Patents

Literature

788 results about "Pressure grouting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure grouting or jet grouting involves injecting a grout material into otherwise inaccessible but interconnected pore or void space of which neither the configuration or volume are known, and is often referred to simply as grouting. The grout may be a cementitious, resinous, or solution chemical mixture. The greatest use of pressure grouting is to improve geomaterials (soil and rock). The purpose of grouting can be either to strengthen a formation or to reduce water flow through it. It is also used to correct faults in concrete and masonry structures. Since first usage in the 19th century, grouting has been performed on the foundation of virtually every one of the world’s large dams, in order to reduce the amount of leakage through the rock, and sometimes to strengthen the foundation to support the weight of the overlying structure, be it of concrete, earth, or rock fill. It is also a key procedure in the creation of post-tensioned prestressed concrete, a material used in many concrete bridge designs, among other places.

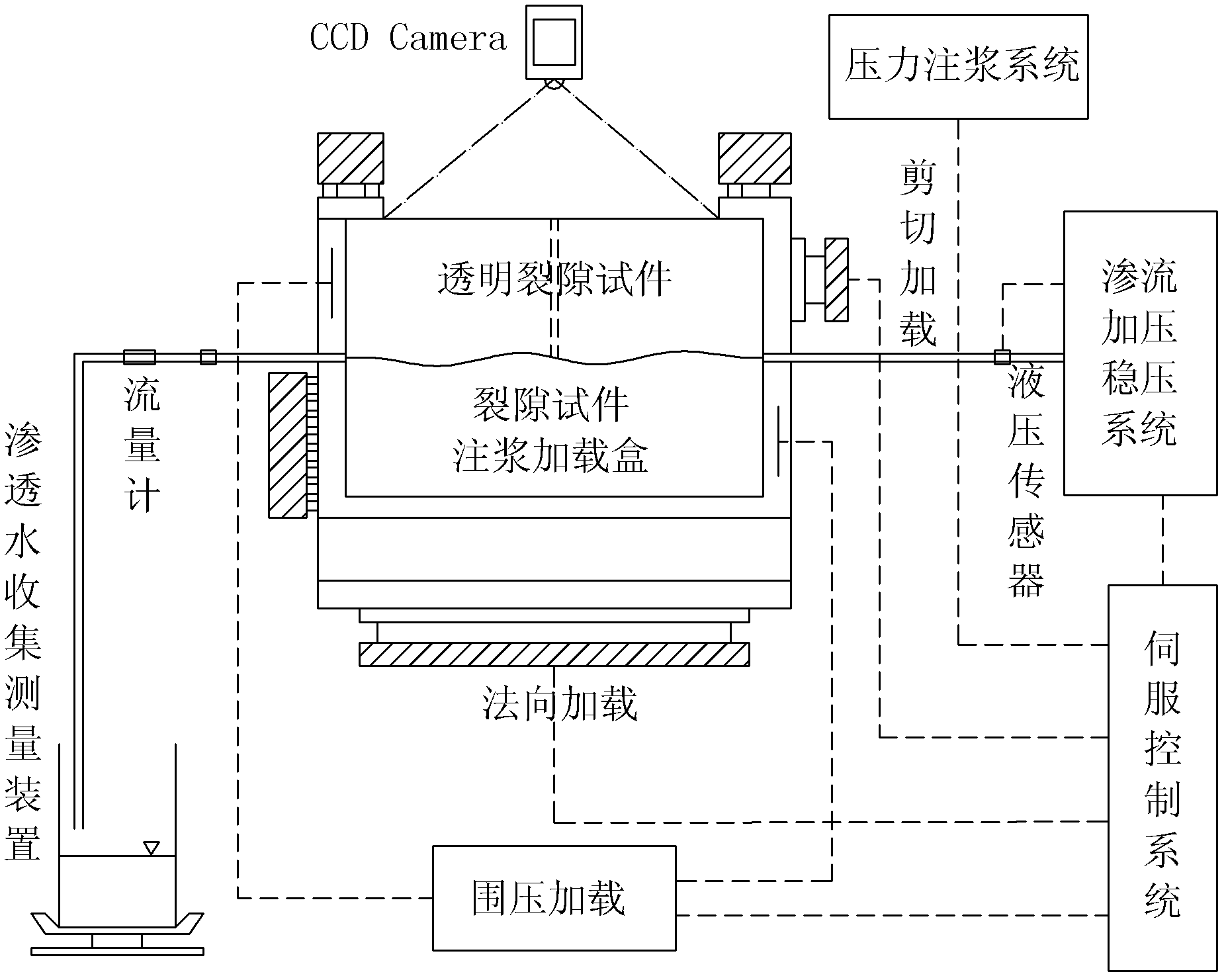

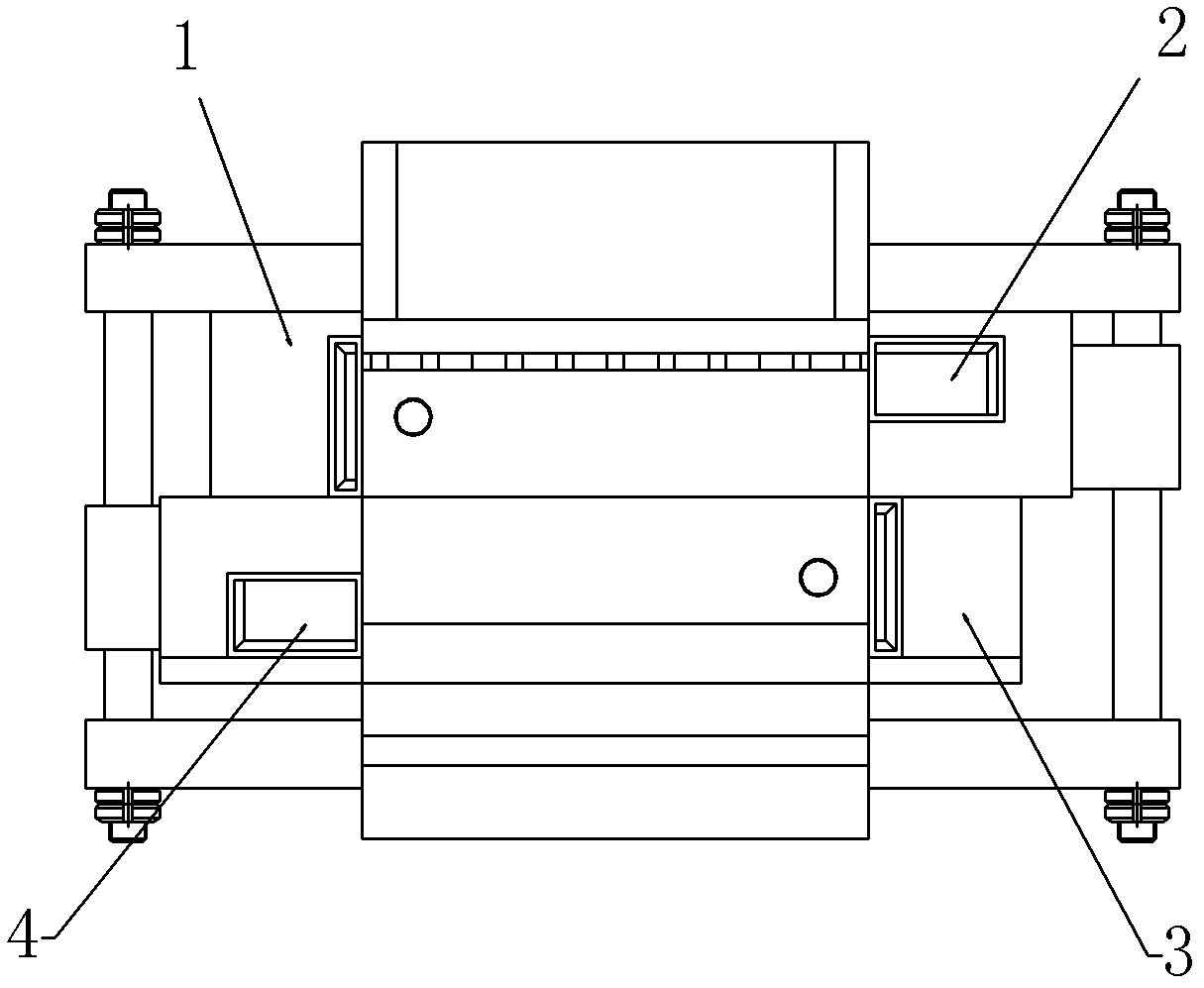

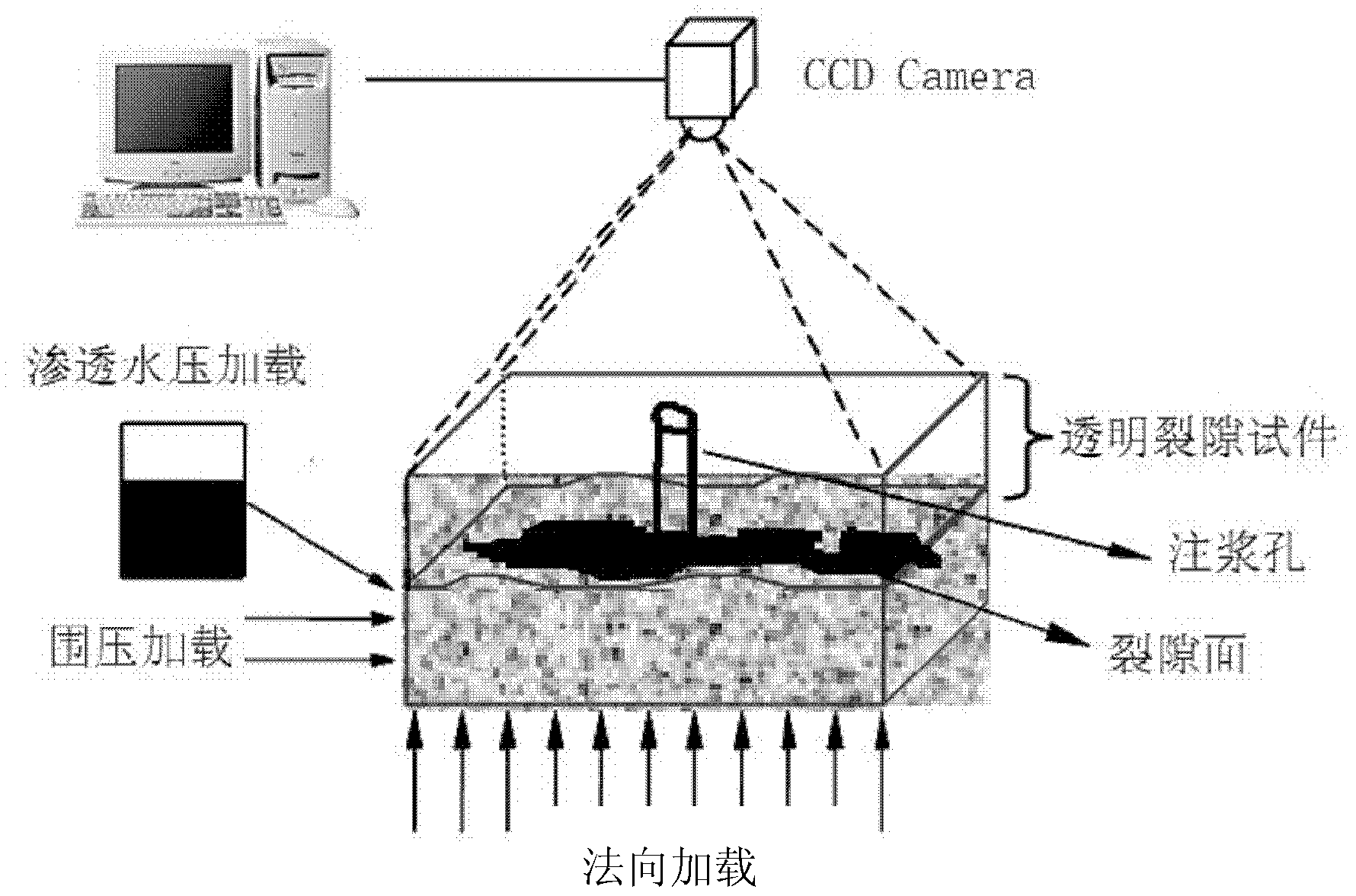

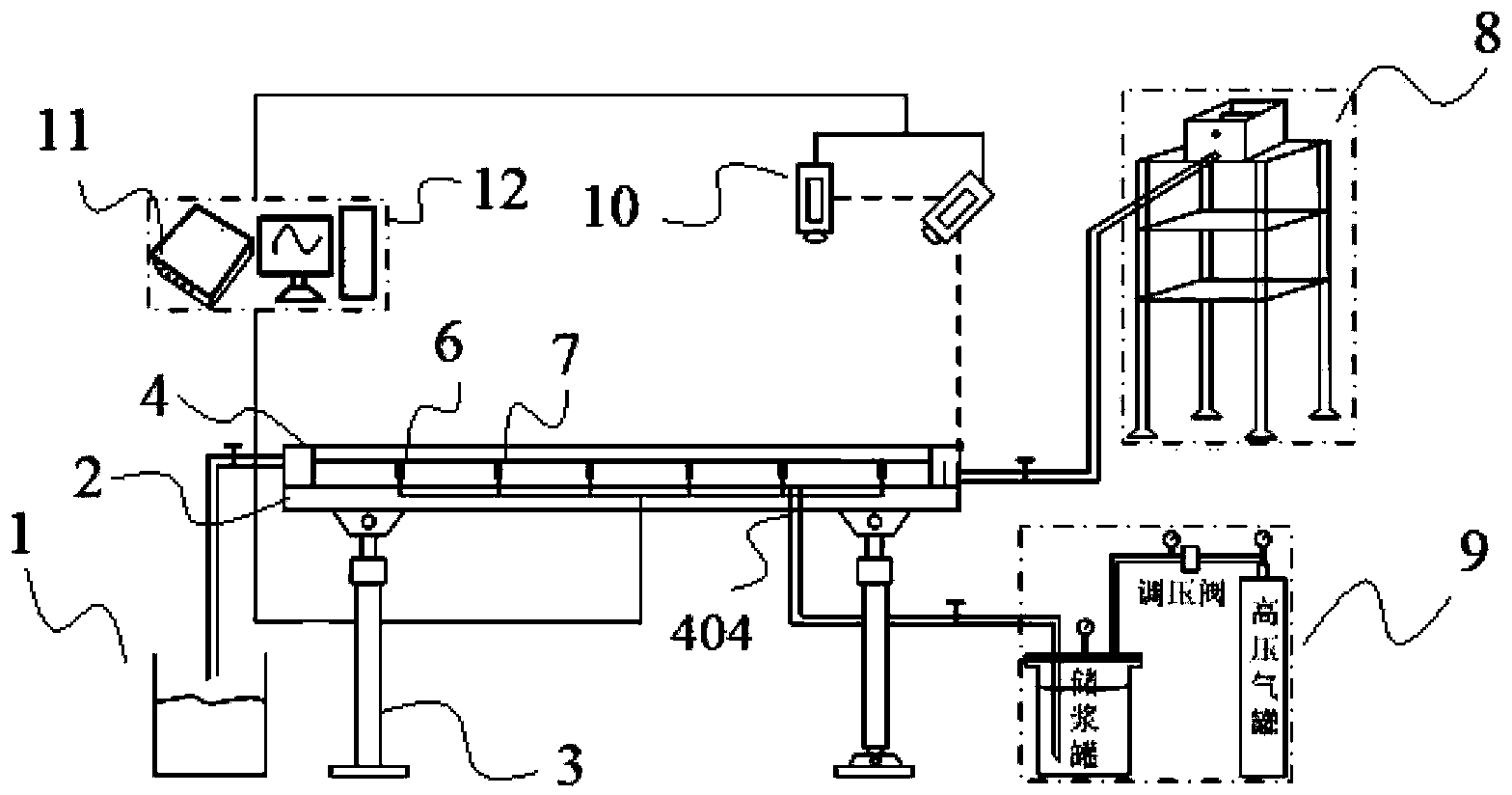

Crack grouting visualization tester under complex conditions

ActiveCN102419303ARealize visualizationRealize automatic controlSurface/boundary effectFoundation testingEngineeringWater collection

The invention discloses a crack grouting visualization tester under complex conditions, comprising a tester frame for testing, a crack sample grouting loading box, an axial loading mechanism, a tangential loading mechanism, a confining pressure loading mechanism, a hydraulic pressure loading mechanism, a pressure grouting system, a circulating water collection tester, and a visualization system.

Owner:SHANDONG UNIV OF SCI & TECH

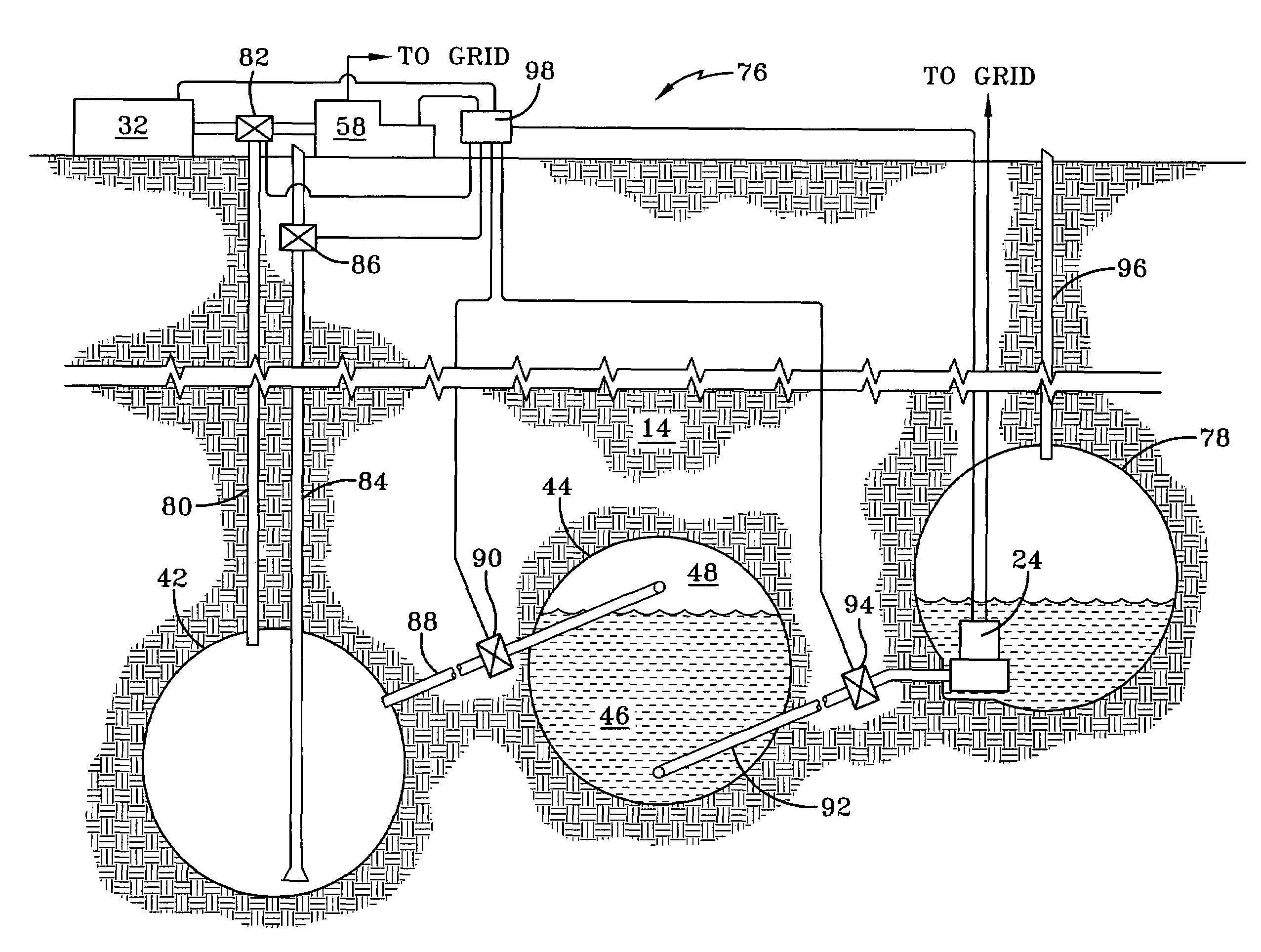

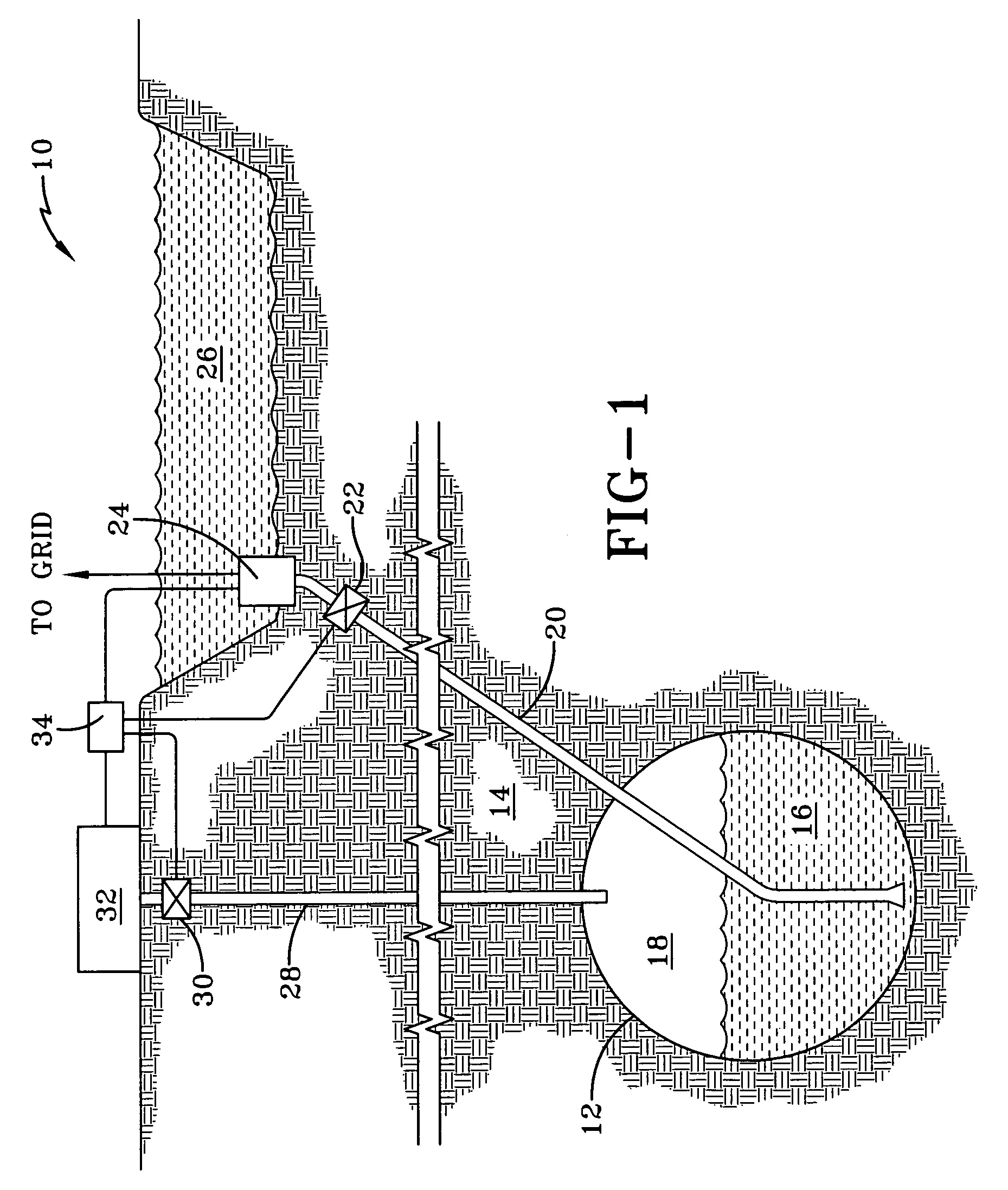

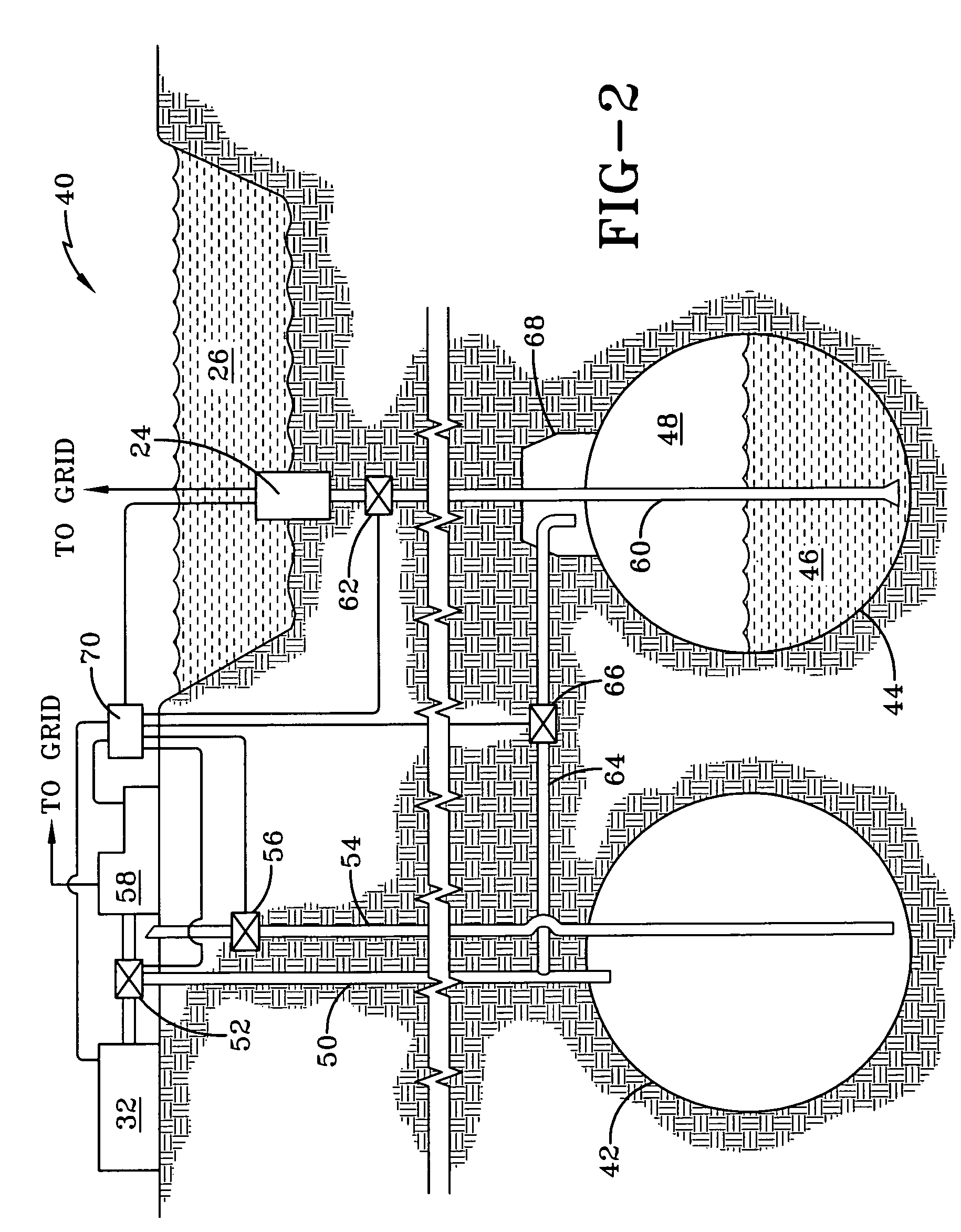

Compressed air pumped hydro energy storage and distribution system

InactiveUS7281371B1Improve efficiencyCost-effective mannerFluid couplingsHydro energy generationThermal energy storageLow demand

A compressed air pumped hydro energy storage and distribution system includes a first reservoir of water and a second reservoir of air and water. An air pressure source, connected to the second reservoir, develops a pressure head in the second reservoir. A pump / turbine-motor / generator, received by the first reservoir, is connected to a regional energy grid. During peak demand periods, the pressure head forces water through the pump / turbine-motor / generator to generate power, delivered to the grid. During low demand periods, the pump / turbine-motor / generator pumps water back to the second reservoir, regenerating the pressure head. A third air reservoir interconnected with the second reservoir and a gas turbine generator can be used to generate power during peak demand periods. The reservoirs can be tunnels or abandoned mines, reinforced and sealed by pressure grouting and / or an internal liner, maintained well beneath the earth's surface and intersecting the path of the grid.

