Patents

Literature

527results about "Detonators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-toxic, heavy-metal free sensitized explosive percussion primers and methods of preparing the same

ActiveUS8206522B2Metal azide explosive compositionsMetal fulminate explosive compositionsEngineeringOxidizing agent

A non-toxic, non-hydroscopic percussion primer composition and methods of preparing the same, including at least one explosive component that has been traditionally considered a moderately insensitive explosive or secondary explosive, and at least fuel particle component having a particle size of about 1.5 microns to about 12 microns, which allows the use of moderately active metal oxidizers. The sensitivity of the primer composition is created by the interaction between the moderately insensitive explosive and the fuel agent such that traditional primary explosives such as lead styphnate or DDNP are not needed. The primer composition also eliminates the risks and dangers associated with traditional nano-sized fuel particles.

Owner:FEDERAL CARTRIDGE

Nontoxic, noncorrosive phosphorus-based primer compositions and an ordnance element including the same

A primer composition that includes red phosphorus having an acid scavenger and a polymer thereon. The primer composition includes at least one other component that is substantially free of lead. The other component is at least one oxidizer, or at least one oxidizer and at least one of at least one secondary explosive composition and at least one energetic binder. The primer composition optionally includes at least one element having an ionic charge to ionic radius ratio of 4 or of 8, such as magnesium, zirconium, aluminum, silicon, titanium, tungsten, alloys thereof, and combinations thereof. The red phosphorus and the at least one oxidizer are present in the primer composition at approximately stoichiometric amounts. An ordnance element including the primer composition is also disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

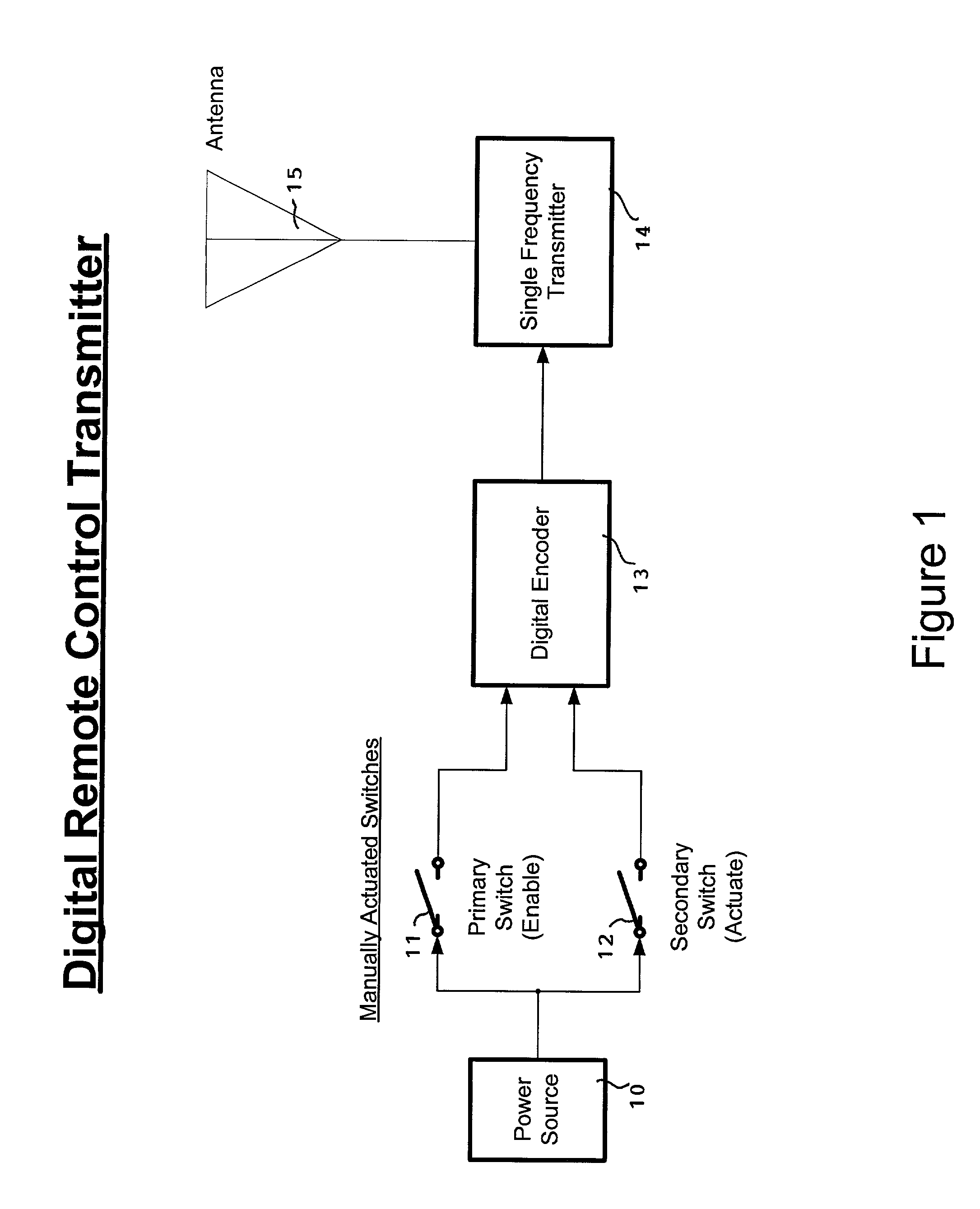

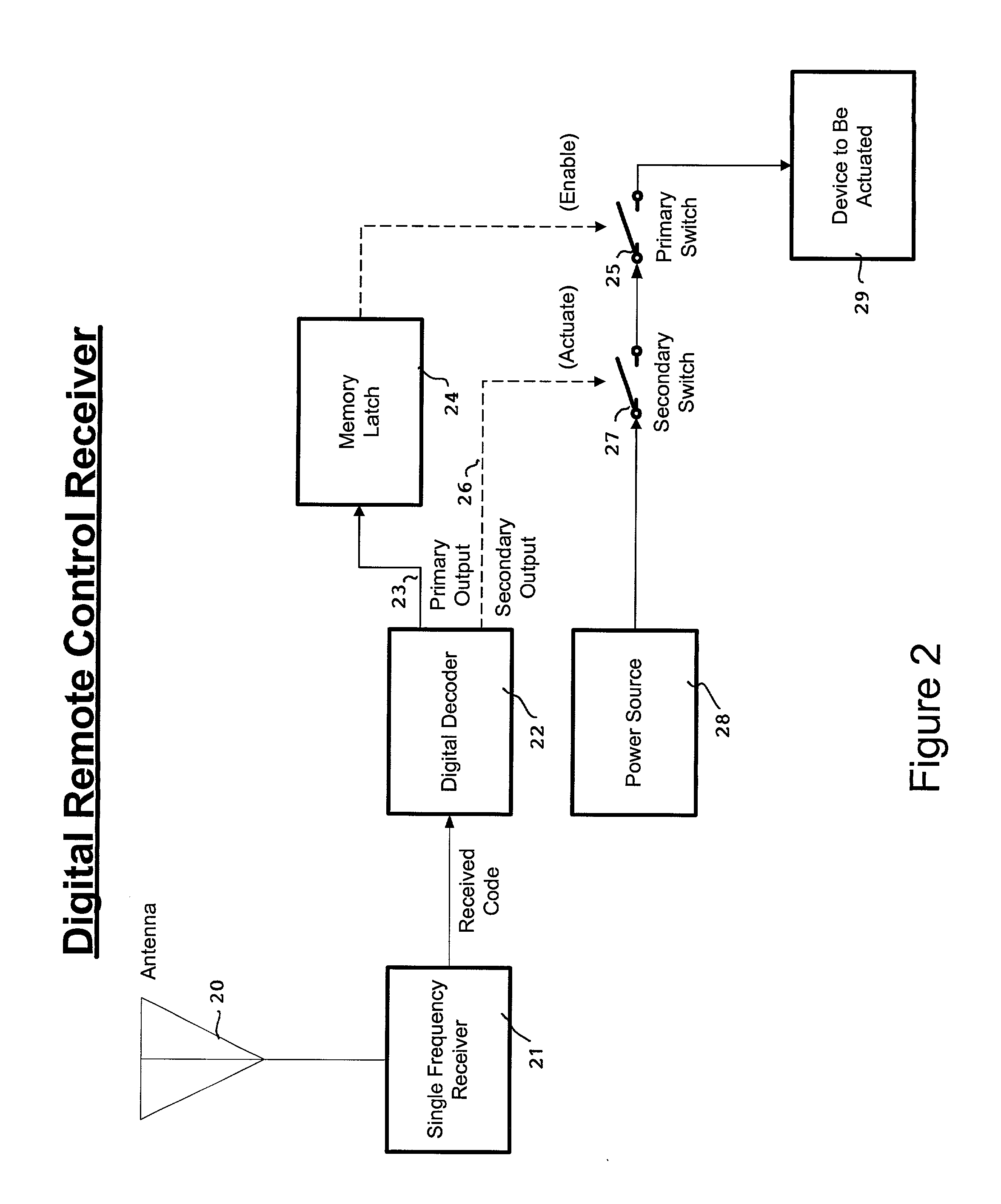

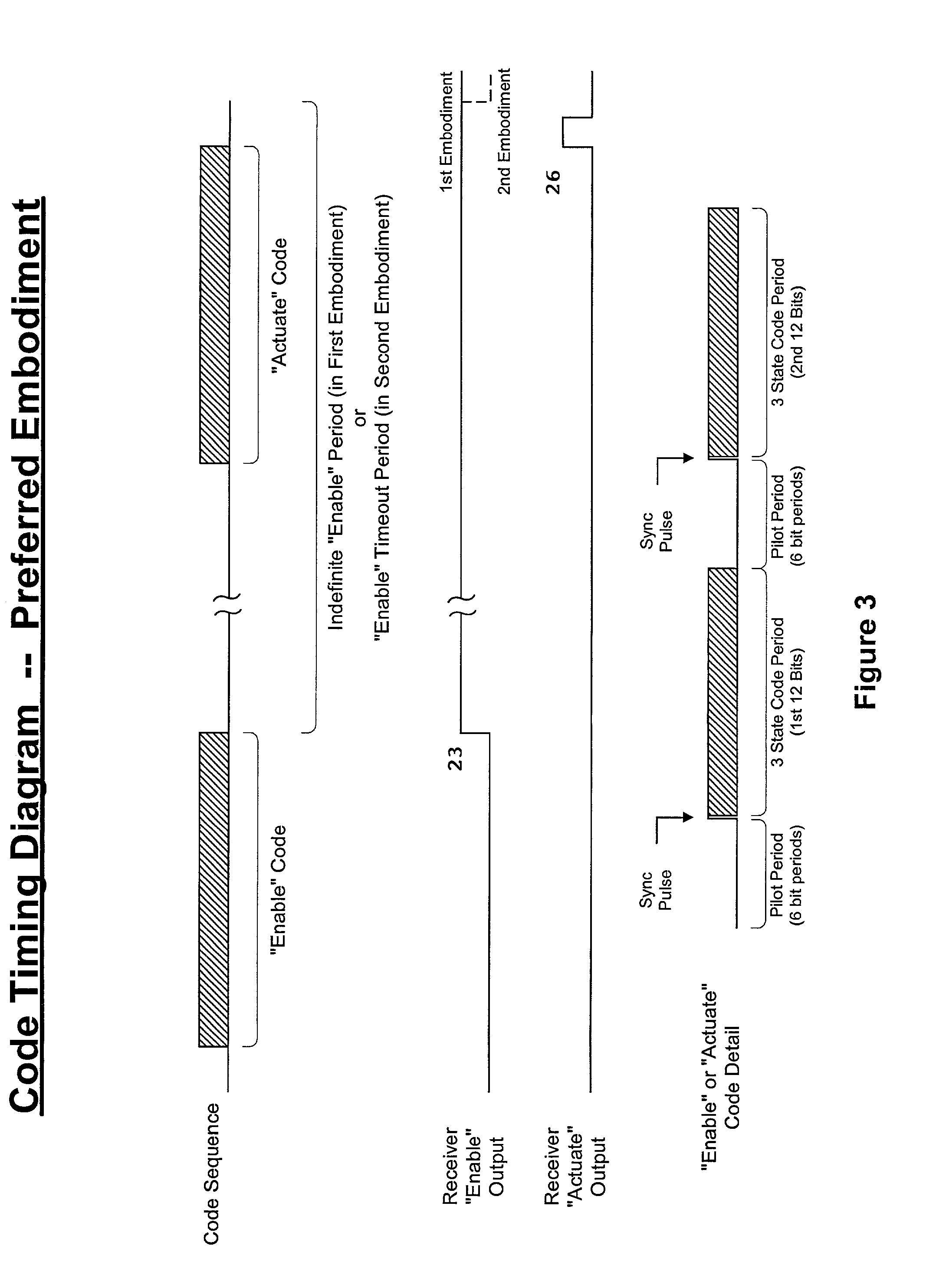

Wireless digital launch or firing system

InactiveUS20010045883A1Simple configurationSaving assemblyProgramme controlElectric signal transmission systemsComputer scienceTransmitter

A wireless digital launch or firing system has a transmitter unit that can transmit separate RF signals representing an "enable" code sequence and an "actuate" code sequence, and a receiver unit which decodes the "enable" code sequence to enable receipt of the "actuate" code sequence, and decodes the "actuate" code sequence to actuate launching or firing. A digital processor receives the code sequences from a receiver circuit and compares them to stored digital code sequences. A memory latch maintains a normally-off primary switch in an "on" condition when the "enable" signal is received. A normally-off secondary switch is set to an "on" condition when the "actuate" signal is received. Preferably, the RF signals are transmitted in pulse code form, and the code sequences include bits that are predetermined and stored in the hardware, bits that are selected for an individual code by the user, and bits that differentiate the "enable" from the "actuate" signal. The memory latch can be set to an indefinite "enable" period, for multiple launchings, or a timed "enable" period, for toys or single launch devices. A sequencer module can be coupled to the receiver unit for sequenced firings.

Owner:HOLDAWAY CHARLES R +1

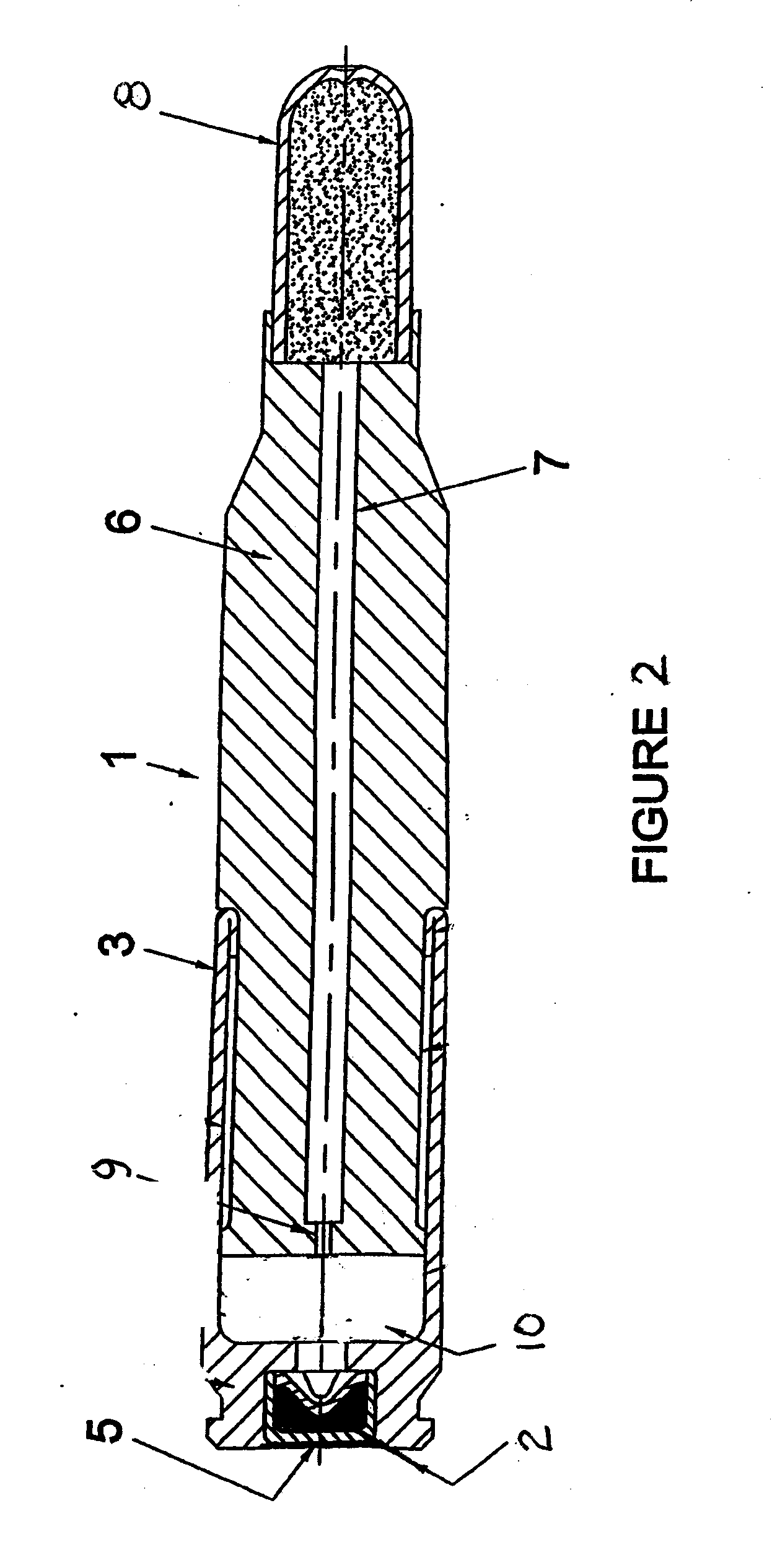

Thermal generator for downhole tools and methods of igniting and assembly

InactiveUS6925937B2Incandescent ignitionFluid removalElectricityElectrical resistance and conductance

Owner:ROBERTSON MICHAEL C

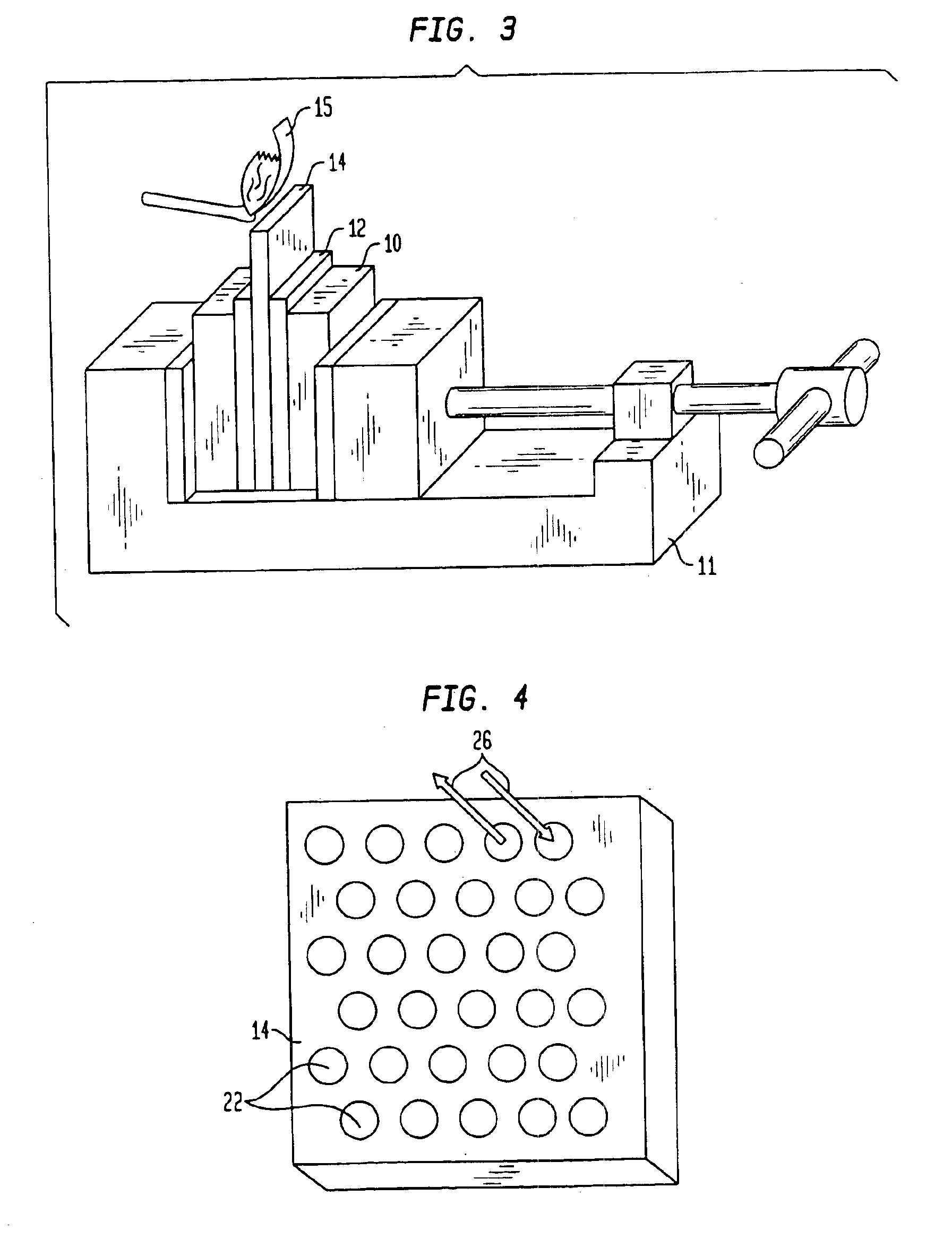

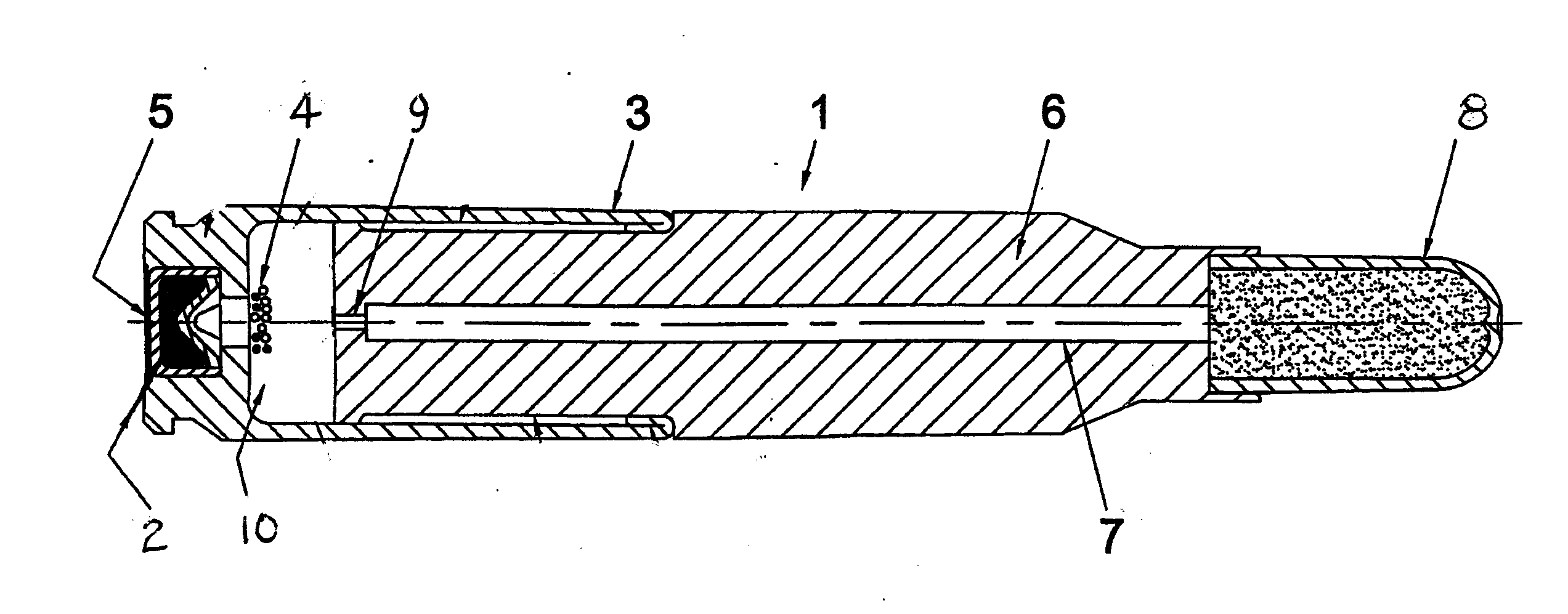

Composite reactive multilayer foil

InactiveUS6863992B2Increase heatFast bondingExothermal chemical reaction heat productionVacuum evaporation coatingThermal energyRoom temperature

Reactive foils and their uses are provided as localized heat sources useful, for example, in ignition, joining and propulsion. An improved reactive foil is preferably a freestanding multilayered foil structure made up of alternating layers selected from materials that will react with one another in an exothermic and self-propagating reaction. Upon reacting, this foil supplies highly localized heat energy that may be applied, for example, to joining layers, or directly to bulk materials that are to be joined. This foil heat-source allows rapid bonding to occur at room temperature in virtually any environment (e.g., air, vacuum, water, etc.). If a joining material is used, the foil reaction will supply enough heat to melt the joining materials, which upon cooling will form a strong bond, joining two or more bulk materials.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Low toxicity primer compositions for reduced energy ammunition

InactiveUS20100300319A1Increased heat generationHigh sensitivityAmmunition projectilesShotgun ammunitionToxic materialOxidizing agent

A primer composition with reduced toxicity suited for reduced-energy ammunition comprises bismuth (III) oxide as the principal oxidizer and contains a portion of propellant composition mixed therein. This composition may also be used in a cartridge which is otherwise substantially free of any other propellant compound and preferably produces a residue which is substantially free of toxic substances.

Owner:GENERAL DYNAMICS ORDNANCE & TACTICAL SYST CANADA VALLEYFIELD INC

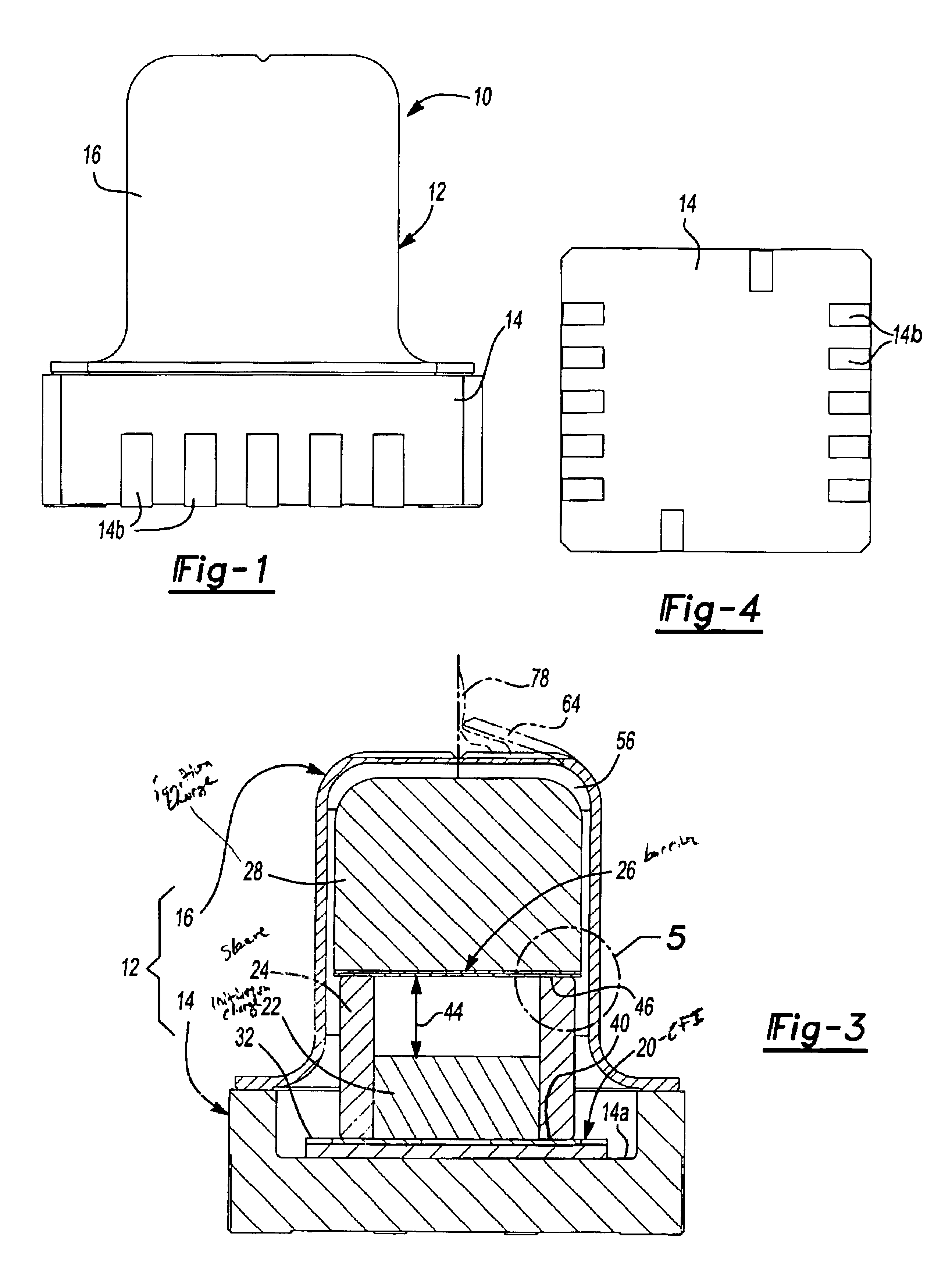

Assemblies including extendable, reactive charge-containing actuator devices

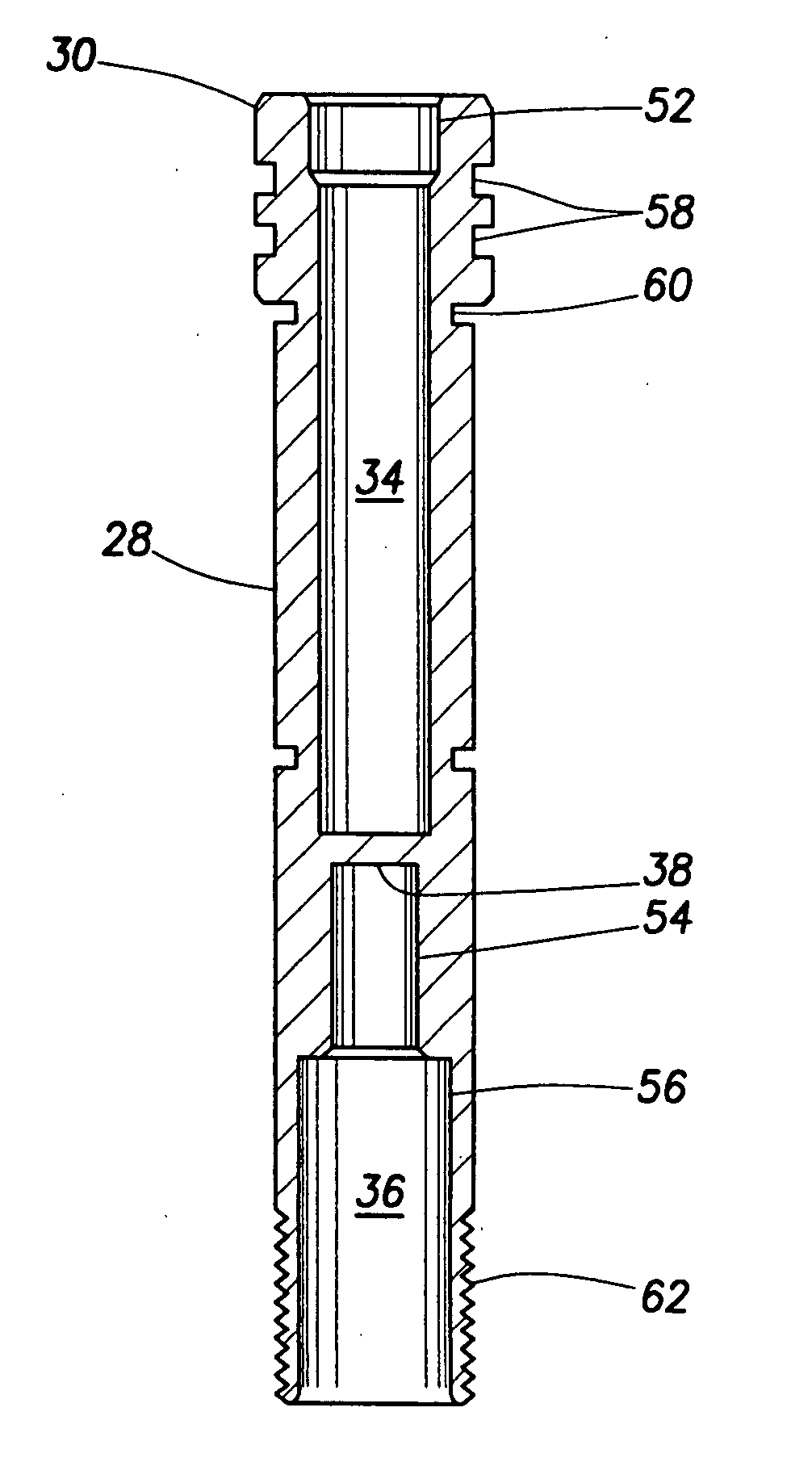

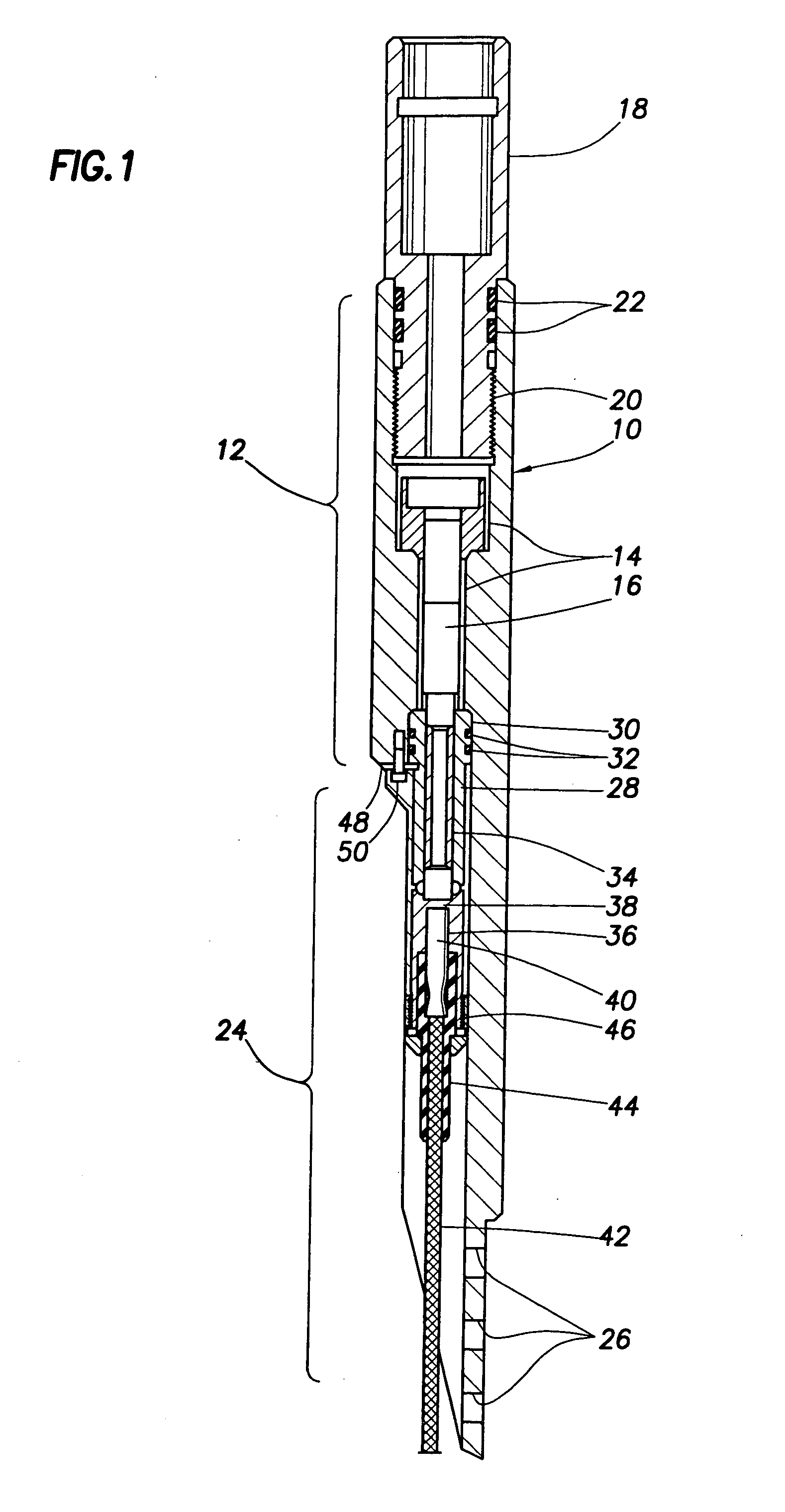

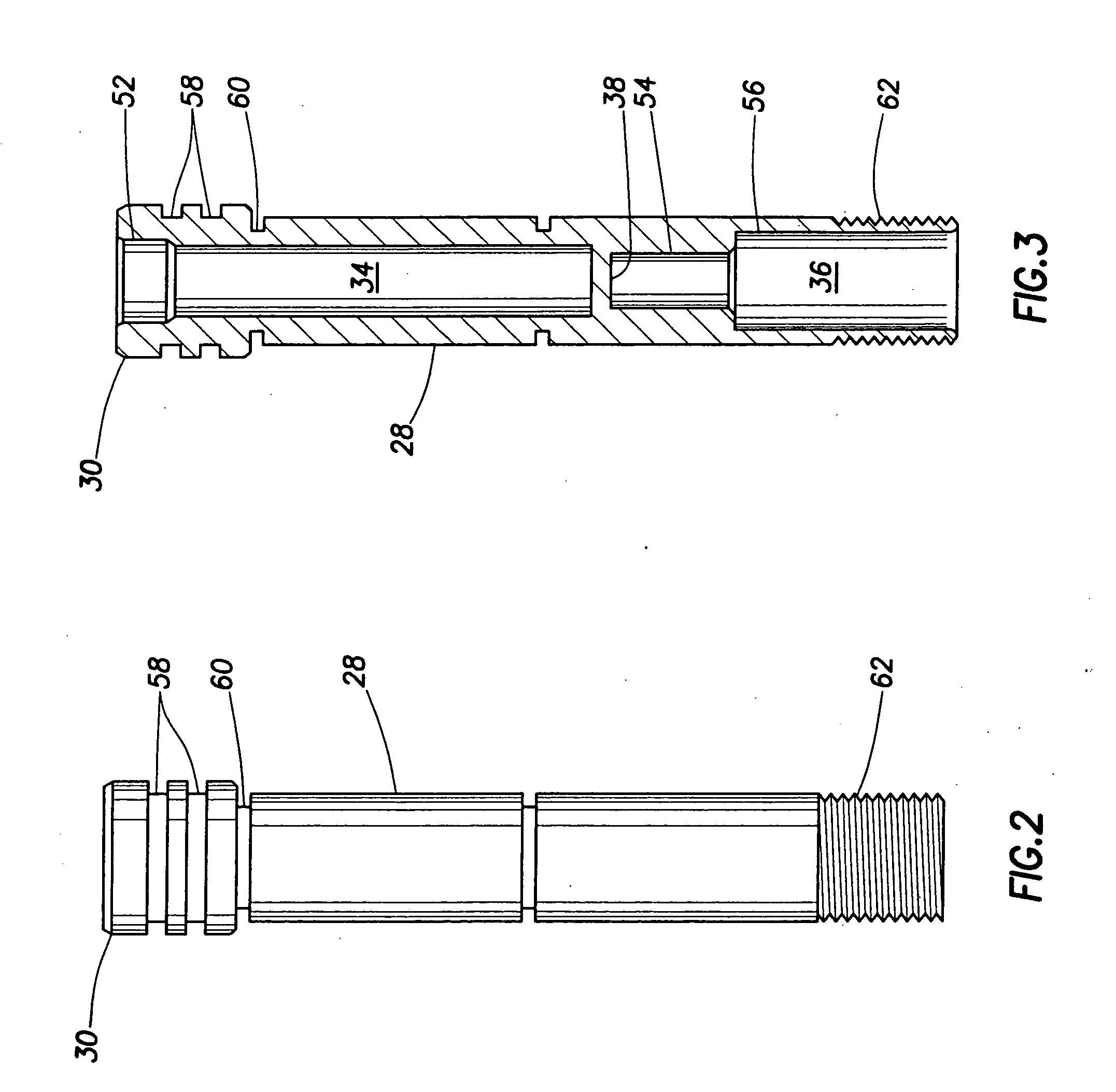

InactiveUS7063019B2Maximal work performanceAvoid breakingIncandescent ignitionPyrotechnical actuatorsElectricityActuator

