Patents

Literature

95results about How to "Achieve pre-positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

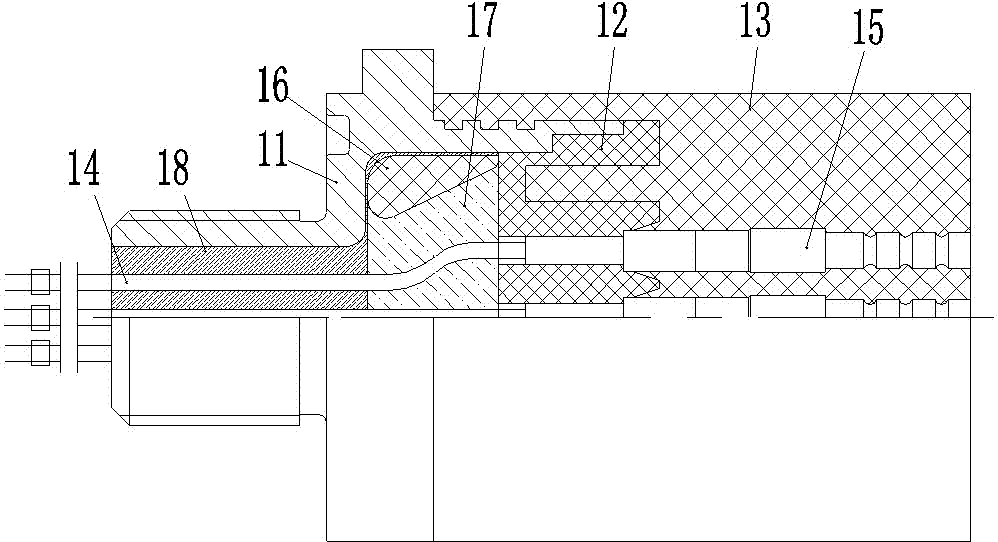

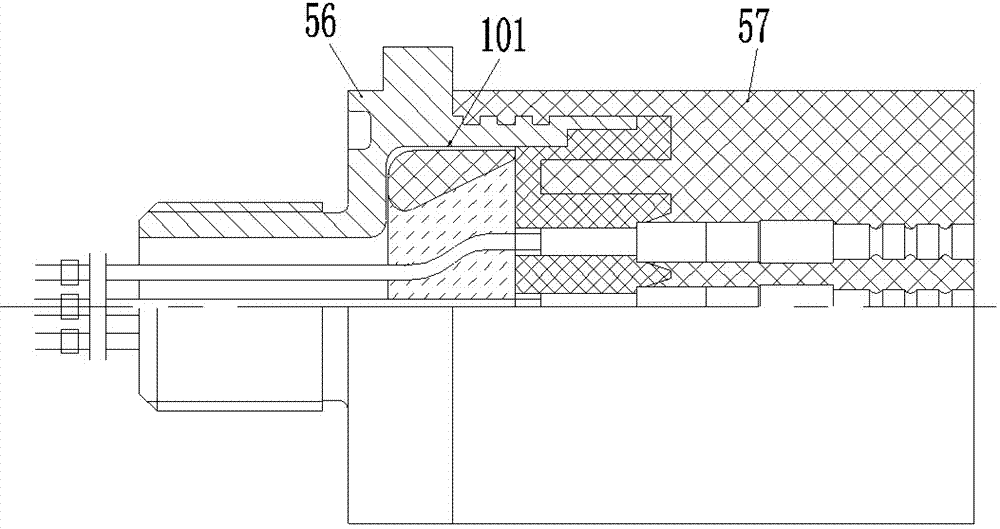

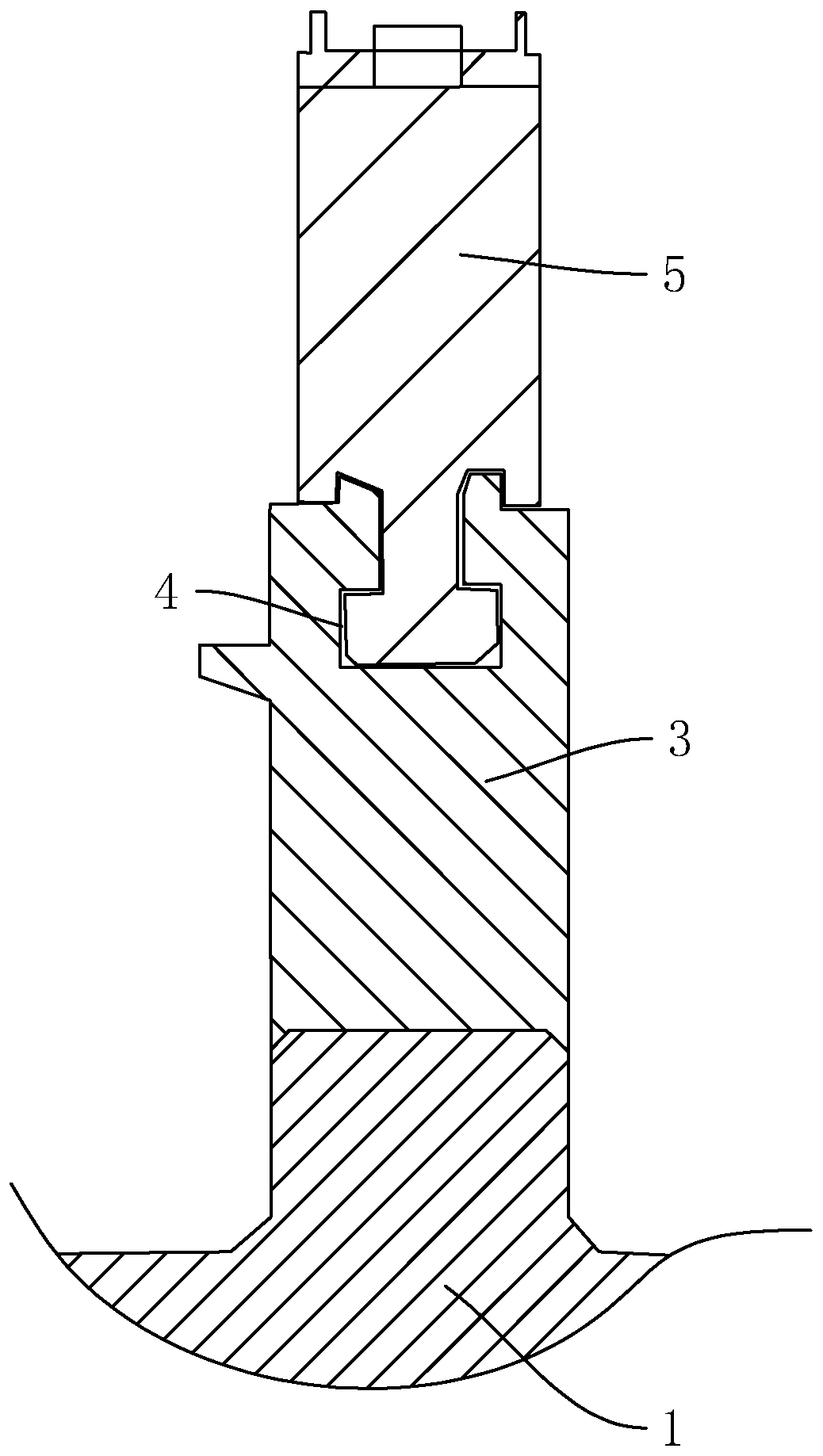

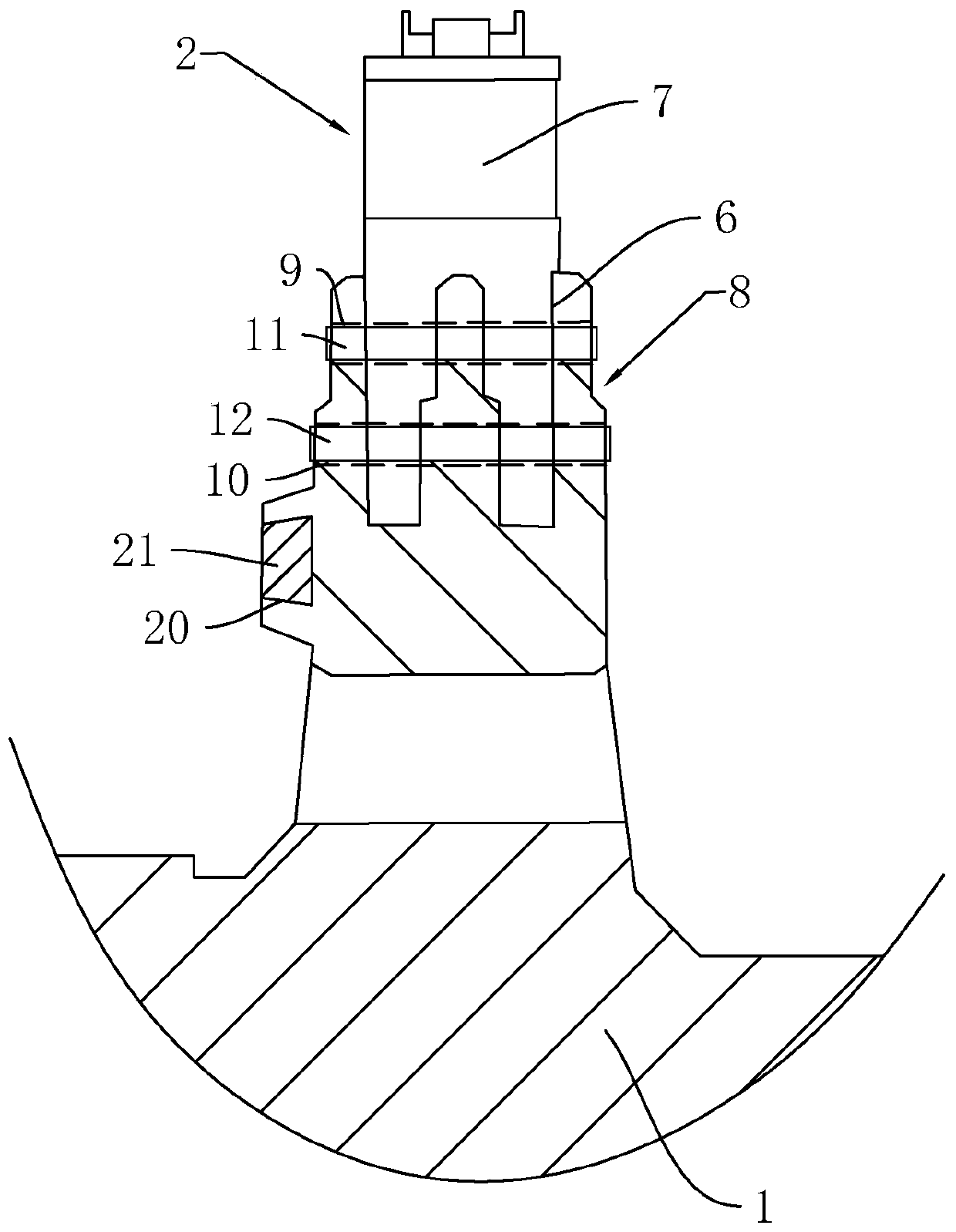

Underwater plug-pull connector and preparation method thereof

InactiveCN103036101ASolve the unreliable sealingStrong enoughContact member assembly/disassemblyCouplings bases/casesVulcanizationEngineering

The invention relates to the field of electric connectors, in particular to an underwater plug-pull connector and a preparation method thereof, wherein the underwater plug-pull connector can be applied to the seafloor and other deepwater environments. The front end of the connector serves as a plug end, the connector comprises a shell, an insulator, a sulfide body and a contact piece connected with a conducting wire, and the contact piece, the insulator and the shell are fixed together in a vulcanization mode through the sulfide body. A locating step surface facing the front is installed inside the shell, a matching step surface which is in check fit with the locating step surface is installed on the outer circumferential surface of the insulator, the contact piece is installed inside an installation hole of the insulator in a plug-in mode, the rear side of the insulator is fixedly connected with a supporting piece, and an air exhaust gap is formed between the supporting piece and the inner wall surface of the shell. The fact that the insulator has enough strength to bear vulcanization injection force can be guaranteed through the supporting piece, and meanwhile, the air exhaust gap is formed between the supporting piece and the inner wall surface of the shell, so that during a vulcanization process, air inside the shell can be exhausted from the rear end of the shell through the air exhaust gap, and therefore, the problem that seal of an existing underwater plug-pull connector is not reliable is solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

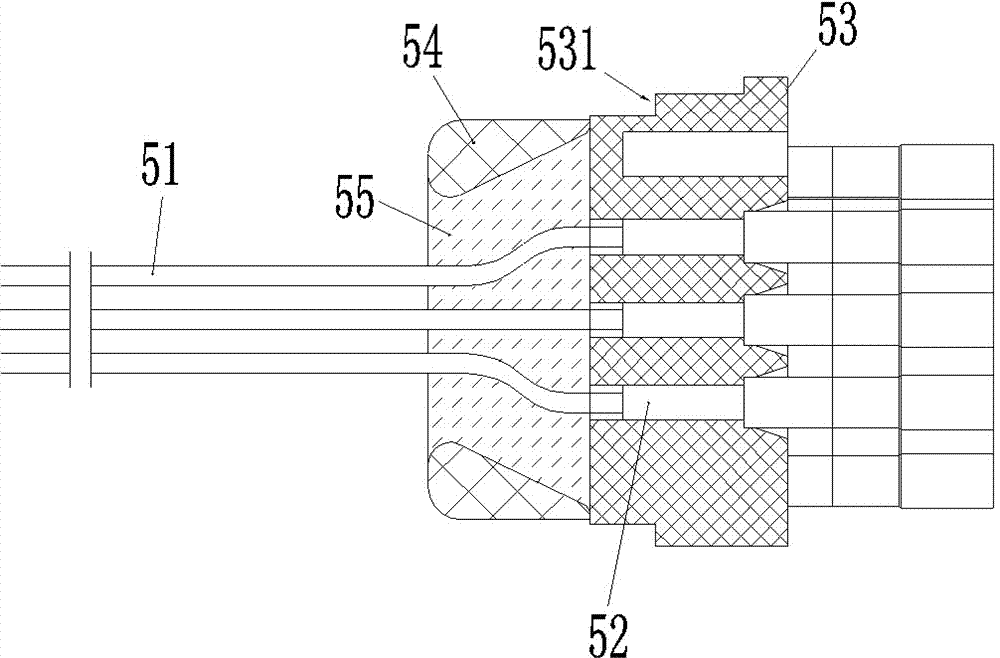

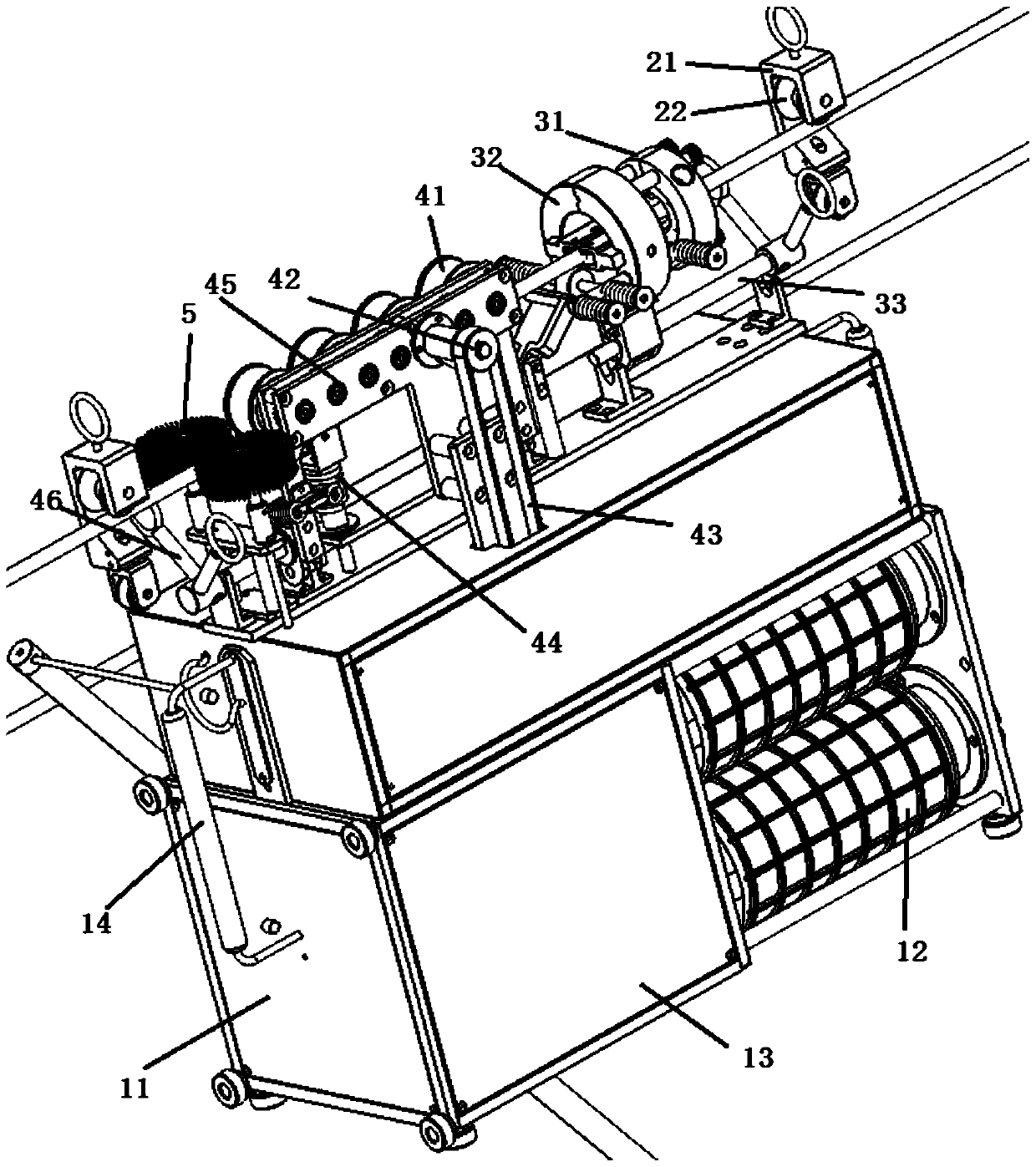

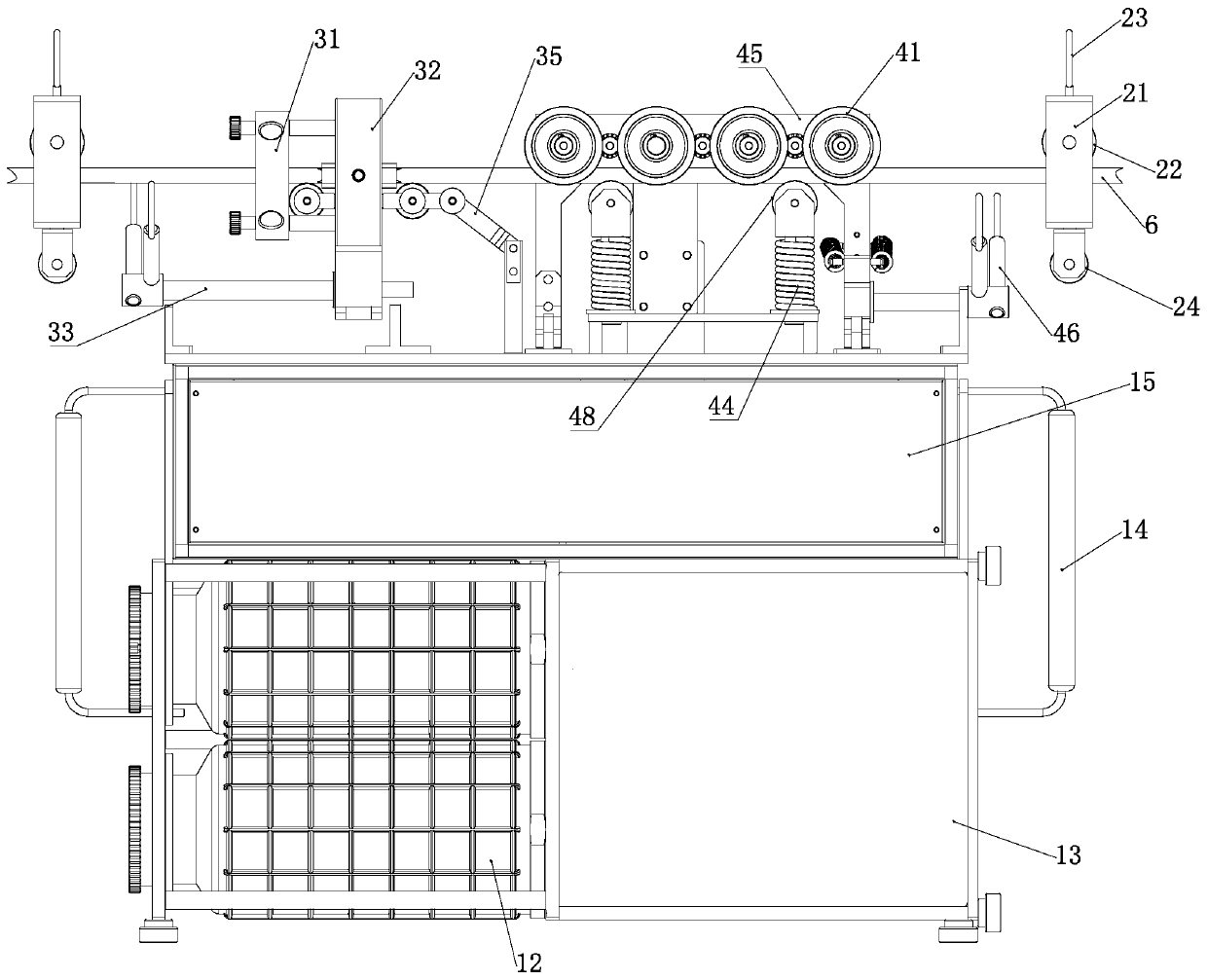

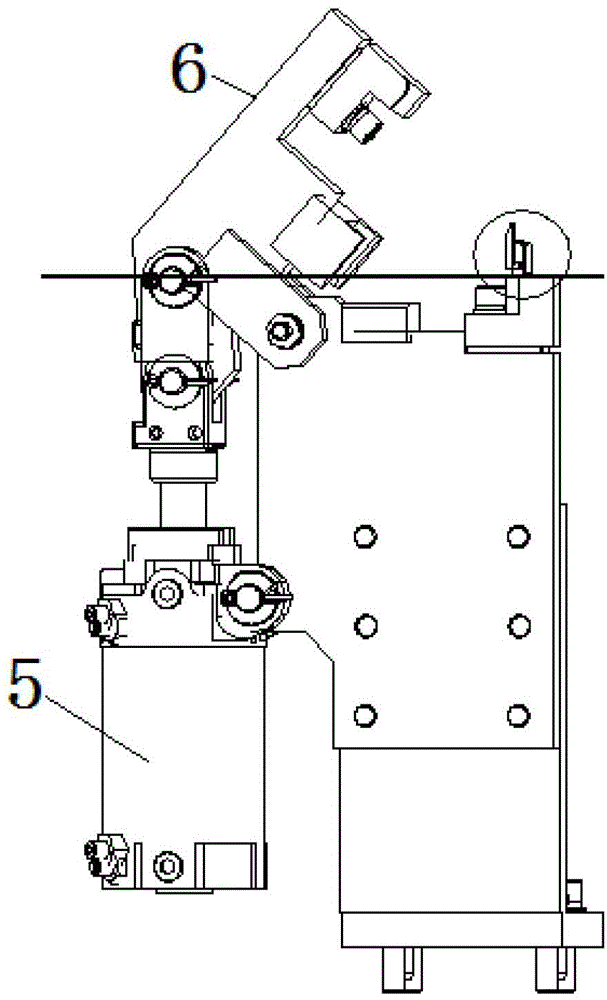

High-voltage charged overhead bare wire intelligent rubber-coated spraying robot

ActiveCN109768498AImproved fixation and laggingImprove lagging effectLiquid surface applicatorsCoatingsEngineeringInjection pressure

The invention belongs to the technical field of electric power systems, and relates to a high-voltage charged overhead bare wire intelligent rubber-coated spraying robot. A glue injection device comprises an opening-shaped fixing seat, clamping arms fixedly mounted on both sides of the fixing seat and an injection pressure ring fixed connected to the clamping arms; a driven wheel and a plurality of second blocking wheels are respectively fixedly mounted on both outer sides of a blocking plate in a transmission device, a driving wheel is fixedly mounted on a rotating motor, a conveyor belt is installed between the driving wheel and the driven wheel, a plurality of meshing gears are evenly mounted between the two blocking plates, the second blocking wheels are fixedly connected to a rotatingshaft of the spaced gears, the driven wheel is fixedly connected with one of the gears through the rotating shaft, a cabinet below the second blocking wheels is fixedly mounted with a plurality of limit posts, and the lower portion of the blocking plates is fixedly connected with an opening-shaped base. The high-voltage charged overhead bare wire intelligent rubber-coated spraying robot solves the problem in the prior art that injecting an insulating layer robot has a poor fixing effect on bare wires, resulting in poor rubber coating effect of the bare wires and easy electric leakage.

Owner:重庆洎皋电力科技有限责任公司

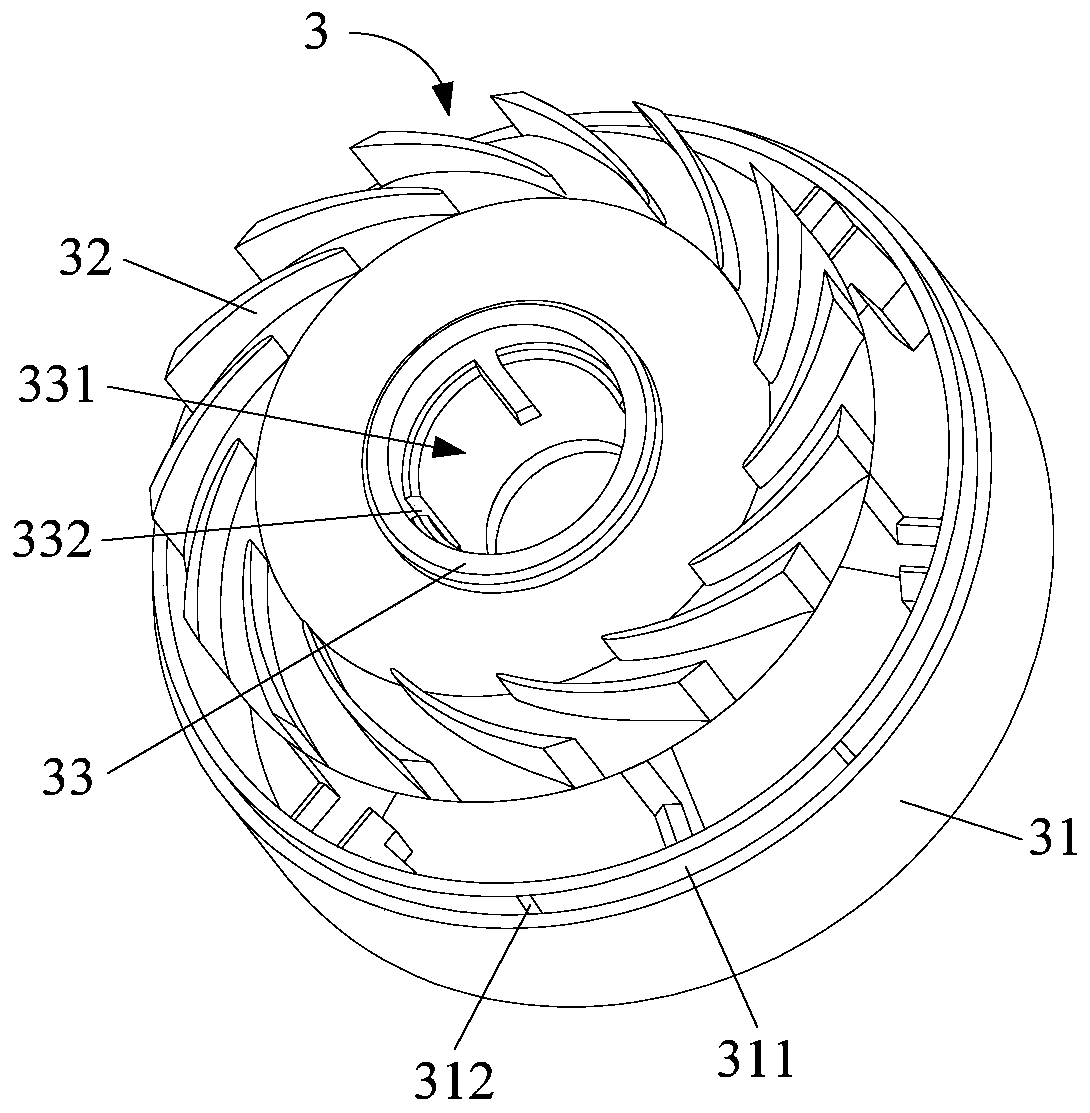

Turbine rotor fork-shaped blade mounting structure and mounting method thereof

ActiveCN110145372AArrange neatlyPrevent looseningBlade accessoriesMachines/enginesTurbine bladeEngineering

The invention discloses a turbine rotor fork-shaped blade mounting structure, and relates to the technical field of turbine blade installation. The invention aims to solve the problem that a mountingclerance cannot be eliminated when a traditional mounting blade is installed. The turbine rotor fork-shaped blade mounting structure is characterized by comprising a rotor and a fork-shaped blade connected to the rotor, a mounting seat is connected to the side wall of the rotor, an annular fork-shaped wheel groove is coaxially formed in the mounting seat and the rotor, a plurality of middle bladesare slidably clamped in the fork-shaped wheel groove, wheel grooves are formed in the side walls of the fork-shaped wheel grooves in the radial direction of the rotor, tail blades are arranged in thewheel grooves in a penetrating mode, and locking assemblies used for locking the tail blades are arranged in the wheel grooves. The turbine rotor fork-shaped blade mounting structure has the advantages of being simple and firm to mount and capable of effectively eliminating the mounting clearance.

