Patents

Literature

9423 results about "Production quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Systems and methods for matching an advertisement to a video

InactiveUS20110251896A1Accurate signatureAdvertisementsSpecific information broadcast systemsHyperlinkScene segmentation

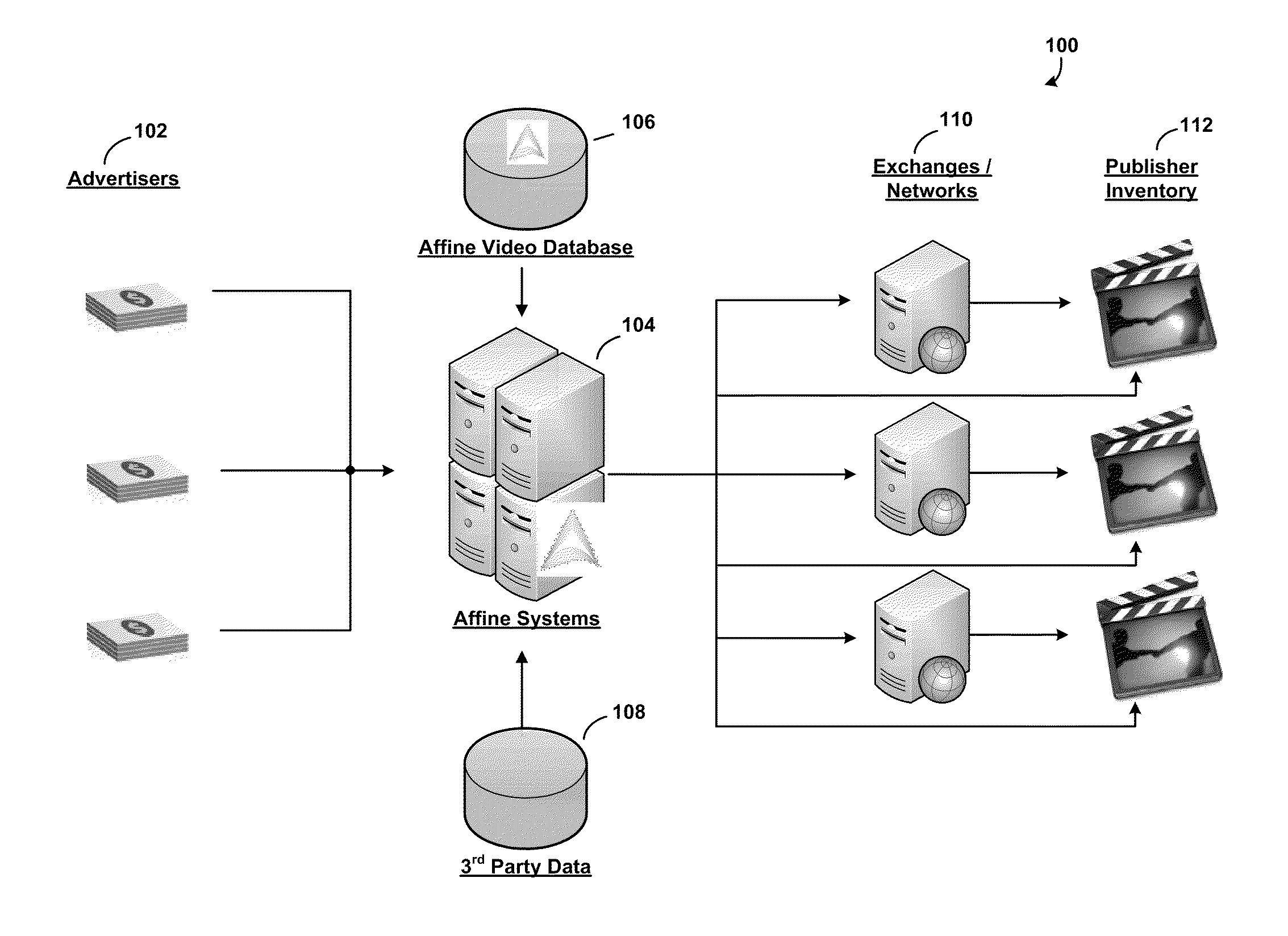

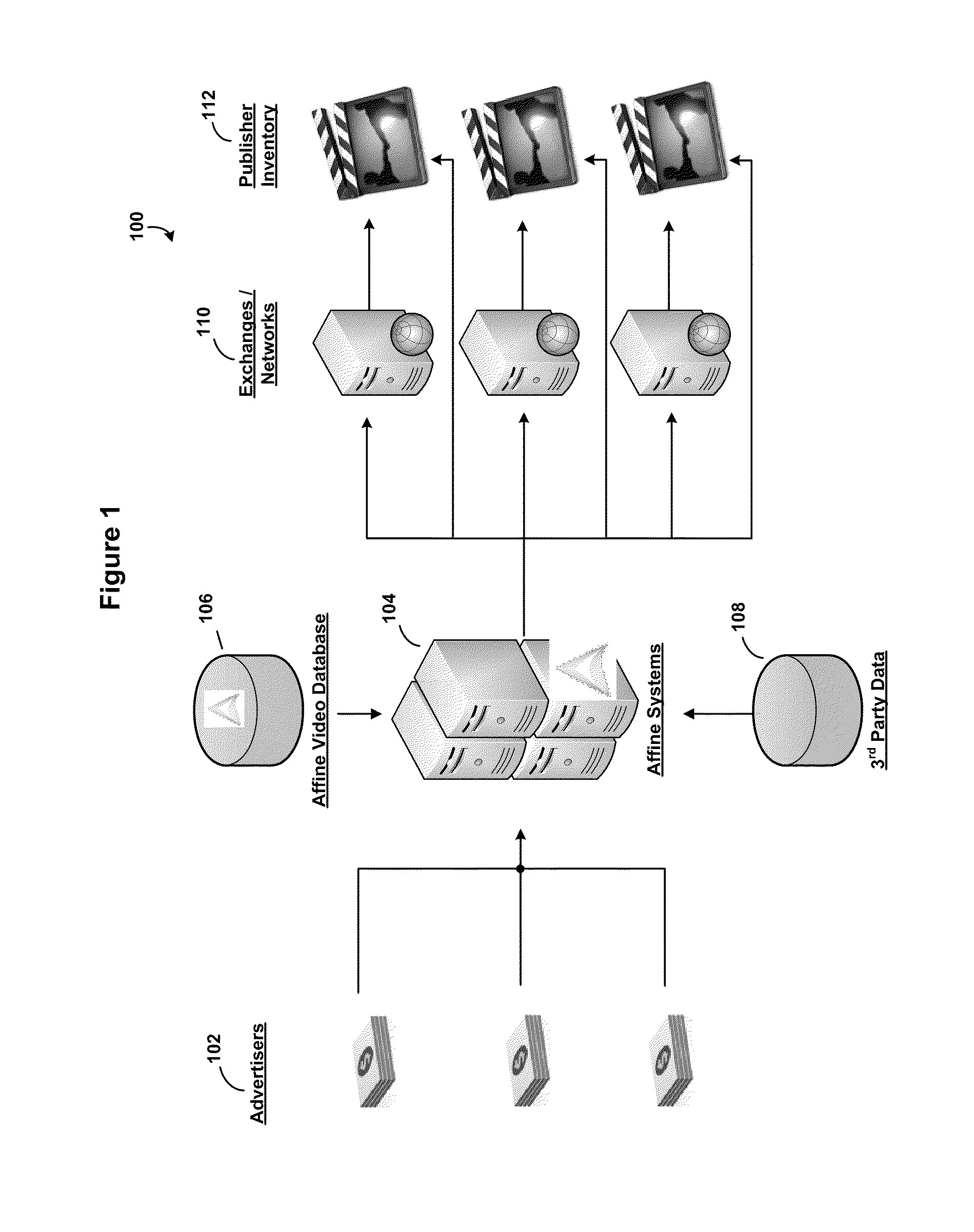

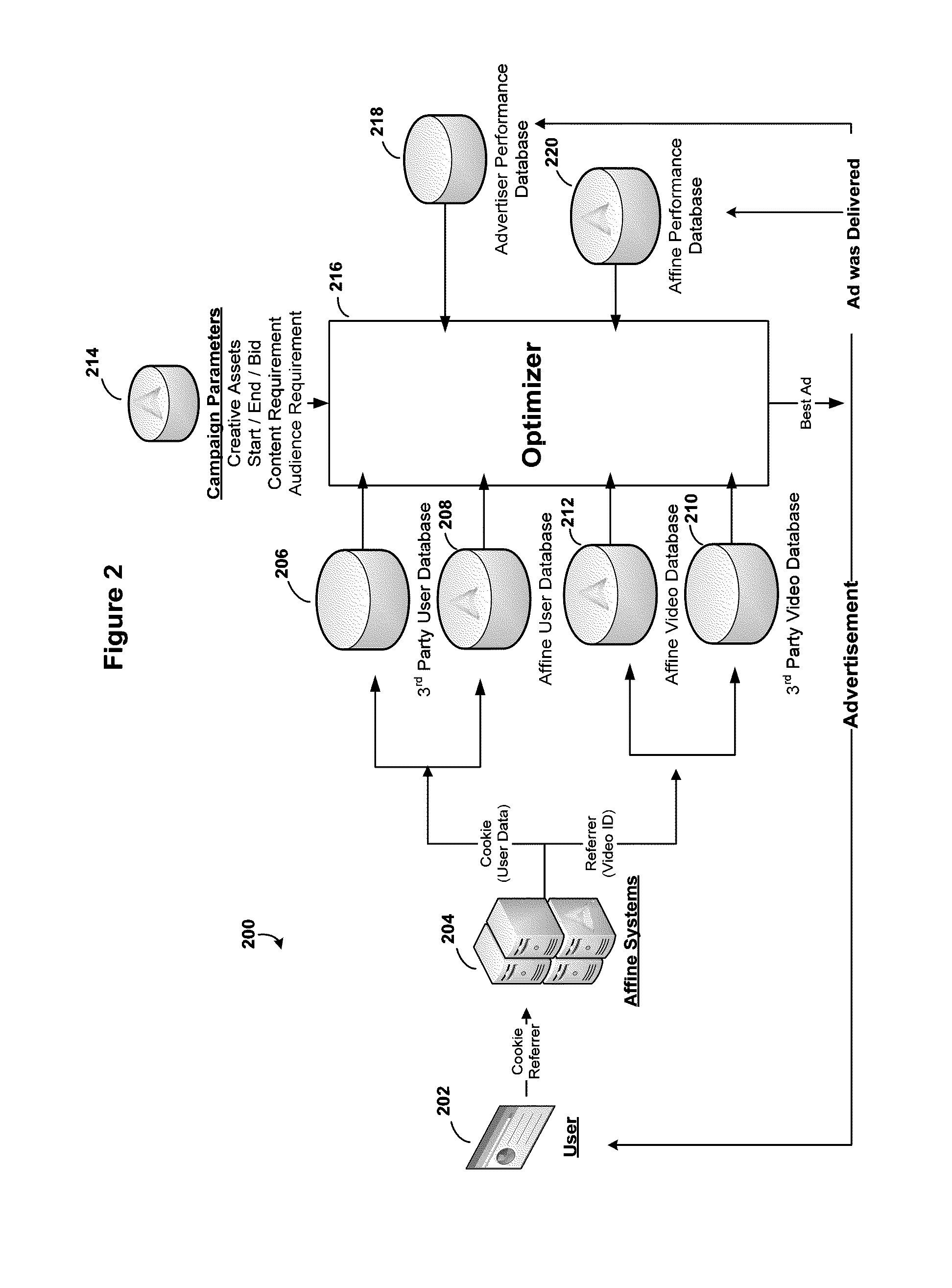

Systems and methods for automatically matching in real-time an advertisement with a video desired to be viewed by a user are provided. A database is created that stores one or more attributes (e.g., visual metadata relating to objects, faces, scene classifications, pornography detection, scene segmentation, production quality, fingerprinting) associated with a plurality of videos. Supervised machine learning can be used to create signatures that uniquely identify particular attributes of interest, which can then be used to generate the attributes associated with the plurality of videos. When a user requests to view an on-line video having associated with it an advertisement, an advertisement can be selected for display with the video based on matching an advertiser's requirements or campaign parameters with the stored attributes associated with the requested video, with the user's information, or a combination thereof. The displayed advertisement can function as a hyperlink that allows a user to select to receive additional information about the advertisement. The performance or effectiveness of the selected advertisements can be measured and recorded.

Owner:CONVERSANT

Processes of improving the quality of oil and products produced therefrom

ActiveUS20070141222A1Decreasing anisidine valueExtended service lifeWort preparationFatty substance preservation using additivesProduction qualityFood products

Oil of improved quality is produced by treating the oil with an active substance capable of reducing the anisidine value of the oil. Food products comprising the oil of improved quality are also disclosed.

Owner:ARCHER DANIELS MIDLAND CO

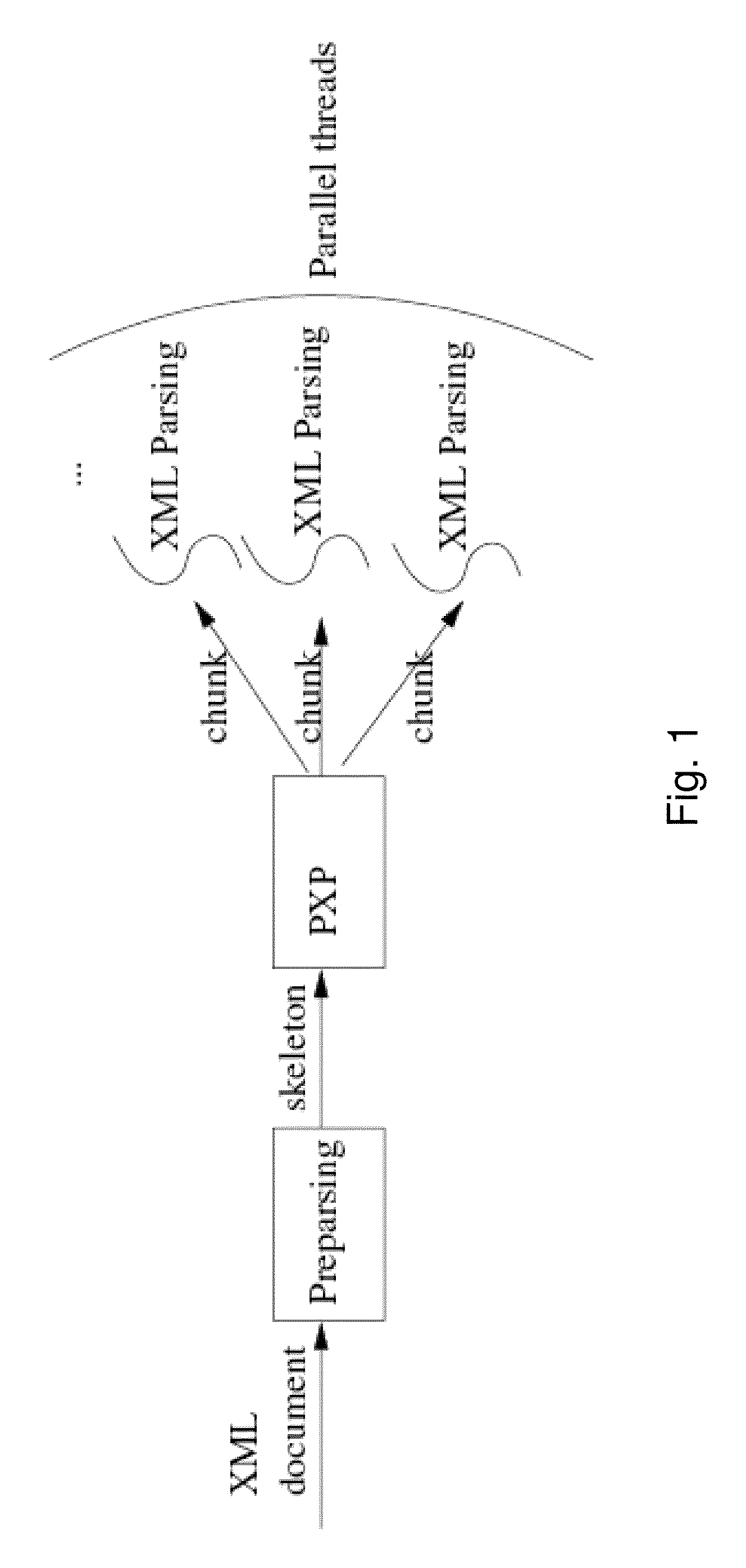

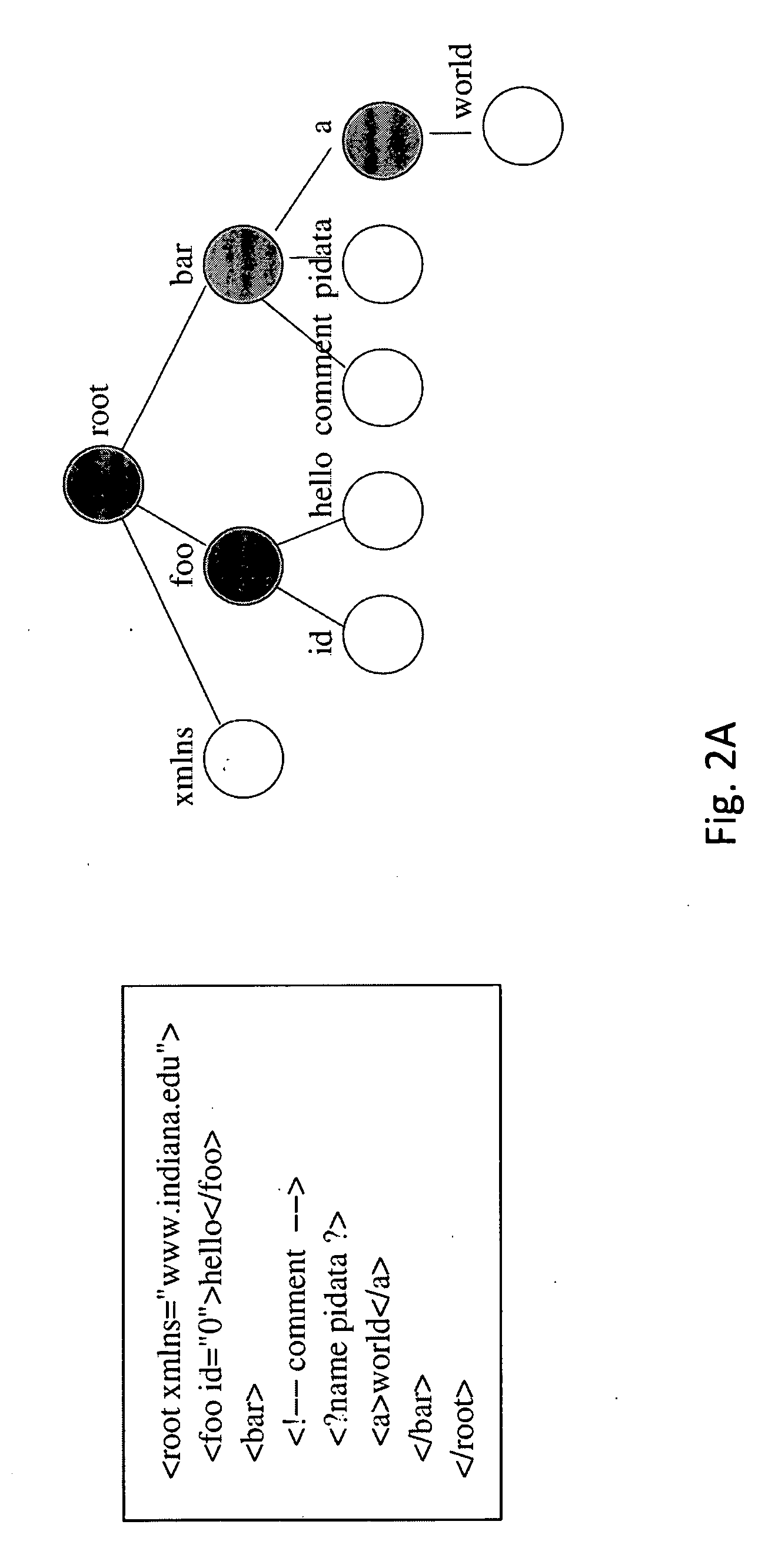

Parallel approach to XML parsing

InactiveUS20090089658A1Flexible performanceImprove readabilityNatural language data processingSpecial data processing applicationsMulticore architectureSchema for Object-Oriented XML

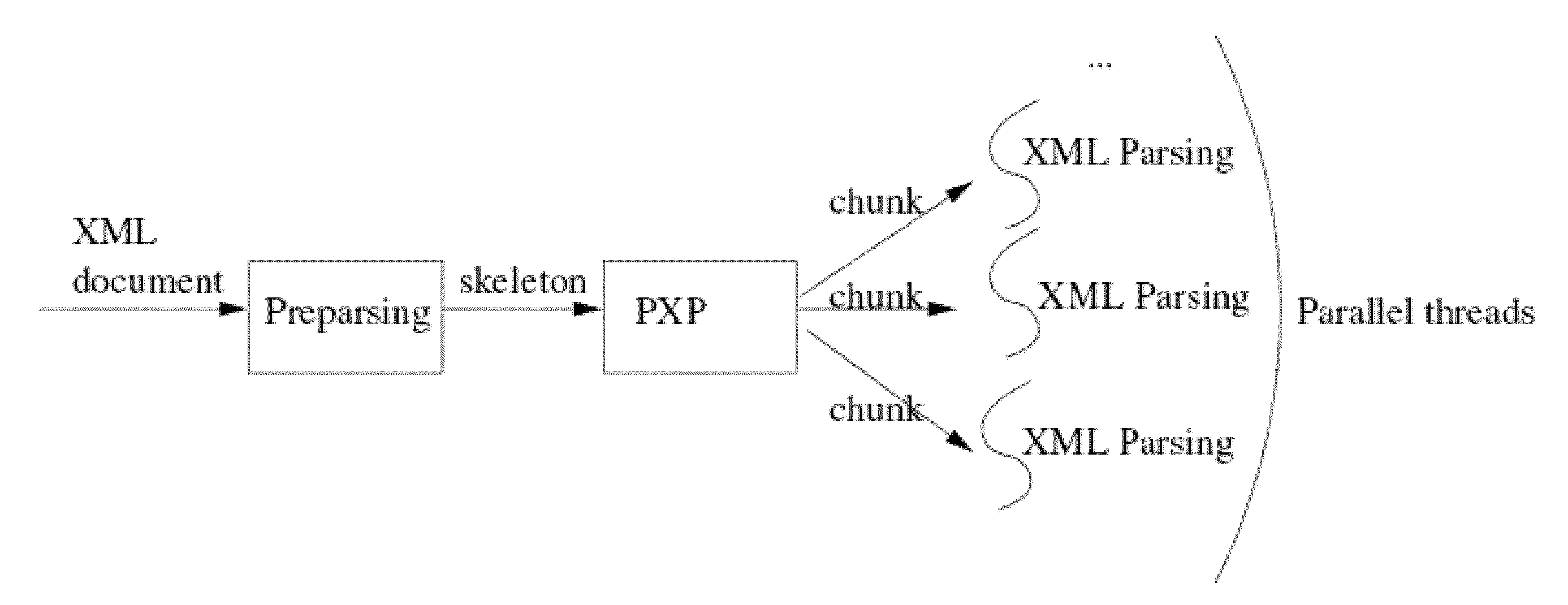

A language for semi-structured documents, XML has emerged as the core of the web services architecture, and is playing crucial roles in messaging systems, databases, and document processing. However, the processing of XML documents has a reputation for poor performance, and a number of optimizations have been developed to address this performance problem from different perspectives, none of which have been entirely satisfactory. Parallel XML parsing leverages the growing prevalence of multicore architectures in all sectors of the computer market, and yields significant performance improvements. The design consists of an initial preparsing phase to determine the structure of the XML document (or other data document), followed by a full, parallel parse. The results of the preparsing phase are used to help partition the XML document for data parallel processing. The parallel parsing phase is, for example, a modification of the libxml2 XML parser, which demonstrates that the approach applies to real-world, production quality parsers. Empirical study shows the parallel XML parsing algorithm can improve the XML parsing performance significantly and scales well.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

