Patents

Literature

462results about How to "Fast bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

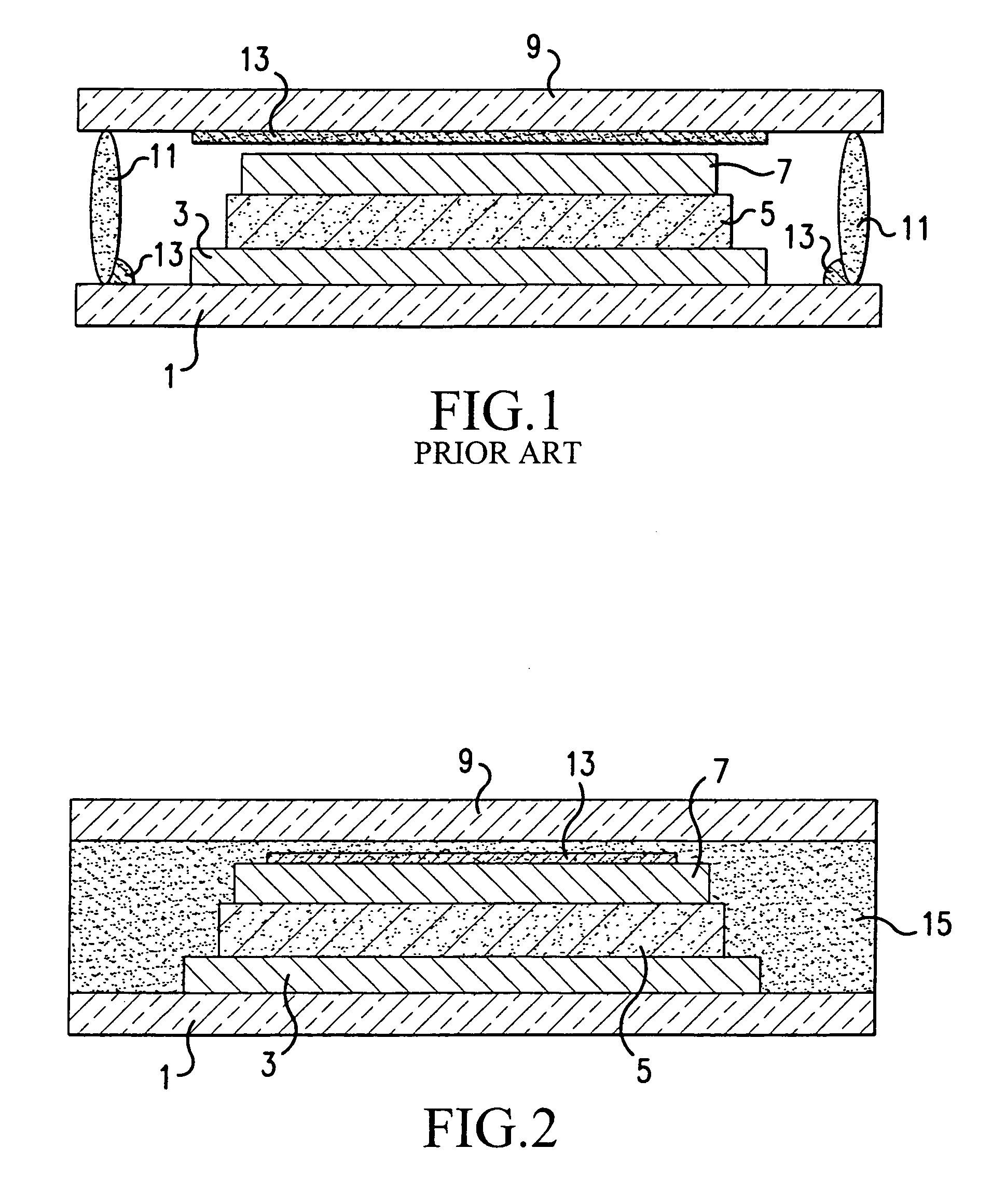

Transformable pressure sensitive adhesive tape and use thereof in display screens

InactiveUS20060100299A1Easy and safe applicationLow level of VOC 'sNanostructure manufactureGas-filled discharge tubesDisplay deviceLight-emitting diode

A transformable pressure sensitive adhesive composition comprised of from about 15 to about 80% by weight of a polymer having a softening point greater than 60° C.; from about 20 to about 85% by weight of a polymerizable resin having a softening point less than 30° C.; a latent initiator in an amount sufficient to cause a reaction between said polymer and said resin; and optionally, a crosslinking agent. The transformable pressure sensitive adhesive has particular applicability in connection with organic light emitting diode display devices, light emitting diode display devices, medical diagnostic testing devices, flexible or rigid LCD display devices, plasma display devices, and electrochromic devices.

Owner:ADHESIVES RES

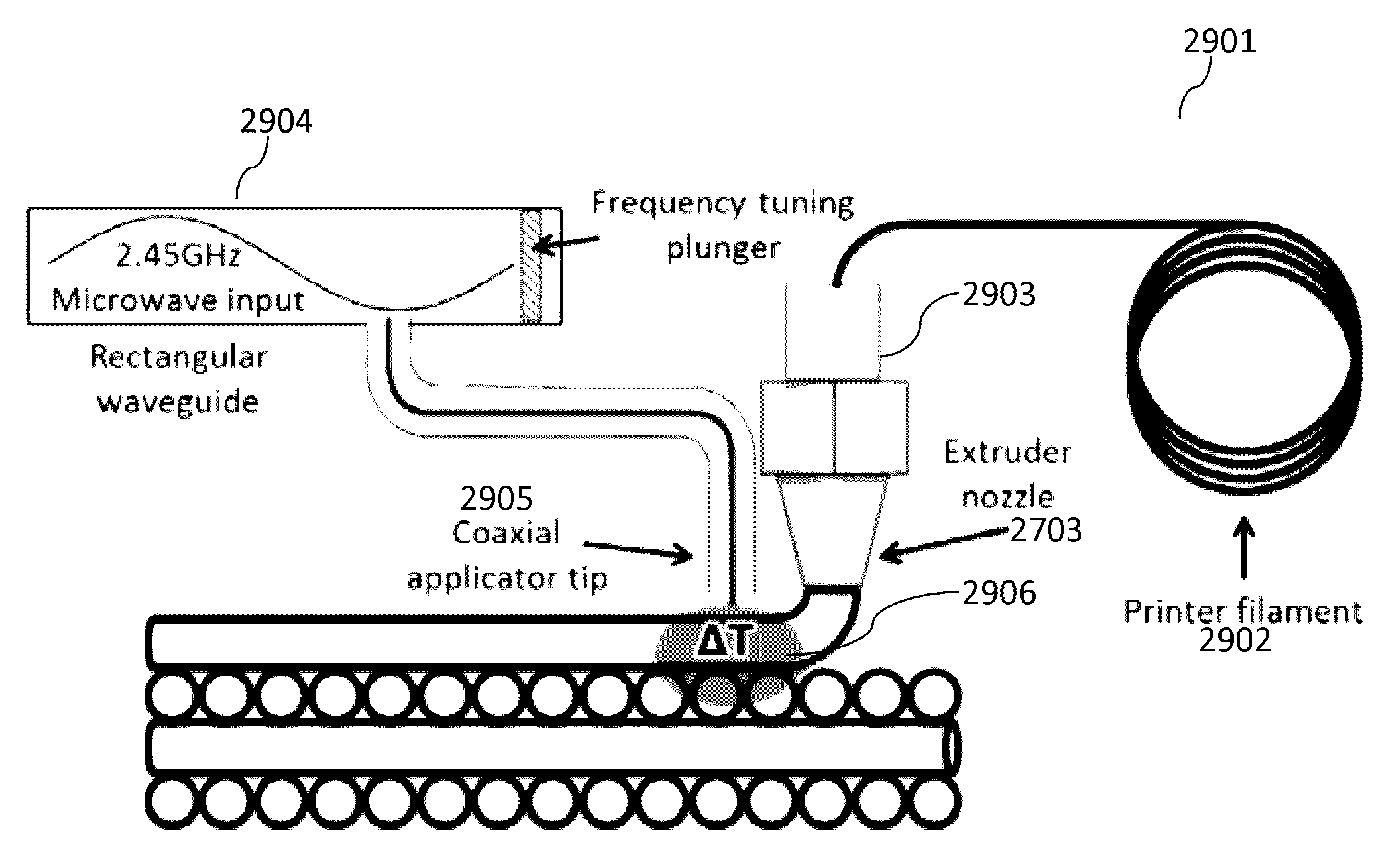

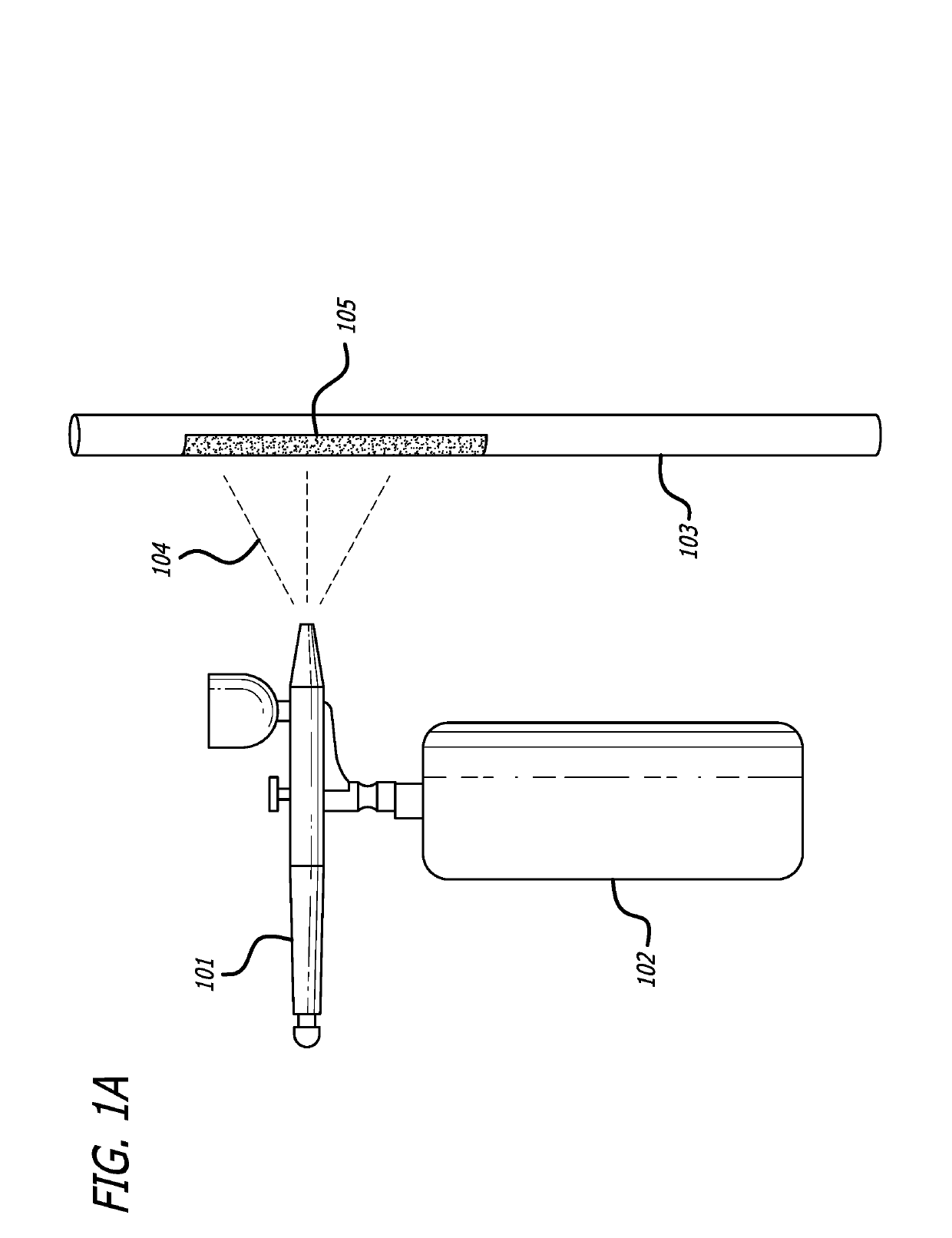

Microwave-induced localized heating of cnt filled polymer composites for enhanced inter-bead diffusive bonding of fused filament fabricated parts

ActiveUS20160325491A1Increase inter-bead bond strengthImprove mechanical propertiesMaterial nanotechnologyElectroconductive/antistatic filament manufacture3d printCarbon nanotube

A microwave-induced heating of CNT filled (or coated) polymer composites for enhancing inter-bead diffusive bonding of fused filament fabricated parts. The technique incorporates microwave absorbing nanomaterials (carbon nanotubes (CNTs)) onto the surface or throughout the volume of 3D printer polymer filament to increase the inter-bead bond strength following a post microwave irradiation treatment and / or in-situ focused microwave beam during printing. The overall strength of the final 3D printed part will be dramatically increased and the isotropic mechanical properties of fused filament part will approach or exceed conventionally manufactured counterparts.

Owner:TEXAS TECH UNIV SYST

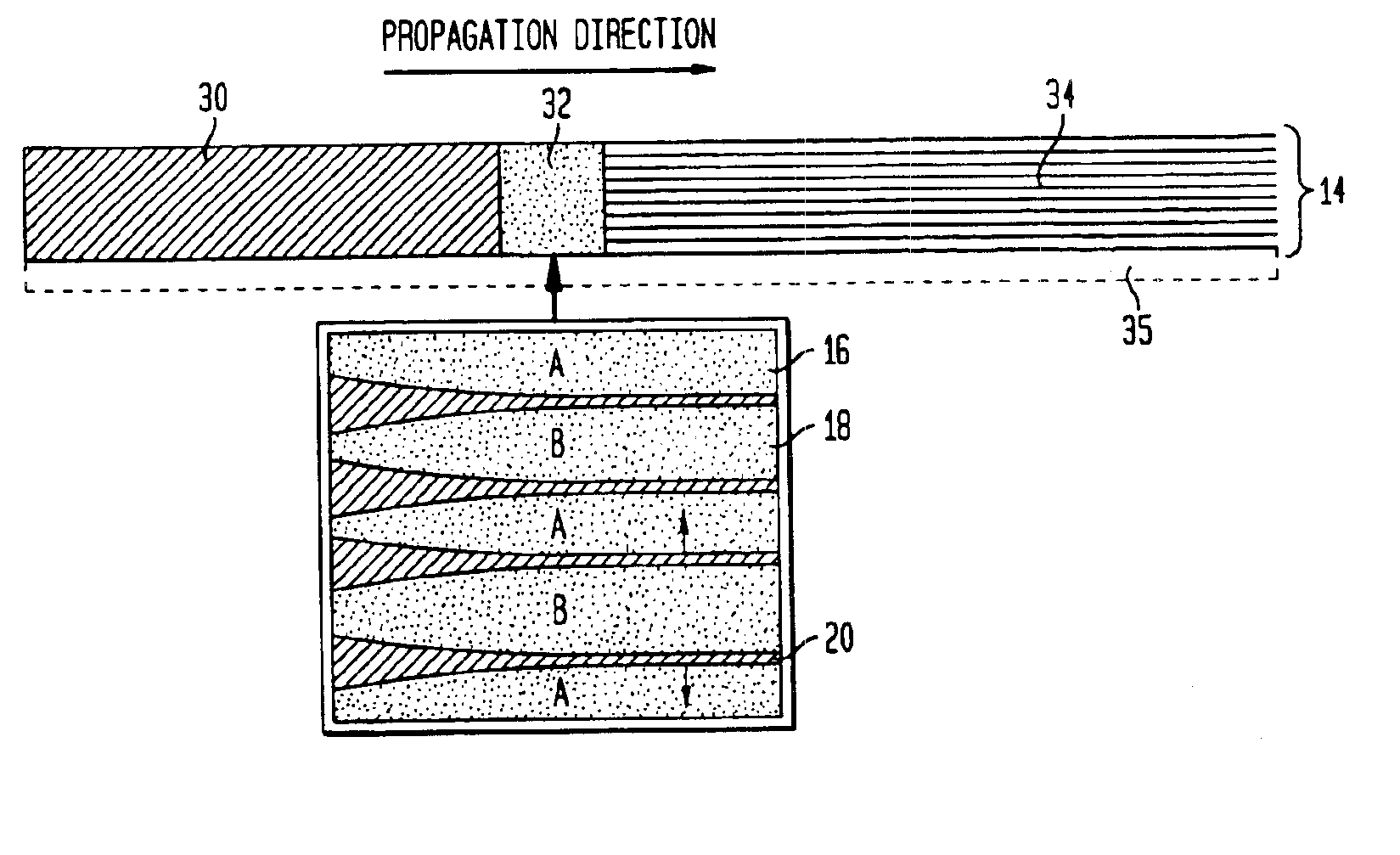

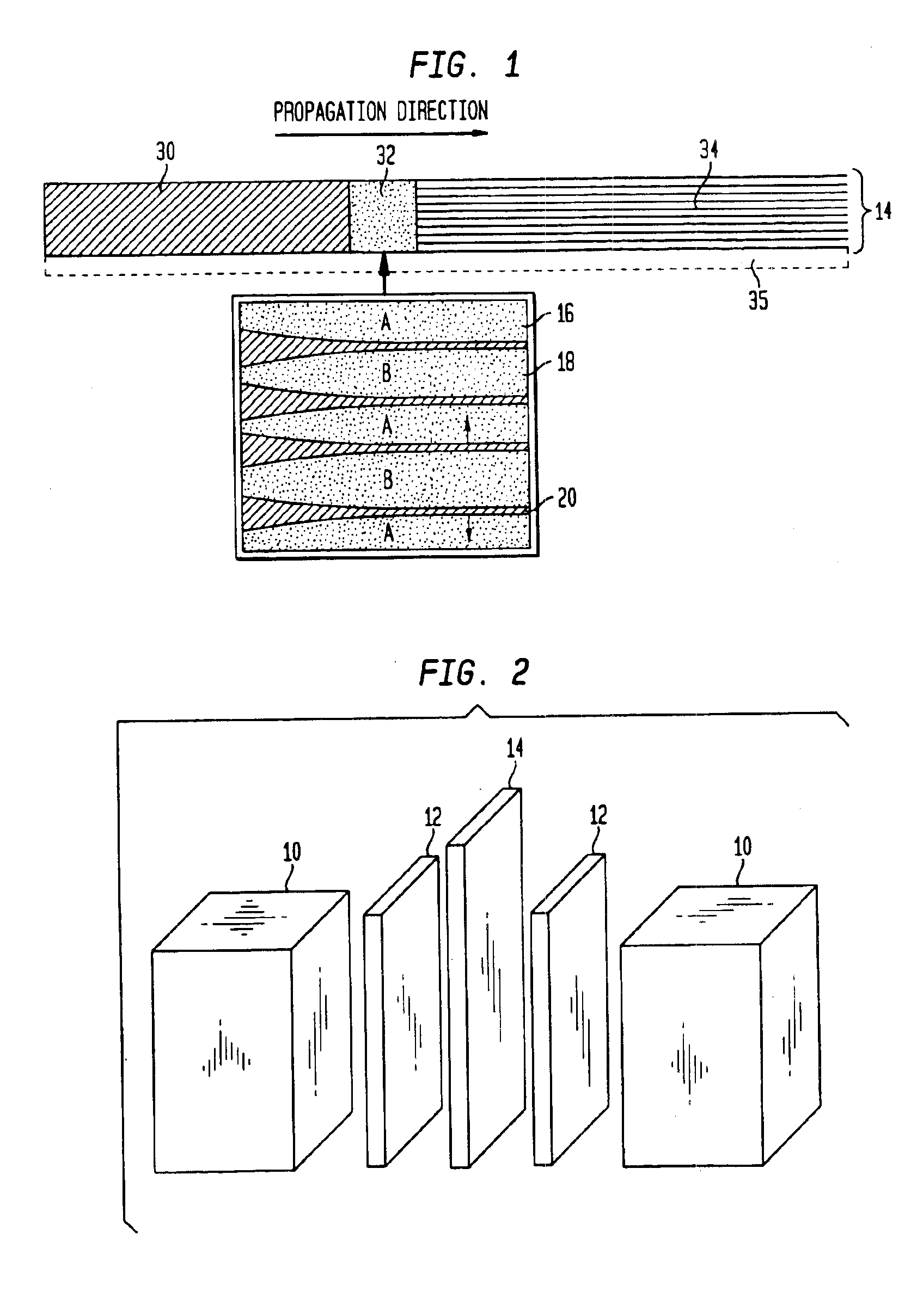

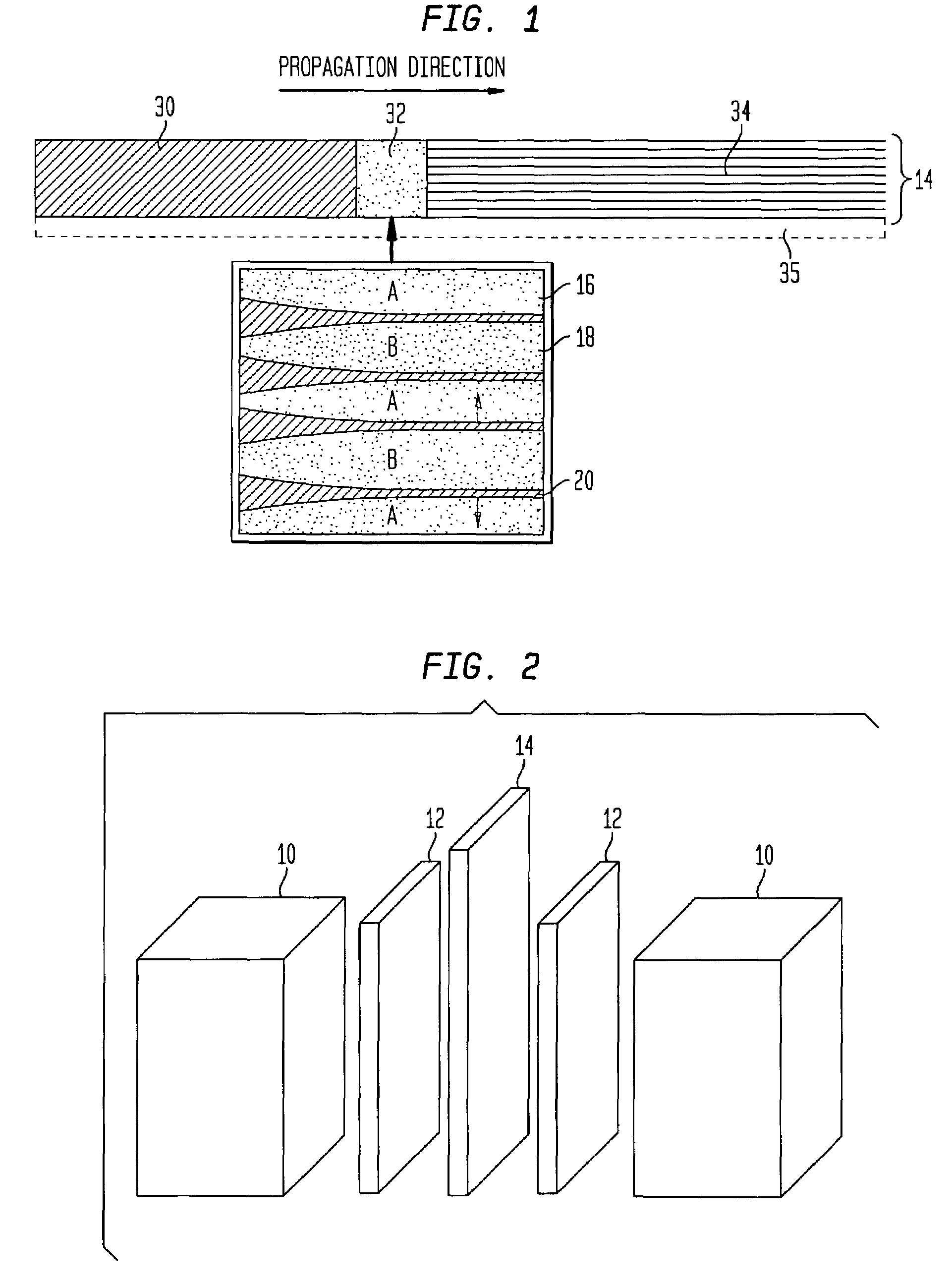

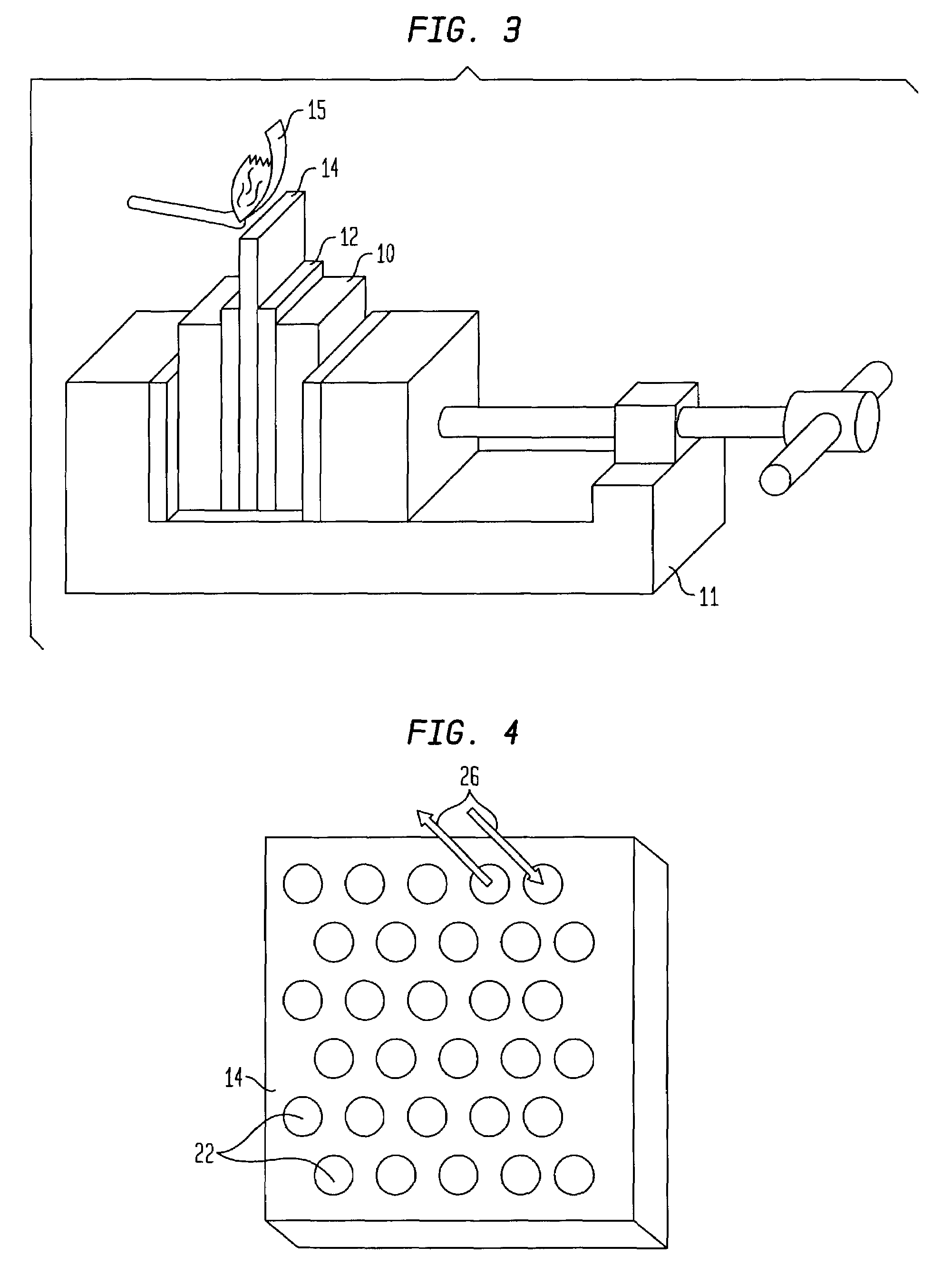

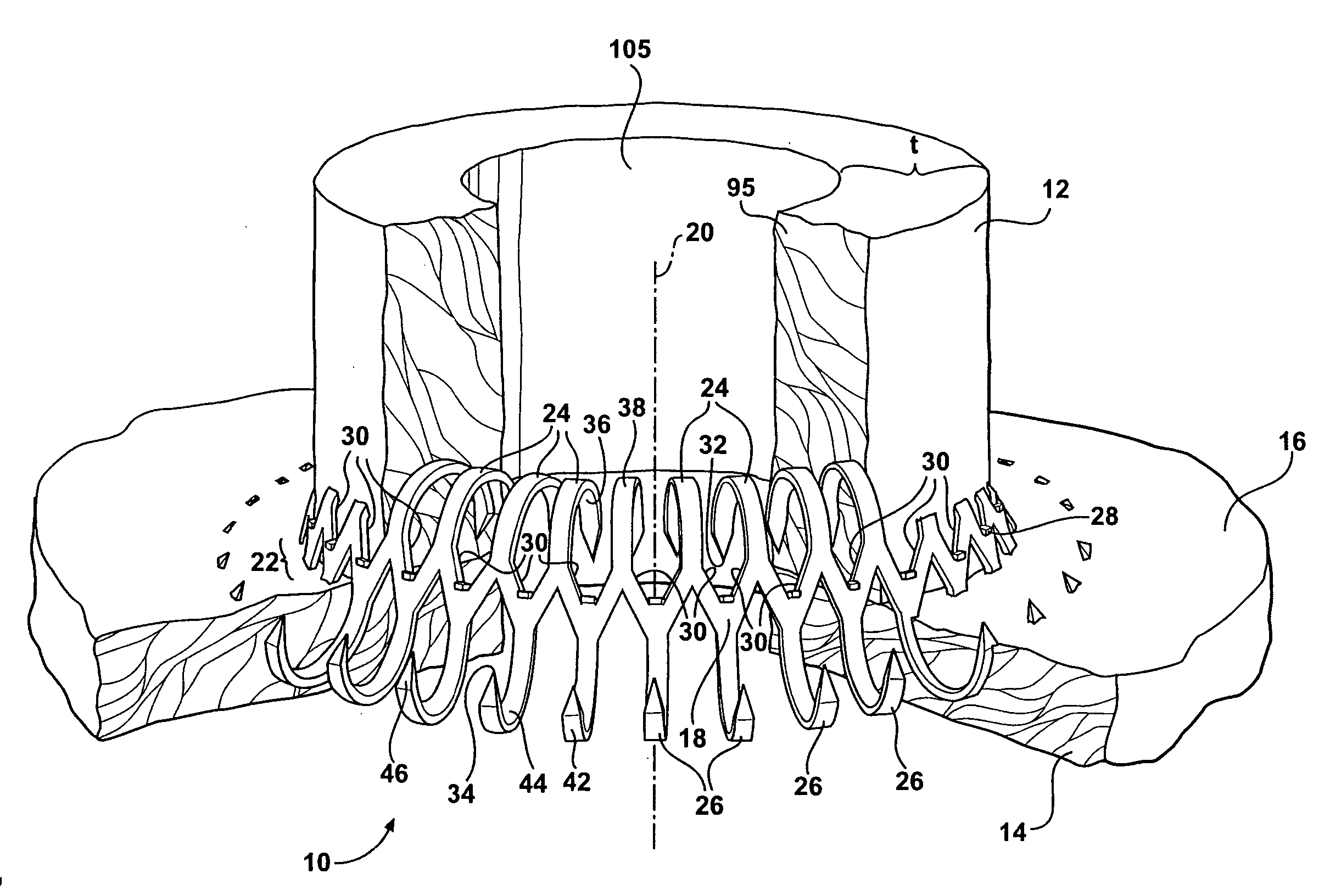

Composite reactive multilayer foil

InactiveUS6863992B2Increase heatFast bondingExothermal chemical reaction heat productionVacuum evaporation coatingThermal energyRoom temperature