Owner:EBO GROUP

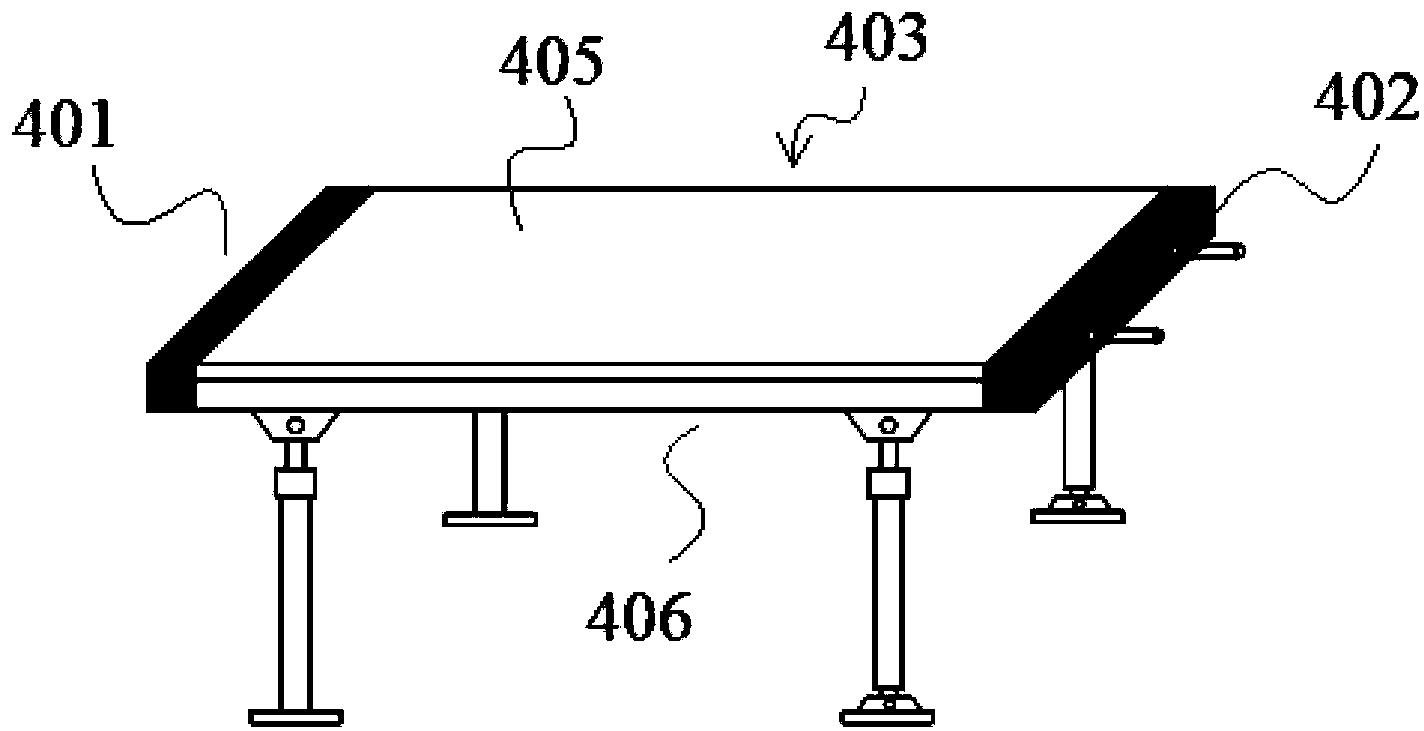

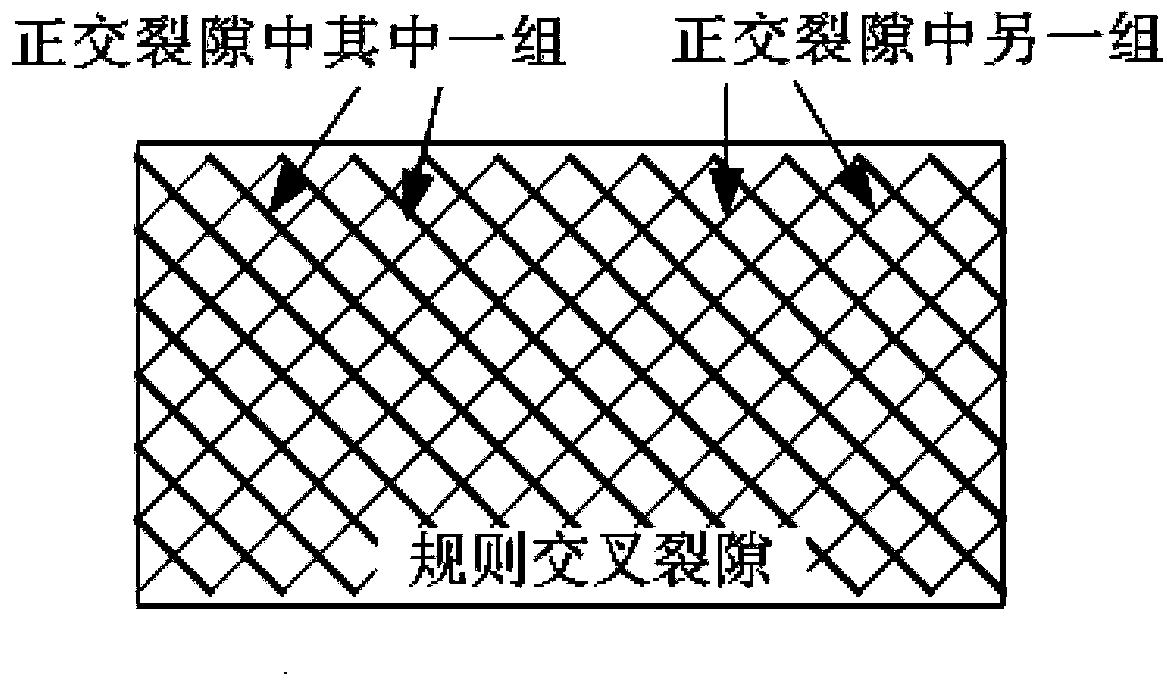

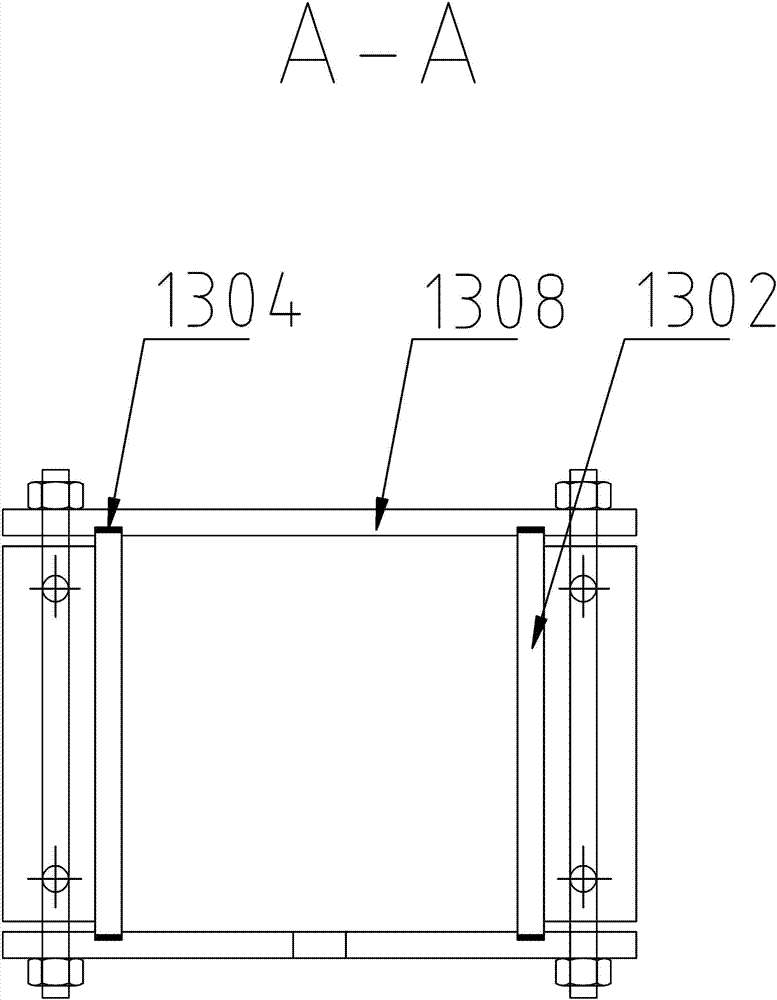

Visual intersected fracture flowing water grouting test device and method

ActiveCN103411751ARealize grouting simulation testRealize analysisHydrodynamic testingSlurryAtmospheric pressure

The invention discloses a visual intersected fracture flowing water grouting test device and method. The visual intersected fracture flowing water grouting test device comprises a grout collection device and further comprises an intersected fracture platform. The intersected fracture platform comprises supporting frames, an intersected fracture test room arranged on the supporting frames, intersected fractures arranged on the inner wall of the intersected fracture test room, flow sensors arranged inside the intersected fracture test room, and pressure sensors arranged inside the intersected fracture test room. The visual intersected fracture flowing water grouting test device further comprises a flowing water supply device used for injecting water for the intersected fracture test room and an air pressure grouting device used for grouting for the intersected fracture test room, and the intersected fracture test room is connected with the grout collection device. The visual intersected fracture flowing water grouting test device and method can achieve grouting simulation test and analysis under the conditions of the intersected fractures and flowing water.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

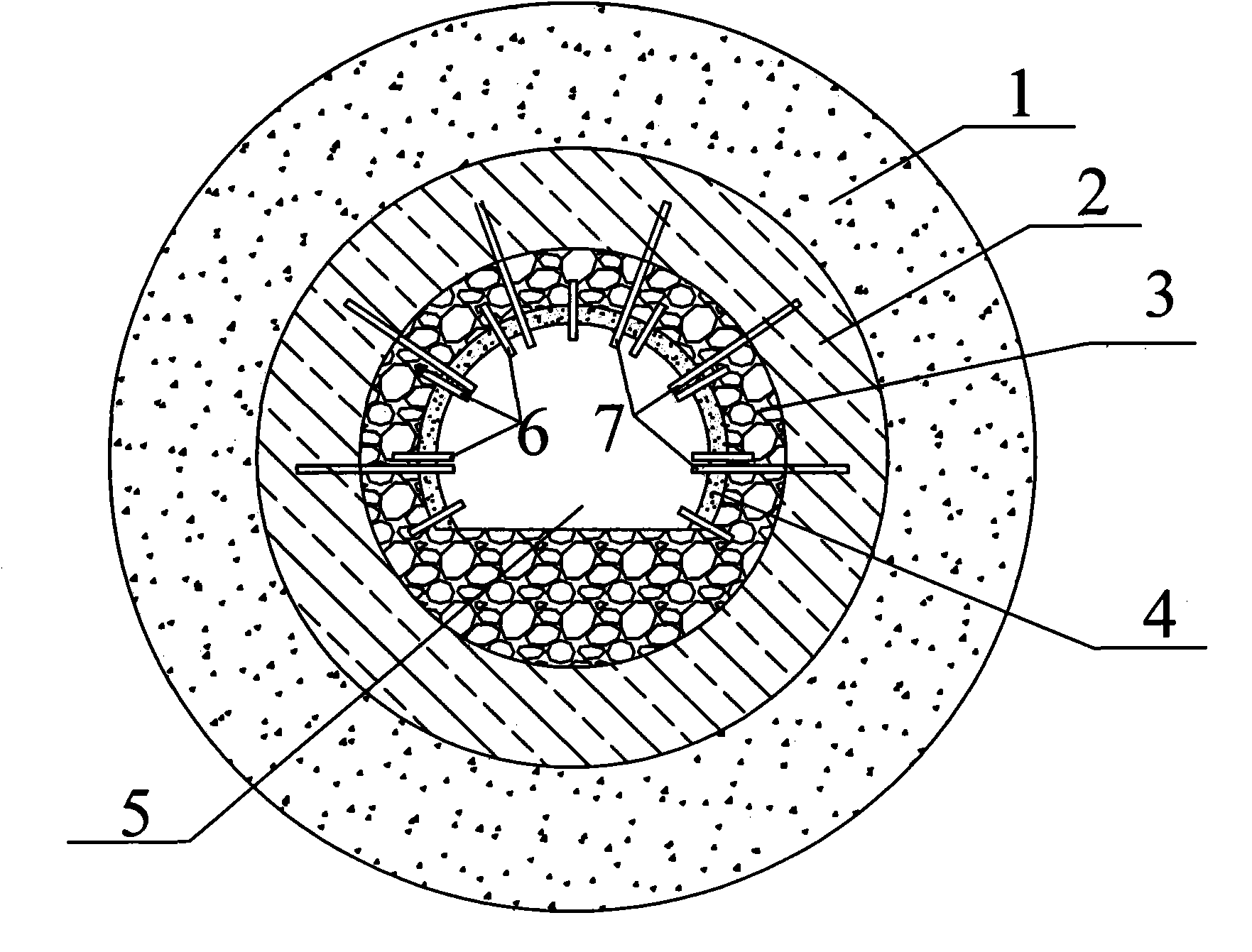

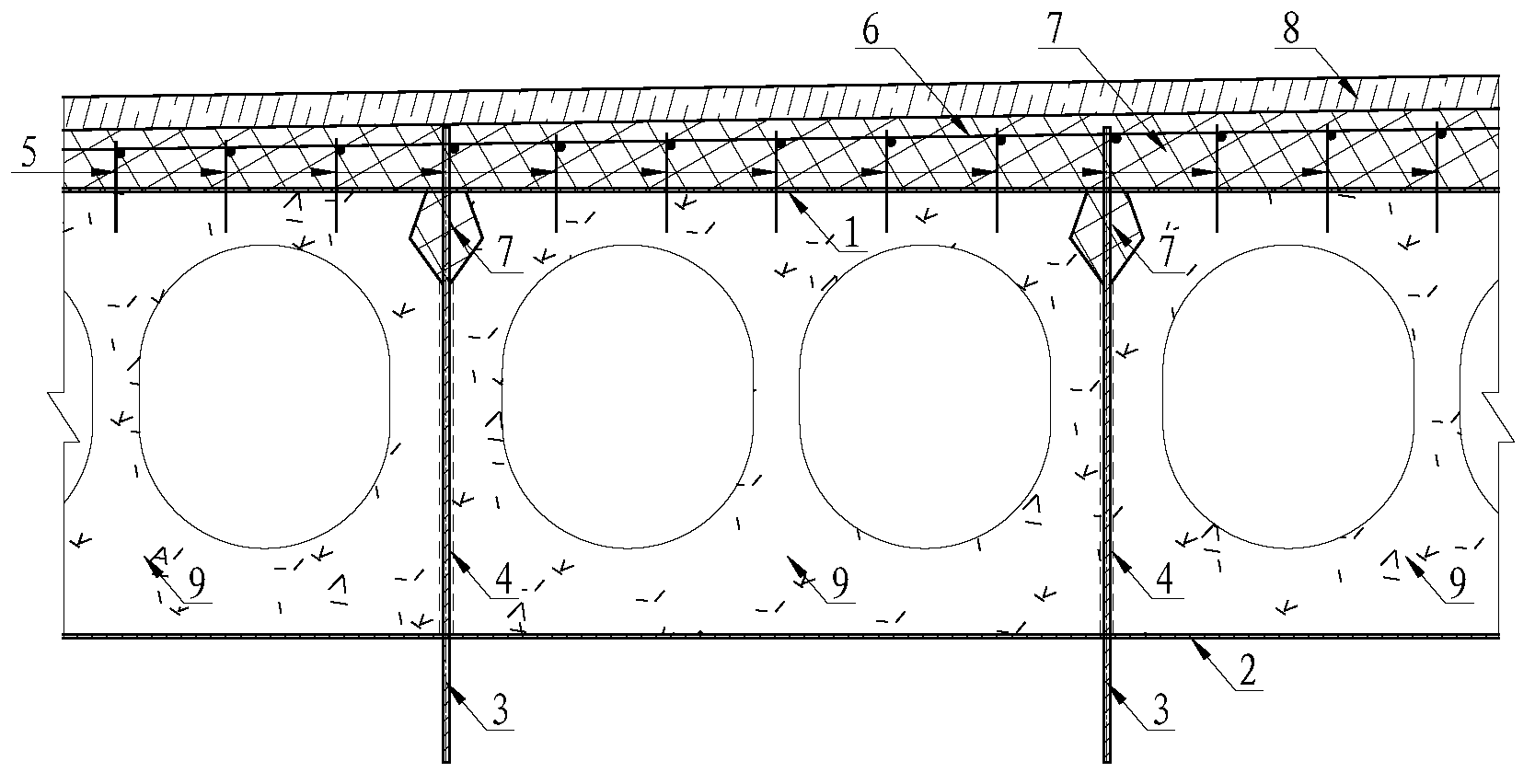

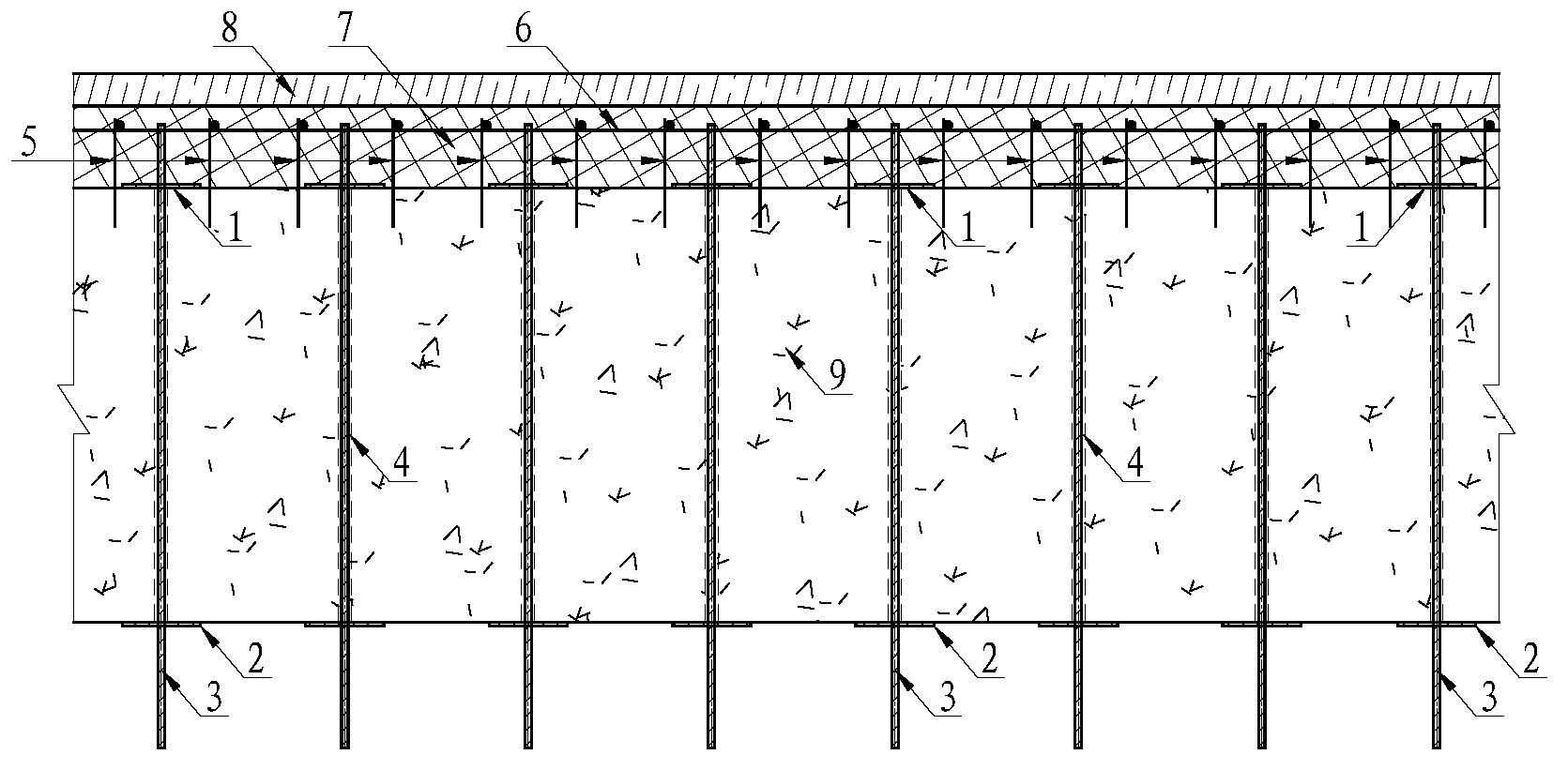

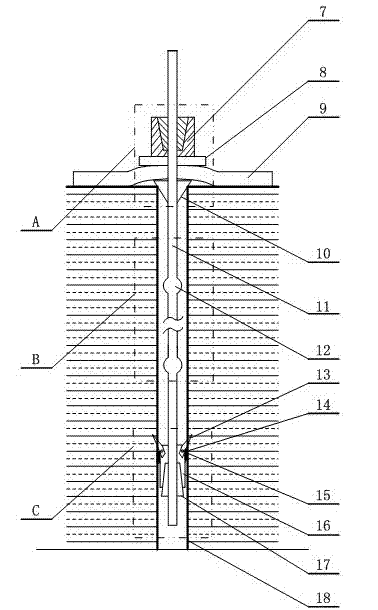

Strengthening and reinforcing method of high-ground-pressure soft rock laneway by hierarchical grouting

InactiveCN101864967AImprove the strengthening effectWill not blockUnderground chambersTunnel liningSlurryHigh pressure

The invention relates to a strengthening and reinforcing method of a high-ground-pressure soft rock laneway by hierarchical grouting. Aiming at the deformation damage and crack distribution rules of laneway wall rock of high-ground-pressure soft rock, a hierarchical grouting mode for a shallow layer and a deep layer is adopted to hierarchically and emphatically strengthen and reinforce the shallow layer and the deep layer by grouting. The method comprises the following steps of: firstly, carrying out shallow-hole low-pressure grouting to a laneway shallow-layer gap development zone and then carrying out deep-hole high-pressure grouting to deep rock bodies; constructing shallow-hole grouting with small grouting pressure so that grout is scarcely diffused into the deep part, and grouting passages, such as a deep gap of the deep part and the like, are well preserved without blockage; and adopting a double-component chemical grout malisan with easy dispersion and strong permeability in constructing deep-hole grouting to realize deep high-pressure grouting on the basis of a formed grout-stopping shielding shell formed by former-period shallow-hole grouting so that the distribution compactness and the dispersion evenness of the grout in the deep grouting are improved, and the strengthening effect of the deep grouting on the wall rock is effectively improved. The method is simple and easy to implement.