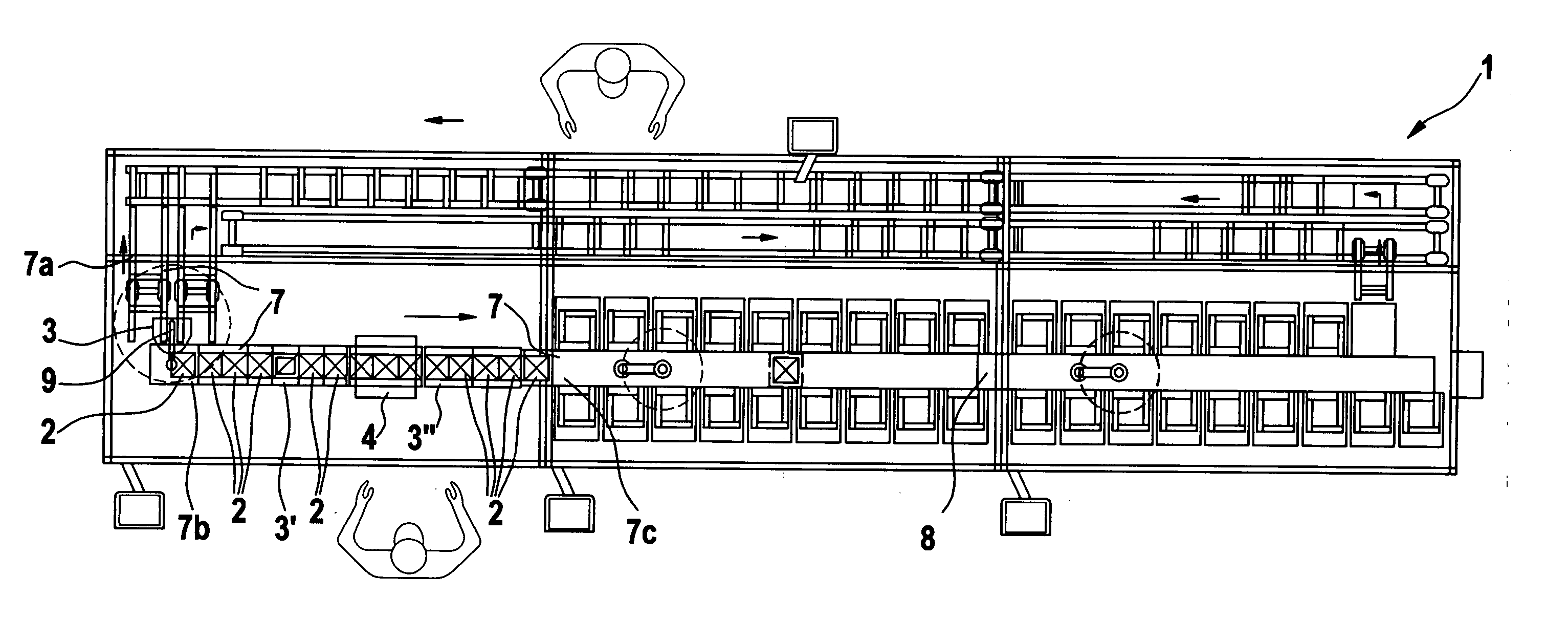

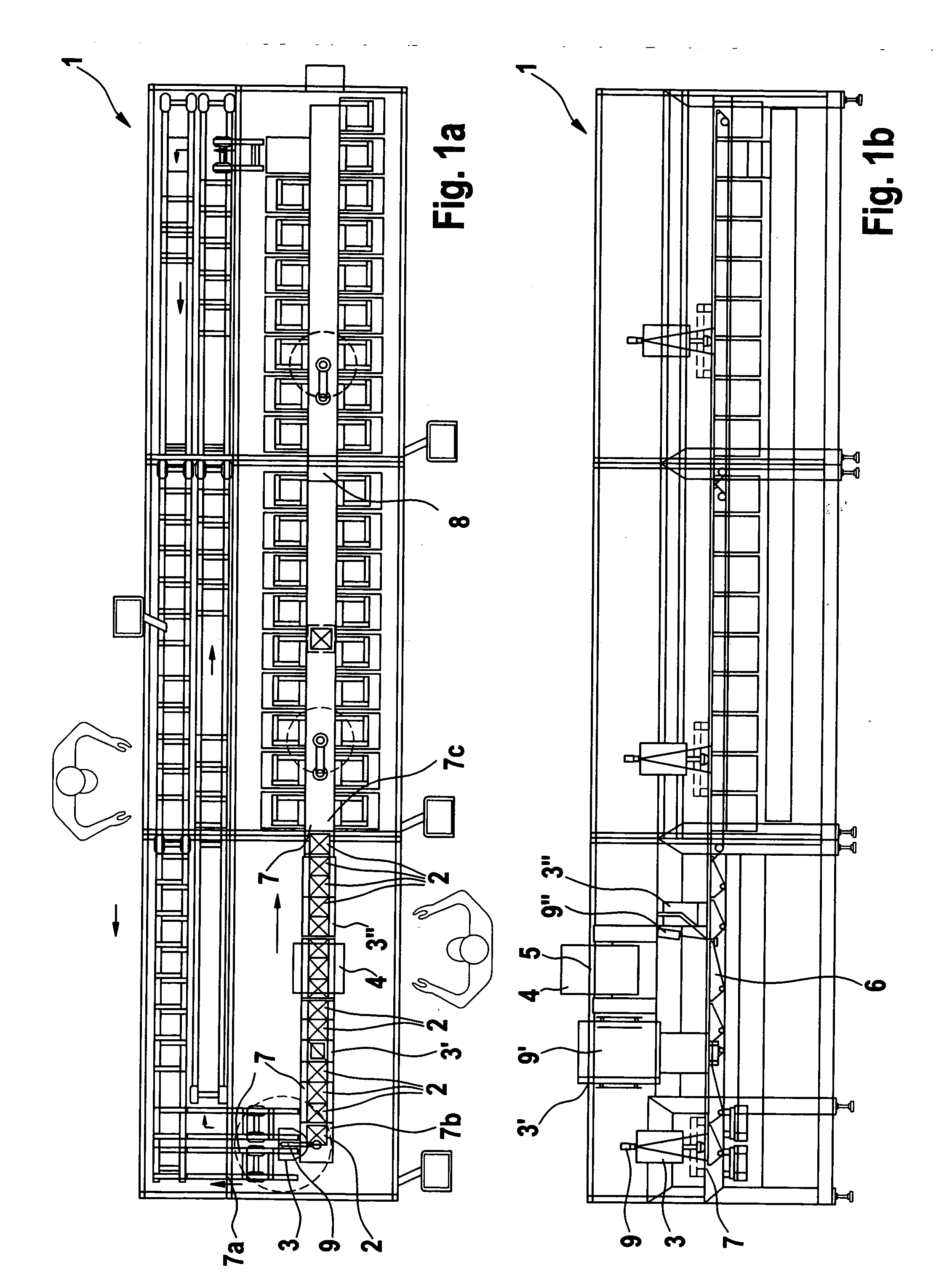

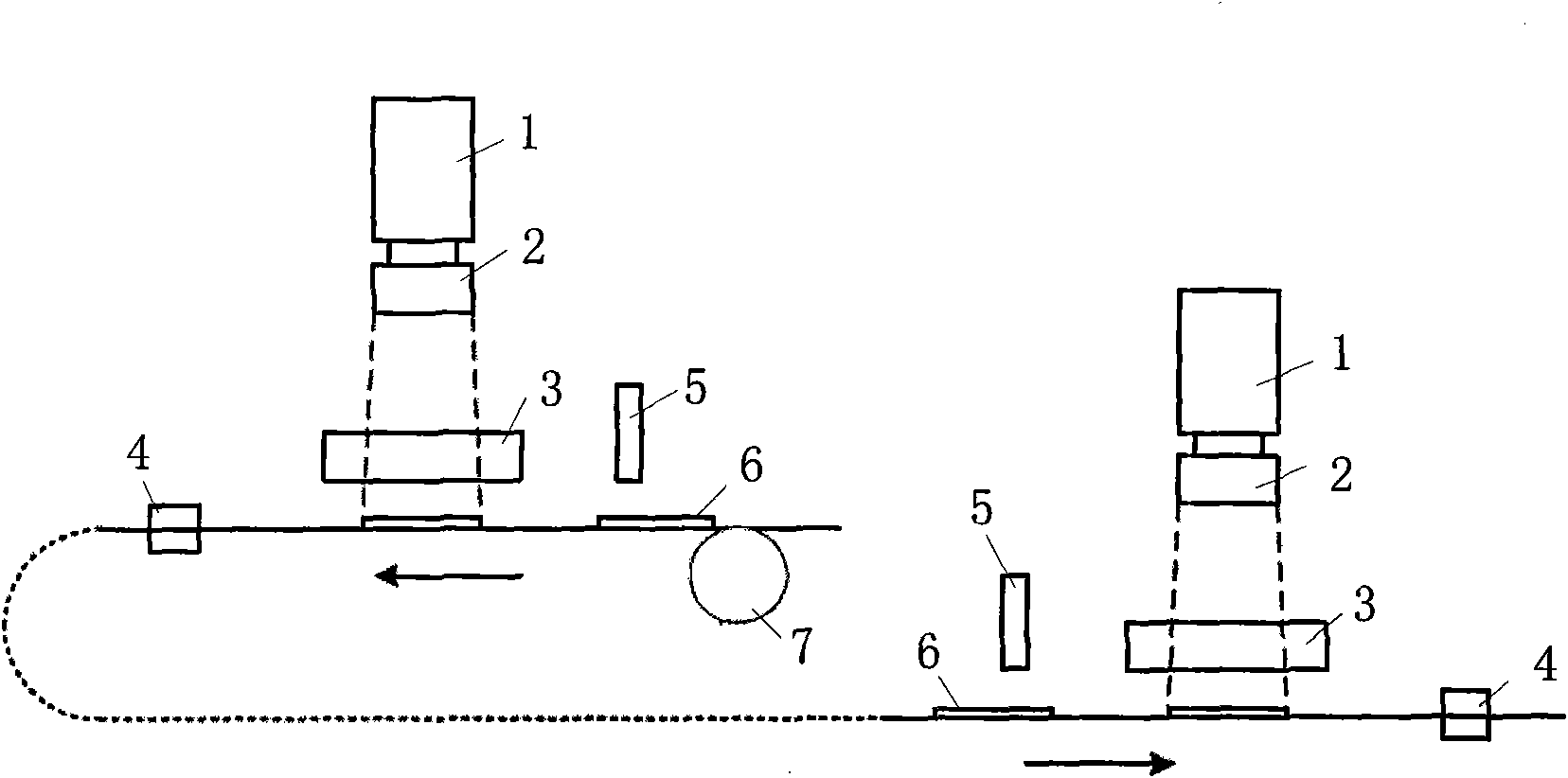

Testing system for solar cells

InactiveUS20060103371A1Improve refinementShorten cycle timePhotovoltaic monitoringElectronic circuit testingElectricityElectrical battery

A testing system for optical and electrical monitoring of a production quality and / or for determining optical and electrical properties of solar cells, comprising a first conveyor device for conveying the solar cells to a test region, a second conveyor device for moving the solar cells through the test region, a third conveyor device for conveying the solar cells out of the test region, an optical checking device located in the test region for visual checking of the solar, and an electrical checking device also located in the test region for checking electrical functions of the solar cells, the electrical checking device including an illumination device for shining light on light-sensitive surfaces of the solar cells and also including an electrical contacting device for picking up voltages and / or currents and electrical contacts of the solar cells, the first, second and third conveyor devices including a common, linear conveyor belt system which passes through the test region and has a vacuum suction device for holding the solar cells on a surface of a conveyor belt system.

Owner:MANZ AUTOMATION

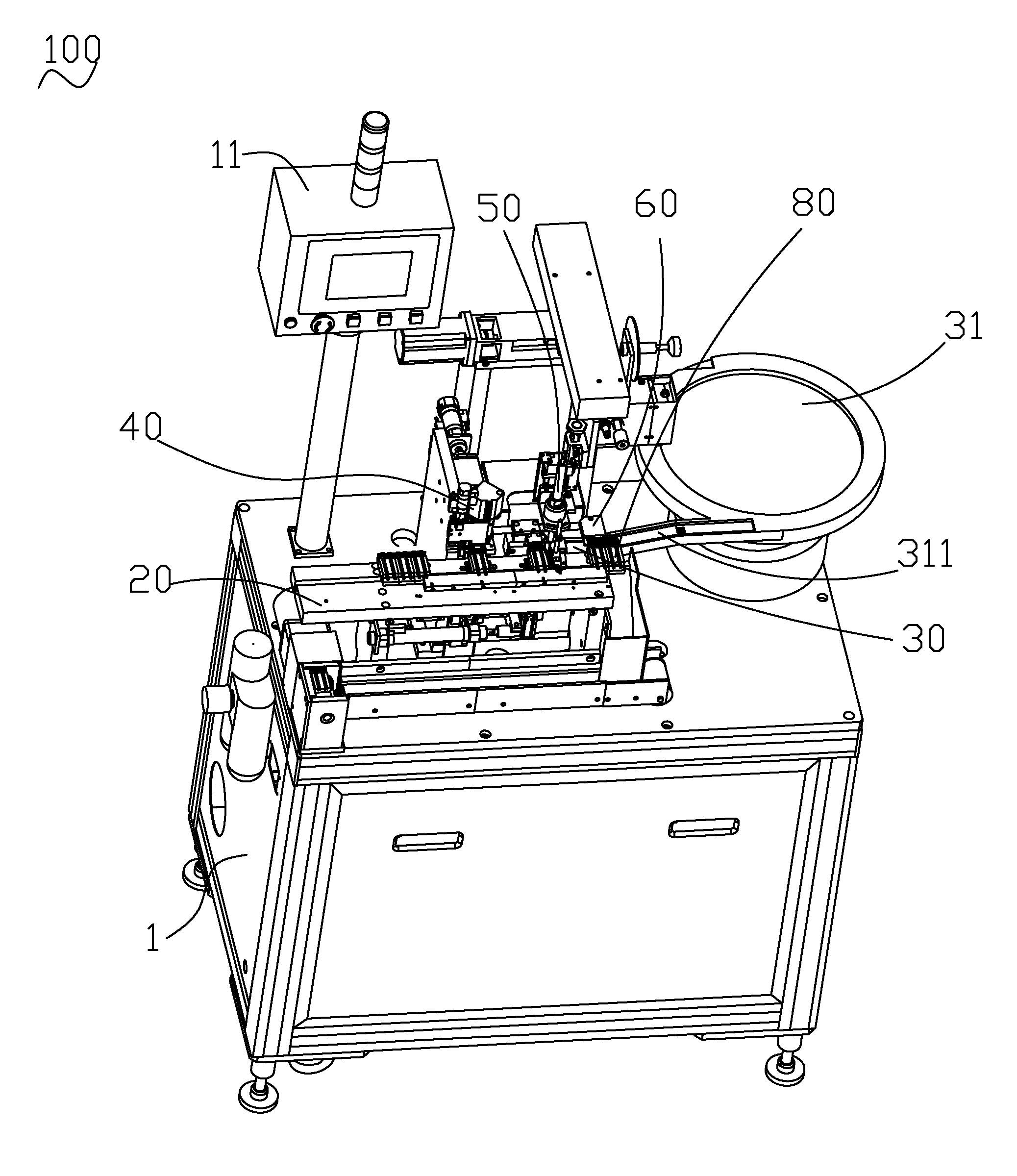

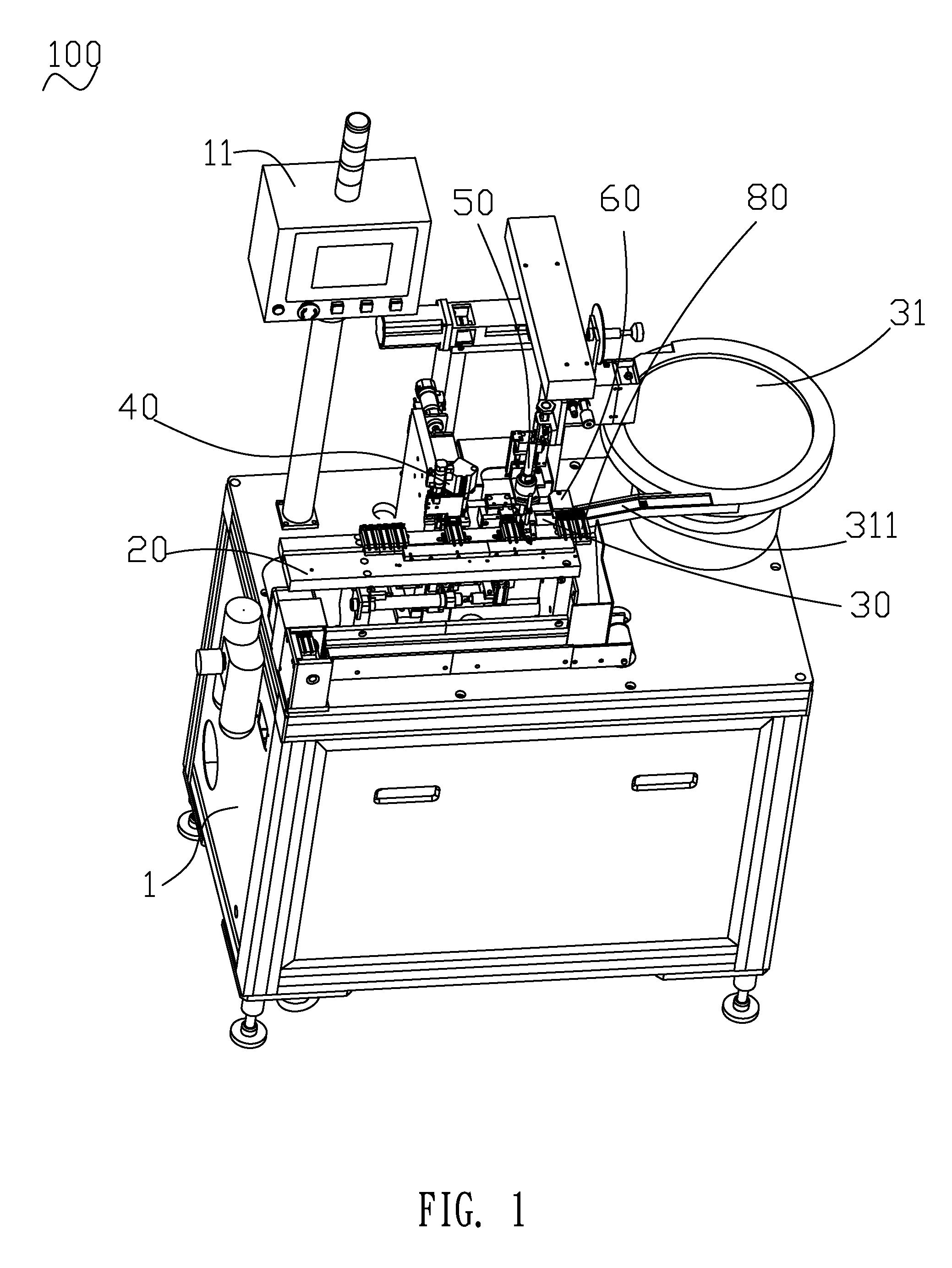

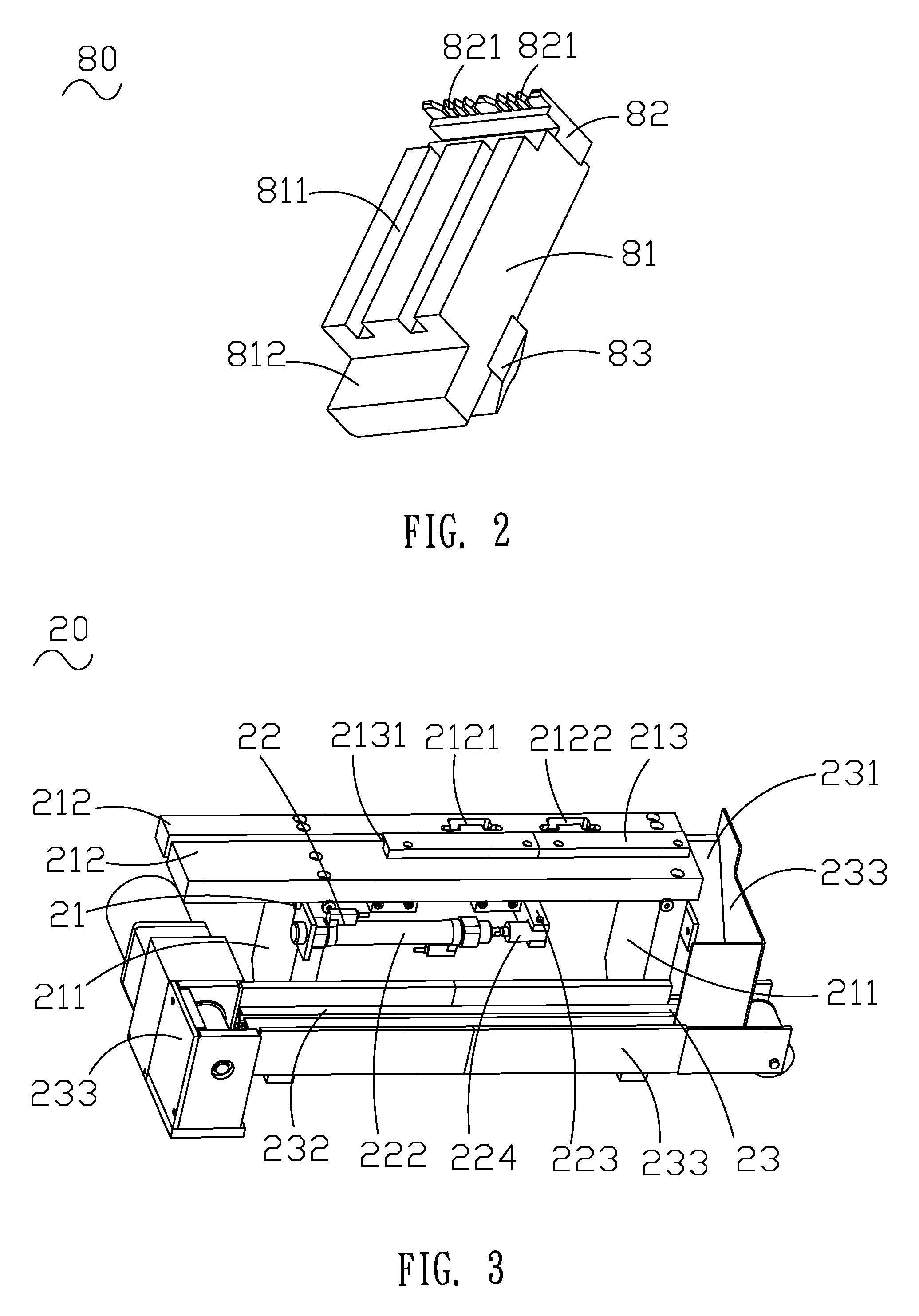

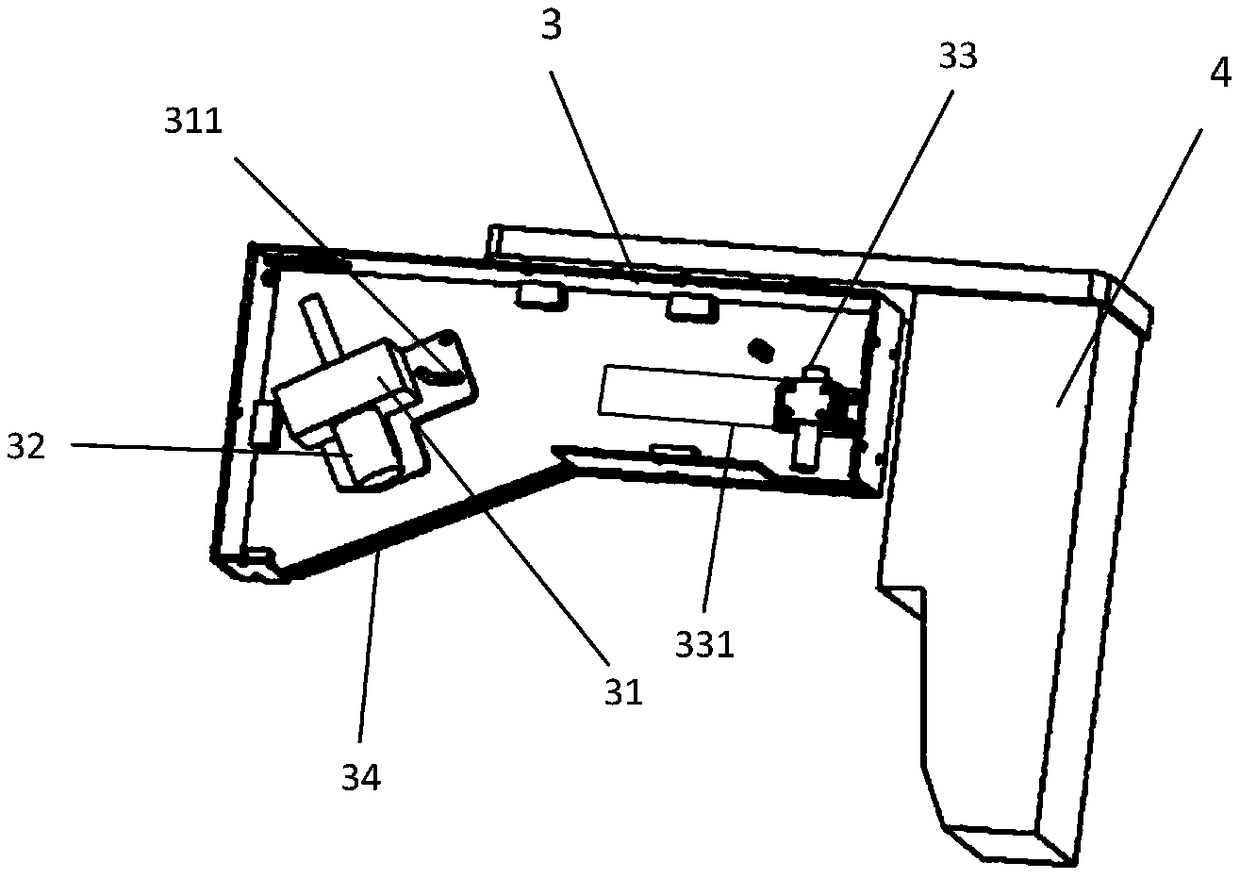

Automatic soldering machine

InactiveUS8011557B1High production efficacyImprove product qualityWelding/cutting auxillary devicesFeeding apparatusControl systemEngineering

An automatic soldering machine for soldering wires, each exposing at least one core wire and electronic components with at least one soldering portion respectively is disclosed. The automatic soldering machine comprises an equipment, a delivery mechanism, a plurality of clamps, a feeding mechanism, an insulation removing mechanism, a soldering mechanism, an unloading mechanism and a programmable control system. The delivery mechanism delivers the wires. The clamps locate the wires. The feeding mechanism conveys the electronic components. The insulation removing mechanism cuts the core wires and strips insulations at tops of the core wires. The soldering mechanism solders the core wires and the soldering portions of the electronic components. The unloading mechanism separates the soldered electronic components and core wires off from the clamps. The programmable control system is connect to the aforesaid mechanisms and controls thereof with high production efficacy and stable production quality.

Owner:CHENG UEI PRECISION IND CO LTD

Powdery attapulgite foaming agent

The invention discloses a powdery attapulgite foaming agent. The technical scheme has the following key points: the powdery attapulgite foaming agent is composed of active attapulgite clay, sodium percarbonate, sodium pyrophosphate, lauryl sodium sulfate, sodium polyacrylate and poly-naphthalene formaldehyde sodium sulfonate. The finished product of the powdery attapulgite foaming agent is prepared by stirring, grinding and packaging the ingredients. The powdery attapulgite foaming agent has the advantages that the foaming agent is high in foaming capacity, more in bubbling times and large in unit volume foam production quality, and enables the outer films of foams to have good toughness so as to guarantee the foams not to be easily broken; the foams are good in stability, can exist for a long time without being defoamed, and are fine and smooth; holes generated in a medium are even in sizes; the water secretion quantity is low; and the used medium is good in compatibility, etc. The products produced by the powdery attapulgite foaming agent not only can effectively control the noise pollution, but also have the functions of heat preservation and air purification; and the powdery attapulgite foaming agent is suitable for producing light weight boards, light weight walls and noise reduction products.

