Patents

Literature

40666results about How to "Increase production capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

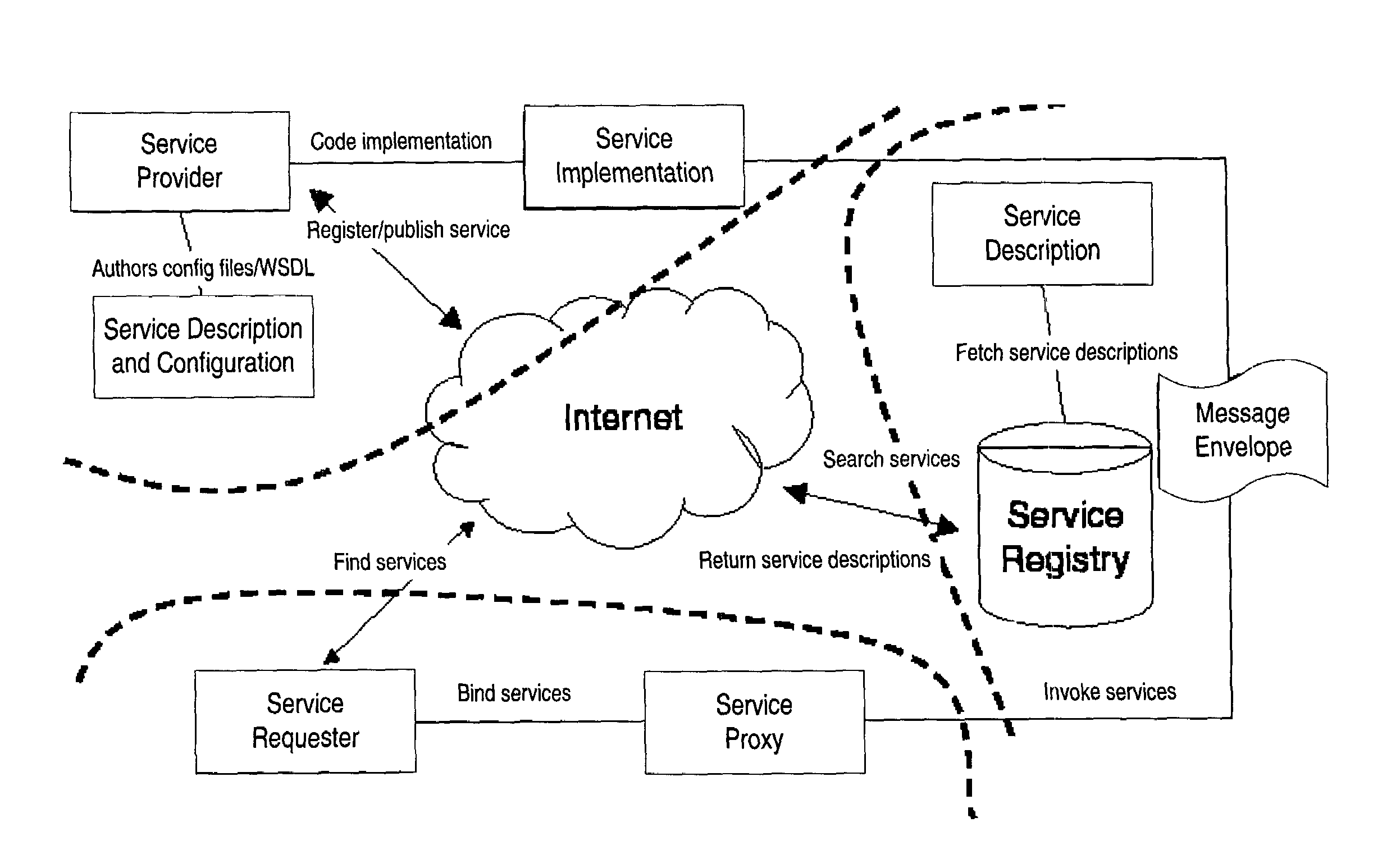

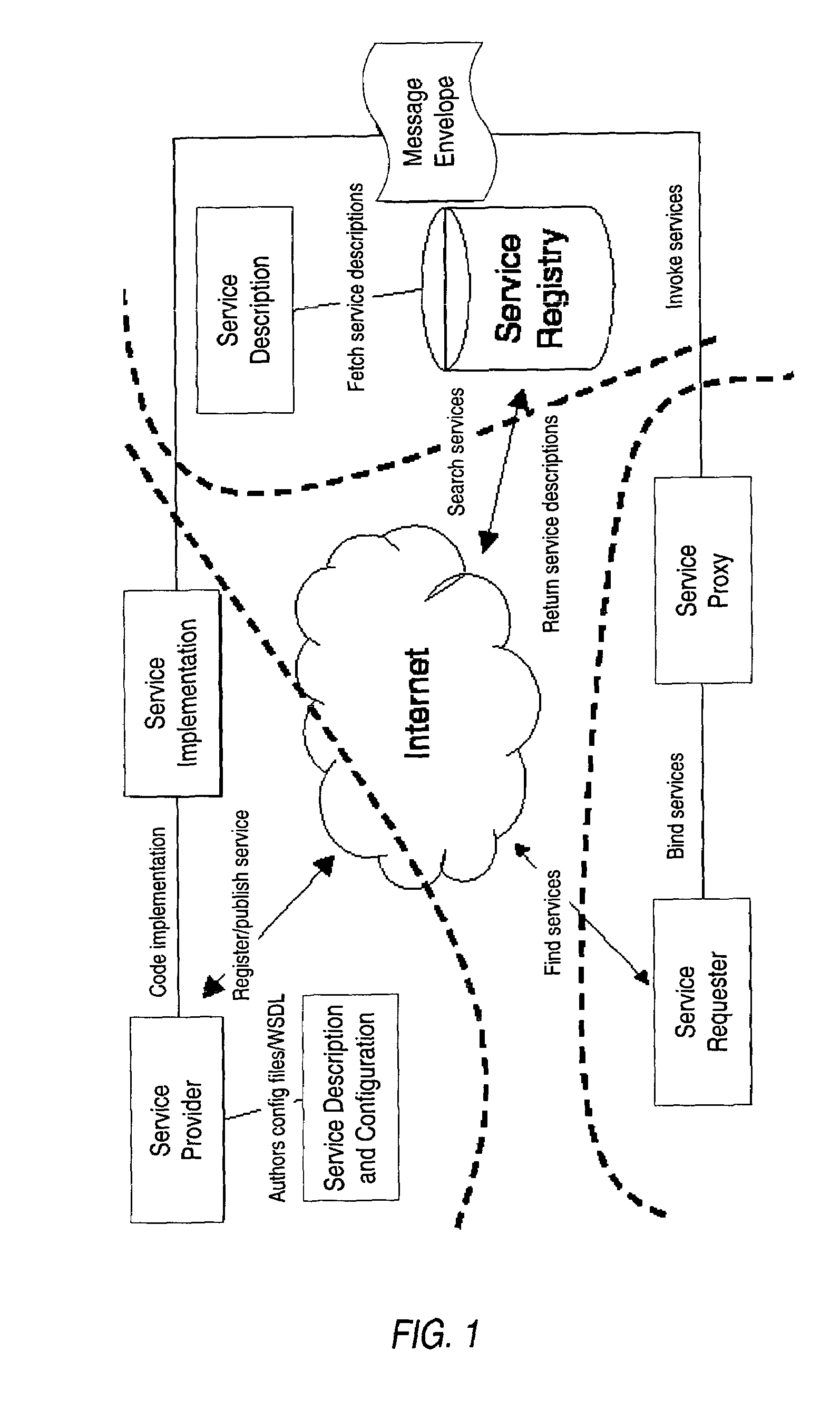

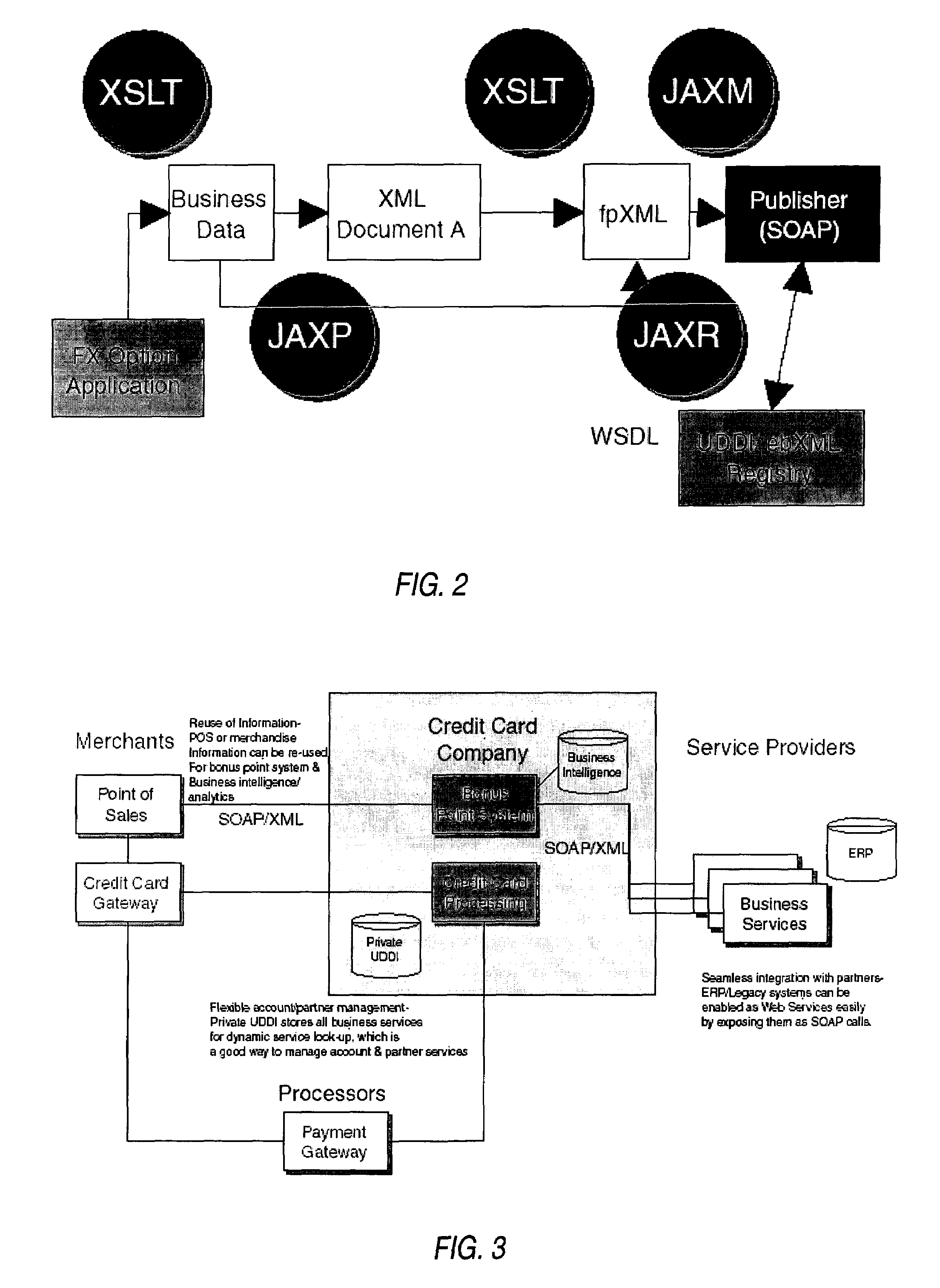

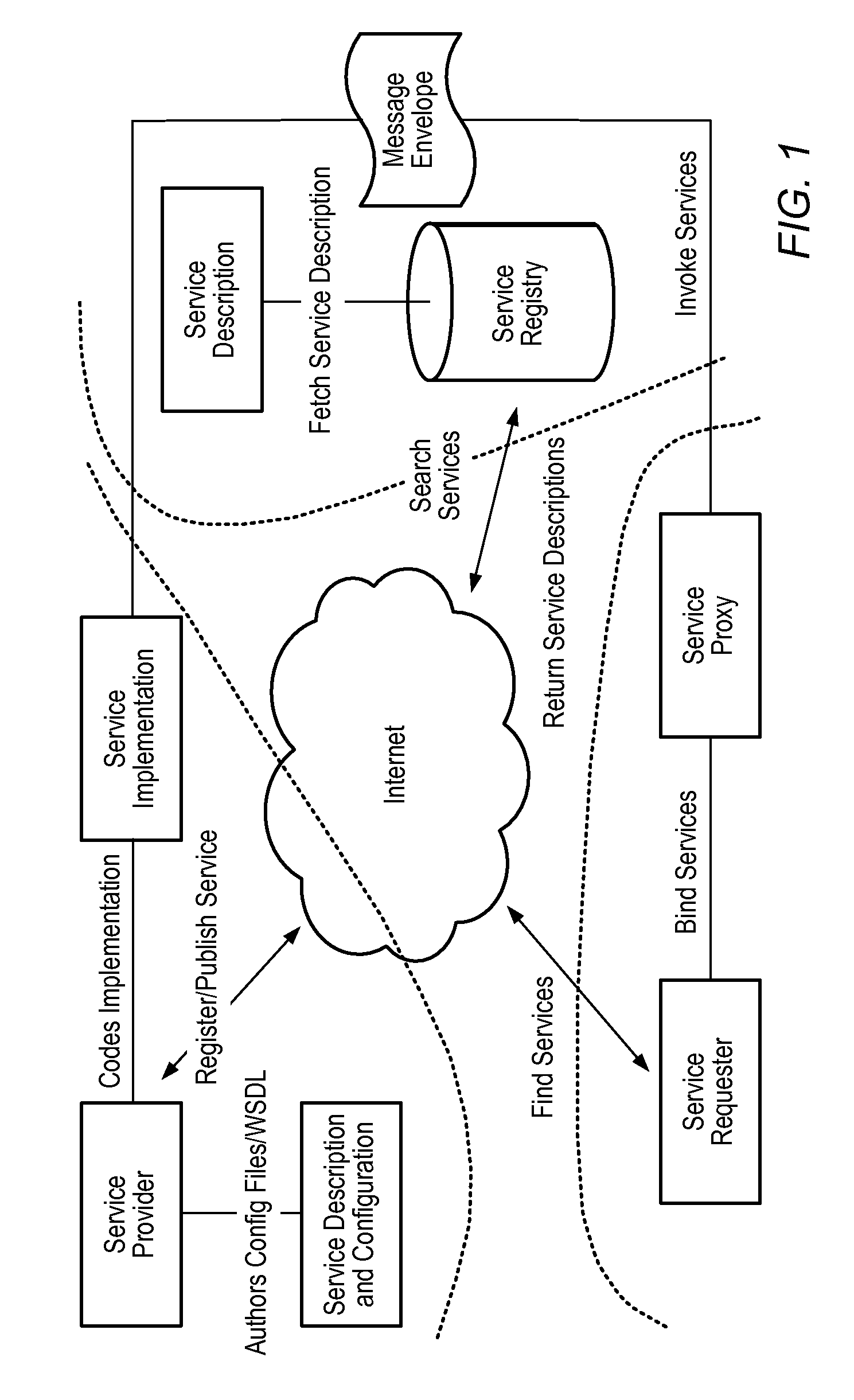

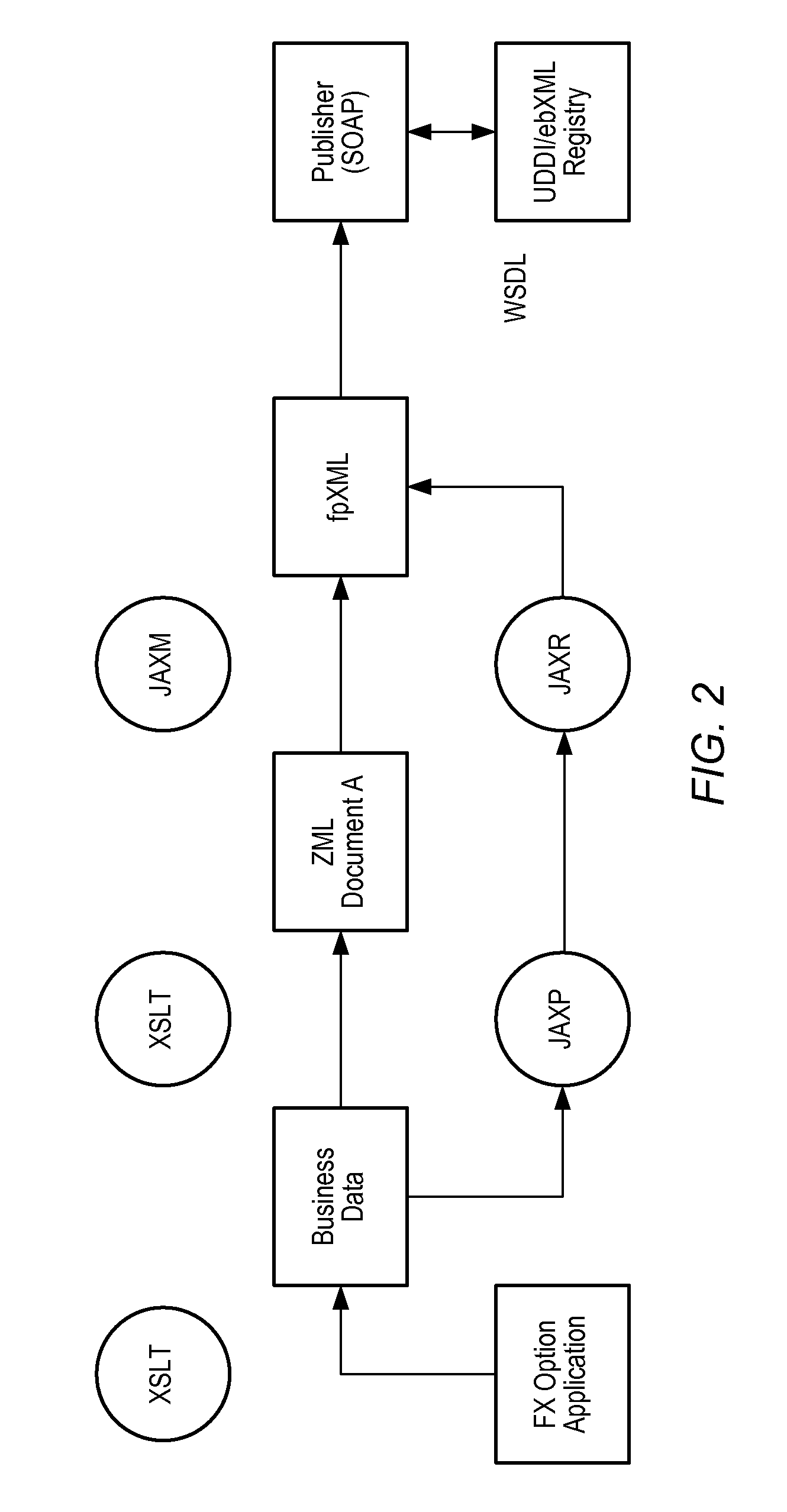

System and method for generating Web Service architectures using a Web Services structured methodology

ActiveUS7698398B1SOAP messaging reliableReduce effortMultiple digital computer combinationsOffice automationEnterprise integrationDesign pattern

System and method for generating Web Services using a Web Services Structured Methodology. One embodiment may be implemented as a Web Services architecture design mechanism. Lifecycles of the Web Services design process may include vision and strategy, architecture design, development, integration, and deployment. In one embodiment, the Web Services architecture design mechanism may implement a structured methodology design process for Web Services. One embodiment may include a reusable Web Services design pattern catalog and a mechanism for maintaining and updating the catalog and for using the catalog to apply design patterns when designing and implementing Web Services. One embodiment may be used for Enterprise And Cross-Enterprise Integration of Web Services. One embodiment may be used for Legacy Mainframe Integration and Interoperability with Web Services.

Owner:ORACLE INT CORP

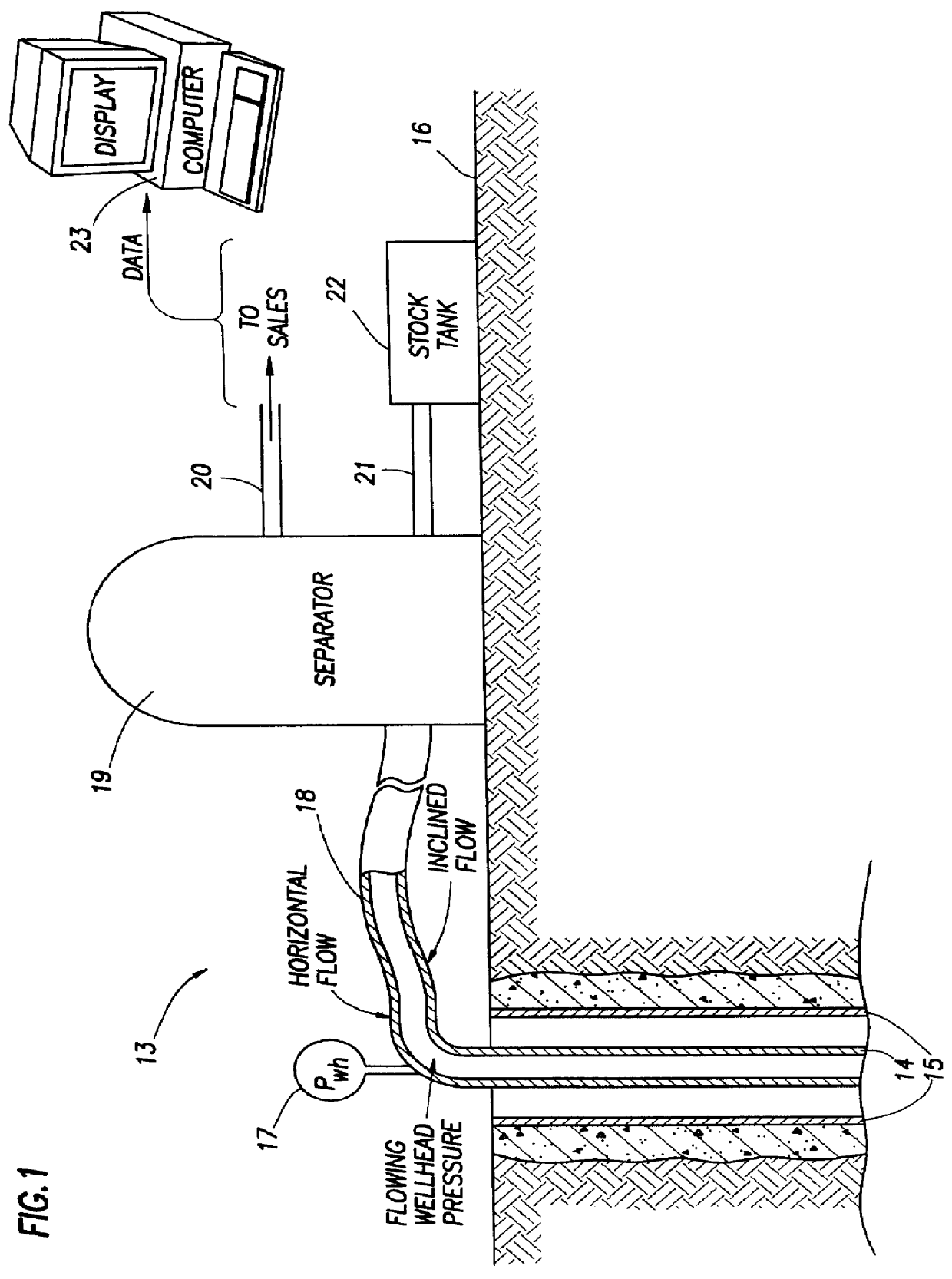

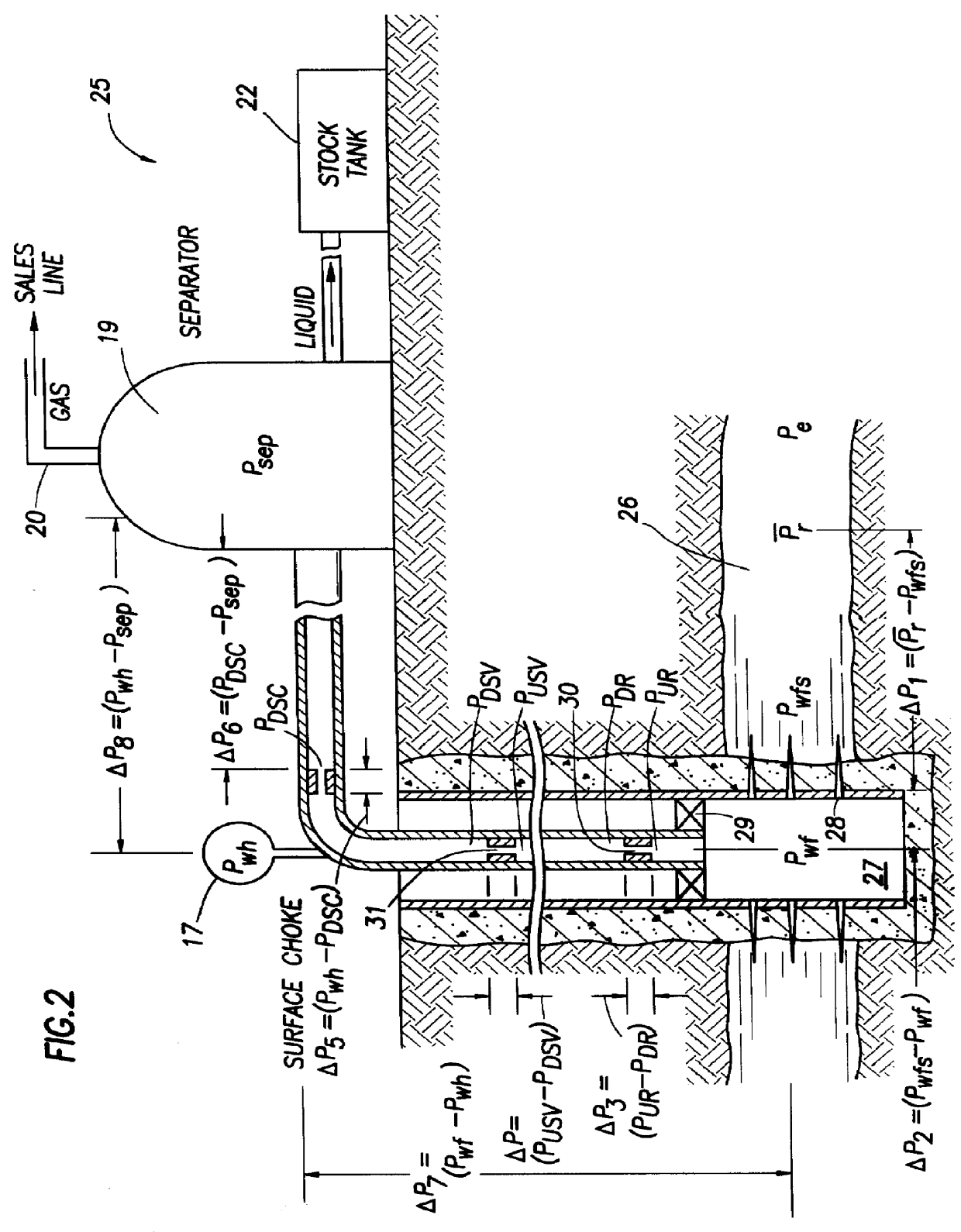

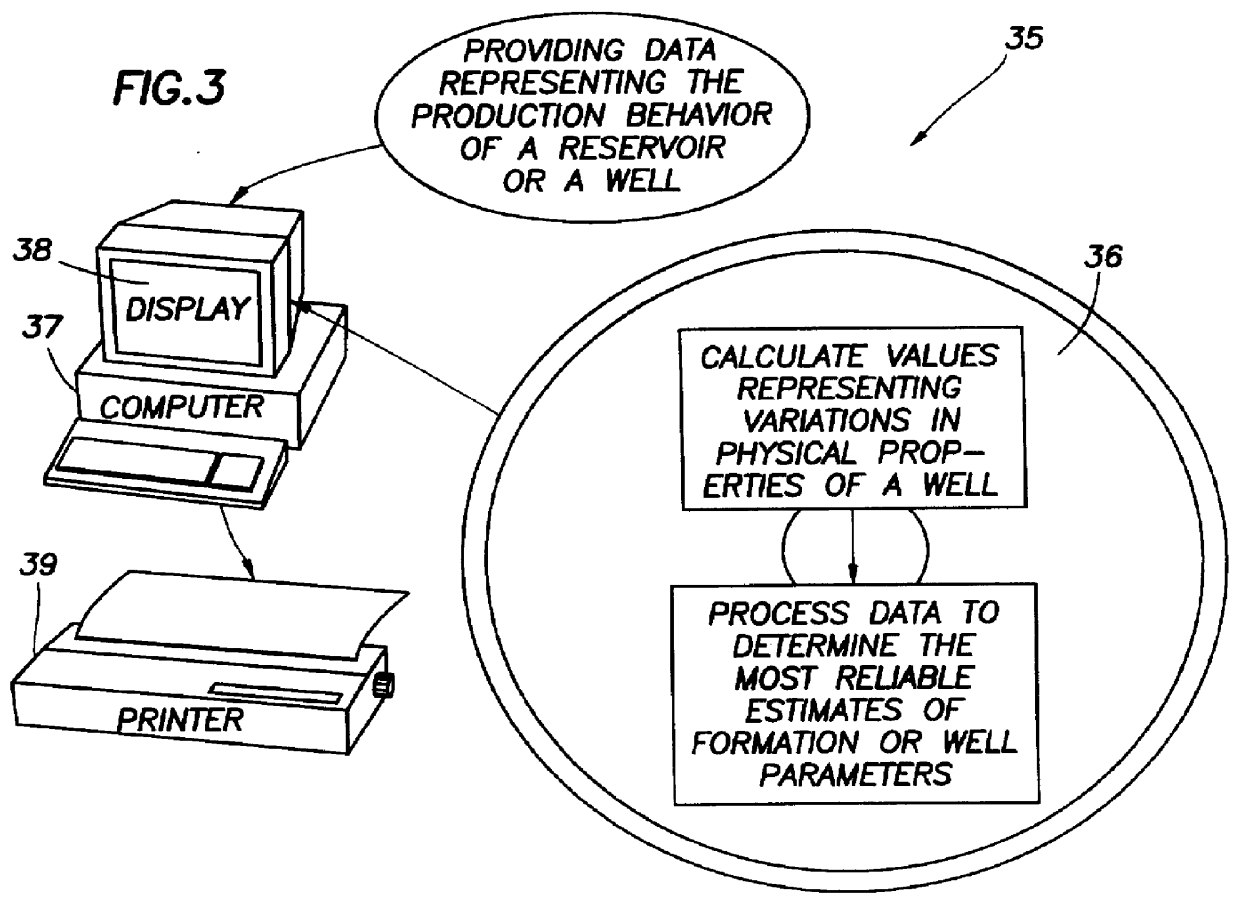

Oil and gas reservoir production analysis apparatus and method

InactiveUS6101447AIncrease production capacityGood specificationElectric/magnetic detection for well-loggingPermeability/surface area analysisComputer generationPetroleum

A petroleum reservoir production modeling apparatus and method is disclosed which incorporates a complete (from reservoir to wellhead) production systems analysis system for the evaluation of petroleum reservoir production performance, using industry accepted techniques of analysis. A computer generated model facilitates the determination of well and formation properties in a computerized methodology, efficiently, reliably and accurately, thereby facilitating subsequent changes in wellbore properties to maximize well production. The method includes a rigorous analytic reservoir inflow performance model for a variety of well types and reservoir outer boundary conditions and drainage area shapes, and uses industry accepted production analysis techniques. These techniques accepted in the industry include material balance, decline curve analysis, and non-linear minimization procedures. Field-recorded production data is evaluated to obtain estimates of the well or formation properties. Statistical techniques are used to minimize or eliminate the effects of outlier (i.e. noise) points in the data.

Owner:SCHLUMBERGER TECH CORP

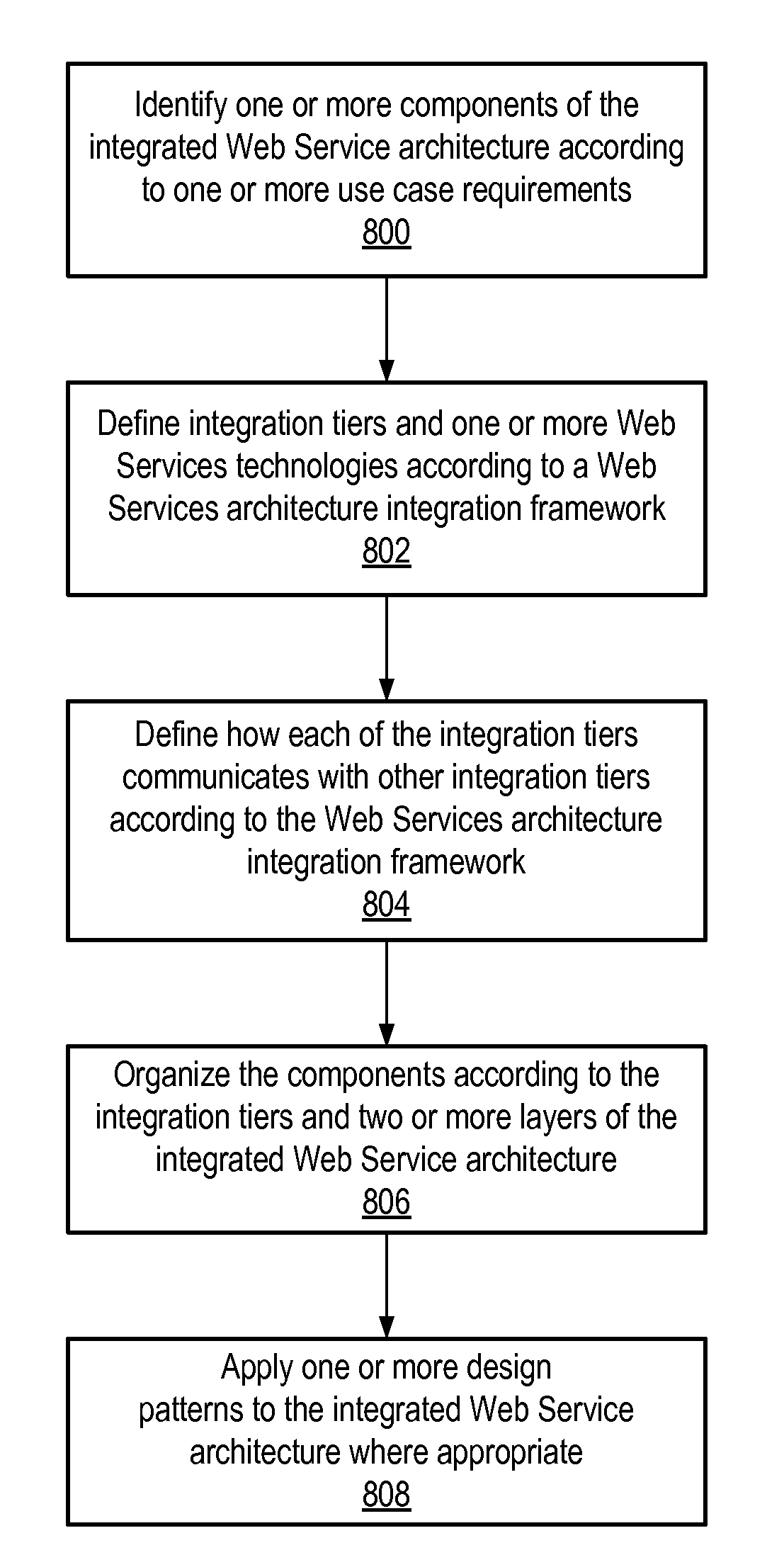

System and method for integration of web services

ActiveUS8069435B1SOAP messaging reliableReduce effortOffice automationBuying/selling/leasing transactionsLegacy systemEnterprise integration

System and method for integrating Web Services using a Web Services Structured Methodology are described. Embodiments of a Web Services Structured Methodology may be used to integrate Web Services in Enterprise and Cross-Enterprise business systems, and to integrate legacy systems (e.g. legacy mainframe systems) with Web Services in Enterprise and Cross-Enterprise business systems. Embodiments may provide an integrated Web Services architecture design mechanism that may be used for Enterprise and Cross-Enterprise integration of Web Services. Embodiments may be used for Legacy Mainframe Integration and Interoperability with Web Services.

