Patents

Literature

451 results about "Friction effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Friction can be defined as the force that resists the relative motion of solid surfaces, fluids, or elements that collide or slide against each other. Its effect would cause the object in motion to slow down. If the friction is increased, more energy is needed by the object to keep its momentum hence it will slow down.

Friction generator

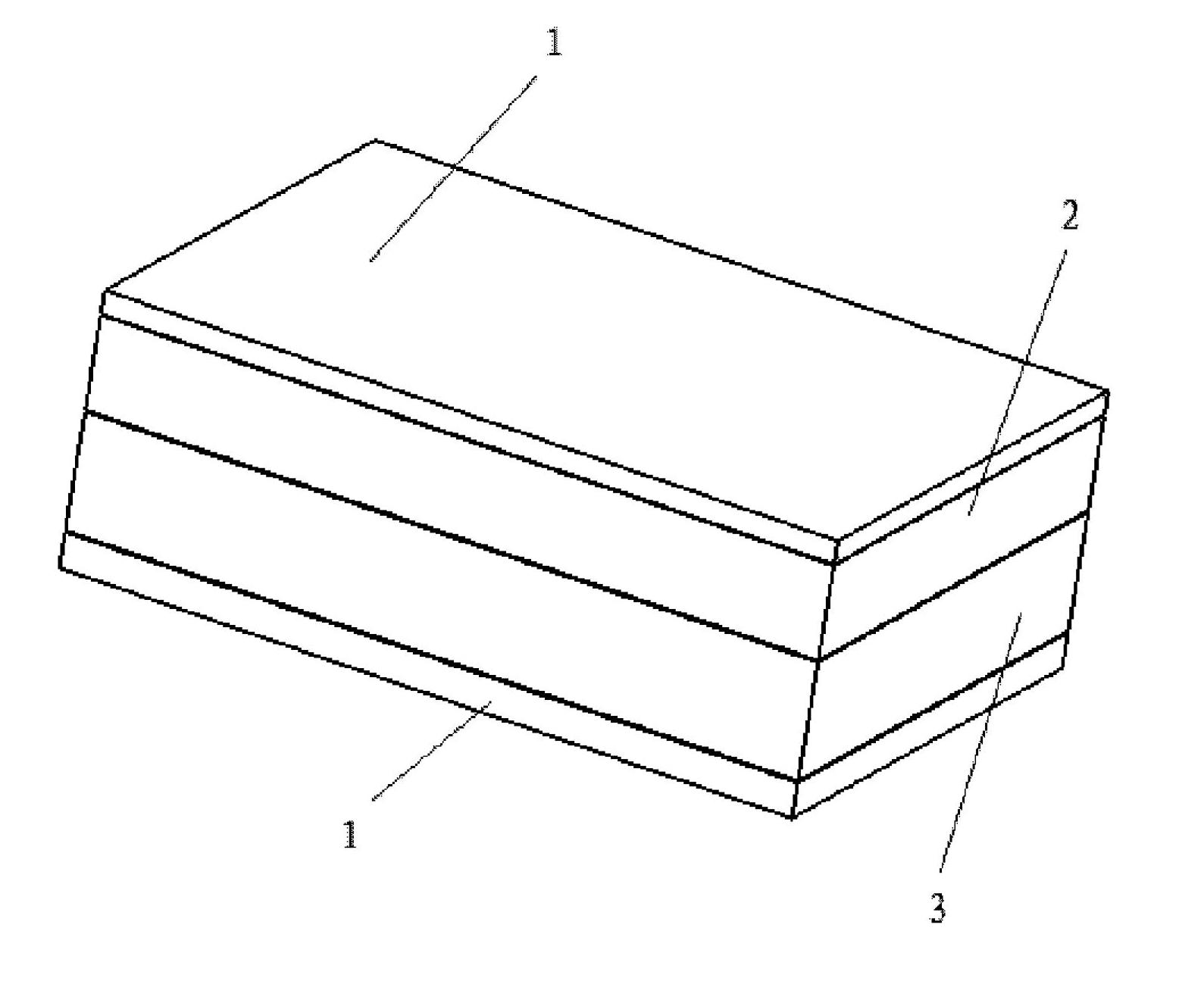

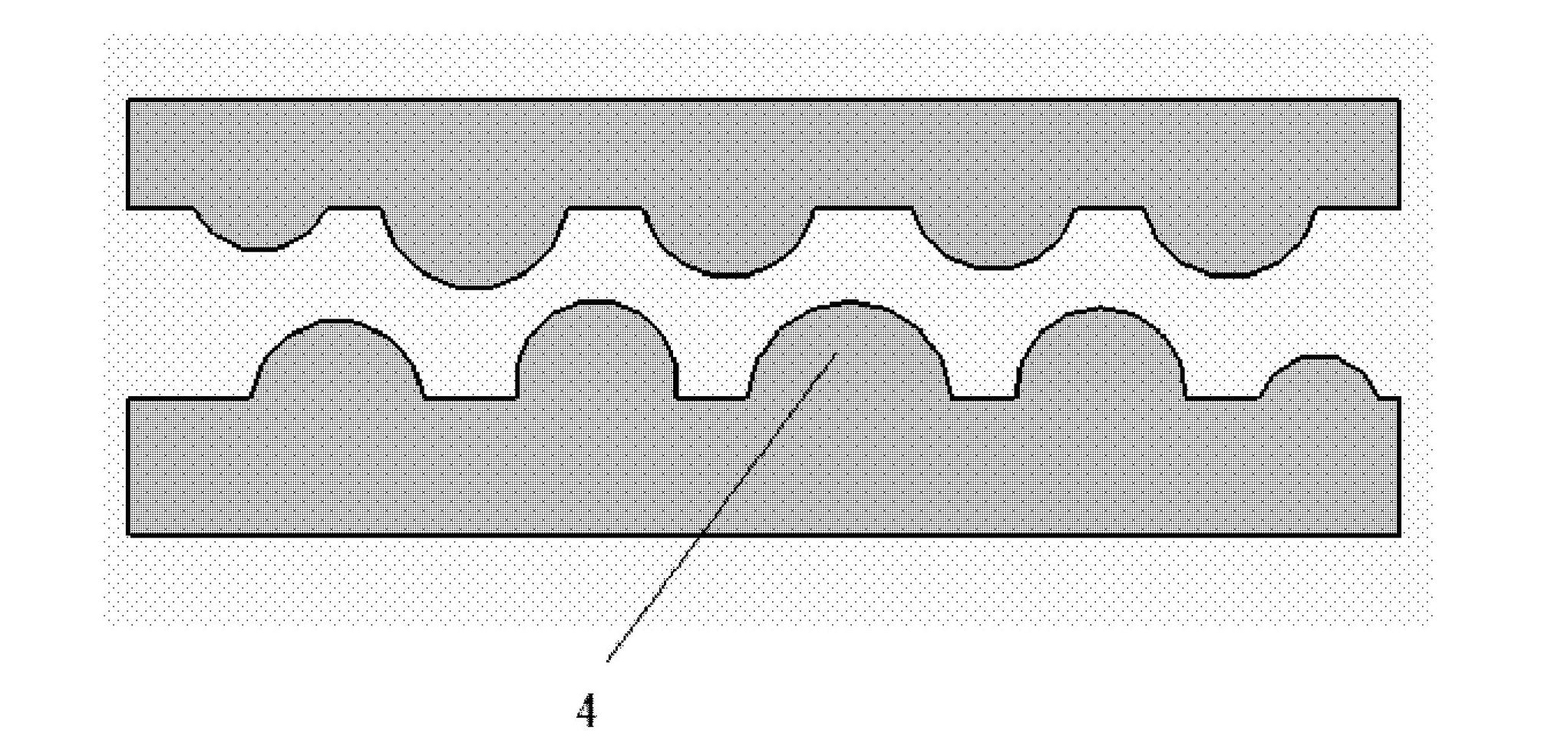

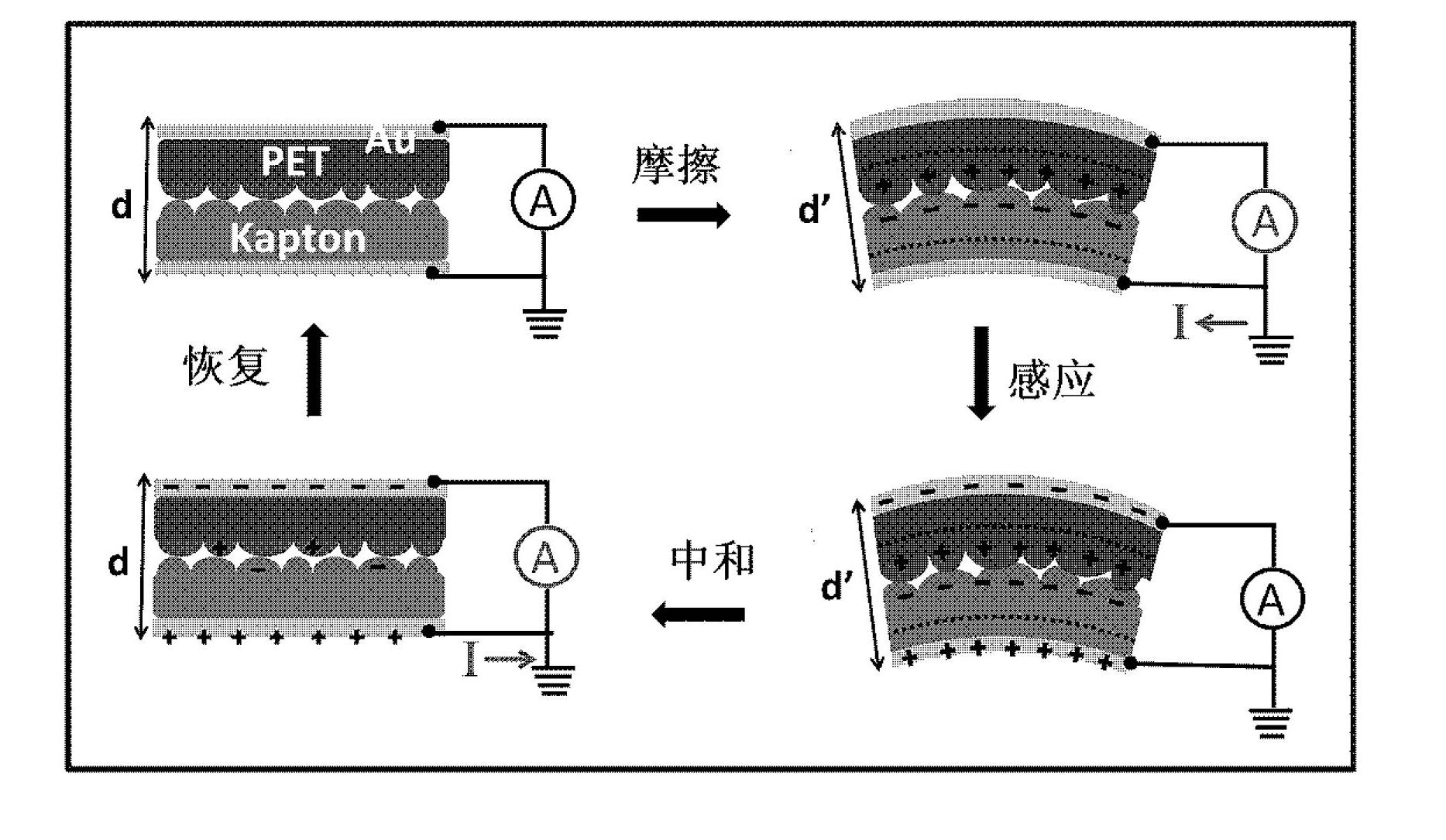

ActiveCN102684546AExtended service lifeLow costFriction generatorsMetal layered productsConvex structureMicro nano

The invention provides a friction generator. The friction generator comprises two electrodes; the electrode comprises a macromolecular polymer insulating layer; a micro-nano concave-convex structure is arranged on one side surface of the macromolecular polymer insulating layer, and a metal film is arranged on the other side surface; the surface of the electrode micro-nano concave-convex structure of one insulating layer is directly attached to the surface of the electrode micro-nano concave-convex structure of the other insulating layer, and the two are fixedly connected through the outer edge; and the metal film is an electrode for outputting voltage and current of the friction generator. The invention provides a novel and effective method for obtaining energy by use of the friction effect. The friction generator generates electric energy by use of the potential change of the internal electrification by friction and the inductive effect of the metal pole plates on the two sides; and the method is simple and efficient and the cost is low.

Owner:NAZHIYUAN TECH TANGSHAN LLC

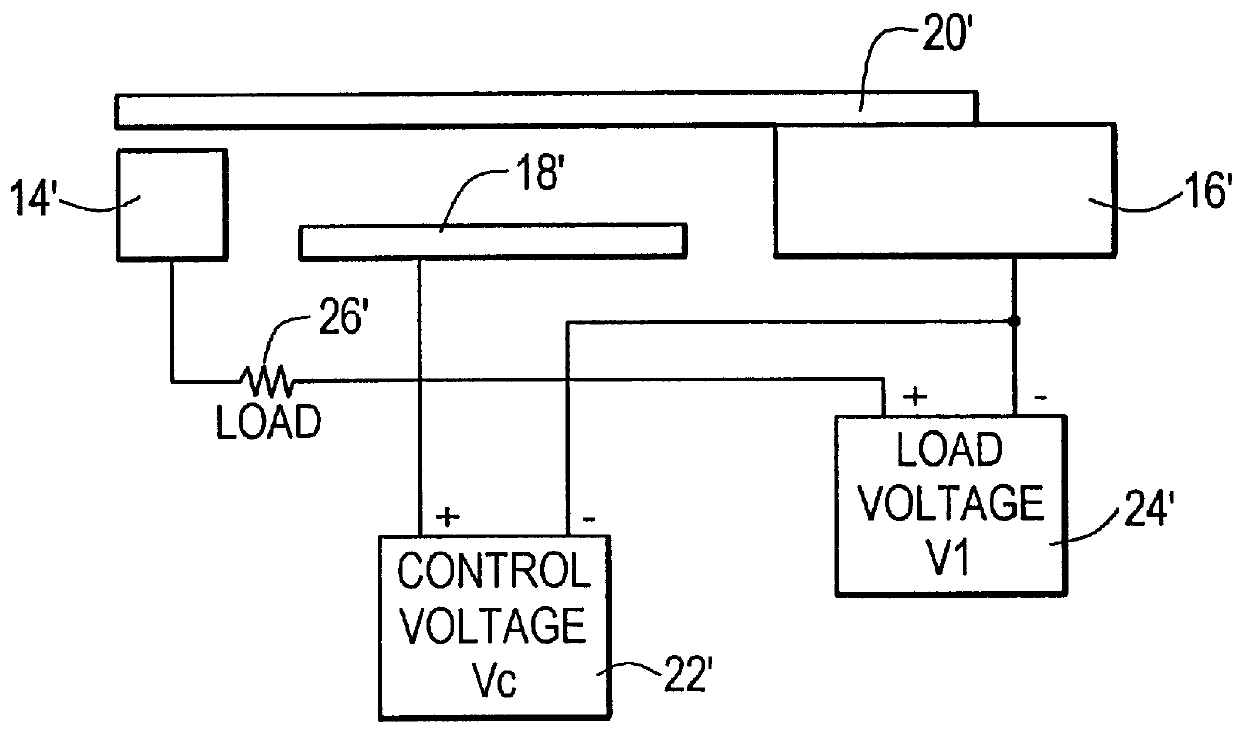

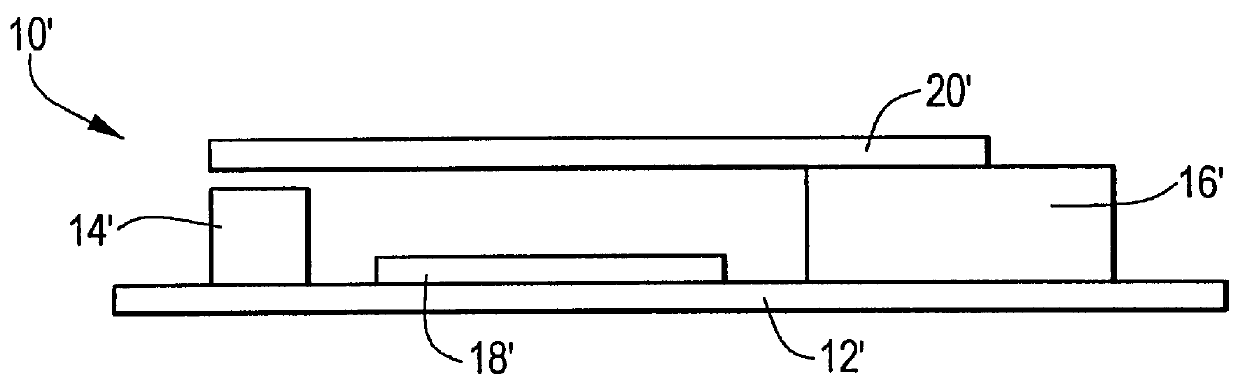

Method and apparatus for an improved micro-electrical mechanical switch

InactiveUS6127744ABatteries circuit arrangementsBoards/switchyards circuit arrangementsElectricityFriction effect

A method, device and circuit which applies an electrostatic repulsion pushing force to a MEM switch armature during an opening process. The repulsive force adds to the spring restoration force on the armature, increasing the opening speed of the switch and aids in overcoming stiction effects. The inventive switch includes a contact electrically connected to a first terminal of the switch. A throw is electrically connected to a second terminal of the switch. Finally, a mechanism is provided for opening the switch by electrostatically causing the throw to disengage the contact. In the illustrative implementation, the mechanism for opening the switch includes a first charge storage structure mounted on the throw and a second charge storage structure mounted in proximity to the first charge storage structure. When charges are applied between the first and the second charge storage structures, a force of repulsion is created or a force of attraction is created depending on the polarity of the potential.

Owner:RAYTHEON CO

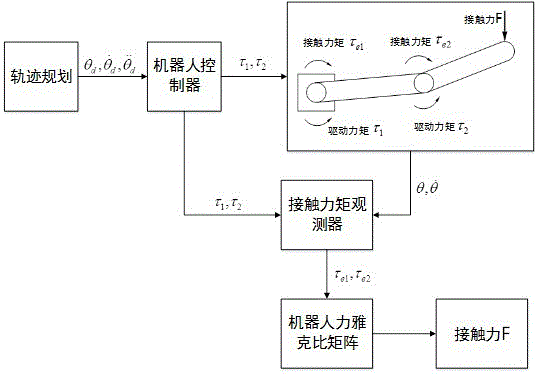

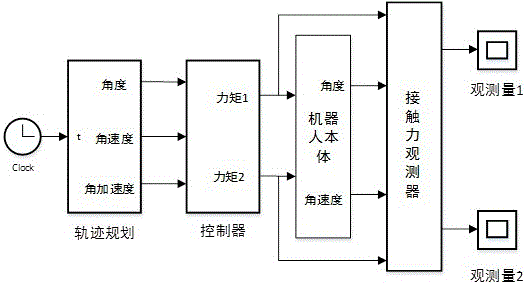

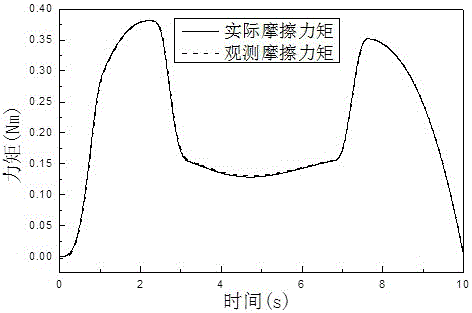

Robot contact force detecting method based on torque observation and friction identification

ActiveCN106426174AImprove detection accuracyProgramme-controlled manipulatorFriction effectFriction torque

The invention relates to a robot contact force detecting method based on torque observation and friction identification. A robot kinetic model and a generalized momentum are adopted to establish a joint torque observer for detecting joint torque change caused by a tail end contact force; a mode of combining an exponential friction model and a sine cosine function is adopted to describe the joint friction effect of a robot provided with a harmonic gear driving structure, a joint torque observation quantity is utilized to identify a joint friction parameter when an end effector of the robot has no contact force effect, and a joint friction torque is calculated according to the identified friction parameter; the torque observation quantity in a theoretical operating state of the robot sis regarded as a system model error, and an accurate joint contact torque observation quantity is finally obtained after the influences of friction and the system model error are considered, and finally a tail end contact force is calculated through a force Jacobian matrix of the robot.

Owner:SHANGHAI ROBOT IND TECH RES INST CO LTD

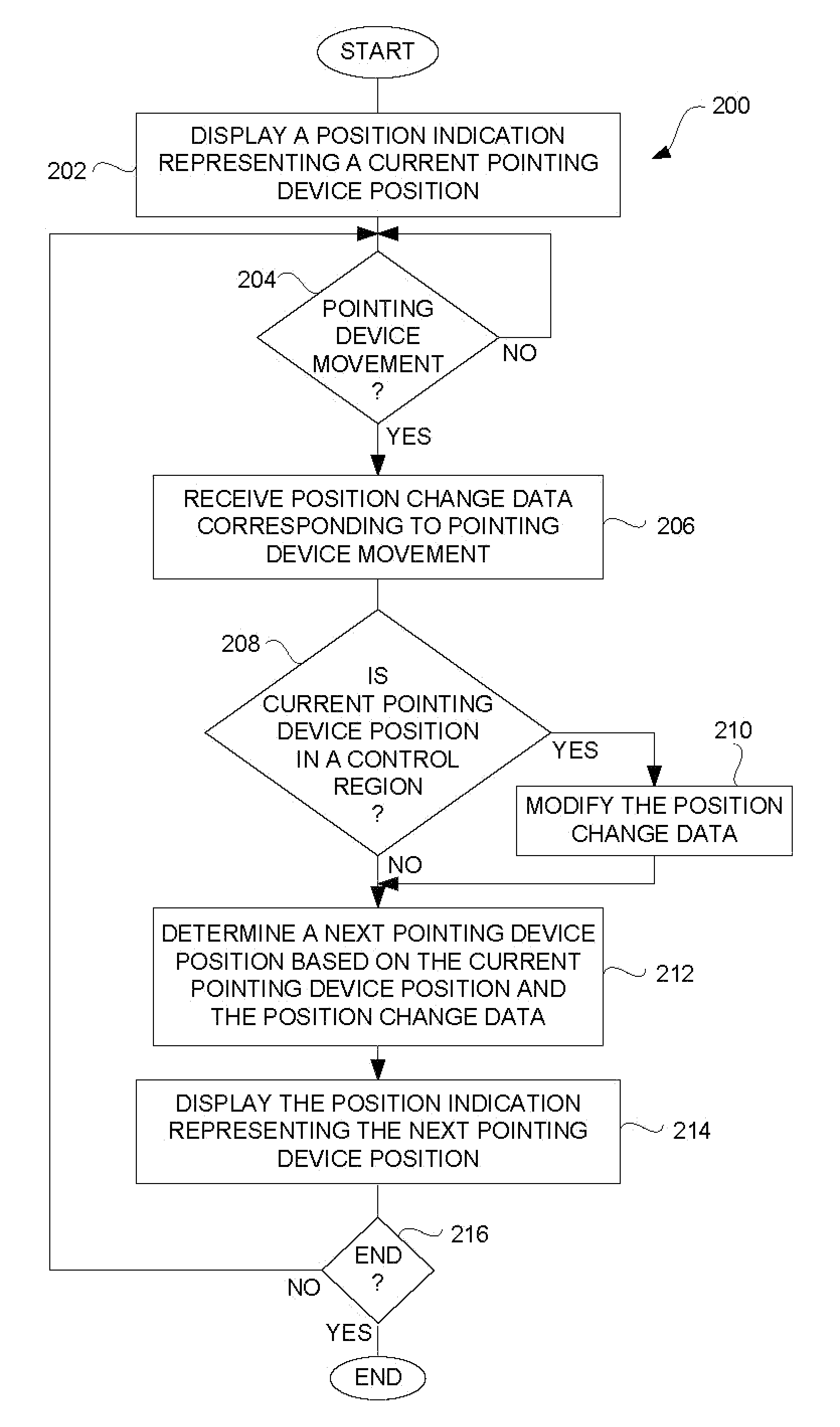

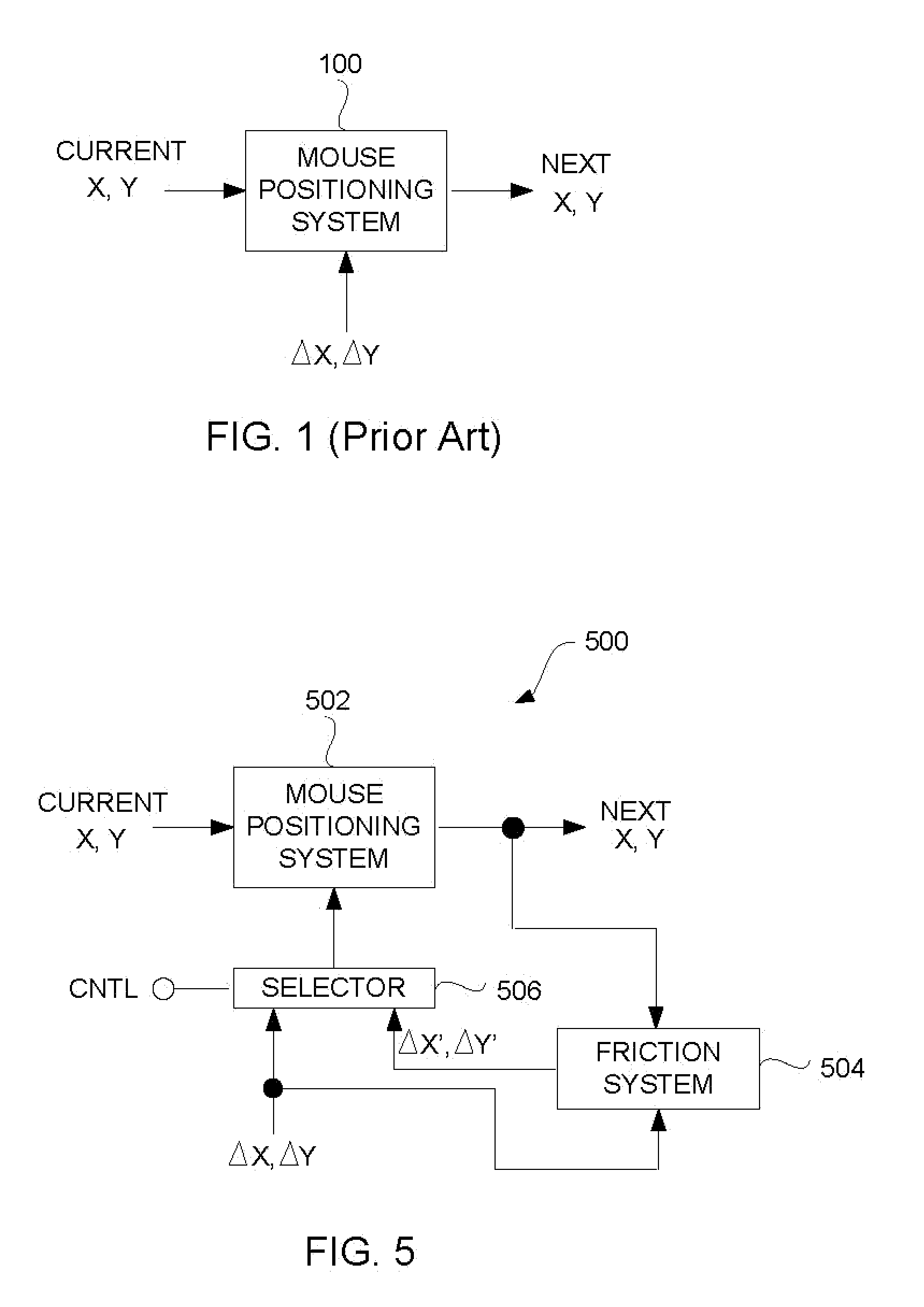

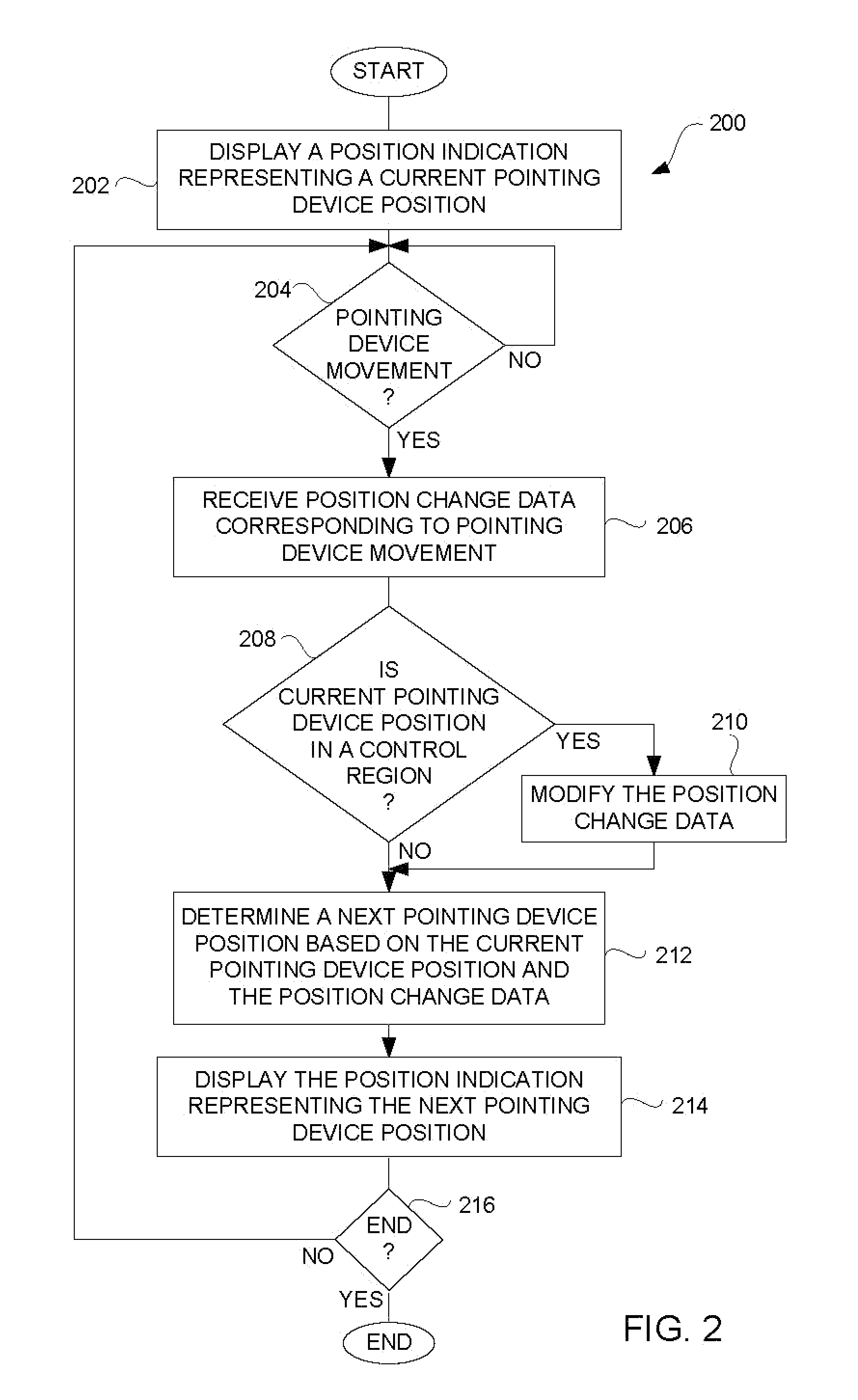

Responsiveness Control System for Pointing Device Movement with Respect to a Graphical User Interface

InactiveUS20090015550A1Improve user interactionEasy to navigateCathode-ray tube indicatorsInput/output processes for data processingGraphicsGraphical user interface

Improved techniques that enable control of responsiveness to user movement of a pointing device with respect to a graphical user interface are disclosed. According to one embodiment, by controlling responsiveness, a friction effect can be imposed at predetermined regions of the graphical user interface. According to another embodiment, by controlling responsiveness, a gravitational effect can be imposed at predetermined regions of the graphical user interface. According to still another embodiment, by controlling responsiveness, frictional and gravitational effects can be imposed at predetermined regions of the graphical user interface. The responsiveness control, e.g., frictional effect and / or gravitational effect, can be used to enhance user interaction with the graphical user interface. For example, user controls, such as buttons, boxes, borders, boundaries, etc., can be more easily navigated and selected by users when the regions associated with such user controls are provided with modified responsiveness control (e.g., frictional effect and / or gravitational effect).