Owner:盱眙泰禾高新科技有限公司

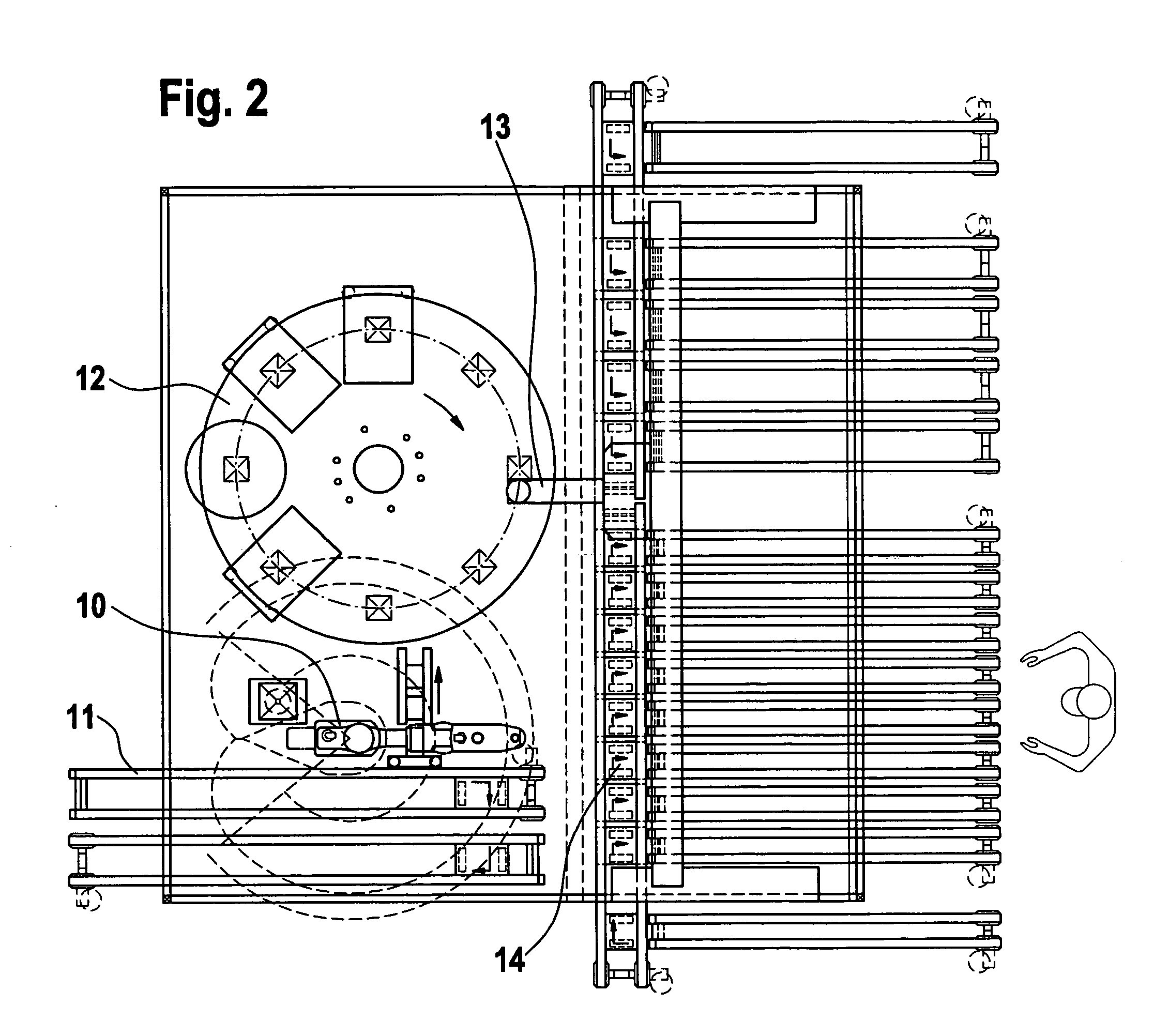

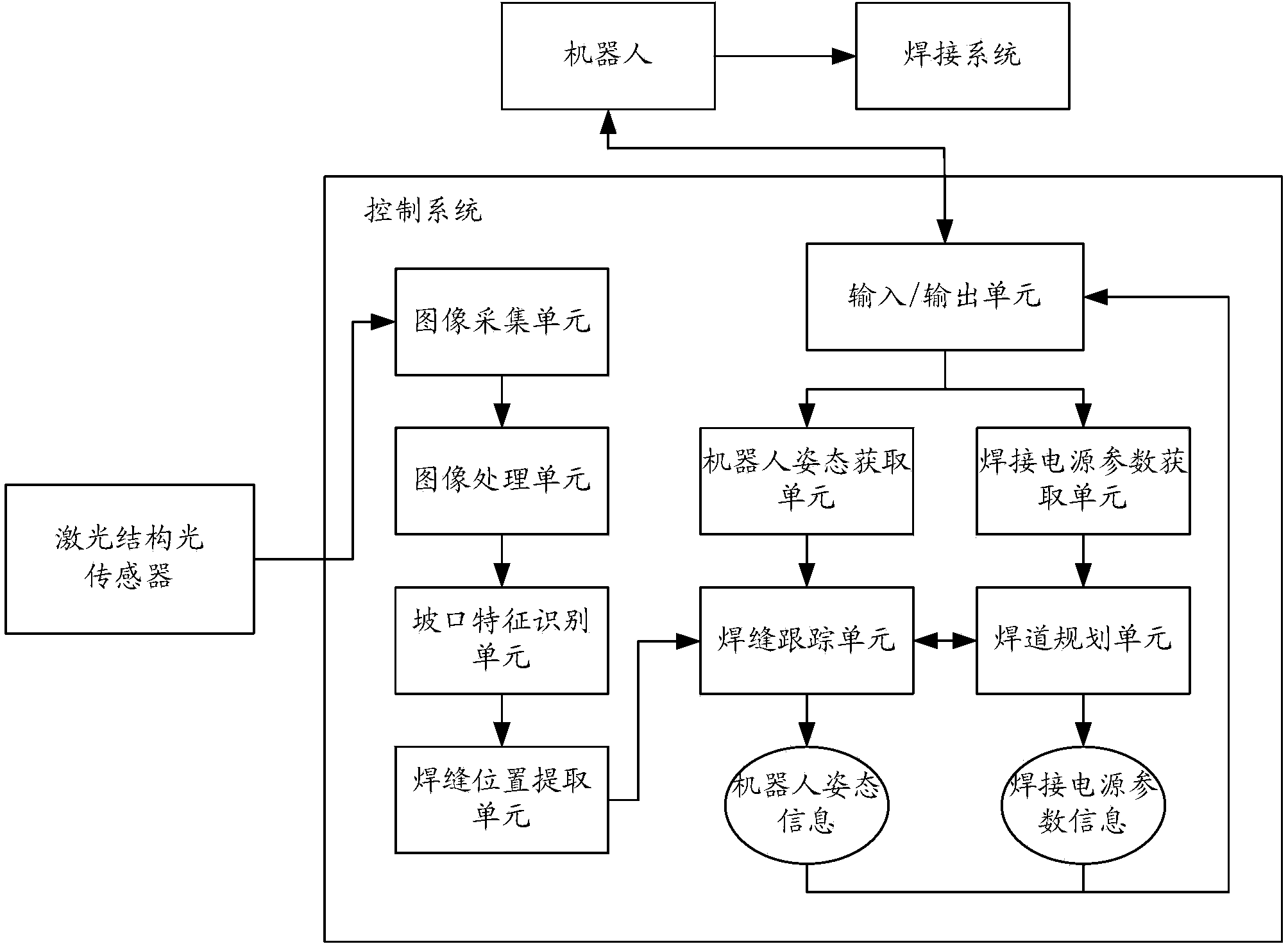

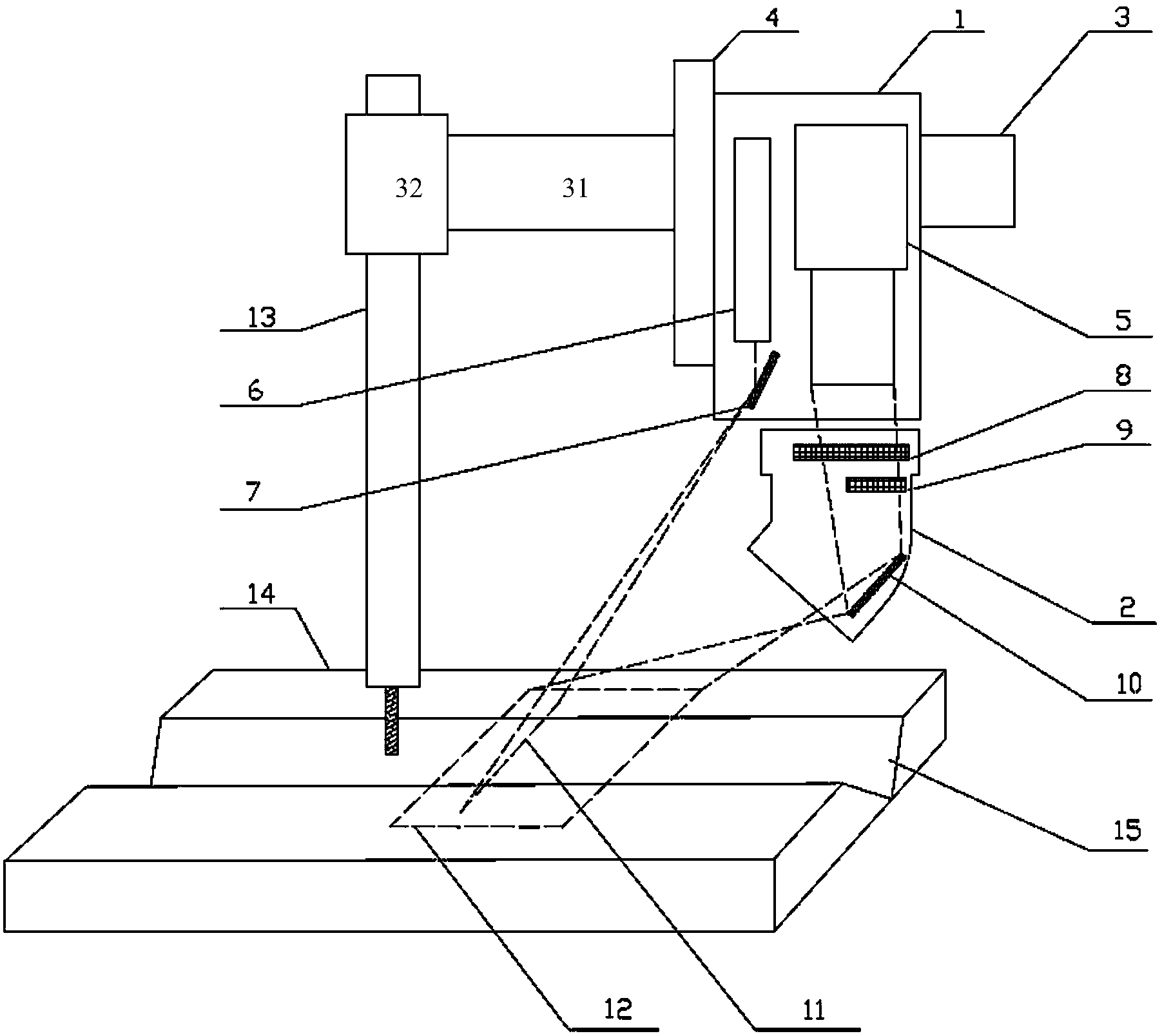

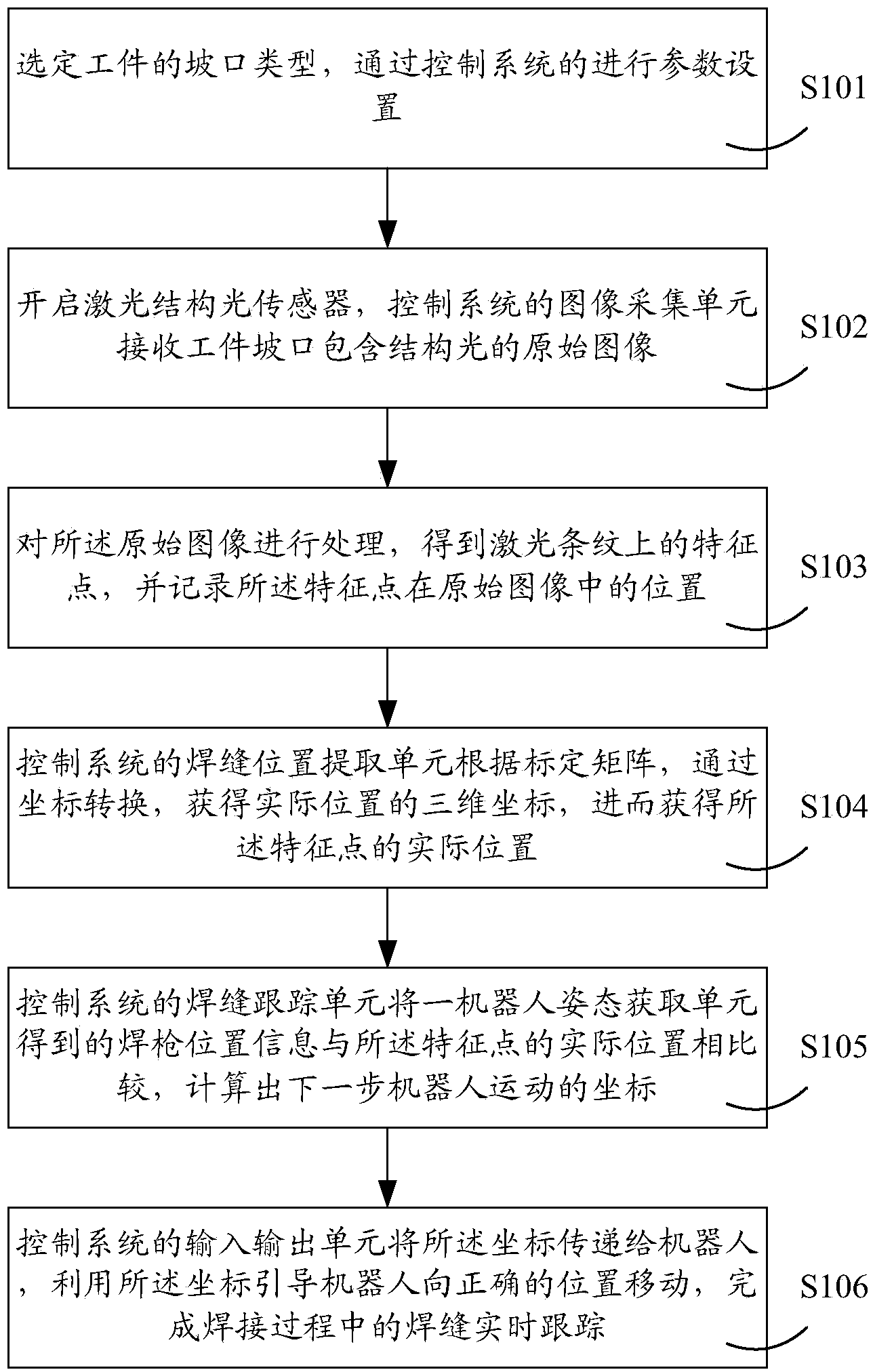

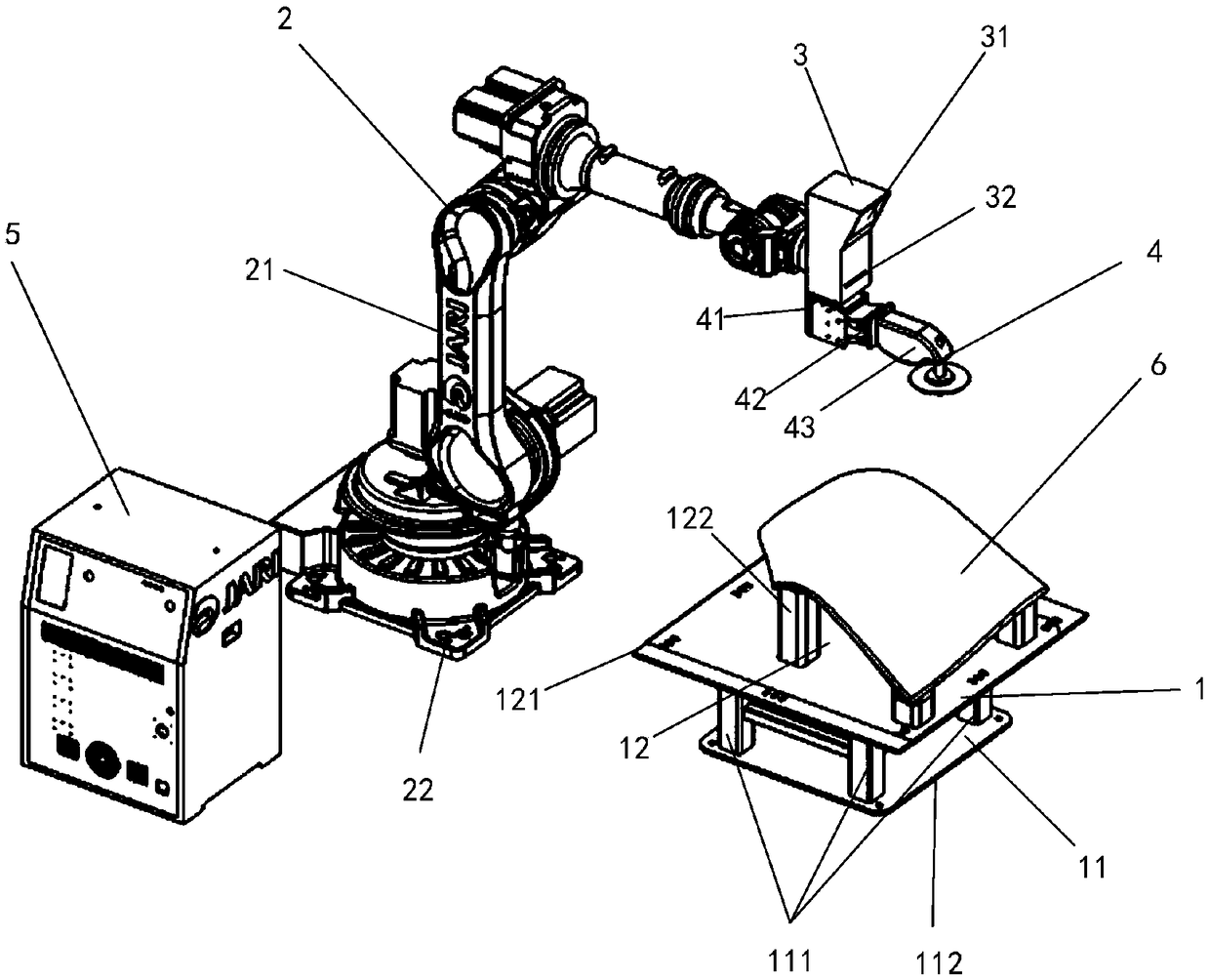

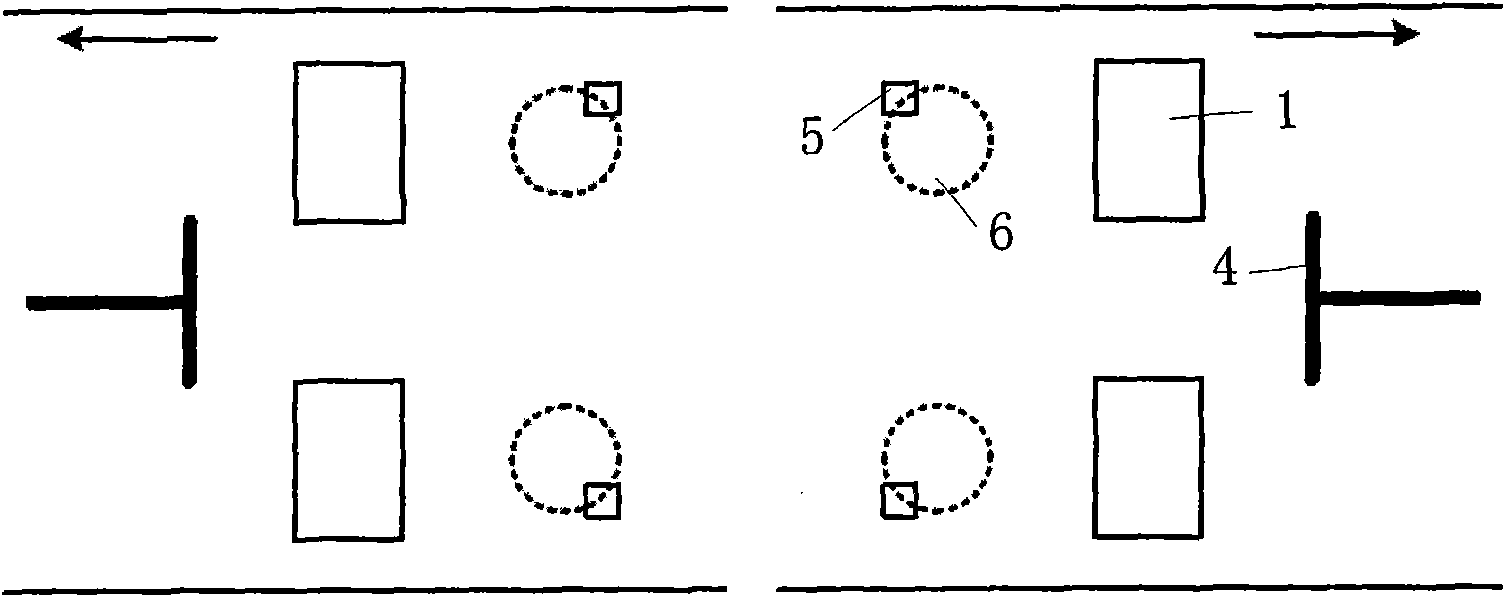

Thick plate robot welding system and multilayer multiple-pass weld real-time tracking and planning method

InactiveCN103934571AEnable real-time planningImprove flexibilityWelding/cutting auxillary devicesArc welding apparatusThick plateControl system

The invention discloses a thick plate robot welding system and a multilayer multiple-pass weld real-time tracking and planning method. The thick plate robot welding system comprises a robot, a laser structure optical sensor, a welding system and a control system. The laser structure optical sensor comprises a main system, an optical system, a clamping system and a cooling system. In the welding process, images containing weld groove feature information can be obtained in real time and transmitted to the control system; the control system obtains the groove information from the images and controls the robot to constantly correct the position of a welding gun in the welding system; meanwhile, the control system adjusts a weld pass track and welding parameters so that multilayer multiple-pass real-time planning can be achieved, and labor efficiency and production quality can be improved.

Owner:SHANGHAI JIAO TONG UNIV +1

Powdery attapulgite foaming agent

The invention discloses a powdery attapulgite foaming agent. The technical scheme has the following key points: the powdery attapulgite foaming agent is composed of active attapulgite clay, sodium percarbonate, sodium pyrophosphate, lauryl sodium sulfate, sodium polyacrylate and poly-naphthalene formaldehyde sodium sulfonate. The finished product of the powdery attapulgite foaming agent is prepared by stirring, grinding and packaging the ingredients. The powdery attapulgite foaming agent has the advantages that the foaming agent is high in foaming capacity, more in bubbling times and large in unit volume foam production quality, and enables the outer films of foams to have good toughness so as to guarantee the foams not to be easily broken; the foams are good in stability, can exist for a long time without being defoamed, and are fine and smooth; holes generated in a medium are even in sizes; the water secretion quantity is low; and the used medium is good in compatibility, etc. The products produced by the powdery attapulgite foaming agent not only can effectively control the noise pollution, but also have the functions of heat preservation and air purification; and the powdery attapulgite foaming agent is suitable for producing light weight boards, light weight walls and noise reduction products.