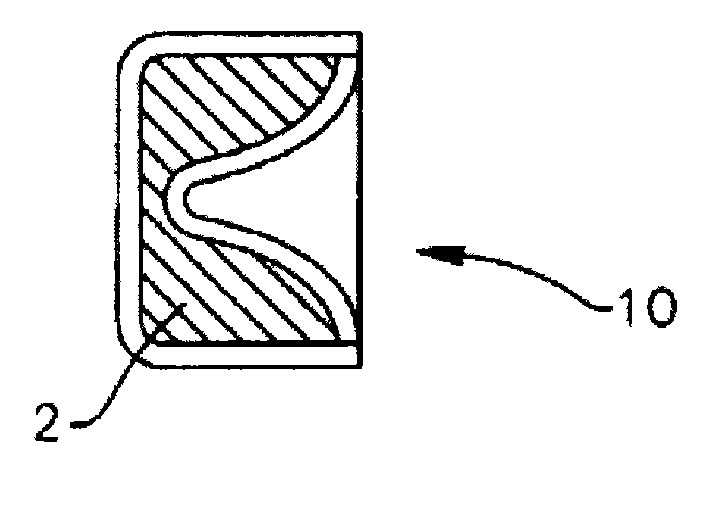

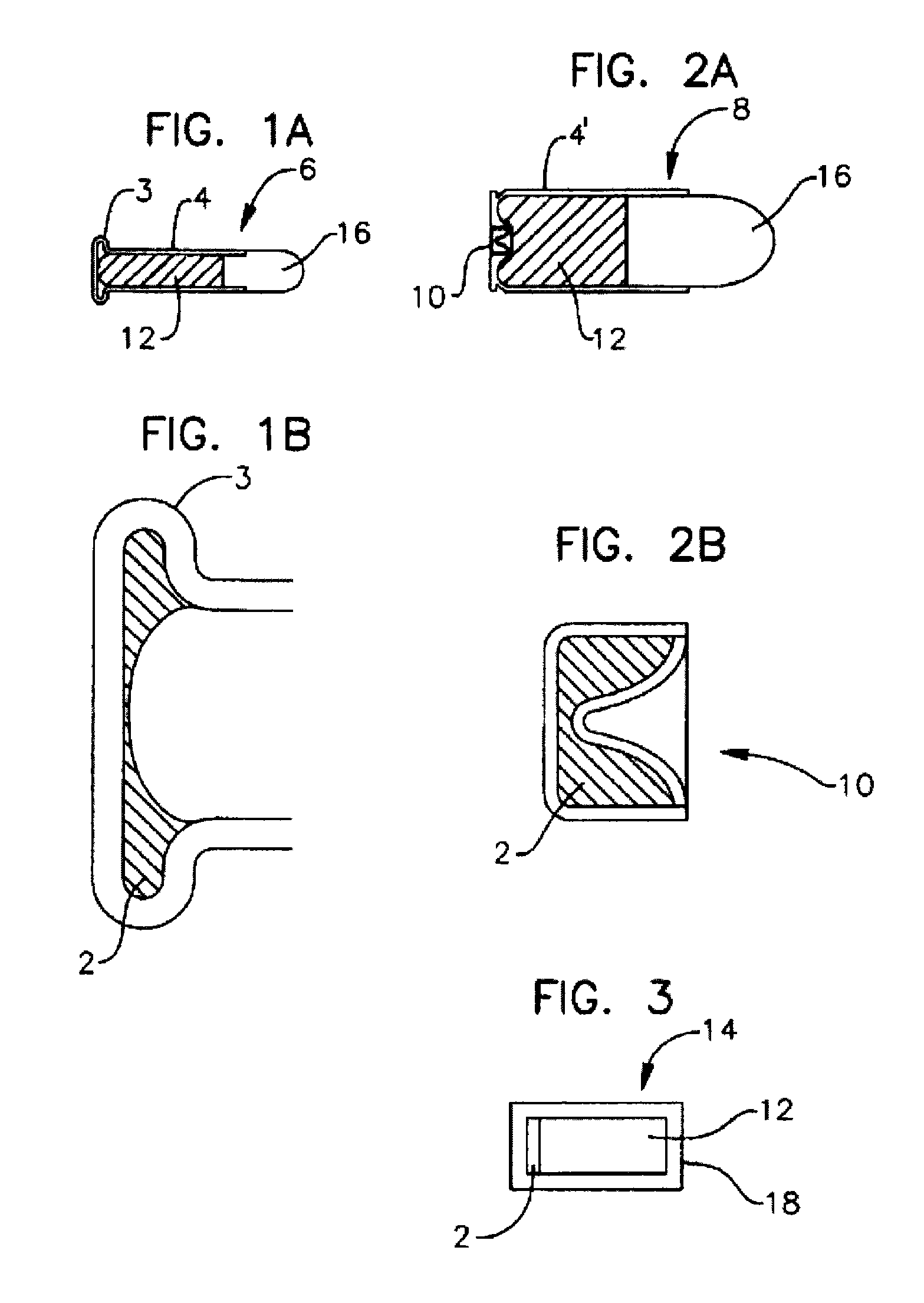

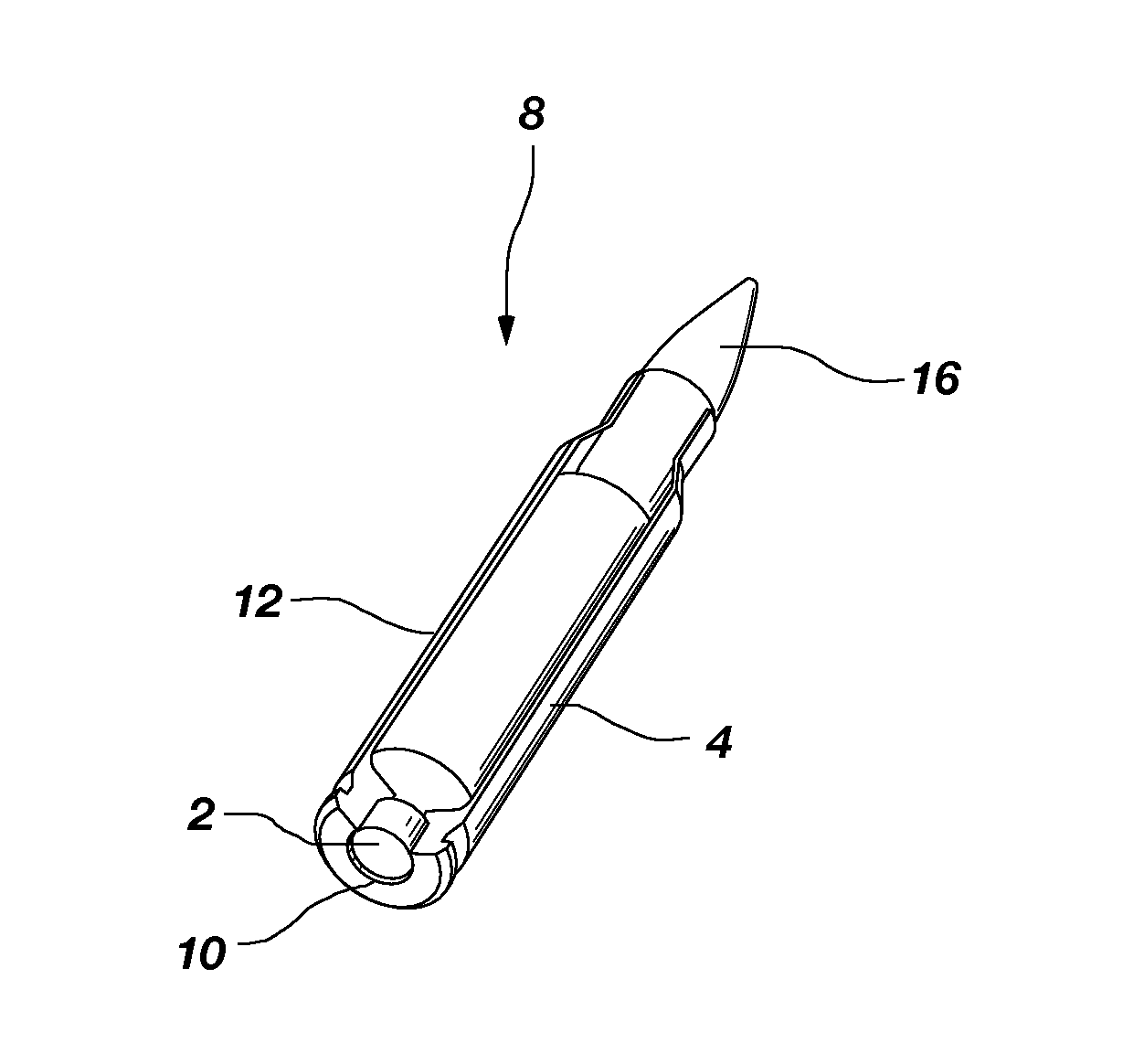

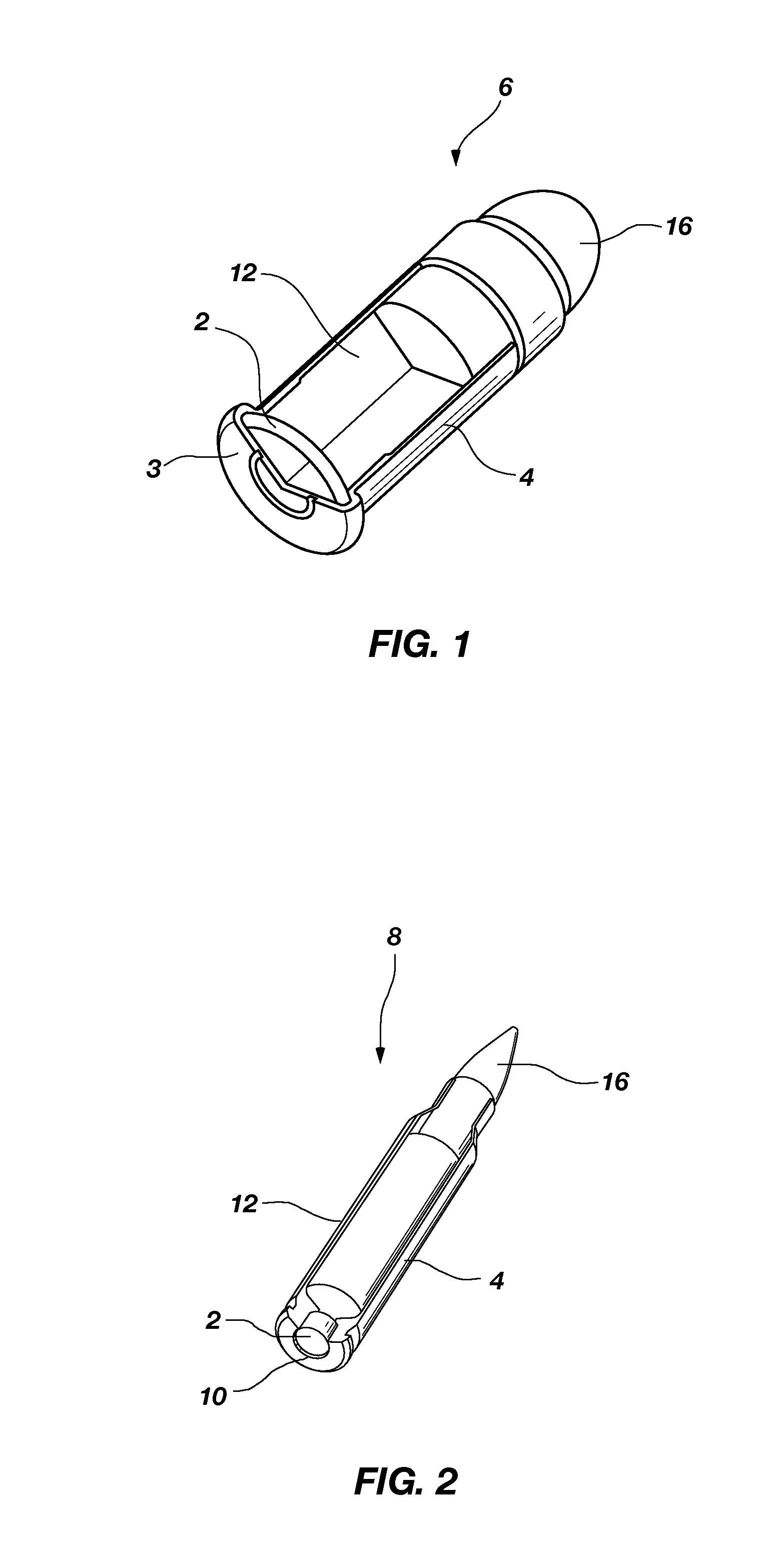

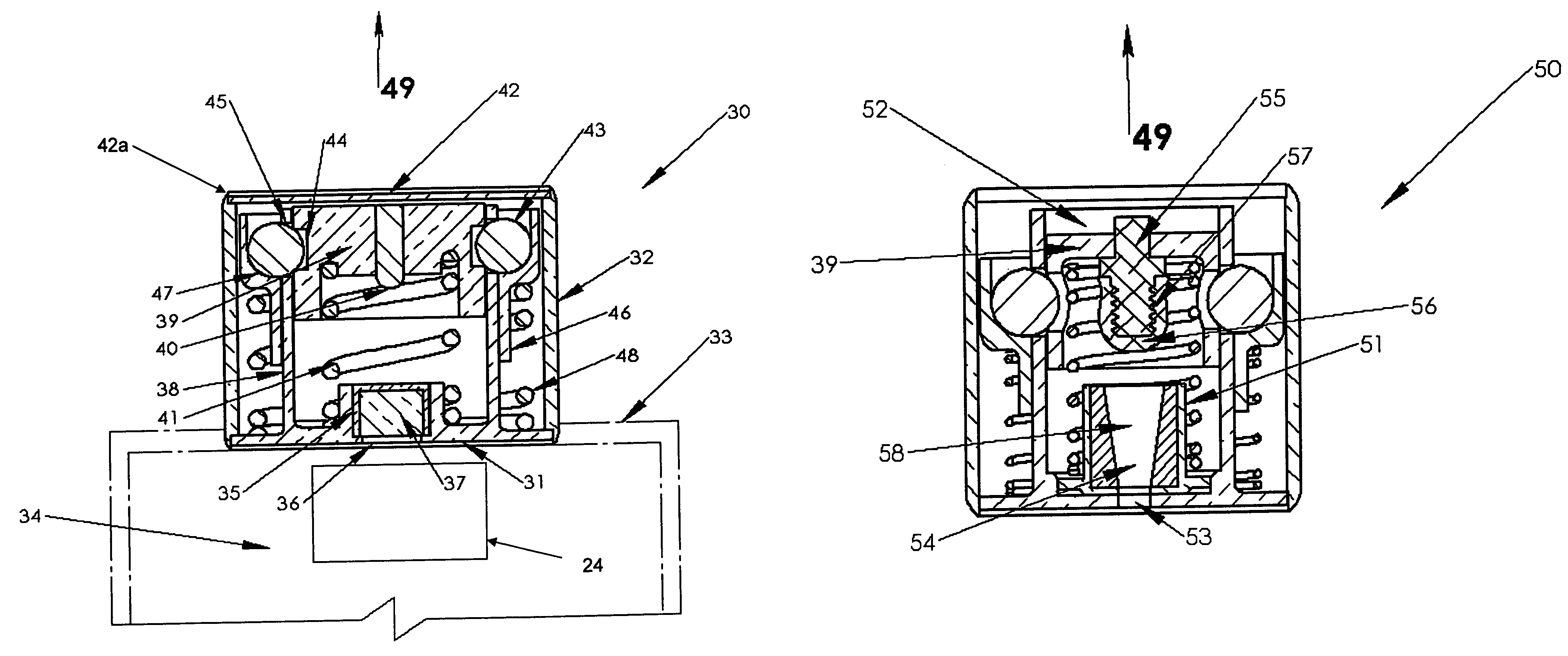

An assembly including a support housing and an actuator device. The actuator device includes an extendable initiator cup including at least one non-random fold and at least in part defining a storage chamber containing a reactive charge reactable to produce reaction products. The extendable initiator cup longitudinally extends from a first length to a second, greater length upon reaction initiation of the reactive charge. The extendable initiator cup is at least partially disposed within a longitudinally extending bore of the support housing. The support housing is effective to limit lateral expansion of the extendable initiator cup upon reaction initiation of the reactive charge. The assembly can include an electrical conductive member or an electrical switch. The extendable initiator cup can extend to sever the electrical conductive member or disengage the electrical switch, thereby interrupting the conduction of electricity through an electrical system. Alternatively, the extendable initiator cup can extend to engage the electrical switch thereby allowing the conduction of electricity through an electrical system.

Owner:AUTOLIV ASP INC

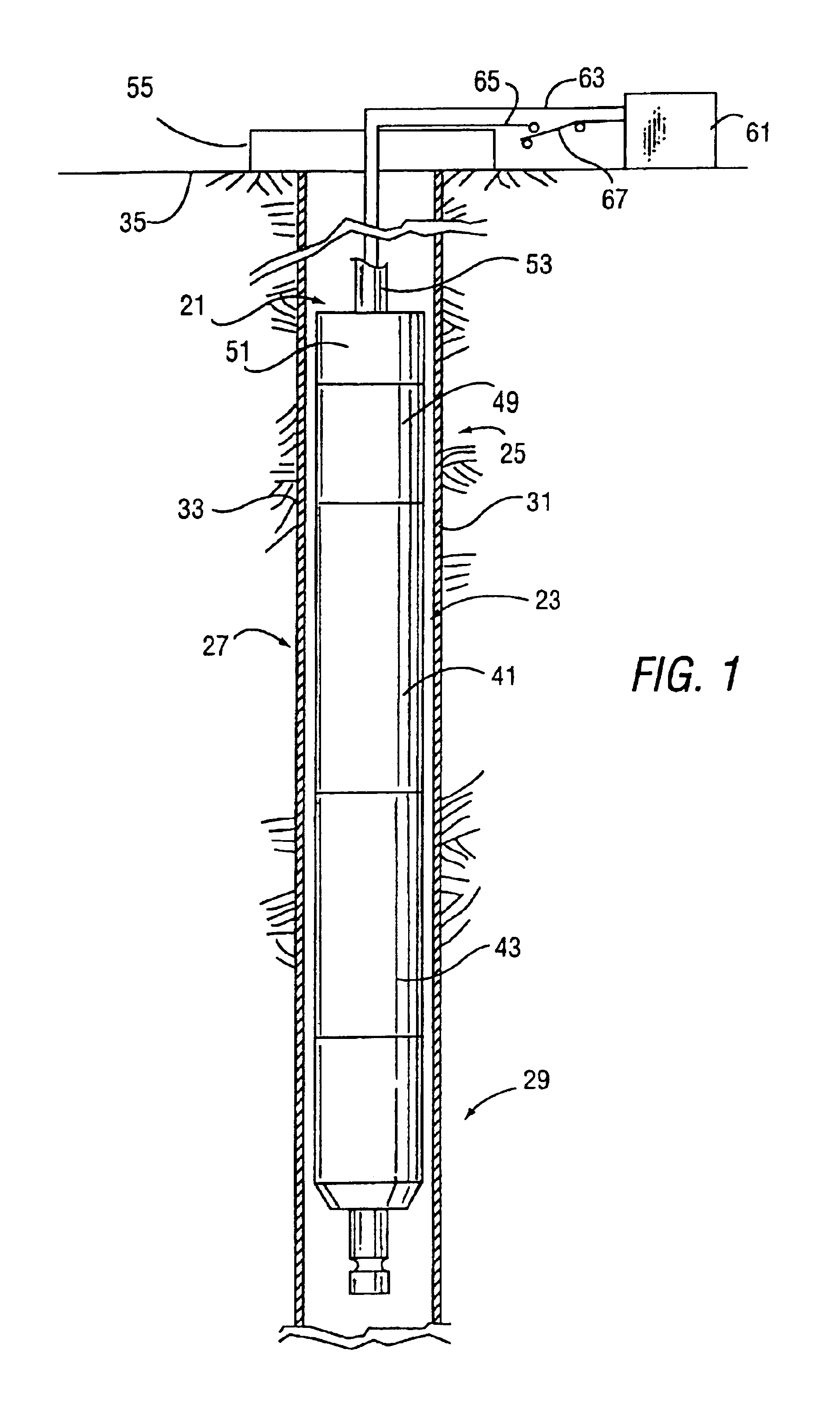

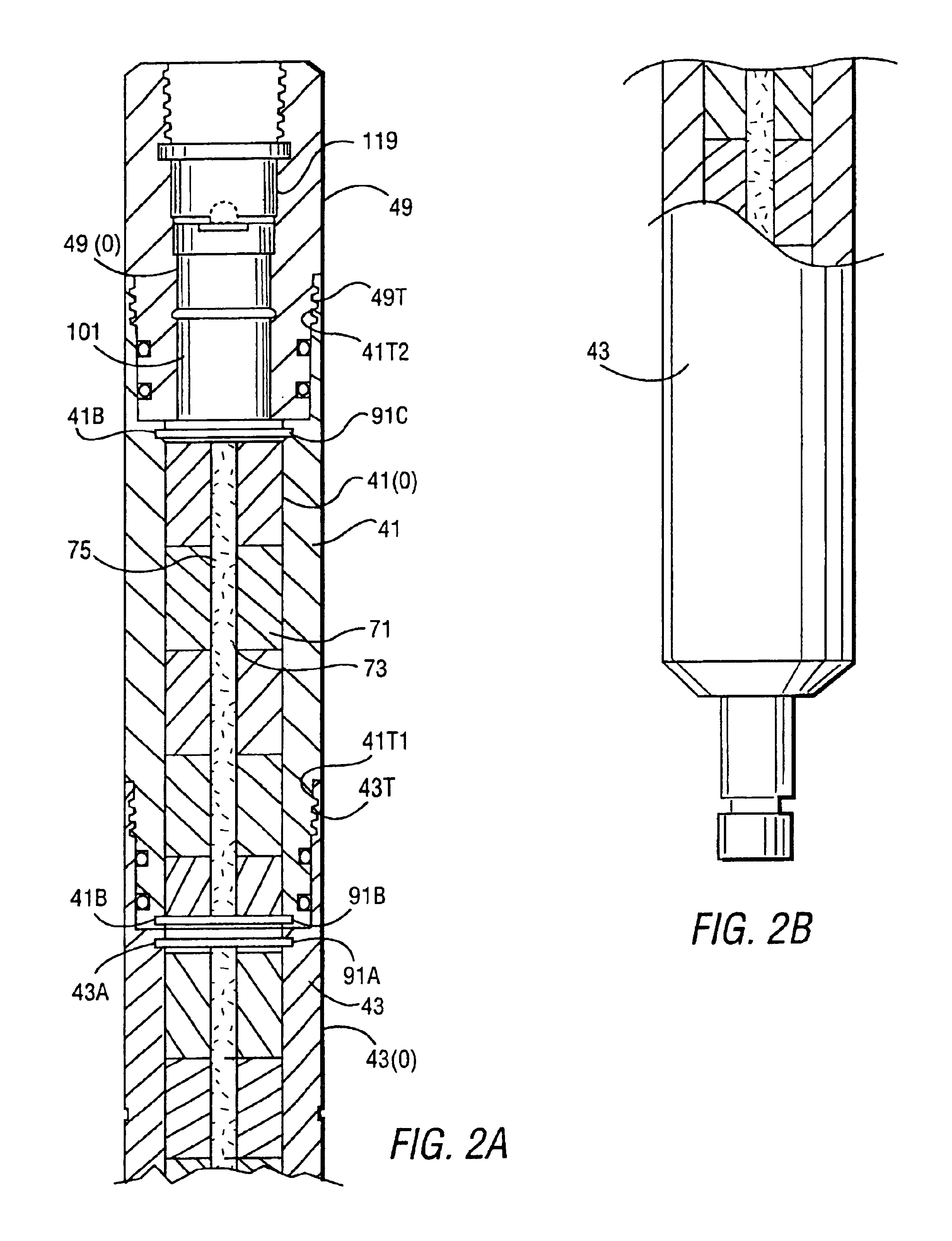

High pressure exposed detonating cord detonator system

A detonator system for borehole systems which include detonating cord exposed to borehole fluids, pressures and temperatures. A firing head has a sealed chamber for an electrically fired detonator and has a booster charge holder forming part of the seal. The chamber is sealed by a wire line firing sub and by the booster holder. The charge holder includes a bulkhead separating the detonator chamber from a booster charge chamber and providing part of the detonator chamber seal. The detonator explosive and the booster charge are positioned on opposite sides of the bulkhead so that upon detonation of the detonator, the bulkhead is ruptured and the explosion transfers to the booster charge and from it to the detonating cord. The firing head includes holes for attachment of borehole tools such as perforating guns or back off tools to be fired by the detonating cord.

Owner:HALLIBURTON ENERGY SERVICES INC

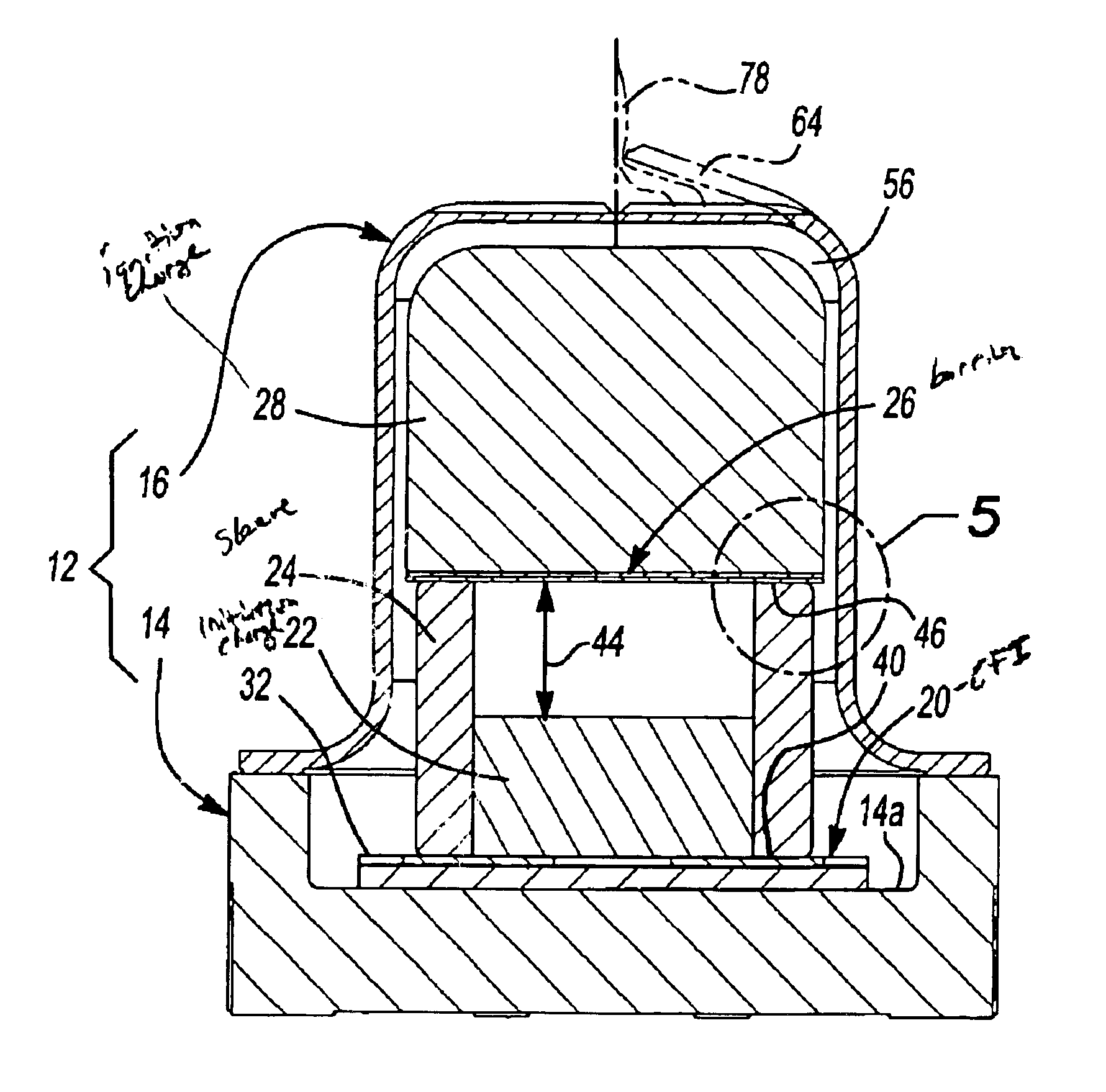

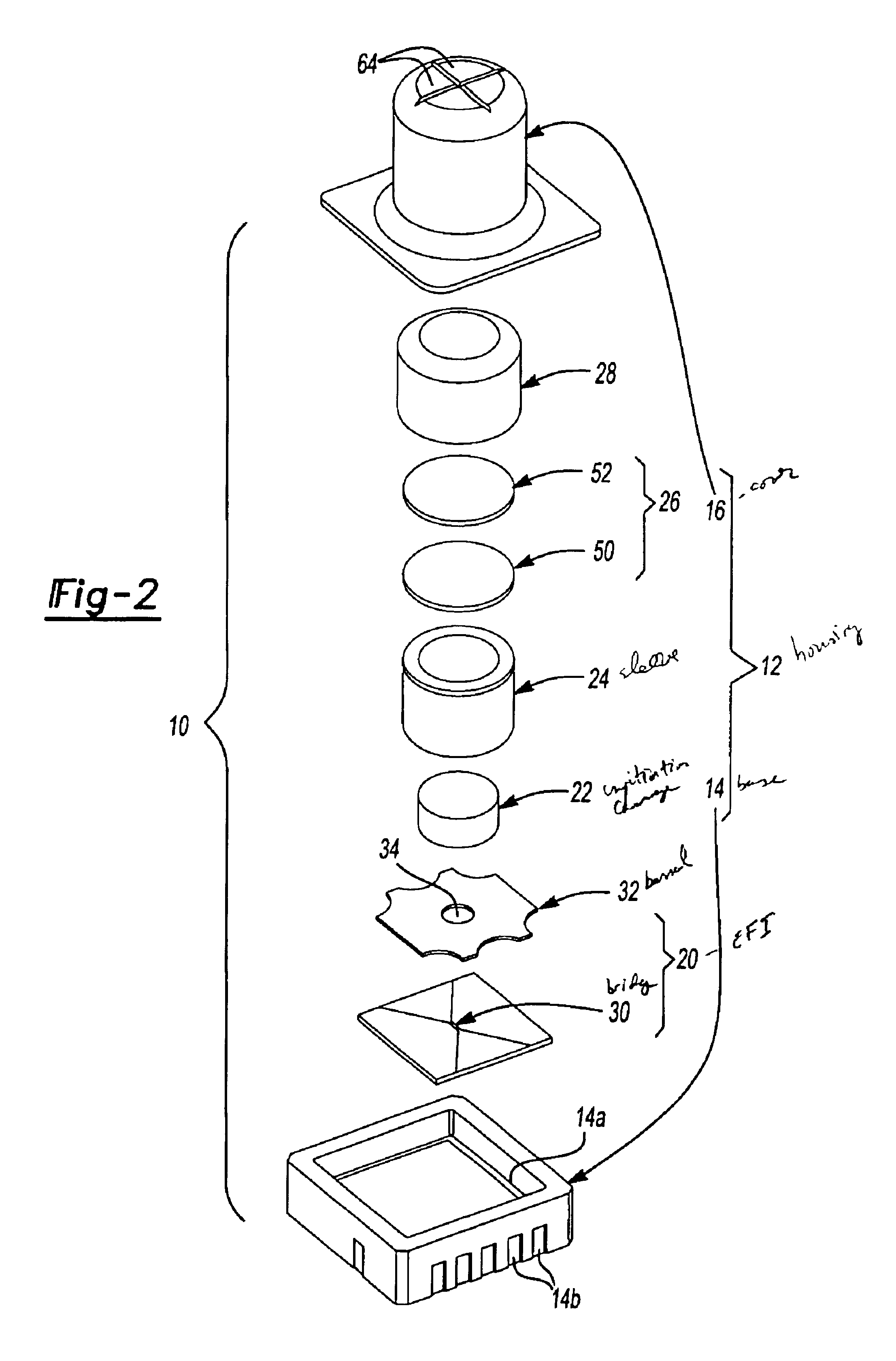

Energetic material initiation device utilizing exploding foil initiated ignition system with secondary explosive material

A device and method that employs a detonation event as an energy source for producing a pyrotechnic output. The device includes an initiation charge that is selectively detonated by an exploding foil initiator. Byproducts from the detonation event are attenuated by a barrier that is disposed between the initiation charge and an ignition charge. The barrier participates in a chemical reaction with the detonation byproducts to oxidize and burn. In this regard, the barrier serves as a fuel that is employed to ignite the ignition charge. The device includes a sealed housing in which the initiator, initiation charge and ignition charges are housed. The housing ruptures in response to the heat and pressure generated by the ignited ignition charge to release the pyrotechnic output.