Owner:APPLE INC

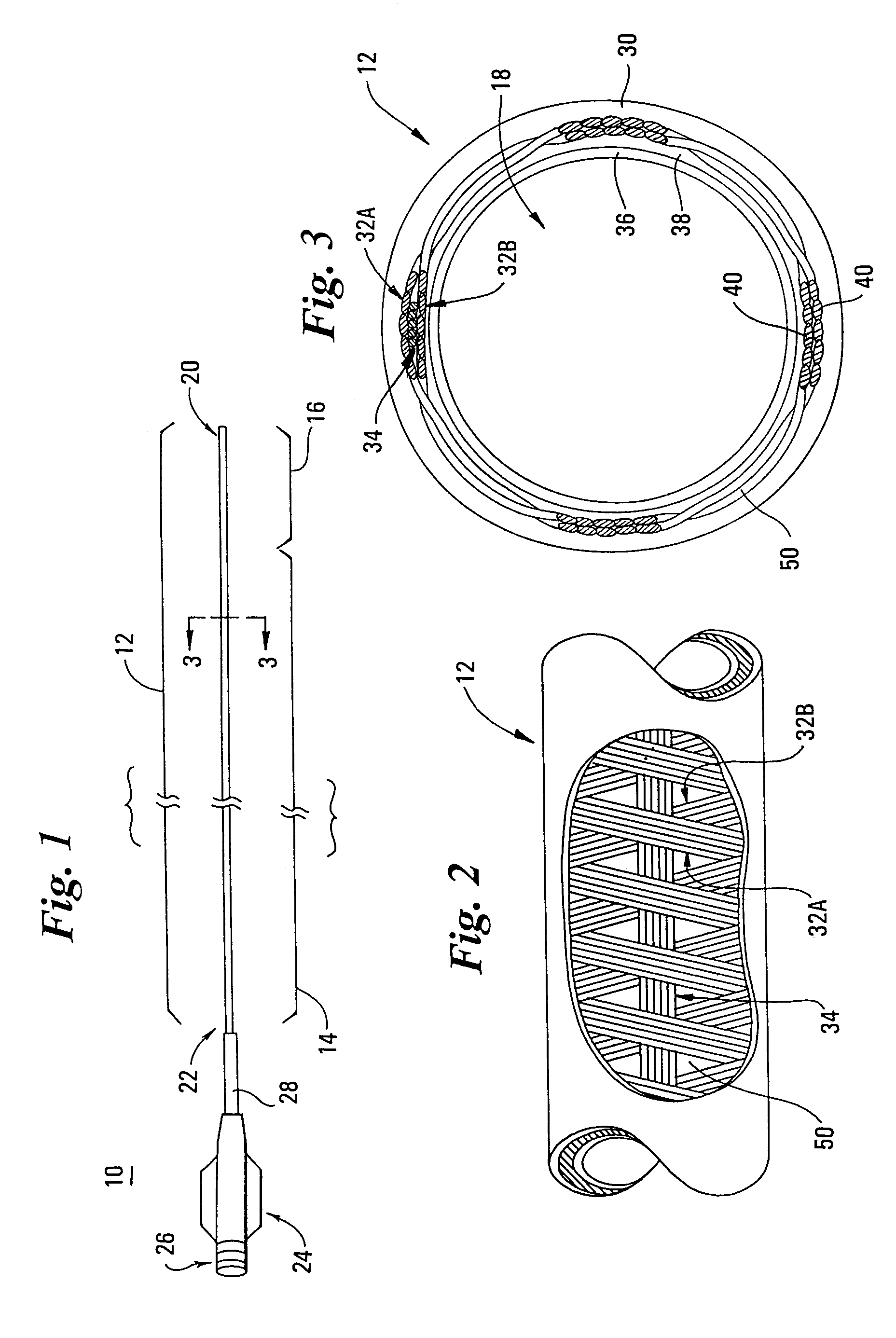

Intravascular catheter with axial member

InactiveUS6942654B1Without undesirable effect of frictionResists elongationCatheterFlexible pipesFiberFriction effect

An intravascular catheter having a shaft, at least a portion of which includes a braid reinforcement with an axial wire or fiber disposed between the helical members that form the braid. The axial member prevents the elongation of the shaft of the catheter thereby maintaining one-to-one correspondence in axial manipulation of the catheter, even when the shaft is placed in tension. By positioning the axial member between the helical members, the axial member does not create a protrusion and does not become fixed to any adjacent polymer layer. Thus, the axial member limits axial strain of the catheter, without creating the undesirable effects of friction caused by an axial protrusion and without creating the undesirable effects of limited flexure caused by an adjacent polymer layer becoming fixed to the axial member.

Owner:BOSTON SCI SCIMED INC

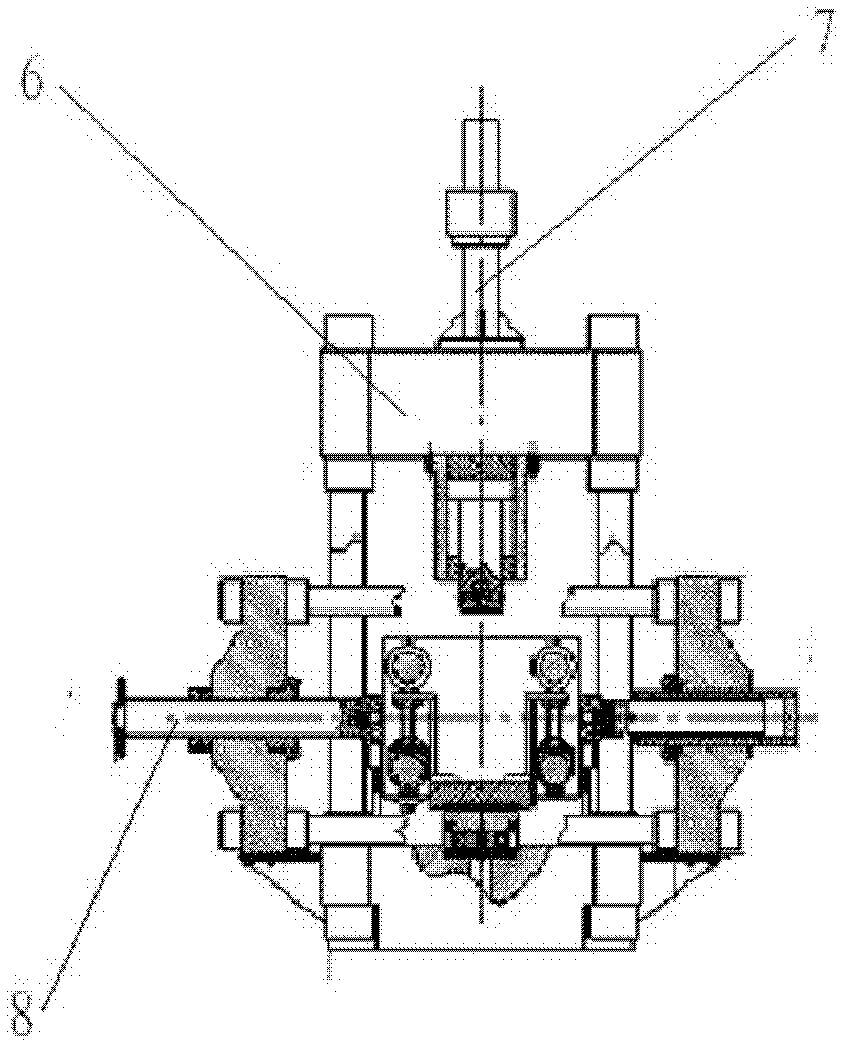

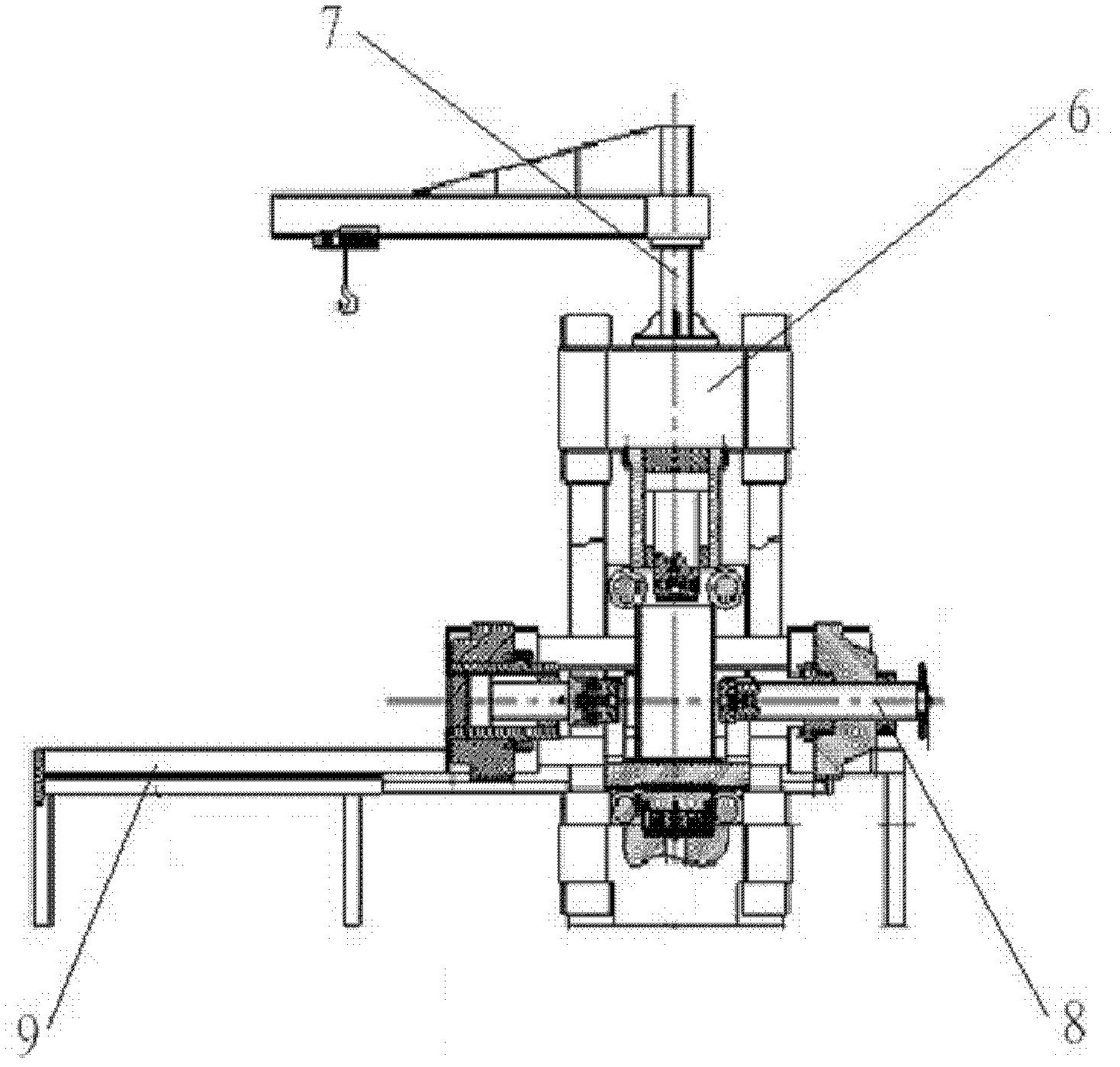

Rock shearing seepage coupling true triaxial test system

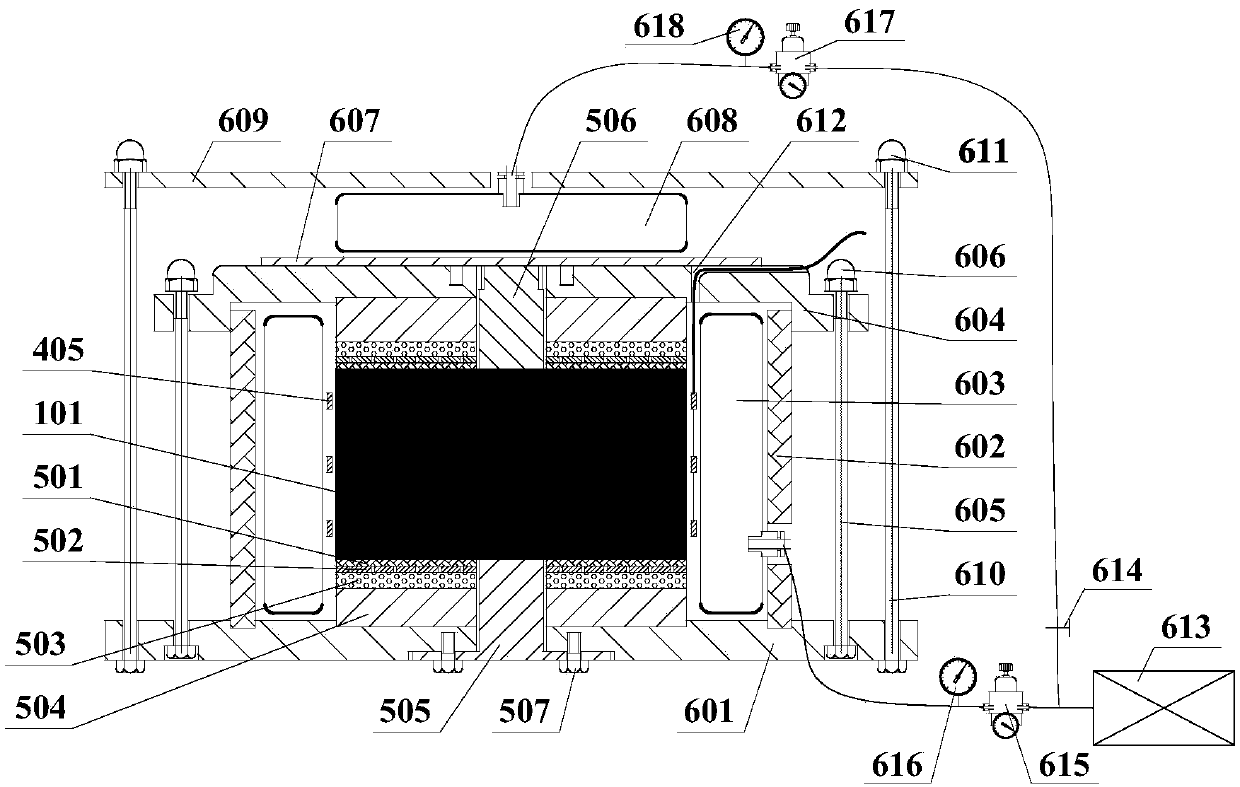

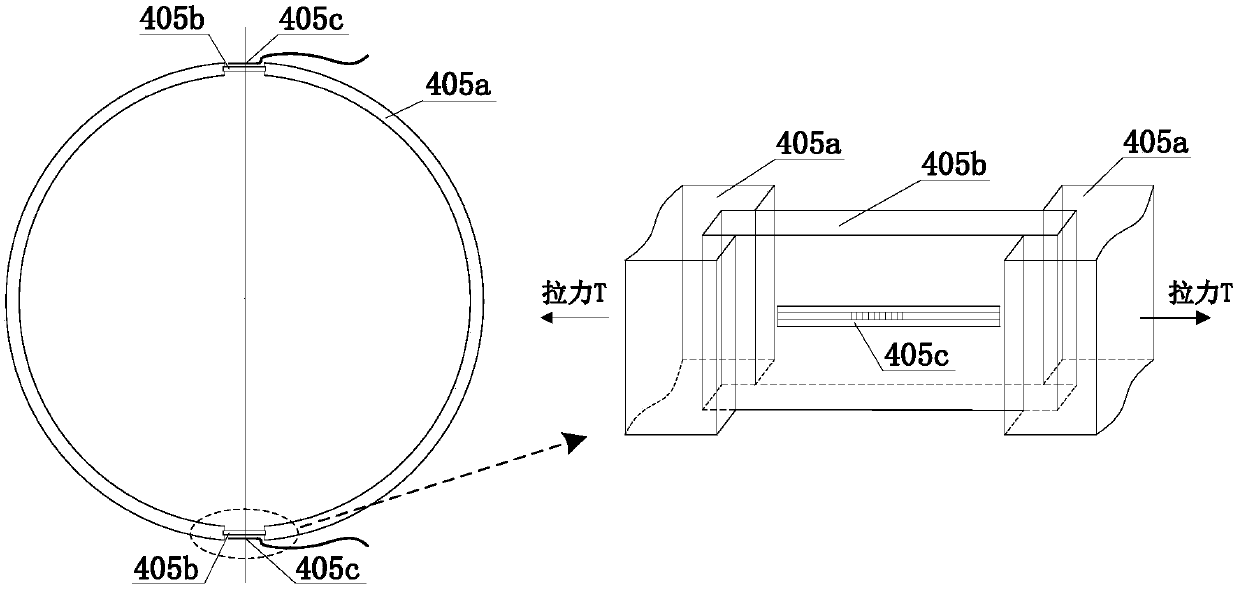

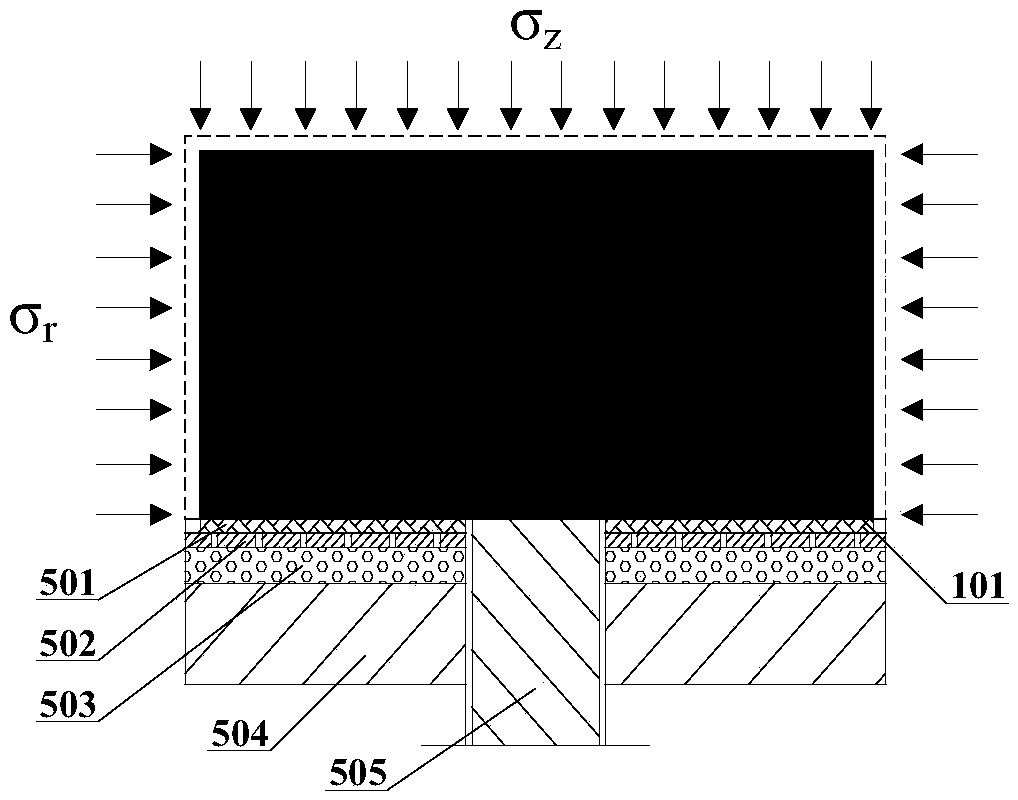

InactiveCN102607950AReduce the effects of frictionReduce corner effectsMaterial strength using tensile/compressive forcesTriaxial shear testFriction effect

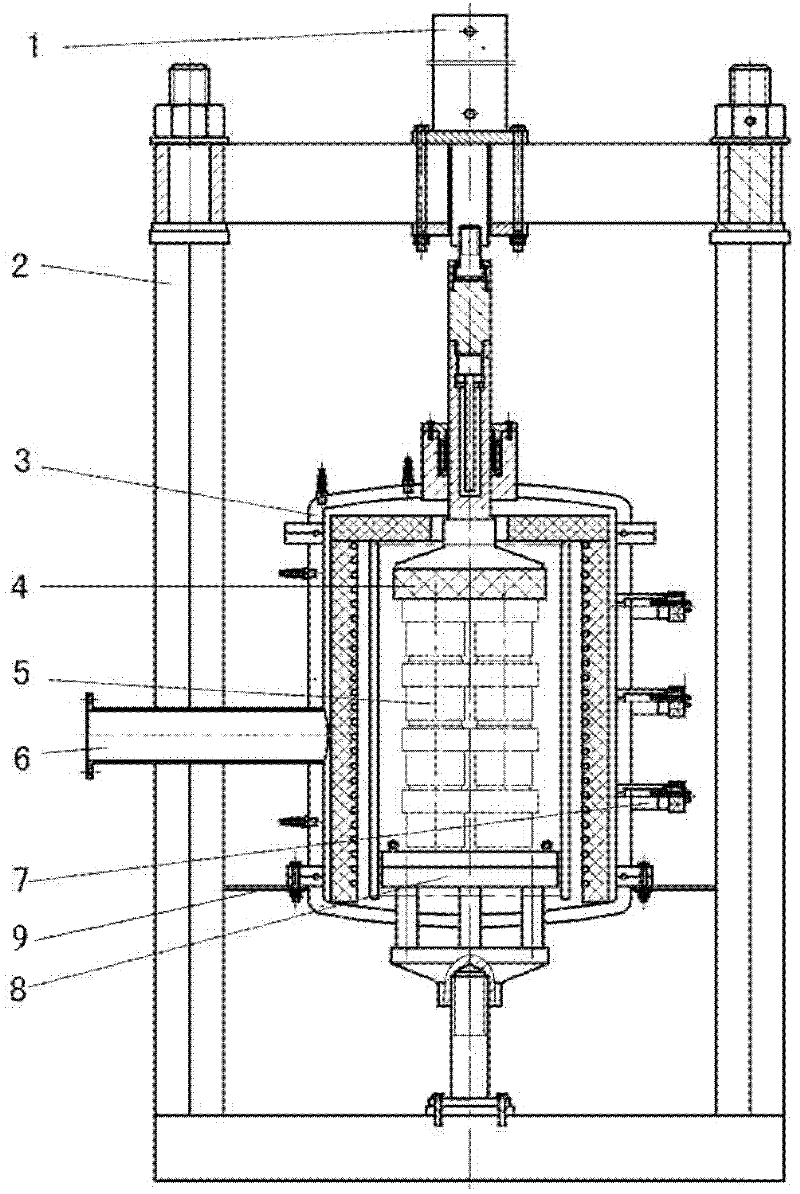

The invention relates to a rock shearing seepage coupling true triaxial test system, which comprises a loading assembly, a test box, a seepage assembly, a detection assembly and a control assembly. The whole system is high in rigid, safe and reliable in high-pressure water injection and sealability, good in sealing reliability, high in loading stability and protection strength and capable of effectively reducing the end-part friction effect and the corner effect and realizing the uniform triaxial stress state as far as possible; a loading test device and a mainshaft loading mechanism are designed in a split manner, and safe high-pressure water injection is achieved; a safety valve and a pressure-stabilizing control device are arranged on a water outlet; and the rock shearing seepage coupling true triaxial test system is stable to control.

Owner:SHANDONG UNIV OF SCI & TECH

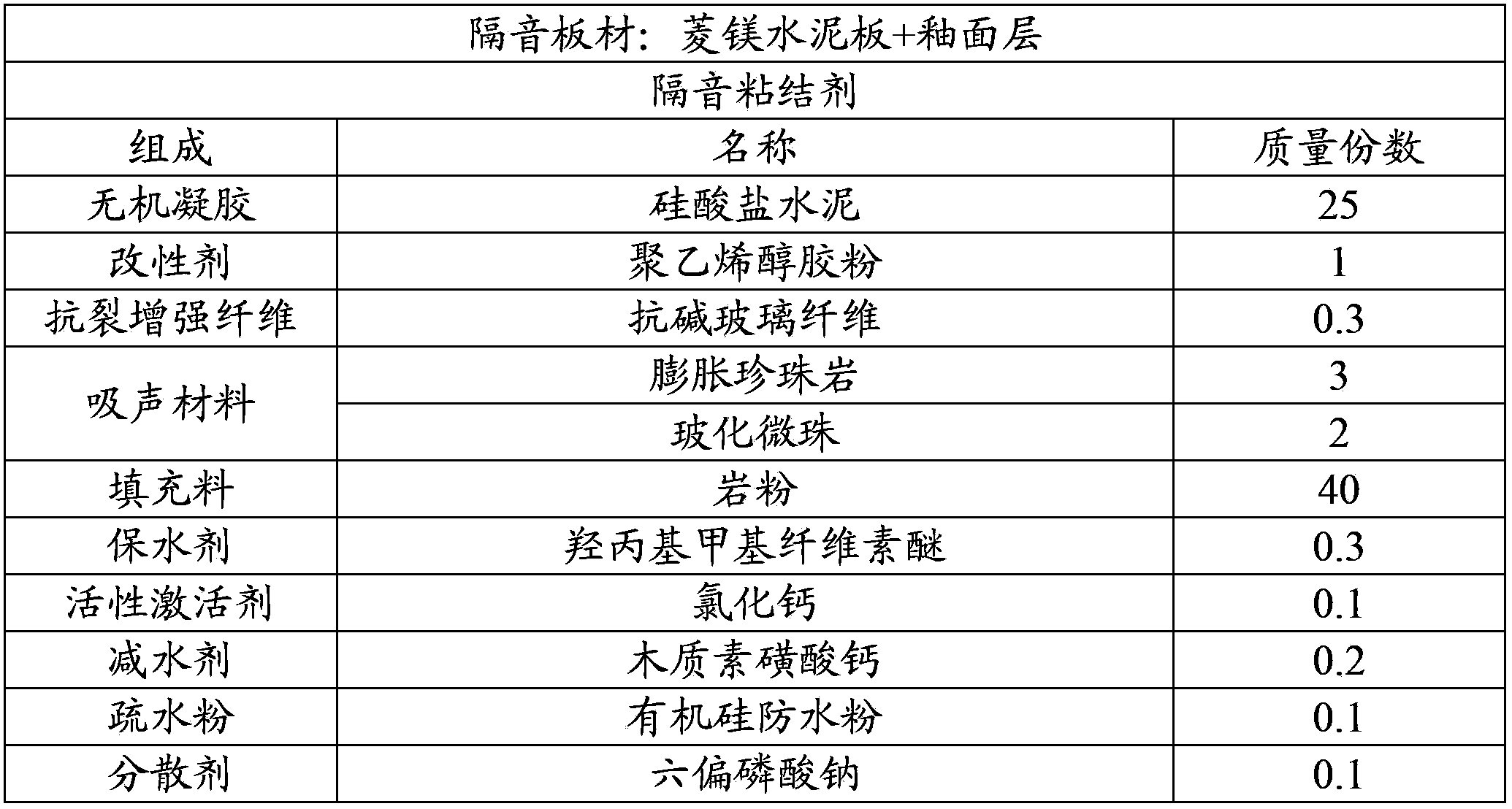

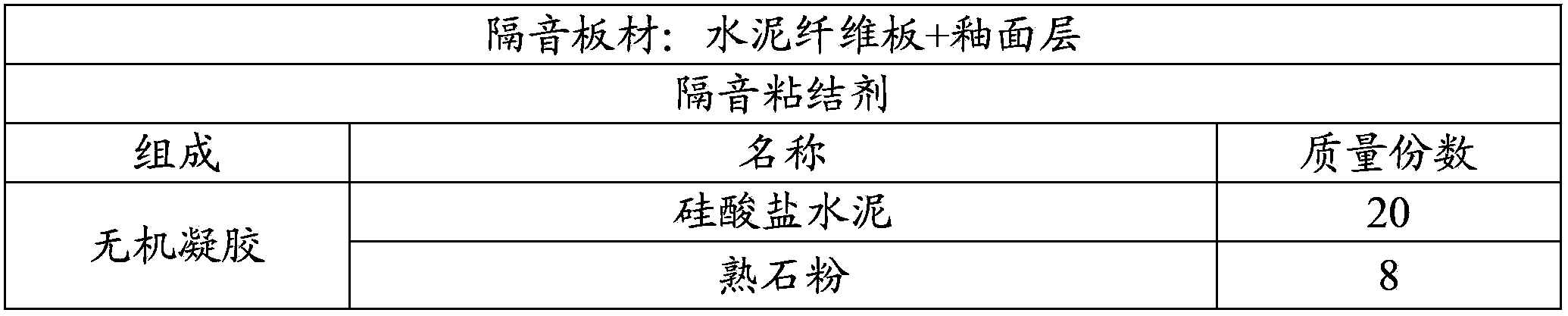

Sound insulation composite wall and floor board

A sound insulation composite a wall and floor board, including a sound insulation sheet material and a sound insulation binder for adhering the sound insulation sheet material to the wall and floor of the building. The sound insulation sheet material comprises a substrate and a glaze layer adhered on the substrate, the sound insulation binder includes, by mass fraction, 25-30 parts of an inorganic gel, 1-5 parts of a modifier, 0.3-0.5 part of anti-cracking reinforced fiber, 5-8 parts of a sound absorbing material, 40-60 parts of a filler, 0.3-0.6 part of a water retaining agent, 0.1-0.5 part of an activation activating agent, 0.2-0.8 part of a superplasticizer, 0.1-0.3 part of a hydrophobic powder and 0.1-0.6 part of a dispersant. The sound insulation sheet material contains a large amount of interconnected micro voids, and sound waves can penetrate deep inside the material along these pores and generates friction effect with the material, so that the acoustic energy is converted into heat energy. In addition, the sound insulation binder contains the sound-absorbing material consisting of an unconsolidated porous material, which has gradually increased sound absorption coefficient from low frequency to high frequency, so that the sound insulation binder has good sound absorption effect on high-frequency and intermediate-frequency sound.