Owner:江苏世澳非金属应用科技有限公司

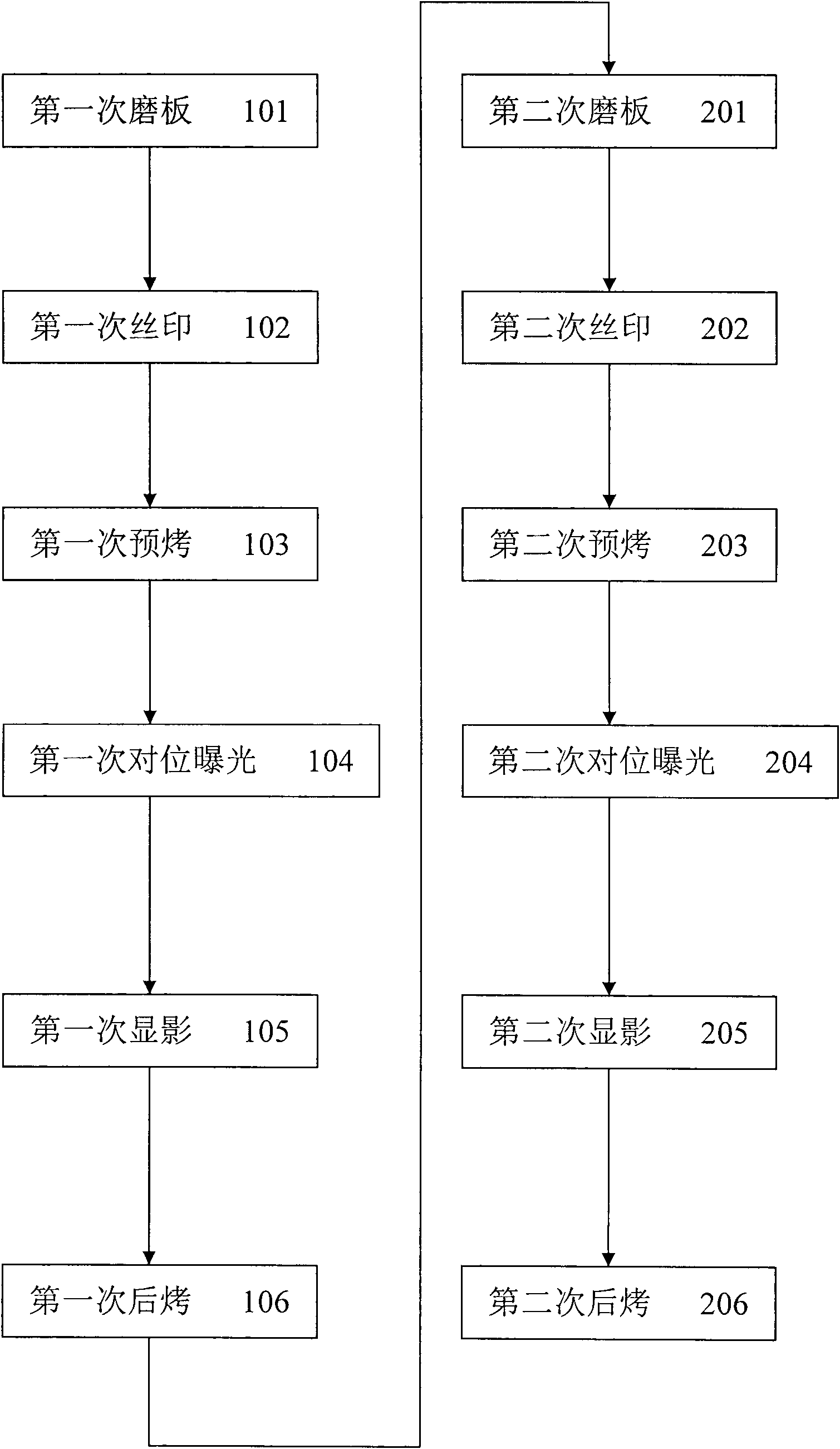

Production technology of PCB (Printed Circuit Board) solder mask

ActiveCN101668390AIncrease productivityImprove product qualityNon-metallic protective coating applicationCooking & bakingProduction schedule

The invention relates to a production technology of a PCB (Printed Circuit Board) solder mask, which comprises the following steps of: a first board grinding, a first silk screen, a first pre-braking,a first contraposition exposure, a first development, a first post-baking, a second board grinding, a second silk screen, a second pre-braking, a second contraposition exposure, a second developmentand a second post-baking, wherein the mesh number of the first silk screen is larger than that of the second silk screen, and the windowing size of the first contraposition exposure is larger than that of the second contraposition exposure. The production technology of the PCB solder mask better eliminates the harmful defects in the solder mask production process that green oil and the like easilysolders an oil plughole, the developing is dirty, the circuit becomes red, and the lateral erosion of a film printing and development is large and the like, thereby improving the production efficiency and the production quality, speeding up the production schedule and reducing the production cost.

Owner:大连崇达电子有限公司

Multi-angle plate polishing device

InactiveCN109571180ARealize multi-degree-of-freedom grindingImprove grinding limitationsEdge grinding machinesGrinding carriagesMulti degree of freedomEngineering

The invention relates to the field of plate processing, in particular to a multi-angle plate polishing device. The multi-angle polishing device is characterized in that a length adjusting component isfixedly connected to the front end of a base; a left plate and a right plate are separately fixedly connected to the two ends of the length adjusting component; an angle adjusting component is connected to the upper end of the left plate; the number of plate clamping pieces is two; the two plate clamping pieces are separately fixedly connected to the inner sides of the angle adjusting component and the right plate; a grinding plate sliding seat component is fixedly connected to the rear end of the base; and a grinding component is connected onto the grinding plate sliding seat component in asliding manner. A plate can be polished from multiple angles and in multiple directions according to the self characteristics and the grinding requirements of a product, the multi-degree of freedom polishing of the plate is realized, or the omni-directional polishing and local polishing of the plate are realized, the polishing limitation of an existing automatic polishing machine is improved, andmanual operation is replaced with mechanical automatic processing, so that the production efficiency is improved, and the production quality of the product is ensured; and the multi-angle plate polishing device is applicable to plates of different sizes or shapes.

Owner:张馨文

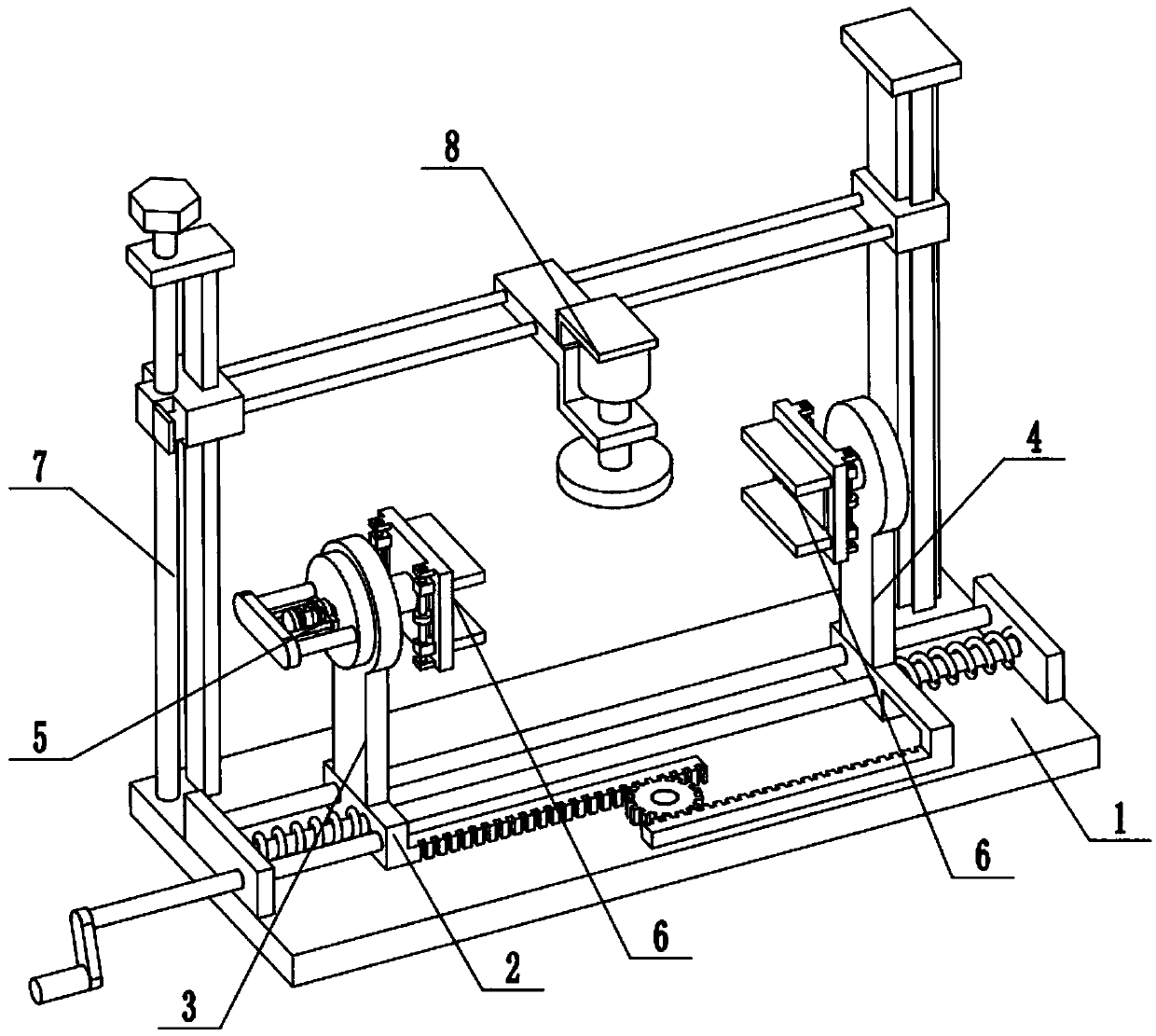

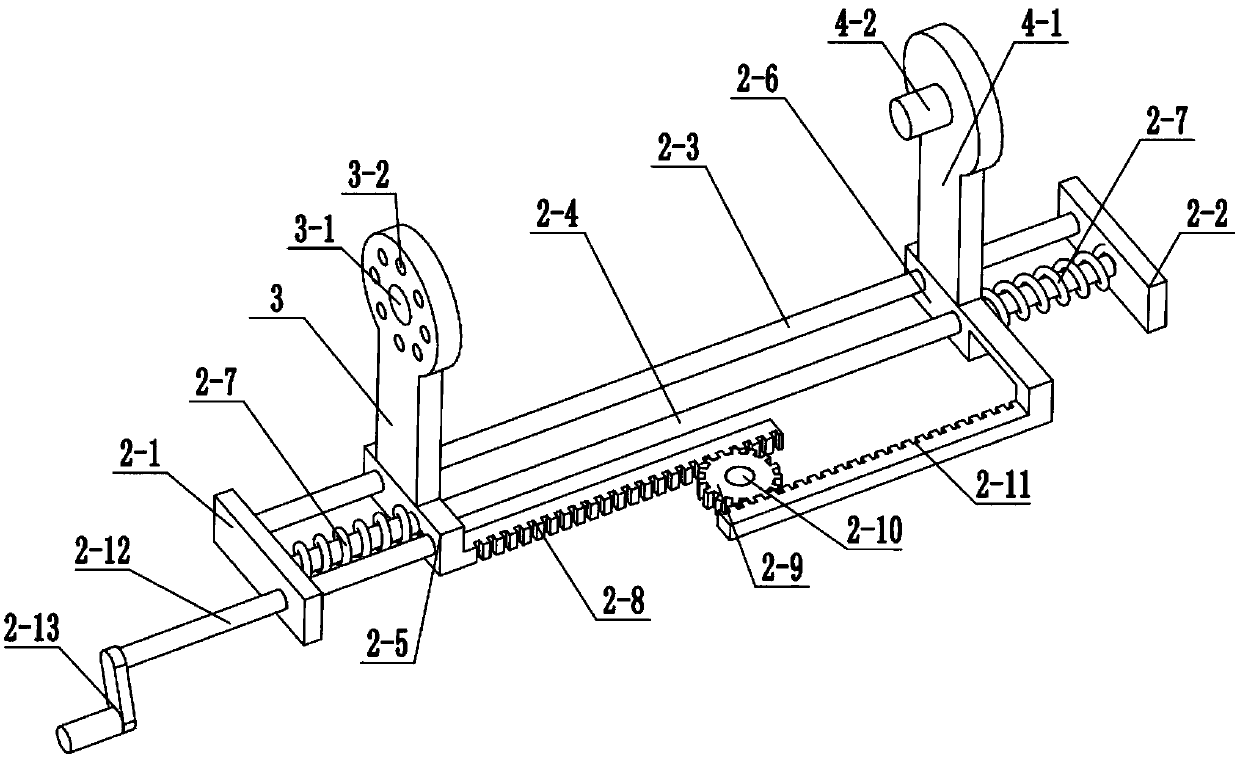

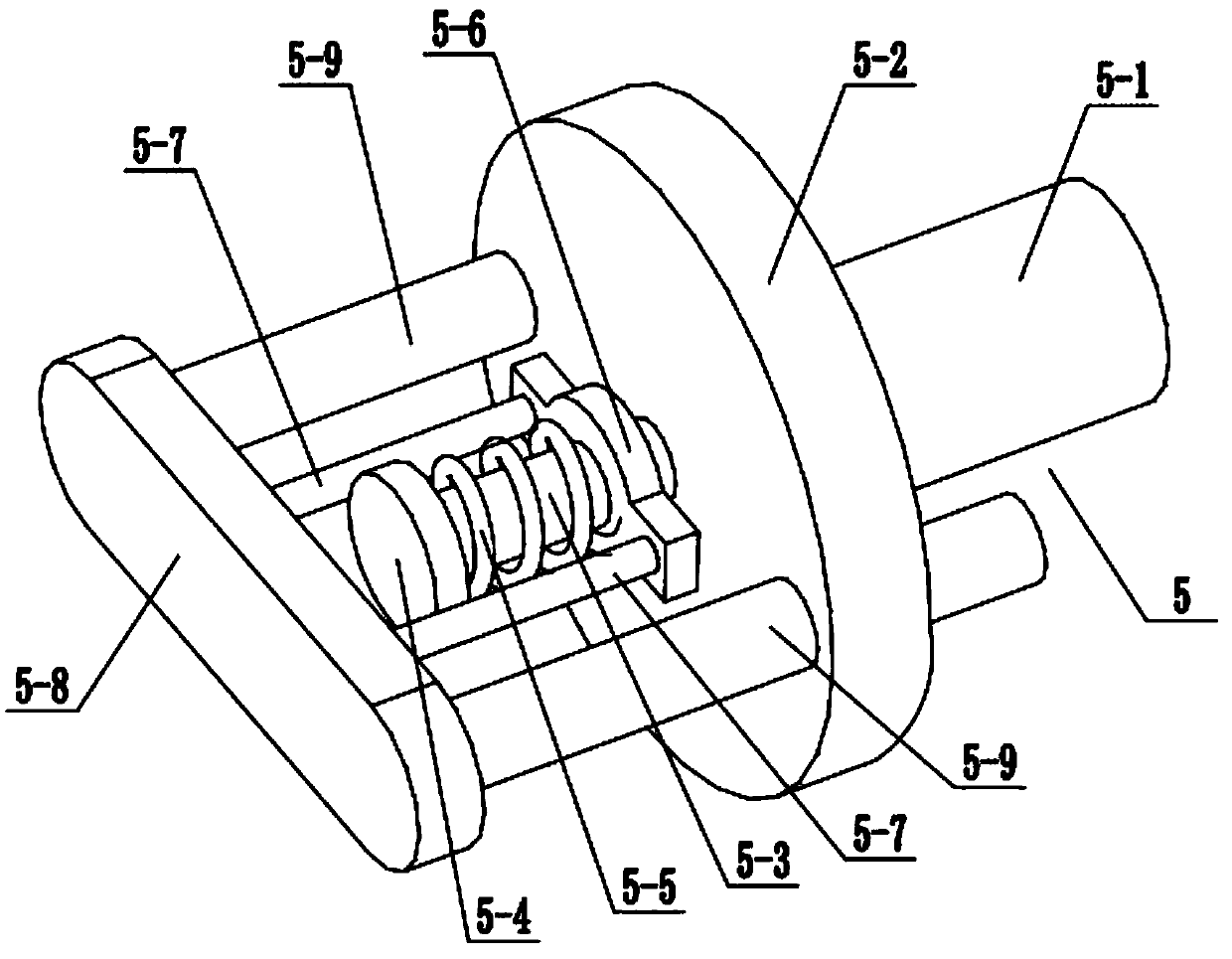

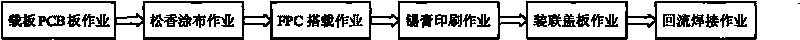

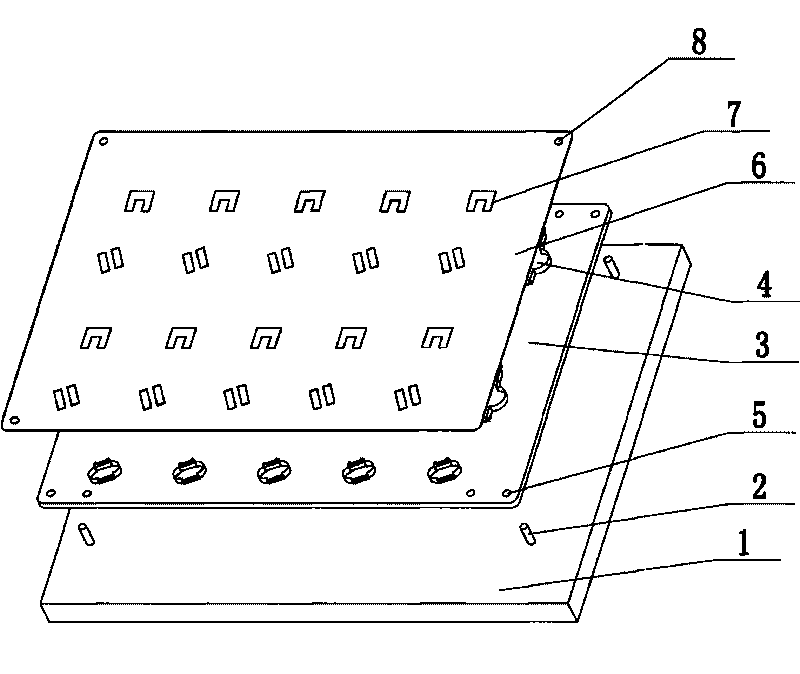

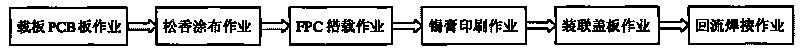

Method for assembly and reflow soldering of PCB and FPC and special positioning fixture thereof

InactiveCN101720172AIncrease productivitySimplify the initial positioning methodPrinted circuit assemblingPrinted element electric connection formationEngineeringProcessing cost

The invention discloses a method for the assembly and the reflow soldering of a PCB and an FPC and a special positioning fixture thereof, which mainly solve the problems of inaccurate positioning, low efficiency of welding efficiency, difficulty for ensuring product quality and the like of manual assembly in the processes of assembling and soldering the PCB and the FPC. The method comprises the following steps: firstly, supporting, positioning and fixing the PCB by using a magnetic carrier board; secondly, carrying the FPC; next, preliminarily positioning the PCB and the FPC with a bonding agent; thirdly, printing a solder paster on a solder pad at the junction of the FPC and the PCB; and finally, pressing a magnetic cover board on the magnetic carrier board, fixing the positions of the FPC and the PCB, and performing the reflow soldering on the FPC and the PCB through a reflow oven. The method for the assembly and the reflow soldering of the PCB and the FPC and the special positioning fixture thereof have the advantages of simple operation, good reliability, great improvement on the production efficiency and the production quality of the FPC and the PCB in the processes of assembling and soldering, and processing cost reduction.

Owner:HUIZHOUSRTY INFORMATION ELECTRONICS

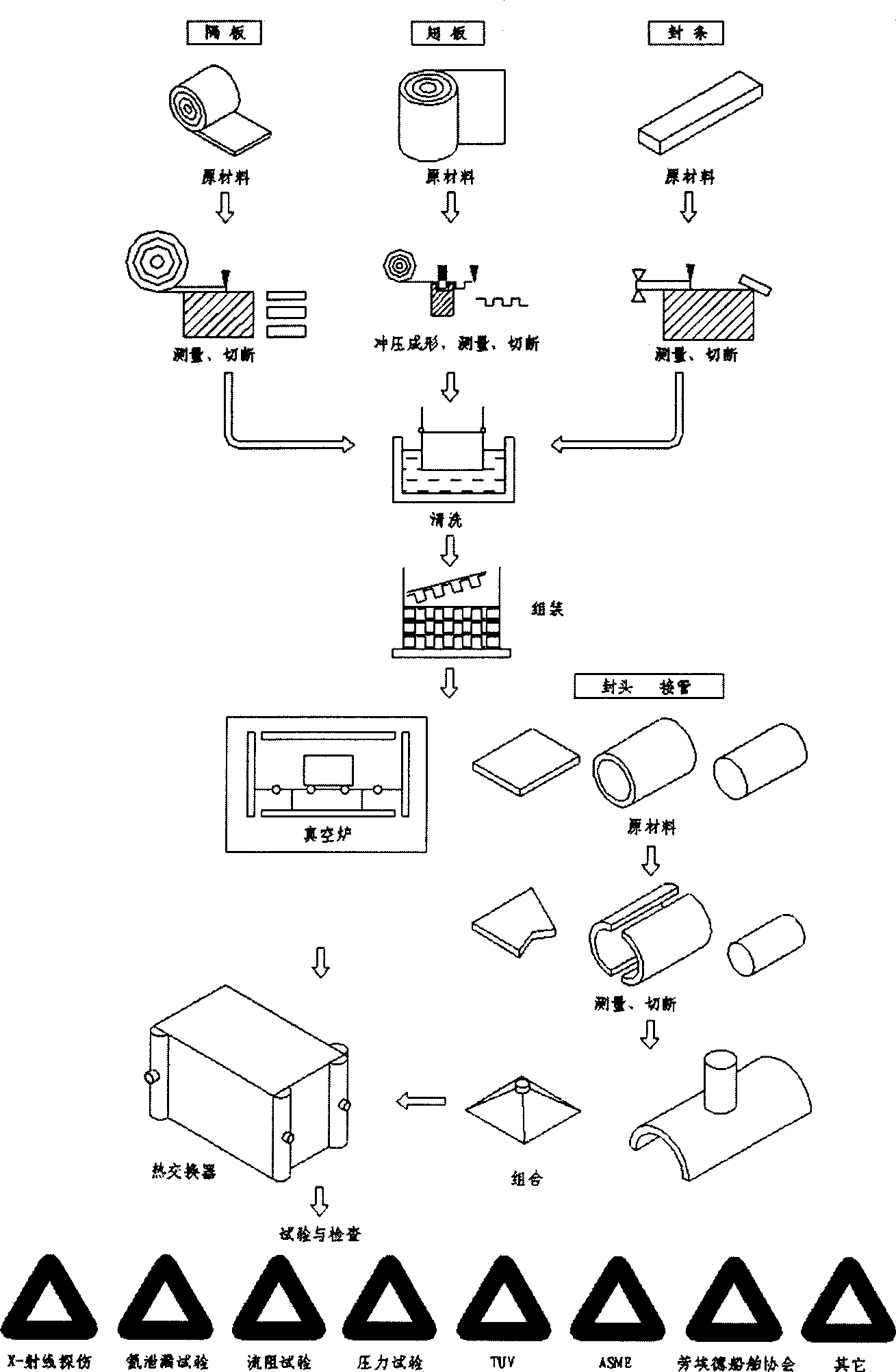

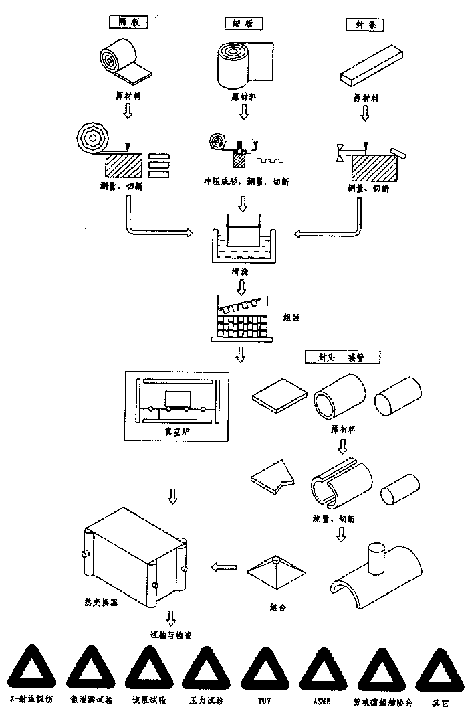

Manufacture of fine-type stainless steel plate heat exchanger

InactiveCN1375374AImprove wettabilityIngredients evenly distributedSoldering apparatusX-rayHigh pressure water

The production method of austenitic stainless steel plate fin heat exchanger includes the following steps: part preparation: partition, sealing strip, fin, sealing head and connecting pipe preparation; cleaning before welding; acid pickling to remove oil, dirt and oxide, and using high-pressure water to wash; element assembling and holding; vacuum braze welding, adopting argon arc welding to weldscaling head and connecting pipe, making general assembly; test and inspection, making x-ray inspection, helium leak detection, flow resistance test, pressure test, TUV, ASME and other test and inspection. Said invented process raise the production quality of said stainless steel plate fin heat exchanger, tensile-strength of connector and its service life.

