Ultrawhite calendering glass kiln

A glass furnace and calendering technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as changes, achieve the effects of improving stability, high production capacity, and avoiding lateral temperature differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

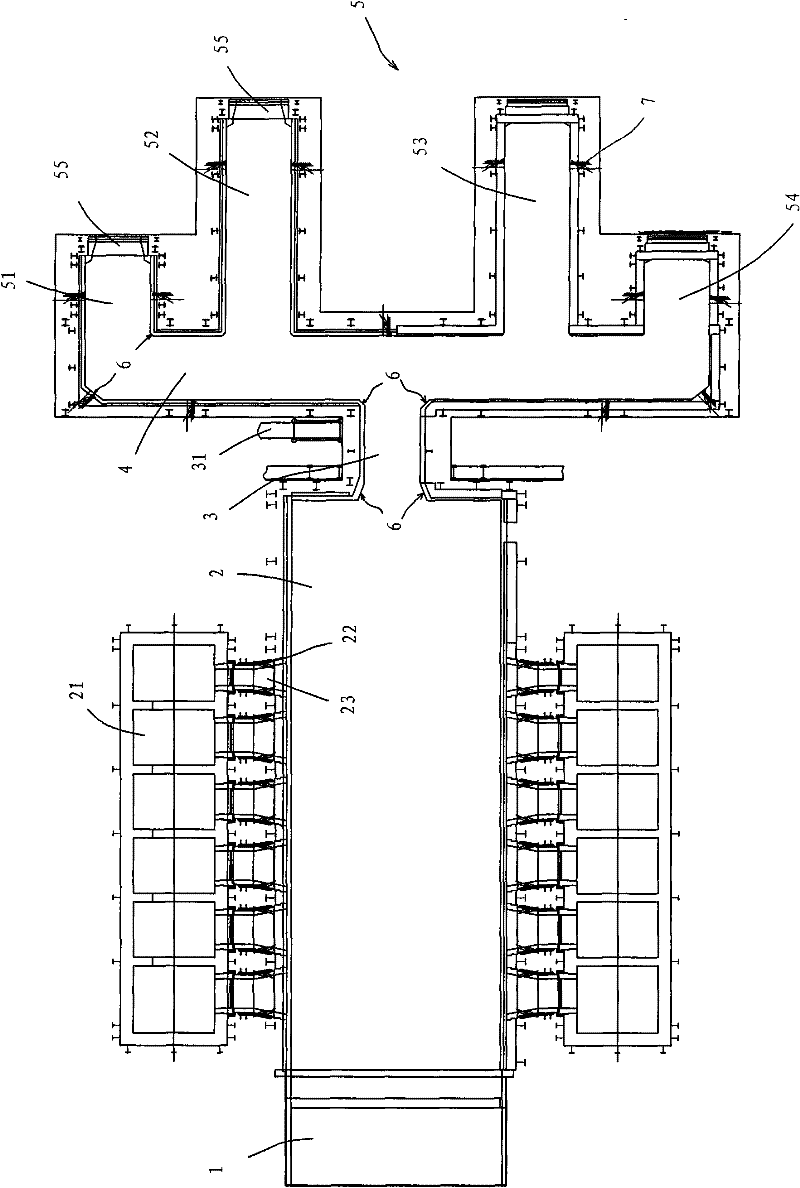

[0030] see figure 1 , the first embodiment of the present invention includes a melting furnace 2, a main flow channel 3, a cross flow channel 4 and four branch flow channels 51, 52, 53, 54 connected in sequence, that is, the molten glass enters the cross flow channel 4 through the main flow channel 3 and is then divided into four There are two branch flow channels, and the molten glass flows through two 90° corners during the flow process and then enters each branch flow channel. Of course, the direction of the branch channel 5 can be as follows figure 1 All shown are in the longitudinal direction, and the first and last branch flow channels can also be optionally extended in the horizontal direction, and overflow ports 55 are provided at the outlet ends of each branch flow channel 5 .