Owner:深圳市爱思宝科技发展有限公司

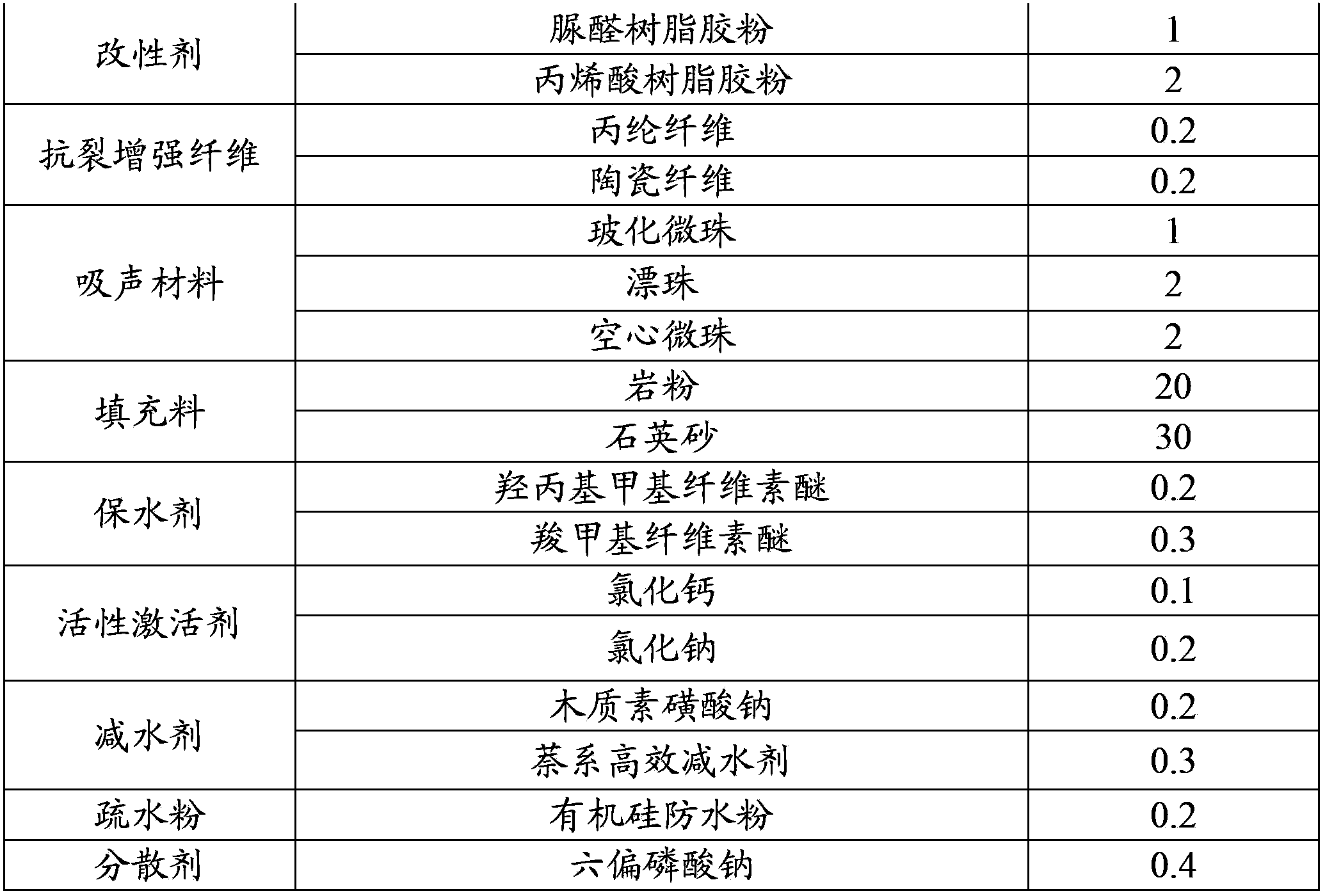

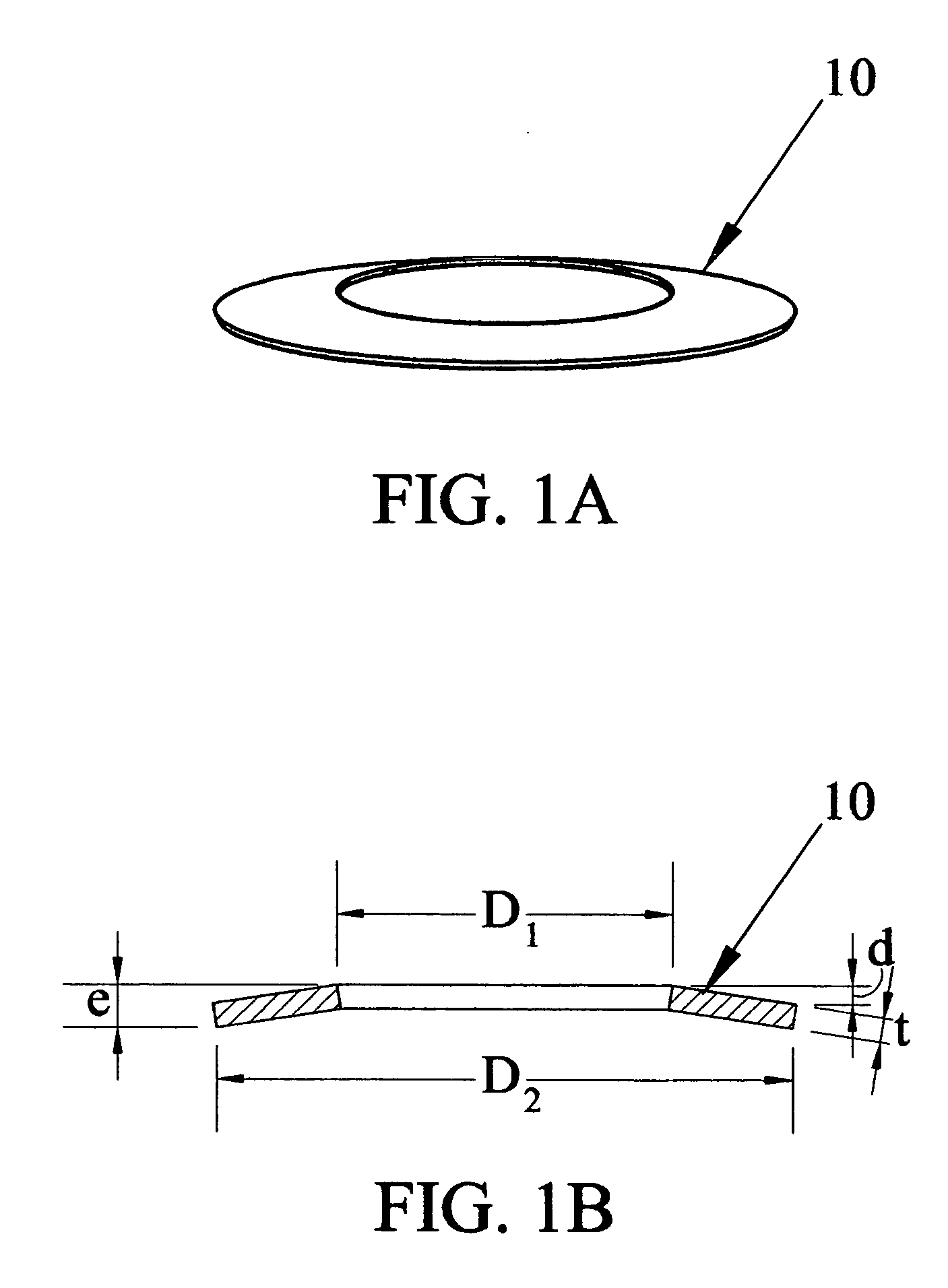

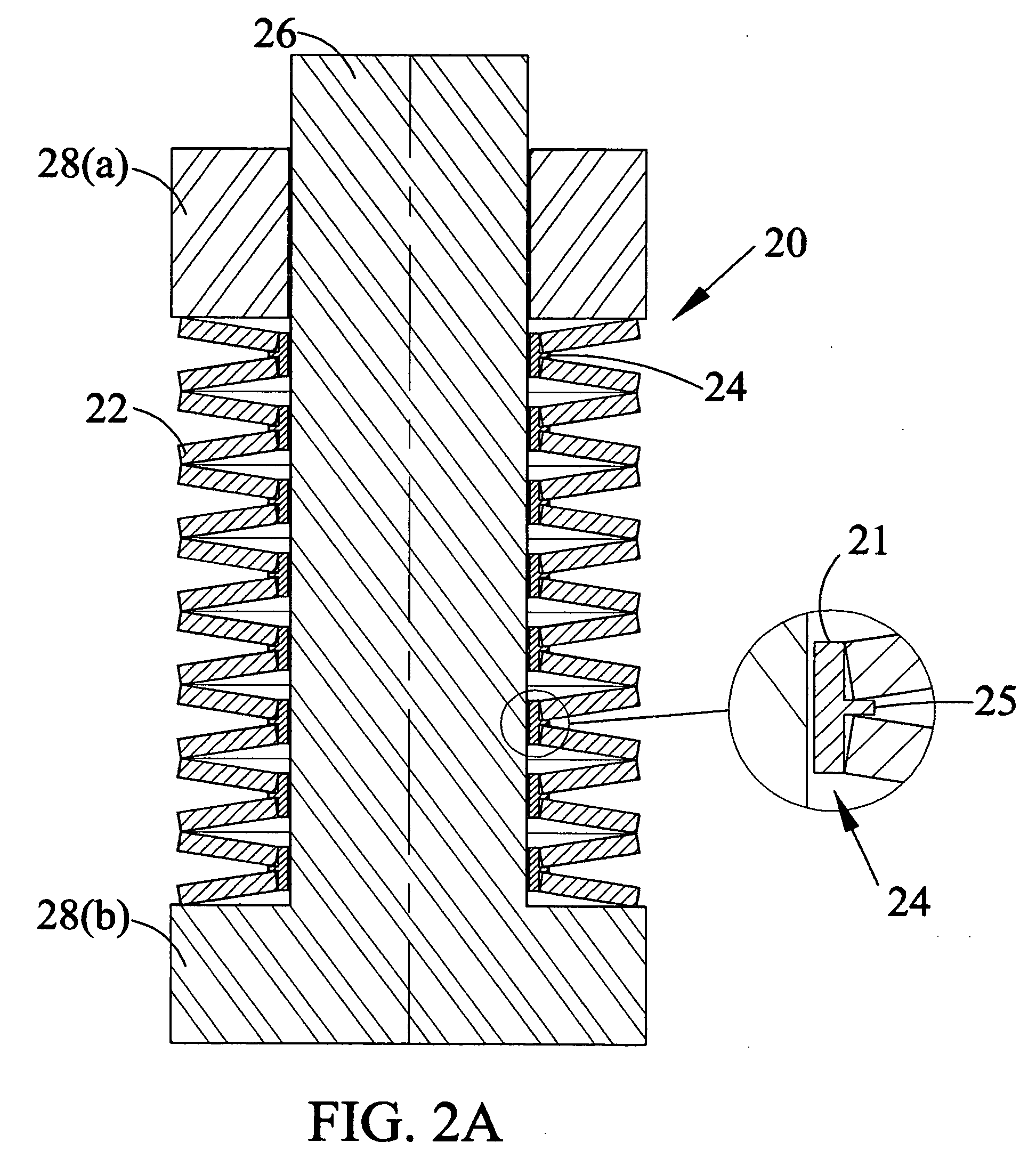

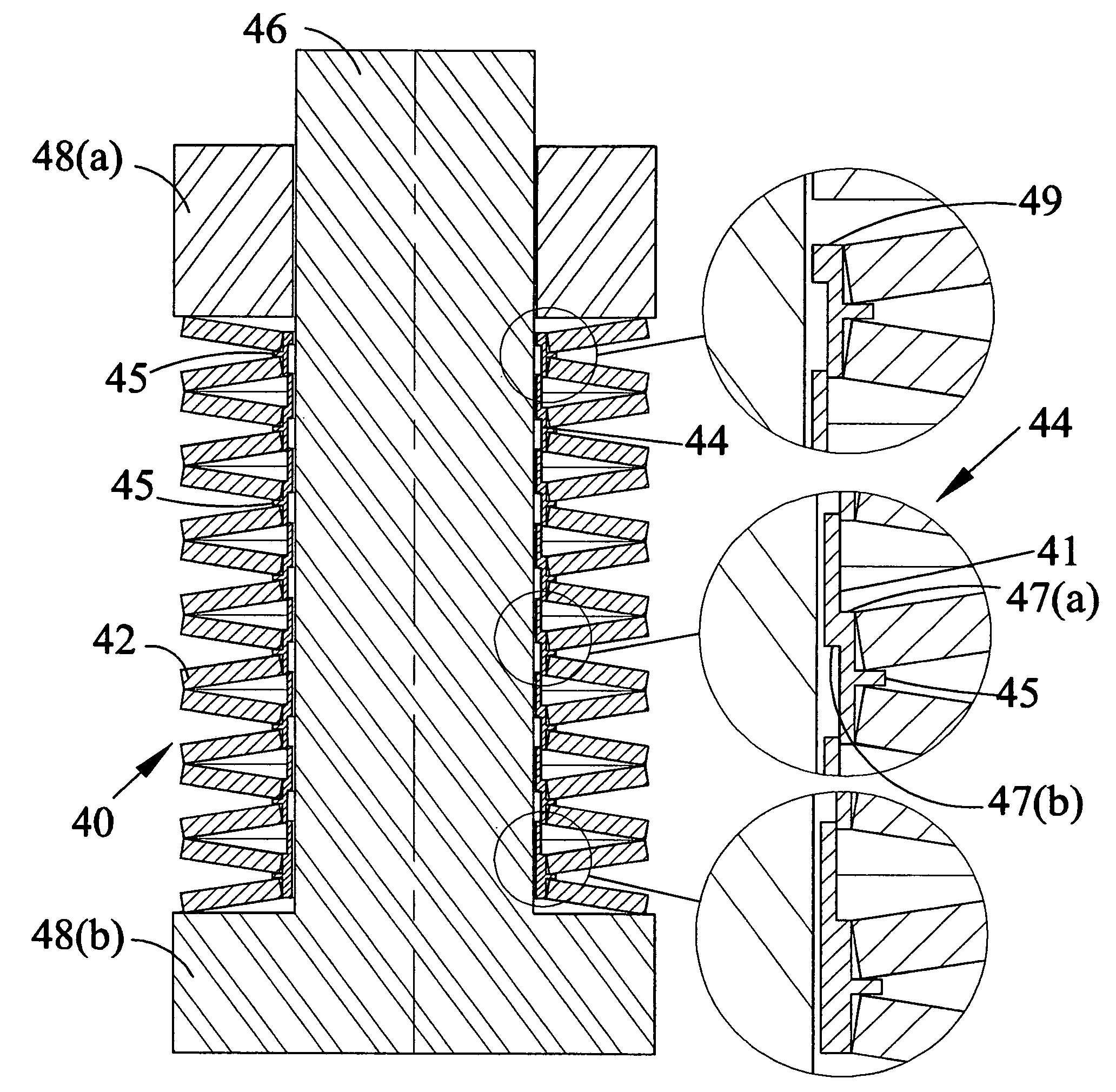

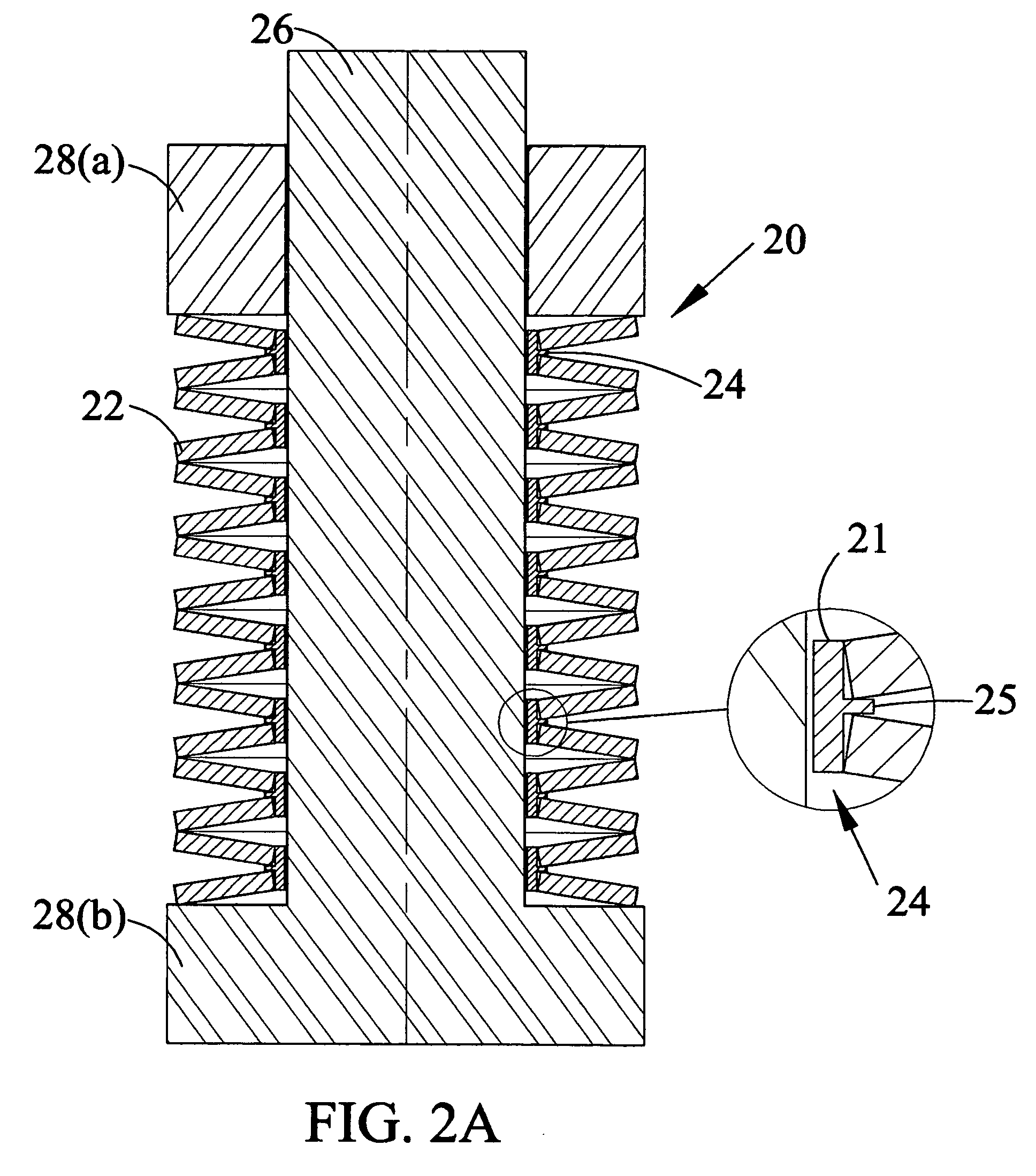

Belleville spring guide system

ActiveUS20070138720A1Reduce frictionReduce lateral forceBelleville-type springsRing springsFriction effectEngineering

Owner:HALLIBURTON ENERGY SERVICES INC

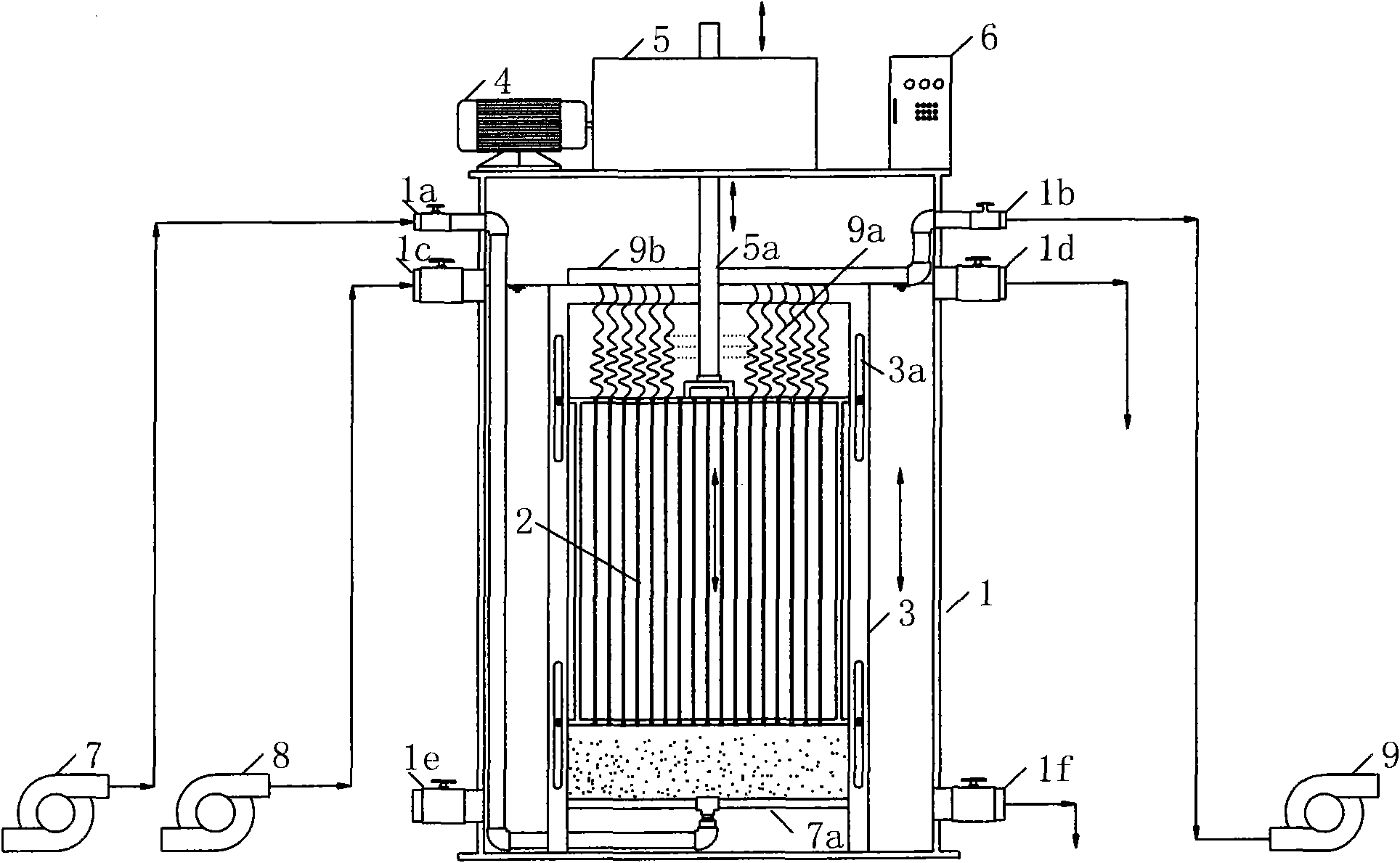

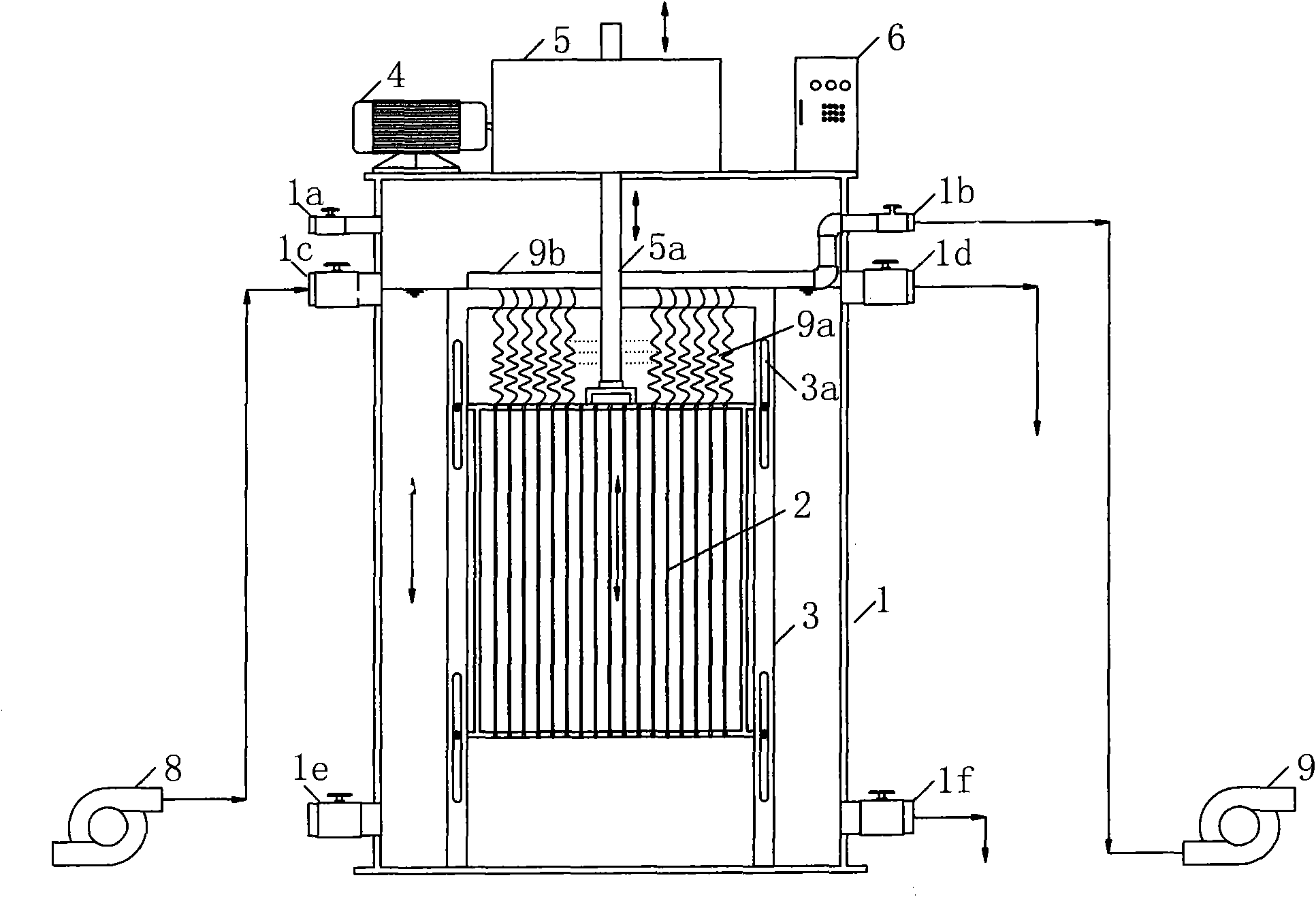

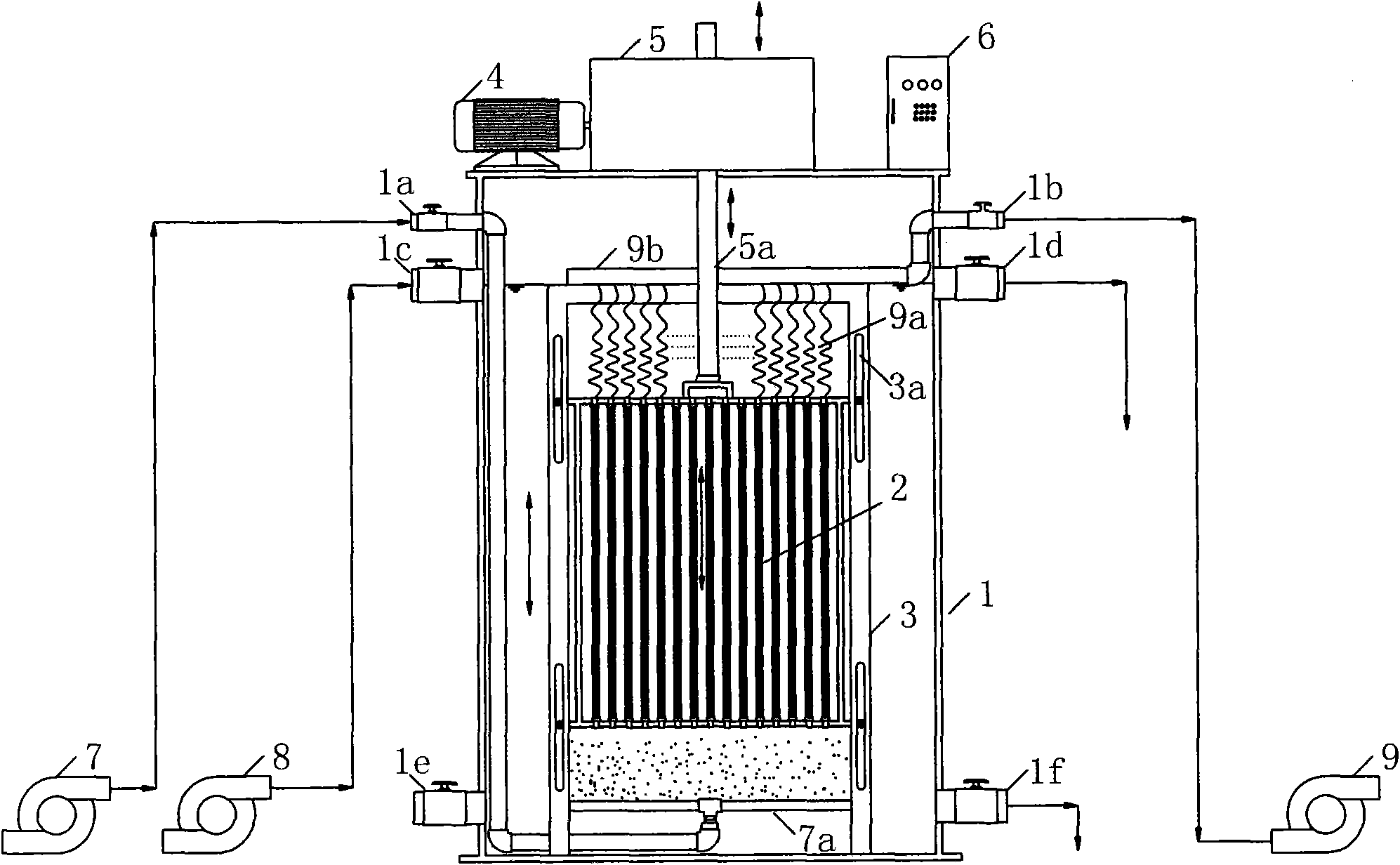

Anti-pollution high-efficiency vibration filtering separation device

InactiveCN101791501AHigh degree of automationPrecision Automatic ControlFiltration separationFriction effectSewage treatment

The invention discloses an anti-pollution high-efficiency vibration filtering separation device, belonging to water environment protection and treatment devices. A filter separation element is installed on a filter separation element holder, and then is installed in a mixed liquor container together with the filter separation element holder; the top cover or the side face of the mixed liquor container is installed with a power mechanism and a motion conversion mechanism; the power mechanism drives the filter separation element to do straight-line reciprocating vibration vertically or horizontally through the motion conversion mechanism; and the exterior of the mixed liquor container is also provided with a control unit, a gas supply unit, a lifting unit and a suction unit which are circumscribed. The filter separation element does linear circulating motion in mixed liquor to be separated, thus enhancing the intensity and frequency of friction effect of the mixed liquor or bubbles on the surface pollutants of the filter separation element, slowing down the pollution course and improving yield of the filter separation element. The filtering separation device can be applied to the separation and collection of algae in surface water, muddy water separation in sewage treatment plants, and other situations requiring solid-liquid separation.