Owner:REYNOLDS SYST

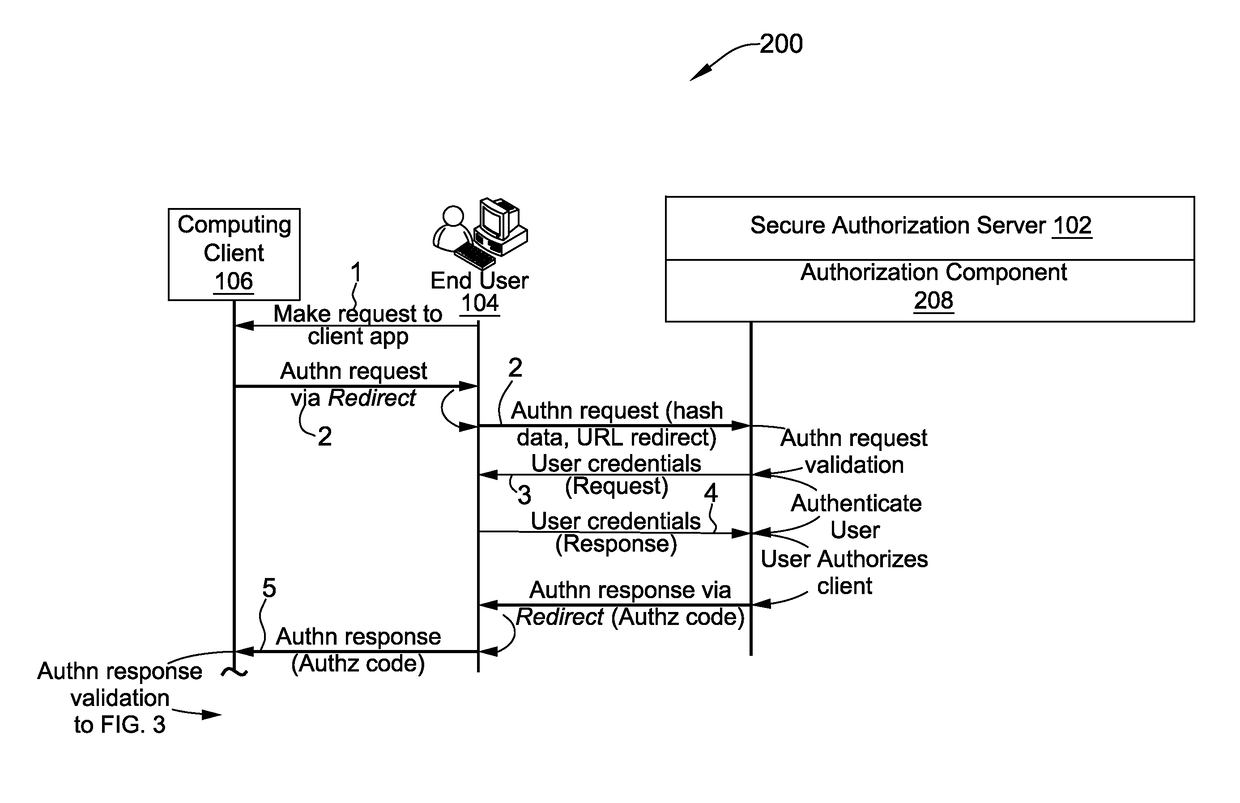

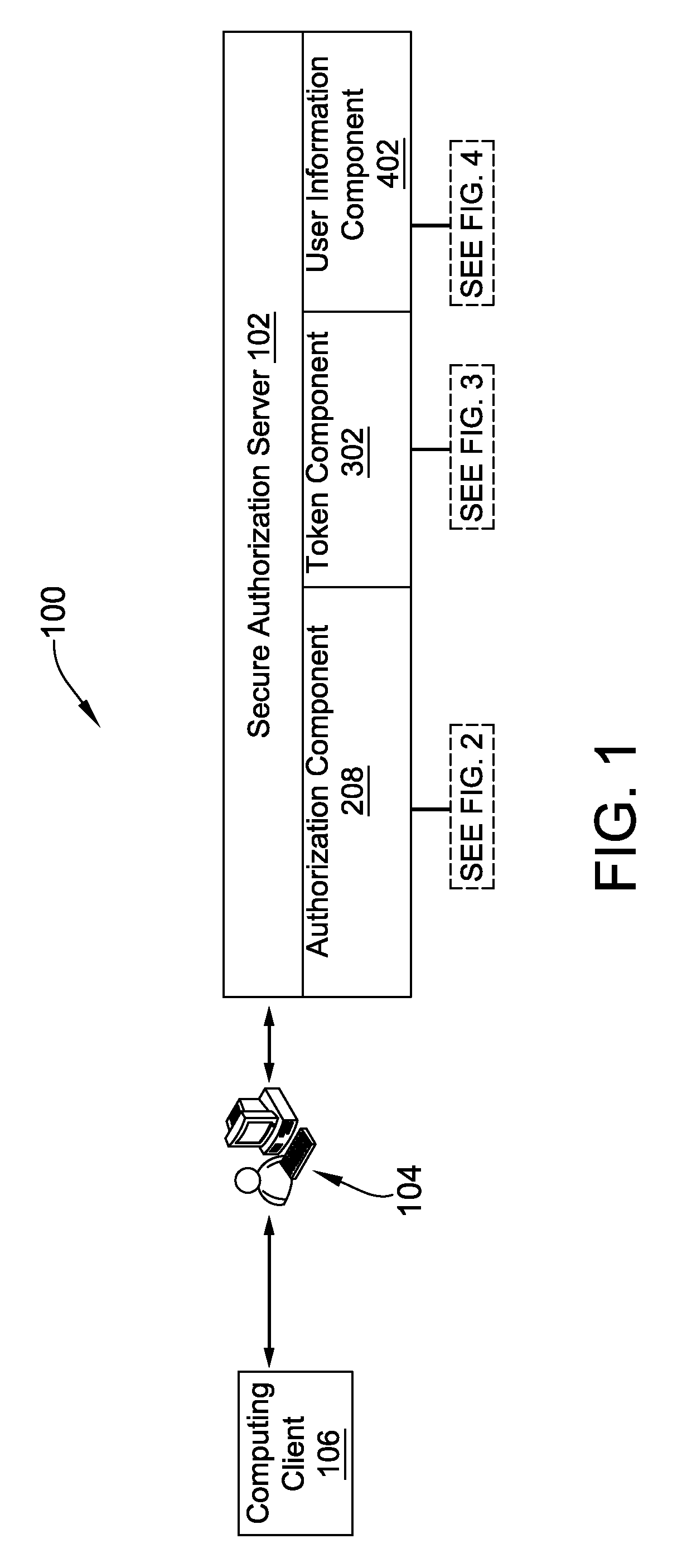

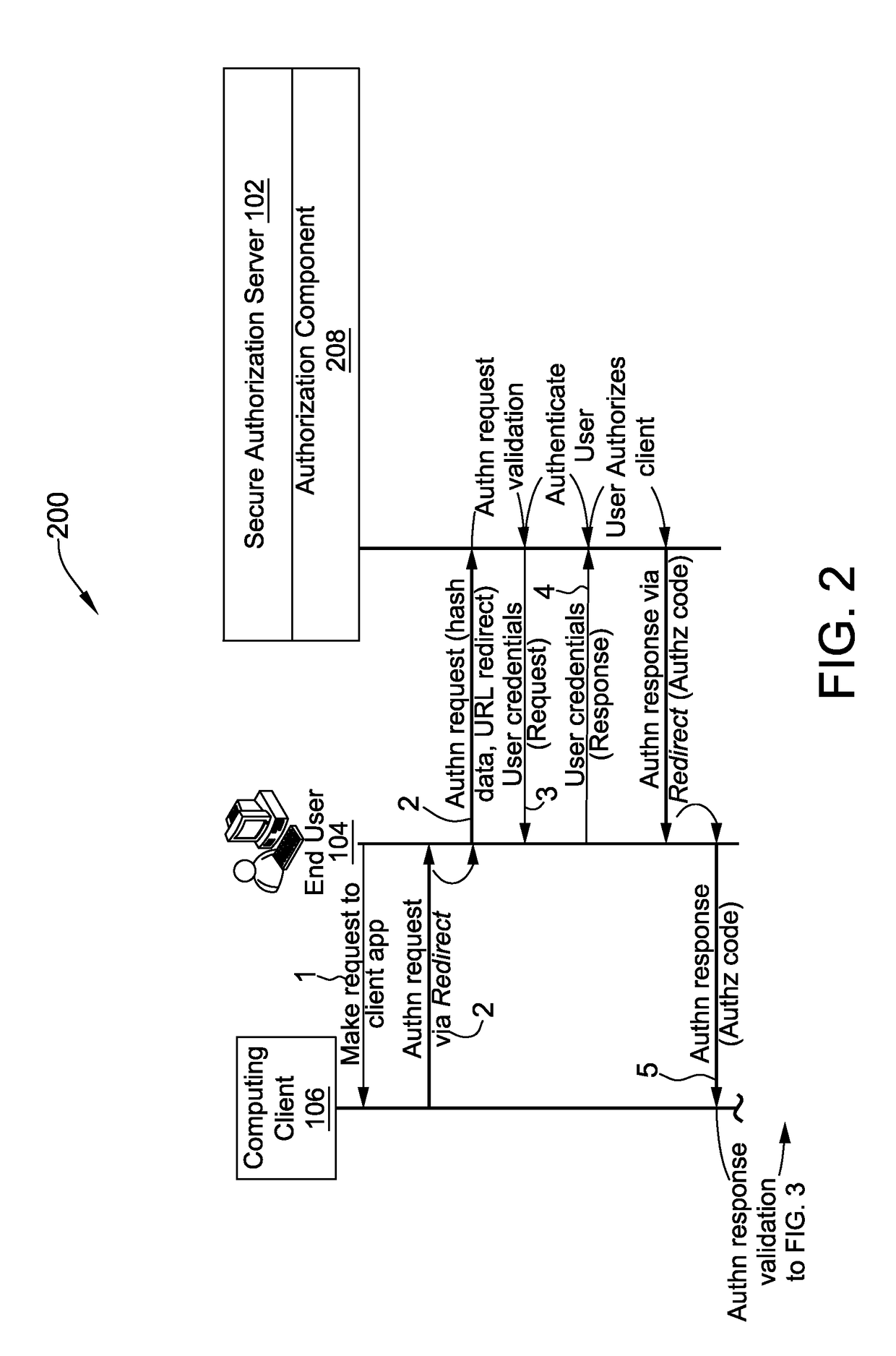

Systems and Methods for Authenticating an Online User Using a Secure Authorization Server

ActiveUS20170142108A1Computer security arrangementsNitrated aromatic explosive compositionsComputerized systemClient-side

A secure authorization server computer system for verifying an identity of an end-user is provided. The computer system is programmed to receive, from a computing client, an authentication request at an authorization component. The authentication request includes a secure authentication request identifier. The computer system is also programmed to validate the authentication request at the authorization component by validating the secure authentication request identifier. The computer system is further programmed to transmit an authentication response from the authorization component to the computing client. The authentication response includes an authorization code. The authorization code represents a validation of the authentication request.

Owner:MASTERCARD INT INC

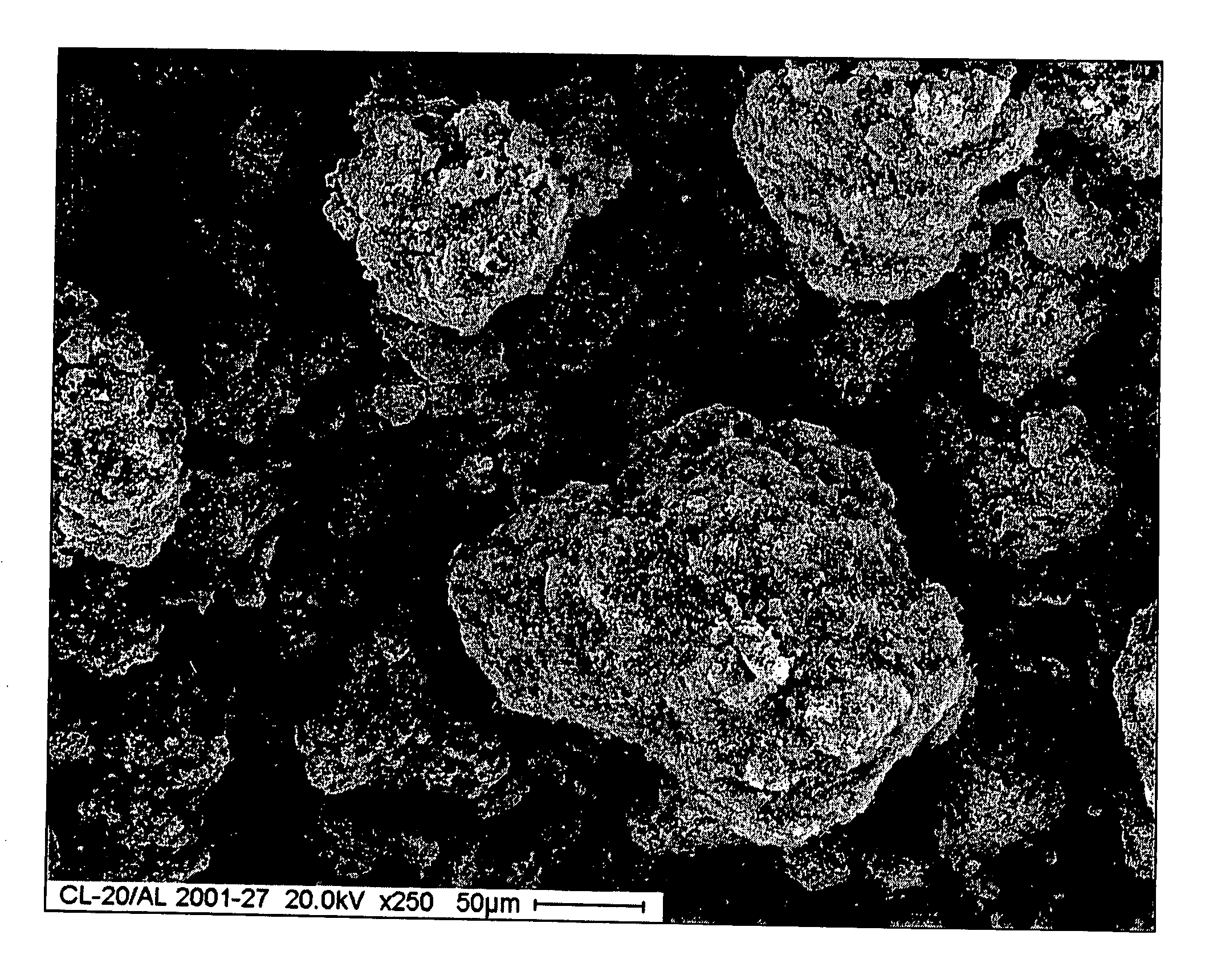

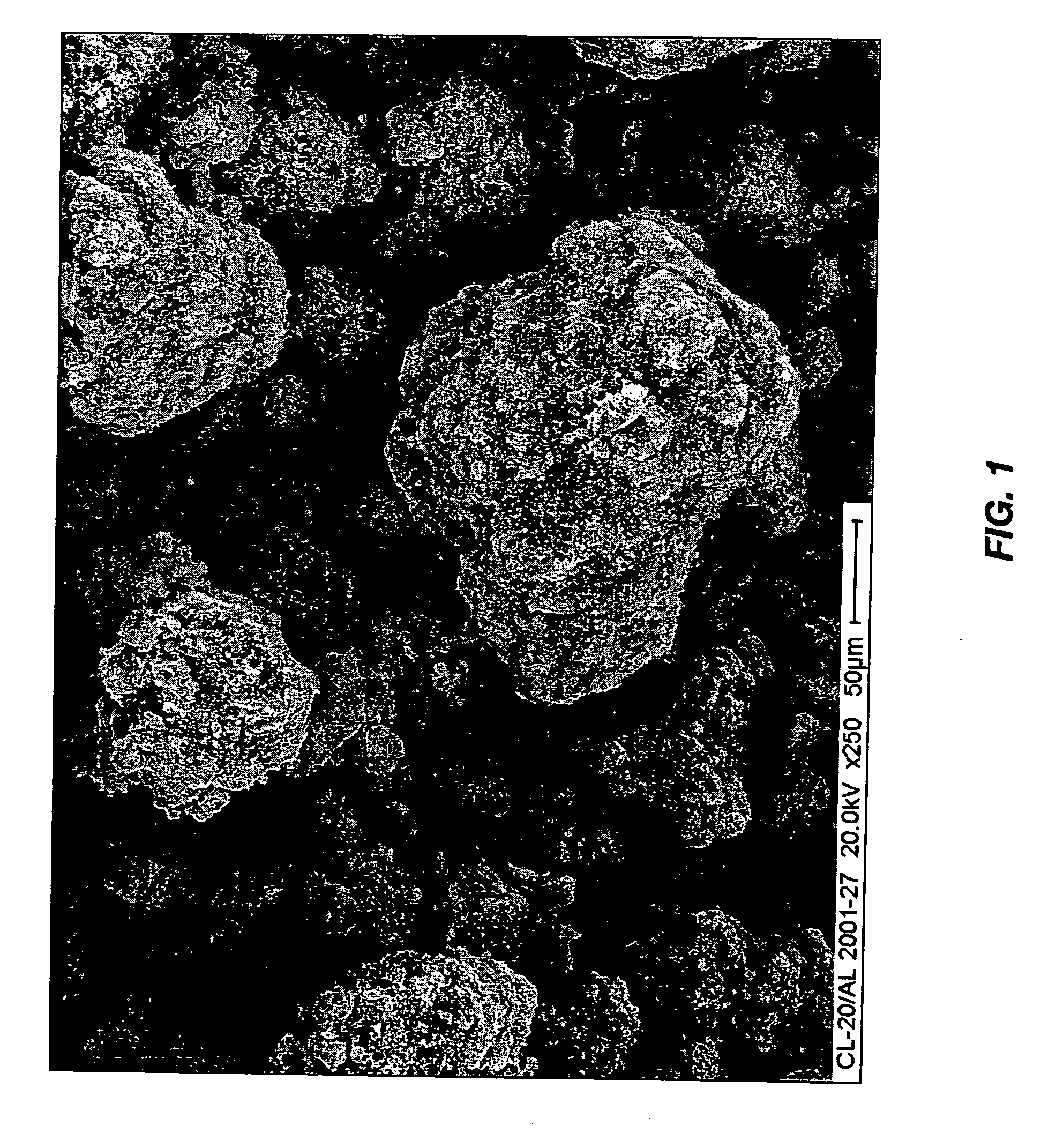

Heavy metal free, environmentally green percussion primer and ordnance and systems incorporating same

A sensitized explosive that comprises an explosive precipitated onto a sensitizer. The explosive is CL-20, PETN, RDX, HMX, or mixtures thereof and the sensitizer is aluminum, titanium, zirconium, magnesium, melamine, styrene, lithium aluminum hydride, or mixtures thereof. The sensitized explosive is used in a percussion primer that includes a bismuth compound and a melt binder. The bismuth compound is bismuth oxide, bismuth subnitrate, bismuth tetroxide, bismuth sulfide, or mixtures thereof and the melt binder is a wax having a melting point above ambient temperature, trinitrotoluene, poly(3,3-bis(azidomethyl)oxetane), poly(3-azidomethyl-3-methyloxetane), ethyl-3,5-dinitrobenzoate, or mixtures thereof. A gun cartridge and other primer-containing ordnance assemblies employing the percussion primer are also disclosed. Methods of forming the sensitized explosive and the percussion primer are also disclosed.

Owner:ORBITAL ATK INC

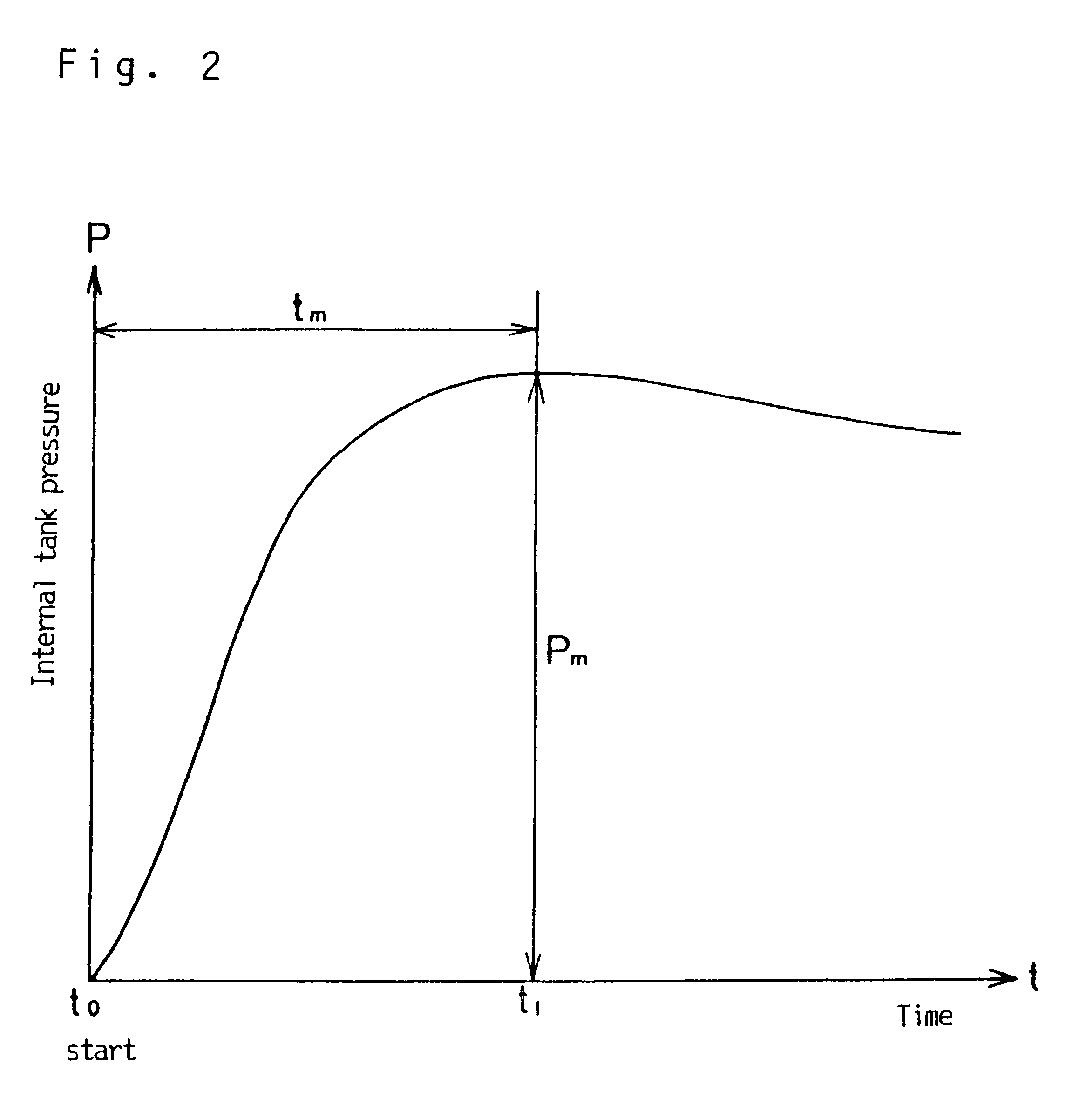

Spontaneous firing explosive composition for use in a gas generator for an airbag

InactiveUS6177028B1More securityEnsure safetyDetergent bleaching agentsNitrated explosive compositionsCombustionEngineering

A spontaneous firing explosive composition for use in a gas generator for an airbag containing a fuel, an oxidizer, a combustion modifier, and a binder.

Owner:NIPPON KAYAKU CO LTD +1

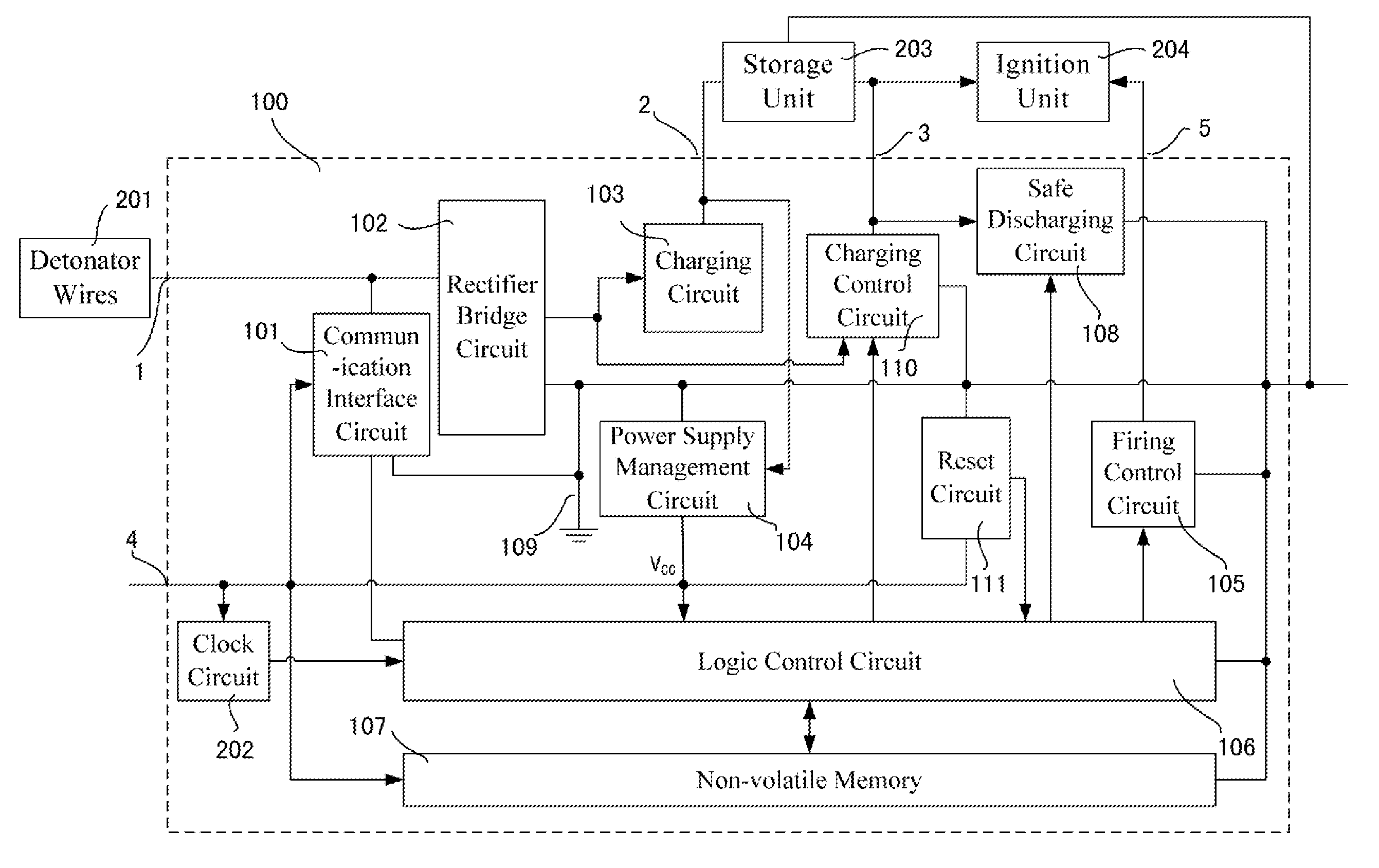

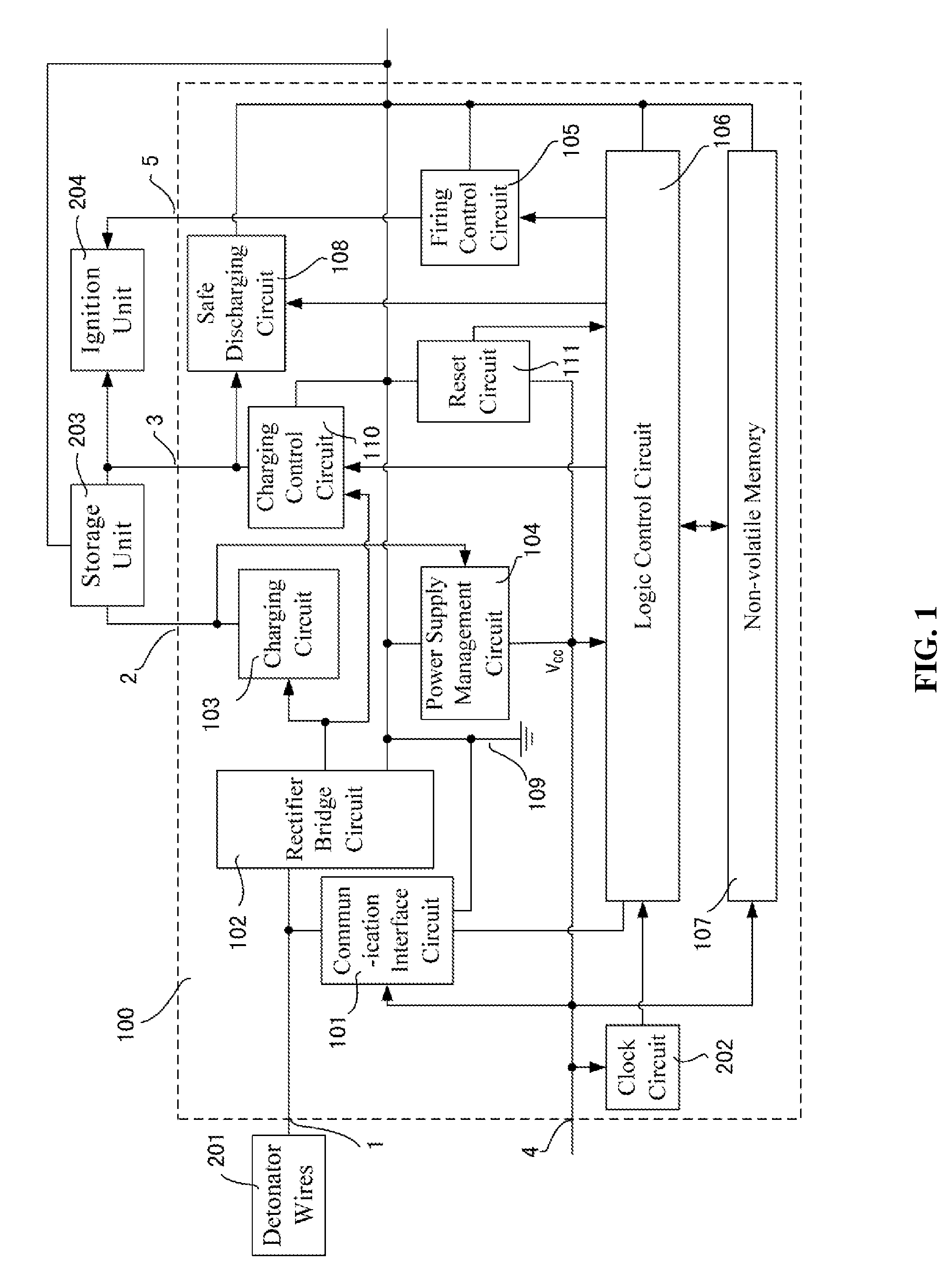

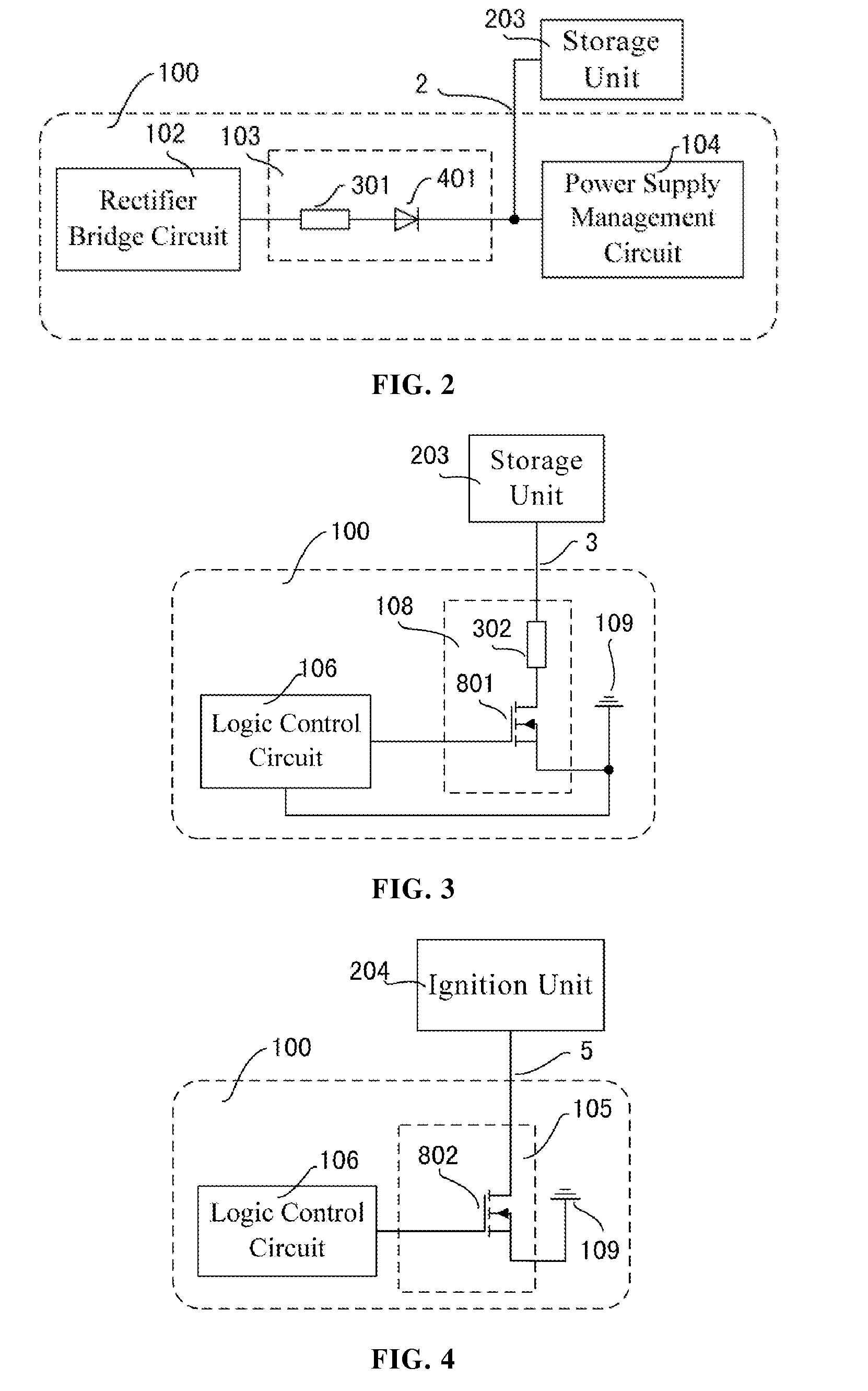

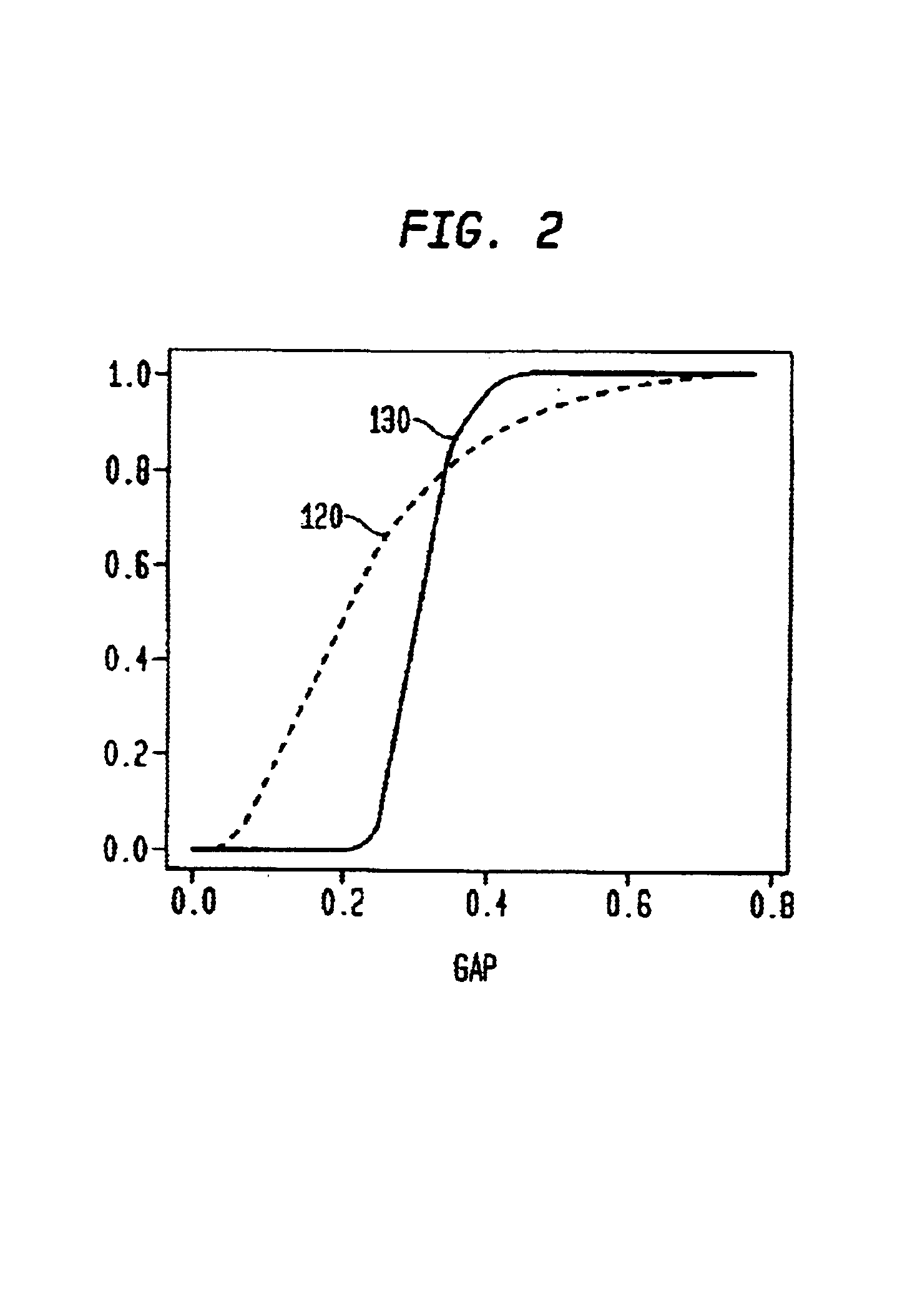

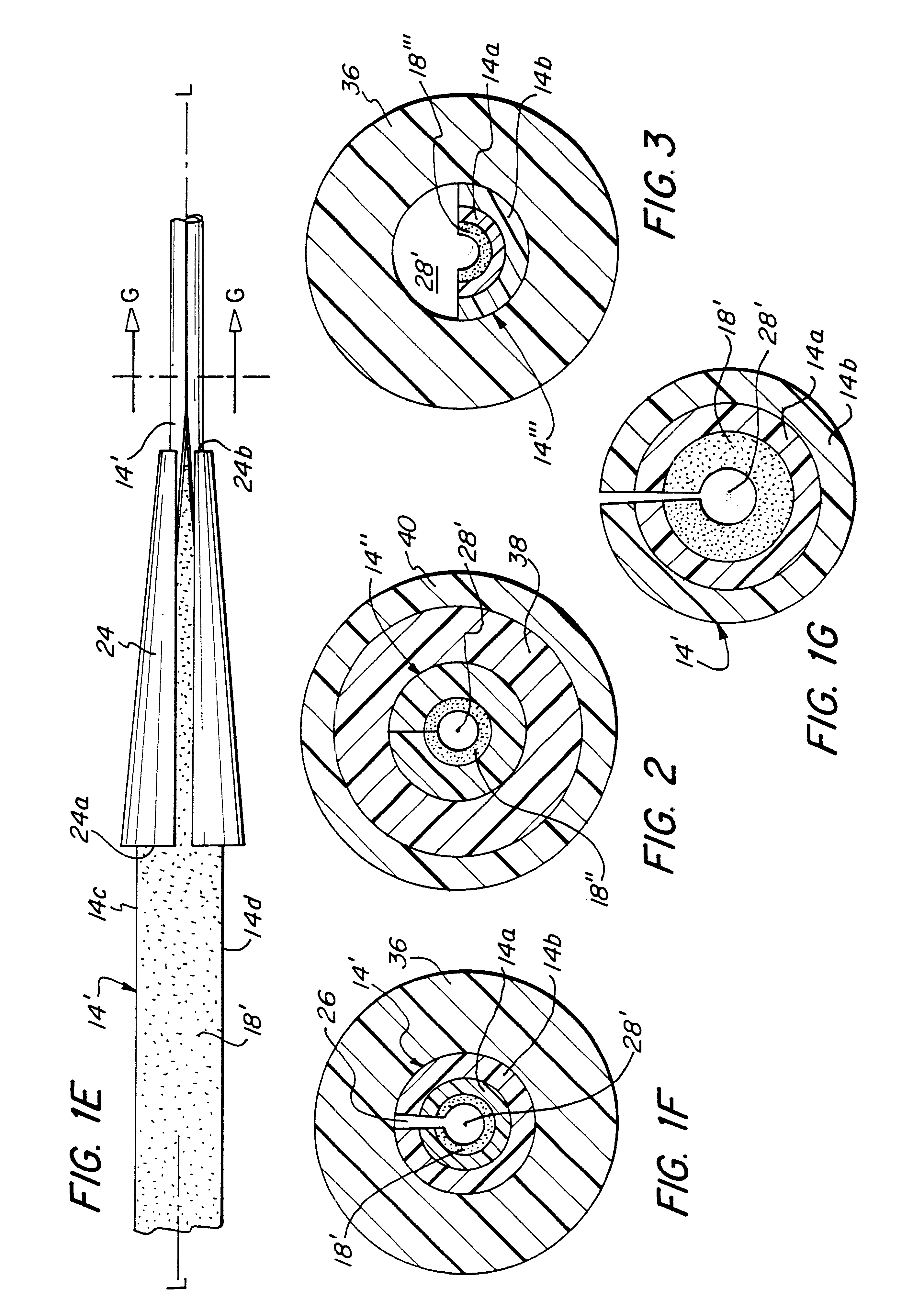

Electronic detonator control chip

ActiveUS20110056399A1Controlling the riskUse of the electronic detonator easier and more secureIncandescent ignitionBlasting cartridgesDetonatorDetonation

An electronic detonator control chip (100) includes a communication interface circuit (101), a rectification bridge circuit (102), a charging circuit (103), a charging control circuit (110), a power management circuit (104), a firing control circuit (105), a logic control circuit (106), a non-volatile memory (107), a reset circuit (111), a safe discharging circuit (108), and a clock circuit (202). Wherein, the communication interface circuit (101) includes a data modulation module (210) and a data demodulation module (211) including two data demodulation circuits (212). The logic control circuit (106) further includes a programmable delay module (281), an input / out interface (282), a serial communication interface (283), a prescaler (284), a CPU (285), and so on. Therefore, the electronic detonator control chip provided by the invention enables to realize the functions of two-wire non-polarity connection, bidirectional communication with a detonation equipment external of the electronic detonator control chip, ID card inside the detonator, control of the detonation process and online program of the delay time and so on.