Owner:ORACLE INT CORP

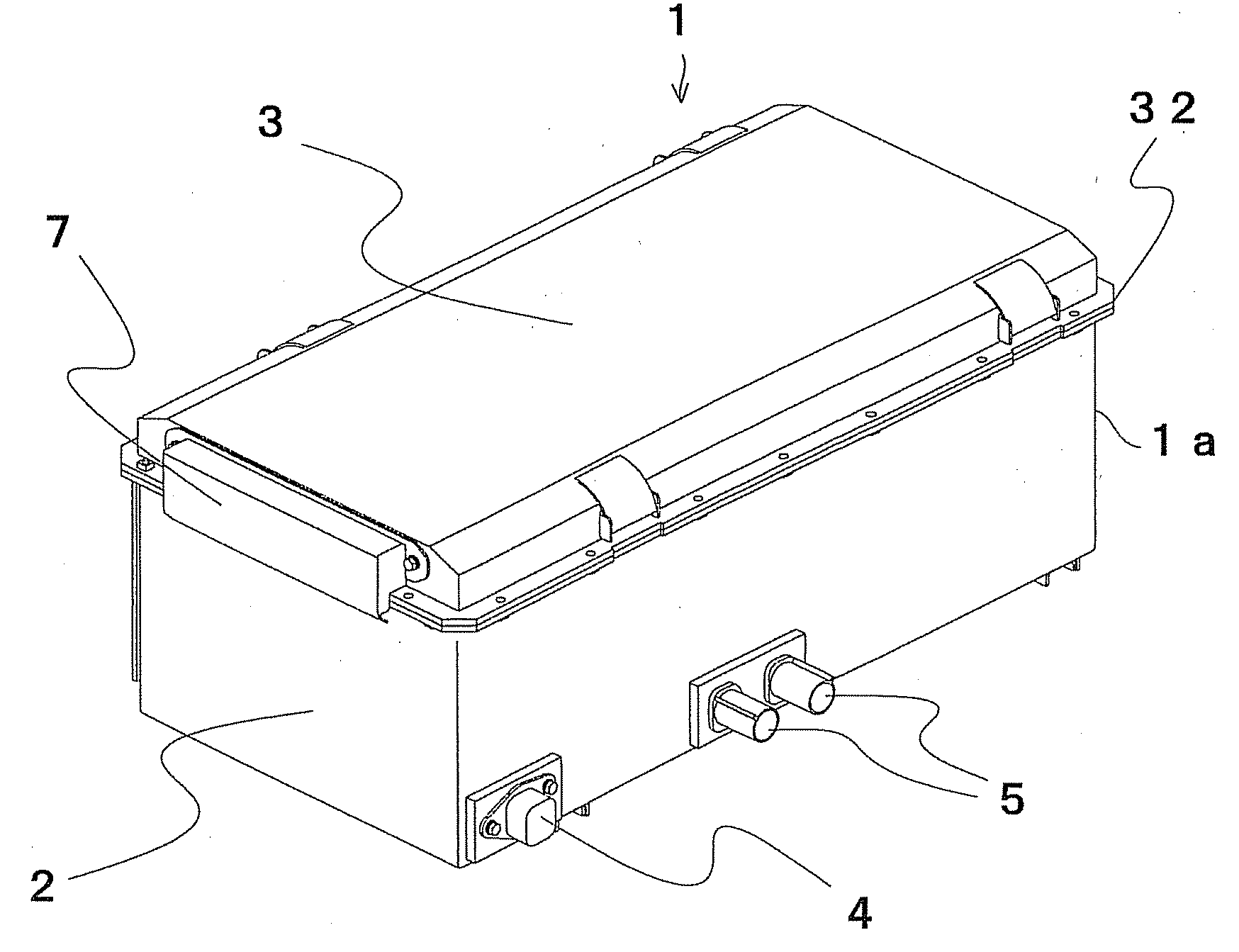

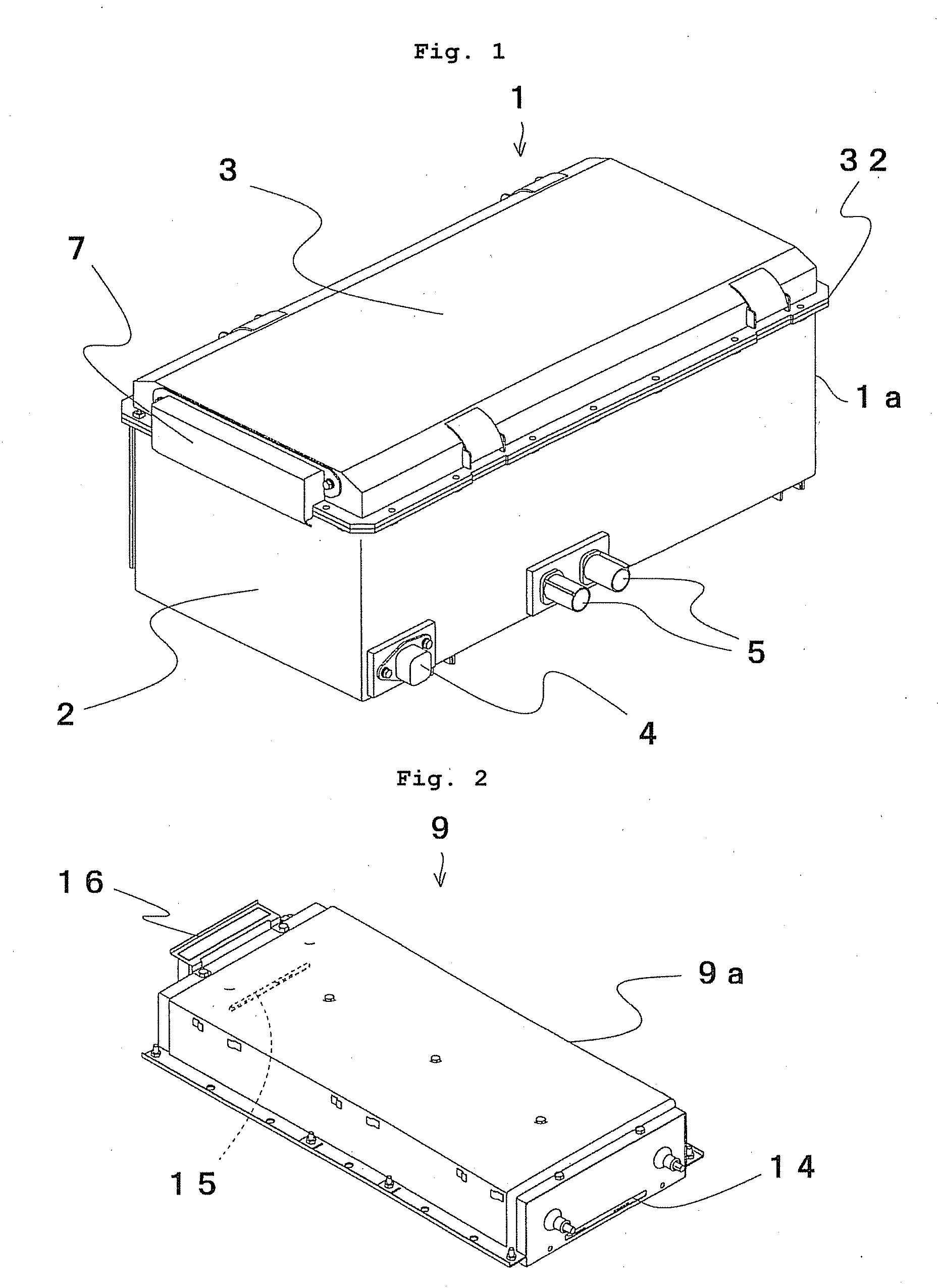

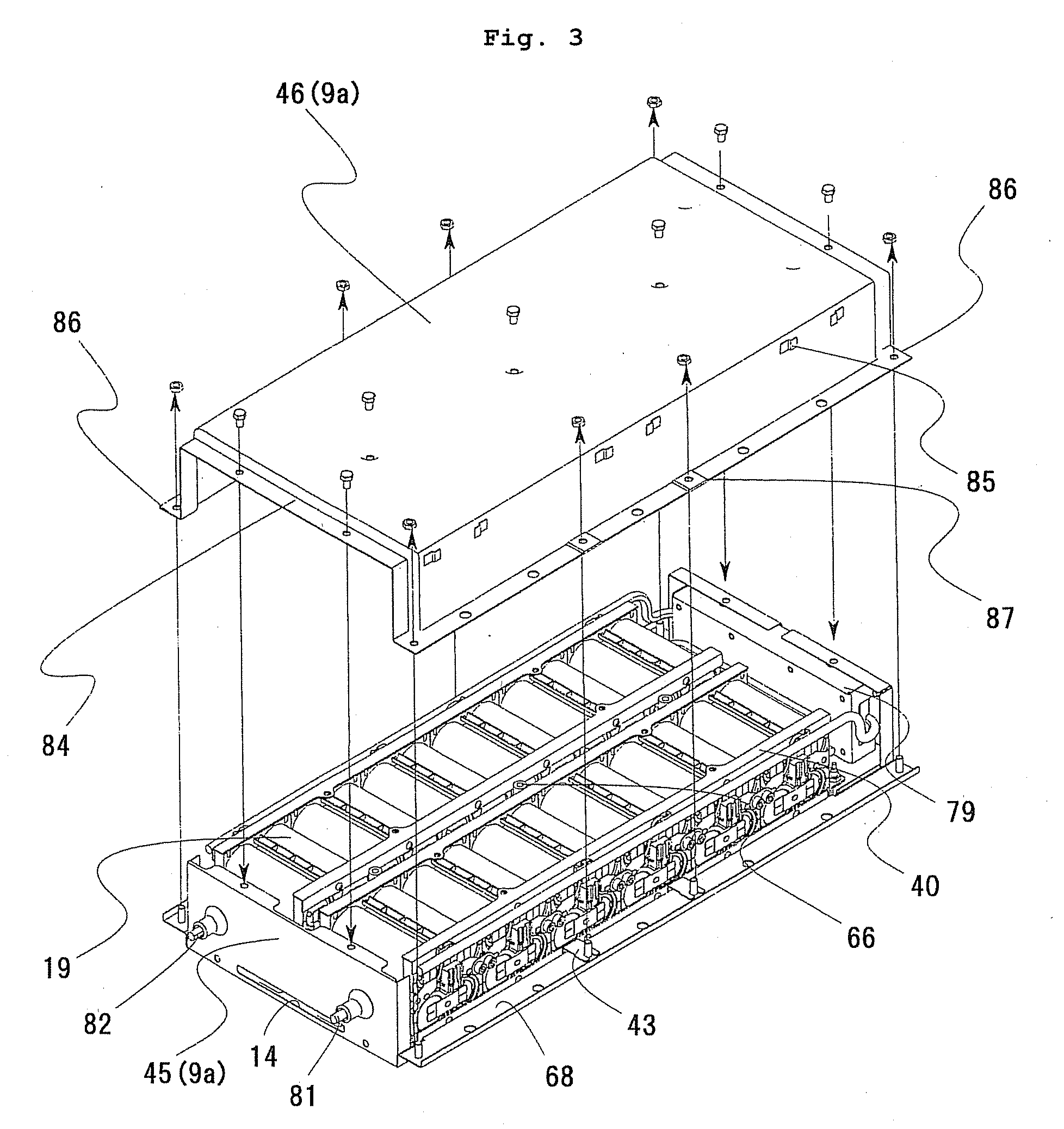

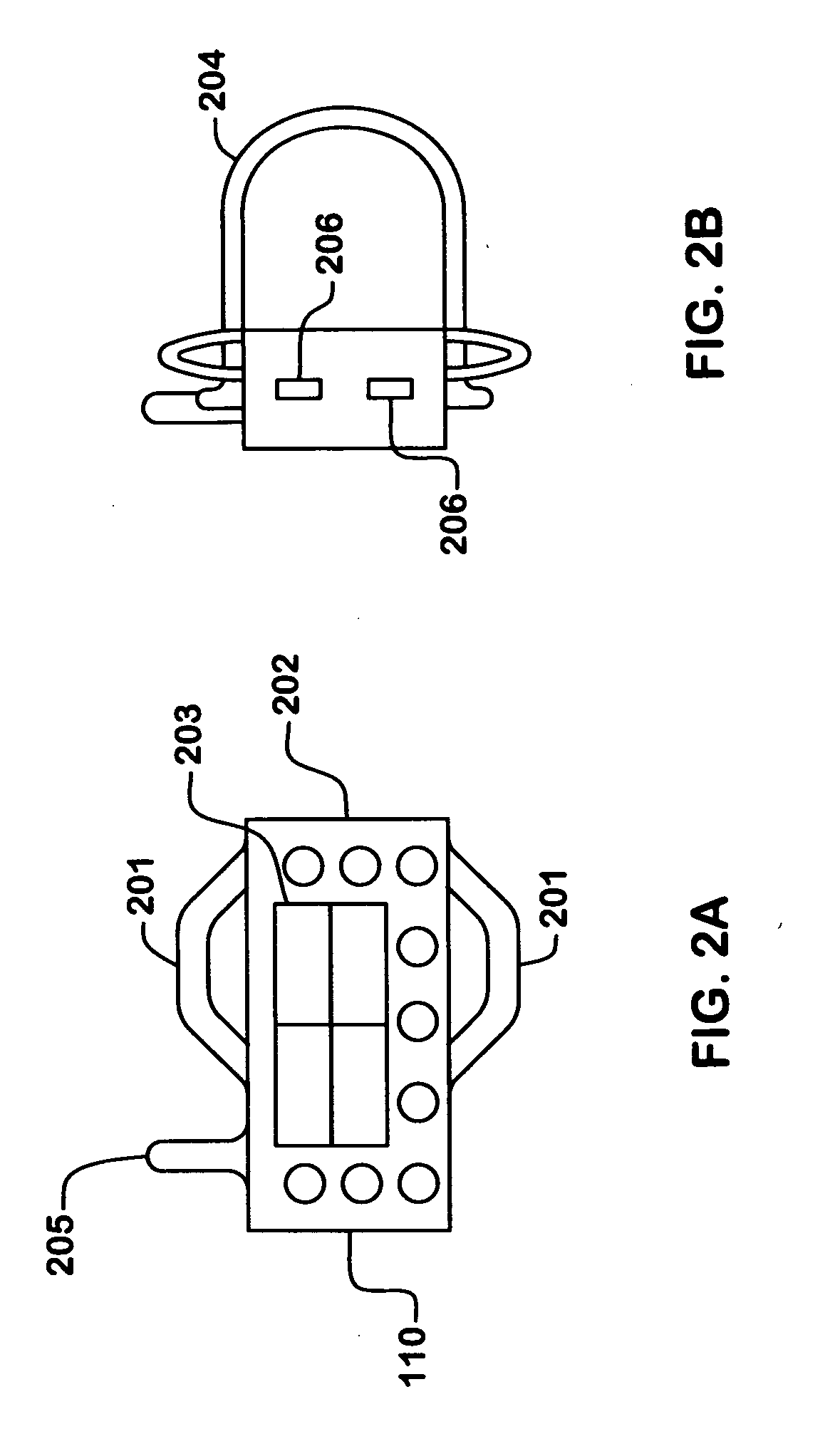

Cell controller, battery module and power supply system

ActiveUS20080050645A1Increase production capacityIncrease productivityBatteries circuit arrangementsCell electrodesProduction ratePotential difference

A cell controller having excellent productivity is provided. A cell-con 80 has 12 ICs IC-1 to IC-2 mounted on a substrate, and these ICs detect voltages of respective cells constituting a cell pack, perform capacity adjustment on the respective cells, and are mounted two by two on rectangular longer sides of a rectangular continuous straight line L-L′ defined on a substrate from the IC-1 on a highest potential side to the IC-12 on a lowest potential side continuously in order of potential differences of the corresponding cell packs. Distances between the rectangular shorter sides of the rectangular continuous straight line L-L′ are the same. On the cell-con 80, between the IC-1 to IC-12 having different ground voltages, each of the ICs has signal output terminals connected to signal input terminals of a lower order IC respectively in an electrically non-insulated state.

Owner:HITACHI ASTEMO LTD

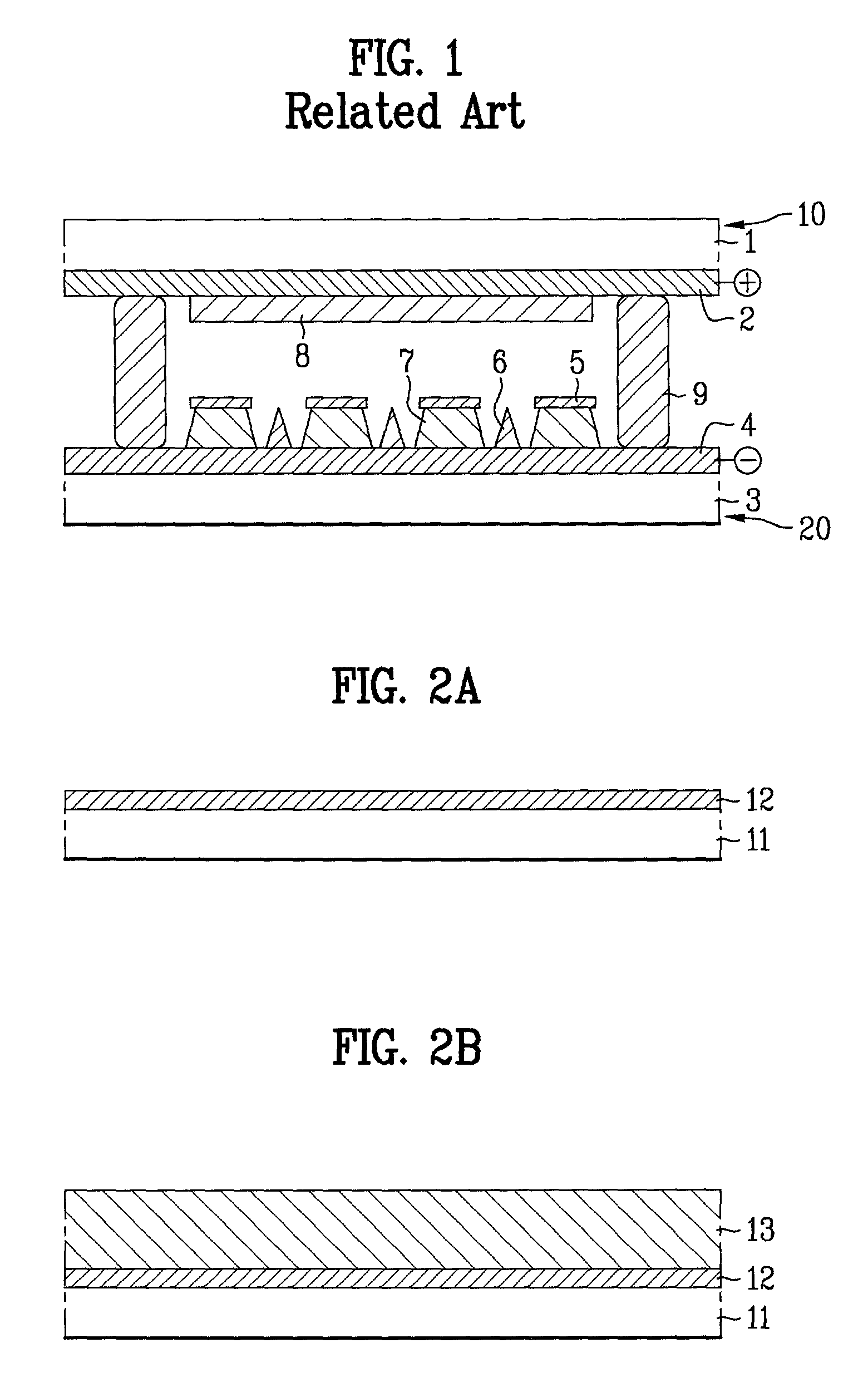

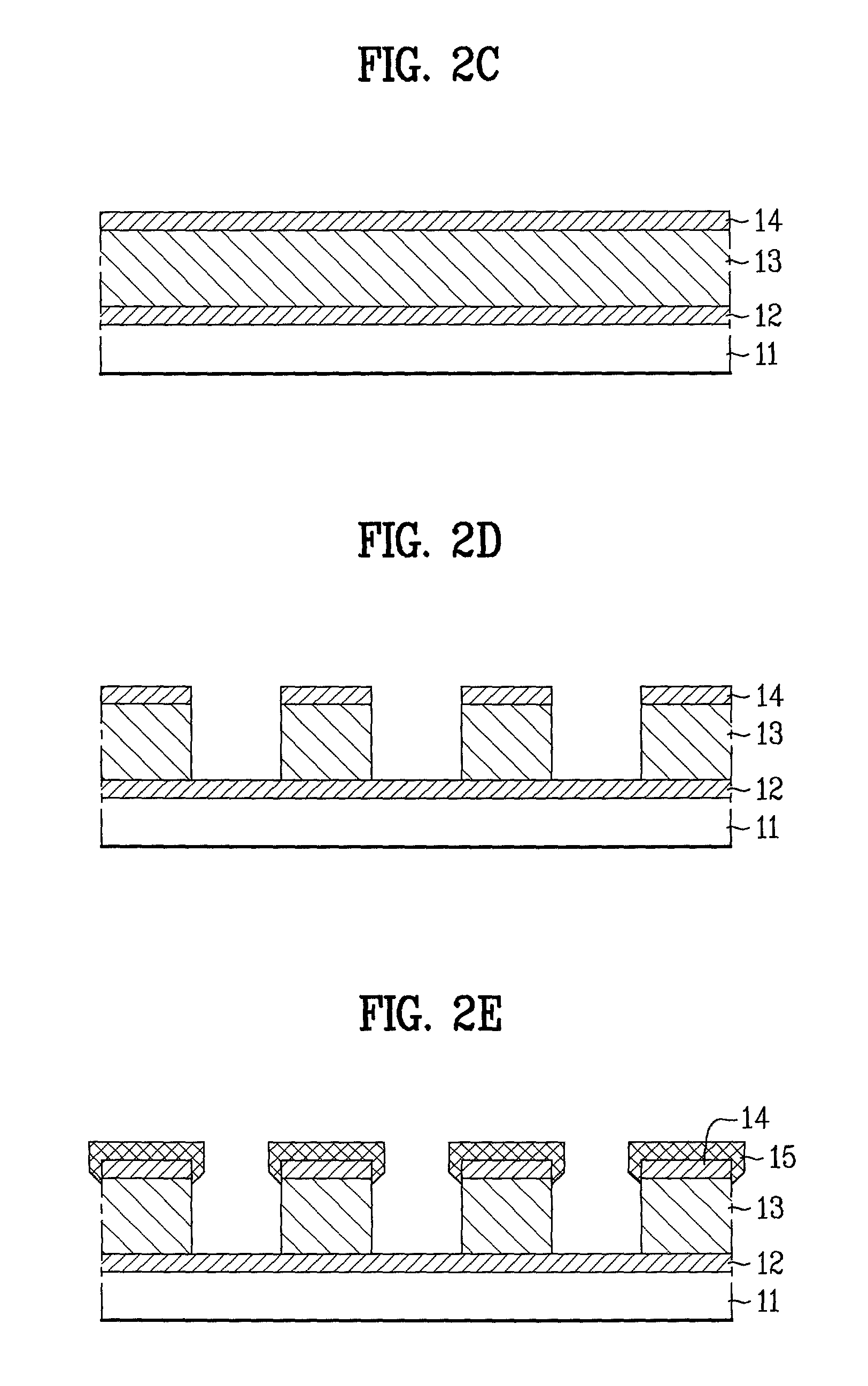

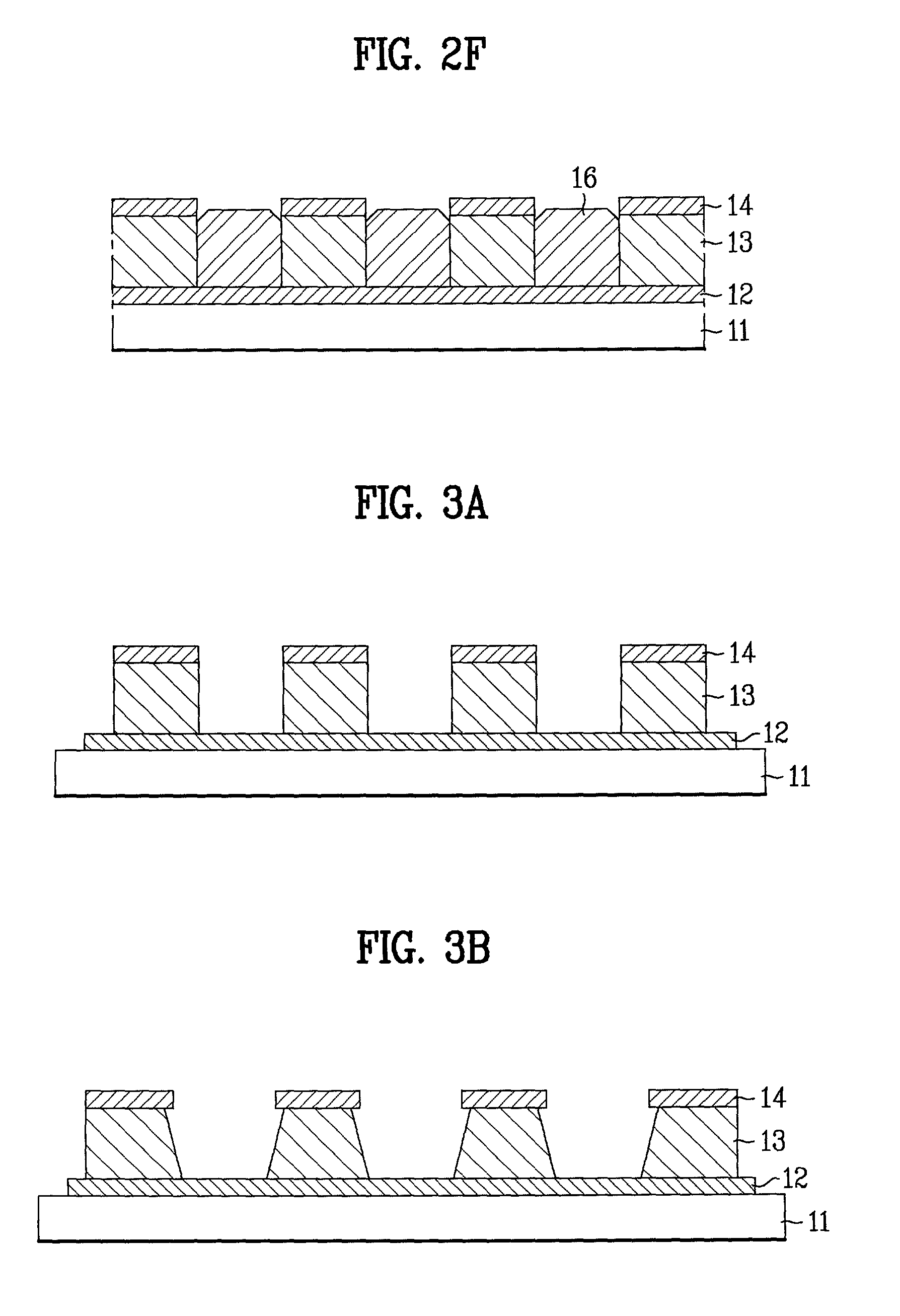

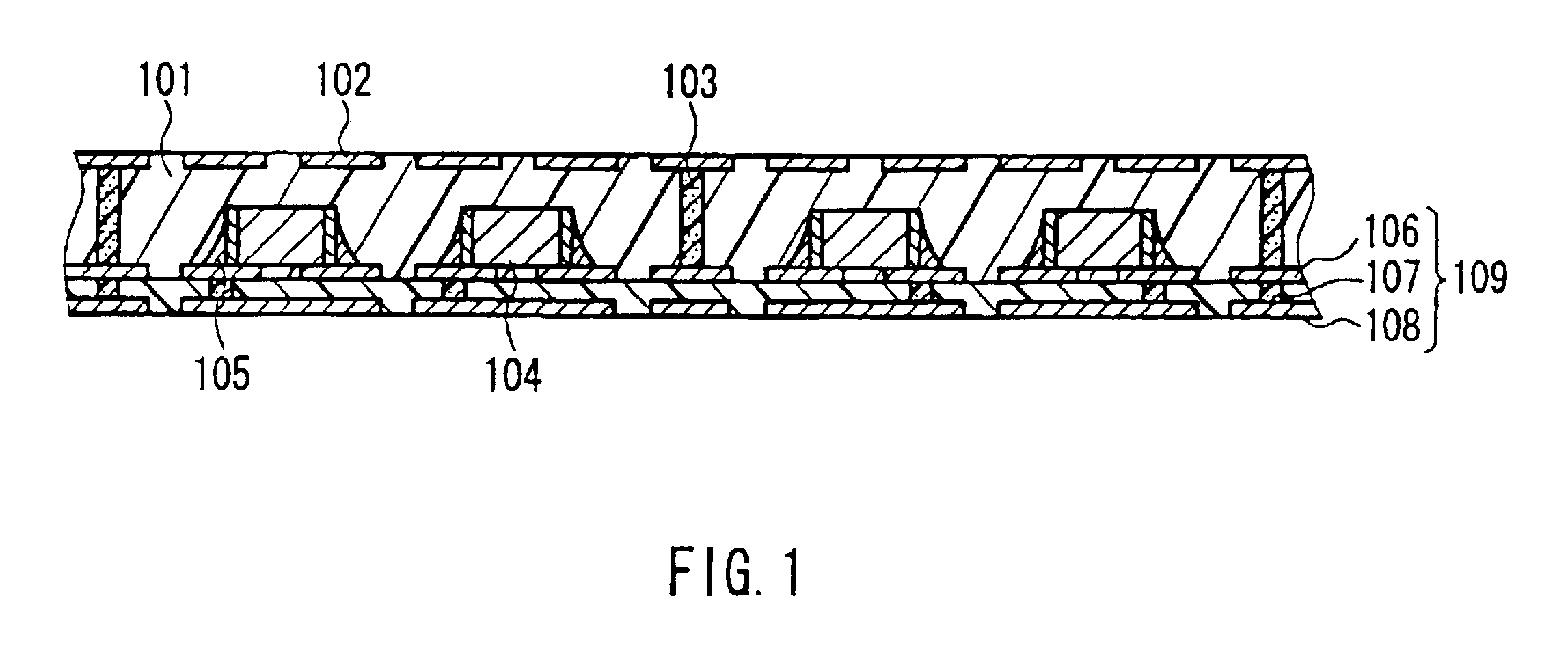

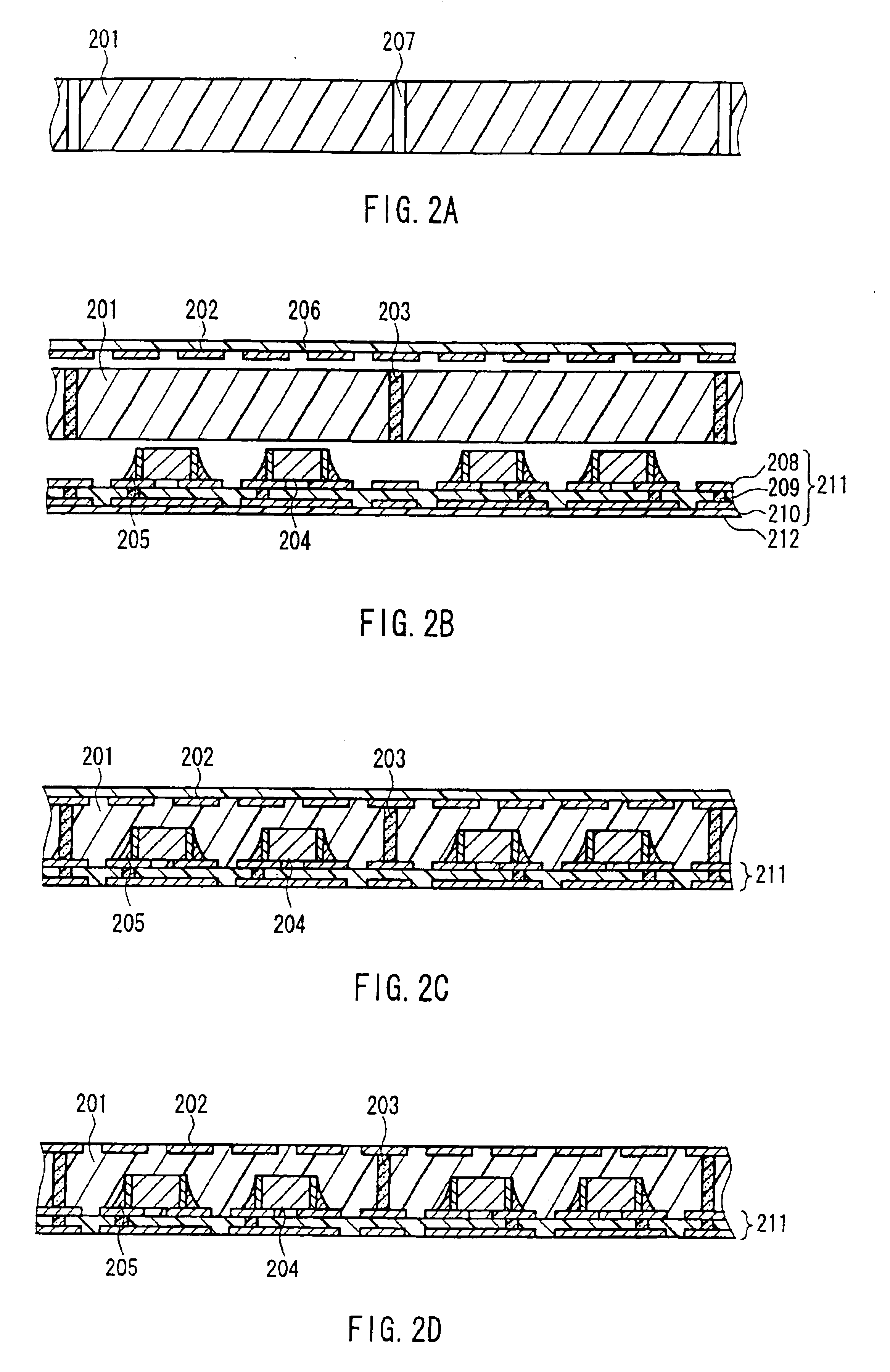

Field emission display and method for fabricating the same

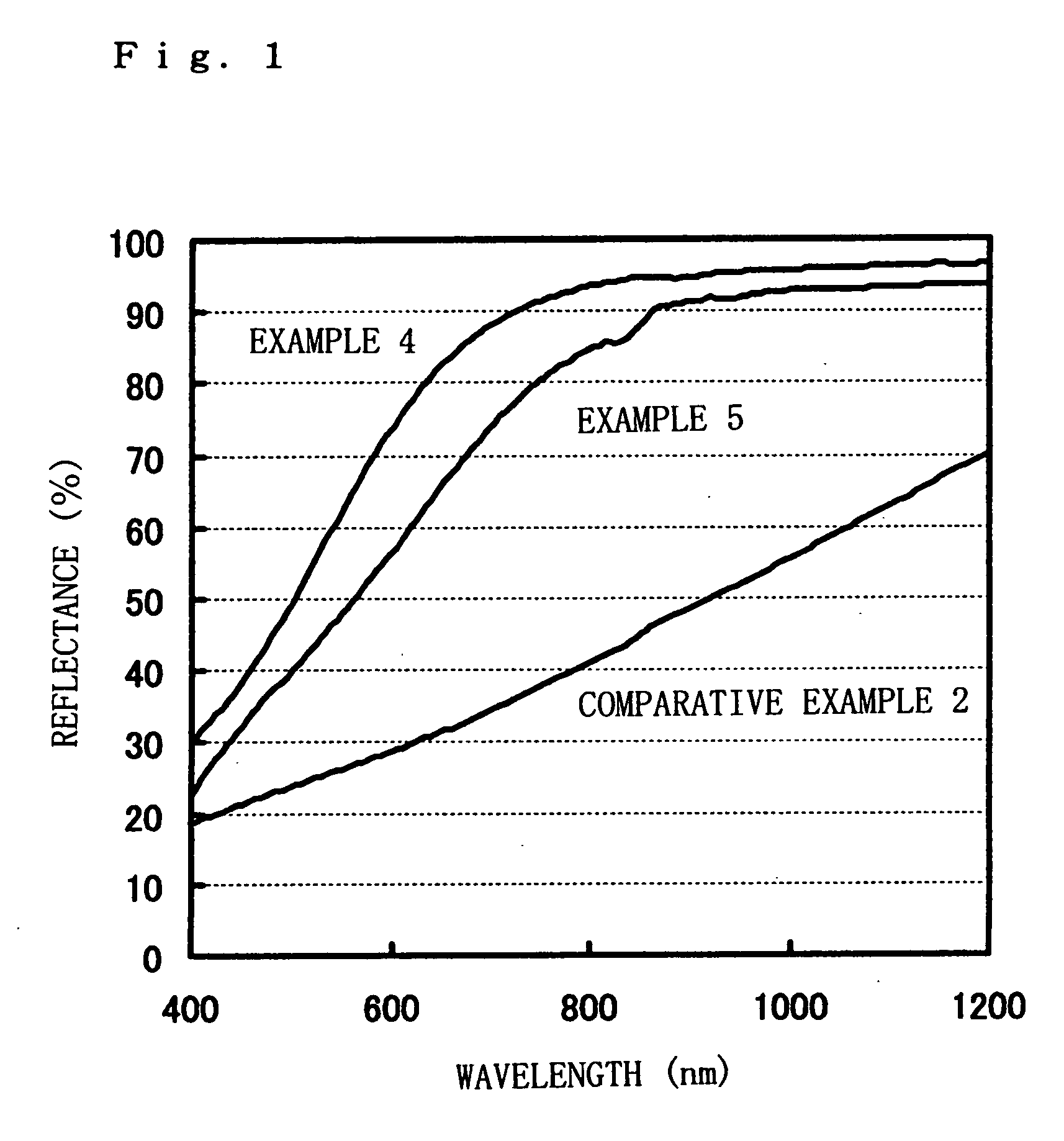

InactiveUS20010004979A1Stable driving voltageUniform characteristicsMaterial nanotechnologyDecorative surface effectsLow voltageCarbon nanotube

Field emission display and method for fabricating the same, the field emission display including a cathode array having a cathode electrode formed on a substrate, insulating layers and carbon nanotube films for use as emitter electrodes formed alternately on the cathode electrode, and a gate electrode formed on the insulating layer, thereby permitting fabrication of a large sized cathode plate at a low cost because the film is formed by screen printing and exposure, which can reduce the cumbersome steps in fabrication of the related art Spindt emitter tip, and both a low voltage and a high voltage FEDs because the carbon nanotube film used as the emitter has a low work function, with an easy and stable electron emission capability.

