Patents

Literature

7029results about "Blasting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nontoxic, noncorrosive phosphorus-based primer compositions and an ordnance element including the same

A primer composition that includes red phosphorus having an acid scavenger and a polymer thereon. The primer composition includes at least one other component that is substantially free of lead. The other component is at least one oxidizer, or at least one oxidizer and at least one of at least one secondary explosive composition and at least one energetic binder. The primer composition optionally includes at least one element having an ionic charge to ionic radius ratio of 4 or of 8, such as magnesium, zirconium, aluminum, silicon, titanium, tungsten, alloys thereof, and combinations thereof. The red phosphorus and the at least one oxidizer are present in the primer composition at approximately stoichiometric amounts. An ordnance element including the primer composition is also disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

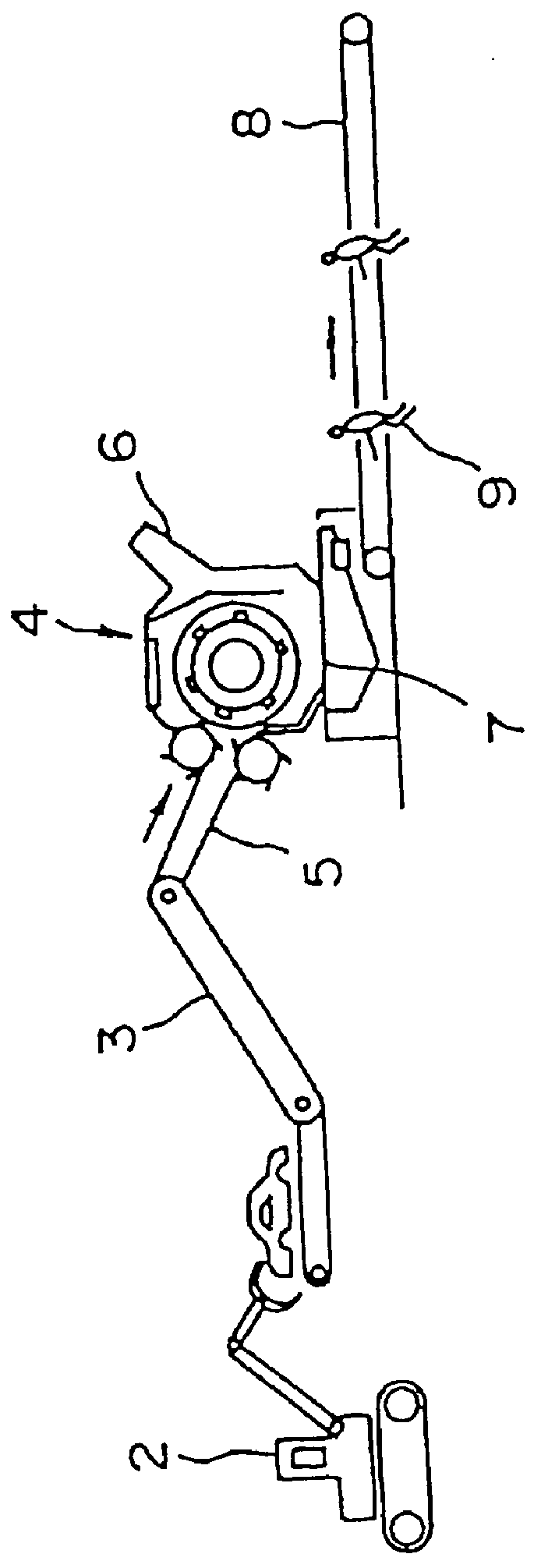

Method for discriminating between used and unused gas generators for air bags during car scrapping process

PCT No. PCT / JP96 / 01644 Sec. 371 Date Sep. 12, 1997 Sec. 102(e) Date Sep. 12, 1997 PCT Filed Jun. 14, 1996 PCT Pub. No. WO97 / 00144 PCT Pub. Date Jan. 3, 1997To provide a method for easily discriminating used and unused gas generators from among gas generators for air bags separated from used cars in a car scrapping process. A method for discriminating between used and unused gas generators according to the present invention is a method for discriminating used and unused gas generators from among gas generators for air bags separated from used cars in a car scrapping process, and this method comprises the steps of: a) crushing used cars mounted with gas generators each having on a surface thereof a material discoloring according to the surface temperatures in actuating the gas generator to separate the gas generators, and b) discriminating the gas generators in which surfaces are discolored and the gas generators in which surfaces are not discolored from among the separated gas generators.

Owner:DAICEL CHEM IND LTD +1

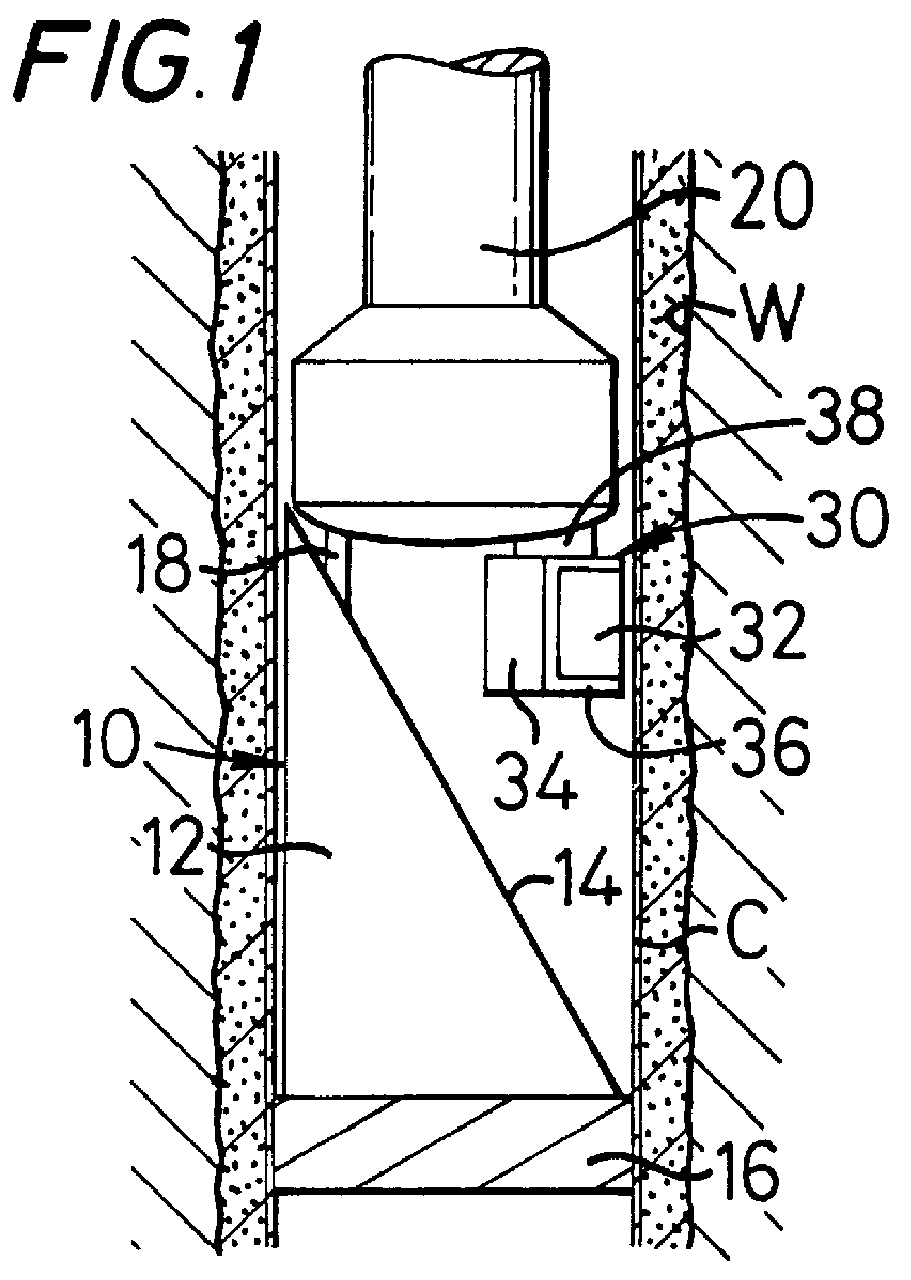

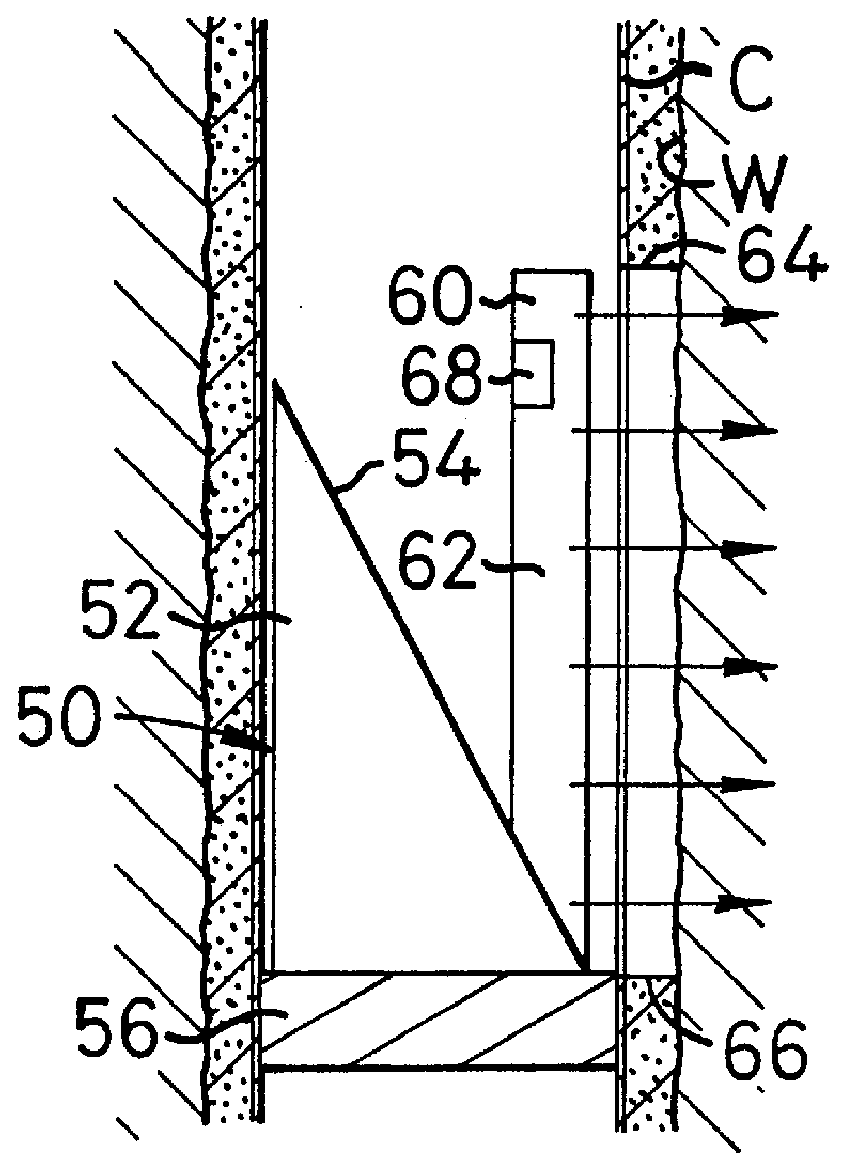

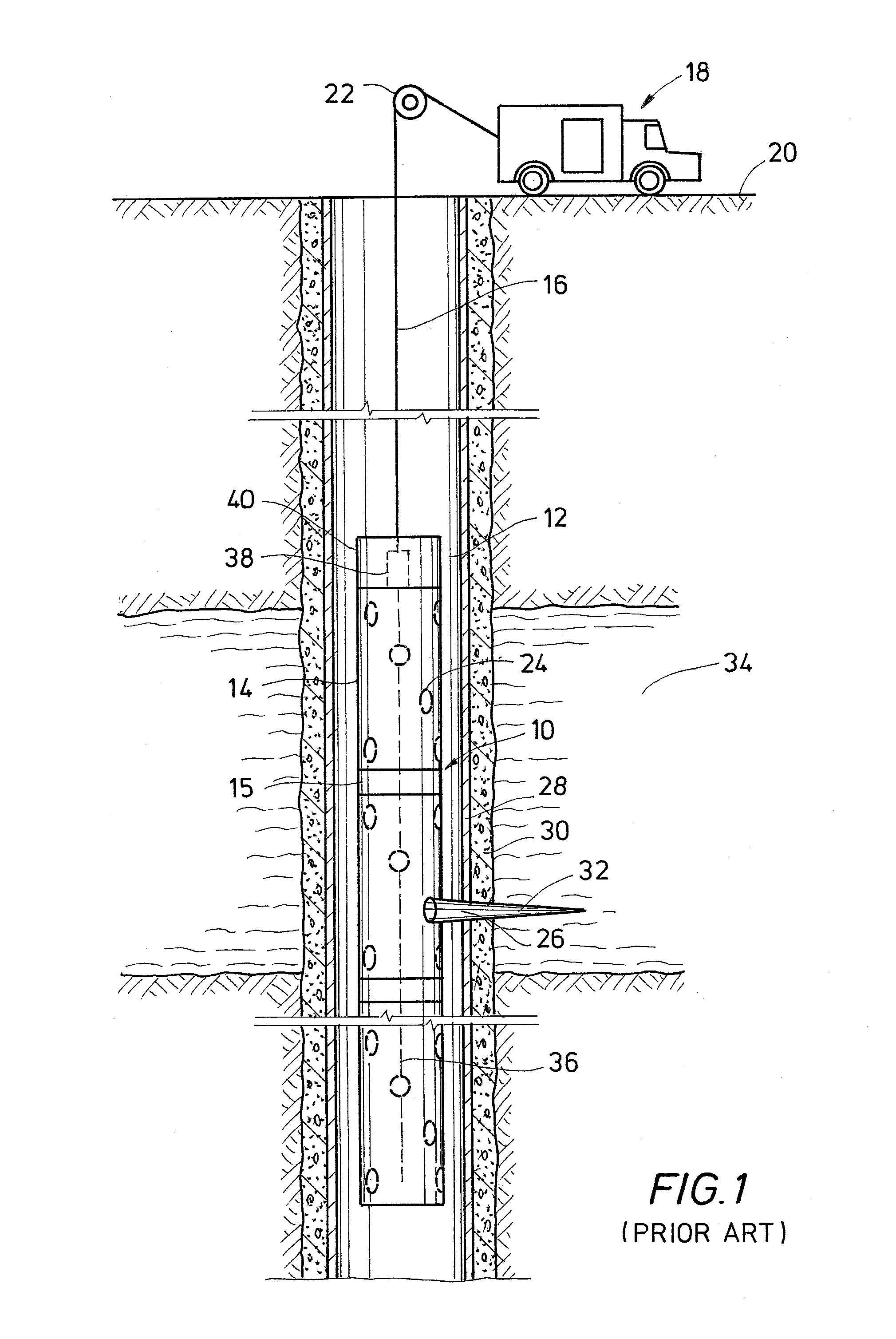

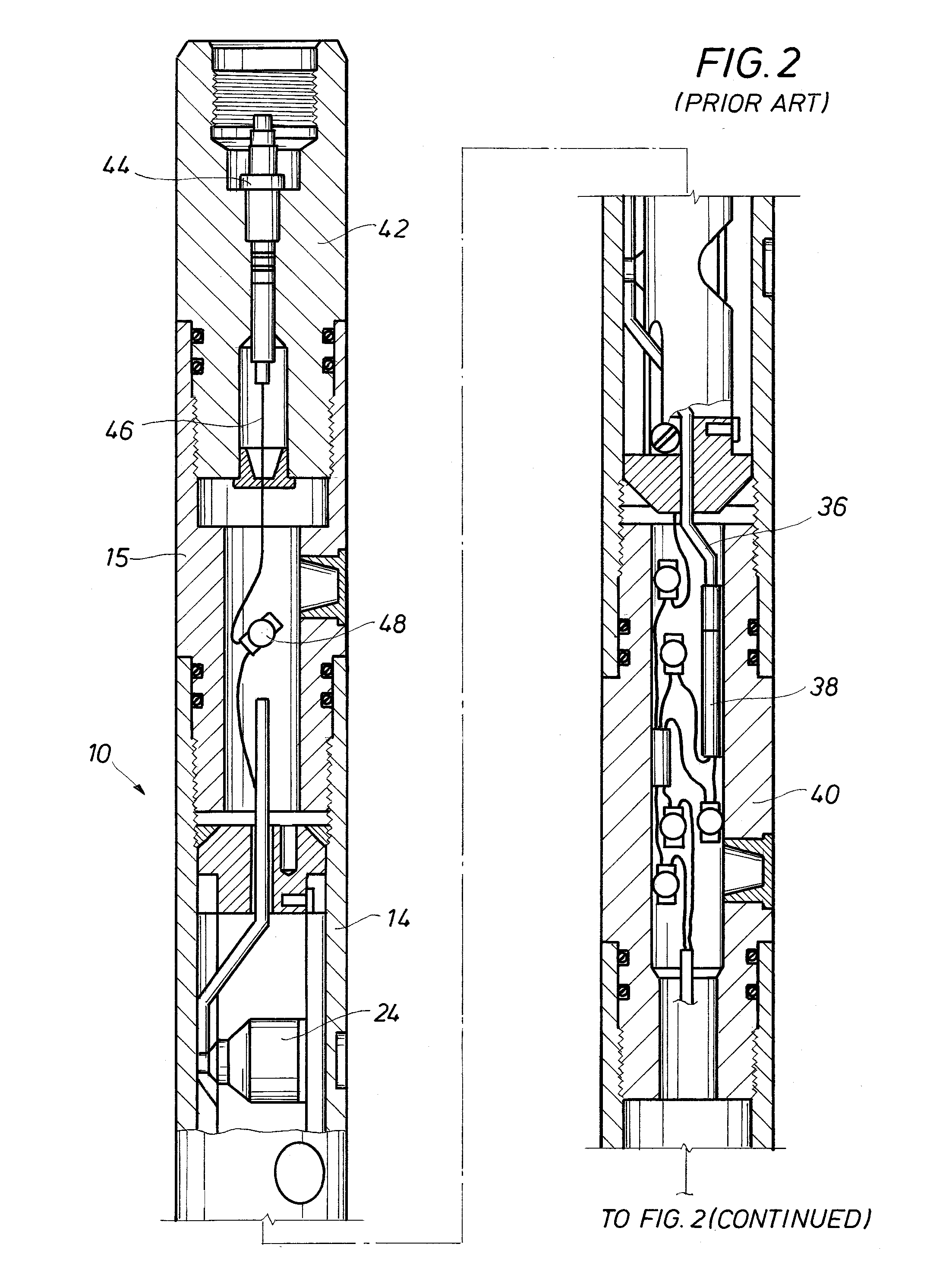

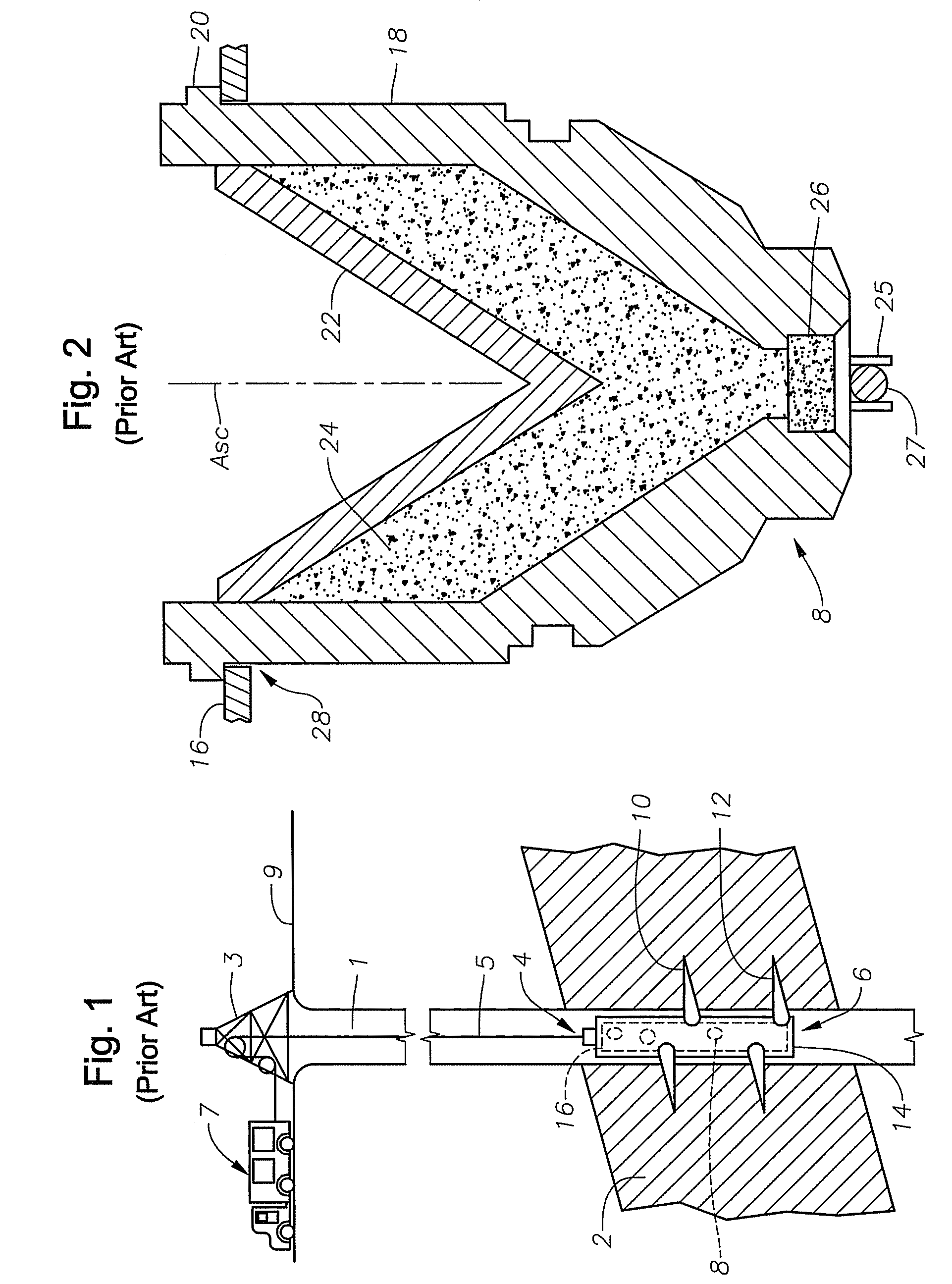

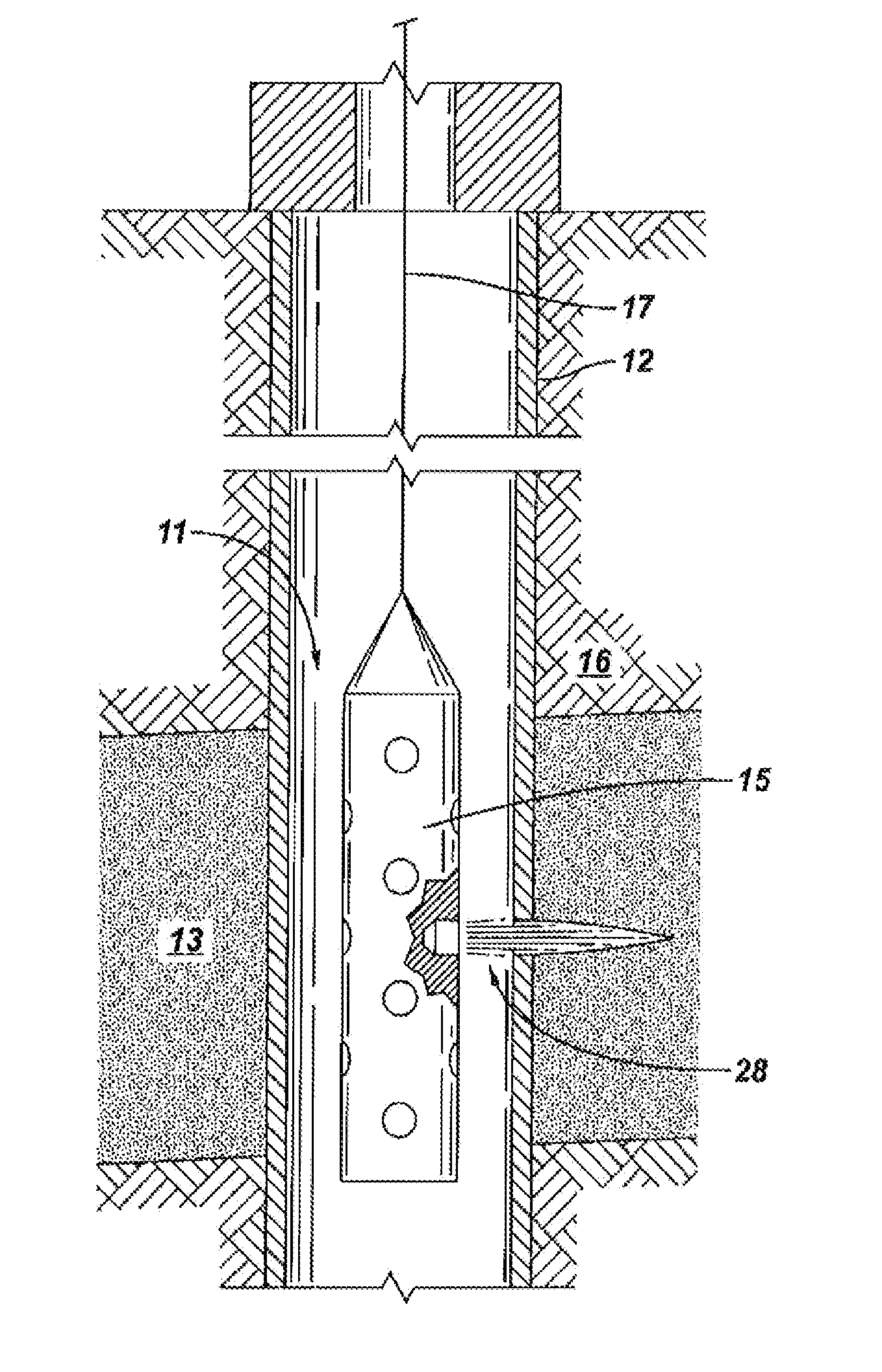

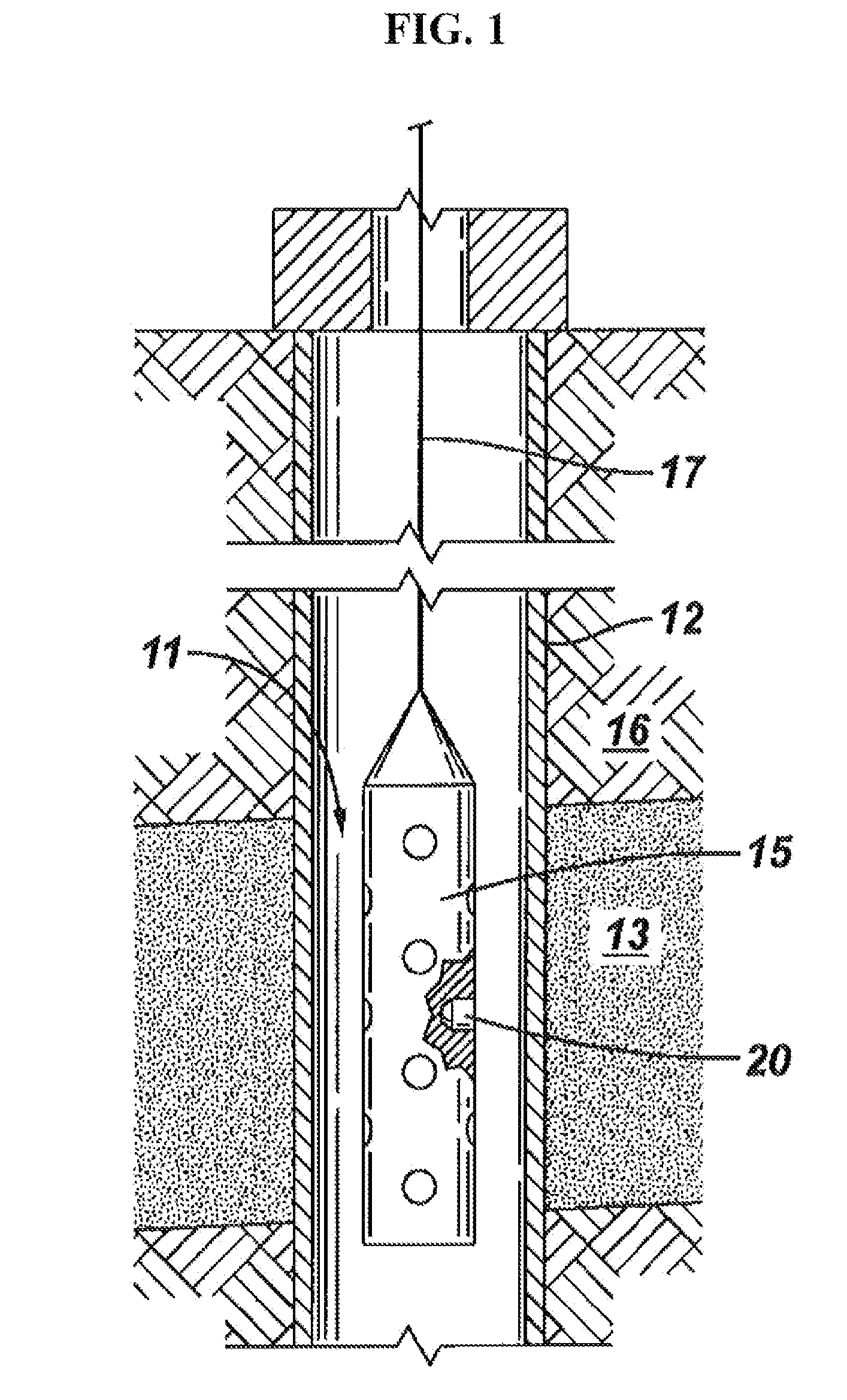

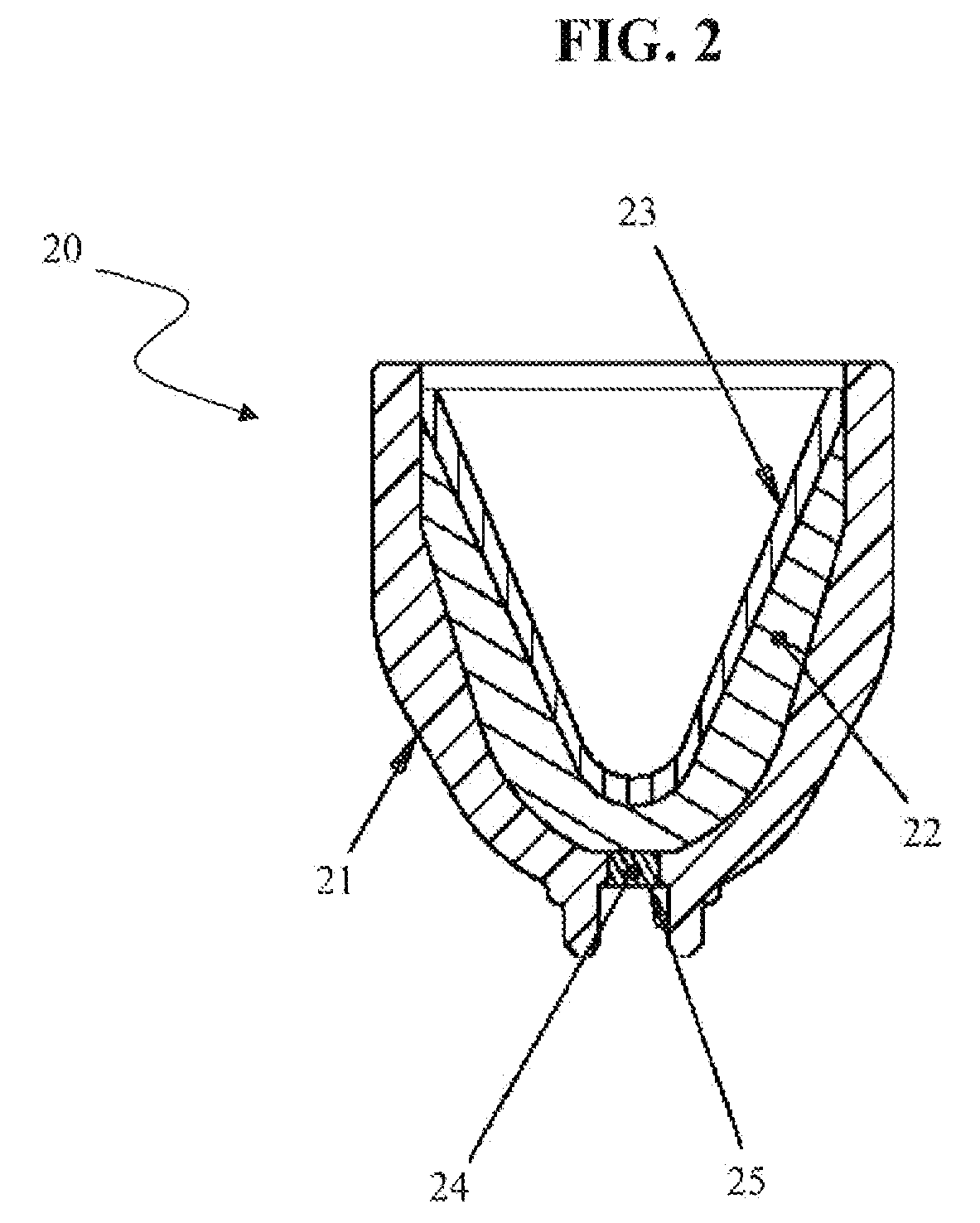

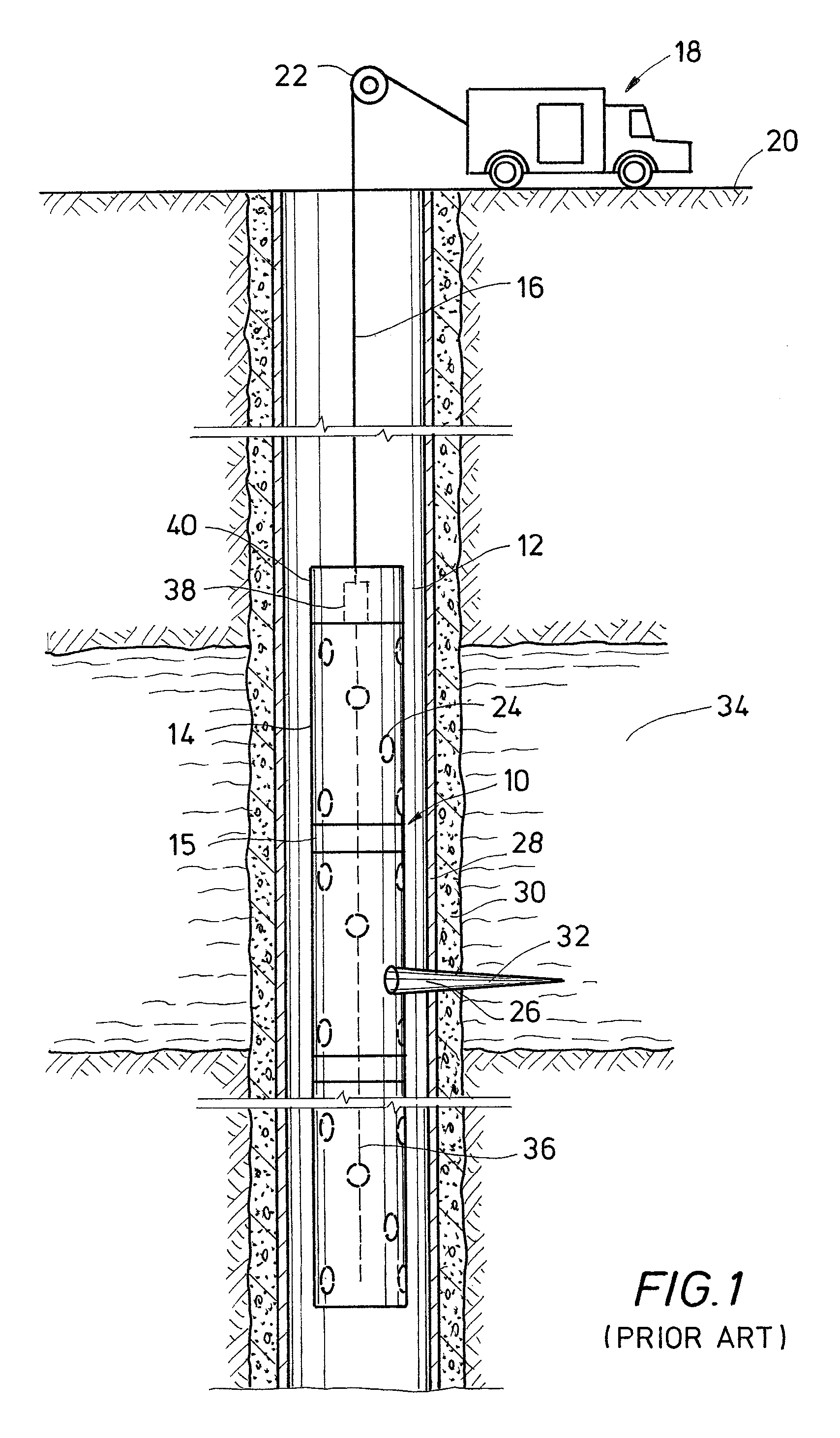

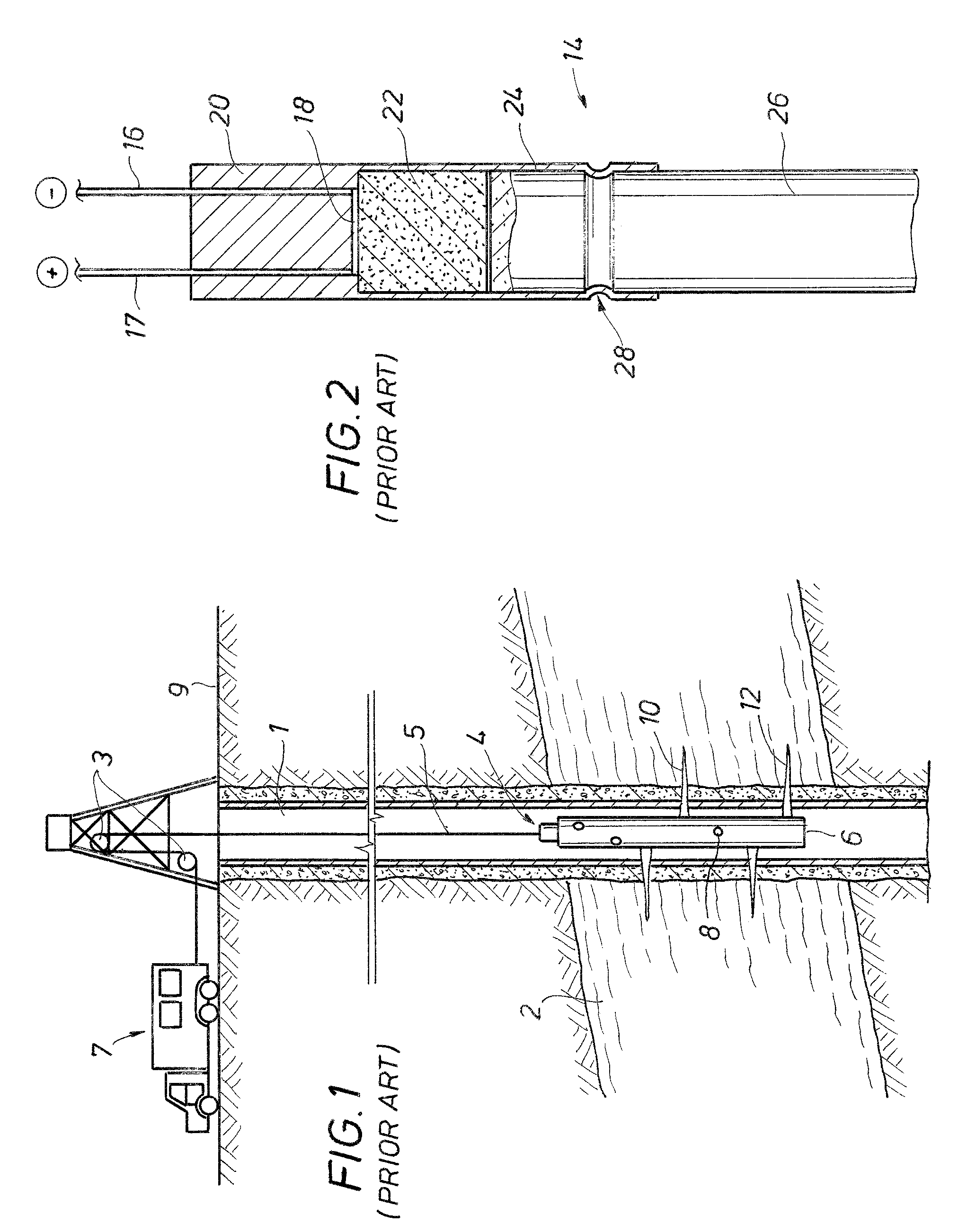

Method for window formation in wellbore tubulars

InactiveUS6024169APreventing coringEasy millingFluid removalDirectional drillingStream flowEngineering

New systems and methods have been invented for explosively forming openings, ledges, windows, holes, and lateral bores through tubulars such as casing, which openings may, in cerain aspects, extend beyond the casing into a formation through which a wellbore extends. In certain aspects openings (e.g. ledges, initial, or completed windows) in wellbore tubulars (e.g. tubing or casing) are made using metal oxidizing systems, water jet systems, or mills with abrasive and / or erosive streams flowing therethrough and / or therefrom.