Owner:BEIJING EBTECH TECHNOLOGY CO LTD

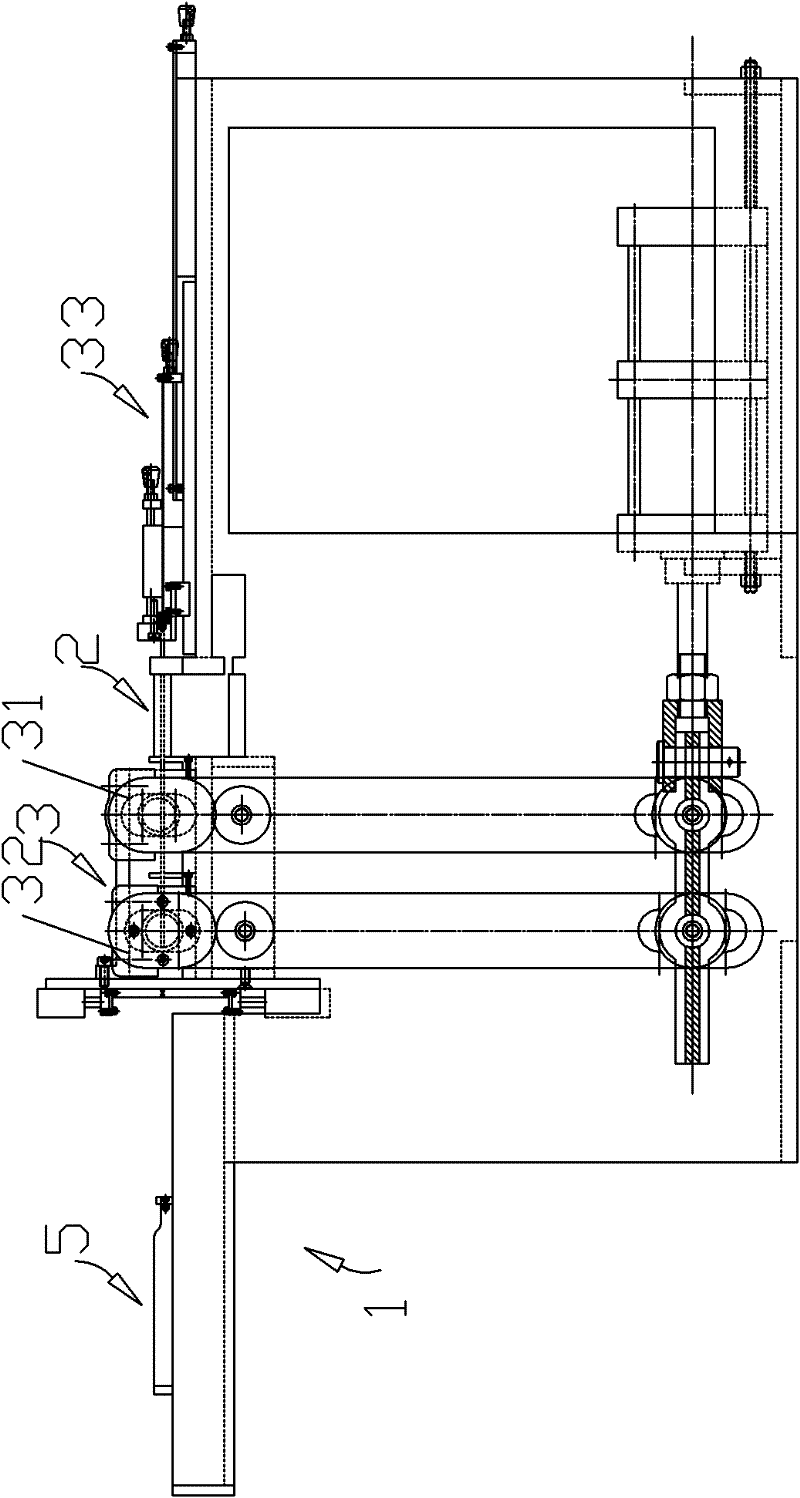

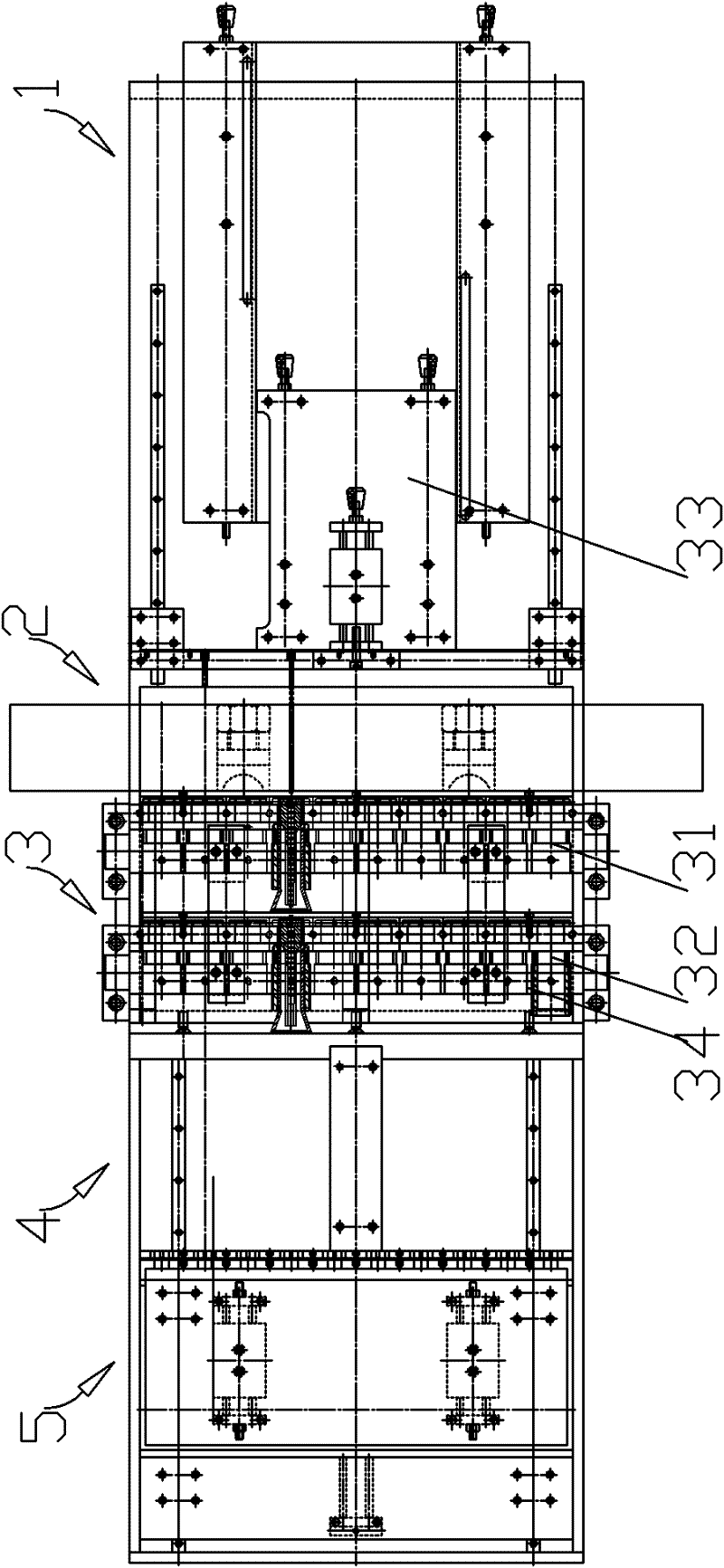

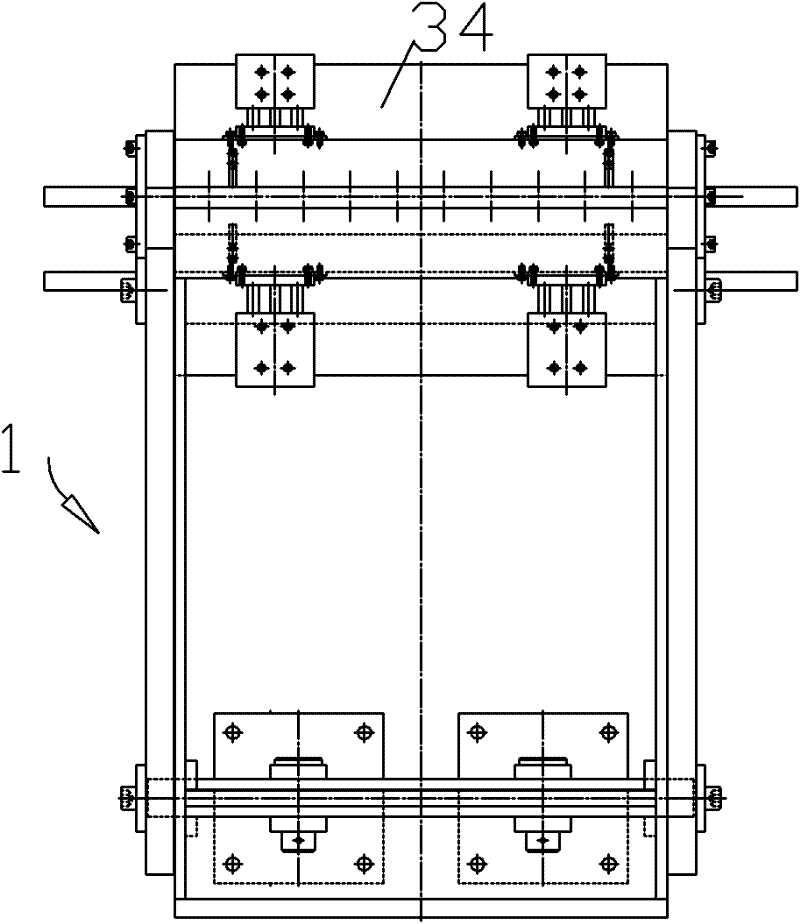

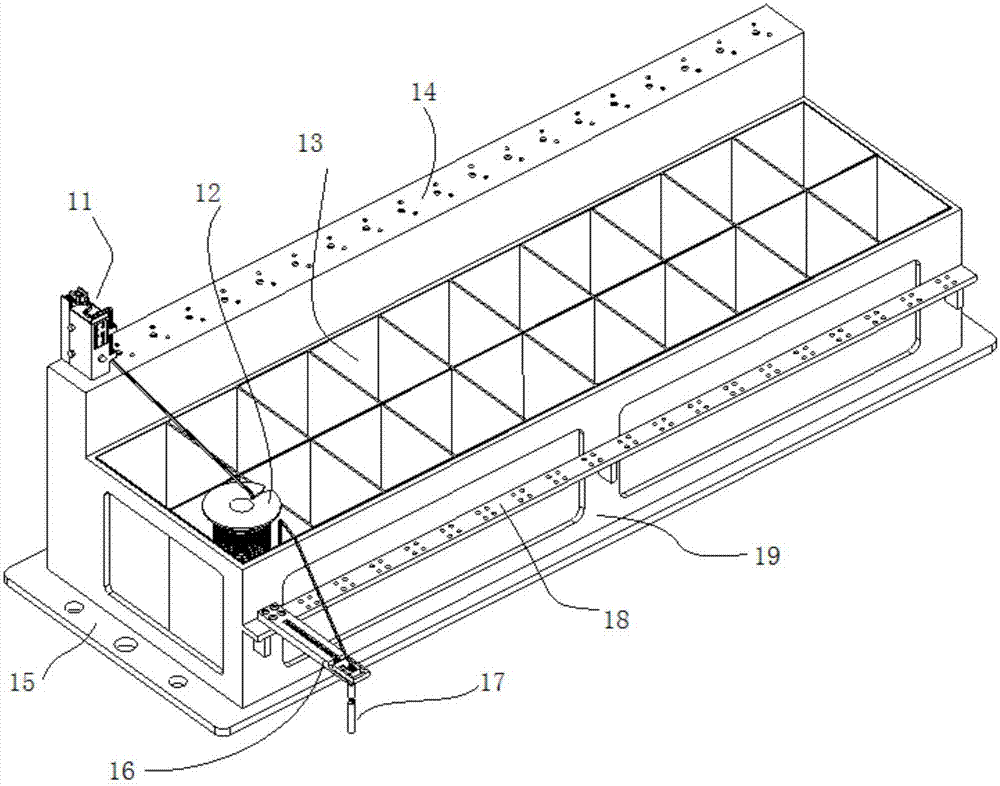

High-efficiency automatic mass detonator card waist bayonet machine

The invention relates to an efficient and automatic group-sanding latch waist-bayonet machine for detonators. The bayonet machine comprises a rack, a special mould, a play-off reel and an electric or pneumatic control device, wherein the rack is provided with the special mould, a group-sending latch waist-bayonet mechanism and a thread feeding mechanism; a group-sanding detonator latch waist and a group-sanding detonator bayonet are integrated on one machine for continuous operation, and more than ten latch waist-bayonet operations can be completed in one work process, thereby greatly improving production efficiency, saving production personnel and reducing labor cost; equipment is compact, thereby greatly reducing detonator production workshops and occupied areas; the whole assembling process is carried out automatically, and dangerous latch waist-bayonet operations are carried out in a protective armor, accidents of operating personnel injury caused by detonator explosion during latch waist and bayonet operations can be avoided, and operation is safe and reliable, thus the latch waist-bayonet machine is suitable for being used in the electric detonator or explosive detonator assembling process.

Owner:深圳金源恒业科技有限公司

Explosive composition and its use

InactiveUS6984274B2Improve structural strengthLess-expensive productionBelt retractorsPedestrian/occupant safety arrangementNitro compoundPorosity

An explosive composition comprises a porous fuel and an oxidizer. The porous fuel is a solid with a structure size measuring between about 2 nm and 1000 nm and has a porosity that lies between 10% and 98%. The oxidizer is solid or liquid at room temperature and is incorporated into the pores of the porous fuel. The oxidizer is selected, in an amount of at least 50% by weight relative to a total quantity of the oxidizer, from the group consisting of hydrogen peroxide, hydroxyl ammonium nitrate, organic nitro compounds or nitrates, alkali metal nitrates or earth alkali metal nitrates as well as metal nitrites, metal chlorates, metal perchlorates, metal bromates, metal iodates, metal oxides, metal peroxides, ammonium perchlorate, ammonium nitrate and mixtures thereof.

Owner:TRW AIRBAG SYST

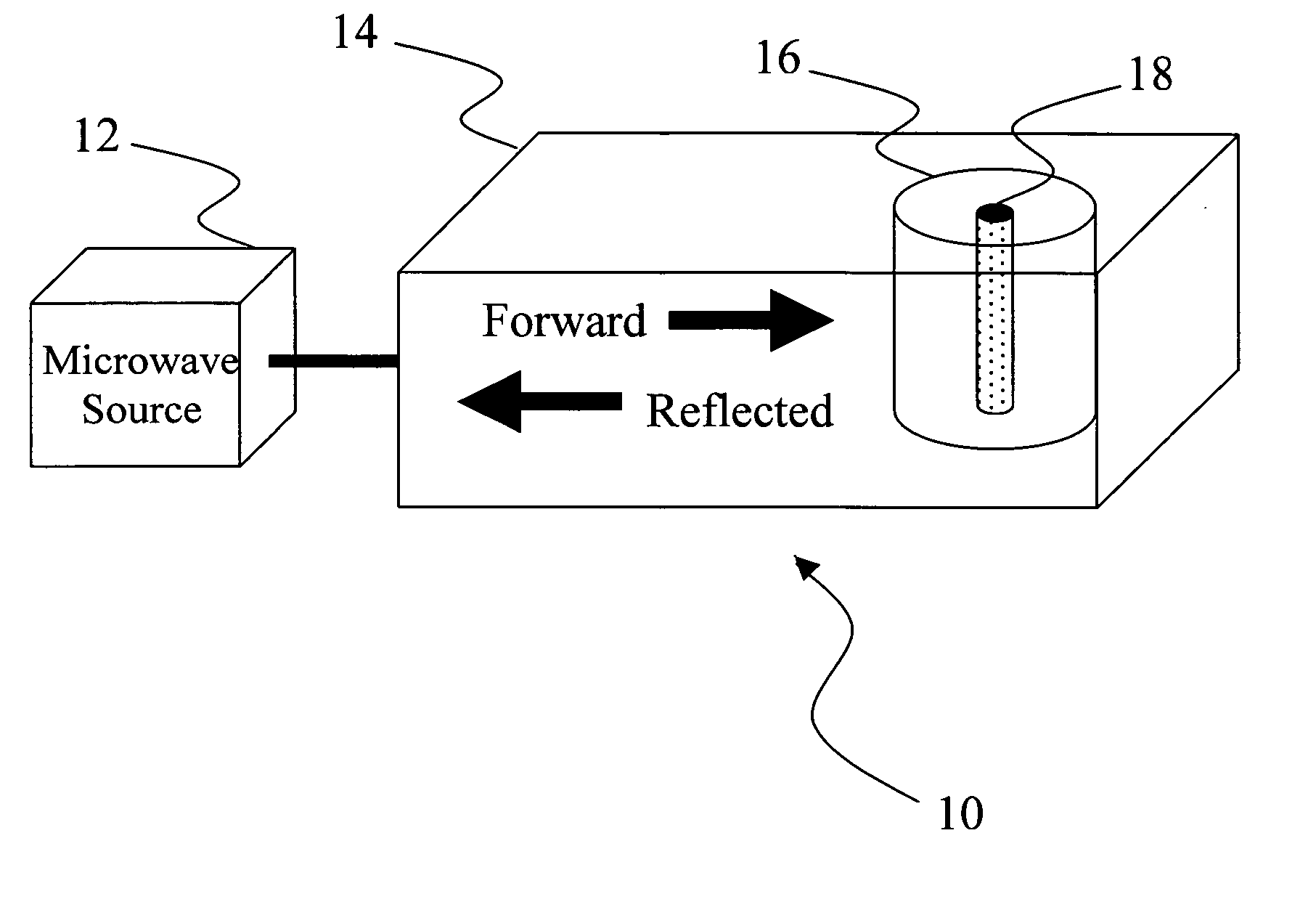

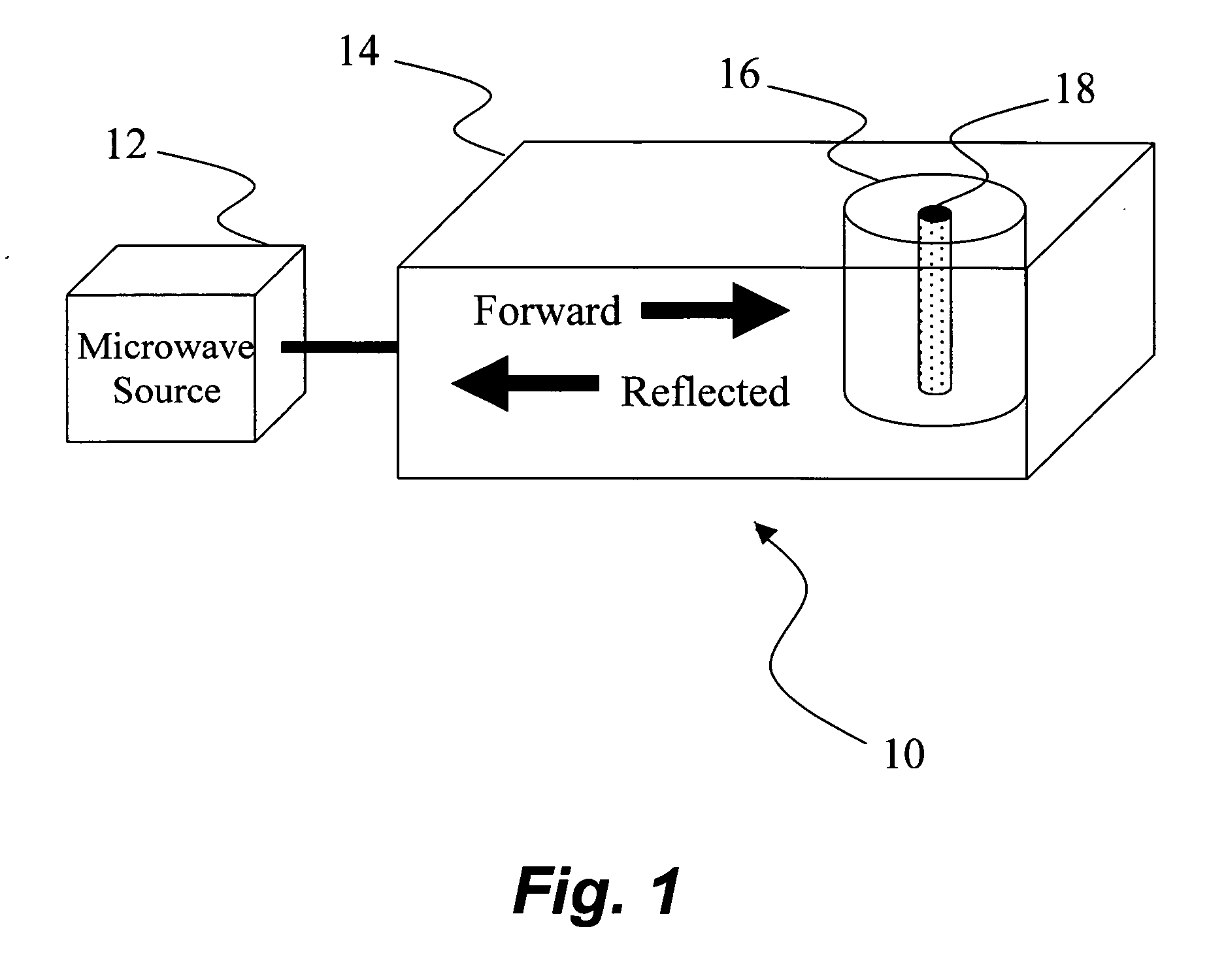

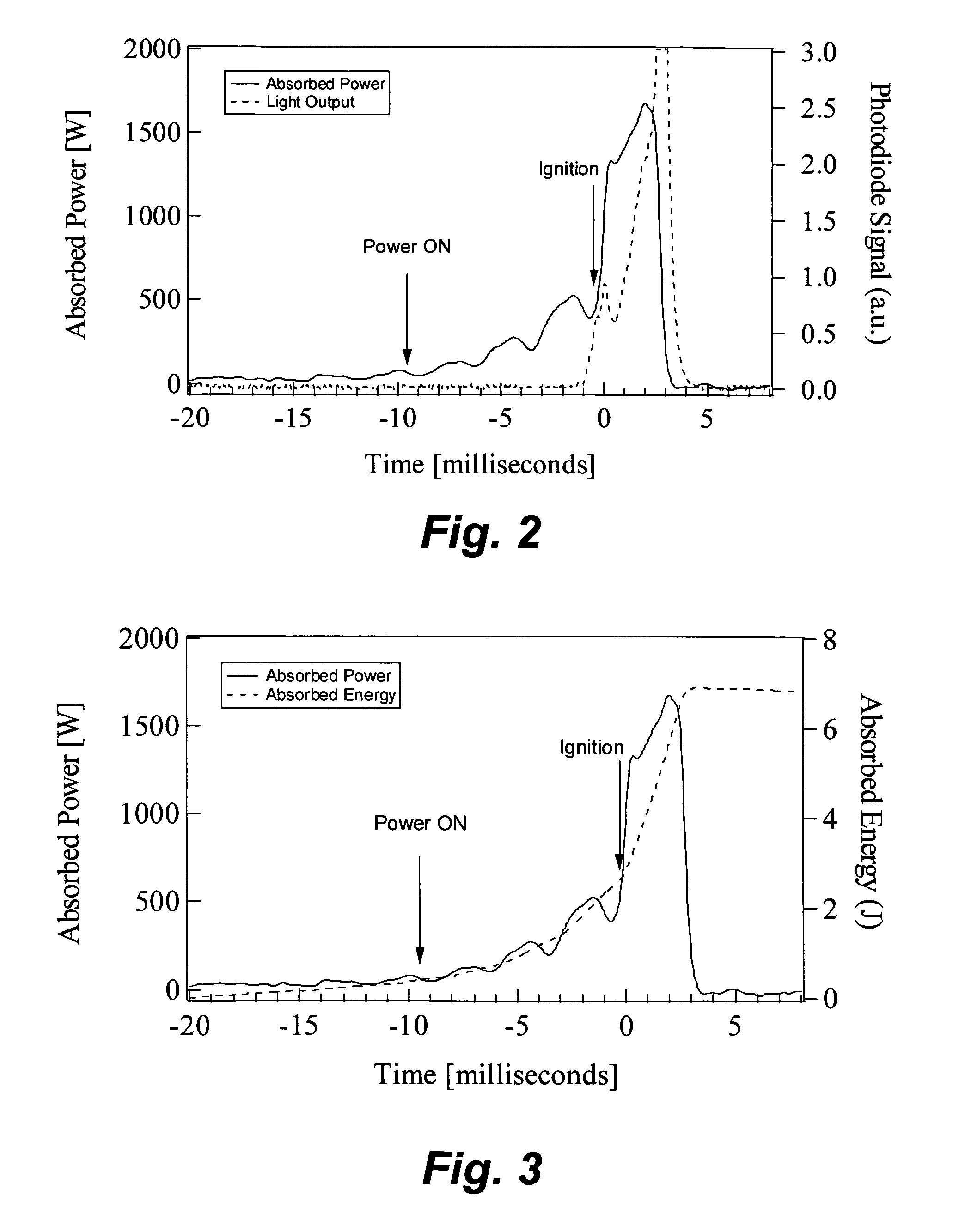

Microwave heating of energetic materials

InactiveUS20060011083A1Material nanotechnologyNon-explosive fillers/gelling/thickening agentsGramDegree Celsius

Mixtures of high explosives with materials that readily absorb microwaves ignite more readily when exposed to microwave energy than the corresponding neat explosives. A charge of HMX (0.5 gram) mixed with carbon nanotubes (1 percent by mass) ignited with 7.5 joules at an average rate of 750 W for 10 milliseconds. To raise a charge of the same mass of neat HMX to an autoignition temperature of 200 degrees Celsius would require much more energy (about 110 joules) for a longer duration (about 150 milliseconds).

Owner:LOS ALAMOS NATIONAL SECURITY

Lead-free nontoxic explosive mix

The present invention is directed to a lead-free, nontoxic pyrotechnic composition, comprising: 30-80 wt % of bismuth subnitrate; and 10-50 wt % of a fuel, wherein all weight percents are based on the total weight of the composition. The present invention is also directed to a lead-free, nontoxic priming composition, comprising: 20-80 wt % of the above nontoxic pyrotechnic composition; 20-50 wt % of an initiator explosive; and 2-10 wt % of a sensitizer, wherein all weight percents are based on the total weight of the composition.