Owner:LG ELECTRONICS INC

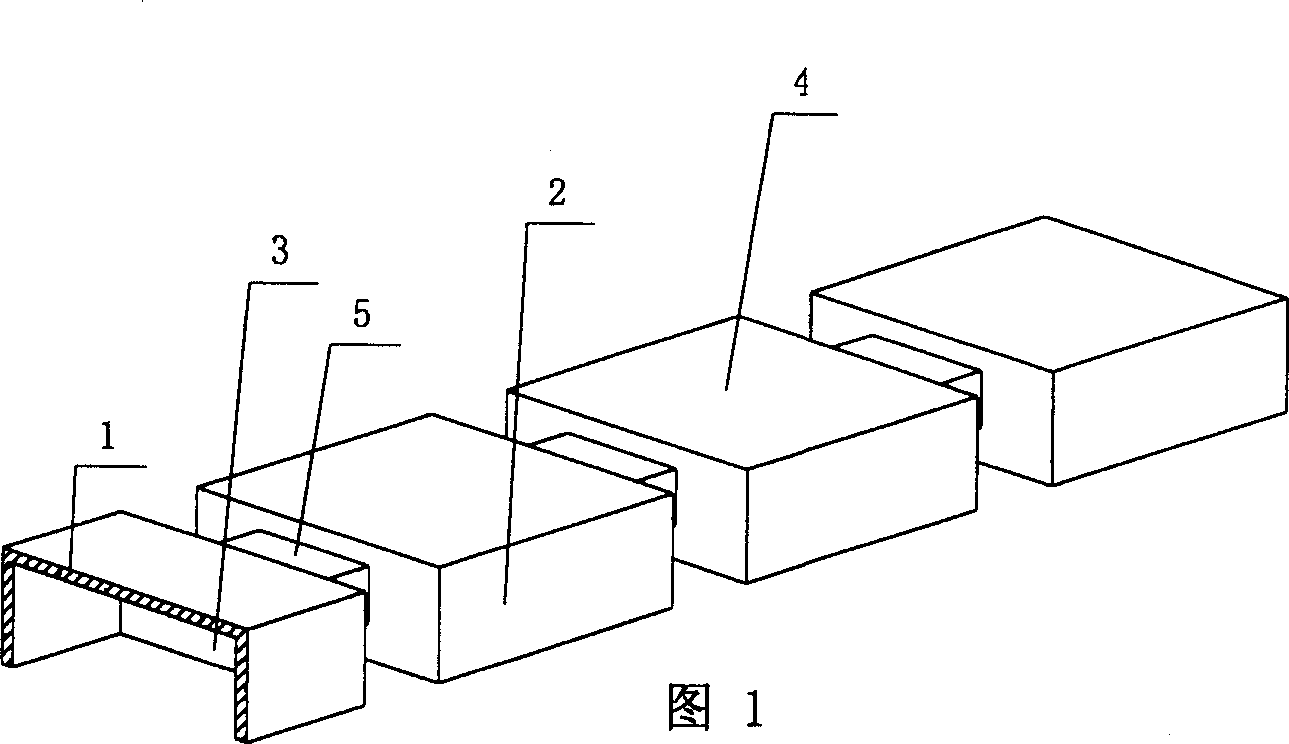

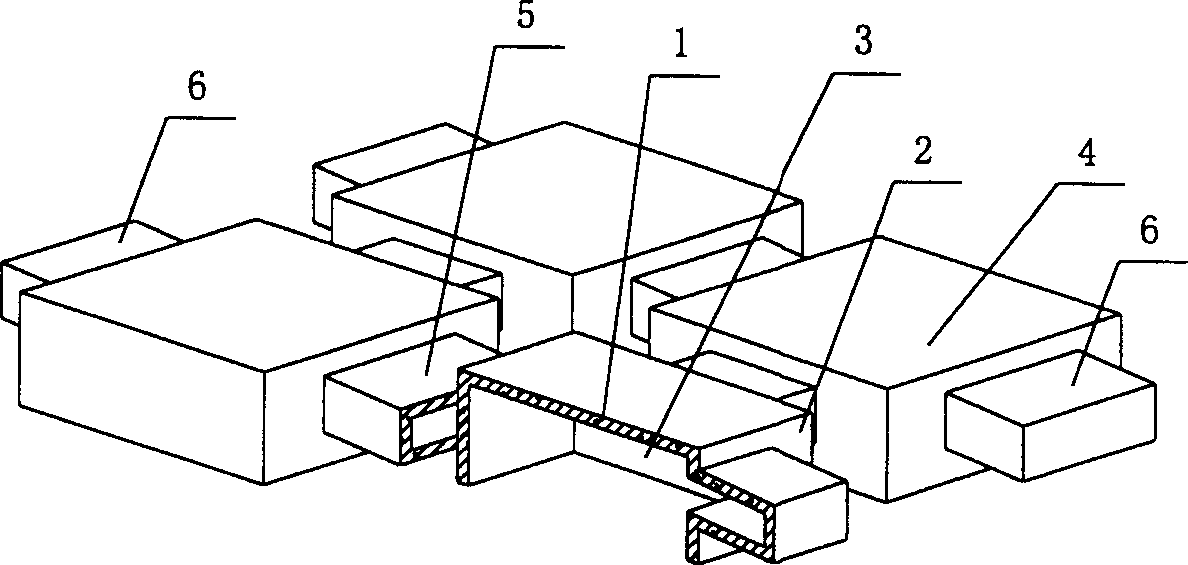

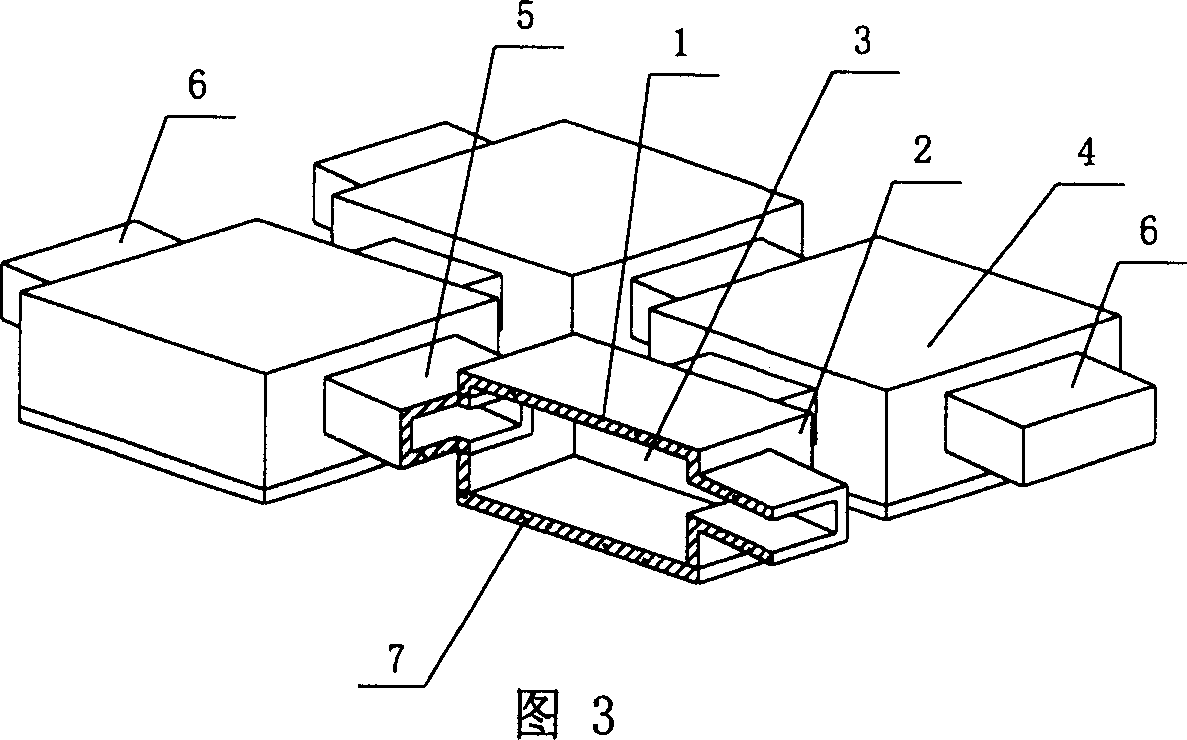

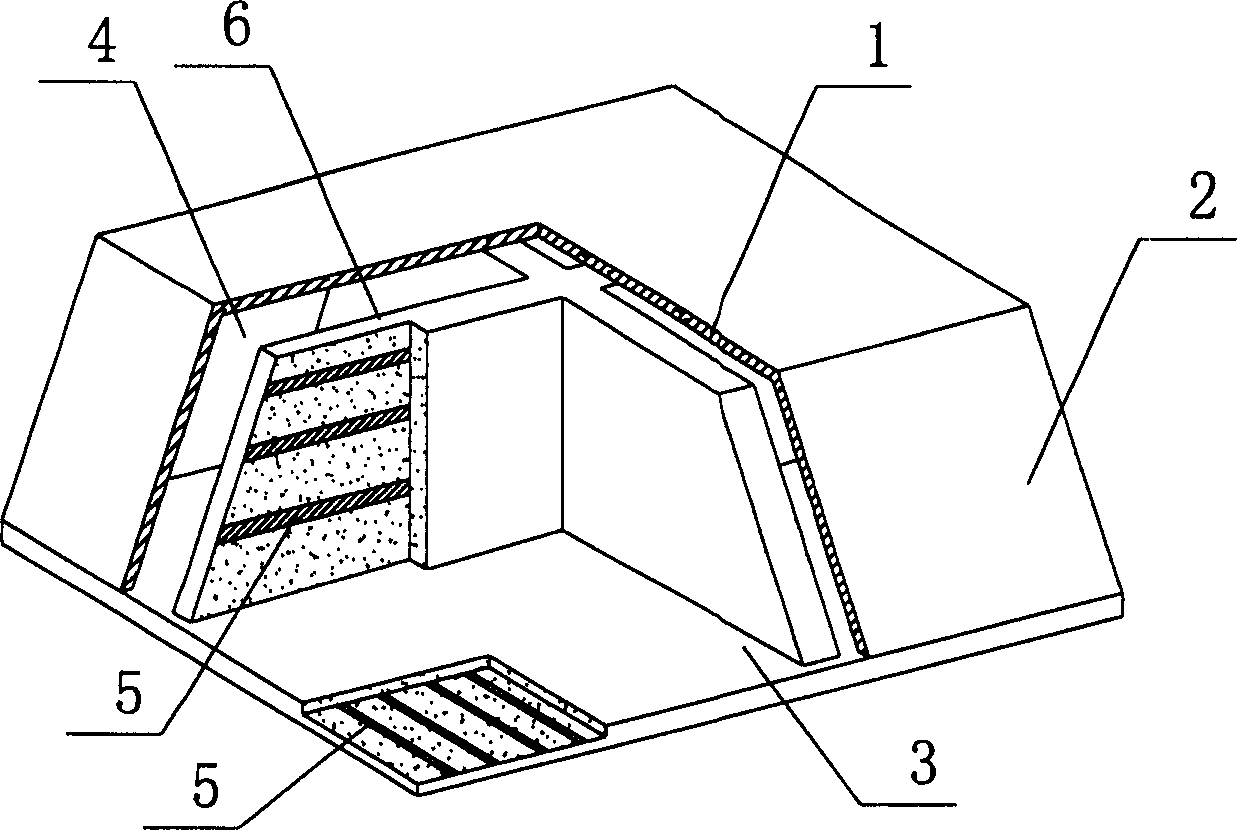

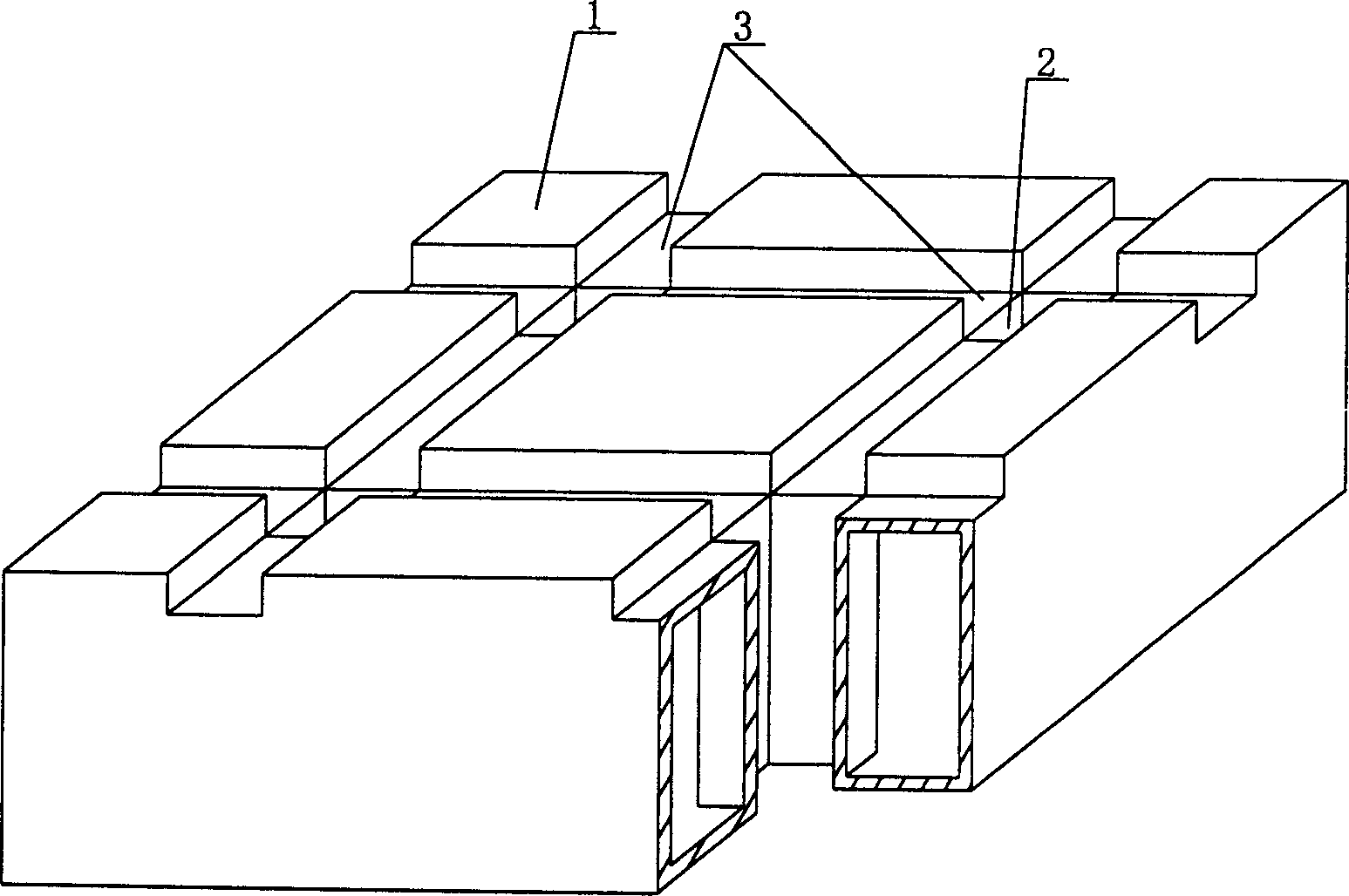

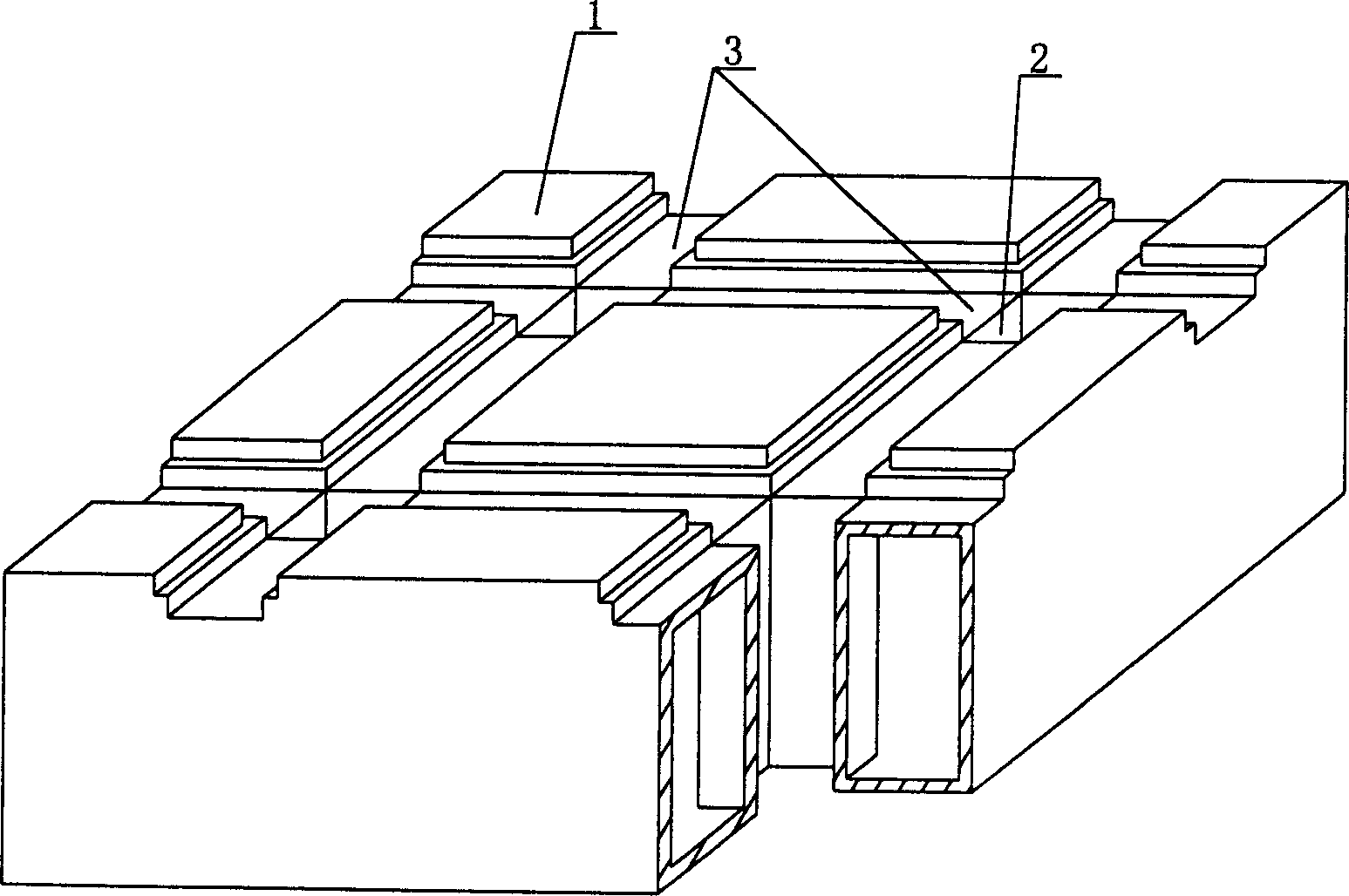

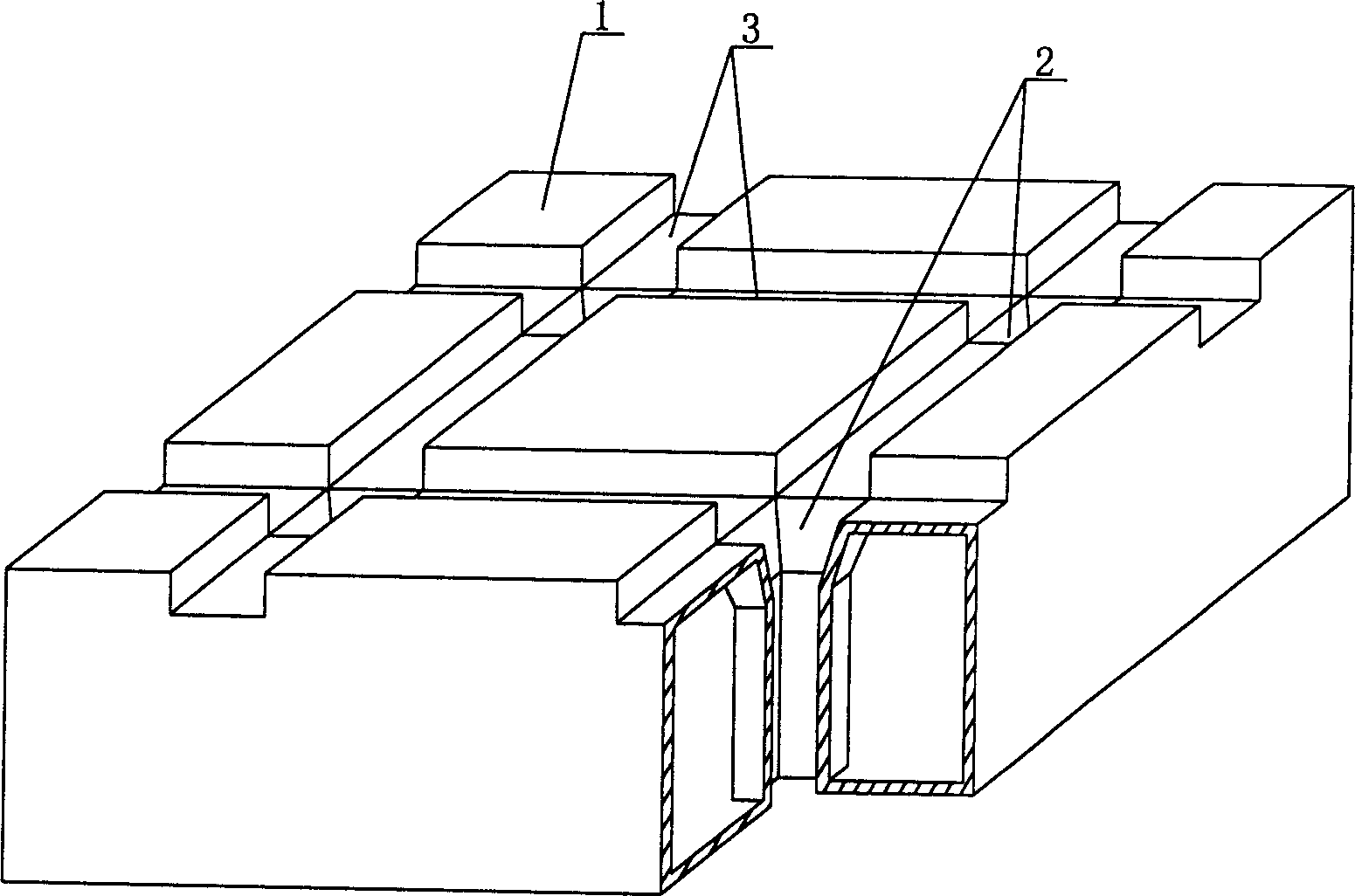

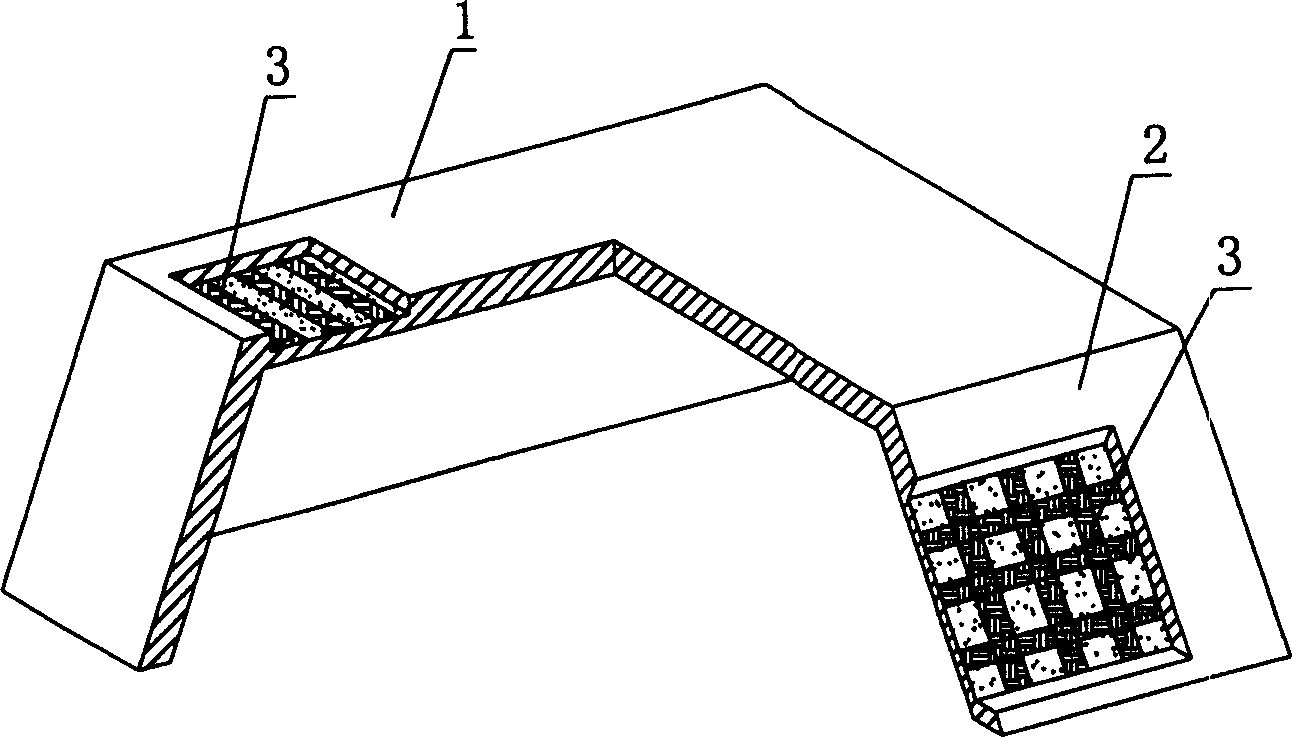

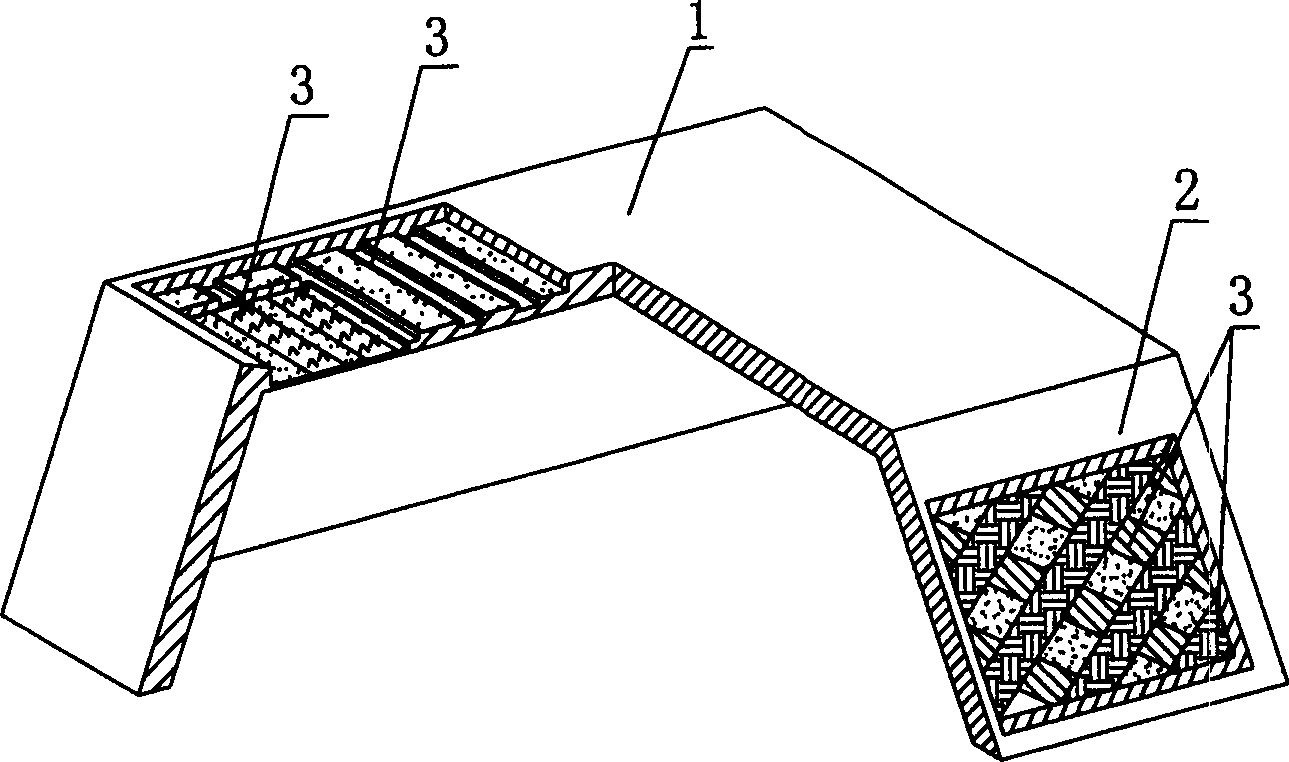

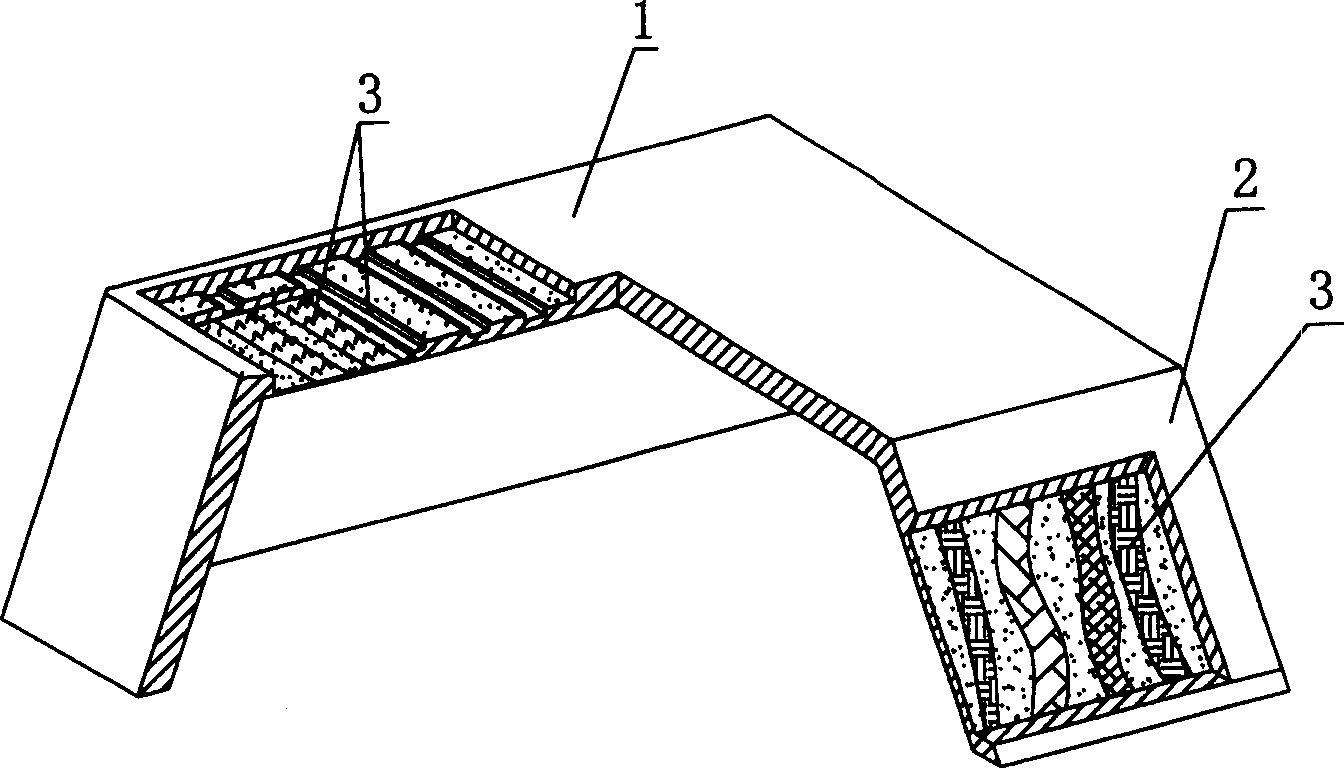

Modular formwork members

InactiveCN1403667ASimple designIncrease production capacityFloorsReinforced concreteUltimate tensile strength

The modular formwork member includes top plate and side walls to constitute cavity formwork. The present invention features that there is at least one connection tube between the adjacent walls of two formworks. When the modular formwork members are used in hollow stringboard, there will be vertical rib formed around the connection tube via in-situ cast and shearing bonding formed in the empty part between the formwork members, so that the hollow stringboard can form reinforced concrete-shearing bonding type bi-directional hollow large board in only once deposition. The present invention has simple formwork, simple construction, low cost and short construction period, and the member has high strength, simple structure, low cost and easy construction.