Owner:NANJING UNIV OF TECH

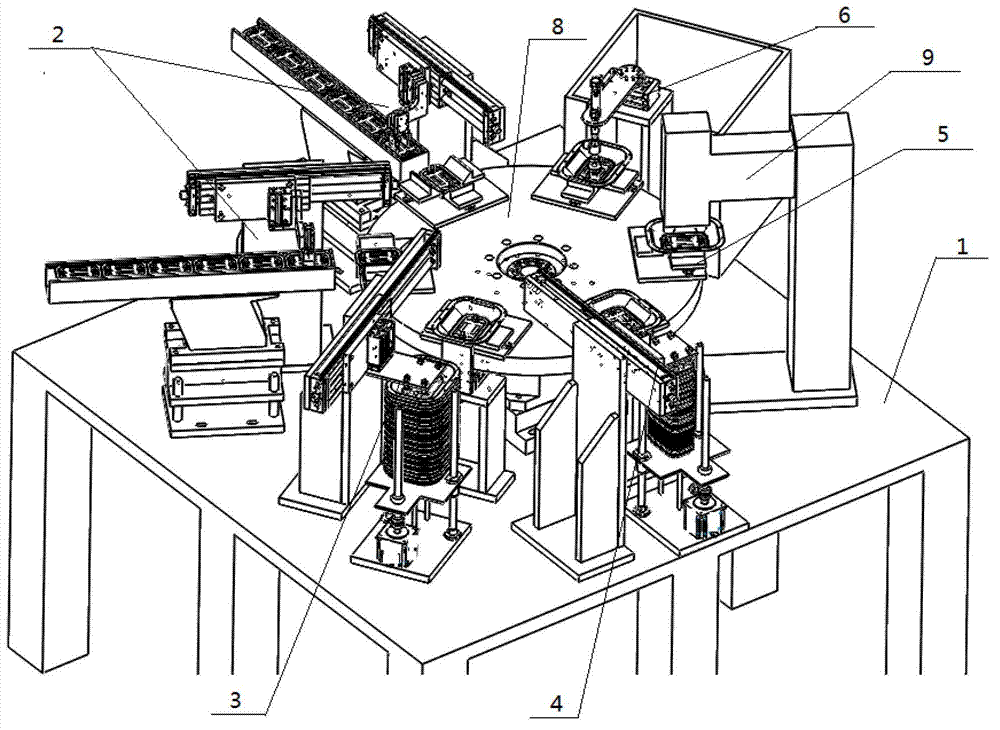

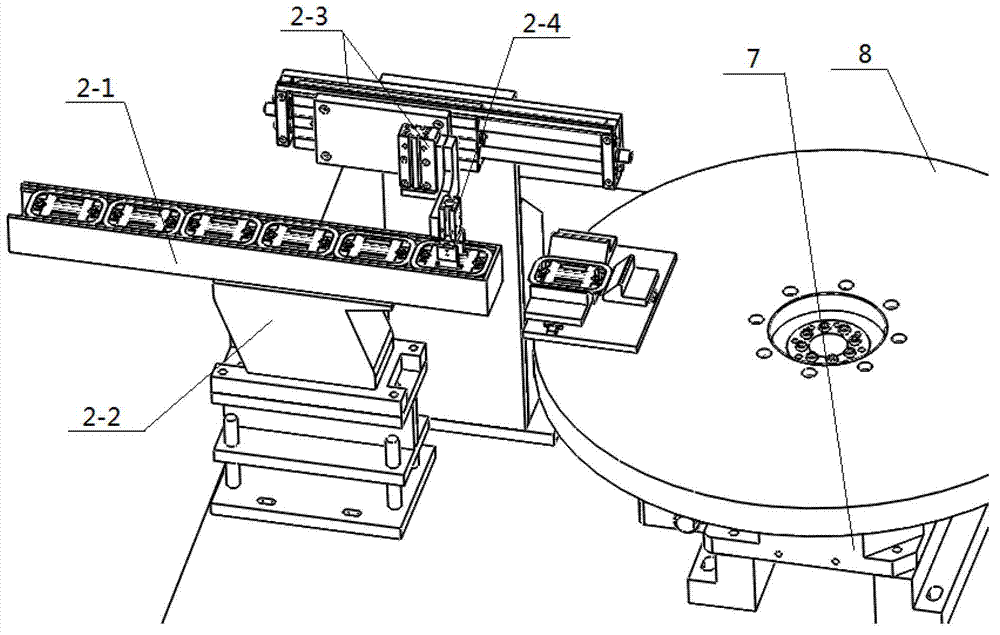

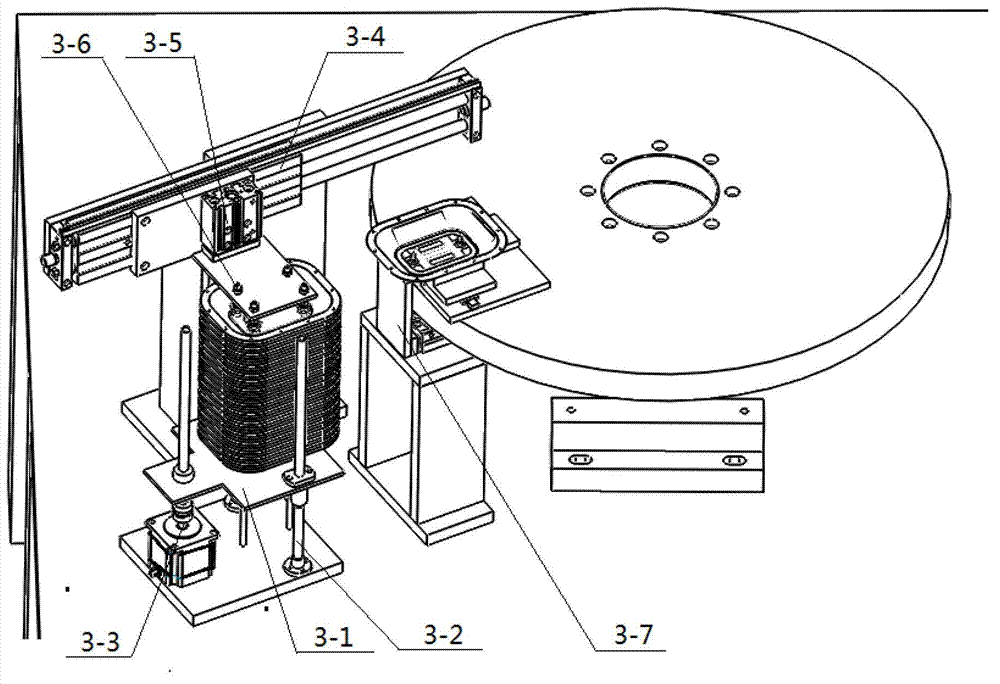

Assembly machine for gas surface membrane component

InactiveCN102814650AExpand the scope of workImprove qualityAssembly machinesDrive motorSurface membrane

An assembly machine for a gas surface membrane component comprises a rack and a turntable indexing drive device, wherein the turntable indexing drive device is fixed on the rack, and comprises a turntable, a drive motor and a divider for converting the continuous rotation of the drive motor into indexing rotation, the drive motor is connected with the divider, and the turntable is fixed on an output flange of the divider; and six groups of adjustable clamps are uniformly distributed on the turntable, and six station working areas are uniformly distributed arranged at the outer part of the turntable indexing drive device, and are sequentially a plastic clamping box assembling station, a membrane assembling station, an aluminum clamping box assembling station, a hot weld station and an unloading station. According to assembly machine for the gas surface membrane component disclosed by the invention, the assembling efficiency can be greatly increased, the employment requirement is lowered, the production cost of an enterprise is reduced, and the production quality of a product is ensured.

Owner:ZHEJIANG UNIV

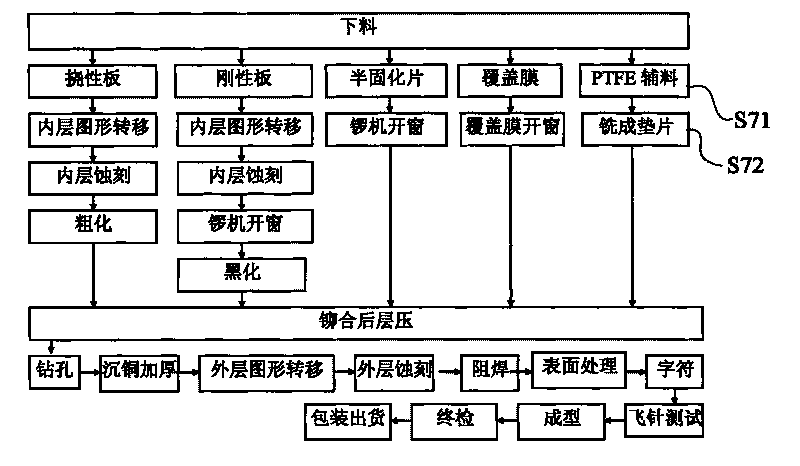

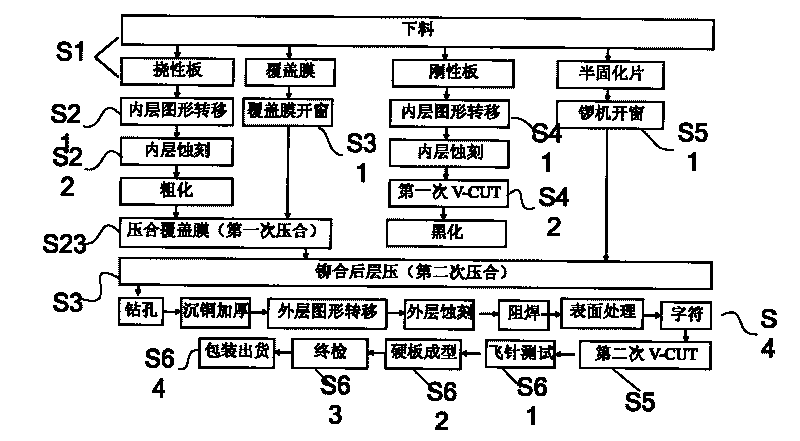

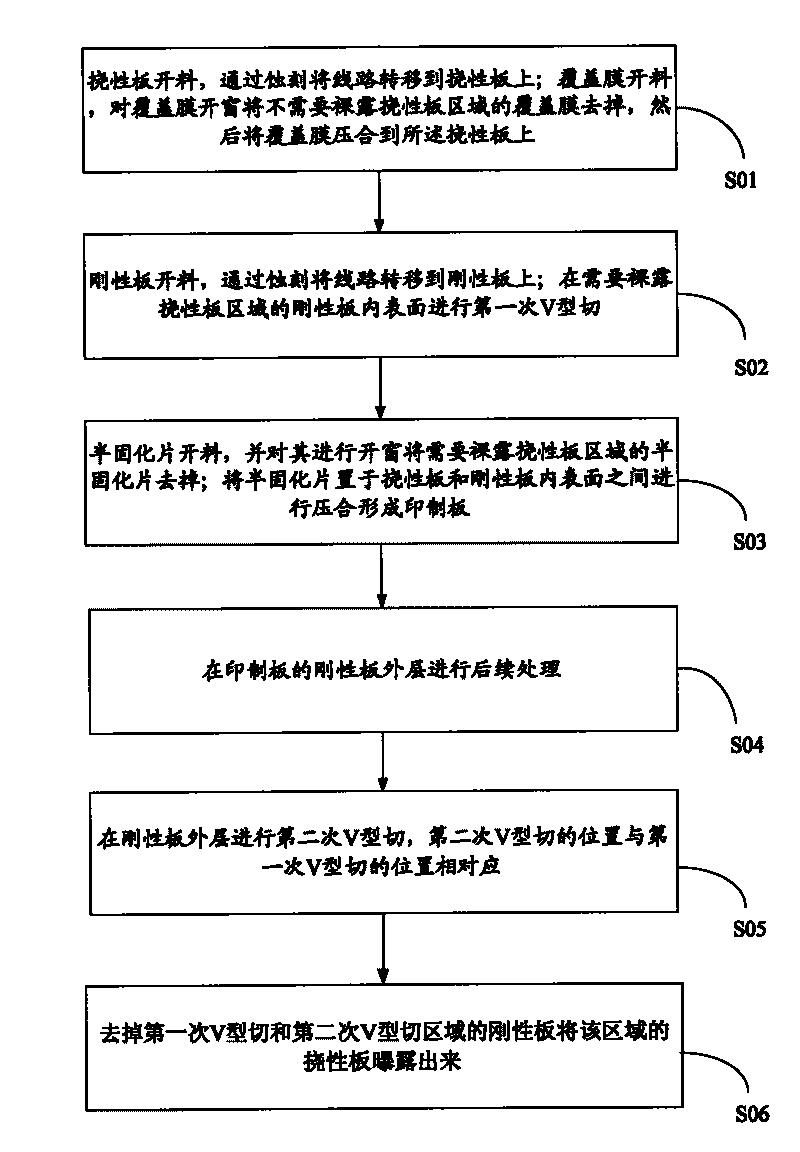

Method for producing printed board combining rigidness and flexibleness

ActiveCN101695217AAvoid product qualityImprove product qualityPrinted circuit assemblingEngineeringProduction quality

The invention provides a method for producing a printed board combining rigidness and flexibleness, comprising the following steps: cutting a flexible board and transferring an inner-layer circuit pattern onto the flexible board; cutting a covering film, implement windowing on the covering film, and pressing the covering film onto the flexible board; cutting a rigid board and transferring the inner-layer circuit pattern onto the rigid board; implementing a primary V type cutting at an outline position needing to baring the flexible board area; cutting a prepreg, implementing windowing on the prepreg and removing the prepreg needing to baring the flexible board area; placing the prepreg between the inner surfaces of the flexible board and the rigid board for implementing pressing so as to form a printed board; implementing subsequent processing at the outer layer of the rigid board of the printed board; implementing a secondary V type cutting at the outer layer of the rigid board, and leading the position of the secondary V type cutting to correspond to the position of the primary V type cutting; removing the rigid board of the primary V type cutting and the secondary V type cutting area; and exposing the flexible board of the area. The method improves the production quality of the printed board combining rigidness and flexibleness.

Owner:SHENZHEN KING BROTHER ELECTRONICS TECH

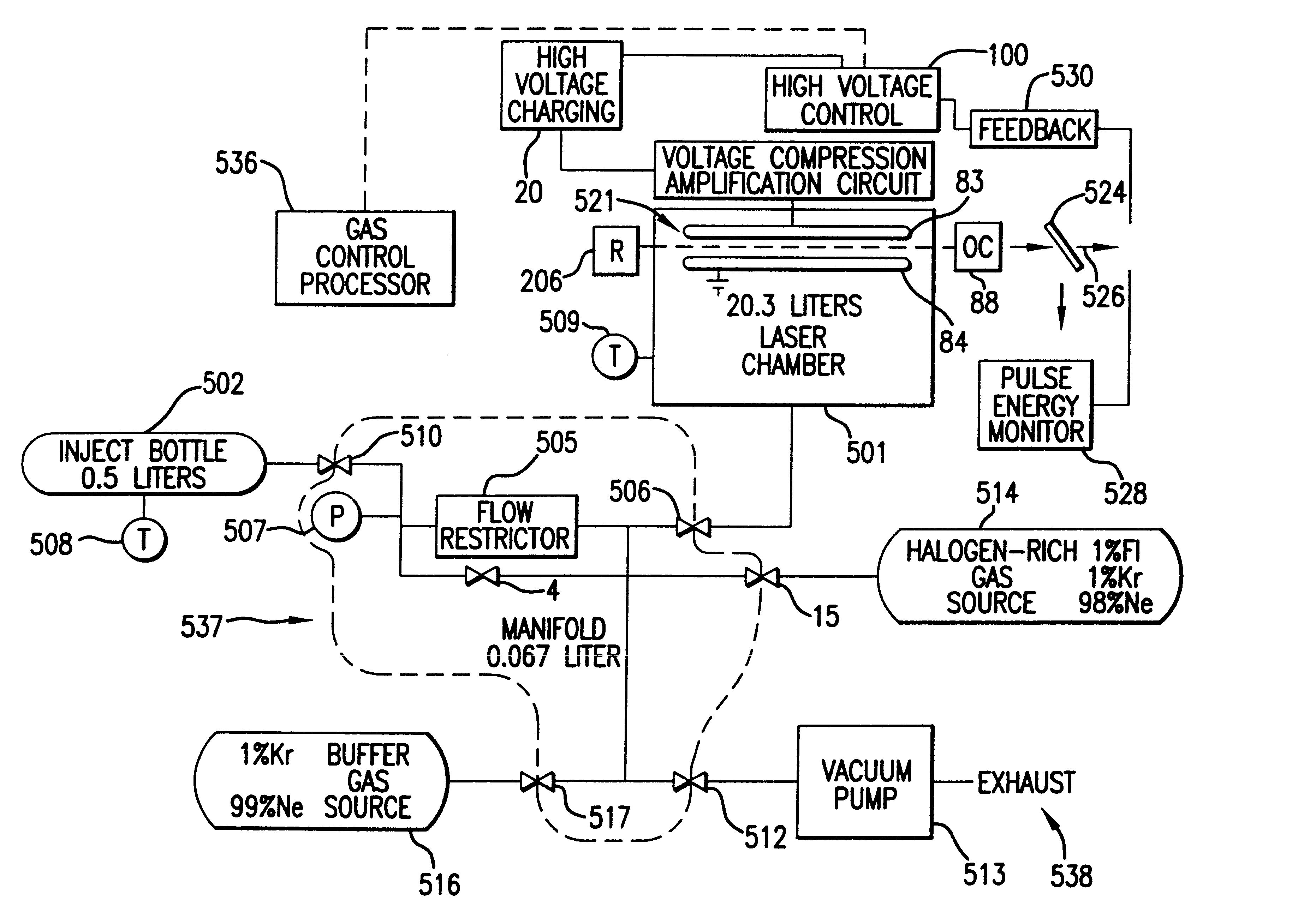

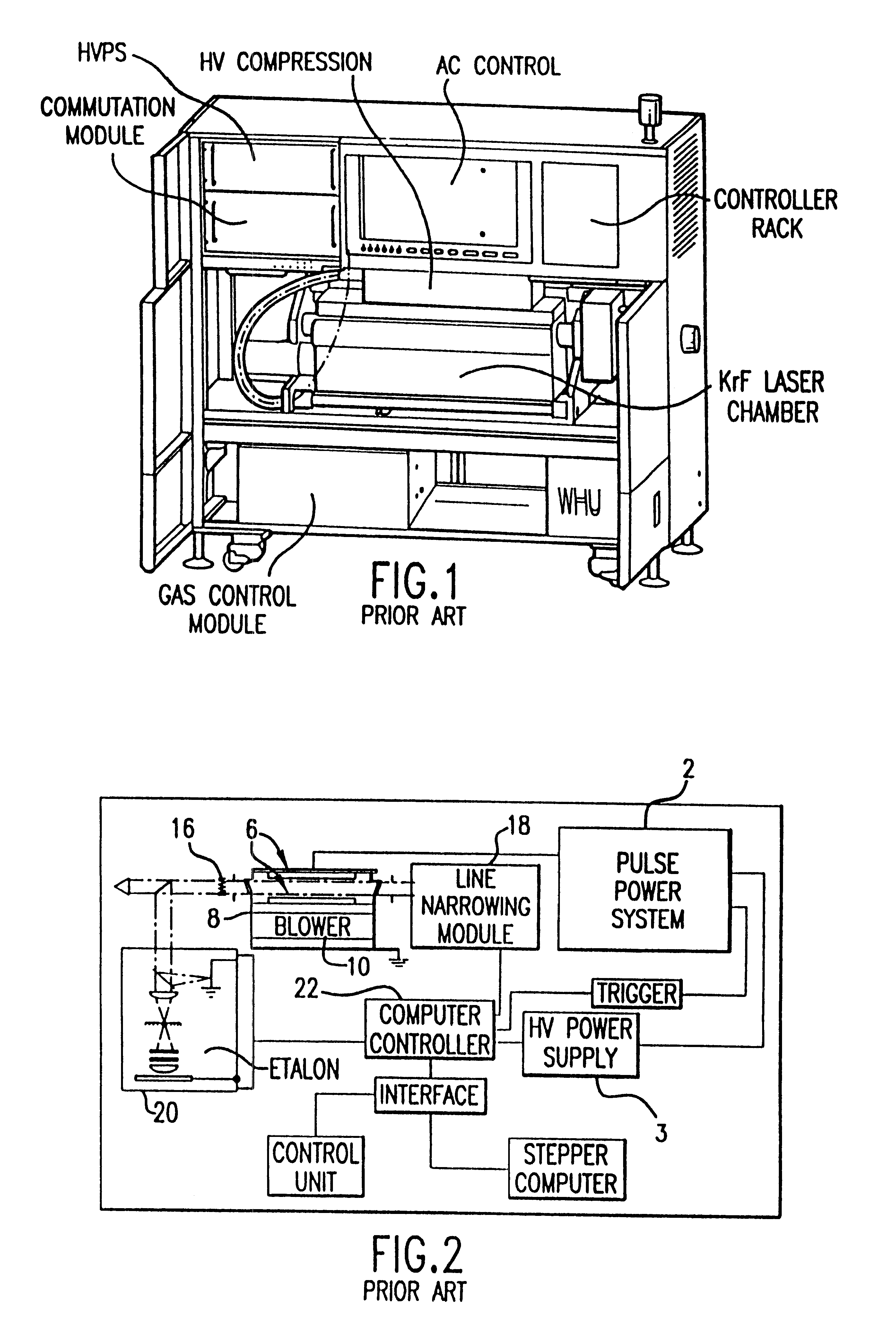

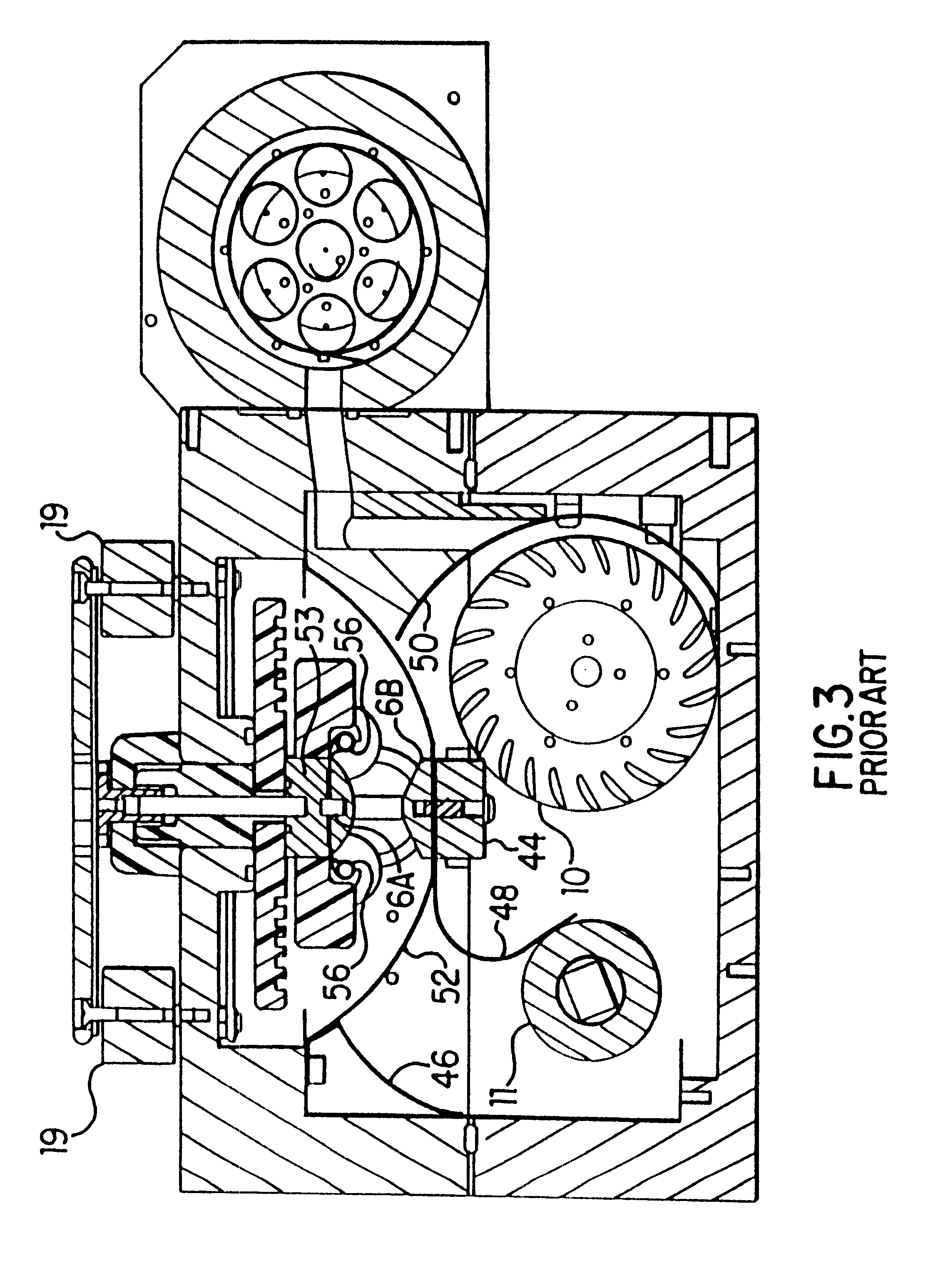

Reliable, modular, production quality narrow-band high rep rate F2 laser

InactiveUSRE38054E1Improve product qualityFast chargingVacuum evaporation coatingSputtering coatingEngineeringHigh pressure

The present invention provides a reliable modular production quality excimer laser capable of producing 10 mJ laser pulses in the range of 1000 Hz to 2000 Hz or greater. Replaceable modules include a laser chamber; a pulse power system comprised of three modules; an optical resonator comprised of a line narrowing module and an output coupler module; a wavemeter module, an electrical control module, a cooling water module and a gas control module. Important improvements have been provided in the pulse power unit to produce faster rise time and improved pulse energy control. These improvements include an increased capacity high voltage power supply with a voltage bleed-down circuit for precise voltage trimming, an improved communication module that generates a high voltage pulse from the capacitors charged by the high voltage power supply and amplifies the pulse voltage 23 times with a very fast voltage transformer having a secondary winding consisting of a single four-segment stainless steel rod. A novel design for the compression head saturable inductor greatly reduces the quantity of transformer oil required and virtually eliminates the possibility of oil leakage which in the past has posed a hazard.

