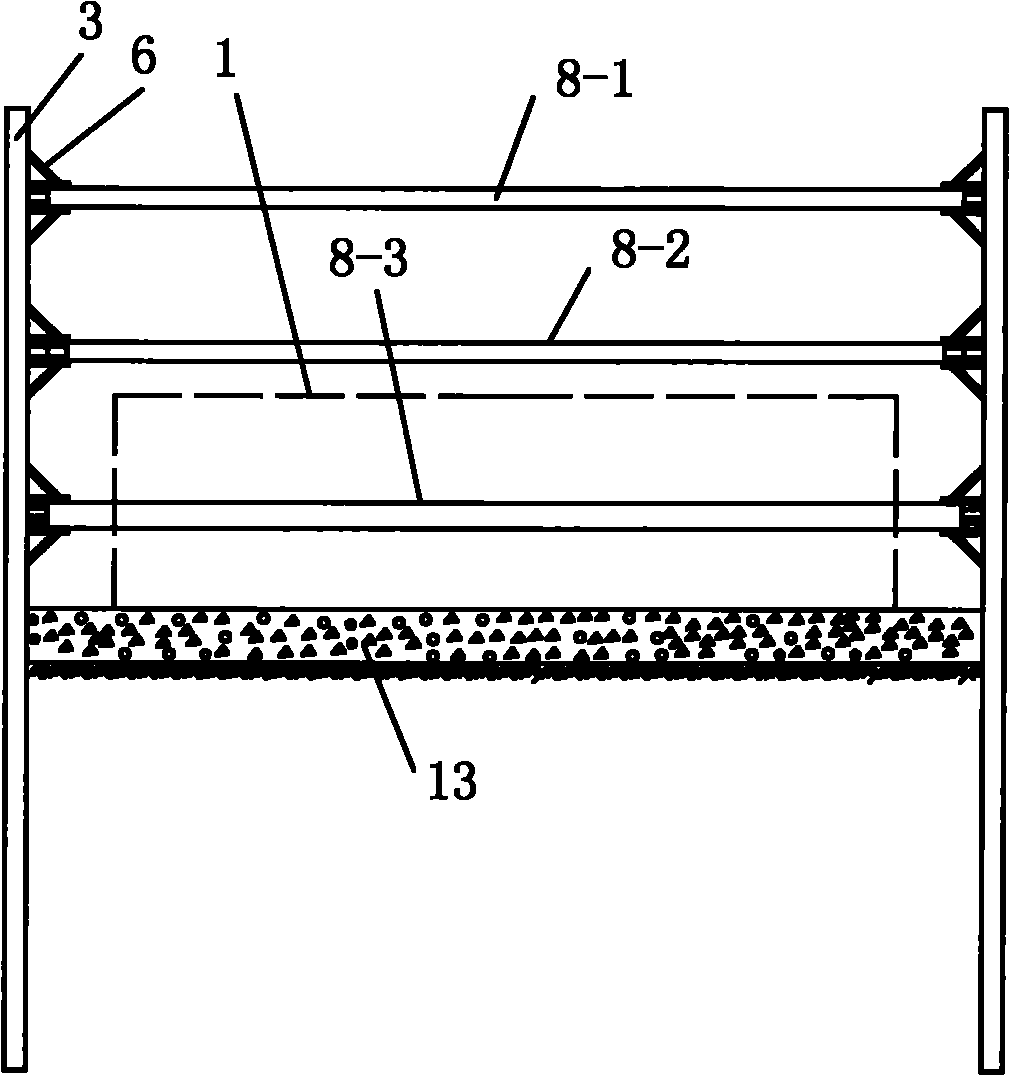

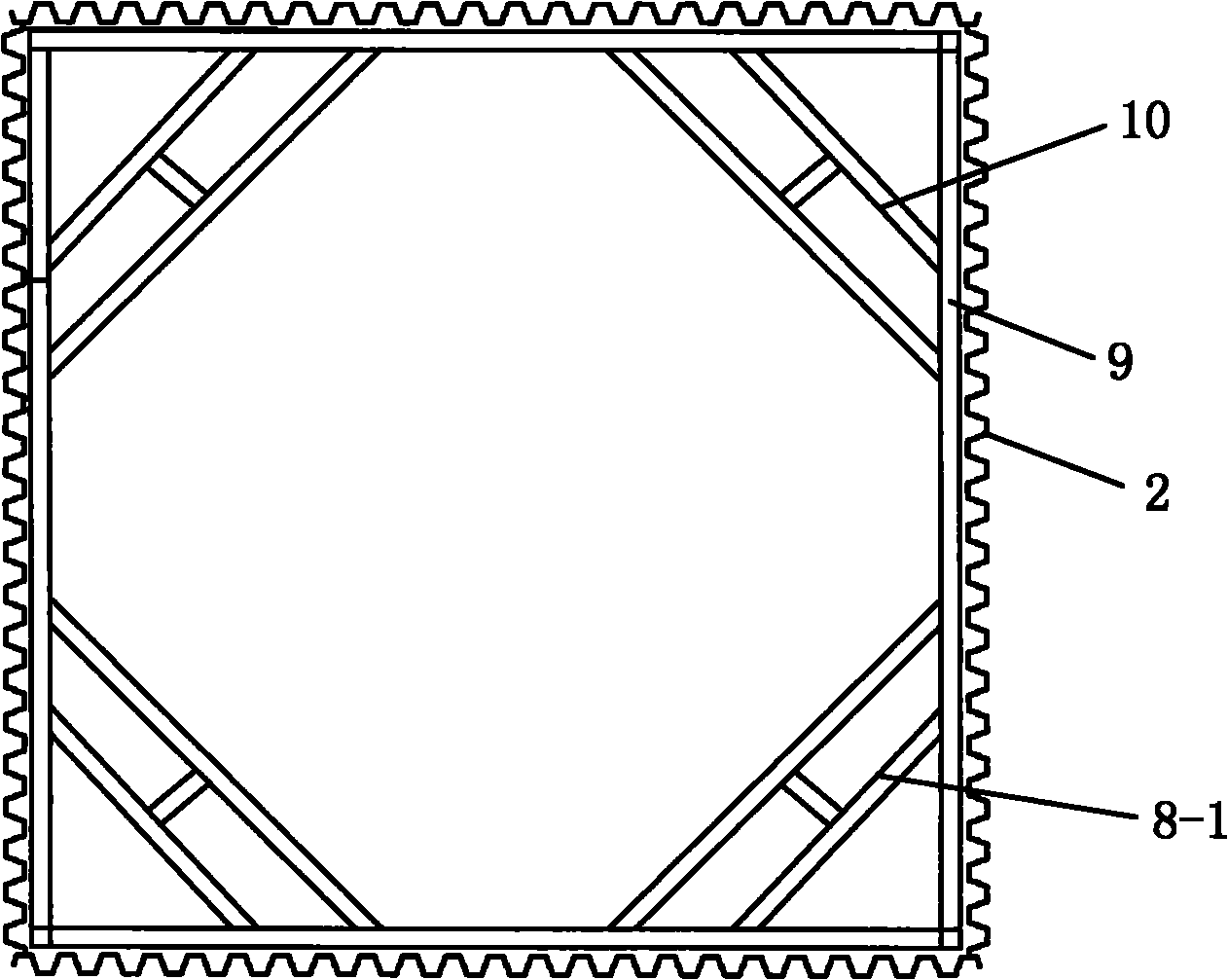

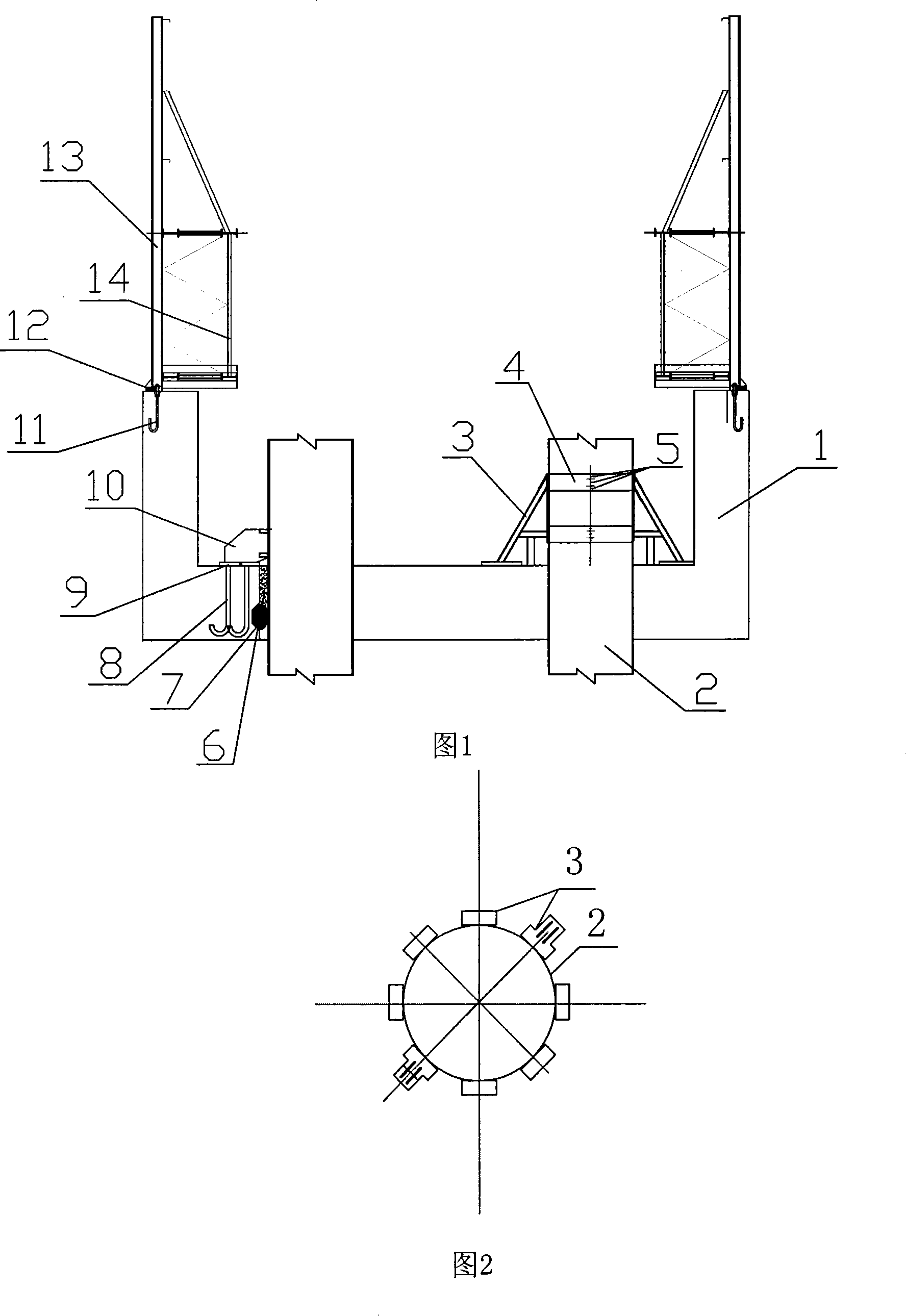

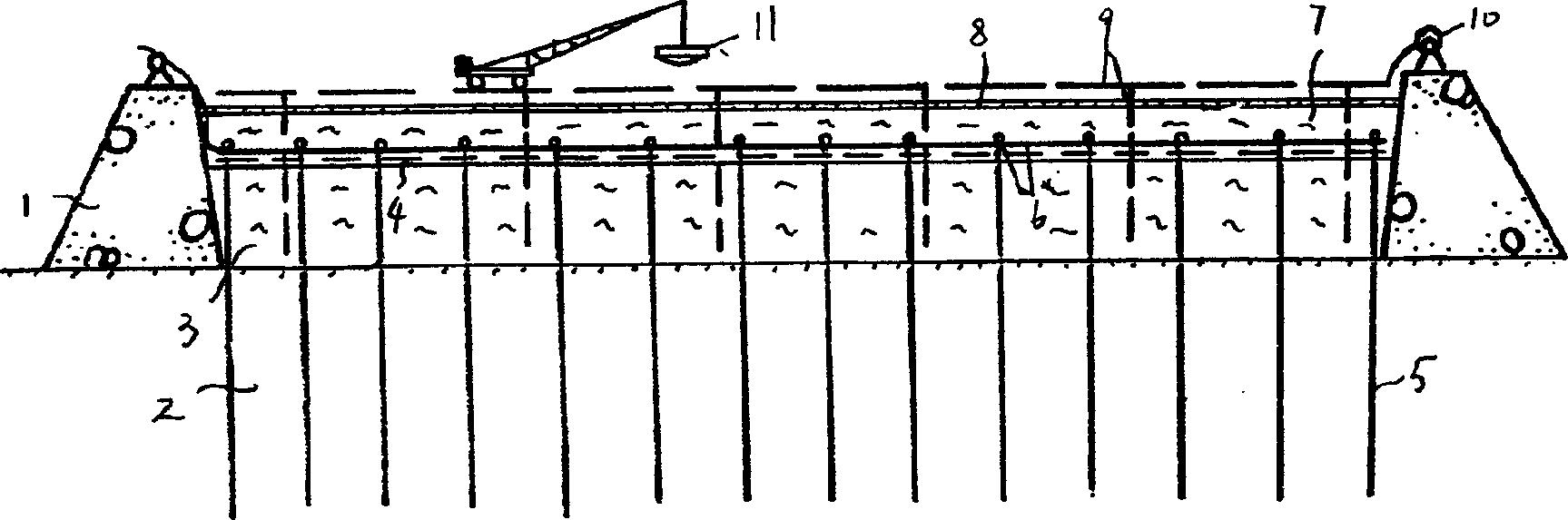

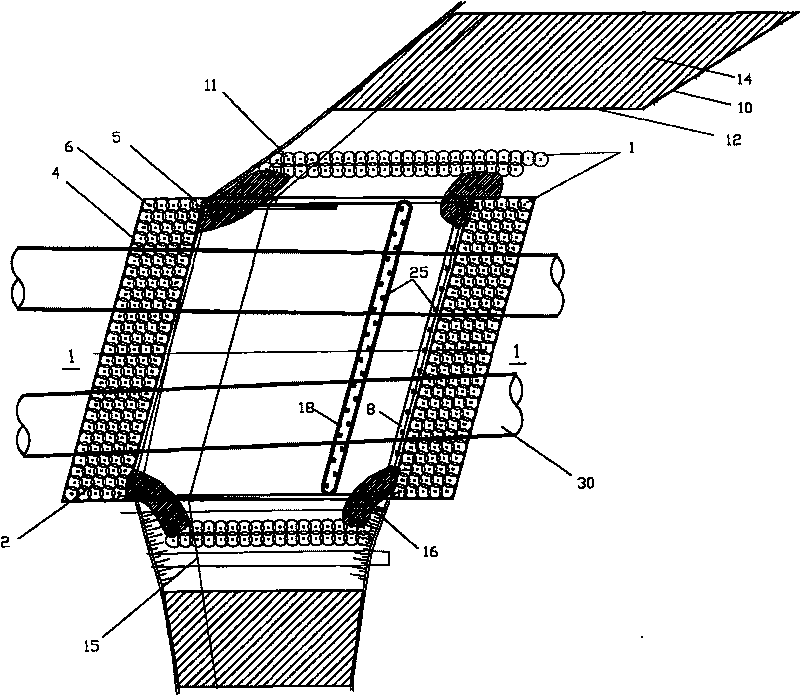

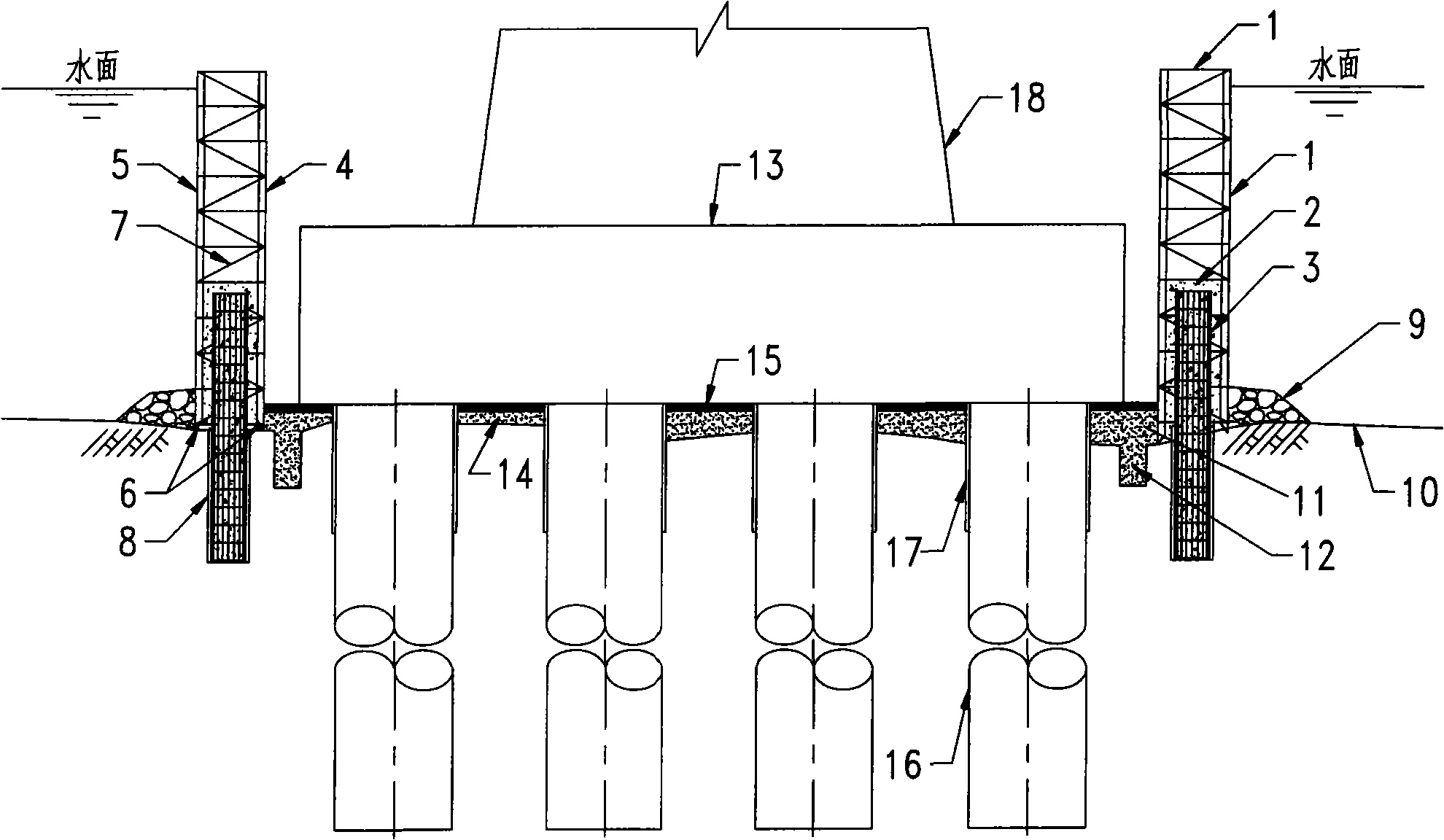

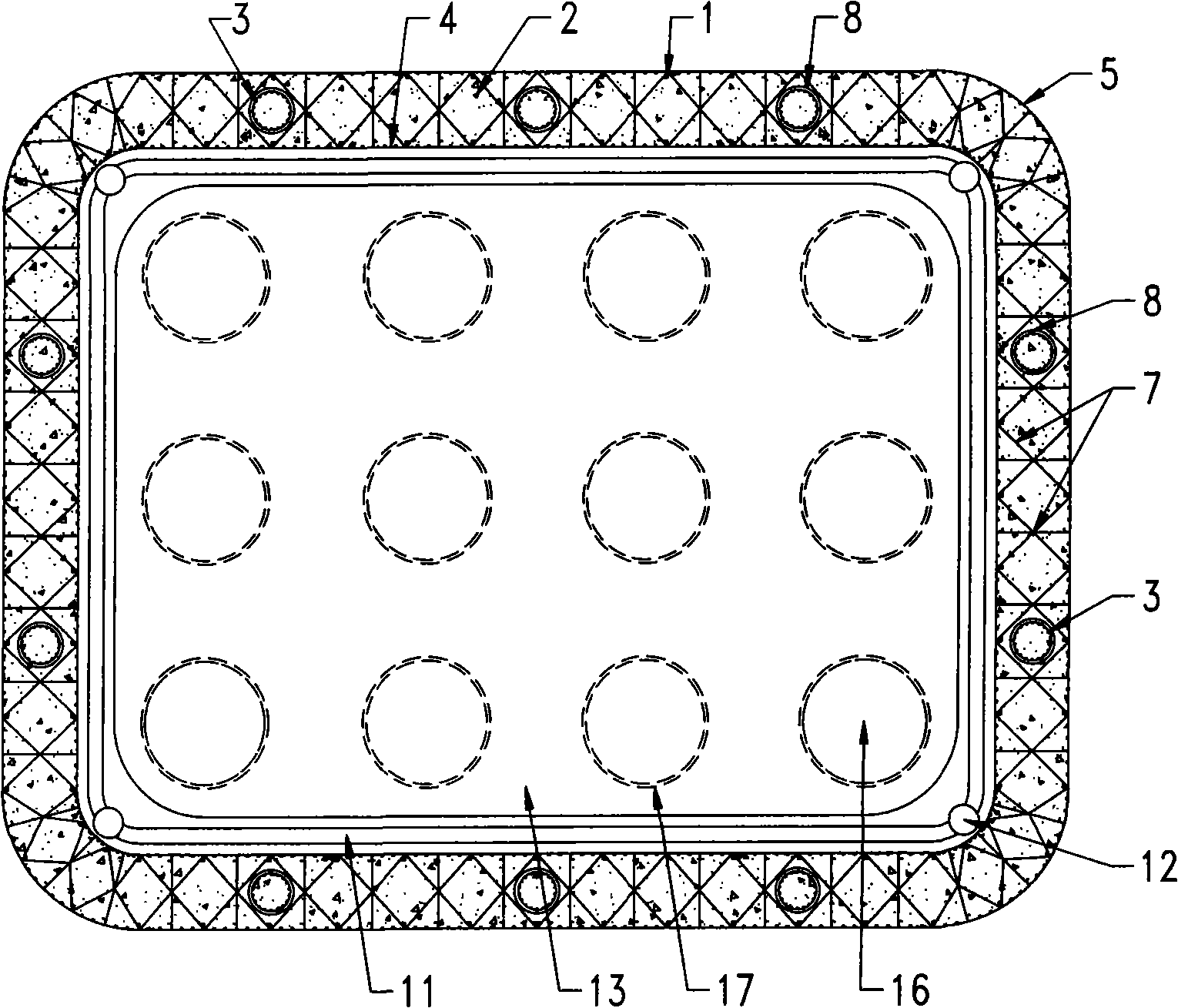

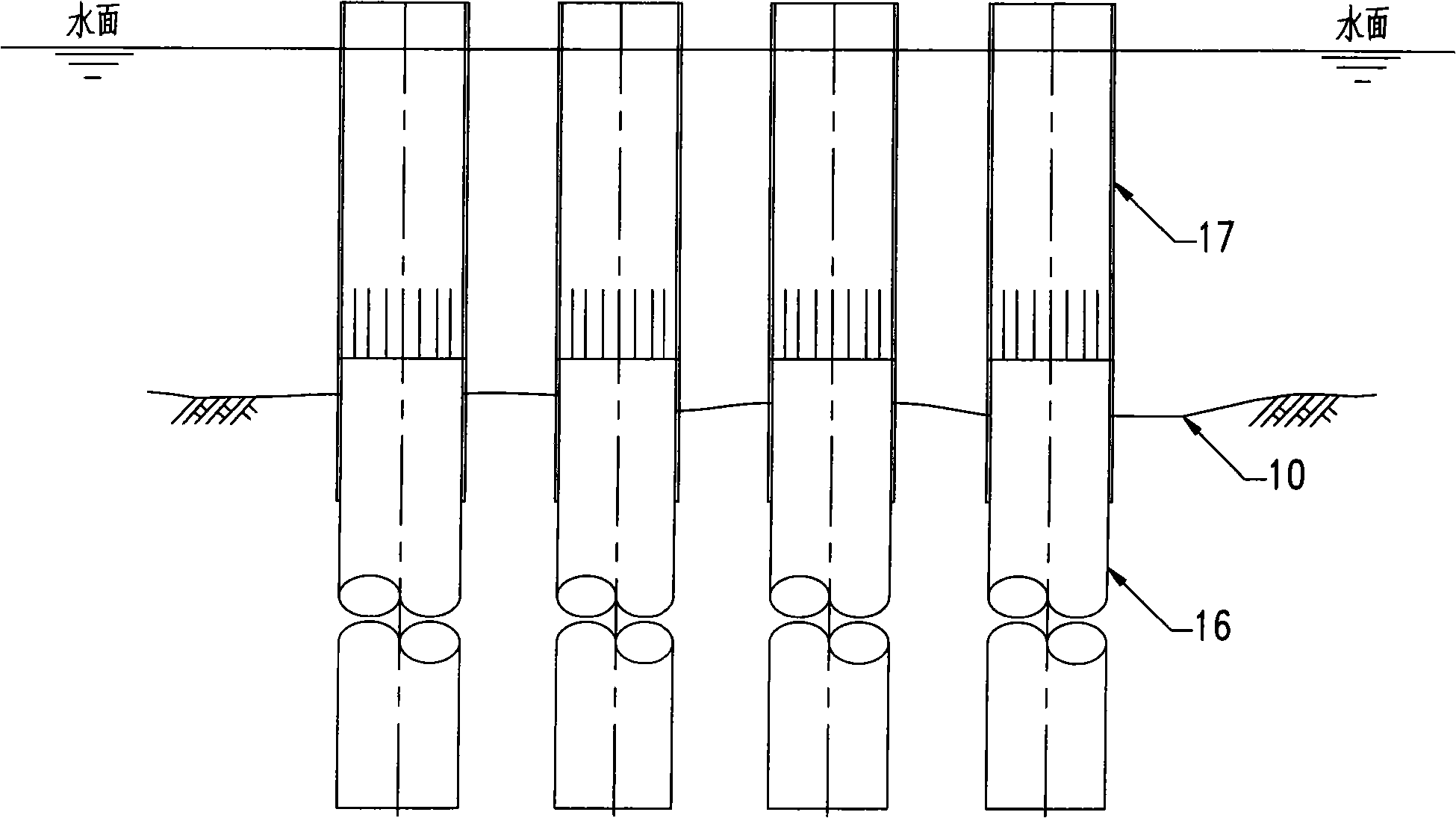

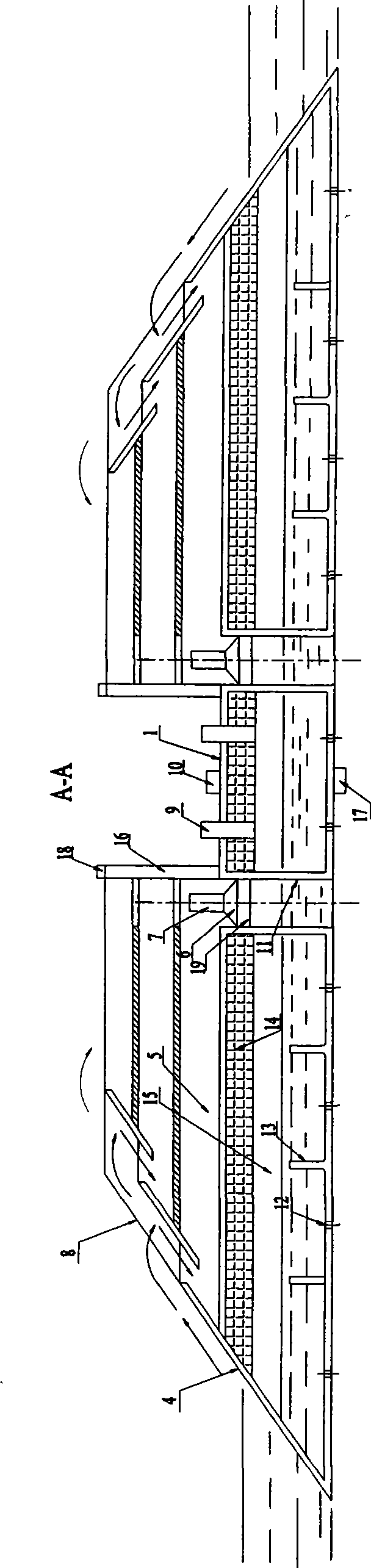

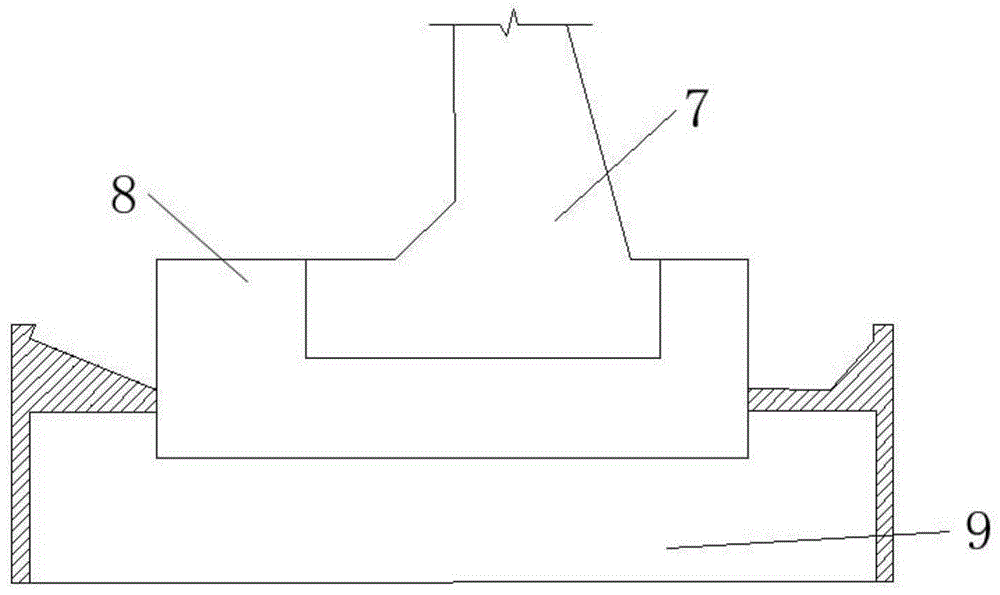

Construction method of marine self-floating type steel soleplate single-wall suspension box cofferdam and single-wall suspension box cofferdam

ActiveCN101775809AIncrease stiffnessReduce assembly processBridge structural detailsFoundation engineeringCofferdamAcceleration Unit

The invention discloses a construction method of a marine self-floating type steel soleplate single-wall suspension box cofferdam and a single-wall suspension box cofferdam, wherein the construction method comprises the following steps of: firstly installing a soleplate suspended shoulder pole girder and lowered guiding device of the cofferdam, then installing a steel soleplate, a lateral plate and an inner support, then carrying out the construction of lowering, fixing and bottom sealing by concrete of the cofferdam and finally carrying out the construction of a bearing platform. The cofferdam can be repeatedly used after being dismantled. The marine self-floating type steel soleplate single-wall suspension box cofferdam comprises the steel soleplate, the lateral plate, the inner support and the soleplate suspended shoulder pole girder and lowered guiding device. The steel soleplate of the invention is of a self-floating type assembled structure, an inner inclined strut of the cofferdam is utilized as a distributing girder suspended on the cofferdam when in the construction of bottom sealing by concrete, the lateral plate adopts a massive integral design, and meanwhile, an inner guide girder and the lateral plate are combined into a whole, thereby improving the integral rigidity of the lateral plate and also reducing the assembled working procedures of the cofferdam. The invention has the advantages of effective acceleration of construction schedule, simple and convenient construction operation, high repeated use ratio, safety, reliability and less cost investment.

Owner:THE 5TH ENG MBEC

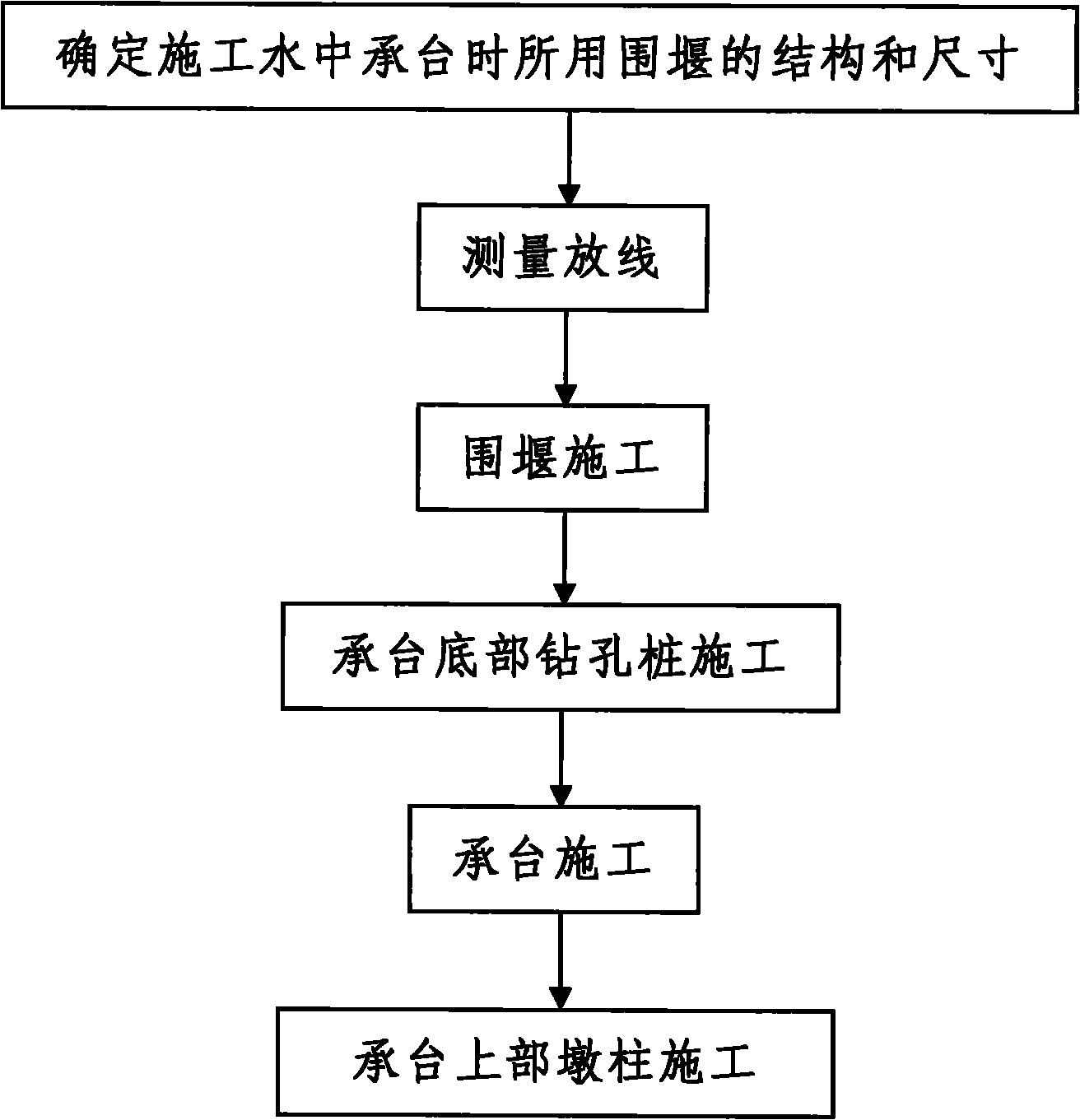

Construction technology of steel sheet pile cofferdam for Yellow River Channel internal support table construction

The invention discloses a construction technology of a steel sheet pile cofferdam for Yellow River Channel internal support table construction. A construction support table is an underwater support table arranged in a Yellow River Channel. The technology comprises the following steps of firstly, determining a structure and the size of a used cofferdam in the process of underwater support table construction; secondly, surveying and setting out; thirdly, constructing the cofferdam; fourthly, constructing a bored pile at the bottom of the support table; fifthly, constructing the support table: carrying out forming construction of the underwater support table on the top of the bored pile after construction when the bored pile construction is finished, and finishing integrative construction of the bored pile and the underwater support table; and sixthly, constructing a pier column at the upper part of the support table. The invention has the advantages of reasonable design, convenient construction and low construction cost, carrys out construction by adopting an integrative construction method of the support table and the bored pile and can efficiently solve the defects of long construction period, large investment, needs of setting up a plurality of construction platforms, large construction difficulty and the like in the successive construction process of the bored pile and the support table in the traditional construction process of the steel sheet pile cofferdam.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