Reactive foils and their uses are provided as localized heat sources useful, for example, in ignition, joining and propulsion. An improved reactive foil is preferably a freestanding multilayered foil structure made up of alternating layers selected from materials that will react with one another in an exothermic and self-propagating reaction. Upon reacting, this foil supplies highly localized heat energy that may be applied, for example, to joining layers, or directly to bulk materials that are to be joined. This foil heat-source allows rapid bonding to occur at room temperature in virtually any environment (e.g., air, vacuum, water, etc.). If a joining material is used, the foil reaction will supply enough heat to melt the joining materials, which upon cooling will form a strong bond, joining two or more bulk materials.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

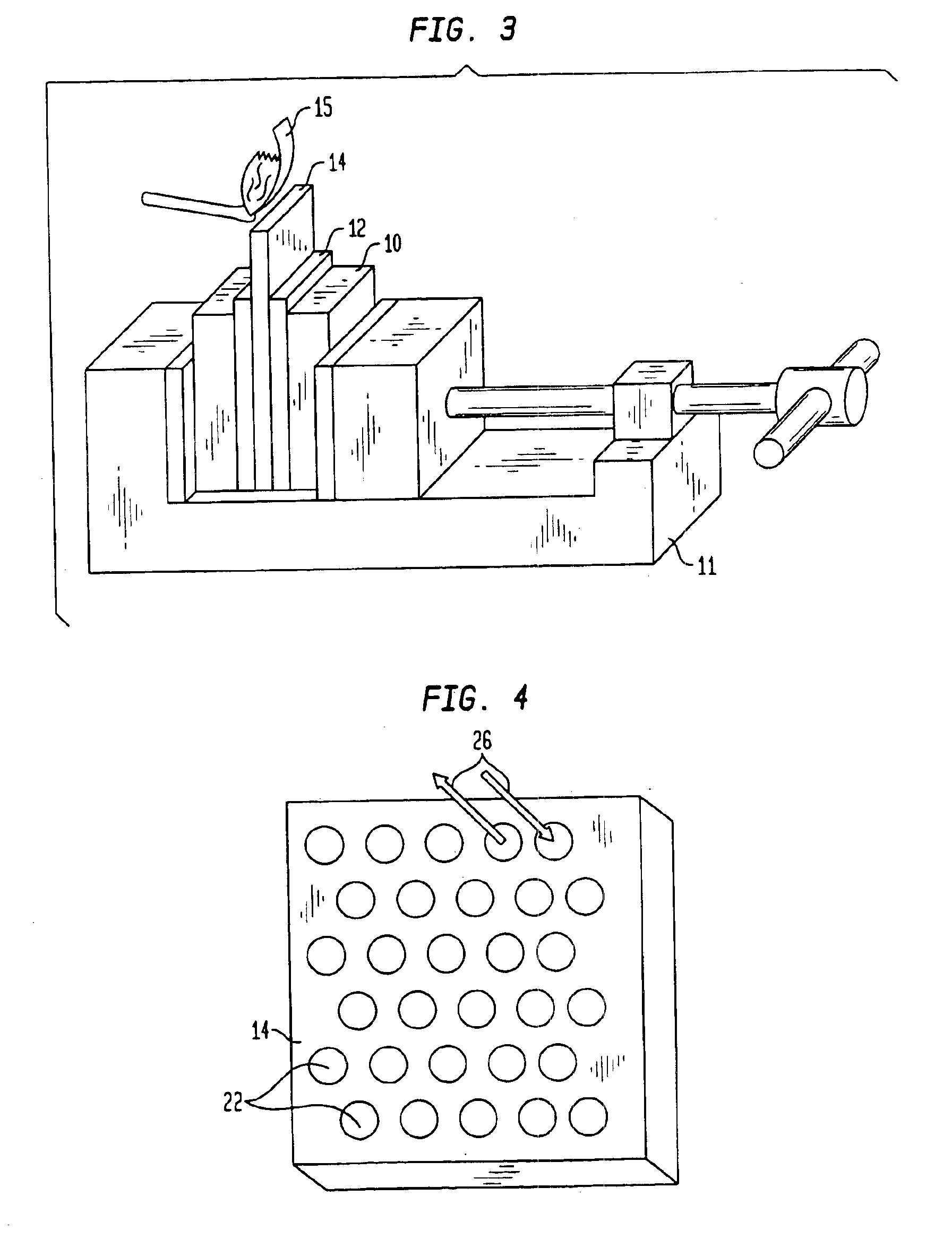

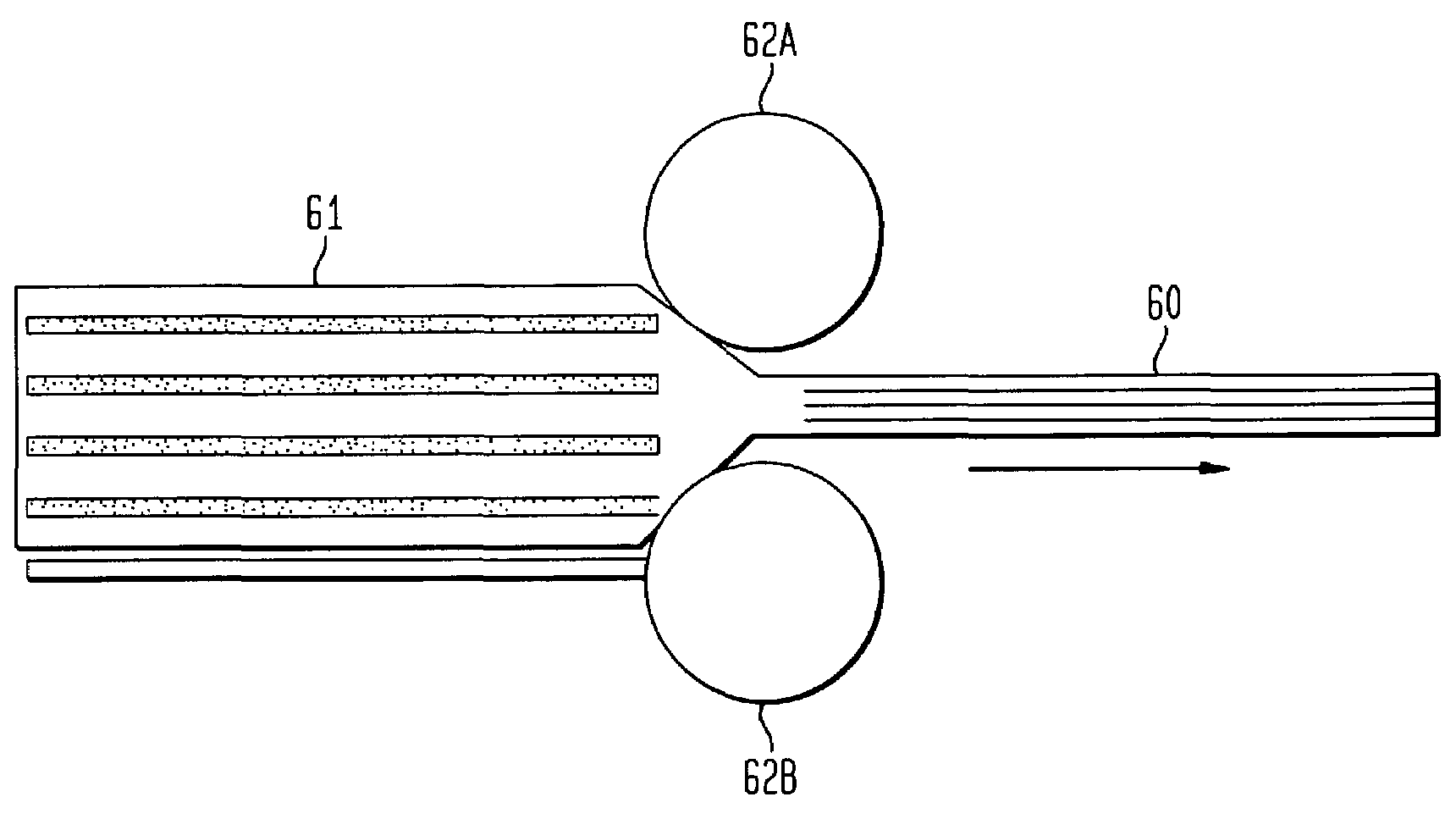

Methods of making and using freestanding reactive multilayer foils

InactiveUS6991856B2High heat energyRapid bondingExothermal chemical reaction heat productionExtrusion containersEngineeringExtrusion

Reactive foils and their uses are provided as localized heat sources useful, for example, in ignition, joining and propulsion. An improved reactive foil is preferably a freestanding multilayered foil structure made up of alternating layers selected from materials that will react with one another in an exothermic and self-propagating reaction. Upon reacting, this foil supplies highly localized heat energy that may be applied, for example, to joining layers, or directly to bulk materials that are to be joined. This foil heat-source allows rapid bonding to occur at room temperature in virtually any environment (e.g., air, vacuum, water, etc.). If a joining material is used, the foil reaction will supply enough heat to melt or soften the joining material, which upon cooling will form a strong bond, joining two or more bulk materials. If no joining material is used, the foil reaction supplies heat directly to at least two bulk materials, melting or softening a portion of each bulk, which upon cooling, form a strong bond. Additionally, the foil may be designed with openings that allow extrusion of the joining (or bulk) material through the foil to enhance bonding.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

High-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards, and preparation method thereof

ActiveCN103205210AHigh bonding strengthImprove heat resistanceFilm/foil adhesivesPolyureas/polyurethane adhesivesElastomerPolyester

The invention discloses a high-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards, and a preparation method thereof. The high-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards is made from, by weight percent, 30-50% of polyester elastomer with above 180 DEG C of melting point, 10-40% of polyolefin copolymer modified by maleic anhydride, 0-40% of polyolefin copolymer, 10-30% of tackifying resin, 0-15% of filler, and 1-3% of functional aid. The components add up to 100%. The high-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards has the advantages of high adhesion strength, instantaneous resistance to the temperature up to 170-190 DEG C, and long-term resistance to the temperature up to 130 DEG C.

Owner:JIANGSU LUSHAN PHOTOVOLTAIC TECH +1

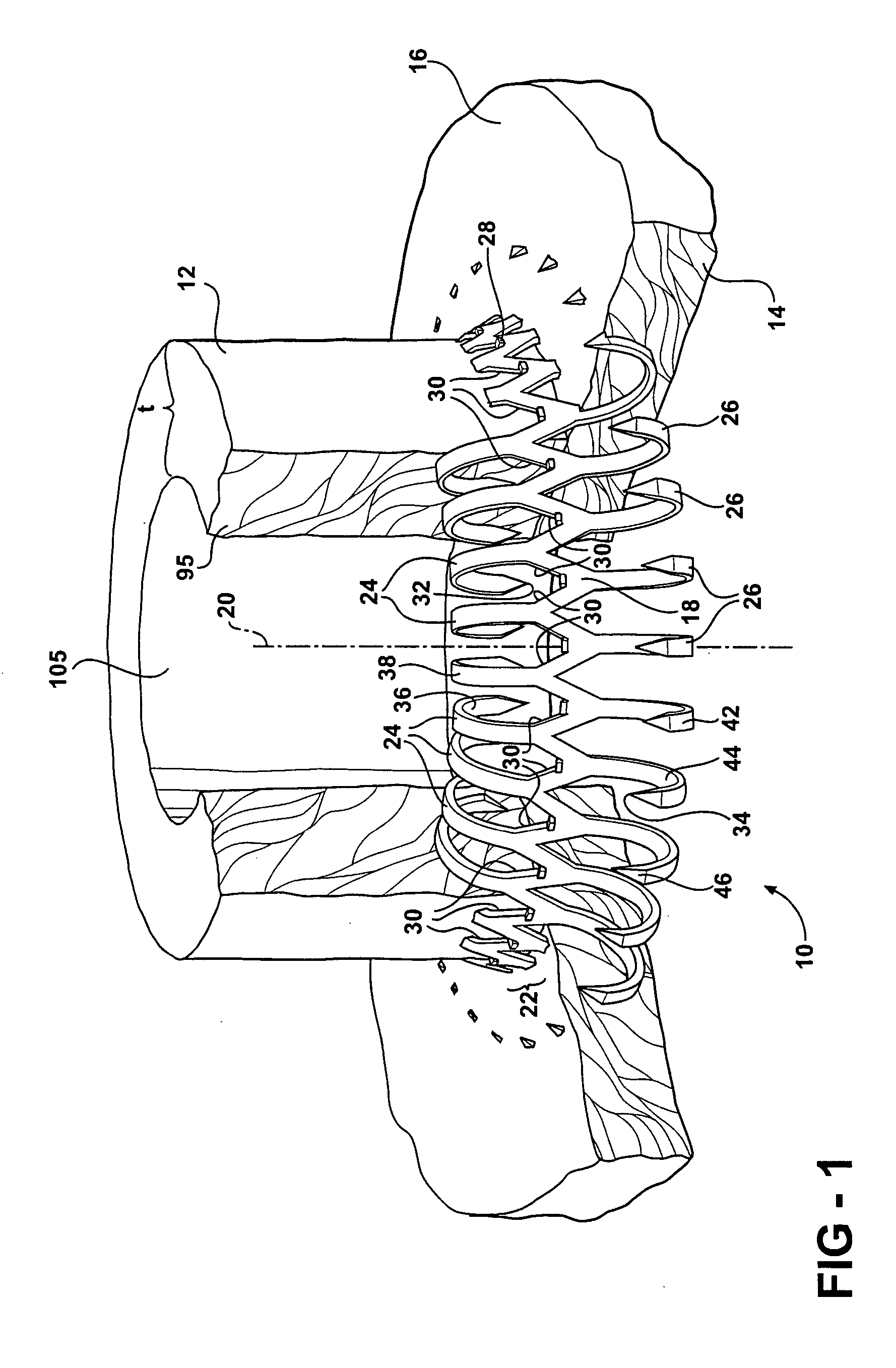

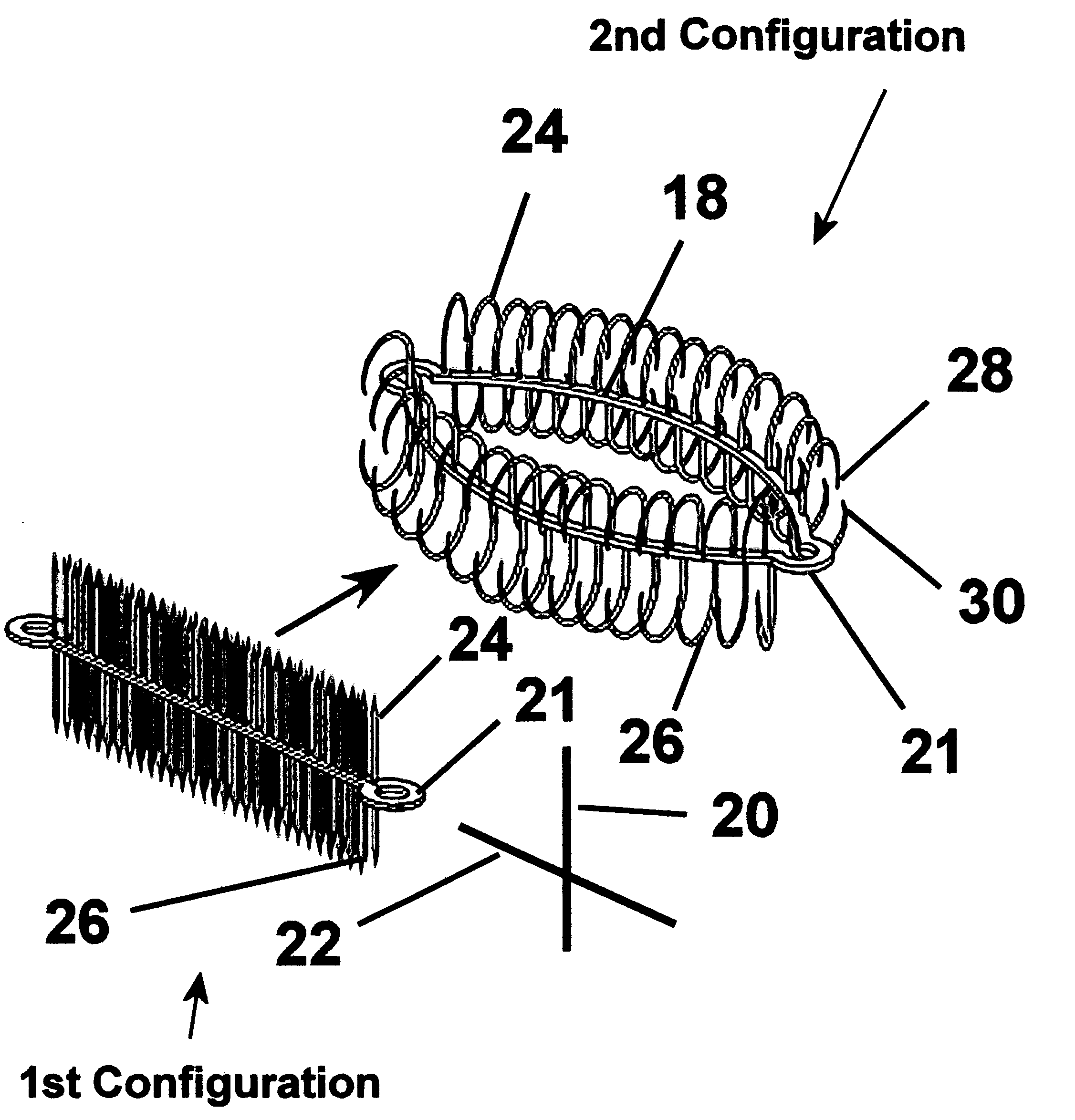

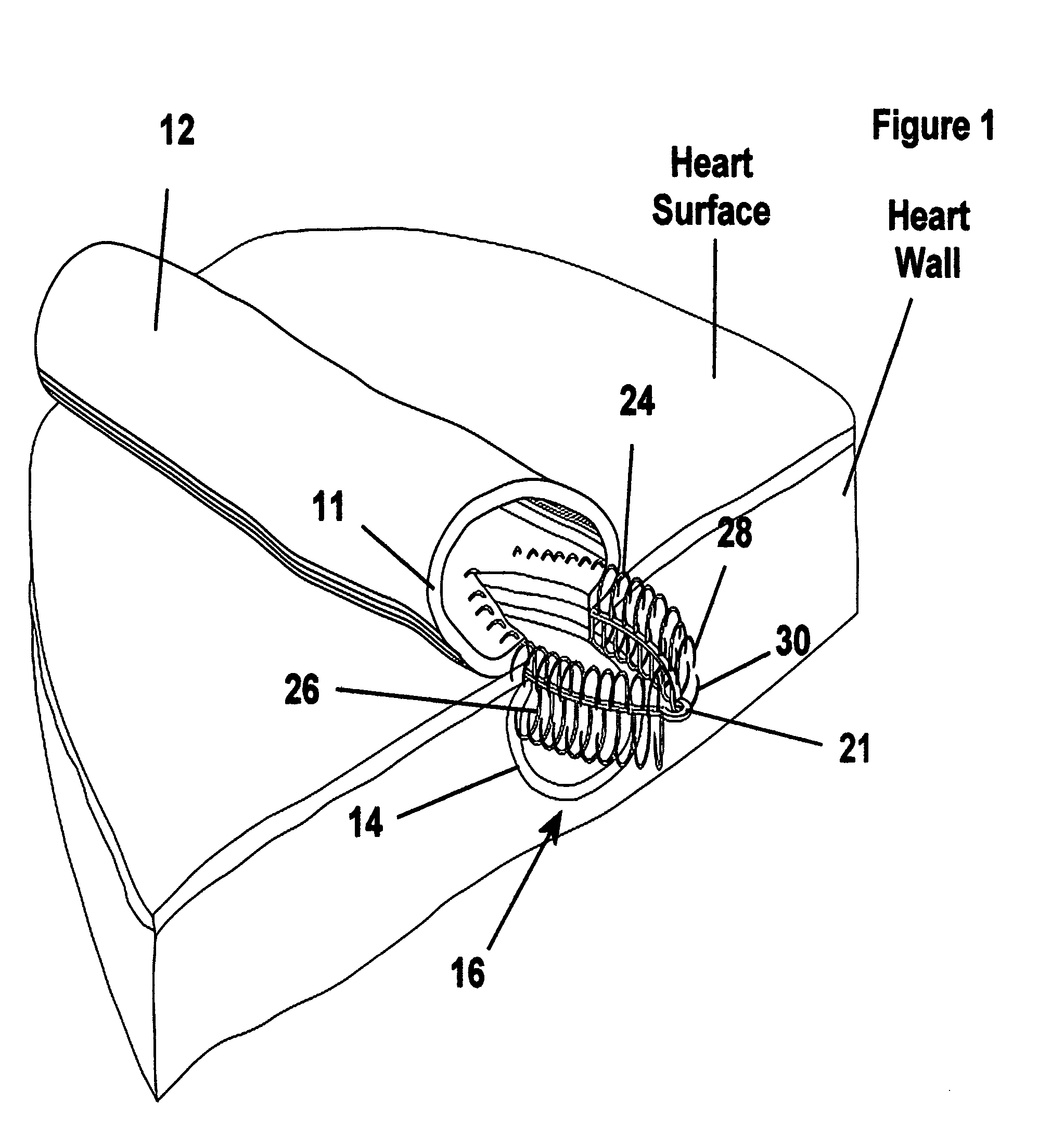

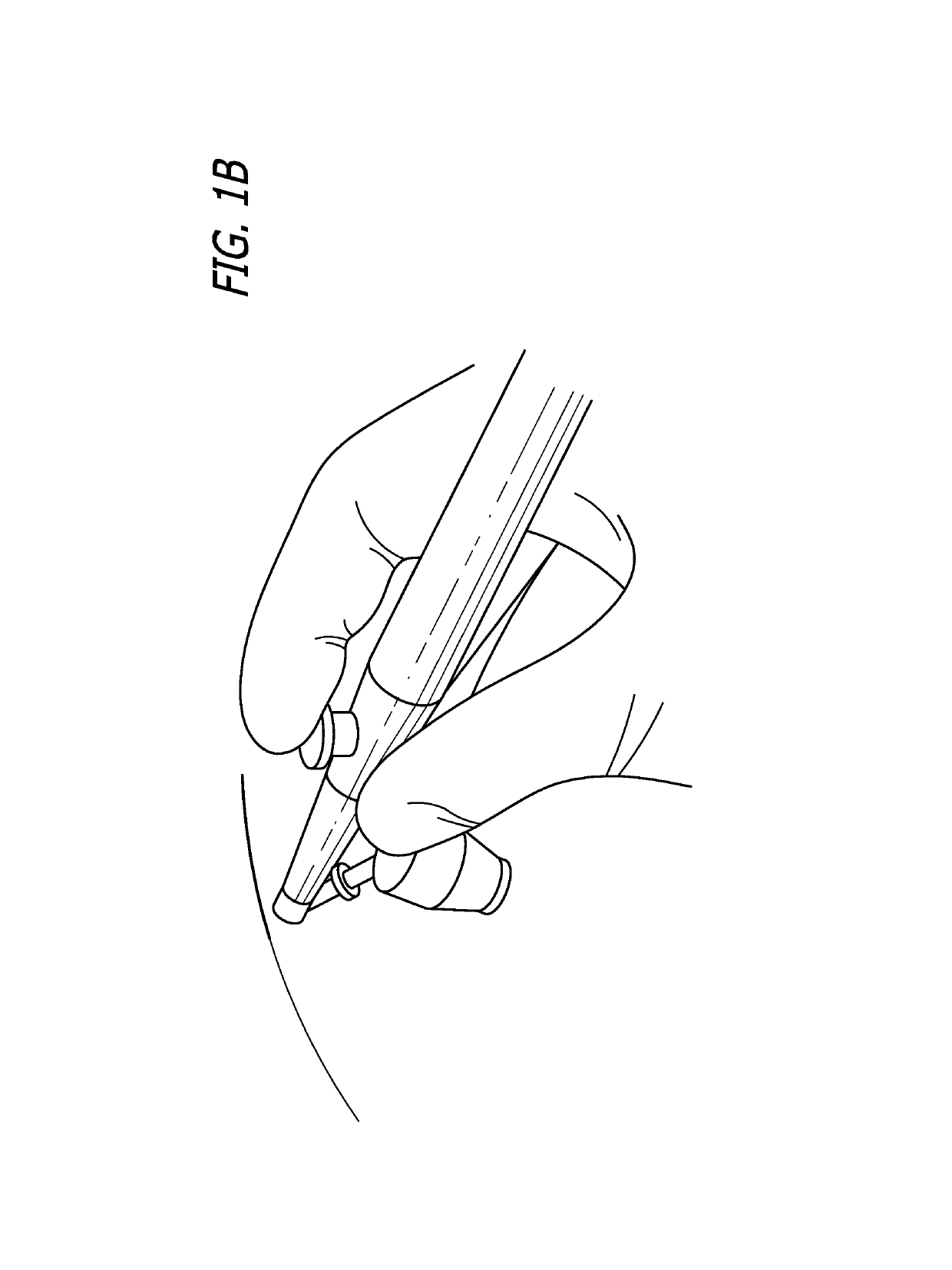

Anastomosis apparatus and methods of deployment and manufacture

A method and apparatus for making an anastomosis between a tubular duct and a vessel has an annulus having a longitudinal axis, a first set of fingers and a second set of fingers. The first set of fingers extend axially from the annulus in one direction and the second set of fingers extending axially from the annulus in another direction generally opposite the direction of the first set of fingers. The first and second sets of fingers are movable to penetrate the tubular duct and the vessel, respectively, as they move from a biased configuration to an unbiased configuration.

