Patents

Literature

771 results about "Radial deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

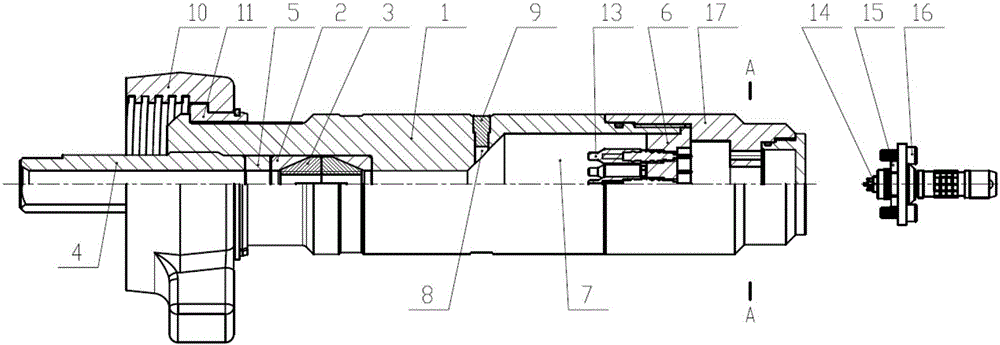

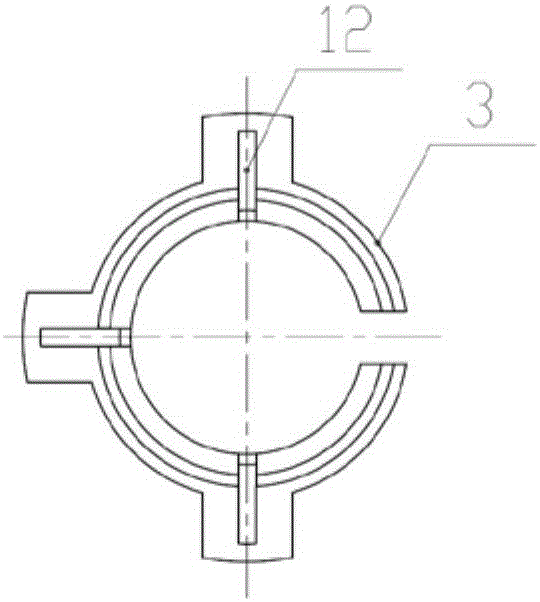

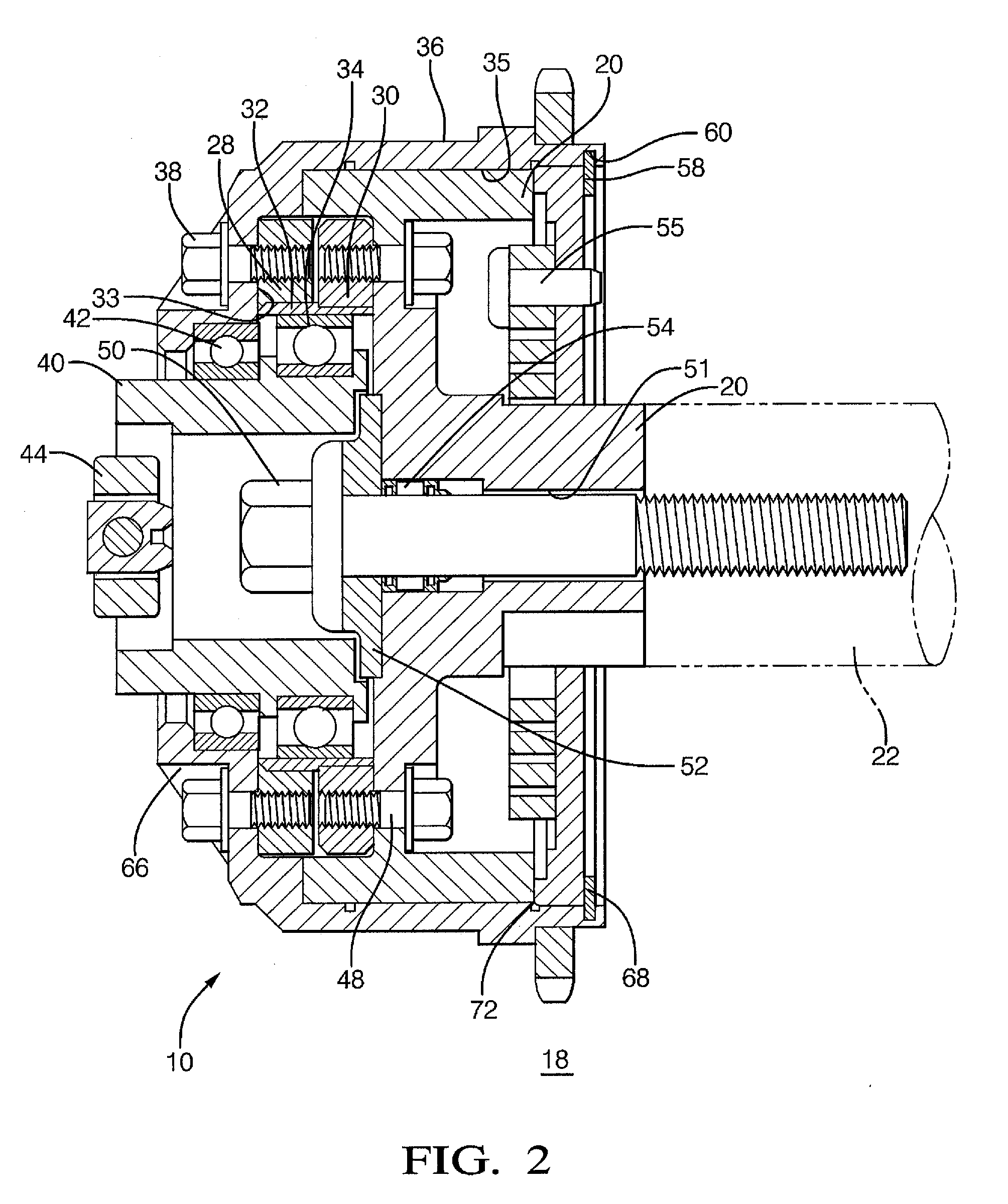

Mine cable hanger

InactiveCN106121577AAchieve suspension fixationLarge amount of deformationDrilling rodsSealing/packingEngineeringMechanical engineering

The invention discloses a mine cable hanger which comprises a main body; fixing components are mounted in an inner cavity of the main body, and comprise slip bowls and slip elements mounted on the slip bowls; a fastening push rod for pushing the fixing components to move axially is mounted in the inner cavity of the main body; the cross sections of the slip elements are C-shaped; and a plurality of gaps are axially formed in the slip elements. According to the mine cable hanger, the slip elements or the slip bowls are pushed to move through the fastening push rod, the slip elements generate radial deformation through the mutually contacted wedge surfaces of the slip elements and the slip bowls, cables in the slip elements are surrounded and locked, and the hanging fixing of the cables is realized. The slip elements are C-shaped and formed openings increase the deformation amounts of the slip elements, and the gaps improving the deformation are additionally formed in the slip elements, so that the deformation degree of the slip elements is further raised, the slip elements can hold the cables to a greater extend, a locking force is increased, and the fastness of the hanging fixing is improved.

Owner:JEREH ENERGY SERVICES

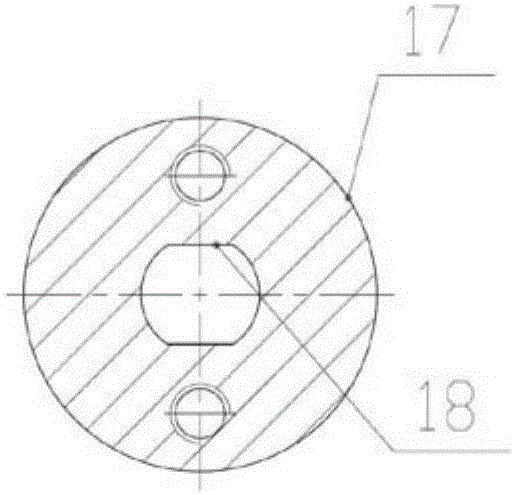

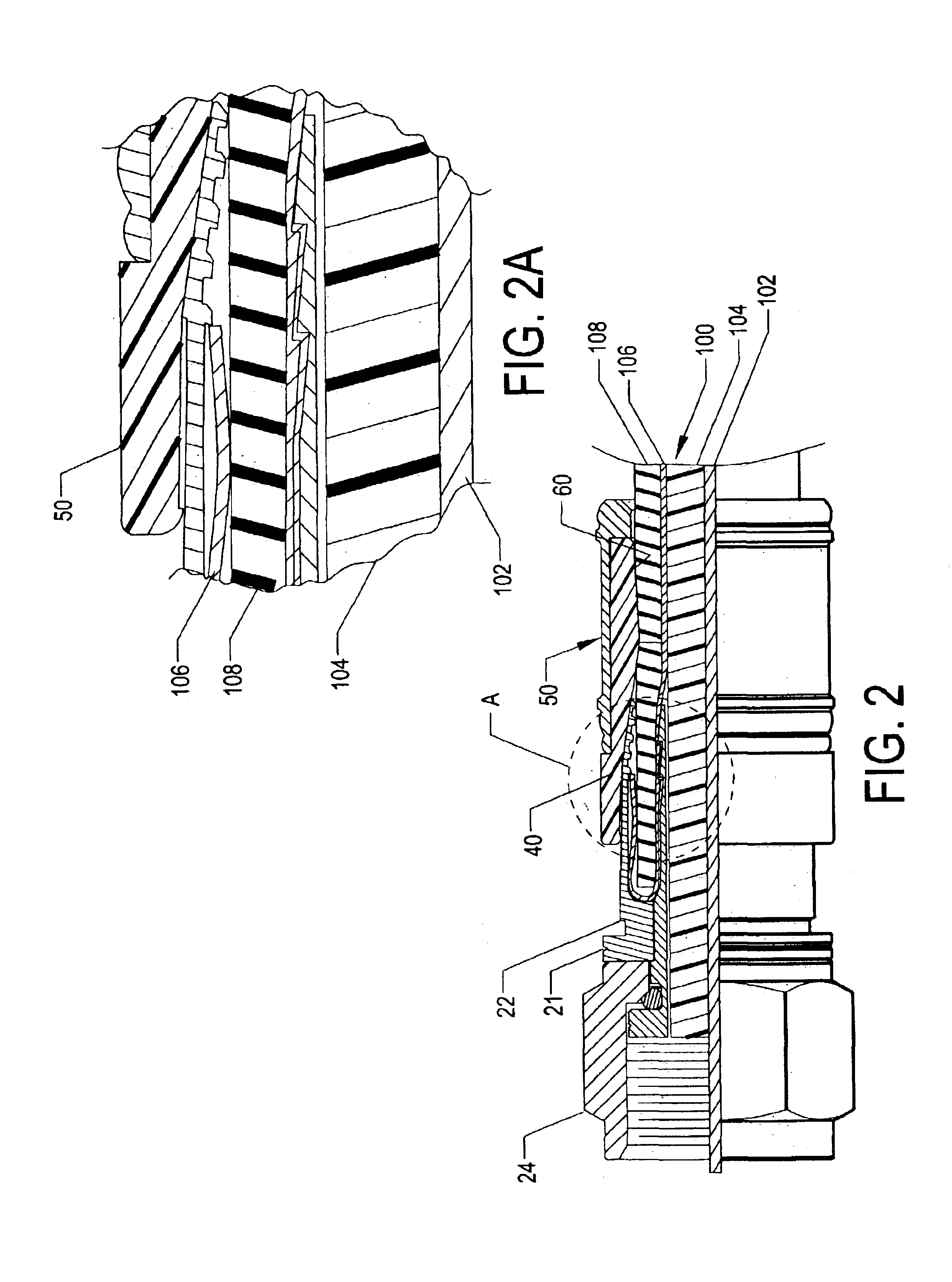

Universal crimping connector

InactiveUS6830479B2Simple wayElectrically conductive connectionsTwo pole connectionsCoaxial cableEngineering

A coaxial cable TV connector is made up of one or more crimping members having inner tapered surface portions which are preassembled onto a crimpable sleeve member of a connector body, the sleeve having an external tapered portion into which the coaxial cable is inserted so that the crimping ring(s) can be preassembled onto the sleeve and axially advanced to cause inward radial deformation of the sleeve into sealed engagement with an outer surface of the coaxial cable, and each size of connector assembly is conformable for use with more than one size of cable.

Owner:PPC BROADBAND INC

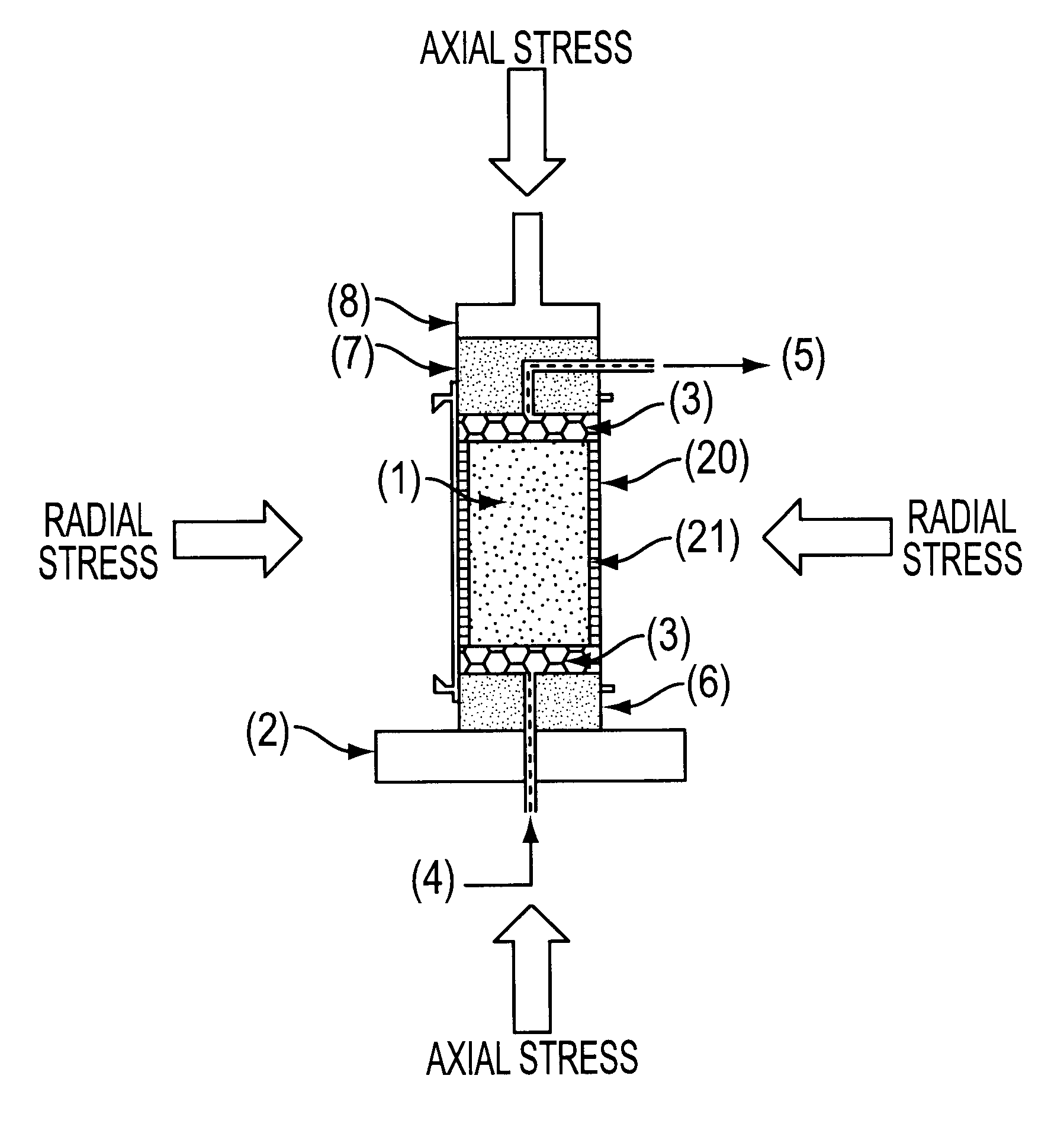

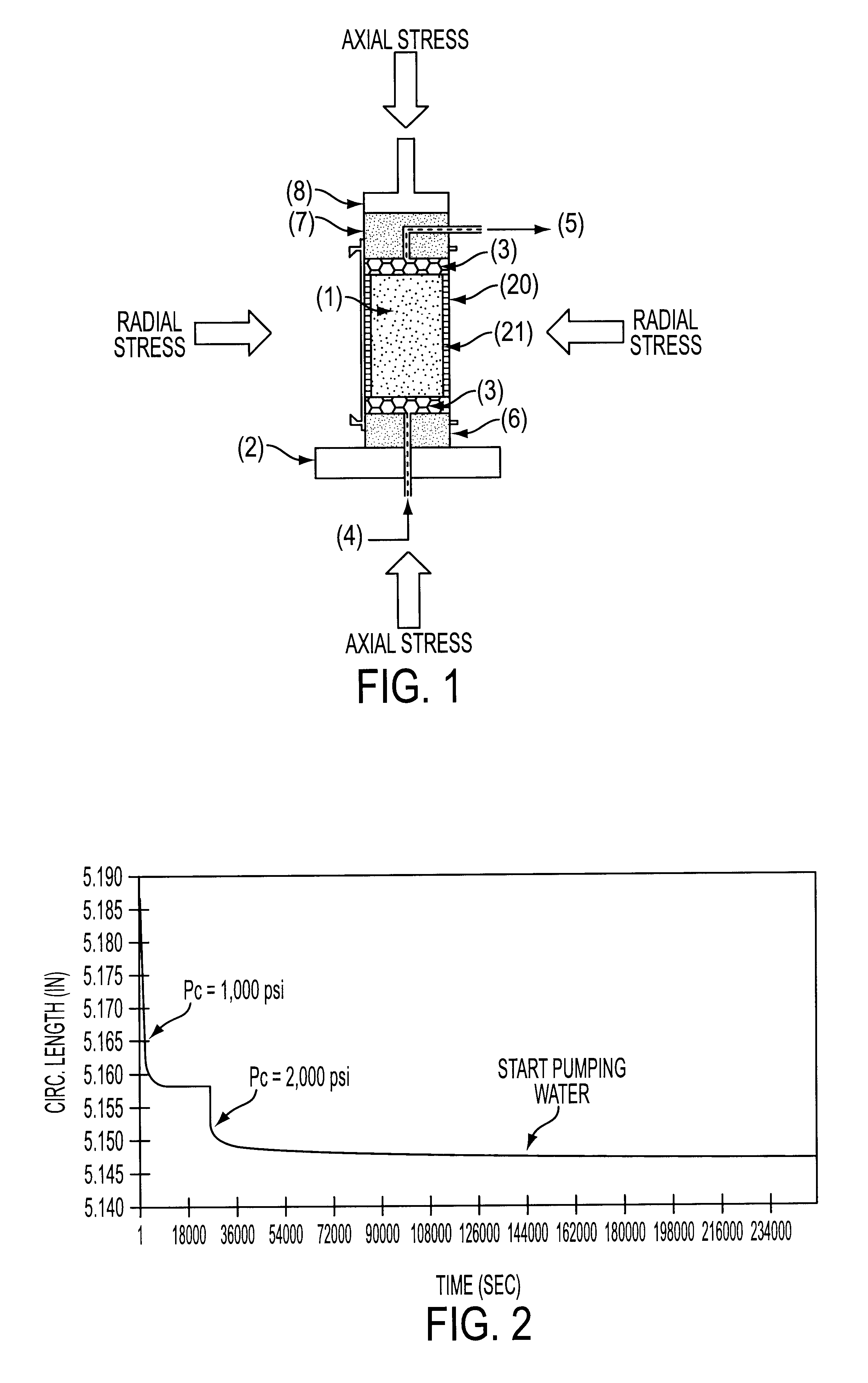

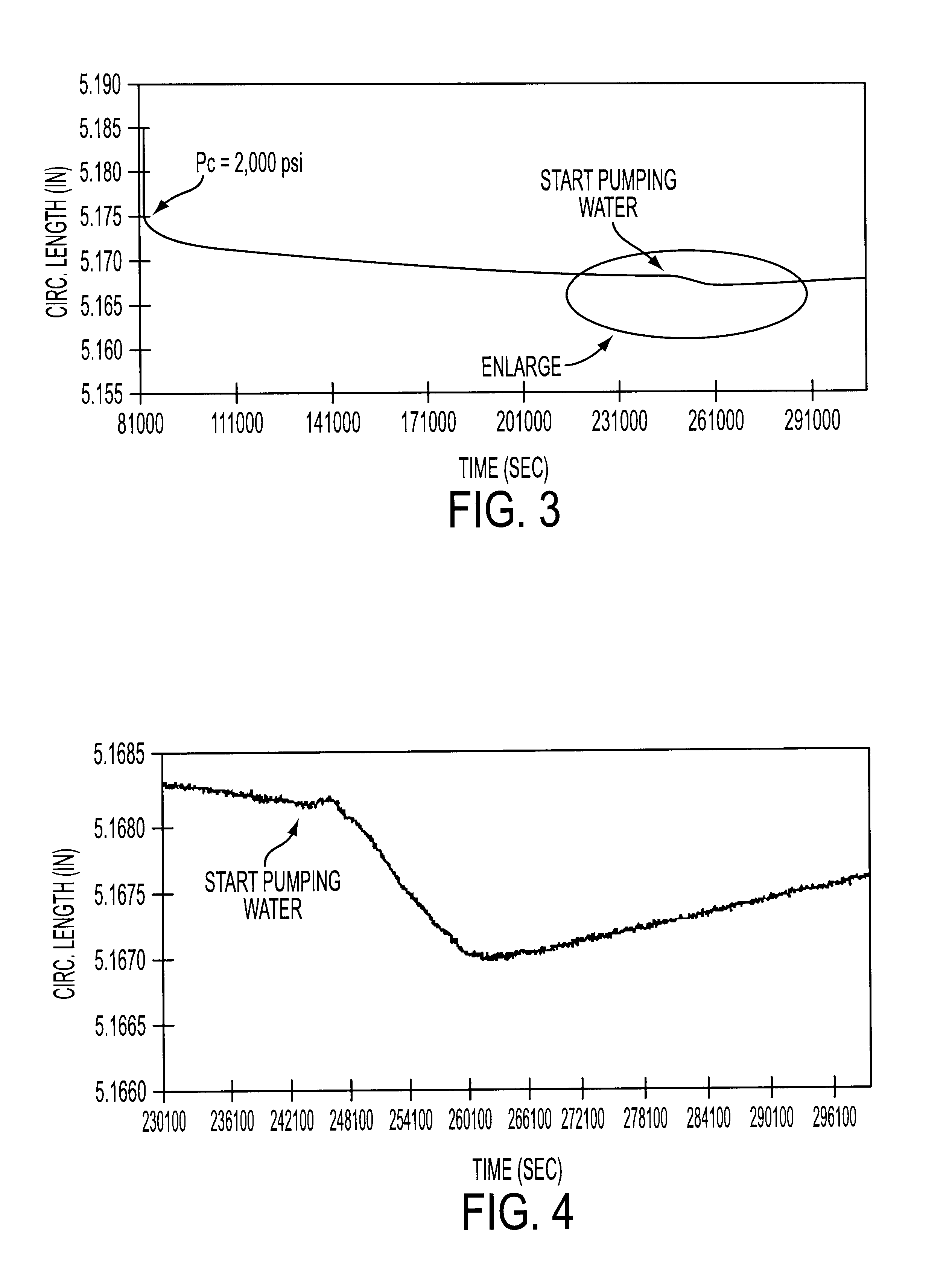

Method for the evaluation of shale reactivity

Shale reactivity is evaluated by testing a preserved test plug of shale sample in a triaxial test machine, the test plug being prepared by collecting a downhole shale sample and keeping it all times immersed in a preserving mineral oil so as to avoid dehydration, then applying radial and axial pressure on the test plug surrounded by mineral oil up to equilibration to overburden pressure, the test fluid being then contacted with the sample and the interaction of fluid and sample being evaluated by axial and radial deformations as measured by a triaxial detector apparatus sensitive to vertical and radial strains occurring across the shale sample, while the shale sample is subjected to any of a set of different conditions including a temperature or thermal potential, a hydraulic potential and / or a chemical potential. Only one fluid is tested on each sample. A sister test at ambient temperature and atmospheric pressure is run in order to constitute a visual counterpart of what is occurring in the triaxial test machine.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

