Patents

Literature

627 results about "Bedrock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bedrock in geology is the lithified rock that lies under loose softer material called regolith within the surface of the Earth's crust or other terrestrial planets.

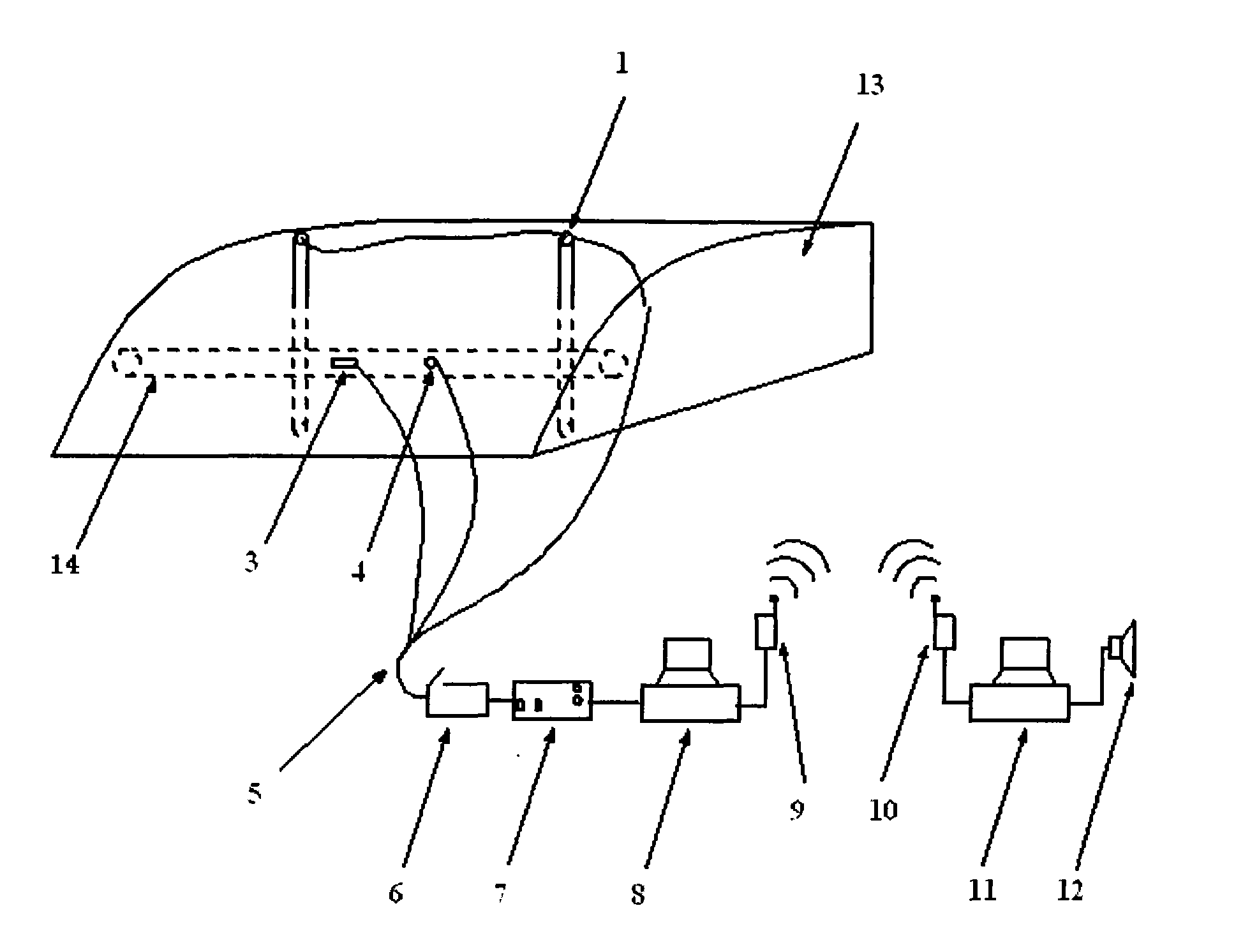

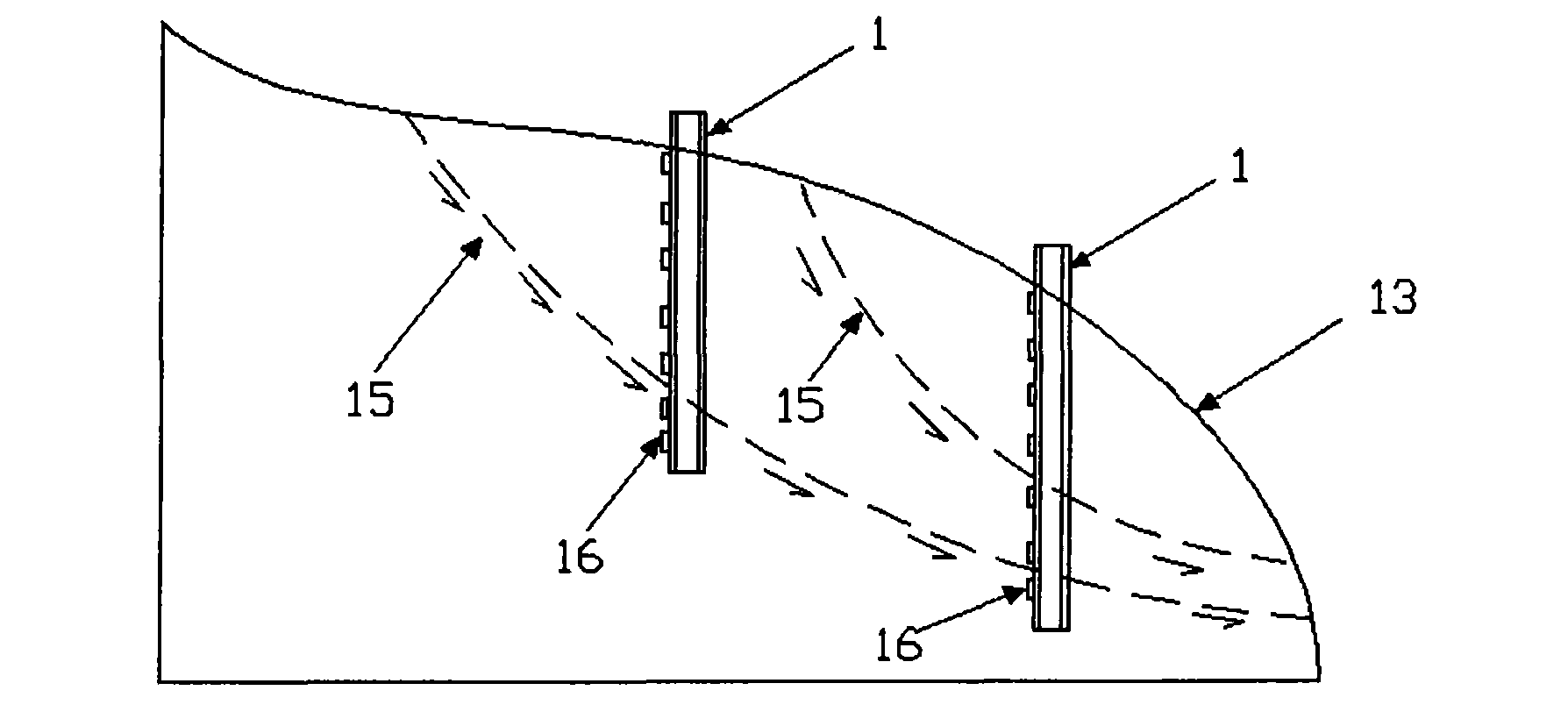

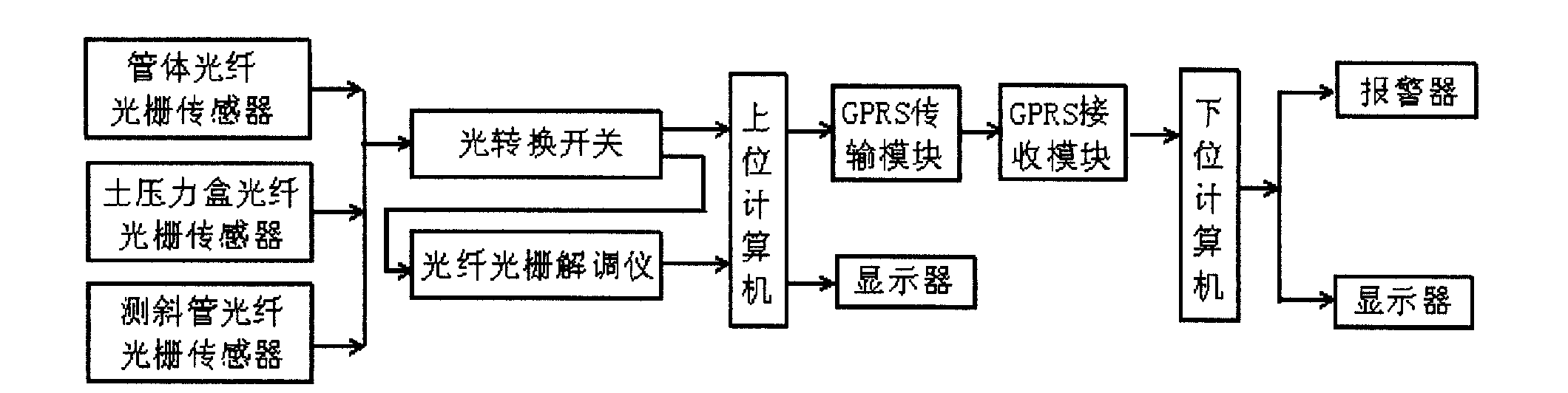

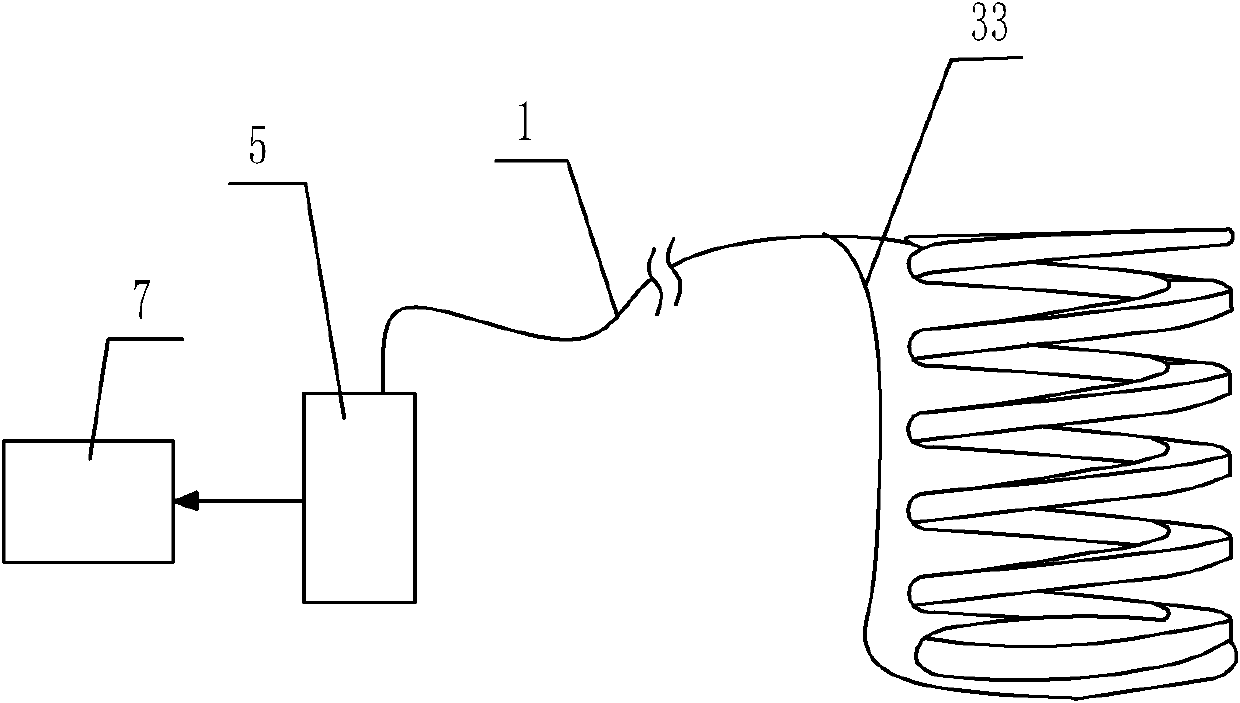

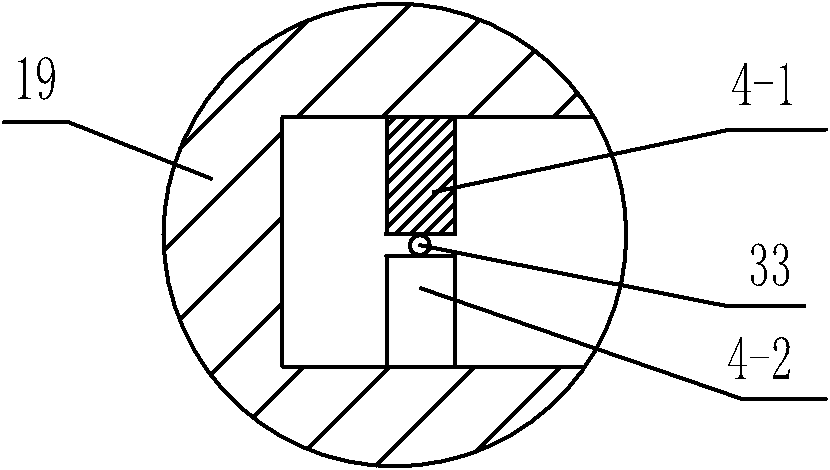

Method and system for monitoring and warning pipeline landslide depth displacement and method for constructing system

ActiveCN101667327ASimple structureReduce volumeForce measurement by measuring optical property variationUsing optical meansFiberGrating

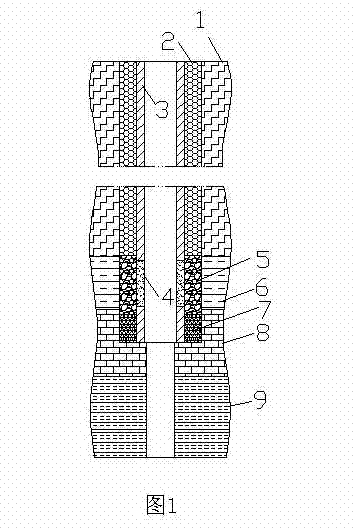

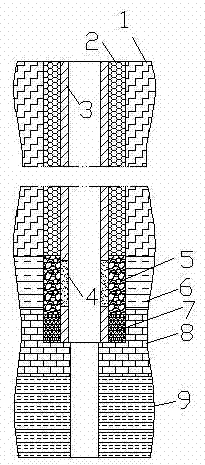

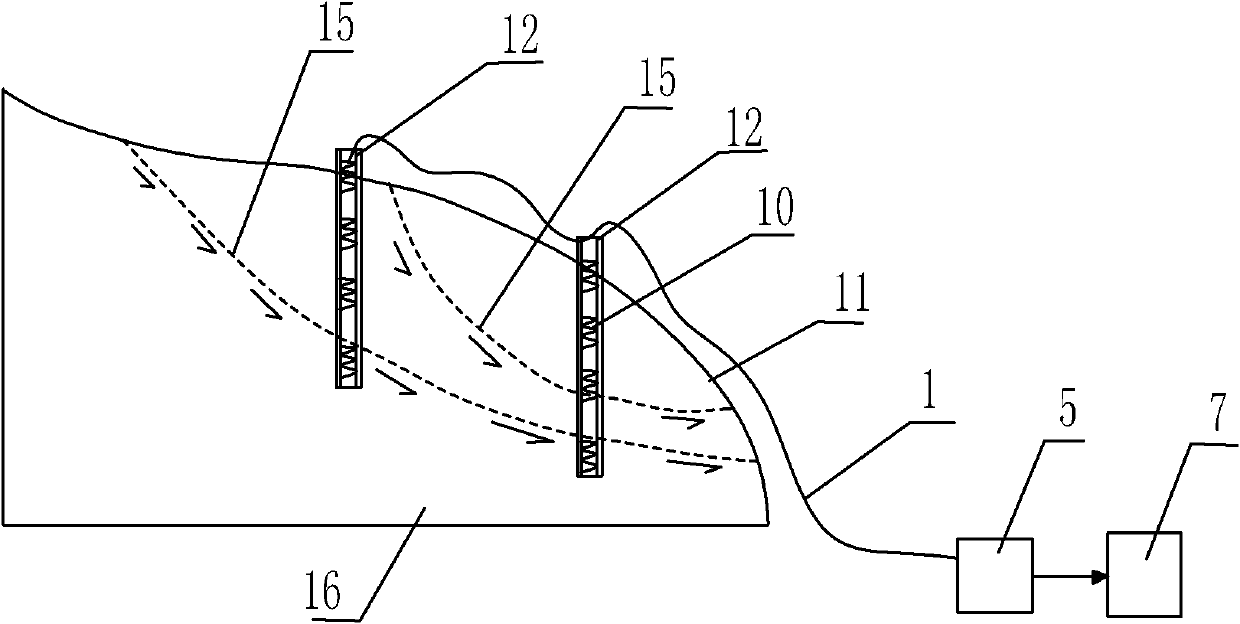

The invention relates to a method and a system for monitoring and warning pipeline landslide depth displacement and a method for constructing the system. The monitoring is divided into three parts including landslide depth displacement monitoring, monitoring of thrust of landslide on a pipeline and pipeline strain monitoring, and comprises the steps of: inserting an inclinometer pipe (1) pasted with a fiber Bragg grating sensor into the landslide (13), penetrating all potential sliding surfaces (15), extending the inclinometer pipe to a drilling hole 3 to 5m deep under a bedrock surface, and measuring the maximum tension strain born by the inclinometer pipe (1); measuring the front thrust of the landslide (13) on the pipeline by using a packaged earth pressure cell fiber Bragg grating sensor (4) fixed on the pipeline (14); and uniformly arranging pipeline (14) monitoring sections on edges on two sides of the landslide and the pipeline (14) in the center of the landslide (13), and uniformly arranging three pipe strain fiber Bragg grating sensors (3) on each monitoring section to monitor the axial strain of the pipeline (14).