Owner:WRIGHT DAVID WALTER

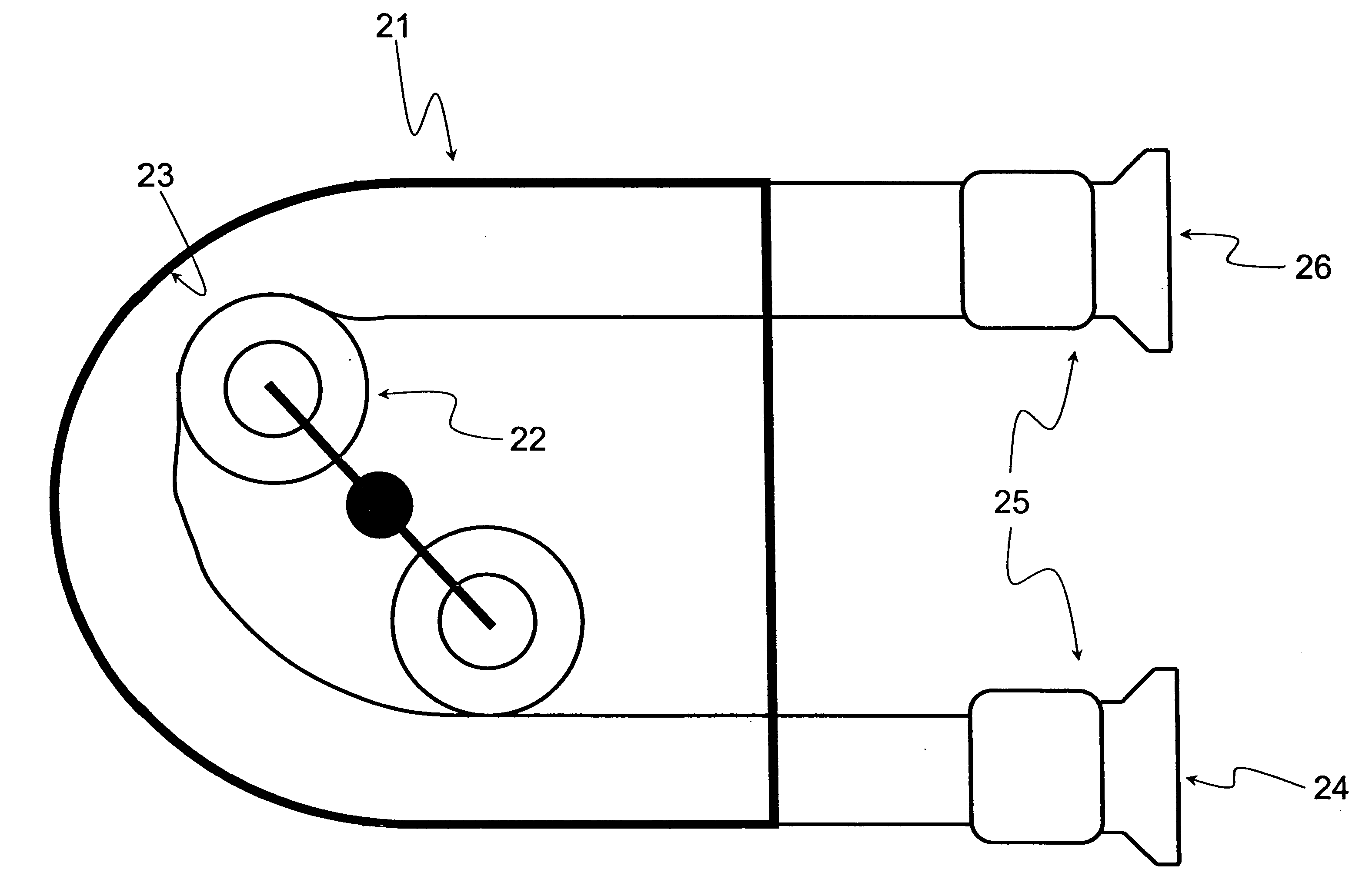

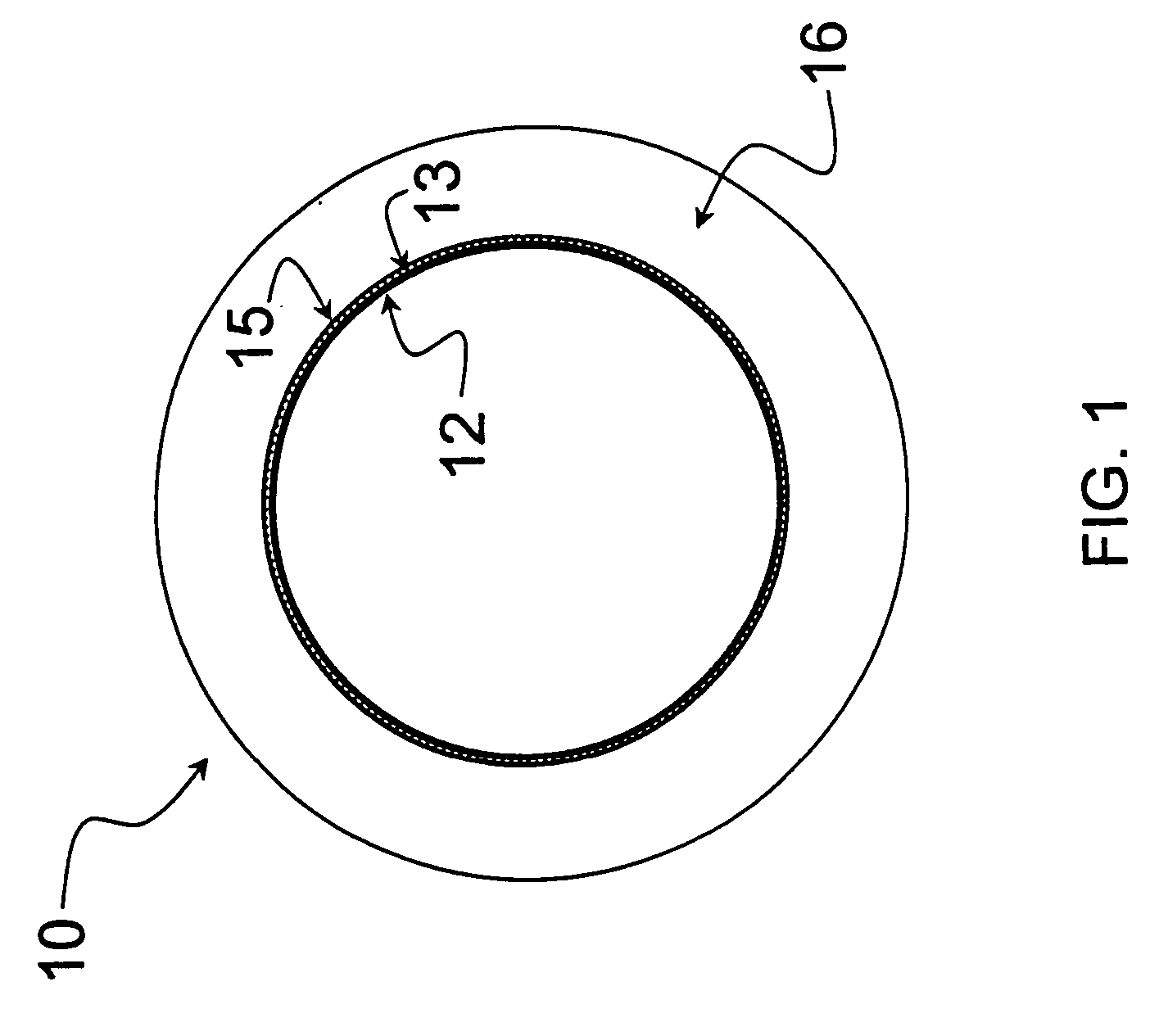

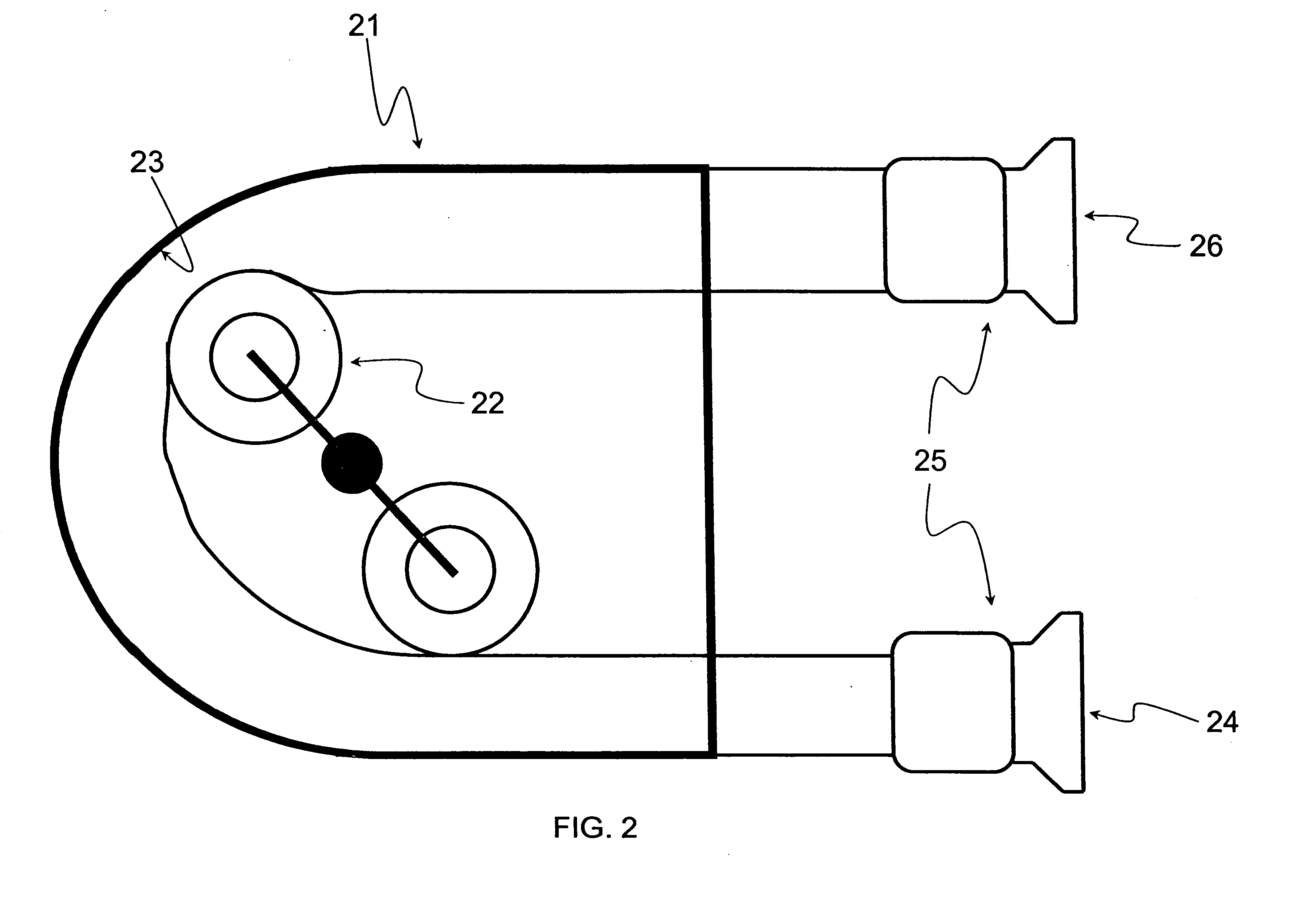

Fluoroplastic composite elastomer

InactiveUS20060018777A1Improve bending resistanceLow costEnvelopes/bags making machineryFlexible member pumpsElastomerFiber

An improved fluoroplastic lined elastomeric tube that can maintain a stable flow rate while pumping aggressive chemicals in a peristaltic pump for an extended period of time and is fabricated in sizes ranging from 0.5 mm to 100 mm in inside diameter. The inner fluoroplastic liner comprises a composite of expanded polytetrafluoroethylene and a fluoroplastic polymer resulting in improved flex life over single component fluoroplastics. The inventive liner is bonded to either an unreinforced elastomer or a fiber reinforced elastomer for use in both low and high pressure peristaltic pump applications.

Owner:MAZTECH

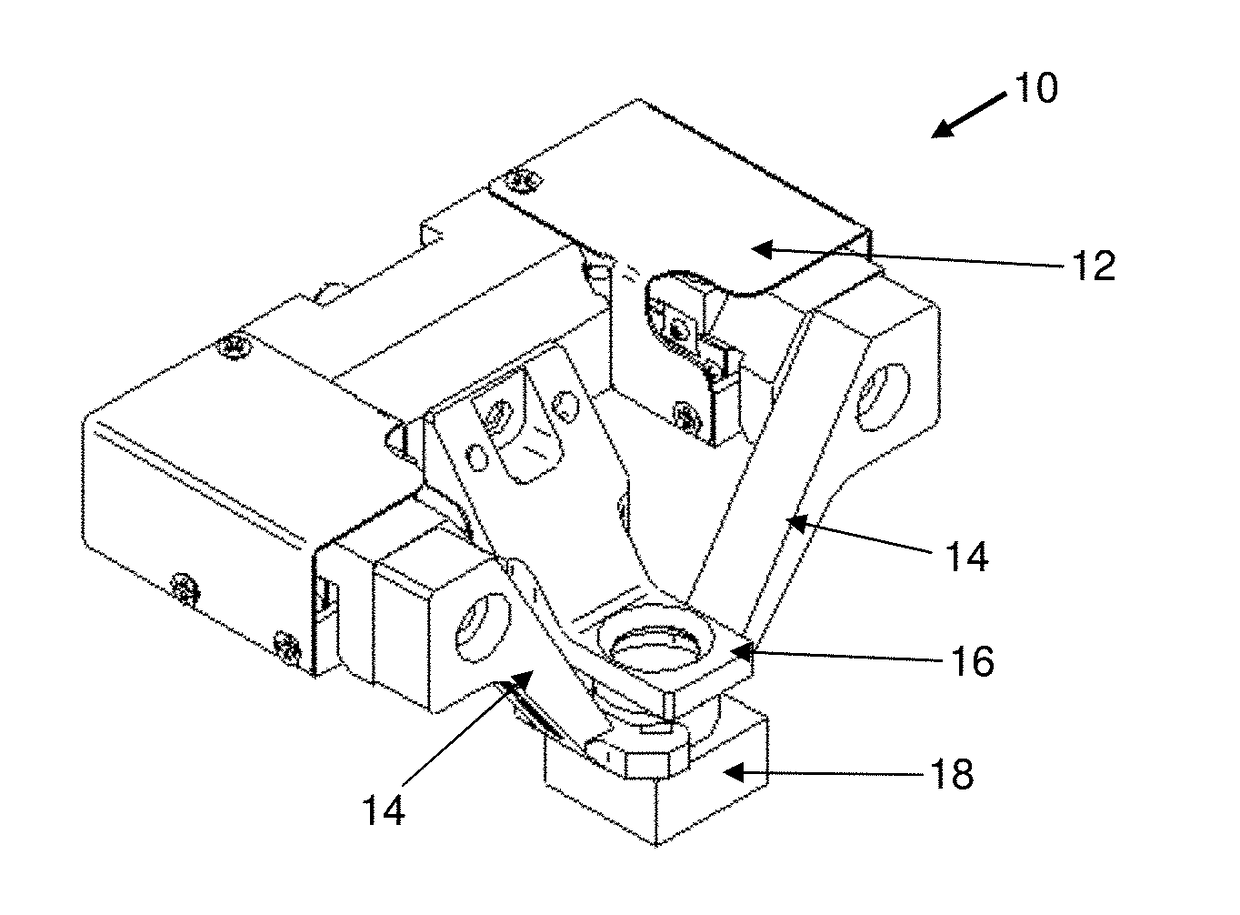

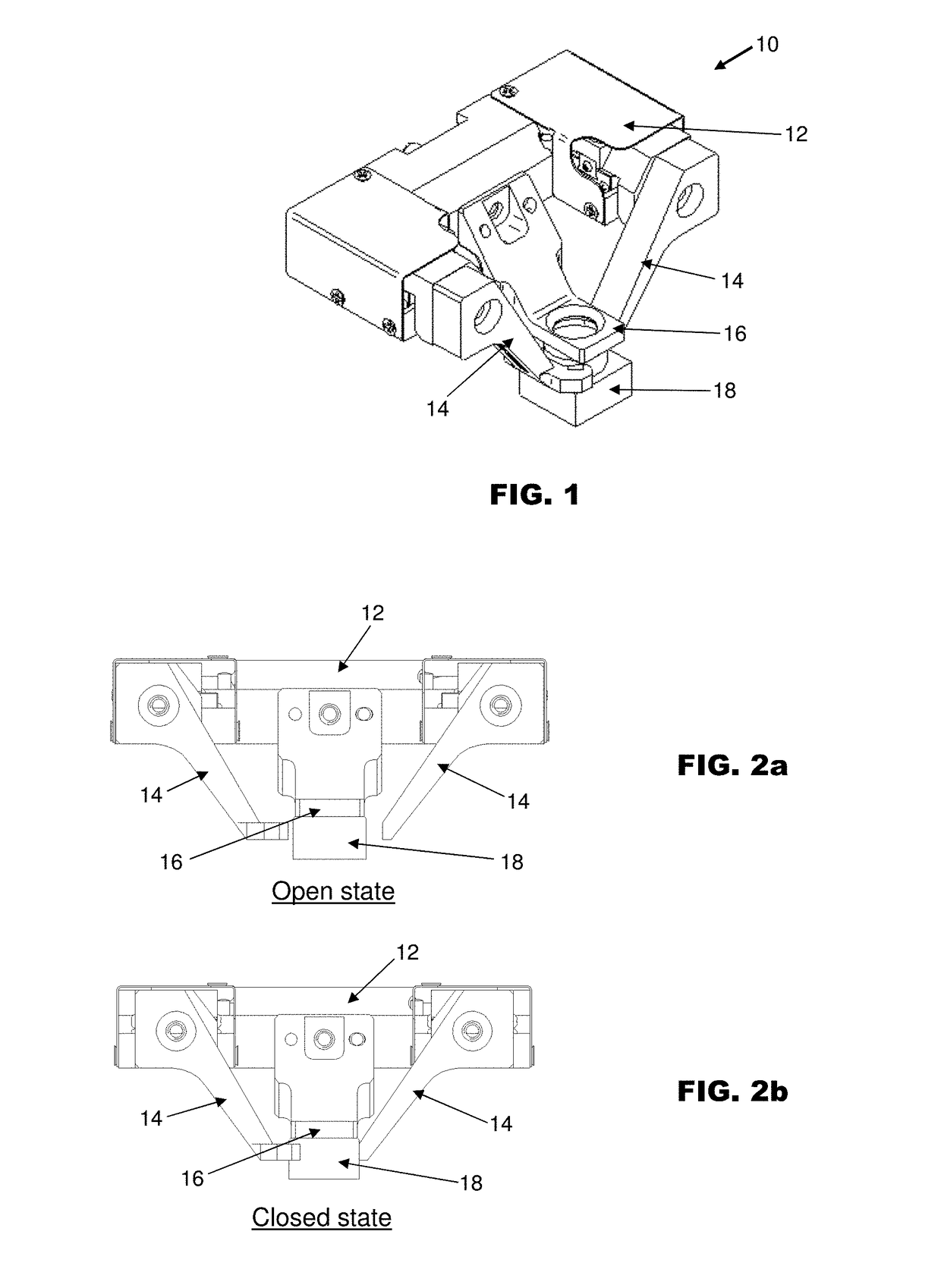

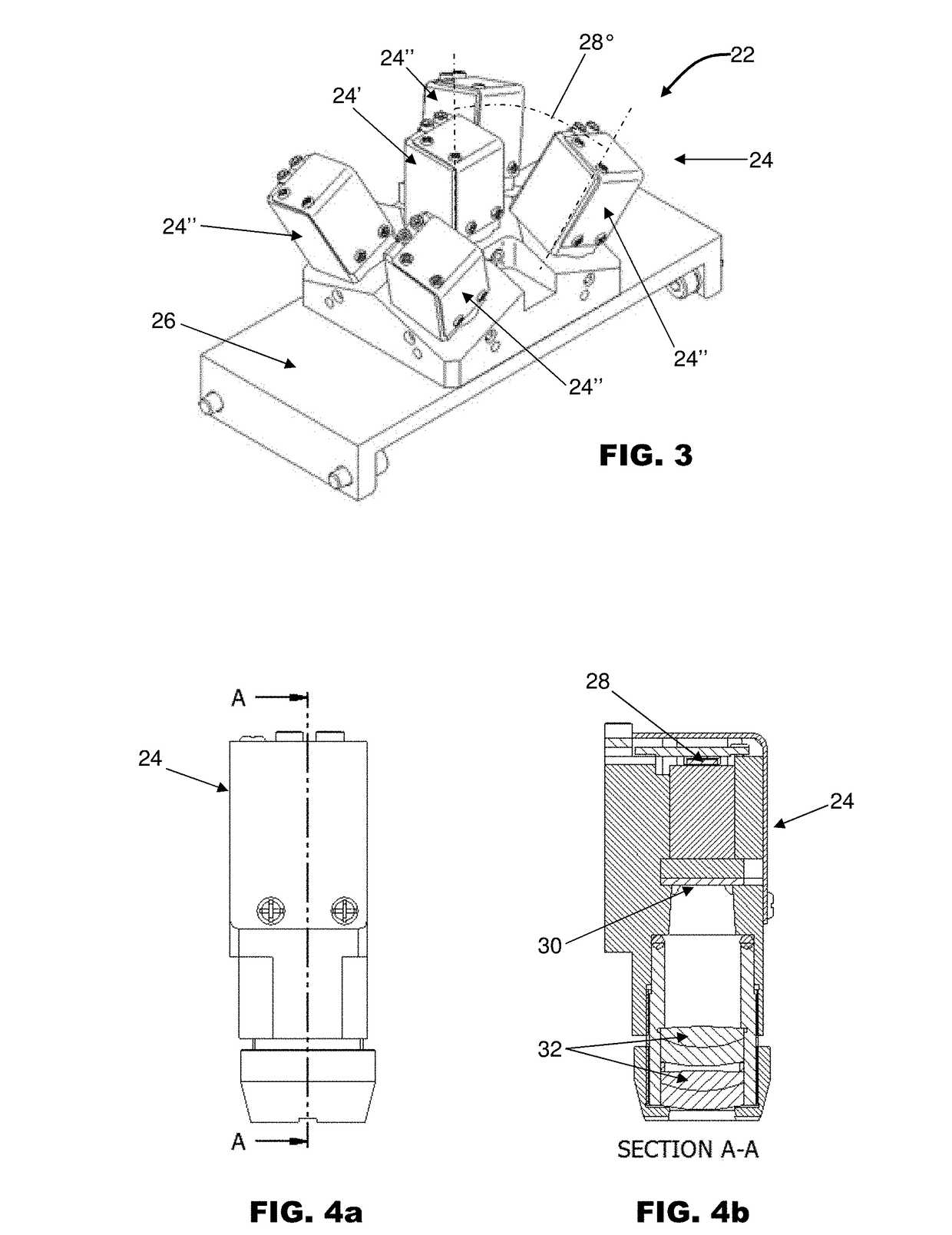

Active lens alignment system

ActiveUS20170201744A1Fast bondingImage enhancementTelevision system detailsCamera lensComputer science

For aligning an image sensor relative to a lens module prior to fixing the image sensor to the lens module, an exposure of the image sensor is turned on and the image sensor is moved to different distances relative to the lens module. At certain predetermined distances between the image sensor and the lens module, a calibration pattern is illuminated and two or more pictures of the calibration pattern which is focused through the lens module are captured with the image sensor to produce at least two pictures of the calibration pattern captured at different distances, the at least two pictures being superimposed onto a calibration image. The exposure of the image sensor is then turned off and the pictures of the calibration pattern are analyzed for determining an alignment between the lens module and the image sensor.

Owner:ASMPT SINGAPORE PTE LTD

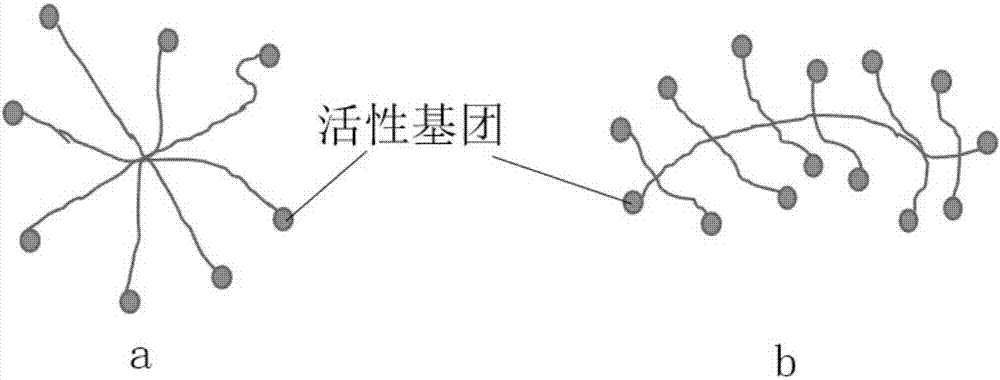

Biological adhesive as well as preparation method and application thereof

InactiveCN107384306AFast bondingRapid responseSurgical adhesivesAdhesivesChemical reactionPolymer science

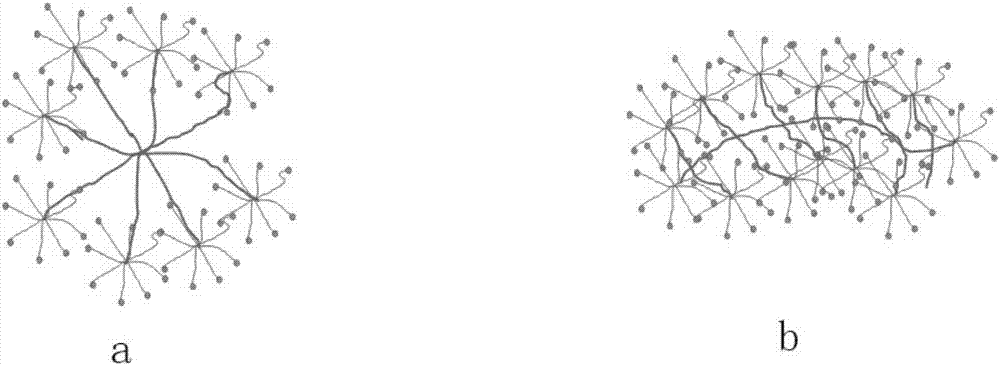

The invention discloses a biological adhesive which comprises a component a, and a component b, wherein the component a is a functional star polymer or / and a functional comb-like polymer, the functional star polymer is provided with one or more active groups, and the functional comb-like polymer is provided with one or more active groups; the component b is a functional polysaccharide which is provided with one or more active groups; and chemical reactions can be carried out between the active groups of the component a and the active groups of the component b so as to form novel chemical bonds. The invention further discloses a preparation method and application of the biological adhesive. The biological adhesive disclosed by the invention is a biocompatible adhesive (glue) formed by rapidly reacting the functional star polymer or / and comb-like polymer with lots of active groups and the functional polysaccharide. The adhesive based on the star polymer or / and comb-like polymer has a star or / and comb structure and has lots of active reactive groups, so that the gel forming reaction is fast, and the adhesive is reacted with tissues so as to realize an adhesive effect.