Owner:浙江合泰热电有限公司

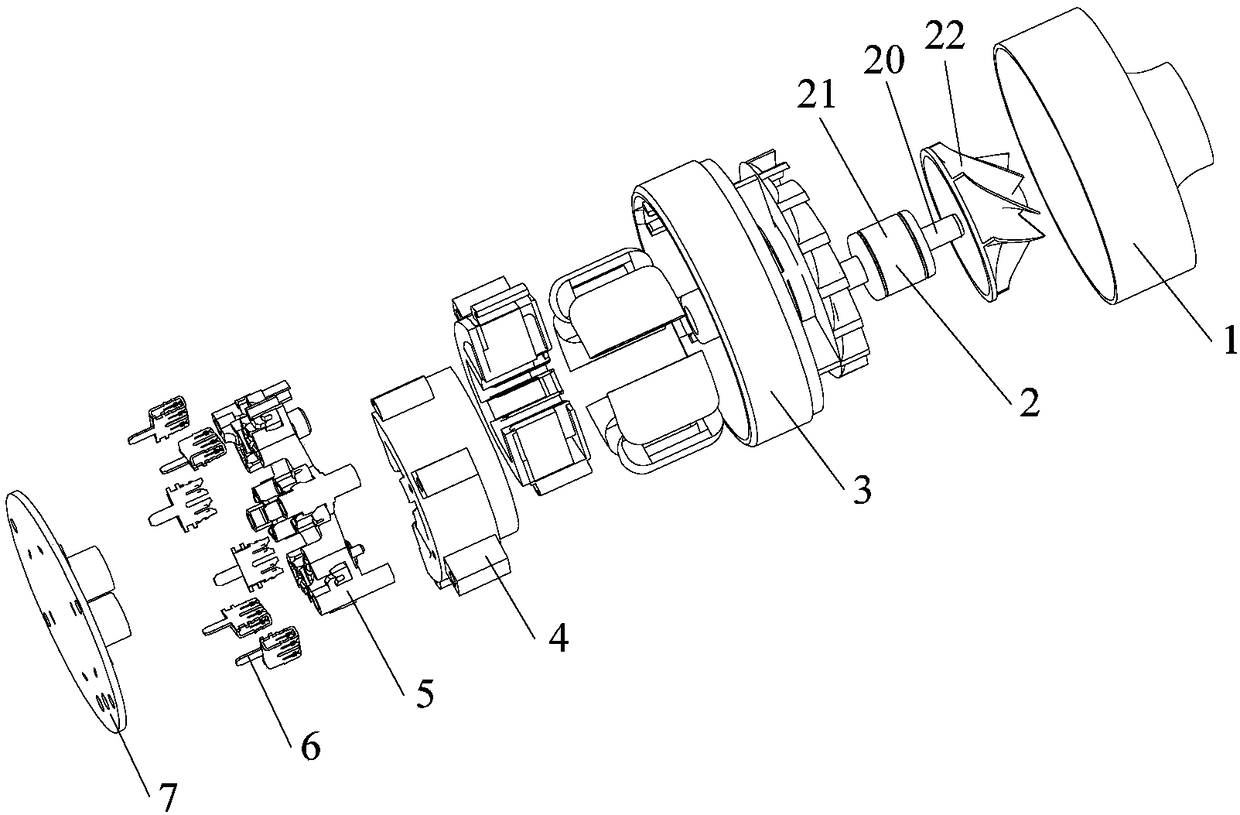

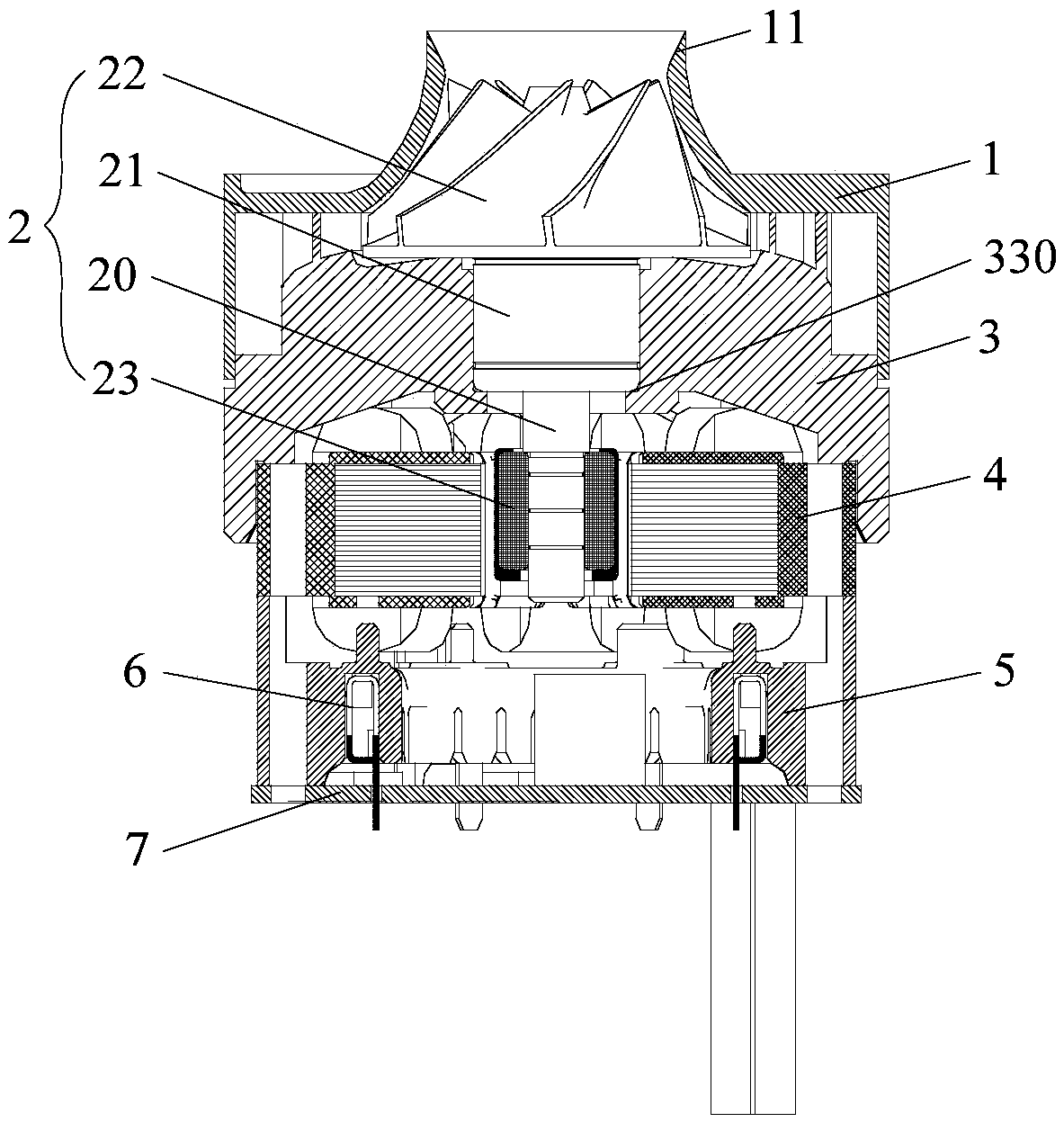

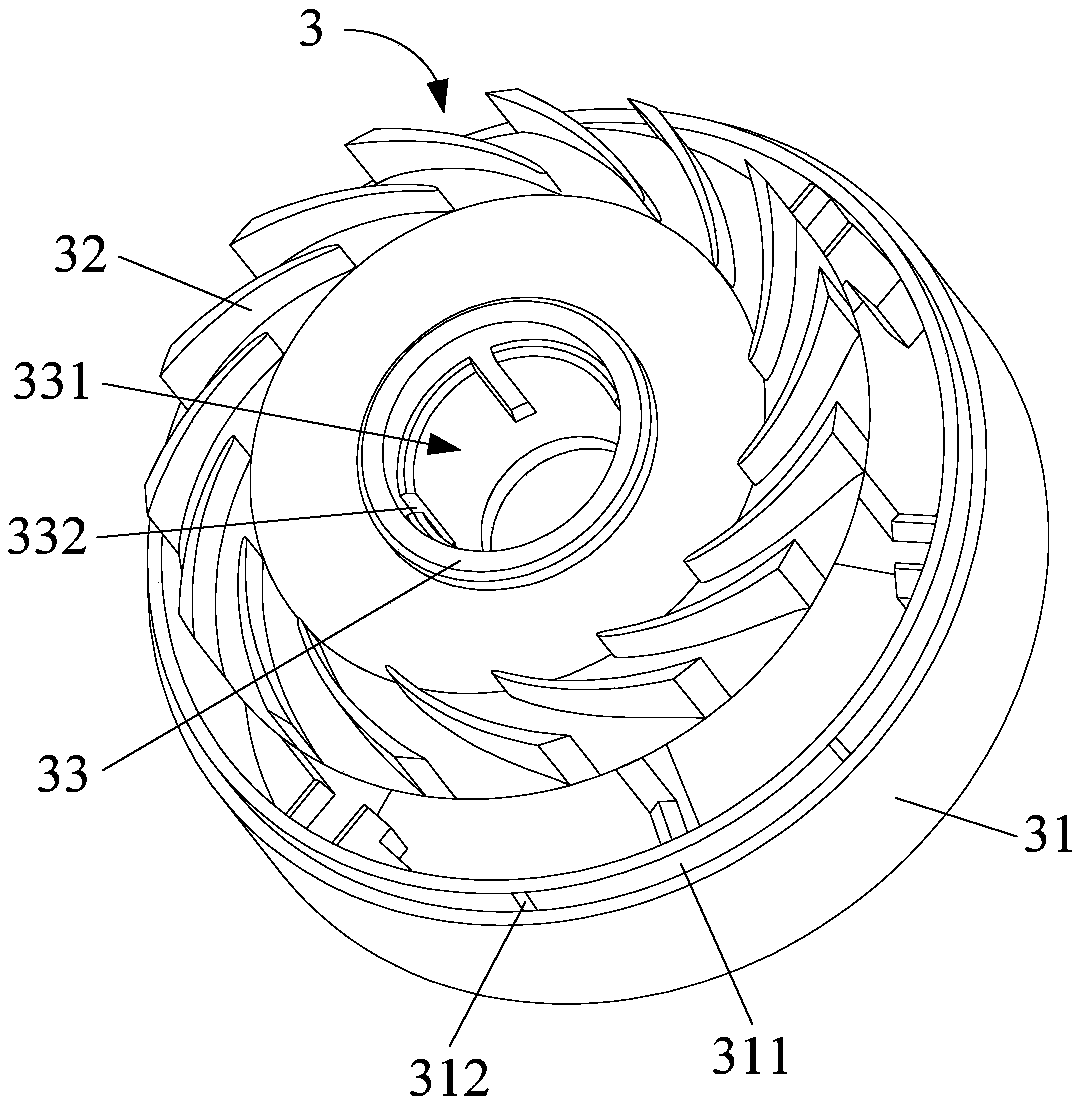

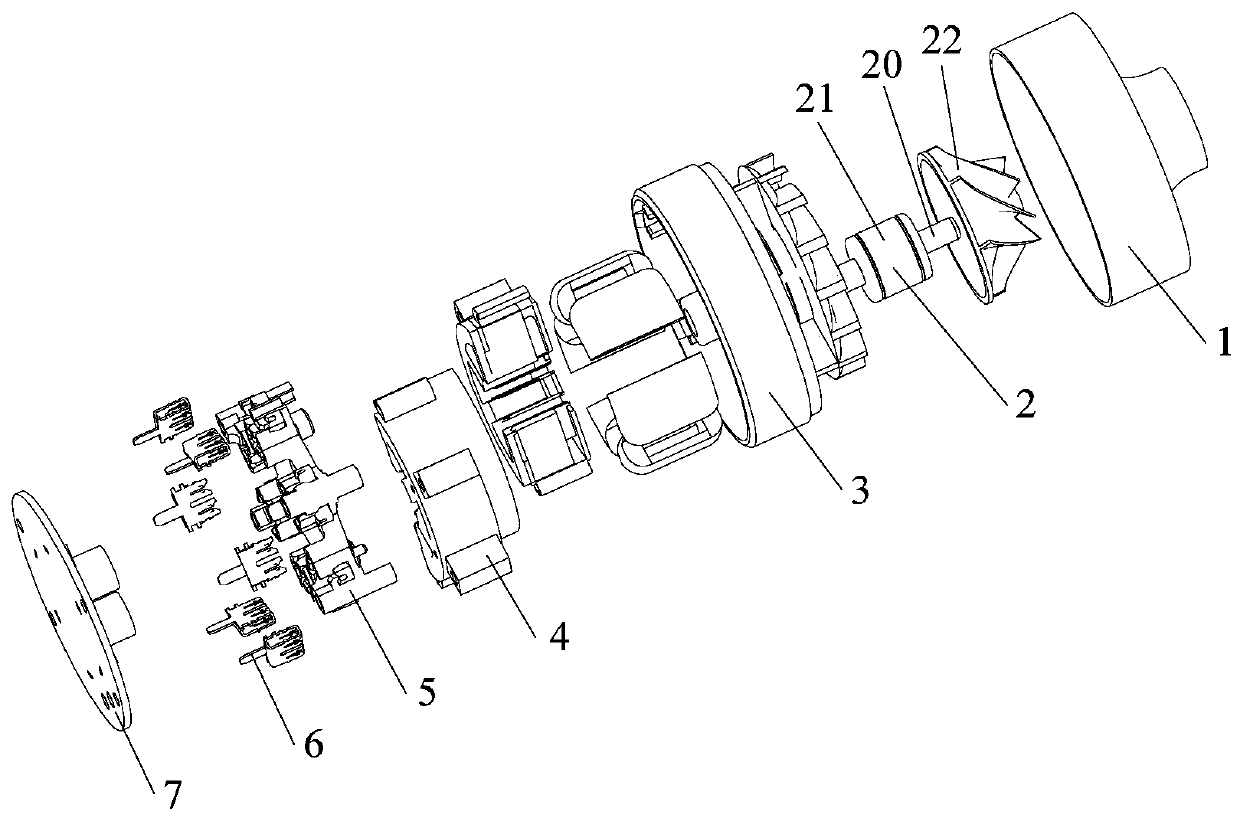

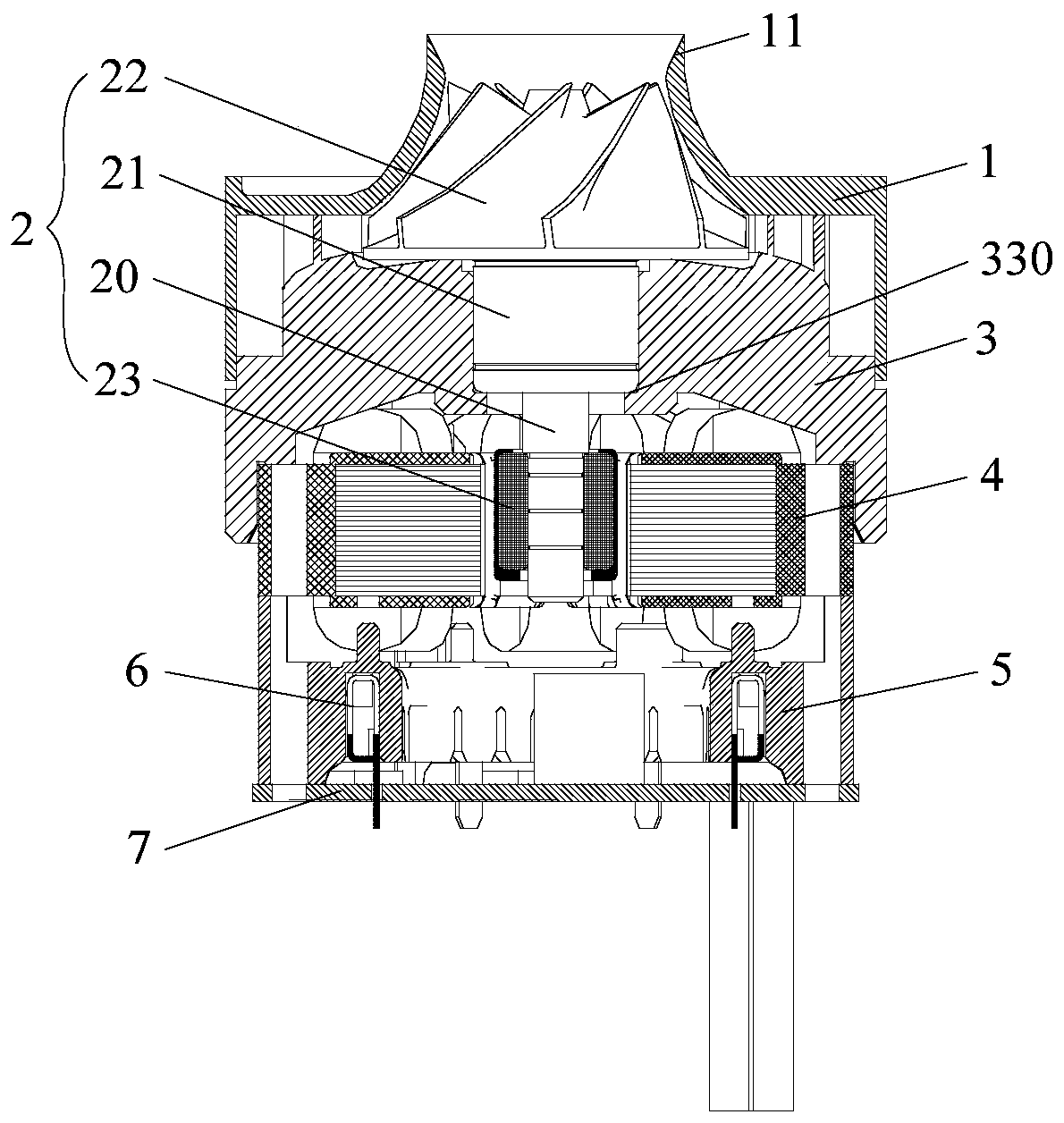

Electric fan

ActiveCN109185196AReduced parts countAssembly accuracy is lowPump componentsWorking fluid for enginesImpellerEngineering

The invention provides an electric fan which comprises a rotor component and a machine shell, wherein the rotor component comprises a bearing, a moving impeller and a magnetic ring; the magnetic ringand the moving impeller are correspondingly mounted at two ends of the bearing; the machine shell is equipped with a bearing chamber; the diameter of the magnetic ring is less than that of the bearingchamber; the magnetic ring is capable of penetrating through the bearing chamber; and after the mounting operation is completed, the moving impeller and the magnetic ring are correspondingly positioned at two ends of the bearing chamber. According to the electric fan provided by the invention, only one bearing is utilized, and the utilized bearing is positioned between the moving impeller and themagnetic ring which are mounted on a rotating shaft; during the assembling process, the magnetic ring penetrates through the bearing chamber; after the mounting operation is completed, the moving impeller and the magnetic ring are correspondingly positioned at the two ends of the bearing chamber; by the adoption of such a rotor component and machine shell assembling mode, the assembling operationcan be facilitated and the assembling process can be simplified; due to the use of only one bearing, the rotor component and machine shell assembling precision requirements are low, and the improvement of the assembling efficiency can be facilitated; and furthermore, the quantity of parts of the electric fan is reduced, so that the reduction of the product cost can be facilitated and the assembling efficiency can be further improved.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

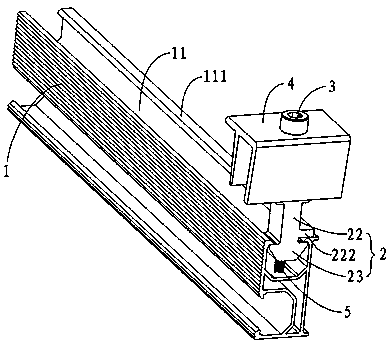

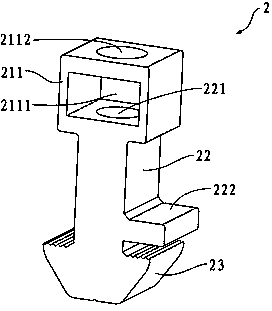

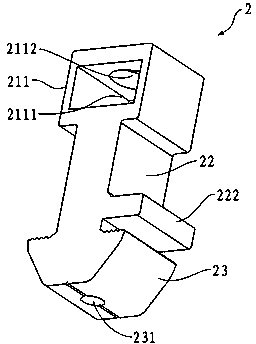

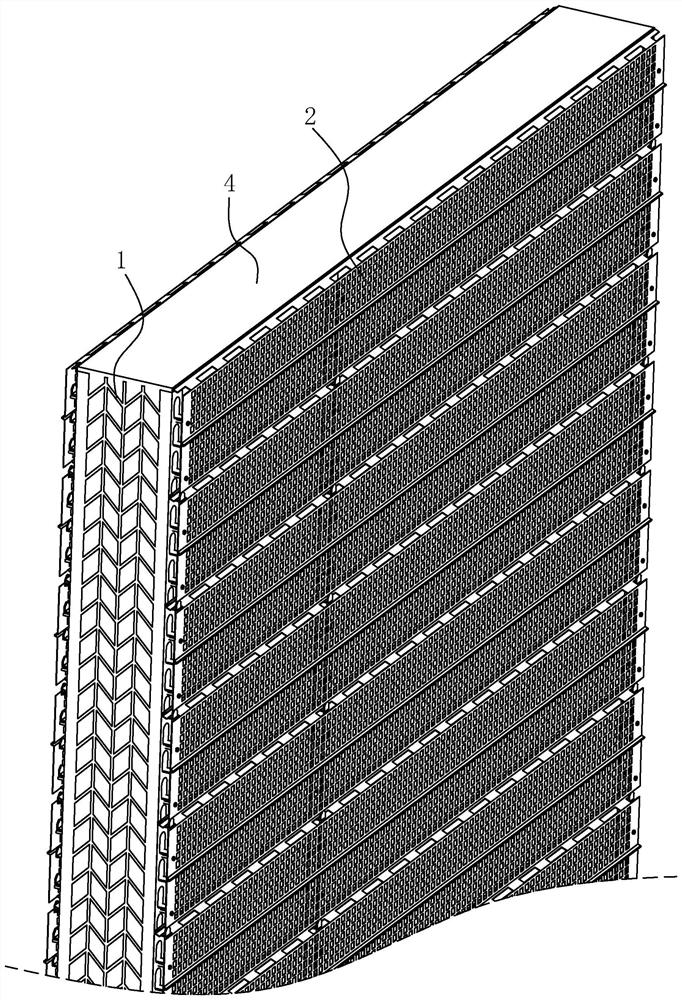

Solar panel tightening device

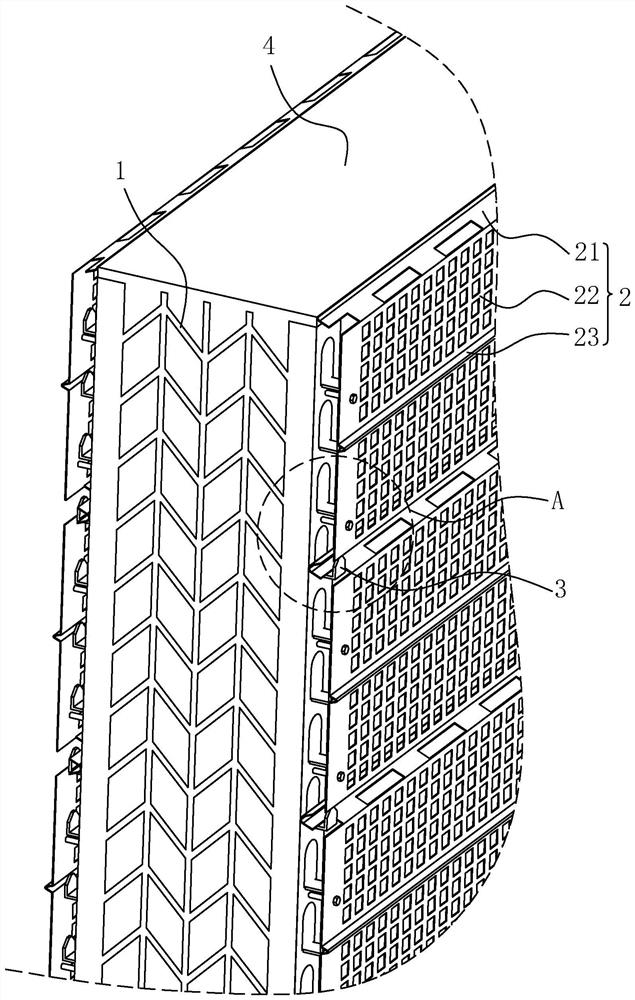

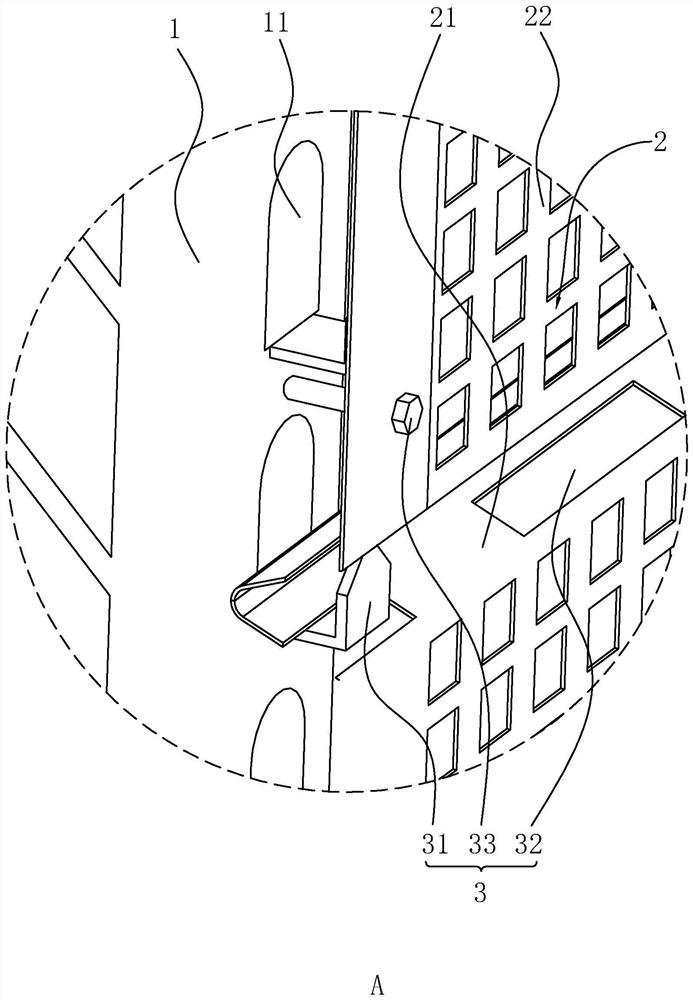

ActiveCN103400879AAvoid fit problemsReduce management costsPhotovoltaic energy generationSemiconductor devicesEngineeringUpper segment

The invention discloses a solar panel tightening device, which comprises a guide rail, a clamping piece, a bolt, a pressure plate and a spring, wherein a clamping block accommodating groove is formed at the upper end of the guide rail; a blocking lead extending inwards is formed at the tail end of the opening of the clamping block accommodating groove; the upper part of the clamping piece is a bolt connecting part; the middle part of the clamping piece is provided with a bolt adjusting part provided with a bolt accommodating space; the lower part of the clamping piece is a clamping block part; a spring mounting hole is formed in the center of the bottom end of the clamping block part; one side of the bolt adjusting part is provided with a support check block matched with the blocking edge; the distance between the support check block and the clamping block part is slightly larger than the thickness of the blocking edge; the bolt is in threaded connection with the bolt connecting part, and extends into the bolt adjusting part; the pressure plate is positioned above the clamping piece and connected with the clamping piece through the bolt; and the upper segment of the spring is fixedly connected in the spring mounting hole. The solar panel tightening device has the characteristics of easiness and convenience in installing and high universality.

