Method for manufacturing interior film-pasting woven bag

A manufacturing method and technology of inner mucous membrane, applied in the field of woven bag manufacturing, can solve the problems of easy damage of the inner bag, and achieve the effects of low damage rate, saving manpower and waste, and smooth bag surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

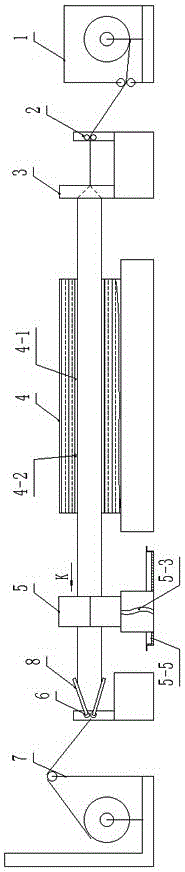

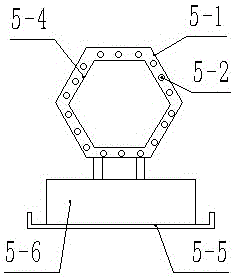

Method used

Image

Examples

Embodiment 1

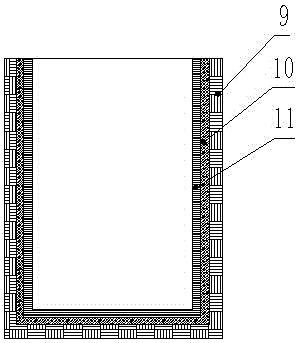

[0022] A kind of manufacture method of inner mucous membrane woven bag, inner mucous membrane woven bag such as image 3 As shown, it includes a plastic outer bag 9 woven from polypropylene plastic, and an ethylene-vinyl acetate film layer 10 and a high-pressure low-density polyethylene film layer 11 are sequentially provided in the plastic outer bag 9;

[0023] Including the following steps:

[0024] A. Making plastic flat wire: Extrude polypropylene plastic particles into plastic strips through a plastic extruder, and the plastic strips are cooled and cut into slices, heated and stretched to make plastic flat wires for later use;

[0025] B. Making double-layer films: heat, melt and plasticize ethylene-vinyl acetate plastics and high-pressure low-density polyethylene plastics, and extrude them through a double-layer co-extrusion blown film machine to form a cylindrical outer layer. The ethylene-vinyl acetate film layer 10 and the inner layer are double-layered films of the ...

Embodiment 2

[0032] The temperature of heating oven 4 is controlled at 90 degrees, and all the other features are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com