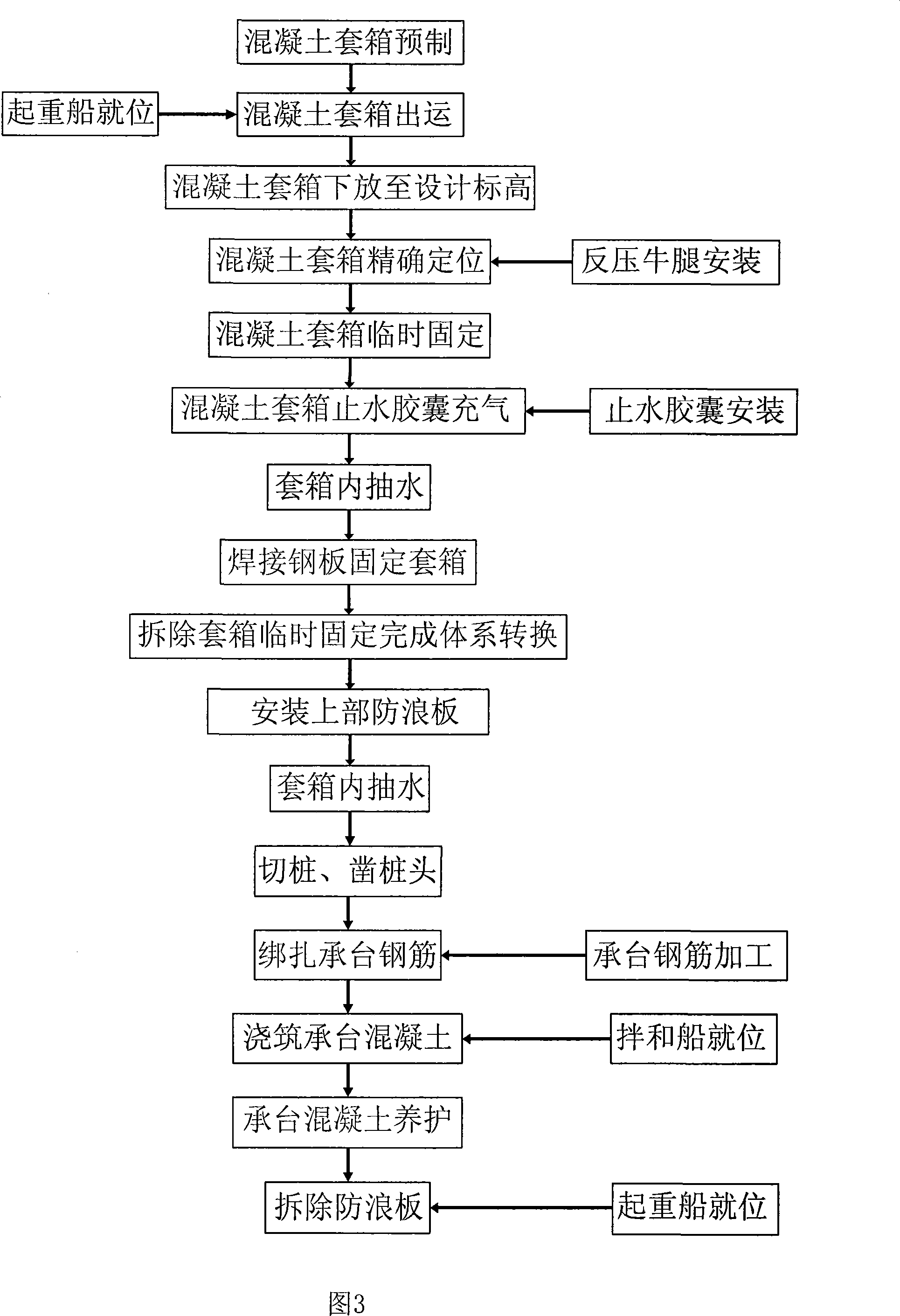

Underwater no-bottom closing concrete boxed cofferdam and method of use thereof

An underwater concrete boxed cofferdam without bottom sealing and an application method solves the shortcomings that the traditional steel cofferdam construction requires to pour thick concrete to seal the bottom; the consumption of steel material is large; the construction period is long; and the bearing platform quality is not easy to be controlled. The underwater concrete boxed cofferdam without bottom sealing is poured together with the concrete bearing platform; an upper part of the concrete boxed cofferdam is provided with a contemporary surf board cofferdam; and the surf board is dissembled after the concrete bearing platform is poured and completed. The concrete boxed cofferdam can be produced by factory prefabrication; the construction quality is easy to be controlled; the installation is convenient, simple and quick, which can accelerate the construction progress; the construction period is shortened reasonably and economically with reliability and safety; at the same time, the boxed cofferdam can play a seawater erosion prevention effect, which improves the durability of the engineering. The invention is mainly suitable for working in shallow water.

Owner:SHANDONG HI SPEED QINGDAO HIGHWAY

Reinforcing method for demixing sole weight, prepressing water discharge concretion combination dynamic consolidation soft ground base

InactiveCN101270571ALess investmentReduce post-construction settlementClimate change adaptationLand reclamationWater dischargeDynamic compaction

A dynamic compaction soft foundation reinforcing method by combing layered dead weight and pre-pressing drain concretion includes: filling a water-isolation cofferdam; a water collecting well is arranged in the middle of the cofferdam; a sand layer of 0.5m to 0.8m is filled by hydraulically filled or manually filled on the original water-drained ground; a horizontal drain pipe is embedded in the sand layer to carry out first earth hydraulic filling; a drain pump is arranged in the water collecting well to continuously drain water; when the thickness of hydraulic filling reaches the designed elevation of the first layer, the hydraulic filling is stopped; when the surface of the hydraulic filling earth forms a hard shell layer with a thickness of 30m to 40m under the actions of vaporizing and dead weight drain, the hydraulic filling to a second layer and a third layer are carried out according to the steps; even a required hydraulic filling height is designed; finally hill-skill soil or mixed backfill soil and sandy soil are back filled on the layers; dynamic compaction is carried out after leveling. The invention has the technical economic indexes of fast speed, saving investment, small settlement after construction and high surface layer bearing capacity, etc., and has remarkable technical advantages on lower ground elevation and the projects of polder reclamation by hydraulically fill the soft soil like silt.