Owner:湖南邱则有专利战略策划有限公司

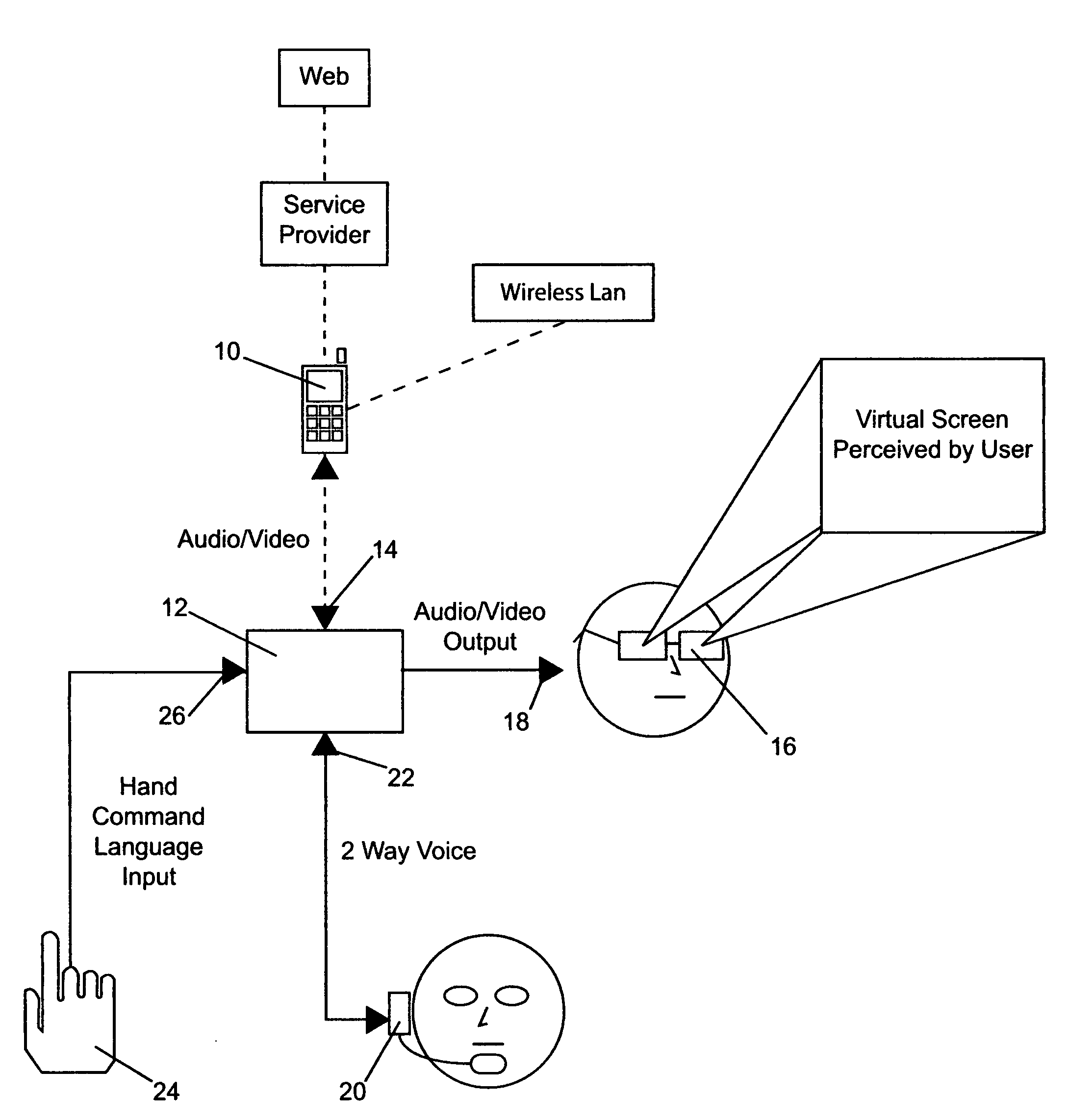

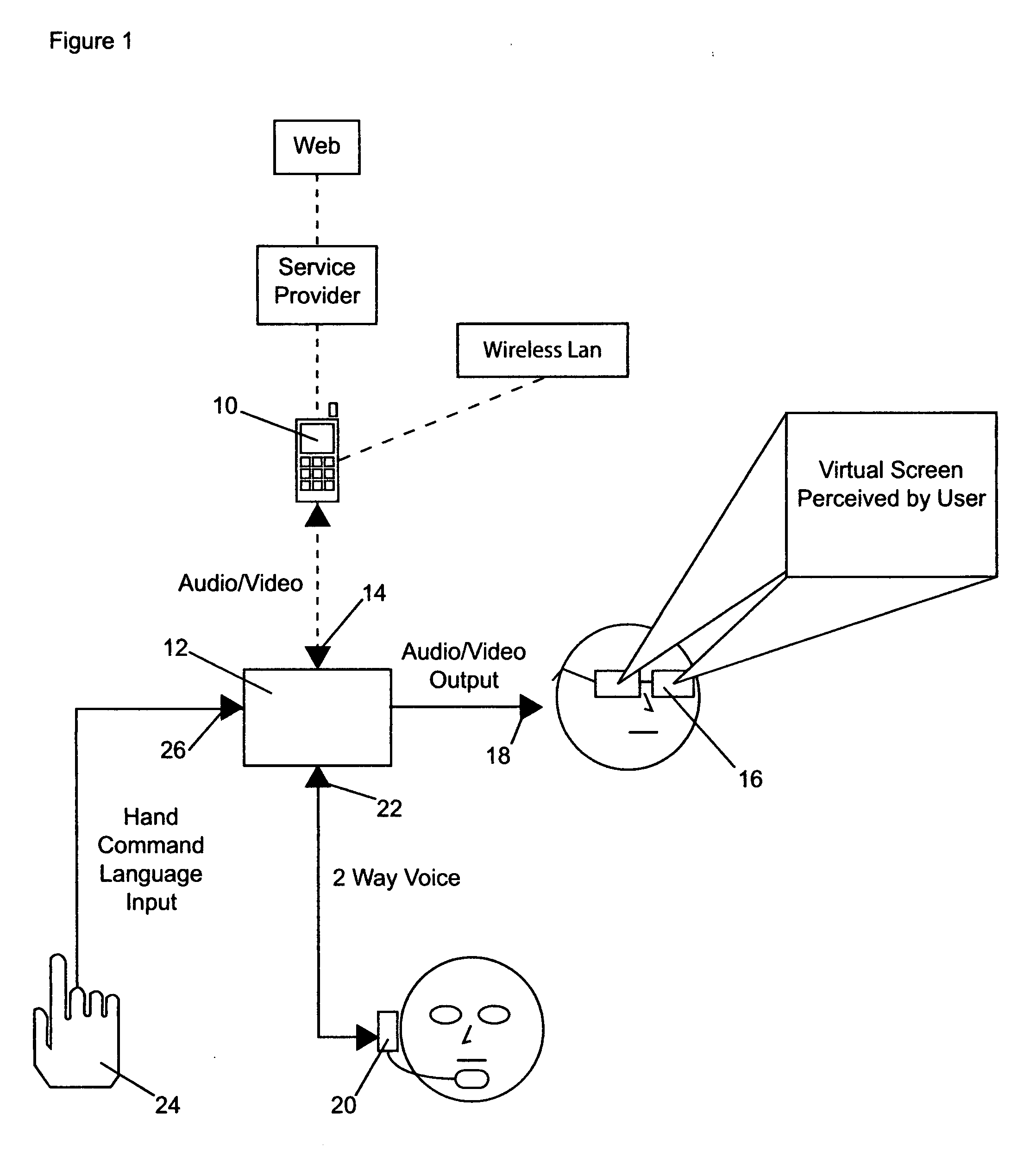

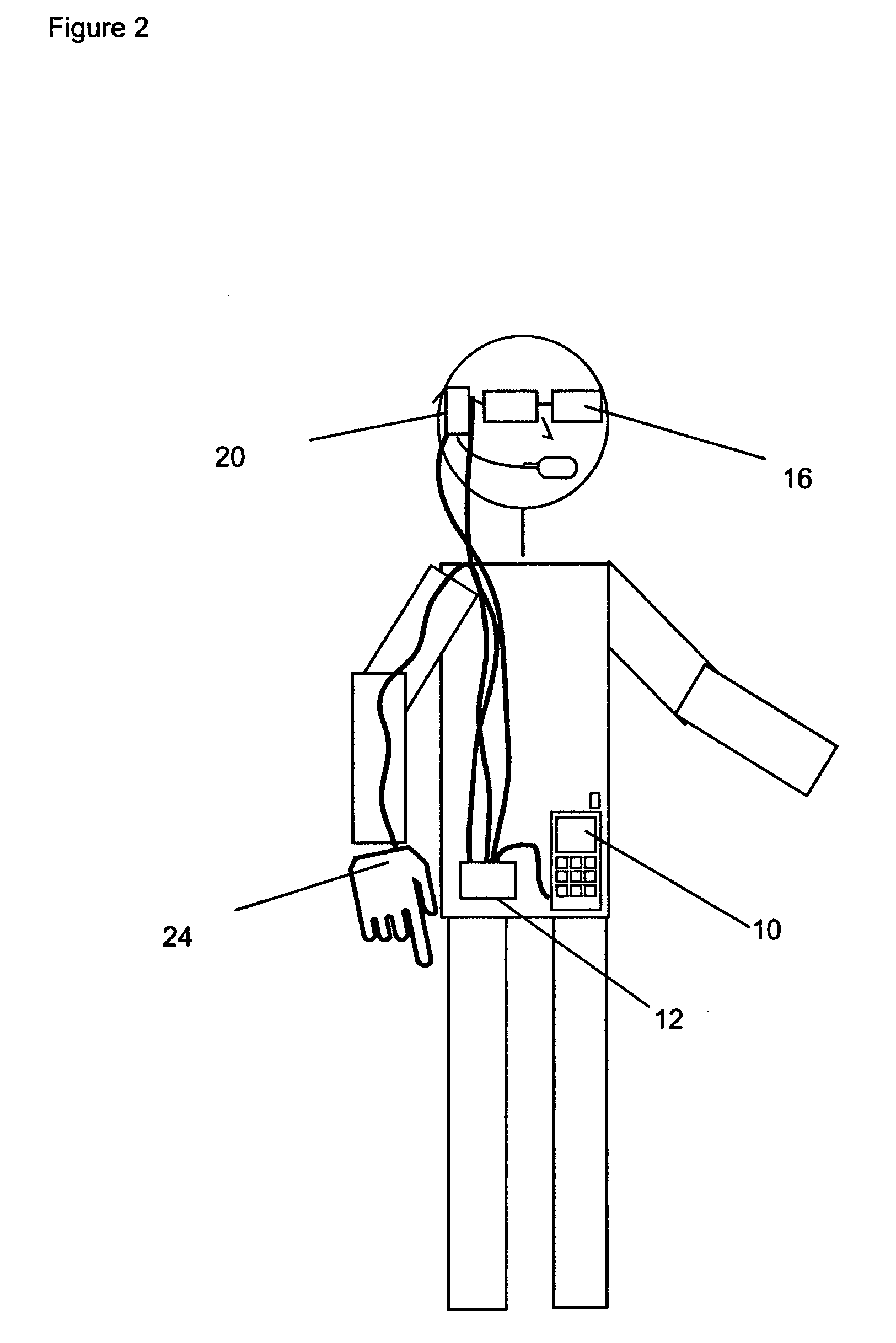

Mobile global virtual browser with heads-up display for browsing and interacting with the World Wide Web

InactiveUS20070220108A1Enlarges the perceived screenSimple processMultiple digital computer combinationsTelephone set constructionsHead-up displayThird generation

This disclosure describes a new method to browse and interact with the World Wide Web and other users while mobile comprising the following components: 1) a mobile communications device including but not limited to Blackberries, personal data assistants, or smartphones; 2) special glasses or viewing surface including but not limited to LCD (liquid crystal display) glasses, 3-dimensional goggles, or Organic LED (light emitting diode) panels; 3) a data input device including but not limited to a data glove, finger sensor, data input pen, or gesturing device; 4) a mobile communications device headset; and 5) a third generation or more powerful wireless carrier, Voice over IP provider, or a wireless LAN technology such as WiFi or, Wi-Max, or Bluetooth.

Owner:WHITAKER JERRY M

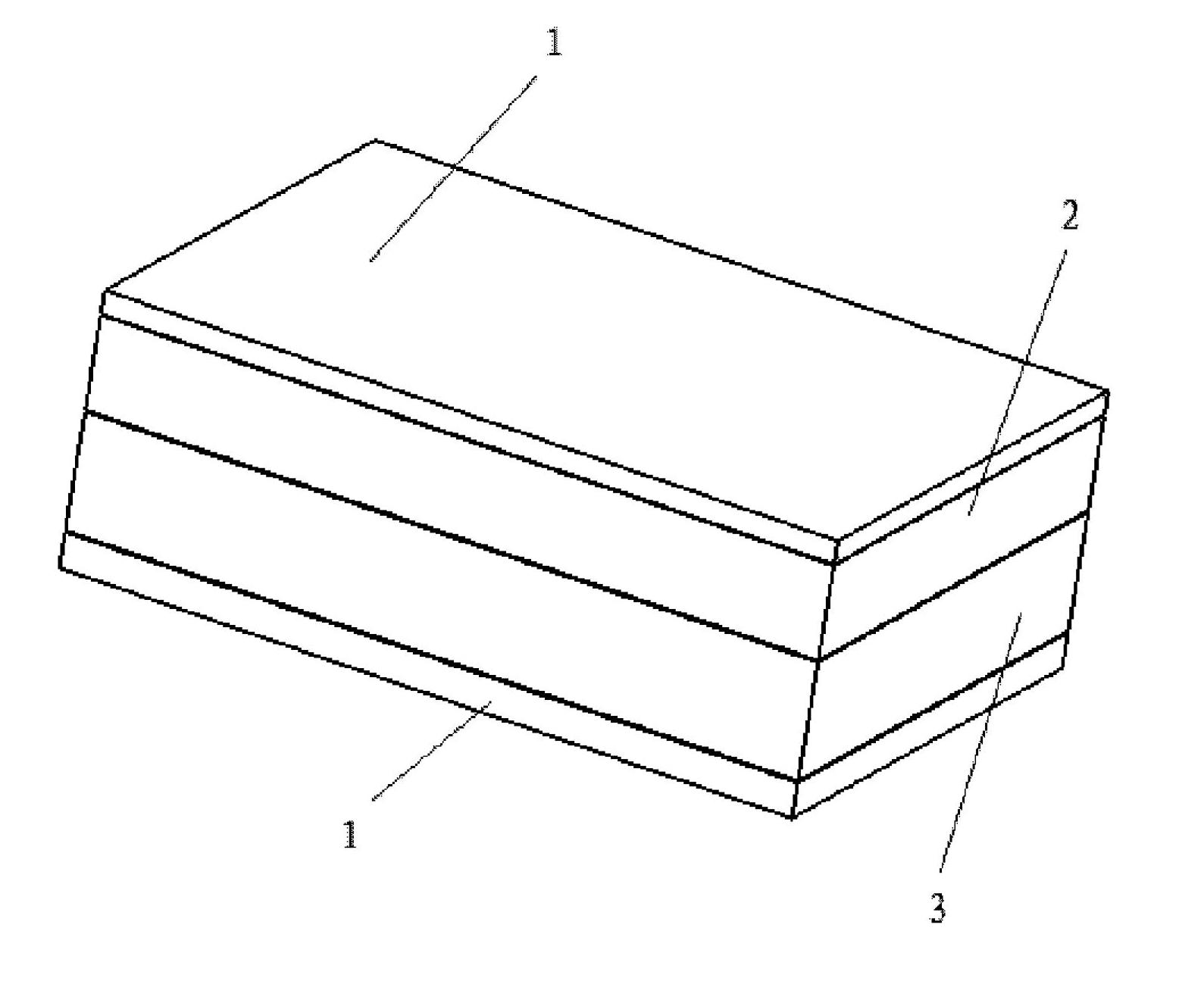

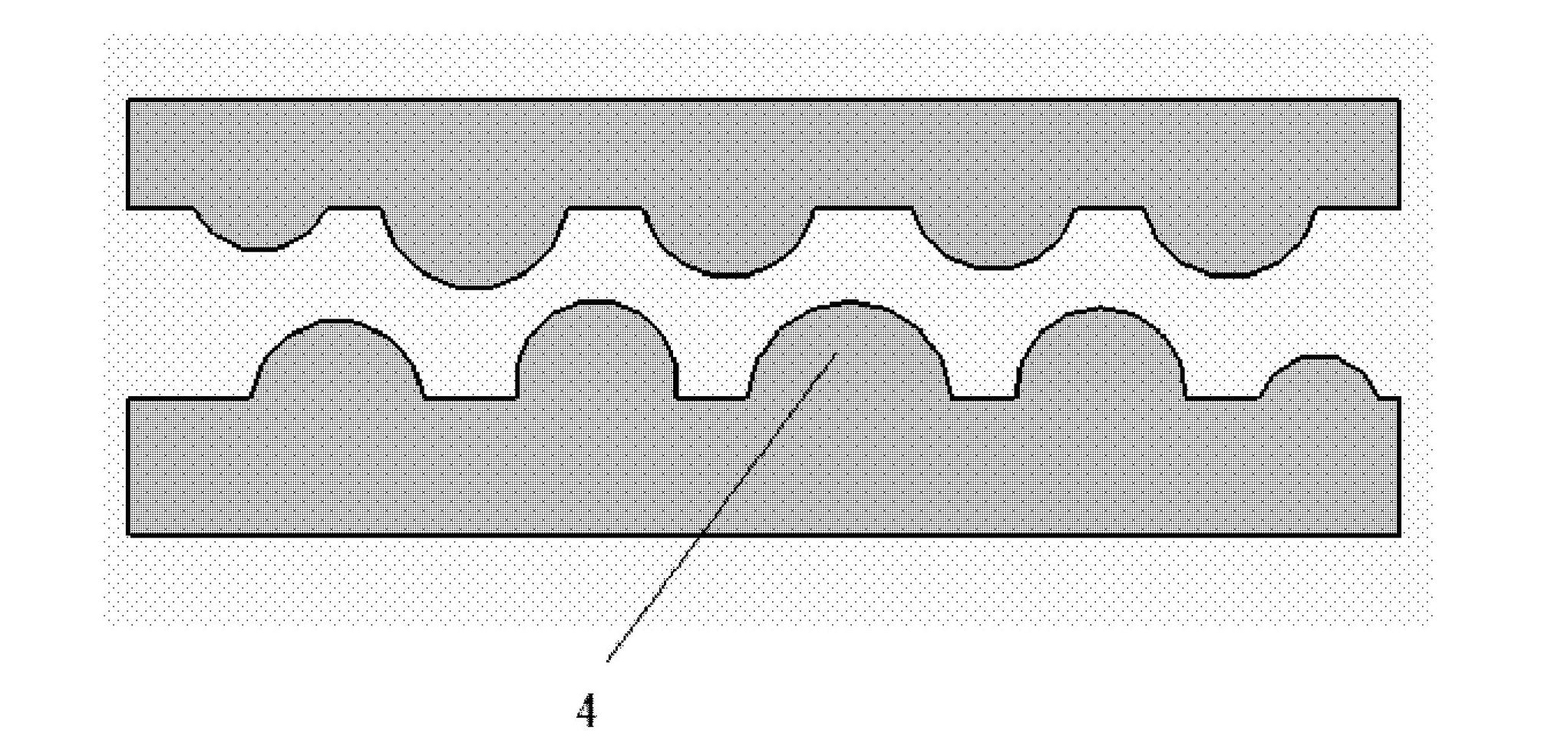

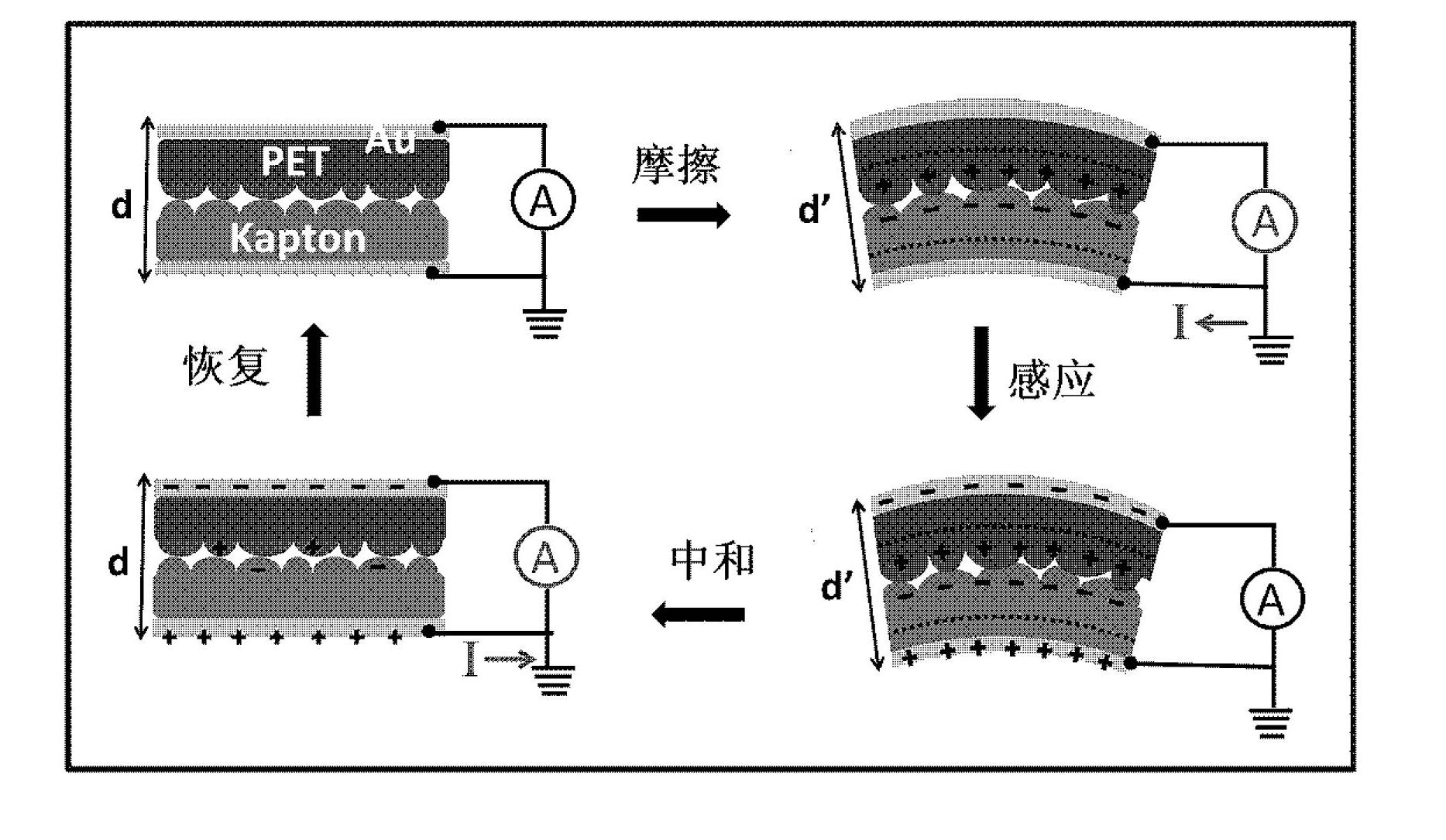

Friction generator

ActiveCN102684546AExtended service lifeLow costFriction generatorsMetal layered productsConvex structureMicro nano

The invention provides a friction generator. The friction generator comprises two electrodes; the electrode comprises a macromolecular polymer insulating layer; a micro-nano concave-convex structure is arranged on one side surface of the macromolecular polymer insulating layer, and a metal film is arranged on the other side surface; the surface of the electrode micro-nano concave-convex structure of one insulating layer is directly attached to the surface of the electrode micro-nano concave-convex structure of the other insulating layer, and the two are fixedly connected through the outer edge; and the metal film is an electrode for outputting voltage and current of the friction generator. The invention provides a novel and effective method for obtaining energy by use of the friction effect. The friction generator generates electric energy by use of the potential change of the internal electrification by friction and the inductive effect of the metal pole plates on the two sides; and the method is simple and efficient and the cost is low.