Owner:PIPECHINA SOUTH CHINA CO

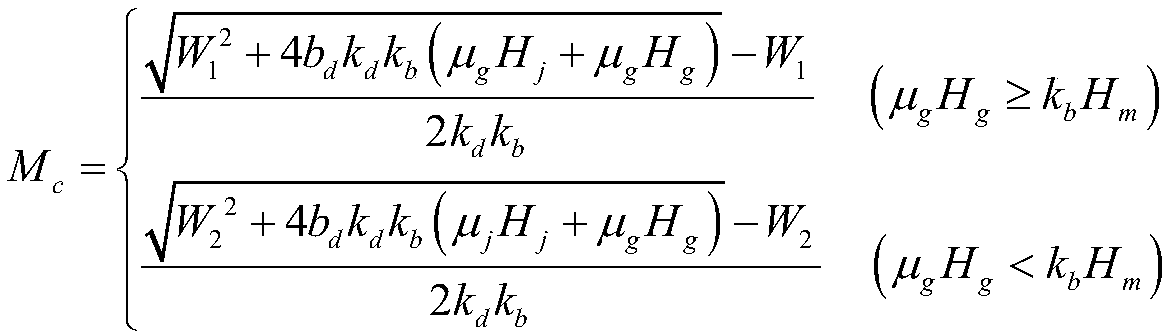

Thin-base-rock shallow coal-layer water-retaining production suitable-condition classification method

InactiveCN101070759AImprove resource recoveryHigh recovery rateUnderground miningSurface miningBedrockReturn ratio

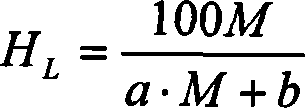

The invention discloses applicable classification method for mining under the shallow bedrock of thin seam keeping water conditions. Apply to thin seam overlying shallow bedrock aquifer water loose the protection of water resources. At first according to the feature of structure or Shallow bedrock, the height of leading water crevasse under different mining height is analyzed and calculated. The estimate formula: HL=9.29M+10.6 can be used to determine the height HL of leading crevasse water under the shallow bedrock of thin seam to the different mining height M. The mining waterproofing security coal rock pillar protector thickness of the thin bedrock shallow submersion coal bed long well working surface is 10 m. According to the classification situation of loose water-bearing stratum water body, the bedrock thickness which is needed is determined under the condition of different mining height. According to classification situation and mining height, mining is separated into reinsurance water mining according to the bedrock thickness. This method has good water resources protection effect, is safe in production, and has high coal resource returns-ratio.

Owner:CHINA UNIV OF MINING & TECH

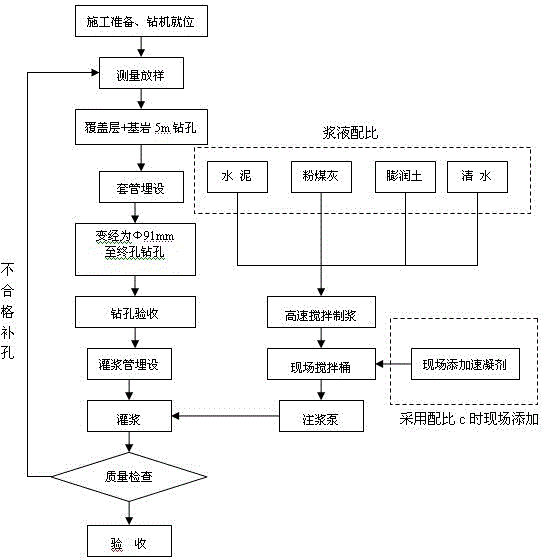

Curtain grouting construction method for treating mined-out areas

The invention discloses a curtain grouting construction method for treating mined-out areas. The curtain grouting construction method includes steps of 1), preparing for construction before drilling; 2), forming curtain grouting holes at boundaries of treatment ranges of the mined-out areas; 3), drilling covering layers and bedrock sections of the mined-out areas; 4), washing drilled holes in the mined-out areas; 5), performing curtain grouting treatment on the mined-out areas by the aid of the drilled holes and performing curtain grouting by the aid of different types of slurry according to conditions of leaking quantities of the drilled holes; 6), inspecting the grouting quality. The curtain grouting construction method for treating the mined-out areas has the advantages that a ground drilling grouting mode is adopted for the boundaries of the treatment ranges of the mined-out areas, so that closed grout stopping curtains with certain strength can be formed, the curtain grouting quantities and curtain grouting diffusion ranges can be effectively controlled, the curtain pack densification and the gravel strength can be greatly improved, problems in the aspect of closing and grout stopping for boundaries of mined-out areas can be solved, and engineering investment can be saved.

Owner:GEZHOUBA GROUP FOUND ENG

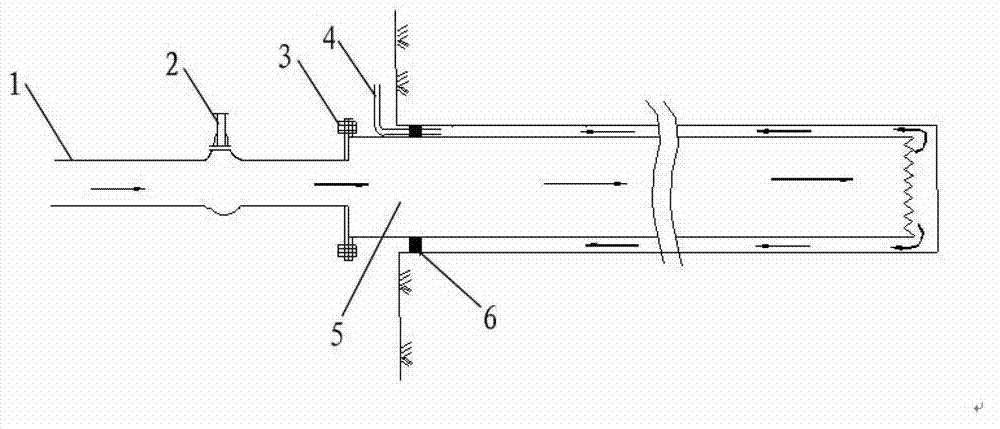

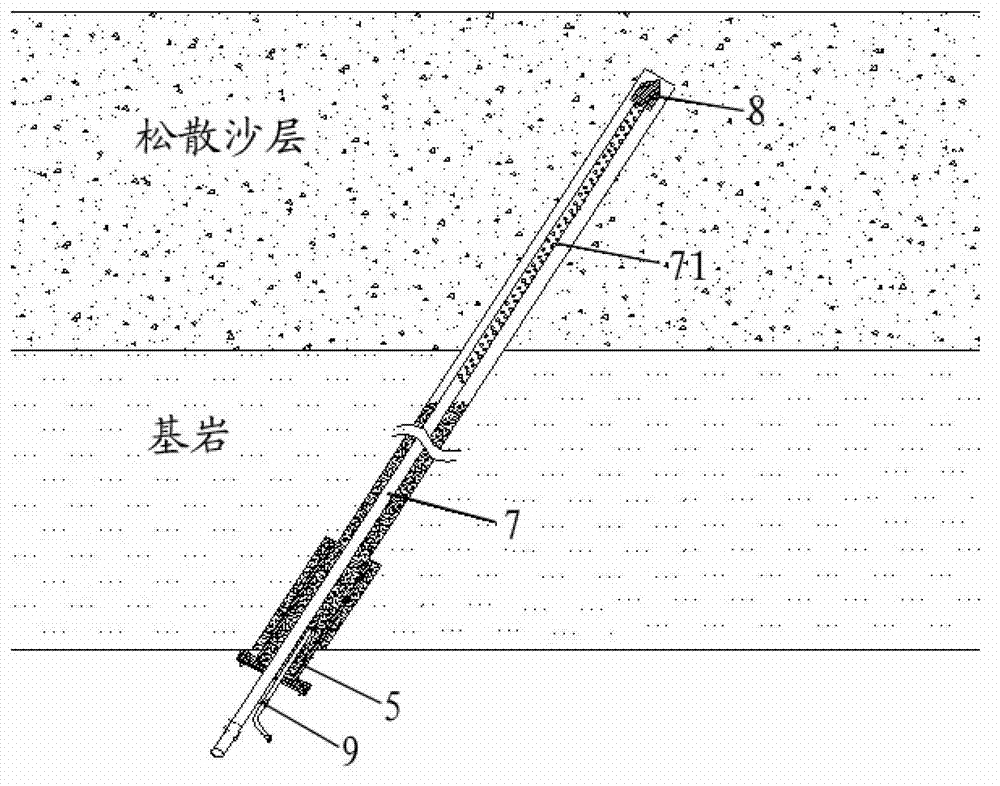

Underground draining and grouting process in thin bedrock and thick loose sand layer rich water areas

The invention relates to an underground draining and grouting process in thin bedrock and thick loose sand layer rich water areas. The underground draining and grouting process includes constructing a first drill hole, installing an orifice pipe, grouting, constructing a second drill hole, installing a deep-hole grouting pipe, draining, installing a shallow-hole grouting pipe and sequentially performing shallow-hole grouting and deep-hole grouting in an exploration entry. By aid of solidifying and grouting for a loose sand layer, the loose sand layer can form a cemented whole body and a block or wrappage, when a working surface extracts to be below a grouting area, the solidified integral loose sand layer can serve as a top plate and the block or wrappage to fill a large-fracture water guide channel formed by top plate bedrock falling, and water bursting and sand collapsing can be prevented. The disposable deep-hole grouting pipe replaces a drilling rod for grouting, and accordingly work efficiency of a drilling machine is improved for several times and drilling rod loss is avoided.

Owner:CHINA SHENHUA ENERGY CO LTD +1

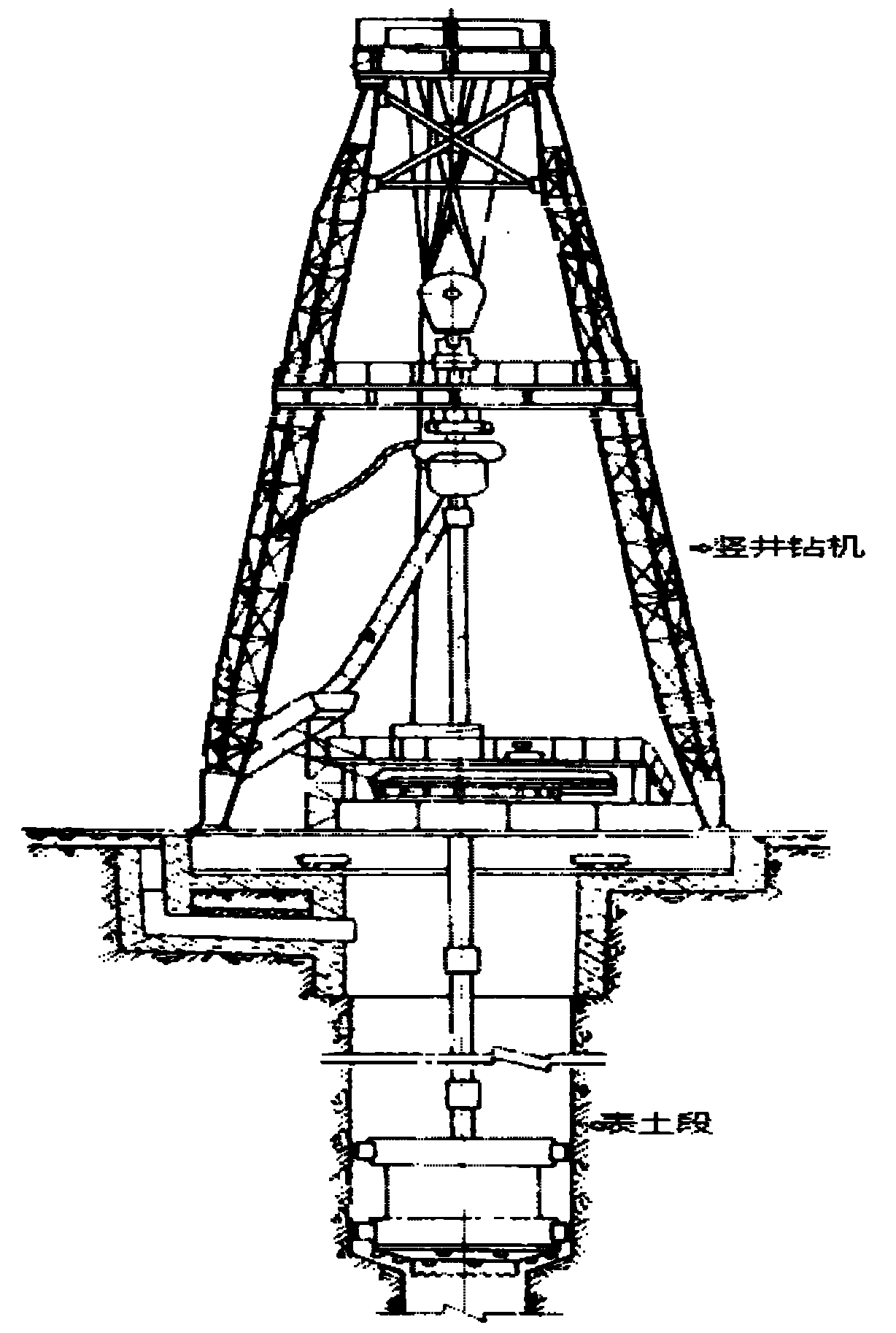

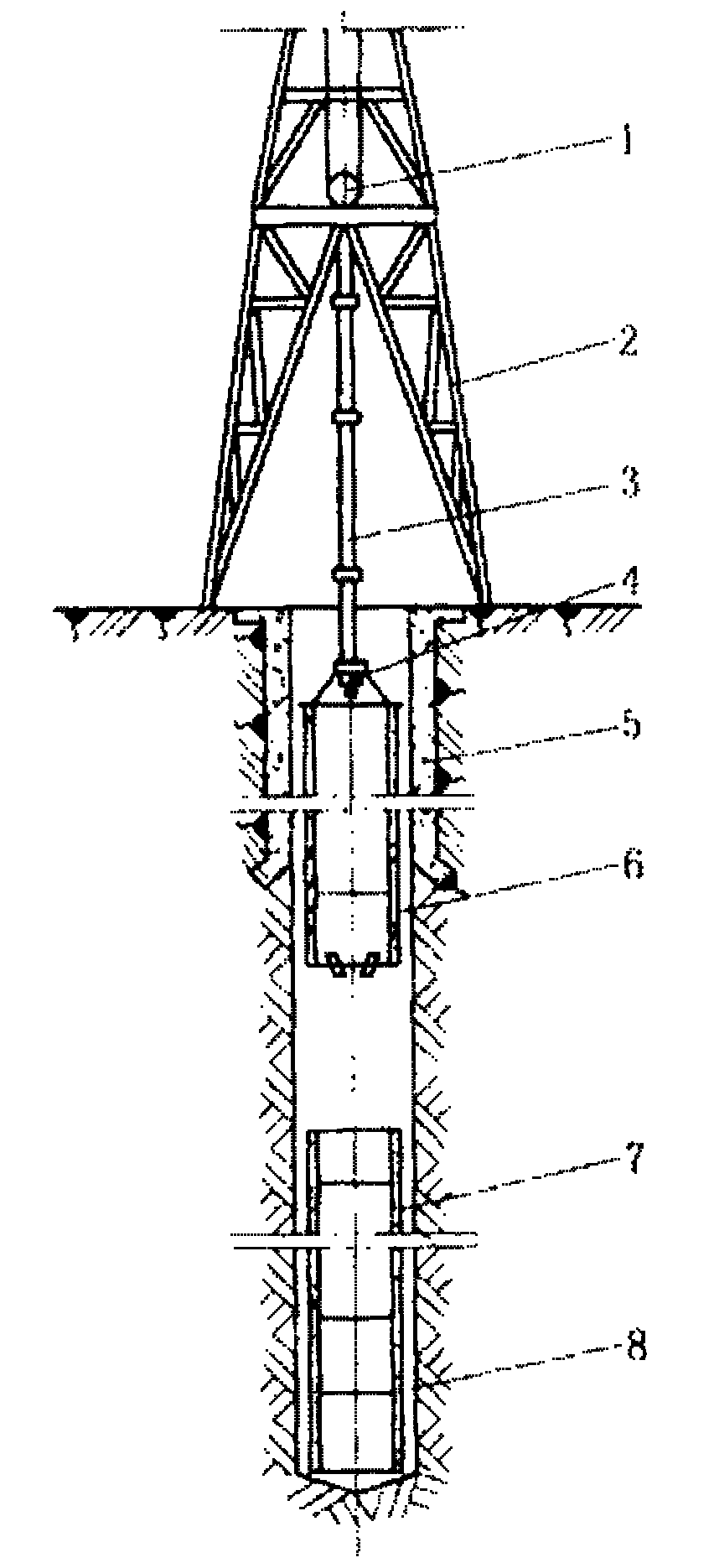

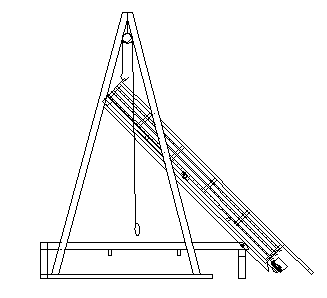

Comprehensive shaft sinking method of positive and raising boring for vertical shaft

InactiveCN102493809AReduce construction costsFast well formationShaft sinkingShaft raisingBedrockWell drilling

The invention discloses a comprehensive shaft sinking method of positive and raising boring for a vertical shaft, which comprises the following steps: drilling into a bedrock section by utilizing a vertical shaft drill machine, forming surface soil section well holes, discharging rock-debris-containing slurry produced during the well drilling process to the ground at high speed through air lifting; prefabricating sections of well walls on the ground; adding counter weight water in the drill well, slowly sinking the sections of well walls to the surface soil section well holes by utilizing buoyancy force of slurry to the well walls in the drill well, and sequentially welding the well walls to the surface soil section well holes; filling grout between the well walls and the rock sides on the outer sides of the well walls, filling cement paste in the lowest layer, then alternatively filling upwards the cement paste and rubbles layer by layer, and obtaining a surface soil section drill well; selecting a suitable raise-bore drilling machine according to practical requirements of the diameter and depth of a bed rock section shaft; lowering the raise-bore drilling machine and fixing the raise-bore drilling machine at the bottom of the surface soil section drill well; inversely expanding the holes by utilizing the raise-bore drilling machine to form bing-holes; and the diameter of the bing-holes is enlarged to preset shaft diameter. The comprehensive shaft sinking method of the positive and raising boring for the vertical shaft greatly improves well forming speed of shaft sinking and is safe, reliable and low in construction cost.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

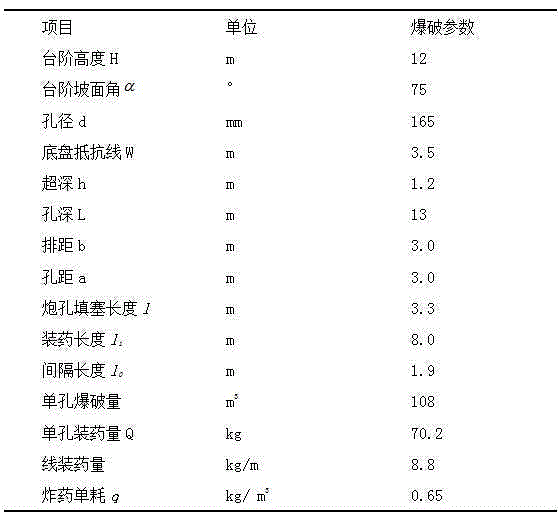

Method for improving bench blasting quality of deep-hole of super-hard rocks

The invention discloses a method for improving the bench blasting quality of a deep-hole of super-hard rocks. The method includes the following steps that blast holes are formed in a step of a blast area, hole mesh parameters are determined, and perpendicular drilling is conducted; explosive loading structures are determined, and the explosive loading structures for segmented explosive loading and mixed explosive loading are adopted in the blast holes at the same time; explosives are determined, wherein the explosives are selected according to according to matching coefficients of explosive wave impedance and rock wave impedance; blasting parameters are determined and include the length W of a resistance line of a base plate, the hole pitch a, the row distance b, the super depth h and the blast hole filling length l; and blasting is conducted, wherein the explosives are loaded, the blast holes are filled with stemming on the tops of the blast holes, reverse blasting is conducted from the bottoms of the blast holes, and blasting is conducted in an inter-hole elementary error sequence. According to the method for improving the bench blasting quality of the deep-hole of super-hard rocks, due to the fact that the hole mesh parameters, the explosive loading structures, the explosives, the blasting parameters, the blasting position and the blasting sequence are reasonably selected, multi-way comprehensive functions are achieved, the performance of the explosives is fully achieved, the sufficient reaction of the explosives is ensured, the utilization rate of the blast holes is increased, and the boulder frequency and bedrocks of rock blasting are reduced.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