Owner:WEATHERFORD TECH HLDG LLC

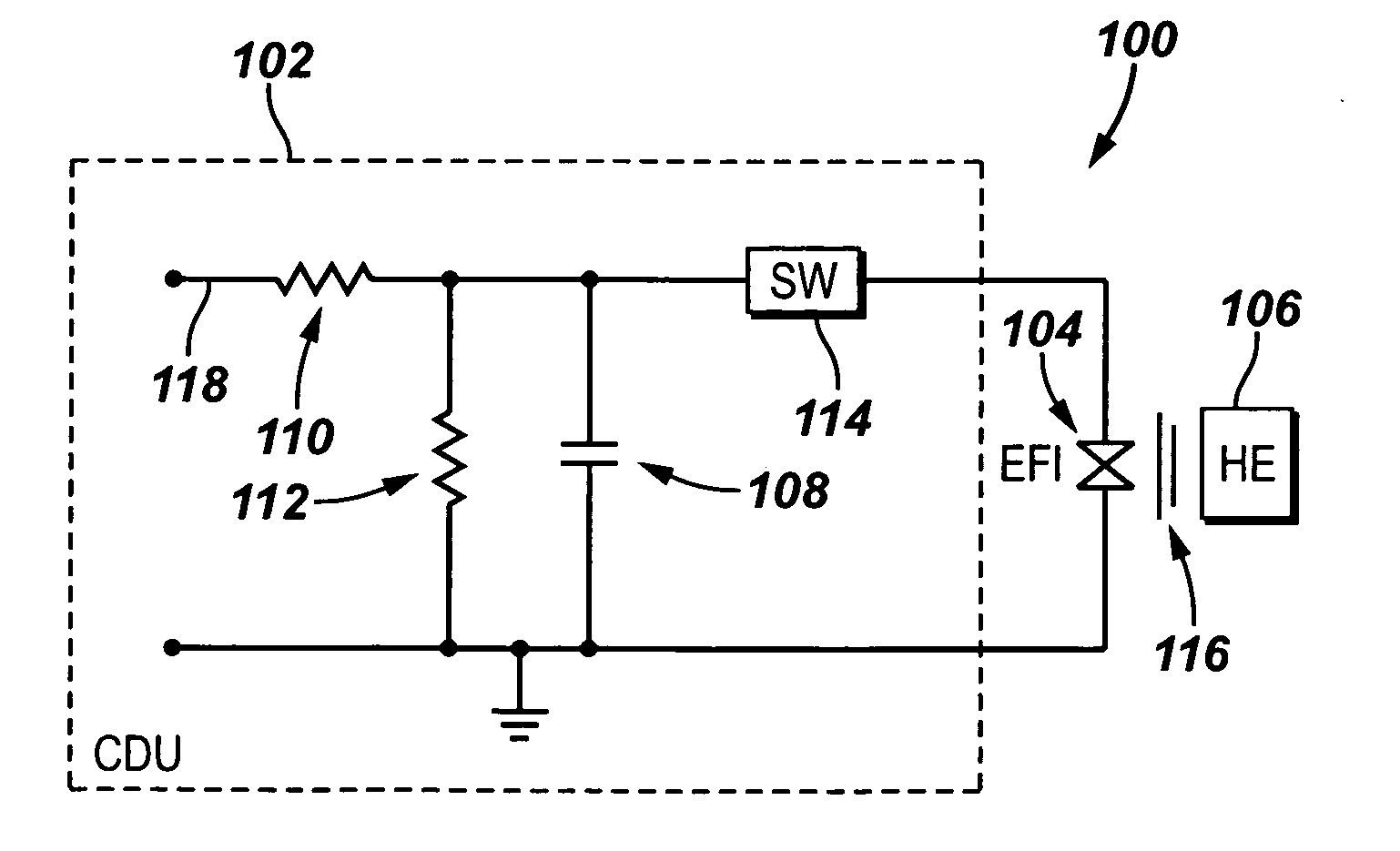

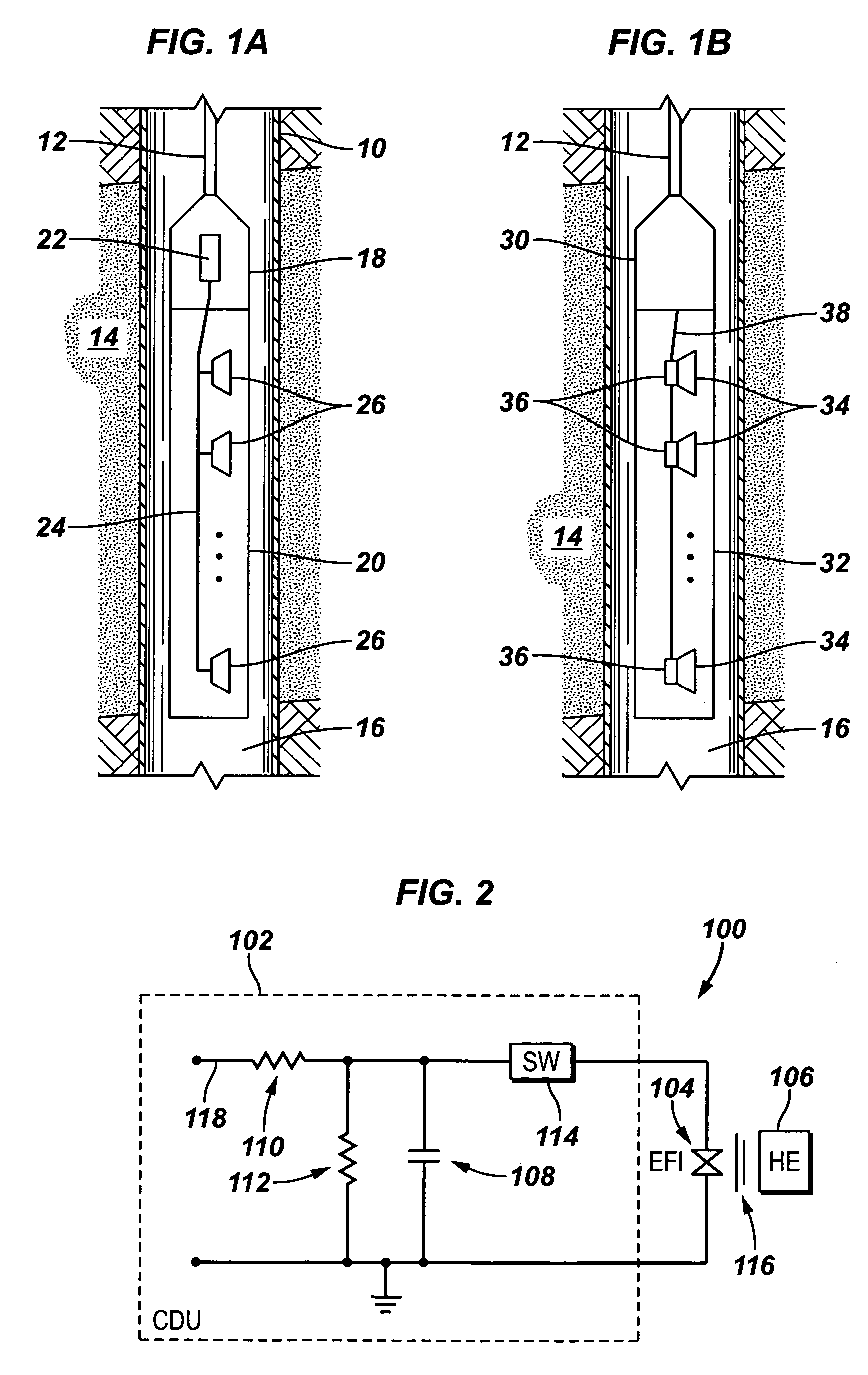

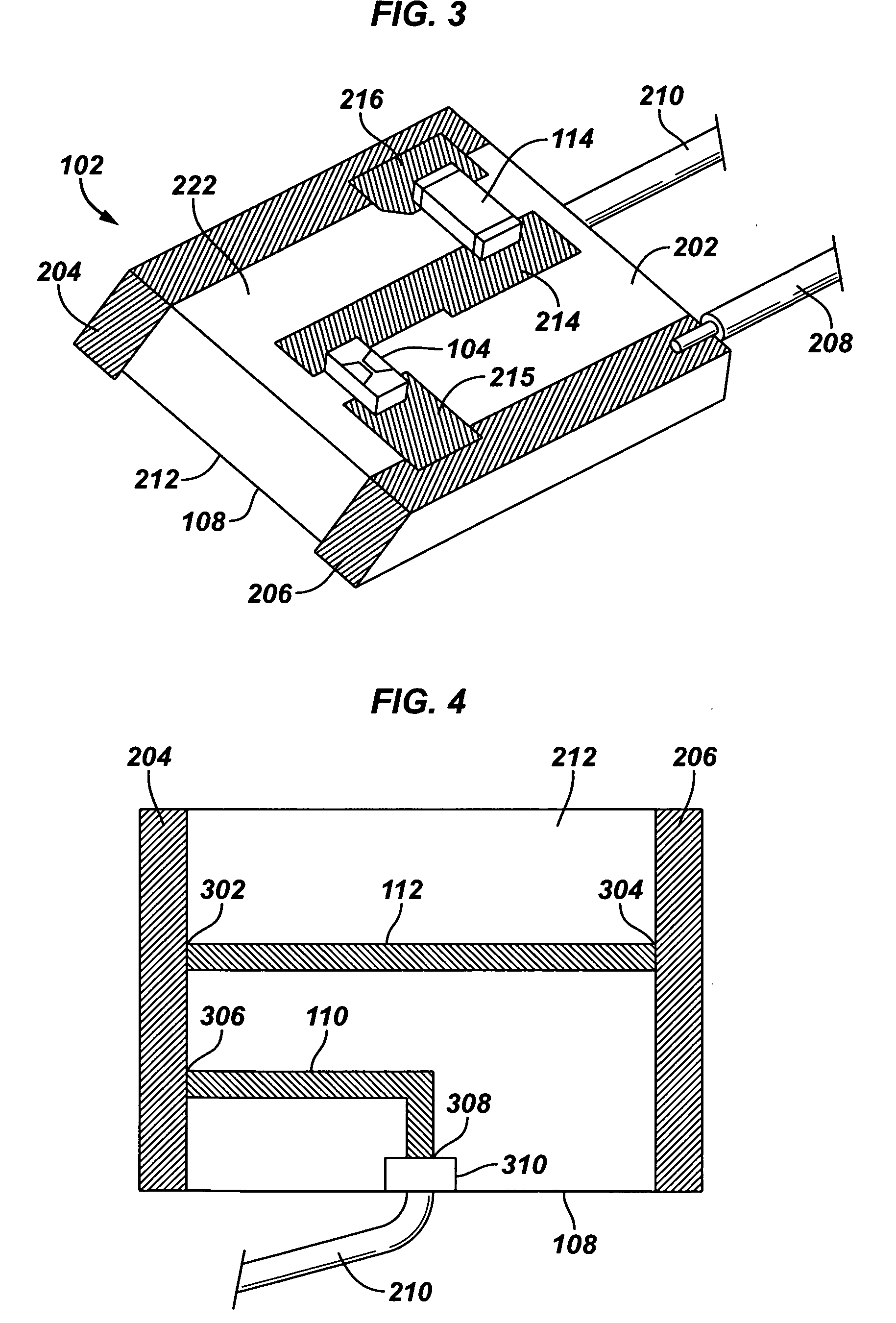

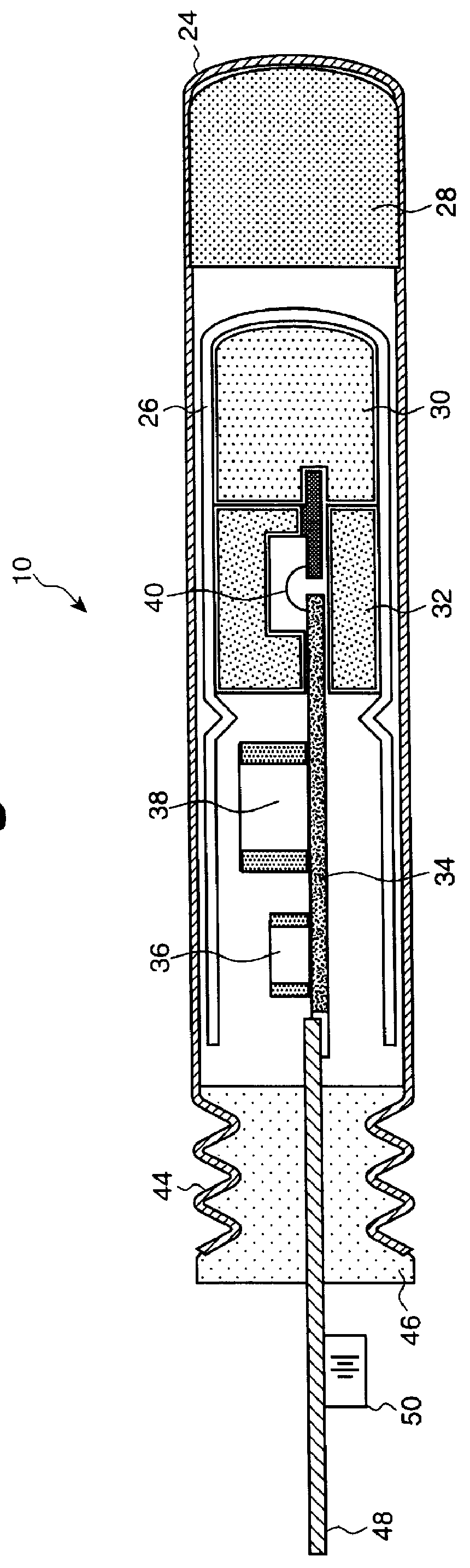

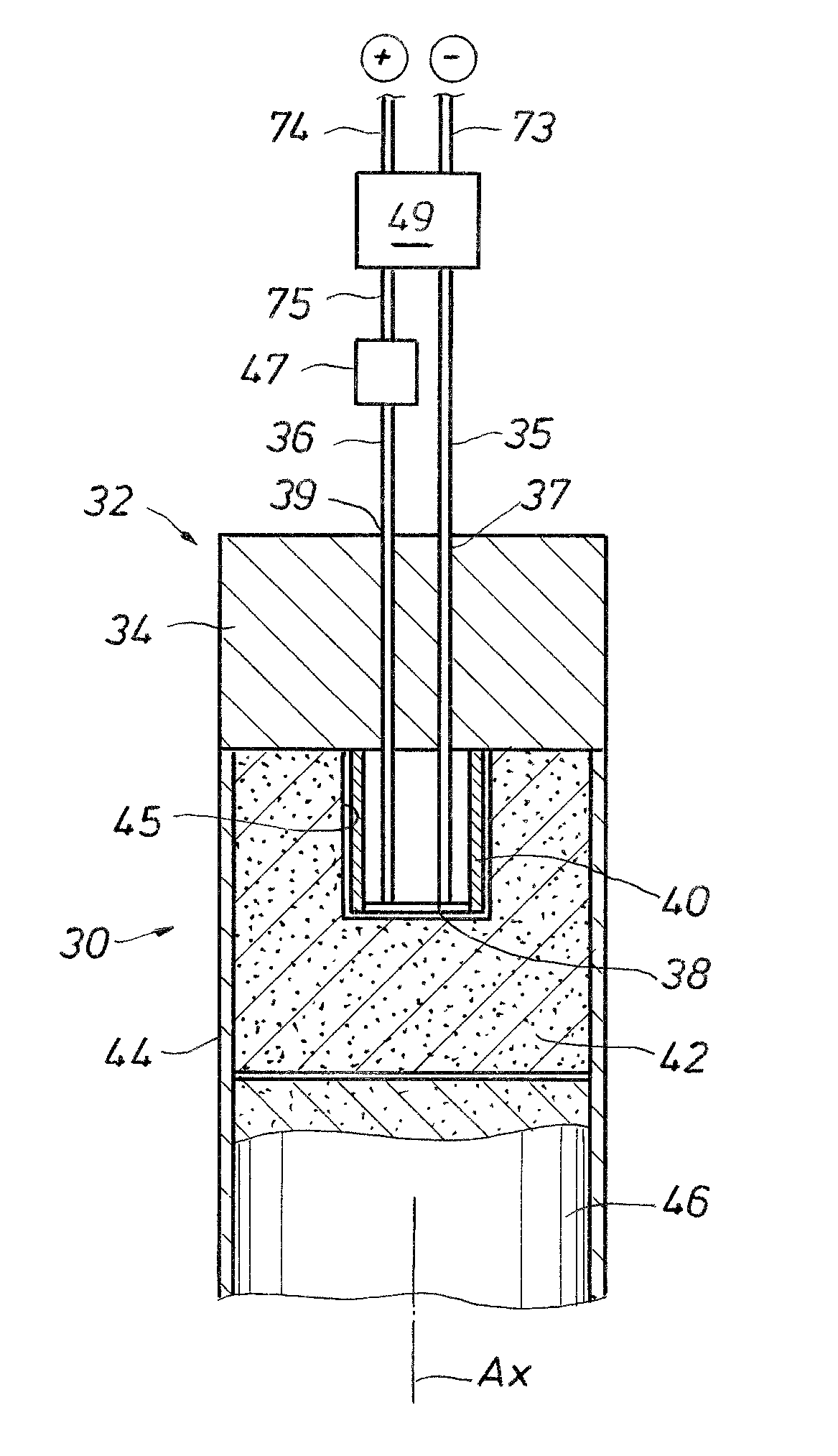

Integrated detonators for use with explosive devices

A detonator assembly is provided for use in oilfield operations to detonate an explosive downhole including a capacitor discharge unit and initiator electrically connected together to form a single unit. It is emphasized that this abstract is provided to comply with the rules requiring an abstract, which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:SCHLUMBERGER TECH CORP

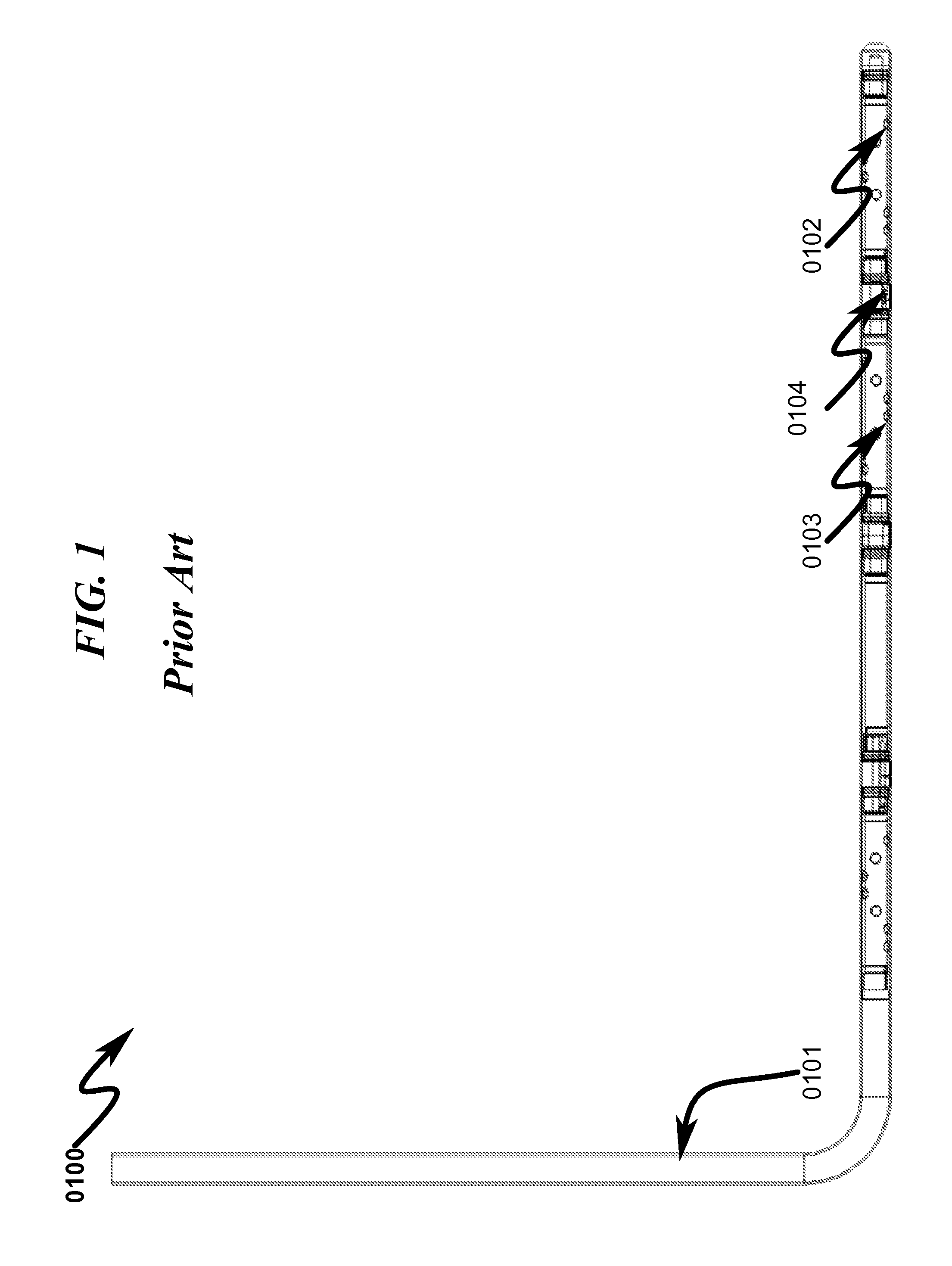

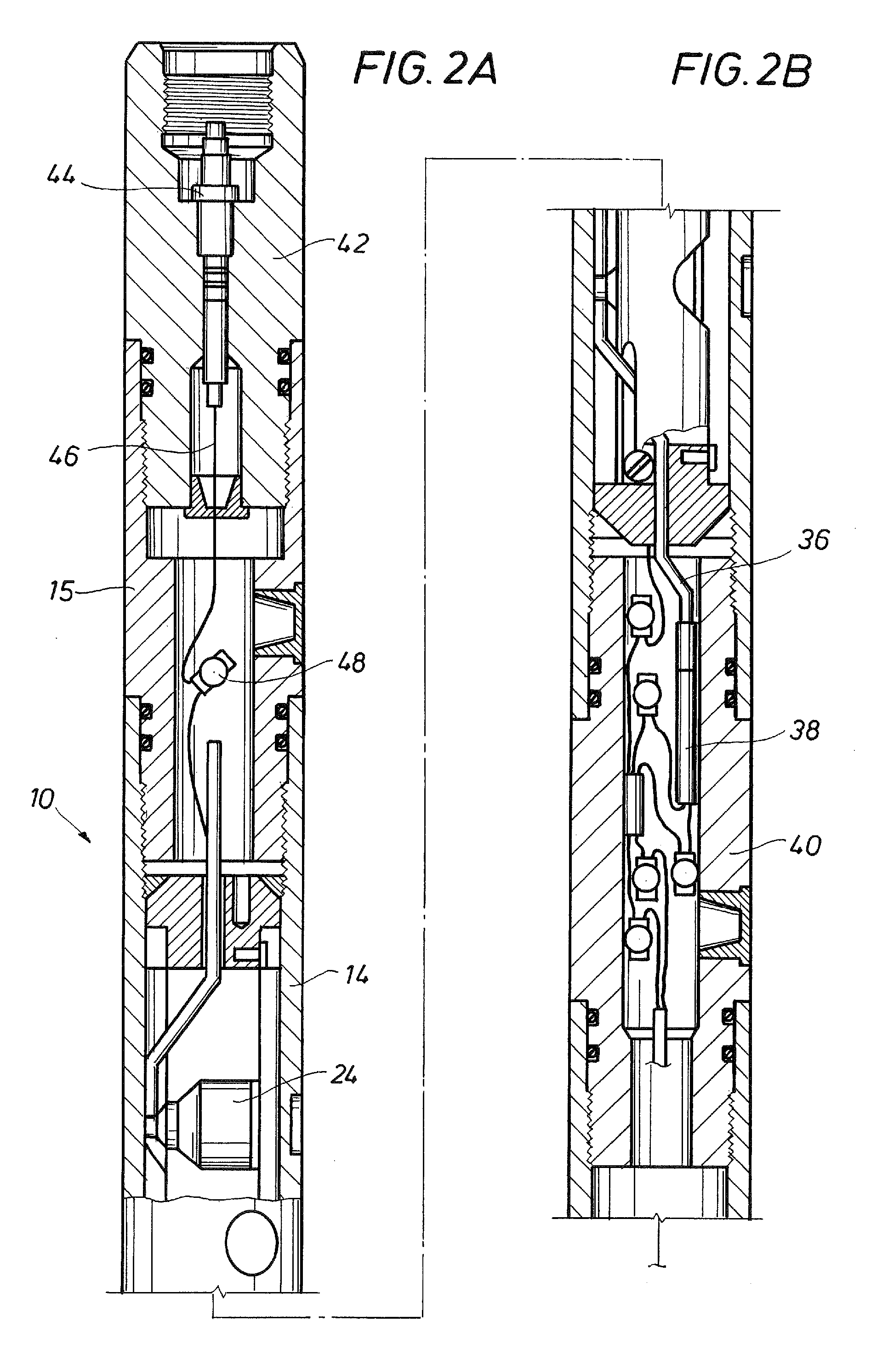

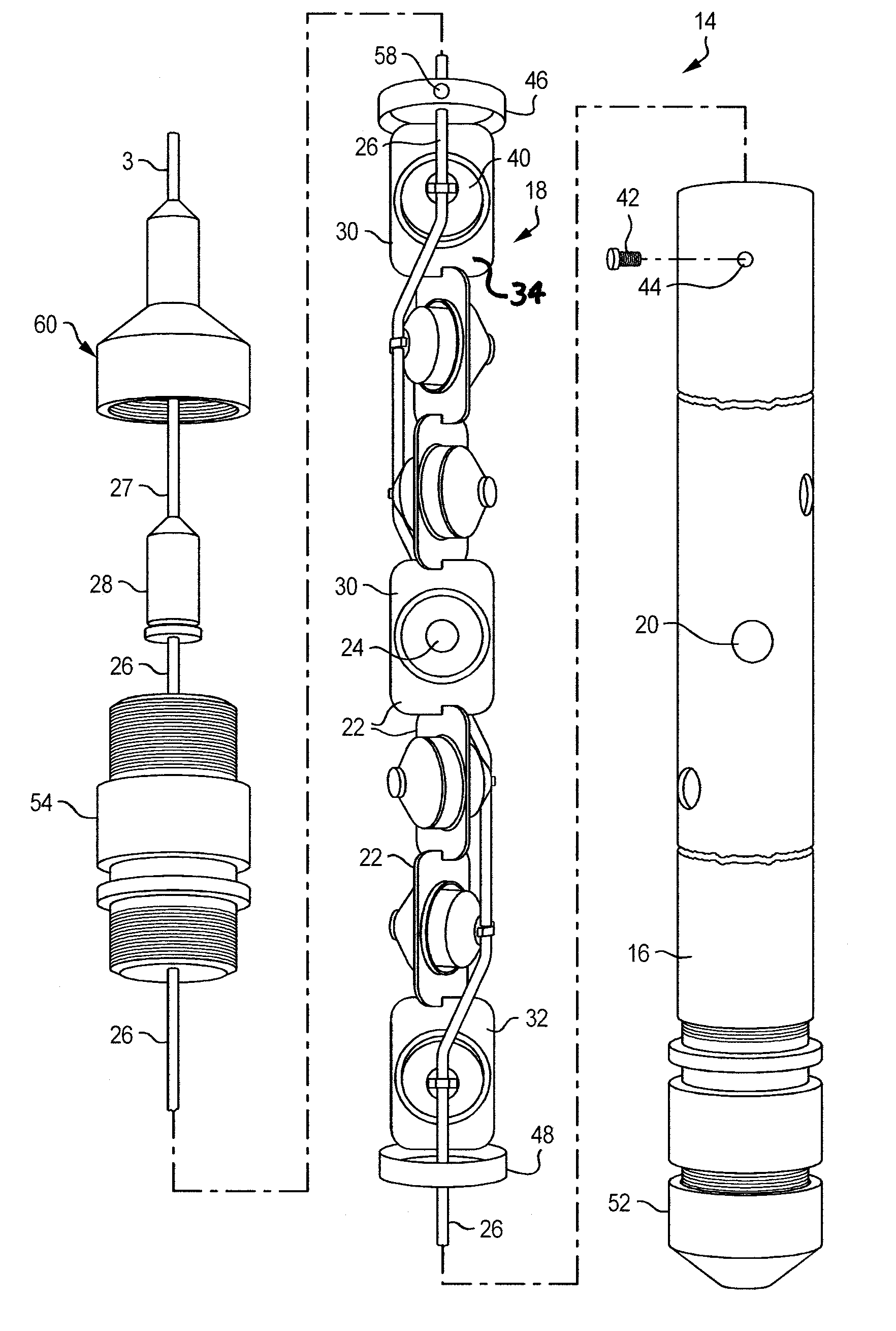

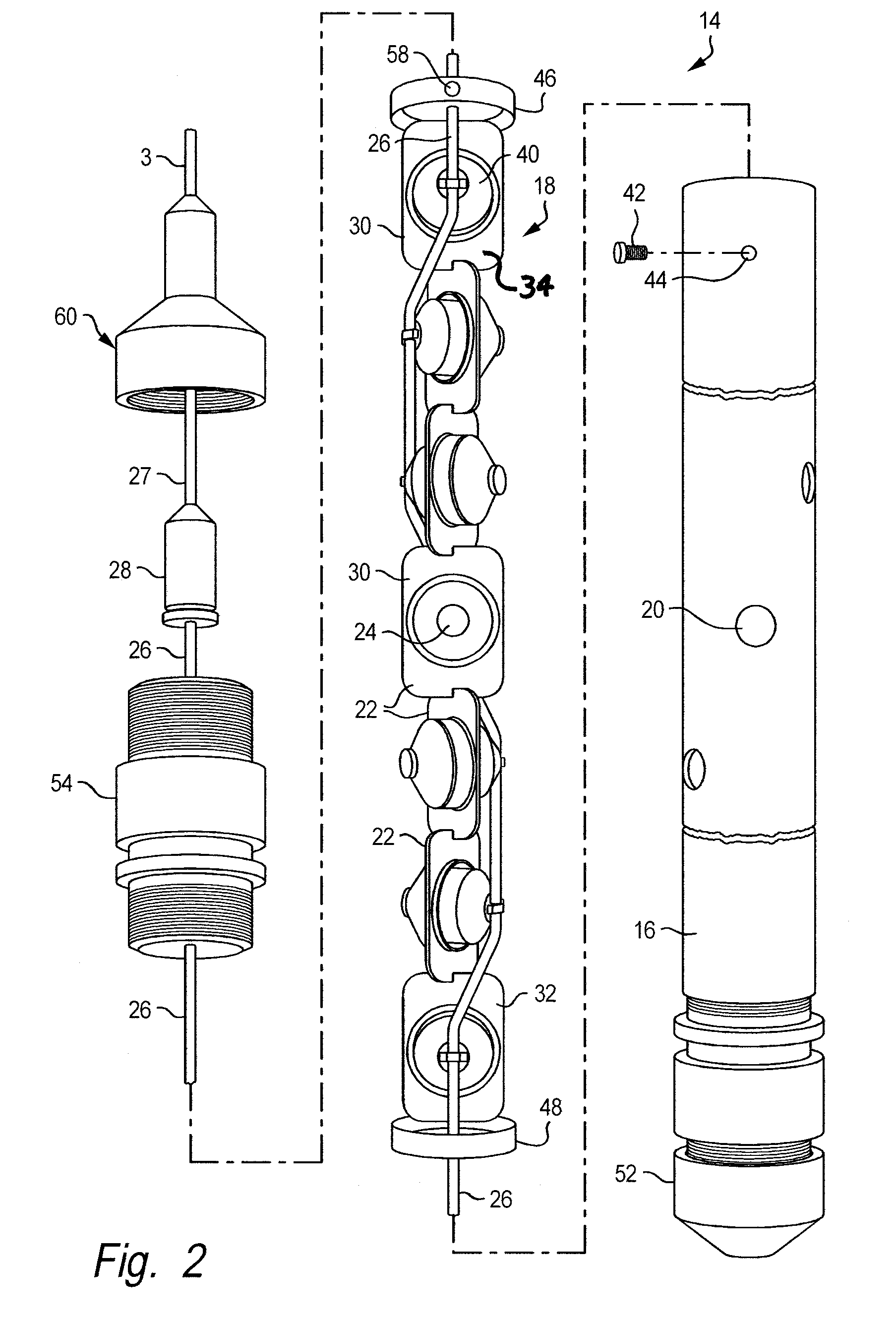

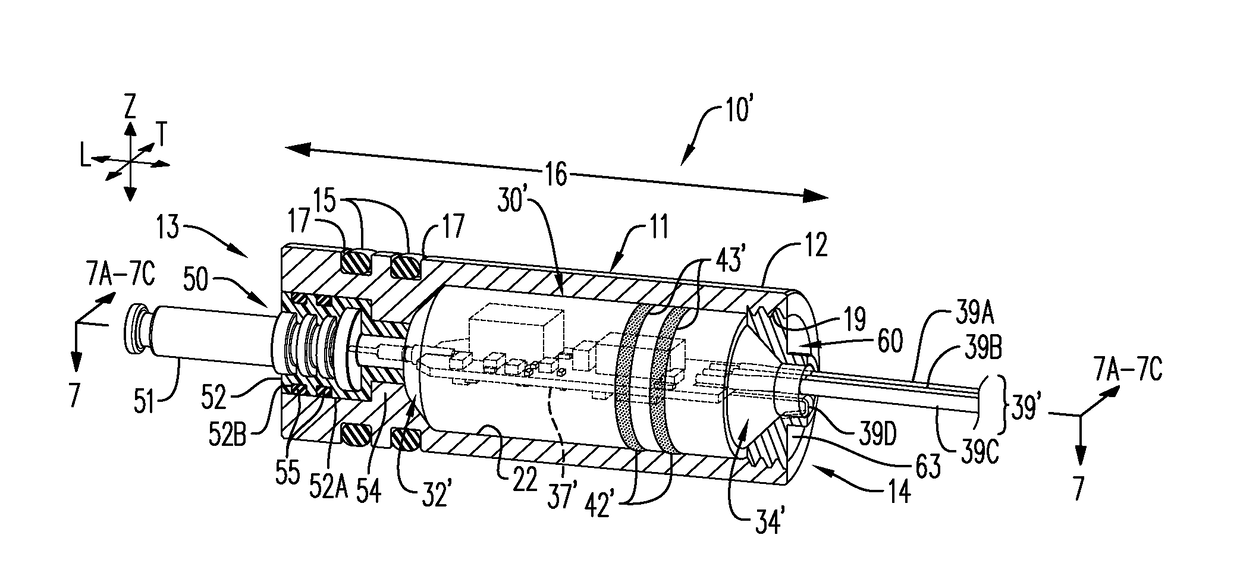

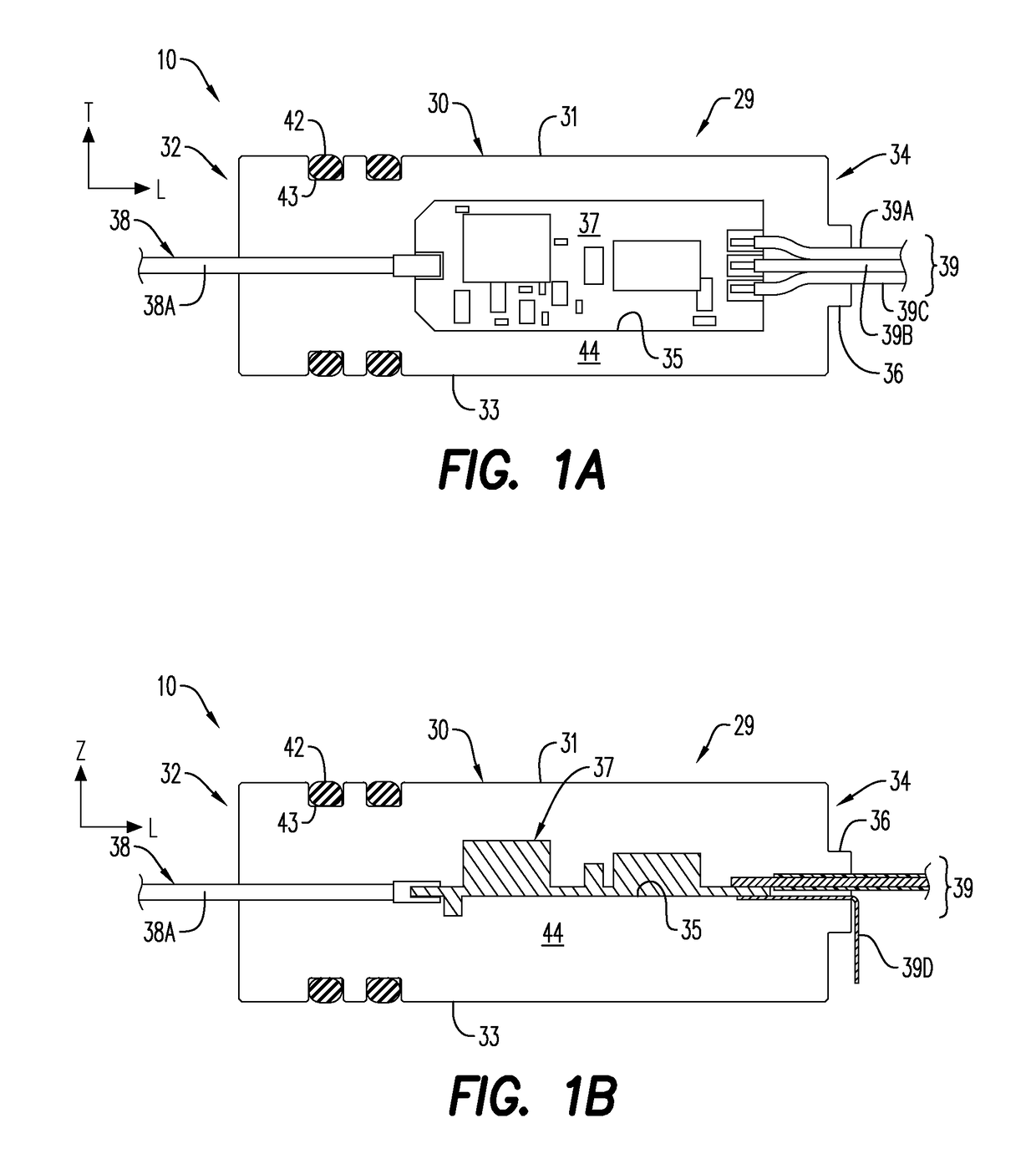

Connection cartridge for downhole string

A cartridge assembly for use with a perforating system having a contact terminal that connects to a perforating signal line when inserted into a receptacle end of a perforating gun. A detonator may be included in an end of the cartridge assembly for initiating a detonating cord in the perforating gun. The cartridge assembly is a modular unit that replaces the manual connections made when assembling a string of perforating guns. The cartridge assembly may optionally include a controller switch for controlling current flow through the cartridge assembly.