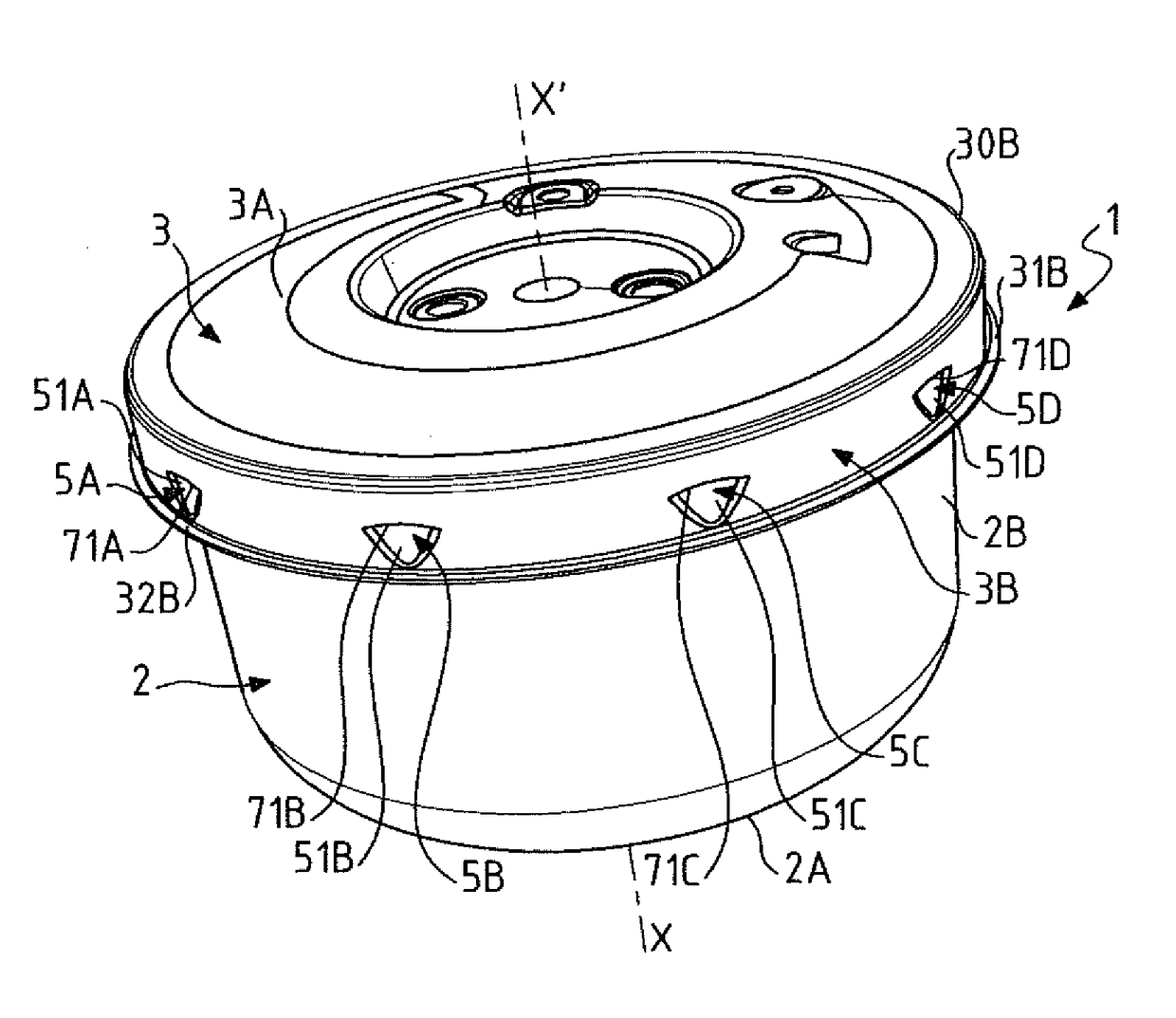

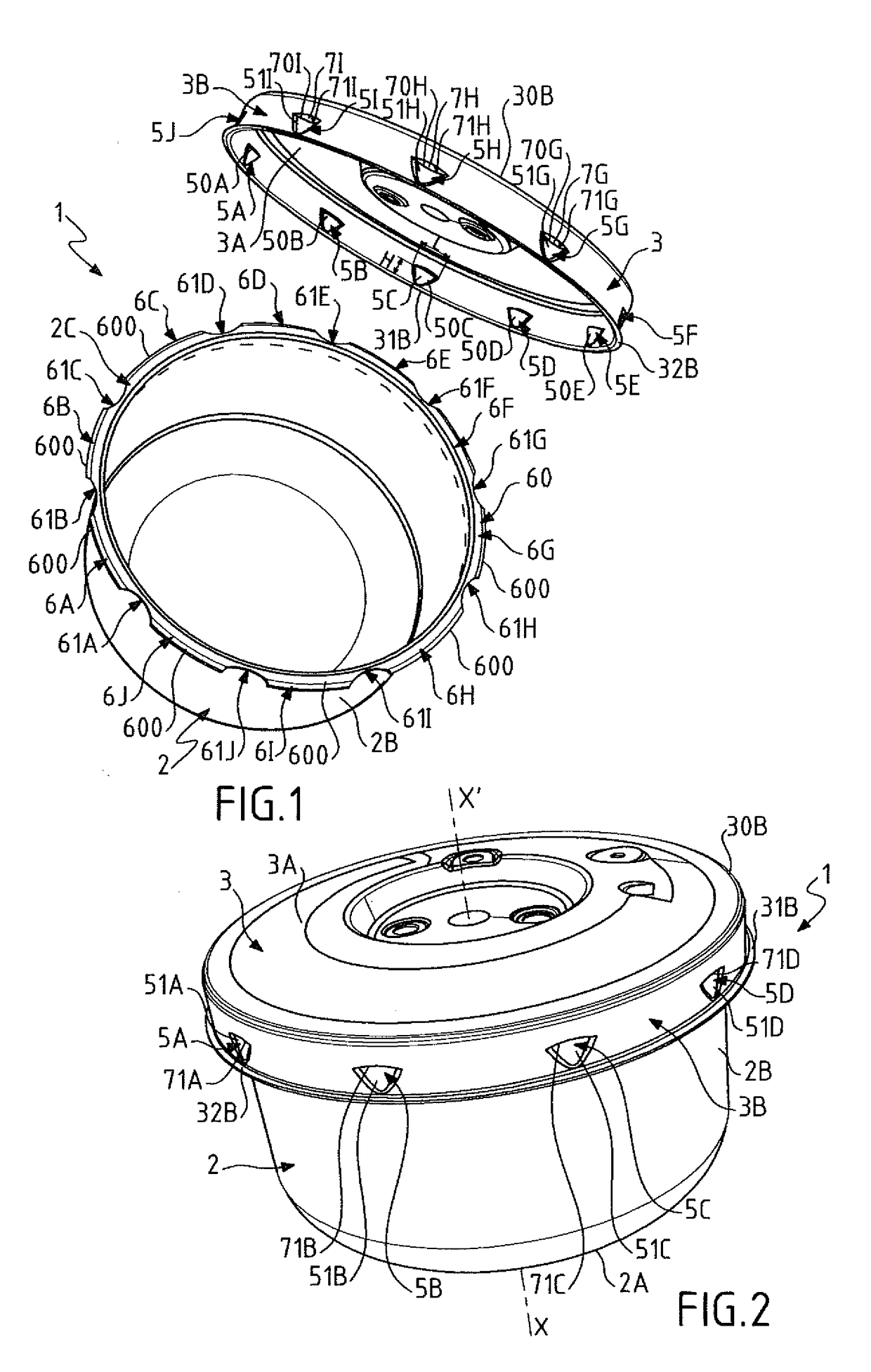

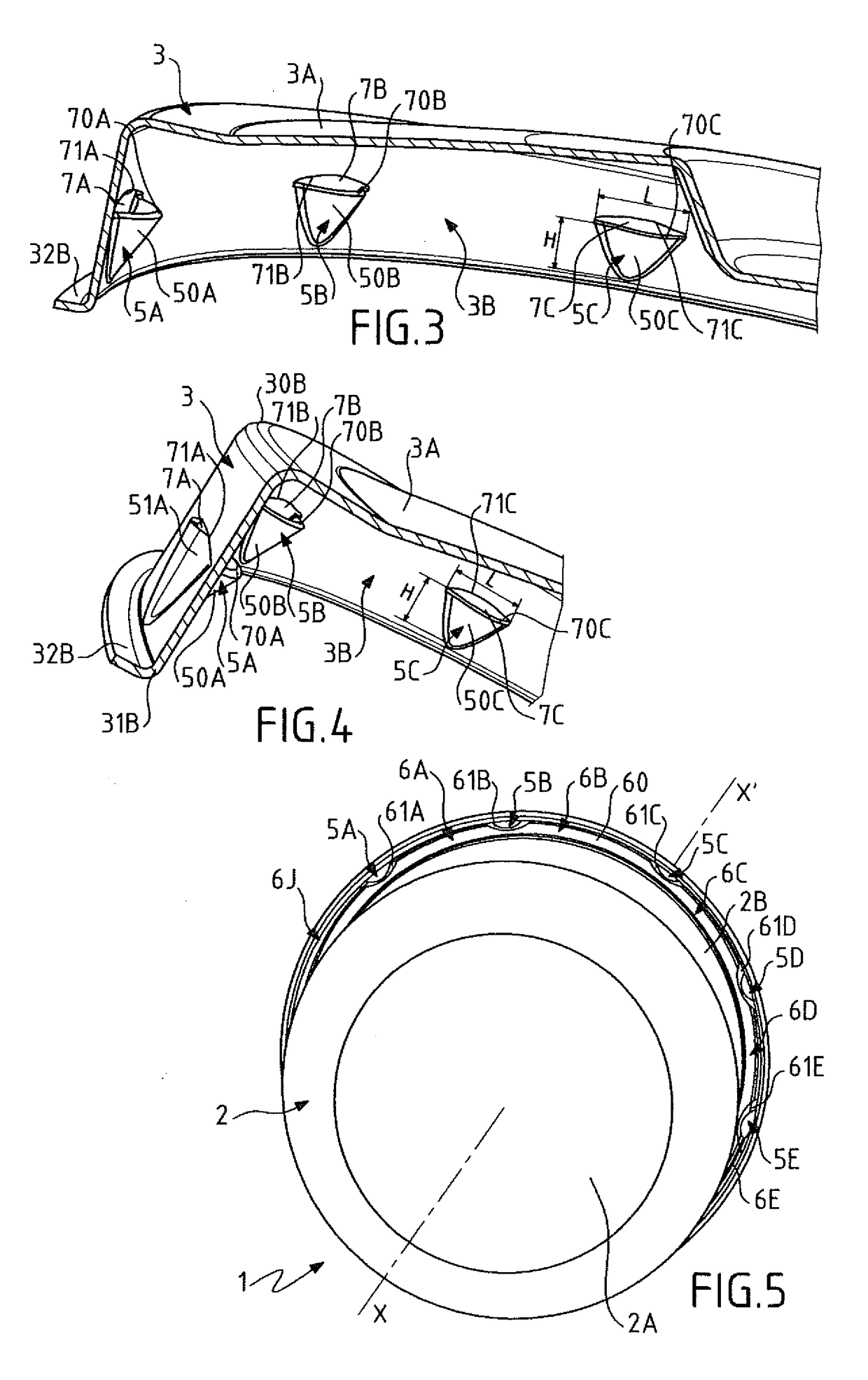

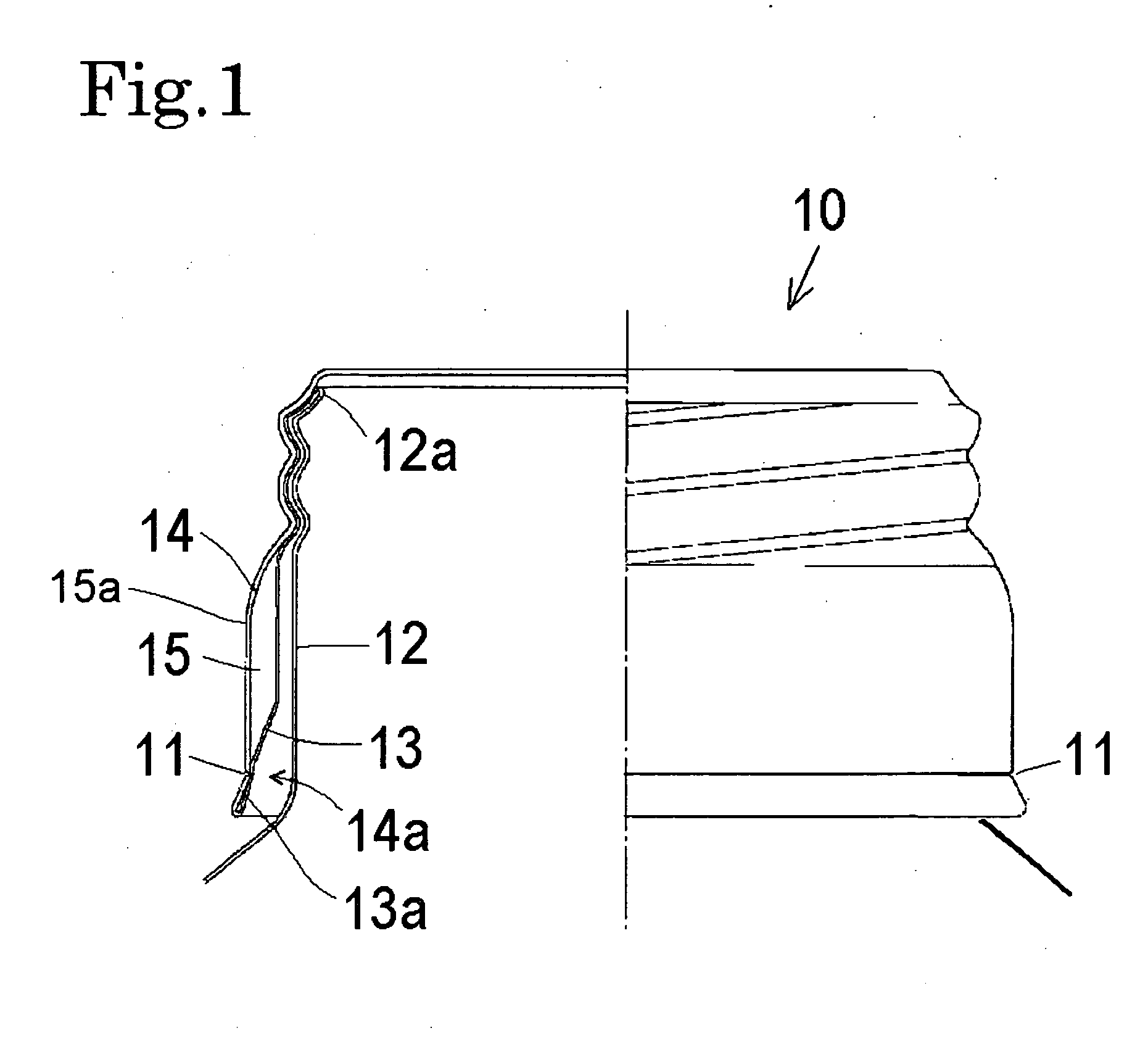

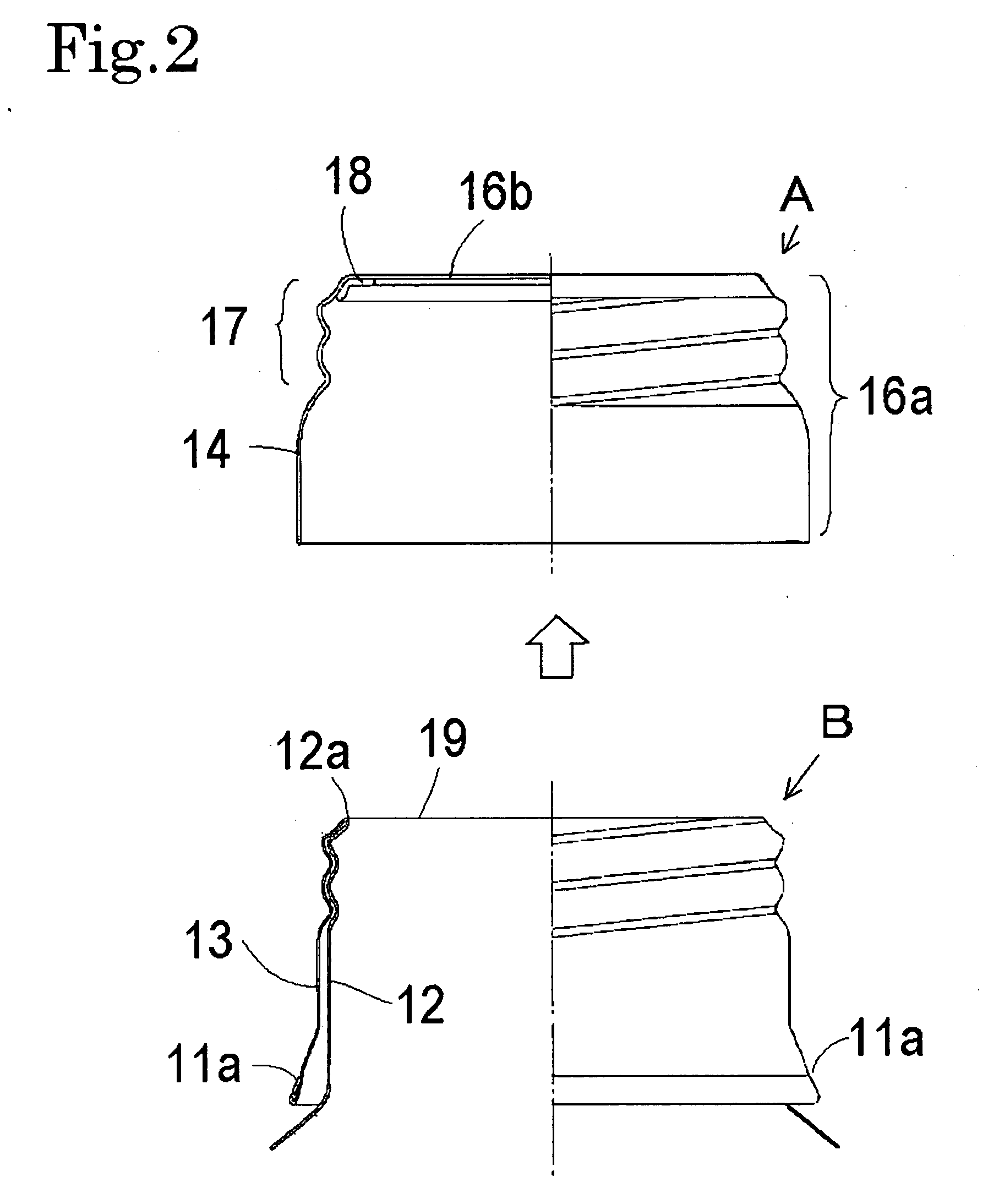

Pressure cooker having bayonet mount and related manufacturing method

ActiveUS20170172335A1Light weightEasy to handleCooking-vessel lids/coversRefuse receptaclesConvex sidePressure cooking

The invention relates to a food pressure cooking appliance including a bowl and a lid intended to be locked relative to the bowl to form with the latter a cooking chamber adapted to rise in pressure. The appliance also including bayonet locking means forming first and second series of protrusions that are integral with the envelope of the lid and the envelope of the bowl, respectively, and that are intended to cooperate with each other to ensure the locking of the lid relative to the bowl. Each protrusion of at least one of said series is consisted by a volume element that has opposite convex and concave faces, and that is formed by a localized radial deformation of the corresponding envelope.

Owner:SEB SA

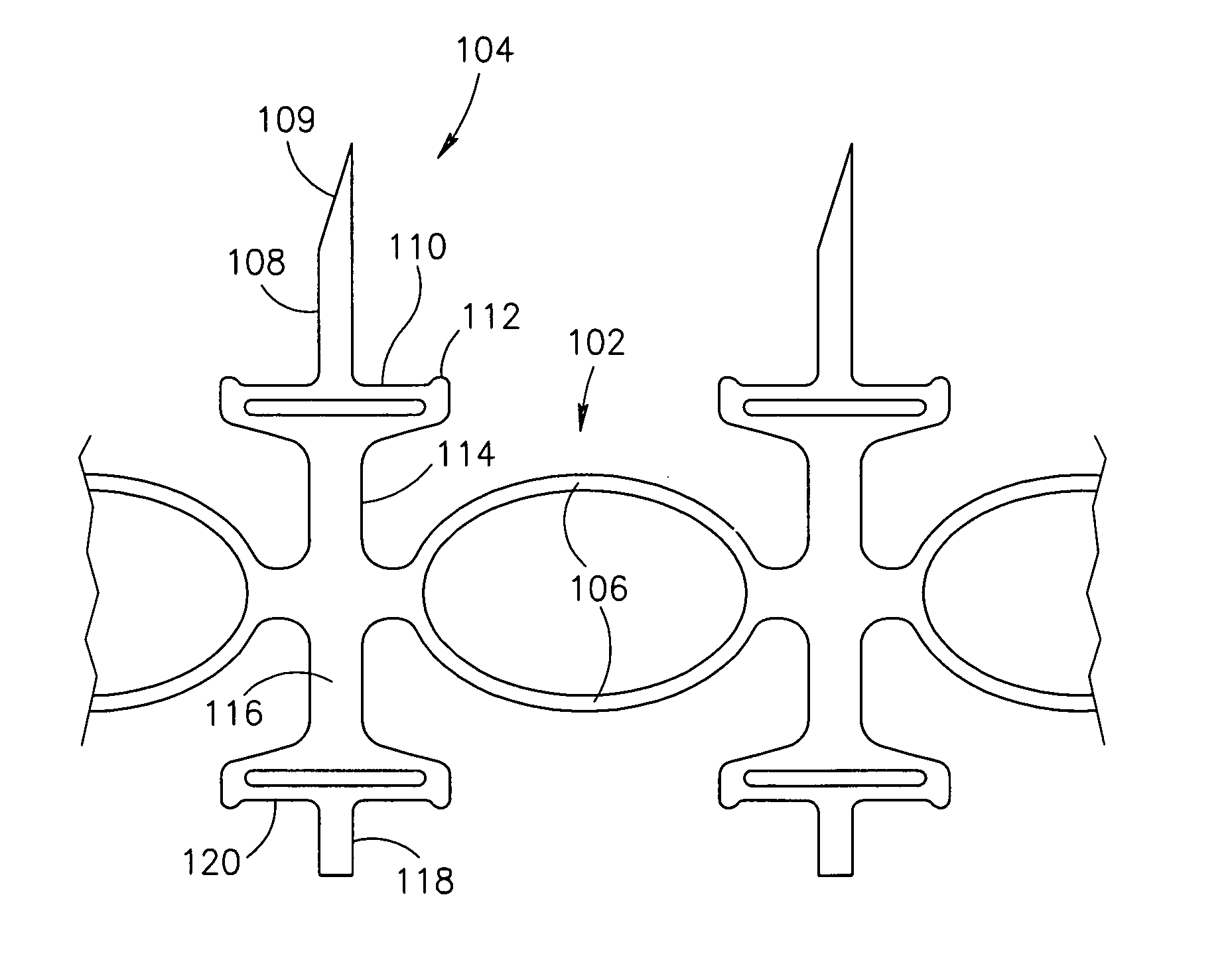

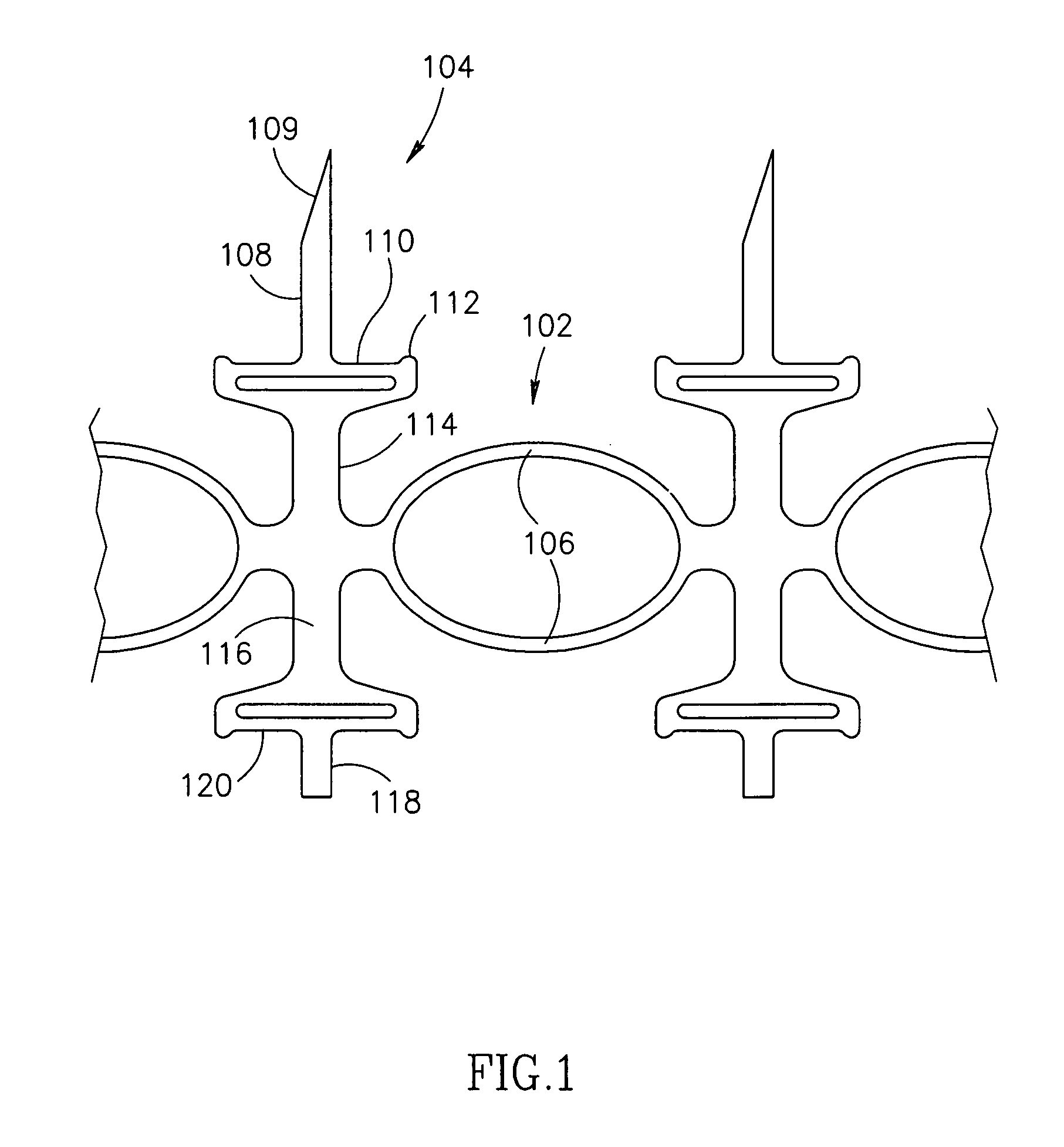

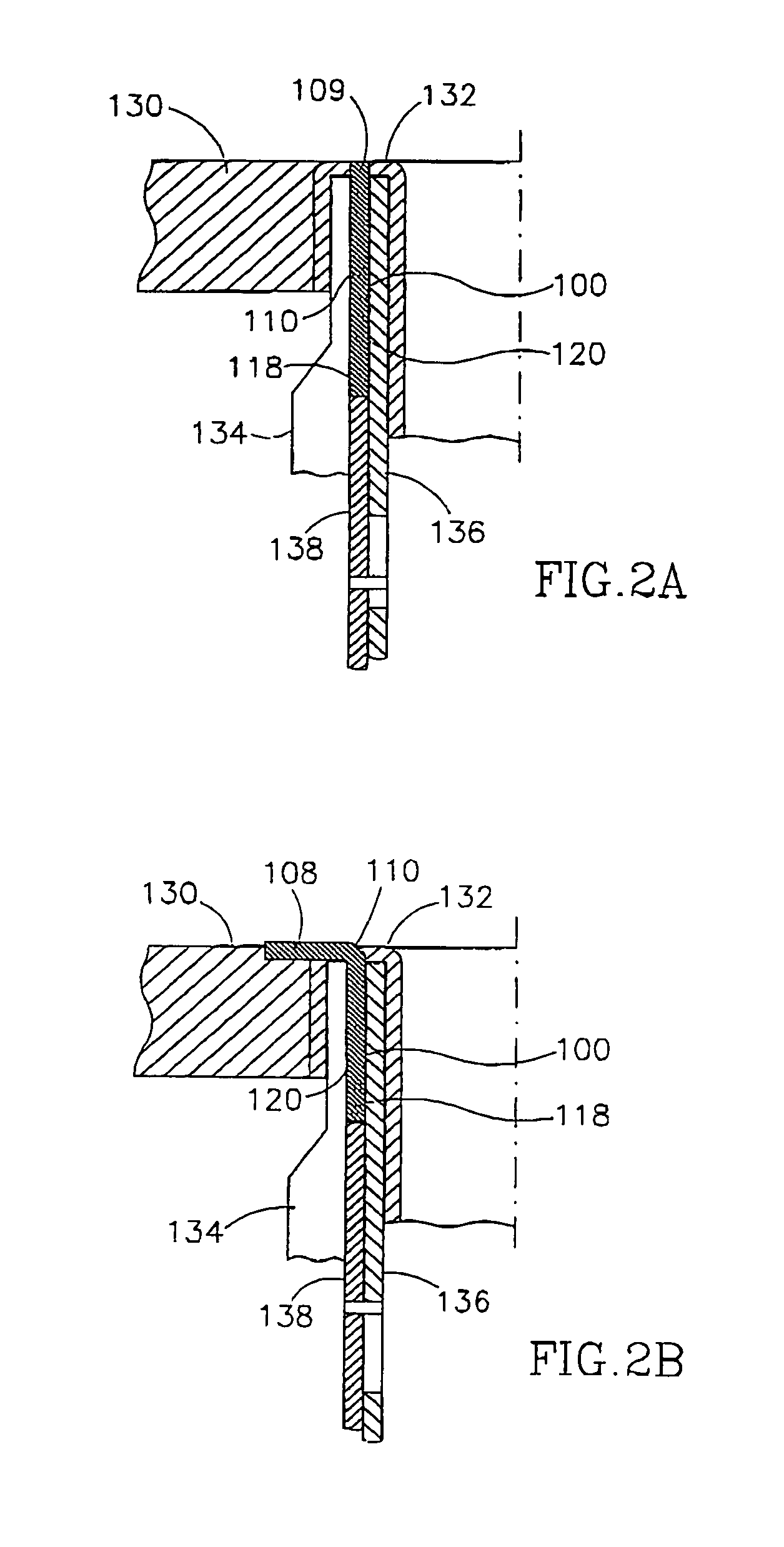

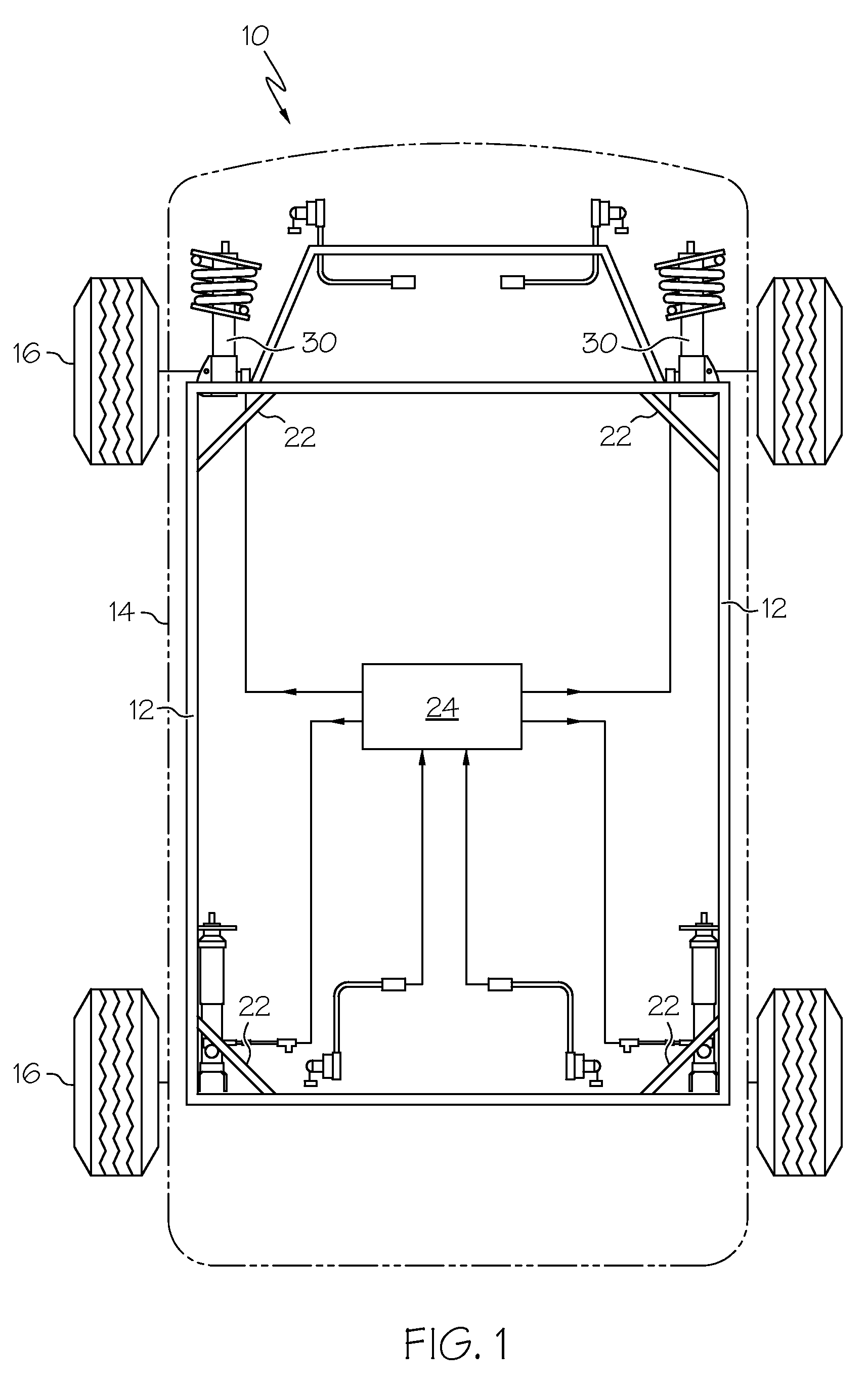

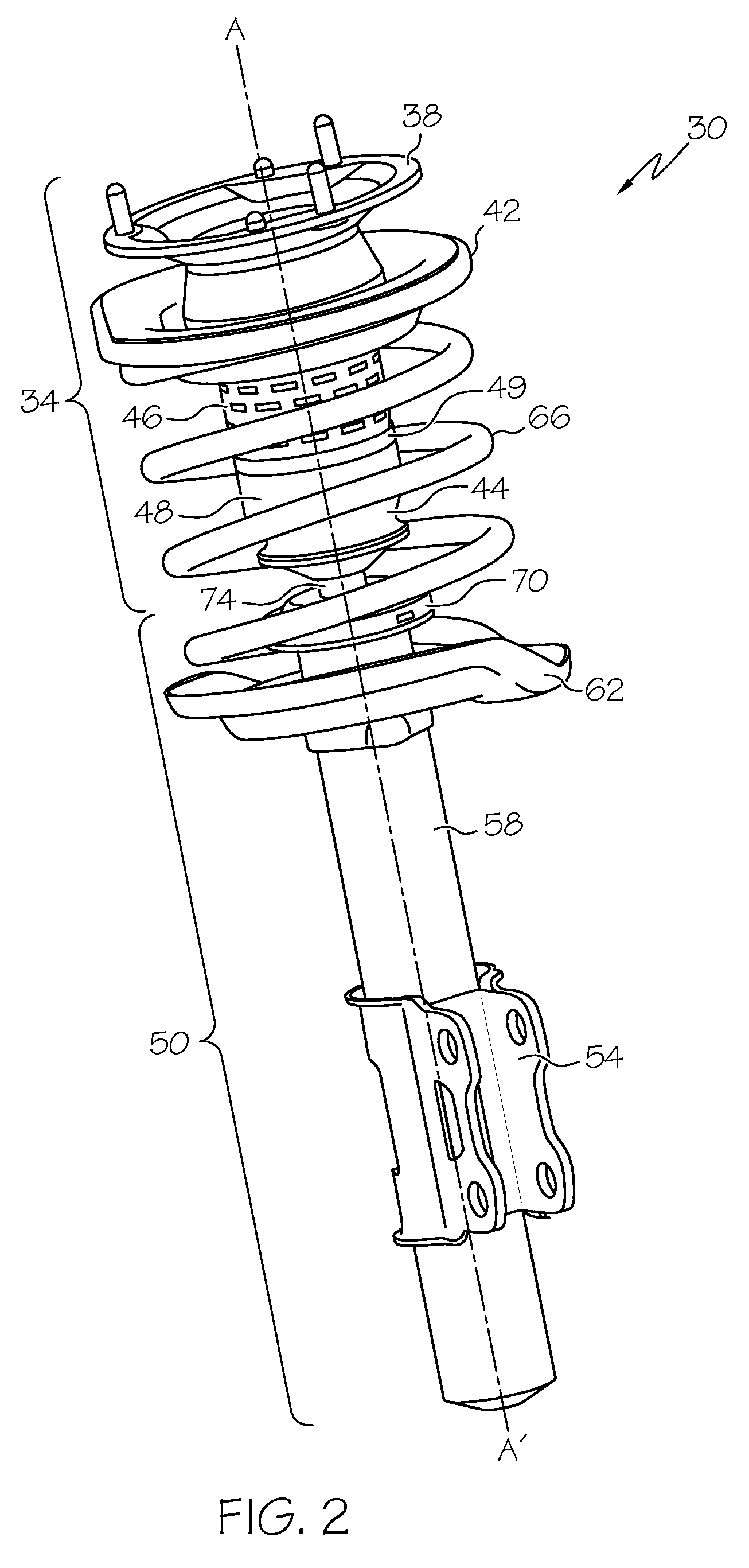

Low profile anastomosis connector

InactiveUS6979338B1Sufficient forceAvoid accidental damageSuture equipmentsSurgical needlesEngineeringMechanical engineering

An anastomosis connector comprises a plurality of ring segments (106), together defining a radially expandable ring-like shape (106) having a lumen; at least one pivot bar (114) coupled to at least one of said ring segments (106); at least one spike (109) mounted on said pivot bar (114) and rotatable around said pivot bar (114), wherein radial deformation of said ring-like shape (106) does not substantially directly affect said spike (109) rotational position.