Owner:OLIN CORP

Fuze explosive train device and method

InactiveUS6640719B1Control delayEasy to controlAmmunition projectilesHand grenadesExplosive trainEngineering

A fuze explosive train device for detonating a munition that uses a stab firing pin within a pressure cartridge, with the stab firing pin located between a gas generator and a stab detonator. The firing pin is capable of transferring an energy from the gas generator into the stab detonator in a manner that initiates the stab detonator to a high order explosive reaction. A method of initiating a stab detonator using a stab firing pin also is disclosed.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

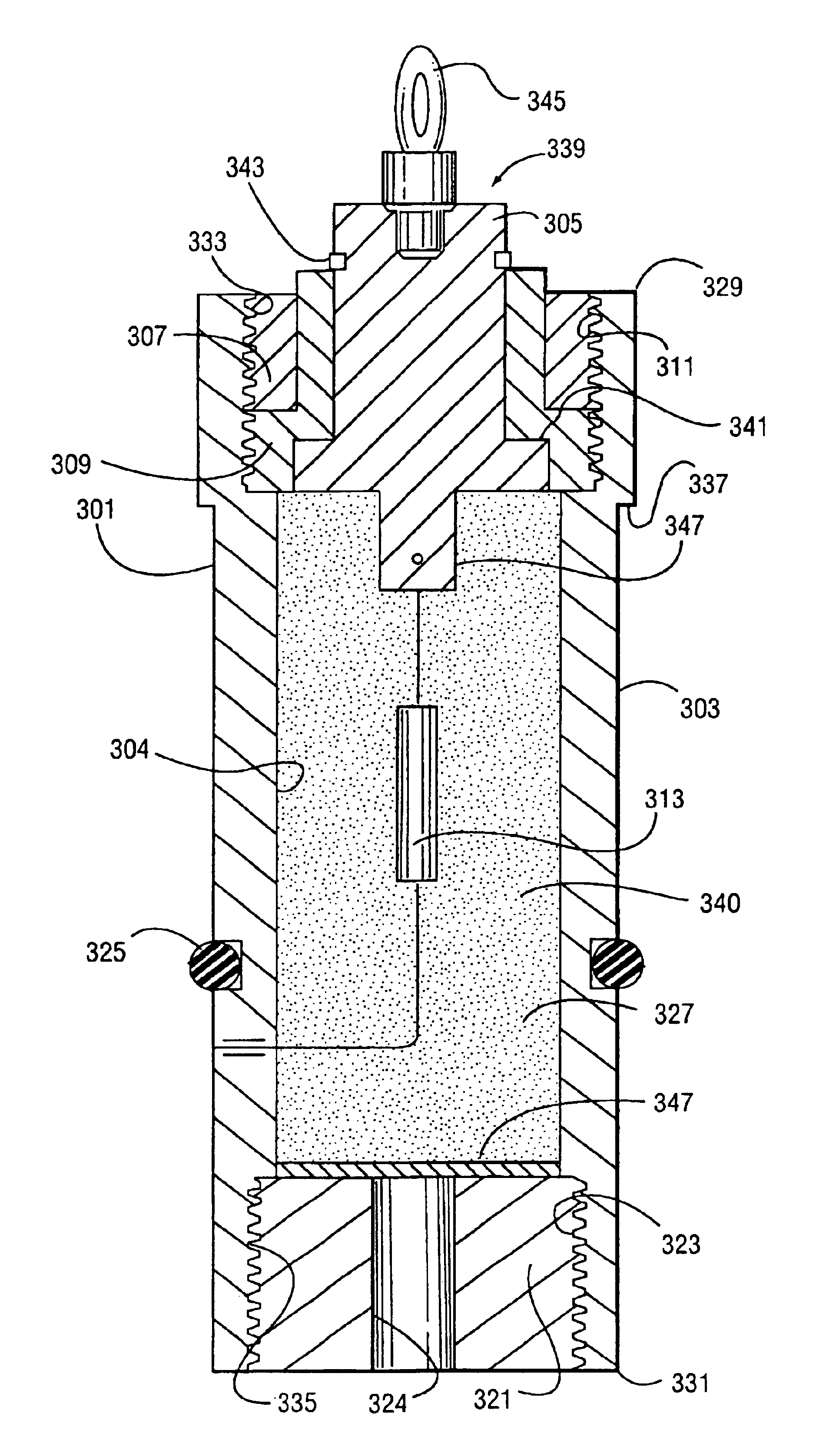

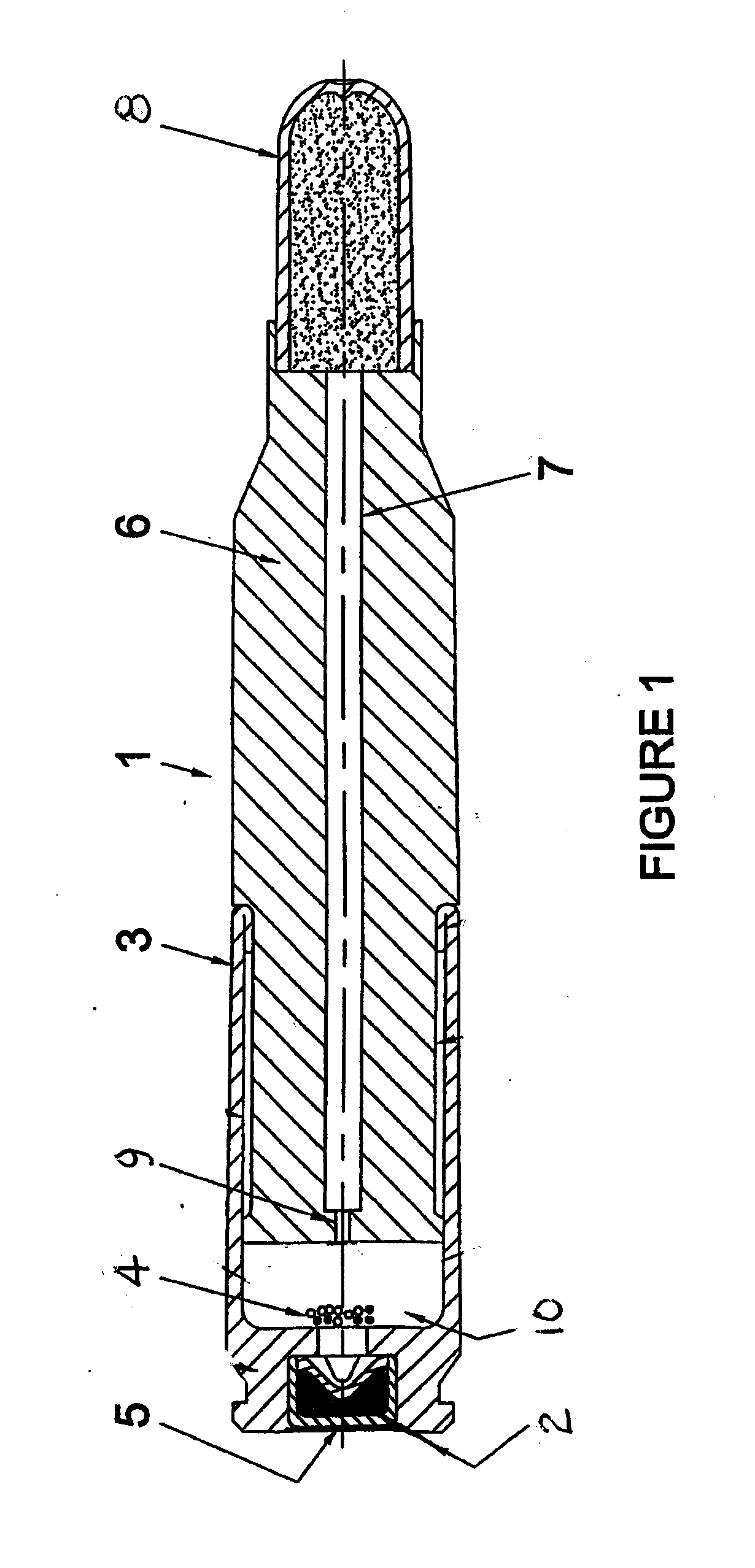

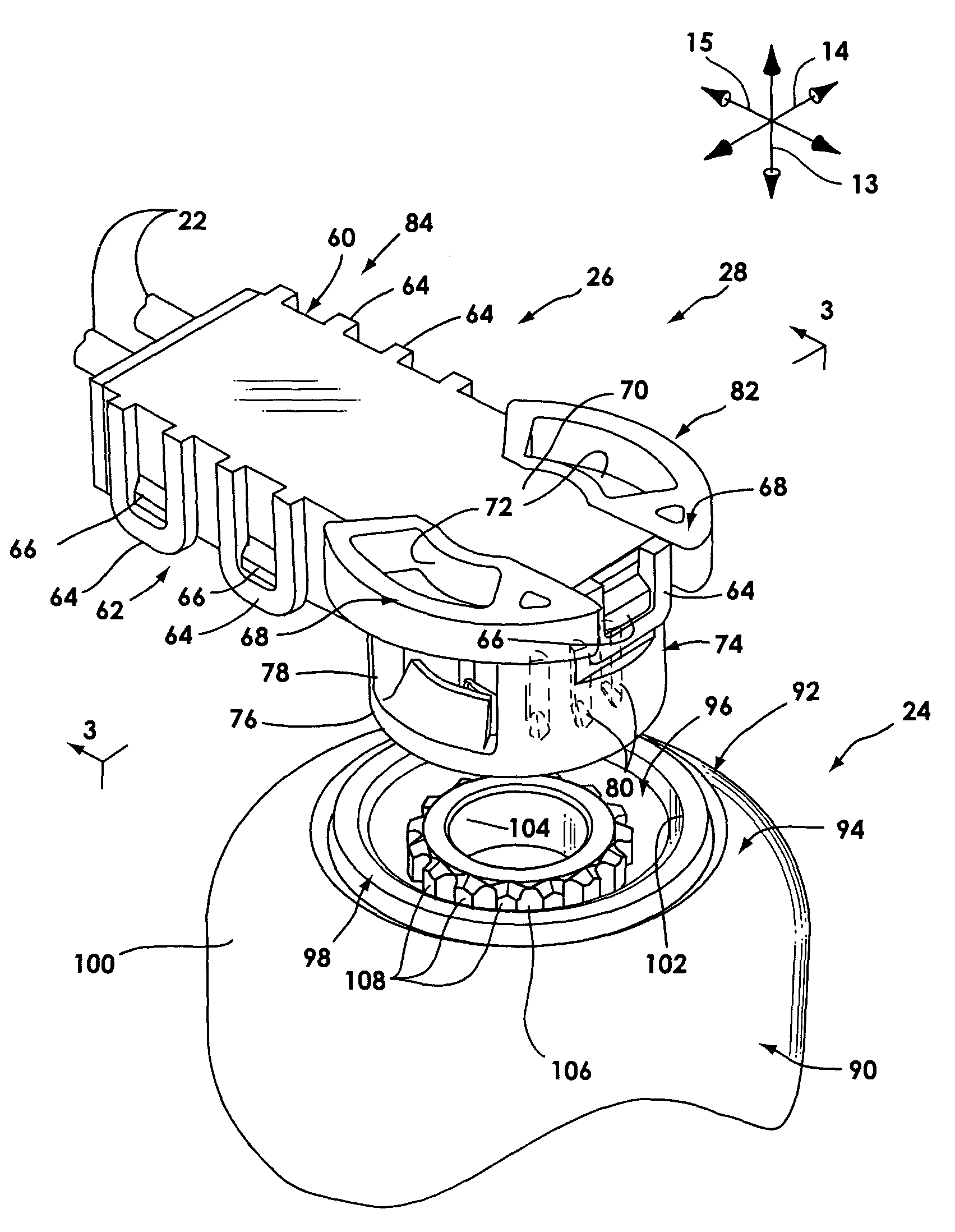

Axially compact mechanical igniter for thermal batteries and the like

An inertial igniter including: a first member having a wall and internal cavity; a second member slidable in the internal cavity, a striker disposed thereon and a first concave portion; a third member slidable on an exterior surface of the wall, a second concave portion; biasing springs for biasing the first and second members in a direction opposite an acceleration; locking balls in the first and second concave portions for preventing movement of the second and third members when the acceleration time profile is below a predetermined threshold; and a percussion cap primer on the first member; wherein when the acceleration time profile is greater than the predetermined threshold the locking balls are released from the concave portions to first permit relative movement of the third member with the first member and after a time delay to permit relative movement of the second member with the first member.

Owner:OMNITEK PARTNERS LLC +1

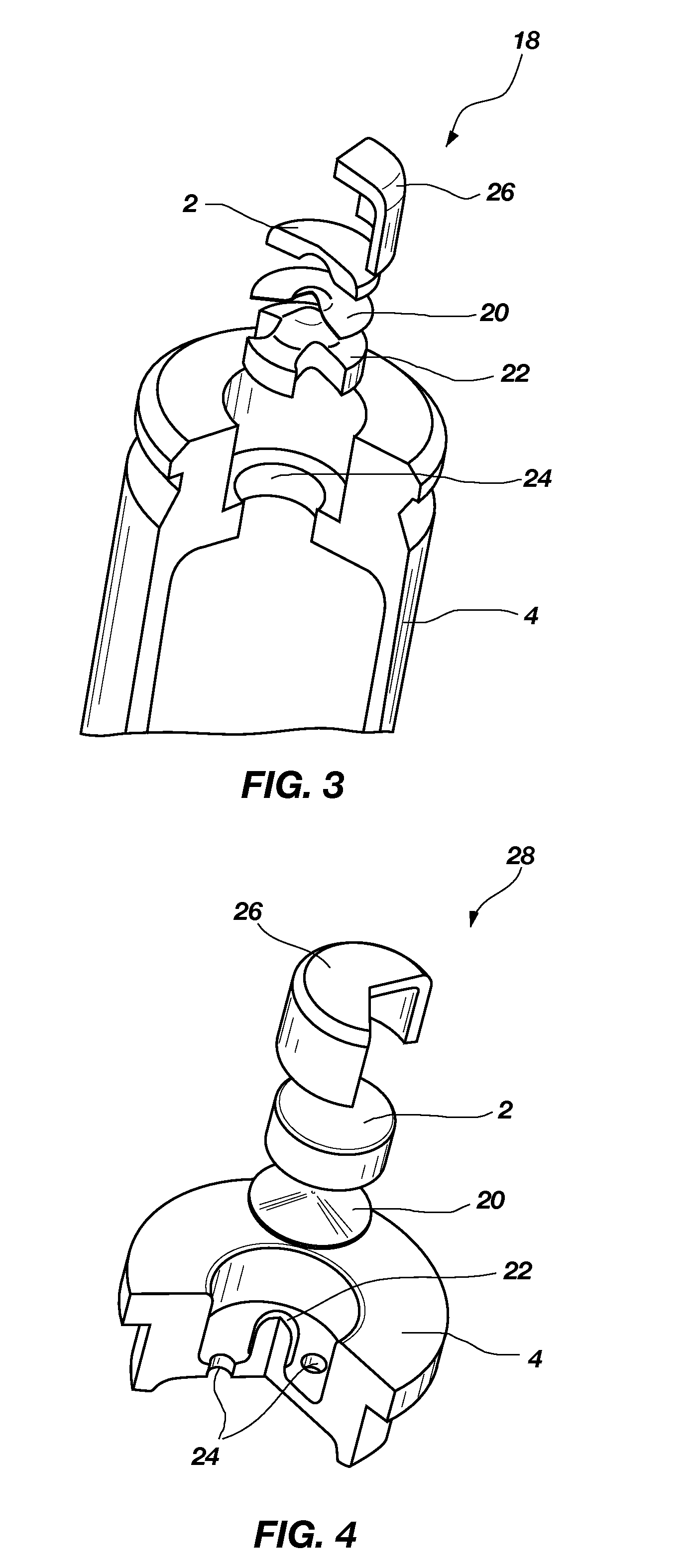

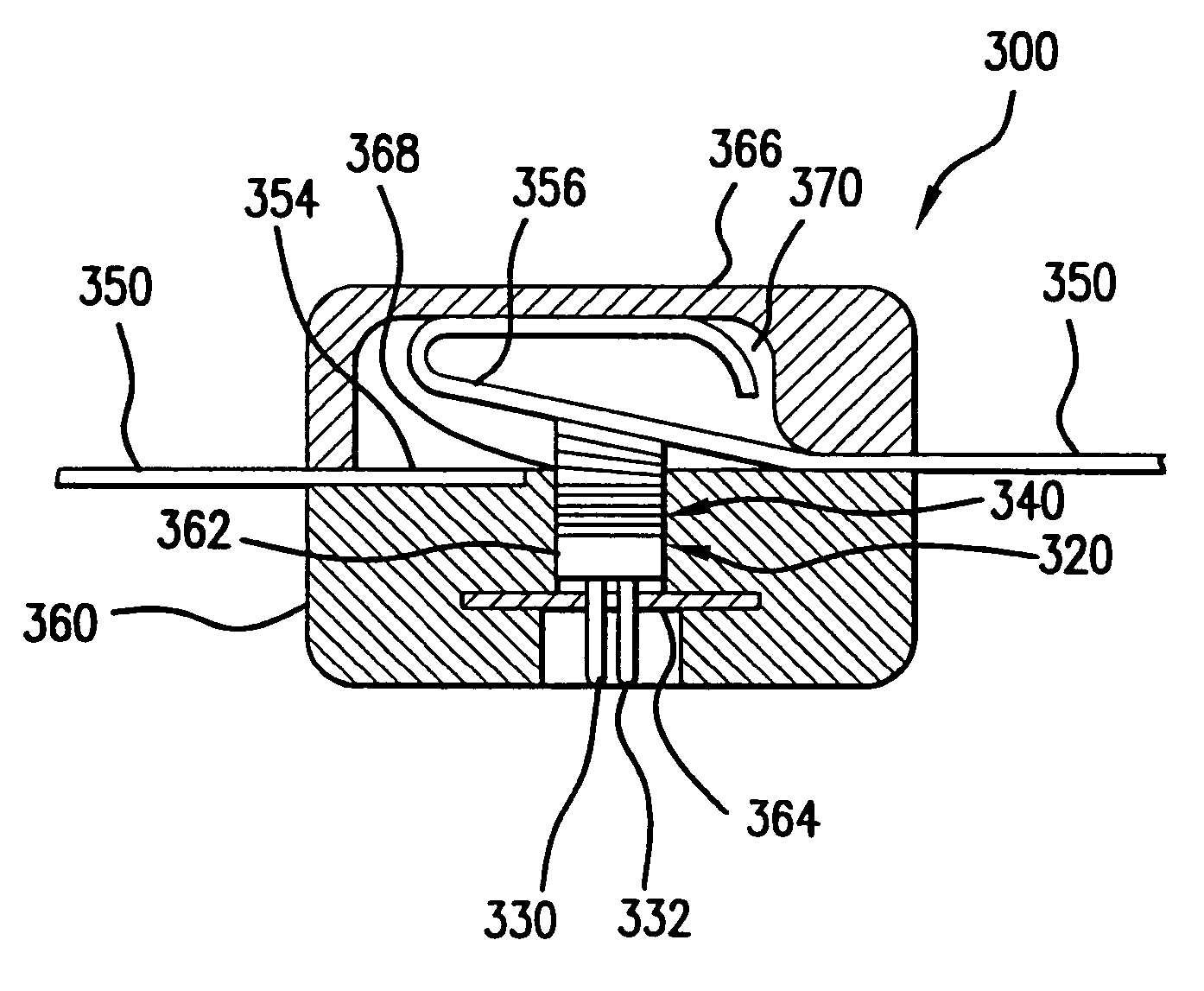

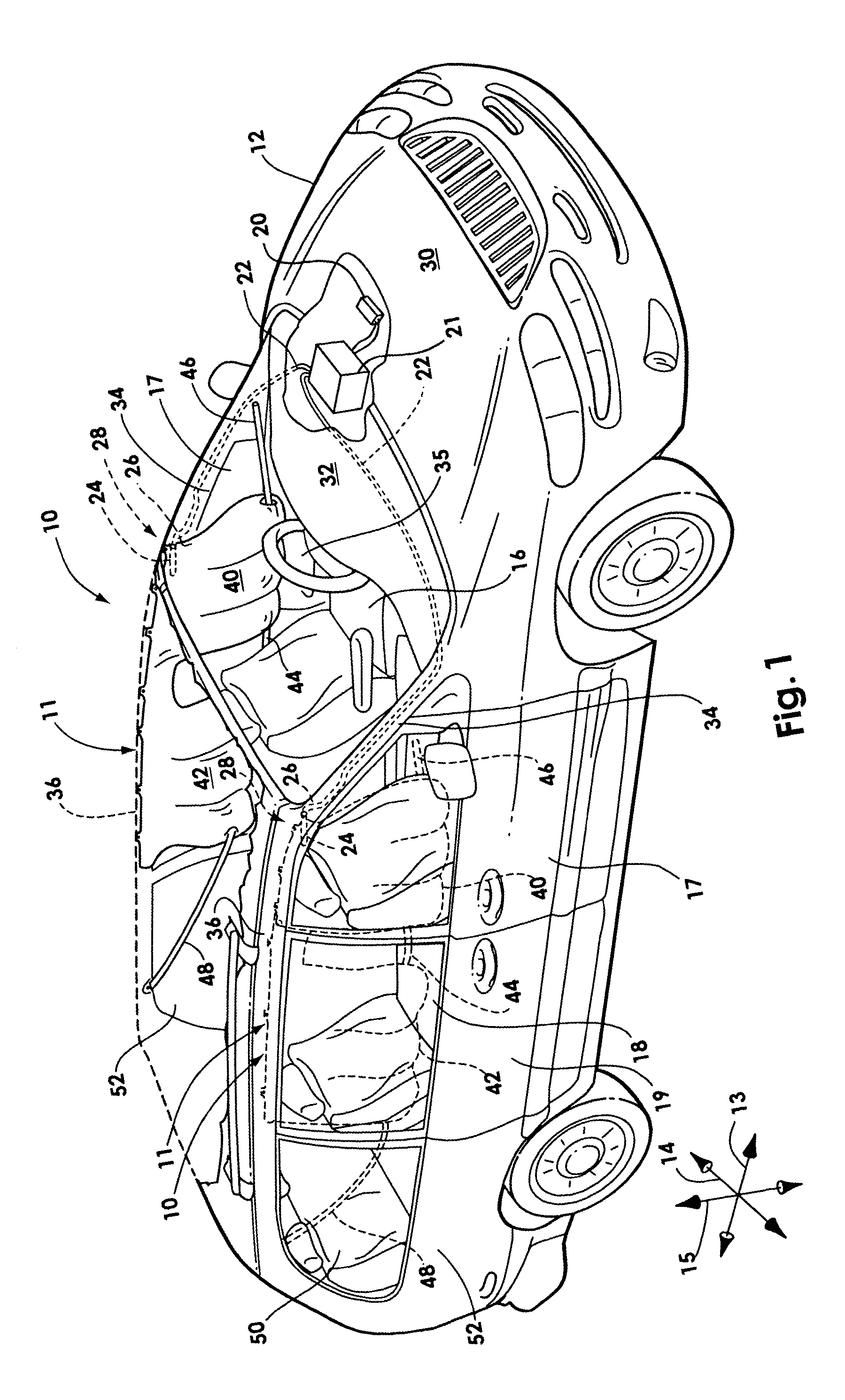

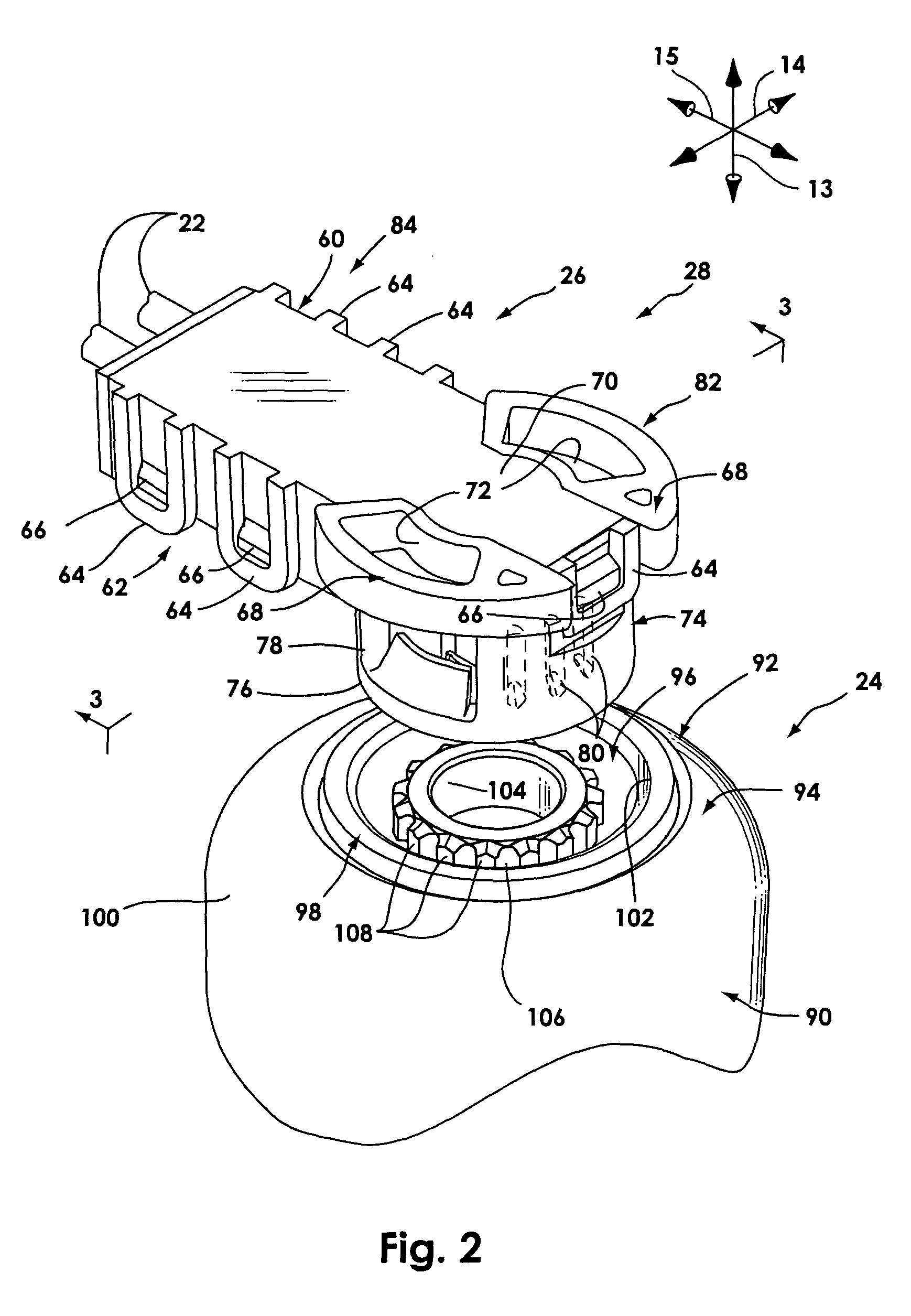

Airbag initiator cover attachment apparatus and method

InactiveUS7077428B2Inexpensive productionSimplifies electrical connectionsIncandescent ignitionPedestrian/occupant safety arrangementMating connectionEngineering

An airbag module has an inflator activated via an electrical connector. The inflator includes an initiation assembly having an initiator and a receptacle that retains the connector. The initiator may have a single, center pin. The initiator may be encased by a body and cover, which may be attached together by molding, vibratory welding, electromagnetic welding, or snap fitting. The connector may have projections that extend from a main body to facilitate retention of the connector by a collar, washer, a retainer attached to the body, or by the inflator housing. The body may be seated in a collar having an annular ridge that presses into the body to form a seal. The connector may have a rib designed to mesh with splines of the receptacle to enable engagement of the connector with the receptacle in multiple orientations, while preventing relative rotation between the connector and the initiator after assembly.

Owner:AUTOLIV ASP INC

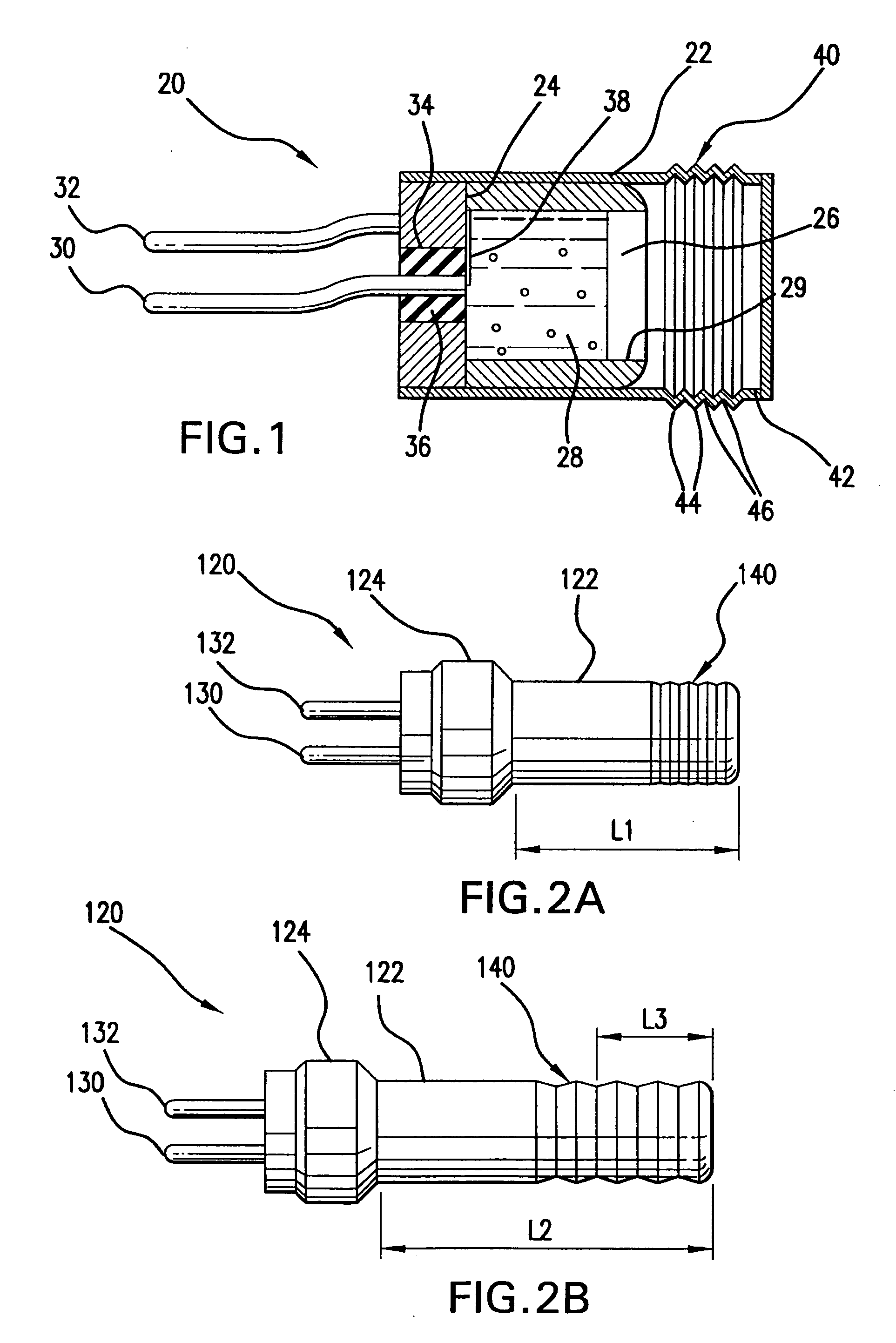

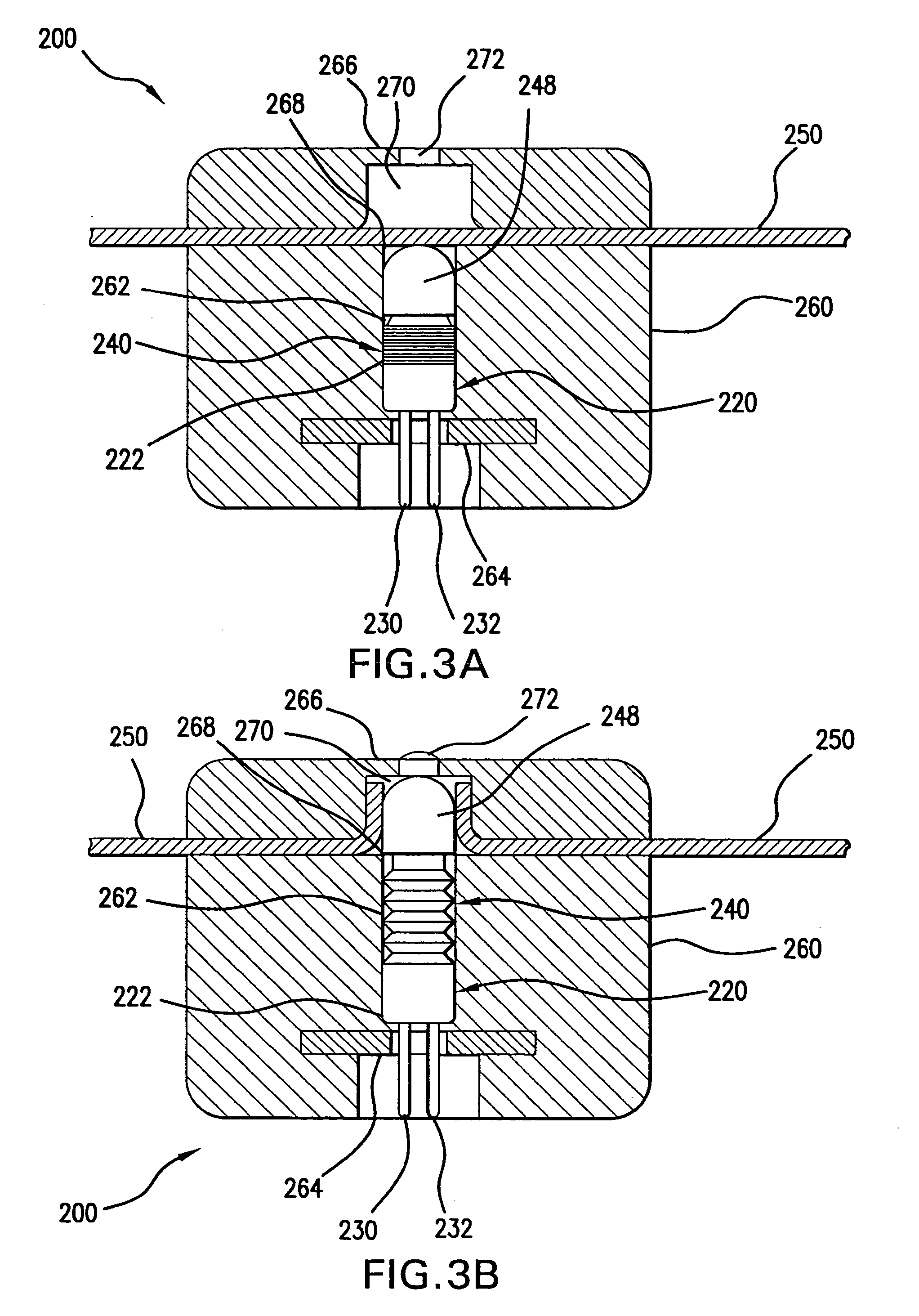

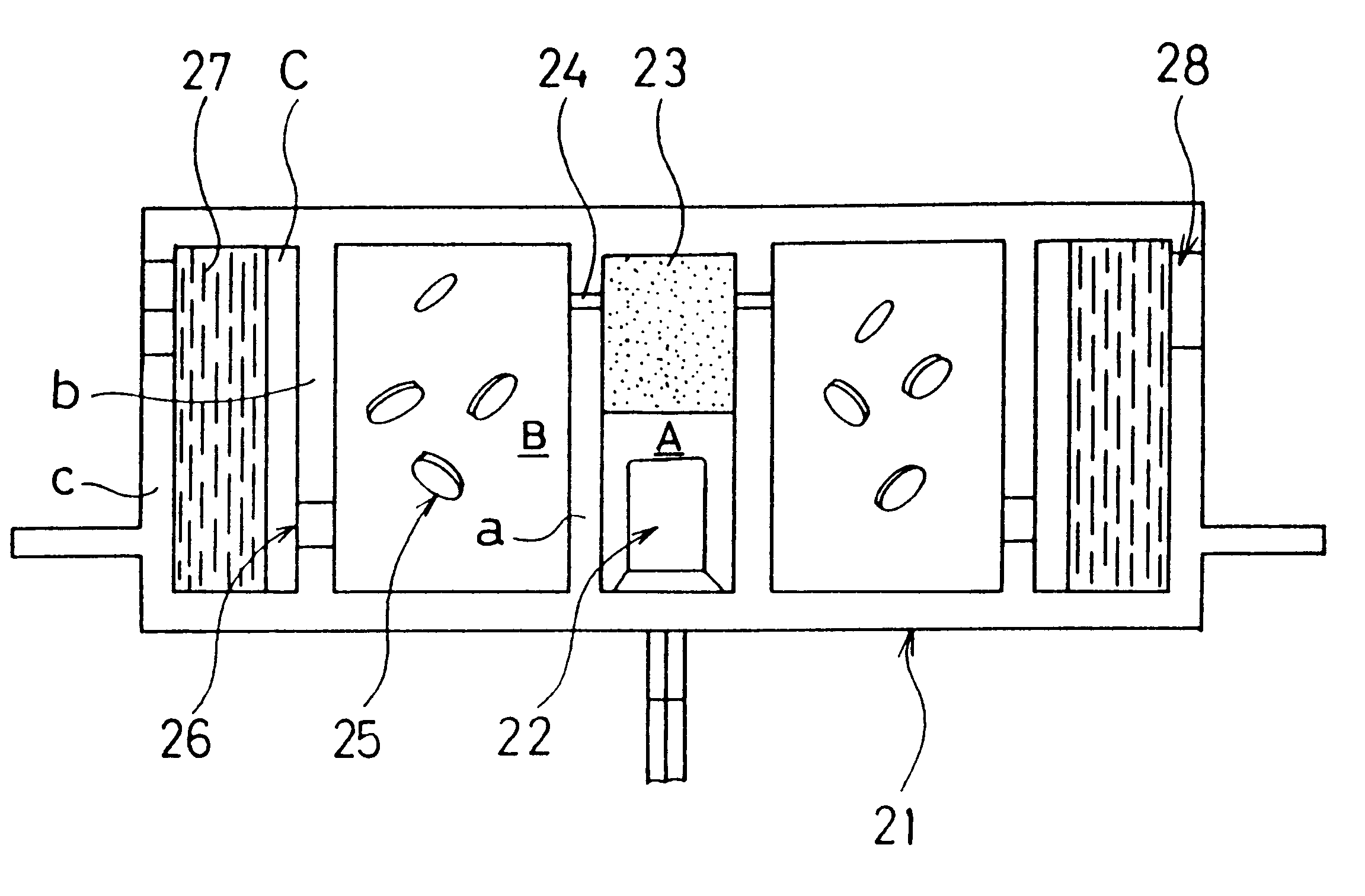

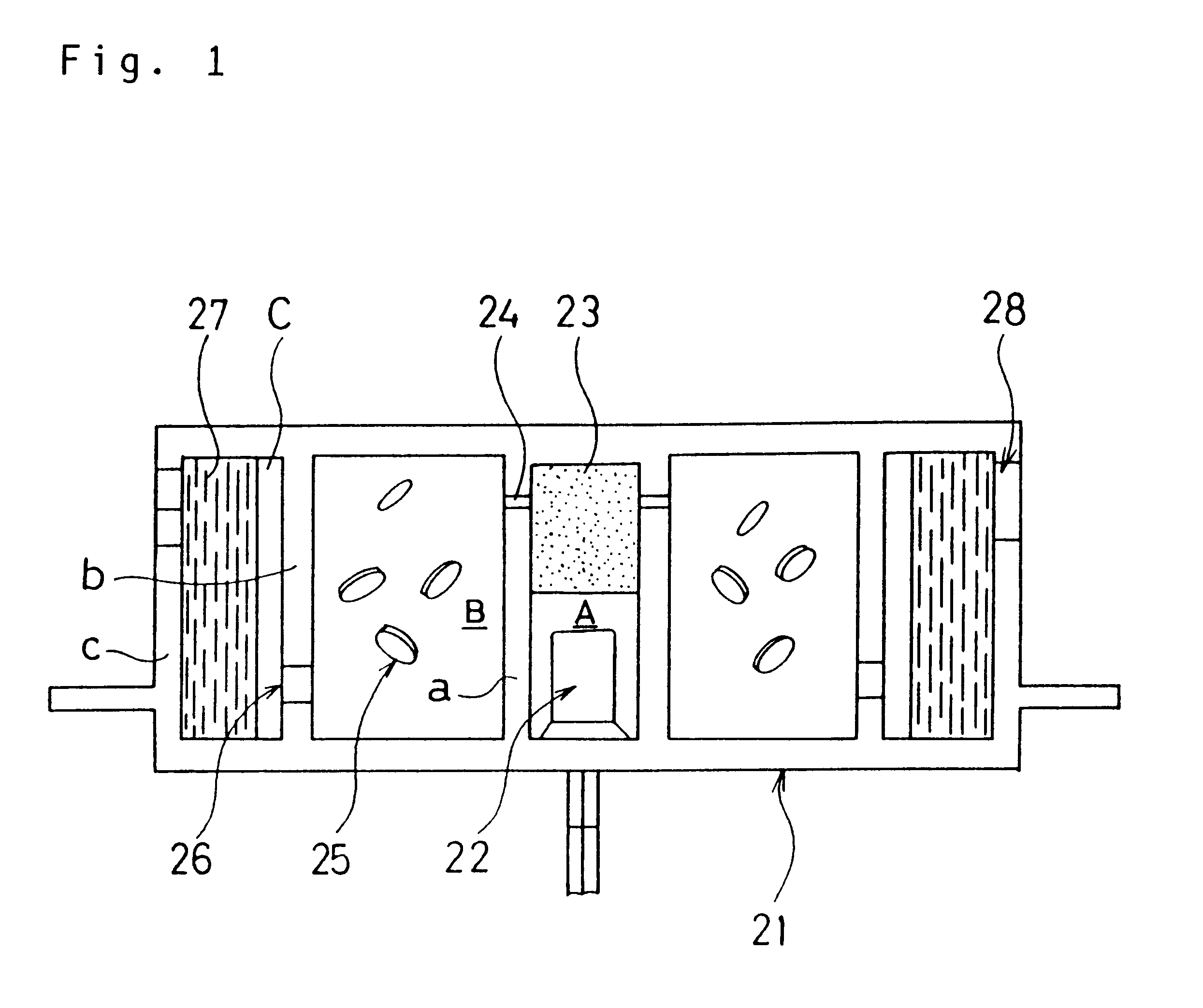

Gas generator

ActiveUS7125041B2Easy to assembleLow production costIncandescent ignitionBelt retractorsEngineeringIgniter Device Component

An igniter includes: an igniter assembly including an igniter main body having an ignition portion adapted to be ignited by an ignition electric current; an igniter collar which accommodates the igniter main body; a cup body having an opening portion, the igniter assembly and the cup body being connected to each other, such that at least the ignition portion of the igniter main body is surrounded by the cup body; and a tubular crimp case that connects and fastens at least a part of an exterior surface of the igniter collar and at least a part of an exterior surface of the cup body from an outside.