Owner:TSINGHUA UNIV

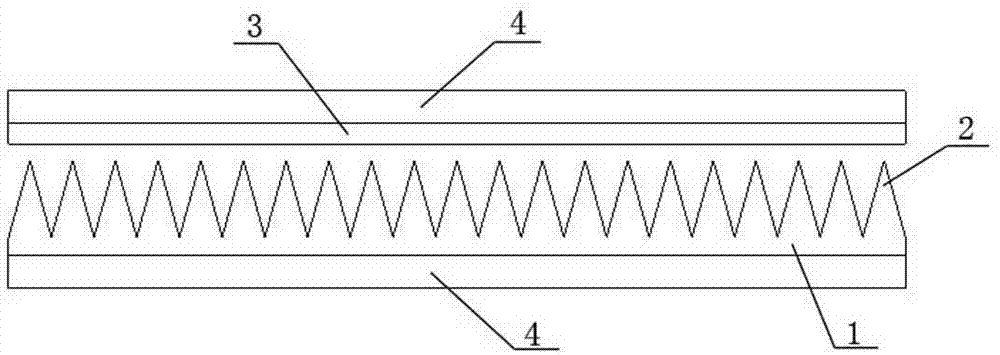

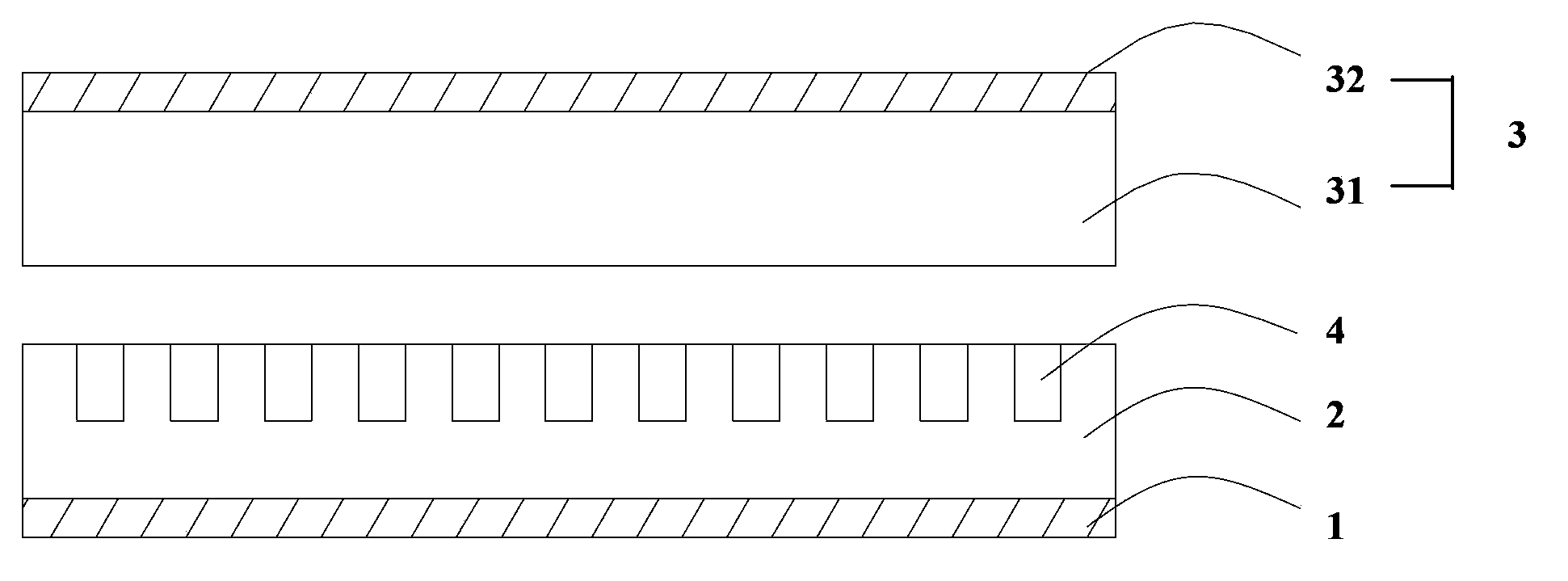

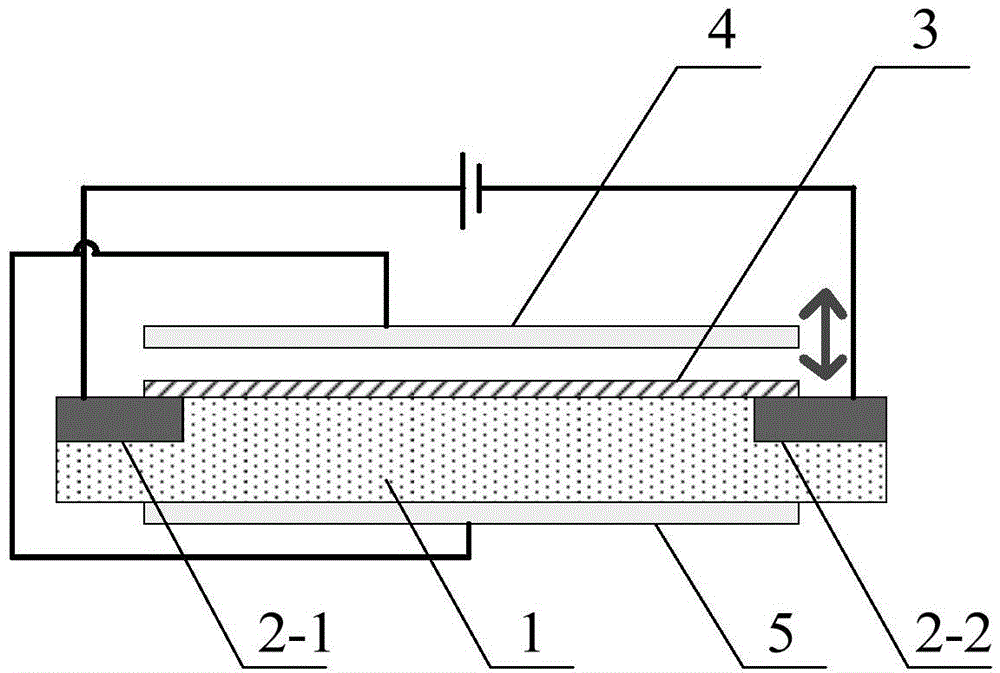

Method for manufacturing high-electrical-property nano generator based on piezoelectric-frictional effect

ActiveCN103490005AExtended service lifeIncrease production capacityMaterial nanotechnologyPiezoelectric/electrostrictive device manufacture/assemblyMicro nanoConvex structure

The invention discloses a method for manufacturing a high-electrical-property nano generator based on a piezoelectric-frictional effect. The small-area high-output-voltage nano generator is manufactured on the basis of the piezoelectric effect and the frictional effect. According to the method, CNT particles and piezoelectric particles in a certain proportion are mixed into liquid PDMS to be manufactured into a composite film, a micro-nano concave-convex structure with rules is manufactured on the surface of the composite film through a micro-processing method, finally electric polarization is carried out on the composite film, and an electrode is arranged in a clamping mode. The method combines the advantages of piezoelectricity and friction, and the manufactured piezoelectric-frictional nano generator with the small area, high sensitivity and high voltage output is low in manufacturing cost and simple in process, has good durability and workability, enables large-scale production and application to be carried out conveniently, and can be easily blended in the design of other products. Self-powered and self-driven equipment is provided for personnel electronic products, environmental monitoring, medical science and the like, and huge commercial and practical potentials are achieved.

Owner:ZHONGBEI UNIV +1

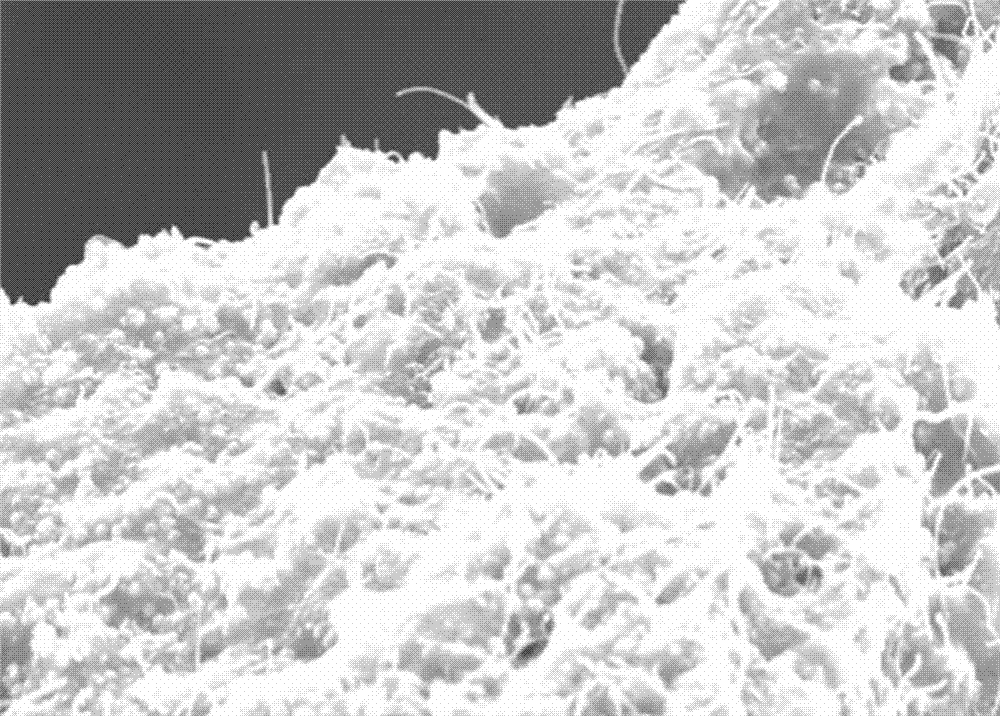

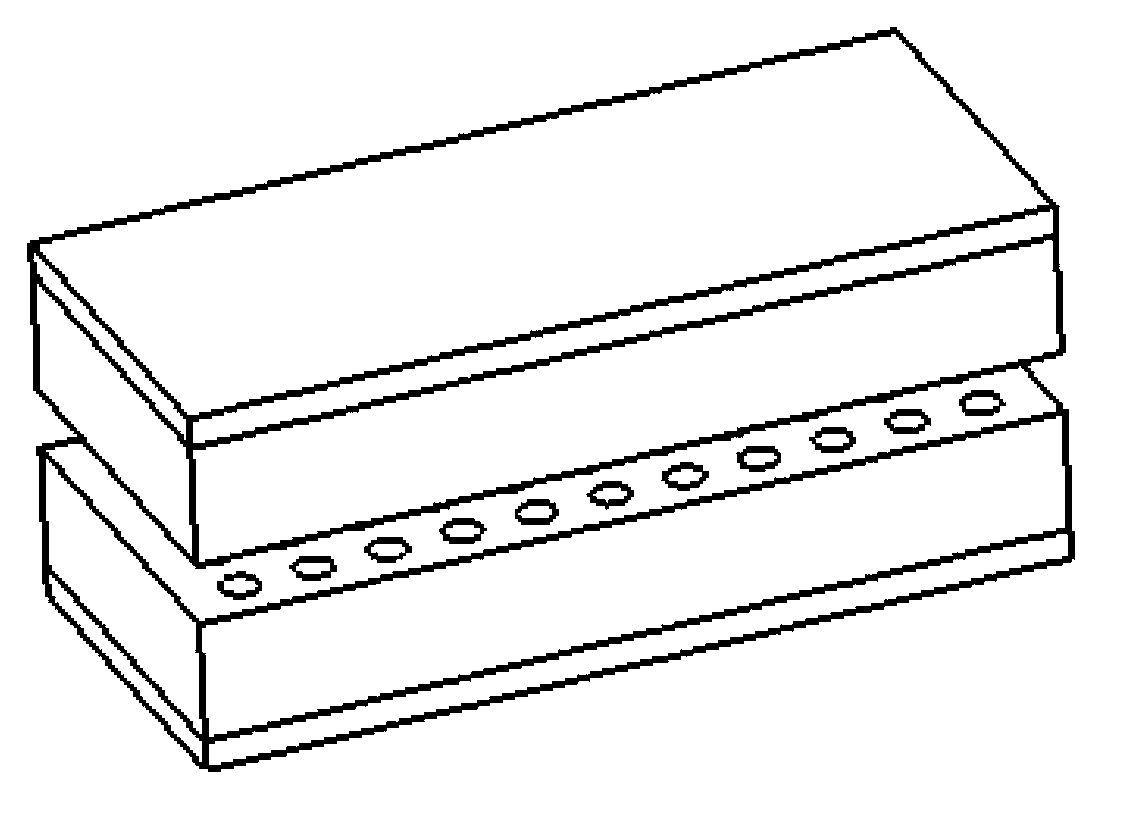

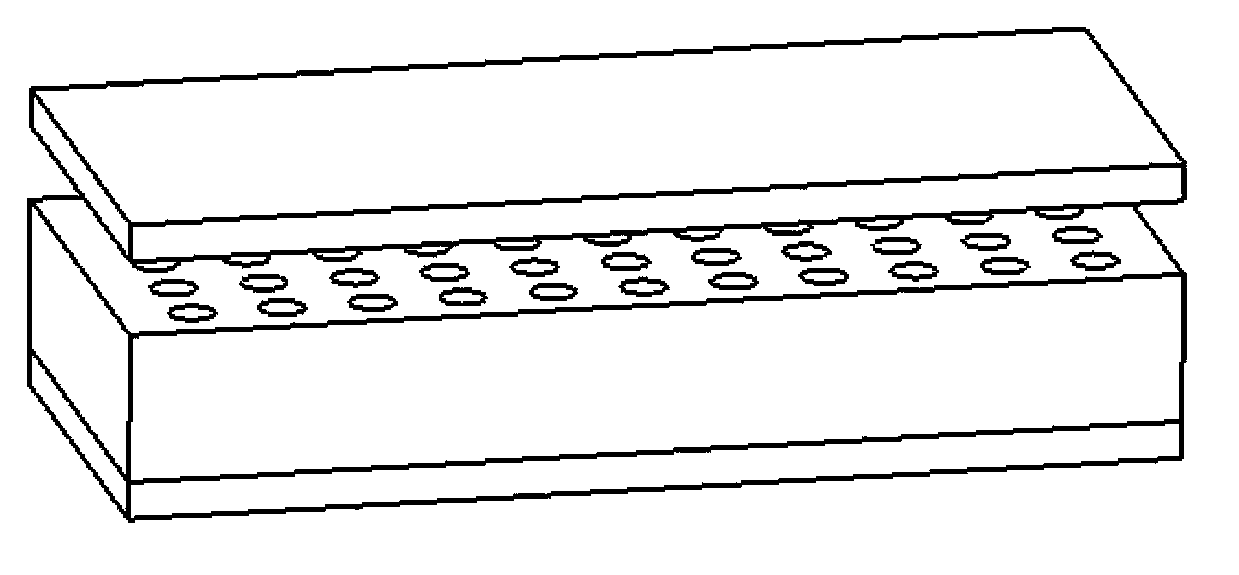

High-power nanometer friction generator and manufacturing method thereof

ActiveCN103856096AIncrease energy outputImprove friction performanceFriction generatorsFriction effectHigh energy

The invention provides a high-power nanometer friction generator and a manufacturing method thereof. The high-power nanometer friction generator comprises a first electrode layer, a macromolecule polymer layer and a friction electrode layer which are sequentially overlaid; the surface, opposite to the friction electrode layer, of the macromolecule polymer layer is provided with a plurality of nanometer holes; the first electrode layer and the friction electrode layer are voltage and current output electrodes of the friction generator. Polyvinylidene fluoride provided with the nanometer holes serves as the macromolecule polymer layer for friction, the friction effect is good, voltage and current output is high, and high-energy output of the friction generator is achieved.

Owner:NEWNAGY TANGSHAN

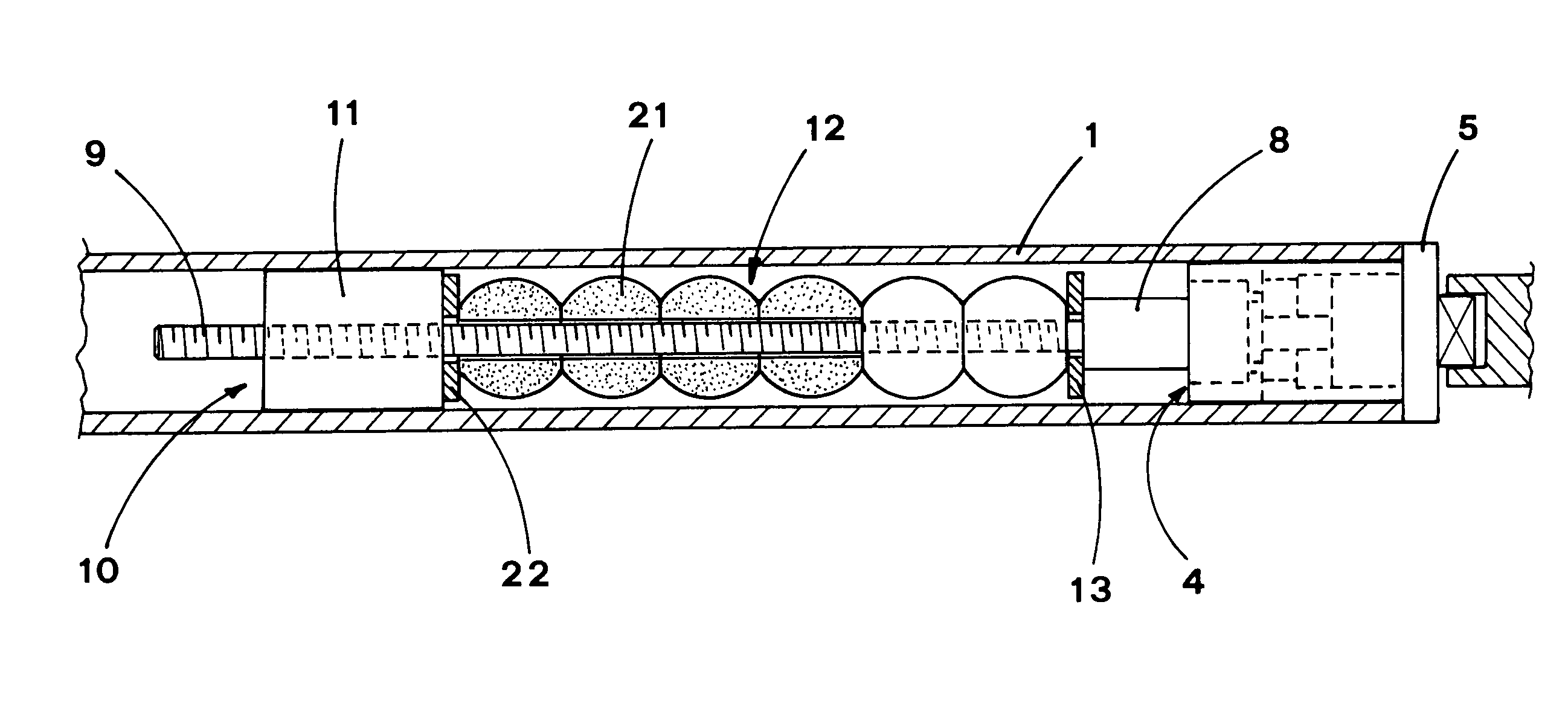

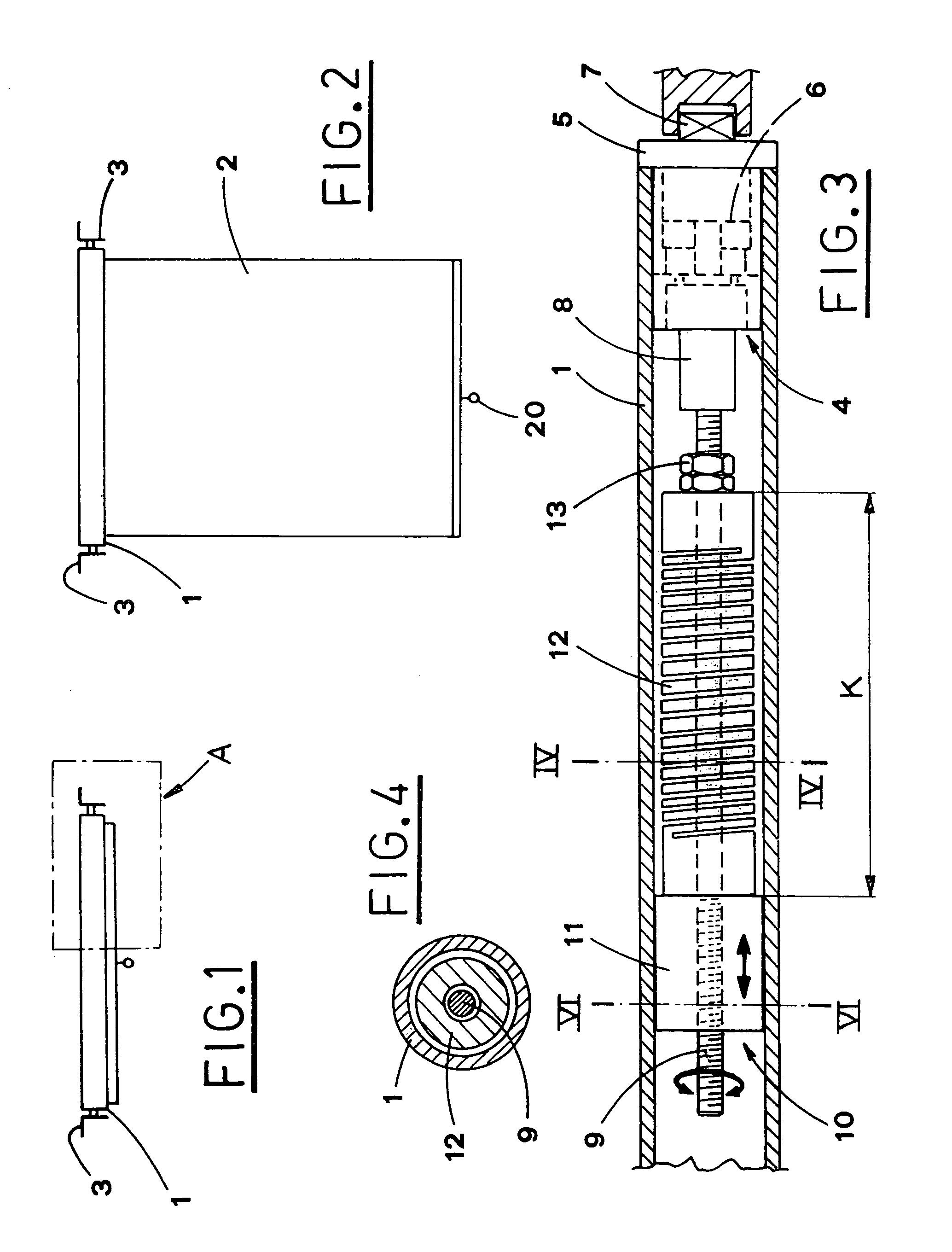

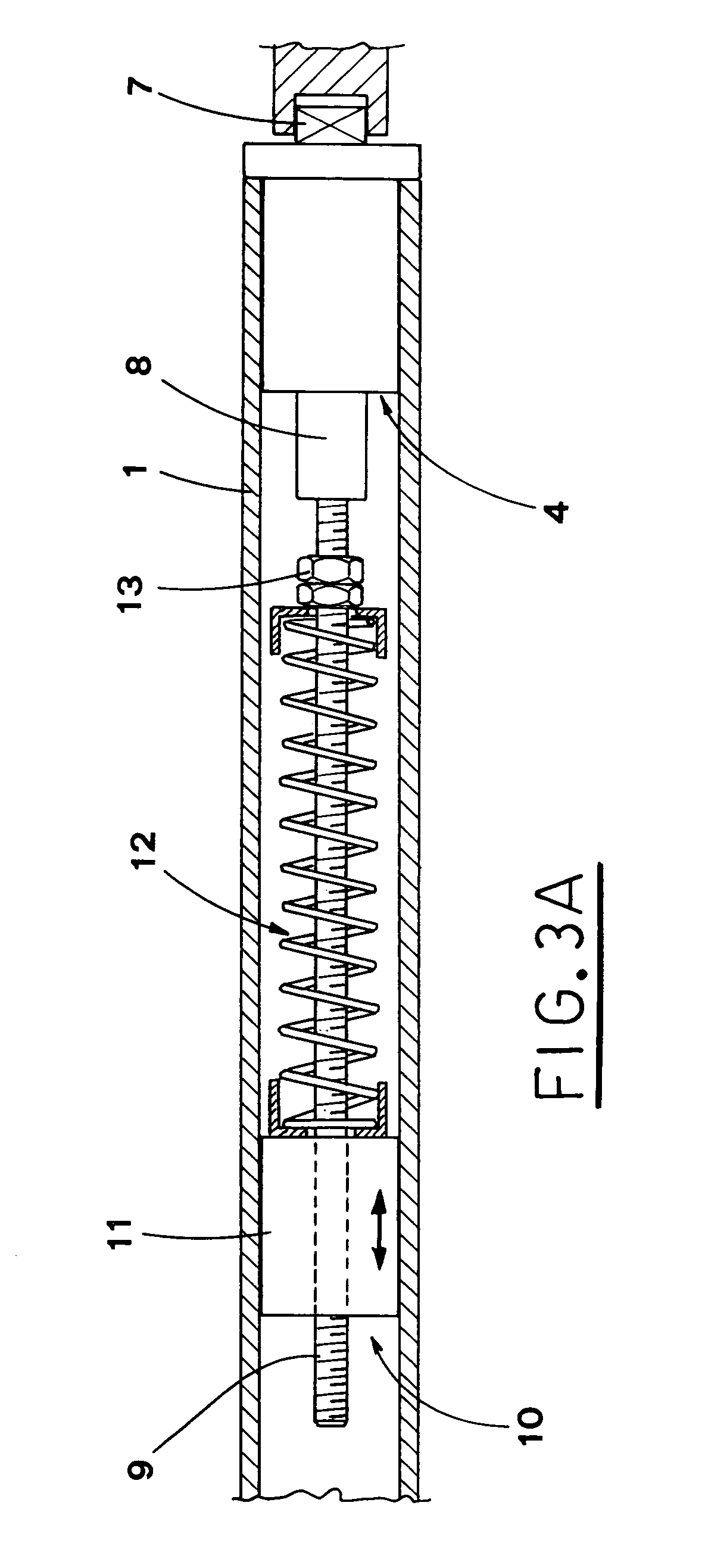

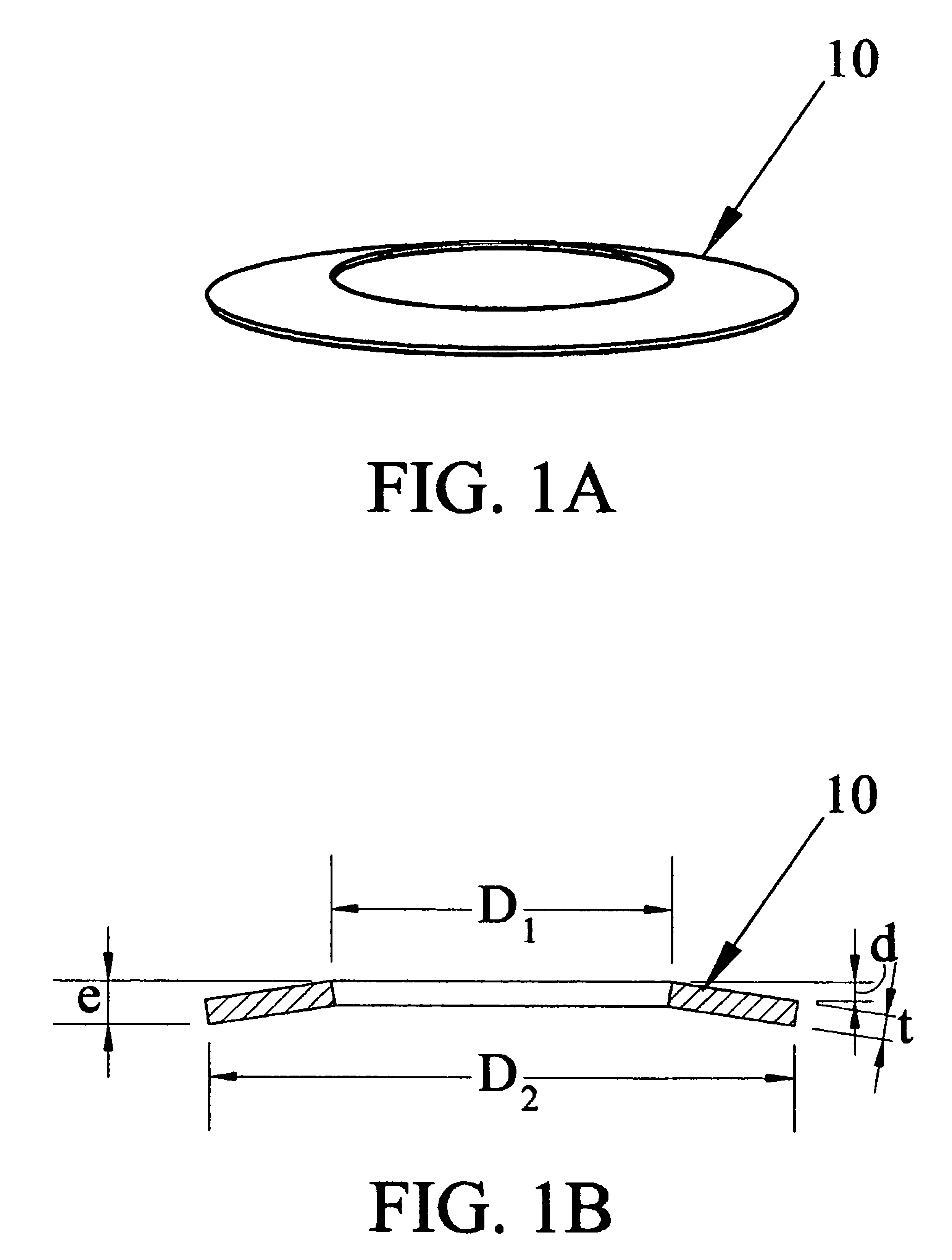

Friction device for roll-up curtains and the like

InactiveUS6955207B2Prevent fallingEasy to processLight protection screensFriction effectHorizontal axis