Owner:张伯谦

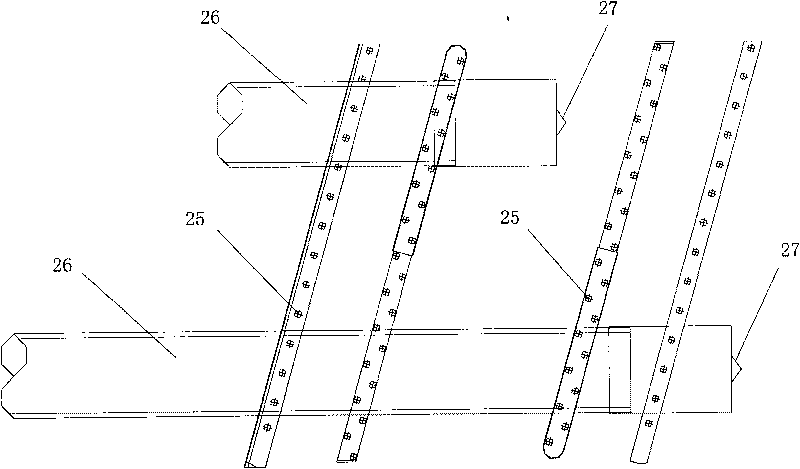

Single and double-wall combined steel cofferdam construction method and its single and double-wall combined steel cofferdam

ActiveCN101368389AThe progress of the project is fastReduce construction difficultyFoundation engineeringDouble wallCofferdam

The invention discloses a single-wall and double-wall combined steel cofferdam construction method and a single-wall and double-wall combined steel cofferdam. The single-wall and double-wall combined steel cofferdam construction method includes the following steps: firstly, assembling the bottom segment side plate of the cofferdam at an assembly field; then floating to the position of a pier; after that, injecting concrete into the foot blade and assembling the top segment of cofferdam and the top segment inclined strut; then positioning, cleaning up the pedestal, building a boring platform, installing a steel casing and stacking the sandbags sequentially; after that, injecting bottom seal concrete, and boring the pier for injection; finally, after the pier pedestal is constructed, pumping the water, cutting off the steel casing, chiseling off the laitance at the head of the pier and beginning the construction of a bearing board. The bottom segment side plate of the cofferdam is composed of circular external and internal wall panels, and the top segment side plate of the cofferdam is fixed on the circular external wall panel. The invention has the advantages of fast engineering speed, small construction difficulty and small cost investment, and the top segment side plate can be used repeatedly and is high in recovery rate; the invention overcomes the difficulties at the time of no bottoming concrete thickness; the circular sealing concrete between the bearing board and the cofferdam also has the effect of resisting water.

Owner:THE 5TH ENG MBEC

Combined method for fastening soft soil ground by dual vacuum prepressing and dynamic extruding method

InactiveCN1818227AEffective secondary reinforcementImprove consolidation indexSoil preservationFilling materialsReduction procedure

A method for reinforcement of yielding soil of large area or hollow land includes the following procedures in order: 1. low position vacuum pre-press procedure as building cofferdam, filling in sludge to certain height, paving cloth and bamboo fence on the top, vertically inserting in water emission plastic boards, laying horizontal vacuum pipe net, installing vacuum pre-press system and sealing with mud layer of 0.8-1.5 m thick then vacuum bumping for pre-press; 2. high vacuum rate well point water reduction procedure as applying a high vacuum rate well point water reduction system on the mud sealing layer, removing well point pipe after the first round of water reduction; 3. low power strong tamping procedure as paving a layer of filling material on the mud sealing layer then tamping. Roller compact the surface after 2-3 rounds of procedure 2 and 3.

Owner:张志铁 +1

Method for increasing elevation of intertidal zone to form suitable land for mangrove forest

ActiveCN102619192ARaise the elevationMaintain securityClimate change adaptationAfforestationMangrove plantsEcological safety

The invention discloses a method for increasing the elevation of an intertidal zone to form a suitable land for mangrove forest. The method mainly includes key steps of determining a target elevation; determining land reclamation boundaries; constructing cofferdams; constructing fences; implementing earth filling; flattening filled earth; constructing artificial tidal creeks; realizing temporary fixing measures; and the like. The inventor aims to increase the elevation of the intertidal zone by the aid of engineering means, requirements of mangrove plants on hydrology, sediment and other conditions can be rapidly met, the suitable land for the mangrove forest is formed and created, accordingly, afforestation success rate is increased, coastal ecological safety and sustainable development of China are promoted, and land safety and ecological safety of coastal zones are effectively maintained.

Owner:GUANGXI MANGROVE RES CENT

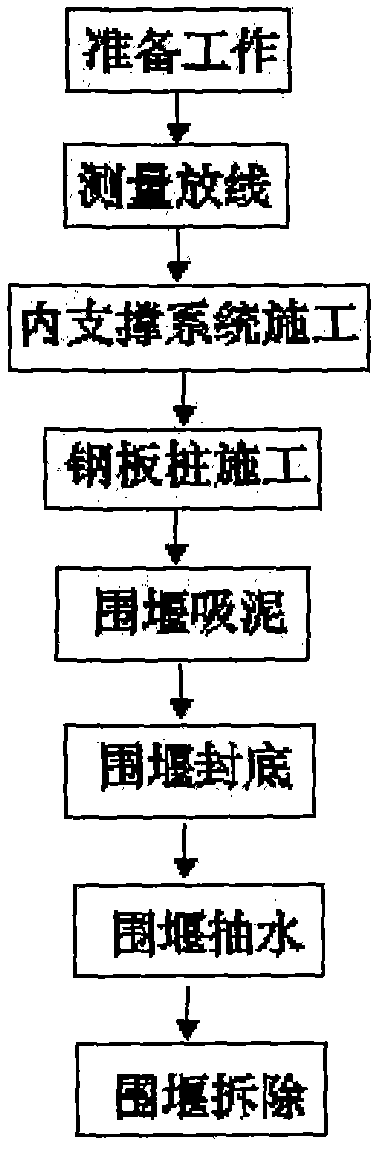

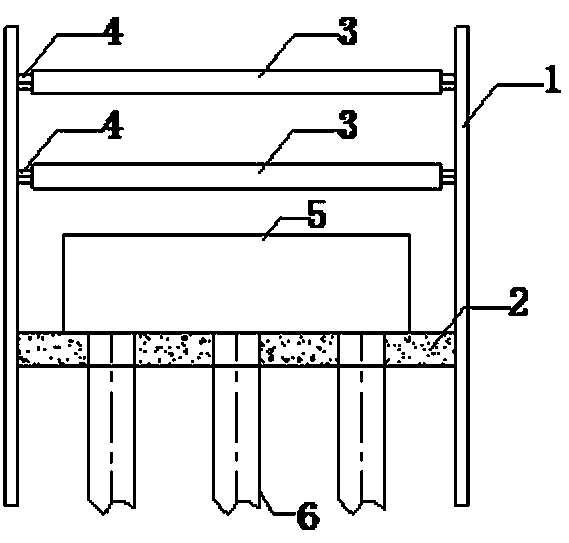

Construction method of steel plate pile cofferdam

InactiveCN102409688AReduce stressShorten the construction periodBulkheads/pilesSupporting systemJoist

The invention discloses a construction method of a steel plate pile cofferdam, which is characterized in that the construction method comprises the following steps: (1) performing construction preparation work; (2) surveying and setting out: surveying and setting out to determine four corner points of the cofferdam according to the design size of the cofferdam and the center position of a support platform, and driving positioning piles at the corner points as control points for positioning the steel plate pile cofferdam; (3) constructing an internal support system constituted by a guide beam, a waling, an inner support, a connecting beam and a supporting beam; (4) firstly welding the waling and the inner support, assembling into a whole, lowering and then inserting and driving steel plate piles for construction; (5) performing mud suction on the cofferdam; (6) sealing the bottom of the cofferdam; (7) performing water pumping and foundation cleaning on the cofferdam; and (8) dismantling the cofferdam.The construction method can further expand the range of applications of the steel plate pile cofferdam by improving the construction sequence and adopting special construction equipment, and successfully realize the steel plate pile cofferdam under the geological condition of a super-thick sandy gravel layer.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

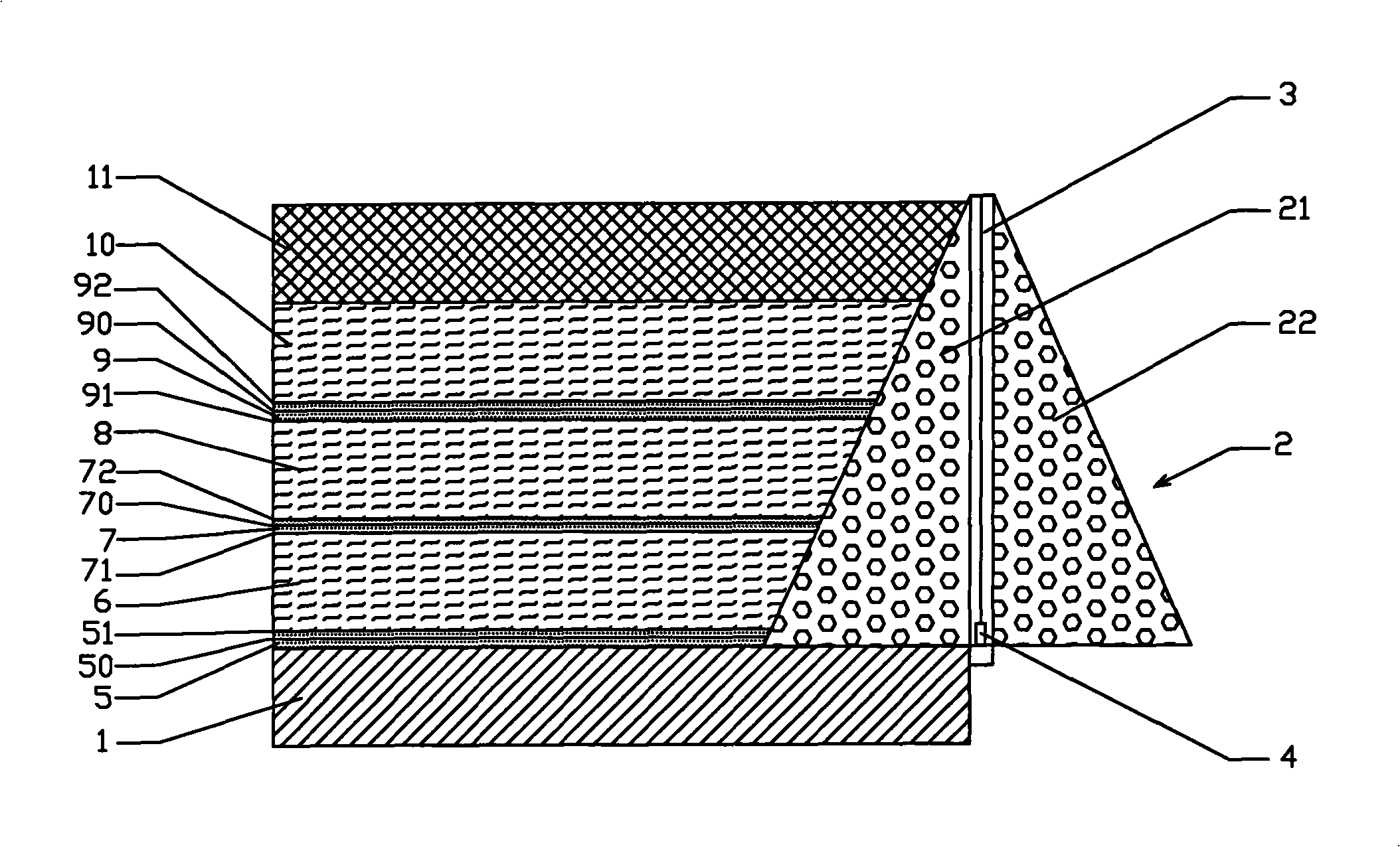

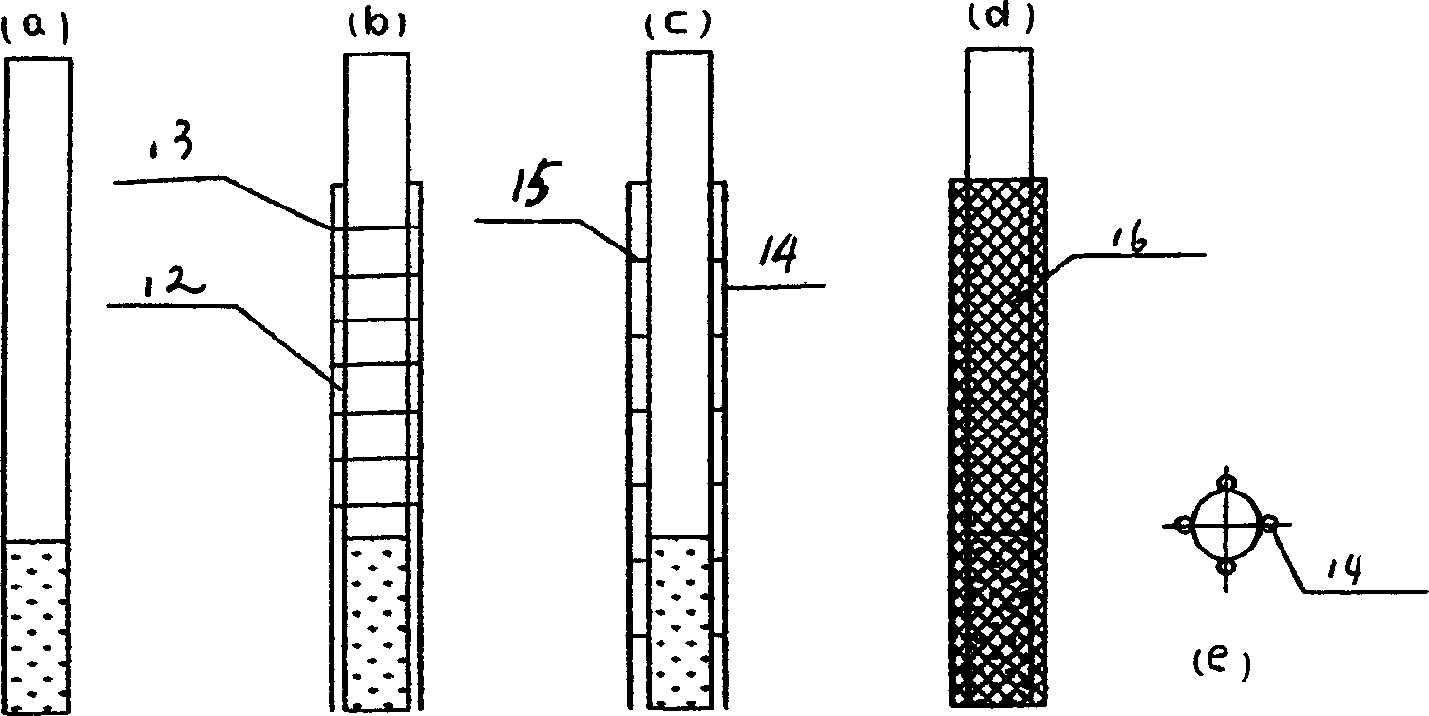

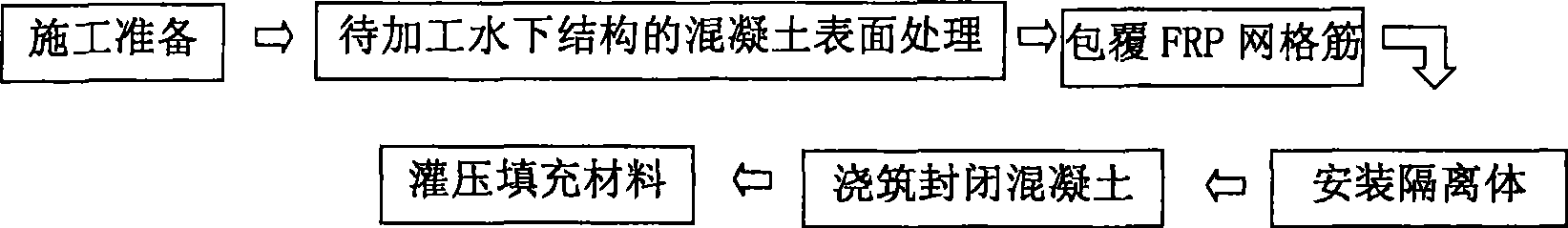

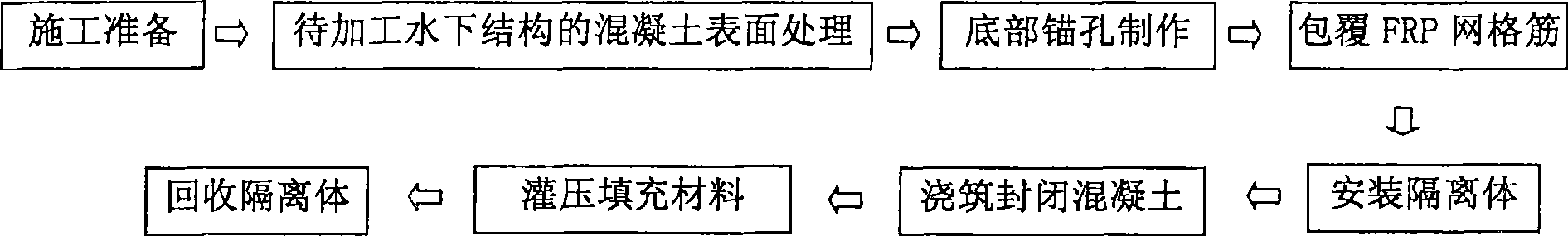

Method for reinforcing underwater structure by fiber-reinforced composite material grid ribs

ActiveCN101503881AMeet emergency repairFast reinforcementArtificial islandsFoundation repairEpoxyUnderwater

The invention relates to a method for reinforcing an underwater structure by using fiber reinforced composite material lattice ribs, which comprises the following steps: treating the concrete surface of the underwater structure to be reinforced; coating at least one layer of the fiber reinforced composite material lattice ribs on the surface of the underwater structure to be reinforced; setting an isolator outside the underwater structure to be reinforced, and making the height of the isolator be more than or equal to the height of the fiber reinforced composite material lattice ribs coated on the surface of the underwater structure to be reinforced; sealing concrete at the bottom of the isolator; and filling underwater epoxy resin or underwater non-dispersed mortar or underwater non-dispersed concrete into the clearance between the isolator and the structure to be reinforced. The process is simple; because the treatment of abandoning and preventing water is not needed during construction, and the periphery of the underwater structure to be reinforced does not need to arrange a cofferdam, the construction process has little influence on a navigation channel; and the reinforcing cost is low, the reinforcing is quick, the construction period is short, and the durability of the structure can be effectively improved.