Owner:BY PASS

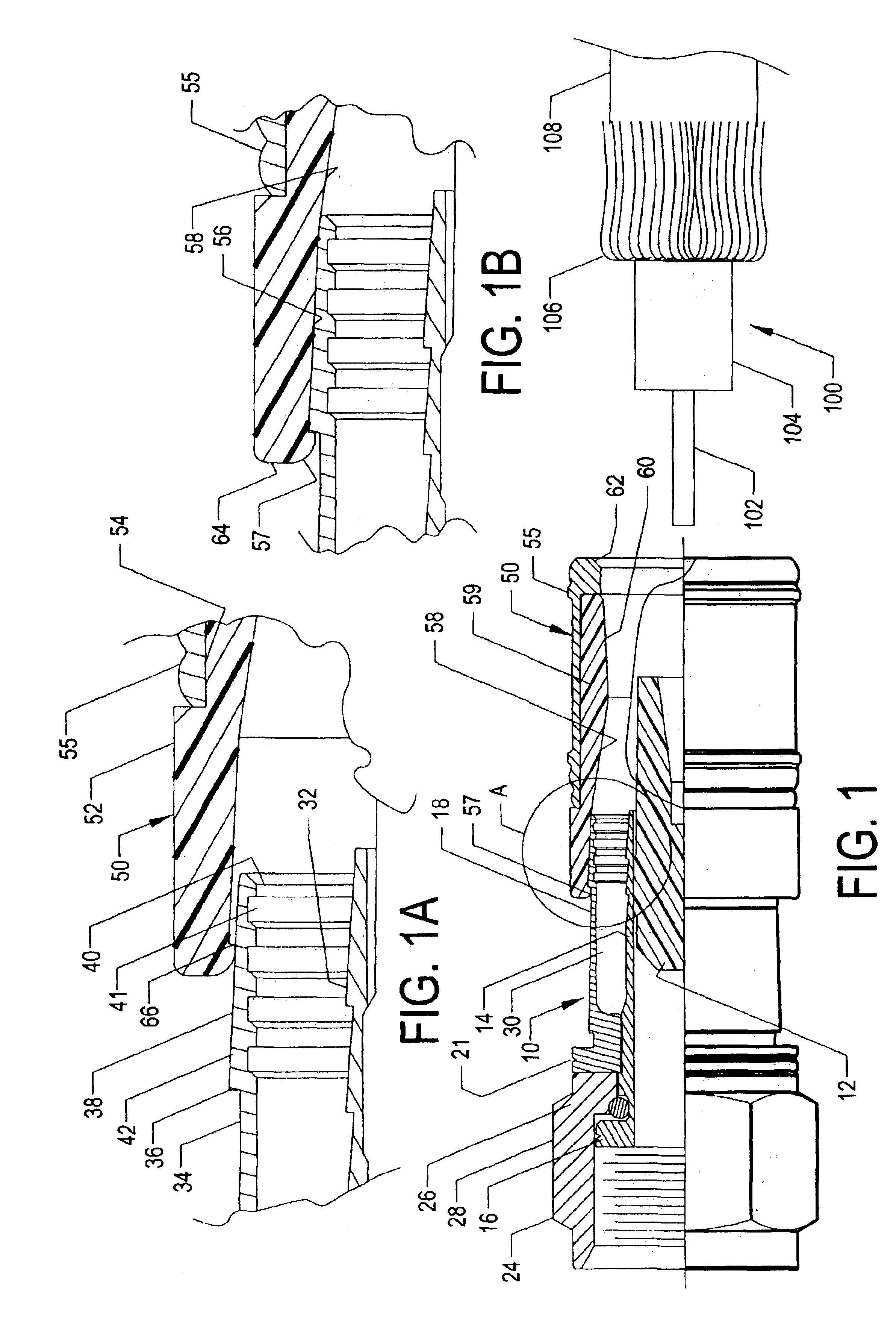

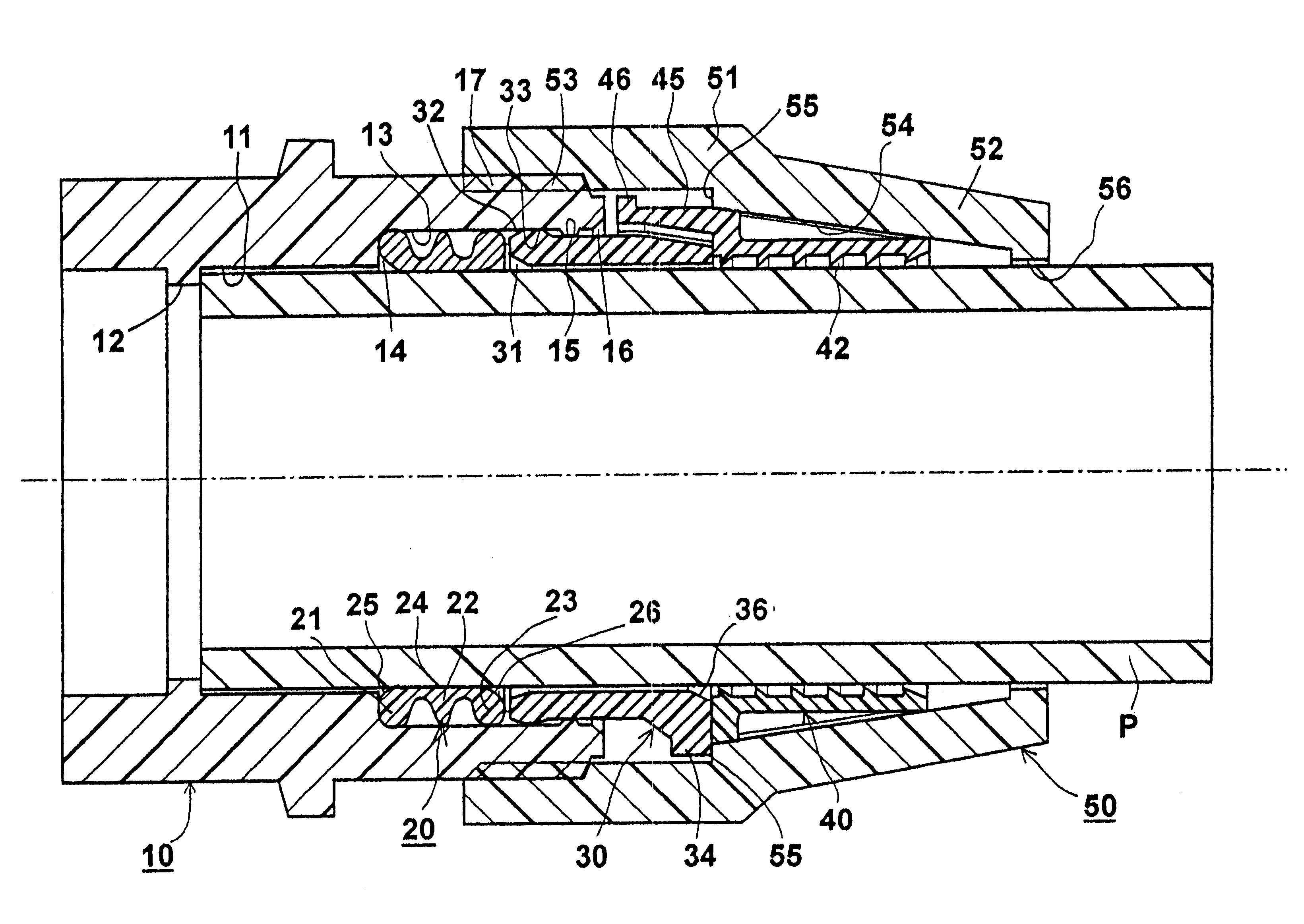

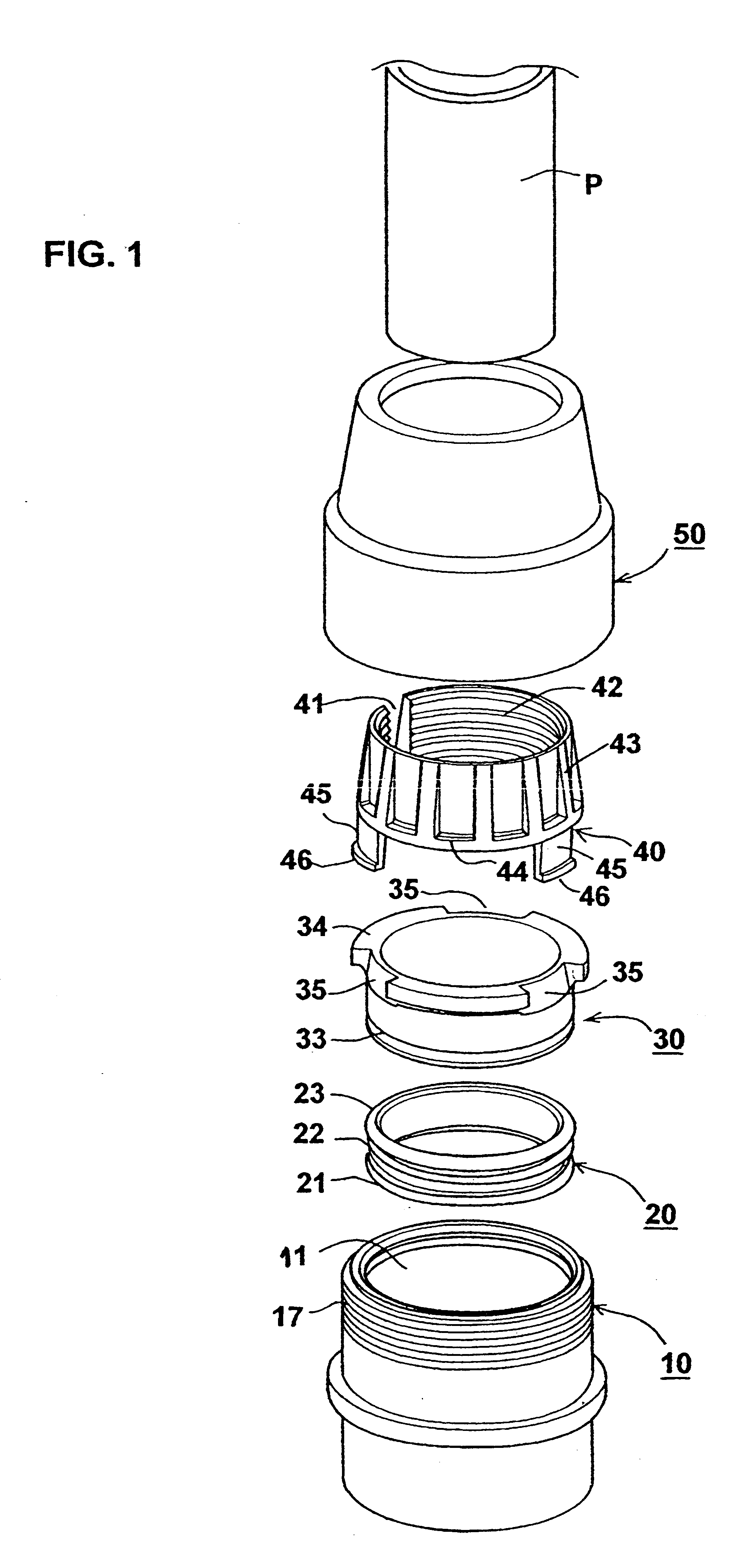

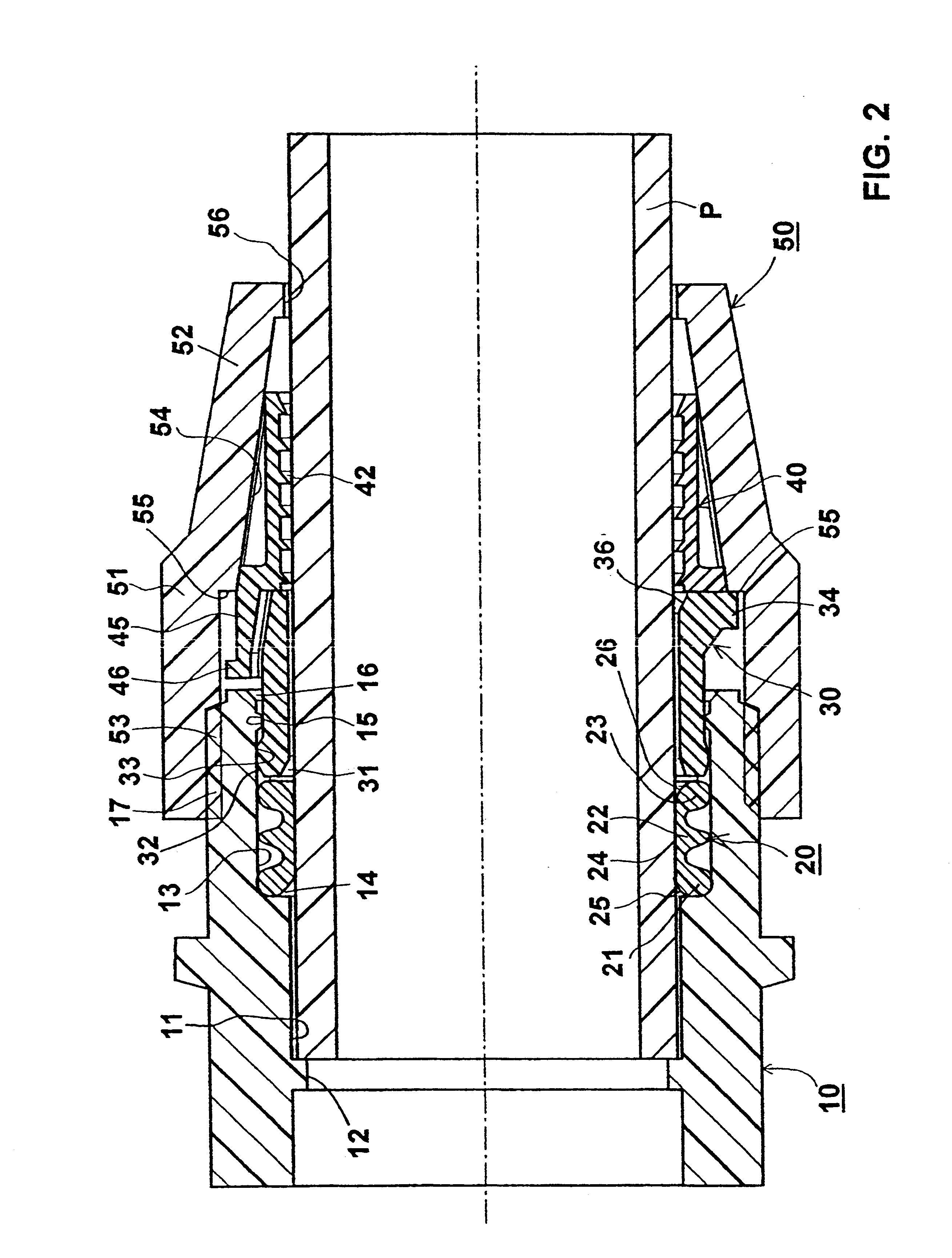

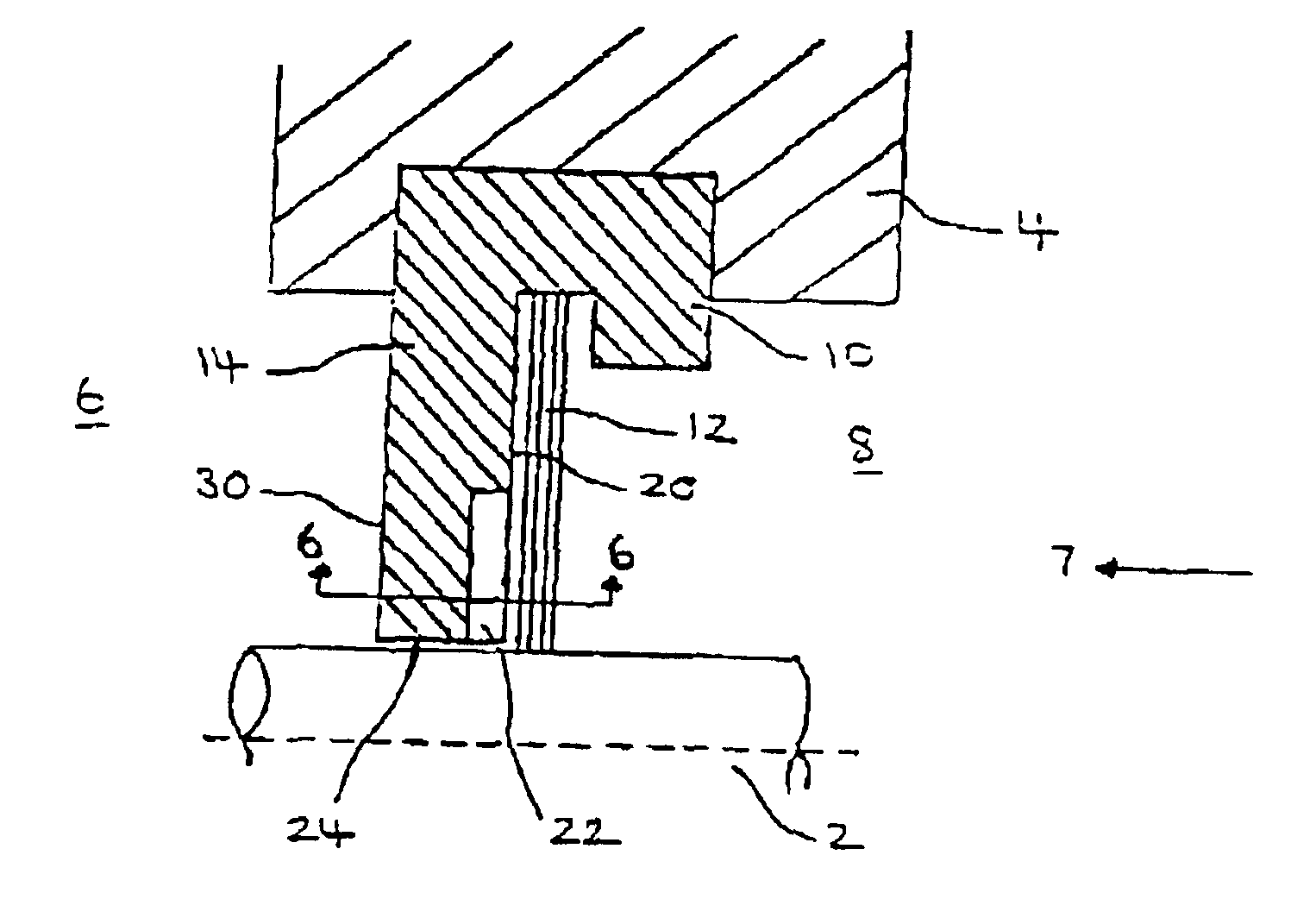

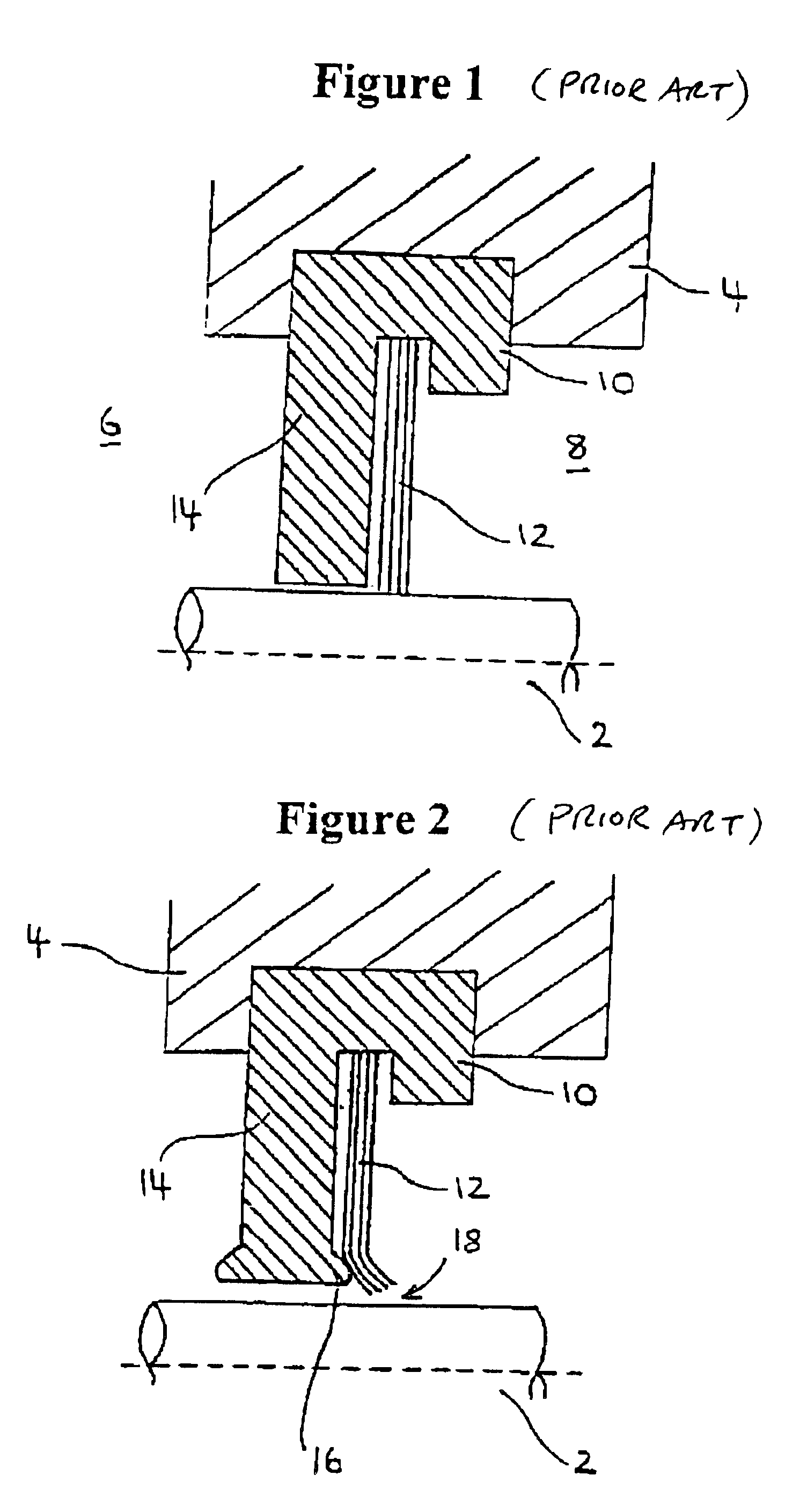

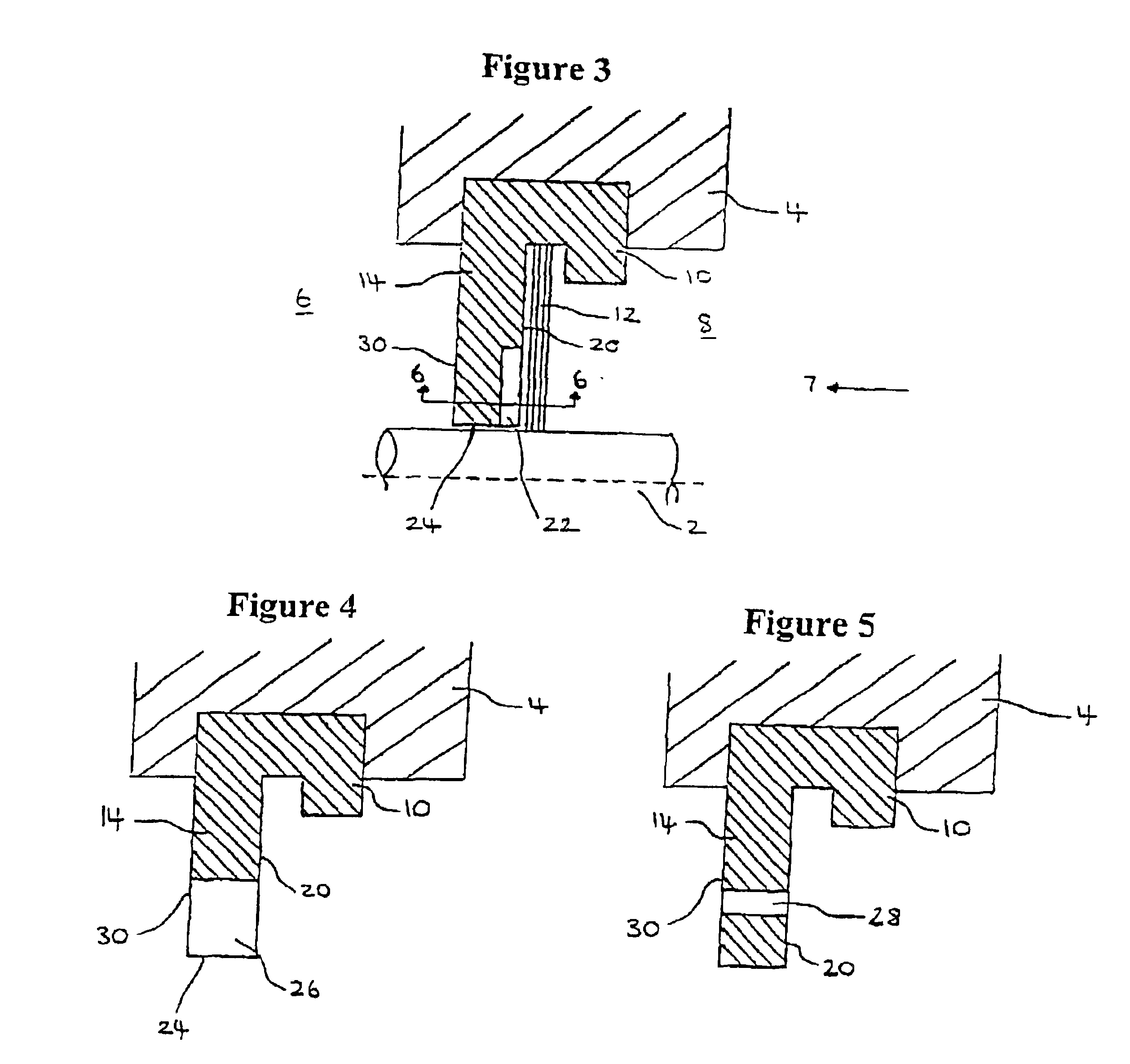

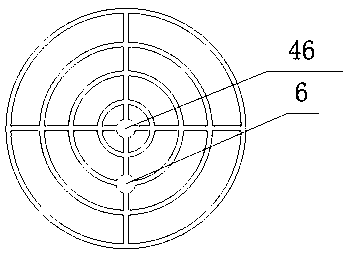

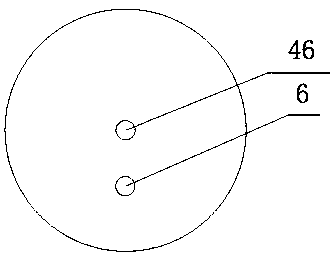

Pipe coupling

A pipe coupling includes a body member (10) formed with a bore (11) for receiving one end of a pipe (P) to be coupled; a sealing ring (20) and a compression sleeve (30) receivable within the bore (11); a radially-deformable gripping ring (40) having one end abuttable against the compression sleeve (30), a securing nut (50) threaded on the body member (10) and engageable with the gripping ring (40) to move the gripping ring (40) axially and to effect a sealing action via the compression sleeve (30) and the sealing ring (20), and also to compress the gripping ring (40) radially to effect a gripping action of the pipe (P) received in the bore (11); and an axially-extending limit element (45) between the gripping ring (40) and the body member (10) effective to cause the nut (50), when tightened; (a) in an initial stage, to move the gripping ring (40) and the compression sleeve (30) until the limit element engages (45) prevents further axial movement of the gripping ring (40); and (b) in a final stage, to radially deform the gripping ring (40) to produce the gripping action, and then to compress the sealing ring (20) against the internal annular shoulder (14) of the body member to produce the sealing action.

Owner:PLASSON LTD

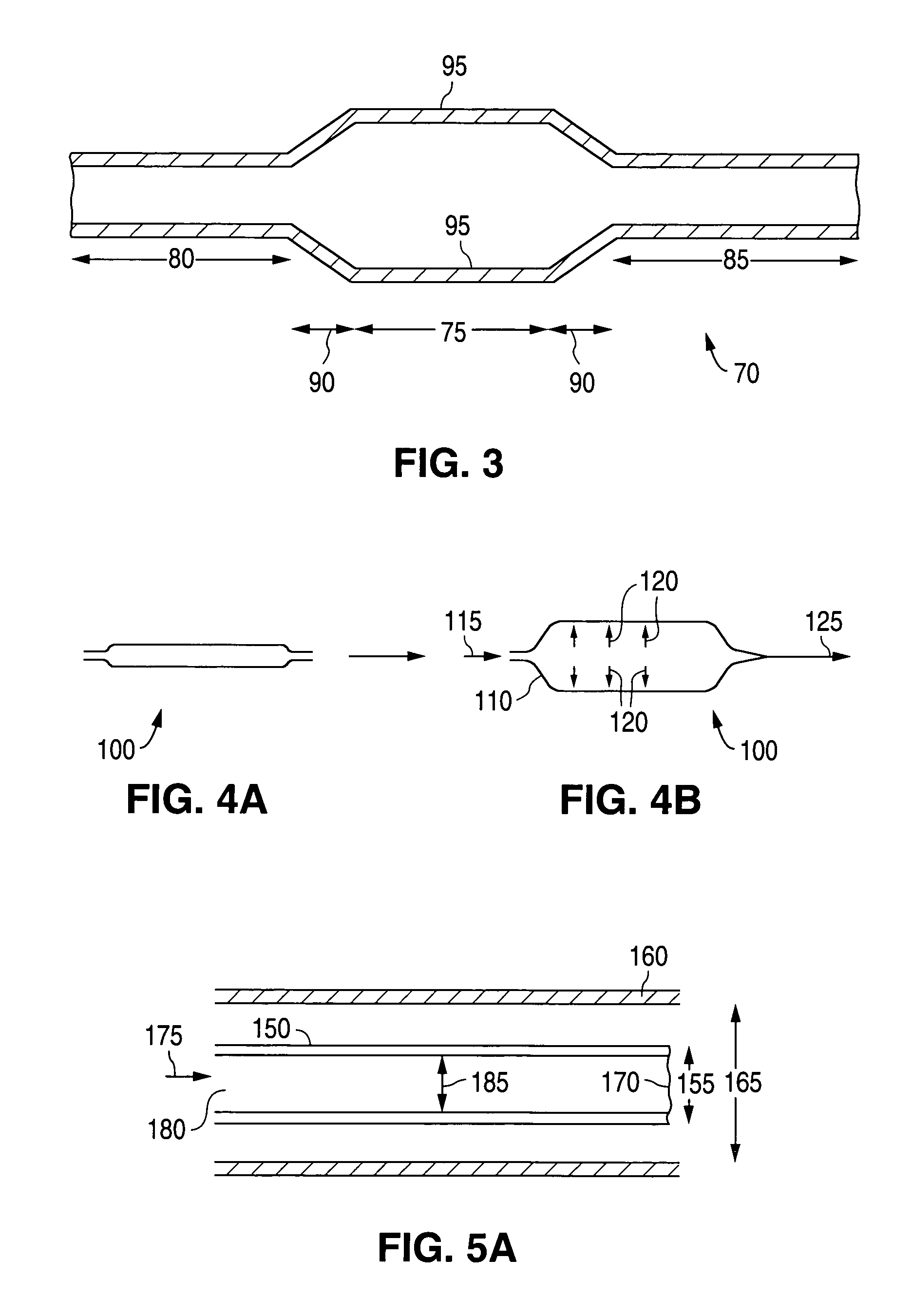

Controlled deformation of a polymer tube with a restraining surface in fabricating a medical article

Methods of manufacturing a medical article that include radial deformation of a polymer tube are disclosed. A medical article, such as an implantable medical device or an inflatable member, may be fabricated from a deformed tube.

Owner:ABBOTT CARDIOVASCULAR

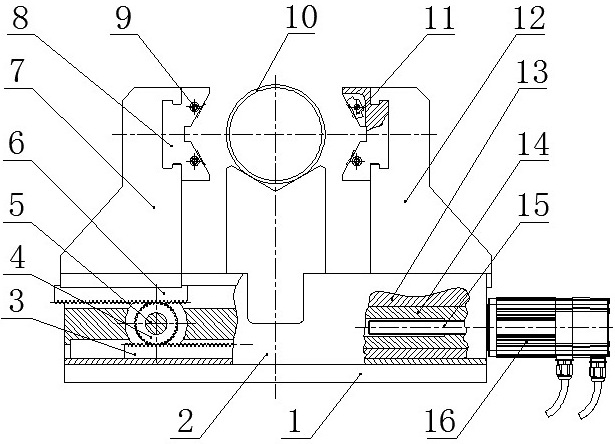

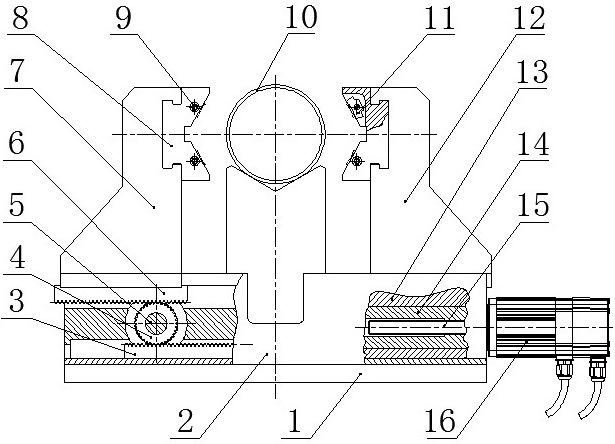

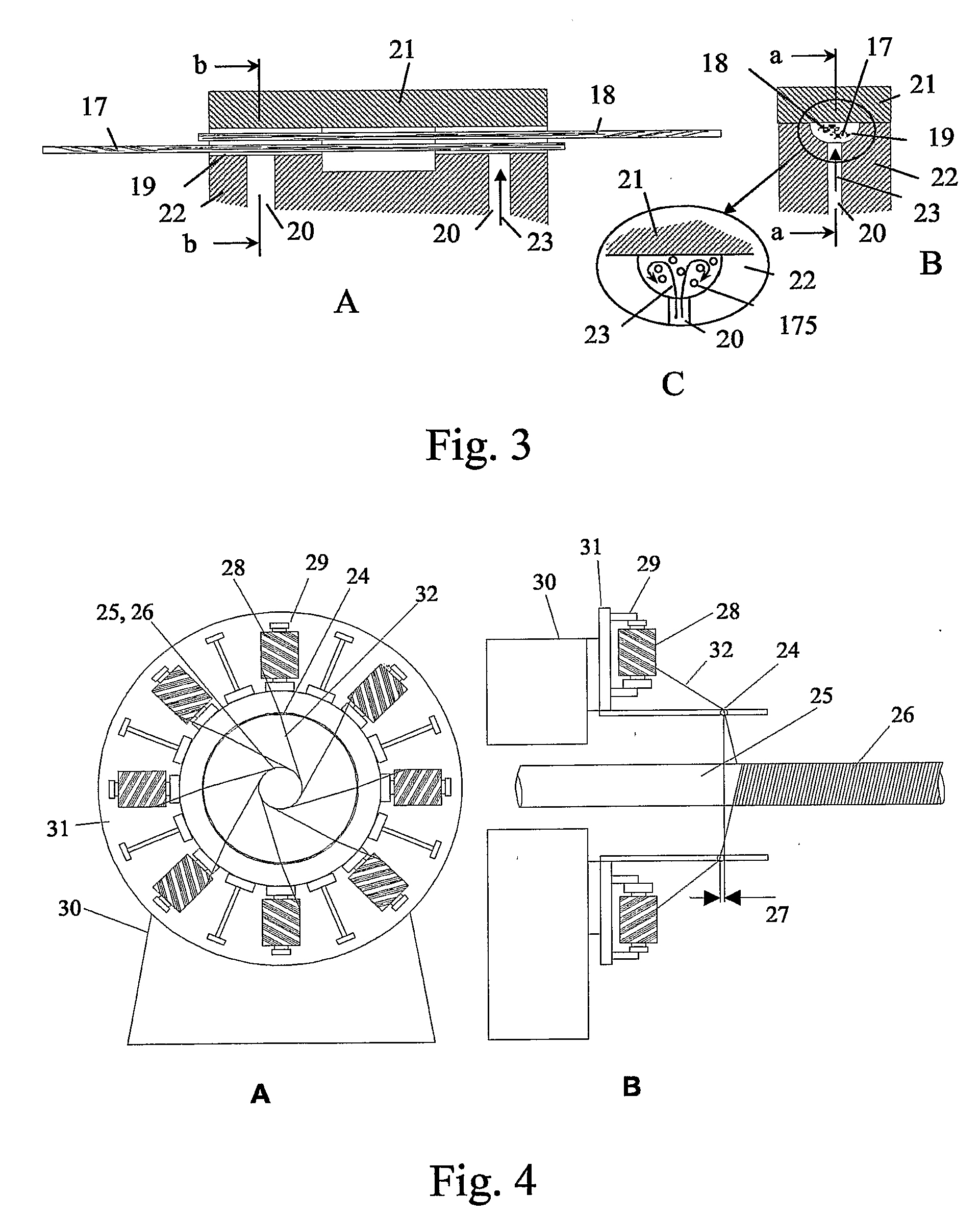

Center-aligning floating clamping fixture

InactiveCN102632404AAvoid deformationDecrease the jump valuePositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a center-aligning floating clamping fixture used in a machine tool for two ends of a steel pipe. The structure of the center-aligning floating clamping fixture comprises a fixture supporting frame, a driving mechanism, a transmission mechanism, a clamping mechanism and a floating aligning mechanism, wherein the transmission mechanism and the clamping mechanism are connected with each other, the clamping mechanism is provided with two chuck uprights which are parallel to each other in opposite directions, the uprights are provided with V-shaped jaws and connected with a bracket, a V-shaped clamp is provided with two pairs of floating clamping blocks, clamping surfaces of the clamping blocks are multidentate clamping surfaces, and the multidentate clamping surfaces are positioned on a same cylindrical surface. The center-aligning floating clamping fixture can be used for special machine tool equipment for machining the two ends of the steel pipe of a DT II type roller of a belt conveyor, and the geometric axis center of the steel pipe to be automatically aligned with the axis center of the machine tool so as to control radial deformation of the steel pipe.

Owner:SHENZHEN CEMCN

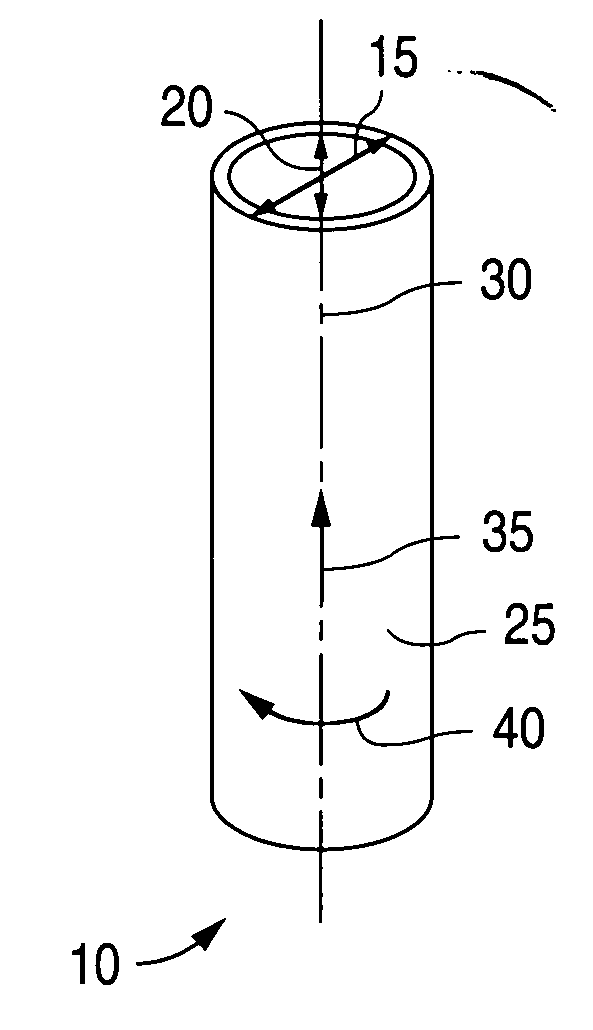

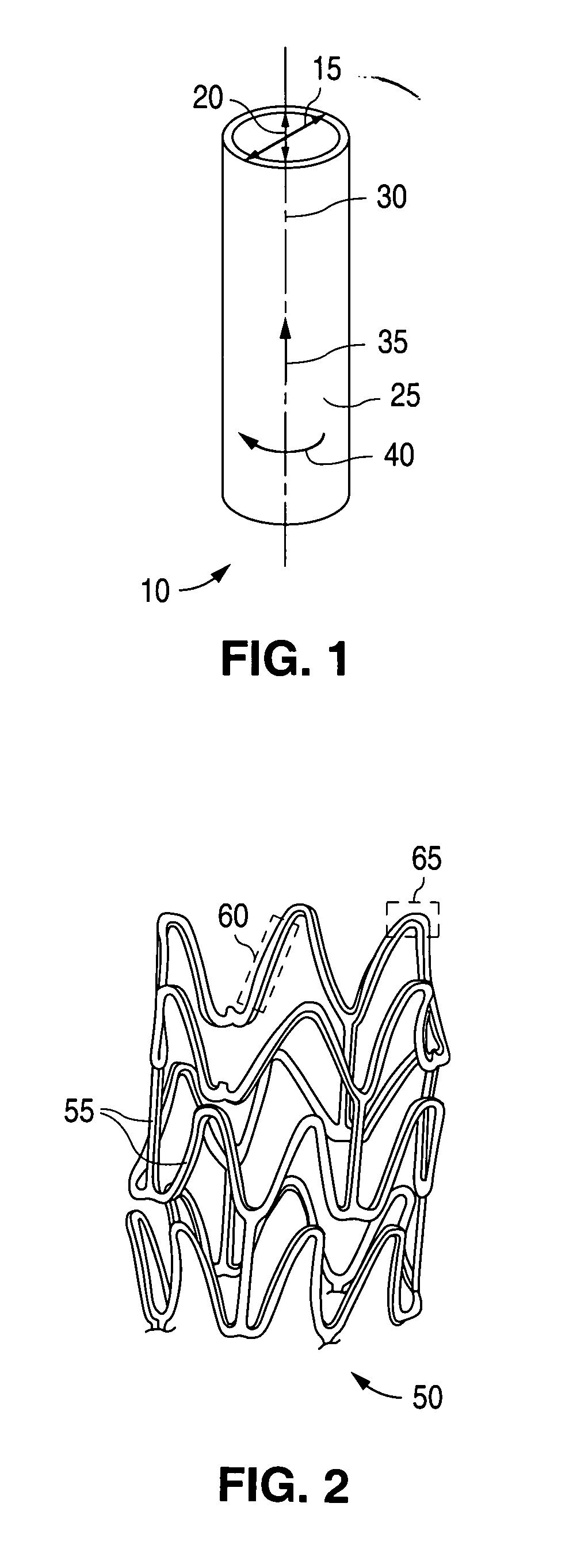

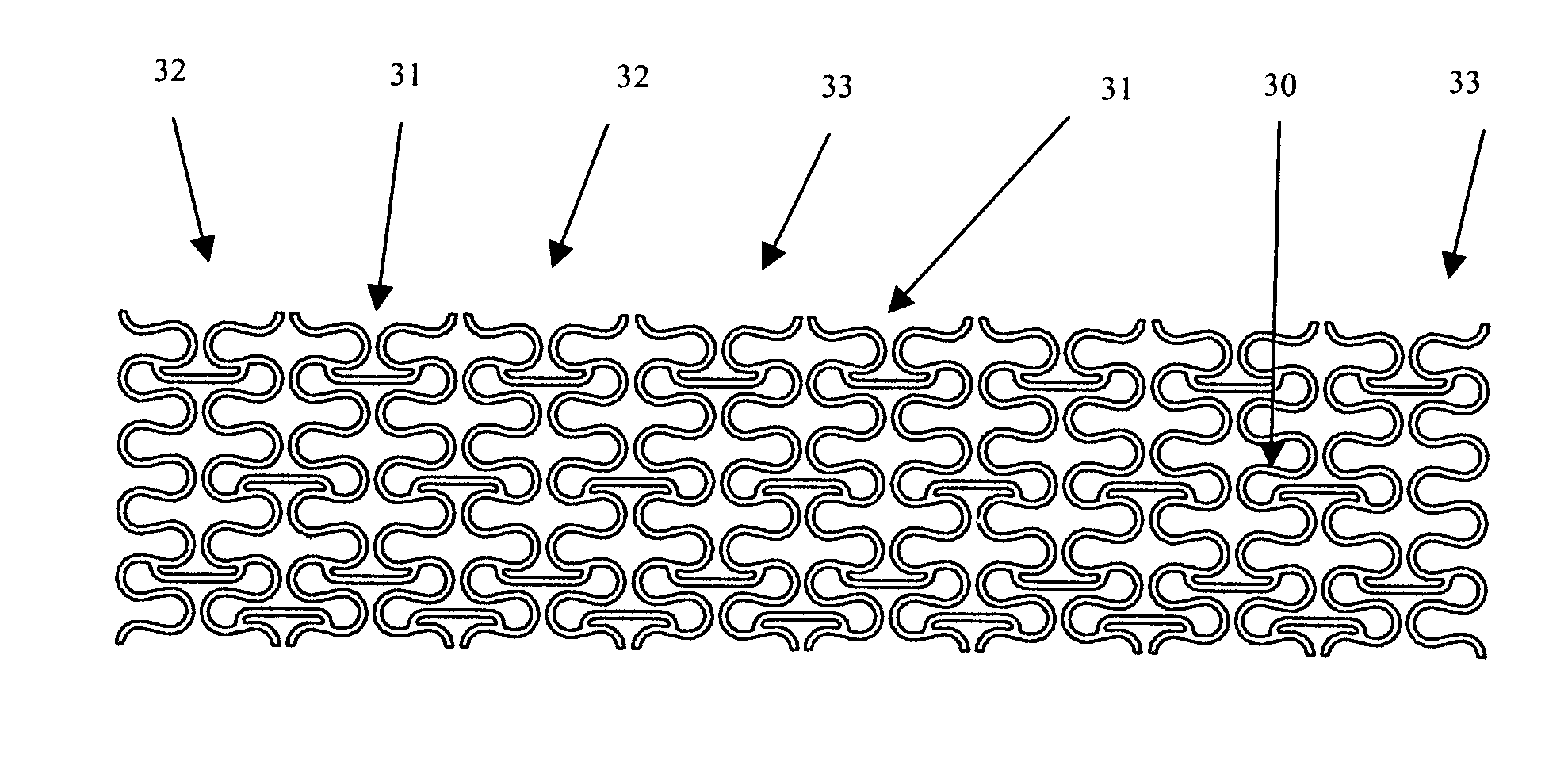

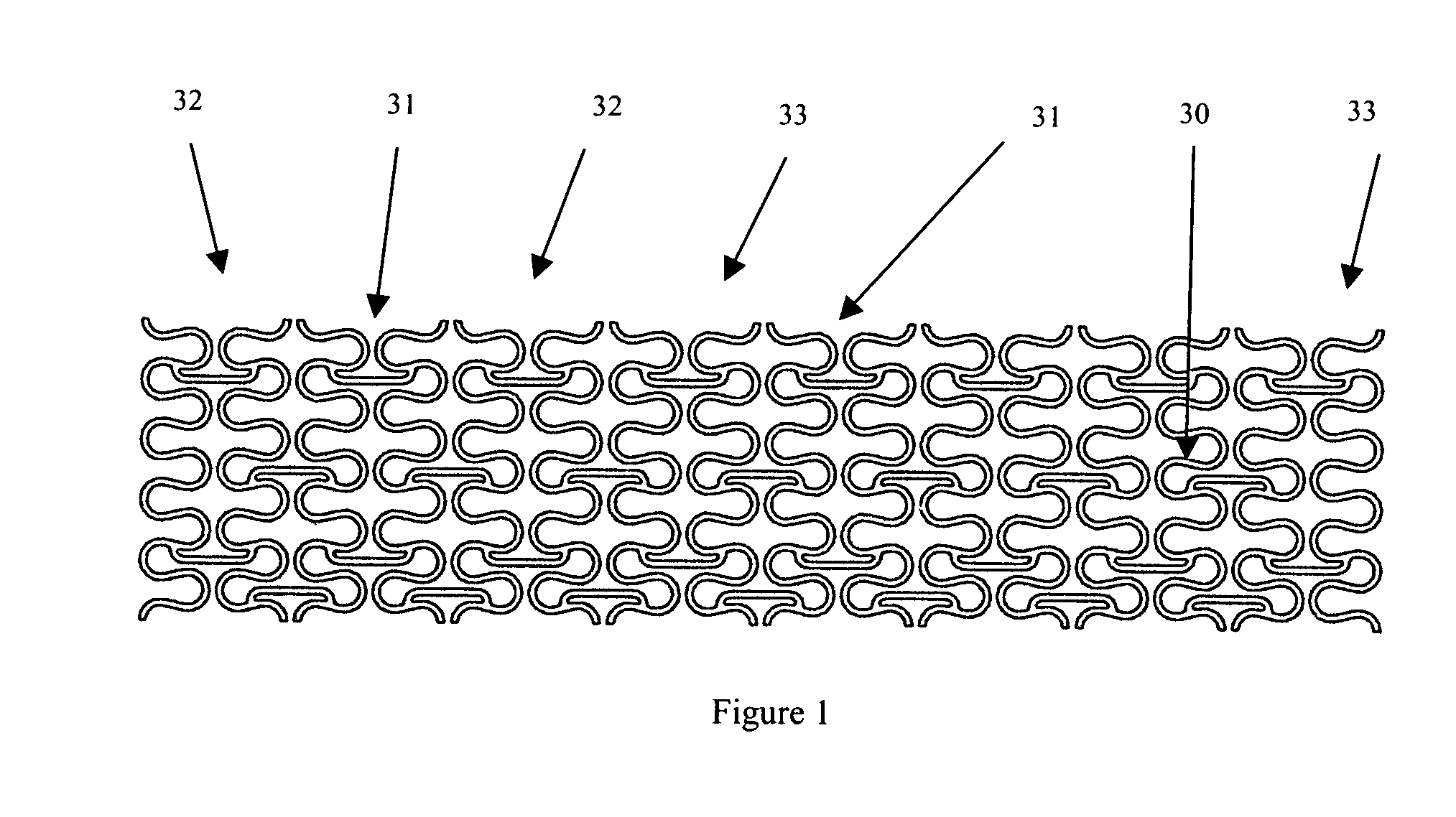

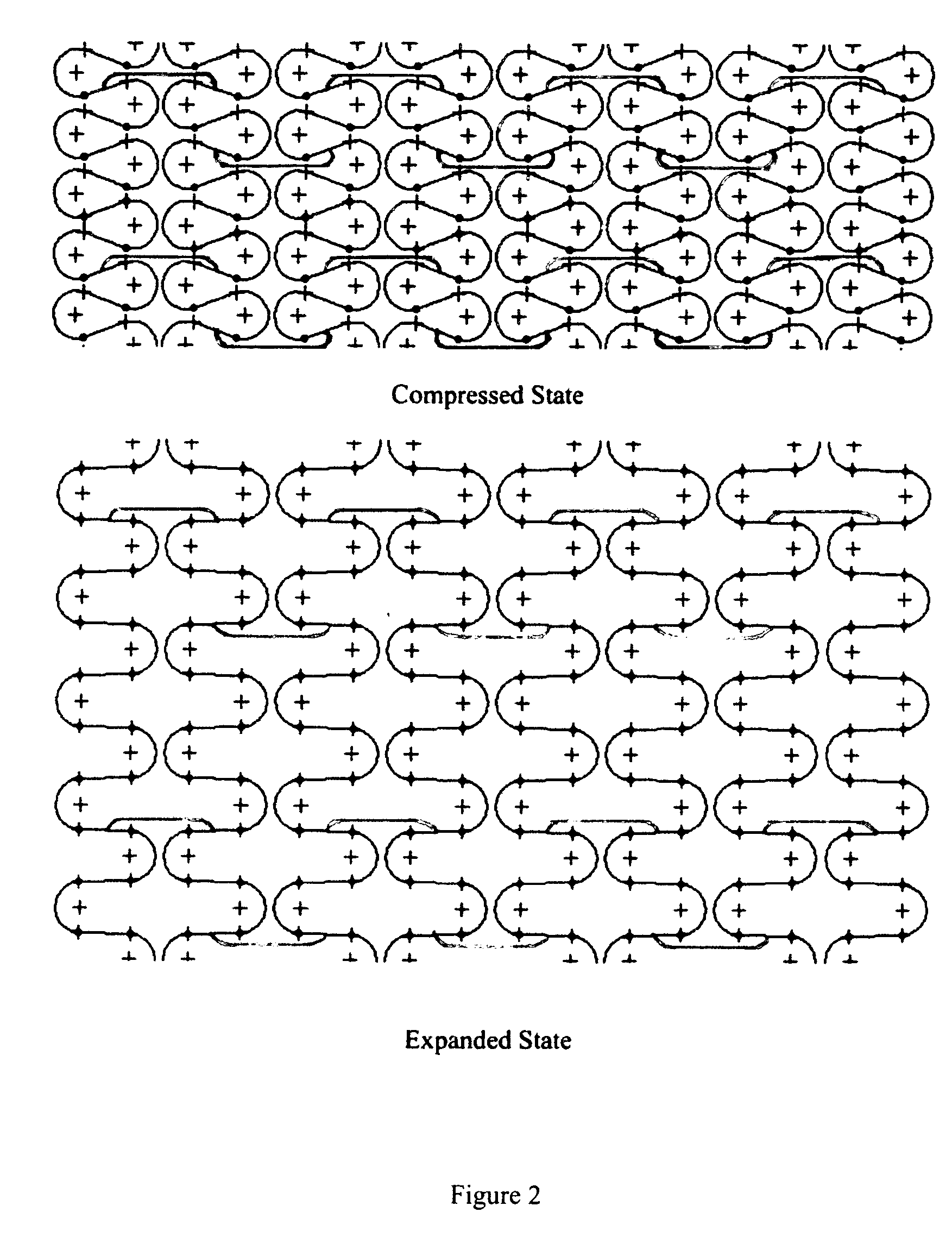

Expandable endovascular stent

InactiveUS20050080479A1Minimize amount of materialSubstantial longitudinal flexibility longitudinalStentsBlood vesselsStress concentrationPercent Diameter Stenosis

Disclosed herein is a tubular endovascular stent comprising a plurality of annular segments connected by one or more bridging elements. Each annular segment takes forms of periodic wavelets with a plurality of alternating symmetric peaks and valleys, preferably consisting of circular arc segments of large radii connected tangentially with straight segments to minimize stress concentration when the stent undergoes radial deformation, transverse to the longitudinal axis of the stent. The points of connection between the bridging elements and adjacent annular segments are so designed that deformations of the bridging elements remain negligible as the stent deforms radially, namely, the longitudinal dimension of the stent does not vary during the radial expansion or contraction of the stent. Hence, the radial strength and the longitudinal flexibility of the stent made according to the principles disclosed by the present invention can be independently controlled by the design parameters for the annular segments and bridging elements, without compromising the longitudinal dimensional stability of the stent. Since stress concentration and deformation in the stent can lead to restenosis, stent made from the invention disclosed here can reduce the probability of restenosis.