Owner:XIAMEN HOPERGY PHOTOVOLTAIC TECH

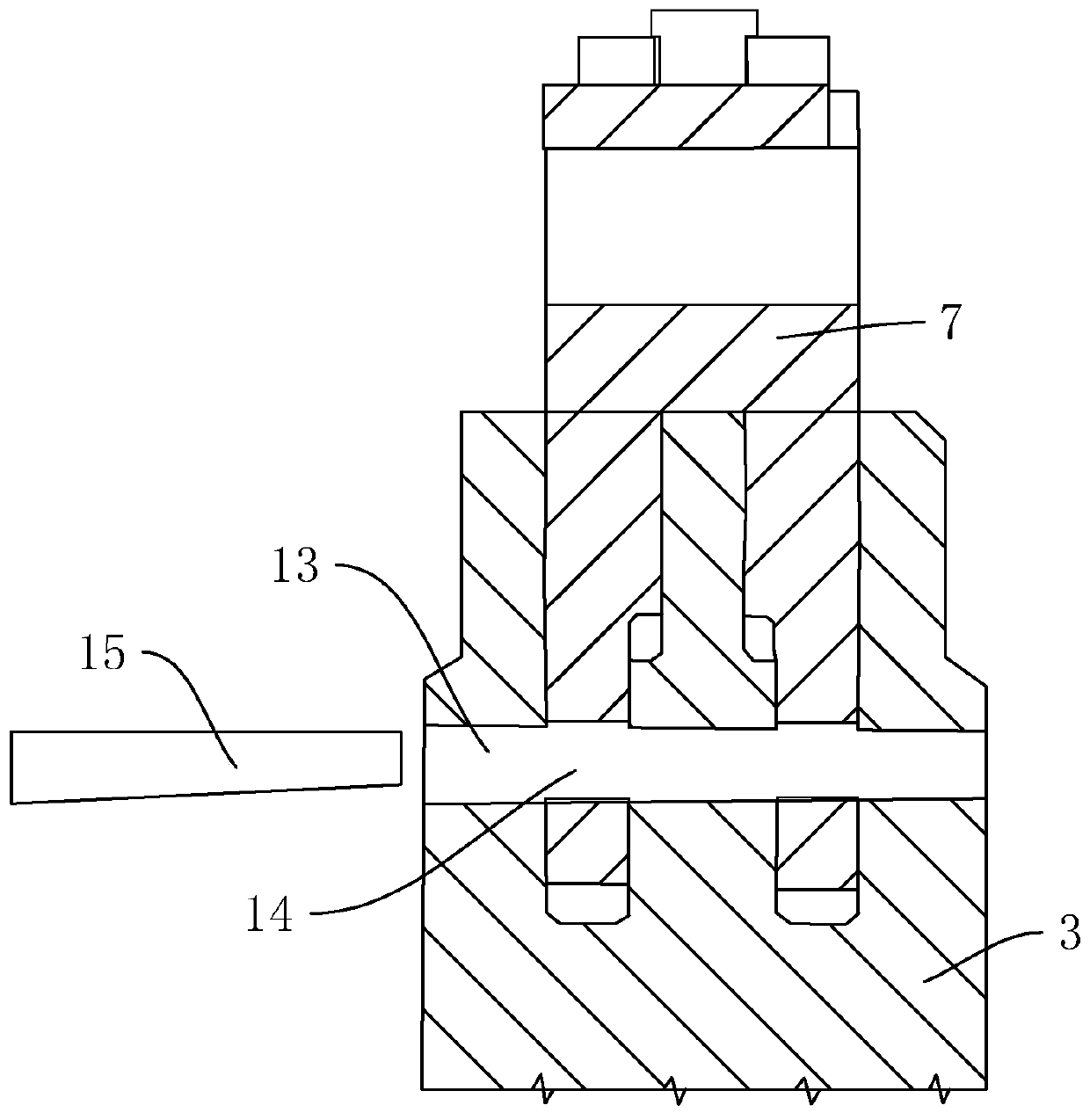

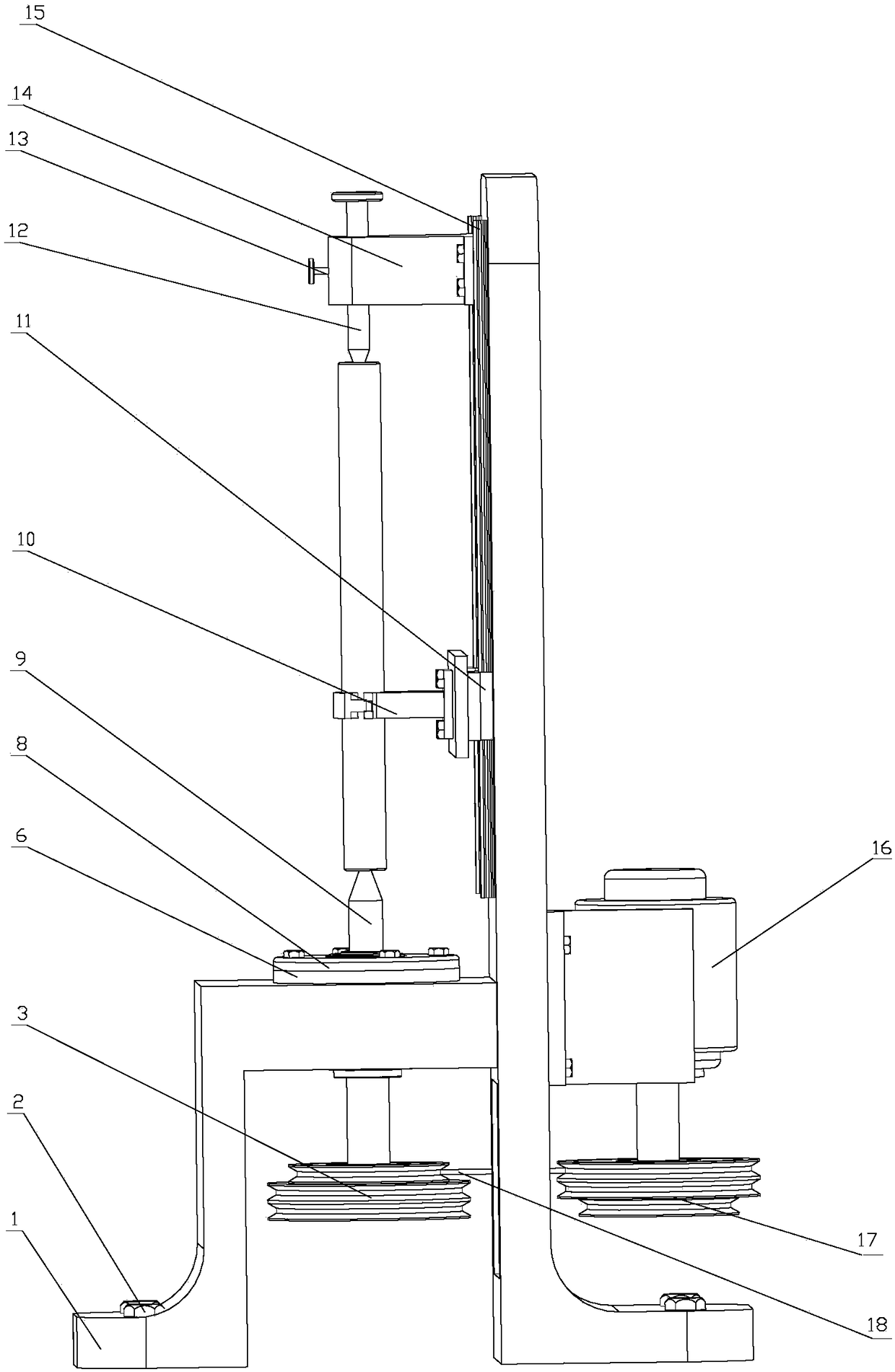

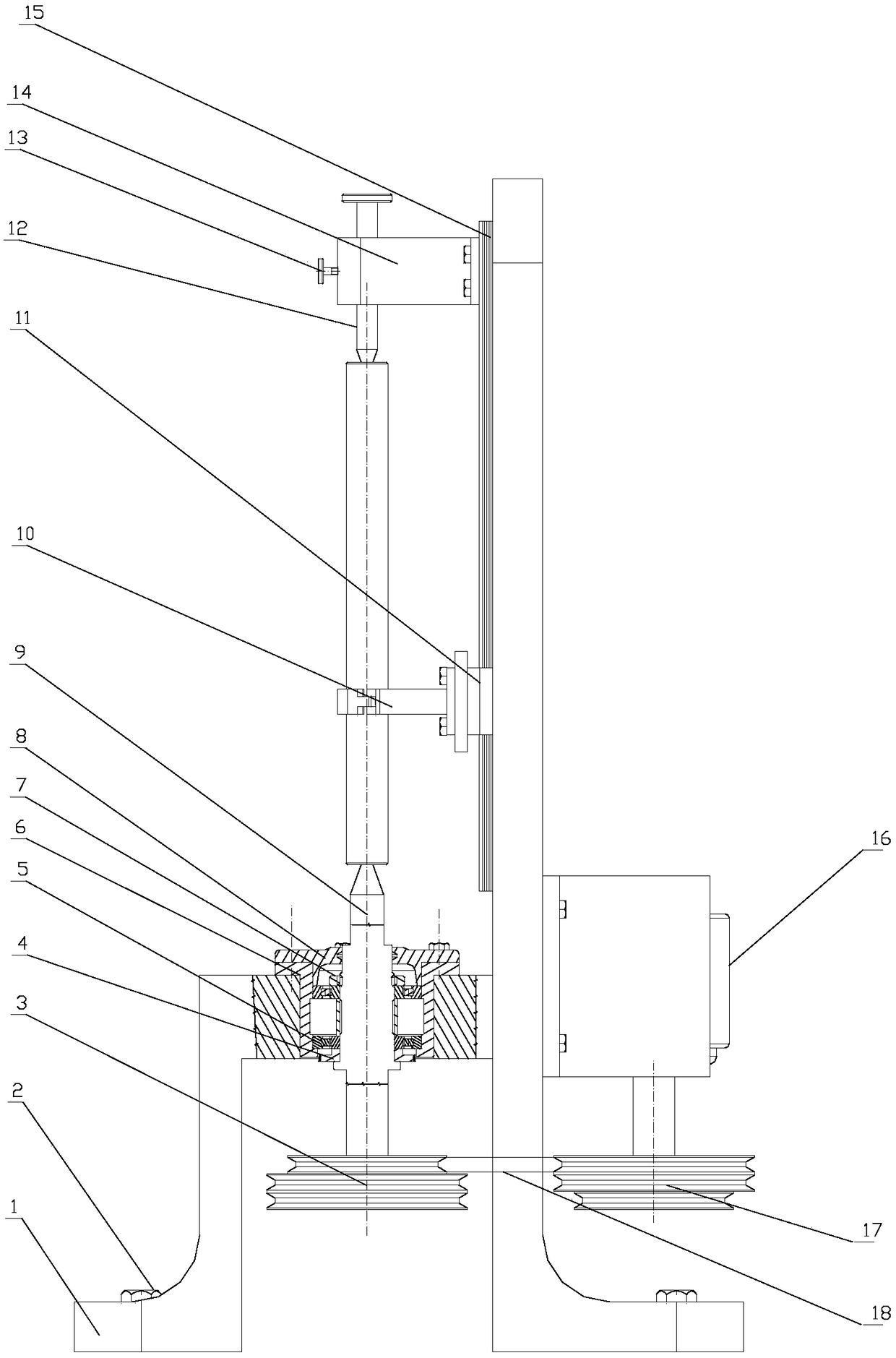

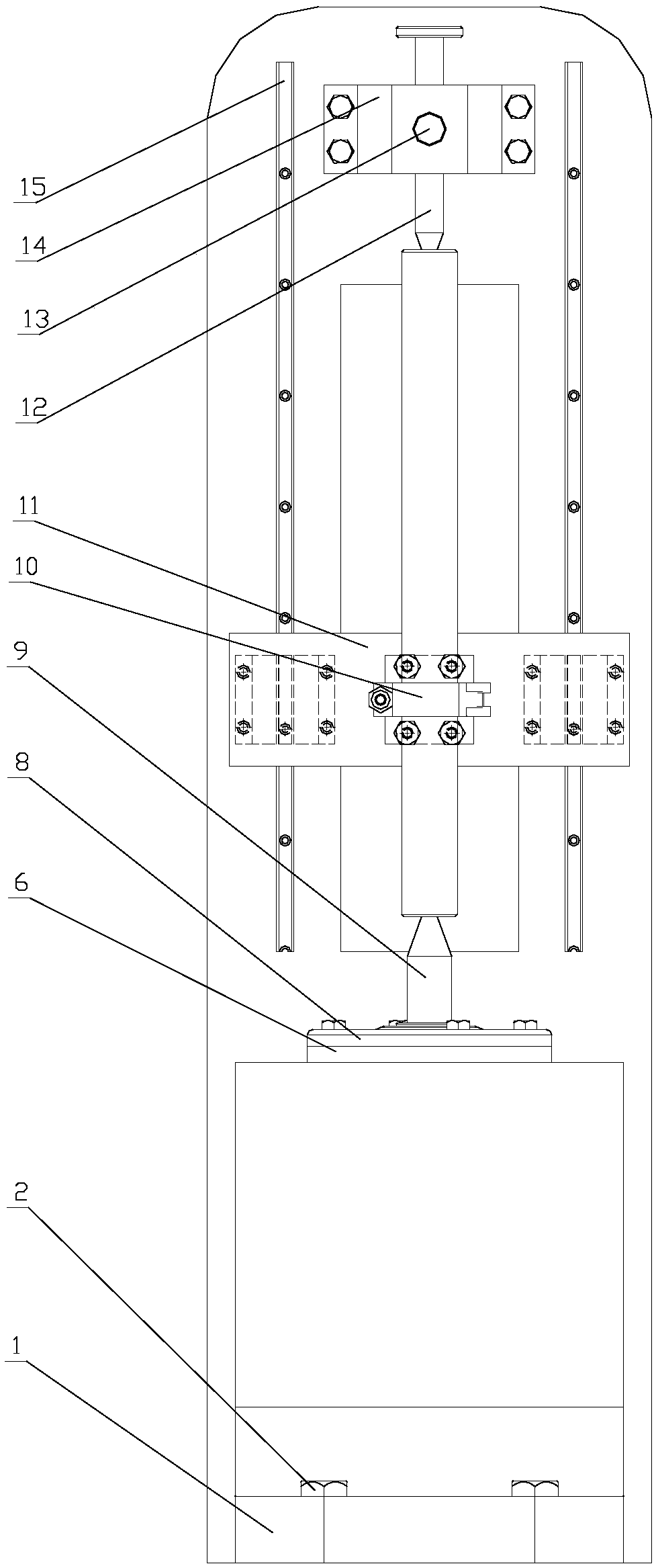

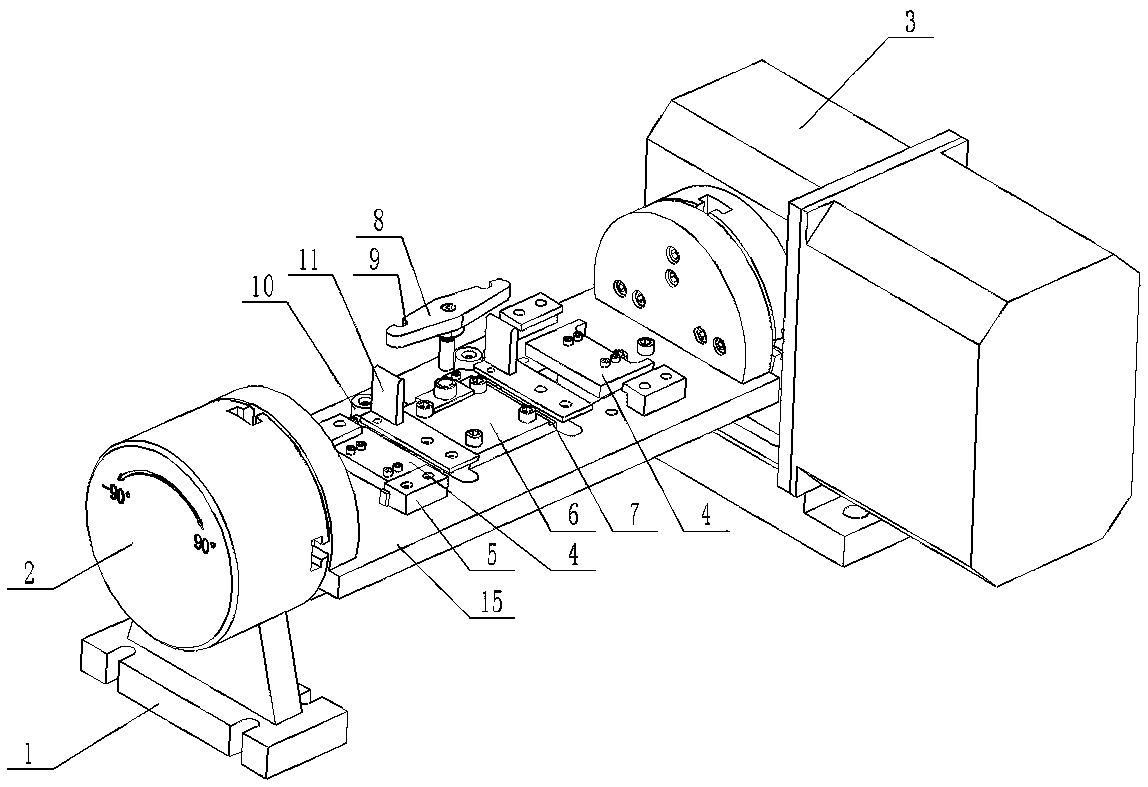

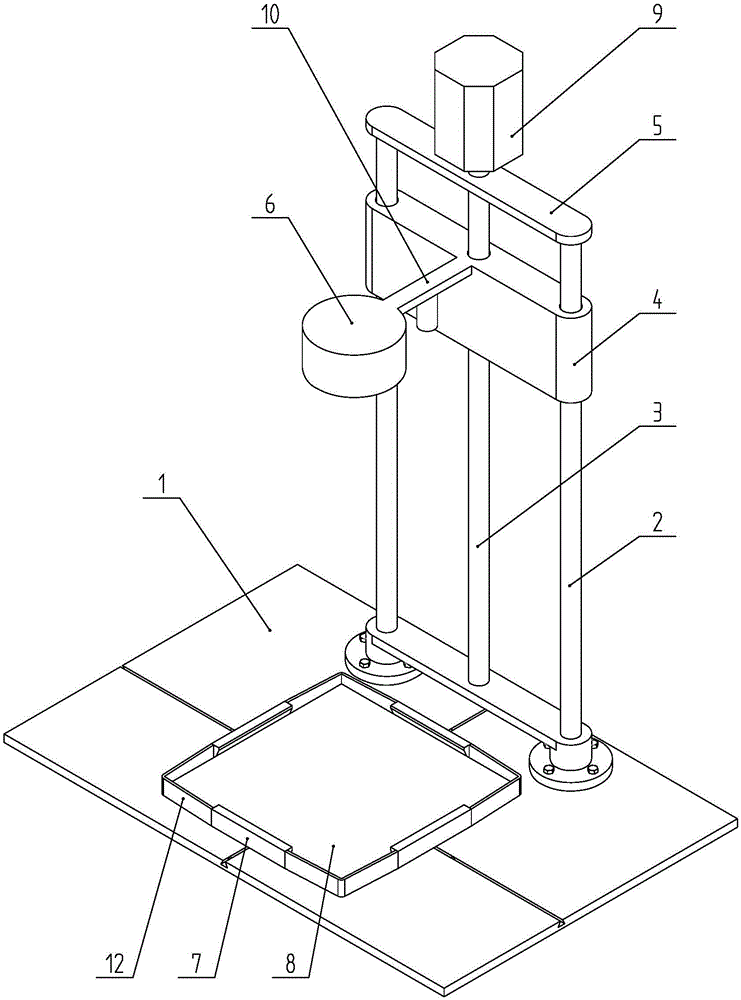

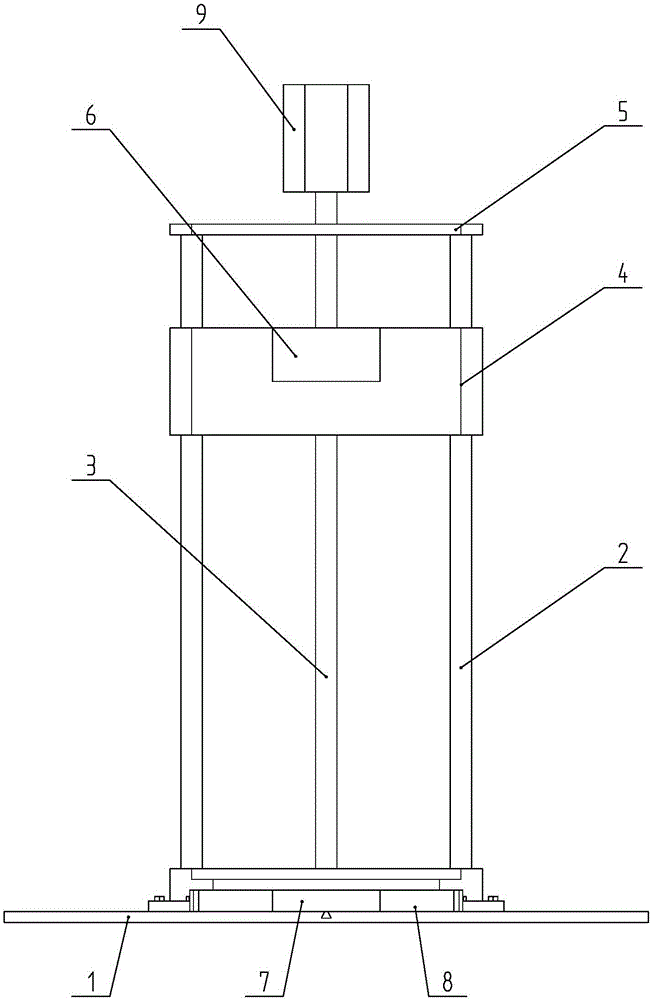

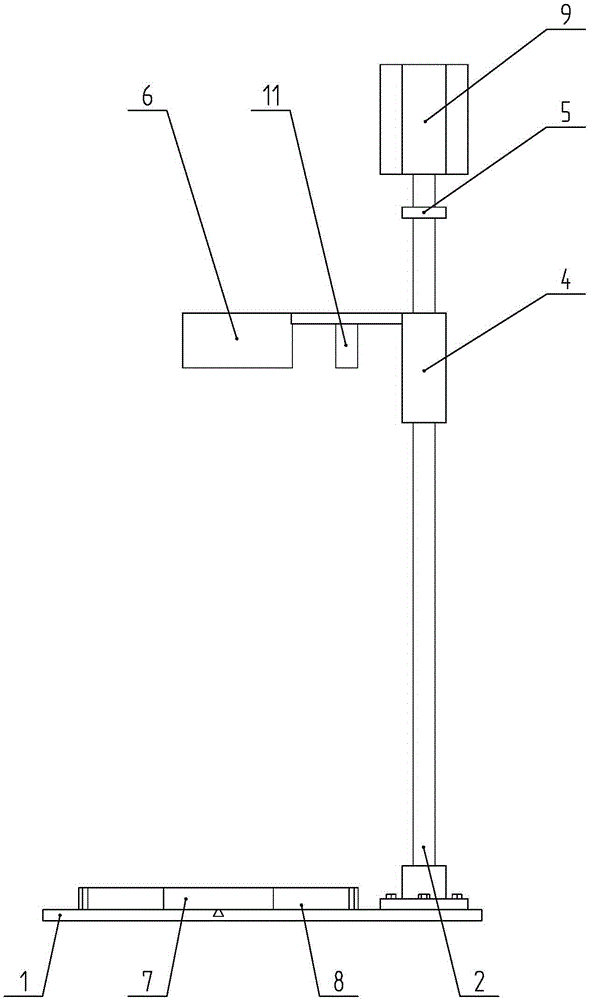

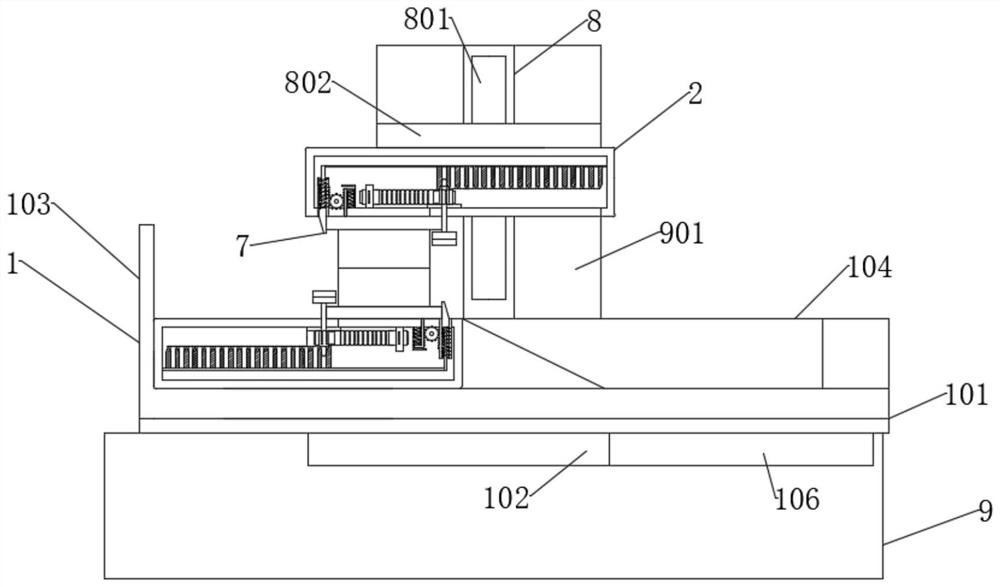

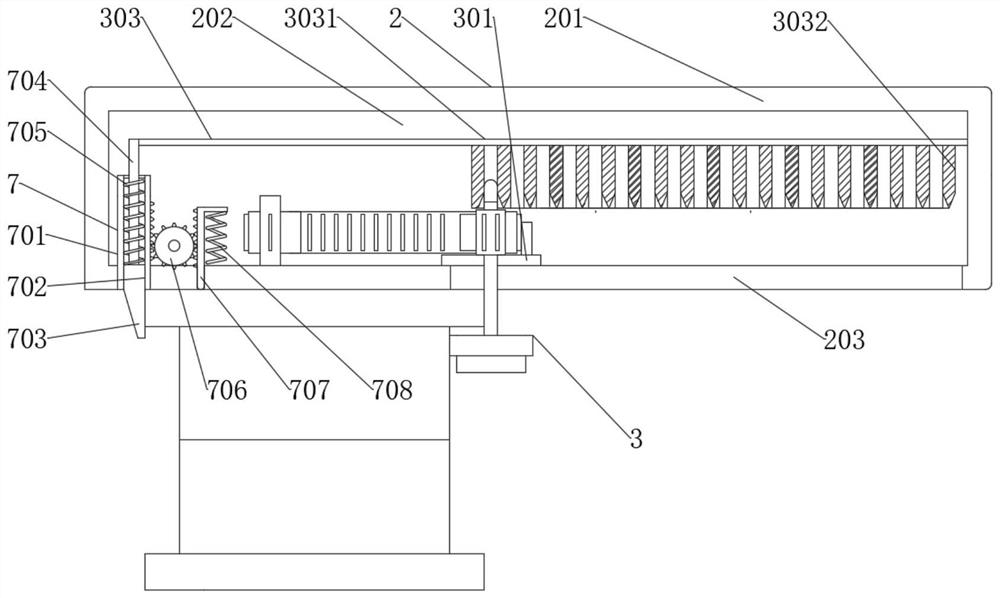

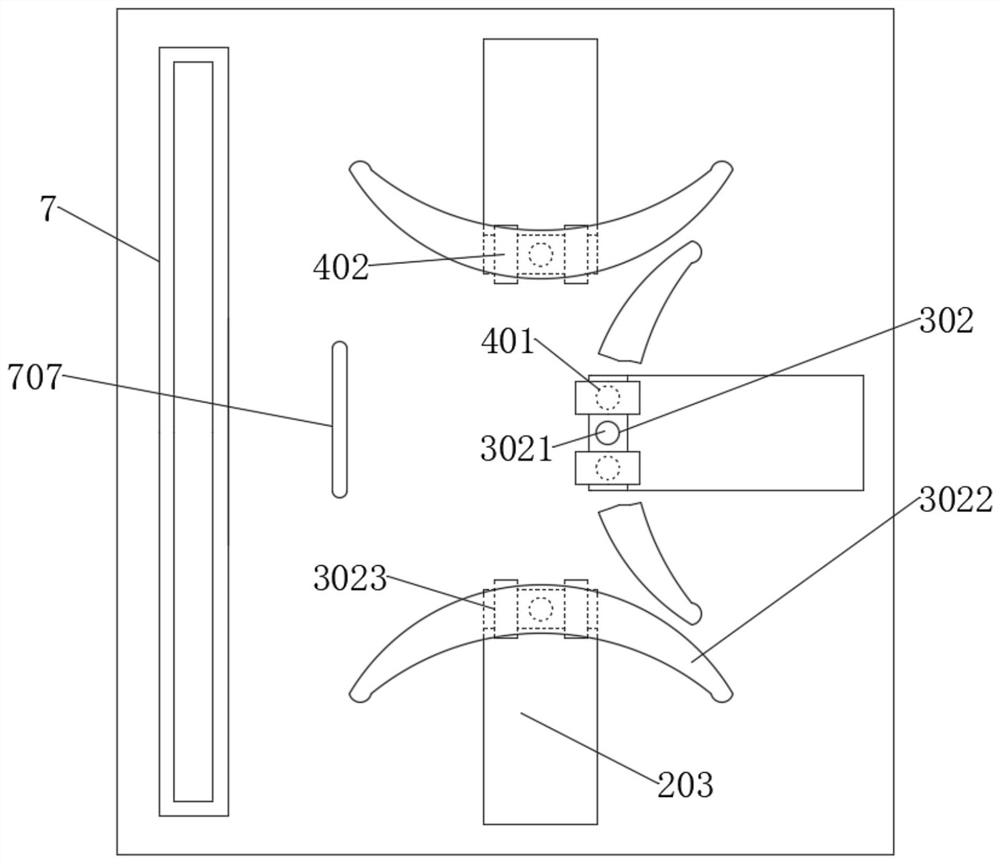

Rotary Shaft Double-head Central Hole Vertical Grinder

PendingCN108115477ASimple structureReduce manufacturing costGrinding carriagesRevolution surface grinding machinesEngineeringMachining process

The invention discloses a rotary shaft double-head central hole vertical grinder, and aims to provide a vertical grinding device which has the advantages of simple structure, convenient operation andhigh efficiency, and can be adjusted according to the size and the length of different shafts. The invention will be realized according to the following technical scheme: an active center (9) is formed on the connecting shaft of the belt wheel (3), the active center is vertically upwards through a rolling bearing assembled by the pi-shaped base (1) platform and its bushing end cover (8), bearing the center hole of one end of shaft workpiece, the shaft-like workpiece is connected to a clamping device (10) on the slide rail (15) of the upright post by sliding method, and the central hole at theother end is coaxial with the tail seat rotary tip (12) of the tail seat bracket (14) above the upright post plate. The invention solves the problem that the traditional manual grinding mode has incomplete grinding and uneven grinding quality on the central hole oxide layer at two ends of the shaft and that it is difficult to guarantee the grinding quality of the central hole, large center jumpingand large error, and is easy to cause the problem of super-difference or rejection of the shaft parts.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

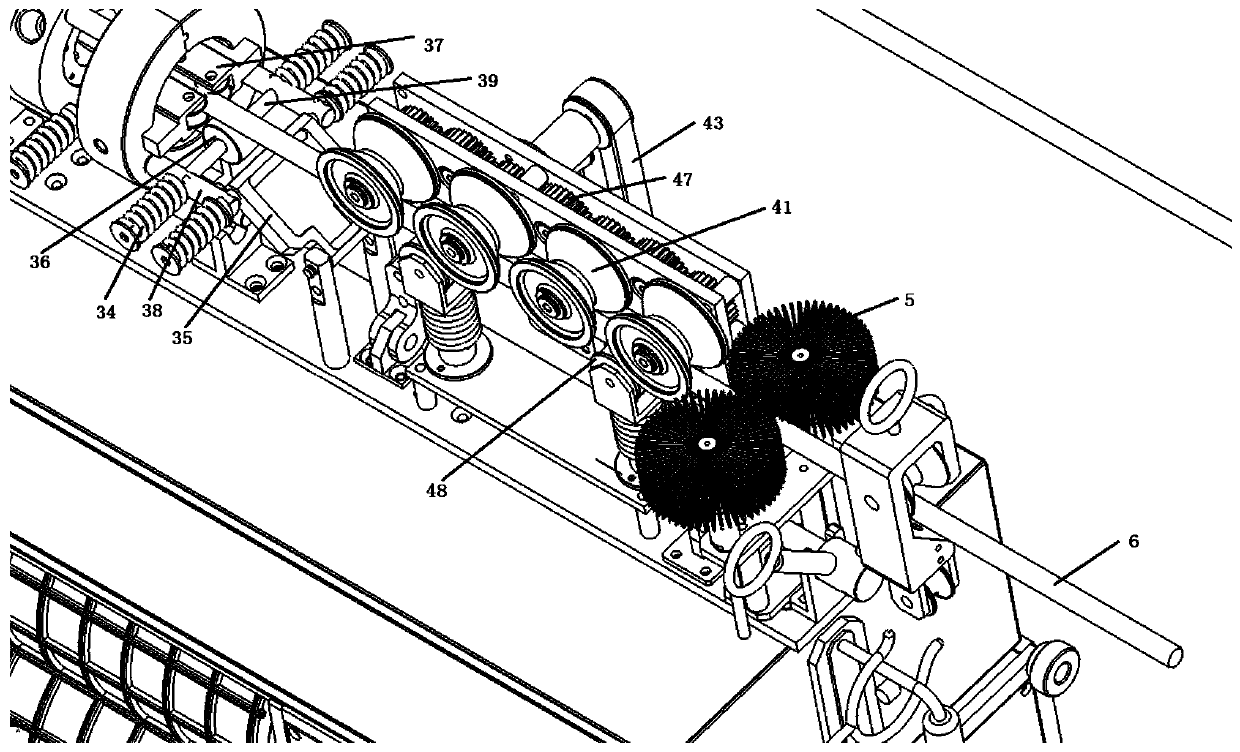

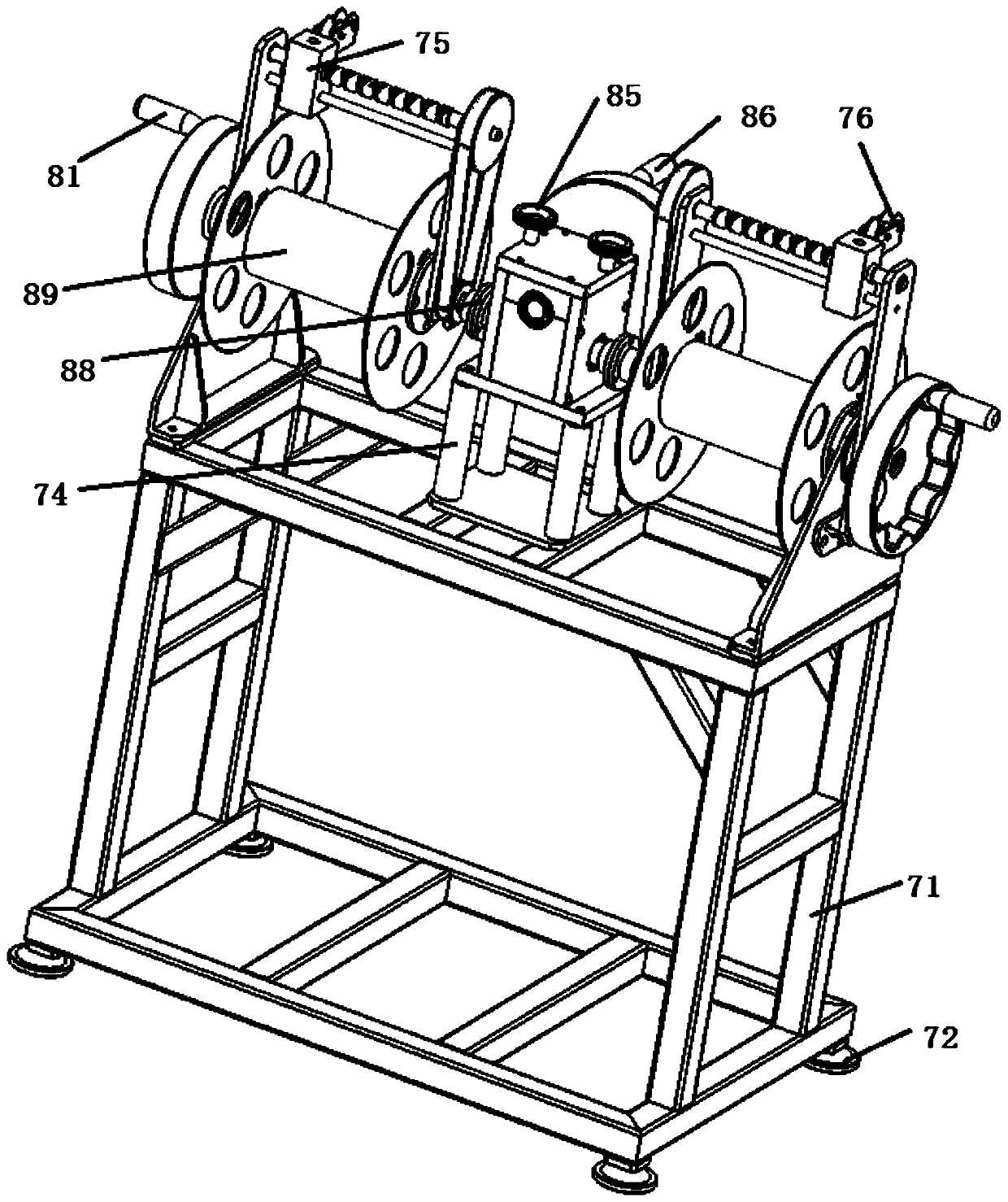

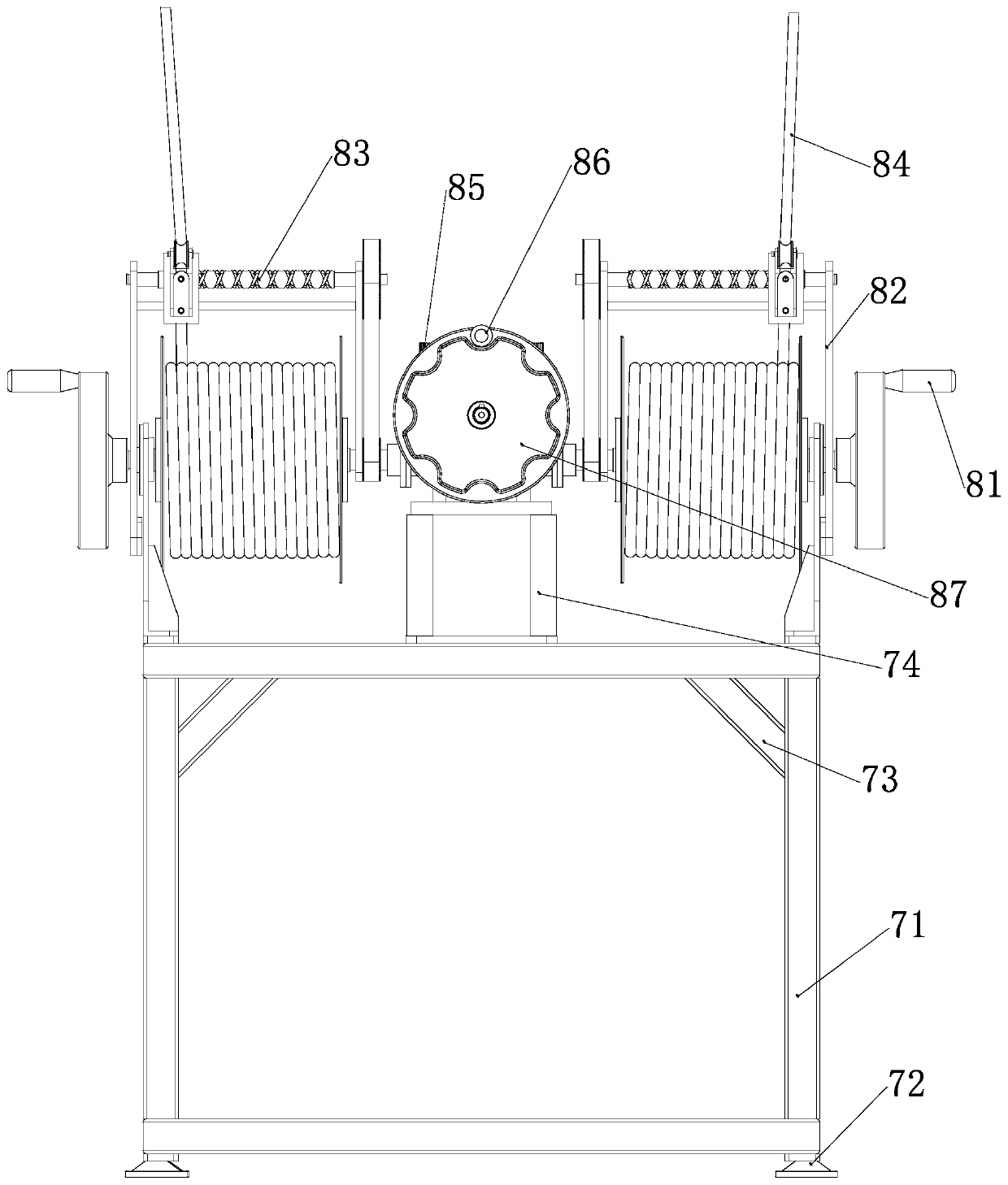

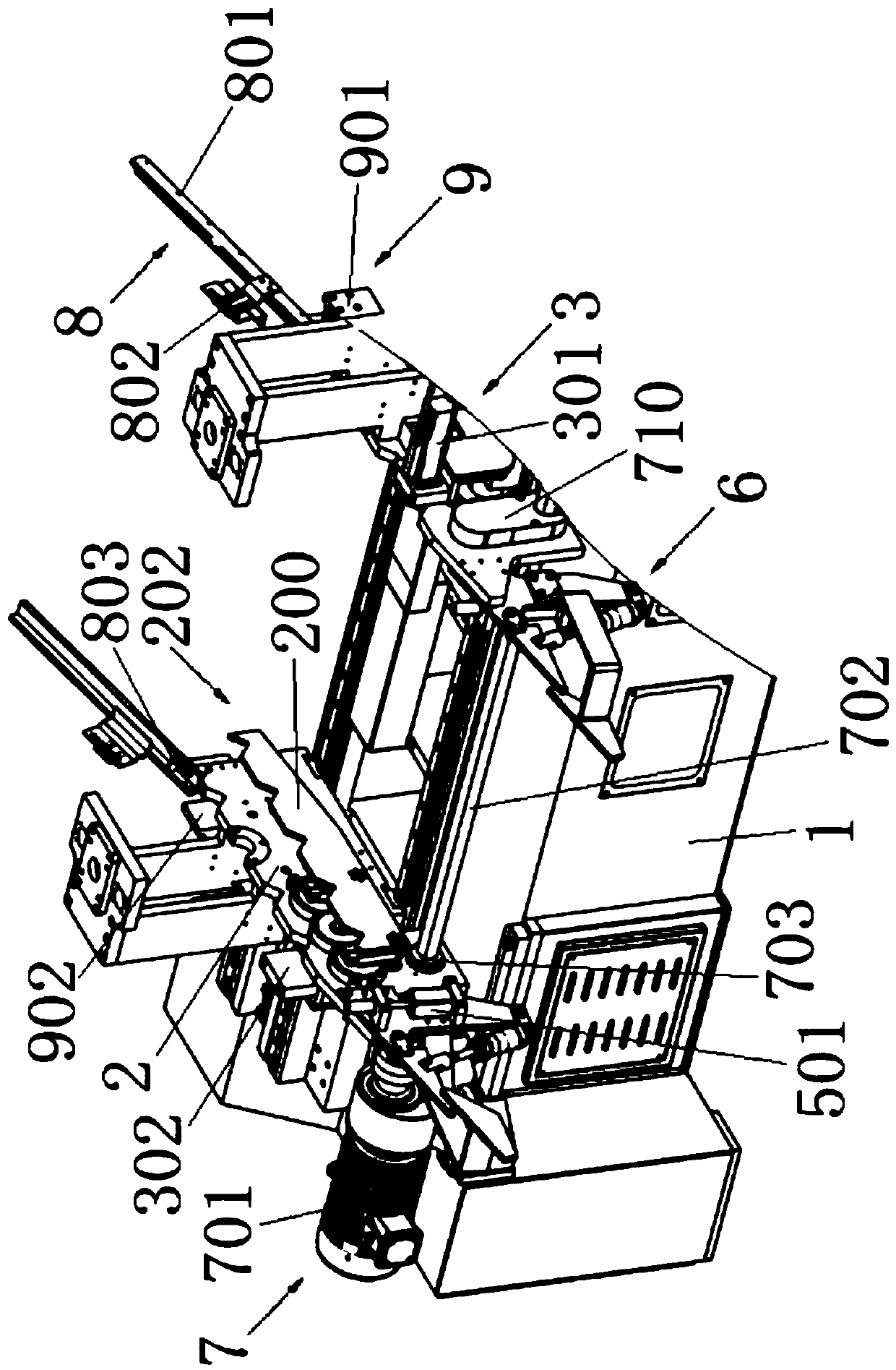

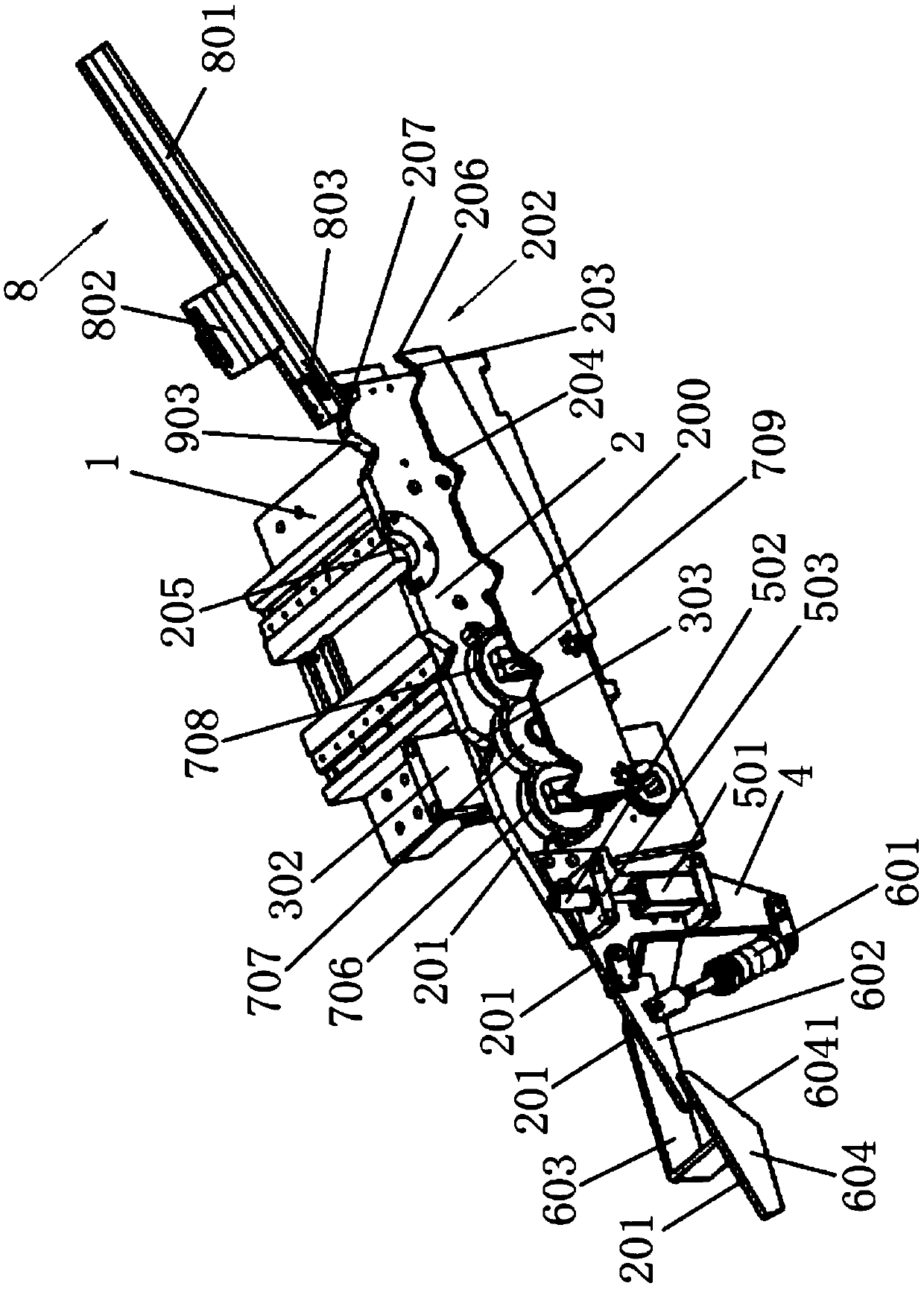

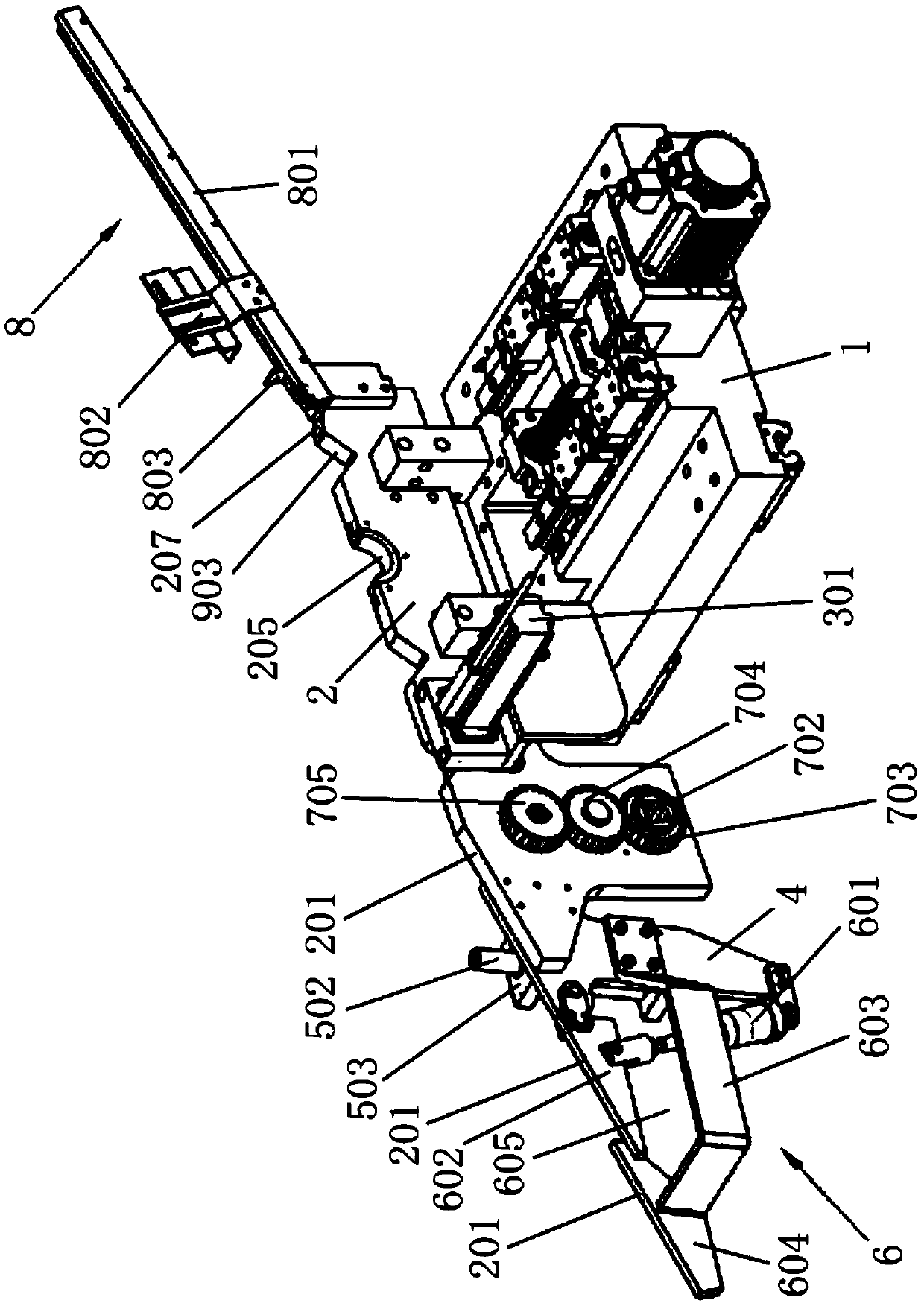

High-voltage electrified aerial bare conducting wire lifting crane and rubber coating spray painting robot thereof