Owner:BEIJING JIUTONGQU TESTING TECHNOLOGY CO LTD

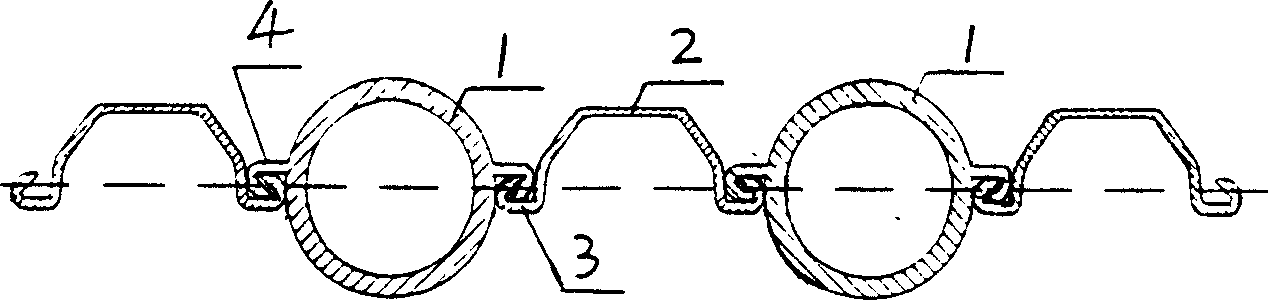

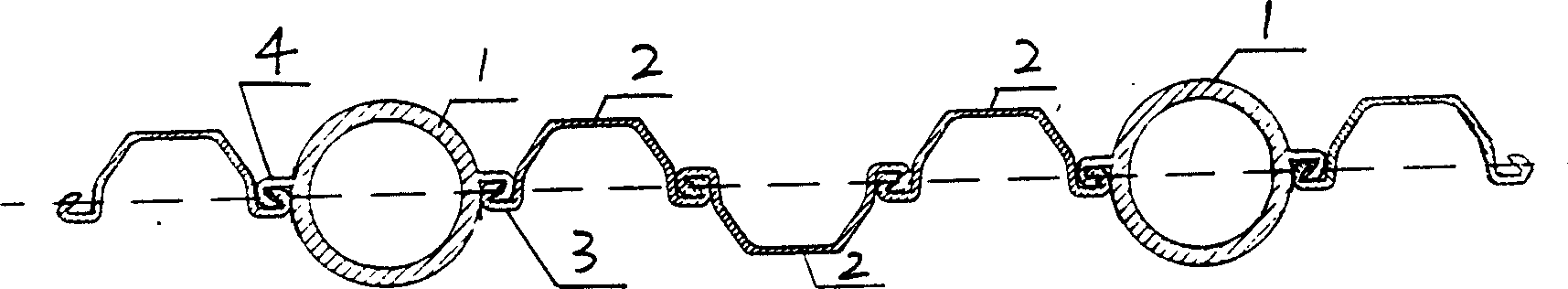

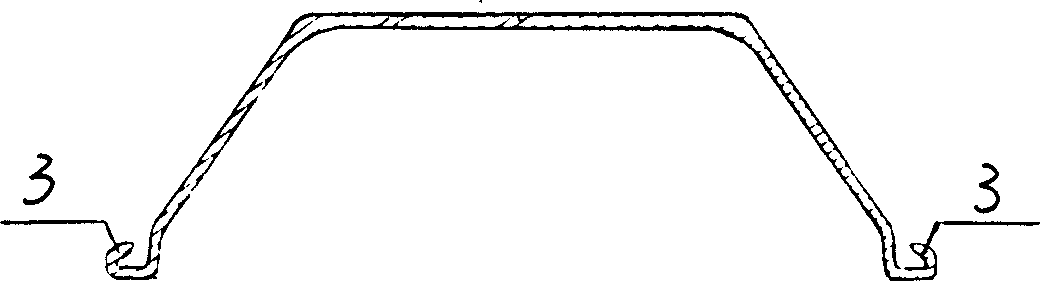

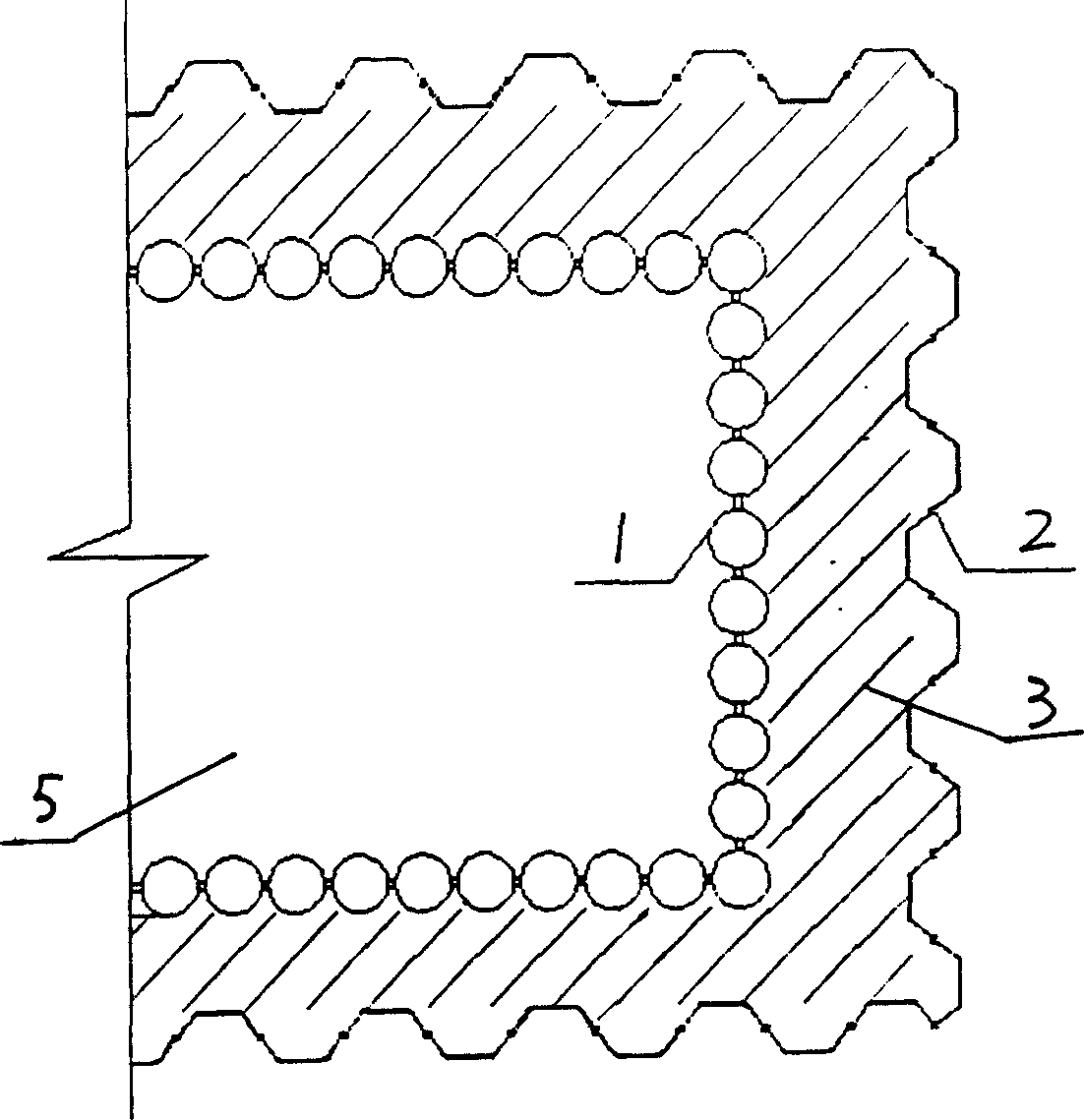

Double-rowed cofferdam and method for manufacturing the same

The invention relates to a dual-row cofferdam and relative method, which is characterized in that: a row of steel plate post cofferdam is arranged at the outer side of steel tube post cofferdam, and a earthwork filling is processed between two rows, and it strengthens them to form the waterproof curtain. The invention utilizes the large rigidity of steel tube post and the better waterproof property of steel plate post to combine them, with lower cost and simple process.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

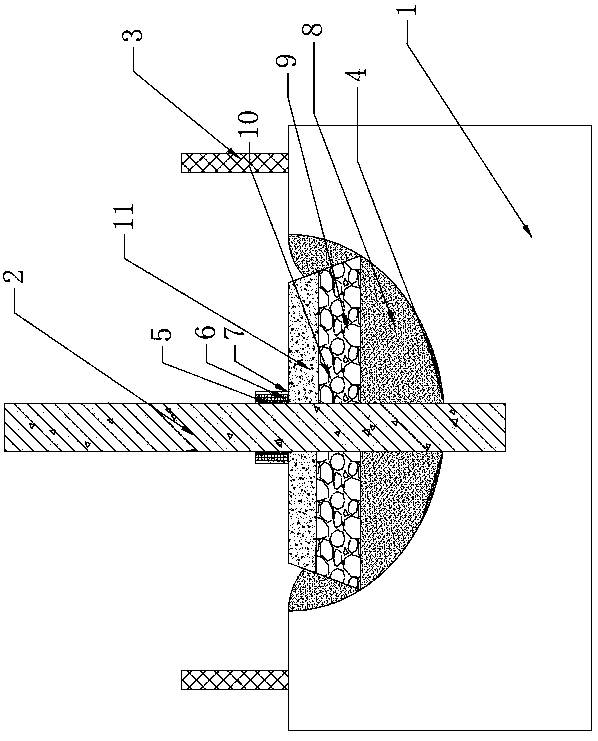

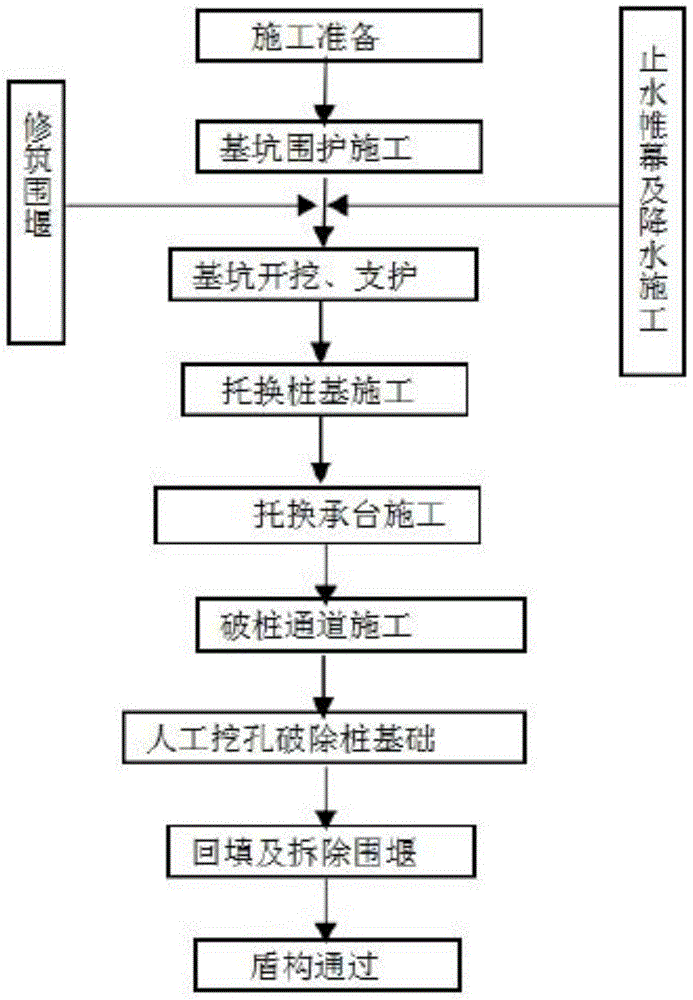

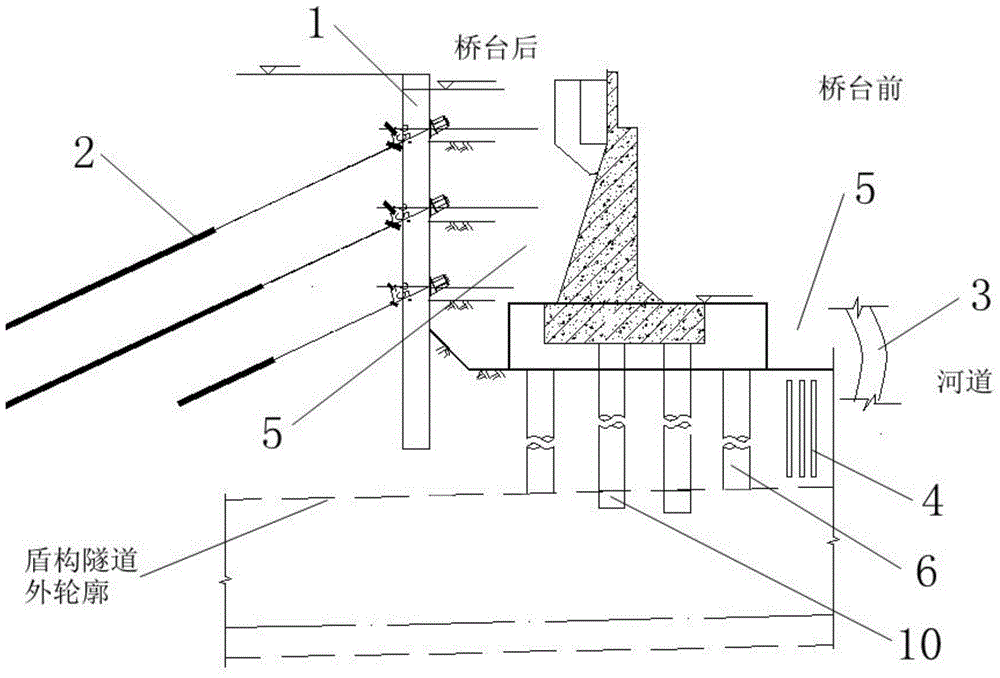

Box-raft pressure-bearing type foundation underpinning and construction reinforcing method for tunnel across pile foundation of bridge above river

InactiveCN101761068AReduce the impactImprove construction levelFoundation repairBulkheads/pilesCofferdamAbutment

The invention relates to a geotechnical and underground engineering technology field, particularly to a box-raft pressure-bearing type foundation underpinning and construction reinforcing method for tunnels across pile foundations of a bridge above a river. The method of the invention comprises: reinforcing abutment foundation of both sides of the bridge, reinforcing the riverbed outside the cofferdam construction and abutment, strengthening bridge supports, excavating pits under cofferdam bridges, strengthening expanding plate-type foundations inside the pits and ground base under the plates, as well as shield tunneling and removing obstructive file base. The method can smoothly complete construction and guarantee smooth shield tunneling while ensuring normal passage of existing bridge structure, further can effectively reduce construction risk, accelerate construction process, reduce cost and reduce influence to environment to a maximal extent.

Owner:TONGJI UNIV +1

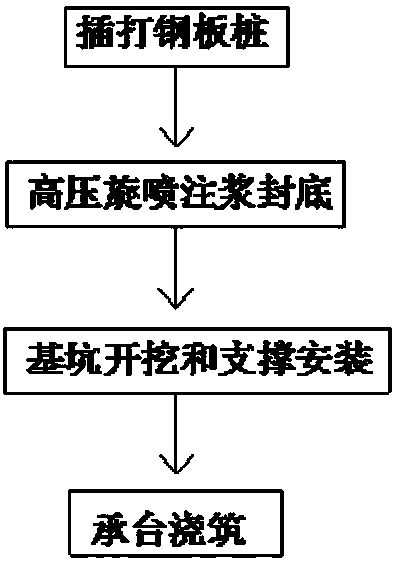

Foundation pit construction method employing steel sheet piles as support cofferdam

The invention discloses a foundation pit construction method employing steel sheet piles as a support cofferdam. The foundation pit construction method is suitable to high-water permeability sand soil geology or high-flow plasticity sludge geology and includes the steps of A, inserting and driving the steel sheet piles to form the steel sheet pile cofferdam; B, performing the ground sealing to a bottom face of the foundation pit to be constructed by employing a high pressure jet grouting method; C, excavating the foundation pit and mounting an inner support of the cofferdam. Compared with the conventional method that the ground sealing is performed to the foundation pit after the excavation, the foundation pit construction method has the advantages that the excavation is performed before the ground sealing, thus cofferdam collapse and piping or upwarp of the cofferdam base never occur in the case of the high-water permeability sand soil geology or the high-flow plasticity sludge geology, and the building-around settlement, caused by drainage and rainfall, is avoided to prevent ground sealing under the water.

Owner:CHINA CONSTR COMM ENG GRP UNITED

Composite boxed cofferdam and building method thereof

The invention discloses a composite casing box cofferdam and a construction method thereof. A double-wall steel cofferdam which consists of an inner wall and an outer wall which are connected is arranged on bedrock, positioned and fixed; mad and sand between the inner wall and the outer wall of the cofferdam are cleared; a bed rock hole is drilled on the bedrock between the inner wall and the outer wall of the cofferdam; steel reinforcement cages are arranged in the bedrock hole and between the inner wall and the outer wall of the cofferdam; bottom sealing concrete is poured into the bedrock hole and between the inner wall and the outer wall of the cofferdam, to construct the composite casing box cofferdam. The invention has the advantages of convenient construction, material saving, stable structure and high positioning precision.

Owner:CHINA MAJOR BRIDGE ENG

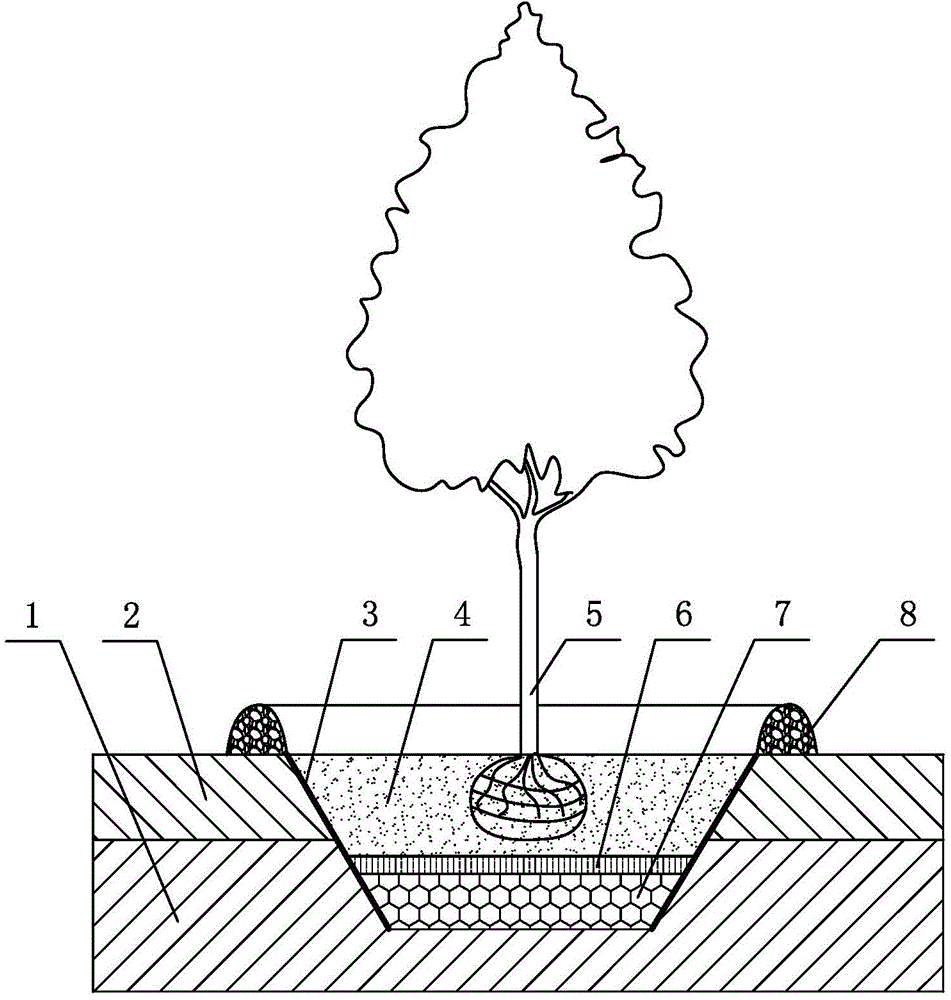

Tree planting method and tree planting structure in coastal saline and alkaline area

ActiveCN103947320AReduce salinityConducive to survival and growthForestrySoil-working methodsTerrainAlkali soil

The invention discloses a tree planting method and a tree planting structure in a coastal saline and alkaline area. The tree planting method comprises the steps of building a cofferdam, arranging a lifting layer, carrying out salt pressing and alkali discharging on the lifting layer, digging planting holes, paving waterproof geotechnical cloth, paving a broken stone water filter layer, paving a straw curtain water filter layer, backfilling planting soil and planting trees. According to the tree planting method disclosed by the invention, after the steps and measures are comprehensively adopted, the salt returning period of saline and alkali soil can be slowed down, good conditions are created for the surviving and the growth of the trees due to the soil fertility of the planting soil, and a greenery landscape can be easily formed after the trees are planted; since the terrain is lifted, saline and alkaline original soil is relatively reduced, alkali discharging pipes are not needed to be paved in specific construction, the period of salt discharging and alkali controlling is reduced, and the cost is reduced. The tree planting method and the tree planting structure, disclosed by the invention, are suitable for being popularized and applied in a greening process of the coastal saline and alkaline area.

Owner:SHANDONG DONGSHENG GARDEN ENG CO LTD

Bidirectional vacuum prepressing blowing filling soft soil foundation treatment method

InactiveCN101235634AIncrease the depth of reinforcementIncrease laying thicknessSoil preservationVacuum pumpingCofferdam

The invention discloses a bidirectional vacuum pre-pressing hydraulically-filled soft ground treatment process, which comprises the following steps that building sealing walls and embedding vacuum pipes on the bottom of a coffer-dam, paving sand cushion with appropriate thickness whose inner portion is provided with filter strainers and vacuum tubes, and the surface is covered with earth-work cloth, building plastic drainage plates whose one section which is exposed on the surface of earth is vertically tied on a bamboo frame upwards, hydraulically filling sands to height mark, installing vacuum-pumping devices, and paving vacuum films. And the process is finished after the design consolidation degree is reached on the earth through starting the vacuum-pumping pump. The process increases the reinforcing treatment depth of vacuum pre-pressing, shortens the construction cycle of hydraulically-filled earth-building project, and saves vacuum film material.