Owner:杭州易敏生物医药科技有限公司

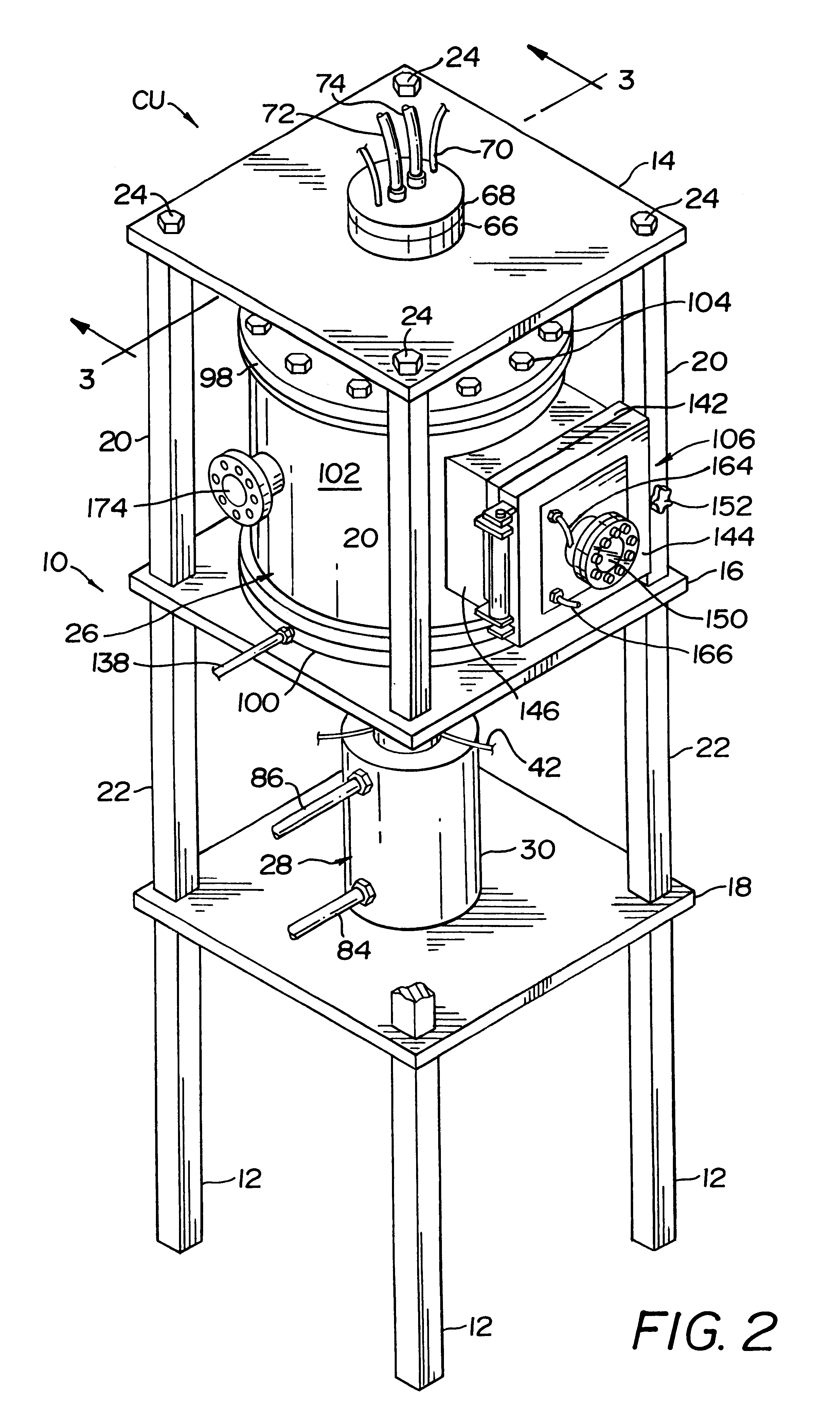

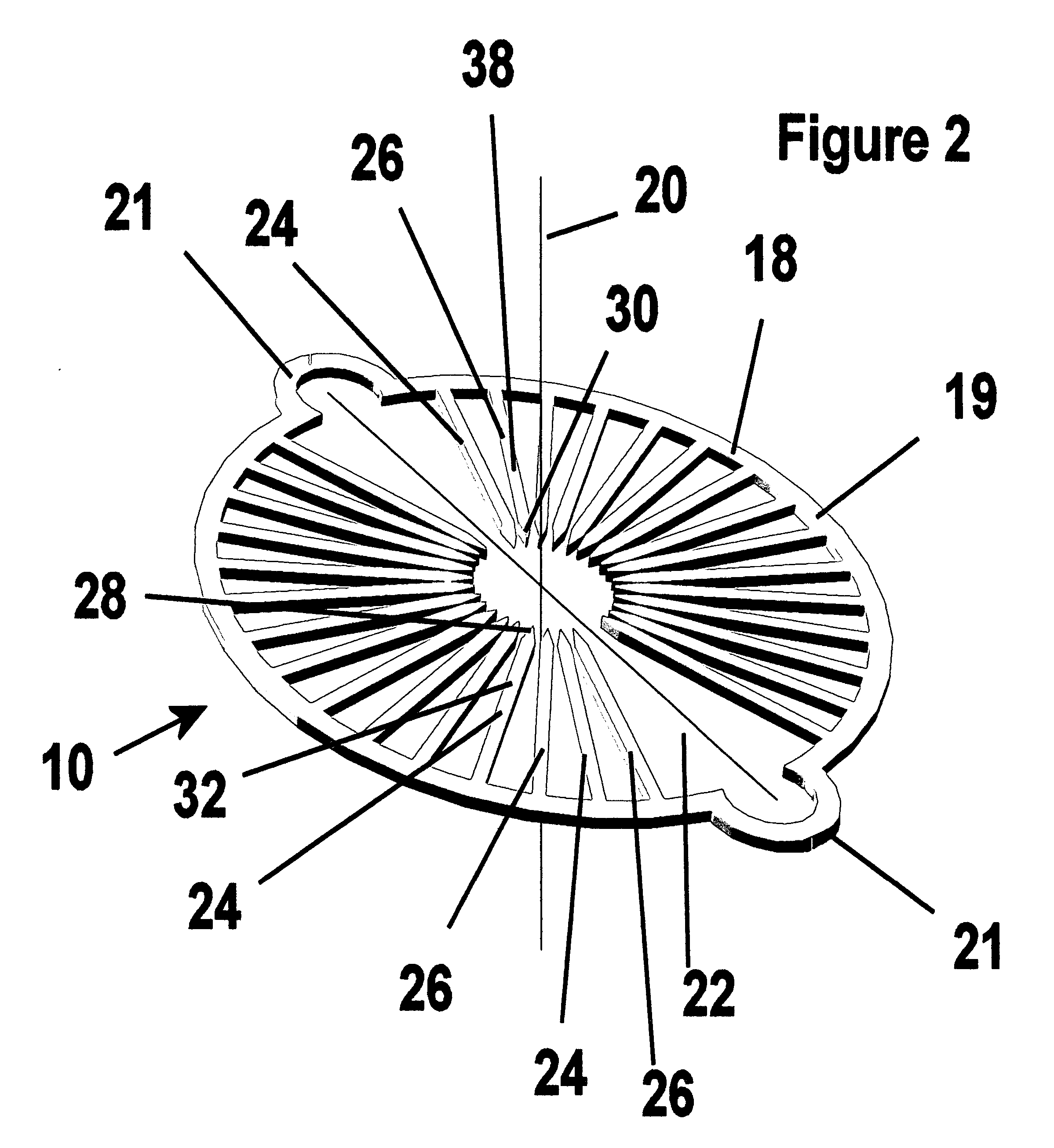

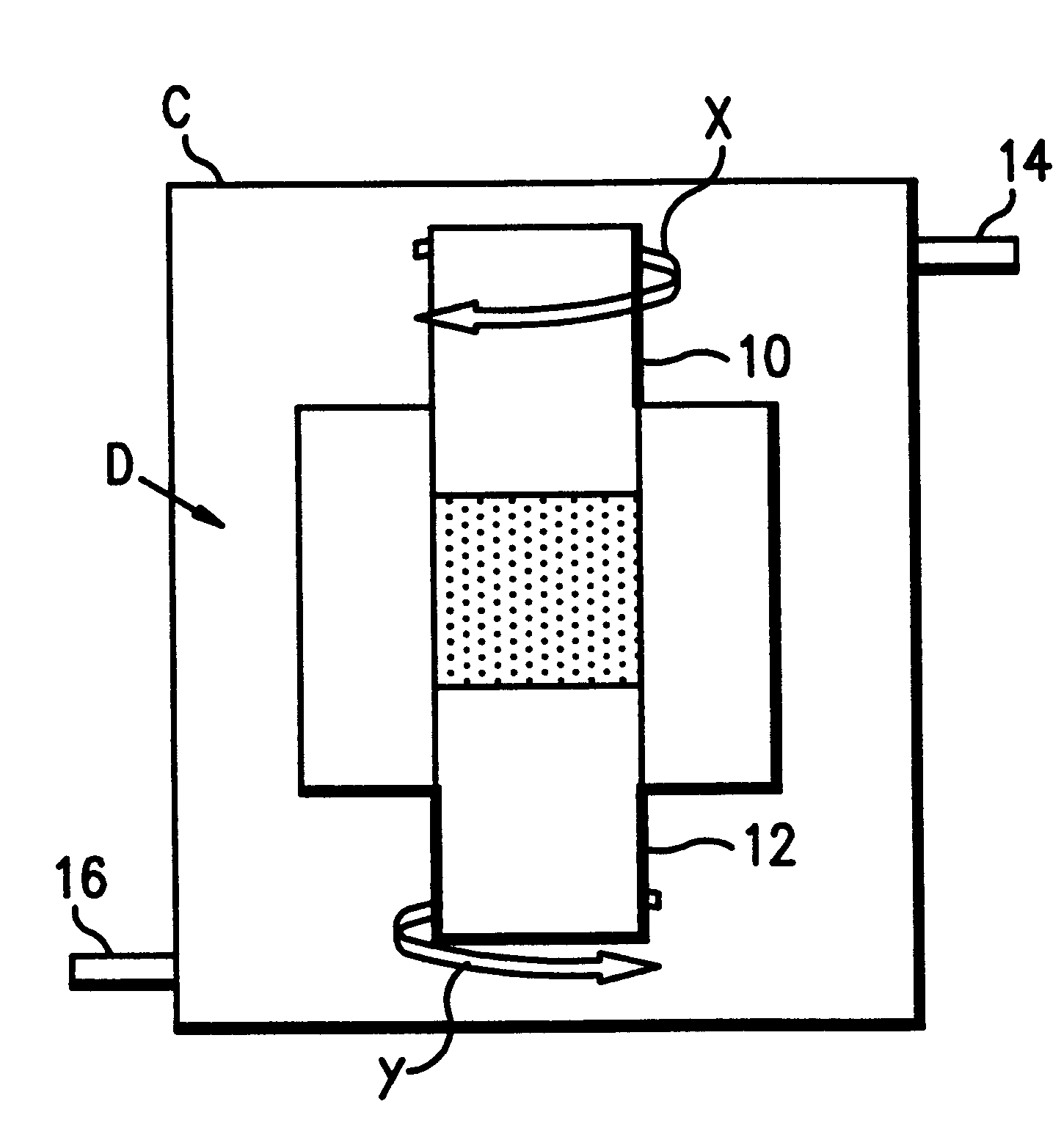

Apparatus for bonding a particle material to near theoretical density

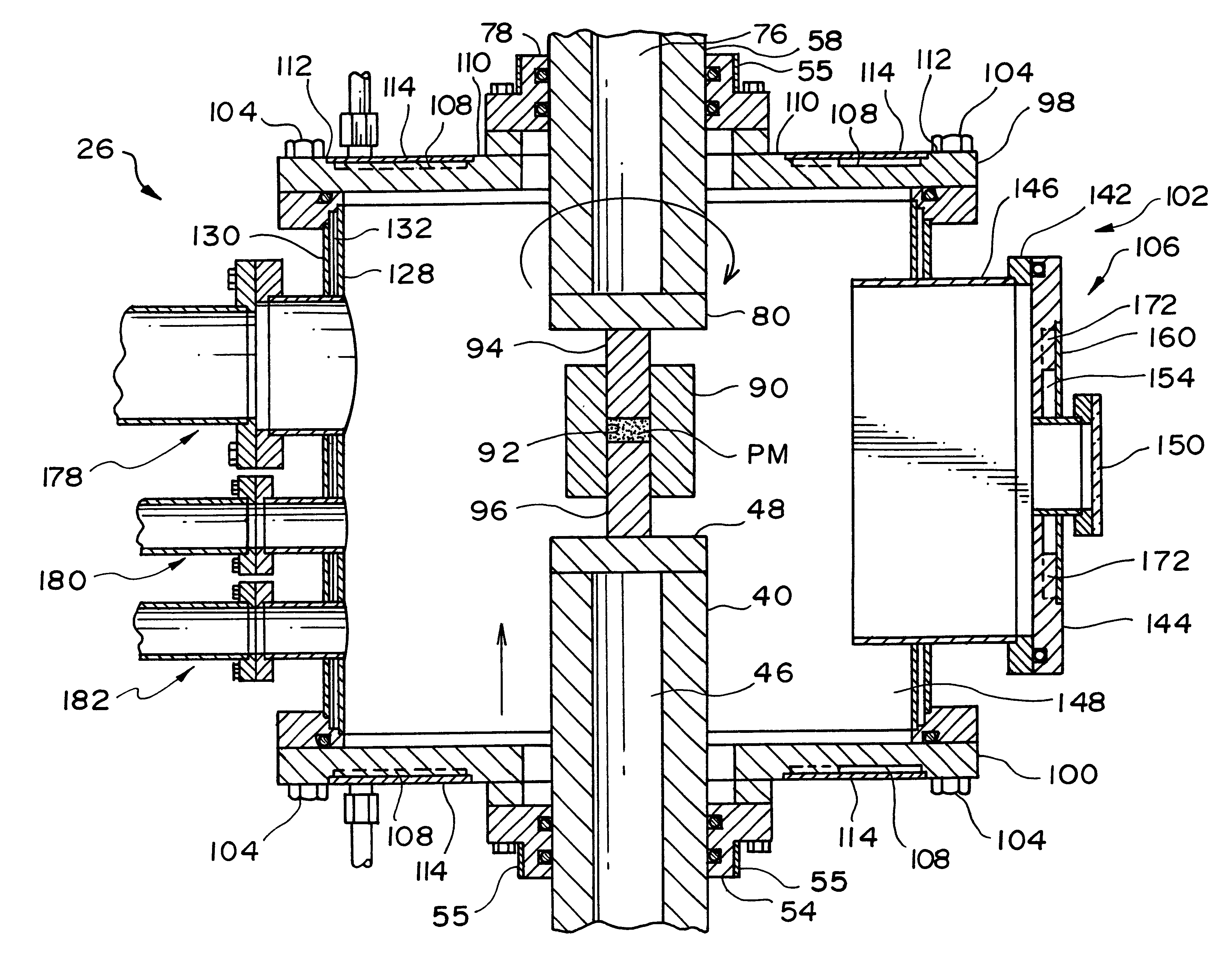

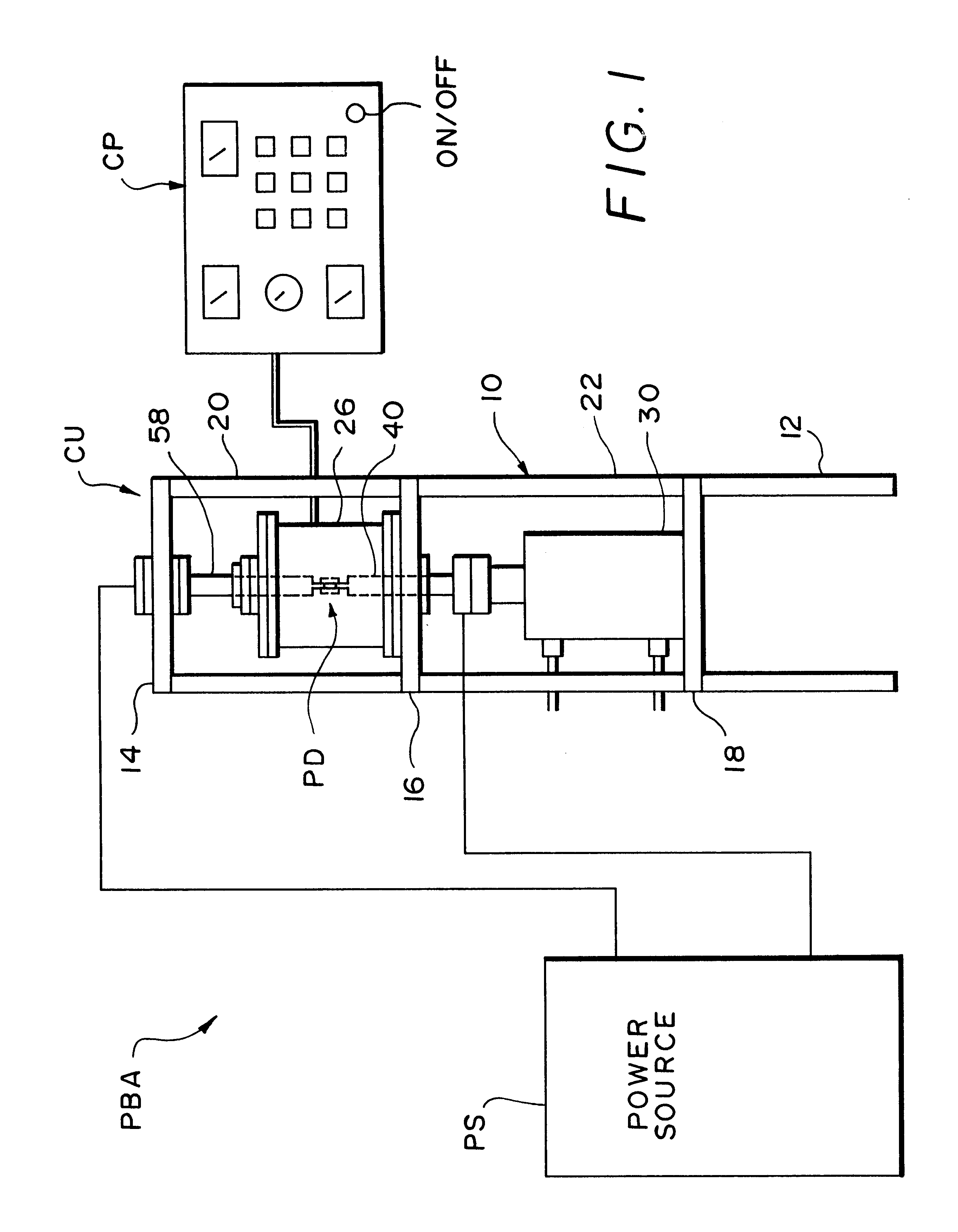

InactiveUS6309591B1High interface integrityMinimal distortionNanotechFurnace typesAxial pressureSingle crystal

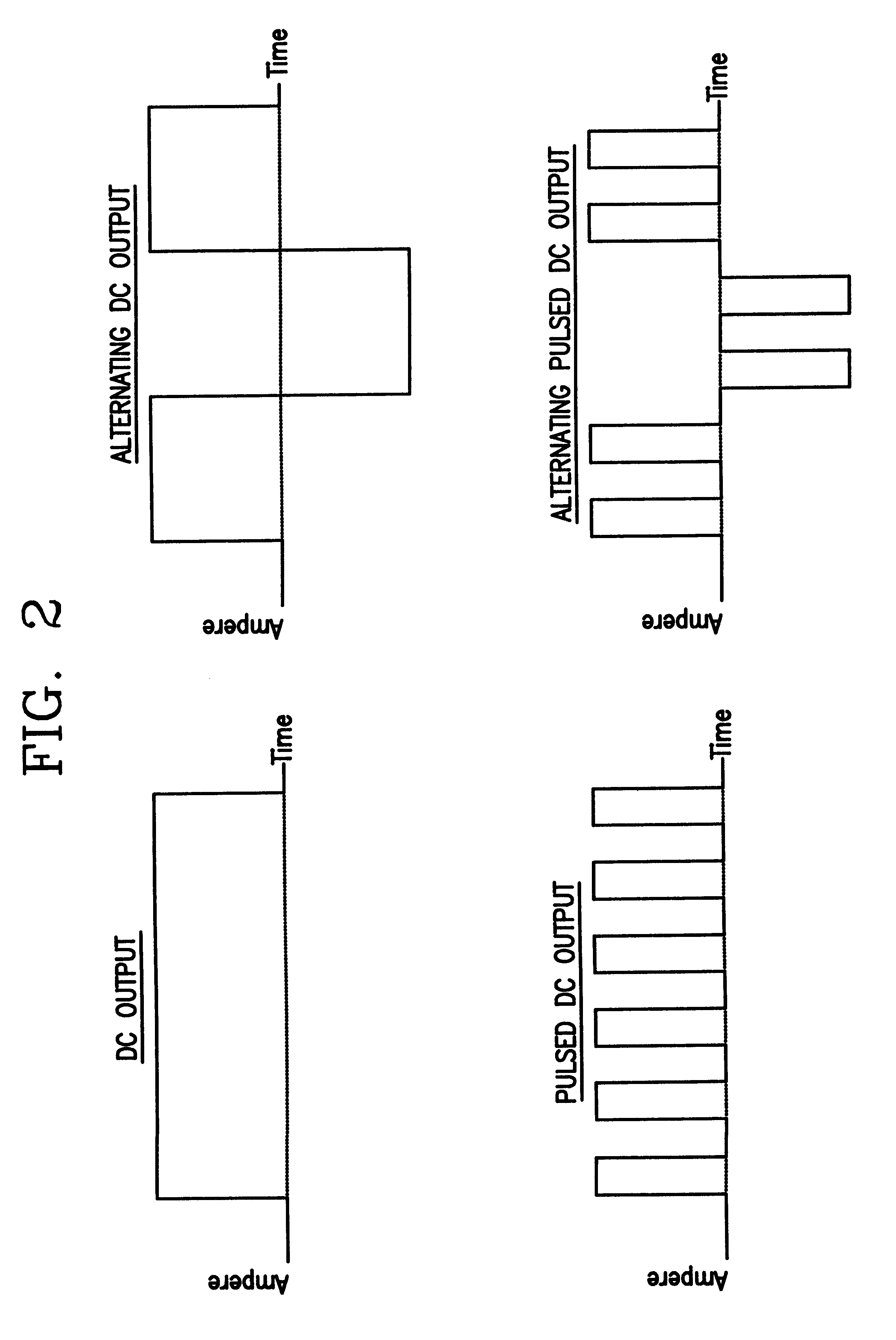

An apparatus for bonding a particle material to near theoretical density, includes a chamber, a punch and die assembly for supporting a particle material, plungers for applying shear and / or axial pressures, and a power supply for applying a current. In the first stage, a pulsed current of about 1 to 20,000 amps., is applied to the particle material for a predetermined time period, and substantially simultaneously therewith, a shear force of about 5-50 MPa is applied. In the second stage, an axial pressure of about less than 1 to 2,000 MPa is applied to the particle material for a predetermined time period, and substantially simultaneously therewith, a steady current of about 1 to 20,000 amps. is applied. The apparatus may be used to bond metallic, ceramic, intermetallic and composite materials to near-net shape, directly from precursors or elemental particle material without the need for synthesizing the material. The method may also be applied to perform combustion synthesis of a reactive material, followed by consolidation or joining to near-net shaped articles or parts. The apparatus may further be used to repair a damaged or worn substrate or part, coat a particle onto a substrate, and grow single crystals of a particle material.

Owner:MATERIALS MODIFICATION INC

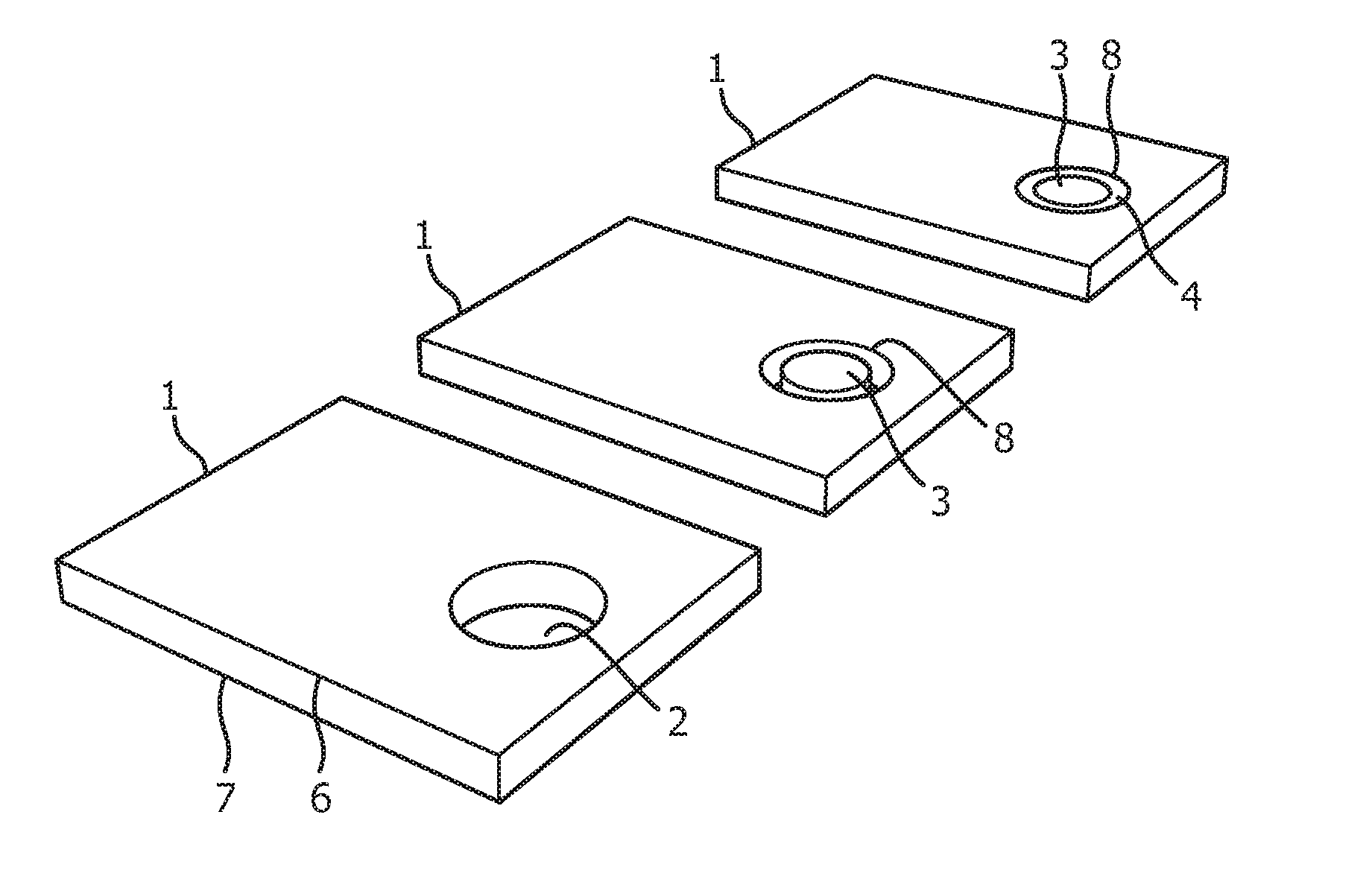

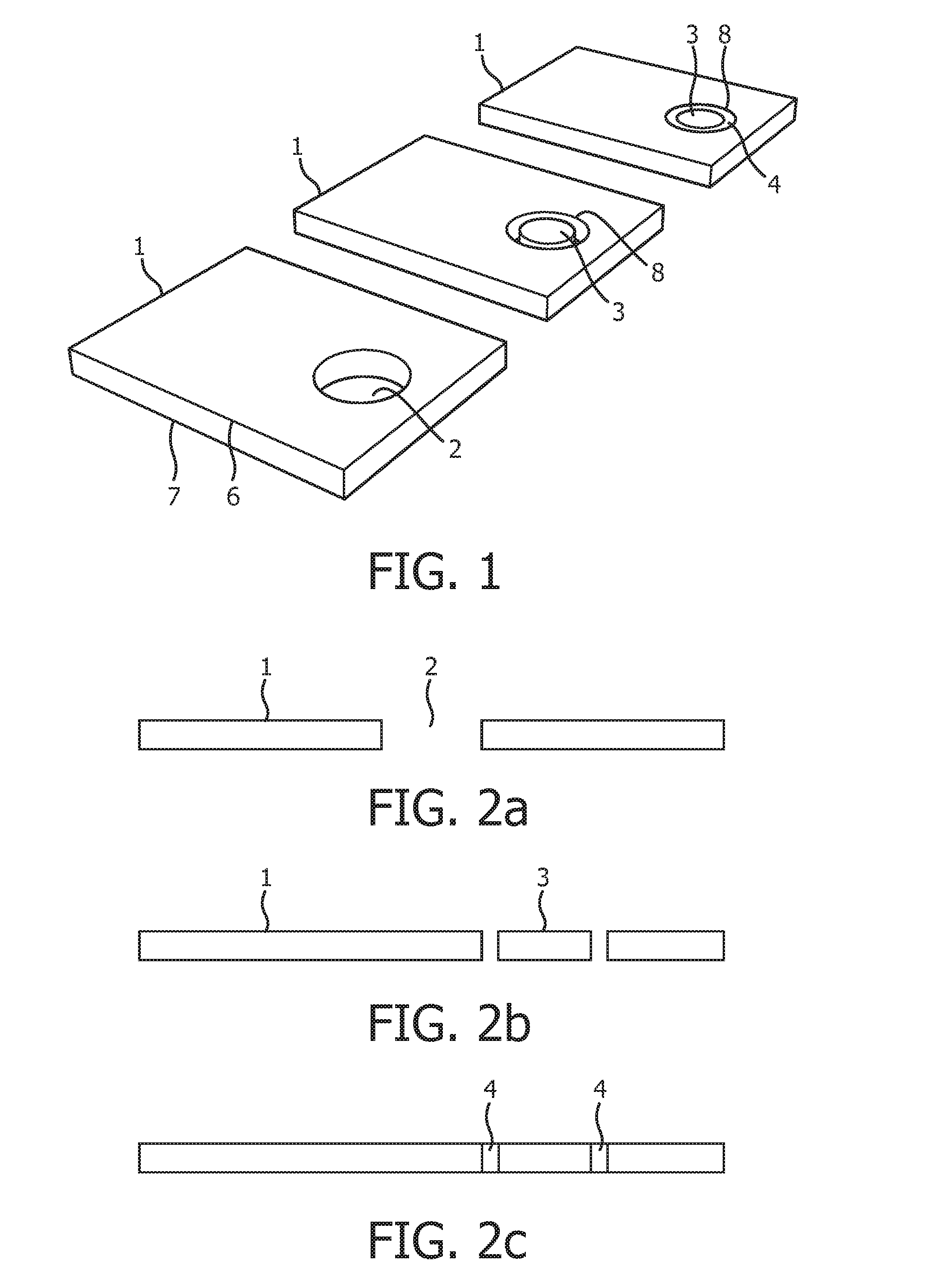

Medical device with ultrasound transducers embedded in flexible foil

ActiveUS20140148703A1Avoid signal interferenceHigh compressive strengthUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostrictive device manufacture/assemblyUltrasound imagingUltrasonic sensor

The invention relates to ultrasound imaging method and apparatus suitable for minimally invasive ultrasound diagnostic devices in cardiac ablation monitoring and in tumor ablation monitoring. The present invention proposes to manufacture a transducers assembly and system on a patterned flexible foil by embedding transducers patches in apertures on the foil surface. This provides great control of the acoustic properties of the transducer.

Owner:KONINKLJIJKE PHILIPS NV

PVC (polyvinyl chloride)/metal bonding hot melt adhesive film and preparation method thereof

ActiveCN103756577AGood adhesionHigh bonding strengthNon-macromolecular adhesive additivesFilm/foil adhesivesPolyolefinPolyvinyl chloride

The invention relates to a PVC (polyvinyl chloride) / metal bonding hot melt adhesive film. The raw material formula of the film comprises the following components in parts by weight: 15-40 parts of maleic anhydride modified polyethylene-ester copolymer, 40-70 parts of polyethylene-ester copolymer, 10-30 parts of polyolefin copolymer, 0.1-1 part of an initiating agent, 0.2-2 parts of silane and 0.1-2 parts of a crosslinking agent. The invention also relates to a preparation method of the hot melt adhesive film, and the preparation method comprises the steps of fully and uniformly mixing the component raw materials according to the formula, granulating through extrusion, and further performing curtain coating to obtain the hot melt adhesive film. Compared with the prior art, the PVC / metal bonding hot melt adhesive film disclosed by the invention can be used for quickly bonding PVC with a metal material, has better adhesive properties, and is green, environmentally friendly and pollution-free.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