Owner:DAICEL CHEM IND LTD

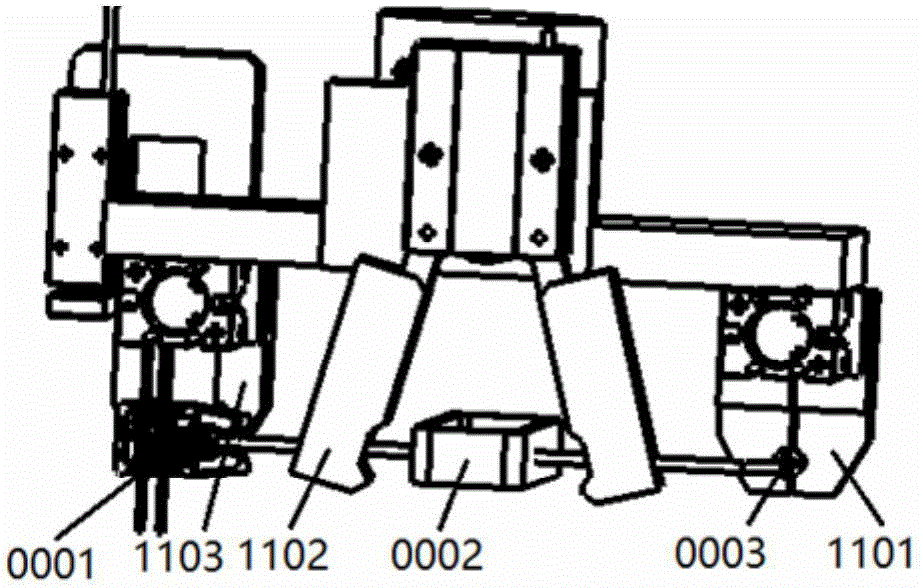

Production system of nonel detonator

The invention discloses a production system of nonel detonators. The production system includes a material feeding mechanism, a material taking mechanism, a waist clamp mechanism, a carrier, a driving mechanism, a transmission mechanism, a rubber plug assembling mechanism, a mouth clamp mechanism, a guidance mechanism and a nonel processing mechanism. A basic detonator of the nonel detonator is arranged on the material feeding mechanism. The material taking mechanism is disposed on the material feeding mechanism and is disposed slidingly between the material feeding mechanism and the waist clamp mechanism. The carrier is arranged at an output end of the waist clamp mechanism. The rubber plug assembling mechanism and the mouth clamp mechanism are respectively arranged at one side of the transmission mechanism. The driving mechanism is arranged on the transmission mechanism. The guidance mechanism is arranged at one side, which is far away from the transmission mechanism, of the mouth clamp mechanism. The nonel processing mechanism is disposed at one side, which is far away from the mouth clamp mechanism, of the guidance mechanism. The production system can automatically process and assemble the nonel detonators, and not only is high in production efficiency but also can reduces operators and production cost.

