Deepwater single-wall steel plate pile cofferdam structure with low buried depth and construction method thereof

A technology of steel sheet pile cofferdam and soil penetration depth, which is applied in the direction of foundation structure engineering, construction, etc., can solve the problem that the depth of steel sheet piles cannot meet the requirements of normal soil penetration depth, and achieve the effects of enhancing rigidity, increasing void ratio, and reducing the degree of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

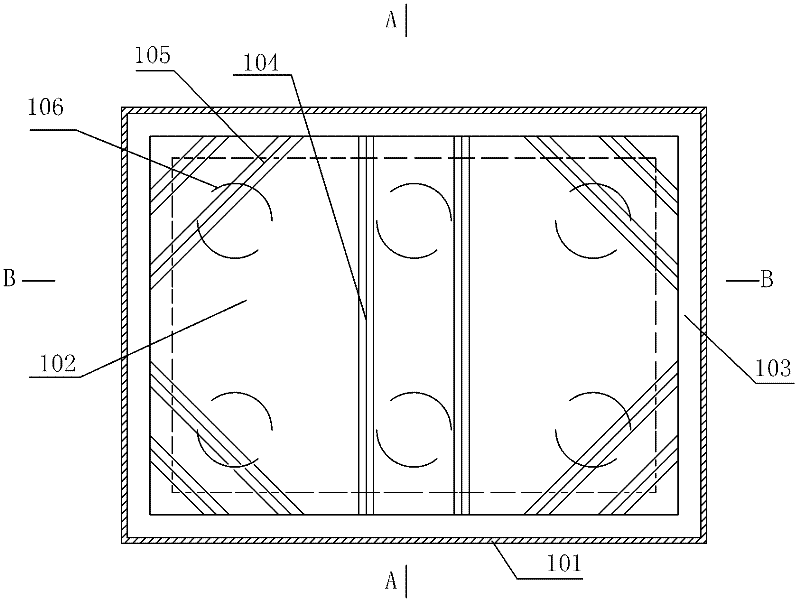

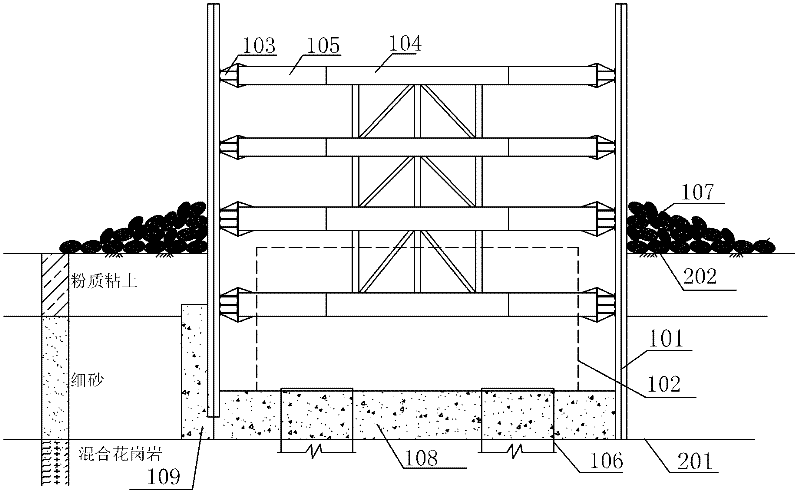

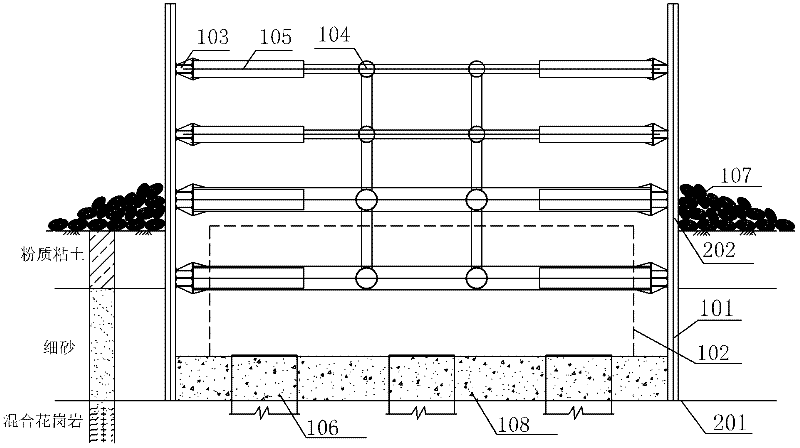

[0054] Such as Figure 1a~1c Shown is a schematic diagram of a steel sheet pile cofferdam structure example of the present invention.

[0055] Now take the construction of a highway bridge in a certain city as an example. The span combination of the main bridge is (80m+200m+80m) self-anchored suspension bridge. The main piers are No. 16 and No. 17 piers, which are located in the Huaihe waterway. The covering layer is mainly composed of silt, clay, fine sand, and gravel sand, and the thickness of the covering layer is 5.5-11m, which varies greatly. The underlying bedrock from top to bottom is fully weathered amphibolite, strongly weathered mixed granite, moderately weathered amphibolite, and moderately weathered mixed granite.

[0056] The rock surface elevation of No. 16 pier provided by the original design drawings is -2.86m, and that of No. 17 pier is -0.76m. Due to the great fluctuation of the rock surface, it was found that the bottom of the steel sheet pile was far from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com