ActiveCN109704220AEasy to operateThere is no potential safety hazard of electromagnetic interferenceLiquid surface applicatorsWinding mechanismsWire speedPaint robot

The invention belongs to the technical field of electric power systems, and relates to a high-voltage electrified aerial bare conducting wire lifting crane and a rubber coating spray painting robot ofthe high-voltage electrified aerial bare conducting wire lifting crane. A lifting device in the lifting crane comprises a wire speed adjusting device and wire winding devices, wherein the wire speedadjusting device is installed in the middle of the upper end of a machine frame, and the wire winding devices are installed on the two sides of the wire speed adjusting device. The wire speed adjusting device comprises a supporting frame, a worm and a worm wheel, wherein the supporting frame is installed on the machine frame, the worm is arranged on the supporting frame, and the worm wheel mesheswith the worm. A second hand wheel is fixedly installed on the outer side of the worm wheel, and a plurality of third hand wheels are evenly and fixedly installed on the upper side of the worm wheel.Each wire winding device comprises a wire winding roller, a guide rod and a first hand wheel. The wire winding rollers are fixedly arranged at the free ends of the worm, the guide rods are fixedly arranged above the wire winding rollers, and the first hand wheels are installed on the outer sides of the wire winding rollers. Sliding blocks are arranged on the guide rod in a penetrative mode, and traction wheels are fixedly installed on the sliding blocks. Pull ropes which are used for lifting the rubber coating robot are wound around the wire winding rollers, and the free ends of the pull ropespass through the traction wheels. The problem that in the prior art, the potential safety hazard exists in the mode that an automatic spray painting robot is conveyed by a control system is solved.

Owner:重庆洎皋电力科技有限责任公司

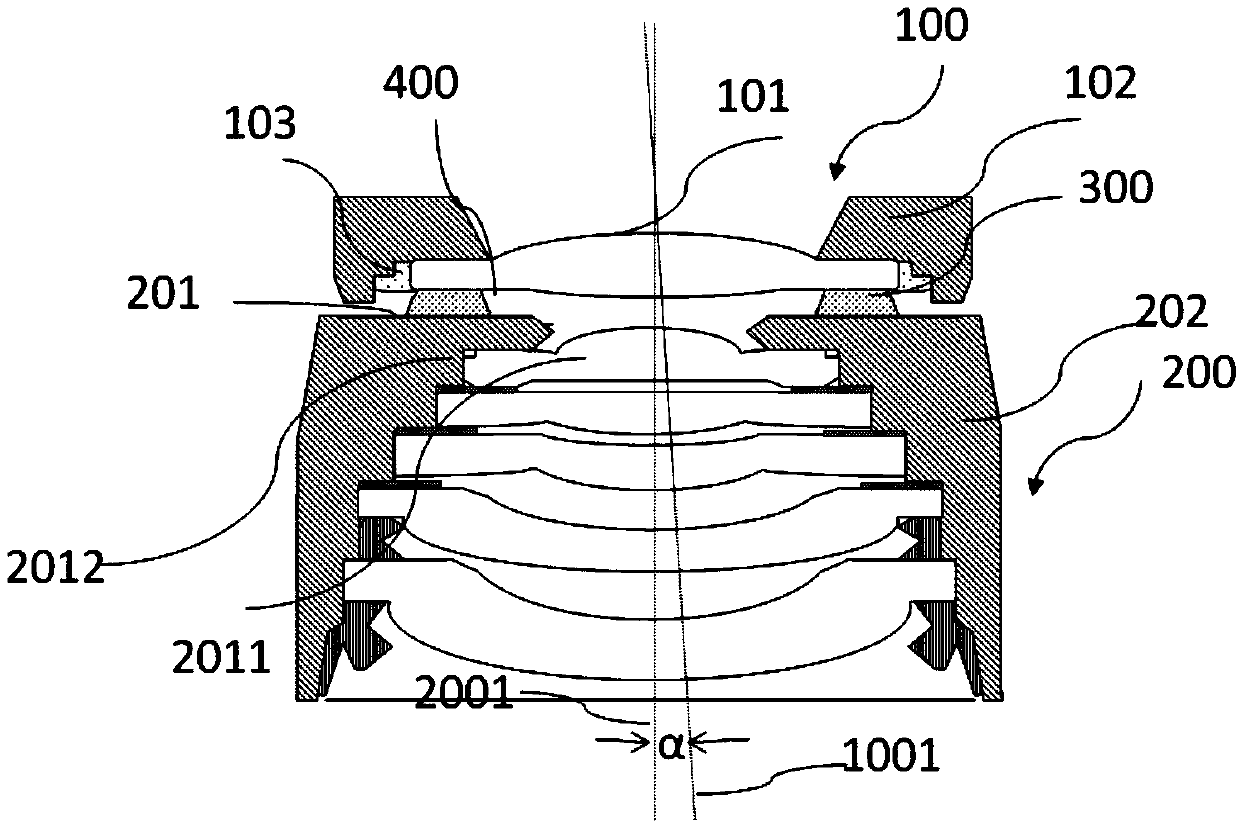

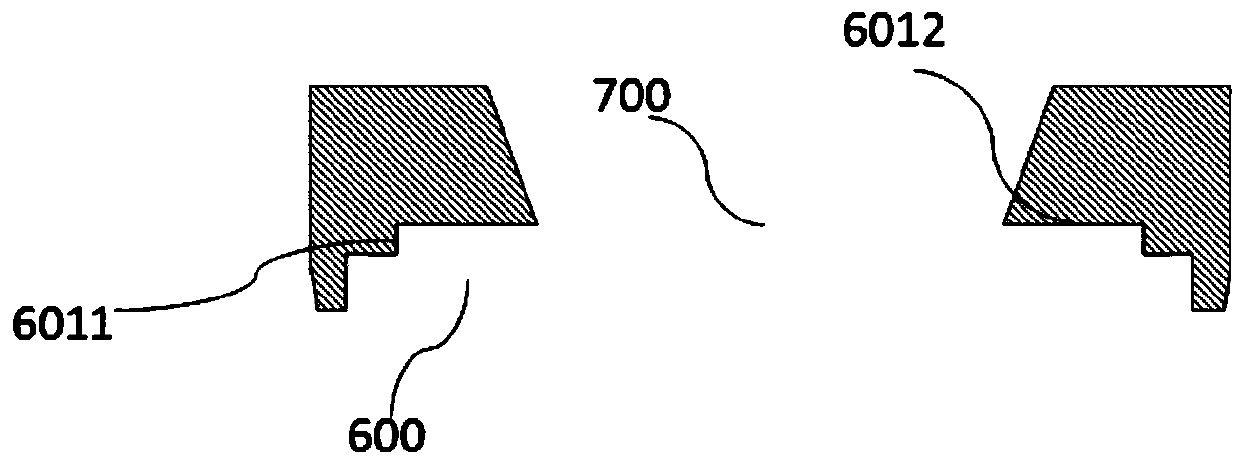

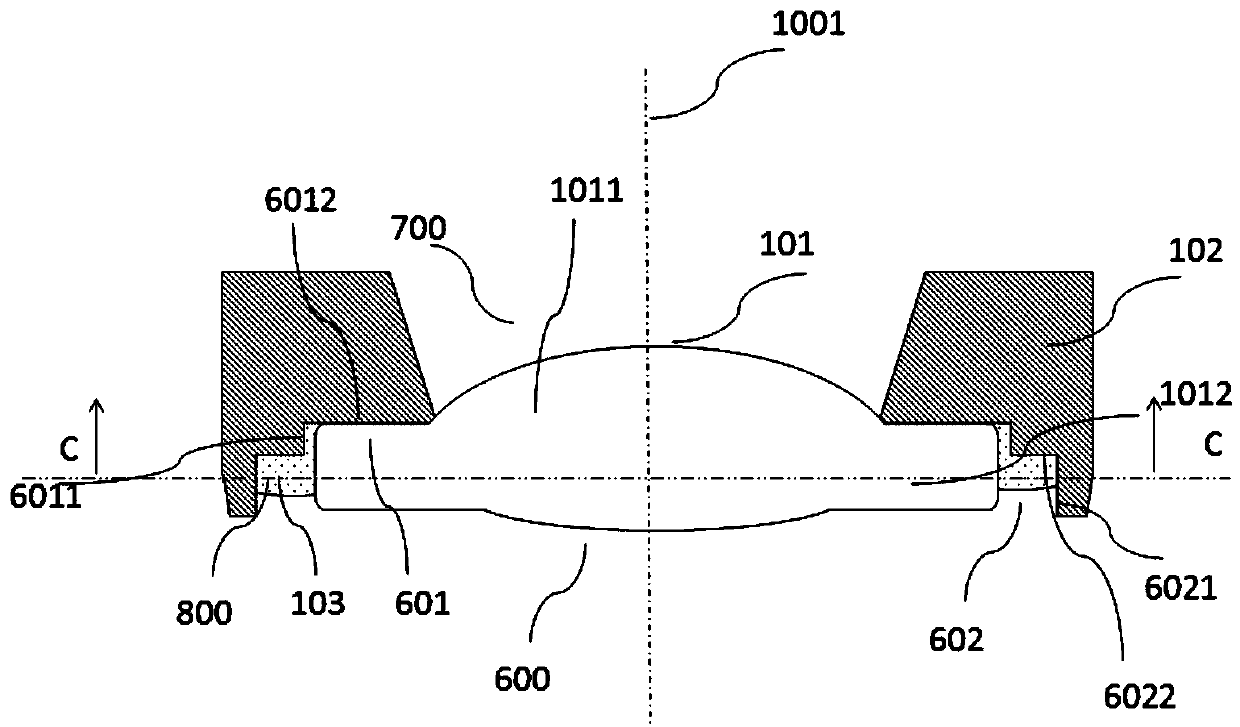

Optical lens, camera module and assembling method thereof

The invention provides an optical lens. The optical lens comprises a first lens part, a second lens part and a first adhesive material, wherein the first lens component comprises a first lens barrel and at least one first lens, and the second lens component comprises a second lens barrel and at least one second lens. All the second lenses and all the first lenses form an imageable optical system,the inner side of the first lens barrel is provided with a first accommodating hole, at least one of the first lenses is embedded into the first accommodating hole; the embedded first lens is providedwith a first outer side surface, and the first outer side surface comprises a contact part which is in direct contact with the side surface of the first accommodating hole and forms close fit with the side surface of the first accommodating hole; and a non-contact part which is not in direct contact with the side surface of the first accommodating hole, and is bonded with the first lens cone through the bonding glue. The invention further provides a corresponding assembling method of the optical lens and the camera module. According to the invention, the lens position offset caused by lens cone deformation can be reduced, the imaging quality of the optical lens or the camera module can be improved.