Owner:FENG JAMES Q +1

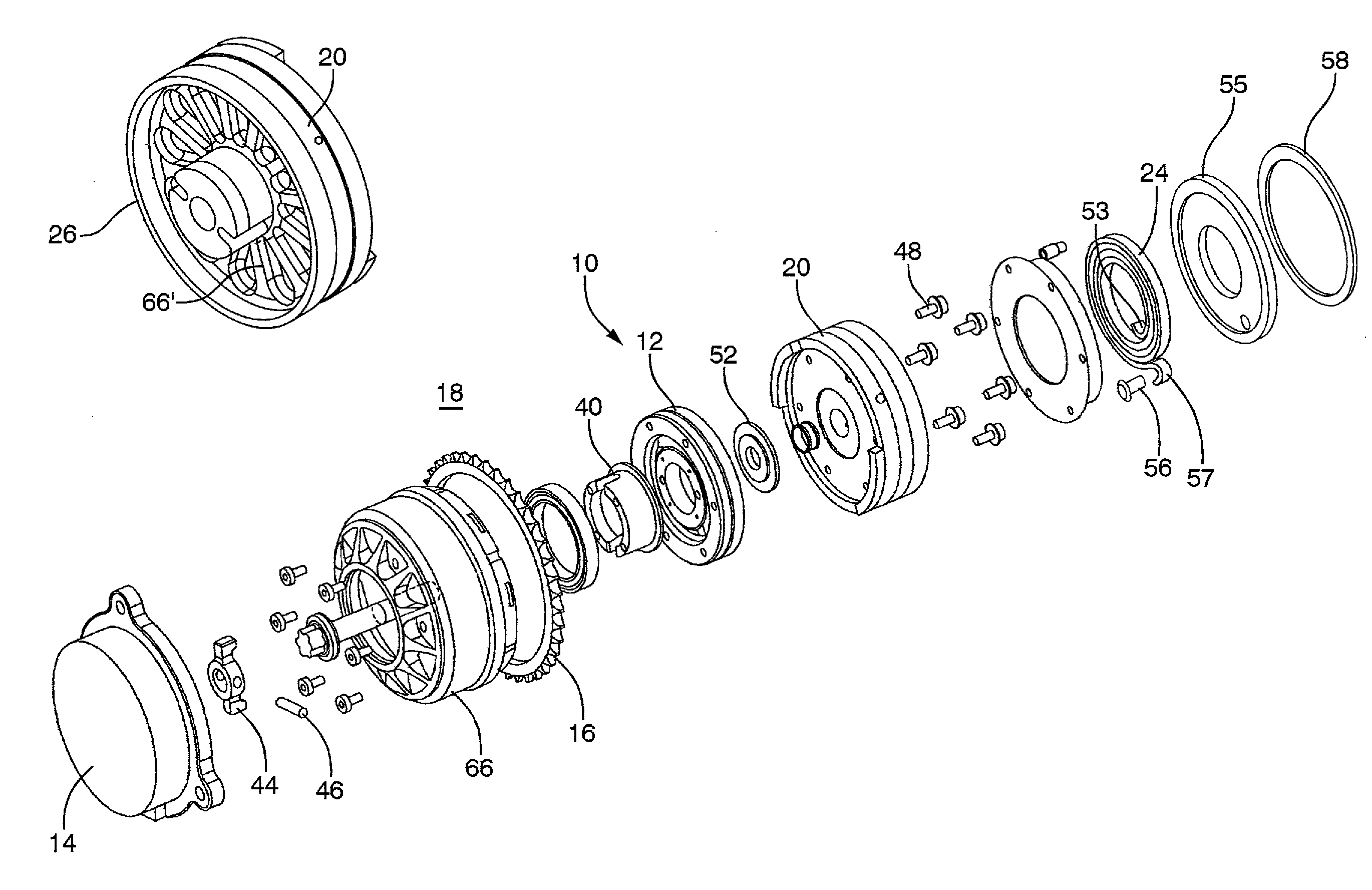

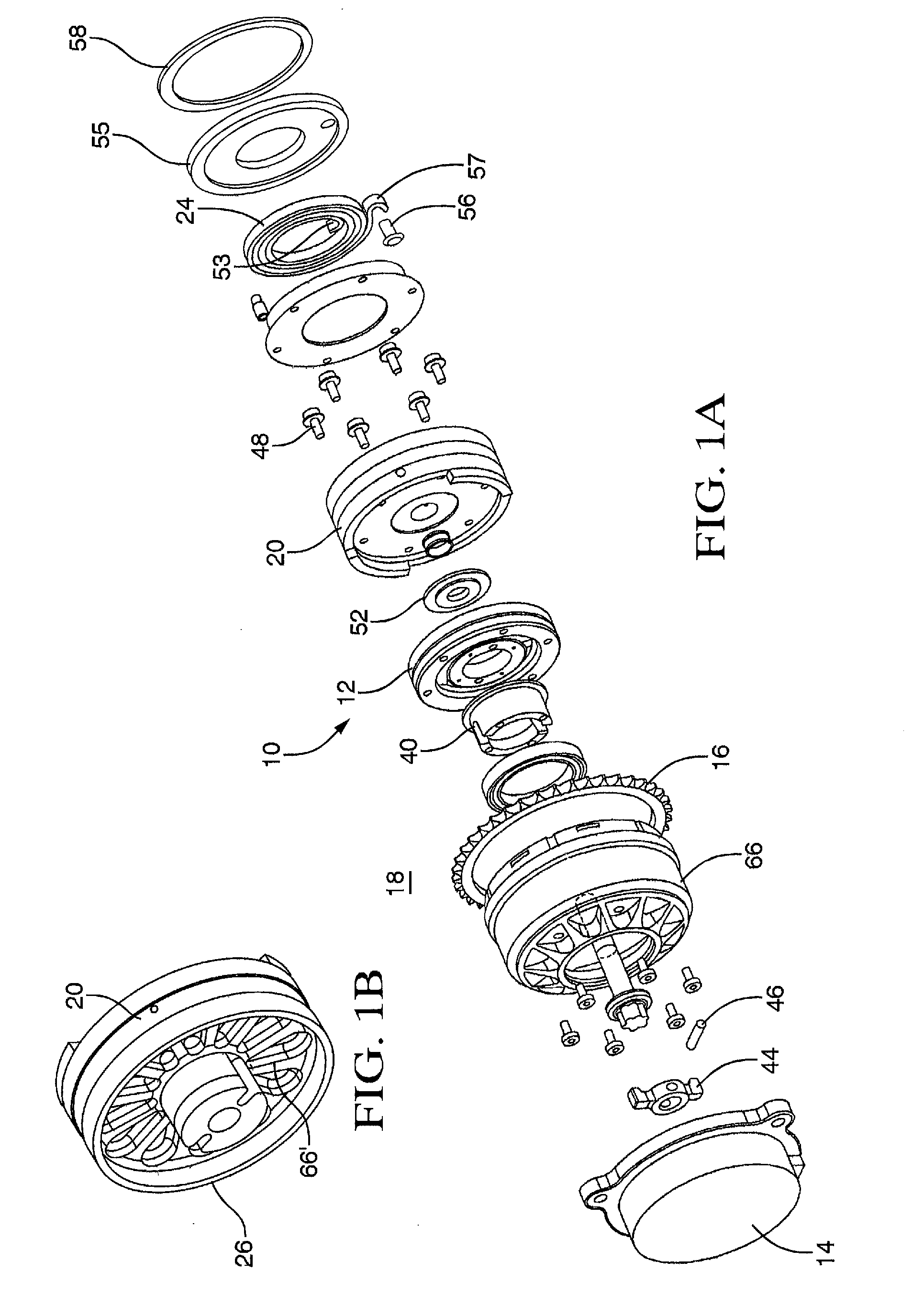

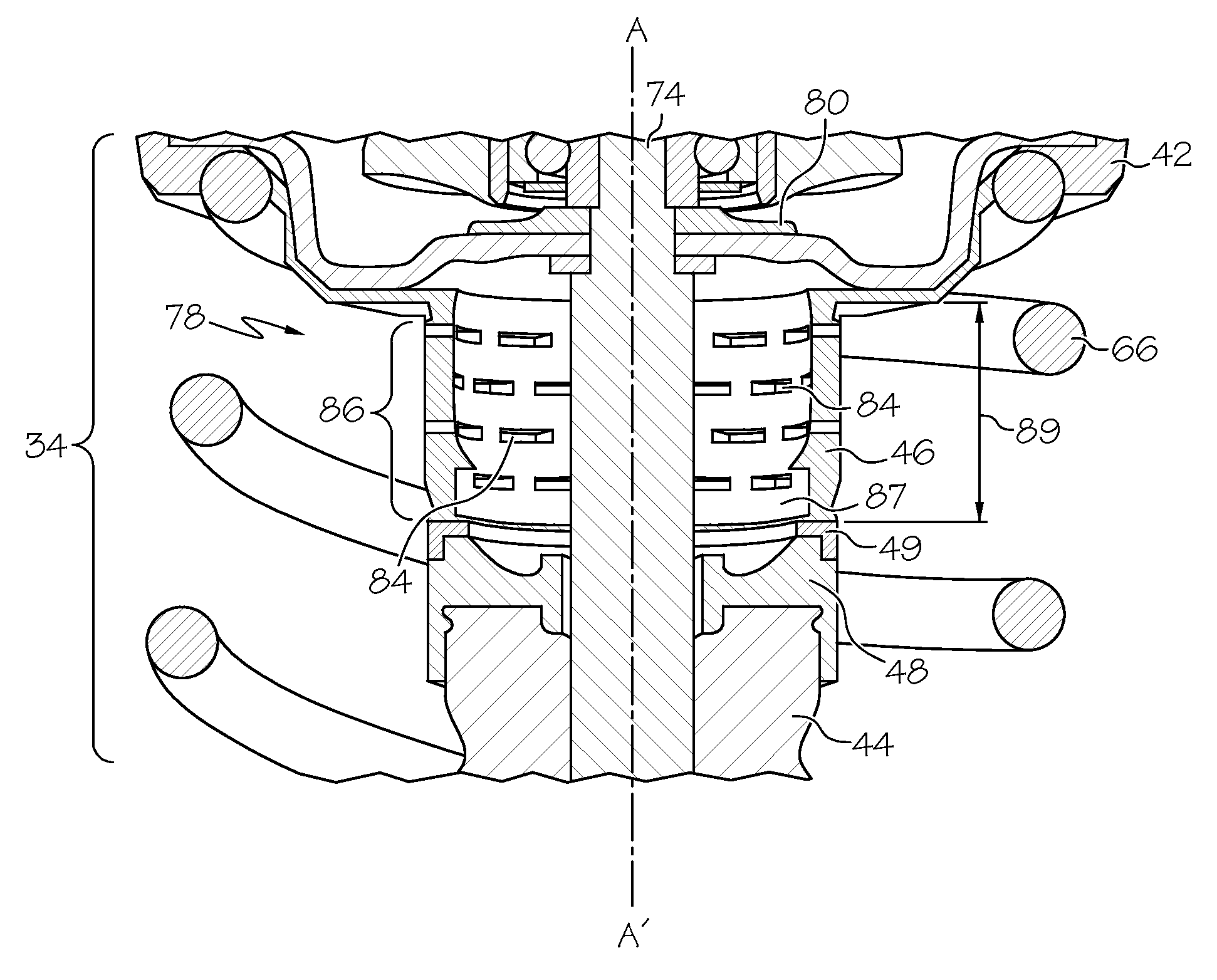

Harmonic Drive Camshaft Phaser with Improved Radial Stability

ActiveUS20110030632A1Obtained inexpensivelyMinimize distortionValve arrangementsMachines/enginesEngineeringHarmonic drive

Improved stiffening and minimized distortion of a housing for an eVCP achieved by forming a plurality of radial housing stiffeners into the housing around the motor mount end and into the eVCP's hub. A back plate is press fit into the rear of the housing, and a straight axial knurl is applied to the surface of the back plate or housing, which knurl permits a larger tolerance-higher press fit class to be used without resulting in significant deformation of the housing. The knurled back plate is harder than the housing, causing the high points of the knurl to plastically deform or plow the housing material during assembly, resulting in less radial deformation of the bore and the journal bearing. An interface between the housing and the hub provides a journal bearing interface to improve axial stability between the hub and housing.

Owner:DELPHI TECH IP LTD

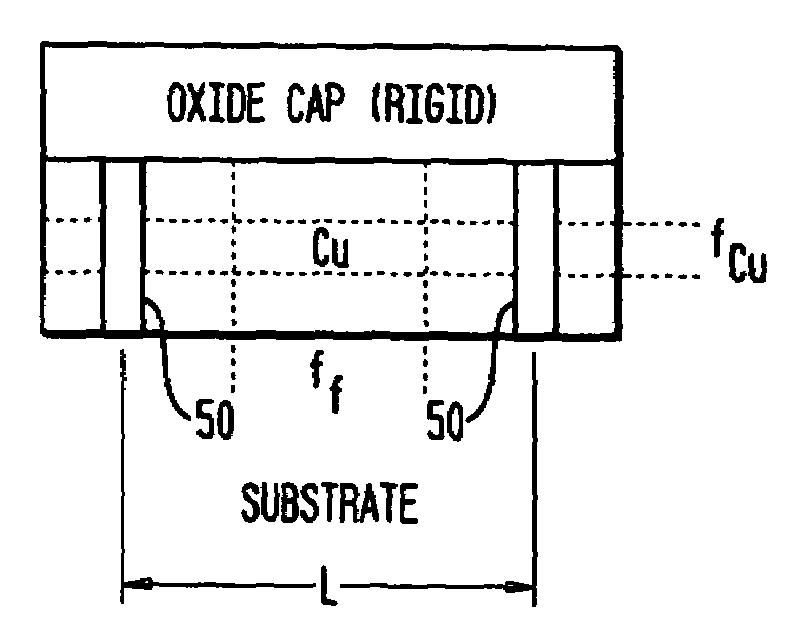

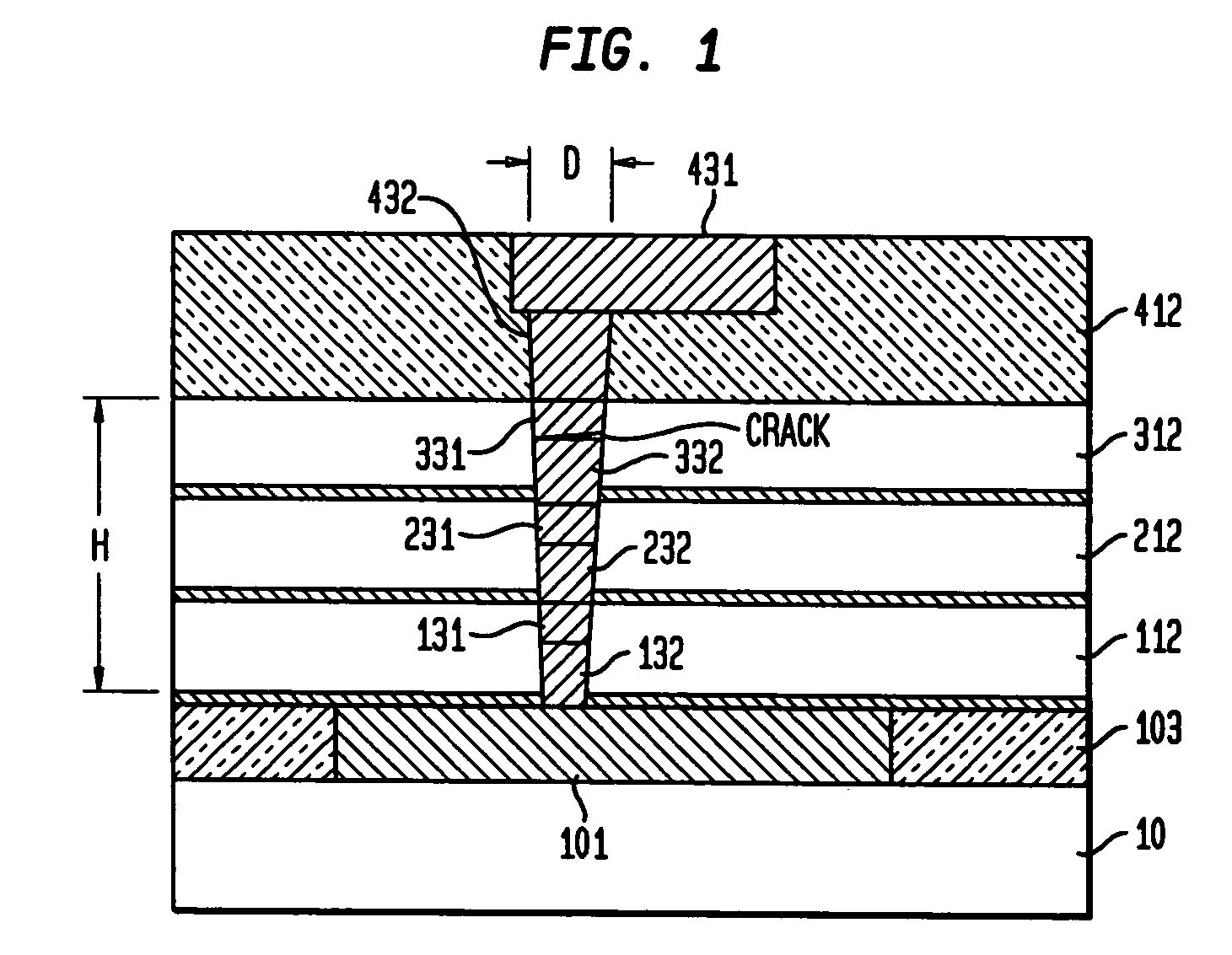

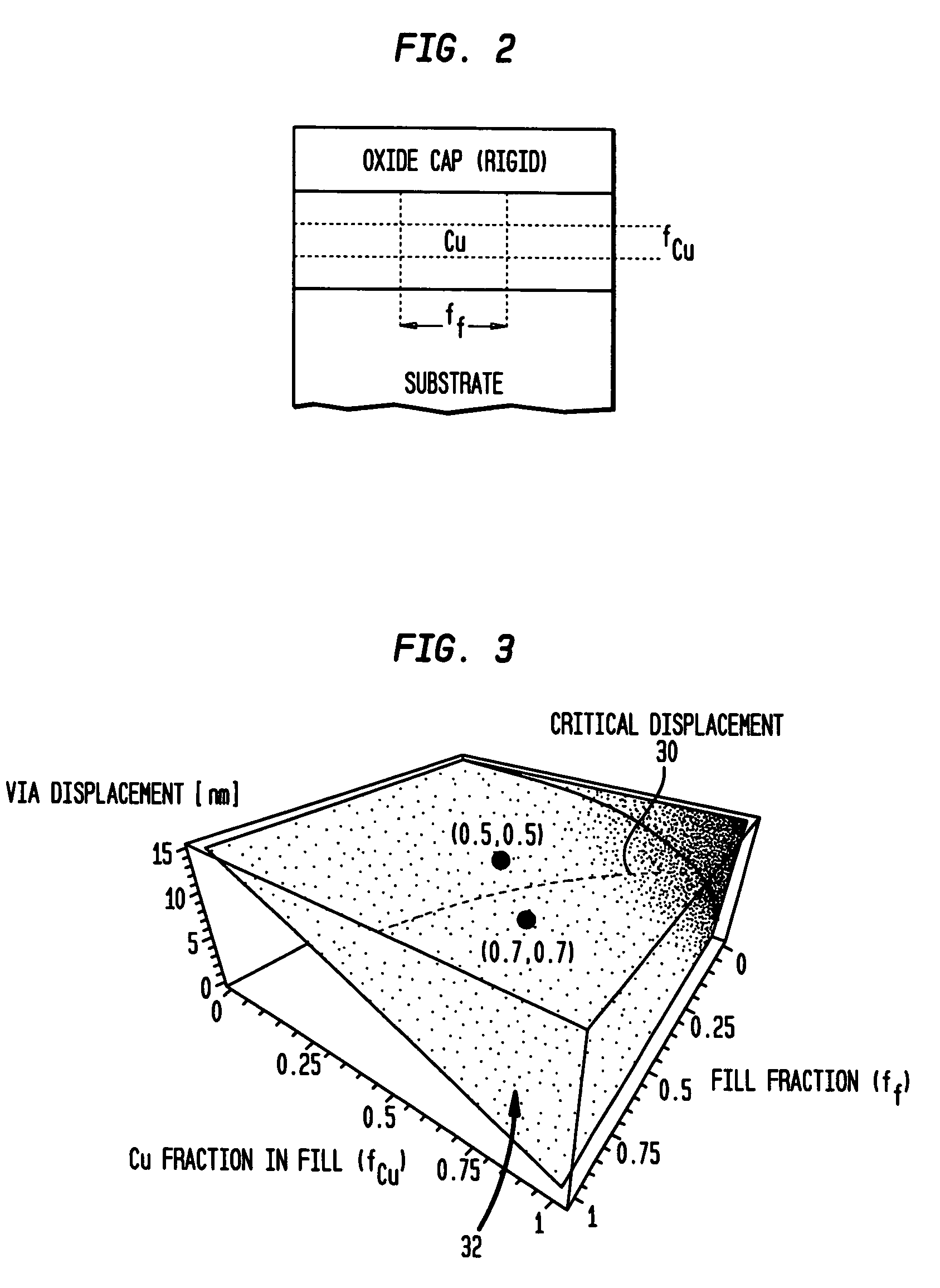

Building metal pillars in a chip for structure support

ActiveUS7067902B2Improve conductivityImprovement factorSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionMetal

Owner:GLOBALFOUNDRIES U S INC

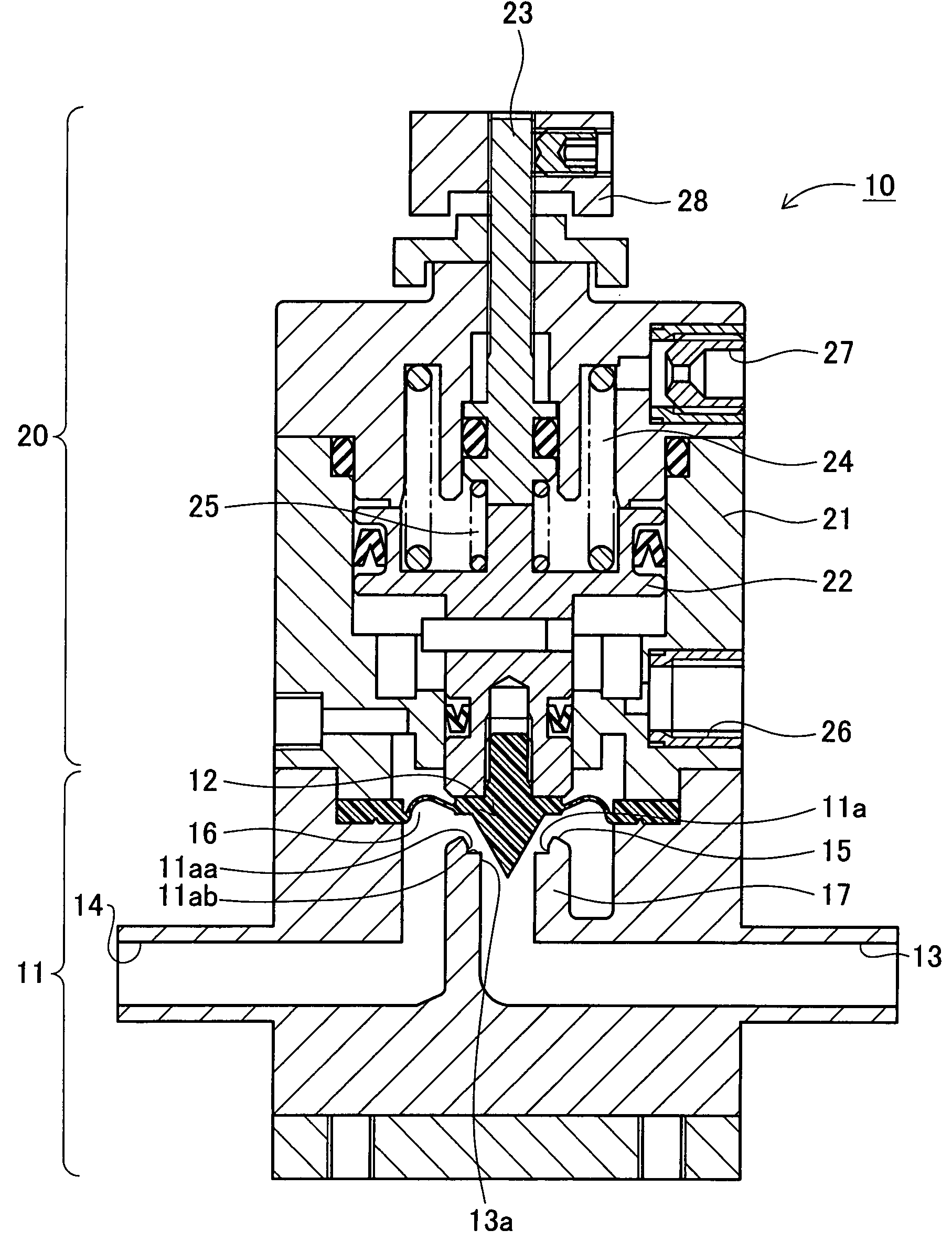

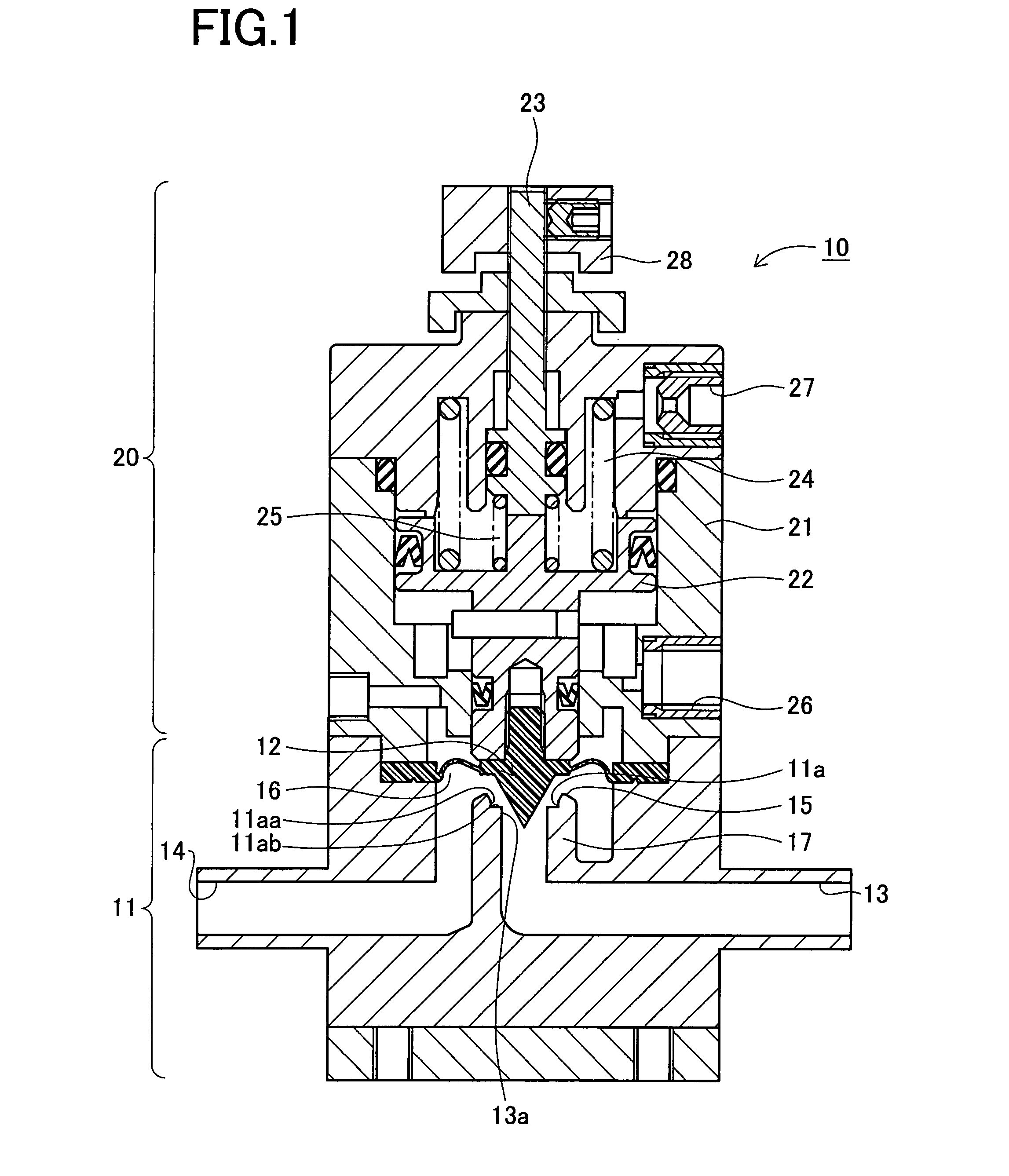

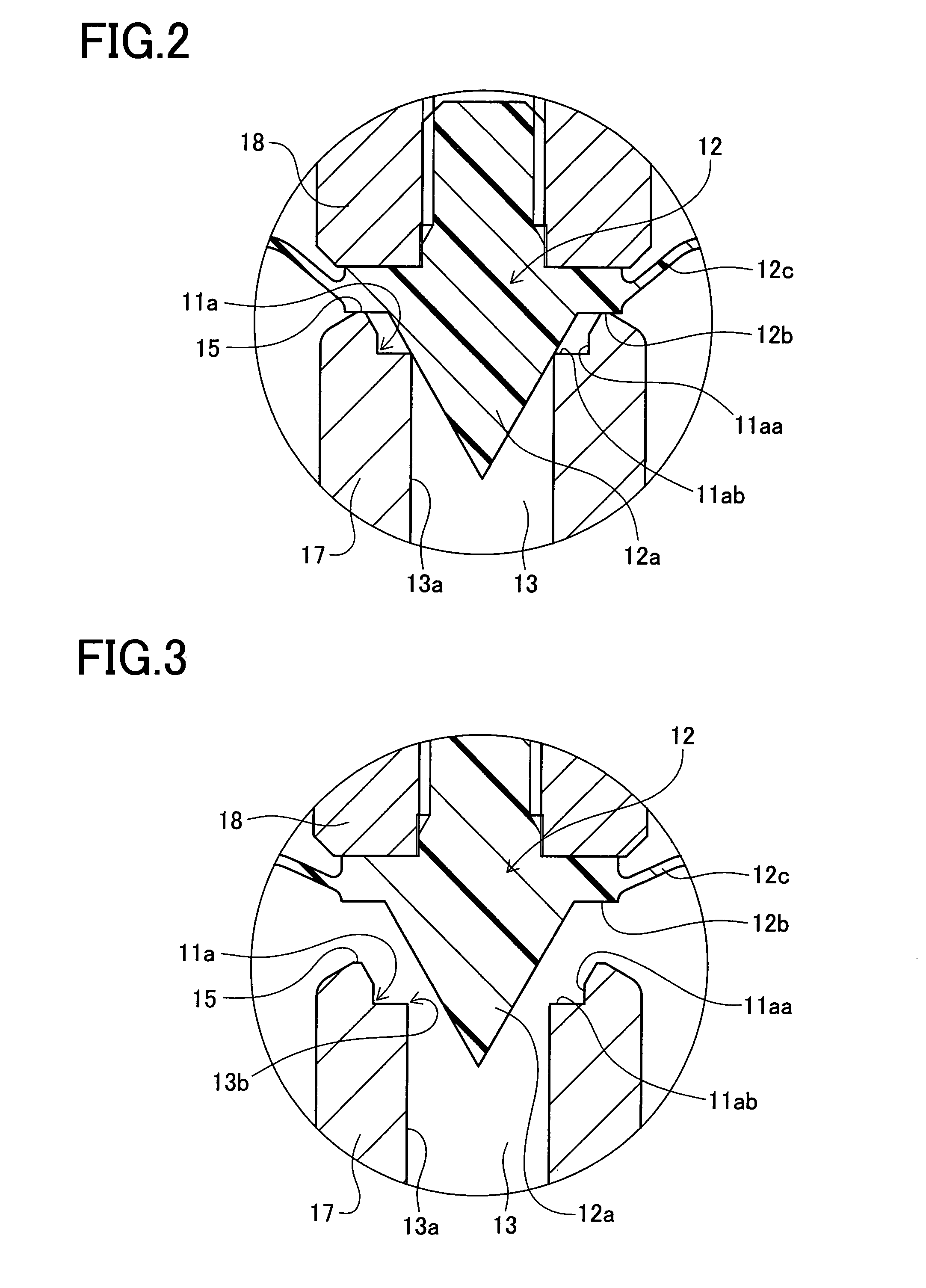

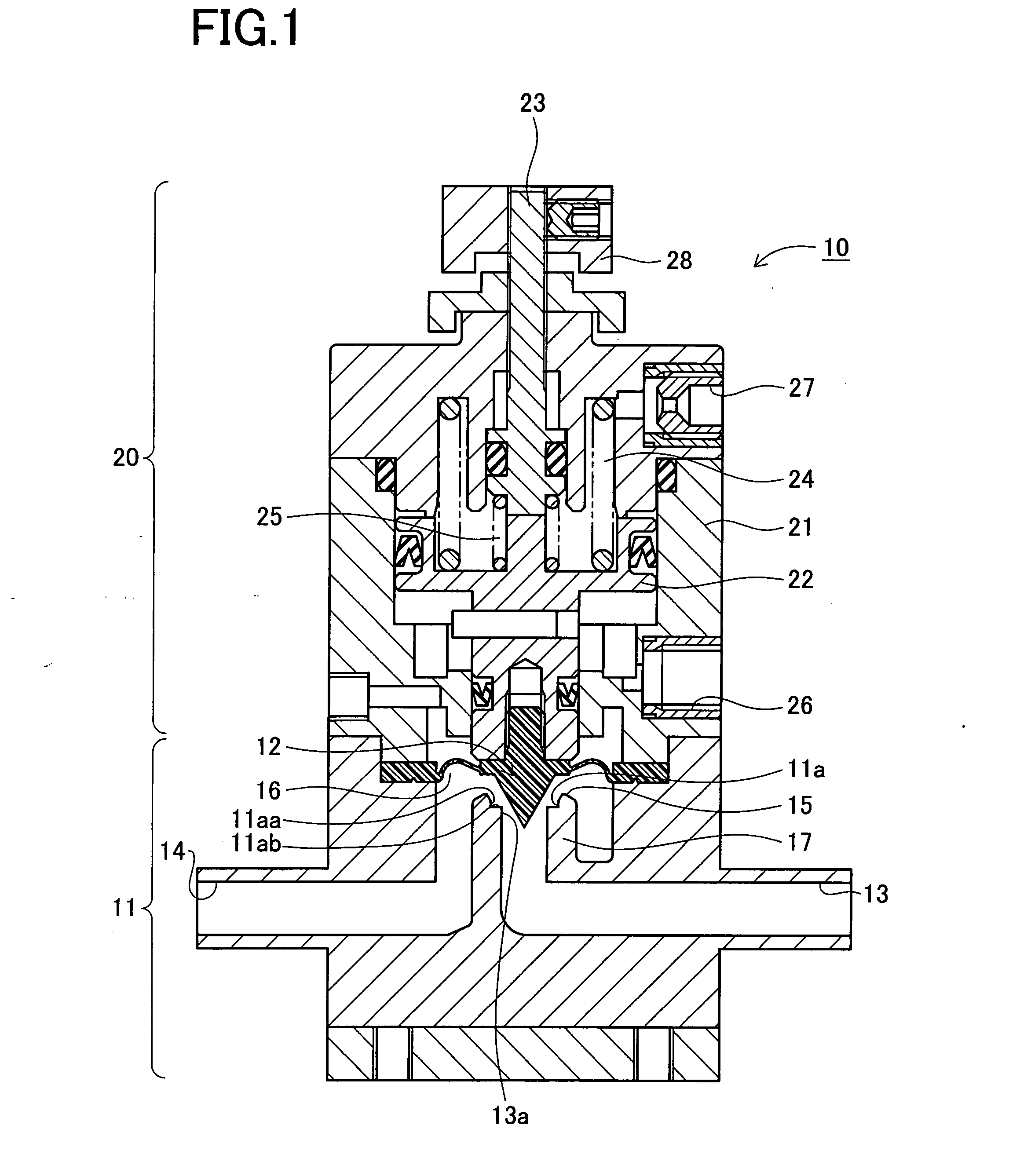

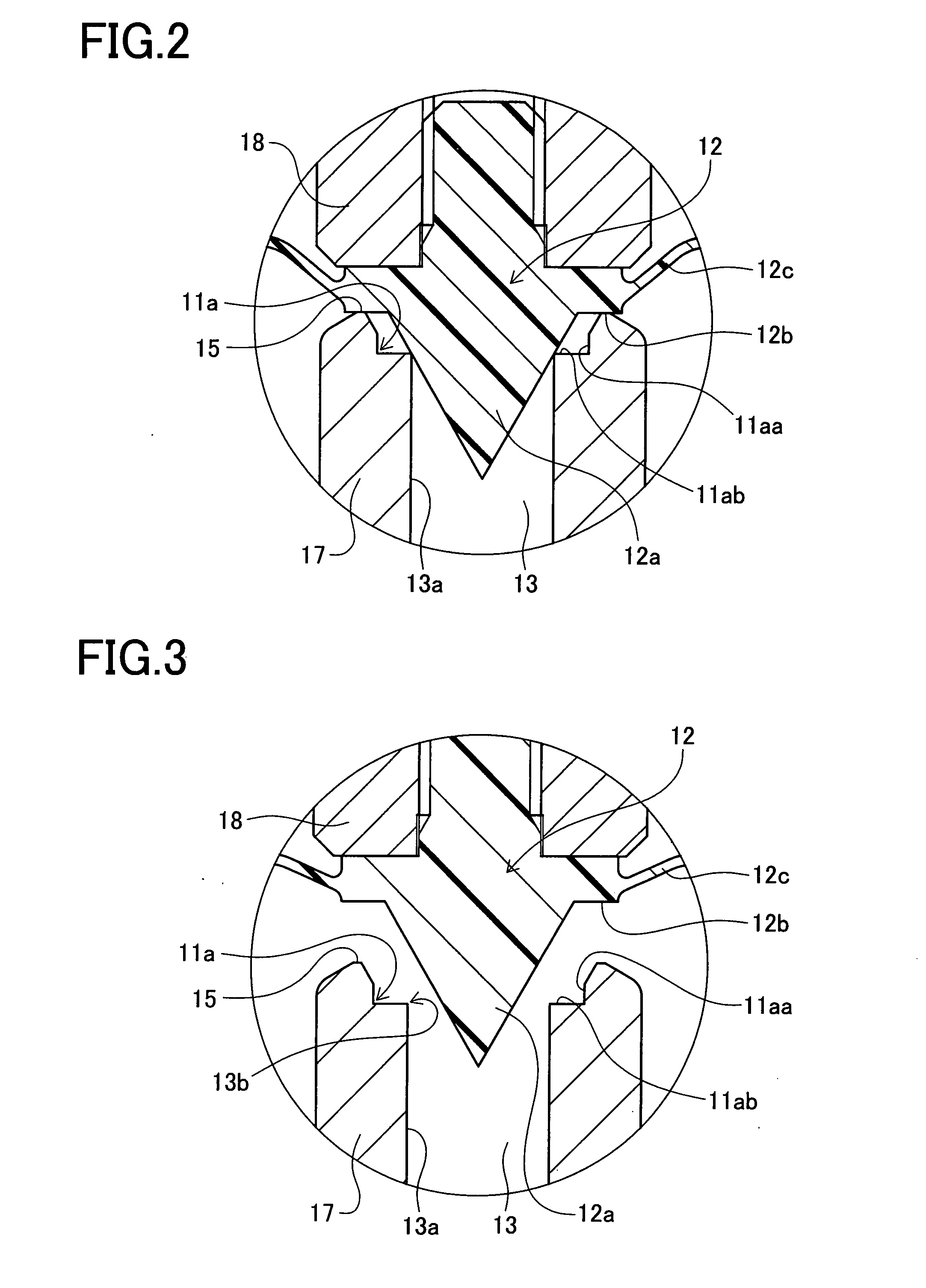

Flow control valve

InactiveUS7537194B2Improve flow stabilityPrevent radial deformationDiaphragm valvesOperating means/releasing devices for valvesEngineeringControl valves

A compact flow control valve with high flow stability is arranged to comprises: a valve body made of resin including; a first passage formed in the valve body; a valve port communicating with the first passage; and a valve seat formed around the valve port; a valve element movable into contact with and away from the valve seat; a valve chamber formed around the valve seat; a second passage communicating with the valve chamber; and a flow adjustment rod for adjusting a flow rate of a fluid allowed to flow in the valve chamber, wherein the flow adjustment rod is adjustable in position to change an opening degree of the valve element relative to the valve seat for adjusting the flow rate, and the flow control valve further comprises an annular recess formed in an inner periphery of the valve seat formed surrounding the valve port and configured to prevent radial deformation of the valve port when the valve element is moved into contact with the valve seat.

Owner:CKD

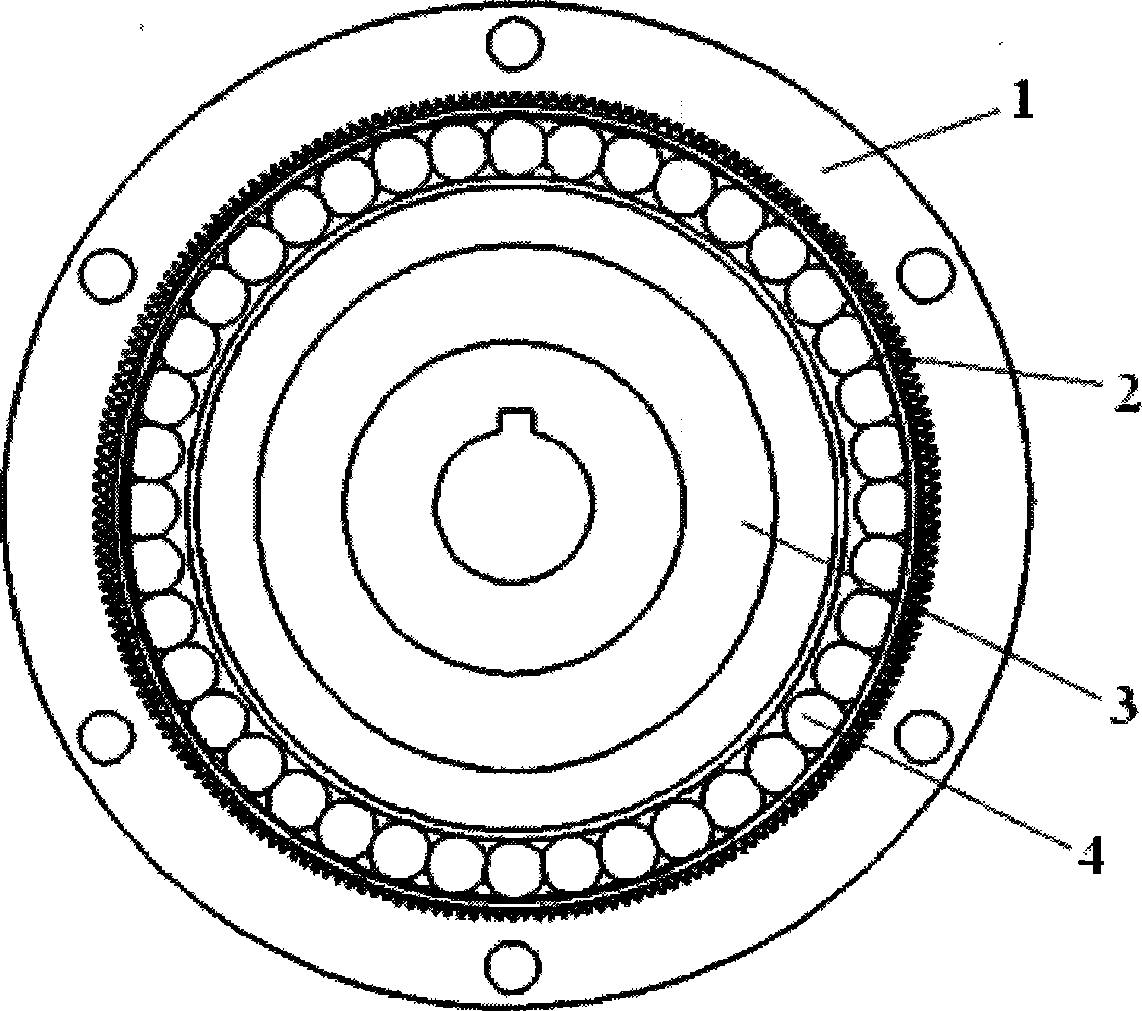

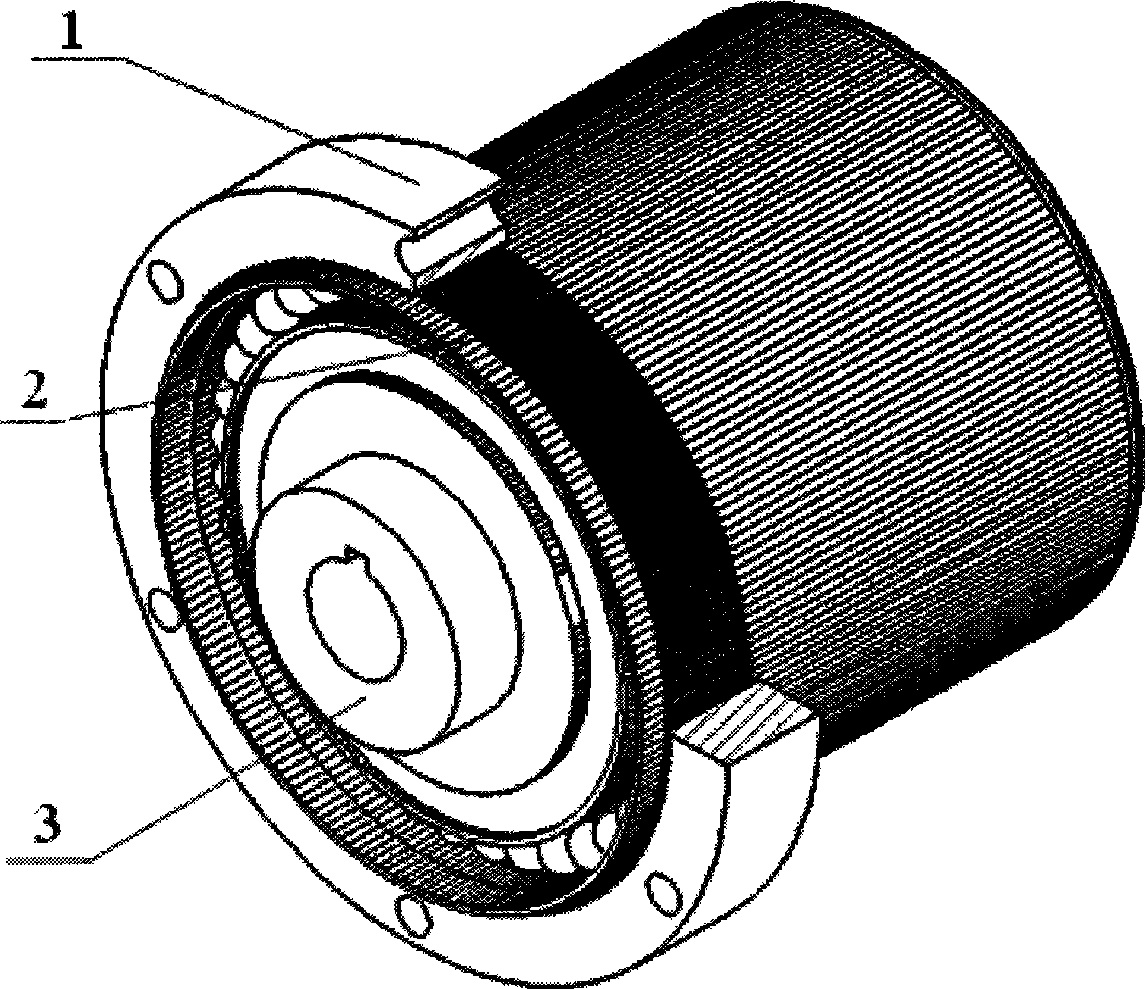

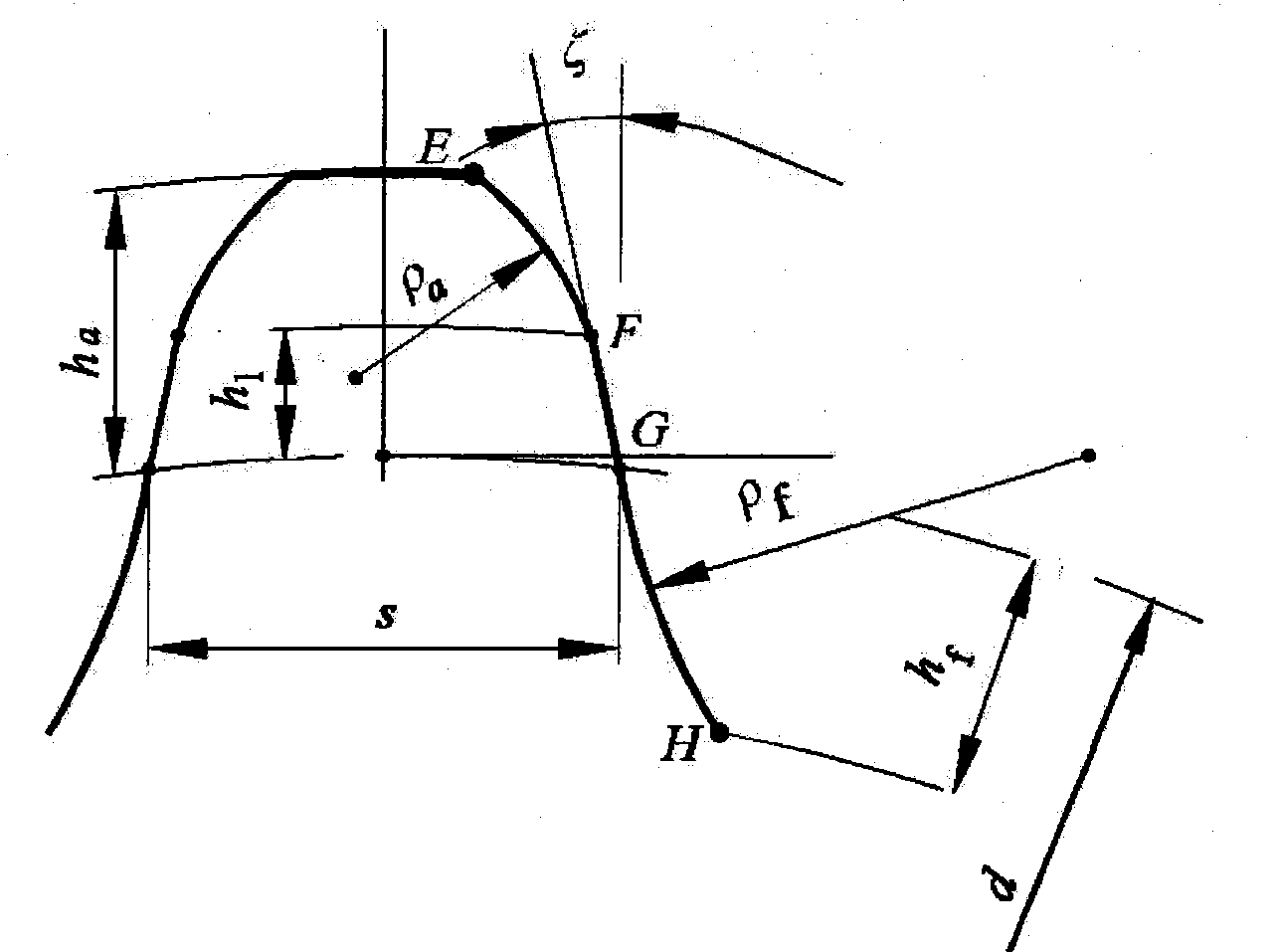

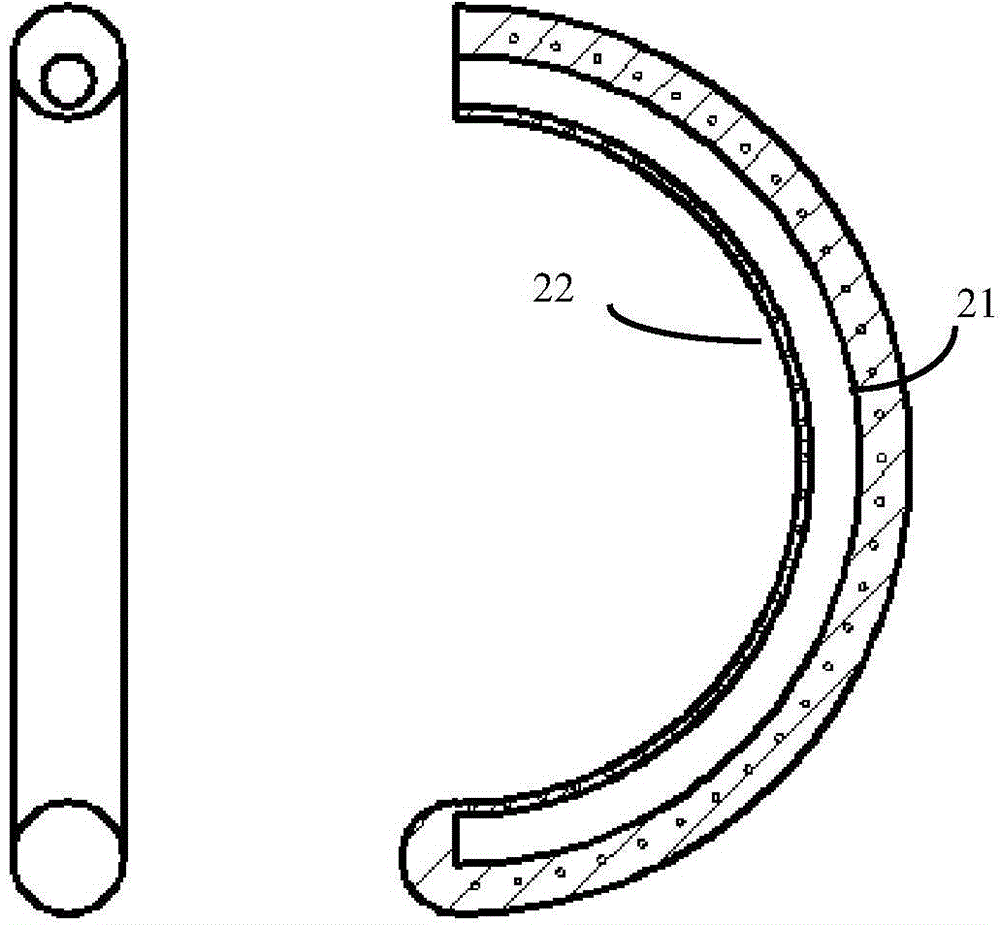

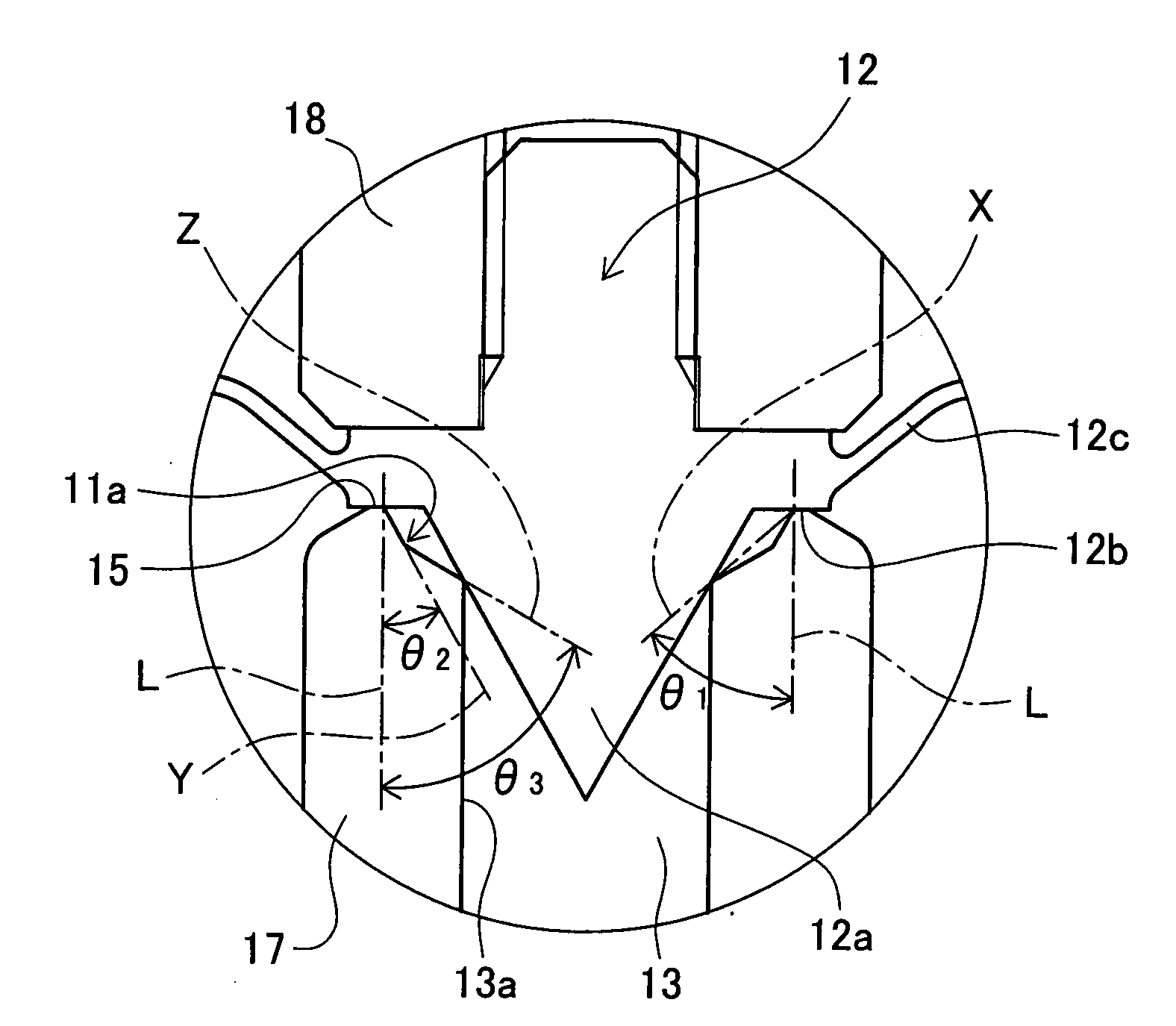

Cup-shaped harmonic gear with common tangent type double-circular arc tooth profile and tooth profile design method of gear

ActiveCN104074948AImprove mechanical propertiesGood meshing effectPortable liftingGearing elementsHarmonicEngineering

The invention provides a cup-shaped harmonic gear with a common tangent type double-circular arc tooth profile. The cup-shaped harmonic gear is composed of a wave generator, a flexible gear and a rigid gear; the tooth profiles of the flexible gear and the rigid gear of the harmonic gear transmission are common tangent type double-circular arc plane tooth profile. The invention also provides a tooth profile design method of the cup-shaped harmonic gear with the common tangent type double-circular arc tooth profile; the tooth profile design method comprises taking the coning deformation of the cup-shaped flexible gear in the axial direction into account, and in order to avoid interference, performing enveloping and fitting calculation on the circular arc part of the tooth root of the rigid gear by use of the movement locus of the gear teeth of the front section of the flexible gear according to the maximum radial deformations on the front, middle and rear sections of the flexible gear and the movement locus difference of the gear teeth of the flexible gear relative to the tooth groove of the rigid gear, and performing enveloping and fitting calculation on the circular arc part of the tooth crest of the rigid gear by use of the movement locus of the gear teeth of the rear section of the flexible gear so that the flexible gear and the rigid gear are in continuous conjugate transmission in the entire engagement interval. The cup-shaped harmonic gear with the common tangent type double-circular arc tooth profile has the advantages of increased number of engaged teeth, increased engagement contact surface, high bearing capacity, long fatigue life and the like.