A friction device (10), applied to roll-up curtains and the like, includes a tubular roller (1), on which the curtain (2) rolls up, and which is rotatably carried on a horizontal axis. The friction device (10) includes a threaded shaft (9), situated axially inside the roller (1) and connected to the roller (1) by interposition of an angular speed reducer group (4). A body (11), mounted sliding axially inside the roller (1), is screw-coupled with the threaded shaft (9), so as to translate axially due to the shaft (9) rotation during unrolling or rolling up of the curtain (2) on the roller (1). One or more elastic members (12), subjected to pressure or counter-thrust, are compressed, on opposite ends, between abutment means (13) and a surface of the body (11), to determine a friction effect, which varies as a function of the rotation direction of the roller (1).

Owner:MINDER CARL EMIL FELIX

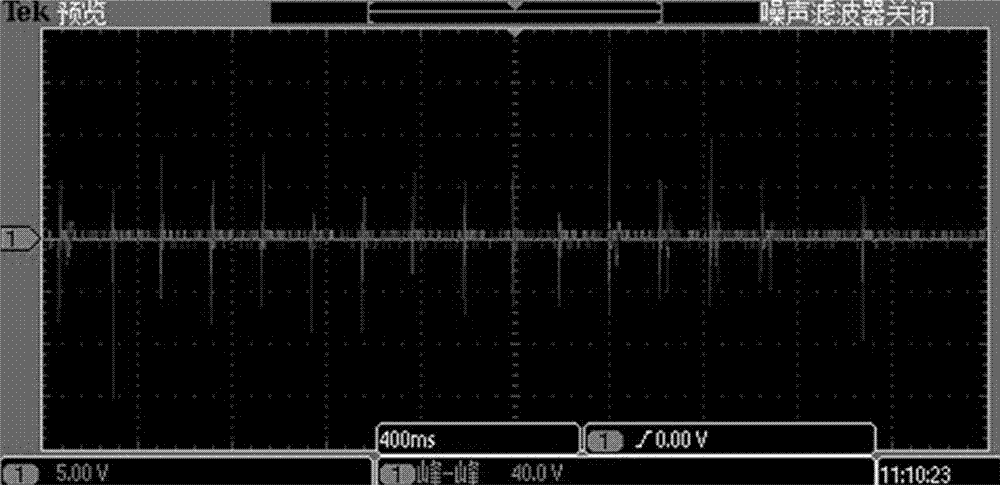

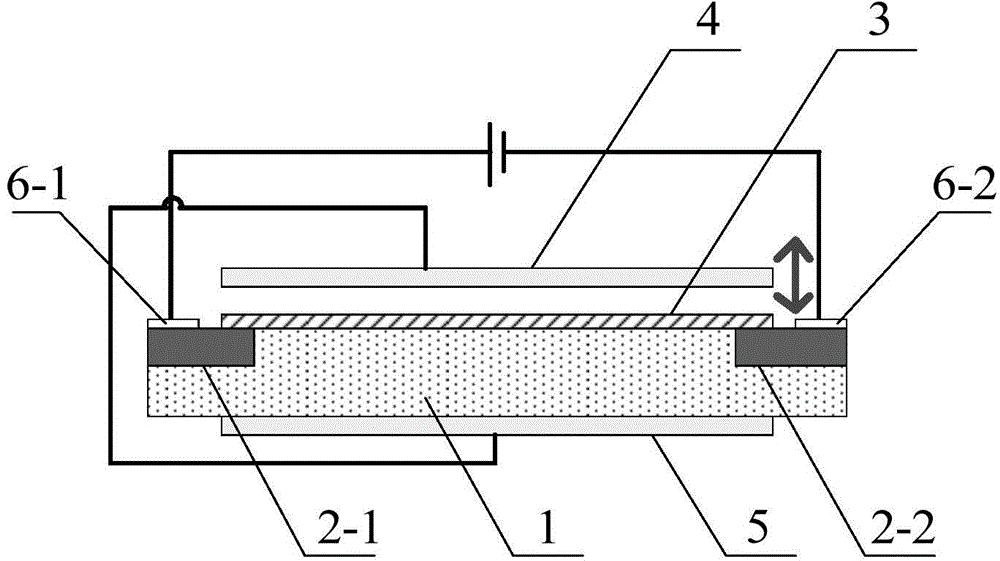

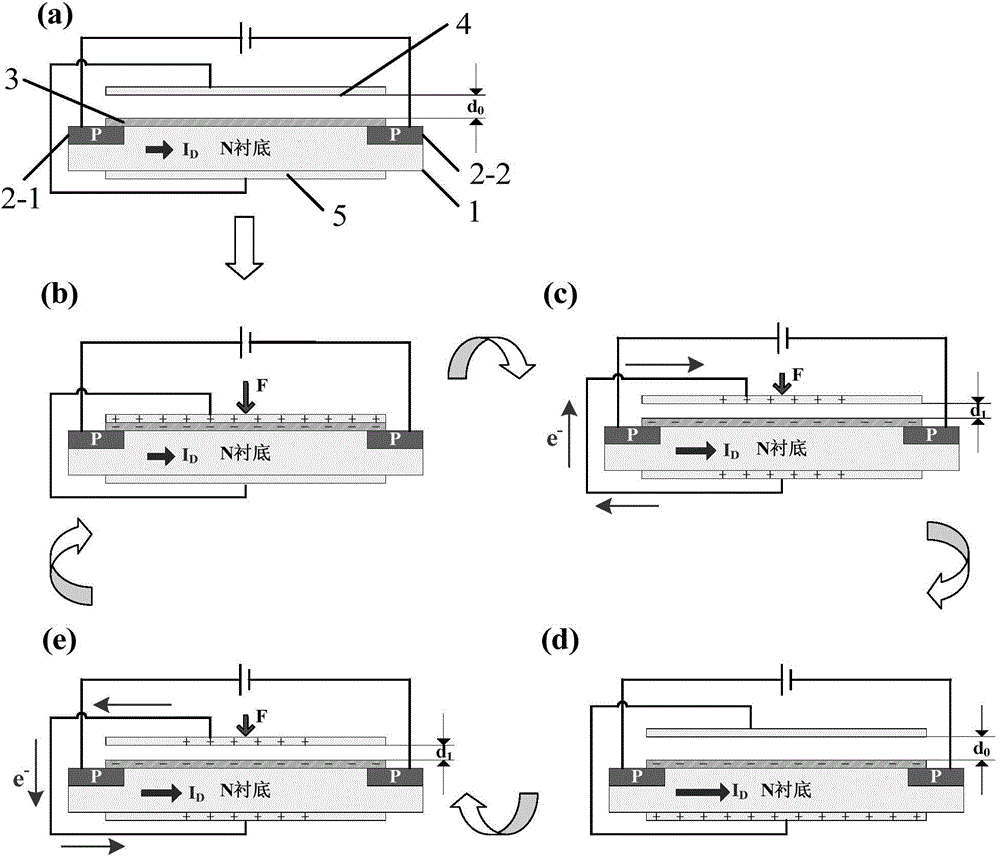

Friction electric field effect transistor

ActiveCN104600114AEnable direct interactionControl of carrier transport propertiesSemiconductor devicesFriction effectControl signal

The invention discloses a friction electric field effect transistor, and belongs to the field of flexible electronic devices. A triboelectric effect and a semiconductor effect are combined; friction is produced by using external force; electrostatic potential is formed as a gate signal to realize adjustment and control over carrier transport characteristic in semiconductor. Mechanical effect stressed on the device can be converted into a local electronic control signal; a new method for adjusting and controlling the carrier transport characteristic in an electronic device by taking the electric potential produced by the friction effect as gate voltage. Different from the conventional field effect transistor, the electronic control signal is generated by the friction electric field transistor by using friction, the gate electrode in the conventional field effect transistor is substituted, direct interaction of the external force and the electronic device is realized, a wider external force sensing range is realized, and the transistor is widely applied to the fields such as human-computer interaction, sensors and flexible electronics.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

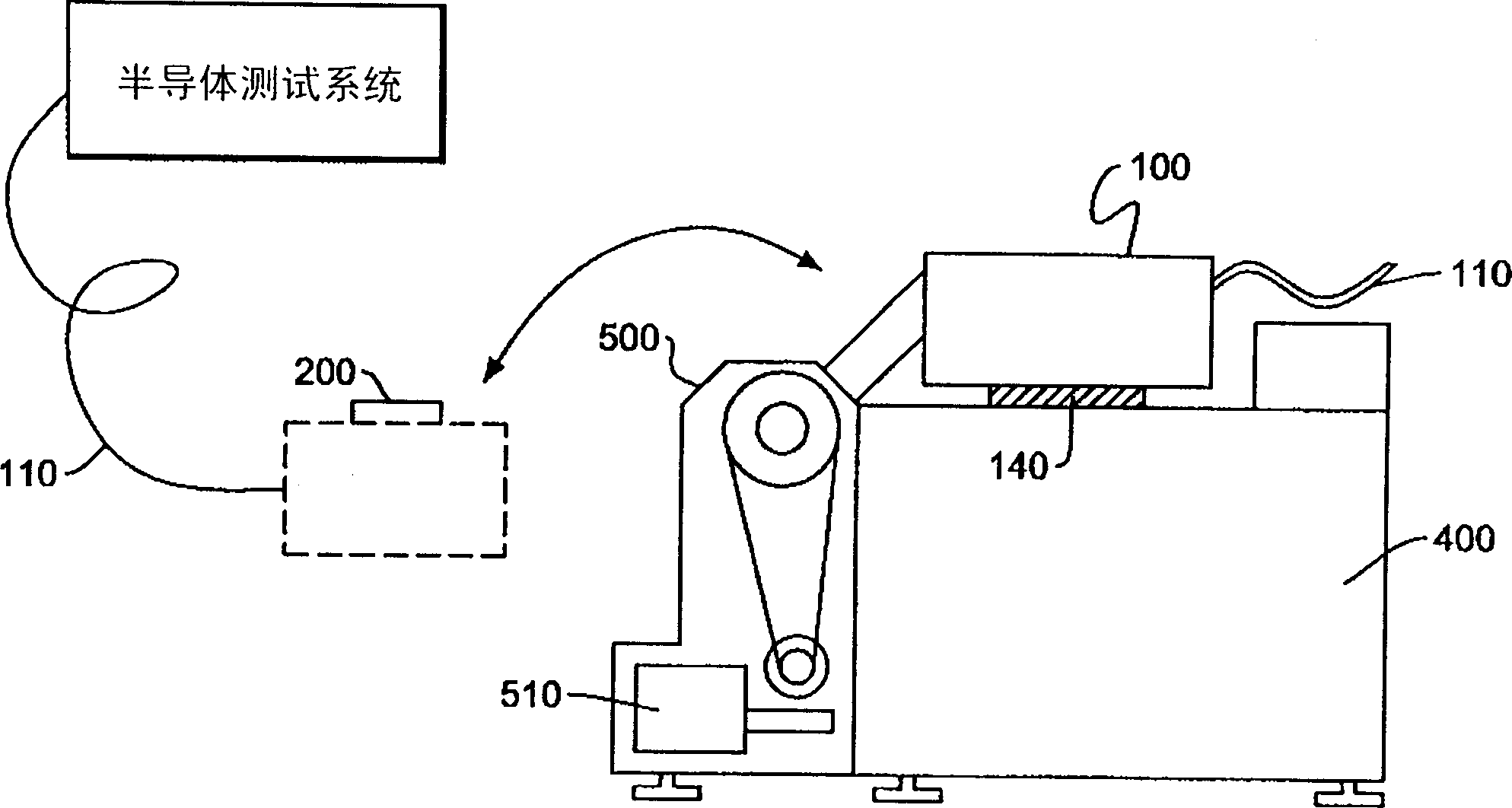

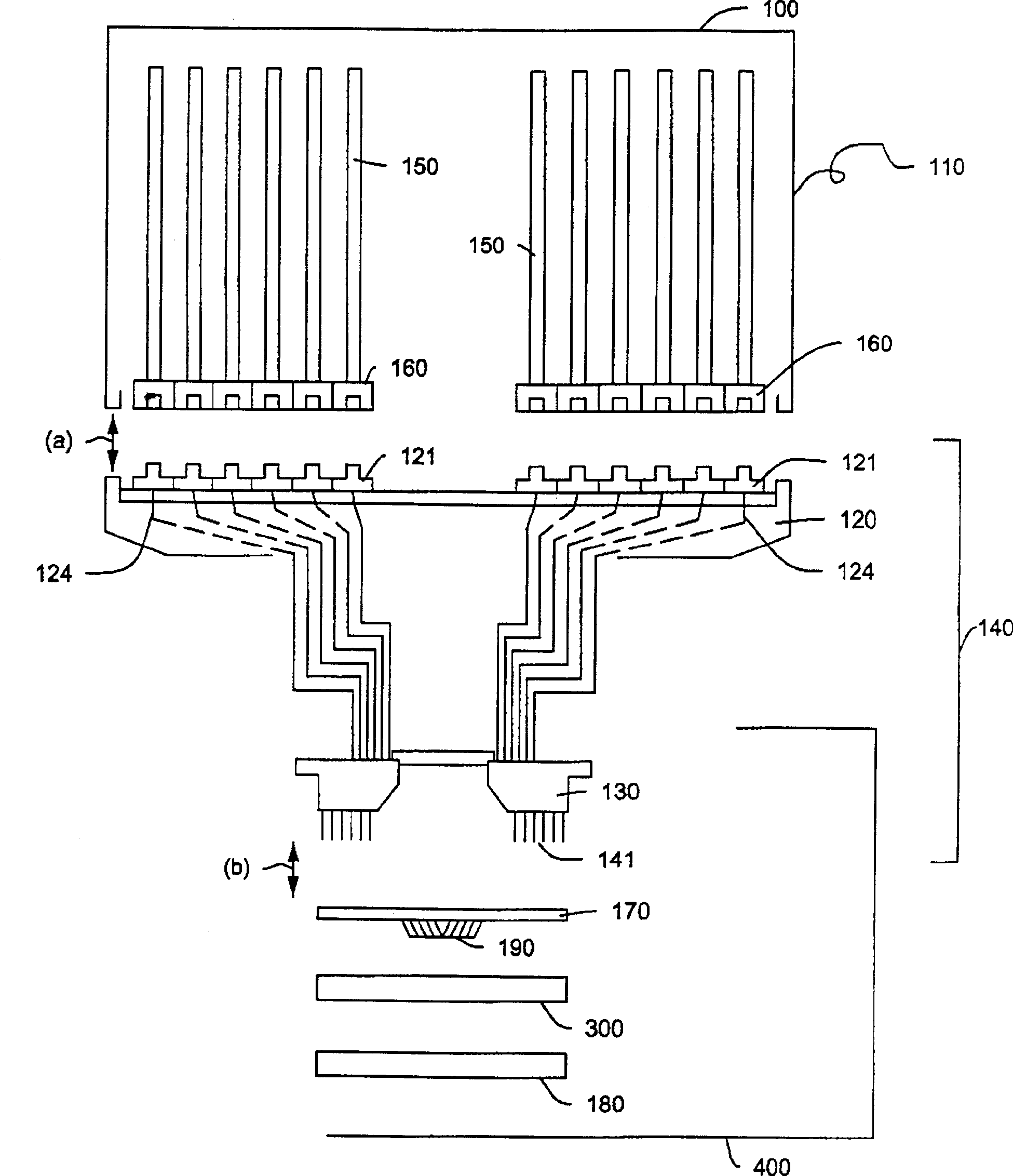

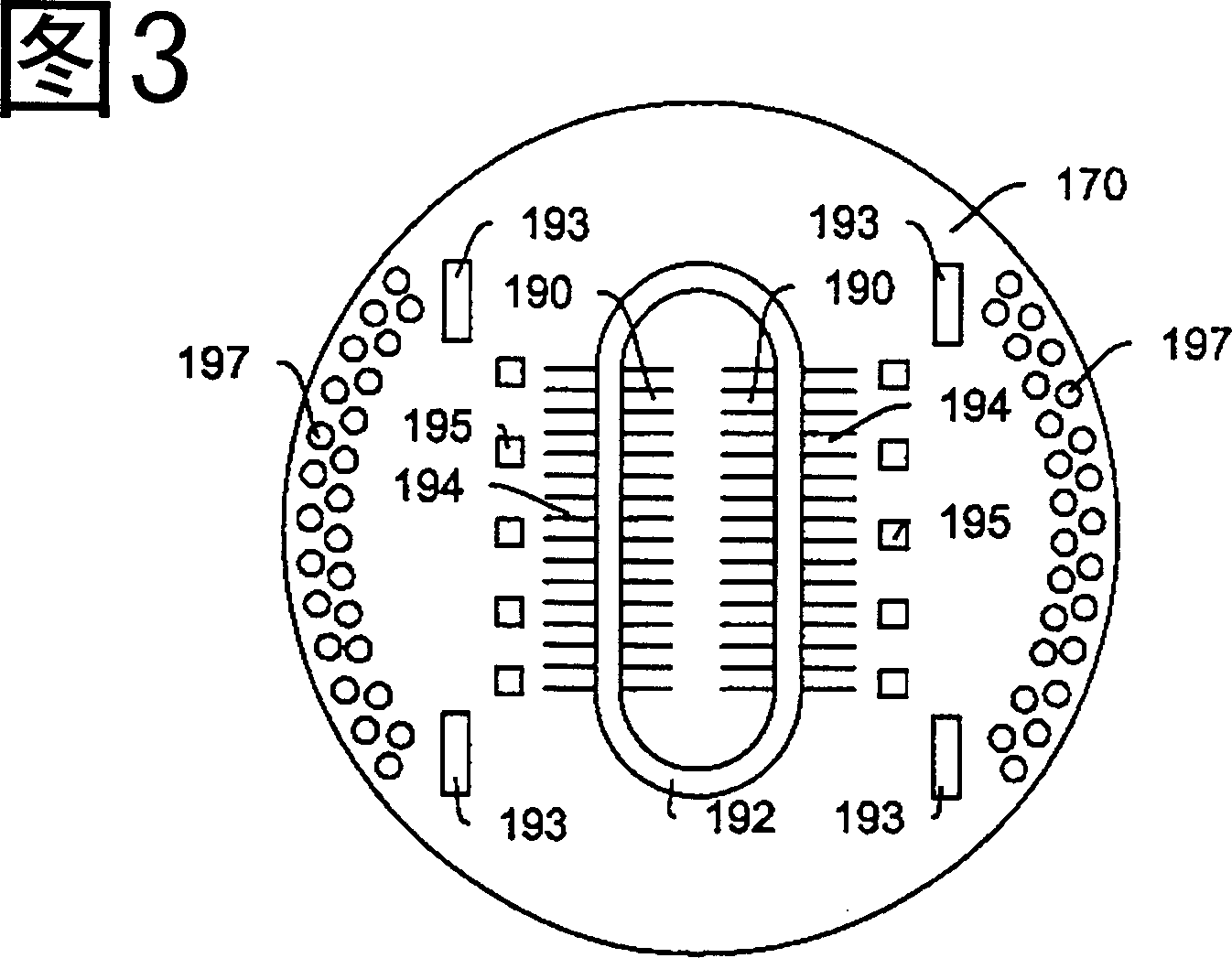

Contact structure having contact block

InactiveCN1397804AIncreased bandwidthIncrease frictionElectrical measurement instrument detailsCoupling contact membersFriction effectConductive materials

A contact structure for creating the electric connection with the object on the substrate to be tested has the TAB form using spherical contactor as contact point. It has more contactors formed by the conductive line on the grounding layer and passing through the dielectric layer, and a substrate for fixing said contactors on it and electrically connecting them to external part. The said conductive line is a microstrip line with a hard boss at its end. When the contact structure is pressed on the substrate to be tested, it is curved to contact with the said boss with a friction effect.

Owner:株式会社鼎新 +1

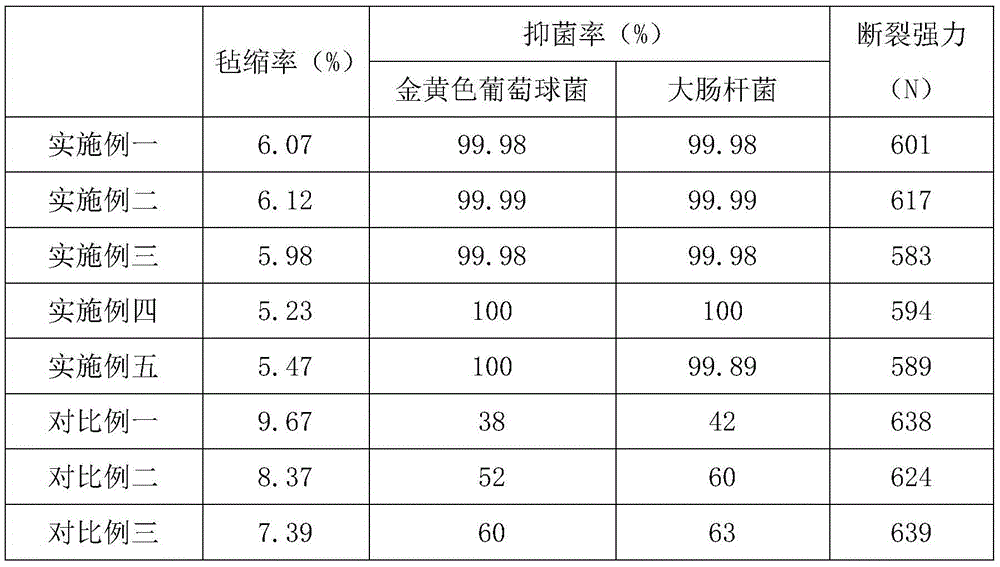

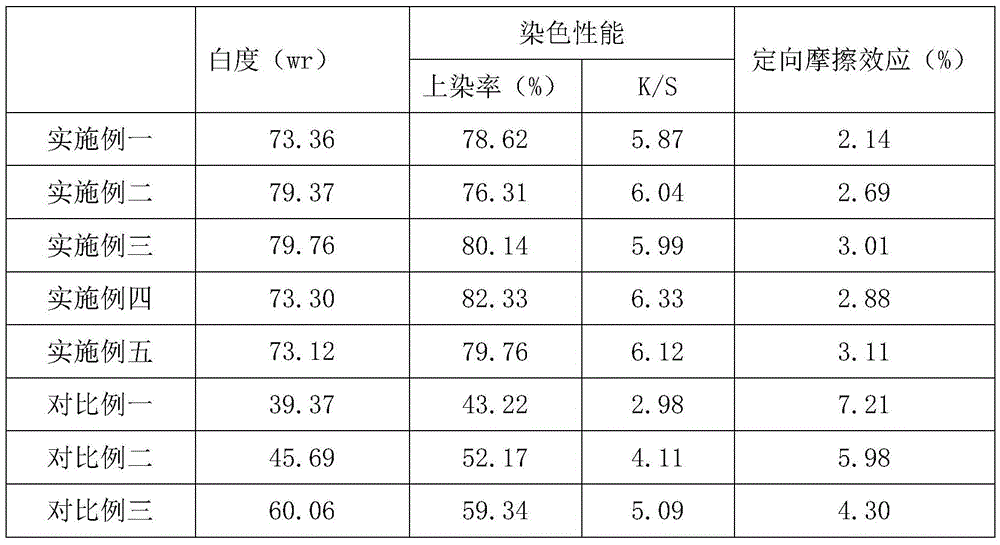

Antibacterial and anti-felting wool fabric finishing method

InactiveCN105544198AImprove antibacterial propertiesPrevent intrusionBiochemical treatment with enzymes/microorganismsShrinking resistant fibresTextile technologyFriction effect

Owner:海阳英伦纺织有限公司

Belleville spring guide system

ActiveUS7854425B2Reduce frictionReduce lateral forceBelleville-type springsRing springsFriction effectMechanical engineering