Owner:NINGBO SUNNY OPOTECH CO LTD

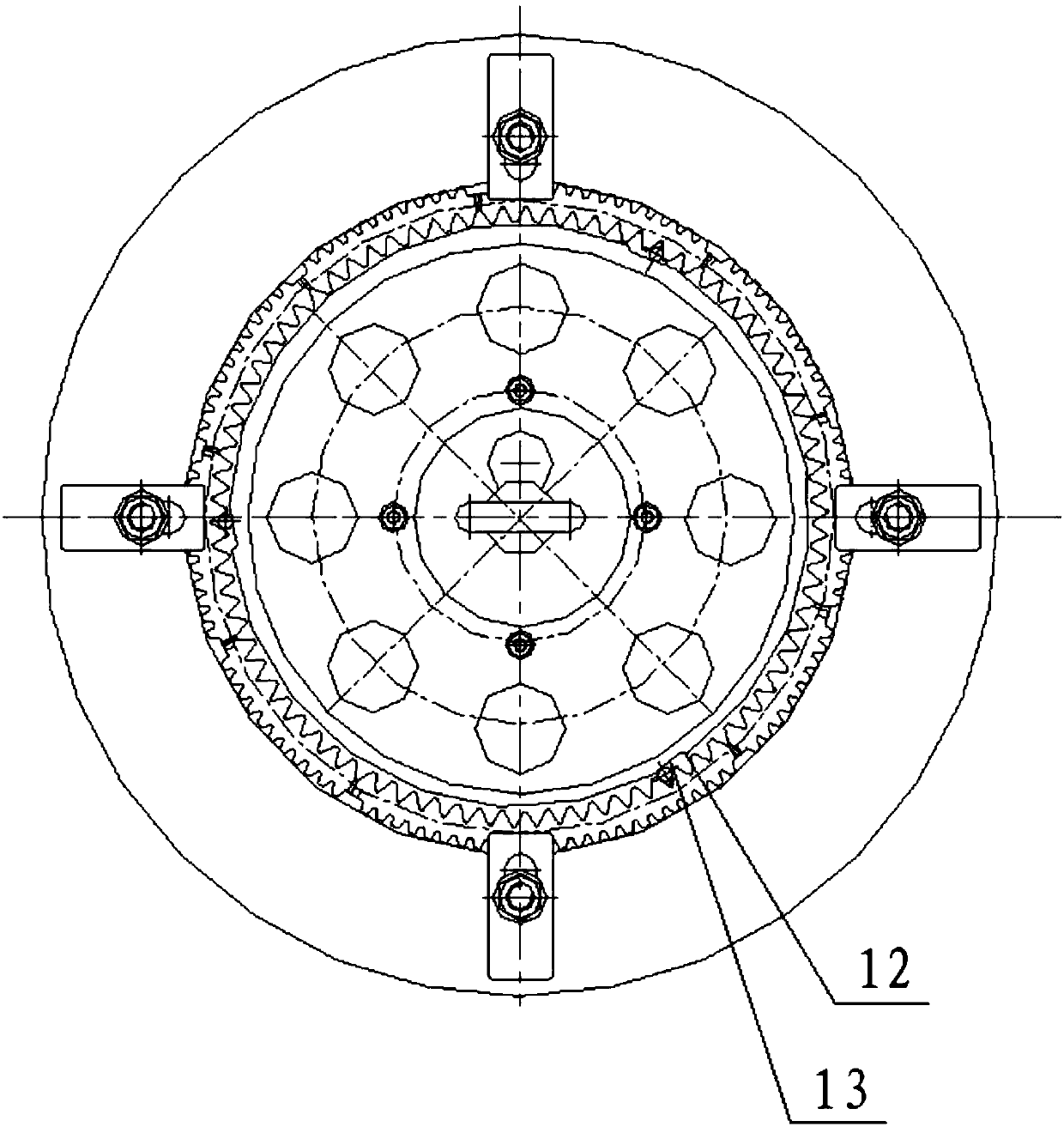

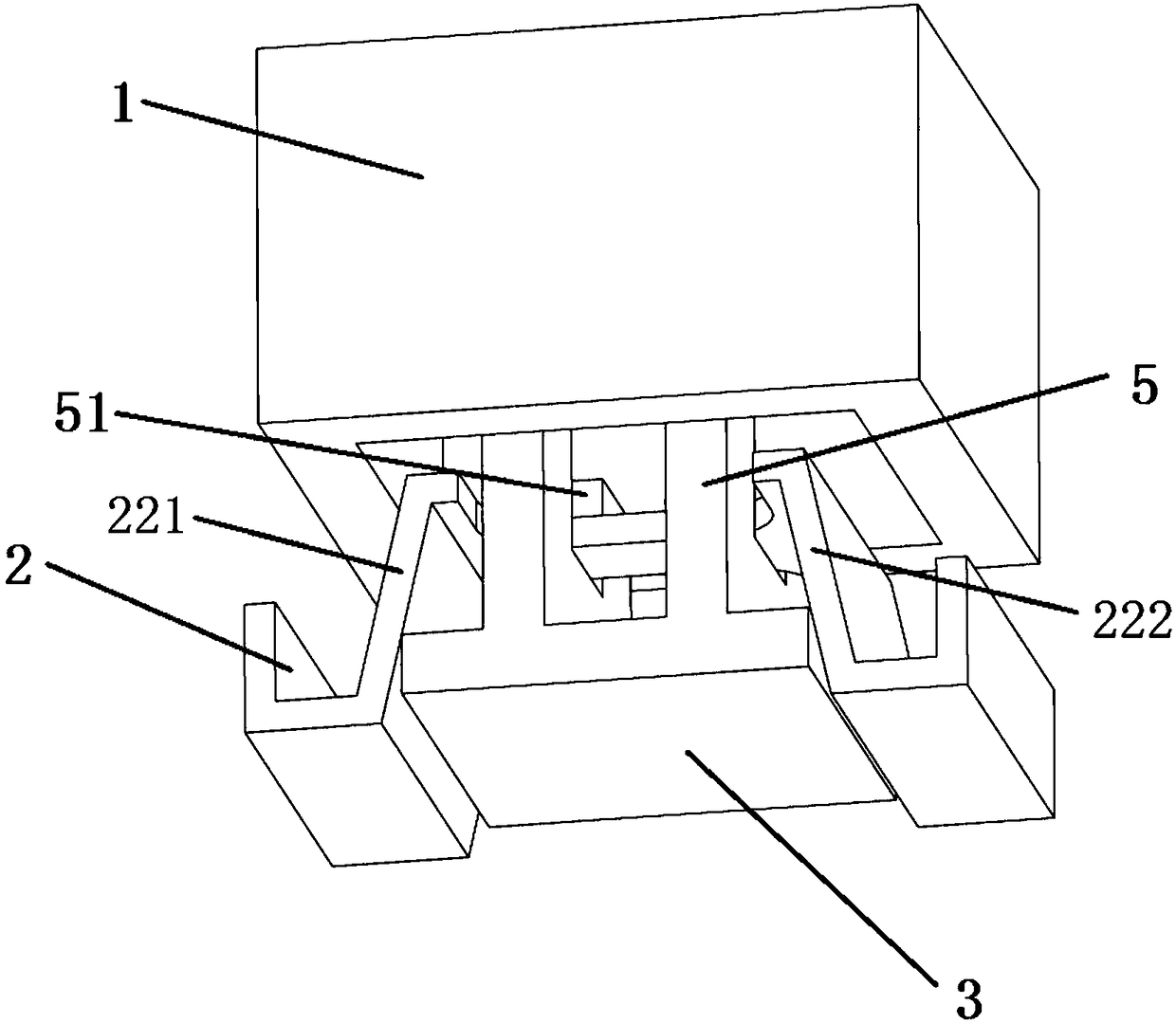

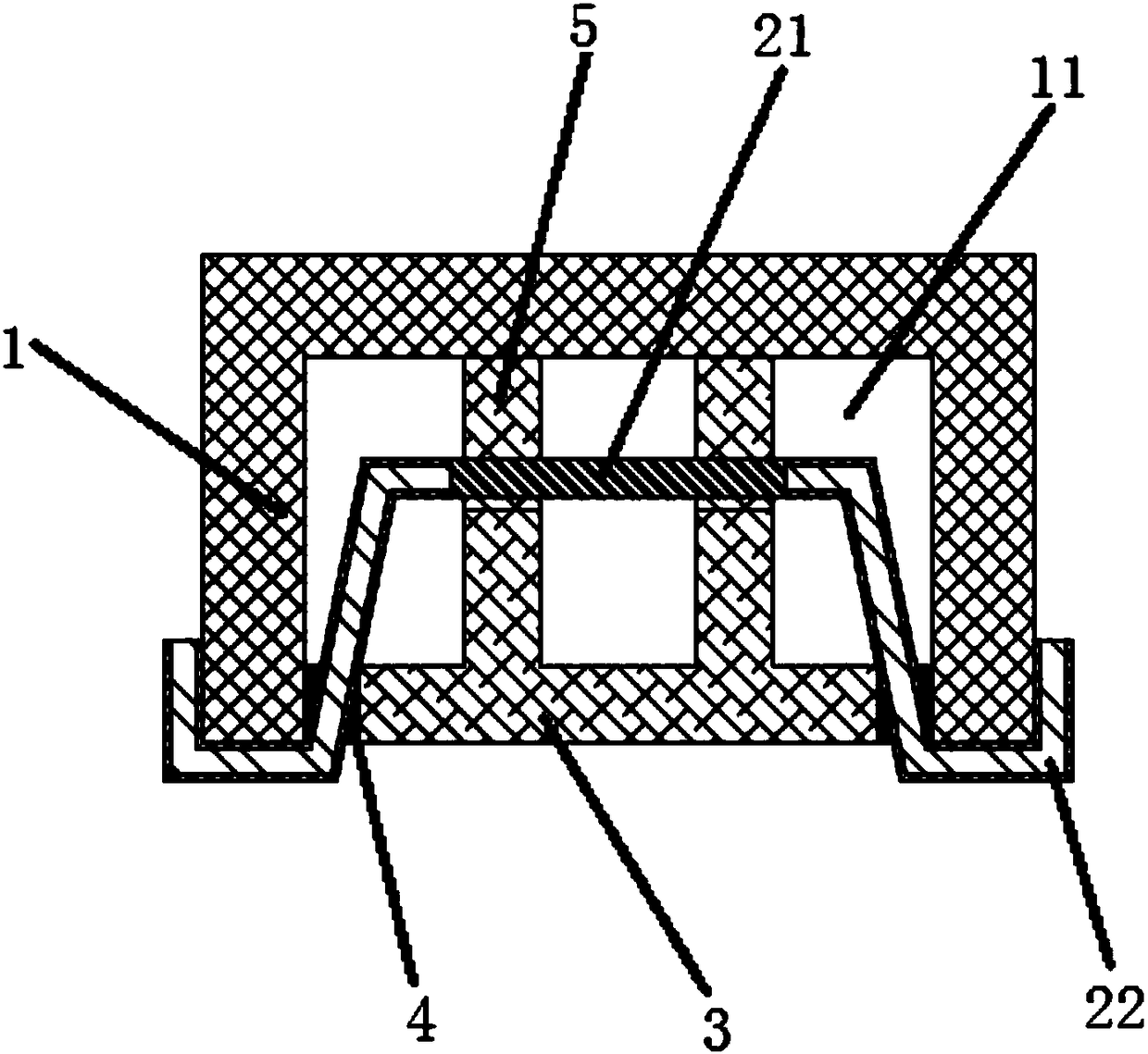

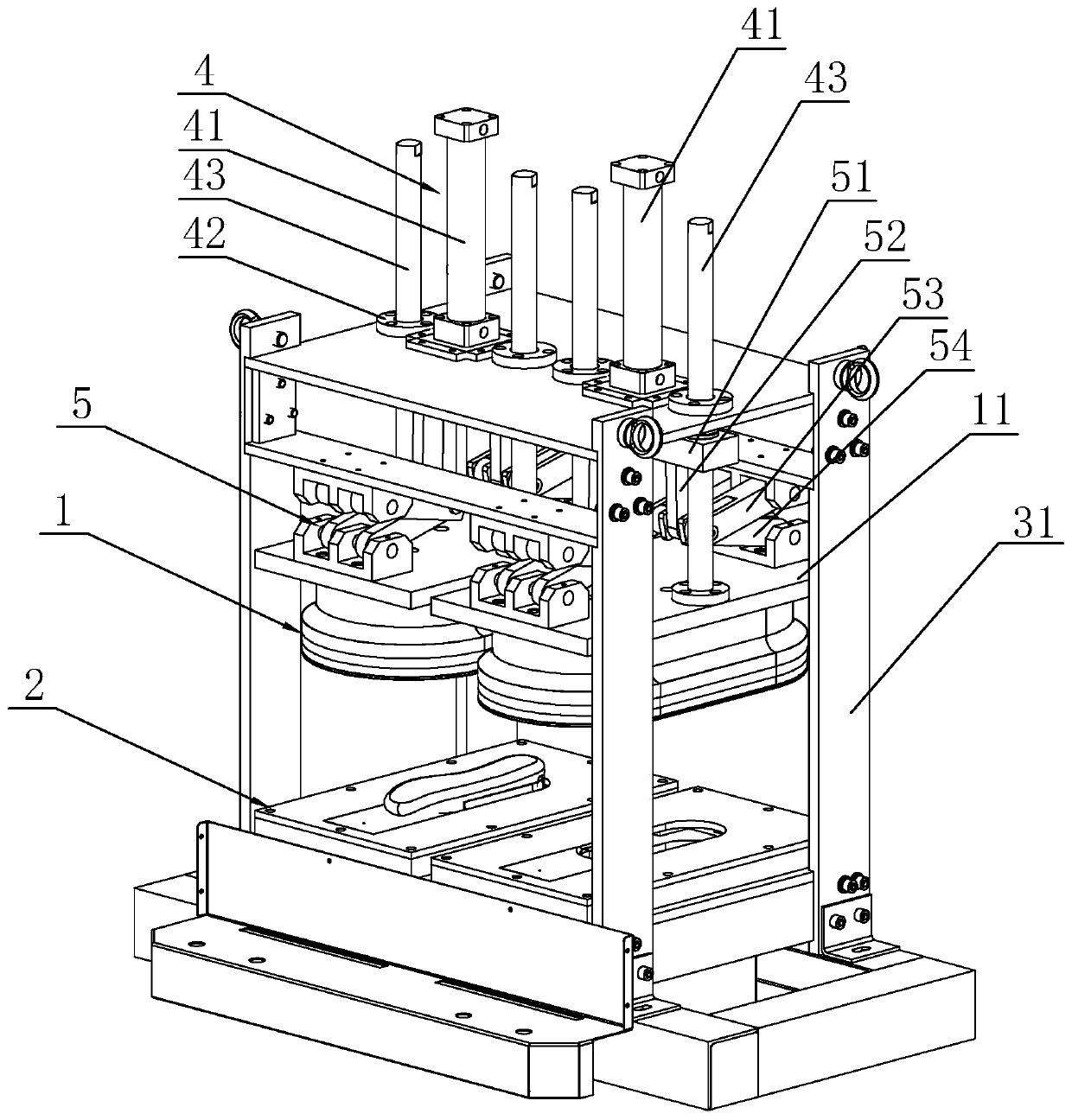

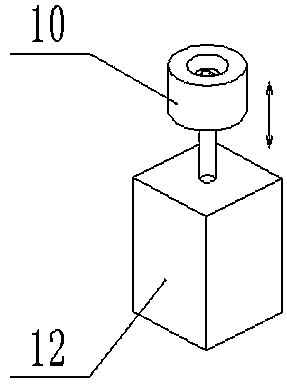

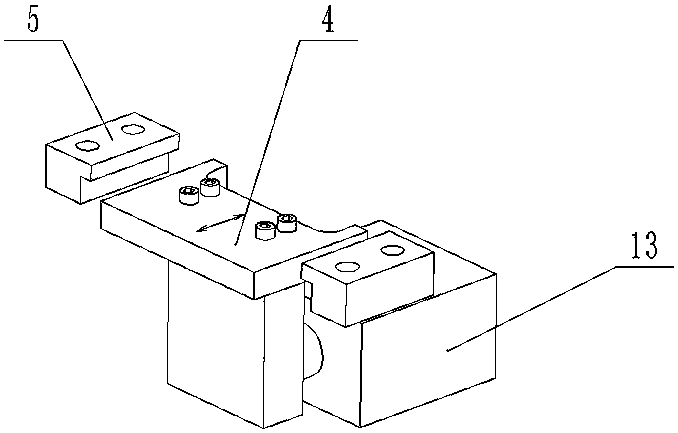

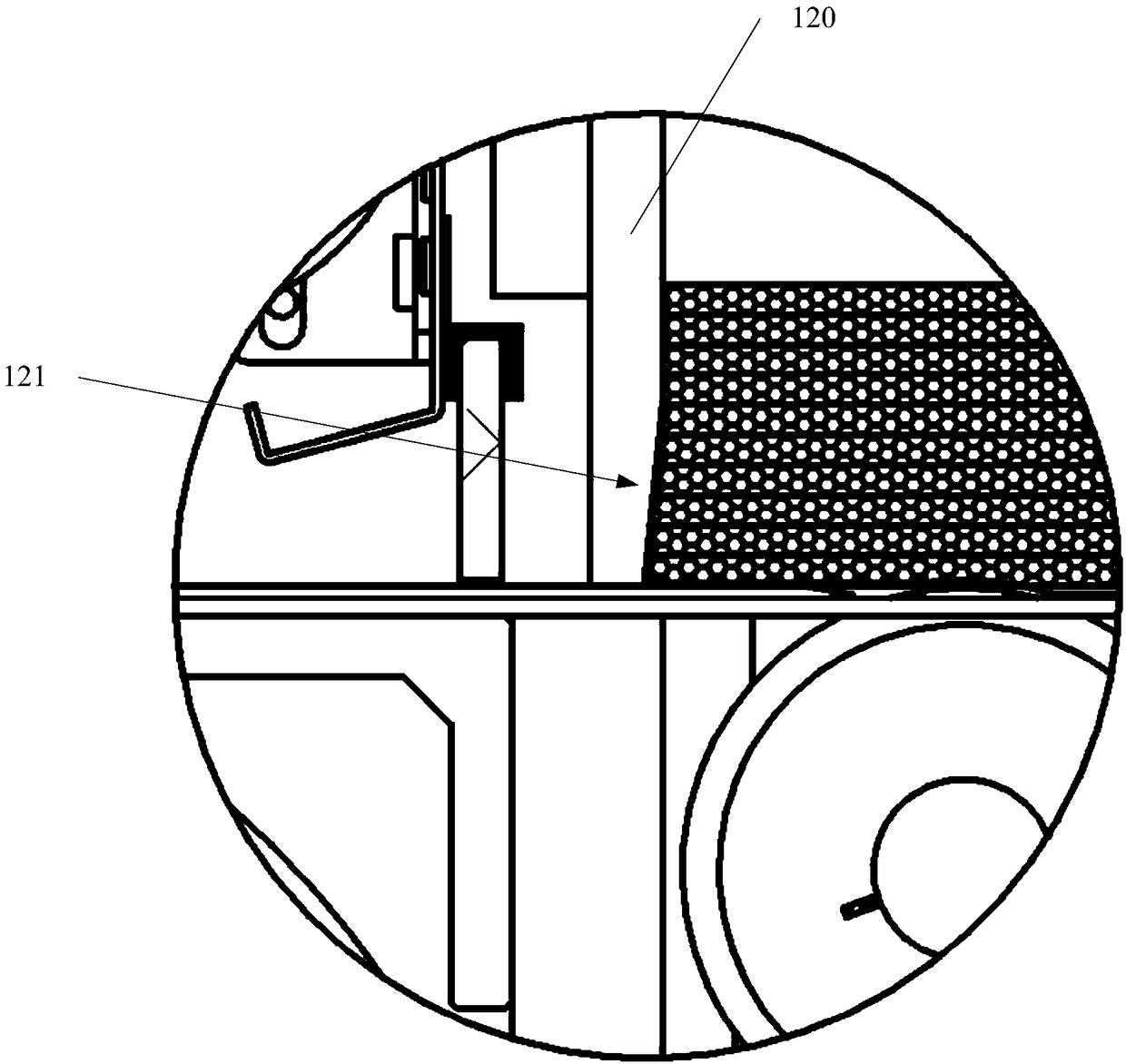

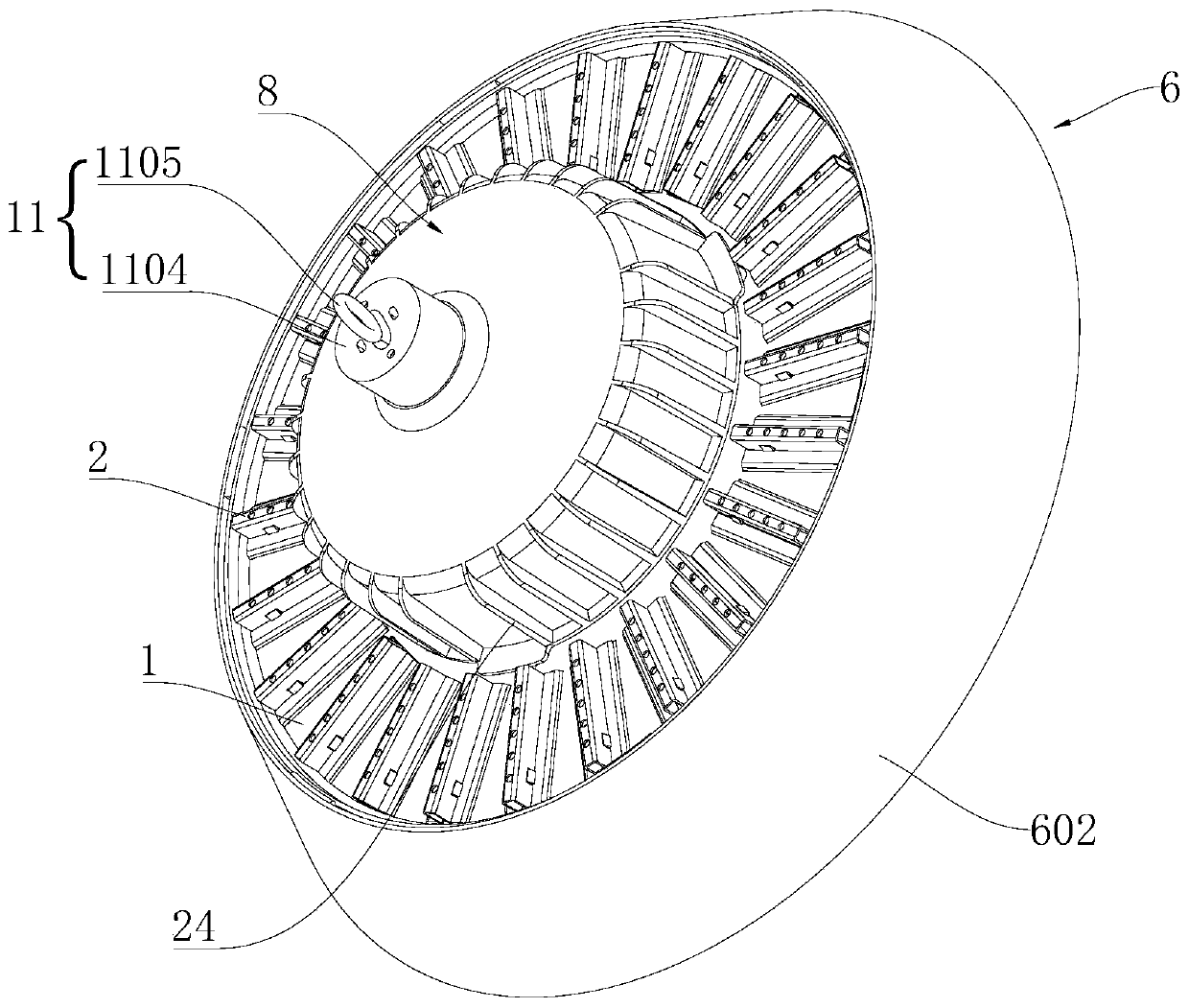

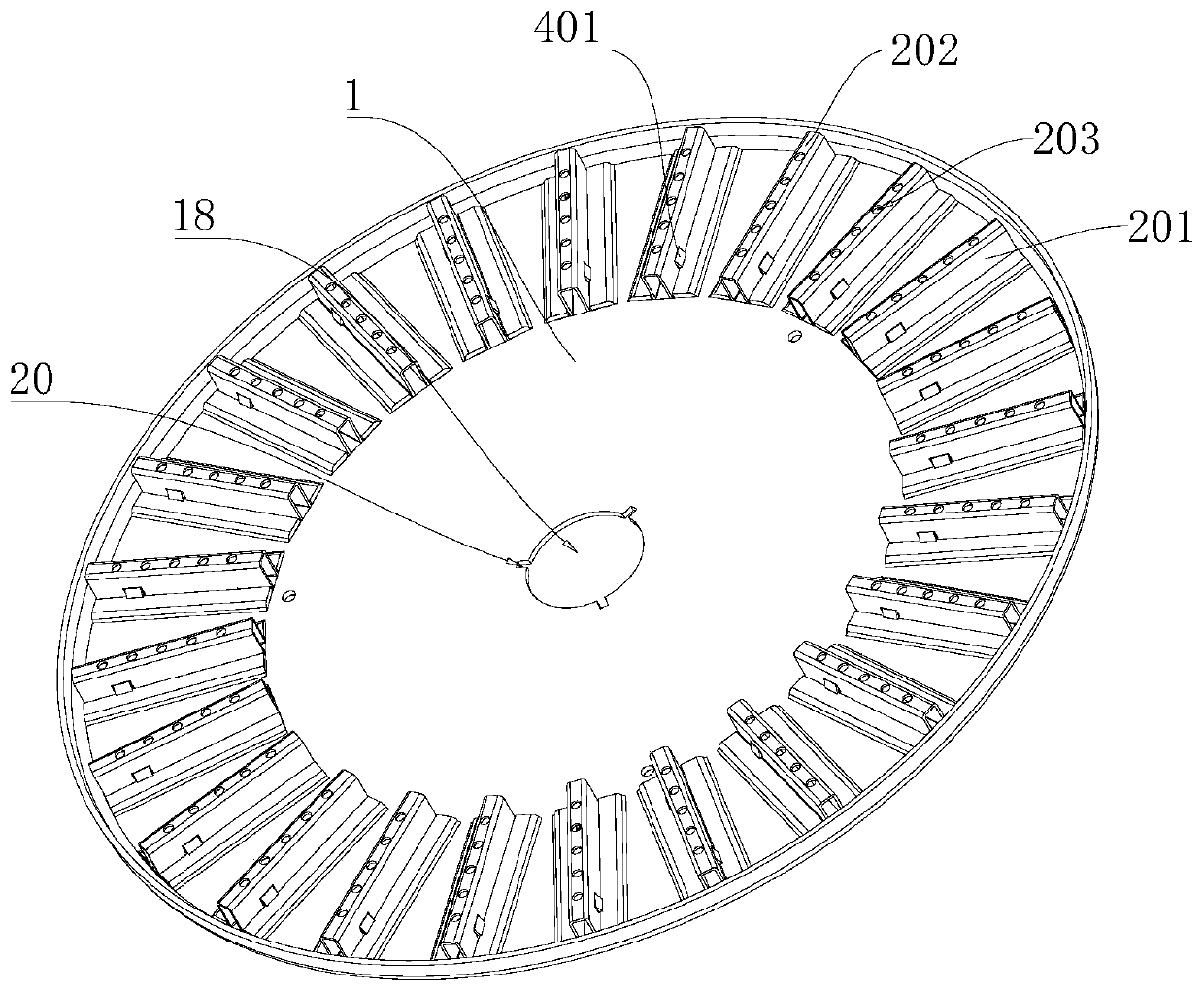

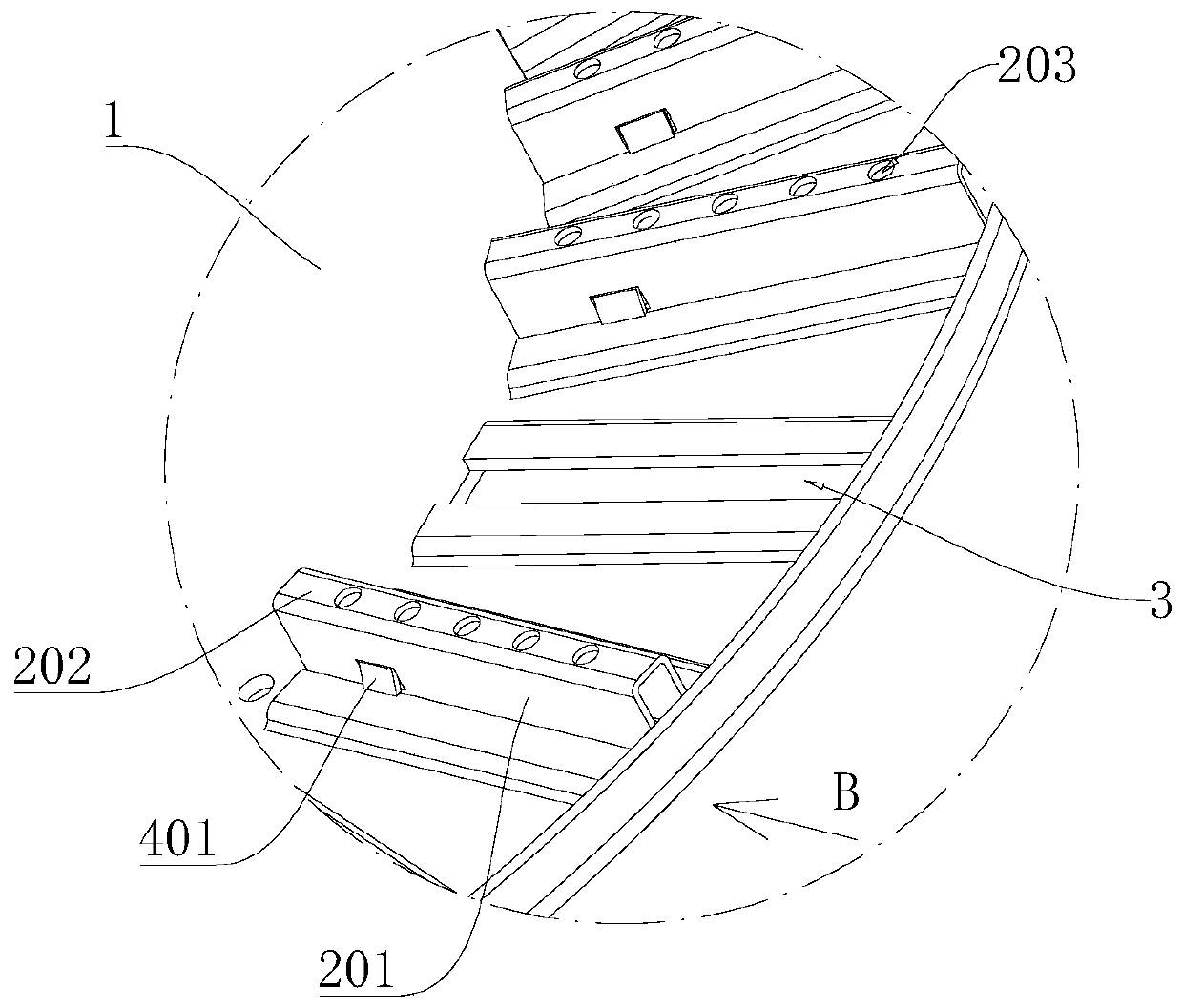

Inner tooth pre-positioning device and inner tooth grinding method

ActiveCN108672840AImprove processing qualityReduce manufacturing costGear-cutting machinesGear teethEngineeringSteel ball

The invention discloses an inner tooth pre-positioning device and an inner tooth grinding method. The inner tooth pre-positioning device comprises a positioning support, a vertical spring, a horizontal spring, steel balls, a guide sleeve, a positioning disc and rolling bars. A gear ring with teeth to be ground is arranged on the positioning disc in a sleeving mode and makes contact with the upperend face of a tooth grinding support. The three rolling bars are arranged in an inner tooth groove of the gear ring along three arc grooves in the positioning disc. The gear ring is rotated, and thenthe rolling bars are pushed by an arc cam surface to achieve non-clearance positioning of the positioning disc and inner tooth pitch circles of the gear ring; and the positioning disc is pushed downwards to reach a tooth grinding position, and then tooth grinding can be conducted. According to the inner tooth pre-positioning device and the inner tooth grinding method, the procedure of tooth tip circle grinding does not need to be carried out, so that the production cost is reduced, and the production efficiency is improved; pre-positioning of the inner teeth is achieved in the inner tooth grinding procedure, and the link of manual alignment of tooth tip circles is omitted, so that the production efficiency in the inner tooth grinding process is improved; and meanwhile, the uncertainty of manual alignment is avoided, and the part machining quality is improved.

Owner:内蒙古第一机械集团股份有限公司

Transmission gear burr removal device

InactiveCN108247139AOvercoming imperfectionsImprove deburring effectPositioning apparatusMetal-working holdersRotational axisEngineering

The invention relates to the technical field of gear machining, and discloses a transmission gear burr removal device. The device comprises a rack, a rotating shaft is in sliding connection to the rack, a burr knife is arranged at one end of the rotating shaft, a cam is arranged on the other end of the rotating shaft in an abutting manner, a spring is connected between the rotating shaft and the top wall of the rack, the rotating shaft is sleeved with an inner ring in a spline manner, the inner ring is rotatably sleeved with an outer ring, two piston cylinders are fixed to the outer ring, andare located on the two sides of the rotating shaft correspondingly, the free end of each piston cylinder is communicated with a suctin cup used for postioning a workpiece, a piston is in sliding connection into each piston cylinder, a piston rod is fixed to each piston, a first electromagnet is fixed to each piston rod, each first electromagnet abuts against the outer wall of the corresponding piston cylinder, a second electromagnet opposite to the first electromagnet in polarity is arranged on the rack, a touch switch is fixed to the rotating shaft, and a swing rod used for starting and stopping the touch switch is hinged to the rotating shaft. A workpiece can be accurately positioned and automatically machined, and machining accuracy and efficiency can be improved.

Owner:NINGBO HAIMAN AUTOMOTIVE TECH CO LTD

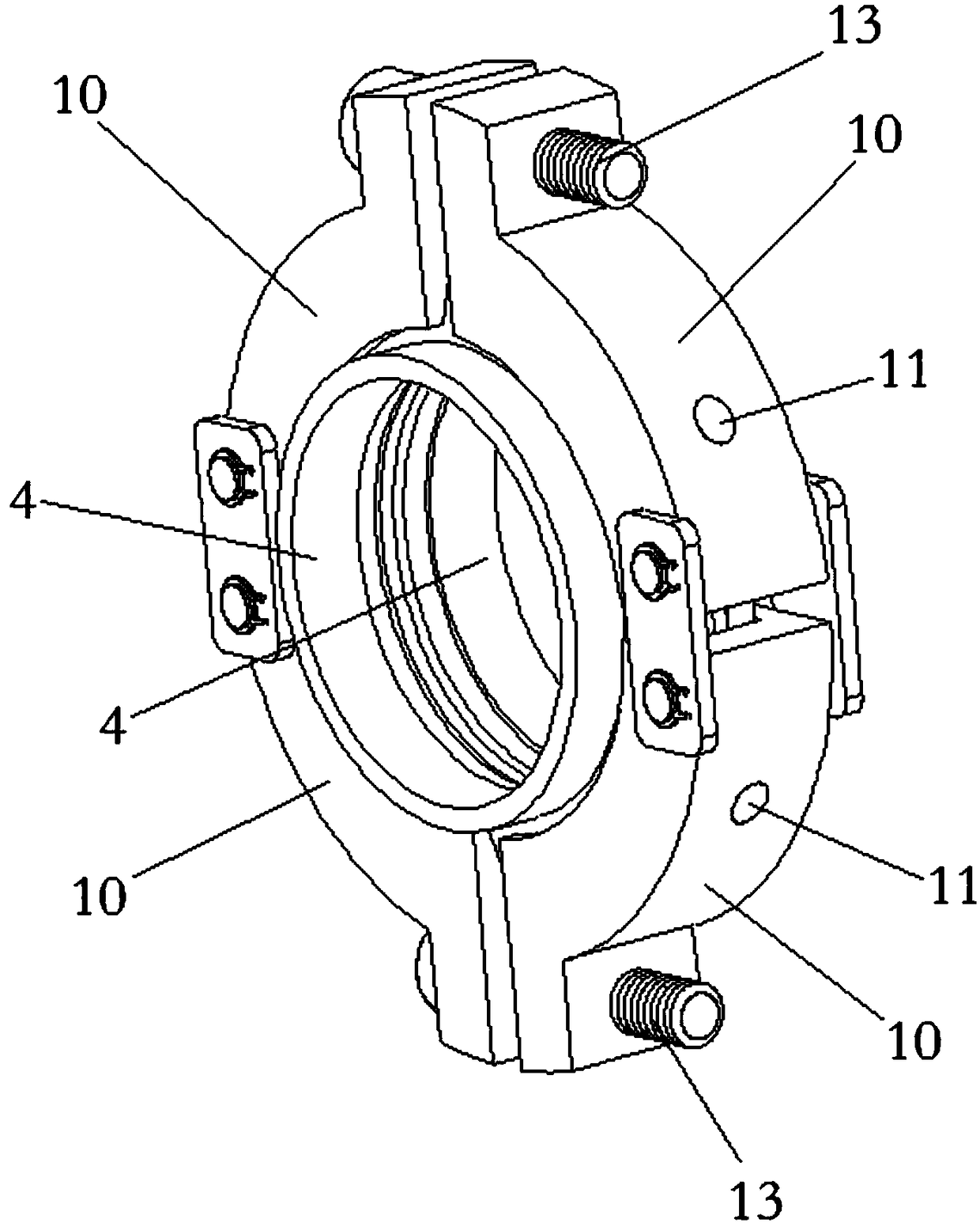

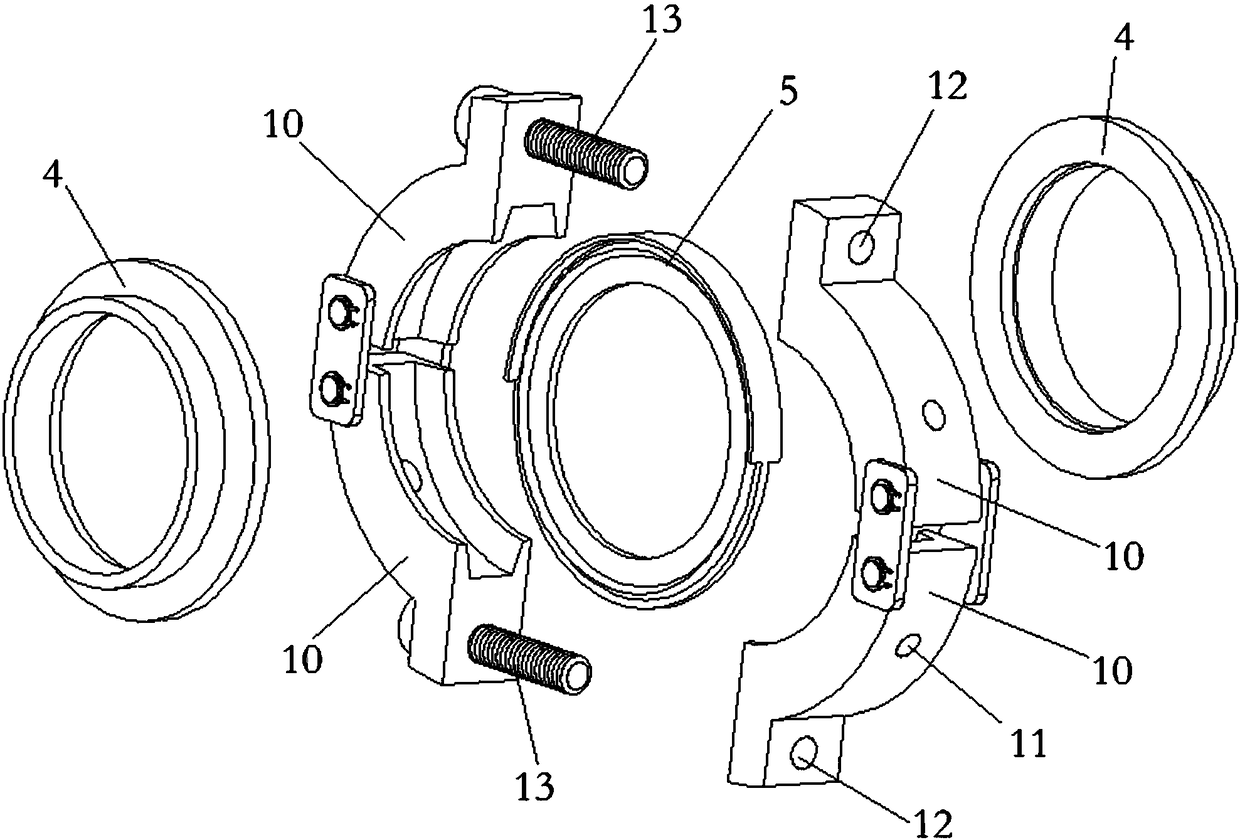

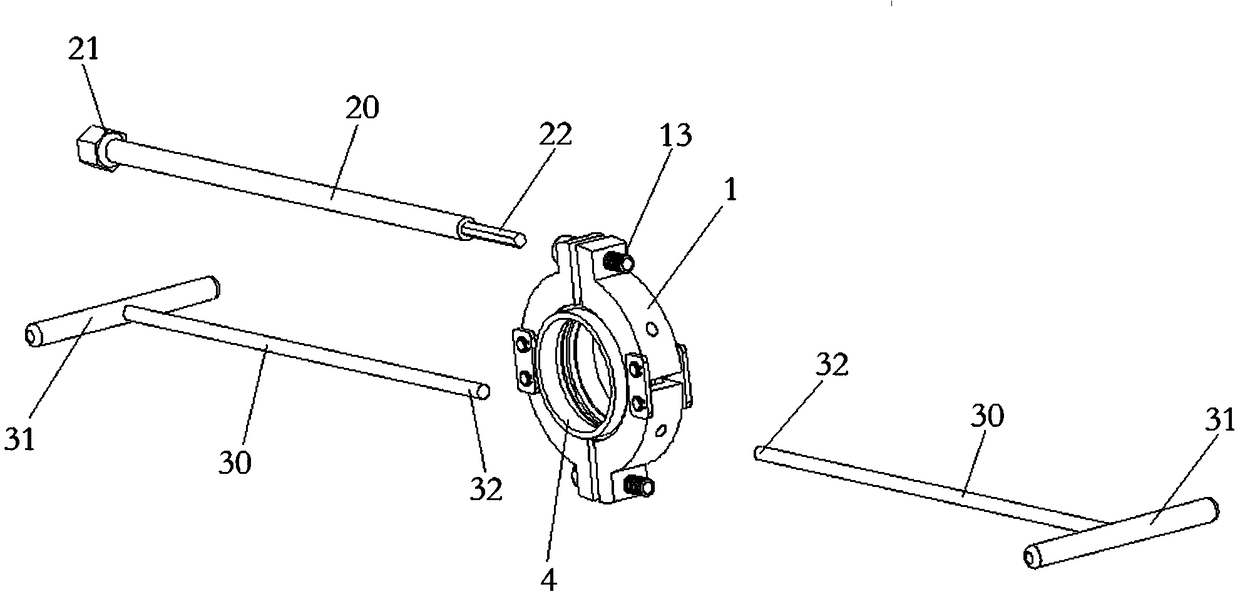

Chain type clamp for butt joint of vacuum flanges, mounting tool and mounting method of chain type clamp

PendingCN108194727AEasy to operateEasy loading and unloadingSleeve/socket jointsMetal-working hand toolsChain typeEngineering

The invention discloses a chain type clamp for butt joint of vacuum flanges, a mounting tool and a mounting method of the chain type clamp. The chain type clamp comprises a chain which can be in buttjoint to form an annular shape, wherein the chain comprises a plurality of clamping clacks which are hinged to each other, a fixing part used for abutting against the mounting tool is arranged on theouter surface of each clamping clack, and fastening screw holes for butt joint are formed in the head end and the tail end of the chain. The method comprises the following steps that firstly, a sealing ring made of metal materials is inserted between two flange surfaces to be jointed; during mounting, each clamping clack of the chain type clamp is fixed through a fixing rod, and preset positioningis achieved; a mounting rod can carry a fixing bolt, and the fixing bolt can be screwed into the butt joint position of the clamping clacks, the sealing ring is extruded through the flanges to enablethe sealing ring to deform and fill the portion between the flange surfaces to realize sealing, so that the non-contact type mounting of the chain type clamp is completed, the operation is simple, and rapid mounting and dismounting can be realized conveniently in a high-radiation environment.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

Surface-mounting fuse and production method thereof

PendingCN108321063ASimple production methodPlay a limiting roleFuse device manufactureSurface mountingEngineering

The invention discloses a surface-mounting fuse, which comprises an insulation housing, one side of which sinks inwards to form an accommodation cavity; a fuse body having two conductive electrodes, afirst bending portion, a second bending portion and a fusing portion arranged between the two bending portions; an insulation cover body covering the accommodation cavity; and binders filling gaps between the periphery of the insulation cover body and the side walls of the insulation housing. The fusing portion and the bending portions are arranged in the accommodation cavity; the conductive electrodes extend out of the accommodation cavity; the insulation cover body is provided with support columns; and the support columns are abutted against the inner top wall of the accommodation cavity. The invention also provides a production method of the surface-mounting fuse. The surface-mounting fuse realizes pre-locating of the insulation cover body during installation; the production method issimpler; assembly difficulty is reduced; fusing performance of the product is more controllable; and meanwhile, an arc barrier is formed between the first bending portion and the second bending portion at the two ends of the fuse body, so that arc extinguishing effect is improved effectively.