Owner:TIANJIN POLYTECHNIC UNIV

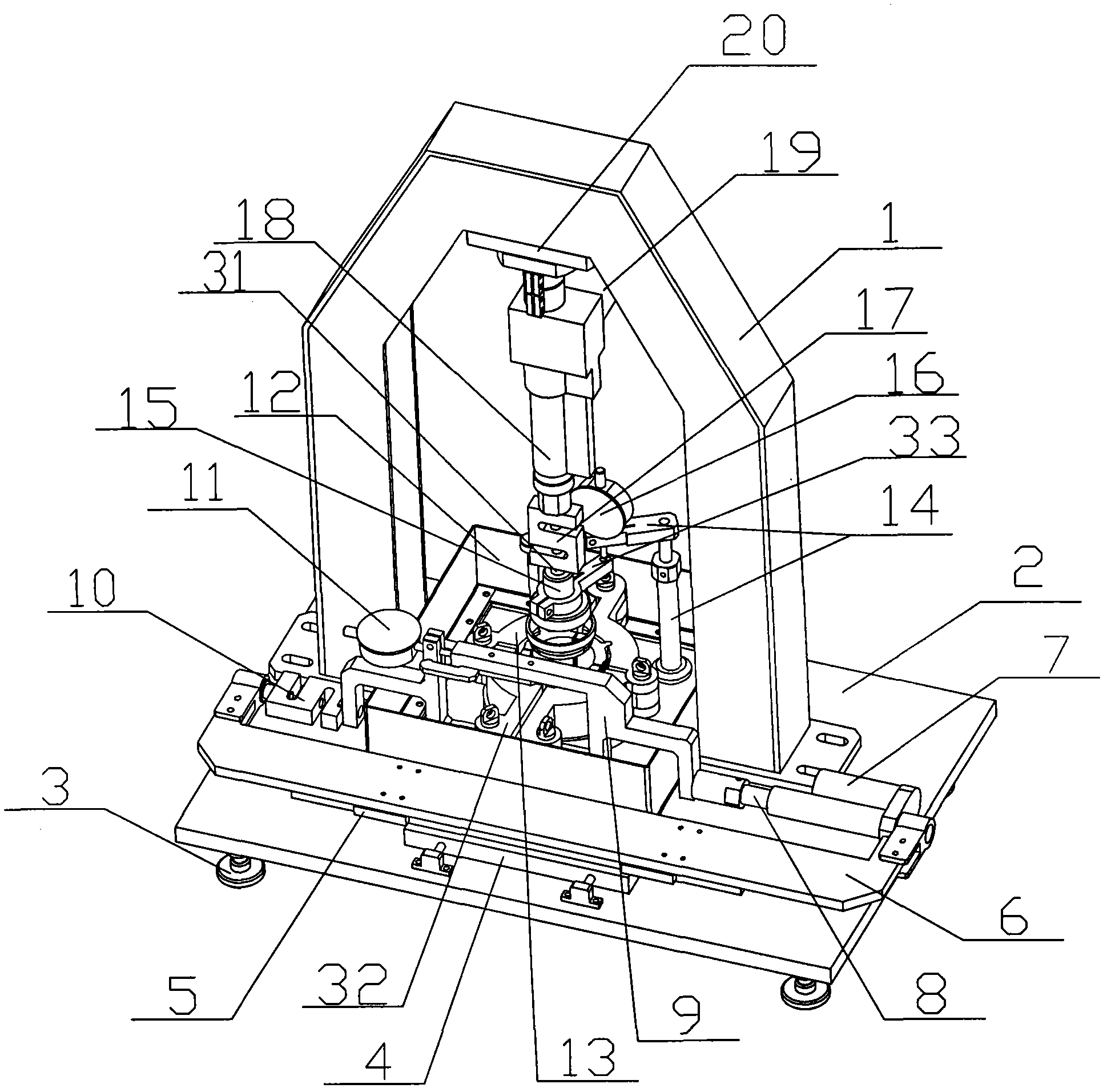

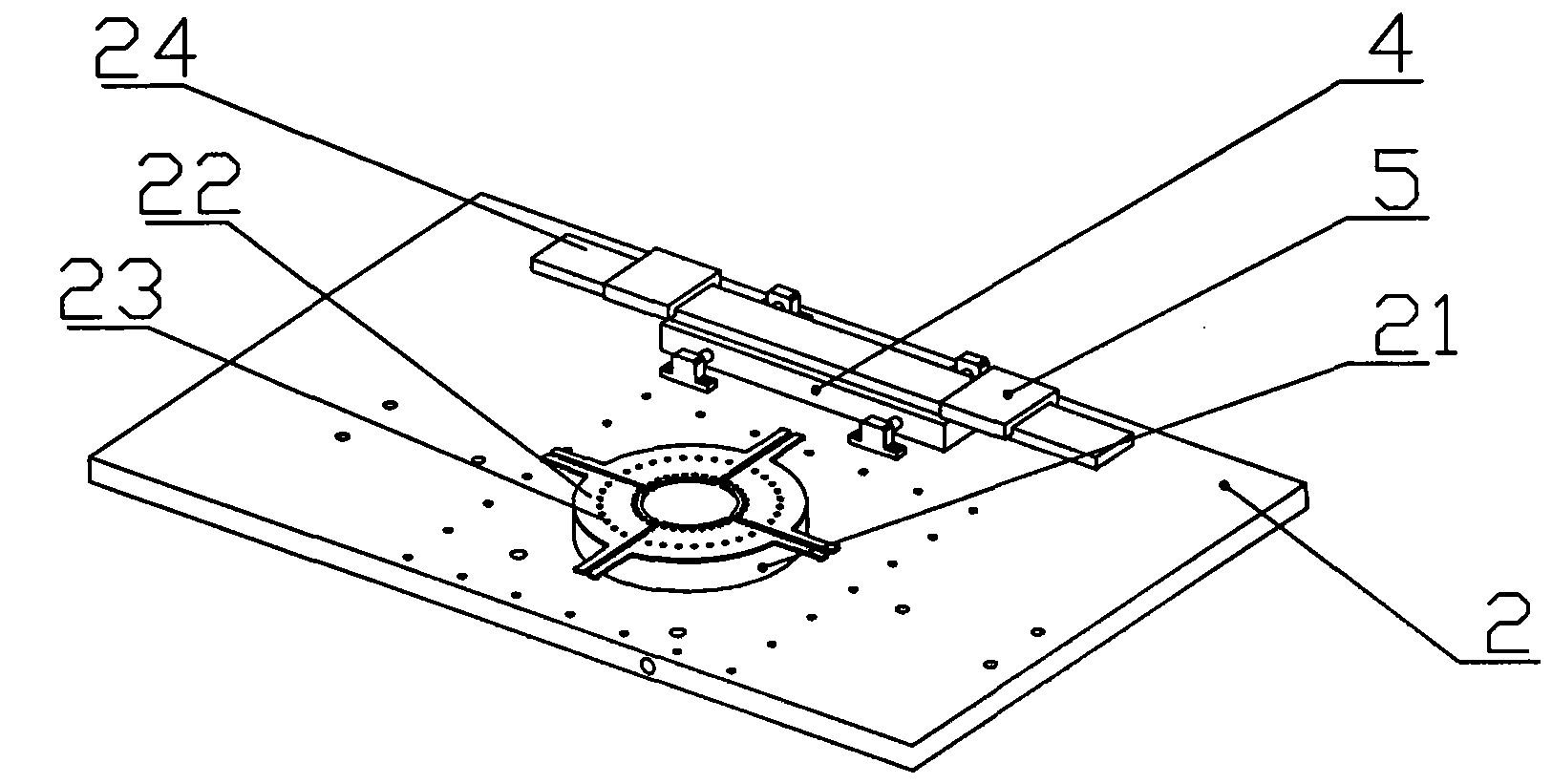

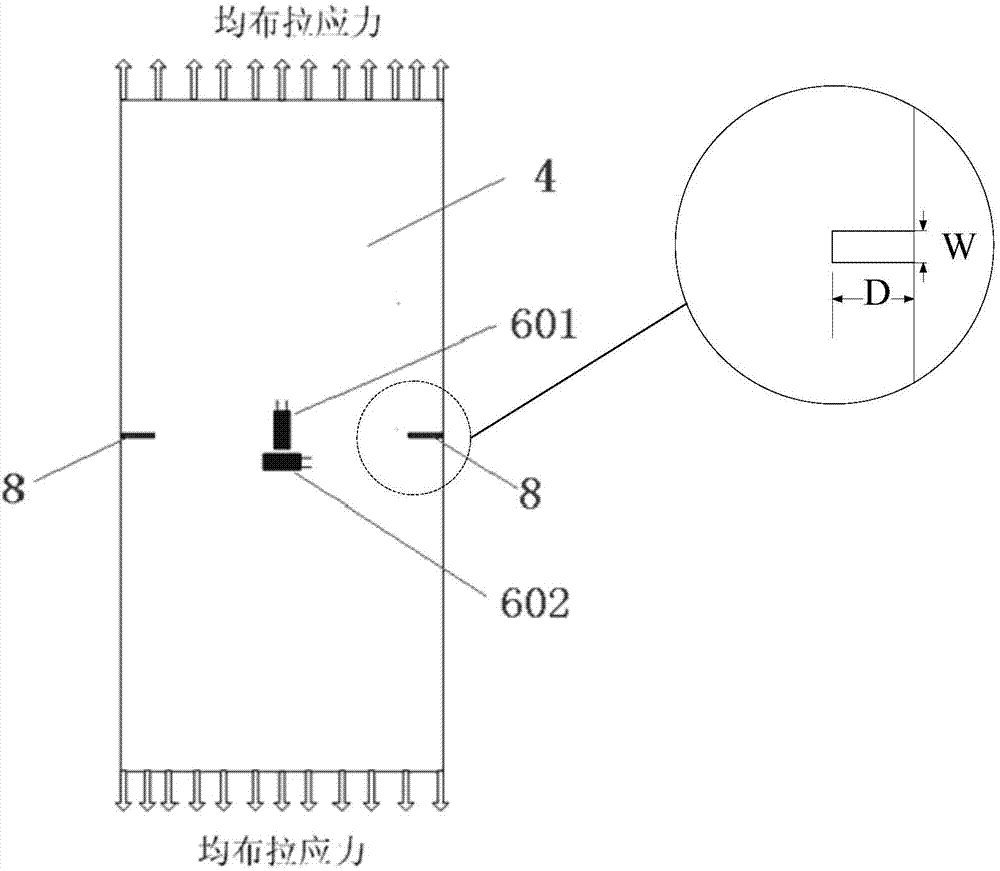

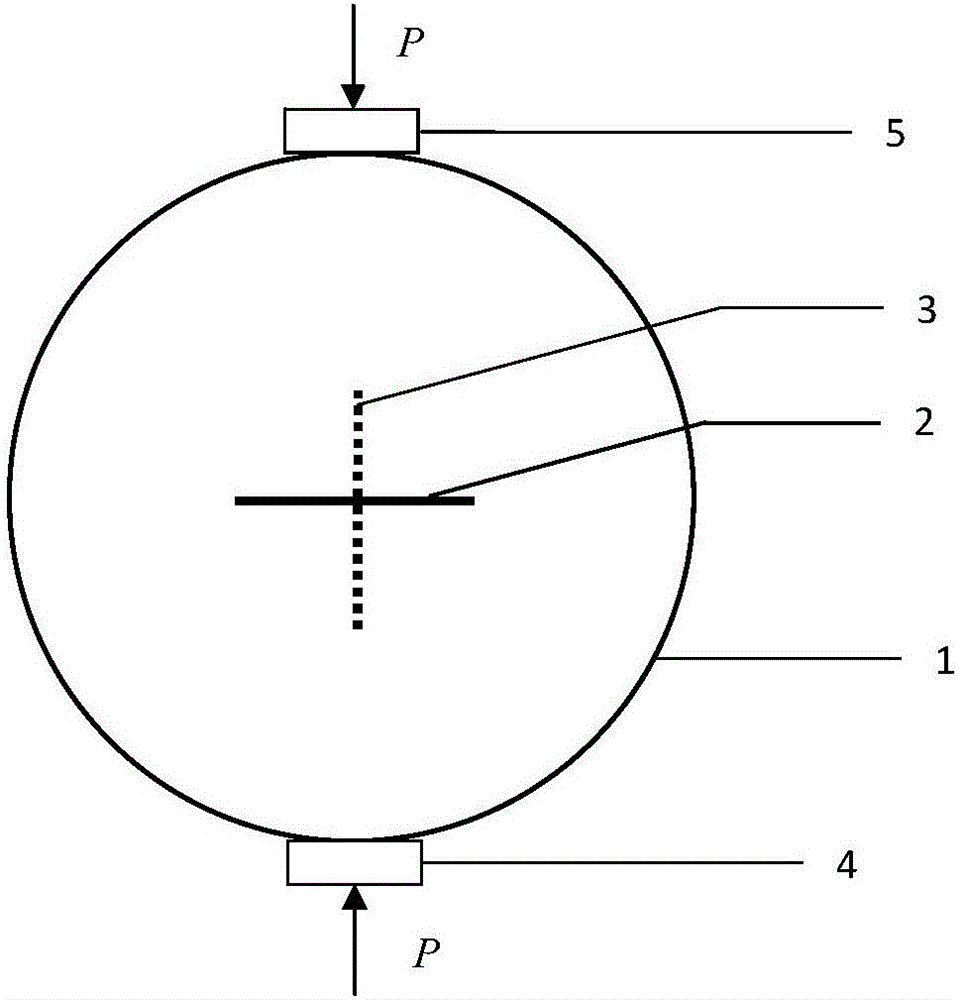

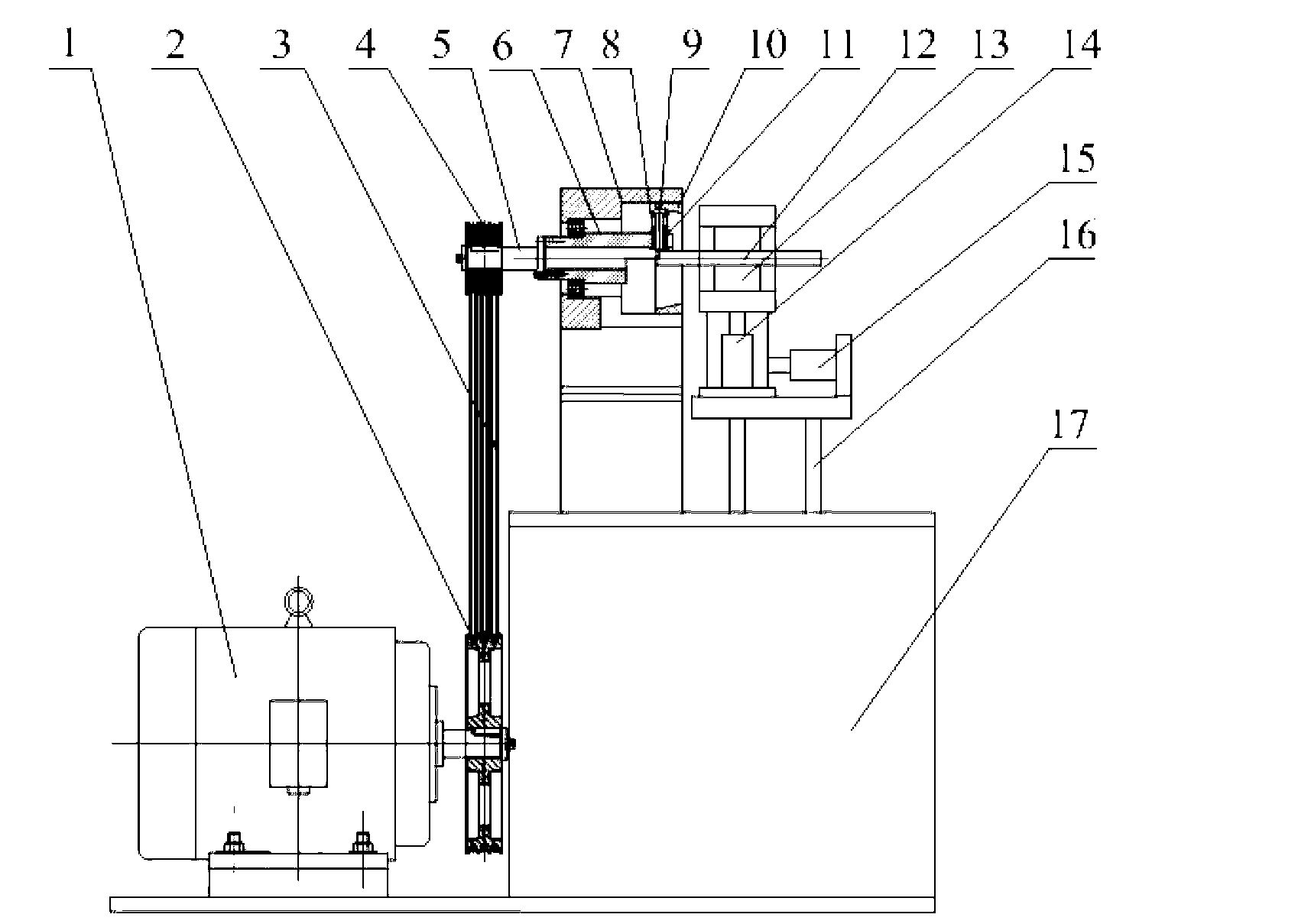

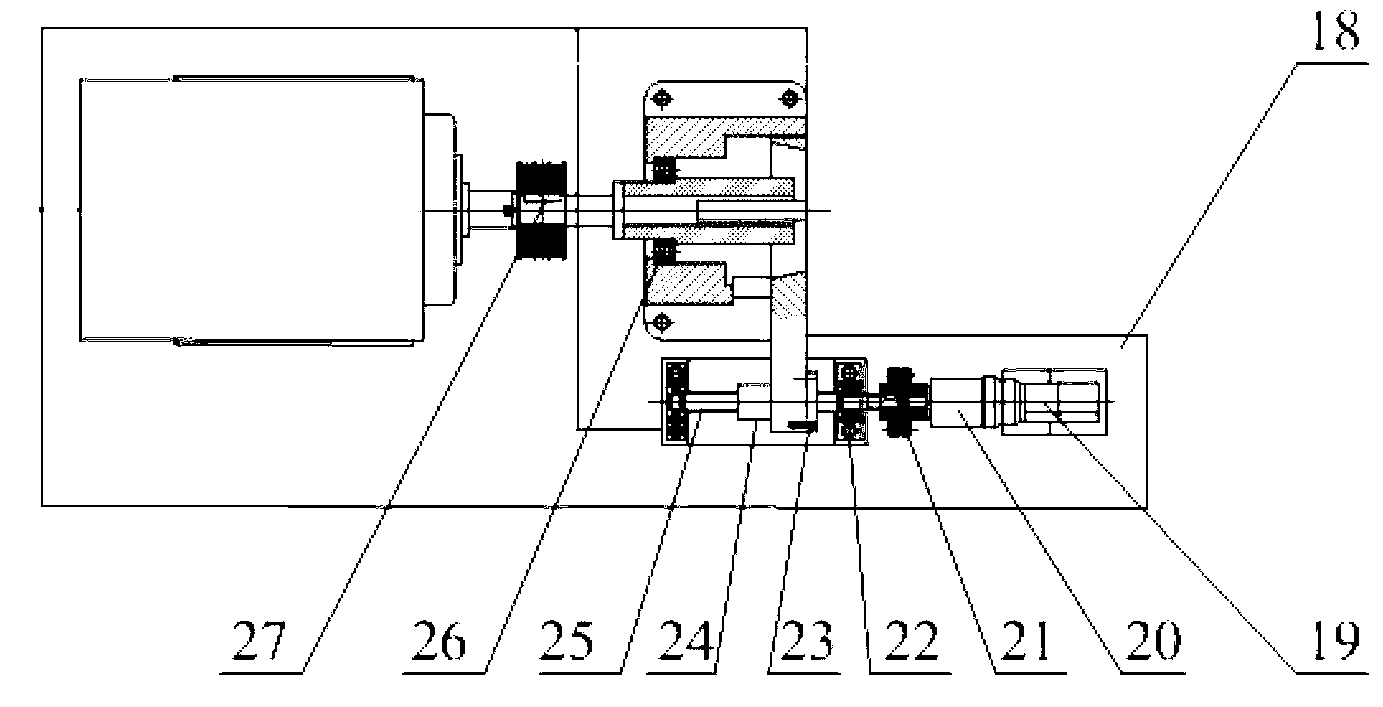

Tester for soil vertical and radial expansive deformation and expansive force relation

InactiveCN102636427ASolve the above deficienciesOvercome deficienciesEarth material testingUsing mechanical meansData acquisitionTester device

The invention discloses a tester for testing soil vertical and radial expansive force and expansive deformation. The tester comprises a frication force reducing device, a sample protecting ring component, a confining pressure and radial deformation testing component, a vertical pressure and deformation testing component and a data acquirer. The friction force reducing device is located in a soaking tank; the sample protecting ring component is placed on the friction force reducing device at the center of the soaking tank; and the data acquirer is connected with sensors in the vertical pressure and deformation testing component and the confining pressure and radial deformation testing component via data lines, and transmits acquired data to a computer. The tester can be used for testing vertical and radial expansive forces in a sample saturation process when vertical and radial displacements are not changed and obtaining the change law of the vertical and radial expansive forces, testing vertical and radial expansive forces under the condition of different vertical displacements in the sample saturation process when the radial displacement is changed or not changed, and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

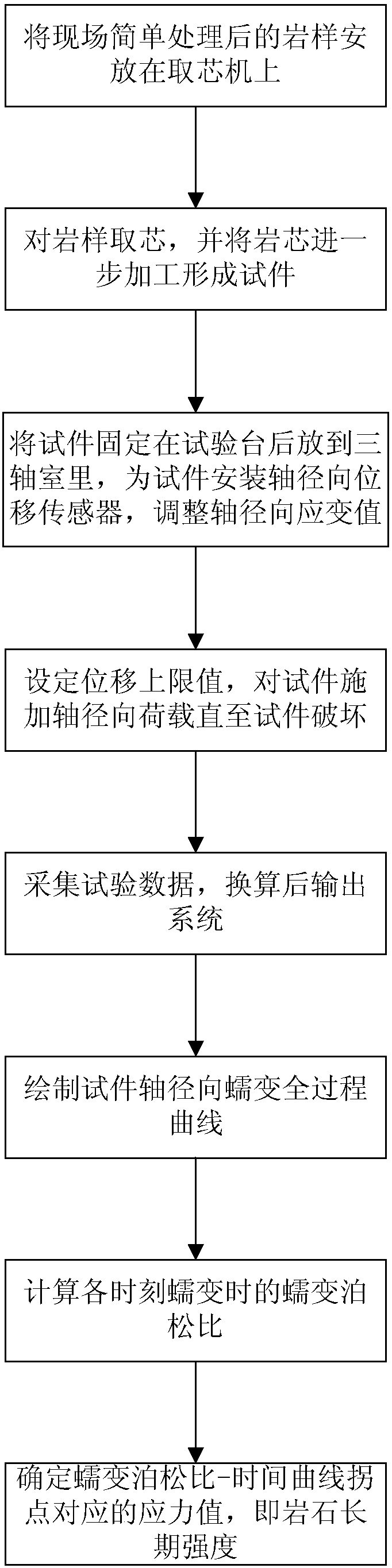

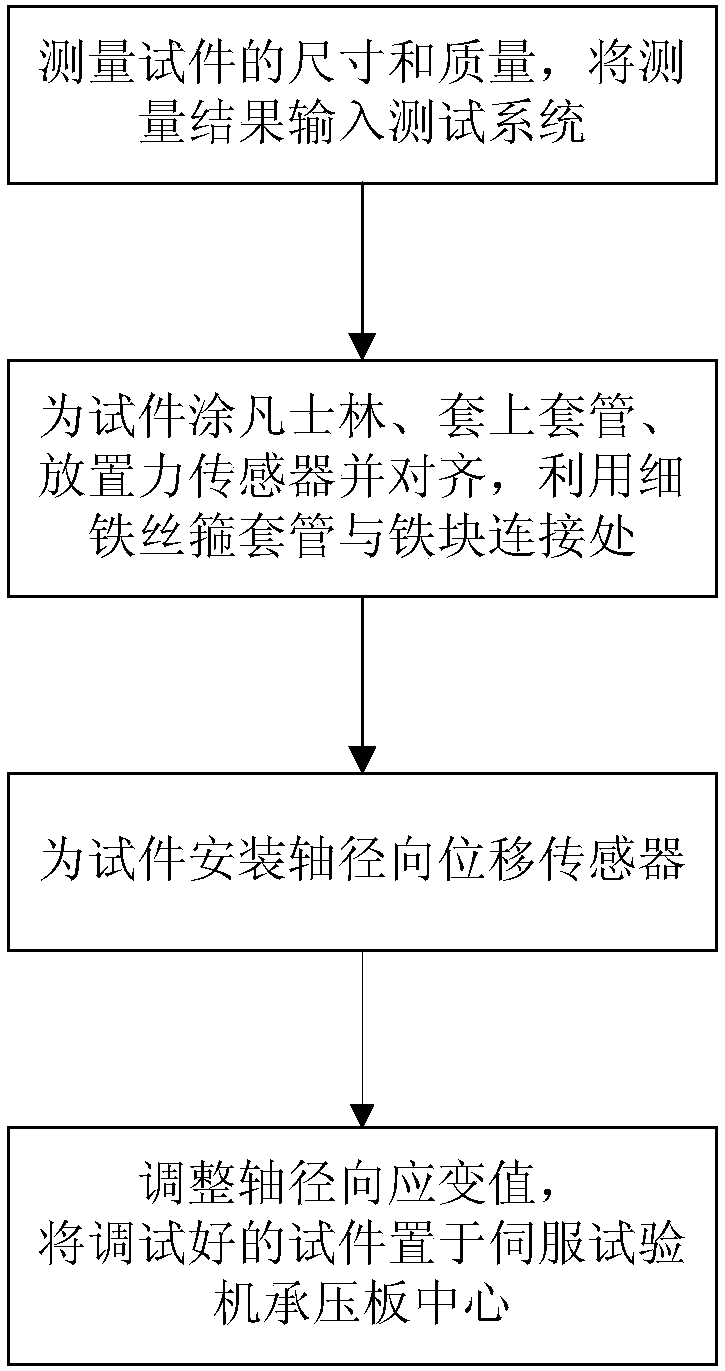

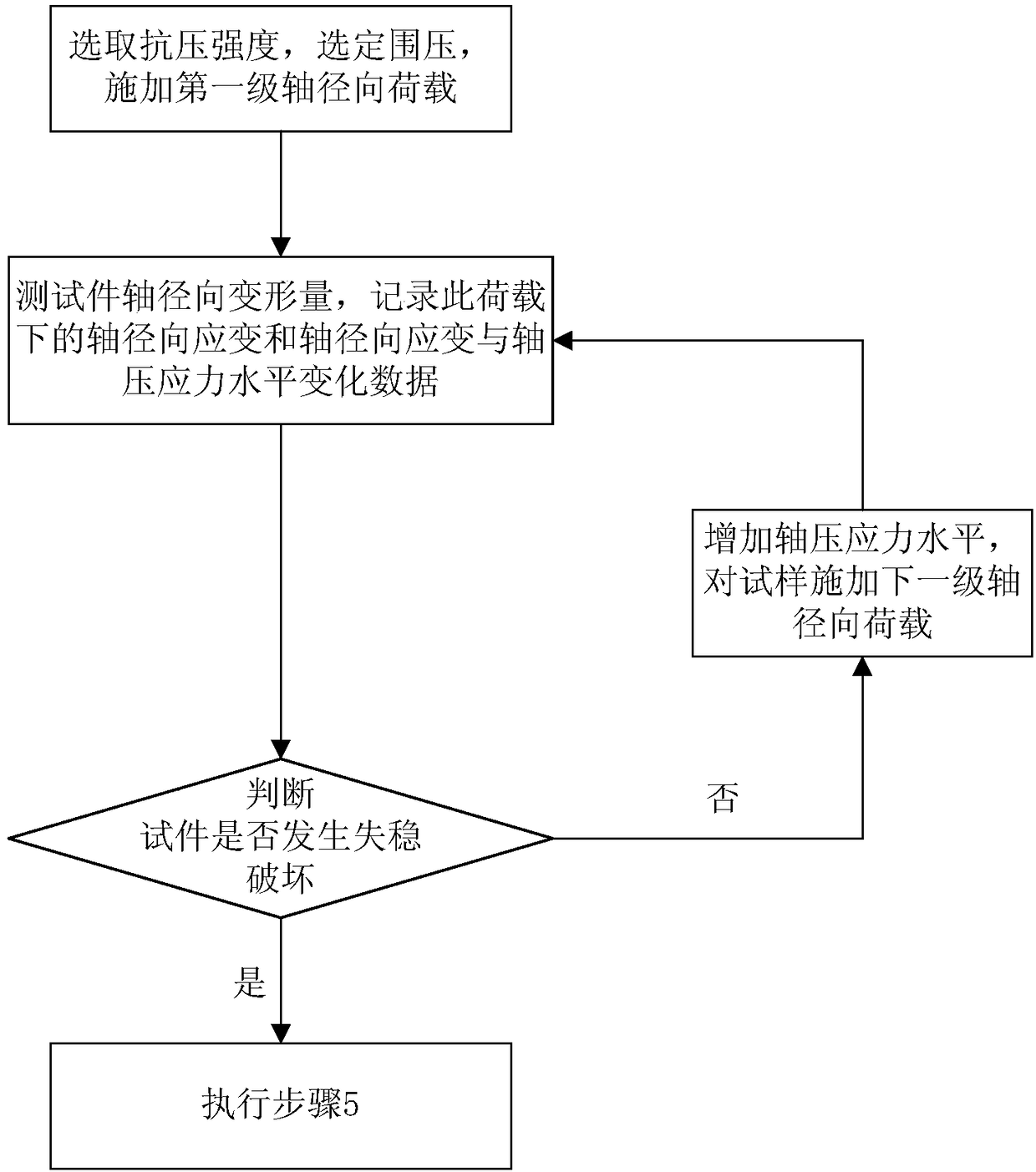

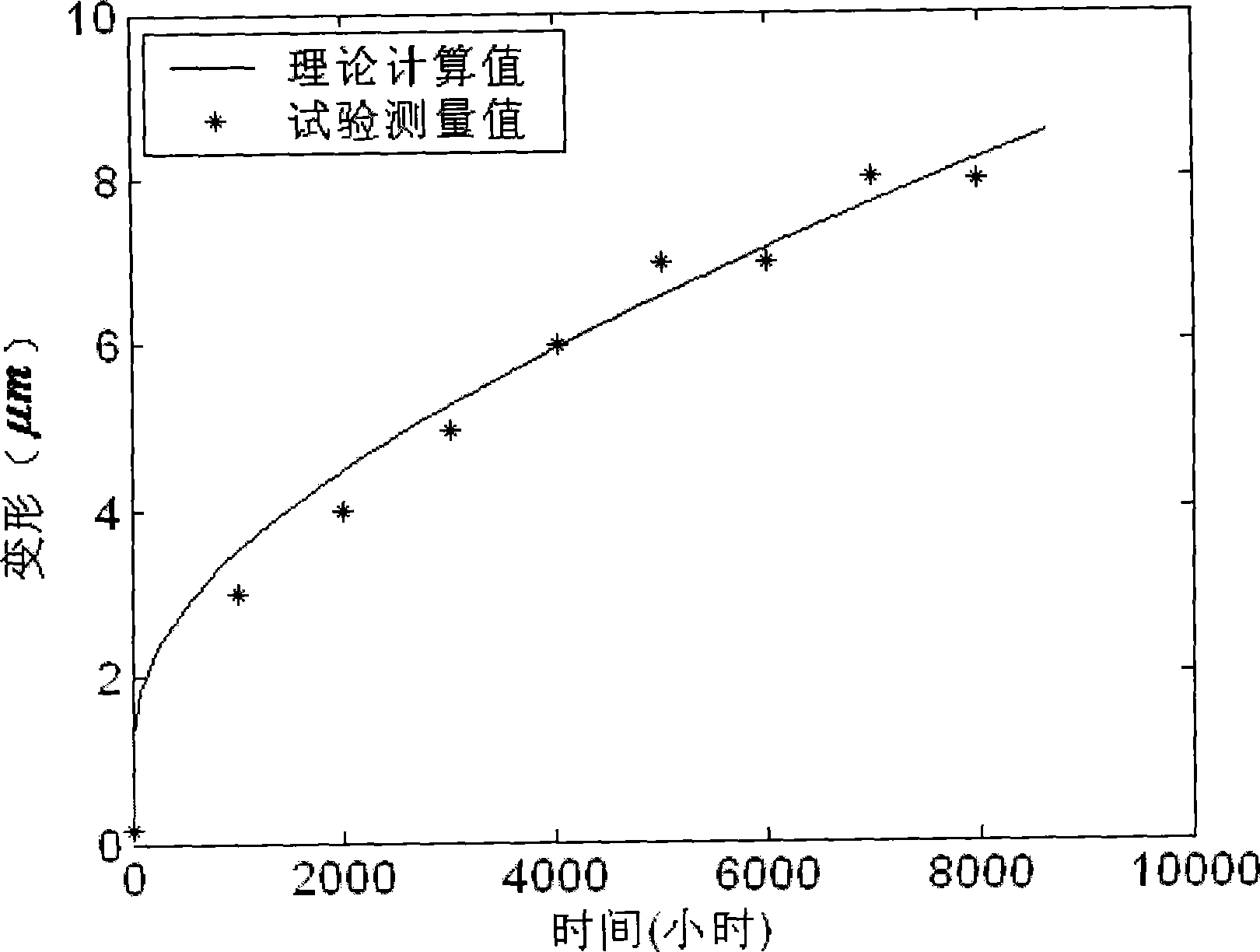

Method of determining long-term strength in rock creep tests

InactiveCN108152137AImprove accuracyMaterial strength using tensile/compressive forcesRock engineeringRock core

The invention provides a method of determining long-term strength in rock creep tests, and relates to the technical field of rock mechanics. The method includes coring field rock samples; processing rock cores to form test pieces; mounting and adjusting axial and radial displacement sensors for the test pieces; applying axial and radial load to the test pieces until the text pieces are destroyed;acquiring test data, and converting and outputting the test dada; plotting axial and radial creep curves of the test pieces; computing creep Poisson ratios at various moments; determining the long-term strength of rock. The method for determining the long-term strength in the rock creep tests has the advantages that influence of axial and radial deformation in the rock creep procedures on the performance of the rock is comprehensively considered according to actual ductile dilation deformation of the rock, the creep time is segmented, creep Poisson ratio -time curves are plotted, the long-termstrength of the rock is determined according to stress corresponding to data of inflection points of the curves, accordingly, the timeliness of the rock can be effectively reflected by the solved long-term strength, subjective judgment can be eliminated, and the method is simple and reliable, is high in accuracy and is easy to popularize and apply to actual rock engineering.

Owner:LIAONING TECHNICAL UNIVERSITY

Deformable brush seal support

InactiveUS6840518B2Improve engine efficiencyAvoid damageEngine sealsLeakage preventionBristleEngineering

A brush seal is provided for sealing between a rotating shaft and a housing. The brush seal includes an annular rim or head portion coaxial with the shaft and mounted on the housing, an annular array of bristles extending from the head portion toward the shaft for contact with the shaft at their ends, and an annular bristle support plate extending from the head portion toward the shaft. The support includes voids arranged to accommodate radial deformation in the support due to rubbing contact between the support and the shaft without incurring any substantial accompanying axial deformation which would distort the bristles and cause deterioration of their sealing function.

Owner:ANSALDO ENERGIA SWITZERLAND AG

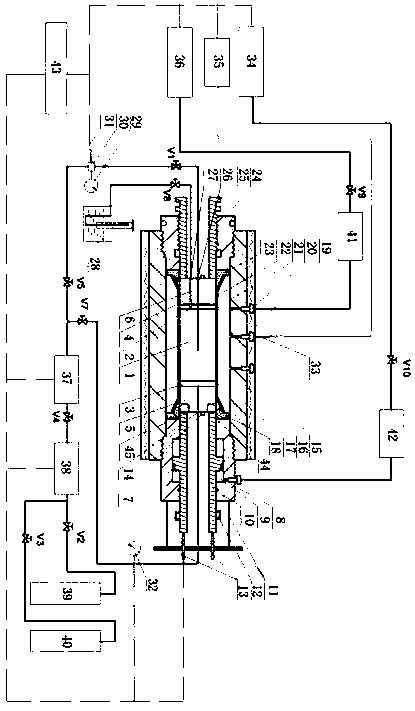

Supercritical carbon dioxide fracture-creepage-seepage test device for high-temperature high-pressure coal petrography

InactiveCN110057739AMonitor pressureRich researchPermeability/surface area analysisEngineeringHigh pressure

The invention discloses a supercritical carbon dioxide fracture-creepage-seepage test device for high-temperature high-pressure coal petrography. The device comprises a triaxial cell, a supercriticalcarbon dioxide generator system, an axle load and confining pressure loading system, an acoustic emission monitoring system, a temperature rise control system, a deformation-pressure monitoring systemand a permeability measuring system. The device is capable of realizing the supercritical carbon dioxide fluid fracture test of coal petrography under high temperature and high pressure, monitoring and recording the temperature and pressure changes of supercritical carbon dioxide and characteristics of fracture cracking and extension in the supercritical carbon dioxide fracture process in real time, monitoring and recording the axial and radial deformations of coal petrography samples in real time, directly and effectively measuring the DH4 permeability of the coal petrography before and after the fracture without unloading the coal petrography sample stress, and measuring the CH4 permeability of the coal petrography after the fracture under the action of creepage. The measurement methodis high in precision, intuitional and high in automation degree, and the device is simple in structure.

Owner:TAIYUAN UNIV OF TECH

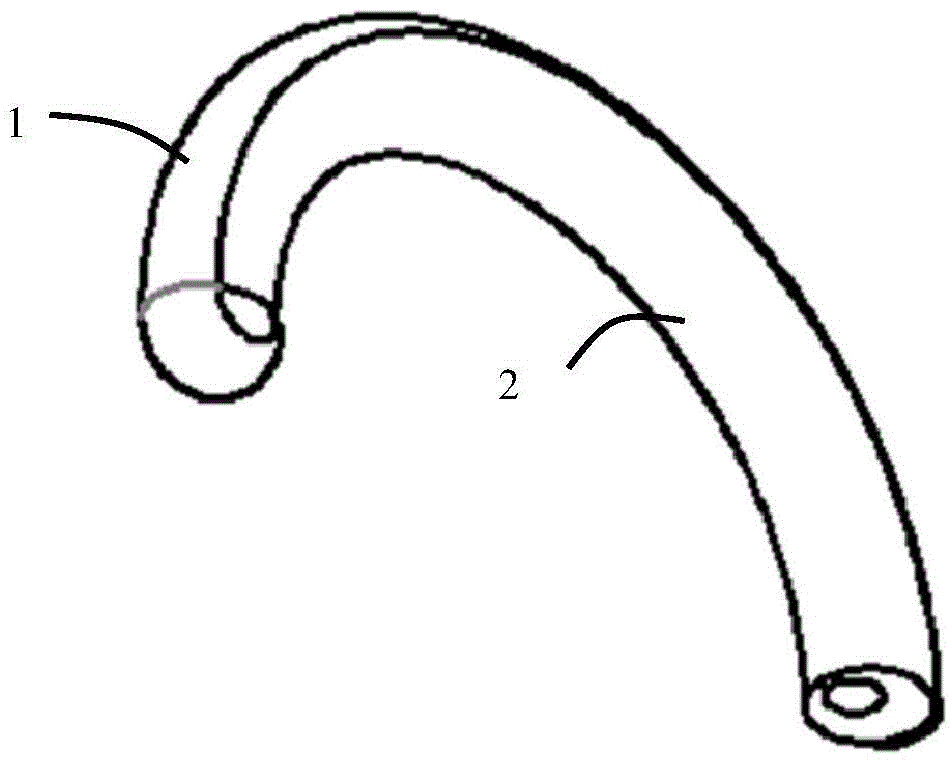

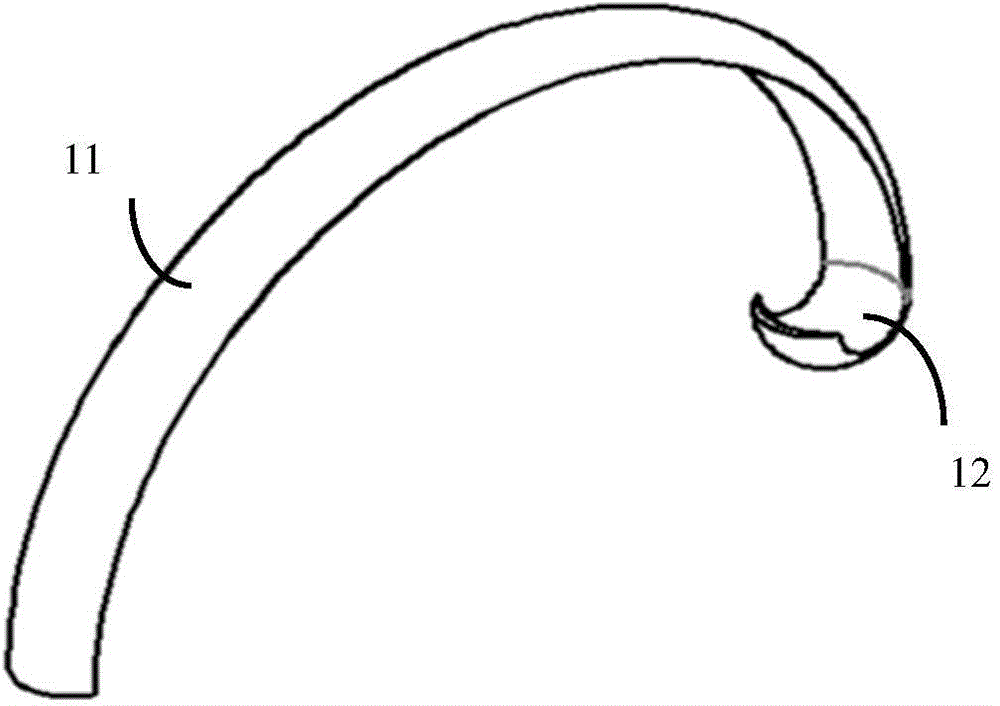

Robot bionic finger

The invention discloses a robot bionic finger. The robot bionic finger comprises a holding frame and an air bag, the air bag is a long-strip cylindrical structure, the holding frame is a long-strip sheet-shaped structure and made of elastic materials, the holding frame is in a bending shape in a natural state, and the holding frame is attached to an air bag wall of the air bag in the axial direction so that the air bag is in a bending shape in the natural state. According to the robot bionic finger, single-air-bag driving is employed, the structure is simple, the control is easy, the air bag is attached to the holding frame, a certain rigidity can be maintained when the air pressure of the air bag is small, the wall thickness of one side of the air bag with small section curvature is greater than the other side so that when the pressure is increased, the expansion amount of the thin wall side is larger than the expansion amount of the thick wall side, the finger can be driven to keep straight, spring wires are embedded into the air bag so that radial deformation of the air bag in the expansion process is reduced, the air bag can be recovered during pressure reduction, the air bag can still maintain the initial shape during negative pressure, and the outside of the air bag is provided with a plurality of protruding points capable of increasing the friction of the air bag so that the grabbing of articles is facilitated.

Owner:NANJIANG ROBOT

Vehicular impact bumper assembly

An impact bumper assembly for a vehicle is provided. The assembly comprises a first member, and a second member coupled to the first member and configured for relative motion therewith. The assembly also comprises a resilient bumper coupled to the first member and interposed between the first and second members, wherein the resilient bumper has an annular wall having a plurality of openings therethrough, and wherein the resilient bumper is configured to deform axially without substantial radial deformation when compressed between the first and second members.

Owner:GM GLOBAL TECH OPERATIONS LLC

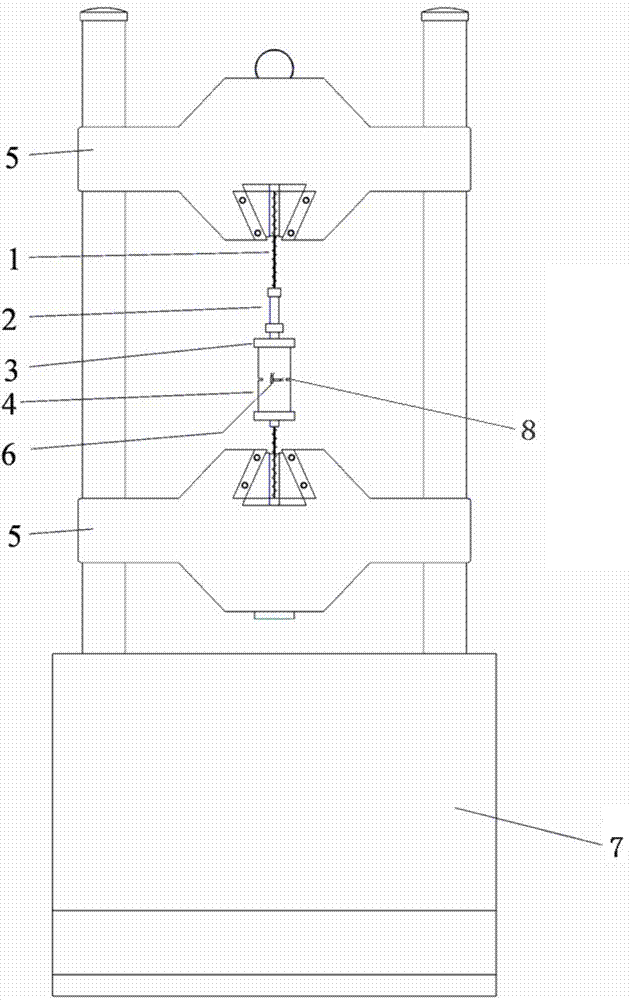

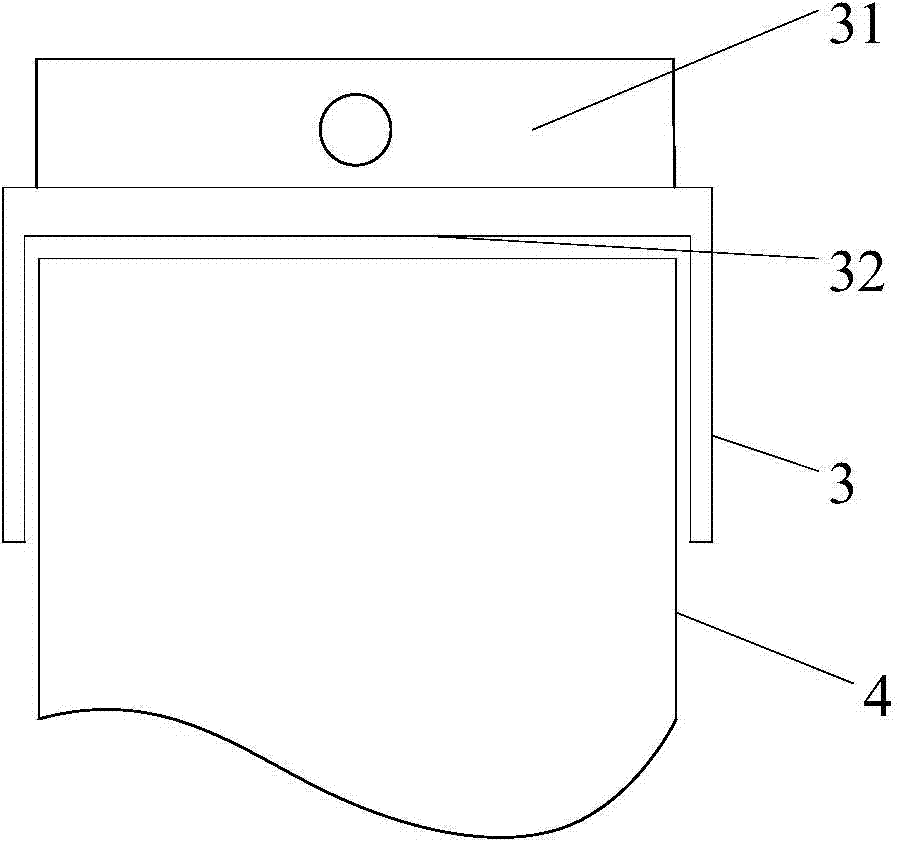

System and method for measuring direct tensile strength and deformation of rock

InactiveCN103674707AAccurately measure deformation dataTroubleshooting Stretch FailuresMaterial strength using tensile/compressive forcesElectrical/magnetic solid deformation measurementStress concentrationRock sample

The invention provides a system and a method for measuring direct tensile strength and deformation of rock by using manual kerfs. The system comprises test loading equipment, a rock sample, metal sleeve caps, a flexible connecting mechanism and a tensile load sensor, wherein the rock sample is cylindrical, two kerfs are symmetrically cut in two sides of the middle position of the rock sample, and the kerf directions are the radial direction of the sample; and an upper metal sleeve cap and a lower metal sleeve cap are arranged at two ends of the rock sample respectively, the upper metal sleeve cap is connected with an upper clamp clamping opening of the test loading equipment through the flexible connecting mechanism and the tensile load sensor sequentially, and the lower metal sleeve cap is connected with a lower clamp clamping opening of the test loading equipment 7 through the flexible connecting mechanism. According to the technical scheme, the defects that the rock sample is prone to bend or produce torsion stress in a direct tensile test are overcome, at the same time, the situation that tensile fracture is not produced during fracture due to the end stress concentration effect of the rock sample is avoided, and the rock tensile strength and the axial and radial deformation of the rock in a stretching process can be accurately and effectively measured.