Owner:CYMER INC

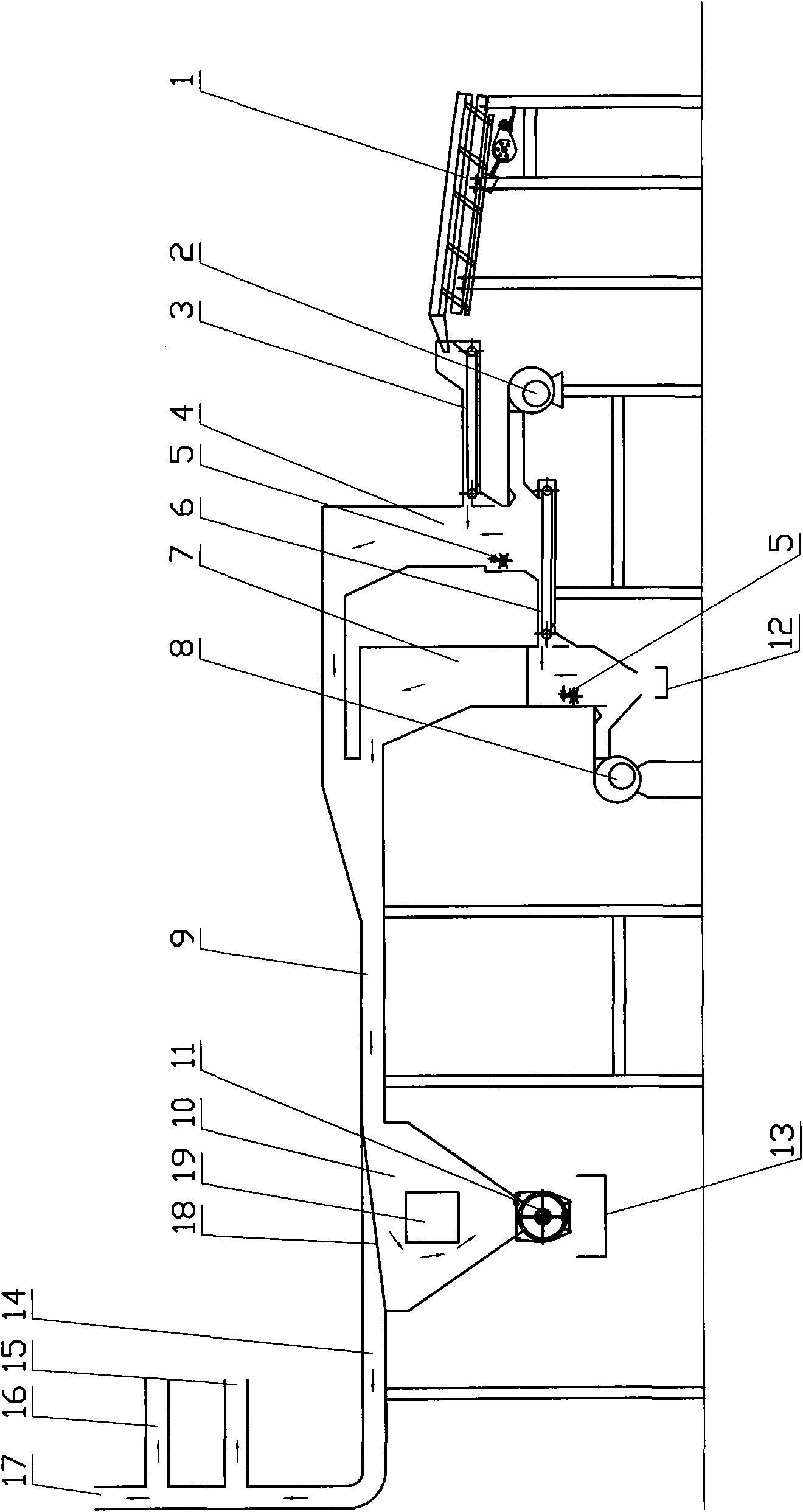

Multistage pneumatic separation device for eliminating stems from tobacco shreds

ActiveCN101548794AAccurate separationReasonable designTobacco preparationGas current separationProduction lineAtmosphere

The invention discloses a multistage pneumatic separation device for eliminating stems from tobacco shreds, belonging to the technical field of cigarette equipment. The device comprises at least two level pneumatic separation mechanisms, and each pneumatic separation mechanism comprises a pneumatic separation box, a rapid leather belt and a blower, wherein an air outlet of the blower is arranged at the lower part of the pneumatic separation box, and a feed opening of the rapid leather belt is arranged on an air outlet of the blower; a filling engine comprising a big wheel and a small wheel isarranged below the front wall of the pneumatic separation box; an air and material separating box is also arranged in front of the last level pneumatic separation box; an exhaust manifold on the air and material separating box is communicated with a plurality of branch pipes among which one is connected with the atmosphere through a dust collector, and other branch pipes are respectively communicated with the air inlet of each level air circulator. The multistage pneumatic separation device has reasonable design, simple structure and convenient operation, can accurately separate tobacco shredsand stems, ensures the production quality and is particularly suitable for being applied on a large capacity production line.

Owner:HUBEI CHINA TOBACCO IND

Robot grinding system with three-dimensional vision and control method thereof

PendingCN109483369ASolve the problem of automatic grindingRealize flexible grinding workGrinding feed controlCharacter and pattern recognitionEngineering3d camera

The invention discloses a robot grinding system with three-dimensional vision and a control method thereof. The robot grinding system comprises a workpiece fixing device, a grinding robot, an opticaldevice, pneumatic grinding equipment, a power supply and a control device. The control method of the robot grinding system with the three-dimensional vision comprises the steps that the grinding robotdrives the optical device to horizontally scan a curved surface workpiece; a laser image collected by a 3D camera is transmitted to the control device in the power supply and the control device; thecontrol device performs the three-dimensional point cloud processing to the image obtained by the 3D camera by using a corresponding function, and the preliminary filtering denoising is carried out; the point cloud segmentation and a slice algorithm are used for performing the further processing on the obtained three-dimensional point cloud; and processing results are analyzed and sent to the control device according to rules, and the robot is driven to perform the wholly grinding operation on the curved surface workpiece in the correct attitude. The robot grinding system with three-dimensional vision and the control method thereof are mainly used for automatic grinding in the field of curved surface structure manufacturing, and the production efficiency and production quality are improvedby improving the automation degree of the industrial grinding field.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP +1

Environmental protection type laser transfer composite aluminium foil paper and its preparation technology

InactiveCN1724811AGood printabilityMeet environmental protection requirementsNon-fibrous pulp additionPaper coatingSolventMaterials science

The invention relates an environmental protection laser transferred composite aluminum foil paper and the preparing technique, mainly solving the problems of the environment pollution and complicated technique caused by separant coating and laser layer protection coating of the existing commonly used solvent laser transferred composite aluminum foil paper. Its mixing proportion (by weight) of the raw materials is: water soluble amino resin 1-20 (or water soluble polyurethane resin 1-30, or water soluble alcohol acid resin 1-30, or water soluble acrylate resin 1-40, or cellulose resin 1-20), assistant 1-10, pigment 0-10, auxiliary solvent 1-30, and water 30-80, or their arbitrary combination, through synthesizing and wet-dispersing to mix into a water laser transfer coating, coating the transfer coating on a carrier thin film, drying, cross-linking curing, laser-mould pressing, and aluminizing to obtain the laser composite aluminum foil paper. It has the characters of improving environmental protection performance, simplifying producing process, saving energy sources, reducing production cost, stable production quality, etc.

Owner:张学毅

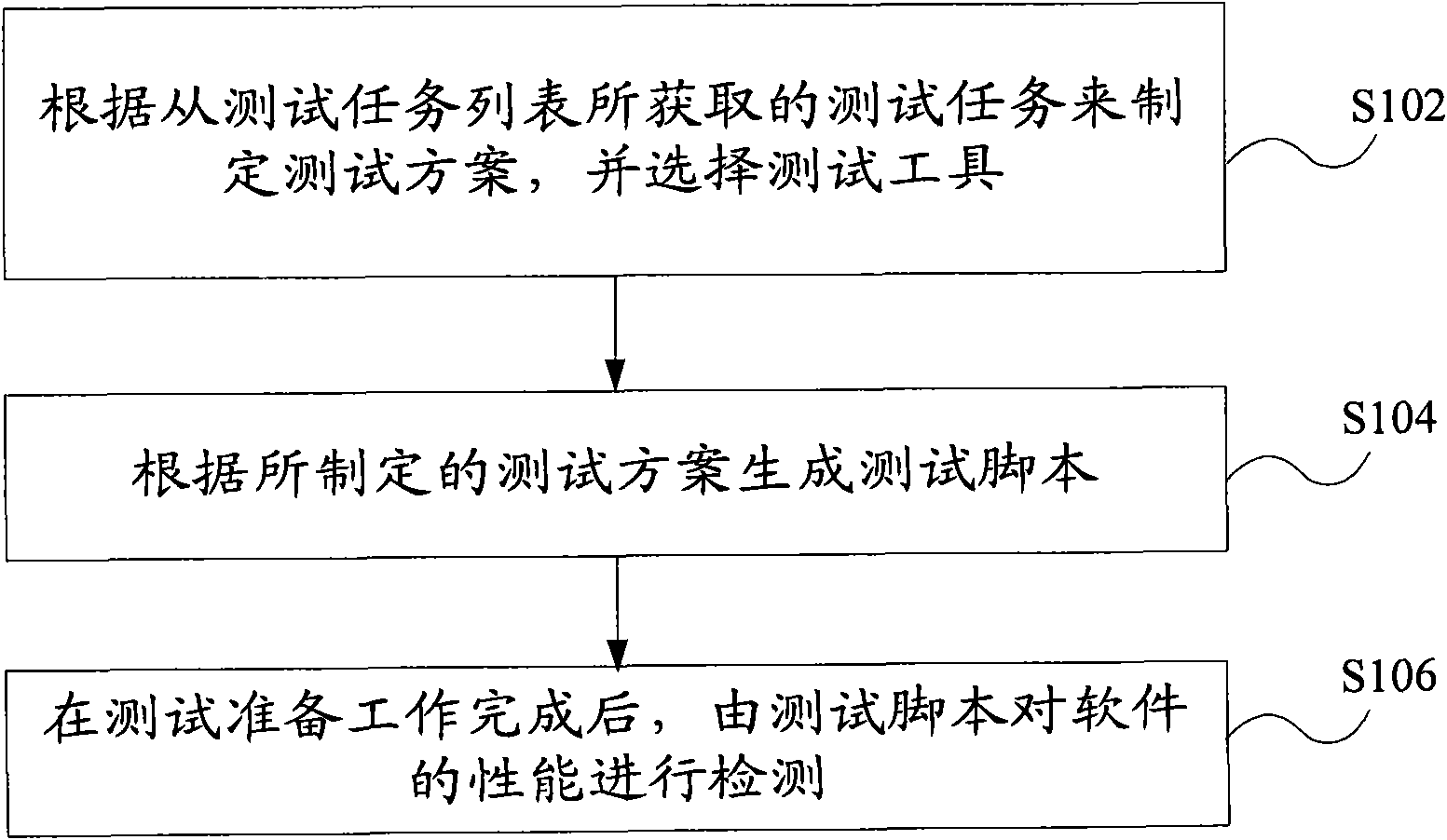

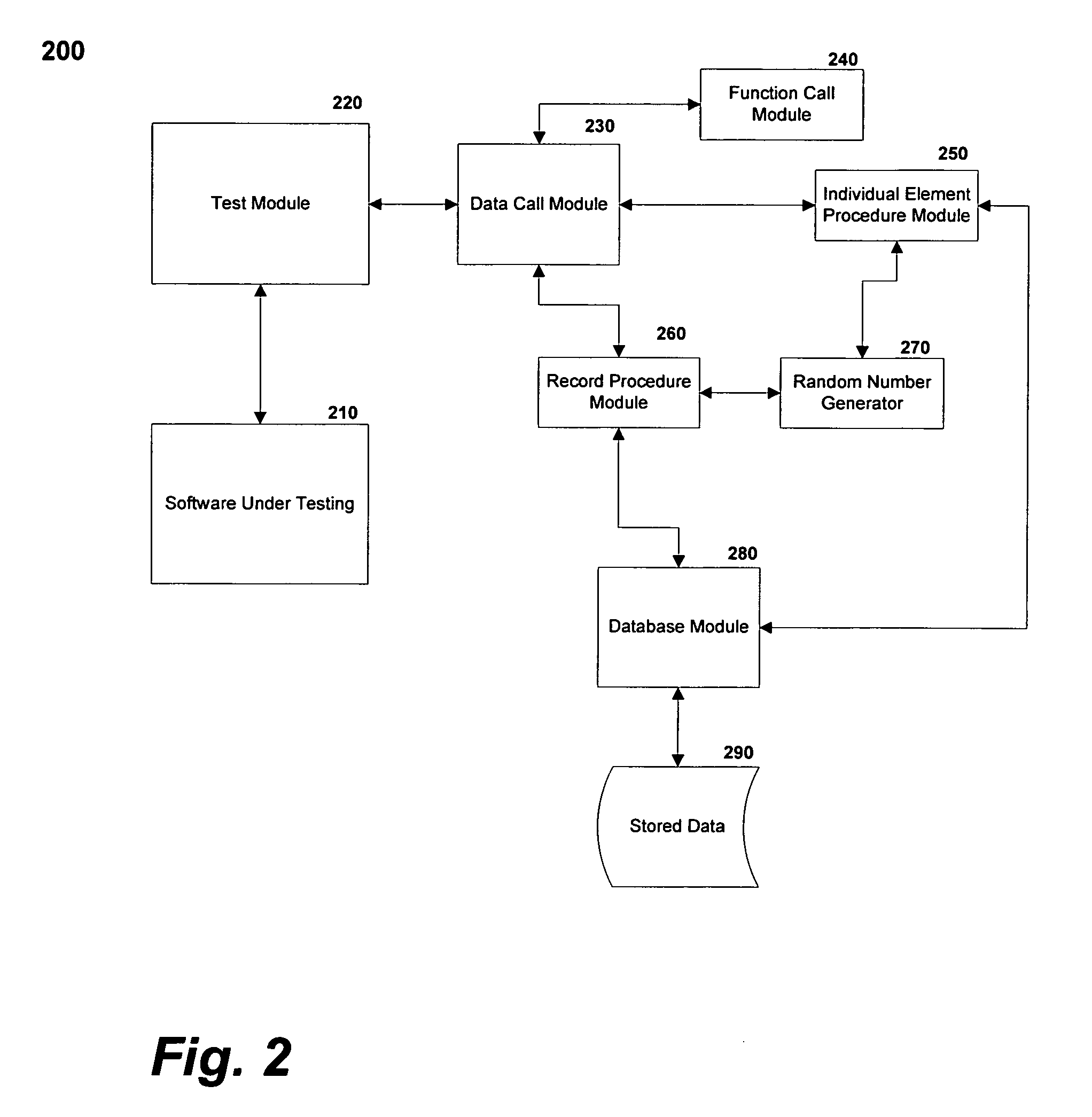

Method for testing software performance

The invention provides a method for testing software performance. The method comprises the following: step 1, formulating a test proposal according to a test task acquired from a test task list and selecting a test tool; step 2, generating a test script according to the formulated test proposal; and step 3, testing software performance through the test script after finishing test preparation work. Therefore, on the basis of software test work in general meaning, the method has further expansion and promotion, establishes an independent test-quality evaluation mechanism oriented to performance innovatively according to production versions, can control production quality more effectively and reduce the production risk and hidden trouble of software product versions by establishing a strict test output-permission evaluation mechanism and utilizing means and methods for testing the performance of the production versions.

Owner:BEIJING SHIJI TUOYUAN SOFTWARE TECH DEV

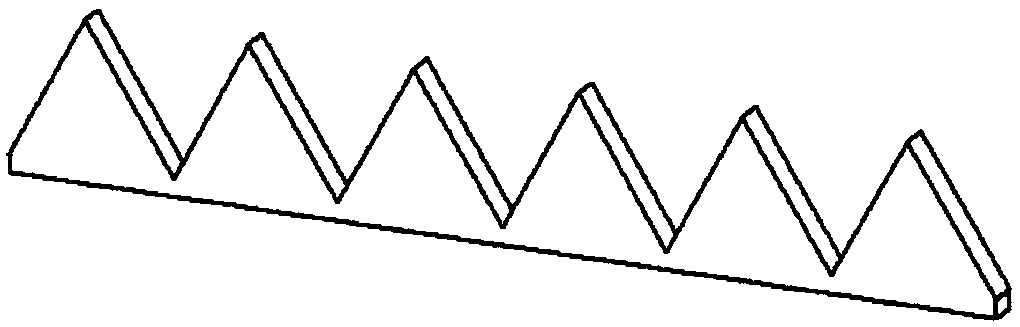

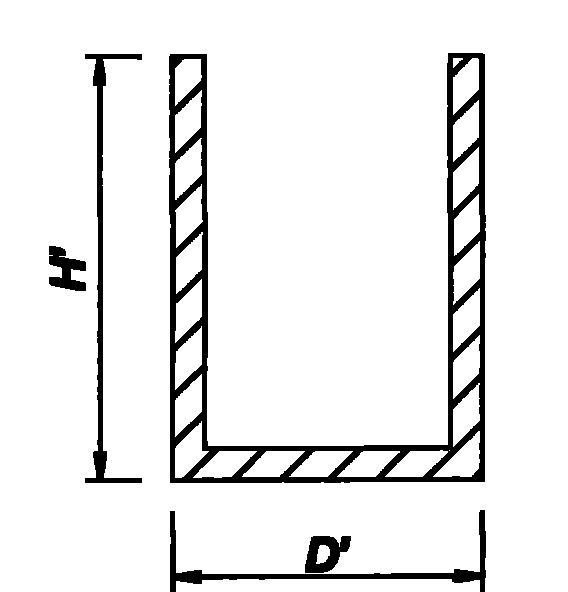

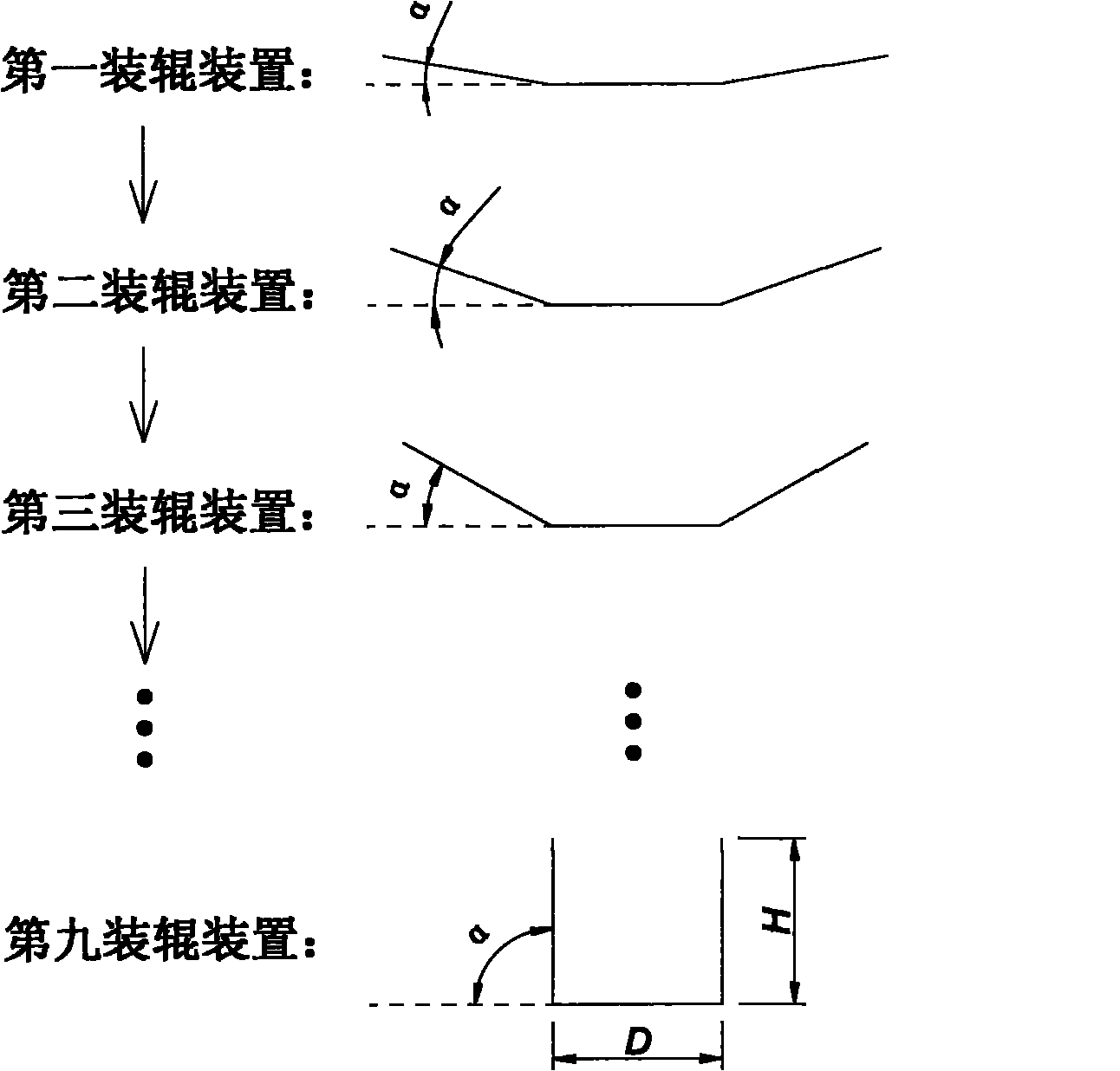

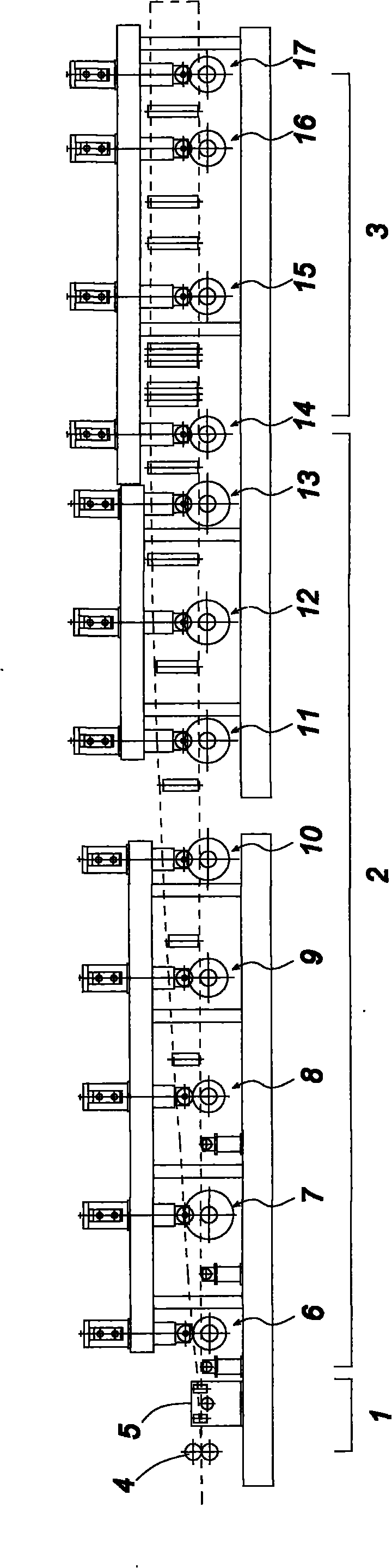

Cold-bending molding technology and production line for producing broad width U-shaped channel steel

The invention provides a cold-bending molding technology and a production line for producing a broad width U-shaped channel steel. The technology comprises the following steps: 1) sheets are pinched synchronously; 2) the sheets pass through a plurality of roll loading devices, the roll loading devices bend both sides of the sheet so as to make both sides of the sheet produce a bending angle alpha, and in the moving direction of the sheet, the rear roll loading device makes the bending angle alpha increased gradually to 90 degrees, so a U-shaped channel steel is initially molded; and 3) the side surface of the U-shaped channel steel initially molded is rectified. With the technology, the flat sheet can be relatively and continuously molded into the integral U-shaped broad width channel steel without welding. The production line of the technology has the advantages of no limit on the total length of the channel steel, high production efficiency, stable production quality, stable operation, low noise and the like.

Owner:山东力丰重型机床有限公司

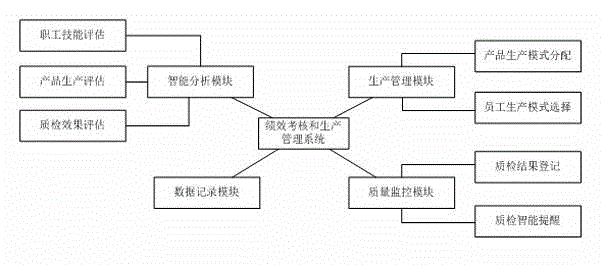

Intelligent production management method

The invention relates to an intelligent production management method, in particular to a comprehensive intelligent production management method. The method includes information data acquisition, specialized data analysis, a workpiece-oriented production mode, a worker-oriented working mode, and a production quality inspection and dynamic quality inspection mode. Each worker who participates in production is digitally registered, and by recording and monitoring the production efficiency of individuals and teams, an intelligent analysis module of a comprehensive management system is utilized to adjust the production mode and the team member assignment structure in time and obtain the most suitable production quality inspection mode. The system is characterized in that by means of the powerful functions of a database and visual analysis, the system can use a piecework-hourly work mixed production work management mode to dynamically adjust the quality monitoring mode and intensity according to the characteristics of individuals and workpieces, thus achieving multiple purposes, such as reasonably arranging productivity, increasing the production rate and guaranteeing product quality.