[0031] The main channel 3 in the first embodiment is a cylindrical, square or rectangular channel, and the main channel 3 or each branch channel 5 is provided with a transition surface 6 at a...

Embodiment 2

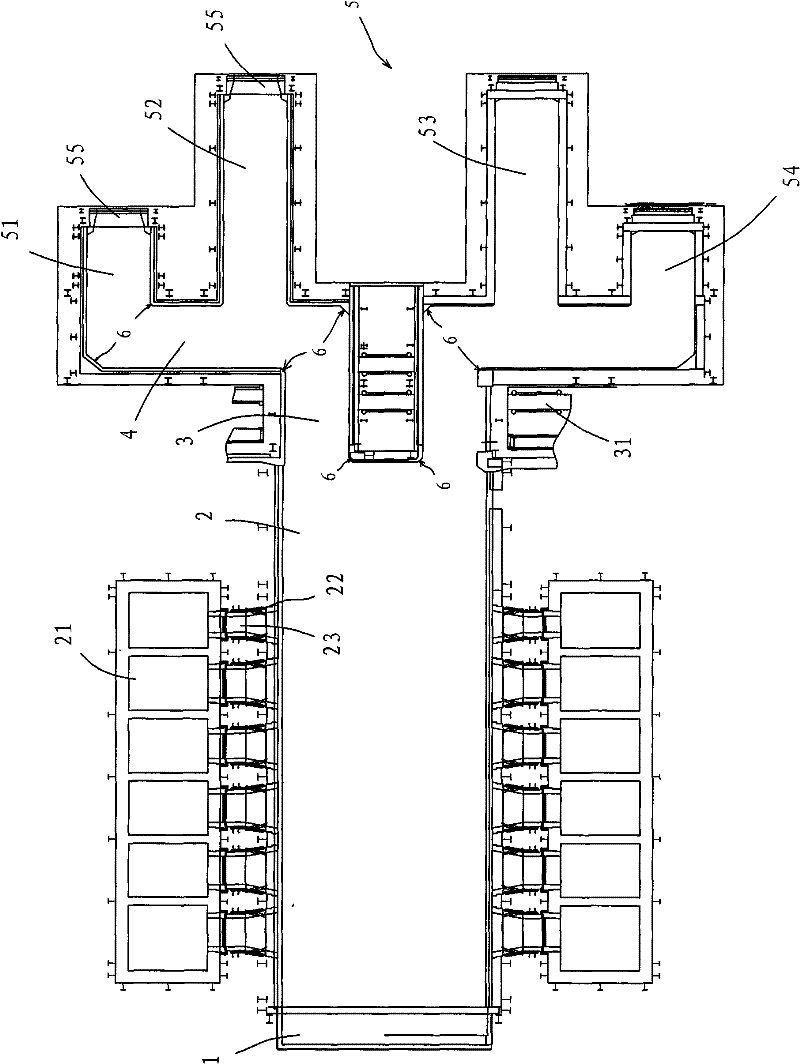

[0040] see figure 2 , the basic structure of the second embodiment is the same as that of the first embodiment, the difference is that the main flow channel 3 is divided into two channels (or more than two channels), which are symmetrically arranged at the outlet end of the melting furnace 1 and connected with the entrance of the cross flow channel 4 The ends are connected, and the cross flow channel 4 also adopts two separated flow channels. This is because, in the design of the ultra-clear glass production line, the flow path through which the molten glass flows should be as short as possible under the premise of meeting the calendering operation, that is to say, under the premise of meeting the various operations of the calender, the glass The stroke of the liquid to reach the forming position should be as short as possible. In the second embodiment, since the main channel 3 is divided into two channels, on the one hand, the intersection of the molten glass at the outlet ...