Owner:AEM COMPONENTS (SUZHOU) CO LTD

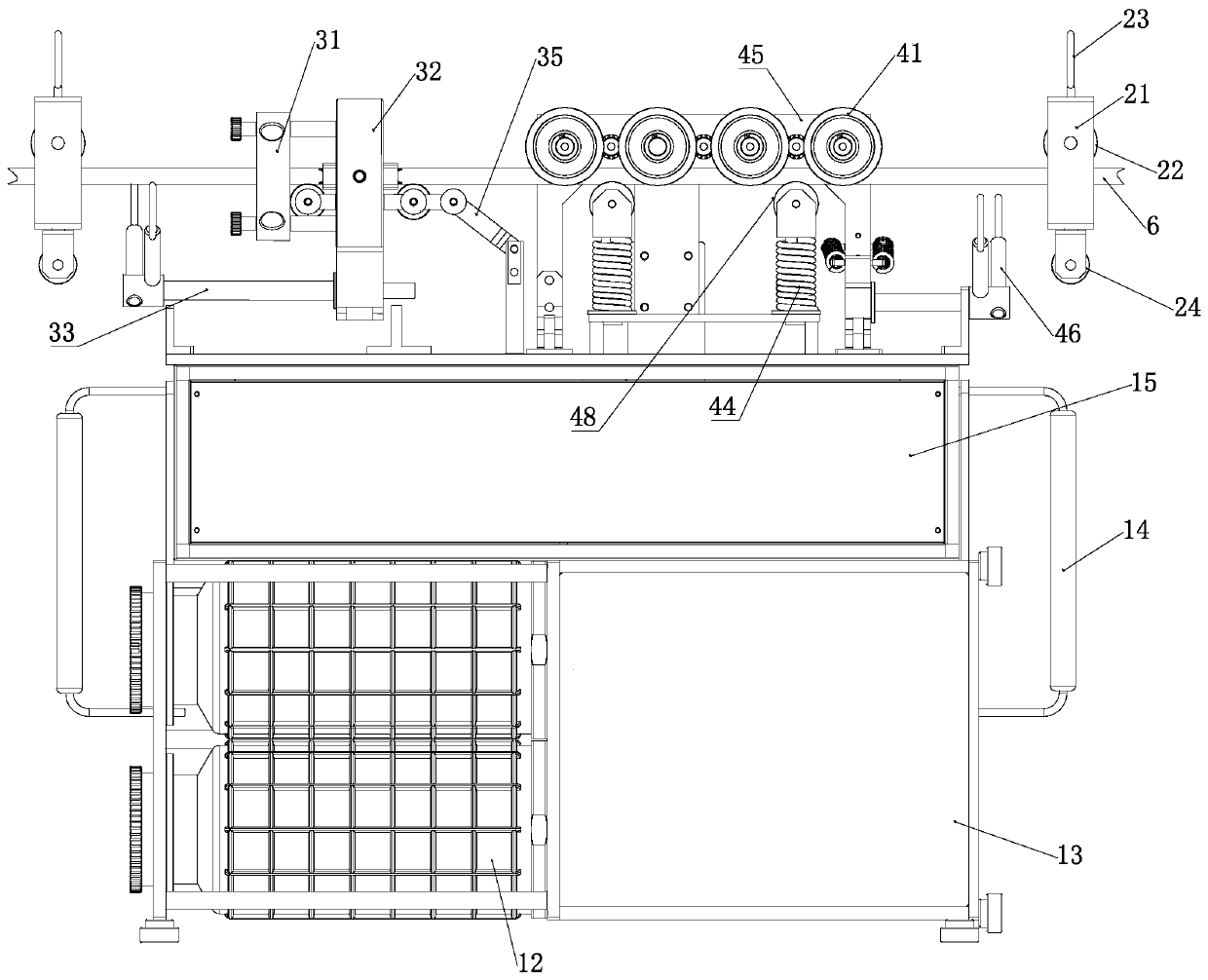

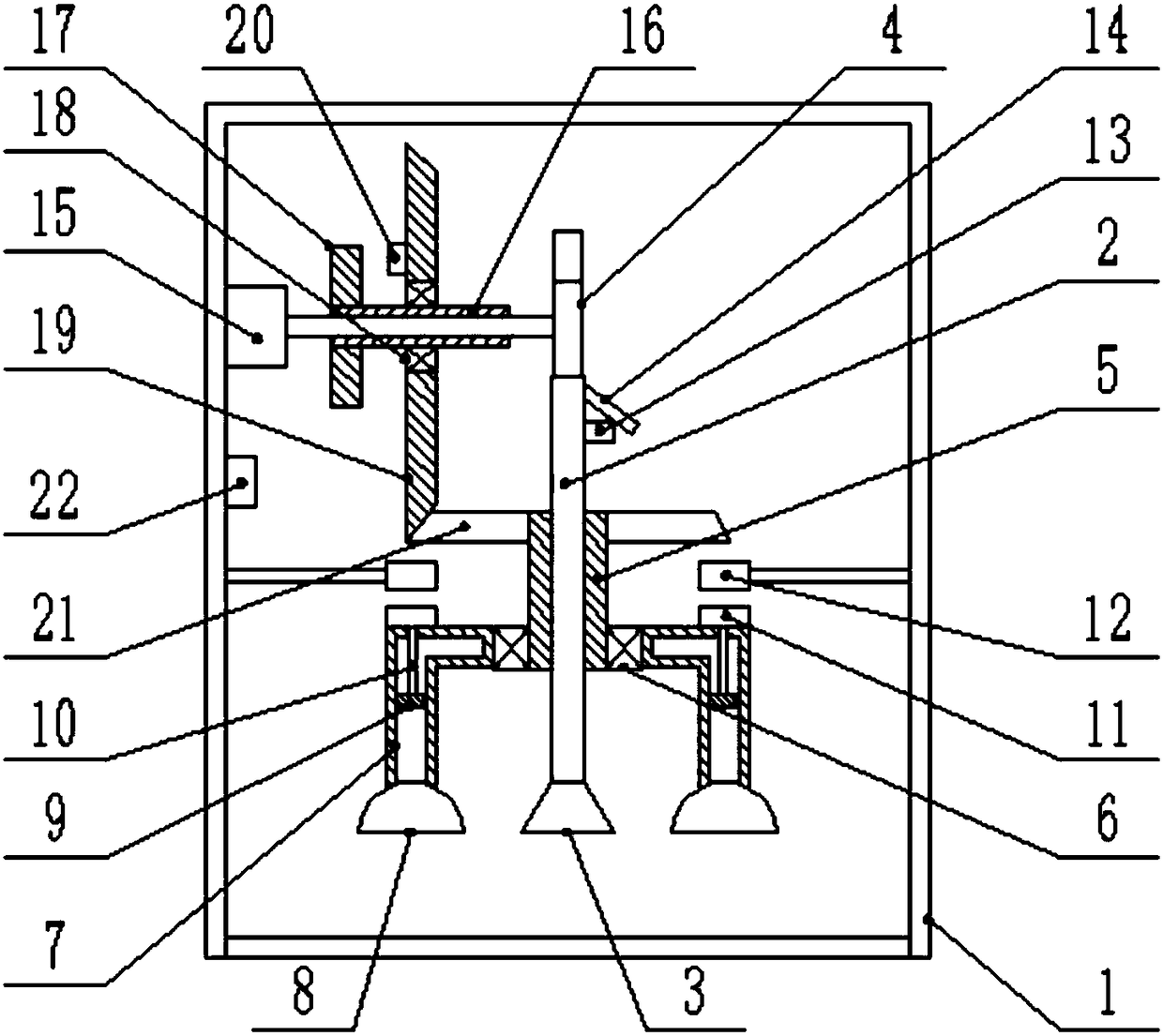

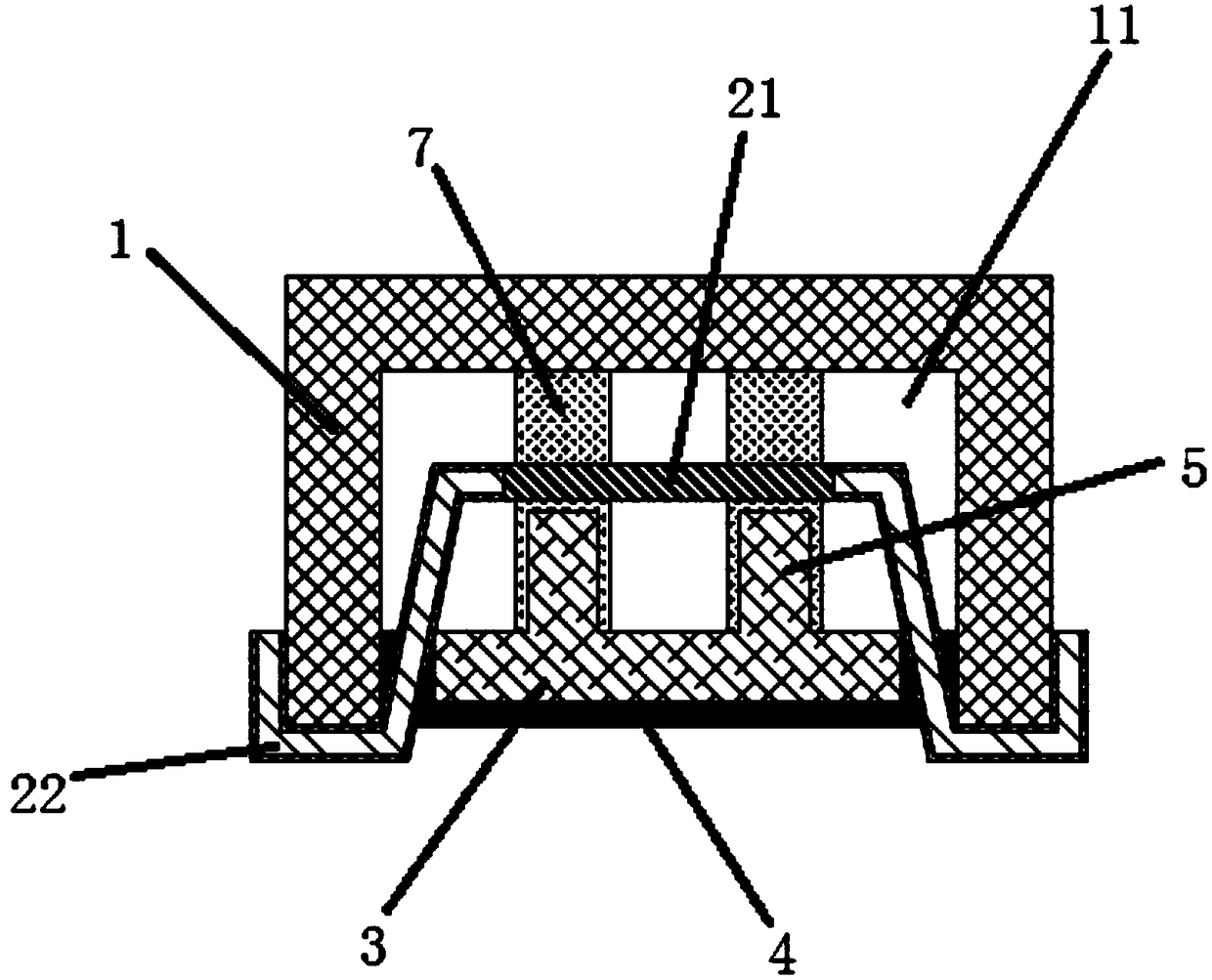

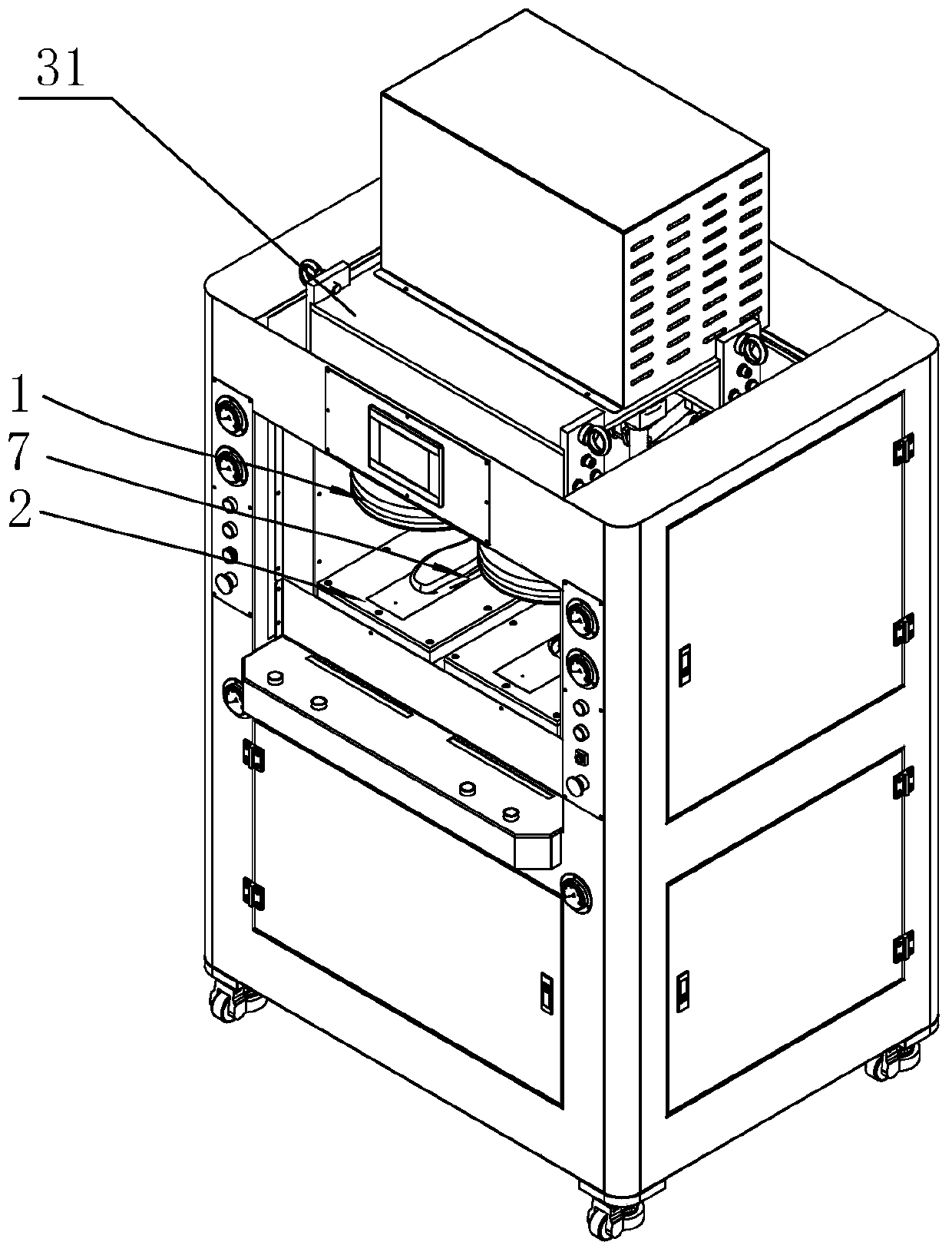

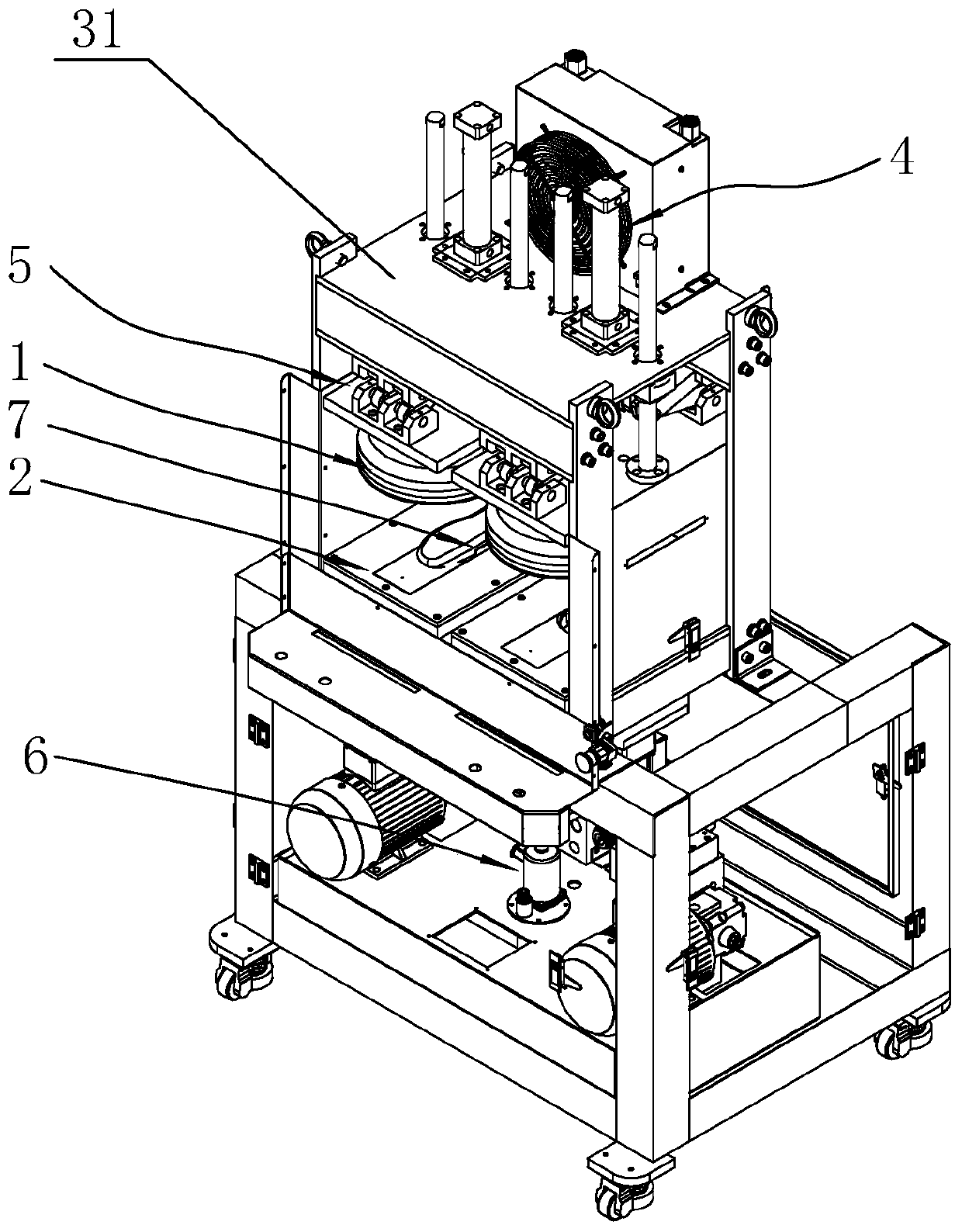

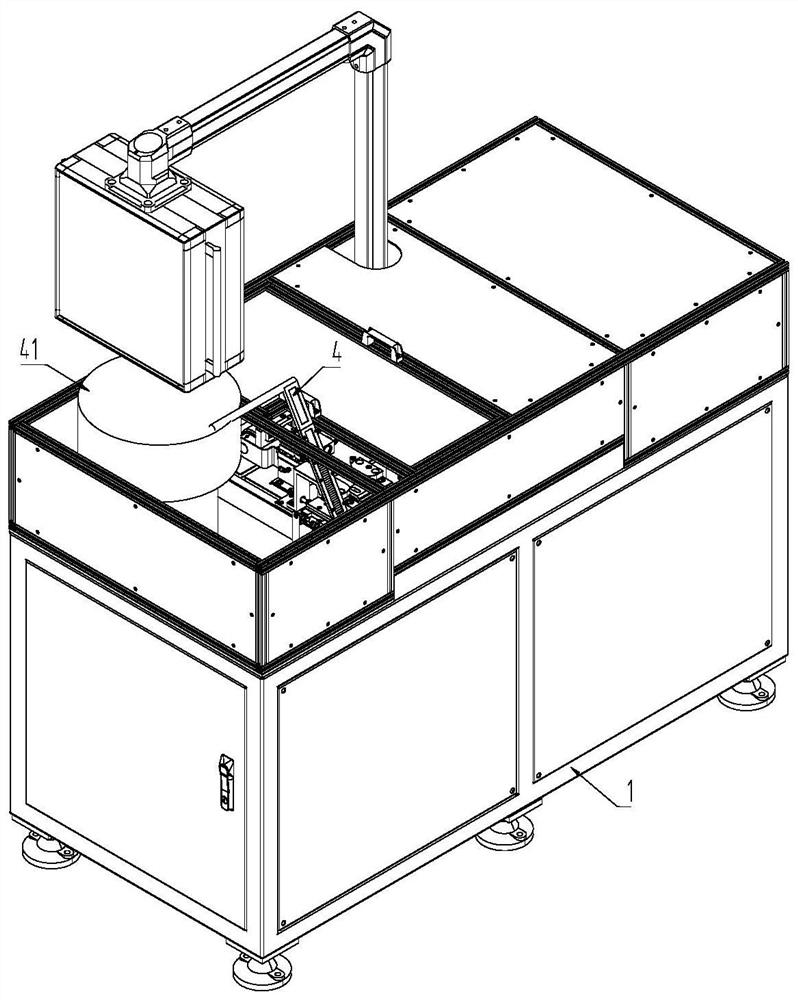

Vacuum die-free forming sole pressing machine and using method thereof

InactiveCN111528583AImprove sealingImprove the pressing effectSolesShoe gluingEngineeringPumping vacuum

The invention relates to the field of shoemaking equipment, in particular to a vacuum die-free forming sole pressing machine and a using method thereof, and is characterized in that the vacuum die-free forming sole pressing machine comprises an upper rack, a pressing driving mechanism, a side pressurizing mechanism, a pressing assembly, a vacuum assembly, a lifting mechanism and a clamping mechanism; the vacuum assembly is fixed to the bottom of the upper rack, the pressing assembly is located over the vacuum assembly, the pressing assembly is driven by the pressing driving mechanism to be attached to or away from the vacuum assembly, and the side edge pressurizing mechanism is connected with the upper rack, the pressing driving mechanism and the pressing assembly in a pivoted mode. According to the vacuum die-free forming sole pressing machine, the pressing assembly and the vacuum assembly can be tightly matched, and the sealing performance and the pressing effect are improved; the shoe tree and the shoe body are positioned and fixed in all directions through the clamping mechanism, and the shoe sole and the vamp are prevented from deviating in the pressing process; the mode of combining hydraulic positioning and vacuumizing positioning is adopted, the operation steps are simple, positioning is accurate, and meanwhile the pressing speed is increased.

Owner:福建中泰德玛智能设备有限公司

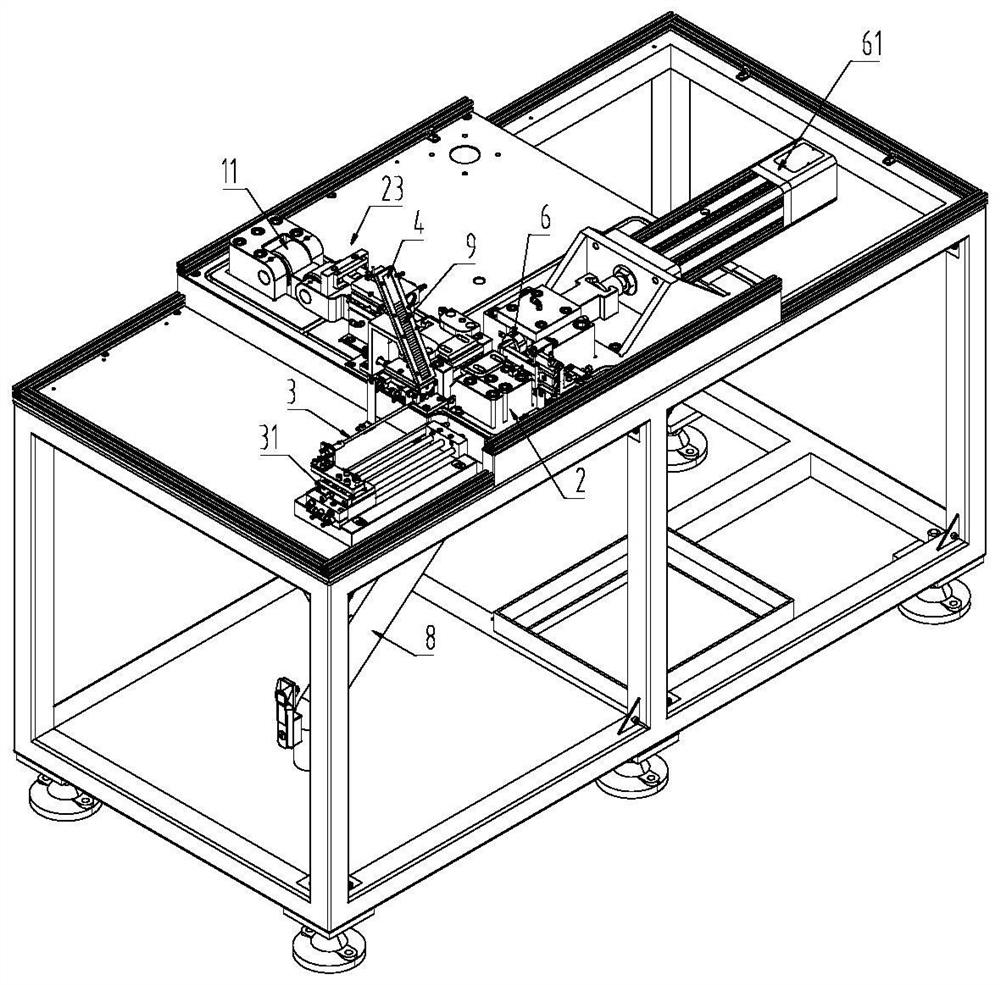

Automobile pipe fitting flaring machine

ActiveCN113172166AReduce labor intensityHigh degree of automationShaping toolsMetal-working feeding devicesPunchingPipe fitting

The invention relates to the technical field of automobile part manufacturing, and discloses an automobile pipe fitting flaring machine. The automobile pipe fitting flaring machine comprises a rack; the rack is provided with a clamping mechanism, a ram and a punching die; the ram and the punching die are distributed on the two sides of the clamping mechanism respectively; the rack is provided with a material pushing plate, a material pushing groove with the lower end facing the material pushing plate, and a material pushing driving piece for driving the material pushing plate to move; the material pushing plate is provided with the material pushing groove; and the rack is provided with a feeding driving part for driving the ram to move so as to feed pipe materials in the pushing groove into the clamping mechanism and a stamping driving part for driving the stamping die to move so as to conduct flaring machining on the pipe materials clamped by the clamping mechanism. The automobile pipe fitting flaring machine has the following advantages and effects that a vibrating disc and a distributing groove are adopted for conveying the pipe materials into the pushing groove of the pushing plate; the ram pushes the pipe materials into the clamping mechanism; then the punching die is used for conducting flaring machining on the ends of the pipe materials; the clamping mechanism loosens the pipe materials after machining; the pipe materials fall into a discharging pipe; the automation degree is high; the machining efficiency is high; the labor intensity of workers is lowered; and the automobile pipe fitting flaring machine is suitable for machining of automobile parts such as automobile air suction pipes and the like.

Owner:荆州市天宇汽车配件有限公司

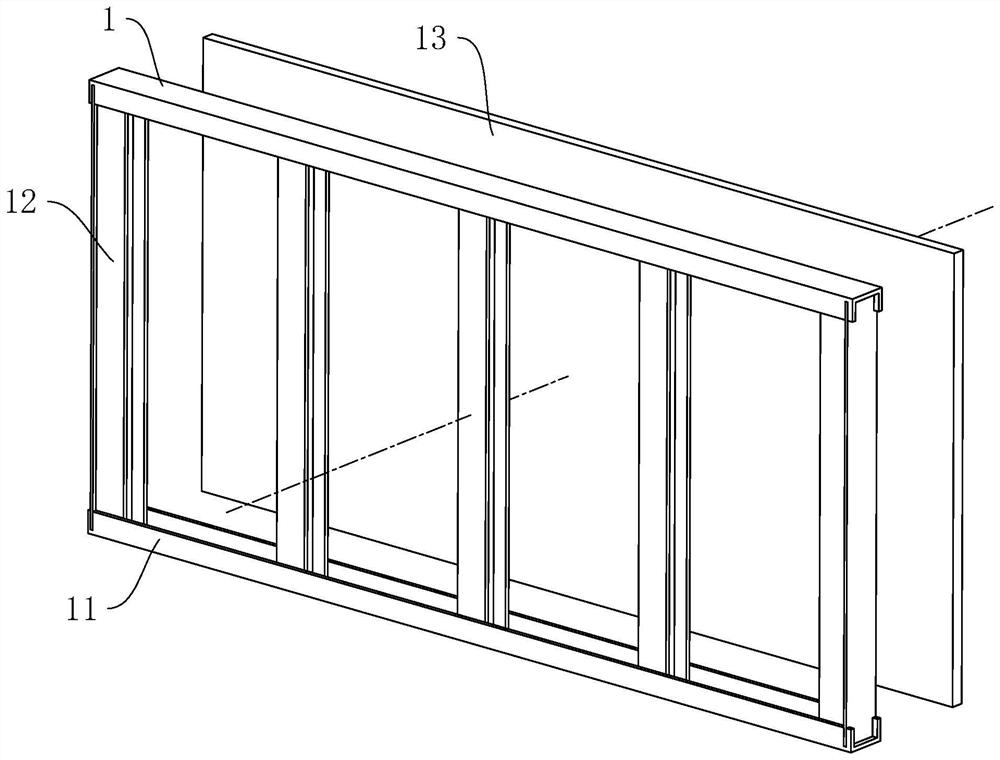

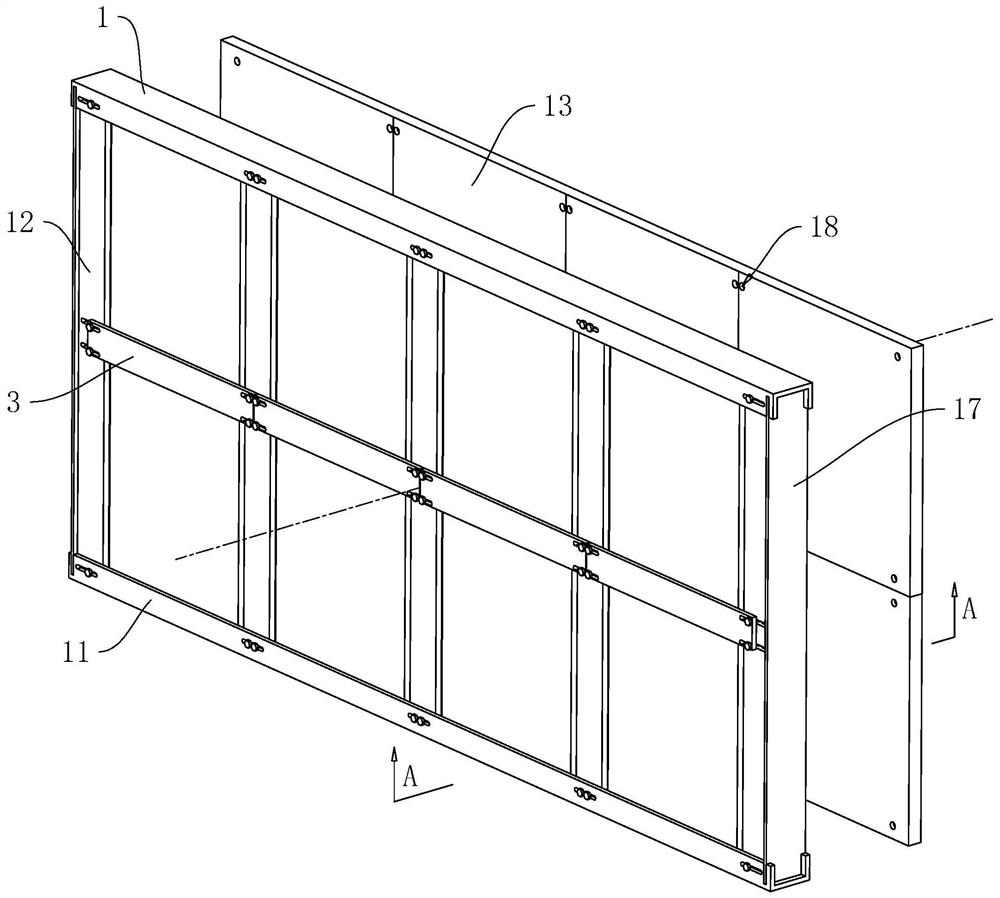

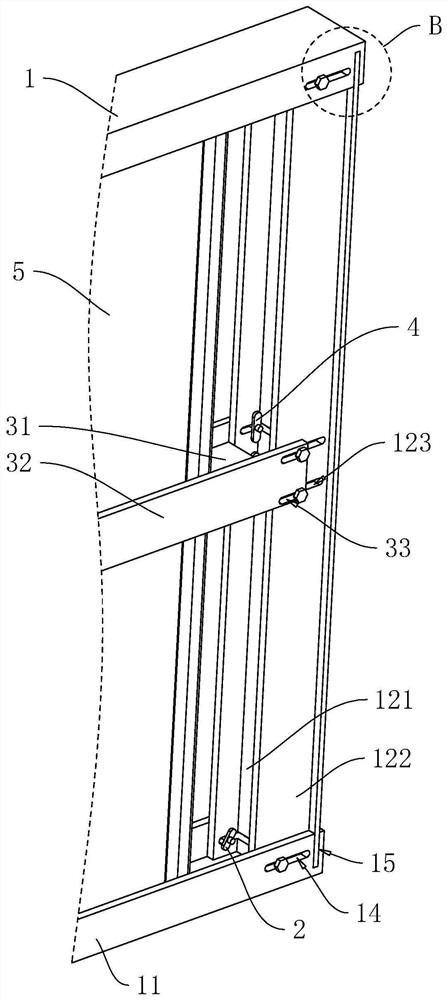

Profile steel reinforced light steel keel partition wall and construction method

ActiveCN112112319AImprove structural stabilityImprove stress resistanceWallsKeelUltimate tensile strength

The invention relates to a profile steel reinforced light steel keel partition wall and a construction method. The profile steel reinforced light steel keel partition wall comprises a top keel, a bottom keel, a plurality of vertical keels and a plurality of wall surfaces arranged on a vertical surface formed by the top keel, the bottom keel and the vertical keels, wherein the top keel is used forbeing connected with a ceiling, the bottom keel is used for being connected with the ground, the upper ends of the vertical keels are arranged on the top keel, and the lower ends of the vertical keelsare arranged on the bottom keel; and a plurality of supporting layers distributed in the vertical direction are arranged between every two adjacent vertical keels, and the supporting layers are vertically arranged and are parallel to one another. The profile steel reinforced light steel keel partition wall has the effect of improving the structural strength of the partition wall.

Owner:北京挚诚华腾建设工程有限公司

Turnover positioning fixture

PendingCN107825164APrevent workpiece movementAvoid interferencePositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention aims at providing a turnover positioning fixture in order to conduct pre-positioning on a workpiece on the premise of not affecting normal machining of the workpiece. The turnover positioning fixture comprises a base and a turnover pedestal rotatably arranged on the base around the horizontal axis. The turnover pedestal is provided with a carrying position for carrying the workpiece.The turnover pedestal is further provided with a pressing mechanism for pressing the workpiece. An end part positioning part is detachably or retractably assembled in the position, located beside thecarrying position, of the turnover pedestal. The end part positioning part is provided with a stop position used for being in stop fit with a to-be-machined surface of the workpiece so as to make thepressing mechanism to press the workpiece and is further provided with a moving position for moving the to-be-machined surface of the workpiece. Through the turnover positioning fixture, the workpiece is pre-positioned on the premise of not affecting normal machining of the workpiece.

Owner:HENAN SENYUAN ELECTRIC CO LTD

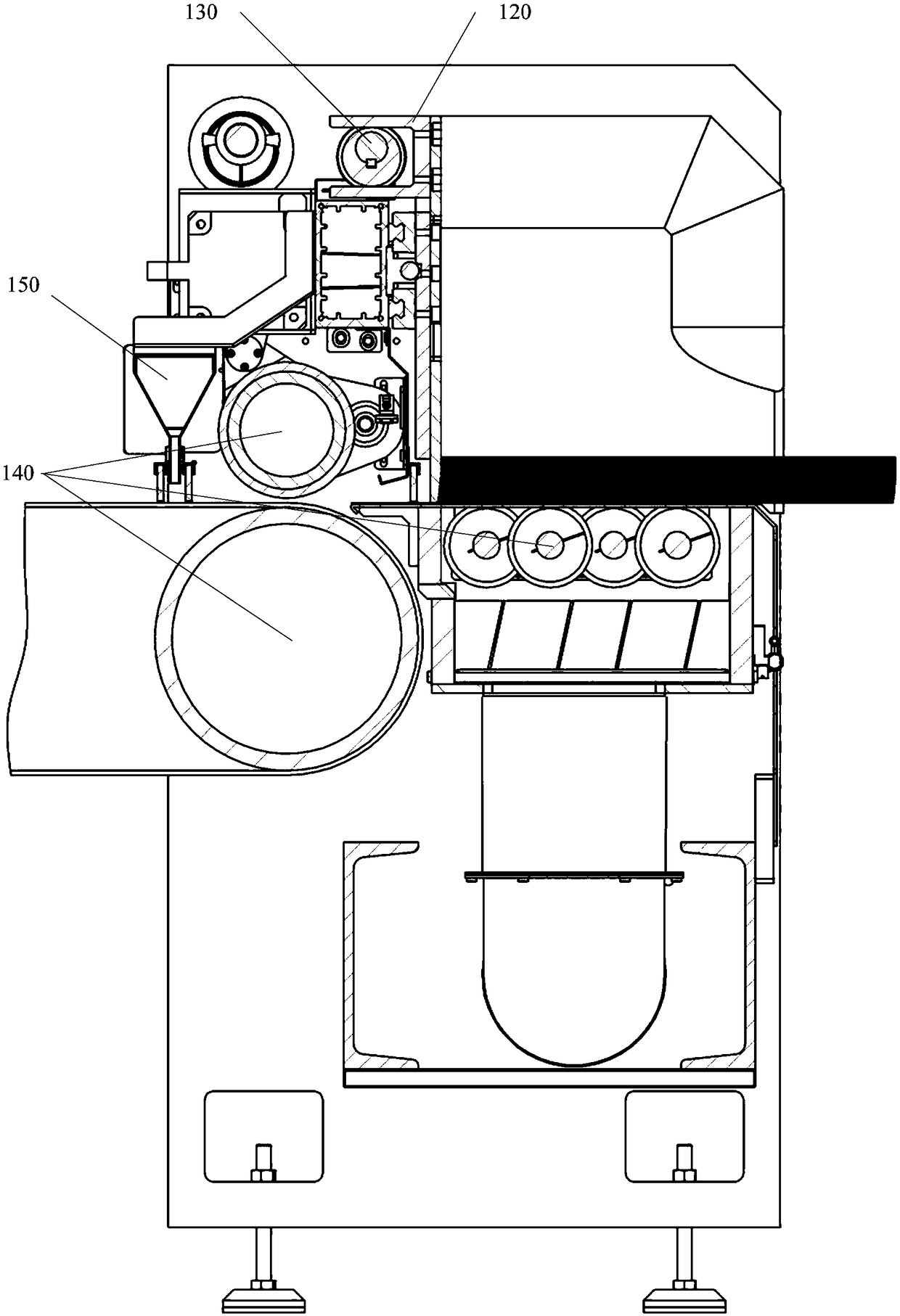

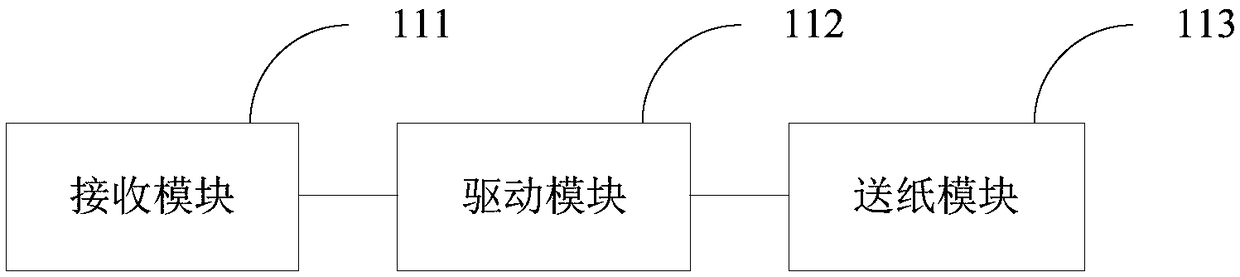

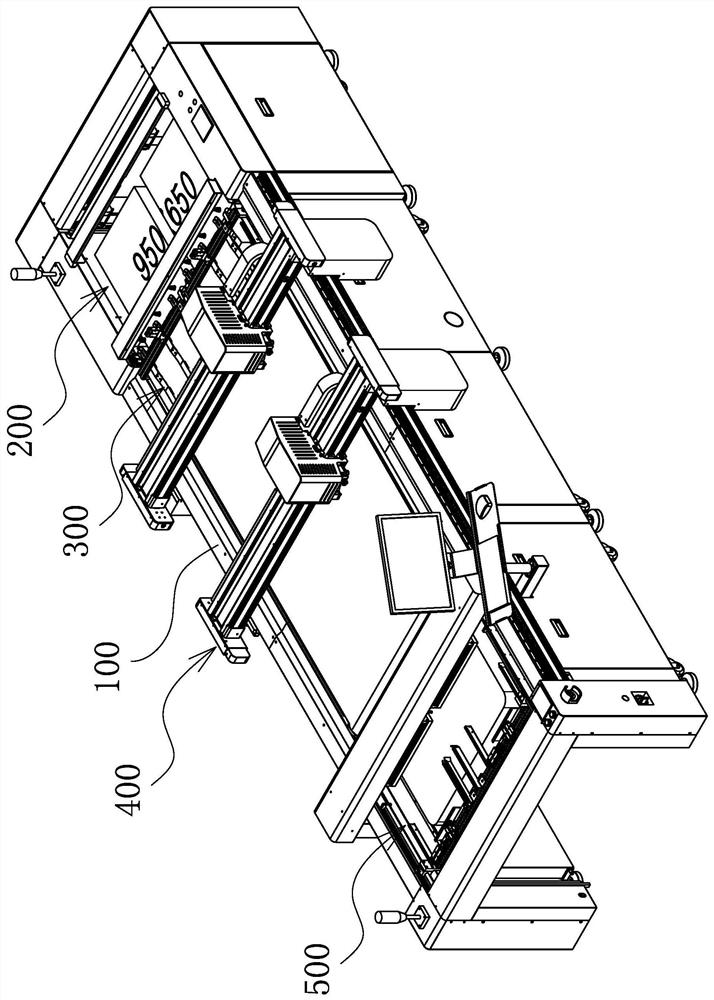

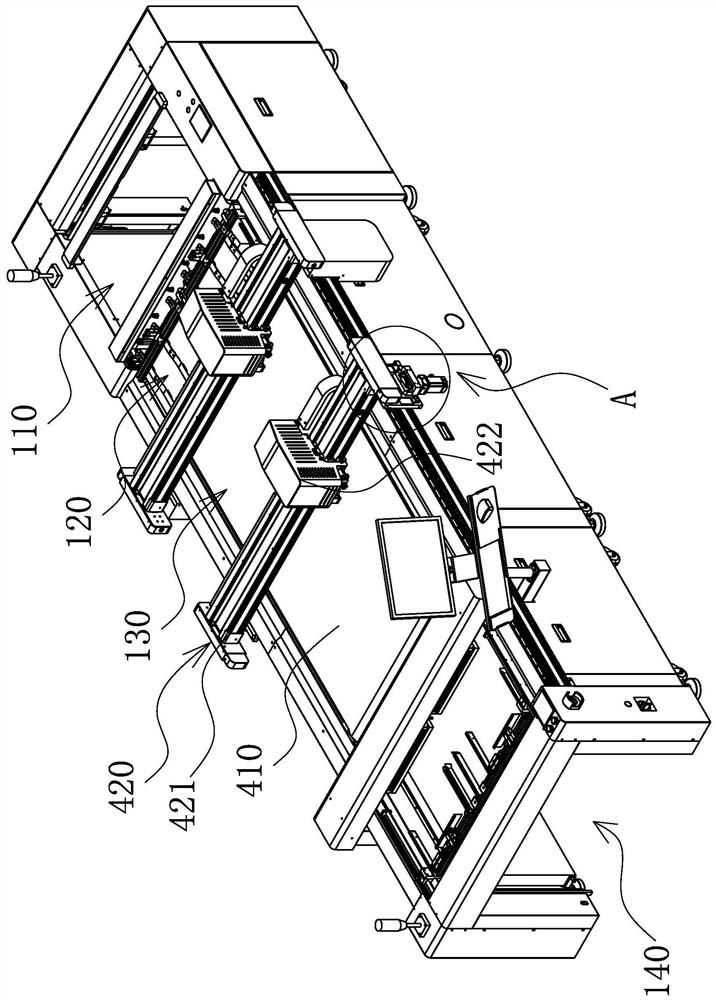

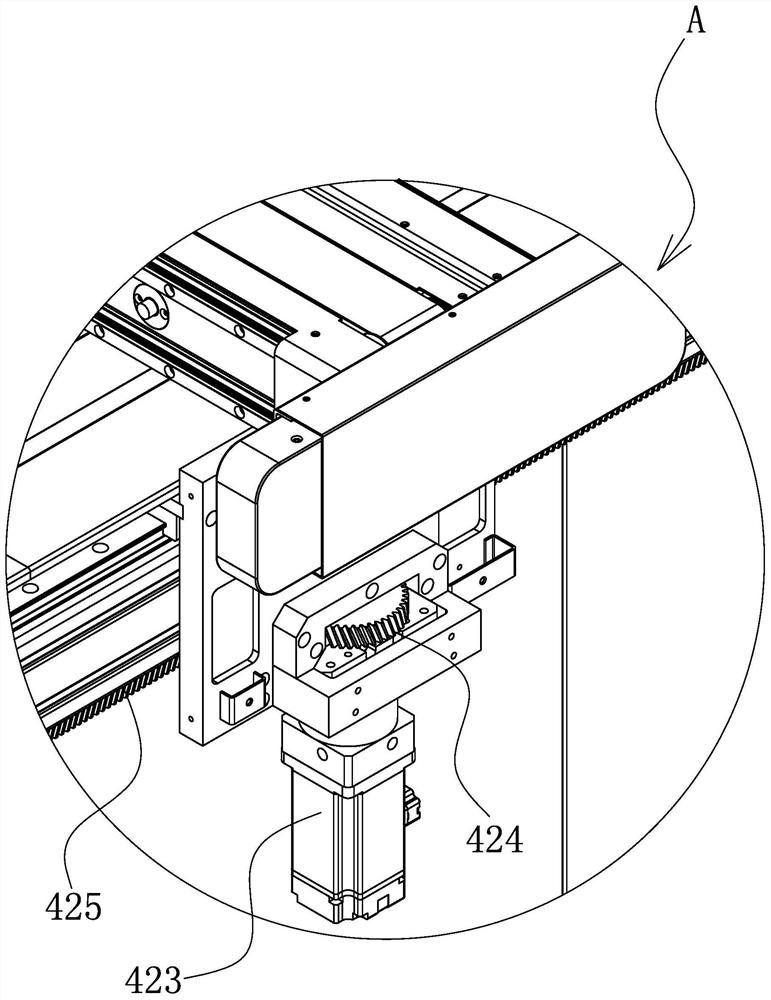

Feeding control device and method and digital spray printing machine

InactiveCN108638661AImprove work efficiencyAccurate printingOther printing apparatusPaperboardEngineering

The invention is applicable to the technical field of printing machinery and provides a feeding control device and method and a digital spray printing machine. The feeding control device comprises a controller, a material baffle and a material baffle driving mechanism driving the material baffle to rise and fall. The controller is used for controlling the material baffle driving mechanism to enable the material baffle to rise or fall. The controller controls the material baffle driving mechanism, then the material baffle at a printer feeding inlet is controlled to fall to the lowest point of the feeding inlet, thus a first corrugated board is close to the feeding inlet side and is attached to the bottom of the material baffle, the first corrugated board is located, thereby being pre-located, the paperboard printed in the first place can be printed accurately, the printing effect of the first paperboard is ensured, and work efficiency of a user is improved.