Owner:无锡中科苏惠自动化技术有限公司

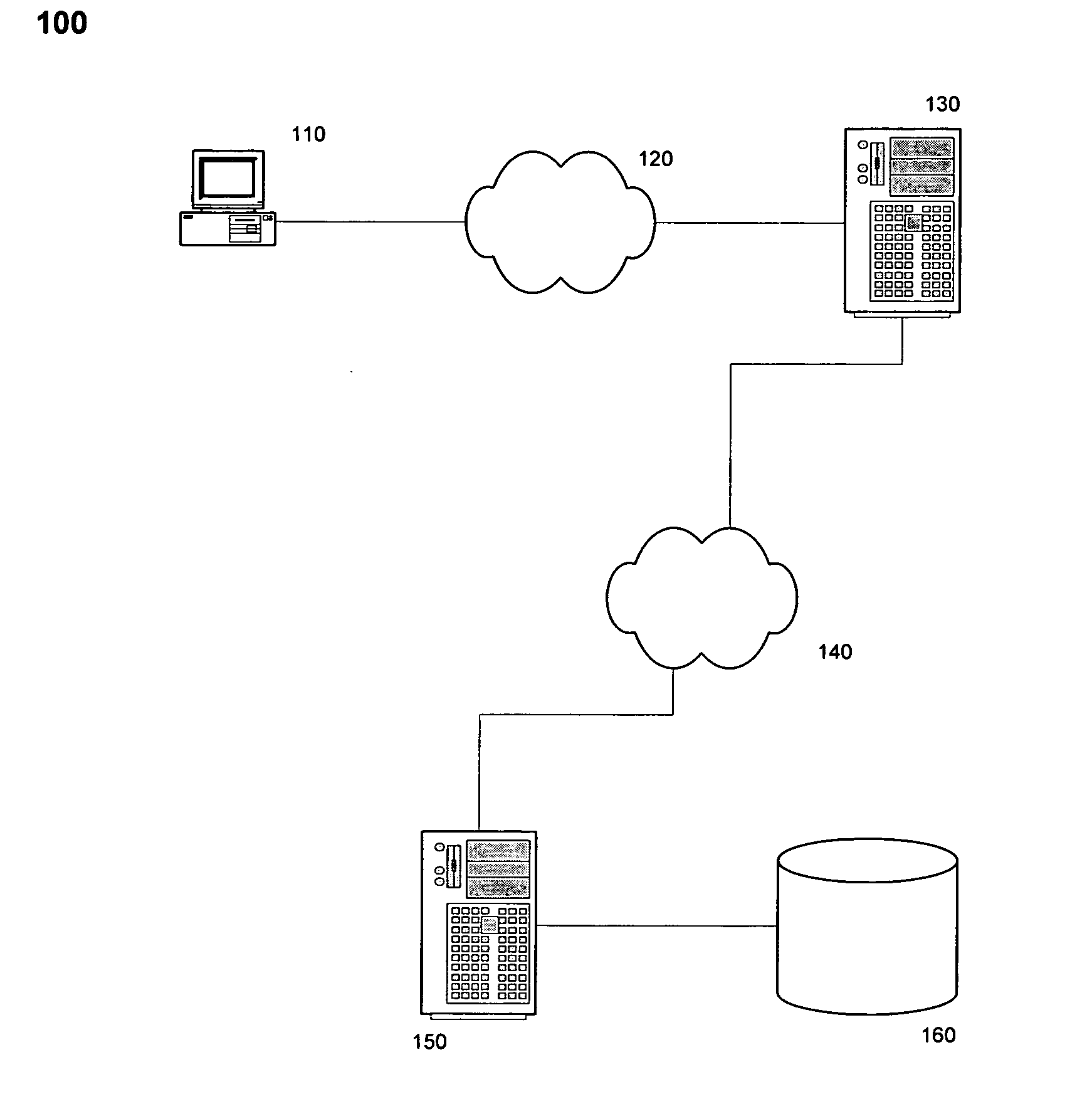

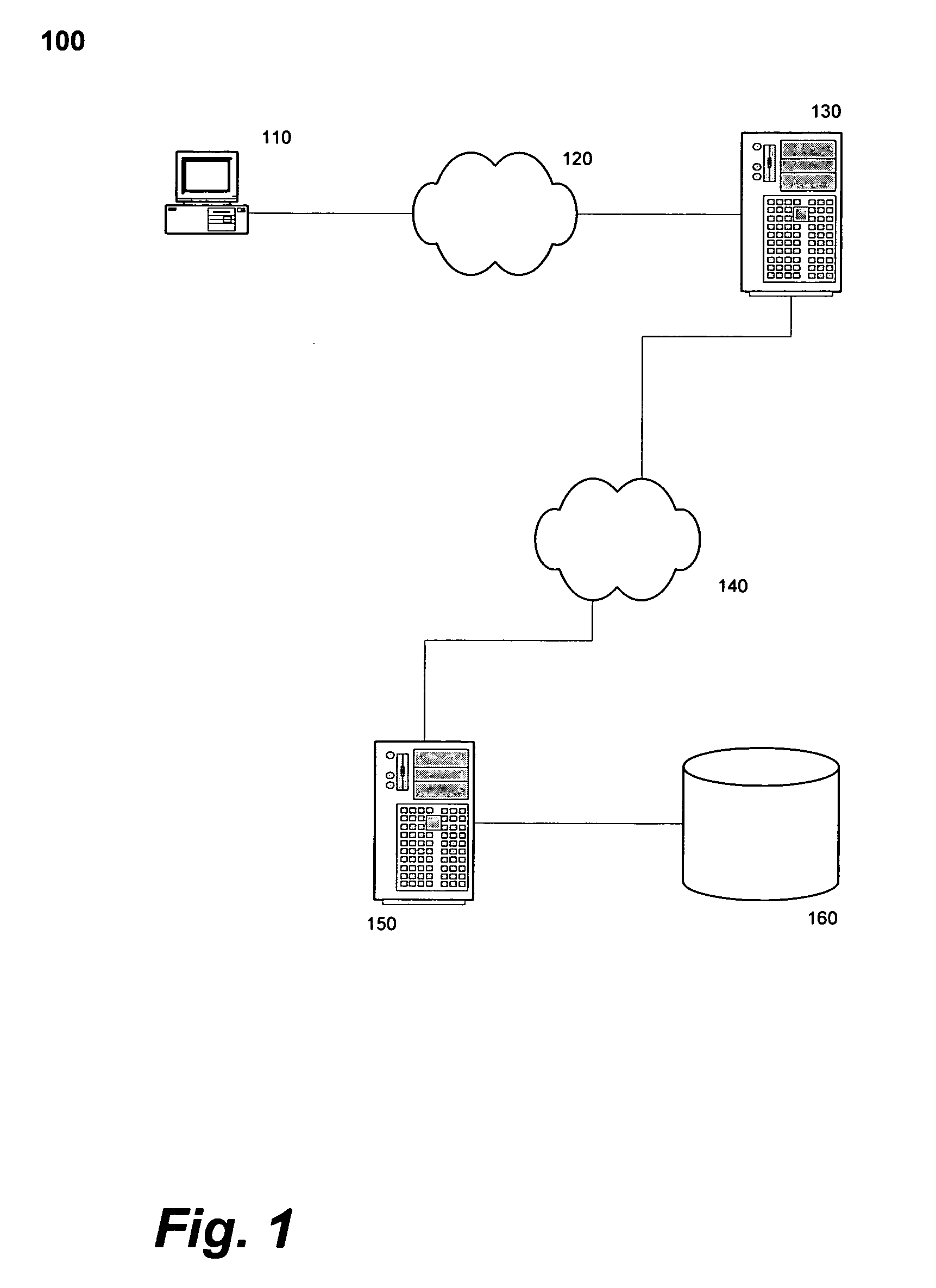

System and method for generating production-quality data to support software testing

Providing data as part of a testing regime for computer software. Random data values can be automatically generated to support the testing of any type of computer software that operates on data as part of its function. This random generation of data values can provide a breadth of data needed to fully stress the software program being tested. Data of any type can be provided to a testing regime and individual data elements may be related such that the provided data reflects realistic situations. Data can be extracted from data tables and / or generated through operating a function designed to generate a specific value type.

Owner:TOTAL SYST SERVICES

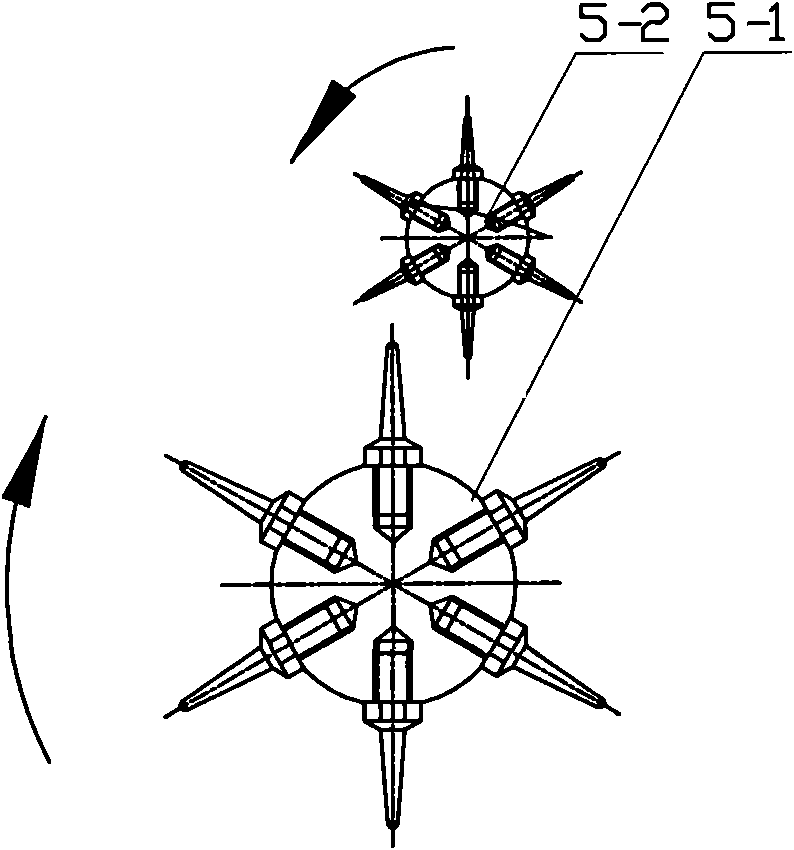

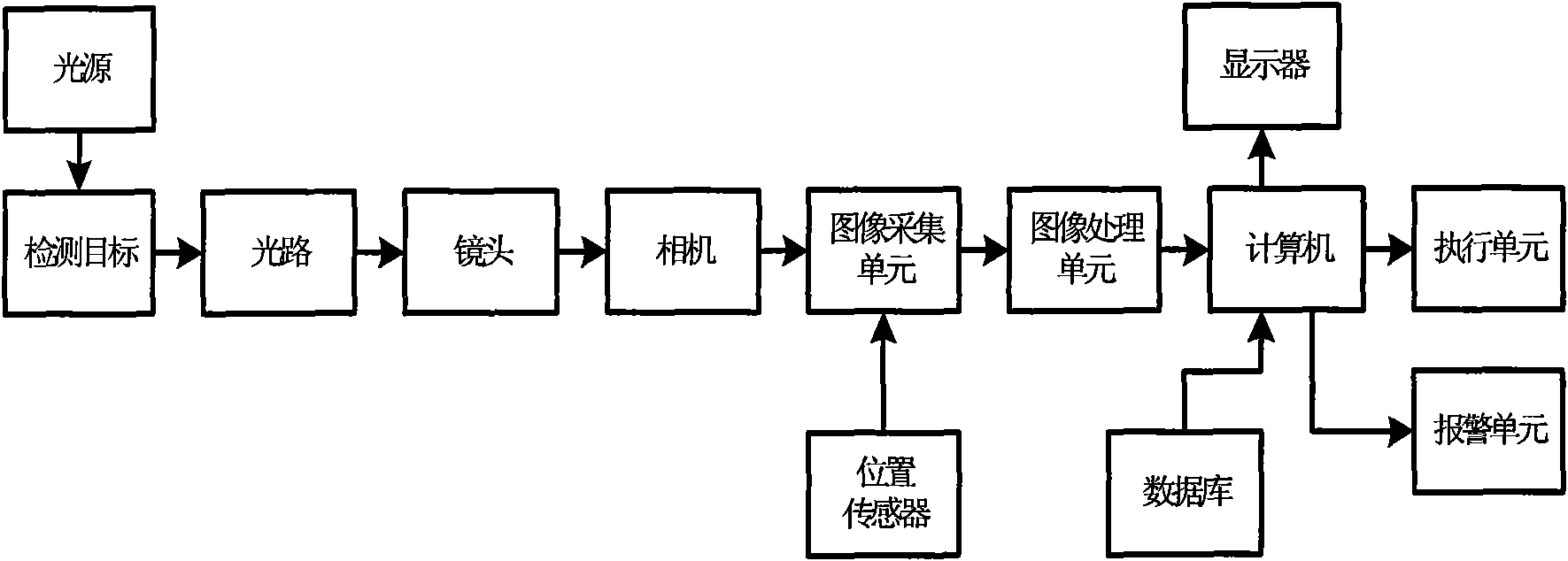

Automatic coin quality detection device

InactiveCN101561948AResolve detectionSolve labor intensityCoin testingCoin countersImaging processingVision based

The invention relates to an automatic coin quality detection device, in particular to a high-precision multifunctional automatic coin production quality detection device based on a visual system, realized by applying an image processing technology. The detection device comprises a combined illumination imaging light source, an image receiving unit, an image processing unit, a result output unit and a damaged coin discarding device, wherein the image receiving unit, the image processing unit, the result output unit and the damaged coin discarding device are sequentially connected; the combined illumination imaging light source adopts a mode that surface light sources at a high angle and a low angle illuminate at the same time; the image receiving unit collects image data on the coin surface; the image processing unit process the collected image data, confirms and discards defective products according to a production standard and transfers real-time detected images and analysis result information to the result output unit; and the damaged coin discarding device discards the ultra-detective products according to the control information of the image processing unit. The invention has the objective detection standard, can quantitatively prescribe, improves the production efficiency, can continuously upgrade the detection speed, emancipates the labor force and improves the automation degree of coinage.

Owner:CHINA BANKNOTE PRINTING & MINTING

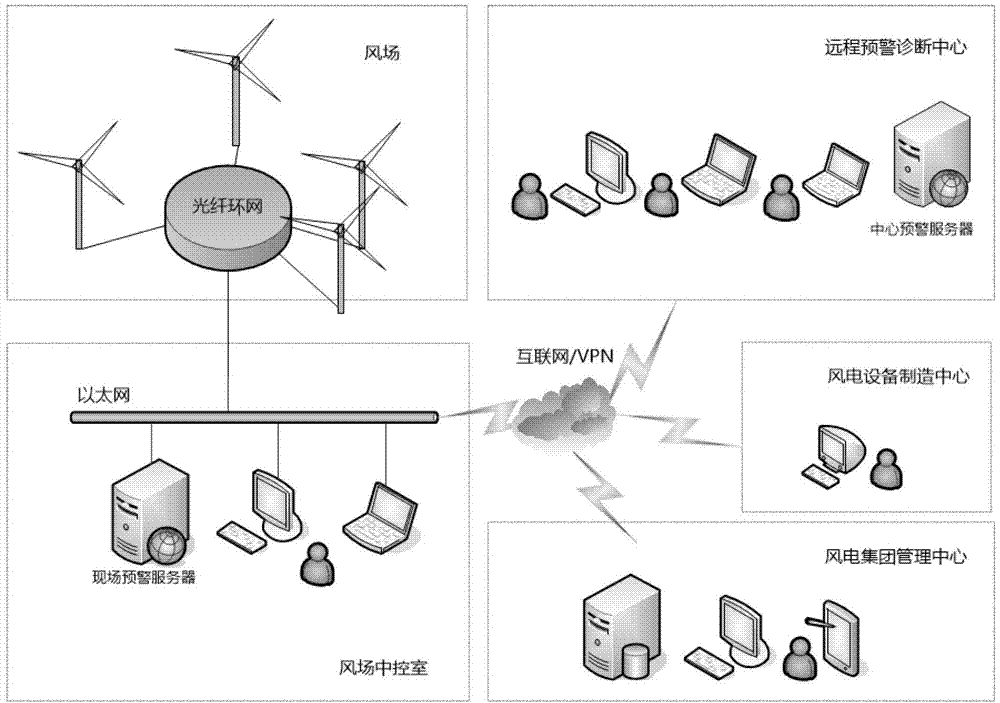

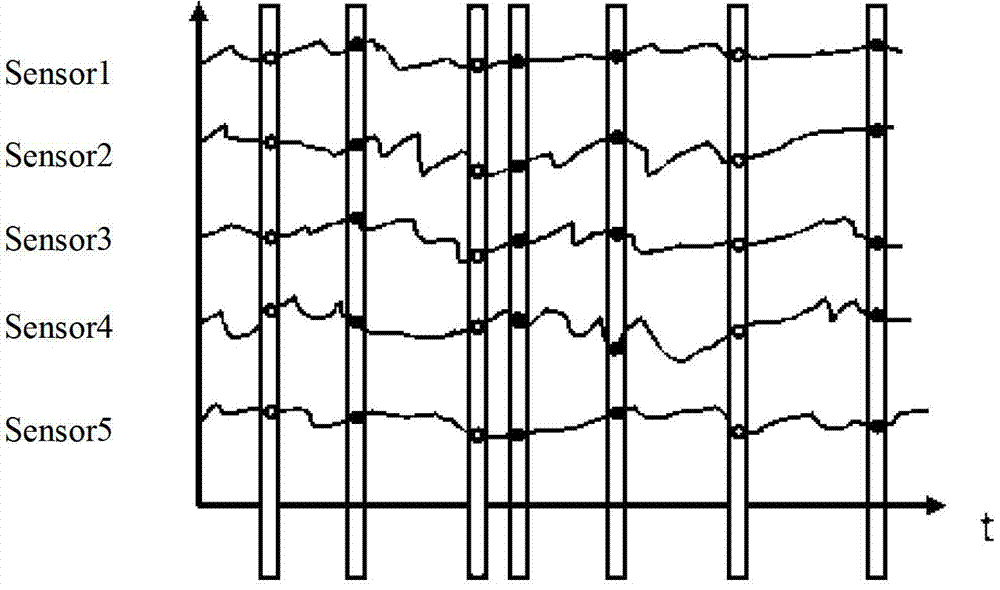

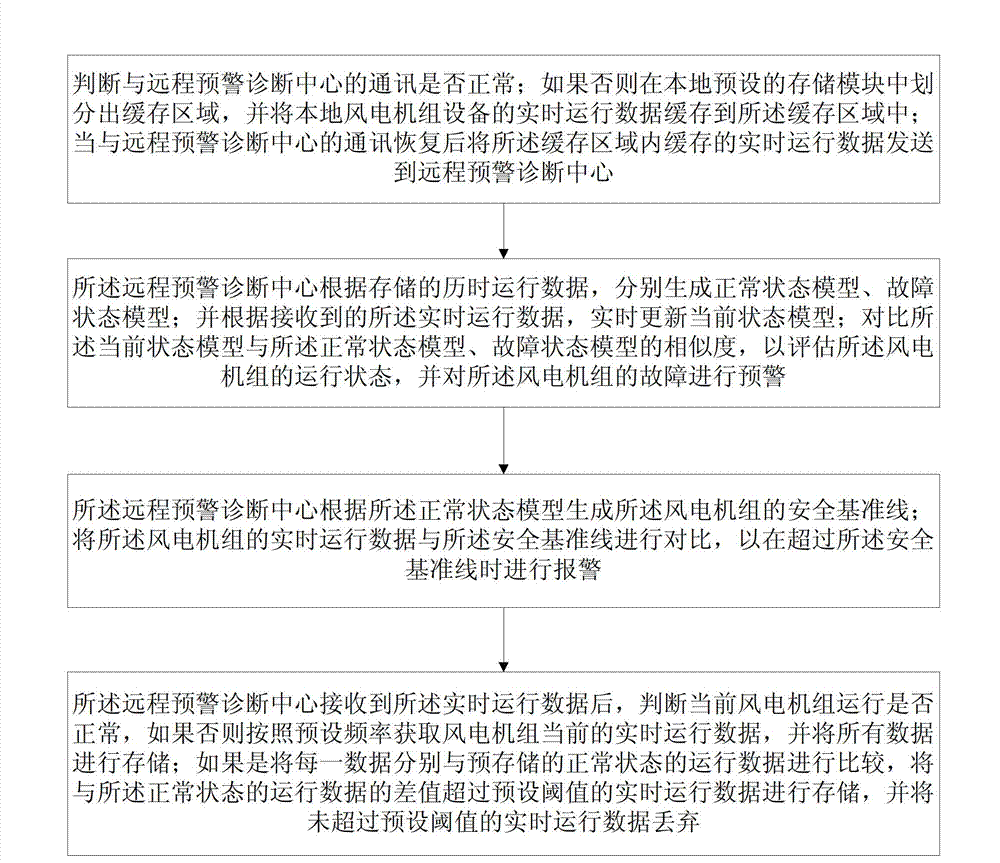

Analytical and diagnostic method for running states of wind turbines

InactiveCN103245912AEasy to operateEffective maintenanceDynamo-electric machine testingElectricityAnalysis tools

The invention provides an analytical and diagnostic method for running states of wind turbines. The method comprises the steps of data transmission, model-based state evaluation, state monitoring and data storage. The method and system of the embodiment of the invention adopt a model of an internet-based distant early warning diagnostic center, which can not only carry out analysis and diagnosis to data of large-scale wind turbine equipment in a centralized manner, but also fully utilize limited human resources of experts and various professional analytical tools to carry out deep analysis to typical and common faults in the running processes of wind turbines. Through the realization of the architecture of the system, a real-time and effective communication network can be built among wind turbine manufacturers and operators as well as experts on wind turbine failure diagnosis, the production quality of the wind turbine manufactures can be improved, and an effective technical support platform is provided for the wind turbine operators to operate and maintain the wind turbines more efficiently.

Owner:中国水利电力物资集团有限公司

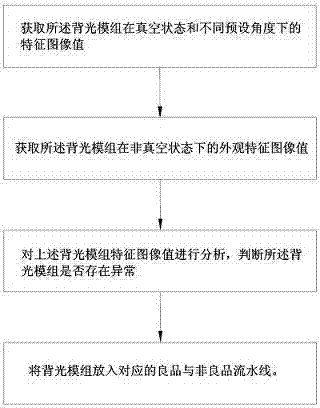

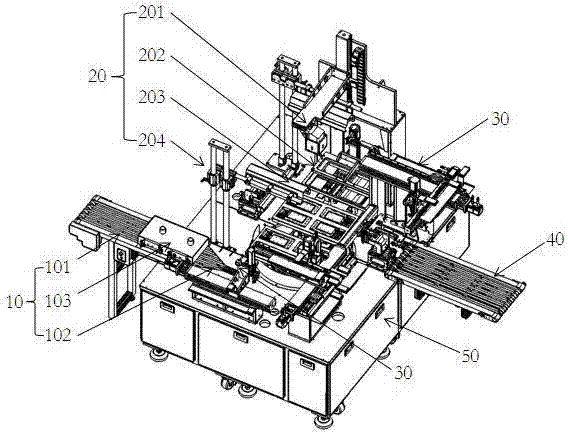

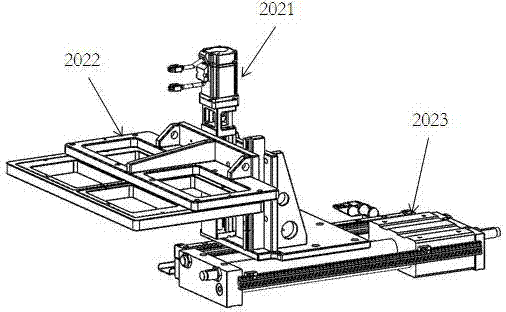

Backlight module detection equipment and detection method

ActiveCN106895961ARealize detection automationImprove detection efficiencyMaterial analysis by optical meansTesting optical propertiesProduction lineControl system

The invention discloses backlight module detection equipment and a backlight module detection method. The detection equipment comprises feeding production lines, a detection station, a manipulator and qualified and non-qualified production lines, wherein the feeding production lines used for providing to-be-detected backlight modules to the detection station, the detection station is arranged at one side of a material supply track and comprises a CCD detection device, a light source, a vacuum assembly and a detection work station, the vacuum assembly and the detection work station are fixed on the detection station, during operation, through arranging the CCD detection device, the vacuum module and a turning rotation disc, internal and external portions of the backlight modules are sequentially detected, after analysis on characteristic image values of the backlight modules is carried out through the CCD detection device, whether abnormality exists is determined, and the backlight modules can be disposed by a background control system through the manipulator to the corresponding qualified and non-qualified production lines. The detection equipment is advantaged in that internal and external detection on the backlight modules can be realized automatically, so whether the backlight modules are abnormal can be determined, detection efficiency is improved, a problem of easily-generated errors because of manual detection can be avoided, manpower cost is reduced, and production quality is improved.