Owner:NAZHIYUAN TECH TANGSHAN LLC

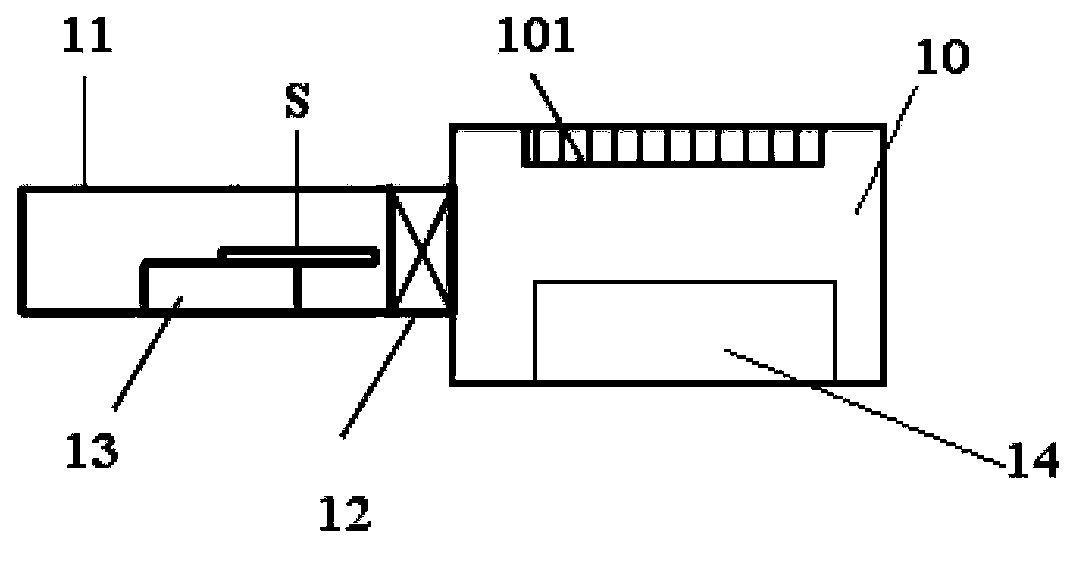

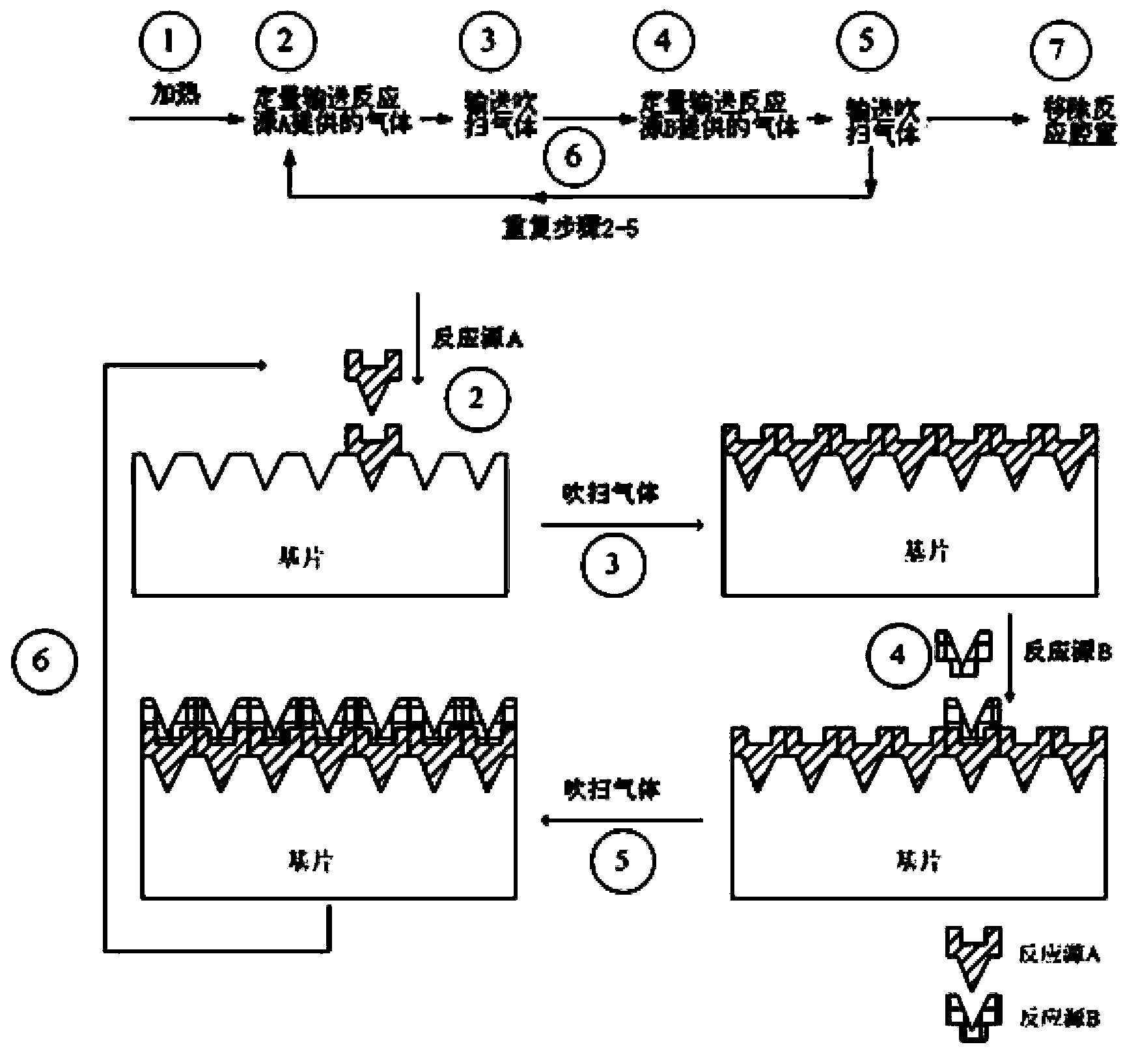

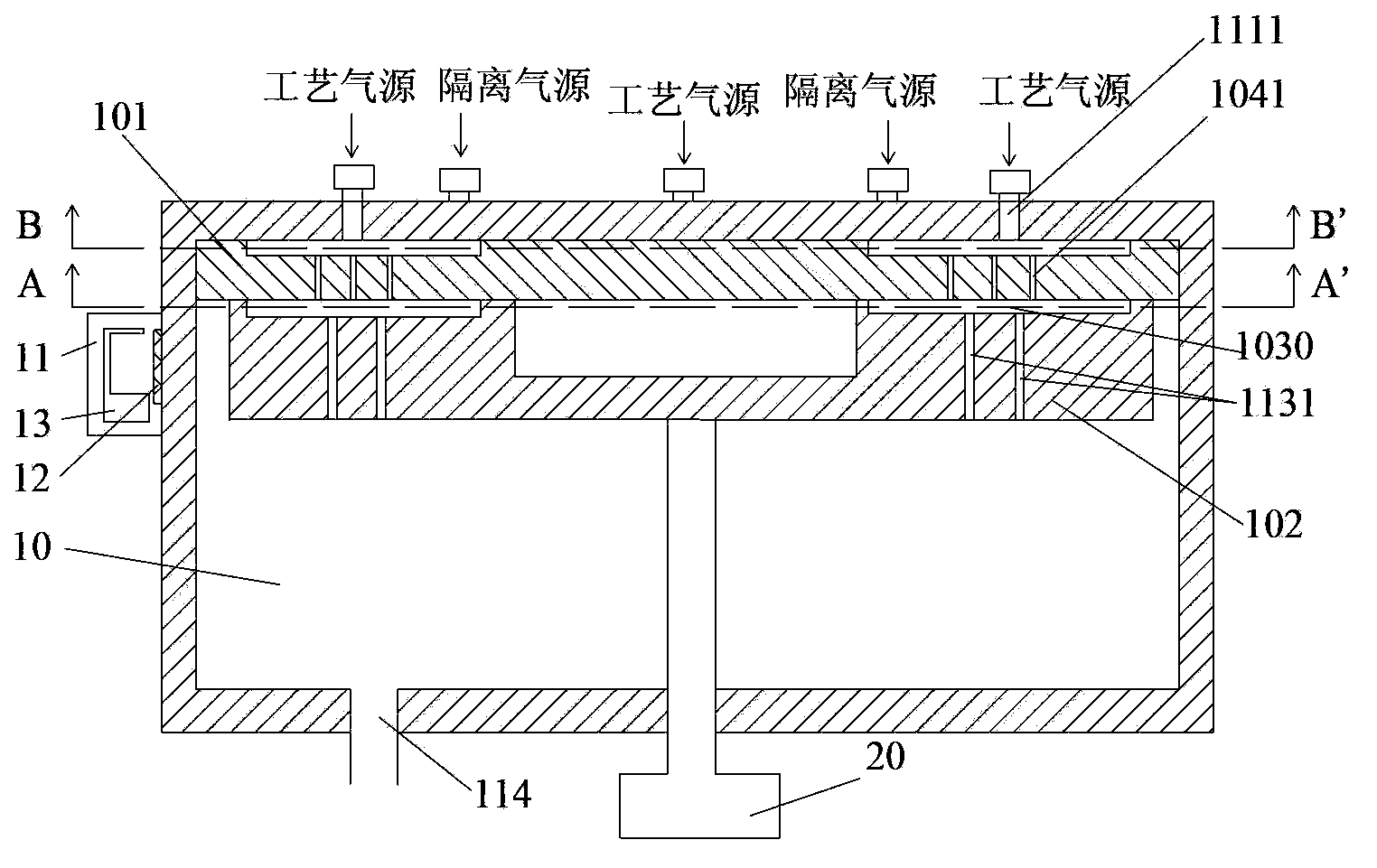

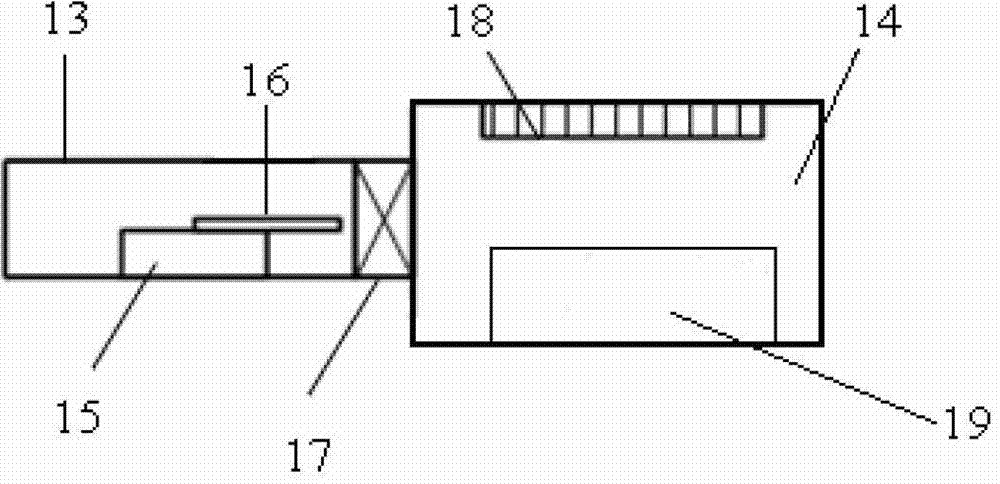

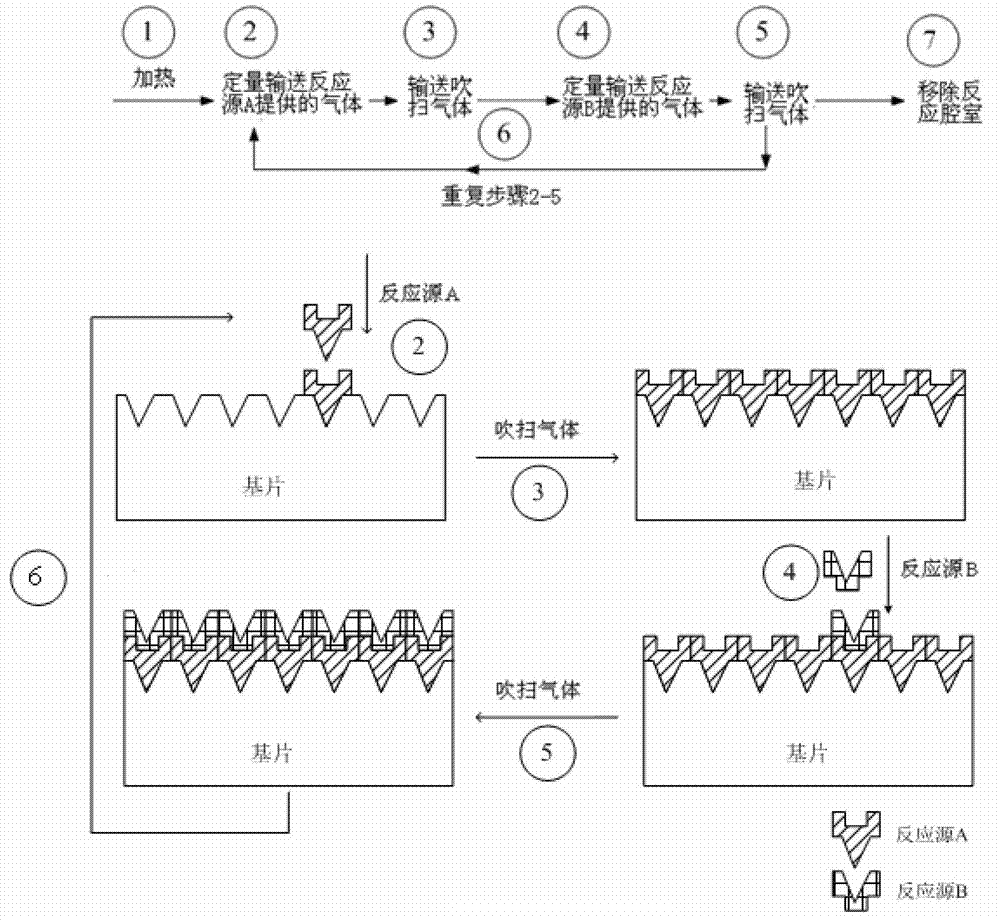

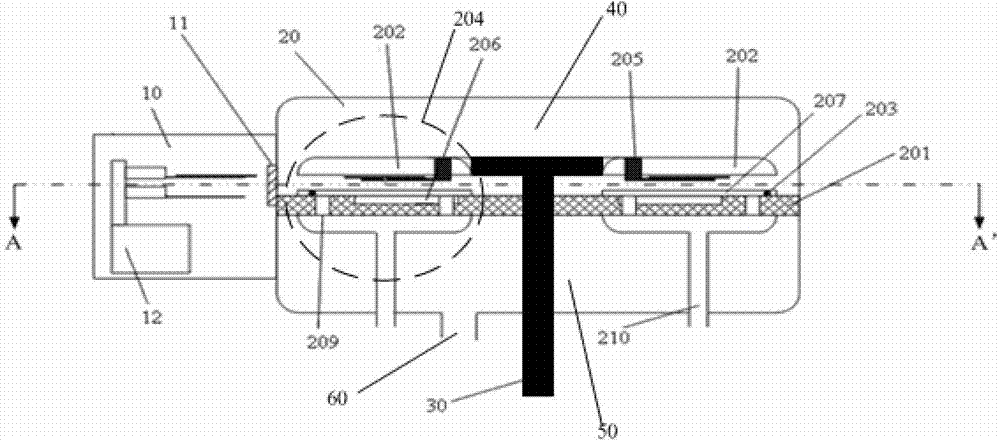

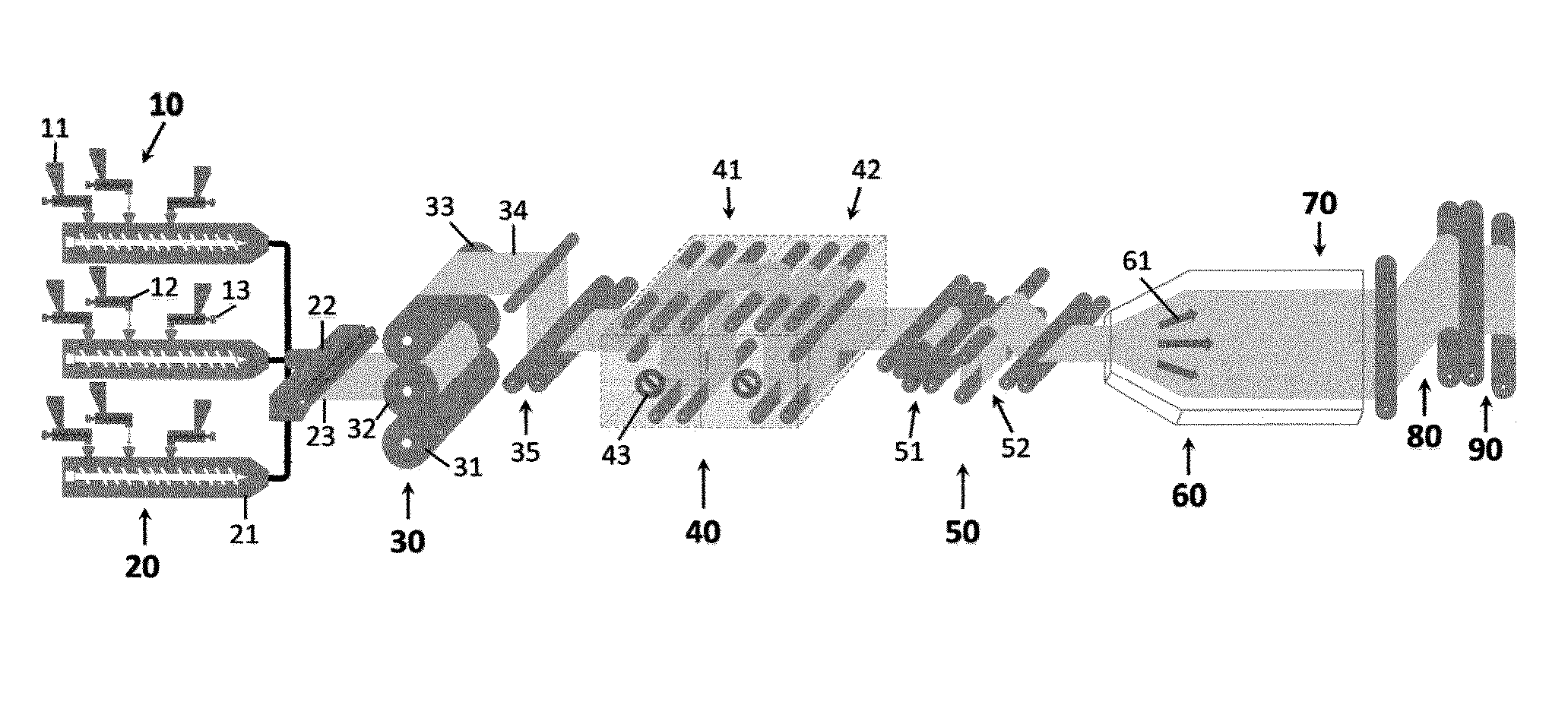

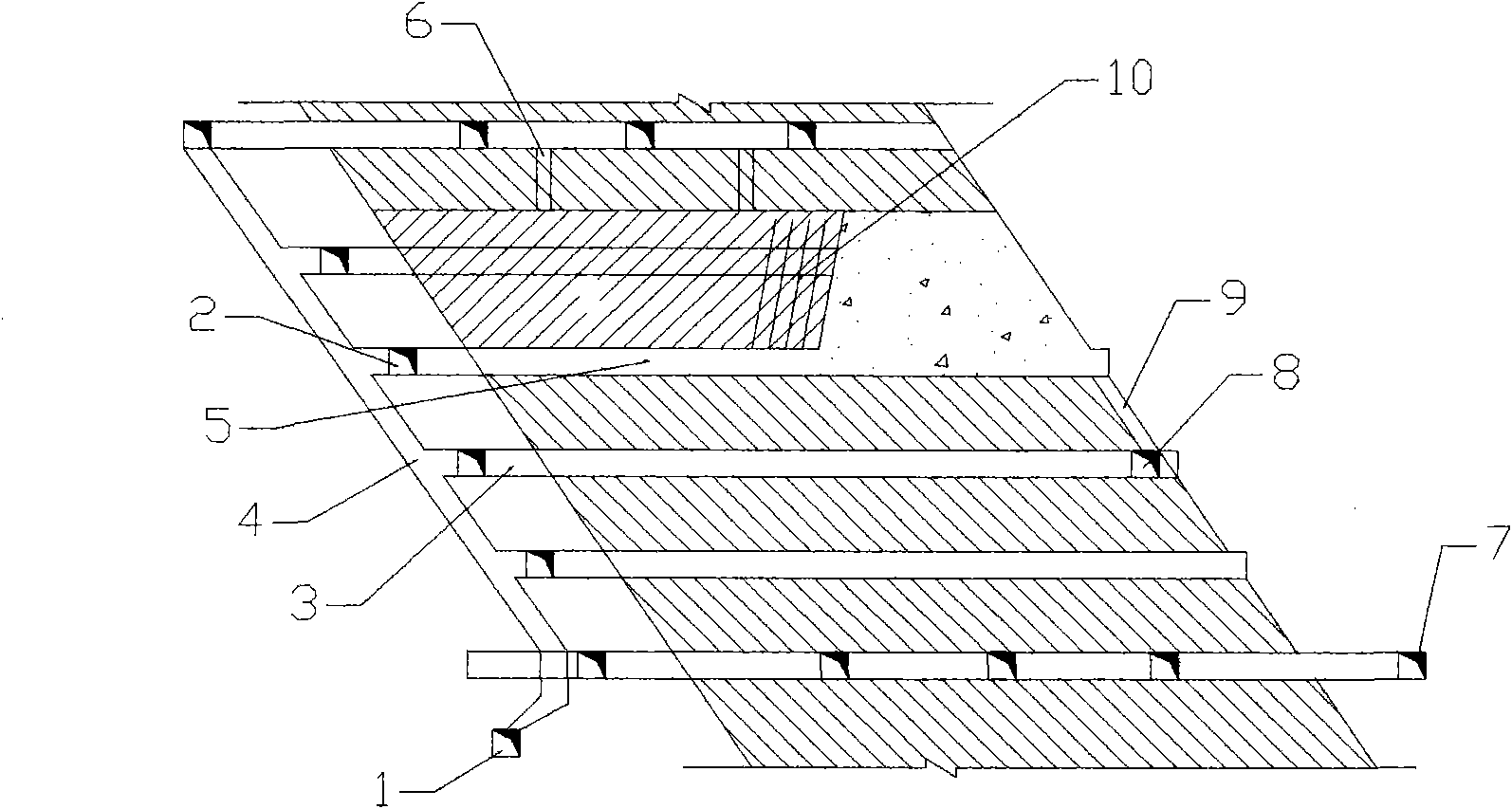

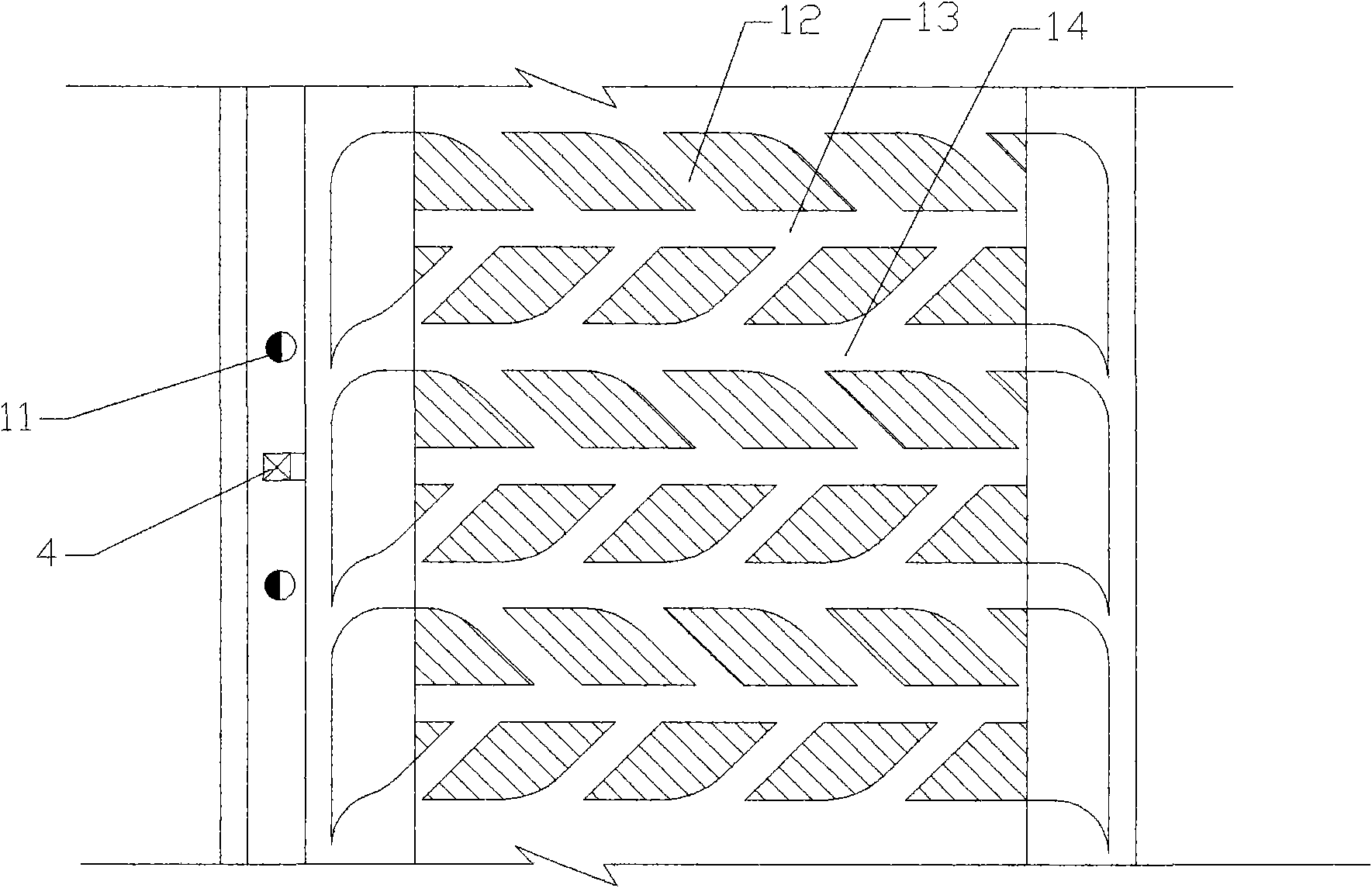

Atomic layer deposition equipment

ActiveCN104342637AImprove processing efficiencyIncrease production capacityChemical vapor deposition coatingEngineeringAtomic layer deposition

Provided atomic layer deposition equipment comprises a reaction chamber and a gas source; the reaction chamber is inside provided with a gas distribution plate arranged at the top, a base disc and a rotary driving mechanism; the upper surface of the base disc and the lower surface of the gas distribution plate are mutually superposed; multiple sub-spaces uniformly distributed along the circumferential direction of the reaction chamber at intervals are formed between the upper surface of the base disc and the lower surface of the gas distribution plate, the multiple sub-spaces are successively arranged according to the operation sequence, and each sub-space is corresponding to one operation in a process of performing once technology on a base chip; and the rotary driving mechanism is used to drive the base disc to rotate relatively to the gas distribution plate so as to enable the base disc to drive all base chips thereon to be successively placed into the multiple sub-spaces for technological processing according to the operation sequence. The provided atomic deposition equipment is capable of processing multiple base chips at the same time by using different operations, thereby improving the technological efficiency and further improving the production power.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Atomic layer deposition equipment

ActiveCN104233226AImprove processing efficiencyIncrease production capacityChemical vapor deposition coatingSingle processProcess efficiency

The invention provides atomic layer deposition equipment. The atomic layer deposition equipment comprises a reaction chamber which comprises a plurality of sub chambers and a drive unit, wherein a plurality of process positions are arranged on the same horizontal plane in the reaction chamber, the plurality of process positions are arranged at intervals along the peripheral direction of the reaction chamber, and are uniformly arranged in sequence according to the sequence of processes, the quantity and positions of the sub chambers are in one-to-one correspondence with those of the process positions, and each sub chamber is used for completing one process of single processes for a substrate in each sub chamber; the drive unit is used for enabling each substrate to complete the corresponding process in the sub chamber placed on the position of each process according to the sequence of the process. The automatic layer deposition equipment provided by the invention can be used for processing a plurality of substrates at the same time by a single process, so that the process efficiency is improved, and thus, the yield is increased.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

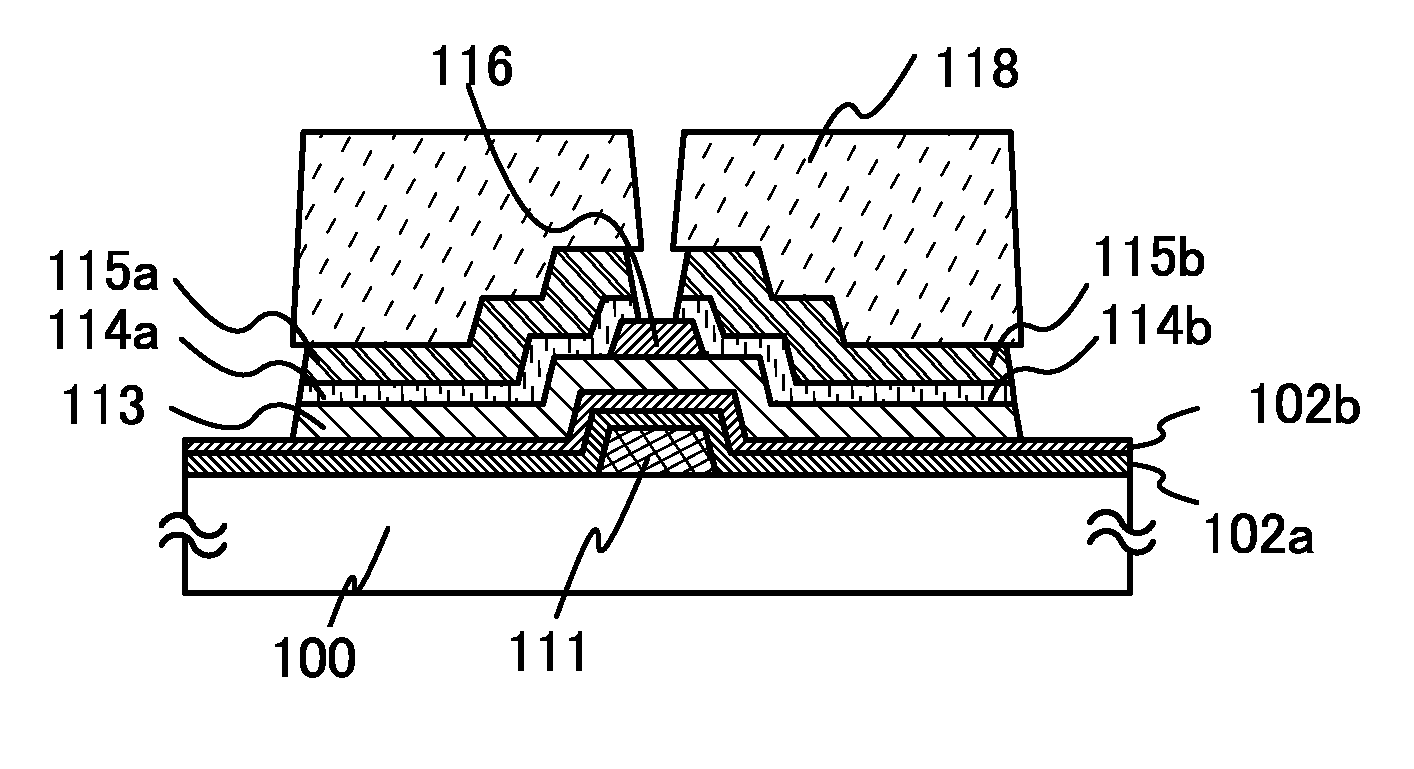

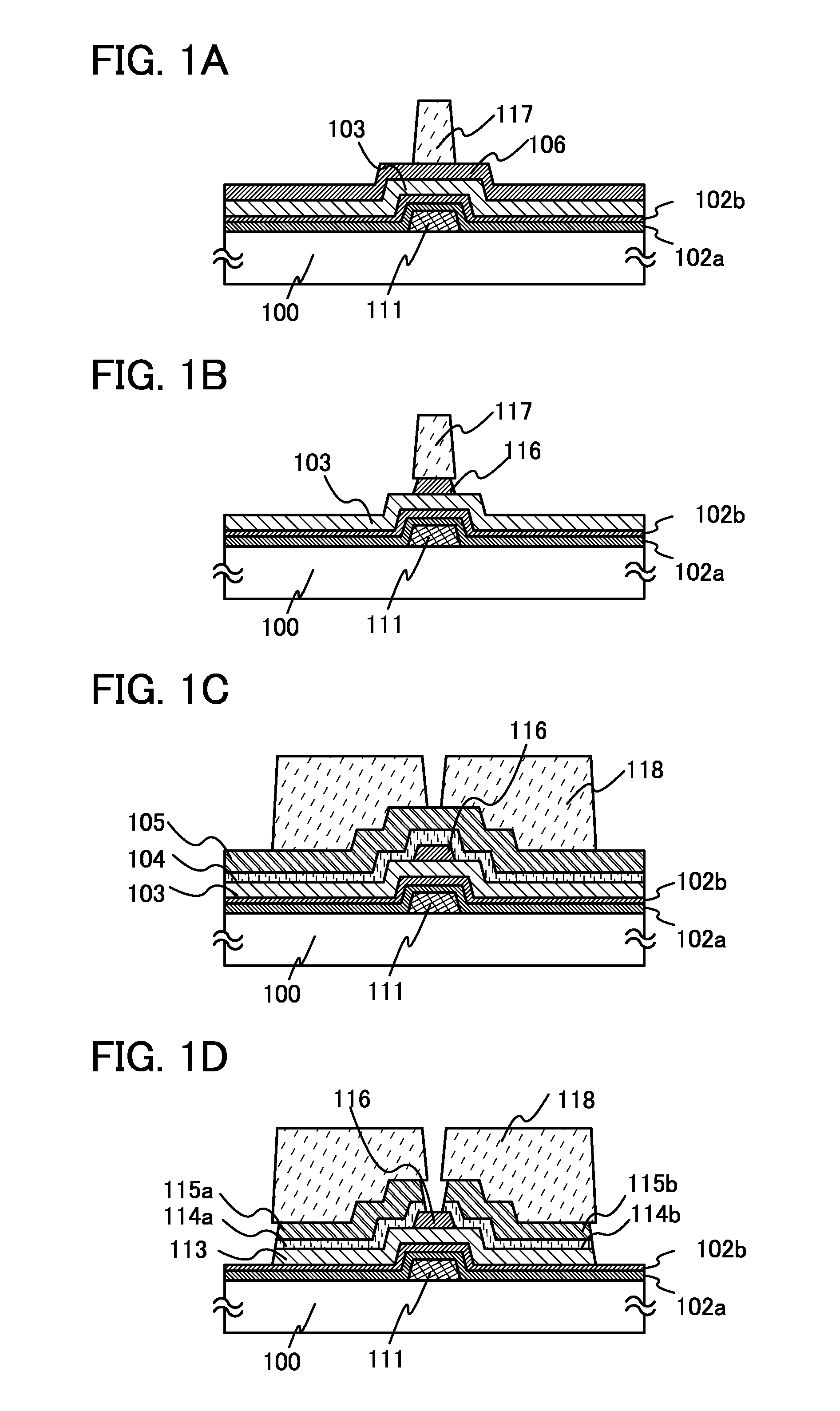

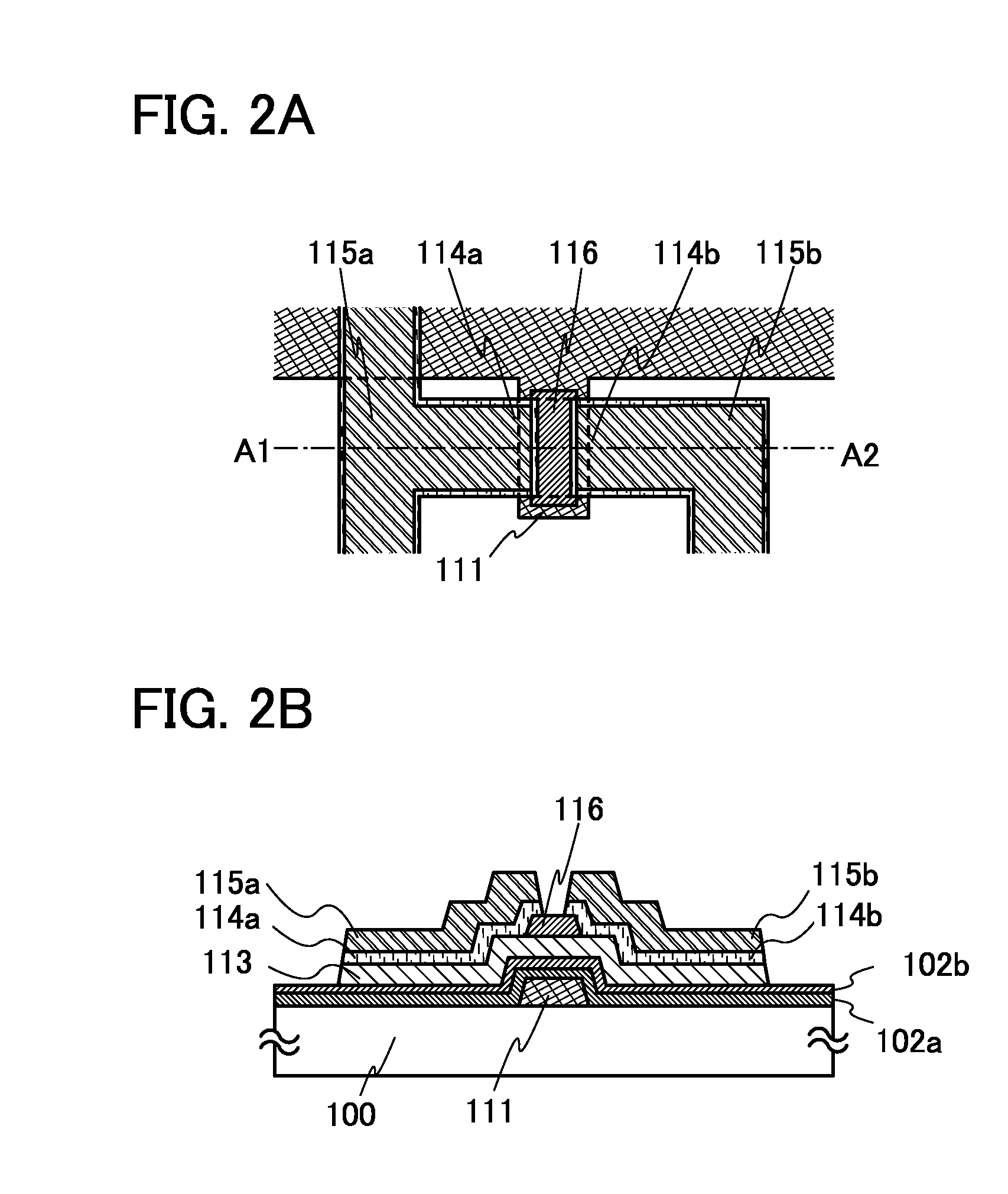

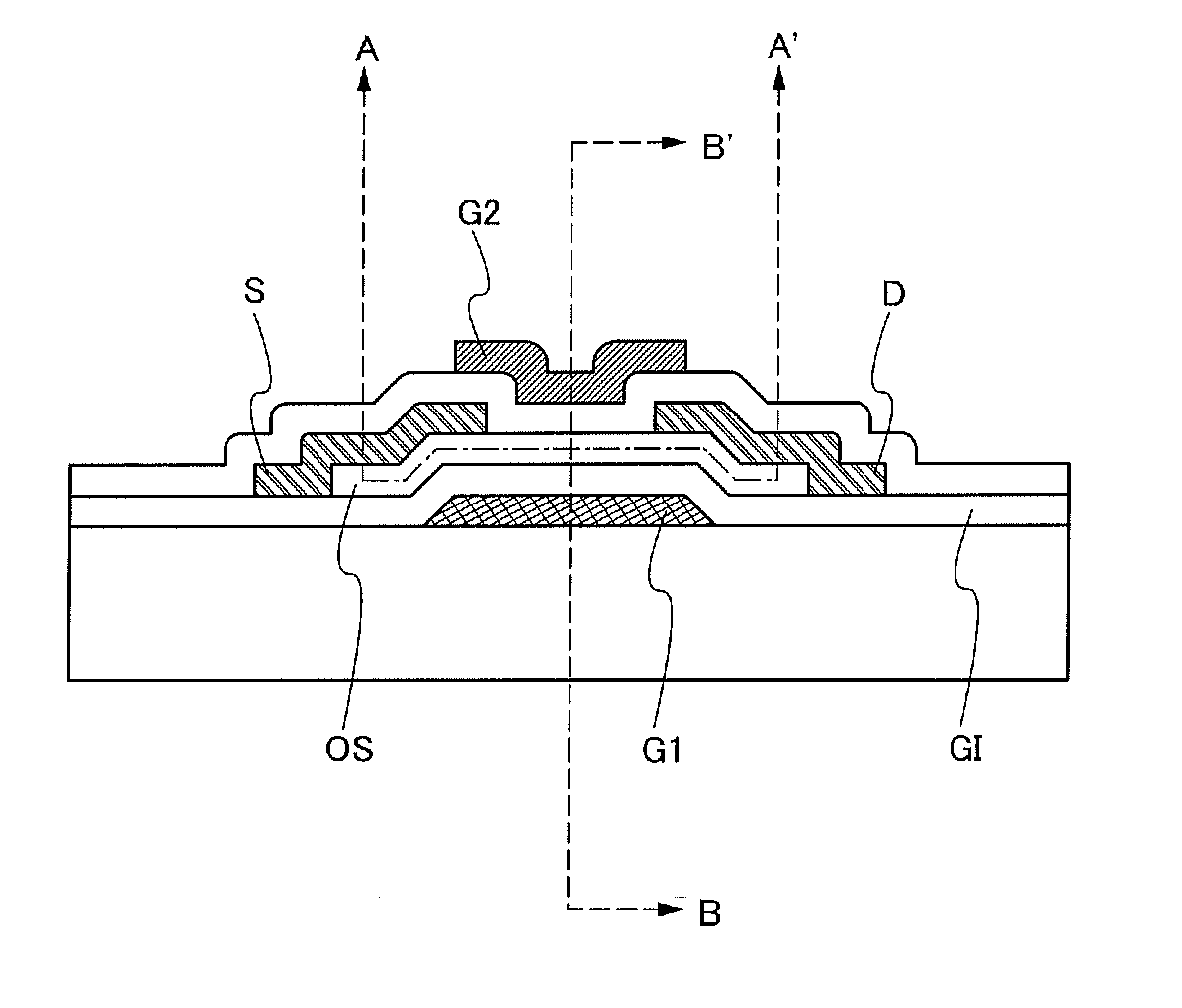

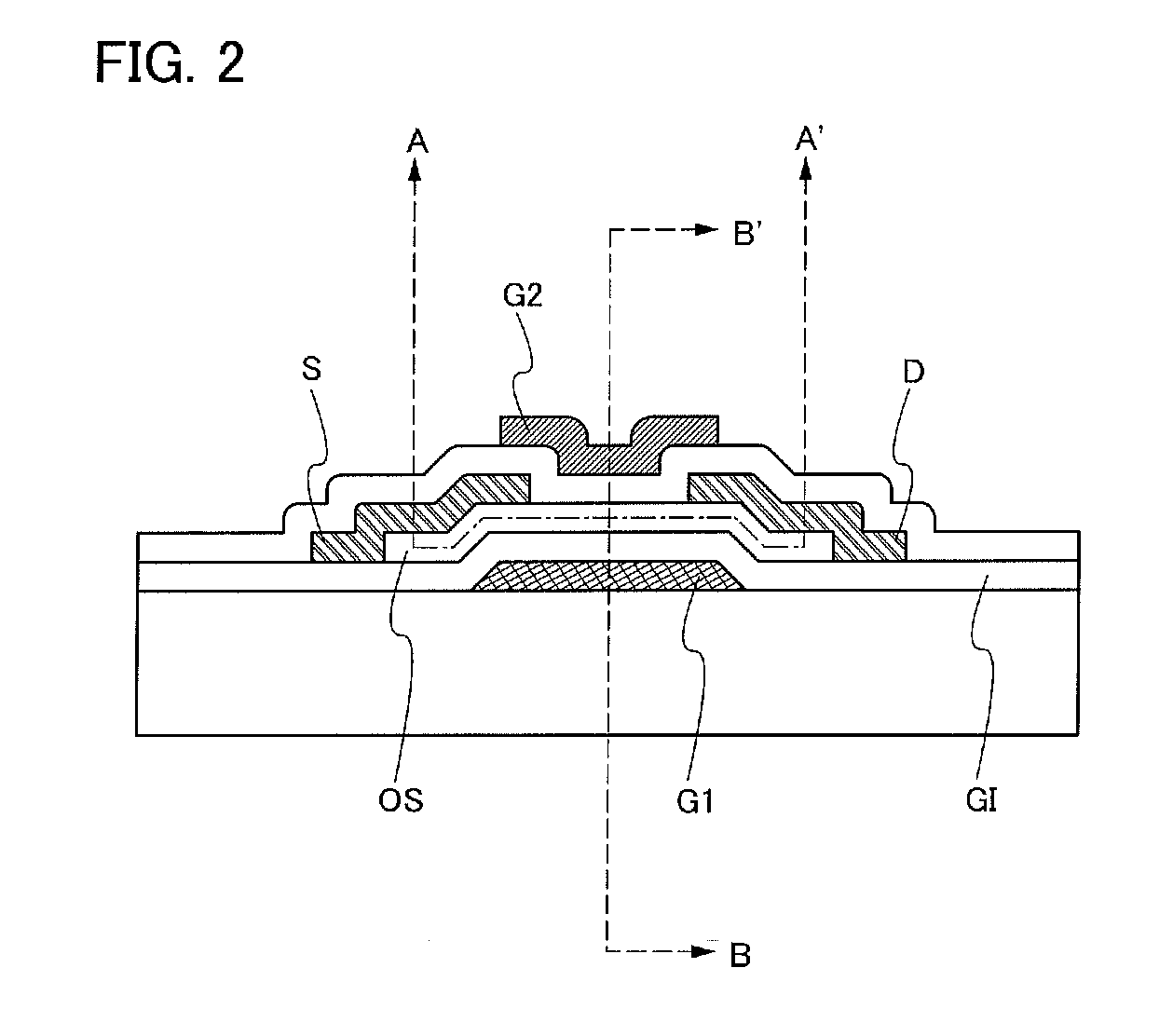

Method for manufacturing semiconductor device

ActiveUS20100035379A1Small photocurrentLow parasitic capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingOxide semiconductorResist

To provide a method by which a semiconductor device including a thin film transistor with excellent electric characteristics and high reliability is manufactured with a small number of steps. After a channel protective layer is formed over an oxide semiconductor film containing In, Ga, and Zn, a film having n-type conductivity and a conductive film are formed, and a resist mask is formed over the conductive film. The conductive film, the film having n-type conductivity, and the oxide semiconductor film containing In, Ga, and Zn are etched using the channel protective layer and gate insulating films as etching stoppers with the resist mask, so that source and drain electrode layers, a buffer layer, and a semiconductor layer are formed.