Owner:DONGGUAN CHUANGZHE AUTOMATION TECH CO LTD

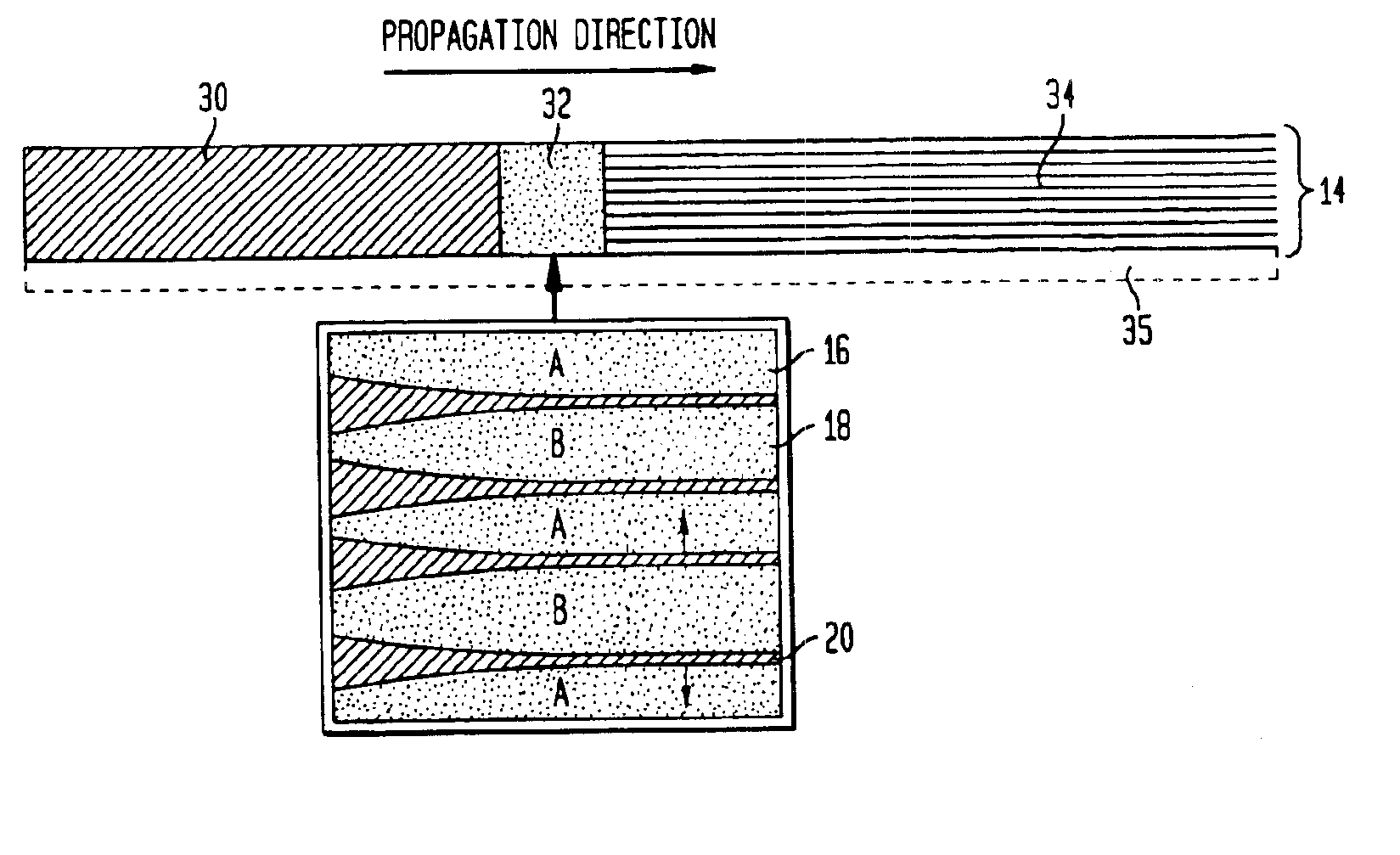

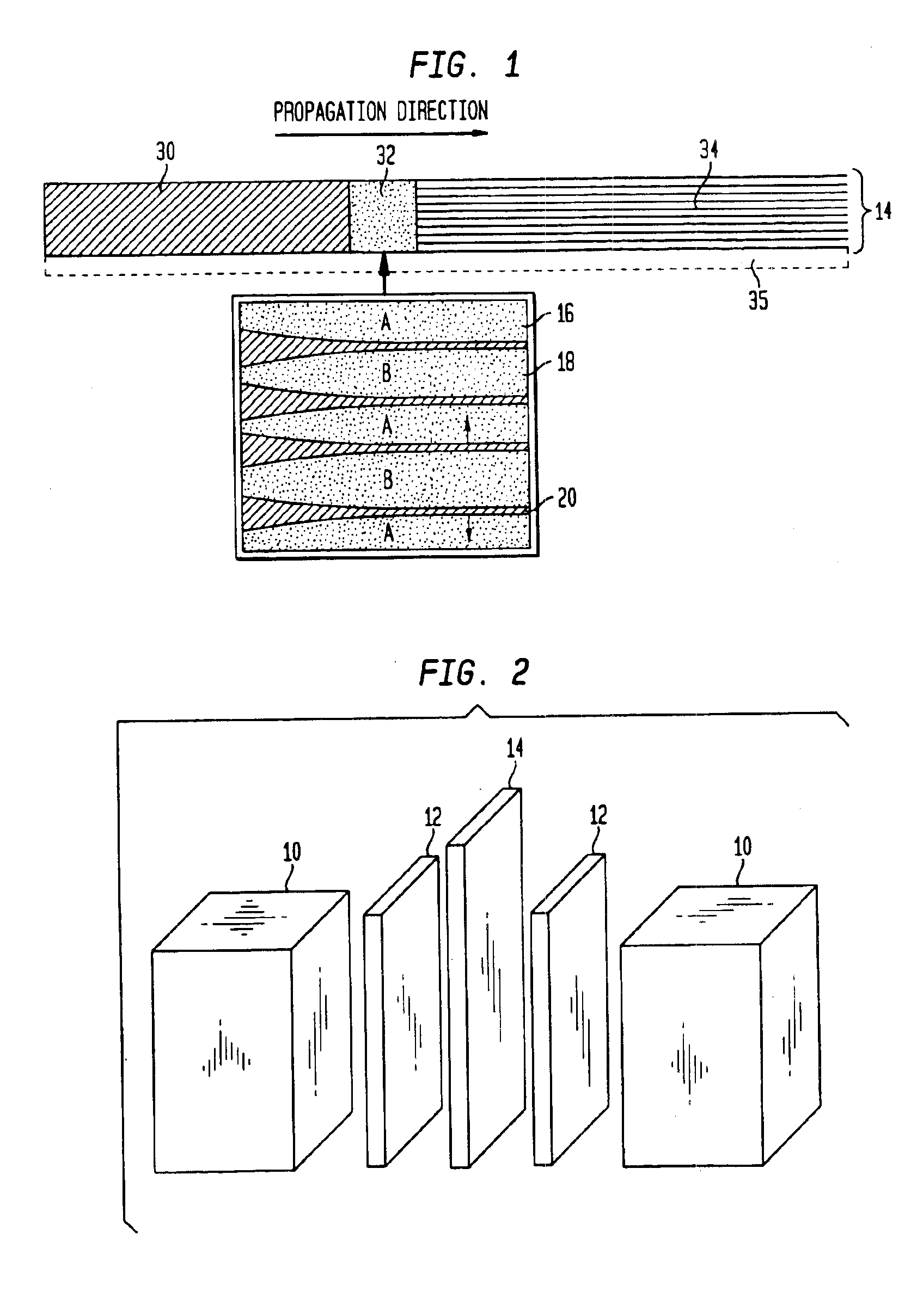

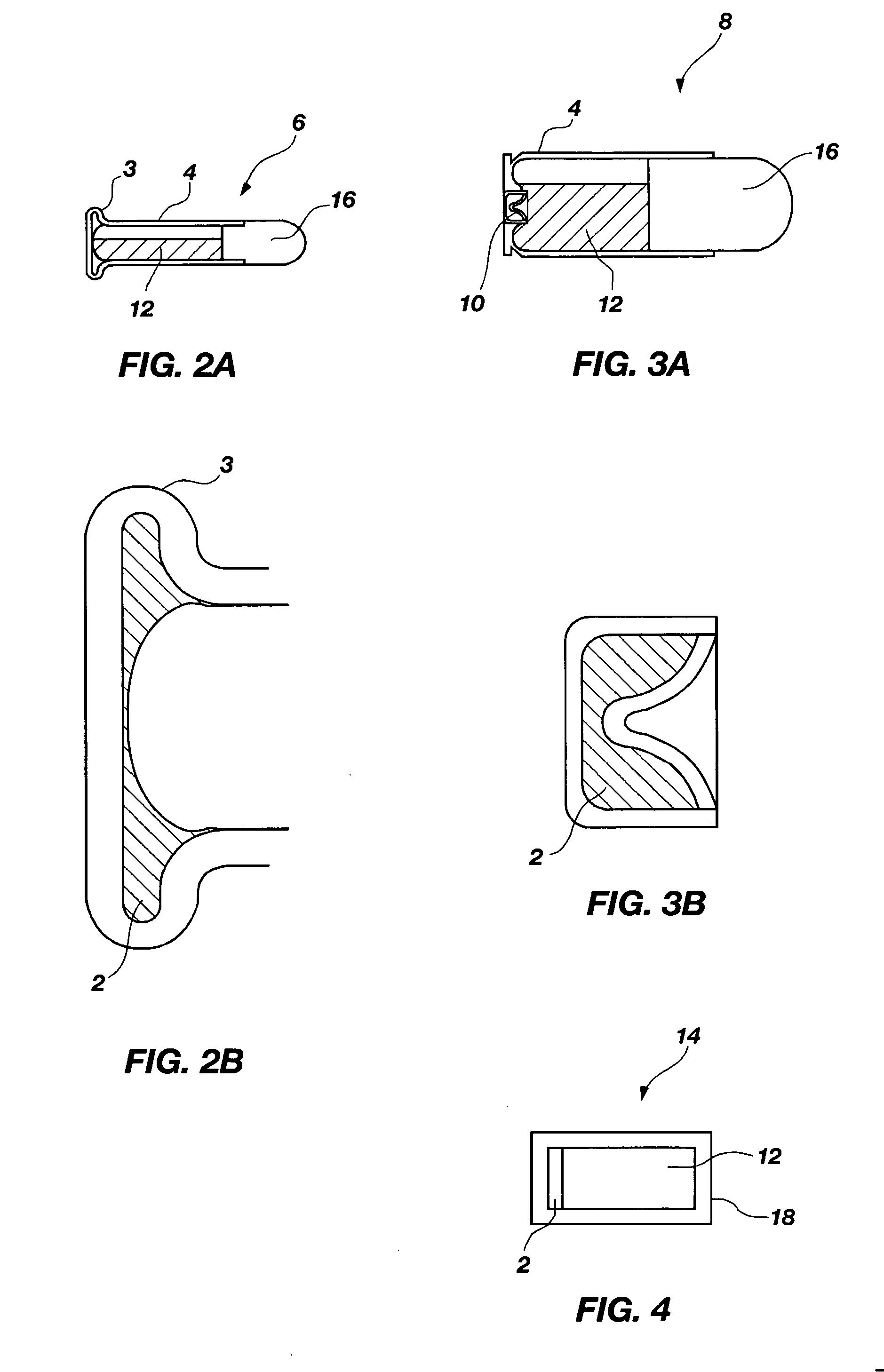

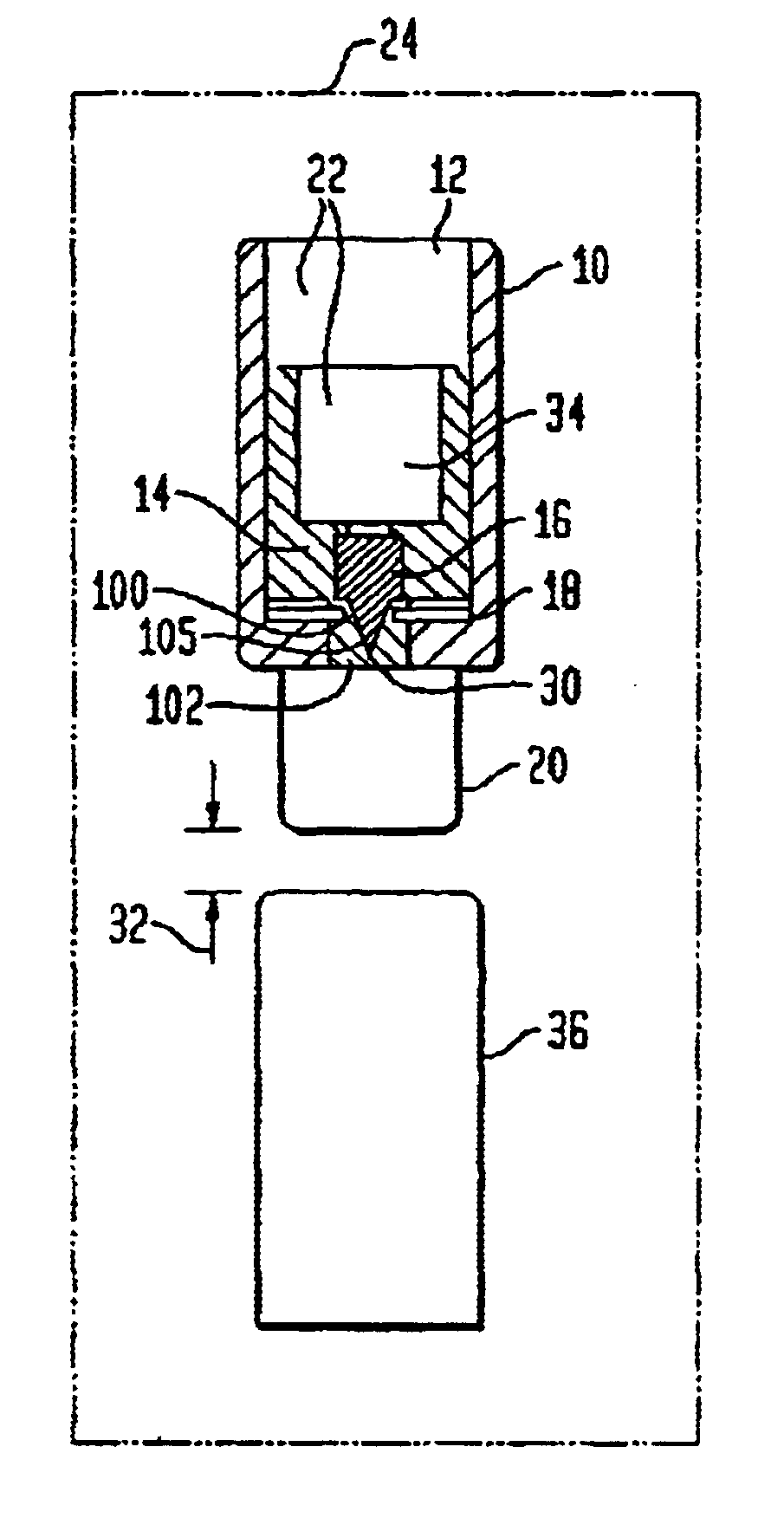

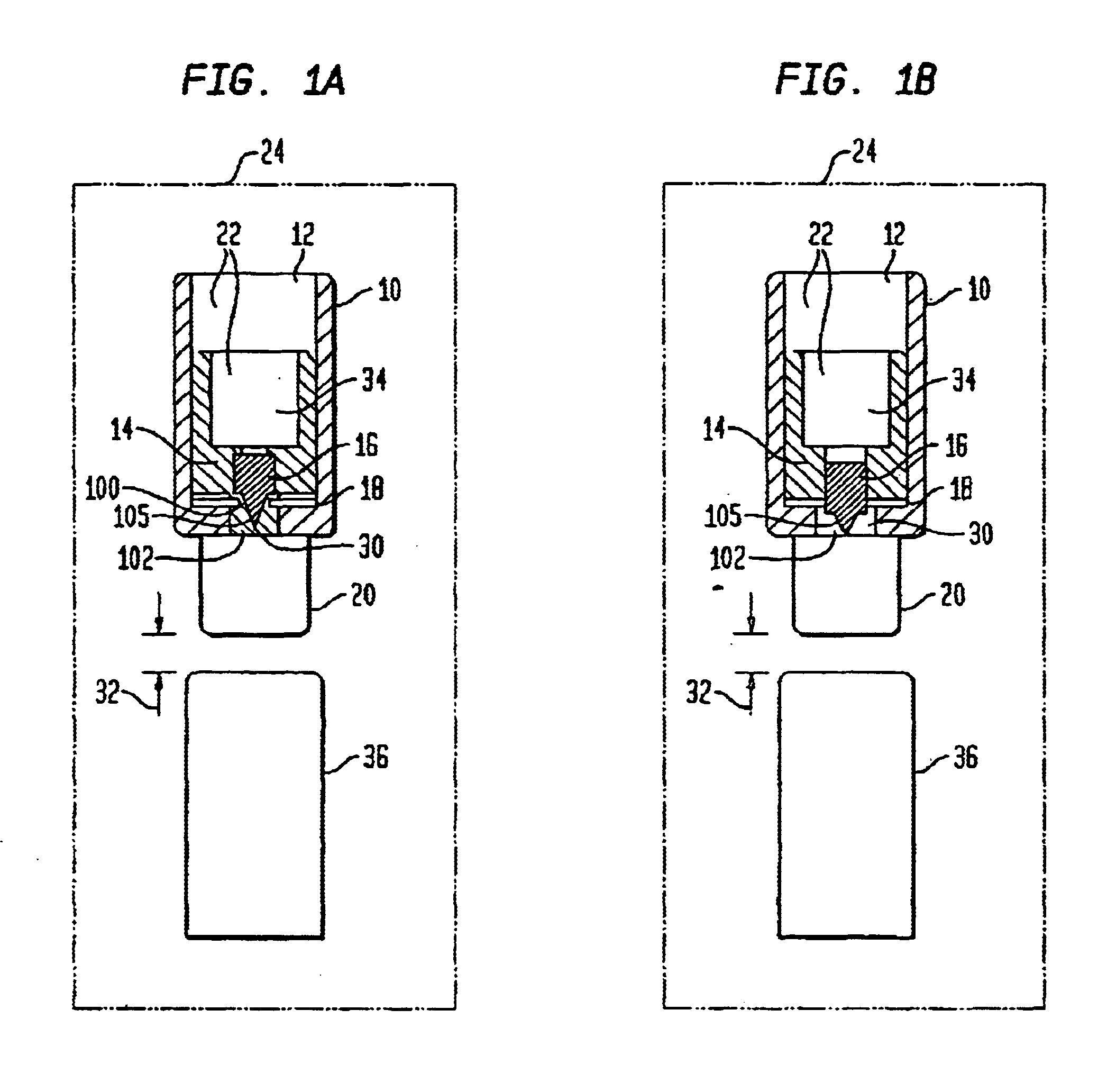

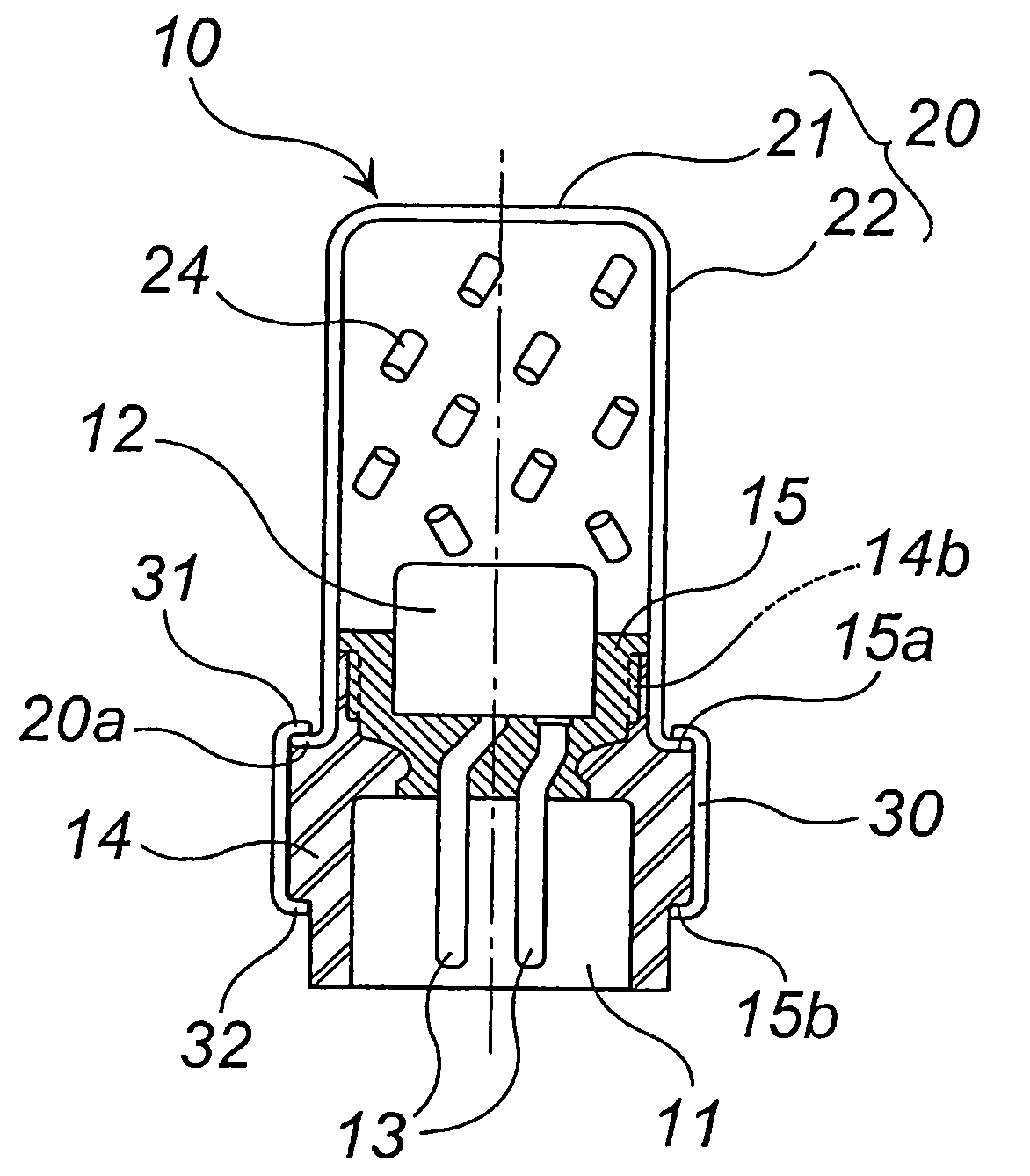

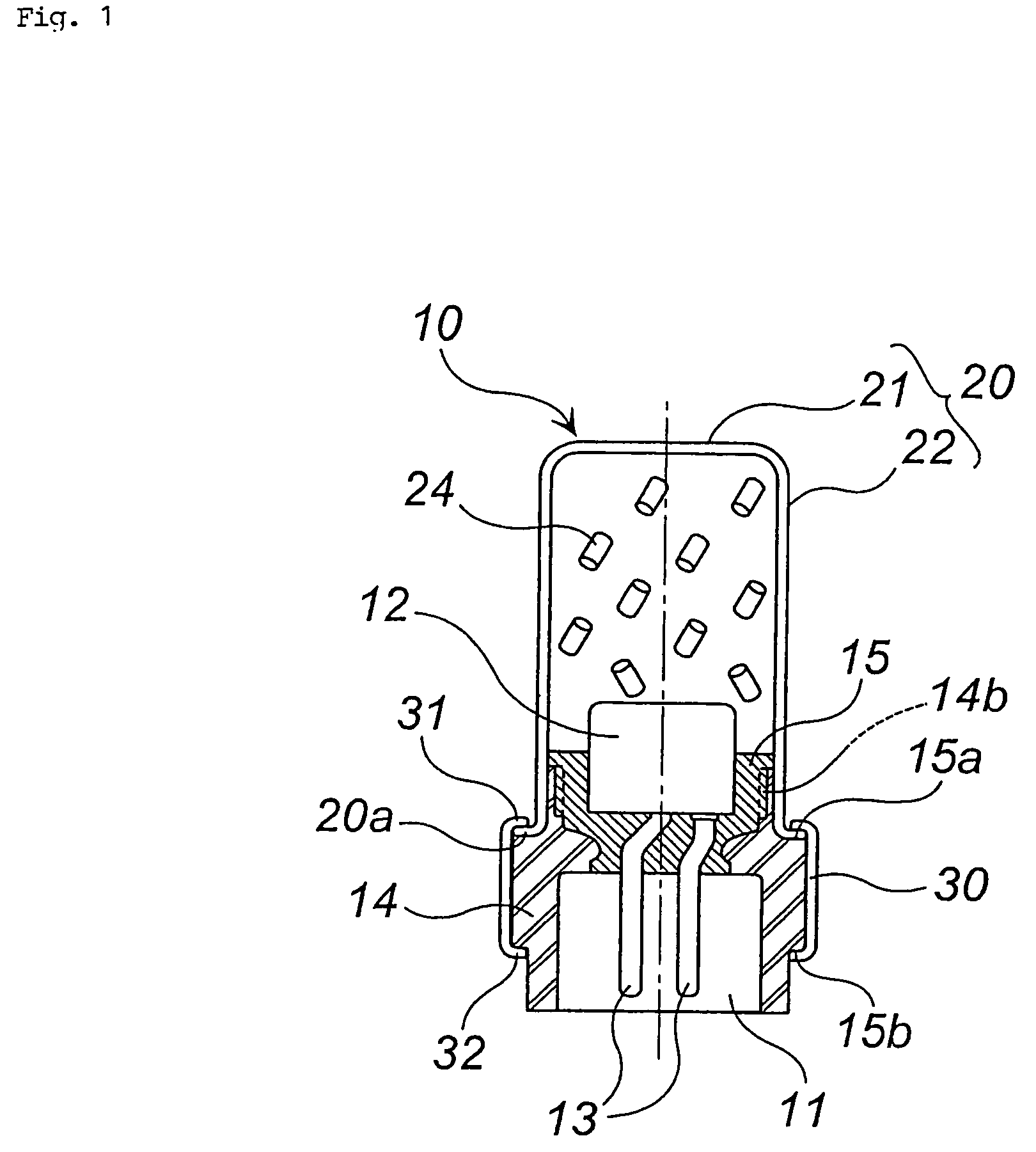

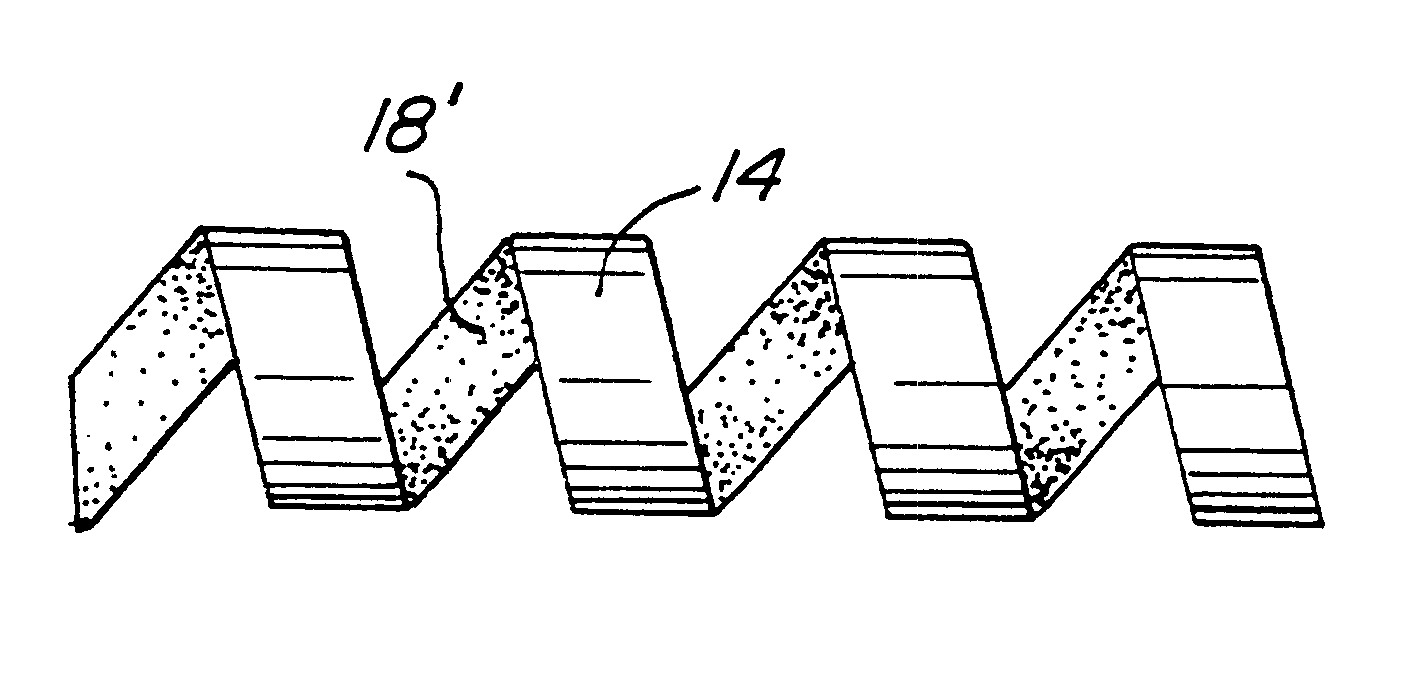

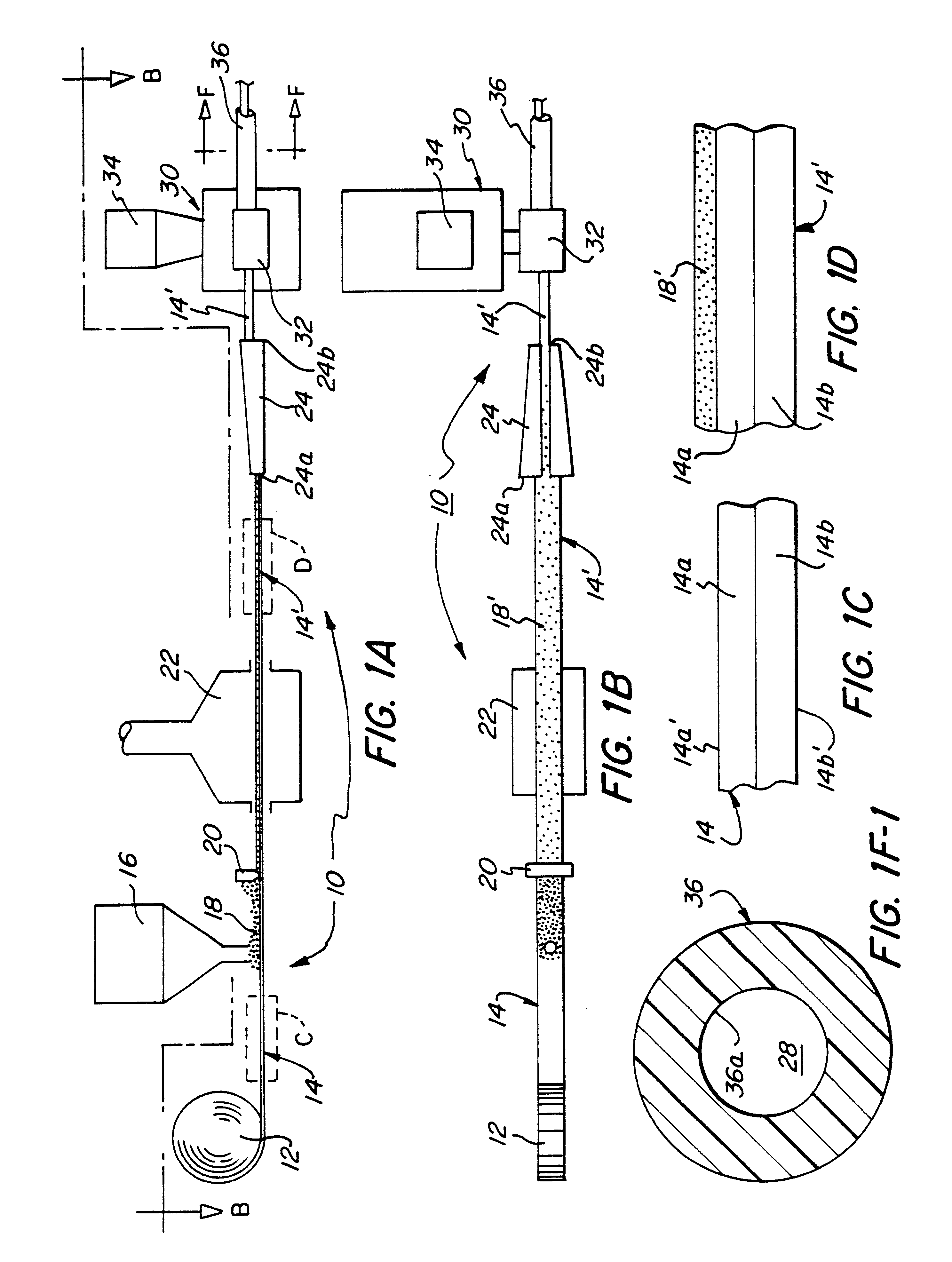

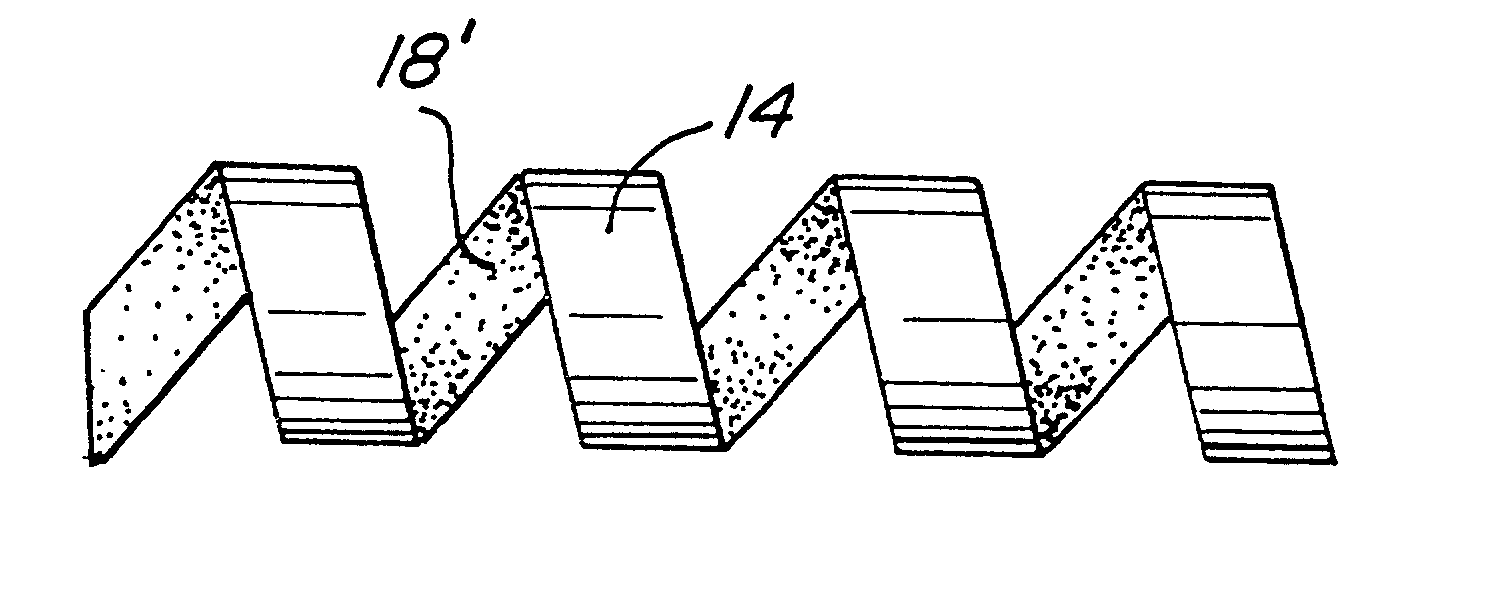

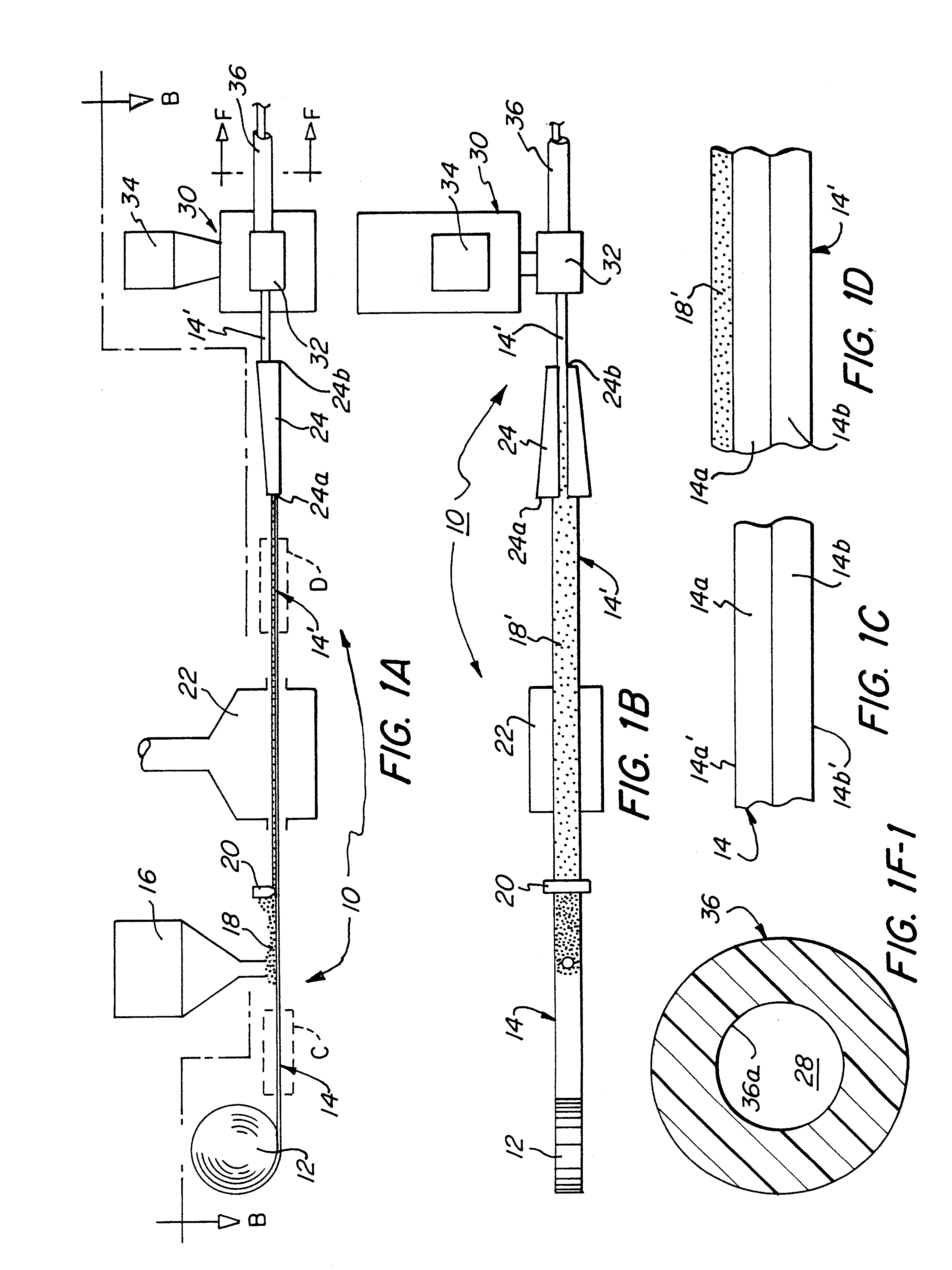

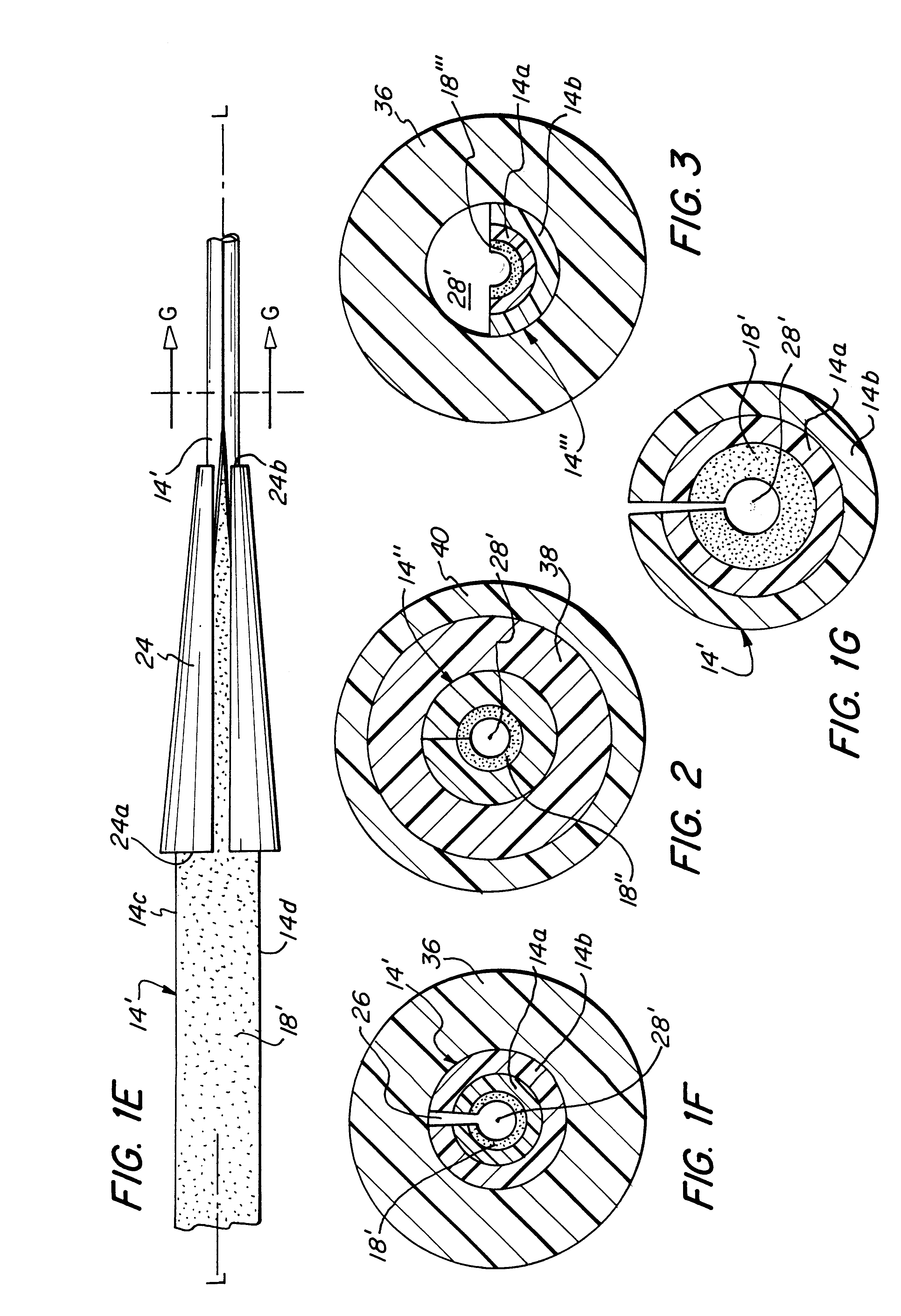

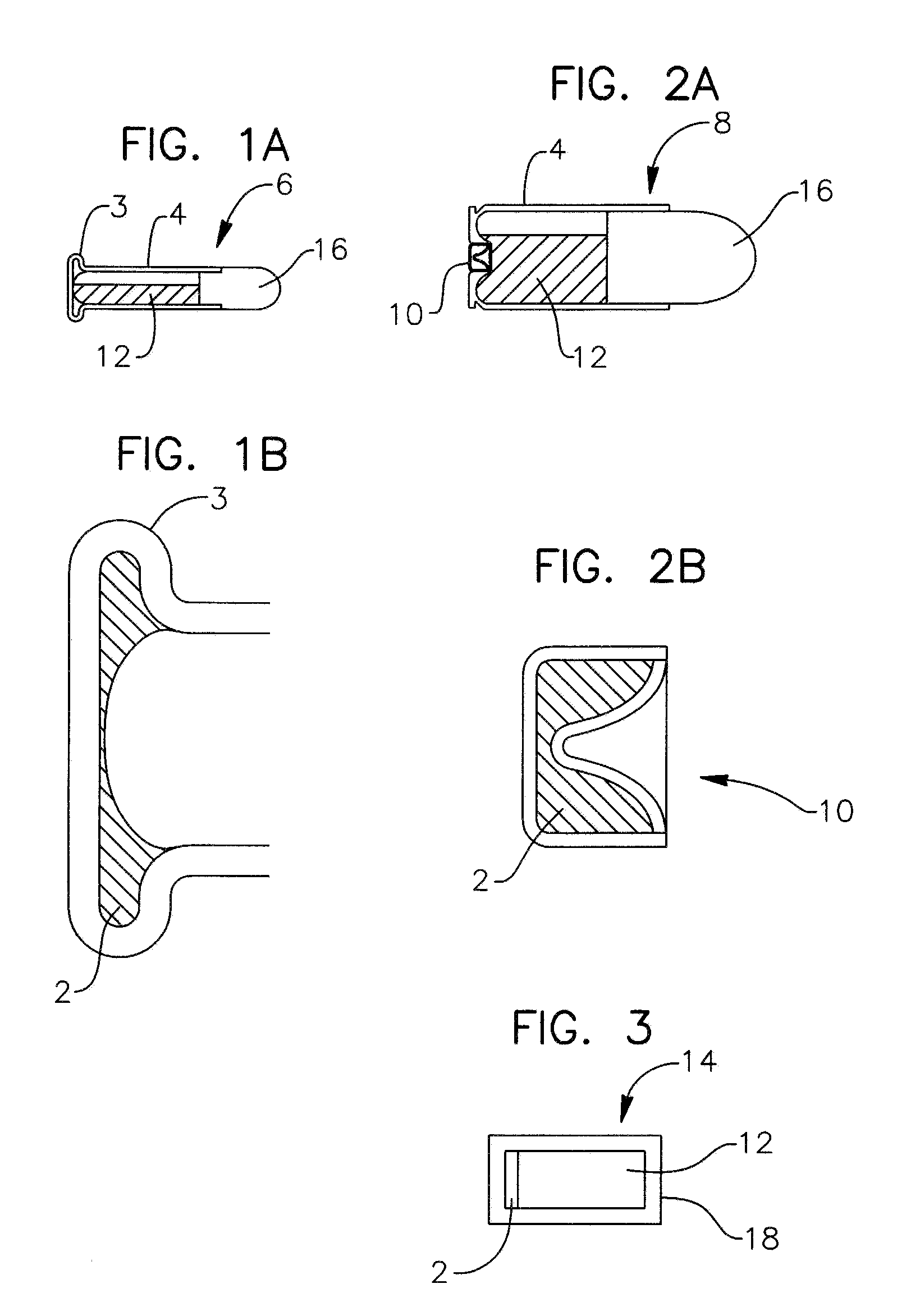

Method of making a signal transmission fuse

InactiveUS6347566B1Avoid less flexibilityEasy loadingBlasting cartridgesExplosive working-up apparatusEngineeringMechanical engineering

A signal transmission fuse is made of a tube (36) which encases a support tape (14) having a reactive coating (18') which is adhered to one side of the tape by a binder. A method of making the signal transmission fuse includes depositing on the support tape (14) a reactive paint (18) including a binder, which paint dries to form a reactive coating (18'). The coated support tape (14') is then folded, i.e., formed into a channel configuration, to provide an inner concave side of the tape on which the reactive coating (18') has been disposed. The coated support tape is then enclosed, e.g., within an extruded plastic tube (36). One side of the support tape may be made of a first material (14a) to which the reactive coating adheres, and a second side may be made of a second material (14b) which bonds or adheres to the inner surface (36a) of the plastic tube (36) enclosing the coated support tape (14'). The binder causes even high loadings of the reactive coating (18') to adhere to the coated support tape (14') to prevent reactive material migration. The support tape also shields the reactive material from the hot, freshly extruded surrounding plastic tube (36) during manufacture.

Owner:DYNO NOBEL INC

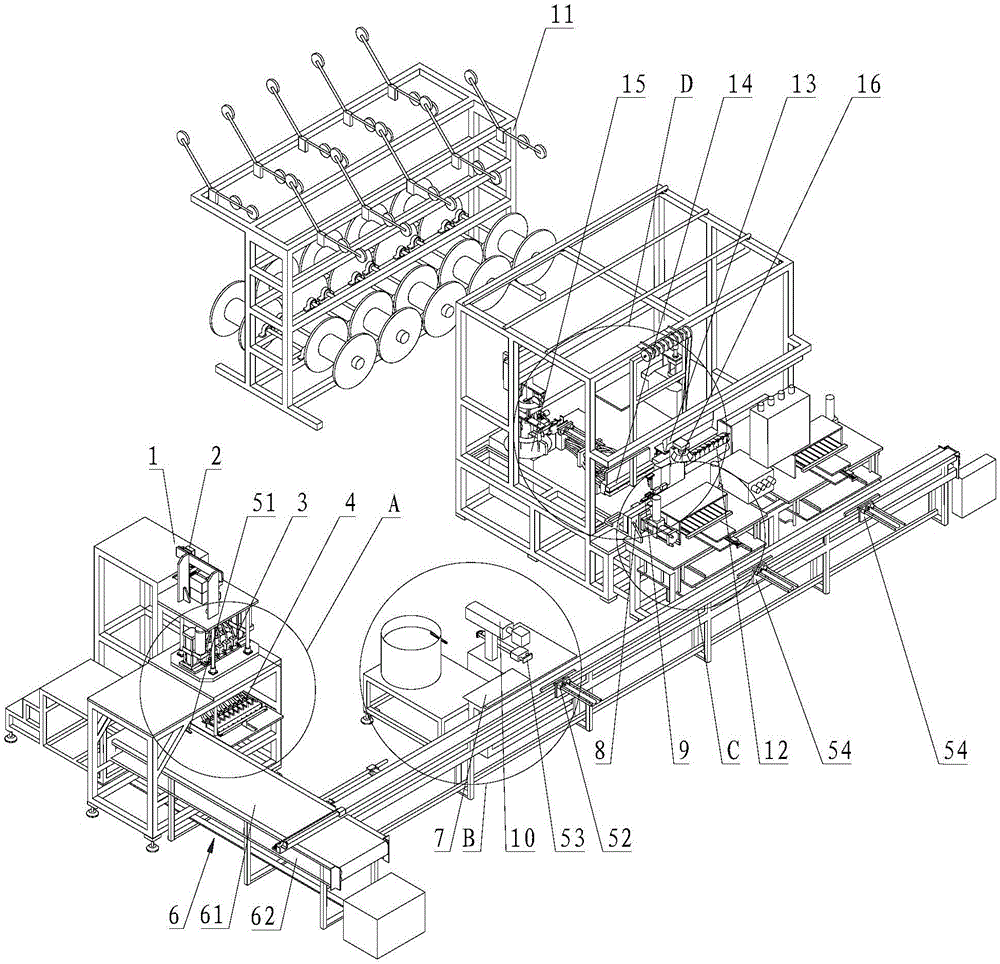

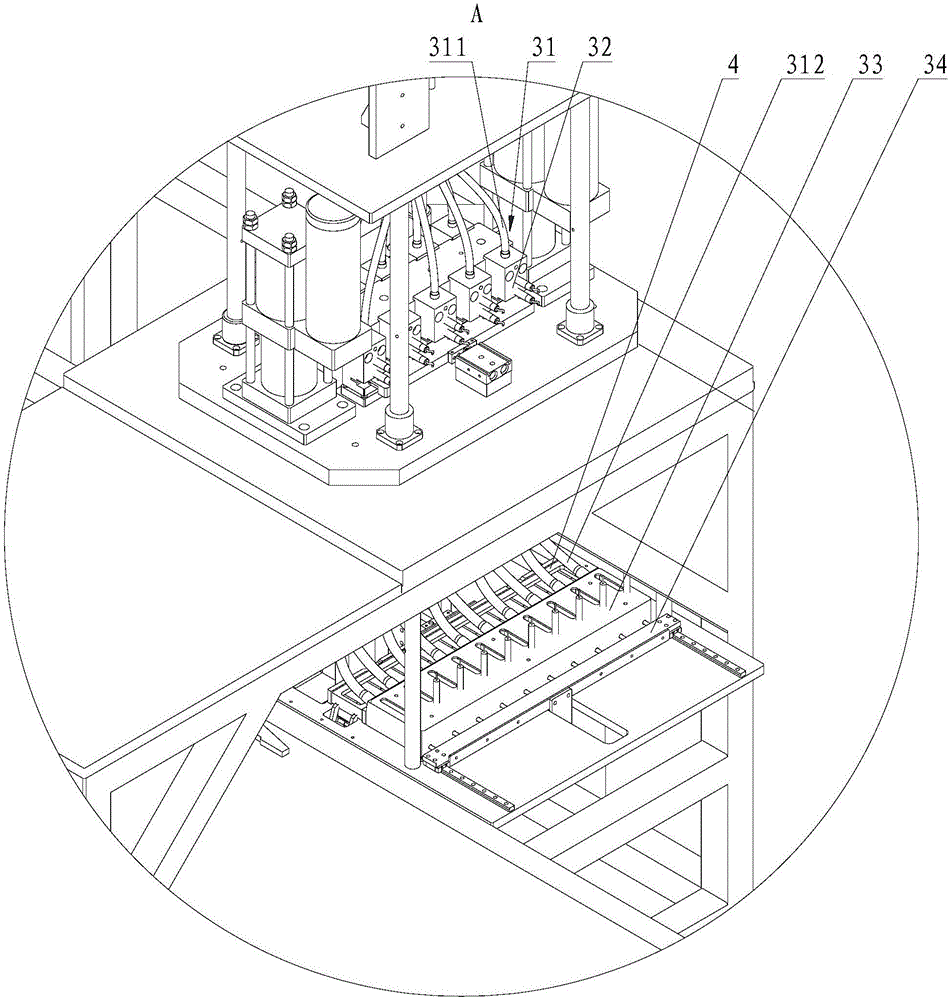

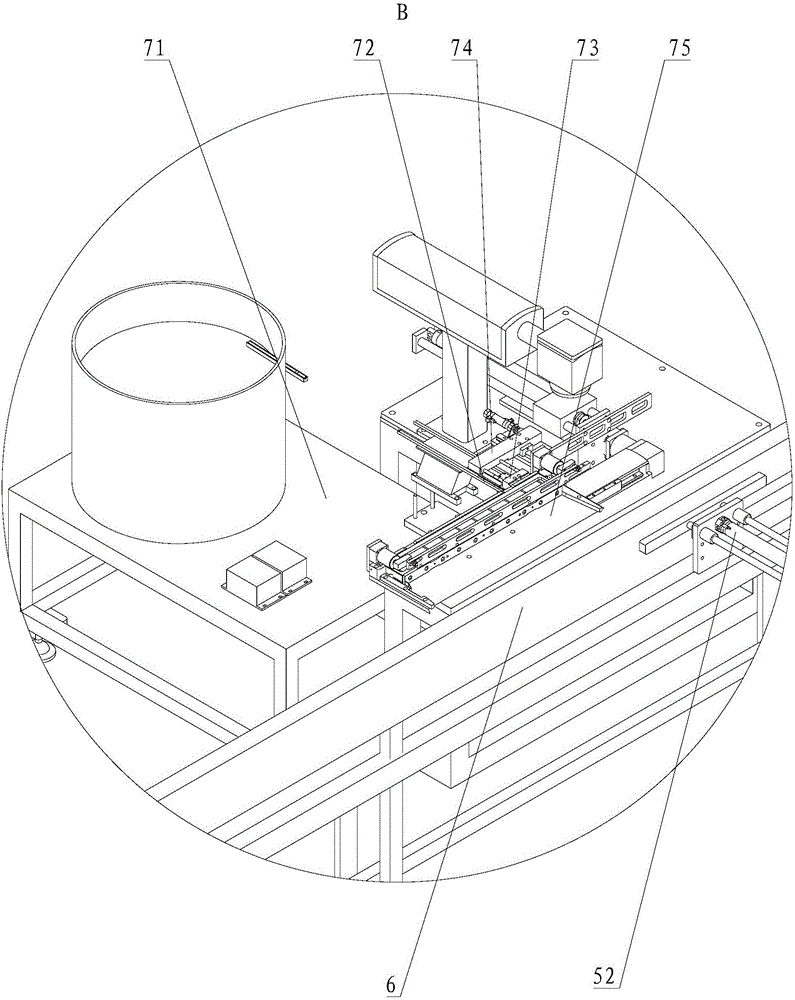

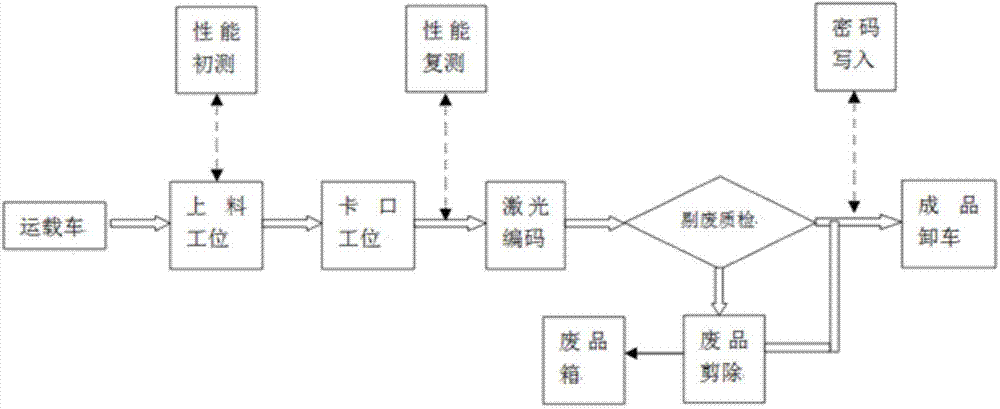

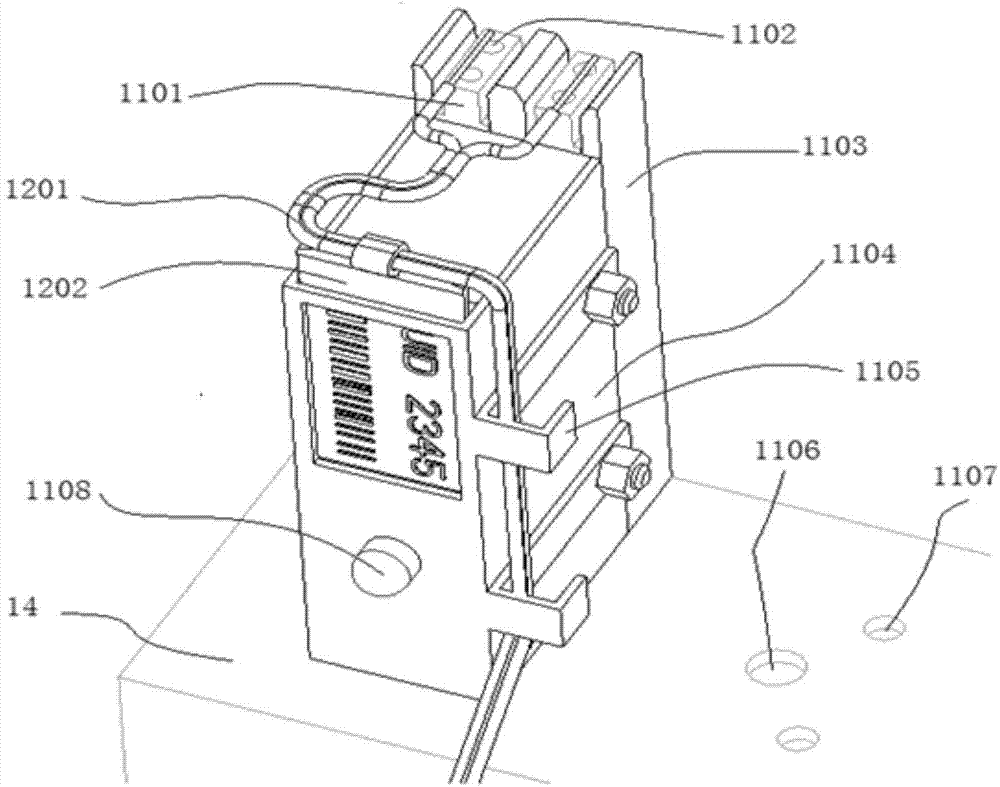

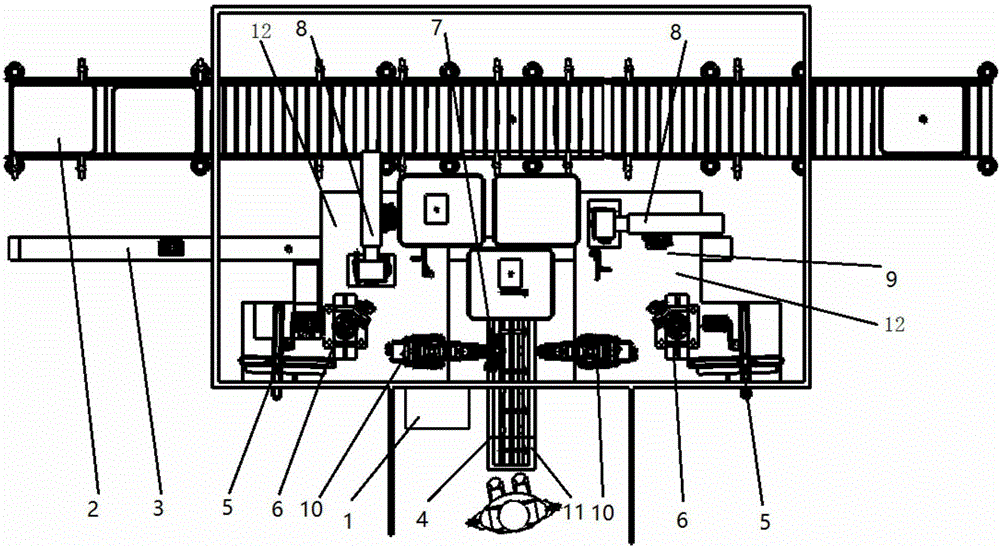

Automatic detonator assembly process and special related apparatus

InactiveCN104710253ANew feature request to implement automatic data bindingHigh degree of automationDetonatorsDetonatorProduction line

The present invention provides an automatic production line assembly process with functions of artificial detonator feeding, automatic bayonet assembly, laser marking, automatic detection and the like, and a special related apparatus. The simple process comprises that: at a feeding working position, a lot of igniters are fixed on a special transporting trolley in columns by a staff; the transporting trolley moves along a conveying track, and the integrated igniter and a detonator shell are integrally pressed by a bayonet at an automatic bayonet assembly working position; at a laser marking working position, the detonator is engraved and marked during advancing; the bayonet appearance and the laser marking quality are detected through the machine vision, and if the unqualified product exists, the unqualified product is automatically removed, the transporting trolley returns to the unloading working position, the finished product is taken out by the staff, the transporting trolley returns to the feeding working position so as to complete the one production process; and a plurality of the same transporting trolleys perform pipeline operations so as to form the automated detonator production line. The process of the present invention has characteristics of high automation degree, high production efficiency, human-machine isolation operation, high safety, and good application prospects.

Owner:北京全安密灵科技股份公司

Signal transmission fuse

InactiveUS6170398B1Avoid less flexibilityEasy loadingBlasting cartridgesFuse manufactureEngineeringReactive material

A signal transmission fuse is made of a tube (36) which encases a support tape (14) having a reactive coating (18') which is adhered to one side of the tape by a binder. A method of making the signal transmission fuse includes depositing on the support tape (14) a reactive paint (18) including a binder, which paint dries to form a reactive coating (18'). The coated support tape (14') is then folded, i.e., formed into a channel configuration, to provide an inner concave side of the tape on which the reactive coating (18') has been disposed. The coated support tape is then enclosed, e.g., within an extruded plastic tube (36). One side of the support tape may be made of a first material (14a) to which the reactive coating adheres, and a second side may be made of a second material (14b) which bonds or adheres to the inner surface (36a) of the plastic tube (36) enclosing the coated support tape (14'). The binder causes even high loadings of the reactive coating (18') to adhere to the coated support tape (14') to prevent reactive material migration. The support tape also shields the reactive material from the hot, freshly extruded surrounding plastic tube (36) during manufacture.