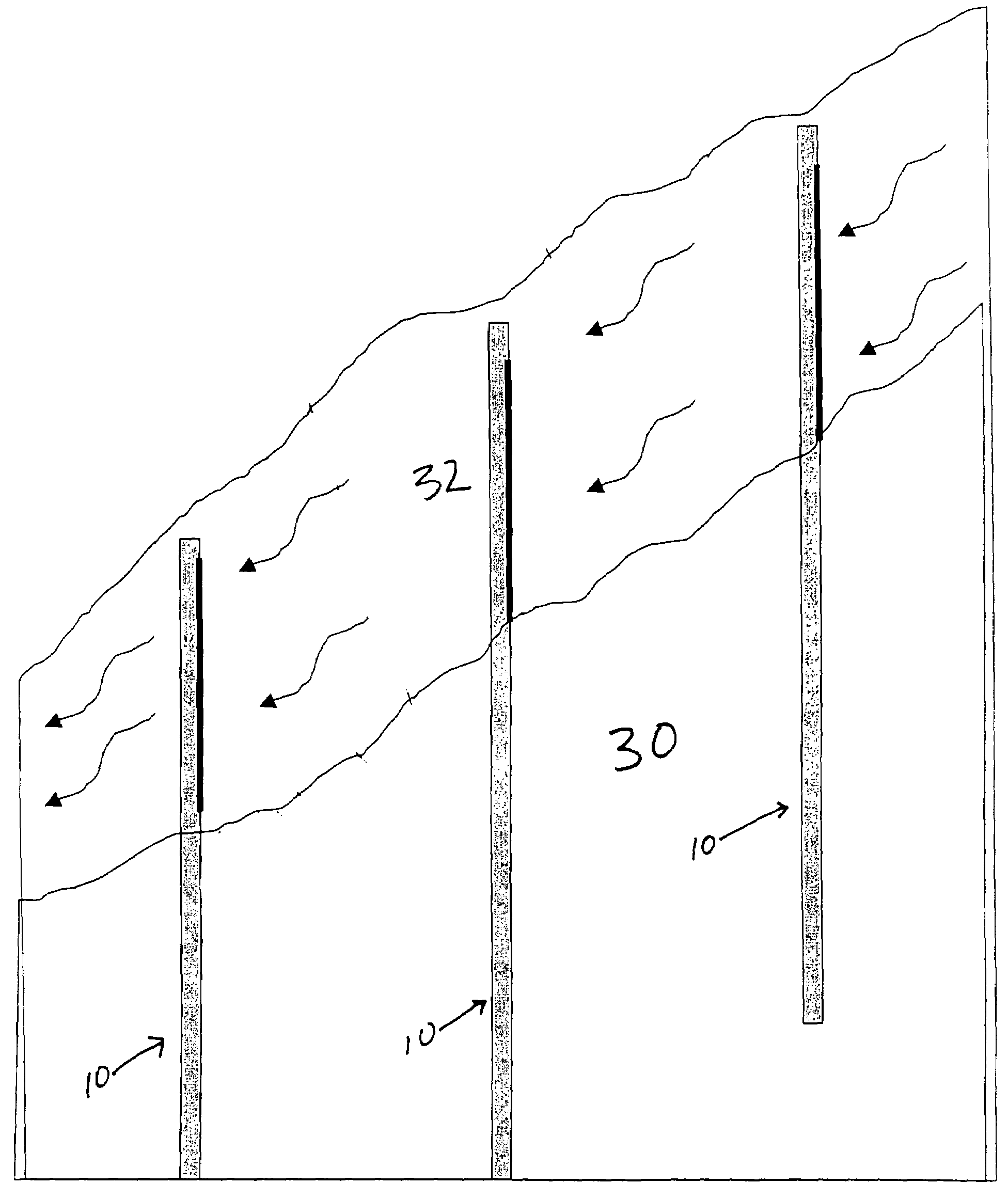

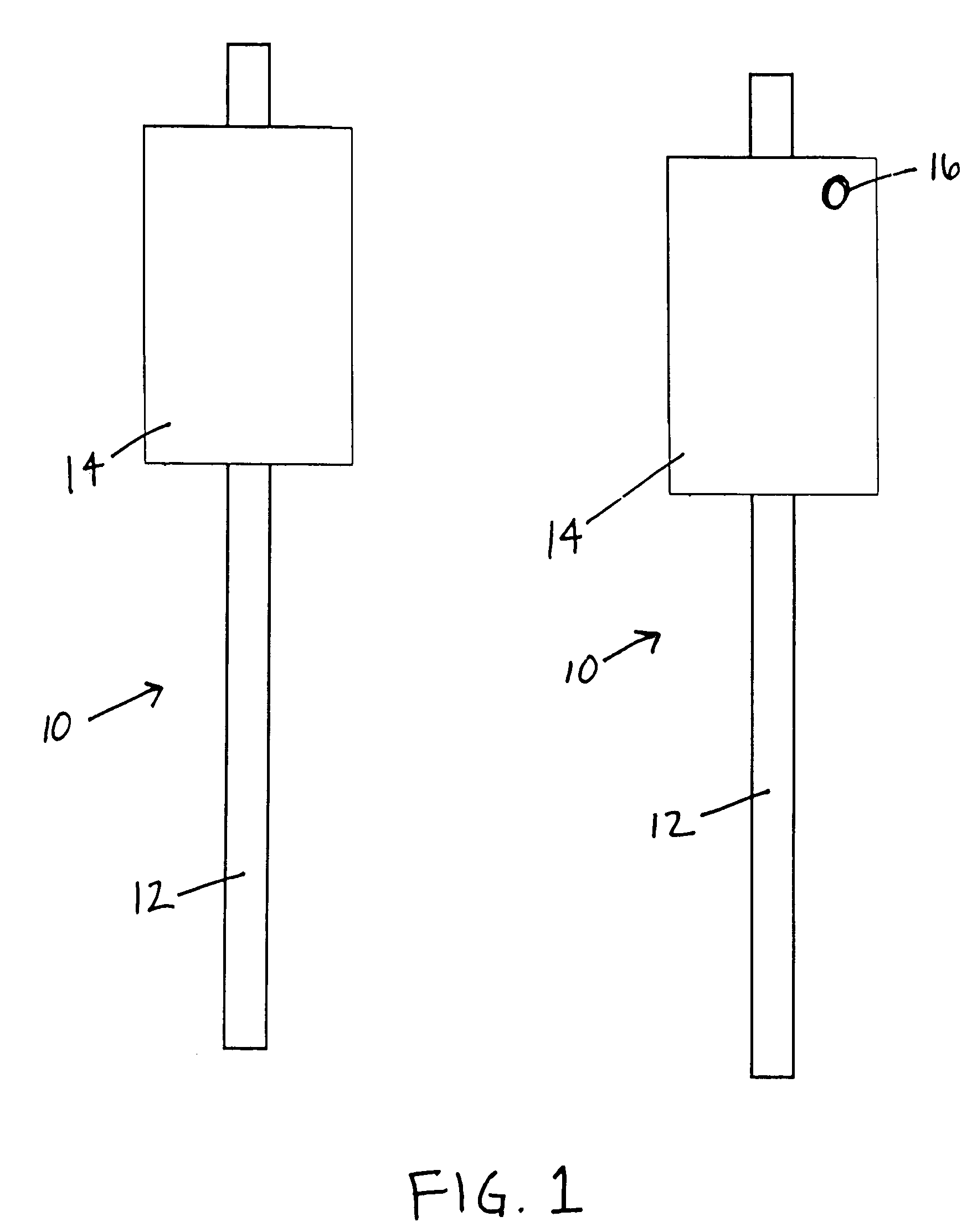

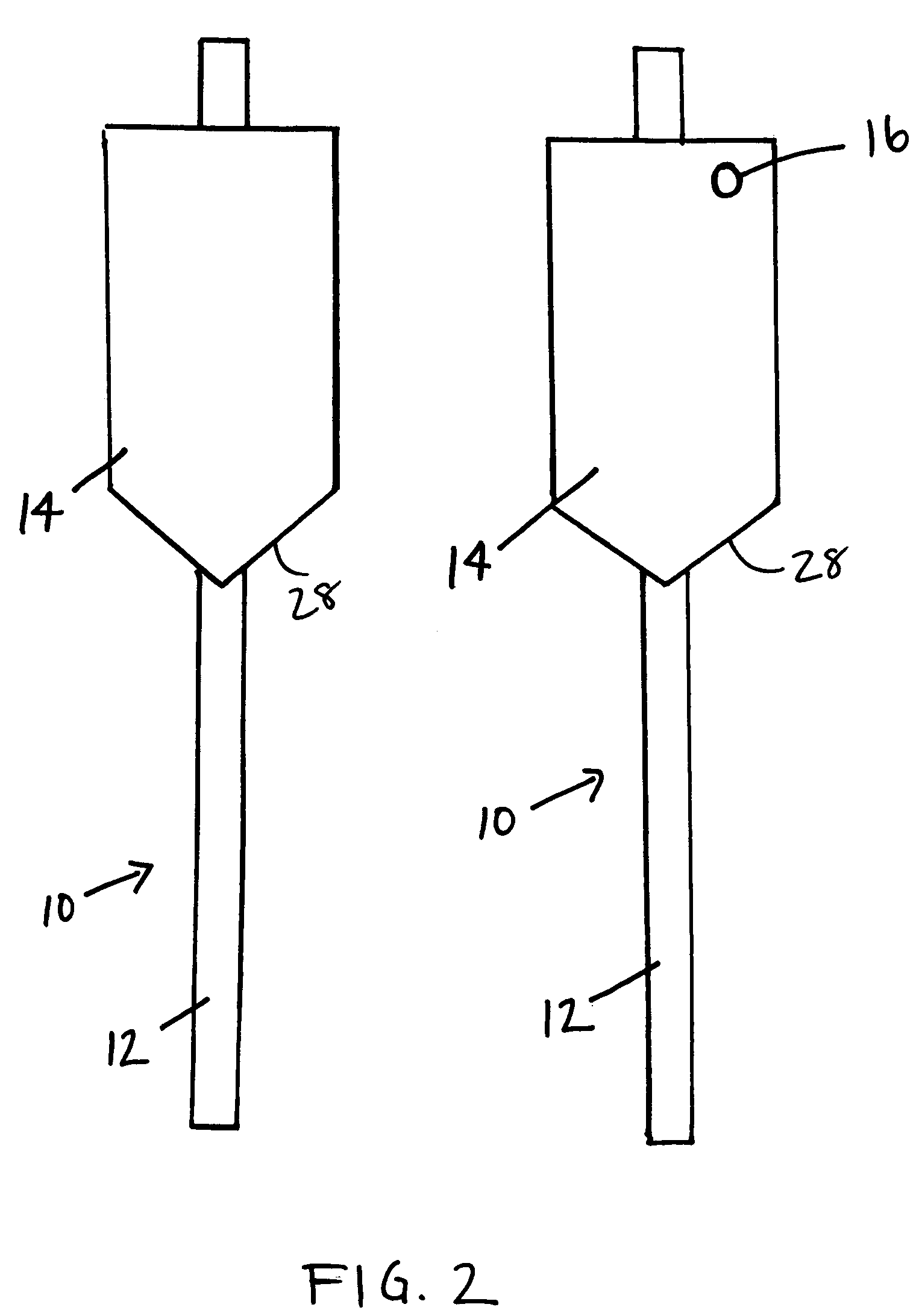

Method and device for stabilizing slopes

ActiveUS7090440B1Preserving aesthetic appearanceEliminate and reduce movementExcavationsOrganic fertilisersBedrockEngineering

A method and device for stabilizing slopes that are at or near failure preferably due to a shallow, translational slides. Once a target slope has been identified, a plurality of plate piles is inserted into the entire at-risk slope to stabilize the slope. The plate piles preferably consist of a steel plate attached to an angle. The plate piles are inserted below the soil surface, with the pile extending into the bedrock, preferably in a diamond-shaped lattice pattern over the entire slope.

Owner:GEOPIER FOUND CO INC

Combined support-excavated geologically solutional deep foundation pit and construction method thereof

ActiveCN101892668APrevent landslidesImprove the support effectExcavationsSoil massReinforced concrete

The invention discloses a combined support-excavated geologically solutional deep foundation pit and a construction method thereof. The deep foundation pit is characterized by consisting of an upper slope foundation pit and a lower vertical foundation pit; the construction method thereof comprises the steps that: in case of vertical excavation of the deep foundation pit, the periphery of the foundation pit is supported and reinforced by reinforced concrete support piles to prevent the foundation pit from collapse owing to lateral pressure of soil mass; then a high pressure jet grouting pile waterproof curtain is adopted for performing water sealing on soil mass outside the support piles and a bedrock internal grouting curtain is adopted for performing water sealing on geological situations in rocks, such as solution cavity, solution, crack and the like; and in the process of layered excavation, an annular continuous concrete slab wall is adopted for the soil mass and the rocks at the periphery of the foundation pit to form a continuous arch ring lagging. The construction method according to the invention can effectively guarantee the safe, stable, fast and effective excavation of the geologically solutional deep foundation pit.

Owner:THE FIRST CIVIL ENG CO LTD OF CREC SHANGHAI GRP

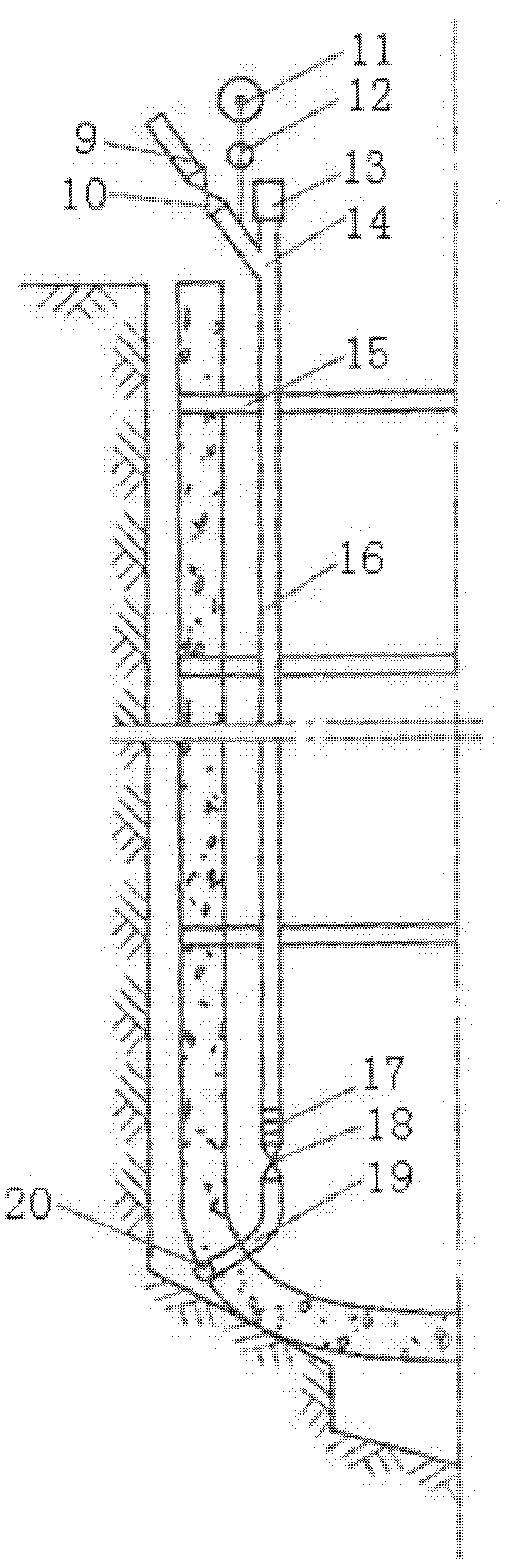

Loose bed and bedrock layer mixed water-intaking and well-forming process for geothermal well

ActiveCN102251760ASolve the well completion rateImprove maximum efficiencyConstructionsFluid removalBedrockSoil science

The invention discloses a loose bed and bedrock layer mixed water-intaking and well-forming process for a geothermal well, and the process provided by the invention comprises the following steps: 1) using a slurry positive circulation well drilling process to perform well drilling till the depth of 5-10m below a complete bedrock surface; 2) sinking pipes, namely sinking a well wall pipe at the section below the bedrock surface and the section of a non-loose porous water layer of a loose bed and sinking a water-permeable pipe below the section of a loose porous water layer of the loose bed; 3)filling annular holes, namely pouring cement slurry into the annular holes corresponding to the section below the bedrock surface, putting a filter material into the annular holes corresponding to the loose porous water layer and putting clay balls into the annular holes corresponding to the section of the non-loose porous water layer of the loose bed; and 4) further using a drill bit with the diameter being 5-10mm smaller than the inner diameter of the well wall pipe to continue drilling in the bedrock layer through a clear water drilling process or a negative circulation well drilling process till a bedrock fracture water layer after the cement slurry waits on cementing for 72 hours and completing the well when the water temperature achieves the design temperature. The well drilling process for the geothermal well is suitable for developing geothermal resources in regions with poor geothermal resources and non-developed bedrock structures.

Owner:河北伟业地热新能源科技有限公司

Foundation integrated processing construction method of cover type karst area

ActiveCN101864763ASpeed up the progress of the projectSave construction fundsSoil preservationBedrockSleeve valve

The invention relates to a foundation processing method, in particular to a foundation integrated processing construction method of a cover type karst area. The method comprises the following steps of: evacuating earth moving machinery when a foundation pit is excavated until a limestone formation is exposed in a large area; basically exposing rocks of the bottom of the foundation pit after excavating, wherein rock buds are exposed from a foundation base, and the storage quantity of damic earth among the rock buds does not influence the next procedure construction; adopting weakened loose blasting operation, aiming at solution cracks, intermountain gulches and locally crushing bedrocks, and mechanically crushing and clearing; adopting a complex geophysical prospecting technological means that a high-density resistivity method is combined with a geological radar, arranging a high-density electrical geophysical prospecting wire in a construction site according to an arrangement rule, meanwhile, arranging a detailed exploratory hole in a building planning position, and mechanically picking the solution cracks, the intermountain gulches and the locally crushing bedrocks; adopting sleeve valve cement flour and coal ash slurry injecting constriction and cement flour and coal ash slurry filling constriction by a solution cavity slurry-injection method; and filling and casting concrete. The invention can quicken a work progress and can save construction cost compared with other foundation processing modes.

