Test method and system for simulating bonding property between rock-soil and anchor under formation pressure

A bonding performance and testing system technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of unable to make the original state of rock and soil compressive stress state, uneven radial deformation of samples, and affecting test results, etc. Achieve high test efficiency, uniform radial deformation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The embodiments of the present invention will be further described below in conjunction with the drawings and examples. It should be noted that the embodiments do not limit the scope of protection claimed by the present invention.

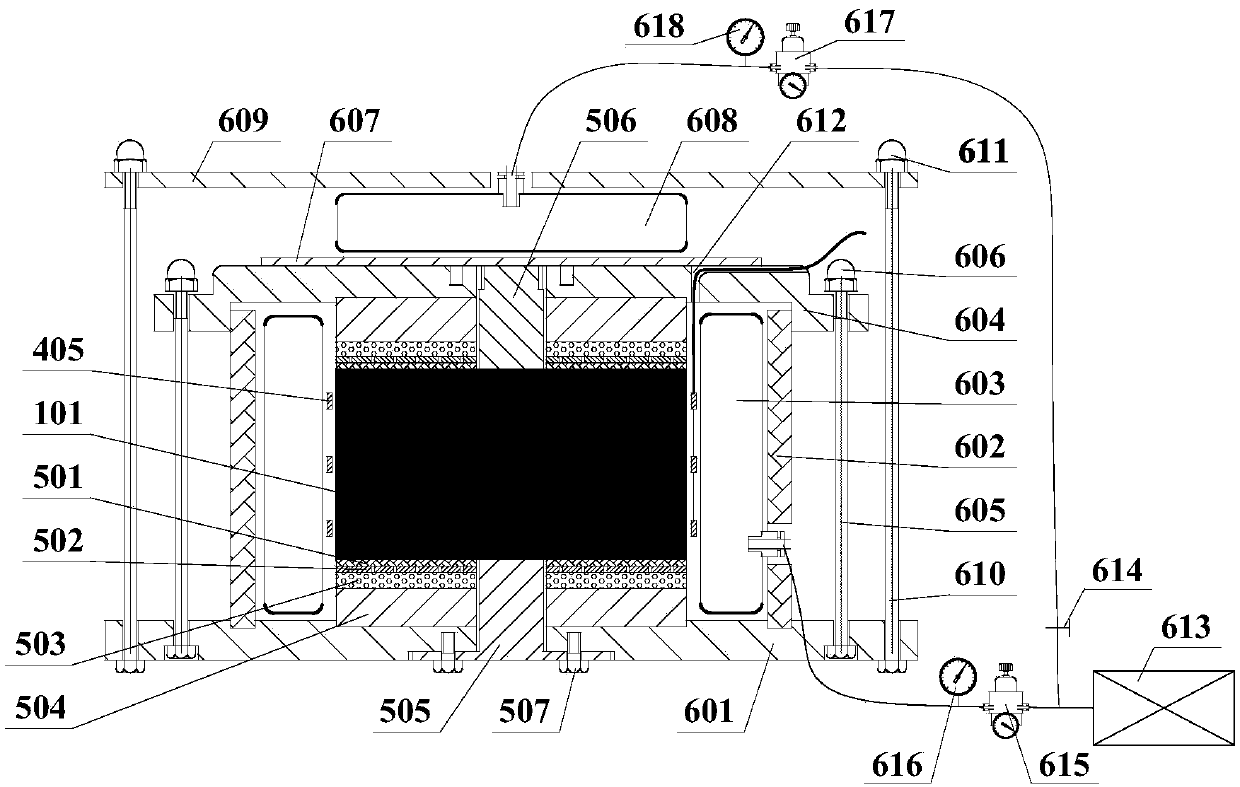

[0054] A system for testing the bonding performance of an undisturbed rock-soil mass and an anchor body under simulated formation pressure mainly includes a measuring device, a sample fixing device, a formation pressure simulating device and a pressure grouting device.