Owner:DYNO NOBEL INC

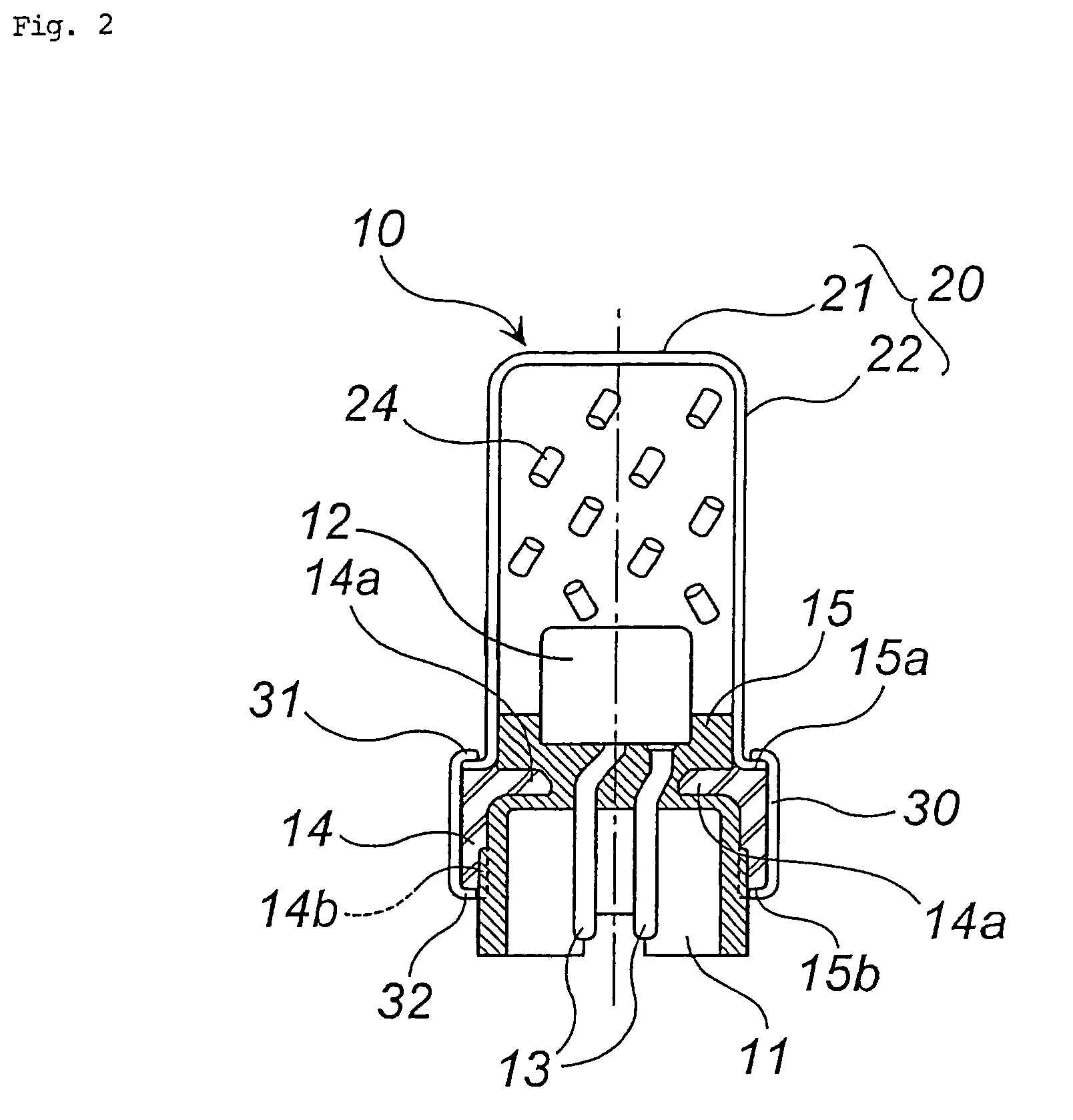

Igniter and gas generator having the same

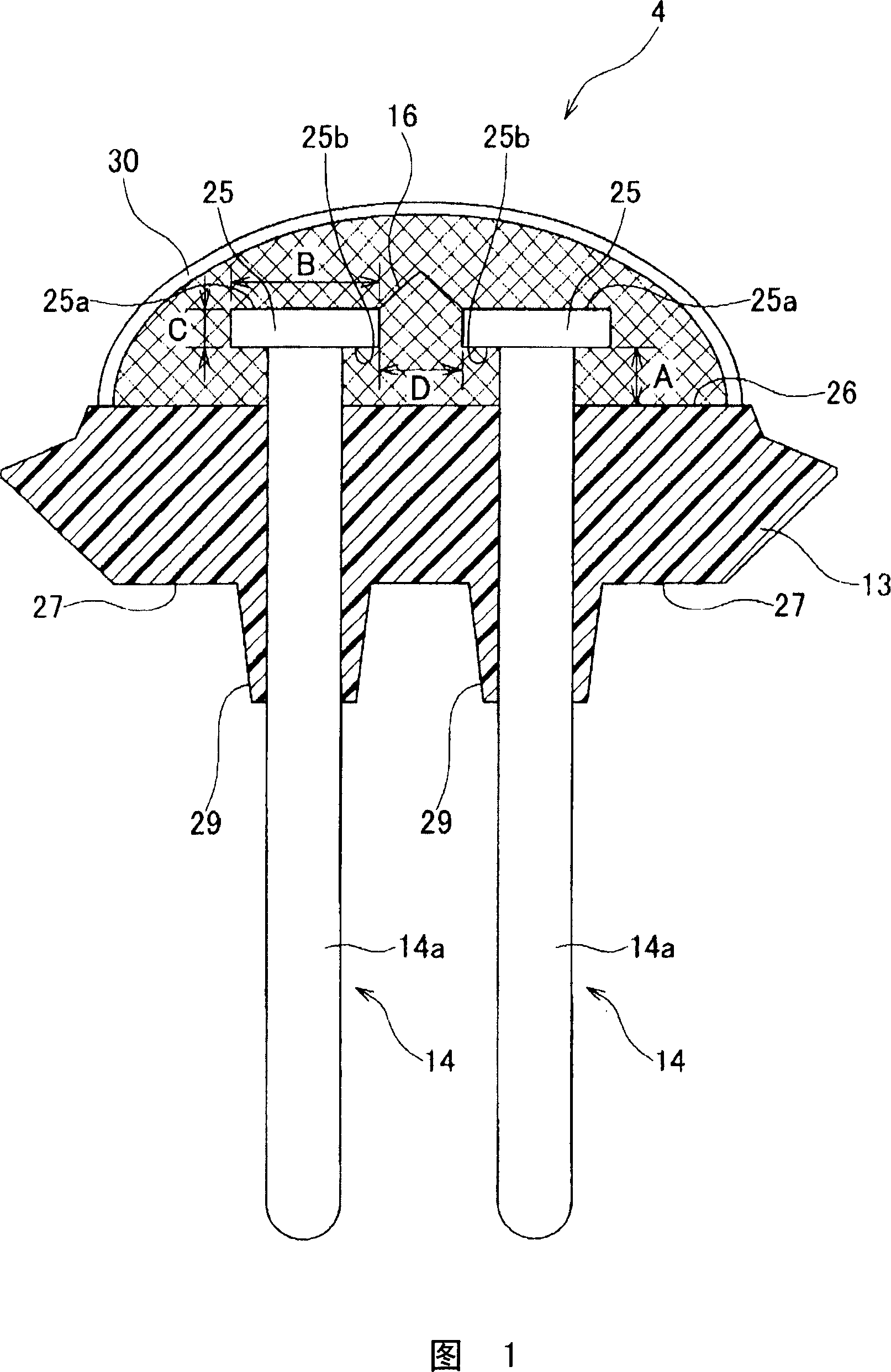

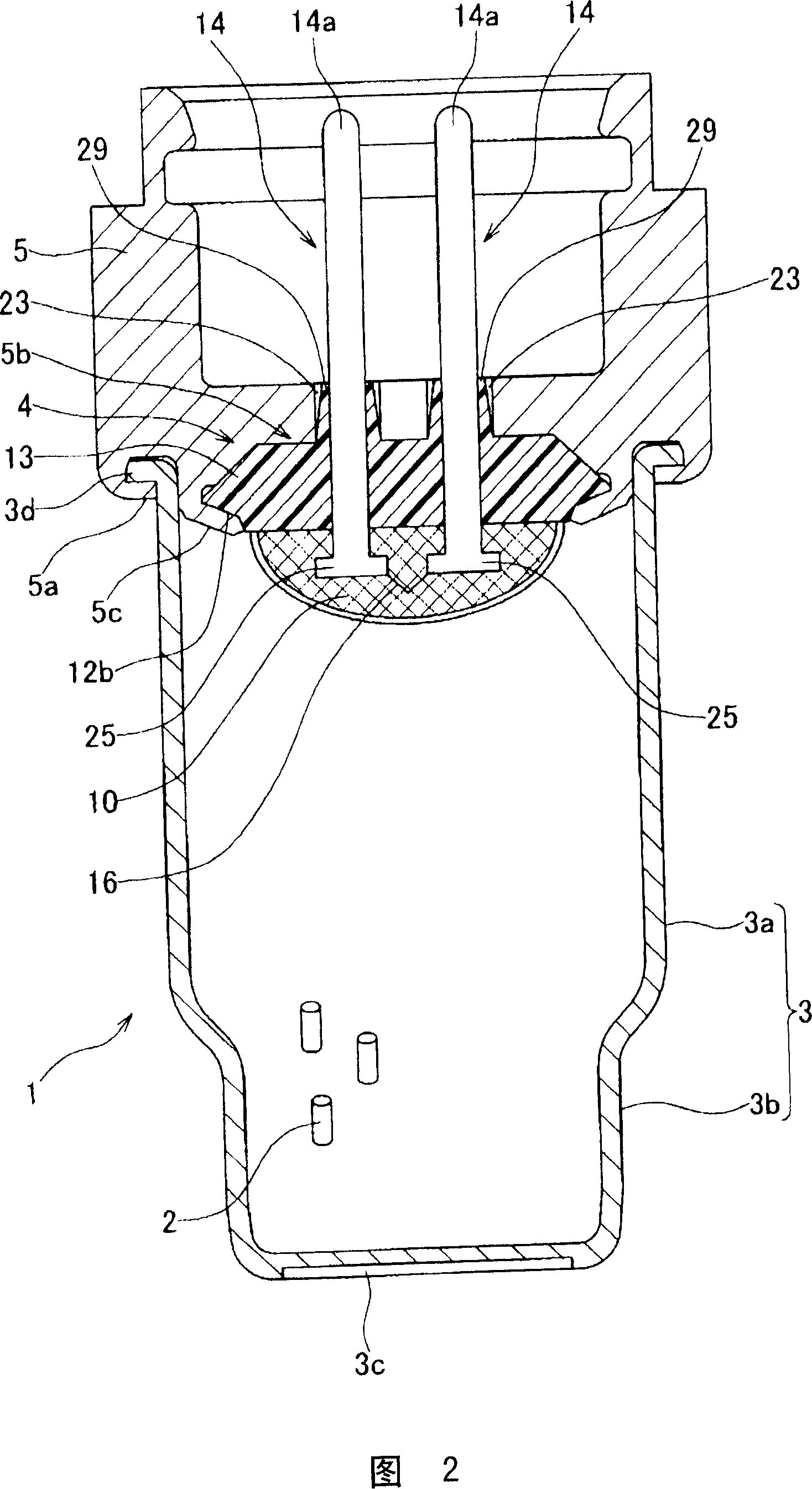

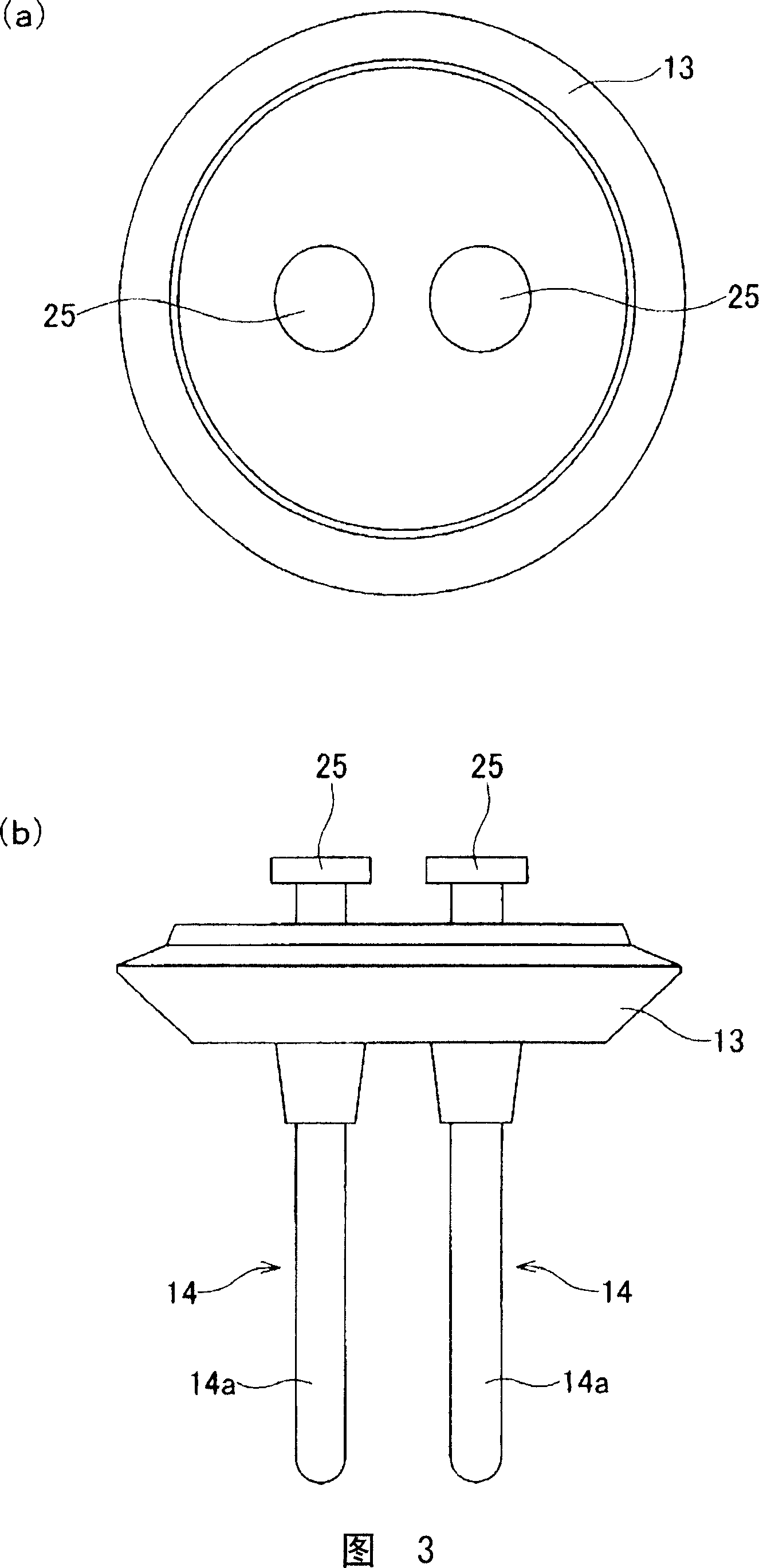

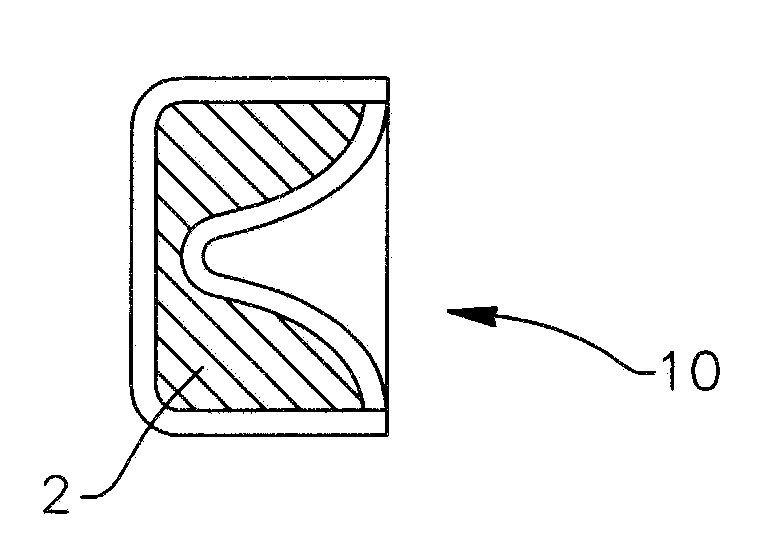

An igniter enabling the normal ignition of a gas generating agent even if the adhered state of a firing charge to a plug is eliminated by vibration or shock and a gas generator having the igniter. The igniter comprises the plug (13), two or more electrode pins (14) passed through the plug (13) and having head parts (25), a bridge wire (16) connecting at least two electrode pins (14) among the electrode pins (14) across the head parts (25), and the firing charge (10) ignited by the bridge wire (16) energized through the electrode pins (14). The plug (13) is formed of a hardened material of a thermosetting resin composition. The electrode pins (14) allowing the bridge wire (16) to be connected to the head parts (25) thereof are passed through the plug (13) at a specified distance (A) between the head parts (25) and the plug (13), and at least the head parts (25) and the bridge wire (16) are surrounded by the firing charge (10) in the form of a solid body and fixed to the plug (13).

Owner:NIPPON KAYAKU CO LTD

Non-toxic percussion primers and methods of preparing the same

Owner:FEDERAL CARTRIDGE

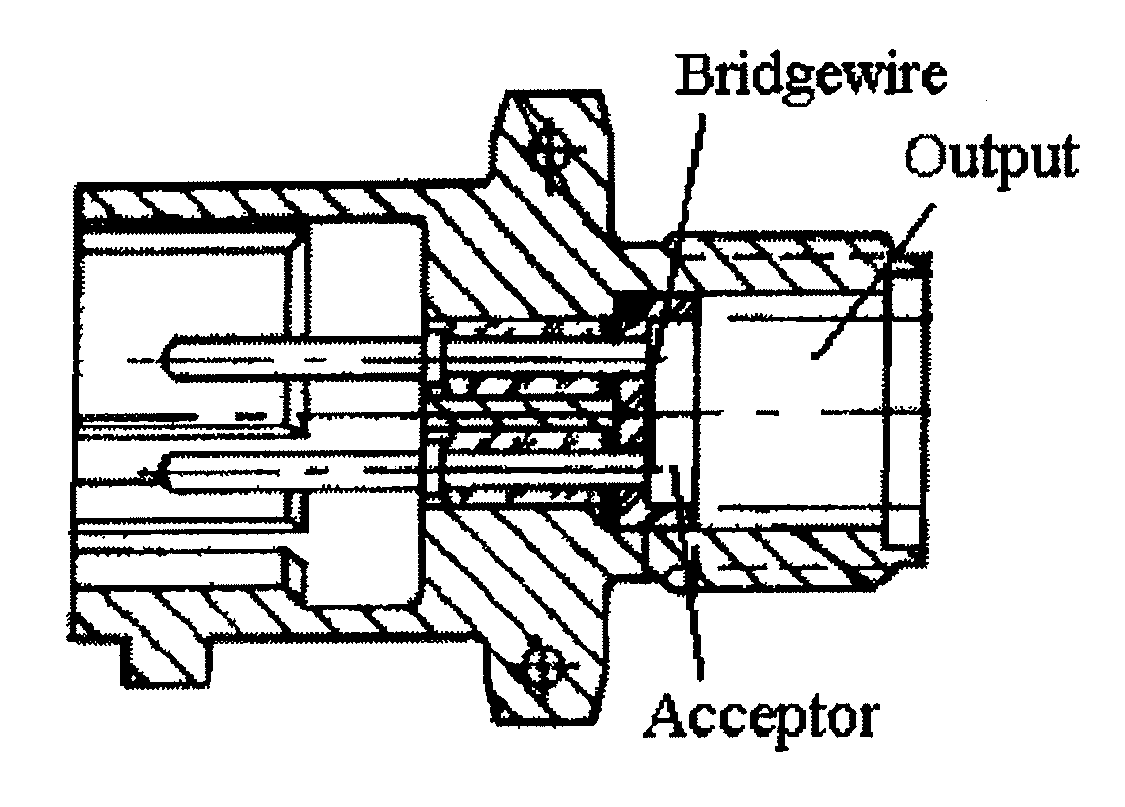

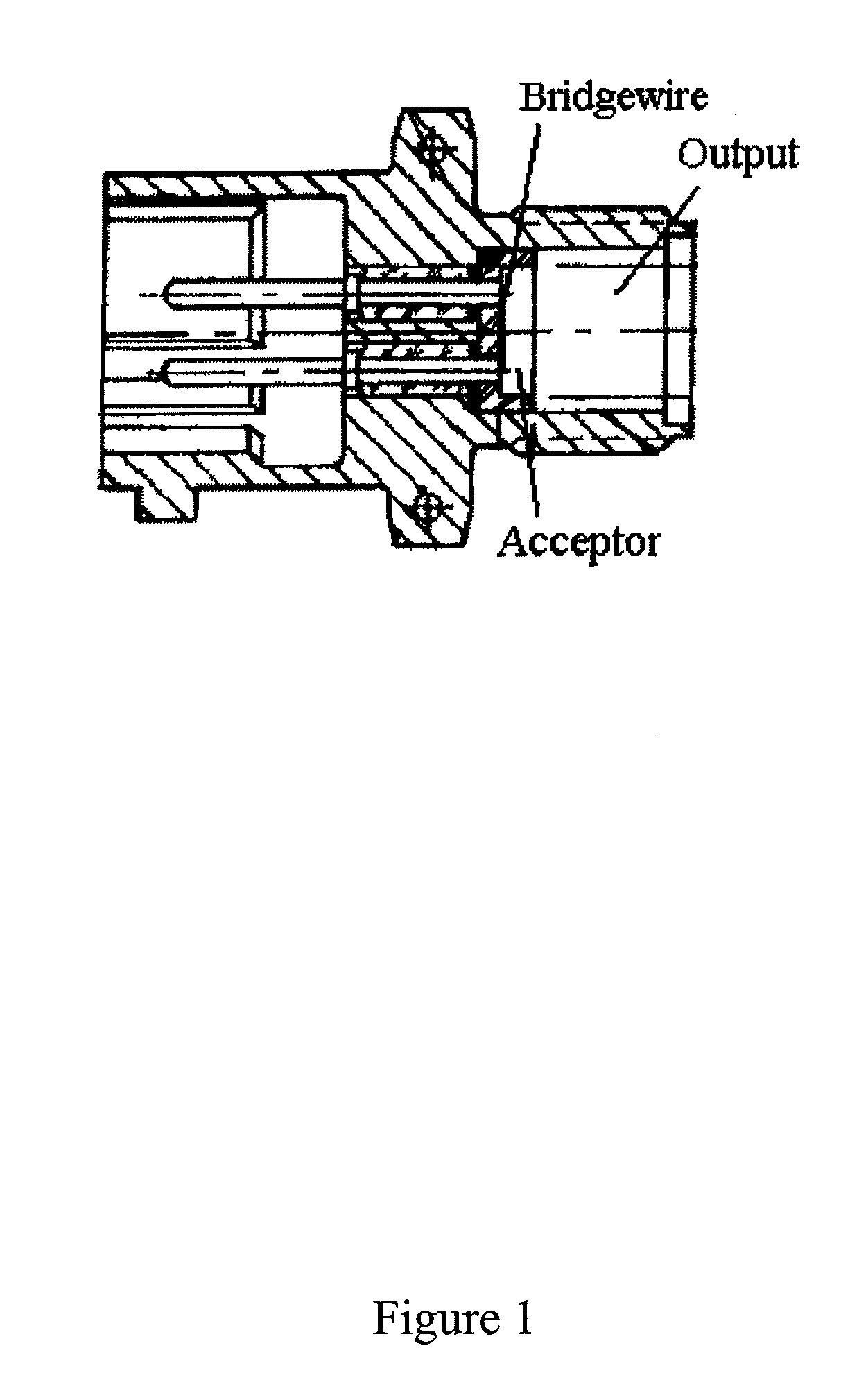

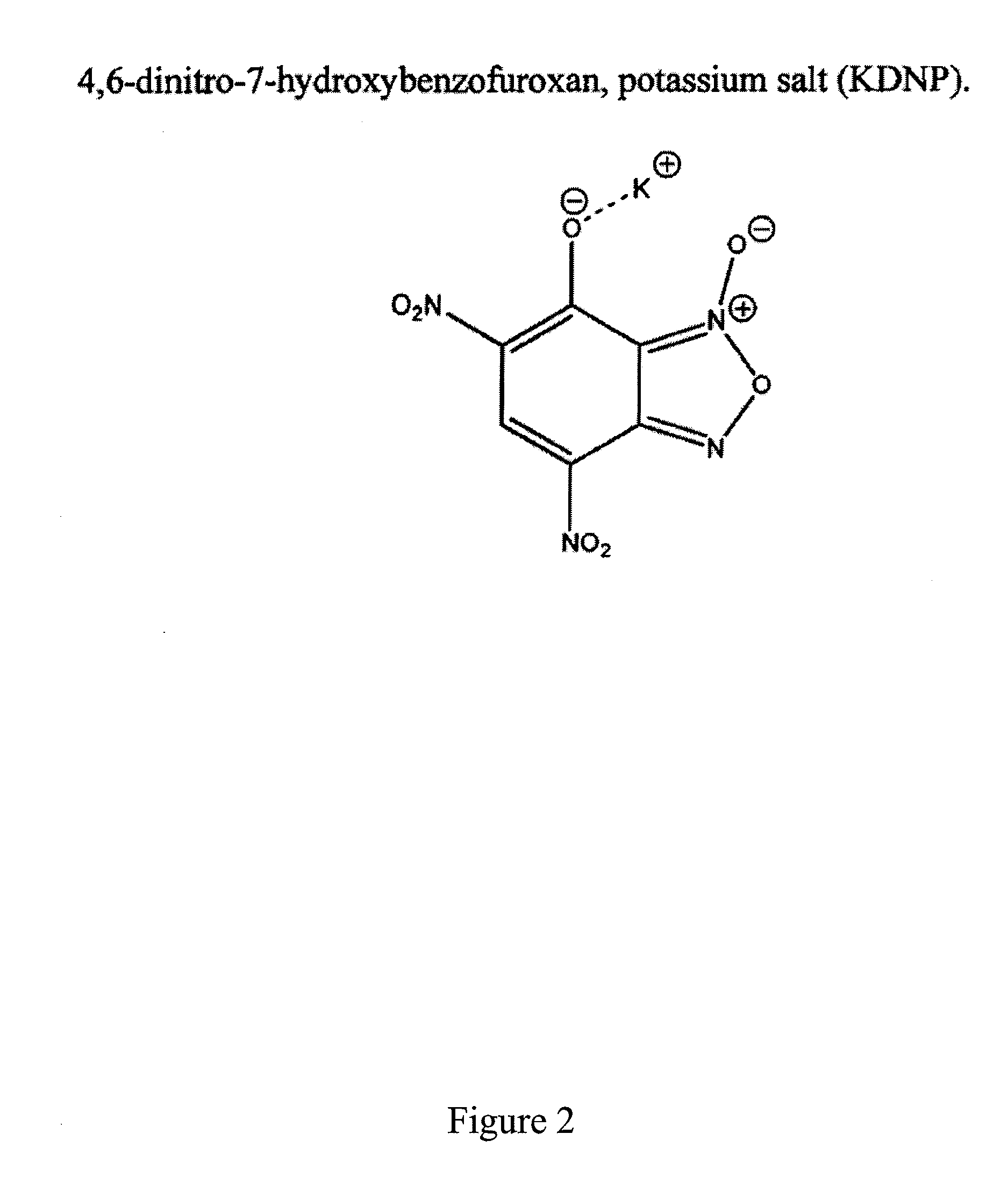

Lead-free primers

Embodiments of the present subject matter provide an improved percussion primer composition and improved hot-wire igniter acceptor, wherein lead styphnate is replaced with a lead-free material, 4,6-dinitro-7-hydroxybenzofuroxan, potassium salt (KDNP). Embodiments of the percussion primer composition include KDNP, a sensitizer, an oxidizer, calcium silicide, a fuel, and a binder. Sensitizers may include tetracene. Oxidizers may include alkali or alkaline earth nitrates, oxides, or peroxides (such as barium nitrate). Fuel materials may include metals, metal sulfides, or other non-metallic materials. Common binders may include nitrocellulose based shellacs, gum arabic / poly vinyl alcohol mixtures, and guar gum / poly vinyl alcohol mixtures. Embodiments of the hot-wire igniter device include a bridgewire, an acceptor, and an output, where KDNP is the acceptor. Power supply may be in the form of constant current / voltage or current flow from a capacitor discharge. Certain embodiments utilize a variety of output formulations, such as BKNO3, black powder, and Red Dot double base propellant.

Owner:PACIFIC SCI ENERGETIC MATERIALS +1

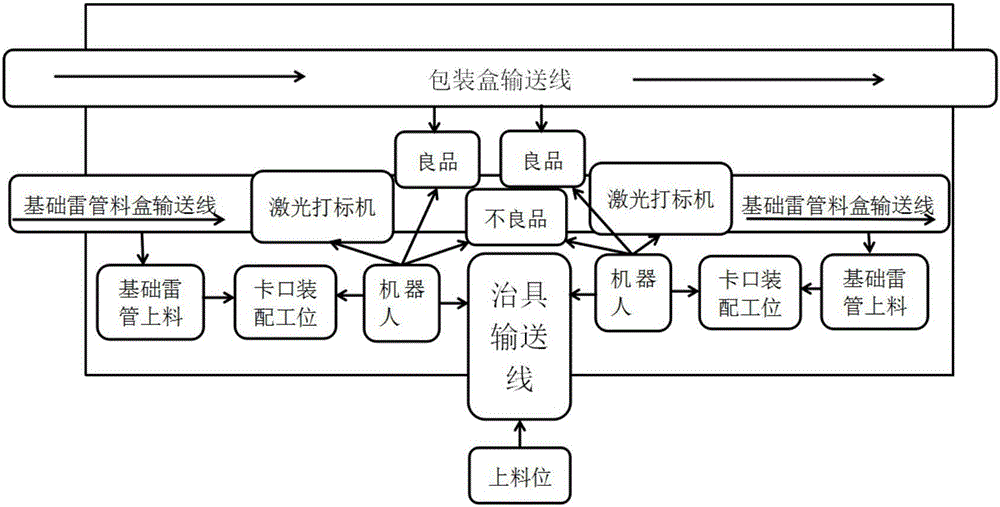

Automatic assembly, detection and marking method and system for electronic detonator

The invention provides an automatic assembly, detection and marking method and system for an electronic detonator. The automation degree can be significantly improved by the method and the system; multi-station parallel production can be achieved through cooperation with a packaging box transport mechanism; the production efficiency is high; the quality and stability of a product are good; man-machine isolation operation of dangerous procedures of feeding, closing, detecting and laser marking of the most dangerous basic detonator in detonator production is completely achieved; the security is extremely high; the new function requirement of binding of a novel electronic detonator password, a UID code and a detonator body laser code can be achieved; and therefore, the automatic assembly, detection and marking method and system for the electronic detonator have extremely high popularization values and application prospects.

Owner:BEIJING QAML OF SCI & TECH CO LTD

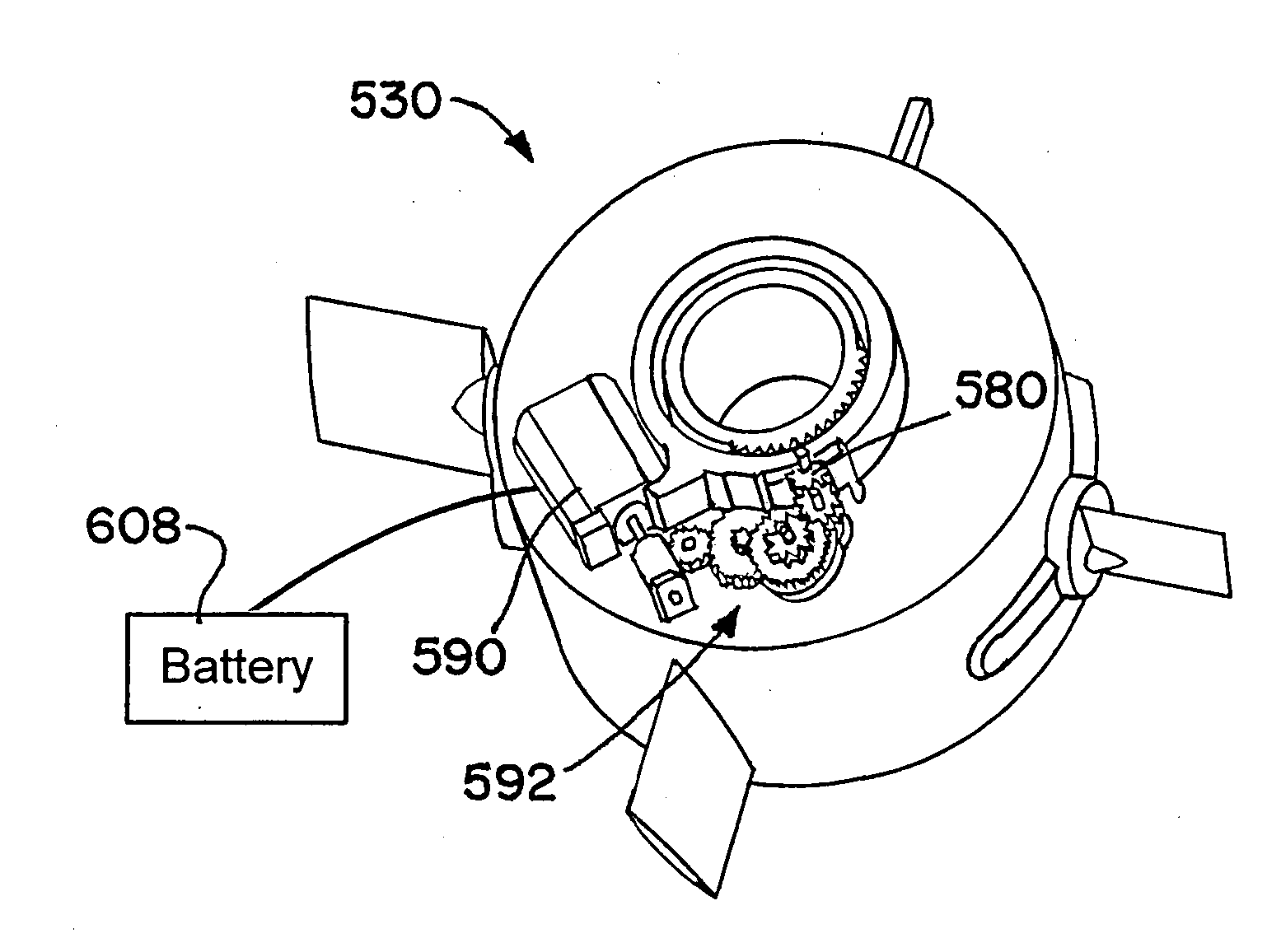

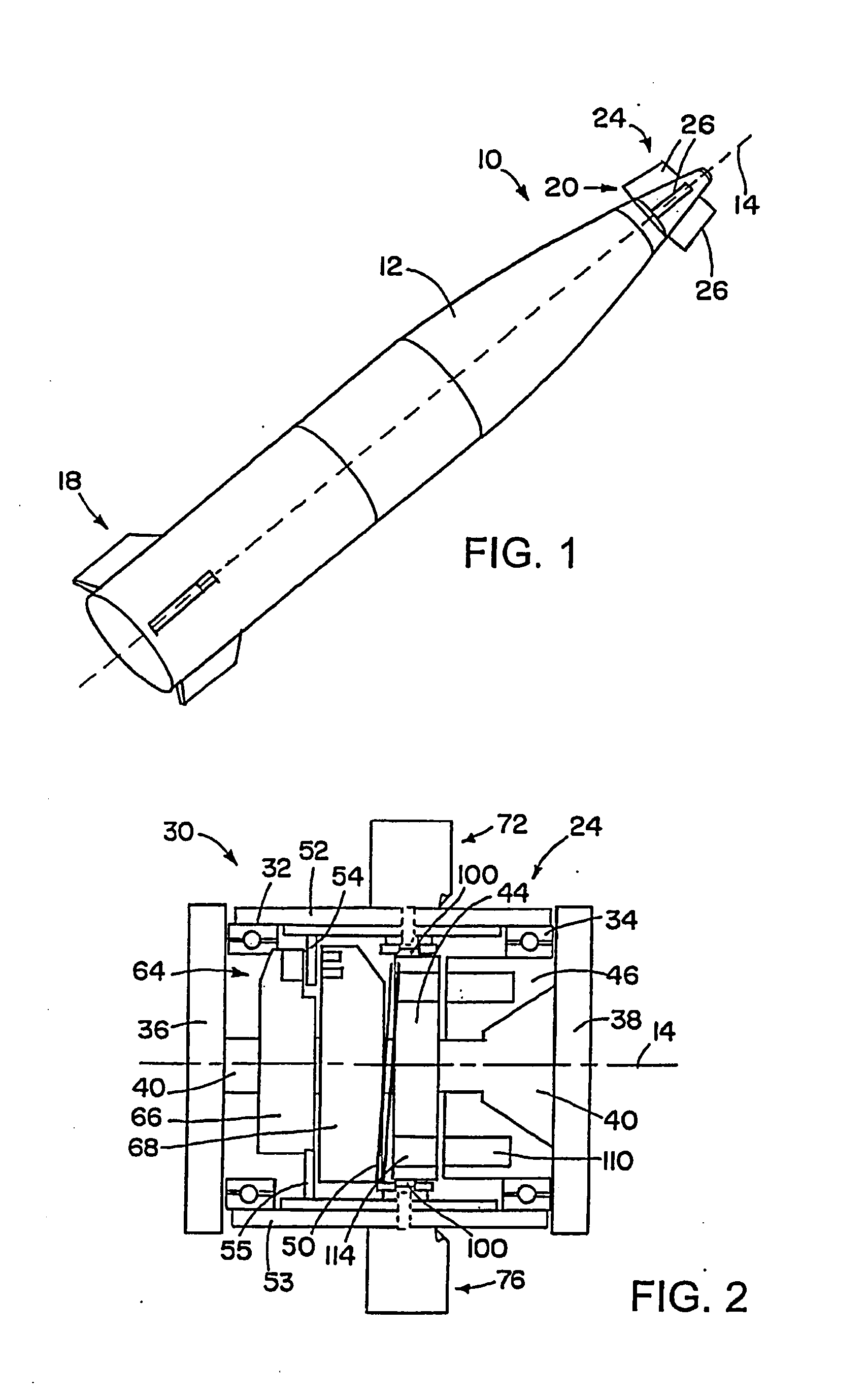

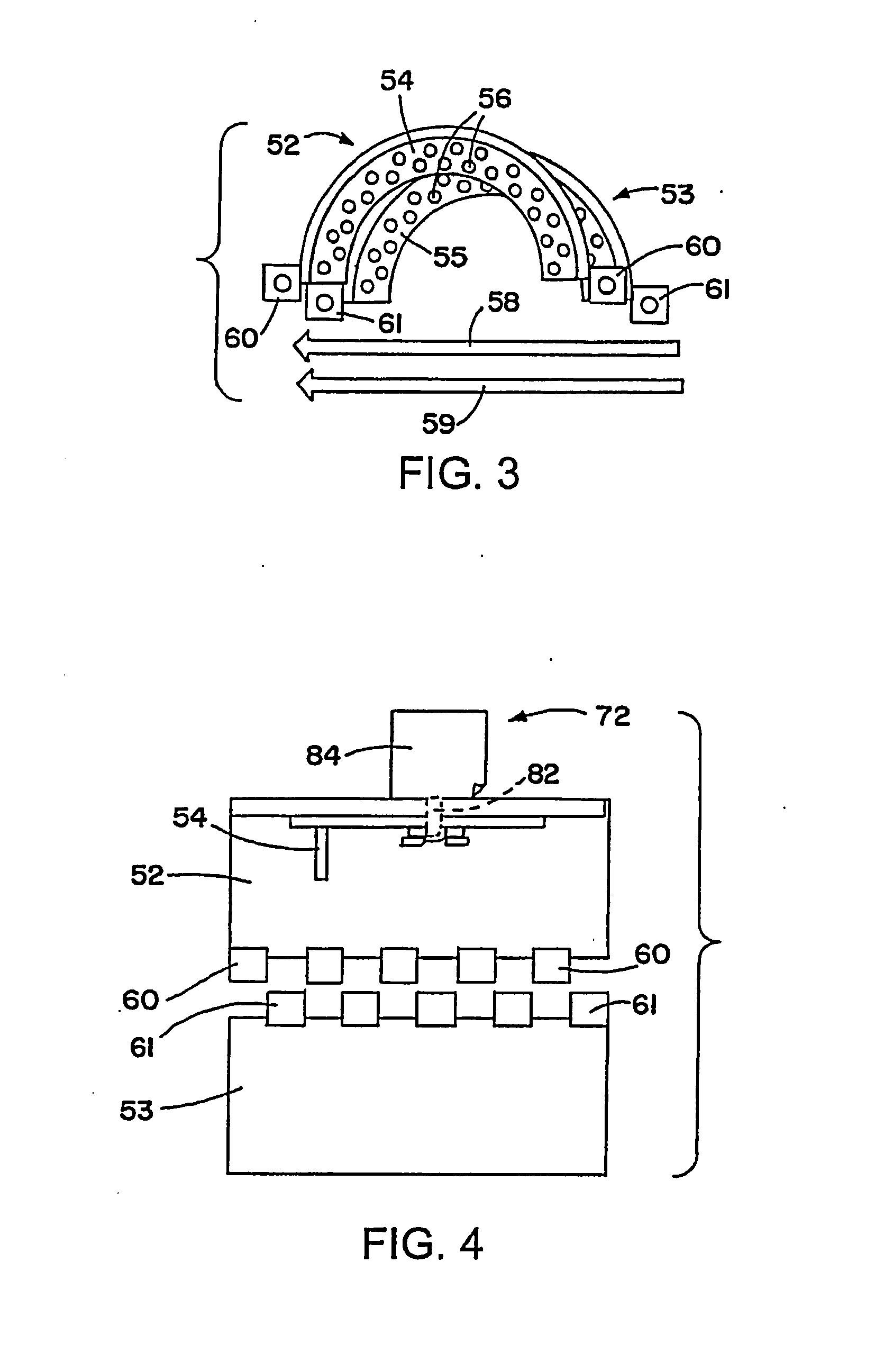

Guidance control for spinning or rolling vehicle

A projectile, air vehicle or submersible craft with a spinning or rolling fuselage, rotating on its axis, has a collar which can be positioned relative to a longitudinal axis of the projectile using aerodynamic forces. Aerodynamic surfaces, such as lift-producing surfaces, for example tails or canards, are coupled to the collar, and rotate with the collar. An actuator system or mechanism controls orienting of the lift-producing surfaces, such as tilting of the lift producing surfaces, to direct the collar into a desired position relative to a longitudinal axis of the projectile, and to maintain the collar in that position. With such a control the projectile is able to be steered using bank-to-turn maneuvering. The actuator system may use any of a variety of mechanisms to move the lift-producing surfaces, thereby positioning the collar.

Owner:RAYTHEON CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com