Owner:HALLIBURTON ENERGY SERVICES INC

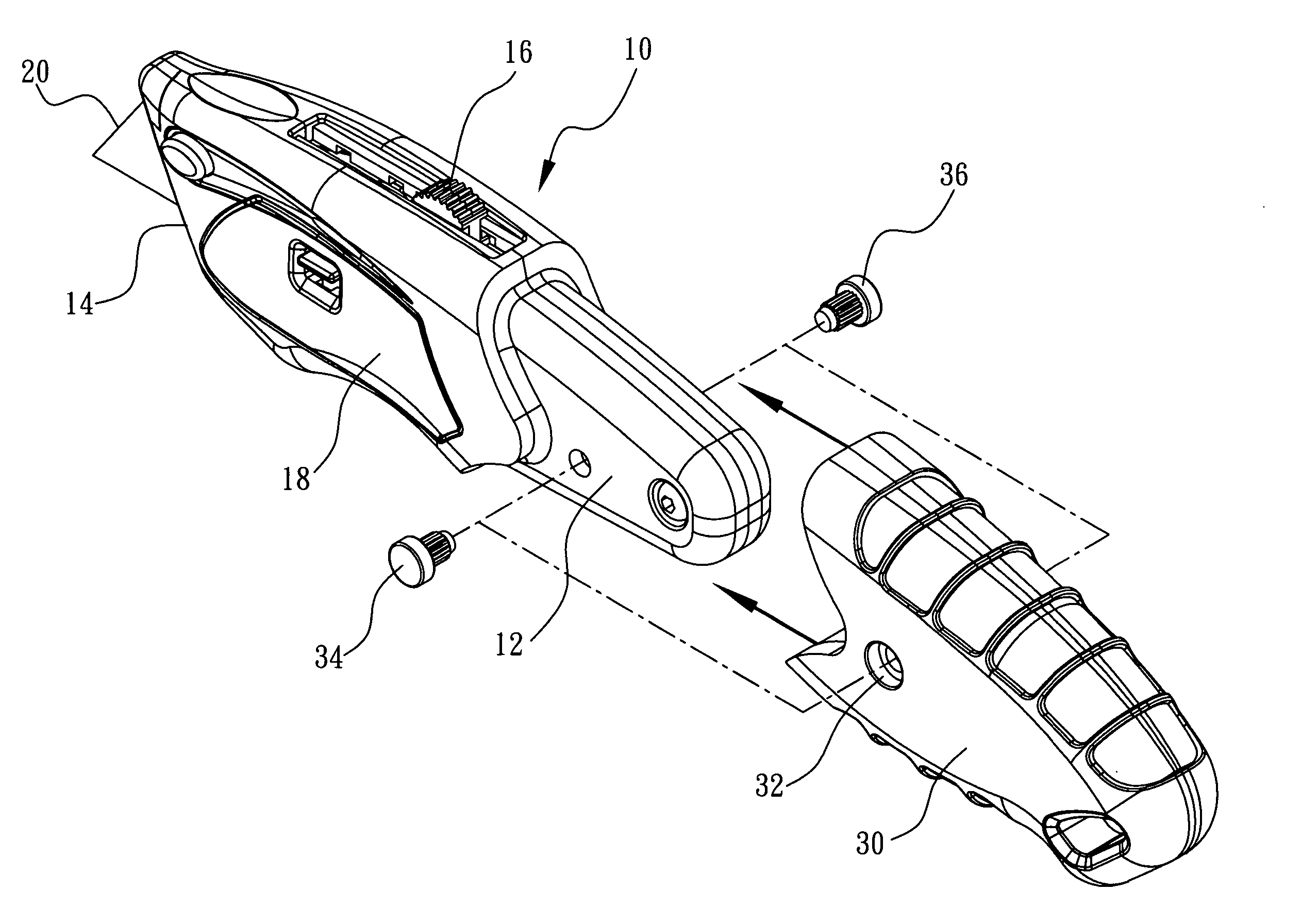

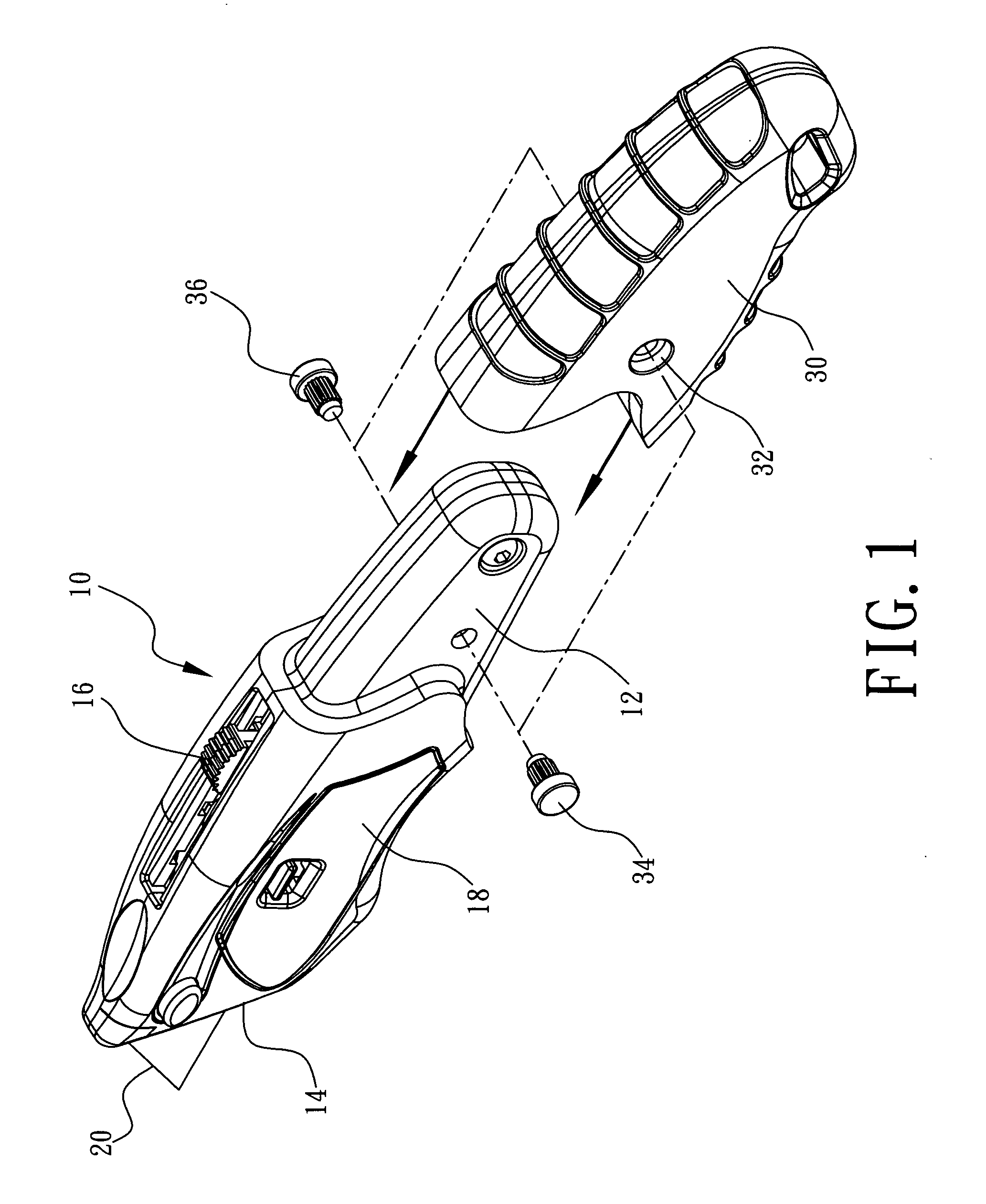

Gigantic strength type cutter knife

InactiveUS20050172496A1Enough friction effectReduce stepsThrusting weaponsWeapon componentsFriction effectEngineering

A gigantic strength type cutter knife includes a knife body has a handle portion, a plurality of blades and a handle shell. The plurality of blades are superimposed and disposed in the knife body. The knife body is provided with a pushing key, which can drive one of the blades to be bulged outside the knife body. The handle shell assembled on the handle portion. The handle shell can be assembled on or taken away from the handle portion or replaced with a new one, whereby the handle portion of the gigantic strength type cutter knife can provide enough friction effect to avoid slipping by means of the handle shell and the shape of the handle shell is further full of variety to meet the requirement of consumer.

Owner:ZENG MIN ZHENG

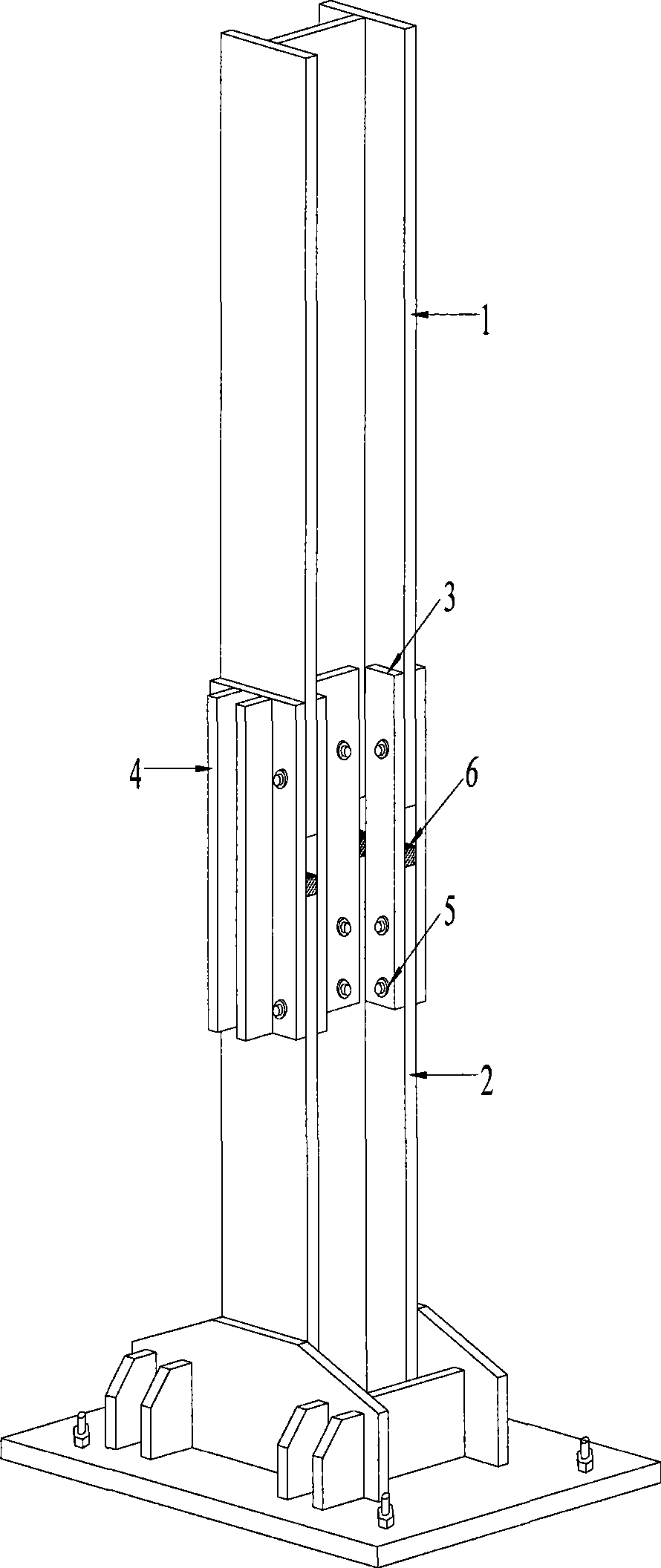

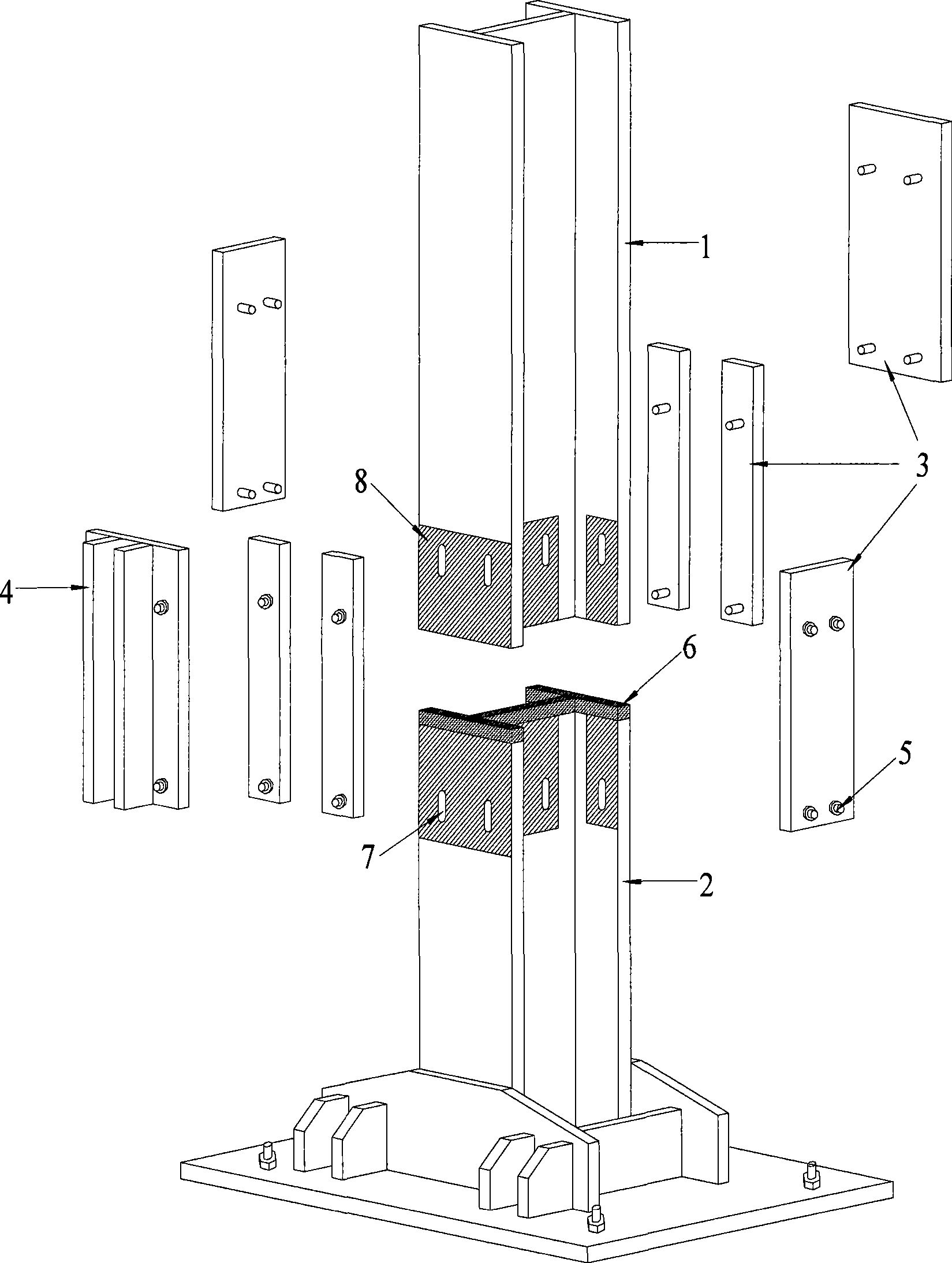

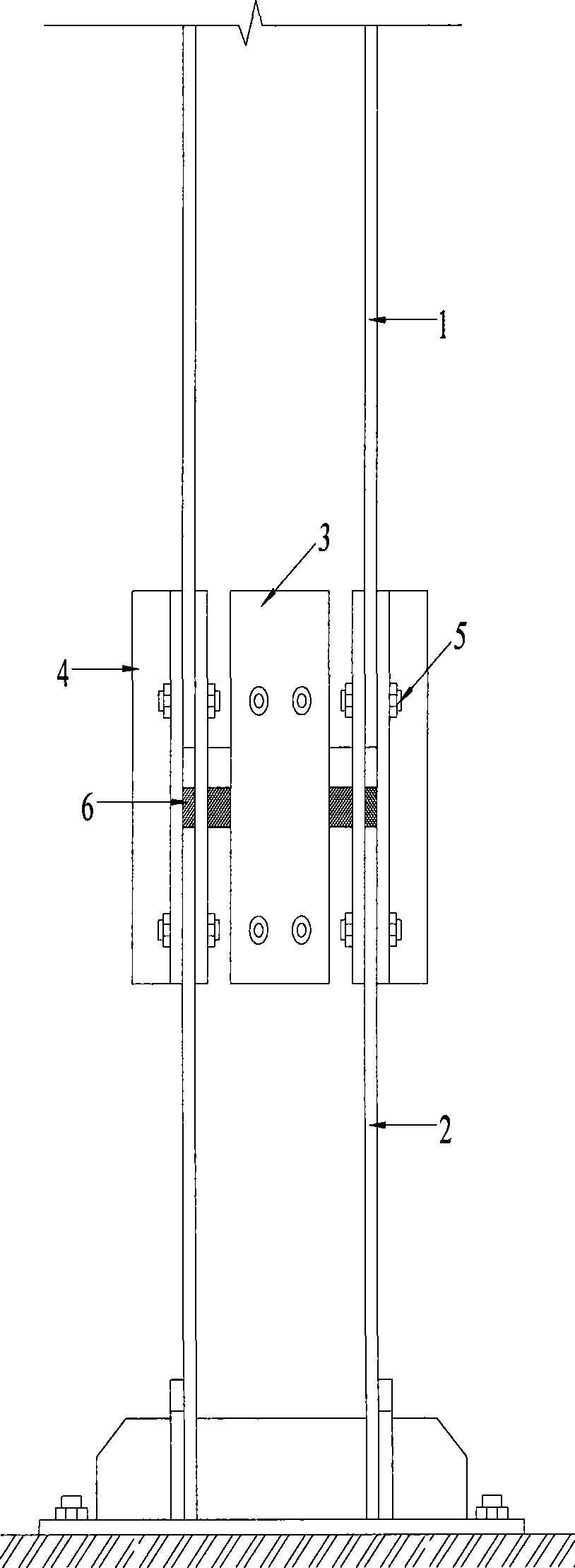

Friction type finite sway shock absorber strut

ActiveCN101372843ALimited lateral movementAvoid overall overturningShock proofingFriction effectShock resistance

The invention belongs to the structural engineering technical field, particularly to a friction-type limitation tilting shock absorption post. The upper and the lower posts of a device are in splicing connection; posts are connected with a splice plate through a high strength bolt, and a ribbed stiffener is arranged on the splice plate on the outer side of a section steel post flange; the section steel post provides vertical bearing force and restoring force, so that the sliding generated by the friction force between the section steel post and the splice plate can be overcome to enable the upper structure to tilt; the arrangement of an oblong hole stops the structure from tilting, thereby enabling the side displacement of the structure not to be too large and preventing the structure from tilting; and the friction between the section steel post and the splice plate can dissipate the earthquake energy, and a friction sheet can increase friction effect and transfer the vertical force through the friction when the posts are fixed. The invention has the advantages of structure side-displacement limitation, small residual deformation, good shock resistance performance, ductility, hysteretic energy consumption capacity, convenient installation and replacement, installations on different floors, and realization of tilting of local floors. Therefore, the shock absorption post is an excellent structural member with shock resistance and energy consumption.

Owner:大象建筑设计有限公司

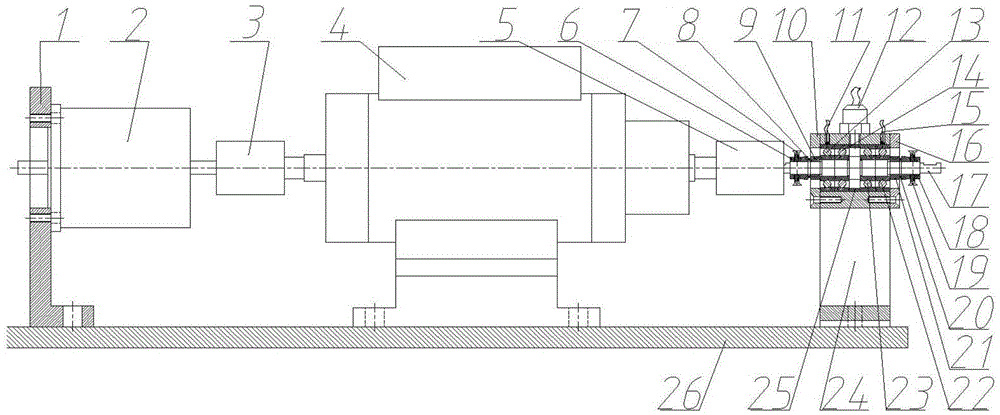

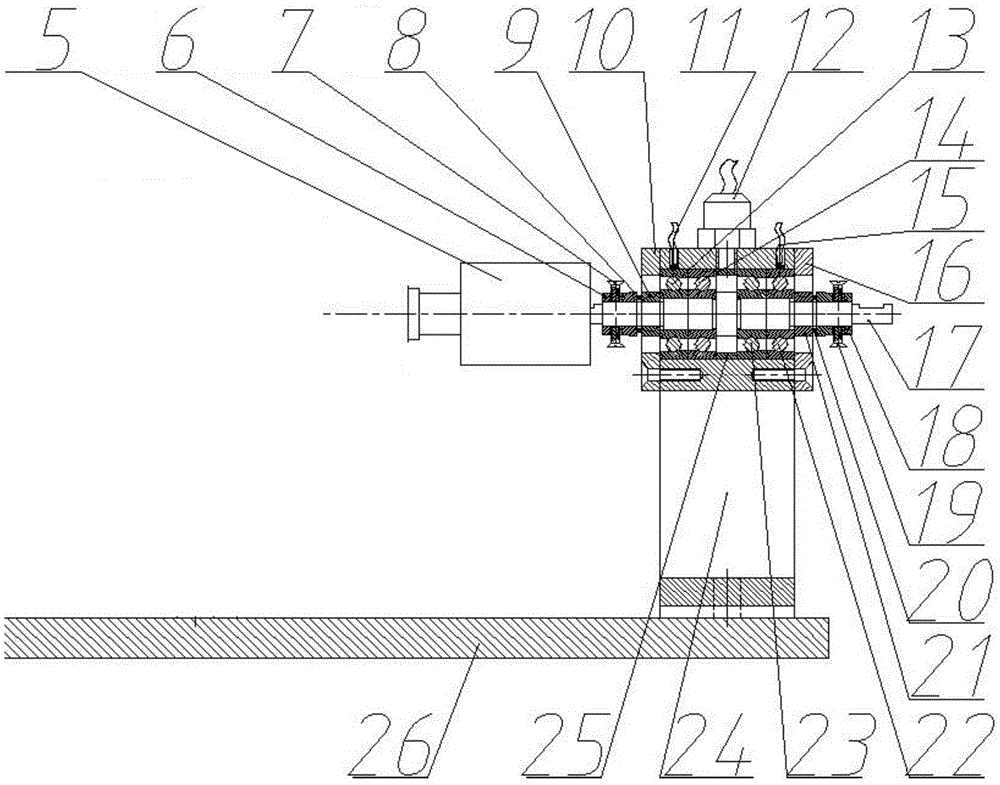

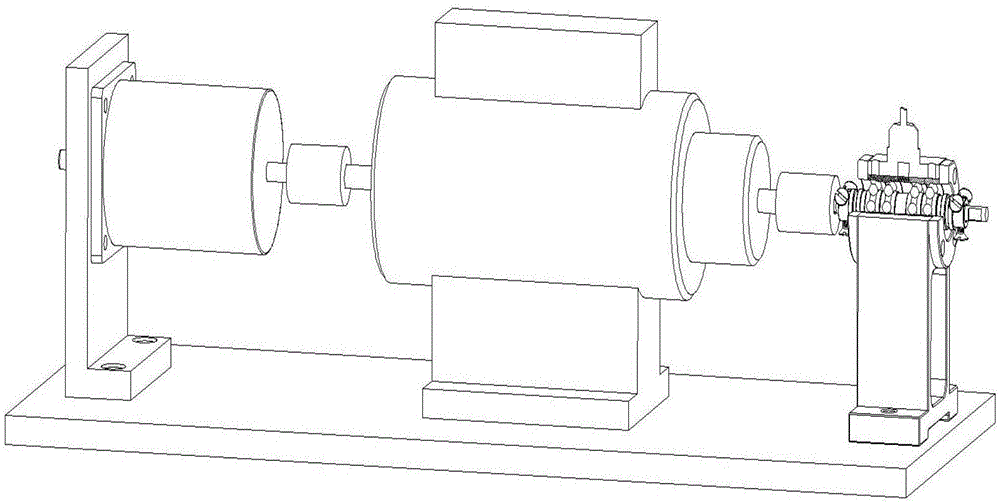

Comprehensive performance testing device for rolling ball bearing

InactiveCN105651514AGet friction torqueGet vibrationMachine bearings testingFriction effectBall bearing

The invention discloses a comprehensive performance testing device for a rolling ball bearing. The comprehensive performance testing device comprises a motor support, a motor, a shaft, a torque sensor, two temperature measurement sensors, an acceleration sensor, an axial load loading device and a test bearing pair. The motor unceasingly rotates at a certain rotating speed and drives the shaft to move in the same way. A test bearing is arranged in a bearing pedestal, and the shaft drives the inner ring to rotate. The torque sensor collects a torque signal generated by the test bearing due to the friction effect in the rotating process. The acceleration sensor is used for collecting a vibration signal generated by the bearing in the rotating process in the vertical direction. The temperature measurement sensors are used for collecting temperature effect signals generated by the test bearing in the running process due to heat generated by friction. Friction torque, vibration and temperature collection are integrated, on-line monitoring and collecting of the running performance of three types of bearings are achieved, and the comprehensive performance testing device has the advantages of being simple in structural design, small in size, convenient to machine and assemble, high in integration degree, and the like.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