Owner:CHINA UNIV OF MINING & TECH

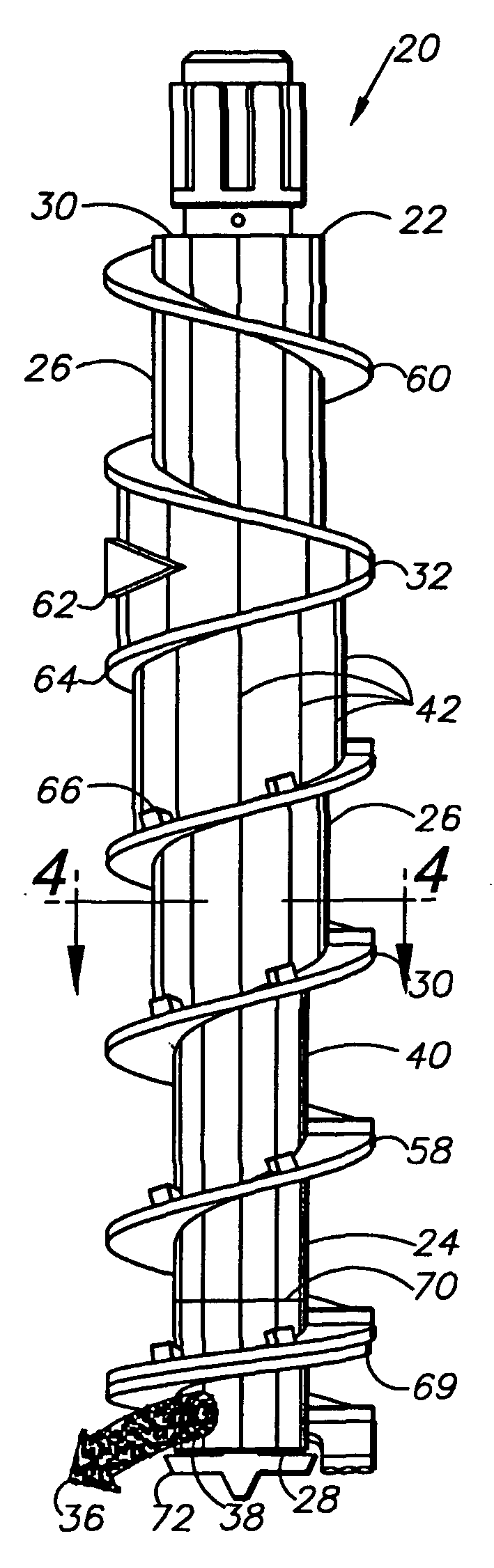

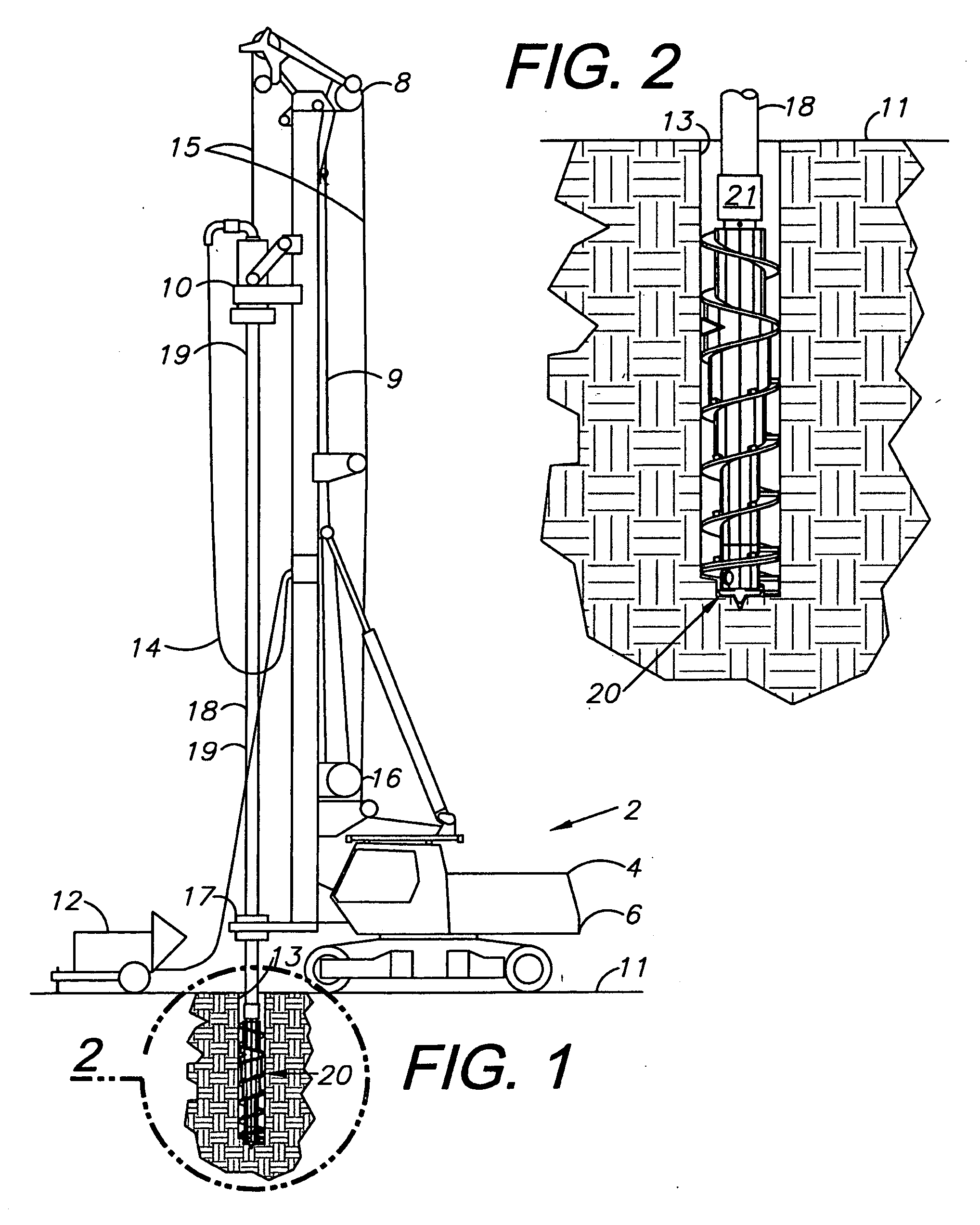

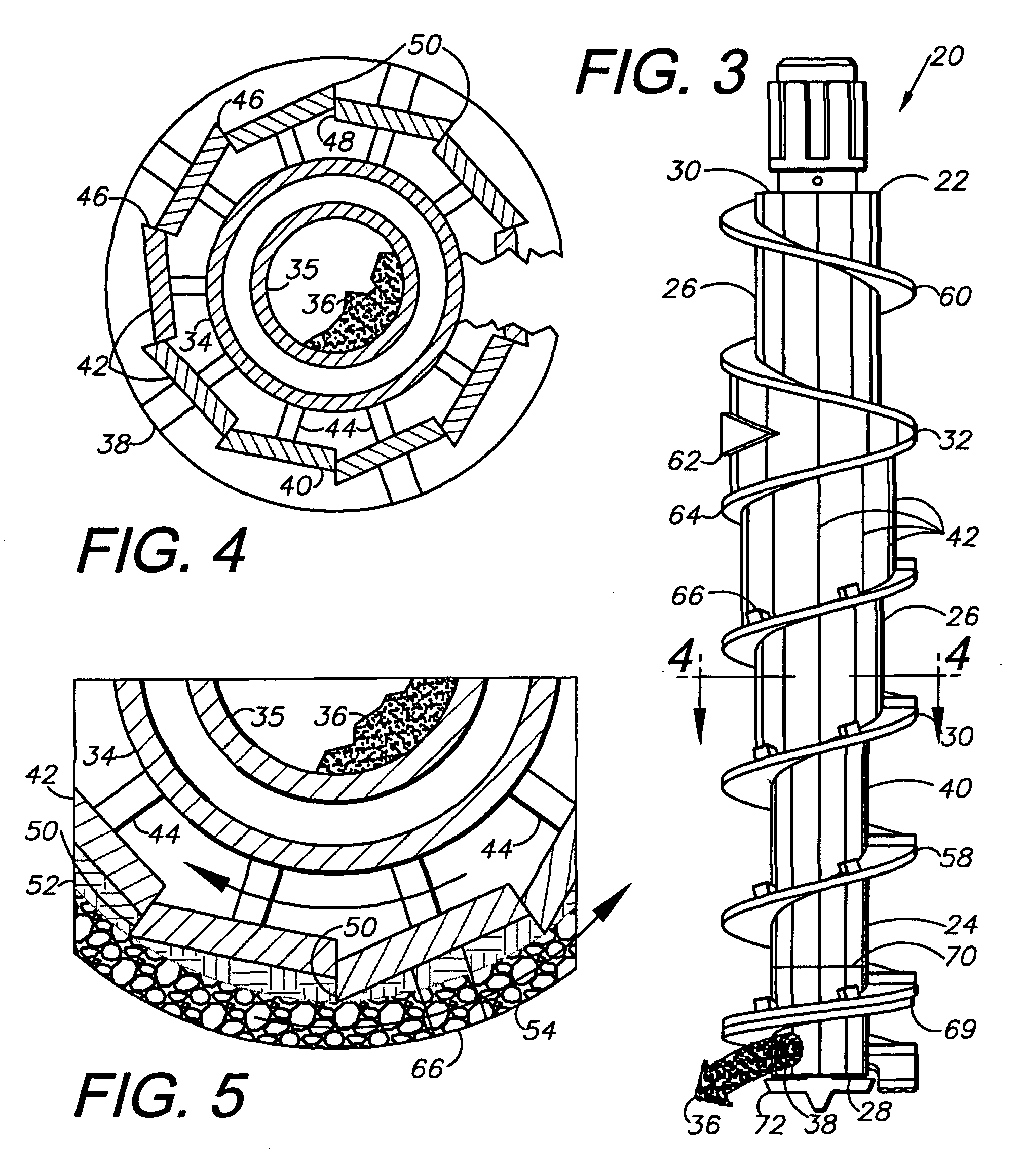

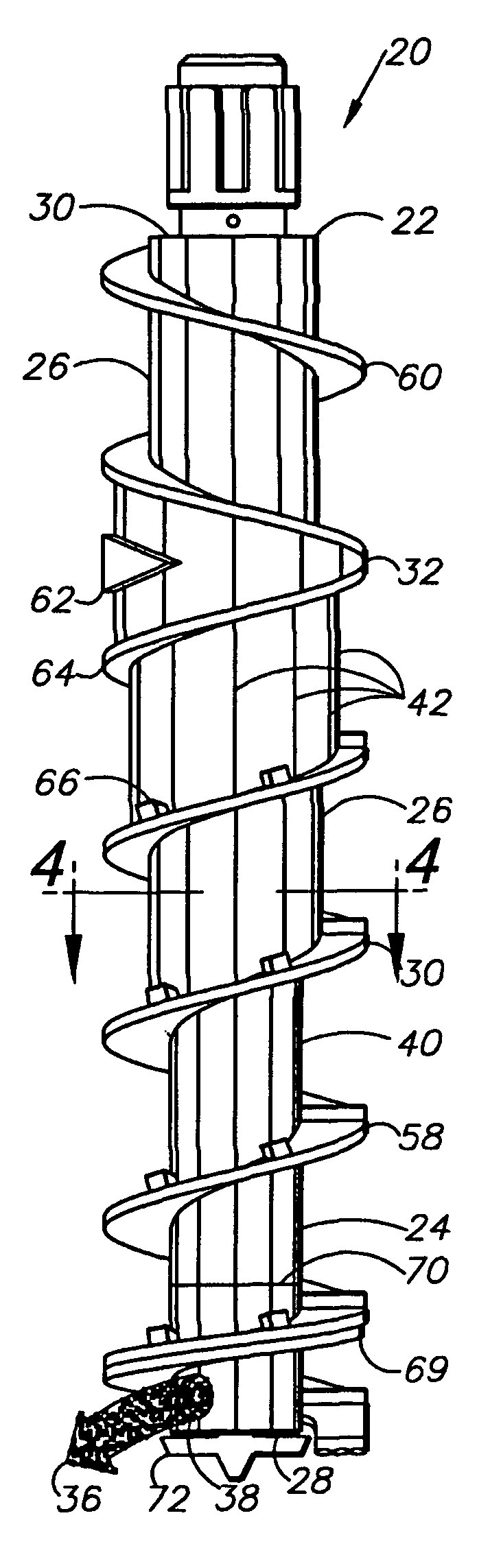

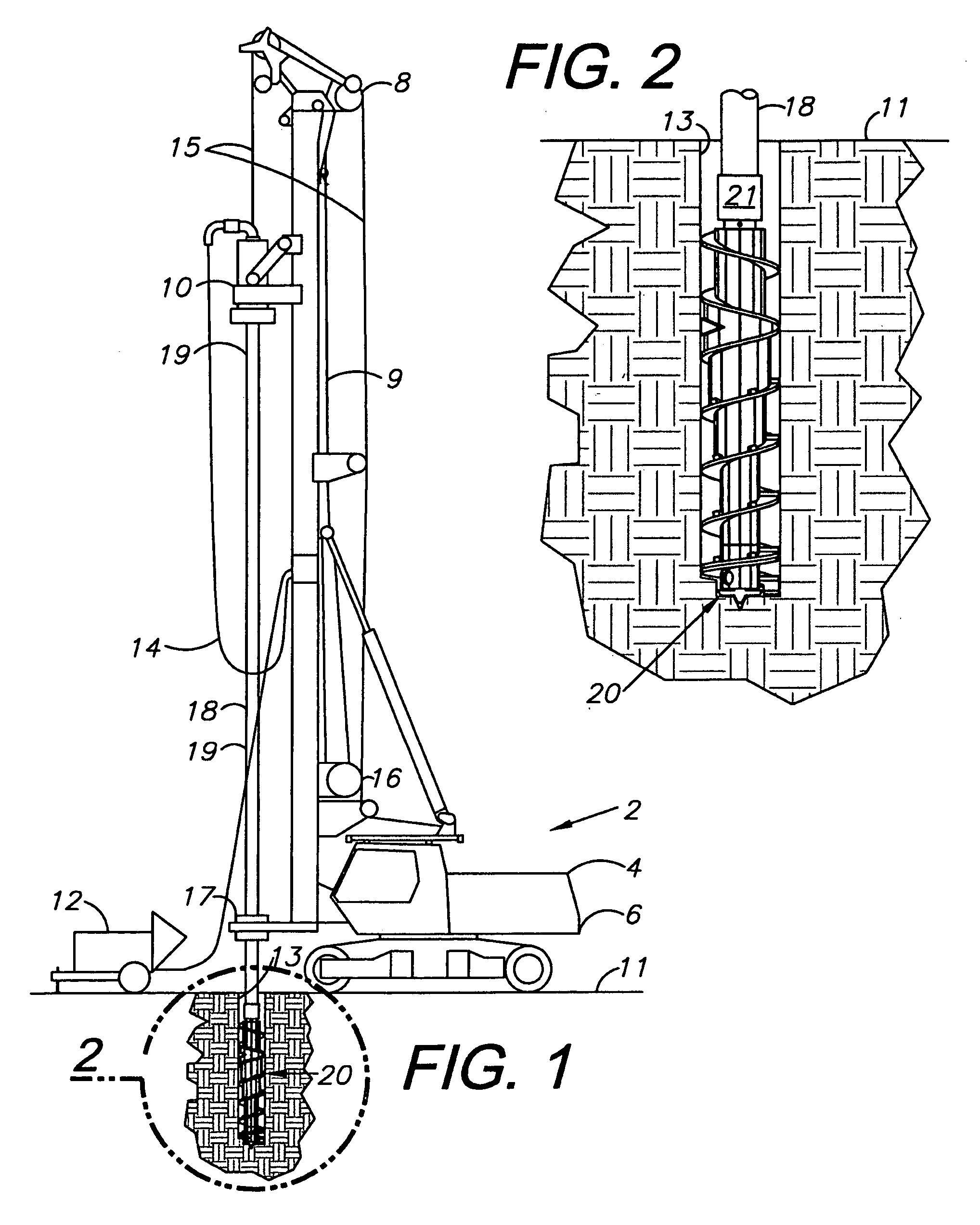

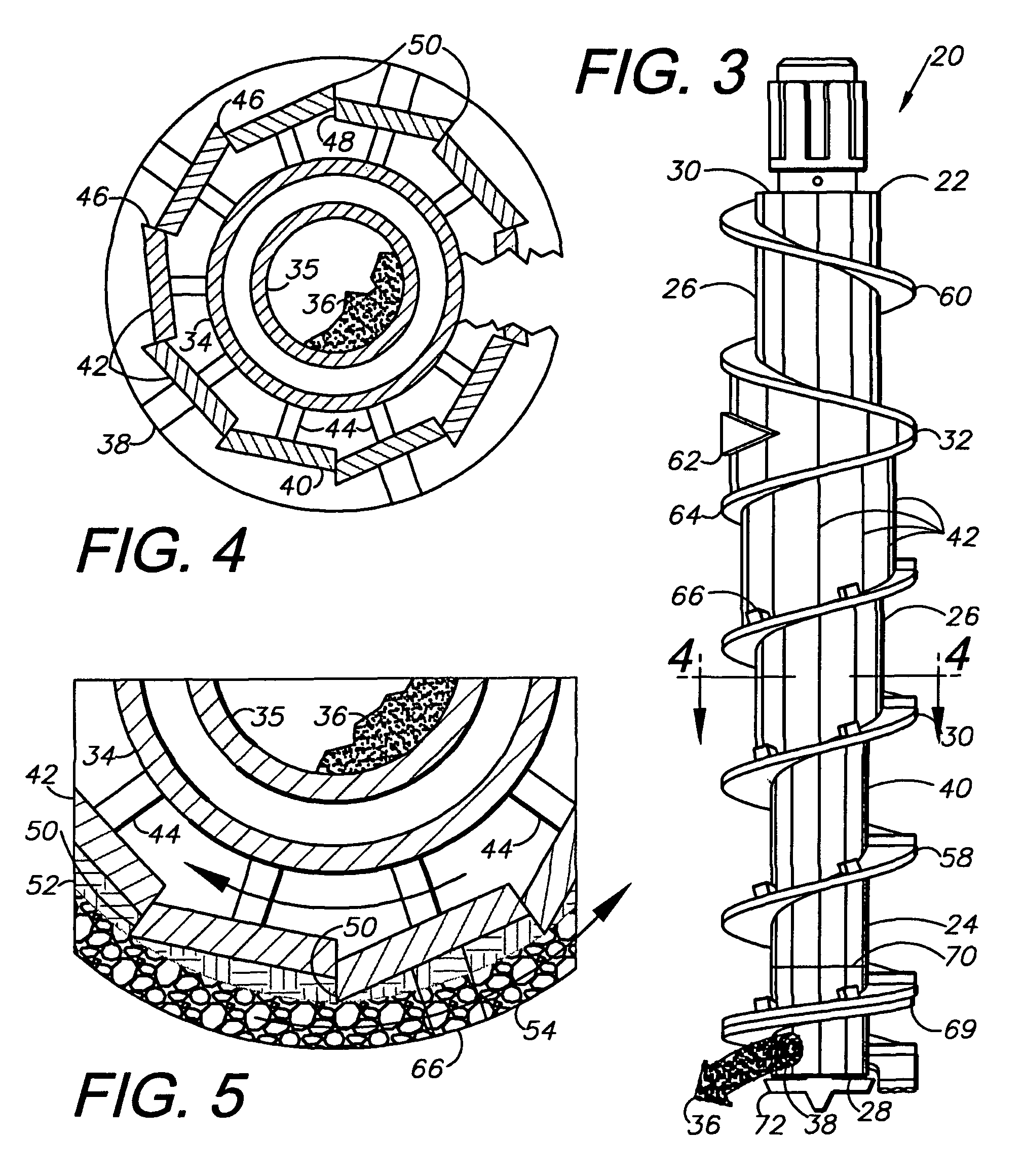

Full-displacement pressure grouted pile system and method

An auger bit is provided for a foundation pile system including a drilling rig adapted for mounting and rotating a grout pipe connected to the auger bit to form an auger. The auger bit includes a stem with lower and upper sections, which taper towards a transition whereat the stem has a maximum diameter. Right-hand flighting is mounted on the stem lower section and converges with left-hand flighting mounted on the stem upper section at a transition. The stem and the flighting have substantially equal diameters at the transition whereby soil is displaced laterally and compacted at the borehole perimeter during drilling of same. A pile foundation forming method includes the steps of providing a drilling rig, forming an auger with a grout pipe coupled to an auger bit, rotating the auger with the rig, forming a borehole with laterally displaced soil, pumping pressurized grout through the auger and into the borehole, placing a reinforcing cage in the wet grout and curing same.

Owner:BERKEL & CONTRACTORS

Combined grouting construction process of reinforcing foundation

InactiveCN1487150AAddress controllabilityAddress reliabilitySoil preservationHigh pressurePressure grouting

The combined grouting construction process of reinforcing foundation includes the following steps: drilling grouting hole; establishing hole top grouting apparatus; high pressure rotary spraying clear water to expand hole; high pressure rotary spraying mortar and static pressure grouting. The present invention combines static pressure grouting technology and high pressure rotary spraying grouting technology with different advantages, so as to reach maximum application range, optimized reinforcing effect, and successive and safe reinforcement.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

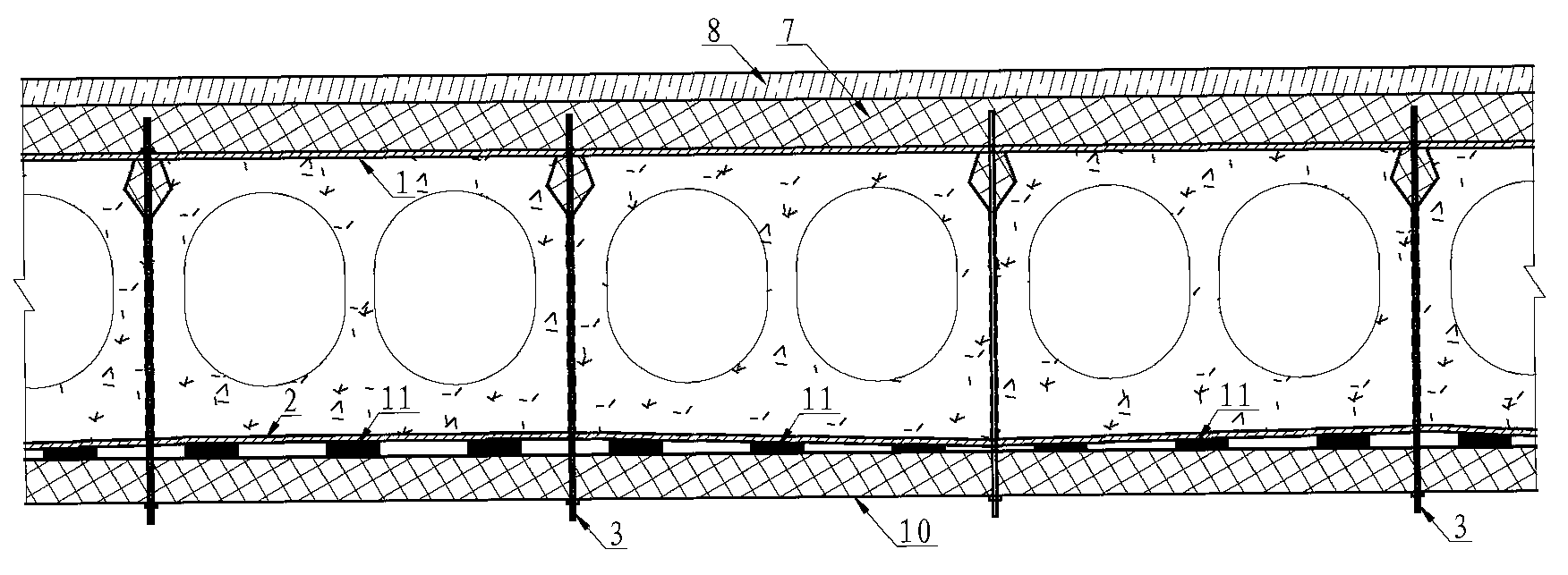

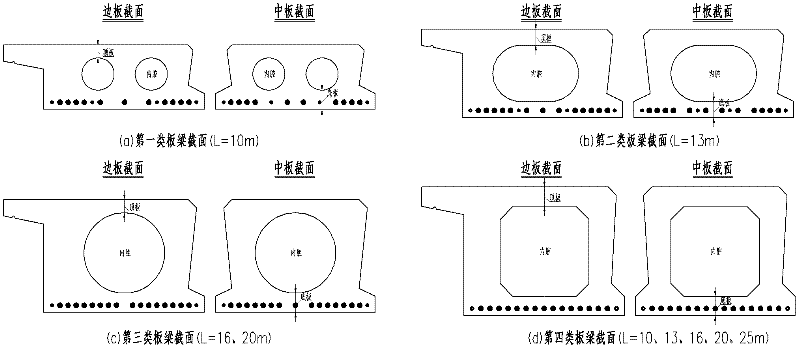

Single plate force-bearing reinforcing method of hollow slab bridge

InactiveCN103061271AAvoid destructionImprove reliabilityBridge erection/assemblyBridge strengtheningWhole bodyBridge deck

The invention relates to a single plate force-bearing reinforcing method of a hollow slab bridge. The single plate force-bearing reinforcing method includes that the original bridge deck pavement is shoveled, hinge joint concrete is removed, defects and cracks of the original hollow slab bridge beam body are processed, strip-shaped steel plates are transversely pasted on the upper surface and the lower surface of the hollow slab bridge in the longitudinal bridge direction at certain intervals, split screws penetrate through drilled holes at the hinge joint position, a counter-force frame is arranged, a wedge-shaped block is embedded between the counter-force frame and the steel plates, and the steel plates are pressurized and pasted in sealing mode and then are positioned and fixed; the counter-force frame is demounted after sticky steel glue is cured; cavities in beam joints are subjected to pressure grouting, shear reinforcements are placed into the top surface of a hollow slab, a reinforcement mesh is reconstructed, and the bridge deck reinforcement mesh and the implanted reinforcements are connected in binding or point welding mode to form a whole body; steel fiber reinforced concrete is poured and waterproof coatings are sprayed; and bituminous concrete is paved. The single plate force-bearing reinforcing method improves transverse load distribution, steel plate pasting reliability and bridge integral force-bearing performance on the premise of preventing hollow slab beam body damage, not changing a structural force-bearing system and not interrupting the traffic.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