Owner:BAKER HUGHES INC

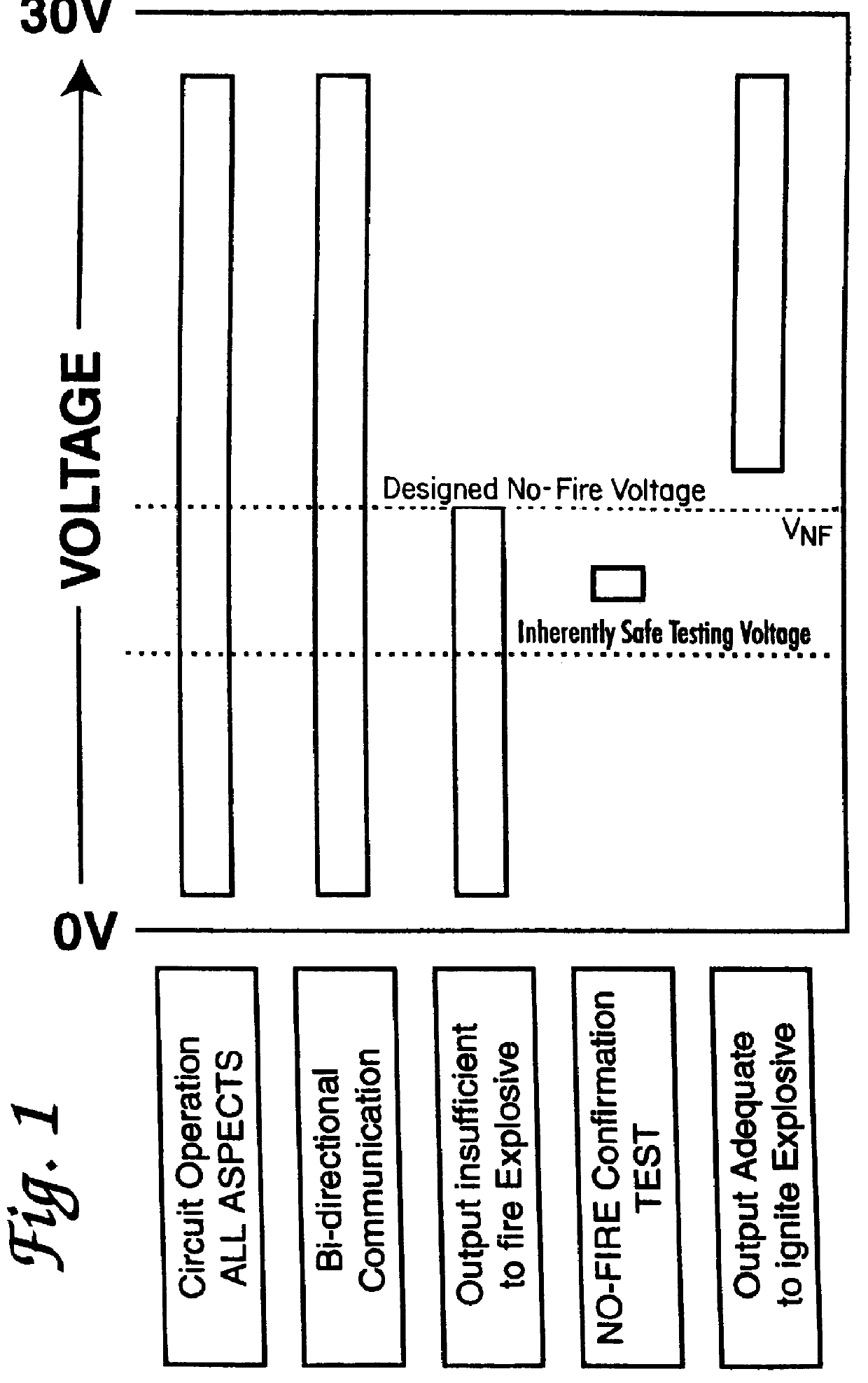

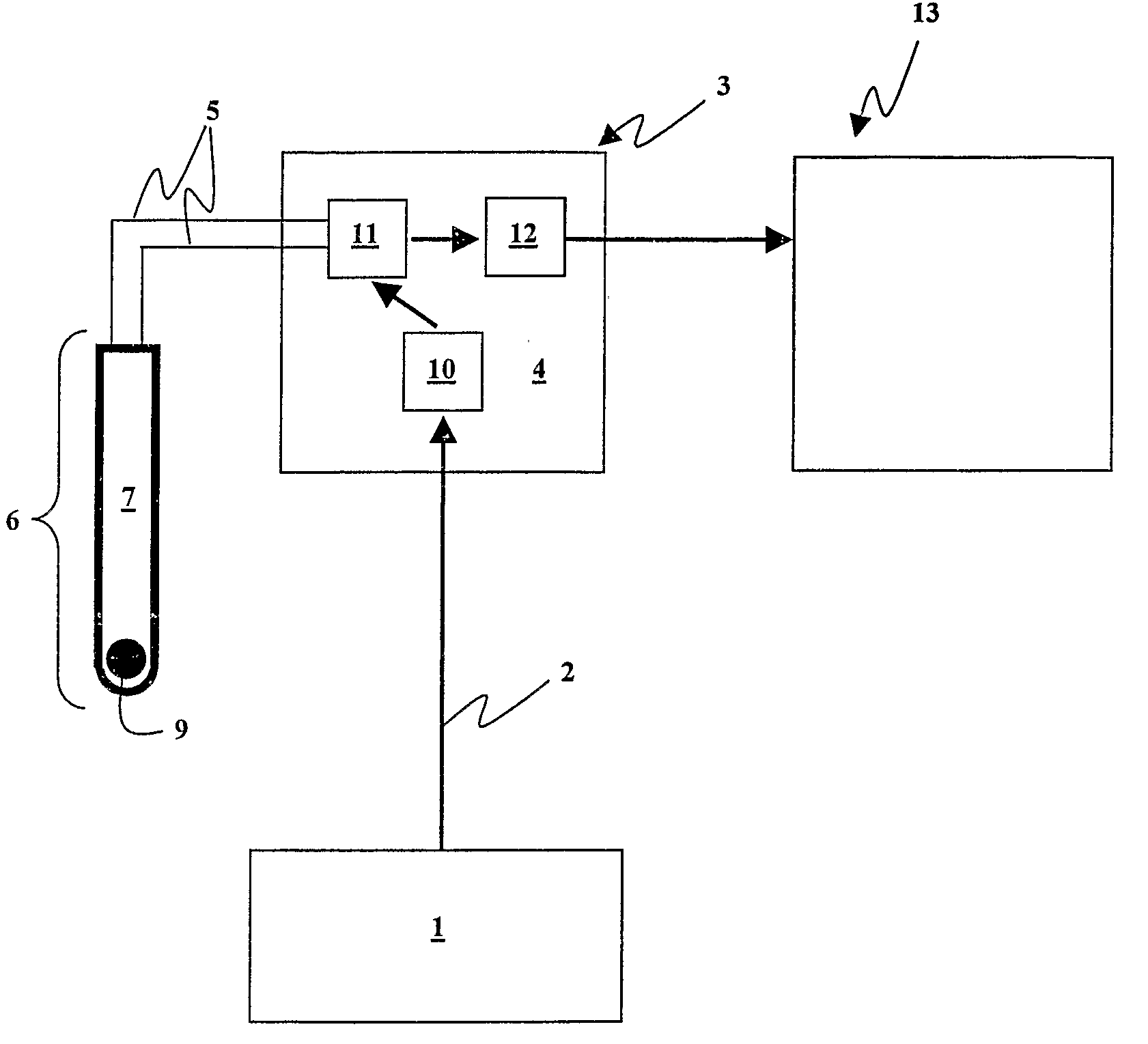

Electronic explosives initiating device

InactiveUS6085659AInherent flexibilityPosition information can be generated with easeIncandescent ignitionBlasting cartridgesVoltageExplosive Agents

PCT No. PCT / GB96 / 02987 Sec. 371 Date Dec. 10, 1998 Sec. 102(e) Date Dec. 10, 1998 PCT Filed Dec. 4, 1996 PCT Pub. No. WO97 / 21067 PCT Pub. Date Jun. 12, 1997An electronic explosives initiating device which includes a firing element which has a designed no-fire voltage and an operating circuit which operates at any voltage in a range of voltages which straddles the designed no-fire voltage.

Owner:ORICA EXPLOSIVES TECH PTY LTD

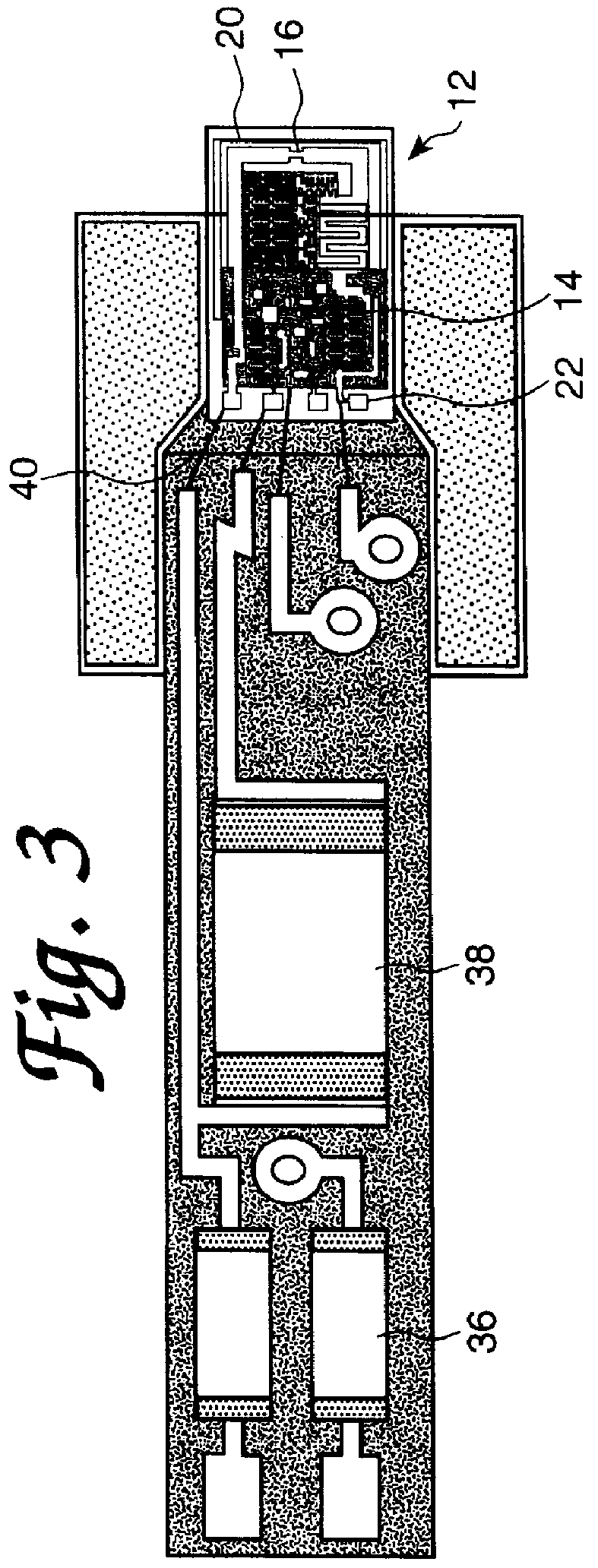

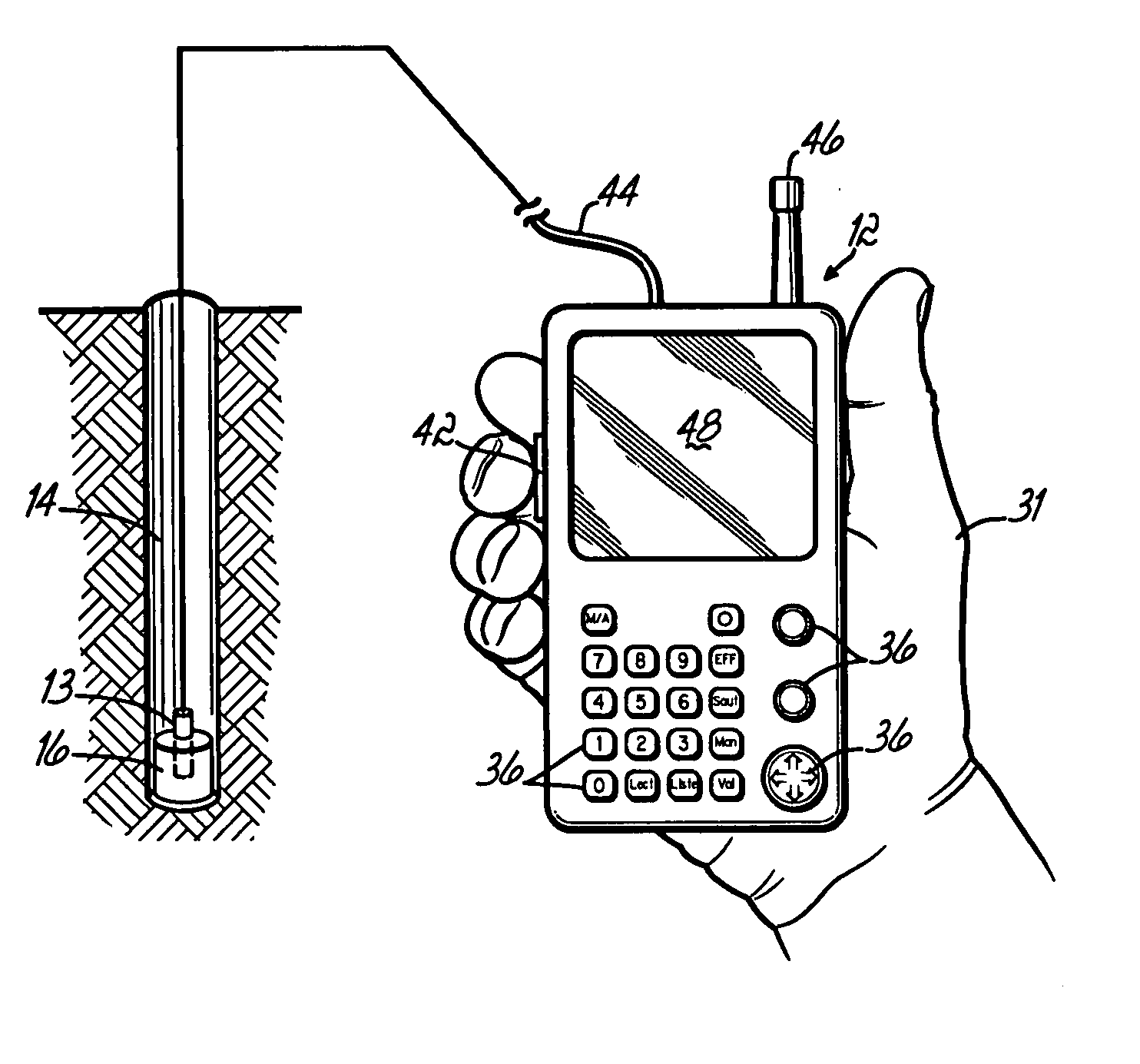

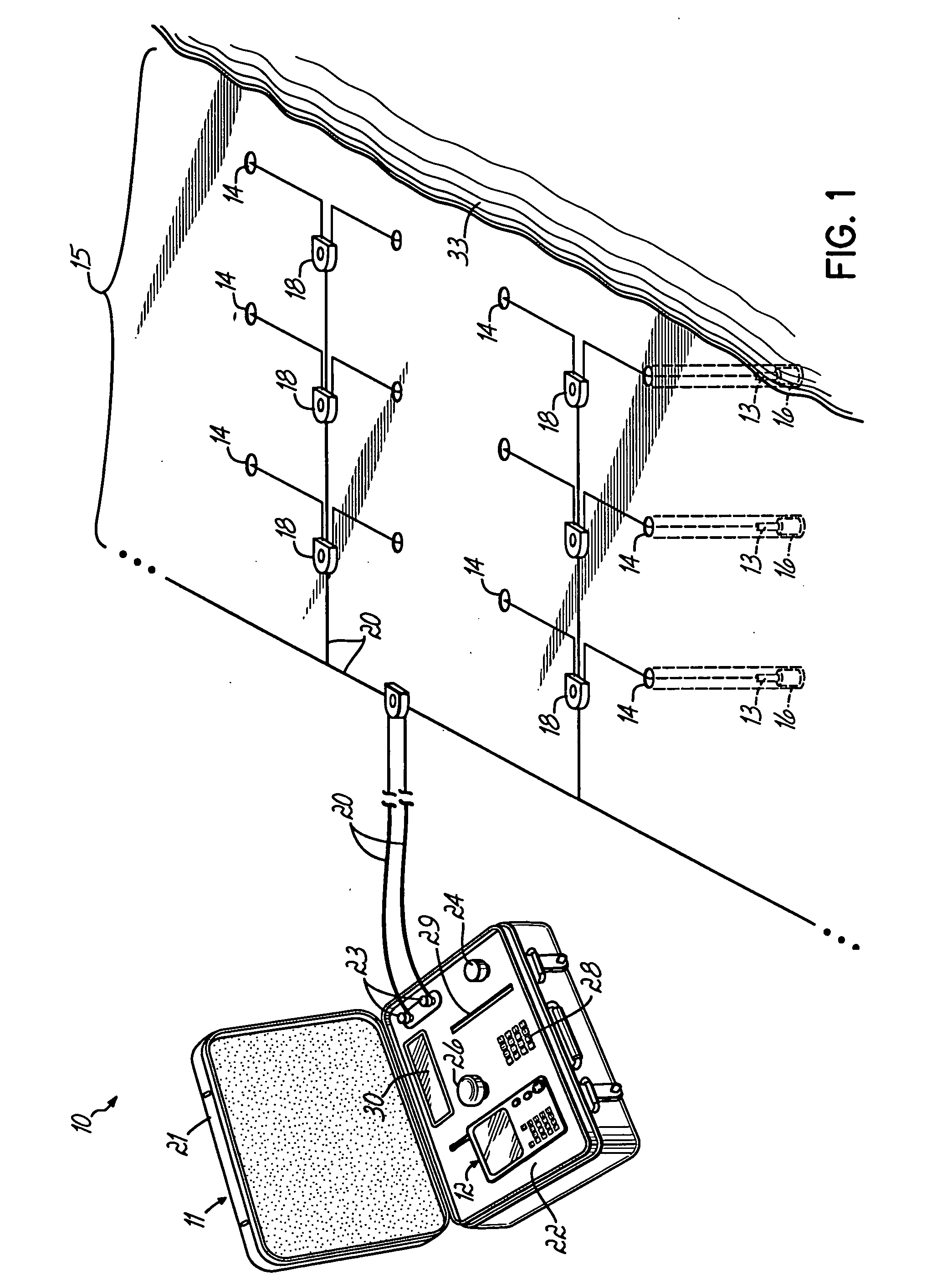

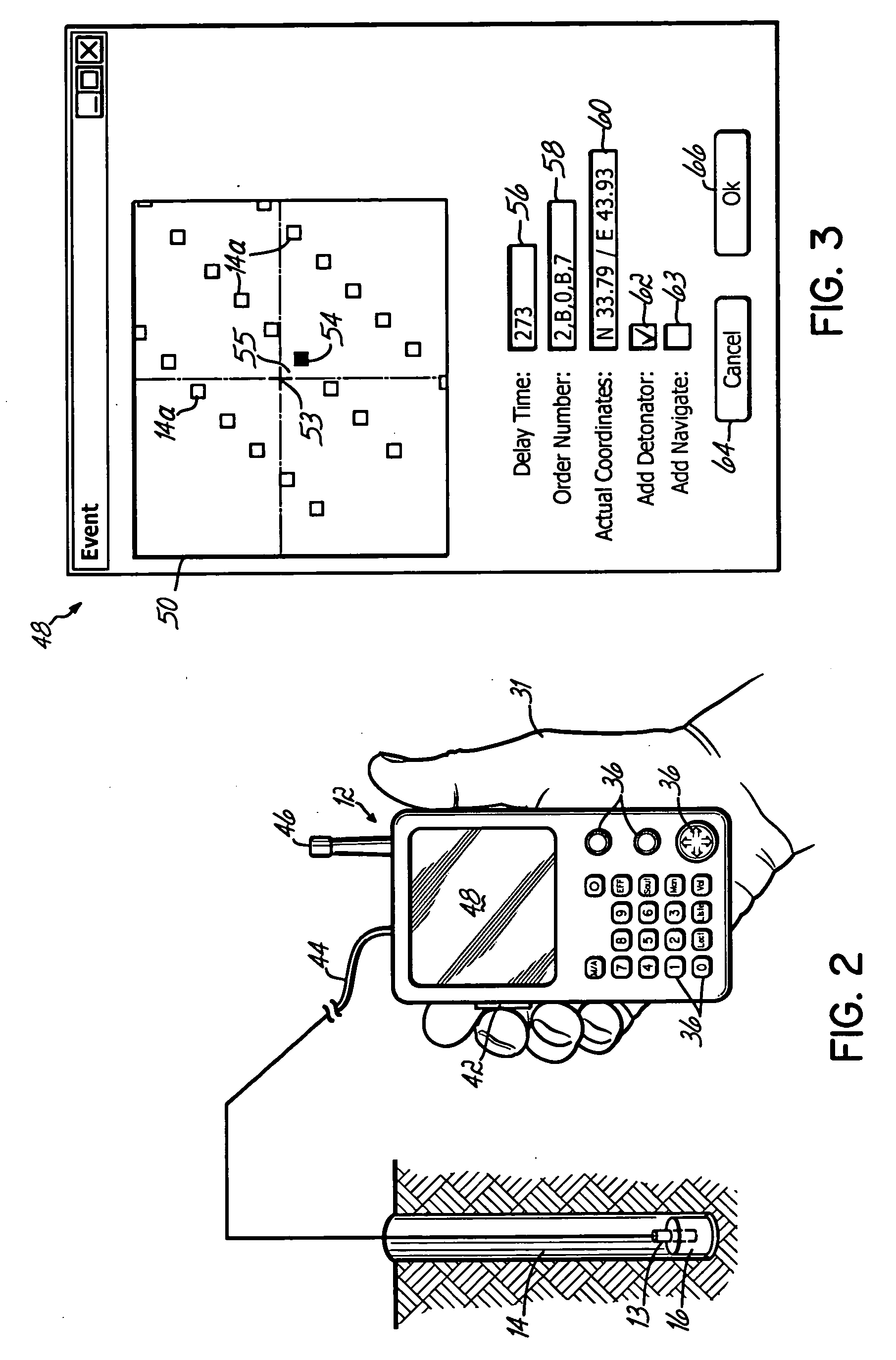

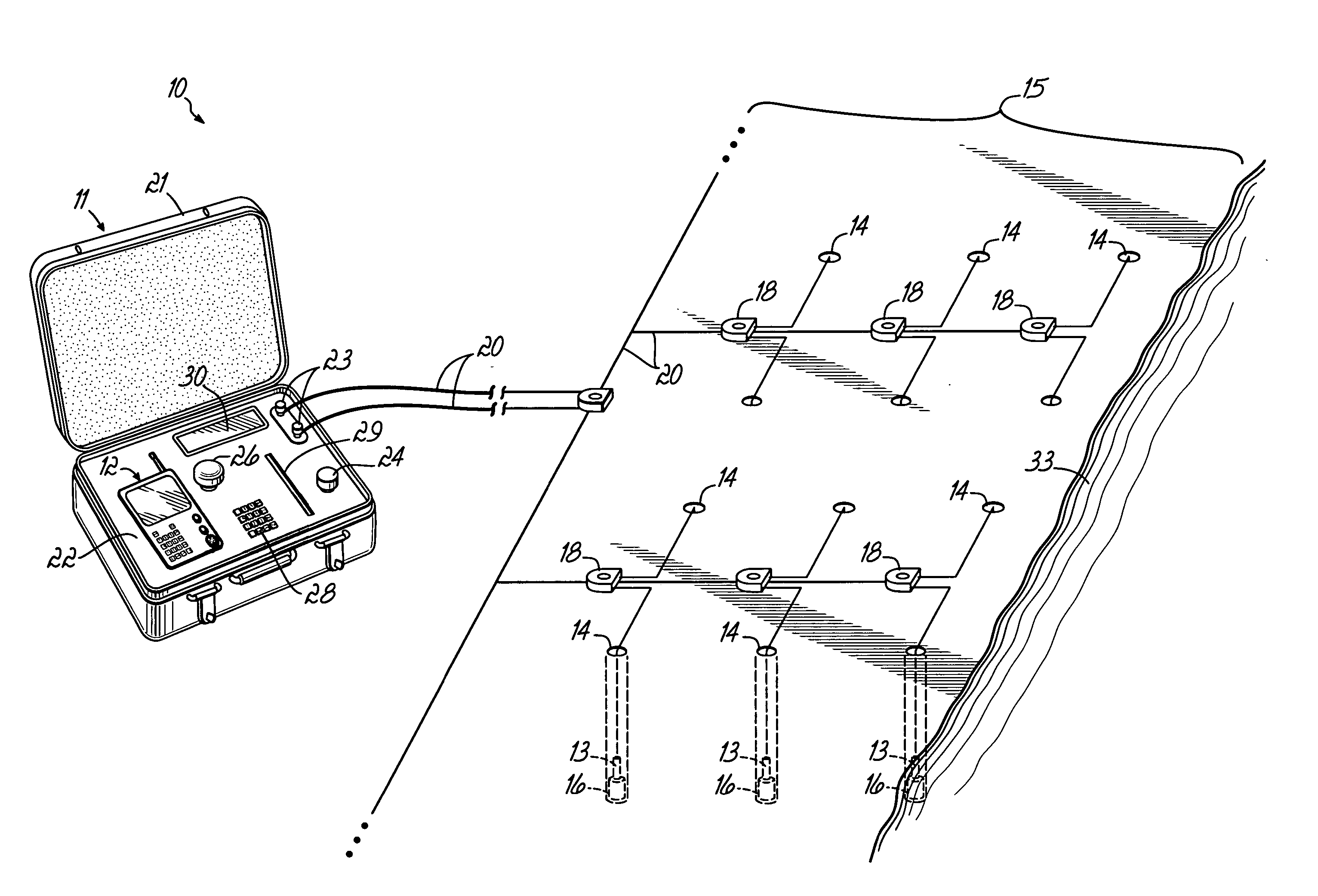

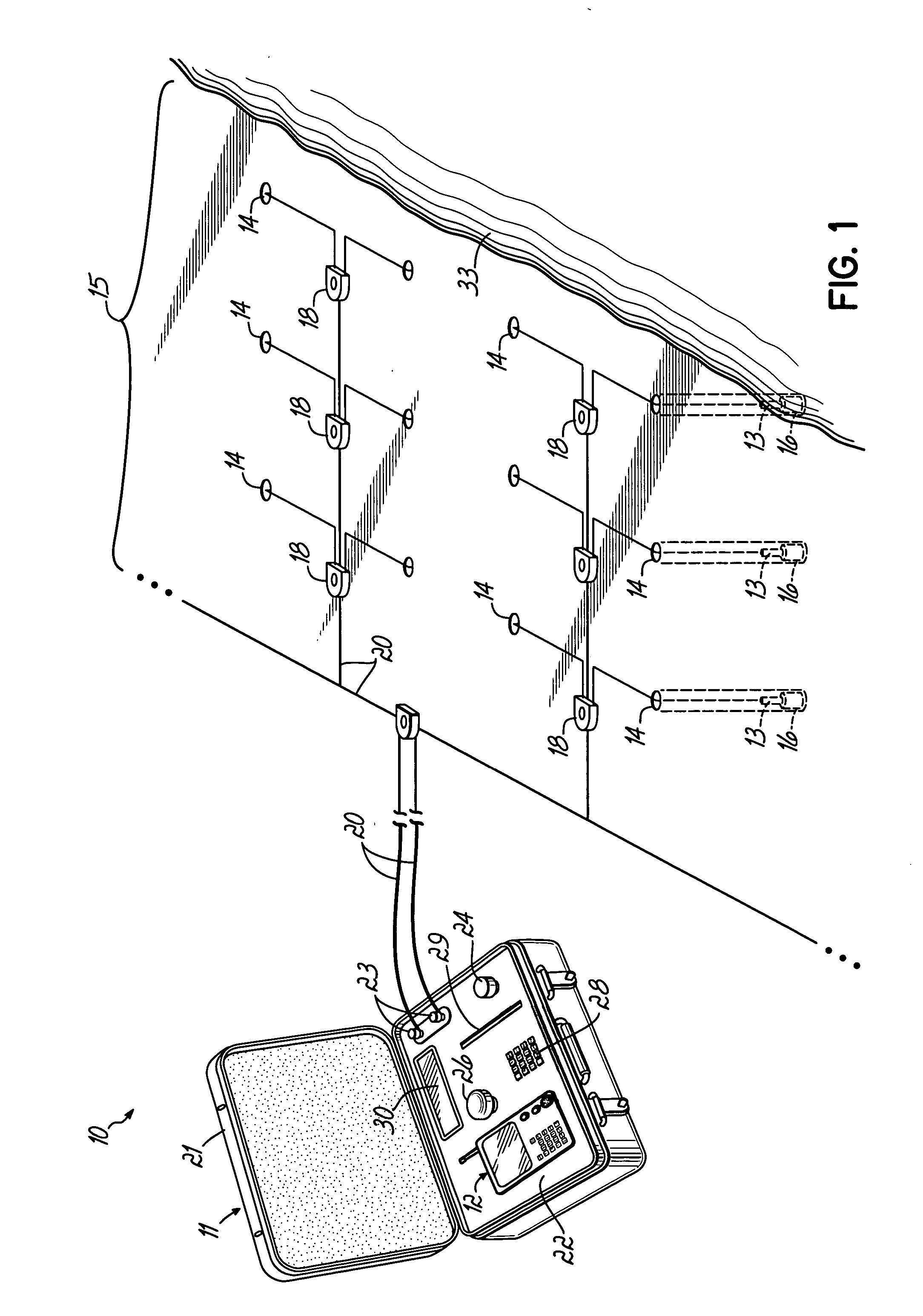

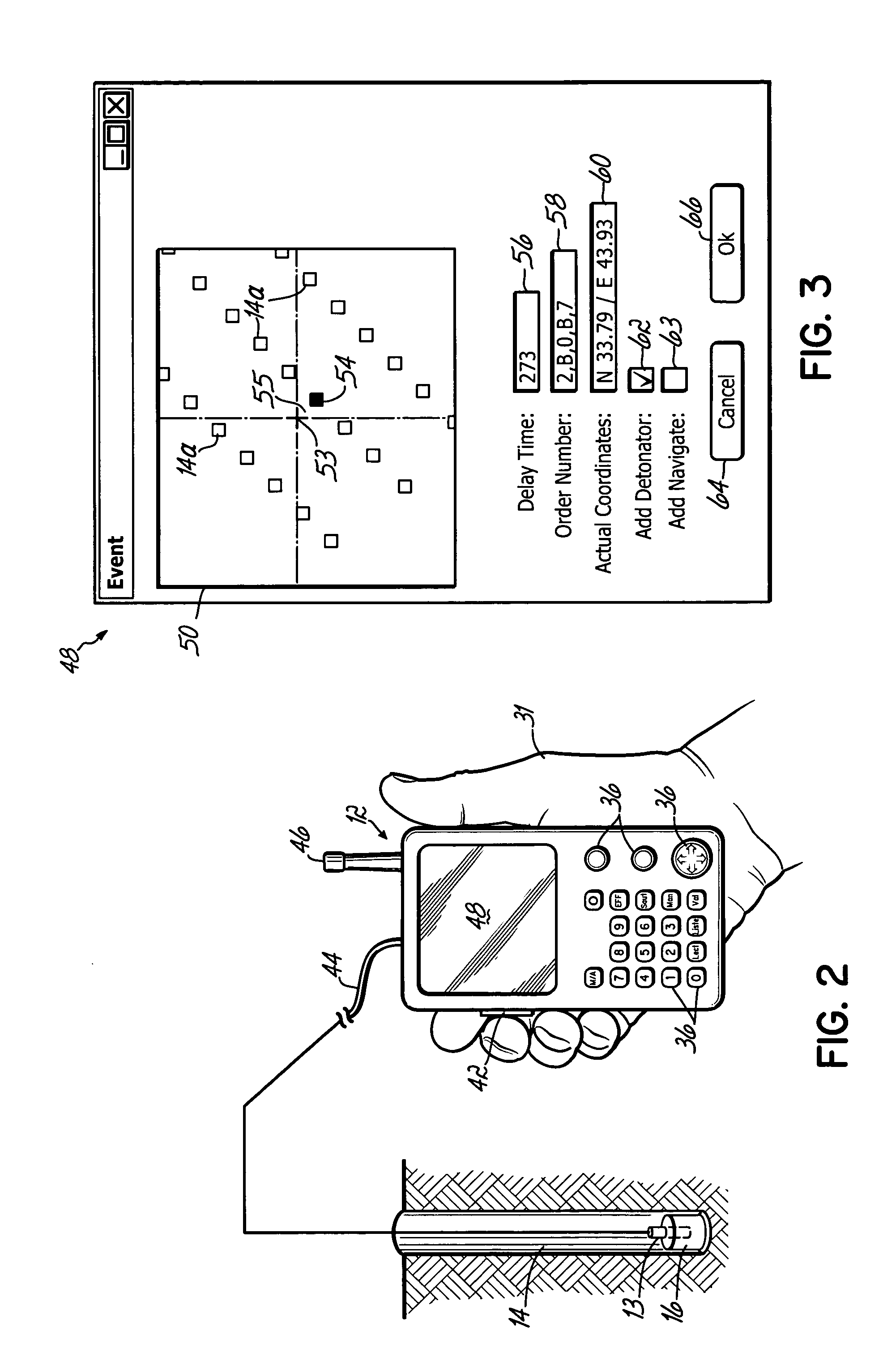

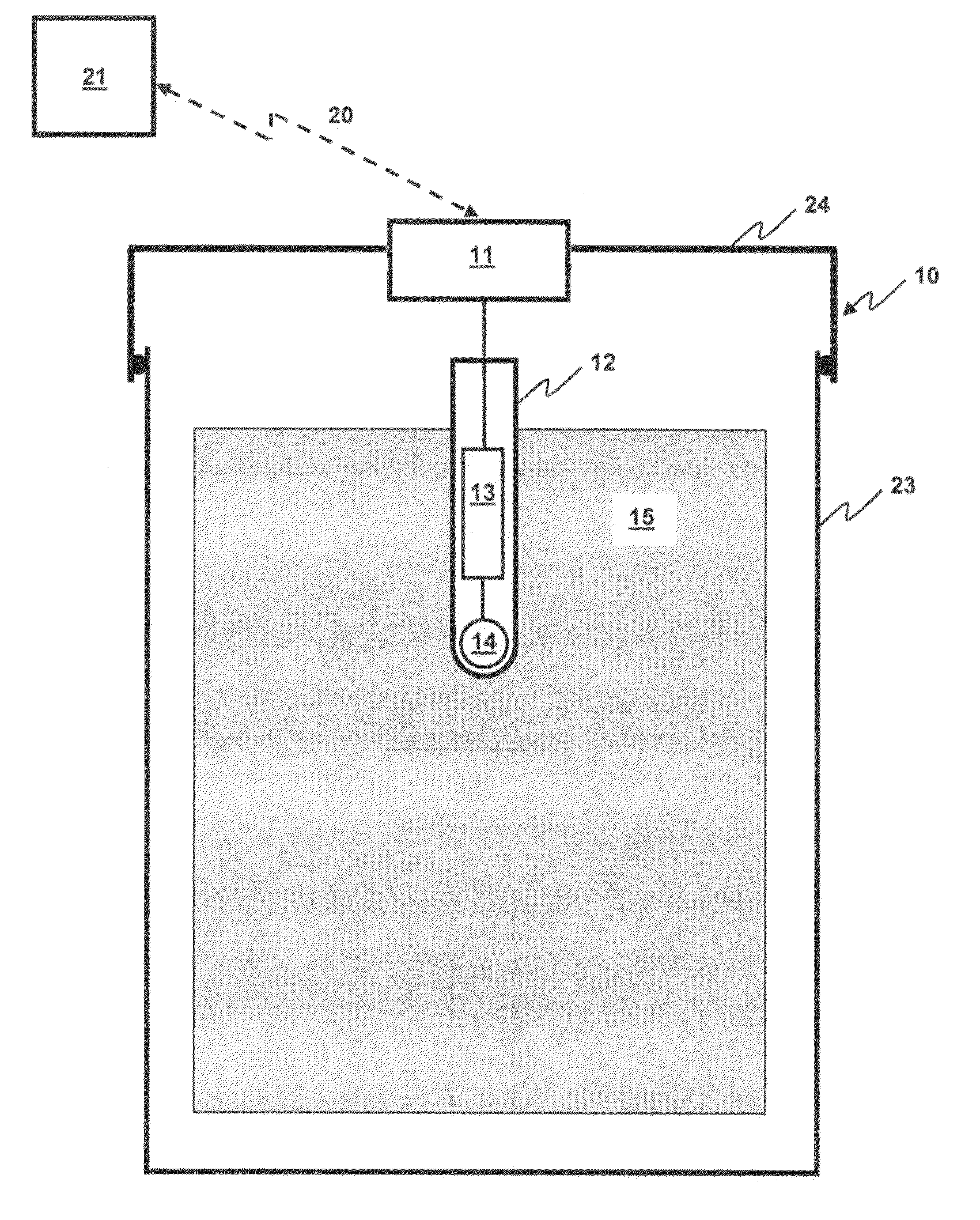

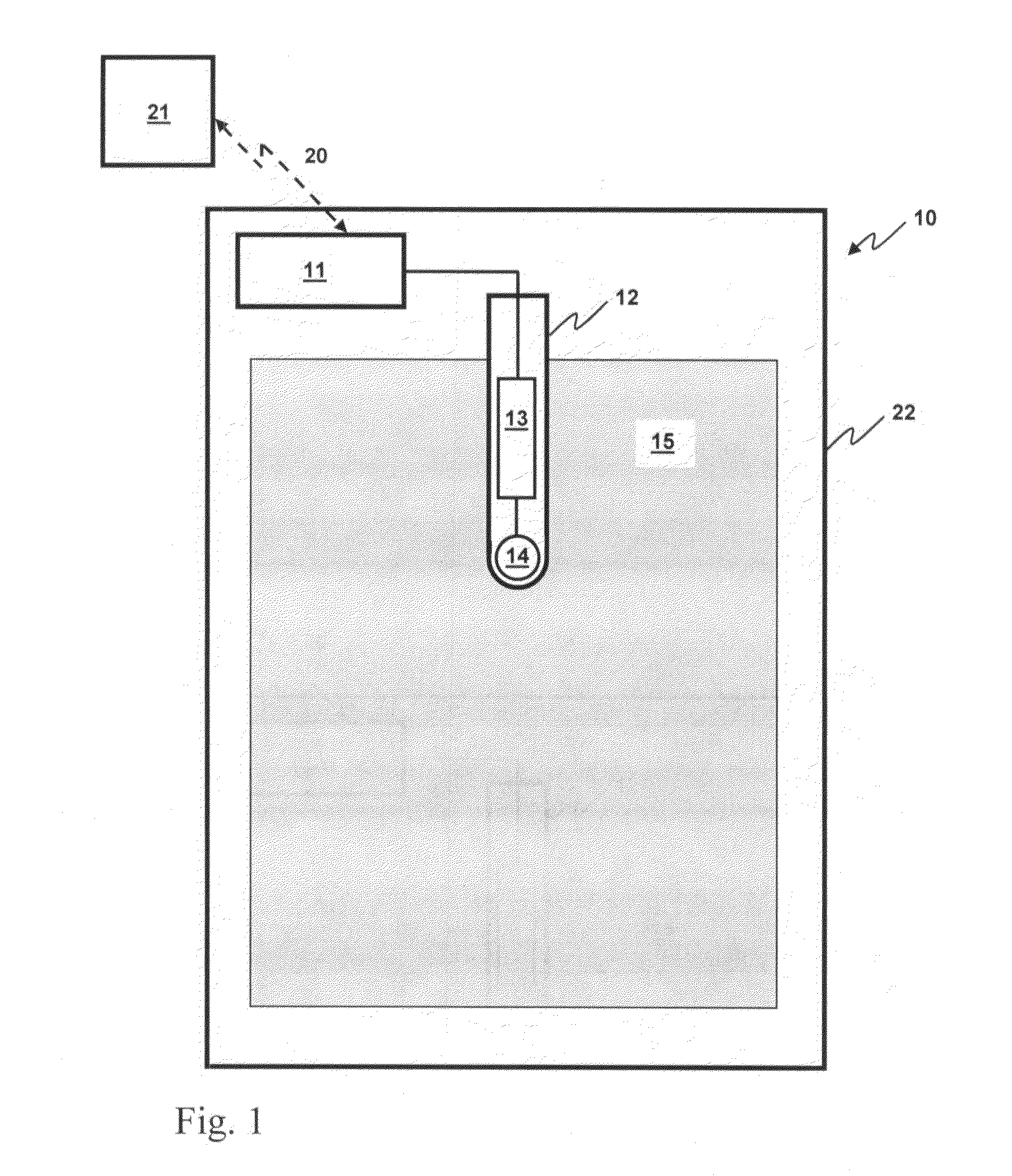

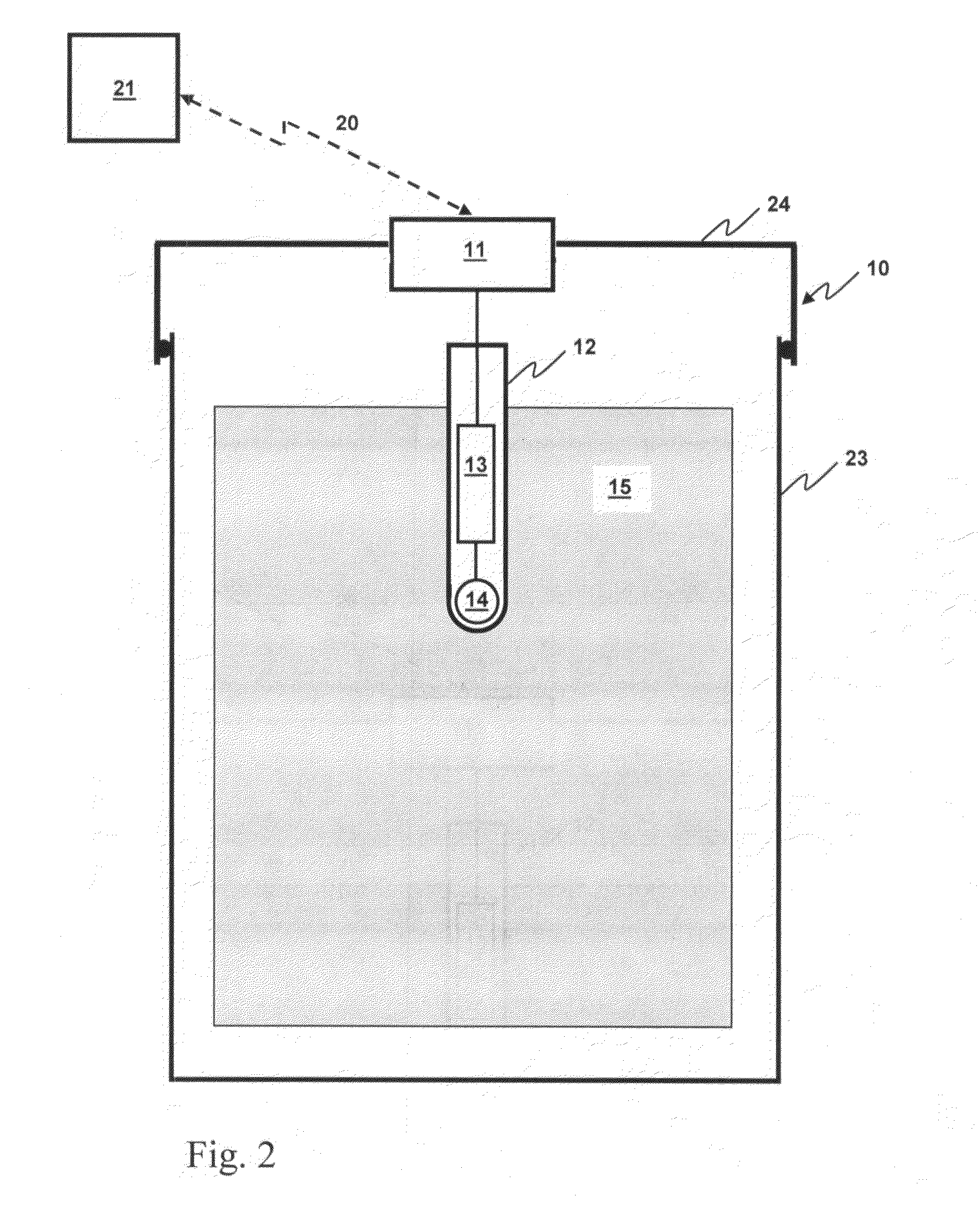

Positional blasting system

InactiveUS20050217525A1Easy to useAccurate locationBlasting cartridgesBlastingDetonatorLocation detection

A blasting system facilitates the actuation of a plurality of programmable detonators according to a desired blasting pattern, to cause the discharge of a plurality of associated charges, by downloading to the detonators blasting information that can be automatically determined by a portable handheld unit that incorporates a positional detecting device, such as a GPS device. The blasting information for any given detonator can be determined by the handheld unit as a function of the distance and the direction of the movement of the unit to the detonator, and / or by the actual GPS location while at the site of the detonator. This automatic determination of blasting information, and particularly the delay times, based on the movement of the unit to the detonator, eliminates error prone human calculations of the delay times needed for multiple detonators at a blasting site. This simplifies the operations and procedures needed for achieving a desired blasting pattern, without sacrificing safety or quality.