Owner:CHINA 22MCC GROUP CORP +1

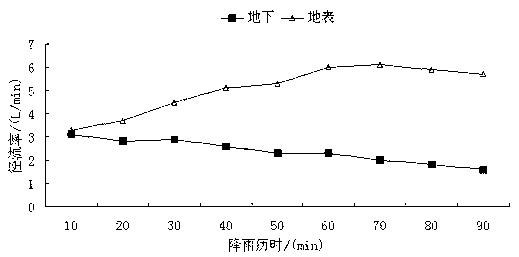

Measuring method for researching runoff and sediment production rule of overland flow and underground pore fracture flow

Owner:GUIZHOU UNIV

In-situ leaching and liquid collecting method for weathered crust leaching-deposited rare-earth ore

The invention relates to an in-situ leaching and liquid collecting method for weathered crust leaching-deposited rare-earth ore. The method comprises the following steps: (1) distributing liquid injection holes, which reach a semi-weathered layer, on the surface of an ore body to form a grid, and inserting a PVC pile into each liquid injection hole so that a leaching agent can reach the semi-weathered layer; (2) drilling liquid collecting guide holes, which are perpendicular to the ore body or are inclined upwards at angle of 2-5 degrees, with a kilometer drill in positions 5-20cm below the interface between the semi-weathered layer and the bedrock of a valley of the ore body, and drilling holes in a circle along the ore body from a lower part of the valley; (3) building a liquid collecting ditch along the ore body from a lower part of the valley so as to lead rare-earth leachate, which flows out of the ore body, into the liquid collecting ditch; and (4) building a liquid collecting pool, which is connected with the lower end of the liquid collecting ditch, at the downstream part of the valley so that the rare-earth leachate flows into the liquid collecting pool via the liquid collecting ditch, pumping the rare-earth leachate in the liquid collecting pool into a hydrometallurgical workshop, and performing treatment and extraction to obtain a rare-earth product. According to the method, rare-earth leachate can be recovered to the maximum extent, the rare-earth recovery ratio is effectively increased, and favorable economic benefits are achieved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Construction method for mine shaft through multilayer goaf

ActiveCN102071940AShorten the construction periodCompletely closedUnderground miningSurface miningSpontaneous combustionBedrock

The invention particularly discloses a construction method for a mine shaft through multilayer goaf, which solves the problem of blankness of the construction method for the conventional mine shaft through goaf. The method comprises the following steps that: 1) the ground and the underground space of the goaf are detected; 2) mechanical analysis is performed on a rock stratum of the goaf; 3) a goaf filling range and filler mechanical property are determined; 4) bedrock is tunneled; 5) a related underground chamber which is integrally connected with a shaft is constructed; and 6) the goaf is filled and reinforced. The construction method fills the blank of the construction method for the shaft through goaf; back filling injection, filling and reinforcing technology is used during the construction of a through goaf of a vertical shaft; the construction method has an advanced, economic and rational technology; the goaf can be completely closed; return current is prevented from entering the goaf, so a coal seam of the goaf has a tendency to spontaneous combustion; thus safe and reliable use of the shaft is guaranteed.

Owner:DATONG COAL MINE GRP

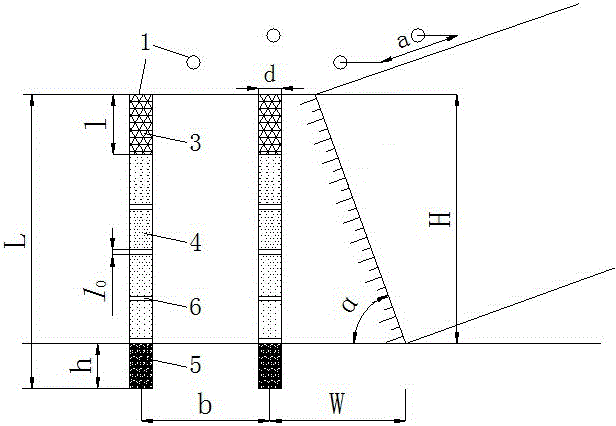

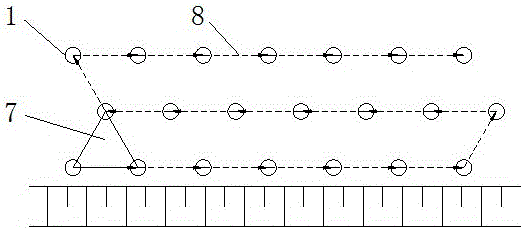

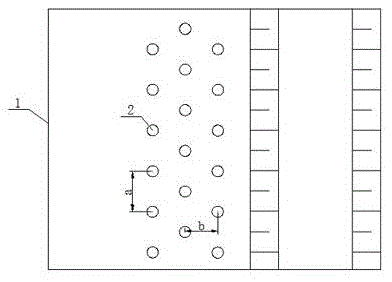

Blasting method capable of effectively reducing blasting boulder yield of surface mine

The invention discloses a blasting method capable of effectively reducing a blasting boulder yield of a surface mine. According to the blasting method, holes are drilled quincuncially in a pre-blasted open-air bench (1) according to designed blast hole net parameters, namely a distance (a) between every two blast holes, and a distance (b) between every two rows of blast holes, so as to form a blast hole net composed of 2-3 rows of blast holes (2); an advanced primer cartridge (3) is arranged in a deepened position of the bottom of each blast hole (2), an in-hole micro-delay initiation technology of first initiation of the advanced primer cartridge (3) and later initiation of a top main charge (6) is adopted, and a micro on-off blasting process is adopted to realize advanced weak crack damage to rock mass at the bottom of the hole; moreover, excessive damage and failure, caused by the blasting effect of the explosive at the top, to the bottom bench rock mass can be effectively avoided, and therefore, the boulder yield of the bottom bench can be controlled; meanwhile, by means of meticulous design, the generation of bedrock can be avoided, the mine exploring cost can be effectively reduced, the production efficiency of an enterprise and the safety of operation can be improved, and favorable economic benefits and social benefits can be created.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

Thin basic rock shallow buried coal seam longwall face water retaining mining method

InactiveCN101021154AReduce breakageAvoid communication problemsUnderground miningSurface miningBedrockResource recovery

The present invention relates to a shallow coal bed long-wall working face water-retaining mining method, specially it is applicable to safety production of shallow coal bed and water resource protection. Said method mainly includes the following steps: according to the coal bed geologic measurement information data defining mining working face; working face adopts hydraulic supporting frame whose strength is above 8000 KN to make support; selecting and using proper matched equipment for quickly driving said long-wall working face is above 200 m; adopting circulating operation to ensure that the dayly driving sped of the long-wall working face is above 15 m and making local filling and reducing local mining height so as to obtain good effect of protecting water resource.

Owner:CHINA UNIV OF MINING & TECH

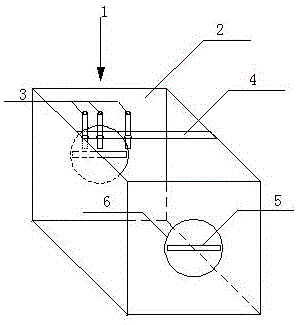

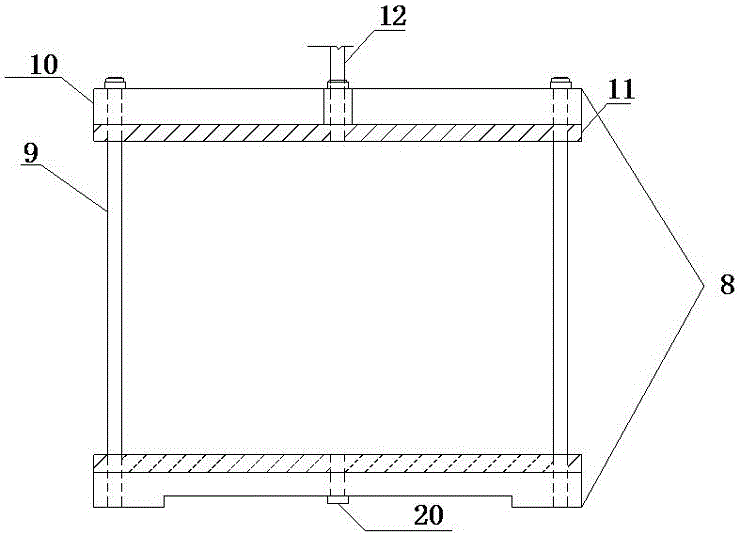

Testing device and testing method for simulating hydraulic fracture characteristic of concrete bedrock contact surface

ActiveCN106442154AImprove sealingThe process is simple and fastPreparing sample for investigationMaterial strength using tensile/compressive forcesBedrockEngineering

The invention discloses a testing device and testing method for simulating the hydraulic fracture characteristic of a concrete bedrock contact surface. The testing device mainly comprises a mold, a steel sheet, pressure measuring guide pipes, a water seal fixture, a water pressure loading system, strain gauges, a clip gauge, a computer and the like. A pair of discs are cut in the mold in a central symmetry mode, can rotate and are used for allowing the steel sheet to be inserted into preformed initial cracks with different thicknesses, widths, roughness and angles; the water seal fixture clamps a test piece in a screwing mode through a screw to seal the water pressure, a high-pressure-resistant water guide pipe is connected with a fixture thread center hole formed in the center of a water seal device through a thread connector, the strain gauges are arranged in the development direction of the cracks, and a coloring agent is added into a water tank connected with the high-pressure-resistant water guide pipe to track the propagation trajectory of the hydraulic fracture cracks. The testing device can be used for studying the hydraulic fracture characteristic of the concrete bedrock contact surface, is simple and convenient to operate and can truly reflect the crack propagation characteristic among contact surfaces of different materials.

Owner:HOHAI UNIV

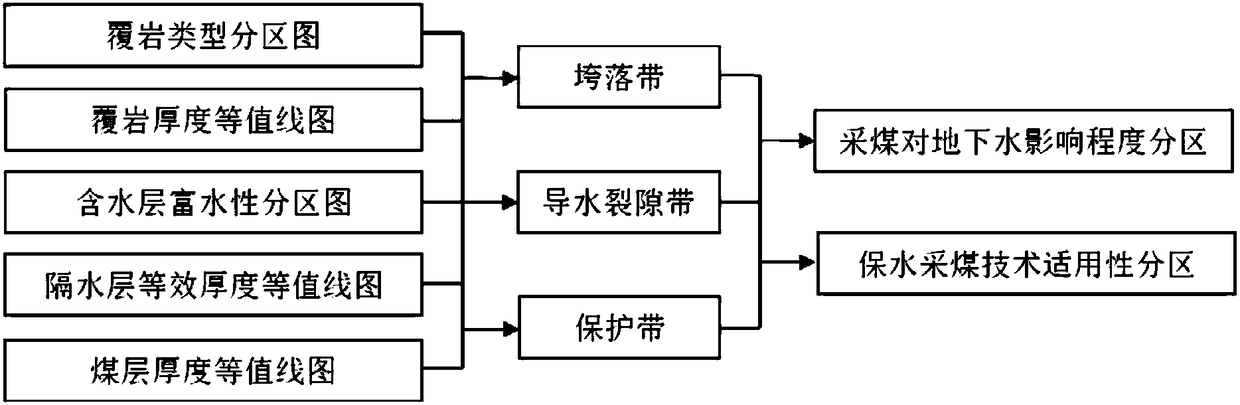

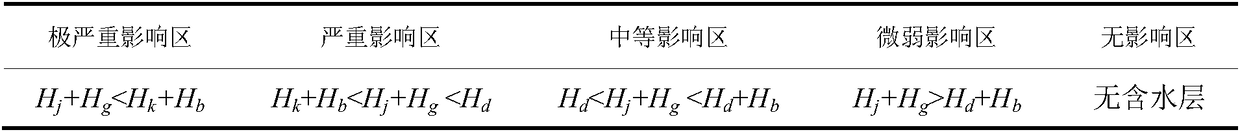

'Five maps-three zones-two partition regions' water-preserved coal mining method

ActiveCN108119142AApplicability analysis crediblePurposefulUnderground miningSurface miningBedrockUnderwater

The invention discloses a 'five maps-three zones-two partition regions' water-preserved coal mining method. The method comprises the following steps: determining an overlying strata type partition map, a bed rock thickness contour map, an aquifer watery partition map, an aquiclude thickness contour map and a coal seam thickness contour map (five maps for short) by analyzing data indexes in engineering of mining areas and hydrogeological data; calculating the heights of a caving zone, a diversion fissure zone and a protection zone (three zones for short) under cleaning mining conditions of overlying strata type partition coal seam; and meanwhile, determining the partition regions of influence degree of underwater caused by coal mining and the partition region of applicability of a water-preserved mining technology (two partition regions for short). The method provides a novel, comprehensive and systematic research method for water-preserved coal mining, the water-preserved coal mining research flow is more standard, the practicability is strong, the operation is simple and convenient, and the method is easy to understand and promote.

Owner:CHINA UNIV OF MINING & TECH

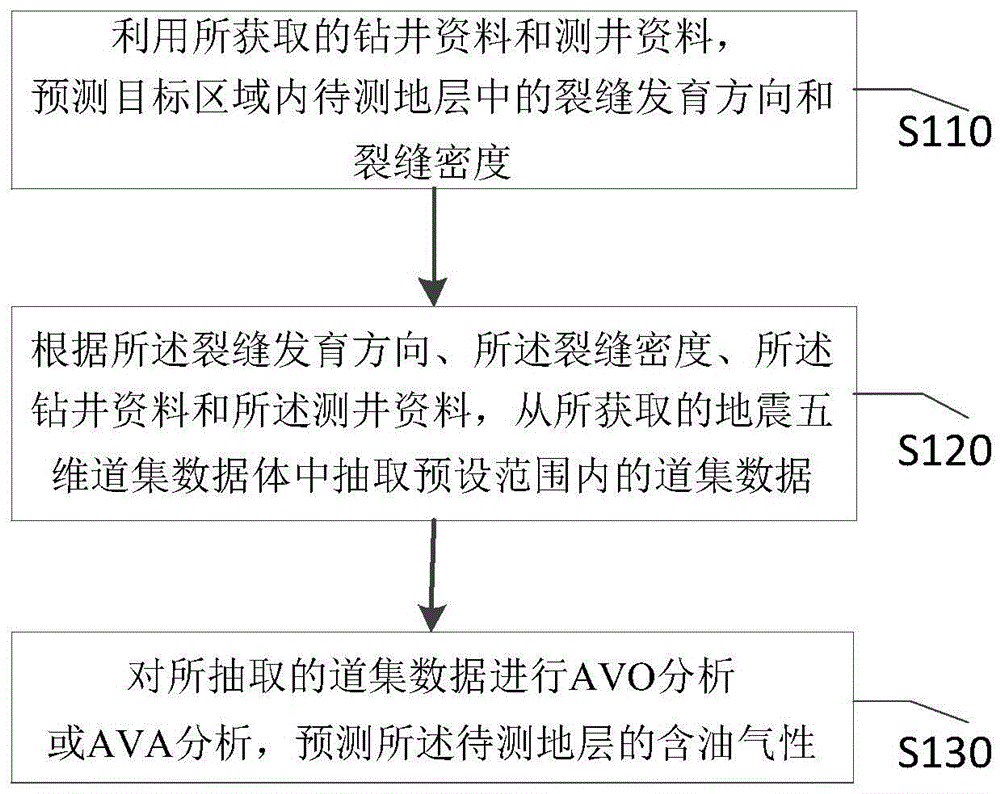

Oil and gas prediction method and oil and gas prediction device

Embodiments of the invention disclose an oil and gas prediction method and an oil and gas prediction device. The method comprises the following steps: quantitatively predicting the fracture development direction and fracture density in a formation to be detected in a target area based on acquired drilling data and logging data; determining the minimum preset threshold of the ratio of the amplitude value of seismic wave in the formation to be detected to the amplitude value of seismic wave in the bedrock according to the fracture development direction, the fracture density and the drilling data and logging data, establishing a corresponding predominant direction data extraction solution, and extracting gather data in a preset range from an acquired seismic five-dimension gather data body; and making AVO analysis or AVA analysis of the extracted gather data to predict the oil-gas possibility of the formation to be detected. By adopting the technical scheme disclosed by the embodiments of the invention, the prediction accuracy of oil-gas possibility in a carbonate rock karst-fissure-cavity reservoir can be improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