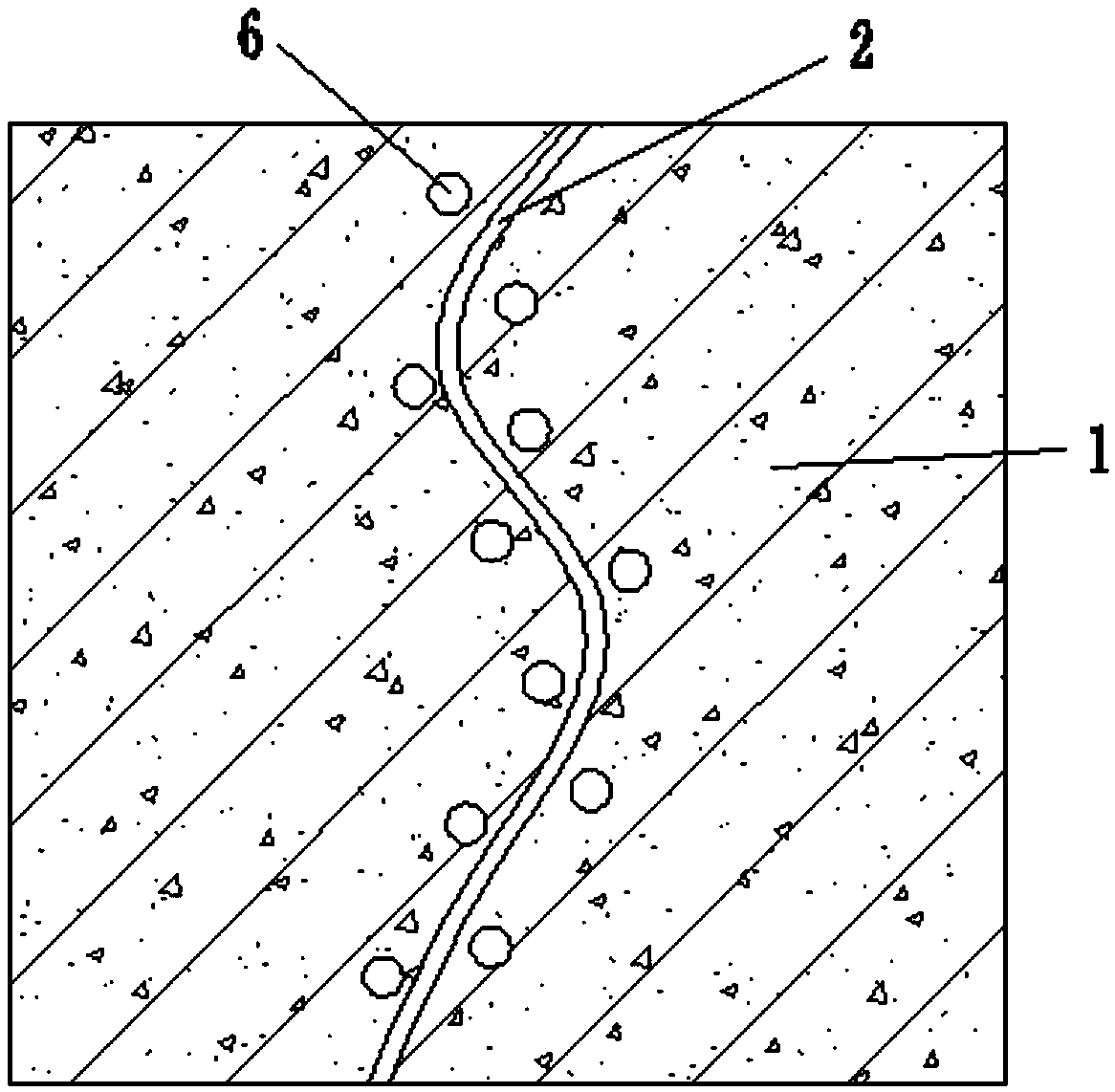

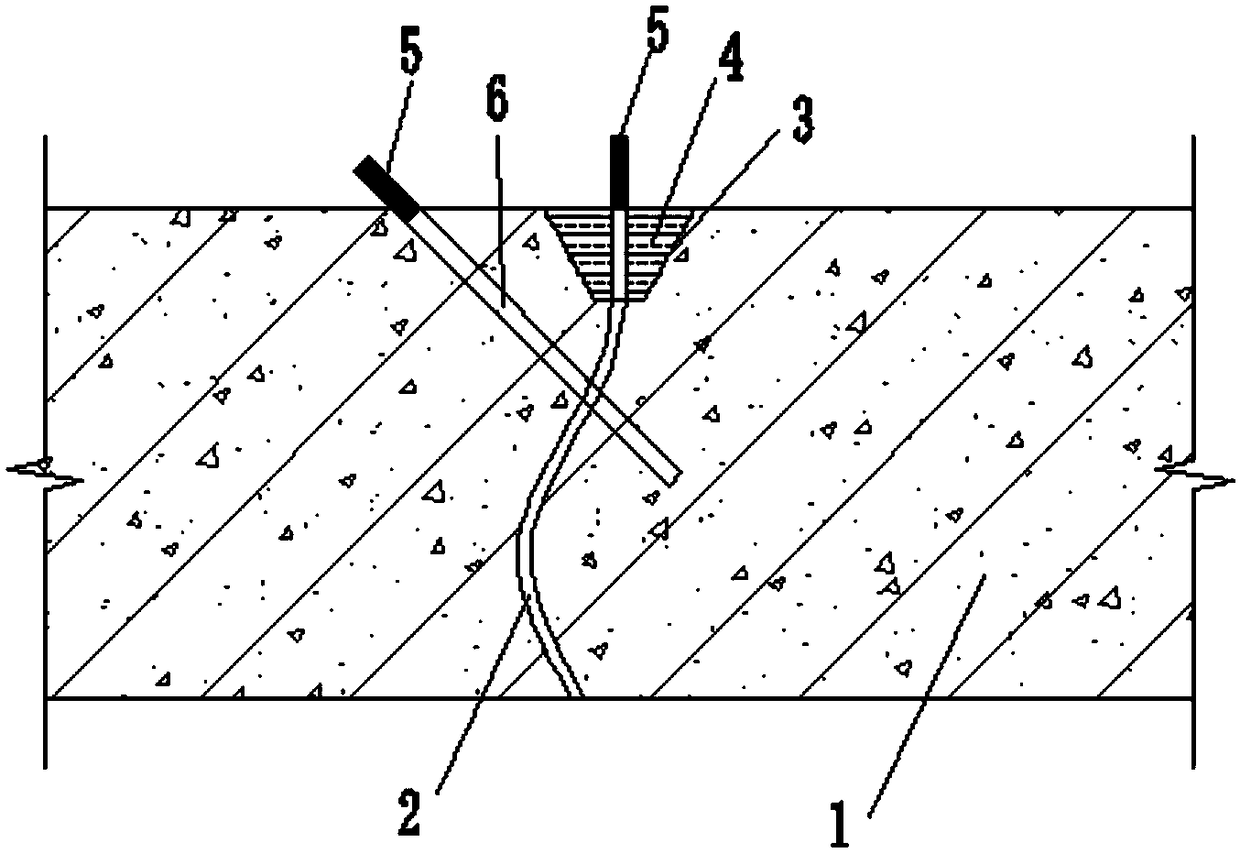

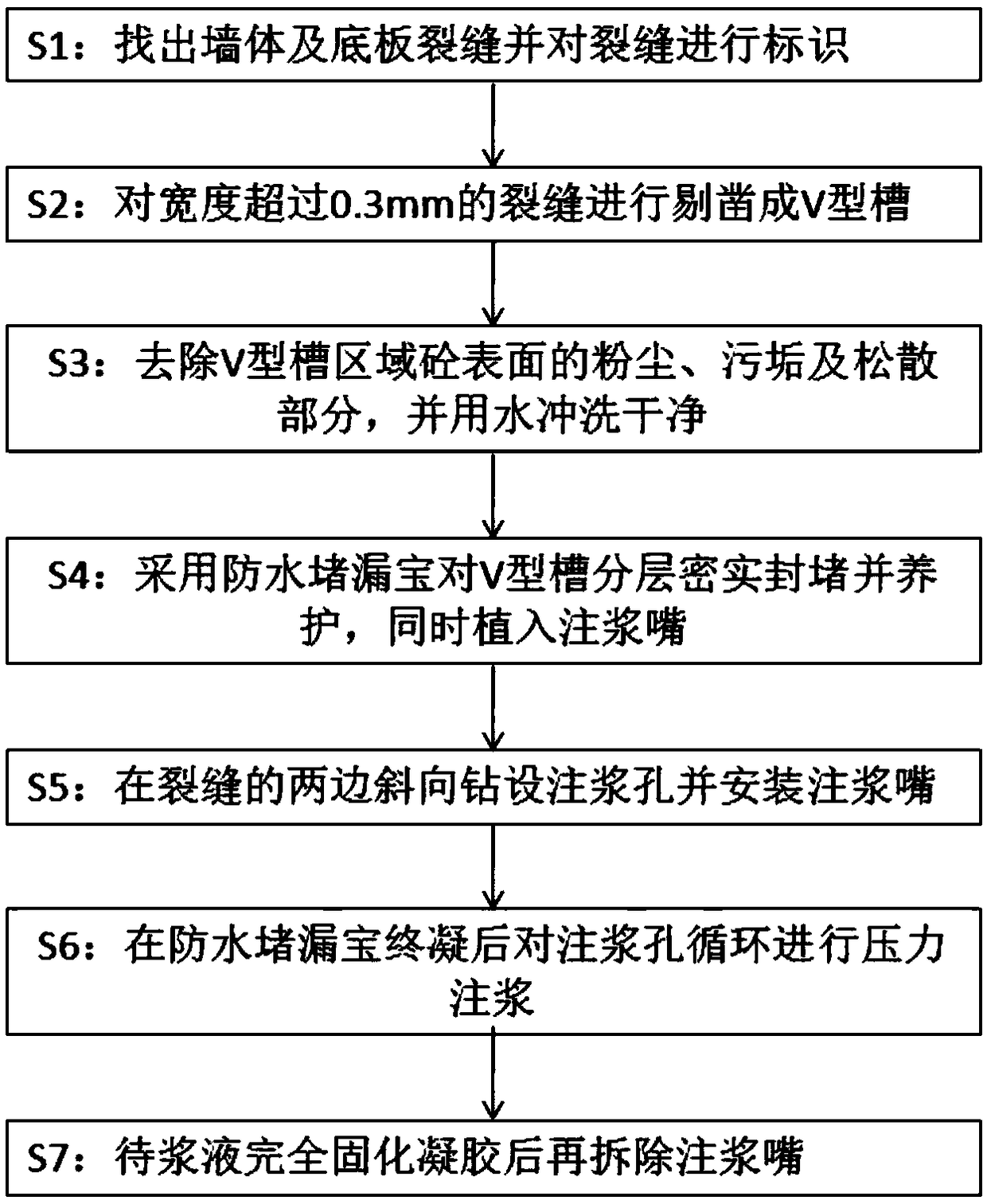

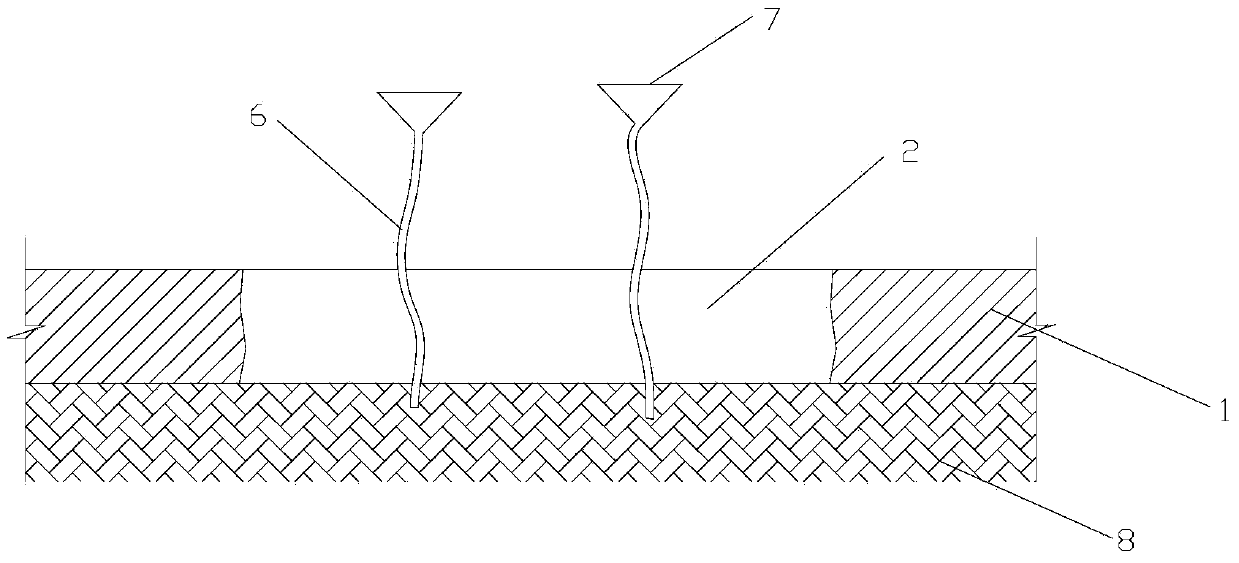

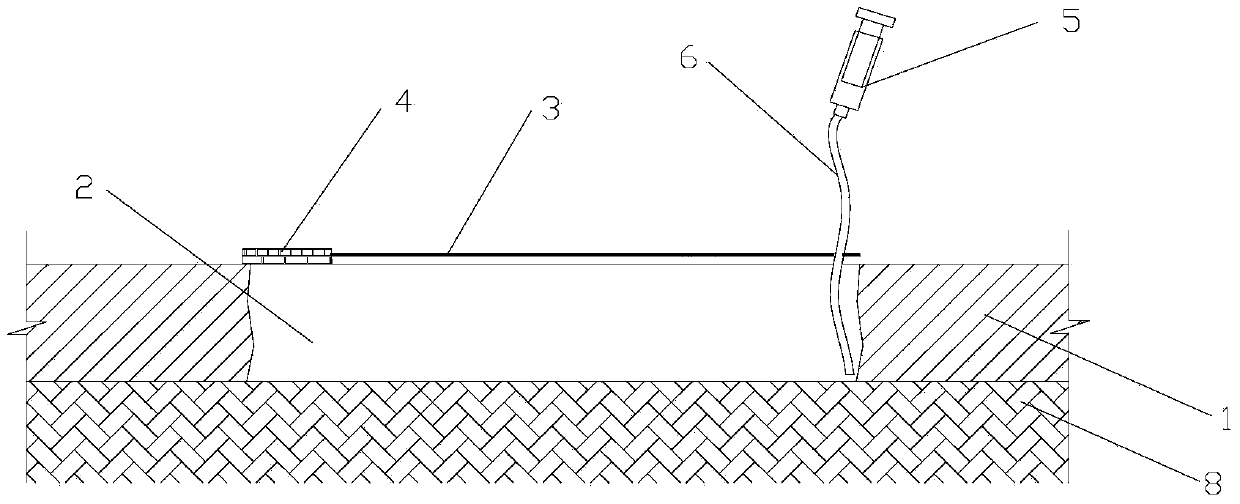

Concrete wall and bottom plate water seepage crack repair method

ActiveCN109457735AAvoid water leakage accidentsReduce water pressureArtificial islandsProtective foundationSlurryPressure grouting

The invention discloses a concrete wall and bottom plate water seepage crack repair method. The method comprises the following steps that wall and bottom plate cracks are found out and marked; the crack of which the width is larger than 0.3 mm is subjected to digging into a V-shaped groove; dust, dirt and loose parts of the surface of concrete in the V-shaped groove area are removed and washed with water; layered dense blocking and maintenance are conducted on the V-shaped groove through a waterproof leaking stoppage part, and meanwhile, a grouting nozzle is implanted; grouting holes are obliquely drilled in the two sides of the crack, and a grouting nozzle is installed; and after final set of the waterproof leaking stoppage part, the grouting holes are circularly subjected to pressure grouting; and after grout is completed solidified, the grouting nozzles are disassembled. According to the method, by obliquely drilling the grouting holes in the two sides of the crack and installing the grouting nozzle, a plurality of channels communicating with the interior of the crack are formed, the water pressure of the interior of the crack can be reduced, grout can be injected into the crackconveniently in the later period, through permeation of the grout, the water seepage crack is sealed after the grout is solidified, and accordingly, the water seepage crack leaking stoppage effect isachieved so that underground construction water seepage accidents can be avoided.

Owner:中铁二十三局集团第四工程有限公司

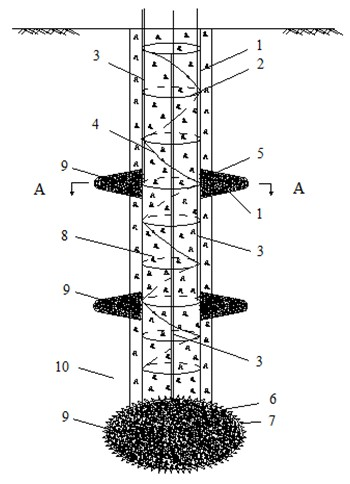

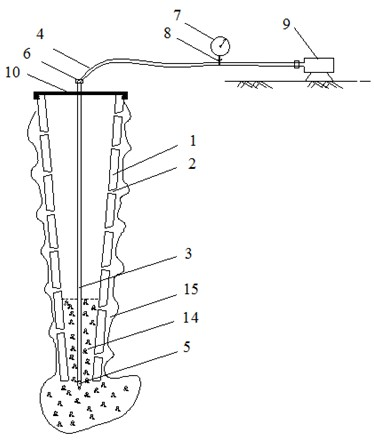

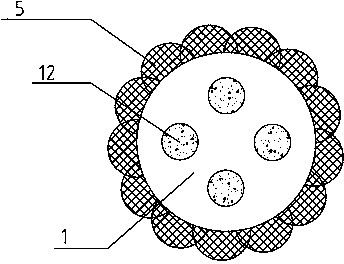

Technology of high polymer material post-grouting squeezed cast-in-place pile

ActiveCN102587358AImprove waterproof performanceImprove protectionBulkheads/pilesEconomic benefitsQuality control

Disclosed is construction technology of high polymer material post-grouting squeezed cast-in-place pile. The technology includes that a conventional bored pile is adopted for forming a hole, a grout filling bag is arranged on a reinforcement cage with a designed depth, the reinforcement cage sinks, concrete is cast, high polymer materials are in pressure grouting for the filling bag at a designed position by the aid of a grouting line after the pile building concrete is initially set, and a high polymer material post-grouting squeezed branch and an expanded-base grouting pile are formed. Construction process of a squeezed branch pile and technology of a post-grouting cast-in-place pile are optimized by a method, and problems of squeezing hole collapse of a traditional squeeze branch pipe, excessive scum at a pile end and the like are avoided. In addition, a large quantity of expenditure and construction period can be saved, the high polymer grouting technology is favorable for environmental protection and energy economization, and the quality is easy to control. Besides, the method is simple in construction process, high in operability, convenient in quality control, and remarkable in economic benefit and the effect of management of a soft soil foundation.

Owner:HOHAI UNIV

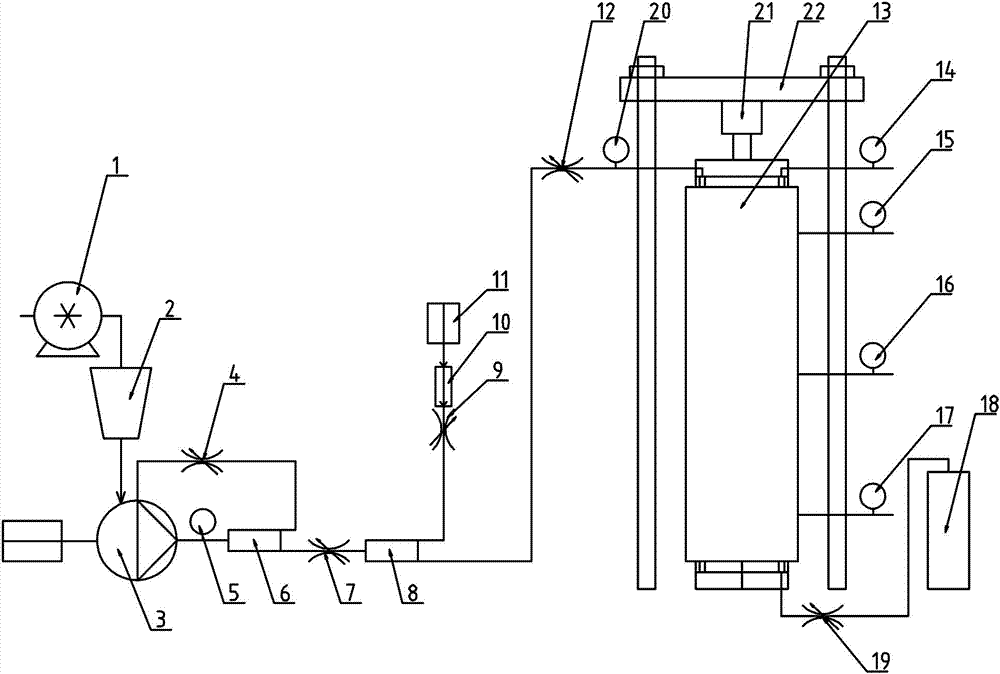

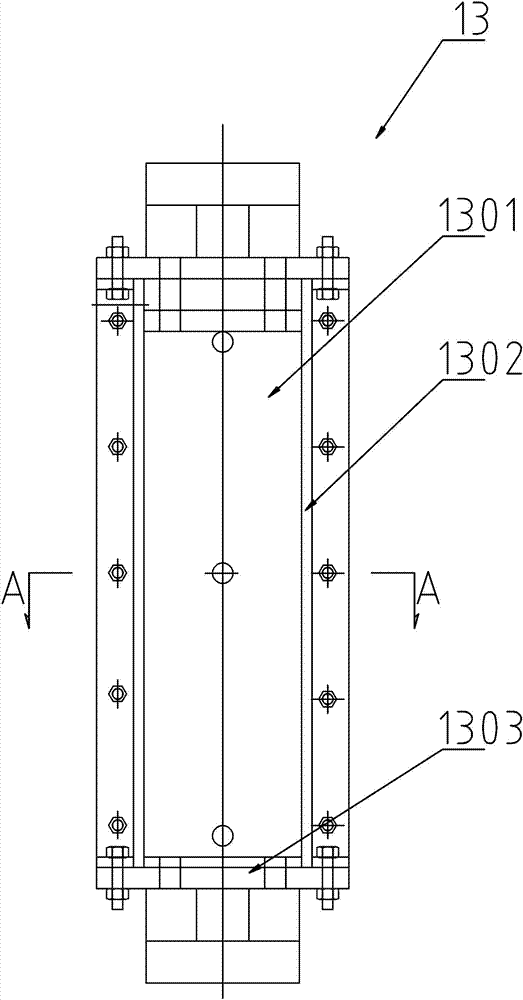

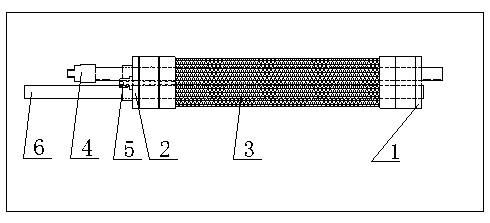

Pressure grouting experiment device

InactiveCN103048439AGuaranteed physical and mechanical propertiesSuitable for useMaterial testing goodsExperimental laboratoryClassical mechanics

The invention provides a pressure grouting experiment device comprising a slurry supplying device, wherein the slurry supplying device is communicated with a slurry hole of an experiment mould; a lower slurry hole of the experiment mould is communicated with a slurry recycling barrel; a plurality of pipelines are arranged on the outer wall of the experiment mould from top to bottom; each pipeline is provided with a pressure gage; and throttling valves are arranged between the slurry supplying device and the experiment mould and also between the experiment mould and the slurry recycling barrel. According to the pressure grouting experiment device disclosed by the invention, grouting stone bodies with the regular shape can be easily and conveniently obtained through using different moulds, and slurry dispersion radiuses under the different conditions can be obtained. In the testing process, pressure P provided by matching the pressure gages and a flow meter with a jack can relatively and effectively analyze influences of a testing parameter to each physical mechanical property of the stone bodies and the slurry dispersion radiuses. According to the pressure grouting experiment device disclosed by the invention, the grouting amount can be quantized, so that components of the stone bodies are also quantized. The pressure grouting experiment device is small and exquisite, convenient and easy to use, and is particularly suitable for being used in a laboratory.

Owner:CHINA THREE GORGES UNIV

Method for plugging cast-in-situ concrete slab or base-plate crack with microbe-sedimented calcium carbonate

ActiveCN104196131AConsistent coefficient of thermal expansionImprove permeabilityBuilding constructionsMicroorganismAdhesive belt

The invention discloses a method for plugging a cast-in-situ concrete slab or base-plate crack with microbe-sedimented calcium carbonate. The method includes preparation of plugging materials, plugging of the cast-in-situ concrete slab crack and plugging of the cast-in-situ base-plate crack. A method for preparation of the plugging materials includes preparation of calcium source solutions, preparation of nutrient salt solutions and preparation of microbial solutions; a method for plugging of the cast-in-situ concrete slab crack includes that the pressure grouting mode is adopted on base of the crack, the top surface and bottom surface of the plugged crack are sealed with rubber tapes, and water solutions are ensured to flow out with bacteria filtered within the crack; a rubber hose is inserted in the bottom of the other end of the crack, and an injector is connected with the rubber tube; the injector is utilized to inject the microbial solutions, the nutrient salt solutions and the calcium source solutions with the volume ratio of 1:1:1, and fluid is ensured to seep from the position of a gauze; grouting work is repeated once every 24 hours for 5 days; the gauge, the rubber tube, the injector and the sealing rubber tapes are removed. By the method, problems of durability of rusting and the like caused by exposure of steel bars inside plates can be effectively solved.

Owner:SHANDONG JIANZHU UNIV

Pile sinking method of Synchronization grouting static pressure precast pile

InactiveCN101182716AImprove bearing capacityReduce pile tonnageBulkheads/pilesReinforced concreteSlurry

The method of synchronous grouting and static pressure prefabricated pile sinking belongs to the technical field of reinforced concrete prefabricated pile pile sinking in the field of construction. During the process, the side pile grouting fluid is injected at the same time. After the pile tip reaches the design depth, the pile tip grouting fluid is continuously injected into the pile tip to form a grouting expansion head at the pile tip; Reduce the construction cost and improve the construction quality; overcome the shortcomings of the difficulty of static pressure pile sinking, the application of this method can not only reduce the dynamic pile pressure resistance, improve the pile pressure efficiency, but also improve the pile side resistance and pile end resistance in the later stage, so as to ensure The tonnage of the pile press machine is reduced and the construction efficiency is improved, thereby expanding the application range of the static pressure pile and reducing the project cost.