Owner:DAVEY BICKFORD USA

Positional blasting system

A blasting system facilitates the actuation of a plurality of programmable detonators according to a desired blasting pattern, to cause the discharge of a plurality of associated charges, by downloading to the detonators blasting information that can be automatically determined by a portable handheld unit that incorporates a positional detecting device, such as a GPS device. The blasting information for any given detonator can be determined by the handheld unit as a function of the distance and the direction of the movement of the unit to the detonator, and / or by the actual GPS location while at the site of the detonator. This automatic determination of blasting information, and particularly the delay times, based on the movement of the unit to the detonator, eliminates error prone human calculations of the delay times needed for multiple detonators at a blasting site. This simplifies the operations and procedures needed for achieving a desired blasting pattern, without sacrificing safety or quality.

Owner:DAVEY BICKFORD USA

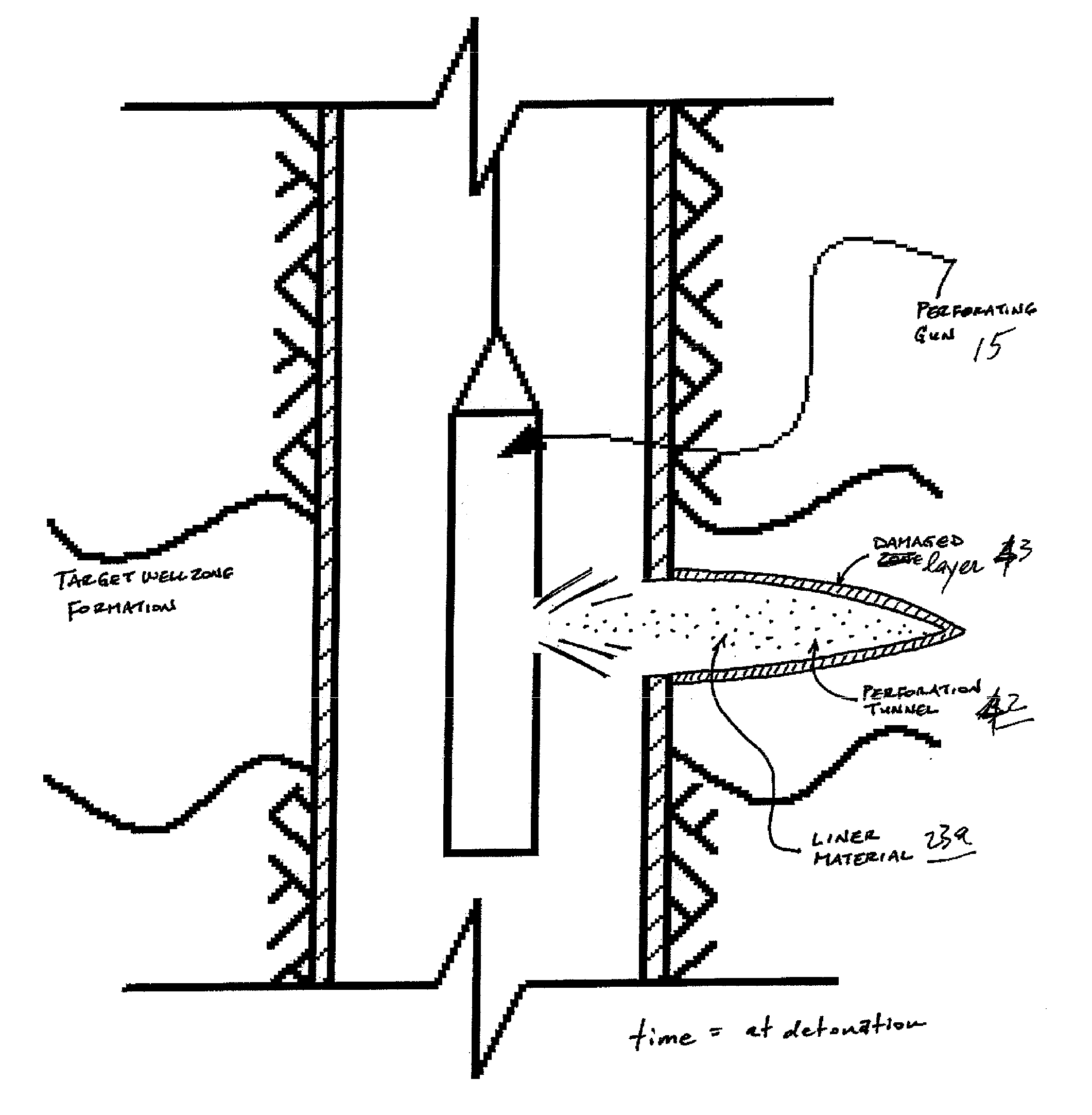

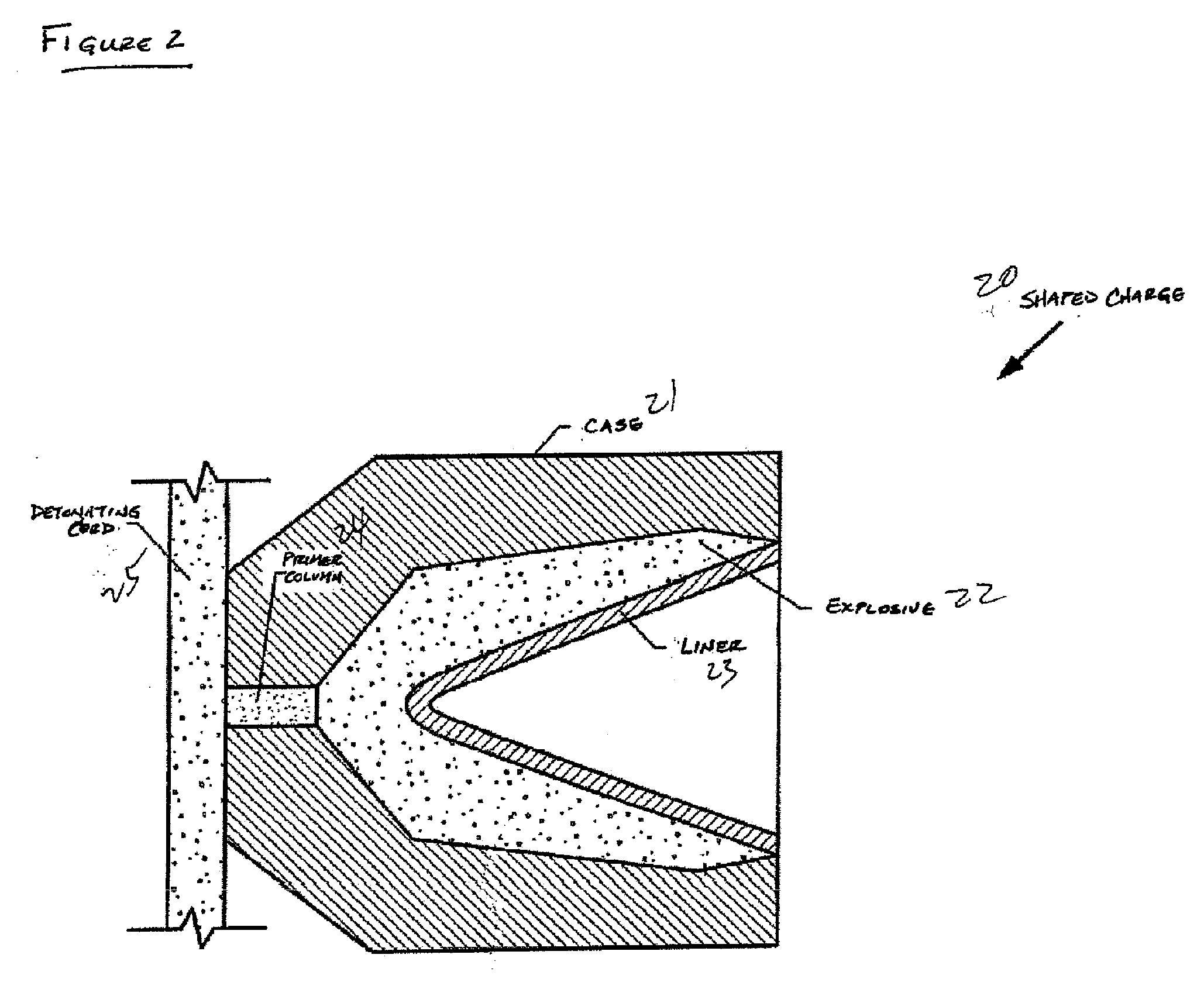

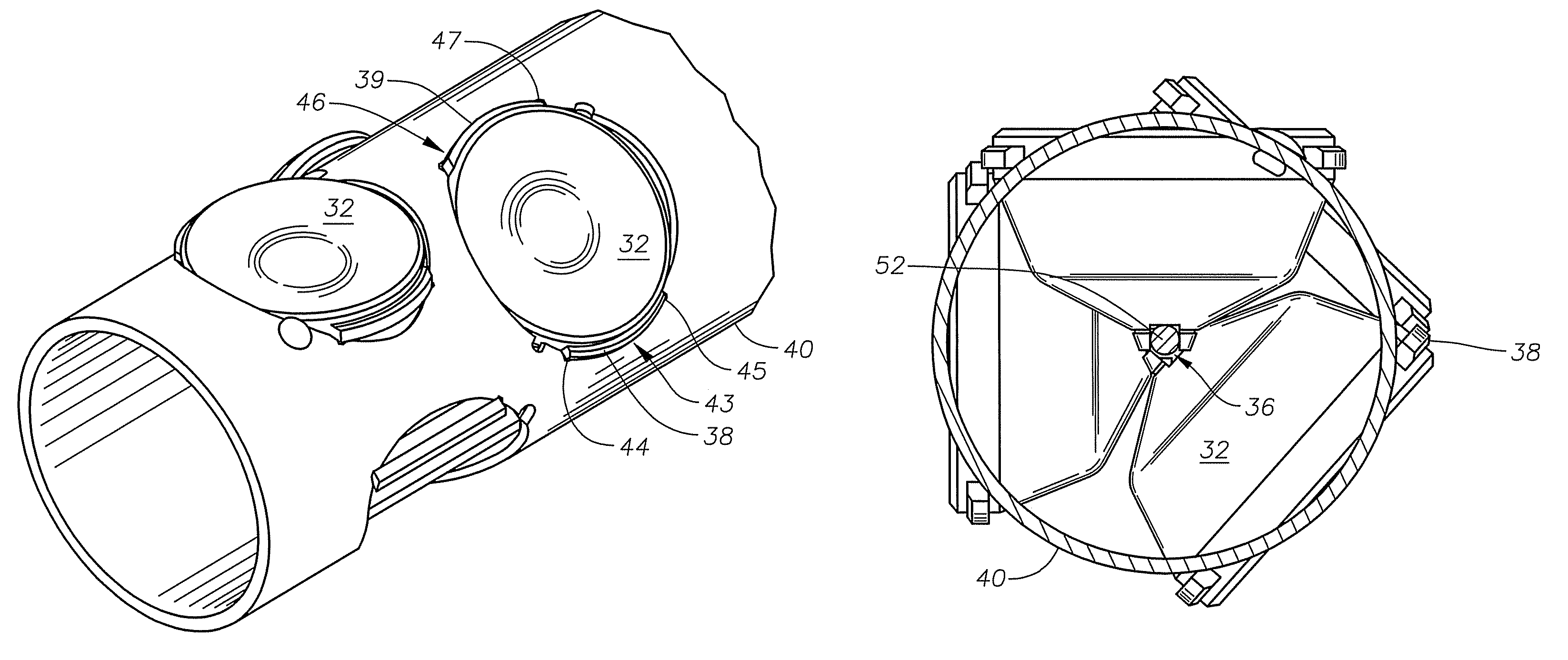

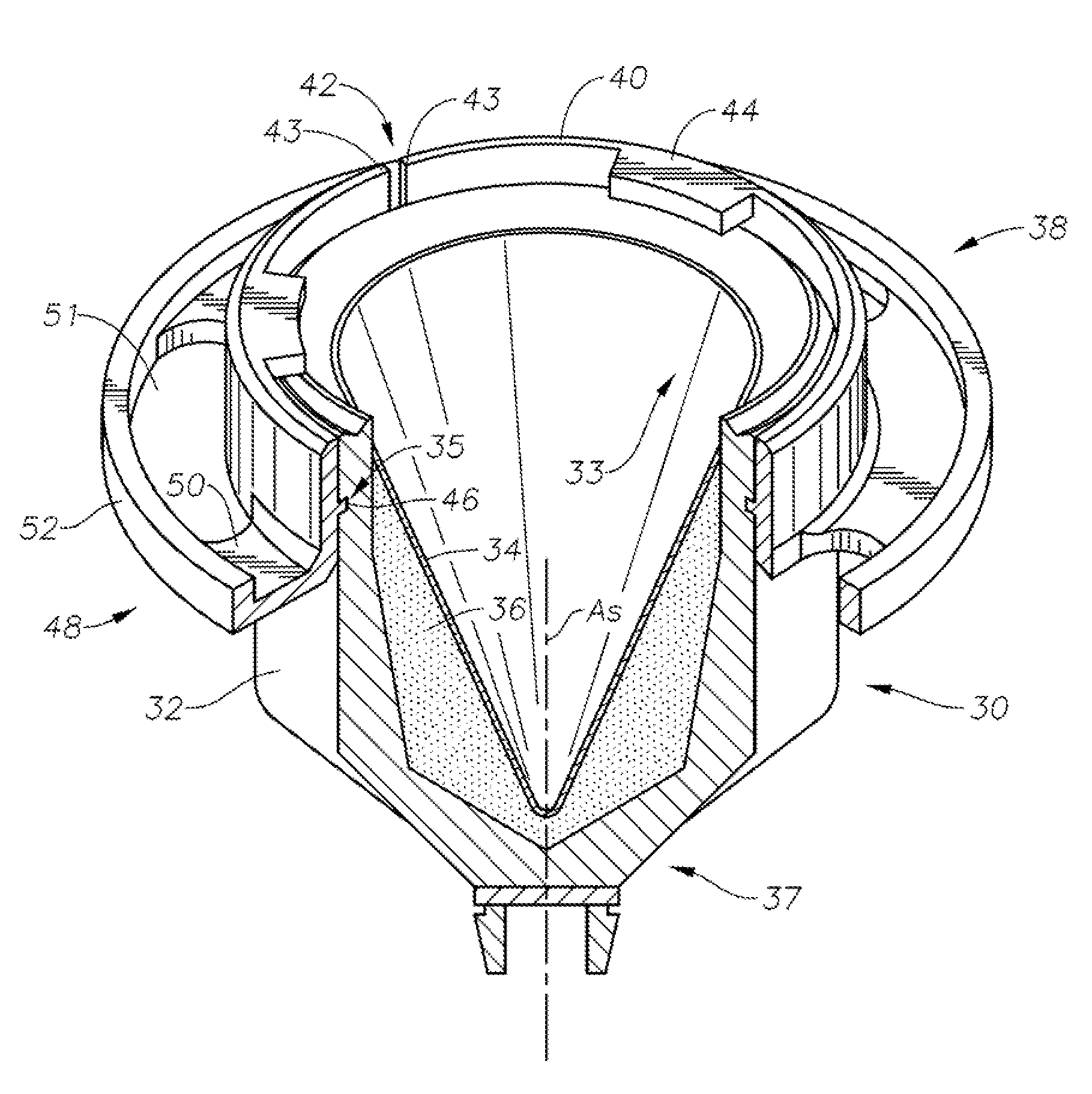

Shaped Charges for Creating Enhanced Perforation Tunnel in a Well Formation

ActiveUS20060266551A1Reduce penetrationDecrease productivityNuclear explosivesFluid removalShaped chargeEngineering

A shaped charge includes a charge case; an explosive disposed inside the charge case; and a liner for retaining the explosive in the charge case, wherein the liner comprises a material reactive with a component of an earth formation. A method for perforating in a well includes disposing a perforating gun in the well, wherein the perforating gun comprises a shaped charge having a charge case, an explosive disposed inside the charge case, and a liner for retaining the explosive in the charge case, wherein the liner includes a material that can react with a component of an earth formation; detonating the shaped charge to form a perforation tunnel in a formation zone; and allowing the material comprising the liner to react with the component of the earth formation.

Owner:SCHLUMBERGER TECH CORP

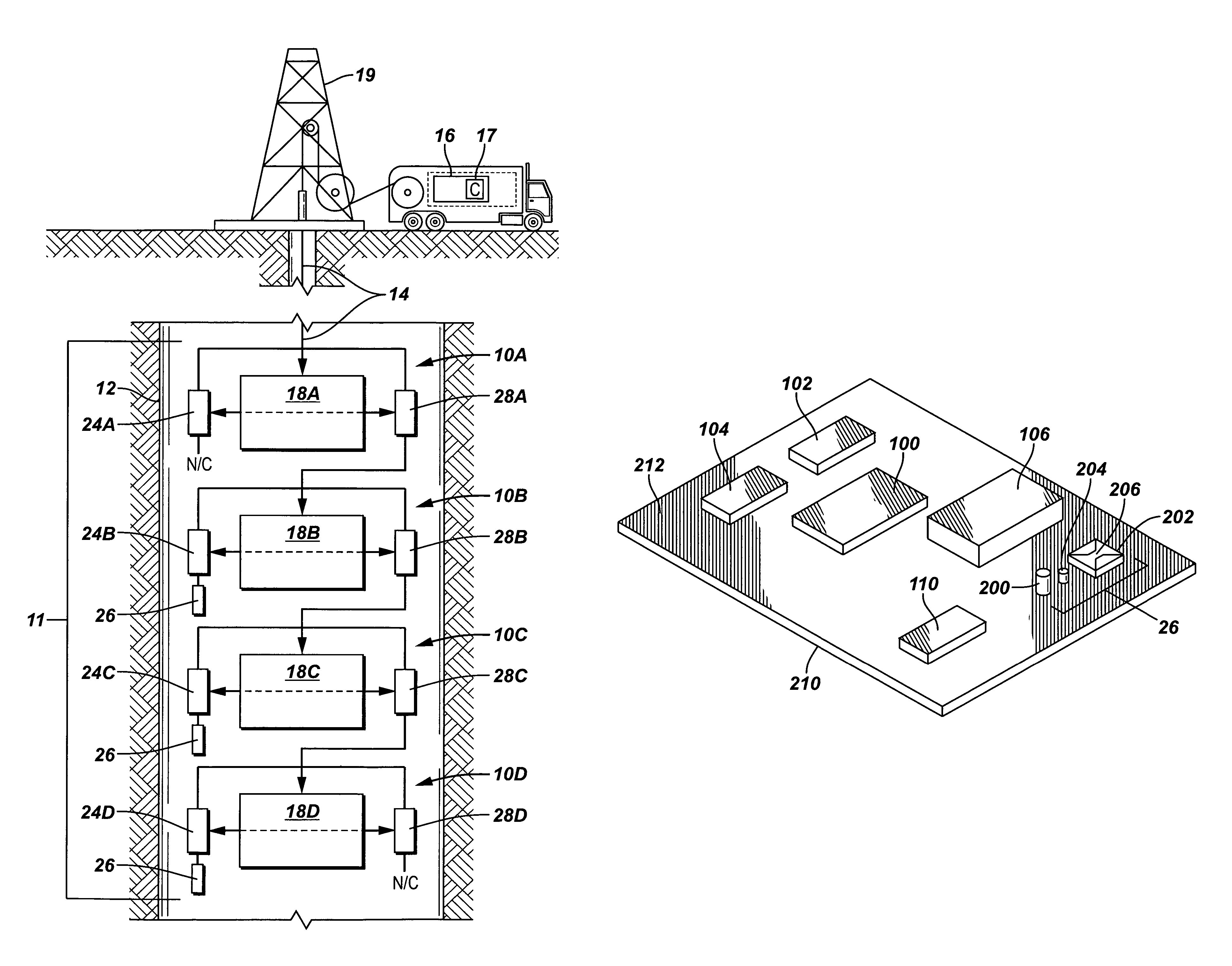

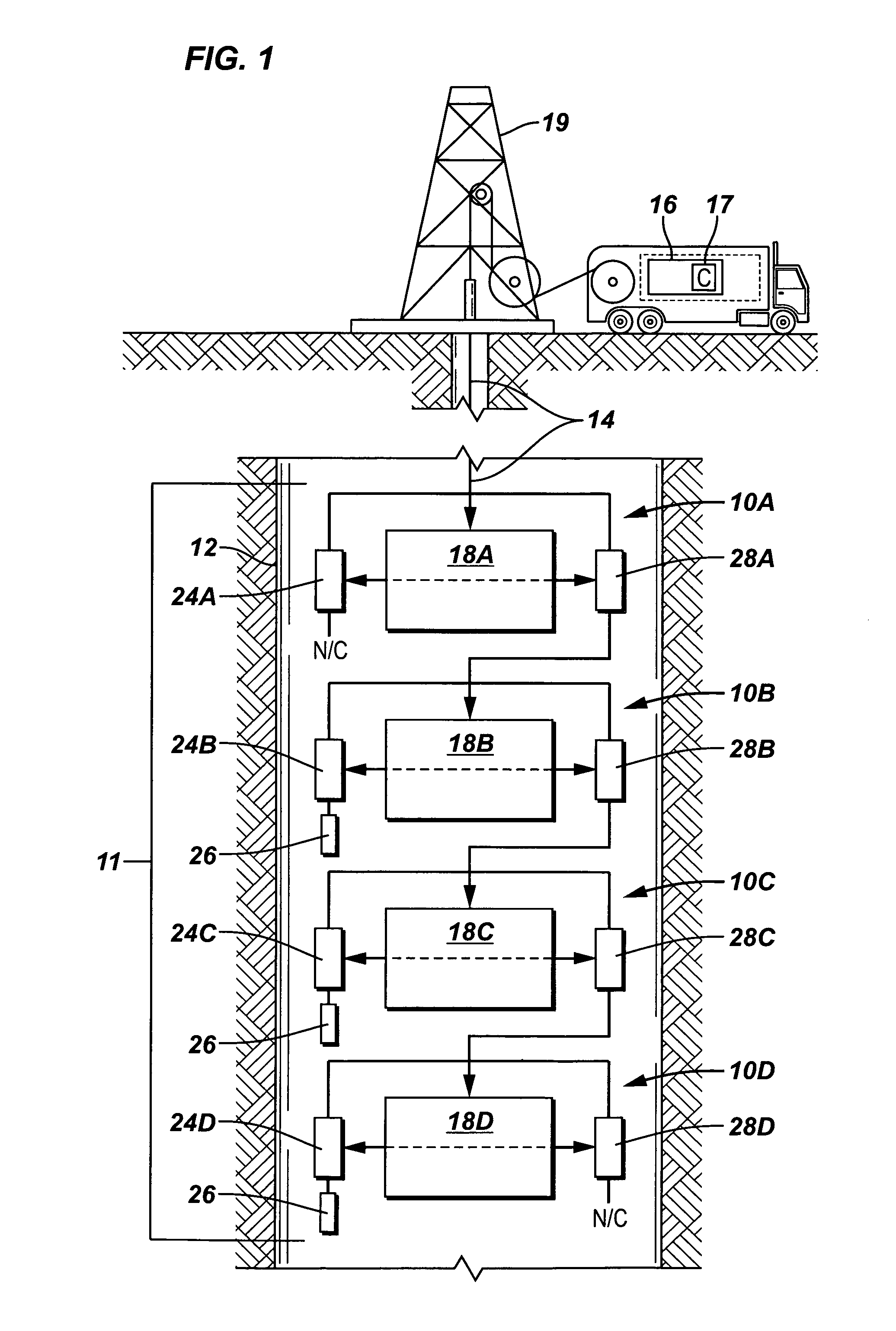

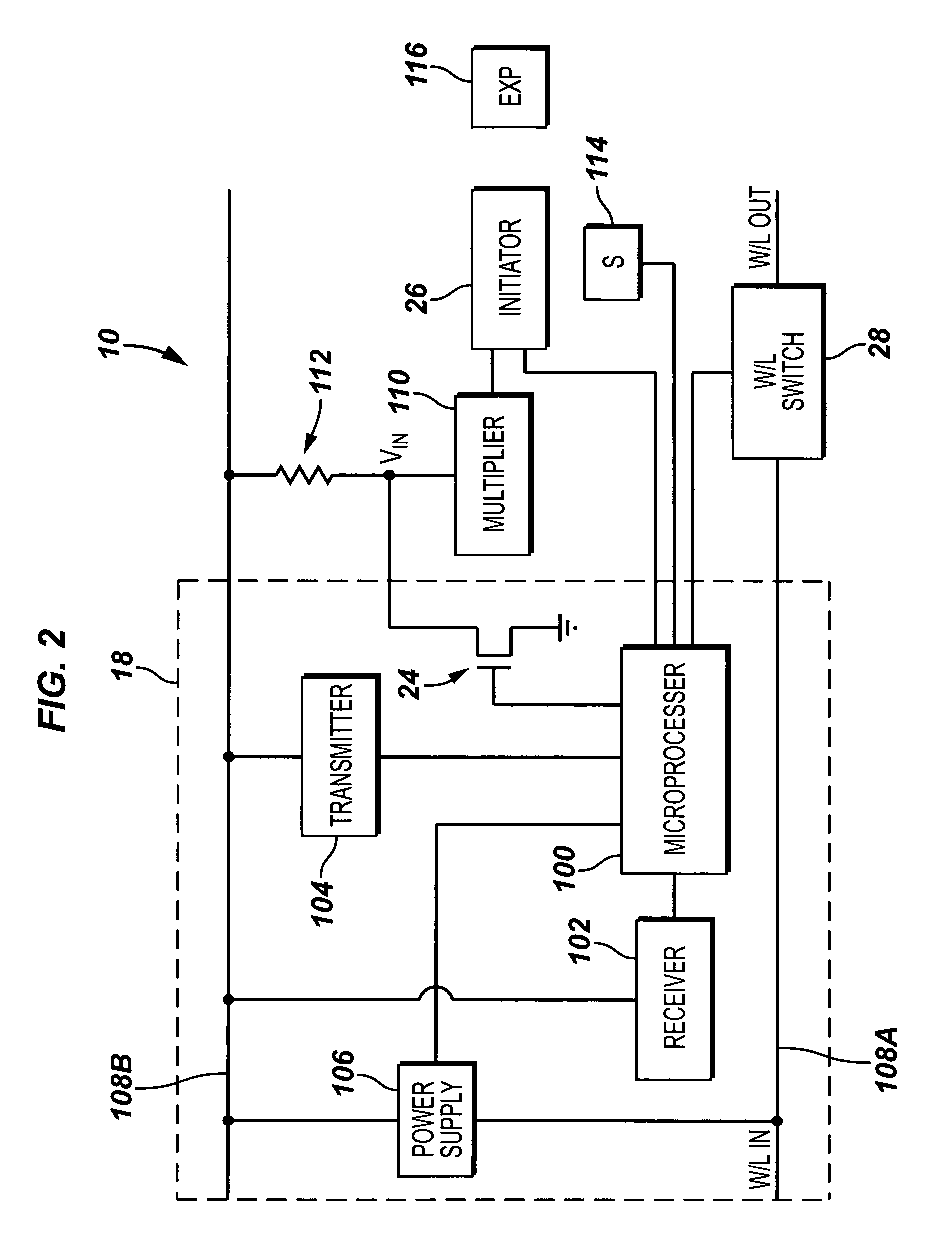

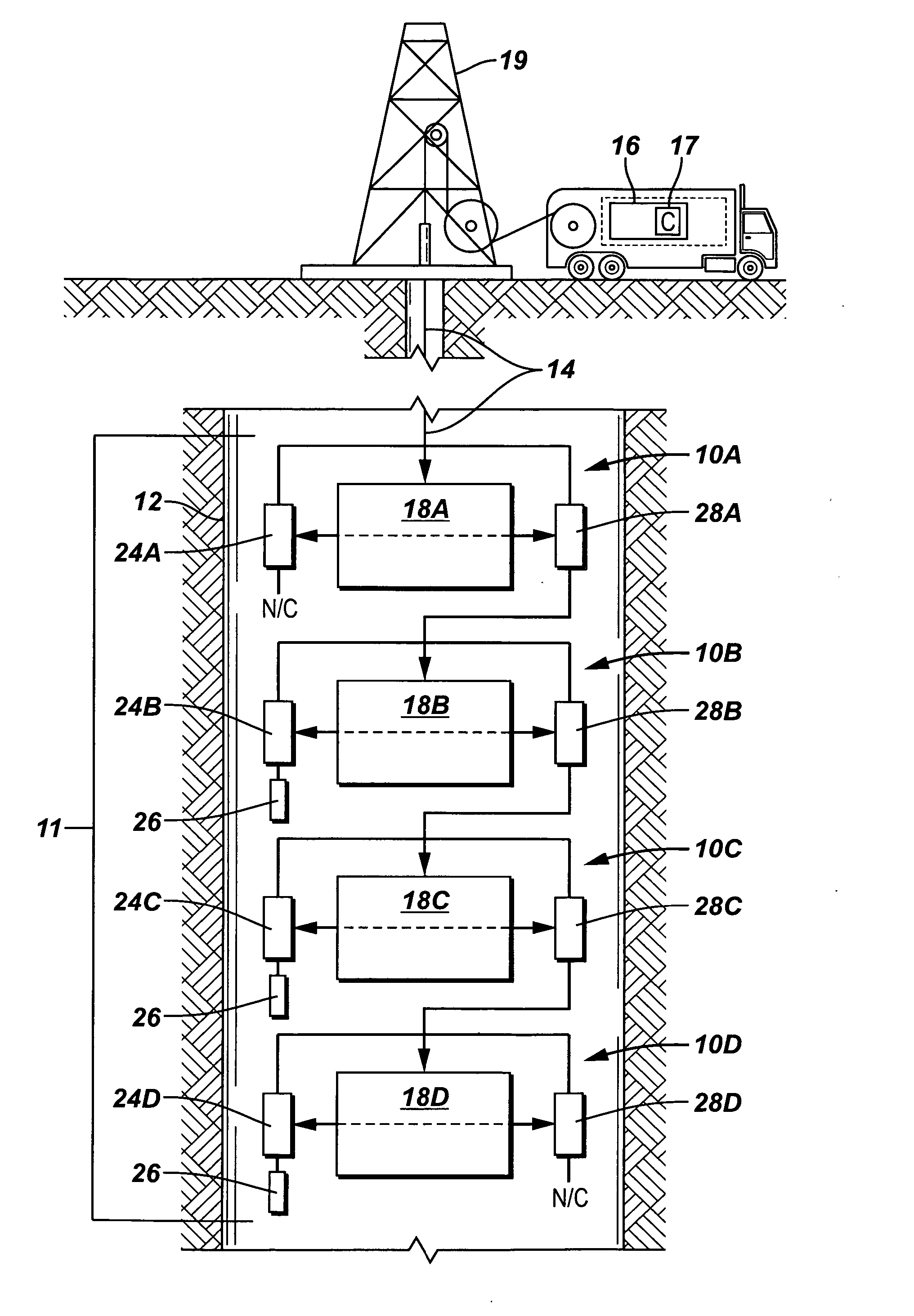

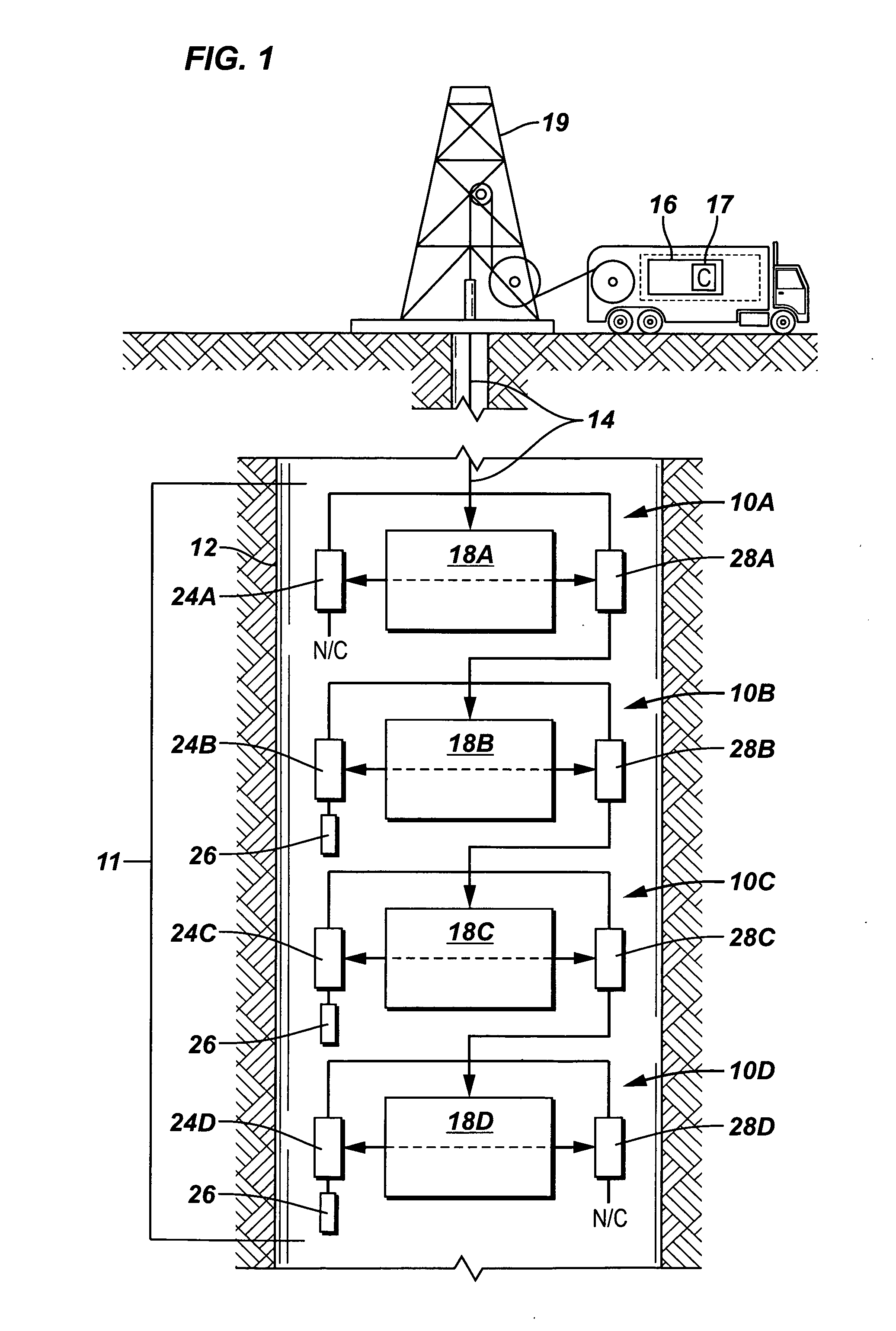

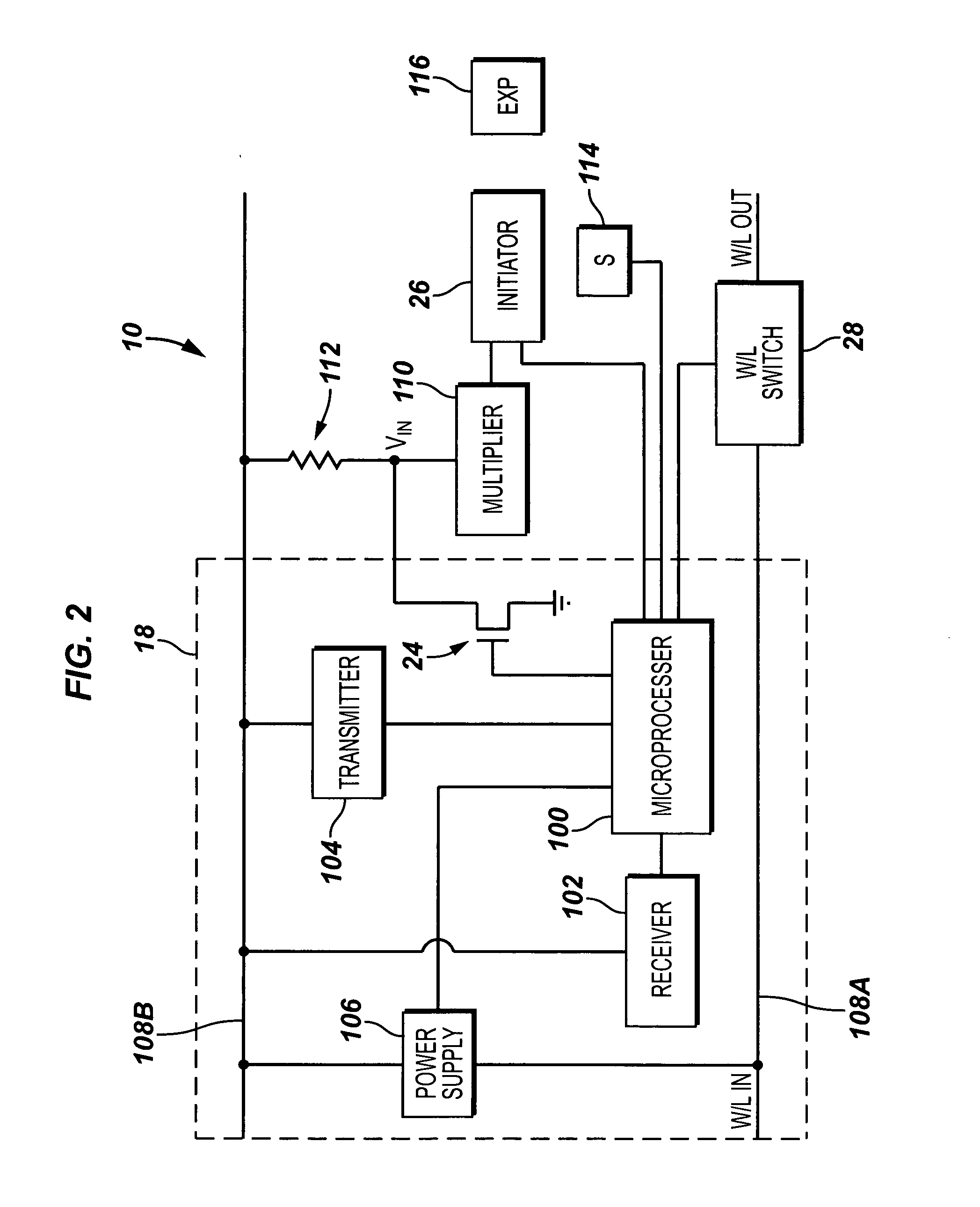

Secure activation of a downhole device

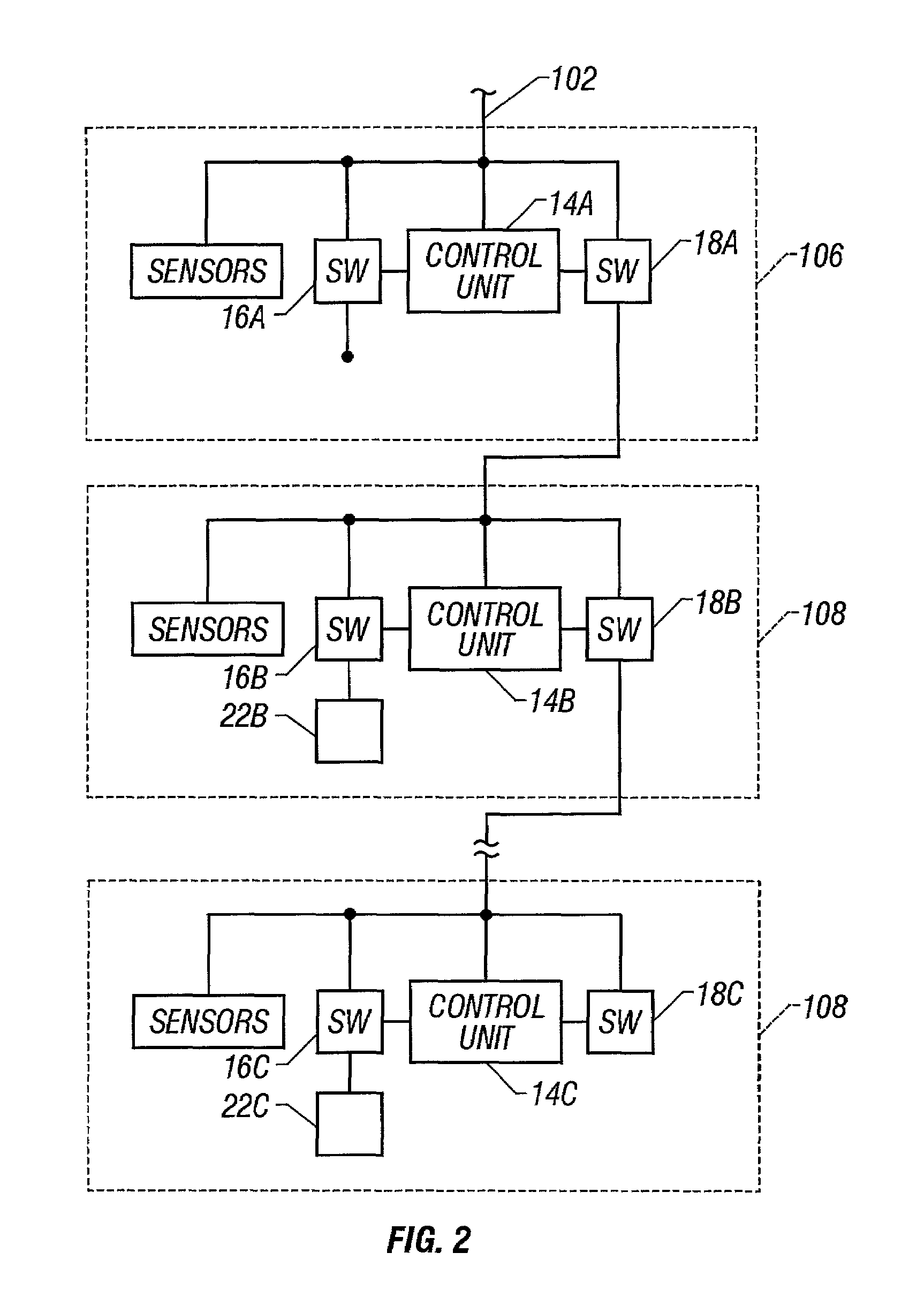

A system includes a well tool for deployment in a well, a controller, and a link coupled between the controller and the well tool. The well tool comprises plural control units, each of the plural control units having a microprocessor and an initiator coupled to the microprocessor. Each microprocessor is adapted to communicate bi-directionally with the controller. The controller is adapted to send a plurality of activation commands to respective microprocessors to activate the respective control units. Each activation command containing a unique identifier corresponding to a respective control unit.