Owner:UNIV OF SCI & TECH BEIJING

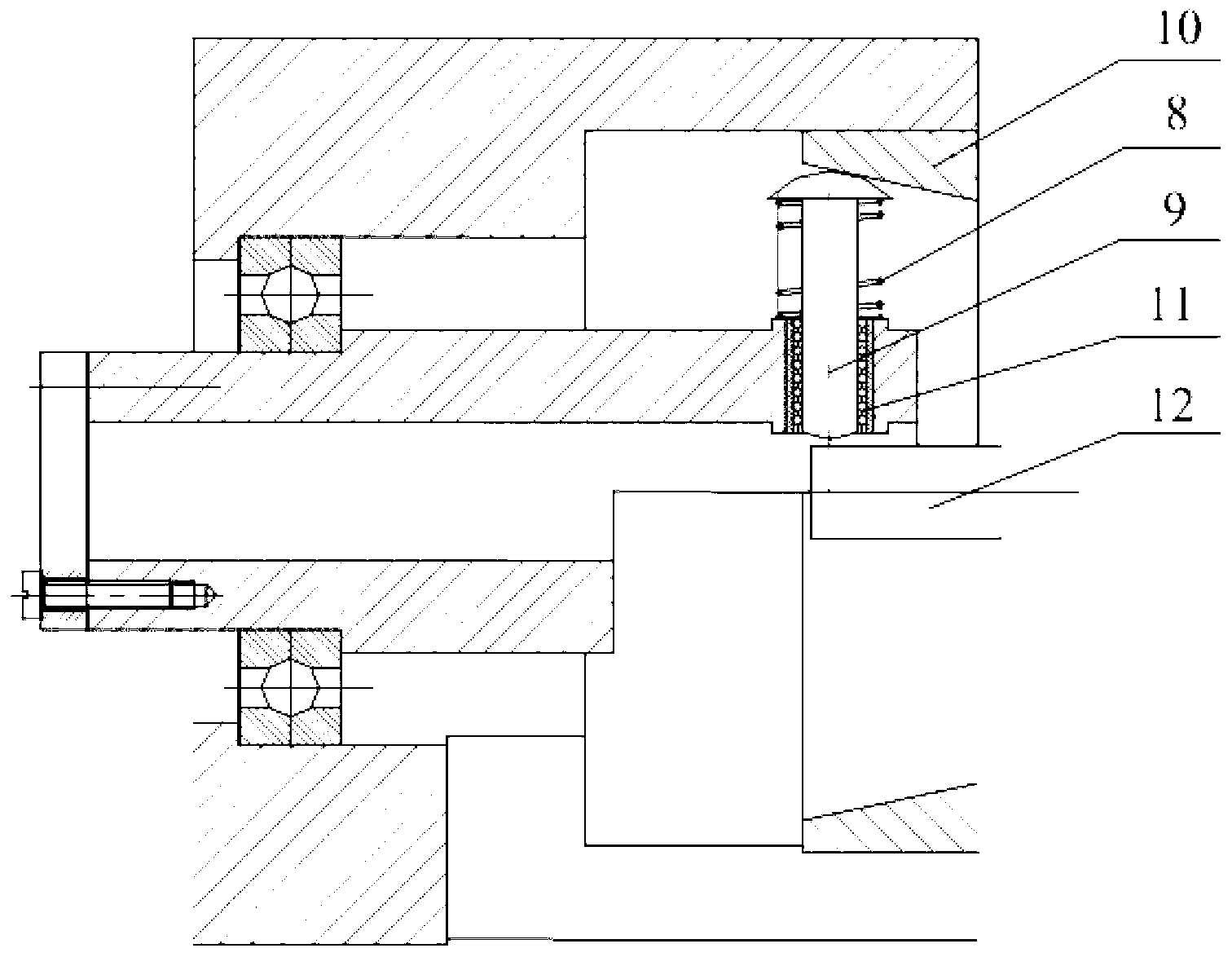

High-temperature pipe fitting radial deformation sensing device

InactiveCN101451813AHigh measurement accuracyImprove linearityMechanical solid deformation measurementsStrength propertiesMeasurement devicePipe fitting

The invention relates to a high-temperature pipe fittings radial deformation sensing device. A clamping device comprises a fixture 5 and a fixture 13. A positioning device is arranged in the median part of the fixture 5 and presses out a detected element 18. Stabilizer rods 15 are symmetrically arranged on the two ends of the fixture 5, are axially perpendicular to the detected element, and presses out the detected element by means of a spring 16 so as to form a stabilizing device. A measuring probe 7 in a measuring device is over against a supporting stick 4 and is arranged on the fixture 13. One end of the measuring probe presses against the detected element by means of a probe spring 17, and the other end is intimately contacted with a fine pitch bolt 8. The free ends of two elastic elements 11 which are provided with strain gauges are contacted with the fine pitch bolt 8 and are intimately jointed with the horizontal plane of a zero adjustment sheet 9. The strain gauges 12 are connected with a test terminal 19. The high-temperature pipe fittings radial deformation sensing device of the invention has the advantages that the installation is convenient, the usage temperature can be 1100DEG C, and the test result is exact and repeatable. The high-temperature pipe fittings radial deformation sensing device of the invention is applicable to the detection of the radial deformation of various metal and nonmetal material cylindrical pipe fittings and specimens.

Owner:EAST CHINA UNIV OF SCI & TECH

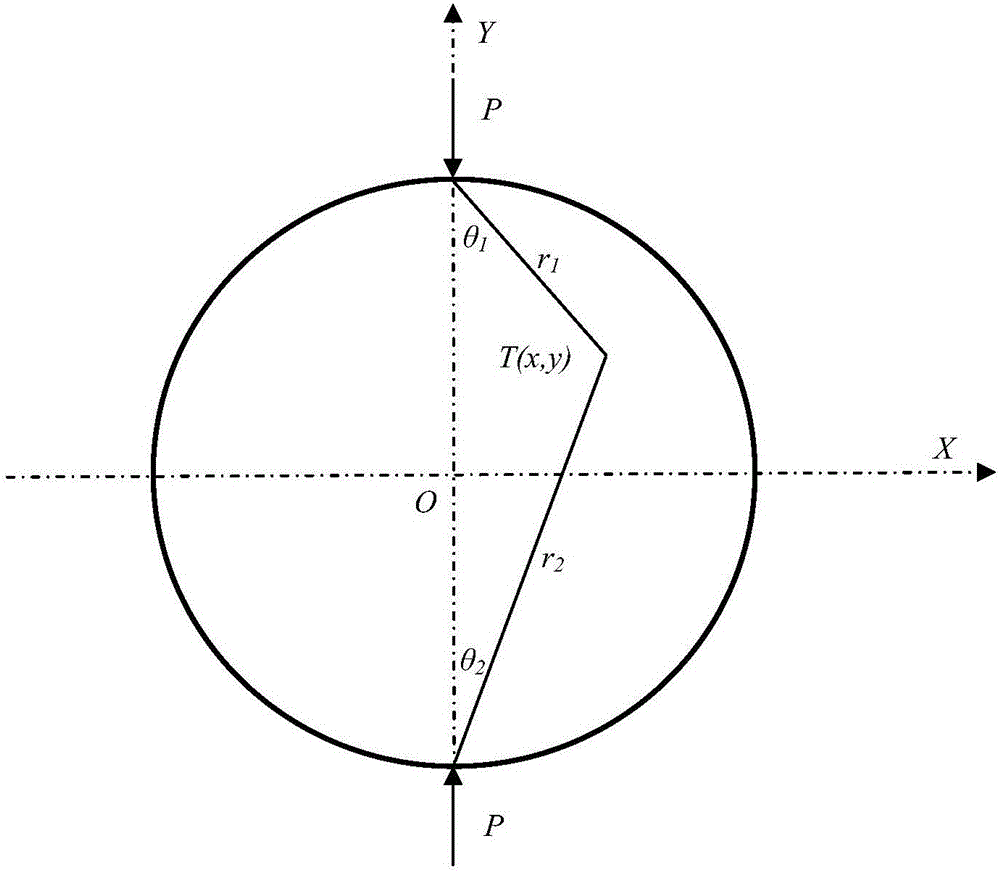

Method and device for synchronously testing tension, compression and split resilience moduli of pavement material

ActiveCN106706422AHigh precisionGuide engineering practice wellMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesTest efficiencyElectrical resistance and conductance

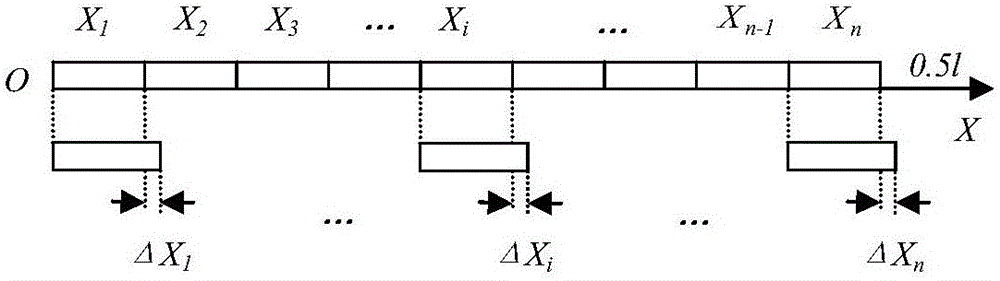

The invention discloses a method and device for synchronously testing tension, compression and split resilience moduli of a pavement material. The method comprises the following steps: performing a split loading test on a test sample through an MTS multifunctional material testing system, and deducing computing formulae for the tension modulus and the compression modulus of the pavement material test sample during split loading; and respectively pasting resistance strain gages on horizontal radial and vertical radial centers in the front and back parts of the test sample, measuring the average tension strain and the average compression strain of the center positions of the test sample, measuring the horizontal radial deformation of the test sample through a displacement sensor, and substituting in the formulae to obtain the testing results of the split modulus, the tension modulus and the compression modulus of the material. According to the invention, the three moduli of the material can be simultaneously measured through a single test, thereby improving the modulus testing precision and test efficiency of the pavement material and lowering the indoor test and testing cost; and accurate design parameters can be provided for scientific design of a durable pavement considering the difference in the tension and compression moduli of the material.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Flow control valve

InactiveUS20080001110A1Improve flow stabilityDownsizingDiaphragm valvesOperating means/releasing devices for valvesEngineeringControl valves

A compact flow control valve with high flow stability is arranged to comprises: a valve body made of resin including; a first passage formed in the valve body; a valve port communicating with the first passage; and a valve seat formed around the valve port; a valve element movable into contact with and away from the valve seat; a valve chamber formed around the valve seat; a second passage communicating with the valve chamber; and a flow adjustment rod for adjusting a flow rate of a fluid allowed to flow in the valve chamber, wherein the flow adjustment rod is adjustable in position to change an opening degree of the valve element relative to the valve seat for adjusting the flow rate, and the flow control valve further comprises an annular recess formed in an inner periphery of the valve seat formed surrounding the valve port and configured to prevent radial deformation of the valve port when the valve element is moved into contact with the valve seat.

Owner:CKD

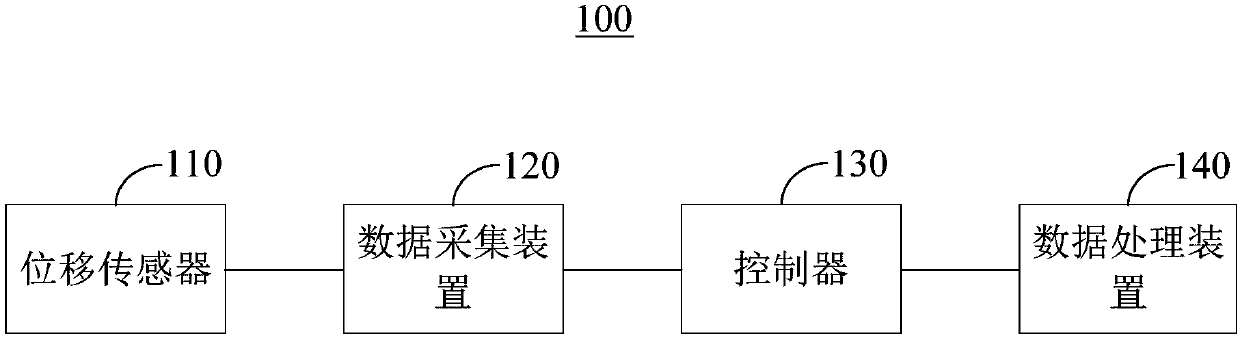

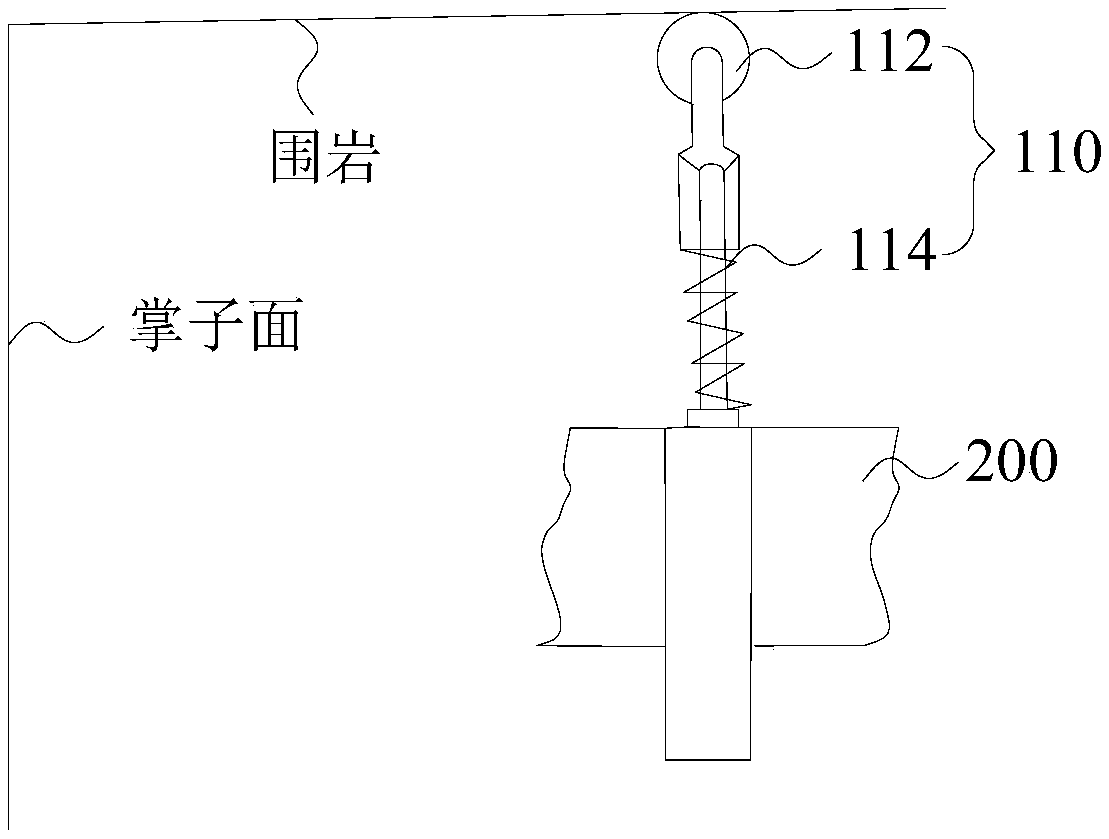

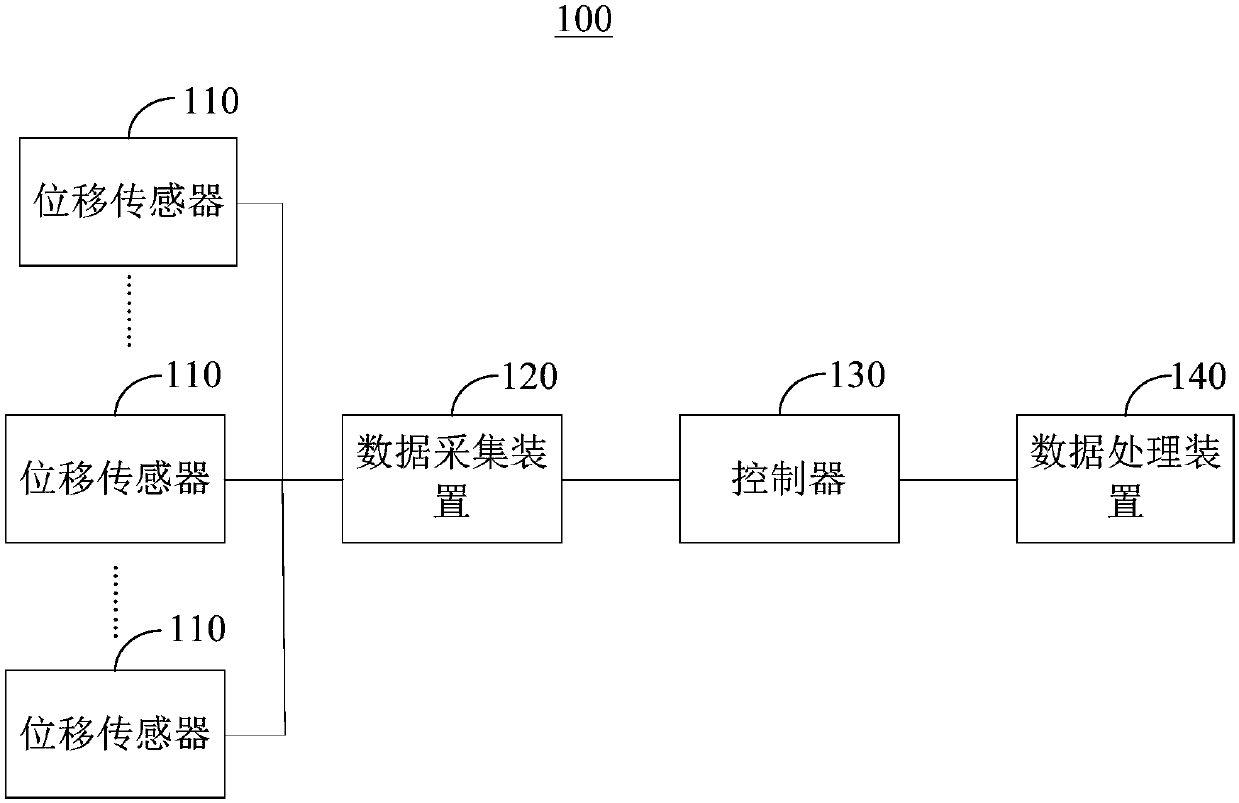

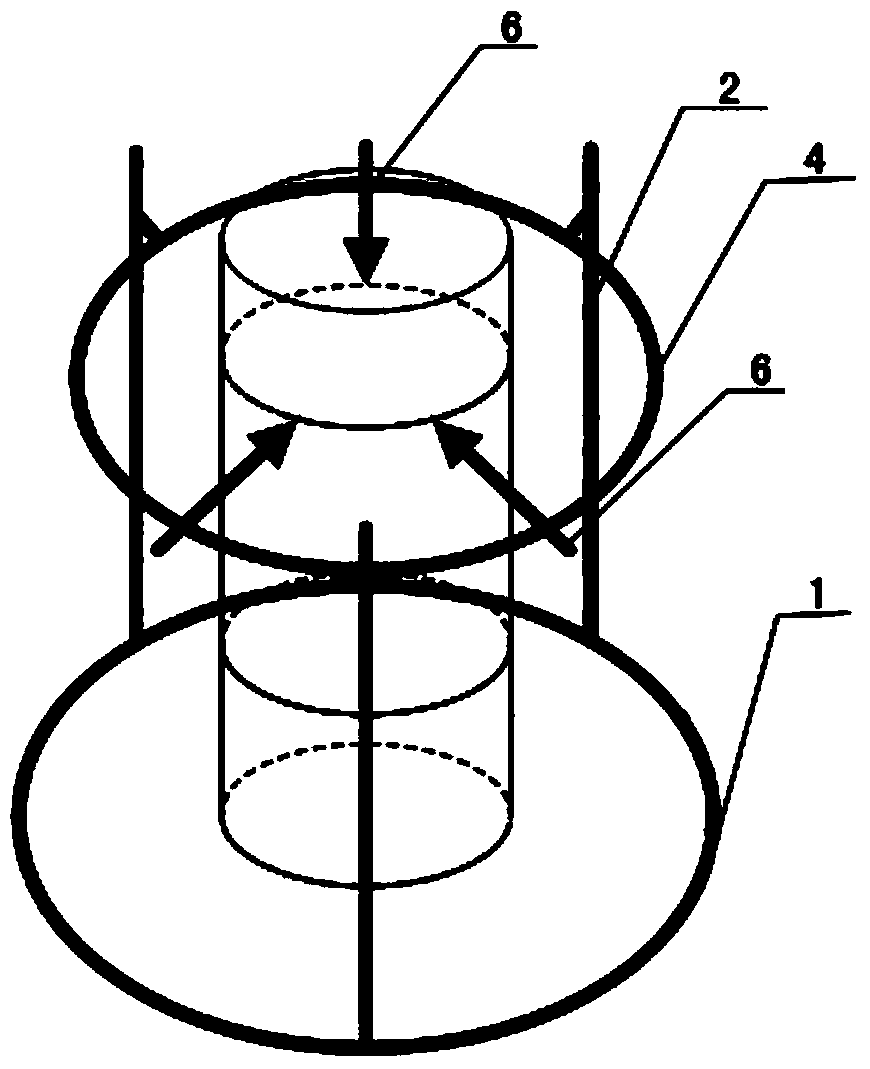

Monitoring system for deformation of TBM surrounding rock

The invention discloses a monitoring system for deformation of TBM surrounding rock. The monitoring system for deformation of TBM surrounding rock includes: a displacement sensor, which is installed in the TBM shield shell to monitor the radial deformation data of surrounding rock and can radially expand against the shield shell; a data-collecting device, which is electrically connected with displacement sensor and is used t collect radial deformation data; a controller, which is electrically connected with the data-collecting device and is used to receive the radial deformation data collectedby the data-collecting device or controls the data-collecting device; and a data-processing device, which is used to process the radial deformation data, so as to the correspondent data information of a tunnel. The monitoring system for deformation of TBM surrounding rock can achieve the monitoring of the radial deformation of the surrounding rock and can provide prediction for people to avoid that the radial deformation of the surrounding rock is so large that a tunnel-boring machine might break down as a result of the surrounding rock's pressure on the shield shell.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

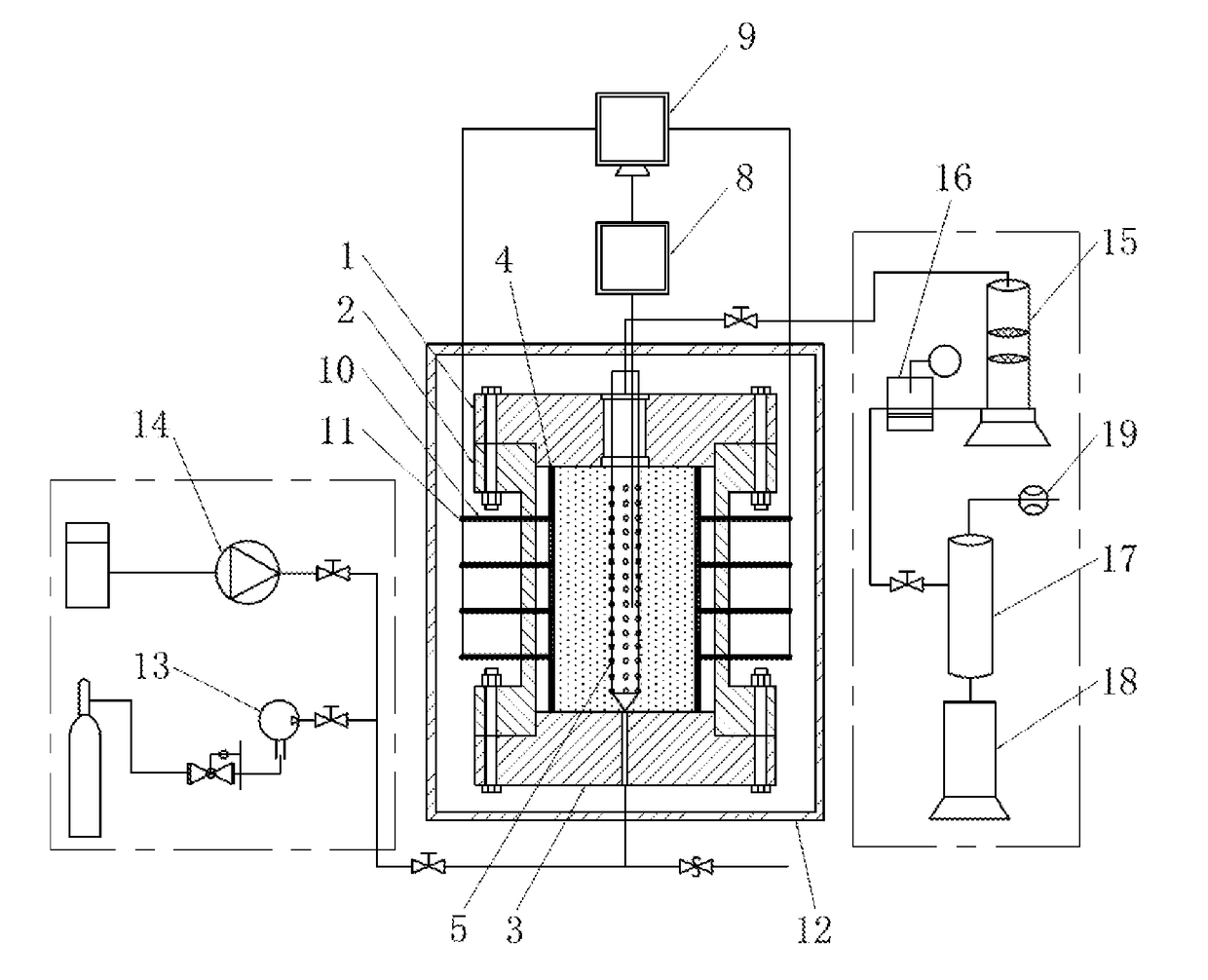

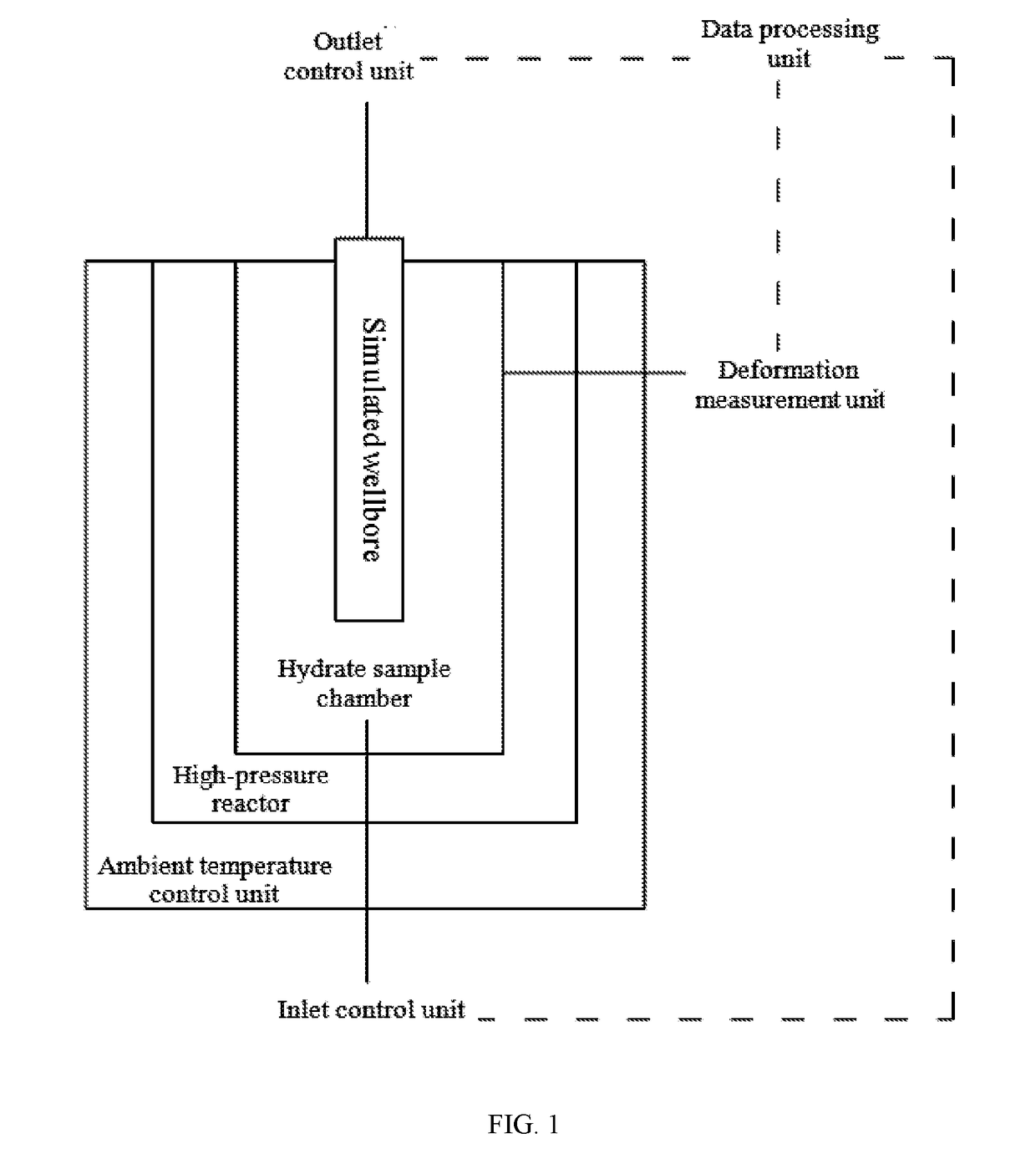

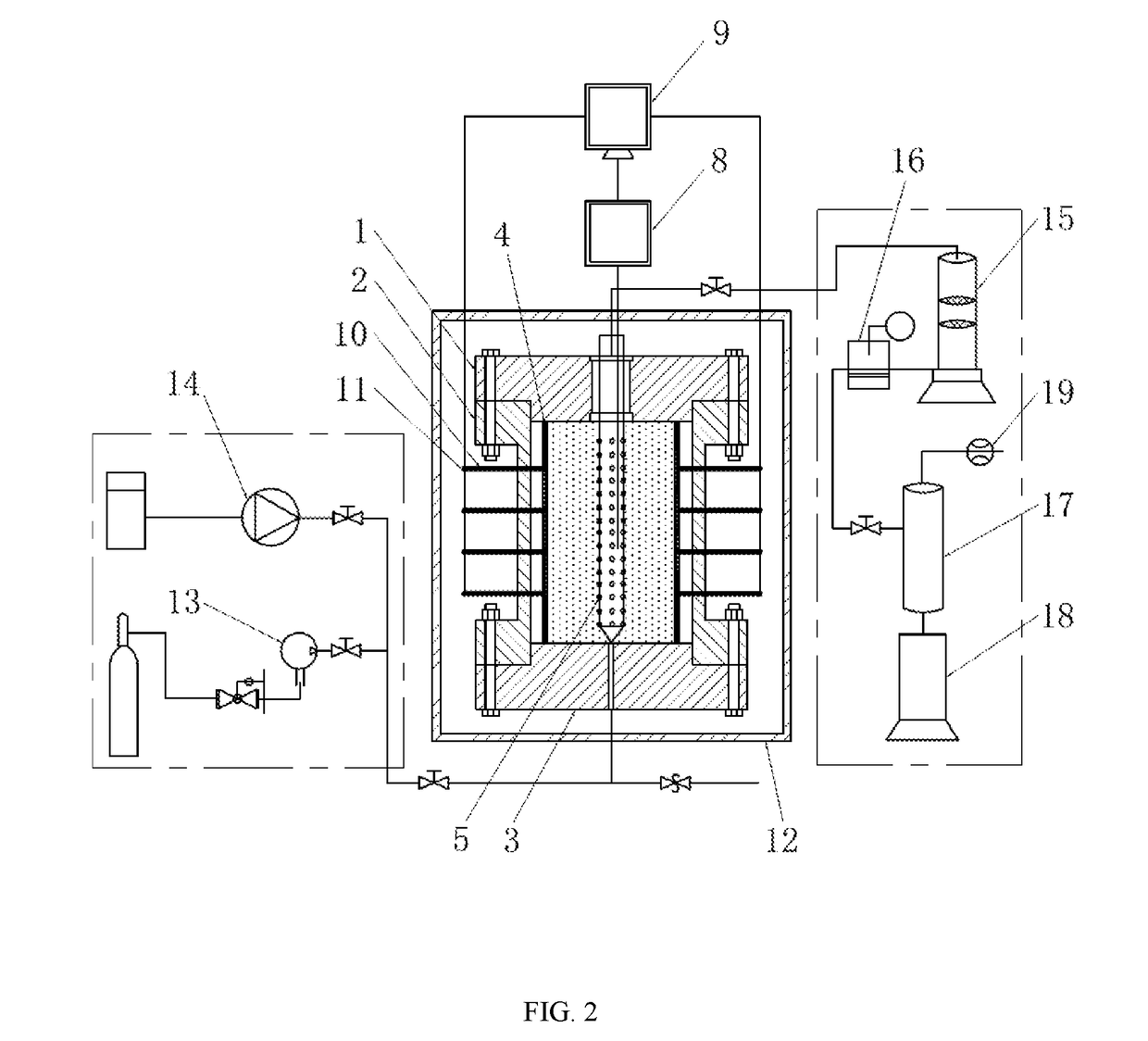

Experimental device and method for studying relationship between sediment yield behavior and radial deformation of porous media during exploitation of natural gas hydrates

ActiveUS20180172574A1Accurate measurementGood effectEarth material testingPressure/vacuum vesselsDecompositionPorous medium

Disclosed is an experimental device for studying the sediment yield behavior and the radial deformation of porous media during the exploitation of natural gas hydrates, comprising a high-pressure reactor, a hydrate sample chamber, a simulated wellbore, a deformation measurement unit, an ambient temperature control unit, an outlet control unit, an inlet control unit and a data processing unit. Further disclosed is a method using the above-mentioned experimental device to carry out experiments. The experimental device and method according to the present invention can conveniently measure the deformation of the porous media during the decomposition of the hydrates and simulate the sediment producing situation in the wellbore, can simulate the sediment yield problem during the exploitation of natural gas hydrates as well as the gas-liquid-solid flowing problem in the wellbore during the exploitation of natural gas hydrates, and can accurately obtain the gas-solid-liquid three-phase yields in real time during the decomposition of natural gas hydrates. Being simple to operate and easy to control, and suitable for various sizes and shapes of reactors, it can provide basic experimental data and a theoretical basis for the technologies of hydrate exploitation.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