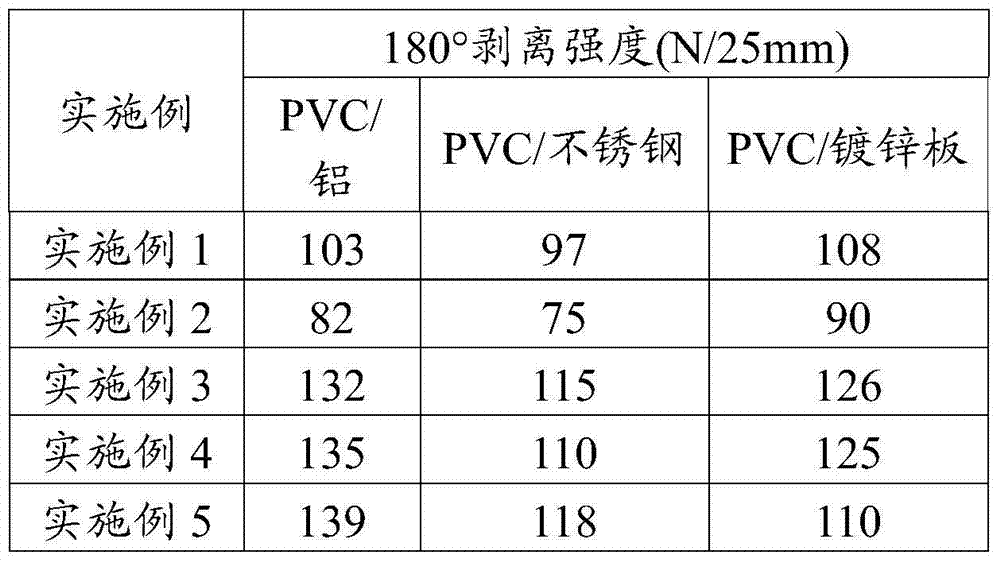

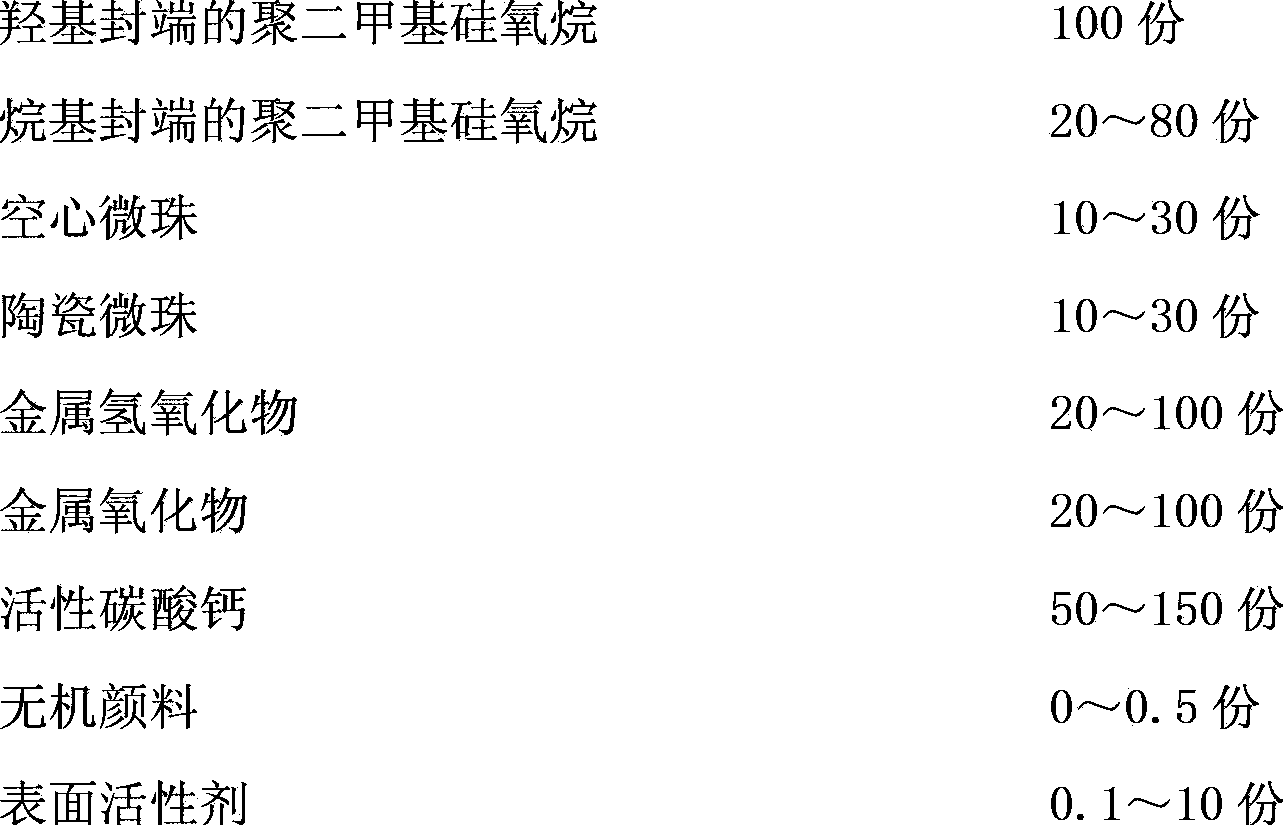

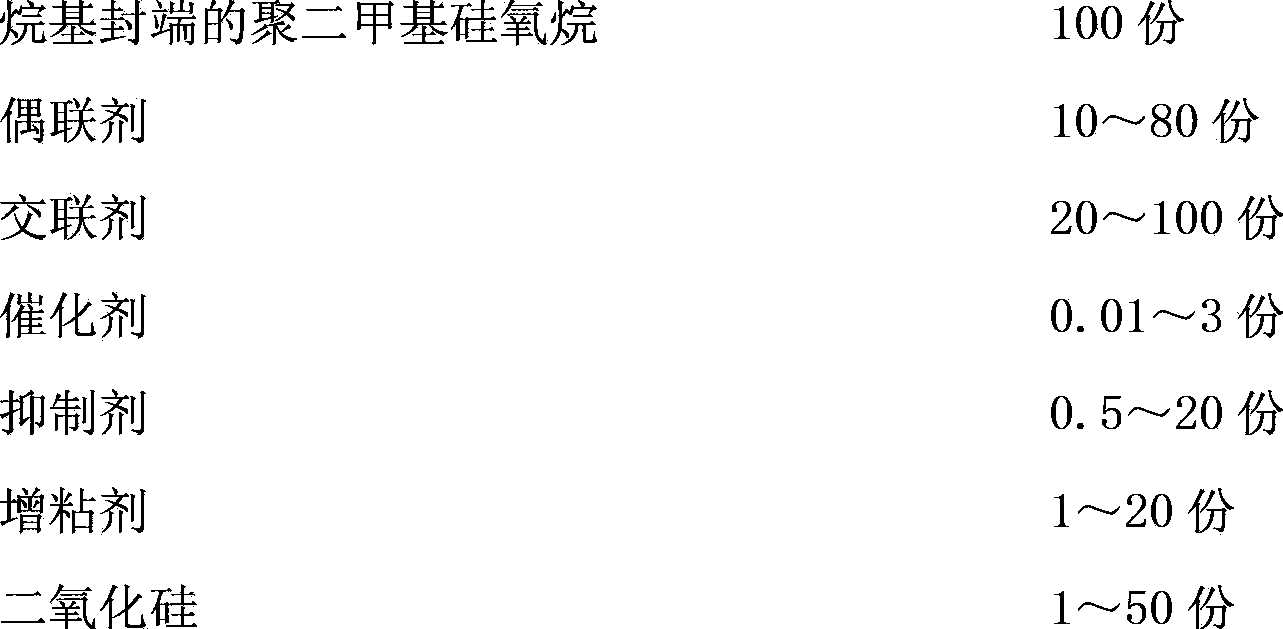

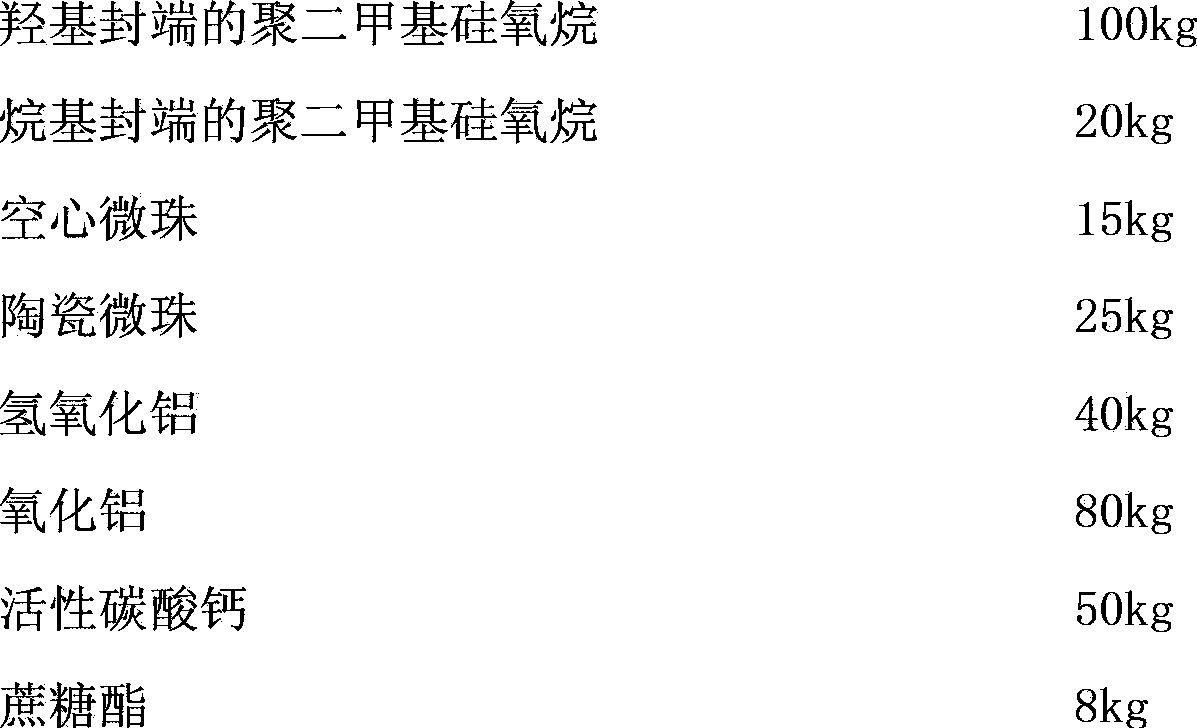

Double-component silicone structural sealant for heat mirror hollow glass and preparation method thereof

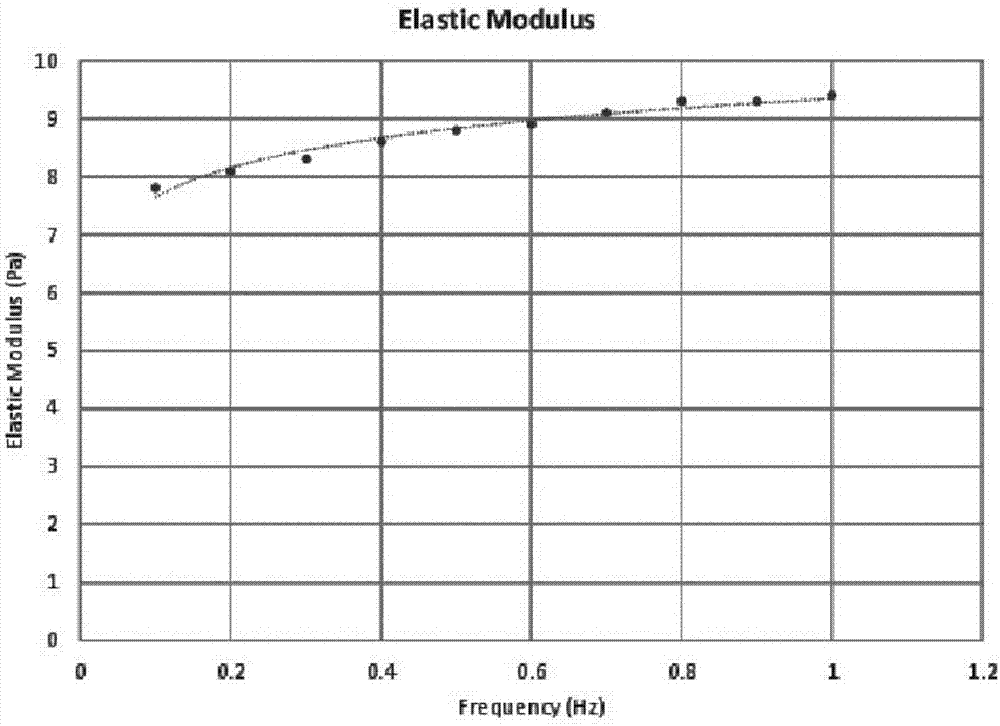

ActiveCN103820072AIncreased crosslink depthFast bondingNon-macromolecular adhesive additivesCross-linkMicrosphere

The invention discloses a double-component silicone structural sealant for heat mirror hollow glass and a preparation method of the sealant. The sealant comprises a component A and a component B, wherein the component A comprises hydroxyl-terminated polydimethylsiloxane, alkyl-terminated polydimethylsiloxane, hollow microsphere, ceramic microbead, metal hydroxide, metal oxide, activated calcium carbonate, inorganic pigment and a surfactant; the component B comprises alkyl-terminated polydimethylsiloxane, a coupling agent, a cross-linking agent, a catalyst, an inhibitor, a thickening agent, and silicon dioxide. The preparation method of the sealant comprises the following steps: 1) taking each ingredient in the component A to be mixed uniformly under the vacuum condition; 2) taking each ingredient in the component B to be mixed uniformly under the vacuum condition; 3) mixing the component A and the component B at room temperature according to the weight ratio of (8:1) to (20:1), and at last obtaining the sealant. The double-component silicone structural sealant is good in adhesiveness, high in curing speed, good in sealing performance, high in hardness and modulus, and excellent in thermal barrier effect, and suitable for sealing and bonding of heat mirror film, glass and metal materials etc.