Owner:SHENZHEN HANDWAY IND DIGITAL EQUIP CO LTD

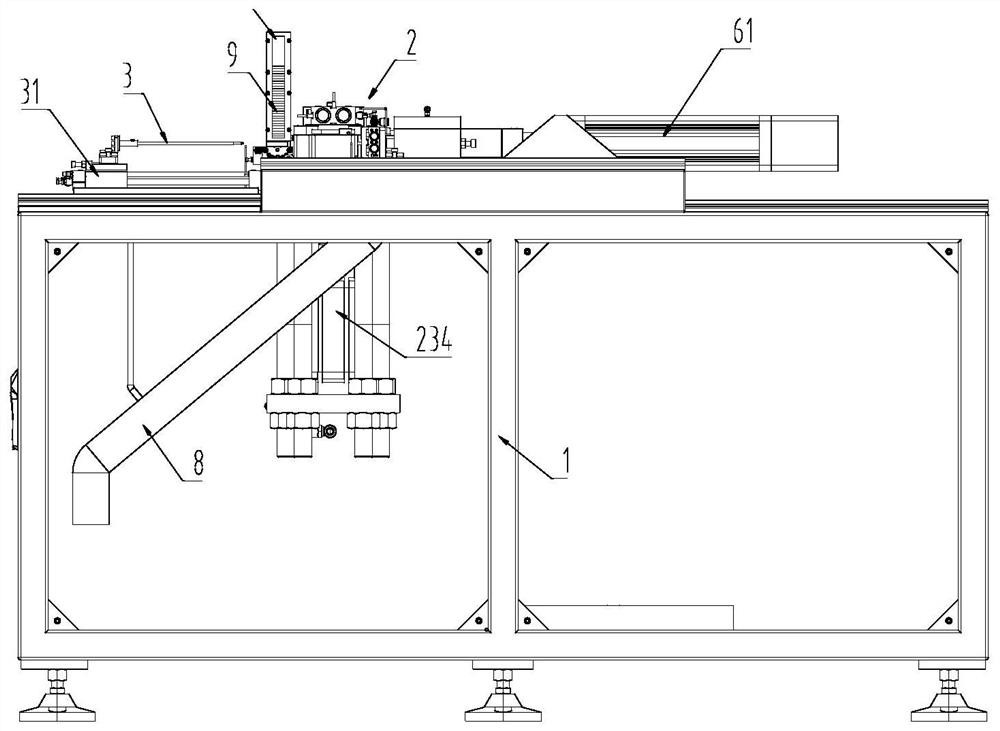

Feeding device for pipe end forming machine

PendingCN109665301ARealize automatic feedingRealize online detectionConveyorsSortingMolding machineMachining

The invention discloses a feeding device for a pipe end forming machine. The feeding device comprises a machine body provided with two supporting plates. Two rotary feeding mechanisms synchronously driven by the same power mechanism are arranged on the two supporting plates correspondingly. The same ends of the two supporting plates are both provided with inclined pipe conveying brackets, and theother ends of the two supporting plates are both provided with pipe rejection mechanisms. The portion, located on the upstream of the corresponding pipe rejection mechanism, of each supporting plate is provided with a pipe stop mechanism. A pipe detection mechanism is arranged between the portions, located between the two supporting plates, of the upstream of each pipe stop mechanism. Guide conveying parts are arranged on the tops, located on the downstream of the pipe detection mechanisms, of the two supporting plates. The guide conveying parts are inclined towards the pipe stop mechanisms and extend onto the pipe rejection mechanisms. The feeding device realizes automatic feeding of pipes during all the working procedures of a forming machine, online detection of machined pipe ends and rejection of unqualified pipes. The consistency between every two adjacent working procedures is good. The cycle of the pipe end machining and detection working procedures is greatly shortened. The working efficiency is greatly improved.

Owner:张家港市润泰机械有限公司

Image-text cutting machine

ActiveCN113276177AIncrease storage spaceReduce labor intensityMetal working apparatusArticle feedersPaperboardElectric machinery

The invention provides an image-text cutting machine, and belongs to the technical field of cutting. The image-text cutting machine comprises a rack, wherein a feeding area, a paper separating area, a cutting area and a discharging area which communicate with one another are arranged on the rack, a feeding mechanism, a paper separating mechanism, a cutting mechanism and a discharging mechanism are arranged in the feeding area, the paper separating area, the cutting area and the discharging area respectively, the feeding mechanism comprises a feeding channel, a gear motor, a transmission assembly connected with the output end of the gear motor and a bottom plate connected with the transmission assembly are arranged in the feeding channel, a tray used for bearing paperboards is arranged on the bottom plate, and the transmission assembly adopts chain wheel and chain transmission. Through meshing transmission between chain wheels and chains, paper can be conveniently loaded, the labor intensity of operators is reduced, and in addition, the storage space of the bottom plate for loading the paperboards to be cut is enlarged.

Owner:NINGBO JINGWEI SYSTEMTECHNIK LTD

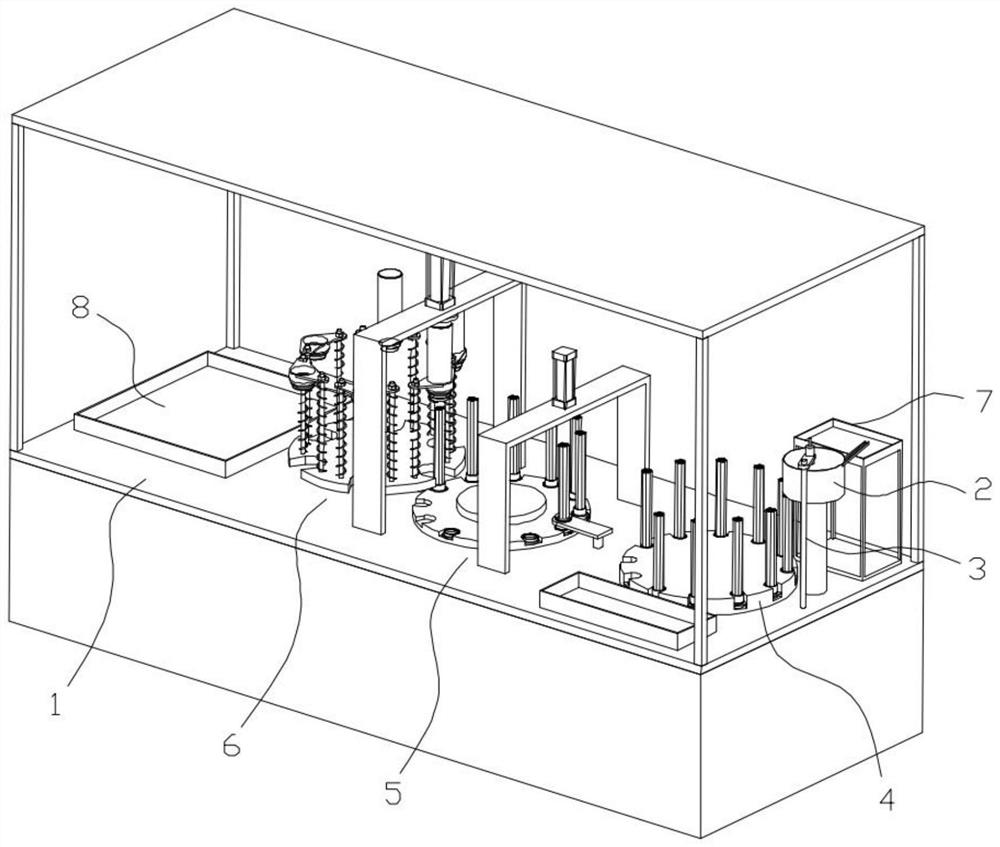

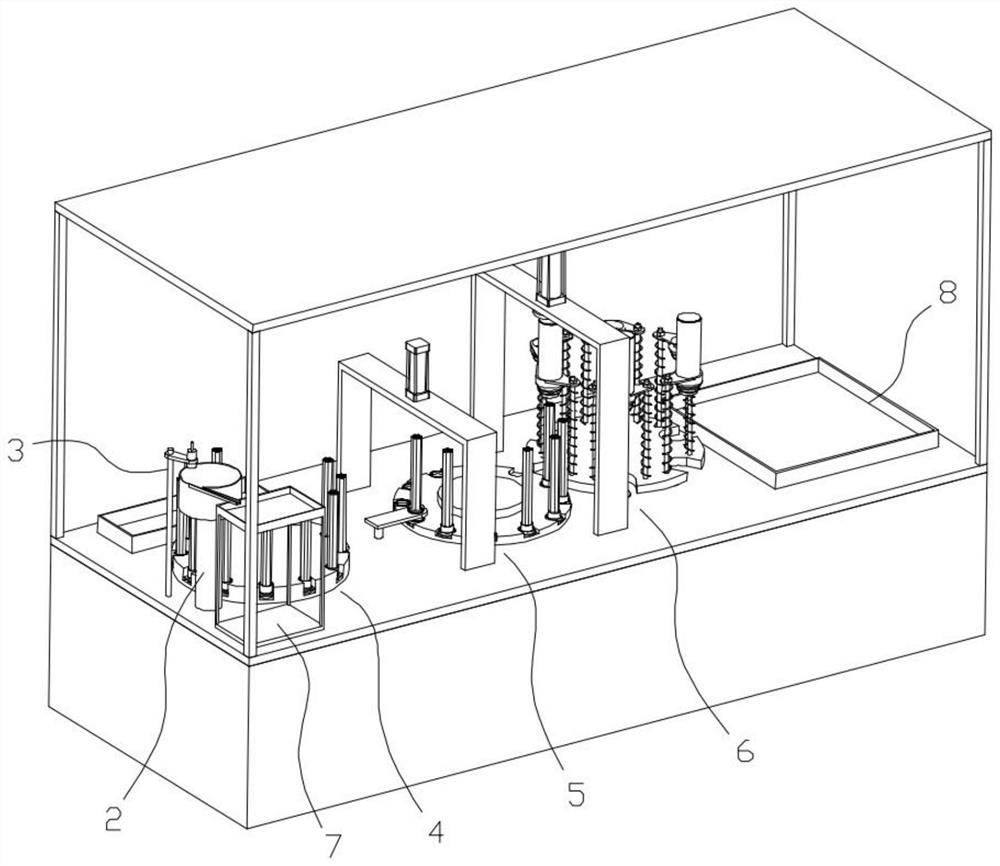

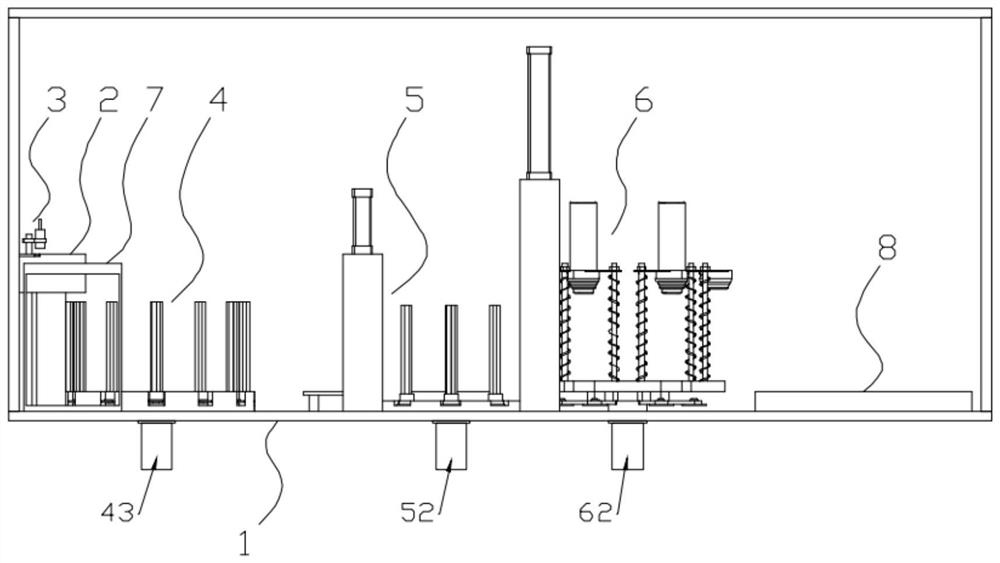

Pre-filling equipment for sterile solid medicine granules

ActiveCN112407429AIncrease contactImprove filling efficiencyPackaging automatic controlStopper feedingProcess engineeringAssembly line

The invention discloses pre-filling equipment for sterile solid medicine granules, and relates to the field of automatic equipment. The pre-filling equipment comprises a workbench, a feeding vibrationdisc, a medicine granule dispersing mechanism, a weighing mechanism, a rubber plug press-fitting mechanism and a bottle body press-fitting mechanism. The pre-filling equipment achieves automation inthe whole process based on assembly line type filling and automatic weighing; compared with traditional manual filling, the filling efficiency and the weighing precision are remarkably improved, and operation errors are reduced; and in the whole filling process, solid medicine granules can be in good contact with a pre-filling needle tube and are not prone to scattering.

Owner:WUHU SIMCERE ZHONGREN PHARM

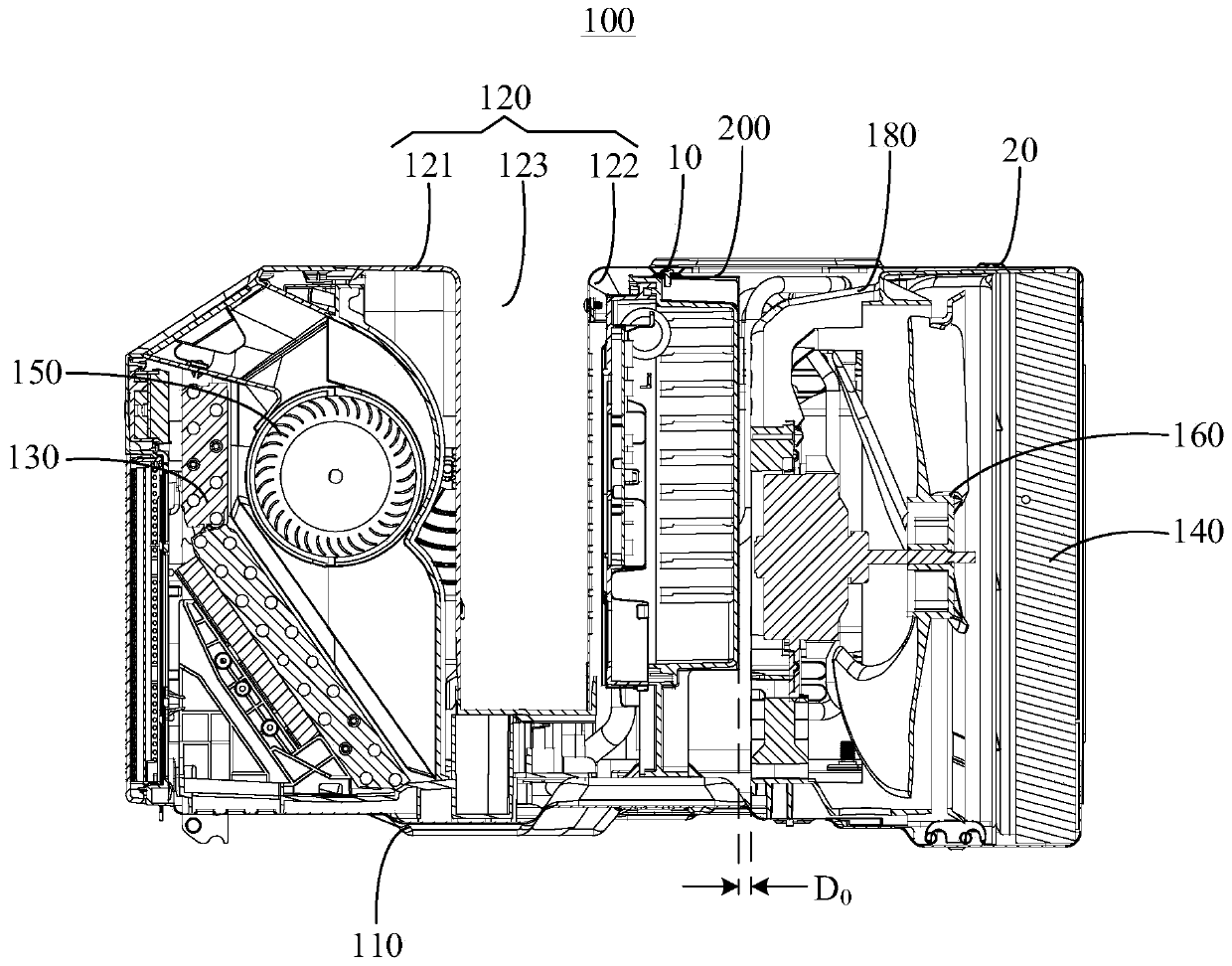

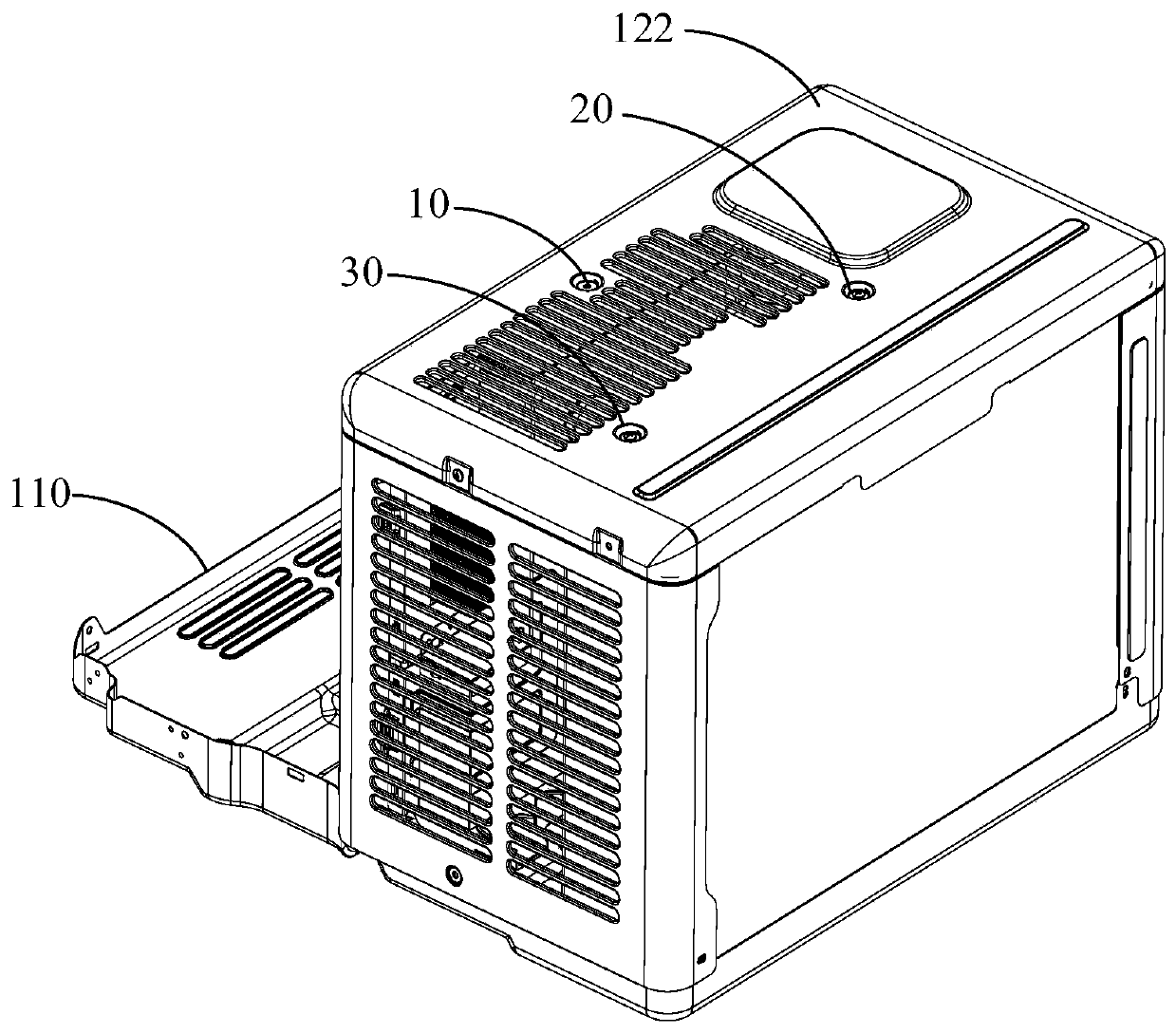

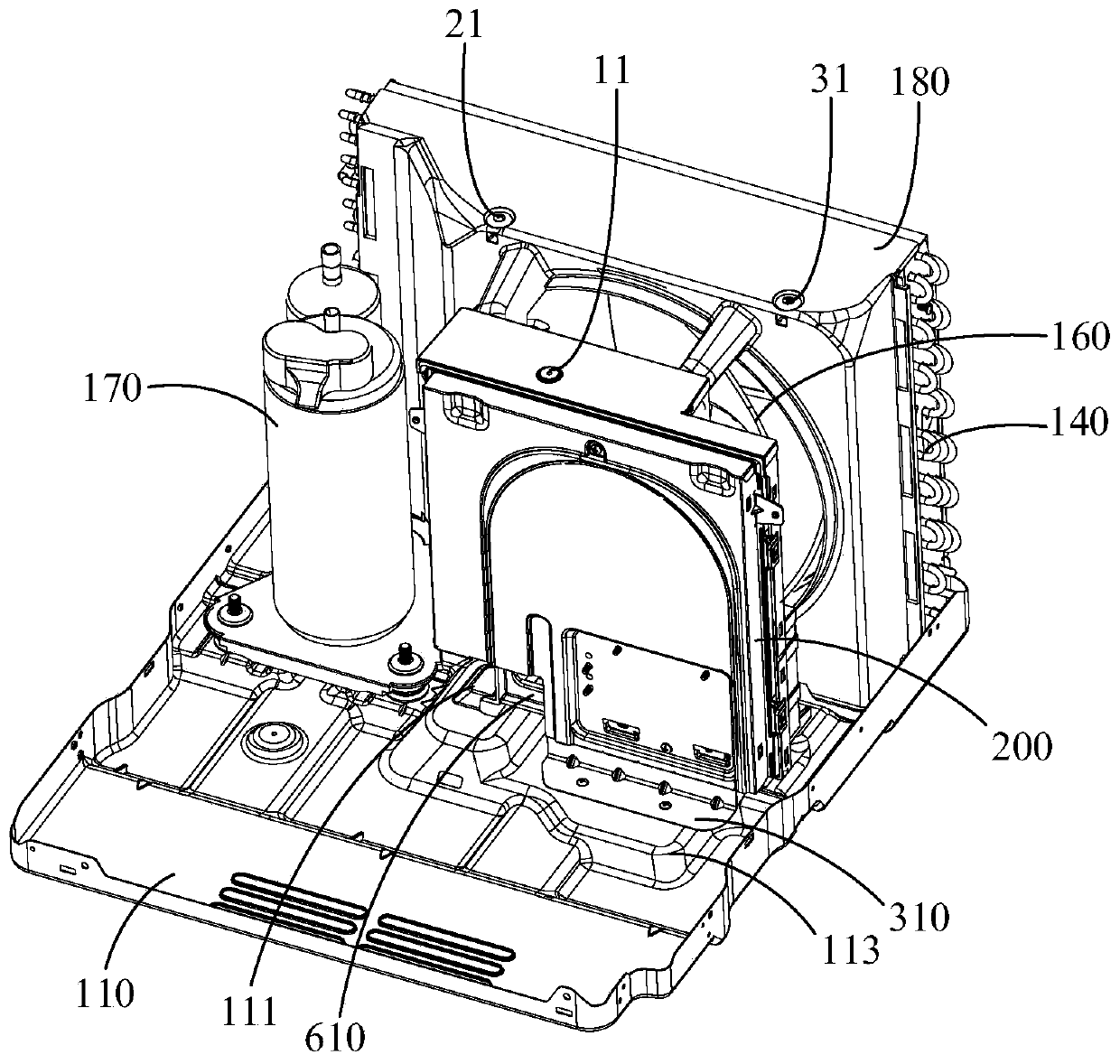

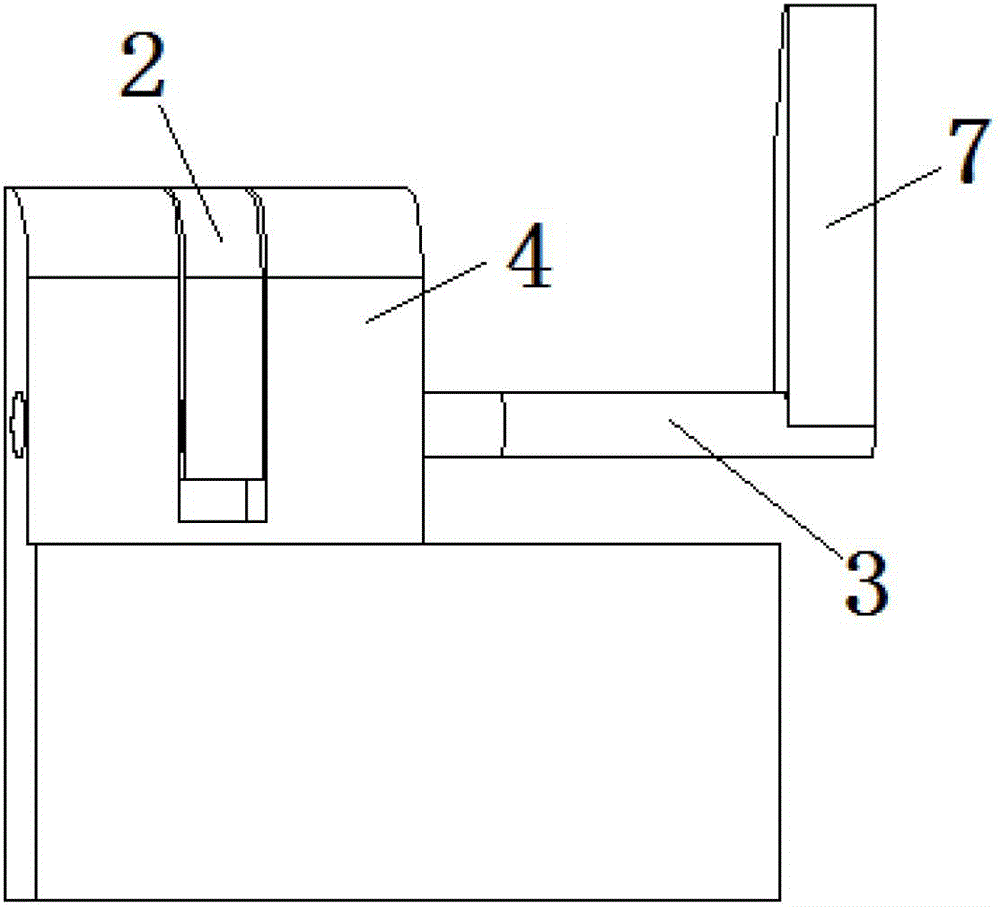

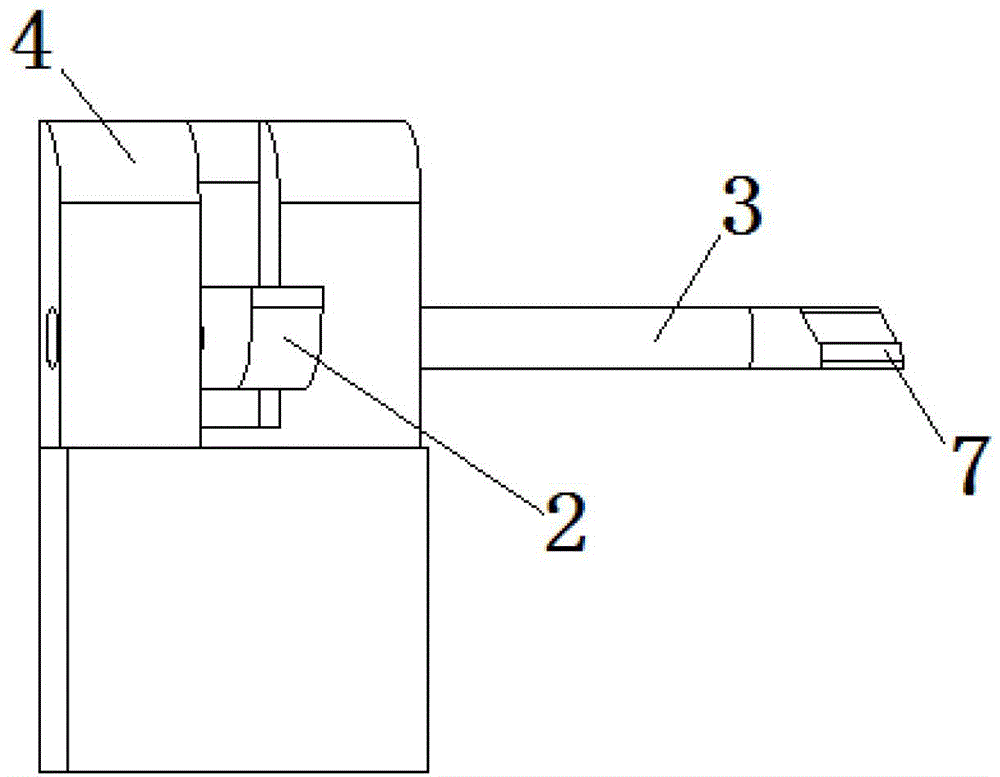

Air conditioner

PendingCN110906459AAchieve pre-positioningDifficult to moveMechanical apparatusLighting and heating apparatusElectric controlPhysics

The invention discloses an air conditioner. The air conditioner comprises a base plate and an electric control box, and the electric control box is vertically installed on the base plate. A pre-positioning piece and a fixing structure are constructed at the bottom of the electric control box, an inserting part corresponding to the pre-positioning piece is constructed on the base plate, and the electric control box is suitable for being inserted and positioned with the inserting part of the base plate through the pre-positioning piece and then fixedly connected with the base plate through the fixing structure. According to the air conditioner, the mounting difficulty of the electric control box can be reduced, so that the mounting efficiency of the electric control box is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Body side buckles automatically-folding device and folding method thereof

The invention discloses a body side buckles automatically-folding device and a folding method. The folding device comprises a guide block, wherein a compaction block which can relatively rotate around a guide surface of the guide block is arranged on the guide block; a rotating shaft used for connecting the compaction block is arranged on the guide block; one end of the rotating shaft extends out of the guide block. The body side buckles automatically-folding device and the folding method have the advantages that the buckles on side body plates can be automatically bent to an angle meeting technological requirements in manufacturing technology equipment of automobile welding, so as to realize pre-position of body side plates; the uniformity of buckles bending can be guaranteed, the bending effect is guaranteed, and further the assembling quality is guaranteed; the manpower and buckles bending time are saved, and the work efficiency is improved.