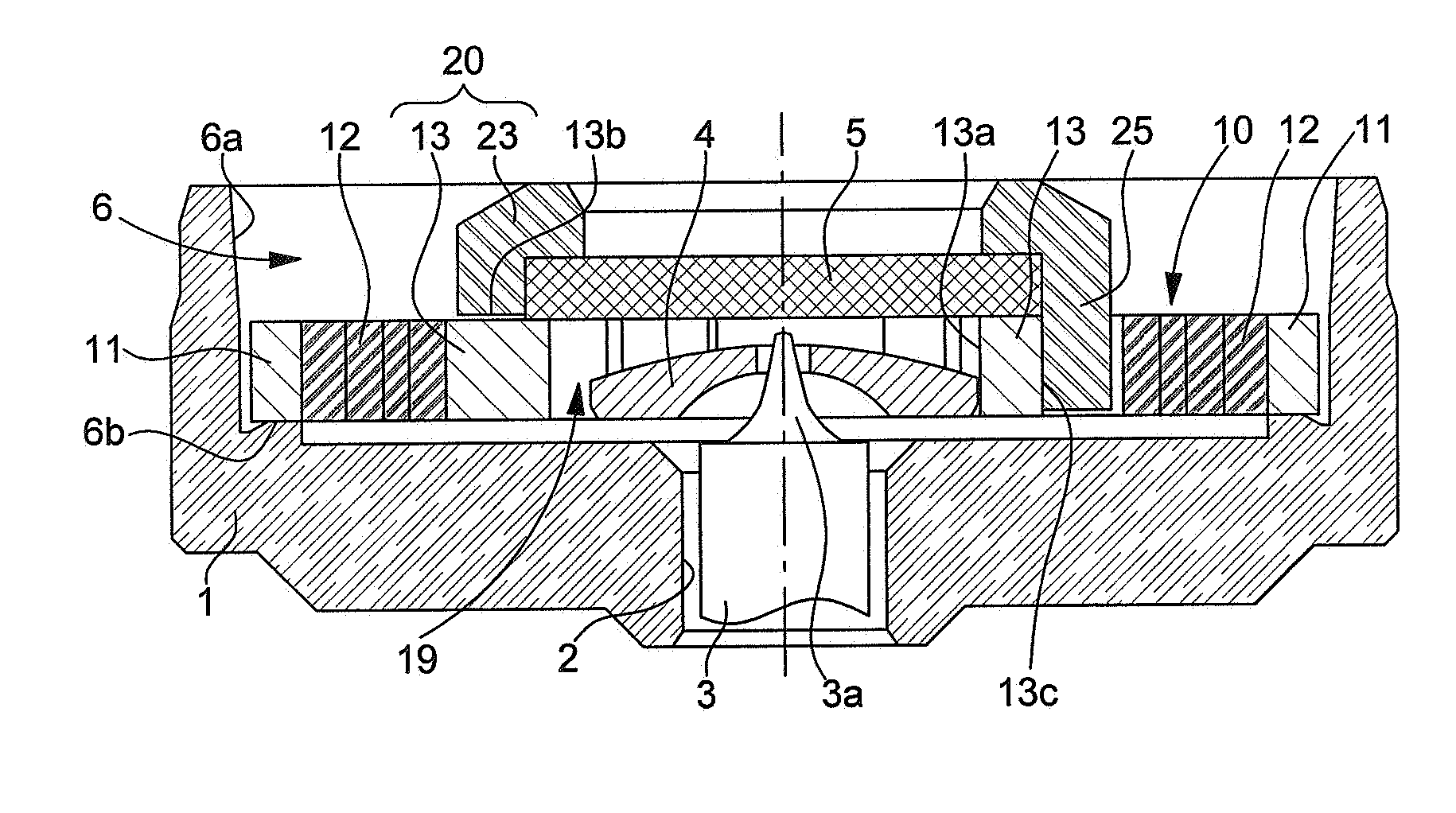

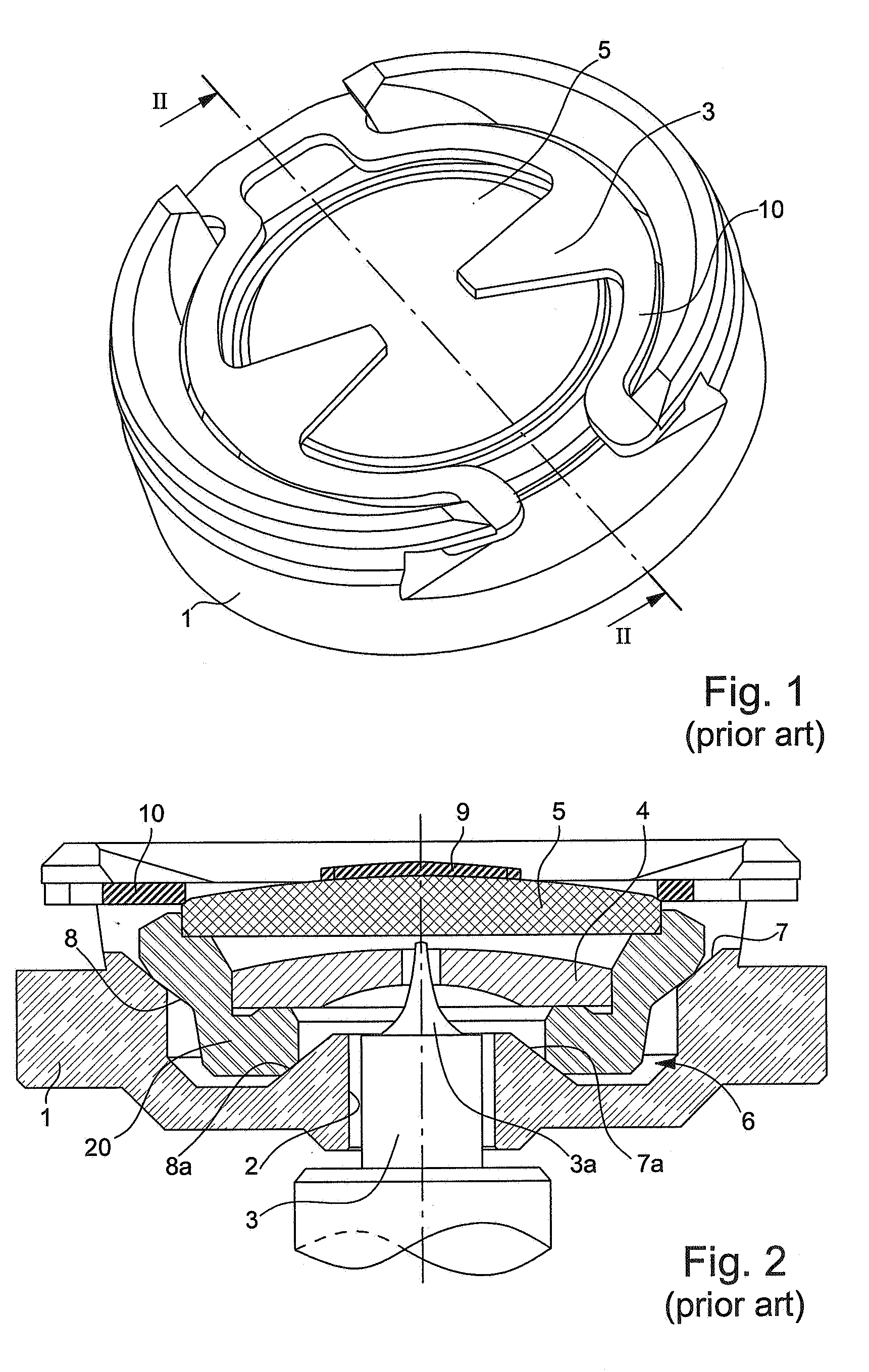

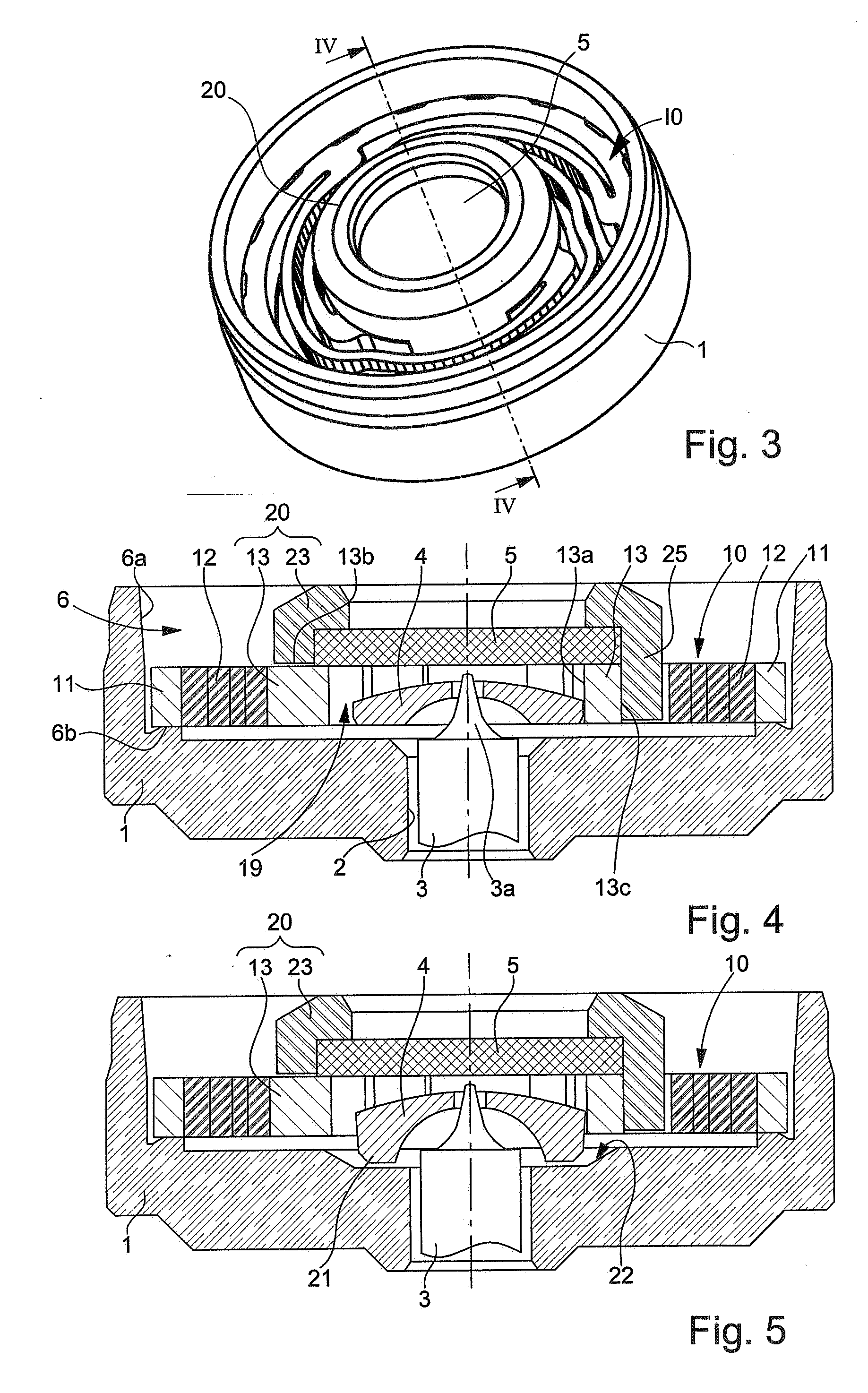

Shock absorber bearing for a timepiece

ActiveUS20060187767A1Wide manufacturing toleranceEliminate frictionFrameworksHorological bearingsShock absorberRadial deformation

The housing (6) of the bearing block (1), locks the peripheral ring (11) of a spring (10) with axial and radial deformation further comprising a substantially annular rigid central support (13) which cooperates with a cap (23), fitted by means of lugs (25) to the outside of the central support (13), to hold the pierced stone (4) and the endstone (5). The resilient part (12) of the spring (10) is for example formed of bent arms.

Owner:ETA SA MFG HORLOGERE SUISSE

Variable-speed circumferential low-stress bending fatigue crack precise blanking machine and blanking method thereof

InactiveCN103286249AReduce utilizationLower the thresholdPower hammersHandling devicesStress concentrationBall bearing

The invention discloses a variable-speed circumferential low-stress bending fatigue crack precise blanking machine and a blanking method of the variable-speed circumferential low-stress bending fatigue crack precise blanking machine. The variable-speed circumferential low-stress bending fatigue crack precise blanking machine comprises a variable-frequency motor, a large belt pulley, a V-shaped belt, a small belt pulley, a two-stage gear accelerator, a high-speed main shaft, a sliding rail supporting seat, a screw compression spring, a columnar hammer head, a feeding sleeve, a ball guide bushing, metal bars, a clamping hand, a clamping cylinder, a feeding cylinder, a hydraulic clamping feeding mechanism support, a machine body, a seat plate, a servo motor, a speed reducer, a coupler, a ball screw supporting seat, a screw, a nut, a ball screw, a deep groove ball bearing and a key. The variable-speed circumferential low-stress bending fatigue crack precise blanking machine is high in geometric precision of blanking workbanks, free of corner collapse and radial deformation, perpendicular and smooth in fracture section, few in burrs, and high in use ratio of material. The stress concentration effect, the resonance effect and the bending fatigue of an annular V-shaped groove are utilized to enable the critical value of the impact speed of vibration on the metal bars to be lower than the critical value of the speed in the high-speed shearing process, and the blanking machine is applicable to precise blanking of the metal bars of different materials.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

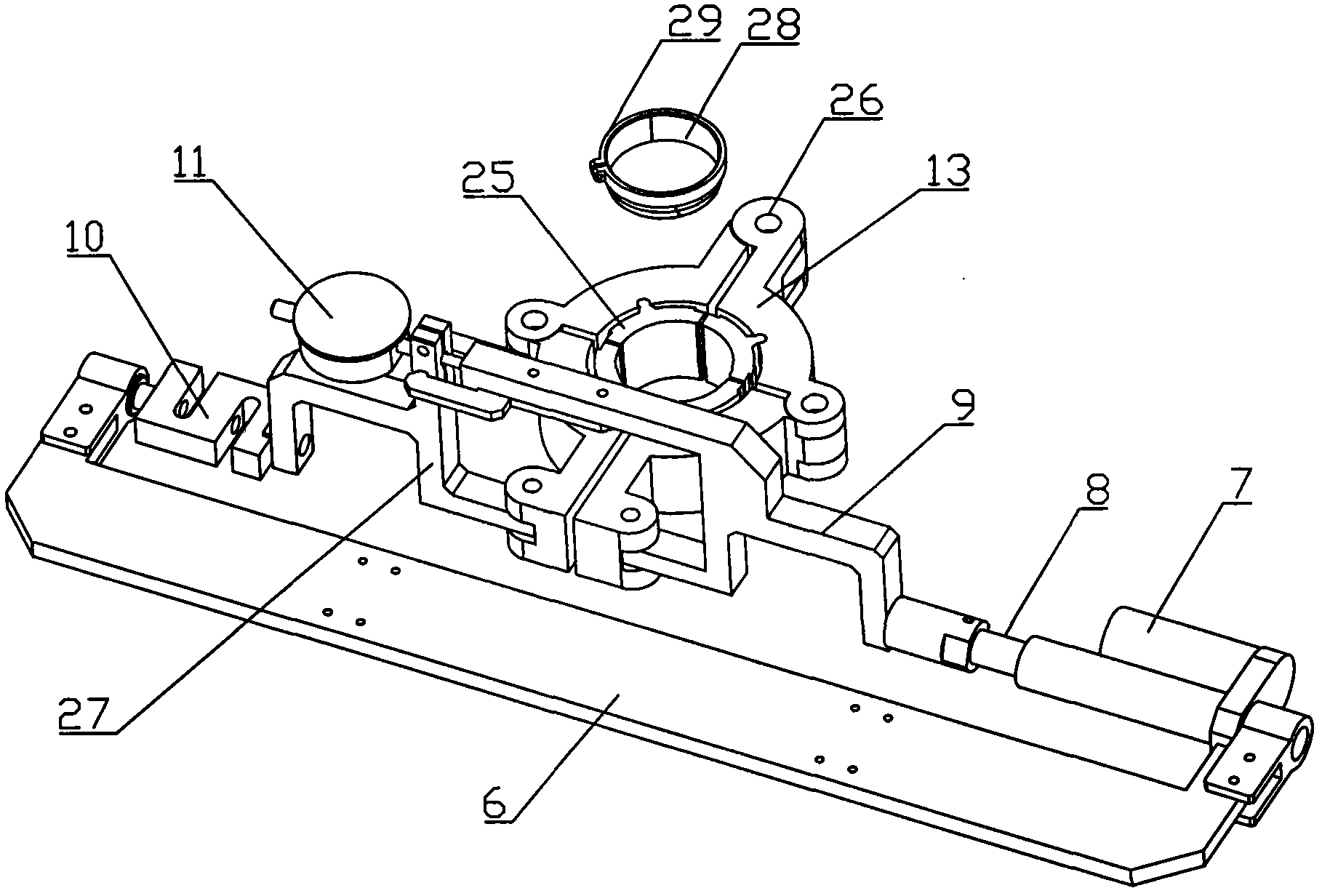

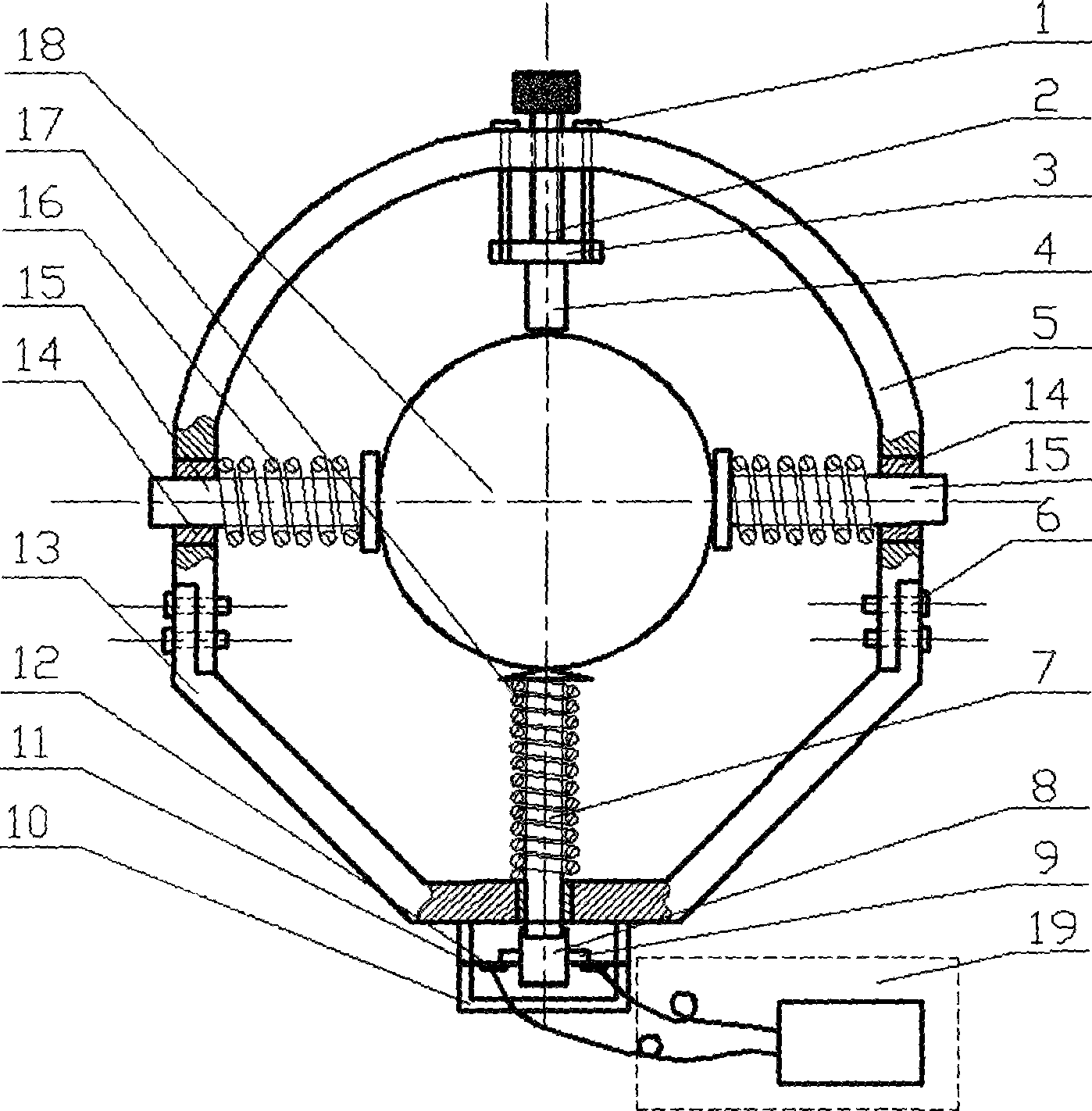

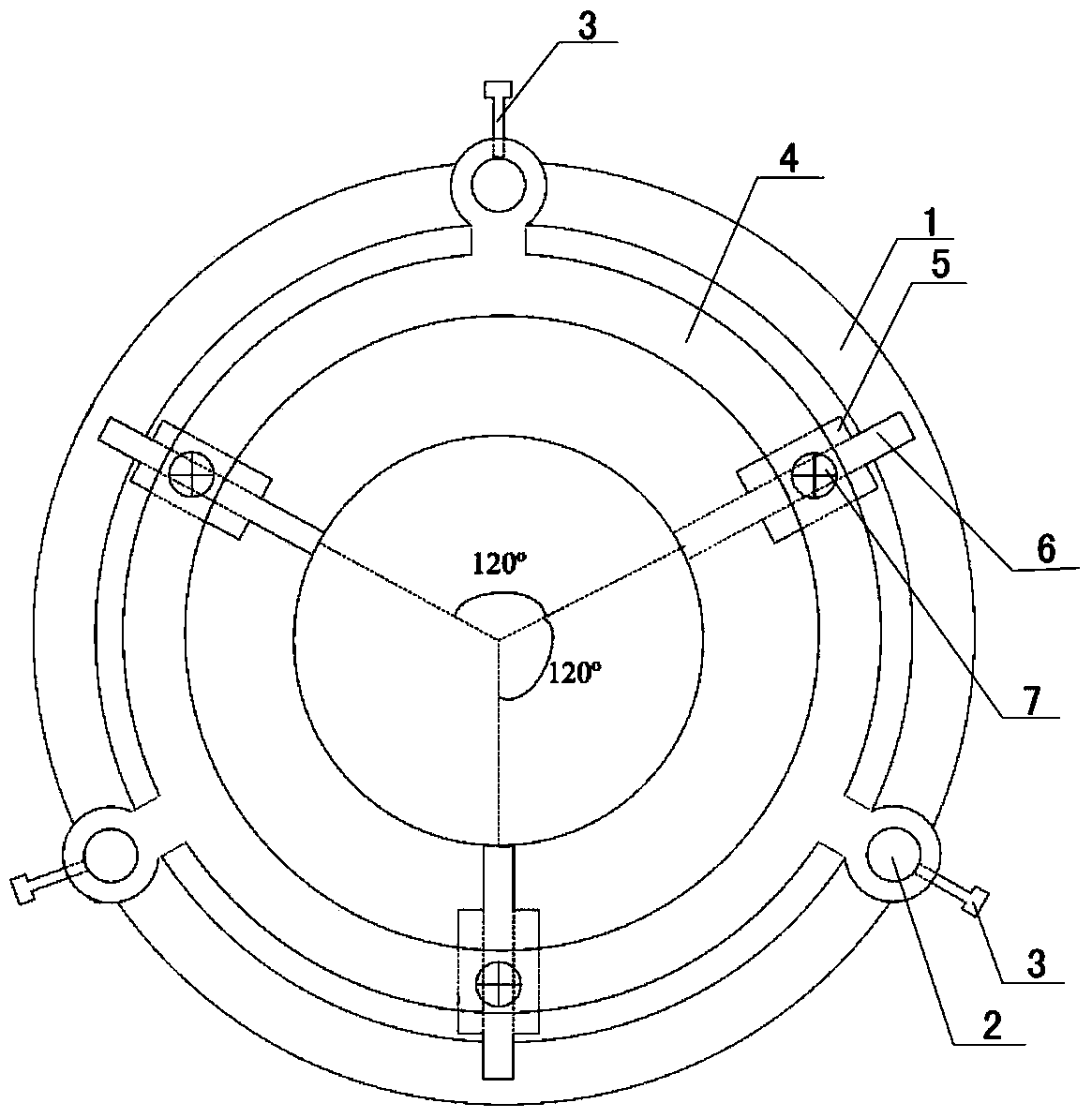

Device for measuring radial deformation of cylindrical test piece

InactiveCN103954262ASolve the measurement problem of radial (transverse) deformationSimple structureMeasurement devicesEngineeringLinear displacement

The invention discloses a device for measuring radial deformation of a cylindrical test piece. The device comprises a base, a stand column, fastening screws, an annular sensor positioning frame and linear displacement sensors, wherein the stand column is installed on the base, the sensor positioning fame is installed on a sliding guide rail of the stand column through the fastening screws, the linear displacement sensors are installed on the sensor positioning fame, the included angle between the axes of every two linear displacement sensors is 120 degrees, sensor portioning sleeves are installed on the linear displacement sensors, sensor positioning screws are installed between the linear displacement sensors and the sensor portioning sleeves, and the linear displacement sensors are LVDT sensors. The device is simple in structure, convenient to operate and low in cost, and achieves the purpose of measuring radial or transverse strain of the cylindrical test piece; accurate centering can be easily achieved, and the force interaction between the device and the test piece does not exist.

Owner:范鹏贤

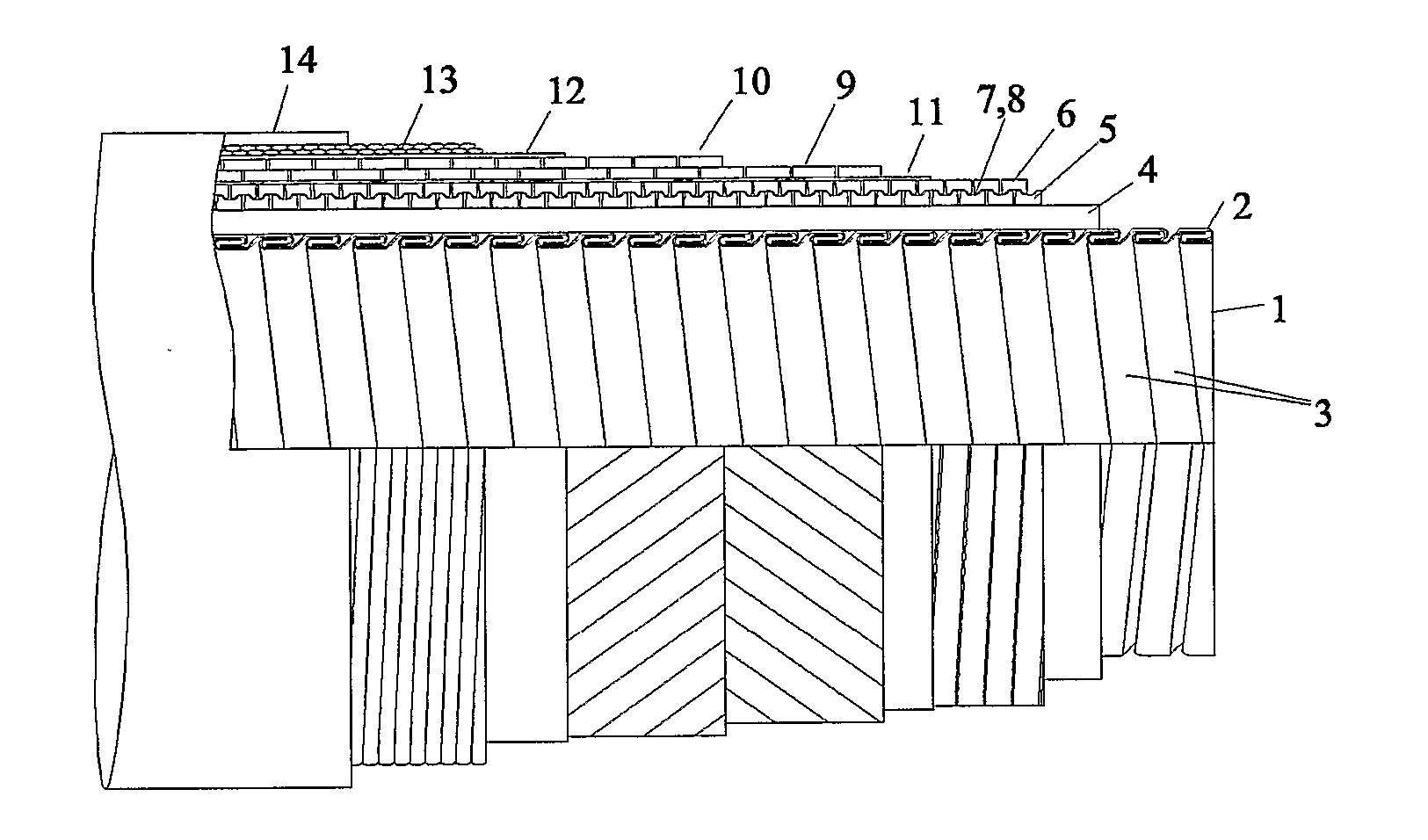

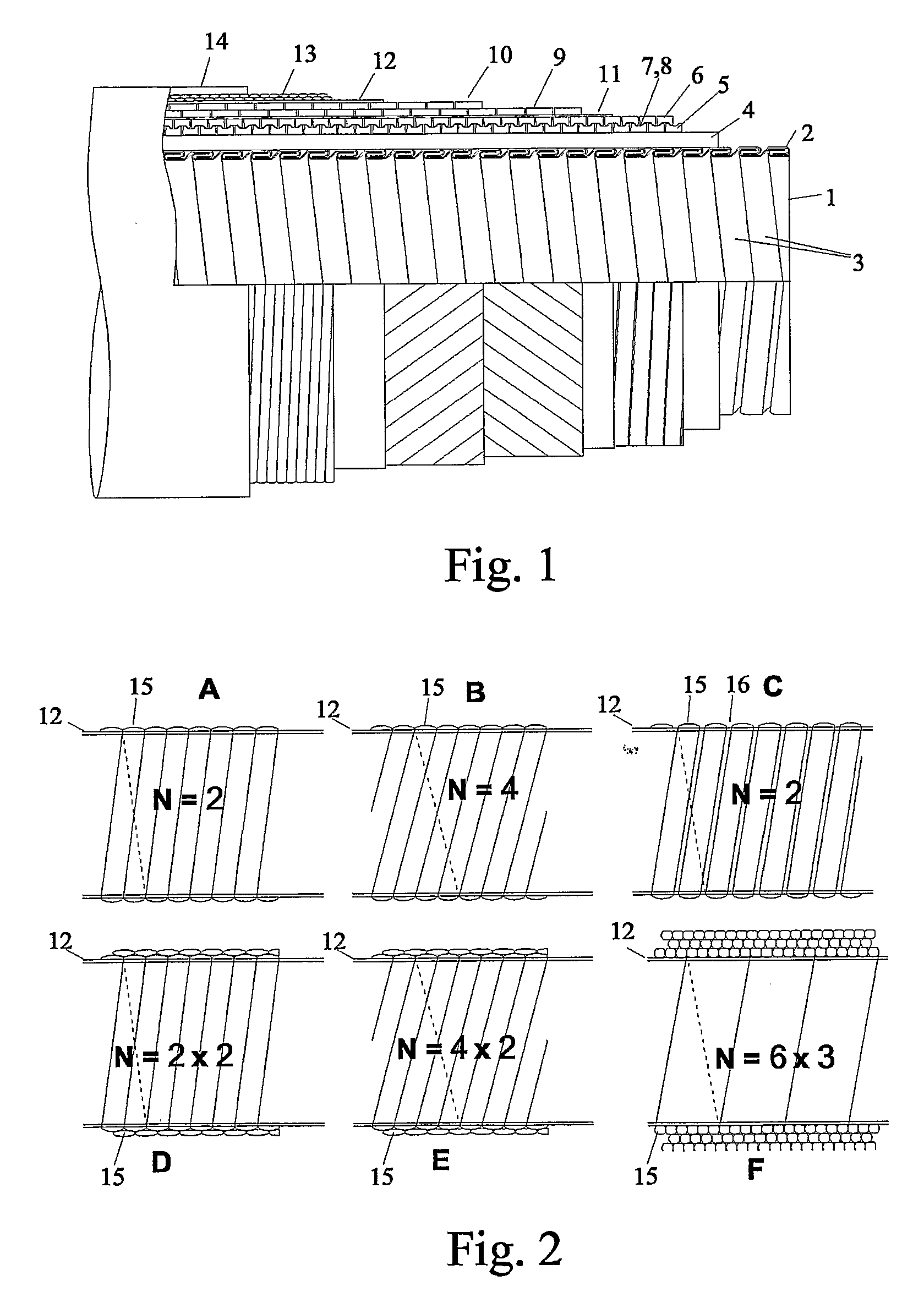

Flexible Pipe, Its Manufacture and Use

InactiveUS20080283138A1Improved of manufacturingLimit radial expansionFlexible pipesMetal working apparatusContact pressurePliability

A flexible, typically un-bonded, armoured pipe, and a method manufacturing a flexible pipe. The pipe has a center axis and comprises an inner liner surrounded by a radial armouring and an axial armouring, the radial and axial armouring each comprising at least one armouring layer of armouring profiles wound with winding angles αi relative to the center axis. The winding angle of the innermost armouring layer αinnermost is larger than the winding angle of the outermost armouring layer αinnermost. The outer radial armouring layer has sufficient strength and flexibility to prevent prohibitively large radial deformations of underlying axial armouring layers without considerably increasing the radial contact pressure on underlying axial armouring layer. At least one fibrous layer, comprising at least two fibrous cords wound on an underlying layer, surrounds the outermost armouring layer. The flexible pipe is useful in terrestrial and / or subsea transport of fluids at elevated temperature and / or pressures.

Owner:NAT OILWELL VARCO DENMARK

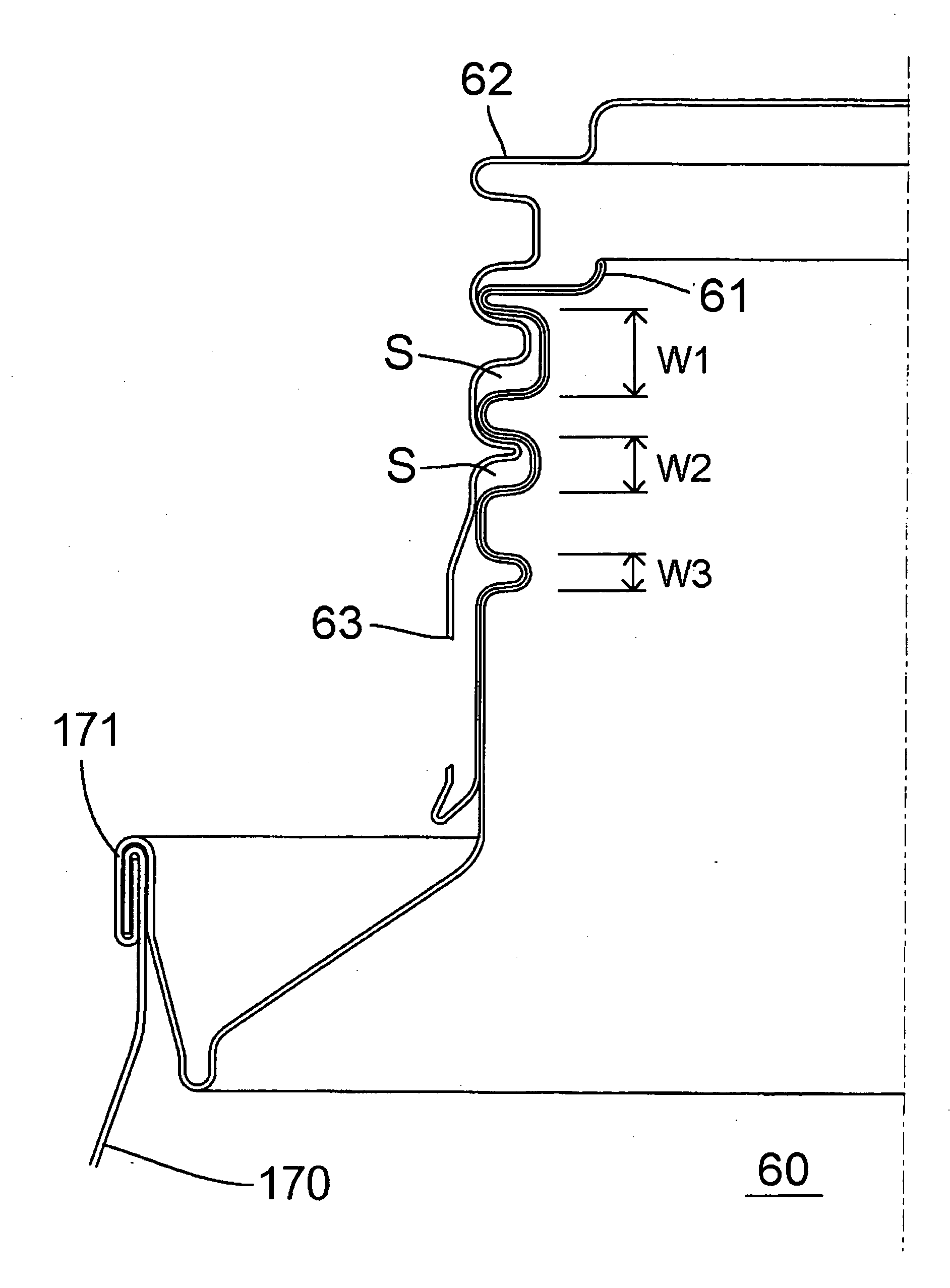

Container opening structure, container provide with the opening structure and method of manufacturing the opening structure

InactiveUS20070062952A1Easy to manufactureIncrease opennessCapsClosure using stoppersEngineeringMechanical engineering

An opening structure of a container easily performs the opening and the resealing. The container continuously and integrally forms a cap portion and a pouring portion. Due to a radial deformation of an easy-to-break portion which is present in a boundary between the cap portion and the pouring portion, the easy-to-break portion is broken and hence the cap portion and the pouring portion are separated, thus opening the container. A manufacturing method for the novel container is also provided.

Owner:TOYO SEIKAN KAISHA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com