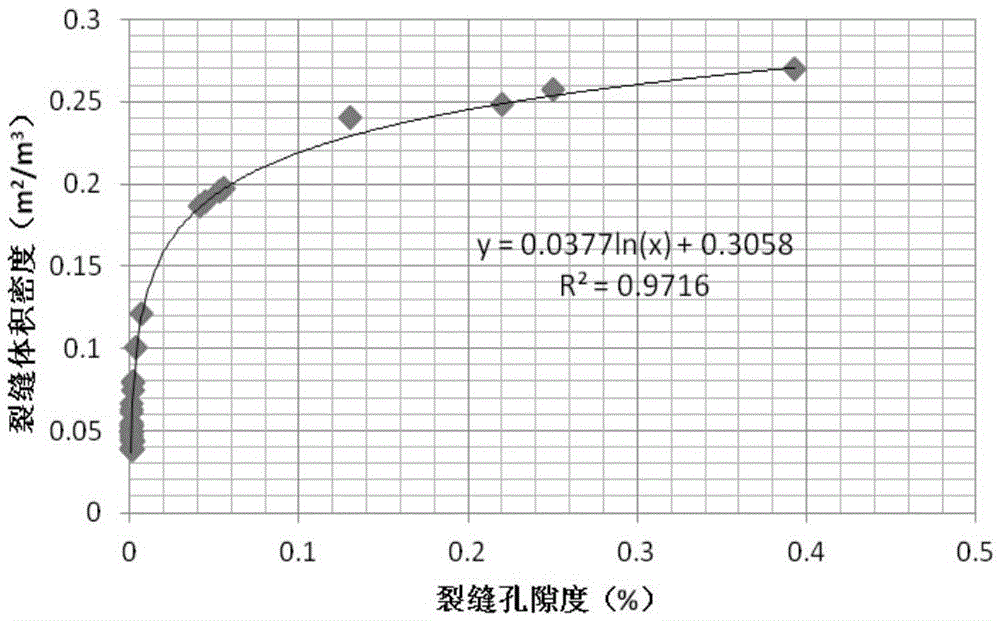

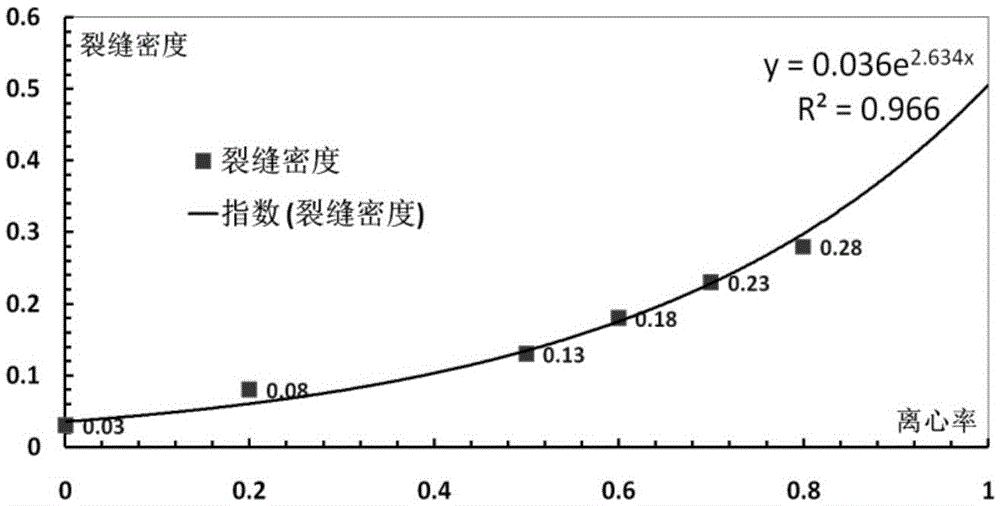

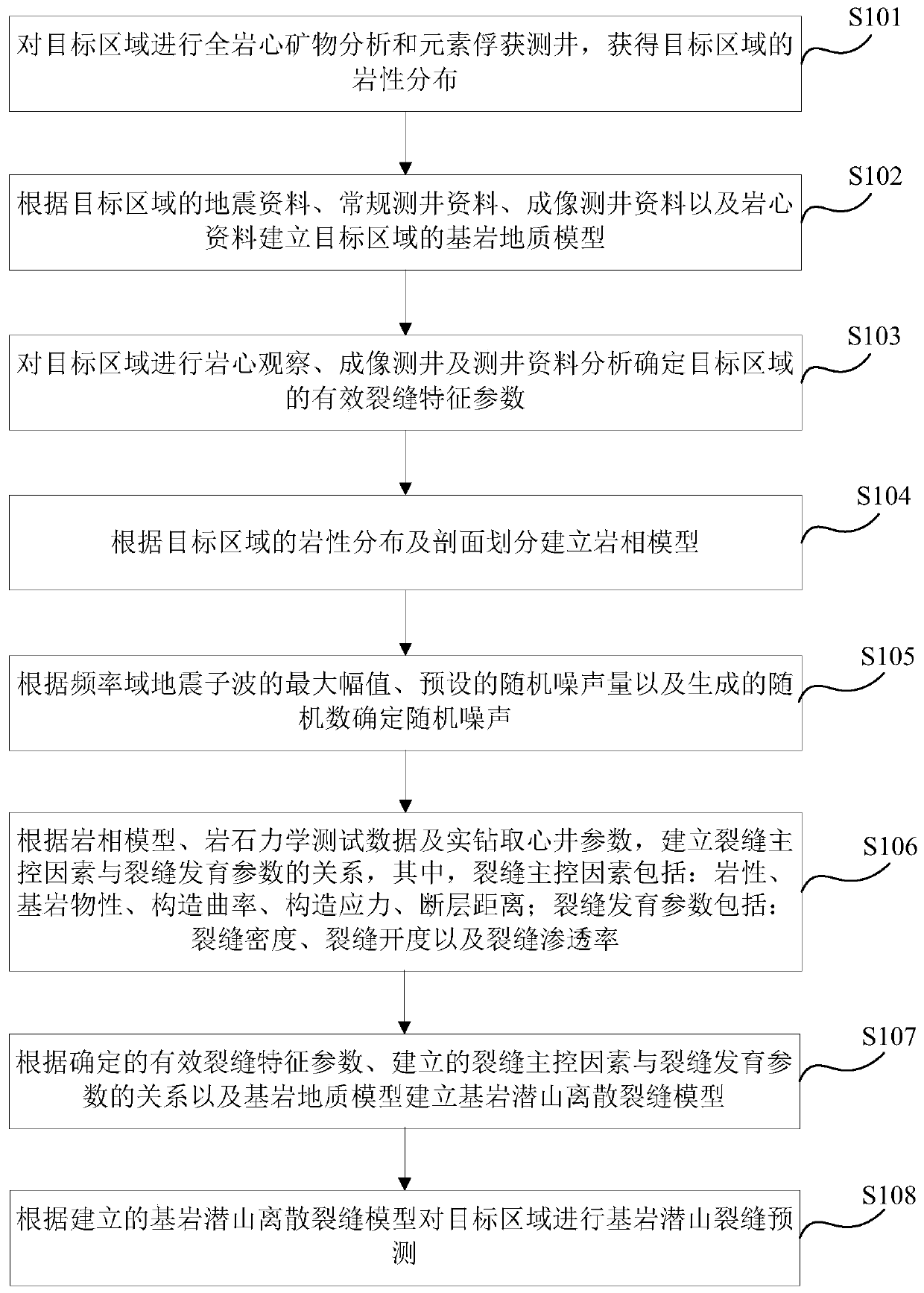

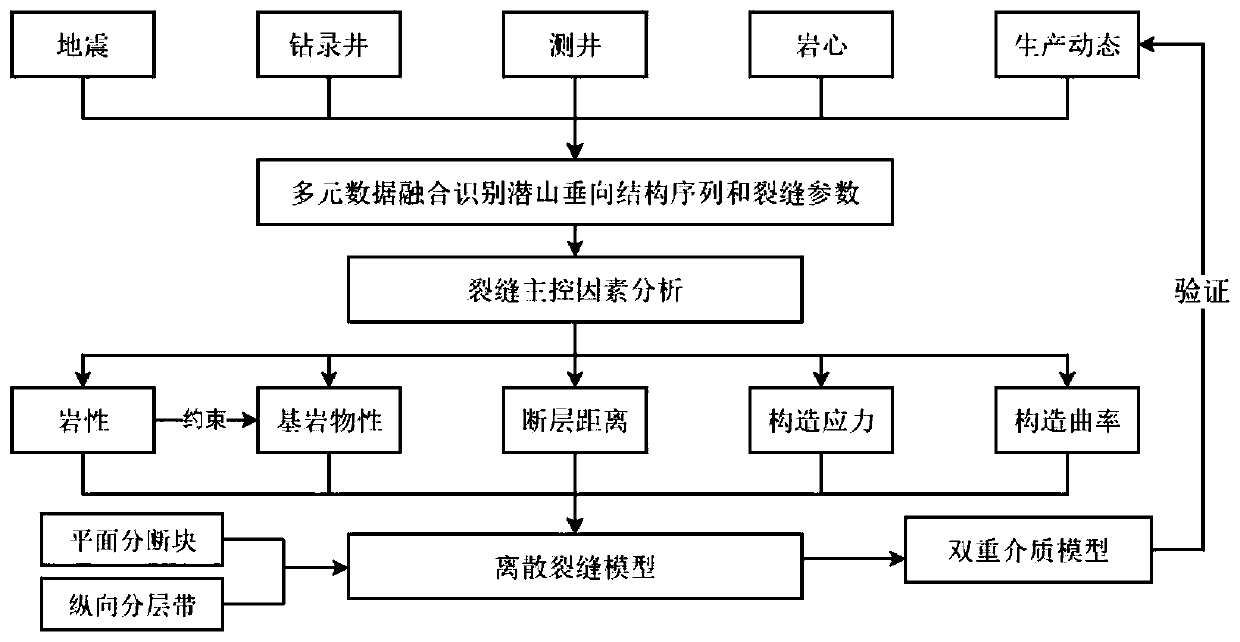

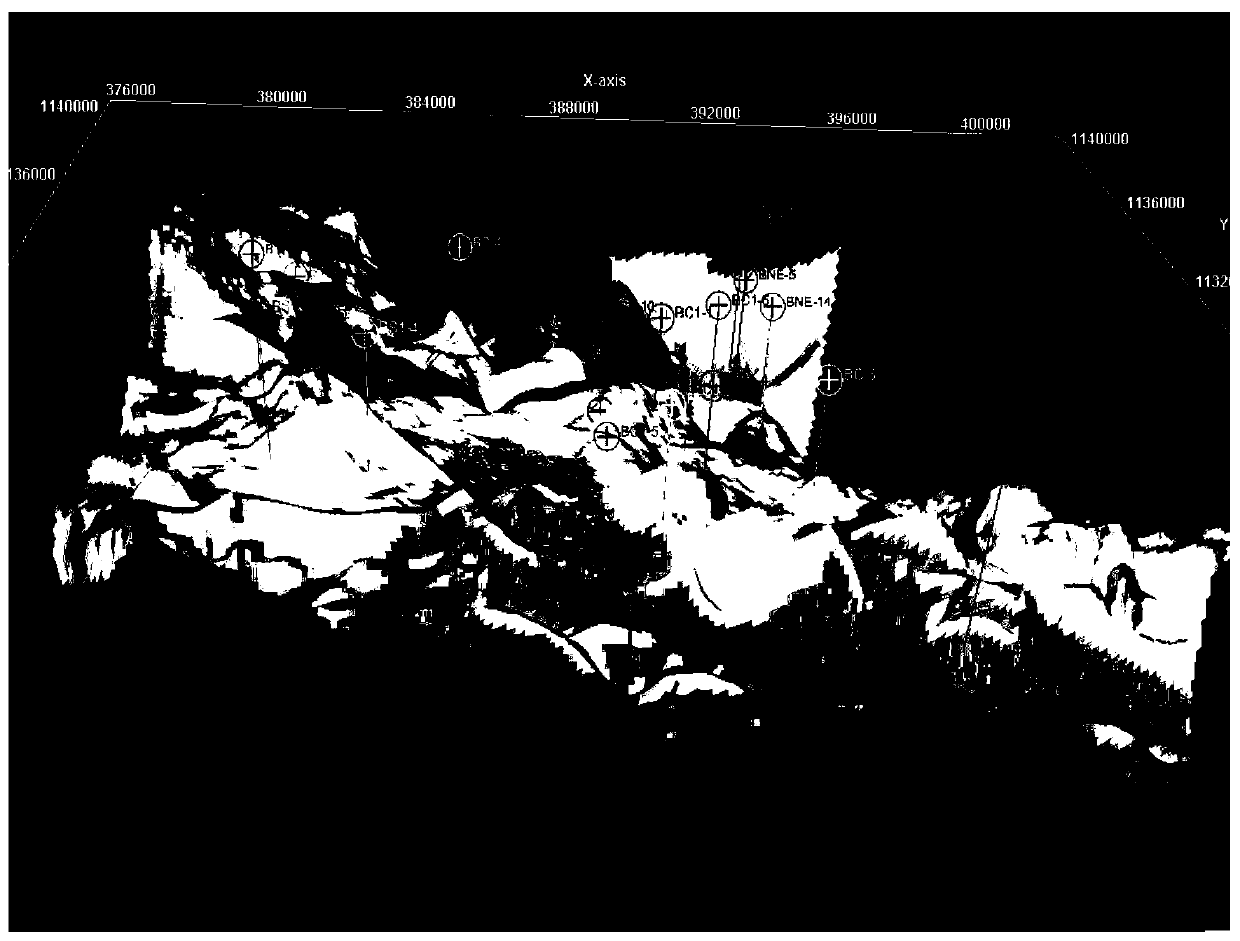

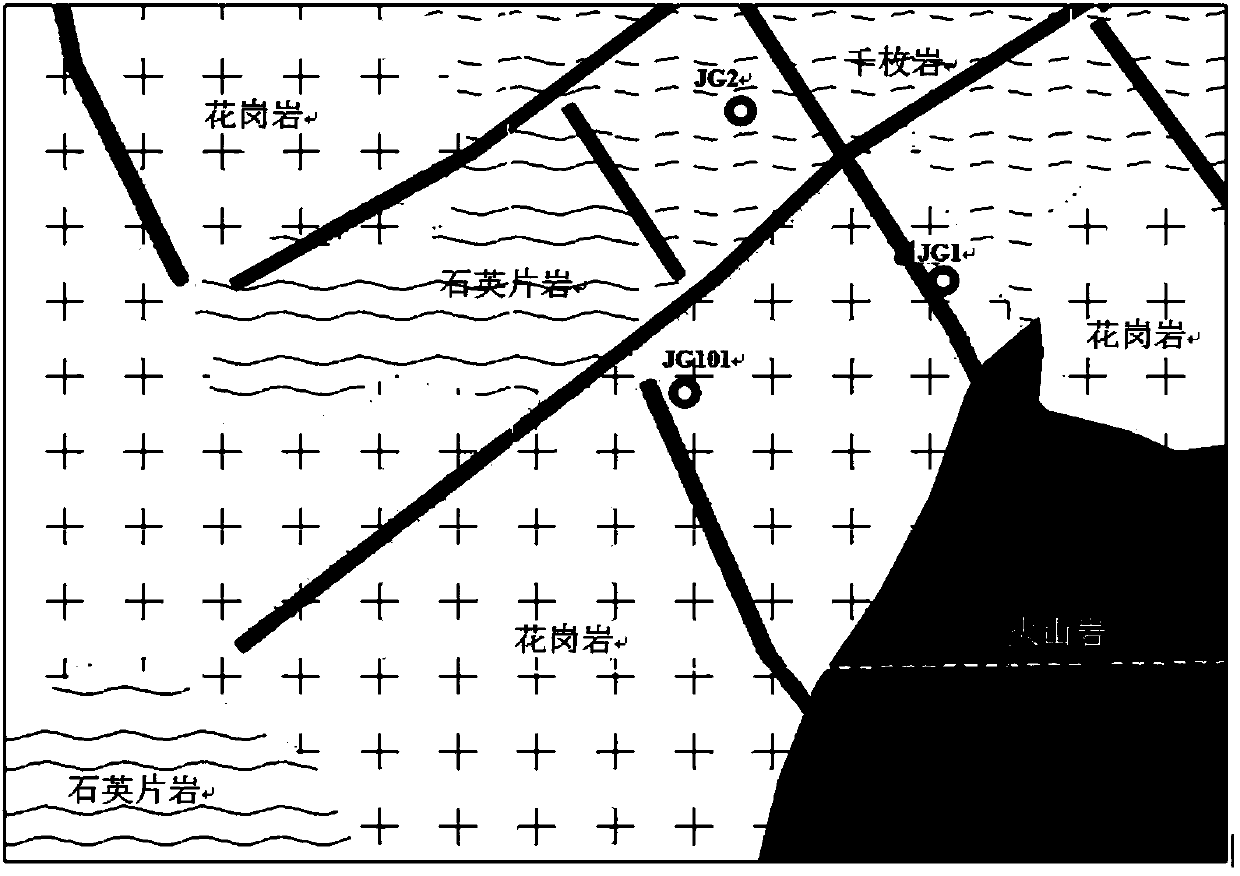

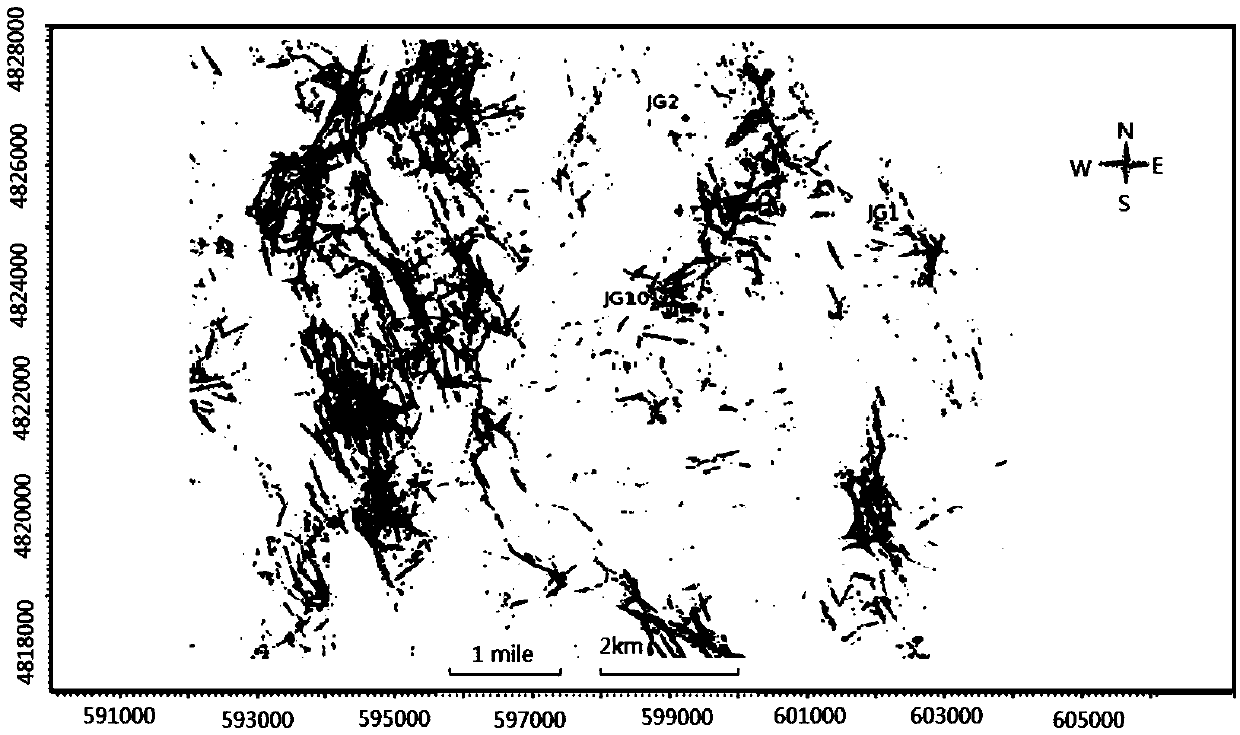

A bedrock buried hill crack prediction method and device

The invention provides a bedrock buried hill crack prediction method and device, and the method comprises the steps: carrying out the full-core mineral analysis and element capture logging of a targetregion, and obtaining the lithology distribution; establishing a bedrock geological model according to the seismic data, the conventional logging data, the imaging logging data and the core data of the target area; performing rock core observation, imaging logging and logging data analysis to determine effective crack characteristic parameters of the target area; performing a rock mechanics testto generate rock mechanics test data; establishing a relationship between the crack main control factors and the crack development parameters; and establishing a bedrock buried hill discrete fracturemodel according to the determined effective fracture characteristic parameters, the established relationship between the fracture main control factors and the fracture development parameters and the bedrock geological model, and performing bedrock buried hill fracture prediction on the target area. By integrating multi-source data and various methods, the crack development of the buried hill bedrock reservoir is identified and predicted, finally, a discrete crack model is established, and exploration and development of the buried hill bedrock reservoir are guided.