Owner:SEMICON ENERGY LAB CO LTD

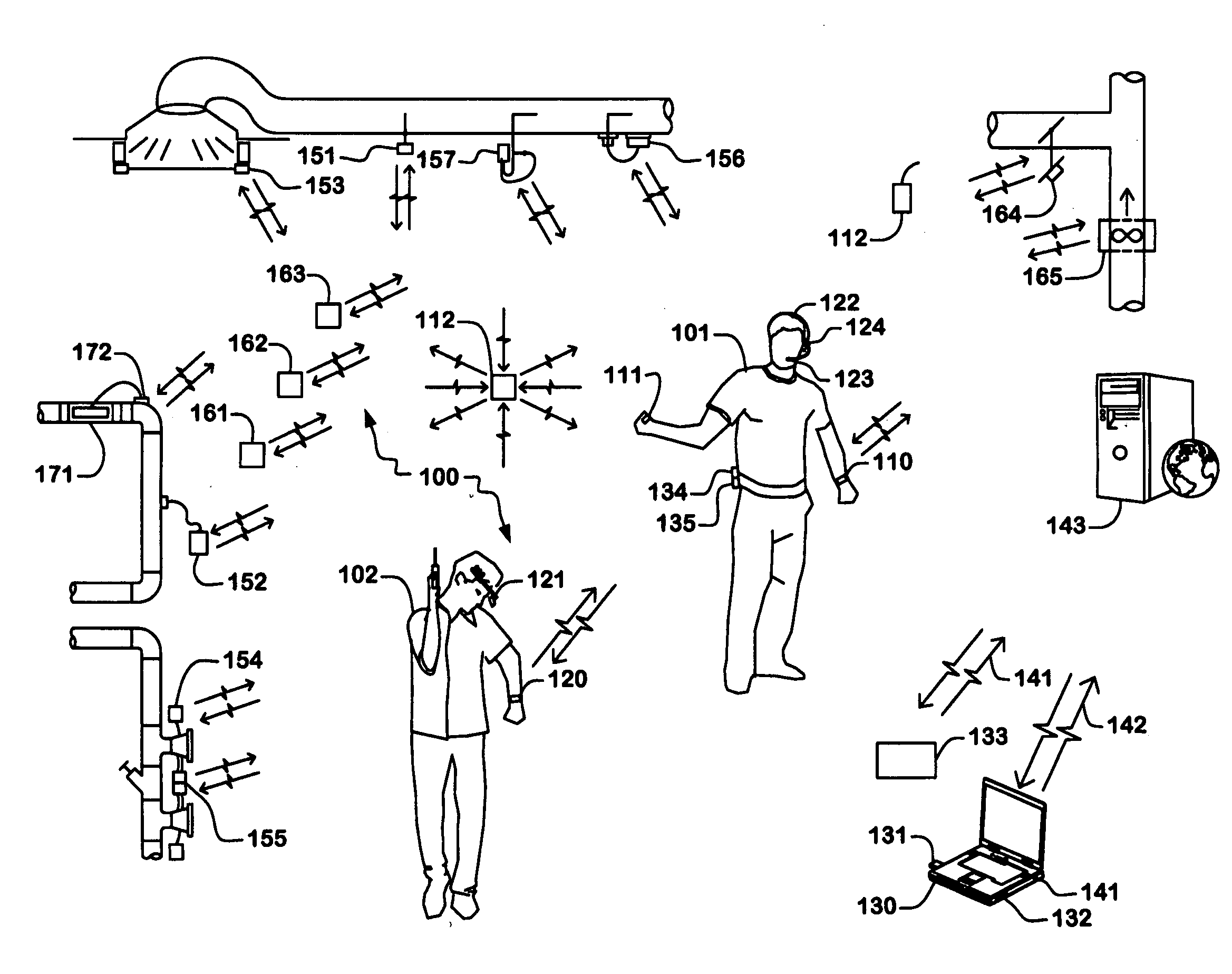

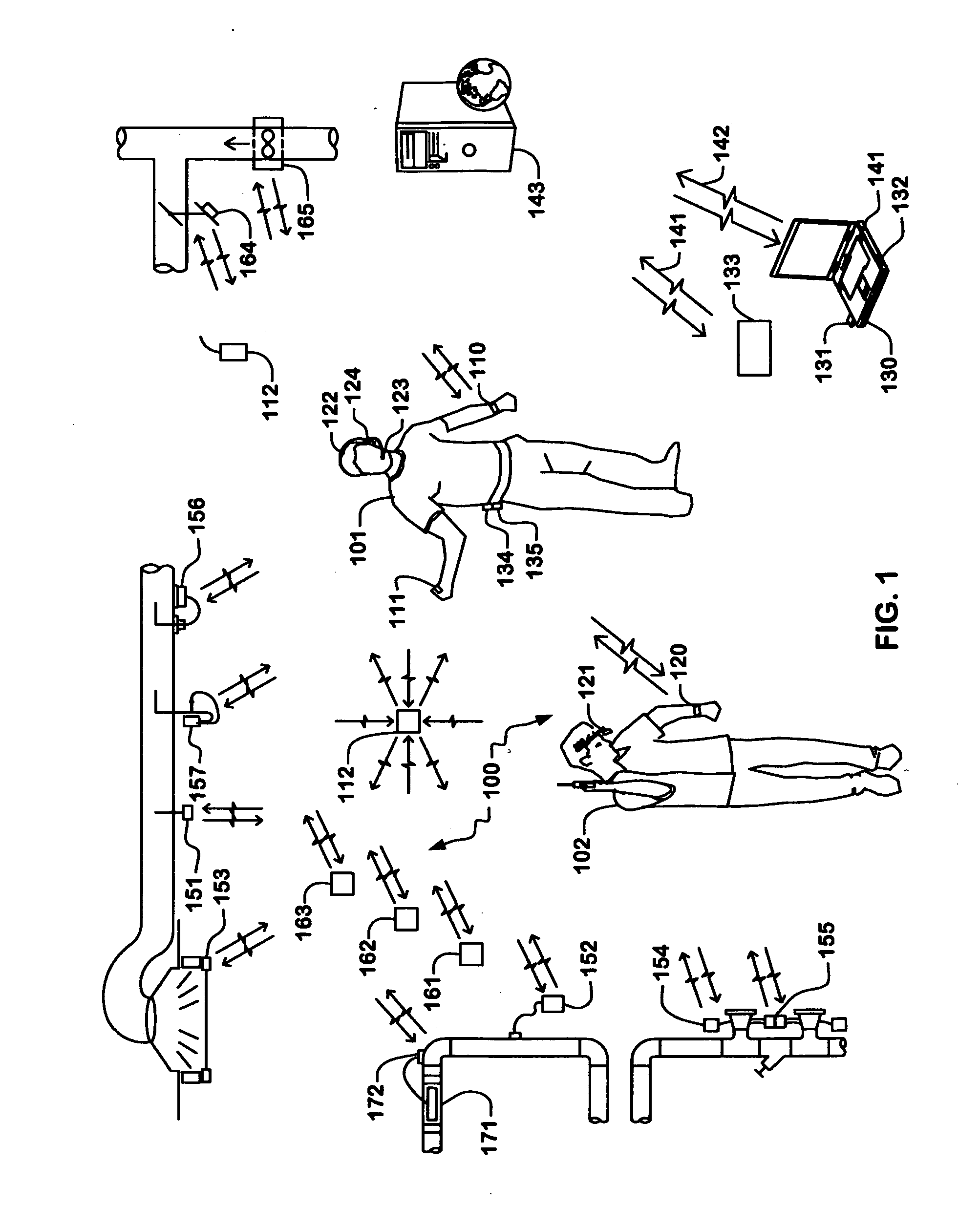

Wireless sensors system and method of using same

ActiveUS20120046792A1Improve understandingAct quicklySpace heating and ventilationTemperatue controlEngineeringWater temperature

An apparatus, system, and methods for measuring environmental parameters are disclosed. The apparatus, system, and methods can be used for a variety of applications, including HVAC air balancing and building commissioning. The system includes a variety of wireless sensing modules and wearable modules for control, display, and storage. Parameters measured include air and water temperature, pressure, velocity, and flow. Also included are sensors for light intensity, CO concentrations, and CO2 concentrations.

Owner:EVERGREEN TELEMETRY LLC

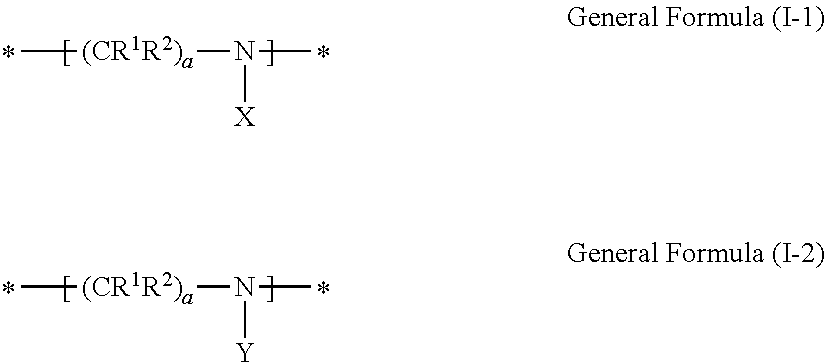

Resin, pigment dispersion, colored curable composition, color filter produced using the same, and method for producing the same

ActiveUS20110003241A1High color purityIncrease contrastPhotosensitive materialsOptical filtersOligomerBackbone chain

A resin including (i) a main chain portion containing a nitrogen atom, (ii) a group X that has a functional group having a pKa of 14 or less and is bonded to a nitrogen atom present in the main chain portion, and (iii) an oligomer chain or polymer chain Y having a number average molecular weight of from 500 to 1,000,000 in a side chain.

Owner:FUJIFILM CORP

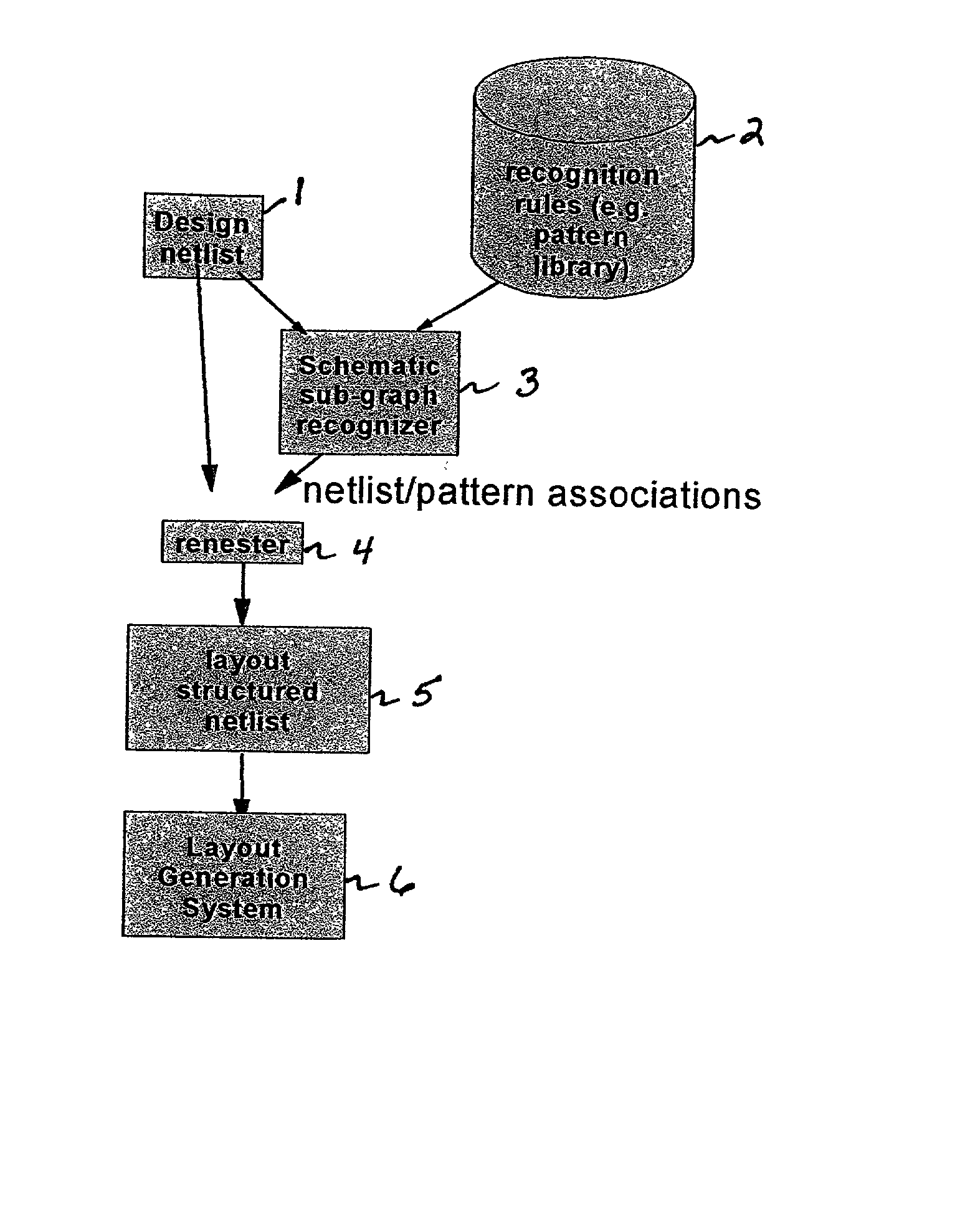

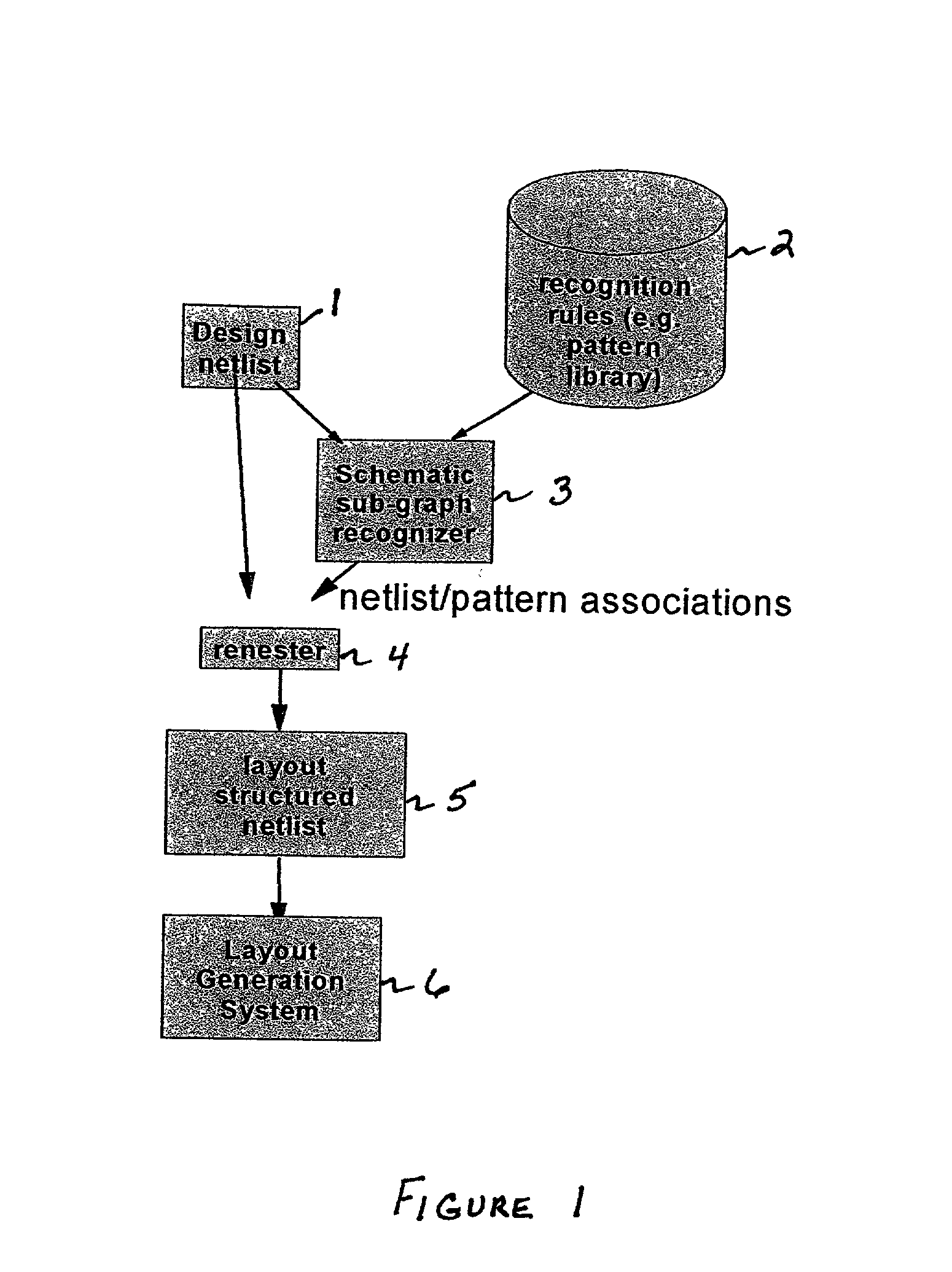

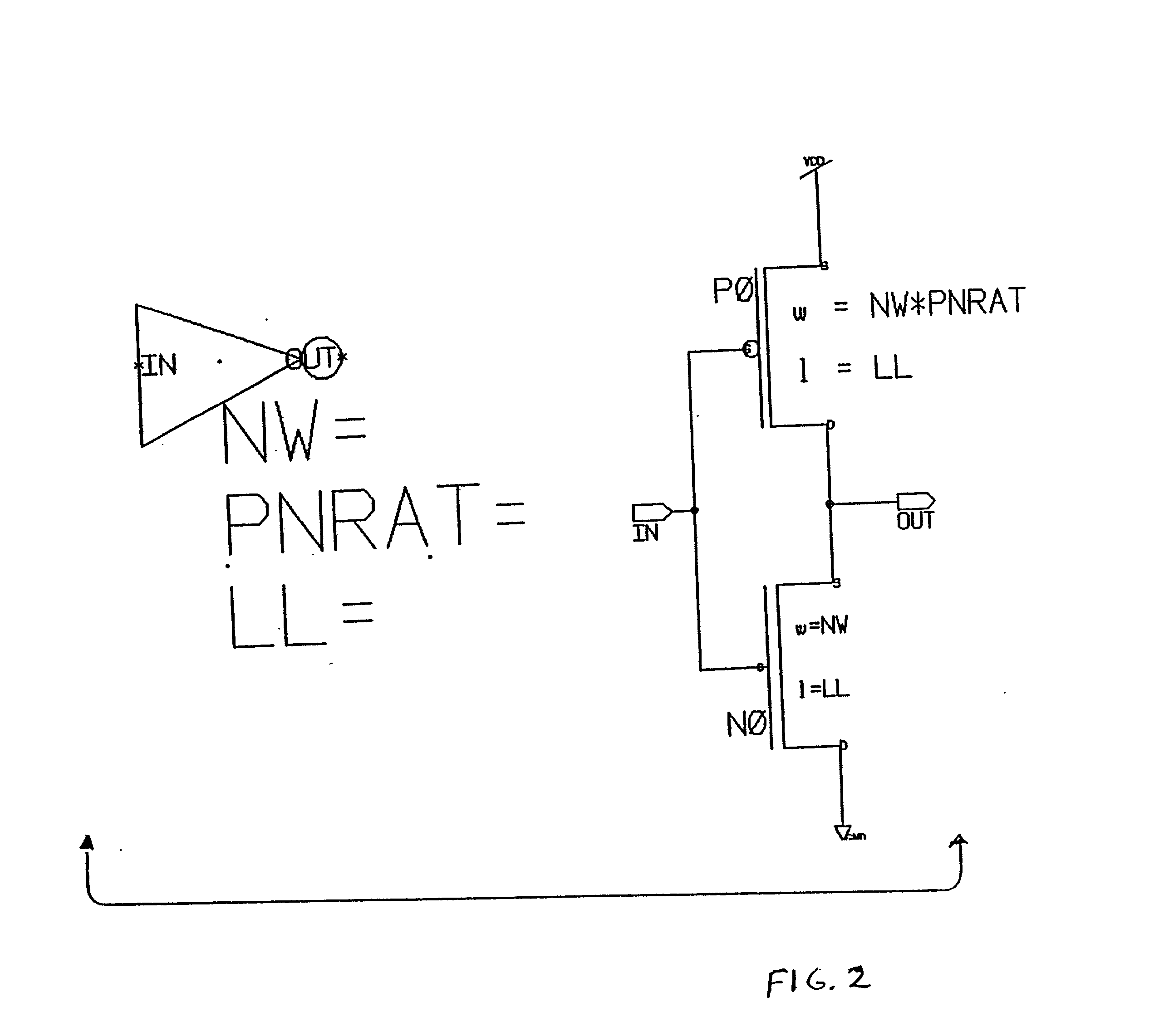

Hierarchical layout method for integrated circuits

InactiveUS20020194575A1Easy to modifyIncrease production capacityCAD circuit designProgram controlComputer architectureGenerative Design

A method for hierarchical layout of an electronic design using an electronic computer aided design system, wherein the method includes generating a parameterized pattern library and using an existing netlist and analyze in a pattern recognizer, from which a list of associations between the pattern library and the netlist is created. Renesting then occurs wherein the netlist using the list of associations is used for generating a hierarchical layout of the electronic components in the design.

Owner:IBM CORP

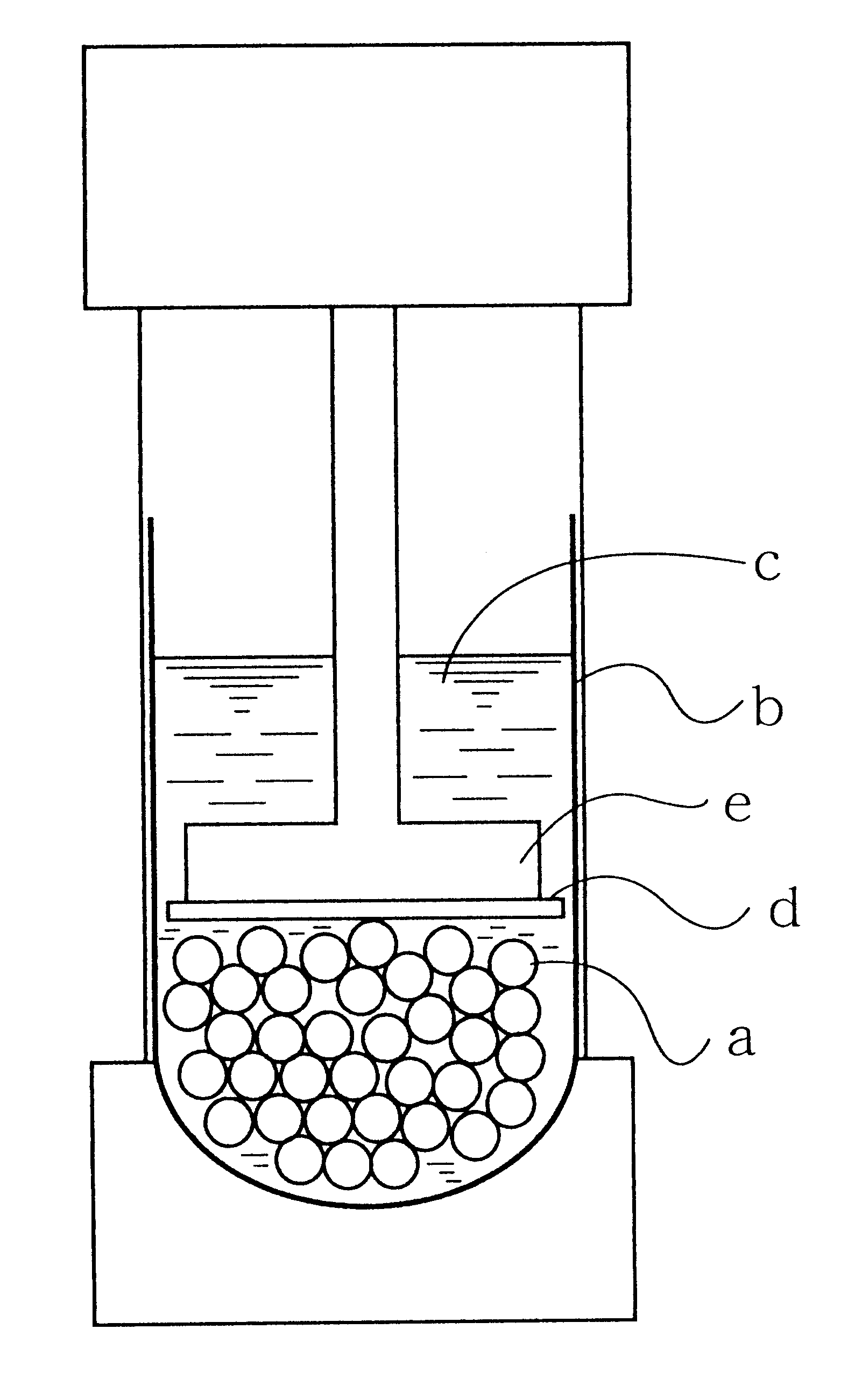

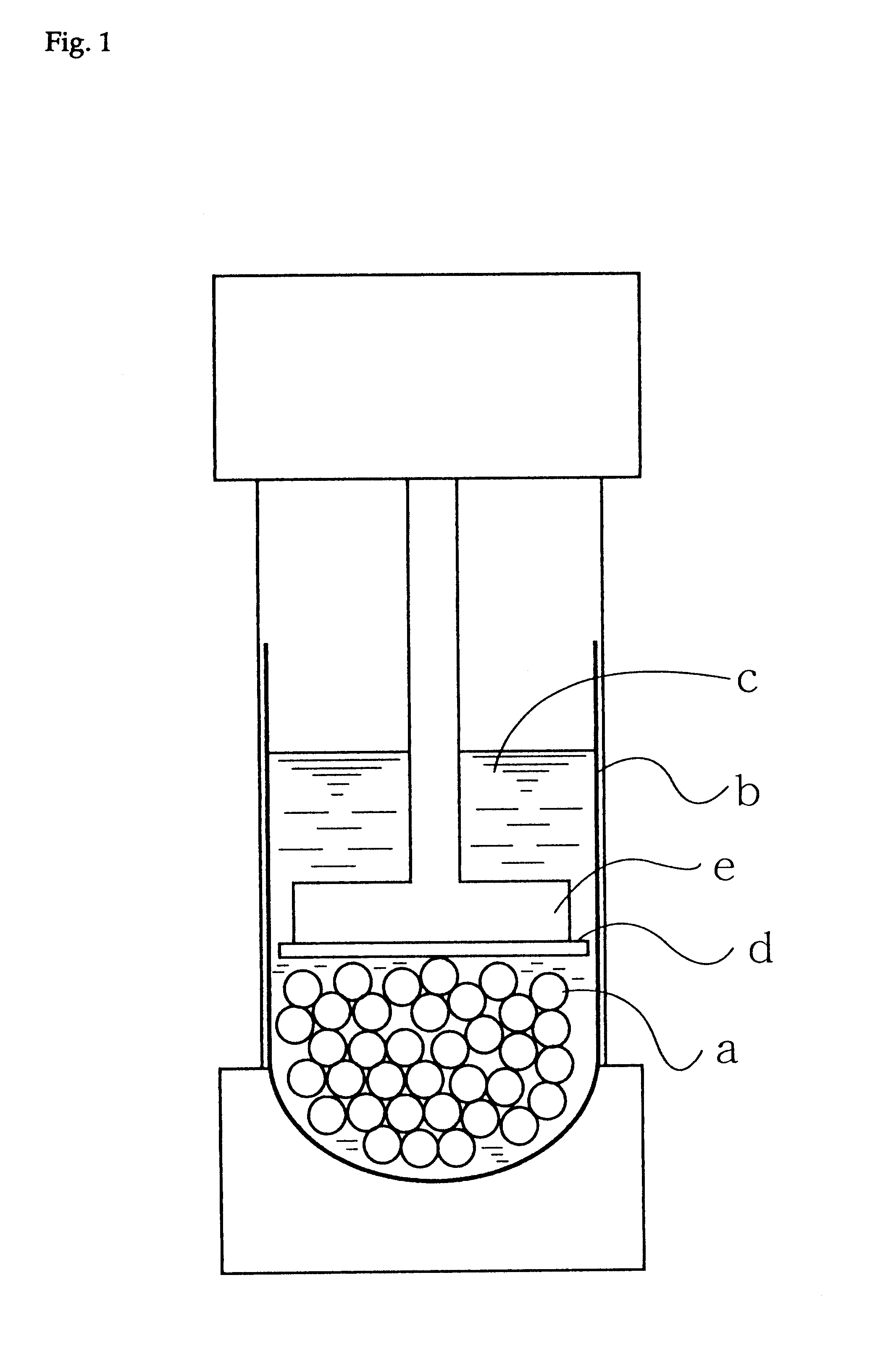

Production process for hydrophilic polymer

InactiveUS6207796B1Low residual monomer contentIncrease production capacityWater contentProduction rate

The present invention provides a production process to obtain a hydrophilic polymer, having a low residual monomer content, with good productivity while keeping the properties of a hydrogel polymer resultant from polymerization. In a drying process for a hydrogel polymer, the hydrogel polymer is dried under normal pressure at a material temperature of not higher than 90° C. until the water content of the hydrogel polymer reduces to 15~40 weight %, and then the hydrogel polymer is kept for not shorter than 10 minutes either in a state where the change of the water content of the hydrogel polymer is within 5 weight % and where the material temperature is in the range of 70~120° C. or in a state where the water content of the hydrogel polymer is in the range of 15~40 weight % and where the material temperature is in the range of 70~120° C., and then the hydrogel polymer is finish-dried.