Owner:ZHONGBEI UNIV

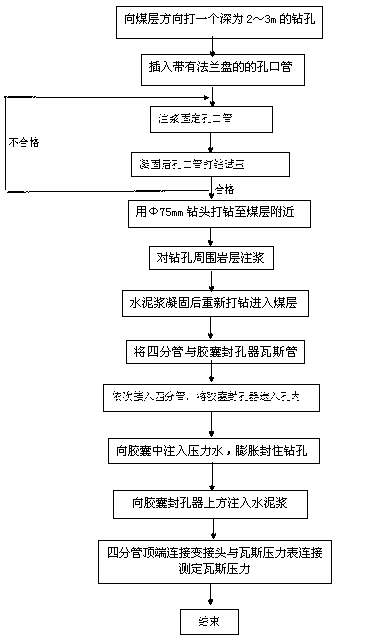

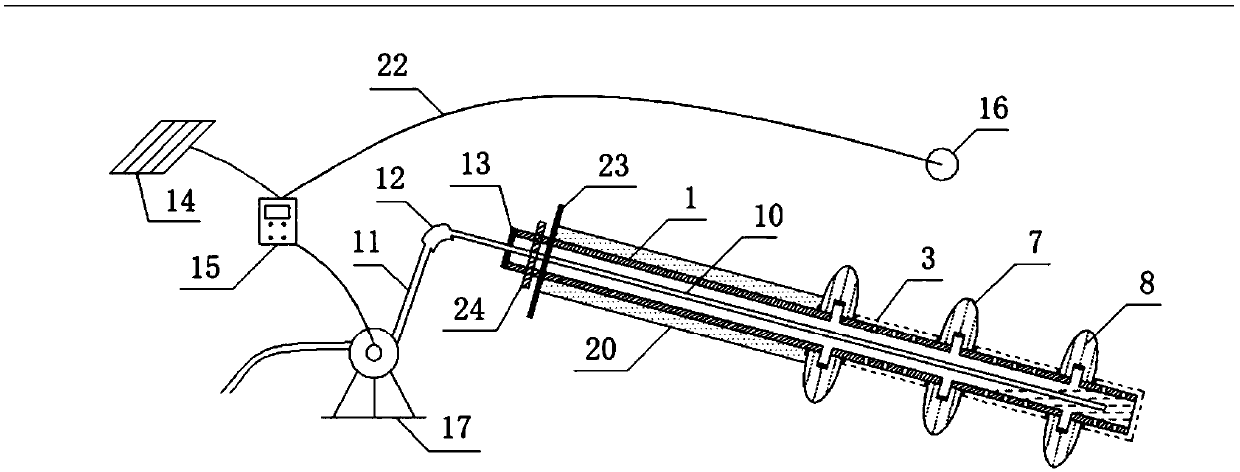

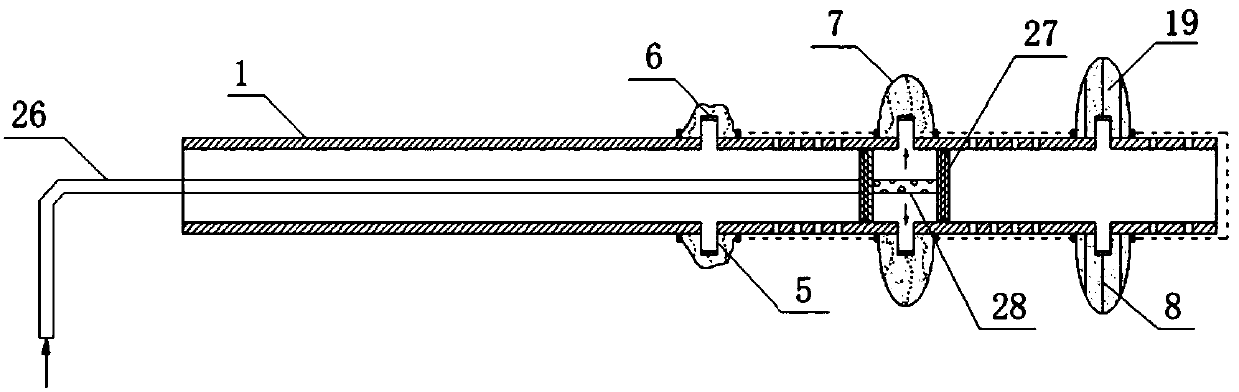

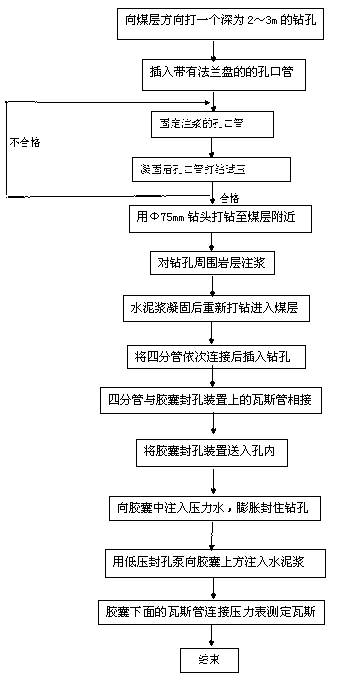

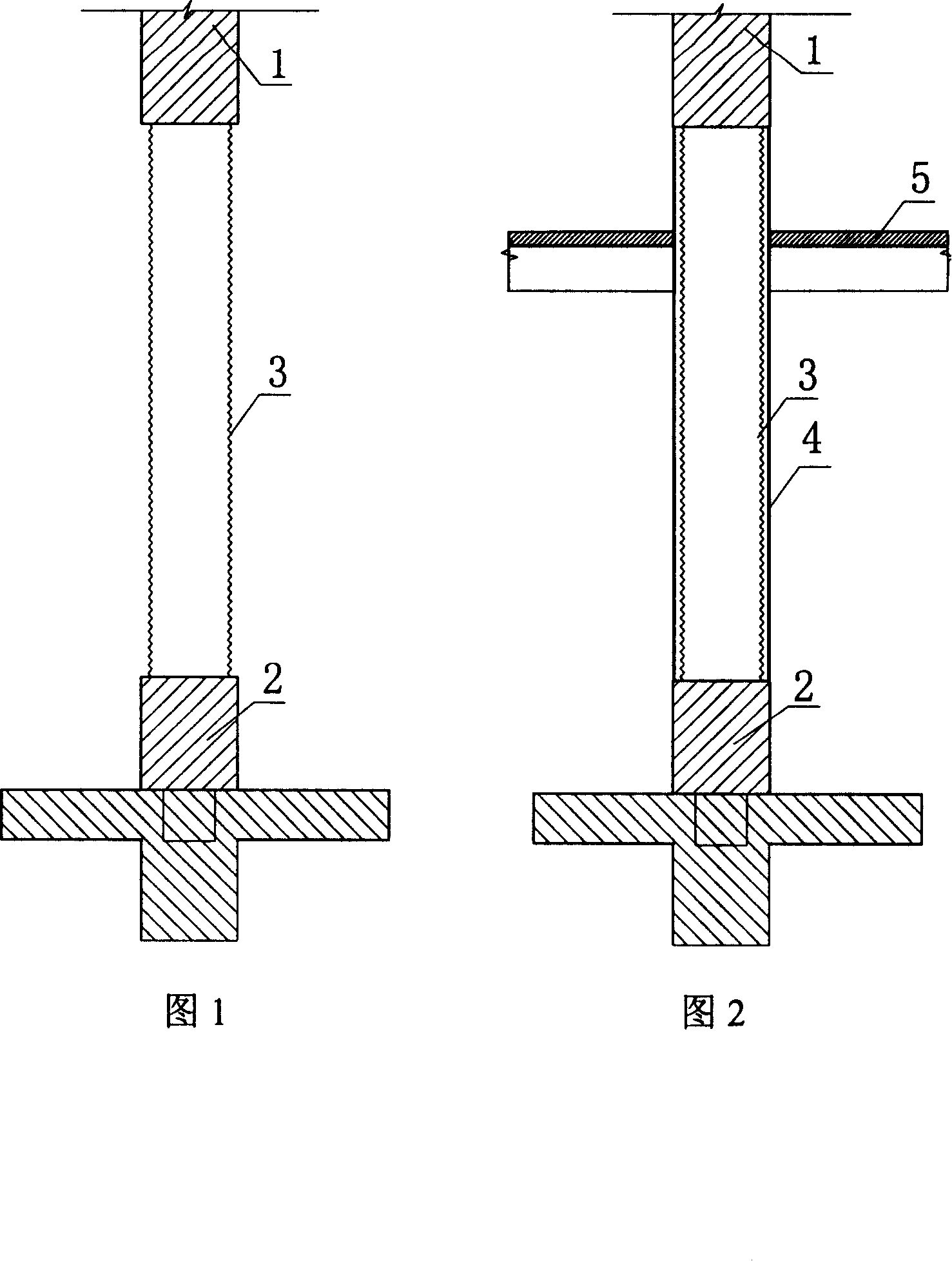

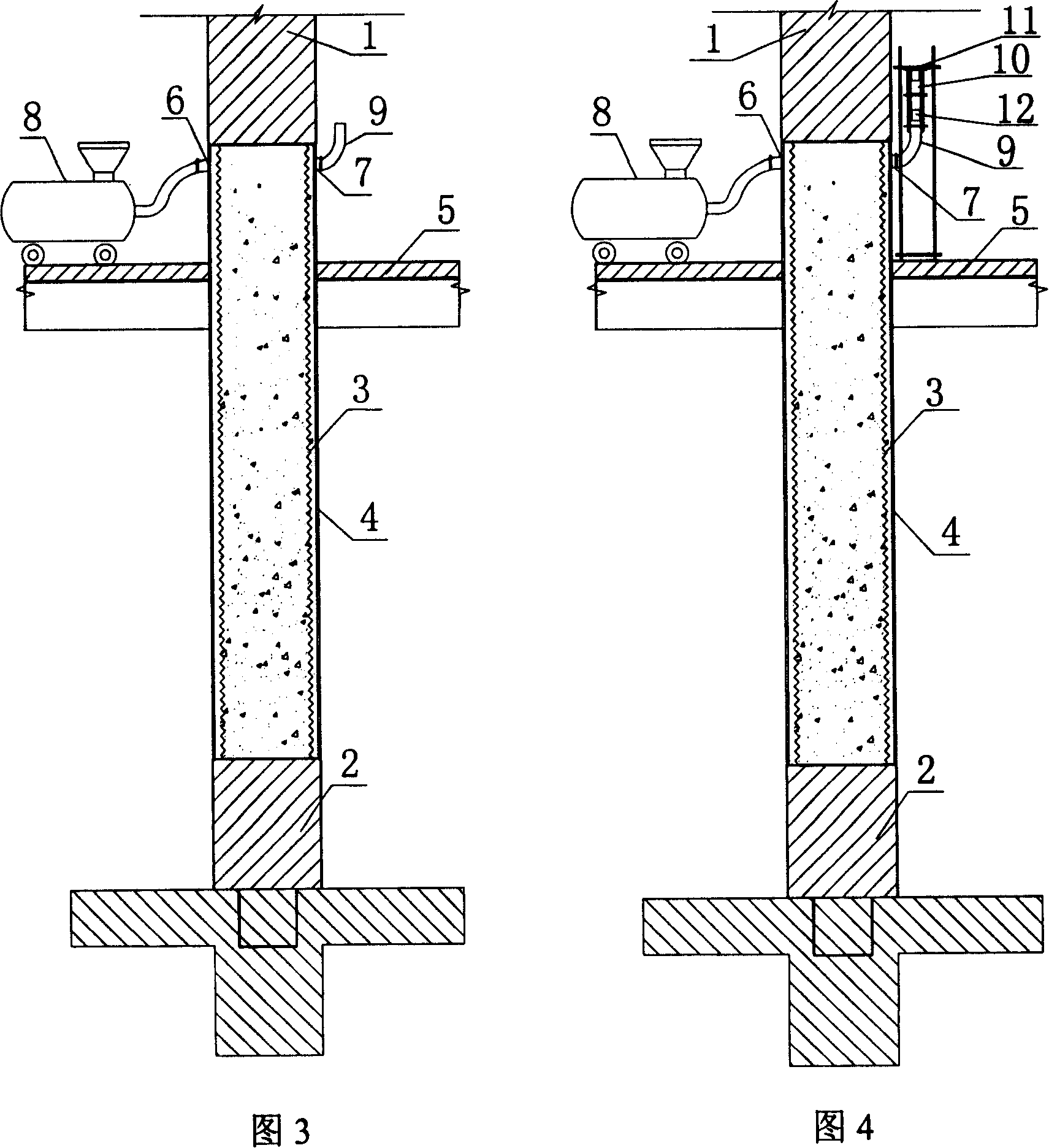

Method and device for quickly determining gas pressure of coal bed in downward superdeep borehole

InactiveCN103075149AReduce leakageThe measured value is accurateSurveySealing/packingCement pasteHigh pressure

The invention relates to a method and device for quickly determining gas pressure of a coal bed in a downward superdeep borehole. The method comprises the steps of: carrying out high-pressure grouting on rock stratums above the coal bed to be determined through the borehole to block various cracks; then, drilling holes to the coal bed, retrieving a drill pipe and inserting a capsule hole packer with a long gas pipe and a water injection tube to the borehole part of the rock stratums on the upper part of the coal bed, and pressing water to the capsule hole packer, so that the capsule is expanded to pre-seal the borehole; then, pouring cement paste to the borehole till the cement paste fills the borehole; connecting a pressure gauge to the gas pipe; and sealing by means of the pre-sealing hole of the capsule in the initial stage, and sealing by means of solidification of cement paste in the later stage so as to determine the gas pressure of the coal bed. The method can be used to determine the gas pressure of the downward superdeep coal bed which is far from 50m, and a heading roadway project for determining the gas pressure of the coal bed can be reduced. The determining device is simple, simple and convenient to operate, immediate to read in the gauge, quick in rise of the gas pressure and accurate in result, and has wide practicality.

Owner:CHINA UNIV OF MINING & TECH

Silicate modified polyurethane high molecular material and preparation method thereof

The invention belongs to the field of chemical synthesis, and particularly relates to a silicate modified polyurethane high molecular material for the reinforcing and plugging of coal-rock mass and a preparation method thereof. The silicate modified polyurethane high molecular material consists of a component A and a component B at a volume ratio of 1:1, wherein the component A is liquid sodium silicate water glass; and the component B consists of 40-50 parts of polyaryl polymethylene isocyanate, 40-50 parts of modified MDI and 0-10 parts of viscosity reducer by weight. The preparation method comprises the following steps of: adding the raw materials of the component B into a reaction kettle and stirring uniformly, and performing nitrogen displacement encapsulation; and mixing the component A and the component B and grouting by a double-liquid grouting pump to obtain the product. Through the invention, the product has good flame retardance; the raw material liquid has low viscosity and good permeability in the coal-rock mass; cohesiveness between the consolidating body and the coal-rock mass is good; the silicate modified polyurethane high molecular material is suitable for the quick reinforcing and plugging treatment of the broken coal bed and rock stratum in various coal mines and tunnels in poor ventilation; and the preparation method adopts the pressure grouting of a double-liquid grouting pump, realizes an excellent pumping property, and is convenient to use.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

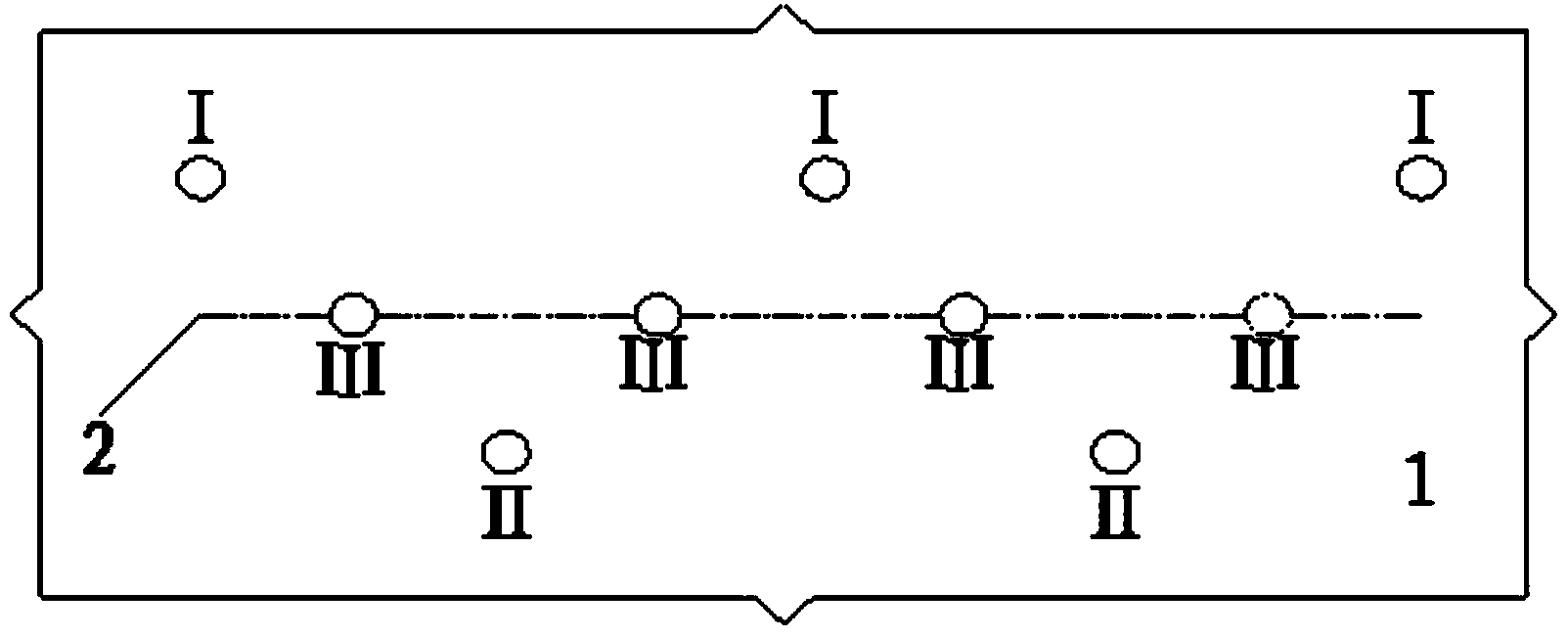

Water seepage plugging construction method of shaft construction seams under high water head

ActiveCN103898873ASuccessful pluggingDoes not affect normal operationFoundation engineeringMarine site engineeringElastomerSlurry

The invention discloses a water seepage plugging construction method of shaft construction seams under high water head. The water seepage plugging construction method includes that I-sequence grouting holes, II-sequence grouting holes and III-sequence grouting holes are arranged within a certain ranges of the seams, and water-soluble polyurethane chemical materials are injected into concrete cracks by the aid of a high-pressure grouting pump; when running into water in the concrete cracks, grout is rapidly dispersed, emulsified, expanded and solidified, so that all the cracks can be filled with solidified elastomers and water flow can be completely blocked out of a concrete structure; chemical grouting materials are filled into gaps between steel plates and wall surfaces on water seepage sides of the cracks, so that seamless integration of the steel plates and the wall surfaces can be guaranteed. Plugging construction on the water seepage side is free of affection of outside water level, normal operation of water conservancy rules is unaffected, and engineering benefits are improved; the water seepage plugging construction method has the advantages of safe construction, fast speed, reliable quality, low cost and the like.

Owner:ANHUI SHUIAN CONSTR GRP CO LTD

Vacuum drainage anchor rod and construction method thereof

ActiveCN109629566AIncrease anchoring forceGood governanceExcavationsBulkheads/pilesSleeve valveSlurry

The invention provides a vacuum drainage anchor rod and a construction method thereof. The anchor rod is composed of an anchoring system and a vacuum drainage system; a thread is arranged at the frontend of each hollow anchor pipe, the middle rear part of each hollow anchor pipe is connected with a slurry outlet pipe, water permeable holes are formed in each hollow anchor pipe which is wrapped bya filter screen, a rubber sleeve valve and a geotextile bag sleeve an opening of each slurry outlet pipe, and each geotextile bag is clamped in the corresponding hollow anchor pipe through a hoop; the hollow anchor pipes are obliquely arranged in a slope, pressure grouting is conducted on the interior and the periphery of the front end of each hollow anchor pipe, and the hollow anchor pipes are anchored on backing plates through anchorage devices; a controller and a vacuum pump are installed outside the slope; moisture meters are embedded in the slope and connected with the controller; waterabsorbing pipes penetrate through sealing covers and are inserted into the hollow anchor pipes, connected with a drain pipe through sealing joints and connected with the vacuum pump; the controller and the vacuum pump are switched on, pumping starts to be conducted, a negative pressure zone is formed in each hollow anchor pipe, and the water in the slope enters a water suction pipe and then is discharged out of the slope. Accordingly, the structure is simple, anchorage and drainage can be achieved simultaneously, a good effect is achieved, construction is easy, and the manufacturing cost is low.

Owner:NINGXIA UNIVERSITY

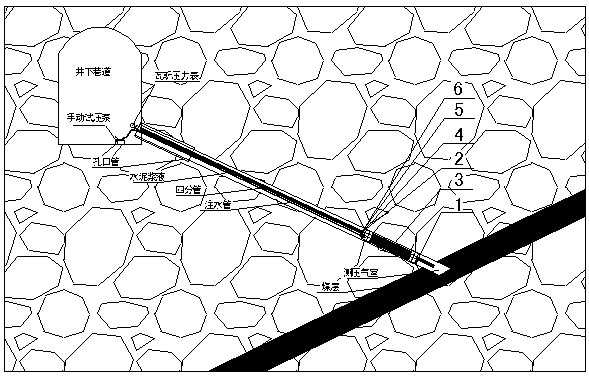

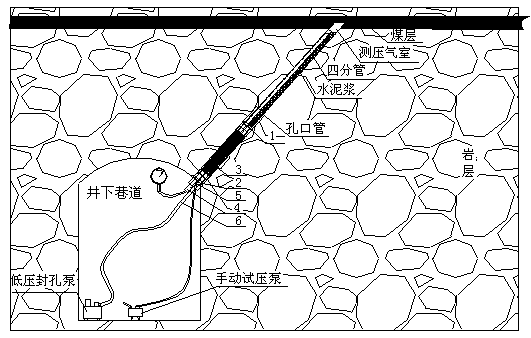

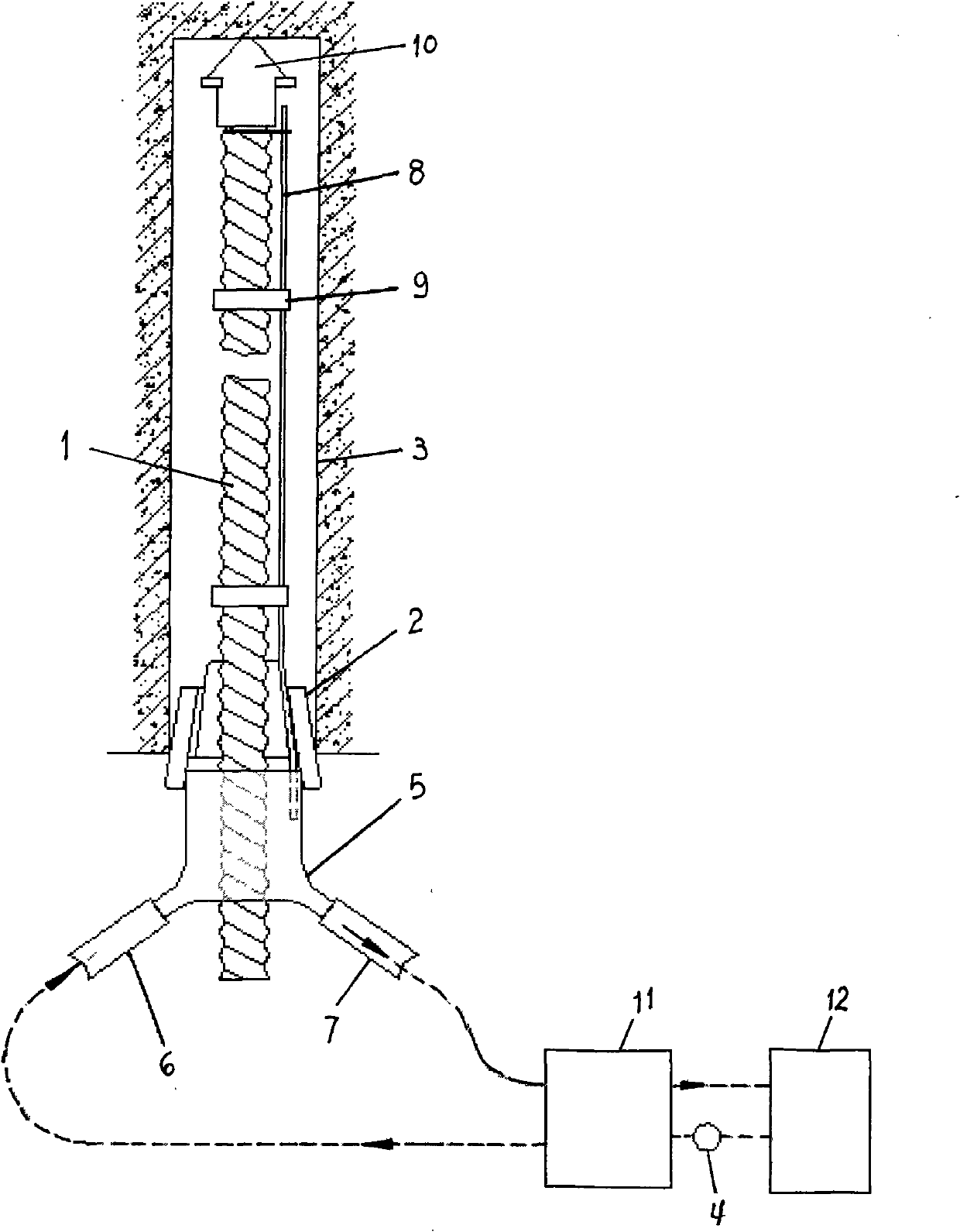

Method and device for fast measuring coal bed gas pressure through upward remote-distance hole drilling

InactiveCN103075148AReduce leakageShorten the stabilization timeSurveySealing/packingCement slurryHigh pressure

The invention relates to a method and a device for fast measuring the coal bed gas pressure through upward remote-distance hole drilling. According to the method, firstly, high-pressure grouting is carried out on each rock stratum under the coal bed to be tested through hole drilling, various cracks are blocked, then, the drilling is carried out into the coal bed, a four-way pipe is inserted, in addition, a capsule hole sealing device provided with a gas pipe, a grouting pipe and a water filling joint is connected to a position near a hole opening of the drilling hole, firstly, a manual pressure test pump is used for filling water into the capsule hole sealing device through a water filling joint so that the capsule hole sealing device is expanded, and the drilling hole is pre-sealed; then, a low-pressure hole sealing pump is connected with the grouting pipe, cement slurry is filled into the drilling hole, after the cement slurry overflows from the gas pipe through the four-way pipe, a pressure meter is connected onto the gas pipe arranged at the hole opening part, and the coal bed gas pressure can be measured. The method and the device can be used for measuring the upward coal bed gas pressure with the distance within 50m, the roadway engineering dug for coal bed gas pressure measurement can be reduced, the measuring equipment is simple, and the operation is simple and convenient.