Owner:ZHENGZHOU ZHONGYUAN SILANDE HIGH TECH CO LTD

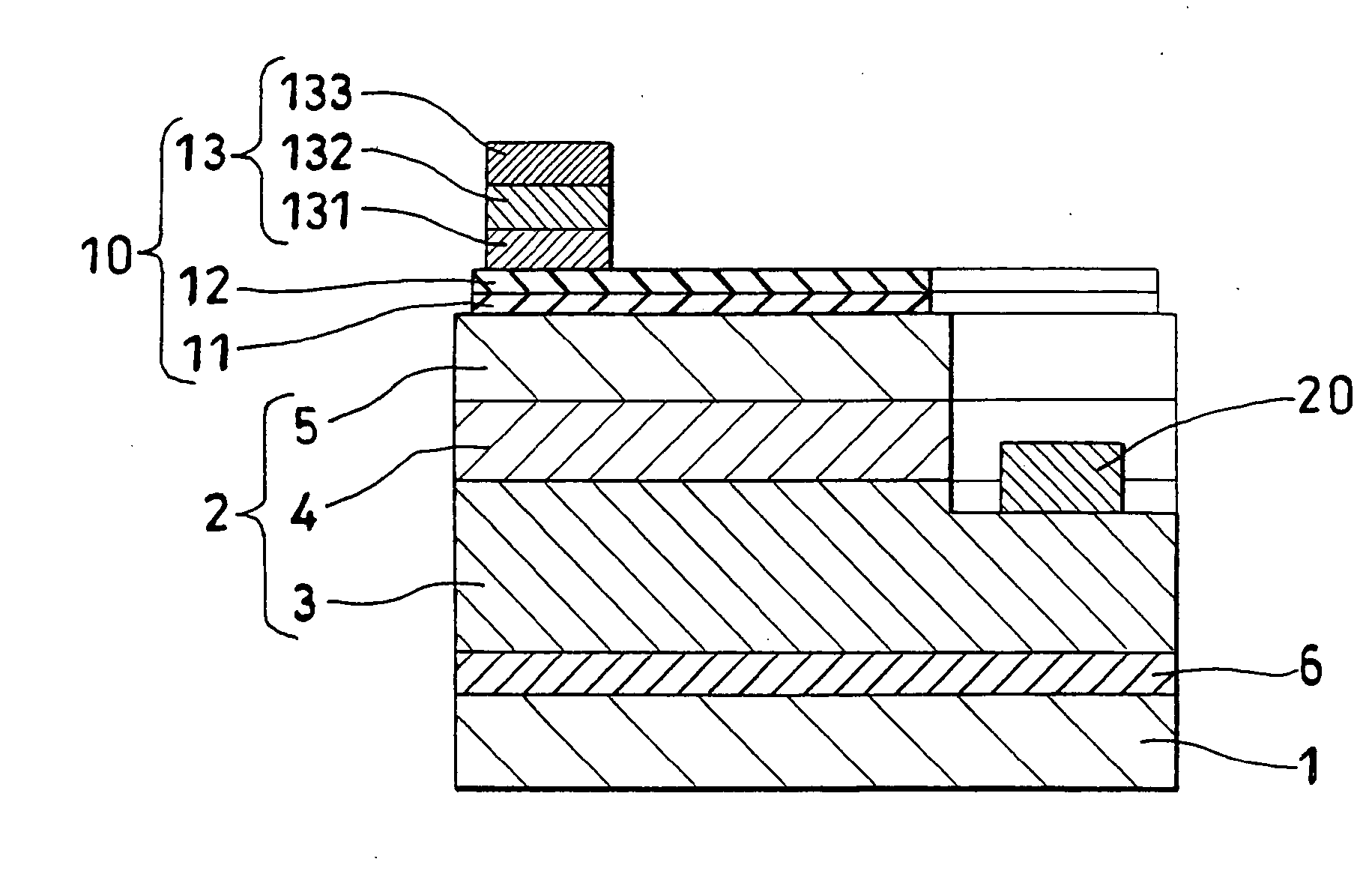

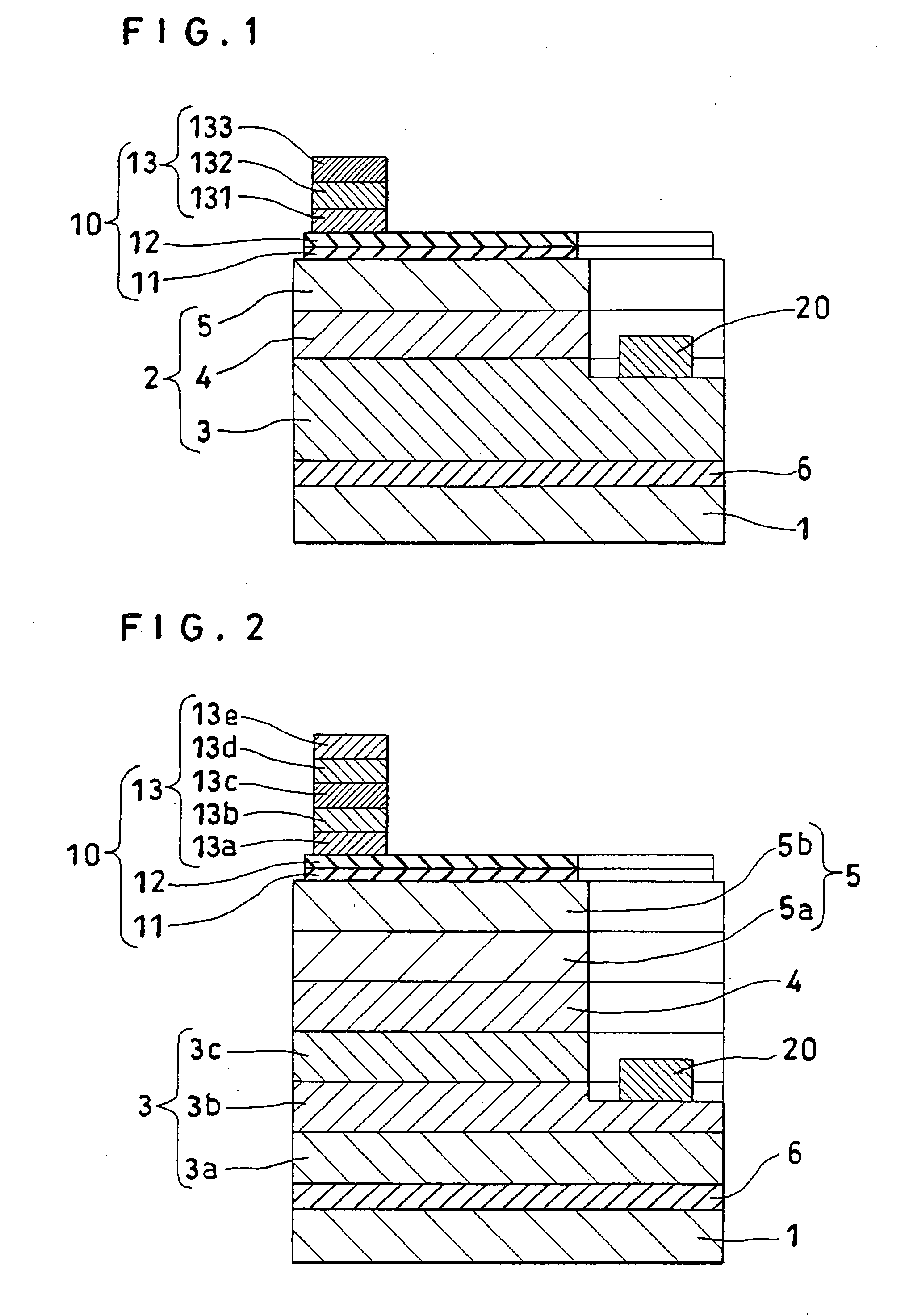

Substrate assembly apparatus and method

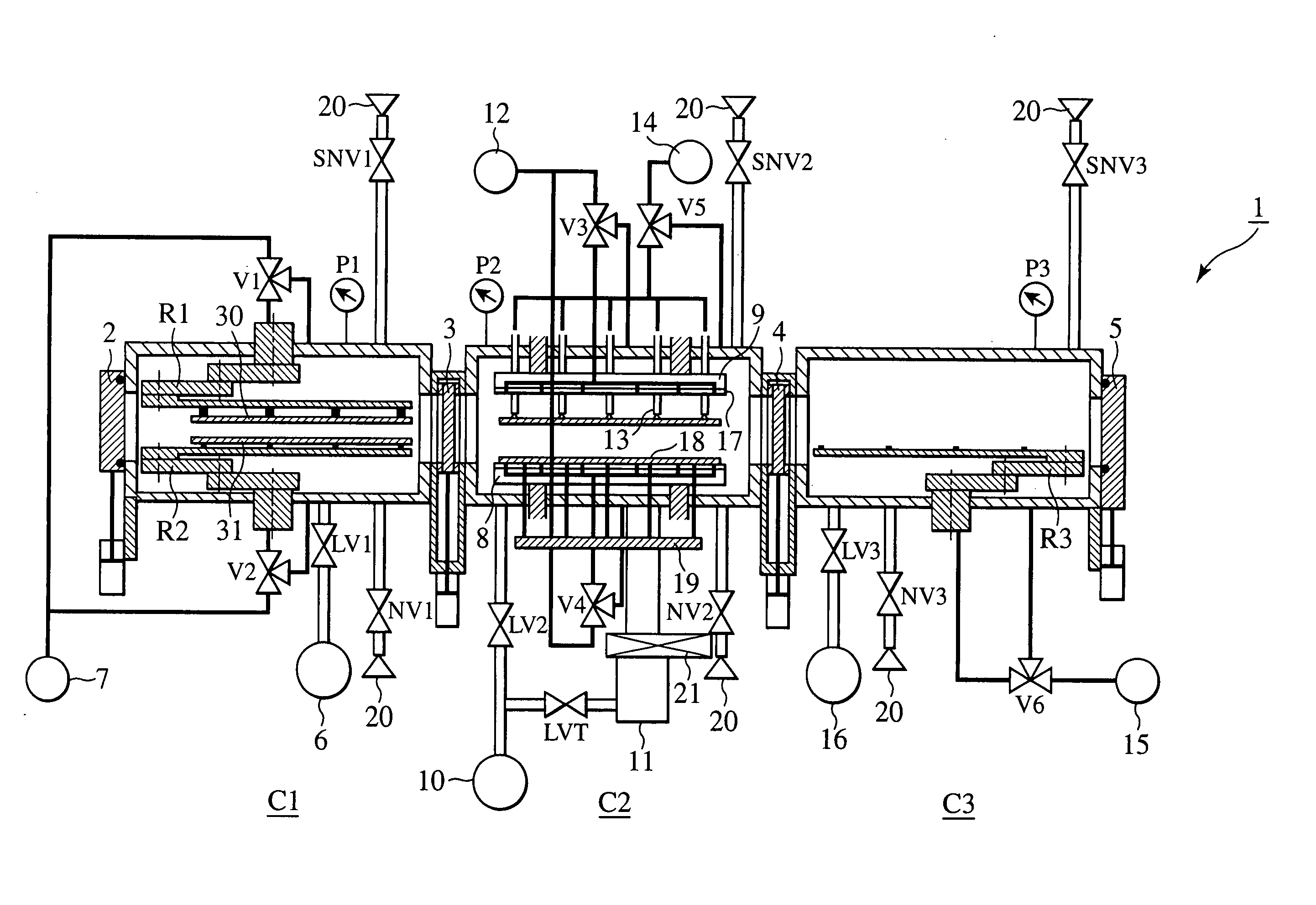

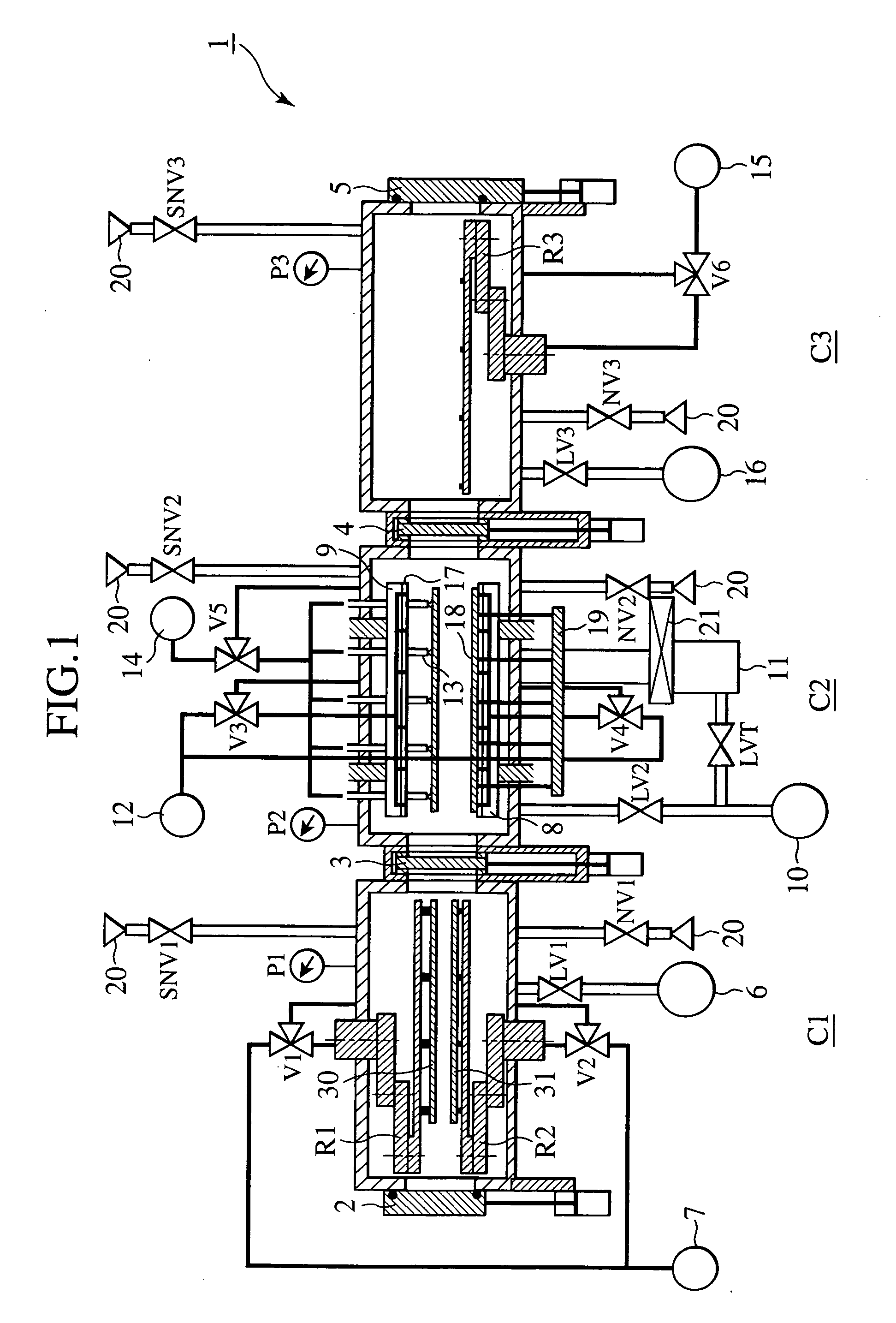

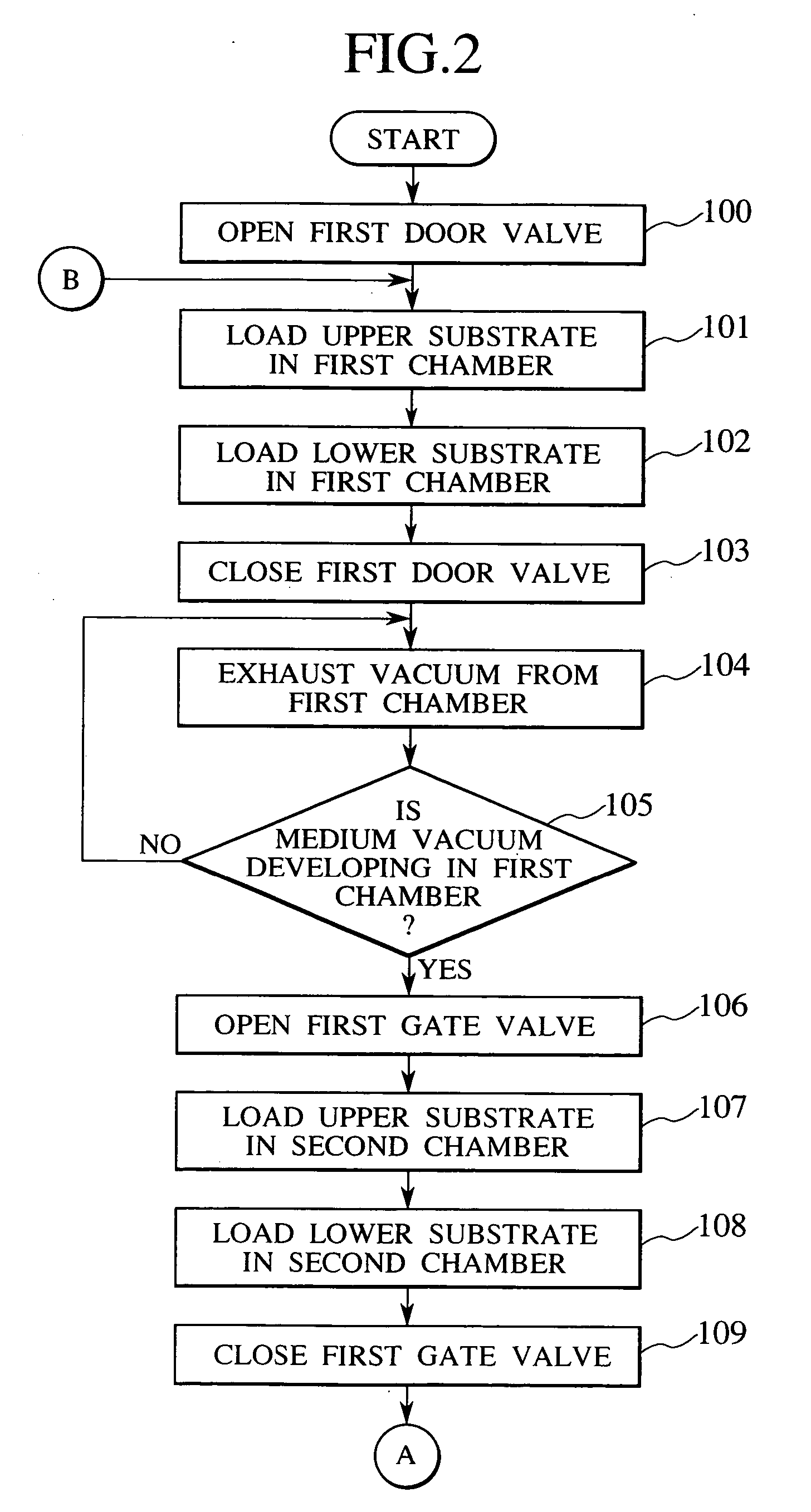

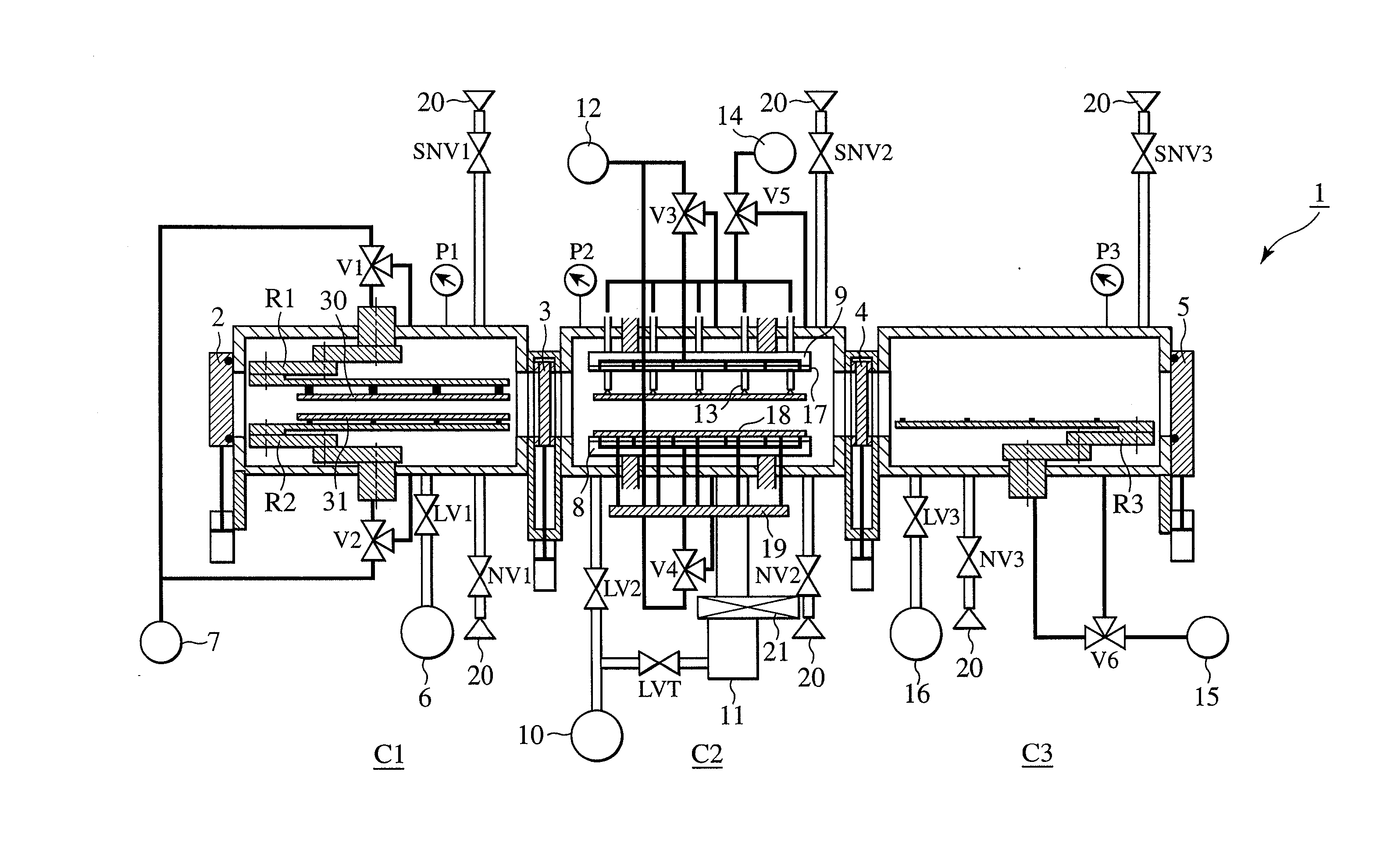

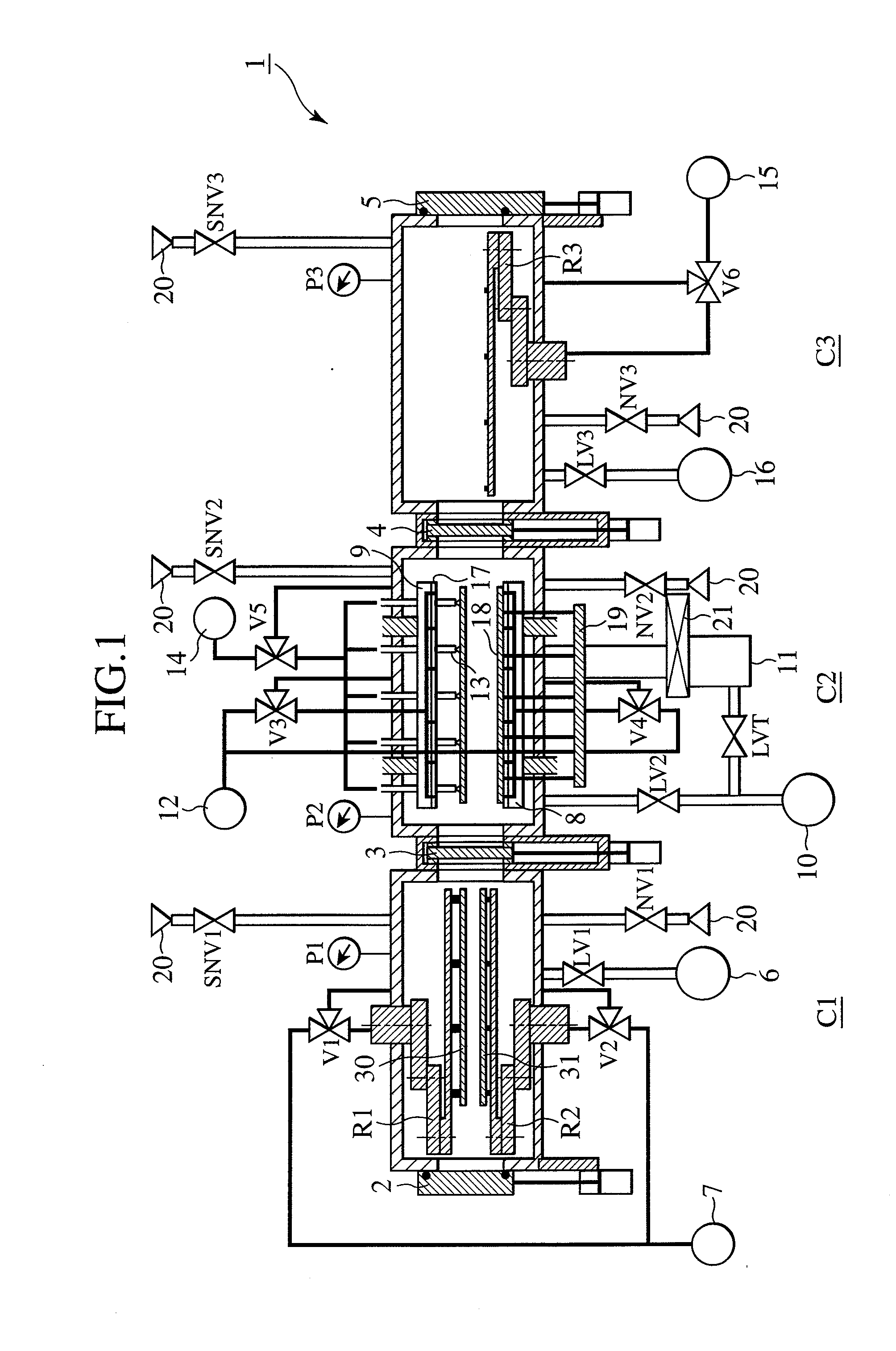

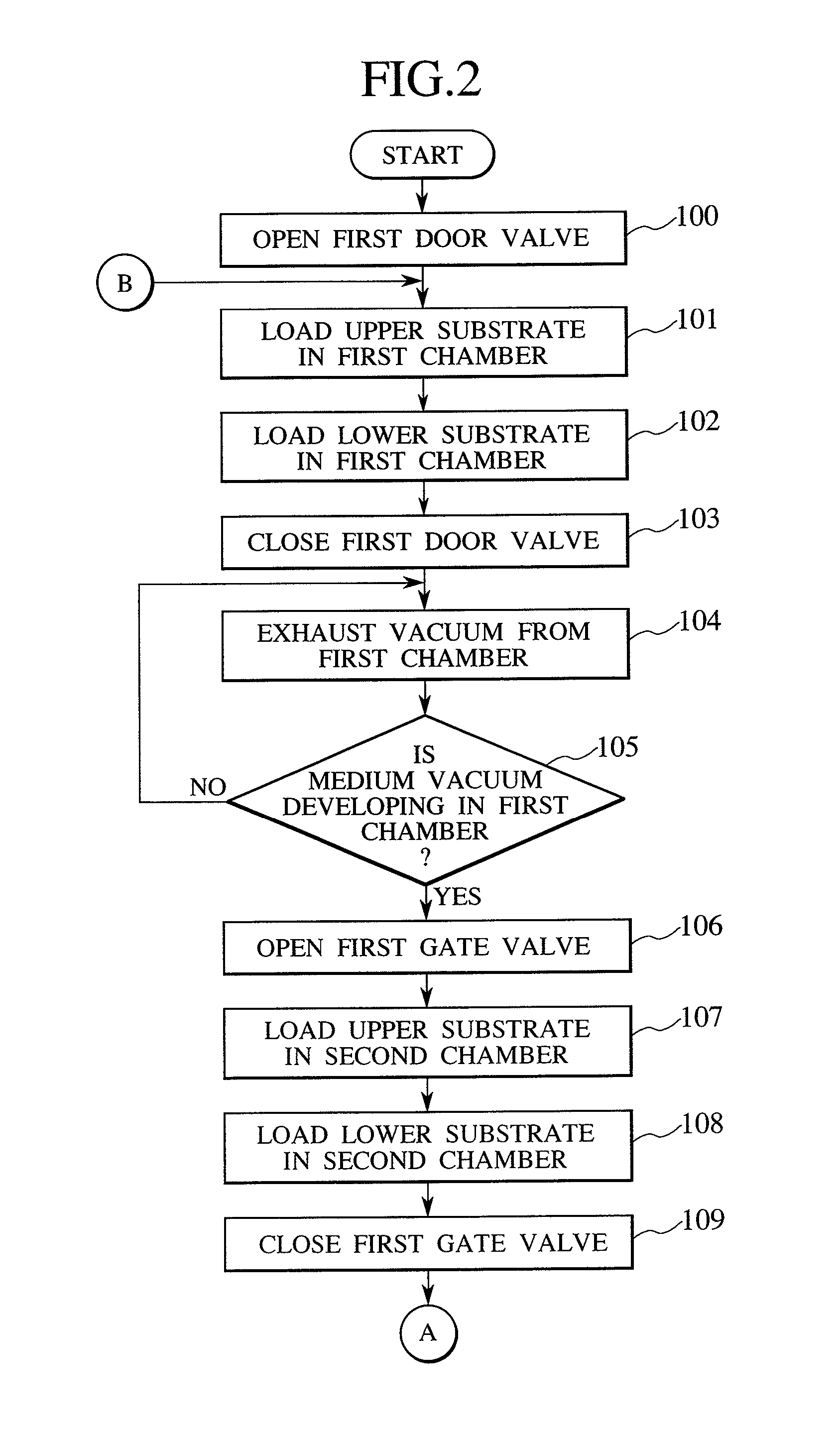

InactiveUS20070051462A1High precisionShorten evacuation timeLayered product treatmentLaminationAtmospheric pressureElectrical and Electronics engineering

A substrate bonding apparatus for bonding substrates together in a vacuum at high speeds, with a high degree of accuracy includes a first chamber C1, a second chamber C2, and a third chamber C3. Two substrates to be bonded together are loaded in the first chamber C1. The two substrates are bonded together in the second chamber C2. The two substrates bonded together are unloaded in the third chamber C3. The first and third chambers are variably controlled from an atmospheric pressure state to a medium vacuum state. The second chamber is variably controlled from the medium vacuum state to a high vacuum state.

Owner:HITACHI PLANT TECH LTD

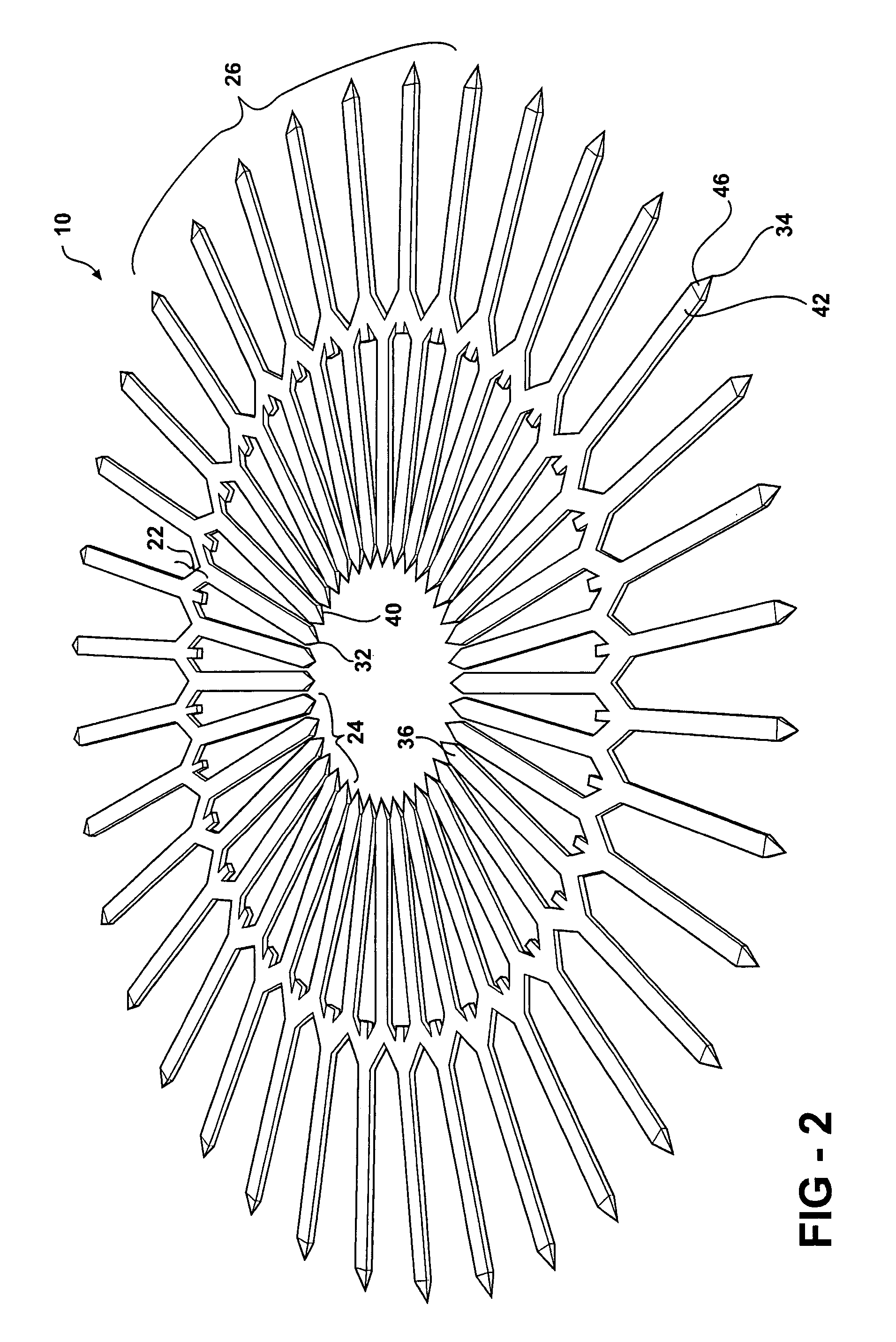

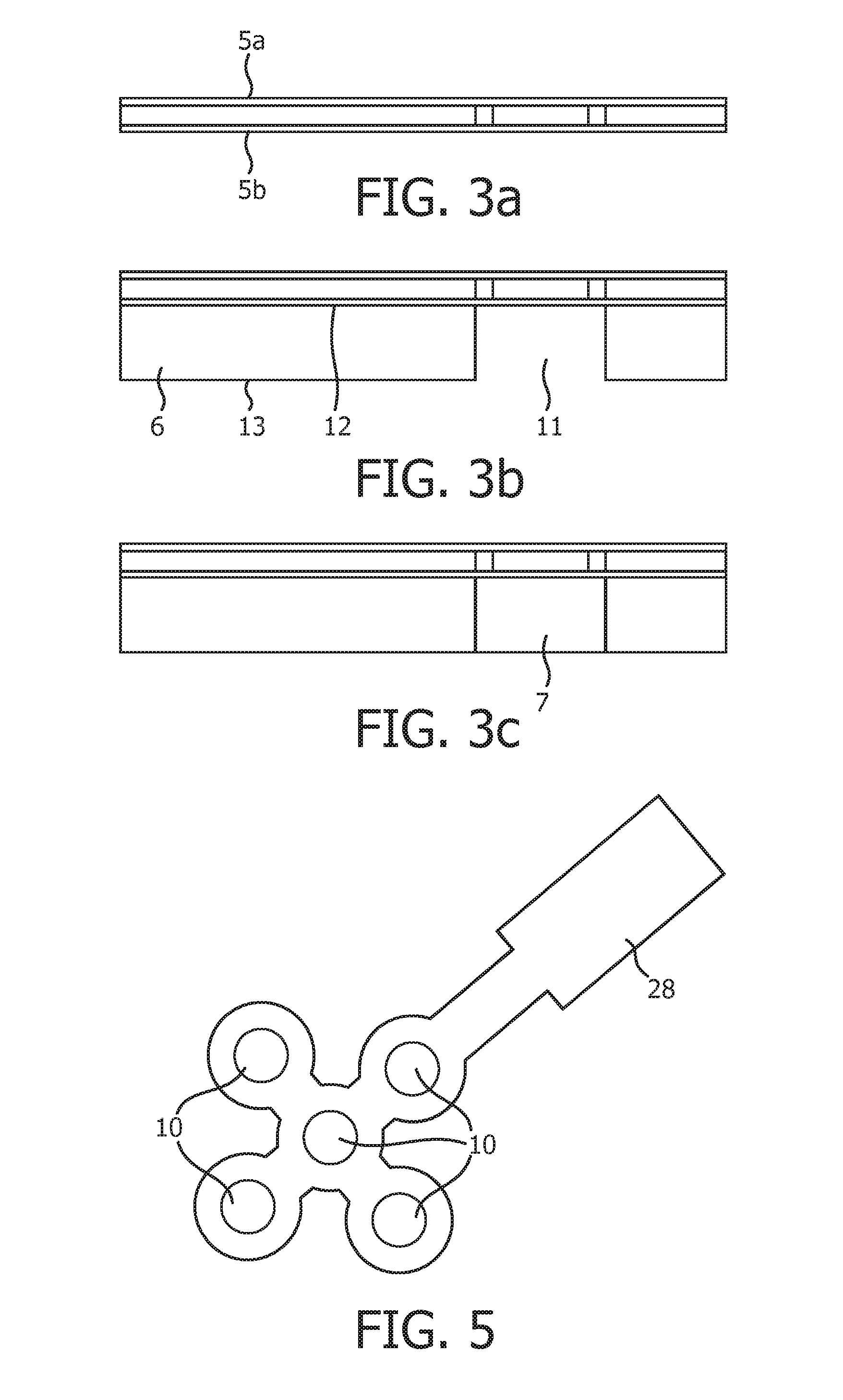

Fastener apparatus for tissue and methods of deployment and manufacture

ActiveUS20060069401A1Fast bondingReadily penetrates tissueSurgical staplesWound clampsArcuate shapeBiomedical engineering

A device for connecting two tubular vessels together in a side-by-side or tangential manner is disclosed. The device has an annulus and at least one series of fingers connected to and extending away from the annulus. In the preferred embodiment there are two sets of fingers connected to and extending away from the annulus in opposite directions. Each finger is preferably biased into an arcuate shape. In use, a deployment apparatus is used to constrain the fingers of the device to be in a relatively planar configuration. The deployment apparatus containing the device is placed between and in contact with the two tubular vessels so that one tubular vessel is above the device and one tubular vessel is below the device and so that the fingers of the device come into contact with the tissue of the vessels. As the fingers penetrate the vessels the constraint on the fingers is removed so that the fingers can assume their biased arcuate shape. In this way, the fingers penetrate and grasp the tissue of the vessels so that the device grasps the vessels and pulls the vessels toward each other.

Owner:WRIGHT DAVID W

Method of bonding a particle material to near theoretical density

InactiveUS6183690B1High interface integrityMinimal distortionNanotechUltra-high pressure processesCombustionAxial pressure

A method of bonding a particle material to near theoretical density, includes placing a particle material in a die. In the first stage, a pulsed current of about 1 to 20,000 amps., is applied to the particle material for a predetermined time period, and substantially simultaneously therewith, a shear force of about 5-50 MPa is applied. In the second stage, an axial pressure of about less than 1 to 2,000 MPa is applied to the particle material for a predetermined time period, and substantially simultaneously therewith, a steady current of about 1 to 20,000 amps. is applied. The method can be used to bond metallic, ceramic, intermetallic and composite materials to near-net shape, directly from precursors or elemental particle material without the need for synthesizing the material. The method may also be applied to perform combustion synthesis of a reactive material, followed by consolidation or joining to near-net shaped articles or parts. The method may further be applied to repair a damaged or worn substrate or part, coat a particle onto a substrate, and grow single crystals of a particle material.

Owner:MATERIALS MODIFICATION INC

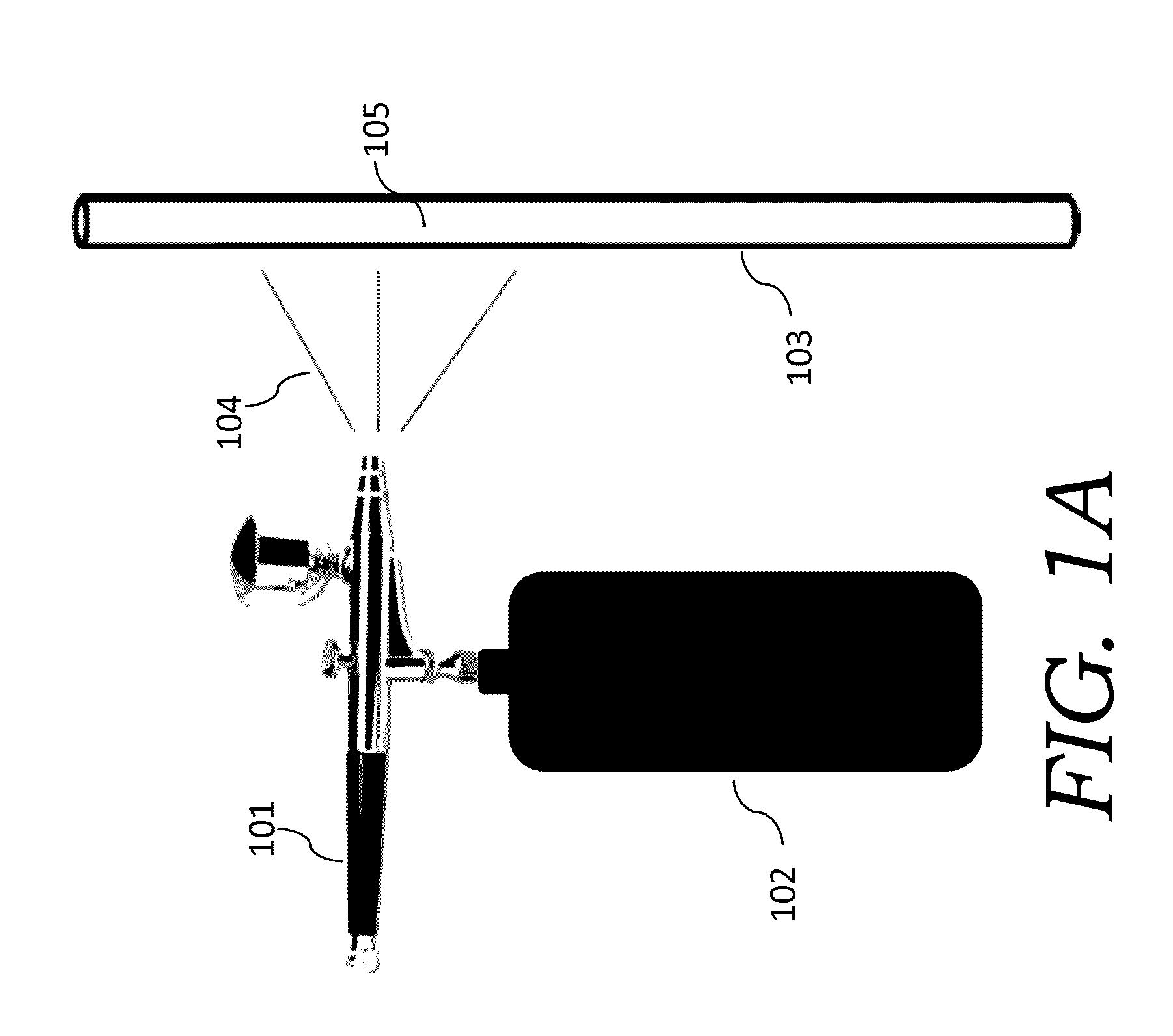

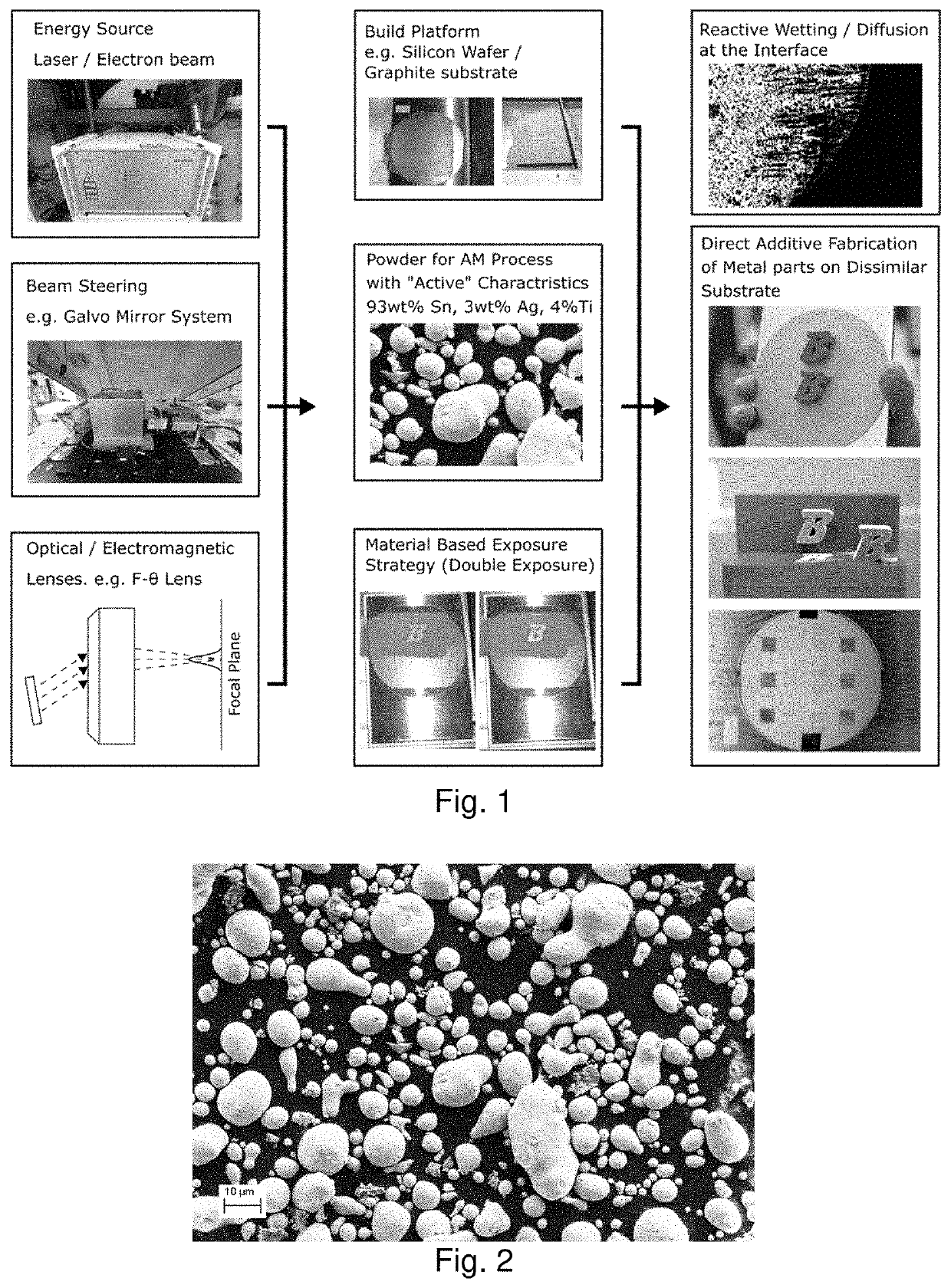

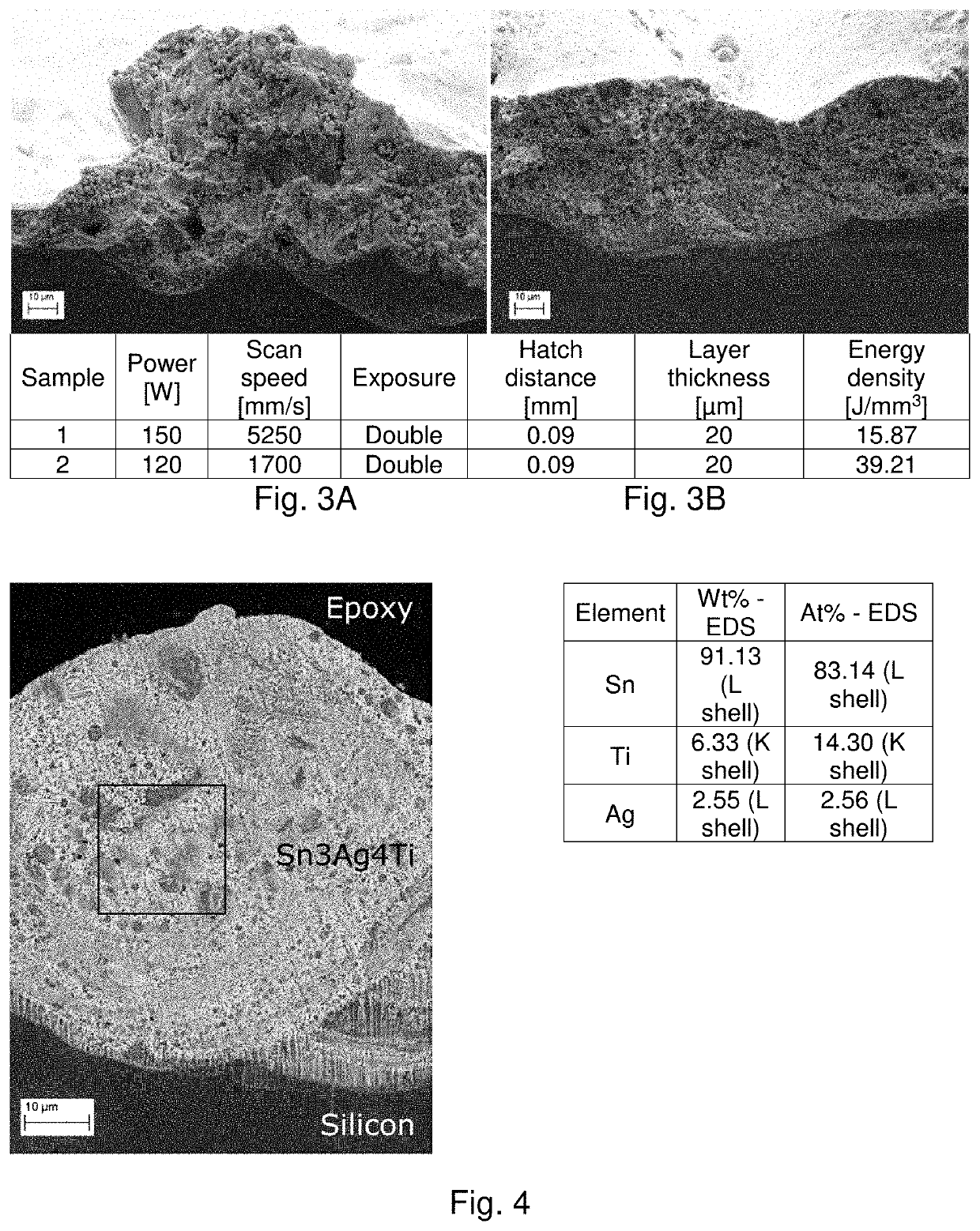

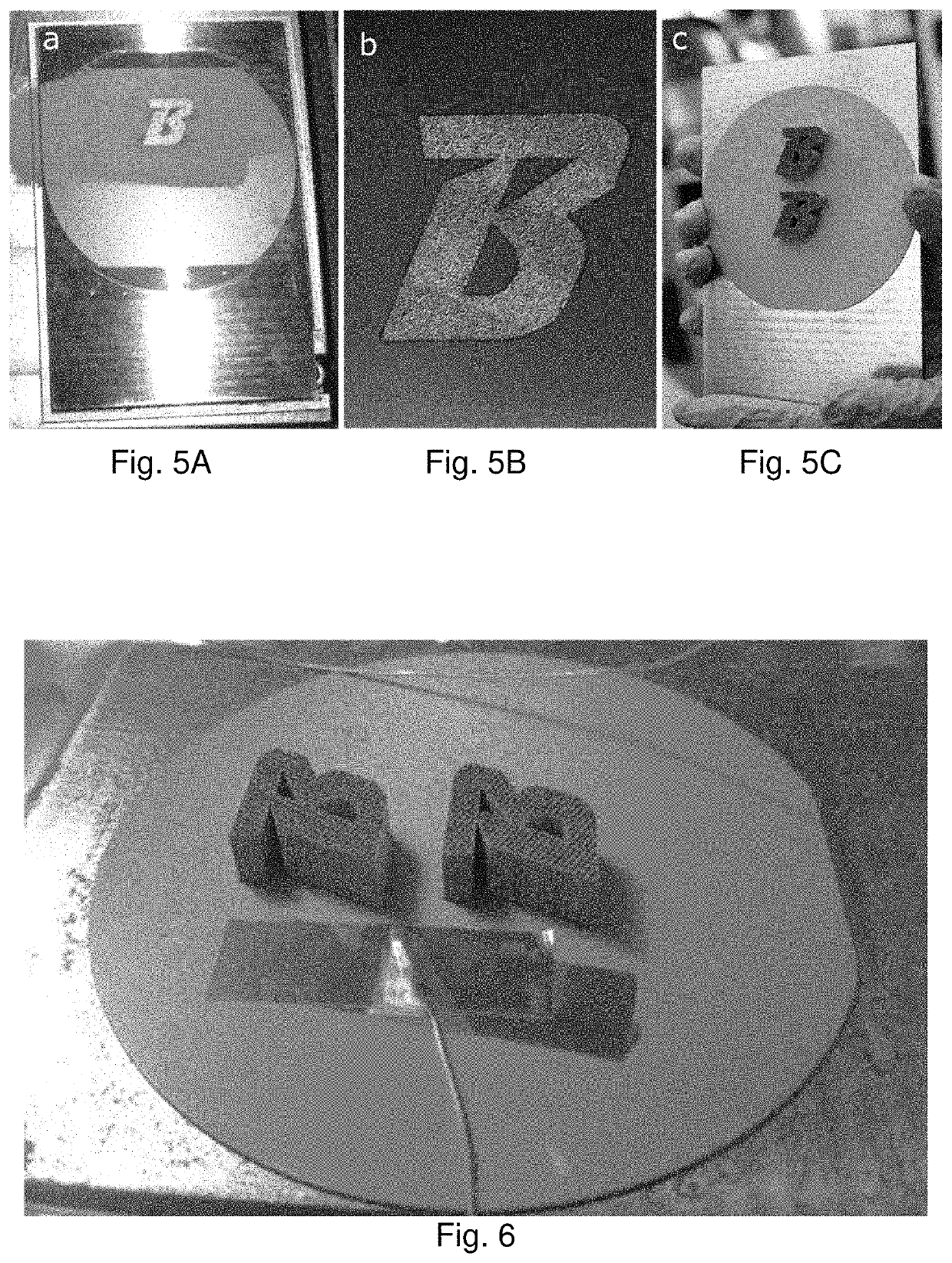

Additive manufacturing processes and additively manufactured products

ActiveUS20200049415A1Advantage for bondingHigh bonding strengthAdditive manufacturing apparatusSemiconductor/solid-state device detailsGraphiteHeat sensitive

A technique to additively print onto a dissimilar material, especially ceramics and glasses (e.g., semiconductors, graphite, diamond, other metals) is disclosed herein. The technique enables manufacture of heat removal devices and other deposited structures, especially on heat sensitive substrates. It also enables novel composites through additive manufacturing. The process enables rapid bonding, orders-of-magnitude faster than conventional techniques.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Electromagnetic wave-induced localized heating of CNT filled polymer composites for enhanced inter-bead diffusive bonding of fused filament fabricated parts

ActiveUS10414147B2Improve adhesionHigh bonding strengthMaterial nanotechnologyElectroconductive/antistatic filament manufacture3d printElectromagnetic electron wave

A electromagnetic wave-induced heating of CNT filled (or coated) polymer composites for enhancing inter-bead diffusive bonding of fused filament fabricated parts. The technique incorporates electromagnetic wave absorbing nanomaterials (carbon nanotubes (CNTs)) onto the surface or throughout the volume of 3D printer polymer filament to increase the inter-bead bond strength following a post electromagnetic wave irradiation treatment and / or in-situ focused electromagnetic beam during printing. The overall strength of the final 3D printed part will be dramatically increased and the isotropic mechanical properties of fused filament part will approach or exceed conventionally manufactured counterparts.