Owner:SCHLUMBERGER TECH CORP

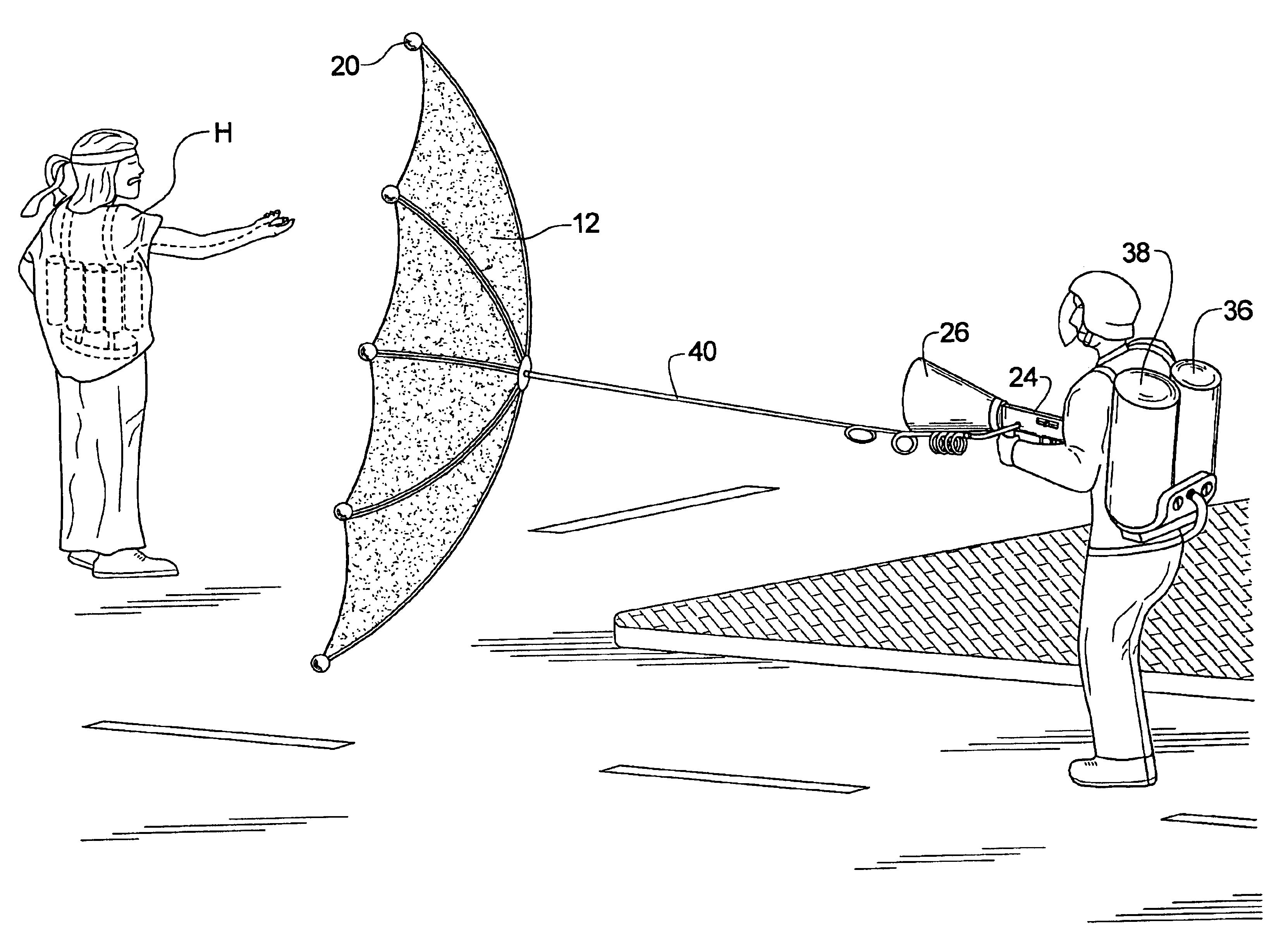

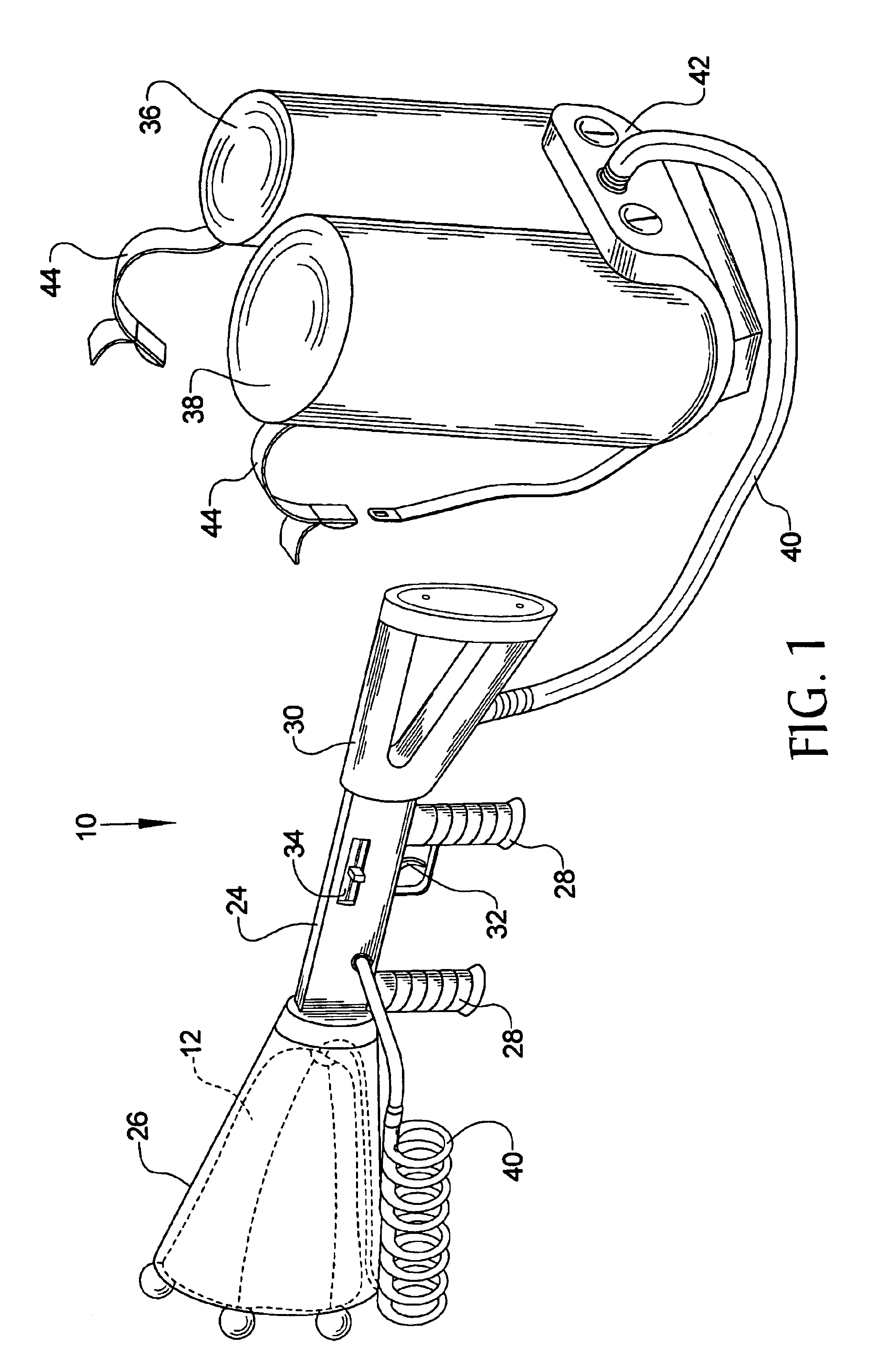

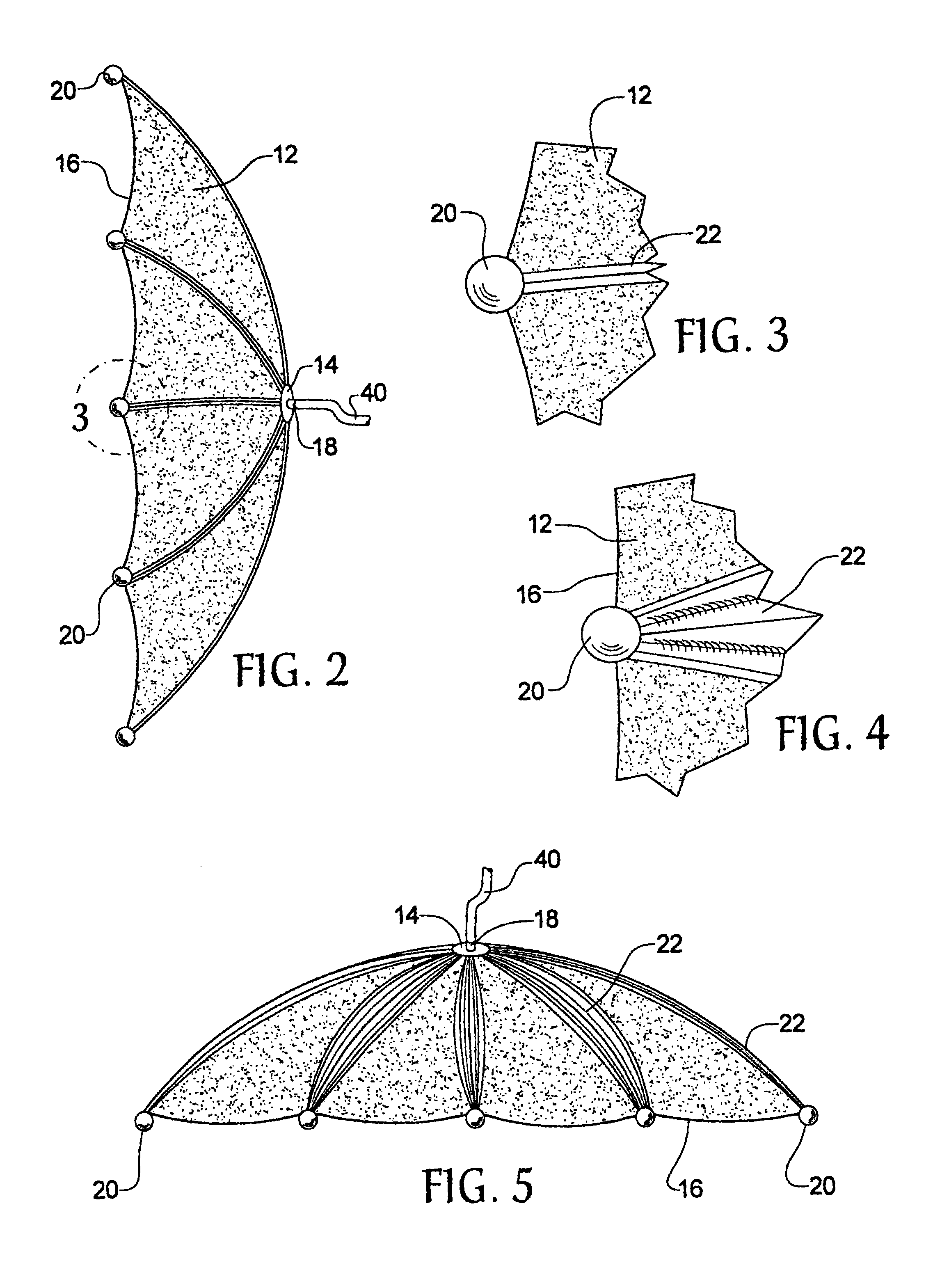

Explosion containment net

InactiveUS6854374B1Minimize and contain explosive blastPrevent serious injuryAmmunition projectilesTraining ammunitionHigh densityEngineering

A net is made from an explosive resistant material such as KEVLAR and is thrown over an explosive-laden device such that the net helps contain the blast force of the explosive-laden device. The net also has a nozzle that is fluid connected to a fire suppressant agent as well as a high density foam, each of which are discharged through the nozzle once the net is thrown over the explosive-laden device, the fire suppressant agent and the high density foam each helping to minimize the blast force of the explosive-laden device. The net can be thrown manually or can be fired from a gun that uses either pneumatic force or a firing cartridge to propel the net at its target.

Owner:BREAZEALE O ALAN

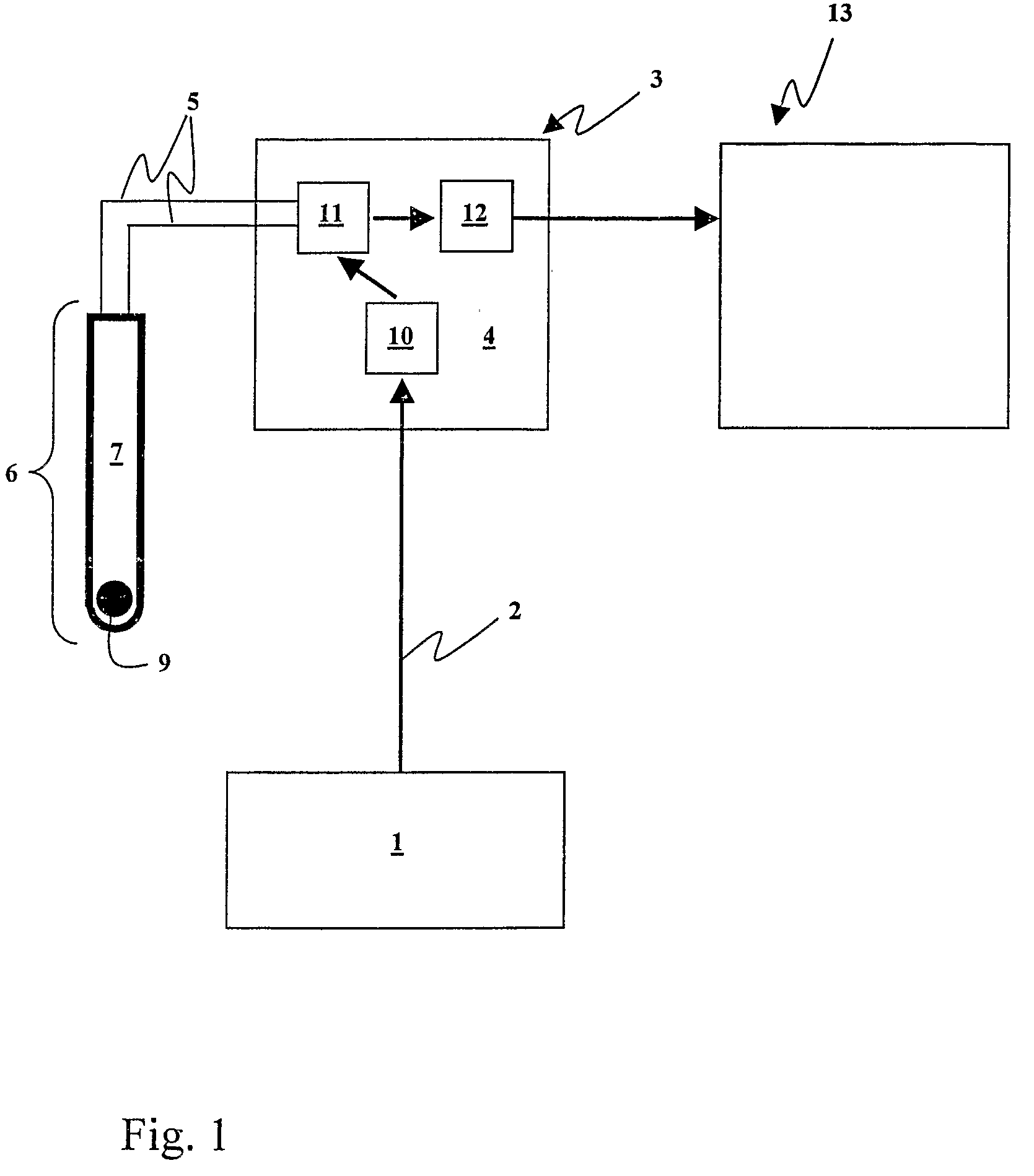

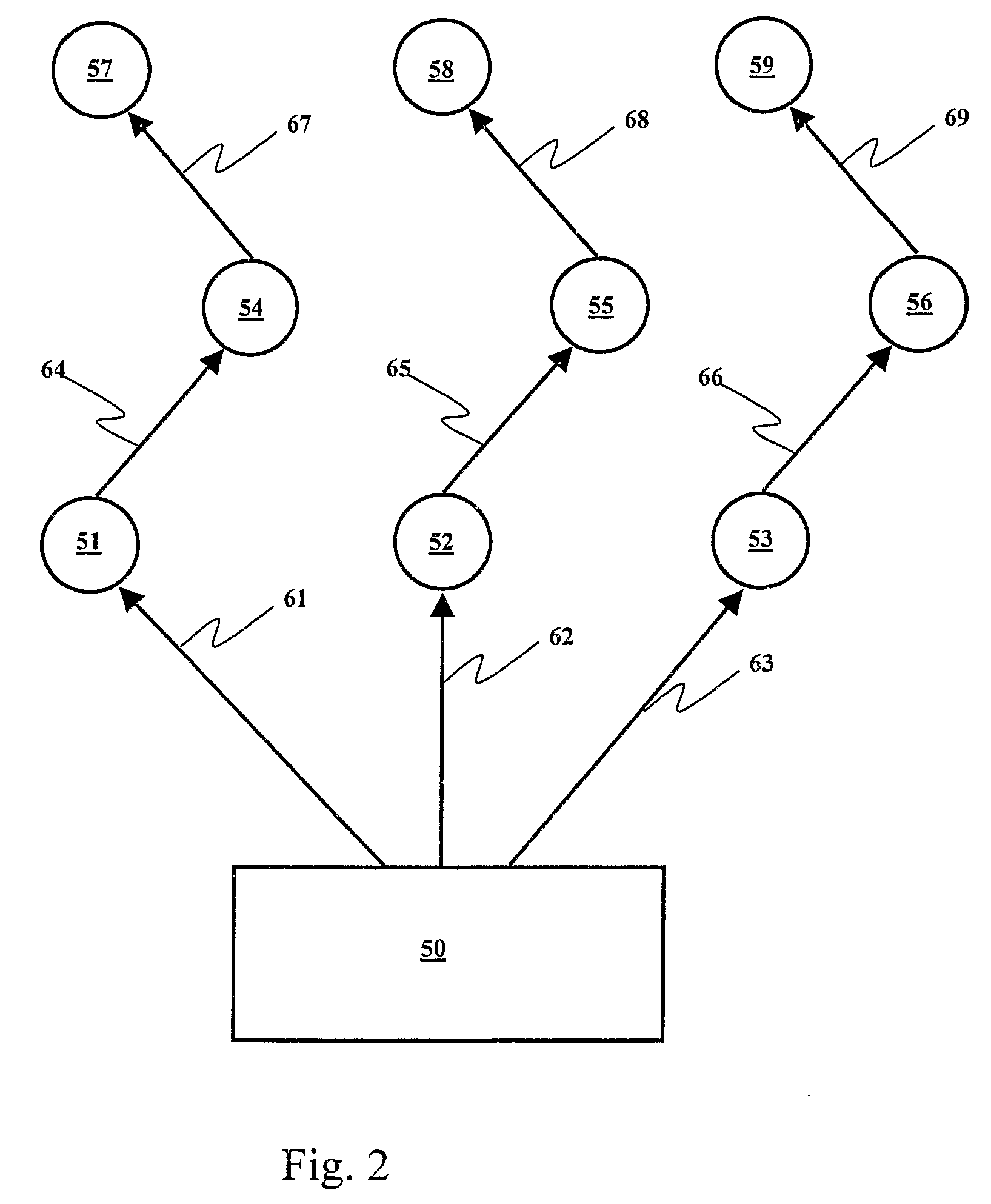

Wireless detonator assemblies, and corresponding networks

Wireless detonator assemblies (51-59) in use, form a cross-communicating network of wireless “detonator assemblies, such that communication of each wireless detonator assembly (57-59) with an associated blasting machine (50) can occur either directly, or via relay of signals (61-69) between other wireless detonator assemblies (51-56) in the network. Wireless detonator assemblies (51-59) can disseminate information (such as status information, identity information, firing codes, delay times and environmental conditions) among all of the wireless detonator assemblies in the network, while compensating for signal transmission relay delays at nodes in the network, thereby enabling the wireless detonator assemblies to detonate the explosive charges in accordance with the delay times. Various wireless detonator assemblies and corresponding blasting apparatus are disclosed and claimed. Methods of blasting using the wireless detonator assemblies and blasting apparatus are also disclosed and claimed.