Owner:PETROCHINA CO LTD

None-full-depth freezing method for penetrating through ultra-thick water-rich bed rock in shaft deepening

The invention discloses a none-full-depth freezing method for penetrating through ultra-thick water-rich bed rock in shaft deepening. According to the method, a shaft penetrates through surface soil, the water-rich bed rock, a water-resisting layer and low-permeability bed rock sequentially from top to bottom, and main freezing pipes penetrate through the surface soil and the water-rich bed rock sequentially from top to bottom, penetrate into the water-resisting layer by 10m-20m and stop in a low-permeability rock stratum; a none-full-depth freezing depth is 240m-260m and a wall-caving-preventing freezing depth is 40m-45m; the main freezing pipes are annularly arranged with the circle center of the shaft as a circle center and the distance between the main freezing pipes and the outer wall of the shaft is 2m; wall-caving-preventing freezing pipes penetrate into the surface soil only by 43m and are annularly arranged with the circle center of the shaft as a circle center, and the distance between the wall-caving-preventing freezing pipes and the outer wall of the shaft is 1m. The method is fast in construction, safe and efficient and capable of preventing water damage caused when underground water damages a horsehead and related chamber rock mass along annular water diversion channels during construction of the horsehead after a full-depth freezing shaft is frozen, wherein the annular water diversion channels are formed by the freezing pipes and temperature measuring pipes; therefore, cost for treating water burst is saved, and safety construction of the horsehead and a chamber is guaranteed.

Owner:陕西彬长矿业集团有限公司 +1

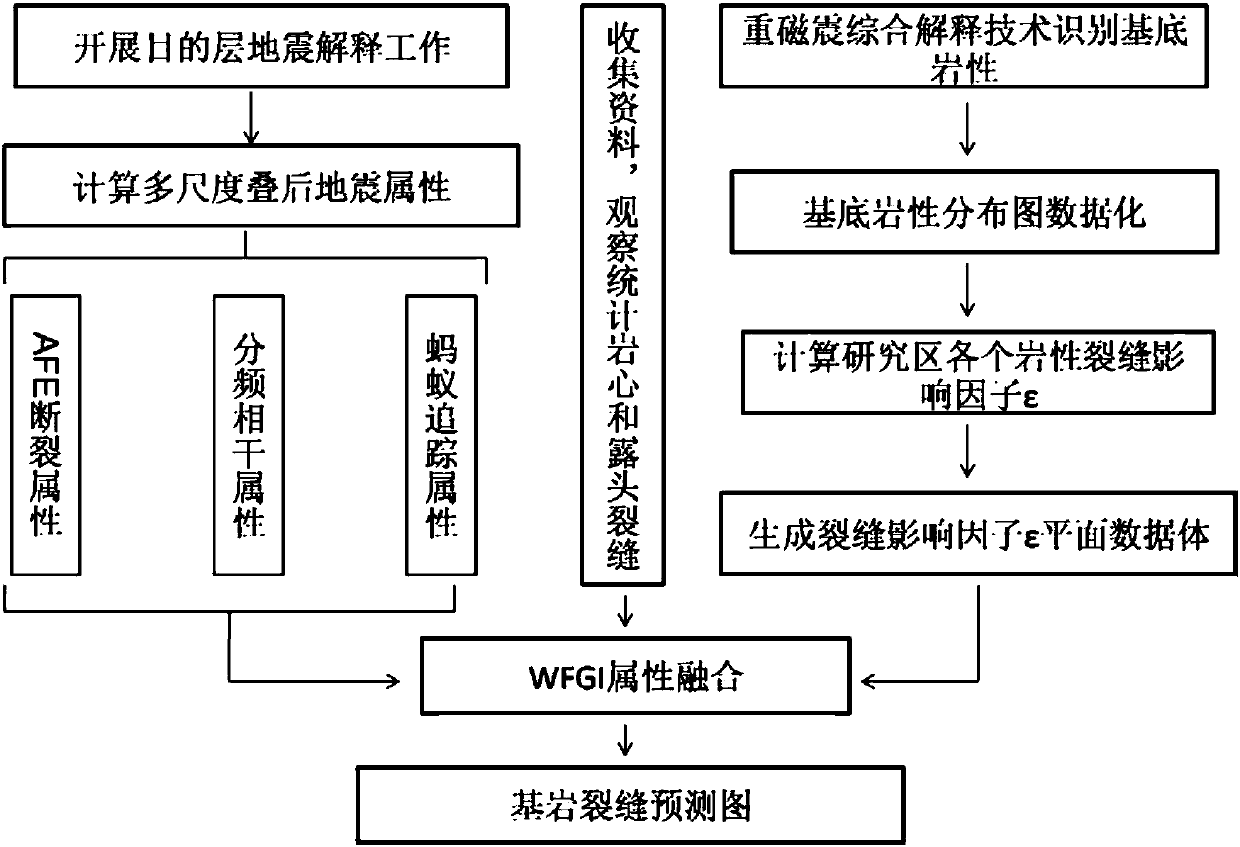

Method for bedrock crack prediction based on multi-attribute fusion

ActiveCN108931814AImprove forecasting efficiencyAccurately determineSeismic signal processingBasementLithology

Owner:CHINA PETROLEUM & CHEM CORP +1

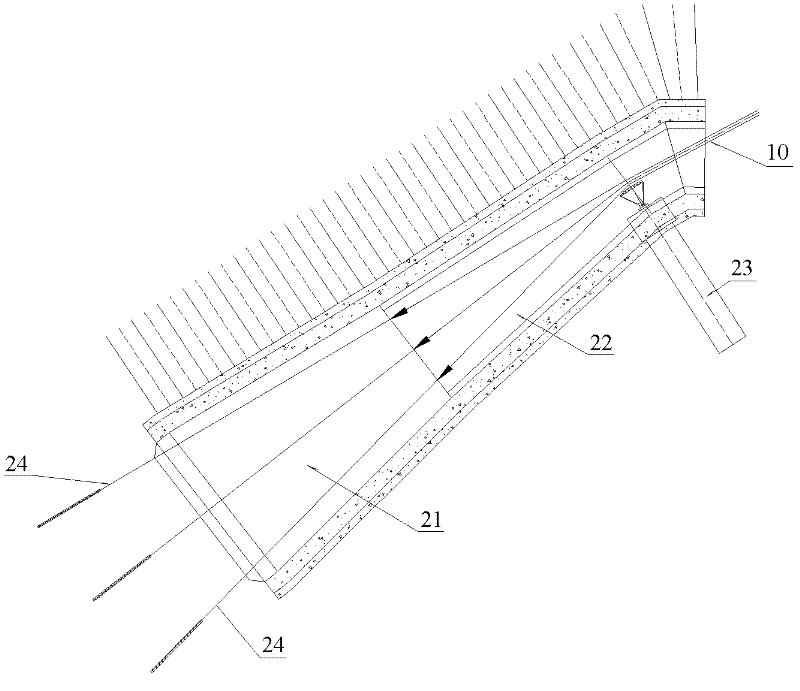

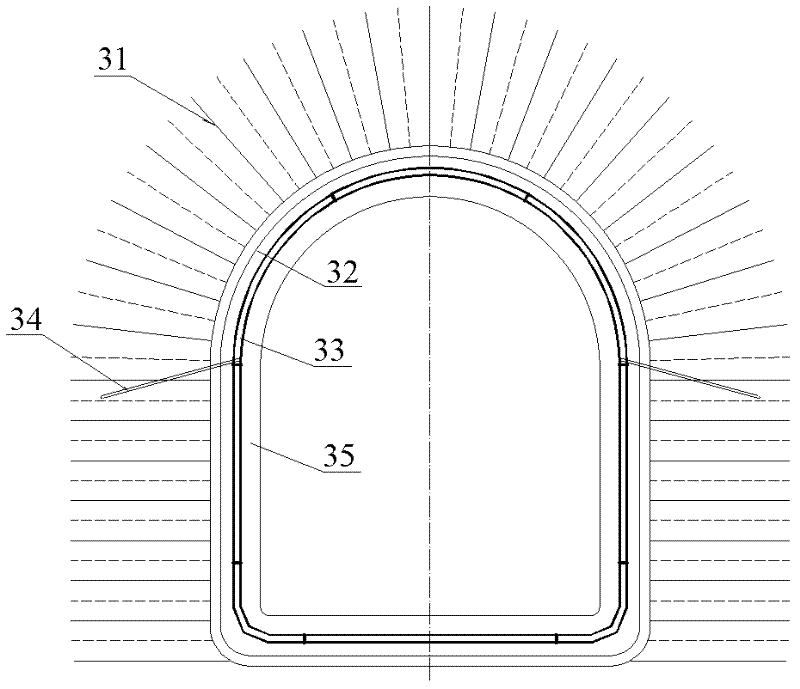

Tunnel type composite anchorage

InactiveCN102352601AImprove bearing capacityReduce stress levelsBridge structural detailsBedrockCavitation

The invention discloses a tunnel type composite anchorage and can effectively solve the problems of the strength and the rheological problems of a bridge location tunnel type anchorage with worse rock quality, and furthermore, the safety of tunnel cavitation is easily guaranteed. The tunnel type composite anchorage comprises a tunnel, an anchor plug body (21) and a front anchor room (22), wherein the anchor plug body (21) is formed by concrete which is filled and poured into the inner section of the tunnel; a rest pier (23) is arranged in the front anchor room (22); a main cable (10) is scattered by a rope scattering saddle at the top of the rest pier (23), and then, is anchored on the front anchor surface of the anchor plug body (21); anchor rods (31) which penetrate into a surrounding rock from the surface of a bedrock are distributed at the arch crown section and two side wall sections of the tunnel at intervals; a primary supporting structure and a secondary lining (35) are inwards arranged in sequence from the surface of the bedrock; a prestressed anchor rope (24) which penetrates through the anchor plug body (21) and the inner end surface of the tunnel and enters a deep rock mass is distributed and arranged along the axial direction of the tunnel; and two ends of the prestressed anchor rope (24) are fixedly connected with the front anchor surface of the anchor plug body (21) and the deep rock mass anchor respectively.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

Process for excavating and constructing micro-steps of tunnels on basis of method for excavating steps

InactiveCN105257295AReduce deformation rateEnsure construction safetyTunnelsAnchoring boltsBedrockEngineering

The invention provides a process for excavating and constructing micro-steps of tunnels. The process includes steps of excavating upper steps without reserved core soil, obliquely and downwardly drilling foot lock anchor rods at arch feet and hermetically attaching the foot lock anchor rods to base rock by means of grouting or by the aid of anchor agents; controlling and keeping the lengths of the upper steps, simultaneously excavating the upper steps and intermediate steps without reserved core soil and arranging foot lock steel pipes and lock anchor rods for the intermediate steps; circularly carrying out the steps by three times; keeping synchronously excavating the upper steps and the intermediate steps, simultaneously erecting trestles, starting to excavate lower steps and close inverted arches without reserved core soil, and then closing the inverted arches; synchronously advancing excavation of the upper steps, the intermediate steps and the lower steps, and carrying out alternate circular operation for synchronously excavating each upper step, the corresponding left intermediate step and the corresponding right lower step and synchronously excavating the upper step, the corresponding right intermediate step and the corresponding left lower step until the tunnels are completely integrally excavated. The process has the advantage that effects of guaranteeing the tunnel construction safety and increasing the construction speeds can be effectively realized.

Owner:CCCC SECOND HIGHWAY ENG CO LTD +1

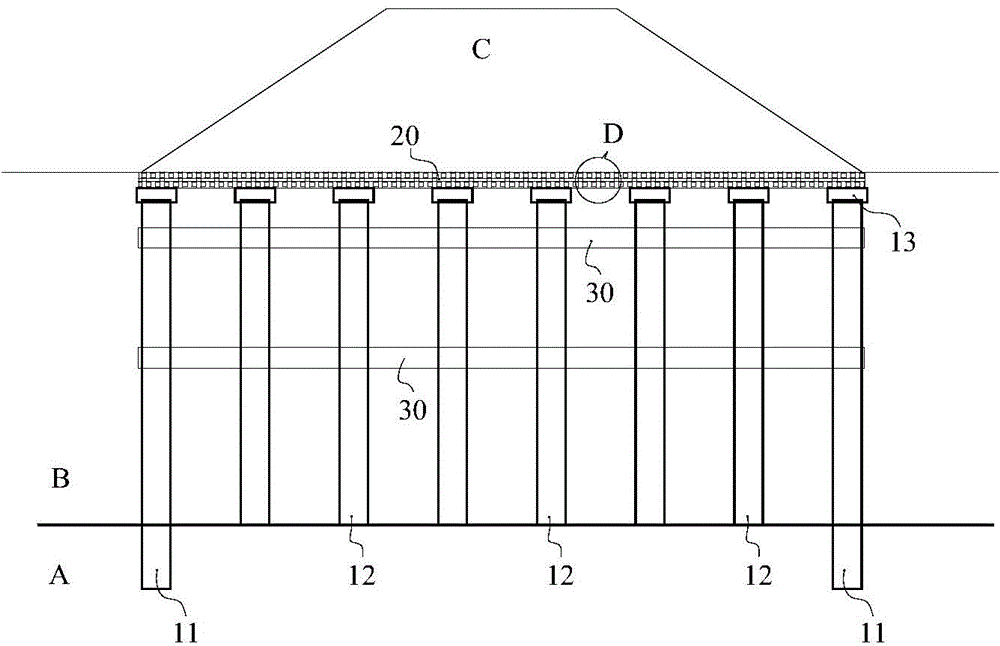

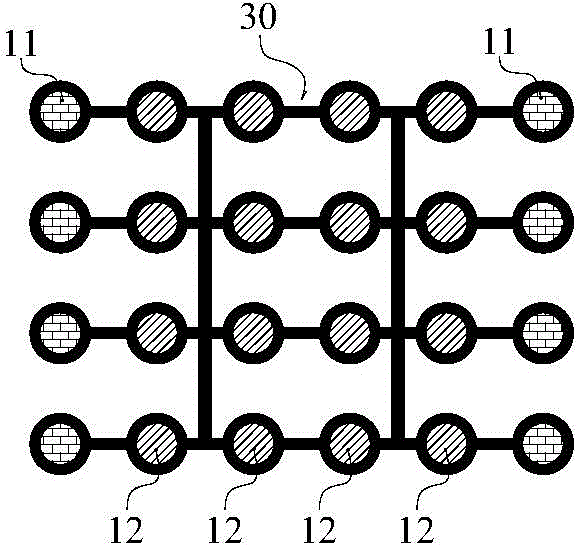

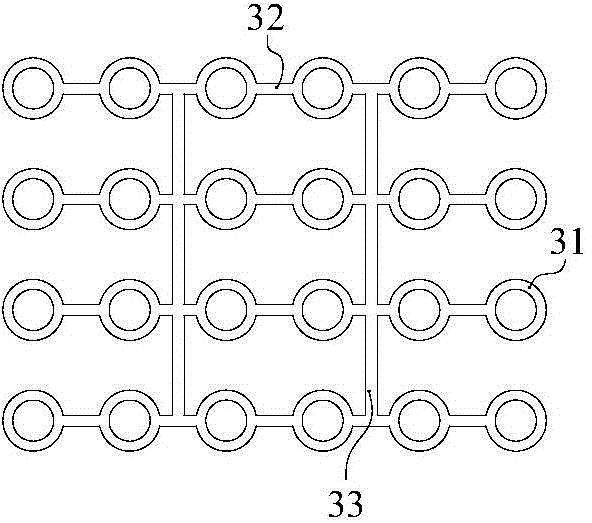

Soft soil foundation combined pile net structure

The invention discloses a soft soil foundation combined pile net structure, aims at effectively improving reinforcing effect and saving project investment and comprises cast-in-place piles, pressed piles, pile caps, guide fixing frame lattices and a cushion body. The cast-in-place piles are arranged around the boundary of a filling body at intervals, bottoms of the cast-in-place piles enter a bedrock layer below a soft soil layer by certain depth, the pressed piles are arranged in the soft soil layer within a range of the cast-in-place piles at intervals, bottoms of the pressed piles are pressed in the top surface of the bedrock layer, the pile caps are arranged at the tops of the cast-in-placed piles and the pressed piles and fixedly connected with the cast-in-placed piles and the pressed piles, the guide fixing frame lattices are positioned in the soft soil layer and transversely restrain the cast-in-place piles and the pressed piles, and the cushion body is laid between the tops of the piles caps and the undersurface of the filling body.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD +1