Owner:CHERY AUTOMOBILE CO LTD

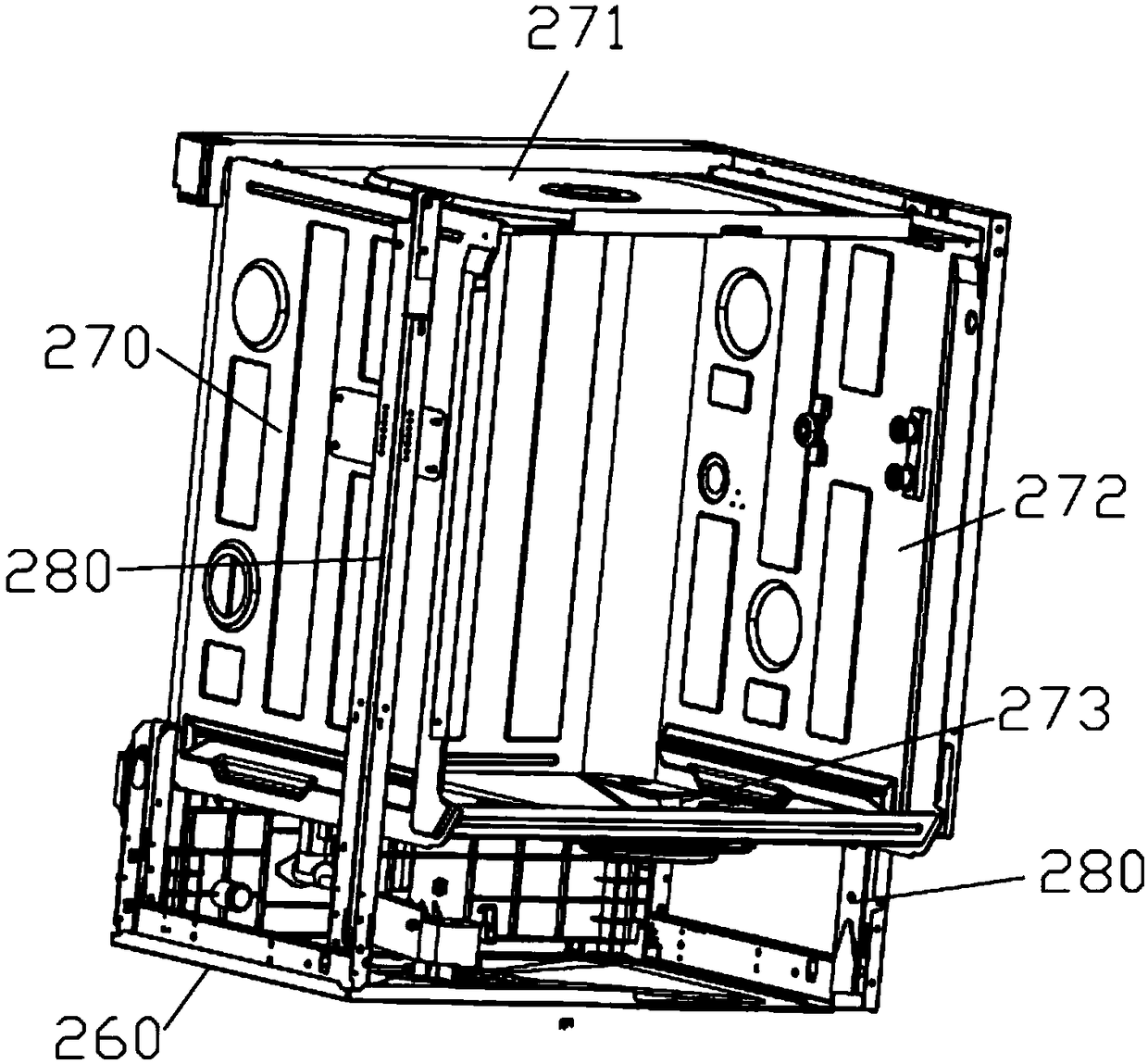

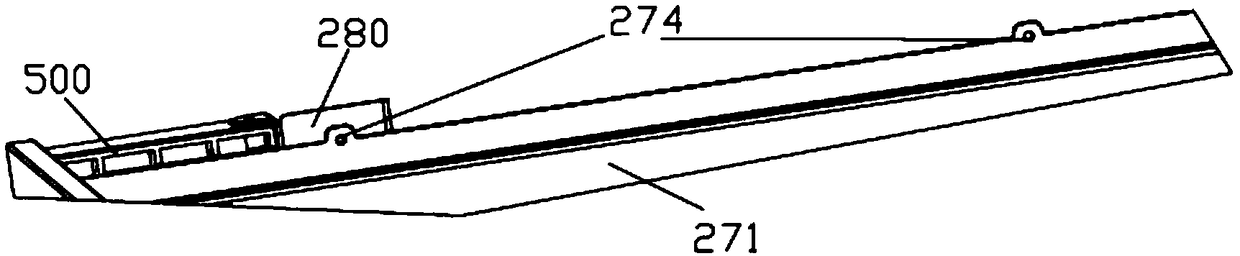

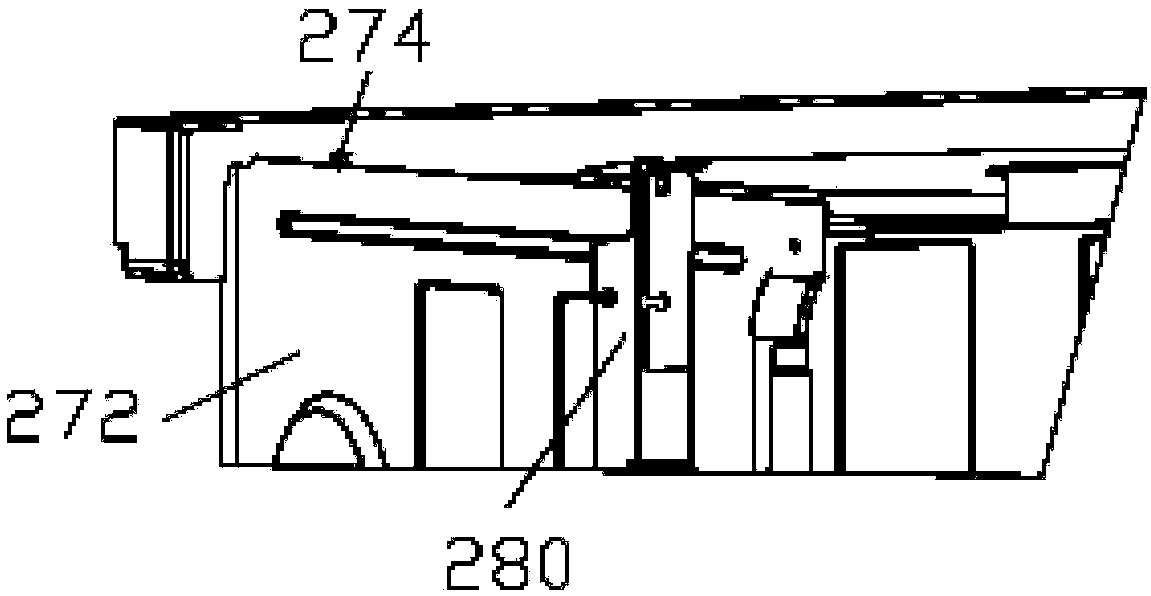

Liner container molding structure and molding method of dishwasher

PendingCN109222834AEasy to formGood structural stabilityTableware washing/rinsing machine detailsWelding/cutting auxillary devicesStructural stabilityEngineering

The invention discloses a liner container molding structure and a molding method of a dishwasher. The inner container includes a middle cover and a top cover and a bottom cover respectively connectedto an upper end and a lower end of that middle cover. An upper flange structure extend upward is arranged at that edge of the top cover. The edge of the bottom cover is provided with a down flanging structure extending downward, the upper flanging structure and the down flanging structure are provided with a predetermined position structure opposite to the middle cover respectively, and the upperend edge and the lower end edge of the middle cover are provided with a predetermined position structure corresponding to the upper predetermined position structure of the up flanging structure and the down flanging structure respectively. As that for structure and the forming method of the inn container of the dishwasher are convenient and quick to form, the structure stability is good, the forming dimension precision is high, and the dishwasher has a good application prospect. The dishwasher inn container is characterized in that the structure and the forming method of the inner container ofthe dishwasher are convenient and fast, the structure stability is good, and the forming dimension precision is high.

Owner:WUHU GUANGYING IND CO LTD

Impact test machine with steel ball self-reset function

InactiveCN105300649AAchieve pre-positioningEasy to fixShock testingMagnetic tension forceEngineering

The invention discloses an impact test machine with a steel ball self-reset function, comprising a test bench. The test machine is characterized in that two pairs of positioning blocks are mounted on the test bench in a sliding manner, and the two pairs of positioning blocks surround a square area; one pair of positioning blocks can move transversely on the test bench, and the other pair of positioning blocks can move longitudinally on the test bench; and the ends of two adjacent positioning blocks are connected by an elastic band. The beneficial effect of the invention is as follows: the elastic bands can provide a certain pre-tightening force to pre-position a tested object, and the elastic bands and the positioning blocks can form an area for limiting the rolling range of a steel ball, so that the magnetic force of a magnetic base can attract the steel ball to a specified position, there is no need to pick steel ball back manually, and time and labor are saved. The positioning blocks can both limit the movement of the tested object in the horizontal direction and limit the movement of the tested object in the vertical direction. Thus, fixation is firmer, and test is facilitated.

Owner:KUSN MINGJIU ELECTROMECHANICAL

electric fan

ActiveCN109185196BImprove reliabilityAchieve pre-positioningPump componentsWorking fluid for enginesImpellerEngineering

The invention provides an electric fan, comprising: a rotor assembly and a casing, the rotor assembly includes a bearing, a moving impeller and a magnetic ring, and the magnetic ring and the moving impeller are respectively installed at two ends of the bearing; the casing has a bearing chamber, and the magnetic ring The diameter is smaller than the diameter of the bearing chamber, and the magnetic ring can pass through the bearing chamber. After the installation is completed, the moving impeller and the magnetic ring are respectively located at both ends of the bearing chamber. The electric fan provided by the present invention only uses one bearing, and the bearing is located between the moving impeller and the magnetic ring of the rotating shaft. When assembling, the magnetic ring passes through the bearing chamber. After the installation is completed, the moving impeller and the magnetic ring are respectively located At the end, this assembly method of the rotor assembly and the casing is convenient for assembly and simplifies the assembly process; since only one bearing is used, the assembly accuracy requirements for the rotor assembly and the casing are low, which is conducive to improving assembly efficiency; The number of parts is beneficial to reduce product cost and further improve assembly efficiency.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

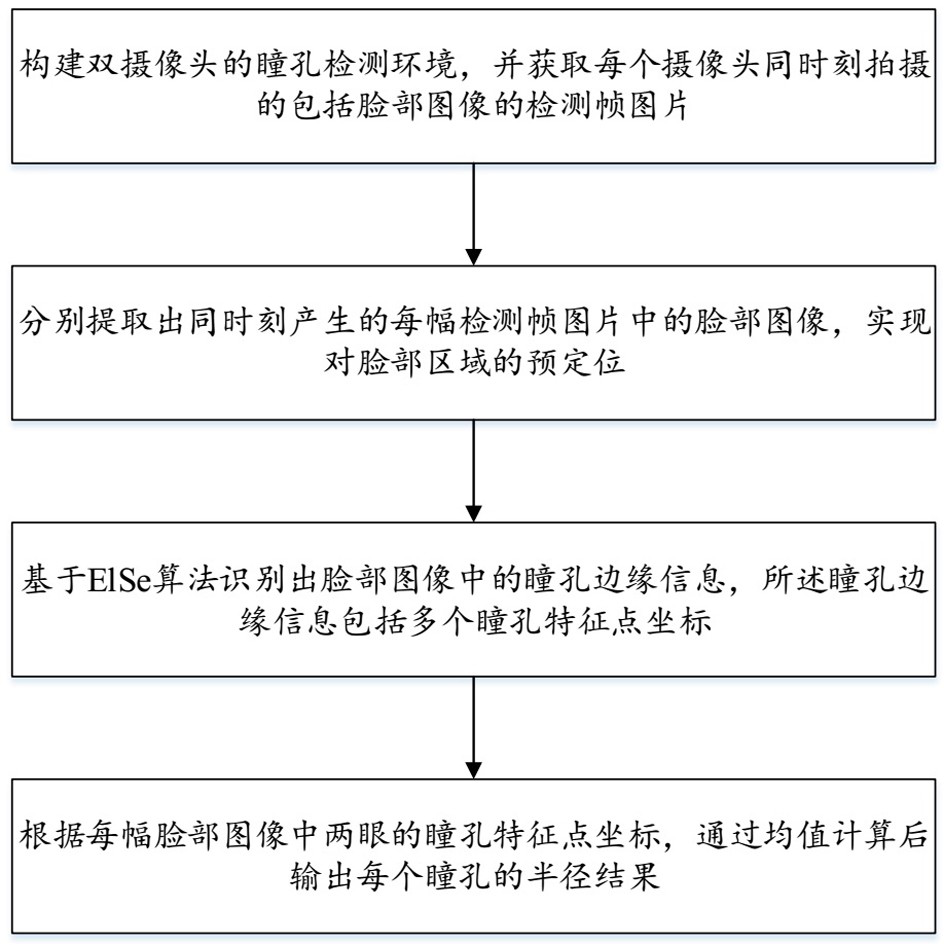

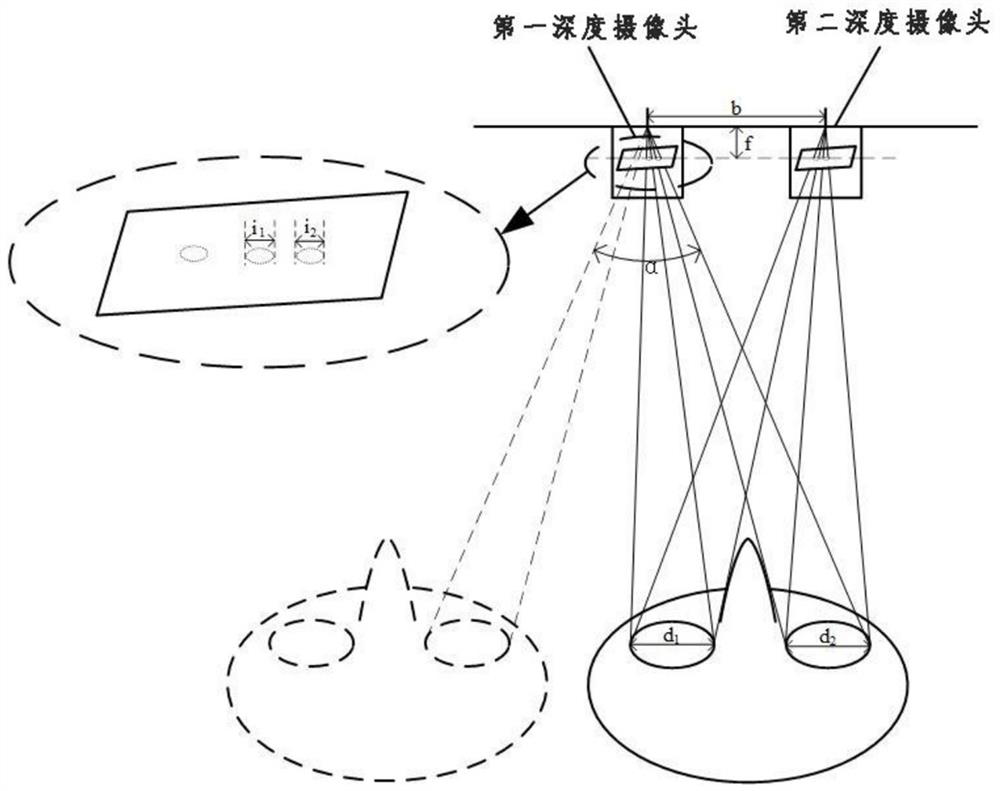

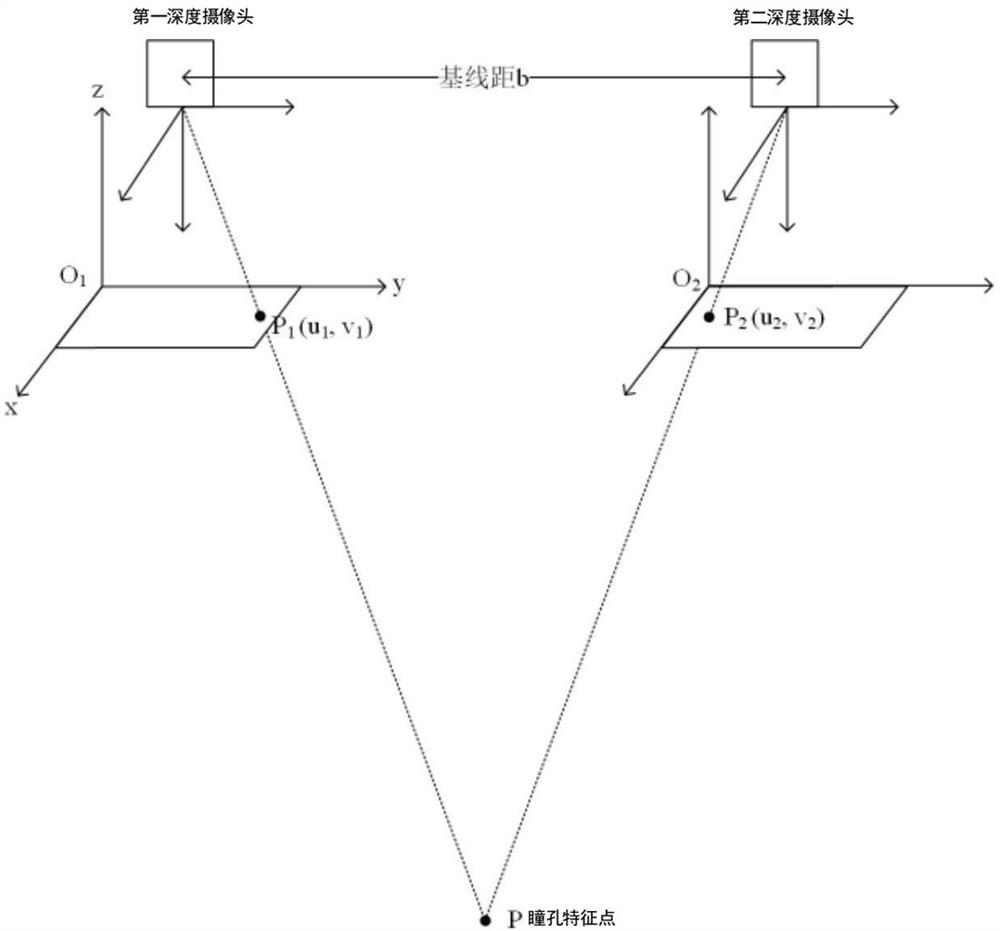

Pupil detection method and device based on double cameras

ActiveCN111738241AImprove accuracyImprove the problem of coordinate offsetAcquiring/recognising eyesOphthalmologyPupil margin

The invention discloses a pupil detection method and device based on double cameras, relates to the technical field of pupil detection, and can improve the accuracy of a pupil detection result by adopting a pupil detection scheme of the double cameras. The method comprises the following steps: constructing a pupil detection environment of double cameras, and acquiring a detection frame picture which is shot by each camera at the same time and comprises a face image; respectively extracting a face image in each detection frame picture generated at the same moment to realize pre-positioning of aface region; identifying pupil edge information in the face image based on an ElSe algorithm, wherein the pupil edge information comprises a plurality of pupil feature point coordinates; and according to the pupil feature point coordinates of the two eyes in each face image, outputting a radius result of each pupil through mean value calculation. The device applies the method provided by the scheme.

Owner:宁波均联智行科技股份有限公司

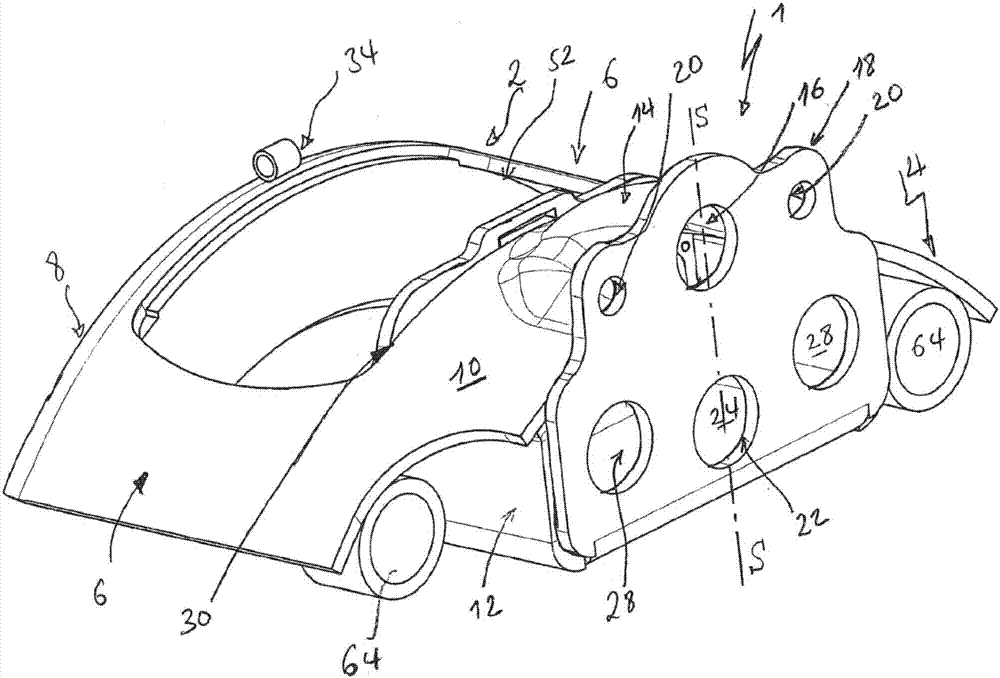

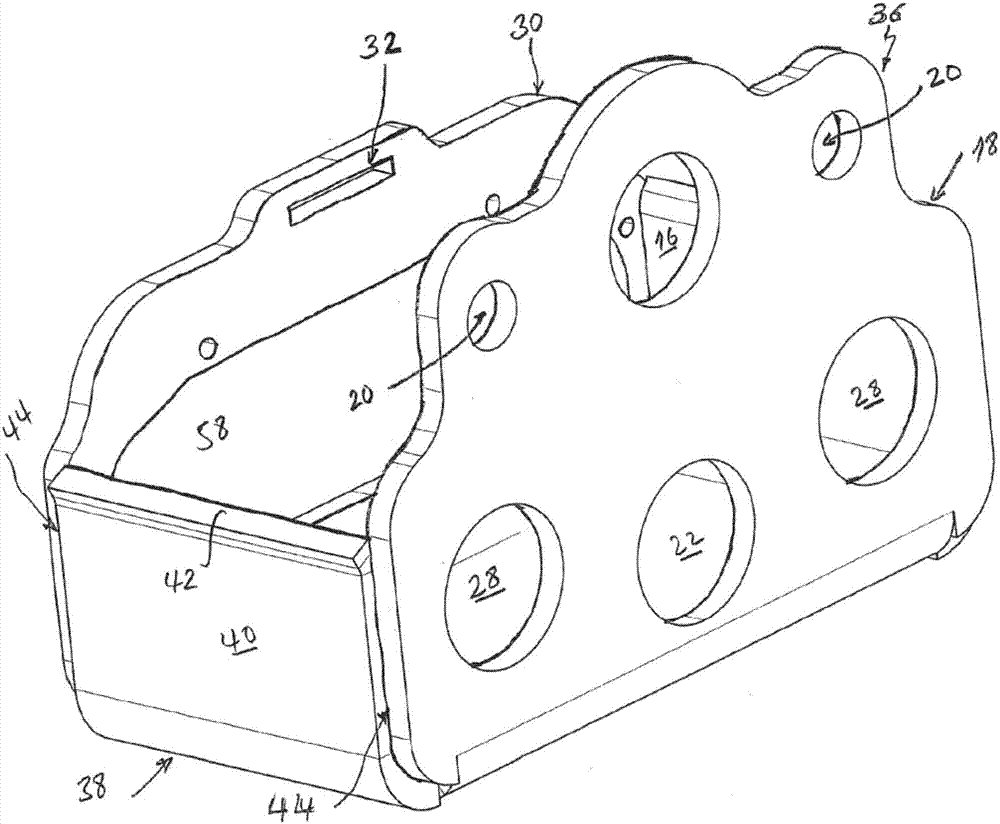

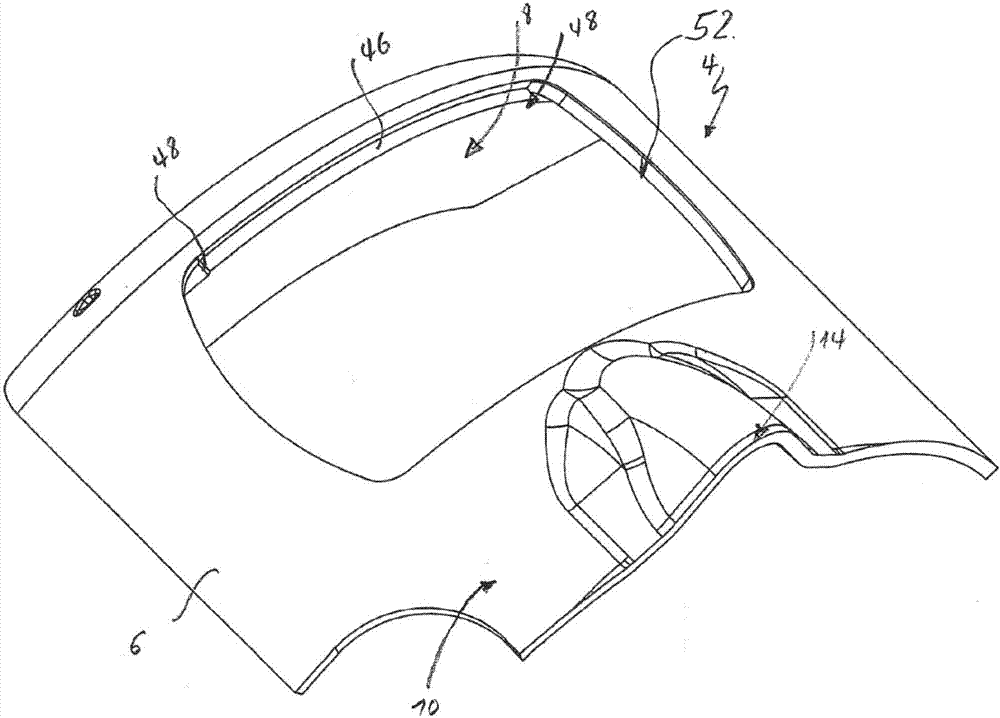

Brake caliper for disk brake

ActiveCN107250591AReduce manufacturing costAvoid enteringAxially engaging brakesBrake actuating mechanismsEngineeringMetal sheet

A brake caliper for a disk brake, has a caliper frame (2) which is configured suitably for engaging over the brake disk, and a housing (12) for receiving a brake application mechanism for applying a braking force to the brake disk. The housing (12) can be configured from an outer segment (18), an inner segment (30) which extends substantially parallel to the outer segment (18), and bottom and cover segments (38; 4) which extend between the outer and inner segments and are manufactured in each case from sheet metal, wherein at least two segments (18, 30, 38; 4, 18, 30) are configured by way of a unitary sheet metal element and / or locating bearings and floating bearings (64) are formed by way of sheet metal tubes (72) which are formed in one piece by way of bending of at least one of the metal sheets which configure at least one segment (74).

Owner:ZF CV SYST EURO BV

Light cast-in-place high-strength formwork non-dismantling wall and construction method thereof

The invention relates to a lightweight cast-in-place high-strength formwork disassembly-free wall and a construction method thereof, and relates to the field of building walls.The lightweight cast-in-place high-strength formwork disassembly-free wall comprises a plurality of vertical keels arranged in the length direction of the wall, latticed formworks are arranged on the two sides of the wall, and connecting assemblies are arranged between the formworks and the keels; a concrete body is poured between the formworks on the two sides of the wall body. The non-bearing wall has the advantages that the construction process of the non-bearing wall is more convenient, and the construction period is shortened.

Owner:秦长城新型建材(天津)有限公司

Lamp heat dissipation structure and ceiling lamp

PendingCN111189039AAchieve pre-positioningSimple connection structureLighting heating/cooling arrangementsLight fasteningsThermodynamicsLight fixture

Owner:LEEDARSON IOT TECH INC

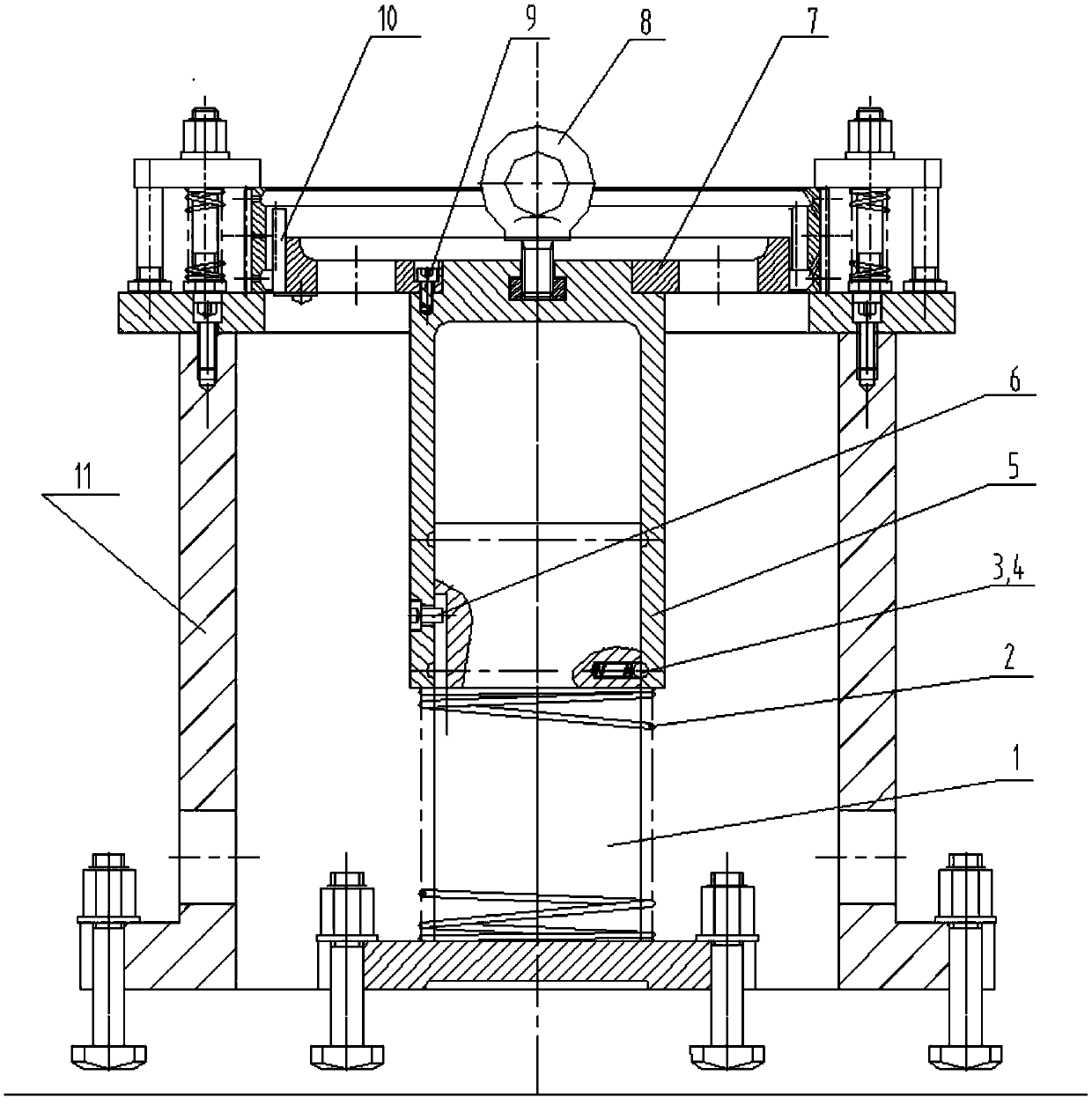

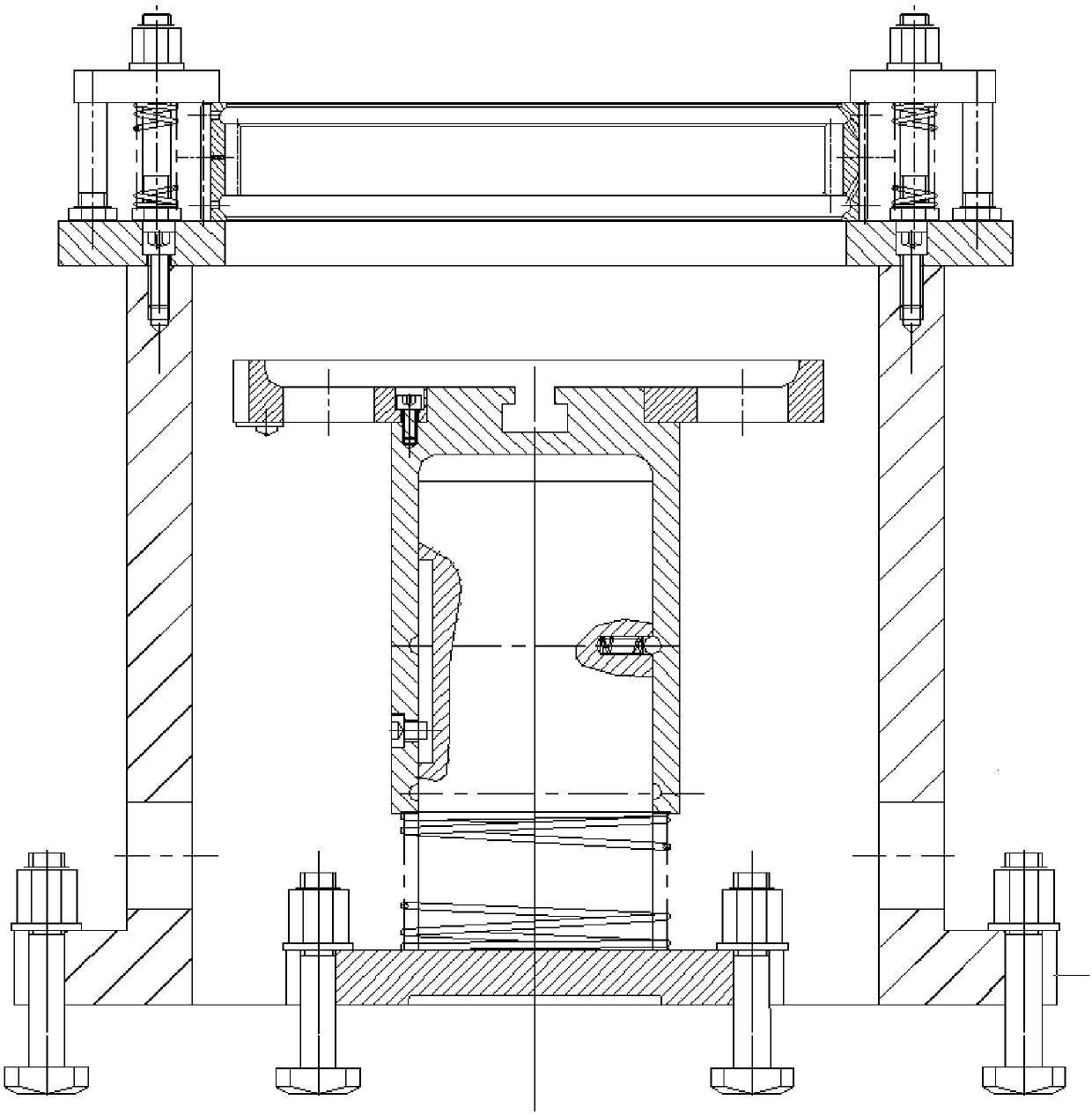

Mold assembling and disassembling device for epoxy resin casting part

The embodiment of the invention discloses a mold assembling and disassembling device for an epoxy resin casting part. The device comprises a workbench, wherein a correction moving mechanism for adjusting the position of a mold is mounted on the surface of the workbench, and a lifting frame is mounted on the workbench. According to the device, the mold can be quickly positioned and fixed through apositioning inserting column and three pushing columns, meanwhile, adjustment can be carried out according to the size of the mold in the fixing process so that molds of different sizes can be fixed,in the implementation process of the device, the mold only needs to slide along the surface of a fixing table, the positioning inserting column can be jacked up in the sliding process of the mold, meanwhile the three pushing columns slide along sliding square holes until the left side surface and the right side surface of a mold base are respectively connected with the positioning inserting columnand the pushing columns, mold pre-positioning is achieved, then a driver drives a clamp holder to clamp and fix the mold base, the whole operation process is simple and convenient, the device can adapt to molds of different sizes, and the application range of the device is wide.

Owner:广州信佳地坪工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com