Owner:NIPPON SHOKUBAI CO LTD

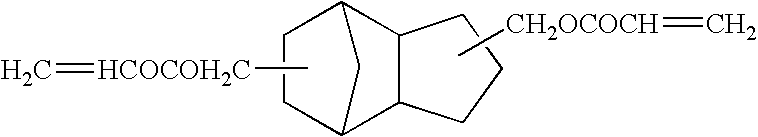

Radiation-curable liquid resin composition for coating optical fibers

InactiveUS6136880AConvenient coatingLow viscositySynthetic resin layered productsYarnPhotoinitiatorChemistry

Owner:DSM IP ASSETS BV

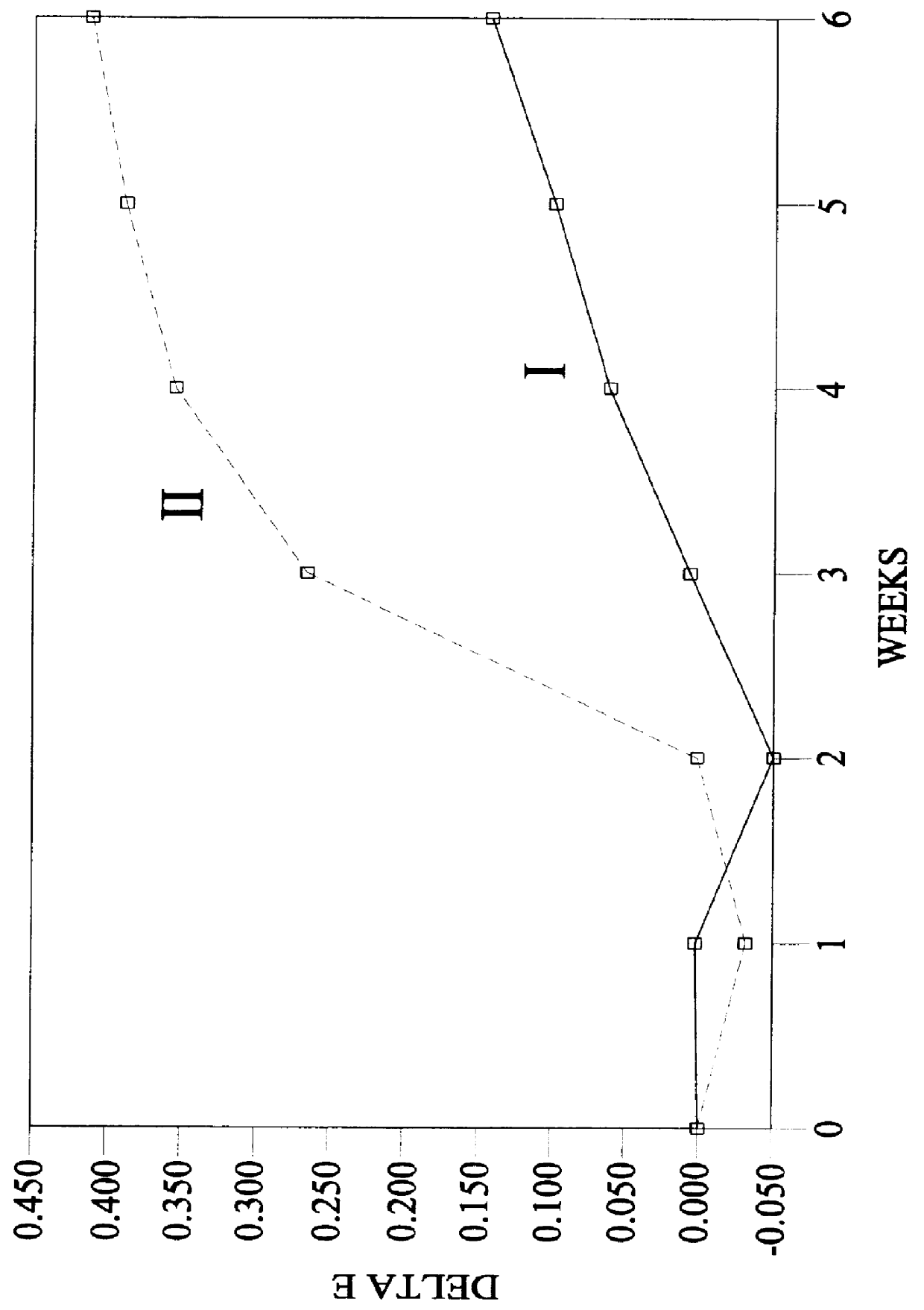

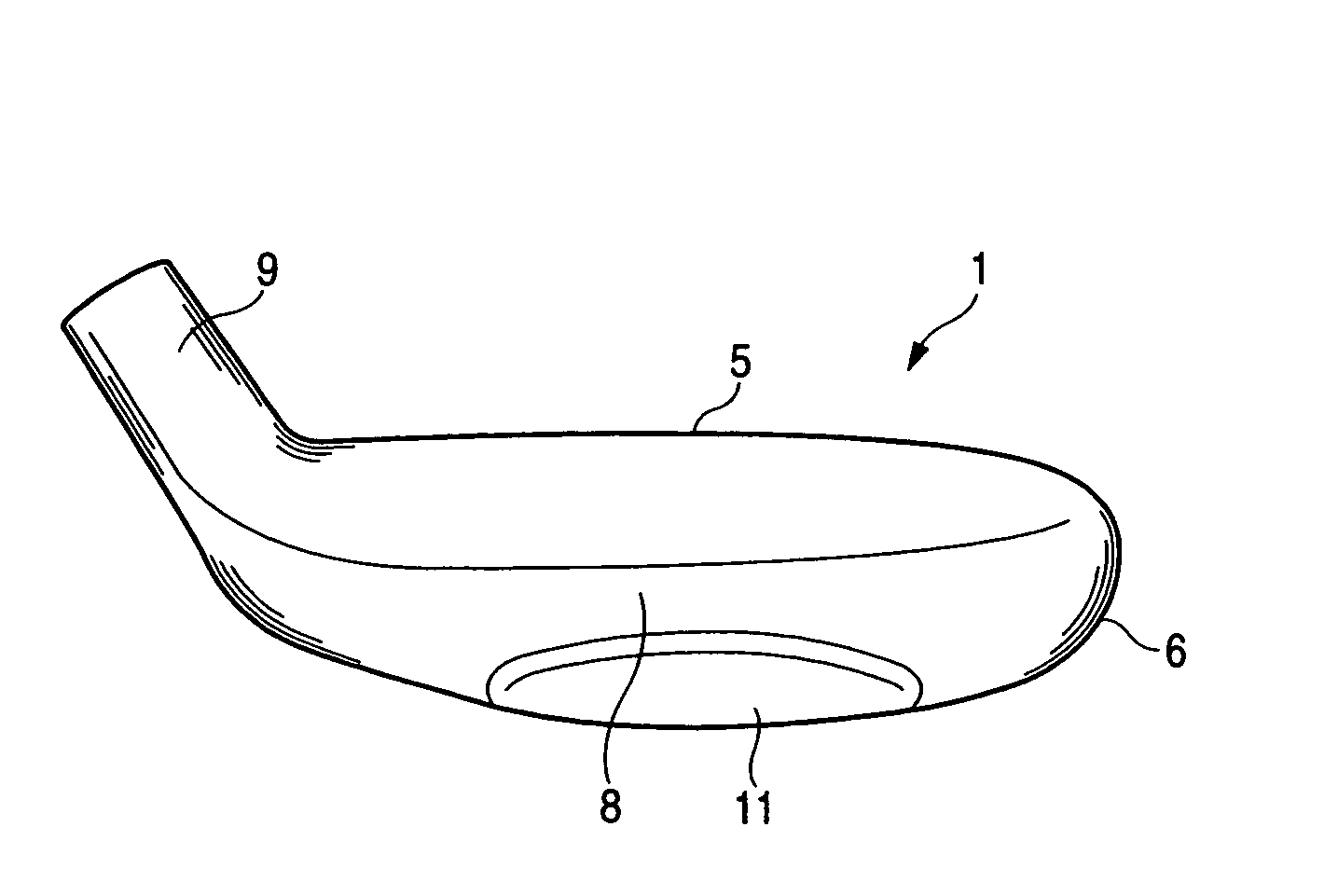

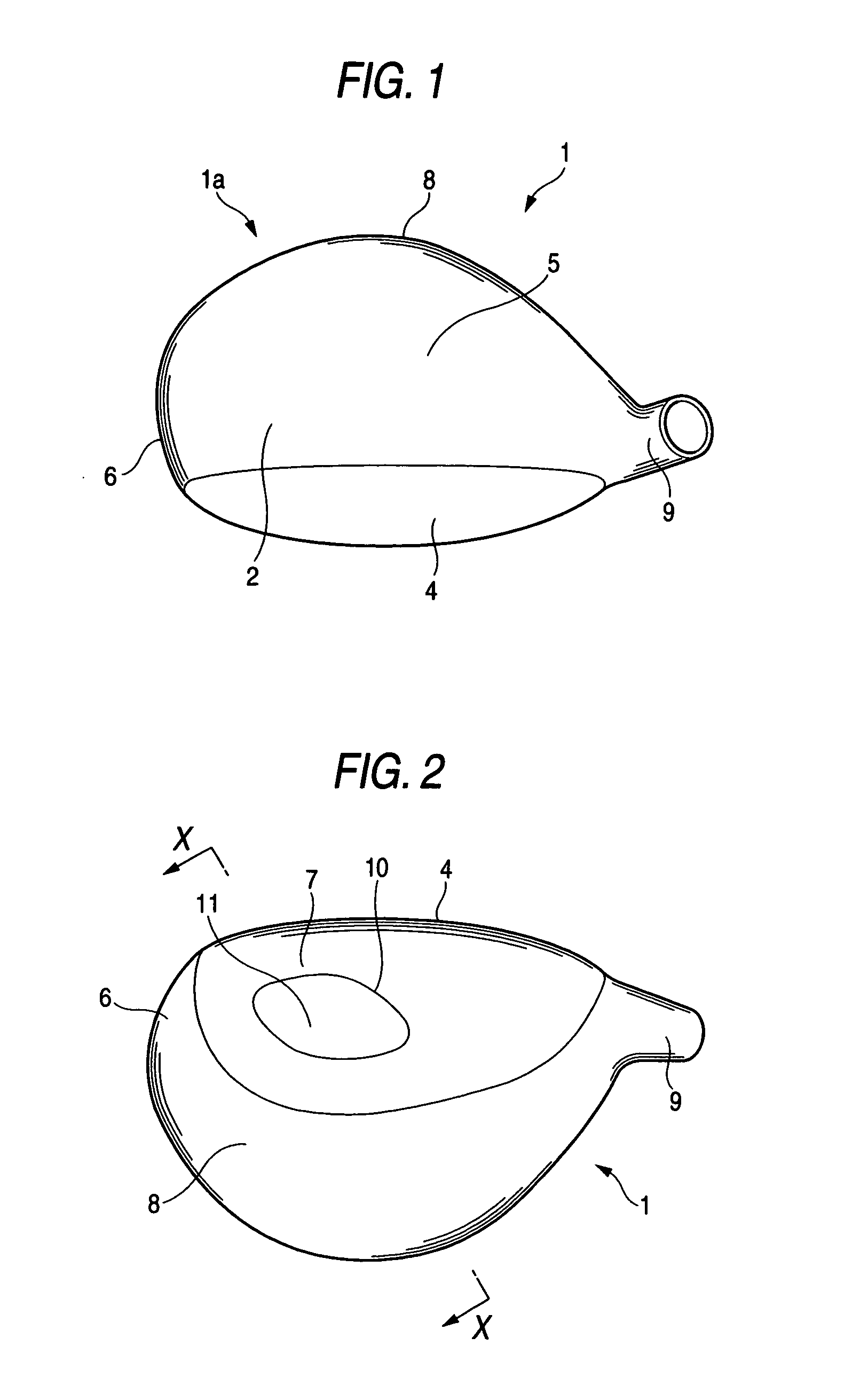

Golf club head

InactiveUS7326472B2Increase production capacityAccurate settingThin material handlingGolf clubsEngineeringGolf Ball

A head body of a golf club head has a hollow portion defined by an outer wall. An opening portion is provided in a part of the head body. A small tungsten alloy piece having a shape fittable to the opening portion so as to cover the opening portion is fixedly attached to the opening portion by welding. The golf club head defines the opening portion in a part of the metal head body and has the small tungsten alloy piece fitted and joined to the opening portion by welding so that the golf club head can be reduced in weight because of provision of the hollow portion. Since the small tungsten alloy piece is joined to the opening portion by welding, difficult plastic forming is not required particularly, and the weight can be adjusted easily and accurately.

Owner:BRIDGESTONE SPORTS

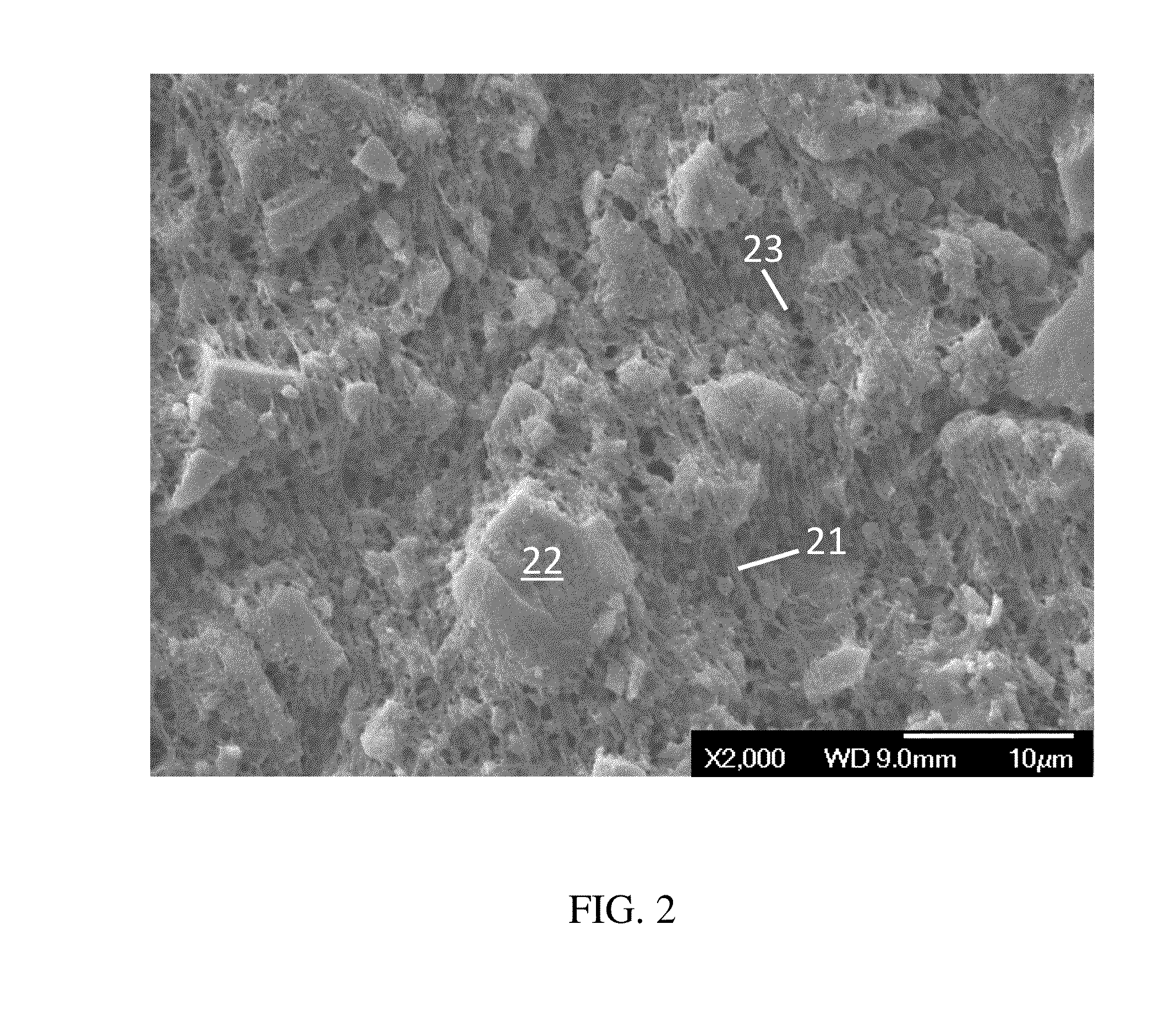

Method for preparing liquid colloidal dispersion of silver particles, liquid colloidal dispersion of silver particles, and silver conductive film

InactiveUS20060264518A1Good dispersionHighly conductive filmMaterial nanotechnologyOther chemical processesScreen printingFiltration

A process for producing a fine silver particle colloidal dispersion which can simply form conductive silver layers and antimicrobial coatings by screen printing or the like. The process is characterized by having a reaction step of allowing an aqueous silver nitrate solution to react with a mixed solution of an aqueous iron(II) sulfate solution and an aqueous sodium citrate solution to form an agglomerate of fine silver particles, a filtration step of filtering the resultant agglomerate of fine silver particles to obtain a cake of the agglomerate of fine silver particles, a dispersion step of adding pure water to the cake to obtain a first fine silver particle colloidal dispersion of a water system in which dispersion the fine silver particles have been dispersed in the pure water, and a concentration and washing step of concentrating and washing the first fine silver particle colloidal dispersion of a water system.

Owner:SUMITOMO METAL MINING CO LTD

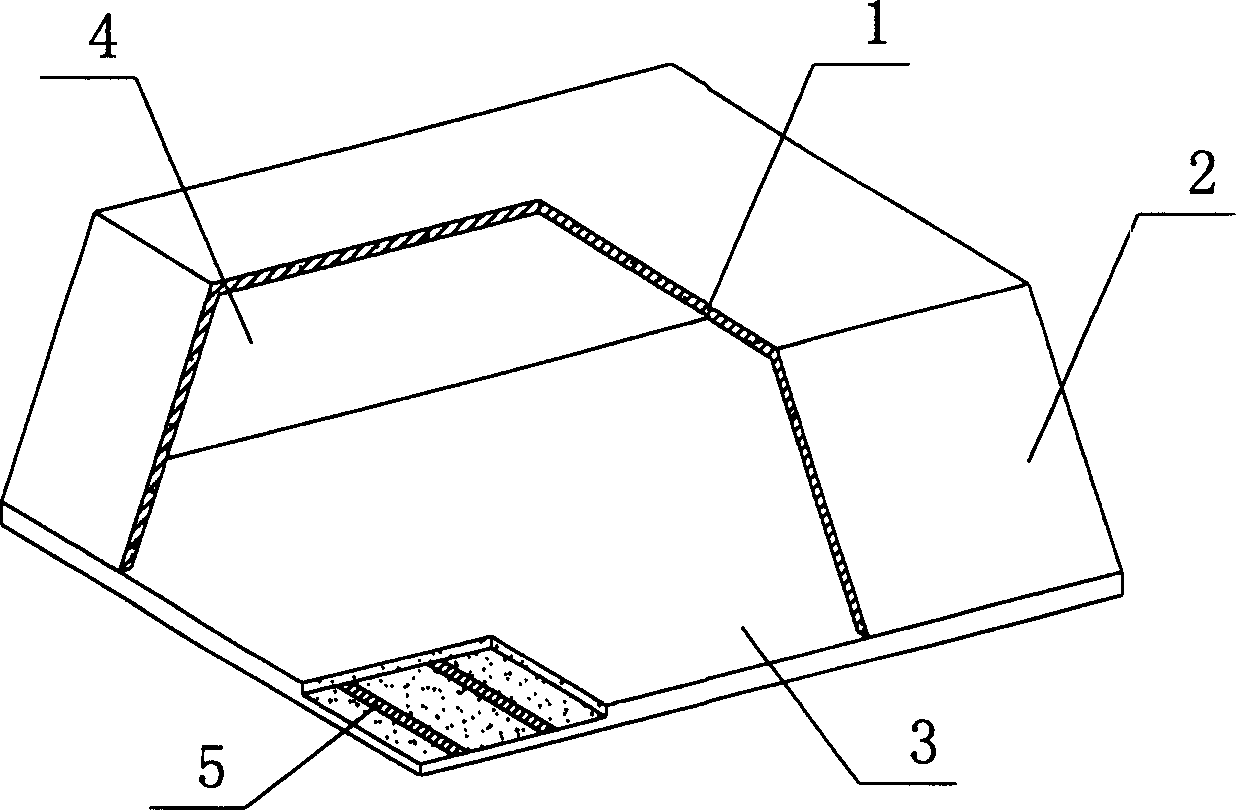

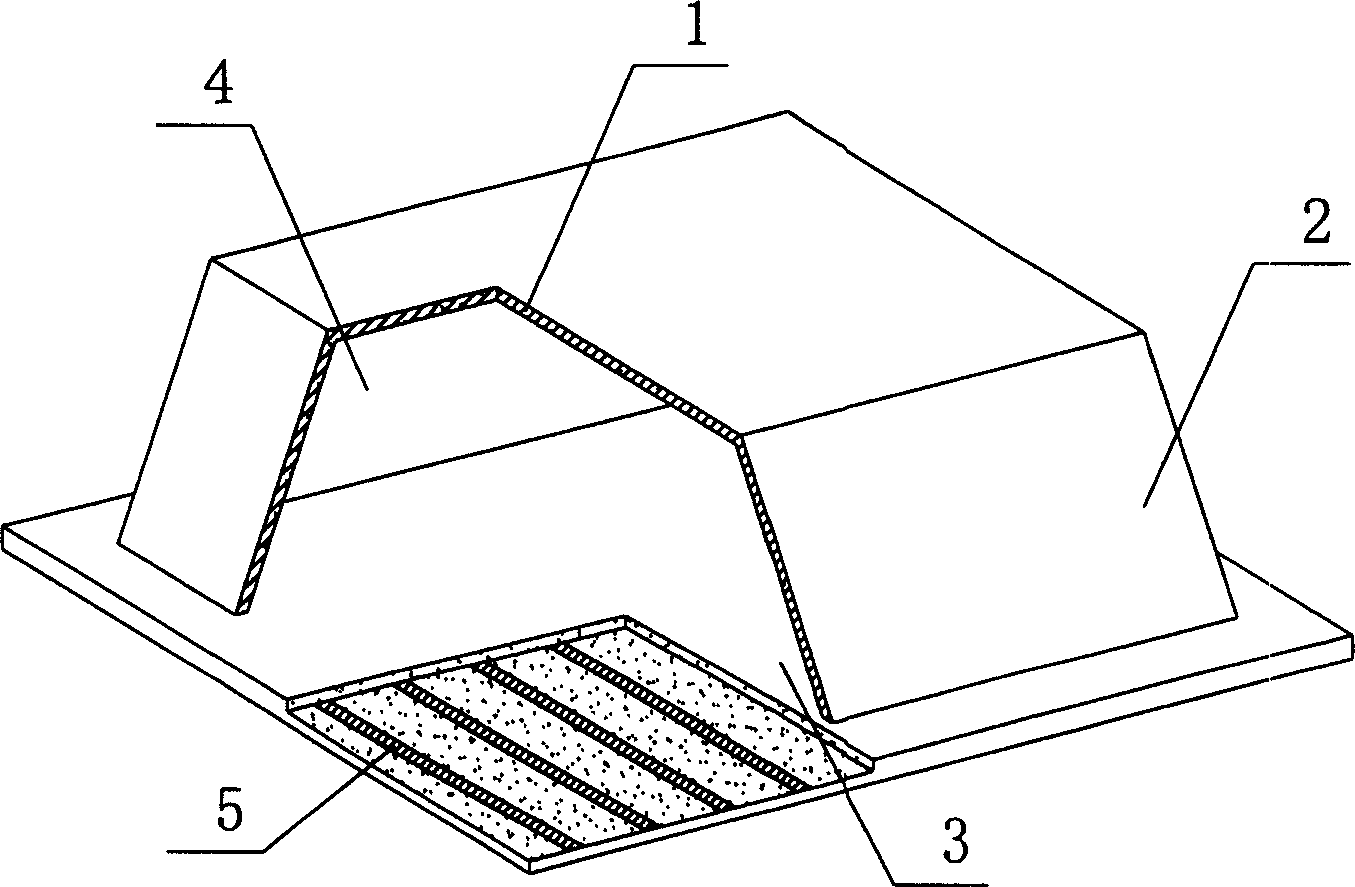

Thin-wall form member for hollowing out concrete

A thin-wall hollow form for concrete to in-situ pour hollow non-beam floor is composed of top plate, peripheral wall and bottom plate, and is characterized by that its bottom plate contains at least one thin strip for improving its resistance to impact and collision. Its advantages are simple structure, high strength, toughness and resistance to deformation and vibration, light weight and low cost.

Owner:湖南邱则有专利战略策划有限公司

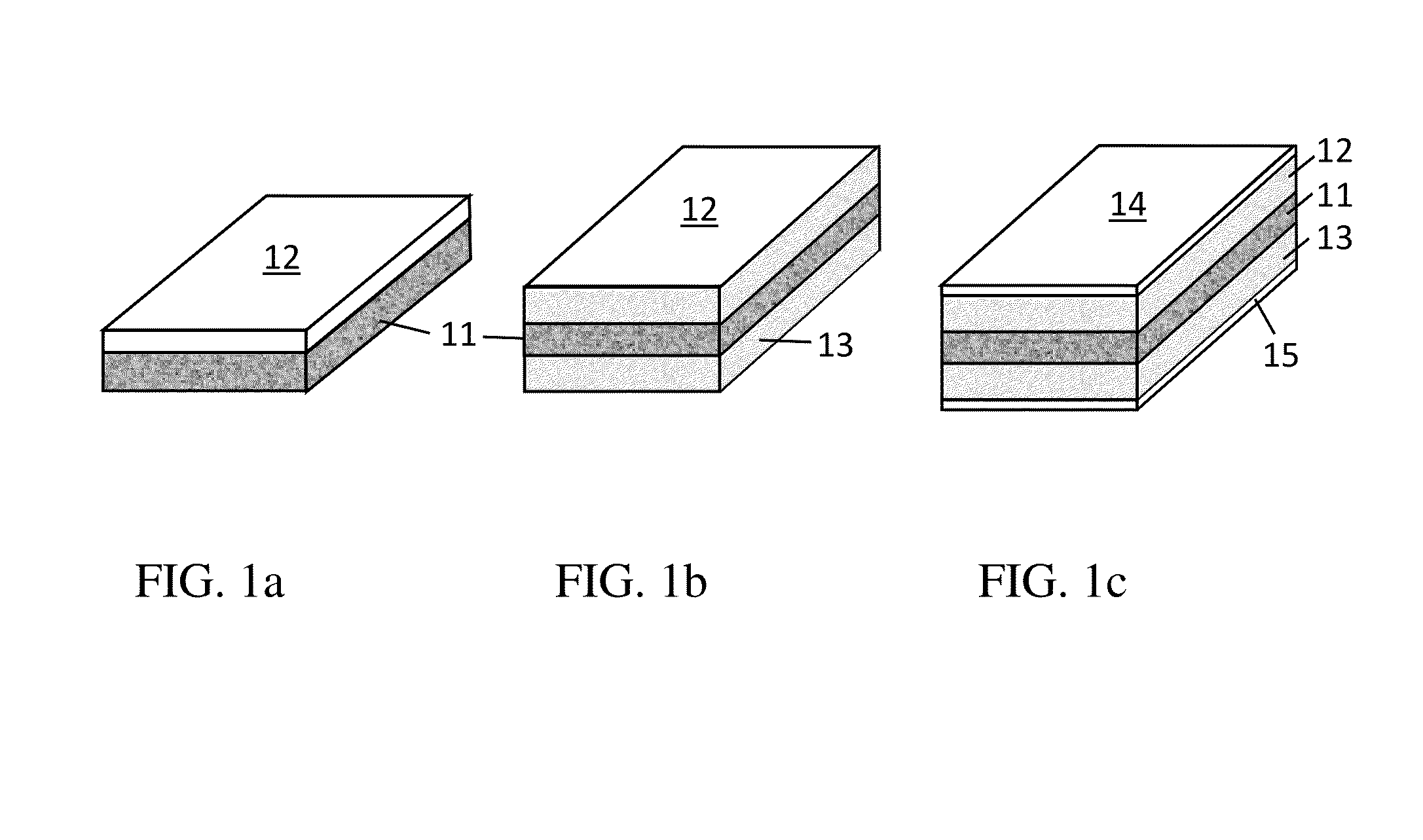

Magnetic recording medium

InactiveUS6939606B2Excellent characteristicsImprove smoothnessMagnetic materials for record carriersBase layers for recording layersNon magneticFerromagnetism

A magnetic recording medium is provided that includes, in order, (1) a non-magnetic support, a radiation-cured layer formed by applying a layer containing a radiation curing compound and curing by exposure to radiation, and a magnetic layer having a ferromagnetic powder dispersed in a binder, or (2) a non-magnetic support, a radiation-cured layer formed by applying a layer containing a radiation curing compound and curing by exposure to radiation, a non-magnetic layer having a non-magnetic powder dispersed in a binder, and a magnetic layer having a ferromagnetic powder dispersed in a binder; the radiation-cured layer including 0.3 to 30 parts by weight of an inorganic powder relative to 100 parts by weight the radiation curing compound.

Owner:FUJIFILM CORP +1

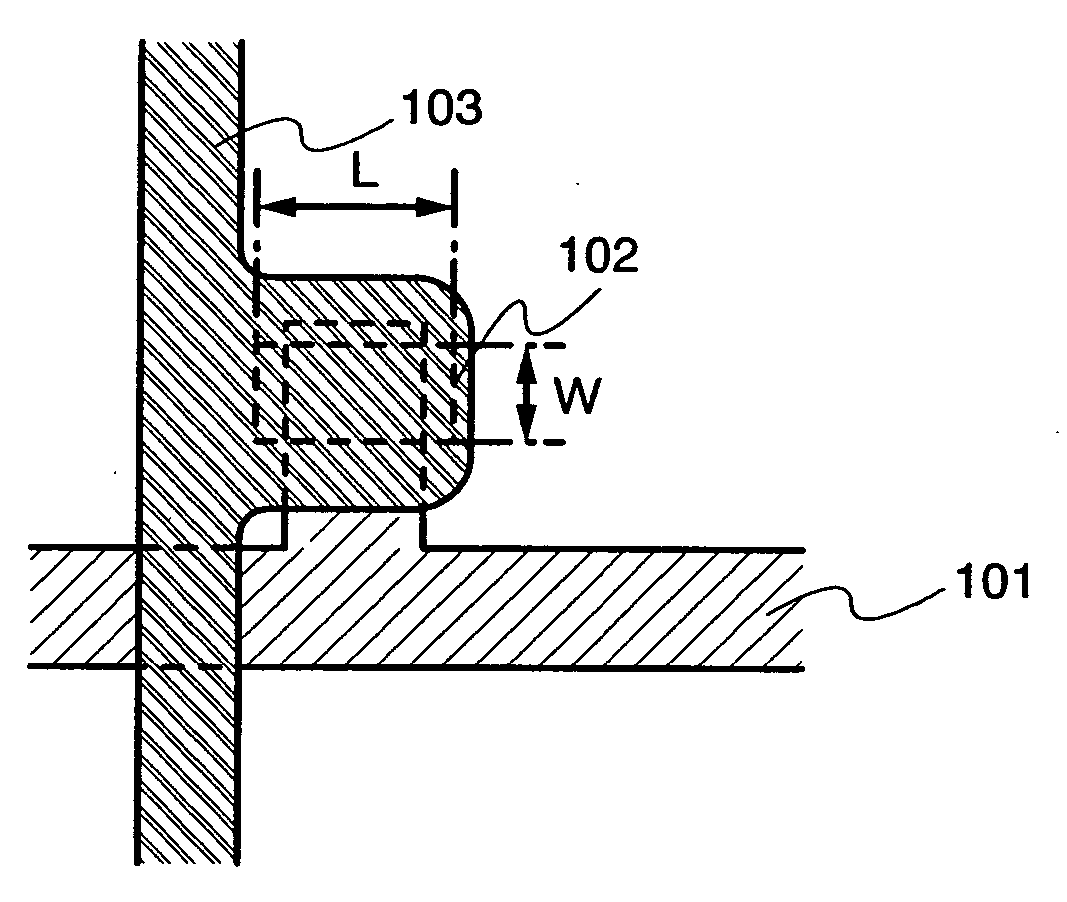

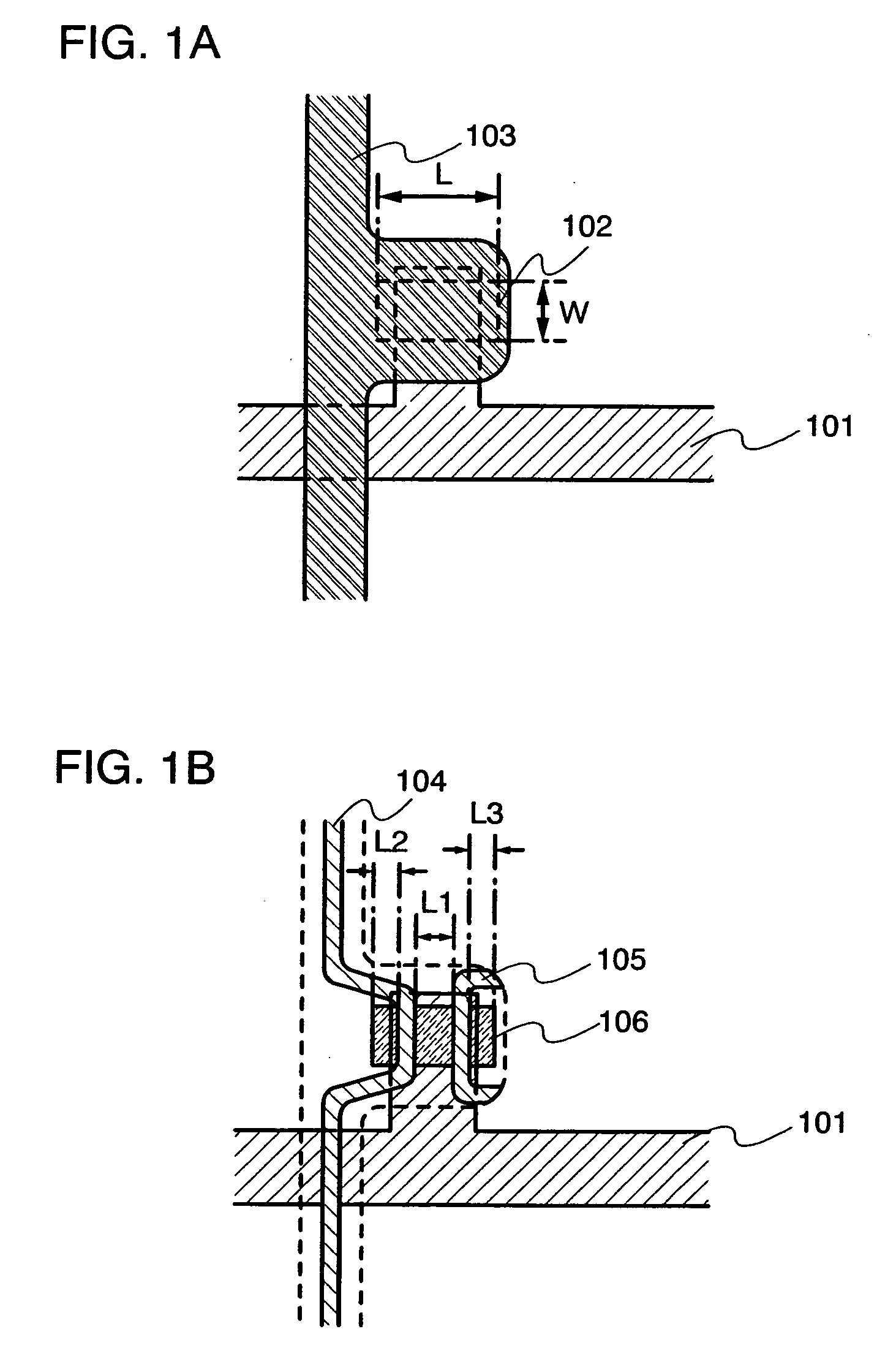

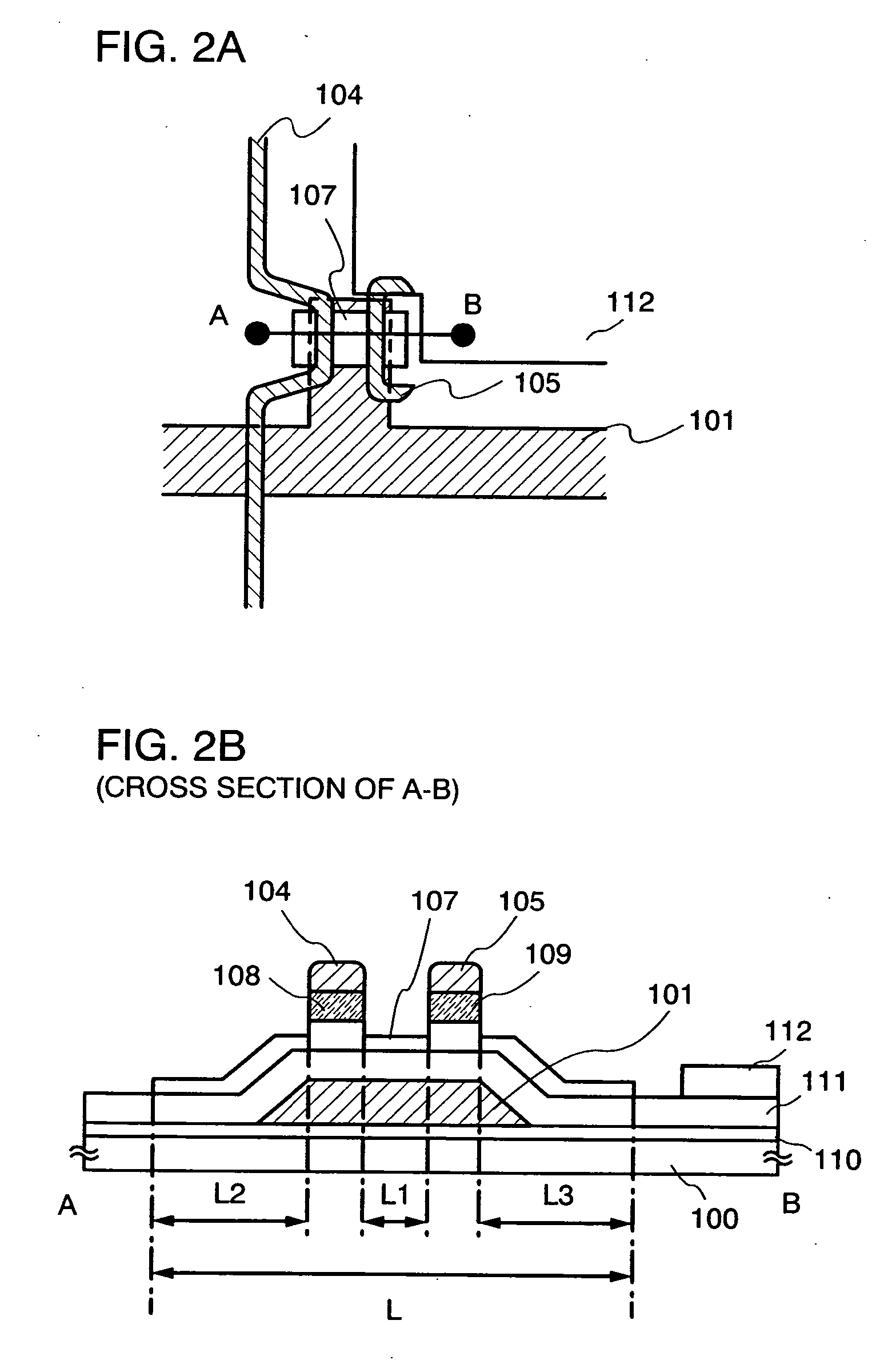

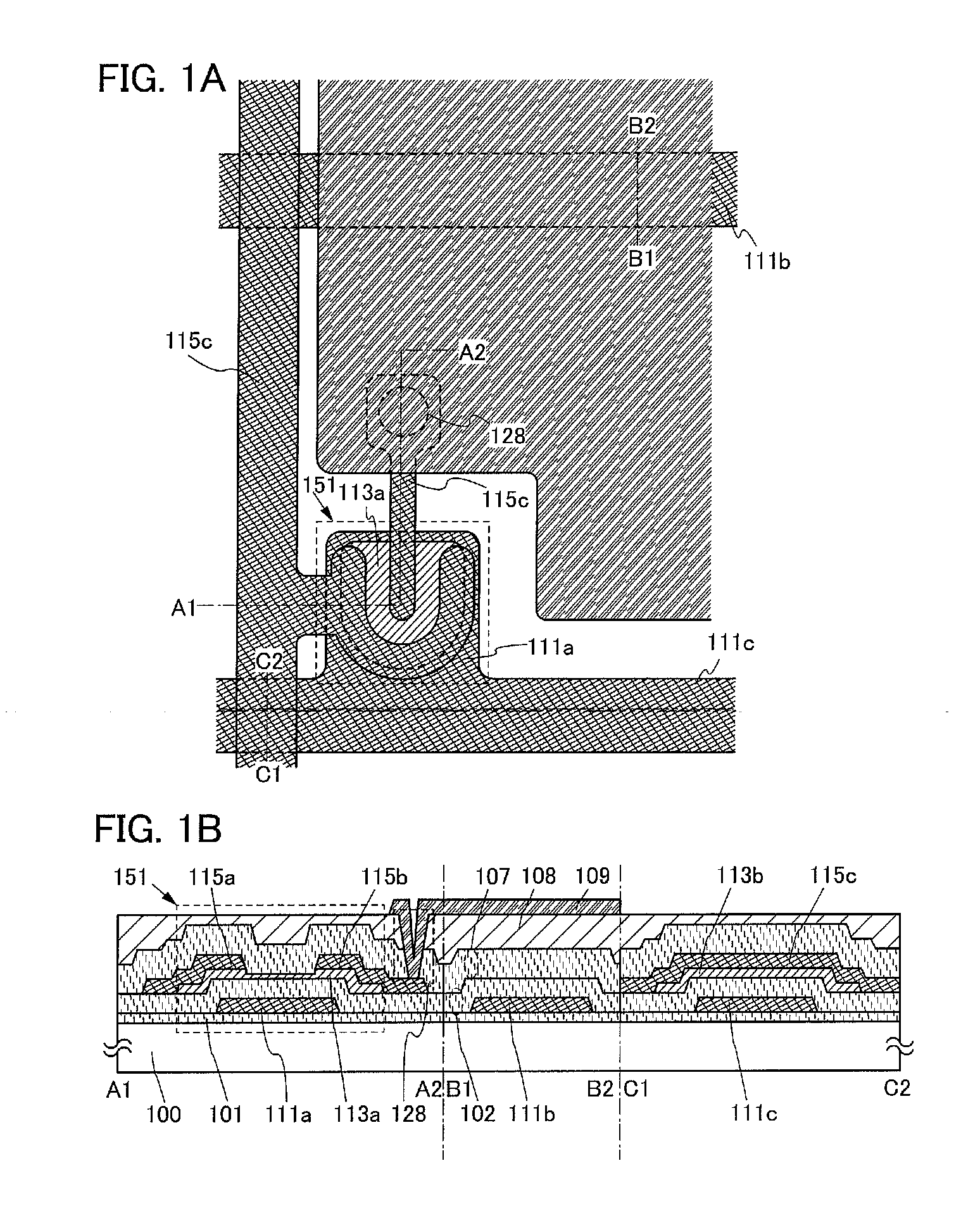

Electronic device, semiconductor device and manufacturing method thereof

InactiveUS20060170067A1Reduce usageLow costTransistorElectroluminescent light sourcesEngineeringLaser light

The present invention provides a manufacturing process using a droplet-discharging method that is suitable for manufacturing a large substrate in mass production. A photosensitive material solution of a conductive film is selectively discharged by a droplet-discharging method, selectively exposed to laser light, and developed or etched, thereby allowing only the region exposed to laser light to be left and realizing a source wiring and a drain wiring having a more microscopic pattern than the pattern itself formed by discharging. One feature of the source wiring and the drain wiring is that the source wiring and the drain wiring cross an island-like semiconductor layer and overlap it.