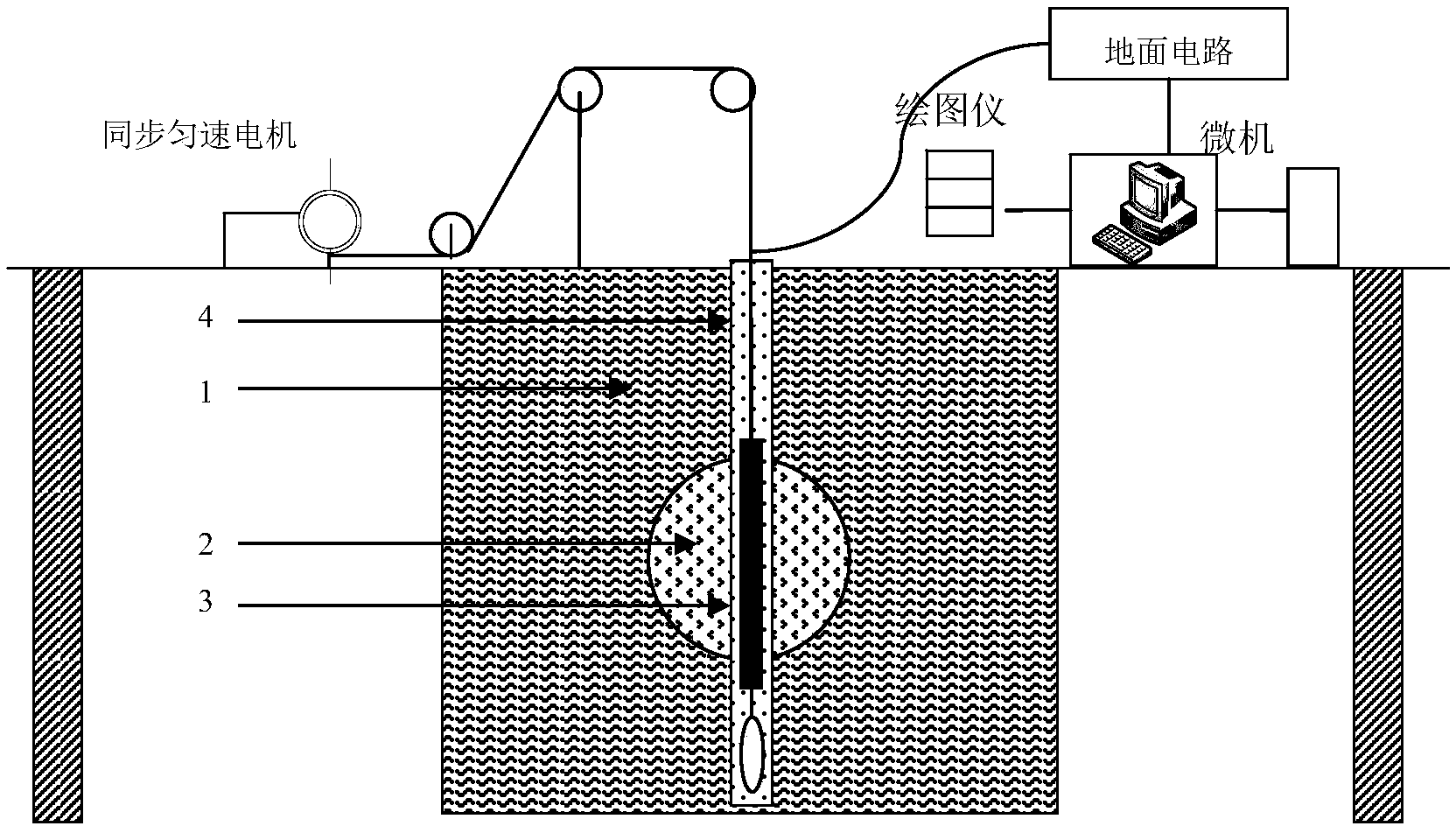

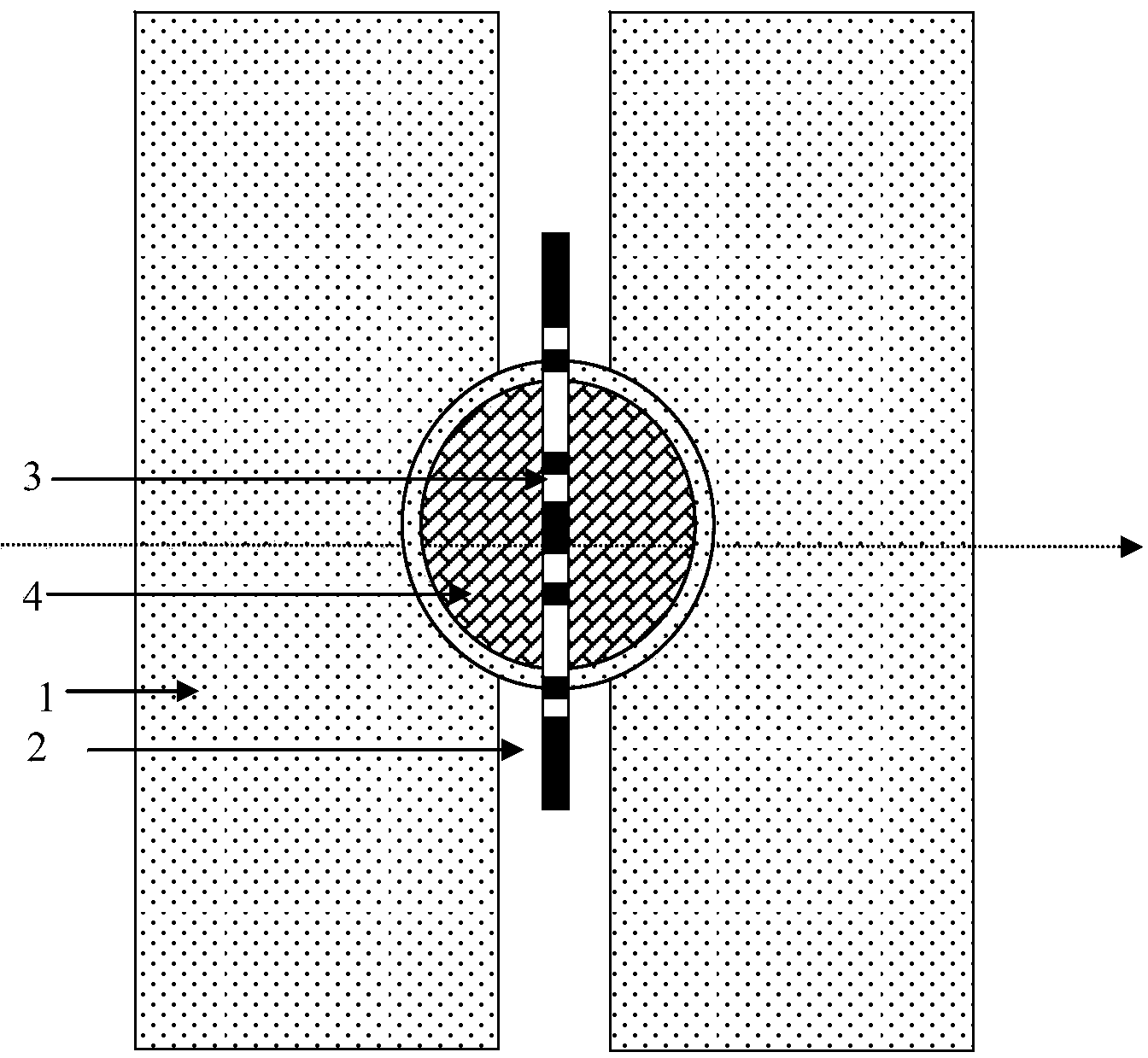

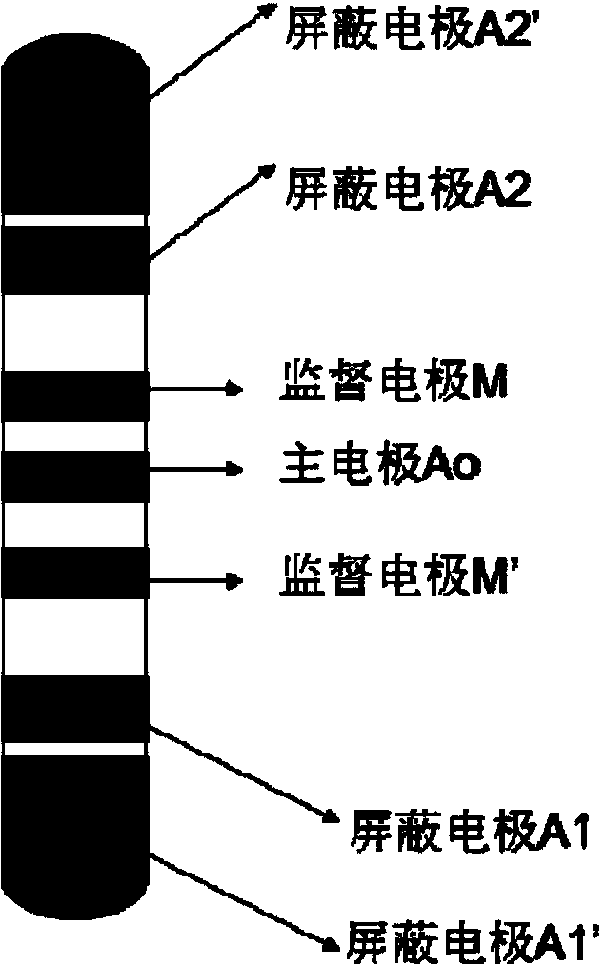

Scaling-down cavernous formation dual laterolog physical simulation device and experimental method

The invention discloses a scaling-down cavernous formation dual laterolog physical simulation device and an experimental method. The simulation device is characterized by comprising a bedrock model, a cave physical model and a scaling-down dual laterolog instrument, resistivity of the bedrock model ranges from 2000 omega.m to 10000 omega.m, the bedrock model is provided with a vertical borehole, the cave physical model is transversely disposed in the bedrock model to form a borehole-passing unfilled cave, resistivity of the unfilled cave ranges from 0.1 omega.m to 500 omega.m, diameter of the unfilled cave ranges from 50mm to 400mm, and the dual laterolog instrument comprises a main electrode, a supervisory electrode and a shielding electrode. By the device and the method, filling substances in the cave, filling degree, development scale and scaling-down dual laterolog response at different positions of the borehole can be simulated by changing the resistivity of the models, and related basis can be provided for carbonatite reservoir space evaluation on the basis of dual laterolog.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

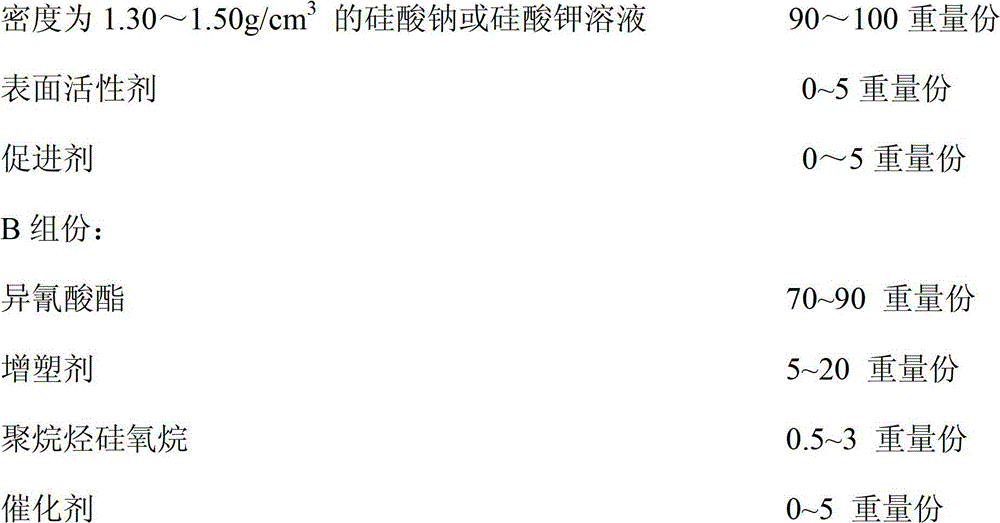

Chemical grouting material for reinforcing loose and broken bedrock

The invention relates to a chemical grouting material for reinforcing loose and broken bedrock. The invention provides a chemical grouting material for reinforcing the loose and broken bedrock, in order to improve the flash point, the burning point and the antistatic performance of the grouting material, reducing the temperature in polymerization reaction and lowering the cost. According to the technical scheme provided by the invention, the chemical grouting material for reinforcing the loose and broken bedrock comprises two components, including a component A and a component B; according to the formulas of the raw materials, the component A comprises 90 to 100 parts by weight of sodium silicate or potassium metasilicate solution, 0 to 5 parts by weight of surface active agent, and 0 to 5 parts by weight of accelerator; the component B comprises 70 to 90 parts by weight of isocyanate, 5 to 20 parts by weight of plasticizer, 0.5 to 3 parts by weight of polyalkane silicone, and 0 to 5 parts by weight of catalyst; the components A and B are uniformly mixed respectively; and in use, the components A and B are mixed according to the volume ratio of 1: 1. The chemical grouting material can be applied to quickly reinforcing the broken coal bed and rock bed and blocking water leakage.