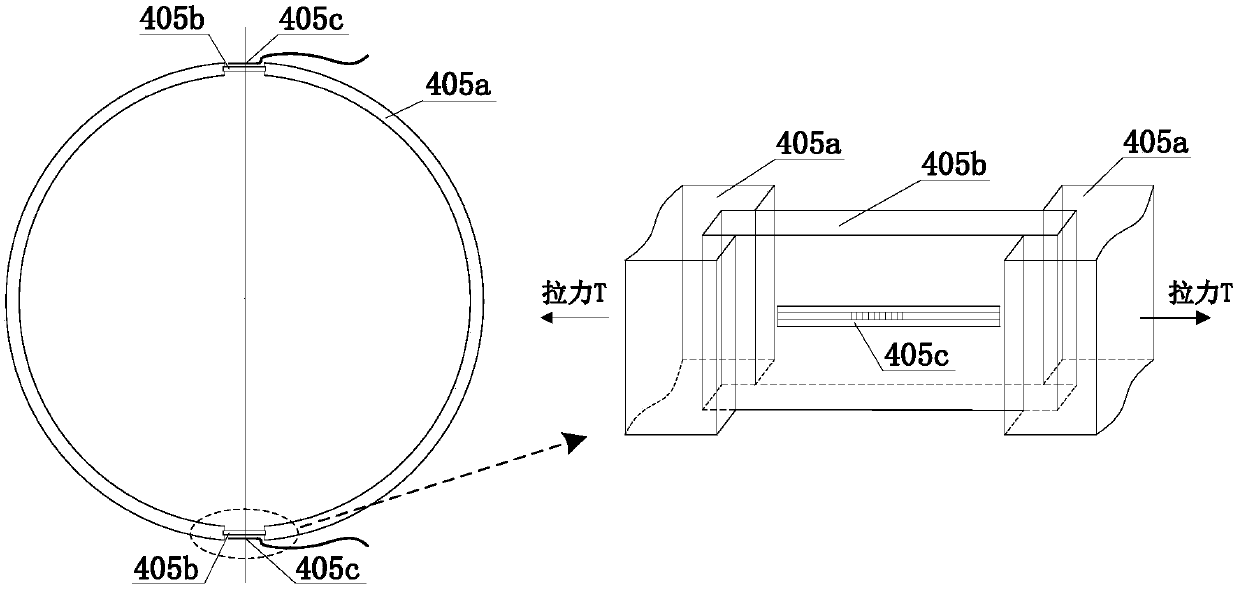

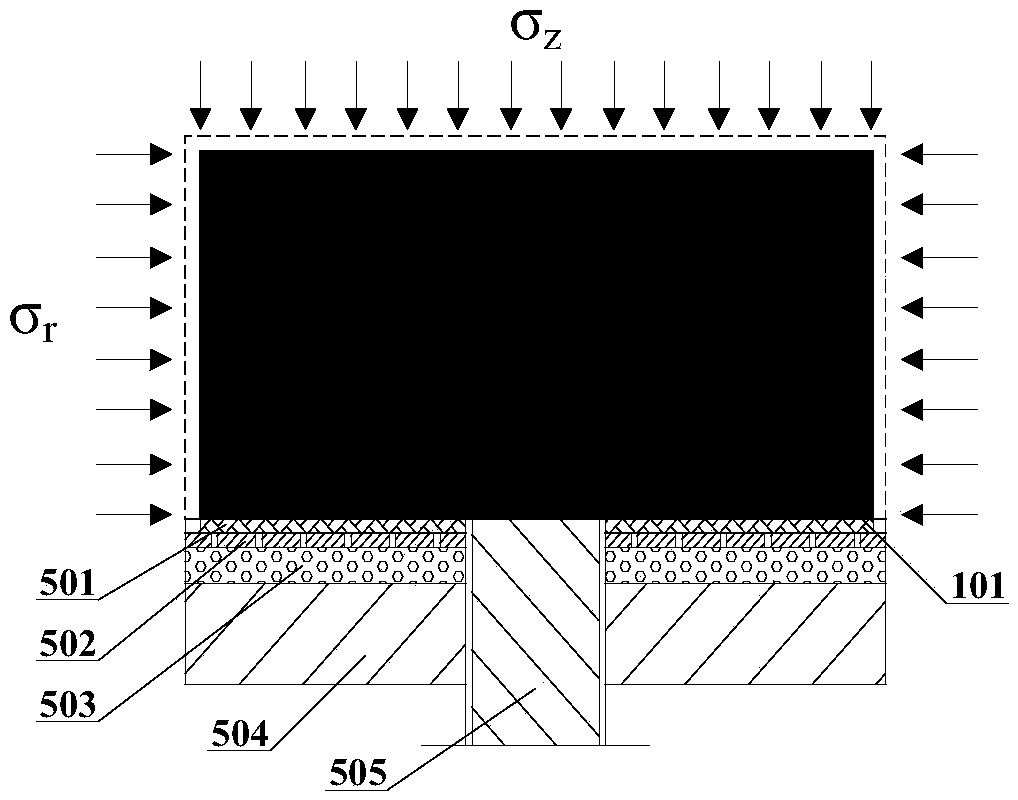

[0055] Such as figure 1 As shown, the upper and lower surfaces of the sample are sequentially installed with silica gel gasket 501, perforated steel sheet 502, permeable stone 503 and backing plate 504; The circular groove of the plate 504 displacement, the sleeve 602 is not in contact with the middle cover plate 604, the top plug 506 is placed in the upper cavity 509 on the top of the soil / rock block 101 and is flush with the top surface of the middle cover plate 604, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com