Owner:NANJING UNIV OF SCI & TECH

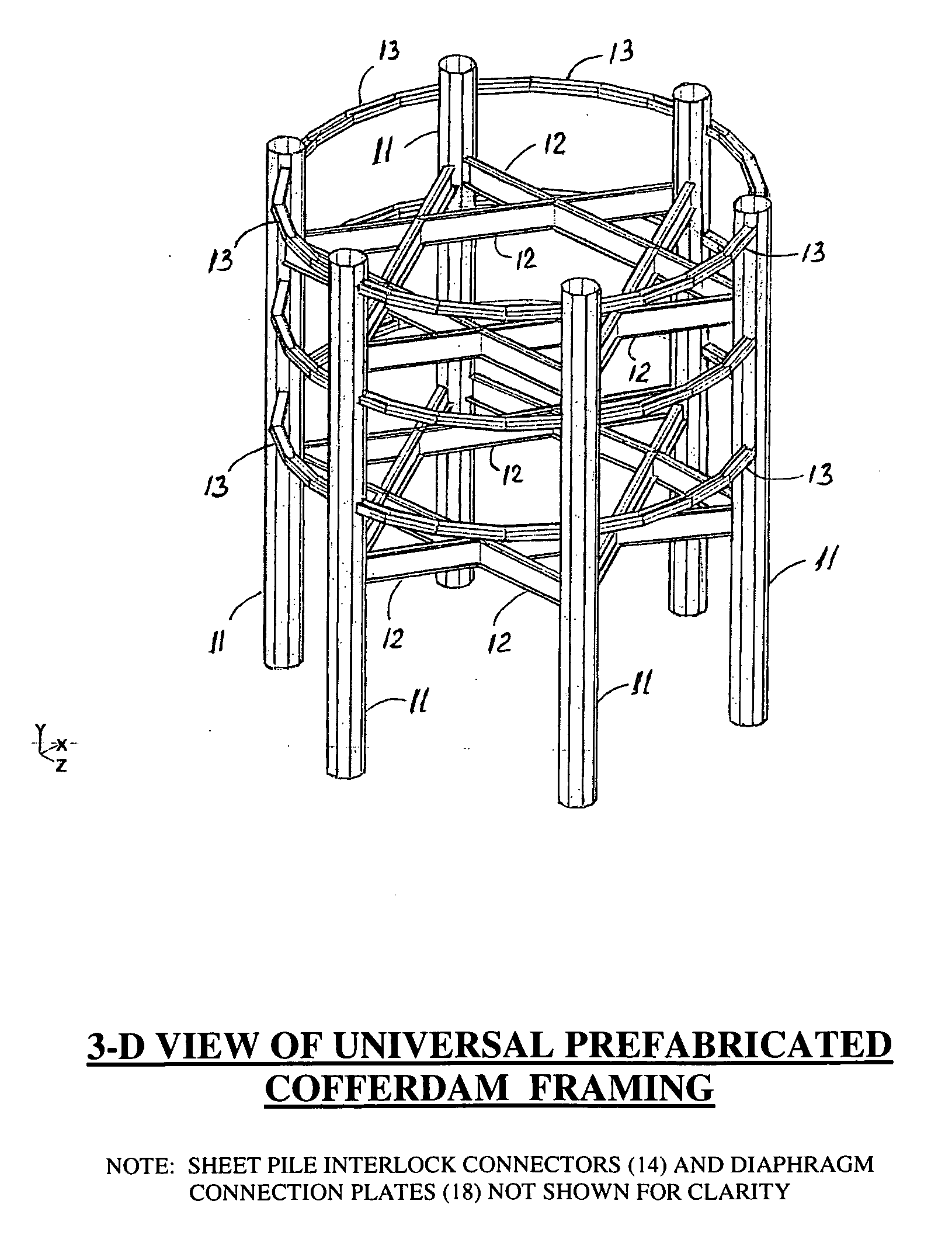

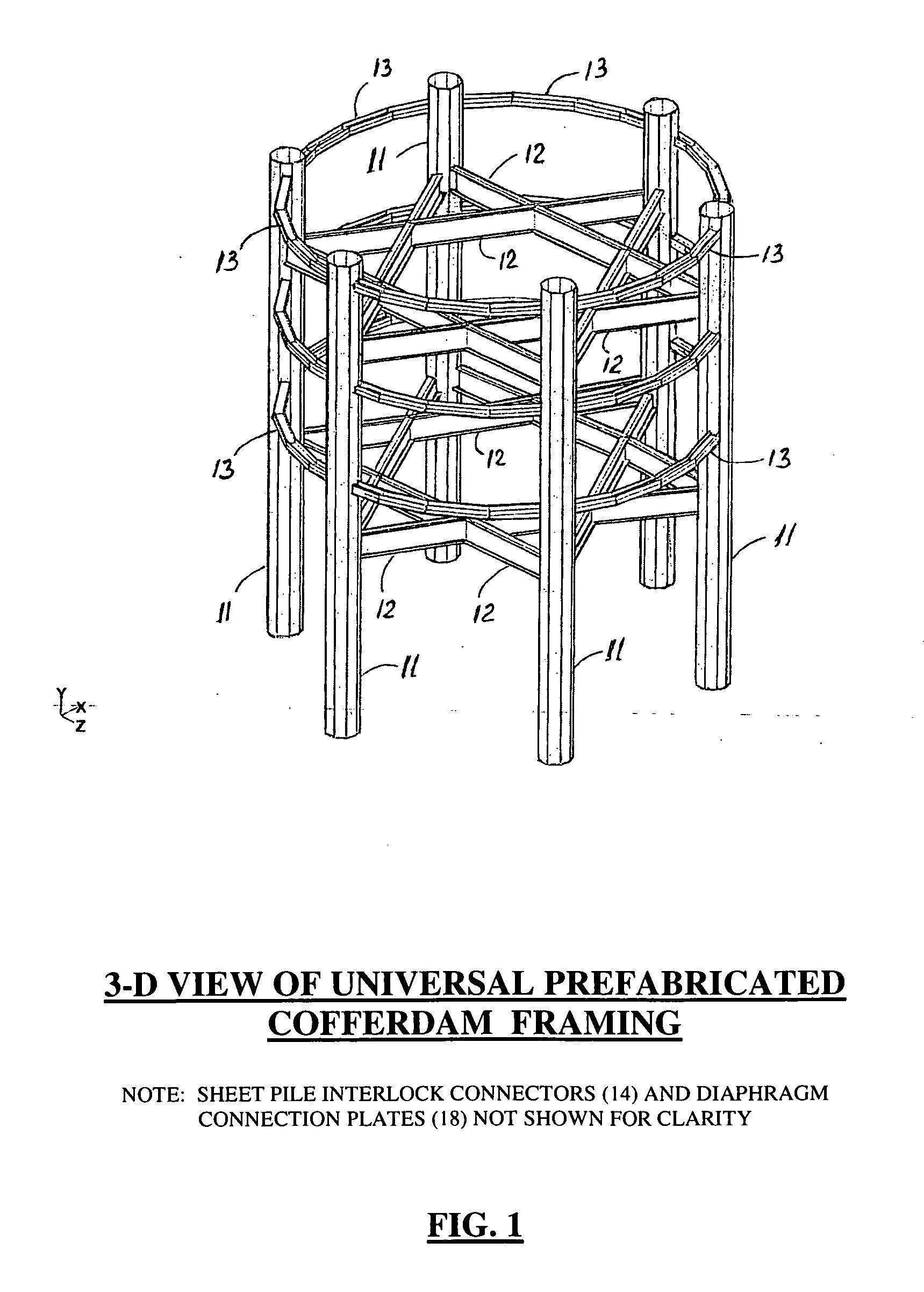

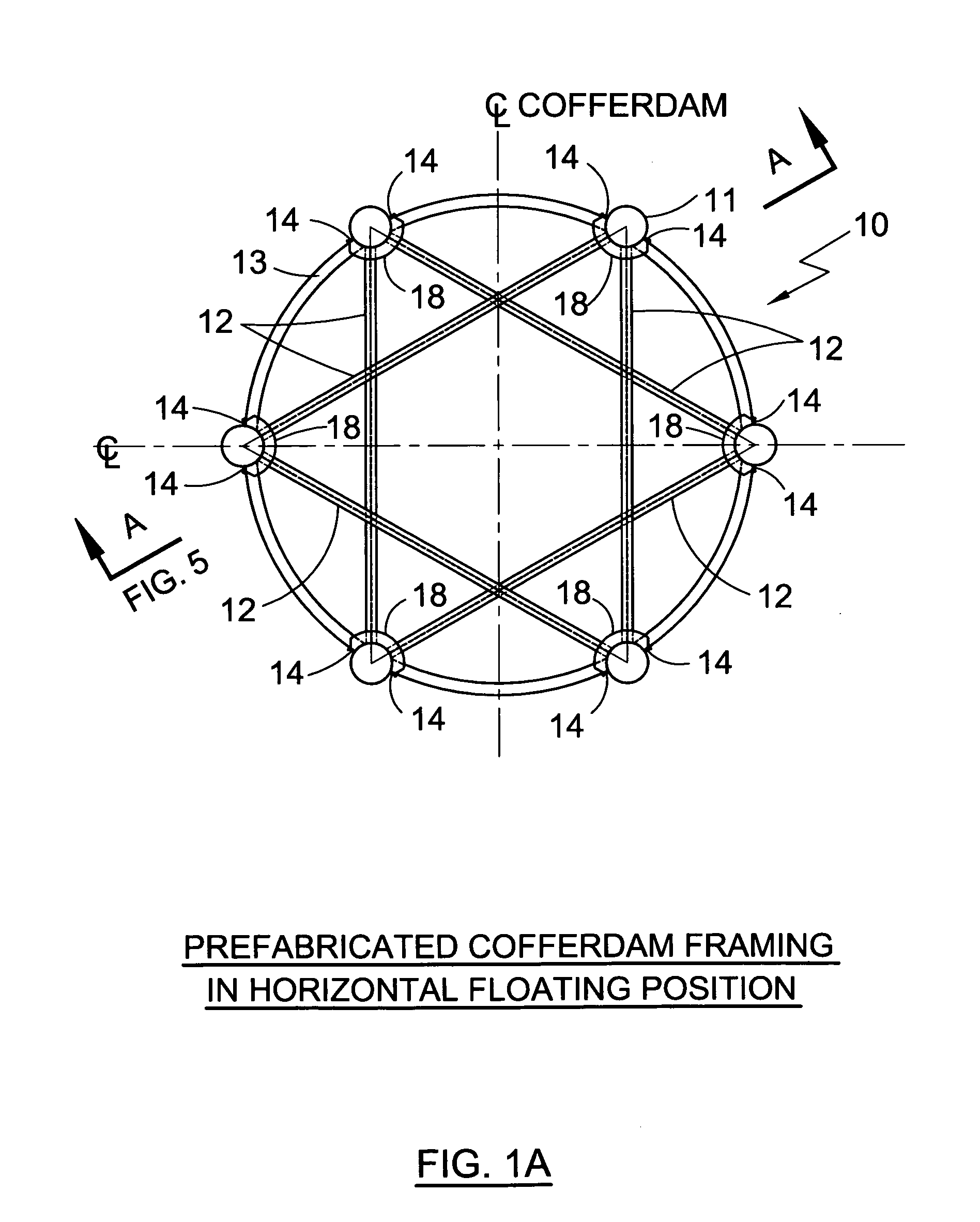

Universal Framed Cofferdam

Universal Framed Cofferdam has prefabricated skeletal steel space framing formed from multiple steel vertical pipes and two levels of horizontal diaphragm trusses rigidly connected to pipe columns. Beams of each diaphragm truss are attached to vertical pipes of the framing with rigid moment connections creating a rigid space frame of the perfectly round form that is used as a false work of the Cofferdam. Wales of the Cofferdam and short pieces of the flat sheet piling are attached to the vertical pipes forming a skeleton of the Cellular structure. The Skeleton of the Universal Framed Cofferdam is prefabricated in the convenience of the Dry Dock and than floated to the site. Buoyancy of the framing allows Cofferdam skeleton transportation without using the barge or otherwise necessary floating devices. Once brought to the site of installation Cofferdam skeleton is installed vertically in position and leveled on the bottom of the river bed. If necessary river silt can be jetted and pumped out of pipe annular space and pipe columns of framing can be simultaneously lowered in position by using vibro—hummer. After space framing installation, rock sockets are predrilled through the annular space of vertical pipes and rock anchors installed. Sheet pile skin of the Cofferdam installed between pipe columns concludes Cofferdam Can erection. Universal Framed Cofferdam Can than filled with compacted gravel and becomes a Hybrid Gravity Caisson / Columnar water front or marine structure that has the best features of the Conventional Cellular Cofferdam and of Columnar Dolphin structure. It has enhanced sliding and overturning stability provided by Rock anchors preloaded by Cofferdam granular fill and has effective mechanism that prevents concave or convex surface of rupture failure that may be suffered by conventional Cellular Cofferdams, and has mechanism that more effectively resists deep surface sliding failure of the Cofferdam base.

Owner:FEYGIN VITAL BORIS +1

Gabion box ecological gabion river channel slope protection construction method

The invention discloses a gabion box ecological gabion river channel slope protection construction method. The gabion box ecological gabion river channel slope protection construction method is mainly characterized in that the defect that only the flood control function, the water diversion function, the drainage function, the impoundment function, the shipping function and the like of a river channel are often considered according to a traditional river channel slope protection structure, and the ecological function of the river channel is rarely considered is overcome. The gabion box ecological gabion river channel slope protection construction method includes the following steps that a cofferdam is constructed, a worktable is arranged, and a footing construction period is carried out; after gabion slope protection construction is over, gaps between surface course dimension stone are recharged with soil and watered, it is ensured that the gaps of dimension stone are filled with soil, and a dimension stone slope is covered by a layer of cultivating and planting soil; aquatic plants are planted underwater, and a lawn is planted on a bank of the river channel. According to a construction technology, water, cement and a formwork are not needed, and construction is convenient. The gaps between building stone can be manually or naturally filled with mud on earth, root systems of the plants can be deeply pricked into the slope through the mud between the building stone, so that engineering measures are combined with vegetation measures, and a soft overall protection face is formed. The requirements for water and soil conservation and environment greening are met, and therefore the original ecological environment is recovered.

Owner:湖北华夏水利水电股份有限公司

Sand dredger filling construction method of soft soil foundation embankment

InactiveCN102605697ASolve the leveling problemGuarantee the construction qualityRoadwaysFlatness problemLand resources

The invention discloses a sand dredger filling construction method of a soft soil foundation embankment. The sand dredger filling construction method comprises the steps of: (1) cleaning the surface of an embankment dredger filling field; (2) measuring and lofting, and setting an elevation mark of the dredger filling construction in a dredger filling region; (3) performing the dredger filling work in a manner of segmenting and layering, to be specific, forming a cofferdam, establishing plastic water discharge plates, building construction roads, distributing grit blasting pipe lines, dredger-filling the embankment, constructing a drain opening, and constructing water collecting wells; and (4) performing stability observation and settlement observation on the dredge-filled sand land of the embankment. The sand dredger filling construction method disclosed by the invention has the advantages of solving the flatness problem of road area at coastal tidelands, rivers, fishponds and the like, performing roadbed filling of municipal administration by fully making use of the characteristics of abundant fin sand resource in the local area, reducing exploitation usage amount of the land resource, decreasing construction cost while guaranteeing construction quality of the roadbed, being simple, convenient, feasible, efficient and practical, increasing working efficiency, saving cost and creating conditions for advanced construction of the next procedure.