Owner:CHINA UNIV OF MINING & TECH

Pressure-grouting construction method for structure consolidation

ActiveCN101139867AGuaranteed compactnessGuarantee the construction qualityBuilding repairsEngineeringPre treatment

The invention relates to a building construction method, in specific to a pressure grouting construction method for structural reinforcement in execution with a reverse operation method. The inveintion comprises the following steps: First of all, perform pre-treatment for reinforcement structural columns; then, make steel forms outside the structural columns, and open grouting ports and air exhausts on the form panels; meanwhile, connect a grouting device and a semi-U shaped tube on a secondary pressure device respectively with the grouting ports and the air exhausts; after the grouting is over and the grout material inside the steel form is initially hardened, the device grouting can fulfill secondary compression for the structural columns through arranging a hydraulic jack; thus, the invention can always guarantee certain pressure maintained on the grouting material during the period that starts with the beginning of grouting, and ends in the intial hardening of the grout material; meanwhile, the inventioin can also ensure compaction rate of the grouting material itself, and that of horizontal joints in vertical structural members. The invention adapts in particular to the following condition: In building reconstruction work, reinforcement is firstly executed from the center or top of structural members, so that it is not possible to perform concrete casting execution as usual from the top to the bottom of structural base layers.

Owner:SHANGHAI NO 7 CONSTR

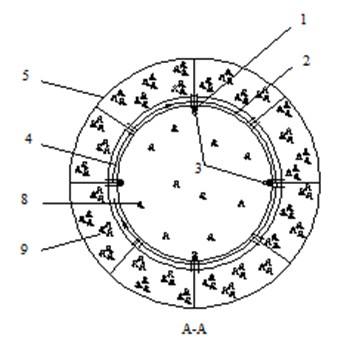

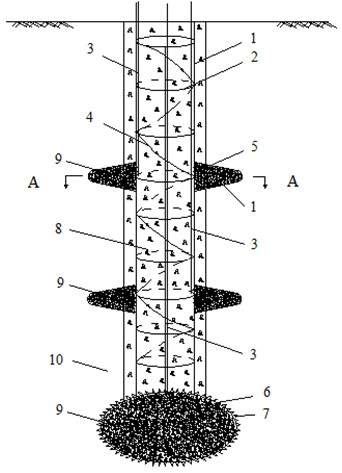

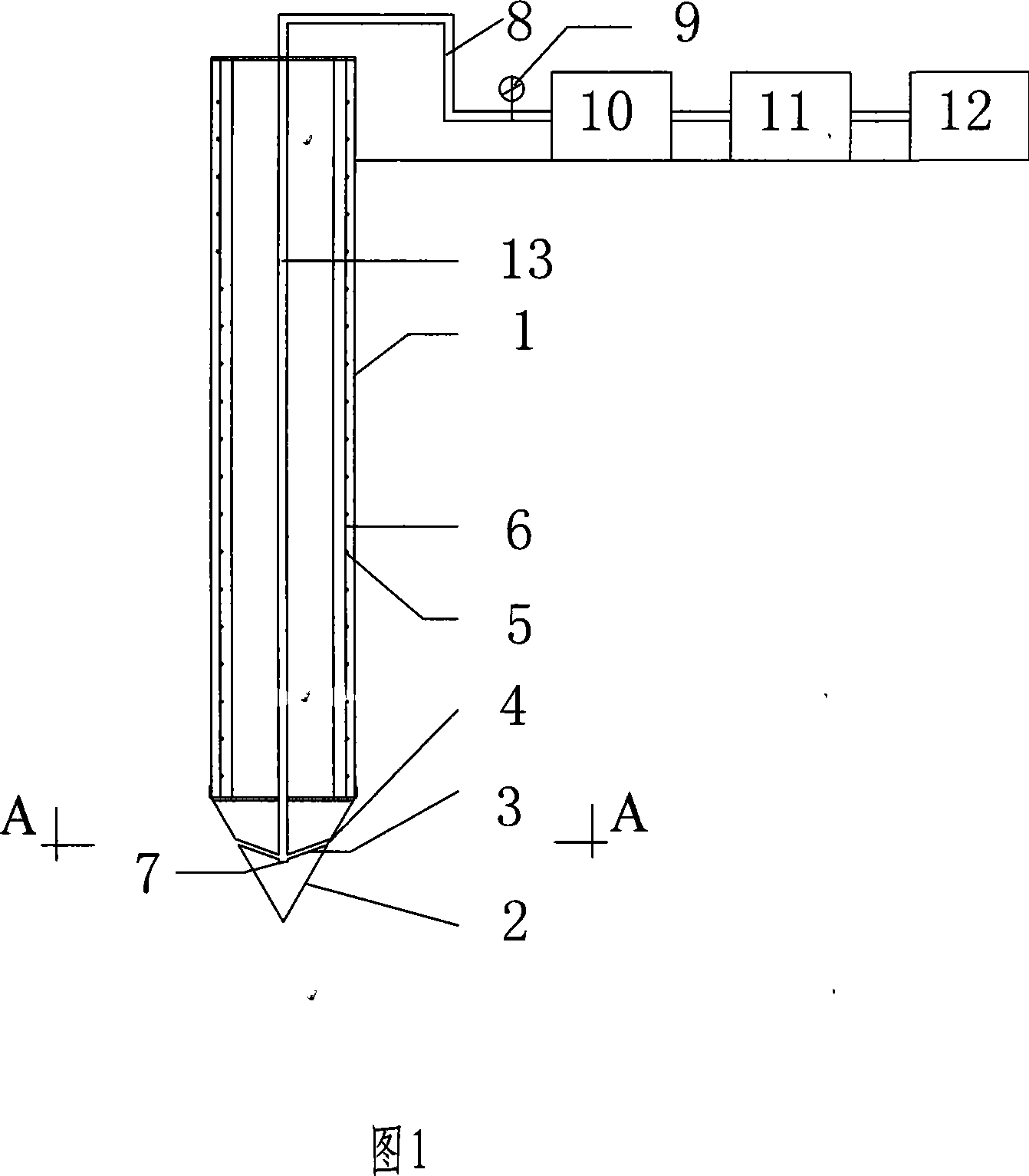

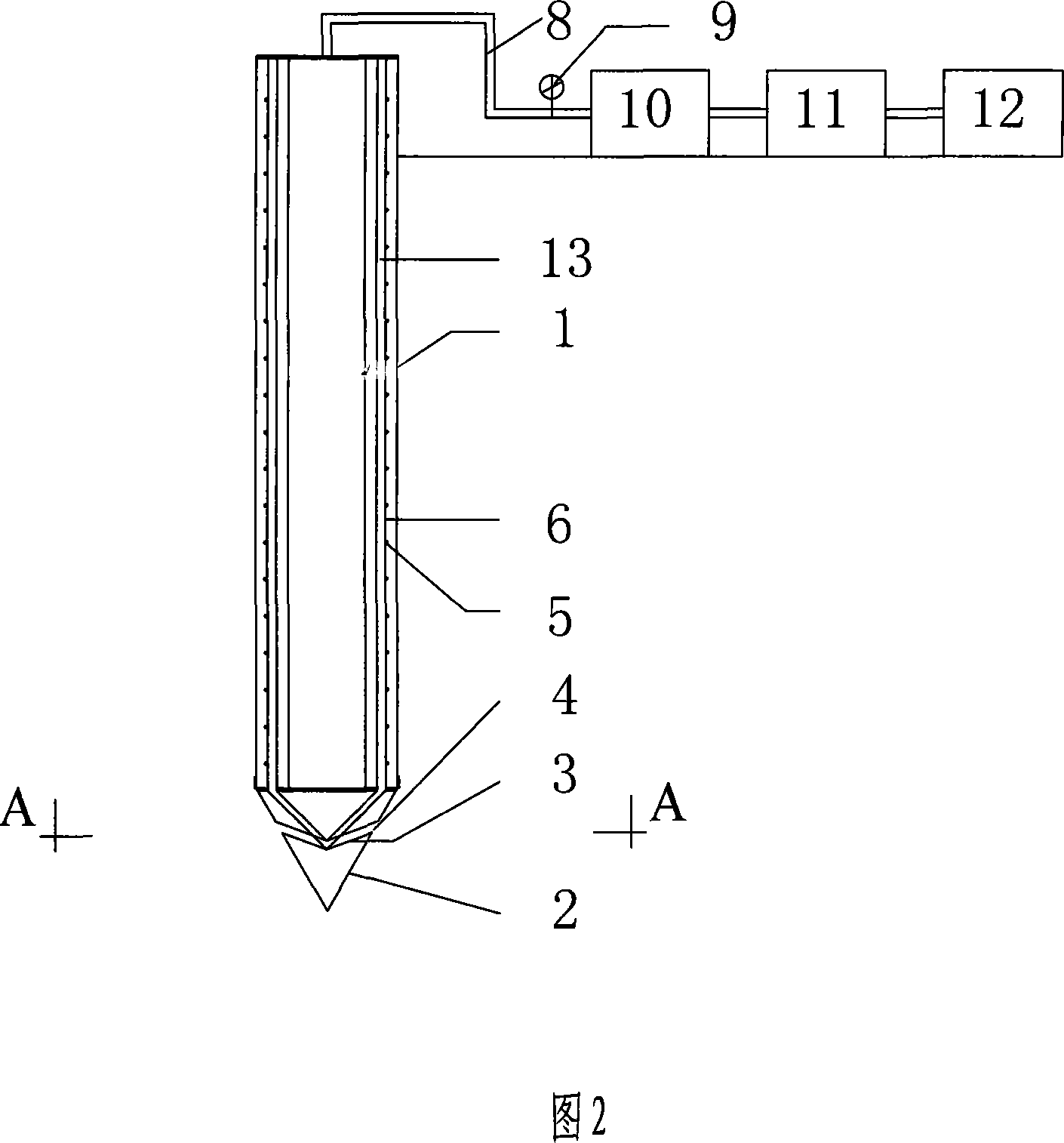

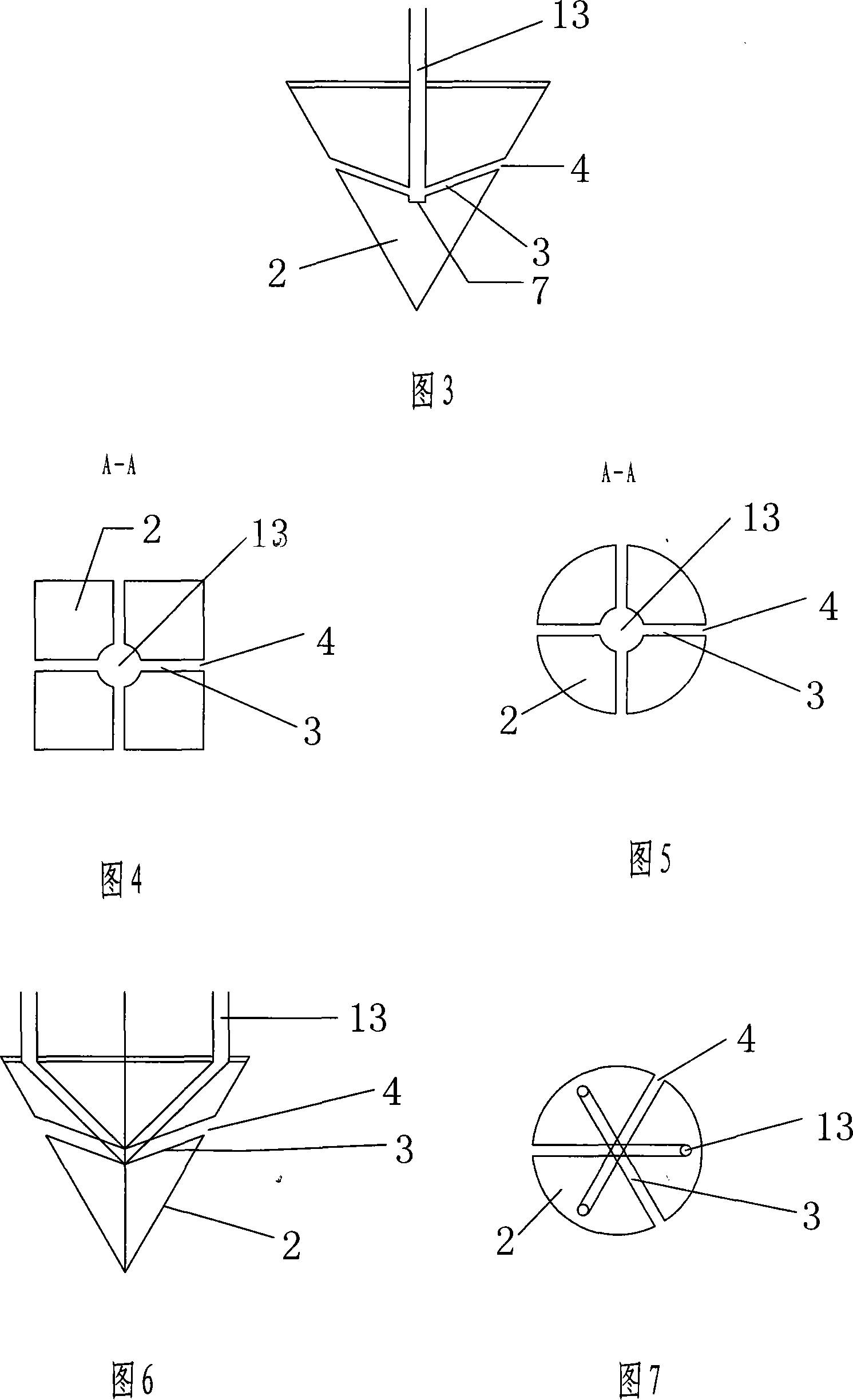

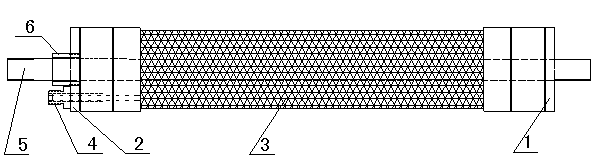

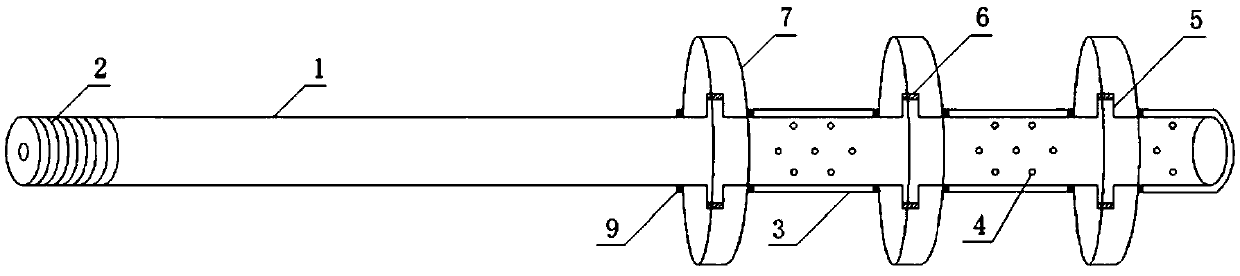

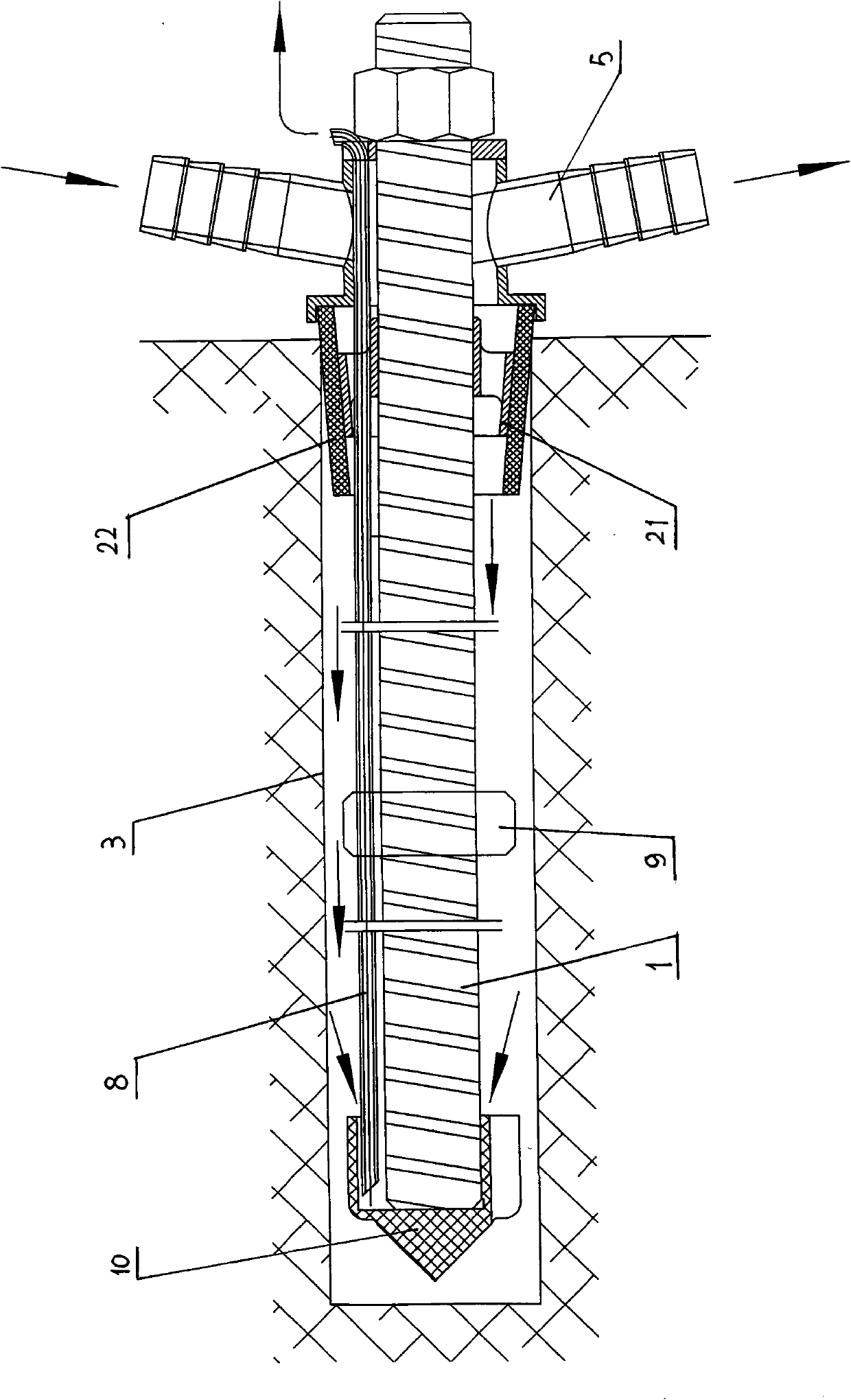

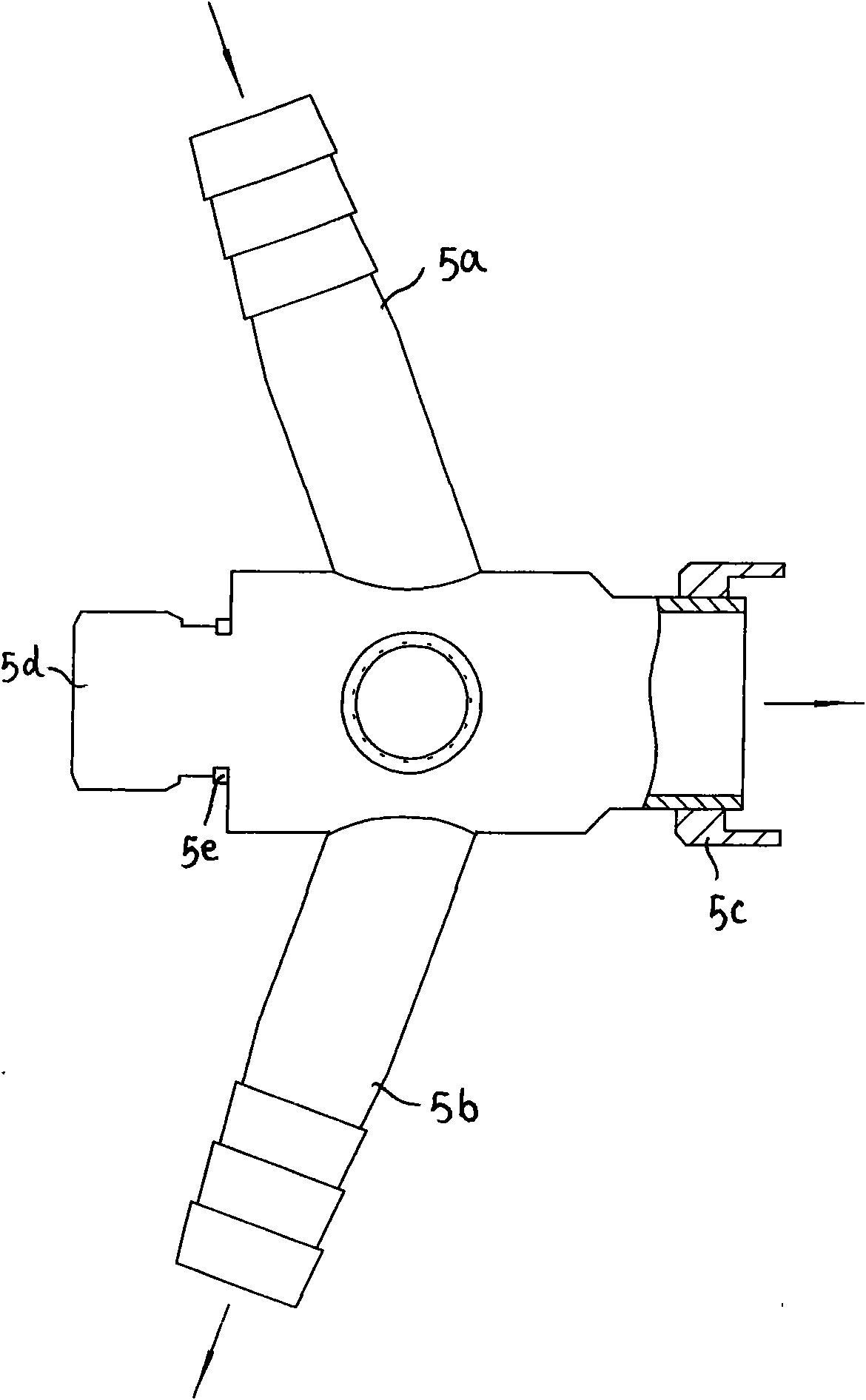

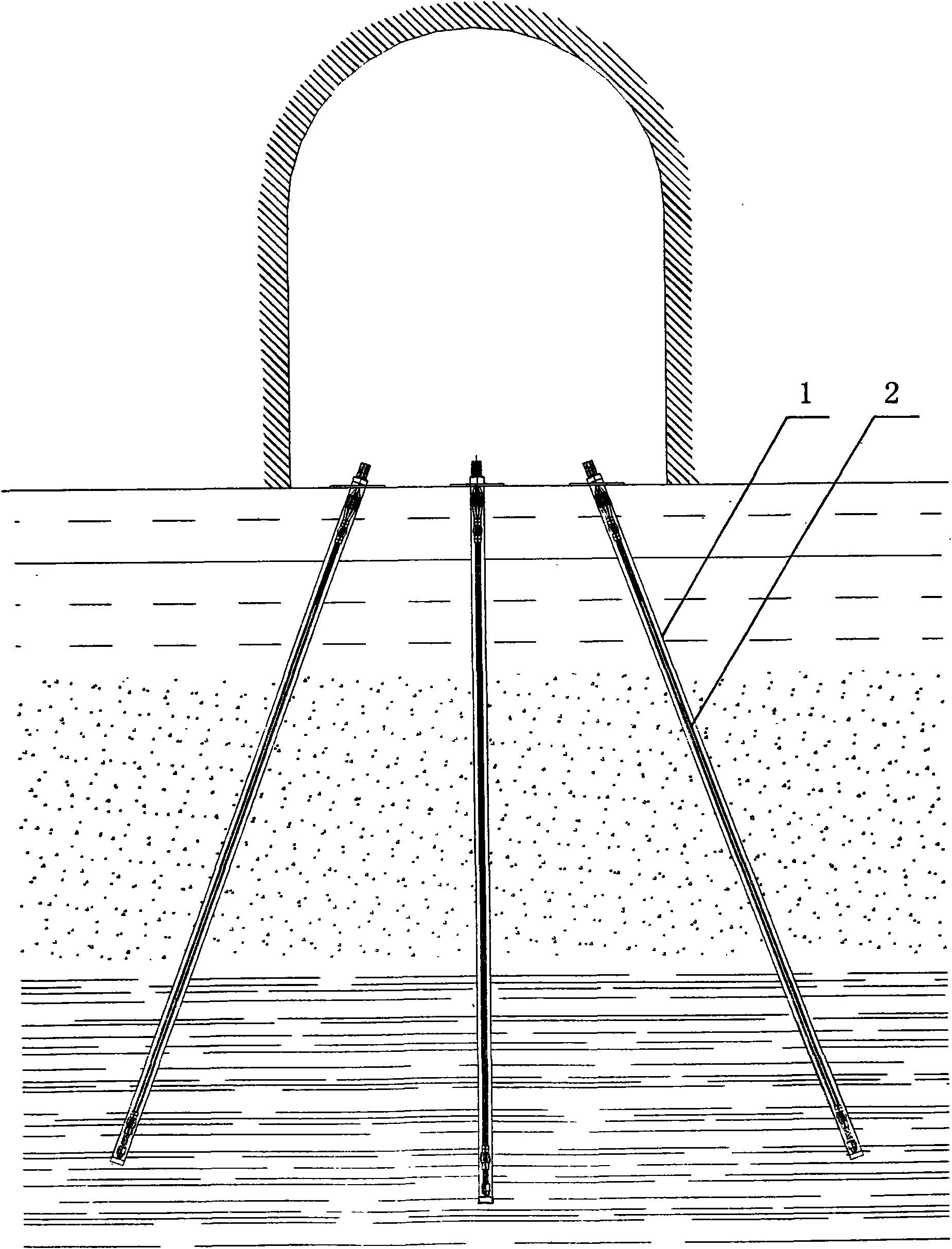

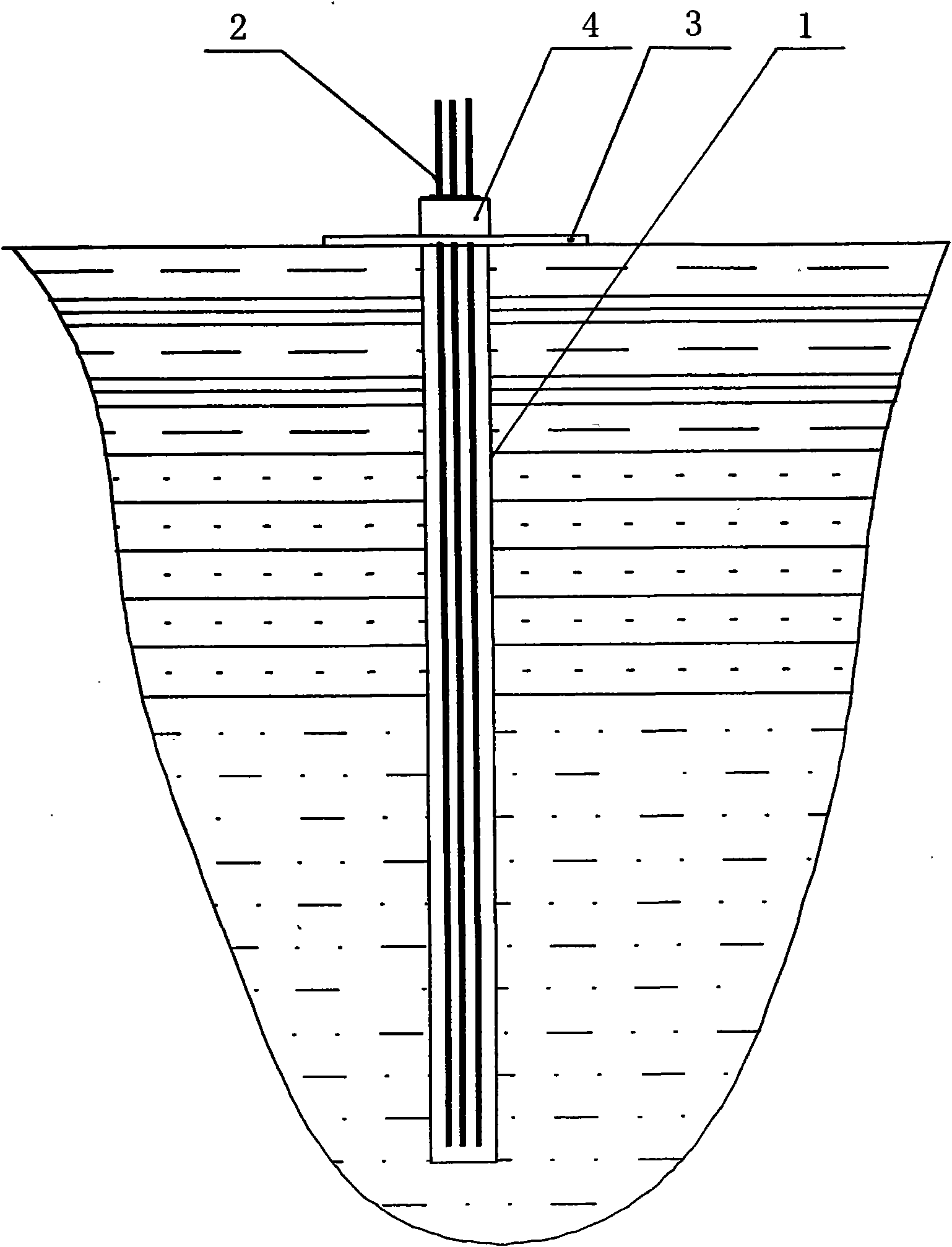

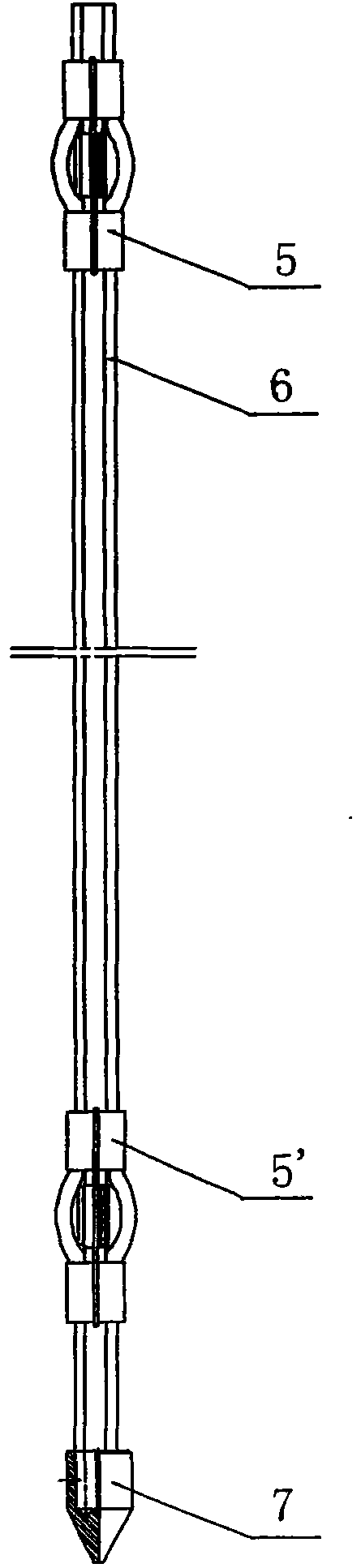

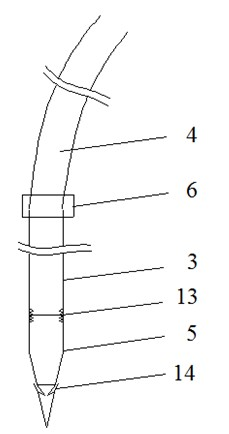

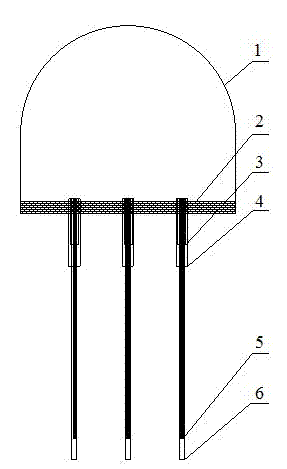

Pressure grouting device for overall length spiral anchor rod and construction process

InactiveCN101768966AConvenient and reliable pressure groutingNo loss of pulpBulkheads/pilesAnchoring boltsSlurryEngineering

The invention provides a pressure grouting device for an overall length spiral anchor rod and a construction process. The front end of the overall length spiral anchor rod is screwed with an anchor head; a pressure stop-grouting plug is formed by nesting a nylon inner plug with a rubber outer plug; the nylon inner plug is provided with a pressure grouting hole; an outlet of a pressure grout injector is connected with the bottom of the pressure stop-grouting plug; an outlet of a grout injector is connected with a grouting pipe and then connected with an inlet of the pressure grout injector; the outlet of the pressure grout injector is connected with a groove of the grout injector after passing through a return pipe; a decompression pipe is fixed on the anchor rod by a positioning central ring; micro-pores are distributed all over the decompression pipe; and an inner end of the decompression pipe stretches into the anchor head, and an outer end of the decompression pipe extends out of an anchor hole after passing through the pressure stop-grouting plug and the pressure grout injector. The device of the invention can conveniently and reliably realize the pressure grouting for an overall spiral mortar anchor rod and has the characteristics of no slurry loss, no slurry leakage and full grouting.

Owner:CHENGDU MODERN WANTONG ANCHOR TECH

Method for soft rock roadway grouting and full-length prestress baseboard anchor cable comprehensive support

The invention provides a method for soft rock roadway grouting and full-length prestress baseboard anchor cable comprehensive support. The method comprises the following steps: fixing one end of a prestress anchor cable in deep surrounding rock at a roadway baseboard by a grouting method; initially stretching so that the stretched anchor cable has a certain prestress; drilling and then carrying out high-pressure grouting within a full-length range; and after slurry is solidified, stretching the combined anchor cable once again into a design anchoring strength. The construction method can ensure the anchor cable has higher prestress within the full-length range, achieve active support of the anchor cable on a broken rock stratum, and effectively control deformation of the roadway baseboard.

Owner:HEBEI TONGCHENG MINING TECH

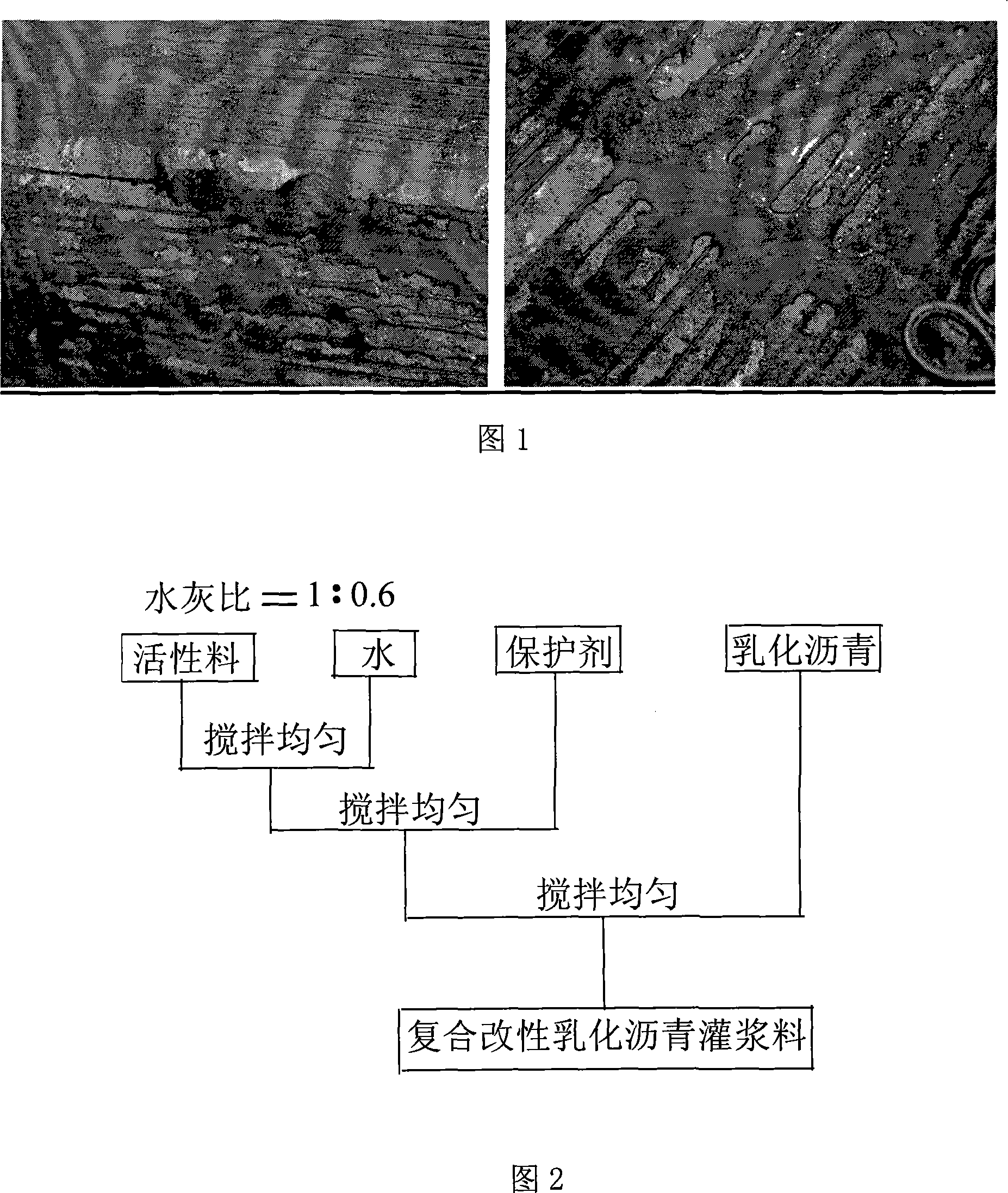

Environmental protection inorganic powder material and polymer composite modified emulsification asphalt grouting material

InactiveCN101148338AEasy to useAdhesiveSolid waste managementPolymer compositesUltimate tensile strength

The present invention is emulsified asphalt grouting material modified with inorganic powder and polymer. The modified emulsified asphalt grouting material may be filling and reinforcing grouting material comprising emulsified asphalt in 25-35 weight portions, inorganic powder in 65-75 weight portions and protecting agent in 10-20 weight portions; or waterproof grouting material comprising emulsified asphalt in 65-75 weight portions, inorganic powder in 25-35 weight portions and protecting agent in 10-30 weight portions. The modified emulsified asphalt grouting material has high grouting performance, high transmission capacity, no demulsification during pressure grouting, high binding with interface, high curing speed, excellent waterproof effect and other advantages. It may be applied for highway maintenance, foundation stabilization and waterproof engineering.

Owner:陈宪宏 +3

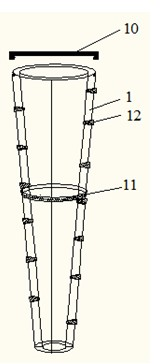

Polymer material grouted wedge precast pile technique