Owner:HANGZHOU GUODIAN DAM SAFETY ENG

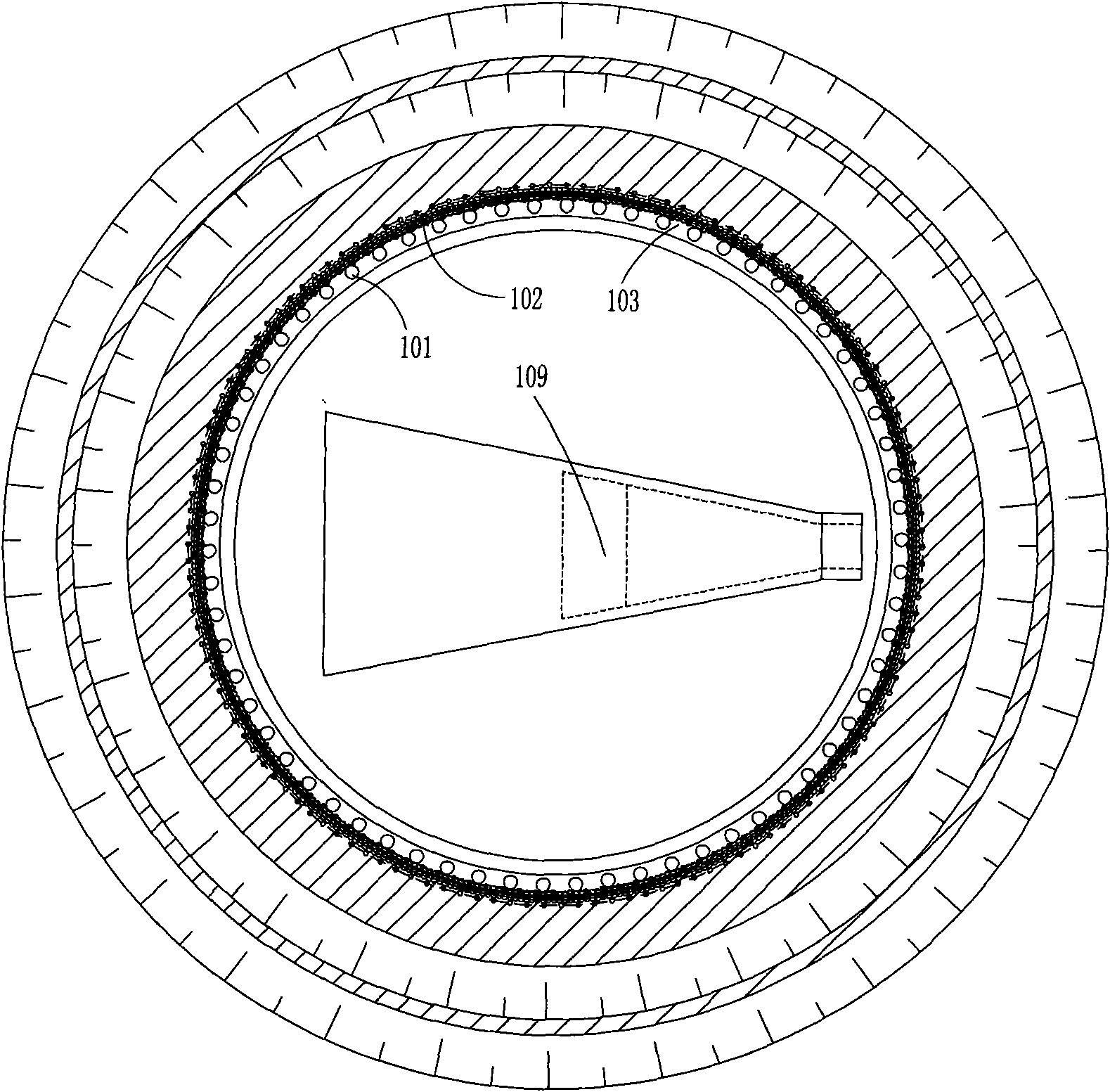

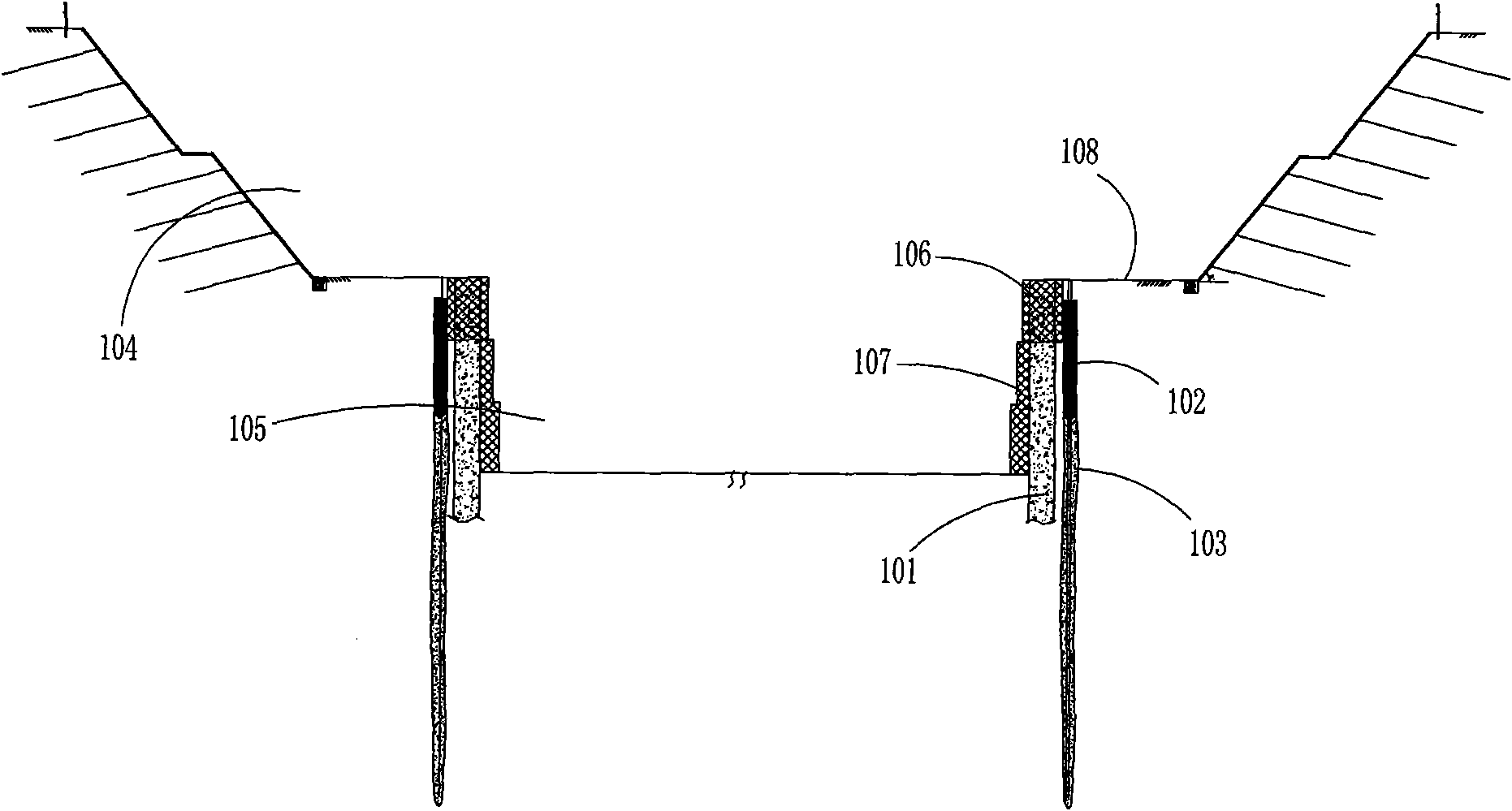

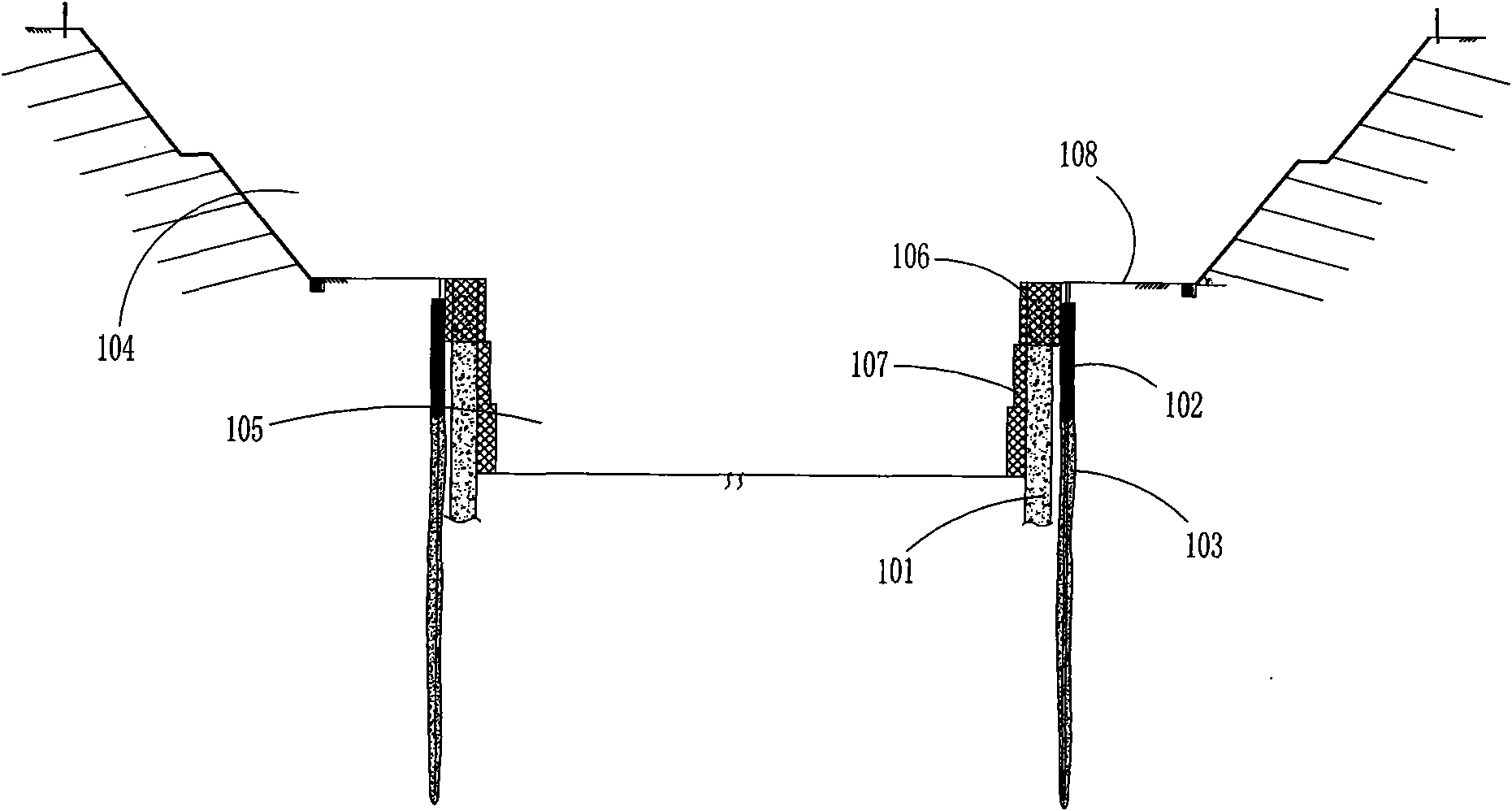

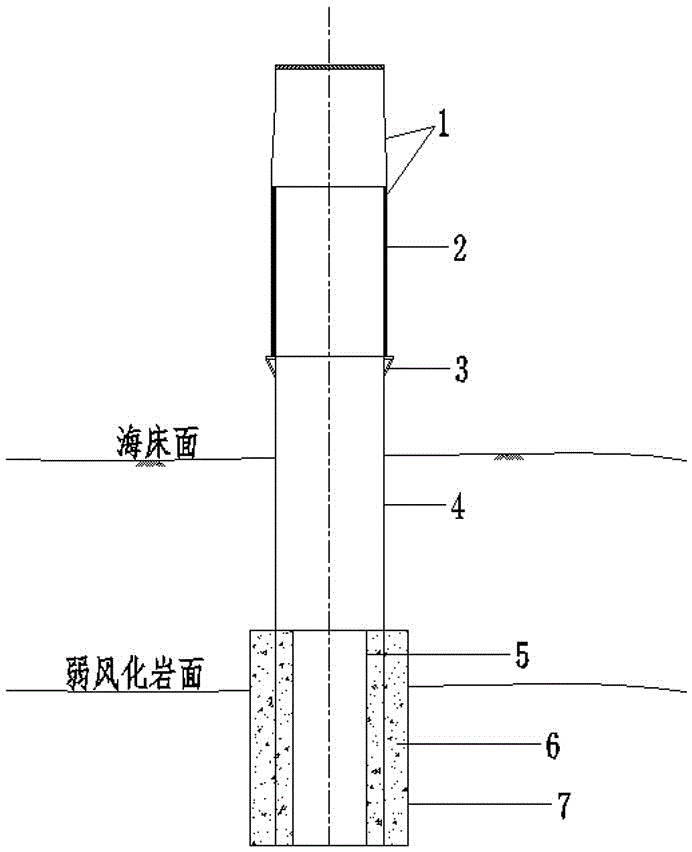

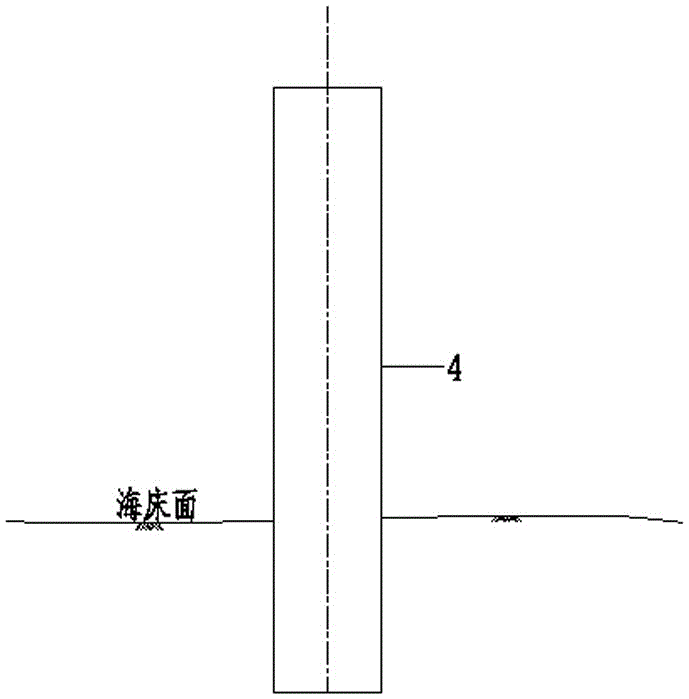

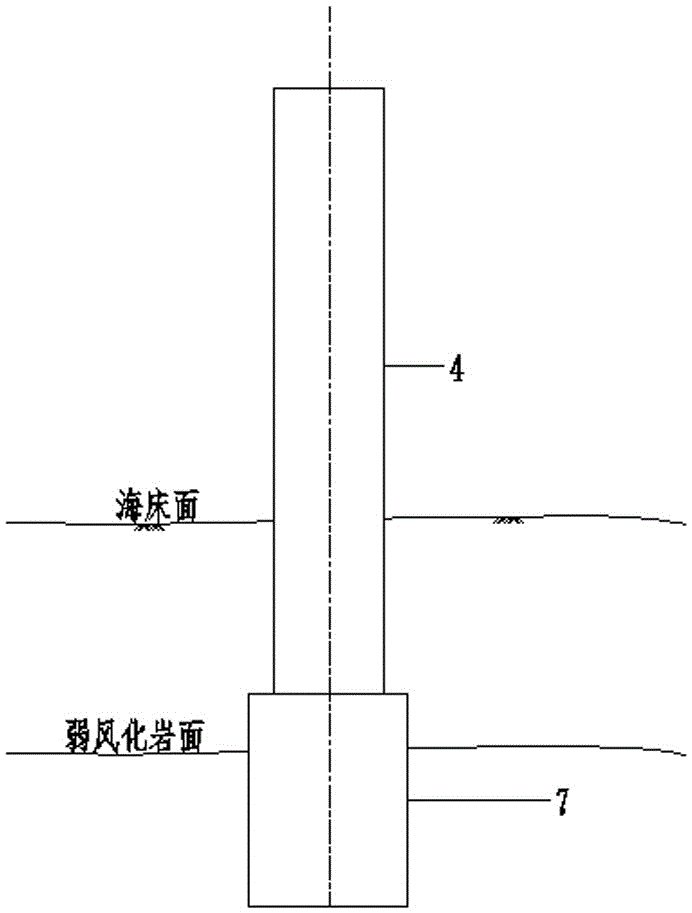

Rock-socketed single pile foundation of offshore wind turbines in batholith seabed and construction method thereof

ActiveCN106759449ATightly boundReduce the effect of slope rateWind energy generationBulkheads/pilesStress concentrationBedrock

The invention relates to a rock-socketed single pile foundation of offshore wind turbines in batholith seabed and a construction method thereof. The rock-socketed single pile foundation comprises a steel pipe pile inserted in a moderately weathered batholith layer. An annular groove located at the periphery on the lower end portion of the steel pipe pile is formed in the batholith. An inner casing is nested within the lower end of the steel pipe pile. A gap is reserved between the inner casing and the inner wall of the steel pipe pile. The inside of the annular groove and the gap between the inner casing and the inner wall of the steel pipe pile are both filled with a high-strength grout having initial setting time of no less than 8 h. The rock-socketed single pile foundation of offshore wind turbines in batholith seabed in the invention is stable and reliable, ensures that the single pile foundation can be tightly bonded with the surrounding batholith, and reliably embedded in the moderately weathered batholith layer. The impact of a large boring diameter and a borehole perpendicularity error on the gradient of the single pile foundation and the problem of local stress concentration of the rock-socketed section of the steel pipe pile due to unevenness of the bored rock surface are reduced. Moreover, the cubic quantity of backfill concrete for the rock-socketed section can be lowered. The critical technical problem of use of the single pile foundation in the batholith seabed is effectively solved.

Owner:福建省水利水电勘测设计院

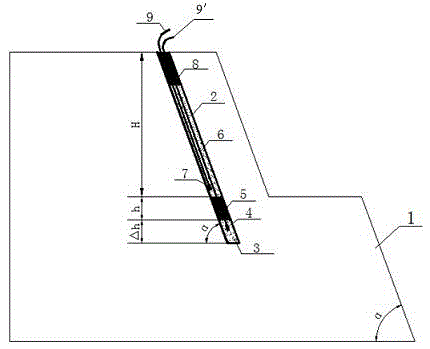

Landslide depth displacement monitoring device

InactiveCN102564312ASimple structureEasy to processUsing optical meansConverting sensor output opticallyTest channelBedrock

The invention discloses a landslide depth displacement monitoring device, which comprises an inclinometer pipe, wherein the inclinometer pipe is inserted on a landslide, and the end part of the inclinometer pipe passes through a potential sliding surface and extends into a drill hole below a bedrock surface; a curved test channel for a signal optical fiber I to pass through is arranged in the inclinometer pipe; the curved test channel comprises a curved support, a plurality of deformation teeth I and a plurality of deformation teeth II which are continuously arranged at the upper side and lower side which are opposite in the curved support; the deformation teeth I and the deformation teeth II are correspondingly arranged in a staggered way; the signal optical fiber I is arranged at the inner part of the curved channel in a penetrating way; at least one row of the corresponding deformation teeth of the deformation teeth I and the deformation teeth II share the same height, pitch and bending curvature of the top part contacted with the signal optical fiber I; the joint of the signal optical fiber I is connected with one end of an optical cable; the other end of the optical cable is led to a monitoring station and is connected with a testing unit; and the testing unit is further connected with an upper processing unit. The landslide depth displacement monitoring device can effectively realize remote monitoring of the landslide depth displacement change.

Owner:XIAN JINHE OPTICAL TECH

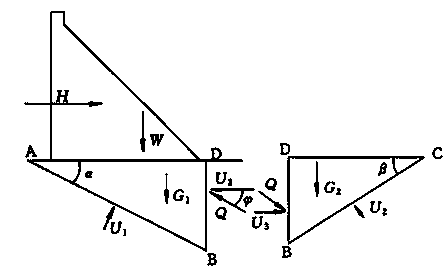

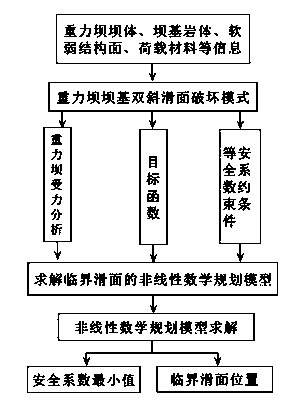

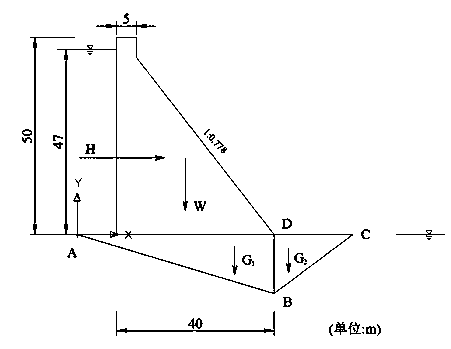

Method of calculating deep antiskid stable critical slipping plane of dam foundation of gravity dam

ActiveCN103469780AMethod concept is clearImprove calculation accuracyIn situ soil foundationBedrockEngineering

The invention discloses a method of calculating a deep antiskid stable critical slipping plane of a dam foundation of a gravity dam and belongs to the field of stability analysis for gravity dams. Aiming at the condition that slip possibly occurs because the low-gradient weak structural plane of the dam foundation of the gravity dam is not exposed but part of downstream bedrock is possibly subjected to clipping, the method comprises the following steps: establishing a nonlinear mathematic programming model of deep antiskid stability analysis for the gravity dam by taking variable of locations subjected to clipping and slipping plane damage on the downstream bedrock as an optimization variable, the deep antiskid stability factor of the gravity dam as an objective function and an equal safety factor normal equation as a constraint condition; solving out a worst critical slipping plane subjected to clipping damage on the downstream rock mass and a safety factor minimal value corresponding to the worst critical slipping plane. The method disclosed by the invention has the characteristics of definite concept, high calculation precision and the like, and can be applied to deep antiskid stability analysis for the gravity dam.

Owner:KUNMING UNIV OF SCI & TECH

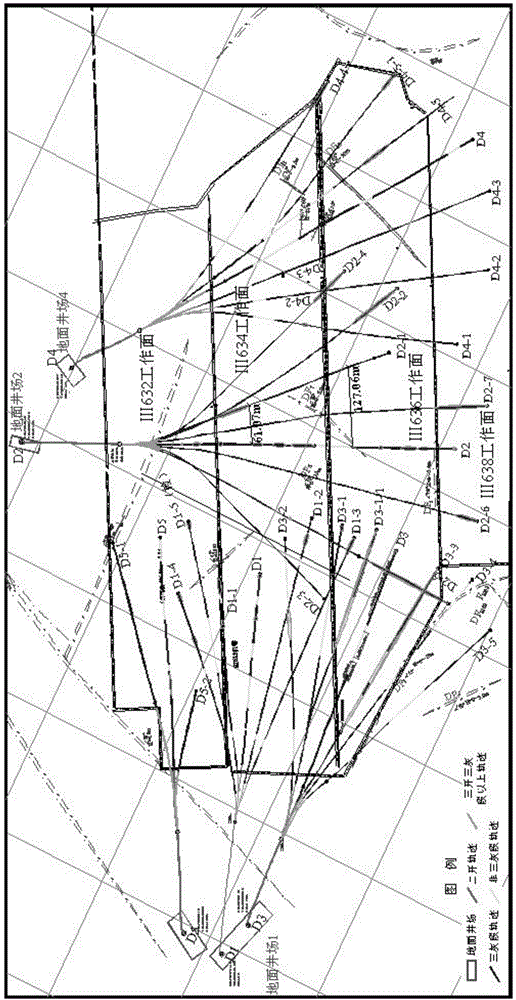

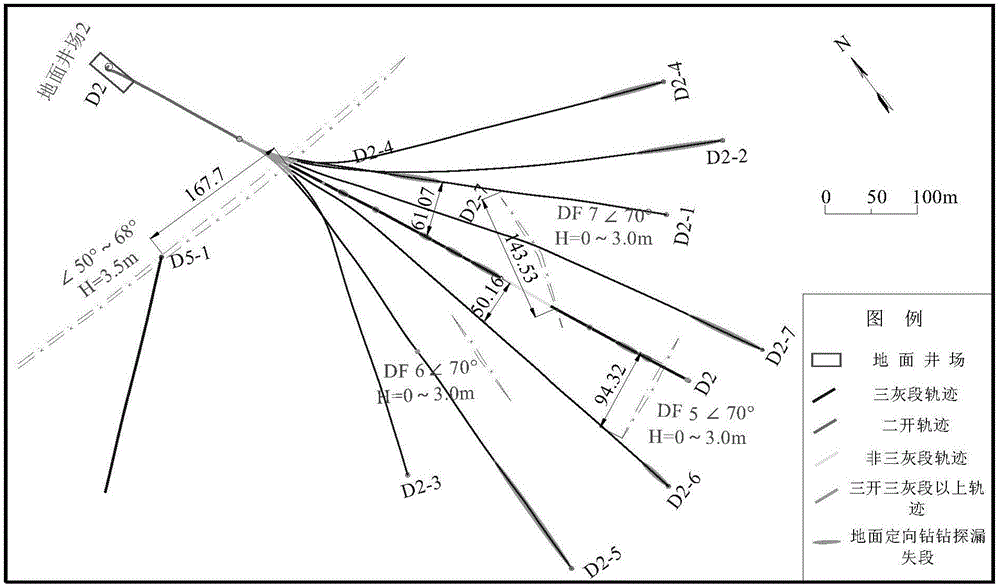

Thin-layer limestone ground directional drilling horizontal multi-stage branch grouting drill hole

InactiveCN106593300AEffective blockingImprove the effect of grouting transformationDirectional drillingBedrockCoal

The invention discloses a thin-layer limestone ground directional drilling horizontal multi-stage branch grouting drill hole. The thin-layer limestone ground directional drilling horizontal multi-stage branch grouting drill hole comprises a ground main hole. The ground main hole vertically extends to the underground, penetrates through a vertically-drilled straight hole section of a base rock layer from the ground to the underground and downwards penetrates through an ash consequently-drilled bedding section along a coal bed. A kickoff point is arranged at the end, away from the ground and close to the coal bed, of the straight hole section. Inclined drilling is conducted between the kickoff point and the middle of lime-cement-flyash below the coal bed, so that a directional inclination guide section is formed. The two ends of the directional inclination guide section communicate with the straight hole section and the bedding section correspondingly. The main hole bedding section is divided into a plurality of first and second stage branch holes distributed in a fan shape in the approximately horizontal direction of the bedding section. By adopting the technical scheme, compared with the former conventional water control technology, the safe reliability is greatly improved, deep mining bottom plate limestone water disaster governance is achieved, bottom plate water disaster accidents are avoided, and safety production is ensured.

Owner:HUAIBEI MINING IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com