Owner:ORICA EXPLOSIVES TECH PTY LTD

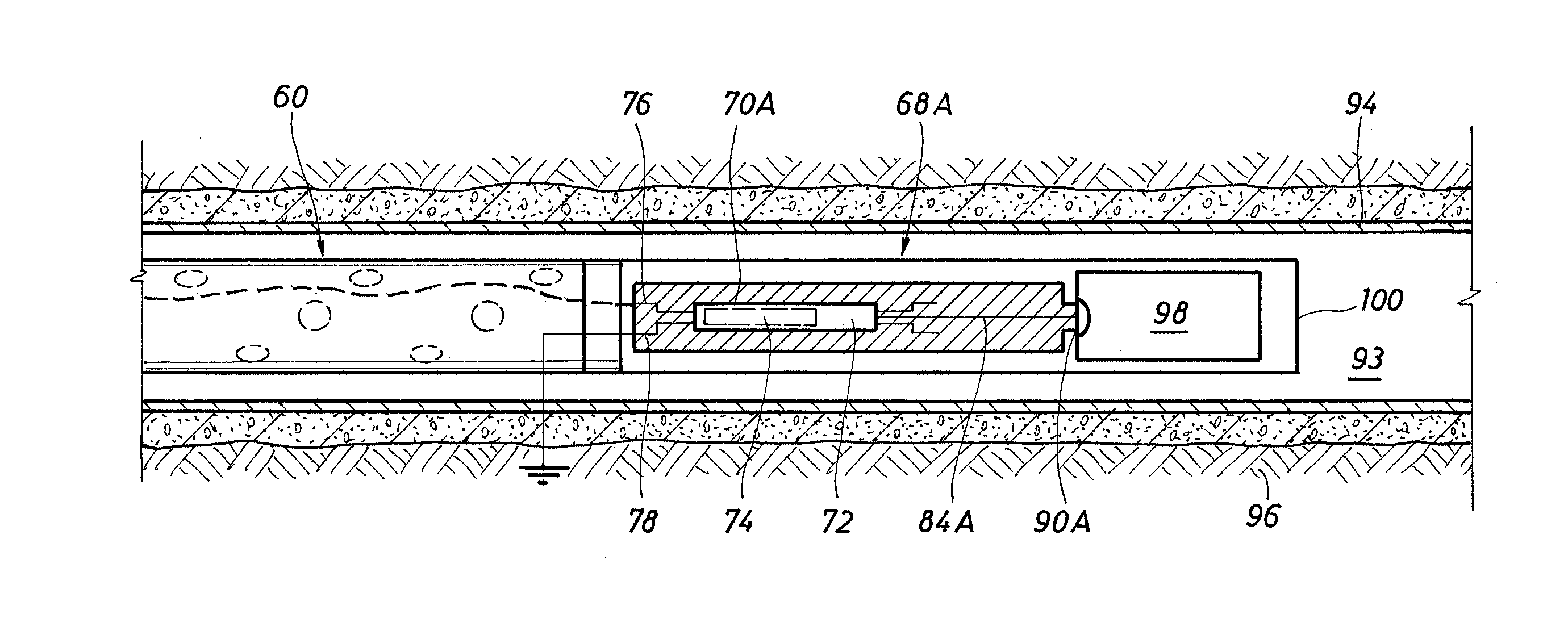

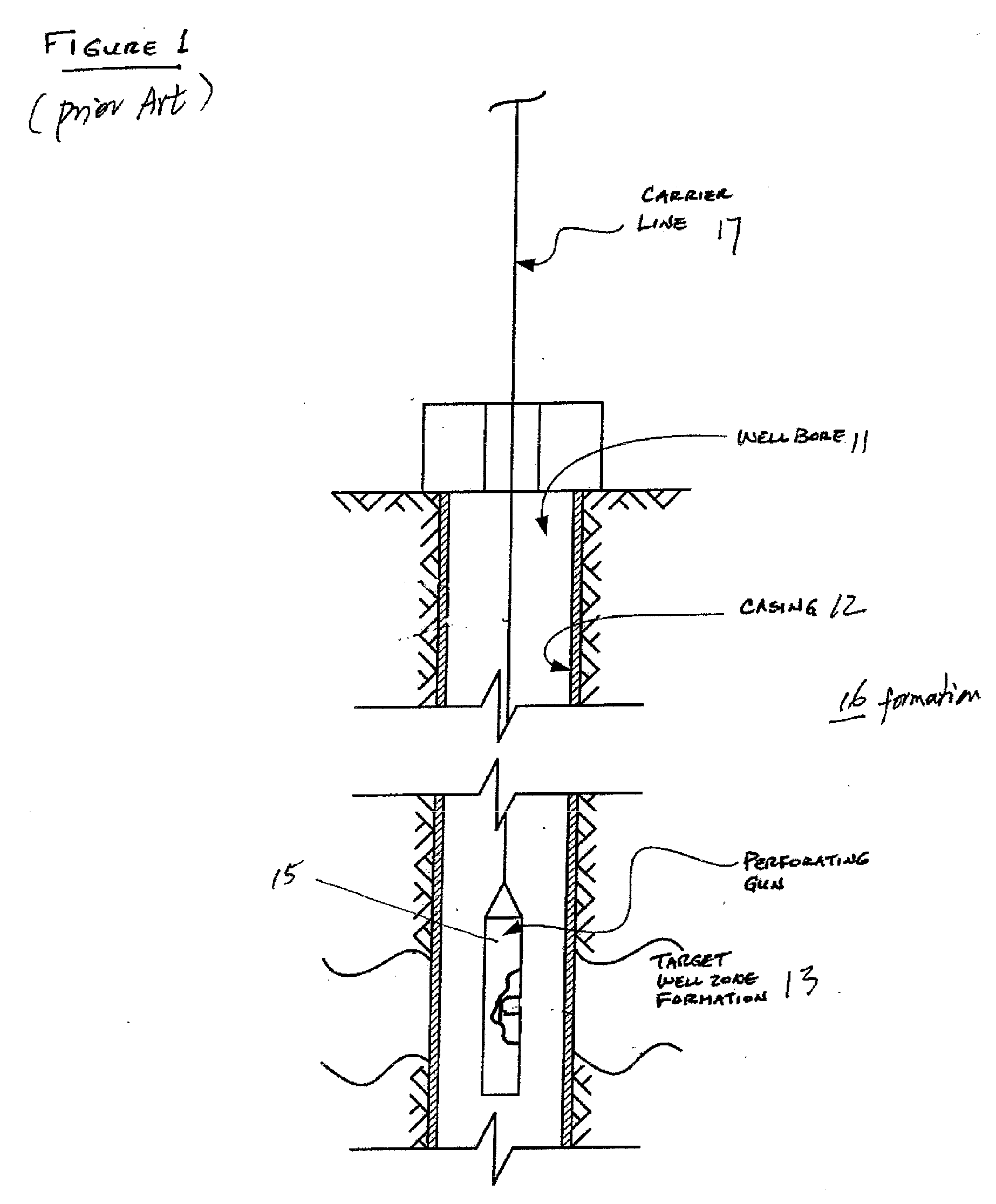

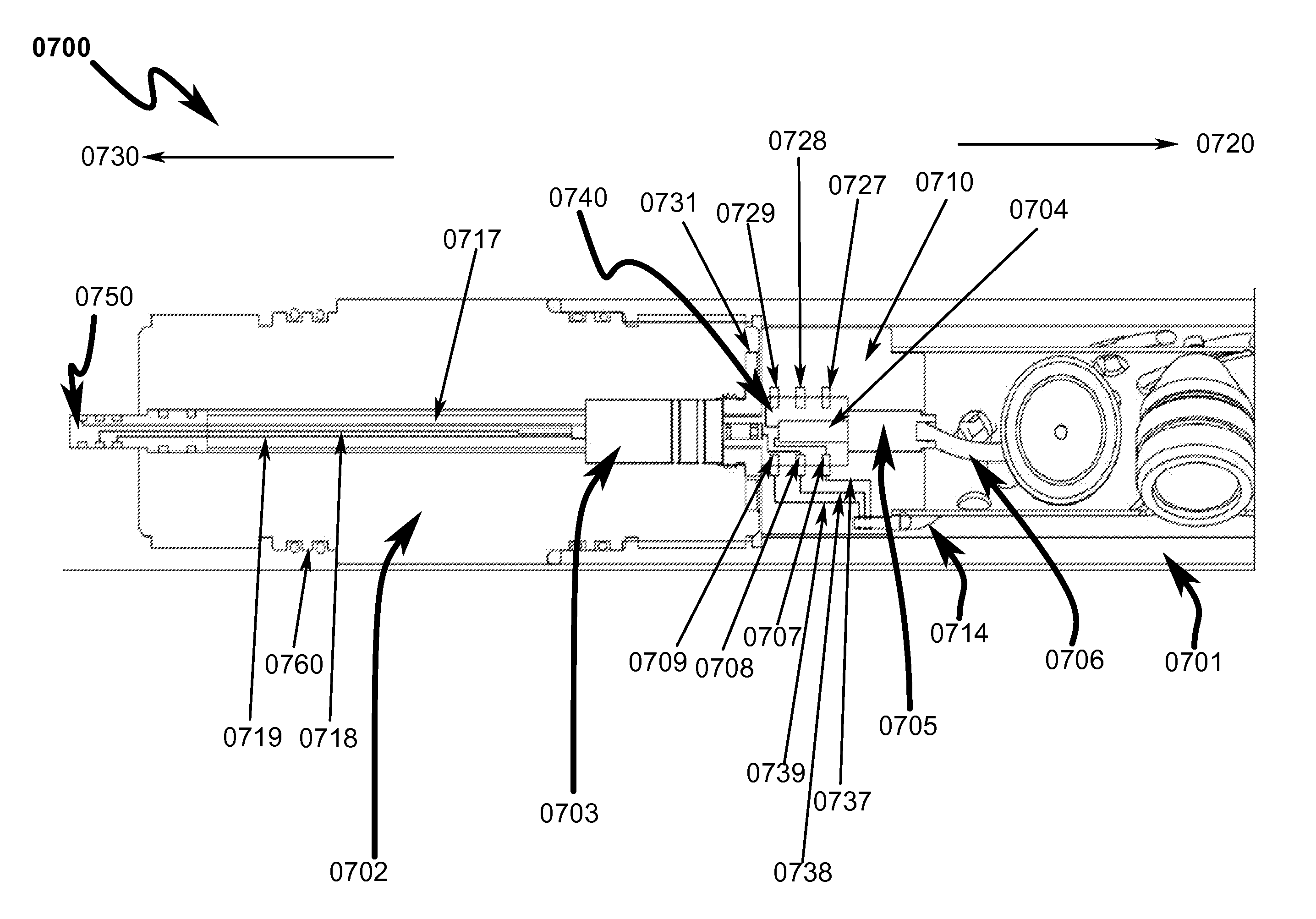

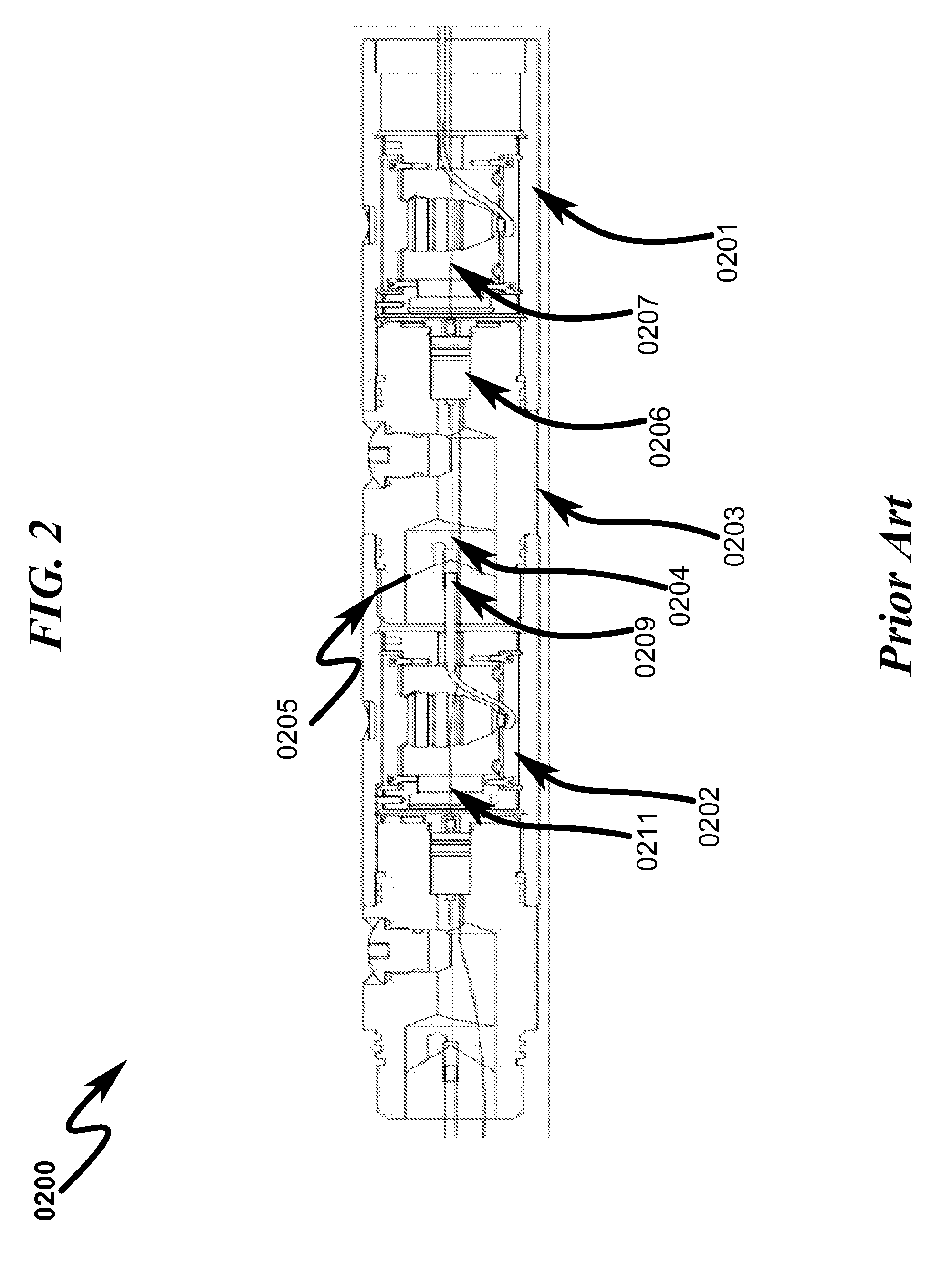

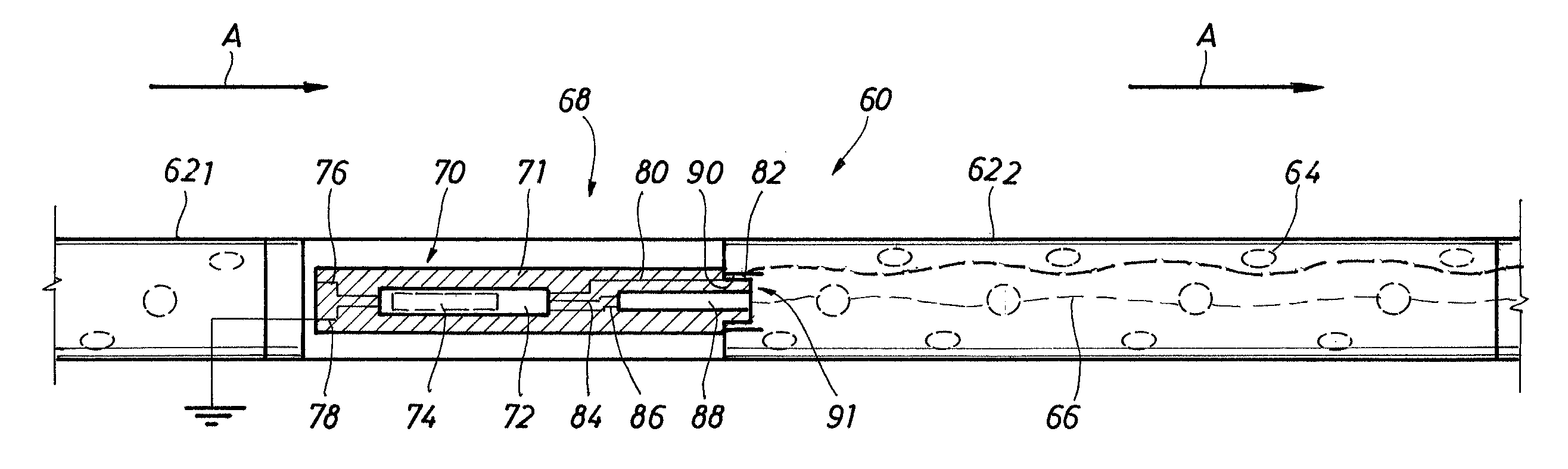

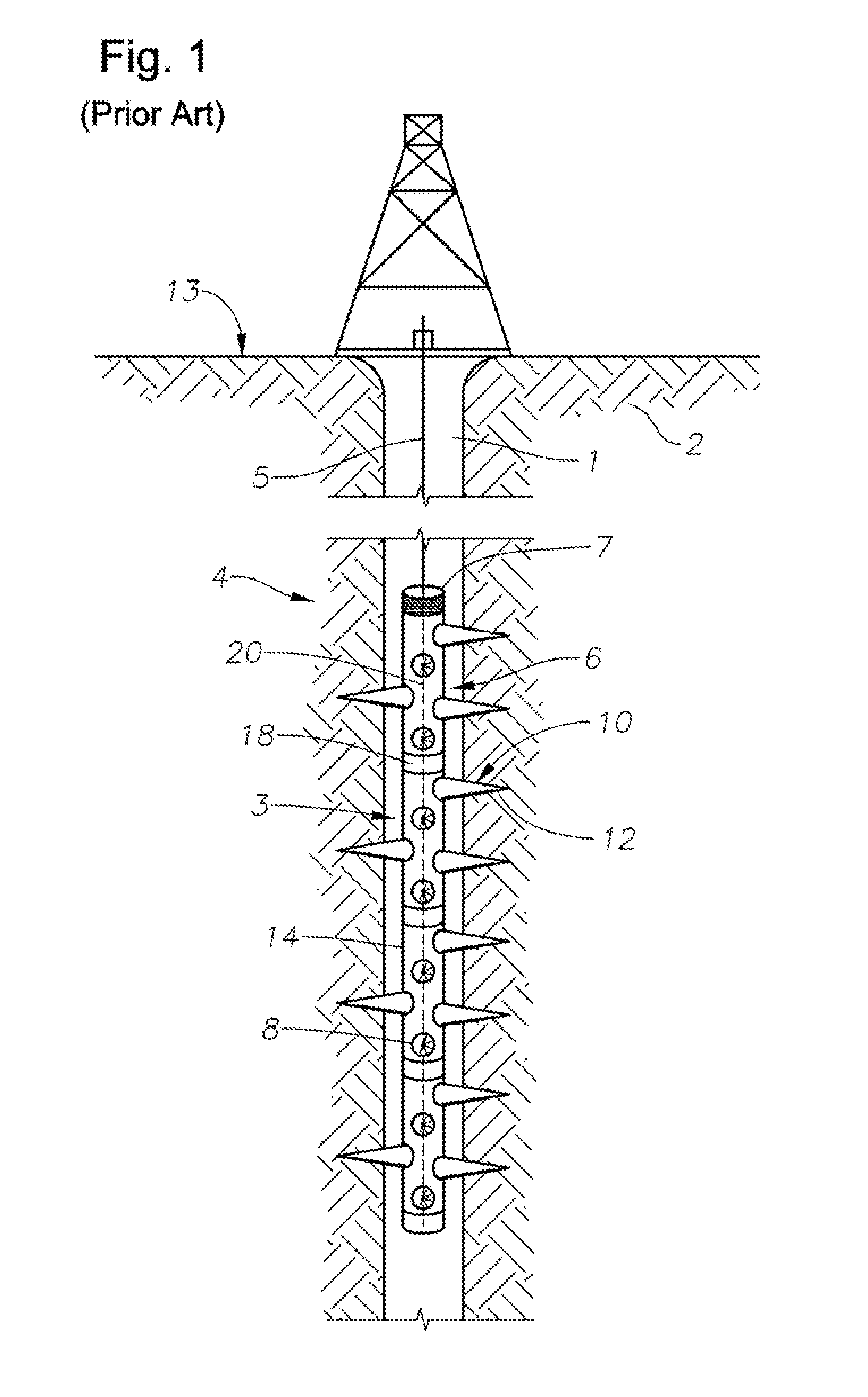

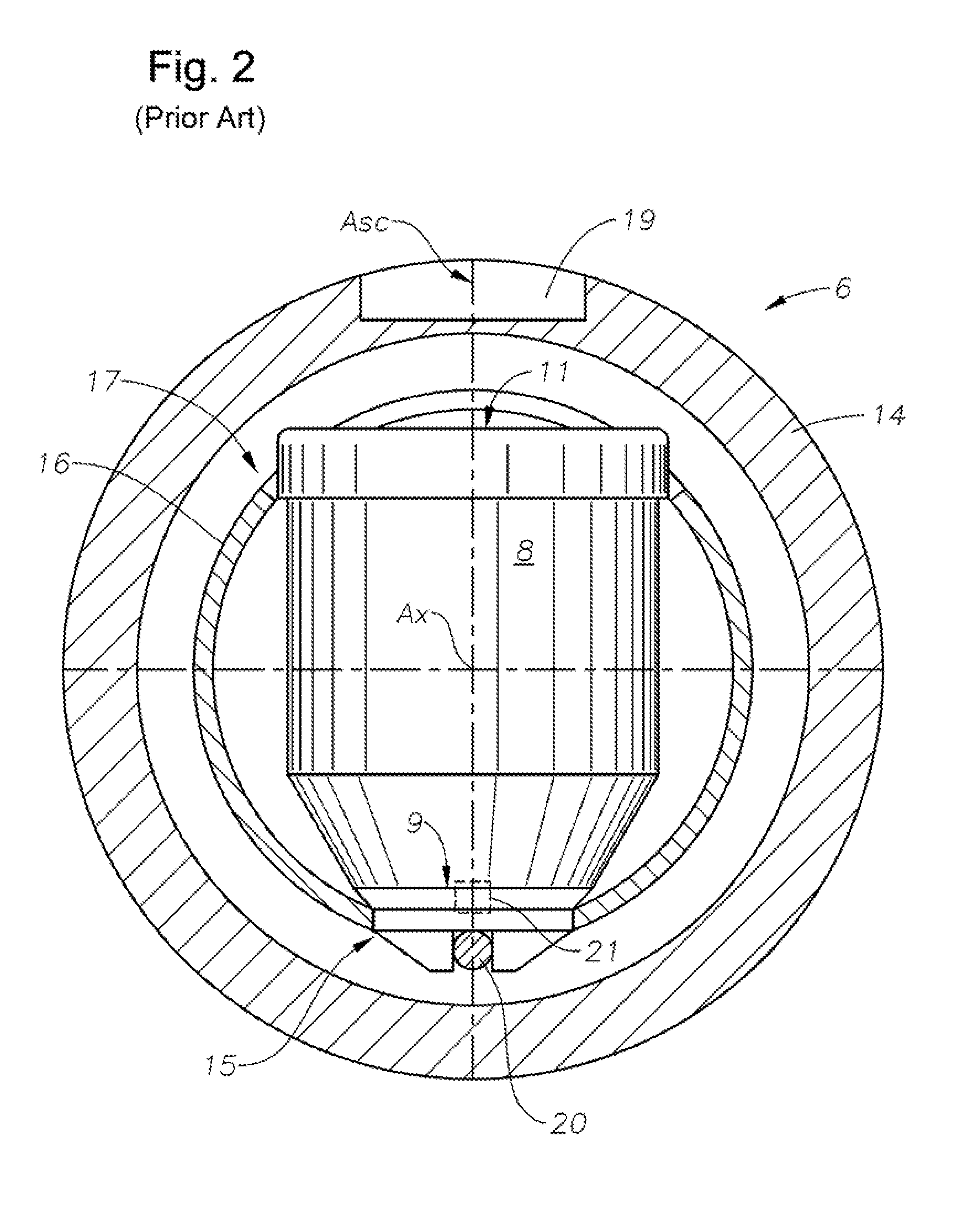

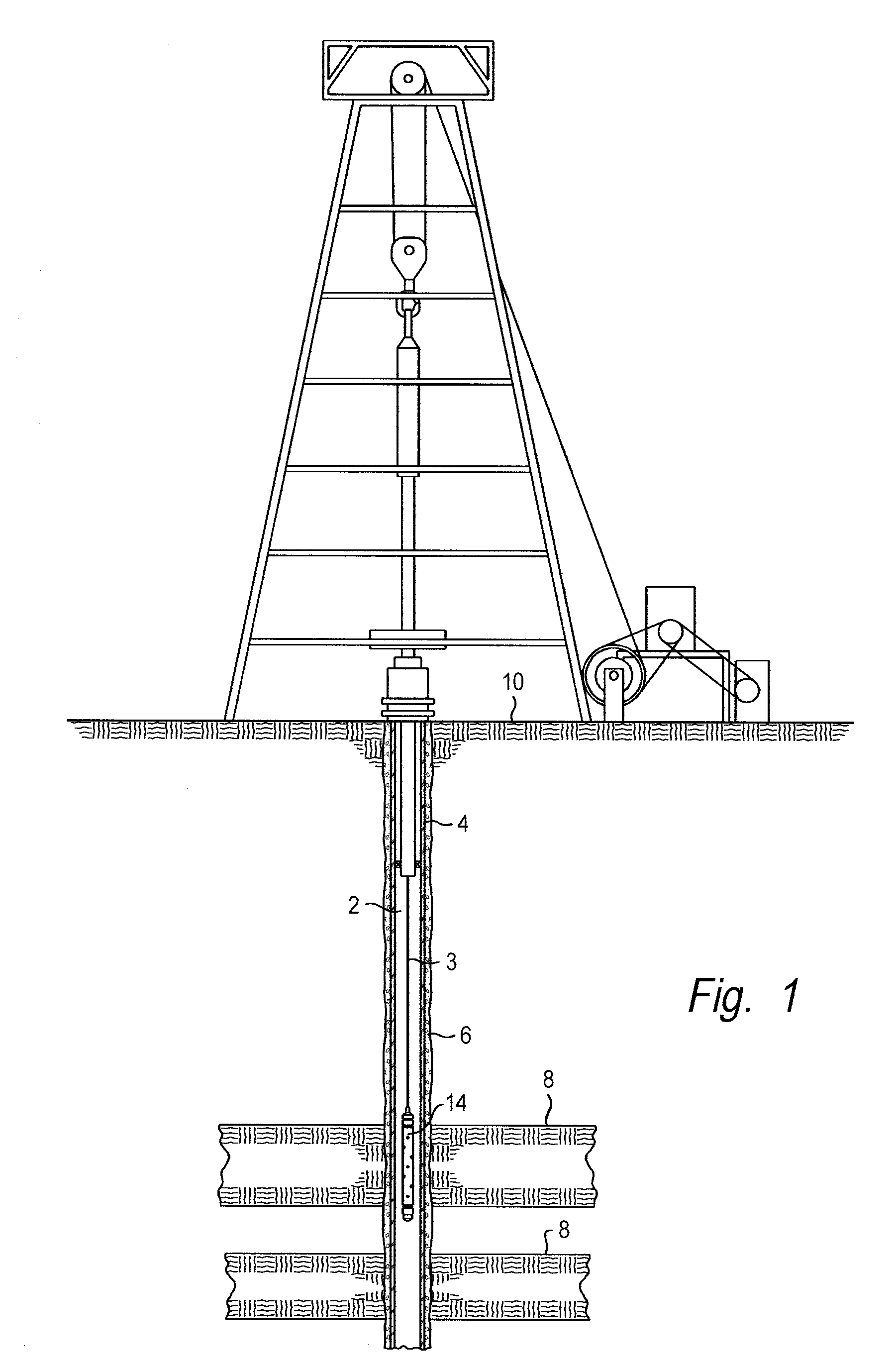

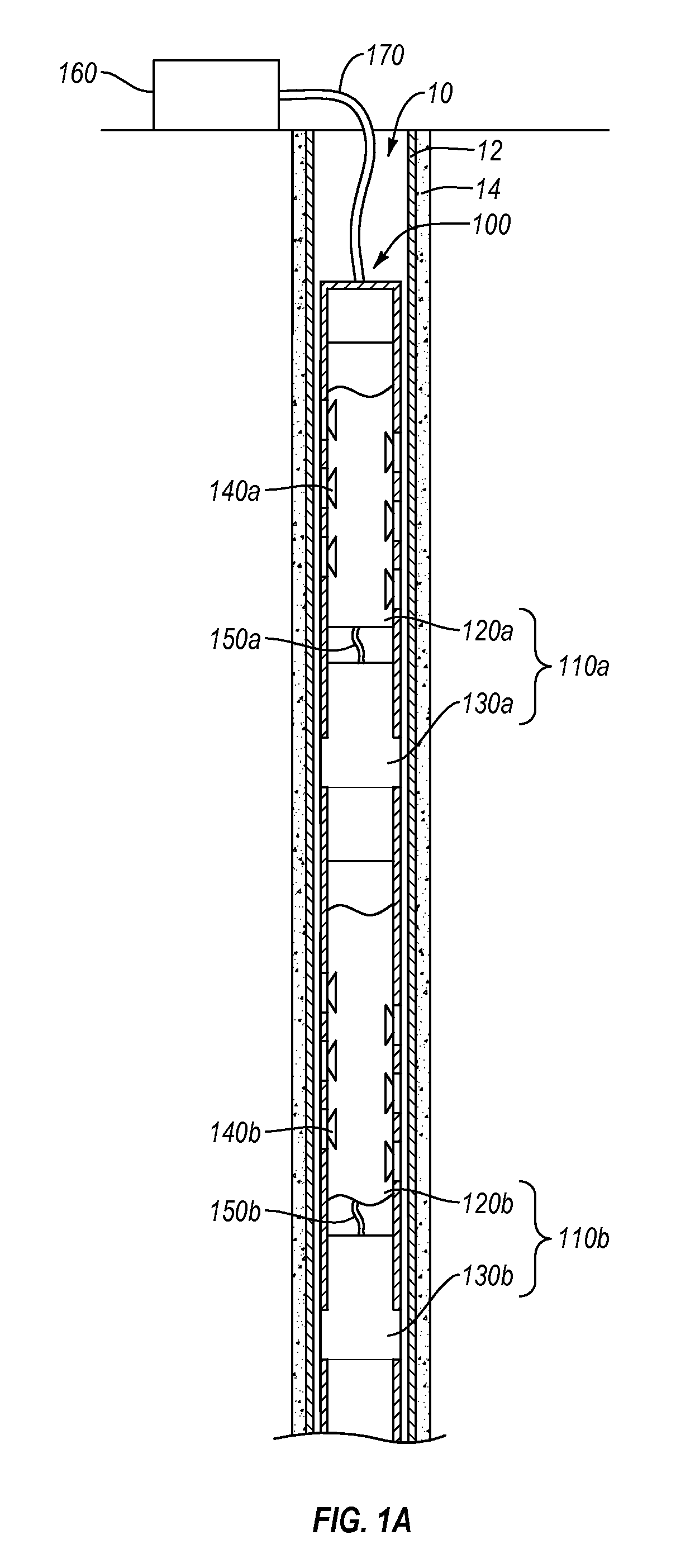

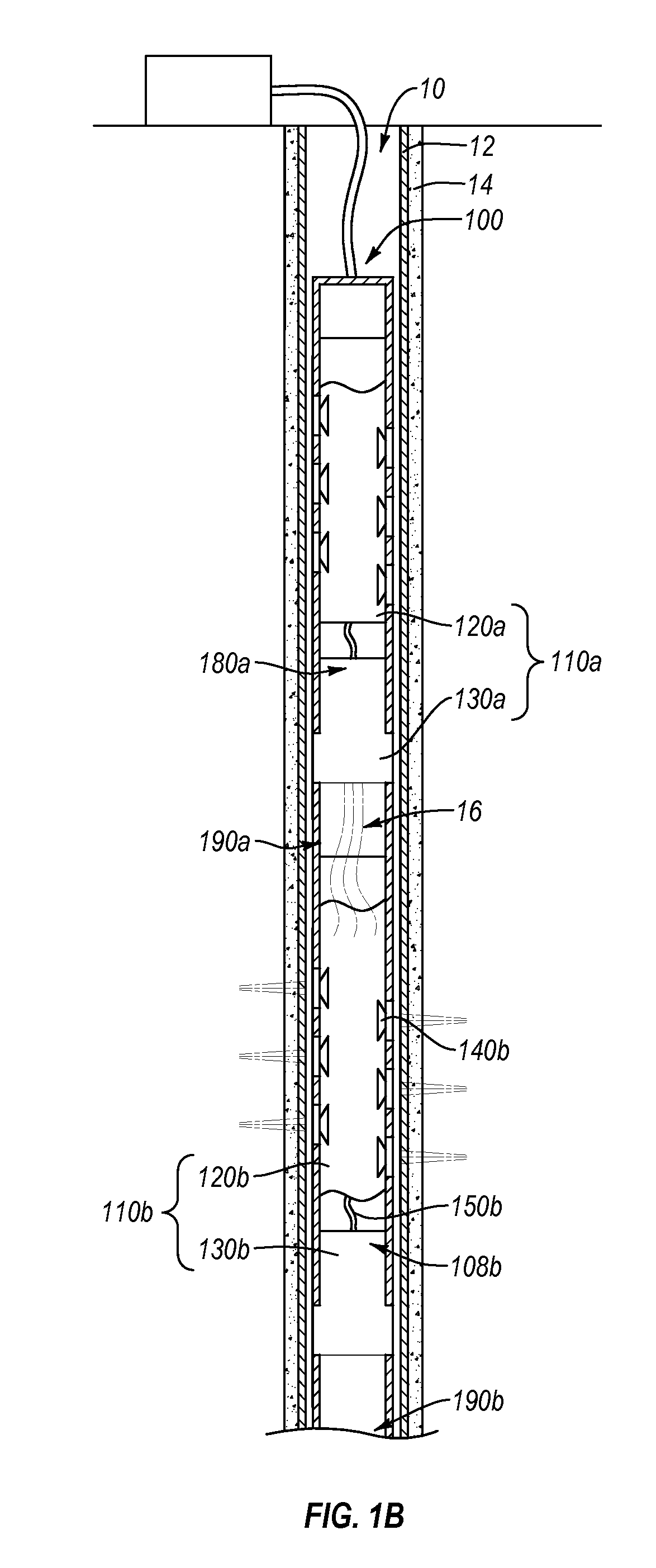

Wellbore gun perforating system and method

A wellbore perforating system and method with reliable and safer connections in a perforating gun assembly is disclosed. The system / method includes a gun string assembly (GSA) deployed in a wellbore with multiple perforating guns attached to plural switch subs. The perforating guns are pre-wired with a cable having multi conductors; the multi conductors are connected to electrical ring contacts on either end of the perforating guns. The switch subs are configured with electrical contacts that are attached to the electrical contacts of the perforating guns without the need for manual electrical connections and assembly in the field of operations. The system further includes detonating with a detonator that is positioned upstream of the perforating gun. The detonator is wired to a switch that is positioned downstream of the perforating gun.

Owner:WELLS FARGO BANK NAT ASSOC +1

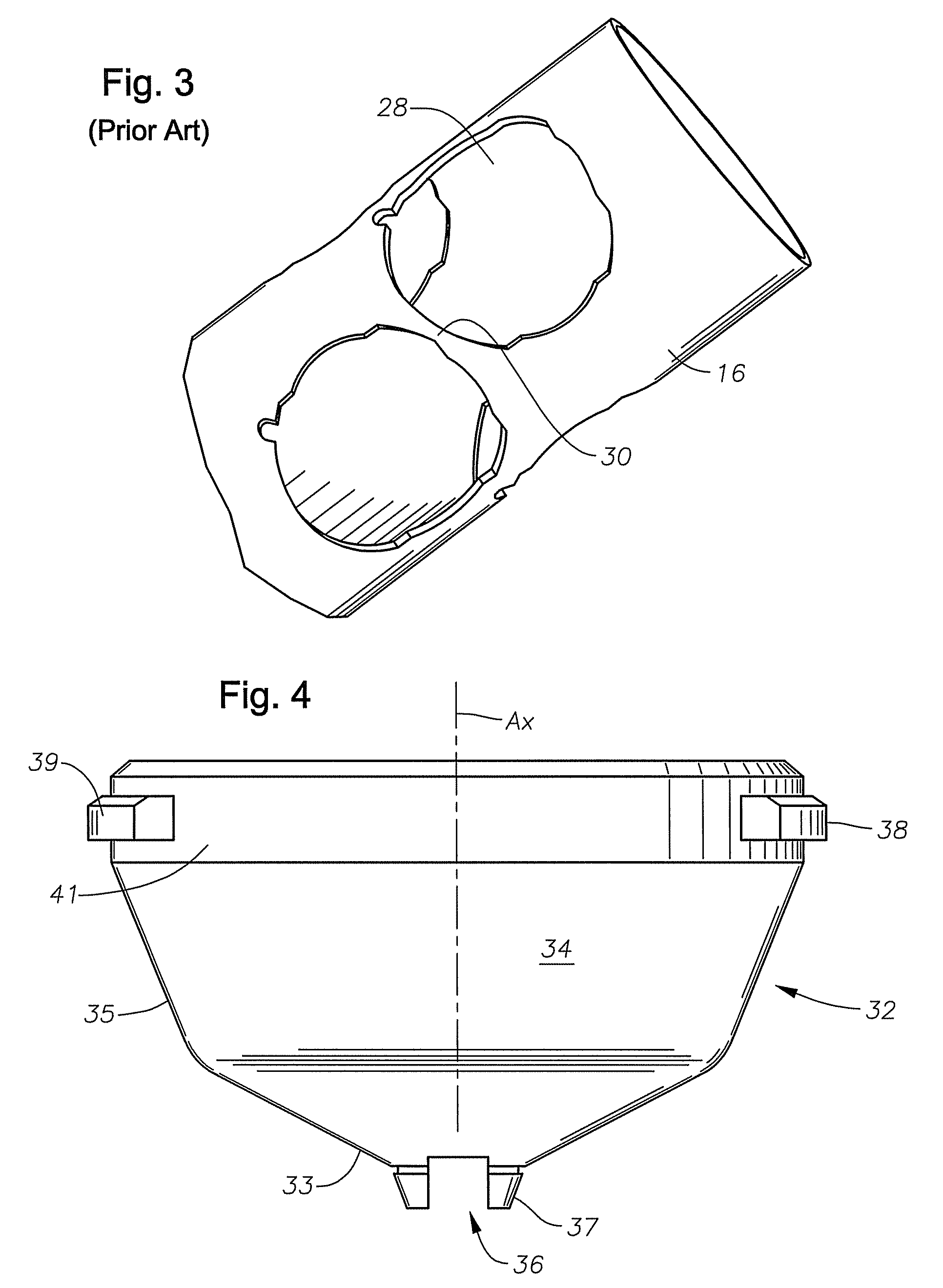

Perforating system with shaped charge case having a modified boss

A perforating gun having a charge case with a boss element partially circumscribing Optionally the pair of bosses may be included that are substantially symmetric about the axis of the charge case. Forming a shaped charge with such a charge case allows for gun strips to be formed with increased web material between adjacent shape charges in the gun strips. The increased web material provides for a more structurally sound gun tube, especially when dealing with high density charges. Notches may be provided in the gun tube on the outer radius of the holes formed to receive the shape charges, the notches are to be aligned with the bosses on the outer periphery of the shaped charge case. This also may orient the charge cases so they are pre-aligned for ready connection to an associated detonation cord.

Owner:BAKER HUGHES INC

Dissolvable Material Application in Perforating

A shaped charge includes a charge case; a liner; an explosive retained between the charge case and the liner; and a primer core disposed in a hole in the charge case and in contact with the explosive, wherein at least one of the case, the liner, the primer core, and the explosive comprising a material soluble in a selected fluid. A perforation system includes a perforation gun, comprising a gun housing that includes a safety valve or a firing valve, wherein the safety valve or the firing valve comprises a material soluble in a selected fluid.

Owner:SCHLUMBERGER TECH CORP

Connection cartridge for downhole string

A cartridge assembly for use with a perforating system having a contact terminal that connects to a perforating signal line when inserted into a receptacle end of a perforating gun. A detonator may be included in an end of the cartridge assembly for initiating a detonating cord in the perforating gun. The cartridge assembly is a modular unit that replaces the manual connections made when assembling a string of perforating guns. The cartridge assembly may optionally include a controller switch for controlling current flow through the cartridge assembly.

Owner:BAKER HUGHES INC

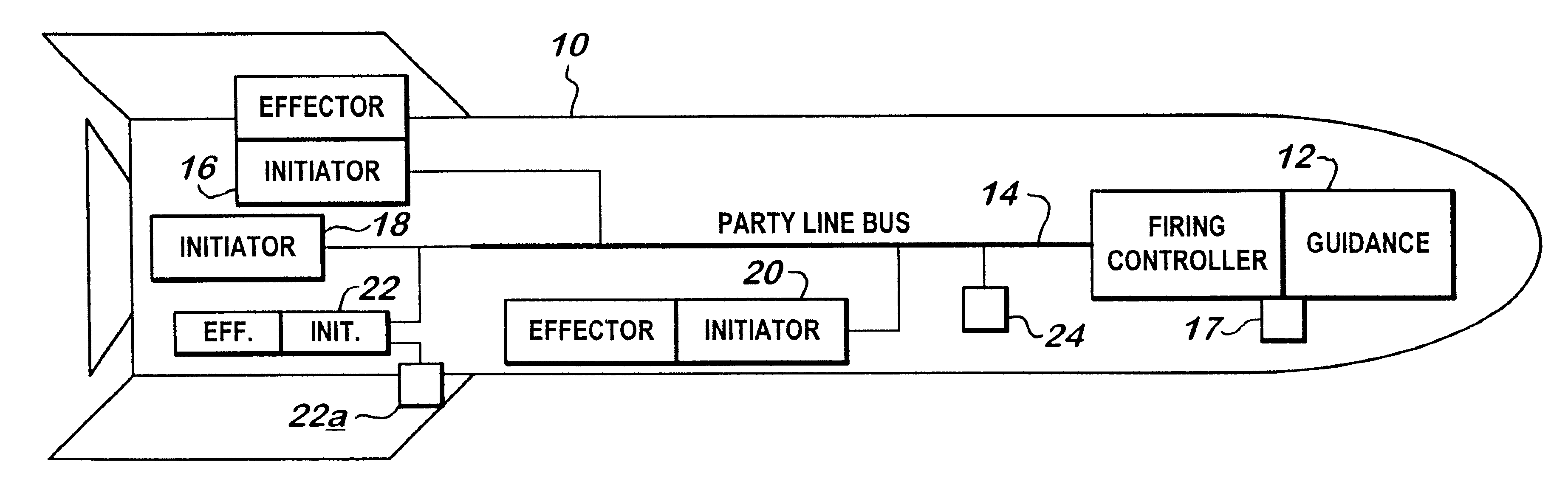

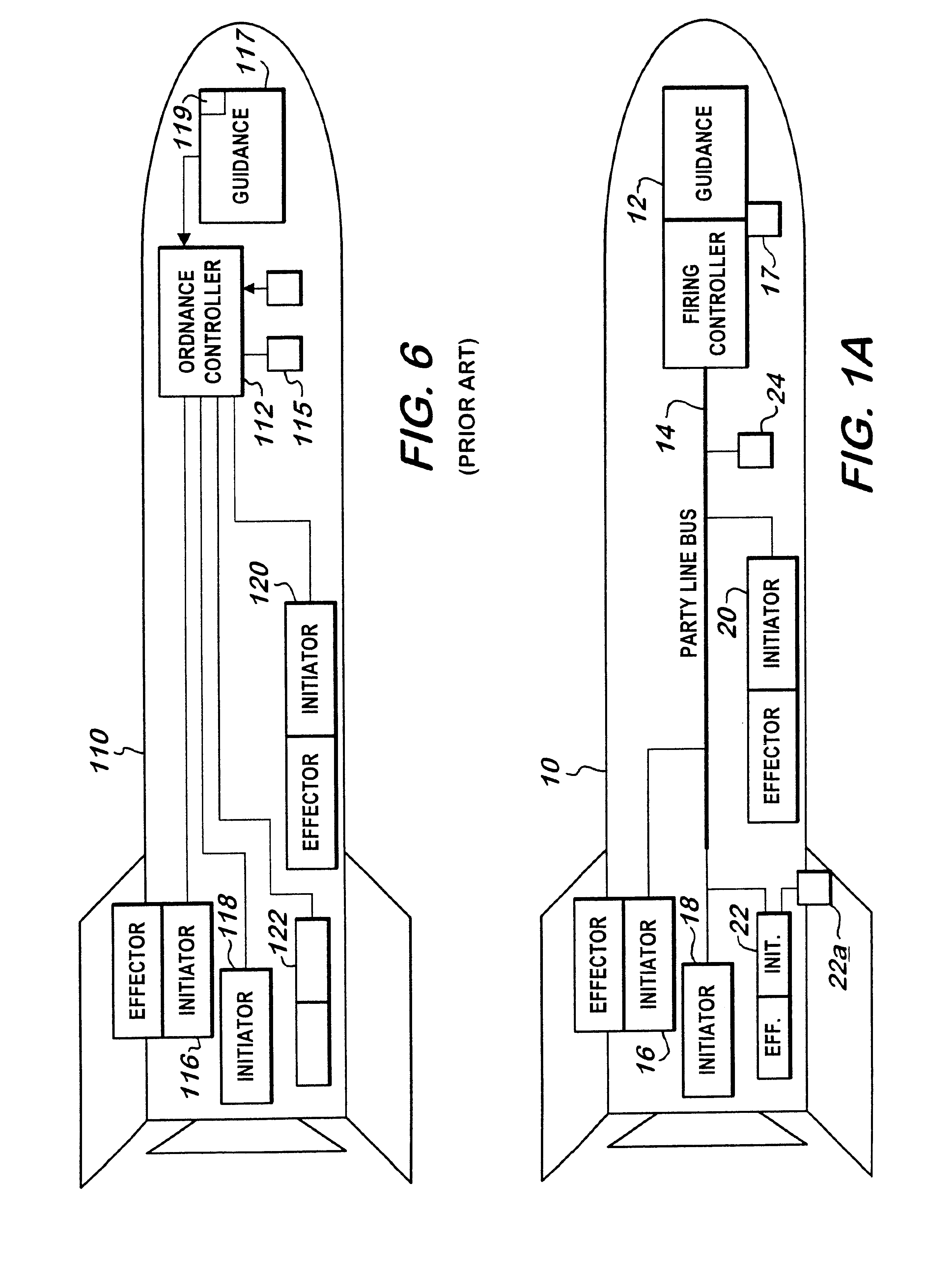

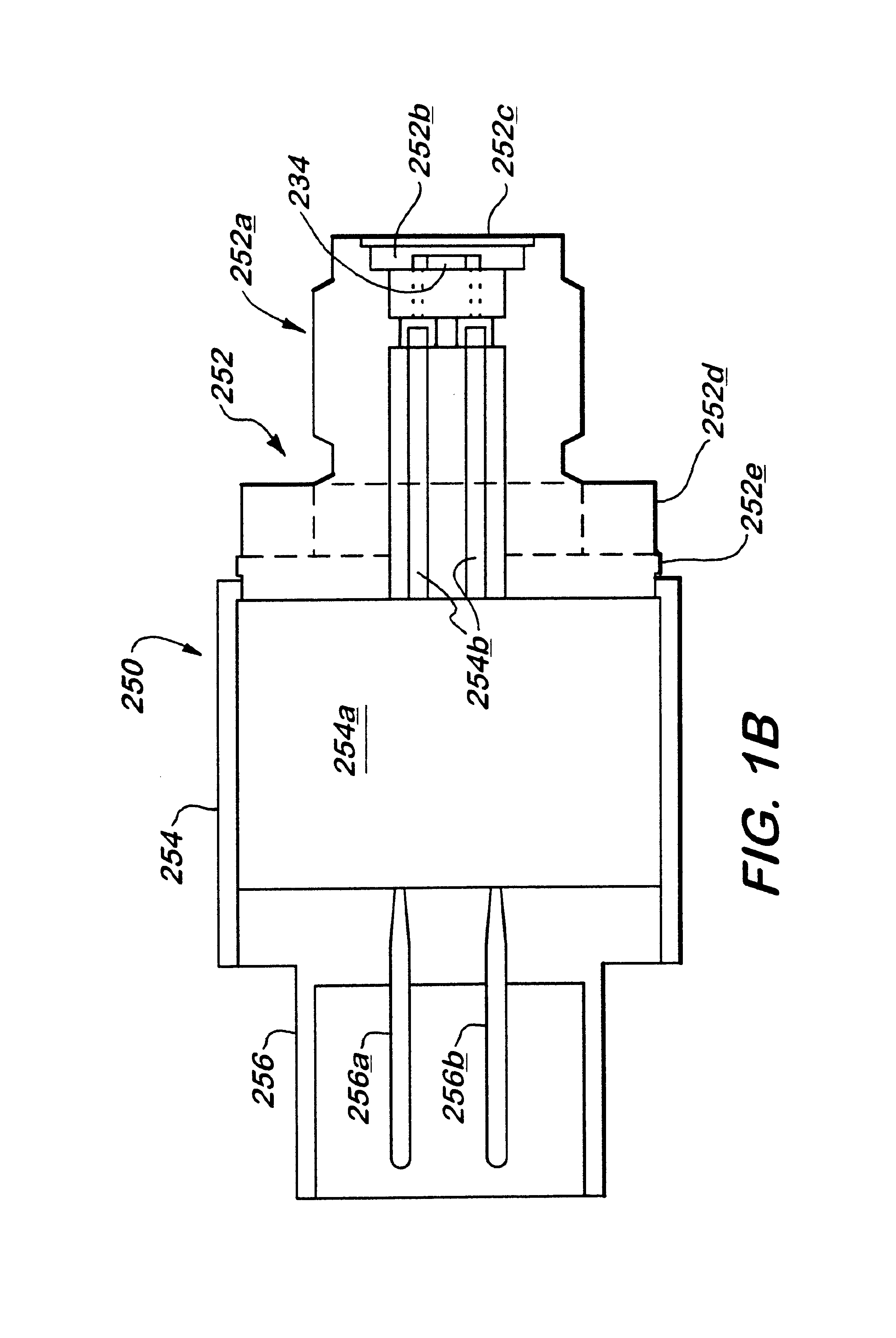

Ordnance firing system

An ordnance system of the present invention may include or feature any one or more of: a control unit, one or more effectors (detonators, initiators, shaped charges and the like), and a two-, three- or four-wire communication bus between the control unit and the effectors; an addressable system in which all the effectors can be connected to the same communication bus and the control unit can issue coded signals on the bus addressed to a specific effector; inductive coupling between the effectors and the communication bus; and a multi-voltage level communication system in which communication signals are carried at a first voltage and arming signals are provided at a second, higher voltage. Other features may include two-way communication between effectors and the control unit and the de-centralization of firing control so that the control unit does not have exclusive control over whether the effectors function. As a result, the individual effectors possess decision-making ability and, for purposes of this invention, may be referred to as "intelligent" effectors. To participate in the decision-making process, effectors of this invention may be equipped with sensors or other diagnostic circuitry whose condition is checked for satisfactory output before functioning is permitted to occur.

Owner:ENSIGN BICKFORD AEROSPACE & DEFENSE

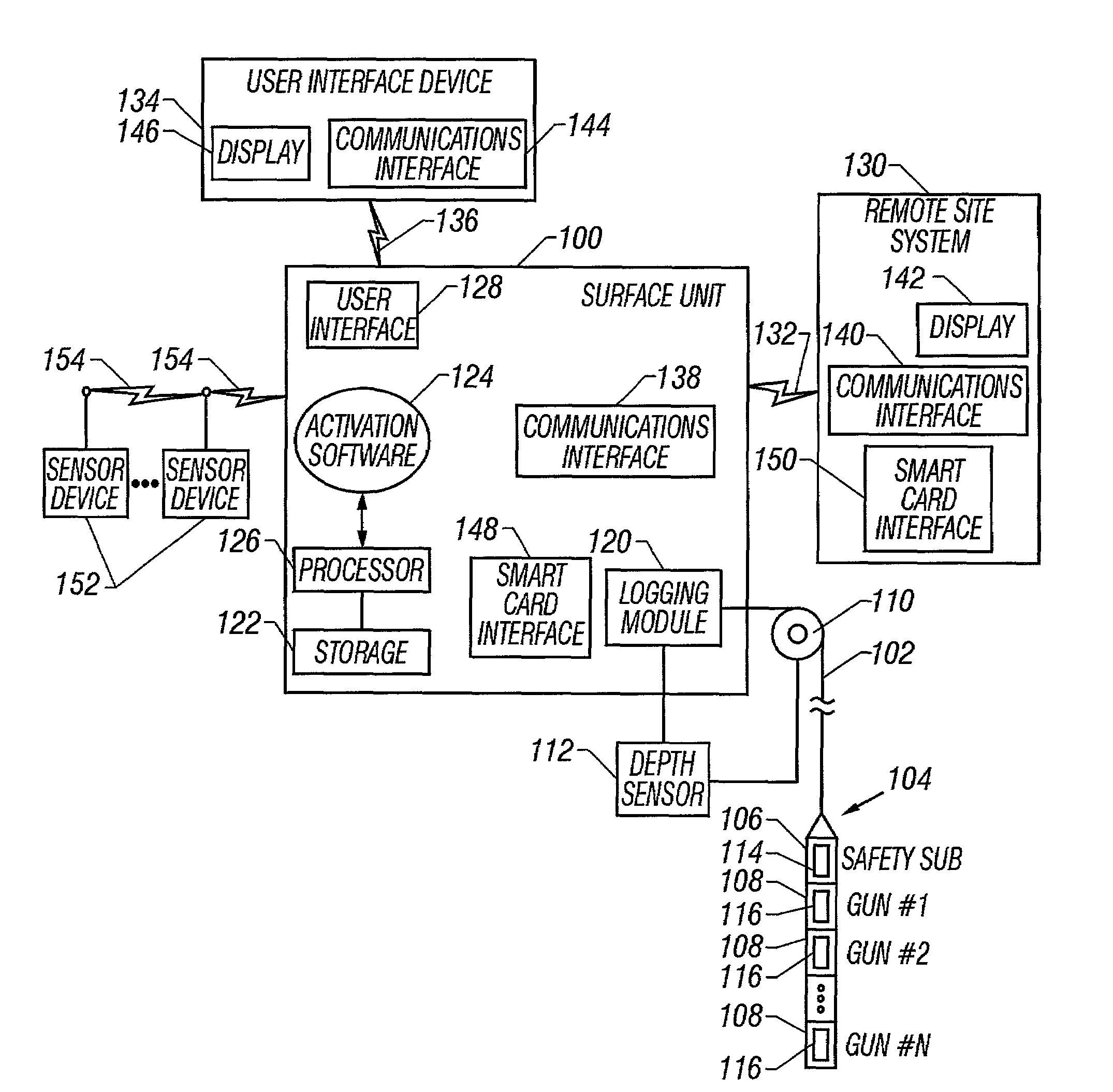

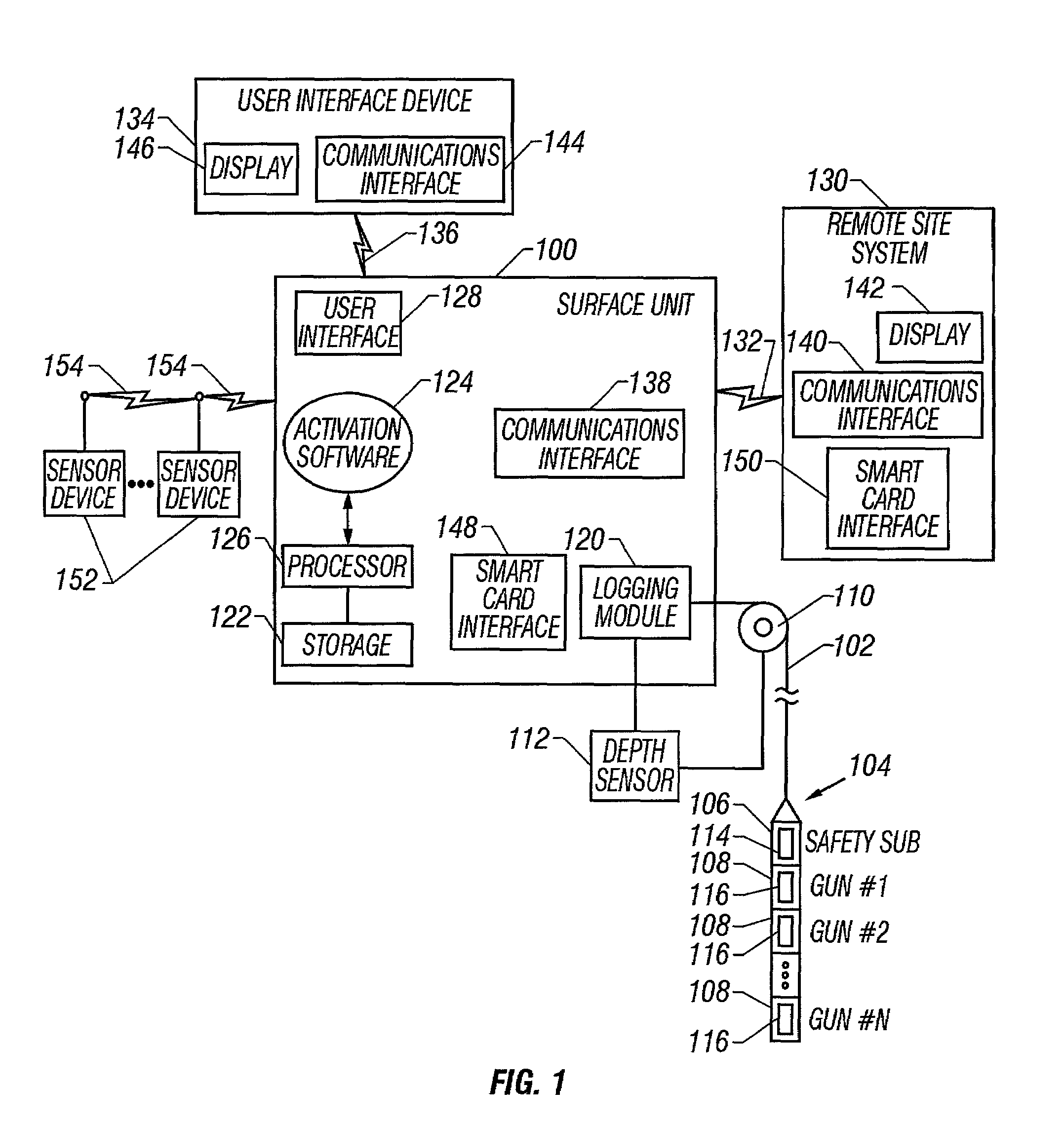

Interactive and/or secure activation of a tool

InactiveUS7383882B2Improve securityIncrease flexibilitySurveyFluid removalProgramming languageSmart card

A tool activation system and method includes receiving an authorization code of a user to verify access rights of a user to activate the tool. In one example, the authorization code is receive from a smart card. The environment around the tool, which can be in a wellbore, for example, is checked. In response to the authorization code and the checking of the environment, activation of the tool is enabled.