Disclosed is a polymer material grouted wedge precast pile technique. Grouting holes are reserved on the lateral wall of a prestressed wedged pipe pile, a polymer material is subjected to pressure grouting on the pile side and the pile ends, and accordingly bearing capacity of the pile side and the pile ends is improved. The polymer material for grouting is excellent in water proofing, and is small in size after swelled, the polymer material is quick in construction, strength improvement is quick, the dead weight of the polymer material is light, volume expansibility of the polymer material is high, and the problems of coagulation of cement slurry in a grouting pipe and the like are avoided. Compared with traditional prestressed pipe pile, the prestressed wedged pipe pile subjected to pressure grouting has improved bearing capacity of the pile side and the pile ends. By means of wedged angles, the form of pile-soil face contact is improved, and side friction of the pile is increased. By the polymer grouting technique compared with the traditional cement slurry grouting technical methods, expenditure and construction period can be reduced greatly, environment protection and energy conservation are benefited, and the quality is easier to control. The technique is simple in construction process, high in operability, convenient for quality control, evident in economic benefit and effective in soft soil foundation treatment.

Owner:HOHAI UNIV

Method for preparing geopolymer grouting material and method for applying geopolymer grouting material to static pressure grouting

ActiveCN106587782AReduce labor intensityLow viscosityCement productionRoads maintainenceSilica fumeSodium silicate

The invention provides a method for preparing a geopolymer grouting material and a method for applying the geopolymer grouting material to static pressure grouting. Raw materials for preparing the geopolymer grouting material include steel slag, mineral slag, sodium silicate, silica fume, calcium bentonite, softened water and a composite alkali activator. The method for preparing the geopolymer grouting material comprises the steps that 1, a component A is prepared; 2, a component B is prepared; 3, a component C is prepared; and 4, the geopolymer grouting material is prepared. The method for static pressure grouting comprises the steps of 1, survey; 2, assessment; 3, pit sounding; 4, hollowing general survey; 5, deflection value check; 6, comprehensive evaluation; 7, measurement and hole arrangement; 8, drilling; 9, grouting; 10, check; 11, grouting hole sealing; and 12, recheck to complete static pressure grouting. The methods have the advantages of environmental friendliness, low viscosity, high elasticity modulus, high cohesiveness, low cost, high efficiency and high durability.

Owner:中能化江苏矿山生态研究院有限公司

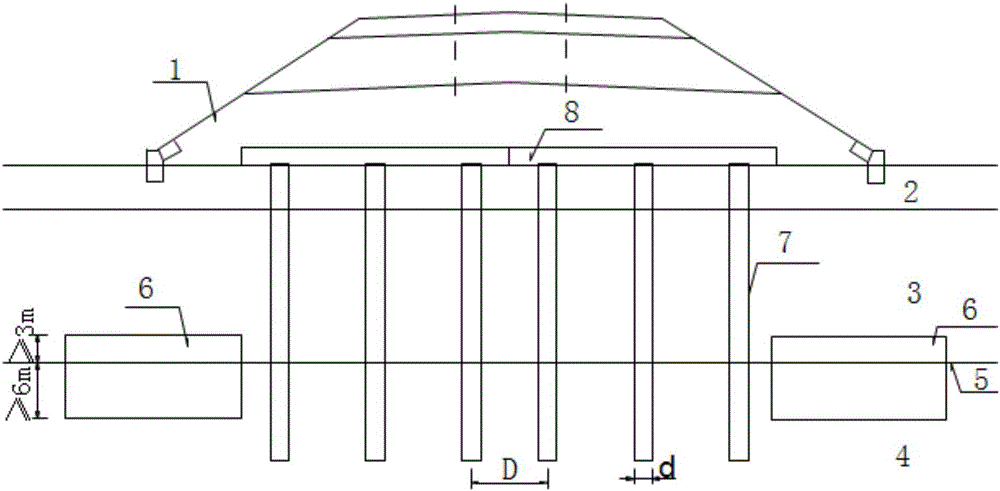

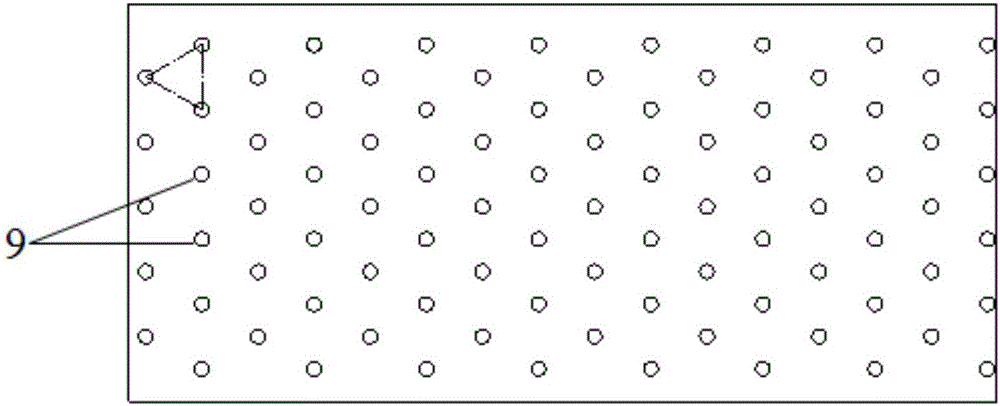

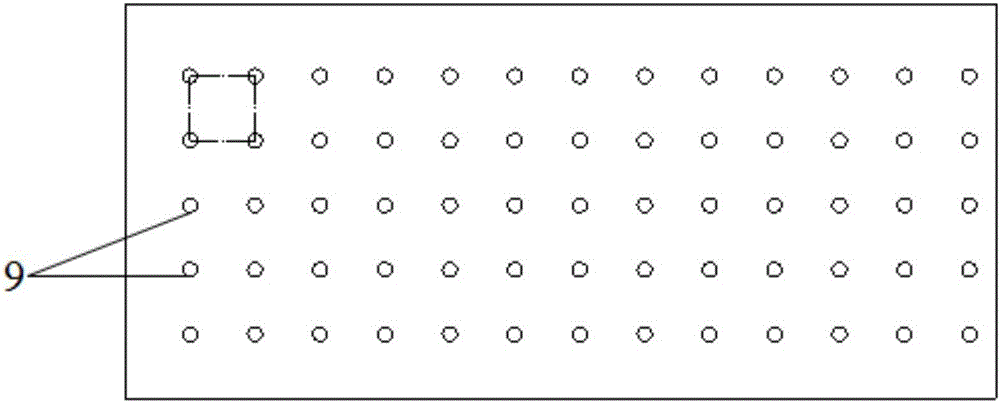

Construction method for reinforcing newly-built railway karst foundation and roadbed structure thereof

ActiveCN105696427AImprove bearing capacityDelay uneven settlementRailway tracksBulkheads/pilesReinforced concreteKarst

The invention discloses a construction method for reinforcing a newly-built railway karst foundation and a roadbed structure thereof. The construction method comprises the steps of longitudinally constructing a plurality of rows of cast-in-situ bored piles along the railway line, wherein the cast-in-situ bored piles are formed through pouring reinforced concrete on site; longitudinally paving a plate girder prefabricated through reinforced concrete along the railway line above the cast-in-situ bored piles and at the top of a soft soil layer, wherein the tops of the cast-in-situ bored piles and the bottom of the plate girder are fixedly connected to form a pile plate structure; carrying out pressure grouting on the connection part of a hard soil layer and a karst layer of the karst foundation on the two sides of the pile plate structure, so as to form a longitudinal continuous grouting reinforcement zone along the railway line; and when the grouting reinforcement zone solidifies, paving a roadbed at the top of the plate girder. According to the roadbed structure provided by the invention, the karst foundation and an upper soil covering layer are reinforced, so that the foundation bearing capacity is improved, and the post-construction settlement of the roadbed is effectively controlled.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

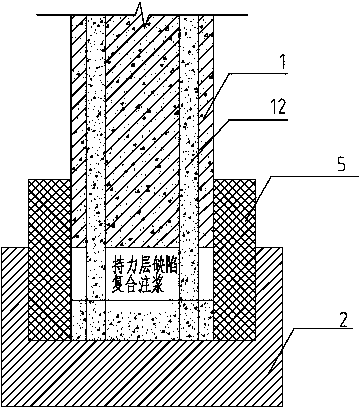

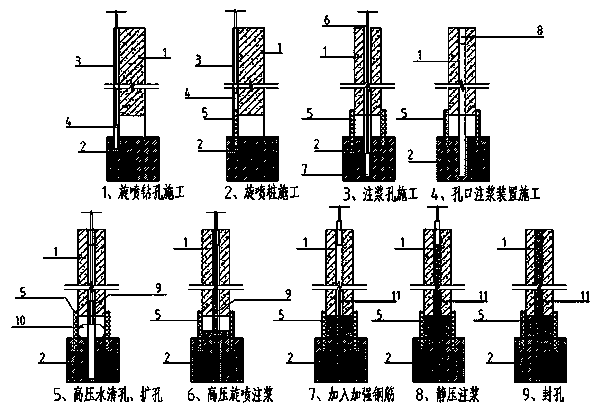

Pile foundation combined grouting reinforcement construction method combining waterproof curtain

ActiveCN103806479AIt has the function of preventing water and sandAvoid cutting large holesFoundation repairBulkheads/pilesArchitectural engineeringRebar

The invention discloses a pile foundation combined grouting reinforcement construction method combining a waterproof curtain. The method comprises the first step of jet grouting pile drilling construction, the second step of jet grouting pile construction, the third step of jet grouting pile hole separation construction and waterproof curtain forming, the fourth step of pile body grouting and drilling construction, the fifth step of orifice grouting device building, the sixth step of pile foundation reinforced position cleaning and chambering, the seventh step of grouting through a high pressure jet grouting mode, the eighth step of reinforcing steel bar adding in grouting holes and the ninth step of grouting in a static pressure grouting mode. According to the method, the waterproof curtain formed by jet grouting piles and the combined grouting method with a static pressure grouting method and a high pressure jet grouting technology combined in a timing sequence are combined, the respective advantages of the waterproof curtain and a combined grouting technology are achieved fully, the respective defects of the waterproof curtain and the combined grouting technology are overcome to carry out the pile foundation reinforcing construction, therefore, the maximum stratum applicability and the optimal reinforcing effect are achieved, and reinforcing reliability and success rate are guaranteed.

Owner:GUANGDONG JIANKE CONSTR ENG TECH DEV CO LTD

Full-displacement pressure grouted pile system and method

An auger bit is provided for a foundation pile system including a drilling rig adapted for mounting and rotating a grout pipe connected to the auger bit to form an auger. The auger bit includes a stem with lower and upper sections, which taper towards a transition whereat the stem has a maximum diameter. A pile foundation forming method includes the steps of providing a drilling rig, forming an auger with a grout pipe coupled to an auger bit, rotating the auger wit the rig, forming a borehole with laterally displaced soil, pumping pressurized grout through the auger and into the borehole, placing a reinforcing cage in the wet grout and curing same.