Owner:TIANJIN 20 CONSTR

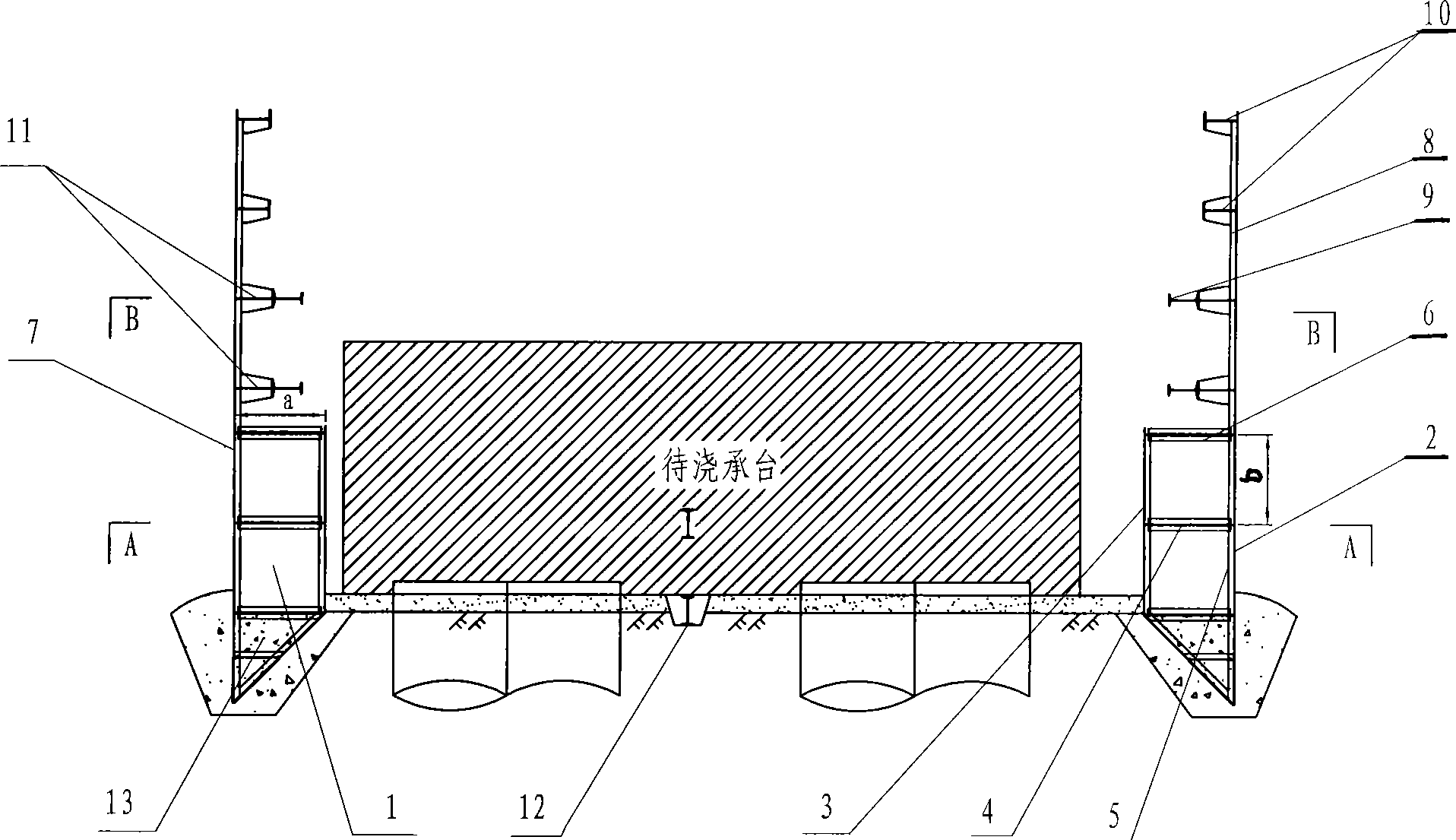

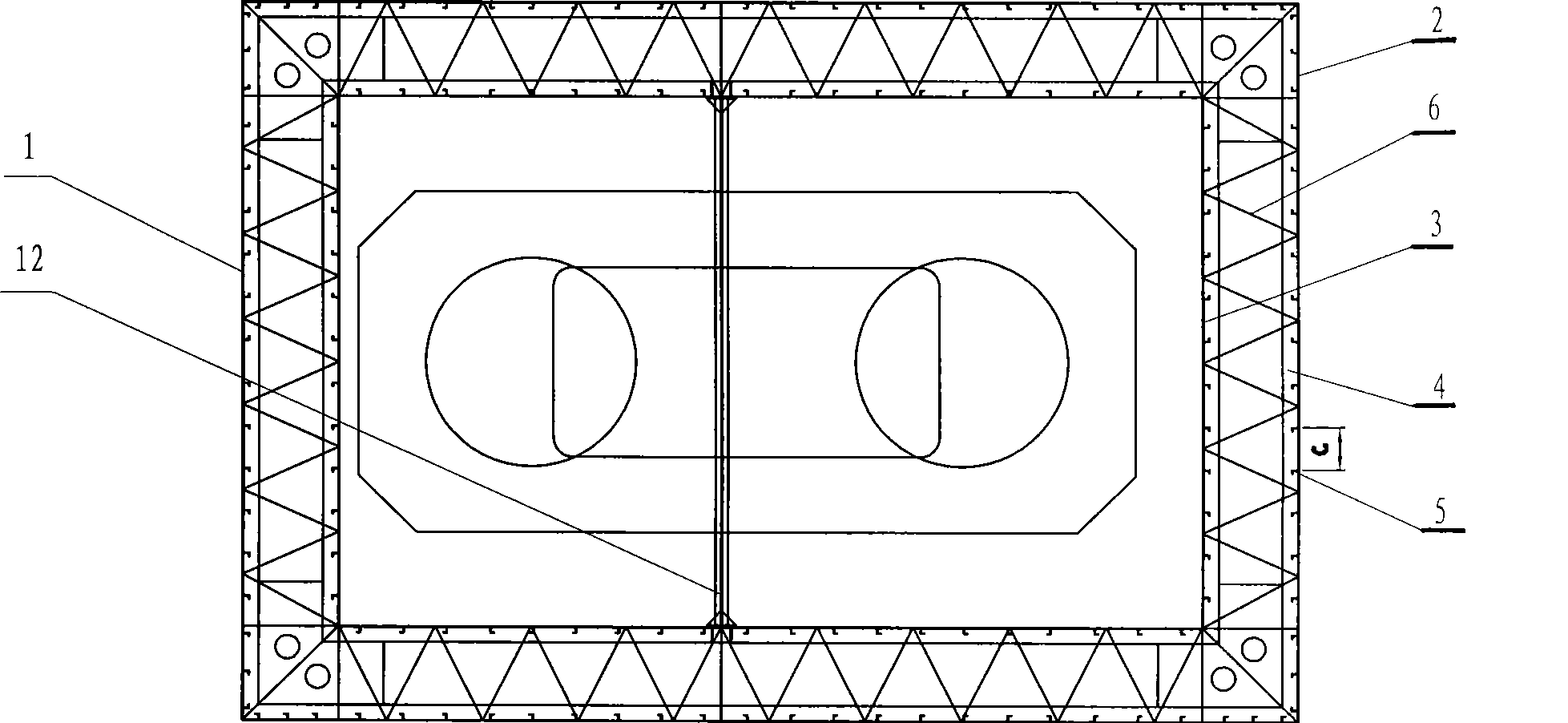

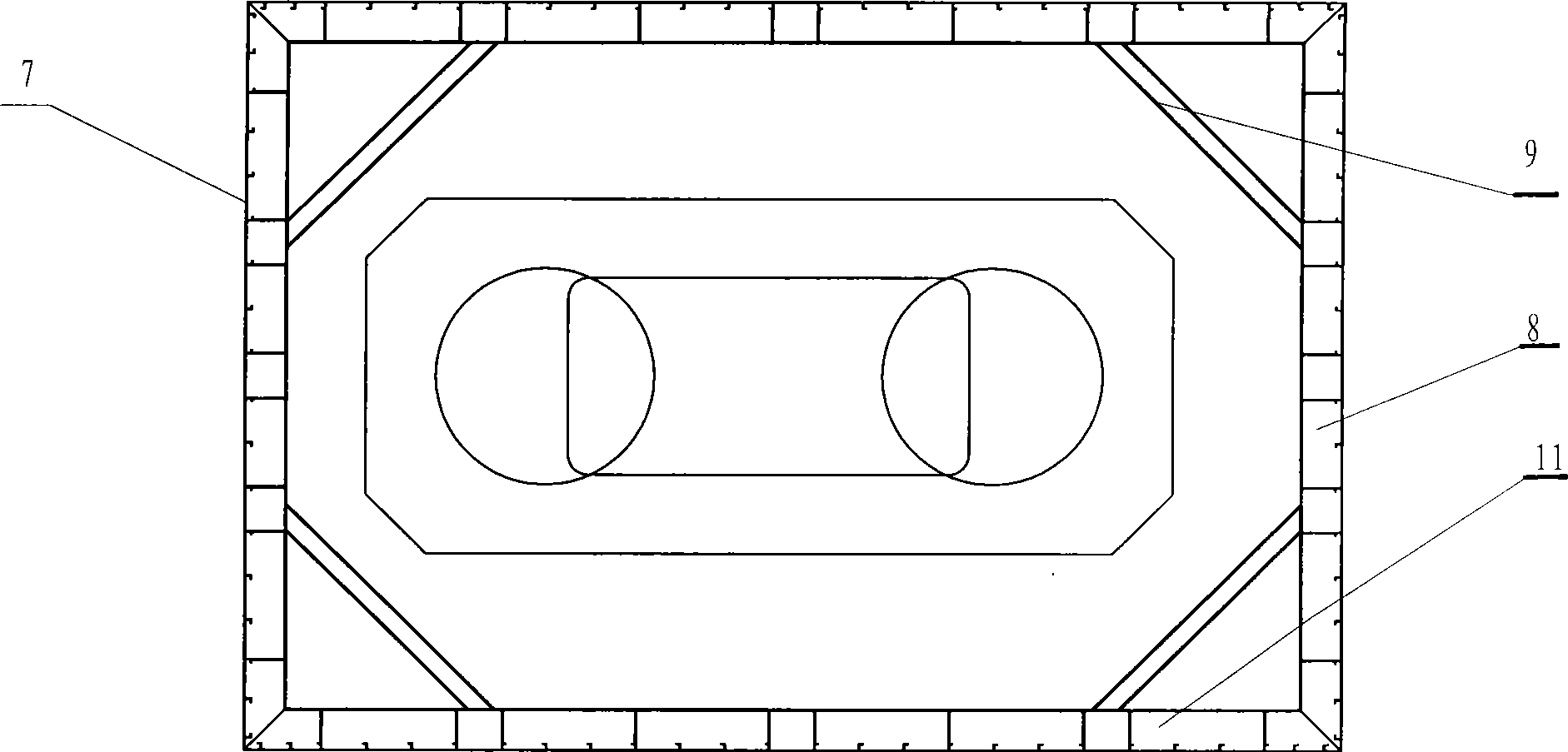

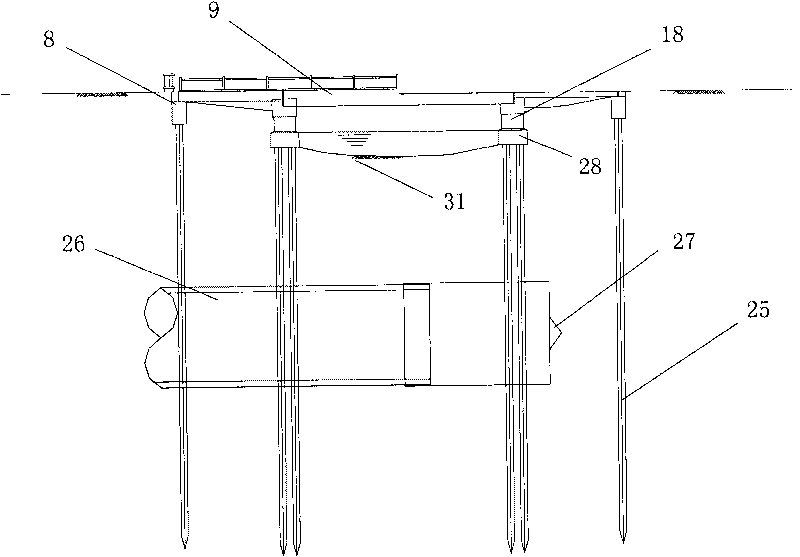

Down-lying, bed-contacting and sinking control technologies of super large steel cofferdam

InactiveCN101205720AAdjustable levelPrecise sinkingFoundation engineeringBridge engineeringCofferdam

The invention discloses a control technology of putting down, touching rocks and settlement of a super cofferdam. The invention belongs to the bridge engineering foundation construction field and is applicable to the cofferdam construction in the bridge high-low pile cap foundation. Namely the invention adopts the control technology of putting down, touching rocks and settlement to realize controllable initiative, adjustable ration, controllable position and adjustable deviation during the settlement of the cofferdam. The technology adopts a uniquely designed lifting system and a horizontal guide device to ensure that the cofferdam is safely and accurately settled to the designed position under the synchronous action of the lifting system and the horizontal guide device and through the wall cabin batch water filling mode as well as under the controllable state that the gravity is greater than the buoyancy. The invention effectively solves the problems of putting down and touching rocks of the super cofferdam as well as the settlement precision in the covering layer under the disadvantageous conditions such as tidal rivers with frequent hydrologic change, bigger riverbed height difference and so on, and improves the installation accuracy of the cofferdam.

Owner:CHINA MAJOR BRIDGE ENG

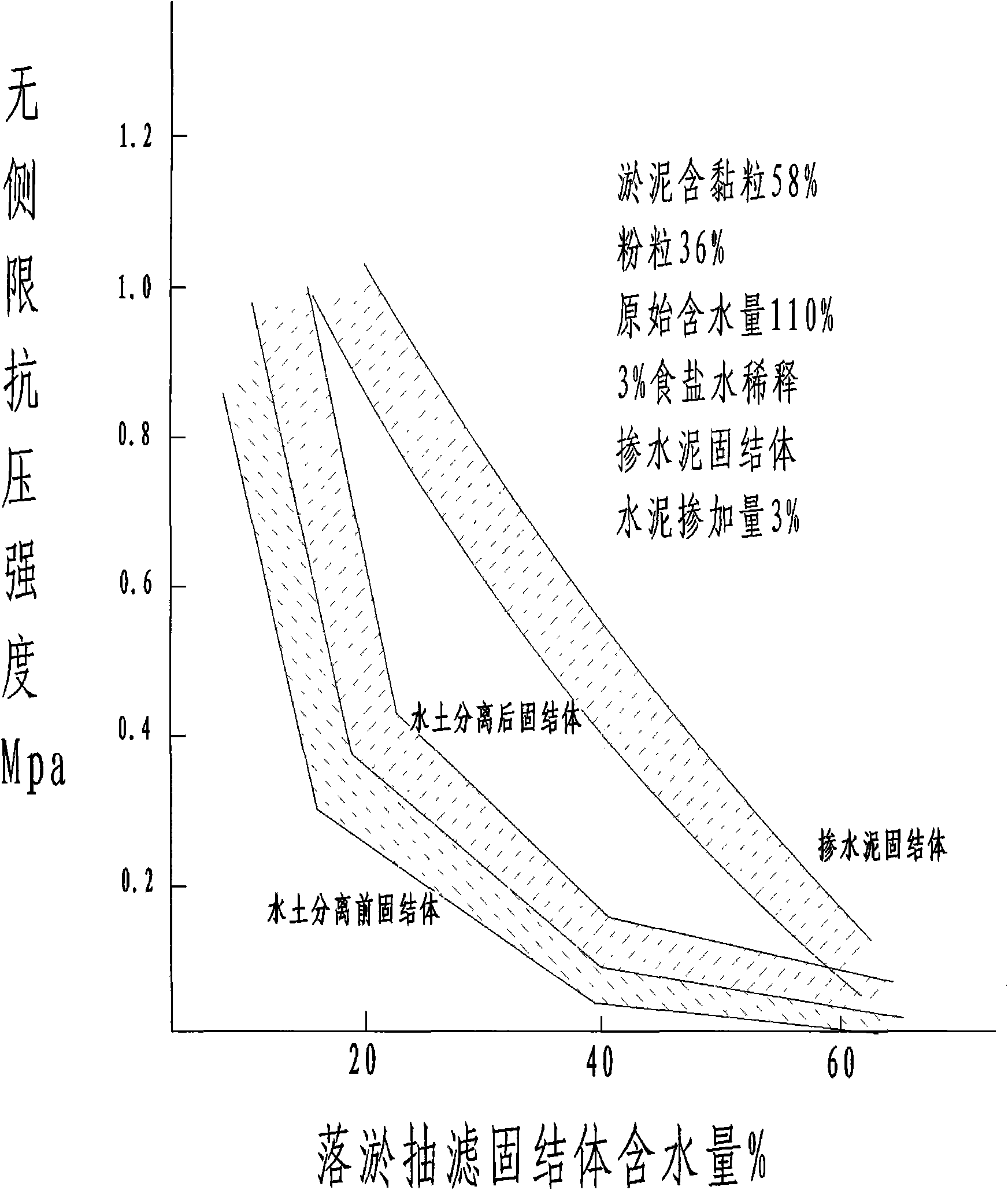

Compound reinforcing method capable of rapidly falling-silt, promoting-seepage, prepressing, reinforcing and blow filling soft clay

The invention relates to a compound reinforcing method capable of rapidly falling-silt, promoting-seepage, prepressing, reinforcing and blow filling soft clay. The method comprises the following steps: mixing water and soil separating agent and sucking silt mud, introducing the mud mixed with the water and soil separating agent into a cofferdam for silt falling, appearing obvious and rapid solid-liquid separation of the mud in the cofferdam, and overflowing and discharging or recycling the separated tail water containing extremely few of solid matters from the far end of the cofferdam; after filling, silt falling and discharging, respectively inserting a plastic drainage plate, laying a plastic drainage pipe, geotextile and a plastic film on the surface layer of the silt, utilizing a vacuum pump to suck to form negative pressure at the lower part of the plastic film, discharging water in silt body on the surface layer by means of atmosphere pressure to lead the bearing capacity of siltbody on the surface layer to be improved rapidly, establishing an operation platform for follow-up soft base treatment, such as vacuum preloading, pile deep stirring, electroosmosis and plate body stabilizing and other technologies, thus realizing the filling-silt overall soft foundation consolidation treatment purpose in the cofferdam. The technology of the invention reduces the construction time of filling soft soil foundation to half and the cost to a half, is popularized and applied, and has extremely economic and social benefits.

Owner:要明伦

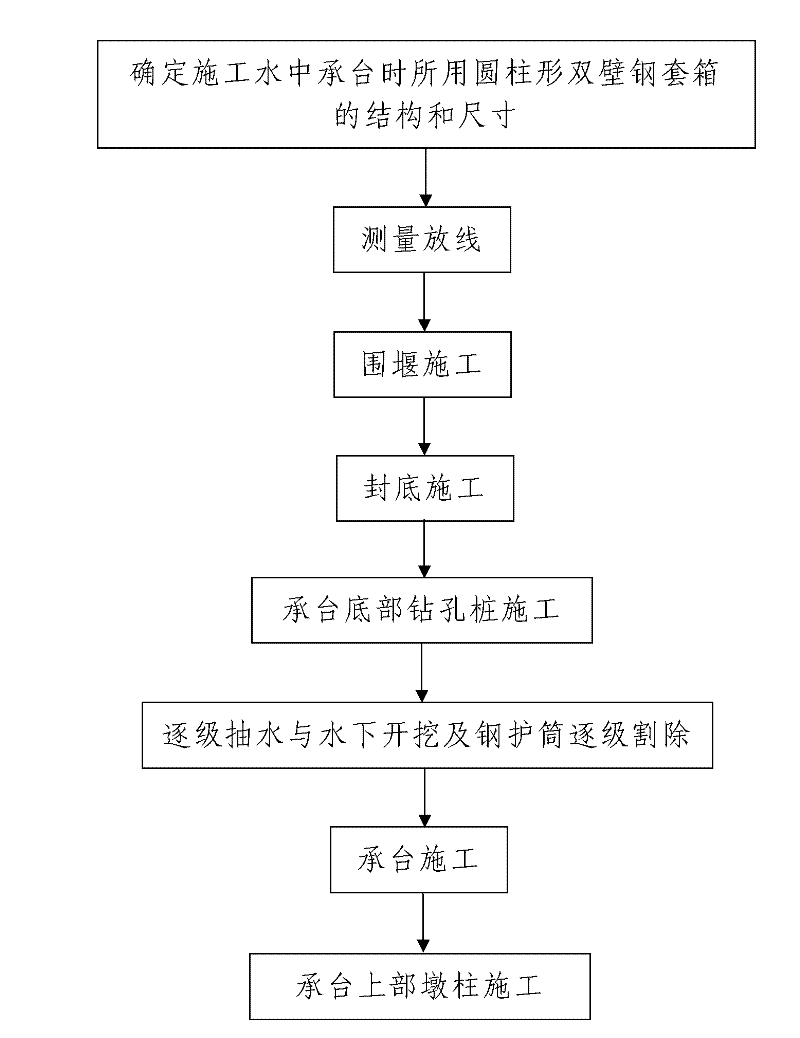

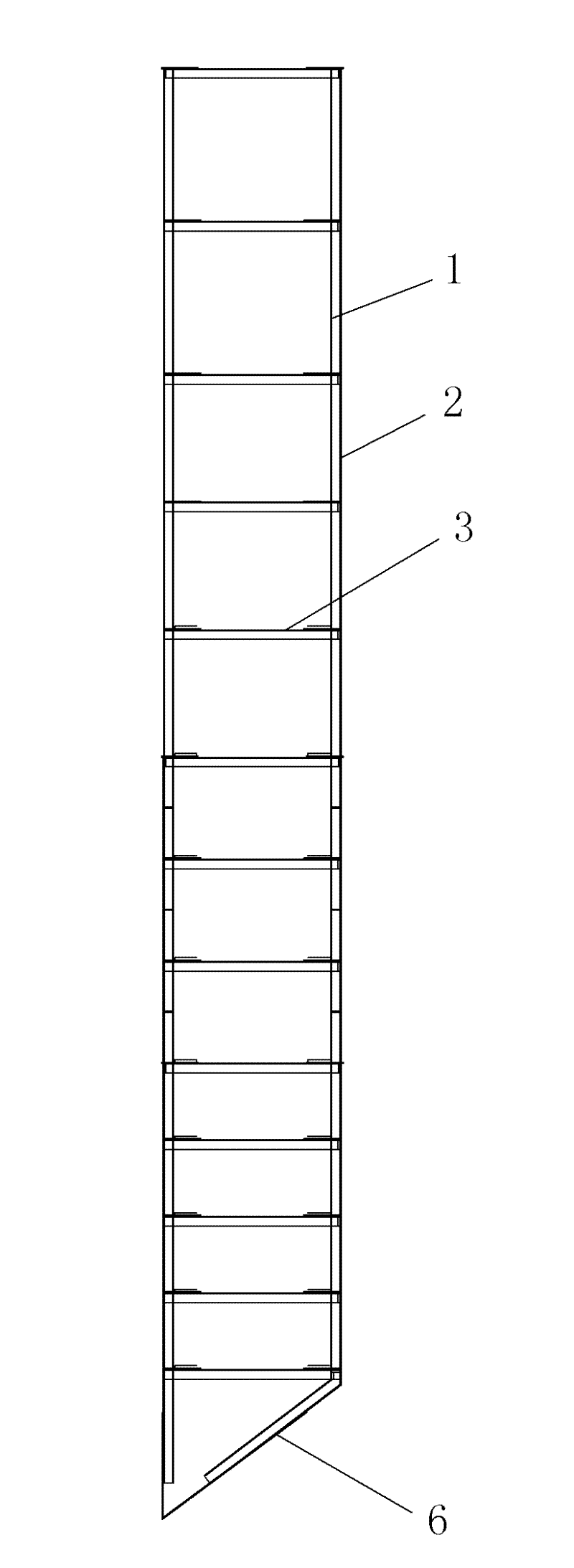

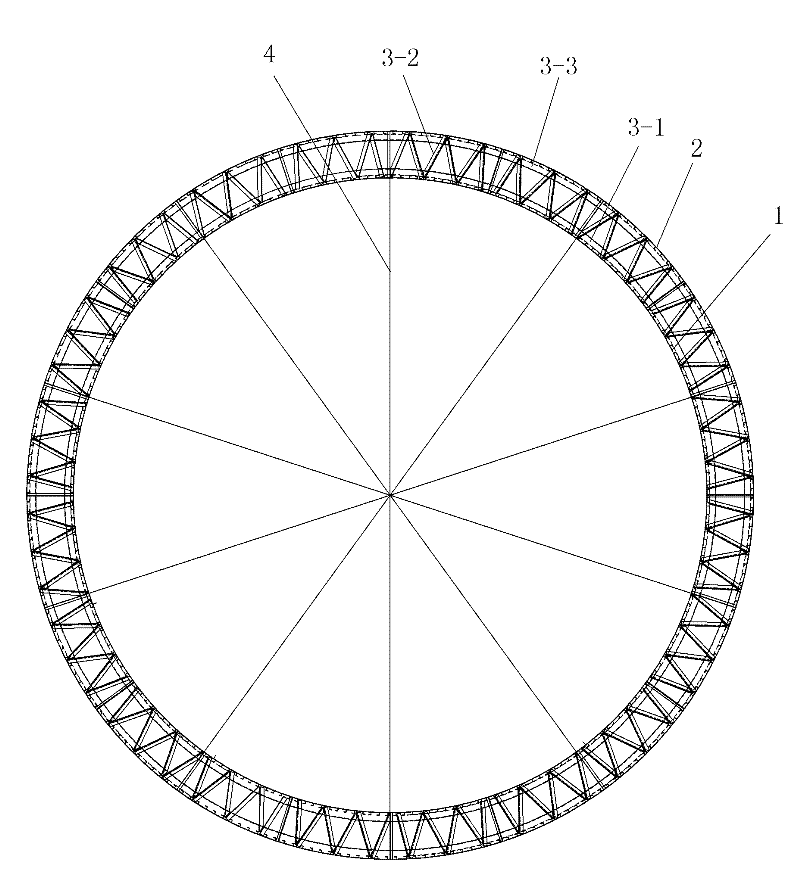

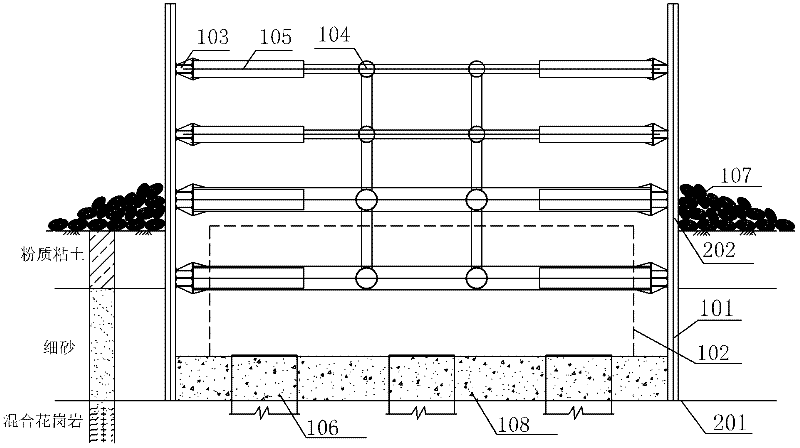

Construction process of double-wall steel cofferdam for construction of pier bearing platform in main river water of Yellow River

ActiveCN102251530ASolve the water stop problemReasonable designFoundation engineeringDouble wallCofferdam

The invention discloses a construction process of a double-wall steel cofferdam for construction of a pier bearing platform in main river water of the Yellow River. The construction process comprises the following steps of: 1, determining the structure and the size of a cylindrical double-wall steel sleeve box used in the construction of the bearing platform in the water; 2, measuring and paying off; 3, performing cofferdam construction: gradually lowering the cylindrical double-wall steel sleeve box to a preset position by adopting hoisting equipment, and fixing the bottom of the cylindrical double-wall steel sleeve box lowered in place by adopting a supporting fixer; 4, sealing the bottom; 5, constructing drilled piles at the bottom of the bearing platform; 6, gradually pumping water, performing underwater digging, and gradually cutting a steel protecting canister; 7, constructing the bearing platform; and 8, constructing pier columns on the upper part of the bearing platform. The process is reasonable in construction step design, convenient in construction, low in construction cost and short in construction period; and integrated construction of the bearing platform and the drilled piles is realized, meanwhile, the sinking operation of the double-wall steel sleeve box can be simply, conveniently and efficiently finished with high quality, and multiple defects in the construction of the conventional double-wall steel sleeve box cofferdam are overcome.