Owner:SCHLUMBERGER TECH CORP

Adapter for shaped charge casing

A shaped charge for use with a perforating gun having an adapter that can couple the shaped charge with perforating gun systems of more than one size. An interference fit can couple the adapter to the open end of a shaped charge. The adapter includes a base section having an outer diameter exceeding the shaped charge outer diameter. The adapter larger diameter can be coupled to perforating gun systems formed to receive shaped charges whose outer diameters exceed the outer diameter of the shaped charge coupled to the adapter. Thus the adapter can couple a shaped charge to a perforating gun that might otherwise have fittings too large to accommodate the shaped charge.

Owner:BAKER HUGHES INC

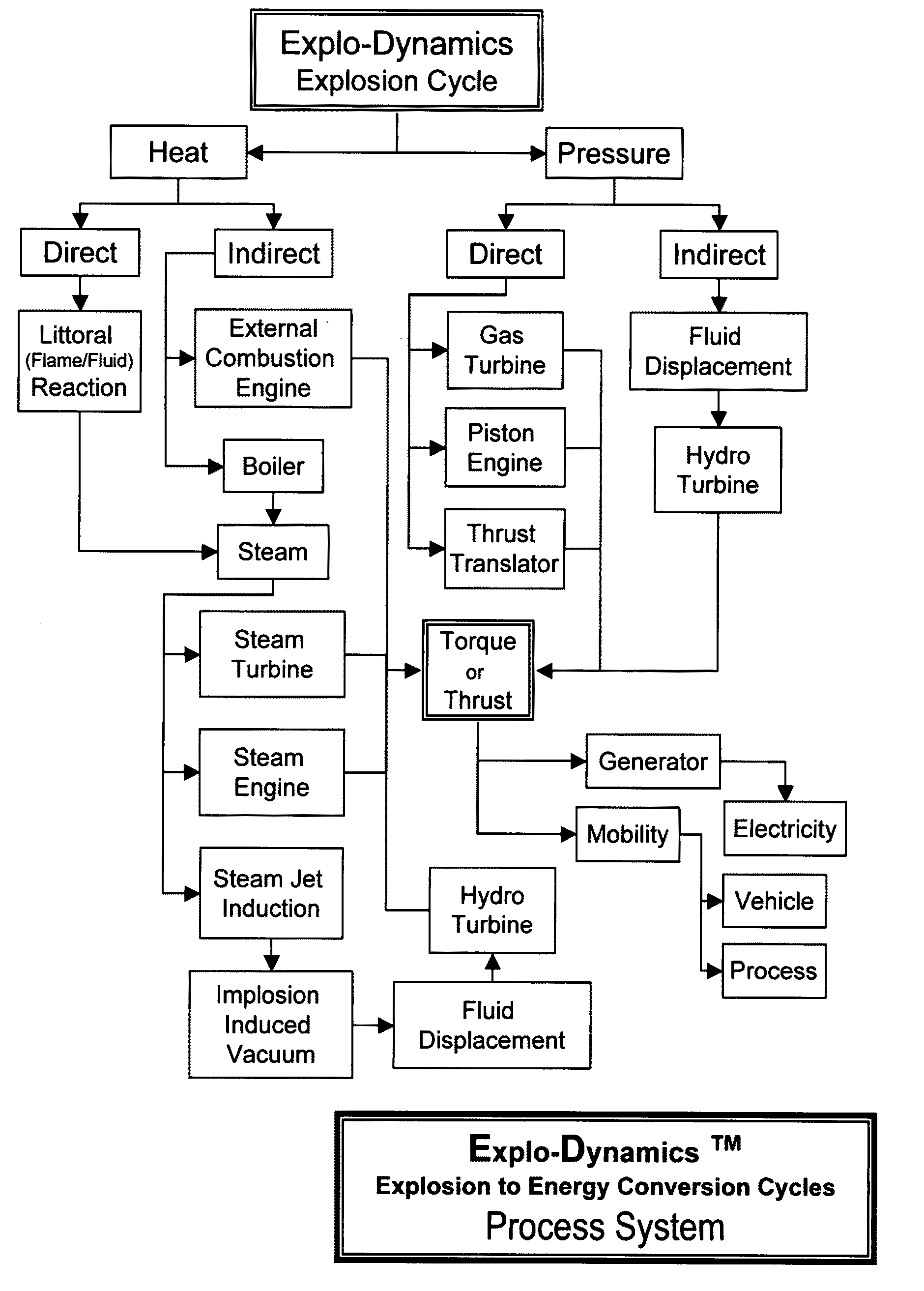

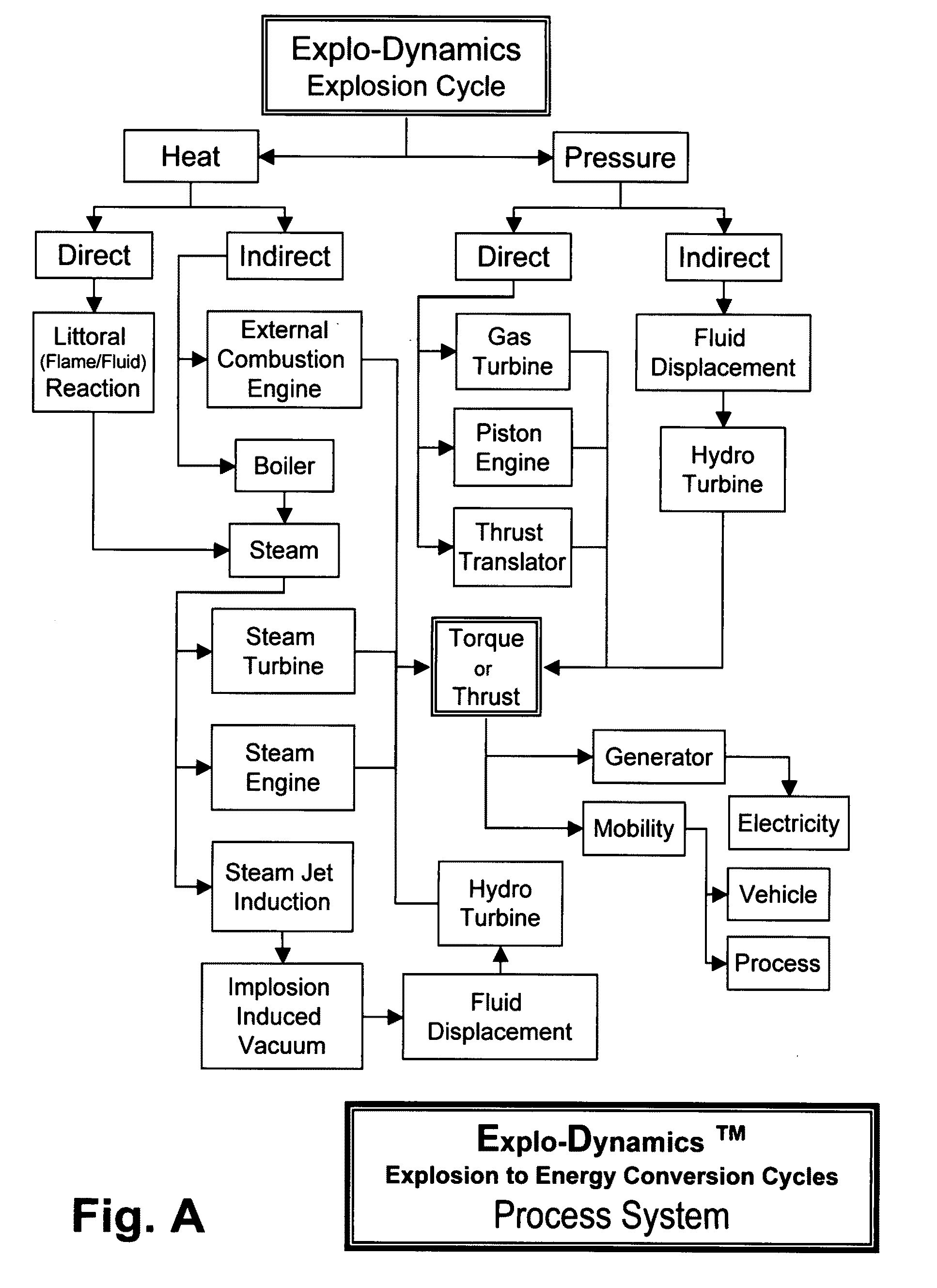

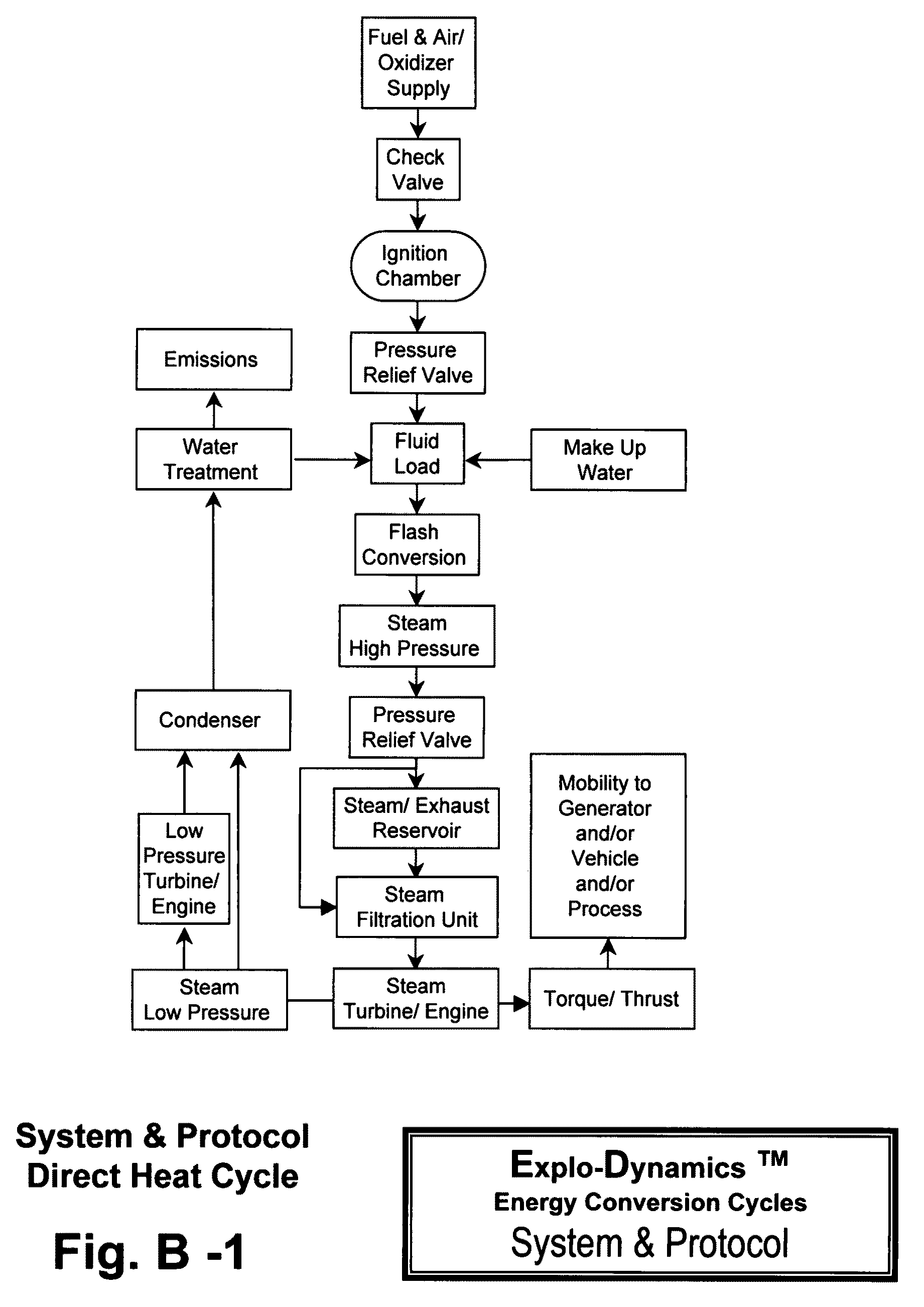

EXPLO-DYNAMICS™: a method, system, and apparatus for the containment and conversion of explosive force into a usable energy resource

InactiveUS20110283705A1Rapidly and more efficiently translated into conversion of steamMore impulse heat per unit of fuel consumedReciprocating combination enginesCombination enginesProcess configurationProcess engineering

Methods, systems, and apparatus for generating energy from a process contained series of explosion cycles is provided. The Explo-Dynamics™ energy generating system includes several embodiments for stimulating the heat and pressure release episodes of the process configurations and translating the released forces into torque, thrust, motive force, and / or super-heat impulses. The methods and systems of the present invention include a comprehensive arrangement of process configurations and components as well as a means of operation.