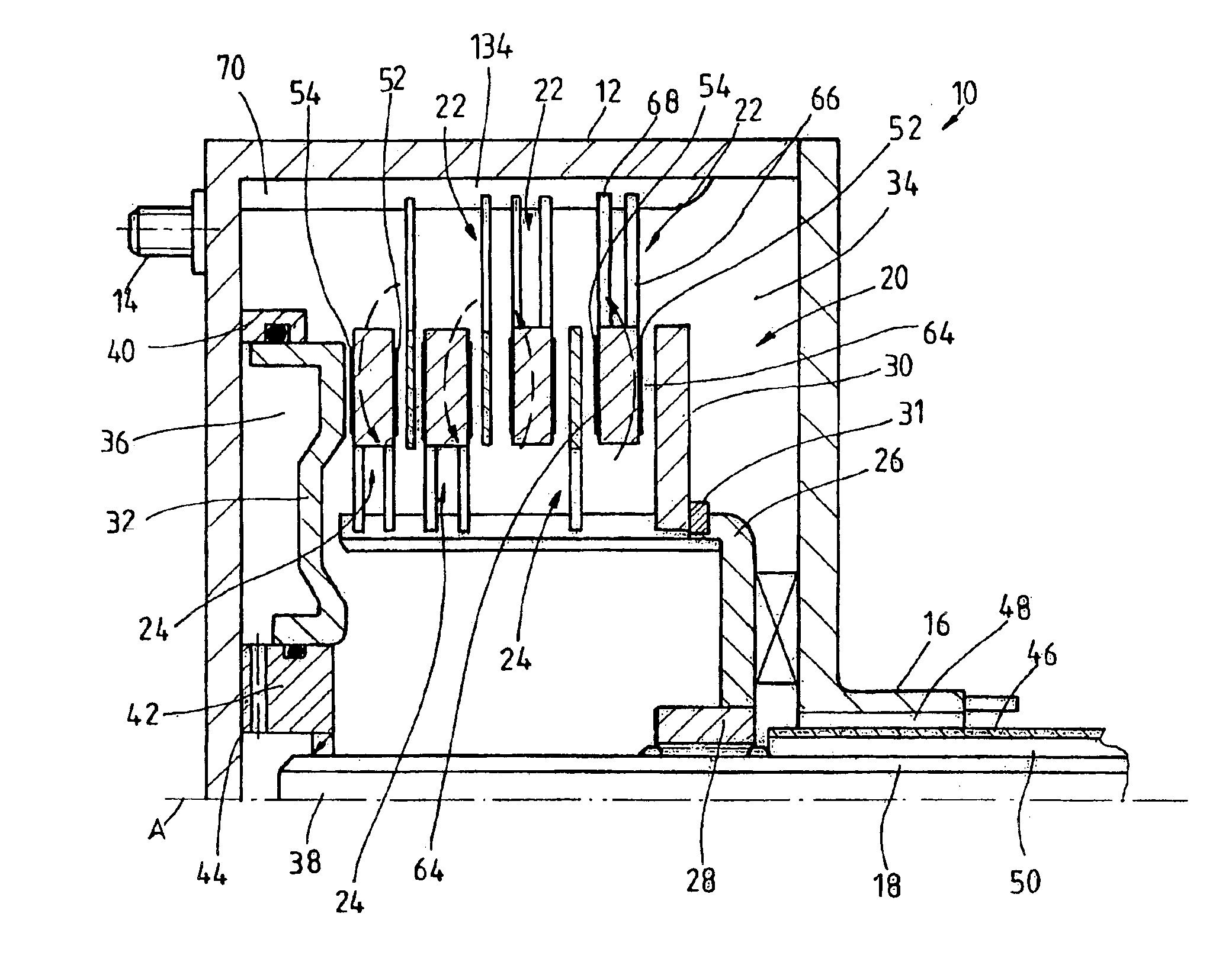

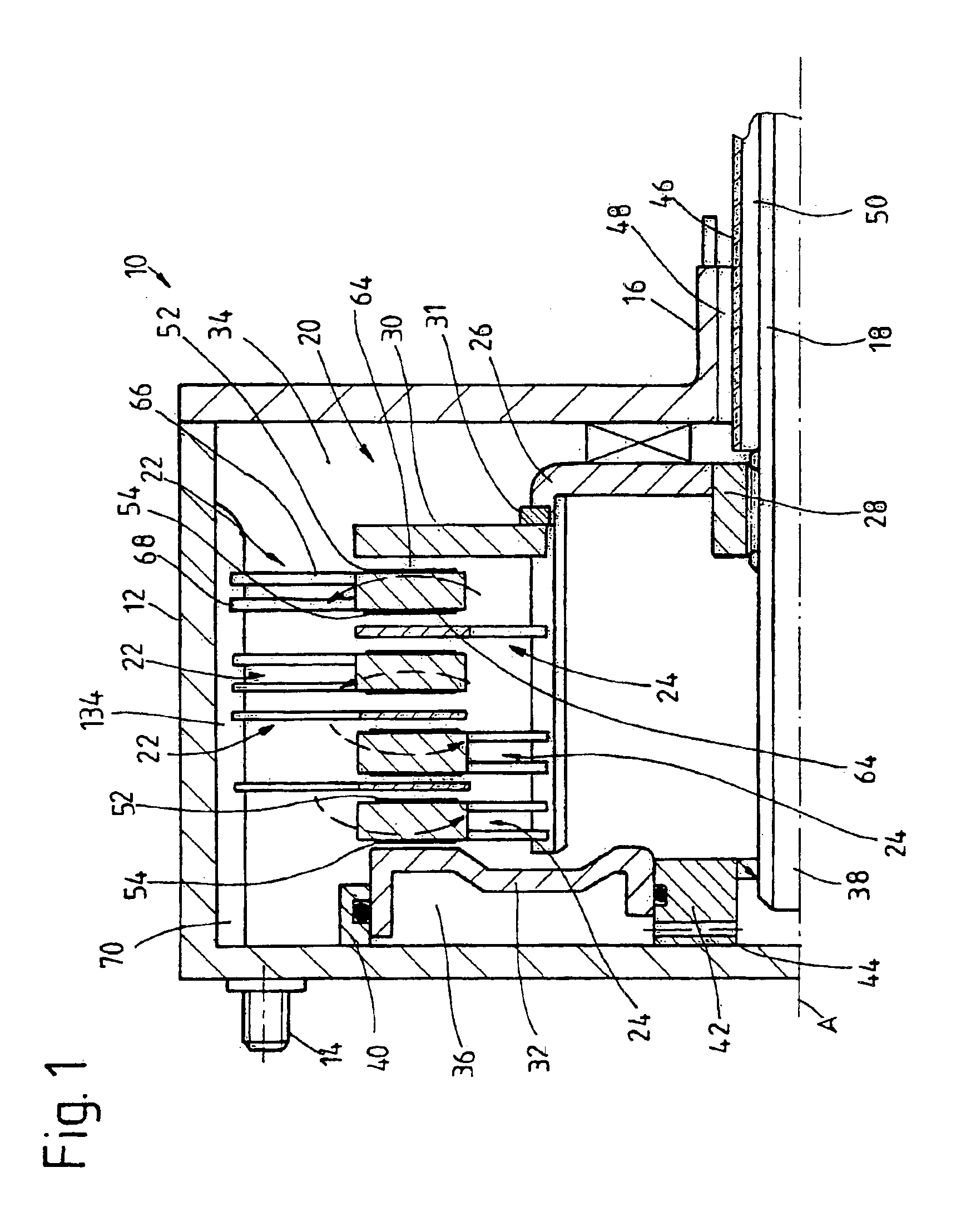

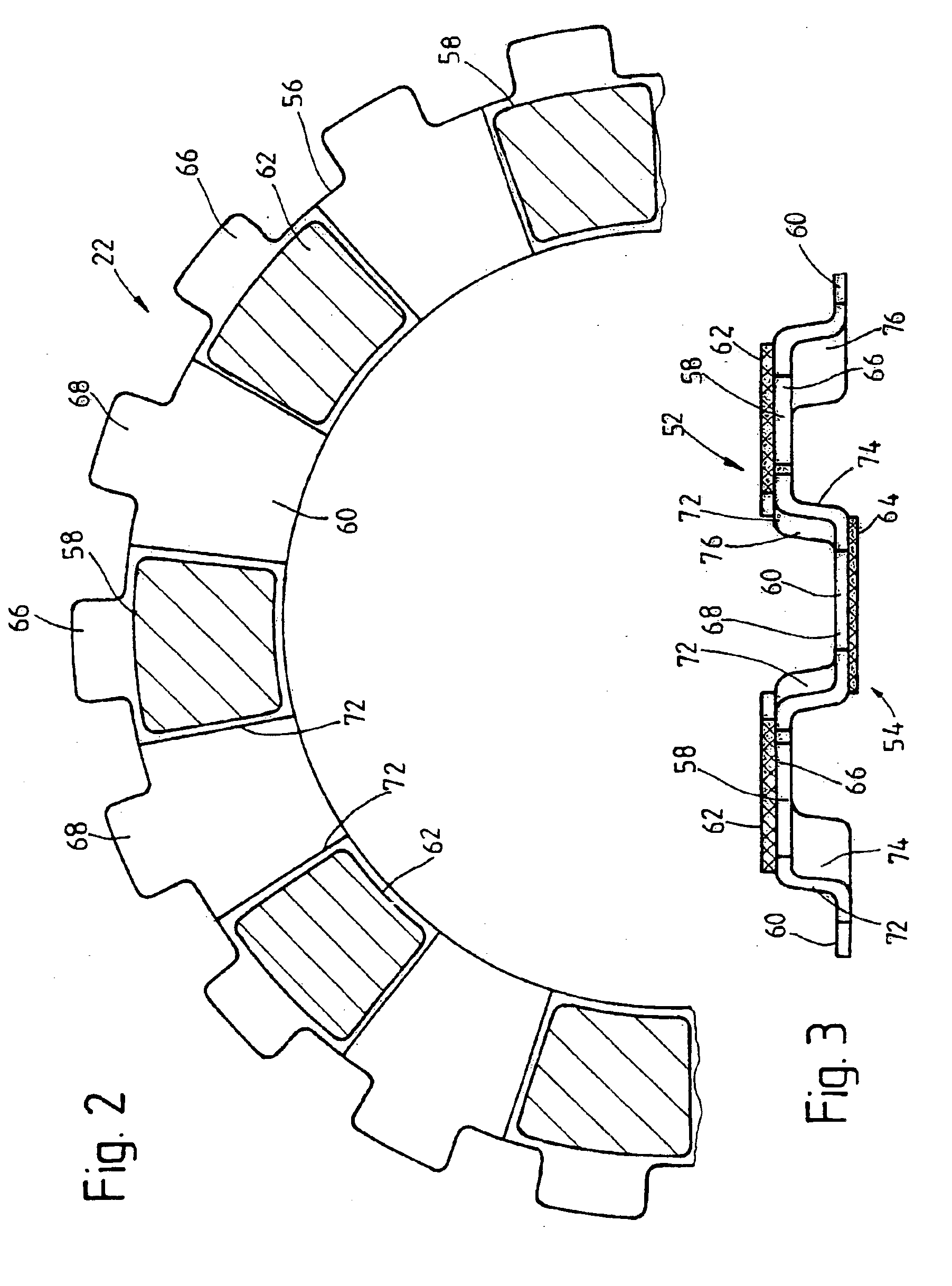

Clutch arrangement

InactiveUS6910561B2Remove heatHigh fluid-conveying efficiencyFluid couplingsFluid actuated clutchesFriction effectEngineering

A clutch arrangement, especially for a motor vehicle, comprising a housing arrangement (12) which is filled or which can be filled with fluid, at least one first friction element (22) which can be jointly rotated with the housing arrangement (12) and at least one second friction organ (24) which can be jointly rotated with an output element (18) and which can be brought to rest against the at least one first friction element (22) in order to produce at least one interactive friction effect. At least one friction element (22, 24) is embodied in such a way that fluid can circulate around at least certain areas of the friction elements (22, 24).

Owner:ZF FRIEDRICHSHAFEN AG

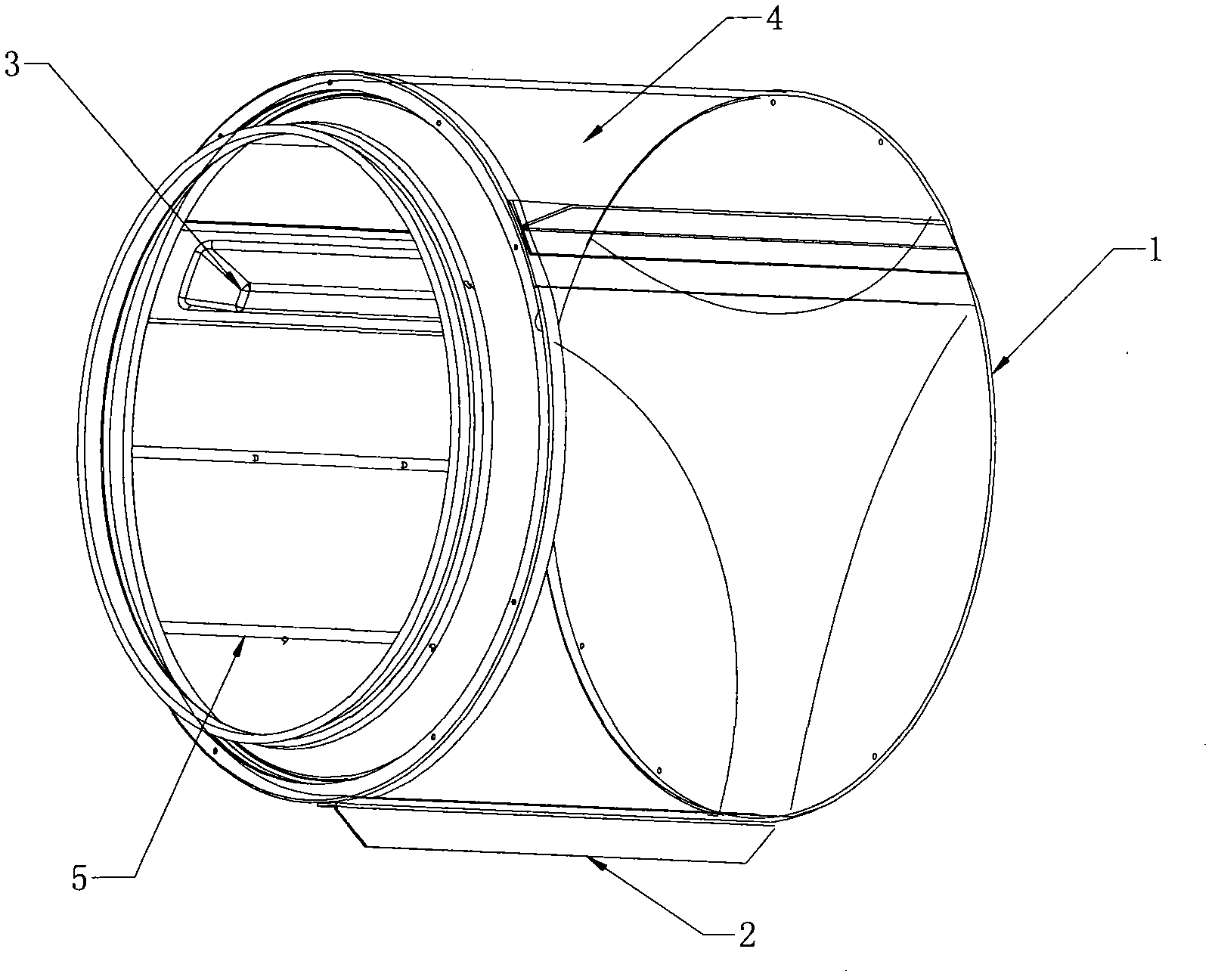

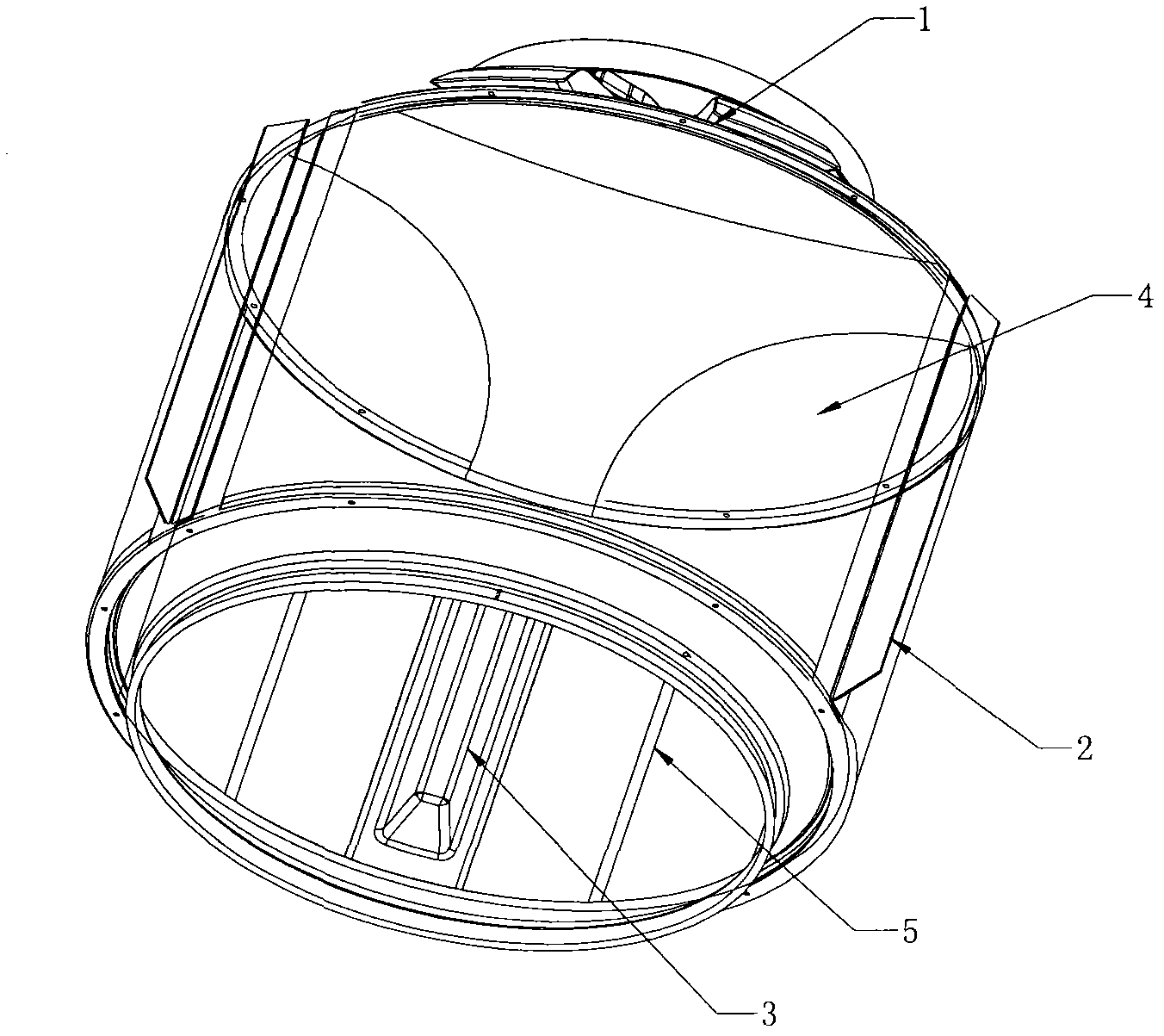

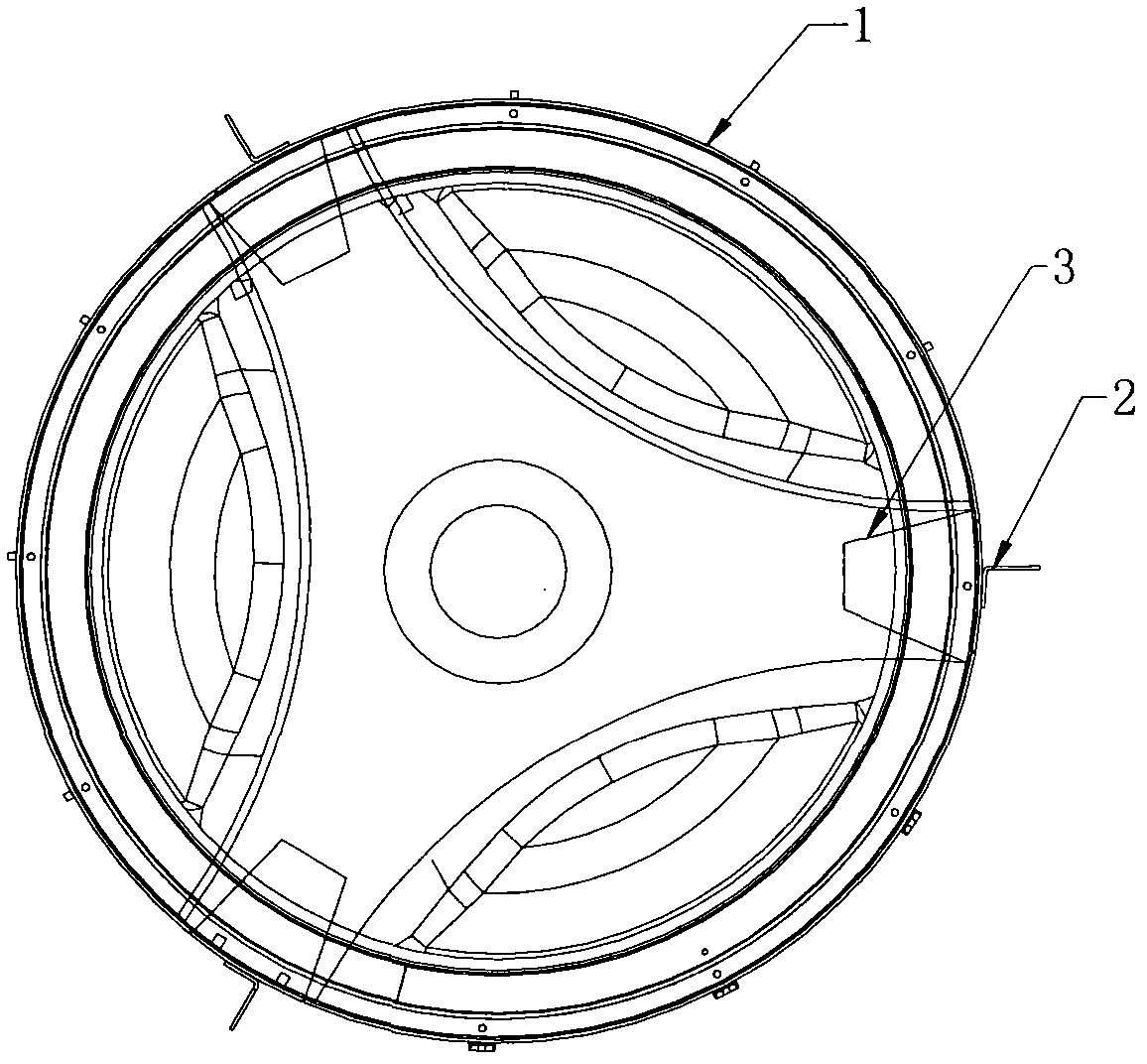

Inner barrel of particle washing machine

InactiveCN102425053AImprove washing effectHigh strengthOther washing machinesTextiles and paperFriction effectEngineering

The invention discloses an inner barrel of a particle washing machine, relating to the field of washing machines. The barrel wall of the inner barrel consists of grids; the diameters of the grids on the barrel wall are larger than those of particles; and a scraping plate is arranged at an axial position on the outer side of the barrel wall. In the invention, the inner barrel has a netlike structure, so that particles enter and exit conveniently without being attached to the inner barrel wall; and the scraping plate arranged on the outer side of the barrel wall is used for driving particles between the bottom of the inner barrel and an outer barrel to move to the upper side of the inner barrel and fall into the inner barrel, so that a complete particle washing cycle is formed. A water pushing sheet is added, so that the turning amplitude of clothes in the inner barrel is increased, and the friction effect of clothes and particles are enhanced. In the scheme of the invention, the inner barrel has a simple structure, and is easy to realize; and the cost is saved.

Owner:XEROS LTD

Test method and system for simulating bonding property between rock-soil and anchor under formation pressure

ActiveCN109540788AAccurate monitoring of radial deformationUniform radial deformationUsing mechanical meansMaterial analysisExhaust valveFriction effect

The invention discloses a test method and system for simulating bonding property between undisturbed rock-soil and an anchor under formation pressure. The test system comprises: a measuring device, asample fixing device, a formation pressure simulating device, and a pressure grouting device. Pressure bladders are mounted on the side surface and the top surface of a sample, respectively. A radialdeformation gauge is mounted on the outside of the sample. One ends of a grouting plug and a stopping plug are topless conical shapes. An exhaust valve is provided on the bottom of a support beam. Thetest system can perform pressure grouting on the sample and monitor the radial deformation. The dual pressure bladder can apply pressure to the lateral and vertical directions of the sample to simulate formation pressure. The silicone gasket and the perforated steel sheet are placed on the upper surface and below surface of the sample to eliminate the end friction effect. The rock / soil was compressed and restored to the initial formation pressure to limit the vertical deformation of the sample. The stress state, the stress path, and the preparation process of the sample are consistent with the actual situation of the anchor, which is suitable for the test of the bonding property between the rock-soil and the anchor under various working conditions.

Owner:HUNAN UNIV

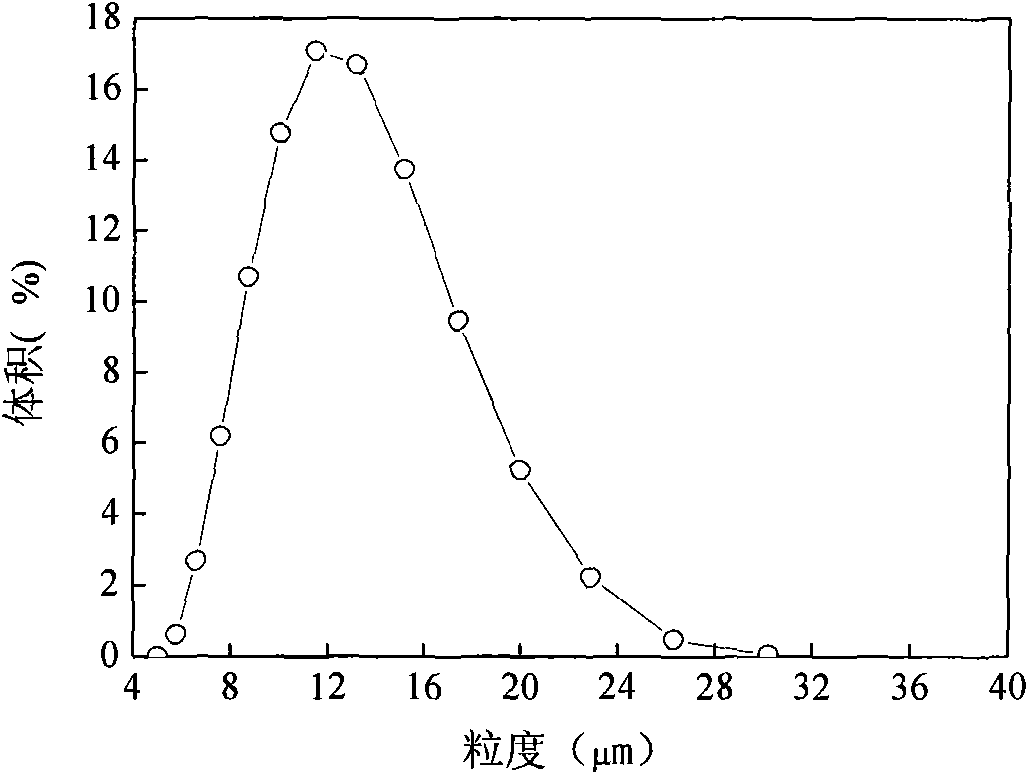

Preparation method of nuclear shell type CaCO3/SiO2 toothpaste abrasive

InactiveCN101637434AGood compatibilityCosmetic preparationsToilet preparationsFriction effectCalcium carbonate

The invention discloses a preparation method of nuclear shell type CaCO3 / SiO2 toothpaste abrasive, comprising the following steps of: preparing spherical calcium carbonate grain with grain diameter being 3-15um; taking the spherical calcium carbonate grain as template and ethyl orthosilicate as silicon source; under the catalyticaction of ammonia, coating silicon dioxide on the surface of the spherical calcium carbonate grain in a collosol-gelatin way; and finally obtaining monodispersed and nuclear shell type CaCO3 / SiO2 composite structure grain. The preparation method mainly comprises the step of preparing the spherical calcium carbonate grain and the step of preparing the CaCO3 / SiO2 toothpaste abrasive. When the nuclear shell type CaCO3 / SiO2 spherical grain is used as the toothpaste abrasive, the method has the advantages of good compatibility with fluoride, decontamination effect and friction effect as the market SiO2 abrasive toothpaste.

Owner:TIANJIN UNIV

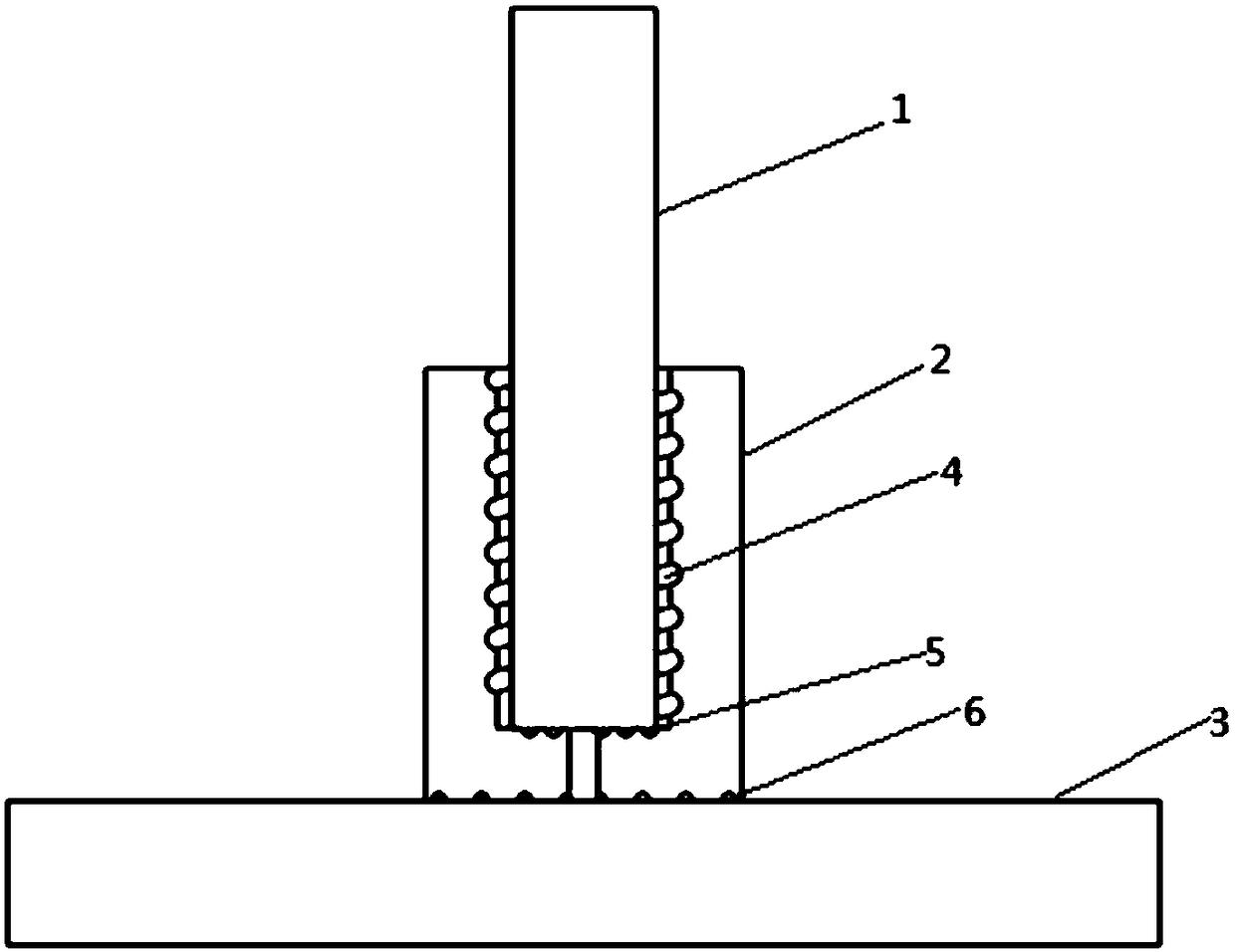

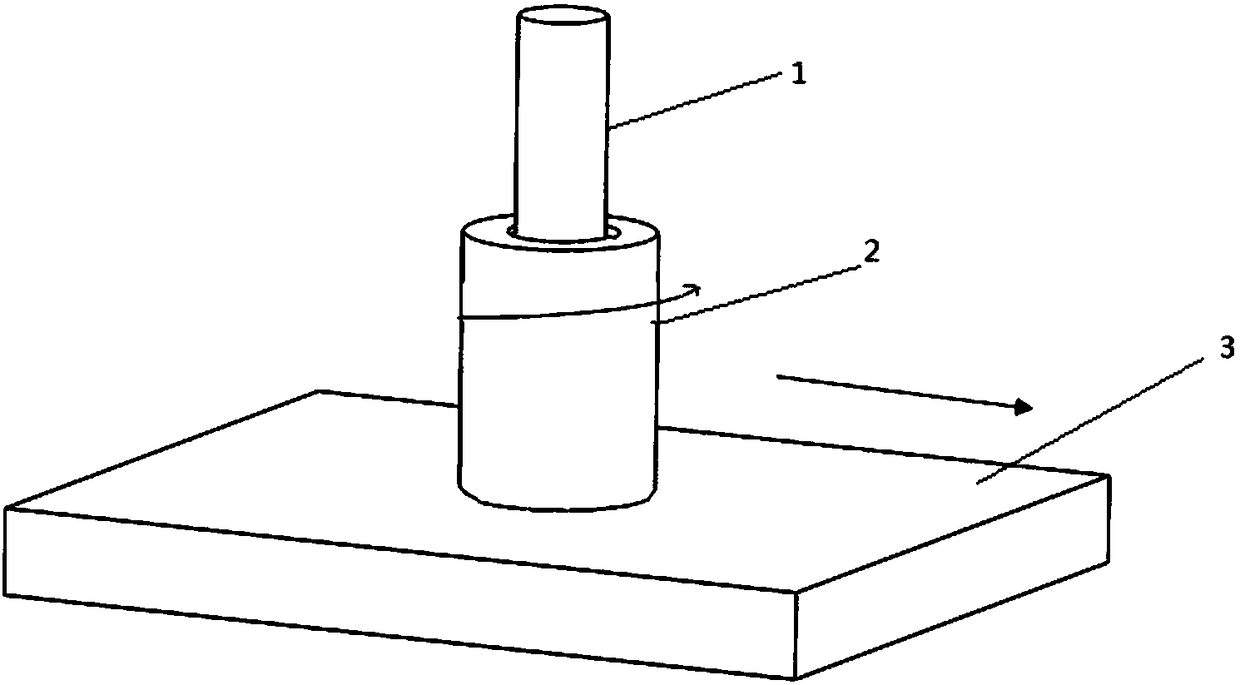

Flowing friction additional material manufacturing device and additional material manufacturing method

ActiveCN109202272AIncrease profitImprove production efficiencyAdditive manufacturing apparatusNon-electric welding apparatusFriction effectAdditive layer manufacturing

