Mine cable hanger

A hanger and cable technology, used in drilling equipment, wellbore/well components, earth-moving drilling, etc., can solve problems such as insufficient fixing of hanging tools, and achieve higher locking force, higher deformation, and enhanced firmness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

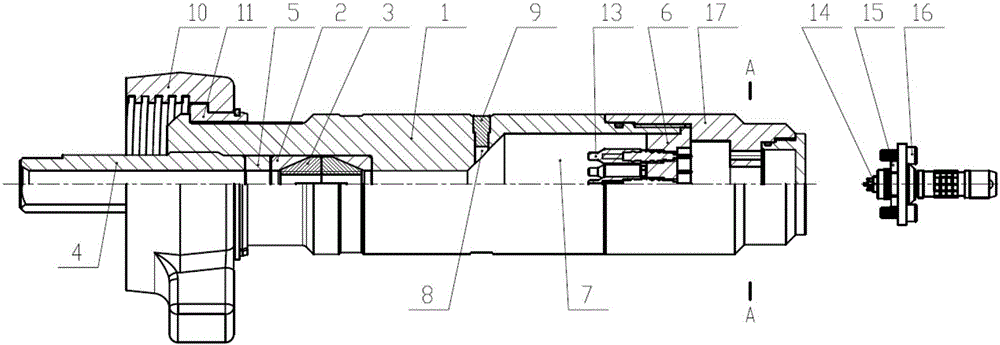

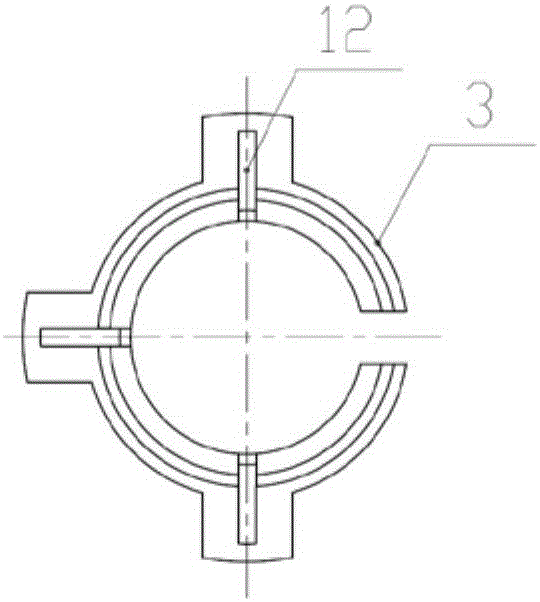

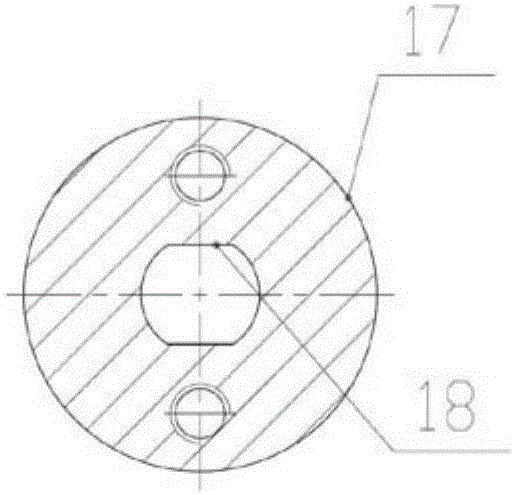

[0022] Such as Figures 1 to 3 As shown, the cable hanger for wells includes a main body 1, and a fixing assembly is installed in the inner cavity of the main body 1. The fixing assembly includes a slip seat 2 and a slip 3 installed on the slip seat 2 , and a fastening push rod 4 for pushing the fixing assembly to move axially is installed in the inner cavity of the main body 1 .

[0023] One side of the slip 3 is open so that the cross-section is C-shaped, and a plurality of slits 12 are provided in the upper axial direction of the slip 3 .

[0024] The cable passes through the fastening push rod 4 and the slips 3, and is sent into the inner cavity of the hanger main body 1. The fastening push rod 4 pushes the fixed assembly, one of the slips 3 and the slip seat 2 is limited by the inner cavity, and the other is pushed by the fastening push rod 4, so that the slips 3 and the slip seat 2 move toward each other. The wedge surface set on the outer wall of the slip 3 and the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com