Owner:OLIVER TROY

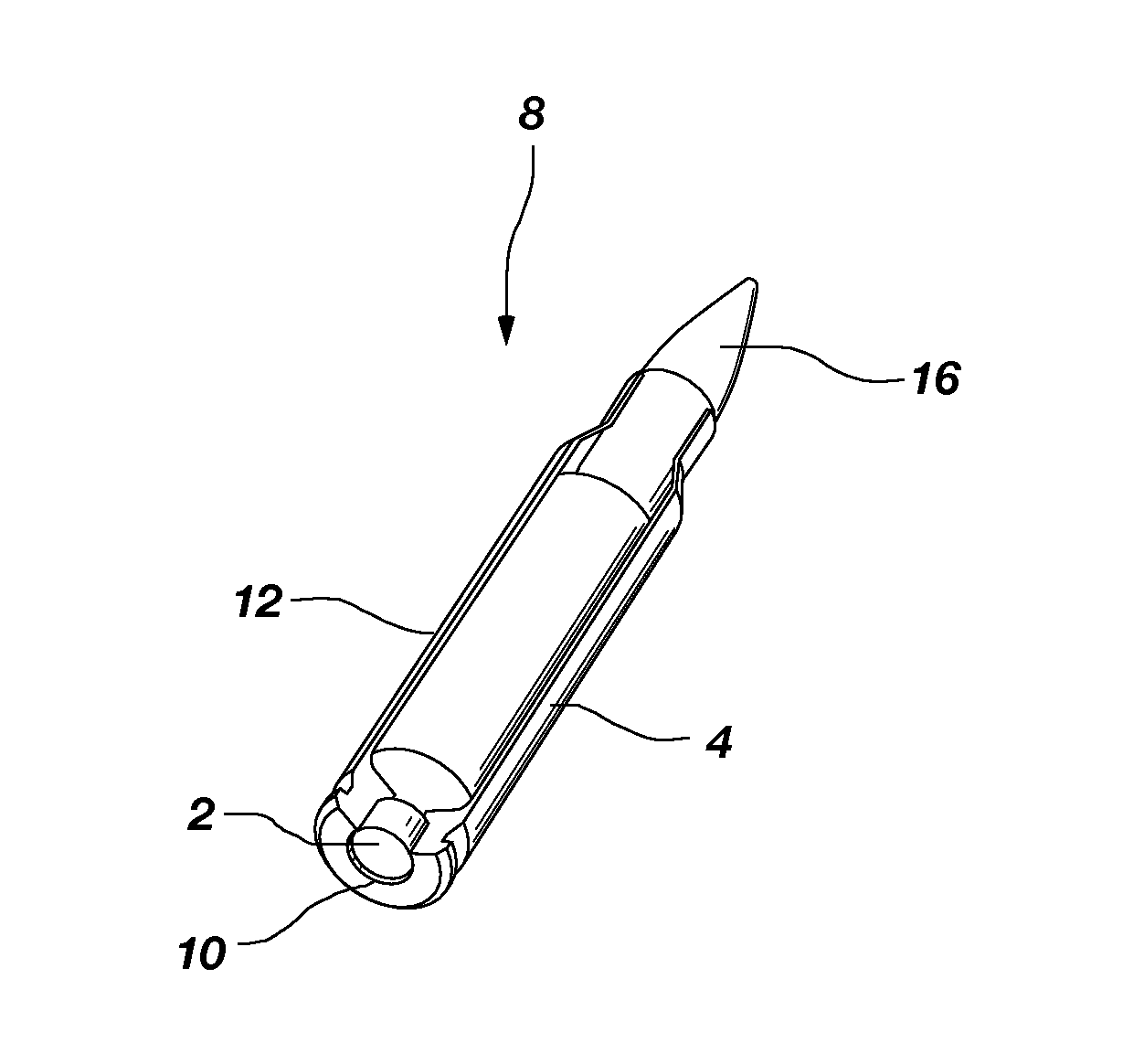

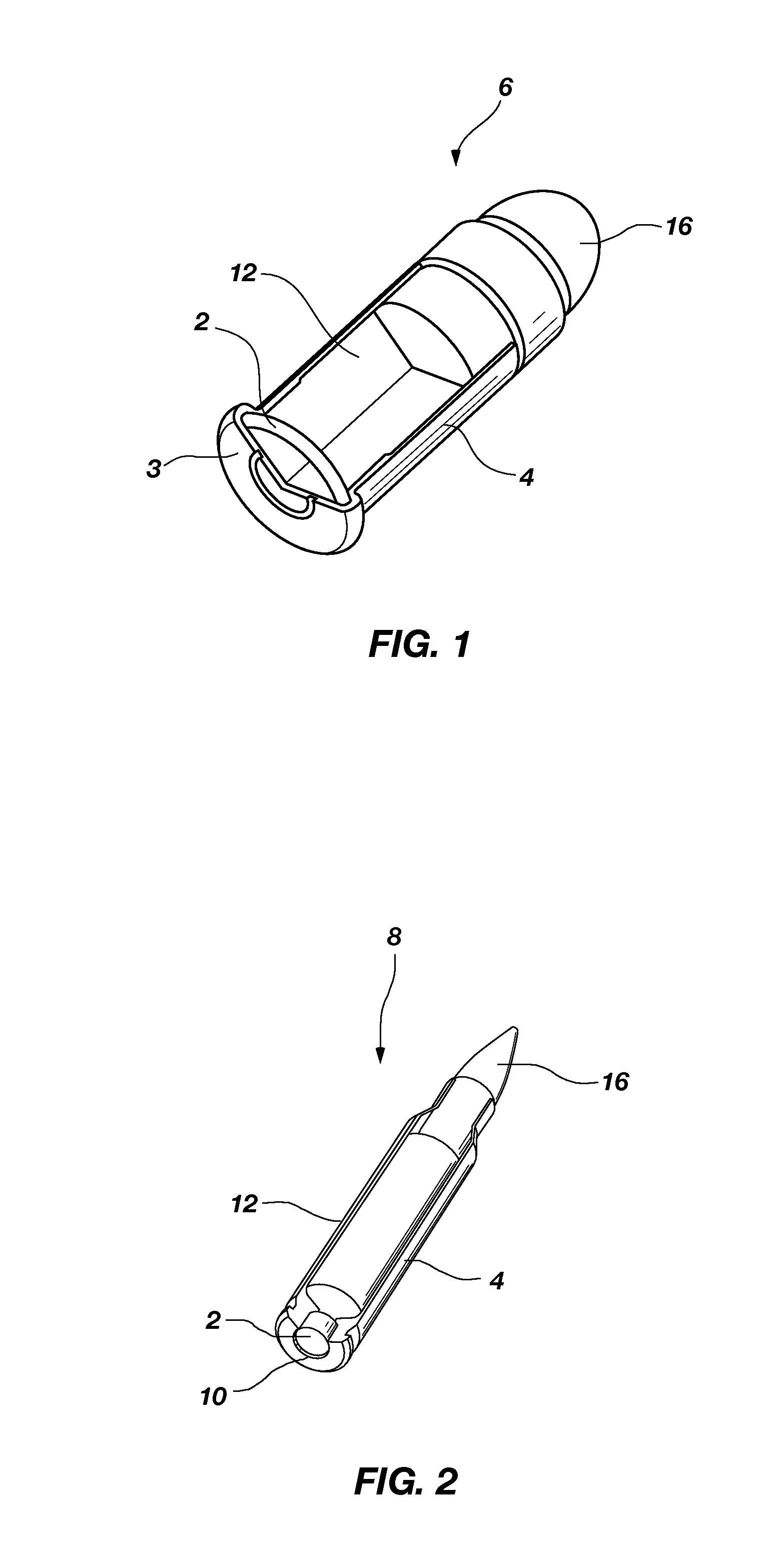

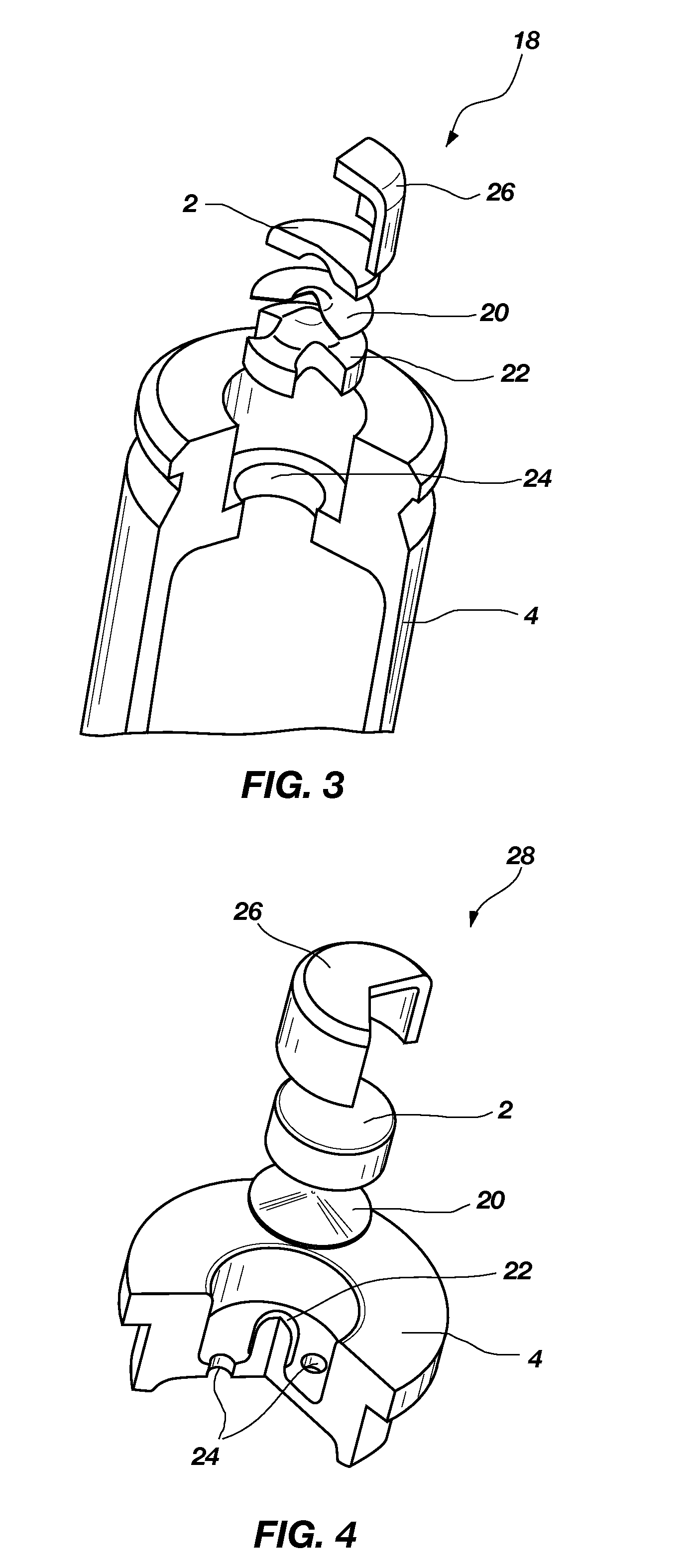

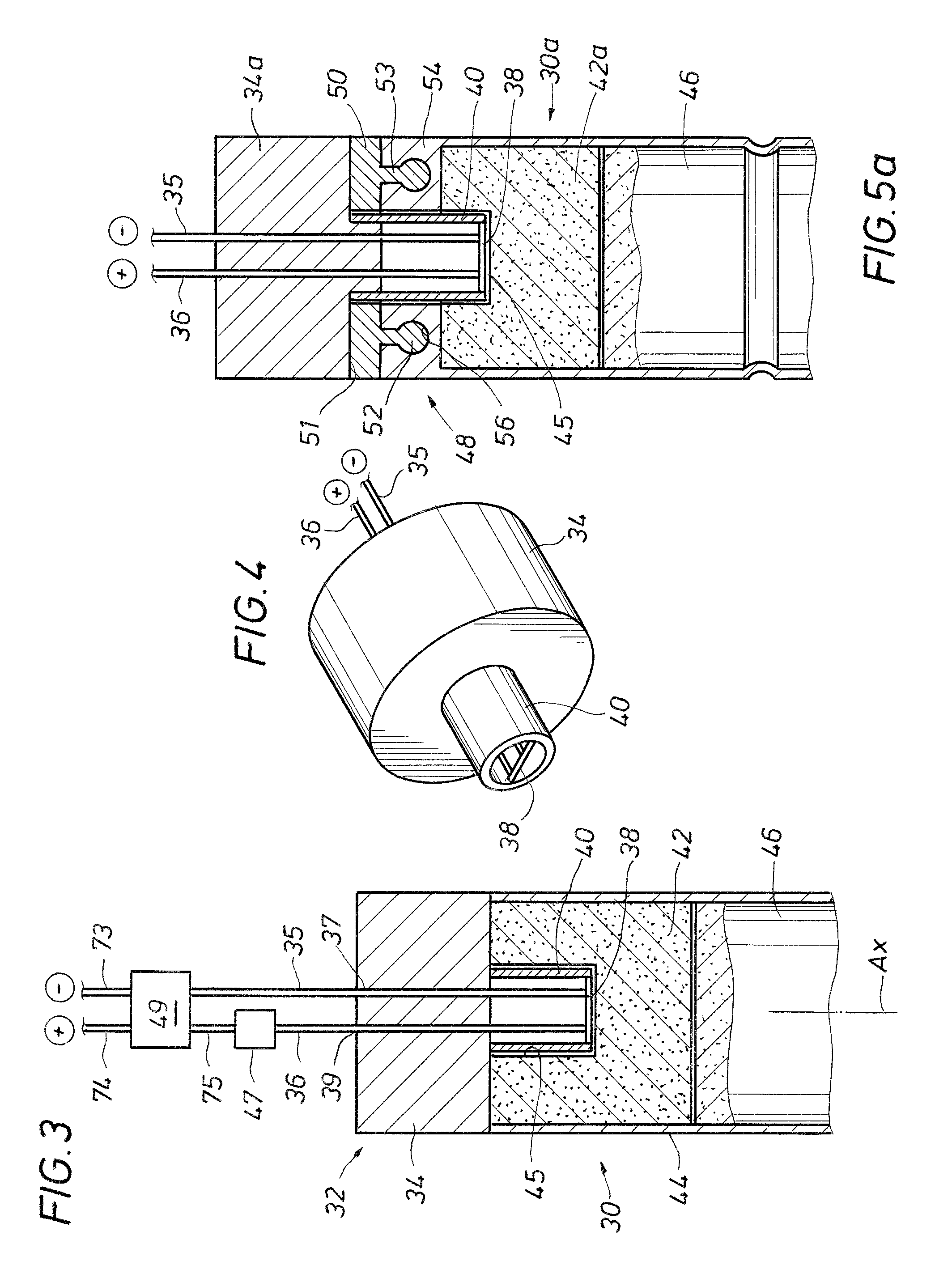

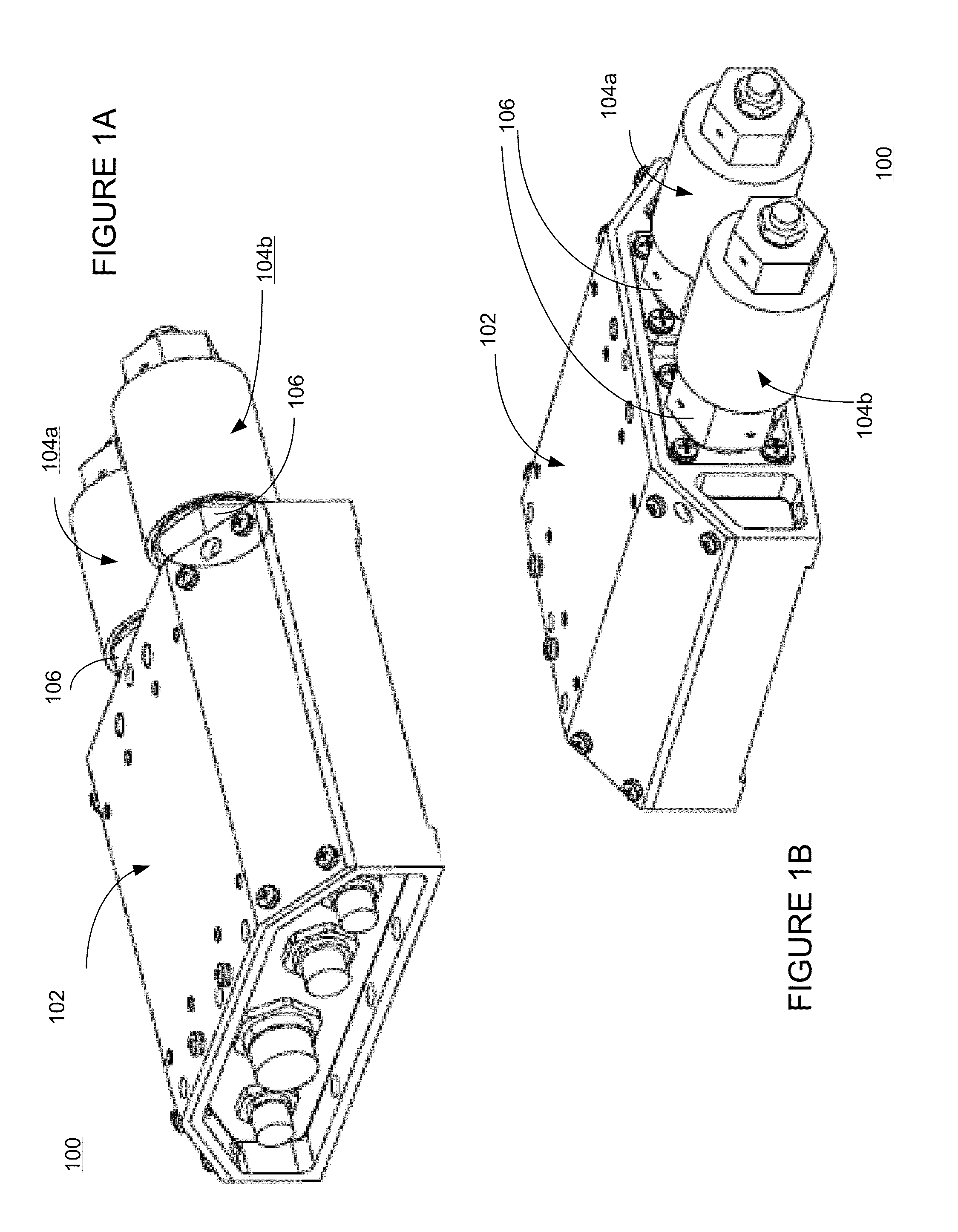

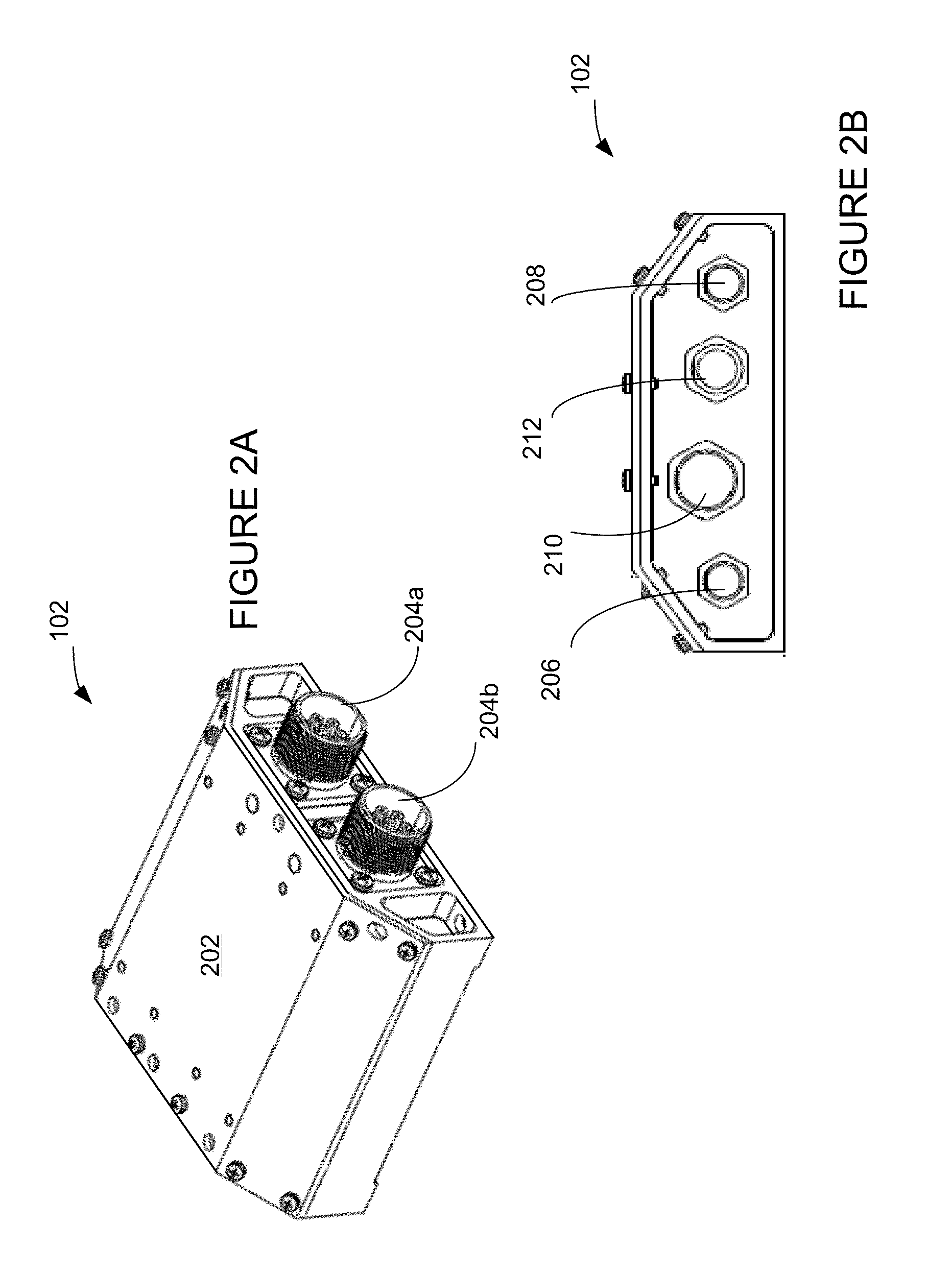

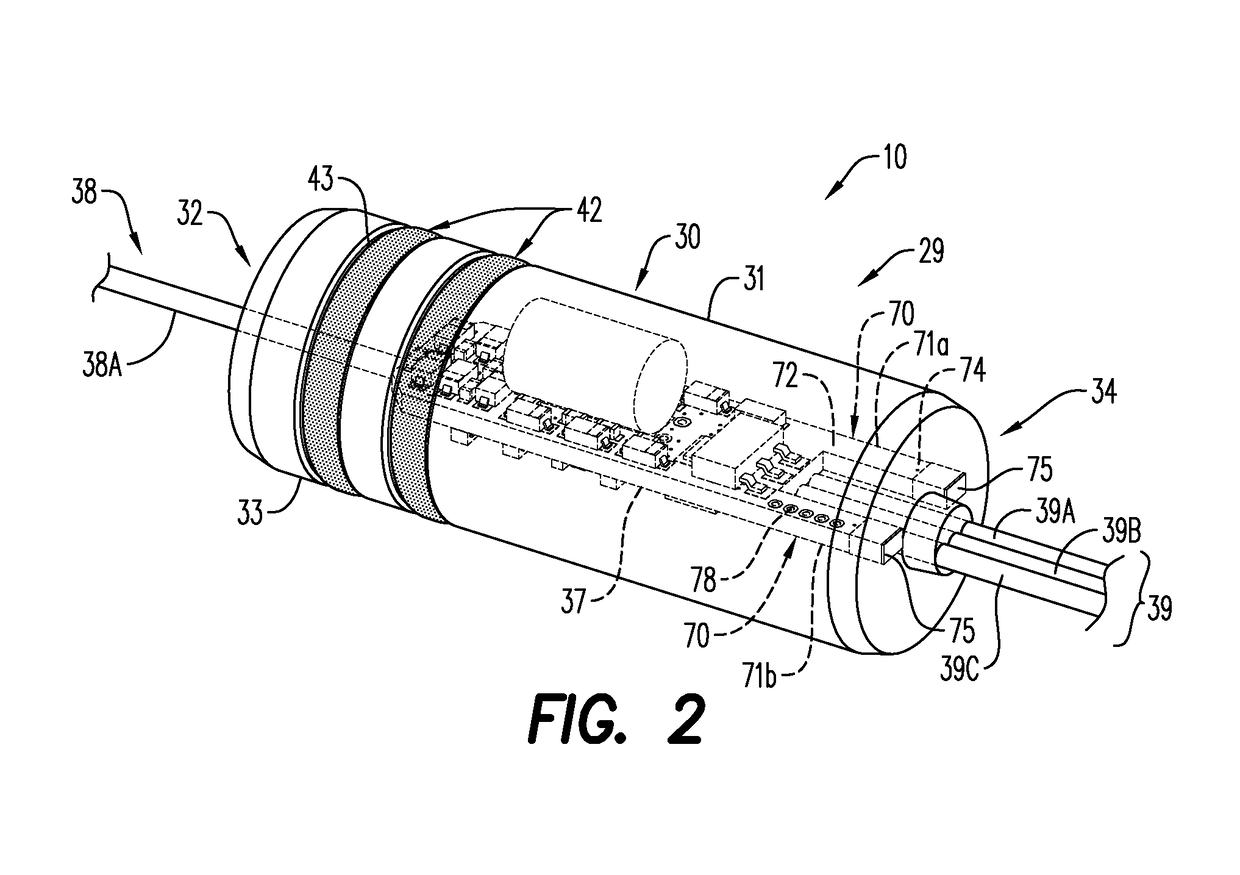

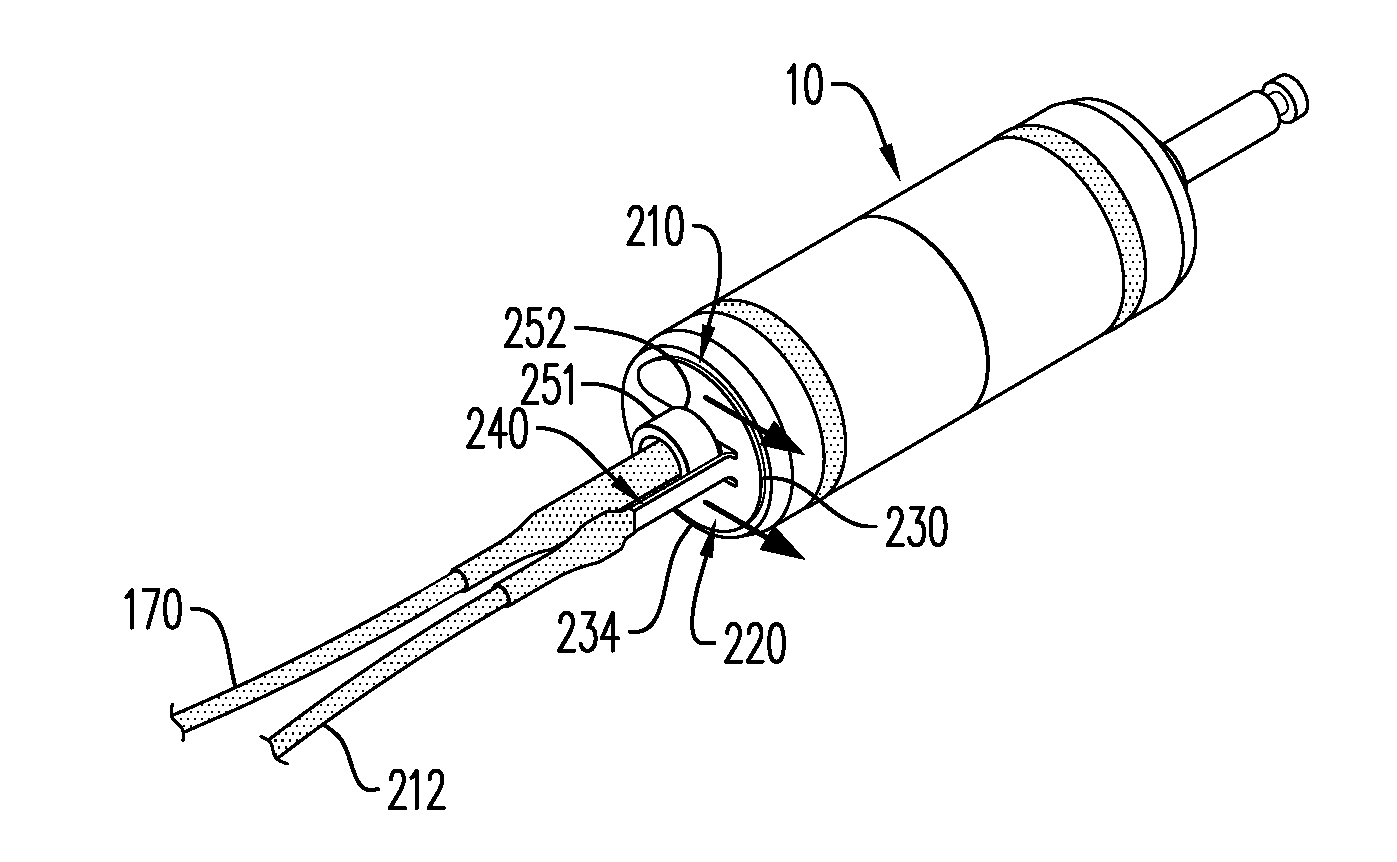

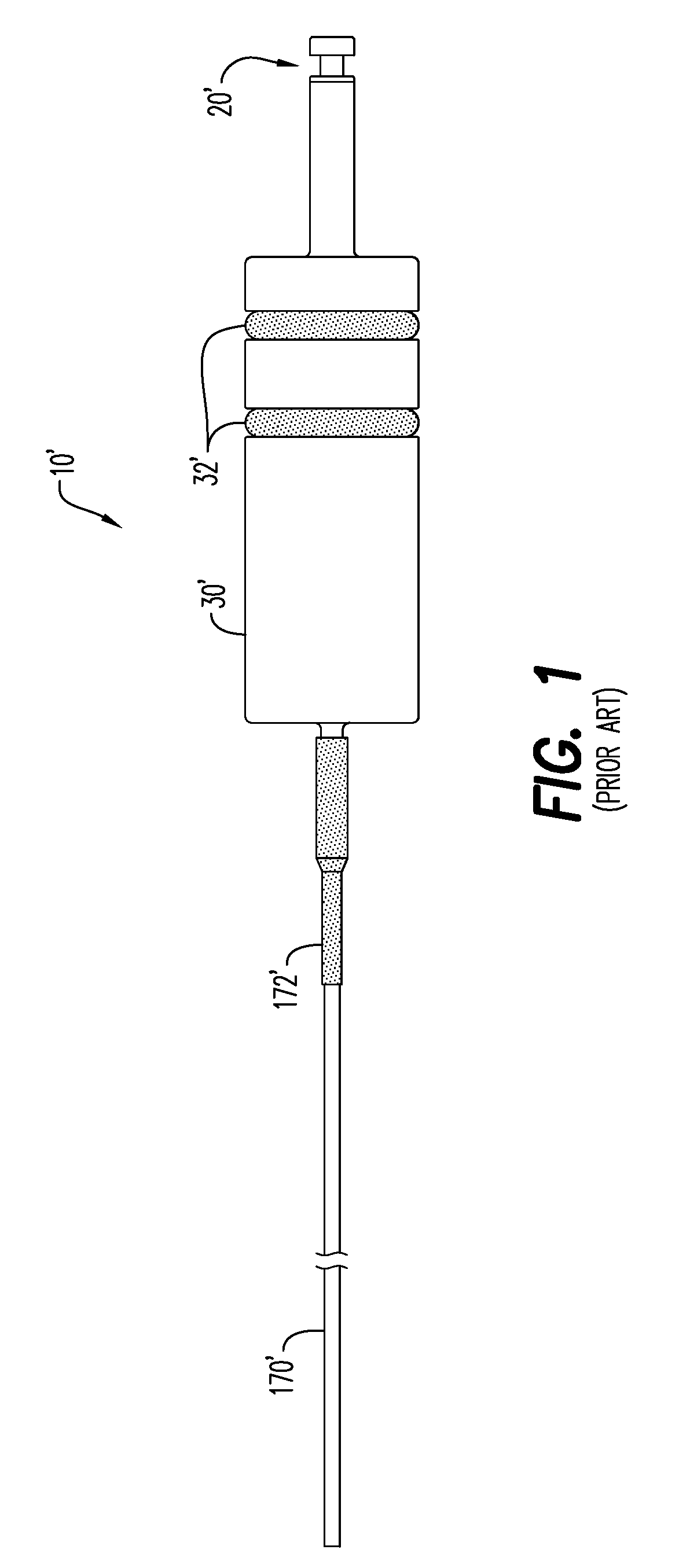

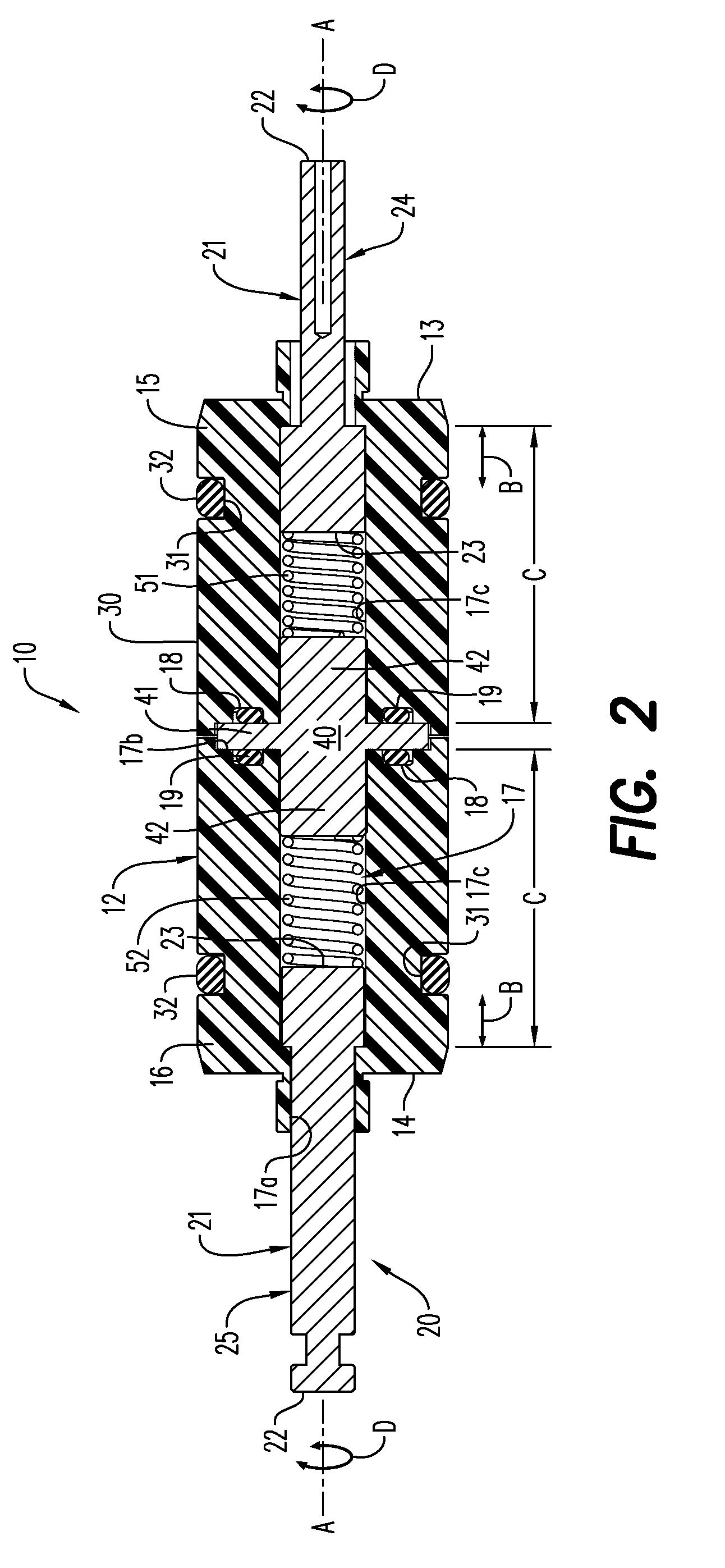

Modular initiator

Owner:BAKER HUGHES HLDG LLC

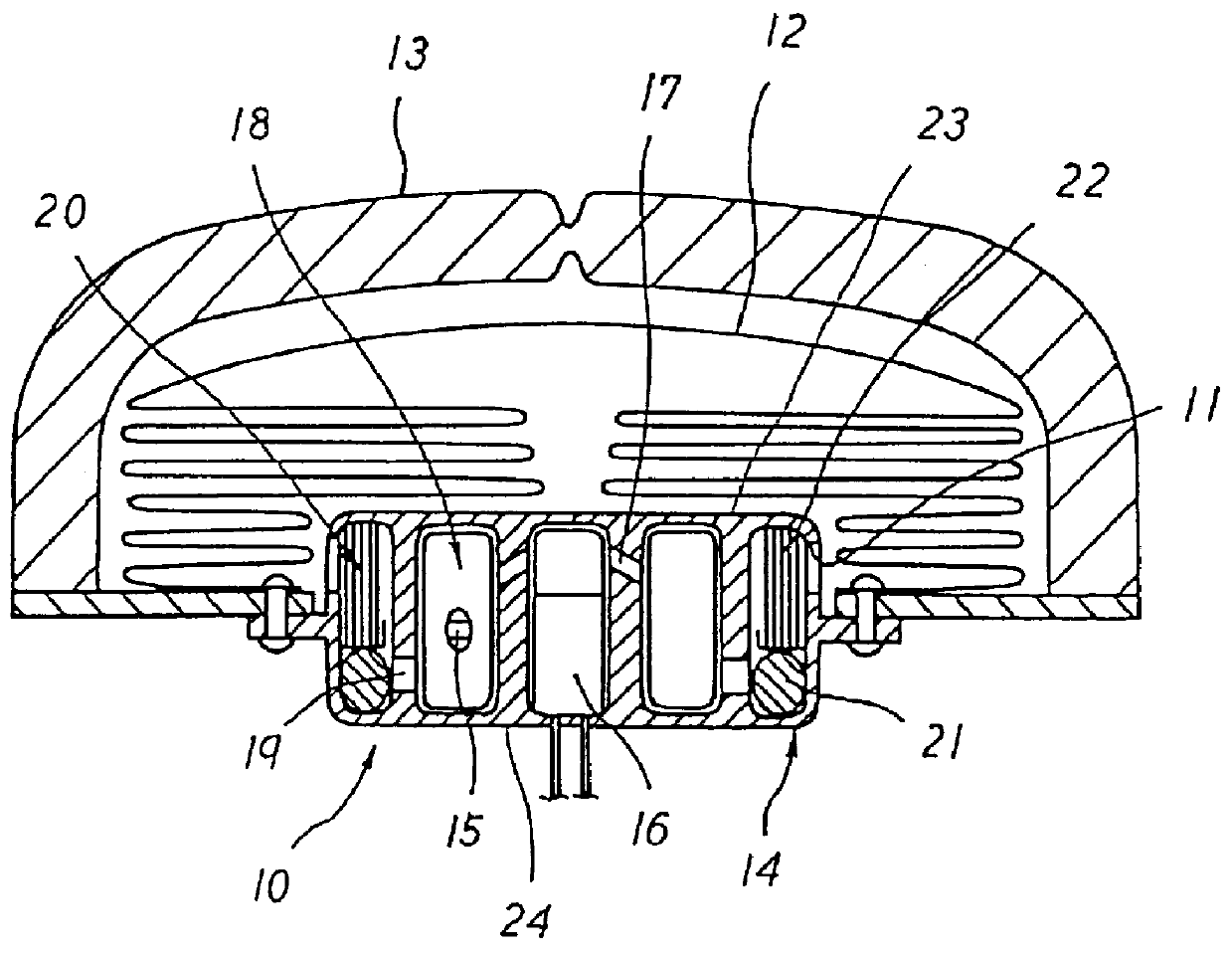

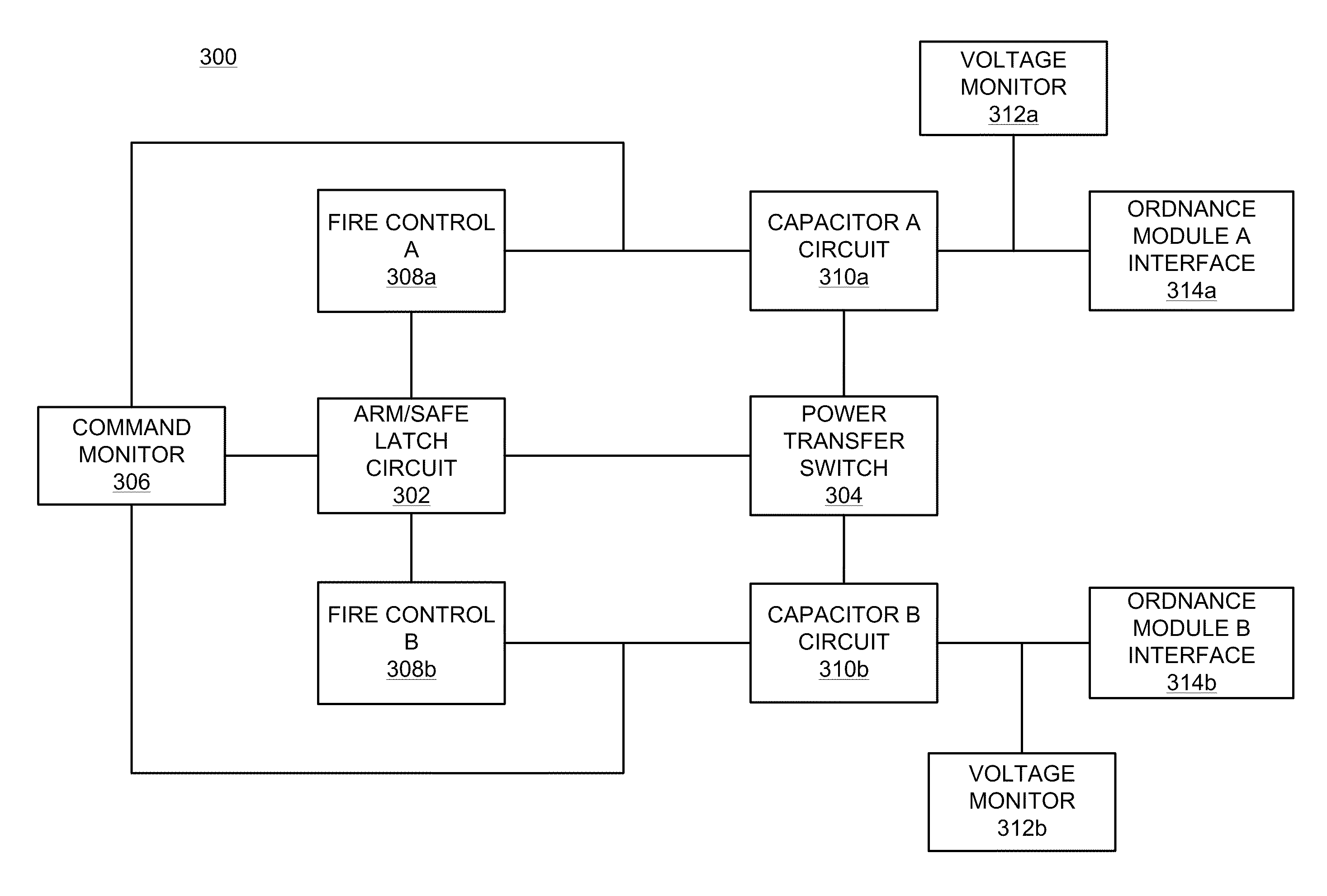

Electronic safe/arm system and methods of use thereof

ActiveUS20110277620A1Low impedance connectionGood adhesionCosmonautic vehiclesIncandescent ignitionDetonatorElectricity

An ordnance firing system is disclosed that includes a reusable electronics module and an ordnance module, each enclosed in a separate, sealed housing. The electronics module housing encloses firing electronics for electrically triggering initiation of a detonator in the ordnance module. The electronics module detachably connects to the ordnance modules via a connector which extends away from the electronics module housing. The housing of the ordnance module is constructed to be blast-resistant to prevent detonation of the detonator from rendering the electronics module inoperable.

Owner:NORTHROP GRUMMAN SYST CORP

Secure activation of a downhole device

InactiveUS20050045331A1More secure communicationSurveyIncandescent ignitionUnique identifierEngineering

A system includes a well tool for deployment in a well, a controller, and a link coupled between the controller and the well tool. The well tool comprises plural control units, each of the plural control units having a microprocessor and an initiator coupled to the microprocessor. Each microprocessor is adapted to communicate bi-directionally with the controller. The controller is adapted to send a plurality of activation commands to respective microprocessors to activate the respective control units. Each activation command containing a unique identifier corresponding to a respective control unit.

Owner:SCHLUMBERGER TECH CORP

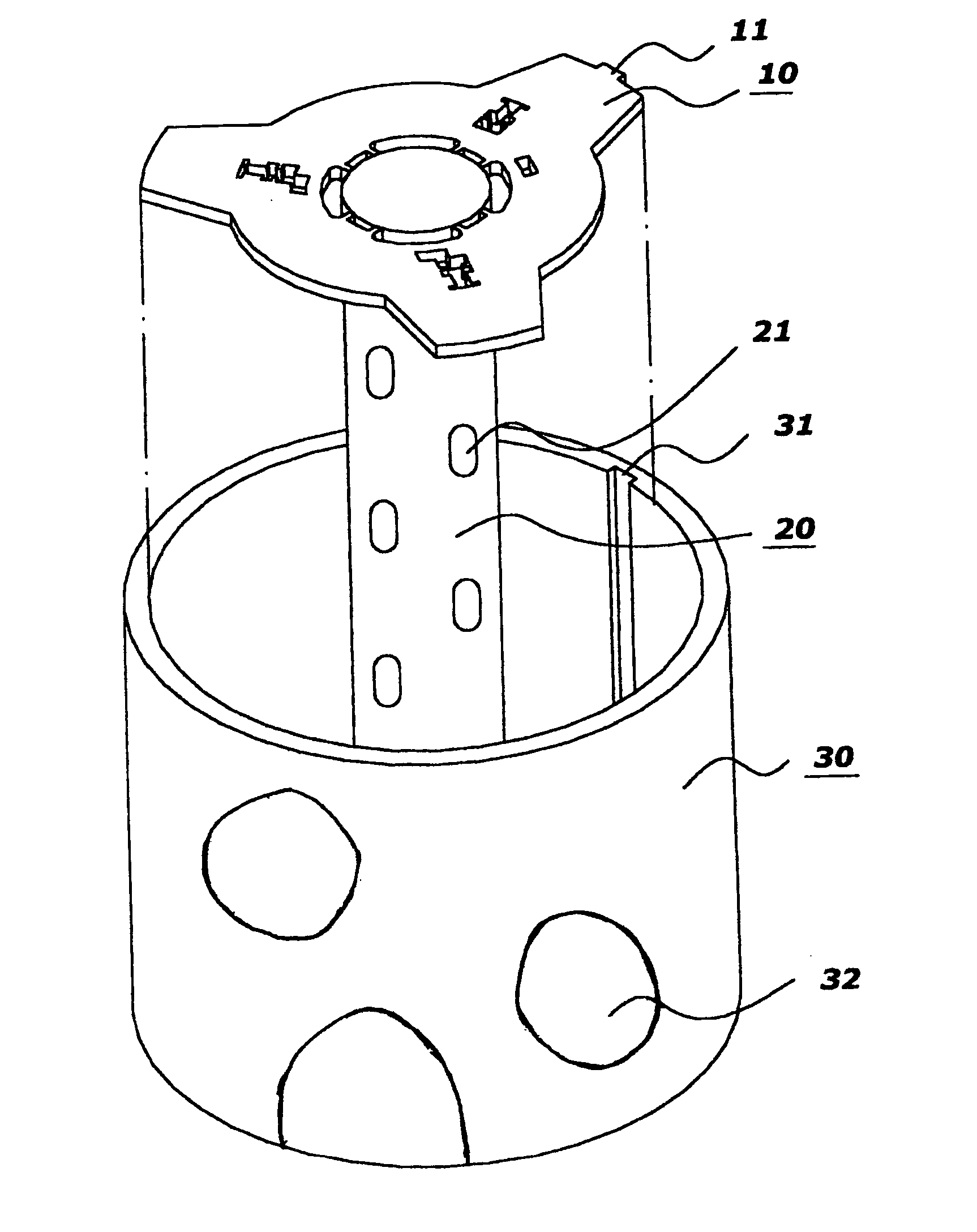

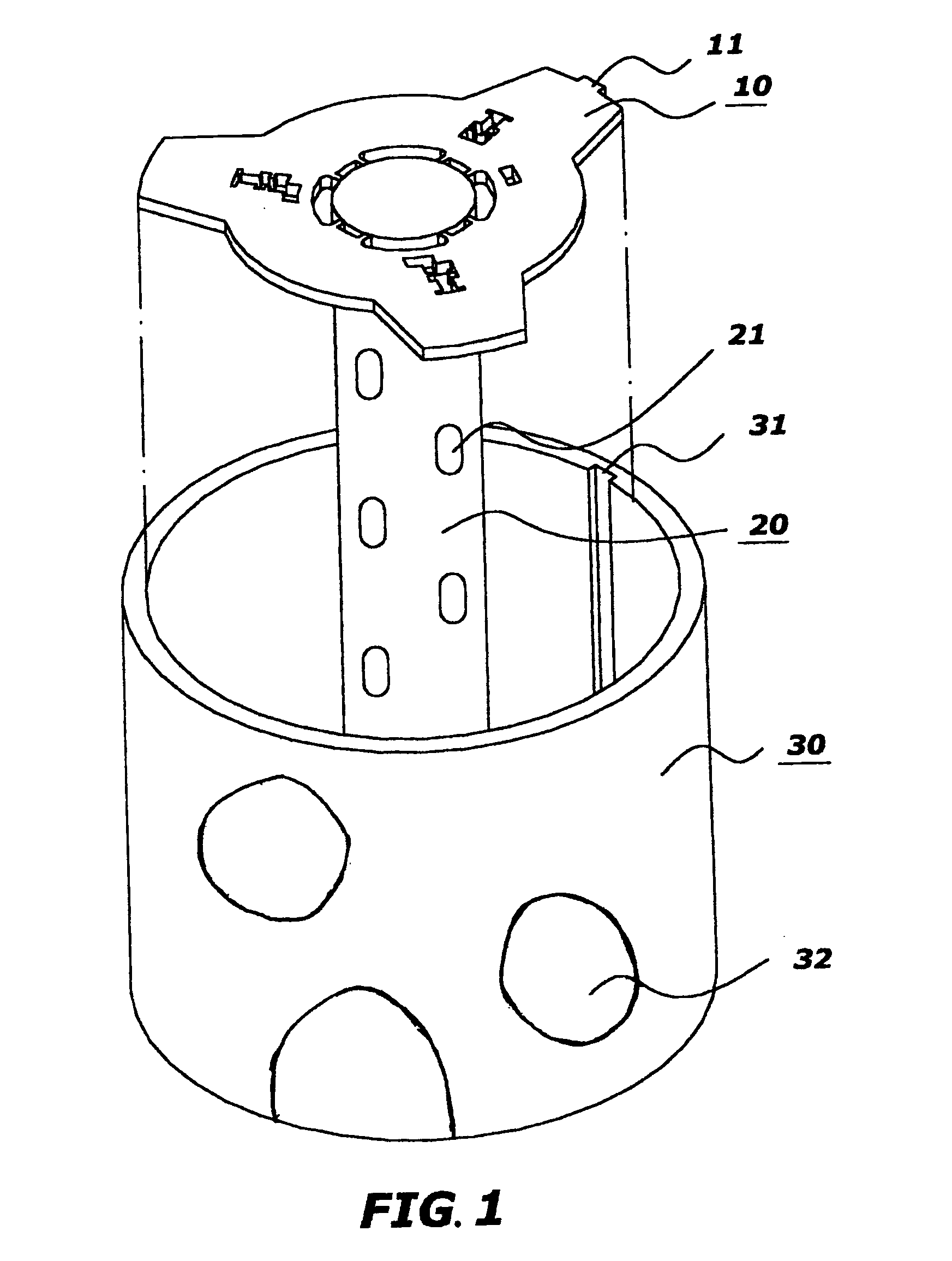

Exposed hollow carrier perforation gun and charge holder

InactiveUS20100089643A1Easily assembled and armedIncrease powerNuclear explosivesFluid removalCharge retentionDetonation

The perforation gun is comprised of a tubular carrier, a charge holder, a plurality of sealed charges, and a detonating cord. The tubular carrier has a length and a plurality of openings. The charge holder has a length and is comprised of a plurality of mounting locations which are each capable of receiving one of the sealed charges. The charge holder is capable of being secured within the carrier. The detonating cord is coupled to at least one sealed charge. In the mounted position and when the charge holder is secured within the carrier, the charges are aligned with the openings in the carrier such that, upon detonation, charge blasts emitted from the charges exit though the carrier openings and perforate a well casing and cement. In one aspect of the invention, the carrier openings are spirally arranged and spaced along the length of the carrier. In still another aspect of the invention, the openings are vertically arranged and spaced along the length of the carrier. In still another aspect of the invention, the carrier is closed at the top and bottom. In still another aspect of the invention, the carrier is capable of capturing debris created by a charge blast emitted from the sealed charges.

Owner:VIDAL MIRABEL

Pass-through bulkhead connection switch for a perforating gun

InactiveUS9145764B2Improve pressure resistanceIncrease temperatureOne pole connectionsCoupling device detailsDetonationEngineering

Embodiments of the present invention relate to systems, methods, and apparatus for reliably communicating a detonation signal and perforating oil and / or gas well casings. Particularly, at least one embodiment includes a pass-through bulkhead connection switch that can reliably withstand high operating temperatures and pressures. Such pass-through bulkhead connection switch can be used in perforating gun assemblies and can eliminate or reduce incidents of failed detonations.

Owner:INT STRATEGIC ALLIANCE LC

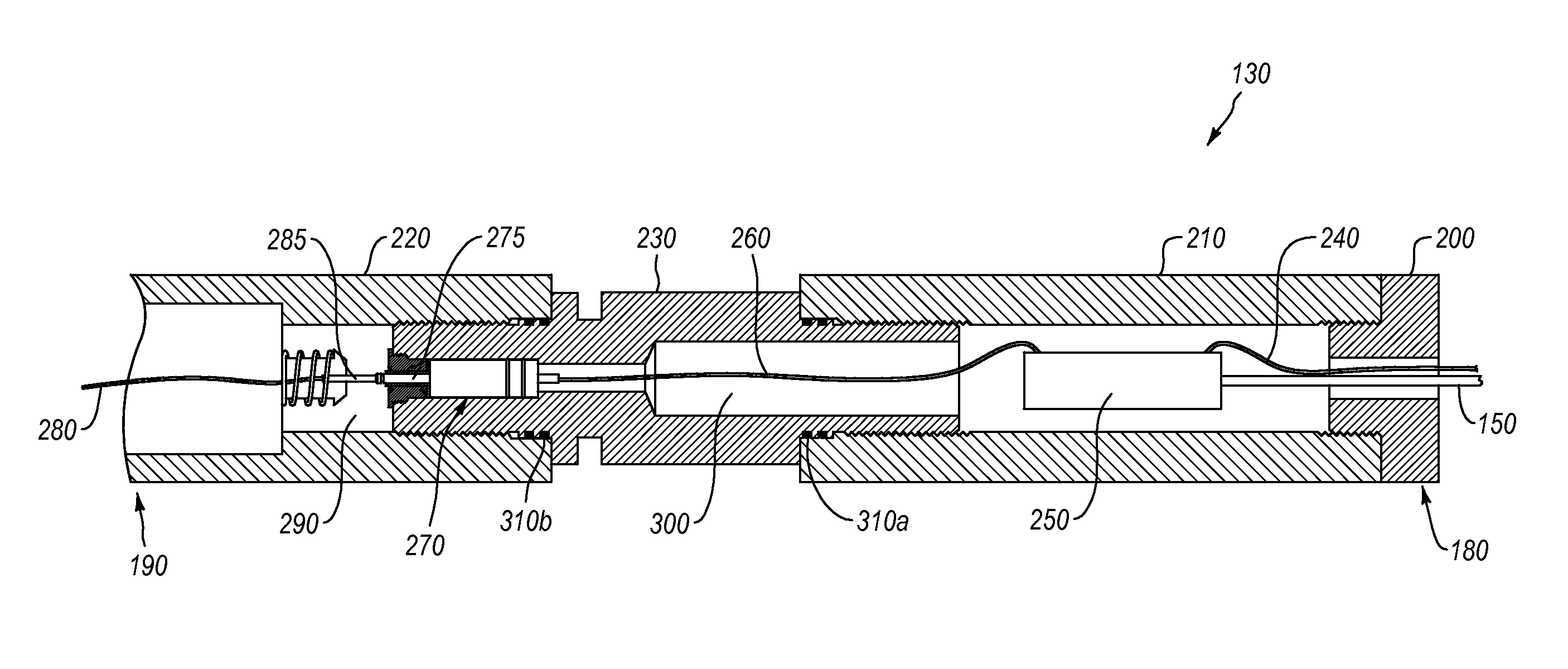

Pressure bulkhead structure with integrated selective electronic switch circuitry, pressure-isolating enclosure containing such selective electronic switch circuitry, and methods of making such

ActiveUS20180299239A1Easily employedEasy to placeCasings/cabinets/drawers detailsFluid removalInternal pressureElectricity

Pressure-isolating bulkhead structures with integrated selective electronic switches circuitry are provided. The pressure-isolating bulkhead structure may be a single unit having the integrated electronic switch circuitry, as well as an electrical connector that includes at least one of a wire and a pin contact. Such integrated selective electronic switch circuitry may be fashioned within a self-contained, inner pressure-isolating enclosure body. Such inner pressure-isolating enclosure body may be produced about the selective electronic switch circuitry such that the inner pressure-isolating enclosure body and switch circuitry are produced as a unit, which can be easily placed within a variety of bulkhead structures, and subsequently within a perforating gun.

Owner:DYNAENERGETICS

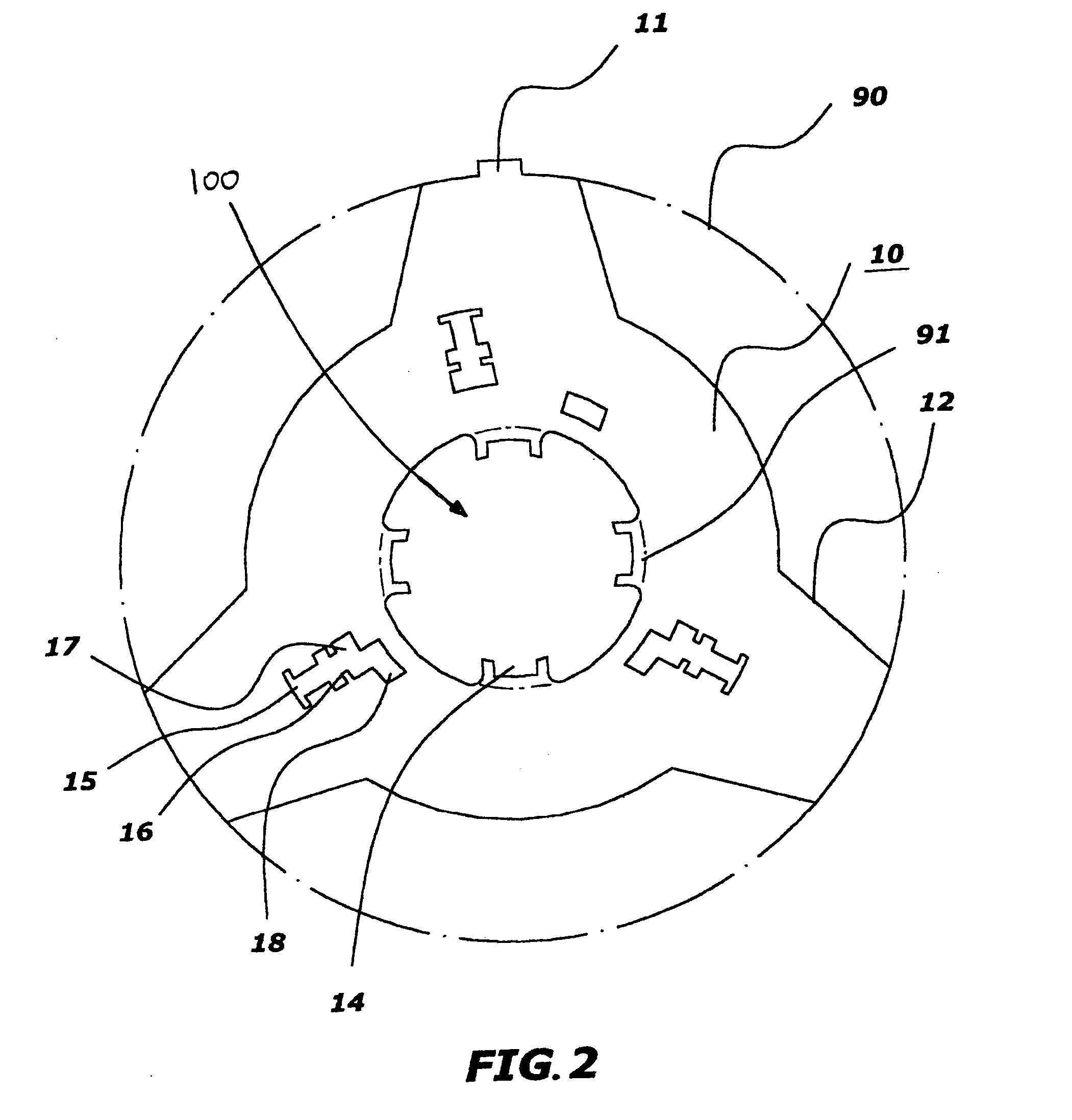

Charge tube end plate

An end plate for securing and orienting a charge tube within a downhole-perforating gun. The end plate includes apertures for receiving locating tabs on the end of the charge tube to ensure the end plate is affixed to the charge tube in a specific orientation. The end plate includes an alignment tab that mates with a corresponding alignment groove in the perforating gun barrel for ensuring insertion of the charge tube into the perforating gun barrel in correct orientation to ensure the perforating charges exit through pre-designed scallops in the perforating gun barrel. A series of apertures may be present within the end plate to allow usage with one of a variety of sizes of charge tube. The end plate may include manipulation spaces along the circumference of the end plate to allow the end plate to be properly positioned or retrieved. The end plate may include an attachment system for attachment of an initiating device.

Owner:NEVES JOHN ANTHONY

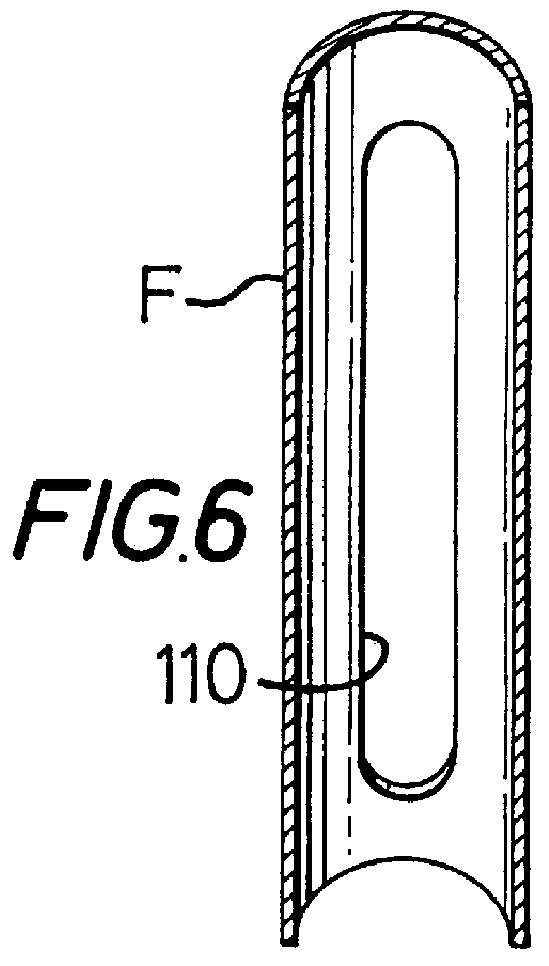

Wireless electronic booster, and methods of blasting

Disclosed herein are boosters that include components sufficient for wireless communications with an associated blasting machine. In selected aspects, there are disclosed wireless electronic boosters that are self-contained and robust. Such boosters are especially suited for underground mining operations, optionally employing automated placement of boosters at a blast site.

Owner:ORICA EXPLOSIVES TECH PTY LTD

Bulkhead assembly having a pivotable electric contact component and integrated ground apparatus

According to an aspect a bulkhead assembly is provided having particular application with a downhole tool, in particular for oil well drilling applications. The bulkhead assembly includes a bulkhead body and an electrical contact component disposed within the bulkhead body, wherein at least a portion of the electrical contact component is configured to pivot about its own axis, without compromising its ability to provide a pressure and fluid barrier. In an embodiment, a ground apparatus is provided to provide an electrical connection for at least one ground wire. The ground apparatus may be positionable on the bulkhead body of the bulkhead assembly. In an aspect, a downhole tool including the bulkhead assembly and ground apparatus is also generally described.

Owner:DYNAENERGETICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com