Owner:BERKEL & CONTRACTORS

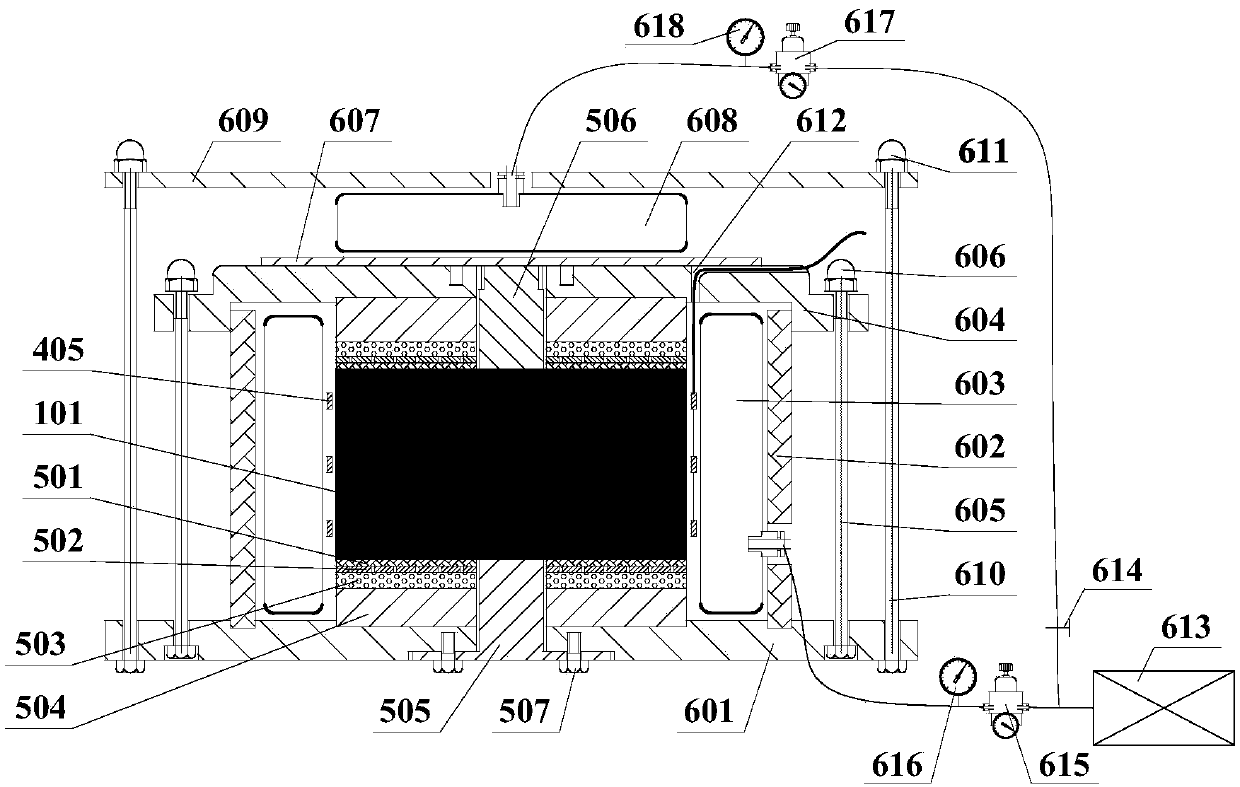

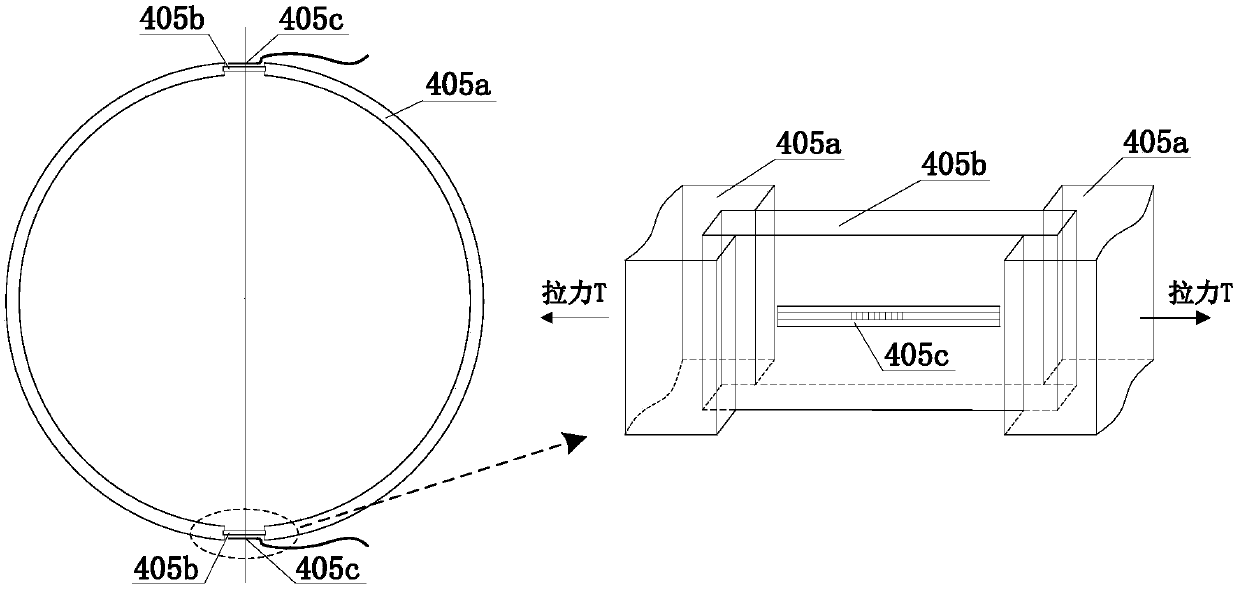

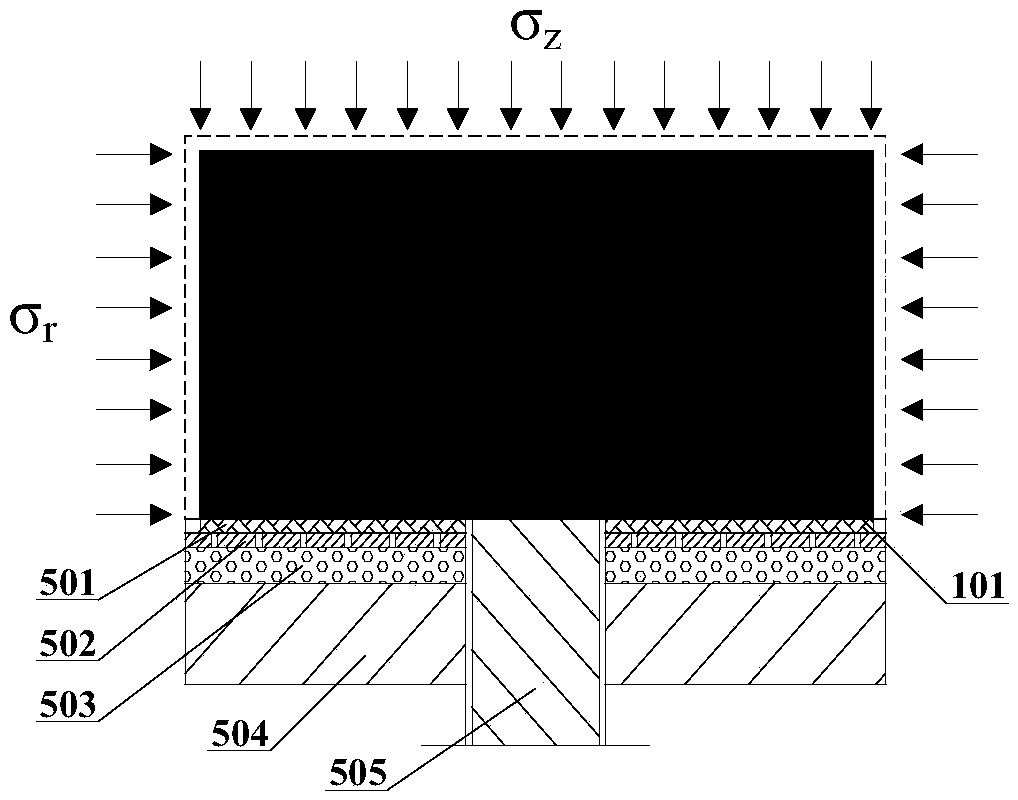

Test method and system for simulating bonding property between rock-soil and anchor under formation pressure

ActiveCN109540788AAccurate monitoring of radial deformationUniform radial deformationUsing mechanical meansMaterial analysisExhaust valveFriction effect

The invention discloses a test method and system for simulating bonding property between undisturbed rock-soil and an anchor under formation pressure. The test system comprises: a measuring device, asample fixing device, a formation pressure simulating device, and a pressure grouting device. Pressure bladders are mounted on the side surface and the top surface of a sample, respectively. A radialdeformation gauge is mounted on the outside of the sample. One ends of a grouting plug and a stopping plug are topless conical shapes. An exhaust valve is provided on the bottom of a support beam. Thetest system can perform pressure grouting on the sample and monitor the radial deformation. The dual pressure bladder can apply pressure to the lateral and vertical directions of the sample to simulate formation pressure. The silicone gasket and the perforated steel sheet are placed on the upper surface and below surface of the sample to eliminate the end friction effect. The rock / soil was compressed and restored to the initial formation pressure to limit the vertical deformation of the sample. The stress state, the stress path, and the preparation process of the sample are consistent with the actual situation of the anchor, which is suitable for the test of the bonding property between the rock-soil and the anchor under various working conditions.

Owner:HUNAN UNIV

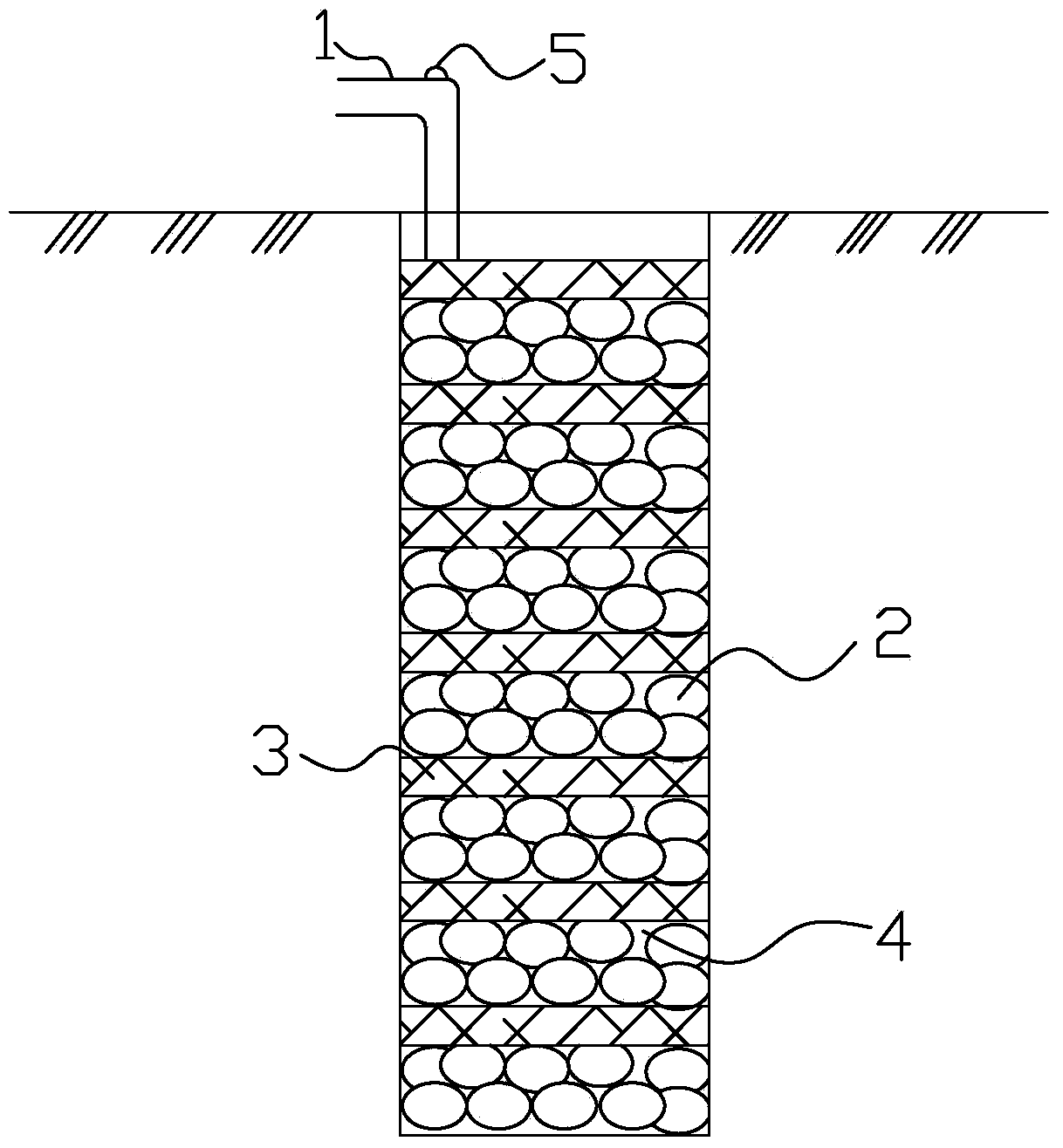

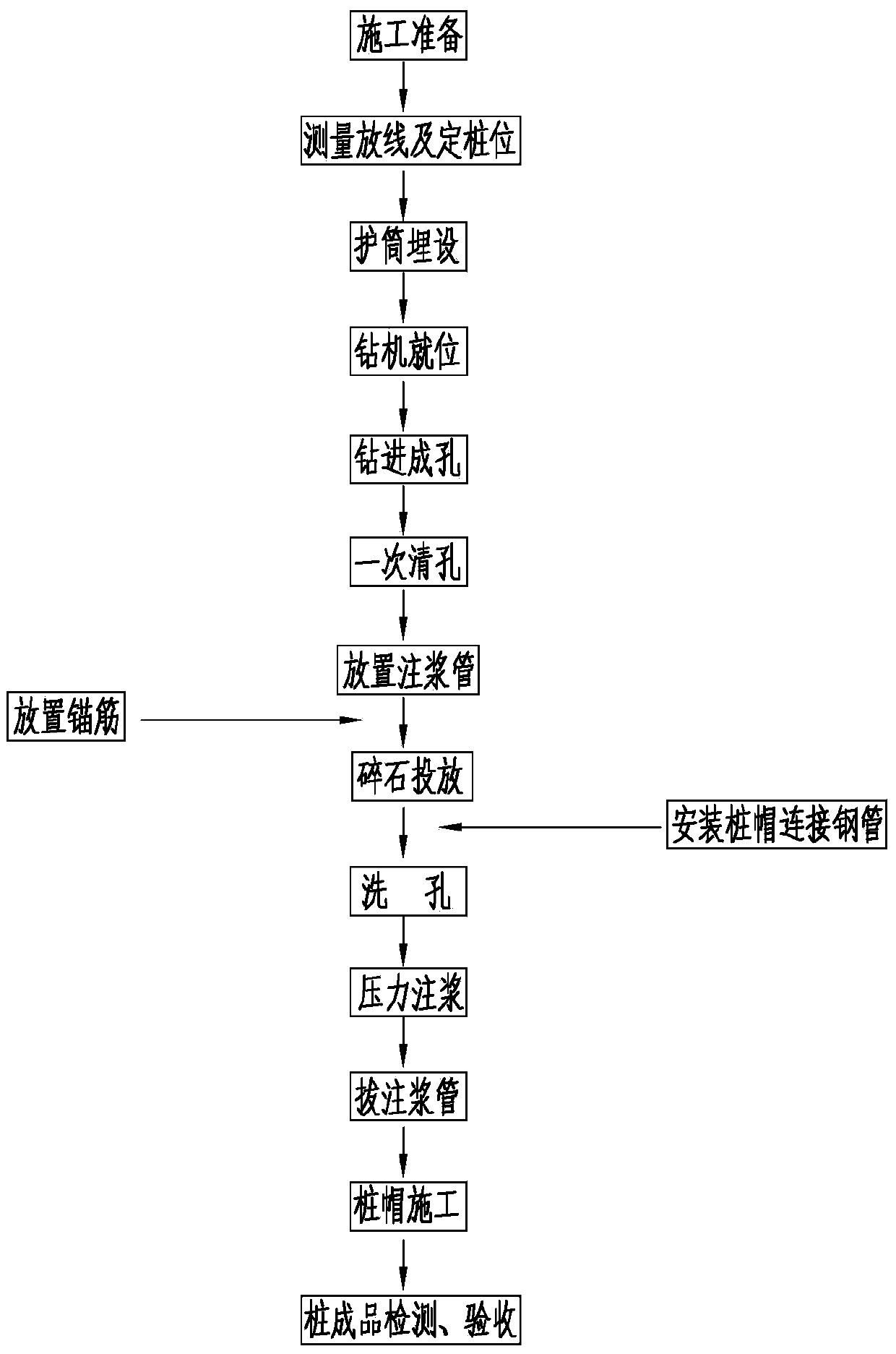

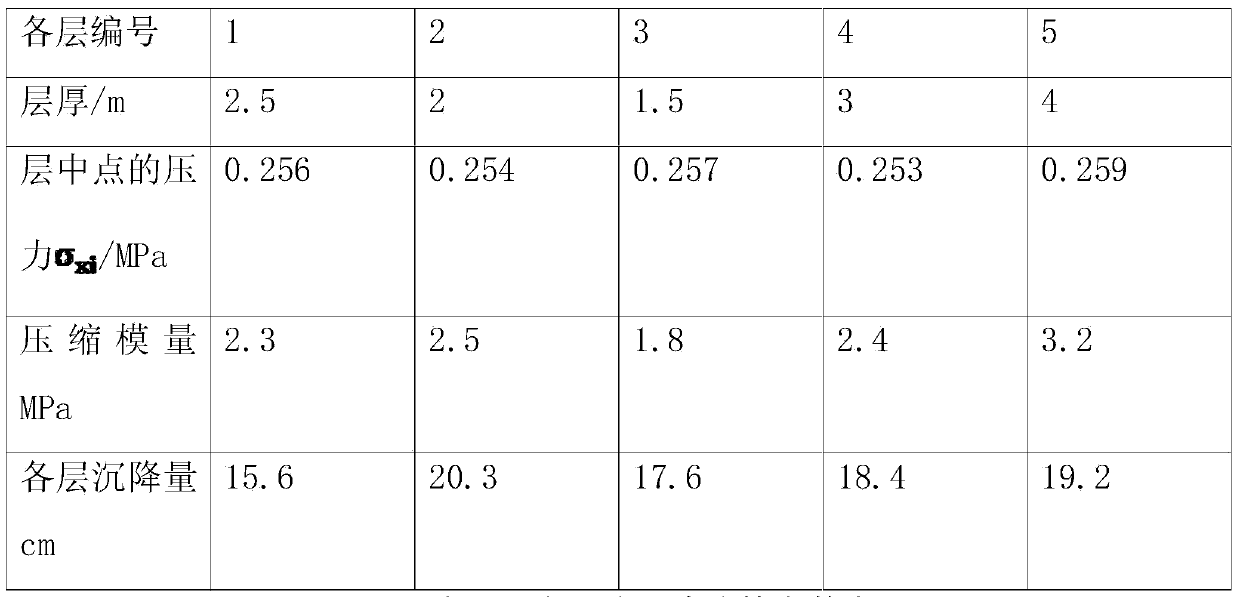

Construction method of gravel grouting pile

The invention discloses a construction method of a gravel grouting pile. The construction method comprises the following steps: (1) preparing for construction, (2) conducting measurement, paying off and positioning of the pile, (3) embedding a protective canister, (4) placing a drilling machine in place, (5) forming a hole by drilling, (6) cleaning the hole at a time, (7) placing a grouting pipe, (8) placing an anchor bar, (9) putting gravels in the hole, (10) installing a pile cap connecting steel pipe, (11) cleaning the hole, (12) conducting pressure grouting, (13) pulling the grouting pipe out, (14) constructing a pile cap, and (15) conducting detection and acceptance inspection on the finished pile. According to the construction method of the gravel grouting pile, the construction speed is high, the construction period is shortened, and compared with soft foundation treatment such as a prestressed pipe pile and a Y-type pile, the engineering investment is saved; the labor intensity is low, the construction is safe, and the construction method can be widely popularized and used; the gravel pile formed by cement and gravels is high in integrality and stability. The engineering drilling machine is adopted in a soft foundation to drill the hole in a rotating and cycling mode to form the pile, the disturbance to the foundation and the surrounding buildings is small, ground depression is controlled, and the construction method is small in vibration and low in noise during the construction and has good social benefits.

Owner:NINGBO SHENGHONG CONSTR ENG

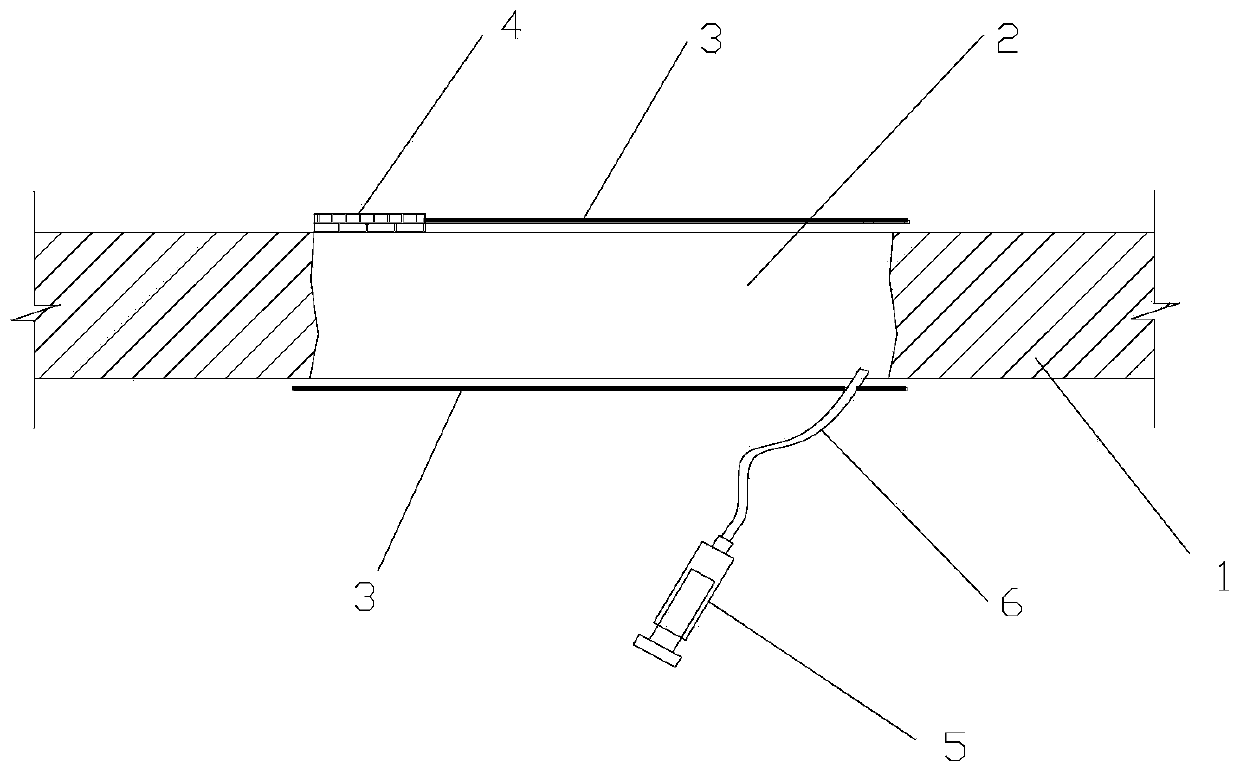

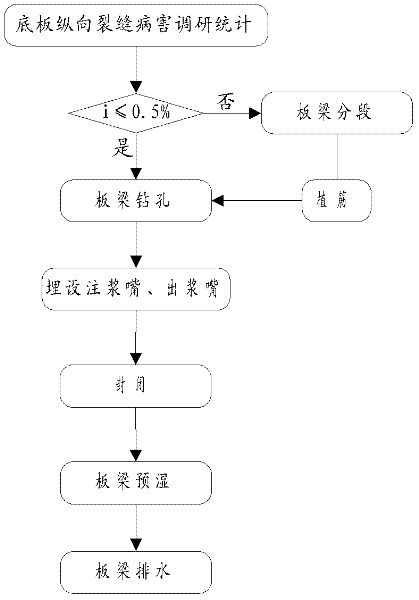

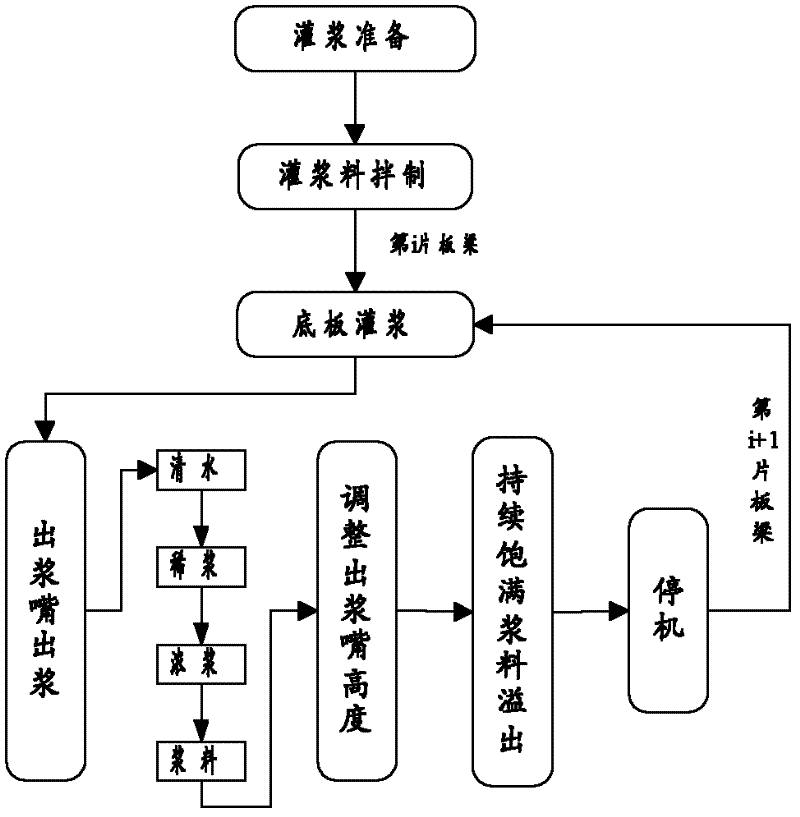

Vertical crack grouting and reinforcing method of prestressed concrete hollow slab bridge bottom plate

ActiveCN102392420AReduce transverse tensile stressImprove the forceBridge erection/assemblyBridge strengtheningPre stressPrestressed concrete

The invention provides a vertical crack grouting and reinforcing method of a prestressed concrete hollow slab bridge bottom plate. According to the method, pressure grouting equipment is mainly adopted to pour a cement-based grouting material into a prestressed concrete hollow plate cavity with a certain thickness, wide, deep and long vertical cracks on the bottom plate can be actively sealed fundamentally through effective adhesion of the grouting material and bottom plate concrete, thereby preventing leakage water inside plates and steams, as well as steam and harmful media and the like in air from entering the cracks to result in rust corrosion and breakage of prestressed steel stranded wires, and further improving the durability and safety of a bridge structure.

Owner:刘其伟

Step-by-step strengthening method by anchoring and forming hole in downward sleeve of cracking medium

InactiveCN102900446ASolve the problem of collapsed holesSmall overall deformationSealing/packingAnchoring boltsSlurryMechanical engineering

The invention relates to a step-by-sep strengthening method by anchoring and forming a hole in a downward sleeve of cracking medium. According to the strengthening method, a hollow grouting anchor rope of a related large-aperture pretension bottom plate comprises a fastening section A, a grouting section B and an anchoring section C, and the strengthening method mainly aims at solving the difficulties that holes are not easy to form in a weak and broken roadway bottom plate, a hole forming wall is poor in stability and suffers from hole collapse easily, and the bottom plate is difficult to anchor and strengthen. According to the strengthening method, the large-aperture wall protecting sleeve at the shallow part is grouted, so that the problems of hole collapse of the hole wall is solved, meanwhile high-flow high-pressure grouting is realized, the grouting time is saved, the slurry dispersion range is enlarged, a whole support structure is formed by utilizing a grouting anchor rope and a steel beam, the anchoring and the common loading of the anchor rope are realized simultaneously when a cracking rock body is grouted for fixing, and the great deformation of the bottom plate is solved effectively, and in addition, according to the method, the construction is easy, the operation is simple and convenient, the effect is obvious, the safety and the reliability are realized, and wide practicability is achieved.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com