Owner:中铁二十局集团第二工程有限公司

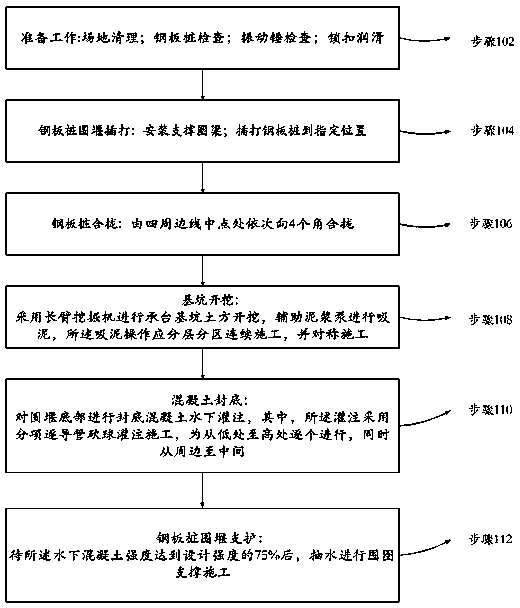

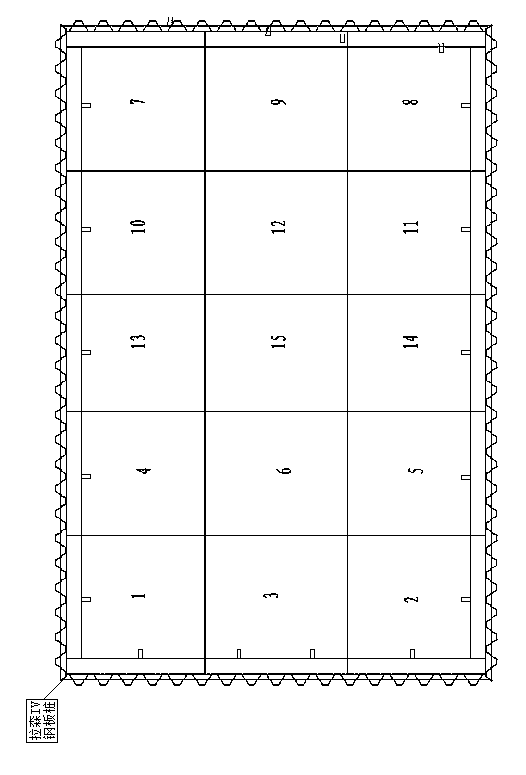

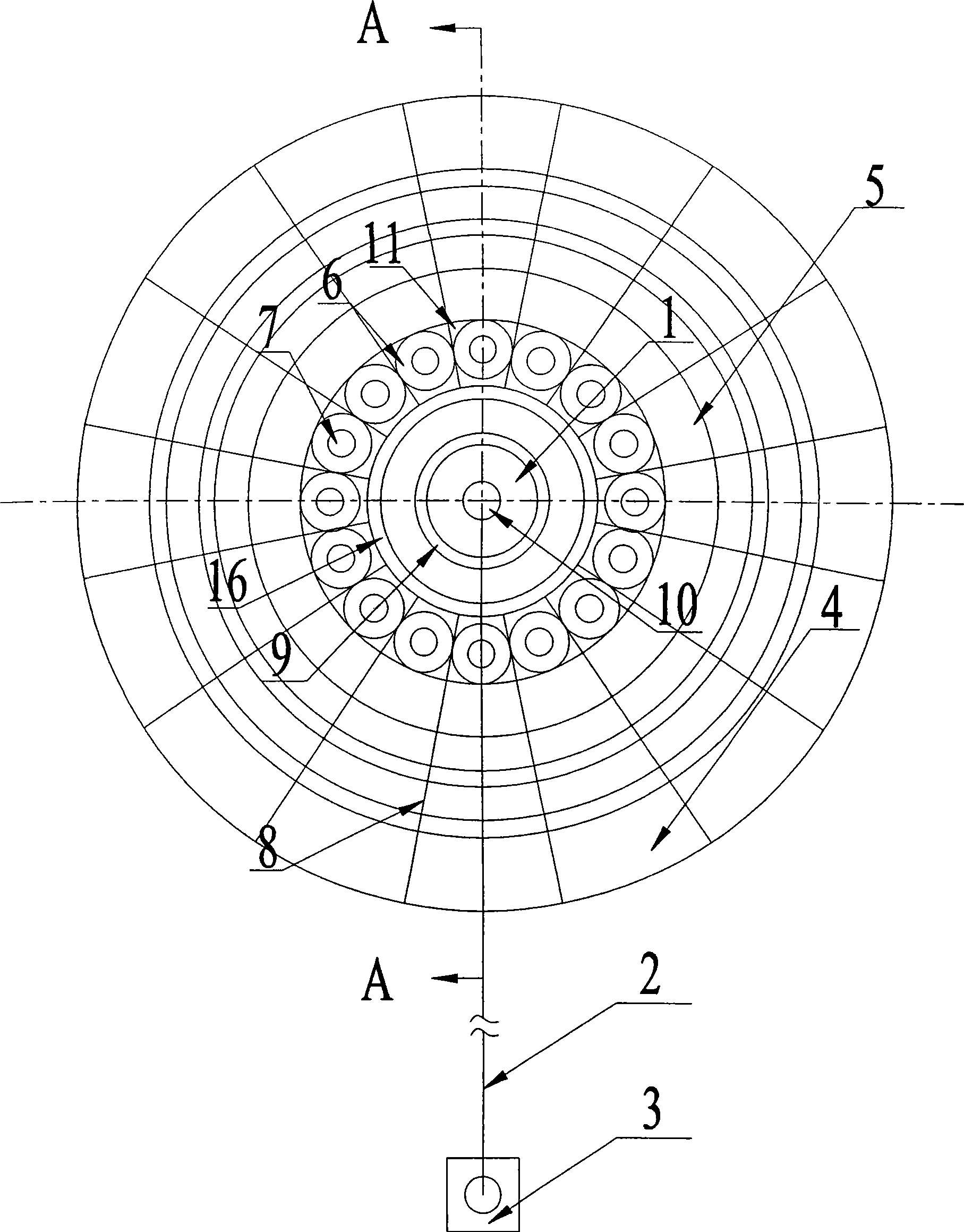

Steel sheet pile cofferdam constructing method

InactiveCN104294835ASafe and fast constructionImprove build qualityBulkheads/pilesUnderwaterCofferdam

The invention relates to the technical field of cofferdam construction, particularly to a steel sheet pile cofferdam constructing method. The method comprises (1) preparation; (2) steel sheet pile plugging and driving including mounting a first support ring beam as a guide frame for pile plugging and driving, during the pile plugging and driving, enabling the backs of steel sheet piles to be close to the guide frame, slowly lowering a lifting hook over the pile plugging and driving to ensure alignment and straightness of the steel sheet piles; (3) steel sheet pile closure including closing the steel sheet piles in the plugging order from the surrounding sides to the four corners; (4) foundation pit digging including performing cap foundation pit earth digging through a high-front shovel, and sucking soil through a mud pump in a layered, partitioned and symmetric mode; (5) concrete ground sealing including performing ground-sealing concrete underwater filling on the bottom of the cofferdam; (6) steel sheet pile cofferdam support including, when the strength of underwater concrete reaches 75% of a design strength, pumping water to achieve wailing support construction.

Owner:SINOHYDRO ENG BUREAU 4 +1

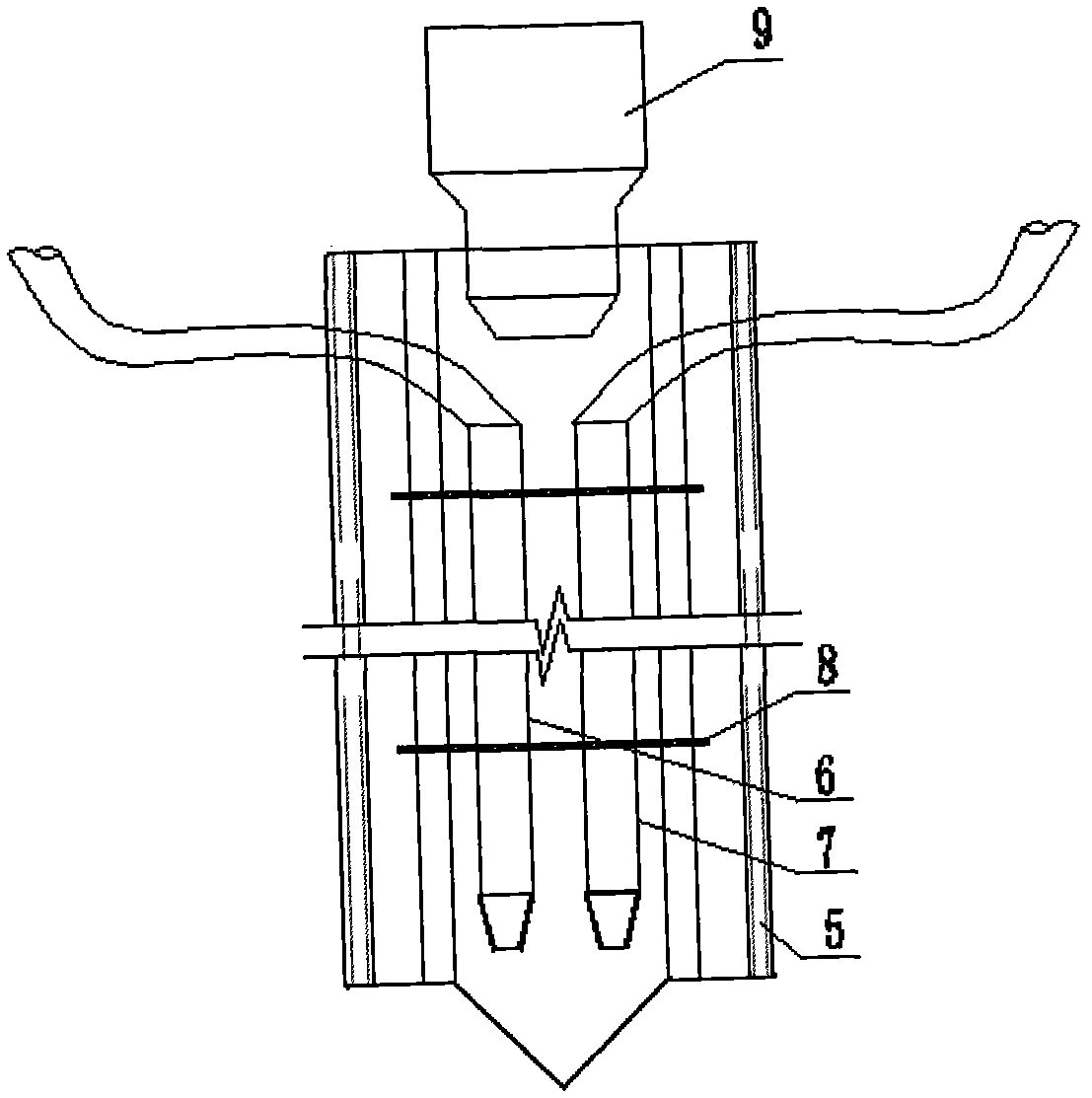

Floating cofferdam type wave generating set

InactiveCN101387260AImprove reliabilityImprove work efficiencyMachines/enginesEngine componentsTerrainWater turbine

The invention discloses a floating cofferdam type wave energy generating set, which comprises a tower convergent wave pool consisting of a platform and a multistage conic pool. The bottom of the tower convergent wave pool is divided into a plurality of ballast tanks and provided with a water level sensor, the upper cavities of the ballast tanks are filled with a buoyancy material, the platform is arranged on the buoyancy material of a groove in the middle of the convergent wave pool, and the platform is provided with a controller, a compressed air system and a baffle wall; the baffle wall is provided with a sensor, the low level of each stage of the convergent wave pool is provided with a pipeline leading to the sea level, the pipeline is internally provided with a Kaplan turbine and an asynchronous generator, the floating cofferdam type wave energy generating set is connected with anchor pipers with swivel links through anchor chains, and the anchor pipers are anchored at the bottom of the sea. According to the draught height of a wave height adjusting device, the floating cofferdam type wave energy generating set is not influenced by tide level and limited by terrain, always works towards the waves all around, can catch the wave energy as much as possible under various conditions, and has the advantage of high working efficiency; only the Kaplan turbine is the unique movable component so that the reliability of the whole set is improved.

Owner:ZHEJIANG UNIV

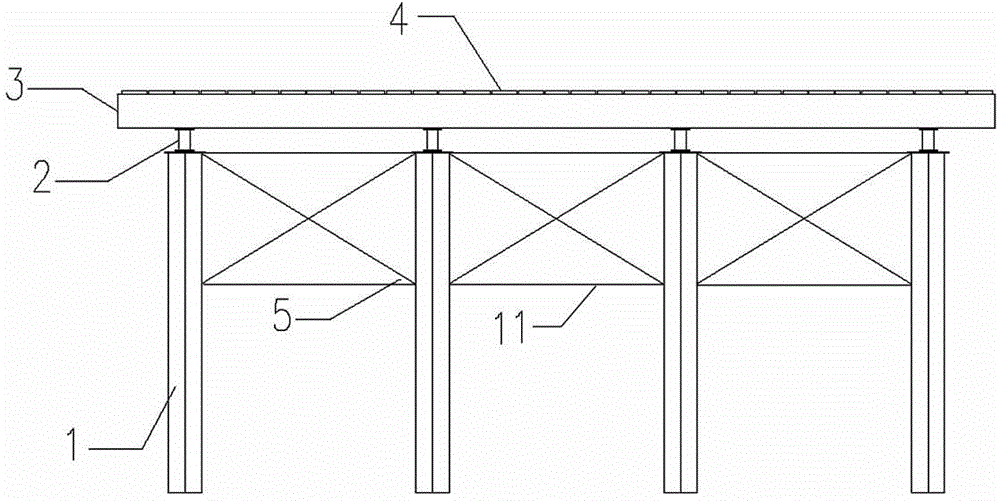

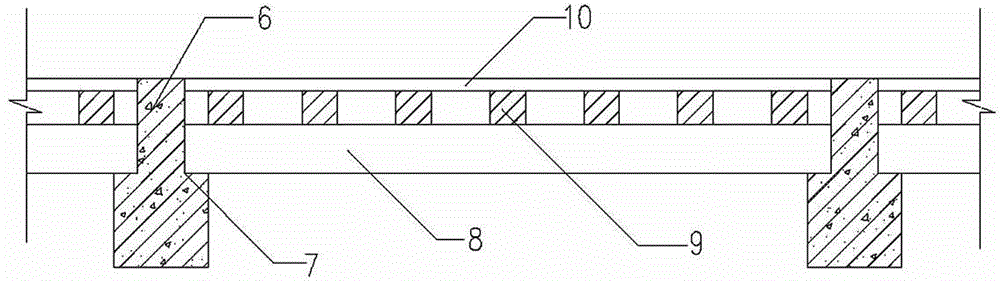

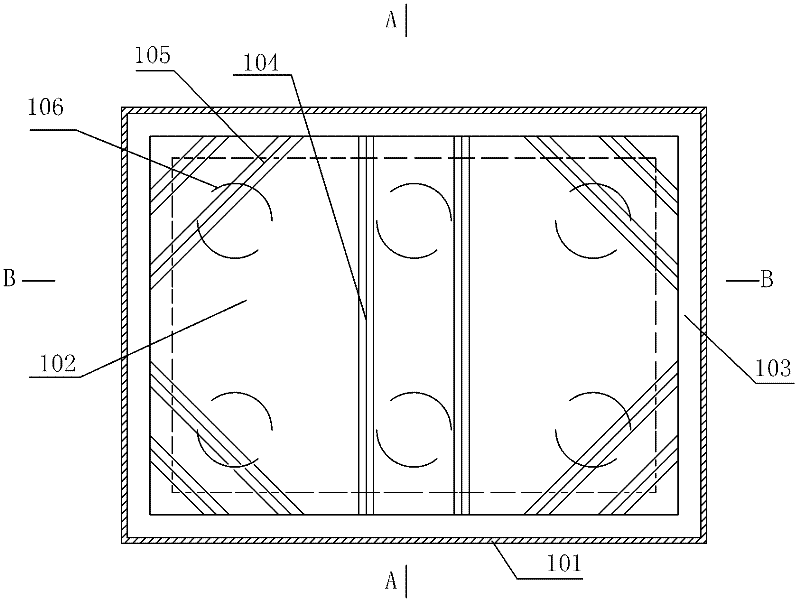

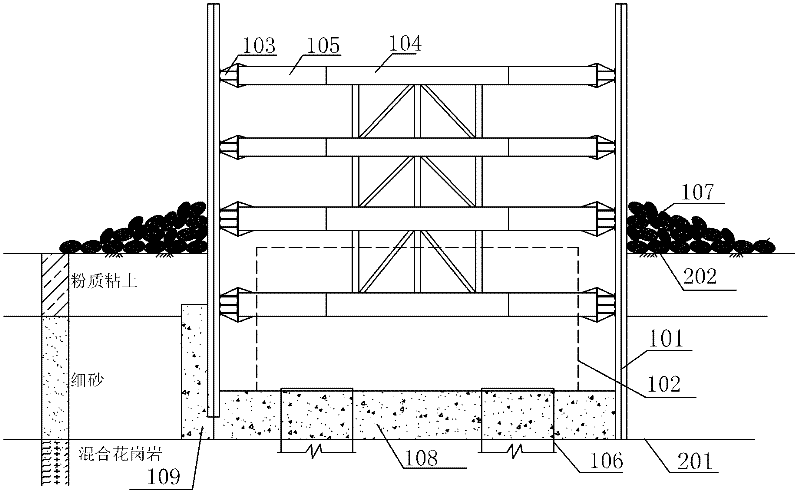

Overwater building construction platform and erecting method and use method thereof

ActiveCN104532813ASolve the demolition problemSolve supportiveArtificial islandsUnderwater structuresFloor slabCofferdam

The invention discloses an overwater building construction platform and an erecting method thereof, as well as a method that uses the construction platform to conduct overwater building construction. The overwater building construction platform comprises a base, a longitudinal beam, a cross beam, a walkway board and a protective barrier. The erecting method of the overwater building construction platform comprises the steps of: steel pipe pile inserting and piling, cross bridging welding, longitudinal beam installing, cross beam installing, walkway board installing, and protective barrier installing. The method using the construction platform to conduct overwater building construction comprises the steps of: construction platform erecting, building pile foundation construction, building beam column construction, construction platform dismantling, and building floor slab construction. For the overwater buildings such as an overwater restaurant, a scenic pavilion and an overwater dock of which the structure bottom elevation above the pipe is higher than the water level elevation, which are located in inland rivers or lakes, the overwater building construction platform and erecting method and use method thereof adopt the cofferdam-free construction scheme, can effectively solve the disadvantages of cofferdam construction, reduces the construction costs, and shortens the construction period.