Owner:SHENZHEN TECHASER TECH

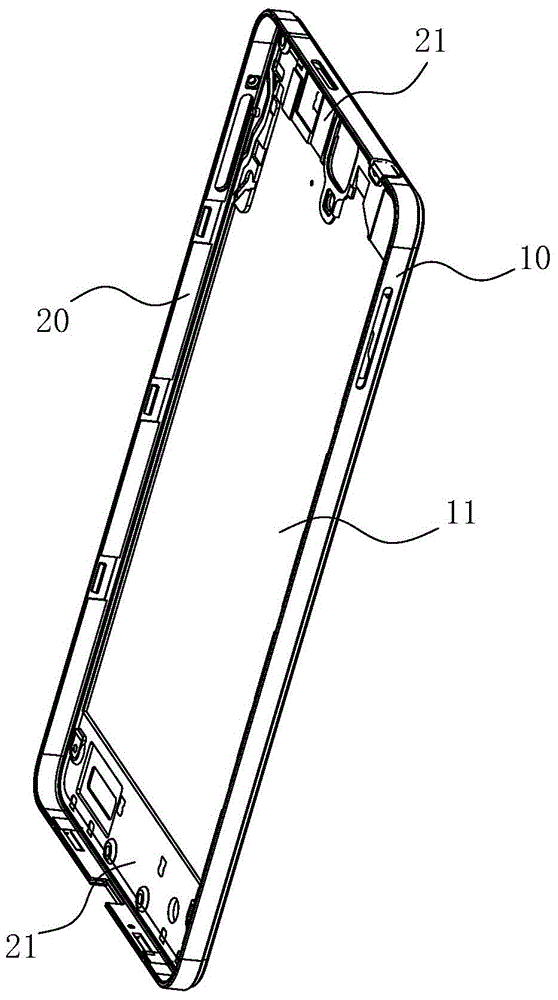

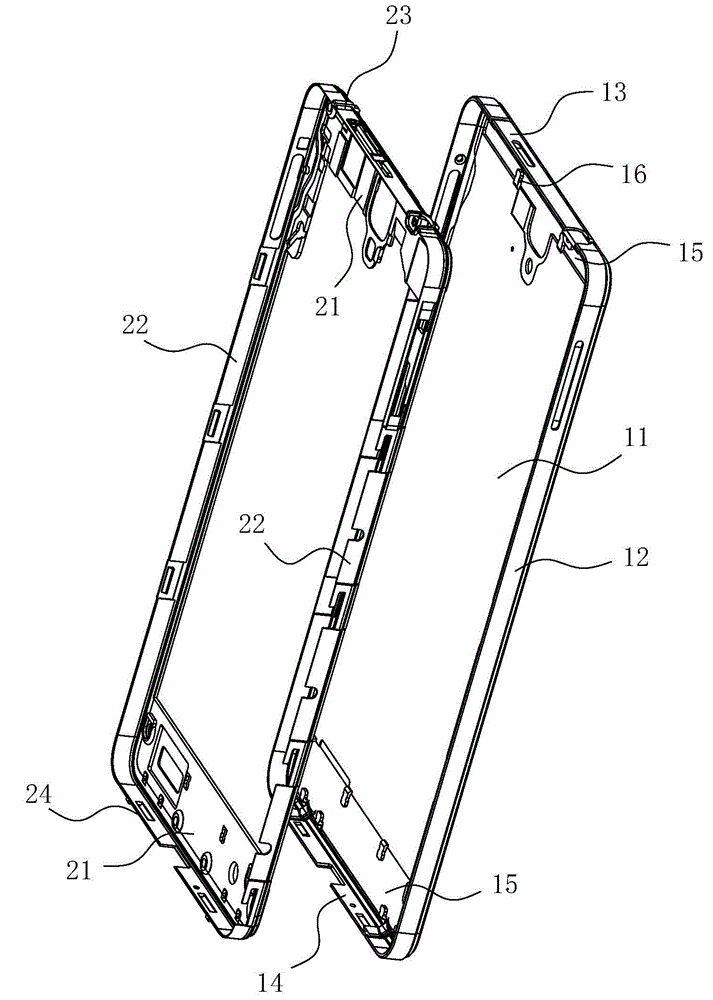

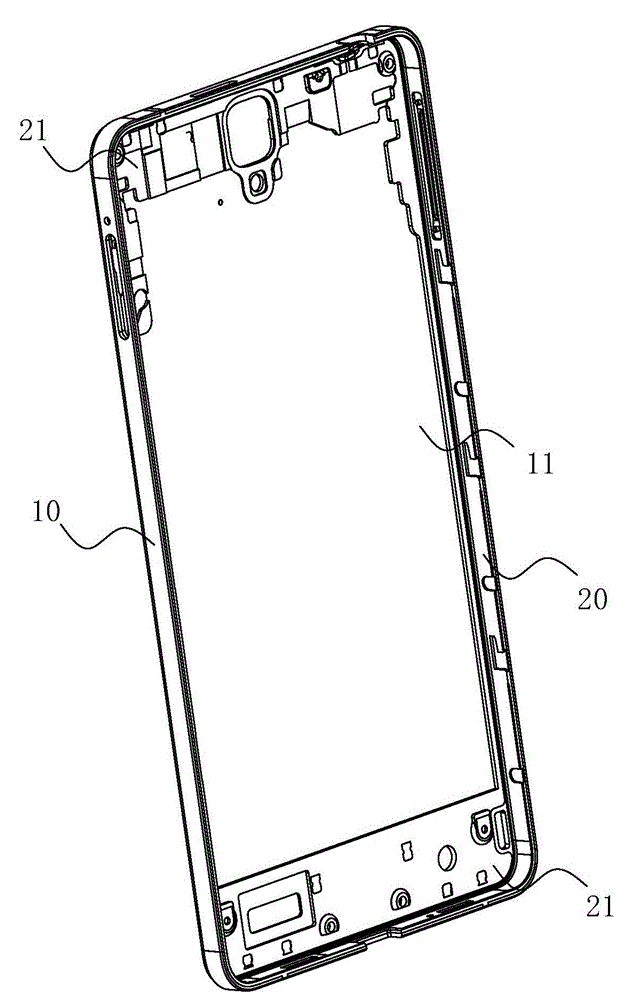

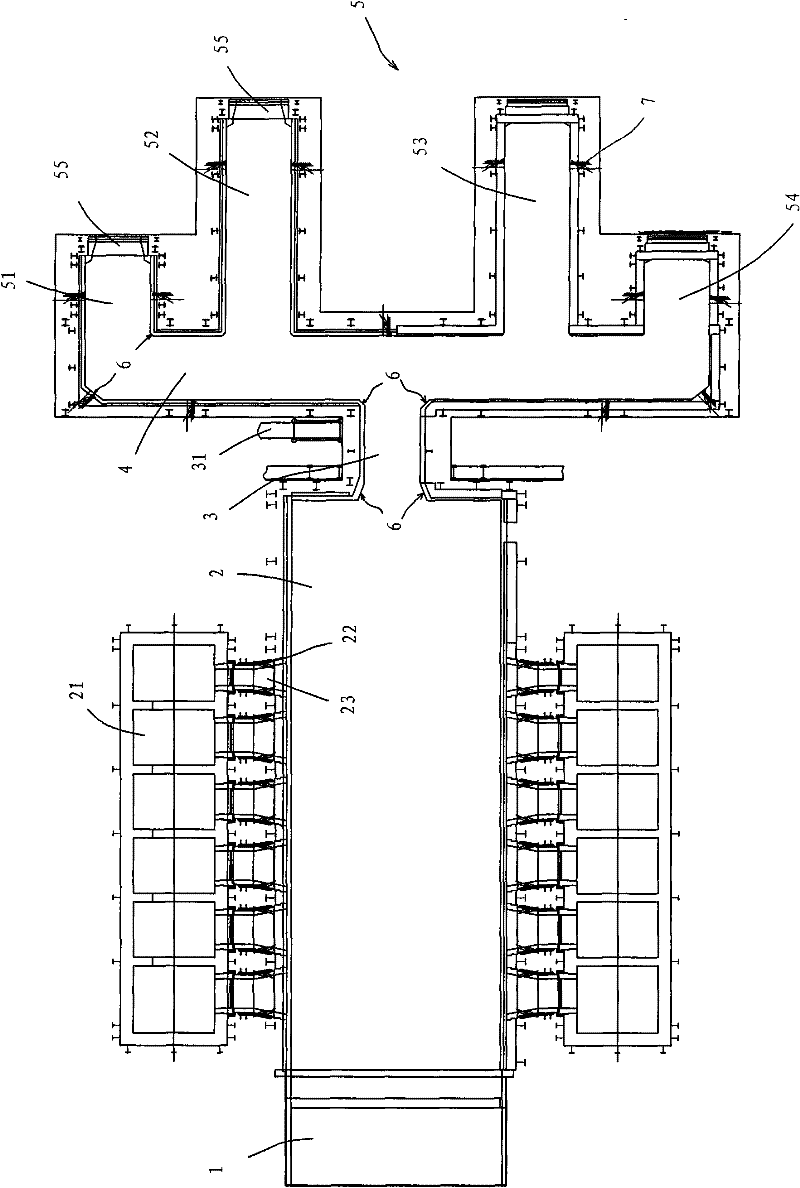

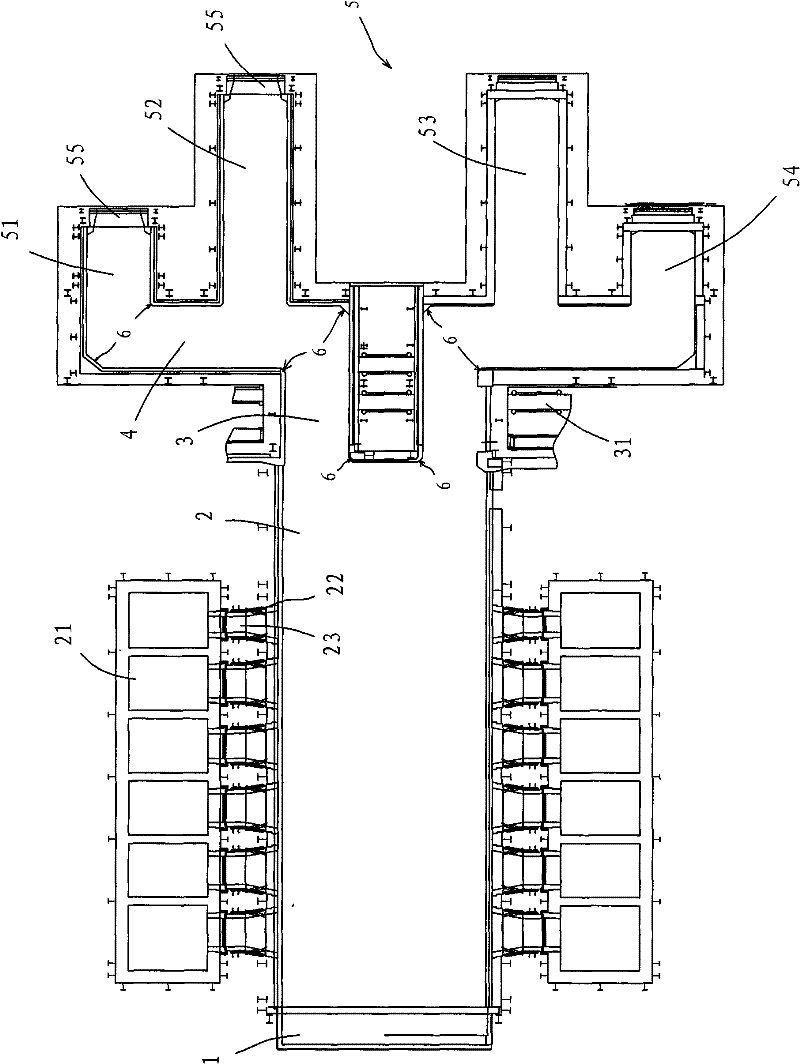

Mobile phone battery case and forming process thereof

InactiveCN104539753ARetain toughnessReduce processing timeTelephone set constructionsElectrical batteryMobile phone

The invention discloses a mobile phone battery case. The mobile phone battery case comprises a metal case and plastic parts fixedly connected to the metal case, wherein the metal case comprises a metal frame and a metal cover board, the metal cover board and the metal frame form an integrated structure, and a partial hollow structure is formed at a position where the metal cover board is connected with the metal frame; the plastic parts consist of a plastic frame and a plastic filling part, the plastic frame and the plastic filling part form an integrated structure, the plastic frame is in tight contact with the metal frame at the inner side of the metal frame, and the hollow structure is filled with the plastic filling part. The invention also discloses a forming process of the mobile phone battery case. By adopting the mobile phone battery case, the appearance expression of the mobile phone product is guaranteed, the structure of the metal case is simplified, the thickness of the metal case is reduced, the processing difficulty and the product cost are reduced, and the product productivity is improved; by adopting the process, the production efficiency is improved while the production quality of the product is guaranteed.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Manufacturing process for step circuit of PCB (Printed Circuit Board)

InactiveCN102651946AReduce copper thickness dropEliminate poor quality defectsConductive material chemical/electrolytical removalProduction scheduleEngineering

The invention discloses a manufacturing process for a step circuit of a PCB (Printed Circuit Board). According to the manufacturing process, different film patterns are adopted twice for manufacturing the circuit, during the primary film pattern circuit manufacture, a positive film circuit pattern is adopted, compensation is carried out a film substrate circuit at different positions according to copper thickness so as to manufacture a special circuit, and sunk copper plate electrification is carried out on the special circuit, so that the copper thickness meets the requirement; then board grinding is carried out by a twice board grinding mode so as to reduce the copper thickness difference of step positions; a dry film is enabled to be fully combined with the step positions by virtue of a film attaching and air compressing mode; and finally, normal circuit pattern manufacturing is carried out by utilizing a high-precision LDI (Laser Direct Imaging) exposure machine. Compared with the prior art, the manufacturing process for the step circuit can be used for eliminating the defects of open circuit at the position of the step circuit, notches, large deckle edges, serious lateral erosion, halfway etching and poor quality of thin lines and the like existing in the step circuit manufacturing process, improving the production efficiency and the production quality, quickening the production schedule and lowering the production cost.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Ultrawhite calendering glass kiln

The invention provides an ultrawhite calendering glass kiln. The kiln is characterized in that: the kiln comprises a melting furnace, a main channel, a lateral channel, and a plurality of branch channels, which are sequentially communicated; and the main channel is a cylinder channel which has a round / quadrate / rectangular / trumpet-like shape, and each corner of each channel is provided with a transition surface. According to the invention, passage sections of the main channel are improved, and simultaneously the corners of all channels are provided with the transition surfaces, so a function of one kiln corresponds to multiple lines is realized, rapid changes of the velocity and the flow of a glass melt caused by a sudden change of a channel area while the glass melt enters another channel when going through the main channel are retarded or reduced, and long-time eddy and scour of the glass melt on the corner can be avoided, thereby a lateral temperature difference generated in a process that the glass melt flows from the outlet of the melting furnace to overflow ports of the branch channels can be reduced or avoided, and the production quality and the quality stability are improved.

Owner:XINYI PHOTOVOLTAIC IND (ANHUI) HLDG CO LTD

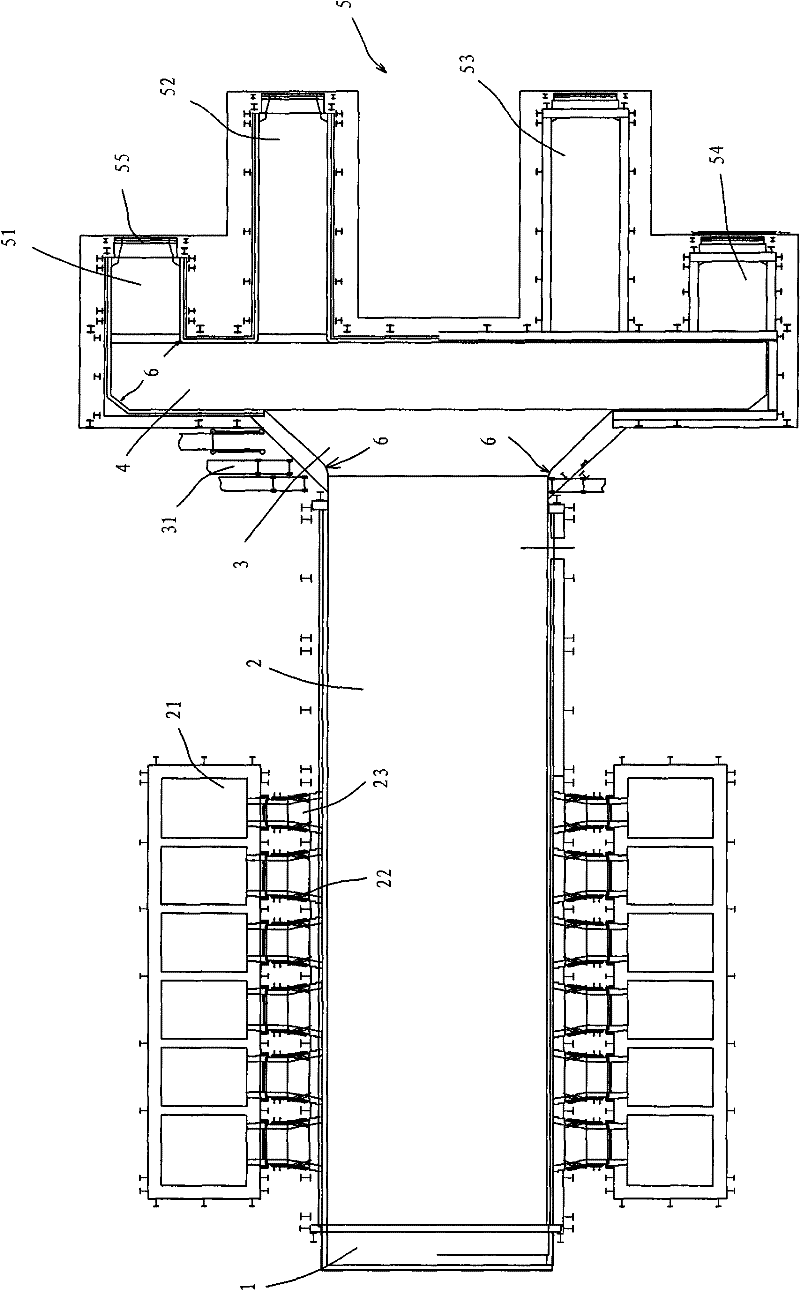

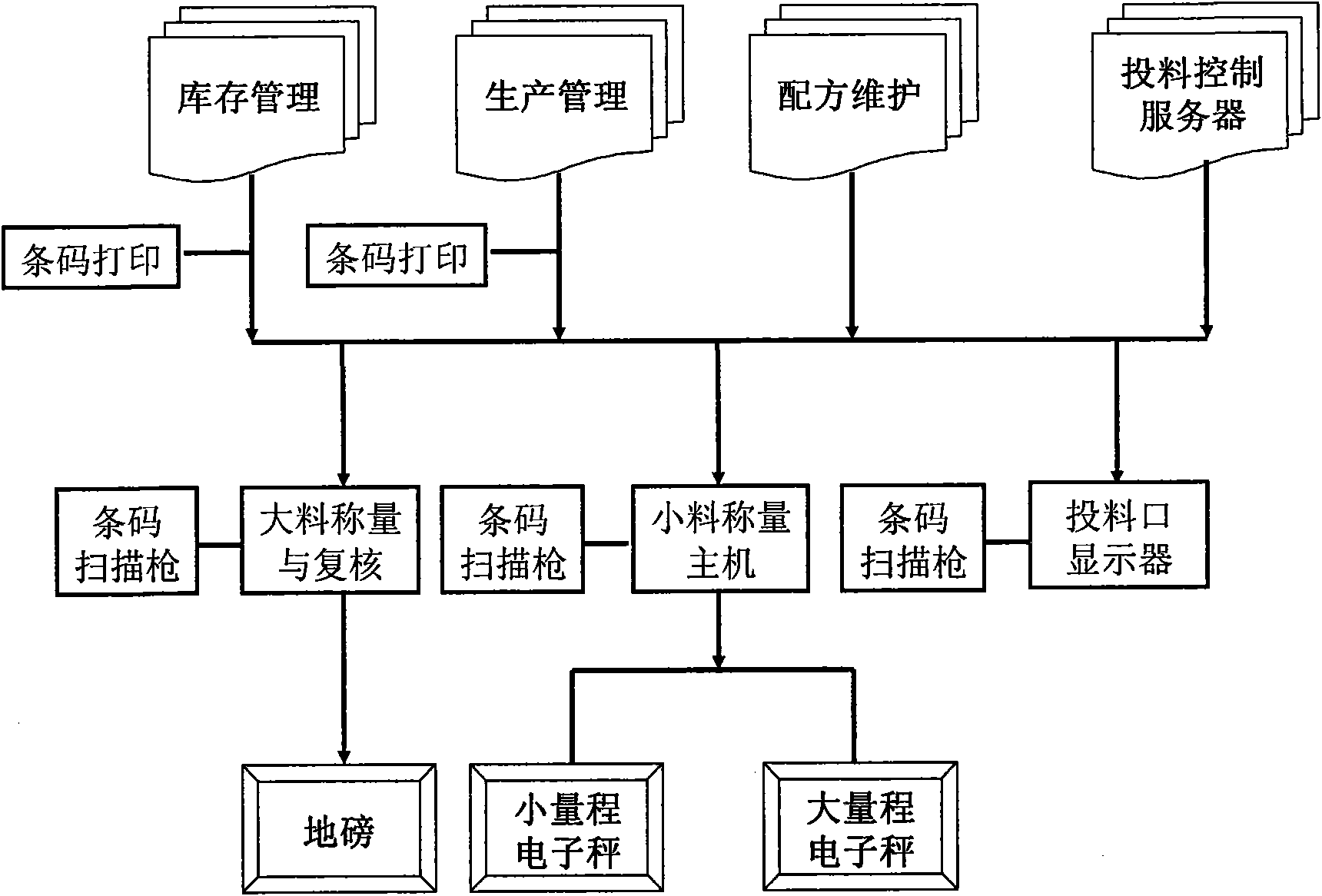

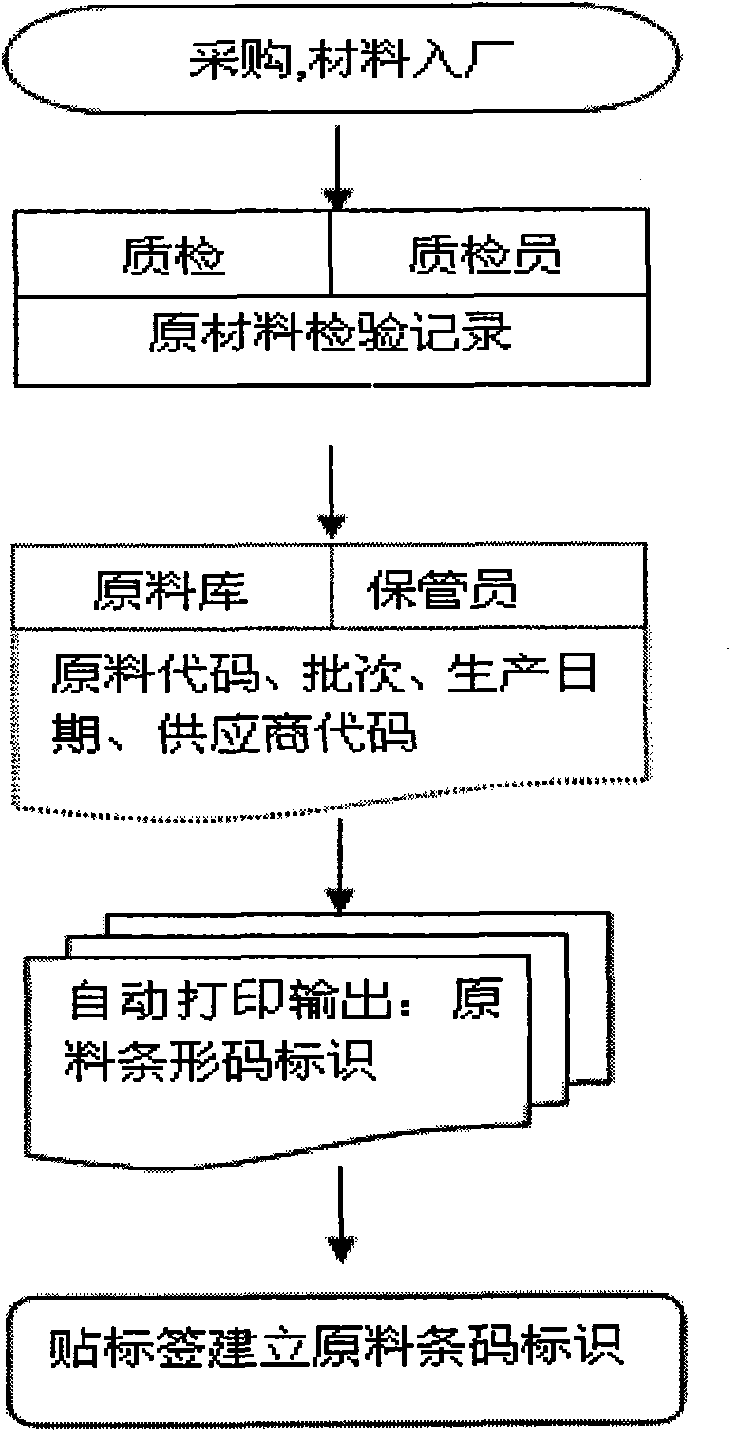

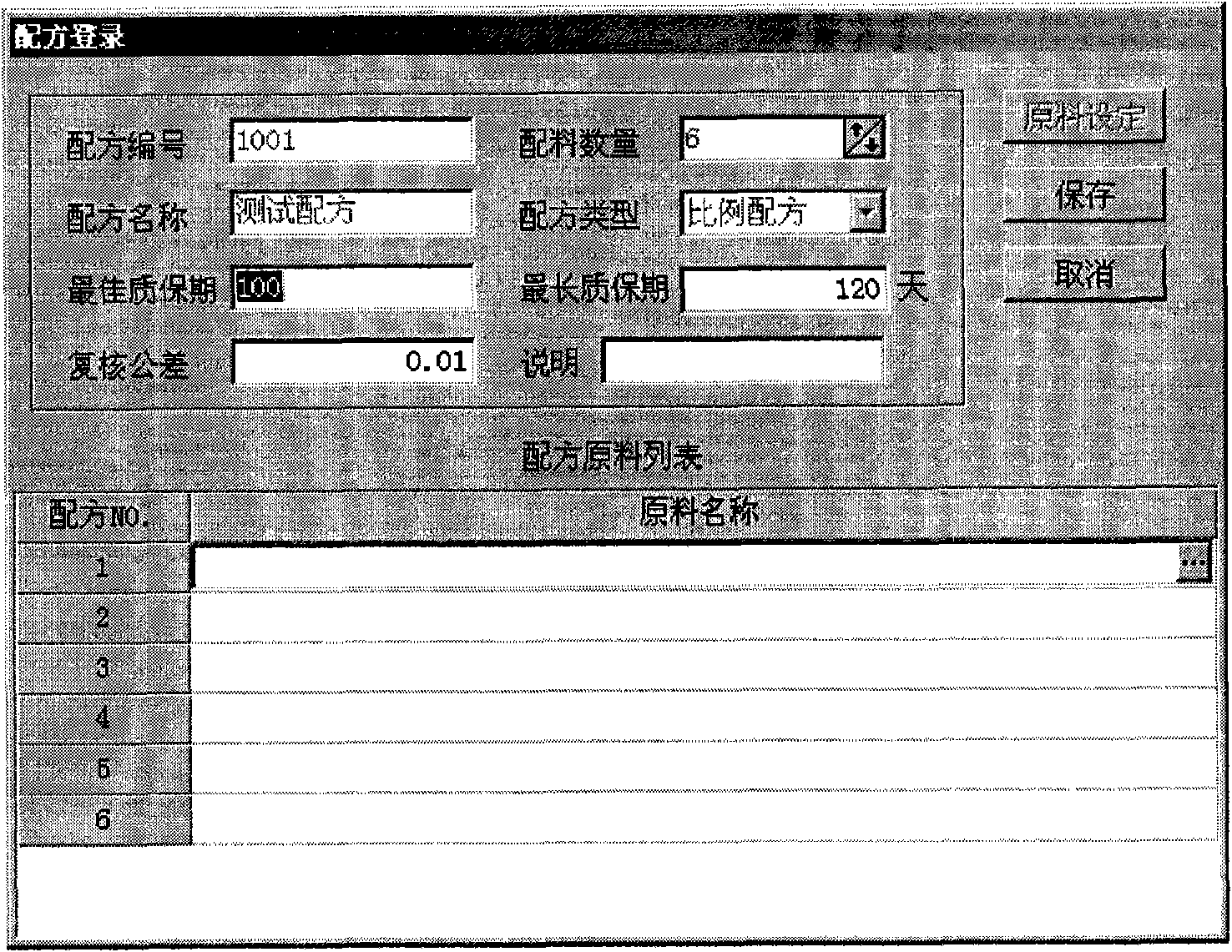

Feed production quality tracking system

InactiveCN101593323AFully transparent management capabilitiesGuaranteed visual controlResourcesAdditive ingredientAccess management

The invention provides a feed production quality tracking system, which comprises a bar code printer, a bar code scanner and a computer software system, wherein the computer software system realizes the following functions for tracking feed production quality together with a bar code technique: (1) raw material labeling and warehouse access management; (2) formula code management and maintenance limitation; (3) production control and production information recording; (4) minor ingredient mixing control; (5) batch feeding control; and (6) finished product batch number control. The system can track back to all production steps and raw materials from the batch number of finished feed to find out problems and provide bases for quality improvement.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com