The invention relates to a flowing friction additional material manufacturing device and an additional material manufacturing method. The additional material manufacturing device comprises a shaft shoulder, a mother material and a base body. A cavity is formed in the shaft shoulder. A center through hole communicating with the cavity is formed in the lower end, below the cavity, of the shaft shoulder. The mother material is placed in the cavity in the shaft shoulder. Upsetting force exists between the mother material and the bottom face of the cavity in the shaft shoulder. Upsetting force exists between the shaft shoulder and the base body. In the additional material manufacturing process, the shaft shoulder rotates and moves on the surface, with materials to be added, of the base body, the mother material does not rotate, the mother material is subjected to heat plastification under the friction effect, the material subjected to heat plastification flows out along the center through hole in the lower end of the shaft shoulder under the effect of the upsetting force, and under the relative rotating effect of the outer end face of the shaft shoulder and the surface, with the materials to be added, of the base body, and under the upsetting force effect, the material is dispersed and deposited on the surface, with the materials to be added, of the base body. According to the device and the method, the material utilization rate can be increased, the manufacturing efficiency can be improved, and the problems that the working allowance of stirring friction additional material manufacturing is large, and the material utilization rate is low are solved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

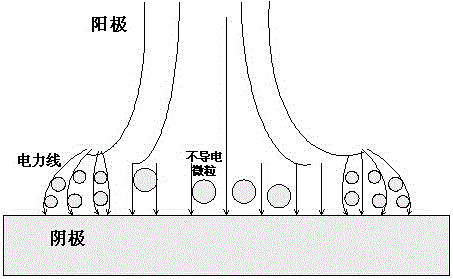

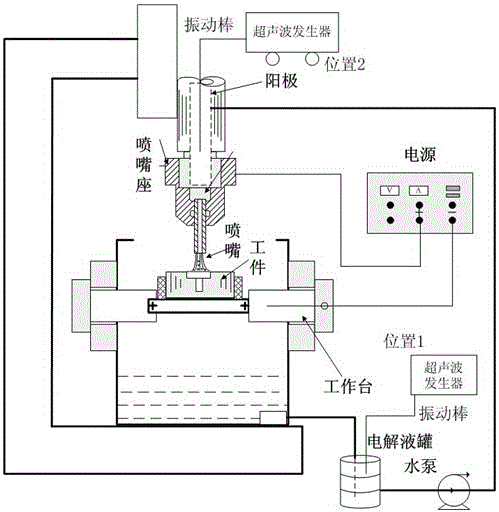

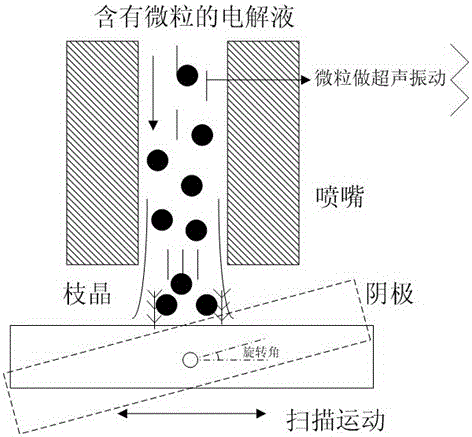

Method for improving homogeneity in jet electrodeposition processing process

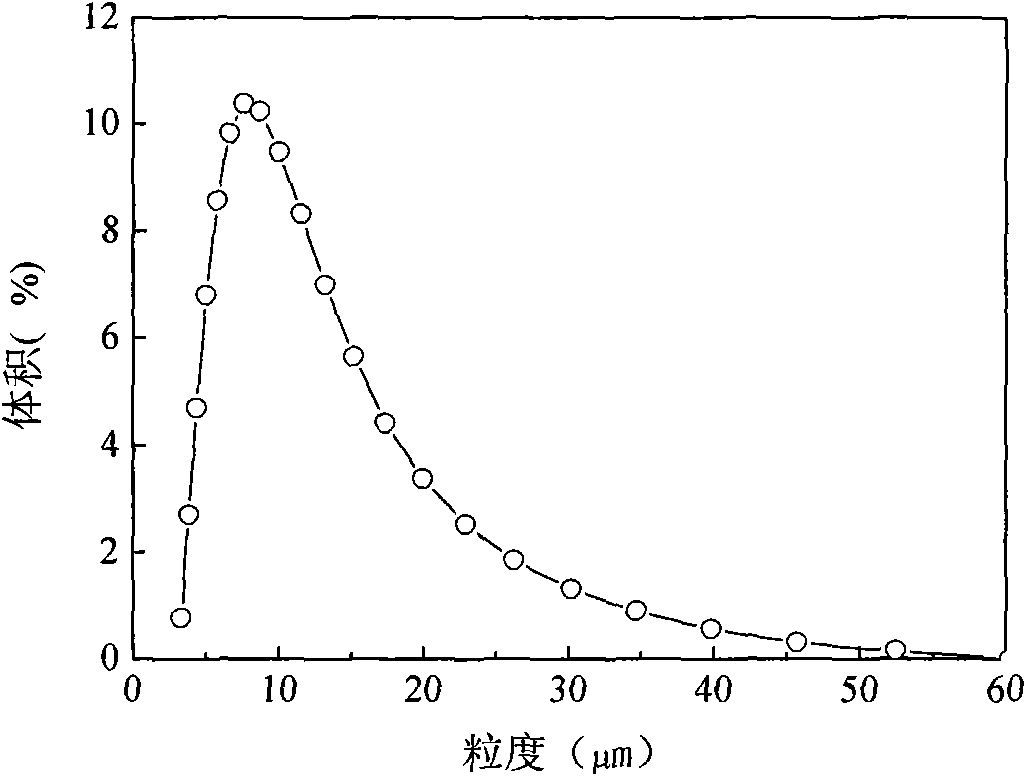

The invention discloses a method for improving homogeneity in a jet electrodeposition processing process. The method includes the following steps that a substrate is subjected to surface pretreatment, polishing, surface cleaning, surface etching treatment, thorough cleaning with distilled water and drying up for standby; an electrolyte is prepared and pretreatment of micro particles is carried out, specifically, before electrodeposition, micron-grade aluminum oxide or silicon carbide particles are mixed with the electrolyte, the mixture is stirred for two hours and subjected to ultrasonic stirring for 30 minutes, so that the particles are fully wetted and evenly dispersed, and the addition amount of the micron-grade aluminum oxide particles is 10-30 g / L; numerical control programs are set; and during processing, an ultrasonic vibration bar is in contact with the electrolyte directly, and the electric field redistribution of the electrolyte on the surface of a negative pole is affected and changed through the micro particles. The growth process of crystal particles on the deposition layer is changed through the micro particles, and accordingly grain refinement is promoted. The micro particles achieve the vibration and friction effects during electrodeposition. By means of the method, the leveling performance of a deposition surface is improved to a certain extent.

Owner:XUZHOU NORMAL UNIVERSITY

Hydrophobic glass preparation method and hydrophobic glass

The invention provides a hydrophobic glass preparation method and hydrophobic glass. In the hydrophobic glass preparation process, nano elastomer with good durability is added in a hydrophobic film layer of the glass surface. With the nano elastomer, the hydrophobic film layer under the friction effect of solid particles in the air obtains buffer protection, and a damaging effect of the friction against the hydrophobic film layer is lessened or even eliminated. The hydrophobic glass prepared by the method not only has good hydrophobicity, but also has better durability against friction.

Owner:CHERY AUTOMOBILE CO LTD

Premix material for friction material and processing method thereof

InactiveCN101812283AReduce surface hardnessIncrease the real contact areaOther chemical processesFiberFriction effect

The invention discloses a premix material for a friction material and a processing method thereof. The premix material comprises the following components in percentage by weight: 45 to 70 percent of natural crystalline flake graphite, 15 to 30 percent of jute fiber, sisal fiber or a mixture of the two, 4 to 8 percent of nitrile butadiene rubber, 8 to 12 percent of ethylene propylene terpolymer, 0.5 to 3 percent of zinc oxide, 0.8 to 1.5 percent of sulphur and 0.7 to 1.5 percent of accelerator M. The nitrile butadiene rubber, ethylene propylene terpolymer, zinc oxide, natural plant fiber, natural crystalline flake graphite, accelerator M and sulphur are sequentially added into a rubber fining mixer to be mixed and then the raw materials are crushed into grains with a crushing machine so as to obtain the finished product. The premix material for the friction material has the advantages of effectively regulating the surface hardness of the friction material product, improving the friction effect, reducing the abrasion and improving the comfort of the friction material during use.

Owner:焦龙

Method of forming a structural component having a NANO sized/sub-micron homogeneous grain structure

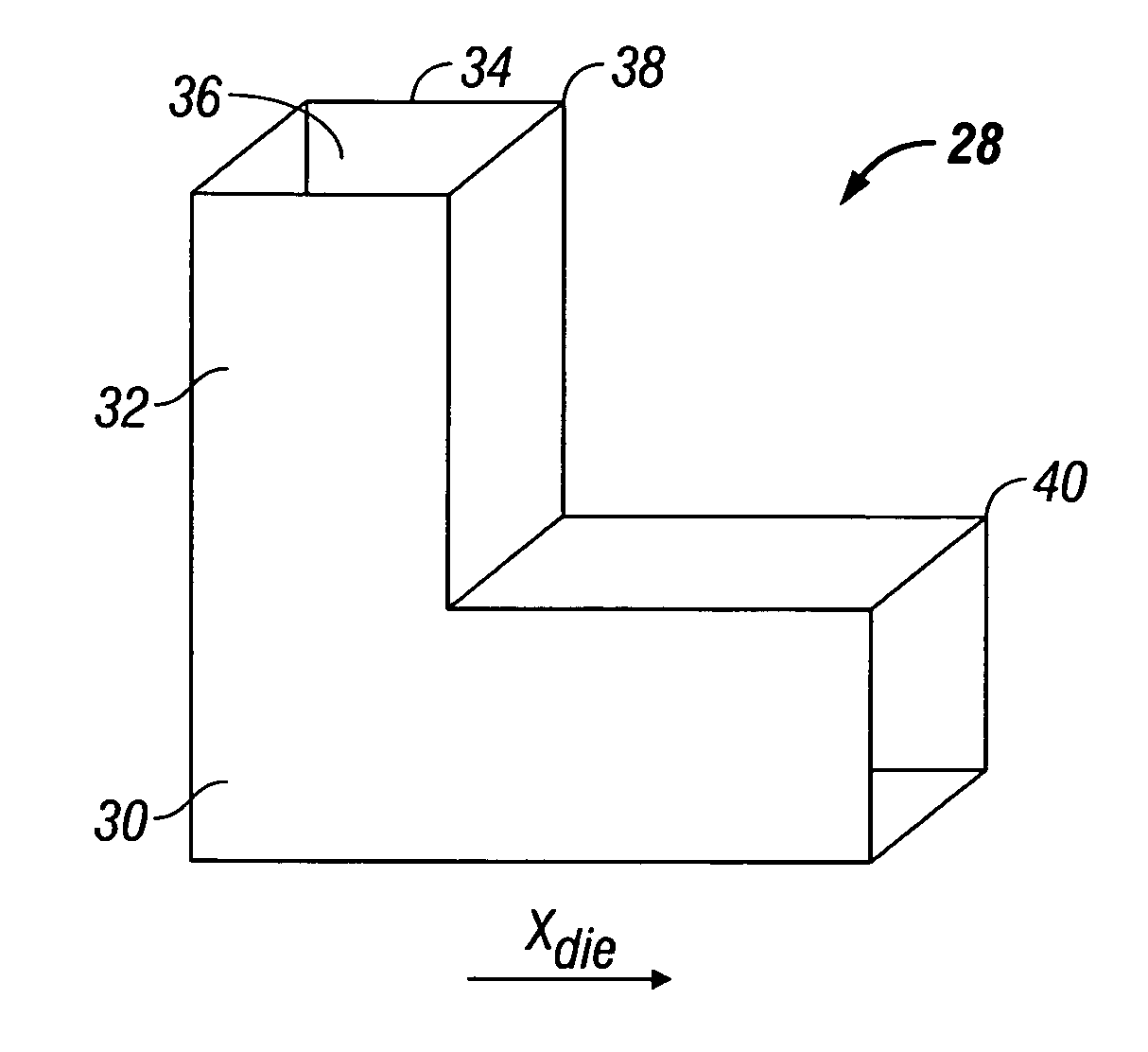

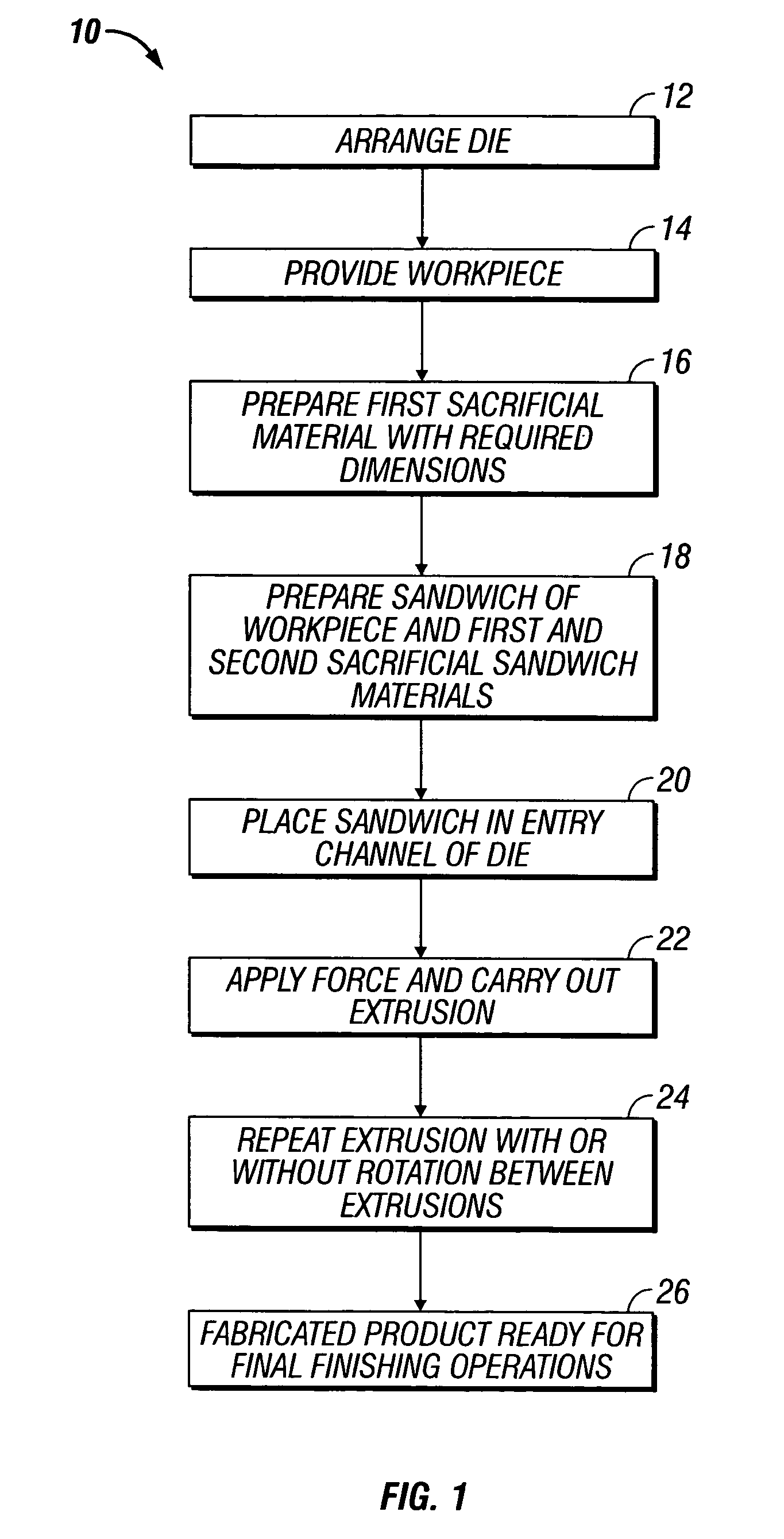

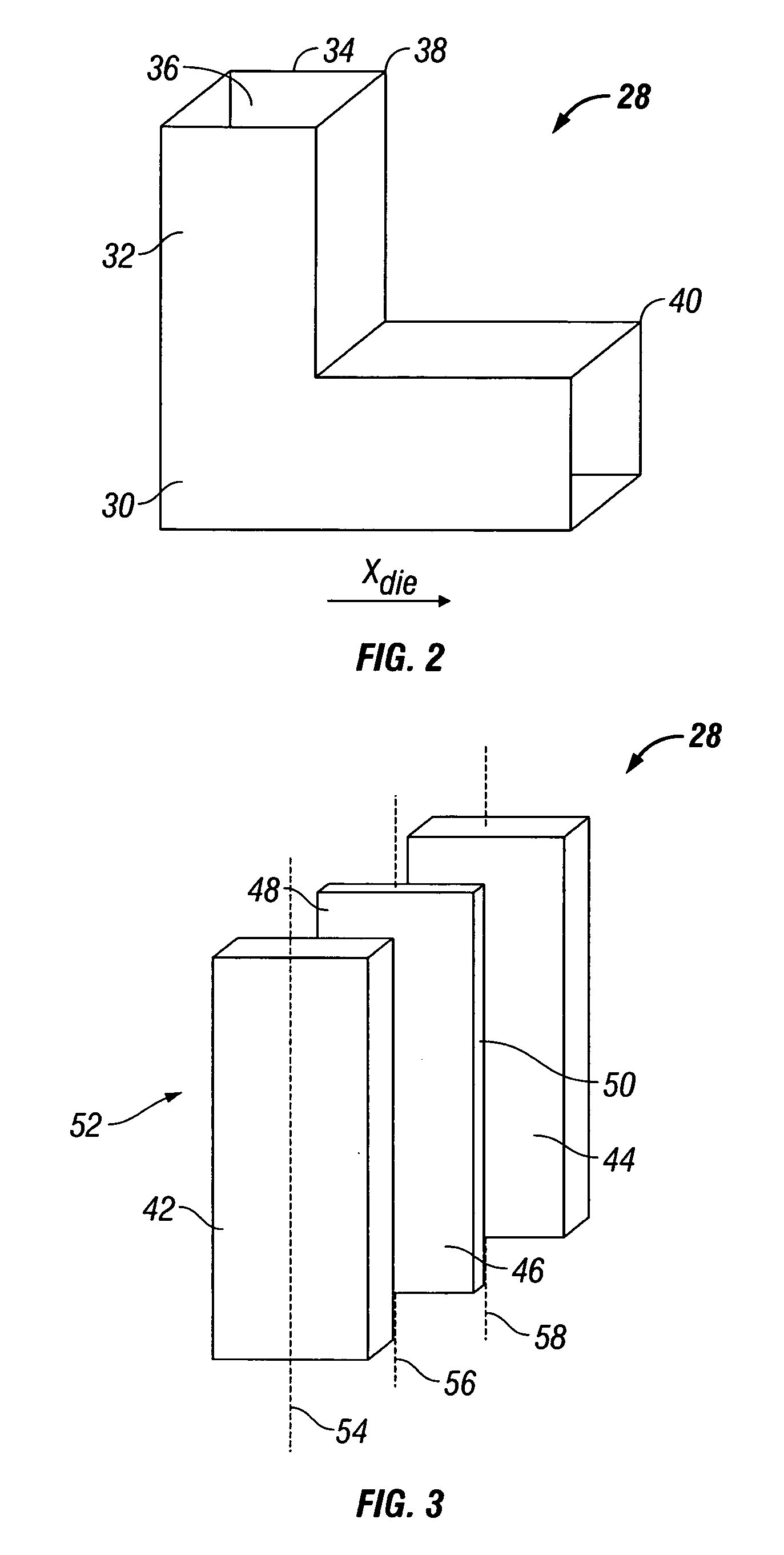

A method of making nano / sub-micron sized grains in a work piece material having a lateral side has the steps of providing a die. The die has an entrance channel with a longitudinal axis and an exit channel. The entrance channel and the exit channel are connected to one another to form an angle. The method has the step of providing a first sacrificial material with a complementary size to the work piece and placing the sacrificial first material and the work piece in an entrance channel. The first sacrificial material and the work piece are aligned with the longitudinal axis. The method has the step of extruding the combination of the first sacrificial material, and the work piece through the intersection of the entrance and the exit channels. The resulting shear deformation forms the nano / sub-micron sized grains in the work piece. This configuration reduces frictional effects thereby producing homogenous nano grain structure. This configuration reduces applied load and enables equal channel angular extrusion of thin sheets.

Owner:GENERAL ELECTRIC CO

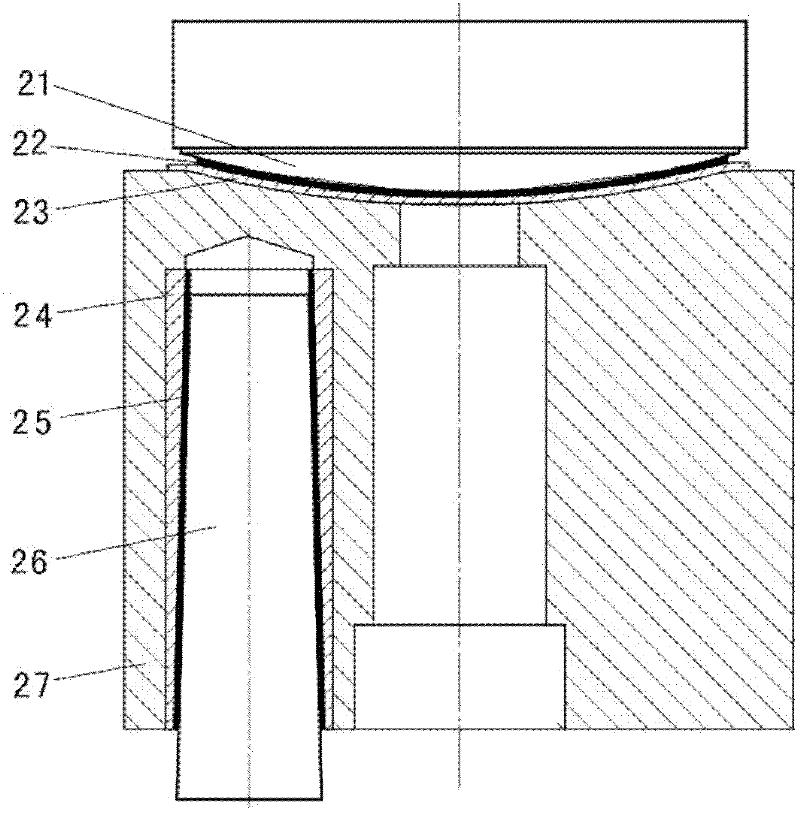

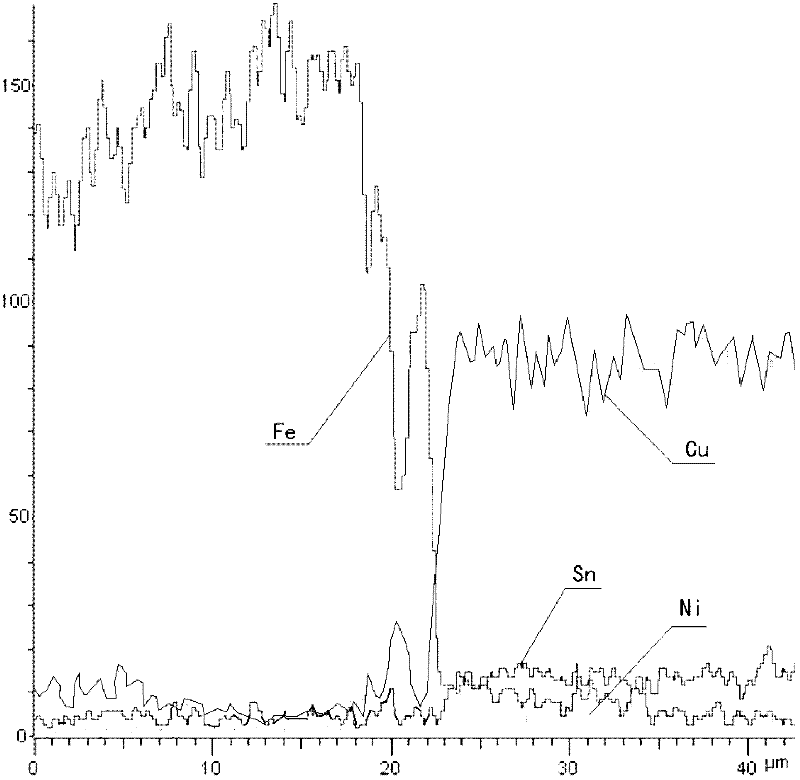

Bimetal vacuum diffusion welding method of hydraulic pump/motor cylinder body

ActiveCN102528264AStress reliefEliminate microscopic defectsNon-electric welding apparatusFriction effectInsulation layer

The invention relates to a bimetal vacuum diffusion welding method of a hydraulic pump / motor cylinder body. The bimetal vacuum diffusion welding method comprises the following implementation steps of: (1) manufacturing all parts and assembling: pressing a copper alloy sleeve into each plunger hole, inserting a plunger hole expansion core into a hole of each copper alloy sleeve, placing a spherical surface copper alloy plate on the hemispherical surface at the upper end of a basal body, placing plunger hole heat insulation layers between the plunger hole expansion cores and the copper alloy sleeves, and placing hemispherical surface heat insulation layers between hemispherical surface pressure heads and the spherical surface copper alloy plate; (2) charging into a furnace: respectively placing the hemispherical surface pressure head on the upper surface of each cylinder body component, and laying asbestos cloth between layers of each cylinder body component; (3) sintering: controlling the vacuum degree, the heating-up process and the pressurizing process in a vacuum hot-pressing furnace; and (4) firstly uniformly cooling down, and then naturally cooling to the normal temperature. According to the bimetal vacuum diffusion welding method disclosed by the invention, interatomic mutual diffusion bonding of a copper alloy and carbon structural steel of the basal body can be realized, the structure of the copper alloy is more compact, the anti-friction effect is further improved and the working life is significantly prolonged.

Owner:西安东瑞增材科技股份有限公司

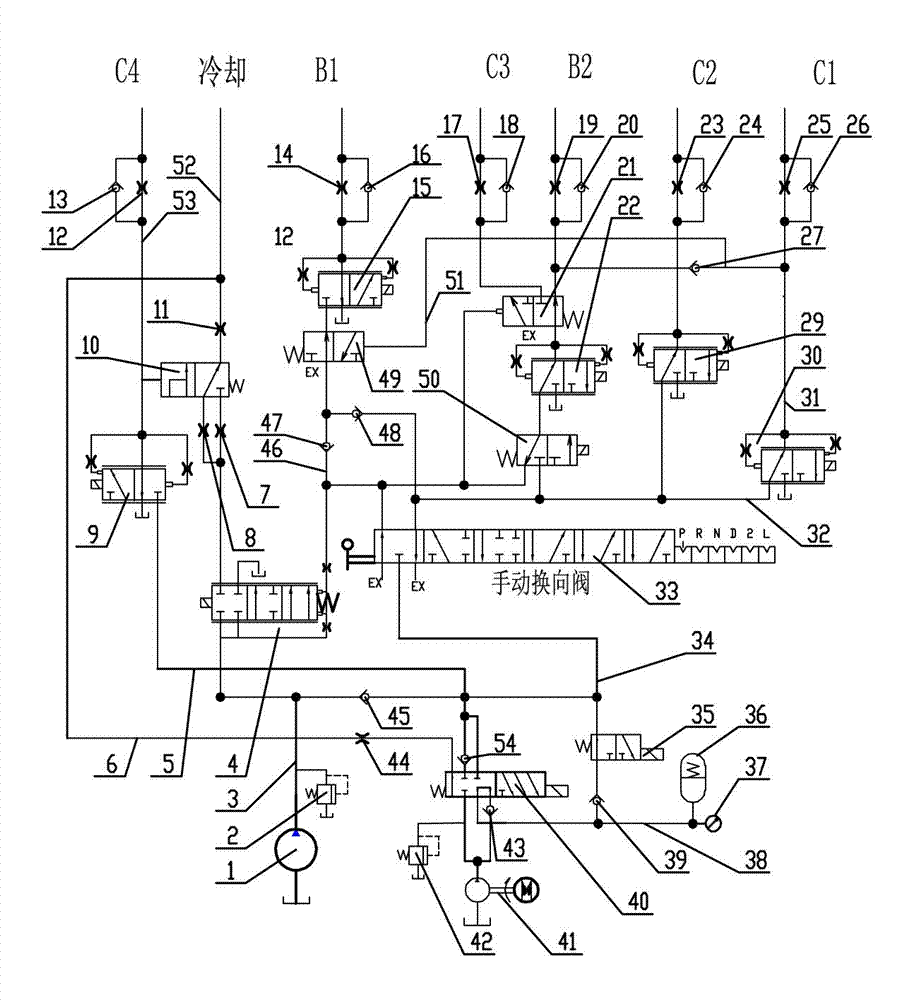

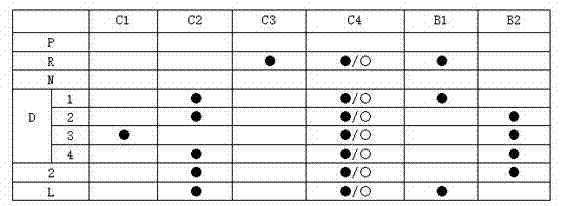

Hybrid power hydraulic control system

The invention discloses a hybrid power hydraulic control system which comprises an automatic gear transmission with a gear control oil path. An oil pump in the automatic gear transmission supplies power to the gear control oil path. A motor pump used for supplying oil to the gear control oil path and an energy storage device used for storing hydraulic energy of the motor pump are further arranged on the automatic gear transmission. The system utilizes the energy storage device to store the hydraulic energy of the motor pump, can utilize the energy storage device to drive a clutch in the automatic gear transmission before a vehicle starts, prevents the clutch from generating sliding and friction effect and improves working efficiency of the vehicle. The hybrid power hydraulic control system is suitable for various hybrid power vehicles, improves working efficiency, and saves energy.

Owner:HYCET TRANSMISSION TECH HEBEI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com