Owner:JIANGXI PROVINCE URBAN CONSTR GRP

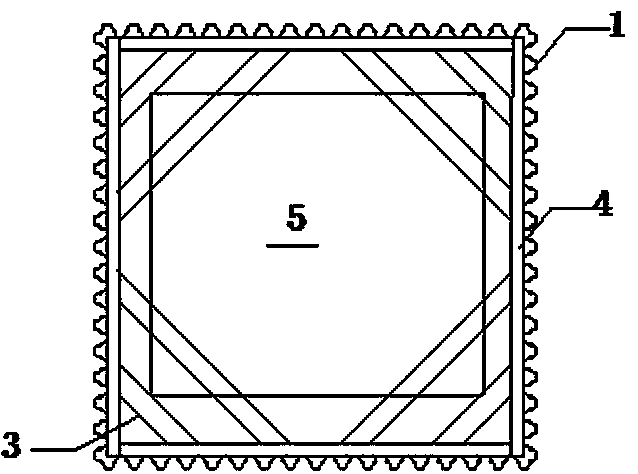

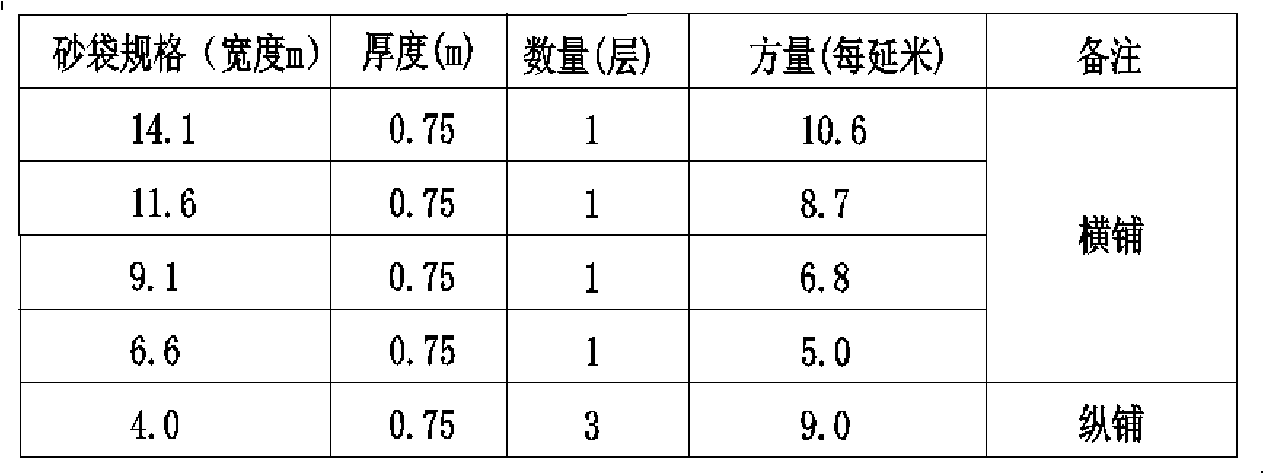

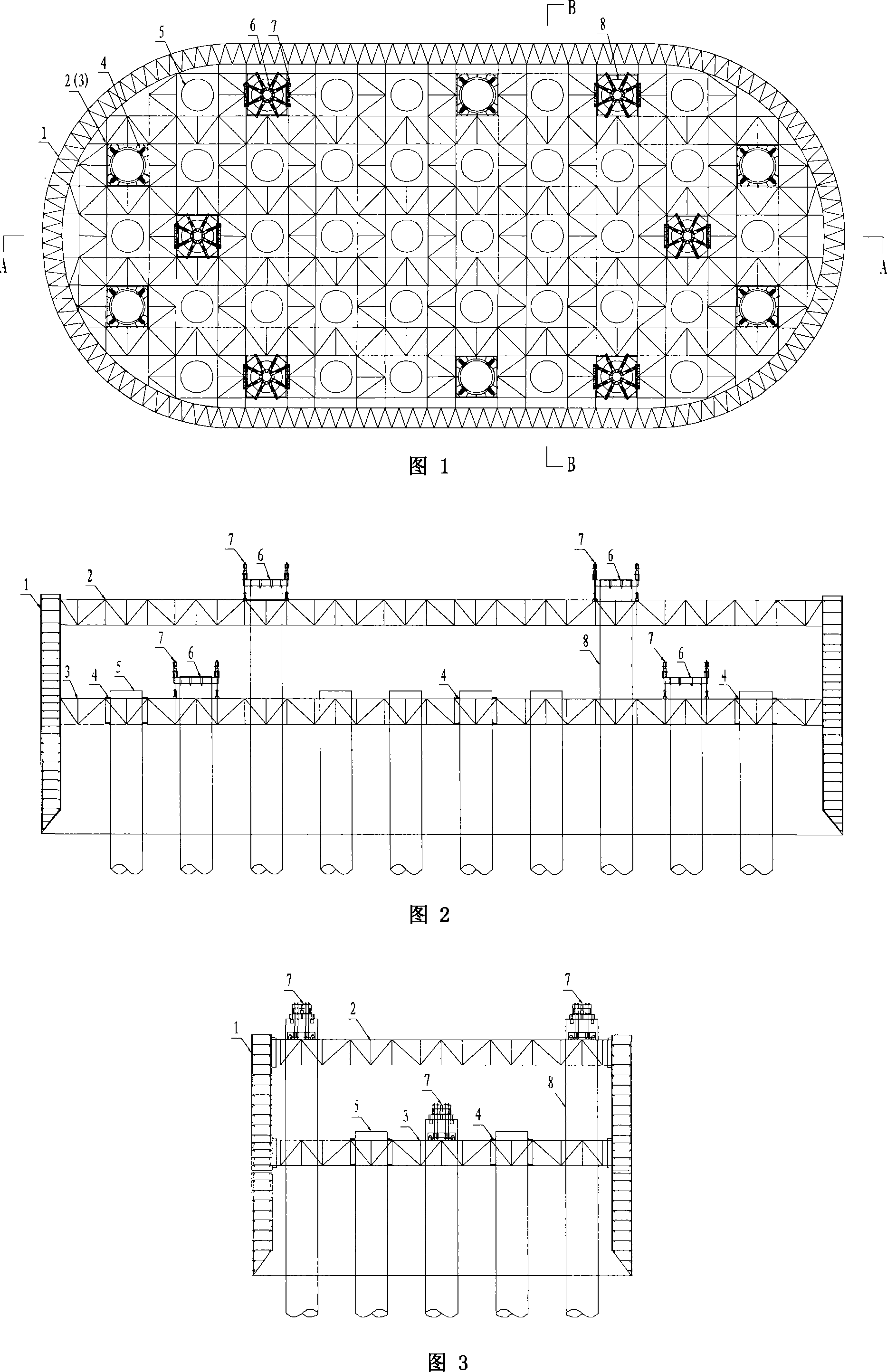

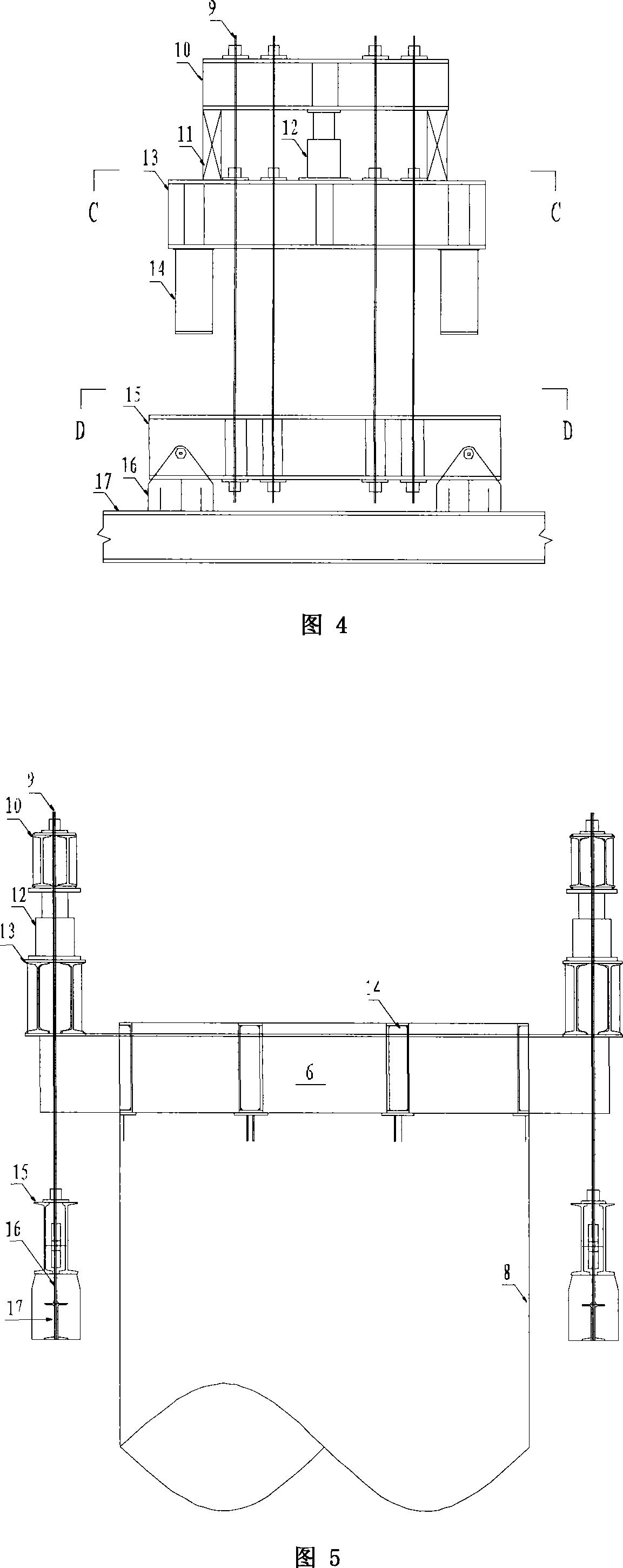

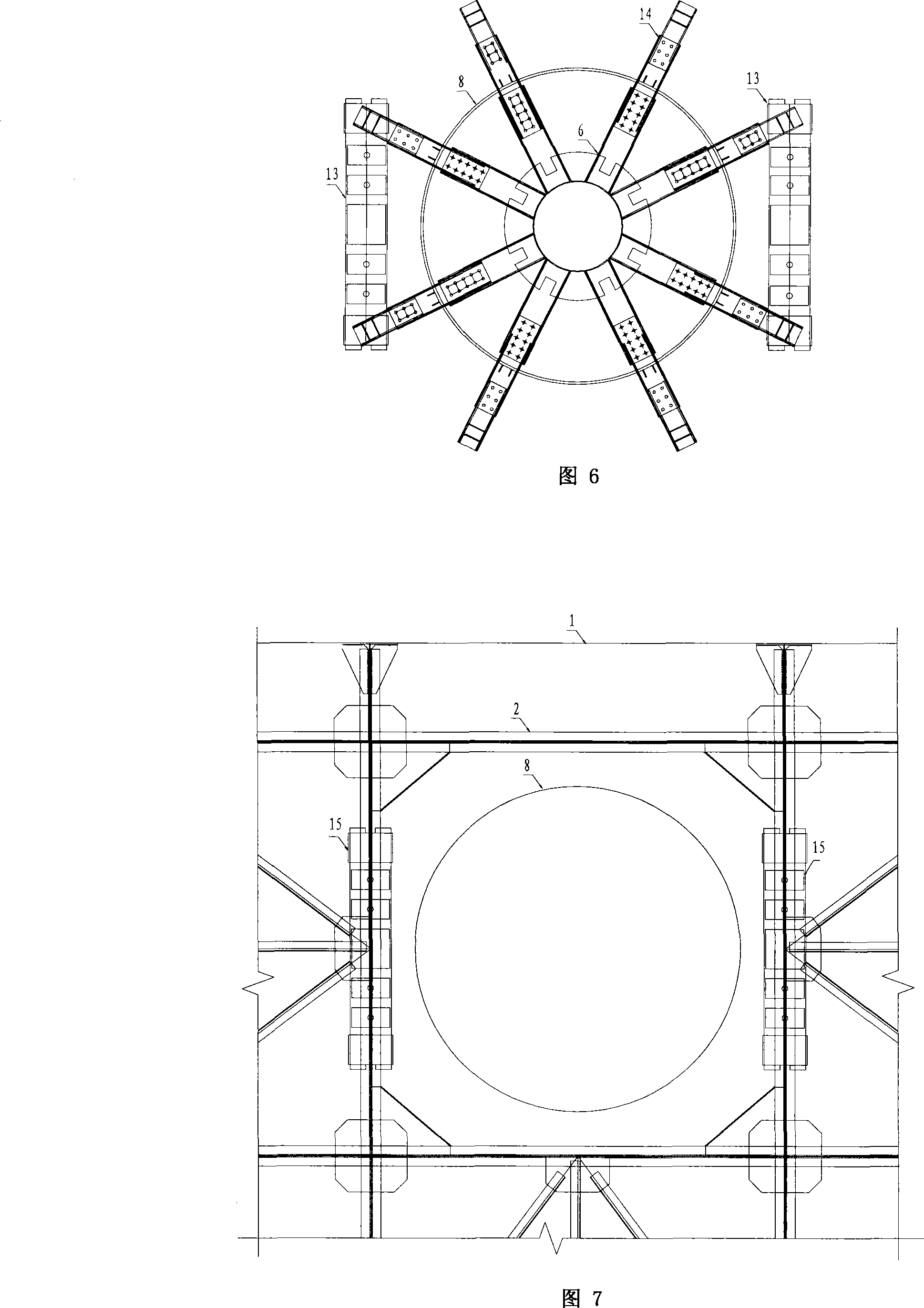

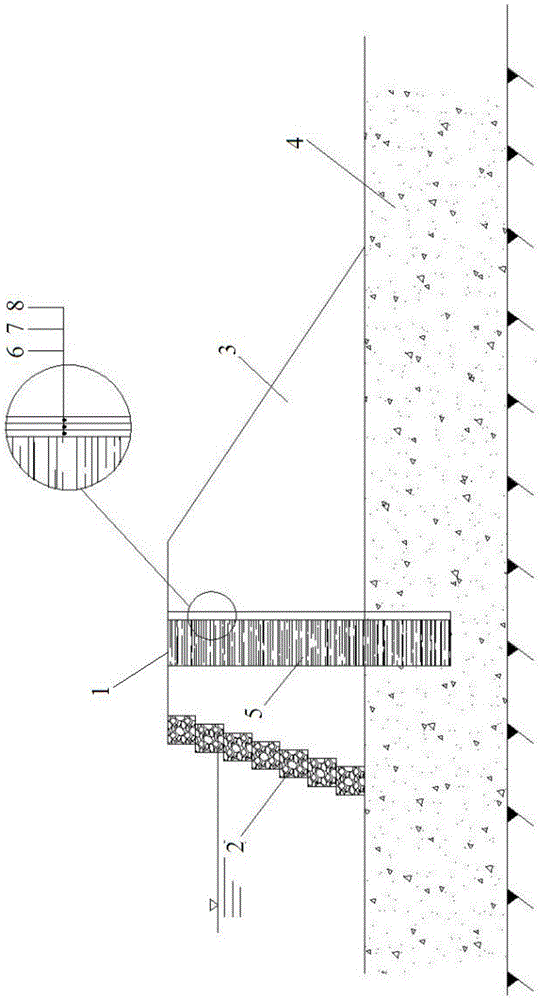

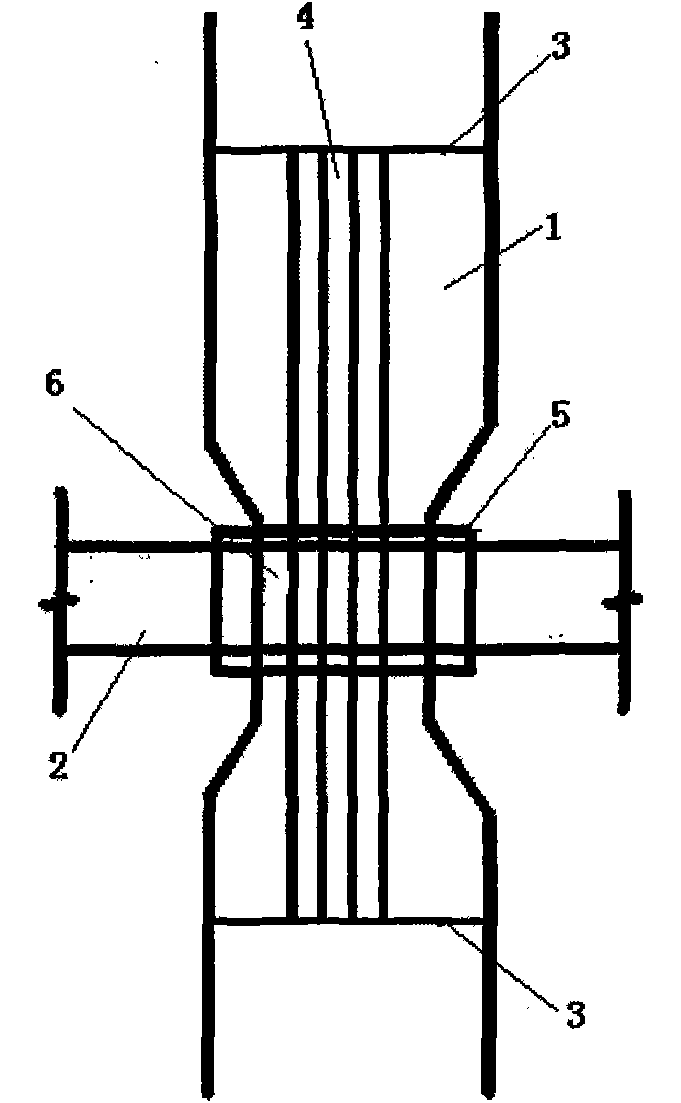

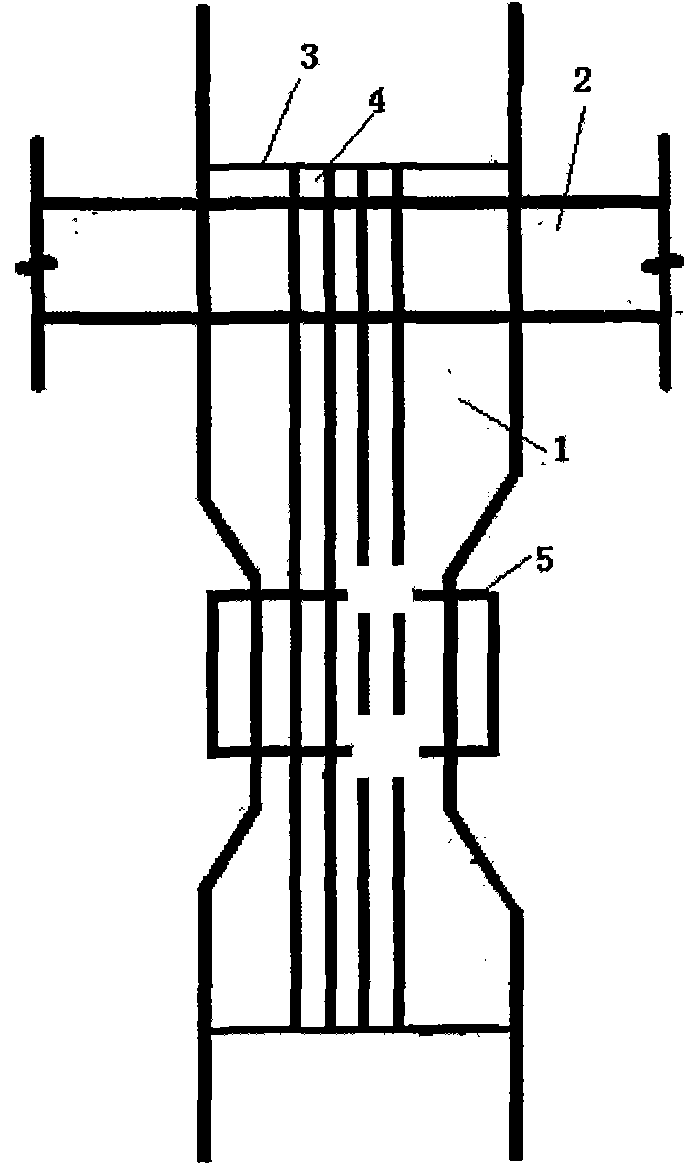

Deepwater single-wall steel plate pile cofferdam structure with low buried depth and construction method thereof

The invention discloses a deepwater single-wall steel plate pile cofferdam structure with low buried depth. The structure comprises a plurality of bored piles, a steel plate pile cofferdam around the bored piles, bagged sand positioned outside the cofferdam and arranged on the surface of a river bed, and high-pressure rotary jet piles constructed in the cofferdam and outside the bored piles, wherein the plane size of the cofferdam is greater than that of a bearing platform to be constructed so as to reserve a construction space. By using the steel plate pile cofferdam, the deepwater low pile bearing platform and the underwater part of a pier of a bridge can be constructed with relatively low cost and minimum construction risk, and a double-wall steel cofferdam scheme with relatively high cost does not need to be adopted for construction, so that the turnover steel consumption of the cofferdam serving as a temporary project is saved, and the application range of the deepwater steel plate pile cofferdam construction technology is enlarged.

Owner:THE FIRST ENG OF CCCC FOURTH HARBOR ENG +1

Anti-seepage cofferdam structure and construction process

ActiveCN104153380ASimple construction methodSimple structureFoundation engineeringGeomembraneCofferdam

The invention relates to anti-seepage cofferdam structure and a construction process. The cofferdam structure comprises a vertical anti-seepage body arranged in the middle of the end face of a cofferdam, wherein the bottom of the anti-seepage body extends to be embedded into a river bed covering layer, a main body of the anti-seepage body is formed by filling a multi-layer gel and sand gravel mixture, a vertical anti-seepage insulating layer is arranged on one side of the anti-seepage body and is a layer of geomembrane clamped between two geotextiles, a trapezoid cofferdam body is arranged on the other side of the anti-seepage insulating layer, and a lead wire gabion is arranged on the other side of the anti-seepage body. The construction process comprises using a backhoe excavator to remove large stones in a basic region after a temporary cofferdam is built; then using the backhoe excavator to dig a groove with 1.2m width and 3m depth along the cofferdam axis, and back filling the multi-layer gel and sand gravel mixture in layers to construct the anti-seepage cofferdam structure. The anti-seepage cofferdam structure is simple in structural style, the construction method is easy, and the anti-seepage effect is good. A construction period is shortened, fund is saved, and a simple and effective method is provided technically.

Owner:SINOHYDRO BUREAU 11 CO LTD

Construction method of structural system of river under no-cutoff working condition

ActiveCN101892632AKeep the water flowingGuaranteed continuous flowArtificial islandsBuilding repairsSupporting systemCofferdam

The invention relates to a construction method of a structural system of a river under a no-cutoff working condition, comprising the specific steps as follows: 1, constructing cofferdams and shortcuts; 2, removing river channel bridges and pile foundation; 3, constructing a base pit of the river channel segment; 4, constructing the parts at both sides of a new river bridge; and 5, removing the cofferdams and recovering water transportation of the river. The invention has the advantages that: 1, the road or underground pipeline is ensured to be uninterrupted in the construction period; 2, the pile foundation is arranged or fillers are filled below a drainage pipe in the paving process of the drainage pipe to ensure that the drainage pipe maintains the water-on state at the preset height after the cofferdam is gathered; 3, the drainage pipe is cut in the connection-after-disconnection manner when the underground passage ground wall is constructed to cut separately for alternative construction so as to ensure that the river is not cutoff in the construction process of an enclosing structure; and 4, the drainage pipe is supported by a lattice column support system during construction of the underground structures and bridges so as to ensure the stability of the drainage pipe and no cutoff of the river in the construction process of the underground structure.

Owner:SHANGHAI FOUND ENG GRP

Method for repairing pile foundation and scour pit underwater

InactiveCN108411802AEasy constructionEasy to processFoundation repairBridge structural detailsUnderwaterPortland cement

The invention relates to a method for repairing a pile foundation and a scour pit underwater. The method includes the following steps that (1), a steel plate pile cofferdam is adopted for conducting construction around the local scour pit of a pier needing to be repaired; (2), a concrete cushion layer is laid within the range 2 m away from the pier; (3), the condition that the pier is damaged dueto scouring and corrosion is checked, and the pier is repaired firstly; (4), natural backfill soil is packed in the scour pit; (5), multiple stones are packed in the scour pit; and (6) ordinary Portland cement mortar is laid flatly on a macadam grouting protection layer, an RPC material is packed in the portion at the depth 15% of the remaining depth of the scour pit, an RPC layer is formed untilthe RPC layer is flush with the bottom face of a riverbed, and a soil layer is backfilled in the portion, around the RPC layer, in the scour pit. By the adoption of the method, the effect that the scoured and damaged pier foundation and the scour pit can be repaired, the bearing capacity of the original structure is improved, the service life of the structure can be prolonged by the adoption of the RPC material, and maintenance cost is saved.

Owner:YANGZHOU UNIV

Construction method for cropping bridge pile foundation at sandy gravel stratum of abyssal region

InactiveCN105672348ALow costConstruction quality is easy to controlBulkheads/pilesSocial benefitsCofferdam

The invention discloses a construction method for cropping a bridge pile foundation at a sandy gravel stratum of an abyssal region. A passive underpinning principle is adopted; firstly, an enclosing structure is constructed behind an existing bridge abutment by a certain distance, and a temporary cofferdam is constructed in a river, so that operation space is provided; an underpinning pile foundation and an underpinning bearing table are constructed in the enclosing structure, and dead loads of an existing bridge is transferred to an underpinning pile and the underpinning bearing table; and a pile breaking channel is dug below the underpinning bearing table, and the pile is finally removed with a manual hole digging method. According to the method, on the premise that the construction quality is guaranteed, the construction schedule can be quickened, the manufacturing cost is reduced, and influences of underpinning construction on existing buildings, pipes and ground transportation are reduced; and the construction method has the technical advancement and has social benefits and economic benefits.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com