Owner:TEXAS TECH UNIV SYST

Vertical cotton breathable bra cup pad with silica gel net and preparation method thereof

The invention relates to the technical field of bra cup pad, and specifically relates to a vertical cotton breathable bra cup pad with a silica gel net and a preparation method thereof. The vertical cotton breathable bra cup pad comprises a vertical cotton outer layer and a vertical cotton inner layer; a vertical cotton interlayer is arranged between the vertical cotton outer layer and the vertical cotton inner layer; an adhesive layer is arranged between the vertical cotton interlayer and the vertical cotton inner layer; and a silica gel net layer is arranged between the vertical cotton outer layer and the vertical cotton interlayer. The vertical cotton breathable bra cup pad is prepared by a combined technology of hot pressing and cold pressing. The pad is made of vertical cotton, and is light, comfortable, and breathable. A silica gel layer is arranged between vertical cotton layers, the performance of the pad on resisting water washing is enhanced, the anti-collapse effect is good, three-dimensional effect of the cup pad is long-lasting and stable, and the deformation is difficult to happen.

Owner:HONGJI UNDERWEAR CO LTD

Calcium-doped inorganic nanocomposite material for 3D printing and preparation method of calcium-doped inorganic nanocomposite material

The invention discloses a calcium-doped inorganic nanocomposite material for 3D printing. The calcium-doped inorganic nanocomposite material comprises the following components in percentage by weight: 73-80% of ceramic precursor powder, 5-10% of nano-powder reinforcing material, 2-5% of calcium powder, 2-5% of a surfactant, 2-5% of an organic solvent, 1-4% of an inorganic binder and 5-10% of a low-temperature curing agent, wherein the particle size of the nano-powder reinforcing material is 20-200nm. By adopting the surfactant to perform deaggregation treatment on nano-powder, the nano-powder has excellent dispersivity; by adding the nano-powder into the ceramic precursor powder, the density and strength of ceramic can be improved, and the toughness of a product can be further upgraded; by mutually coordinating and matching the inorganic mixed powder, the inorganic binder and the low-temperature curing agent, the fast binding can be realized at low temperature; and the inorganic nanocomposite material can be used as a molding raw material of a 3D printing fast molding machine, the fast molding on the 3D printing machine can be effectively realized, and the calcium-doped inorganic nanocomposite material can be applied to a variety of types of 3D printing machines.

Owner:QINGDAO MATE RUIOU NEW MATERIAL TECH CO LTD

Material for rapid three dimensional printing forming and preparation method thereof

Owner:广州魁科机电科技有限公司

Molded parts from hot melt adhesives

InactiveUS20090291288A1Rapid and secure applicationFast bondingMonocarboxylic acid ester polymer adhesivesLamination ancillary operationsPolyesterPolyolefin

The invention relates to a molded part for bonding to metal or plastic substrates for use as a fastening element. Said molded part comprises a hot melt adhesive, said hot melt adhesive being based on polyamide, polyolefins, polyesters, polyacrylates or polystyrene. The molded part according to the invention is characterized in that the hot melt adhesive has a softening point between 100° and 250° C., a tensile stress at yield of between 1 and 35 MPa and the molded part consists entirely of the hot melt adhesive. The invention also relates to a method for bonding molded parts from hot melt adhesives to substrates by way of inductive heating.

Owner:HENKEL KGAA

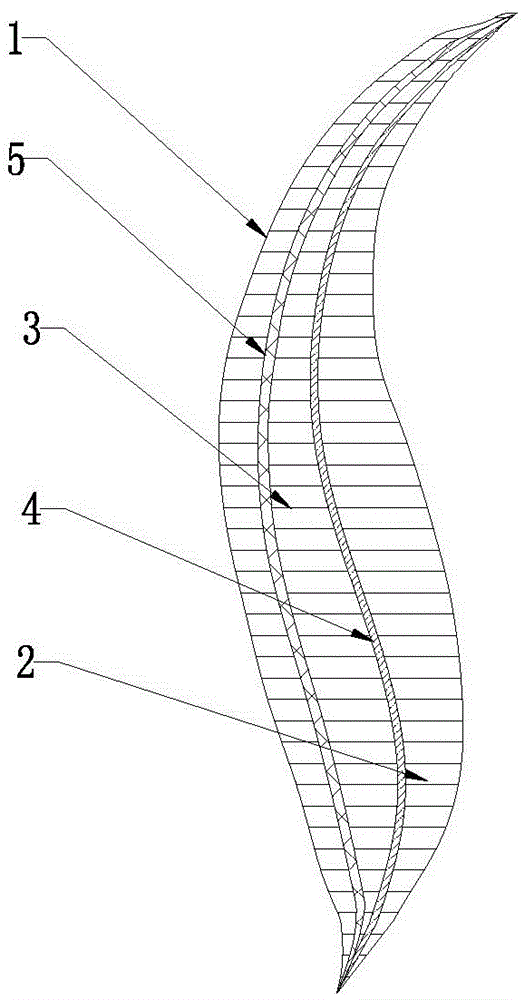

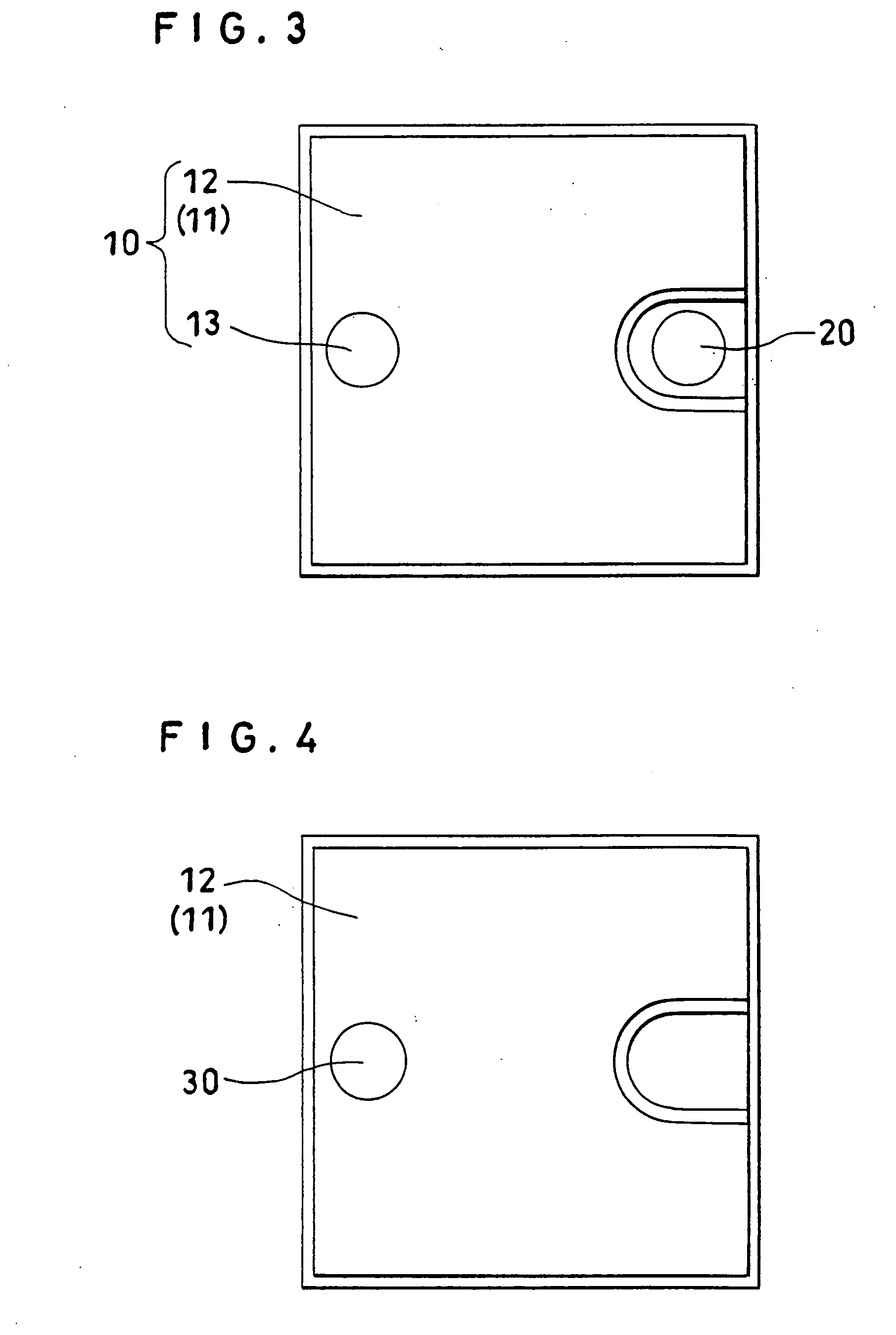

Transparent electrode for semiconductor light-emitting device

ActiveUS7498611B2Good ohmic contactMagnitude of resistivitySemiconductor devicesOhmic contactGallium nitride

Owner:TOYODA GOSEI CO LTD

Substrate assembly apparatus and method

InactiveUS20080053619A1Improve productivityPrecise BondingLayered product treatmentLaminationEngineeringAtmospheric pressure

A substrate bonding apparatus for bonding substrates together in a vacuum at high speeds, with a high degree of accuracy includes a first chamber C1, a second chamber C2, and a third chamber C3. Two substrates to be bonded together are loaded in the first chamber C1. The two substrates are bonded together in the second chamber C2. The two substrates bonded together are unloaded in the third chamber C3. The first and third chambers are variably controlled from an atmospheric pressure state to a medium vacuum state. The second chamber is variably controlled from the medium vacuum state to a high vacuum state.

Owner:NAKAYAMA YUKINORI +2

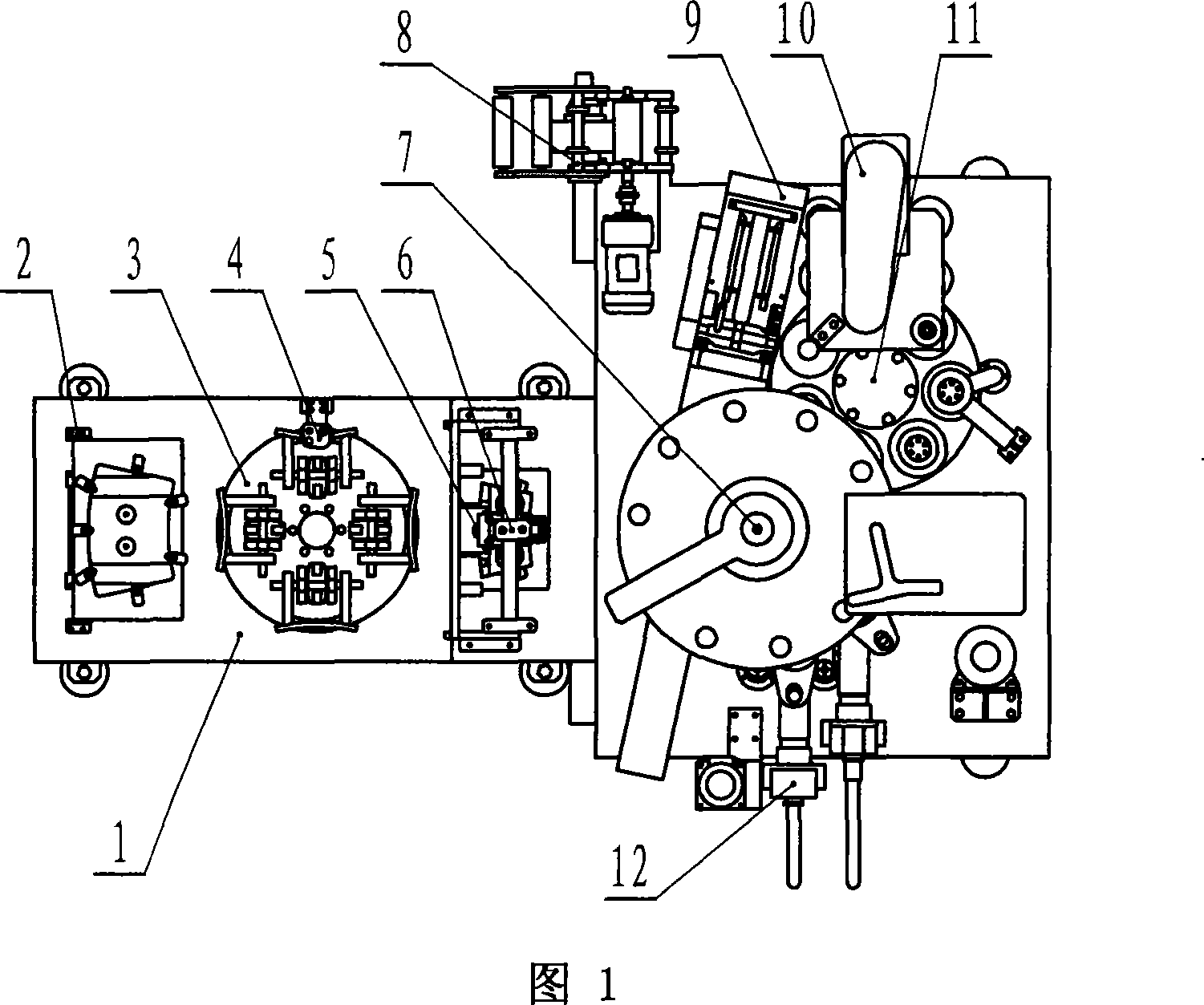

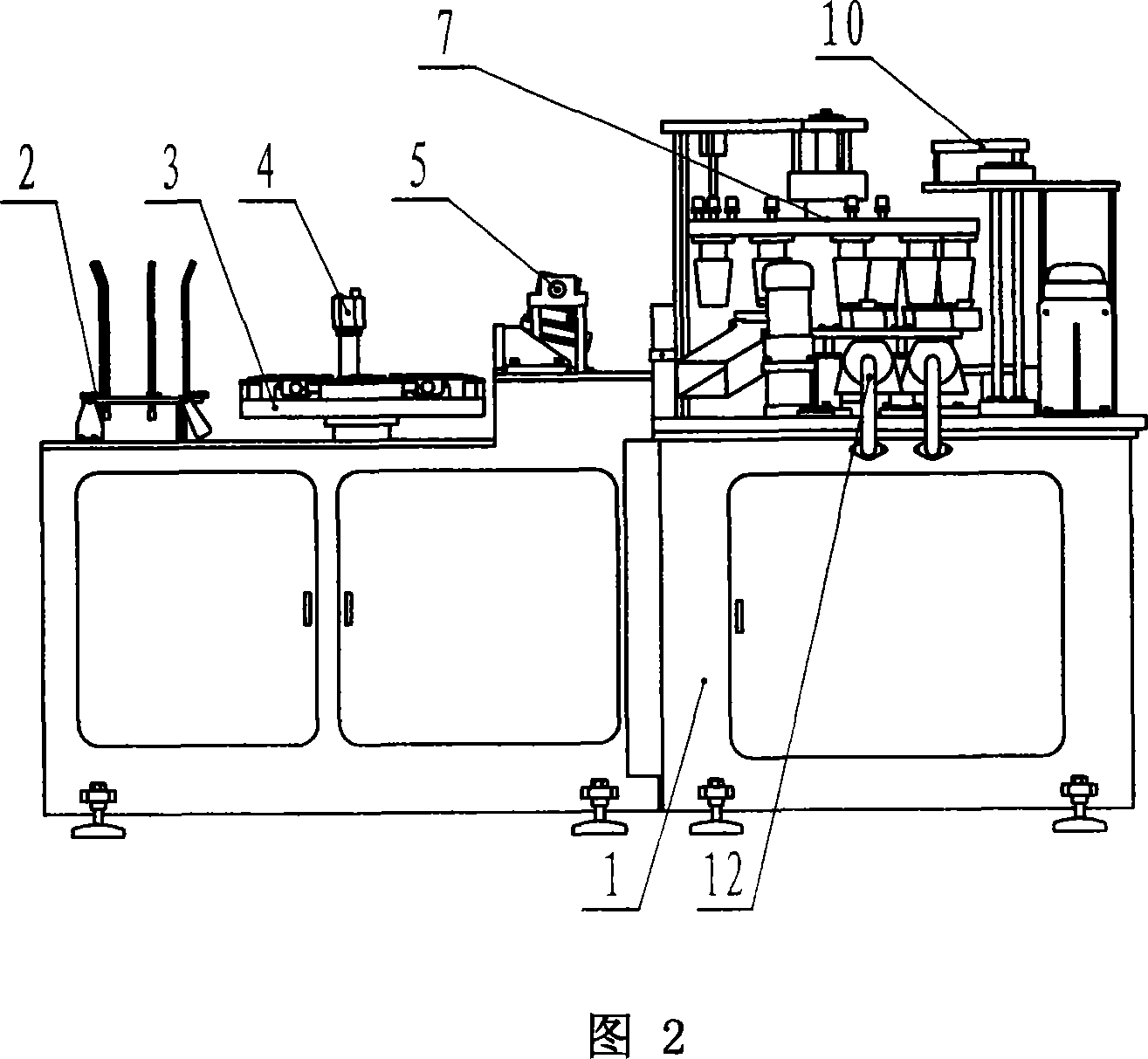

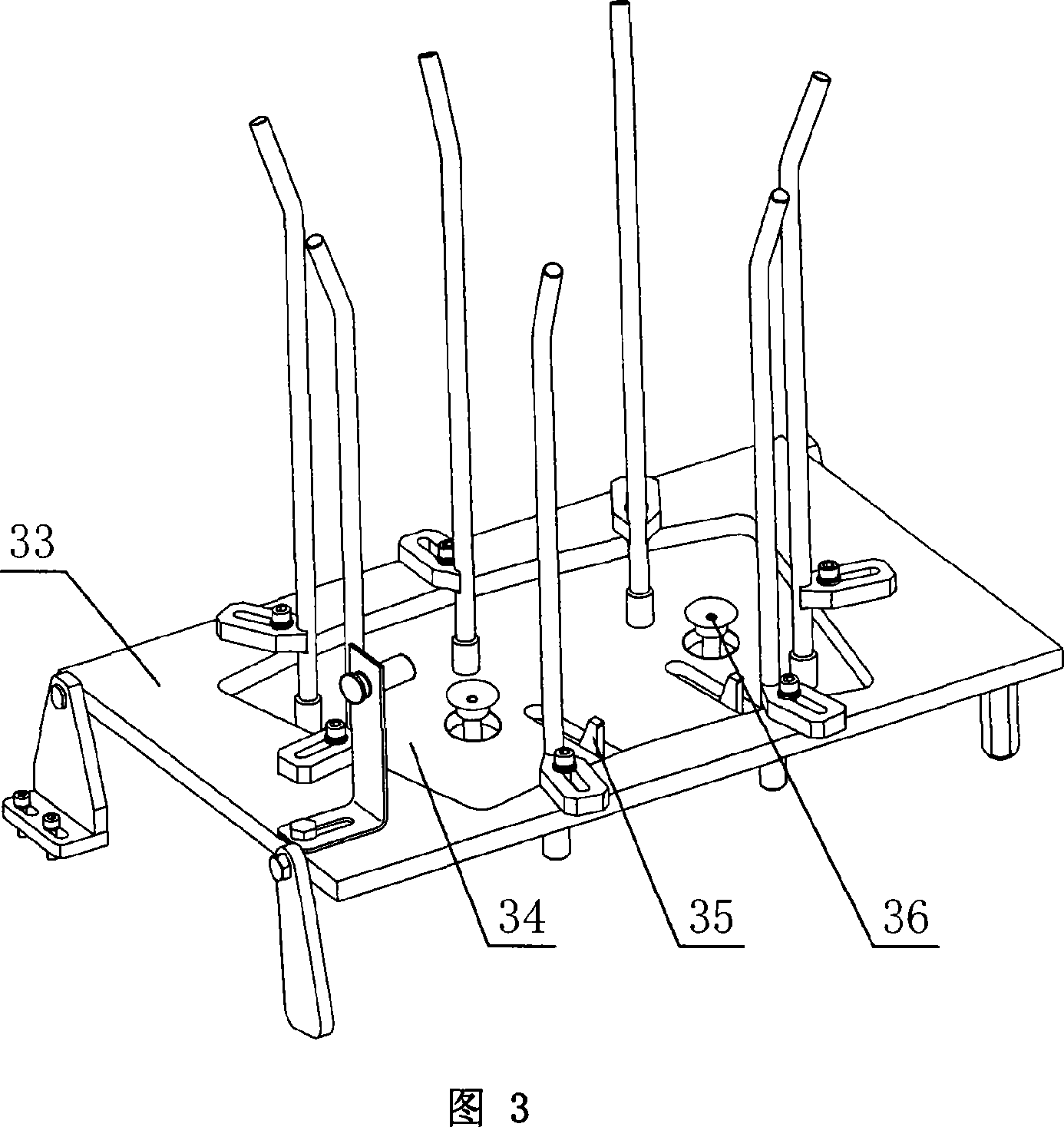

Machine for forming paper container

ActiveCN101073927AEffective protectionAvoid Ultrasonic RadiationPaper/cardboard wound articlesUltrasonic radiationMolding machine

The invention is concerned with the mechanical equipment for making and forming the paper container, includes the stander: sets the paper feeding equipment, the delivery plate, the sidewall preheating arrangement, the sidewall forming equipment, the sidewall bonding equipment, the hemline preheating arrangement, the hemline forming equipment, the hemline bonding equipment, the bottom paper conveying appliance, the bottom paper feed apparatus, and the hemline reinforcing equipment on the stander; sets the motor and drive gear in the stander. The invention can avoid ultrasonic radiation, improve the bonding speed, in order to improve the working efficiency. The invention uses the pneumatic control and air conveying to improve the yield; the complete machines shorts the power stroke farthest, improves the stability and processing speed of the equipment.

Owner:ZHEJIANG SEE MACHINERY

Method for manufacturing interior film-pasting woven bag

ActiveCN105109803AReduce human wasteIncrease productivityEnvelopes/bags making machineryPaper-makingLow-density polyethyleneManufacturing technology

The invention discloses a method for manufacturing an interior film-pasting woven bag, and relates to the technical field of woven bag manufacturing. The interior film-pasting woven bag comprises an outer plastic bag body formed by weaving polypropylene plastics. An ethylene-vinyl acetate film and a high-pressure low-density polyethylene film are sequentially arranged in the outer plastic bag body. The method includes the following operation steps: A, manufacturing plastic ribbon-like filaments; B, manufacturing the two films; C, manufacturing the outer plastic bag body with the double films; D, manufacturing an interior film-pasting woven bag reel by an interior film pasting combining machine through the outer plastic bag body, obtained in the step C, with the double films; and E, carrying out cutting and sewing on the interior film-pasting woven bag reel obtained in the step D, and completing manufacturing of the interior film-pasting woven bag. Compared with the prior art, the method can solve the problem that an inner bag body of an existing interior film-lining woven bag is prone to being damaged.

Owner:GUANGXI LUZHAI GUIZHE PLASTIC PACKAGE CO LTD

Medical antibacterial adhesive and preparation method thereof

InactiveCN104434542AImprove adhesionImprove antibacterial propertiesImpression capsDentistry preparationsEpoxyCellulose

The invention relates to a medical antibacterial adhesive and a preparation method thereof, and belongs to the technical field of adhesives. The medical antibacterial adhesive comprises the following constituents in parts by weight: 16 to 20 parts of epoxy resin, 2 to 10 parts of crylic acid, 4 to 10 parts of editic acid, 12 to 18 parts of polyurethane, 2 to 5 parts of polyvinyl alcohol, 2 to 8 parts of methylol cellulose, 1 to 3 parts of citric acid, 3 to 9 parts of nanometer silicon micro powder, 10 to 14 parts of titanium dioxide, and 20 to 30 parts of glycol. The medical antibacterial adhesive has good bonding property, and can rapidly realize bonding even at low temperature; the medical antibacterial adhesive has excellent antibacterial property; the preparation method is simple, convenient to carry out, and suitable for large-scale promotion and application.