Owner:SEMICON ENERGY LAB CO LTD

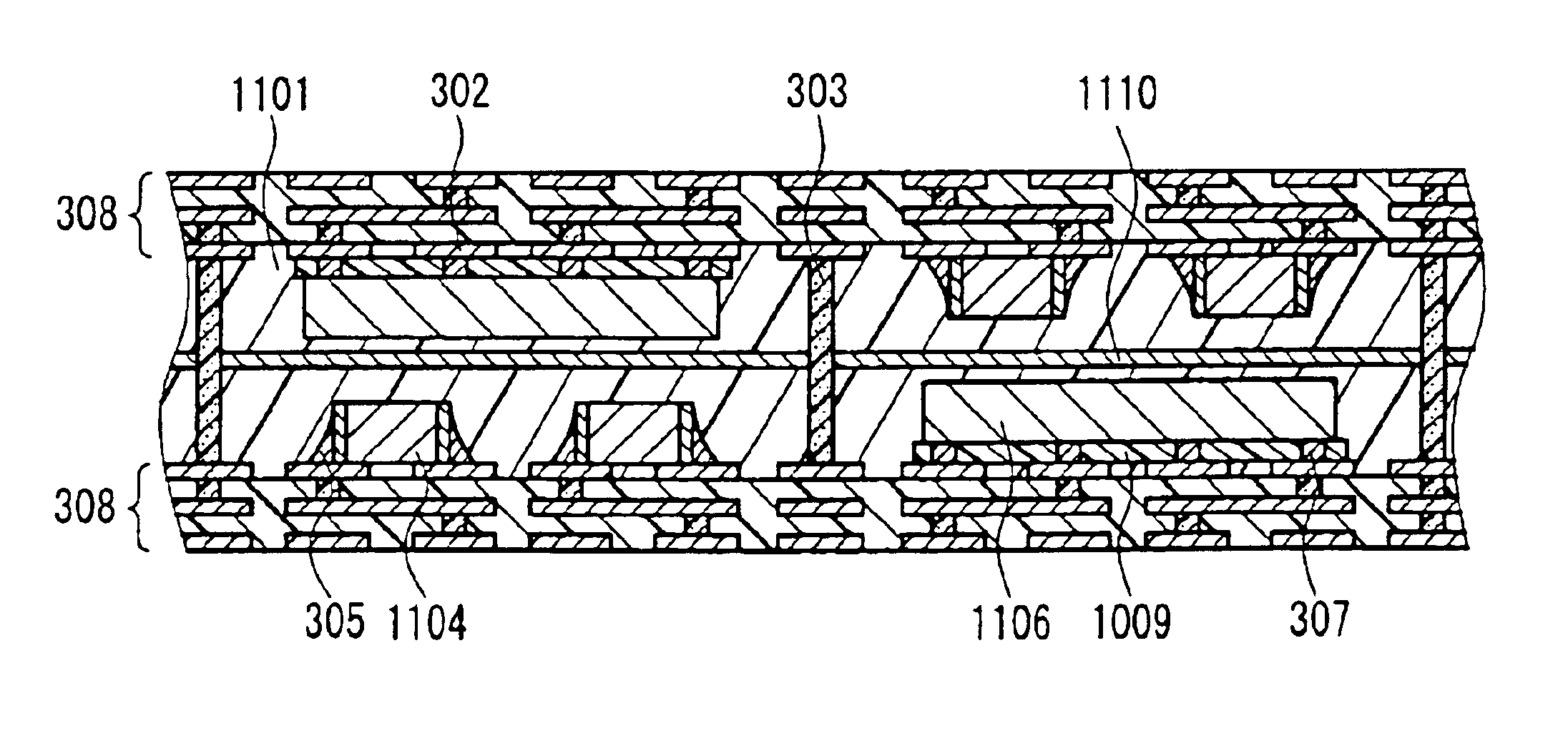

Component built-in module and method for producing the same

InactiveUS6975516B2Increase productionHigh strengthFinal product manufactureSemiconductor/solid-state device detailsEngineeringElectronic component

A component built-in module includes an insulating layer, wirings integrated with both surfaces of the insulating layer, a via connecting the wirings, and one or more components selected from an electronic component and a semiconductor, which is embedded inside of the insulating layer. In this module, at least one of the wirings is formed on a surface of a wiring board, and the components embedded inside of the insulating layer are mounted on and integrated with the wiring board before embedding. This configuration allows the components such as a semiconductor to undergo a mounting inspection and a property inspection before embedding. As a result, the yields of the module can be improved. In addition, since the components are integrated with the wiring board and embedded, the strength thereof can be enhanced.

Owner:TESSERA ADVANCED TECH

Multilayer Polymeric Membrane and Process

ActiveUS20160243525A1Improve adhesionImprove wettabilityOther chemical processesAlkali metal oxides/hydroxidesProduction rateSorbent

Provided is a novel continuous single-step method of manufacturing a multilayer sorbent polymeric membrane having superior productivity, properties and performance. At least one layer of the polymeric membrane comprises sorbent materials and a plurality of interconnecting pores. The method includes: (a) coextruding layer-forming compositions to form a multilayer coextrudate; (b) casting the coextrudate into a film; (c) extracting the film with an extractant; and (d) removing the extractant from the extracted film to form the multilayer sorbent polymeric membrane. The sorbent membrane of this disclosure can find a wide range of applications for use in filtration, separation and purification of gases and fluids, CO2 and volatile capture, structural support, vehicle emission control, energy harvesting and storage, device, protection, permeation, packaging, printing, and etc.

Owner:LISO PLASTICS L L C

Semiconductor device and method for manufacturing the same

ActiveUS20110127524A1Increase production capacityImprove reliabilitySolid-state devicesNon-linear opticsPower semiconductor devicePower flow

Disclosed is a semiconductor device comprising a thin film transistor and wirings connected to the thin film transistor, in which the thin film transistor has a channel formation region in an oxide semiconductor layer, and a copper metal is used for at least one of a gate electrode, a source electrode, a drain electrode, a gate wiring, a source wiring, and a drain wiring. The extremely low off current of the transistor with the oxide semiconductor layer contributes to reduction in power consumption of the semiconductor device. Additionally, the use of the copper metal allows the combination of the semiconductor device with a display element to provide a display device with high display quality and negligible defects, which results from the low electrical resistance of the wirings and electrodes formed with the copper metal.

Owner:SEMICON ENERGY LAB CO LTD

Ecological scale breeding method of green shell egg laying hens

InactiveCN103098756AIncrease production capacityReduce morbidityAnimal husbandryGrazingMortality rate

The invention discloses an ecological scale breeding method of green shell egg laying hens. The method mainly includes the following steps: (1) selecting breeding hens; (2) stocking in a rotational grazing mode in woodland and meadow; (3) selecting hatching eggs; (4) incubating the hatching eggs with an incubator; (5) managing broods of the green shell egg laying hens; (6) managing feeding of the green shell egg laying hens; and (7) preventing epidemic diseases of the green shell egg laying hens. The method is strong in systematicness, changes traditional breeding technology of the green shell egg laying hens, combines with effective breeding measures, improves quality of the breeding hens and the hatching eggs and production capacity of the green shell egg laying hens, increases egg weight and egg yield, and lowers morbidity and mortality rates of the green shell egg laying hens.

Owner:铜仁市万山区畜禽品种改良站

Light weight structural piece for use of filling concrete

InactiveCN1415815ASimple designIncrease production capacityFloorsStructural engineeringUltimate tensile strength

Owner:湖南邱则有专利战略策划有限公司

Thin-wall form for filling concrete

A thin-wall form for filling concrete in it to in-situ pour hollow non-beam floor is composed of top plate and peripheral wall, and is characterized by that at least one of said top plate and peripheral wall contains at least one thin strip for improving its resistance to impact and collision. Its advantages are simple structure and high resistance to deformation and vibration.

Owner:湖南邱则有专利战略策划有限公司

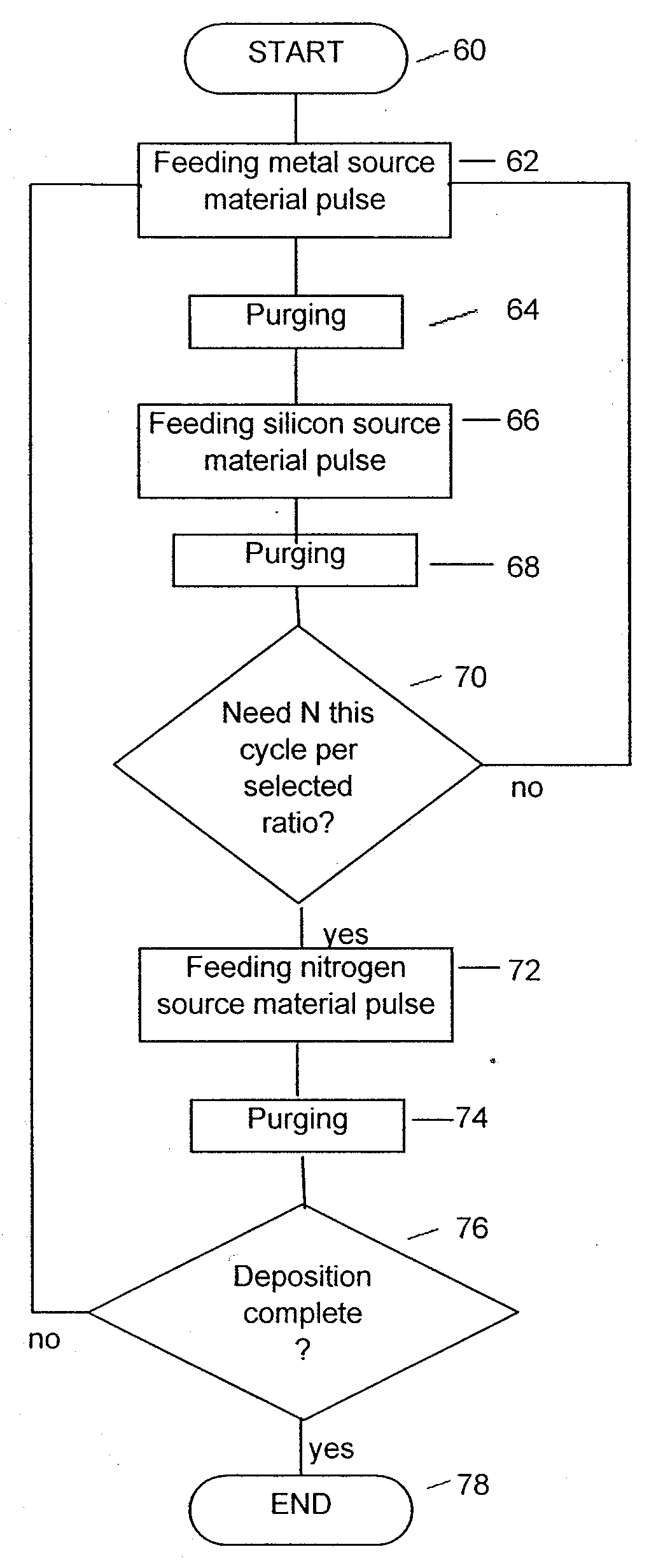

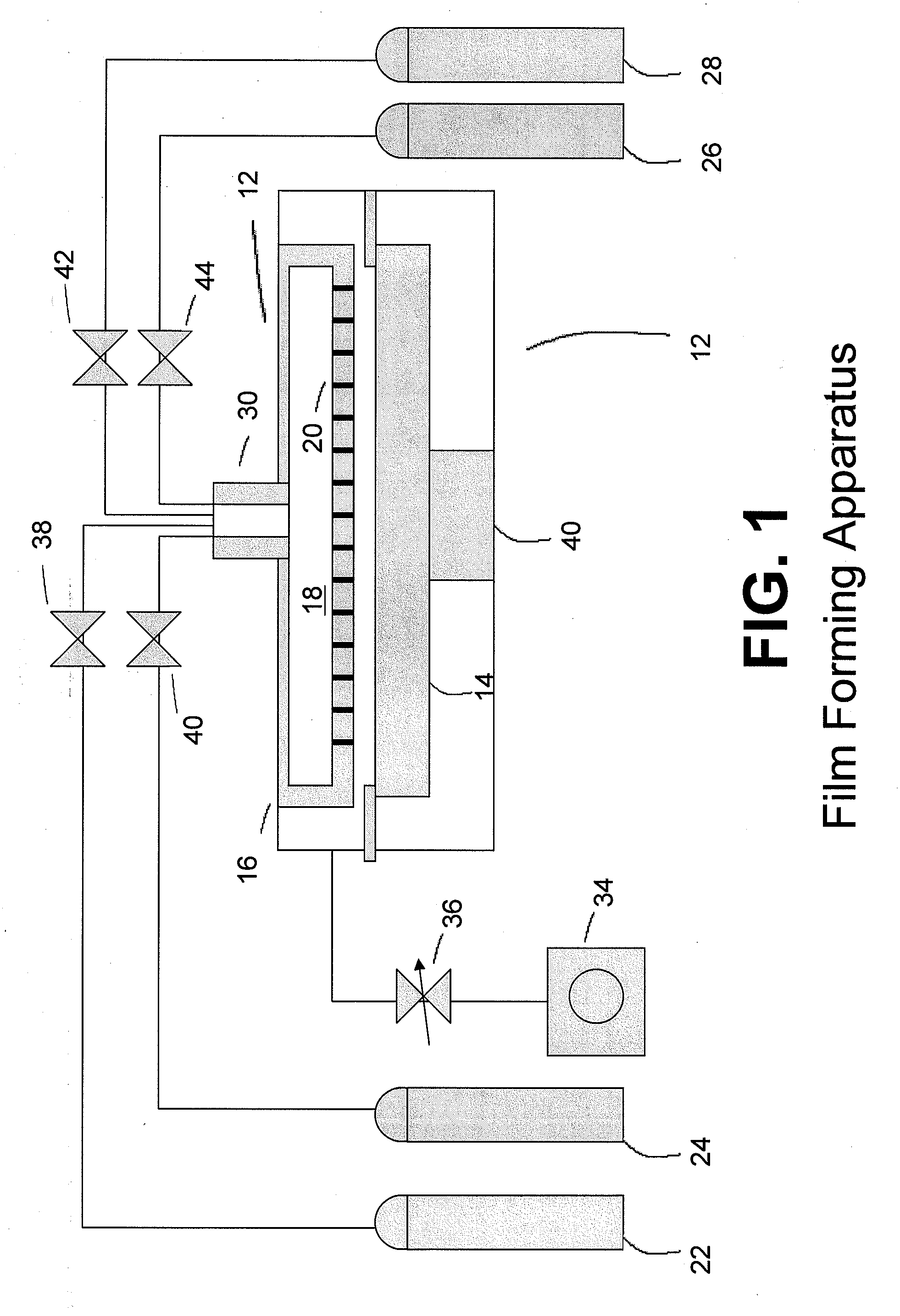

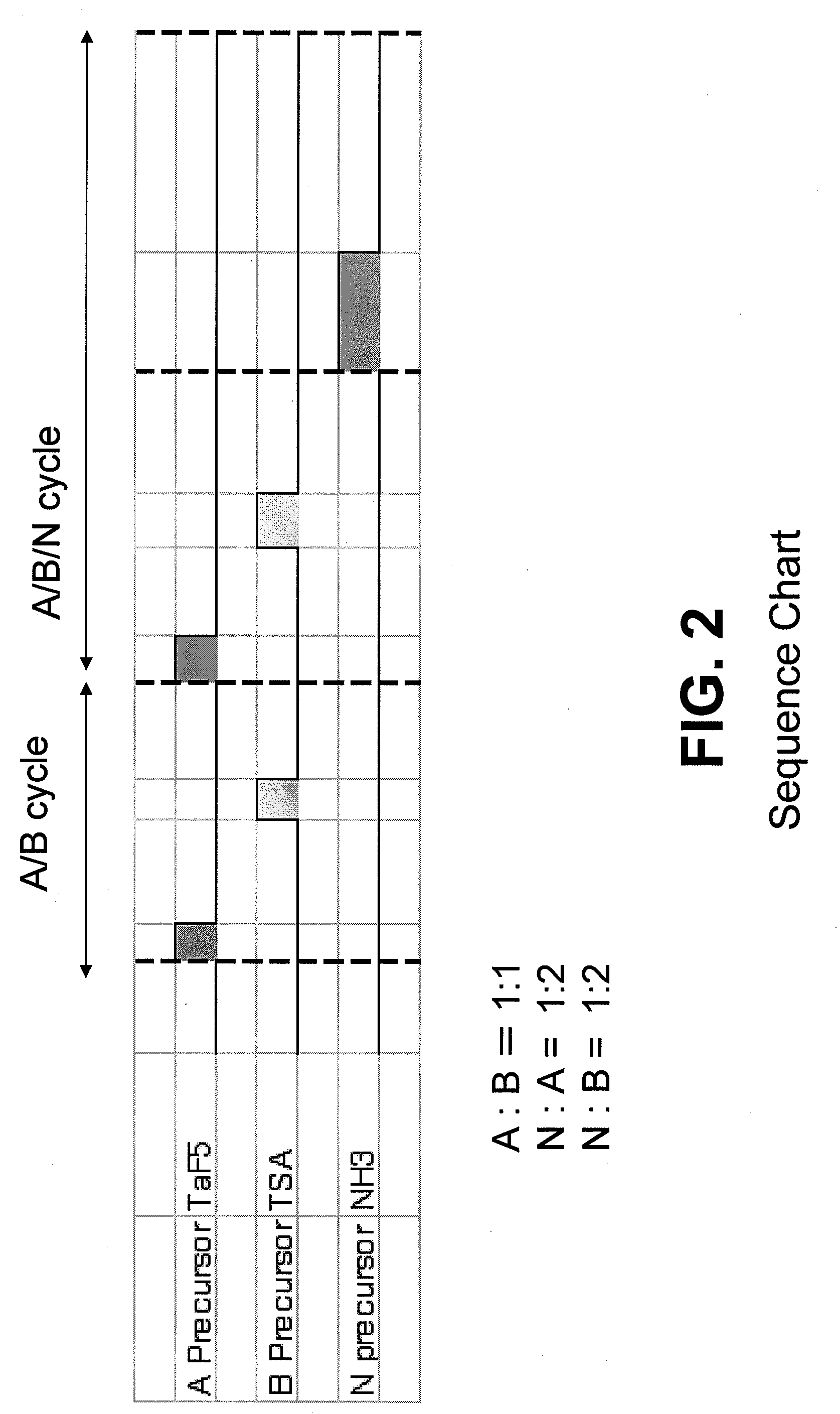

Process for forming high resistivity thin metallic film

InactiveUS20100136313A1Good productivityIncrease production capacitySynthetic resin layered productsSpecial surfacesHigh resistivityPhysics

A process for forming metallic nitride film by atomic layer deposition (ALD), which comprises steps for feeding into a reaction space vapor phase alternated pulses of metal source material and silicon source material in a plurality of cycles, and feeding into the reaction space vapor phase pulses of nitrogen source material. wherein a nitrogen source pulse is fed intermittently in selected cycles such that a ratio of nitrogen source pulses to silicon source pulses is less than 1:1 and a ratio of nitrogen source pulses to metal source pulses is less than 1:1, the ratio selected to produce the thin film with a resistivity between 1,000 μΩcm and 15,000 μΩcm.

Owner:ASM JAPAN

Sublevel shrinkage caving stage open stope afterwards filling mining method

InactiveCN101881169ALarge amount of filling at one timeIncrease production capacityUnderground miningSurface miningEarth surfaceComputer science

The invention discloses a sublevel shrinkage caving stage open afterwards filling mining method. In the earlier stage of stoping, caved ores are utilized to support surrounding rocks on a top tray, and in the later stage of stoping, a goaf area is filled with fillers to control ground pressure so as to achieve safe and efficient mining. Ore blocks are mined in two steps, mining blocks in step two are stoped after the mining blocks in step one are stoped and filled. After the ores are completely let out, the goaf area is filled with the fillers to control the ground pressure. Because the stoping modes of sublevel ore caving, sublevel shrinkage, final ore drawing and empty area afterwards filling are adopted, the mining method has large one-time filling amount and low cost; the method adopts middle-deep hole drilling and blasting and carry scraper ore removal, and the device has high level and large production capacity; the method has the advantages of large production capacity of the sublevel caving method and the stage open stope method, high recovery rate of the filling method, and earth surface protection; the safety is good, and drilling, ore removal and other operations are all carried out in a sublevel drilling and ore removal approach roadway; and the ores can be removed in advance, and the ores can be removed partially after the first sublevel is ready.

Owner:NORTHEASTERN UNIV +1

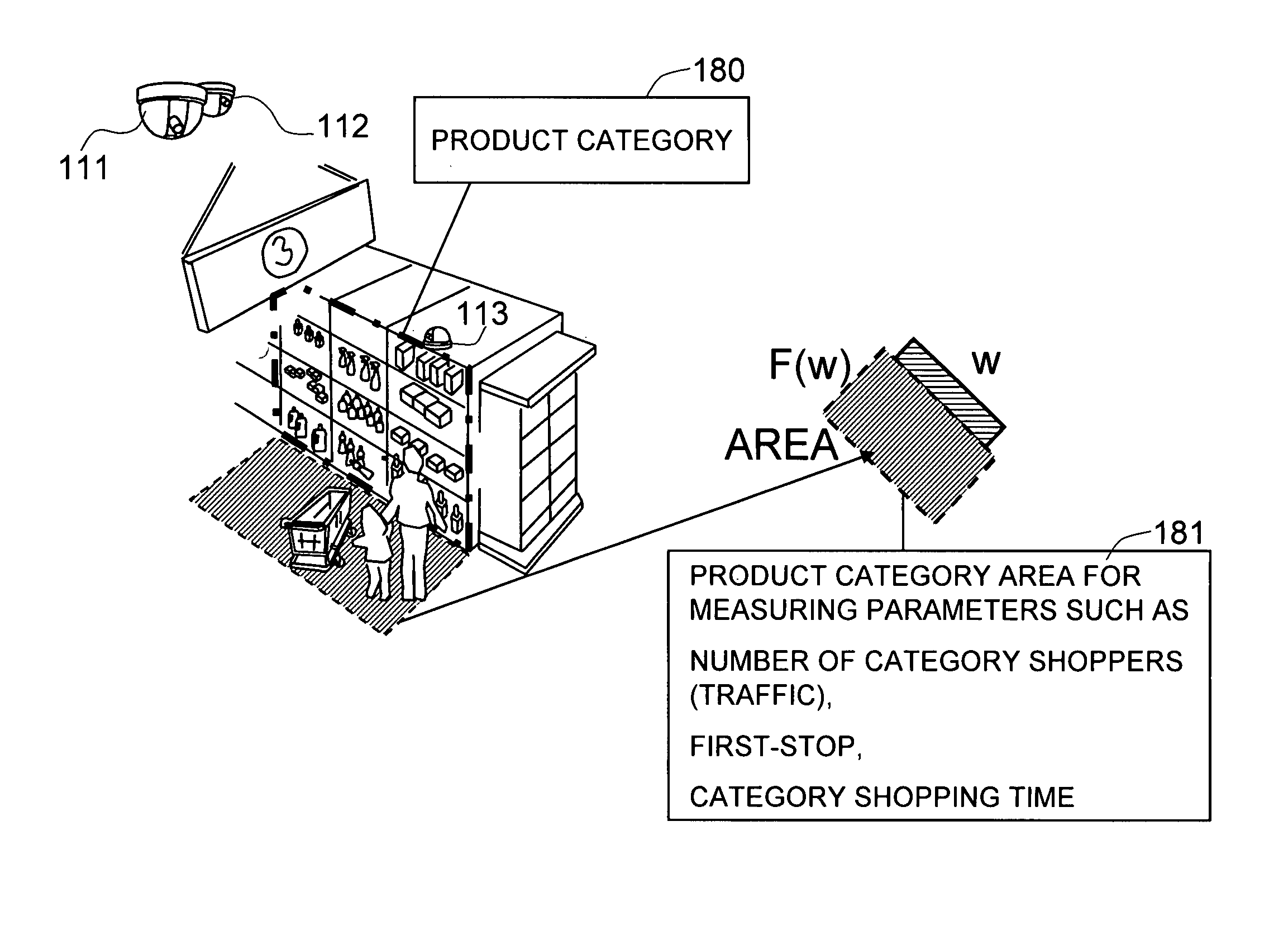

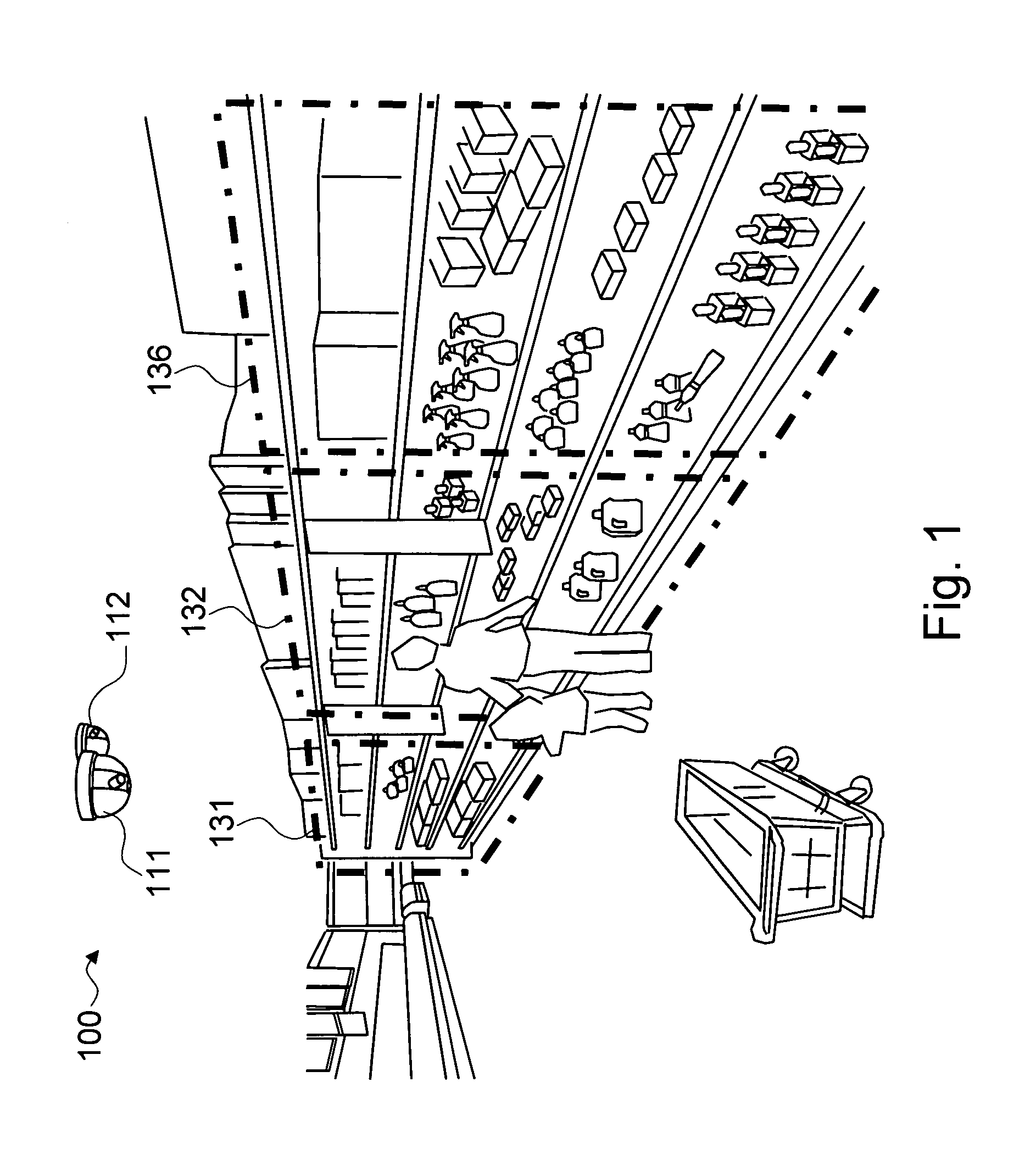

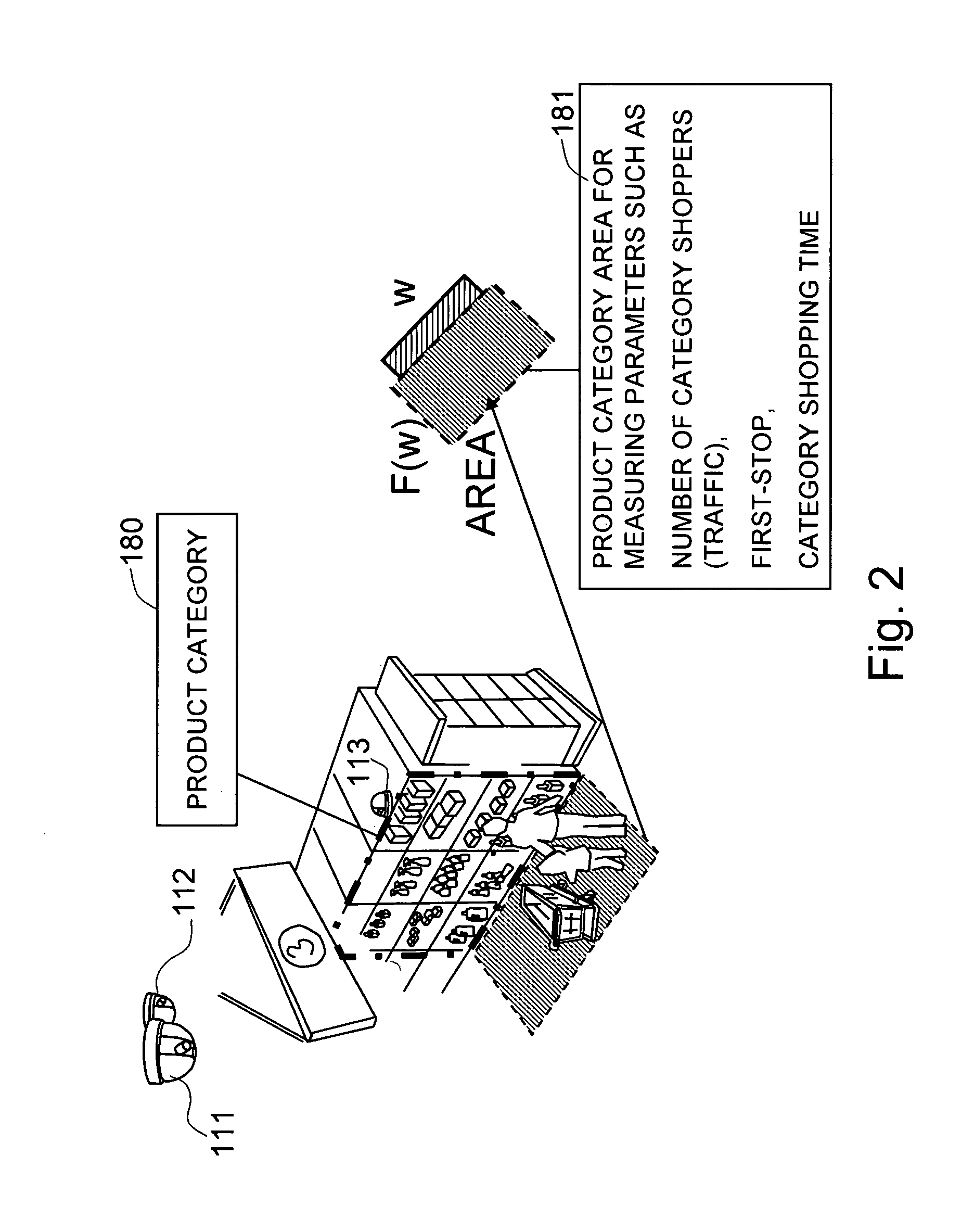

Method and system for rating the role of a product category in the performance of a store area

The present invention is a method and system for measuring a set of shopper behavior metrics that represent the strength of a product category or a group of categories in the performance of a store area. A set of rating parameters are defined in order to provide a unified and standardized rating system. The rating system represents the effectiveness of the product category in a store area. The metrics are defined in a manner that is normalized so that they can be used across different types of product categories. The datasets are measured per category or group of categories over time to identify how the strength has varied over time, and to monitor trends in the category performance. The measured datasets are further analyzed based on various demographic groups and behavior segments. The analysis facilitates a better understanding of the strength of the category for different shopper segments, which in turn can be applied for developing better store area optimization strategies.

Owner:VIDEOMINING CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com