Embodiment 3

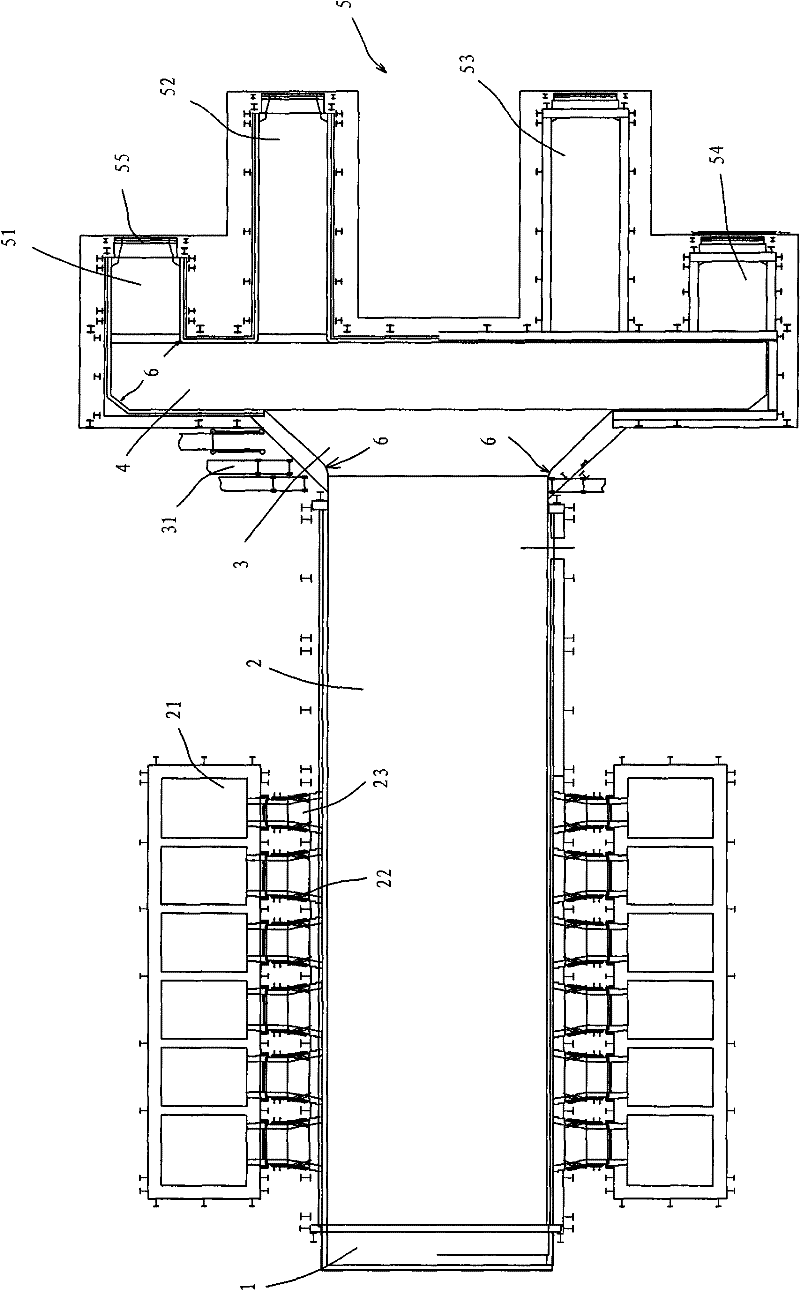

[0043] see Figure 3A-Figure 3C The basic structure of the second embodiment is also the same as that of the first embodiment, except that the main flow channel 3 is a reverse trumpet-shaped structure in which the cross-section of the outlet end of the melting furnace 2 is larger than that of the cross-flow channel 4 inlet end. In this way, the molten glass at the outlet end of the melting furnace 2 can have a gentle transition when flowing to the transverse channel 4, so as to avoid the huge change of the speed and flow rate of the molten glass due to the sudden narrowing of the channel area, so as to keep the molten glass flowing During the process, the temperature changes within a small range, so as to ensure that the temperature of the molten glass entering the subsequent calendering process is within the required range.

[0044] see Figure 3A , the cross-section of the main channel 3 inlet end of structure one of the present embodiment is equal to the cross-section of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com