Owner:SUZHOU BEC BIOLOGICAL TECH

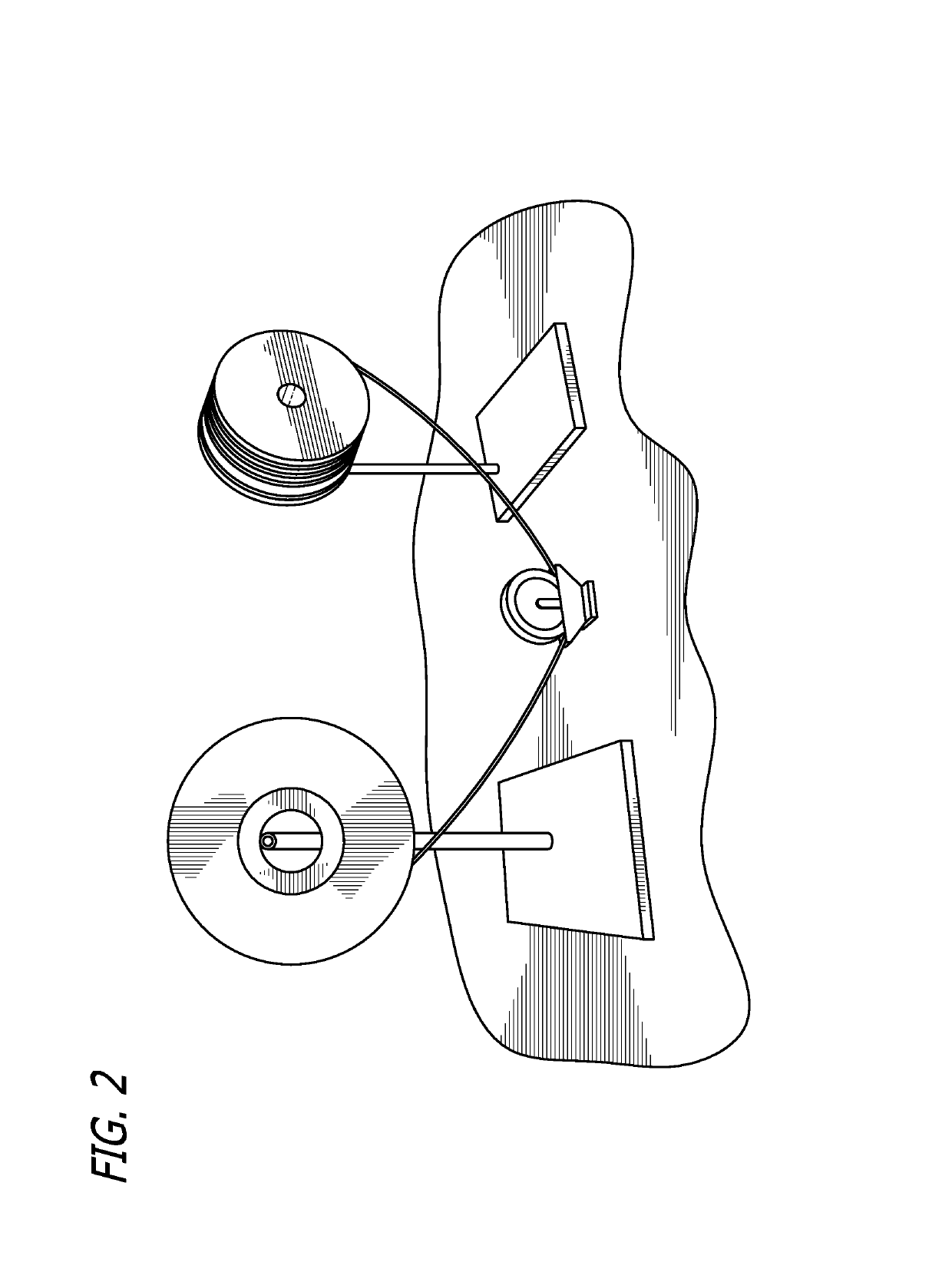

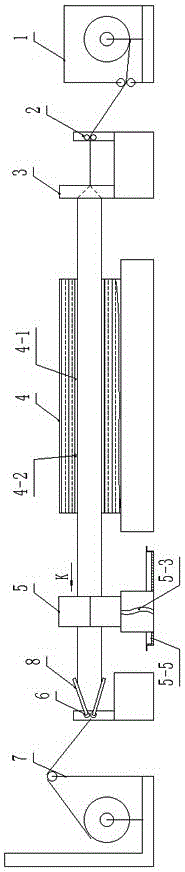

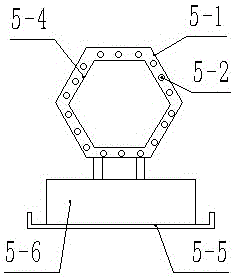

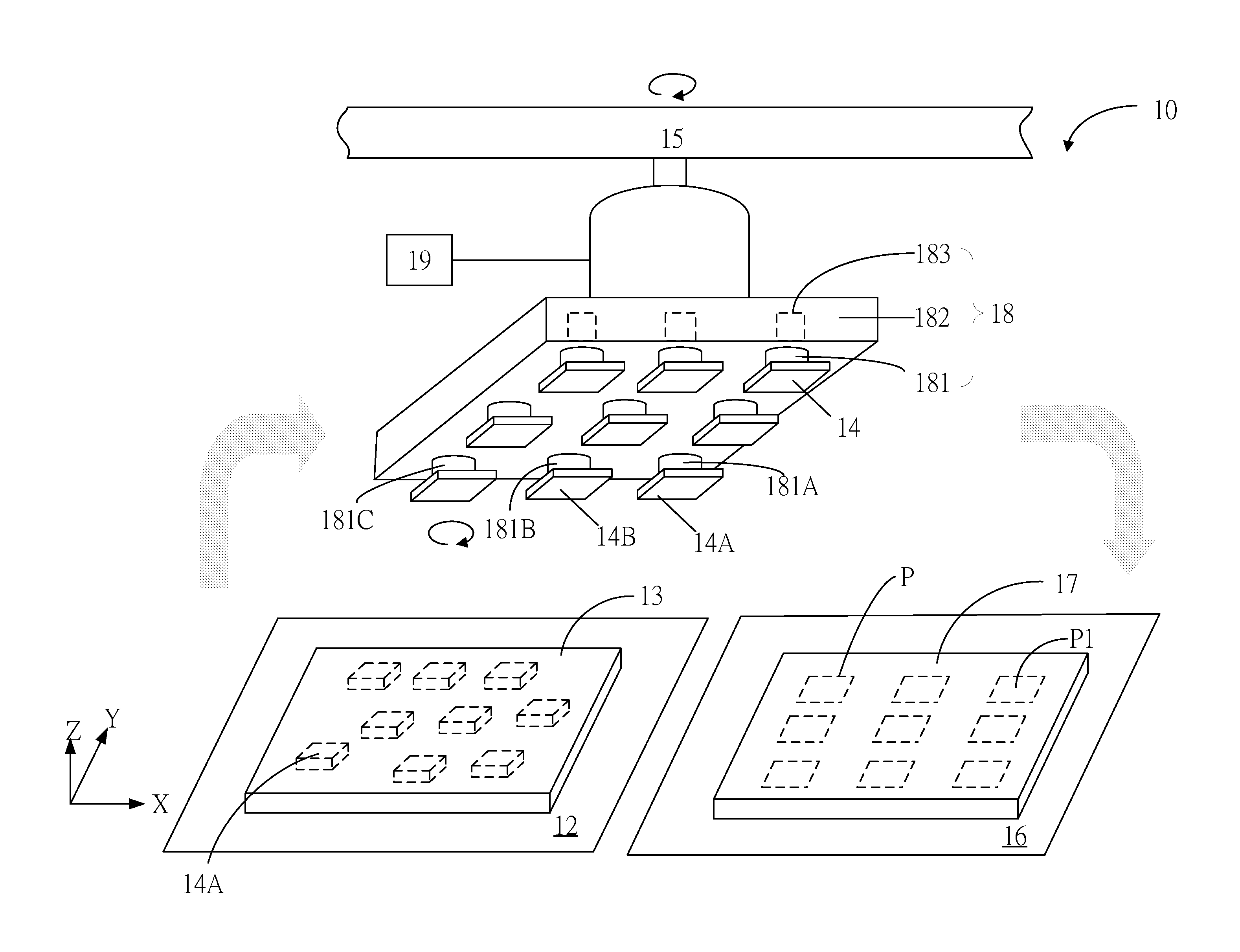

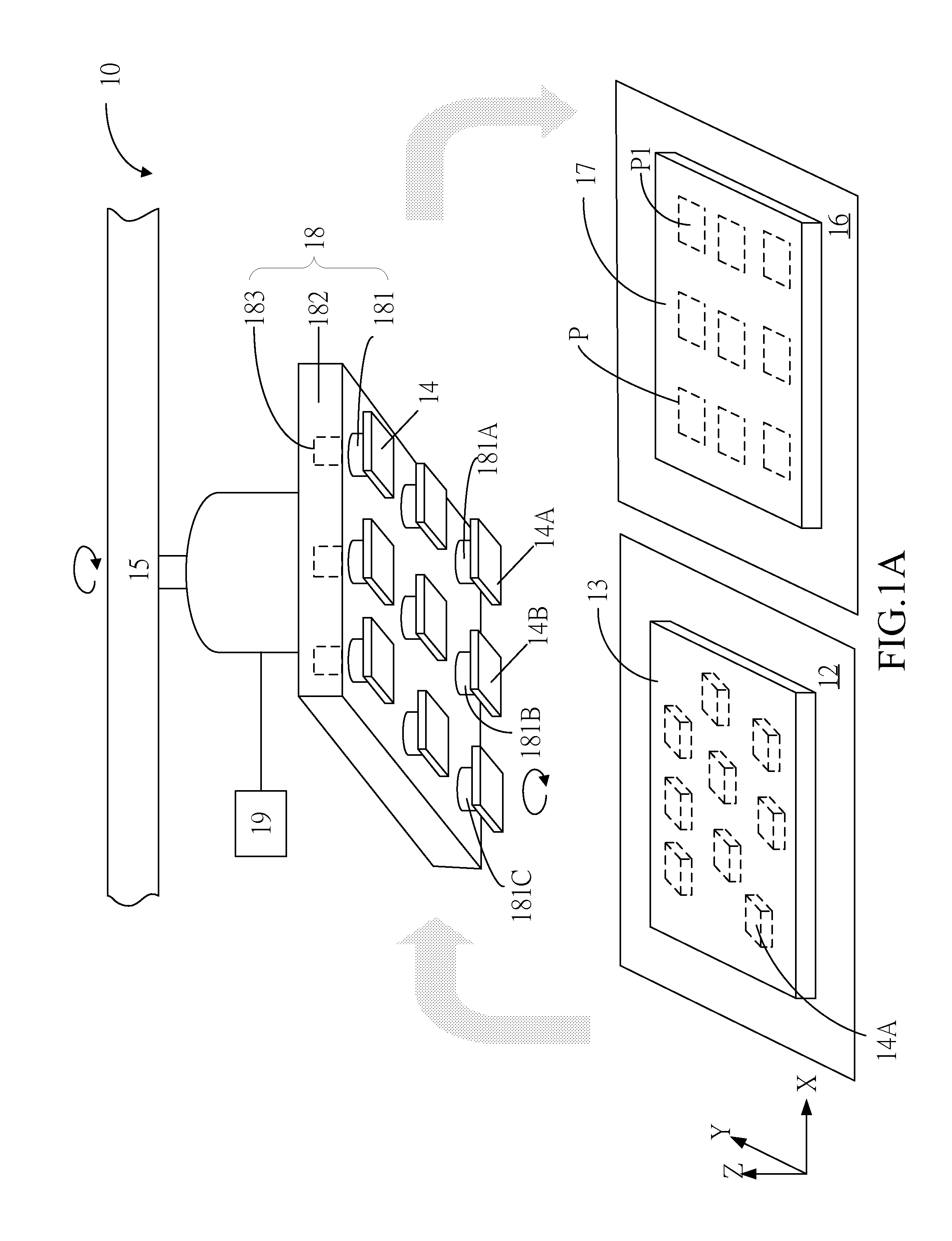

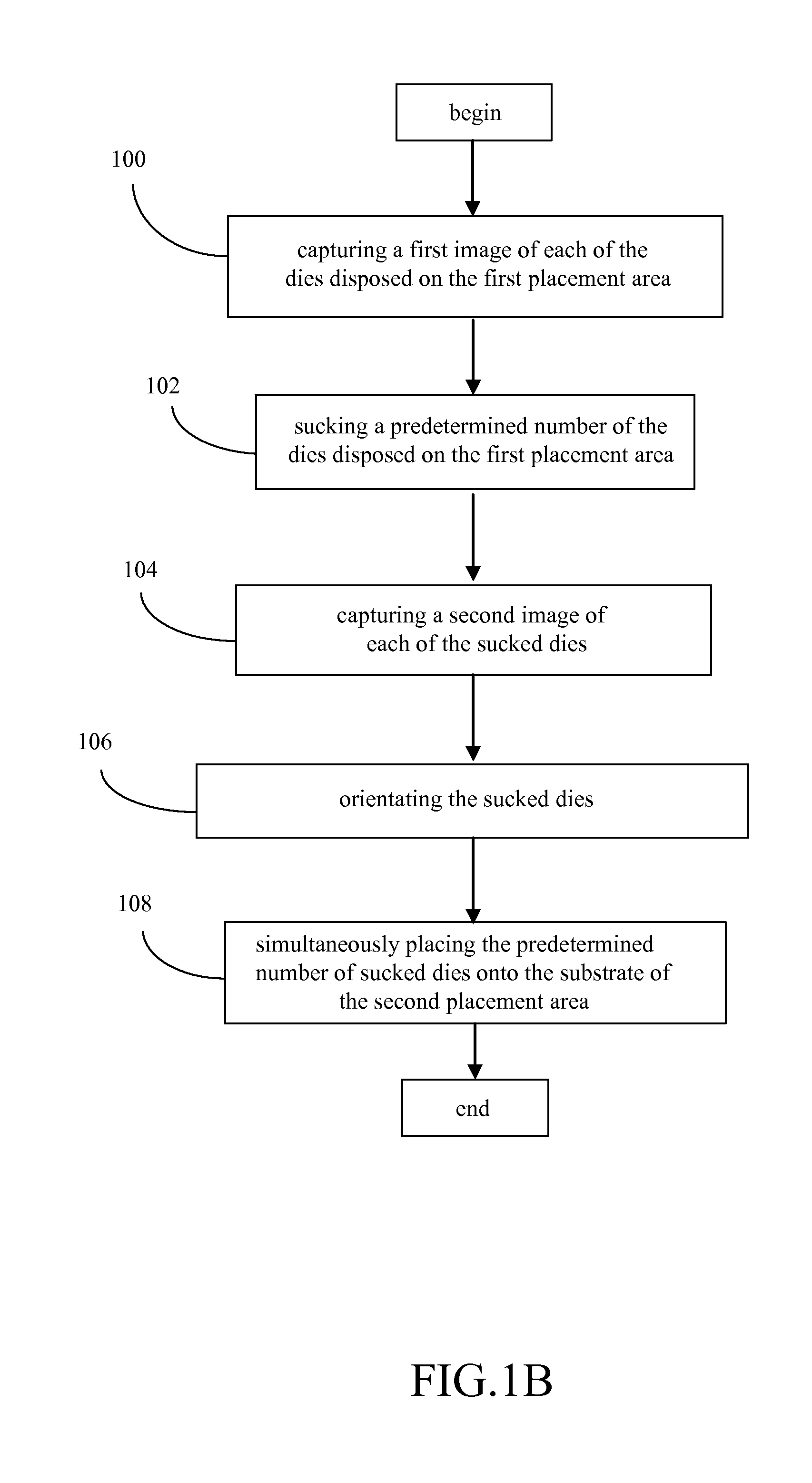

Apparatus and Method for Die Bonding

InactiveUS20130122610A1Fast die bonding speedDesirable bonding accuracyLamination ancillary operationsSemiconductor/solid-state device testing/measurementEngineeringDie bonding

A die bonding apparatus and a die bonding method are provided, which are capable of simultaneously bonding a plurality of dies from a first placement area onto a substrate disposed on a second placement area. The die bonding apparatus includes a die sucking device which is movably located above the first placement area and a second placement area. The die sucking device includes a plurality of nozzles. The nozzles can suck the dies disposed on the first placement area, and then simultaneously bond the dies onto the substrate.

Owner:WALSIN LIHWA

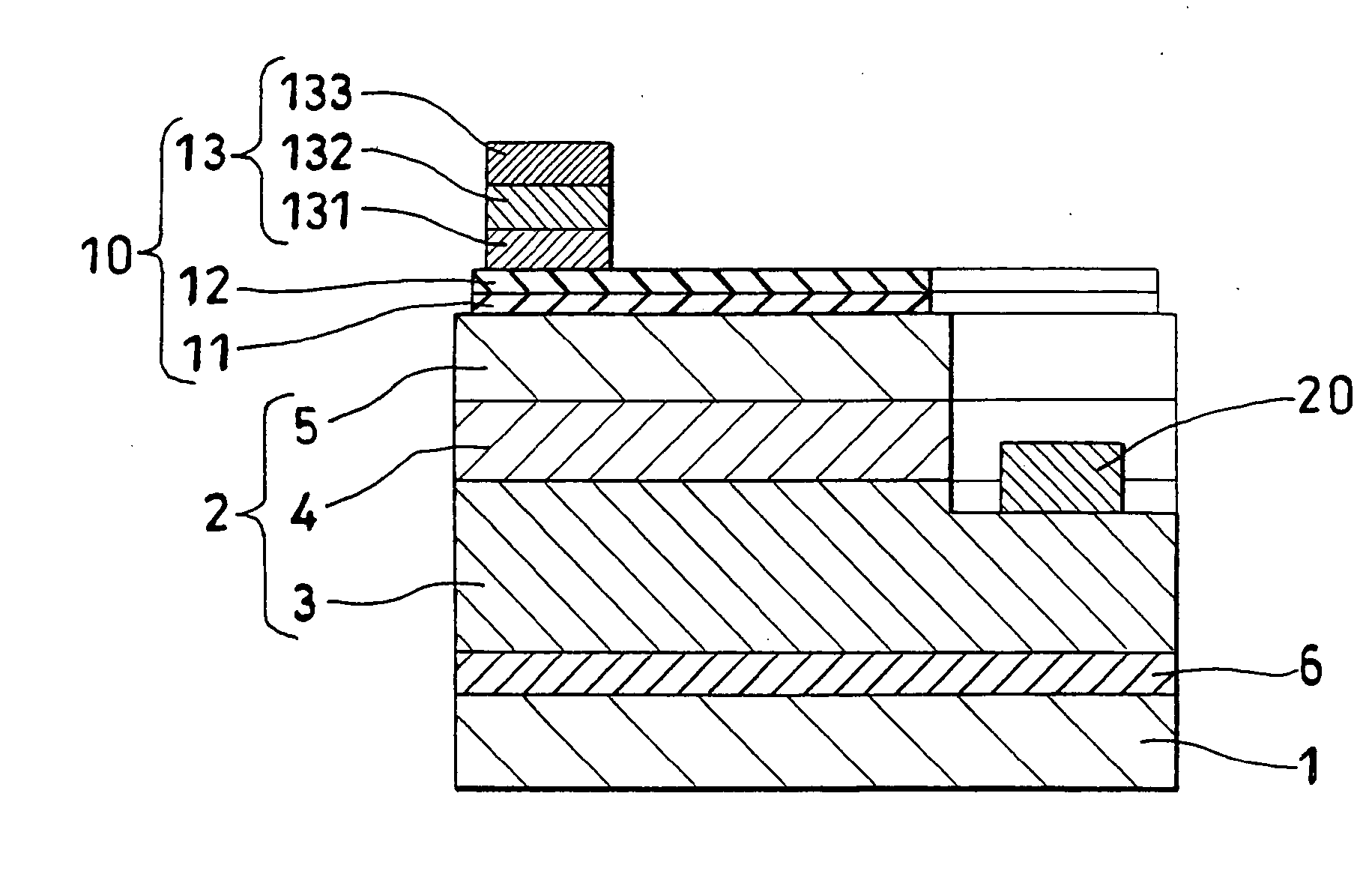

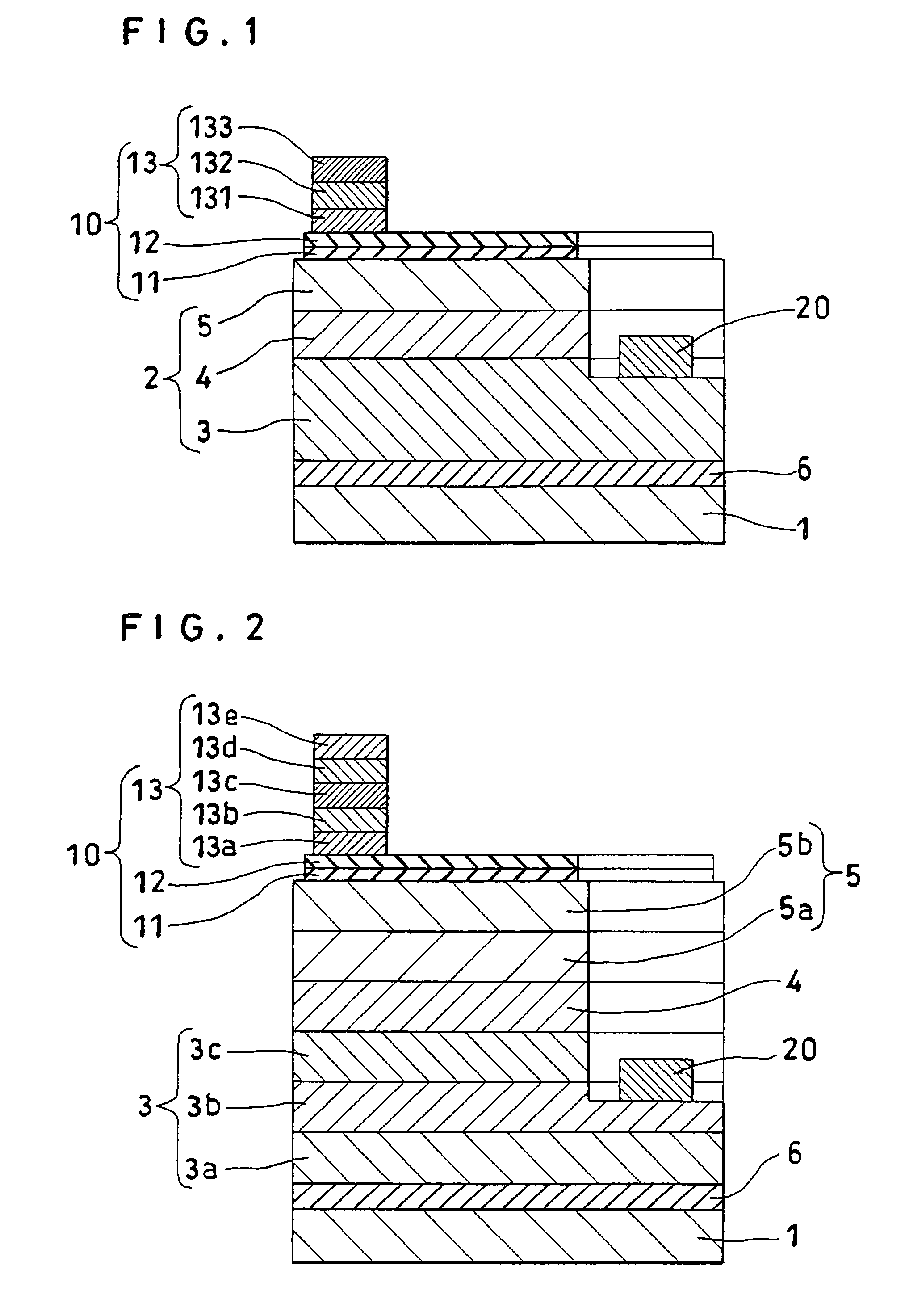

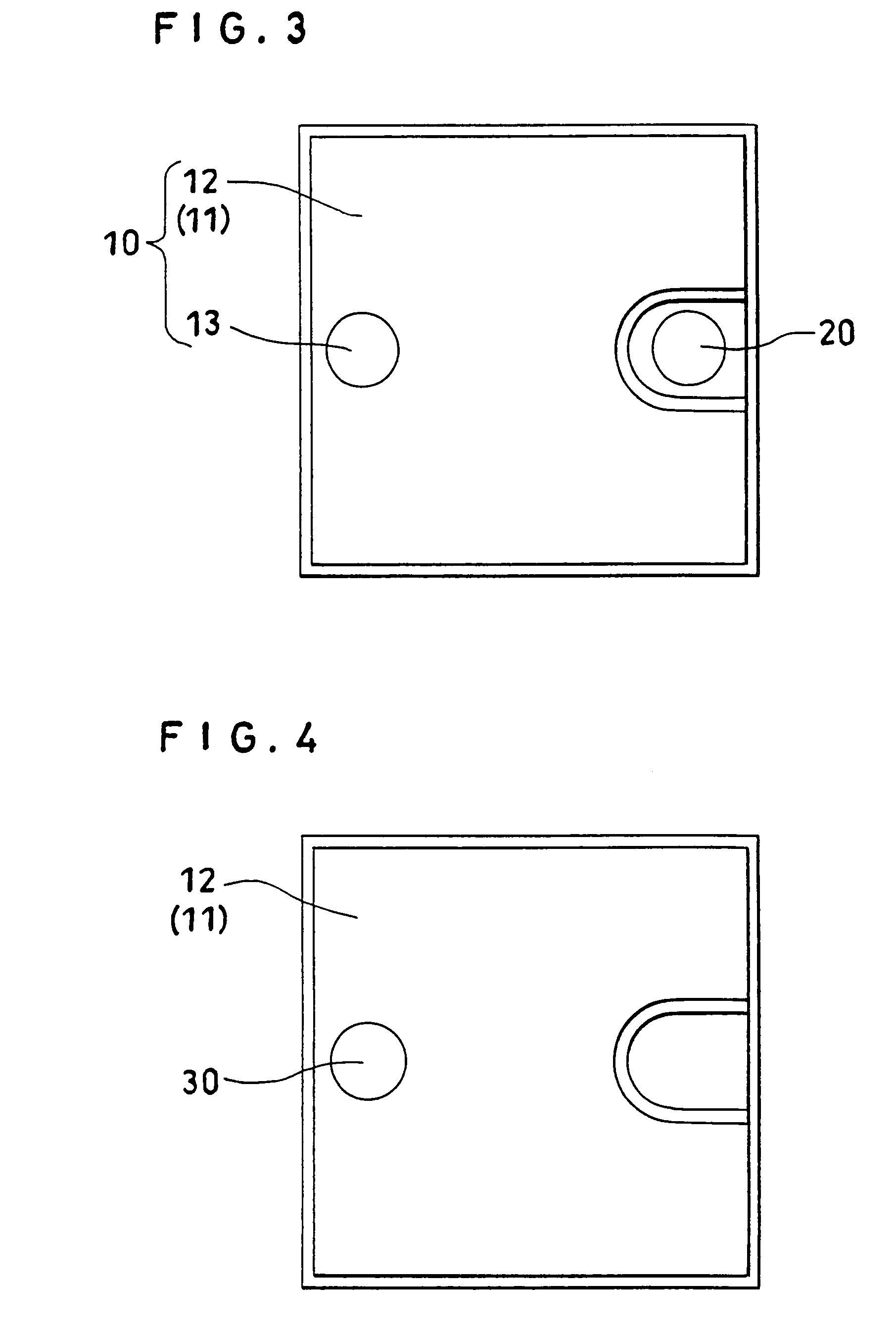

Transparent Electrode for Semiconductor Light-Emitting Device

ActiveUS20080042159A1Good ohmic contactMagnitude of resistivitySemiconductor devicesOhmic contactGallium nitride

A transparent electrode for a gallium nitride-based compound semiconductor light-emitting device includes a p-type semiconductor layer (5), a contact metal layer (1) formed by ohmic contact on the p-type semiconductor layer, an current diffusion layer (12) formed on the contact metal layer and having a lower magnitude of resistivity on the plane of the transparent electrode than the contact metal, and a bonding pad (13) formed on the current diffusion layer. The transparent electrode is at an advantage in widening the surface of light emission in the p-type semiconductor layer, decreasing the operation voltage in the forward direction, and enabling the bonding pad to provide excellent adhesive strength.

Owner:TOYODA GOSEI CO LTD

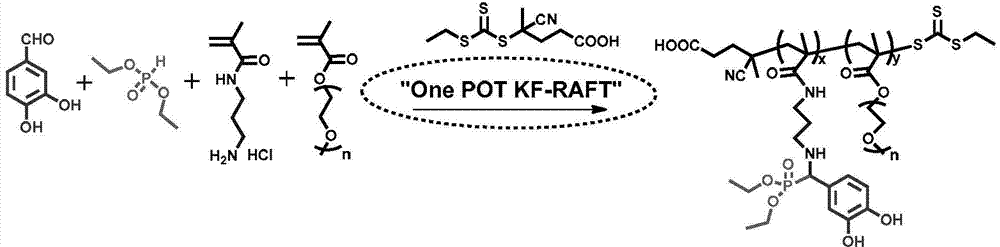

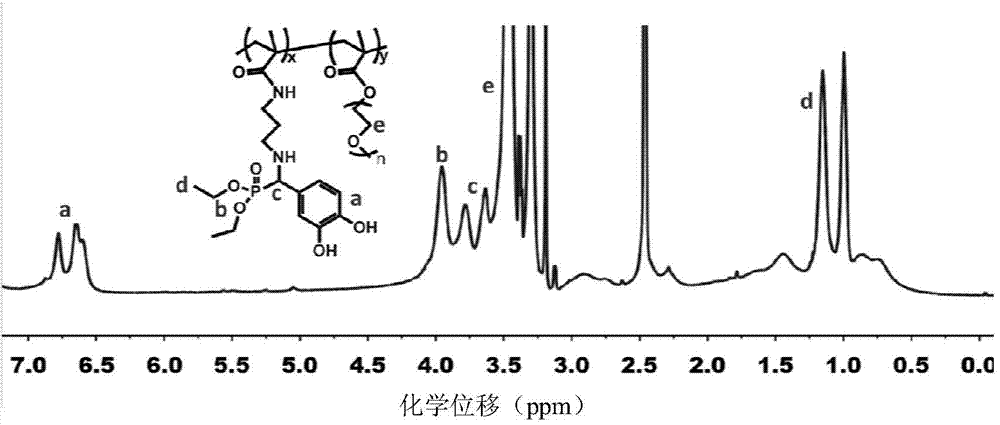

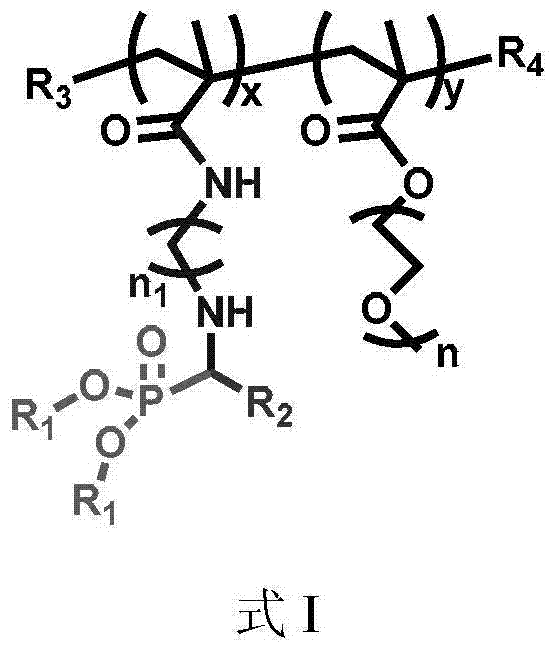

Macromolecular adhesive containing dopamine phosphate ester structure as well as preparation method and application of macromolecular adhesive

ActiveCN104774295APlay a role in bondingEasy to buyAdhesive processesGraft polymer adhesivesWater basedPolymer science

The invention discloses a polymer represented by a formula I as well as a preparation method and application of the polymer. In the formula I, the molecular weight is 50000-120000; the ratio of x to y is 1:(0.25-0.75); n is 10-50; n1=2 or 3; R1 is any one selected from the group of C1-C4 alkyl and phenyl; and R2 is anyone selected from the group of groups represented by a formula II and a formula III. The preparation method comprises the step of reacting N-(3-amino alkyl) methacrylamide hydrochloride containing amino, dyhydroxyl substituted ortho aromatic aldehyde, phosphite ester and methylacrylic acid polyethylene glycol single methyl ether in an organic solvent in the presence of triethylamine, an initiator and a chain transfer agent. The macromolecular adhesive prepared by the invention is a water-based adhesive, which is mussel-mimetic and environmentally friendly; the macromolecular adhesive is applied to adhering among a plurality of substrates; adhesion can be realized under a variety of conditions; the macromolecular adhesive has good adhesive power; furthermore, the macromolecular adhesive is simple in preparation method, abundant in raw material source and low in cost; and therefore, the macromolecular adhesive is a potential excellent adhesive material.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com